Patents

Literature

37 results about "Staking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Staking is the process of connecting two components by creating an interference fit between the two pieces. One workpiece has a hole in it while the other has a boss that fits within the hole. The boss is very slightly undersized so that it forms a slip fit. A staking punch is then used to expand the boss radially and to compress the boss axially so as to form an interference fit between the workpieces. This forms a permanent joint.

Multi-piece primer insert for polymer ammunition

The present invention provides a two piece and a three piece primer insert for ammunition piece. Each of the individual pieces may be formed by punching, pressing, stamping, molding, milling, coining, or by additive manufacturing. The individual pieces may be joined by clinching, pressing welding soldering, sintering, adhesive gluing, staking, and iterative addition by forming one piece into another piece.

Owner:TRUE VELOCITY IP HLDG LLC

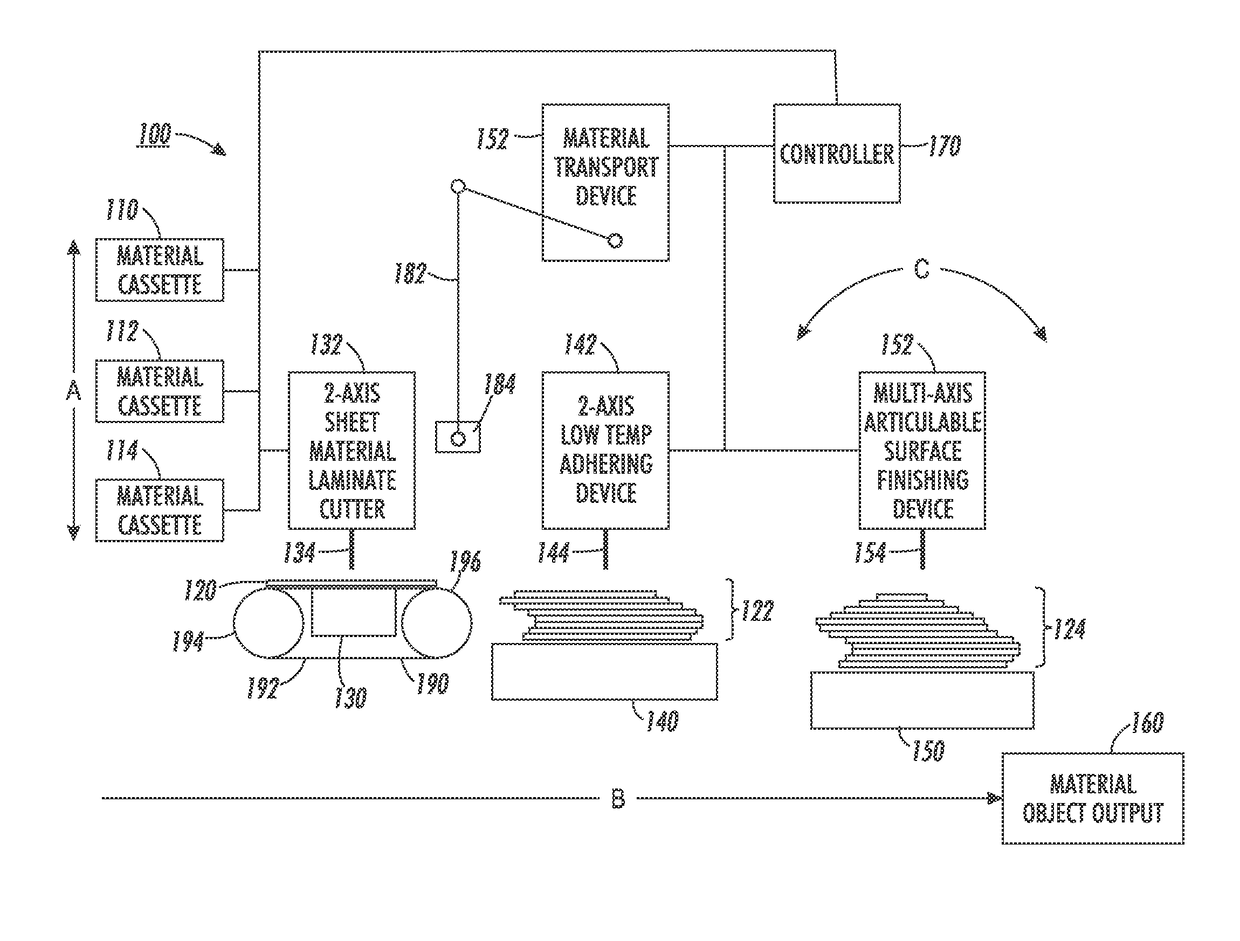

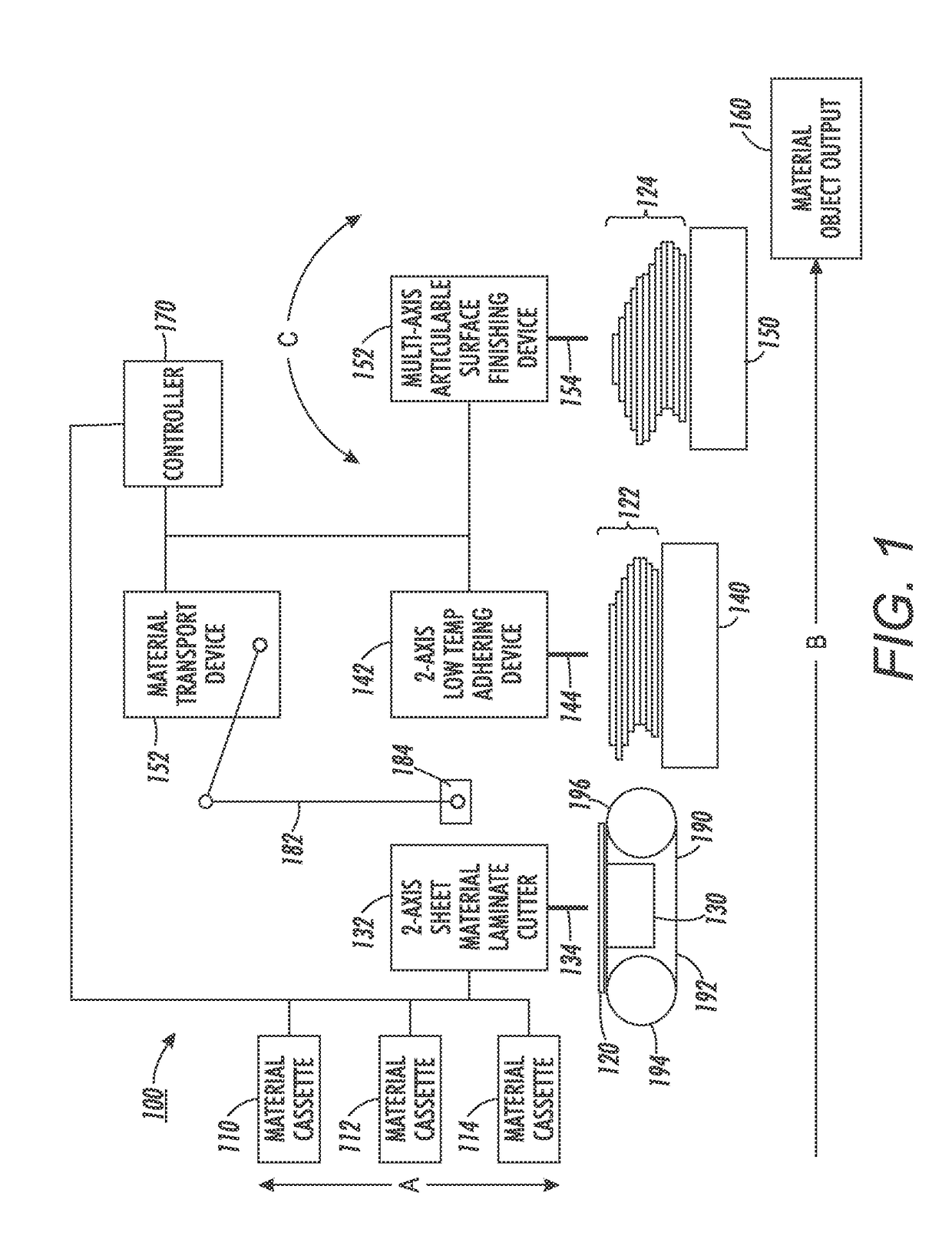

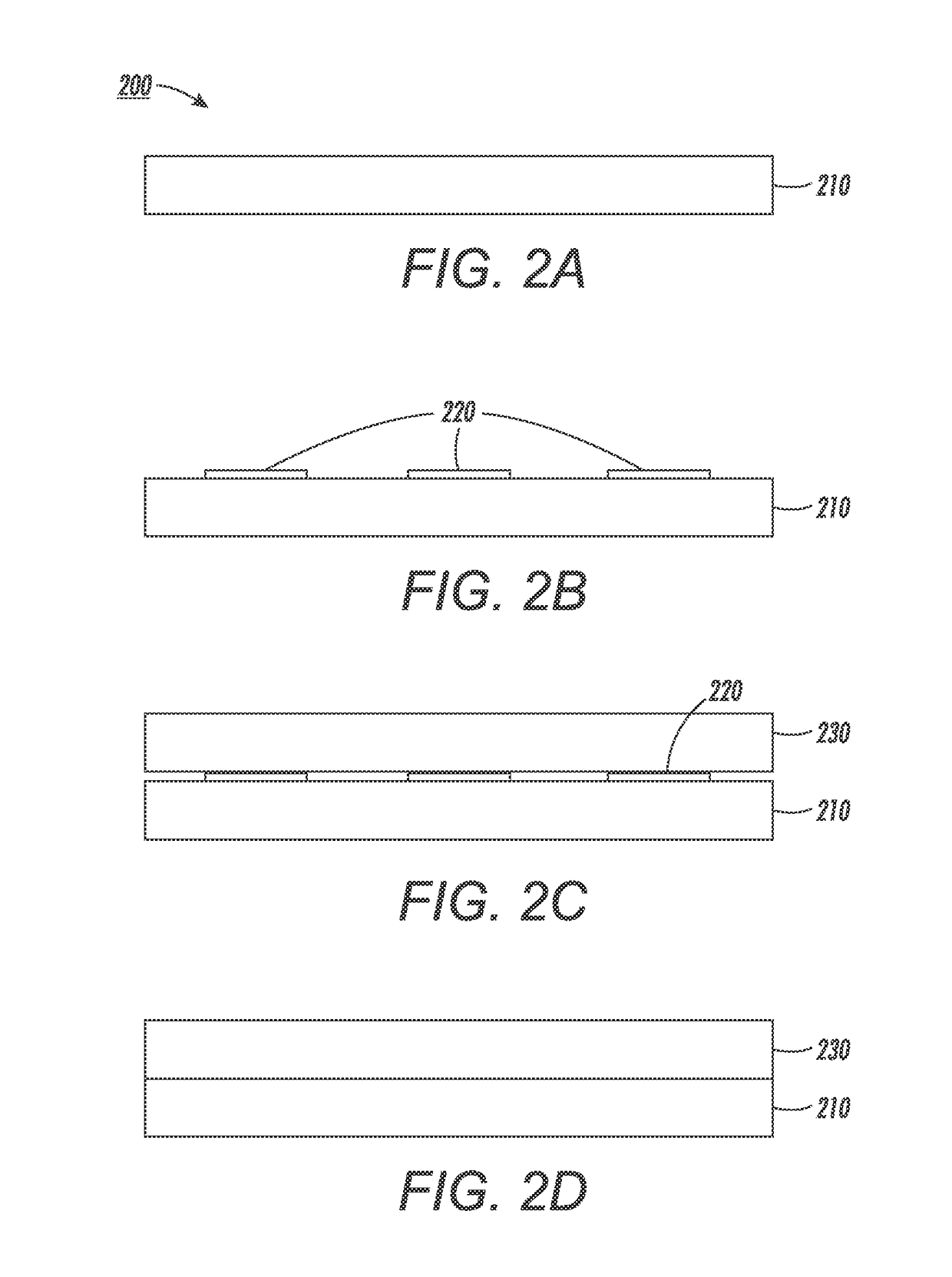

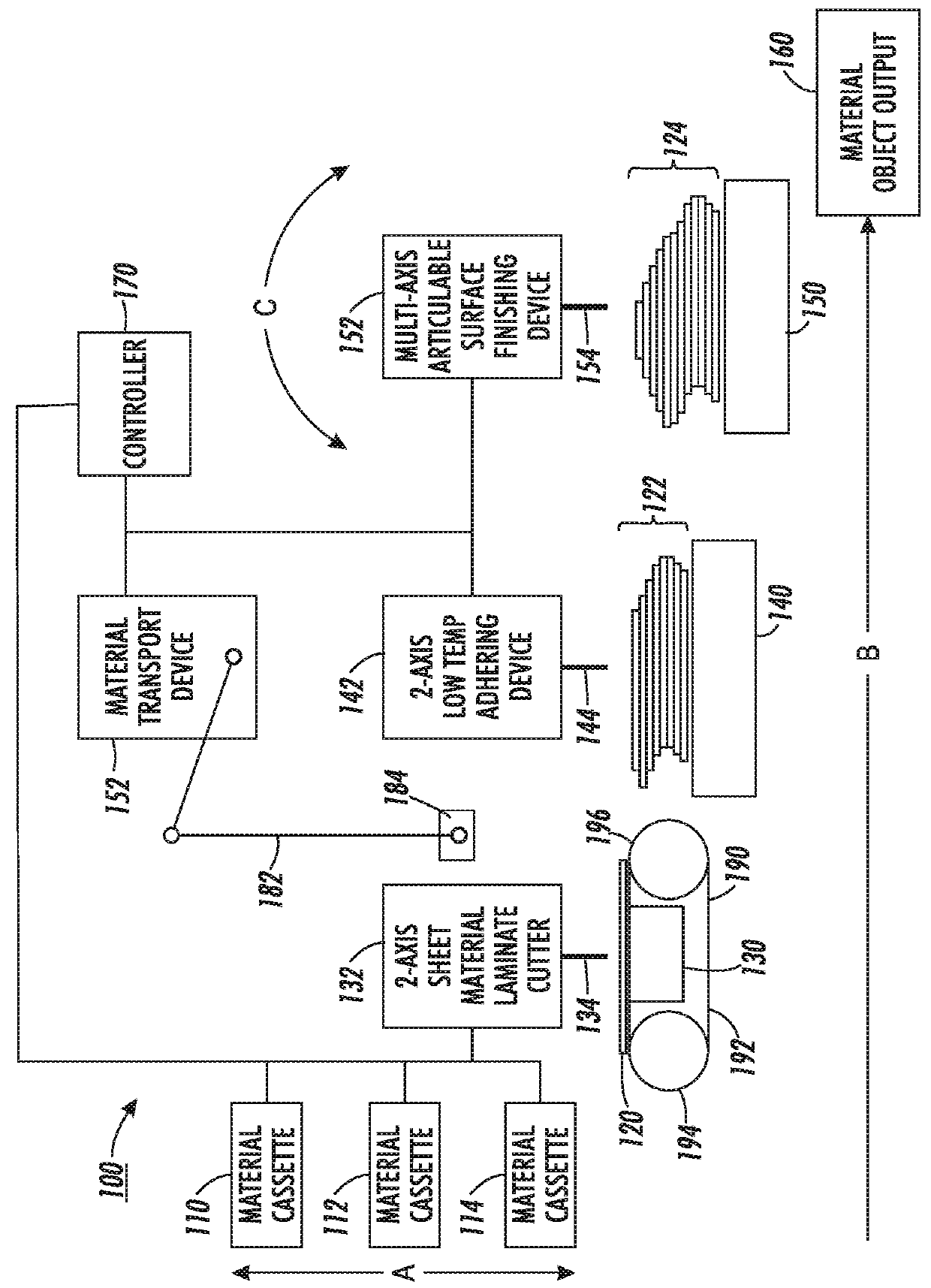

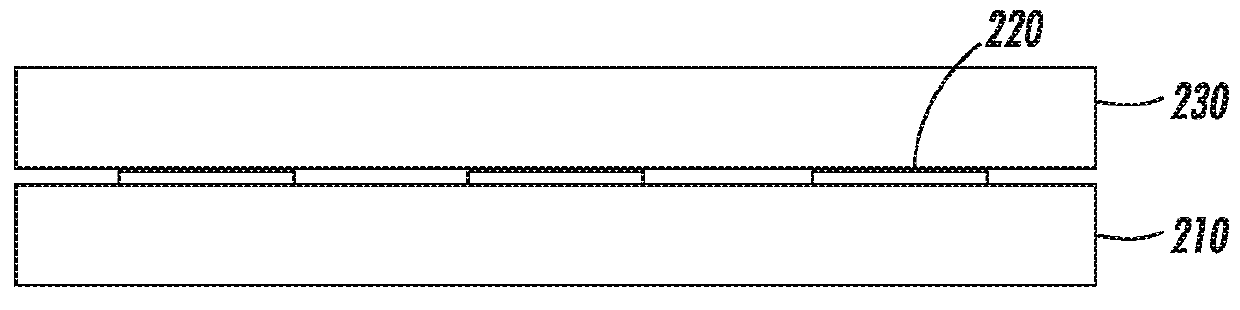

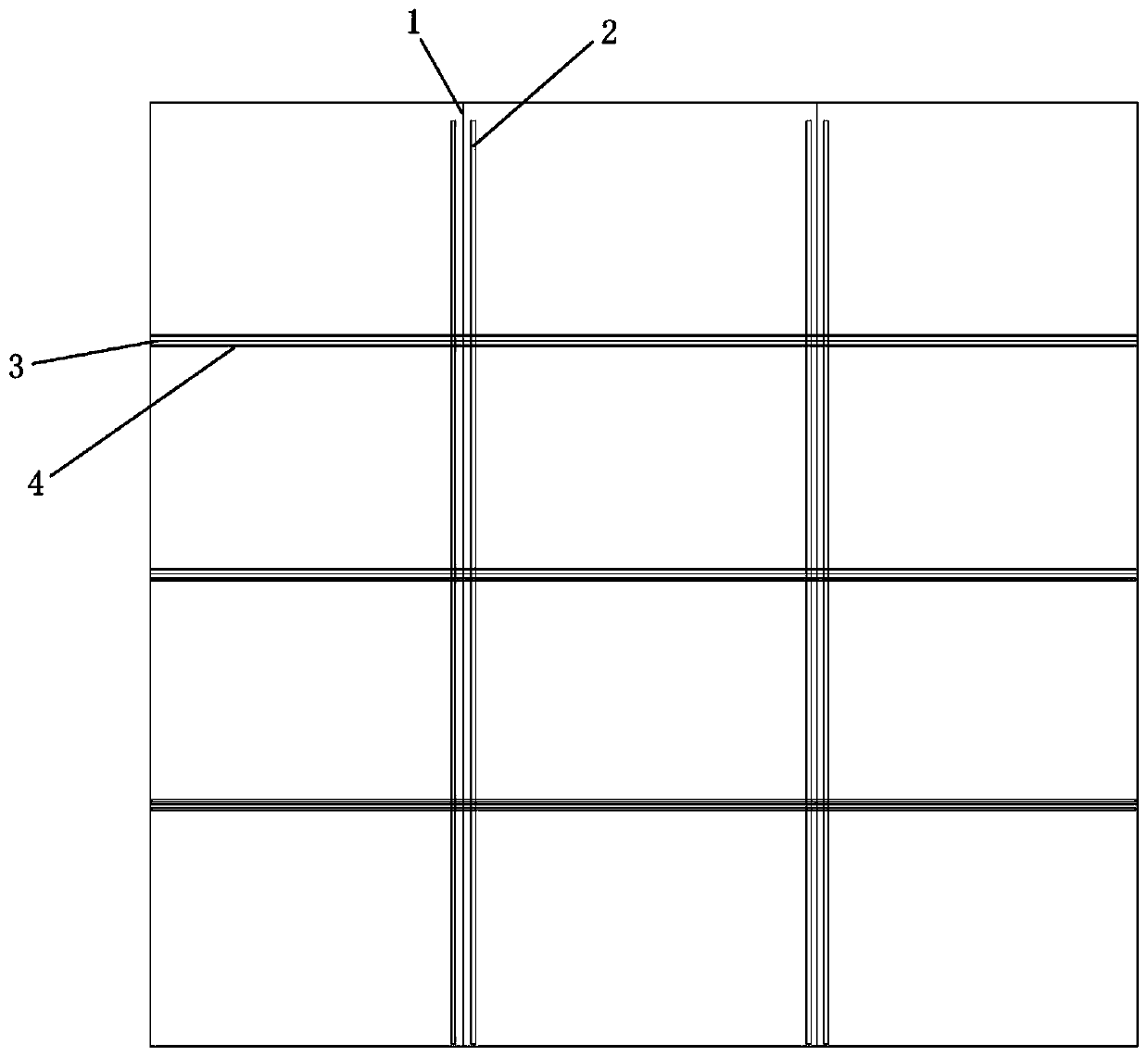

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including displacement/vibration welded or heat staked laminates

ActiveUS20170144426A1High build rateSolve the slow construction speedLamination ancillary operationsLaminationSurface finishingEngineering

A system and method are provided for implementing relatively low temperature joining processes, including displacement / vibration welding techniques and / or heat staking techniques, in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components in additive material (AM) manufacturing systems. A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through comparatively low temperature welding or other mechanical joining (including displacement / vibration welding or heat staking); and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

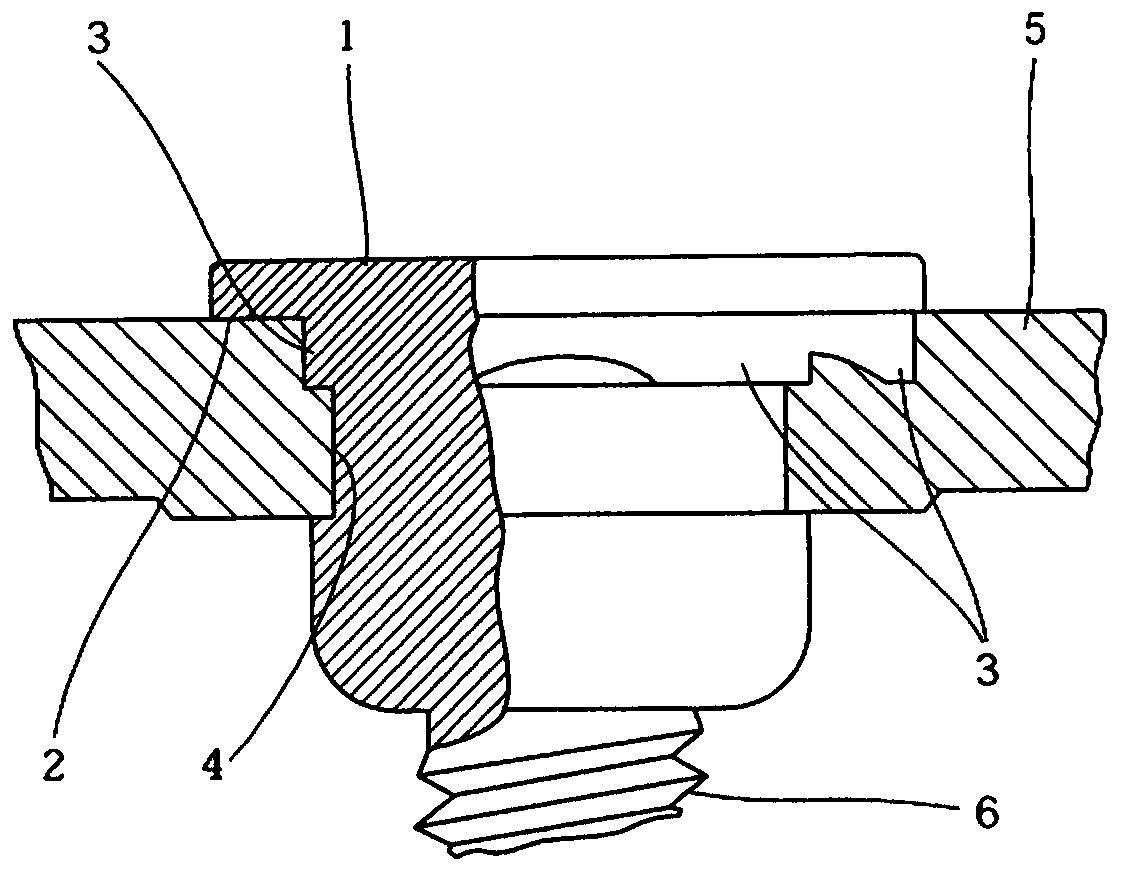

Attachment of bearing elements by deformation

A method of installing an annular bearing element within a centrifugal pump utilizes a mechanical staking operation. The bearing element locates within a receptacle of a pump stage that is surrounded by a retaining wall. Once the bearing element is located within the retaining wall, the retaining wall is permanently deformed at various points against the bearing element. The bearing element, if of a hard wear resistant metal, may have flats for the circumferentially spaced apart deformations to locate within. The bearing element may be a thrust washer for transmitting downward thrust, or it may be a radial support bearing sleeve.

