Patents

Literature

2018 results about "Axial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

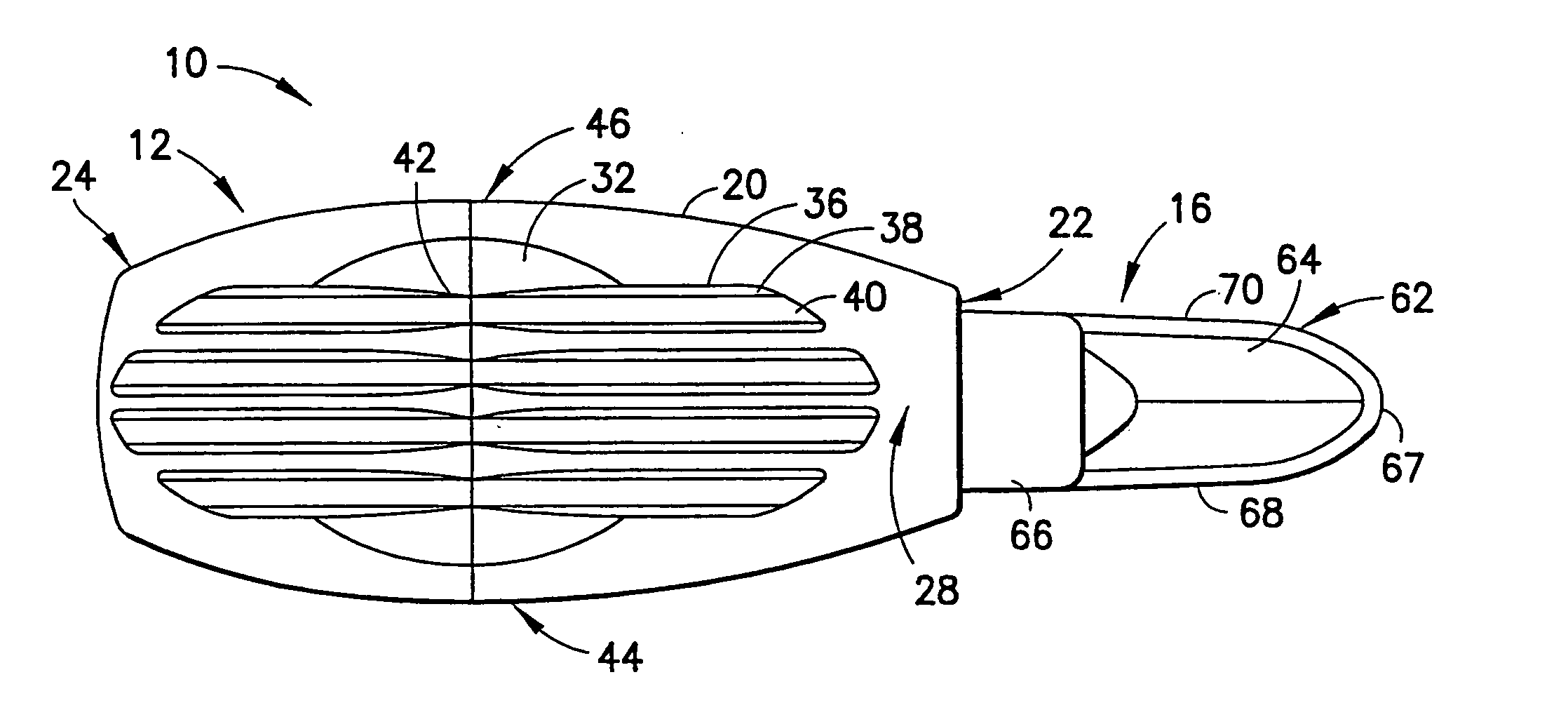

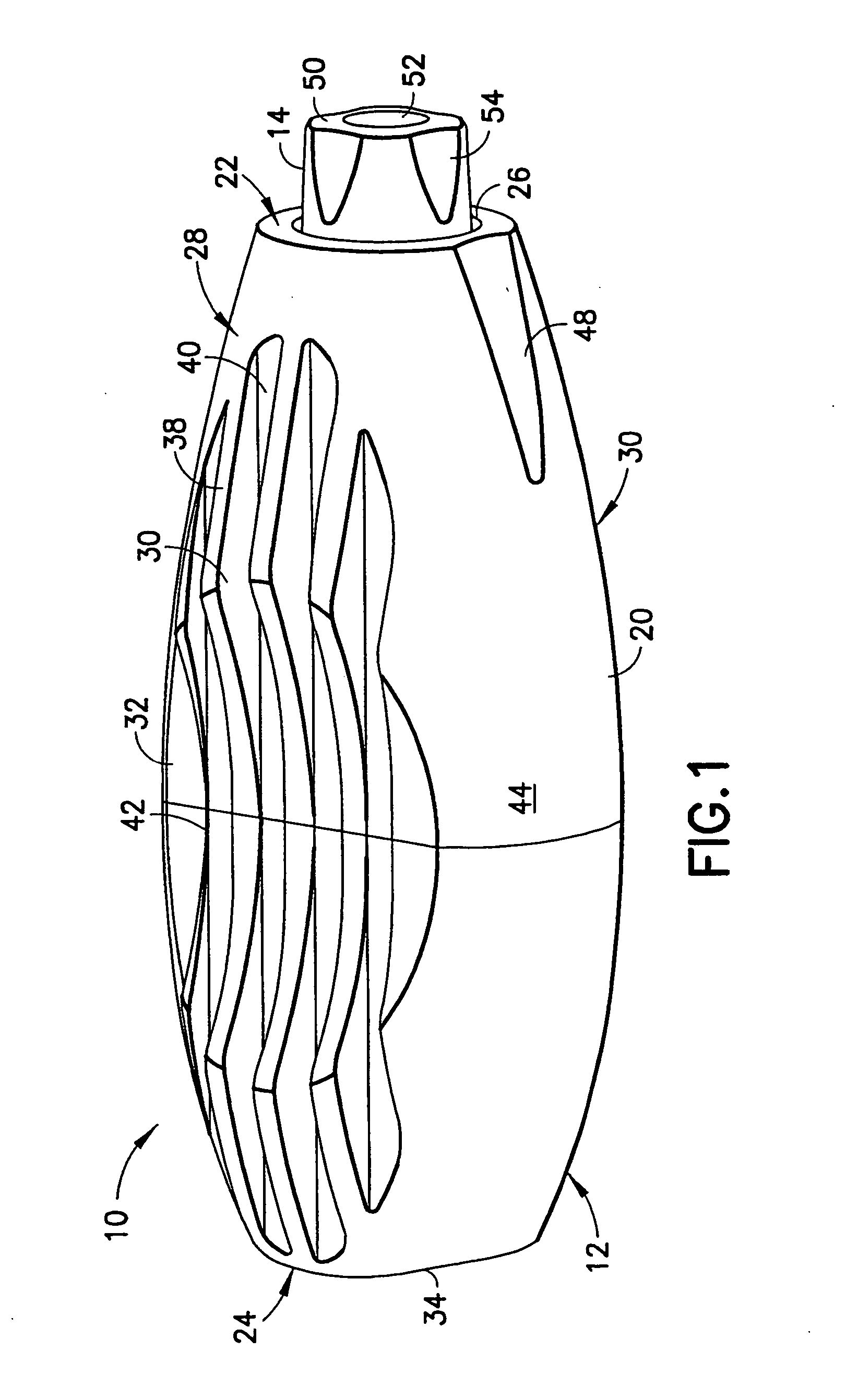

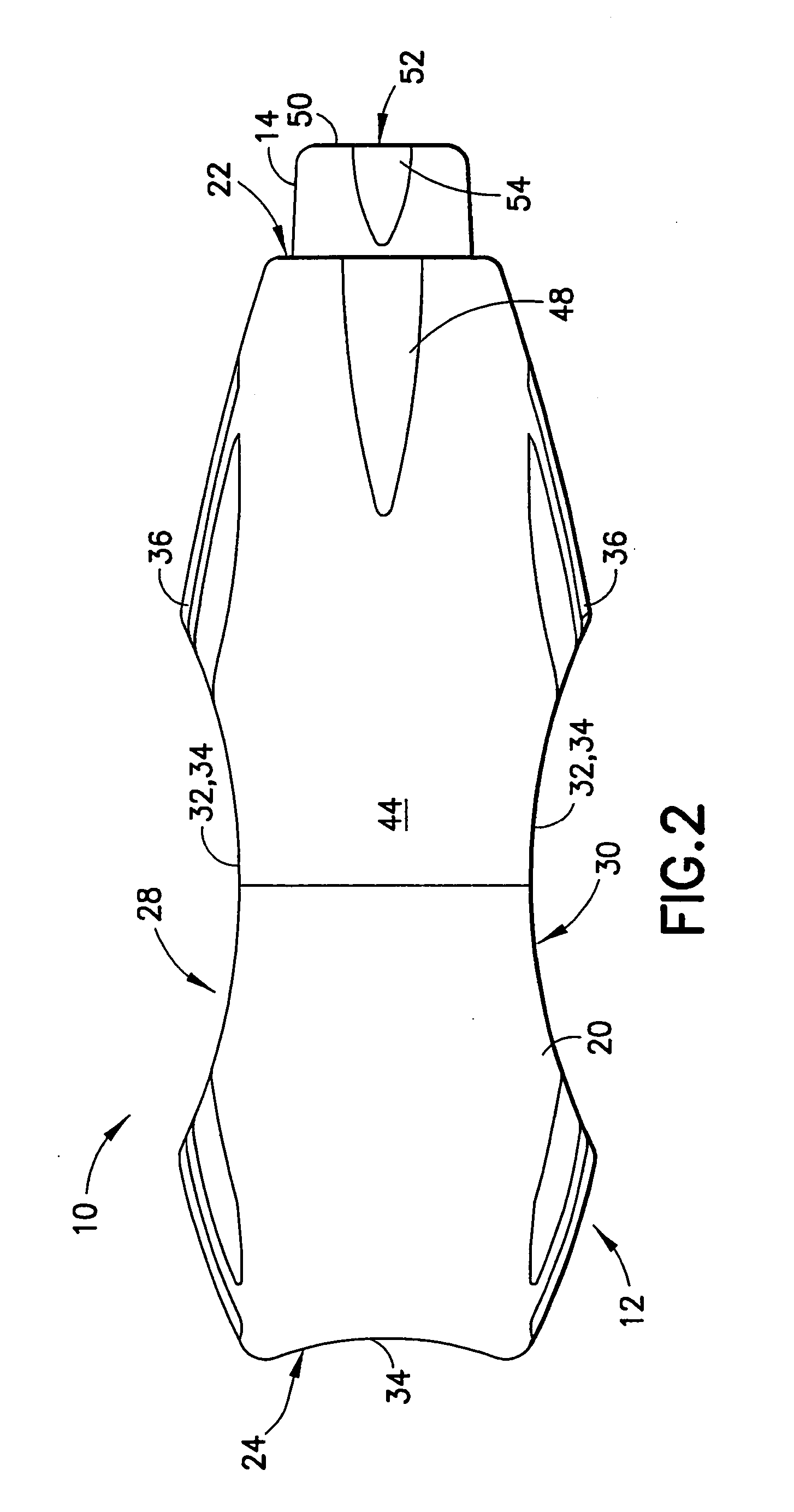

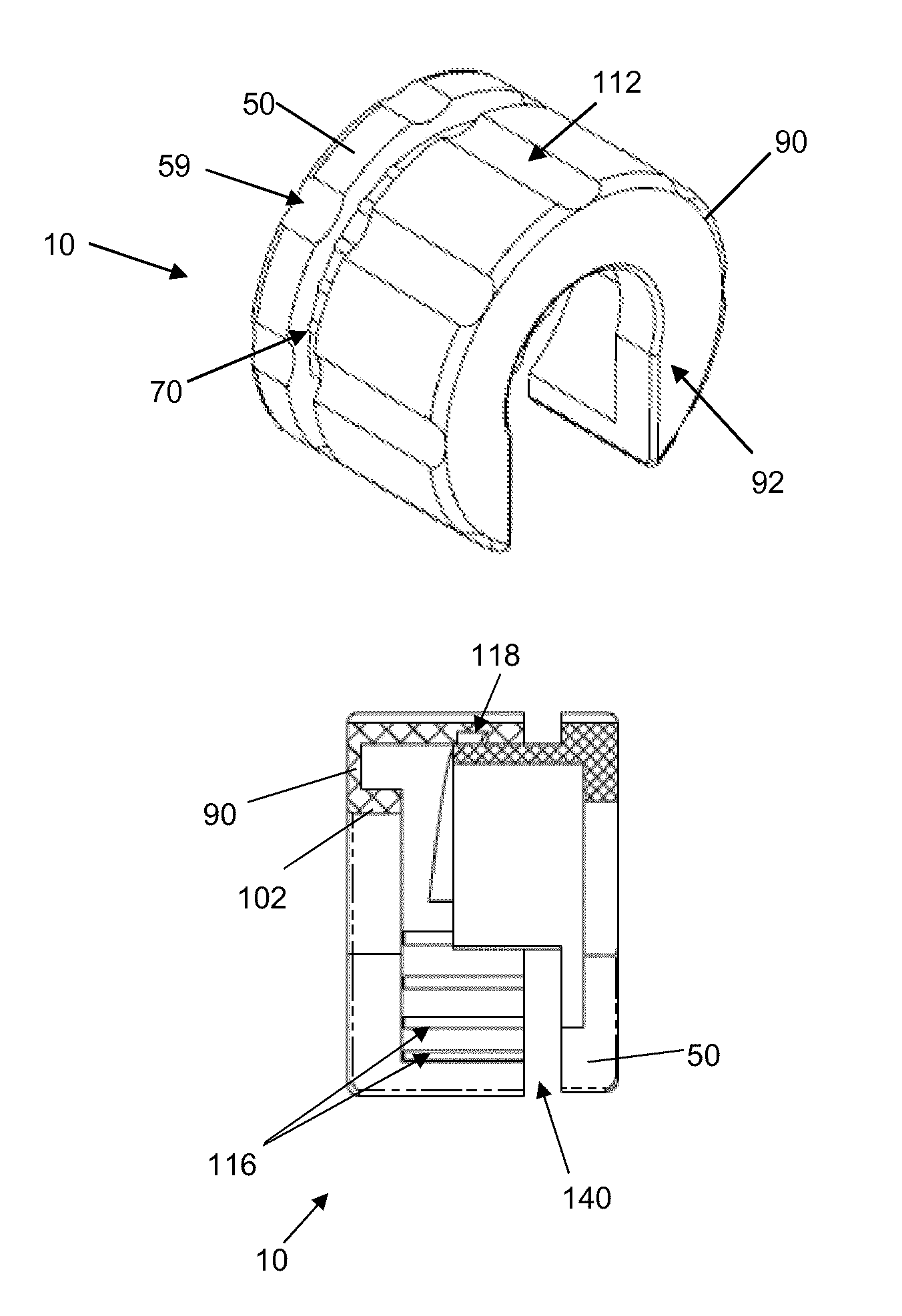

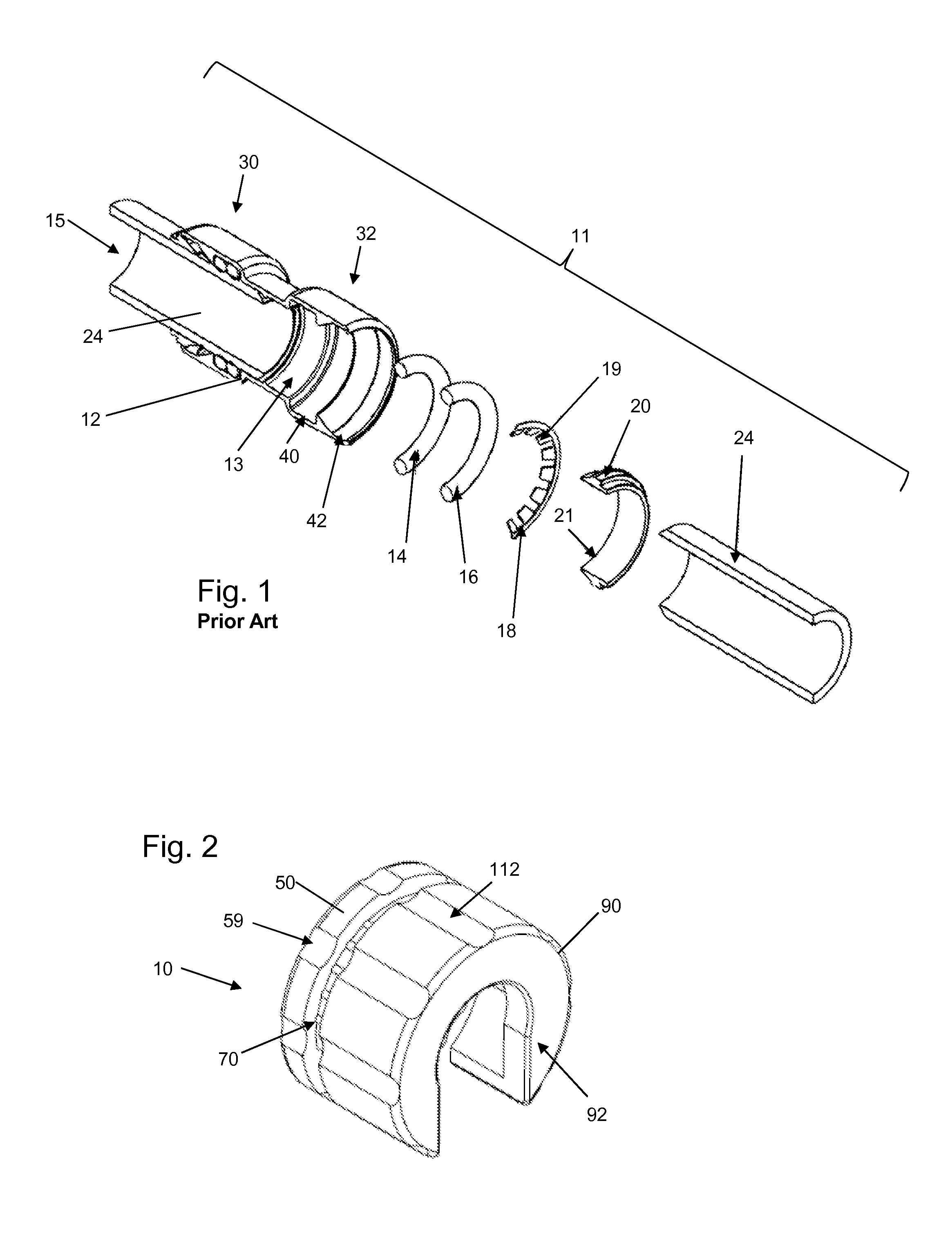

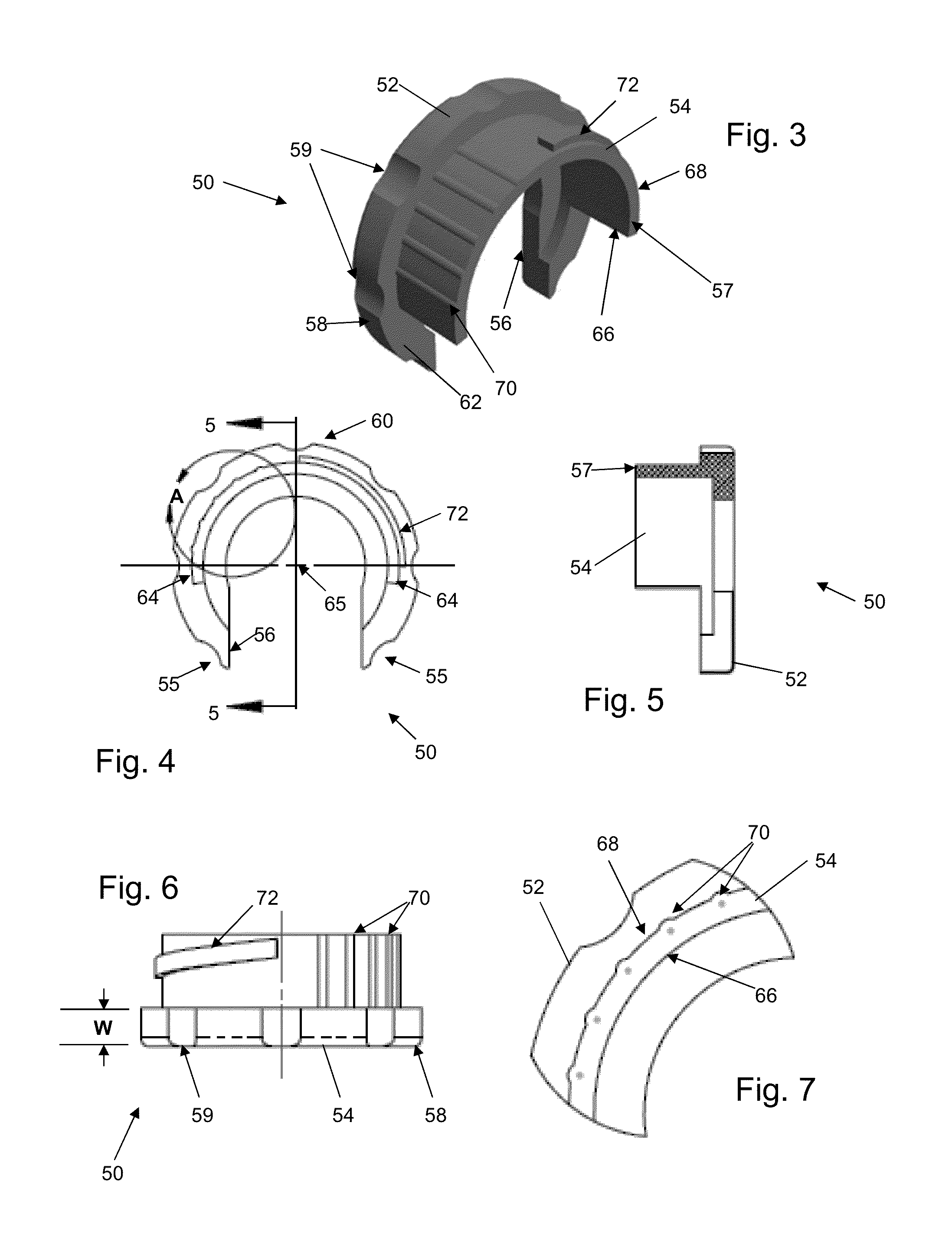

Lancet device

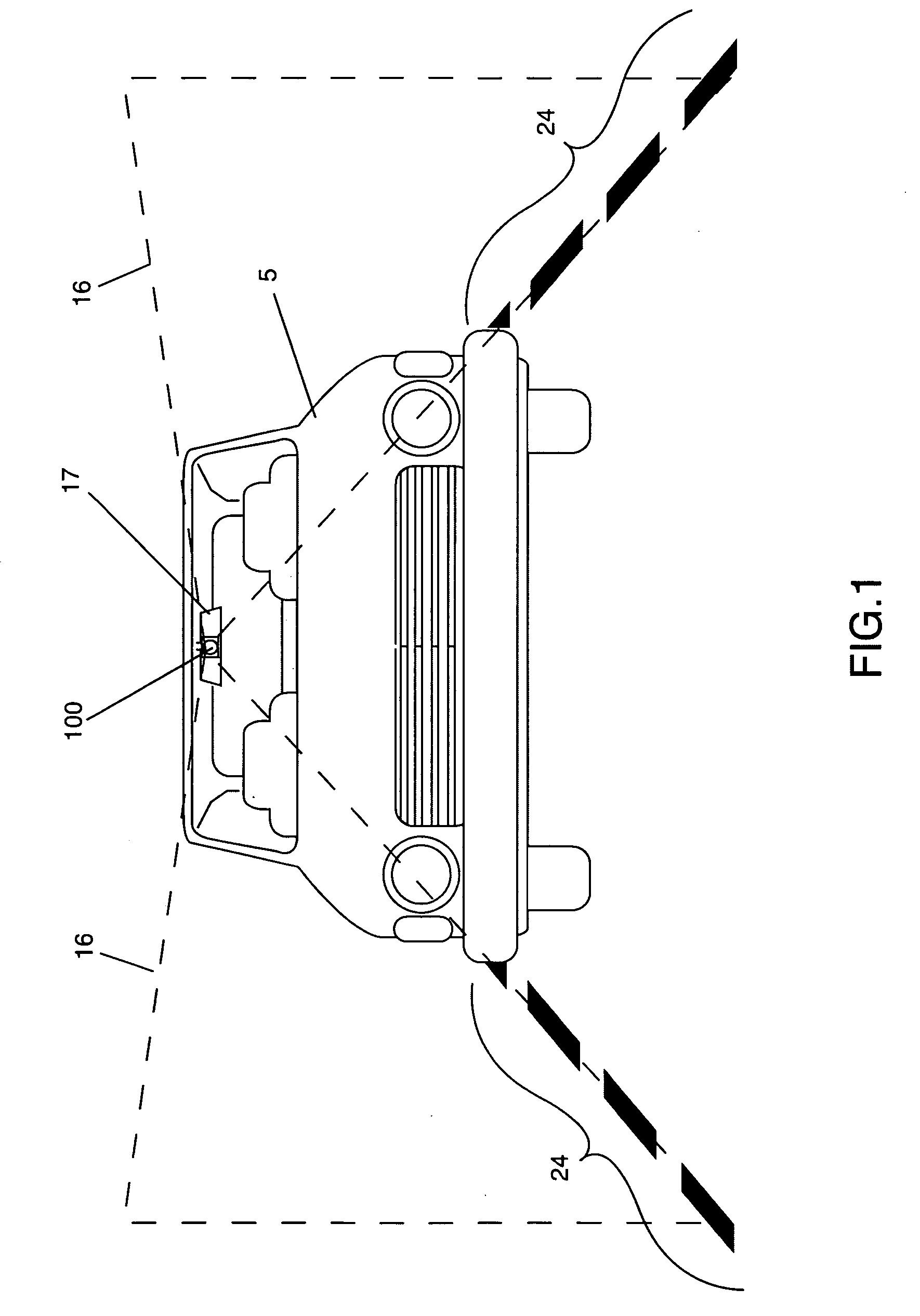

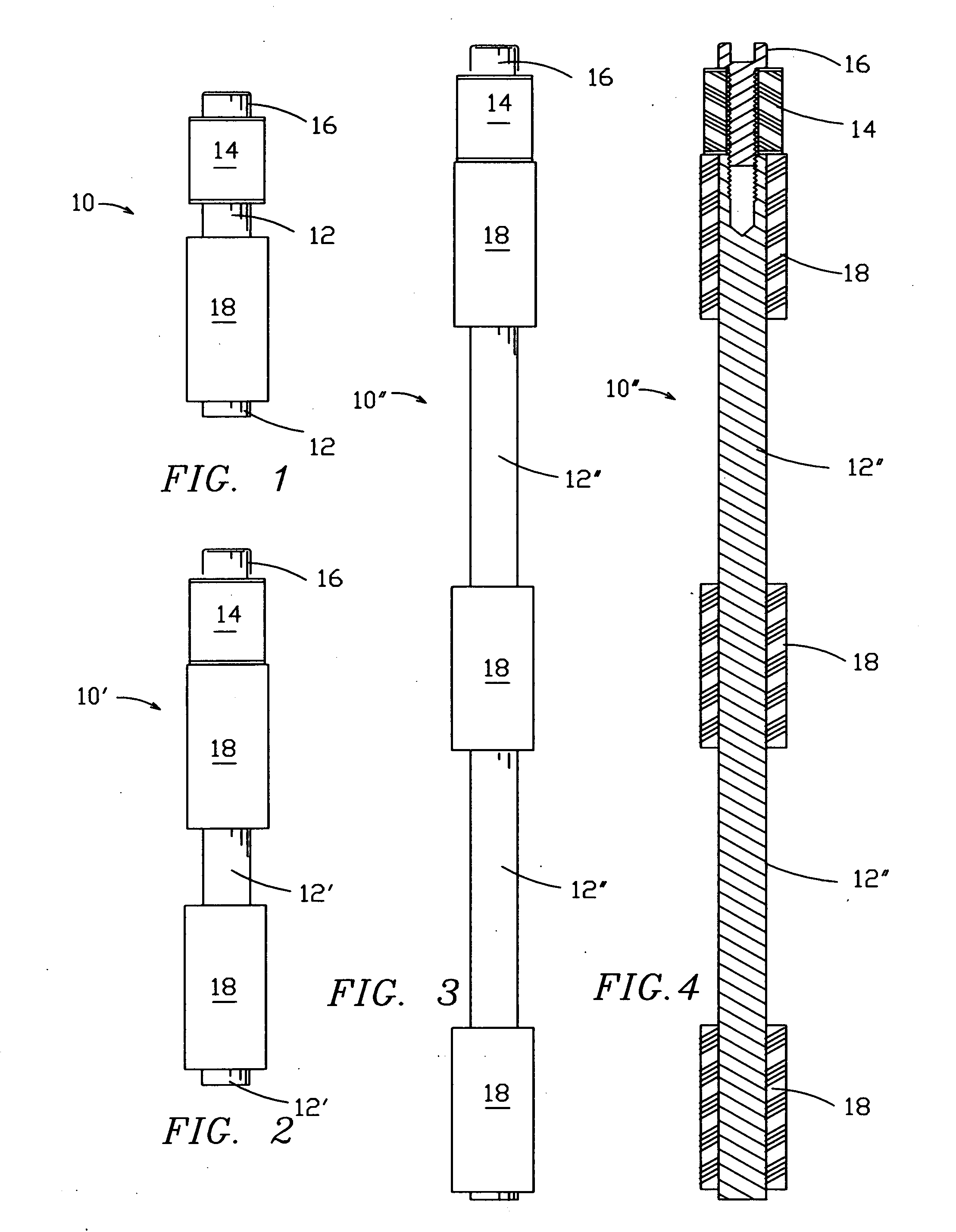

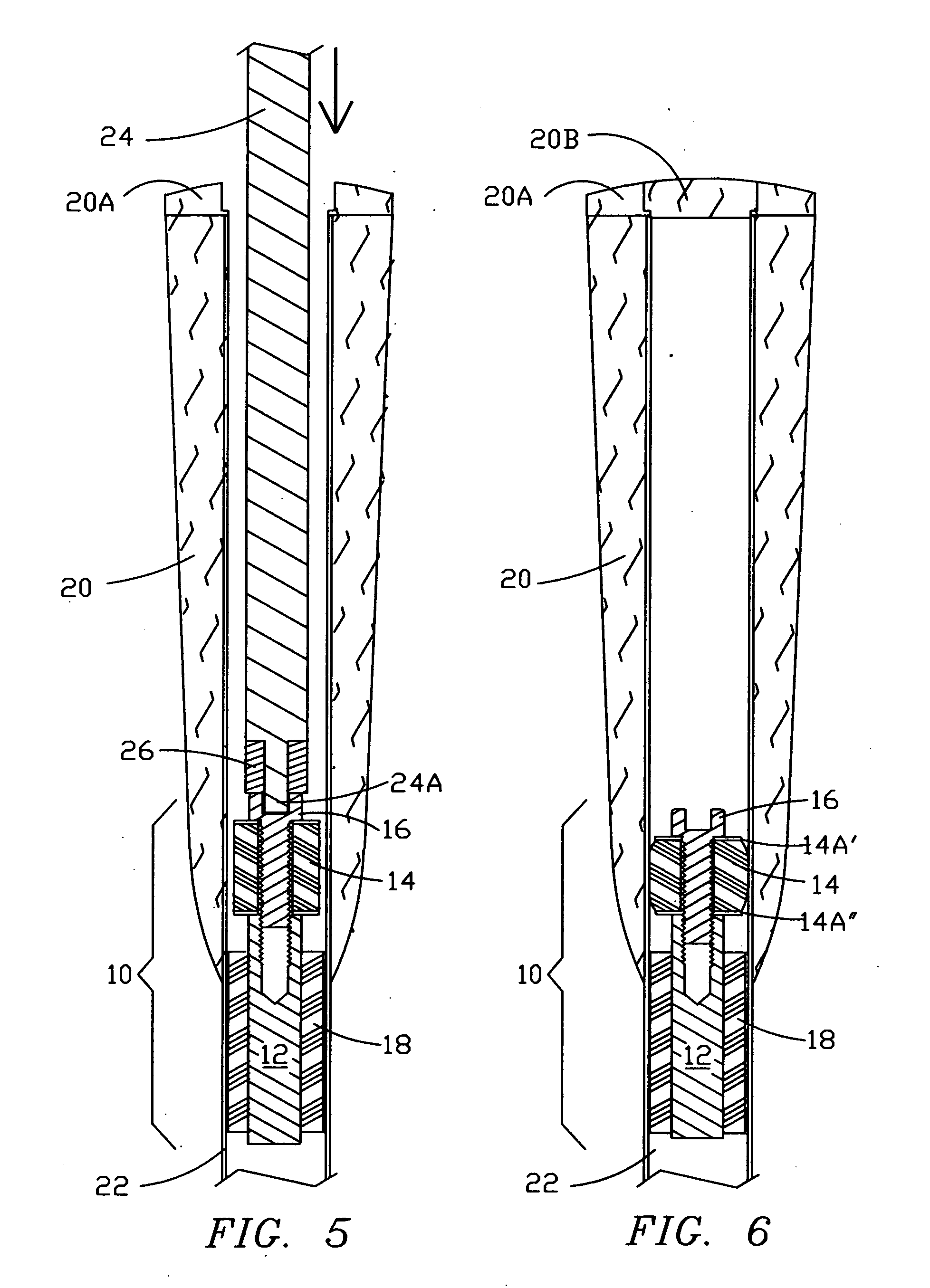

A lancet device generally includes a housing having opposing lateral sides extending between a forward end and a rearward end, and a shield coaxially and movably associated with the housing. The housing includes a plurality of longitudinal ribs extending along a portion of at least one of the opposing lateral sides. The plurality of longitudinal ribs form a finger grip on at least one of, and typically both of the opposing lateral sides. The shield is generally movable from a first position in which the shield extends outwardly from the forward end of the housing to a second position in which the shield is at least partially moved within the housing, based on axial pressure applied by the user against the finger grip formed by the longitudinal ribs.

