Patents

Literature

1470 results about "Vertical force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

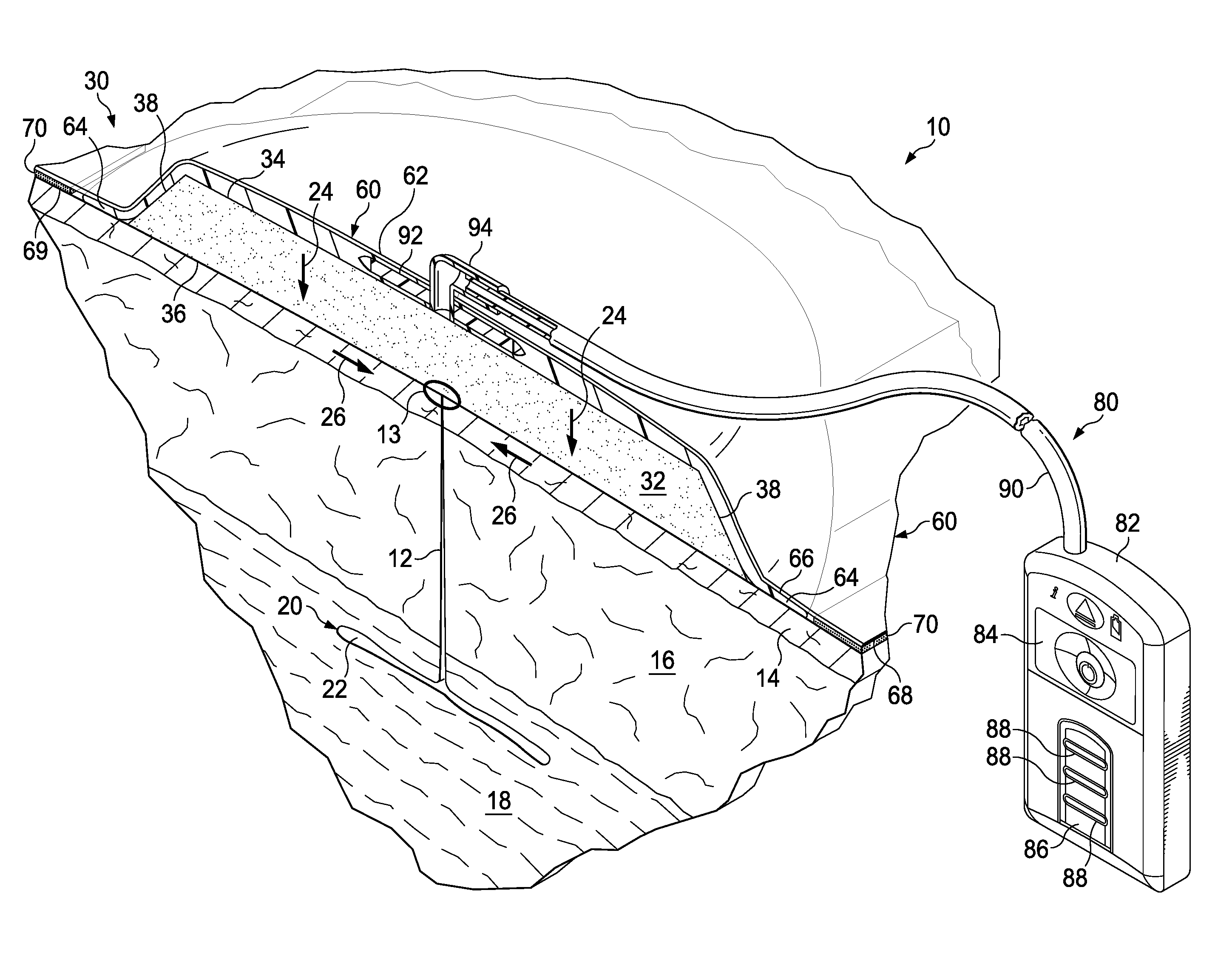

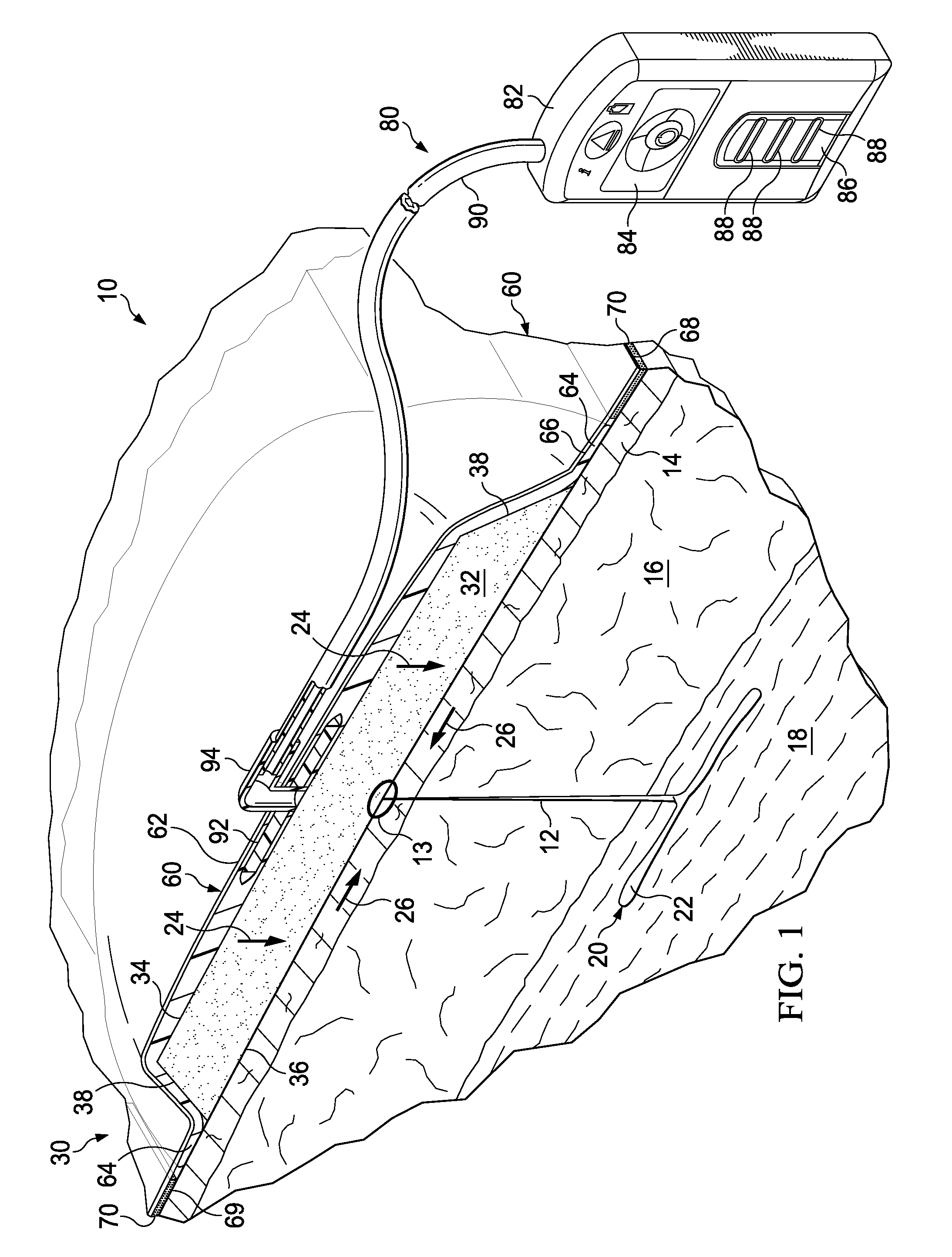

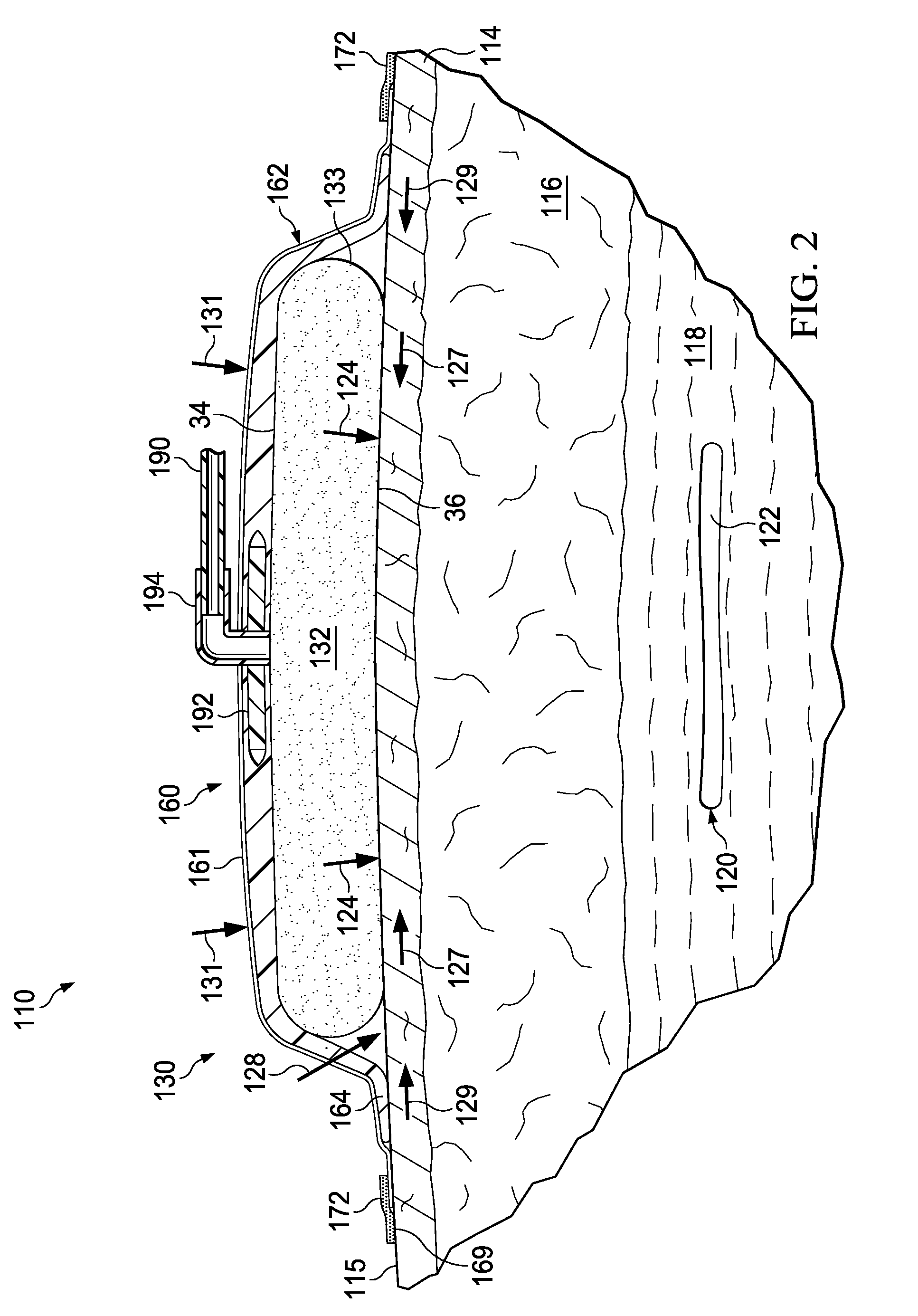

Reduced-pressure surgical wound treatment systems and methods

ActiveUS20090299257A1Reduce pressureNon-adhesive dressingsChiropractic devicesPressure systemSubcutaneous tissue

A reduced-pressure system for treating tissue, such as damaged subcutaneous tissue, includes a shaped dressing bolster for placing on the patient's epidermis and substantially sized to overlay the damaged subcutaneous tissue. The system further includes a sealing subsystem for providing a fluid seal over the shaped dressing bolster and a portion of the patient's epidermis, and a reduced-pressure subsystem for delivering a reduced pressure to the sealing subsystem. The reduced-pressure system may develop a force, which may include a vertical force that is realized at tissue site deeper than the epidermis or a closing force directed towards the incision. The shaped dressing bolster is shaped to evenly distribute the force. Other methods and systems are included.

Owner:3M INNOVATIVE PROPERTIES CO

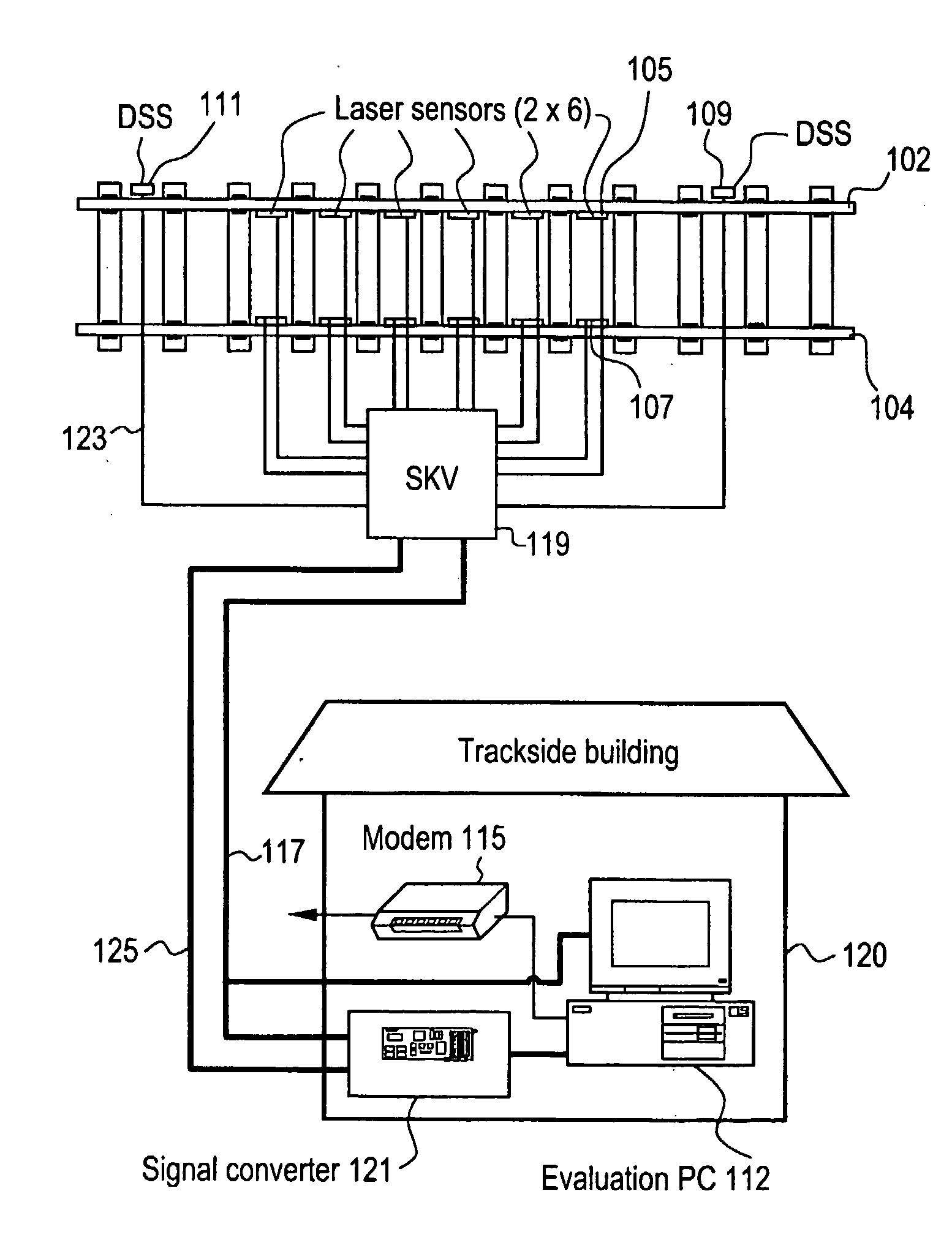

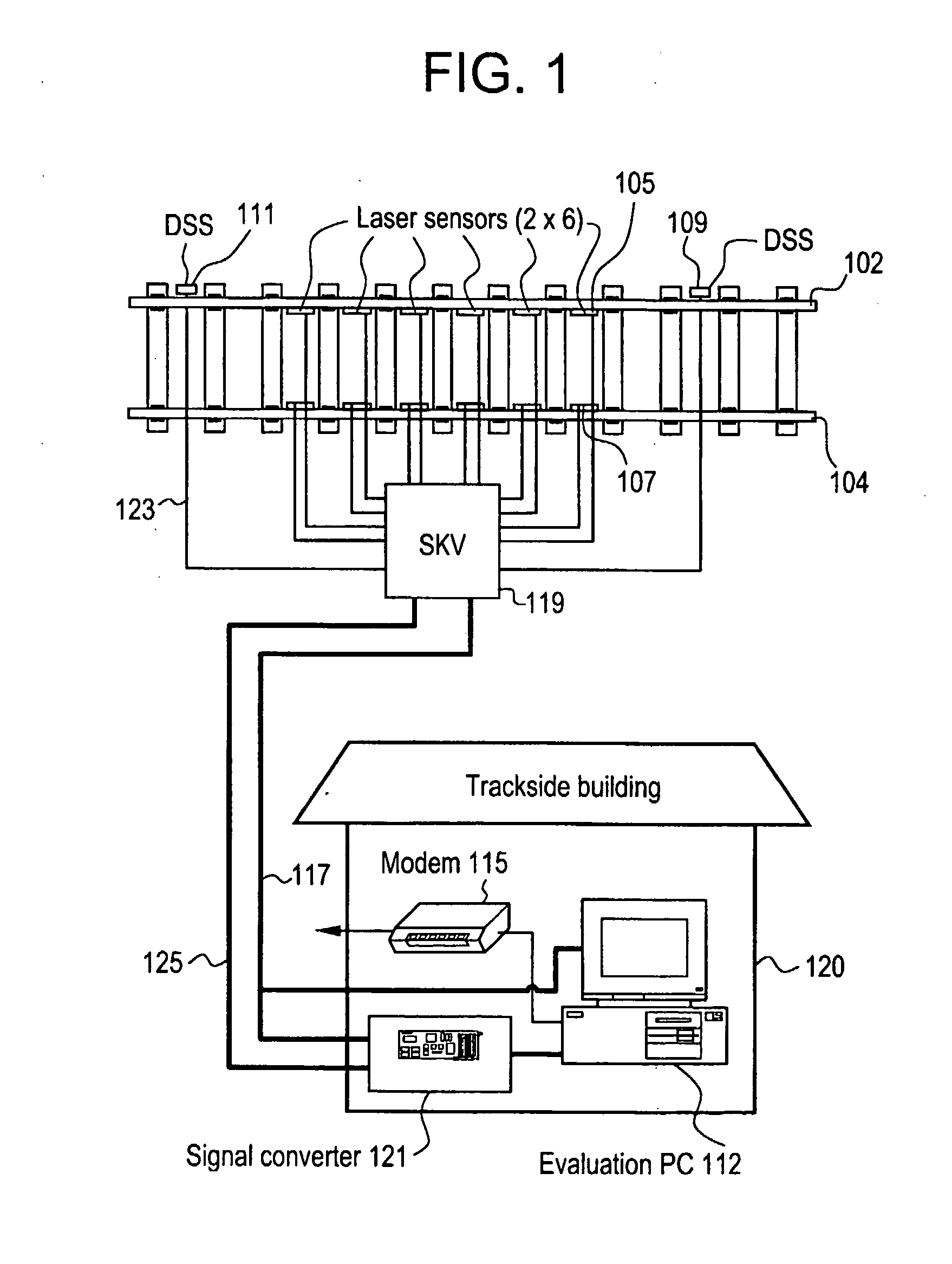

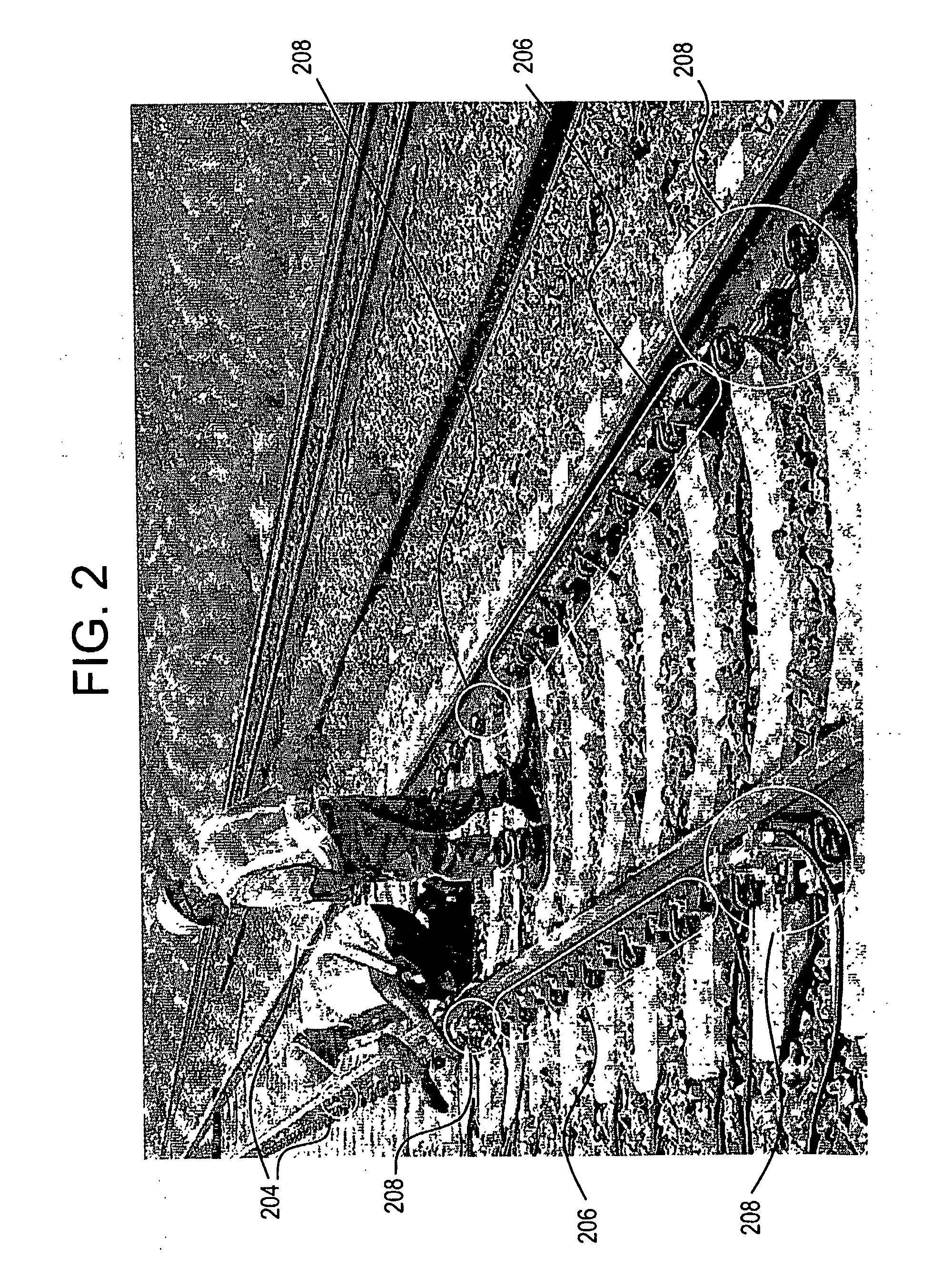

Rail Sensing Apparatus Method

ActiveUS20080304065A1Measure directlyMaterial analysis by optical meansUsing optical meansBogieLaser sensor

A rail sensing and analysis system utilizes a laser sensor 105, 107 to detect displacement of a rail 102, 104 resulting from loads imposed by a passing rail vehicle. Vertical and / or lateral displacements / loads may be sensed. Signatures in the resulting signals are indicative of useful information about the rail vehicle; such as wheel condition, bearing condition, truck condition, degree of bogie hunting, total load, load distribution, etc. The ratio of Lateral over Vertical force (L / V) may be used as an evaluation criterion.

Owner:PROGRESS RAIL SERVICES

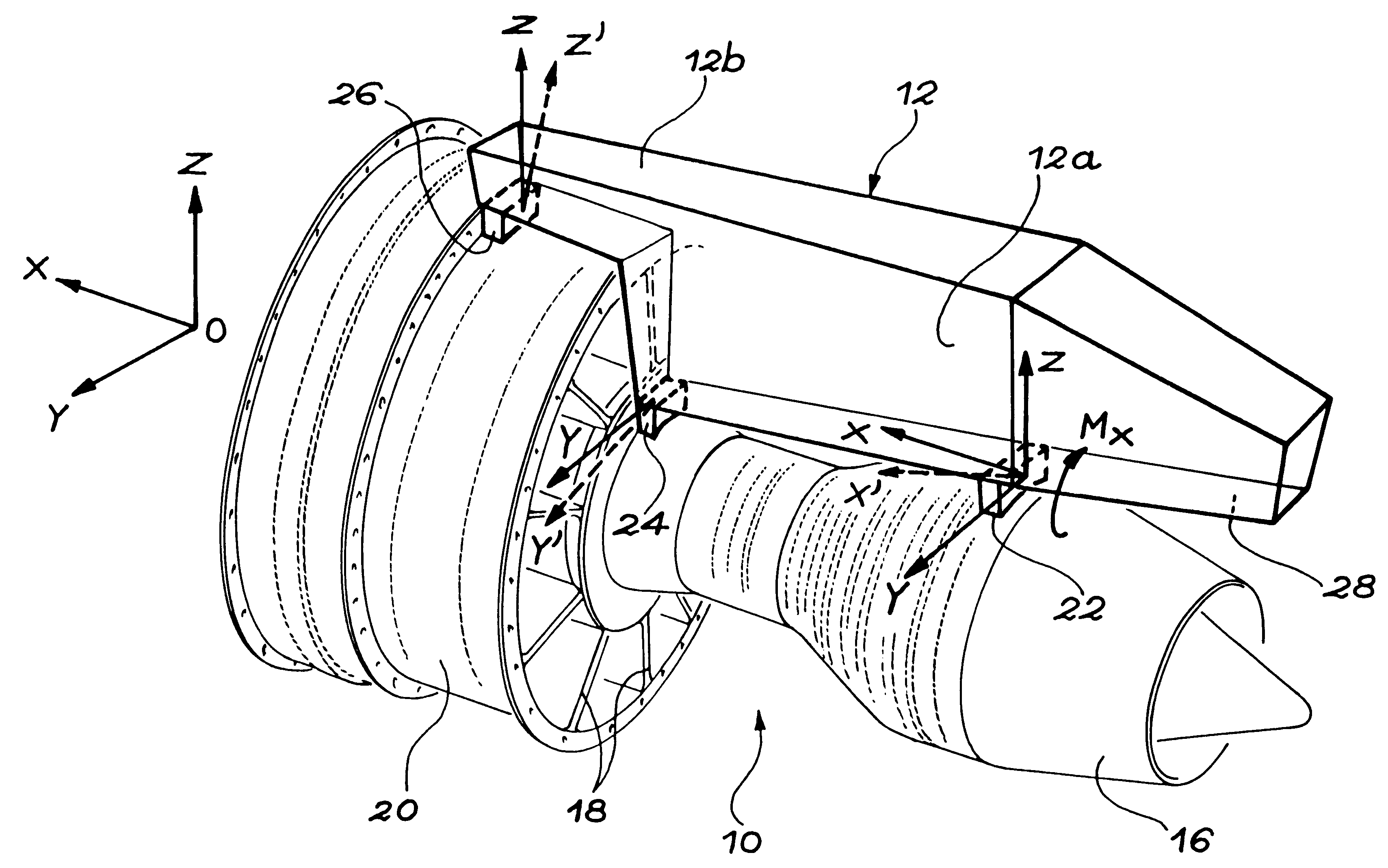

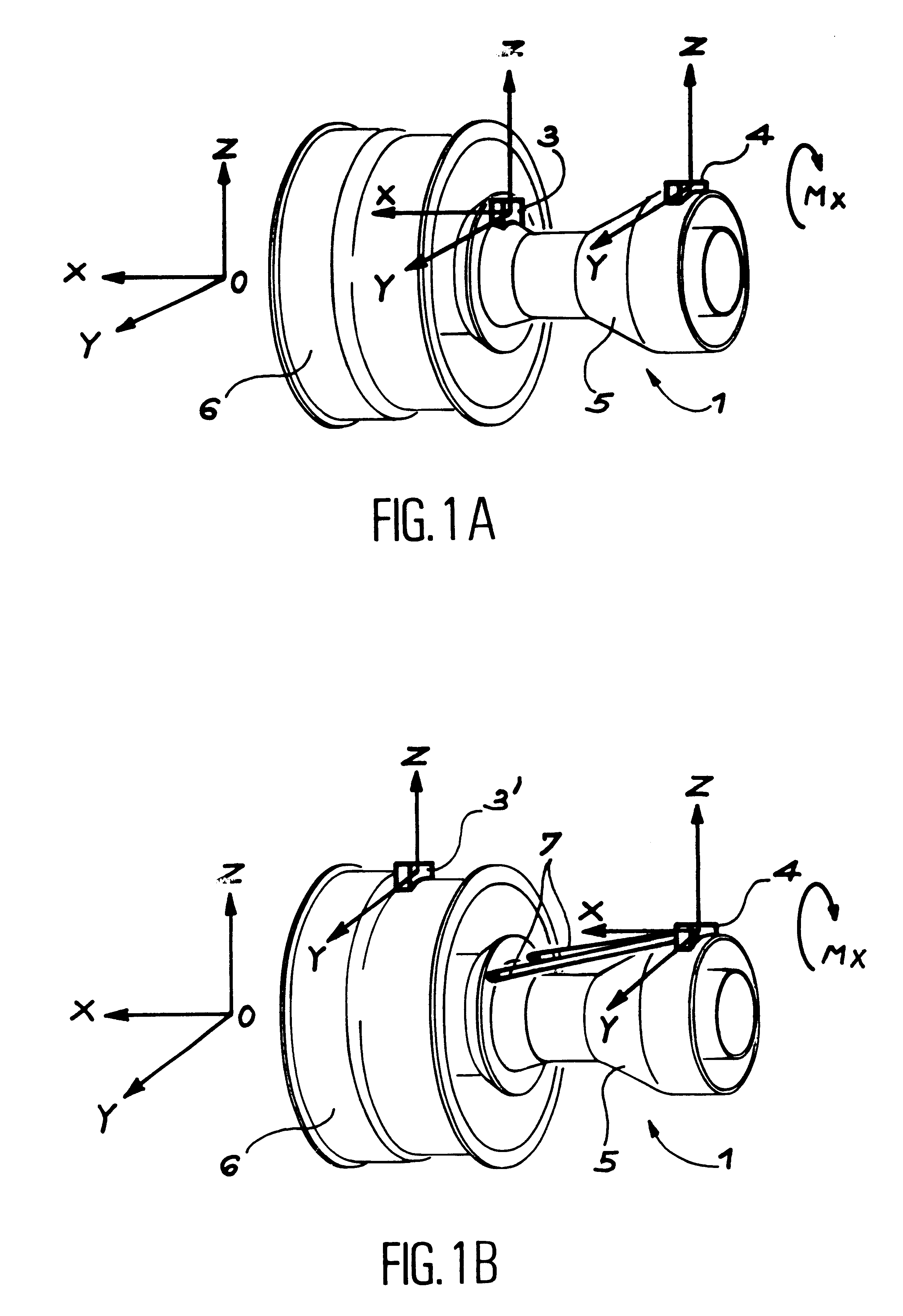

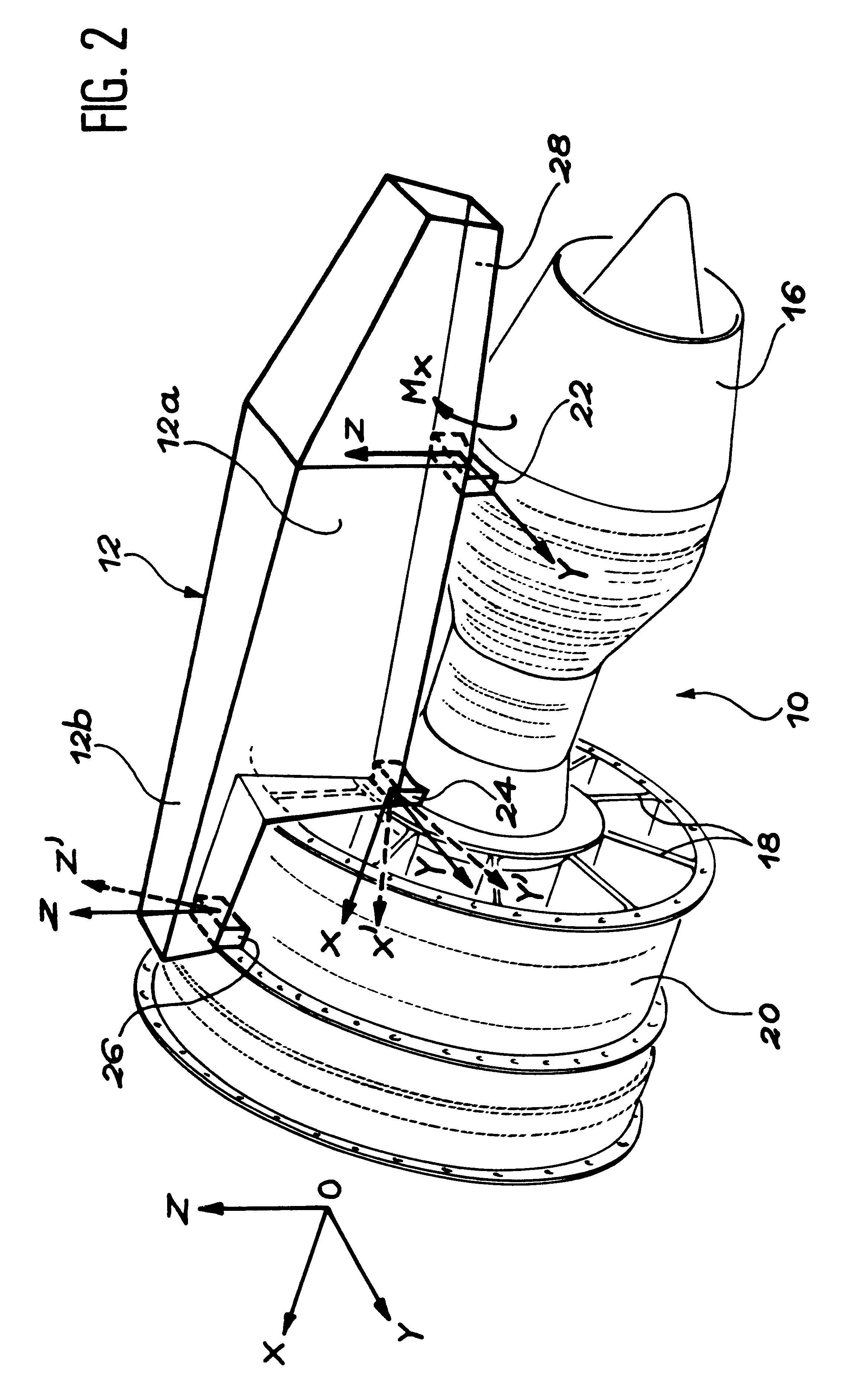

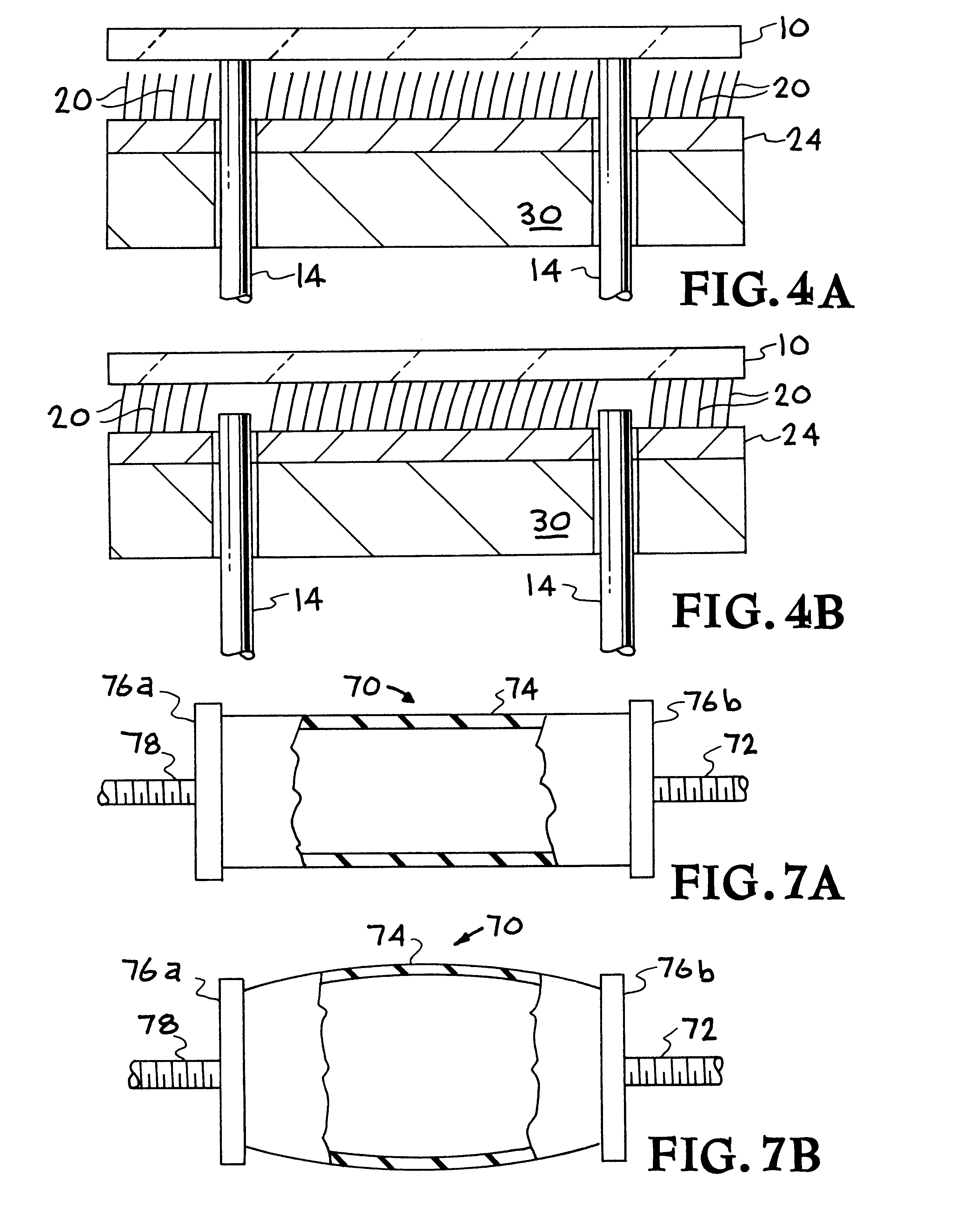

Device for fixing an aircraft propulsion system to a strut and a strut adapted to said device

An aircraft propulsion system (10) is connected to a strut, fixed to the wing or fuselage, by a fixing device comprising at least one rear mount (22) and two front mounts (24, 26). The rear mount (22) and a first (24) of the front mounts connect a main part (12a) of the frame (12) of the strut to the central casing (16) of the engine. The other front mount (26) connects a front part (12b) projecting from the strut frame (12) to the fan stator case (20) and mainly takes up the vertical forces (Z). Thus, the first front mount (24) can be simplified and bending or sagging of the engine is reduced.

