Patents

Literature

57 results about "Railhead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The word railhead is a railway term with two distinct meanings, depending upon its context.

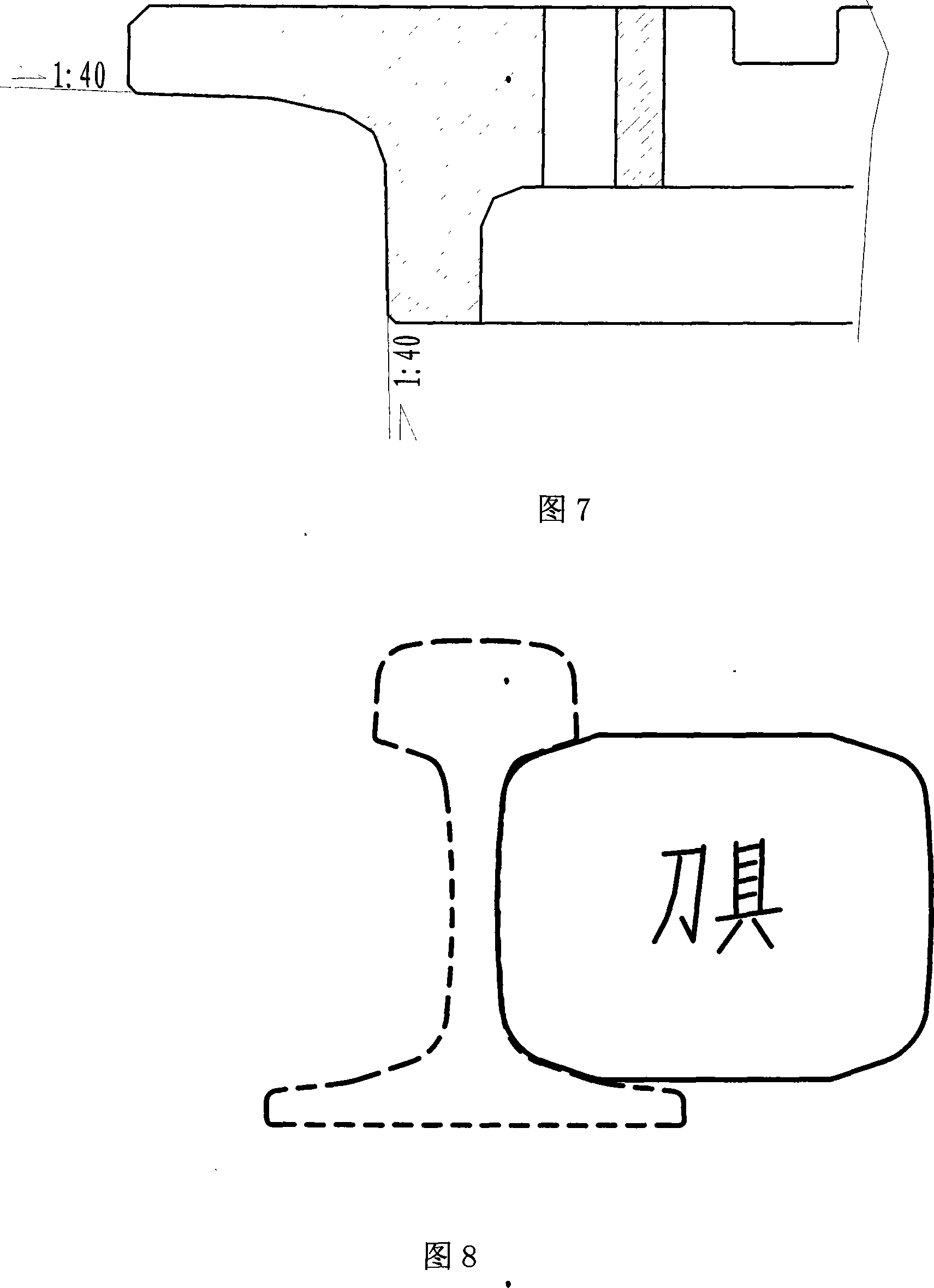

Method for forging and pressing heel of AT steel rail

ActiveCN101912945AHeating to meetMeet the needs of different heating lengthsRailway componentsForging/hammering/pressing machinesRailheadHeating furnace

The invention discloses a method for forging and pressing the heel of an AT steel rail, which comprises the following steps of: 1, heating the AT steel rail to the temperature of between 1,160 and 1,250 DEG C in an electric induction heating furnace; 2, forging and pressing the AT steel rail heated by the step 1 by using a three-station forming die on a press; 3, trimming the AT steel rail in a one-station trimming die cavity on the press to remove flash formed at the head and the bottom of the steel rail in the third step of the step 2; and 4, longitudinally withdrawing the AT steel rail from the one-station trimming die cavity to make the AT steel rail at an upright position that a railhead is upward and a rail base is downward and conveying the AT steel rail to a discharging table. The method can improve the heating quality, forming quality and production efficiency of the heel of the AT steel rail.

Owner:CHINA RAILWAY CONSTR HEAVY IND

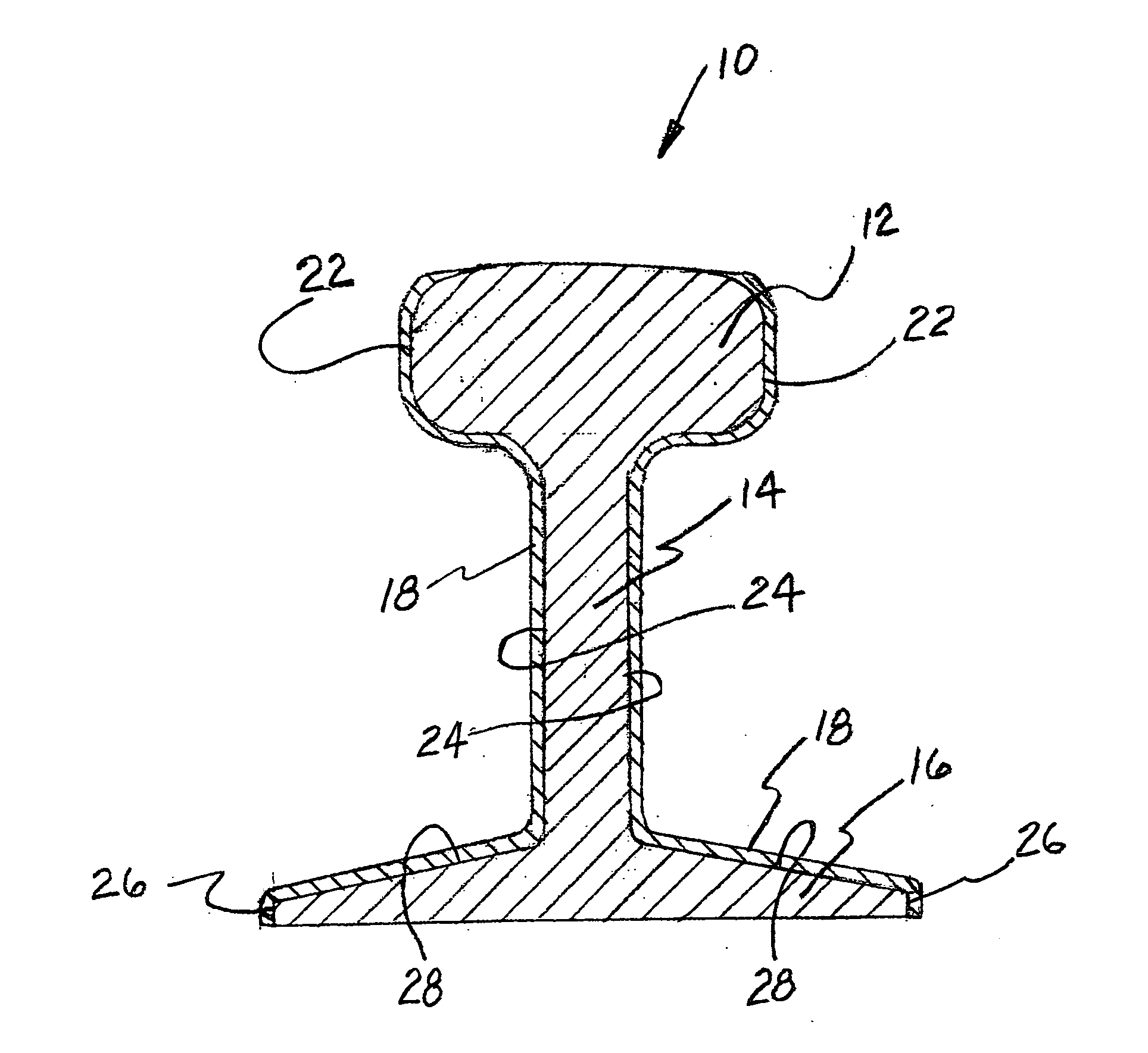

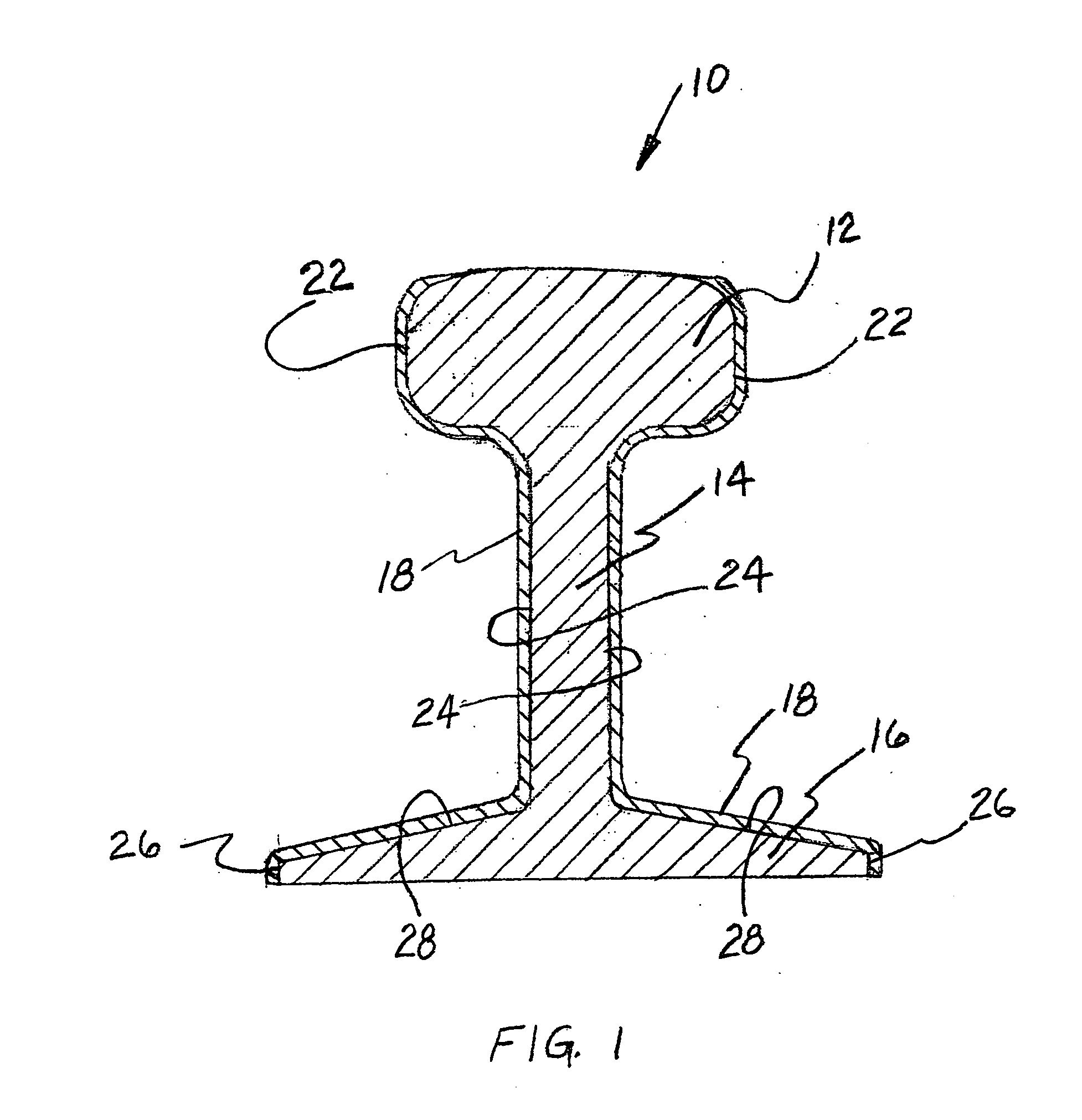

Railroad rail having thermal insulation below the railhead either coated in the field or at the rail production facility