Owner:BECTON DICKINSON & CO

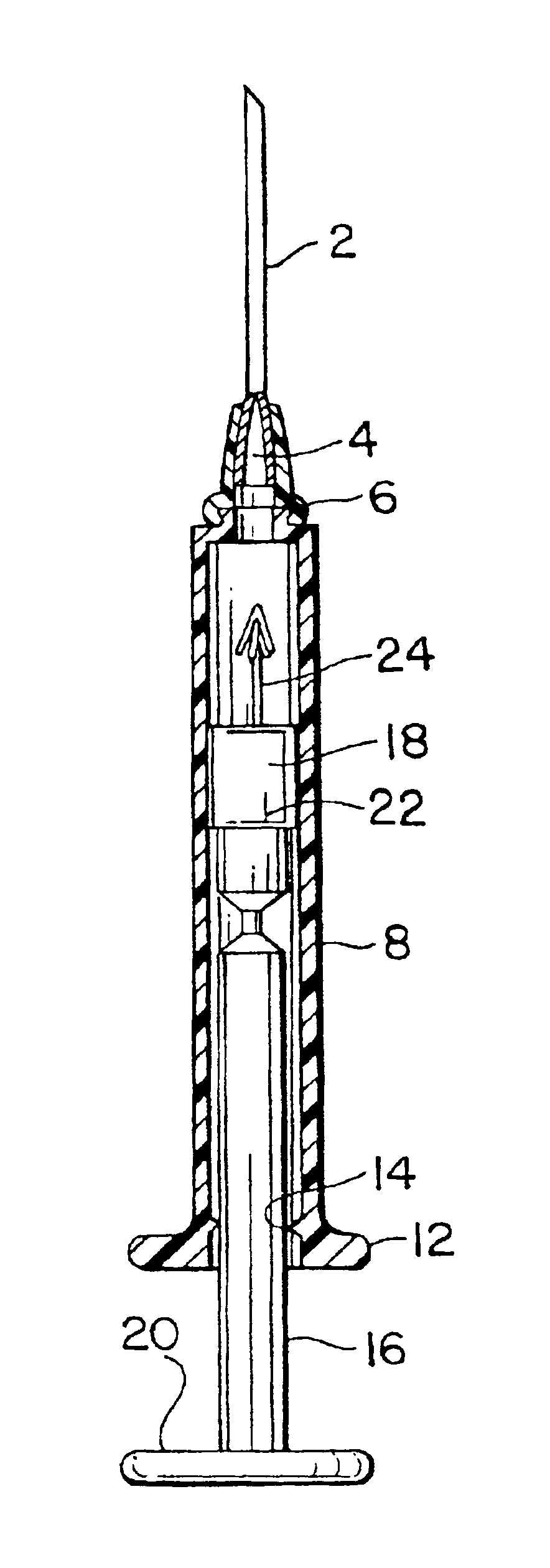

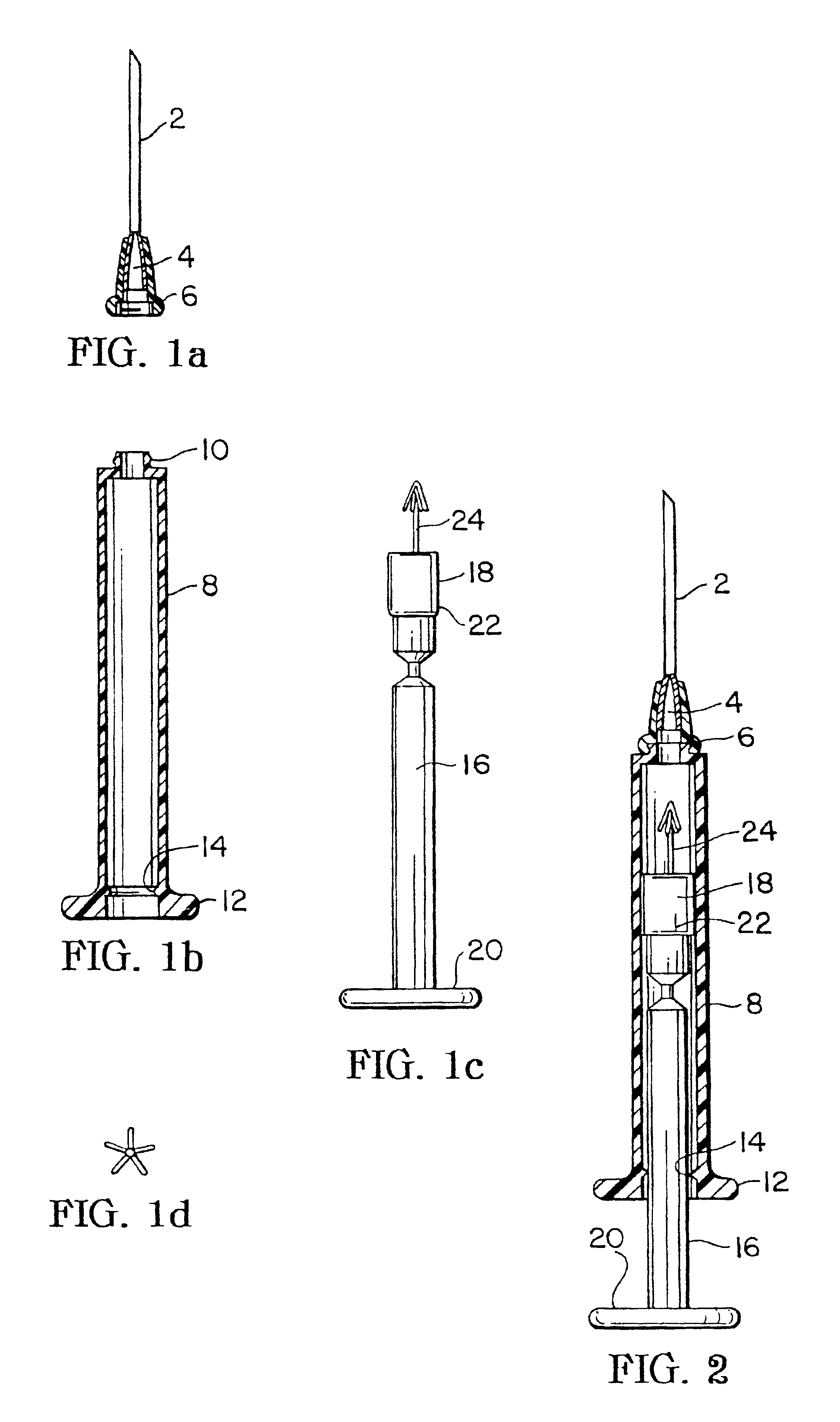

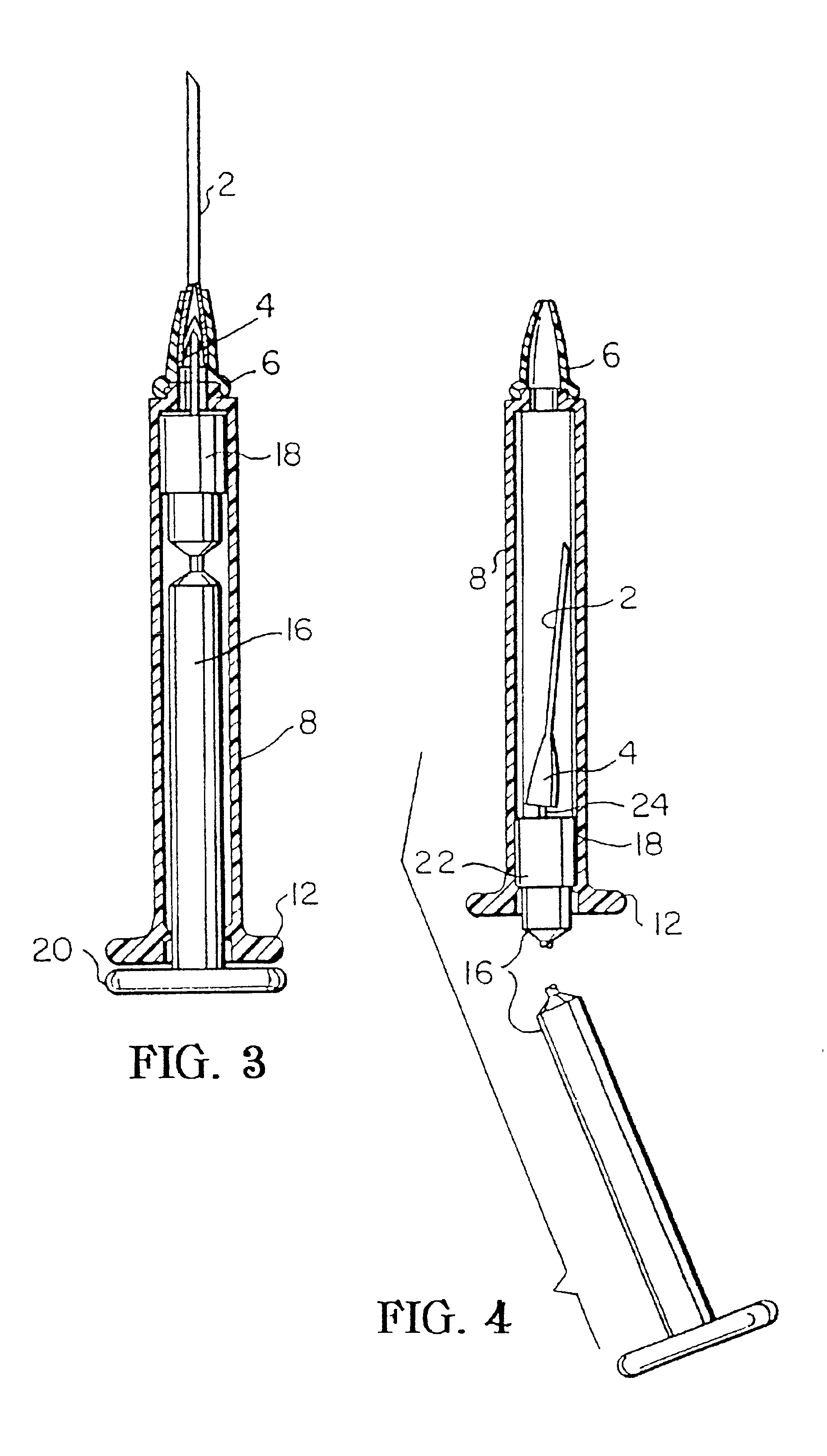

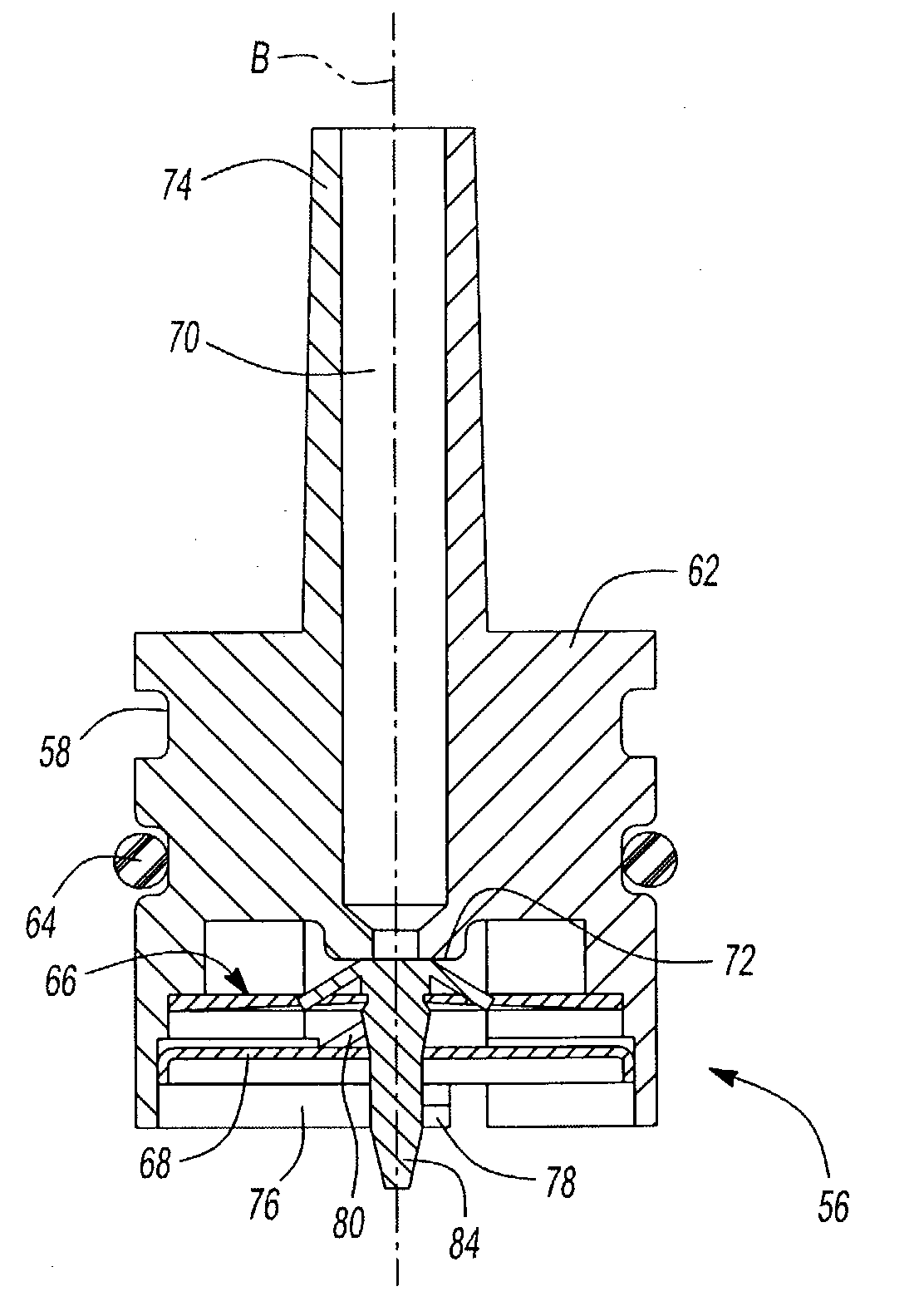

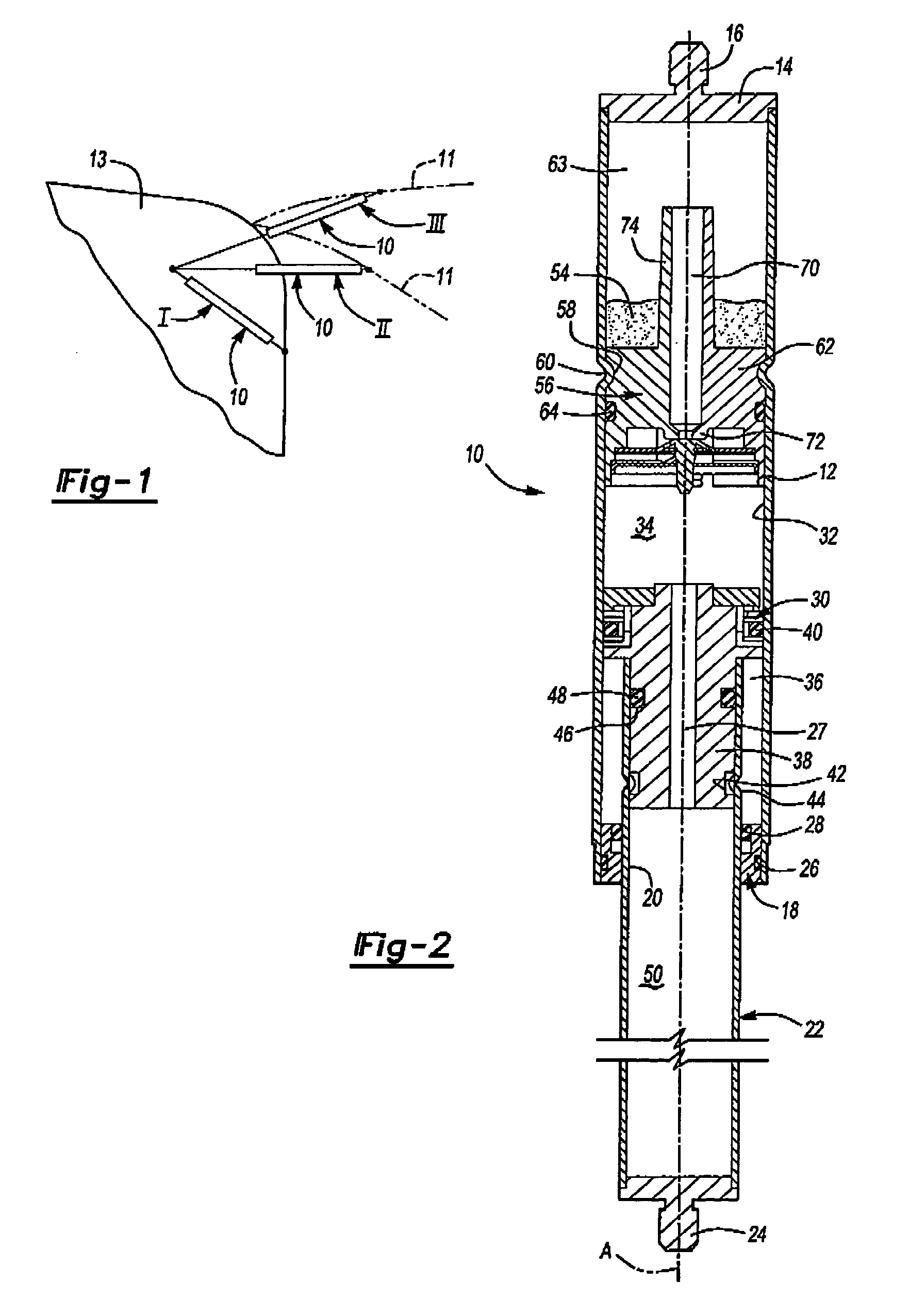

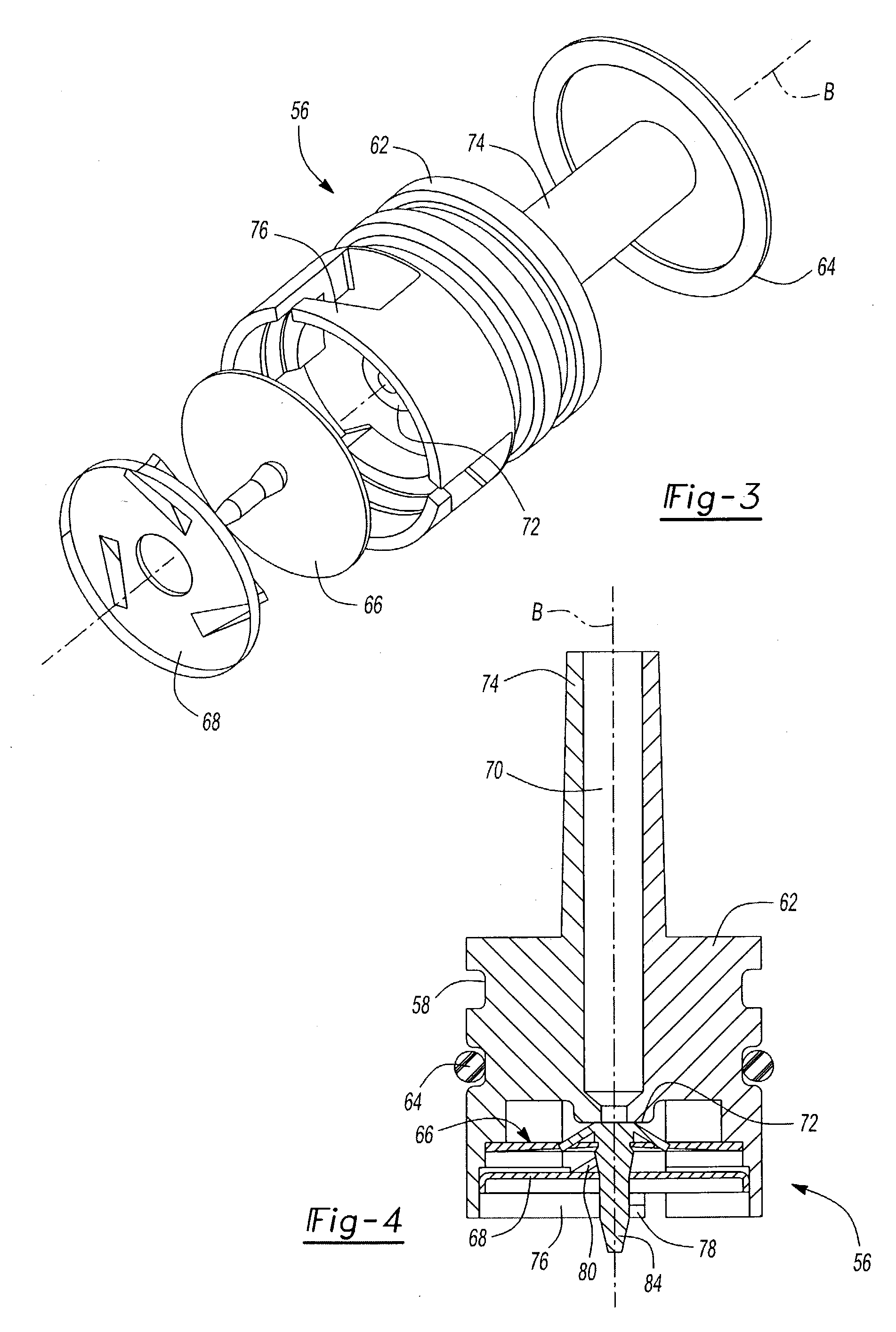

Safety syringe needle device with interchangeable and retractable needle platform

InactiveUS6878131B2Eliminate generationAvoid pollutionInfusion syringesPharmaceutical containersAxial pressureEngineering

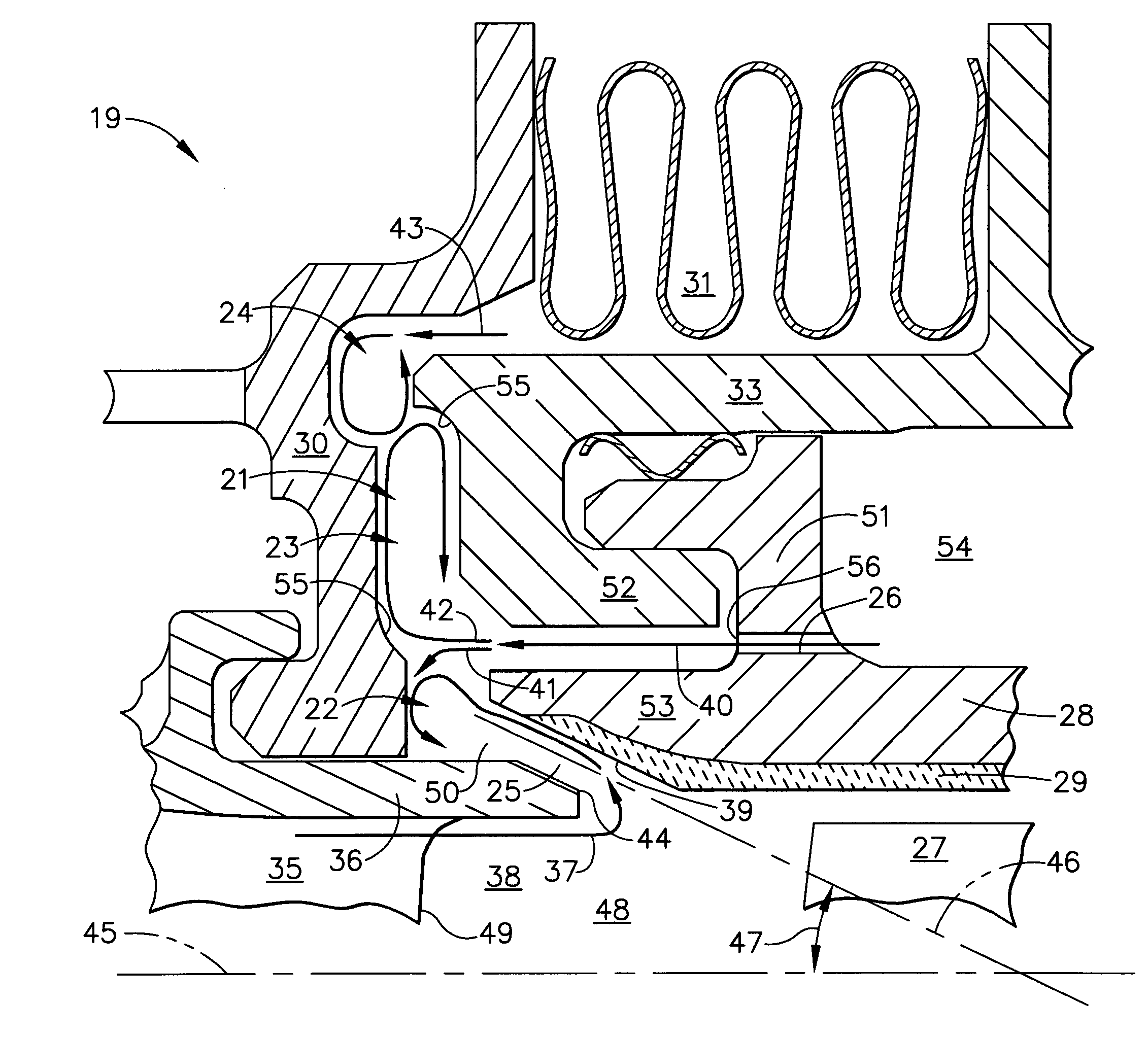

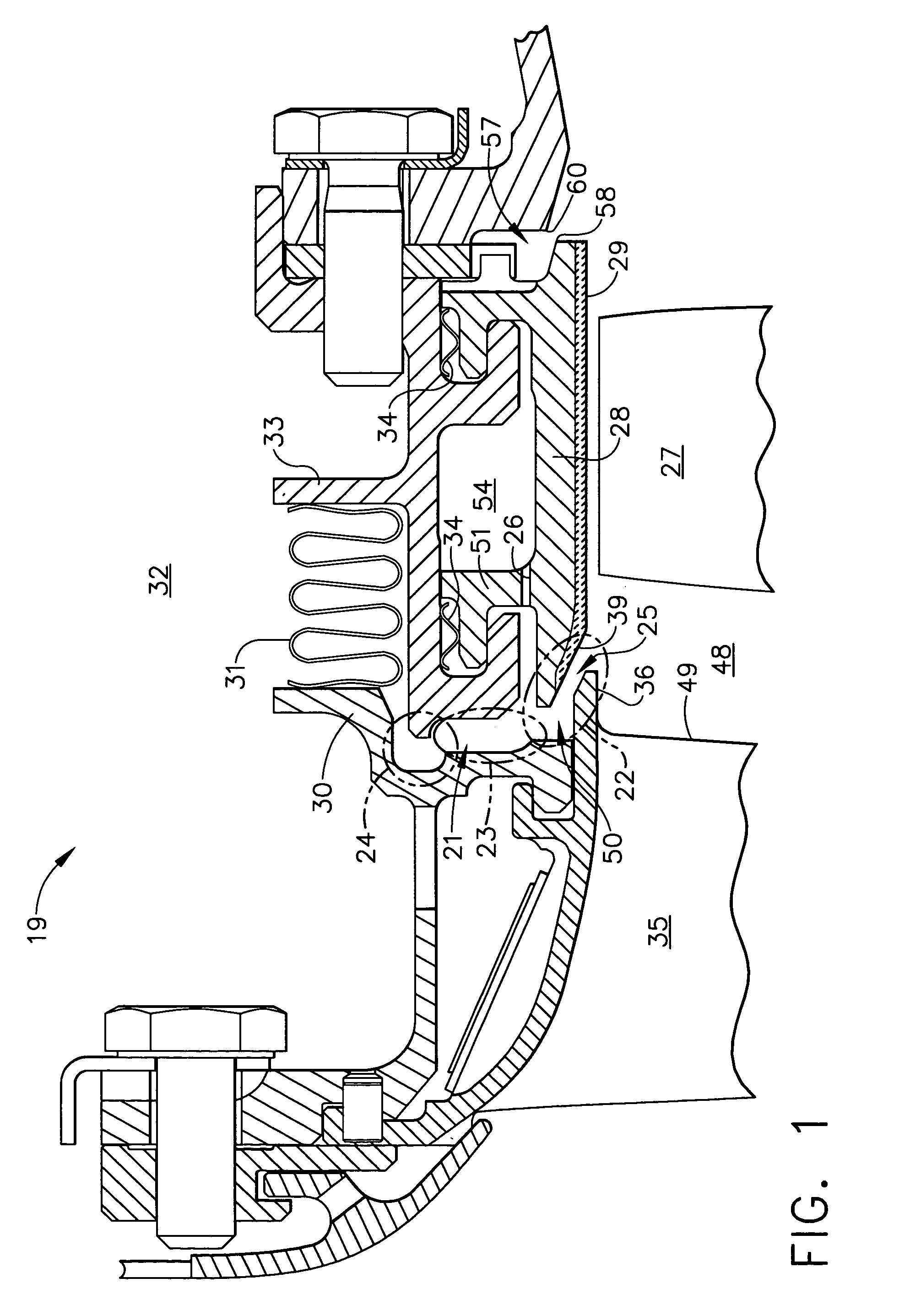

The syringe includes a barrel, a plunger, and an adapter for mounting the needle in the distal end of the barrel. The adapter includes a protrusion projecting away from the needle end and into the barrel defining an annular space between the barrel and the protrusion. The plunger and protrusion have complementary surfaces whereby the plunger may grip the adapter for removal of the adapter into the interior of the barrel after use. These complementary surfaces afford initial resistance to further axial movement of the plunger toward the adapter, signalling the user that further axial pressure will permanently lock the plunger and adapter to one another whereby, upon application of full axial pressure on the plunger, the complementary surfaces of the plunger and adapter permanently lock to one another to enable joint unitary movement of the plunger and adapter together with the needle carried by the adapter into the barrel. The adapter includes vent passages communicating between the central passage through the adapter and the annular space whereby air can be vented from the barrel after receiving fluid within the barrel and prior to injection. Thus, the syringe may be oriented in a vertical position needle end uppermost with the vent passages forming the most superior portion of the barrel interior whereby air may be vented.