Owner:BAKER HUGHES INC

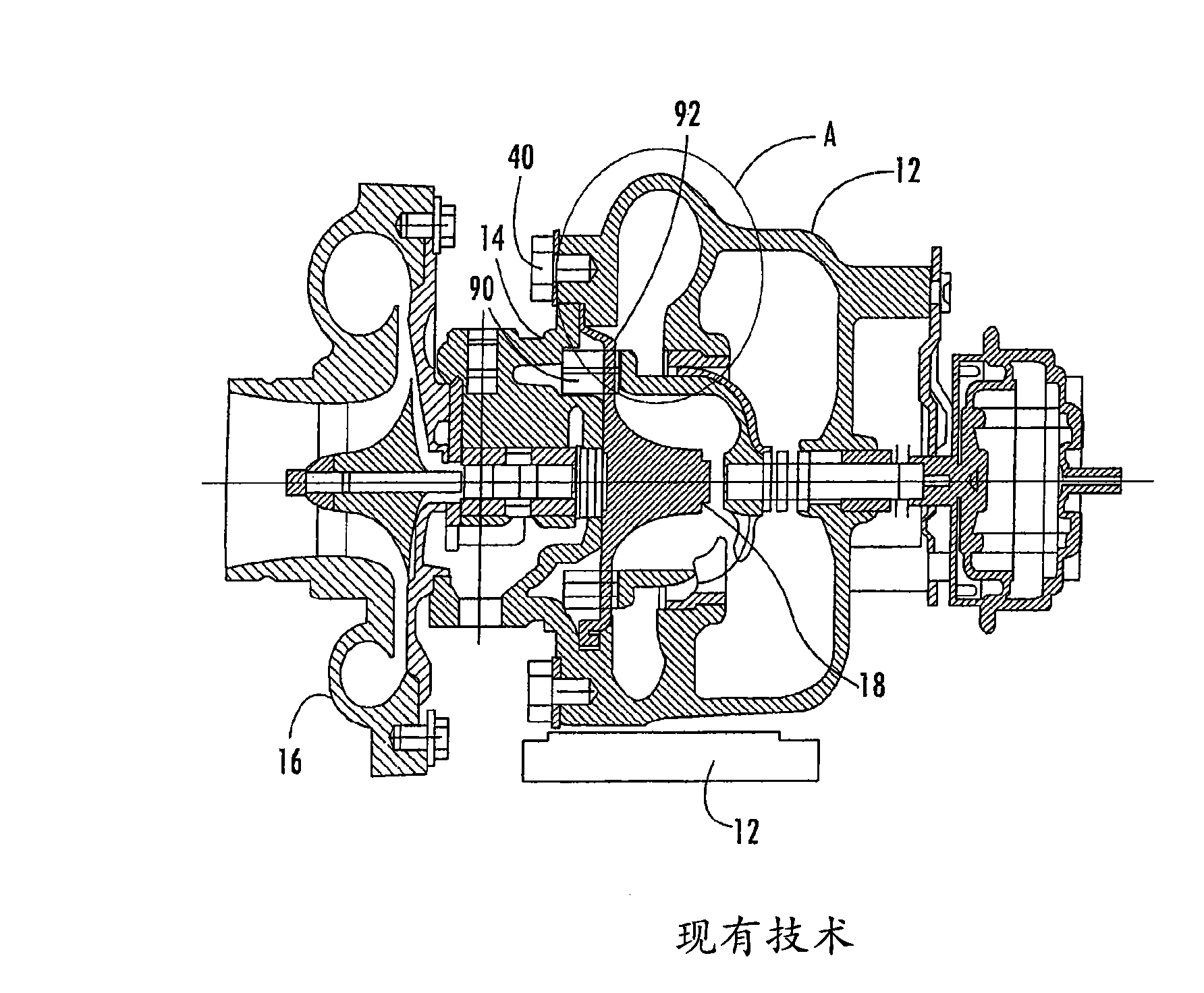

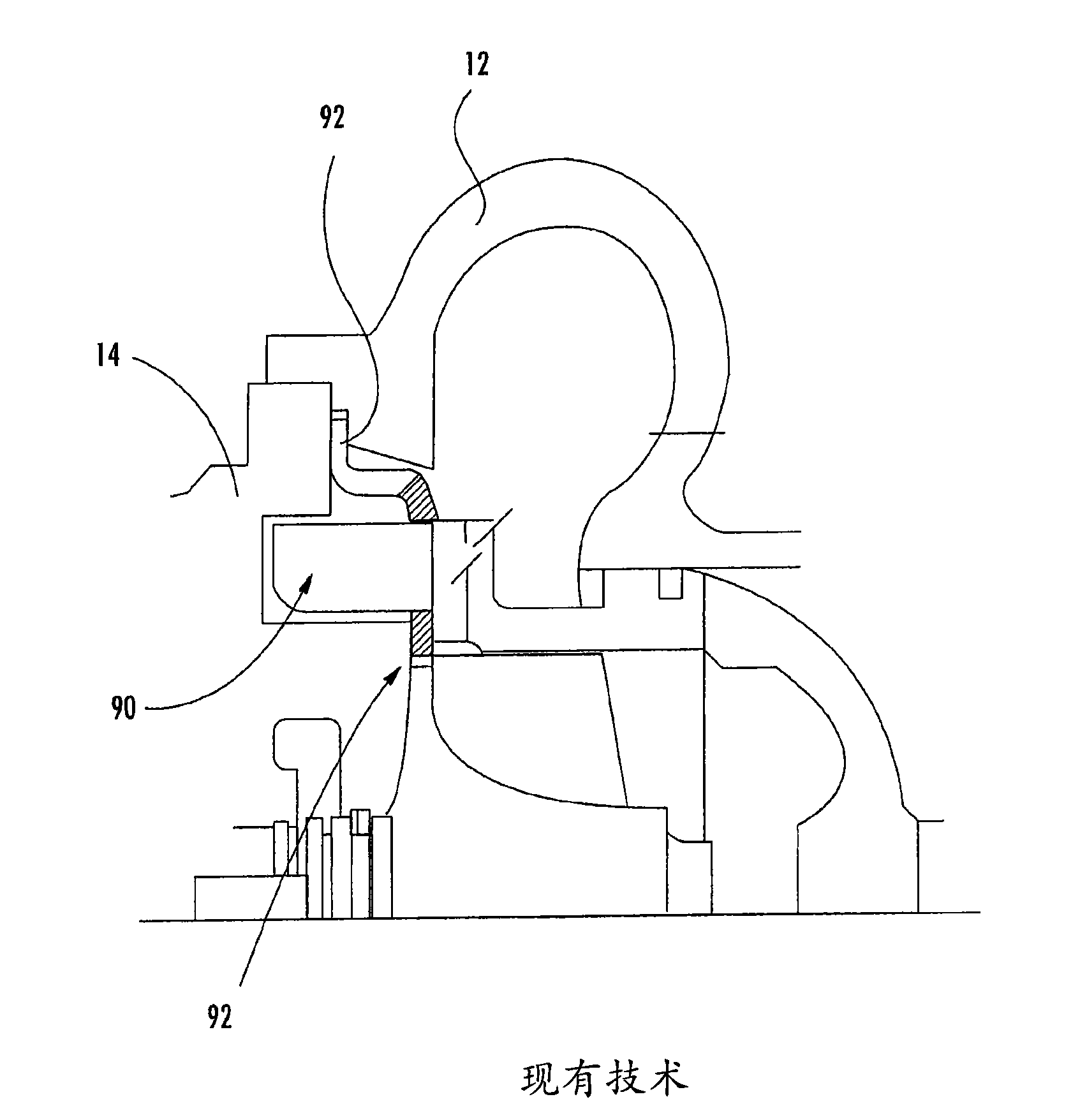

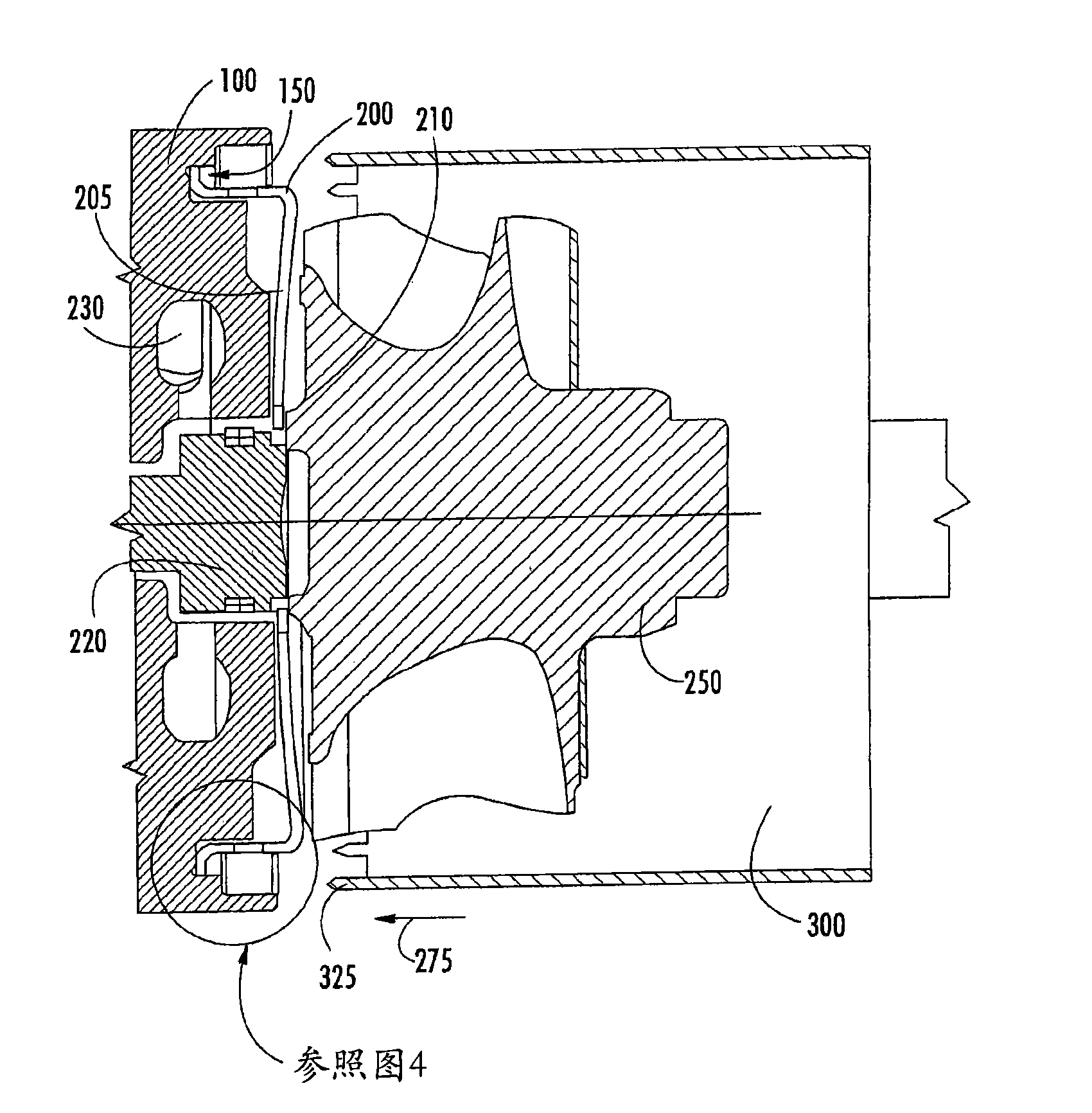

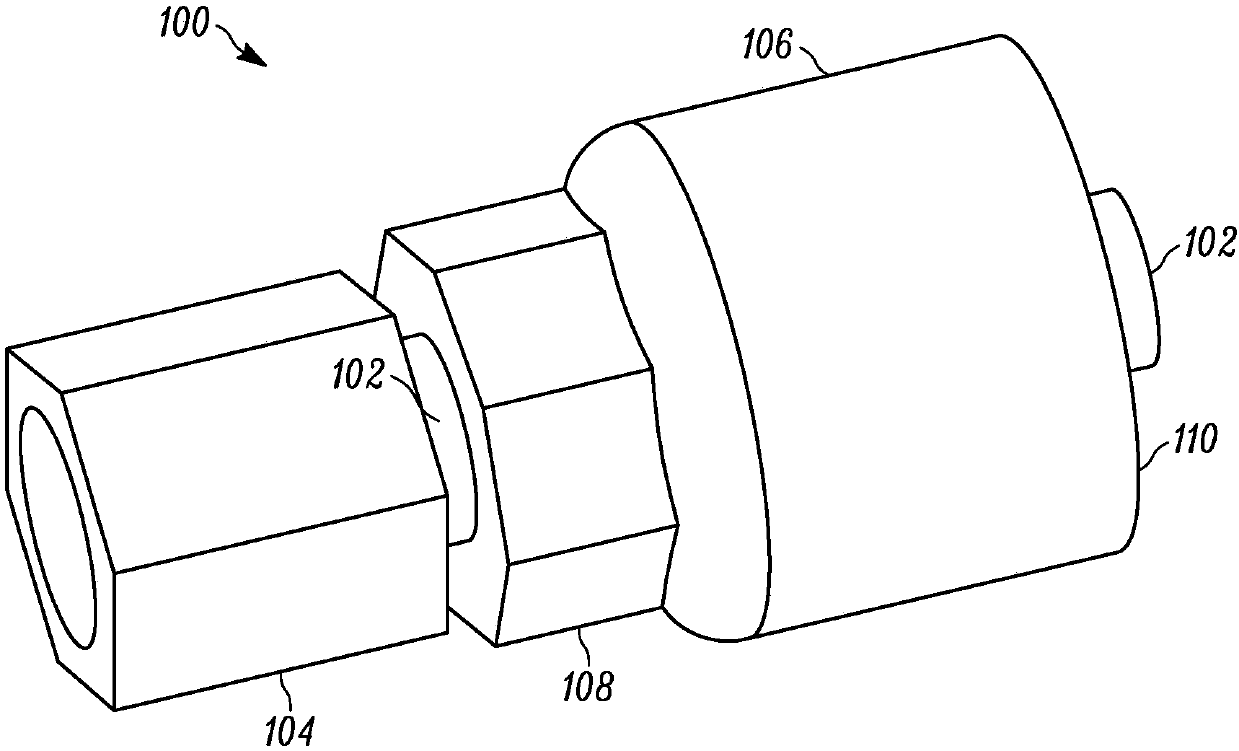

Turbine heat shield assembly

A turbocharger is provided having a bearing housing (100) and a heat shield (200) staked thereto. The staking process can be a compression staking process that deforms one or more portions of the bearing housing (100). The bearing housing (100) can have an annular channel (150) and the compression staking can be done to an outer edge (160) of the annular channel (150) to form one or more compression projections (400). The size and shape of the annular channel (150) can be substantially the same as the size and shape of an outer portion of the heat shield (200) to allow for a press-fit therebetween.

Owner:BORGWARNER INC

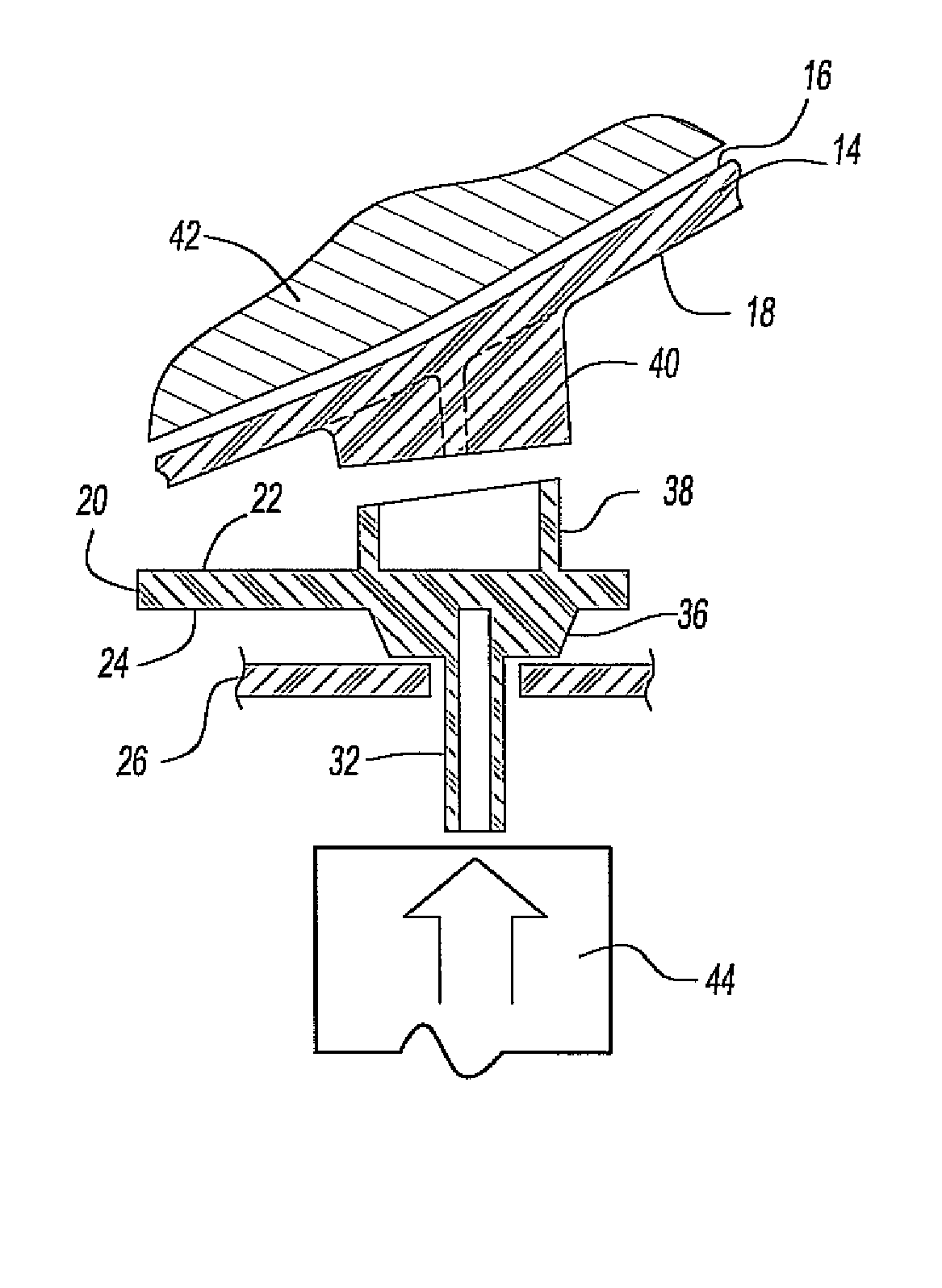

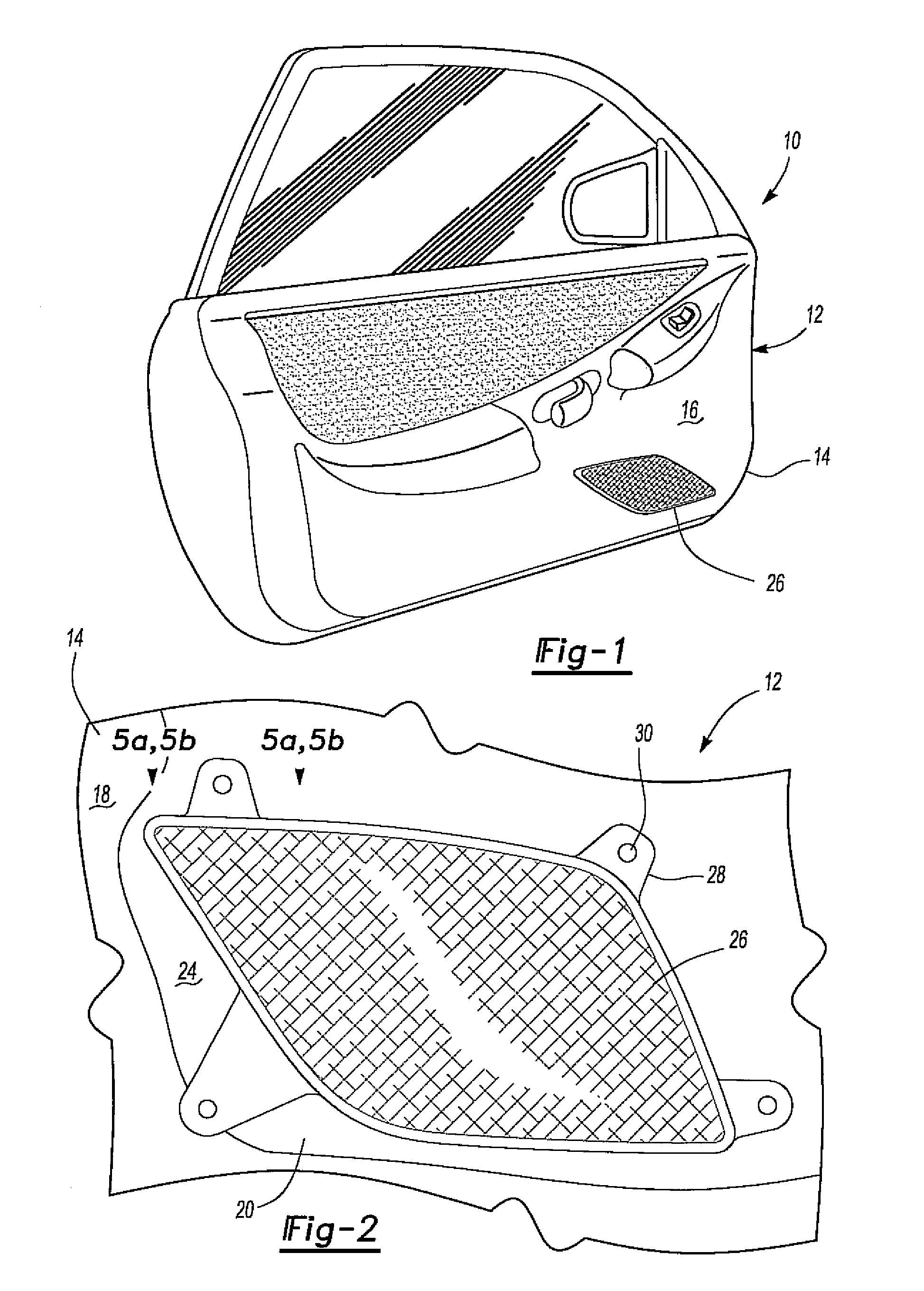

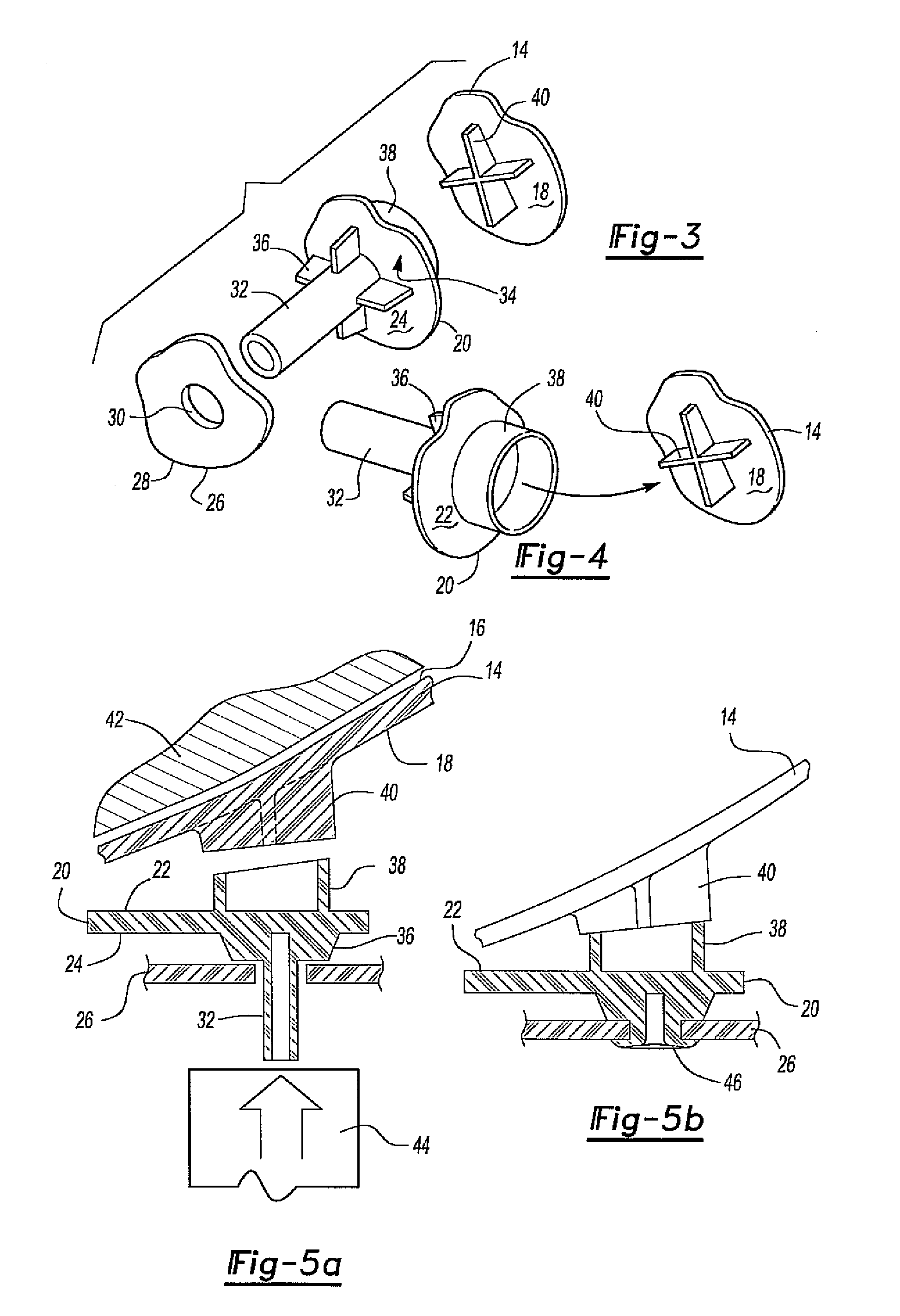

Three panel heat stake structure

InactiveUS8167347B2Inhibition formationReduce the overall heightDomestic articlesMonocoque constructionsEngineeringFace sheet

A trim panel assembly which provides support for the interior panels during a heat staking process, even when the interior panels overlap an outer panel, is provided. The trim panel assembly includes a first support boss extending from an inner surface and an outer surface which is adjacent a weld horn backing plate during the heat staking process. A second panel includes an outwardly extending elongated stud extending from an inner surface, and a support boss extending from an outer surface. An accessory panel having an aperture is aligned with the second panel such that the elongated stud passes through the aperture. During the heat staking process pressure is applied to the stud of the second panel which is supported by the weld horn backing plate through the contact between the support boss of the first panel and the boss of the second panel.