Owner:JONES PAUL

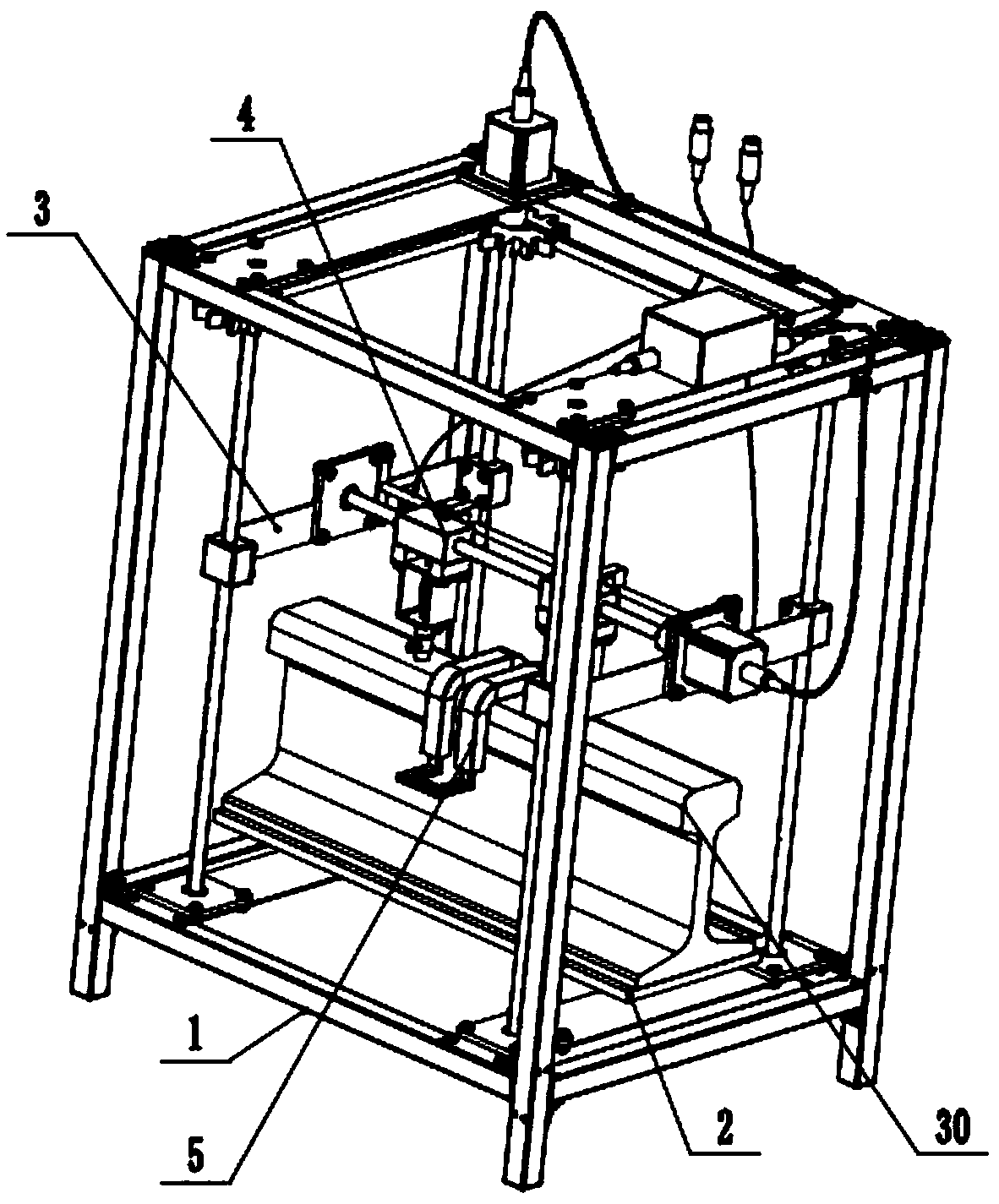

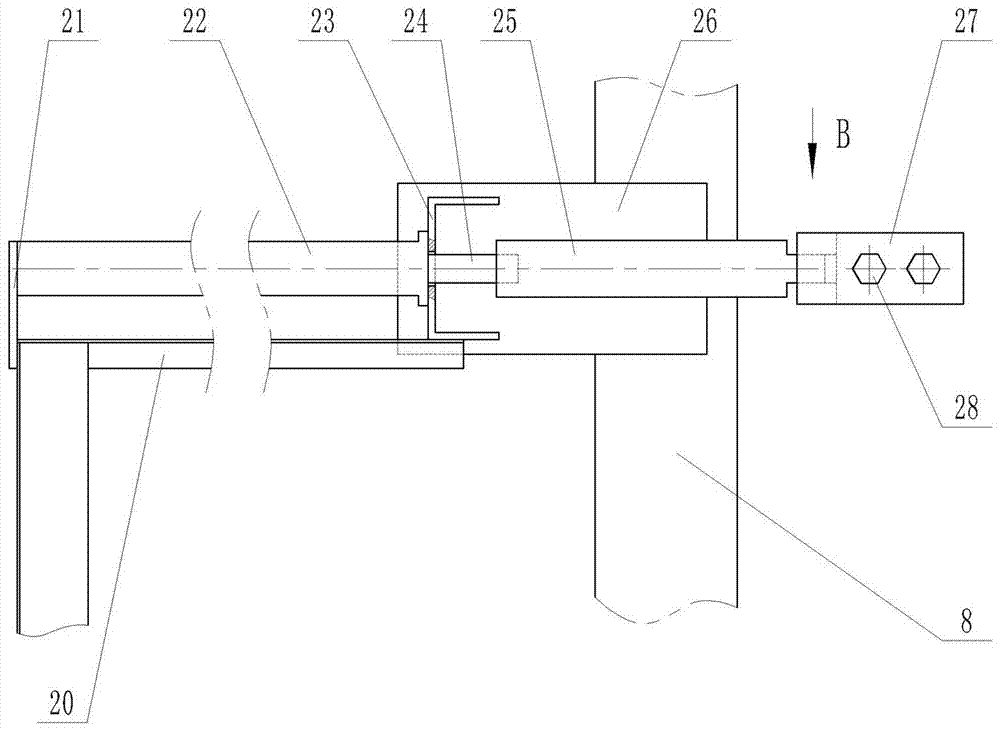

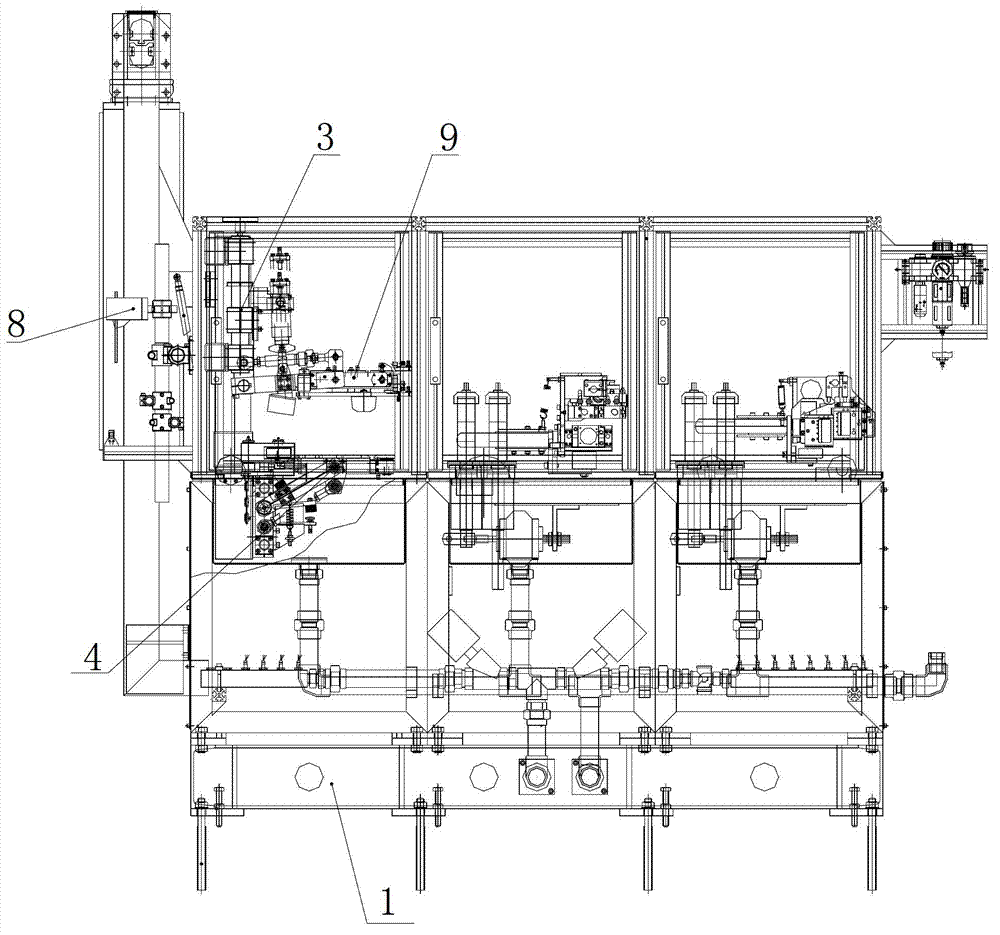

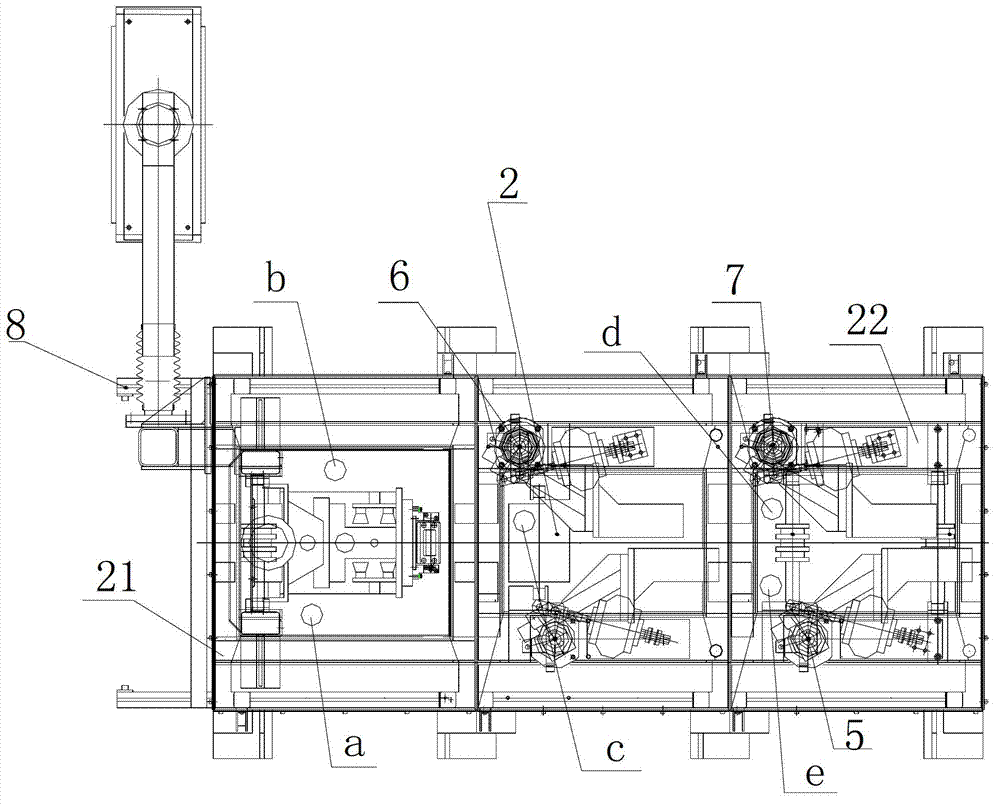

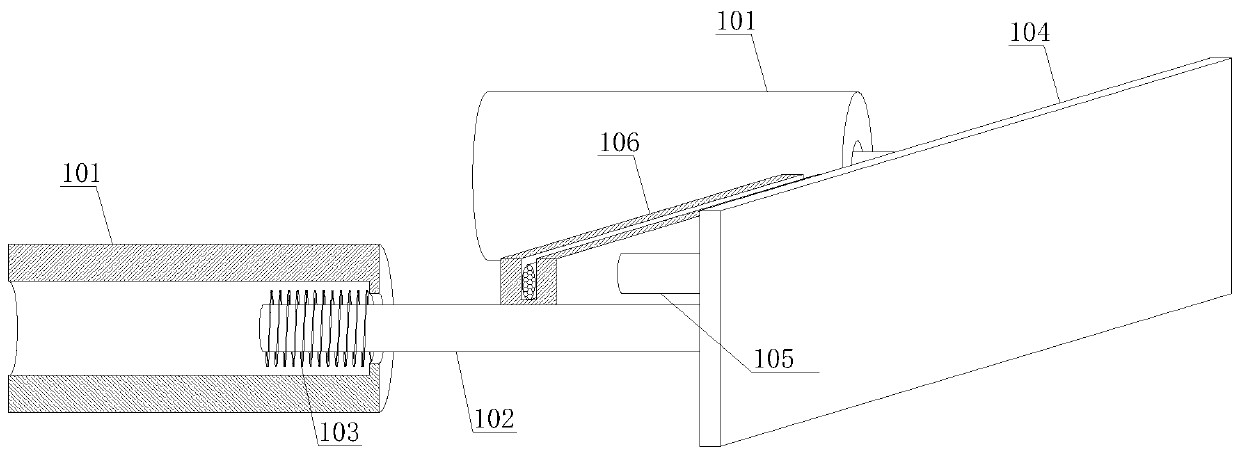

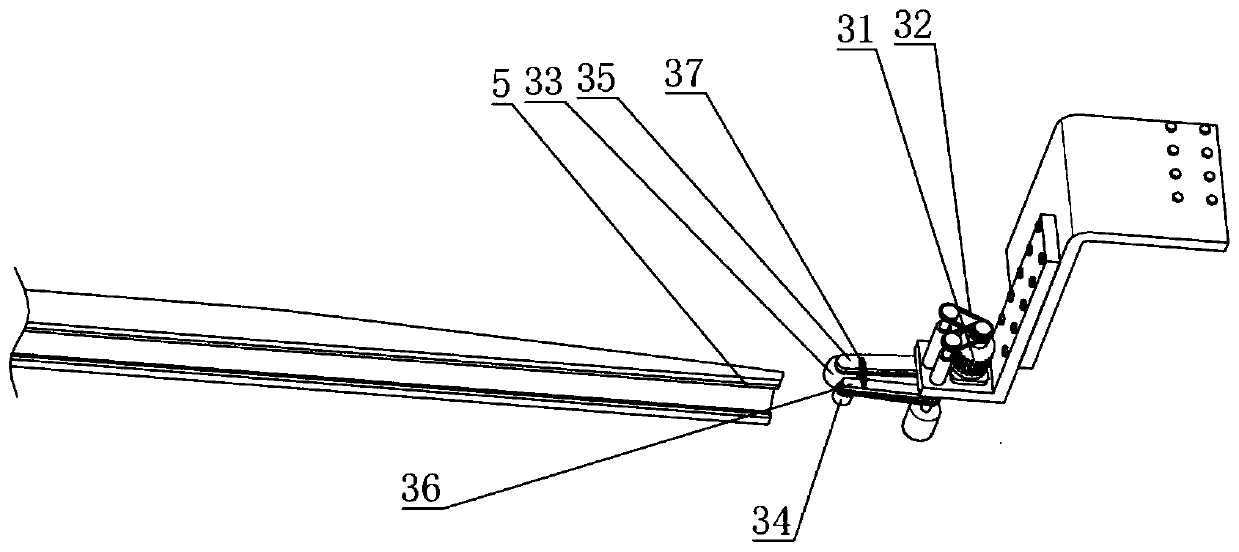

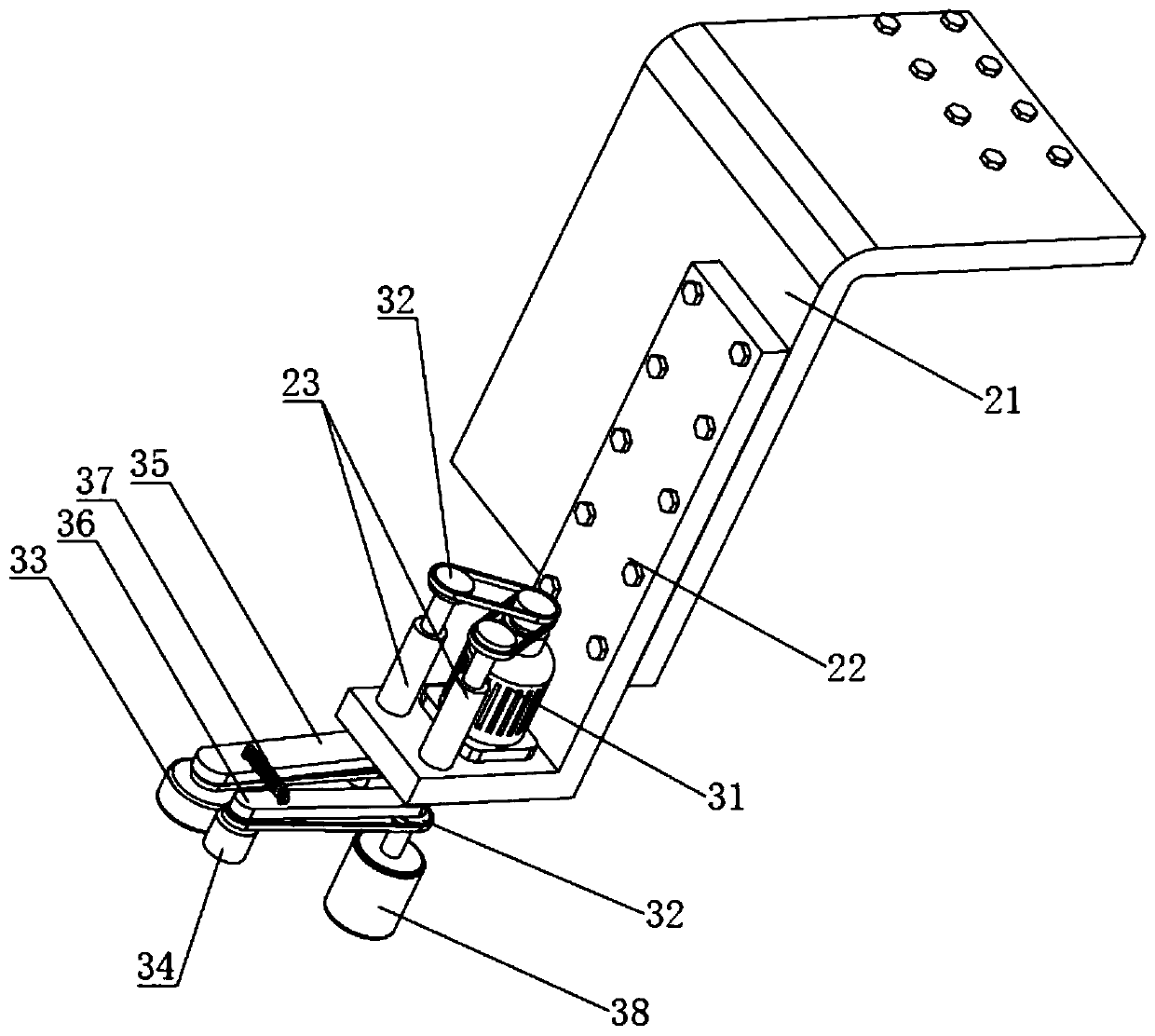

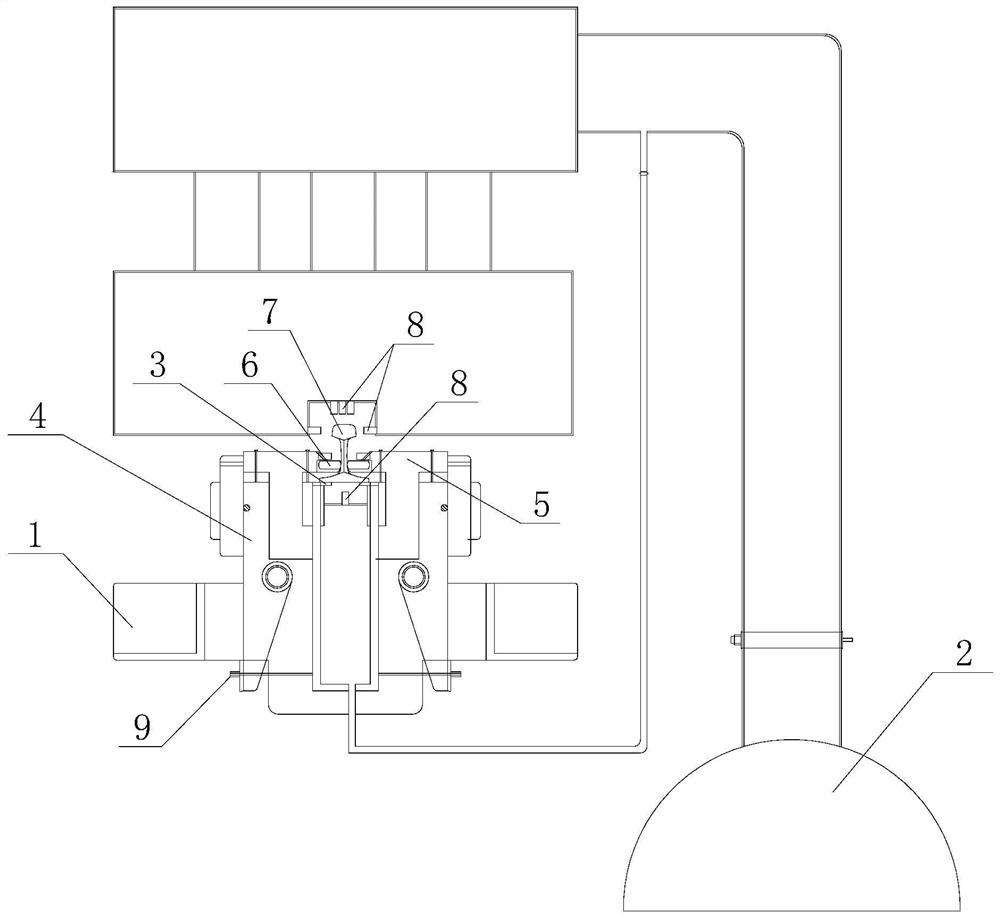

Device and process for pulse-current-assisted online induction heating of steel rail

ActiveCN109234501AImprove quality requirementsIncrease productivityIncreasing energy efficiencyFurnace typesGraphiteTread

The invention discloses a device and a process for pulse-current-assisted online induction heating of a steel rail. According to the process, a pulse-current-assisted online induction heating method is applied to remove residual stress of the steel rail; an induction coil is located on the tread surface and the side surface of a railhead of the steel rail, so that the induction heating area of therailhead of the steel rail can be increased, the flux density per unit area of the railhead can be increased, and the heating efficiency of the railhead of the steel rail per unit time is improved; during induction heating, the temperature of the tread surface of the railhead is higher than the temperature of the side surface of the railhead; the distance between a pulse current applying mechanism and the steel rail is adjusted through a lifting mechanism, the distance between two graphite rods is adjusted, and the graphite rods are abutted against the steel rail; an auxiliary pulse current is applied to the railhead, so that most of the pulse current can be concentrated on the side face of the railhead, and a reinforcement layer of the railhead is specifically improved. By the device forpulse-current-assisted online induction heating of the steel rail provided by the invention, the quality requirements for and the production efficiency in heat treatment of the steel rail are improved, and the environmental pollution caused by heat treatment of the steel rail is avoided at the same time.

Owner:太仓吉井机械有限公司

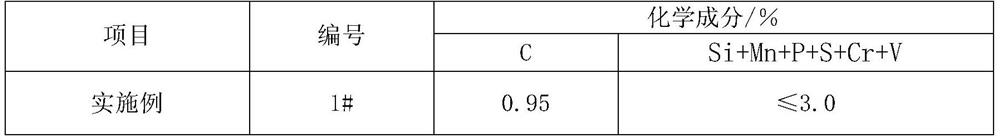

Heat treatment production method of steel rail for mixed passenger and freight traffic railway and obtained steel rail

The invention relates to the field of steel making, in particular to a heat treatment production method of a steel rail for a mixed passenger and freight traffic railway and the steel rail obtained by the method. The method includes the steps that the railhead tread center, the two sides of a railhead and the rail base center of the steel rail obtained after rolling are sequentially subjected to accelerated cooling, slow cooling and air cooling; the starting cooling temperature of accelerated cooling is 650-950 DEG C, the cooling speed is 2.5-7 DEG C / s, and the final cooling temperature is 400-600 DEG C; the cooling speed of slow cooling is 0.1-1.5 DEG C / s, and the final cooling temperature is 180-300 DEG C. The steel rail comprises, by weight, 0.71%-0.82% of C, 0.13%-0.60% of Si, 0.65%-1.25% of Mn, 0.05%-0.25% of Cr, 0-0.1% of Al, 0-0.025% of P, 0-0.025% of S and 97.01%-98.46% of Fe. By the adoption of the method, hardness of the steel rail can be controlled within the appropriate range of 350-380 suitable for the mixed passenger and freight traffic railway under the premise of guaranteeing the tensile property of the steel rail.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

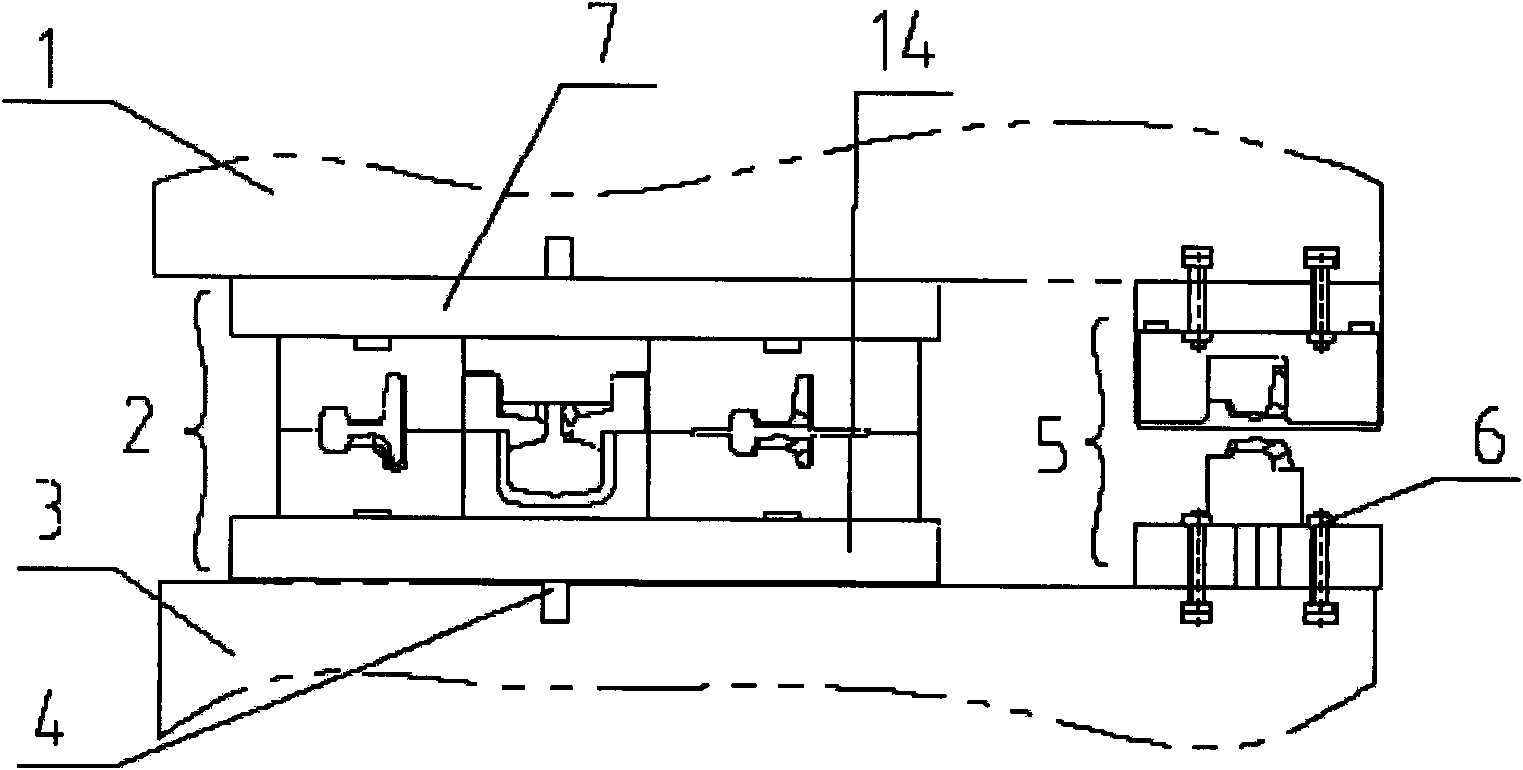

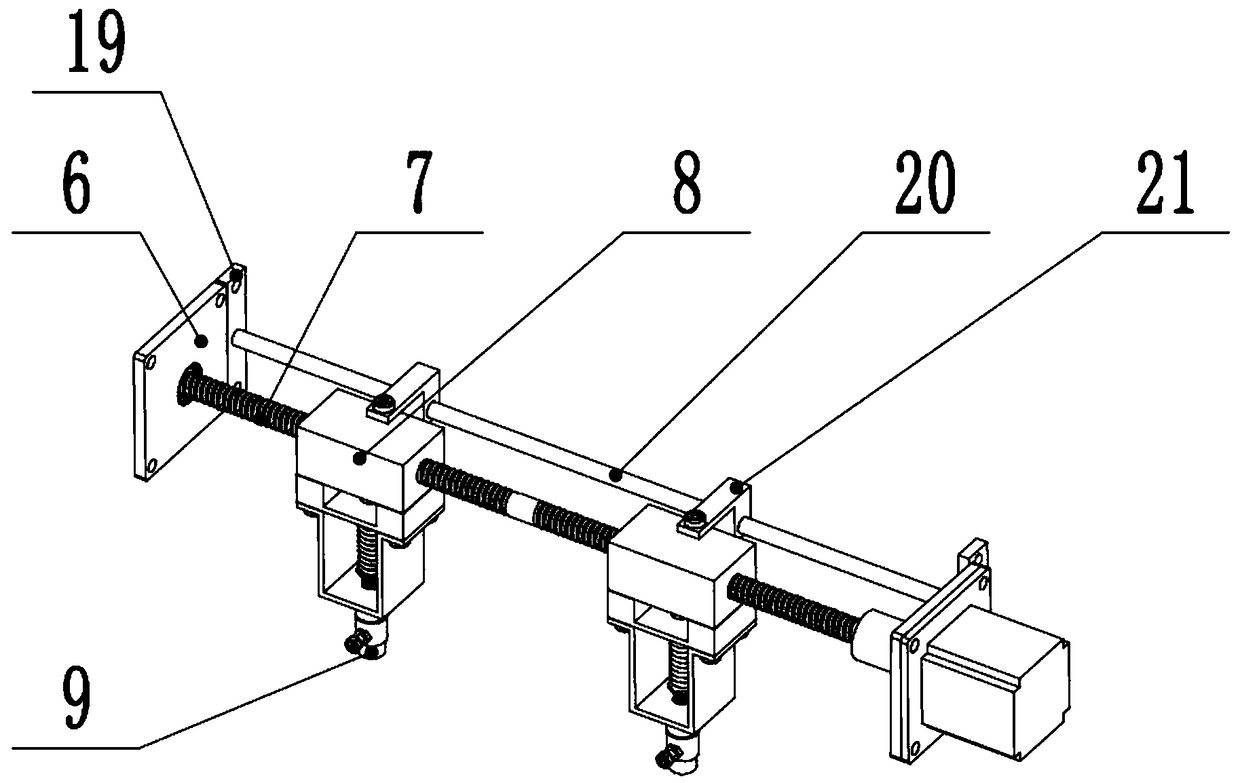

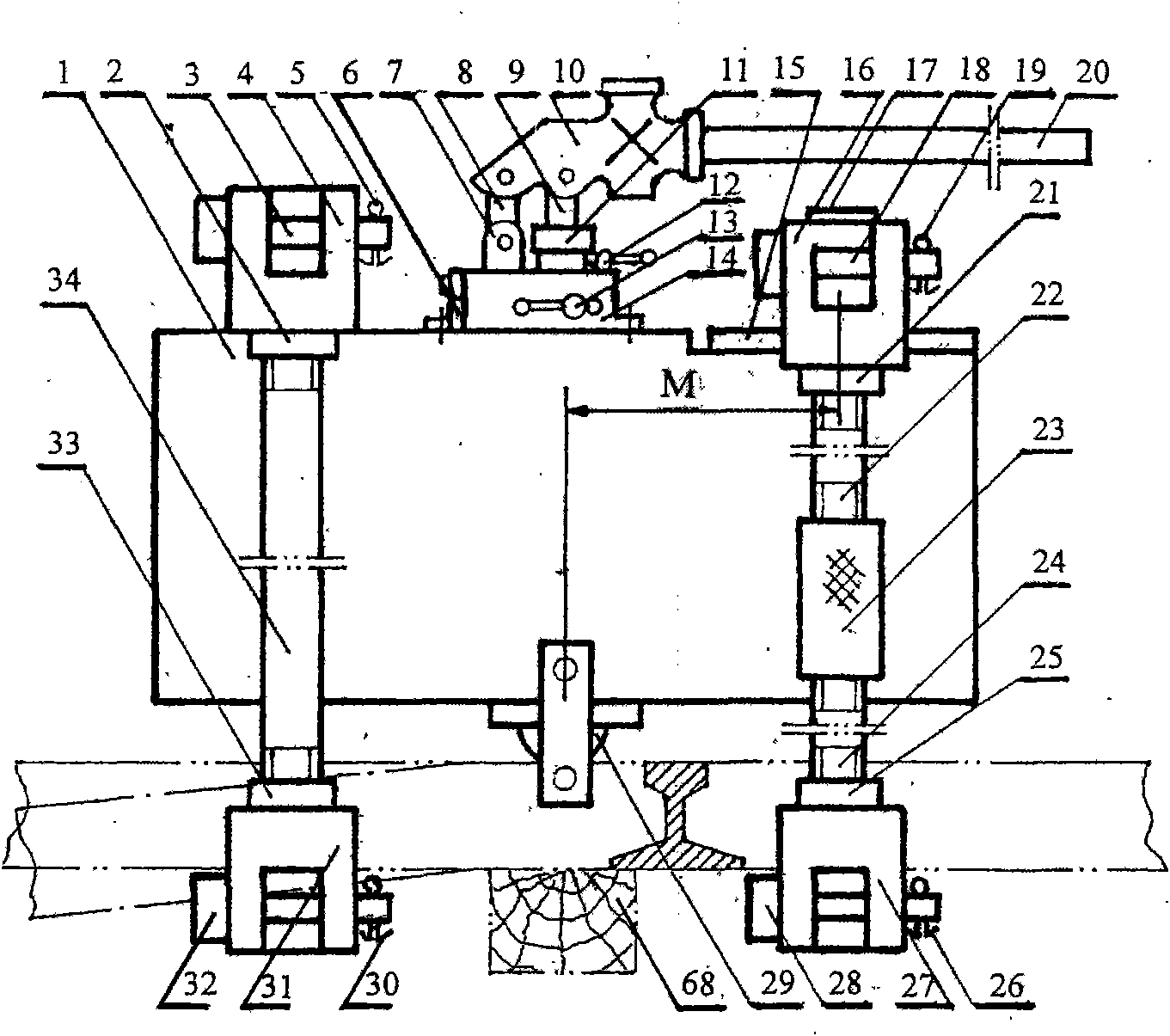

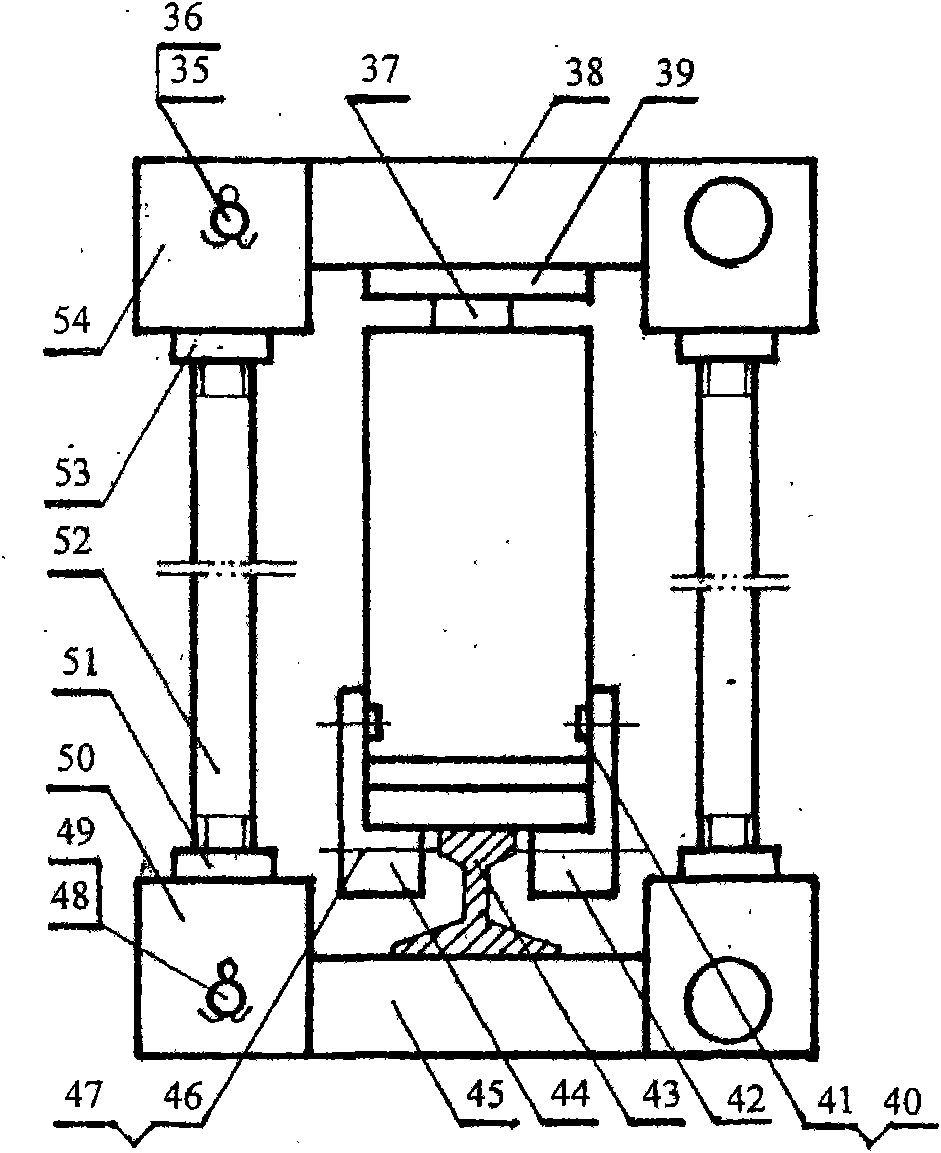

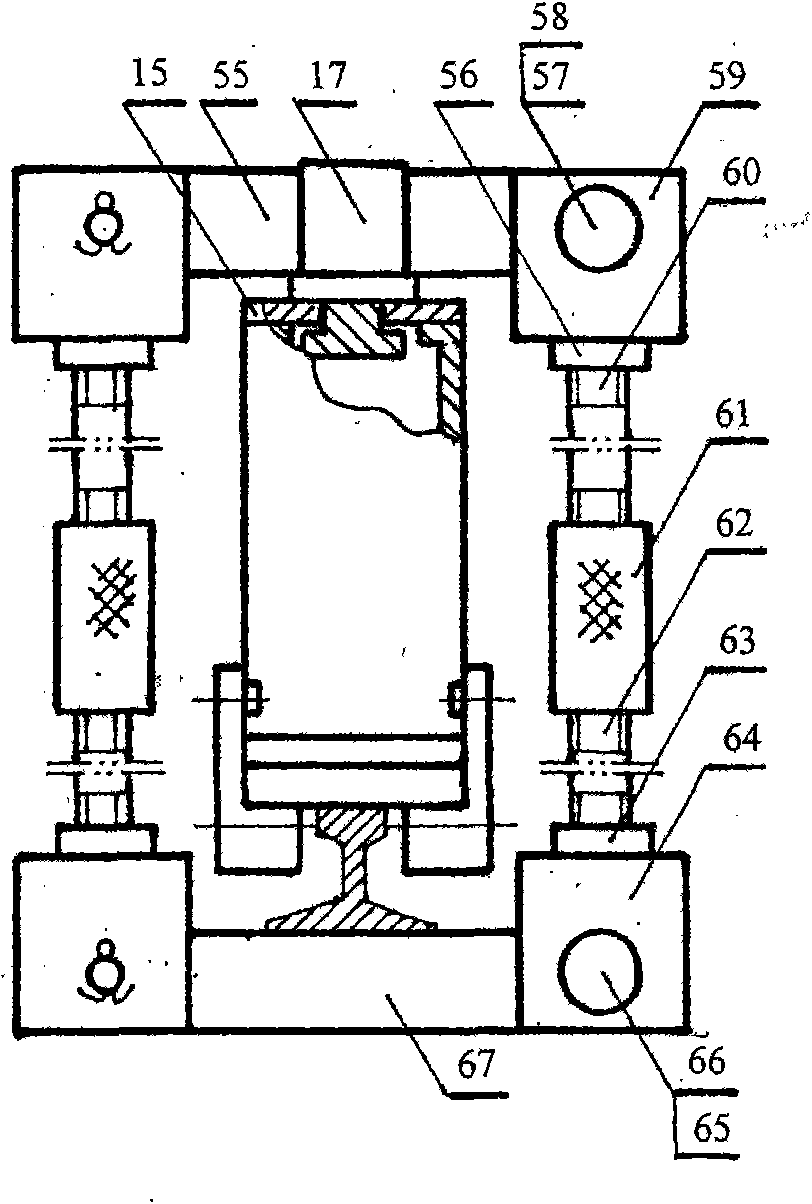

Method foe straightening pendulous railhead on site and hydraulic pressure railhead straightener thereof

The invention discloses a method for straightening pendulous railhead on site. In the method, the rails are not dismantled, torque support M can be adjusted, and the methods of artificial force application on leverage and hydraulic transmission are used. The invention also discloses a hydraulic pressure railhead straightener, which mainly comprises a body 1, a hydraulic pressure plunger pump, a hydraulic oil pump, a main clamp frame component, an assistant clamp frame component, a jack support component 29, a following position shield component 17 and a leverage force application mechanism. The invention is applicable to straightening pendulous railhead in mine, and is also applicable to other fields. The hydraulic pressure railhead straightener is one of indispensable instruments in orbit standardization safety operation in mine, which is safe, labor-saving, effective and portable when operation is carried out on site.