Owner:INVIRO MEDICAL DEVICES LTD

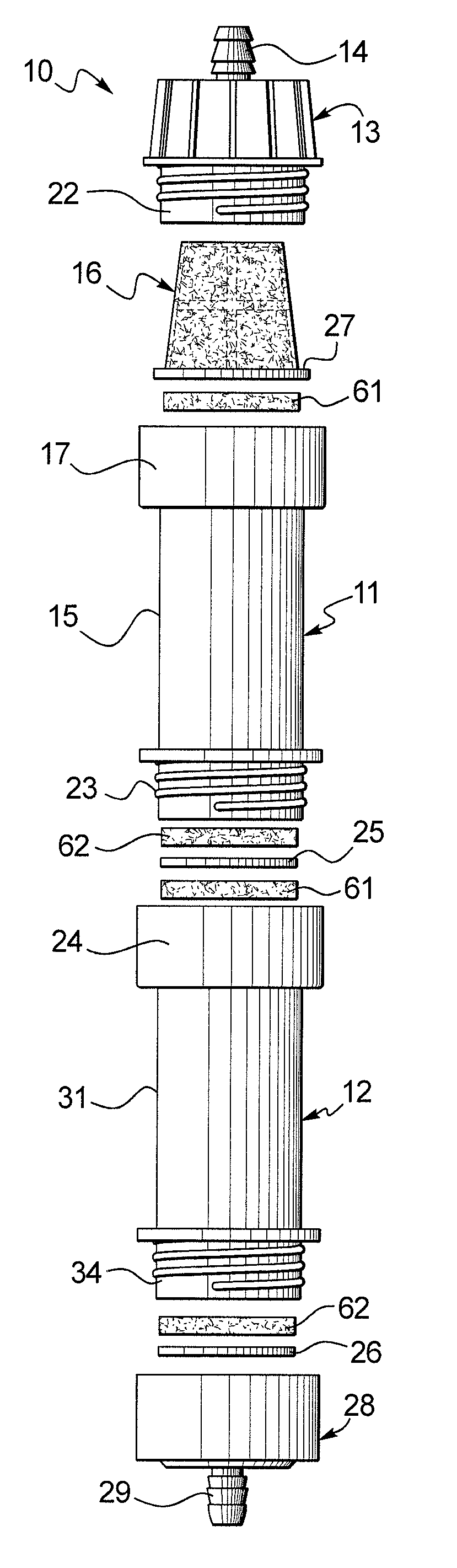

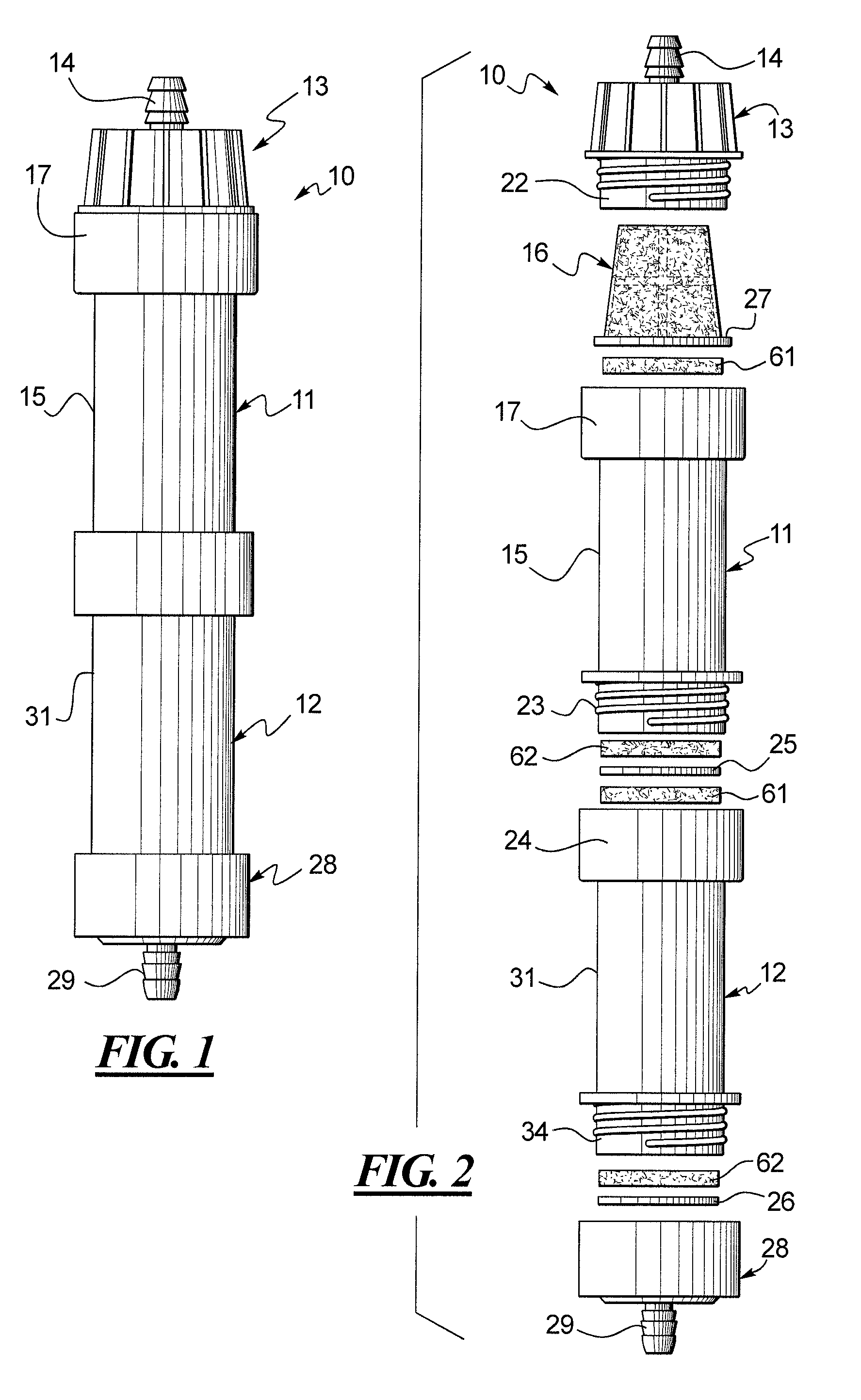

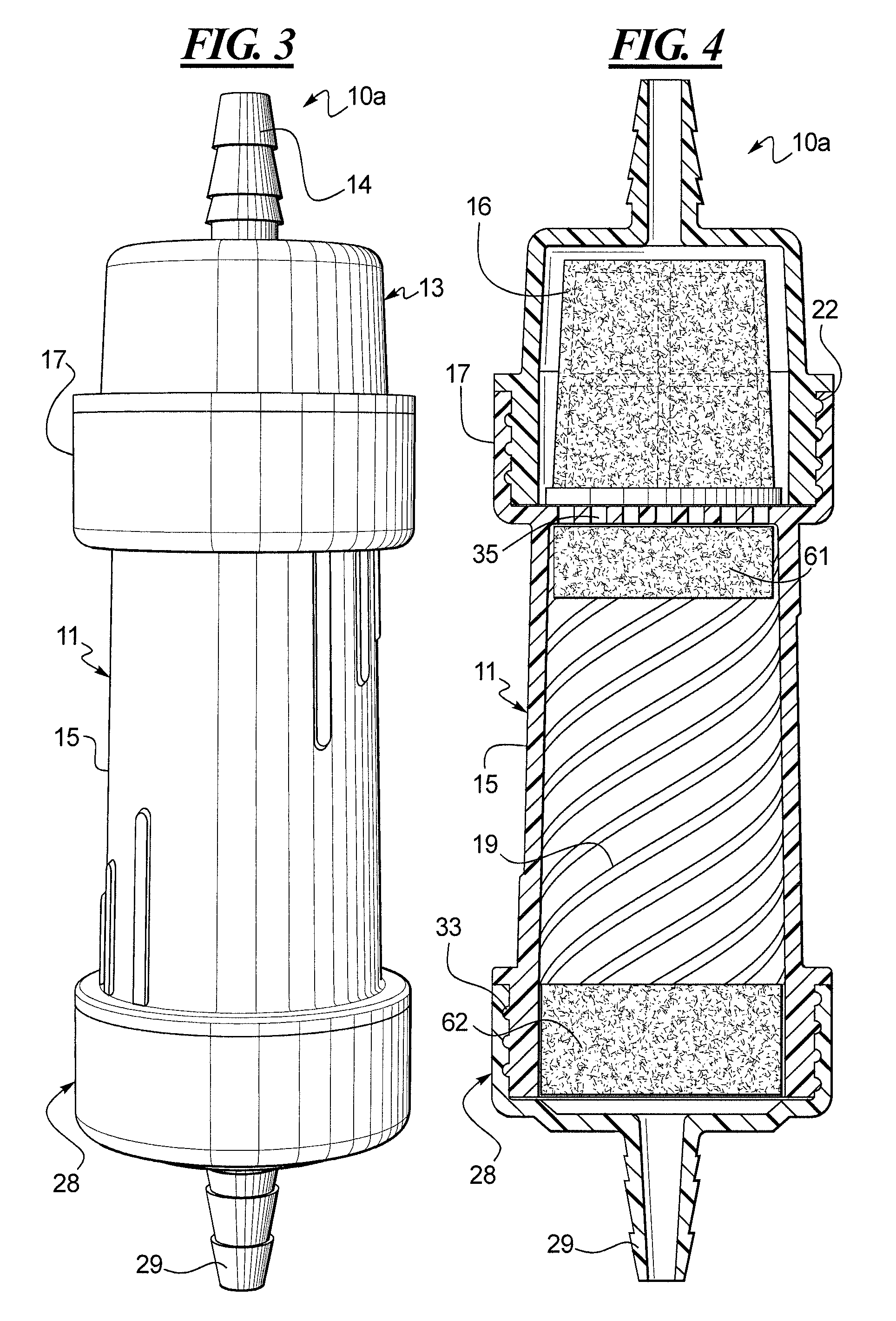

Modular Water Purification and Delivery System

InactiveUS20090008318A1Maximize capacityFlattening or eliminating the parabolic fluid flow profileUltrafiltrationWater/sewage treatment by ion-exchangeFiberHollow fibre

A modular filter system is provided with one or more modules that can be interchangeable, depending upon the specific application or specific health or environmental issue presented. Disclosed combinations can include one or more of any of the following modules in any relative position to one another: (a) a microbiological contaminant mitigation module, preferably in the form of an inverted u-shaped hollow fiber filter module wherein the fibers have ends potted on the downstream side and that consists essentially of hydrophilic fibers for water filtration with a small amount of hydrophobic fibers for venting of entrapped air; (b) a first chemical mitigation module, preferably in the form of an adsorption module comprising carbon or the combination of carbon and a deionization resin; and (c) a second chemical mitigation module, preferably in the form of a deionization resin module. Modules including a carbon bed or a resin bed may be equipped with a pair of hydrophobic foam bed restraints that apply opposing axial pressure to the bed in all operating conditions.

Owner:PRISMEDICAL CORP

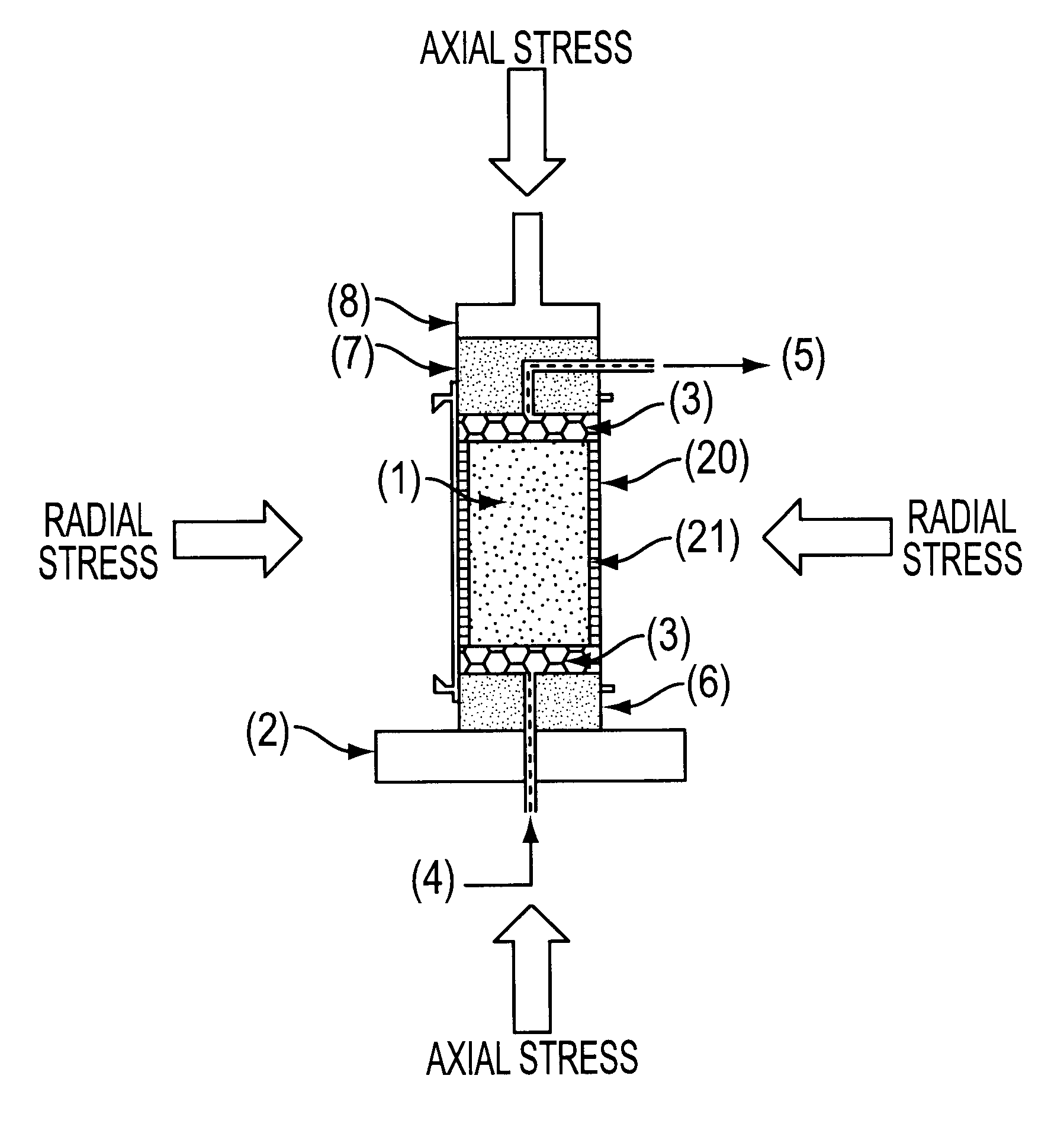

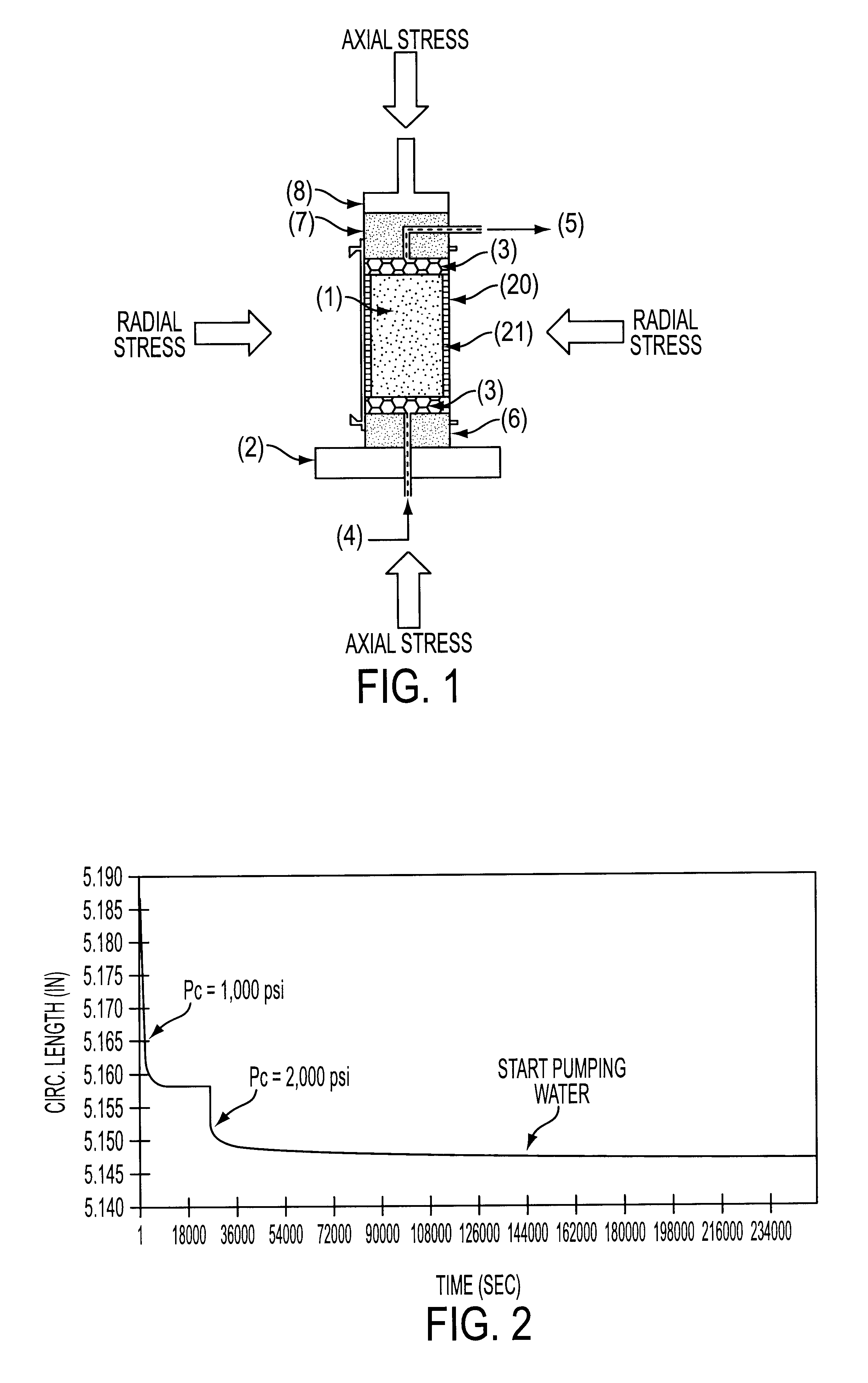

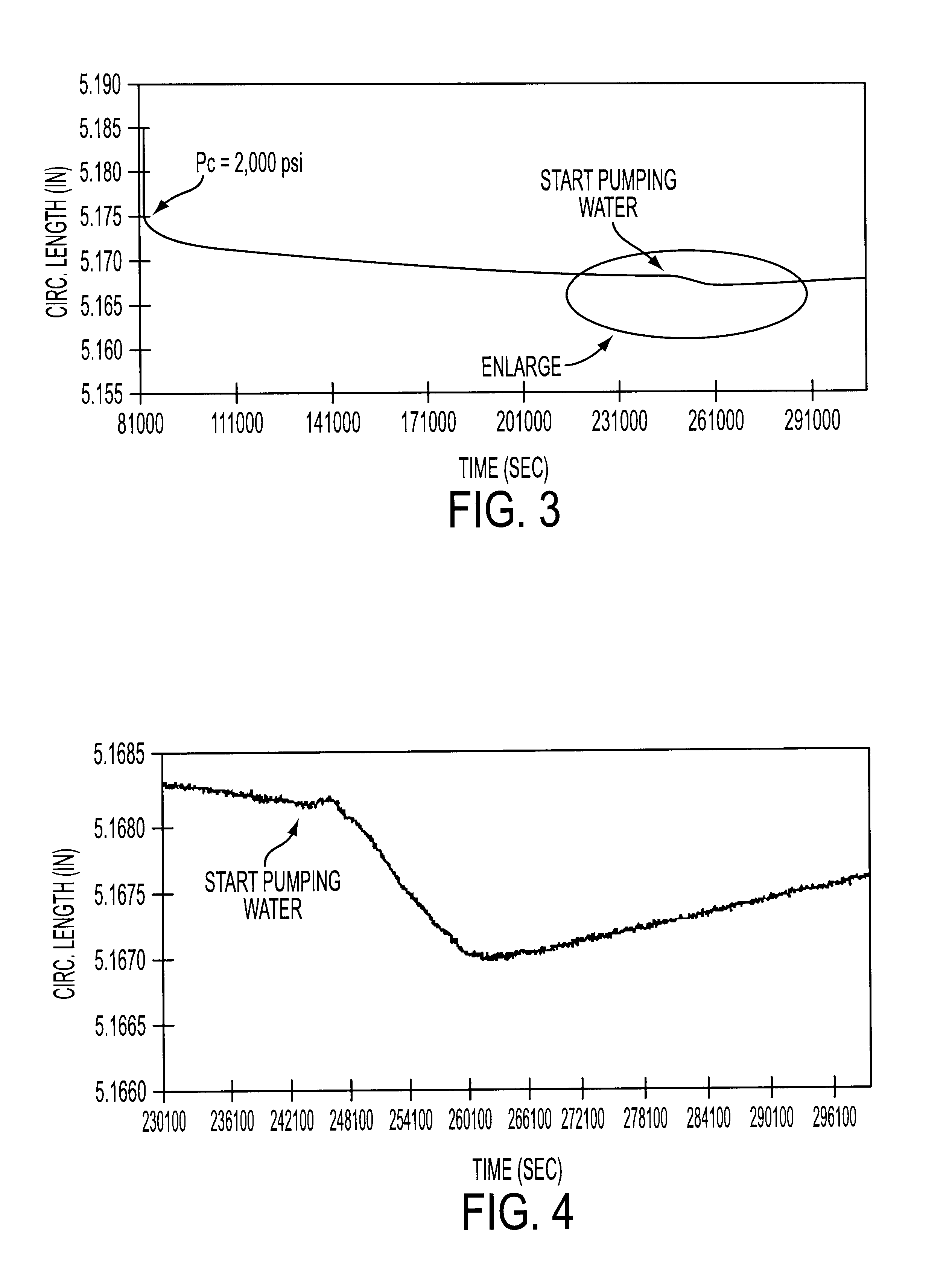

Method for the evaluation of shale reactivity

Shale reactivity is evaluated by testing a preserved test plug of shale sample in a triaxial test machine, the test plug being prepared by collecting a downhole shale sample and keeping it all times immersed in a preserving mineral oil so as to avoid dehydration, then applying radial and axial pressure on the test plug surrounded by mineral oil up to equilibration to overburden pressure, the test fluid being then contacted with the sample and the interaction of fluid and sample being evaluated by axial and radial deformations as measured by a triaxial detector apparatus sensitive to vertical and radial strains occurring across the shale sample, while the shale sample is subjected to any of a set of different conditions including a temperature or thermal potential, a hydraulic potential and / or a chemical potential. Only one fluid is tested on each sample. A sister test at ambient temperature and atmospheric pressure is run in order to constitute a visual counterpart of what is occurring in the triaxial test machine.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

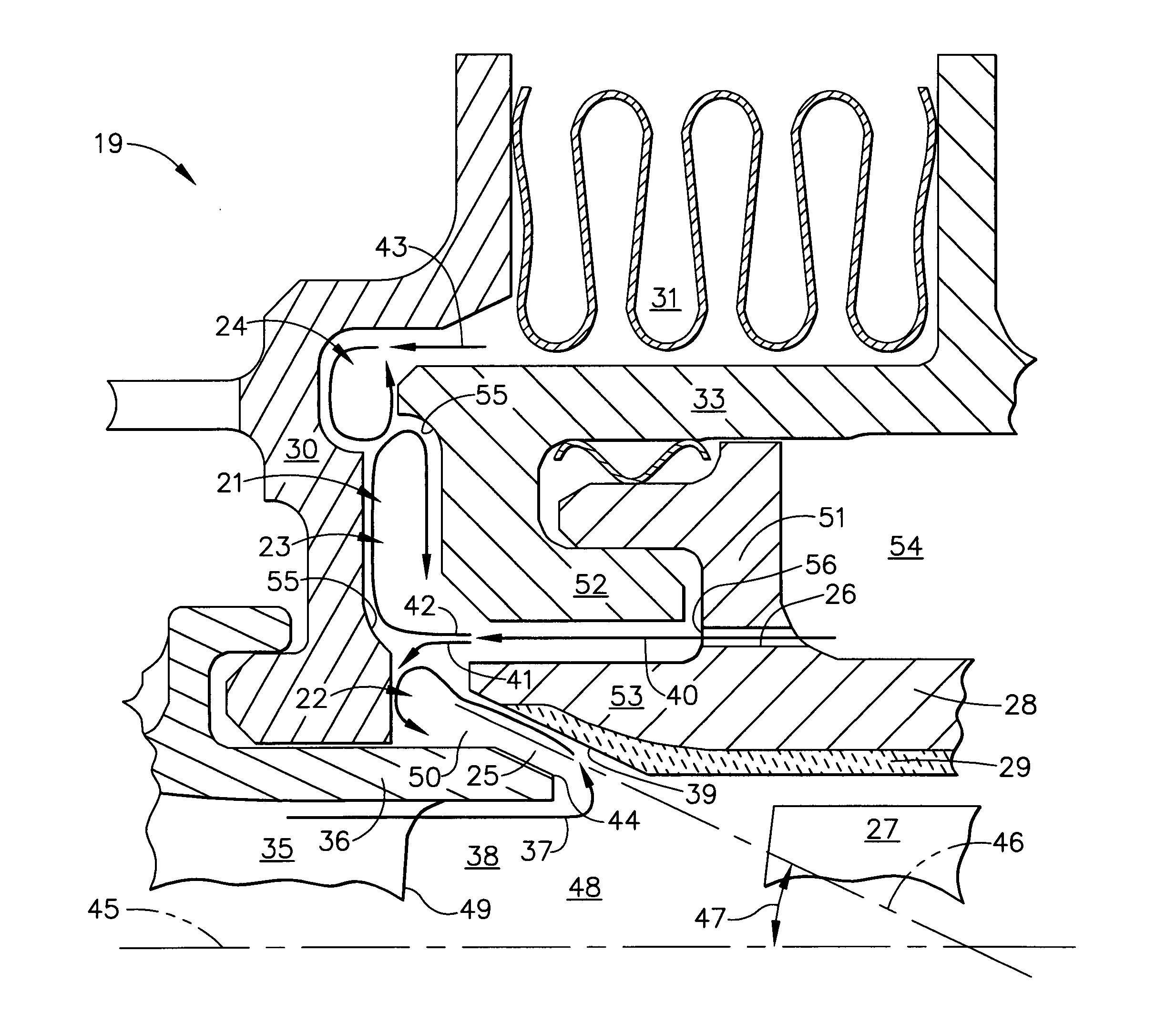

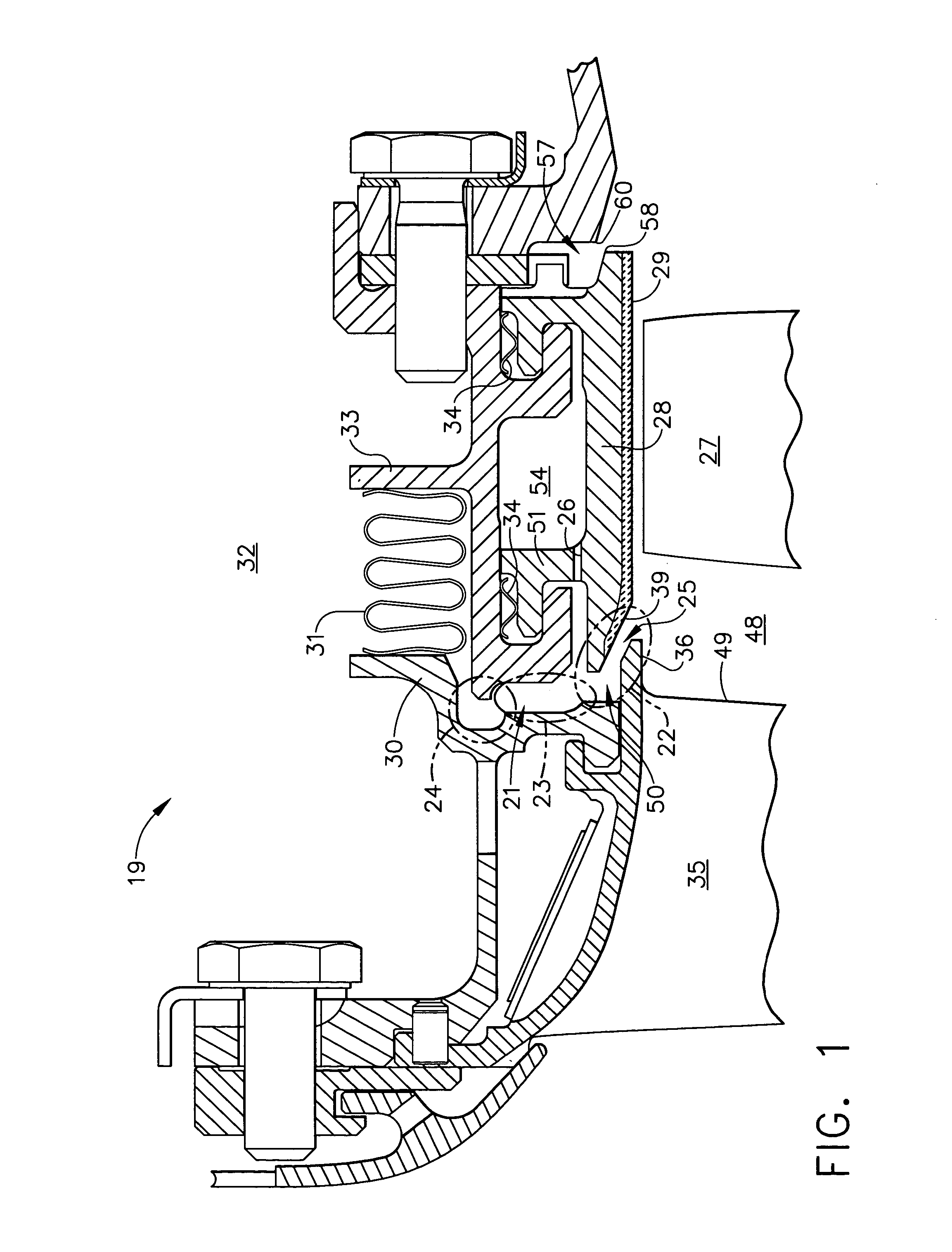

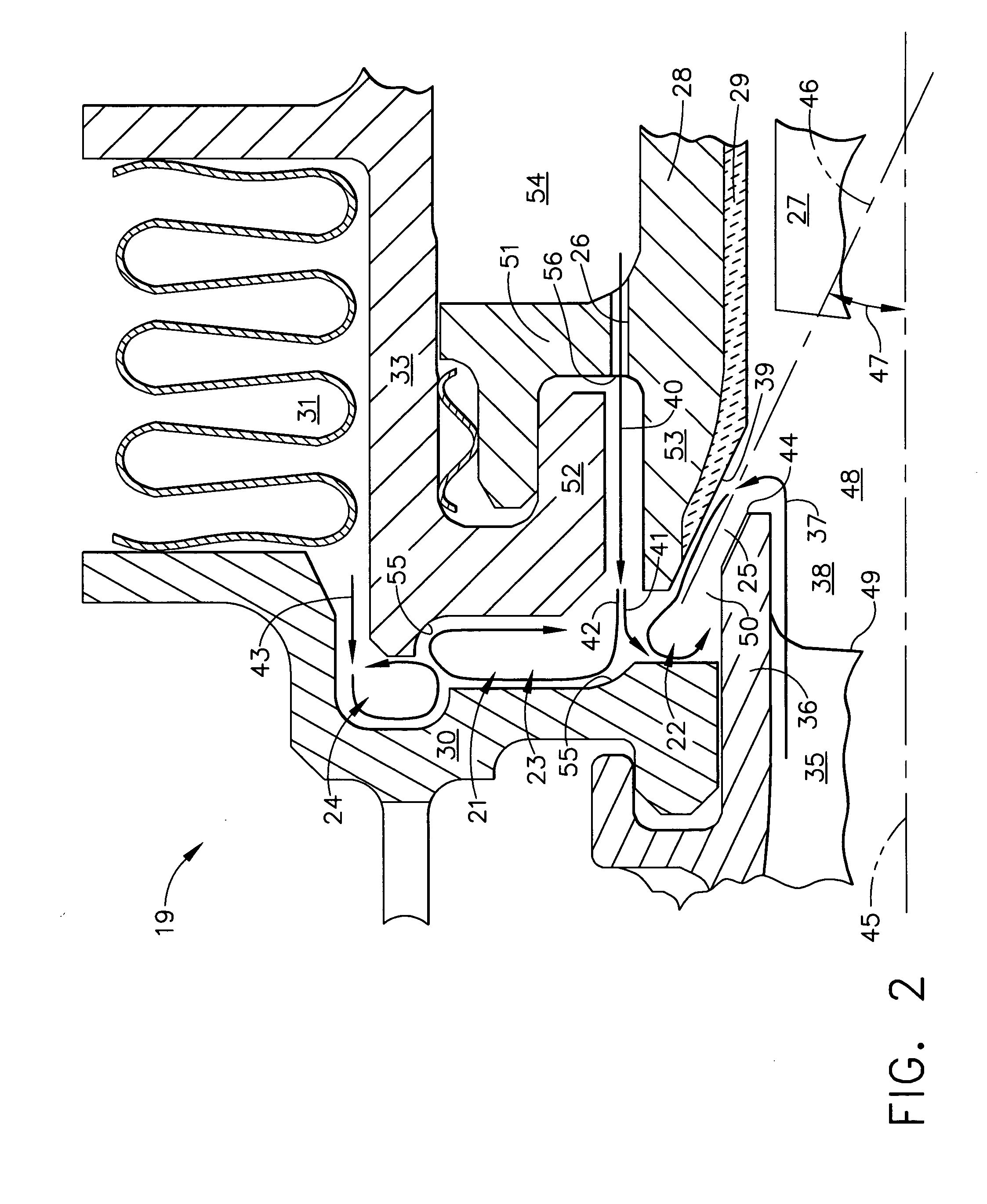

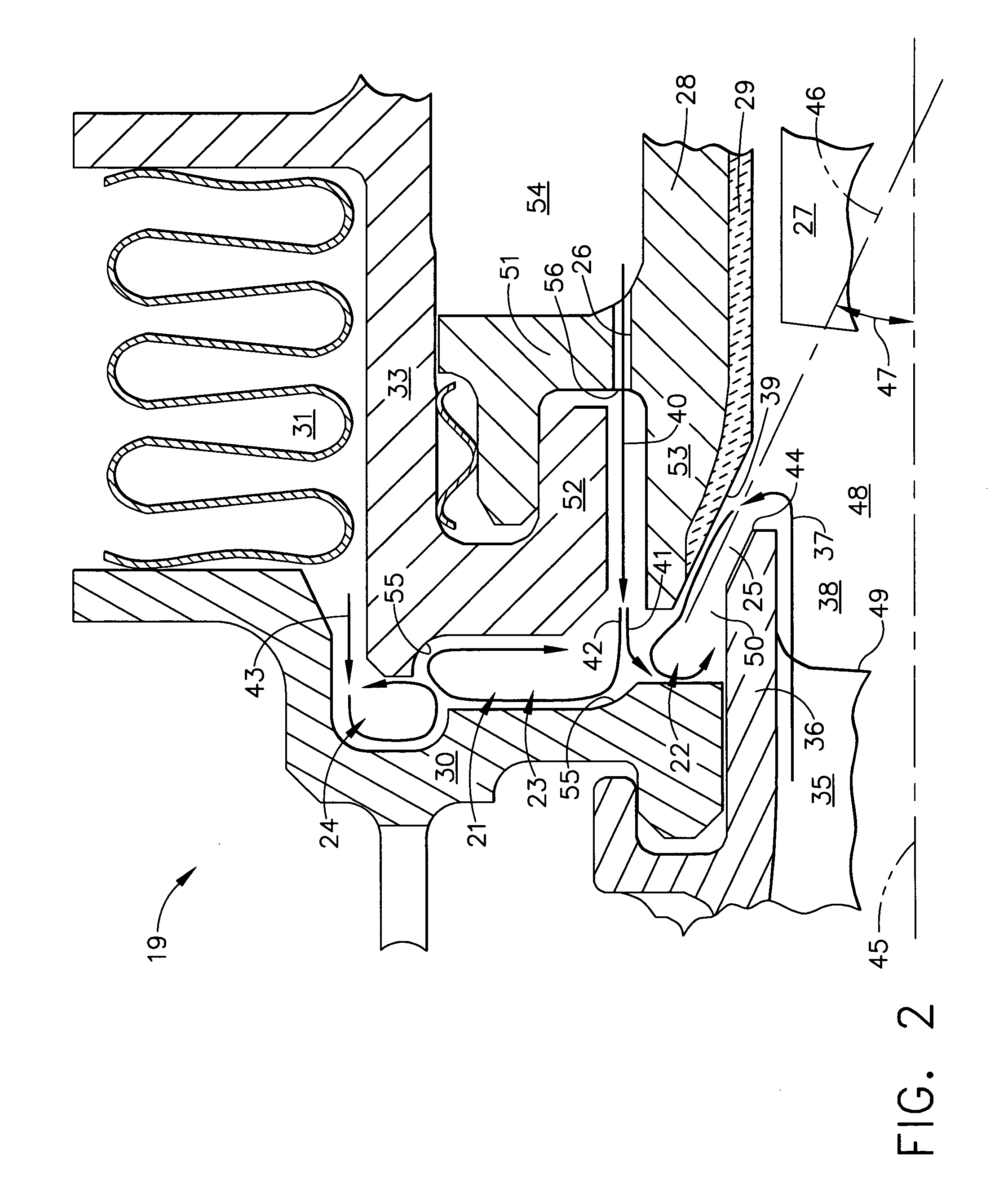

Gas turbine cooled shroud assembly with hot gas ingestion suppression

A cooled shroud assembly includes an angled slot and a plurality of dilution jet openings. The shroud forward cavity is modified such that at least one recirculation zone is produced. The angled slot forces an axial change in momentum of the hot gas flow and increases radial and axial pressure variation attenuation. The cooled shroud assembly isolates the shroud structure and seals from the hot flow path and a cooling flow from the dilution jet openings dilutes the hot gas flow. A series of recirculation zones shields the shroud carrier and high pressure seals from the hot gas flow.