Owner:AEROSPATIALE AIRBUS

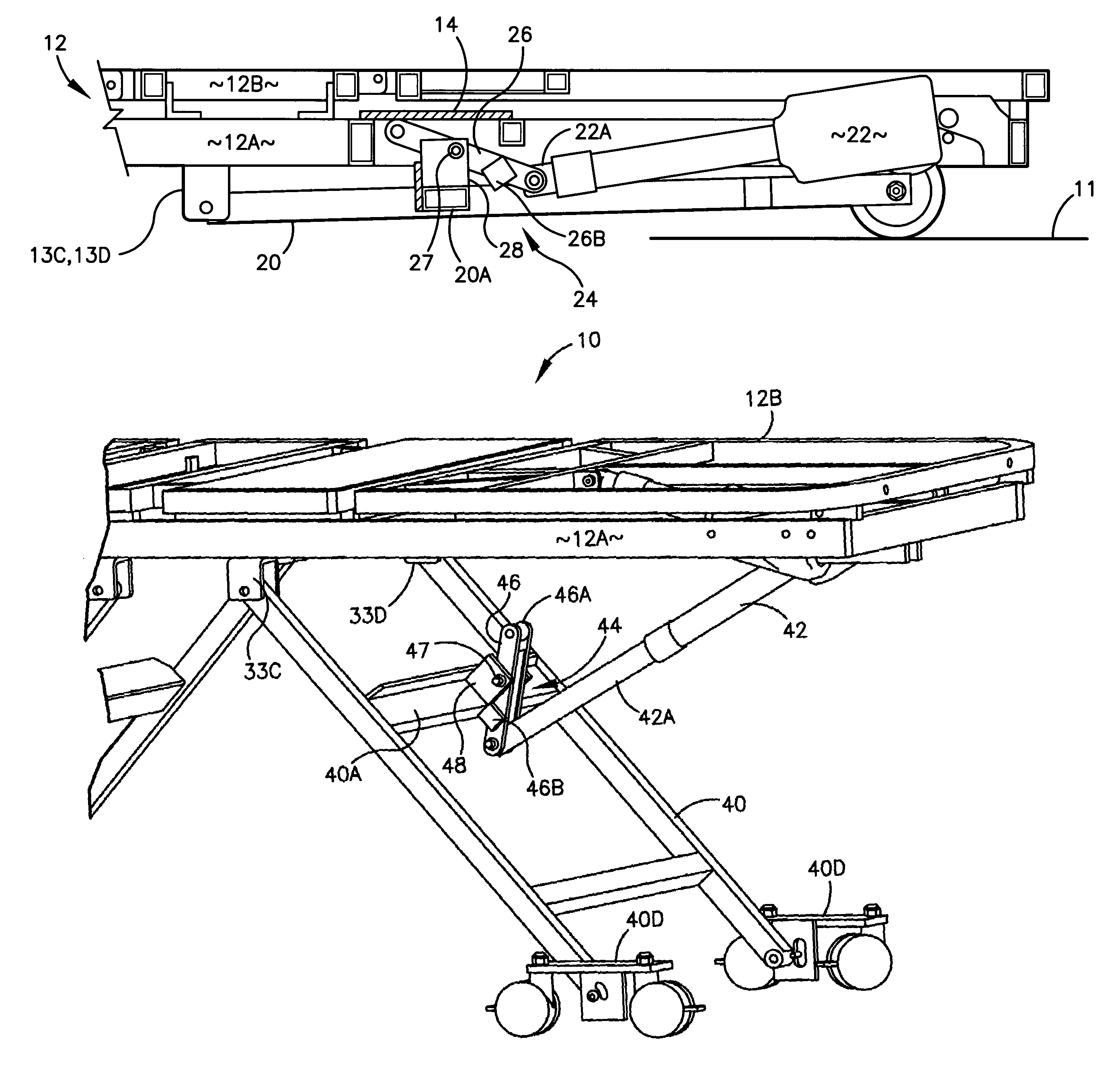

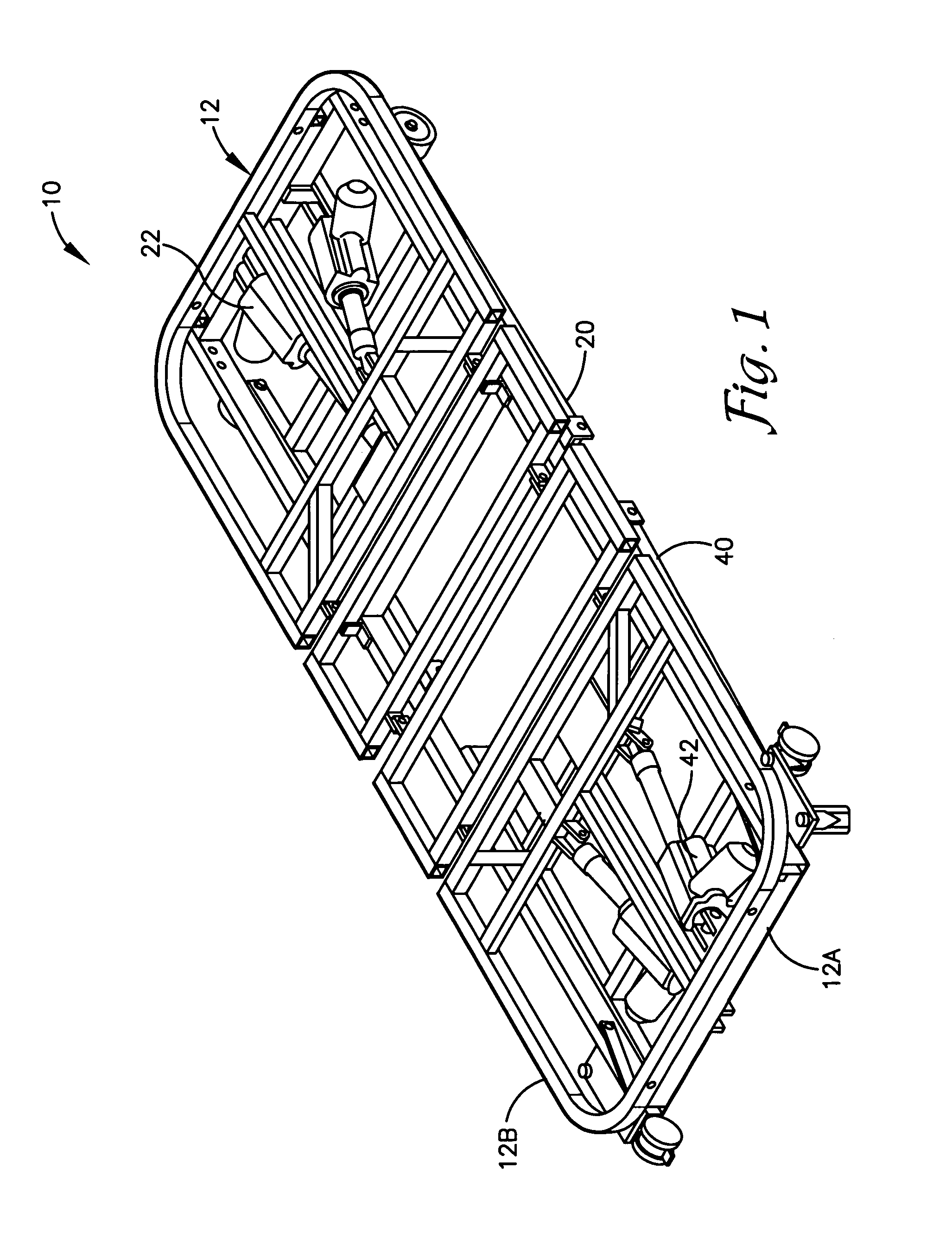

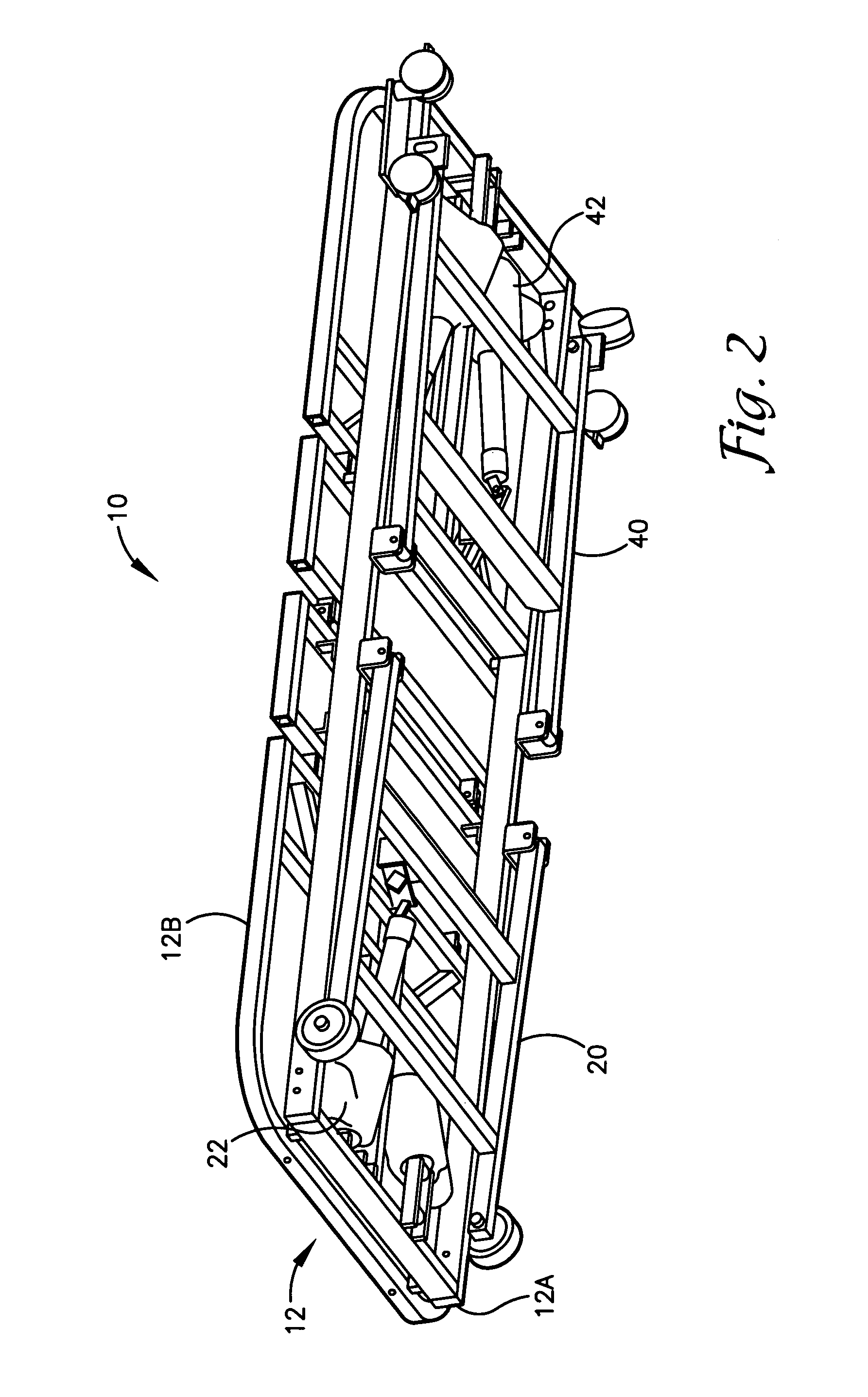

Low profile hospital bed

A low profile hospital bed includes a mattress support frame and pivotably mounted wheel frames. Lift actuators connecting between the mattress support frame and the wheel frames move the wheel frames between a folded position and an unfolded position. When the wheel frames are in the folded position, the lift actuators are relatively horizontal and thus unable to provide enough vertical force to move the wheel frames. Accordingly, connecting between the actuators and the wheel frames are leverage members which rotate and urge the wheel frames away from mattress support frame during an initial, first stage of movement as the wheel frames partially unfold. After the first stage of movement, the leverage members function as simple mechanical links between the lift actuators and the wheel frames as the lift actuators continue to power the complete unfolding of the wheel frames.

Owner:SIZEWISE RENTALS

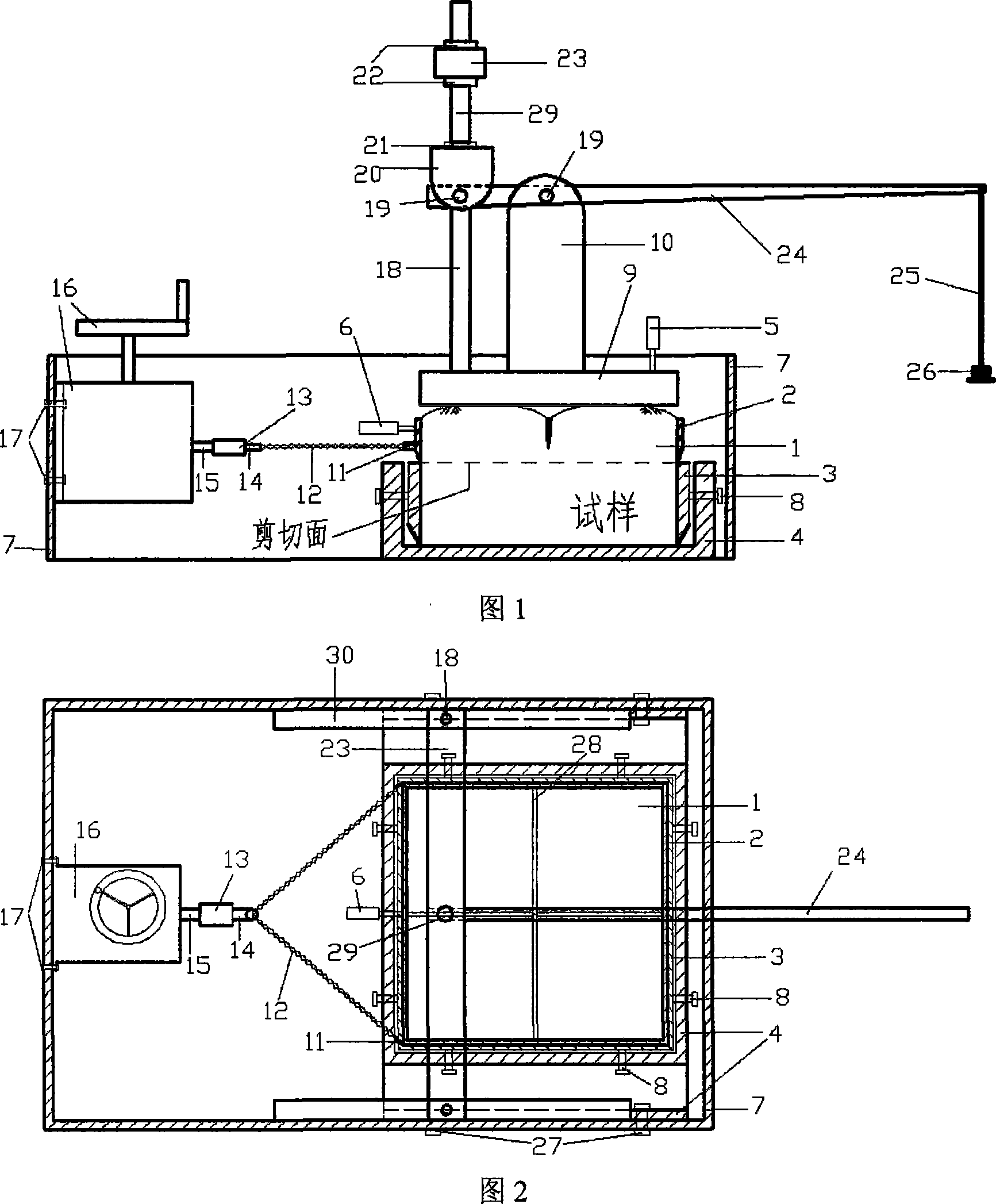

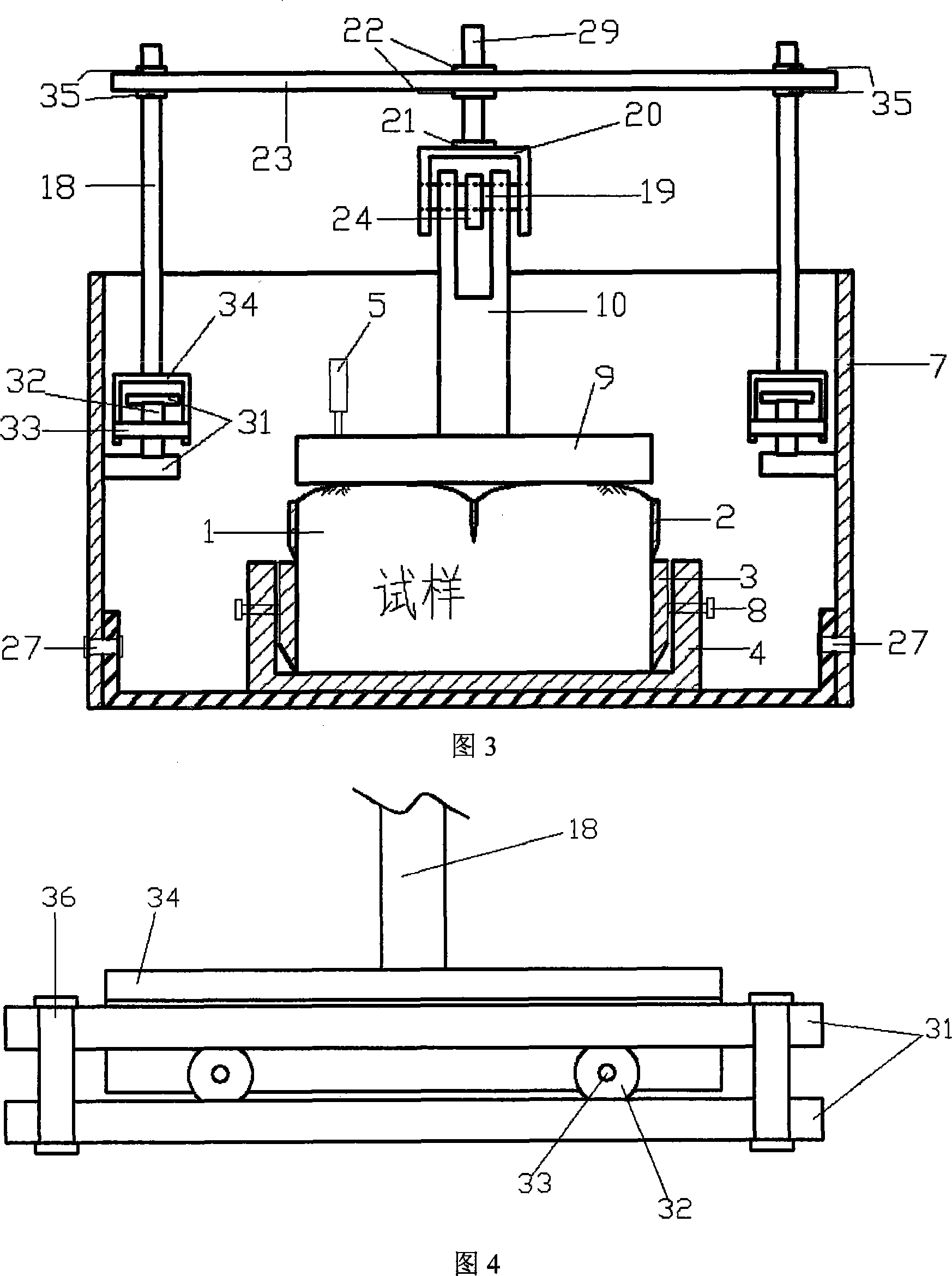

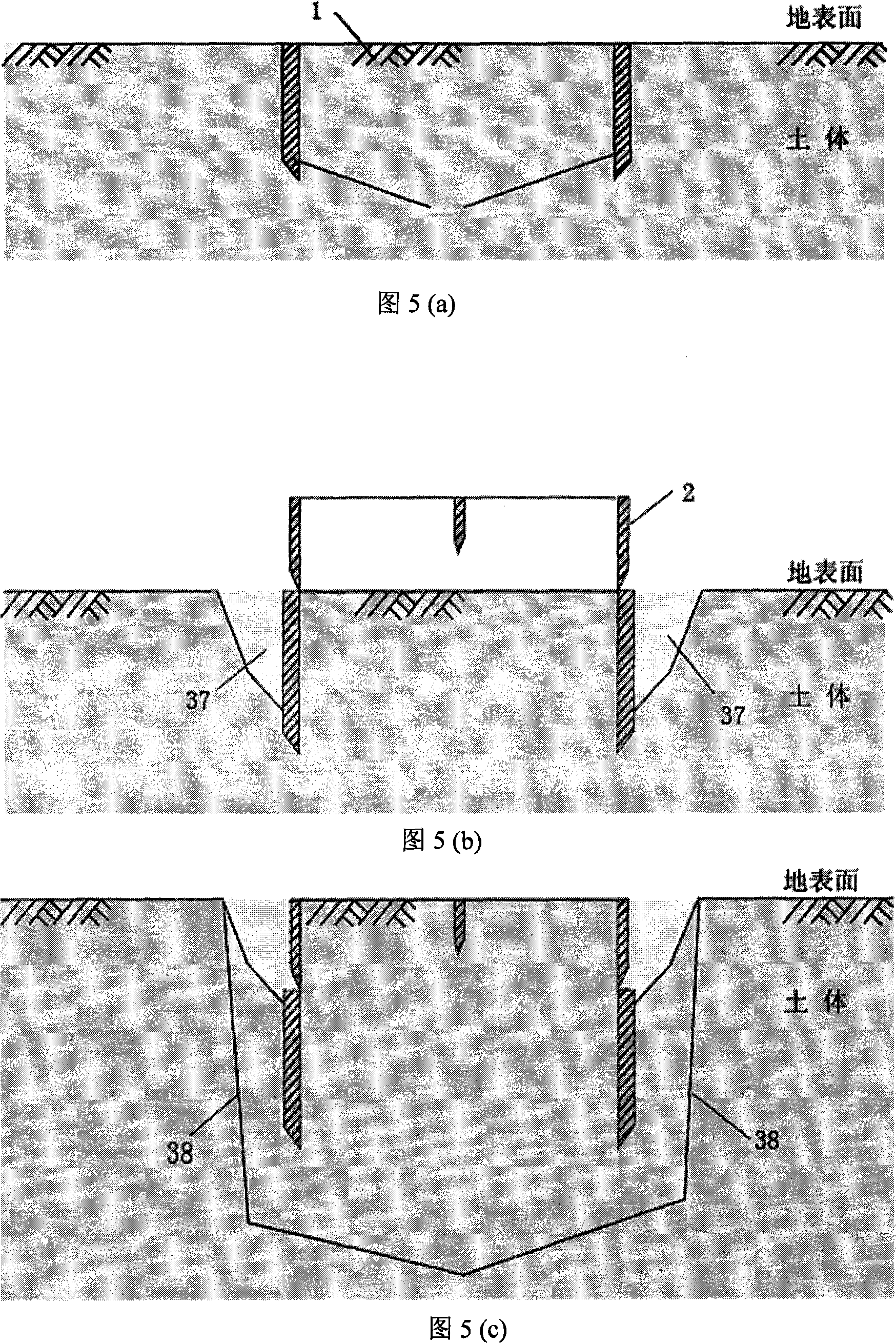

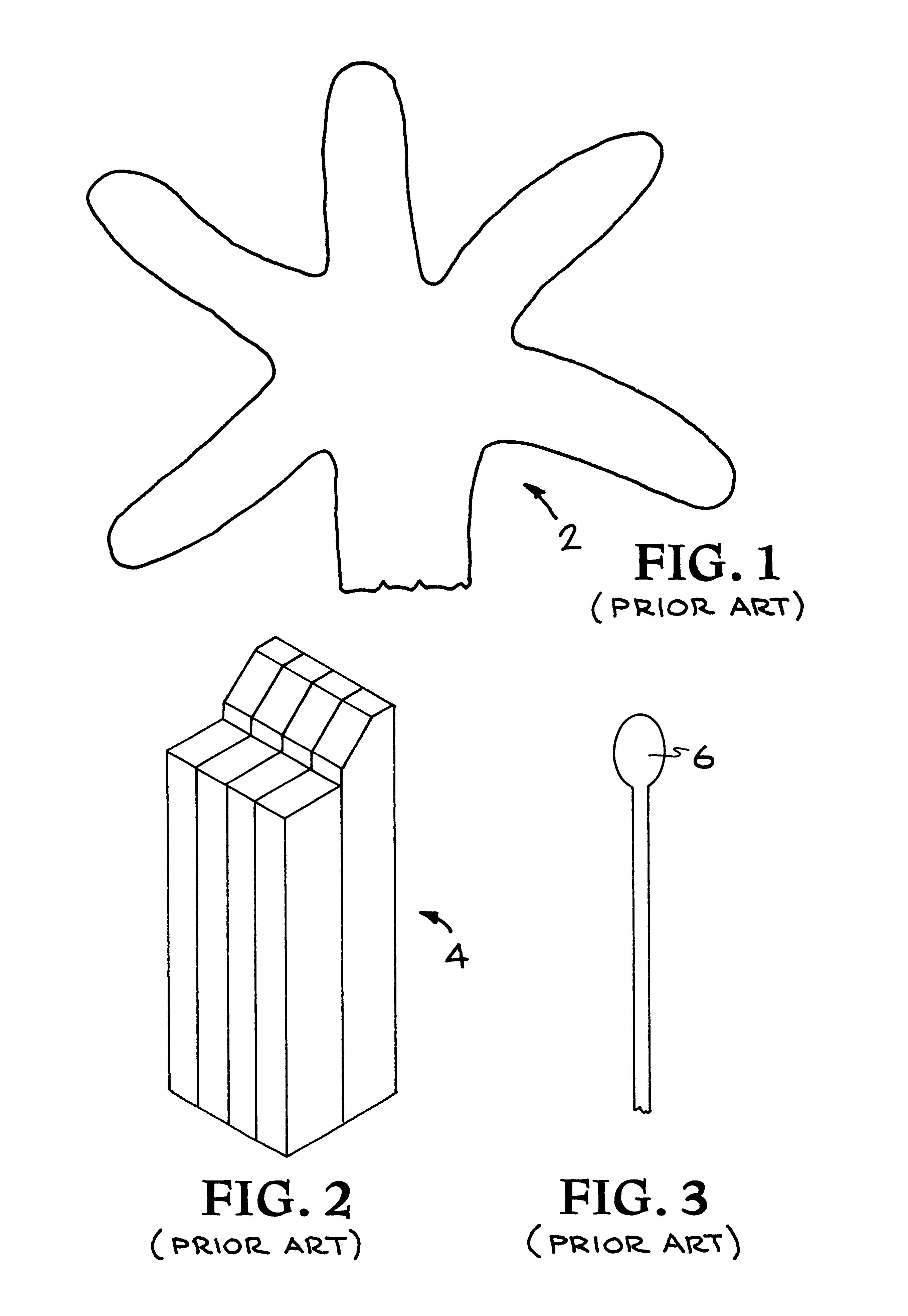

Portable on-spot and indoor dual-purpose direct-cutting experiment instrument and its sampling method

InactiveCN101105433AEasy detectionTruly reflect the volume changeWithdrawing sample devicesMaterial strength using steady shearing forcesField testsEngineering

A direct shear tester for both portable field test and indoor test and a sampling and testing method are provided. The tester comprises a sampling device, a portable vertical load system and a horizontal shear system. The testing method comprises burying a rigid frame together with a cruciform shear frame in the soil of a place to be test, digging out the whole soil containing the rigid frame and the cruciform shear frame to obtain an integrated sample with less interference, placing and fixing the integrated sample in a rigid frame base on a box-shaped frame, applying a vertical force by using the portable vertical load system on the box-shaped frame, and measuring the strength of the sample by using the shear frame. During the test process, the volume change of the sample in the vertical direction is not limited. The tester has simple structure, easy operation and good portability. The testing method employs flexible tension shear mode instead of the rigid top-bunt shear mode, overcomes the friction and sampling problems, and avoids the vertical pressure offset during the test process by using the portable vertical loading system, thereby increasing the test accuracy.

Owner:HOHAI UNIV

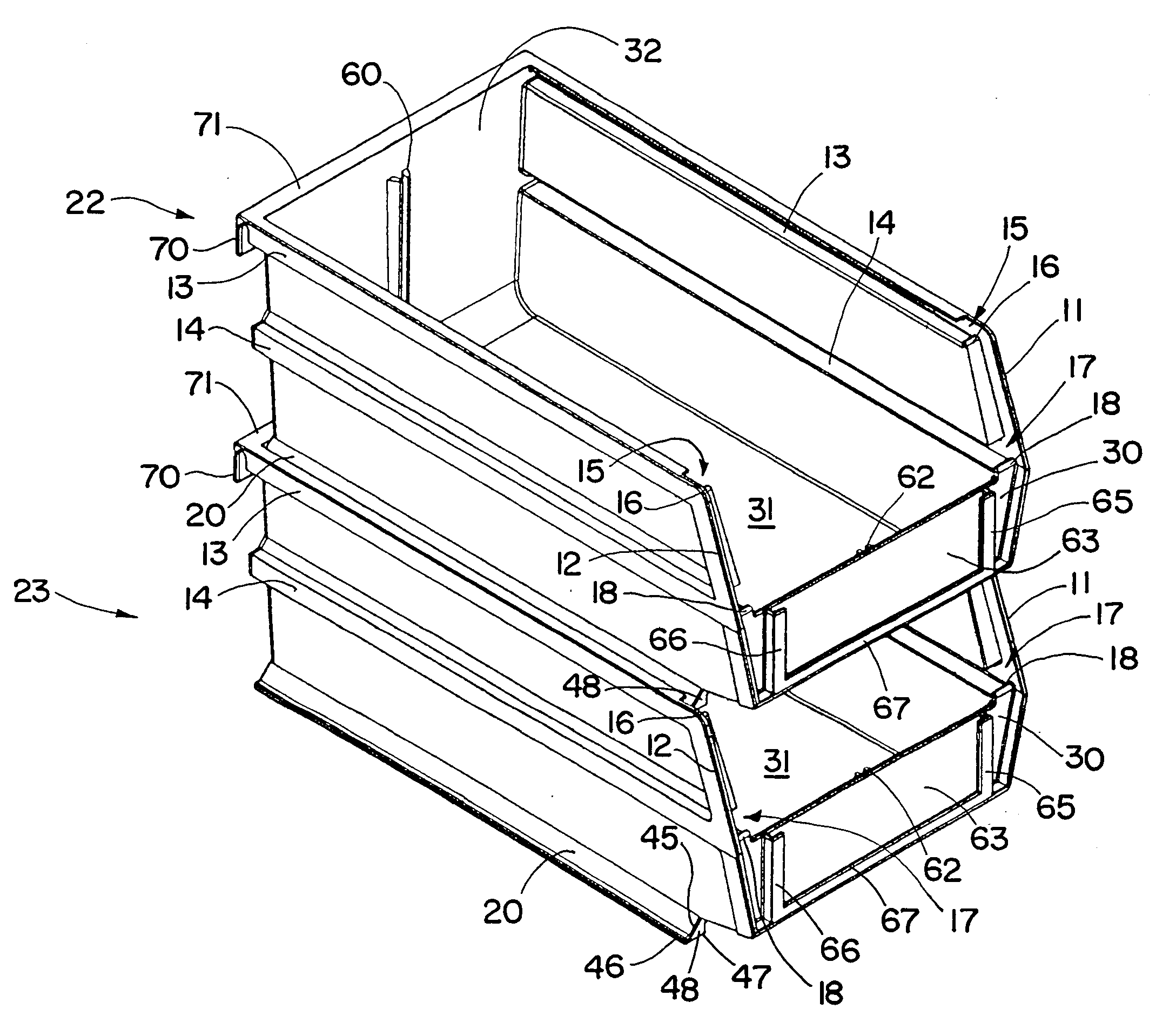

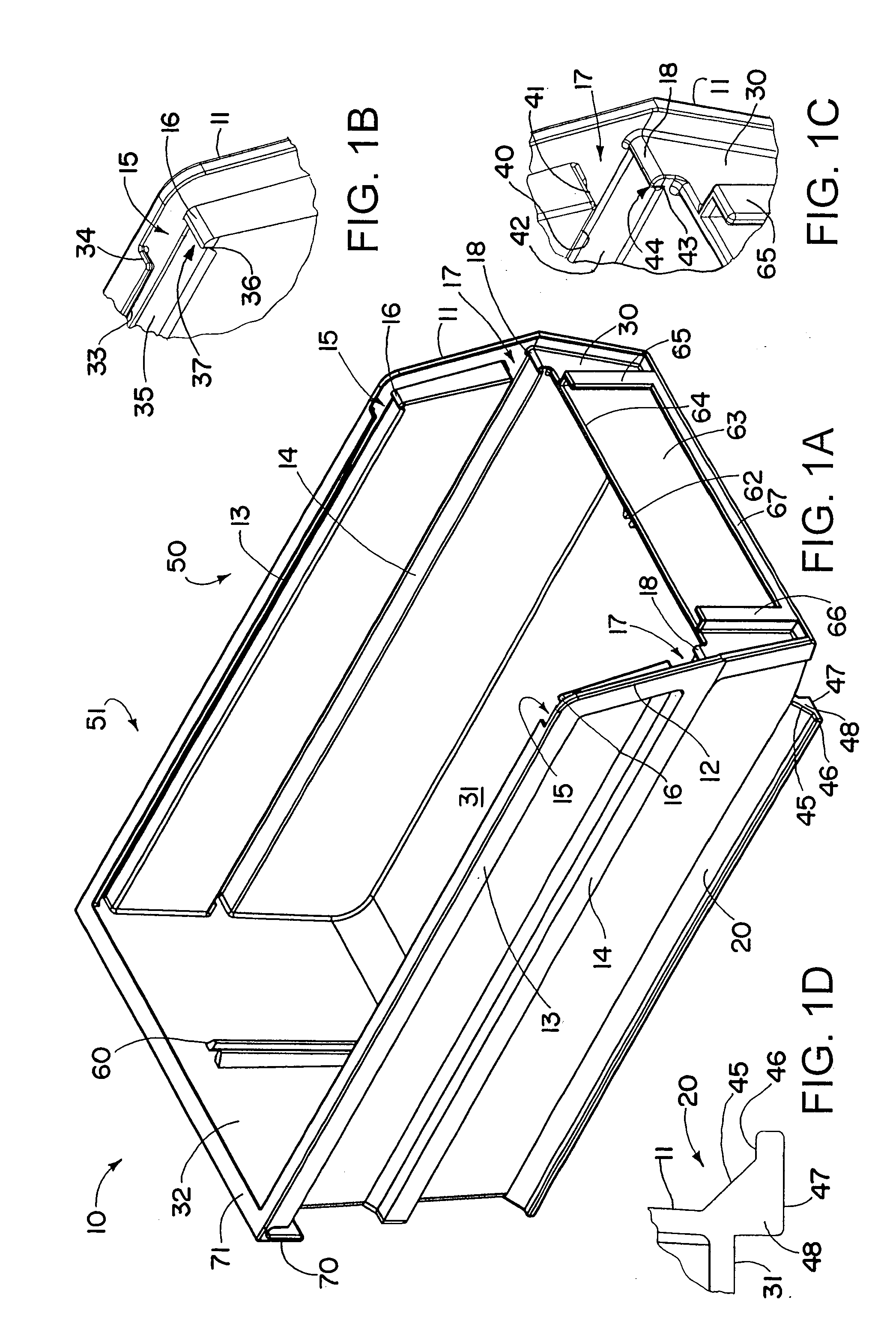

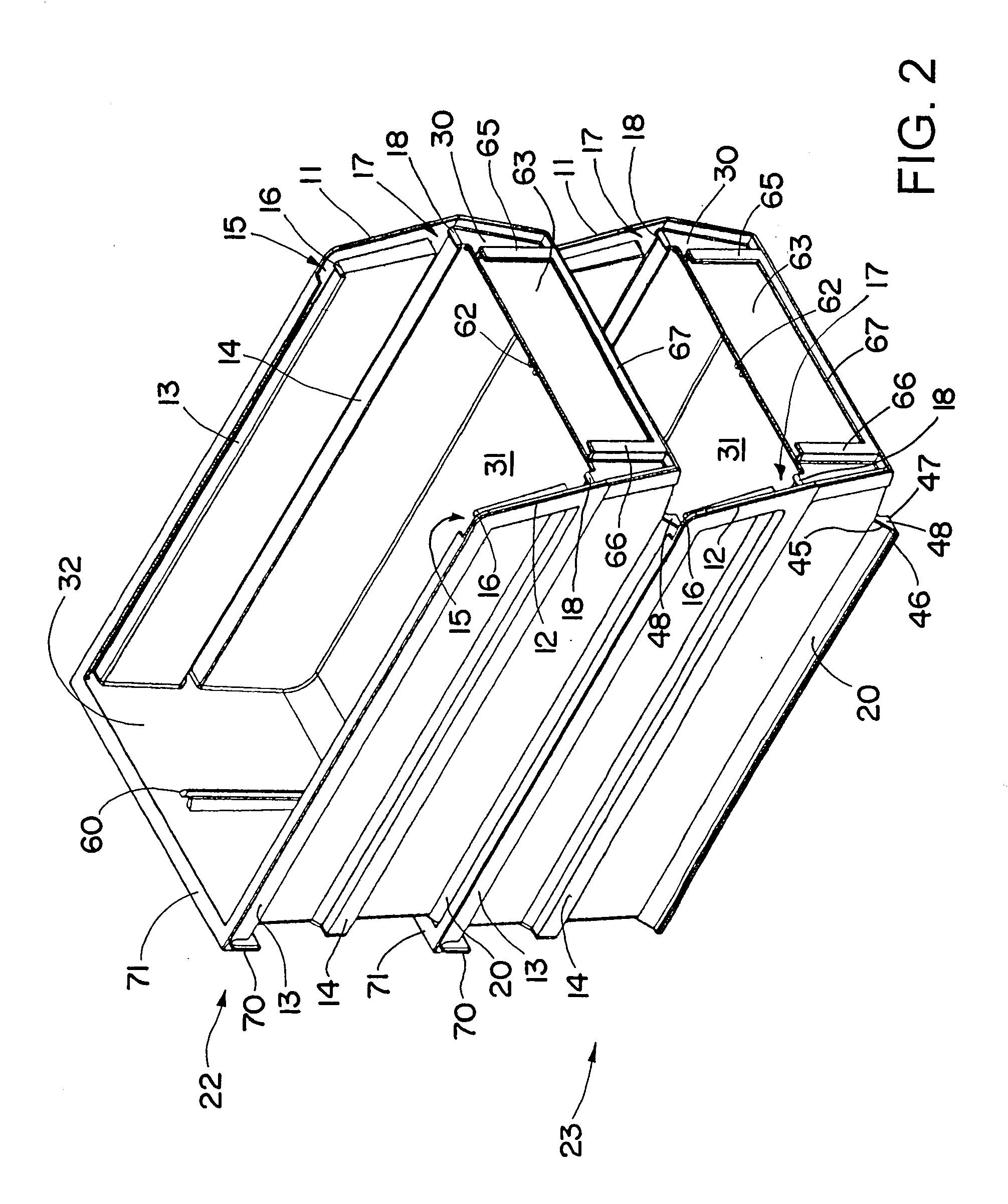

Multi-function storage bin

InactiveUS20090178989A1Limit horizontal movementShow cabinetsKitchen equipmentHorizontal forceEngineering

A storage bin having two side walls, each having an upper channel and a lower channel. The upper and lower channels have a point of entry that is partially blocked by a tab. The storage bin also has a pair of feet, which are insertable into the upper channels to stack the bins, or the lower channels to nest the bins. The tabs partially block the points of entry and act as a barrier to inhibit removal of the feet from the channels. Removal of the feet from the channels generally requires a vertical force to lift the feet over the tab and a horizontal force to slide the feet out of the channel. The channel and tab configuration therefore reduces the risk that the bins will fall into one another, tip over and separate or crack from placing unnecessary stress on the side walls of the bin when inserting and removing the feet from the channel. These as well as other features of the storage bin, are described more fully below.