Owner:李保国

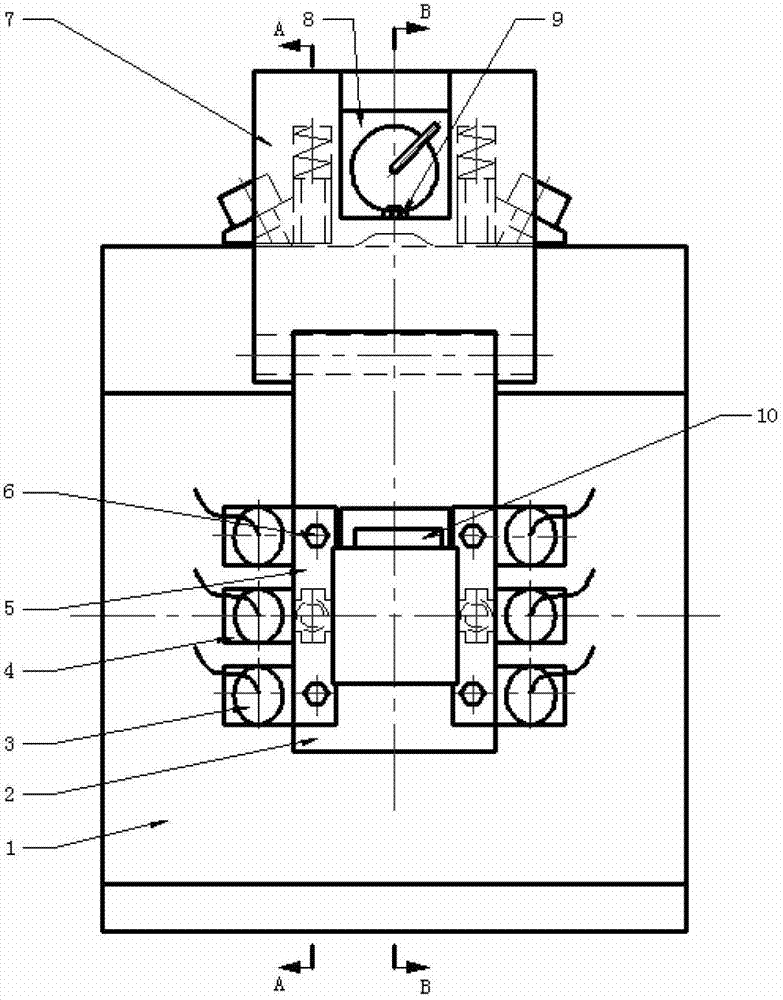

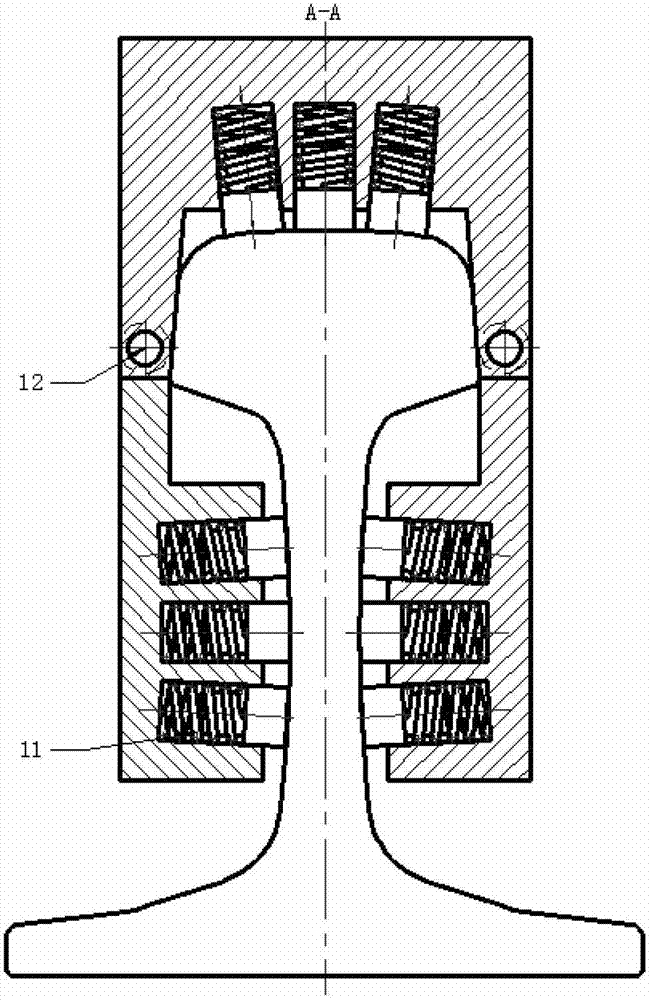

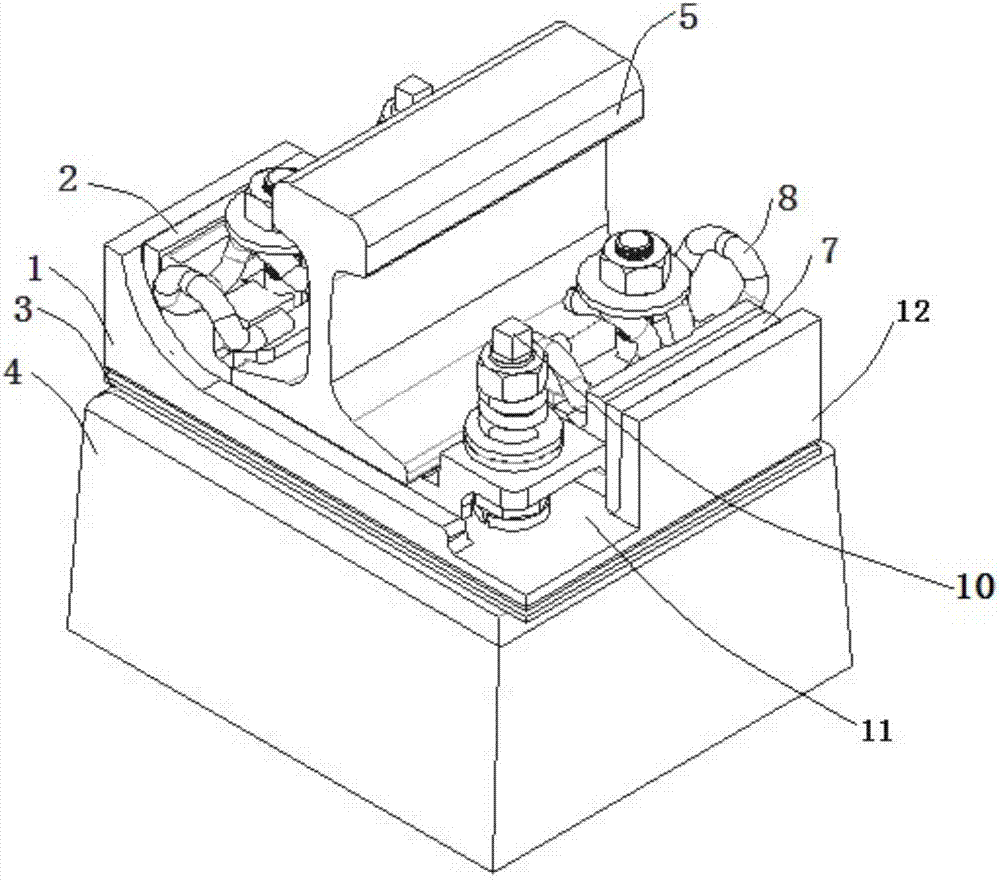

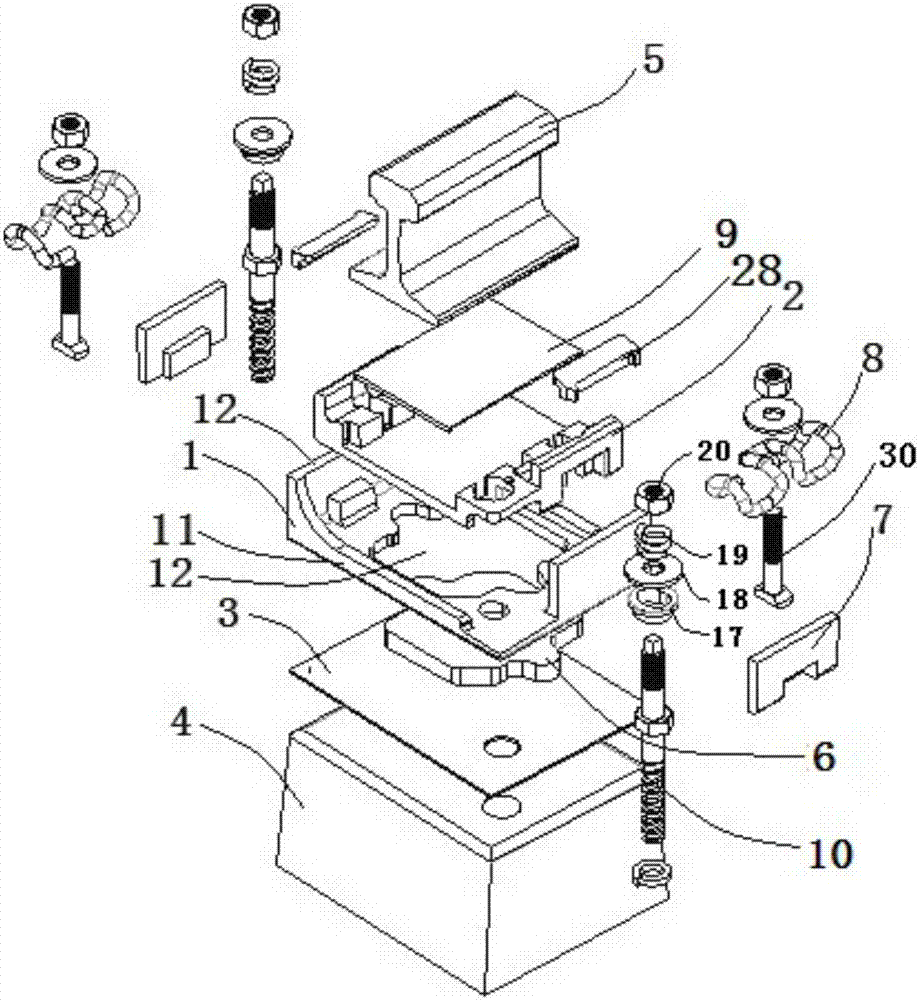

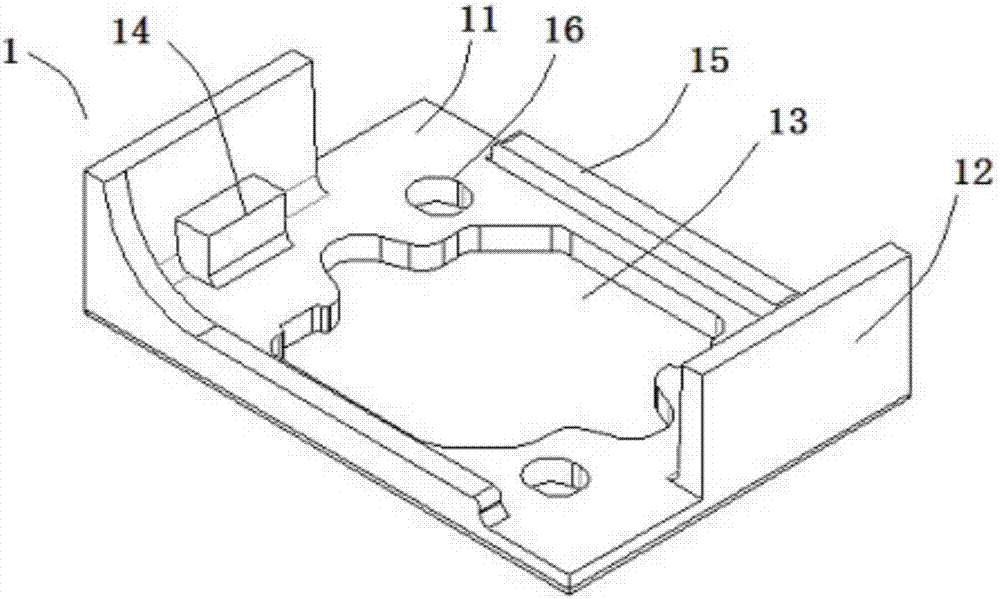

Simple clamping device for ultrasonic inspection of residual stress of steel rail

The invention relates to a simple clamping device for ultrasonic inspection of the residual stress of a steel rail. Mainly aiming at the problem that stress measurement of a railhead and a rail web cannot be simultaneously carried out in the traditional nondestructive inspection process of the residual stress of the steel rail, the invention provides a simple clamping device for measuring the residual stress of a steel rail, which is capable of automatically compensating the abrasion of organic glass wedge blocks and making up the thickness inconsistence of a coupling layer caused by the unsmooth surface of the steel rail by means of the elasticity of a spring and has a magnetic self-absorption function. The device is convenient to use, simple in operation and adjustable in magnetic absorption force and the elasticity of the spring so as to meet the testing requirements for locating, pre-tightening and accurately measuring the surfaces of steel rails with different specifications under different use conditions. The simple clamping device is simple in structure, replaceable in all parts, suitable for experiments for inspection of residual stresses of various steel rails and capable of being popularized to the experimental inspection activity of the residual stress of various rolled section steel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

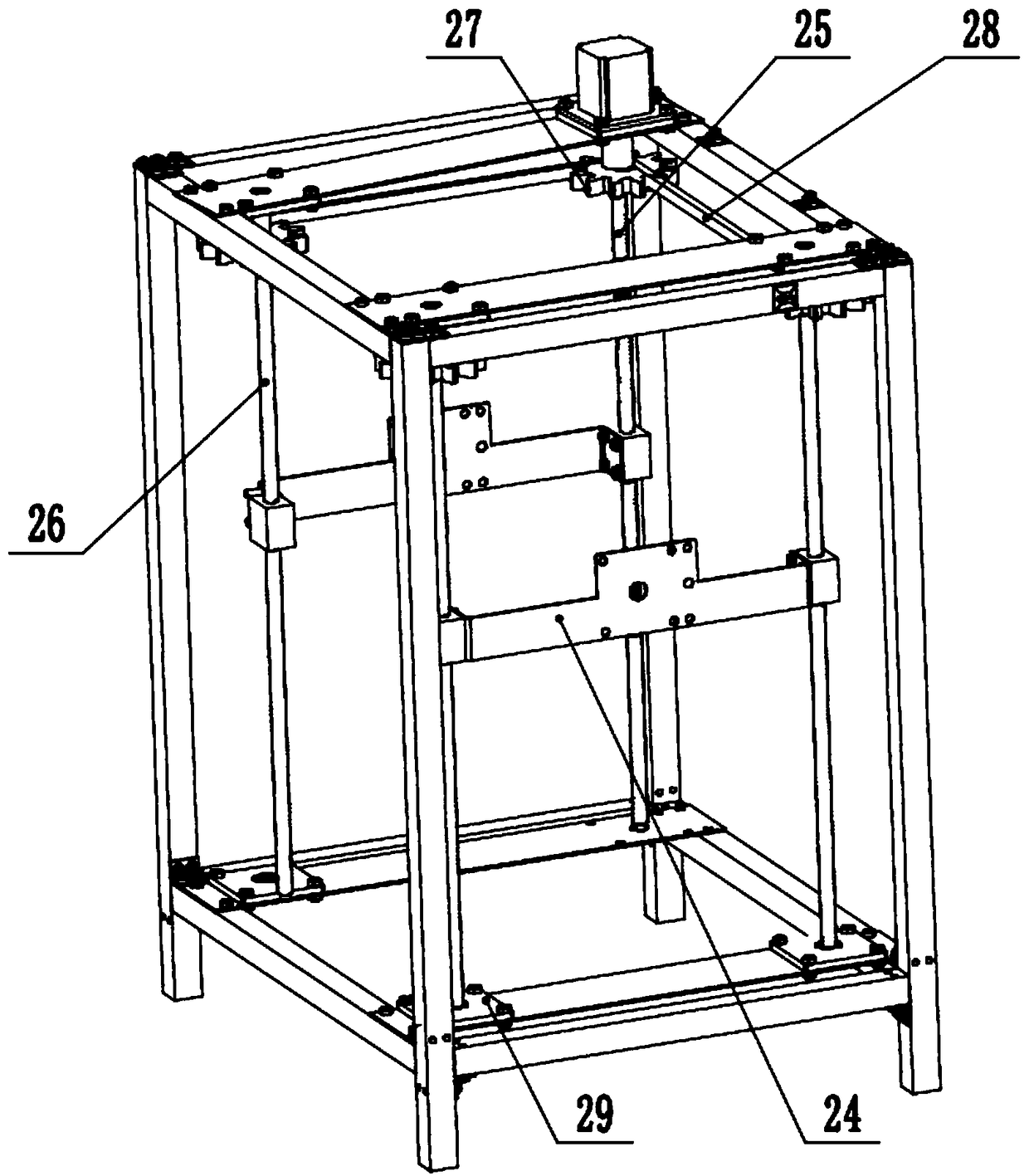

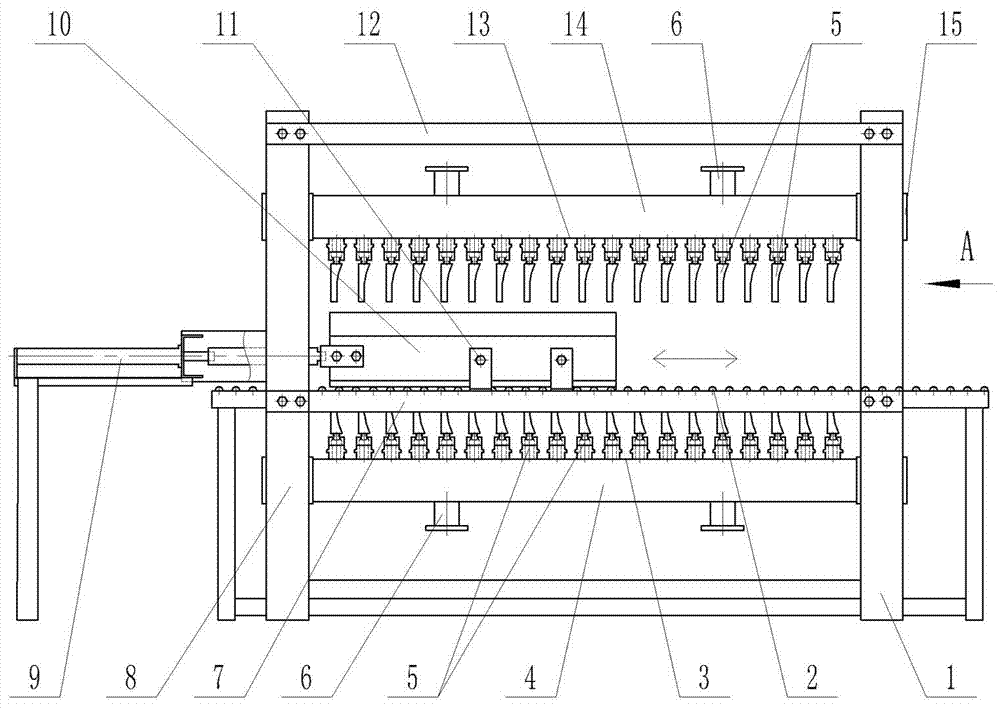

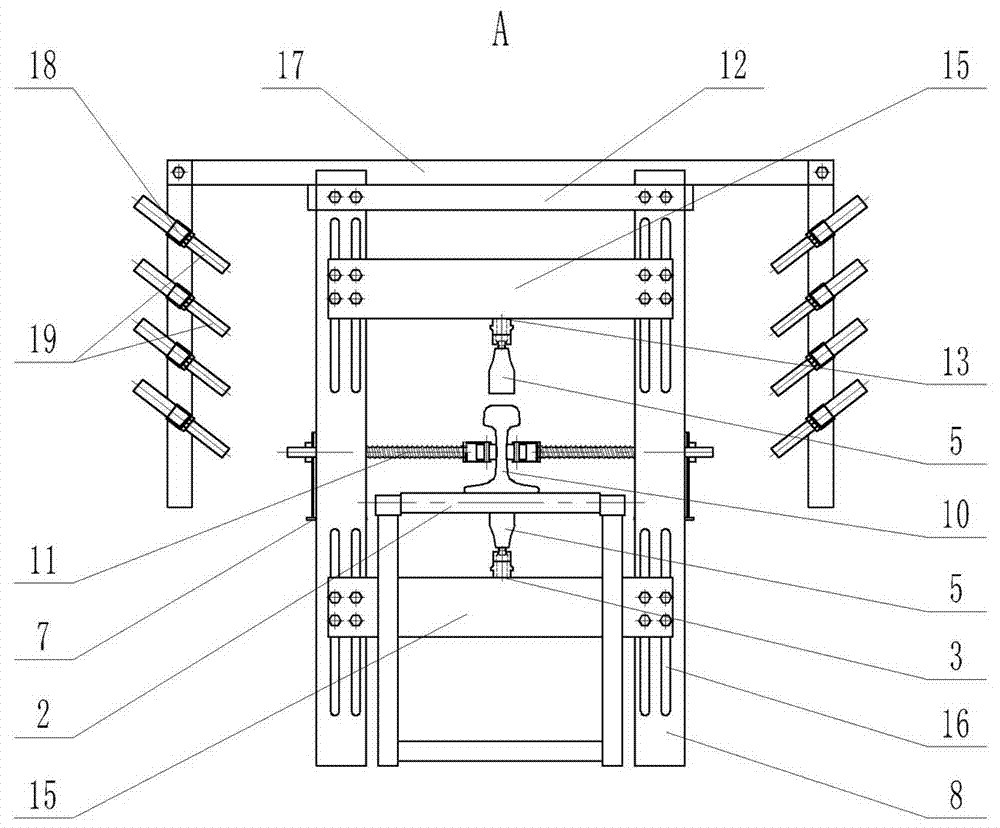

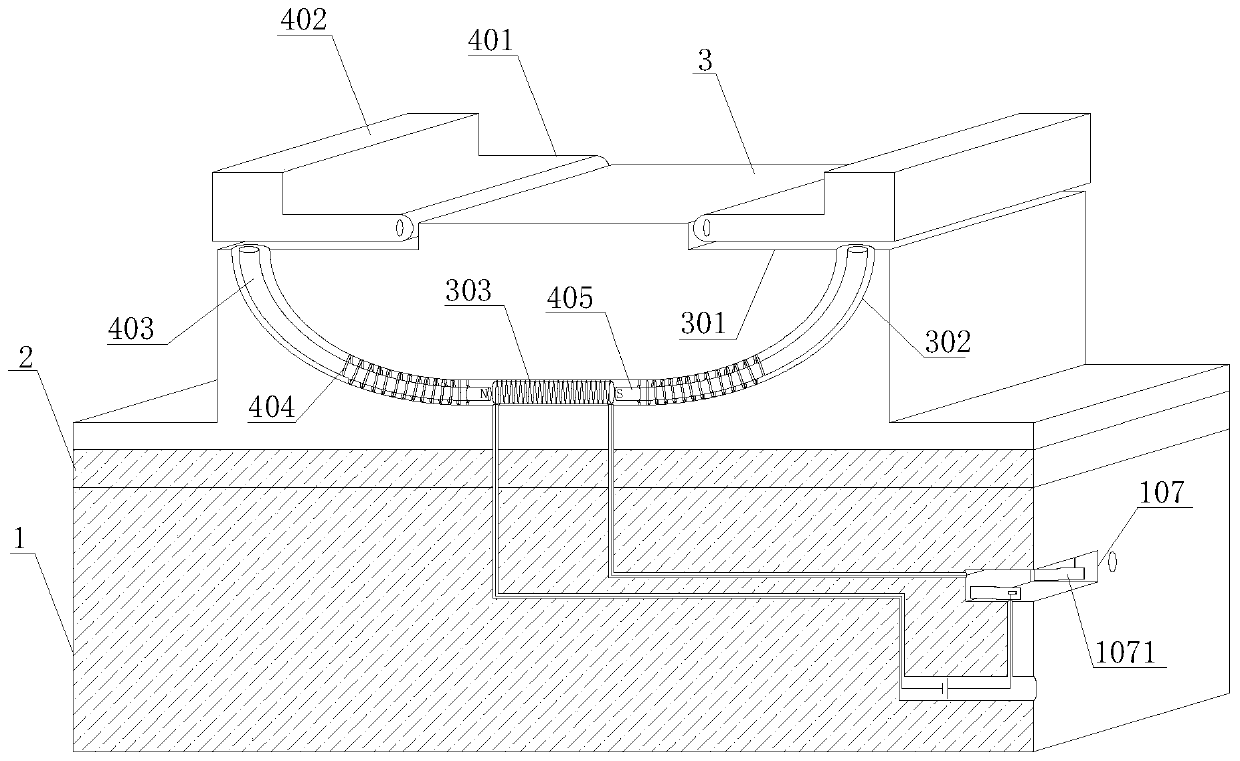

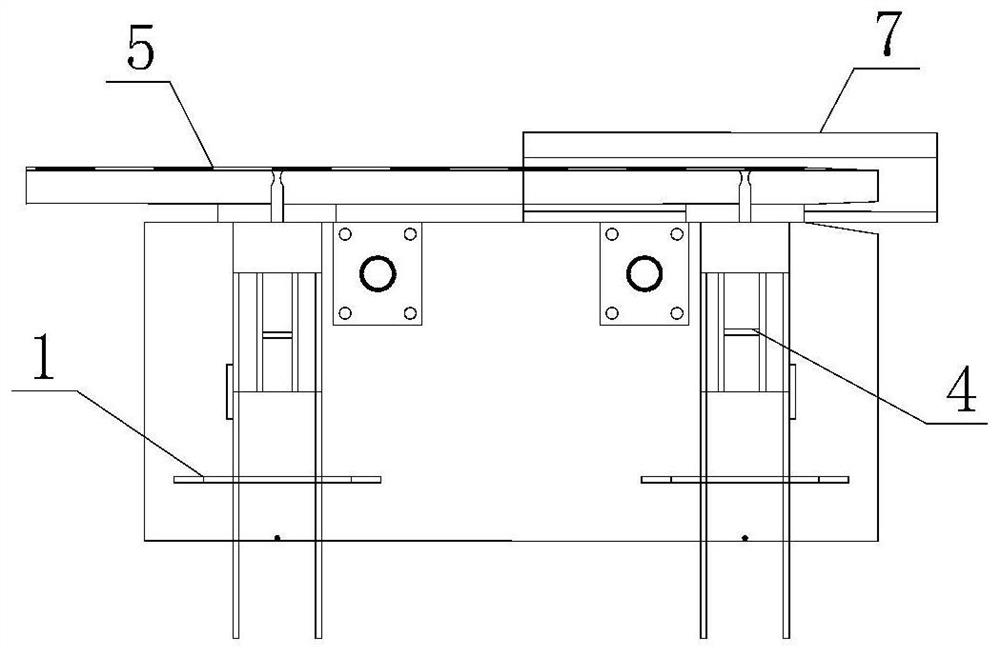

Steel rail integral air blast quenching experimental device

ActiveCN107400764AReduce deformation stressReduce residual stressFurnace typesHeat treatment furnacesBraced frameRailhead

The invention relates to a steel rail integral air blast quenching experimental device, and can solve the problems that air blast quenching can only be applied to railheads, bending deformation and residual stress are likely to occur to steel rails and experimental data have poor accuracy in the prior art. The experimental device comprises a support frame, and is characterized in that the support frame is internally provided with a transmission roller, an upper air cooling apparatus is arranged above the transmission roller, a lower air cooling apparatus is arranged below the transmission roller, and both the upper air cooling apparatus and the lower air cooling apparatus are equipped with several groups of air blast components. The upper air cooling apparatus and the lower air cooling apparatus are in flexible connection with stand columns at two ends of the support frame respectively through connection end plates at both ends. One end of the transmission roller is equipped with a steel rail reciprocating motion mechanism, and two steel rail guide mechanisms are disposed opposite to each other at two sides above the transmission roller. The experimental device provided by the invention has the characteristics of reasonable design and compact structure, can perform air blast cooling to the railhead and rail bottom of a quenched steel rail, the air blast angle and pressure are adjustable, the experimental process approaches to actual production, and the research result is accurate.

Owner:UNIV OF SCI & TECH LIAONING

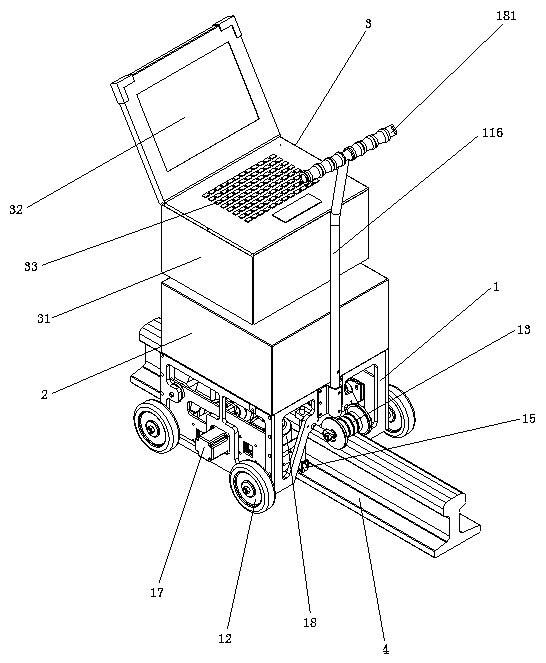

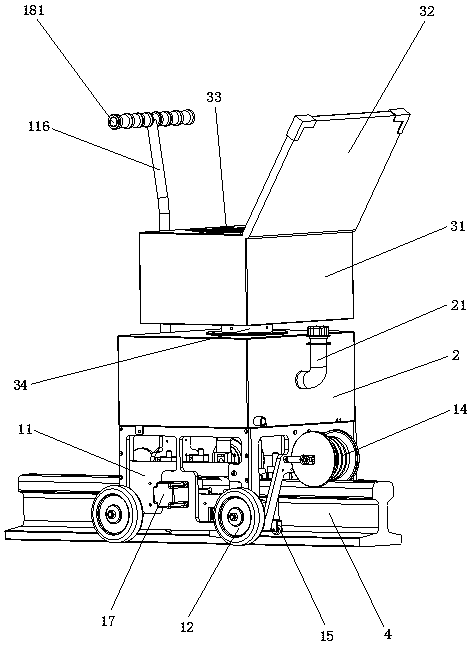

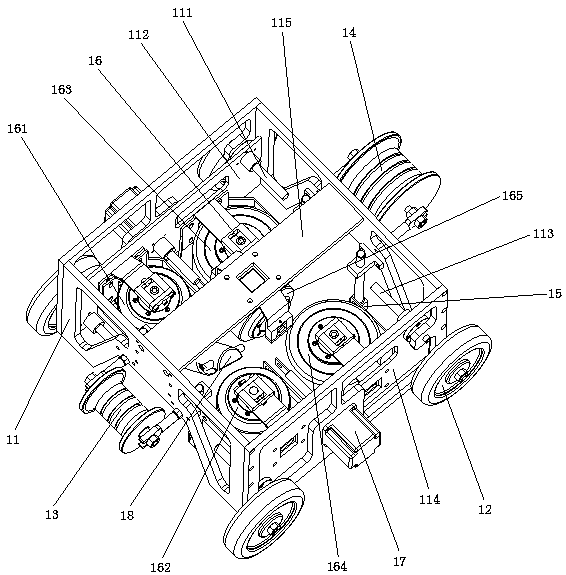

Steel rail ultrasonic flaw detection vehicle

PendingCN110412137ASolving Surface Coupling IssuesGood for finding rolling defectsMaterial analysis using sonic/ultrasonic/infrasonic wavesRailheadCoupling

The invention relates to a steel rail ultrasonic flaw detection vehicle. The steel rail ultrasonic flaw detection vehicle comprises a flaw detection mechanism, a water tank and an industrial control host; the flaw detection mechanism comprises a detection frame, wheel type probes, a wheel type probe stepping motor and a coupling agent spray pump; the detection frame is provided with land walking wheels and a pre-mounted encoder guide wheel; the portions, corresponding to the two sides of the railhead, two sides of the rail web and the rail top, of the detection frame are provided with the wheel type probes respectively, and each wheel type probe is provided with a coupling agent spray head; the coupling agent spray heads are connected with the coupling agent spray pump through pipelines, and a spray coupling agent is sprayed onto the surface of a steel rail under the compression of the coupling agent spray pump; the detection frame is also provided with a spray switch of the spray heads; the water tank is fixed to the upper portion of the detection frame, and one side of the water tank is provided with a water injection port used for adding a flaw detection coupling agent. The steel rail ultrasonic flaw detection vehicle has the advantages that the use is convenient, finding of the rolling defect of the steel rail is facilitated, the defects in the manufacturing process of thesteel rail can be comprehensively and effectively detected, and the detection accuracy and efficiency can be effectively improved while the labor intensity is reduced.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