Owner:HONEYWELL INT INC

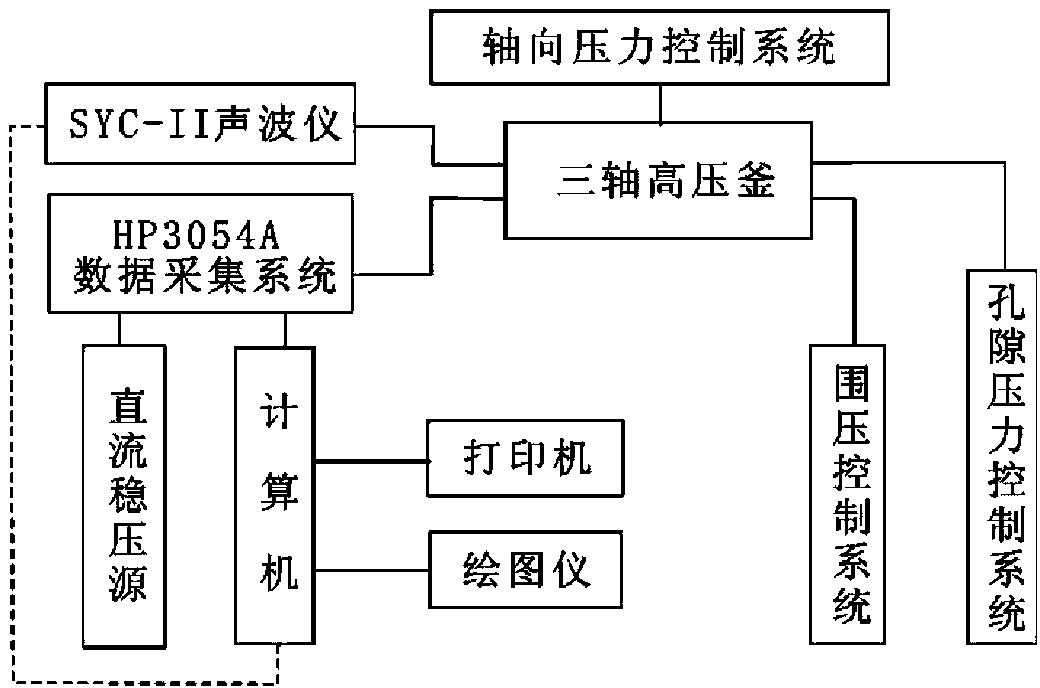

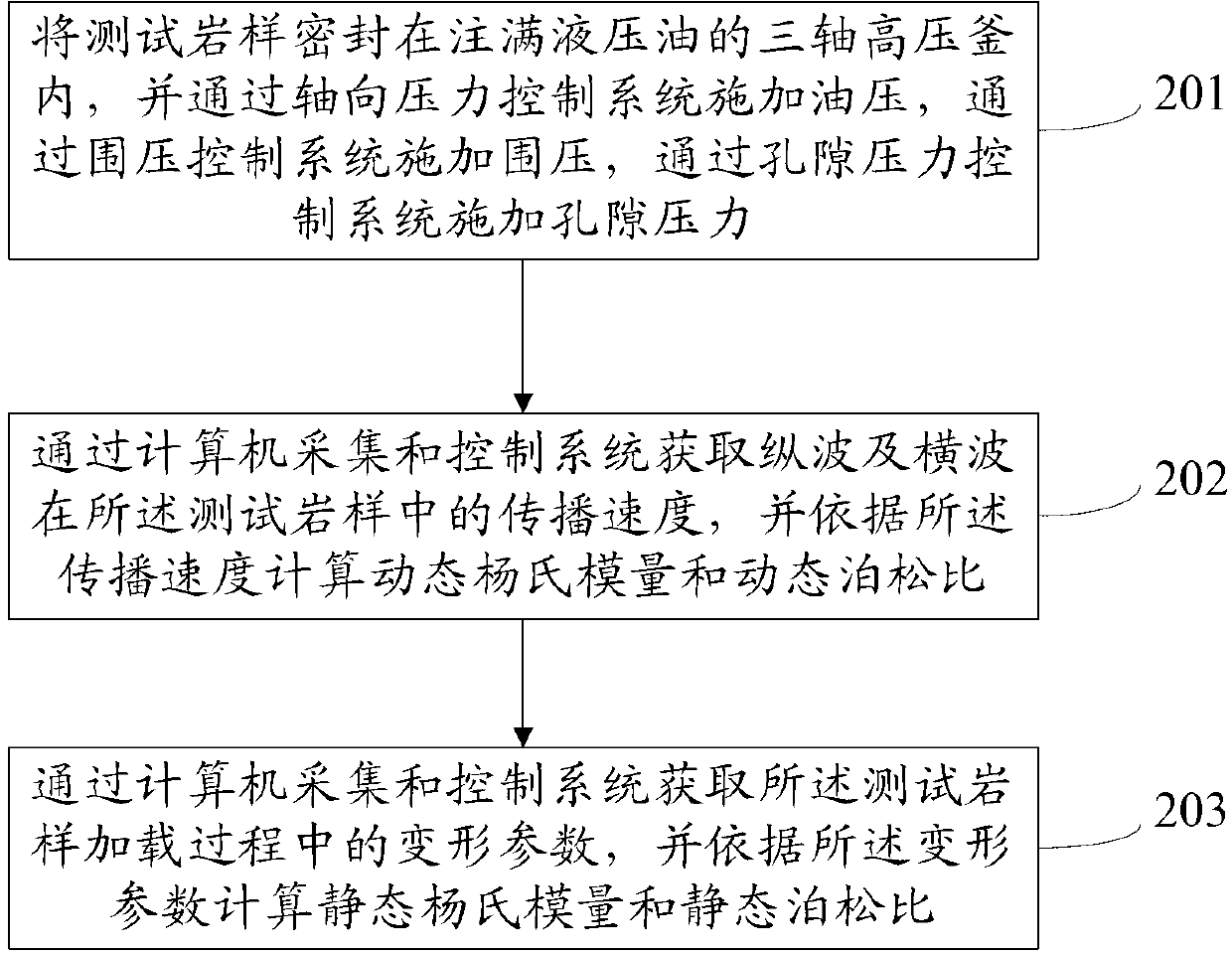

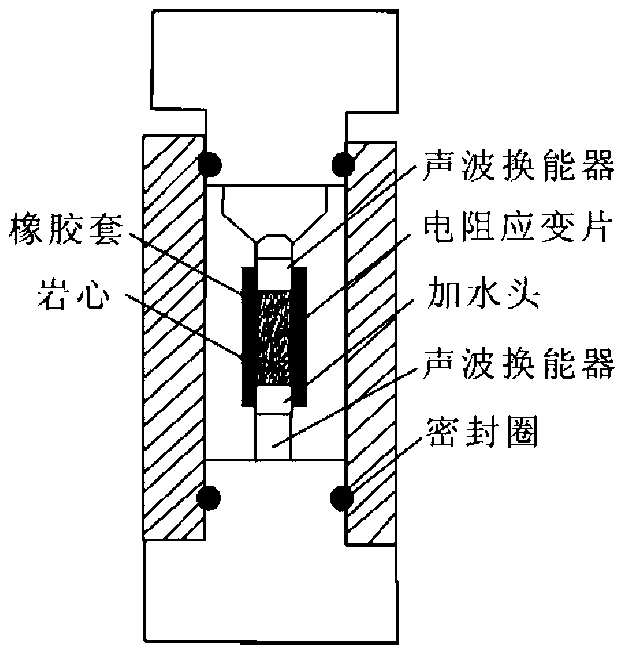

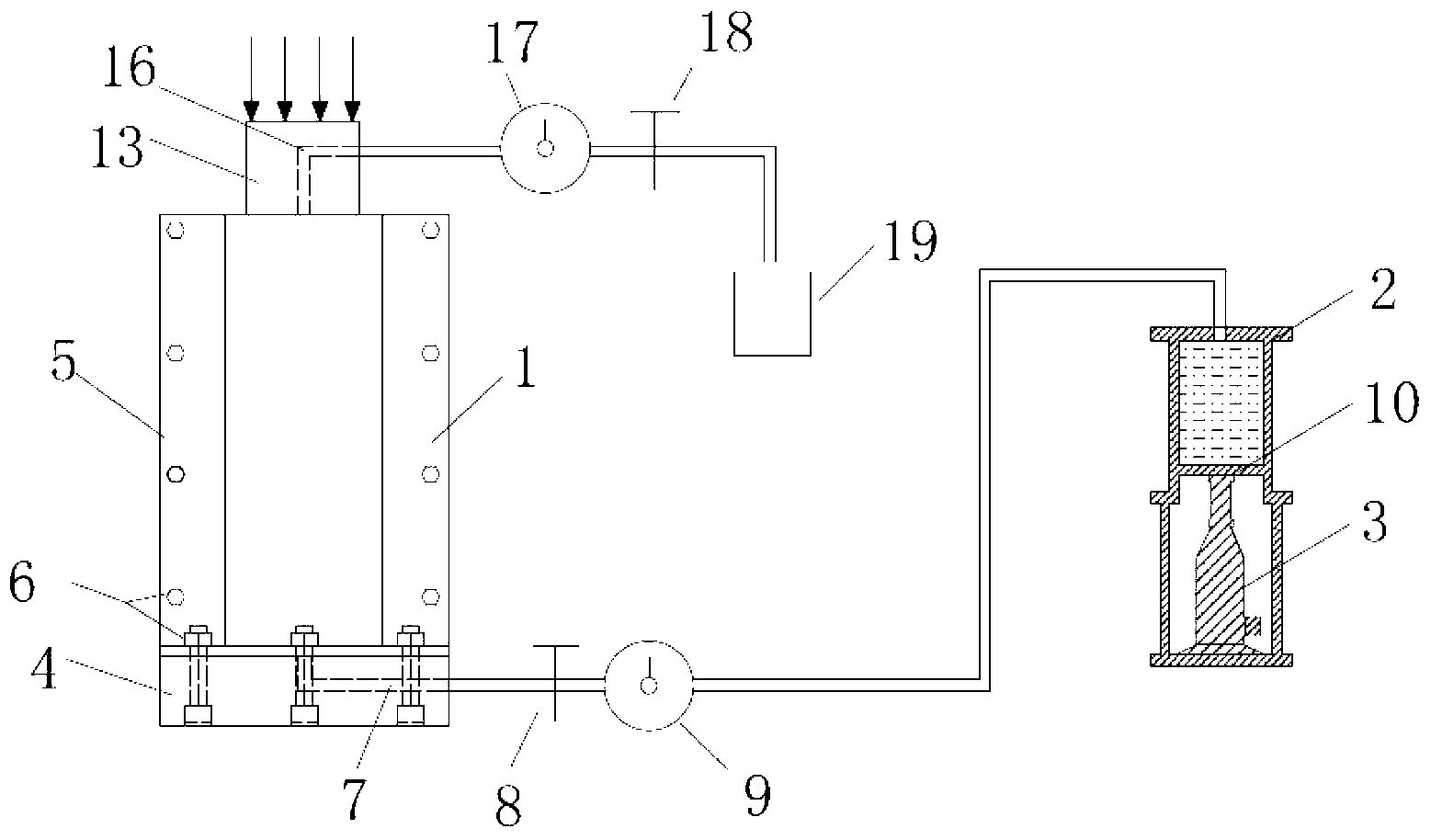

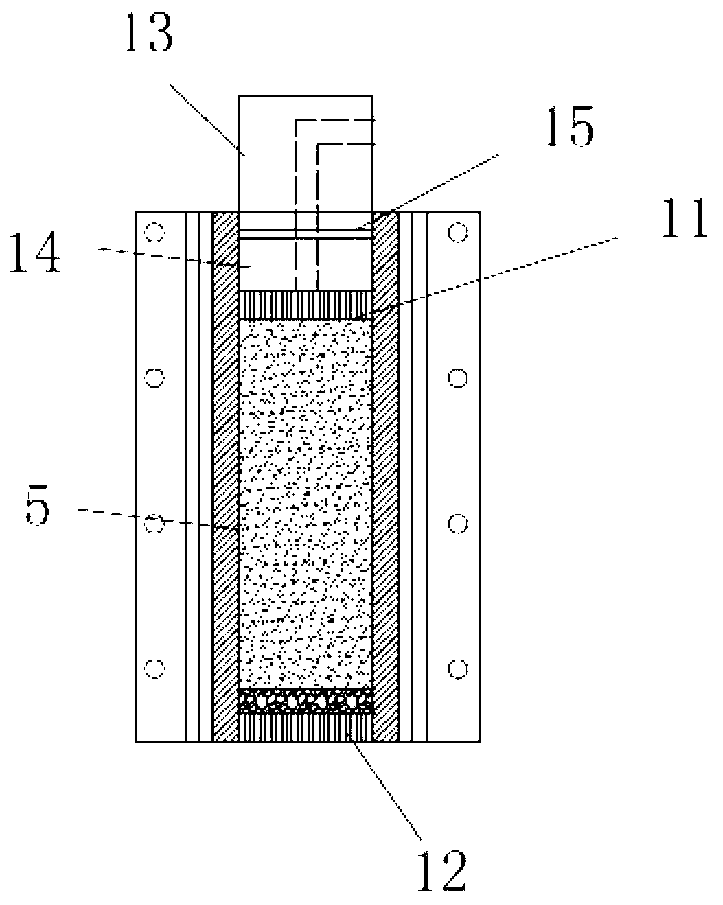

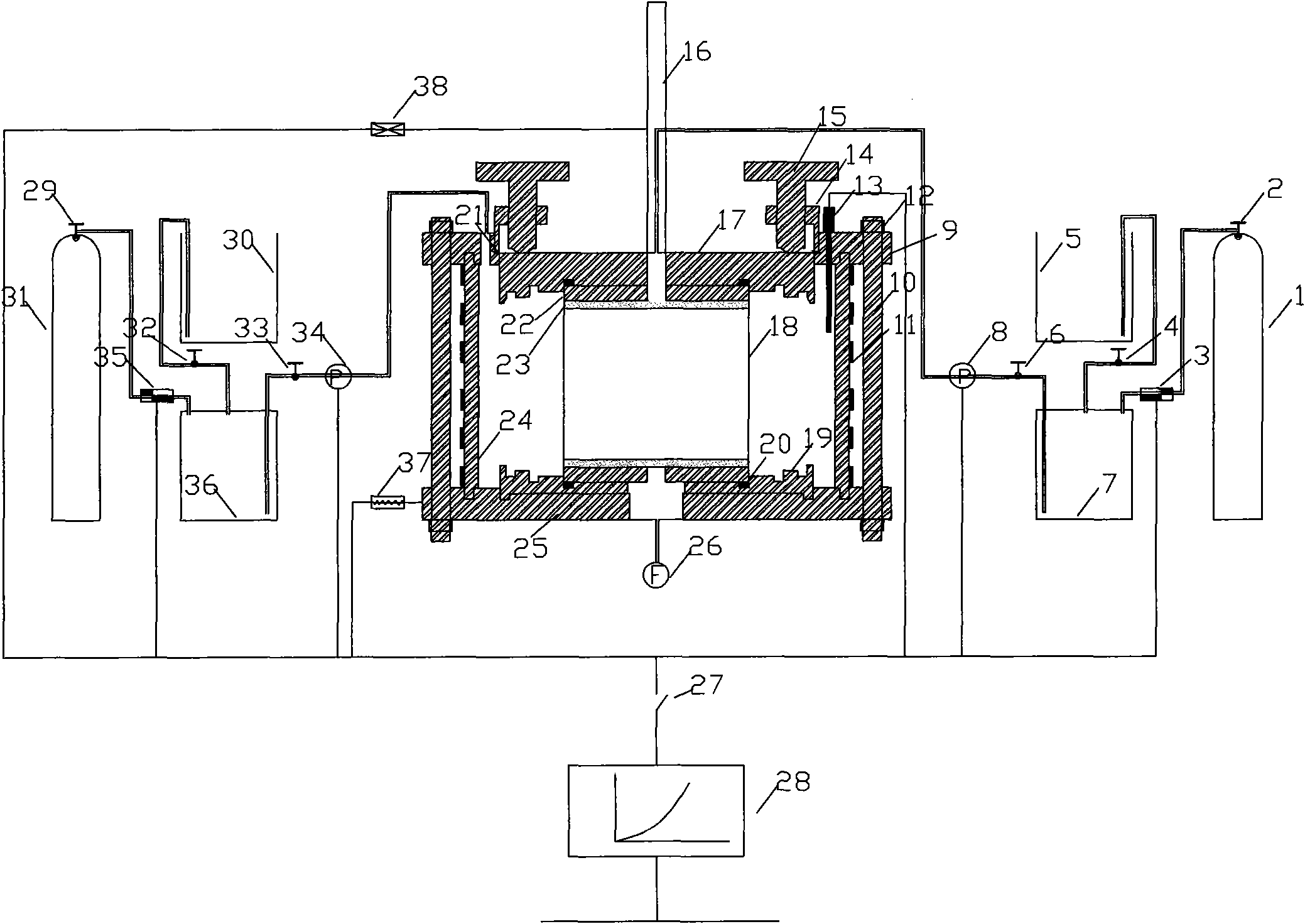

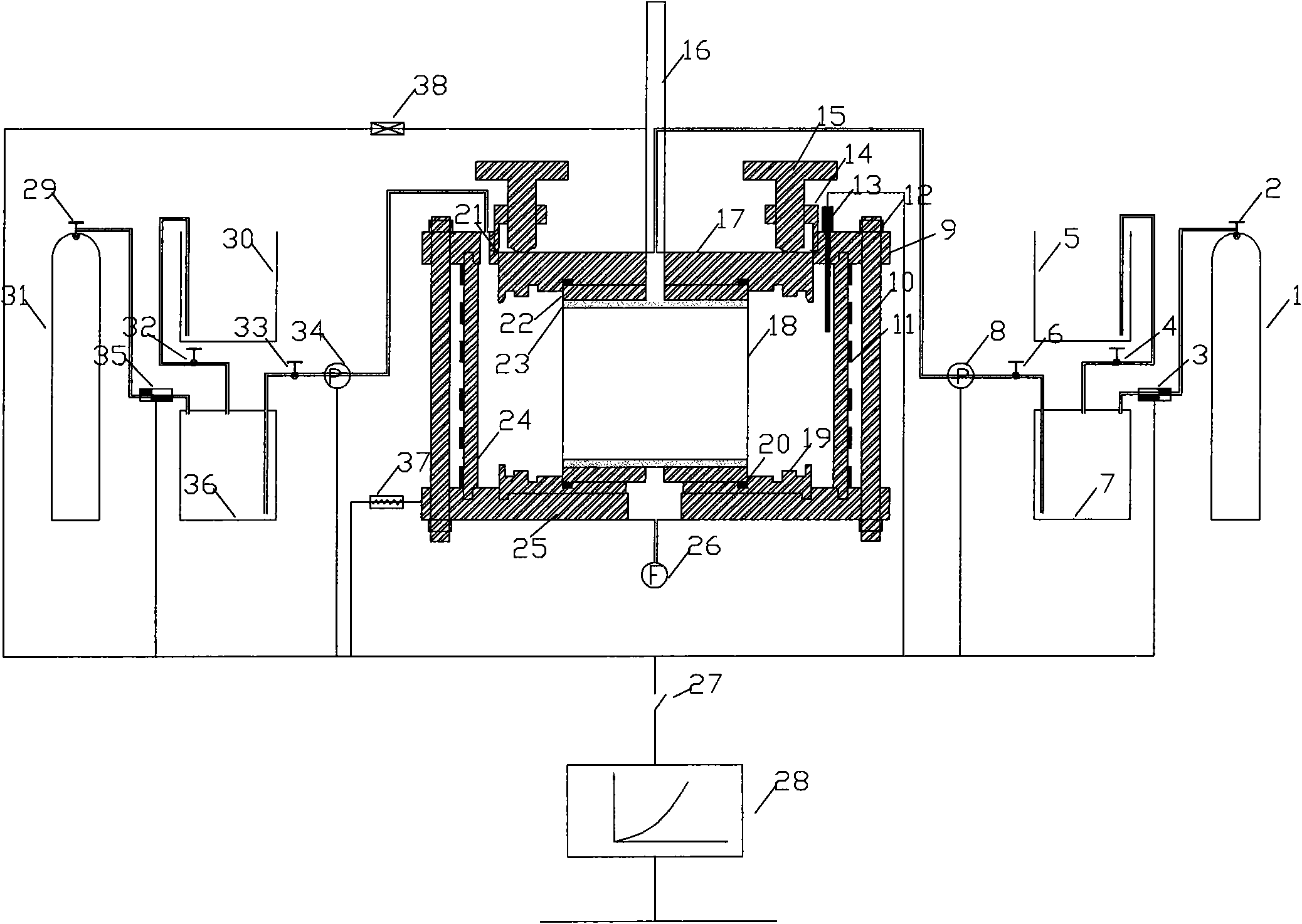

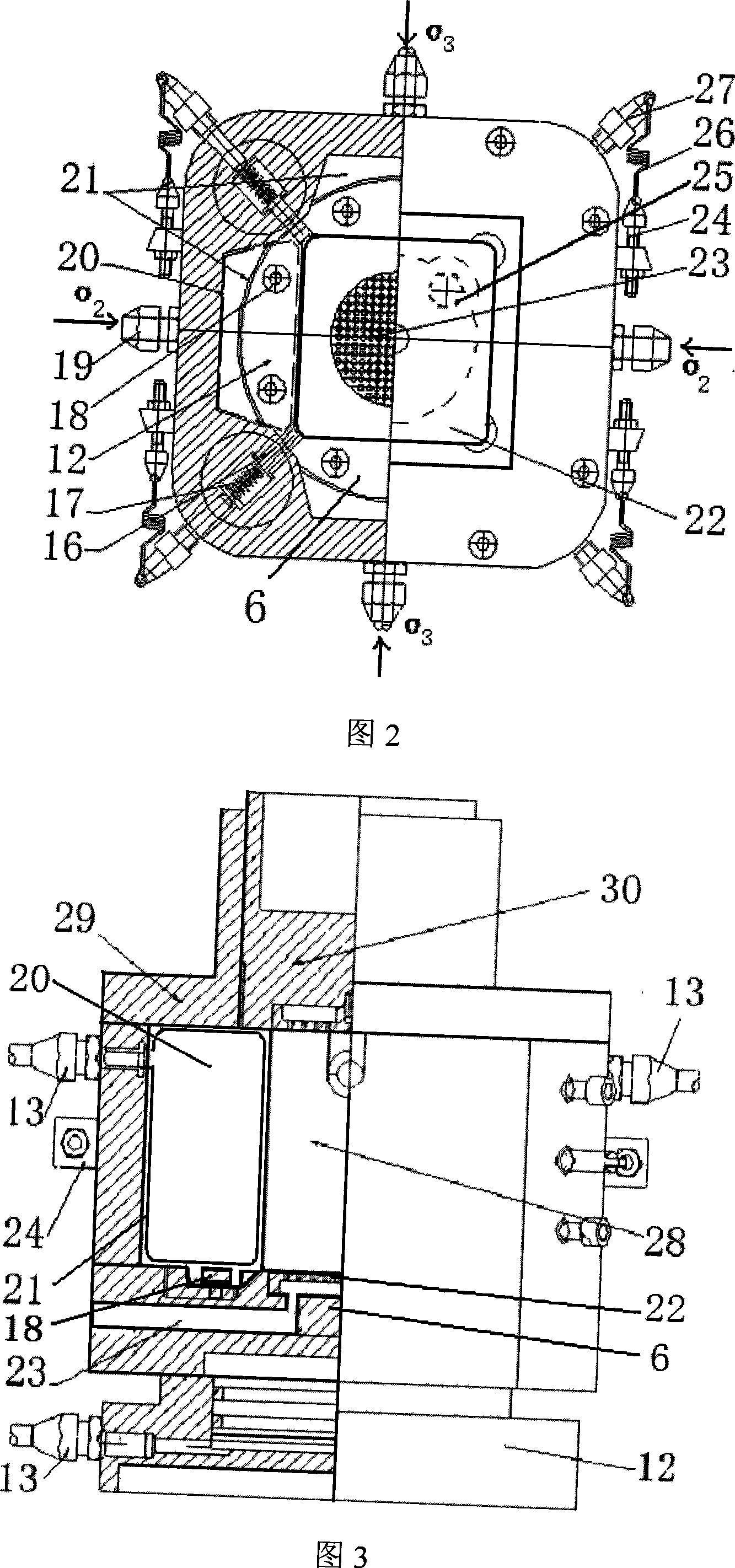

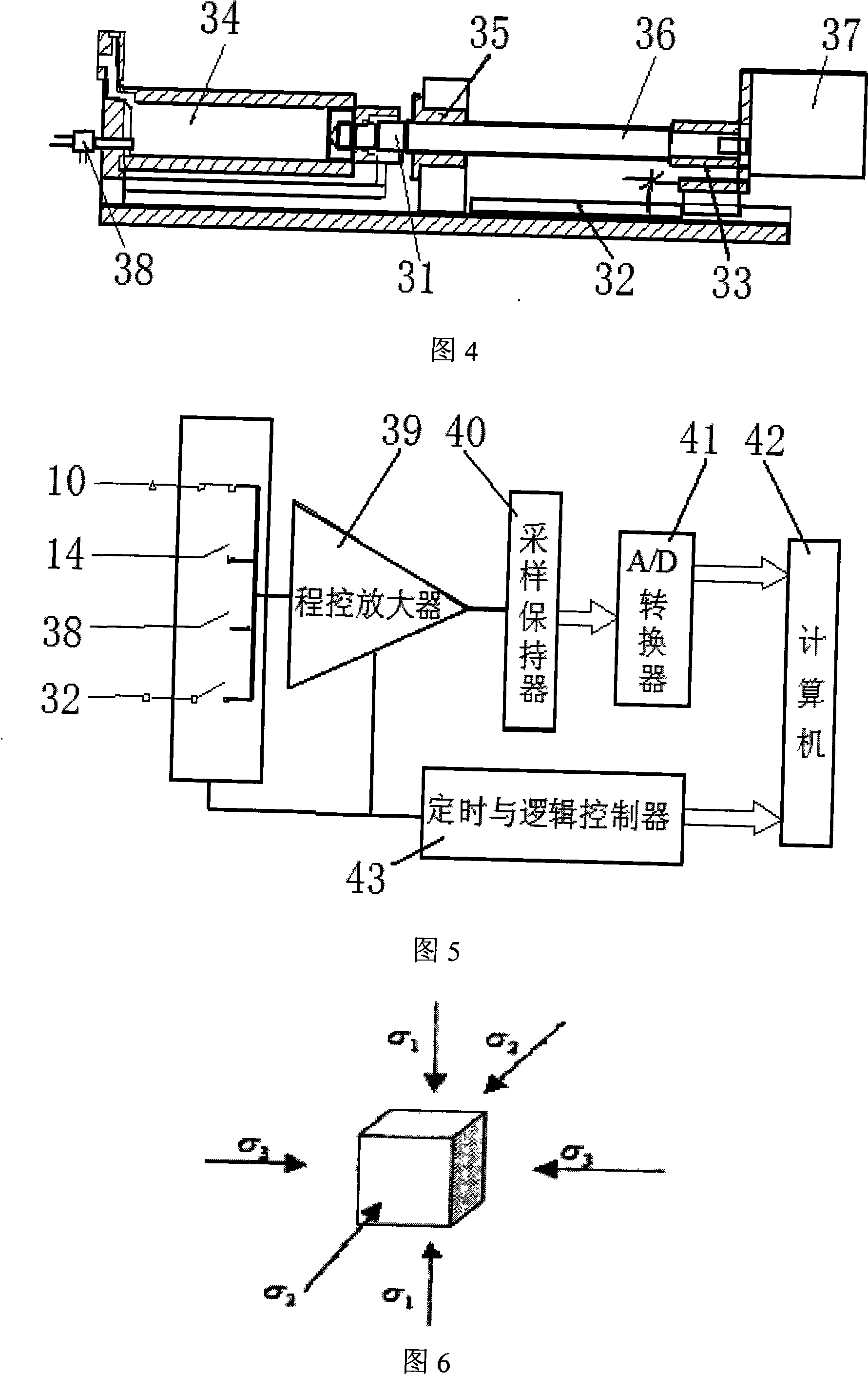

Method for synchronous measurements on dynamic and static elastic parameters of rocks

InactiveCN103278389AGuaranteed validityGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesControl systemAxial pressure

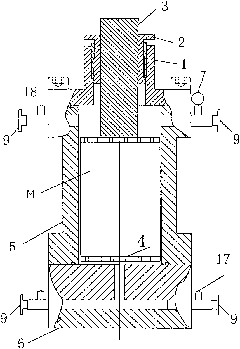

The invention provides a method and a device for synchronous measurements on dynamic and static elastic parameters of rocks by using a rock triaxial anti-compression testing device. The method comprises: sealing a test rock sample in a triaxial autoclave filled with hydraulic oil, applying an oil pressure by an axial pressure control system, applying a confining pressure by a confining pressure control system, and applying a pore pressure by a pore pressure control system; acquiring propagation speeds of longitudinal waves and transverse waves in the test rock sample by a computer acquisition and control system, and calculating the dynamic Young modulus and the dynamic Poisson ratio according to the propagation speeds; and acquiring deformation parameters of the test rock sample during a loading process by the computer acquisition and control system, and calculating the static Young modulus and the static Poisson ratio according to the deformation parameters. The method and the device can ensure validity and accuracy of hydrocarbon reservoir rock mechanical parameter measurements in thousands of meters deep underground and under the conditions of complex confining pressure, high temperature, high pore pressure and polyphase fluid.

Owner:PEKING UNIV

Pressure bearing permeation grouting strengthening test apparatus and method

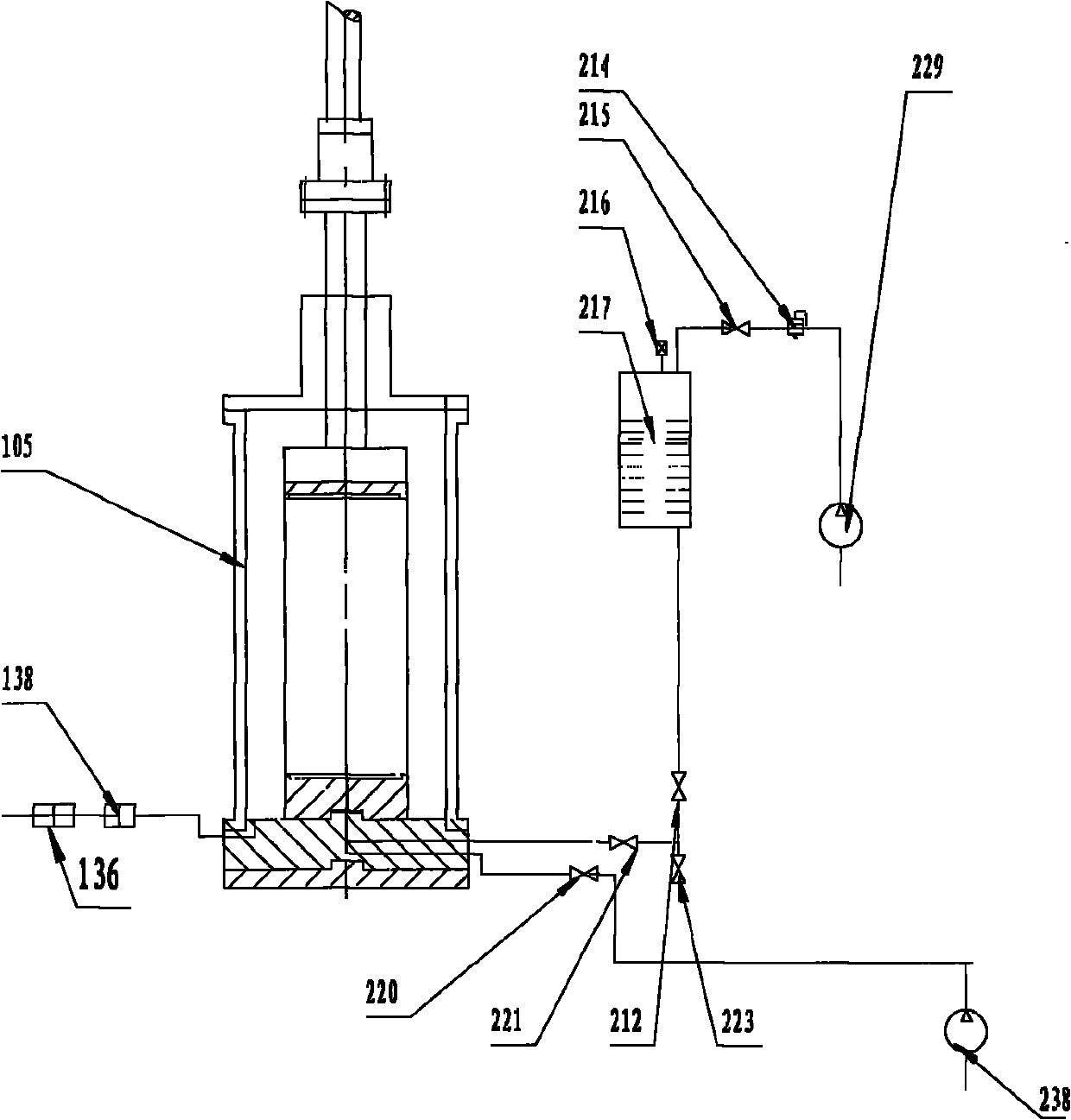

InactiveCN103267722AEasy to manufactureSimple structurePreparing sample for investigationPermeability/surface area analysisAxial pressureMicro fracture

The present invention relates to a pressure bearing permeation grouting strengthening test apparatus and a method. The apparatus mainly comprises a grouting bucket, a slurry storage device and a manual grouting pressurization device, wherein the grouting bucket comprises a base, a bucket body and a pressing head, a grouting hole is arranged in the base, and is connected with the slurry storage device through a high pressure soft pipe, the slurry storage device is provided with a piston, and the manual grouting pressurization device is placed below the piston. With the test apparatus, influence of axial pressure, confining pressure and other factors of the upper portion of the micro fracture (pores) geology on the grouting can be simulated; the grouting conditions of the geological bodies with different physical and mechanical properties under different grouting parameters and different grouting process conditions can be simulated so as to analyze a mechanism and an effect of grouting strengthening; and with the test apparatus, broken coal rock bodies, soil samples and sand samples can be made into complete samples, can be processed into standard samples through a cutting machine, and then are subjected to related uniaxial and triaxial tests. In addition, the test apparatus has characteristics of simple structure, easy manufacturing, low cost, easy operation, and reliable use.