Owner:TOYOTA MOTOR CO LTD

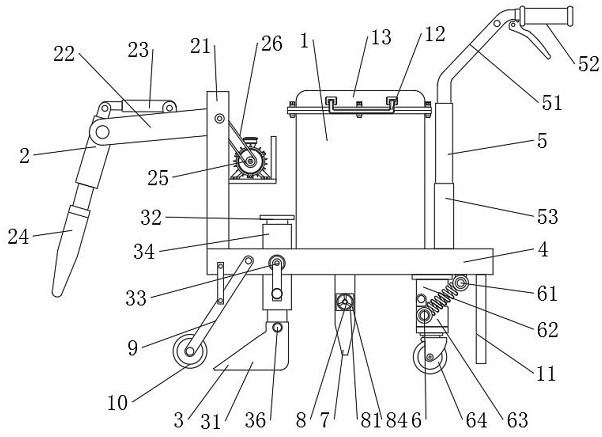

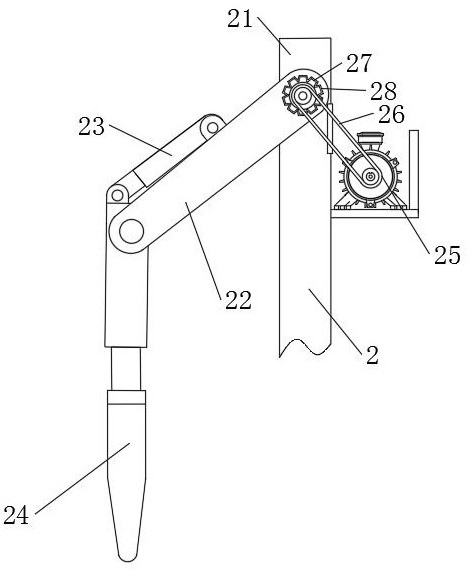

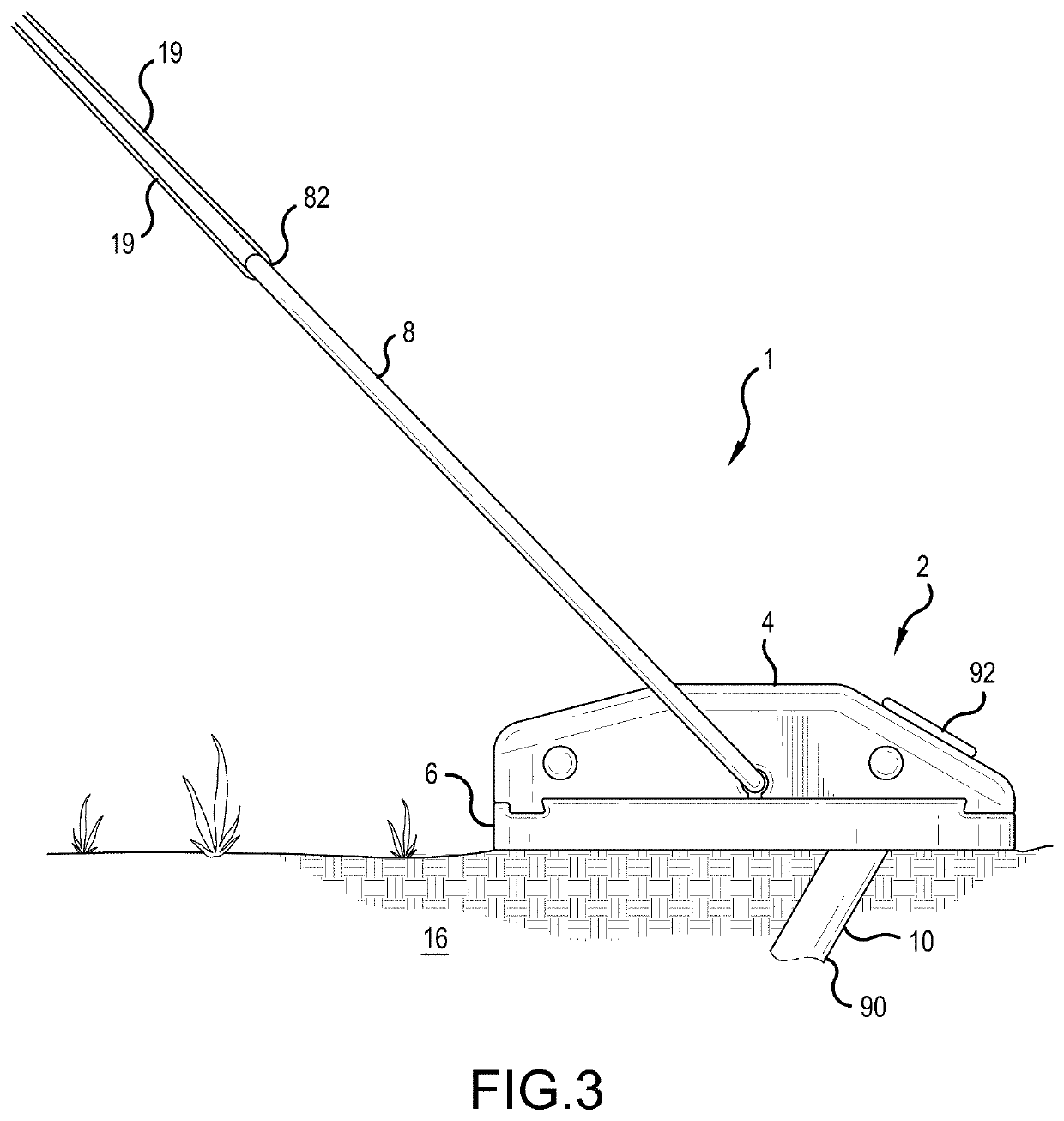

Concrete crack repairing device in road and bridge construction

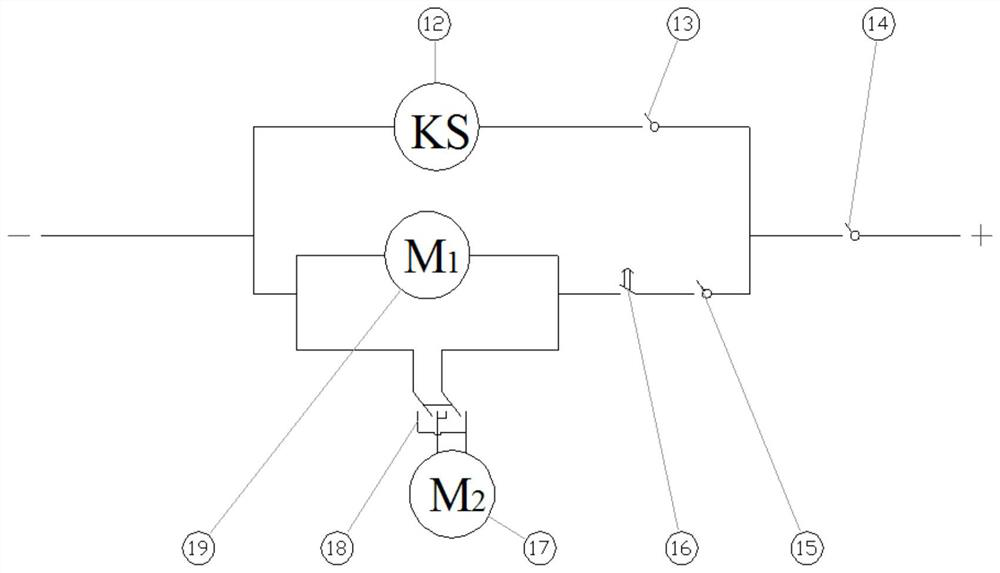

PendingCN112921778AWon't blockEasy to cleanRoads maintainenceArchitectural engineeringElectric machinery

The invention relates to the technical field of road and bridge crack repairing, in particular to a concrete crack repairing device in road and bridge construction, which comprises a slurry barrel and a fixing plate, the left side of the slurry barrel is fixedly provided with a beating and trimming assembly, the beating and trimming assembly comprises a connecting rod, and the left side of the connecting rod is fixedly provided with a first connecting rod; a second connecting rod is movably mounted at the top of the first connecting rod, a staking head is movably connected to the bottom of the first connecting rod, a second connecting rod is movably mounted at the top of the staking head, a crawler belt is movably connected to the right side of the connecting rod, and a motor is fixedly connected to the bottom of the crawler belt; and the middle of the slurry barrel and the middle of the connecting rod are fixedly connected with an ash removal assembly. According to the device, cracks can be beaten and trimmed, so that the cracks are neat, concrete can be matched with a pavement, secondary cracking is not likely to happen, sandy soil existing in the cracks is convenient to clean, the cracks cannot be blocked, and repairing is convenient.

