Seamless rail welding structure for improving welding bearing capacity and left and right operating stability

A bearing capacity, seamless rail technology, applied in the joints of rails, tracks, roads, etc., can solve problems such as left and right vibration, derailment, and up and down bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0043] In practical application, the roadbed is the existing reinforced concrete ballastless roadbed, and the steel rail 7 is various types of steel rails used by the existing heavy-duty trains, high-speed trains and urban rail trains. Plate fixing bolts and fasteners are completely unchanged.

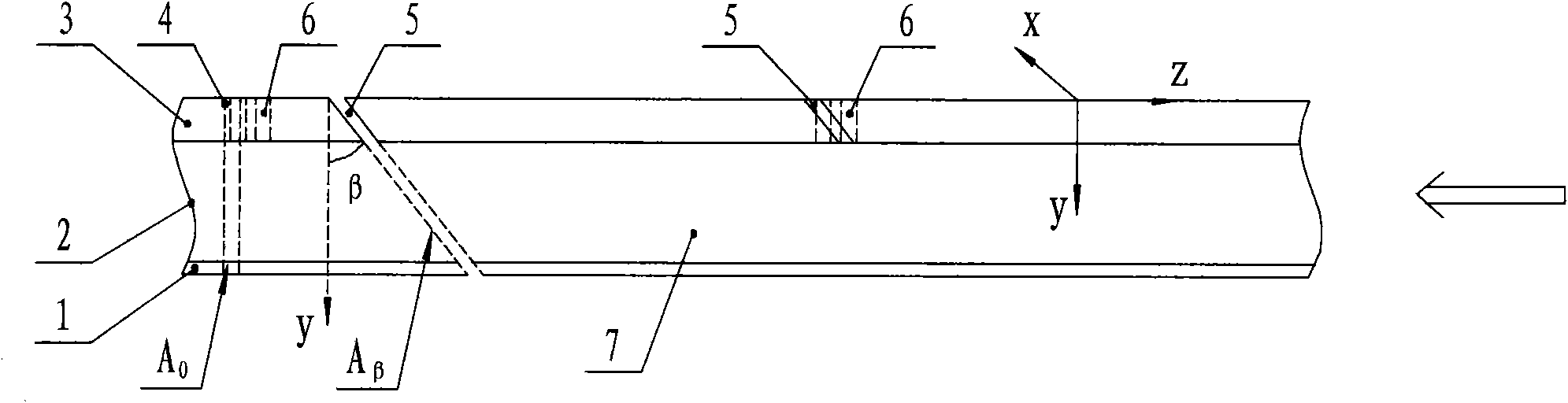

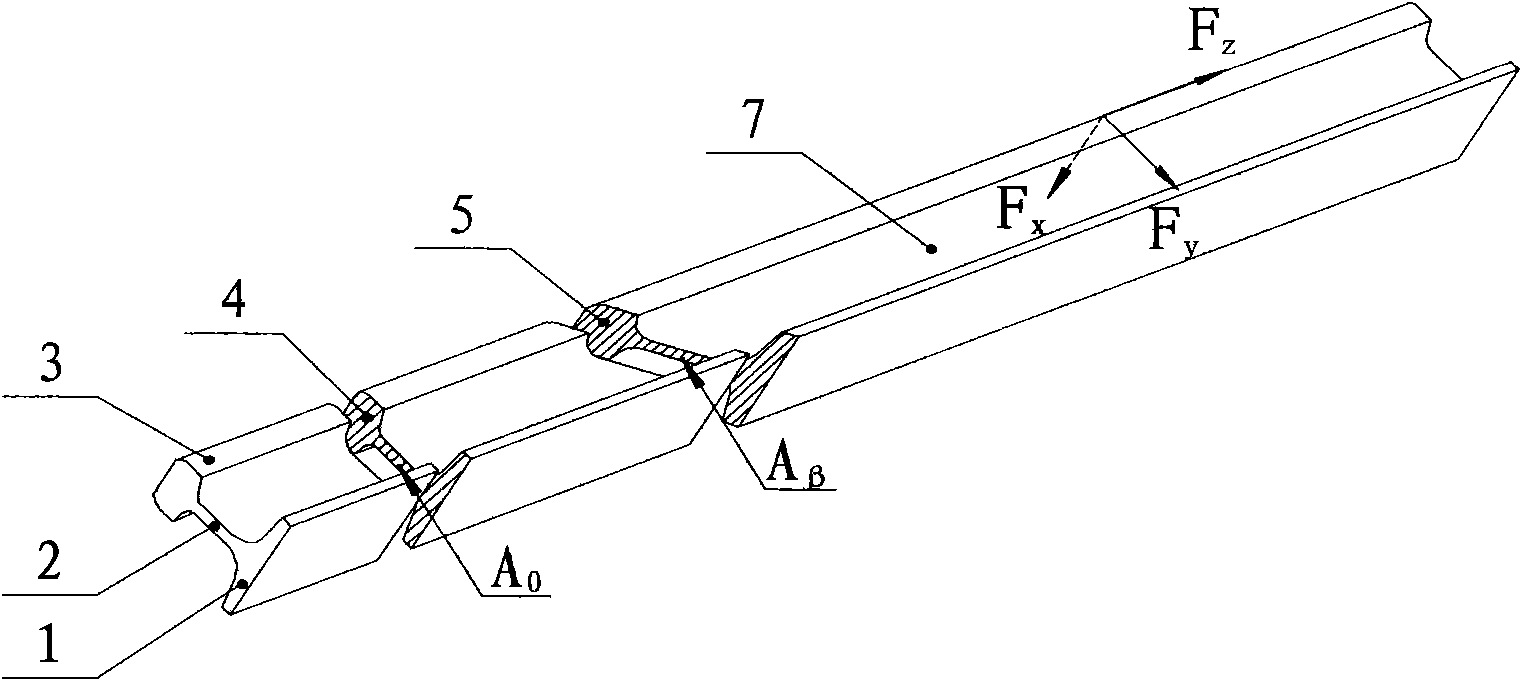

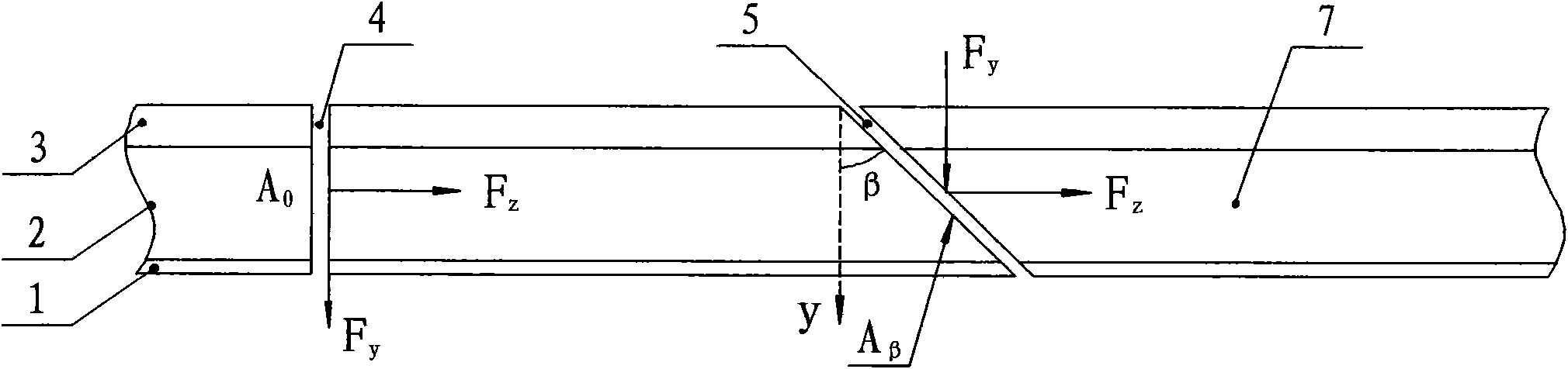

[0044] Use a band saw or a toothless saw to saw the ends of the two rails to be welded into a single slope parallel to the x-axis of the rail 7 and form a β angle with the y-axis of the rail 7, then align up and down, left and right, and reserve appropriate The weld seam 5 is welded by the aluminothermic welding process, followed by pushing, grinding, and heat treatment to complete the welding of the single-slope joint.

[0045] Due to the vertical force F of the running wheel tread on the rail head y Greater than the force F that the wheel tread passes through the rear of the rail to the front of the rail z , so τ 0y >σ 0z , set σ 0z / τ 0y = 2, 6, corresponding to (1) ~ (4) form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com