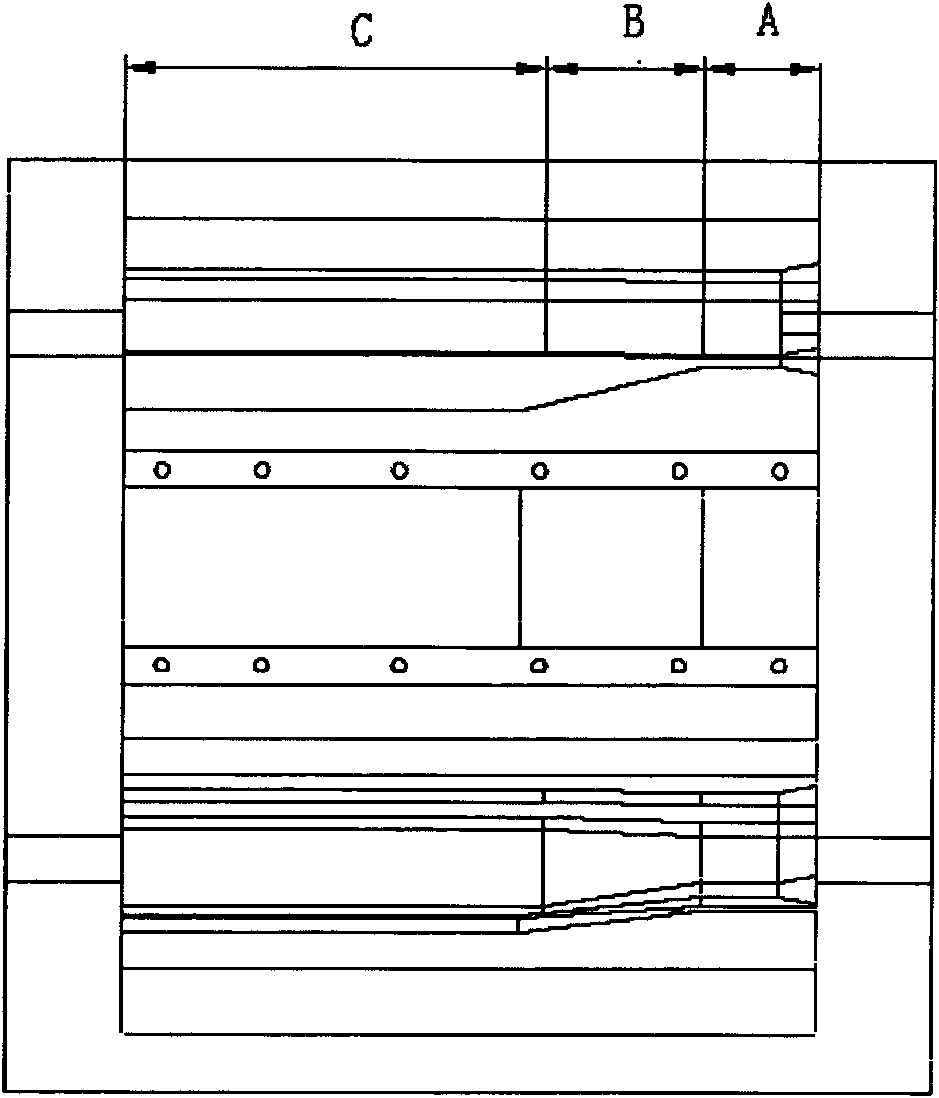

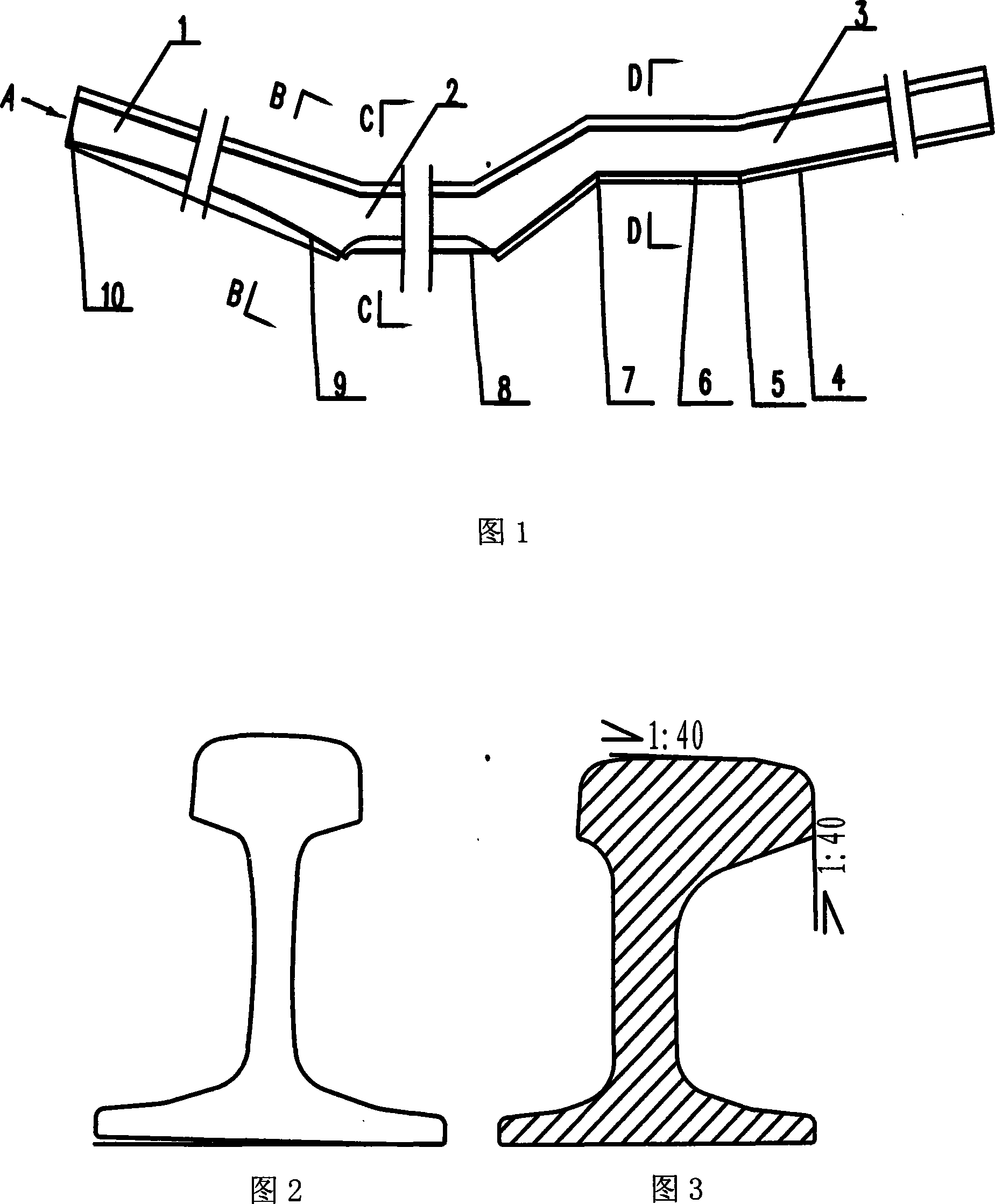

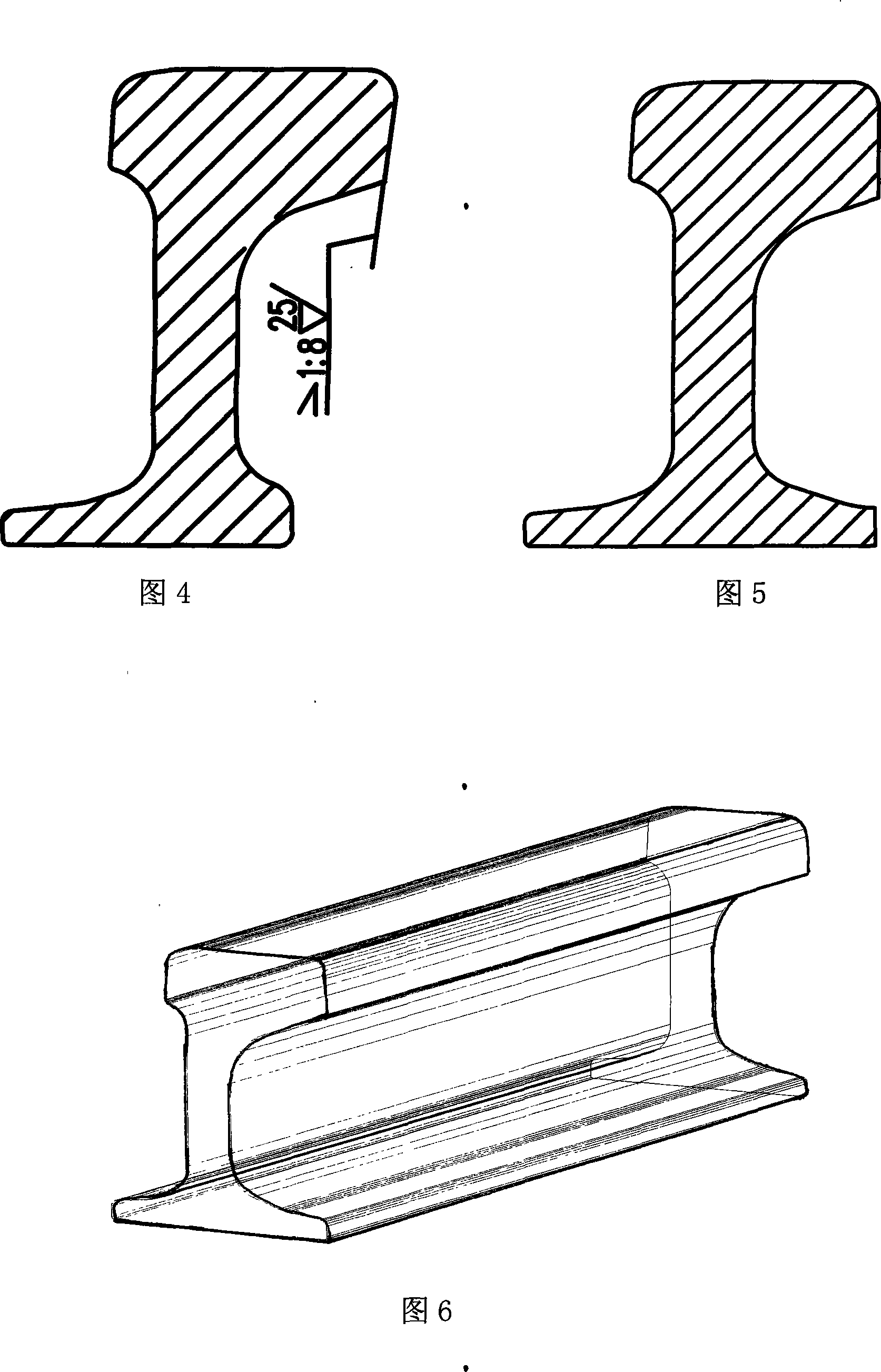

Production line of special section wing rail and manufacturing method thereof

ActiveCN101642773AProduct quality is stableMeet construction needsGuiding/positioning/aligning arrangementsRoll mill control devicesManufacturing engineeringProduction line

The invention discloses a production line of special section wing rail and a manufacturing method thereof. The production line comprises a cogging mill and a universal machine set, and is characterized in that the cogging mill comprises an asymmetrical caliber which leads a working edge of a railhead of the special section wing rail is arranged toward the direction below a rolling line, support platforms are mounted on an upper guide and a lower guide at an outlet side of a second edger and a universal finishing mill of the universal machine set to control tapping torque. By adopting the invention, the problems such as reversing, bending and the like caused by uneven deformation due to the asymmetrical section of the special section wing rail can be effectively controlled, and the specialsection wing rail with a 75m length can be manufactured, which has stable product quality and can satisfy the requirement of high-speed railway construction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

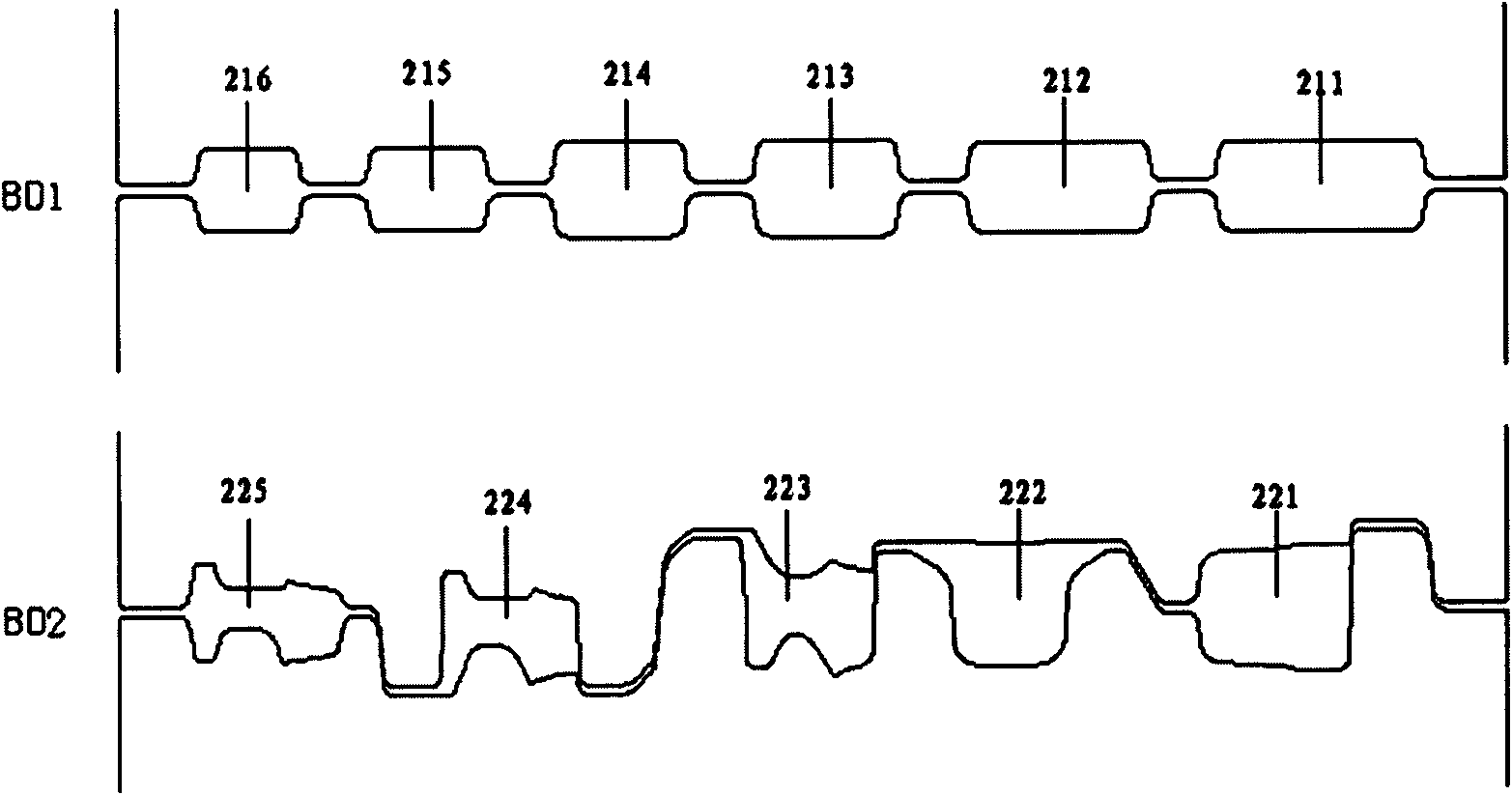

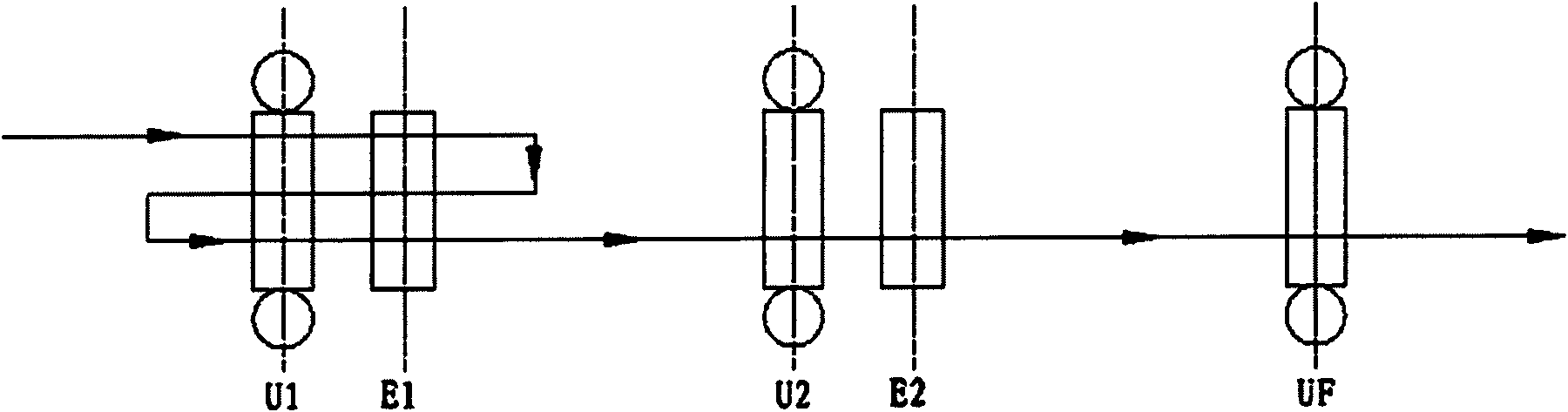

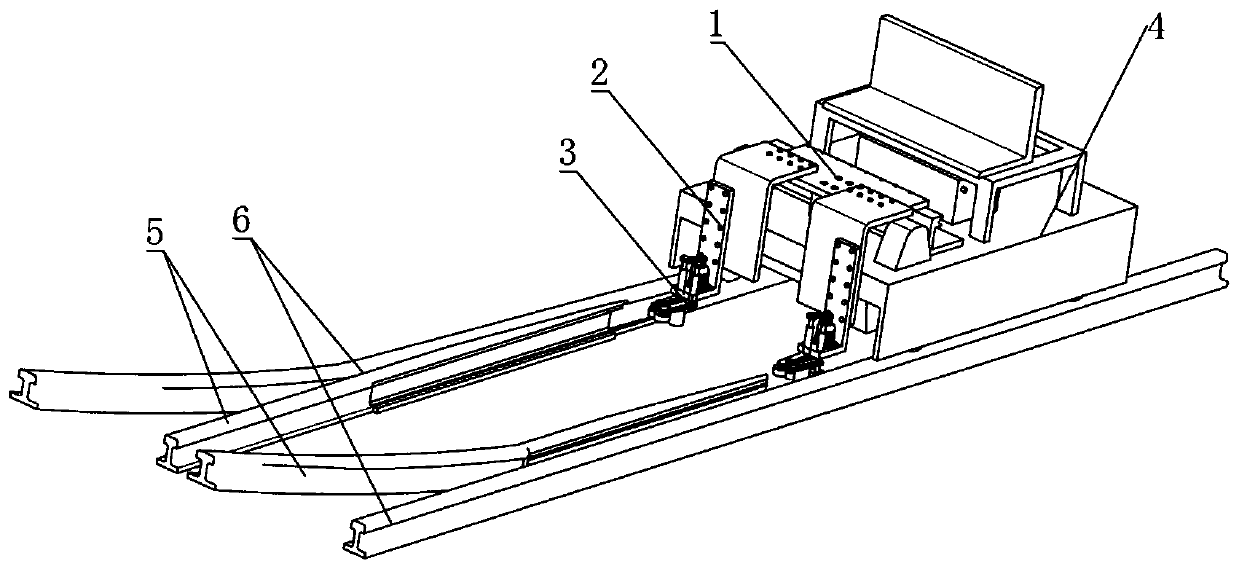

Steel rail ultrasonic on-line detection system and control method thereof

ActiveCN102818848AWide detection rangeMultiple track typesAnalysing solids using sonic/ultrasonic/infrasonic wavesRailheadEngineering

The invention provides a steel rail ultrasonic on-line detection system and a control method thereof. The steel rail ultrasonic on-line detection system comprises a support, a roller way, a railhead tread undercarriage, a rail base undercarriage, a railhead right undercarriage, a railhead left undercarriage, a rail web left undercarriage, ultrasonic probes, a photoelectric correlated cell I, a photoelectric correlated cell II, a photoelectric correlated cell III, a photoelectric correlated cell IV, a steel rail position detection device, a steel rail shape detection device, a controller and an ultrasonic tester. When the photoelectric correlated cells induct a steel rail, the controller controls the corresponding undercarriage to lift or drop so that the ultrasonic probe on the corresponding undercarriage is driven to act and thus flaw detection on all parts of the steel rail is realized. When an internal defect of a steel rail is found, the steel rail position detection device outputs a specific position of the internal defect of the steel rail and flaw detection is stopped. The steel rail ultrasonic on-line detection system has the advantages of wide detection range, fast detection rate and high detection precision.