Owner:TRITON PROD

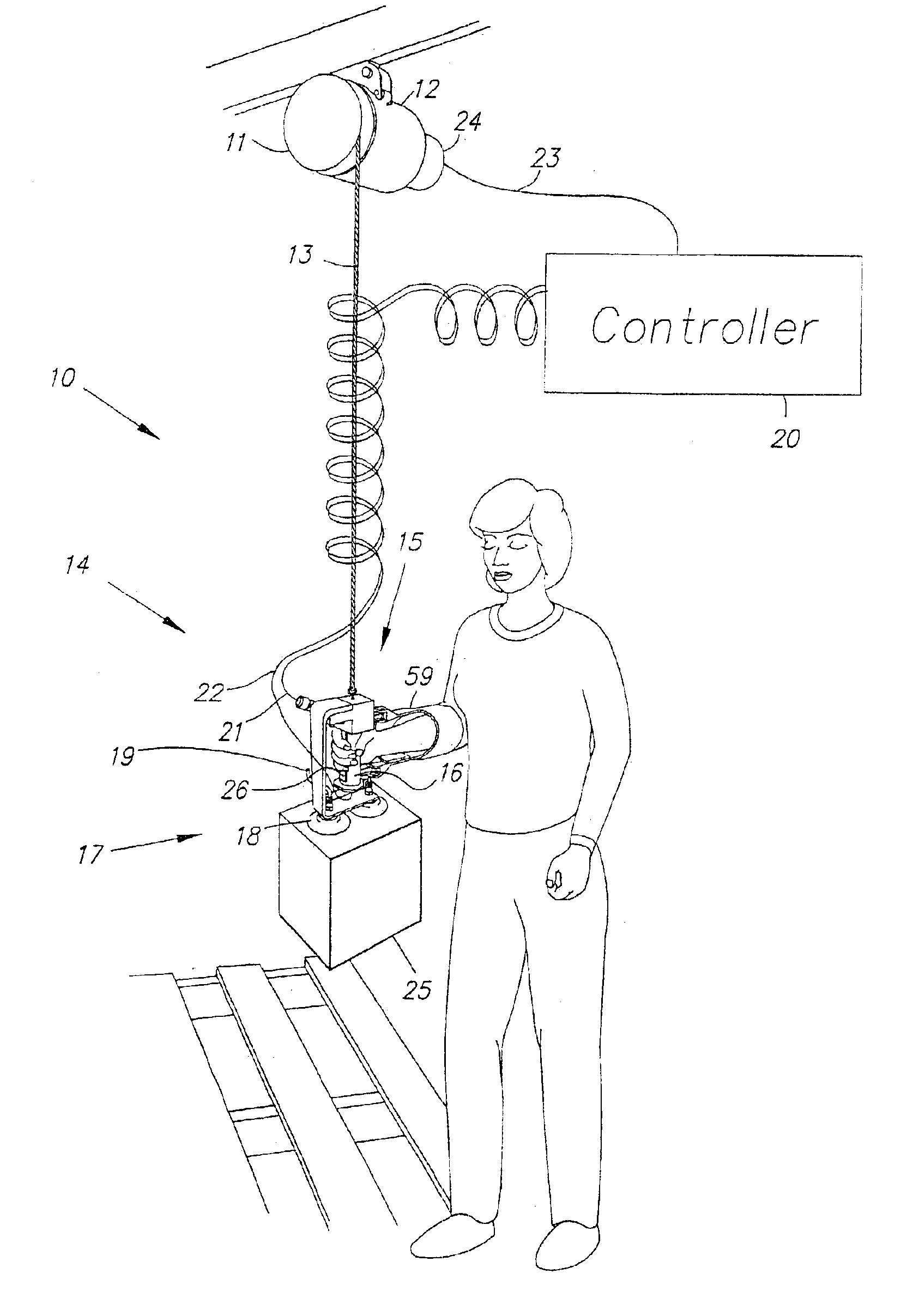

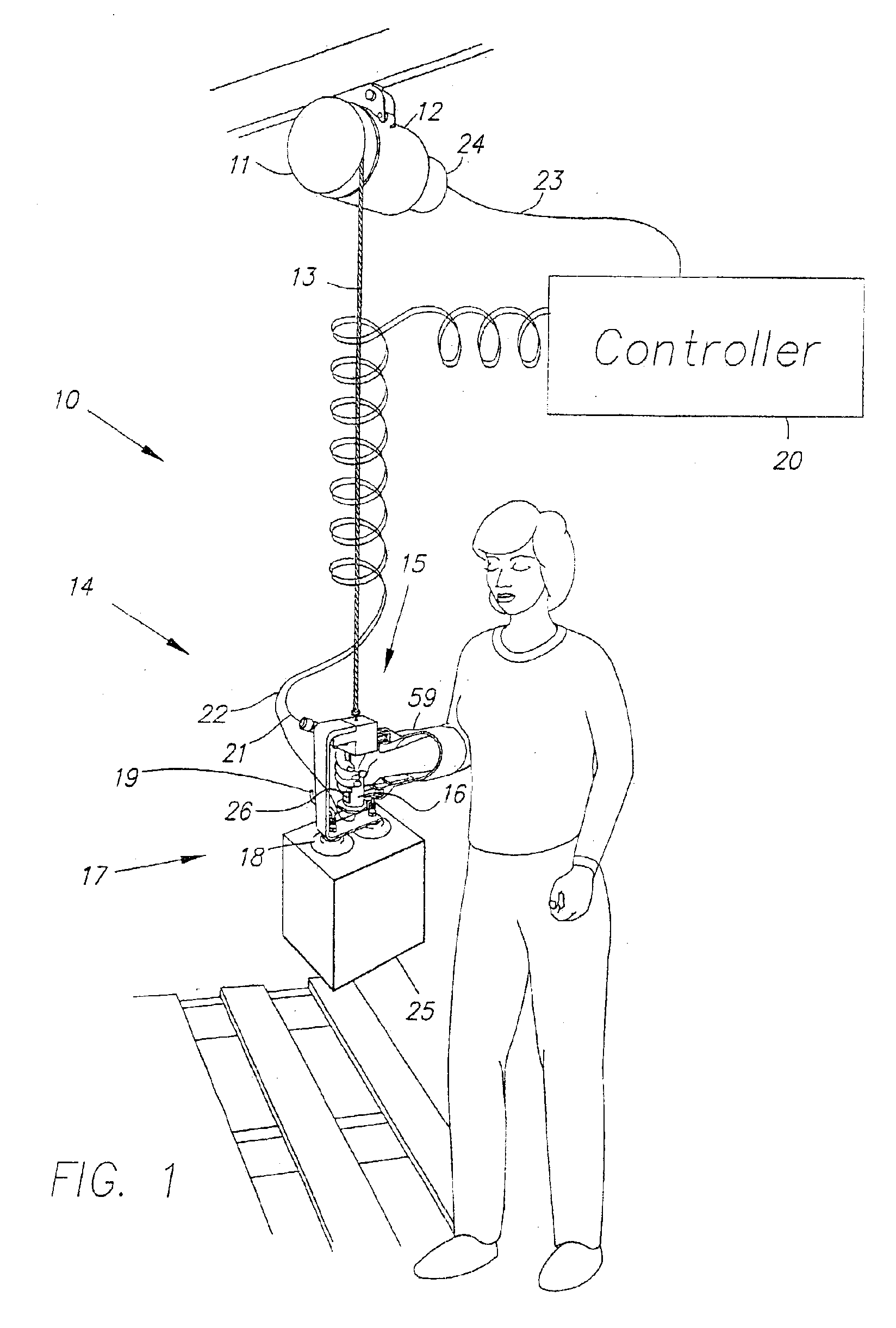

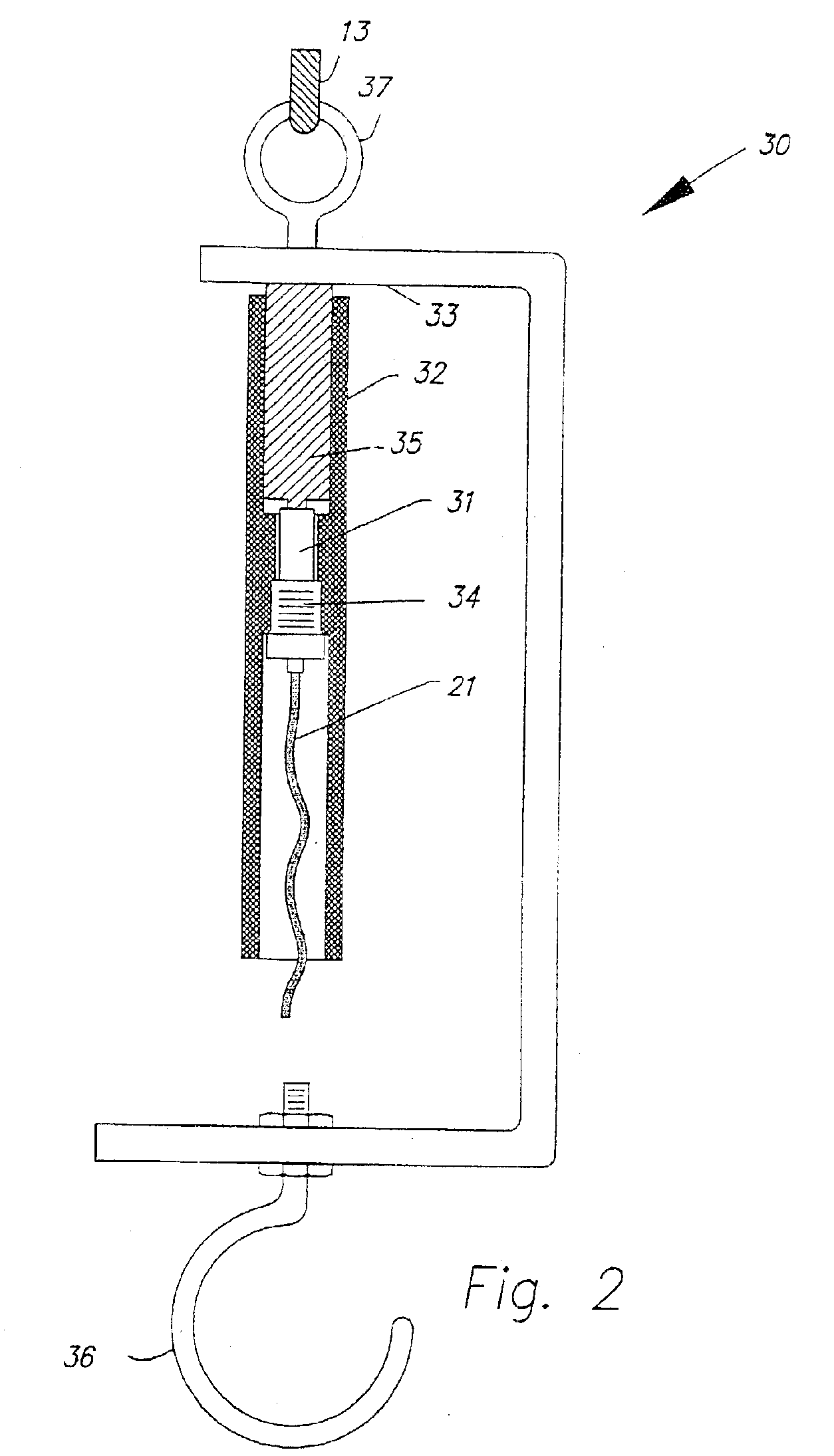

Human power amplifier for lifting load with slack prevention apparatus

InactiveUS6886812B2Avoid slackEfficient driveGripping headsPortable liftingAudio power amplifierActuator

A human power amplifier includes an end-effector that is grasped by a human operator and applied to a load. The end-effector is suspended, via a line, from a take-up pulley, winch, or drum that is driven by an actuator to lift or lower the load. The end-effector includes a force sensor that measures the vertical force imposed on the end-effector by the operator and delivers a signal to a controller. The controller and actuator are structured in such a way that a predetermined percentage of the force necessary to lift or lower the load is applied by the actuator, with the remaining force being supplied by the operator. The load thus feels lighter to the operator, but the operator does not lose the sense of lifting against both the gravitation and inertial forces originating in the load.

Owner:GORBEL INC

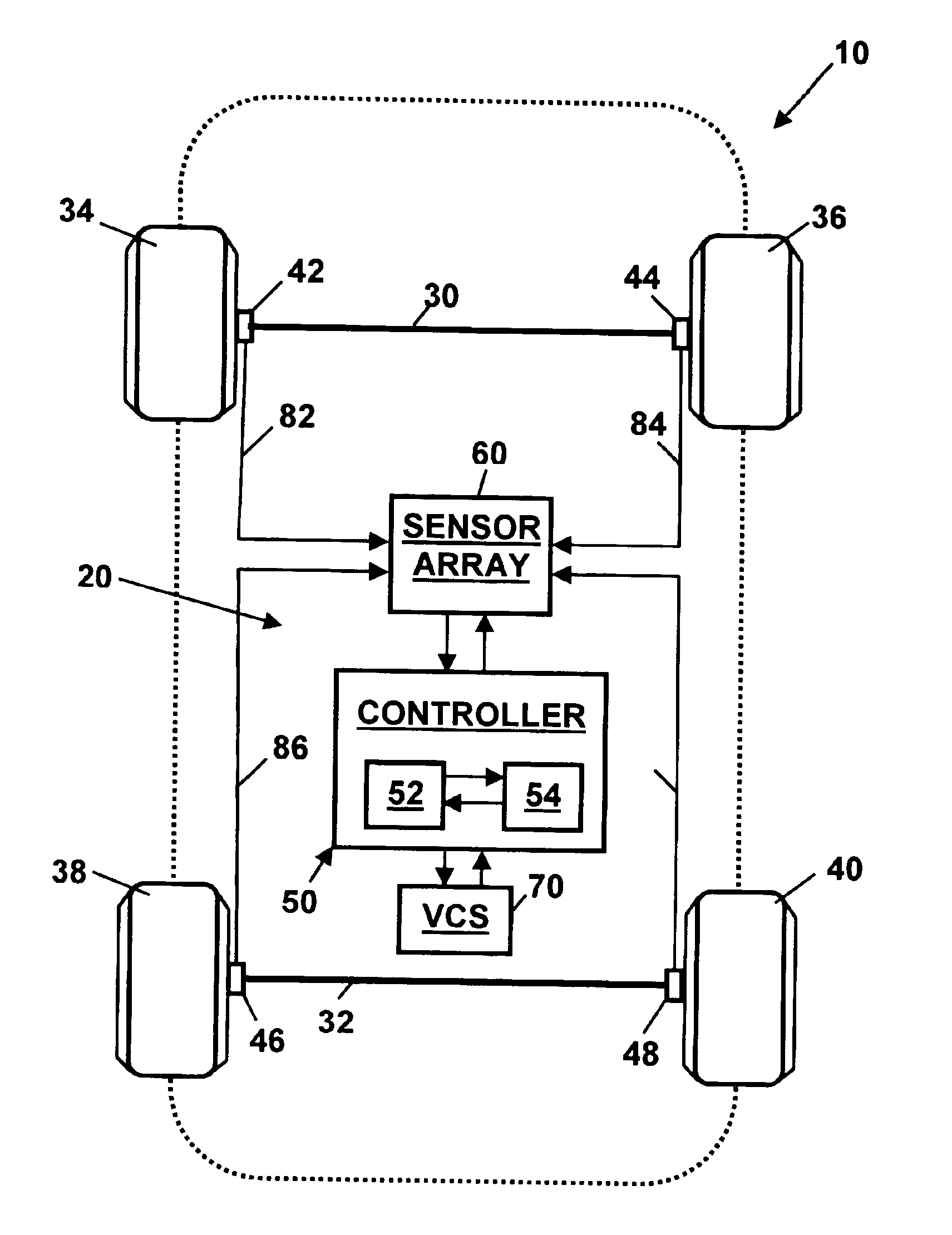

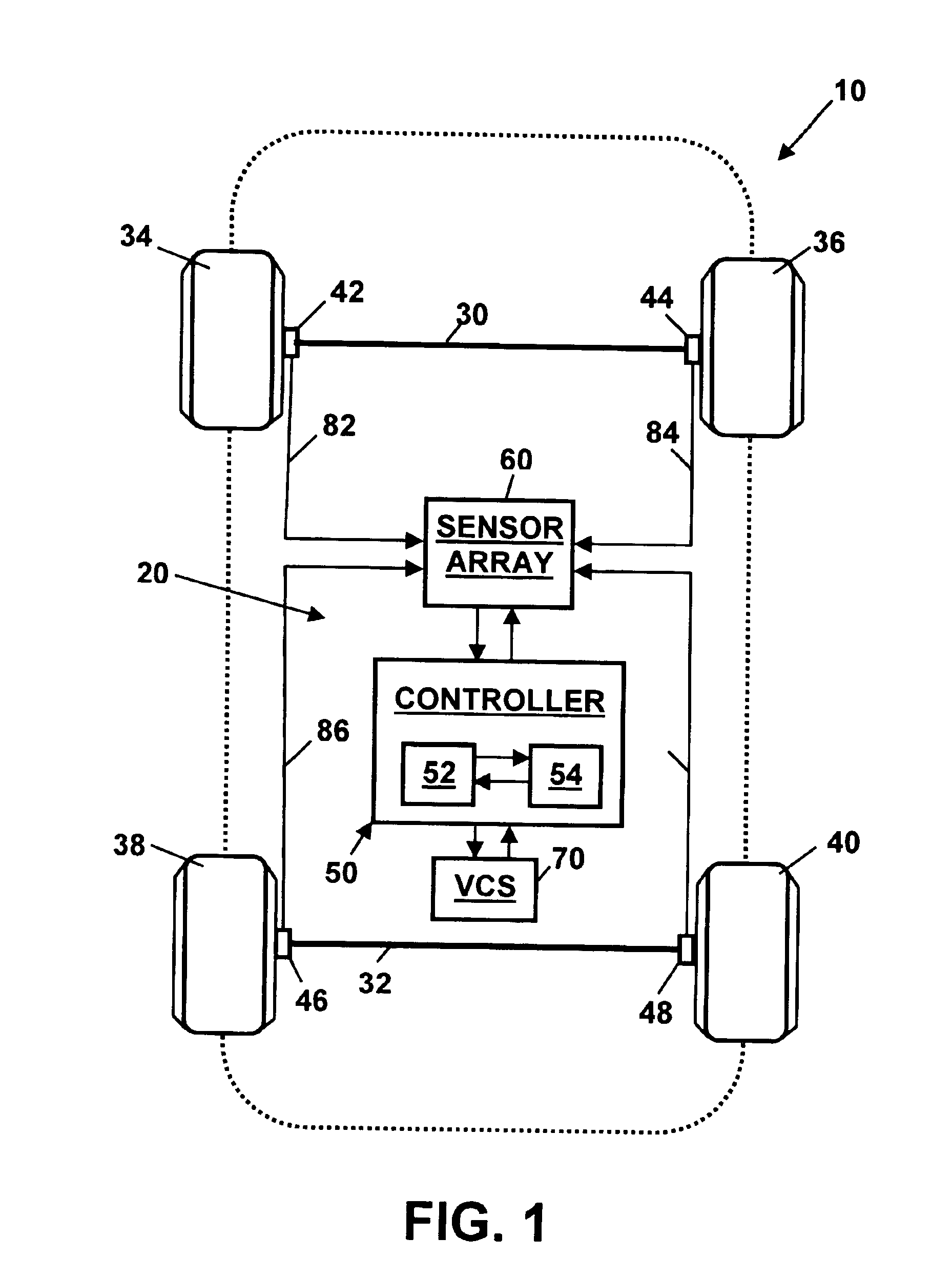

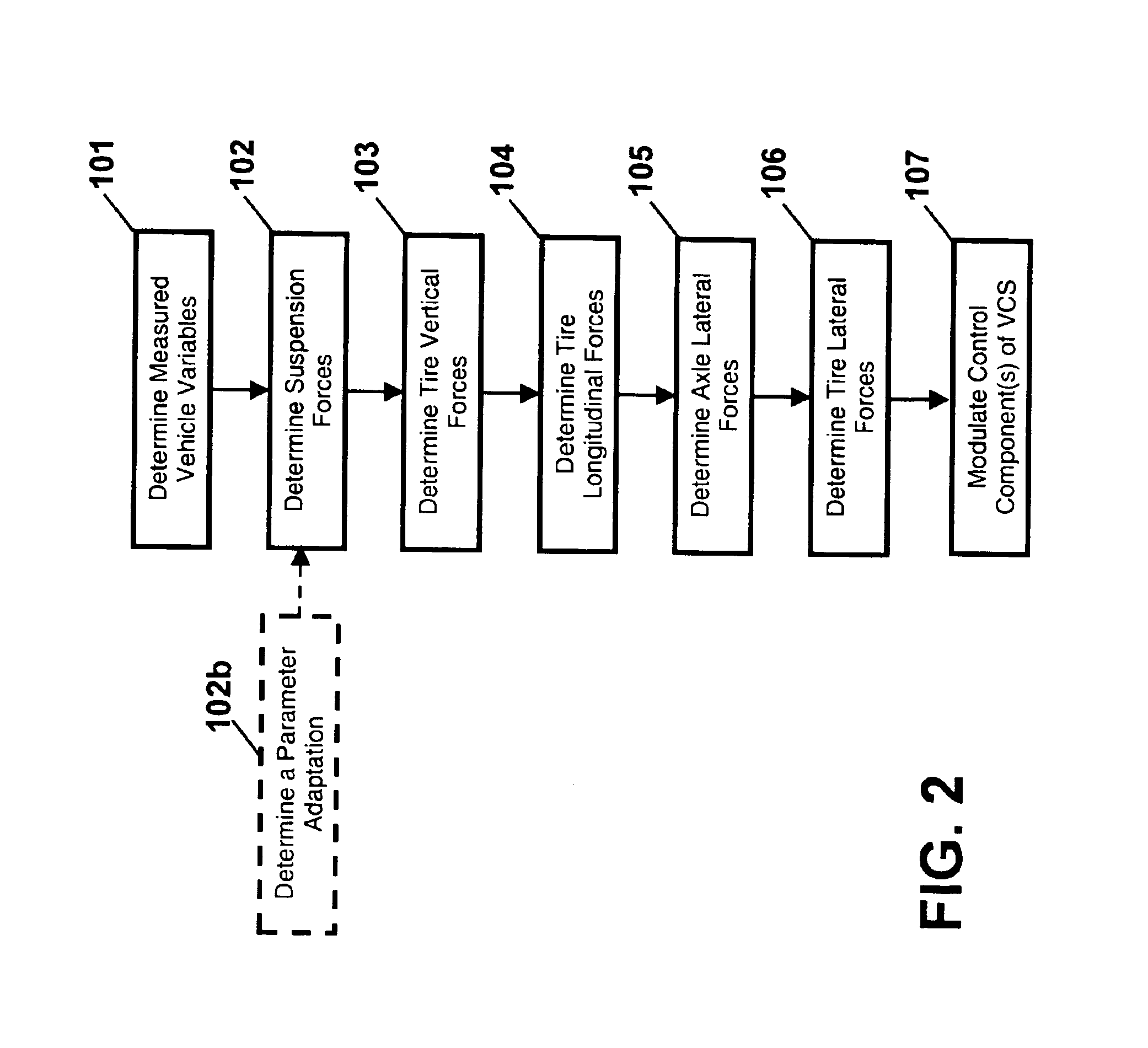

Operating a vehicle control system

The invention provides a method, a computer usable medium including a program, and a system for operating a vehicle control system. A plurality of measured vehicle variables is determined. At least one suspension force is determined based on at least one of the determined measured vehicle variables. At least one tire vertical force is determined based on the at least one determined suspension force and at least one of the determined measured vehicle variables. At least one tire longitudinal force is determined based on at least one of the determined measured vehicle variables. At least one axle lateral force is determined based on at least one of the determined measured vehicle variables. At least one tire lateral force is determined based on the at least one determined axle lateral force and the at least one determined tire vertical force. At least one control component of the vehicle control system is modulated based on the at least one determined tire vertical force, the at least one determined tire longitudinal force, and the at least one determined tire lateral force.

Owner:BWI +1

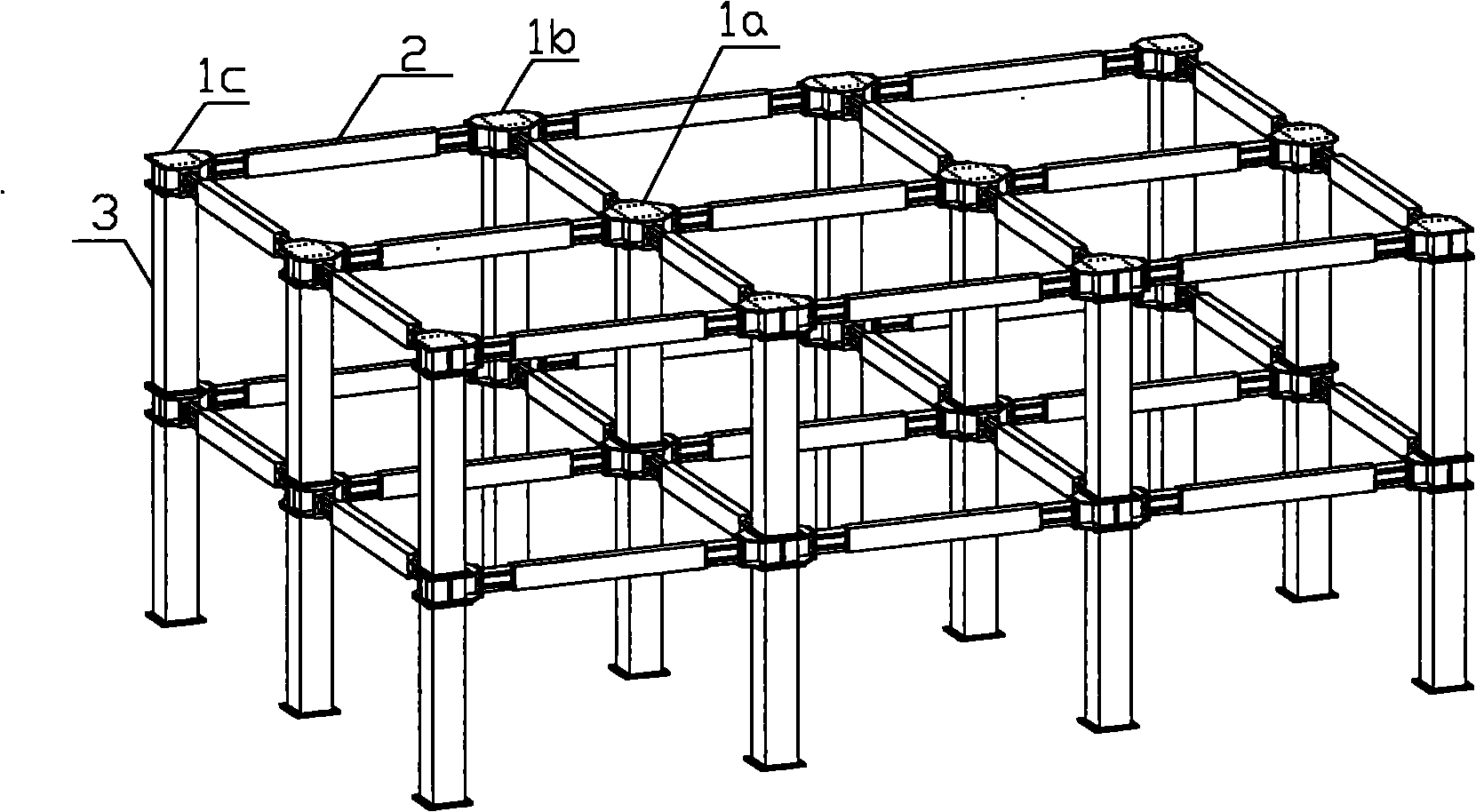

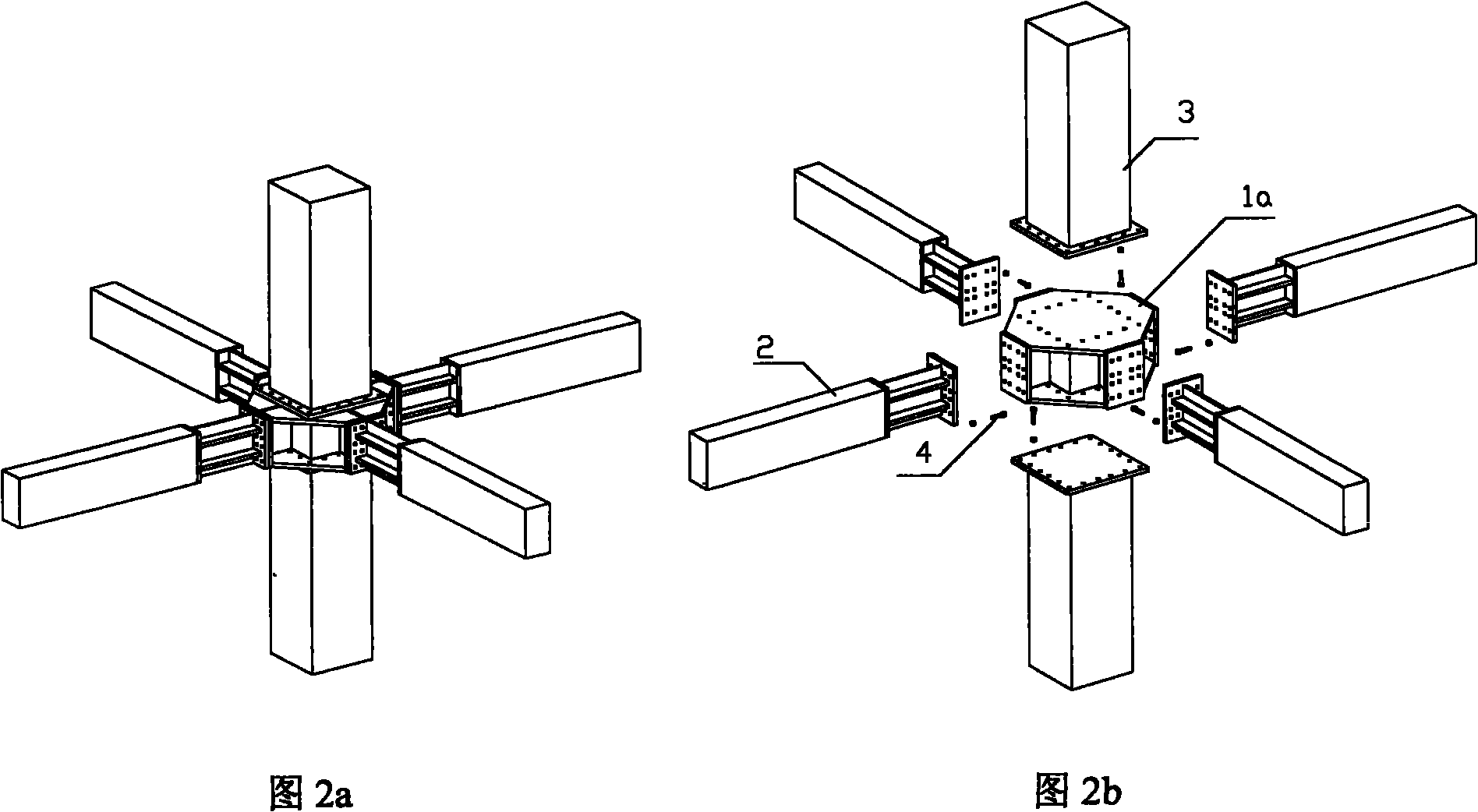

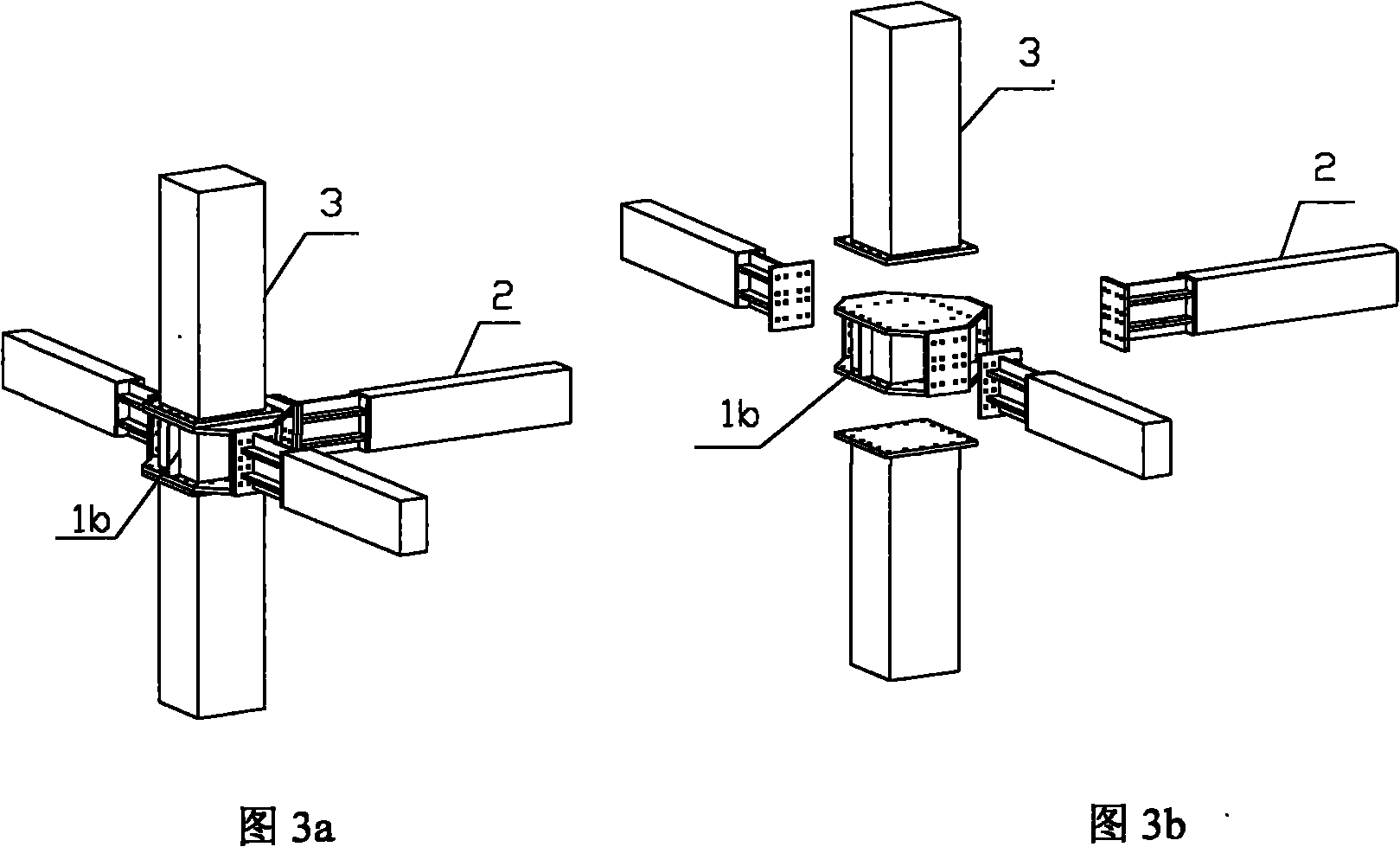

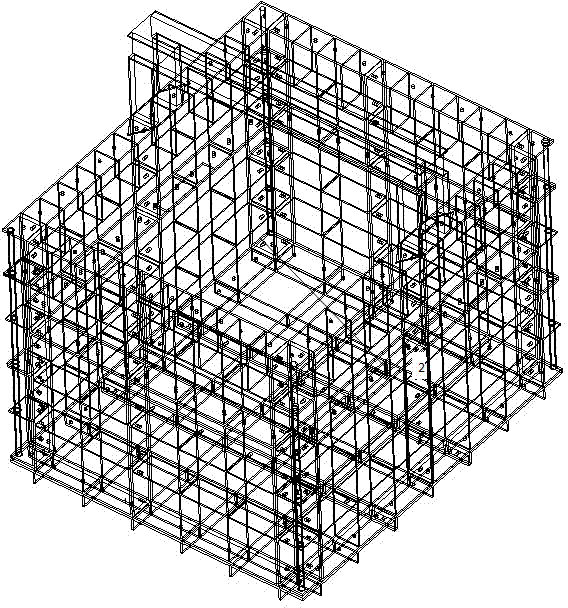

Steel joint precast and assembled reinforced concrete frame structure

InactiveCN101818521AEasy to replace and maintainEasy to replaceBuilding constructionsReinforced concrete columnRebar

The invention discloses a steel joint precast and assembled reinforced concrete frame structure, which comprises precast beam members, precast column members and joints, wherein each of the nodes comprises a steel plate box in which annular horizontal reinforced rib plates and vertical reinforced rib plates are arranged; the upper and lower surfaces of the steel plate box are respectively provided with an upper force bearing plate and a lower force bearing plate; the outer surface of the steel plate box is provided with rib plates which are respectively connected with the upper and lower force bearing plates; the rib plates are connected with vertical force bearing plates which are respectively connected with the upper and lower force bearing plates; each precast beam member comprises a precast reinforced concrete beam; a beam-end precast steel plate is precast on the end part of the precast reinforced concrete beam, and is connected with a shaped steel beam which is connected with a beam-end force bearing plate; each precast column member comprises a precast reinforced concrete column; a steel plate enclosure box is arranged on the lateral surface of the end part of the precast reinforced concrete column; studs are arranged on the inner lateral surface of the closure box; the end part of the steel plate closure box is provided with a column-end steel force bearing plate; the upper and lower force bearing plates of each joint are respectively with the adjacent columns; and the vertical force bearing plates are connected with adjacent beams.