Owner:CHINA UNIV OF MINING & TECH

Temperature responsive valve assembly for a pneumatic spring

InactiveUS6959921B2Reduce manufacturing costEasy to assembleLiquid springsGas based dampersAxial pressureGas spring

A temperature responsive valve assembly for a gas spring includes a valve body, a seal, a bi-metal valve and a locking member. The valve body includes a flexible radial member defined along the outer periphery of the valve body. Each radial member includes a radially inward extending tab which engages the outer diameter of the locking member. The construction allows the temperature responsive valve assembly to be essentially “snapped” together. The locking member further includes axial spring feet which provide axial pressure upon the bi-metal valve to maintain engagement with the valve seat.

Owner:AVM INDS

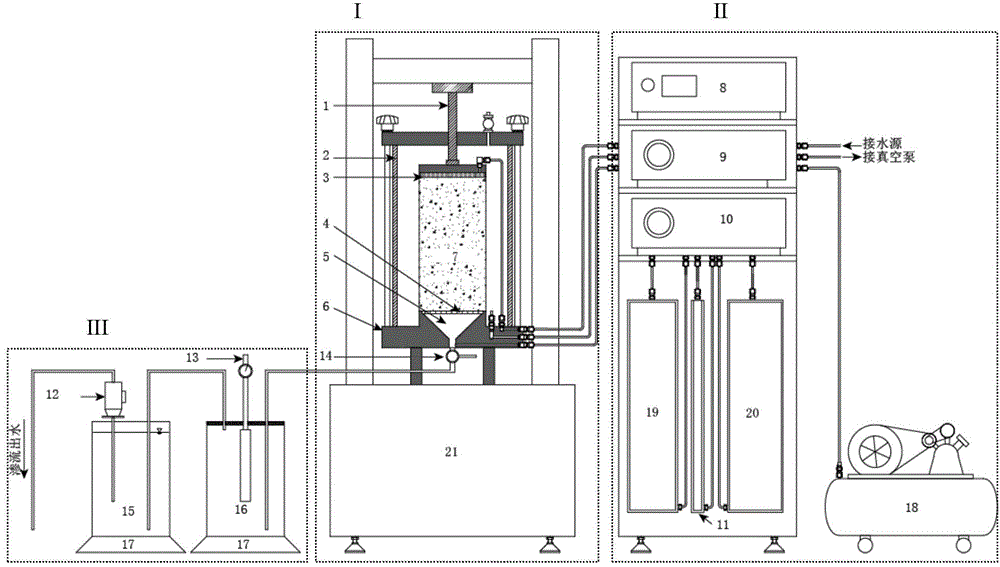

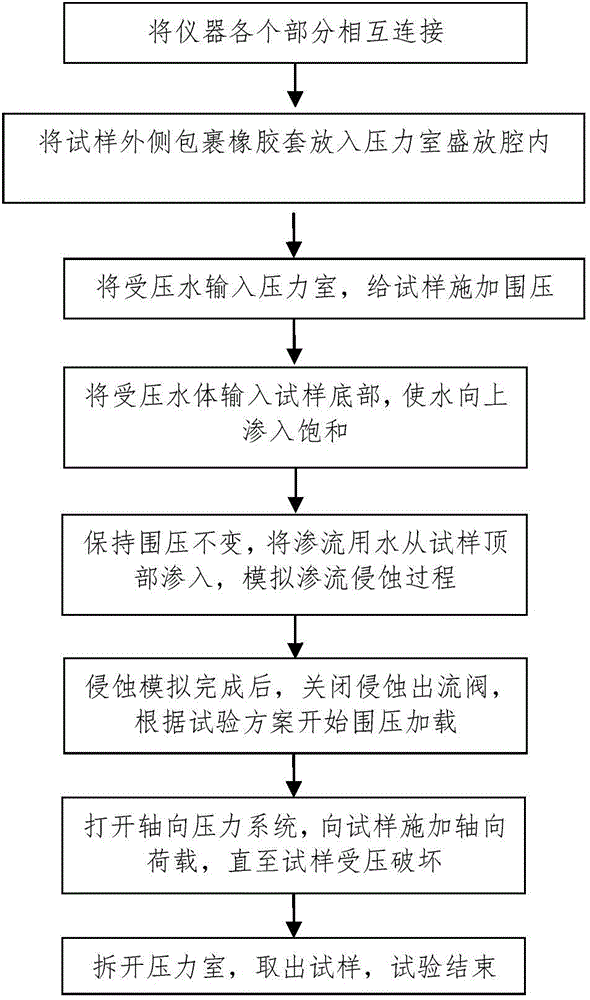

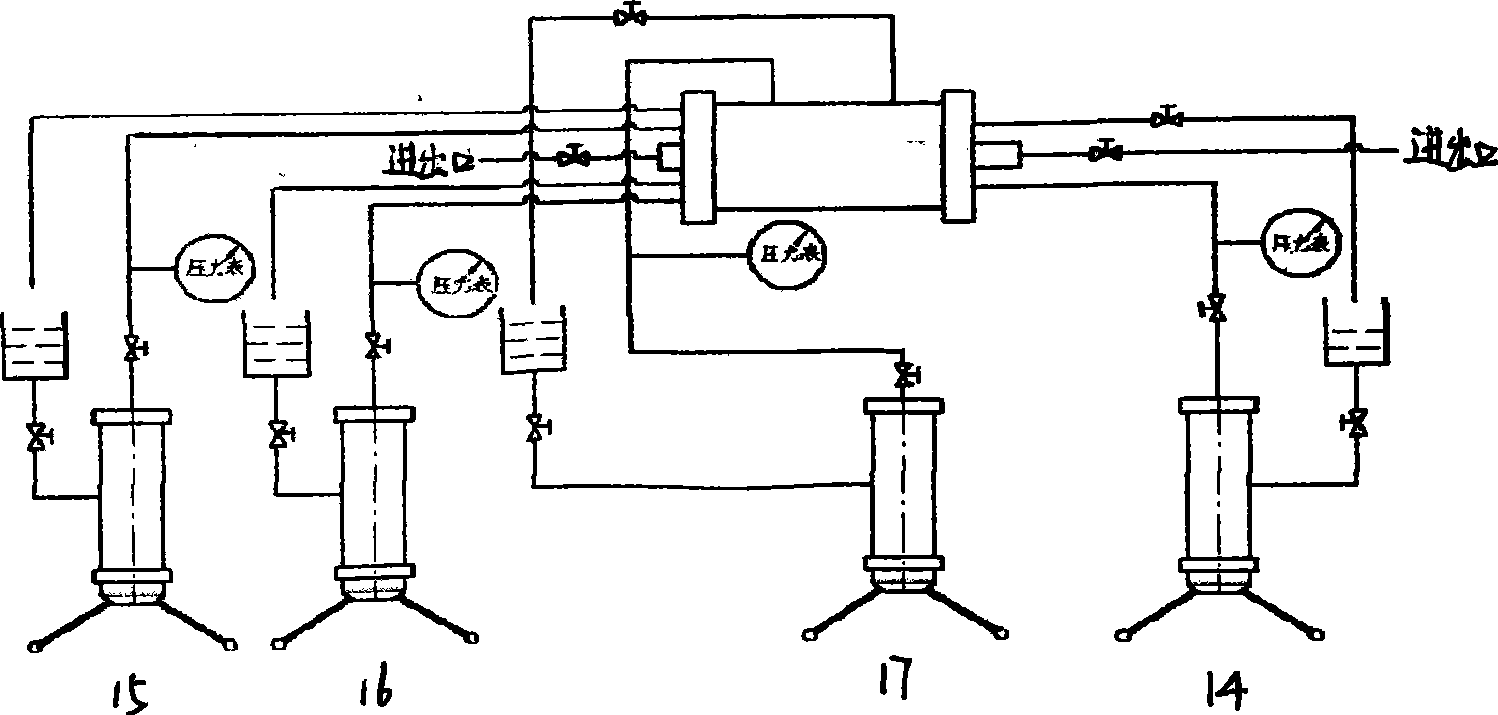

Penetration and corrosion triaxial testing apparatus for gravel soil and testing method thereof

InactiveCN104535470AImprove permeabilityAchieve strengthMaterial strength using tensile/compressive forcesPermeability/surface area analysisAxial pressureEngineering

The invention provides a penetration and corrosion triaxial testing apparatus for gravel soil. The penetration and corrosion triaxial testing apparatus comprises a pressure control system, a penetration and corrosion triaxial testing system and a sand-water separation system, wherein the penetration and corrosion triaxial testing system is used for containing gravel soil samples and can form a penetration and corrosion environment with a multistage water head and complex stress condition through self-loaded axial pressure as well as confining pressure and water pressure, provided by a pressure supplying system; the contained gravel soil samples can flow out of the penetration and corrosion triaxial testing system in the penetration and corrosion environment and then enter the sand-water separation system. The invention also provides a testing method of the triaxial testing apparatus. According to the triaxial testing apparatus, the samples are placed in a pressure chamber with confining pressure to be saturated, so that the multistage water head can realize penetration, corrosion and strength testing under a condition that the real environment stress state is simulated; corroded particles are discharged through a porous chassis of the pressure chamber, the mass of the corroded particle can be weighed in real time after sand-soil separation, and the penetration and corrosion triaxial testing process with the multistage water head and the complex stress condition can be effectively carried out.

Owner:SHANGHAI JIAO TONG UNIV

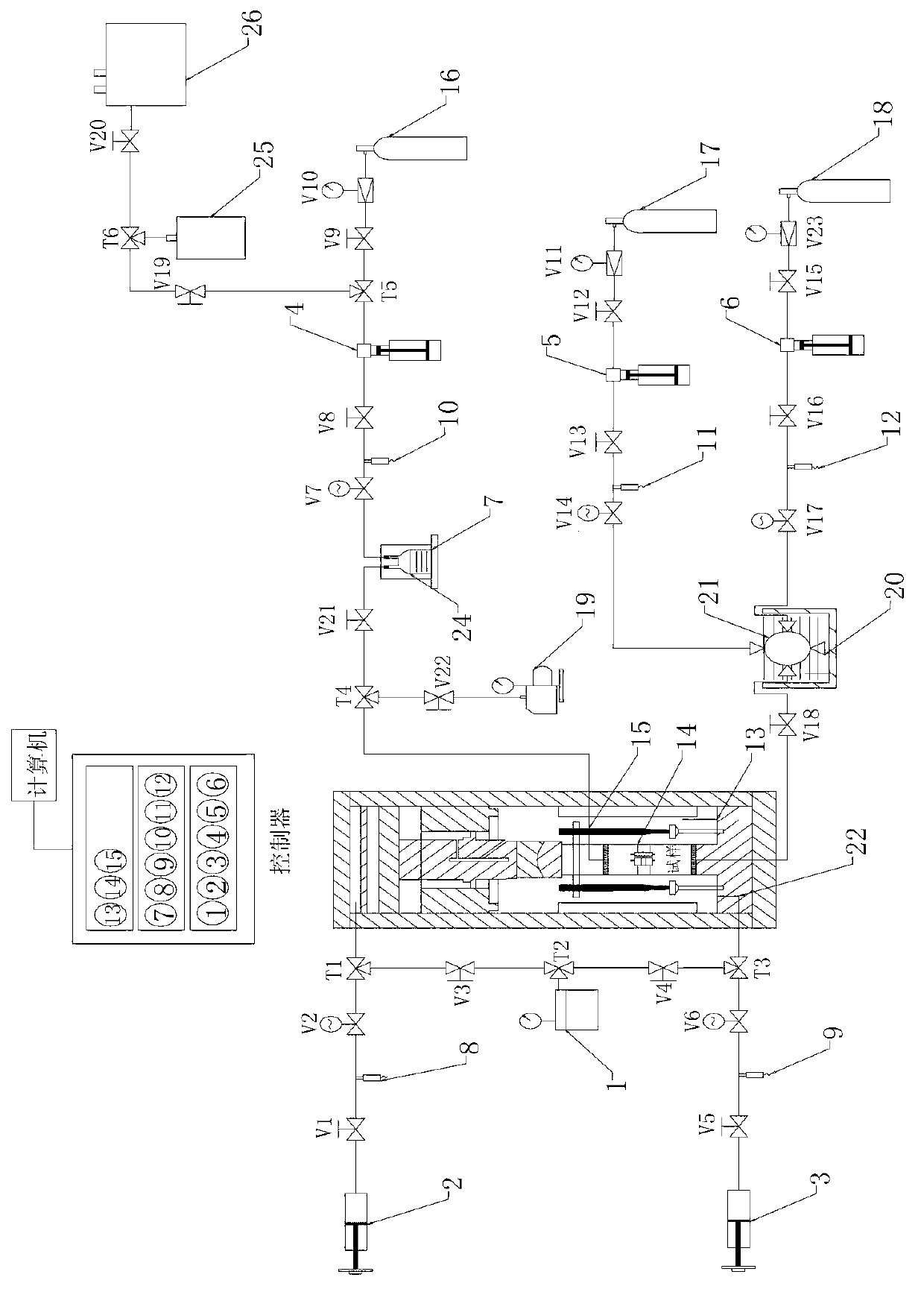

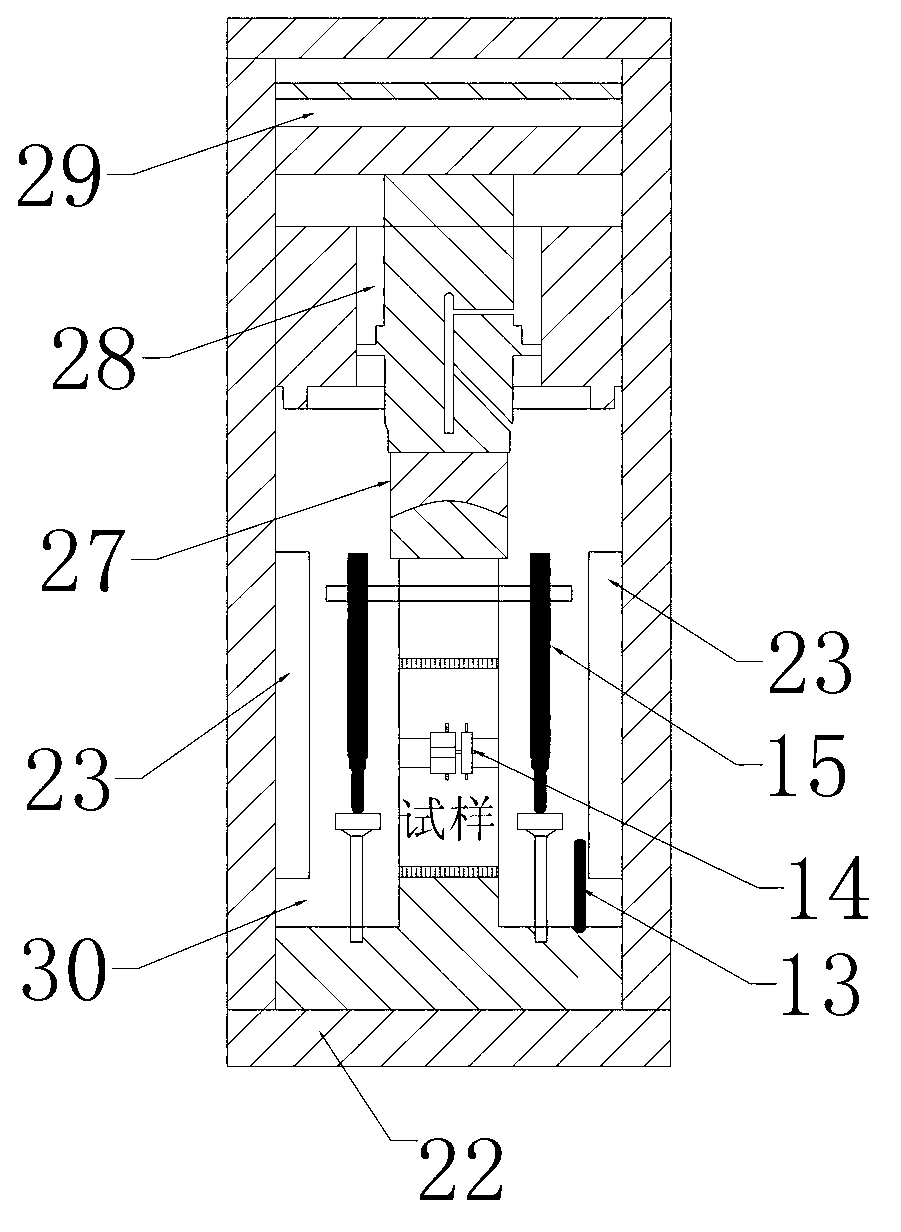

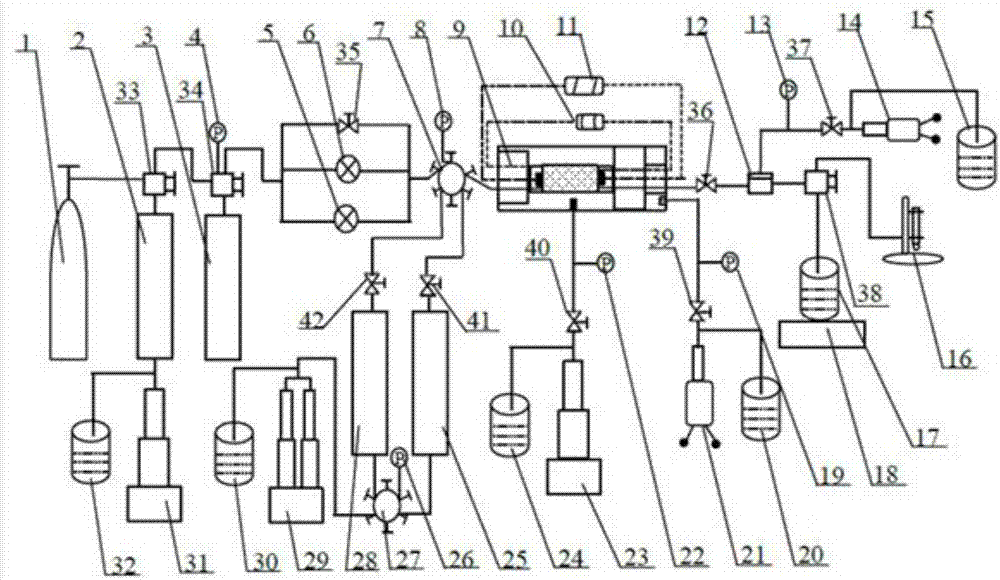

Device and method for gas bearing shale-seepage-temperature coupling and displacement experiment

ActiveCN103278428AEnables permeability determinationImprove stabilitySurface/boundary effectMaterial strength using tensile/compressive forcesRock engineeringAxial pressure

The invention belongs to the field of rock engineering, and in particular relates to a device and a method for a gas bearing shale-seepage-temperature coupling and displacement experiment. The experimental device comprises a triaxial pressure cavity, an axial pressure loading system, a confining pressure loading system, an upstream gas pressure loading system, an upstream liquid pressure loading system, a downstream gas pressure loading and collecting system, a downstream liquid collecting system, a multi-component mixed gas collecting system, a vacuumizing device, a heating system and a data collection control system. The experimental method comprises the following steps of: fixing a test piece; applying confining pressure; applying axial pressure; heating; vacuumizing; applying upstream liquid pressure (or pre-saturated methane); applying upstream gas pressure (or applying upstream gas pressure); injecting multi-phase mixed fluid (or applying another upstream liquid pressure); performing pre-adsorptive saturation by the test piece (injecting multi-component constant-proportion mixed gas); and collecting. The experimental device can be used for applying triaxial stress to the test piece according to the actual stress condition, and remolding a stress environment according to the fact.