Owner:四川曜诚无损检测技术有限公司

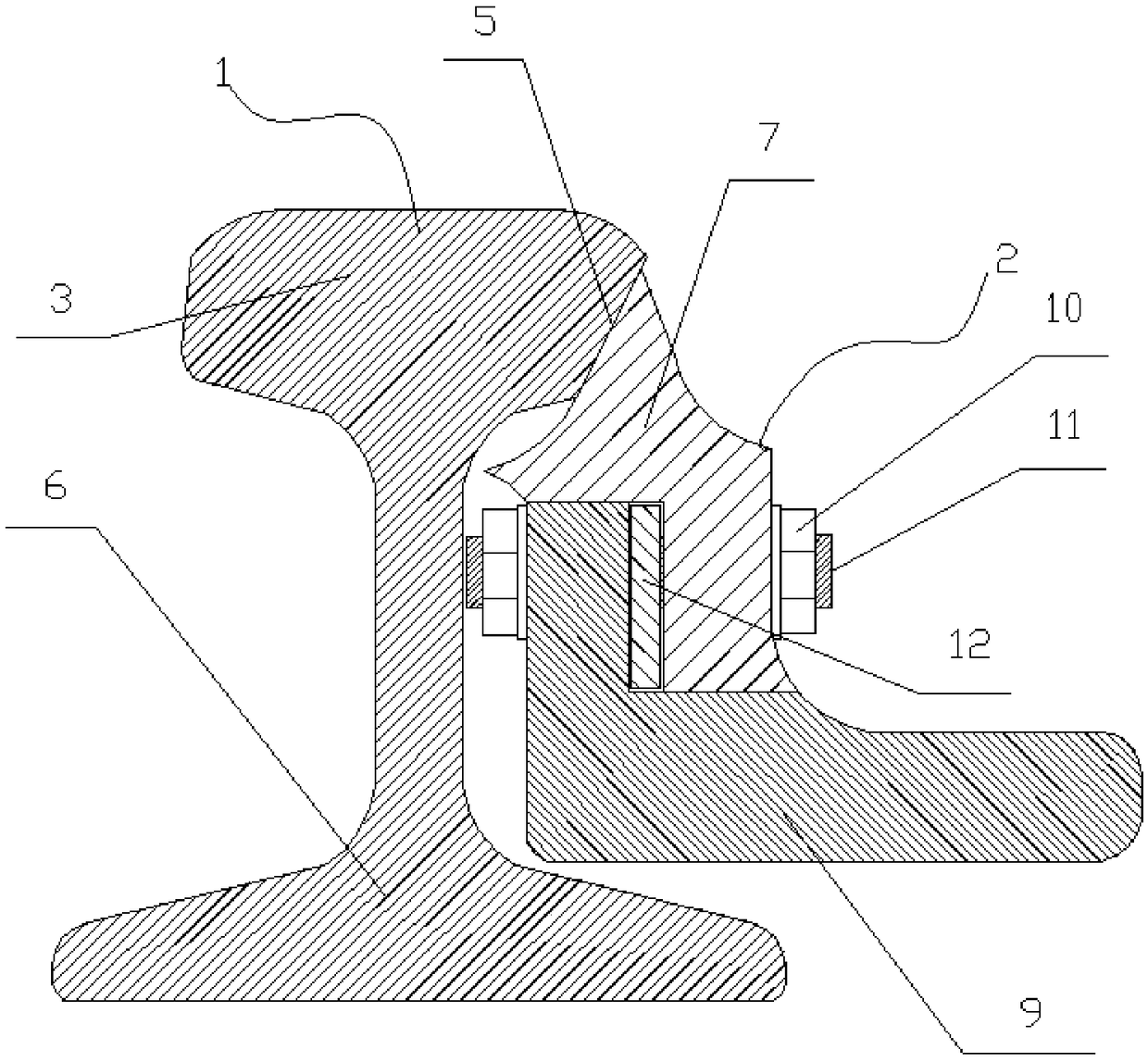

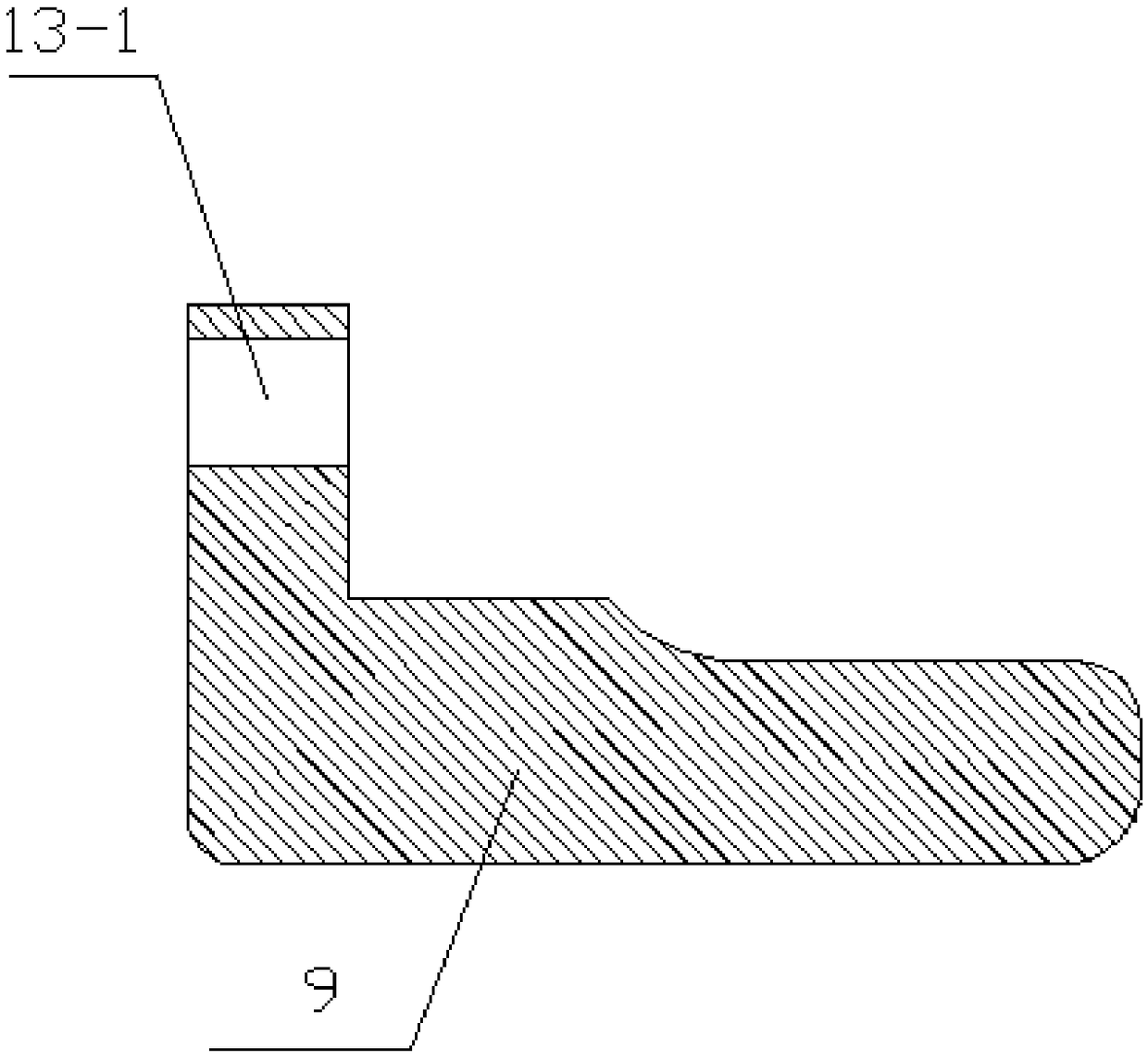

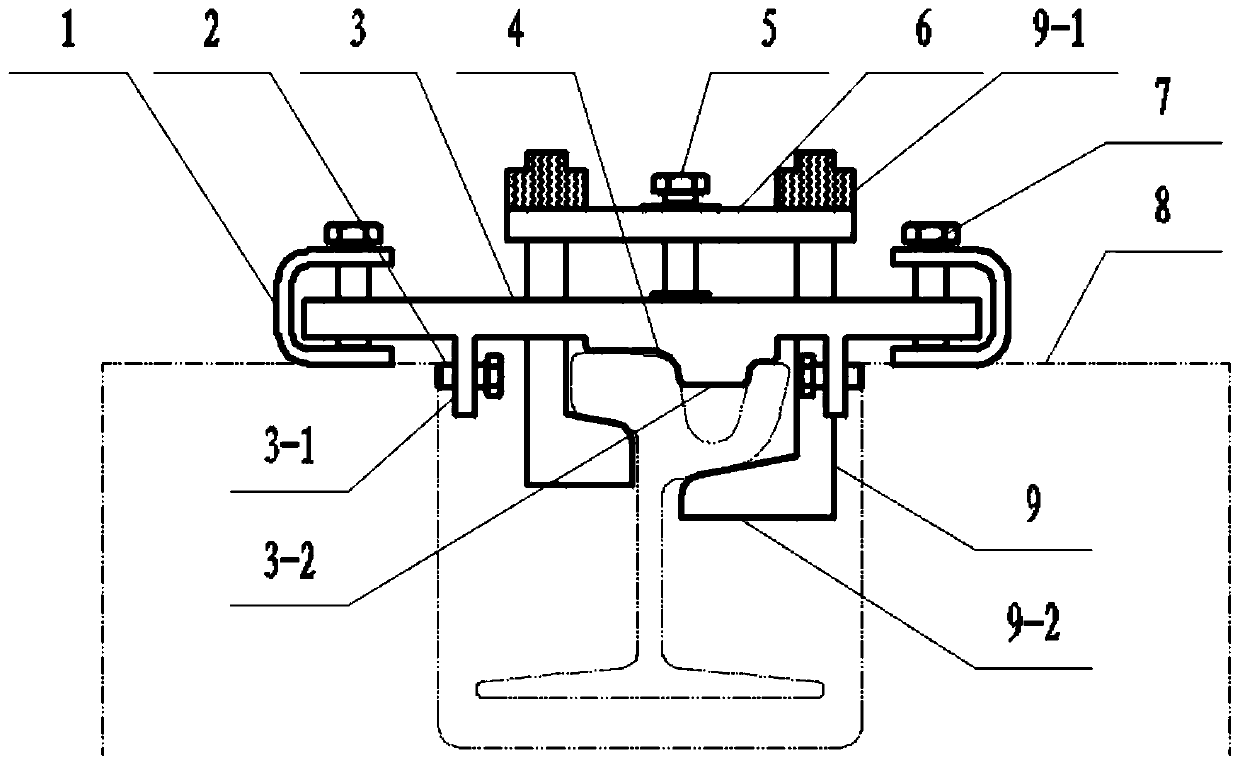

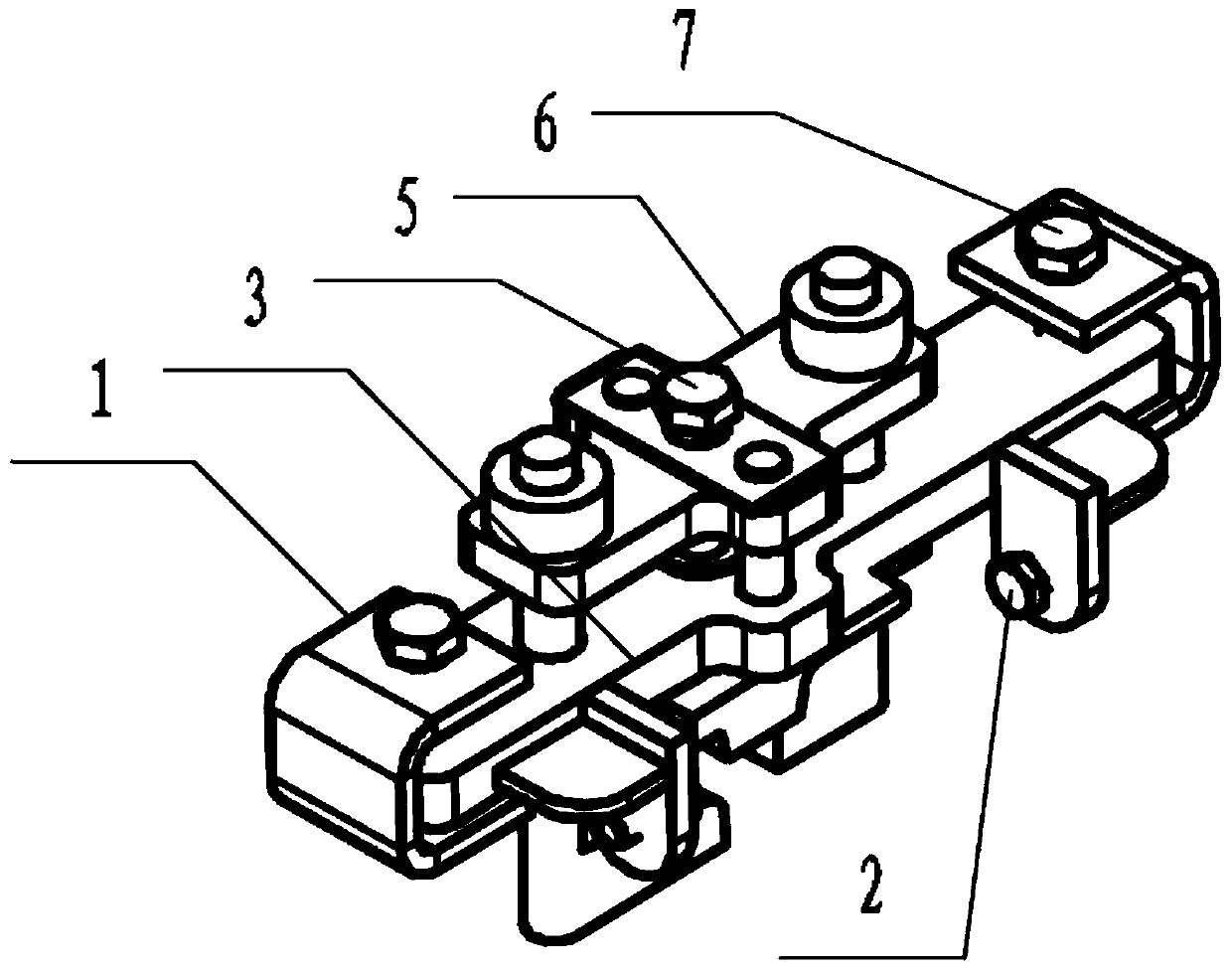

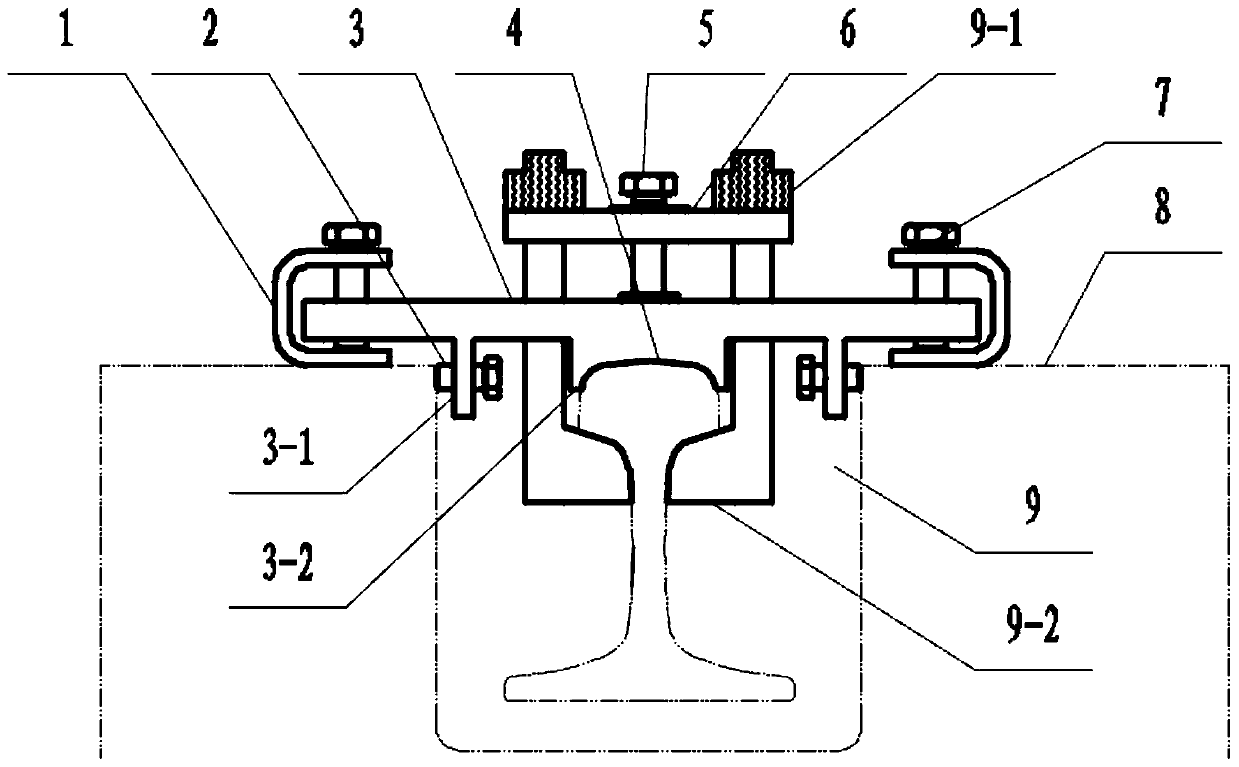

Steel rail damping fastener used for depot line of metro depot

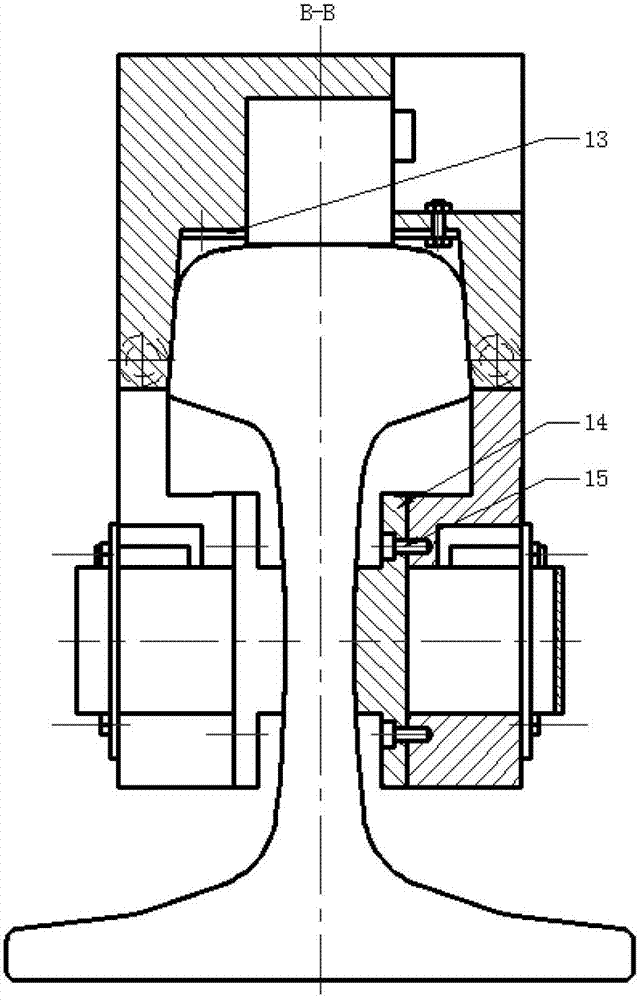

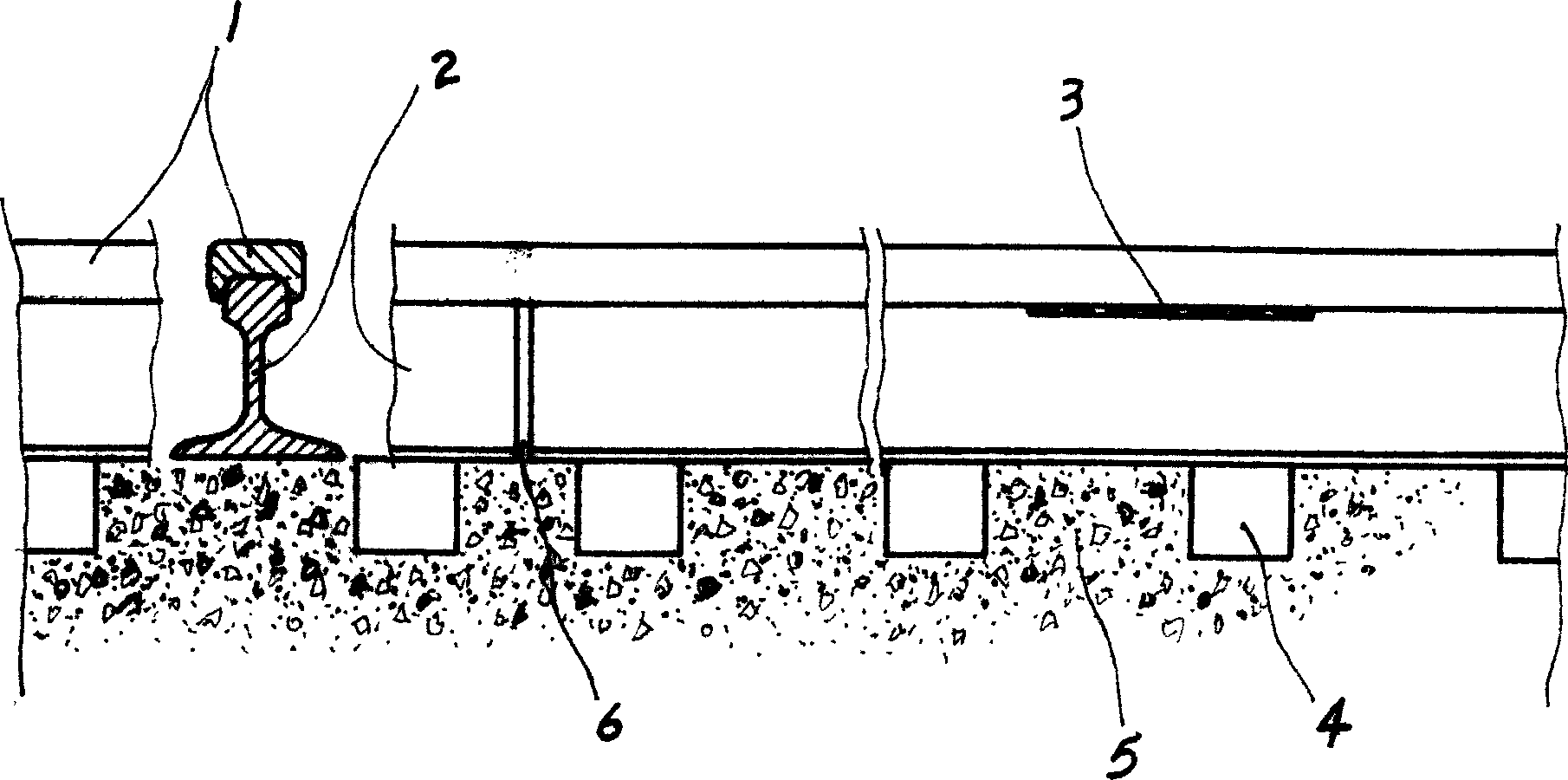

ActiveCN106930160AEnsure driving safetyGood vibration isolationRail fastenersChinese charactersRailhead

The invention discloses a steel rail damping fastener used for a depot line of a metro depot. The steel rail damping fastener comprises a base, a base plate under a plate, a vibration insulation cushion, a floating iron base plate and a lateral displacement constraint layer. The base is arranged on a rail bearing. The base plate under the plate is clamped between a base iron base plate and the rail bearing. The vibration insulation cushion is clamped between the base iron base plate and the base plate under the plate and arranged to be like a Chinese character 'zhong' and extends out of a cavity arranged to be like the Chinese character 'zhong'. The floating iron base plate is arranged on the base. The lateral displacement constraint layer is clamped between the side wall of the floating iron base plate and a blocking shoulder. The floating iron base plate is floated by the vibration insulation cushion and the lateral displacement constraint layer, namely the floating iron base plate does not make contact with the base iron base plate. The steel rail damping fastener can constrain transverse movement and vertical movement of a steel rail, namely the vibration insulation cushion constrains the vertical buffering capacity of the steel rail, and the lateral displacement constraint layer limits transverse movement of a railhead. The mutual influence of the two constraints is low, and the rigidity values, in the two directions, of the fastener can be independently designed according to actual requirements, so that the good vibration insulation is achieved under the condition that traveling safety is guaranteed.

Owner:BEIJING INVESTMENT & TECH BEIJING CO LTD

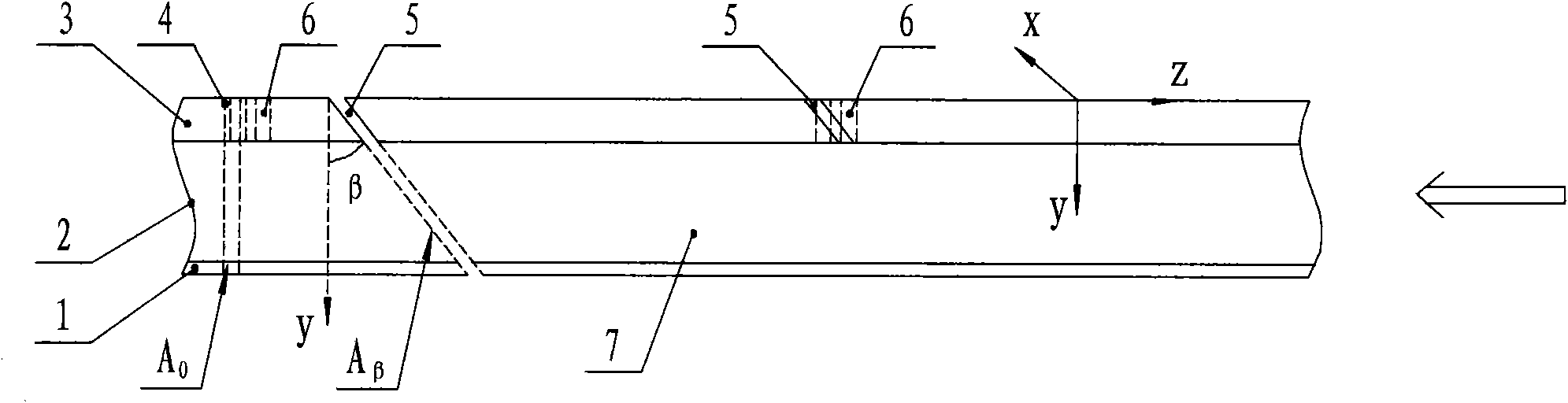

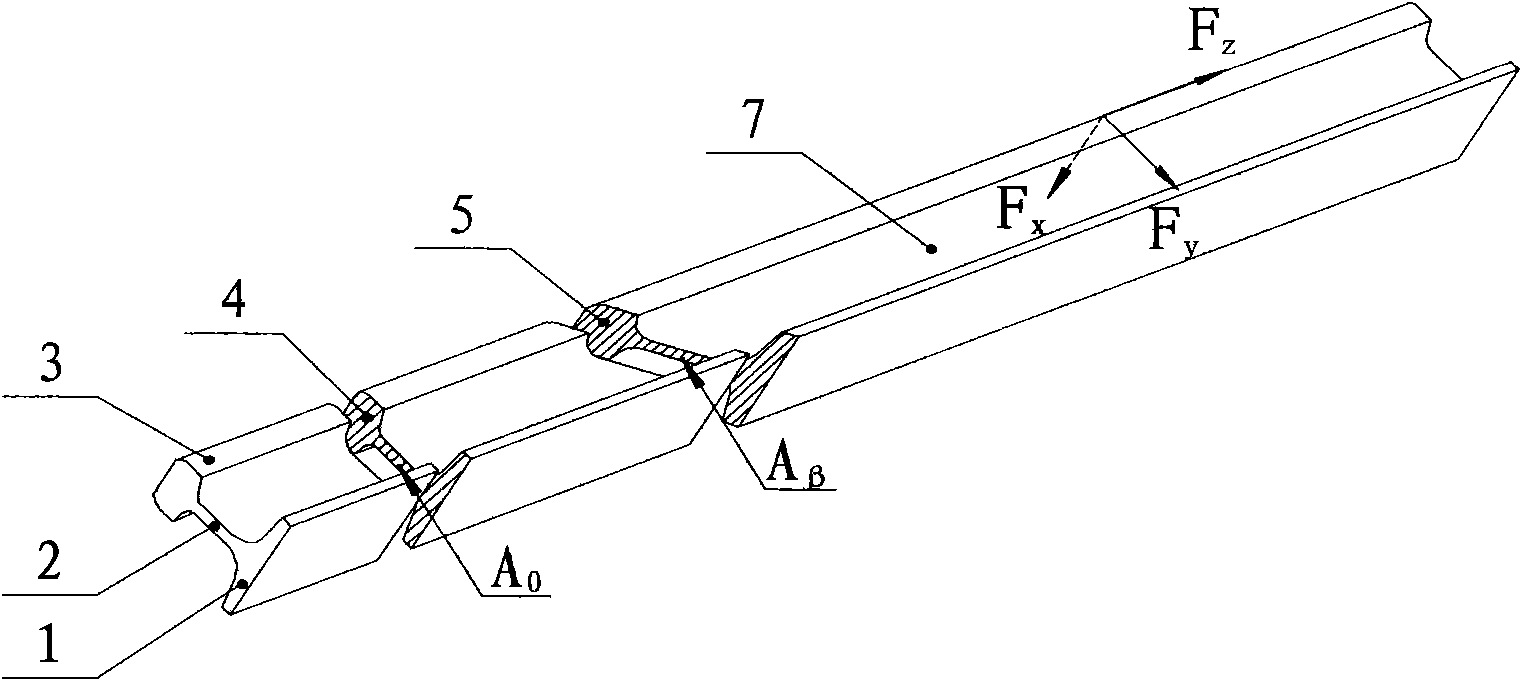

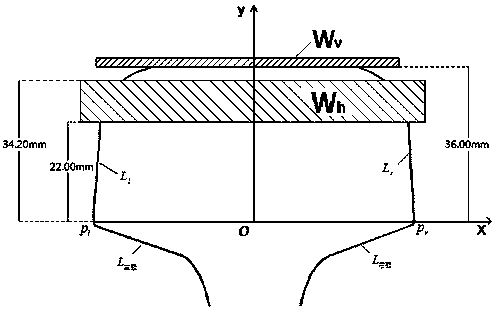

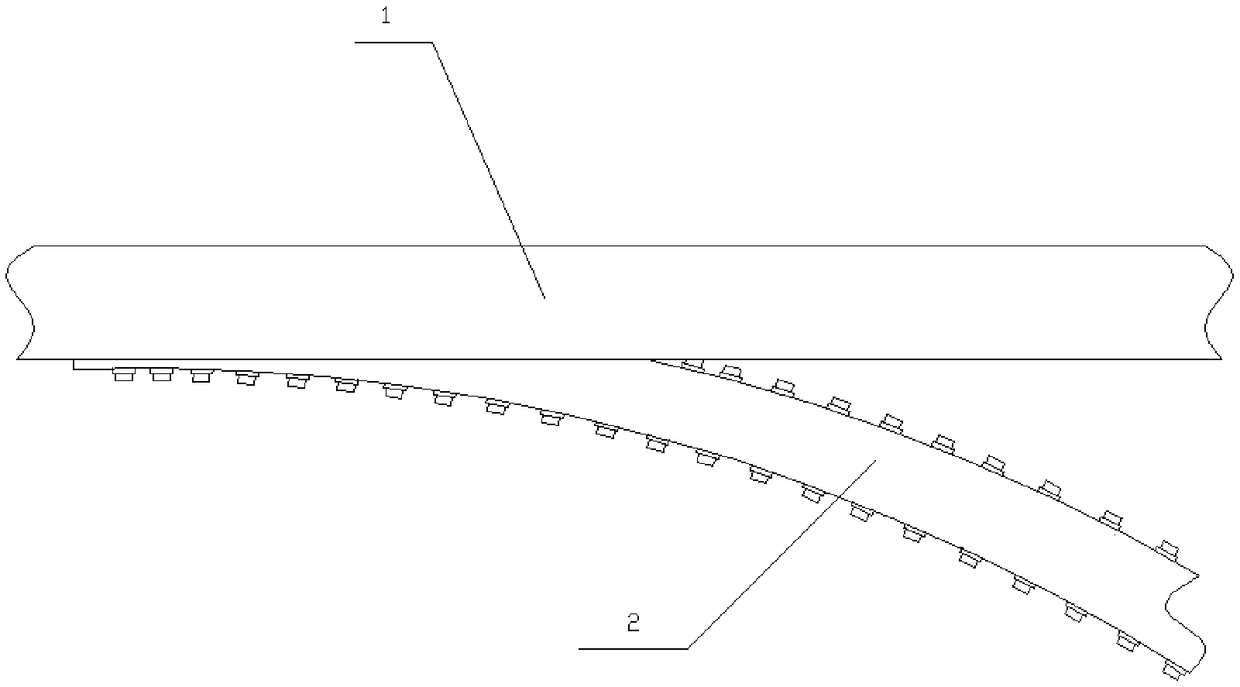

Seamless rail welding structure for improving welding bearing capacity and left and right operating stability

InactiveCN101914880AEliminate side to side vibrationPure shear stress reductionRail jointsRailheadHeavy load

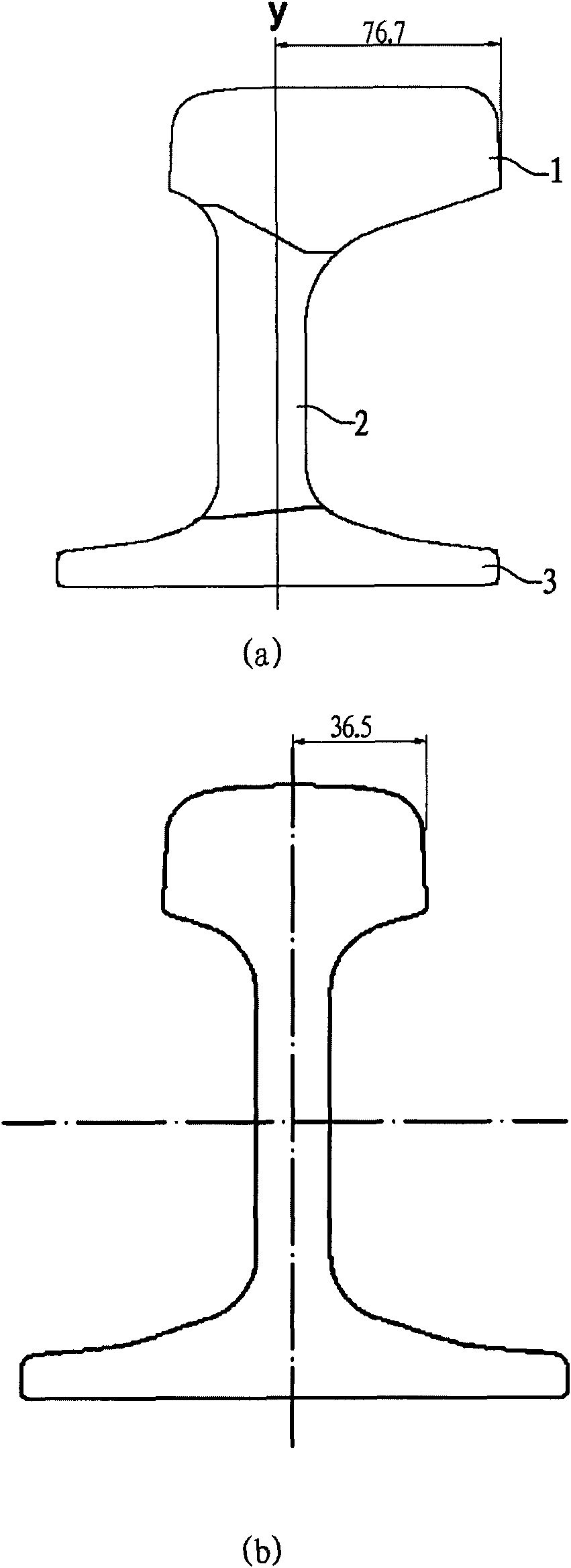

The invention discloses a seamless rail welding structure for improving welding bearing capacity and left and right operating stability and belongs to the technical field of railway train seamless rail welding. The seamless rail welding structure consists of rails and welding lines, wherein the welding lines of the rails are in an inclined plane; the inclined plane is parallel to an X axis of the rail and forms an angle of beta with a Y axis of the rail; the angle of beta is 45 degrees or 60 degrees; the inclined plane is connected through welding technology, and the welding technology is thermit welding; the rails are two parallel rails; the welding lines on the rails are staggered; and the staggered length is greater than the length of a railway carriage. The seamless rail welding structure can eliminate left and right oscillation of wheel rims when the wheel rims pass through welding lines on the side of a railhead, can improve the wheel set bearing capacity of the rails, can improve the smoothness and stability for welding seamless rails, can apply the conventional thermit welding technology to the welding of the seamless rails, improve the welding efficiency, simplify the welding technology and save the welding cost, and can be subjected to in-service welding. The seamless rail welding structure is particularly applied to long seamless rails of heavy-load trains and high-speed motor train units, and seamless rails of urban railway trains.