Owner:中海外交通建设有限公司

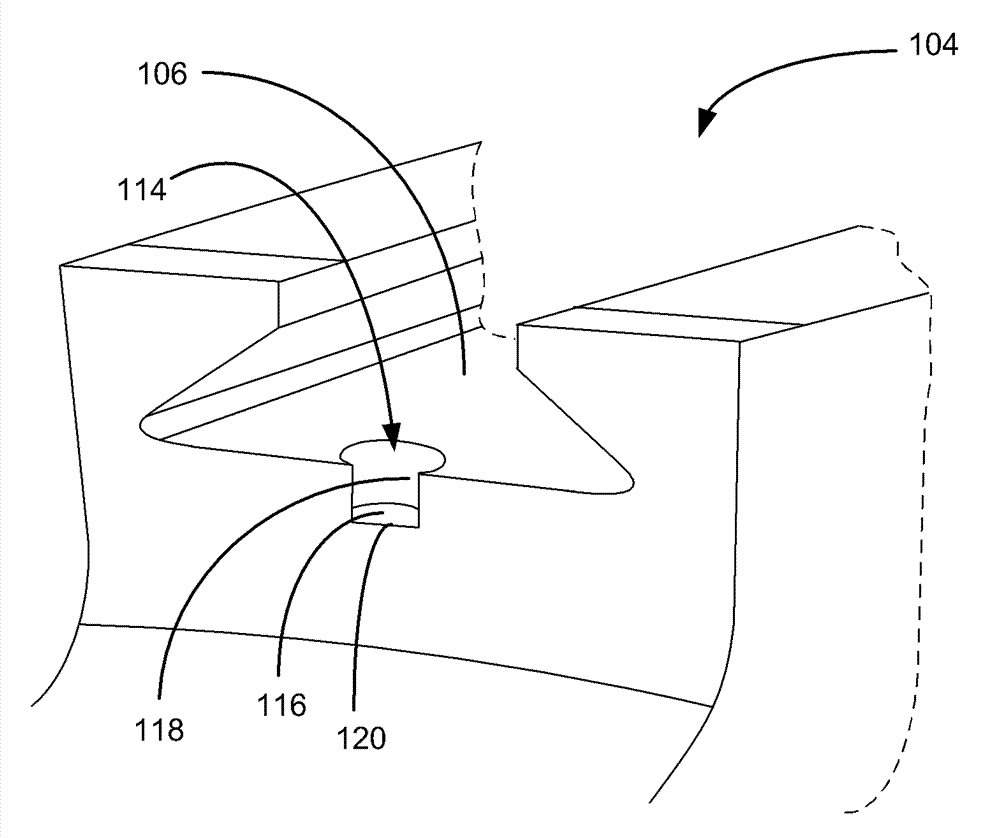

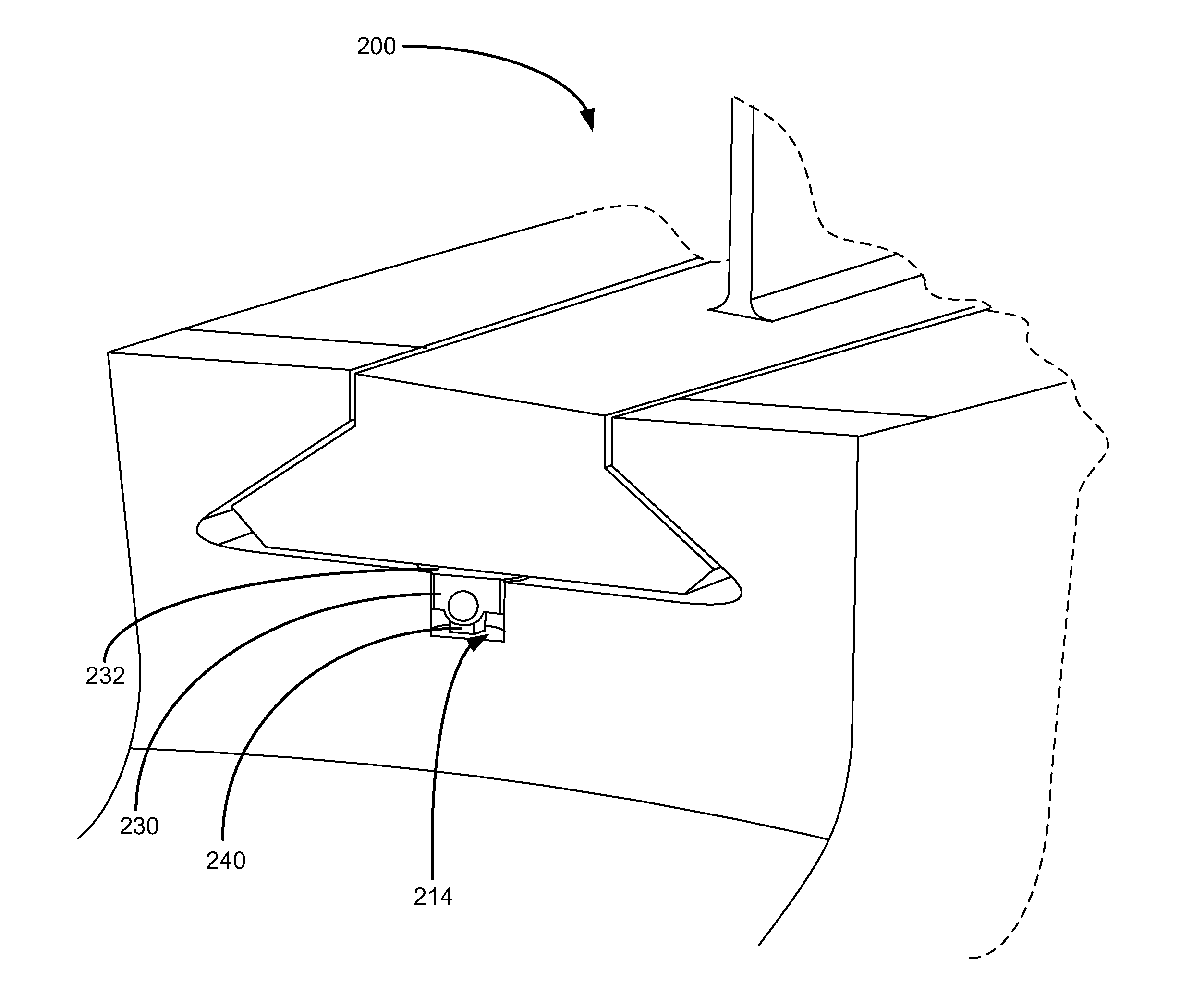

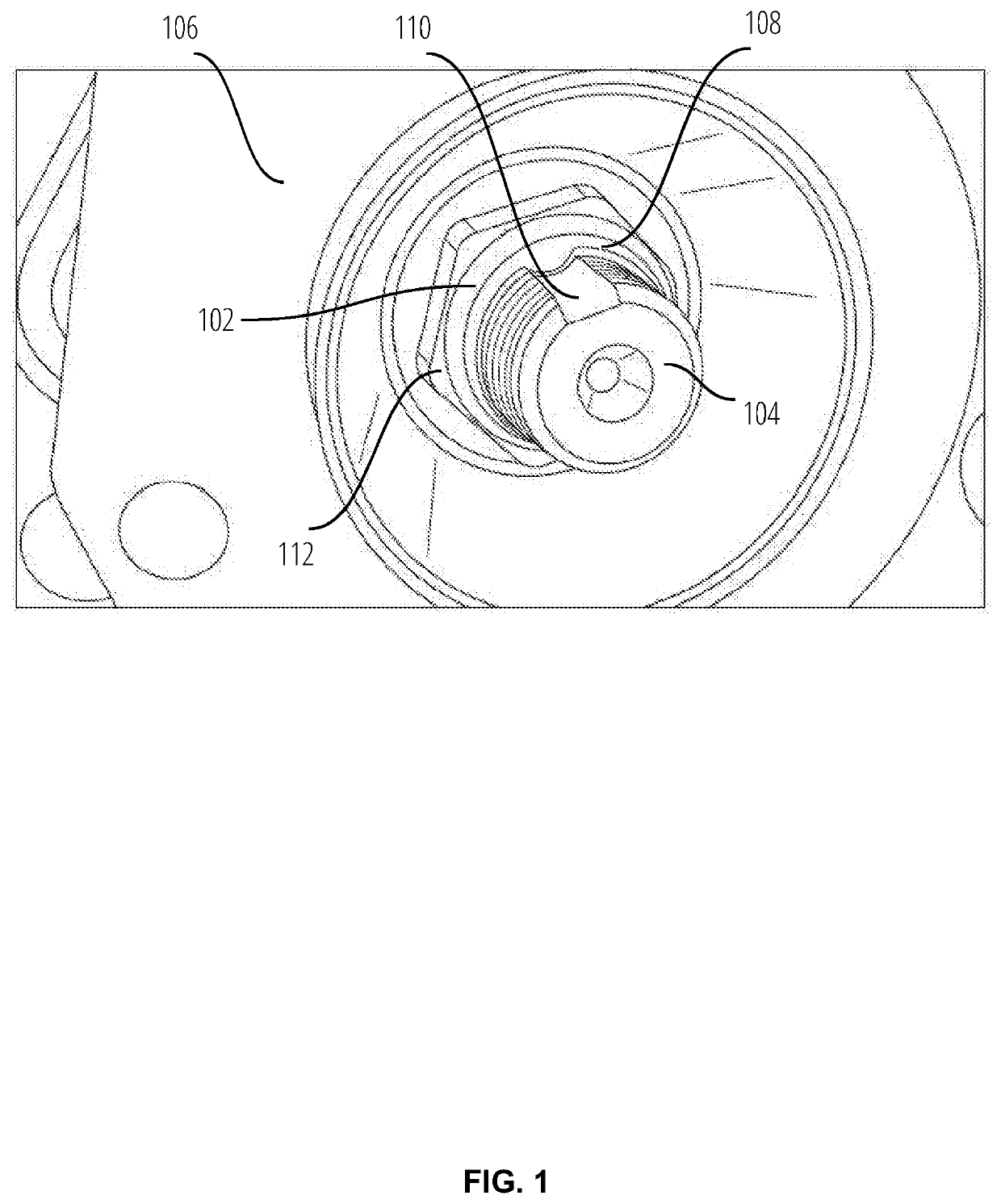

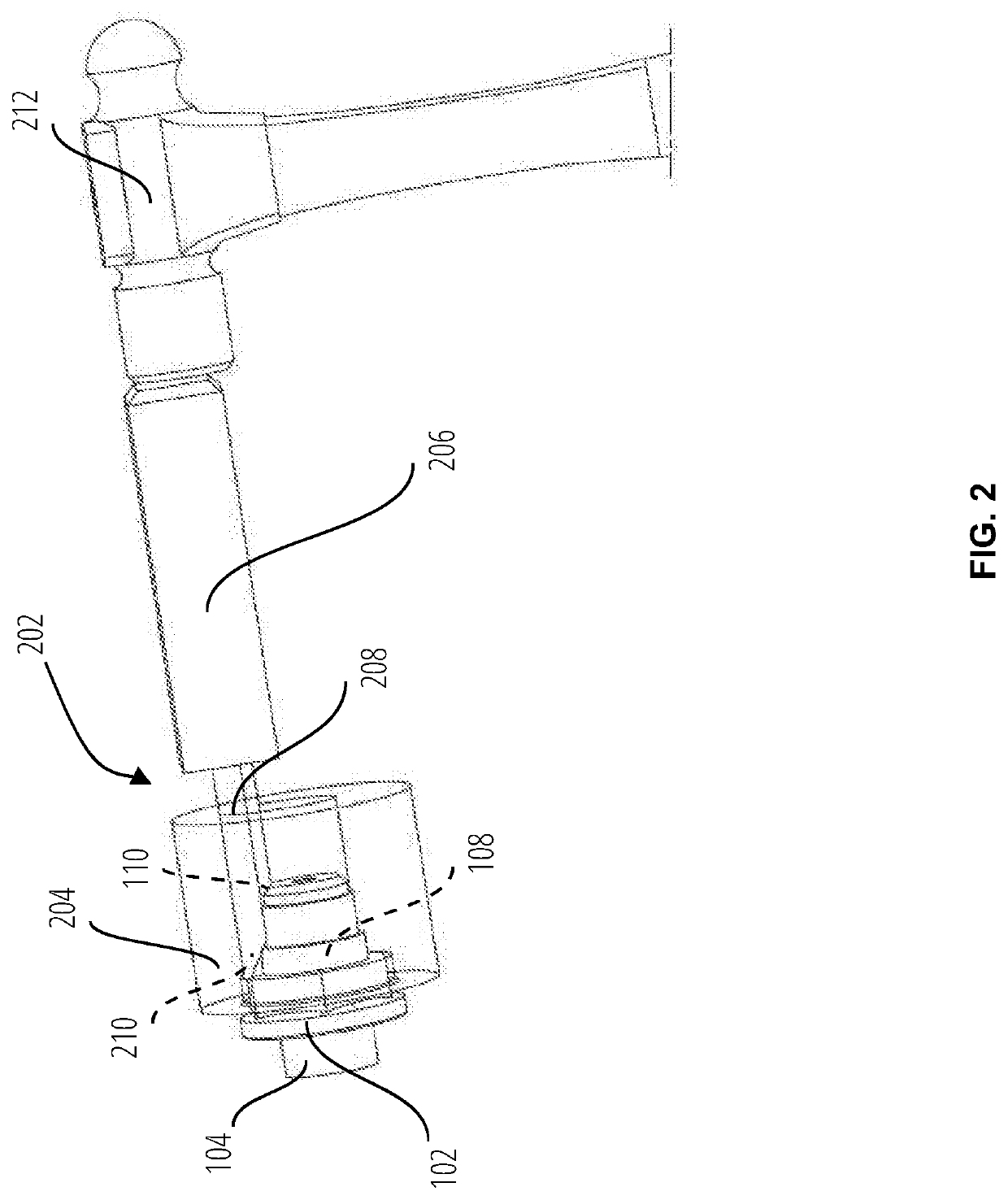

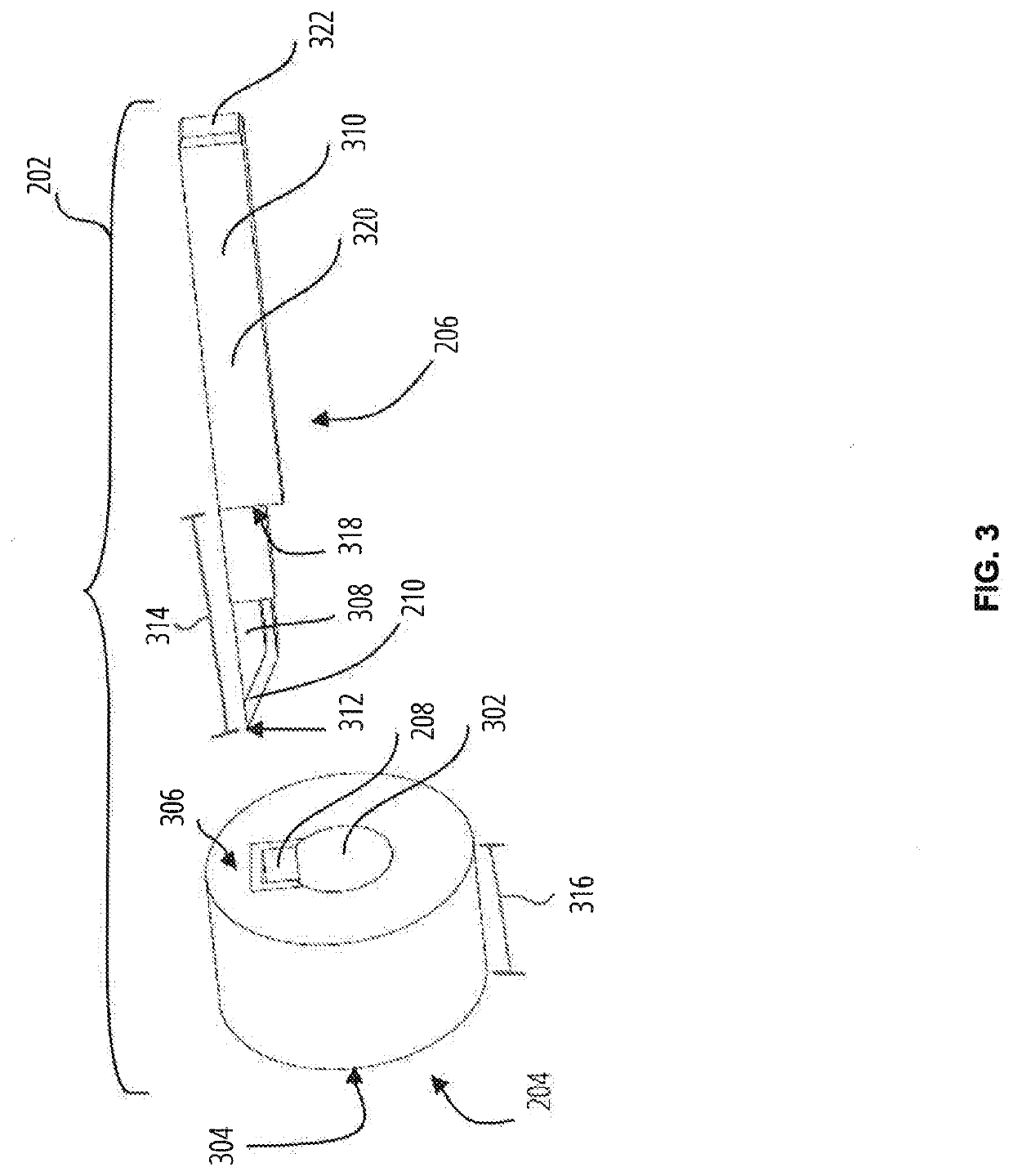

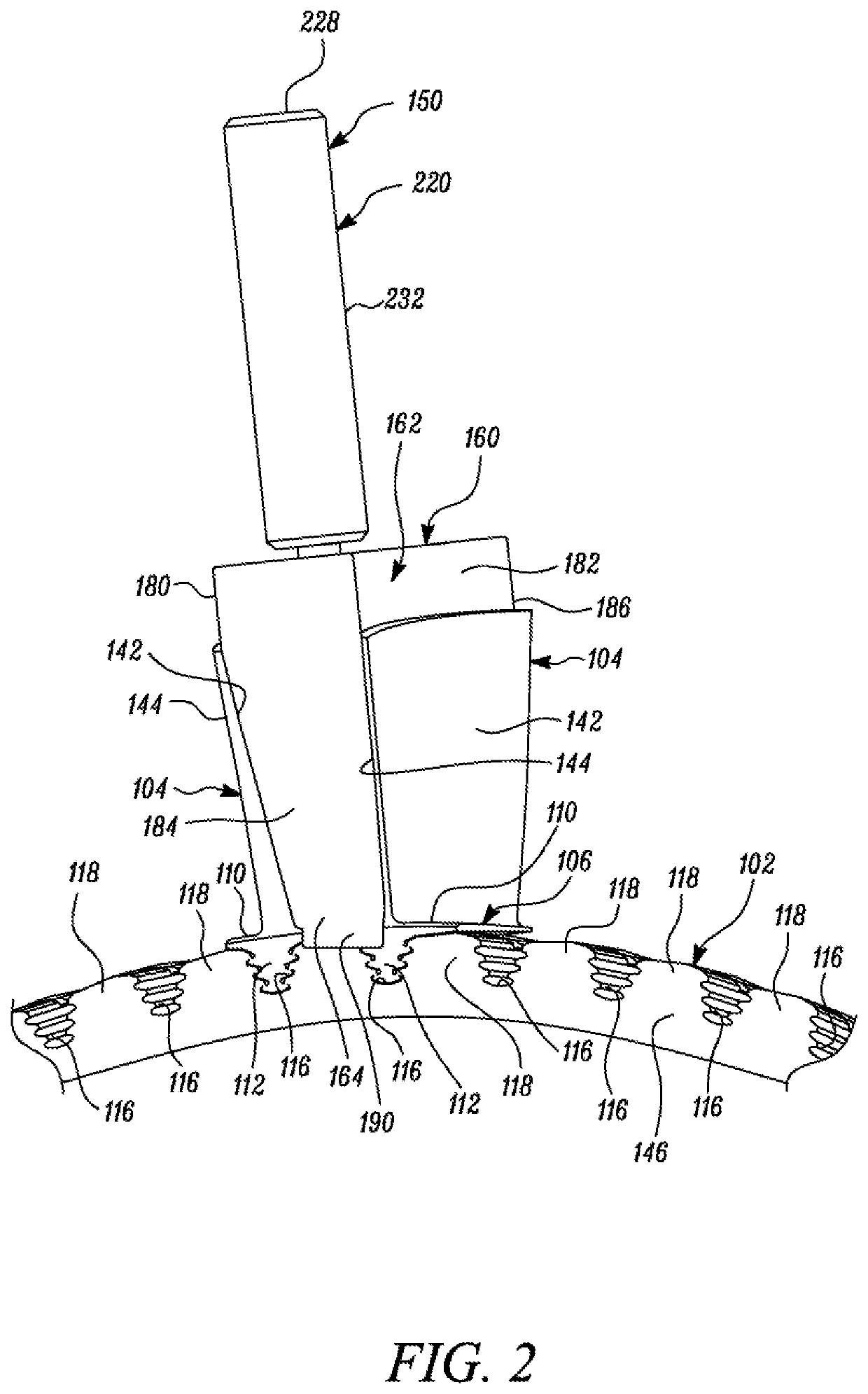

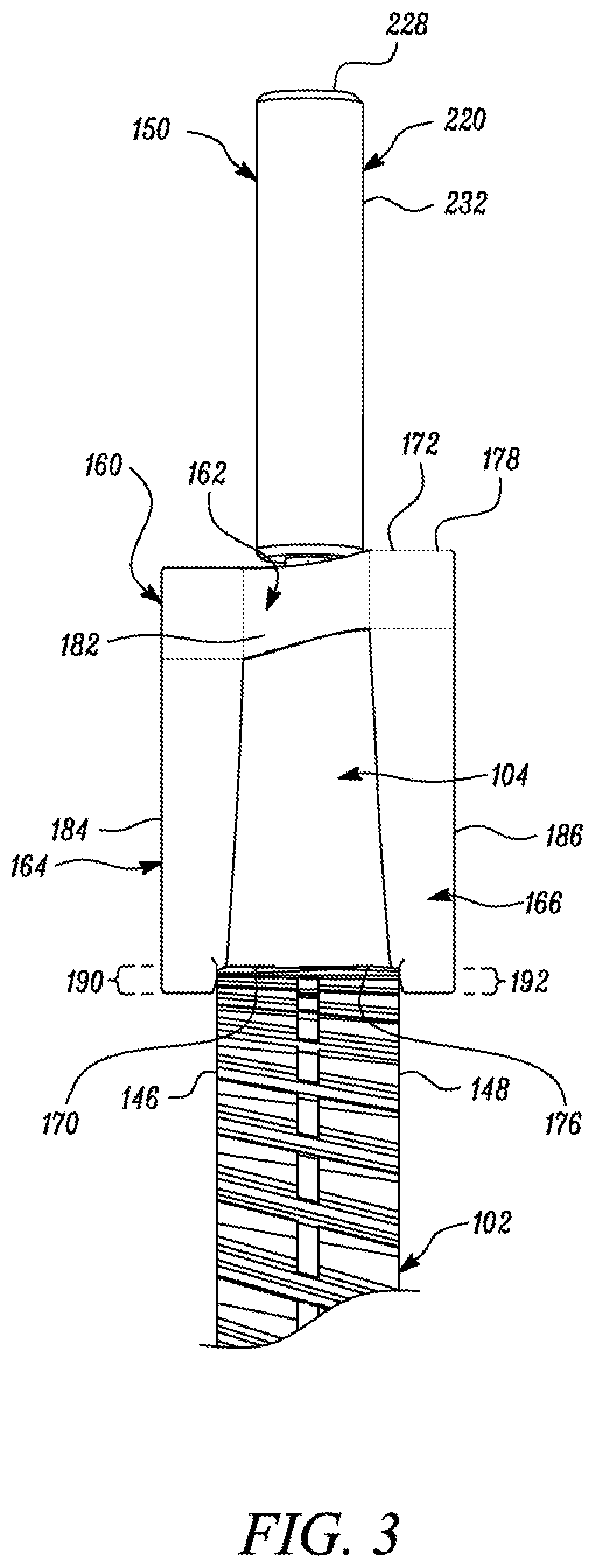

Replaceable staking insert assembly and corresponding method

The invention relates to a replaceable staking insert assembly and a corresponding method. The rotor assembly includes a rotor, at least one axial slot positioned about the rim of the rotor having a first staking recess positioned therein, a blade positioned within each of the axial slots having a second staking recess positioned therein, a staking insert having a base portion and a projection extending therefrom with the base portion being disposed within the first staking recess and the projection being disposed within the second staking recess, and a shim positioned within the first staking recess adjacent to the base portion, opposite the projection, of the staking insert. The first staking recess retains the staking insert while the projection of the staking insert retains the blade in both the aft and forward directions.