Owner:NORTHEASTERN UNIV

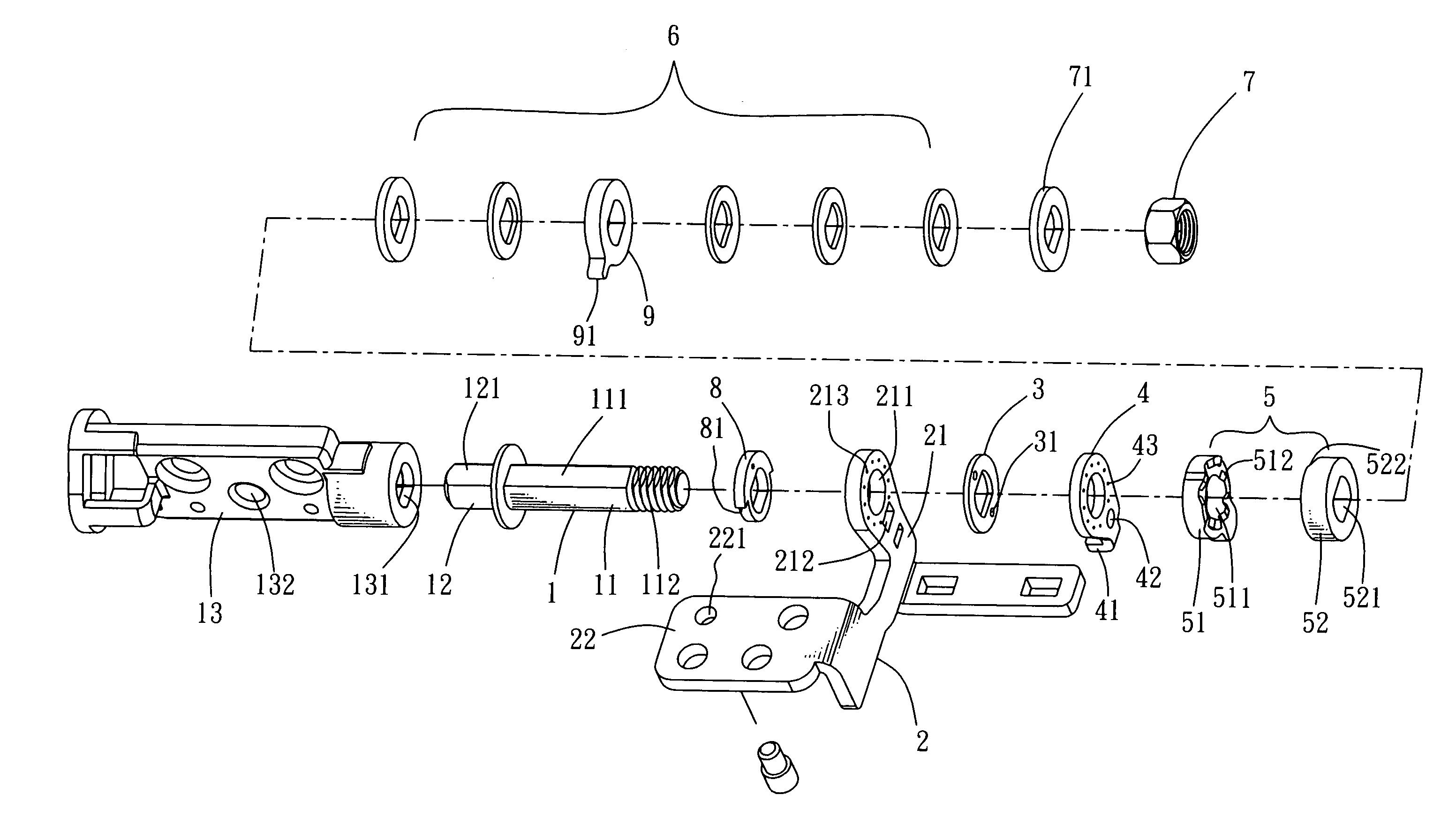

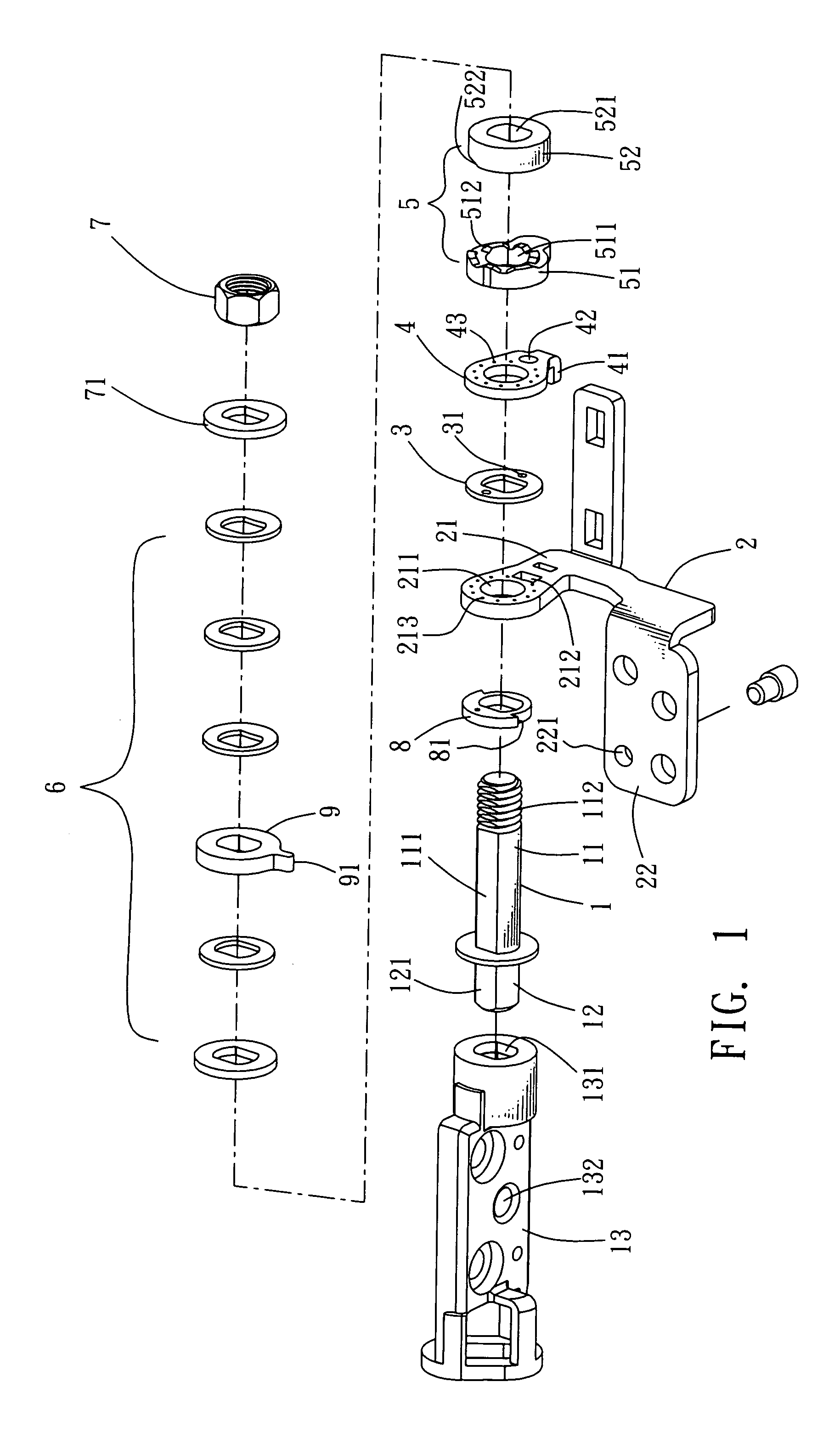

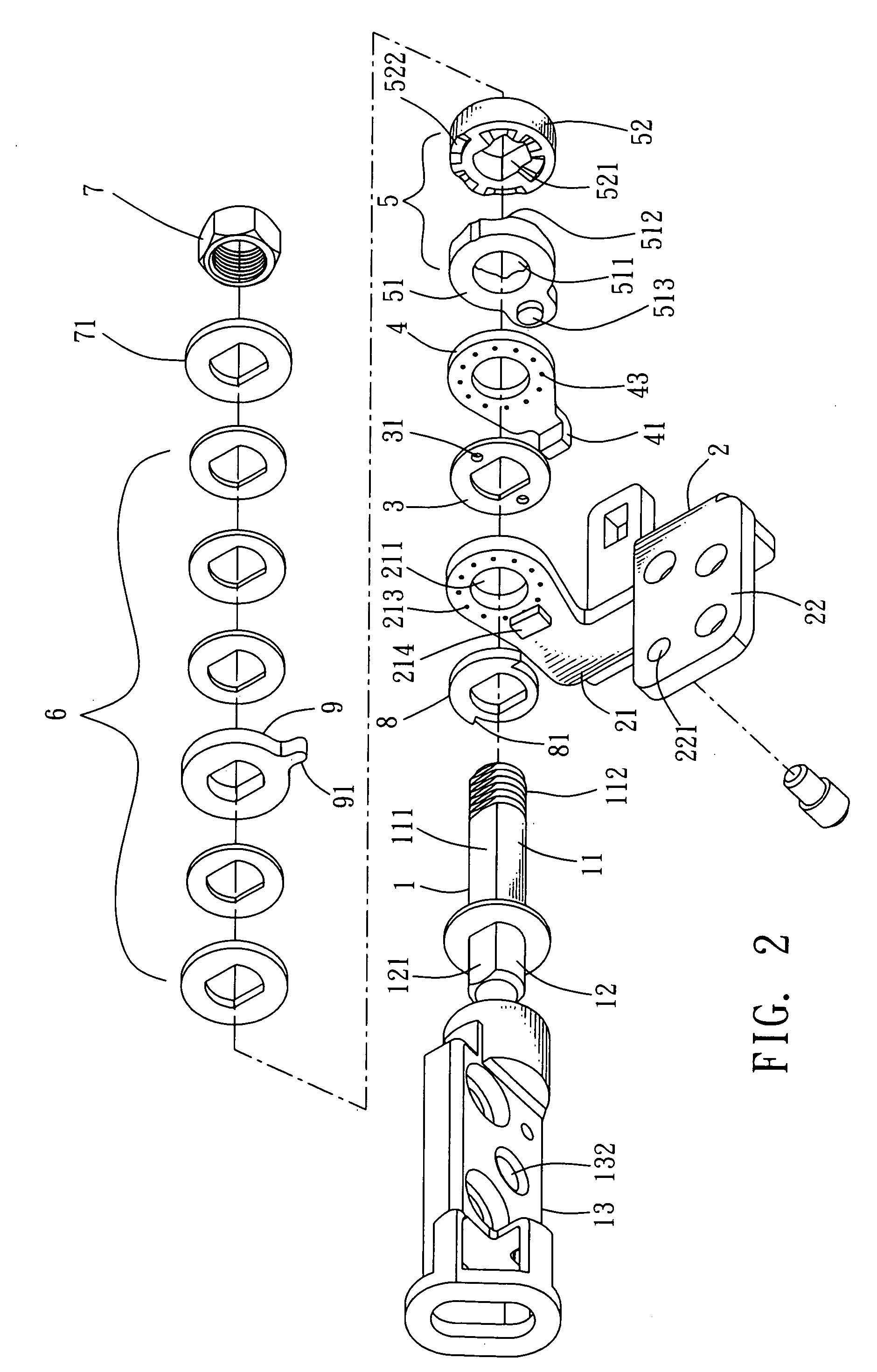

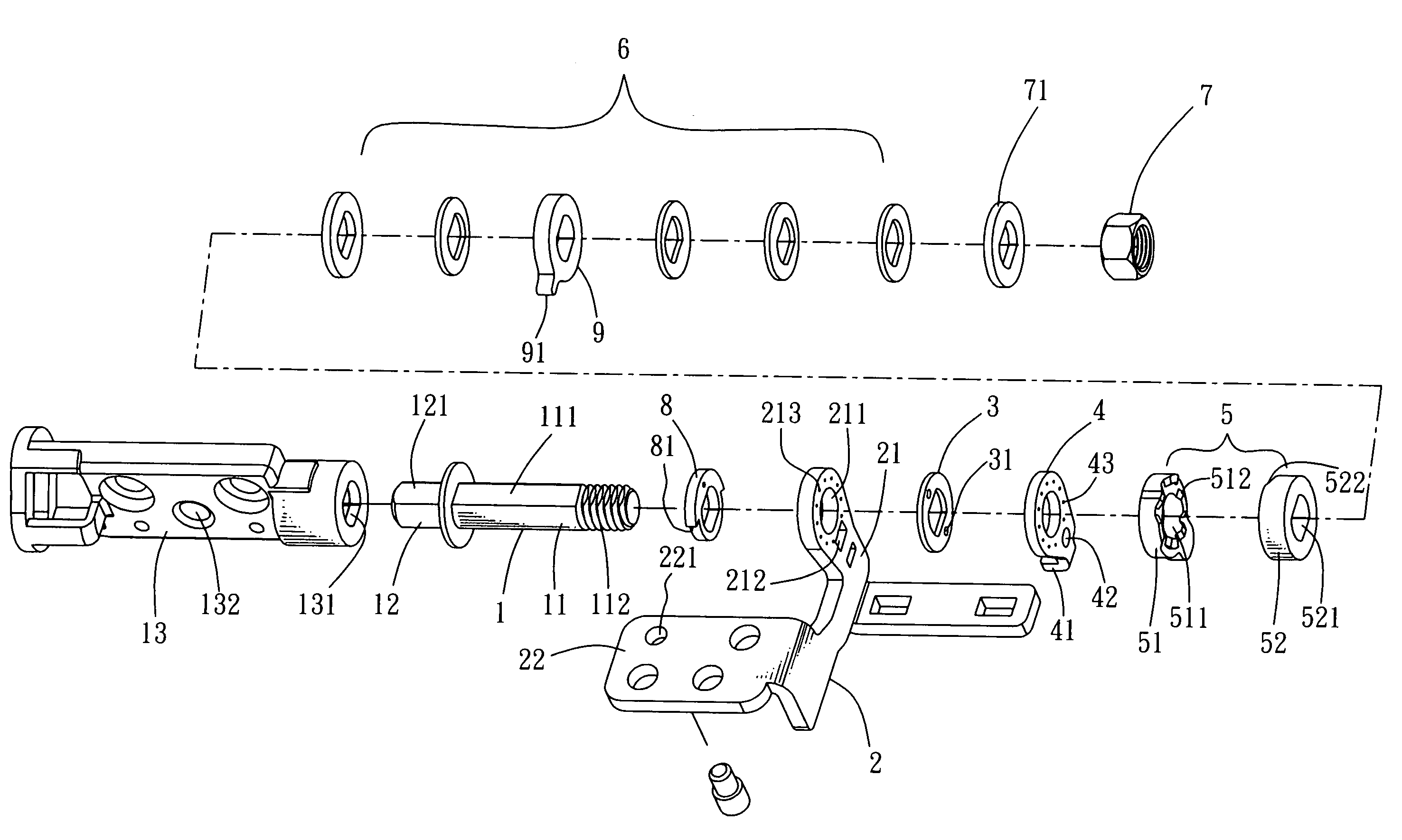

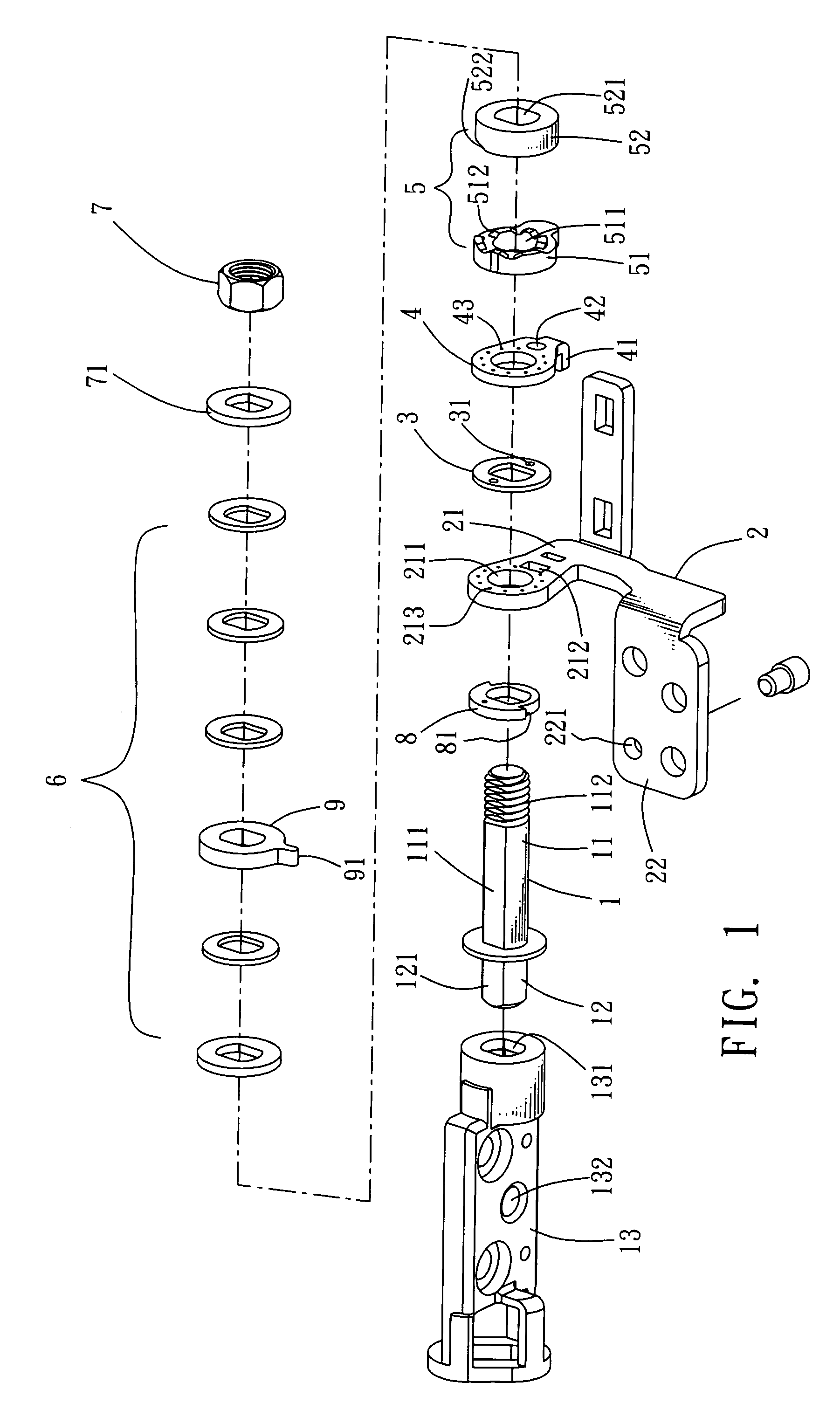

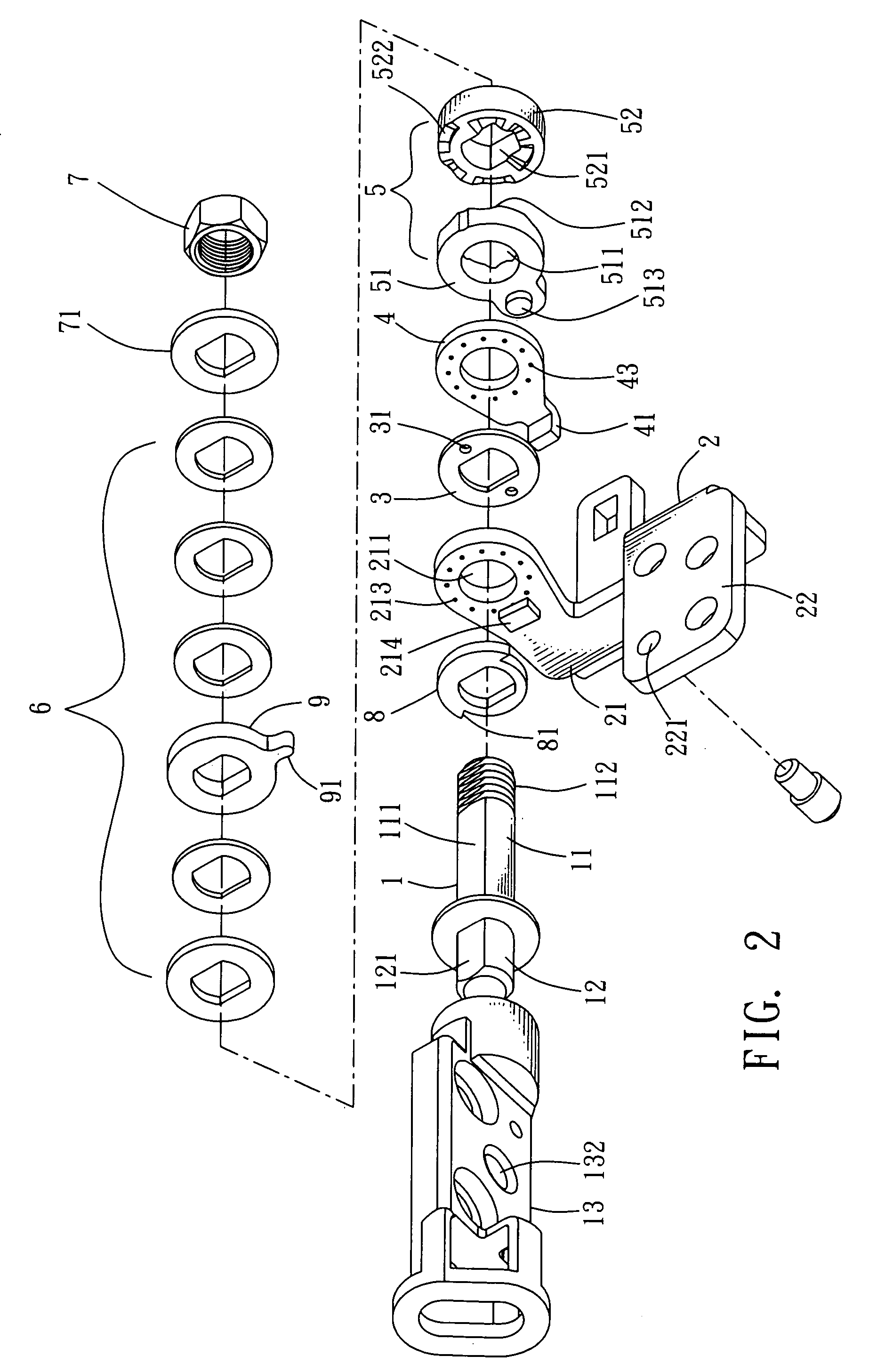

Rotating shaft structure with automatic locking mechanism

ActiveUS20070169312A1Limit angle movementWing accessoriesSubstation equipmentCircular discAxial pressure

The present invention discloses a rotating shaft structure with automatic locking mechanism, characterized in which a shaft extending axially from an axial member passes through, in sequence, the core hole of the upright frame plane of the main frame, a friction disc, a disc-like connecting part connected with the frame plane, a cam member comprising a fastening part and a sliding part, at least an elastic body, and a connecting segment on the free end of the shaft connected with a end enclosure so as to form axial pressure to constrain the elements described above. The shaft and the main frame are provided with a linking portion and a connecting portion, respectively. The outer and inner edges of the adjoining planes between the fastening part and the sliding part are provided with at least a wedge block and at least a wedge slot alternately so as to connect the fastening part and the sliding part together. Consequently, when the axial member rotates, the inclined plane of the wedge slot of the sliding part moves upward along the inclined plane of the wedge block and thus axially presses the elastic body so as to prompt the contact plane of the sliding part to rotate along the wedge blocks of the fastening part. When the axial member rotates reversely, the wedge slots of the sliding part move to the wedge blocks of the fastening part and, under the extending action of the elastic body, the wedge slots are engaged into the wedge blocks so as to form an automatic locking of butting joint.

Owner:HO CHI JUNG +2

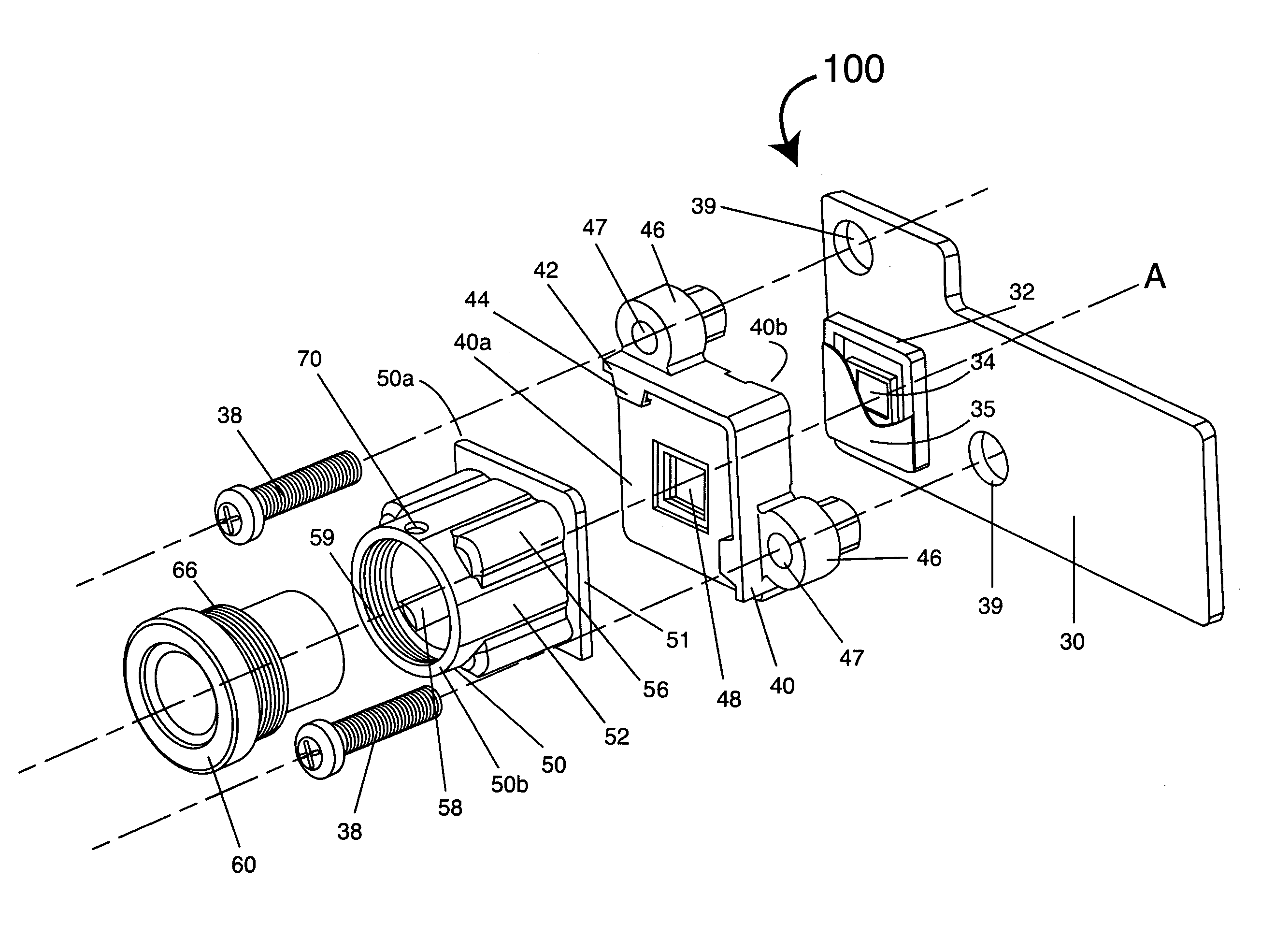

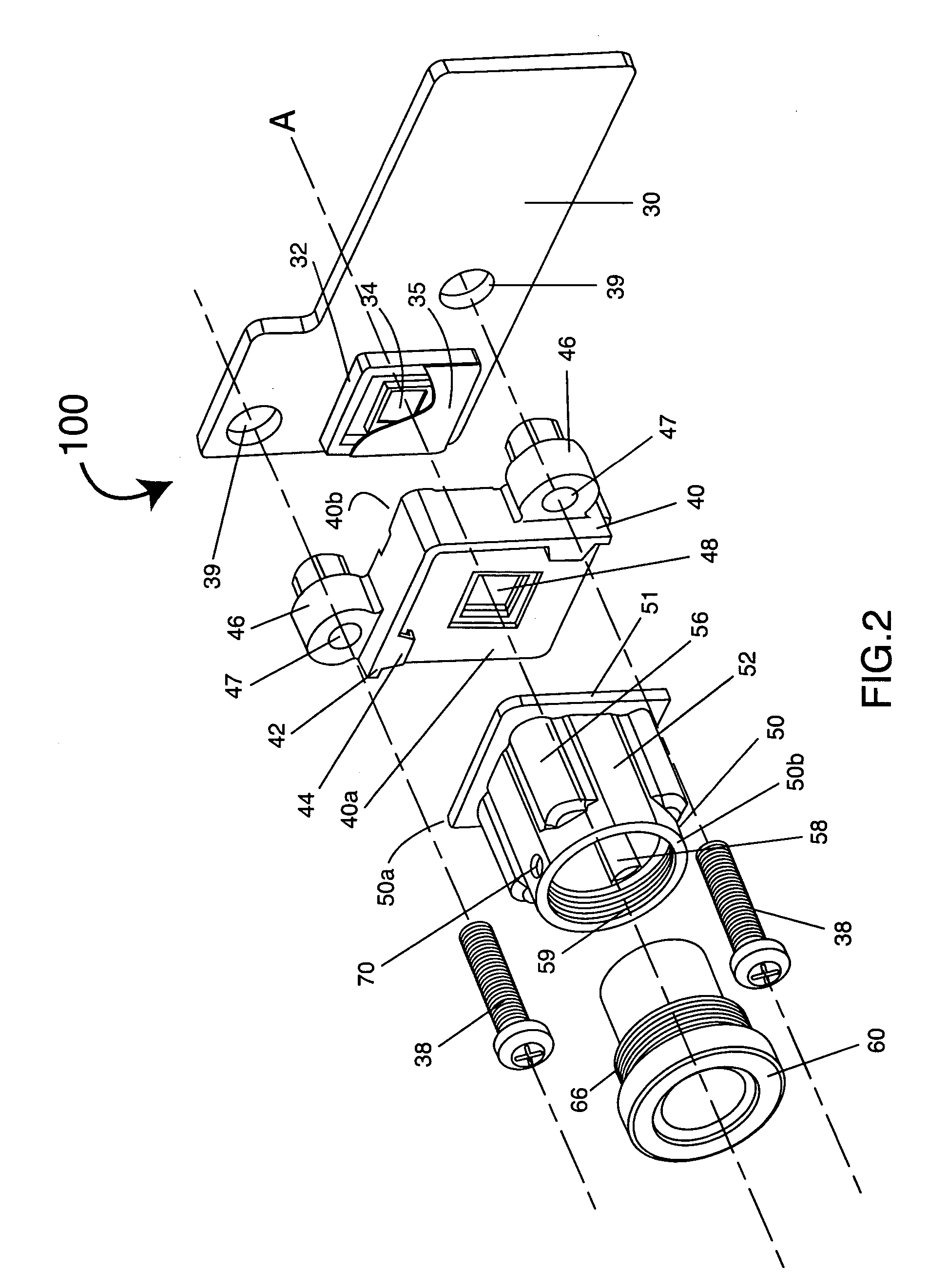

Self-adjusting lens mount for automated assembly of vehicle sensors

InactiveUS20060054802A1Material analysis by optical meansPhotoelectric discharge tubesCMOSAudio power amplifier

A two piece lens mount system for mounting a lens in correct focus and alignment relative to a CMOS imaging device such that the optical axis of the lens is coincident with and perpendicular to the center of the active area of the imager array. The lens is secured by the axial pressure of flexible ribs that are symmetrically spaced around the internal bore of a lens holder and act on a smooth surface on the outside of the lens. This arrangement eliminates translation of the lens across the imager array. Another portion of the body of the lens is threaded such that the lens, when rotated about its optical axis may be focused or axially aligned. When a focus or axial alignment point is reached, a staking fluid may be added to the lens thread, through a hole in the lens holder to prevent de-focusing. The second component of the lens mount system, the lens mount base, is fixedly secured to an imager board on which is mounted a CMOS imager. The upper wall of the lens mount base is in close, parallel proximity to the optical flat of the imager and has a rectangular opening which restricts light from the lens to the active area of the imager, and more specifically prevents light from falling on the column amplifiers of the imaging device. The design of both components is such that they may be moved relative to each other with external fixturing, in front of a known target, until it is decided that the lens is directly over the center of the imager array. The lens holder and the lens mount base are then fixed together permanently using a laser weld process or any other plastic bonding technique.

Owner:ITERIS INC +1

Gas turbine cooled shroud assembly with hot gas ingestion suppression

A cooled shroud assembly includes an angled slot and a plurality of dilution jet openings. The shroud forward cavity is modified such that at least one recirculation zone is produced. The angled slot forces an axial change in momentum of the hot gas flow and increases radial and axial pressure variation attenuation. The cooled shroud assembly isolates the shroud structure and seals from the hot flow path and a cooling flow from the dilution jet openings dilutes the hot gas flow. A series of recirculation zones shields the shroud carrier and high pressure seals from the hot gas flow.

Owner:HONEYWELL INT INC

Device for testing durability of water pressure resistant grouted rock

InactiveCN101813604APrecise temperature controlAccurate measurementPermeability/surface area analysisAxial pressureEngineering

The invention discloses a device for testing the durability of a water pressure resistant grouted rock, which comprises a pressure chamber, a control cabinet, heating equipment, pressurizing equipment, measuring equipment and accessory equipment, wherein the heating equipment can supply a stable heat source for the pressure chamber; the pressurizing equipment can provide confining pressure and osmotic pressure for the pressure chamber; the pressure chamber can apply an axial pressure by means of a universal test, is corrosion resistant and can realize annular and vertical penetration tests of three kinds of standard samples of different dimensions at different temperatures and pressures; the measuring equipment can realize accurate measurement of temperature, pressure and flow rate; and the control cabinet can realize the accurate control of pressure and temperature. The device can be used for indoor researches on the durability of tunnel water pressure resistant grouted rock or dam impervious curtain in an environment of high-water-pressure and corrosive environment, and at the same time, realizes the researches on the change rule of the permeability of a rock sample under the coupled actions of a temperature field, a seepage field, a stress field and a chemical field.

Owner:TONGJI UNIV

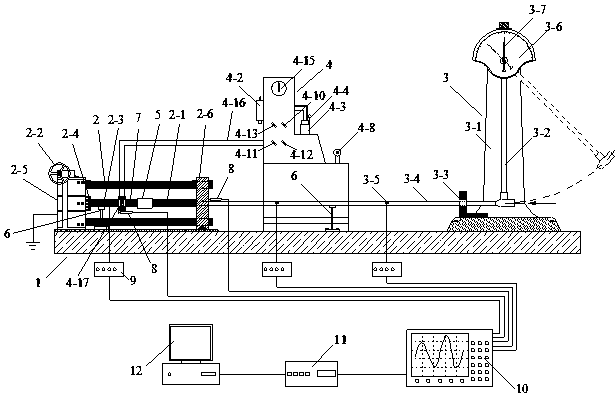

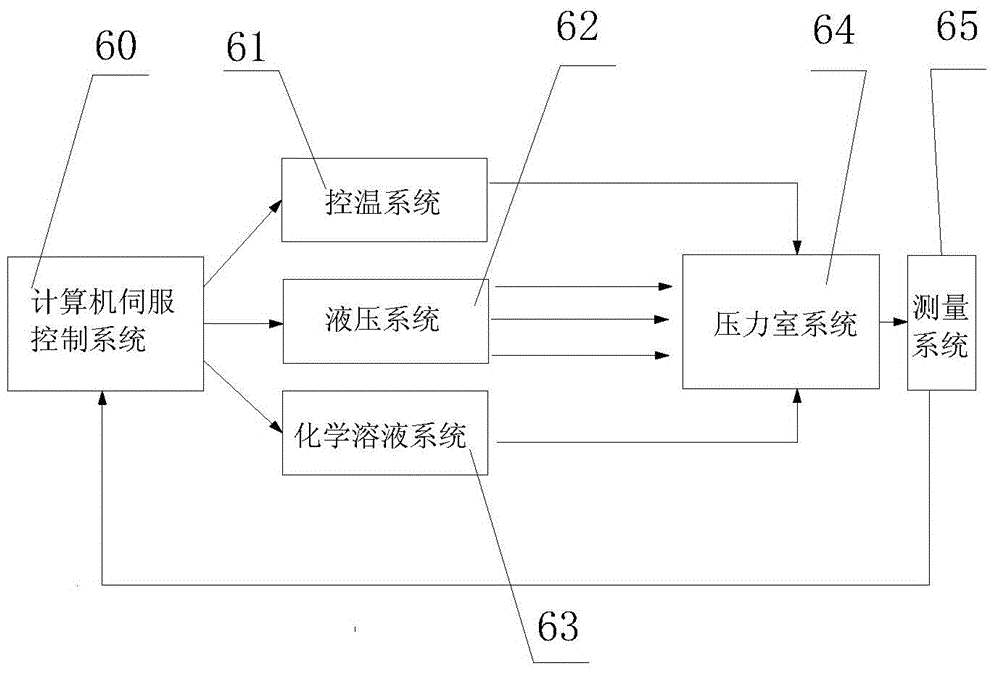

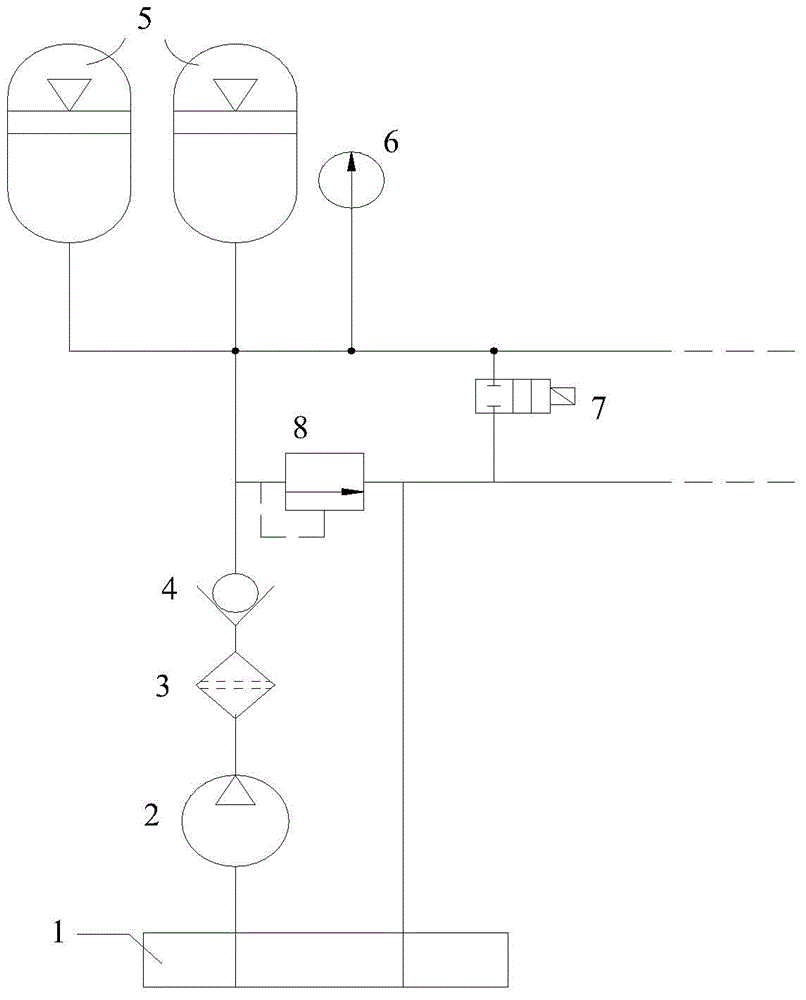

Microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method

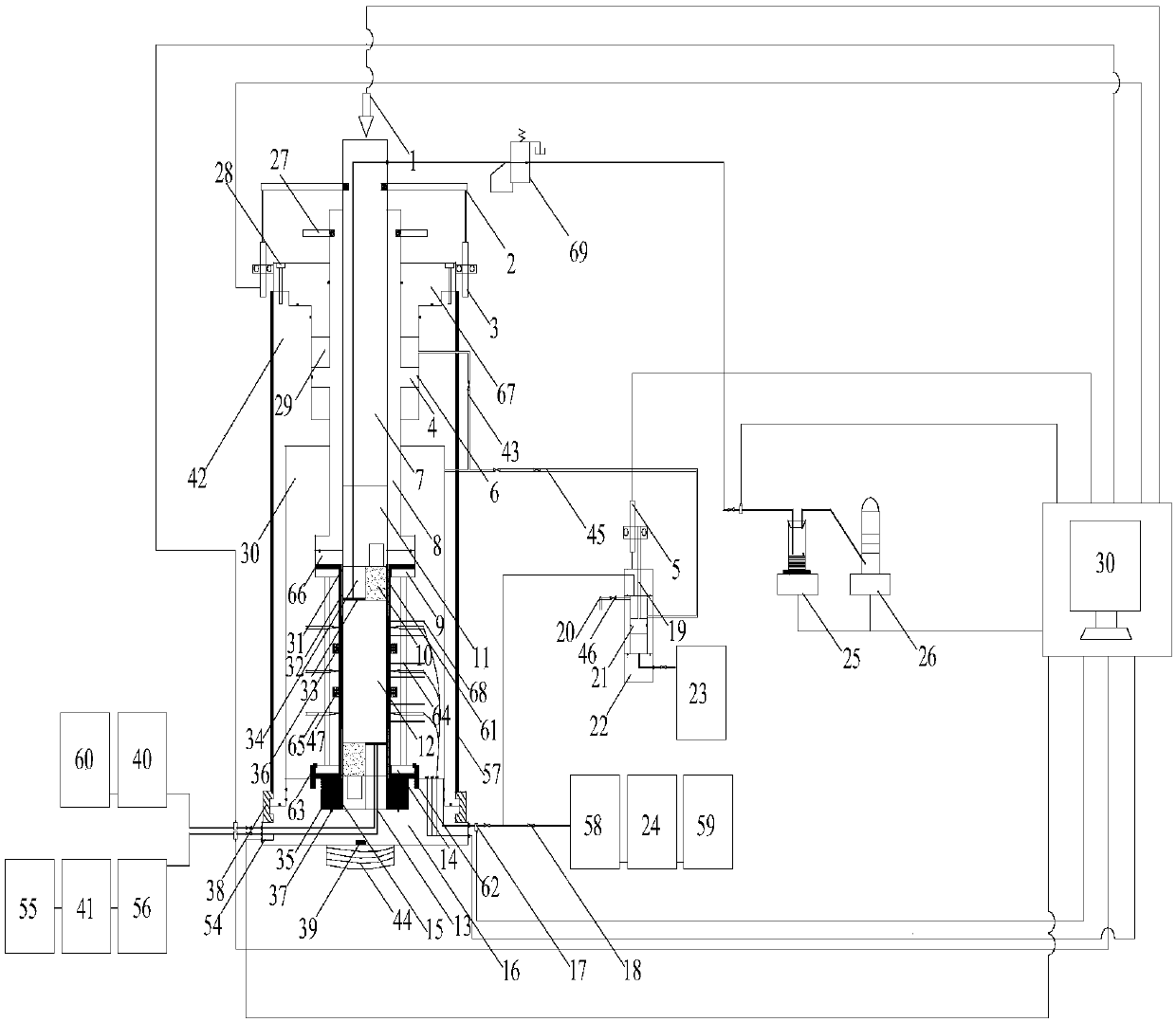

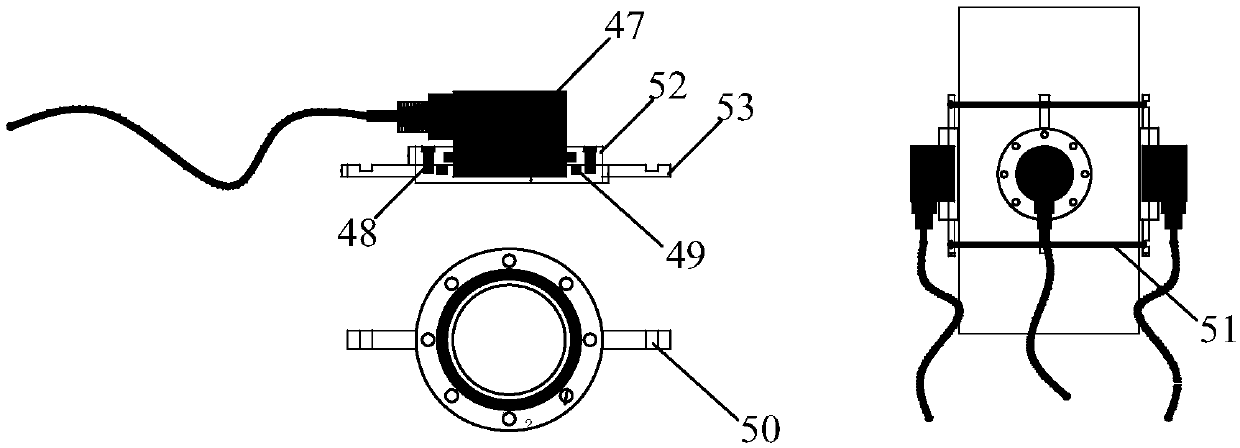

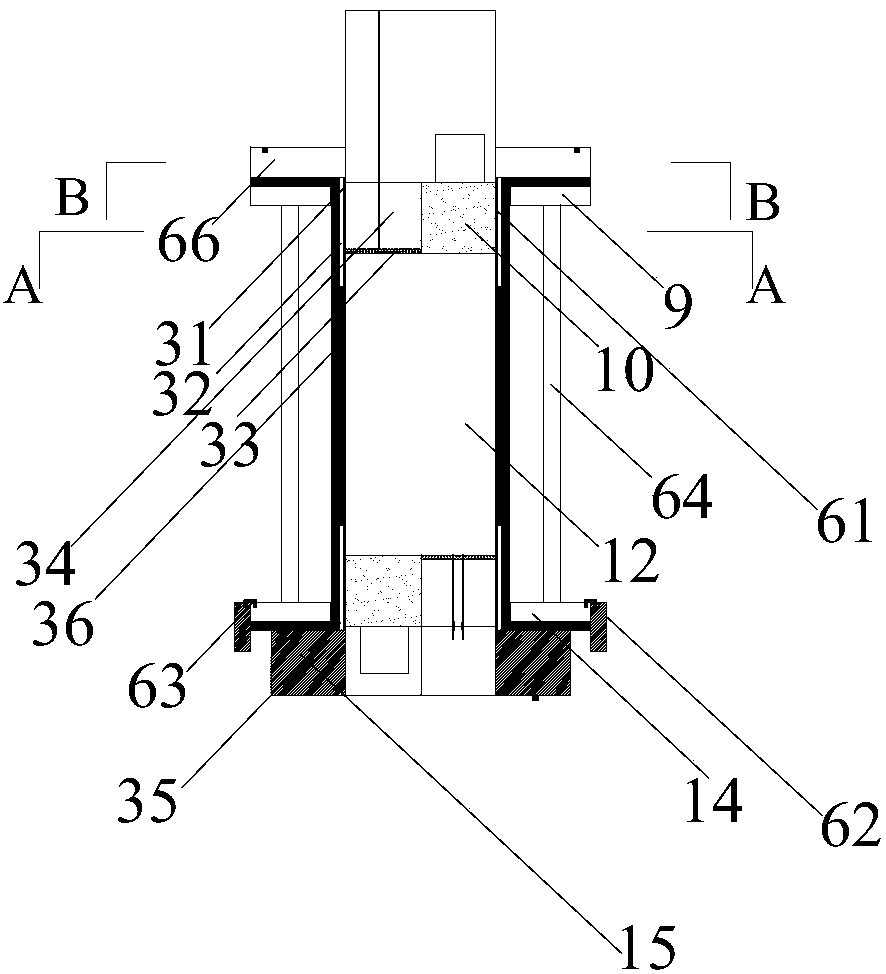

ActiveCN107748110AOvercoming direct shear-seepageEasy to disassembleMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAxial pressureData acquisition

A microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method belongs to the technical fields of rock mechanics and engineering technology and is characterized in that a test apparatus is composed of a loading system, a sealing system, a multiphase fluid injection system, an acoustic emission monitoring system, a deformation monitoringsystem and a data collection system. The test method not only solves technical problems that a tri-axial pressure chamber cannot be used for performing large displacement shear-seepage coupling of rocks under high confining pressure and high seepage pressure, and also can achieve various extended functions on the basis of the technology. The apparatus can achieve servo control loading of force, displacement and strain rate in shear direction and injection seepage of a multiphase fluid during dynamic shear. In addition, the apparatus is equipped with a temperature control system for performingconstant temperature control to the tri-axial pressure chamber at 0-200 DEG C; therefore, a series of extended experiments of dynamic shear-seepage coupling features of rocks under effect of temperature can be carried out.