Owner:宋玉泉

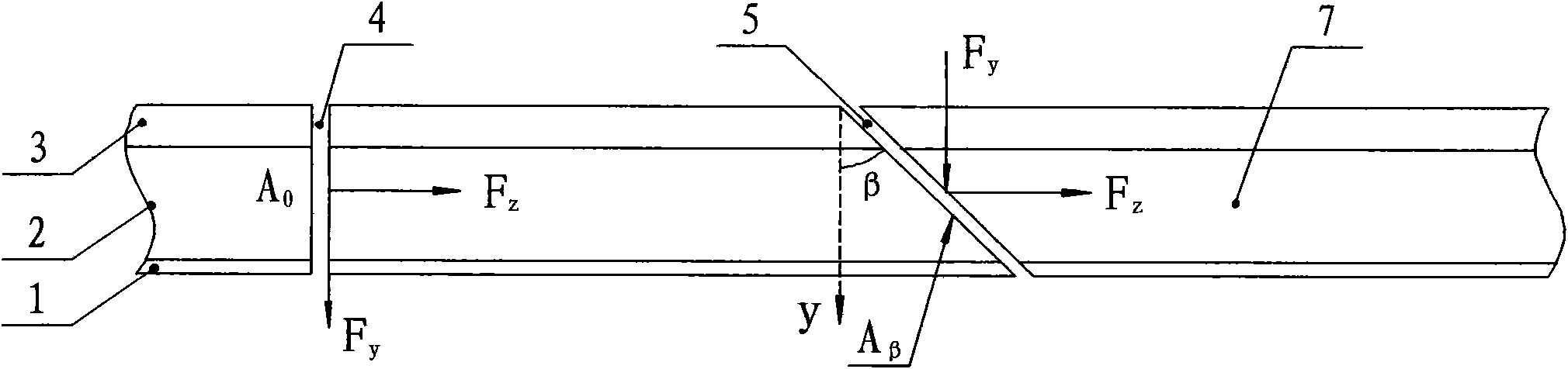

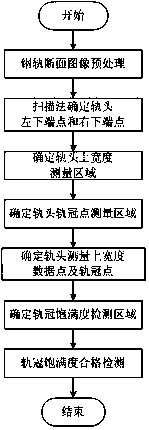

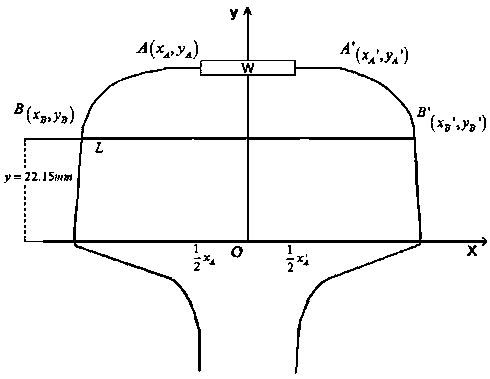

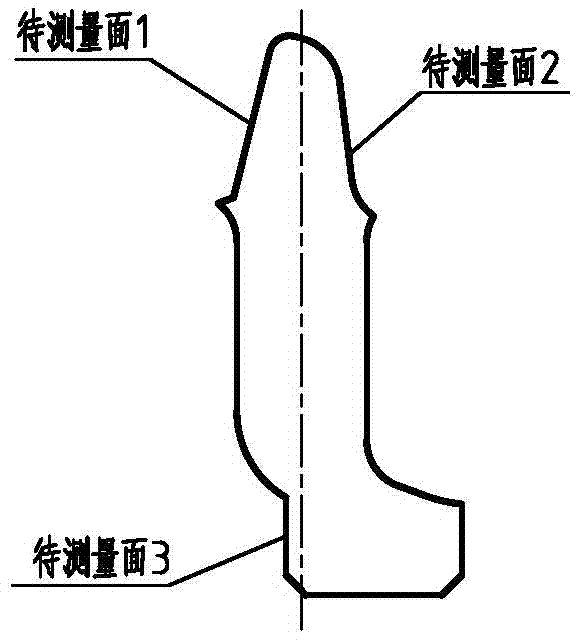

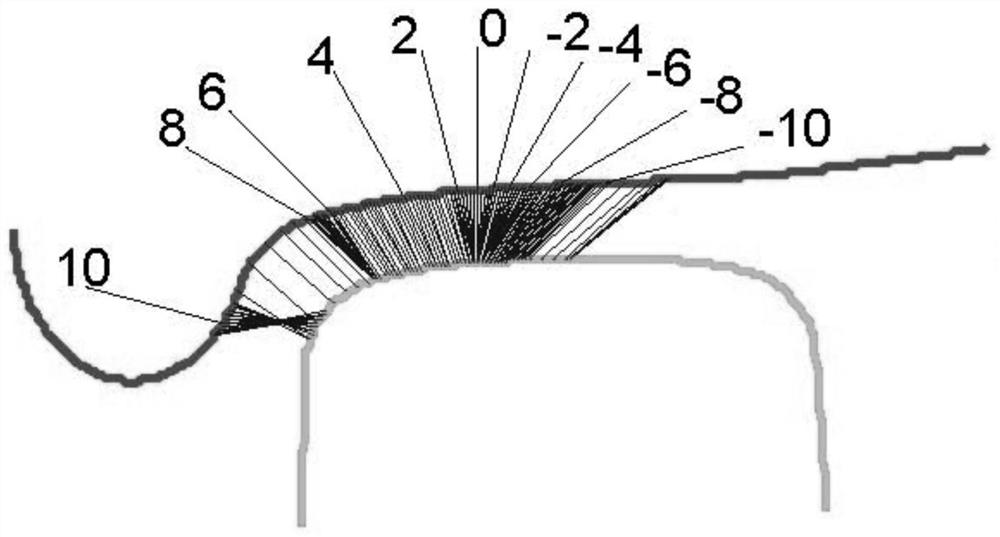

Image-based method for detecting qualified property of dimension of railhead cross-section contour

InactiveCN107228626AHigh positioning accuracyEasy to storeUsing optical meansNon destructiveImaging processing

The invention discloses an image-based method for detecting a qualified property of the dimension of a railhead cross-section contour. The method comprises: preprocessing of a cross-section image of a steel rail is carried out; with a scanning method, a lower left end point and a lower right end point of a railhead are determined; a width measuring region at the railhead is determined; a measuring region of a rail crown point of the railhead is determined; a width data point and a rail crown point of railhead measurement are determined; on the basis of least square circle fitting, a data point and a rail crown point are determined by combining a circle center vector method; a rail crown plumpness detection region is determined; and rail crown plumpness qualification detection is carried out. The method has the following advantages: a singular point is removed by using a least square straight line fitting method, so that the edge positioning precision is improved; with a circle center vector method, a control point is selected, so that the rail crown positioning precision is improved; and non-destructive and non-contact detection is carried out on the railhead cross-section contour dimension by using an image processing method. The image-based method has characteristics of high automation degree, convenient operation, high efficiency and precision, and convenient storage of a quantized detection result.

Owner:NANCHANG HANGKONG UNIVERSITY

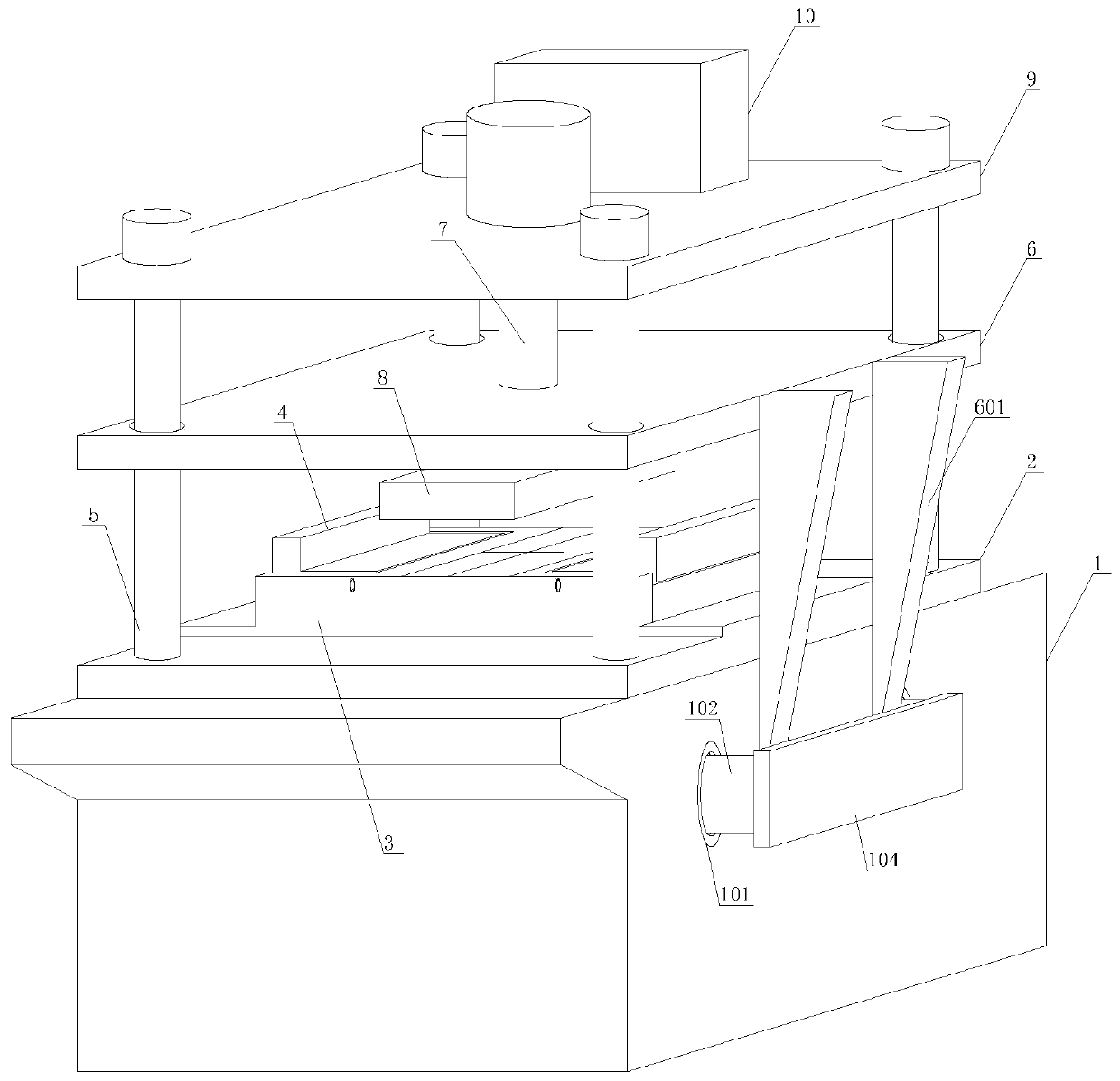

Large railhead precision forging press

ActiveCN110369671AImprove work efficiencyReduce processing timeRailway componentsForging/hammering/pressing machinesRailheadFuel tank

The invention discloses a large railhead precision forging press. The large railhead precision forging press comprises an anti-impact base, a disassembling and assembling platform, a forging and pressing base, side forging and pressing mechanisms, a positioning column, a guide table, a forging and pressing column, a forging and pressing block, a fixed table and an oil tank, wherein the bottom of the disassembling and assembling platform is fixedly connected with the top of the anti-impact base by virtue of a bolt, the bottom of the forging and pressing base is fixedly connected with the top ofthe disassembling and assembling platform, the side forging and pressing mechanisms are arranged on both sides of the forging and pressing base, the guide table is installed on the positioning columnin a lifting mode, the bottom of the forging and pressing column is removably installed on the top of the guide table, the top of the forging and pressing block is removably installed at the bottom of the guide table, and the bottom of the fixed table is connected with the top of the positioning column. According to the large railhead precision forging press, the forging and pressing operation issynchronously performed on multiple surfaces, so that the processing time of excessive forging and pressing can be shortened, the forging and pressing efficiency is improved, and the problems of sputtering and splashing of oxides on side surfaces during falling are avoided when a railhead is extruded to deform.

Owner:方杰

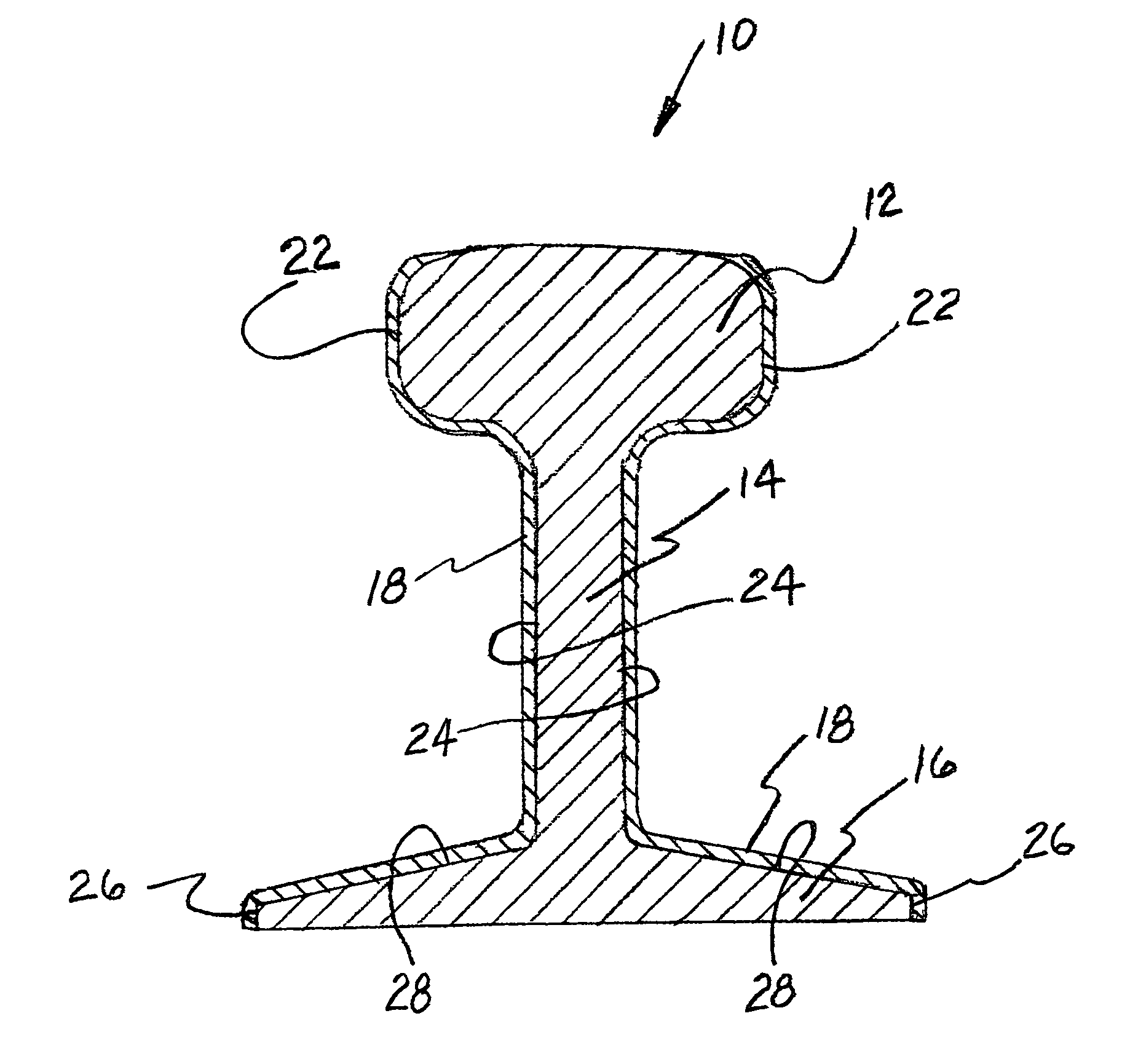

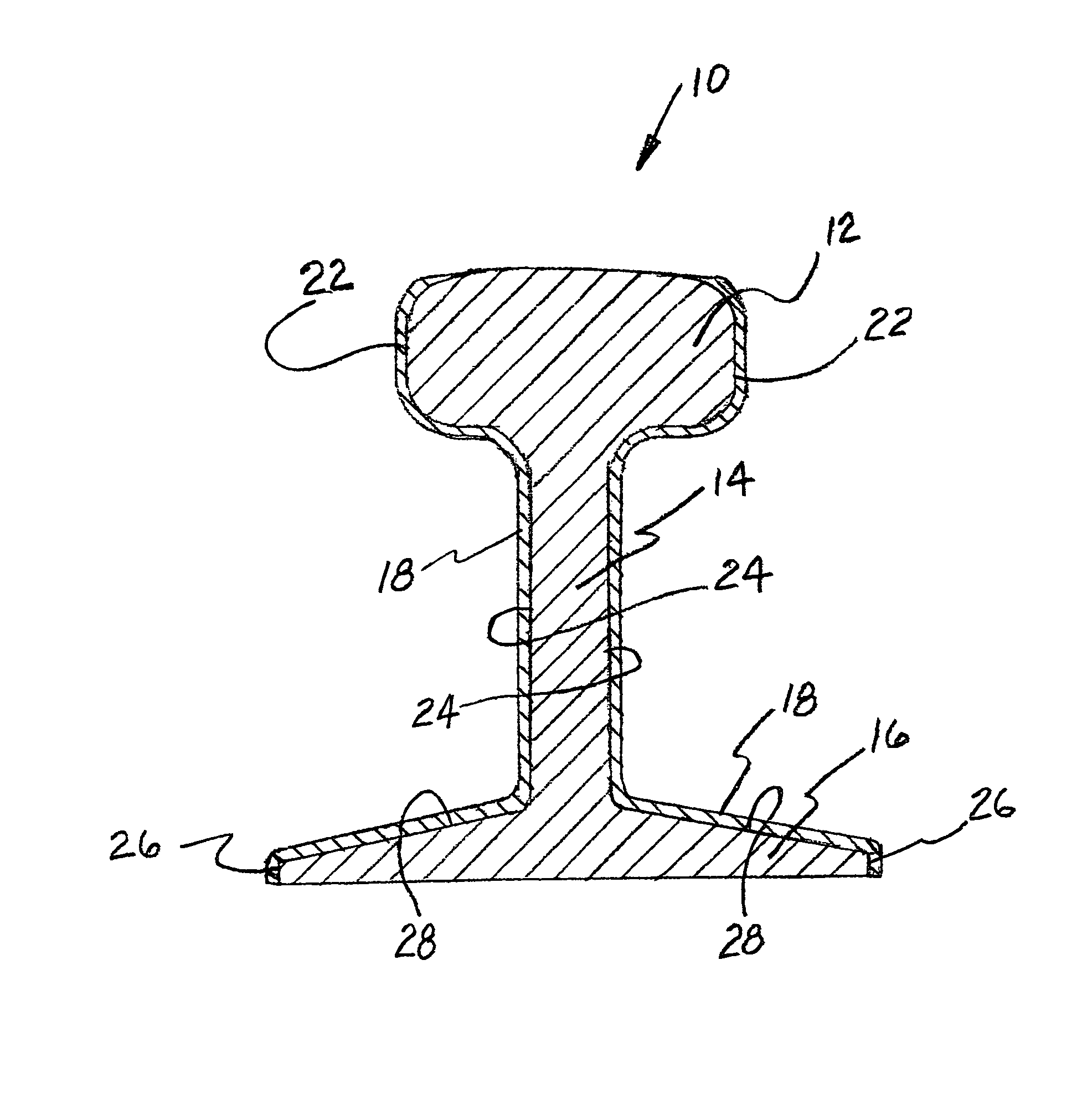

Railroad rail having thermal insulationbelow the railhead either coated in the field or at the rail production facility

A railroad rail having superior thermal expansion characteristics. Such railroad rail comprising a rail having a predetermined weight and a predetermined length and a ceramic based insulating type paint having a predetermined capability of resisting heat buildup in such rail adhered to predetermined areas of such rail.

Owner:JONES PAUL

High-speed railway lateral turnout wing rail processing technique

ActiveCN101214608AGuaranteed machining accuracyMeet the requirements of batch processingBatch processingRailhead

A processing technique of the wingrail of the lateral turnout of a high-speed railway includes ten steps: (1) cutting and boring; (2) the milling of a point-hiding section and the inner working edge rail limb of the rear section; (3) the milling of the inner railhead working edge of the rear section; (4) the milling from the front-end rail waist to the rail waist of a standard steel rail; (5) the skewing of the front end; (6) the milling of the front section of inner railhead working edge after the push bending of the front section; (7) the push bending of the rear section; (8) the milling of the point-hiding section; (9) shape-righting adjustment; (10) burnishing and derusting. The present invention is the processing technique method of a whole wingrail, the advantages of a numerically controlled miller are sufficiently exerted, the processing utilizes a moulded cutter, so the processing precision is high, the processing cost is low, as a result, the requirements of batch processing are satisfied, and the productivity effect is increased. The present invention is particularly suitable for the processing of wingrails used by the No. 18 lateral turnout of the 60 kg / m steel rail of the 350 km / h passenger-dedicated line.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

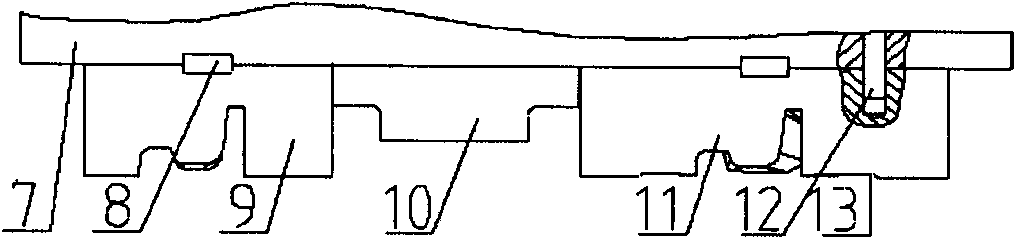

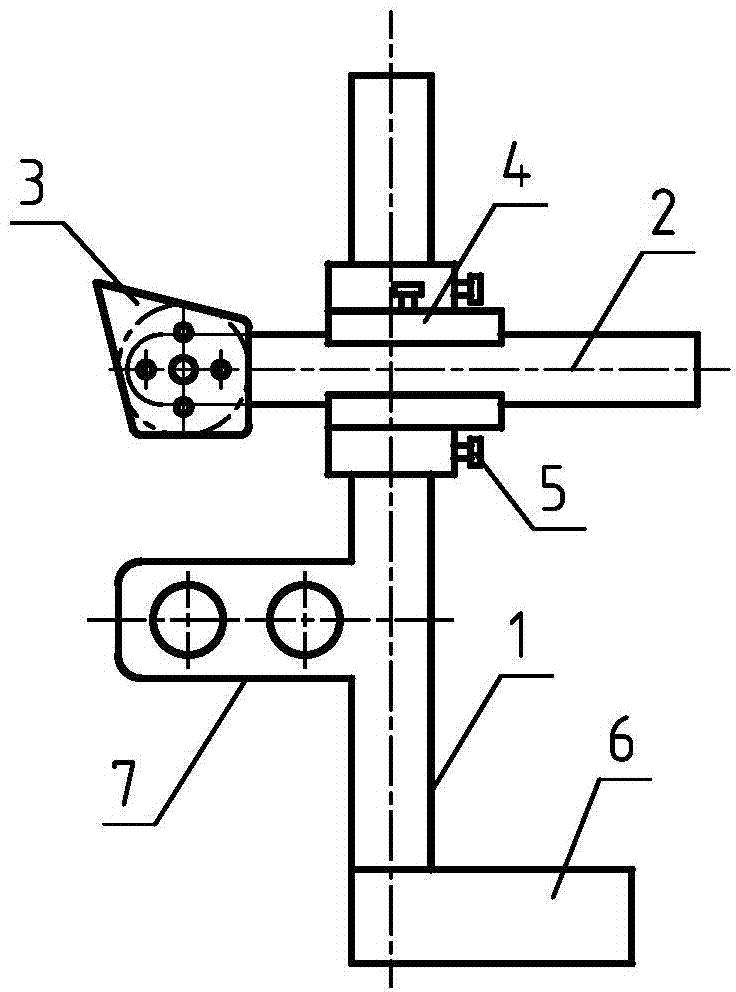

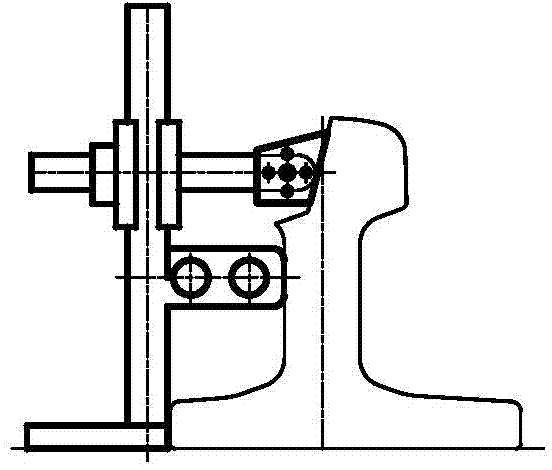

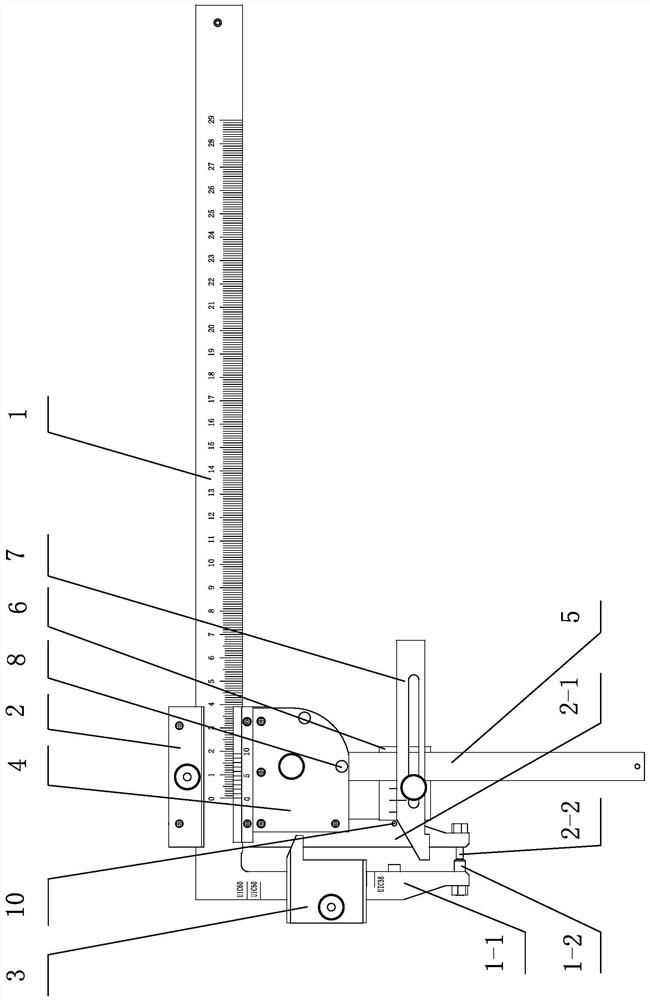

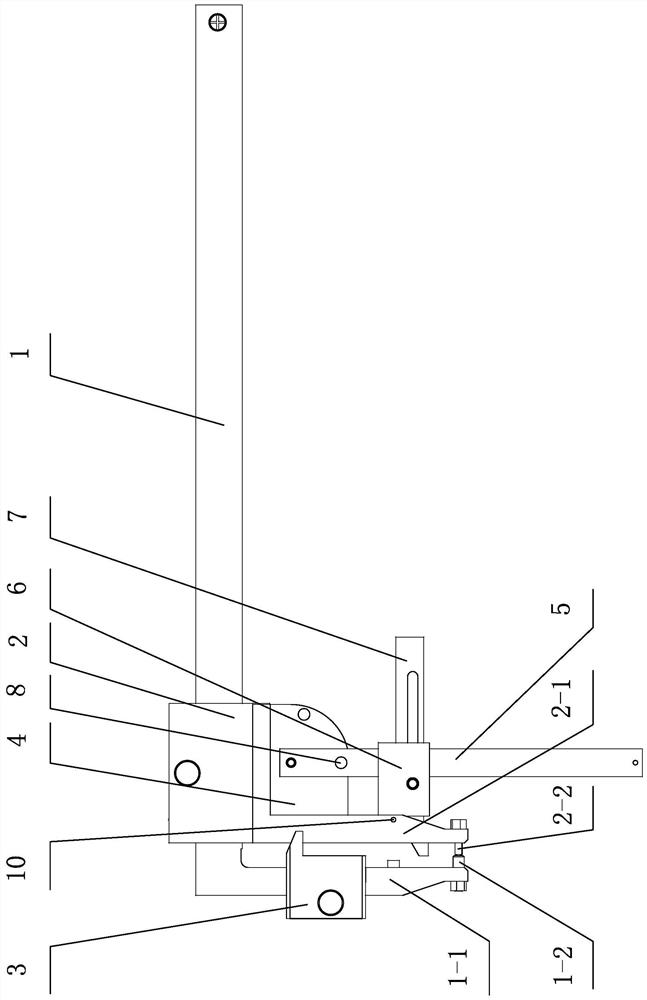

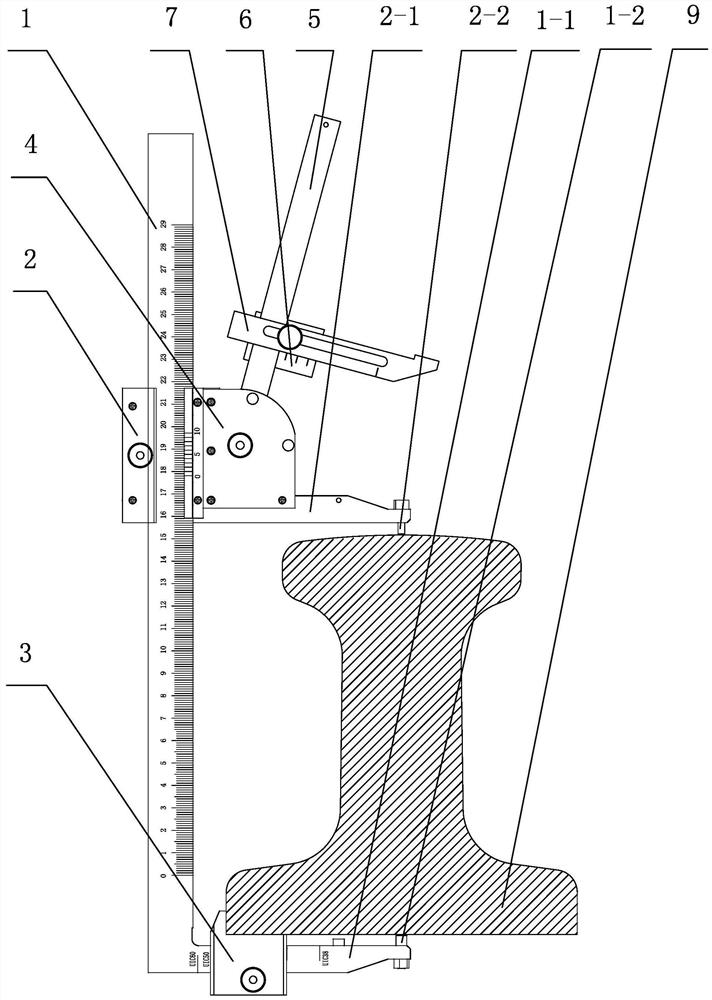

Vernier caliper for dimension measurement of rail profile

The invention discloses a vernier caliper for dimension measurement of a rail profile. The vernier caliper comprises a base (6), a benchmark claw (7) and a measuring main scale, and also a measuring piece (3) and a support (4); the measuring main scale of the vernier caliper is composed of a height main scale (1) and a depth main scale (2); the height main scale (1) is connected with the depth main scale (2) by virtue of the support (4); the measuring piece (3) is connected to the depth main scale (2). The vernier caliper for the dimension measurement of the rail profile has the advantages that the railhead inclinations of different profiles of different steel rail pieces can be detected by using the vernier caliper instead of previous sample plates, so that the management cost of lots of sample plates is saved and easy verification can be realized, and the width of a rail limb of a steel rail and the width of a railhead of the steel rail can be detected by using the vernier caliper instead of a previous tooth vernier and a common vernier caliper. The vernier caliper is unified in measurement reference and seldom affected by manual measurement skills, and is high in detection accuracy.