Owner:SOUTHEAST UNIV

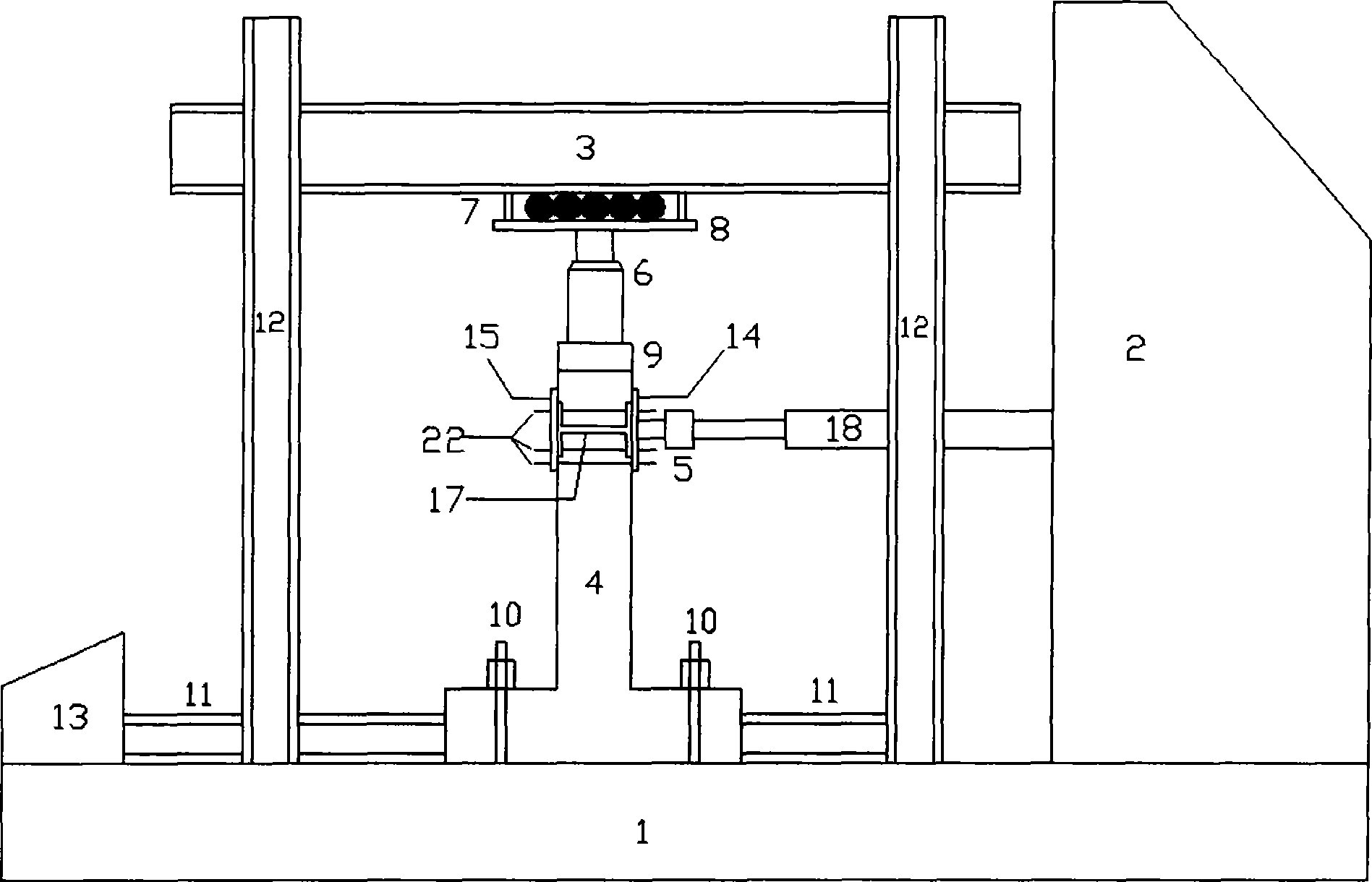

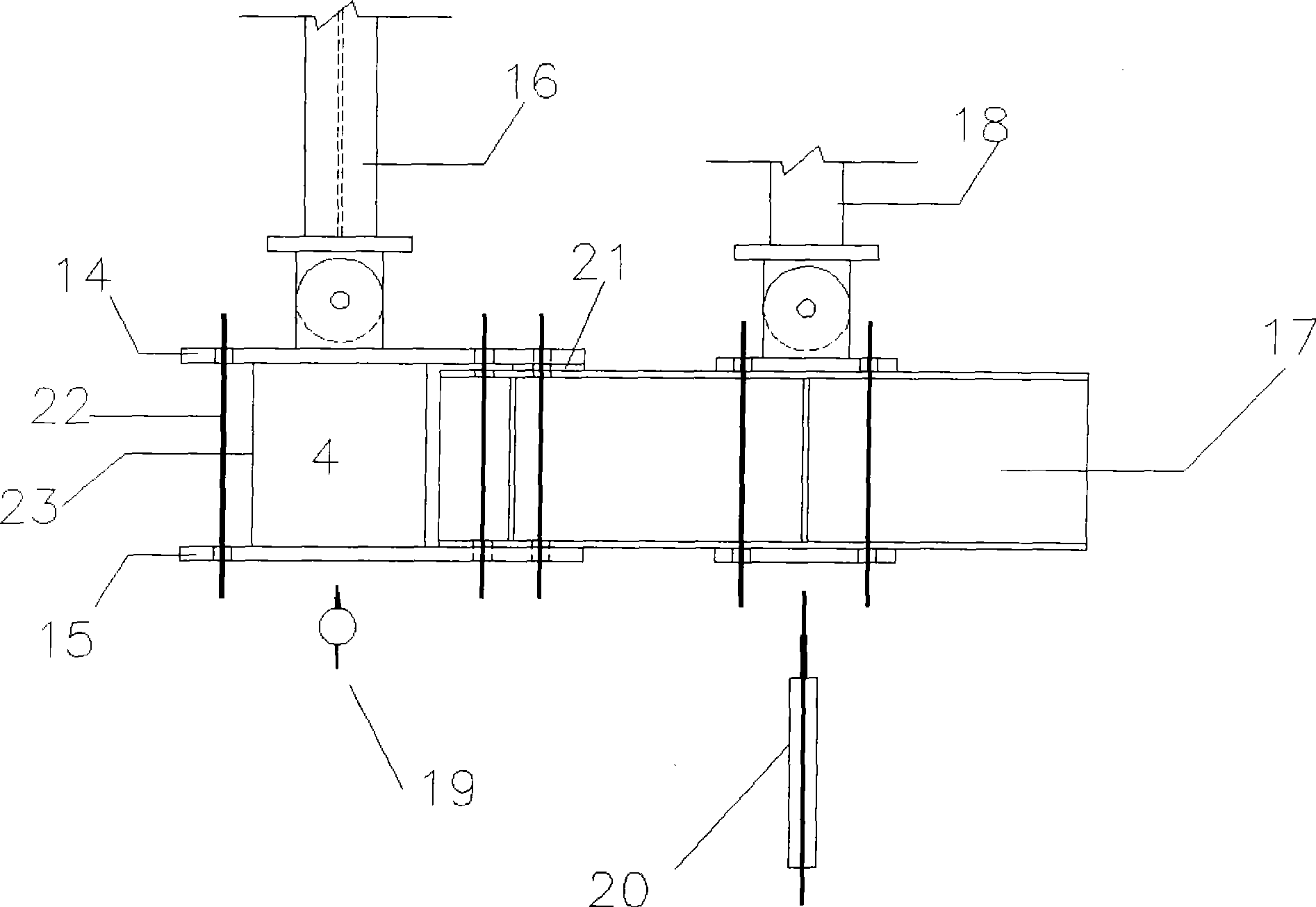

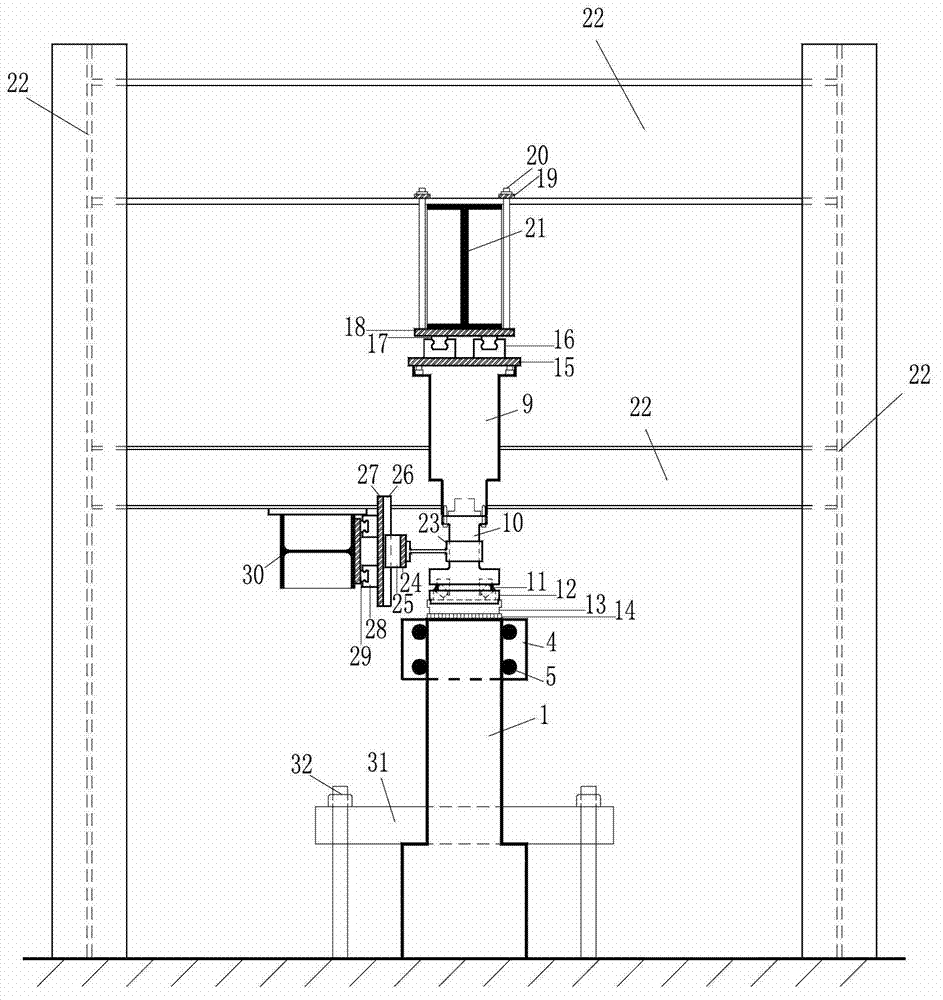

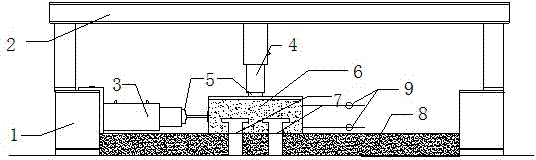

Component pressing and twisting experimental device and method thereof

InactiveCN101498625AObservation forceEasy to measureStructural/machines measurementMaterial strength using steady torsional forcesHorizontal forceAxial pressure

The invention relates to a device and a method for component compression-torsion testing, belonging to the technical field of architecture structure test. The device comprises a pedestal, a reaction beam, a reaction wall, a vertical force jack, a front clamp plate, a back clamp plate, a pure torsion loading beam, a loading beam and a horizontal force jack, wherein a component is fixed on the pedestal; the vertical force jack is connected at the lower surface of the reaction beam and corresponds to the component in position; the top of the component is tightly clamped between the front clamp plate and the back clamp plate; the loading beam is fixedly connected with the front clamp plate and the back clamp plate; one end of the pure torsion loading beam is articulated with the front clamp plate and the other end is fixedly connected with the reaction wall; one end of the horizontal force jack is articulated with the loading beam by a force sensor and the other end is fixedly connected with the reaction wall. In a test, the vertical force jack applies axial pressure to the component and the horizontal force jack applies horizontal force to the component to form the torque to the component. The device for component compression-torsion testing has simple structure and convenient assembly, can be used instantly after the assembly and can be used repeatedly.

Owner:BEIJING UNIV OF TECH

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

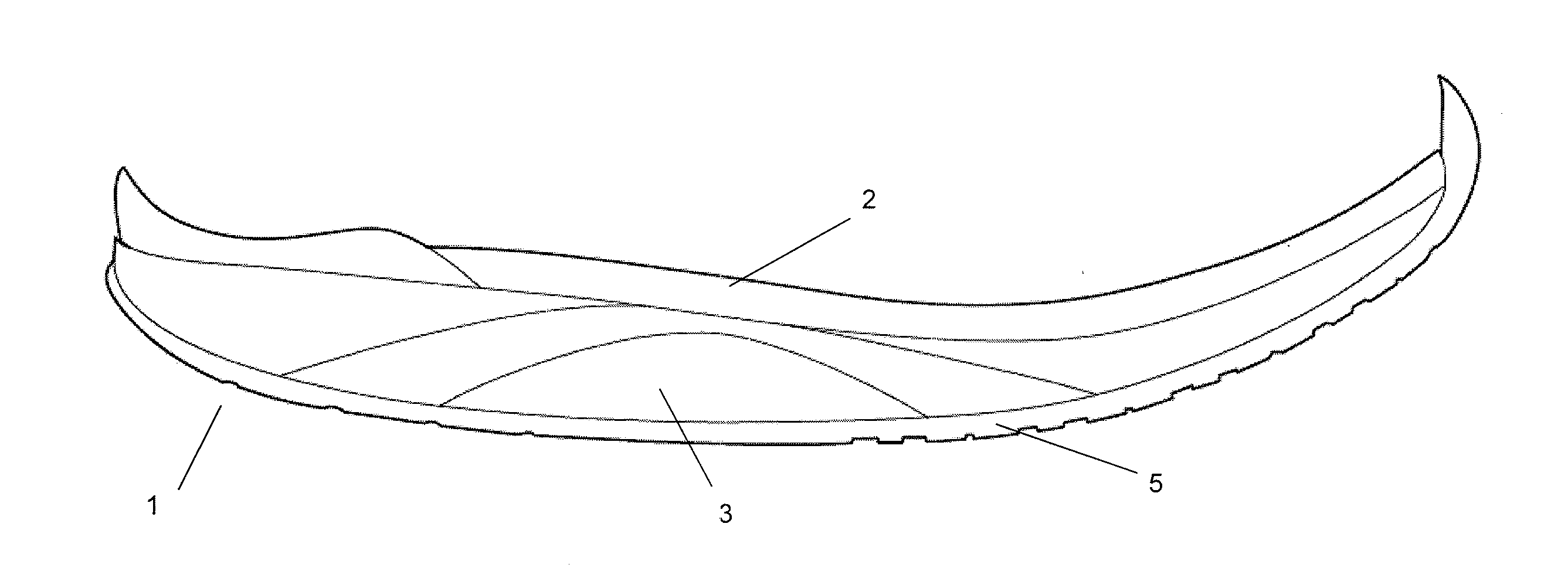

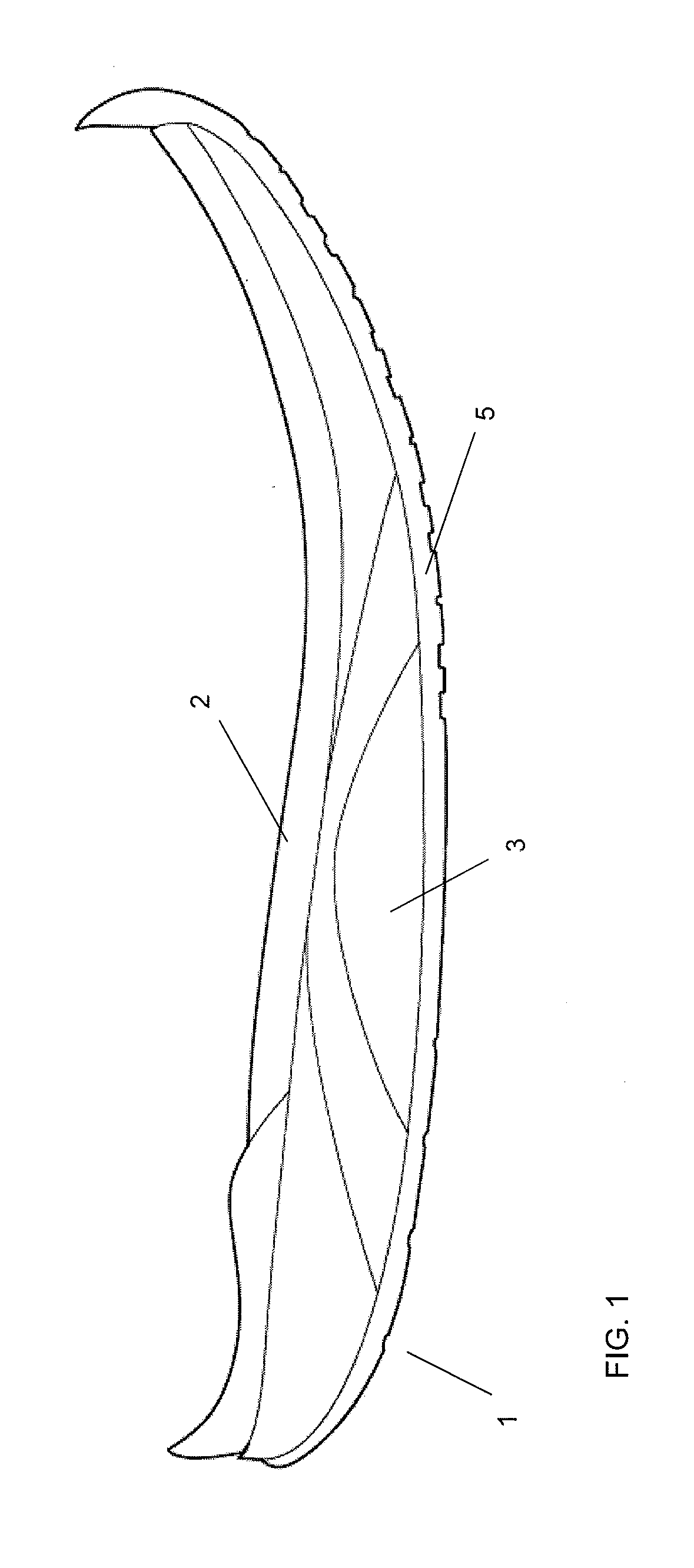

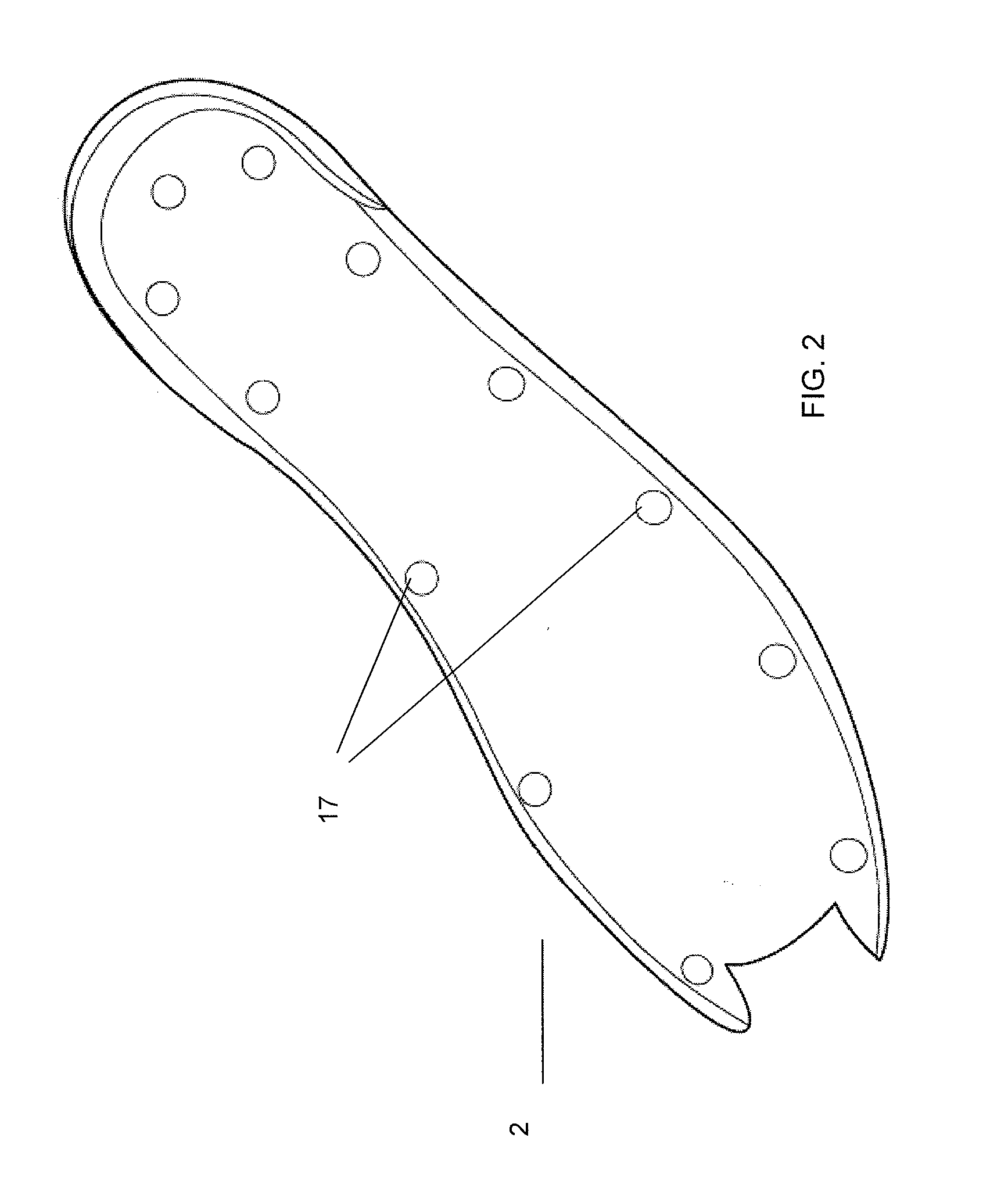

Sole for footwear

The invention relates to an improved sole for footwear with a convex or rounded shape, provided with a stabilizer, with a damping system and with an internal system for the rotation of air, which modifies the phase of contact of the foot with the ground in a roller, such that it transforms the process of reception of the ground (with the heel of the foot) and forward translation of the propelling forces (by means of the area of the metatarsus and toes) in a roller effect, obtaining the damping / stability / impulse effects, and the actuation of the airing system by means of a pad / wedge, the outsole thus configured allowing a rotation on the ground such that the inertia of the body and the vertical forces applied from the heel of the foot are more easily converted into horizontal propelling forces.

Owner:PIKOLINOS INTERCONTINENTAL

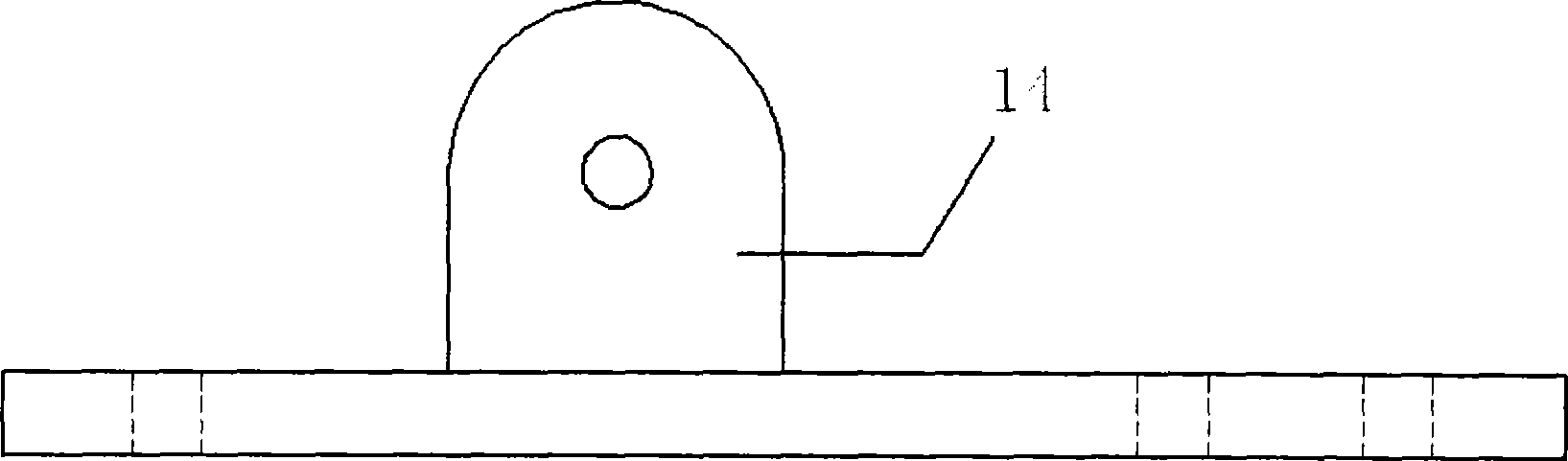

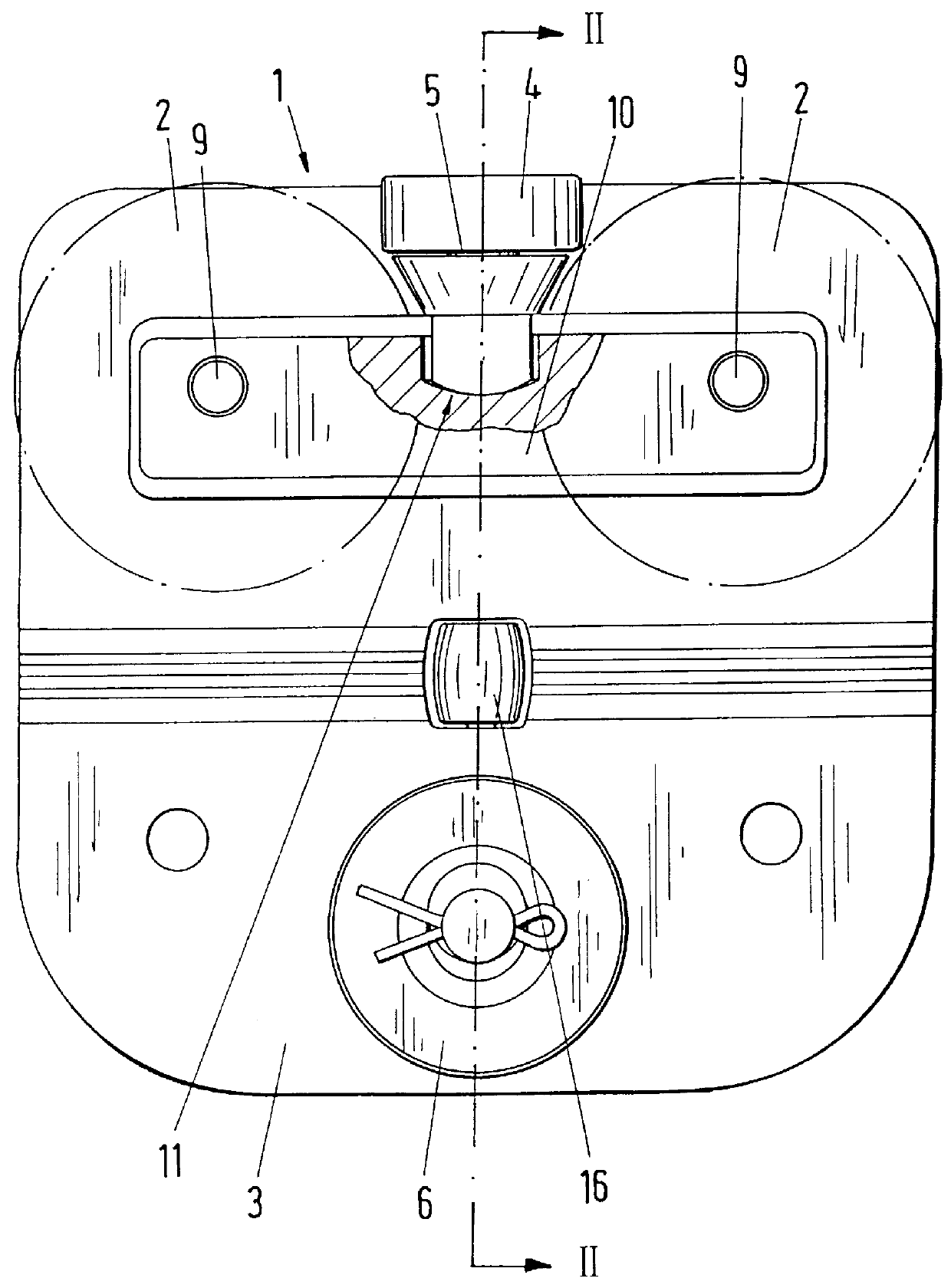

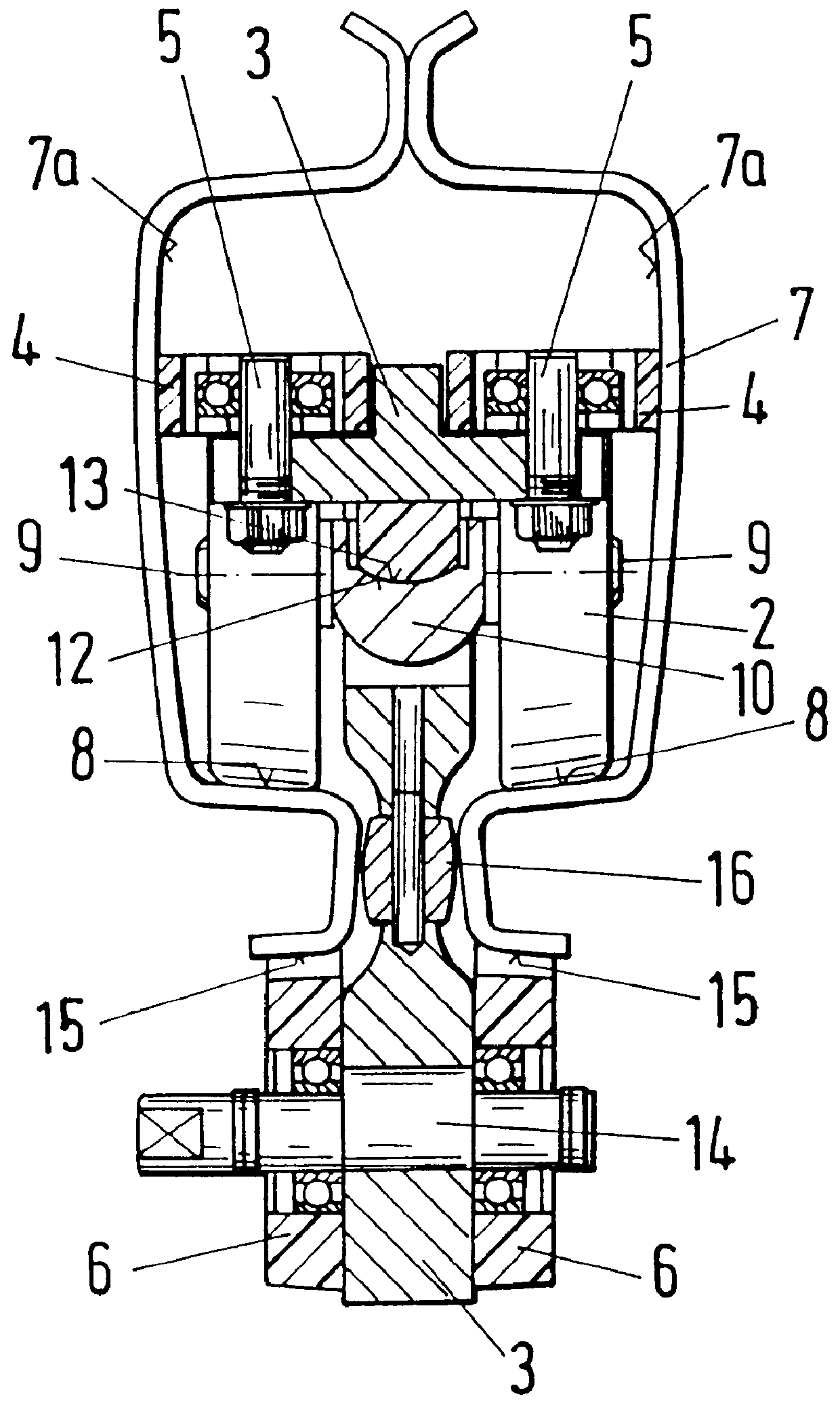

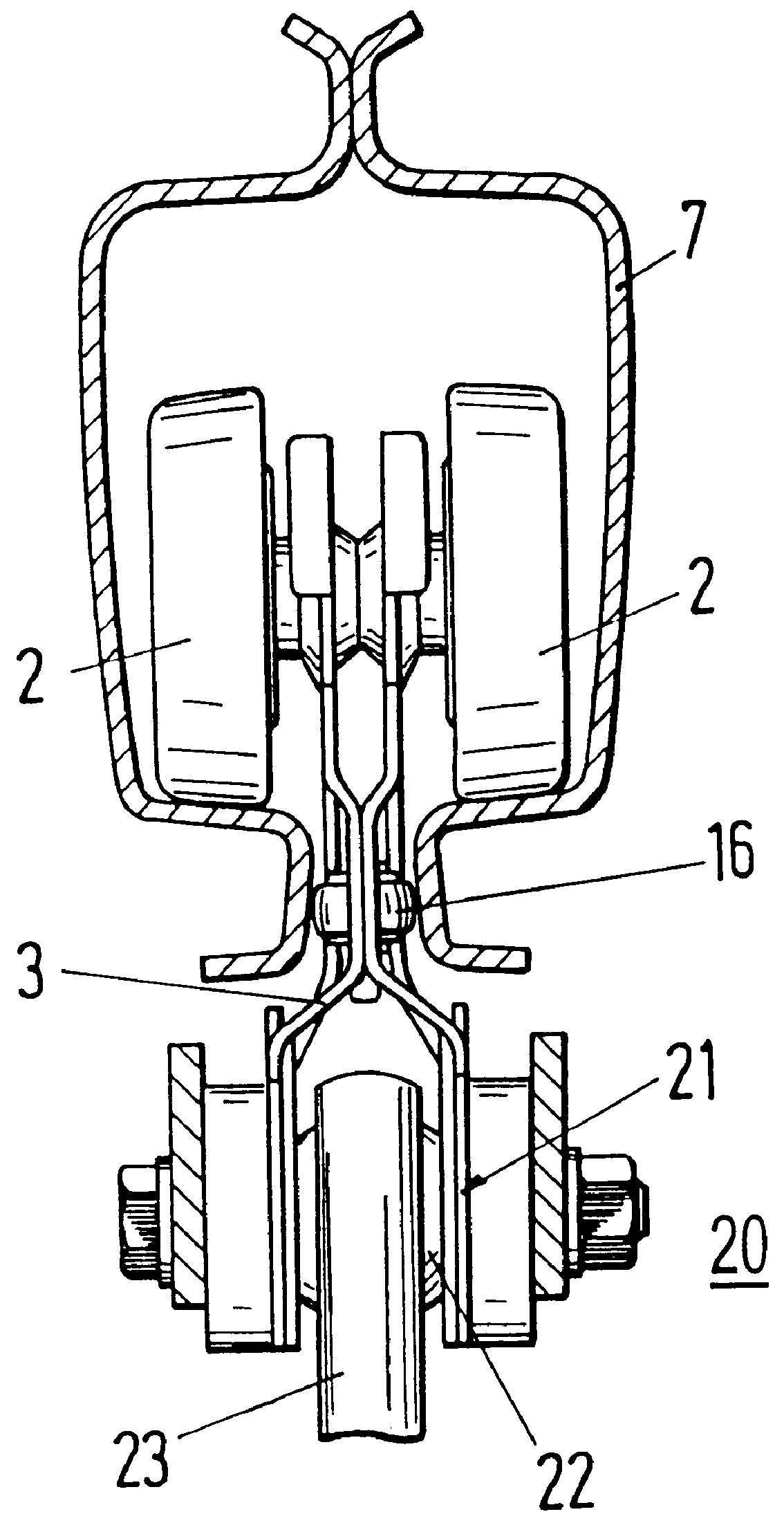

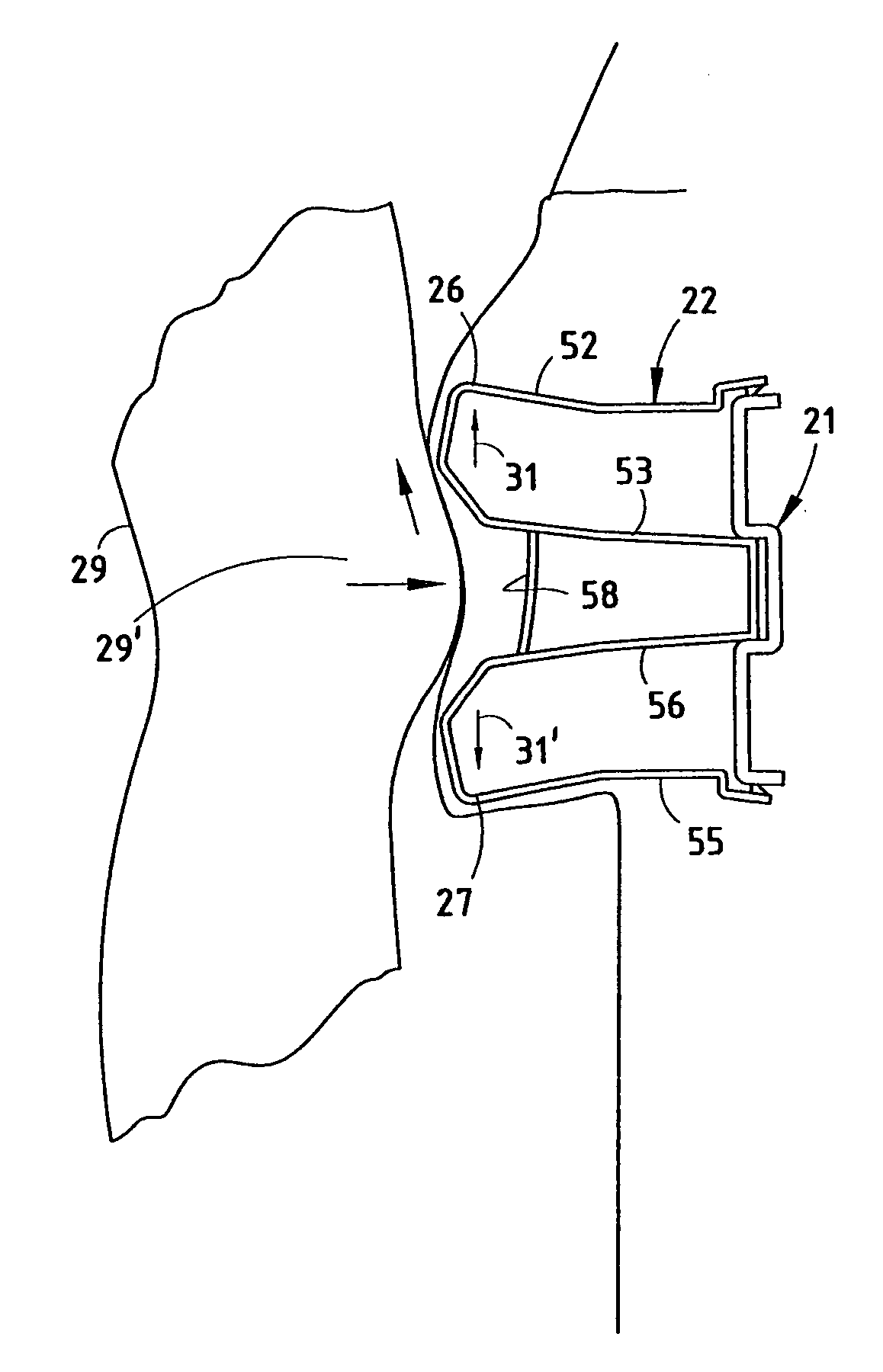

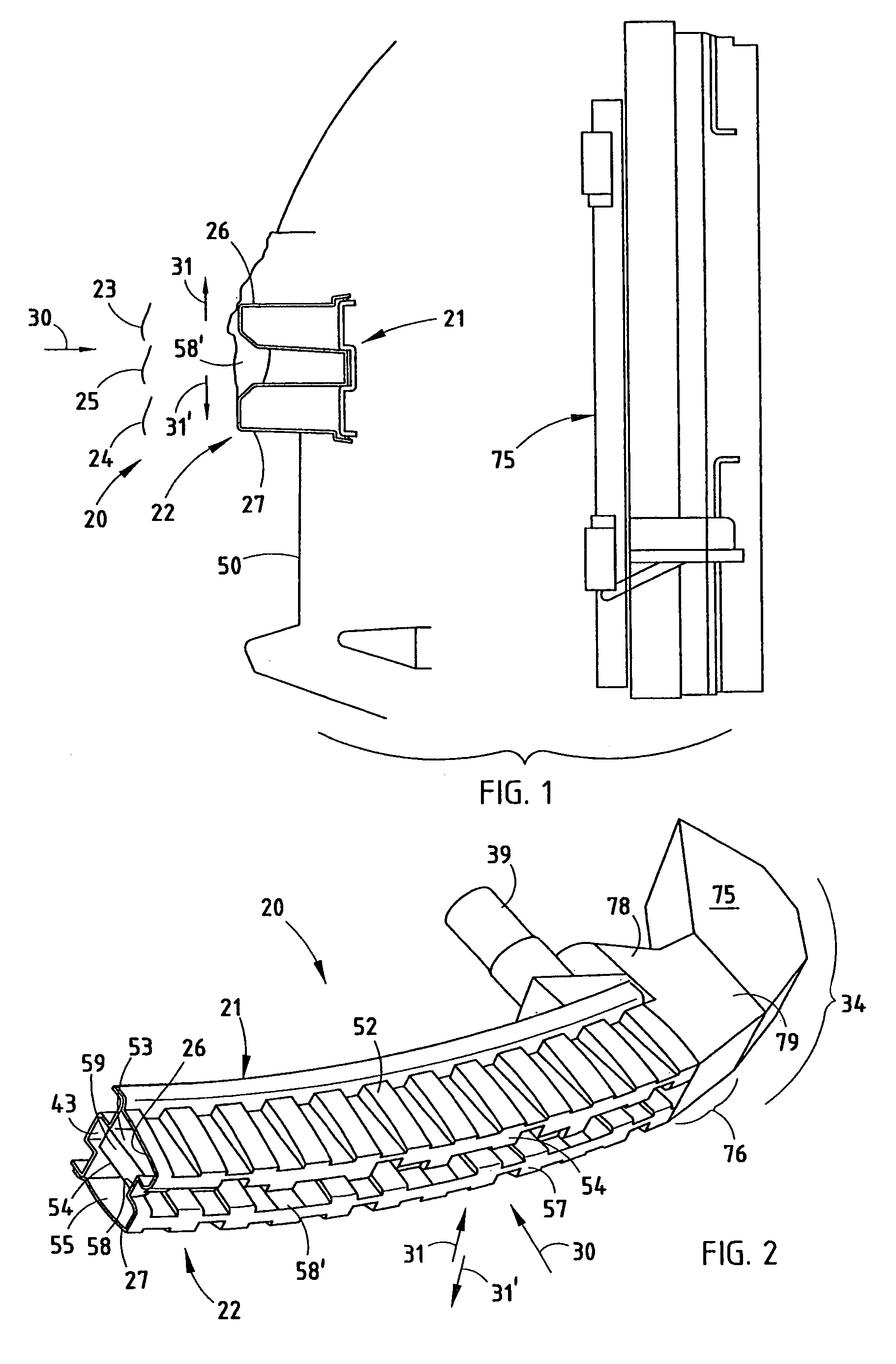

Traveling mechanism in a lifting arrangement which is moveable on rails

InactiveUS6058849AGuaranteed uptimeAvoid destructionMonorailsRailway componentsHorizontal forceFree rotation

A traveling mechanism for a lifting device, especially for a lifting device having a laterally cantilevering boom, is movable on rails with at least two running wheels. A connection element for attaching a load to said traveling mechanism is supported in the rail by the running wheels which are arranged on both sides of the connection element. The connection element has, at the region projecting down out of the rail, at least one running roller which is freely rotatable about a horizontal axis and rolls on a horizontal outer running surface of the rail. To effectively divert horizontal forces and uniformly distribute the vertical forces to the running wheels, running wheel axles are rigidly connected with a running wheel carrier, and the running wheel carrier and connection element are swivelably connected by a universal type joint. In addition, at least one support roller is rotatably mounted at the connection element in the interior of the rail. The support roller freely rotates about a vertical axis and rolls along at least one of the side surfaces to transmit horizontal forces to the rail.