Owner:GENERAL ELECTRIC TECH GMBH

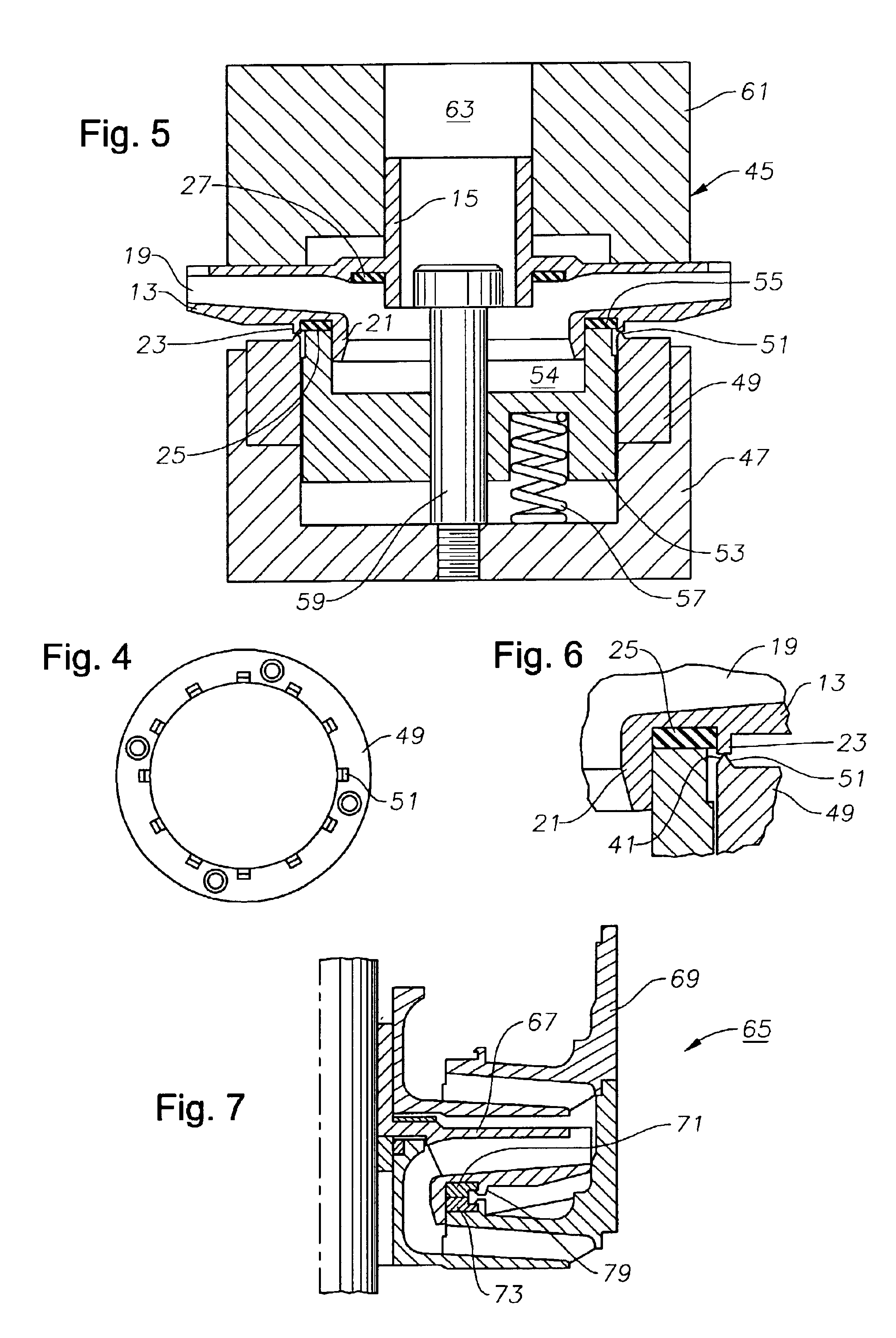

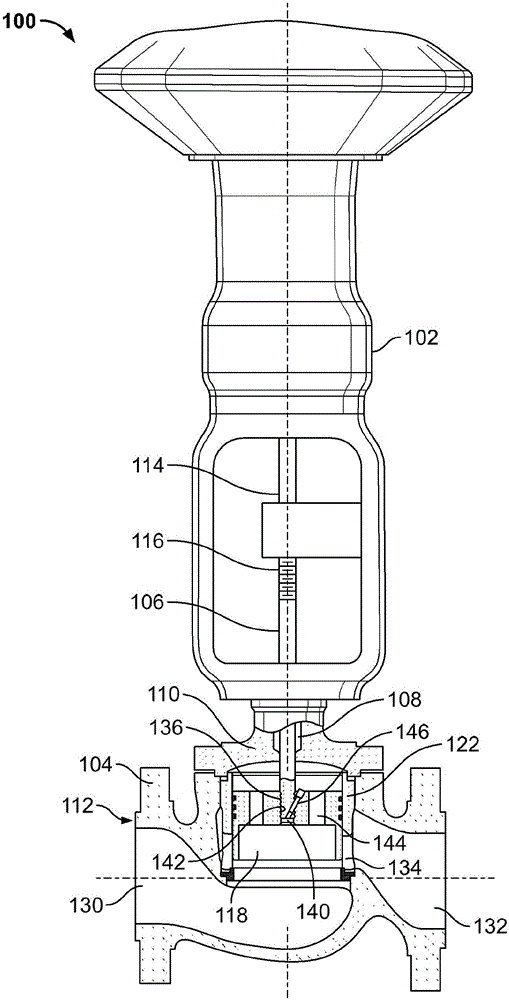

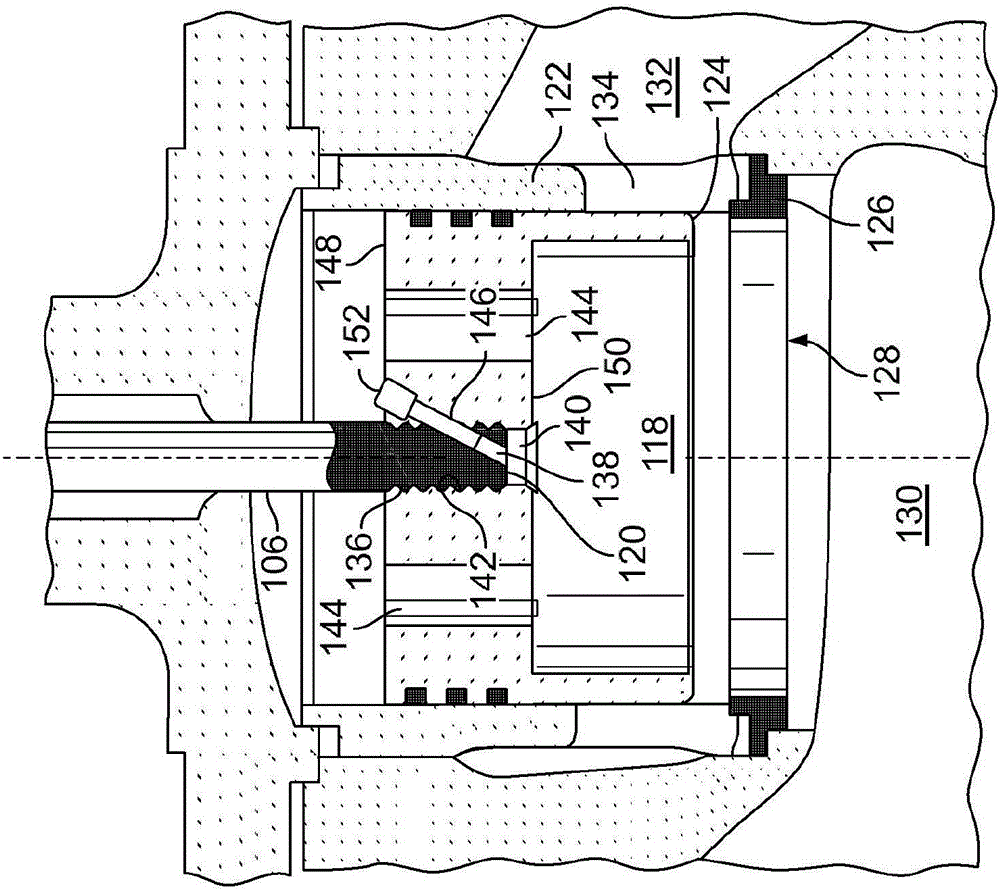

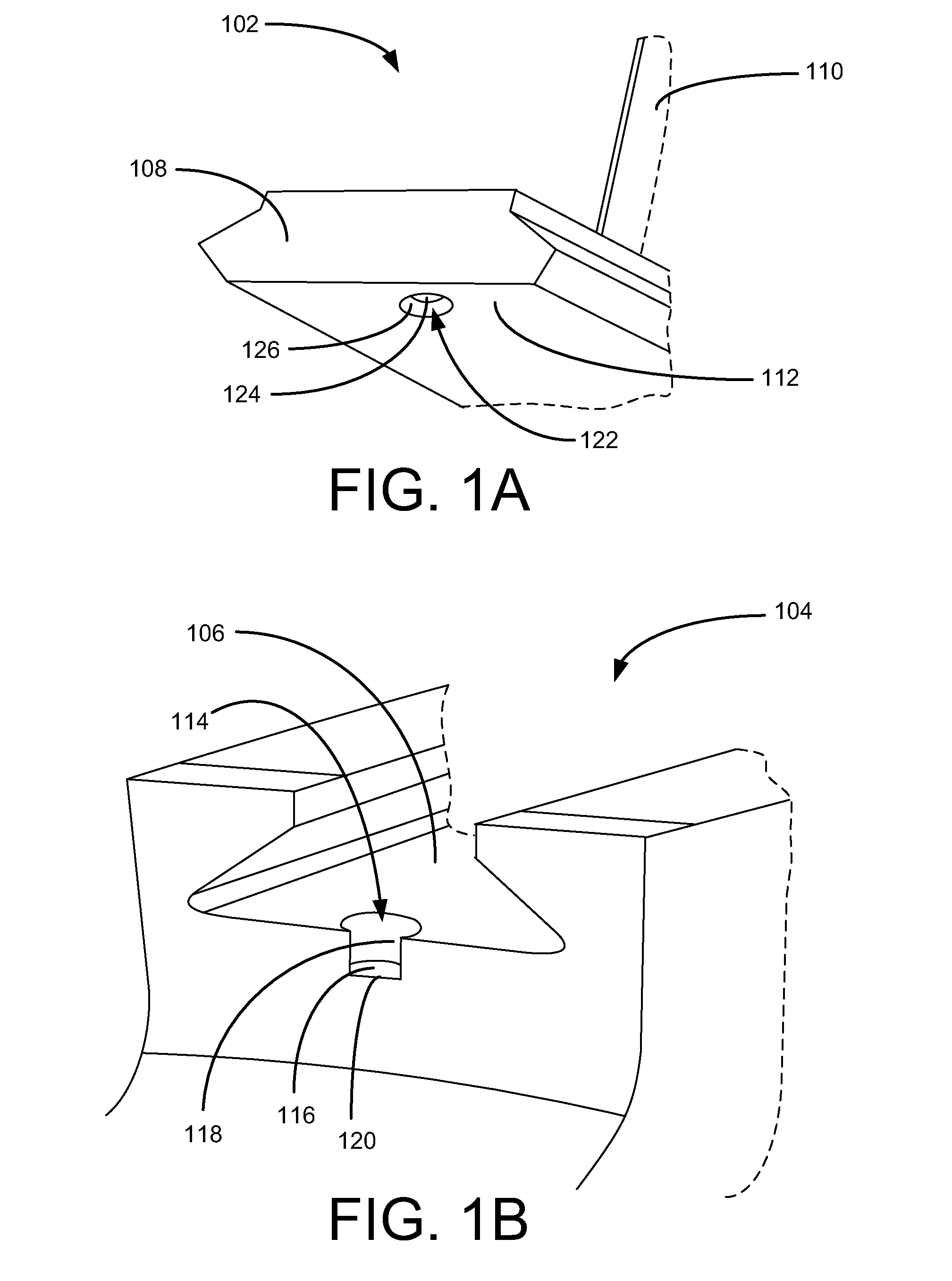

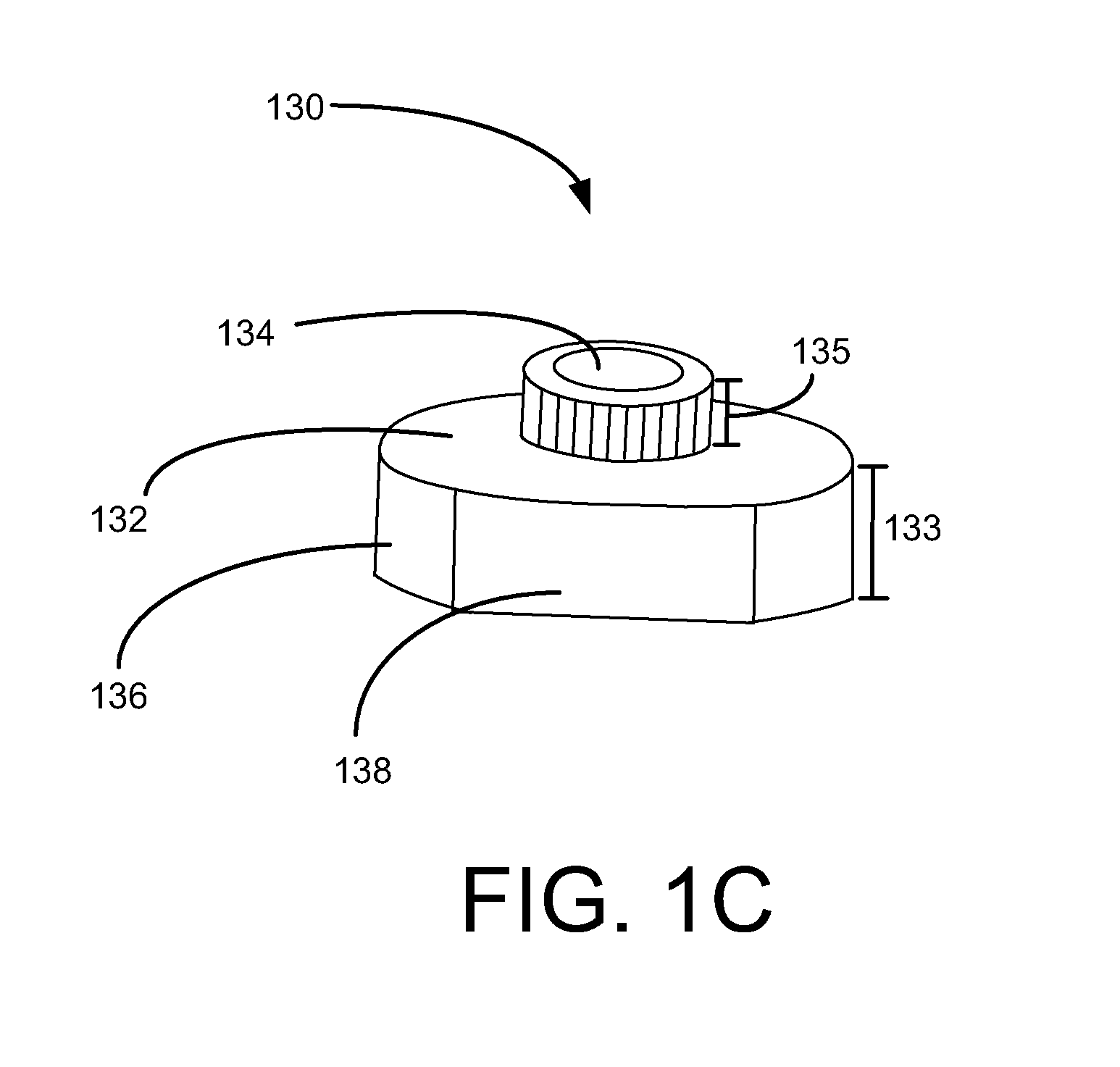

Valve stem and plug connections and staking tools

Example valve stem and plug connections and example staking tools are described herein. An example apparatus includes a valve plug having a first side, a second side opposite the first side and a bore extending from the first side to the second side. A first portion of the bore is tapered from a first diameter to a second diameter smaller than the first diameter. A valve stem is disposed within the bore of the valve plug. The valve stem includes a first section, a second section and a third section between the first and second sections. The third section is tapered from a third diameter to a fourth diameter smaller than the third diameter. The tapers of the first portion of the valve plug and the third section of the valve stem, when engaged, create a frictional force that resists movement of the valve stem out of the bore.