Owner:CHINA RAILWAY BAOQIAO (NANJING) CO LTD

Compound railway track and construction method thereof

The invention relates to a complex railway rail that covers a seamless rail on the common quasi rail steel railhead that has seam on it, and jointing at the middle of the connection section to make the seamless rail and the steel rail combine together firmly. The construction method is the following steps: heating the seamless rail to the temperature above the highest in the whole year, jointing the middle section of the seamless rail and the steel rail. Pre-stressing force would be formed between seamless and the middle point of the corresponding two steel railways. The pre-stressing force would form balance force against with portrait resistance of ballast bed, and the seamless rail would be tightened. And the tightening state would change followed the temperature changing of environment. Thus, the one-off changing toward ultra length rail from common railway would be realized.

Owner:钟志勇

Switch rail polishing device for rail maintenance vehicle

ActiveCN110227997ARealize grinding and derustingReduce workloadGrinding drivesGrinding machinesRailheadSlide plate

The invention discloses a switch rail polishing device for a rail maintenance vehicle. The switch rail polishing device for the rail maintenance vehicle comprises a transverse moving mechanism, mounting structures and polishing mechanisms. A sliding plate of the transverse moving mechanism is provided with the mounting structures; the polishing mechanism is mounted on each mounting structure; twobelt wheel axles are rotatably mounted on each mounting structure and the two belt wheel axles are connected to an output shaft of a driving motor through a belt transmission mechanism; a rotating armI and a rotating arm II are rotatably mounted below each mounting structure; one belt wheel axle penetrates from the axe of the rotating arm I while the other belt wheel axle penetrates from the axleof the rotating arm II. By arranging a tension spring and the rotating arms, an effect of auto-adapting width change of a railhead of a switch rail in a segment of width change of the railhead as therotating arms rotate is achieved. The positions of the polishing mechanisms are adjusted by the transverse moving mechanism according to change of the switch rail deviated from a base rail, so that the switch rail of the change part of the railhead is polished and derusted.

Owner:WUHU CRSIC JIFU RAIL CO LTD

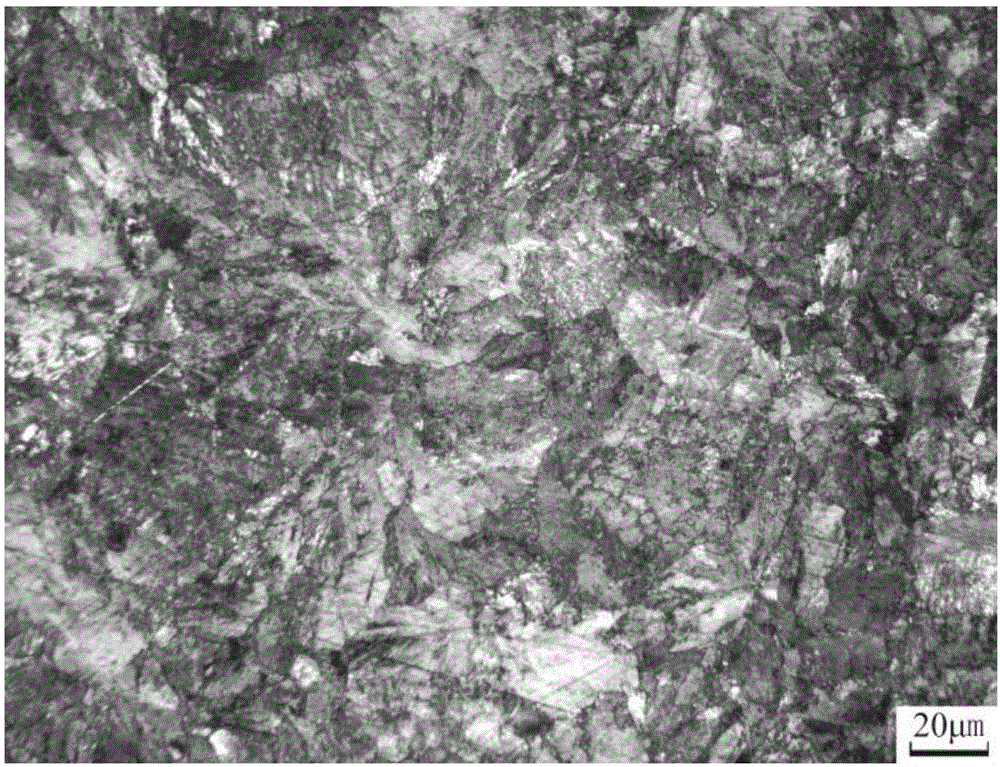

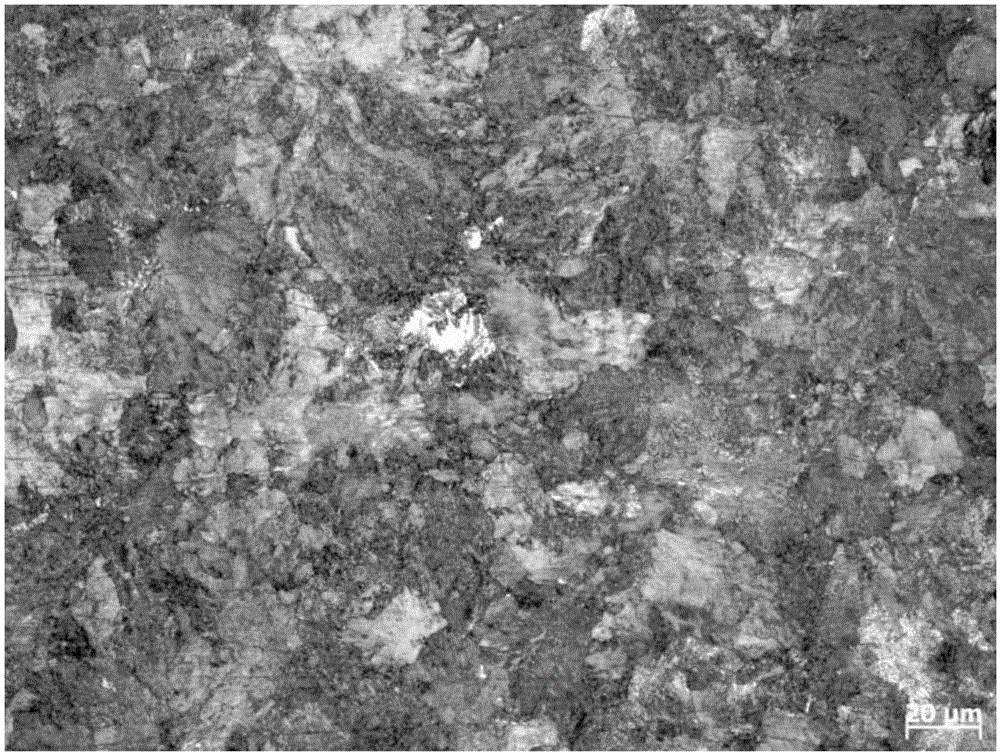

High-carbon and high-strength and toughness pearlitic rail and manufacturing method thereof

InactiveUS20190105694A1High strengthImprove toughnessTemperature control deviceFurnace typesHigh carbonRoom temperature

In view of the problem of uneven performance of railhead sections of pearlitic rail manufactured with existing technique and the poor performance of the pearlitic rail obtained, the invention provides a manufacturing method for high-carbon and high-strength and toughness pearlitic rail, including the following steps to: a. hot roll the steel billet into rail, with a final rolling temperature of 900-1000° C.; b. blow a cooling medium to the top surface of railhead, wherein, the two sides of railhead and the lower jaws on two sides of railhead when the center of top surface of rail is air-cooled to 800-850° C.; then air-cool the rail to room temperature after the center of top surface of rail is cooled to 480-530° C. By controlling the composition of steel and adopting a two-stage accelerated cooling, a high-carbon rail is produced with better strength and excellent toughness which is suitable for heavy-haul railway.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

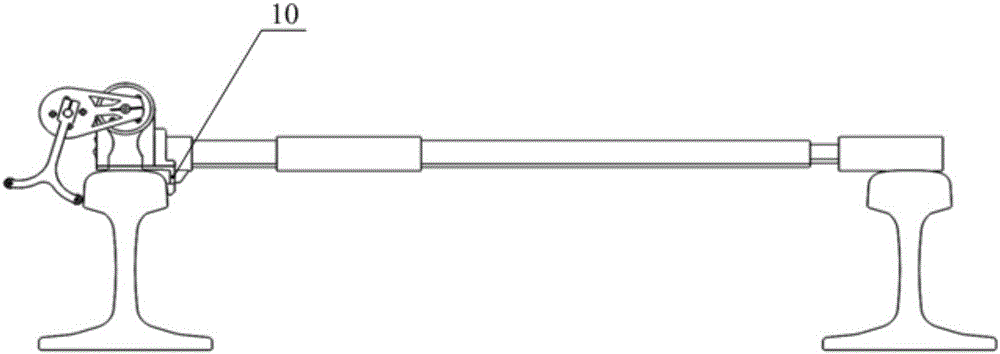

Full-rail type railhead abrasion measuring device

The invention discloses a full-rail type railhead abrasion measuring device. The full-rail type railhead abrasion measuring device comprises a caliper body and a caliper frame sliding on the caliper body front and back, wherein a measuring block sliding up and down to adjust the measuring position is arranged on a caliper body measuring claw; a right-angle positioning bayonet is formed in the rearside of the measuring block; a supporting plate is arranged on the rear side of a caliper frame measuring claw; one end of a swing rod is hinged to the supporting plate; a sliding block is arranged on a rod body of the swing rod; a measuring rod is arranged on the sliding block in the direction perpendicular to the rod body in a sliding mode; a right-angle measuring head composed of a bottom measuring face and a top measuring face is arranged at the front end of the measuring rod; a stop pin for limiting the swing rod in the vertical position is arranged on the supporting plate; the top measuring face of the measuring rod is aligned with the caliper frame measuring head; and a reading ruler II on the measuring rod and a dividing ruler II on the sliding block are aligned to zero. The full-rail type railhead abrasion measuring device can measure abrasion of the tops and the side faces of different rail type guide rail railheads, the types and the number of detection tools needing to bearranged are reduced, the operation process is simplified, and the cost of the detection tools is reduced.

Owner:卜少明

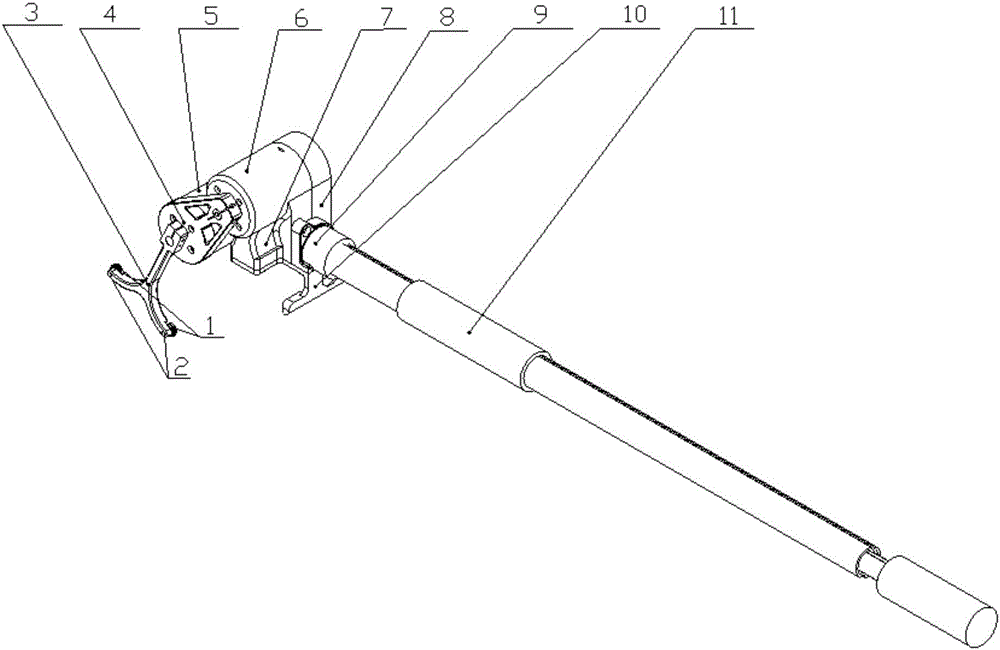

Steel railhead profile measuring instrument

InactiveCN106352834AEasy to scanImprove measurement efficiencyMeasurement devicesRailheadMeasuring instrument

The invention provides a steel railhead profile measuring instrument. The steel railhead profile measuring instrument comprises a measuring support arm, an encoder connecting rod, a first encoder, a second encoder, a fixed seat, a USB interface and a telescopic support rod, wherein the measuring support arm is herringbone, and detection wheels are arranged at two ends in the horizontal direction of the herringbone measuring support arm; the top end of the herringbone measuring support arm is connected with the first encoder, the first encoder is connected with the second encoder through the encoder connecting rod, the second encoder is fixed on the fixed seat; the telescopic support rod is connected with the fixed seat through a telescopic support rod seat, and a datum bottom plate is connected below the telescopic support rod seat. The steel railhead profile measuring instrument can be used for rapidly and conveniently scanning profiles of the left side and the right side of a steel railhead, more importantly, the steel railhead profile measuring instrument can be used for measuring a profile curve, which cannot be measured in the prior art, of a lower jaw part of the steel railhead, thereby having quite high measuring efficiency and accuracy and being simple in structure and convenient to use.

Owner:华夏高铁技术有限公司 +1

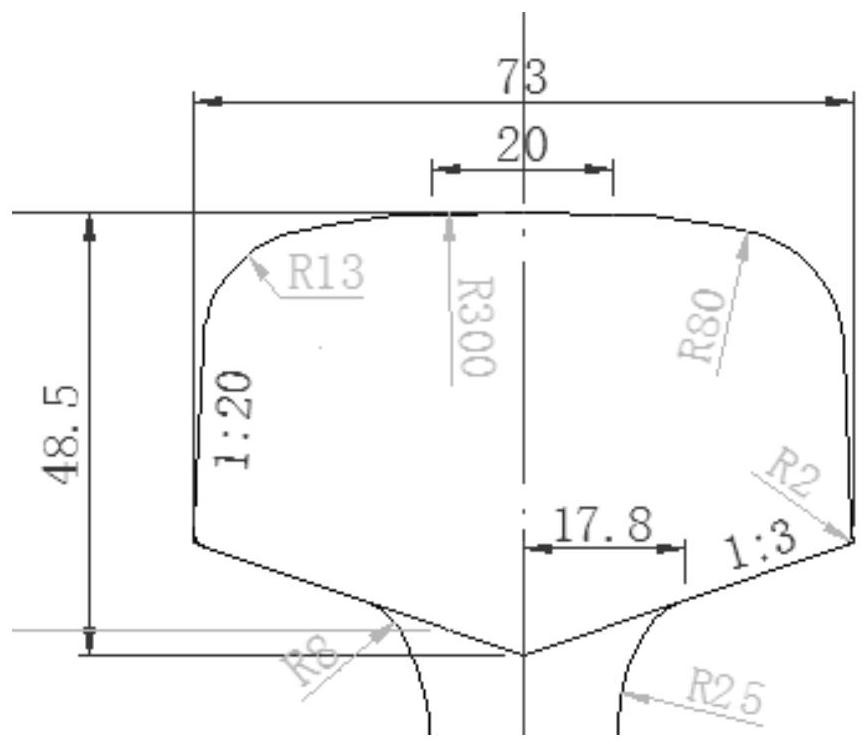

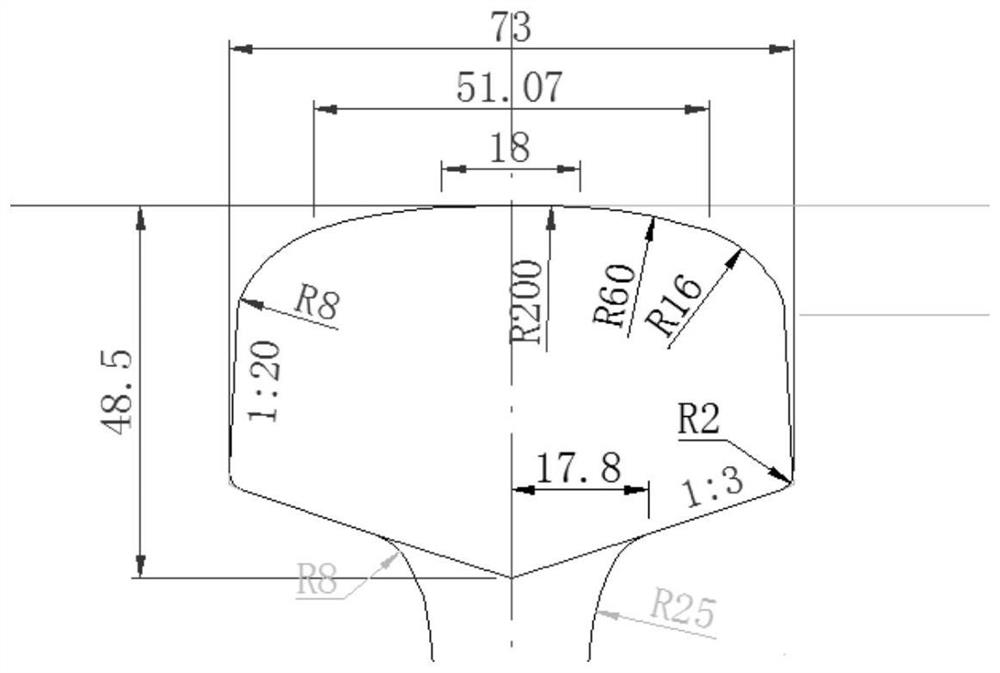

Novel railhead profile steel rail and production method thereof

InactiveCN111691242AExtended service lifeImprove compatibilityRailsTemperature control deviceRailheadEngineering

The invention discloses a novel railhead profile steel rail and a production method thereof. The novel railhead profile steel rail is composed of a steel rail base and a top outline. Specifically, thesteel rail base is a 60 steel rail base, the top outline is of a bilateral symmetry structure and is provided with seven sections of arcs, the radius of a middle arc is 200mm, and the radiuses of thearcs in the direction from the middle to the two sides are 60mm, 16mm and 8mm respectively. According to the novel railhead profile steel rail, wheel-rail profile matching can be achieved, thereforethe service life of the steel rail is prolonged.

Owner:BAOTOU IRON & STEEL GRP

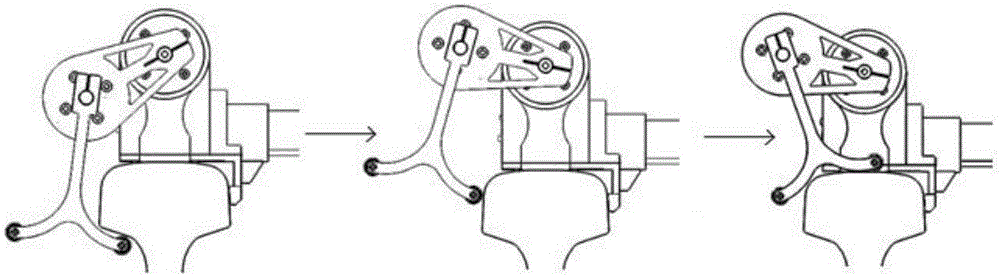

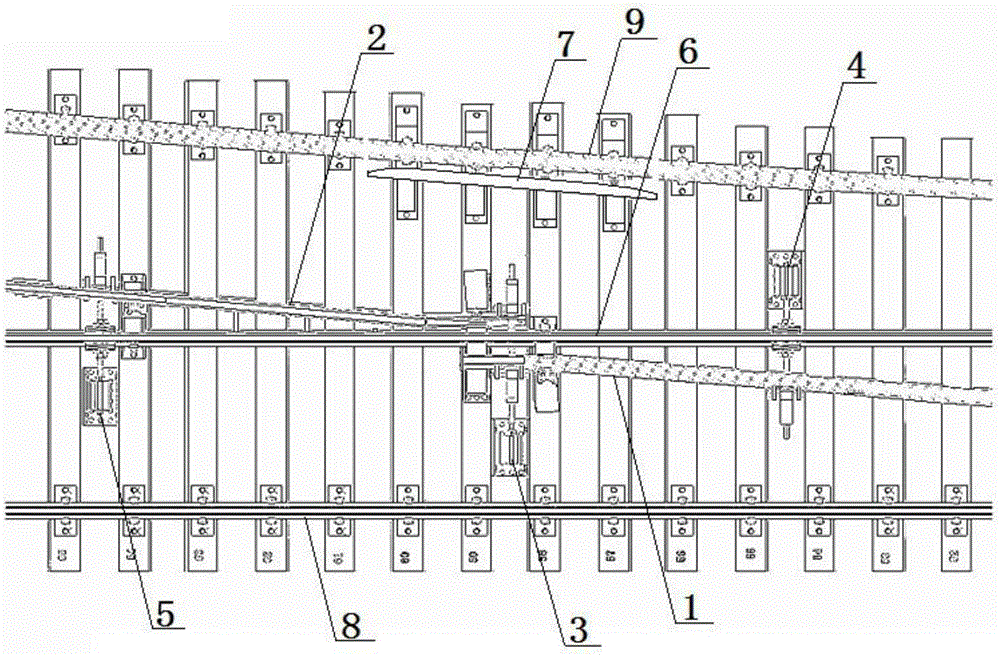

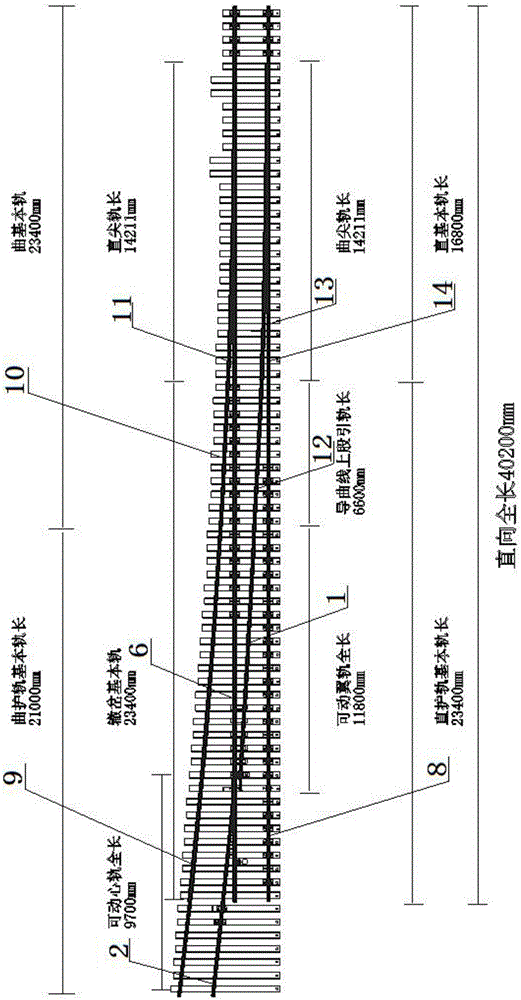

Runover frog and railway turnout with same

The invention discloses a runover frog which comprises a frog stock rail, a movable wing rail, a movable point rail, a frog switch machine main unit, a movable wing rail switch machine auxiliary unit and a movable point rail switch machine auxiliary unit. The movable wing rail and the movable point rail are respectively positioned on two sides of the frog stock rail; on one side where the movable wing rail and the movable point rail are in abutted connection, railhead lower jaws of the movable wing rail and the movable point rail are identical with the top face of the frog stock rail in height, and a shape formed by the railhead lower jaws is coincident with that of an apex angle of the frog stock rail; one ends at which the movable wing rail and the movable point rail are in abutted connection are connected through a first screw of the frog switch machine main unit. Straight rails of the runover frog and the railway turnout eliminate harmful space of common turnouts, and side rails also eliminate harmful space, so that a train is stable in running; the runover frog is made of P75-type steel rails, so that frequent replacement of the movable point rail and the movable wing rail can be reduced, and high economic benefit can be brought about within a full service life period of the frog.

Owner:张伟

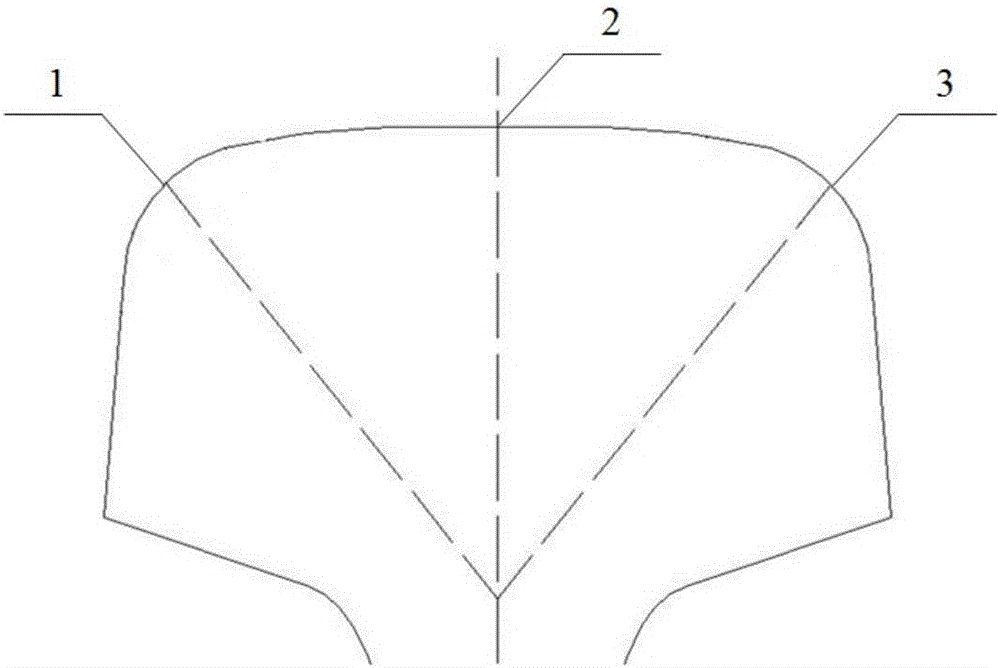

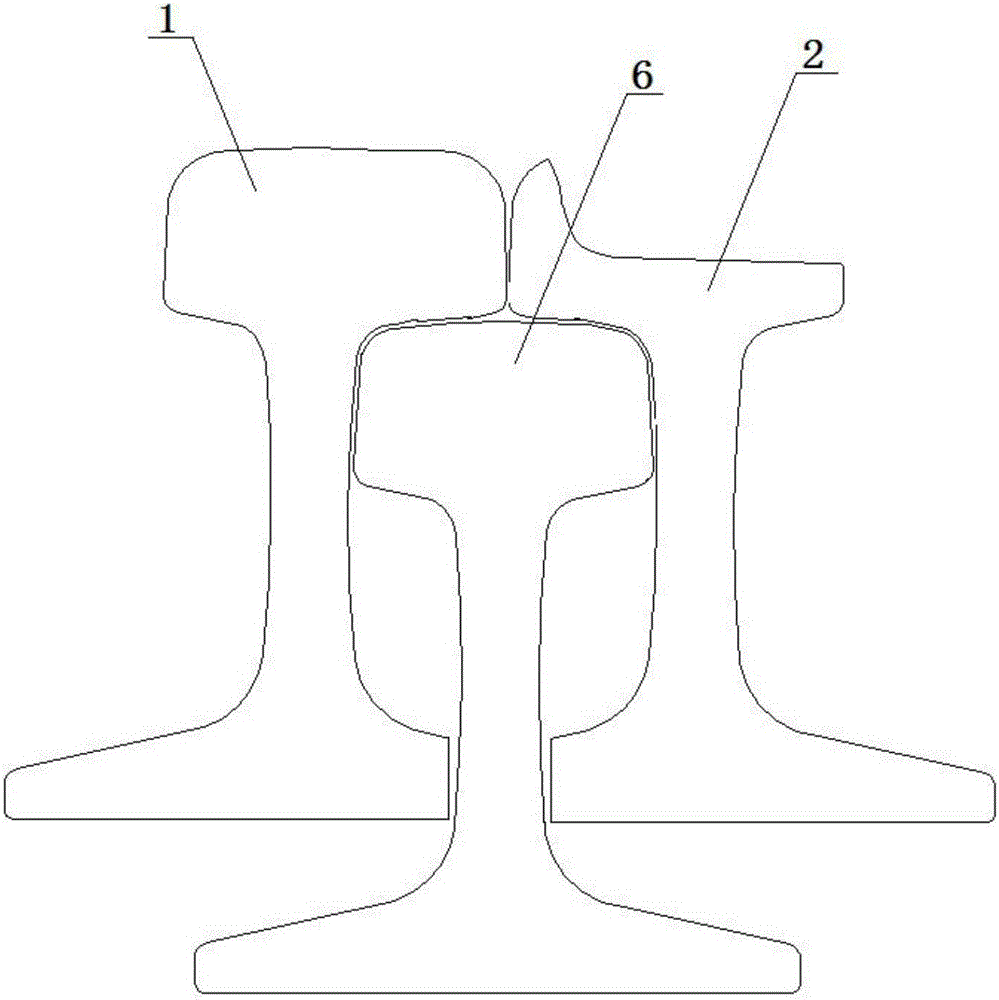

Stock rail and switch rail railhead configuration form

The invention discloses a stock rail and switch rail railhead configuration form, and relates to the technical field of rail components. A stock rail and a switch rail are included, the stock rail comprises a railhead and a rail chair, and the railhead is arranged above the rail chair; the width of the railhead is 10-20 mm, a working side in contact connection with a switch rail railhead on the switch rail is arranged on the railhead, and the inclination degree of the contact surface of the working side and the switch rail railhead is 1 / 5-1 / 3; extra 2-5 mm machining treatment is conducted on the working side inward, the extra machining portion is divided into two sections, the length of the first section is 50-200 mm, and the length of the second section is greater than 500 mm; the inclination degree is 1 / 1000-1 / 300, and the switch rail railhead is 23 mm lower than the outer edge of a wheel. According to the stock rail and switch rail railhead configuration form and the characteristicof the tangent line type switch rail, under the circumstance of not changing the impact angle, the stock rail railhead portion closely fitting the switch rail is extra machined, the width of the switch rail railhead is increased, and therefore the strength of the switch rail is increased.