Owner:TEREX MHPS

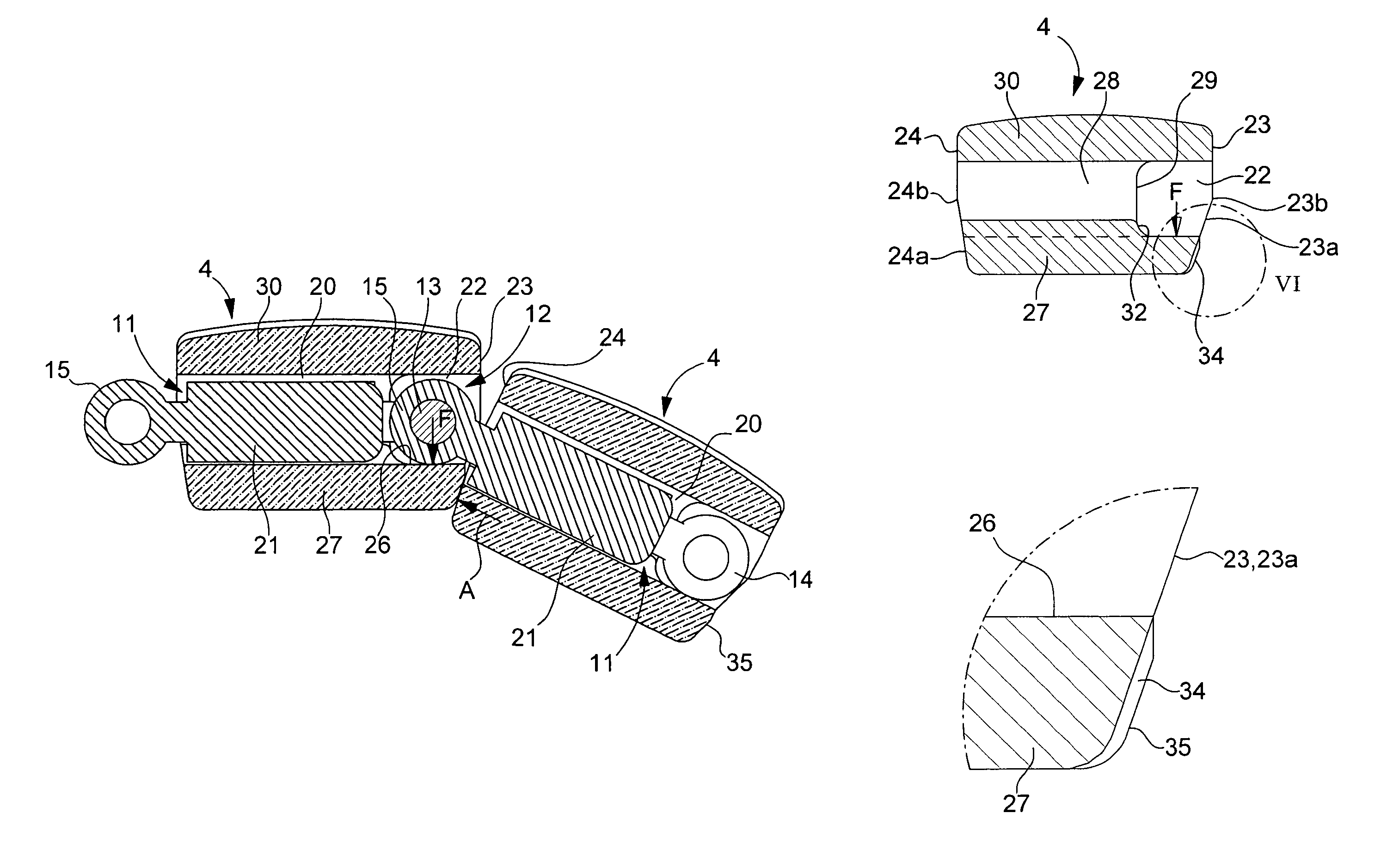

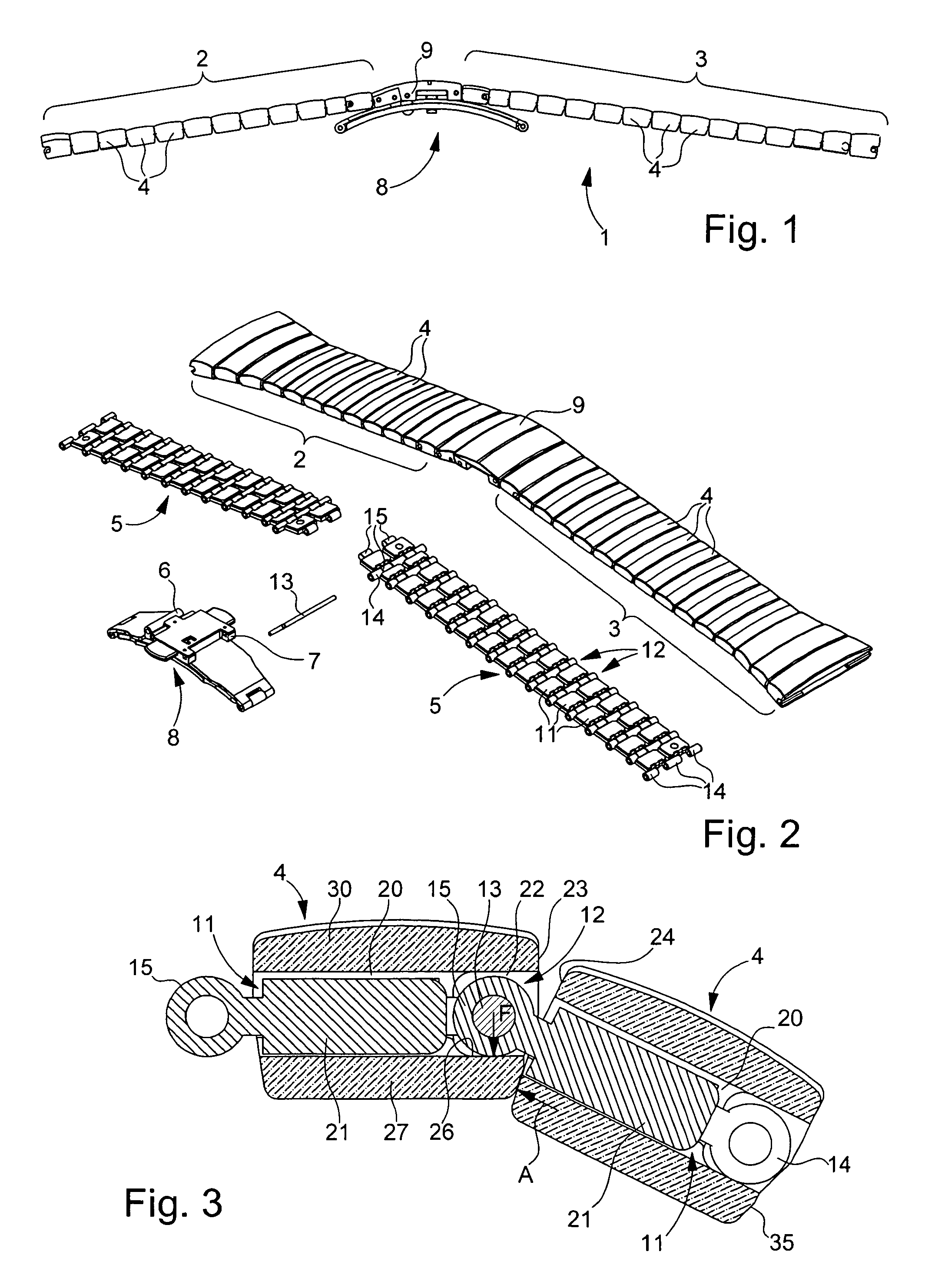

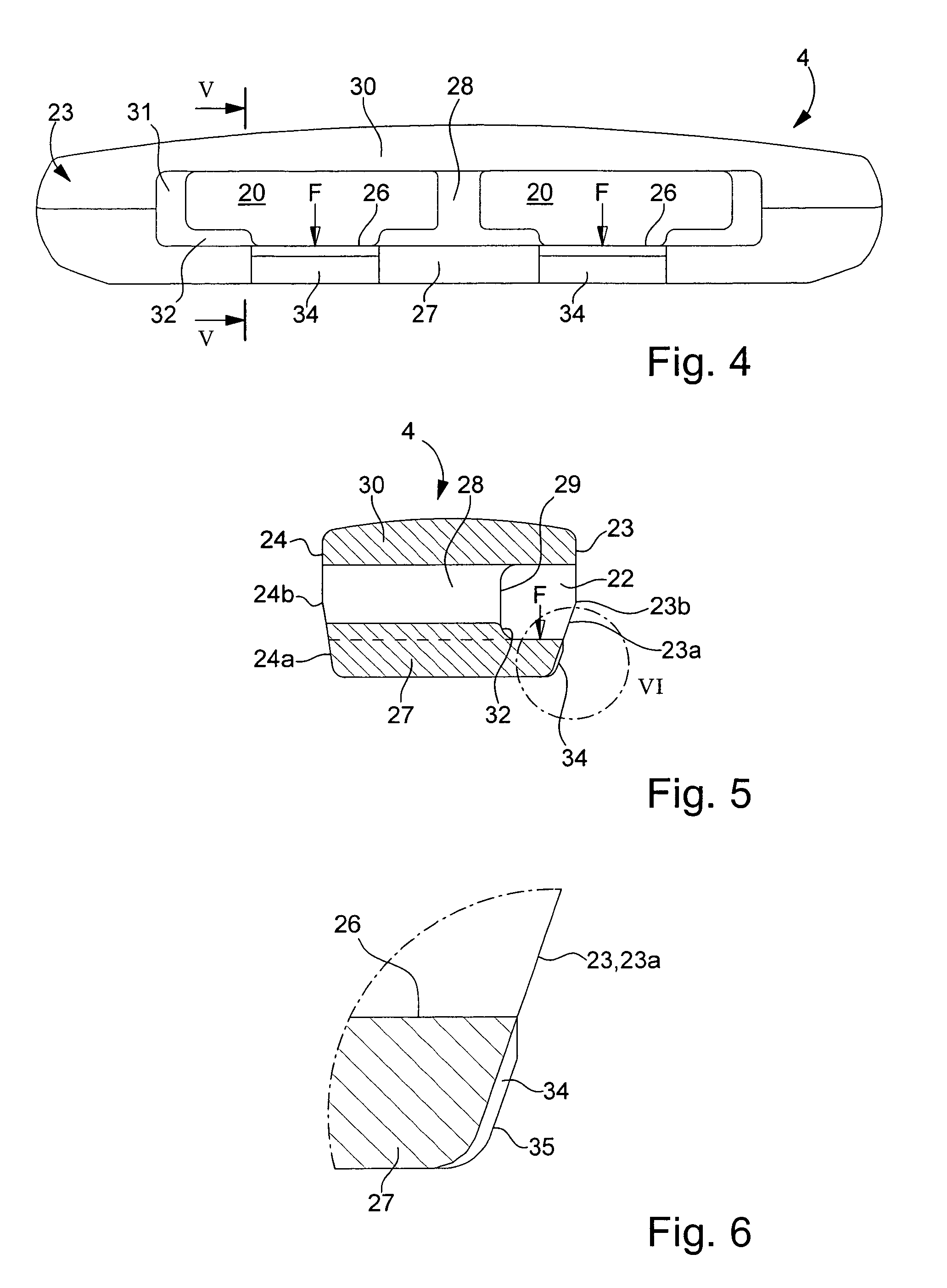

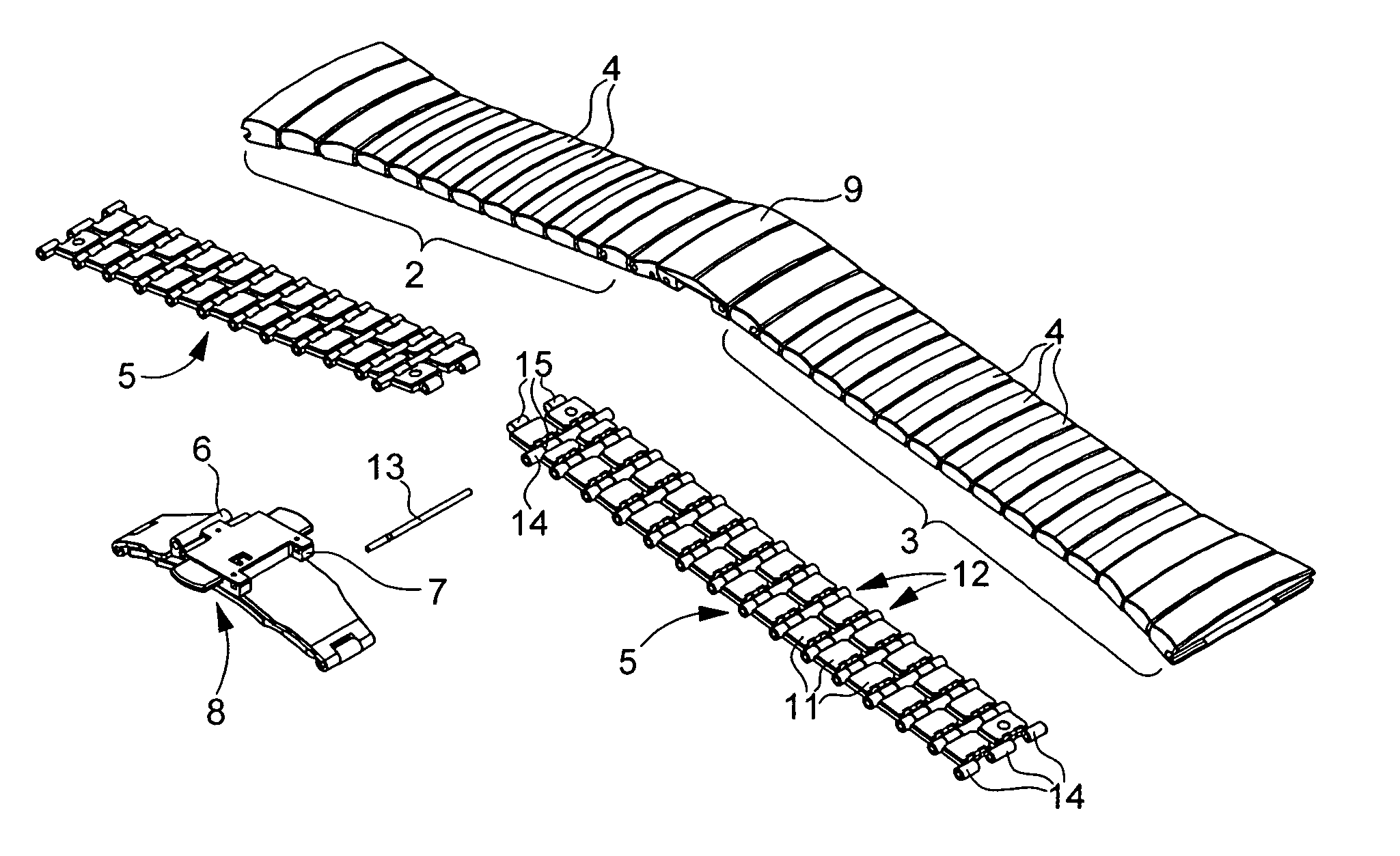

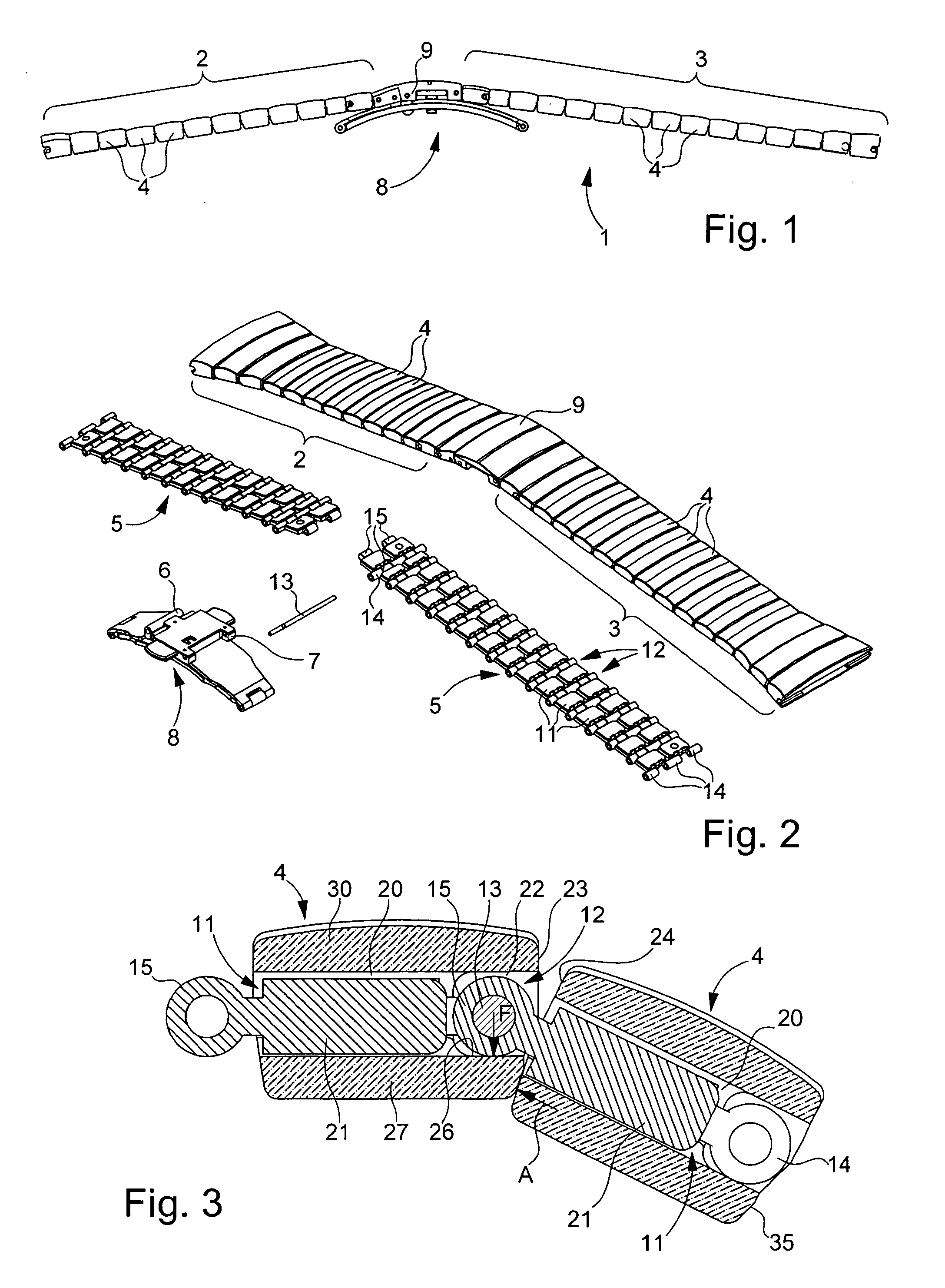

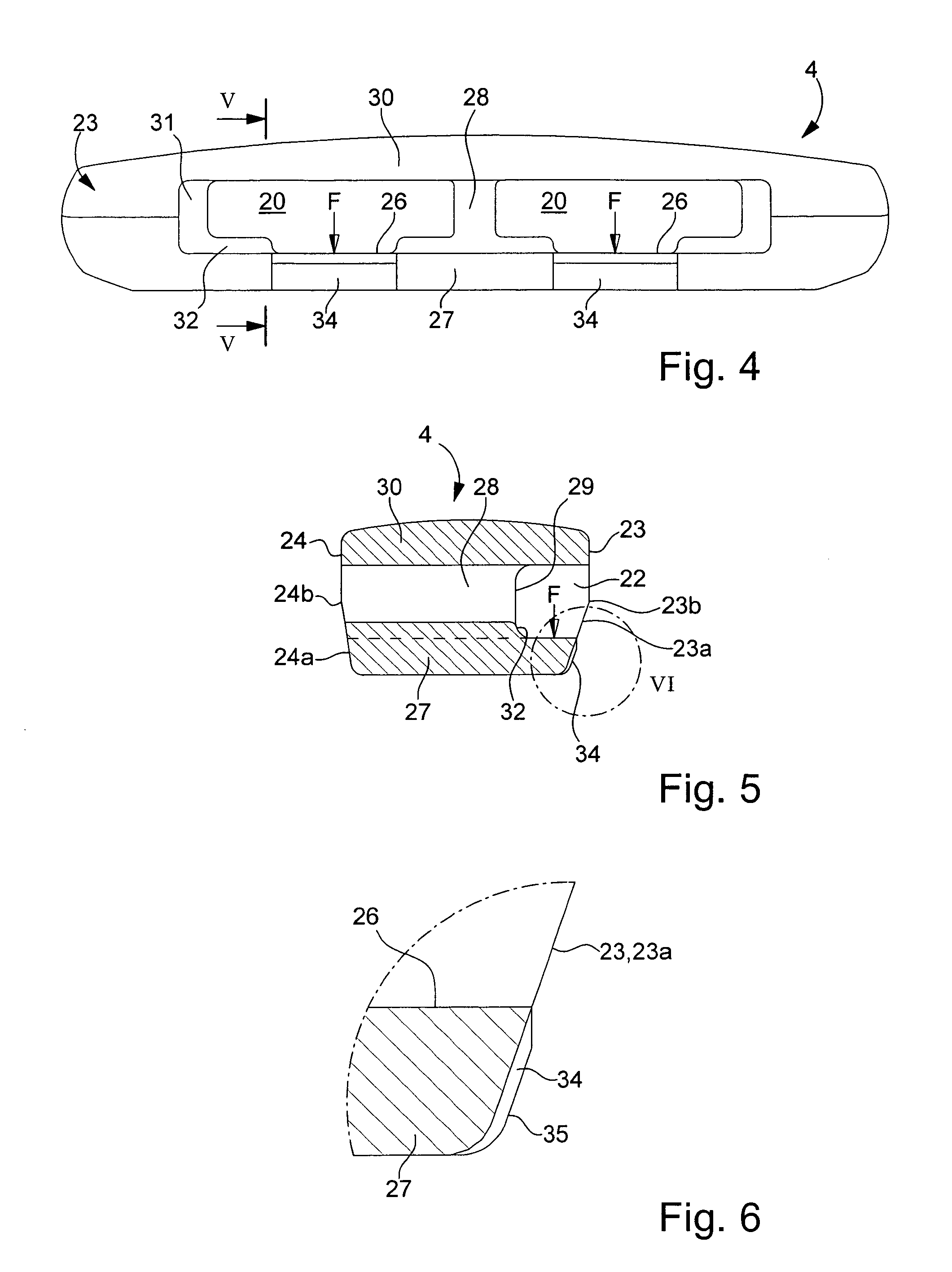

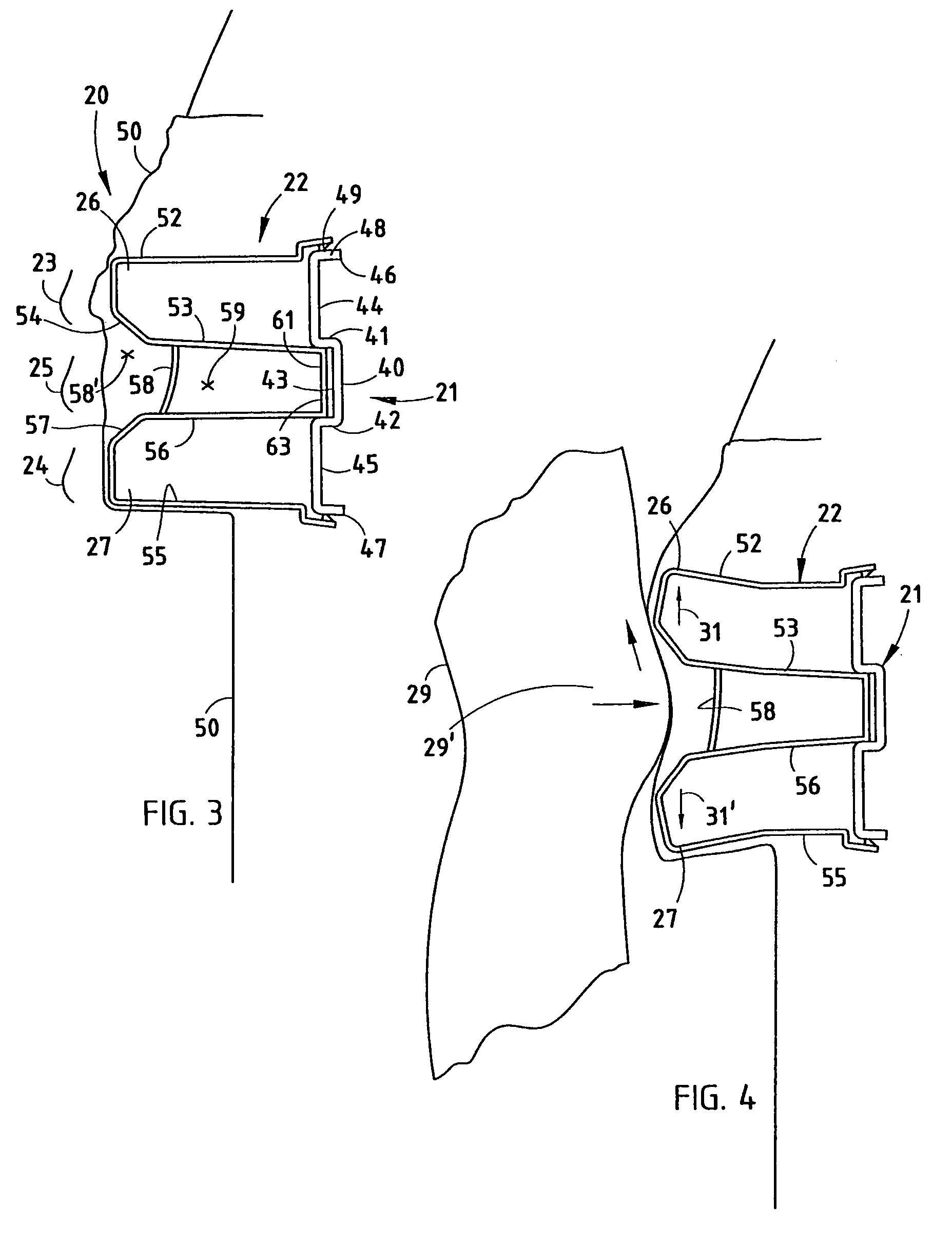

Articulated bracelet including decorative links threaded onto a chain

ActiveUS7013631B2Reduce stressSuppression reductionBraceletsHorseshoeEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

Articulated bracelet including decorative links threaded onto a chain

ActiveUS20050210857A1Reduce stressSuppression reductionBraceletsWrist-watch strapsEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

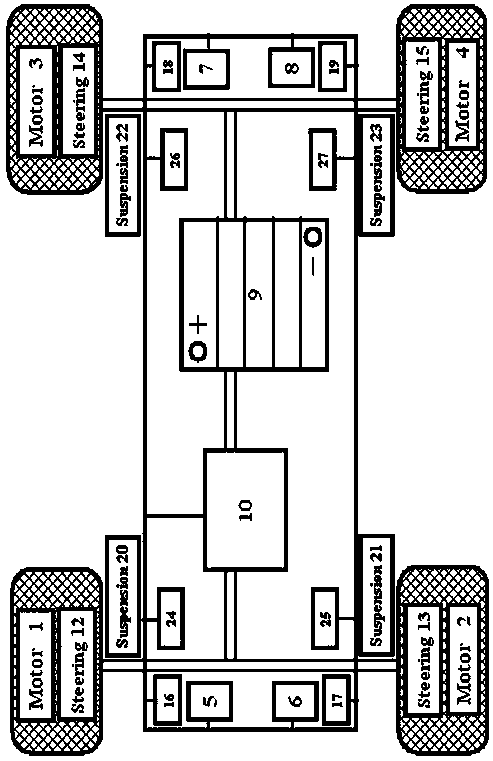

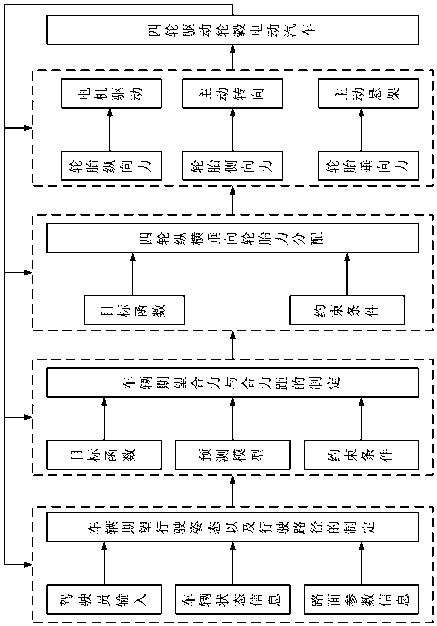

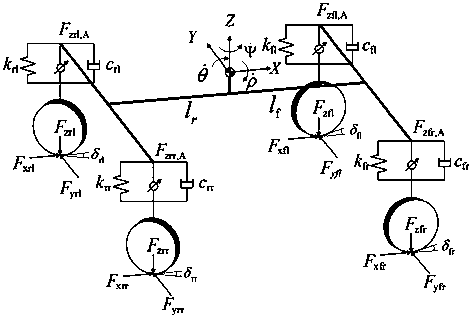

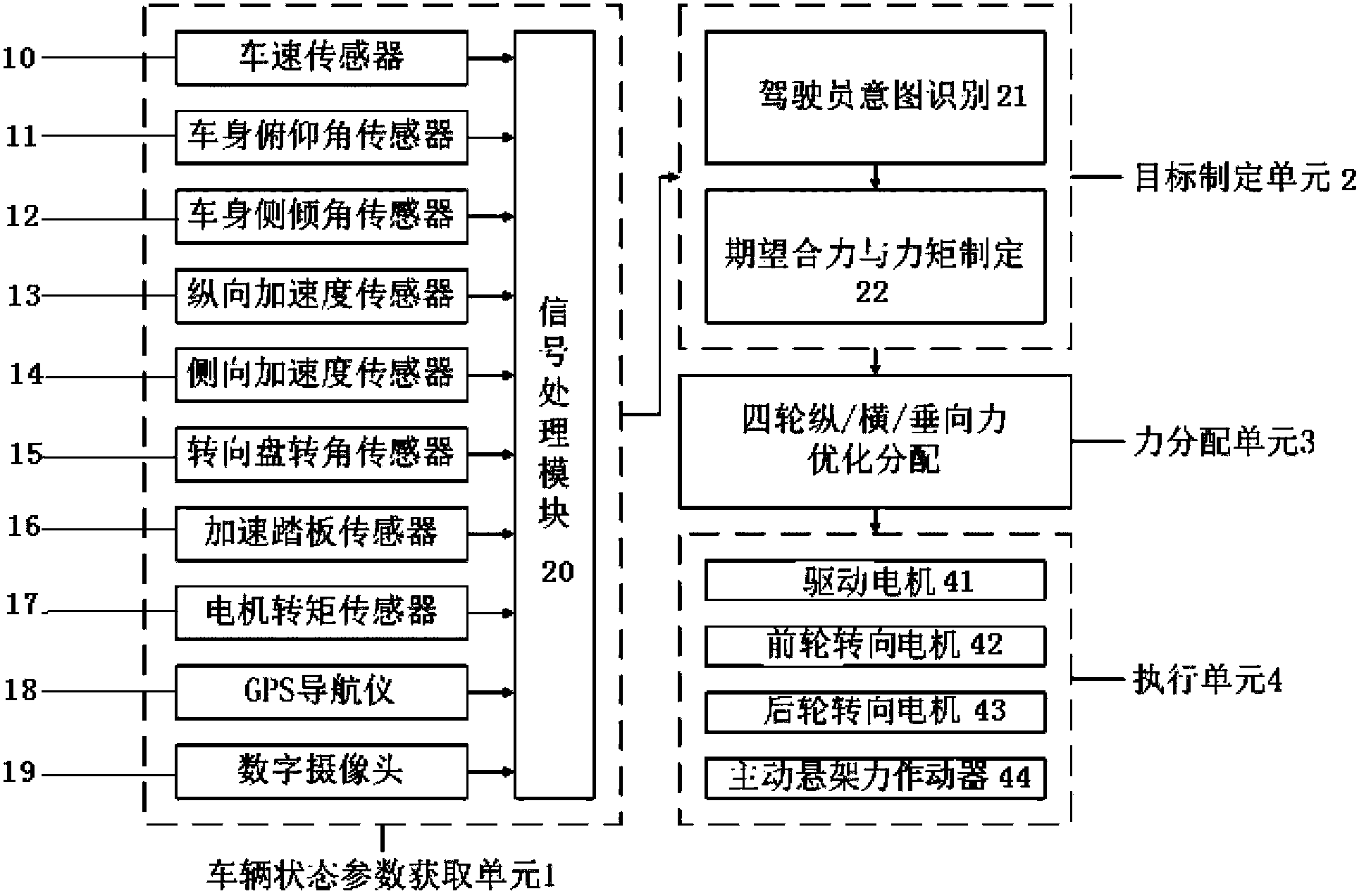

Longitudinal, transverse and vertical force integrated control optimization method for electric vehicles driven by hub

ActiveCN109204317AImprove handling stabilityImprove road tracking performanceKinematicsElectronic control system

A longitudinal, transverse and vertical force integrated control optimization method for electric vehicles driven by hub belongs to that technical field of electric vehicle control. The object of theinvention is to adopt a layered cooperative control structure so as to solve the four shortcomings existing in the prior art control system of a longitudinal, lateral and vertical force integrated control optimization method of an electric vehicle driven by a hub. The invention brings the relationship between vehicle resultant force and four-wheel tire force into the vehicle body six-degree-of-freedom equation to obtain the expected values of vehicle kinematics control target longitudinal speed, lateral speed, vertical speed, pitch angle, roll angle and yaw angle, thereby optimizing the vehicle kinematics control target. The layered longitudinal, lateral and vertical force unified optimal distribution integrated control method eliminates the conflict between different chassis electronic control systems and enhances the complementarity, and comprehensively improves vehicle handling stability and vehicle driving posture, which is embodied in the improvement of vehicle road tracking performance, safety, maneuverability, stability and comfort.

Owner:JILIN UNIV

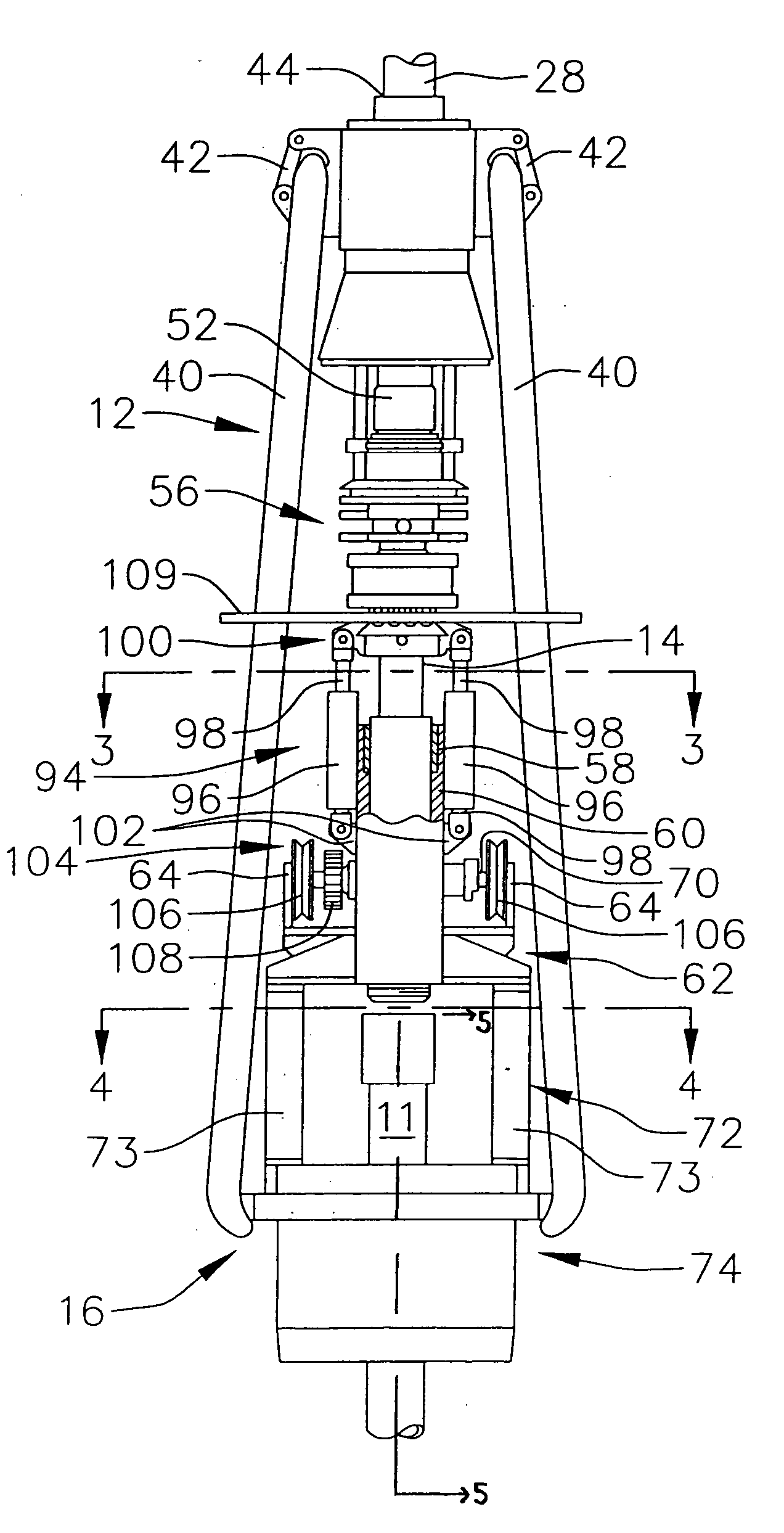

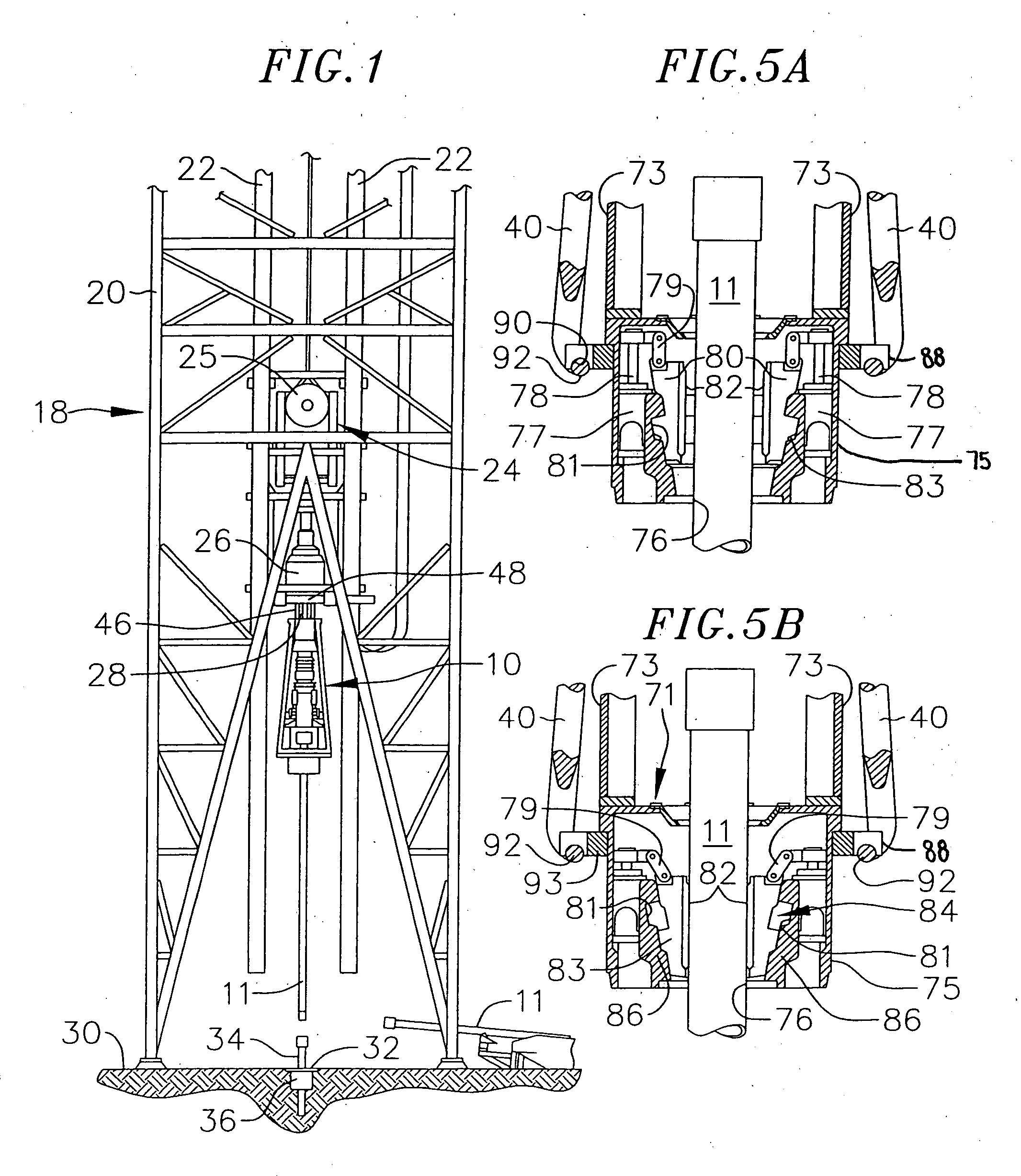

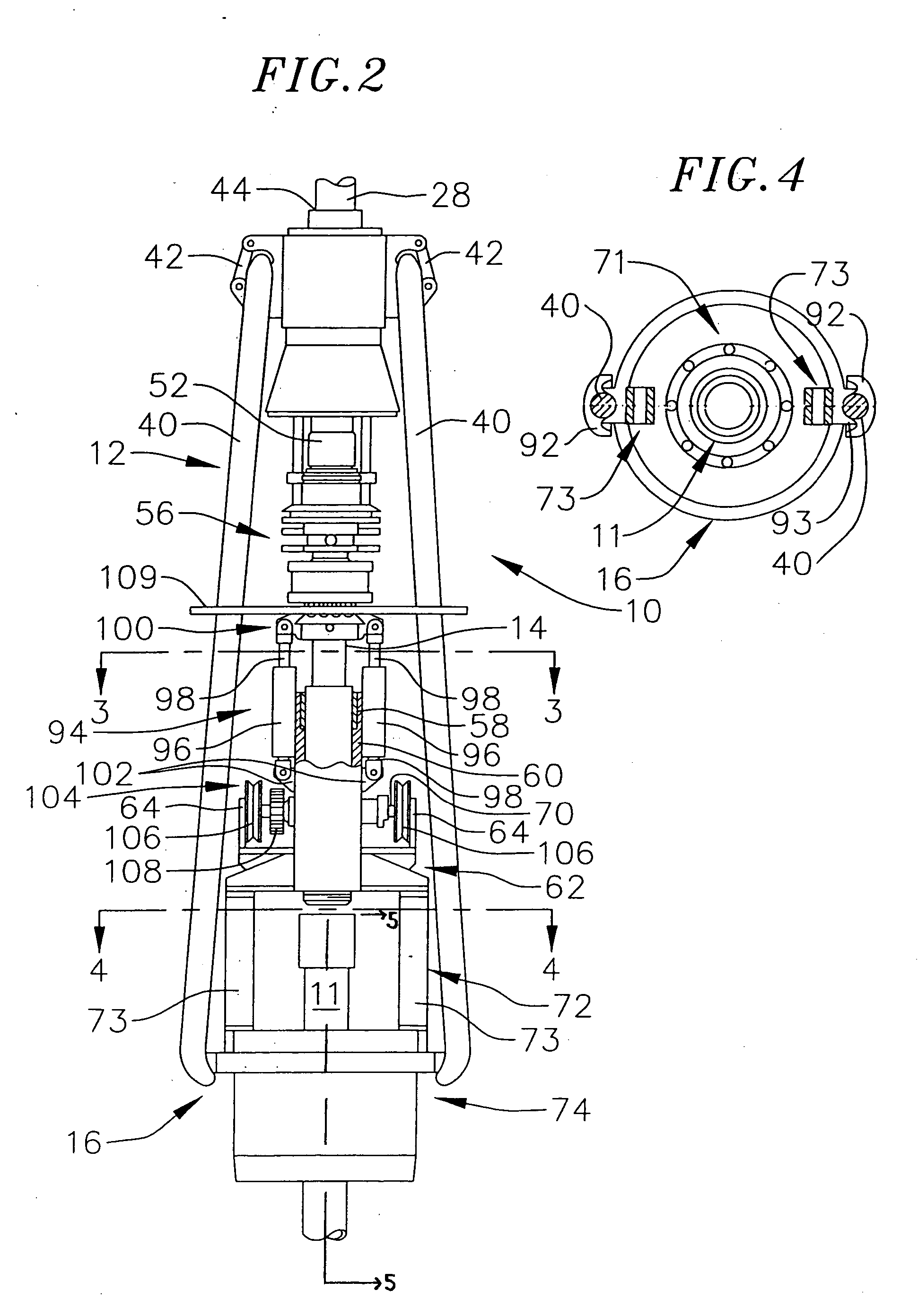

Pipe running tool having internal gripper

A system for coupling a pipe segment to a pipe string is provided that includes a top drive assembly having an output shaft; and a pipe running tool coupled to the top drive assembly and rotatable by the output shaft of the top drive assembly. The pipe running tool includes an internal gripper for insertion within an internal diameter of the pipe segment and a tapered slip cone section, which slidably receives corresponding tapered surfaces of a plurality of slips, such that a vertical force on the slips causes the slips to move radially outwardly into gripping engagement with the internal diameter of the pipe segment, and wherein the vertical force applied to the slips is sufficient to allow the gripping engagement of the slips with the internal diameter of the pipe segment to transmit a torque from the top drive output shaft to the pipe segment.