Owner:FISHER CONTROLS INT LLC

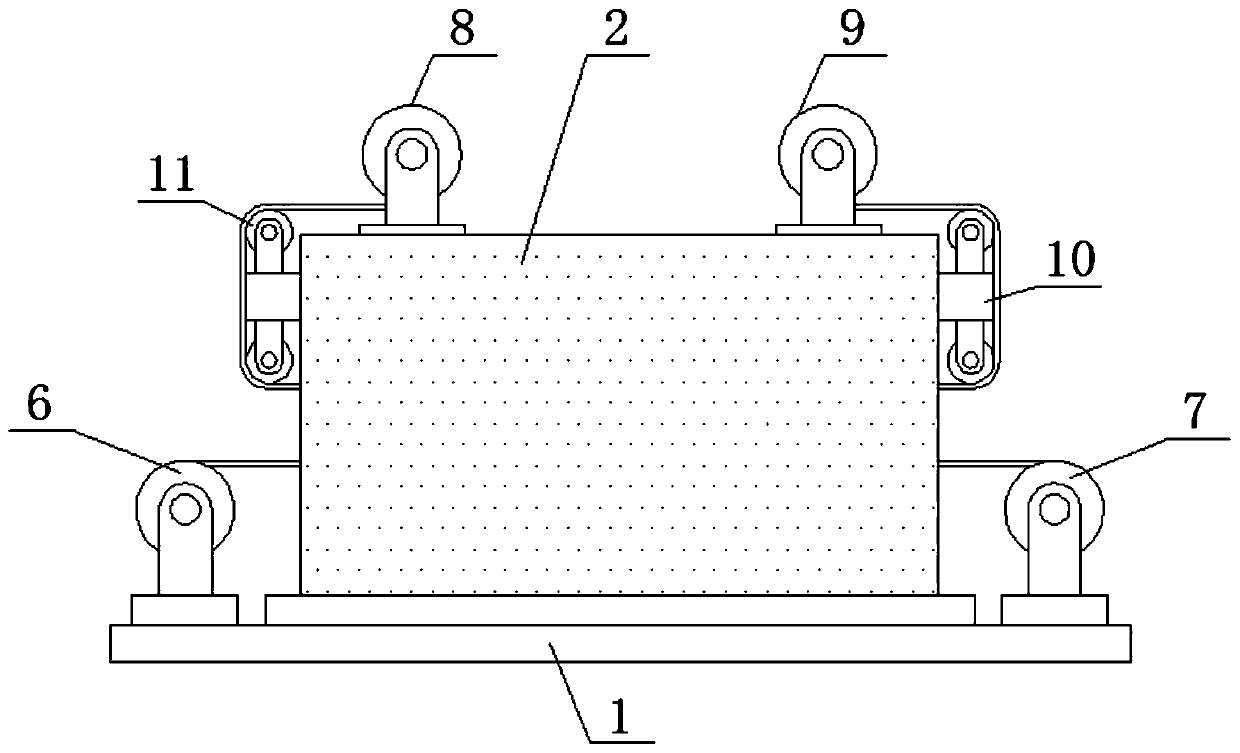

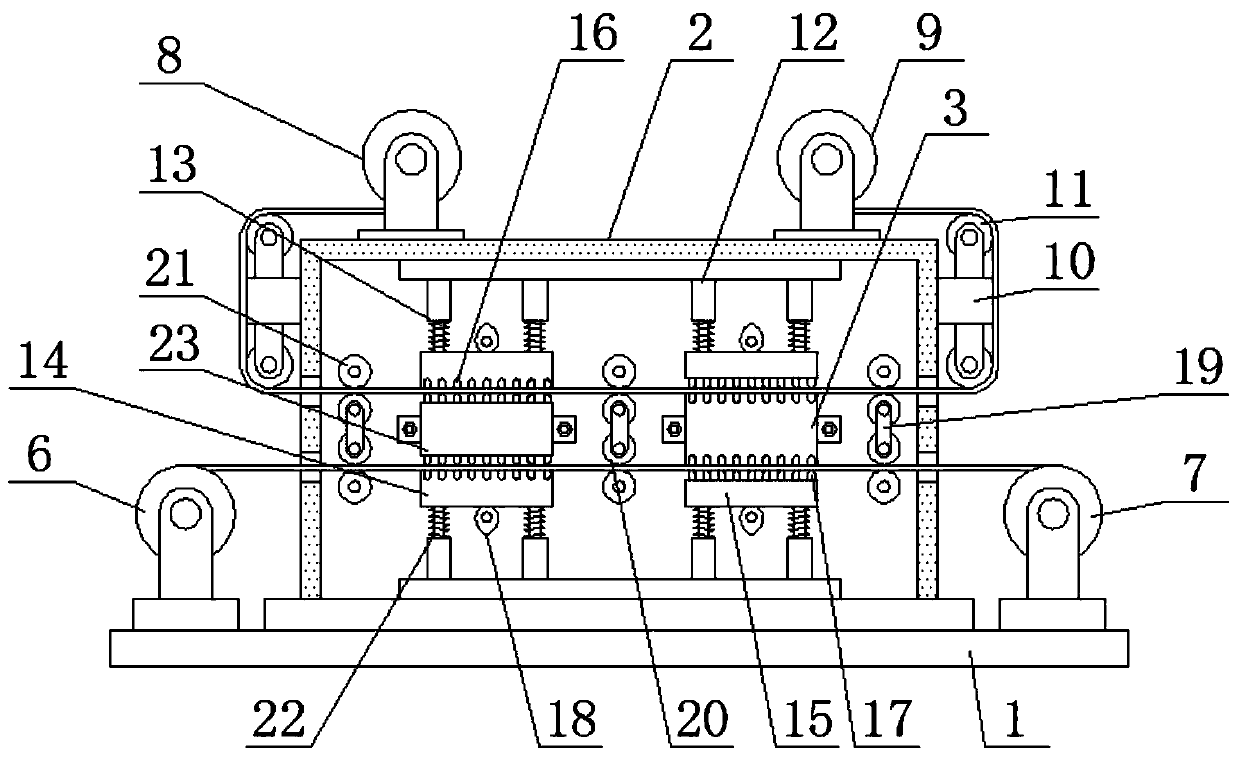

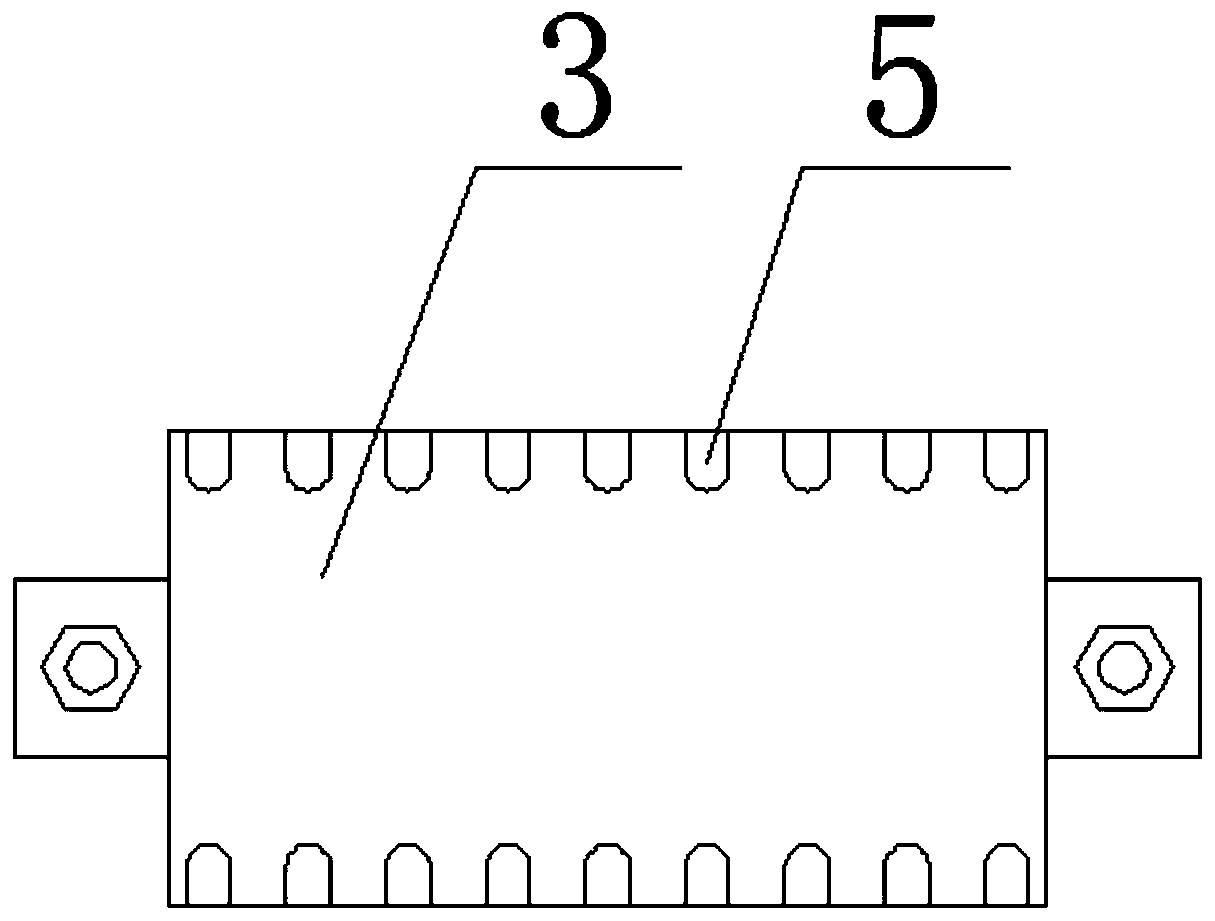

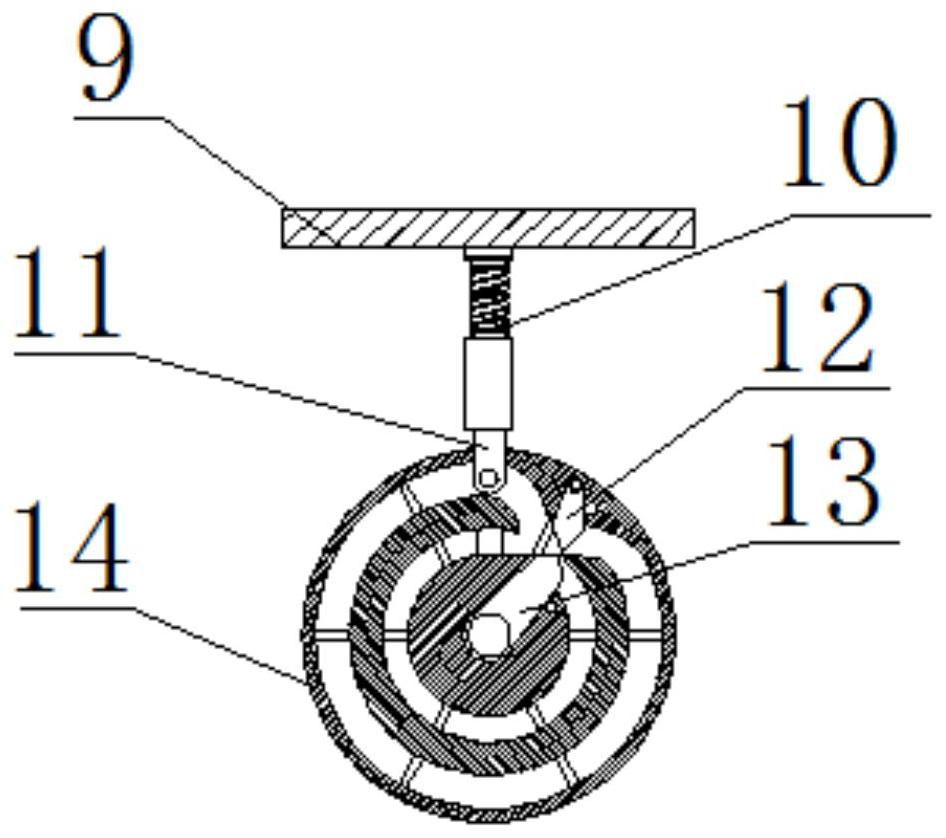

Multi-station traceless staking machine for leather machining

InactiveCN110819744AImprove softening effectImprove practicalitySkins/hides/leather/fur manufacturing apparatusLeather softeningStructural engineeringMachine