Owner:TAIYUAN UNIV OF TECH

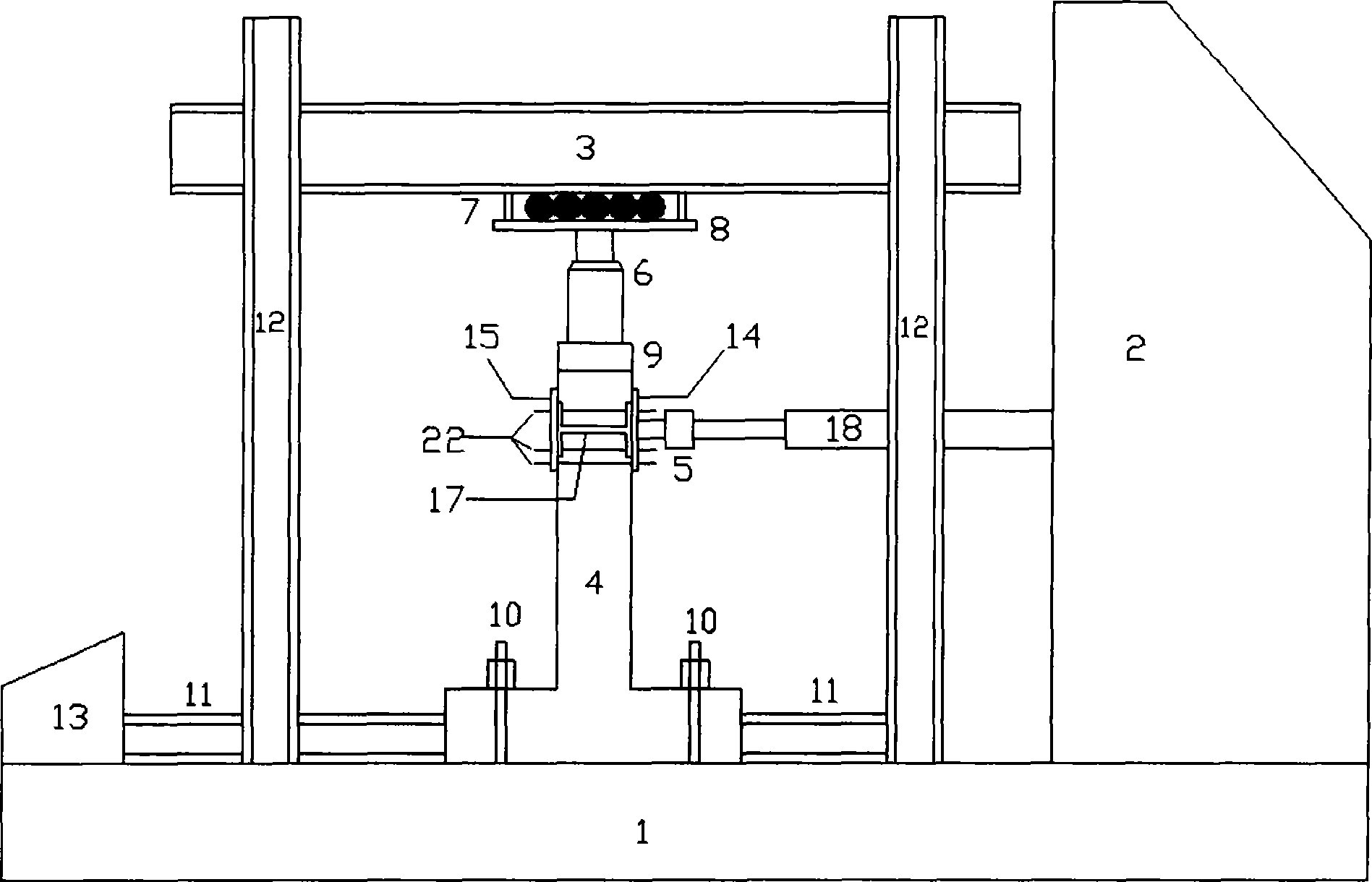

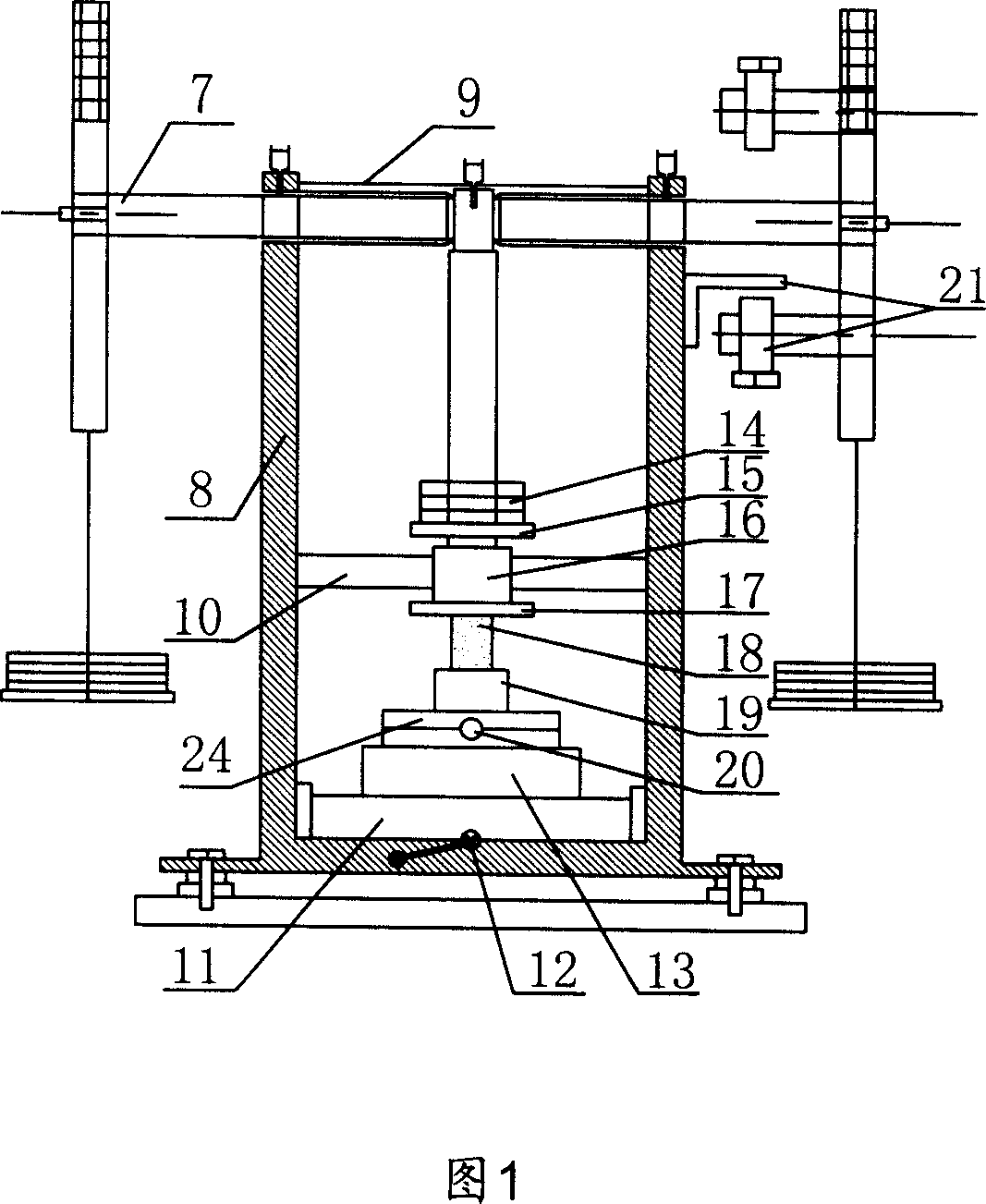

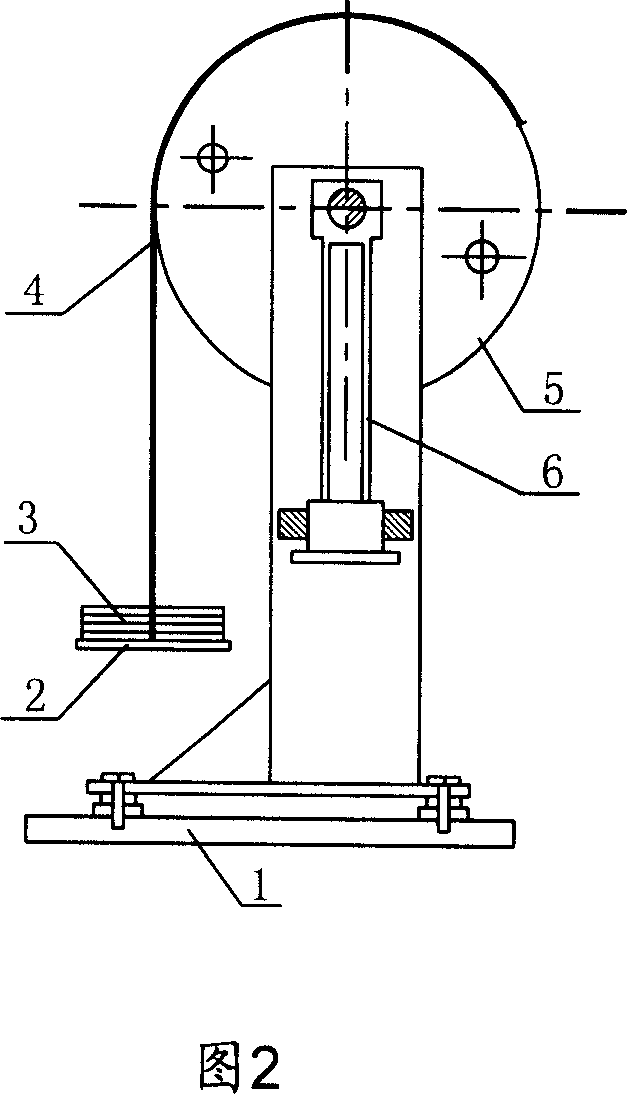

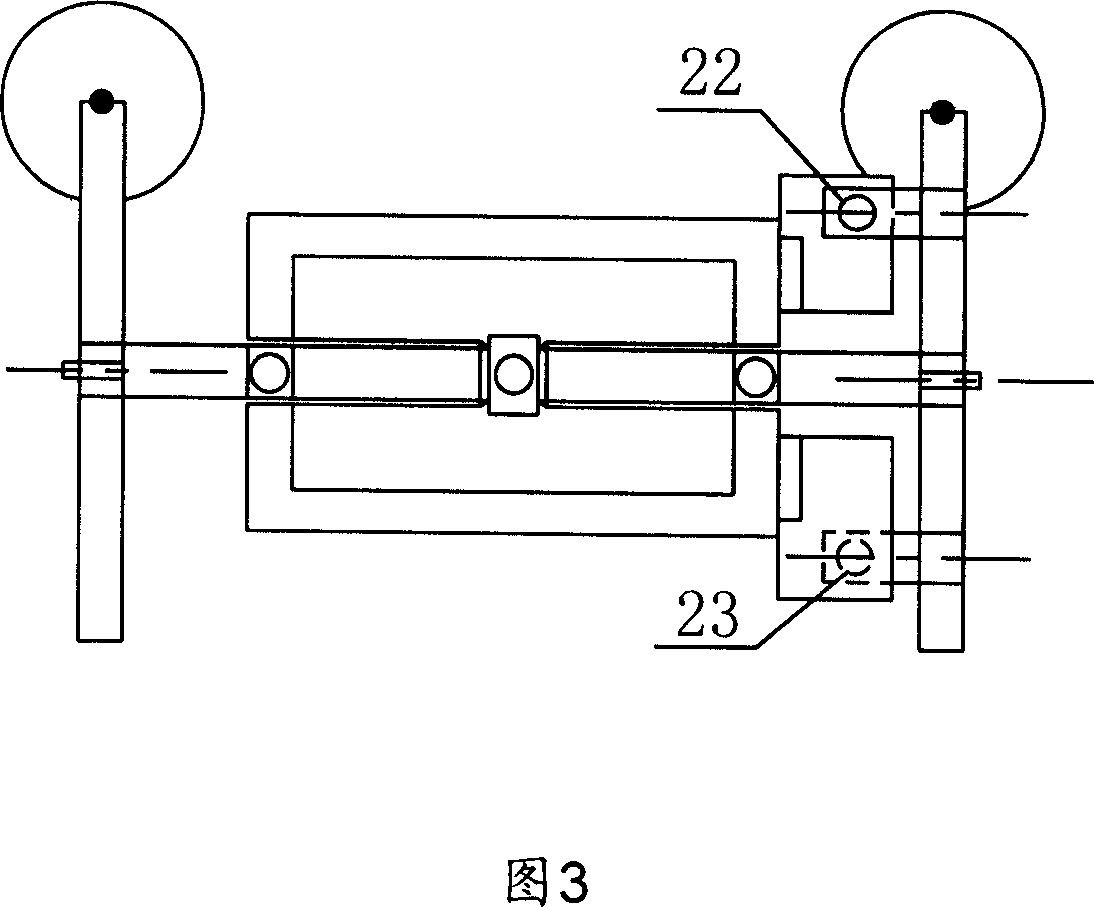

Component pressing and twisting experimental device and method thereof

InactiveCN101498625AObservation forceEasy to measureStructural/machines measurementMaterial strength using steady torsional forcesHorizontal forceAxial pressure

The invention relates to a device and a method for component compression-torsion testing, belonging to the technical field of architecture structure test. The device comprises a pedestal, a reaction beam, a reaction wall, a vertical force jack, a front clamp plate, a back clamp plate, a pure torsion loading beam, a loading beam and a horizontal force jack, wherein a component is fixed on the pedestal; the vertical force jack is connected at the lower surface of the reaction beam and corresponds to the component in position; the top of the component is tightly clamped between the front clamp plate and the back clamp plate; the loading beam is fixedly connected with the front clamp plate and the back clamp plate; one end of the pure torsion loading beam is articulated with the front clamp plate and the other end is fixedly connected with the reaction wall; one end of the horizontal force jack is articulated with the loading beam by a force sensor and the other end is fixedly connected with the reaction wall. In a test, the vertical force jack applies axial pressure to the component and the horizontal force jack applies horizontal force to the component to form the torque to the component. The device for component compression-torsion testing has simple structure and convenient assembly, can be used instantly after the assembly and can be used repeatedly.

Owner:BEIJING UNIV OF TECH

Pressing-twisting multi-shaft loading testing machine

ActiveCN101949800AGreat effortUniform and controllable dynamic and staticMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesControl systemAxial pressure

The invention discloses a pressing-twisting multi-shaft loading testing machine. The pressing-twisting multi-shaft loading testing machine comprises a machine frame, a sample pressure chamber, an axial pressure controller, a confining pressure controller and an oil source system, wherein the sample pressure chamber is arranged on the machine frame and is used for accommodating samples therein; the axial pressure controller is used for applying axial loads to the samples in the sample pressure chamber; the confining pressure controller is used for applying confining pressure loads to the samples in the sample pressure chamber; the oil source control system is used for controlling the axial pressure controller and the confining pressure controller respectively to apply different paths of loads; and the axial pressure controller and the confining pressure controller are configured in a mode that the axial force is coupled with the confining force when the loading of the samples in the sample pressure chamber is buffered. The pressing-twisting multi-shaft loading testing machine can integrate complicated loading such as pressing-twisting combination, plane strain, true triaxiality and the like and is suitable for the tests of static power units of the common coarse-grained soil and ideal soil simulation materials during engineering construction.

Owner:TSINGHUA UNIV

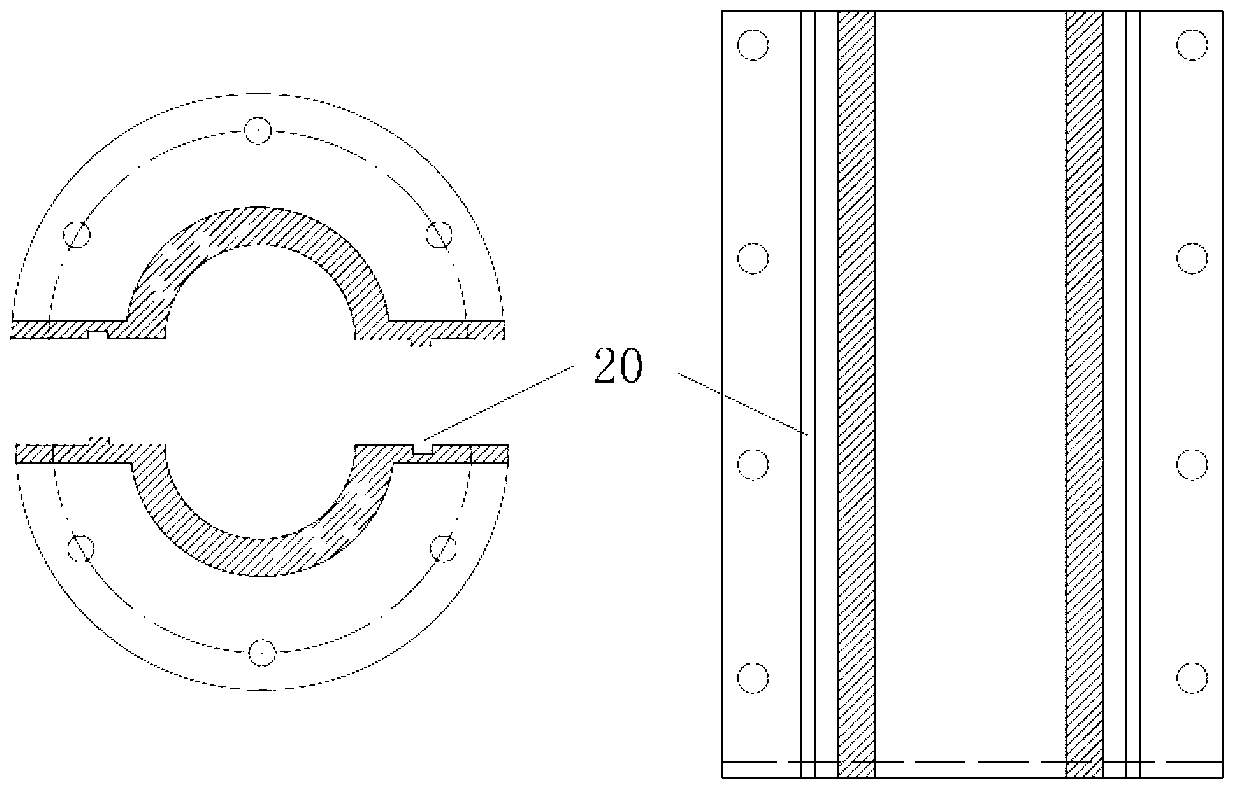

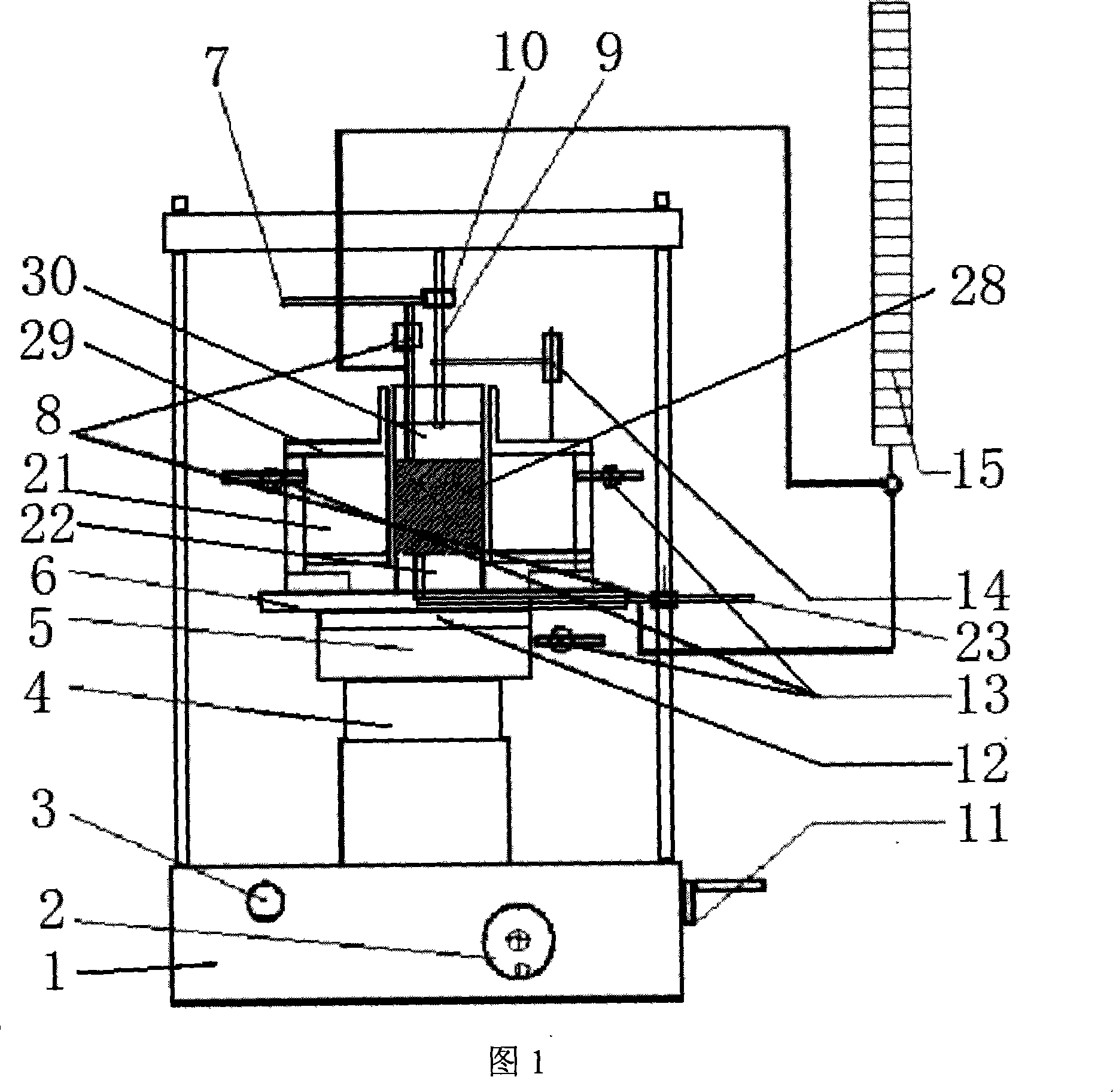

Triaxial independent loading pressure chamber structure true triaxial apparatus

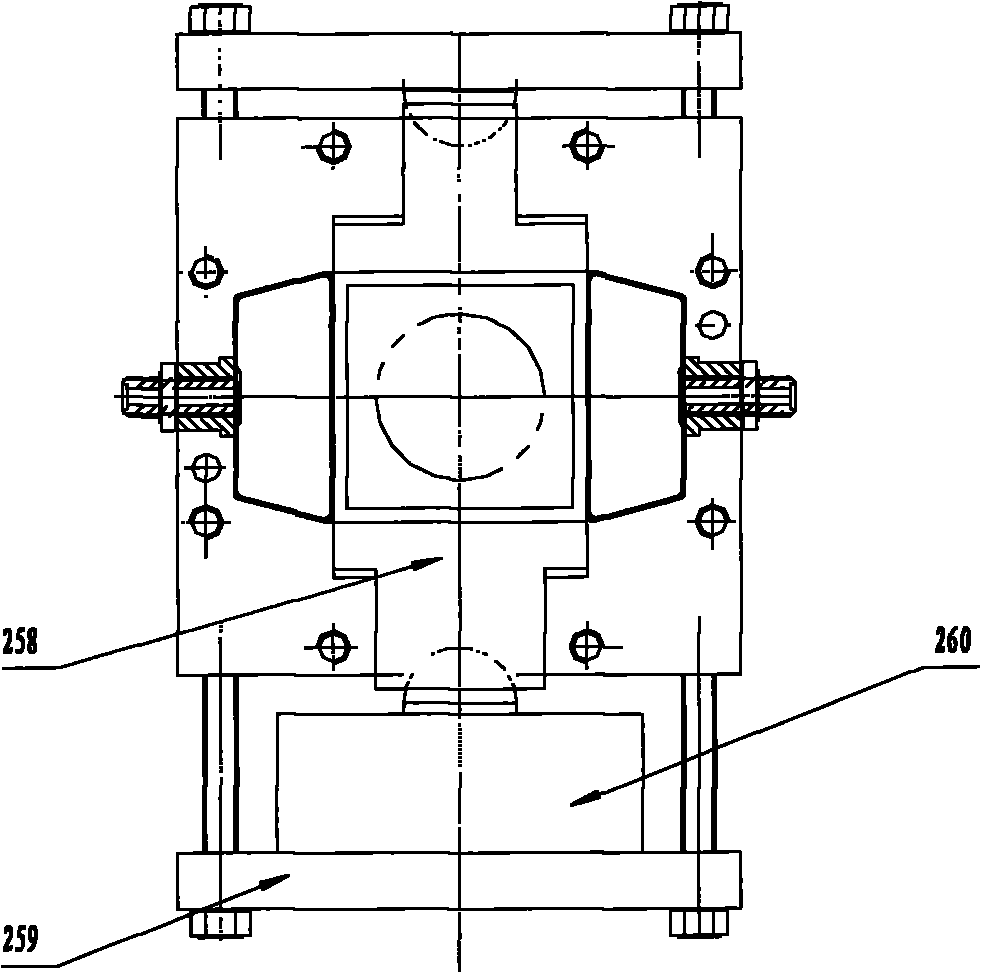

InactiveCN101169356AImproving the Technical Level of Geotechnical Properties TestingStrength propertiesAxial pressureEngineering

The invention discloses a true triaxial apparatus with a three-directional independent loading pressure room structure, wherein, an axial pressure cavity of the main part of the apparatus is connected with the axial pressure source pressure cylinder through a hydraulic pressure conduit. A hydraulic bag is respectively arranged in four side pressure cavities of a sampling base, every hydraulic bag is connected with a lateral pressure source pressure cylinder through lateral pressure inlet conduit; a hydraulic load control part, and a detection signal gathering and control part are both controlled by a control device. The true triaxial apparatus provided by the invention overcomes the disadvantage of the prior true triaxial apparatus that the three major stresses can not be totally separated and the three major stresses are mutually affected in a loading process; and the true triaxial apparatus has the advantage of simulating the trials of various engineering conditions under the dead stress, thus the testing condition is much better in accordance with the practical conditions of the engineering; the true triaxial apparatus also has the advantage of low manufacture cost.

Owner:XIAN UNIV OF TECH

Material flowing deformation disturbed effect testing system and testing method thereof

InactiveCN1948945ASimple structureEvenly loadedFlow propertiesMaterial strength using single impulsive forceMaterials testingAxial pressure

The invention discloses material fluid deformation disturbance effect experimental system and method. It includes dead load loading system realized by loading system, crankshaft force enlarging device, and force transmission connecting rod, disturbance loading system realized by impact and blasting disturbance loading devices, confining pressure loading system realized by tri-axial pressure tank includes closed box set ring capsule. The material fluid deformation disturbance effect experimental system can realize uniaxial and tri-axial fluid deformation experiences, uniaxial and tri-axial fluid deformation disturbance experiments for the testing specimen. It has the advantages of simple structure, low cost, precise testing, suiting for various materials testing specimen to do fluid deformation disturbance experiment, especially for rock testing specimen.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Versatile vibration-damped golf swing-weight system

ActiveUS20100105498A1Reliably securedConveniently releasedMetal working apparatusGolf clubsAxial pressureEngineering

A highly versatile damper-weight system enables the installation of adjustable swing-weight in a vibration-damped manner inside a golf club shaft. A plug assembly of selectable weight is inserted through a circular opening in the golf grip cap with a special tool, moved to any desired location within the shaft and securely fastened in place in a vibration-damped manner by radial expandable of a cylindrical resilient expandable element. A weight rod, made available in different materials, lengths and weights, is spaced from the shaft by one or more resilient damper sleeves to minimize shaft vibration. The expandable element is secured by a machine screw threaded into the upper end of the weight rod, and is dimensioned (unexpanded) to enable easy insertion and location adjustment of said plug assembly. The tool provides dual functions: as a screw head driver to expand / contract the expandable element radially by axial pressure / release as required, and as a removable coupler capable of pulling the plug assembly (with the expandable element unexpanded) upwardly, as well as pressing it downwardly within the shaft for adjustment to any desired location.

Owner:JOHNSON JOHN

Device for testing axial loading/unloading gas permeability of coal

InactiveCN101825555ALow mechanical strength requirementSimple structurePermeability/surface area analysisInlet channelAxial pressure

The invention provides a device for testing the axial loading / unloading gas permeability of coal, comprising a gas pressurizer, a permeability test unit, an axial pressuring and unloading device and a gas collecting device, wherein the permeability test unit consists of a pressure chamber, a bleeder vent plate, a base, the base is provided with a gas inlet channel, a gas outlet channel is arranged at the top part of the pressure chamber and a piston pressure gauge is fixed on the top part; the permeability test device is arranged in the axial pressuring and unloading device which is composed of a lifting table, a triaxial shear instrument, a proving ring arranged at the upper part of the triaxial shear instrument, and the proving ring is provided with a strain dial gauge and a force-measurement dial gauge; the air tube of the gas pressuring device is connected with an air inlet of the base of the axial pressuring and unloading device; and the air header of the gas collecting device is connected with an air outlet at the upper part of the pressure chamber of the axial pressuring and unloading device. The device in the invention is suitable for permeability test for various coal body structures in particular to coal sample construction under the loading and unloading conditions, and has simple structure, convenient operation and good test repeatability.

Owner:CHINA UNIV OF MINING & TECH

Device and method for testing looseness of rock under disturbance of strain rate in loading process of pendulum bob

ActiveCN104181029AImplement relaxation testStress waves are easy to controlStrength propertiesStrain rateAxial pressure

Owner:NORTHEASTERN UNIV

Cross platform grip ring release device and method

The present invention provides, in part, a device that can fit around a fitting retention compartment of a pipe fitting, apply axial pressure to a pipe insertion component so as to flex the teeth of a fastening ring inwardly, which permits smooth insertion and removal of piping elements. In embodiments, the device comprises a two-piece device with mating threads that permit the pieces to move toward and away from one another with minute adjustments.

Owner:QUICK FITTING

Rotating shaft structure with automatic locking mechanism

The present invention discloses a rotating shaft structure with automatic locking mechanism, characterized in which a shaft extending axially from an axial member passes through, in sequence, the core hole of the upright frame plane of the main frame, a friction disc, a disc-like connecting part connected with the frame plane, a cam member comprising a fastening part and a sliding part, at least an elastic body, and a connecting segment on the free end of the shaft connected with a end enclosure so as to form axial pressure to constrain the elements described above. The shaft and the main frame are provided with a linking portion and a connecting portion, respectively. The outer and inner edges of the adjoining planes between the fastening part and the sliding part are provided with at least a wedge block and at least a wedge slot alternately so as to connect the fastening part and the sliding part together. Consequently, when the axial member rotates, the inclined plane of the wedge slot of the sliding part moves upward along the inclined plane of the wedge block and thus axially presses the elastic body so as to prompt the contact plane of the sliding part to rotate along the wedge blocks of the fastening part. When the axial member rotates reversely, the wedge slots of the sliding part move to the wedge blocks of the fastening part and, under the extending action of the elastic body, the wedge slots are engaged into the wedge blocks so as to form an automatic locking of butting joint.

Owner:HO CHI JUNG +2

Device and method for testing expanding and percolation characteristics of microfractures of compact reservoir

ActiveCN107063963AAccurate measurementEasy to assemblePermeability/surface area analysisPressure systemRock core

The invention relates to a device and method for testing expanding and percolation characteristics of microfractures of a compact reservoir, belonging to the technical field of oil-gas field development. The device comprises a triaxial rock core holding device, a microfracture expanding pressure system, a microfracture detection system, a percolation displacement system and a percolation data collection system. The method comprises the following steps: (1) applying an axial pressure to a rock core in the triaxial rock core holding device so as to expand microfractures; (2) monitoring development and evolution characteristics of the microfractures of the rock core by virtue of an ultrasonic fault detector, and monitoring deformation characteristics of the rock core by virtue of a stress-strain detection instrument; and (3) testing percolation characteristics of fluid under different microfracture development conditions of the rock core by virtue of a percolation displacement device. The device and the method disclosed by the invention have the beneficial effects that a measurement result is accurate, the assembling is convenient, the operation is simple, the percolation characteristics of oil, gas and water in the microfractures of the compact reservoir can be tested, and the necessary technical support can be provided for fracture development of the compact reservoir.