Owner:VARCO I P INC

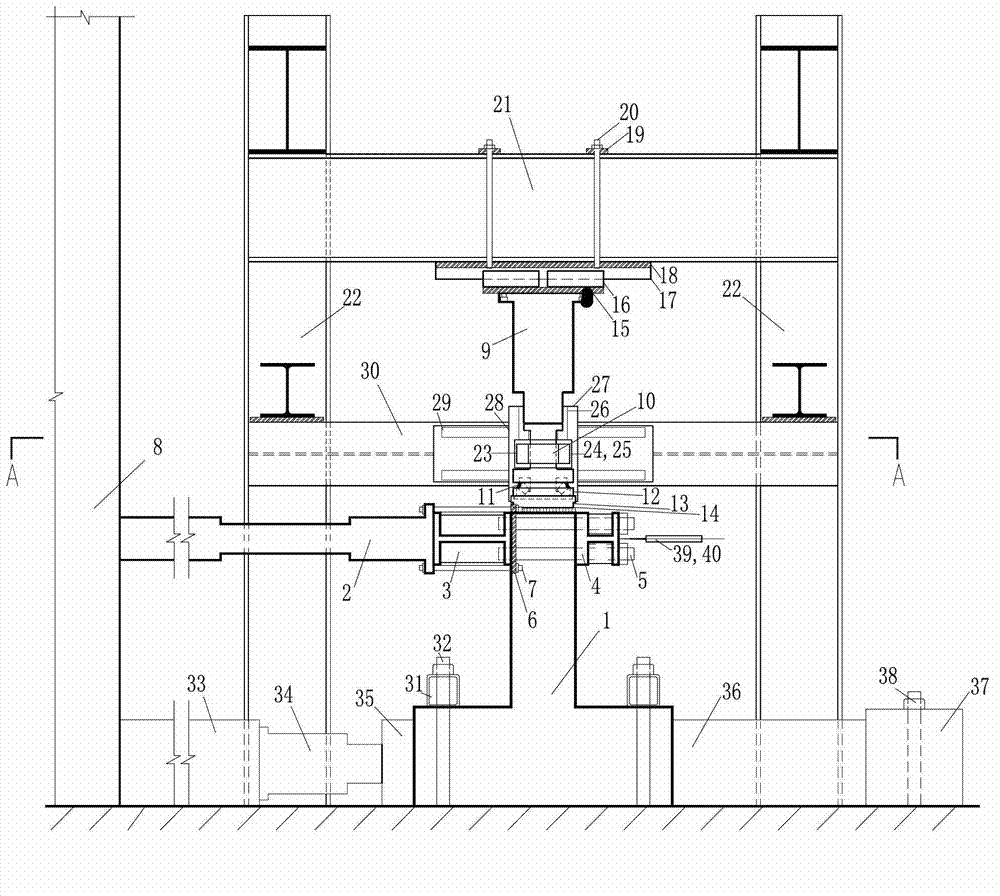

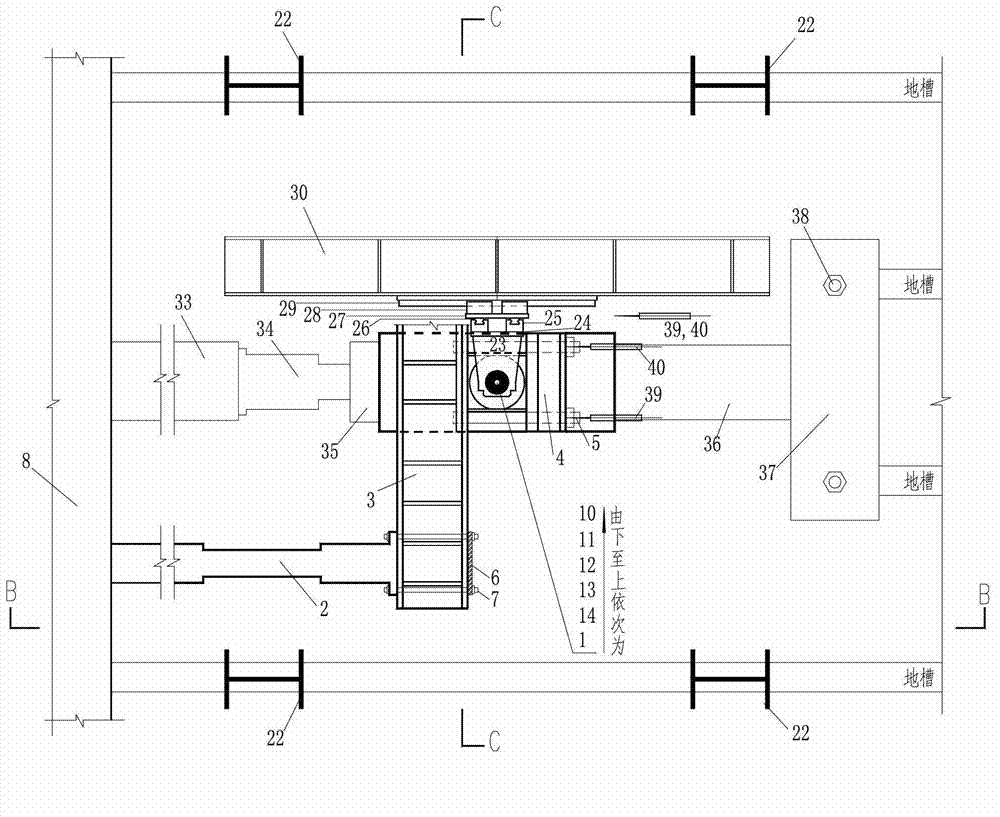

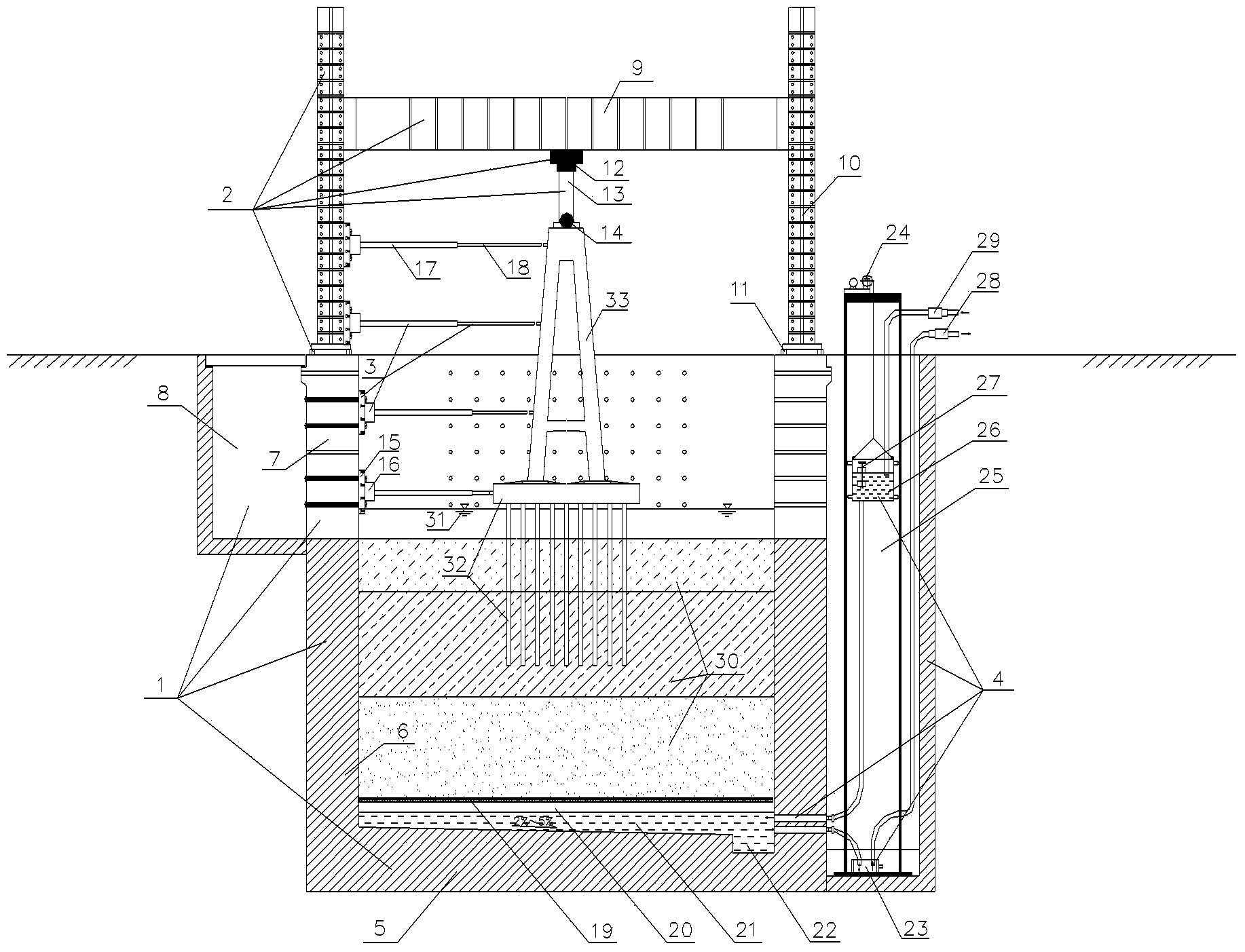

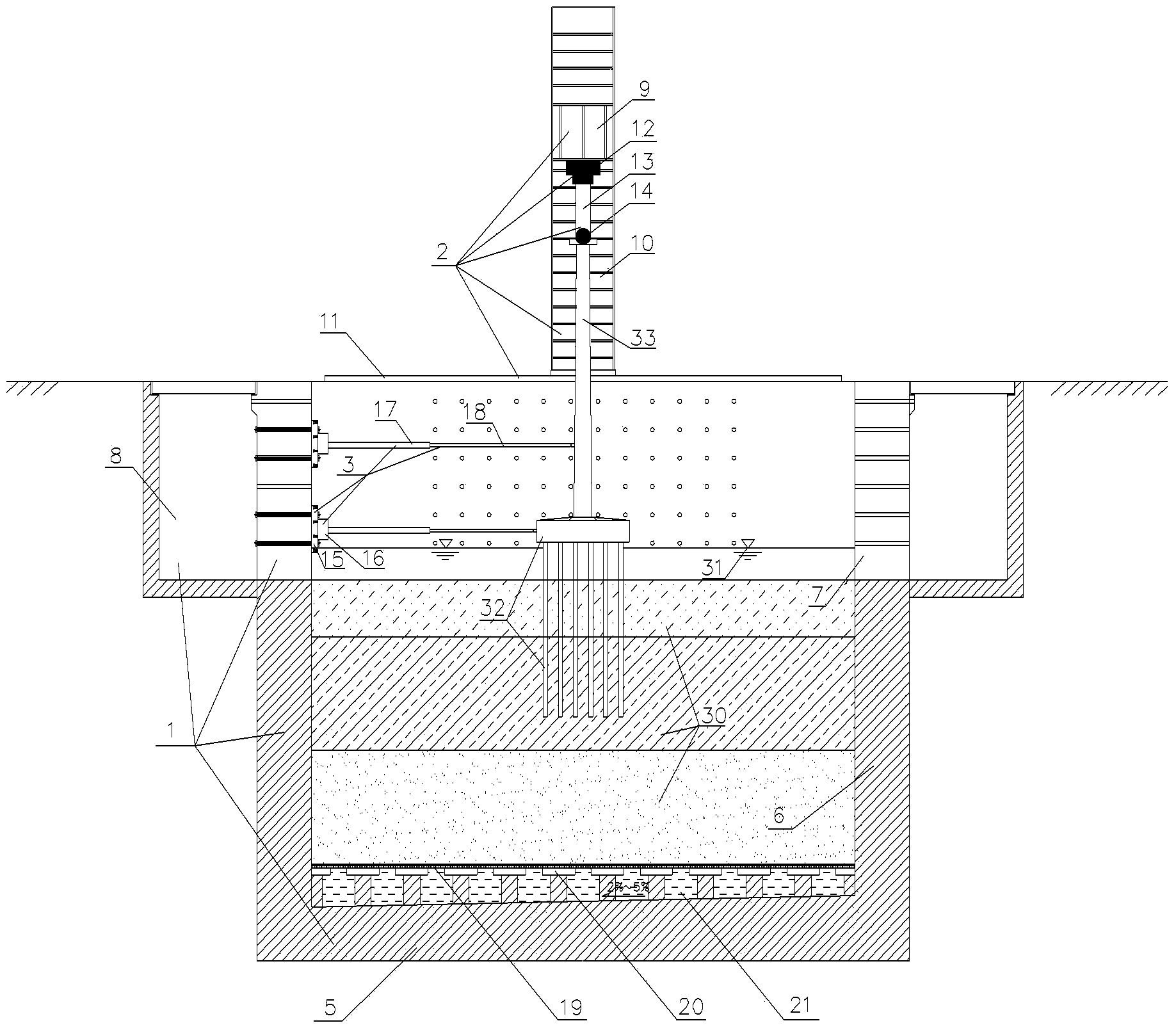

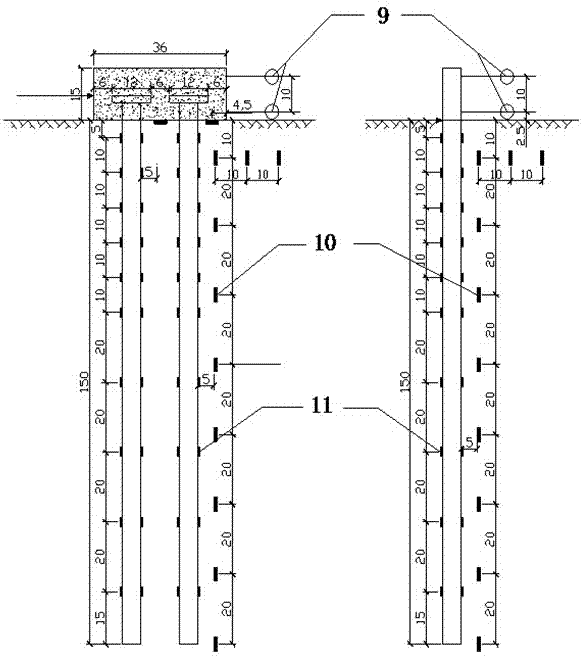

Three-directional static and dynamic loading model test platform for deep water foundations of bridges

ActiveCN103510551ASolve the technical problem of vertical loading influenceSmall sizeFoundation testingHorizontal forceTower

The invention discloses a three-directional static and dynamic loading model test platform for deep water foundations of bridges. The three-directional static and dynamic loading model test platform comprises a test foundation trench, a vertical loading system, a horizontal bi-directional loading system and a water level simulating system. The test foundation trench is used for arrangement of foundation soil, water and models. The vertical loading system used for applying vertical static and dynamic action on the models is installed at the top of the test foundation trench, the horizontal bi-directional loading system used for applying two or more horizontal static and dynamic actions on each model is installed on the upper portion of the inner side wall of the test foundation trench, and the water level simulating system used for water feeding and draining and test water level control in the test foundation trench is installed on the bottom and the outer side of the outer side wall of the test foundation trench. Test and research on the models of bridge deep water foundations such grouped piles, sink shafts, caissons and compound foundations and bridge towers (piles) under three-directional static and dynamic actions such as the vertical static and dynamic action and the horizontal bi-directional static and dynamic action can be carried out by the test platform, and the test platform solves problems about simulation of static and dynamic mutual action of the foundation soil-water-bridge deep water foundation-bridge tower (pile) under the combined working conditions of vertical force, horizontal force, bending moment, torque and the like.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

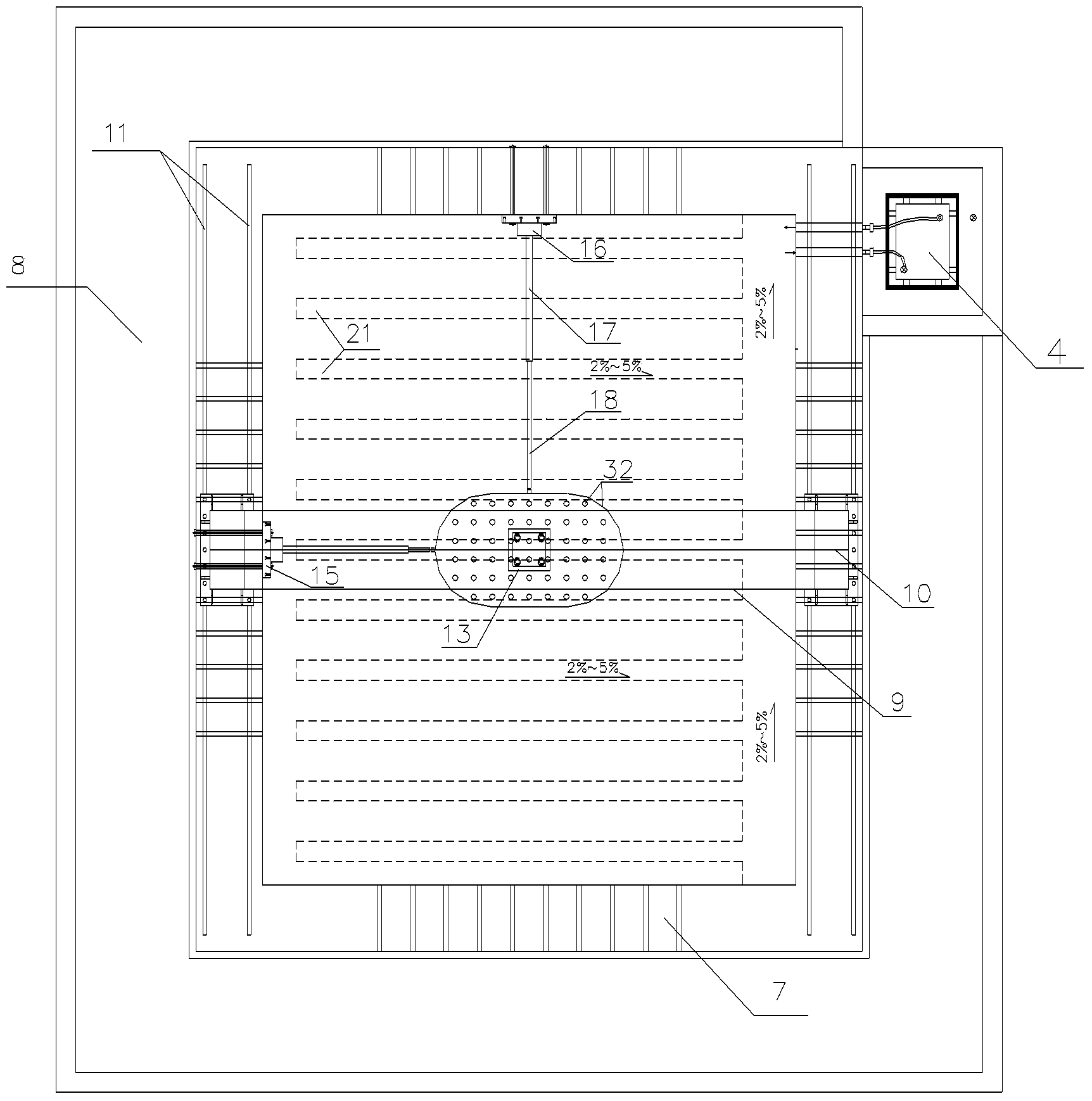

Longitudinal-transverse-vertical force cooperative control method of distributed electrically driven vehicle

The invention relates to a longitudinal-transverse-vertical force cooperative control method of a distributed electrically driven vehicle. The method is implemented by a vehicle control system: 1) formulation of expected resultant force and moment; 2) optimal distribution of longitudinal, transverse and vertical forces of four wheels; 3) specific execution of the forces. The expected values of the resultant force and the moment of the whole vehicle are obtained by utilizing various information of the vehicle, an integrated tyre force optimization problem is formed by establishing a constraint condition and an objective function, and an optimization solution algorithm is designed for the problem, wherein the optimization algorithm comprises a constraint optimization method which adopts a barrier function method and a Newton method, and a feasible region planning method based on vehicle state continuity. The method does not need to implement different control strategies according to different work conditions of tyres, realizes unified optimal distribution and control of the longitudinal, transverse and vertical forces of the tyres, comprehensively improves the operation stability and the driving posture of the vehicle, and can be applied to driverless operation of vehicles in the future.

Owner:TSINGHUA UNIV

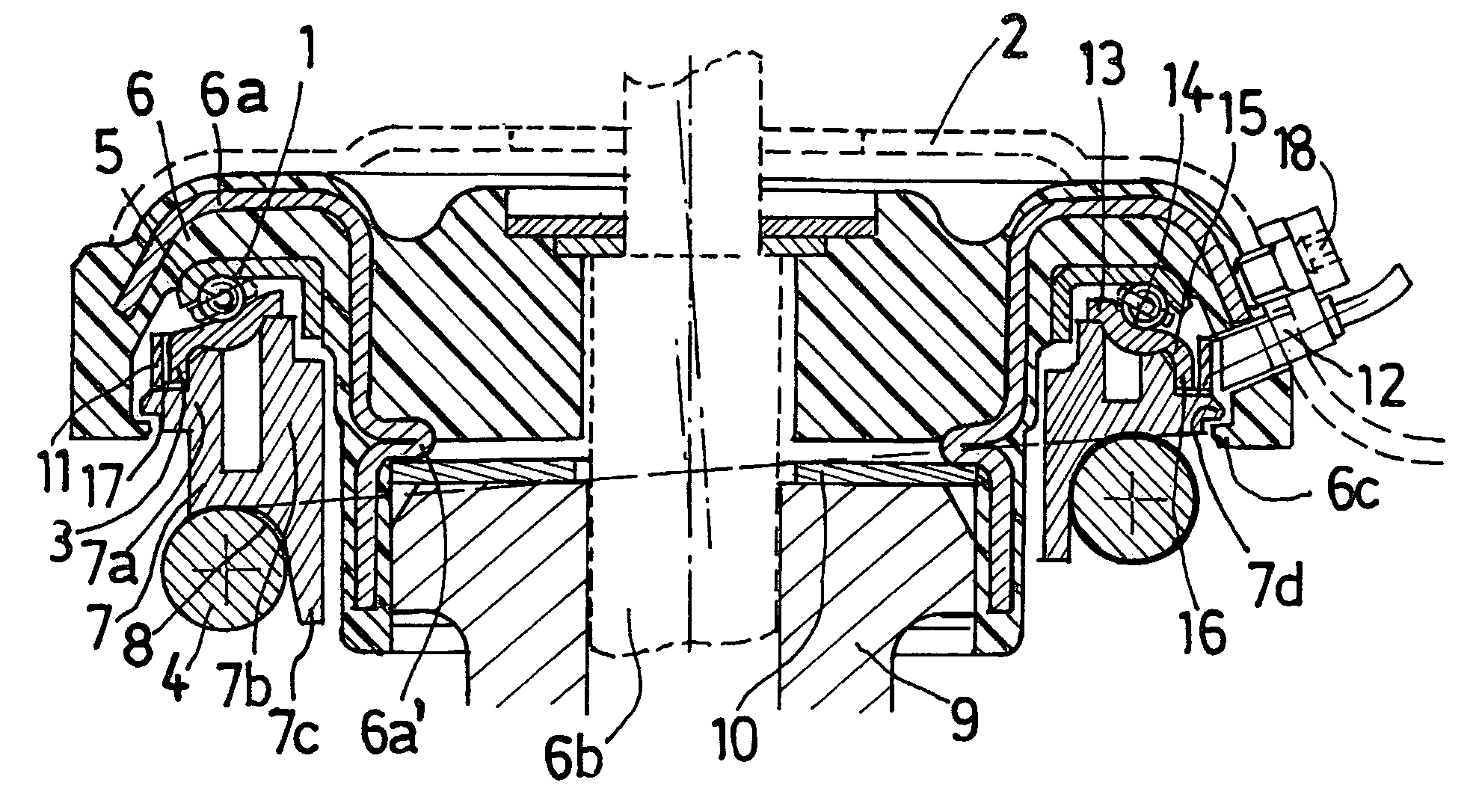

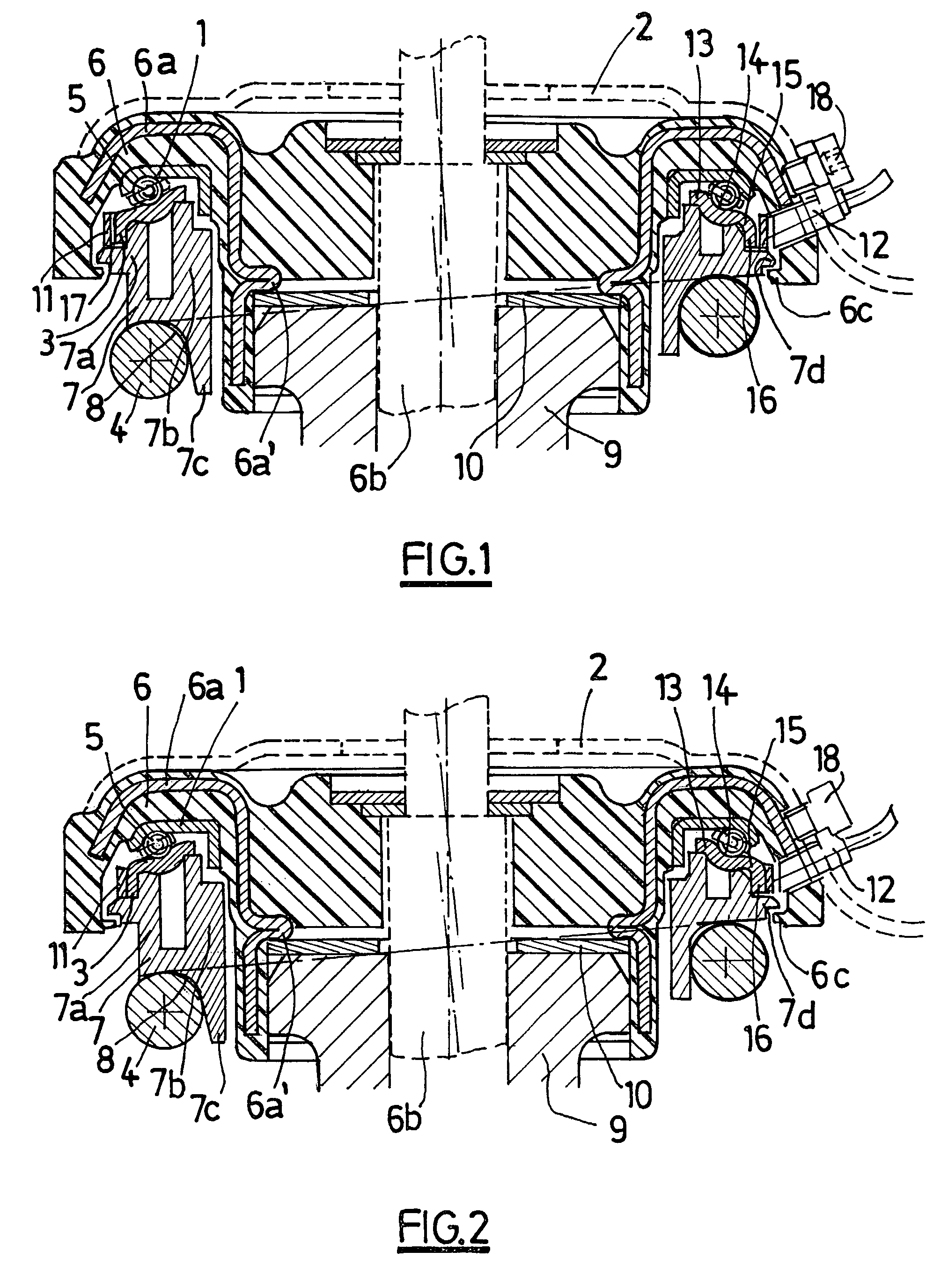

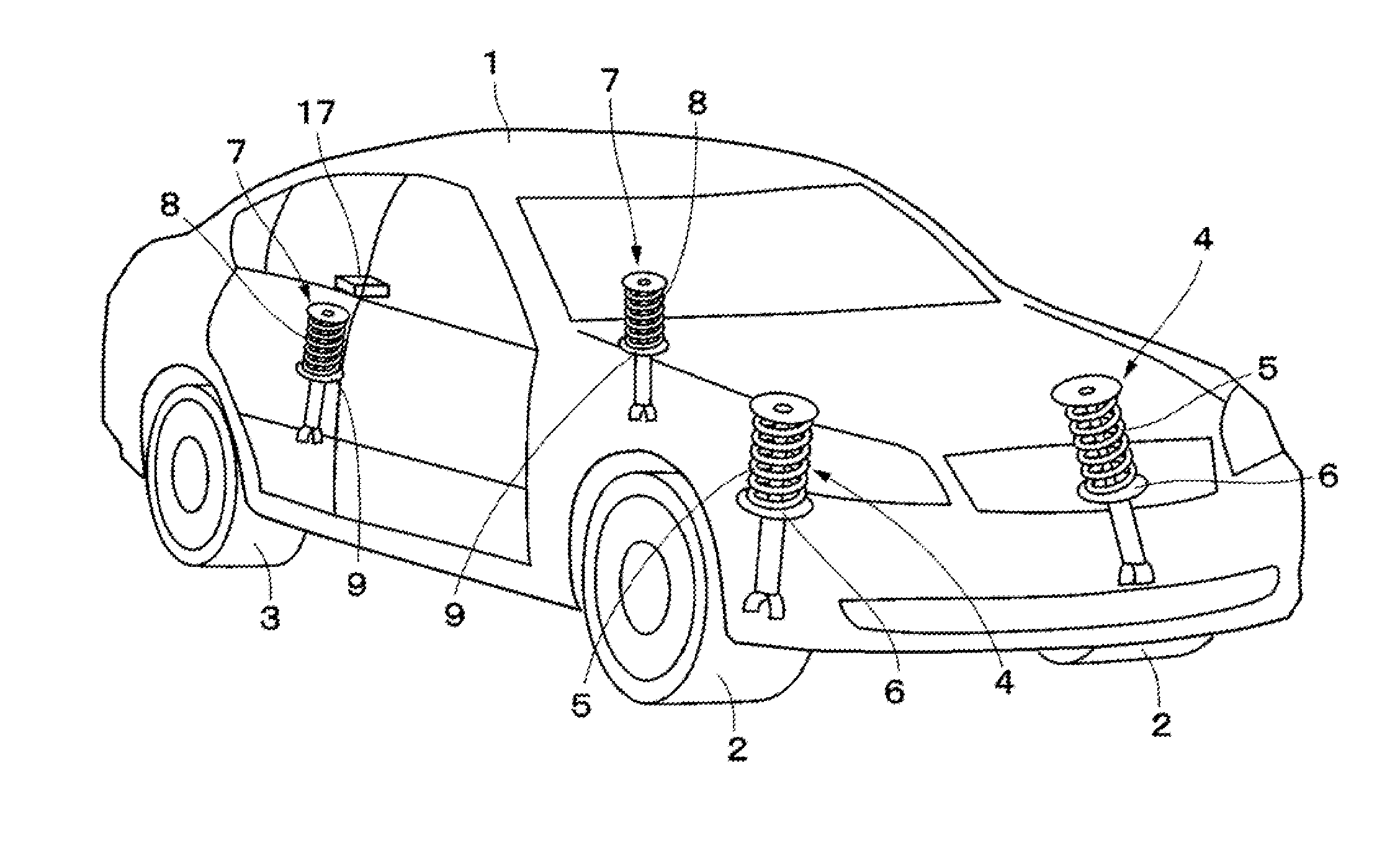

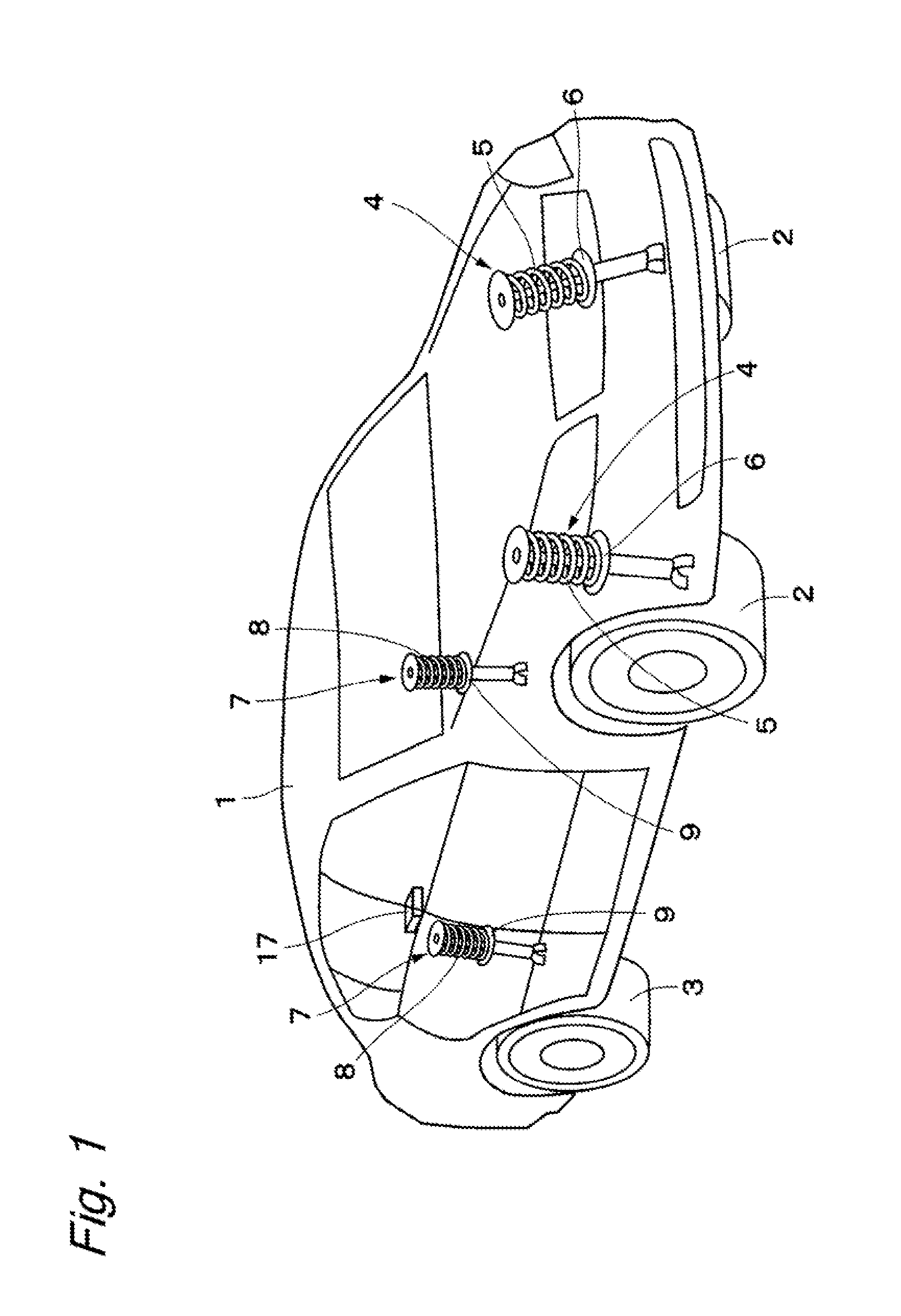

Rotating instrumented suspension stop for measuring vertical forces

A suspension stop for a motor vehicle wheel assembly comprising a fixed member adapted to be fixed to the chassis (2) of the vehicle and a rotating member adapted to be fixed to the suspension spring (4) so as to be rotationally moved under the effect of the forces exerted by the spring. The stop includes a device for measuring the vertical forces applied to the vehicle wheel. The device includes a pulse-generating coder (11) fixed to one of the members, a sensor (12) fixed to the other member which is able to detect these pulses so as to determine the angular position of the rotating member with respect to the fixed member, and a calculation device able, from this position, to calculate the corresponding vertical force applied.A method of measuring the vertical forces applied to a wheel associated with the chassis (2) of a vehicle by such a stop is also provided.