Owner:WUHU CRSIC JIFU RAIL CO LTD

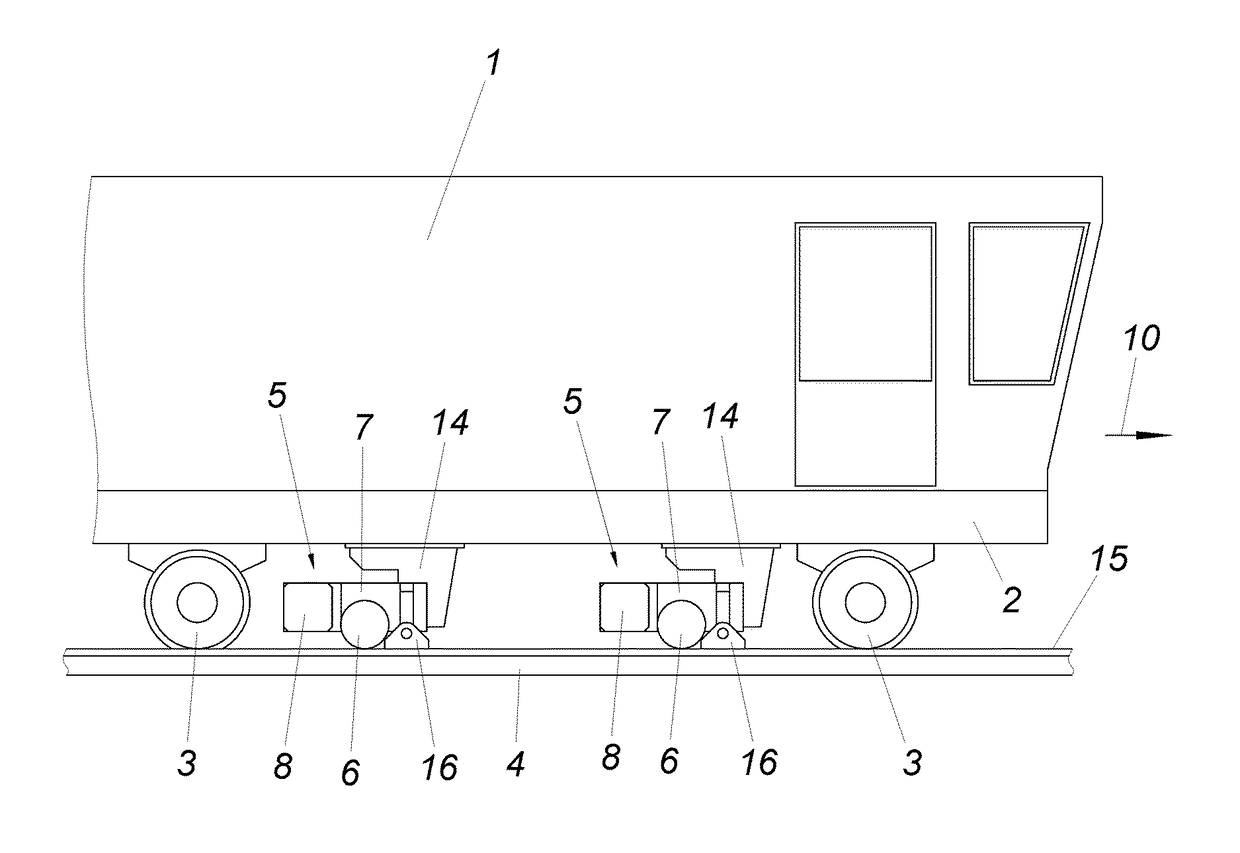

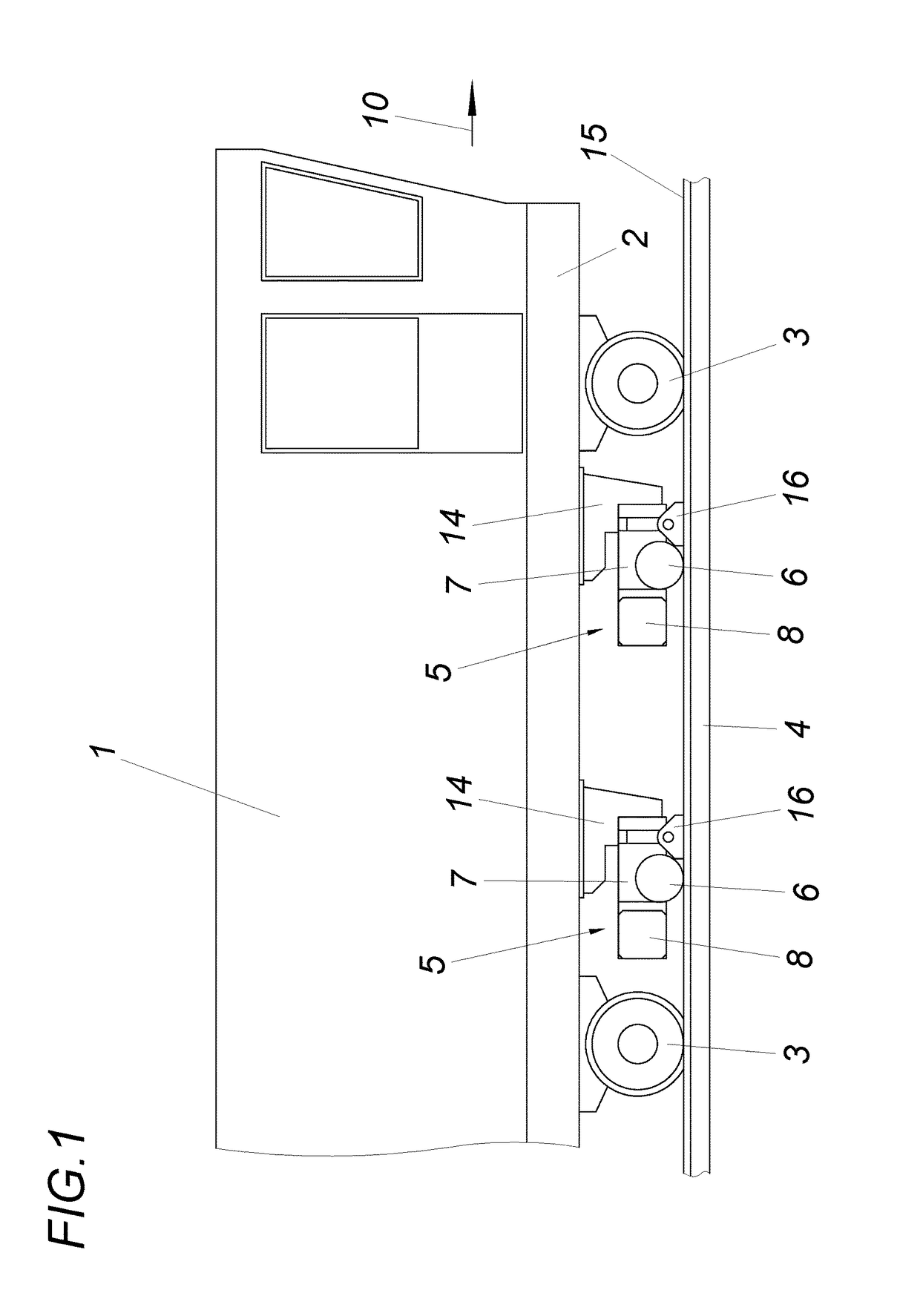

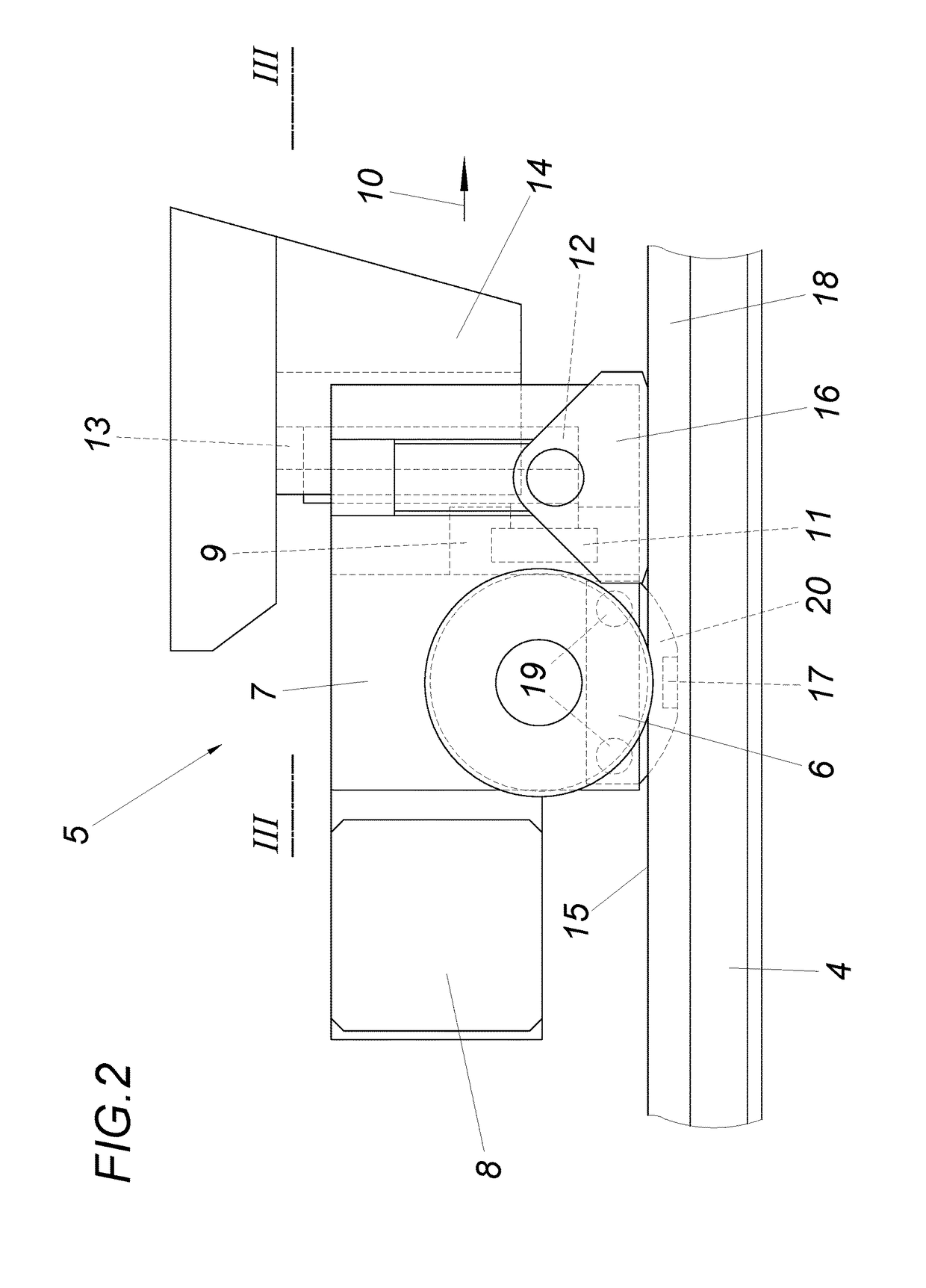

Rail vehicle having a device for finishing the running surface of track rails

A rail vehicle includes a milling device for finishing the running surface of track rails during the travel of the rail vehicle along the track rails. The rail vehicle has a chassis frame having wheel sets. The milling device is provided with a milling head, and includes a framework arranged on the chassis frame having a milling head receptacle, which is displaceable vertically and transversely in relation thereto. The milling head receptacle can be supported for the vertical guiding via a guide shoe on the running surface and for transverse guiding in parallel to the milling head shaft via a guide stop laterally on the railhead. The milling head receptacle forms a transverse carriage, which supports the guide shoe and the guide stop, and the guide path of which, which is vertically displaceable, is provided on the side of the milling head receptacle facing toward the guide shoe.

Owner:LINSINGER MASCHENBAU GES

Hypereutectoid Rail Waist On-Line Heat Treatment Method and Constraint Device

ActiveCN109252038BImprove performanceReduce the temperatureFurnace typesHeat treatment furnacesTemperature controlRailhead

The invention discloses an on-line heat treatment method of a rail web for a hypereutectoid steel rail and a restraint device thereof, and belongs to the technical field of metal heat treatment. The on-line heat treatment method comprises the following steps of firstly, controlling the temperature of the steel rail to be at 700 DEG C to 800 DEG C, and detecting the content, in percentage by mass,of carbon in the steel rail; next, sending the steel rail into the restraint device, and applying, by utilizing the restraint device, an accelerative cooling medium to the center of a tread of a railhead of the steel rail, two sides of the railhead and the center of a rail bottom; and finally, when the temperature of the steel rail is decreased to 450 DEG C to 500 DEG C, sending out the steel railfrom the restraint device. The on-line heat treatment method has the beneficial effects that the steel rail is stabilized by utilizing the restraint device; afterwards, the accelerative cooling medium under different pressures is applied to the railhead and the rail bottom of the steel rail according to the content of the carbon in the steel rail; the temperatures of the railhead and the rail bottom are rapidly decreased; the heat at the position of the rail web is caused to rapidly conduct towards two ends; thus, the residual stress of the rail web of the steel rail is decreased; the contentof secondary cementite of a high-carbon steel rail is inhibited; and finally, the overall performance of a weak position of the steel rail is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Rail regulation device in groove

PendingCN110735366AQuickly adjust postureCompact structureRailway track constructionRailheadControl theory

The invention discloses a rail regulation device in a groove. The device comprises a bracket block, a lateral regulation unit, a vertical regulation unit and a railhead clamping regulation unit, wherein the bracket block has a length which permits the bracket block to be stretched across a rail groove; the bottom surface of the bracket block is symmetrically provided with two lateral regulation bolt brackets; the lateral regulation unit comprises two lateral regulation bolts, wherein the two lateral regulation bolts are independently in threaded connection with the two lateral regulation boltbrackets, and the tail parts of the two lateral regulation bolts can be independently supported on two side walls of the rail groove; the vertical regulation unit comprises two lifting and lowering components installed on two ends of the bracket blocks, and can realize the lifting and the lowering of the bracket block; and the railhead clamping regulation unit comprises a lifting plate, a left suspension loop, a right suspension loop and a pre-tightening regulation bolt; and the railhead of the steel rail can be contained between the bracket block and the left suspension loop or between the bracket block and the right suspension loop. The device disclosed by the invention is simple and compact, can be suitable for regulating the positions of steel rails in all embedded rail grooves, can quickly regulate a gesture in the steel rail groove, saves time and is efficient.

Owner:CHENGDU XINTU TECH

High-toughness and plasticity hypereutectoid rail and manufacturing method thereof

ActiveUS20190105693A1High strengthHigh hardnessFurnace typesMetal rolling arrangementsRoom temperatureEngineering

Provided is a manufacturing method for high-toughness and plasticity hypereutectoid rail, including: a. hot rolling the steel billet into rail; b. blowing a cooling medium to the top surface of railhead, wherein, the two sides of railhead and the lower jaws on the two sides of railhead after the center of top surface of rail is air-cooled to 800-850° C., and cooling the rail until the center temperature of the top surface is 520-550° C.; c. stop blowing the cooling medium to the lower jaws on the two sides of railhead, continue blowing the cooling medium to the top surface of railhead and the two sides of railhead, and air cool the rail to room temperature after the surface temperature of railhead is cooled to 430-480° C. The resulting hypereutectoid rail has higher toughness and plasticity than existing products, which is suitable for heavy-haul railway, especially for small radius curve sections.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

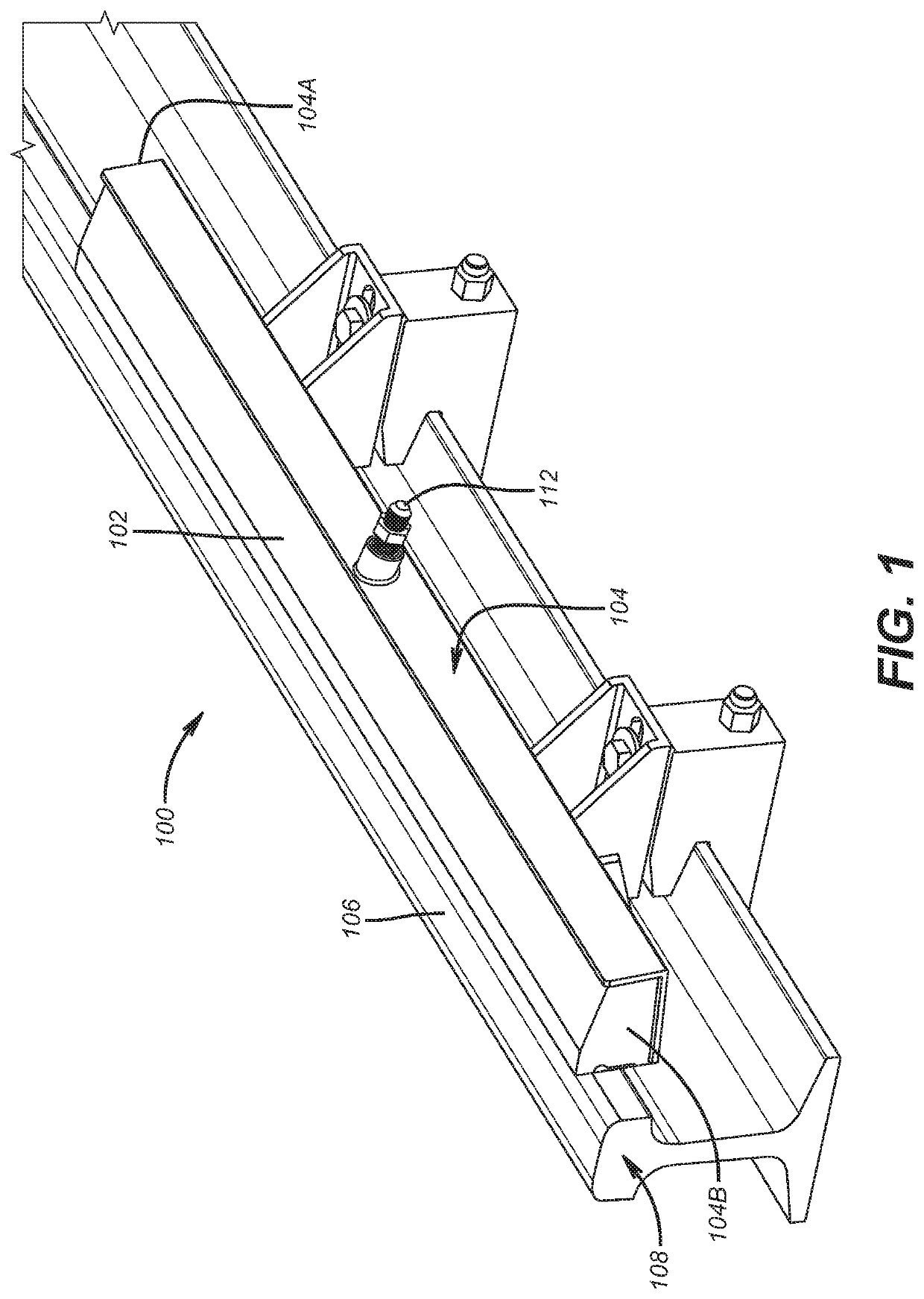

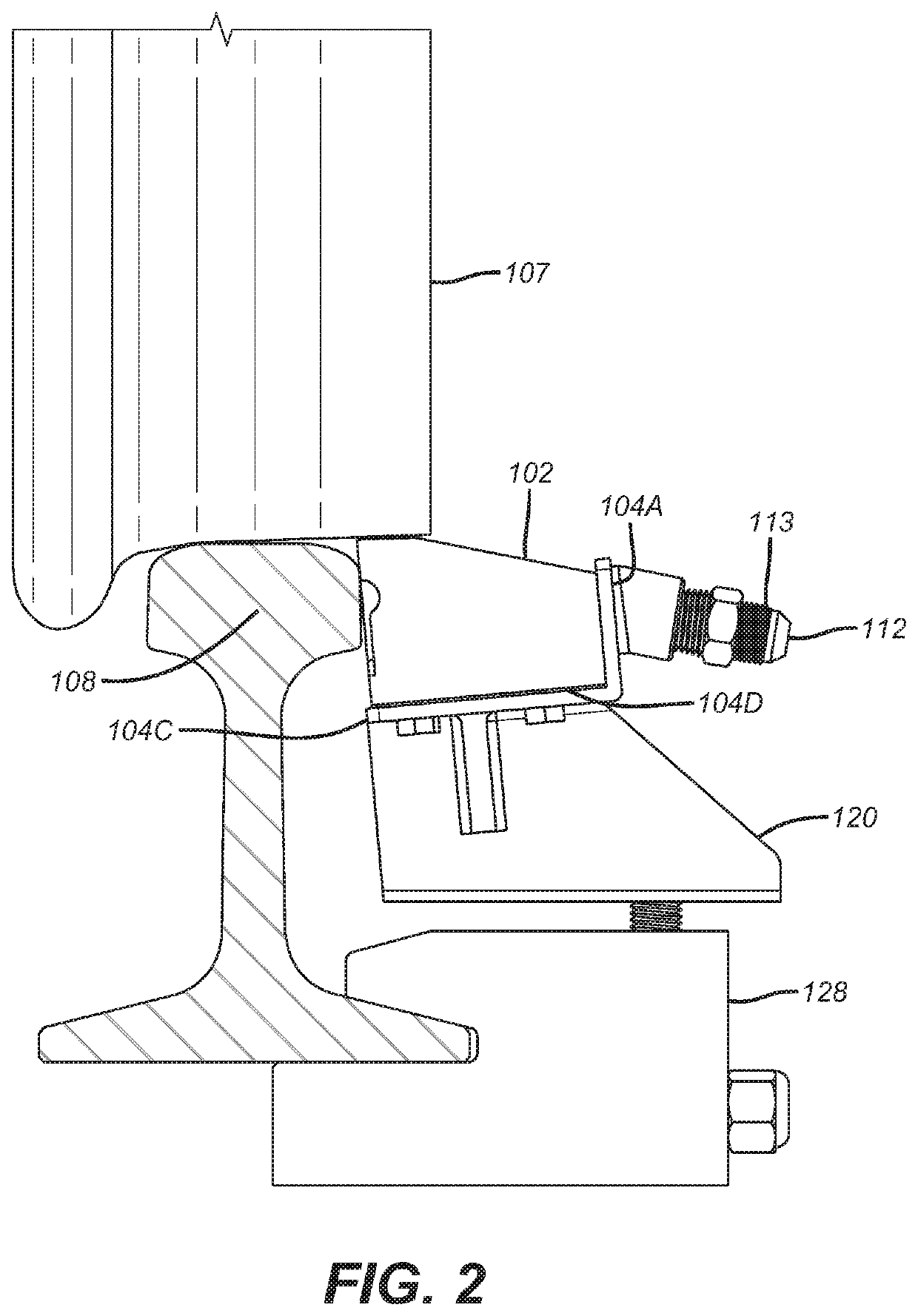

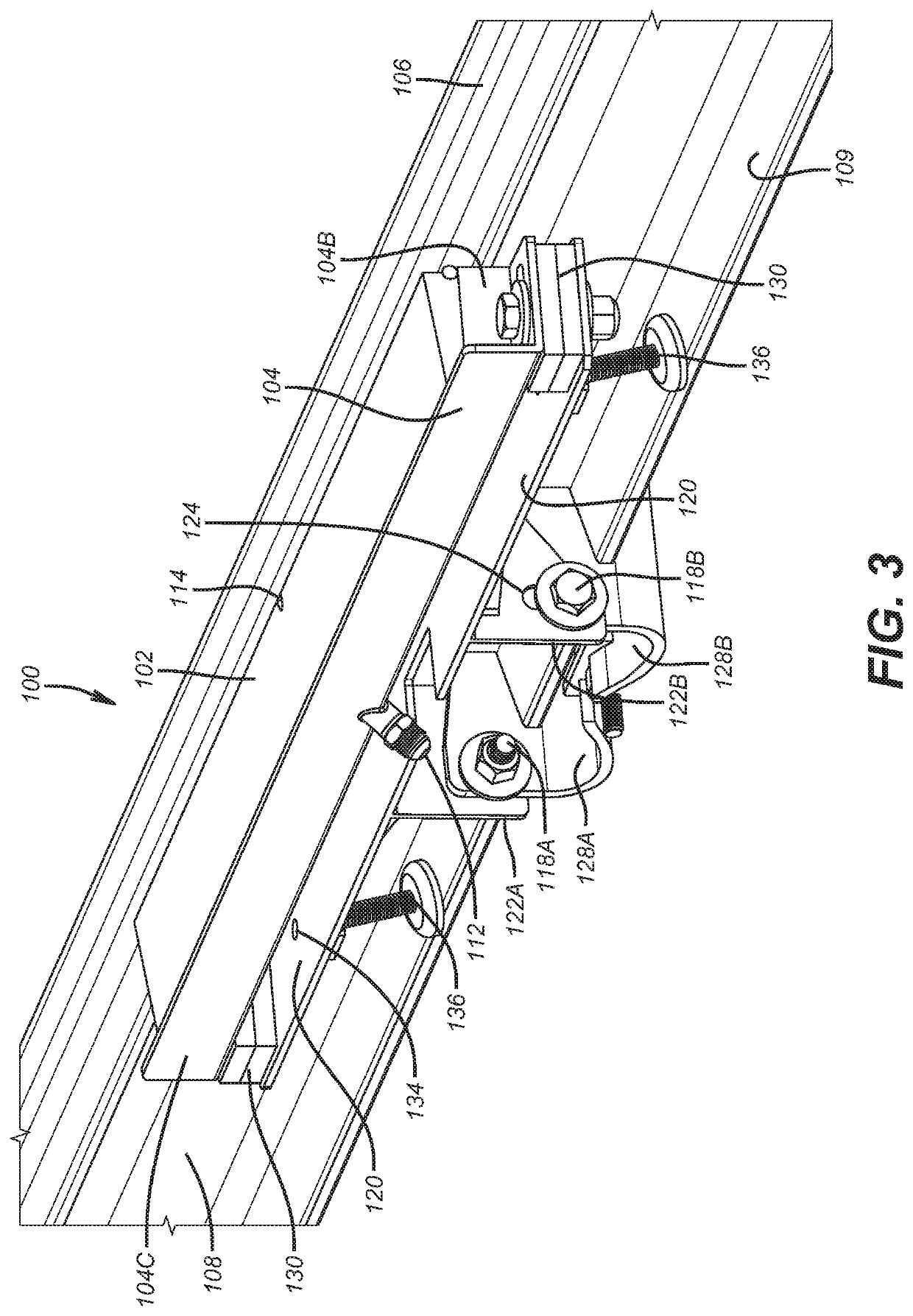

Top of rail applicator

A top of rail (TOR) applicator has a bar positioned in a housing and an exit orifice on the upper portion of the bar for delivering a friction control composition to the crown of a railhead. The upper portion of the bar slopes away from the friction control composition exit orifices. The bar may be composed of an elastomer such as polyurethane. Passageway extend from an inlet or entry orifice to the exit orifices. The friction reduction composition is pumped into the entry orifice, through the passageways to the exit orifices and then onto the crown of the railhead. The friction reduction composition may be thixotropic.

Owner:WHITMORE MFG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com