Owner:ZHEJIANG OCEAN UNIV

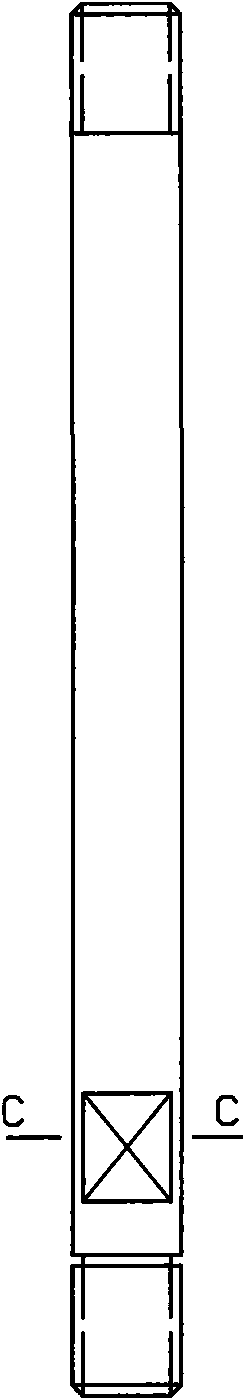

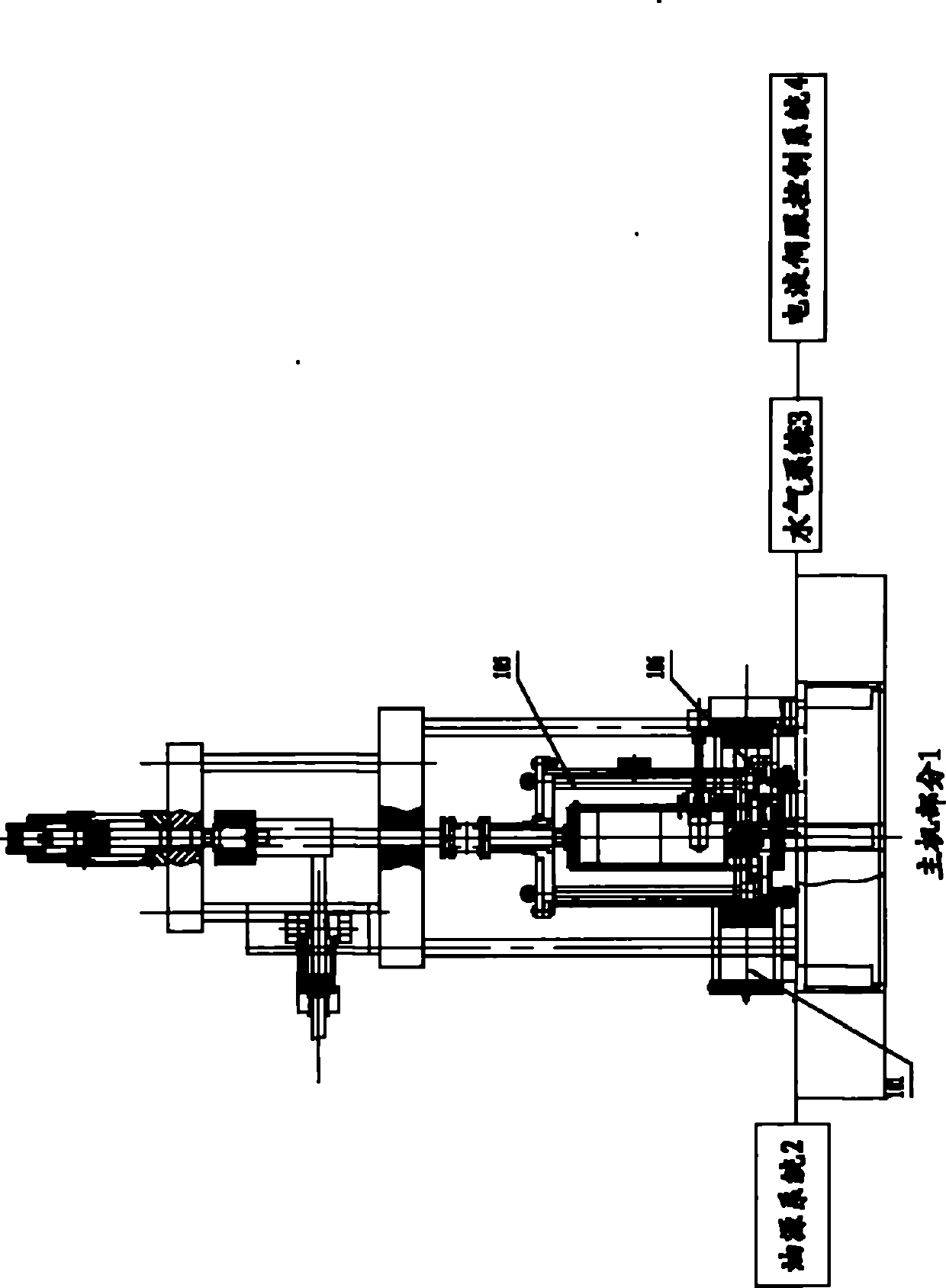

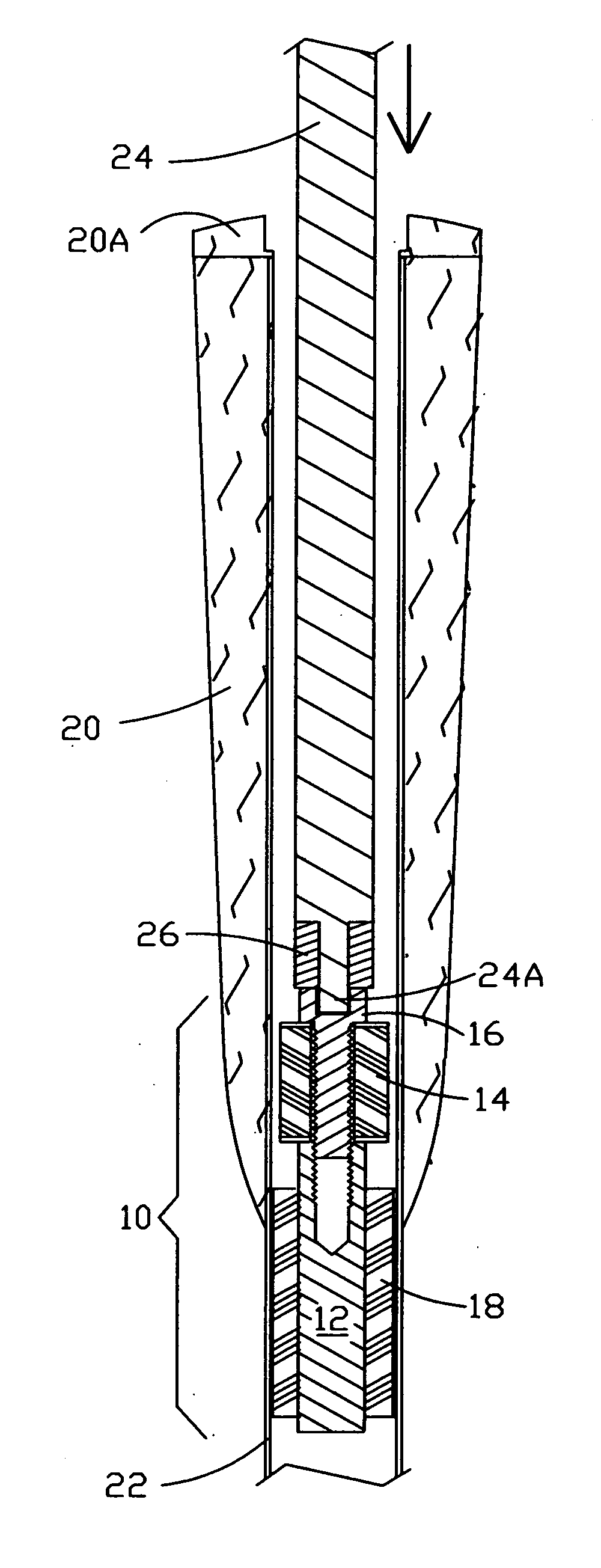

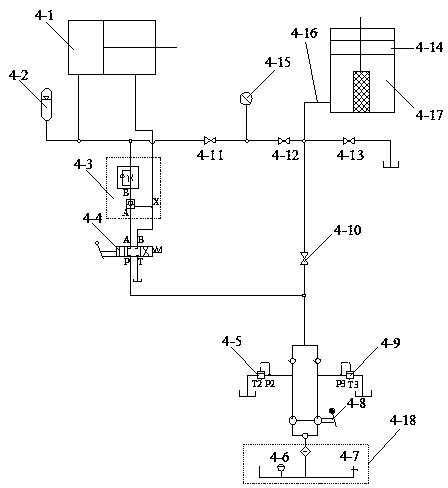

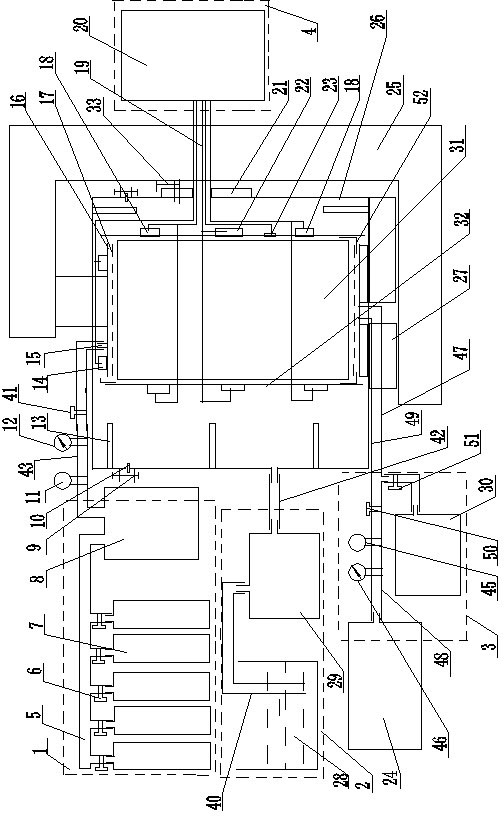

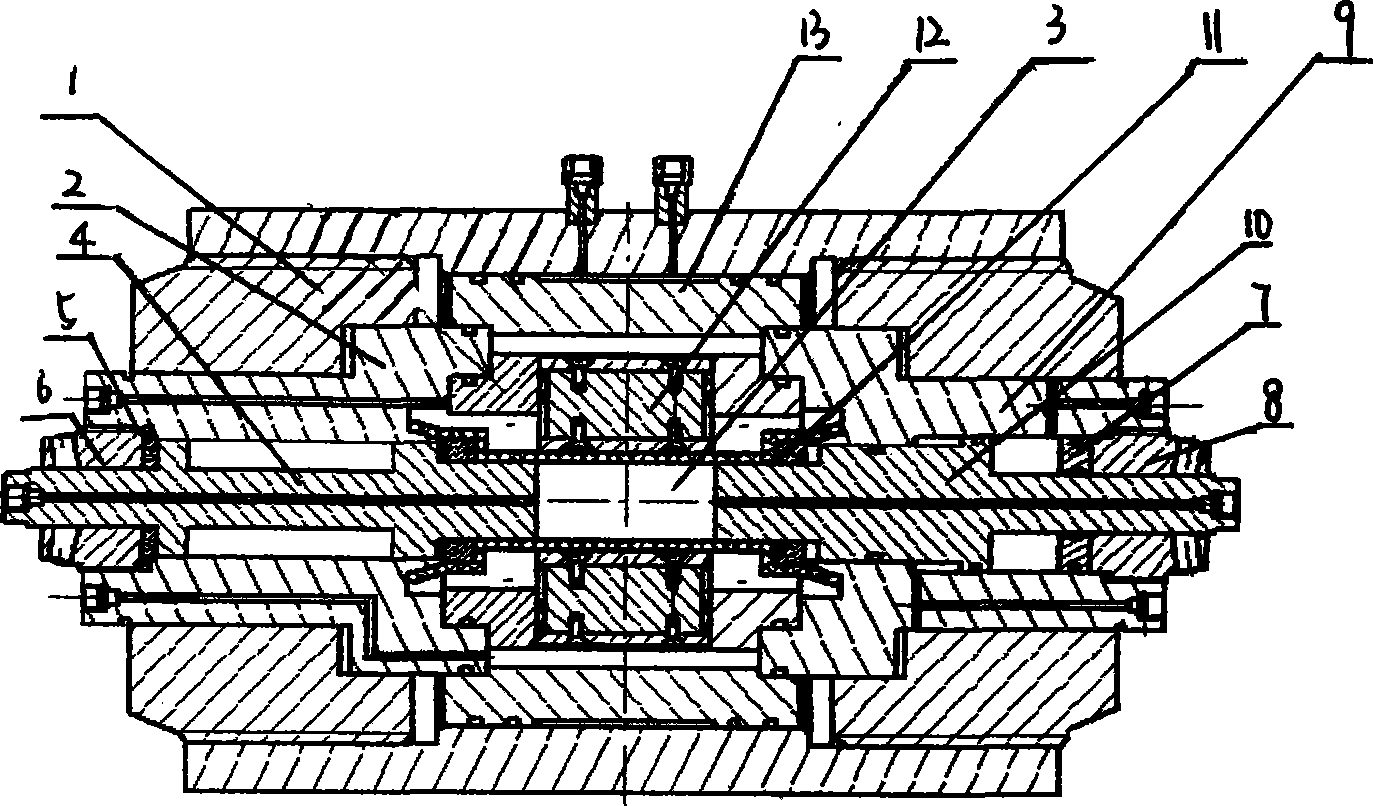

Device for Simultaneous Measurement of Gas Injection Coal Expansion and Permeability under Triaxial Stress Conditions

InactiveCN102288529ASolve the amount of deformationSolve permeabilityPermeability/surface area analysisUsing fluid meansPressure systemStress conditions

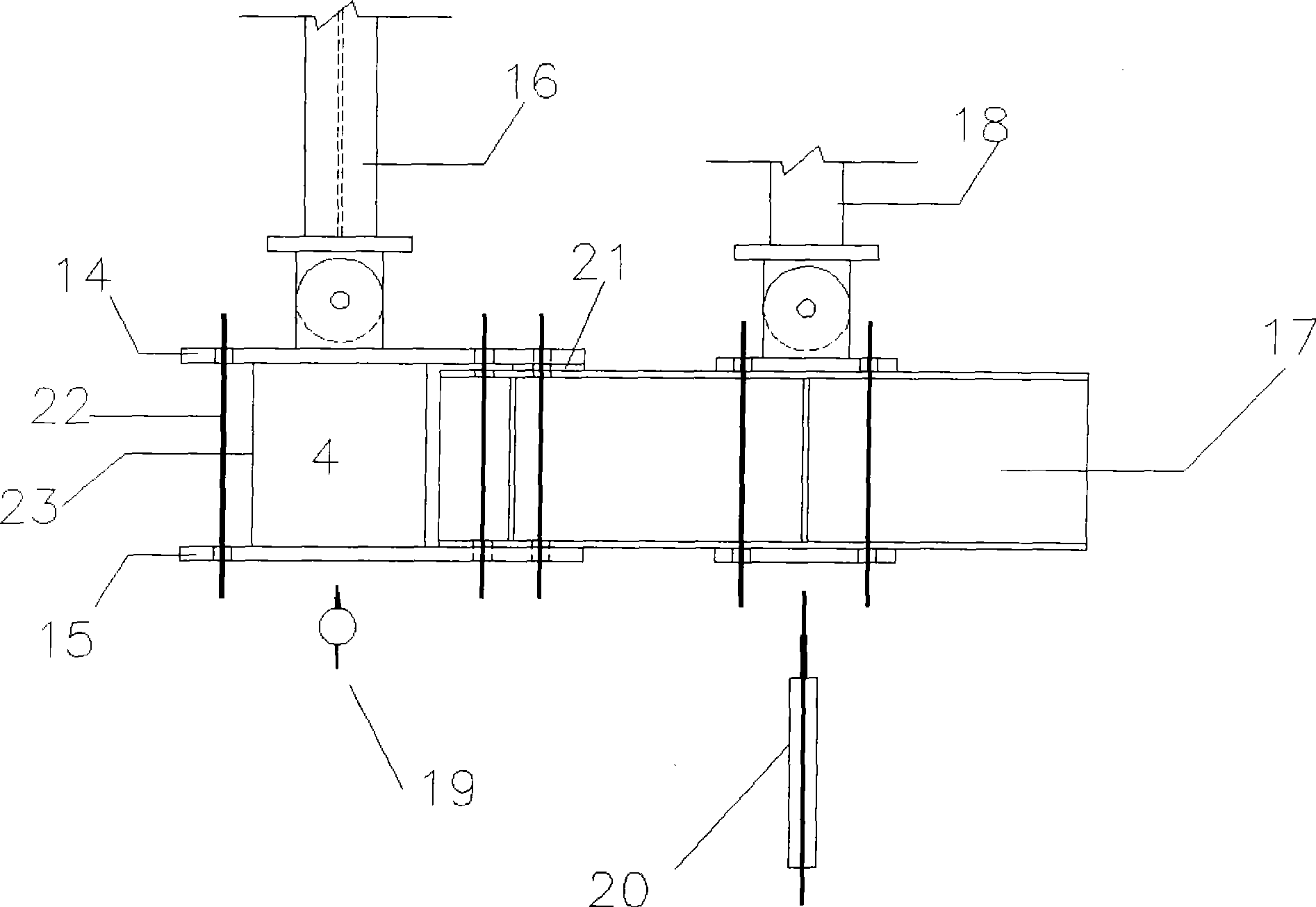

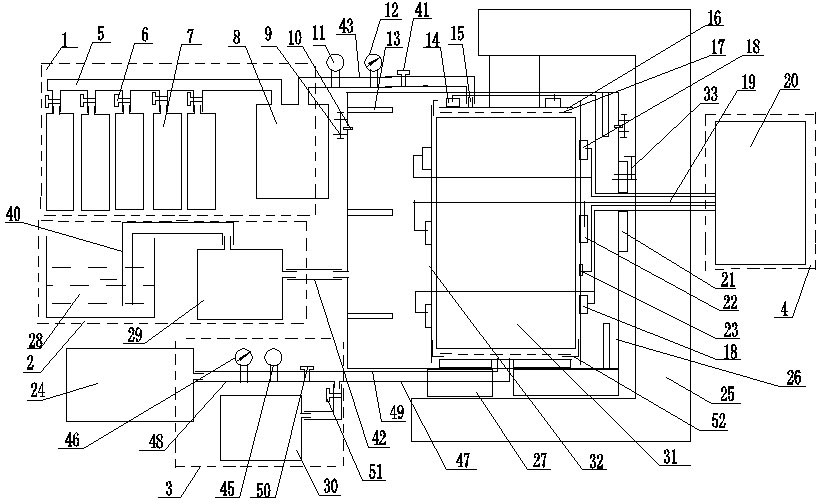

The invention discloses a device for simultaneously measuring expansion and permeability rate of gas injected into a coal rock under a tri-axial stress condition. The device comprises a gas injection system (1), a confining pressure system (2), an axial pressure loading machine (25), a permeability measuring system (3) and a data acquisition system (4), wherein the gas outlet port of the gas injection system (1) is connected with the gas inlet port of the confining pressure system (2) through a high pressure gas inlet pipe (43); the axial pressure loading machine (25) is arranged at the external part of the confining pressure system (2); the permeability measuring system (3) is connected with the gas outlet port of the confining pressure system (2) through a high pressure gas pipe; and the data acquisition system (4) is connected with the confining pressure system (2) through a data line with a sensor. According to the device provided by the invention, the problem of measuring coal-body deformations and permeability variations of different adsorption gases at different temperatures and different pressures is effectively solved; in addition, the permeability and coal-body change laws caused by a gas injection displacement in the process of developing coal bed gases are effectively simulated so that the production practice is beneficial to be further guided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Spherical contact type friction characteristic testing device under ultrasonic vibration

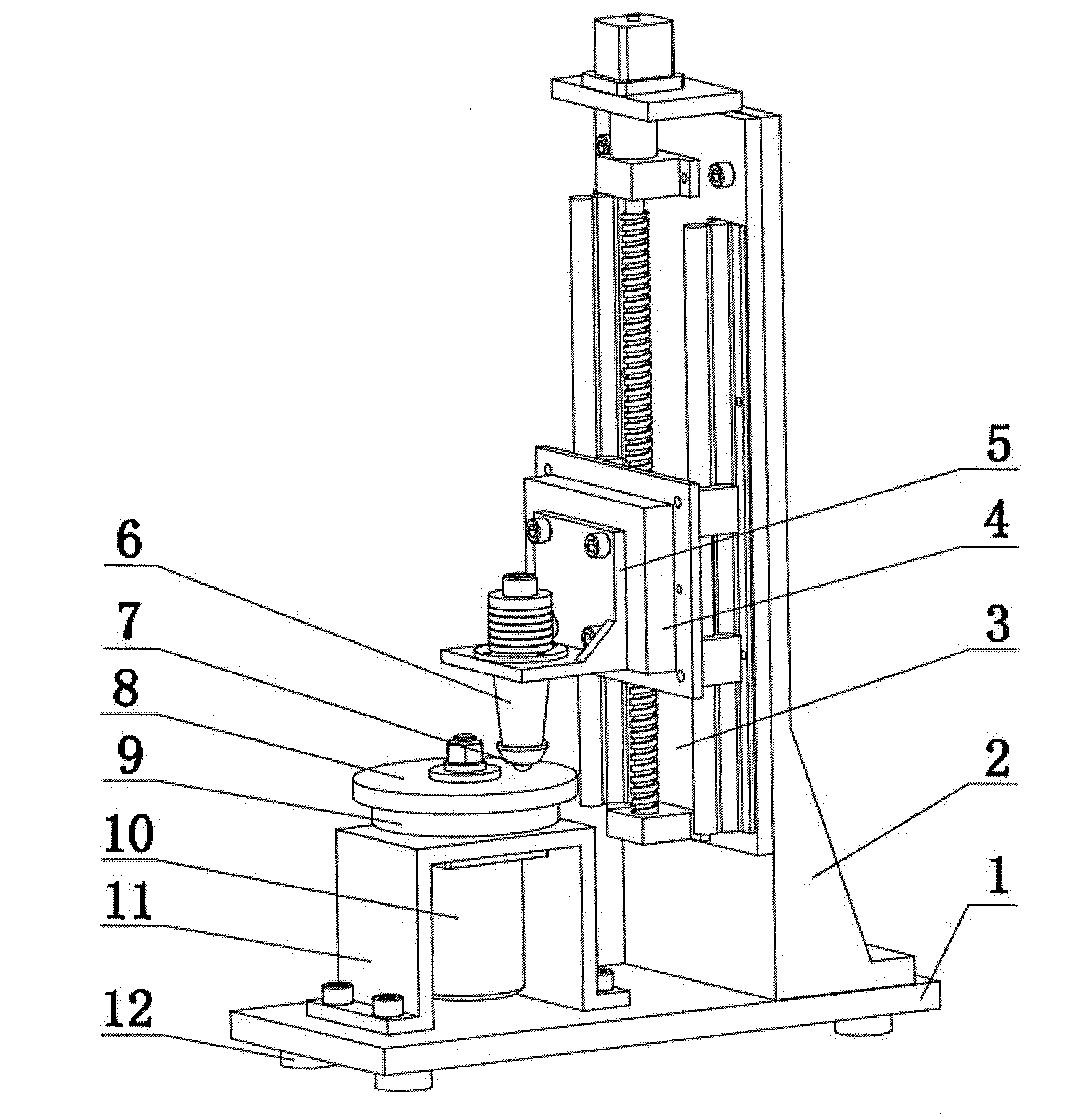

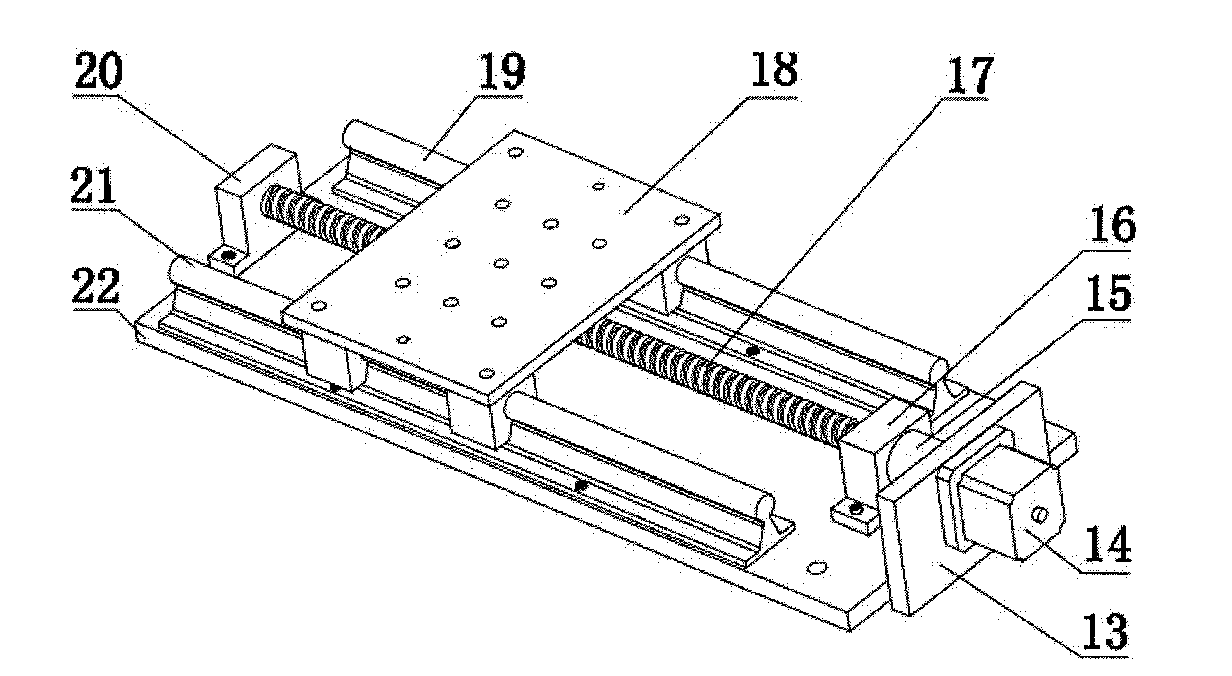

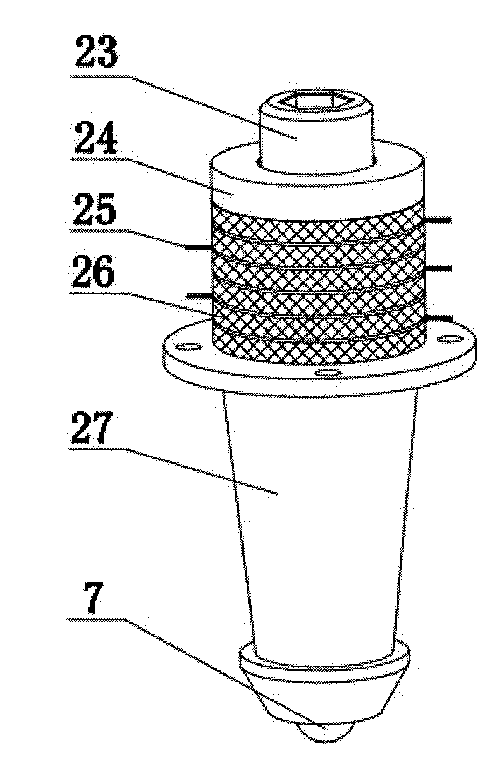

InactiveCN103278411APrecise control of test parametersHigh degree of automationUsing mechanical meansInvestigating abrasion/wear resistanceRotary stageVibration amplitude

The invention discloses a spherical contact type friction characteristic testing device under ultrasonic vibration. The device consists of a main movement unit, a loading unit and a dynamometer unit, wherein the torque output by a step motor is converted into axial pressure of a sliding table through a lead screw nut pair of a trapezoidal screw, and an upper sample and a lower sample which are arranged at the bottom of a piezoelectric micromachined ultrasonic transducer are contacted with each other, and certain pressure is applied to the lower sample; when the piezoelectric micromachined ultrasonic transducer is connected with an ultrasonic power supply, the upper sample produces ultrasonic frequency vibration with micron-grade amplitude in the horizontal direction or the vertical direction, the lower sample rotates together with a rotating platform and forms a friction pair with the upper sample, so that the friction characteristic of the spherical contact under ultrasonic vibration can be tested. The device can be used for accurately controlling the testing parameters, is high in degree of automation, and can be used for performing spherical contact friction experiments of various types of friction materials under different ultrasonic vibration frequencies and vibration amplitudes.

Owner:JILIN UNIV

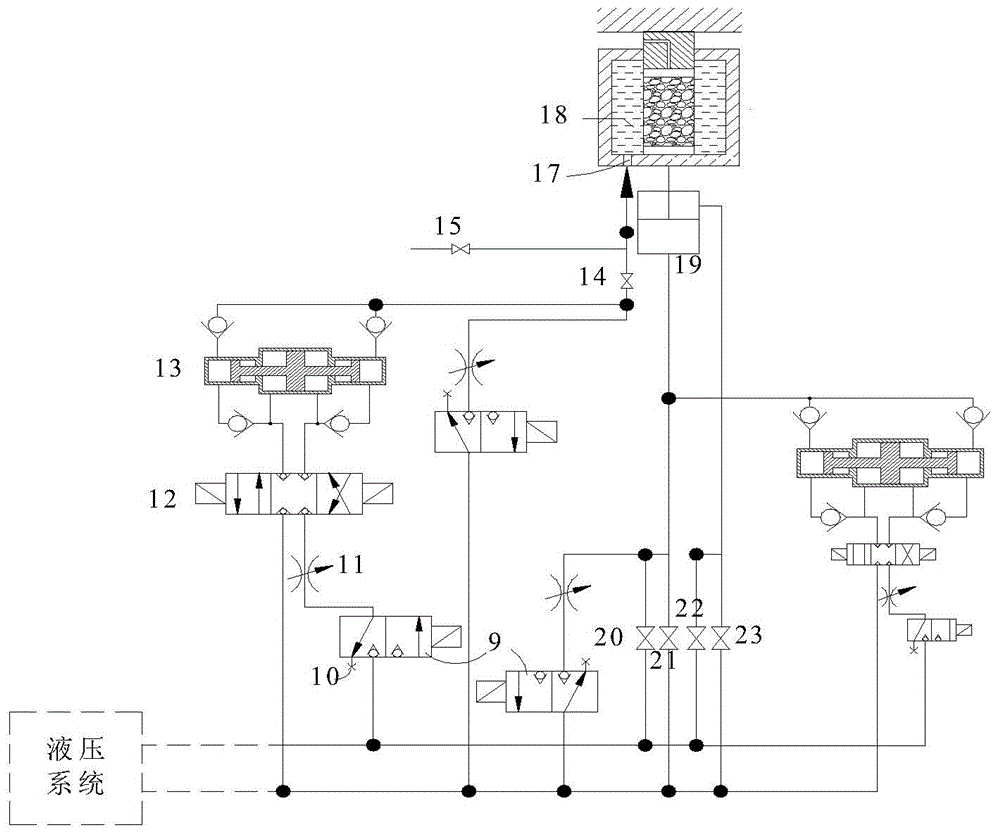

Multi-field coupling penetration test device and method for cracked rock

ActiveCN104819926AGuaranteed real temperaturePermeability/surface area analysisChemical solutionAxial pressure

The invention discloses a multi-field coupling penetration test device and a multi-field coupling penetration test method for cracked rock. The device comprises a computer servo control system, a confining pressure chamber, a hydraulic system, a temperature control system and a chemical solution system, wherein the hydraulic system and the confining pressure chamber are connected by virtue of a confining pressure device, an axial pressure device and a seepage device respectively; the temperature control system is arranged outside the confining pressure chamber; and the chemical solution system is connected with the seepage device. The test method comprises the following steps: opening the hydraulic system, and loading an oil source; putting a sample into a pressure chamber; loading axial pressure and confining pressure; loading the seepage pressure; loading a chemical field; applying temperature; and measuring the data. The four-field loading systems are independent from one another, the evolution test research of permeability characteristics and mechanical properties of the cracked rock can be really simulated under high water pressure, large hydraulic gradient, temperature change and water chemistry complicated conditions, and the whole-process experimental research of rock deformation damage and penetration, stress, chemistry and temperature coupling can be performed.

Owner:HOHAI UNIV

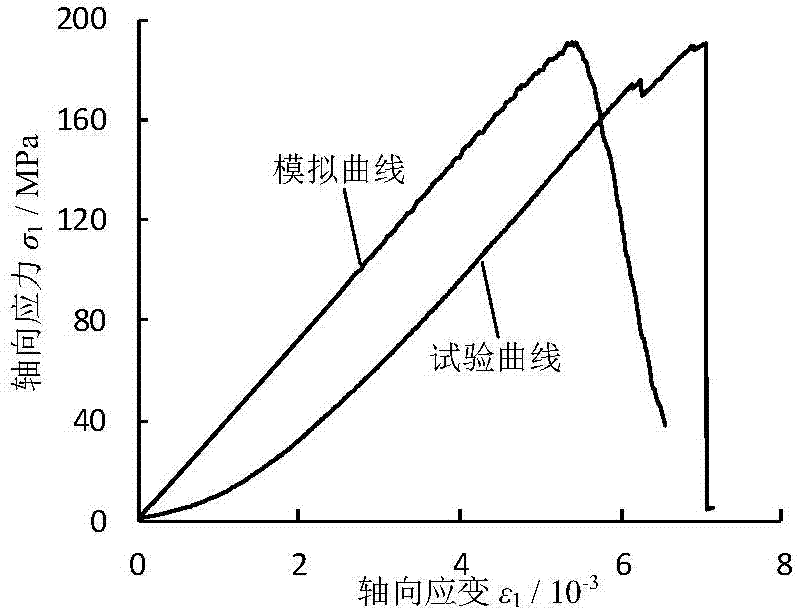

Determination method for mesoscopic parameters simulating mechanical properties of intermittent crack rock

InactiveCN103940666AVerify accuracyDeepen understandingMaterial strength using tensile/compressive forcesParticle flowAxial pressure

Belonging to a rock mechanical determination method, the invention provides a determination method for mesoscopic parameters simulating mechanical properties of an intermittent crack rock. The method includes: firstly sampling an engineering rock mass to be tested, and making a complete and intermittent crack cuboid sample; placing the made sample in a sealed pressure cylinder of a servo test machine, firstly bringing a testing machine pressure head into close contact with the upper end and lower end of the rock sample; applying an axial pressure on the sample according to displacement loading, and conducting loading on the sample till fracture, thus obtaining a sample compression process stress-strain overall process curve, a crack propagation process and a final fracture mode; employing particle flow code in 2 dimensions (PFC2D) to establish a complete sample numerical model, and debugging the mesoscopic parameters continuously to acquire a set of mesoscopic parameters able to reflect complete rock sample test results; establishing an intermittent crack numerical model based on the mesoscopic parameters, carrying out compression process simulation, comparing the simulation results with the intermittent crack rock test results so as to further verify the accuracy of the mesoscopic parameters.

Owner:CHINA UNIV OF MINING & TECH

Triaxial core holder

ActiveCN101446542AHigh simulationMaterial analysis using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisAxial pressureEngineering

The invention relates to a triaxial core holder. A pressure cap, a left plug, a core chamber, a left core plug, a positioning washer and a left small pressure cap are arranged at the left part of the core holder, and an axial pressure piston, a right small pressure cap, a right plug and a right core plug are arranged at the right part thereof. The triaxial core holder is characterized in that a gum cover is arranged on the periphery of the ore chamber and connected with two pairs of pistons through connecting plates; and two pressure-bearing cylinders are connected on the outer sides of the pistons. By adopting three groups of pistons (horizontal, vertical and axial), the triaxial core holder can simulate the holder with two pressures at most than before. The invention can better simulate the three-dimensional stressed situation of the core in a stratum, and the three groups of pressures can be freely adjusted, therefore, the stressed situation of the stratum can be truly simulated, so that the experimental data is closer to actual data inside the stratum. The invention can provide a better manner for petroleum exploration.

Owner:南通市飞宇石油科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com