Owner:SNR ROULEMENTS SA

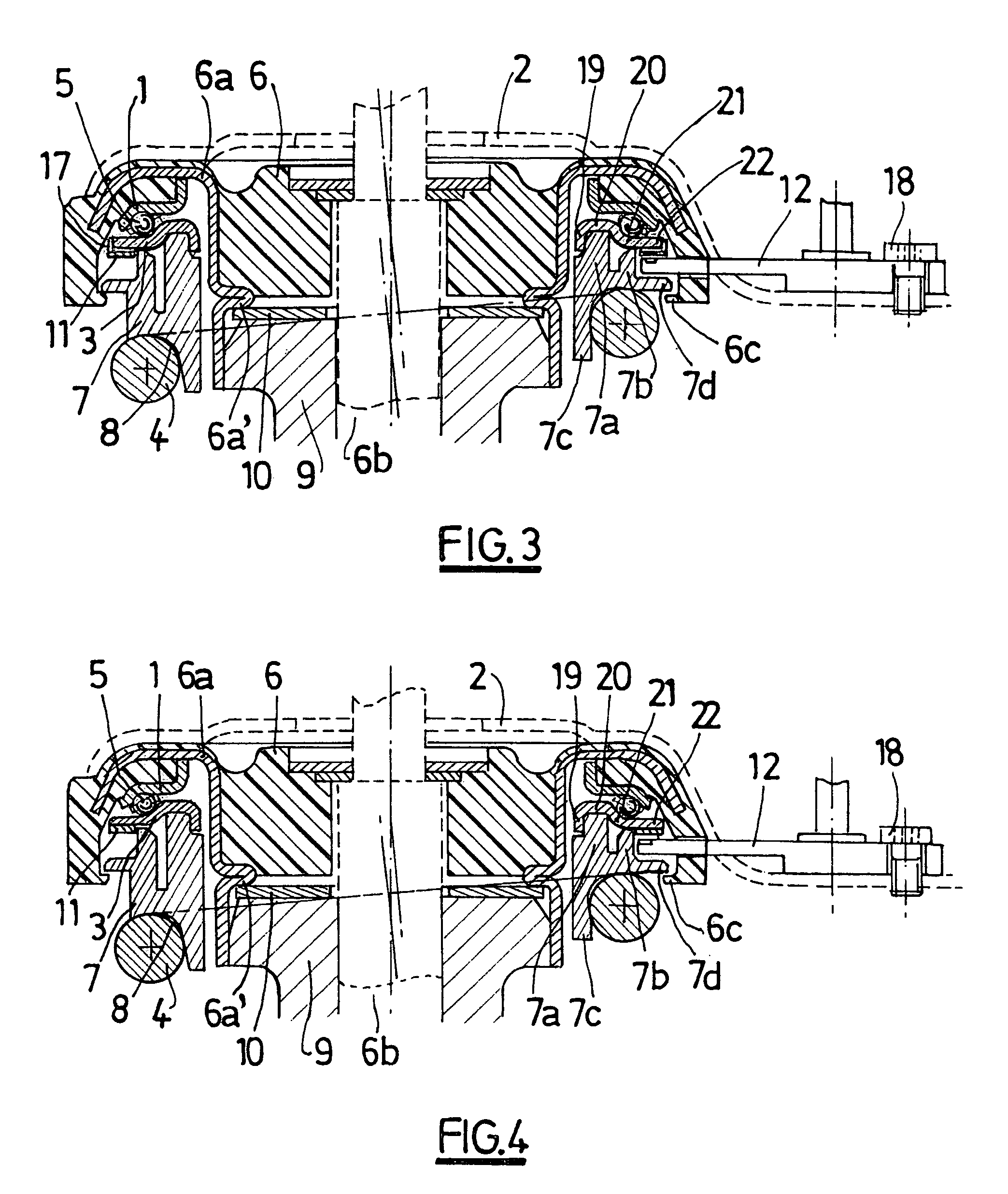

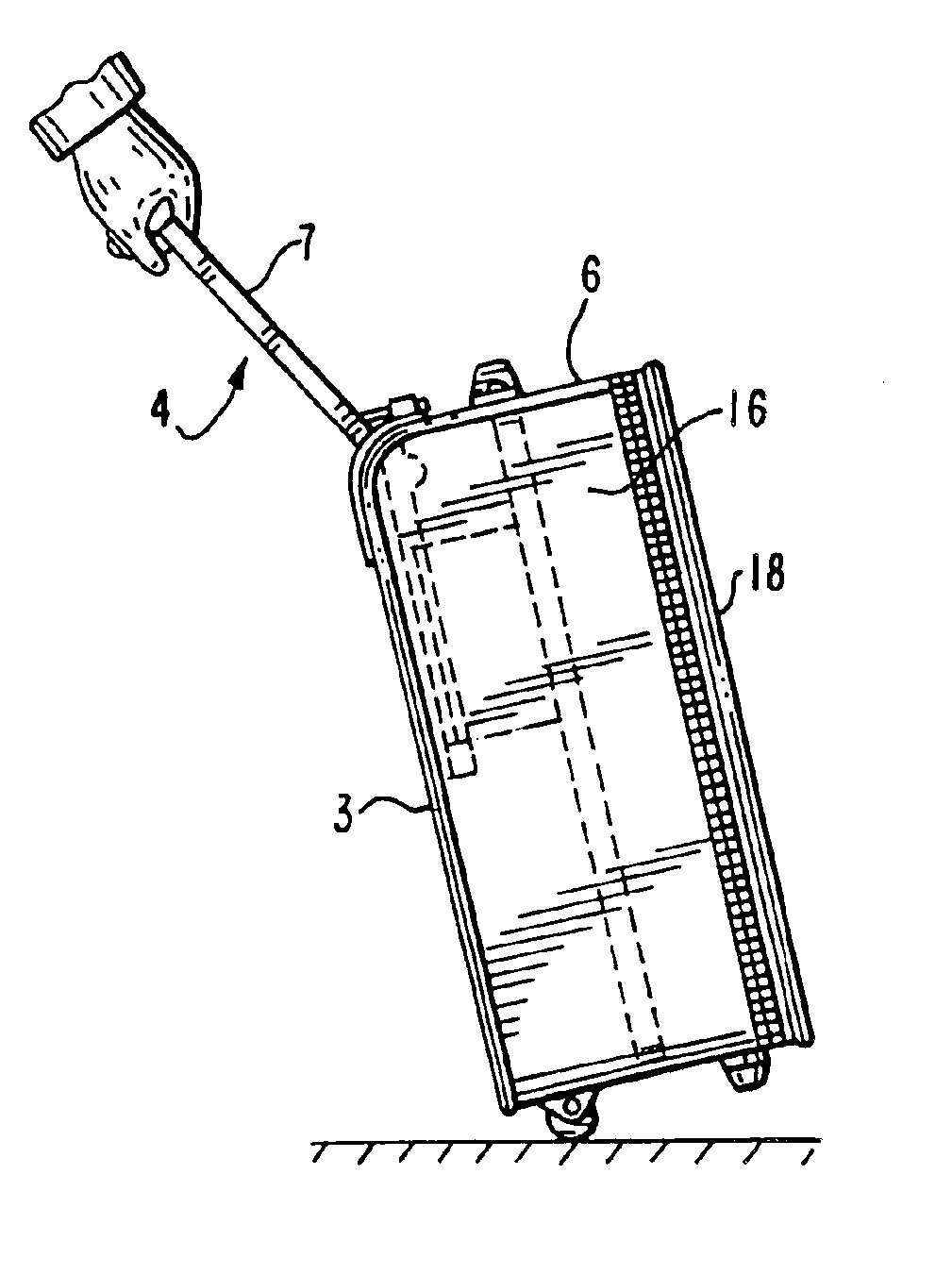

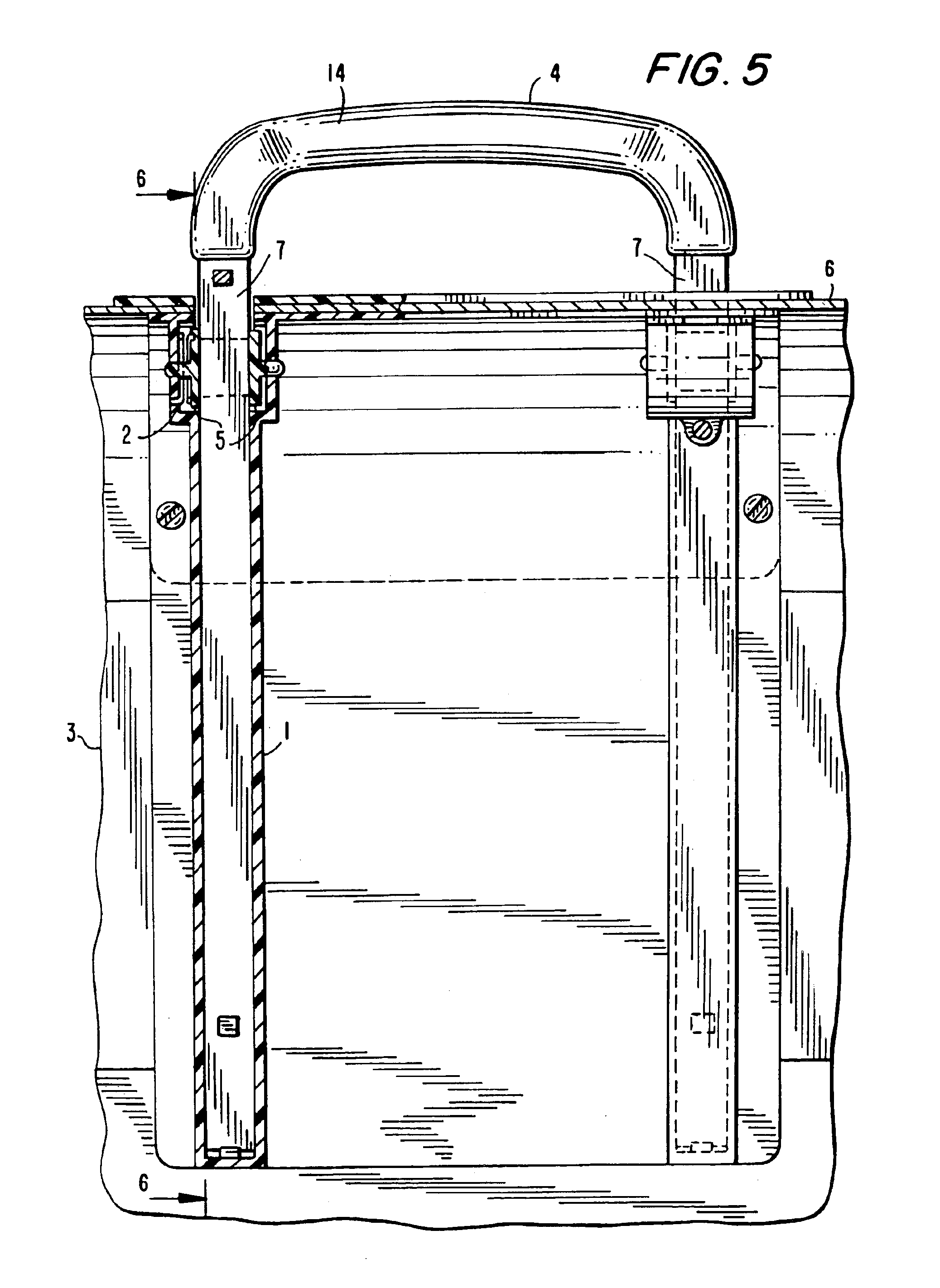

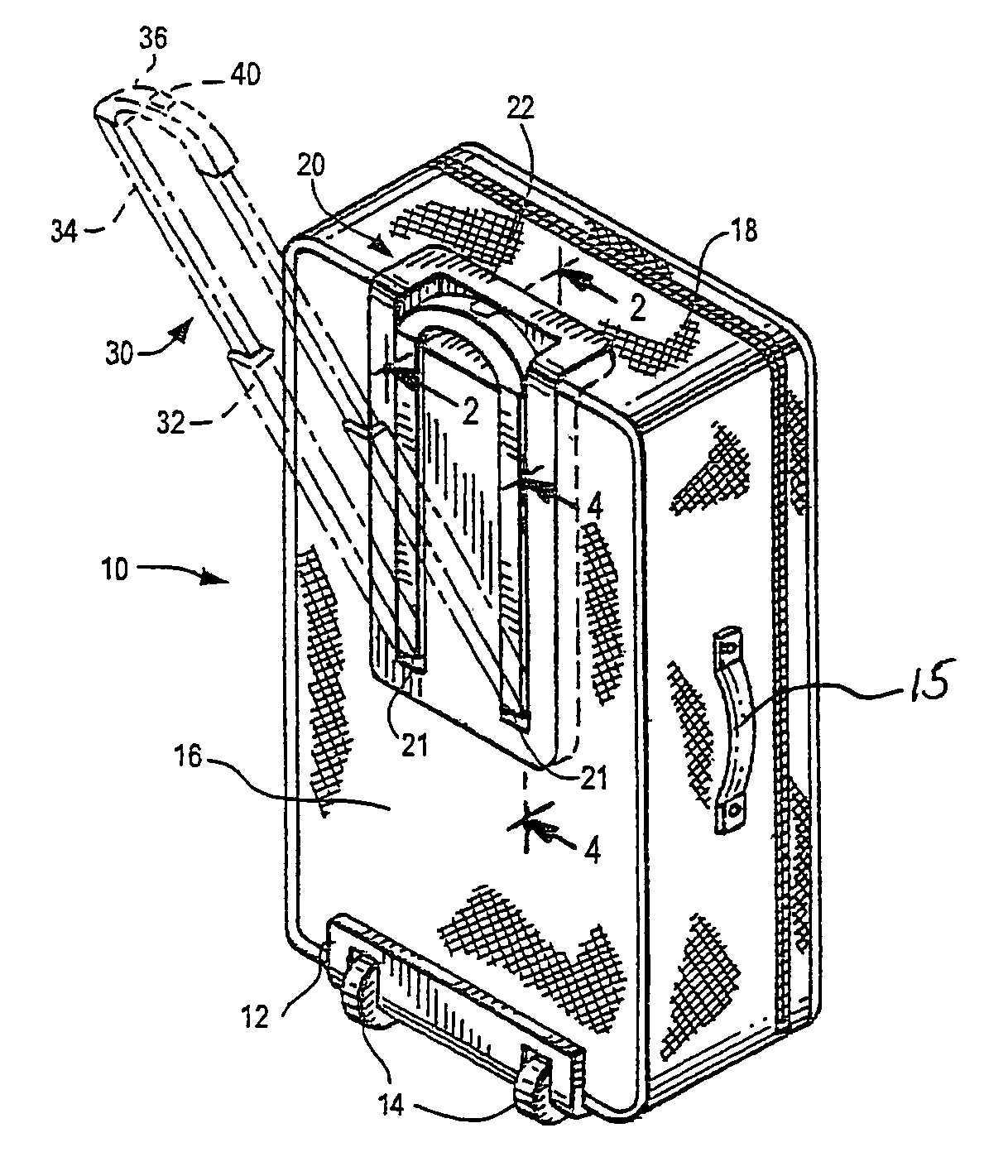

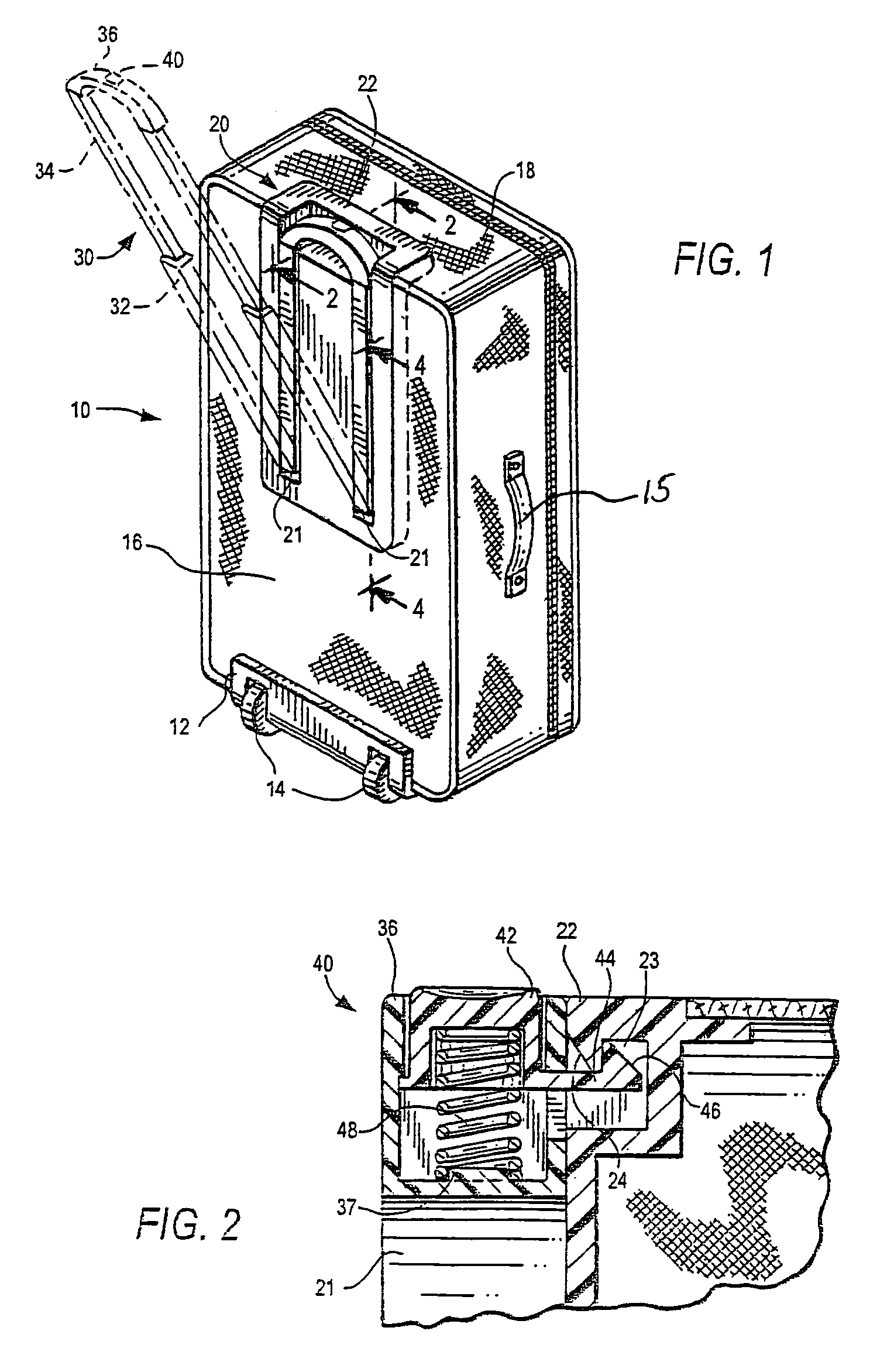

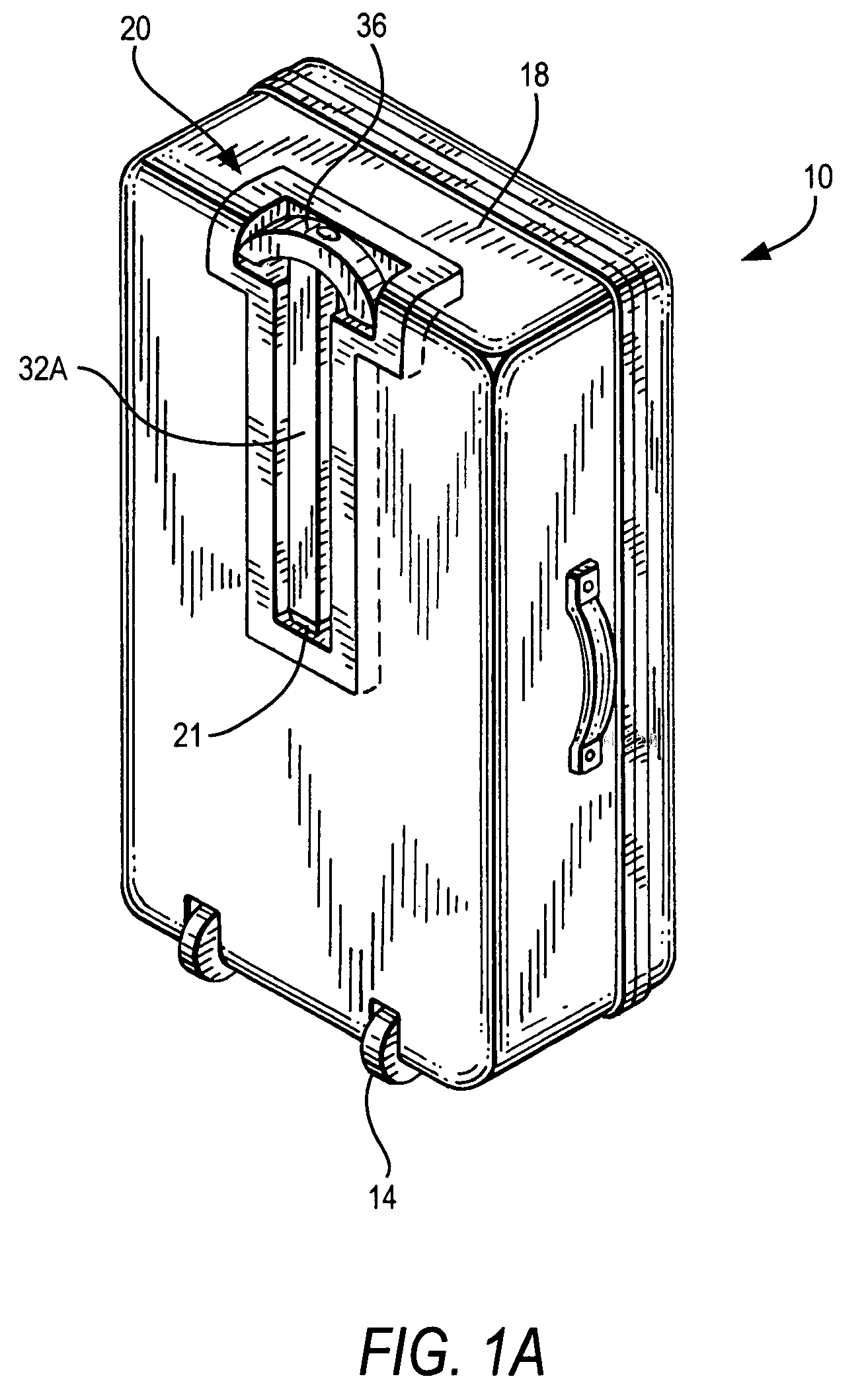

Extendable and angularly adjustable handle for wheeled luggage

InactiveUS7070190B2Optimize towing positionMinimize forceWing handlesUnderstructuresEngineeringAngular displacement

A wheeled luggage case that is tilted for towing is provided with a retractable and, optionally, telescoping handle (4) assembly that is withdrawn from the interior of the case to an extended vertical position at the intersection of the top and rear walls, from which it is angularly rotated by the user to a position that minimizes the vertical force that is required to support the hand grip to comfortably tow the luggage. Preferred angular displacements for a wide range of users and loads positioned in and on the luggage case have been found to be at about 17° and 35° from the vertical position.

Owner:OUTRIGGER

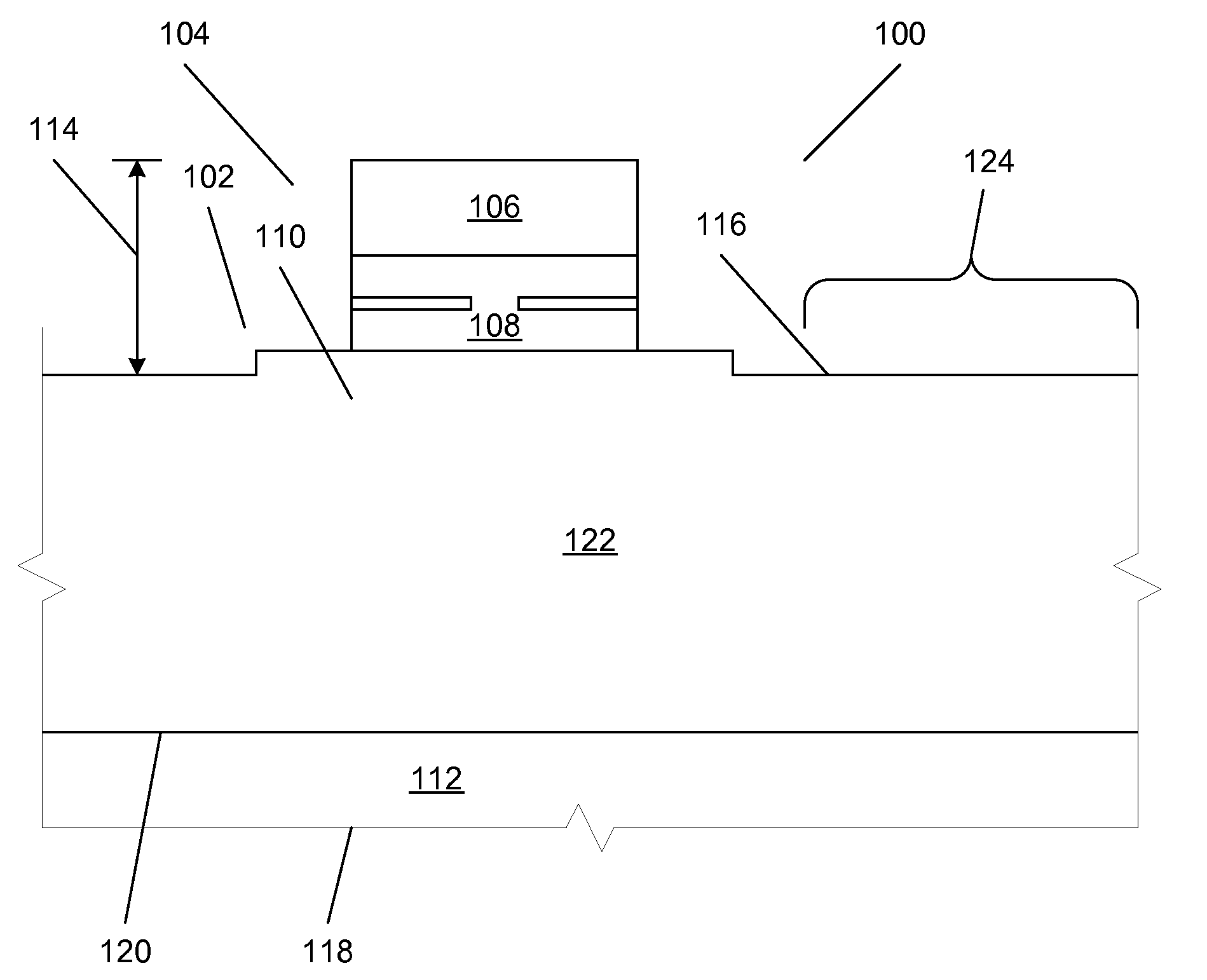

Apparatus and method for removably adhering a semiconductor substrate to a substrate support

A process and apparatus is disclosed capable of removably adhering a semiconductor substrate to a substrate support in a sub-atmospheric environment using a plurality of individual fibers, each mounted at one end adjacent the substrate support, and each having a loose end. When the portions of the fiber adjacent the loose fiber ends are each brought into contact with the under surface of the substrate, Van der Waals forces are exerted between the substrate and the fibers to urge the substrate toward the underlying substrate support. In a preferred embodiment, the substrate and portions of the fiber adjacent the loose fiber ends are first vertically brought into physical contact with one another, and then a horizontal force is applied to horizontally move, with respect to one another, the substrate and the portions of the fibers adjacent the loose fiber ends. After application of the horizontal force, a vertical force is applied between the substrate and the fibers of sufficient strength to urge the substrate and the fibers away from one another without breaking contact between the substrate and the portions of the fiber adjacent the fiber ends to thereby place tension on the substrate to urge the substrate to lie flat against the underlying substrate support.

Owner:KLA TENCOR TECH CORP

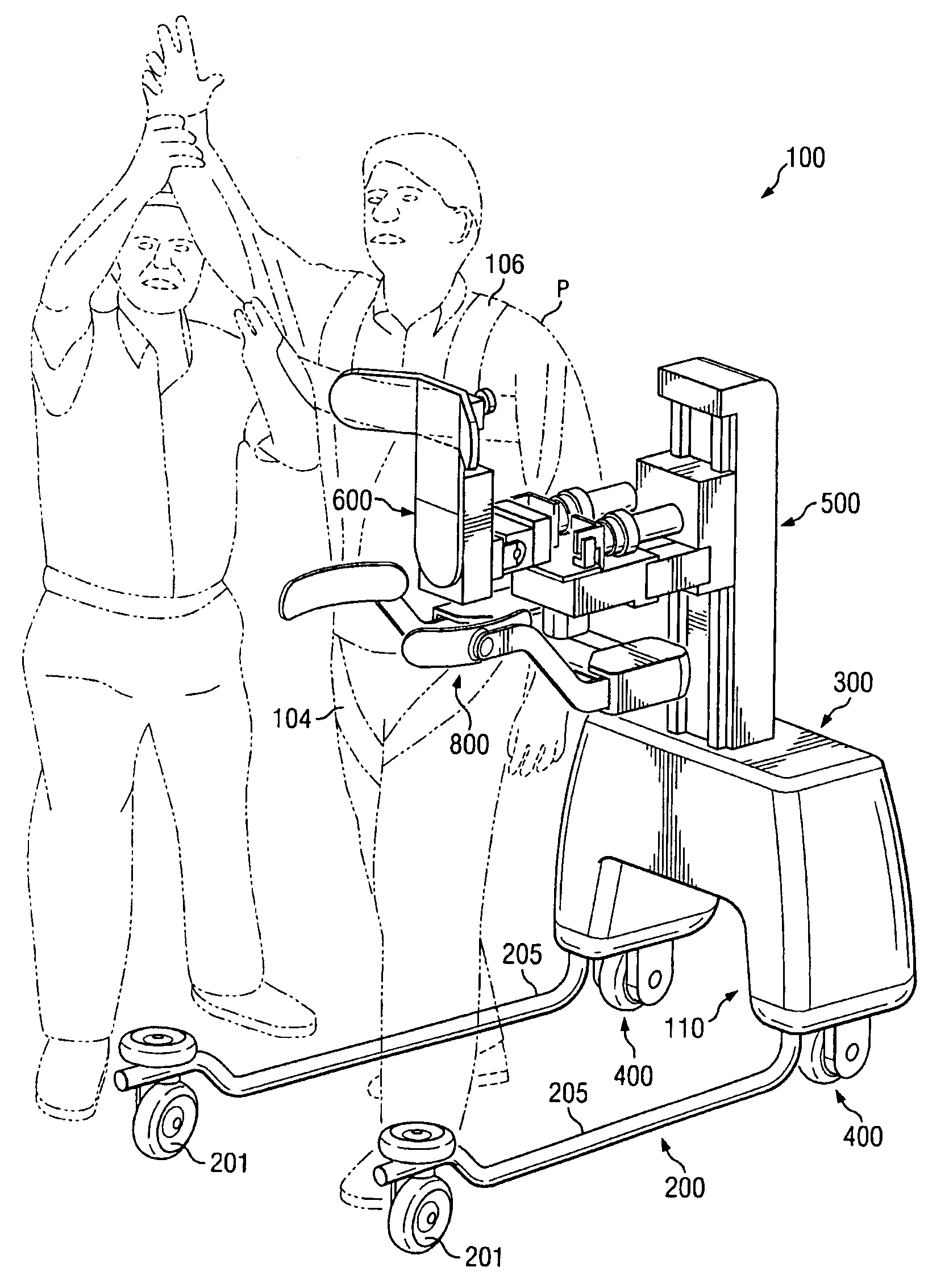

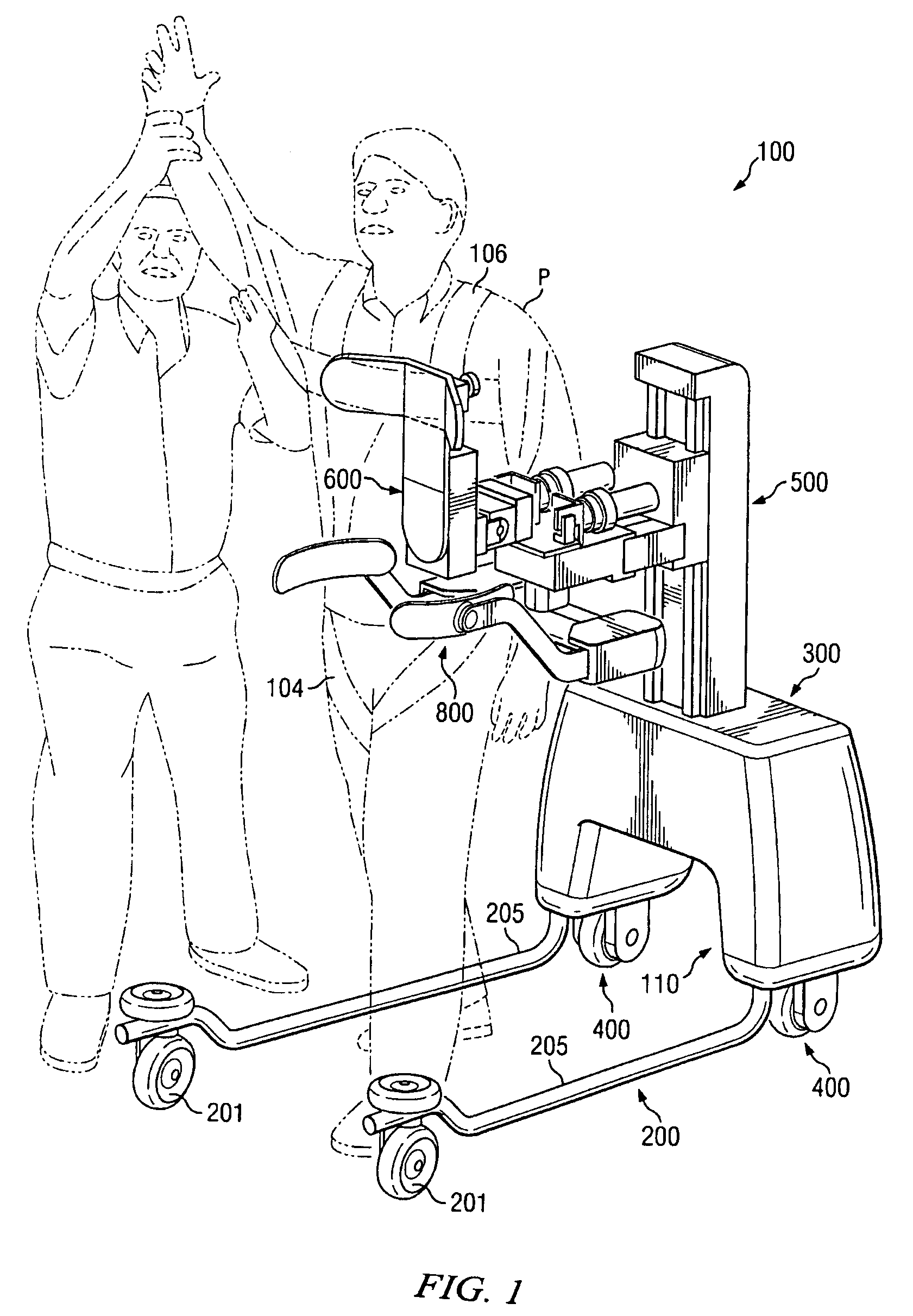

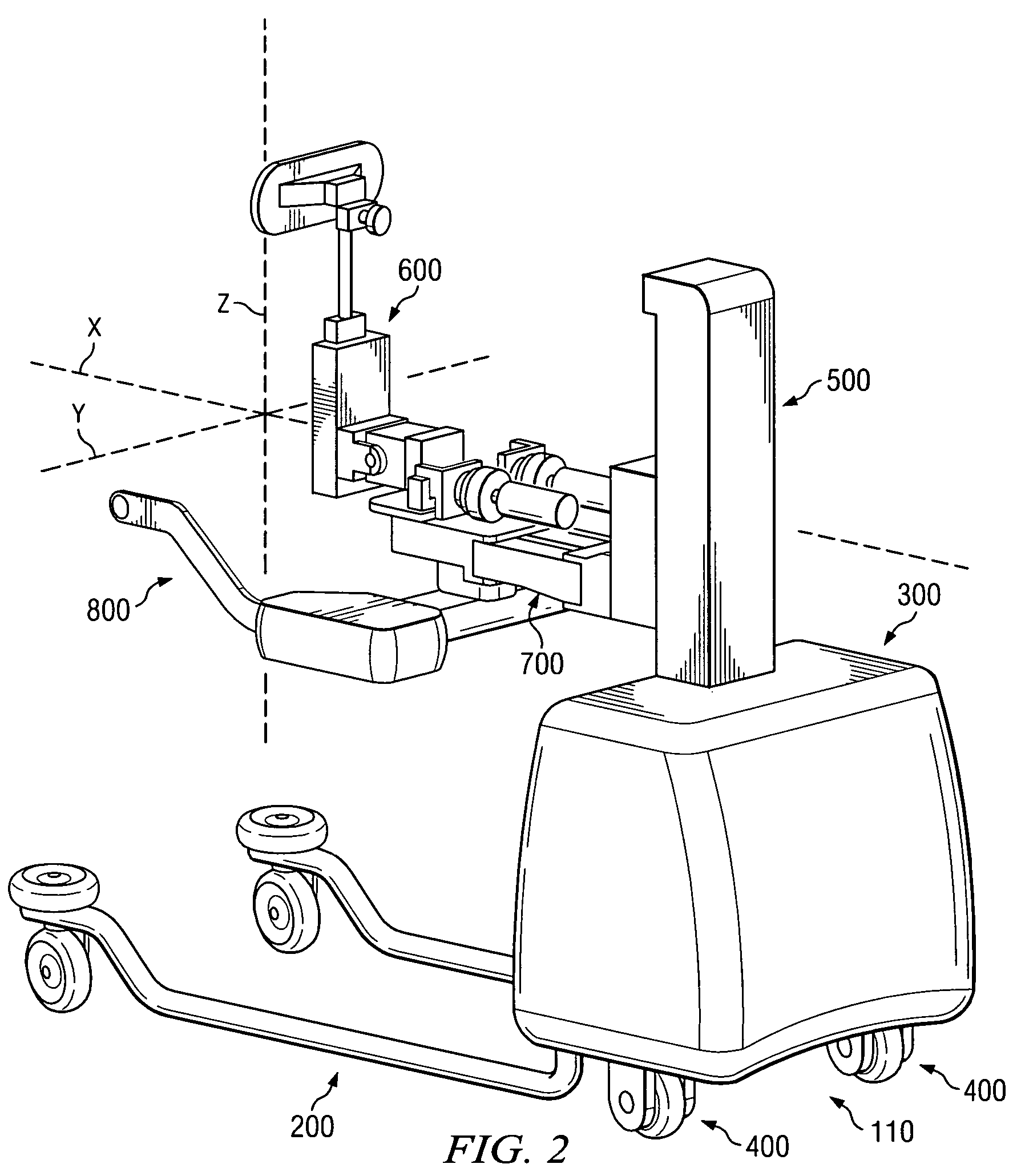

Walking and balance exercise device

A pelvic support unit is coupled to a base by a powered vertical force actuator mechanism. A torso support unit, which is affixed to the patient independently of the pelvic support unit, is connected to the base by one or more powered articulations which are actuable around respective axes of motion. Sensors sense the linear and angular displacement of the pelvic support unit and the torso support unit. A control unit is coupled to these sensors and, responsive to signals from them, selectively control the displacement actuator and articulation(s). Wheel modules are independently powered to both rotate and steer, and, responsive to the control unit, are capable of rolling the exercise device in a direction of travel intended by the patient.

