Controlled-rolling and controlled-cooling high-strength pearlitic steel rail and production method thereof

A pearlitic rail, controlled rolling and controlled cooling technology, applied in the direction of temperature control, heat treatment process control, furnace type, etc., can solve the problem that the strength and hardness of pearlitic rail are difficult to further improve, and achieve easy popularization and application, good toughness and plasticity, The effect of increasing strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

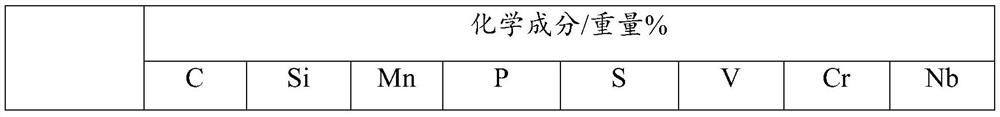

[0038] According to conventional rail smelting and casting methods, the process includes converter smelting, LF refining, vacuum treatment, and continuous casting. Among them, the converter slag alkali is controlled at 2.5-3.8; when the steel water is about 1 / 4, the alloy and a carbonaceous agent such as silicon, manganese, vanadium, and steel flow are added to 3 / 4, alloy, and the carbonaceous compound. Add; LF furnace treatment time should be greater than 40 min; RH vacuum ≤90Pa, pure vacuum processing time should not be less than 20 min, the casting process should be carried out under full protection, preventing contact with air, while casting the steel blank should be cooled. The steel blank is sent to the stepped beam heating furnace heating and heats up, the heating temperature is 1170 ° C, the holding time is 160min, the gas is rolled into a rail, the temperature is 1060 ° C, the final rolling temperature is 860 ° C, and the rails after hot rolling And the rail bottom is car...

Embodiment 2-4

[0040] According to the method of Example 1, the difference is that the heating, rolling and heat treatment process parameters are shown in Table 2, respectively.

[0041] Table 2 Embodiments and contrast acceleration cooling process parameters

[0042]

[0043] The comparative example selects the most mature and application range in the current industry, and the tensile strength, stealing hardness, and broken elongation of the steel rails obtained in the comparative example are inspected in the current industry, according to the method specified in TB / T 2344-2012. Performance indicators such as rate, metallic tissue, cross-sectional rock hardness and fracture toughness, and results are shown in Table 3.

[0044] Table 3 Performance of the embodiment and the proportion

[0045]

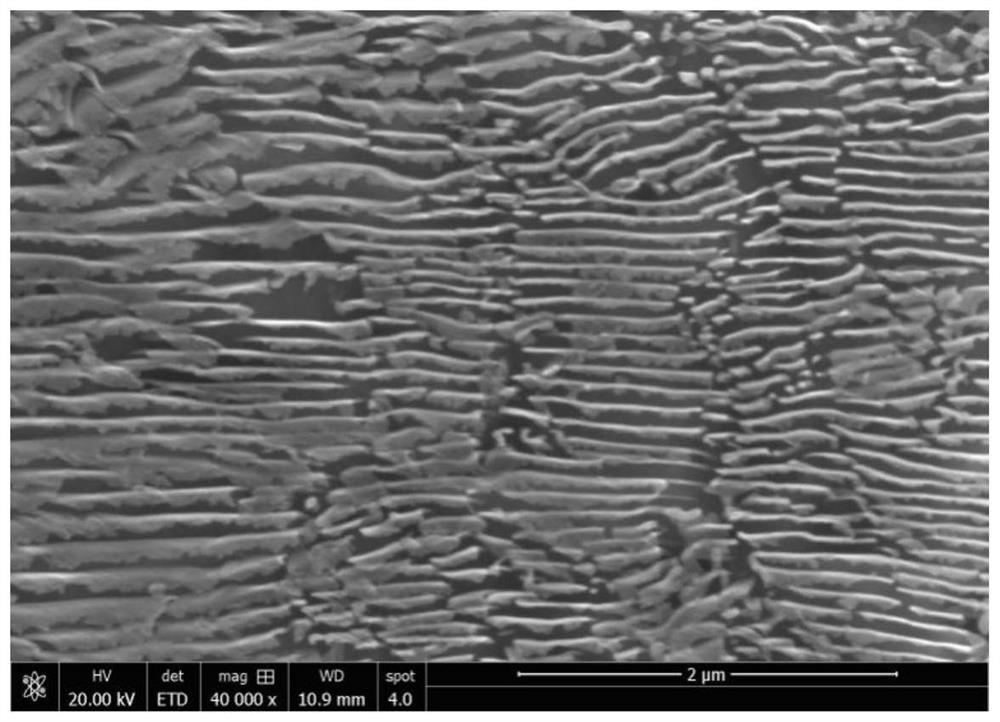

[0046] It can be seen that the rail strength and hardness obtained by Example 1-4 is better than that of the U75V wire-heat-treated rail, and has better tough plasticity, and the metallographic tiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com