Owner:REHABILITATION INST OF CHICAGO

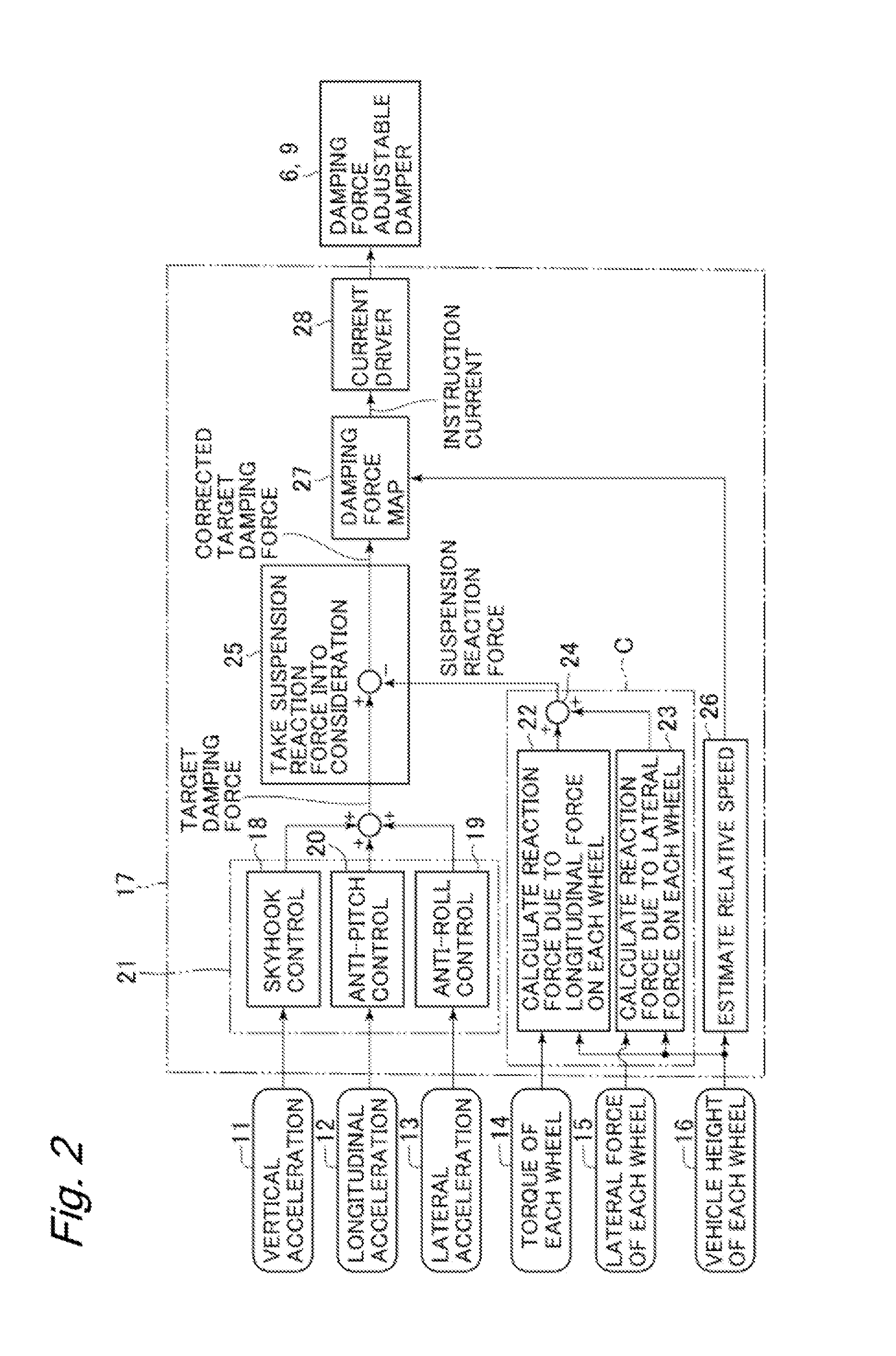

Suspension system

ActiveUS20150088379A1Easy to operateImprove stabilityDigital data processing detailsAnimal undercarriagesEngineeringShock absorber

The present invention is directed to providing a suspension system capable of improving maneuverability and stability. A controller, which controls each of shock absorbers, includes a main control calculation unit, a longitudinal force reaction force calculation unit, a lateral force reaction force calculation unit, an addition unit, and a suspension reaction force consideration unit. The controller subtracts an output from a vertical force calculation unit including the longitudinal force reaction force calculation unit, the lateral force reaction force calculation unit, and the addition unit from an output from the main control calculation unit by the suspension reaction force consideration unit, thereby succeeding in calculating a vertical force applied between a vehicle body and each wheel as a value in consistency with an actual behavior of a vehicle.

Owner:HITACHI ASTEMO LTD

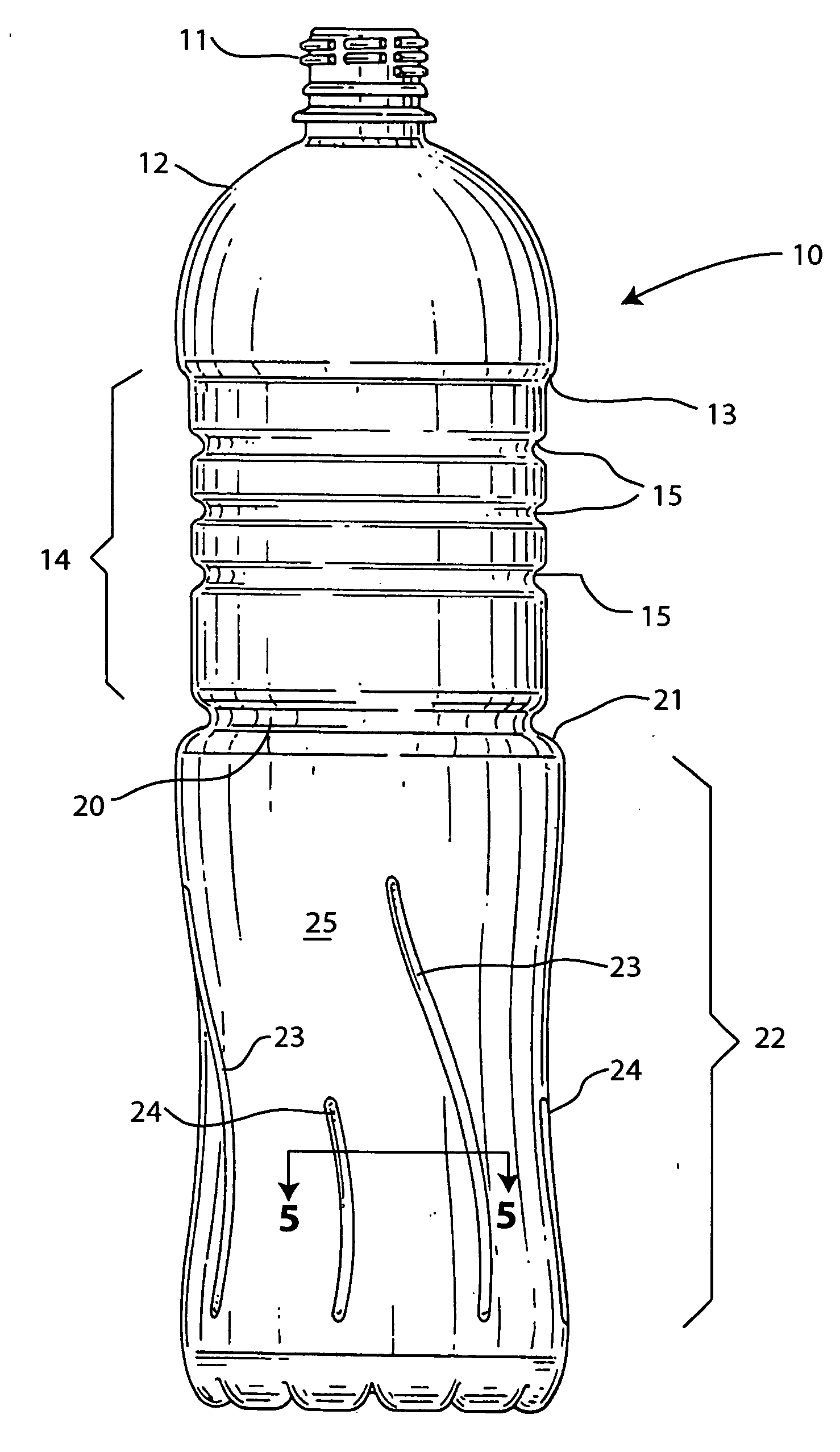

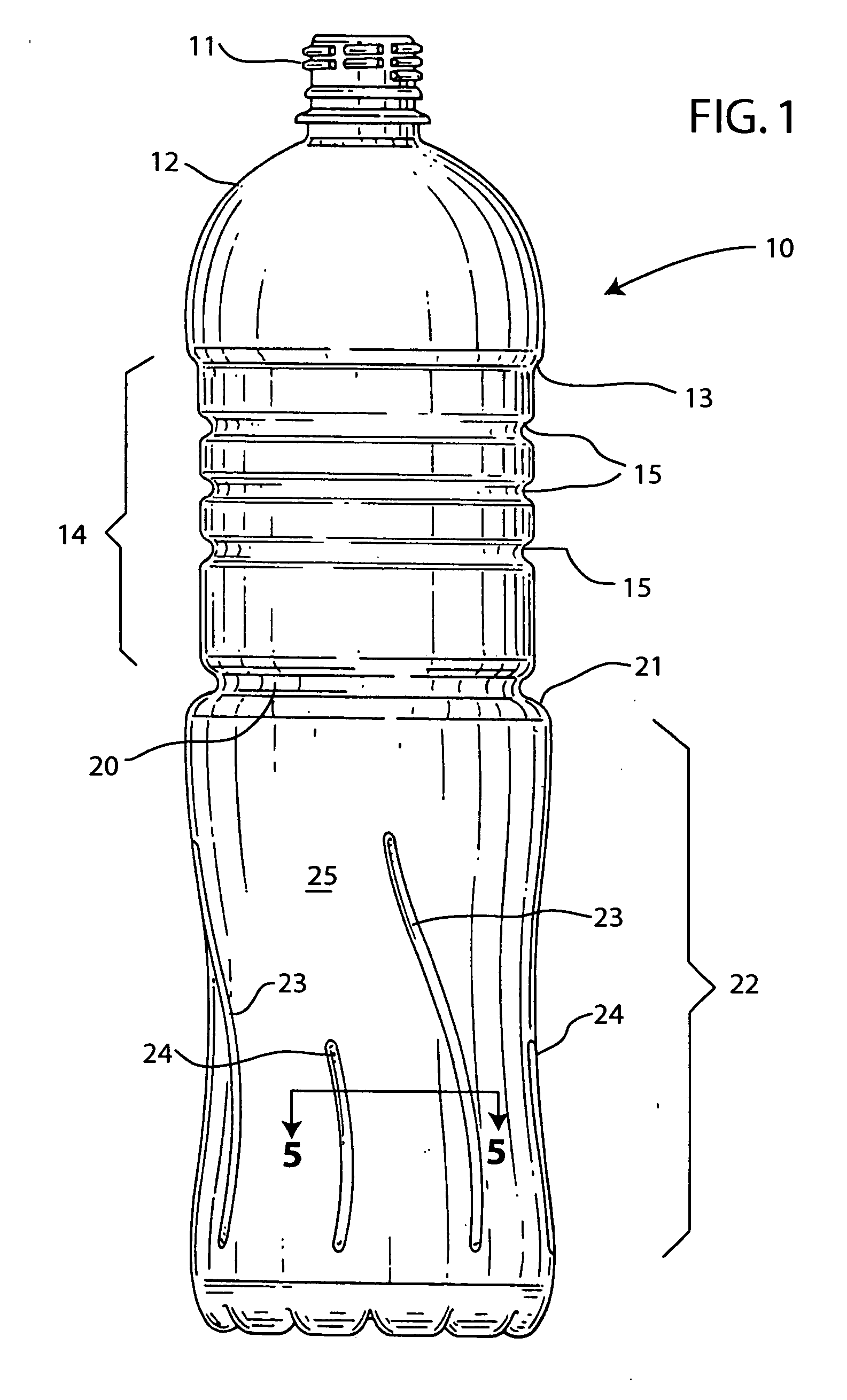

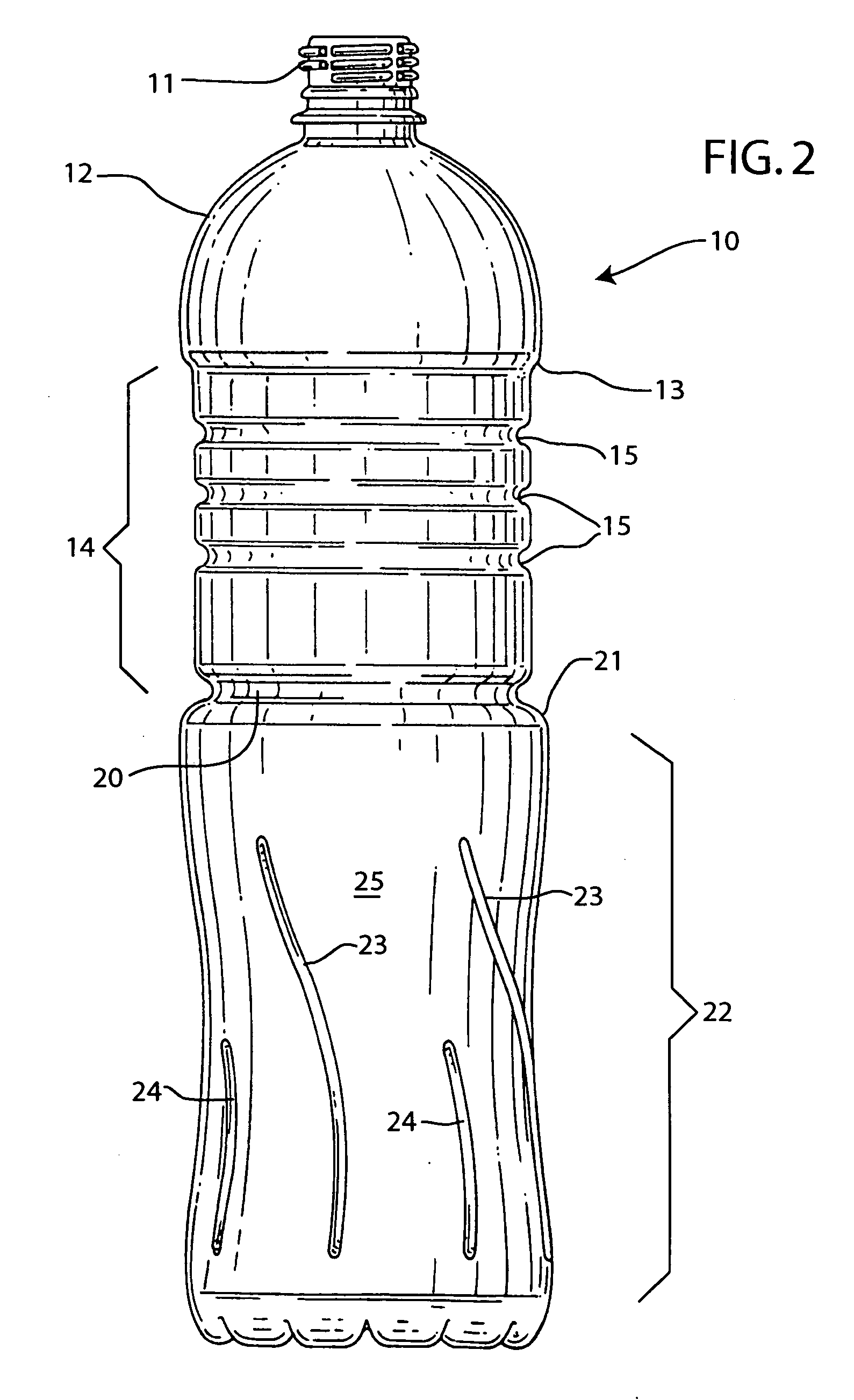

Bottle

InactiveUS20060283832A1Improve the immunityPositively deflectedLarge containersRigid containersEngineeringBottle

A bottle constructed to resist distortion and denting upon handling through distribution and / or expansion and contraction of its contents. An upper portion has a rounded upper shoulder and a series of grooves. A bottom portion is concave and has a plurality of alternating generally vertically extending long and short swirl grooves, the spaces between the long swirl grooves above the short swirl grooves being smooth to easily flex in and out to contract and expand. A main circumferential groove separates the upper and bottom portions and has a depth such that it can flex vertically when a vertical force is applied tending to push the upper portion against the bottom portion.

Owner:KRAFT FOODS INC

Bumper for reducing pedestrian injury

InactiveUS7134700B2Reduce energy absorptionImprove energy absorptionPedestrian/occupant safety arrangementBumpersNoseAbsorbed energy

A vehicle bumper system includes a beam, and an energy absorber with top and bottom horizontal sections and a mid-horizontal section. The horizontal sections form top and bottom nose portions that are semi-rigid but initially collapsible with a parallelogram motion that shifts the top and bottom portions vertically up (or down) upon-impact. Horizontal impact forces are converted in part to vertical forces during an initial stroke of a frontal impact, “catching” an impacted human being. Then during a further continuing impact stroke, the top and bottom horizontal sections provide a “throwing” action. End sections of the energy absorber extend around ends of a bumper beam, forming a collapsible corner that, during impact, initially absorbs energy at a low rate to “catch” a person, and then develops increasing lateral forces that “throw” the person during a continuing impact stroke.

Owner:SHAPE CORP

Angular handle assembly for wheeled luggage

InactiveUS7097181B2Maximize comfortMinimizes effortCarriage/perambulator accessoriesSledgesEngineeringVertical force

Owner:OUTRIGGER

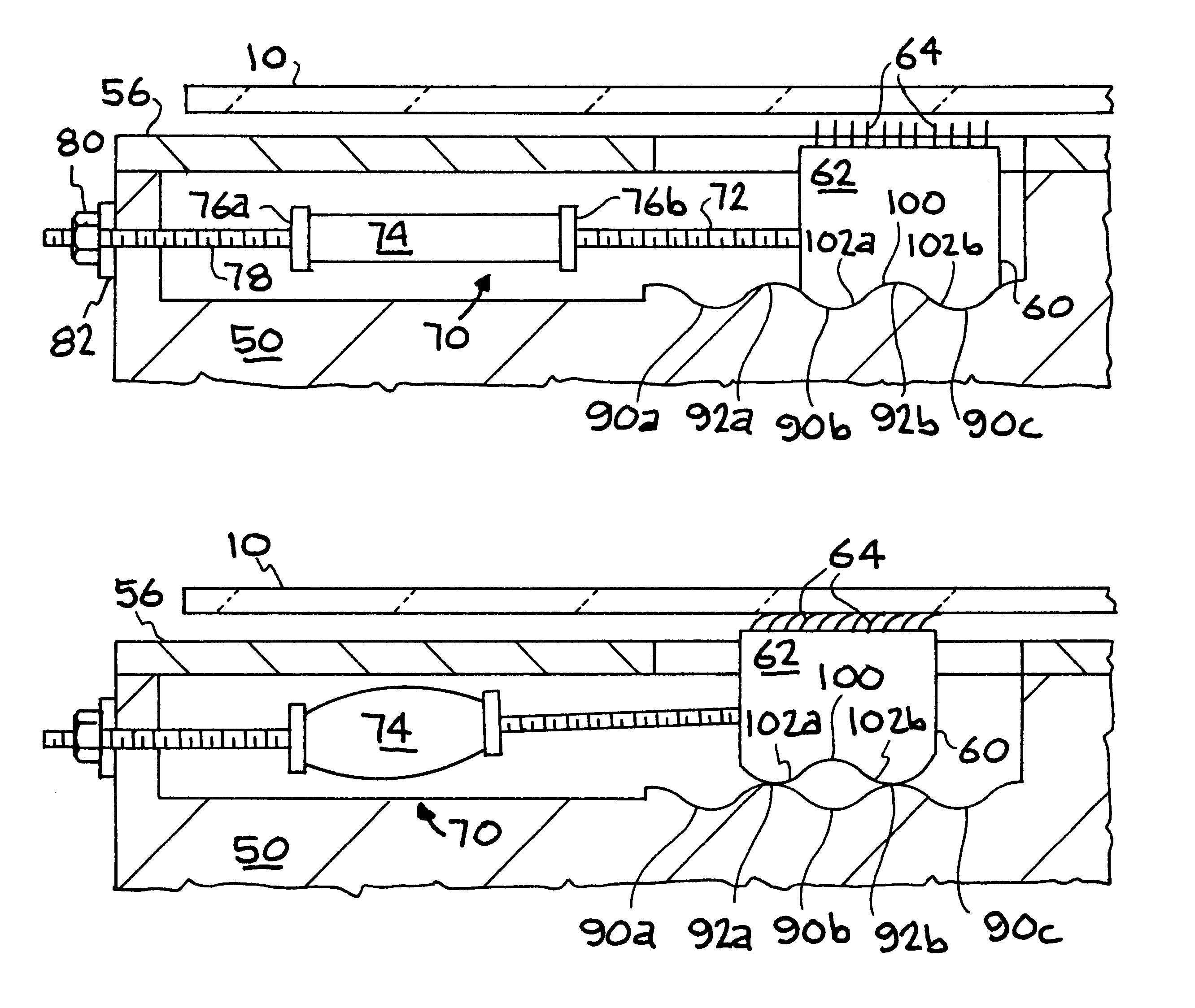

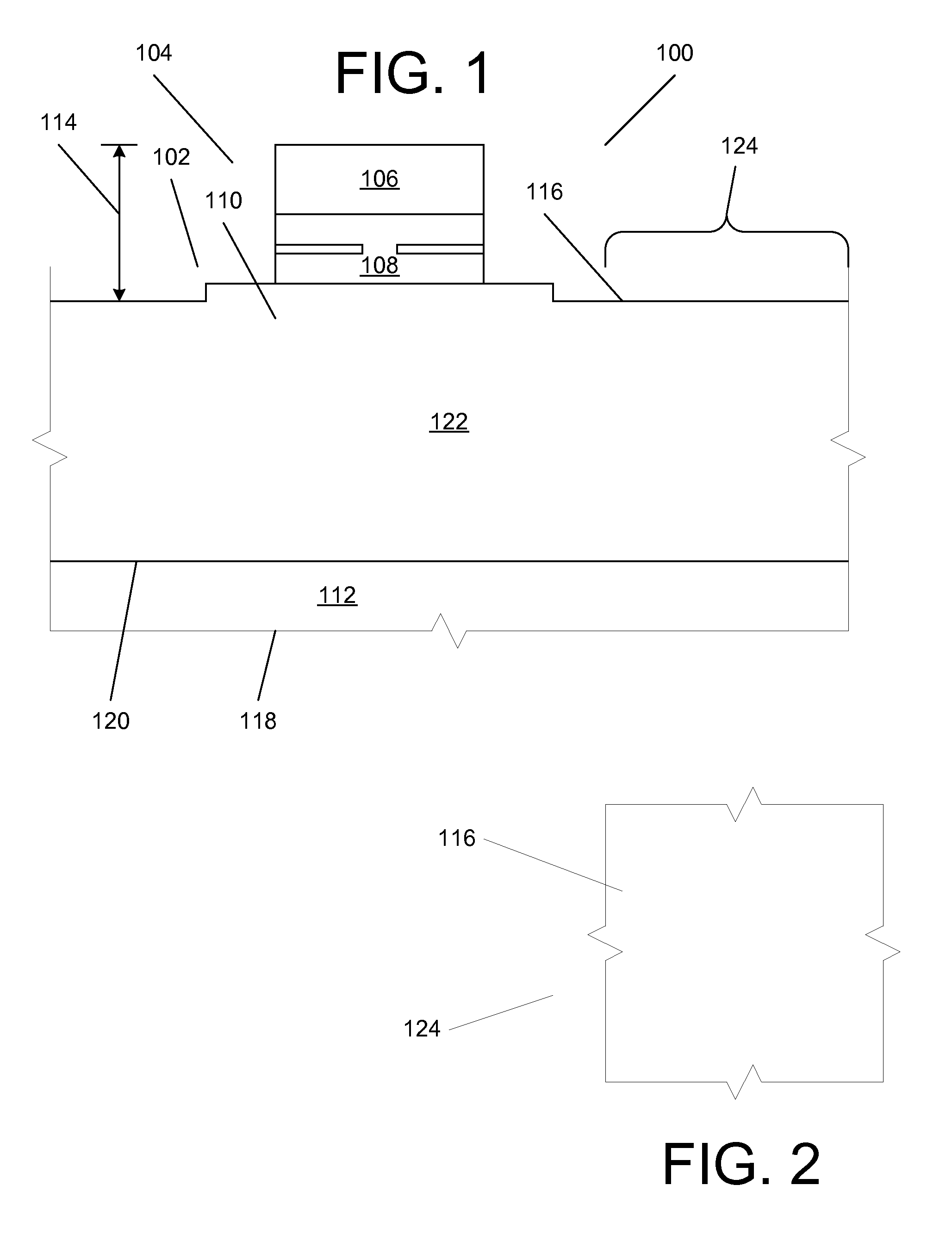

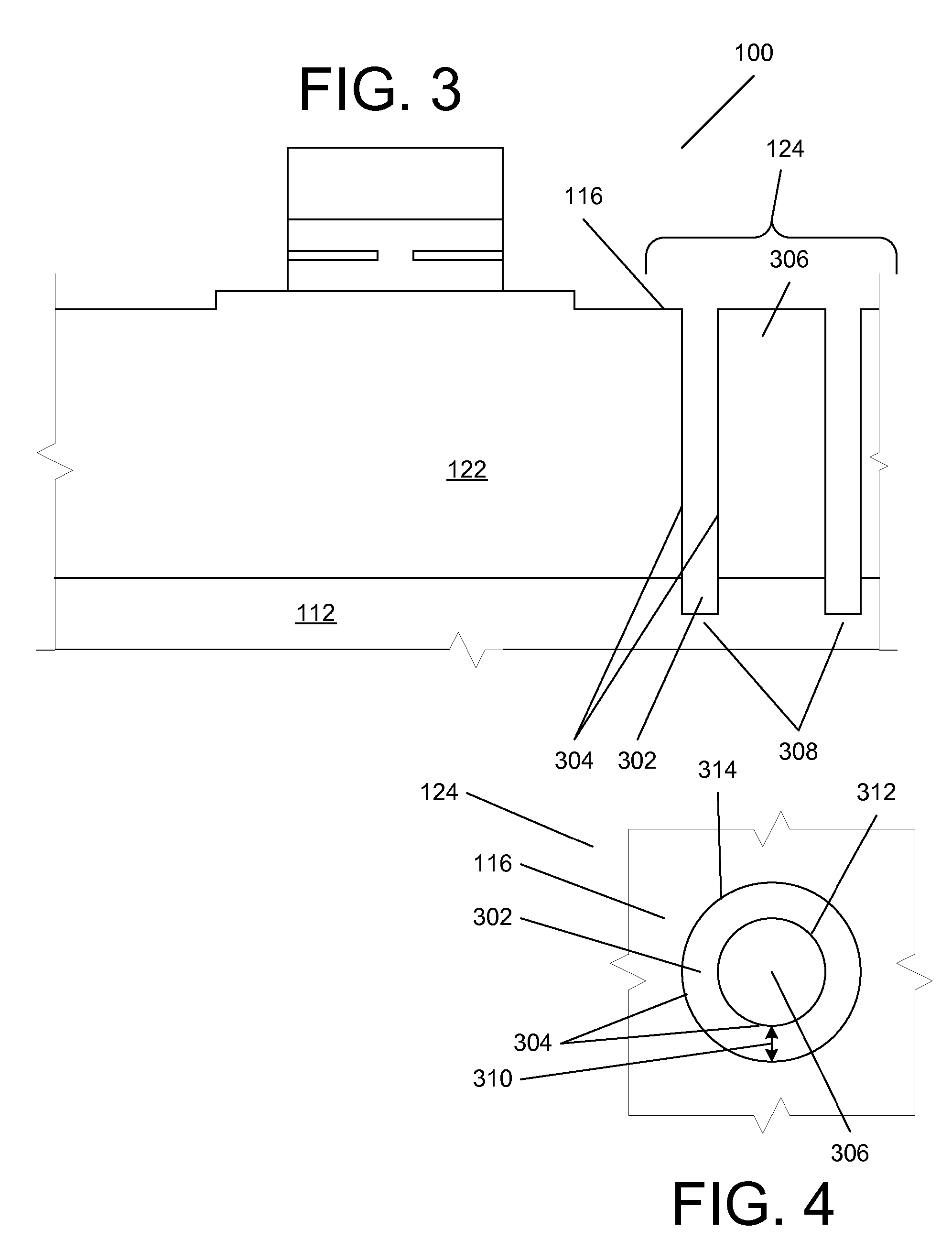

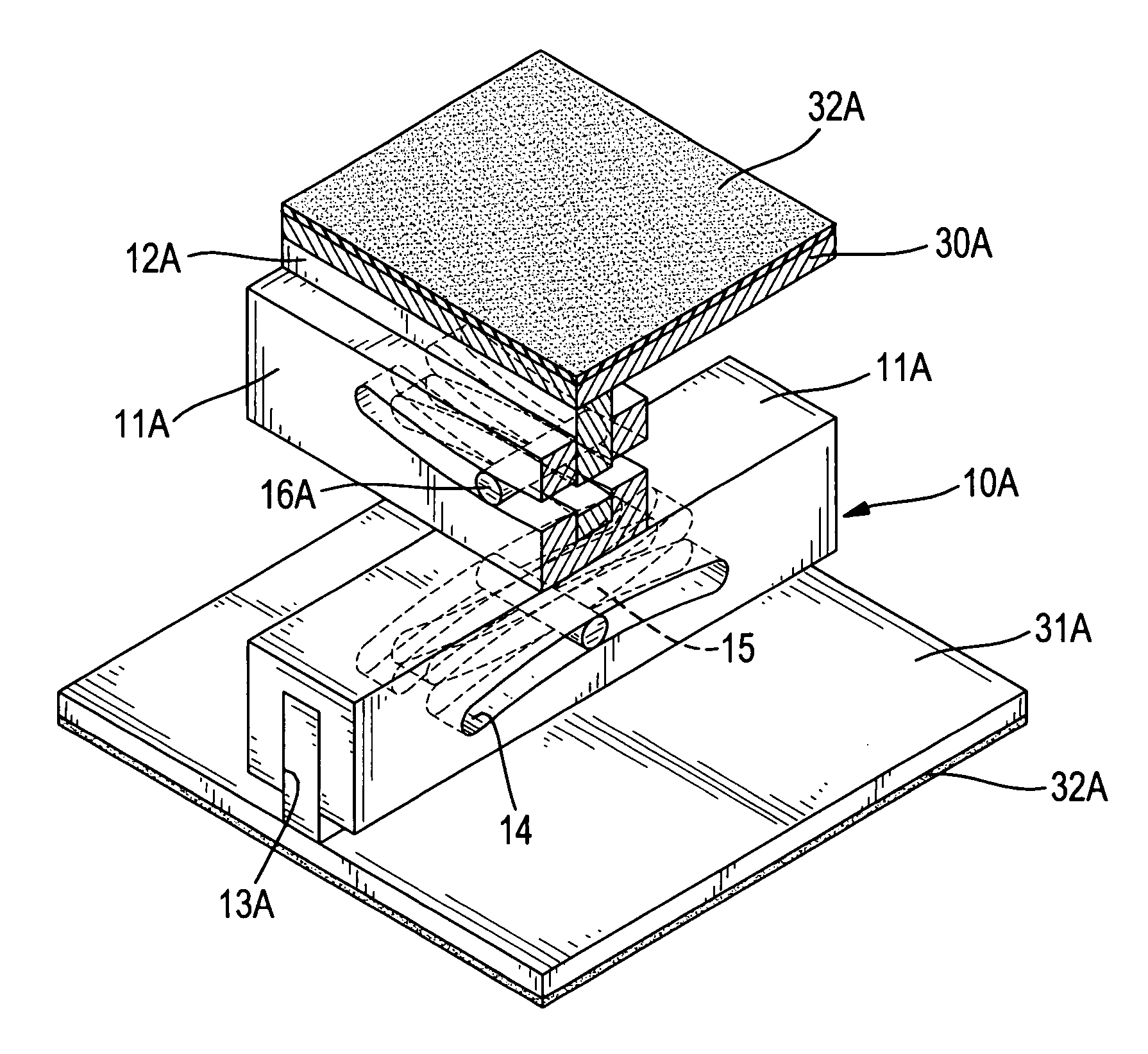

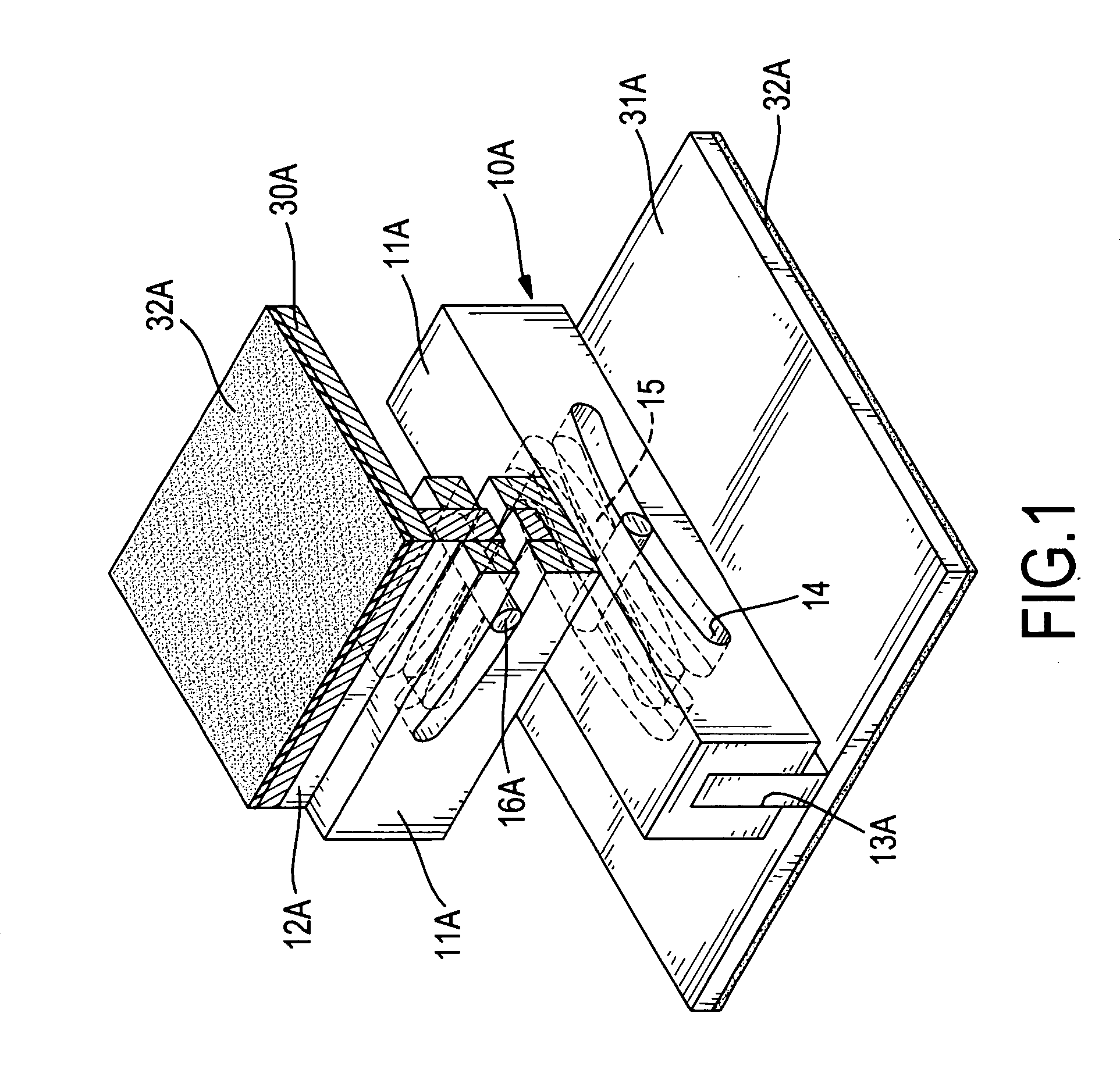

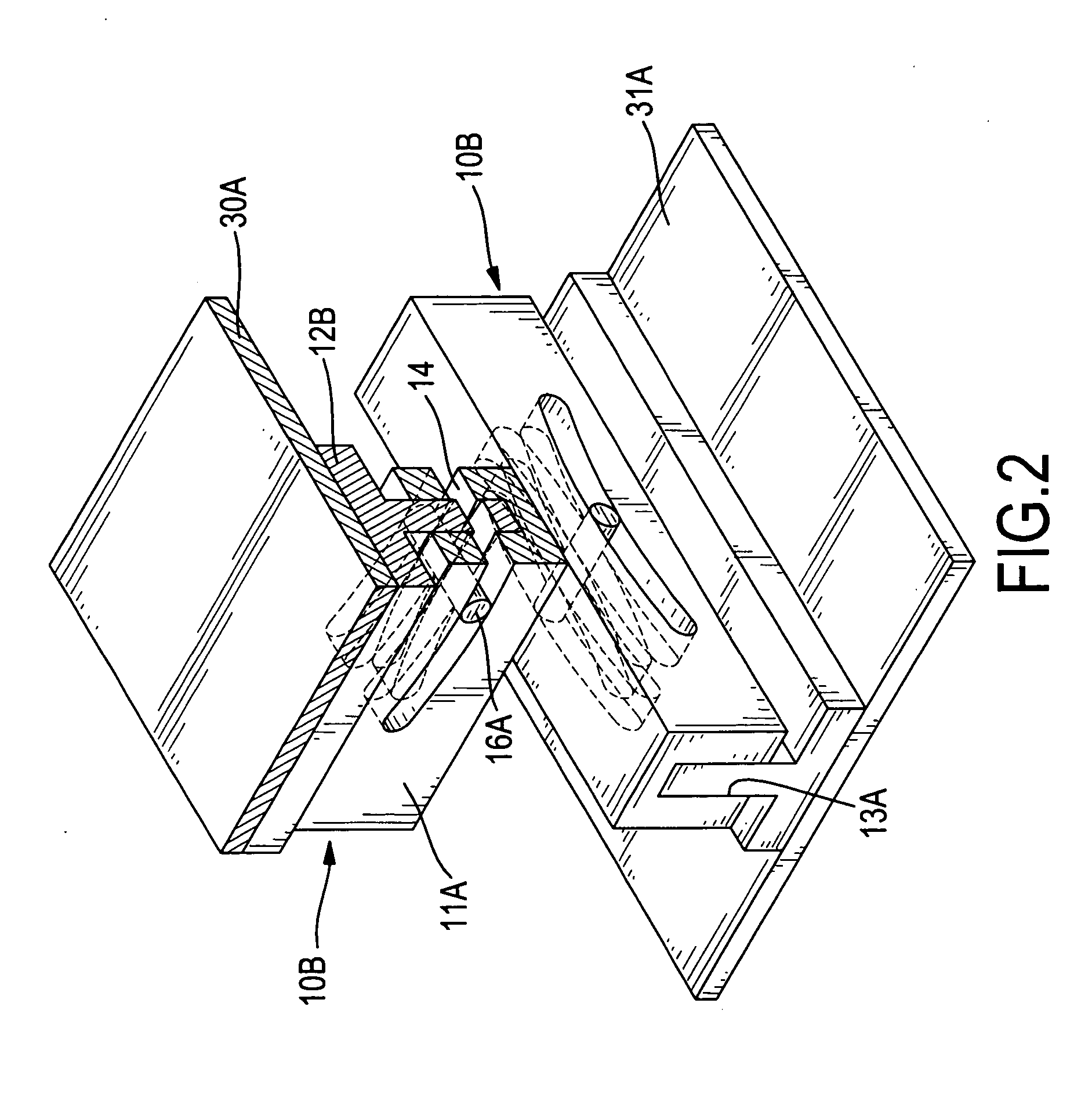

Membrane-based chip tooling

InactiveUS20060278331A1Easy to shapeUniform vertical forceLaser detailsLamination ancillary operationsEngineeringMechanical engineering

A method for use with multiple chips, each respectively having a bonding surface including electrical contacts and a surface on a side opposite the bonding surface involves bringing a hardenable material located on a body into contact with the multiple chips, hardening the hardenable material so as to constrain at least a portion of each of the multiple chips, moving the multiple chips from a first location to a second location, applying a force to the body such that the hardened, hardenable material will uniformly transfer a vertical force, applied to the body, to the chips so as to bring, under pressure, a bonding surface of each individual chip into contact with a bonding surface of an element to which the individual chips will be bonded, at the second location, without causing damage to the individual chips, element, or bonding surface.

Owner:CUFER ASSET LTD LLC

Prestressed concrete pipe pile horizontal bearing characteristic test model and test method

ActiveCN103882894ASimple and fast operationHighly adjustableFoundation testingMaterial strength using tensile/compressive forcesHorizontal forcePre stress

The invention discloses a prestressed concrete pipe pile horizontal bearing characteristic test model and a test method. The prestressed concrete pipe pile horizontal bearing characteristic test model comprises a model groove, a bearing table used for bearing a model pile is arranged in the model groove, and the upper end of the model pile is embedded into the bearing table. A vertical pneumatic loading system exerting vertical force on the bearing table and connected with a counter force frame is arranged above the model groove. The inner side of the model groove is provided with a horizontal pneumatic loading system exerting horizontal force on the bearing table and connected with the model groove. Monitoring devices are arranged on the bearing table, the model pile and the loading system. The invention provides a test device which can well meet the requirement for load conditions of a pile foundation load test, simulate the practical working conditions of the pile foundation more truly and detect the bearing characteristics of a single pipe pile and group pipe piles under the action of horizontal loads.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Anti-shock device

InactiveUS20070125930A1Eliminate vibrationSmall sizePortable framesLiquid springsHorizontal forceVertical vibration

An anti-shock device has at least two sliding members placed in at least two layers. Each sliding member is comprised of a slotted seat, an inner seat, and a rolling shaft. The slotted seat has a slot defined longitudinally in a face and has outer curved rails defined in two sidewalls. The inner seat mounted slidably in the slot has an inner curved rail defined therein, corresponding to and curving in the opposite direction of the outer curved rails. The rolling shaft is mounted rotatably through the outer curved rails and the inner curved rail. When subjected to vibration, the anti-shock device converts the horizontal forces into vertical forces. In addition, an energy dissipation member is provided in the anti-shock device that eliminates vertical vibrations.

Owner:TSAI CHONG SHIEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com