Owner:南通二轻精密装备有限公司

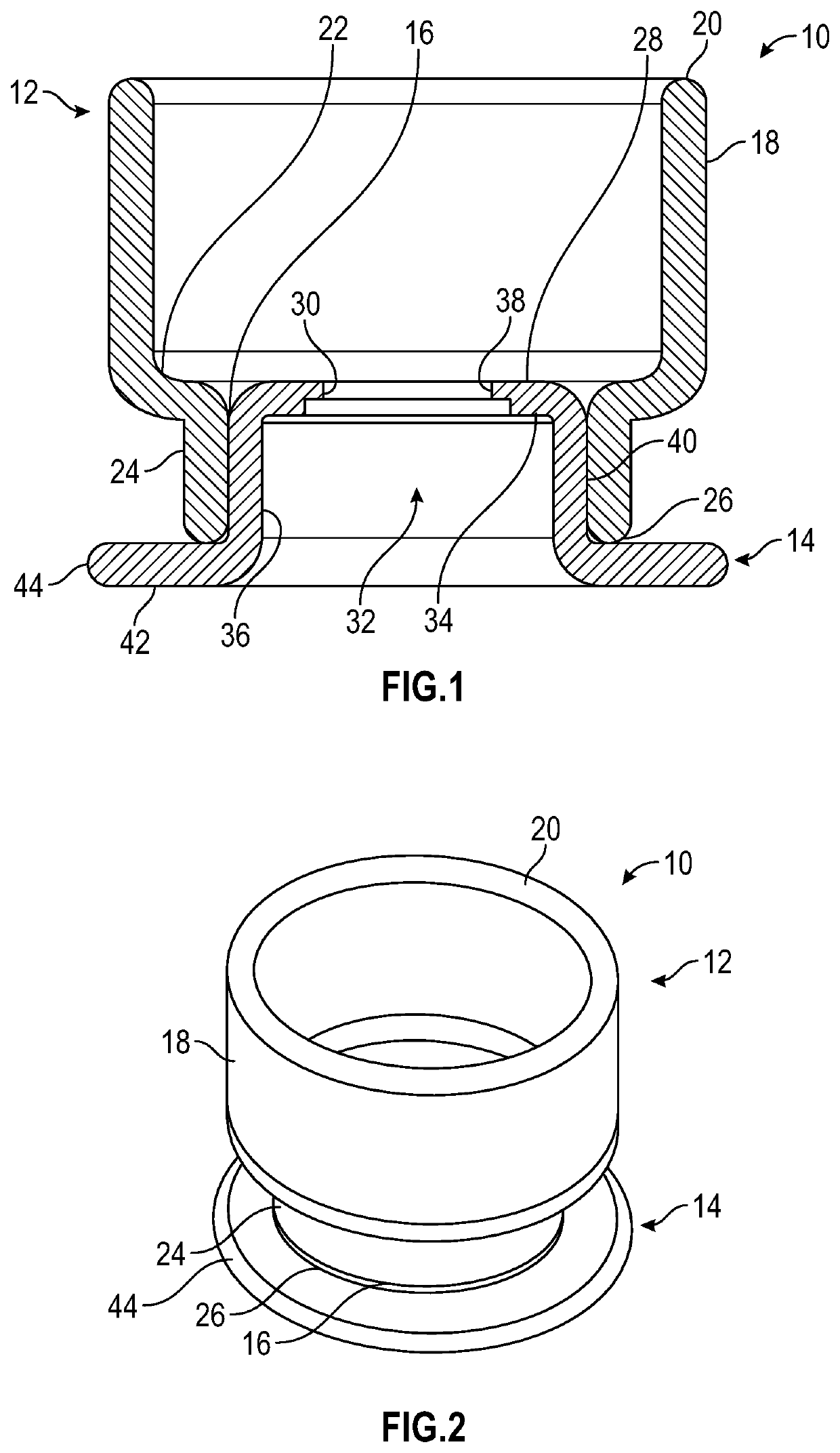

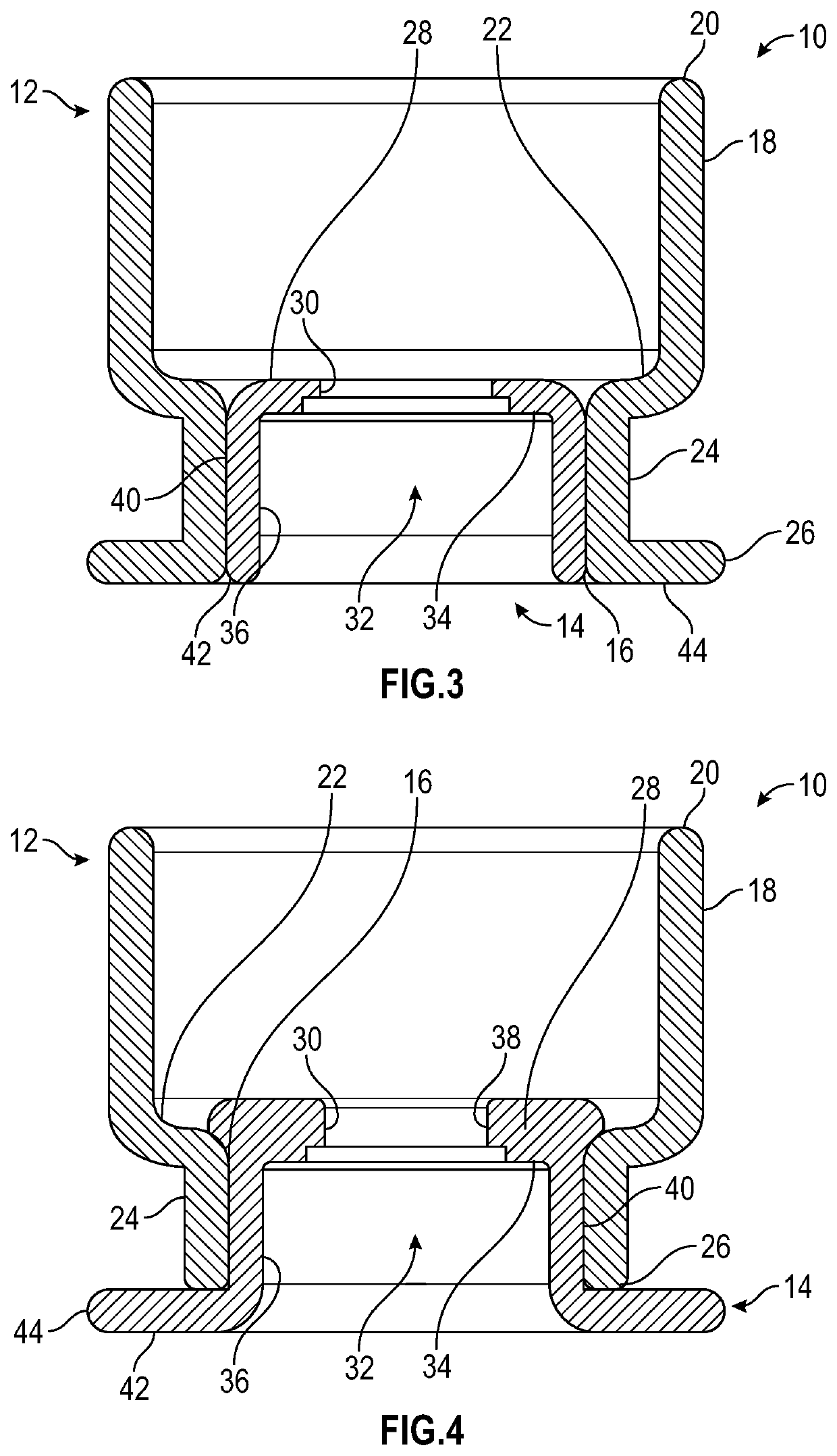

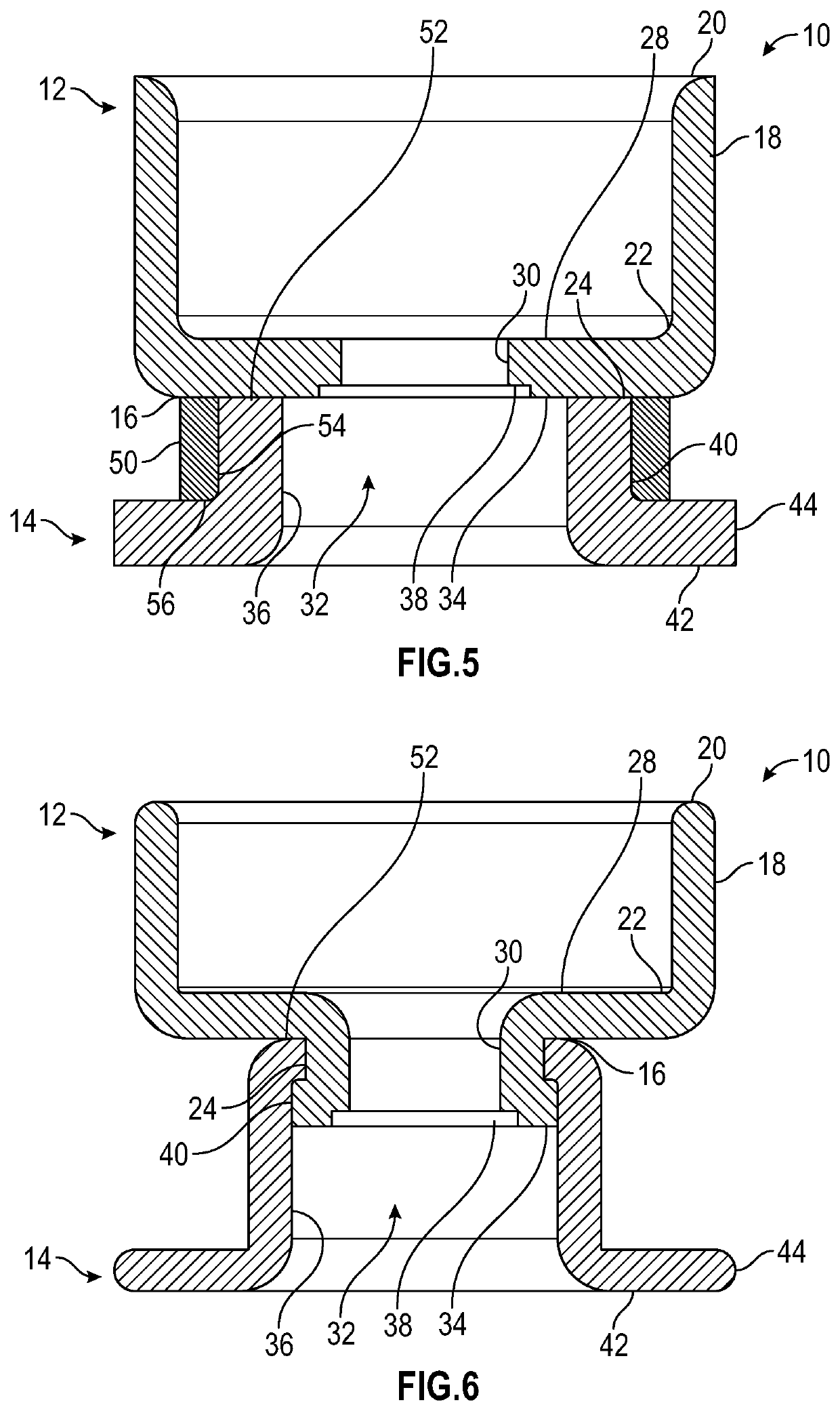

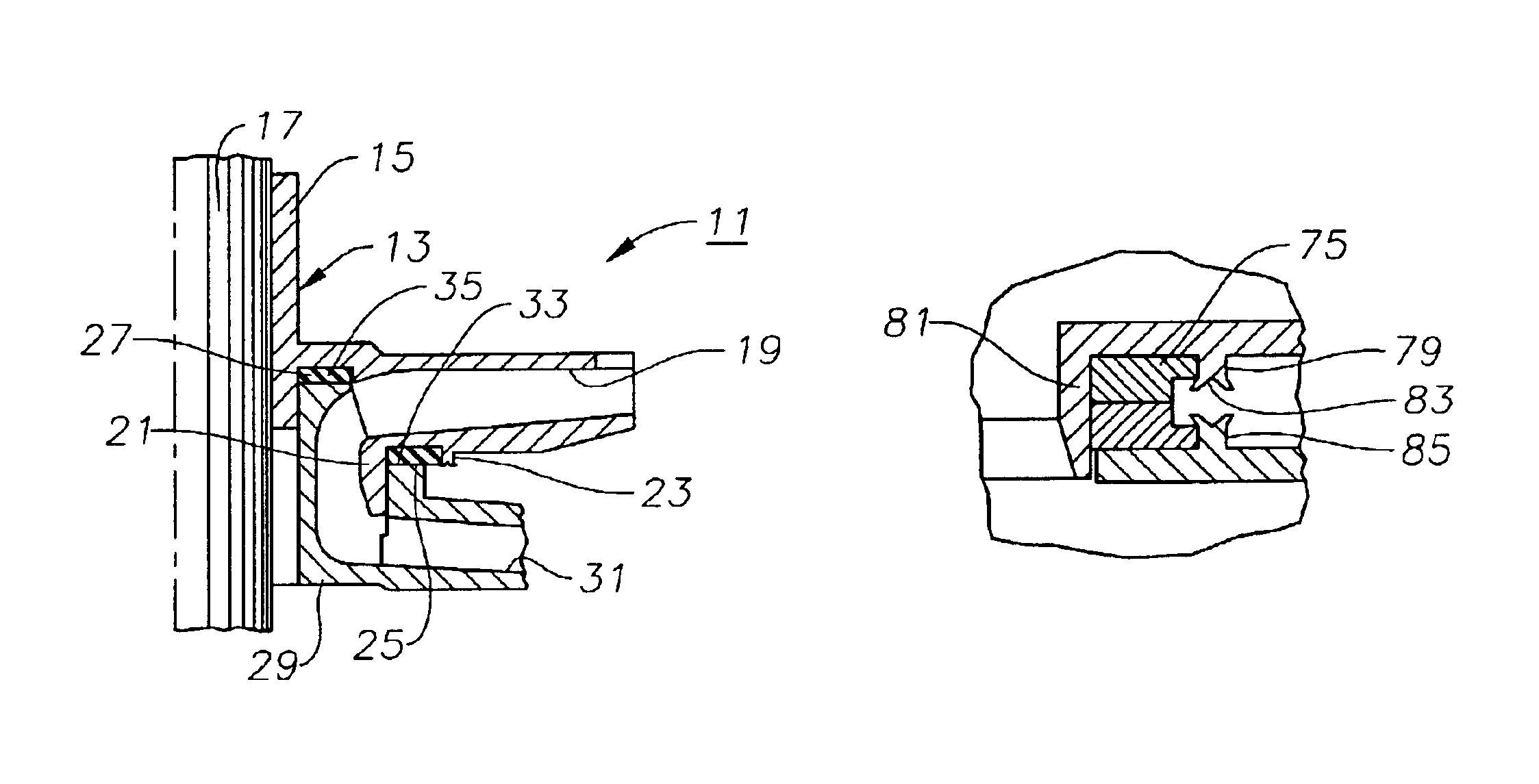

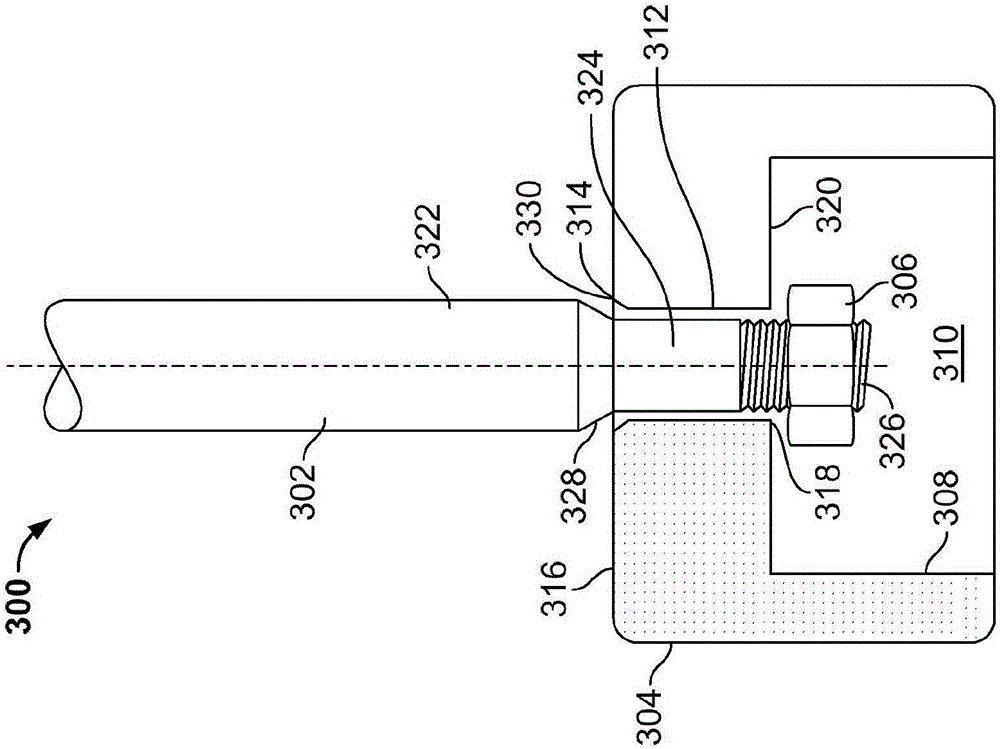

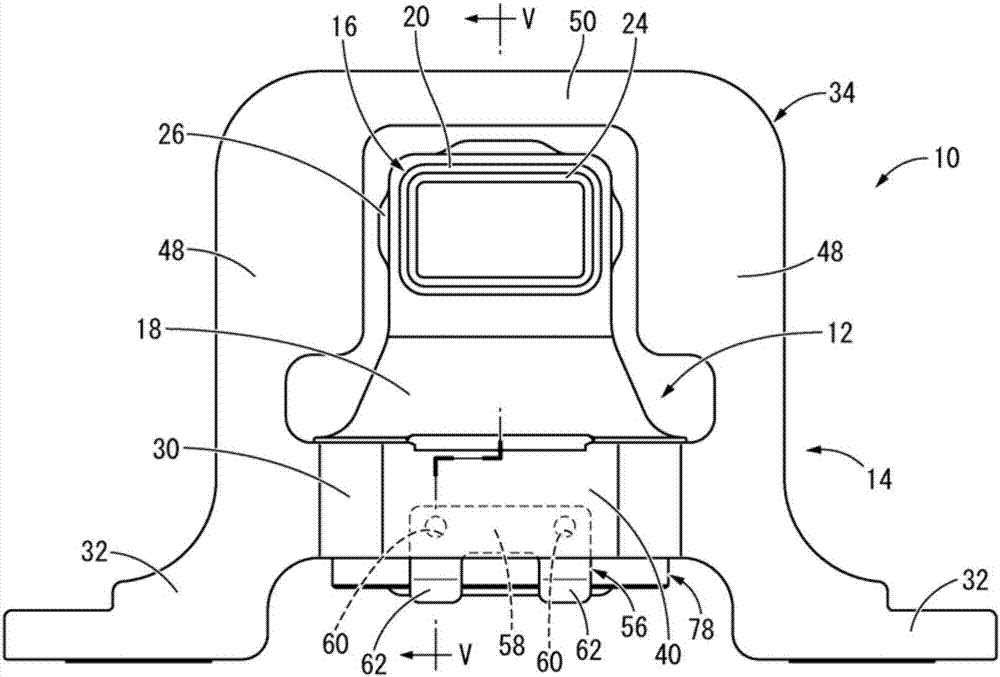

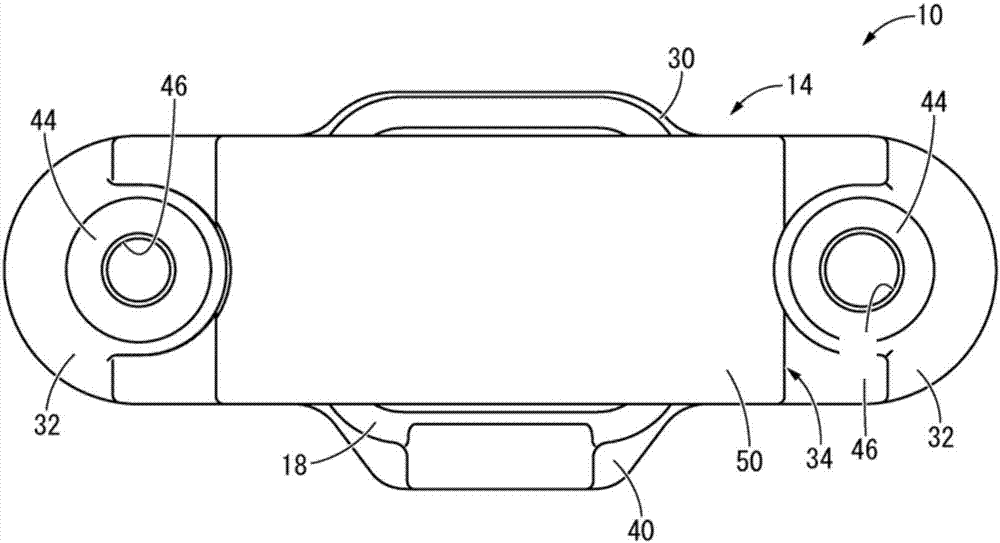

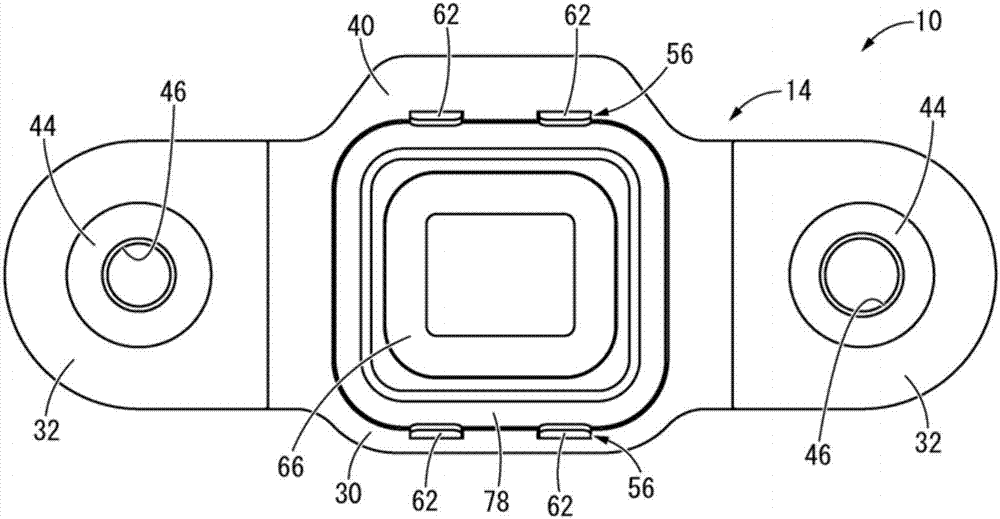

Fluid-filled vibration damping device

ActiveCN107250601AReduce in quantitySimple structureSpringsShock absorbersElastomerRubber elasticity

Provided is a fluid-filled vibration damping device having a novel structure, the fluid-filled vibration damping device being configured so that: the fluid-tightness of a fluid chamber can be ensured while the fluid-filled vibration damping device is simplified in structure by reducing the number of parts; and the fluid-filled vibration damping device can have excellent vibration damping performance. A fluid-filled vibration damping device 10 is configured so that: an inner mounting member 16 and an outer bracket 14 which is formed by molding will be elastically connected to each other by a main body rubber elastic body 18; and the fluid-filled vibration damping device 10 will be provided with a fluid chamber 84 which is filled with a non-compressive fluid and which has a wall, a part of which is configured from the main body rubber elastic body 18. A staking member 56 consisting of a material different from that of the outer bracket 14 is affixed in a protruding manner to the outer bracket 14. Cover members 66, 78 constituting other parts of the wall of the fluid chamber 84 are mounted to the outer bracket 14 by being affixed thereto by staking by means of the staking member 56.

Owner:SUMITOMO RIKO CO LTD

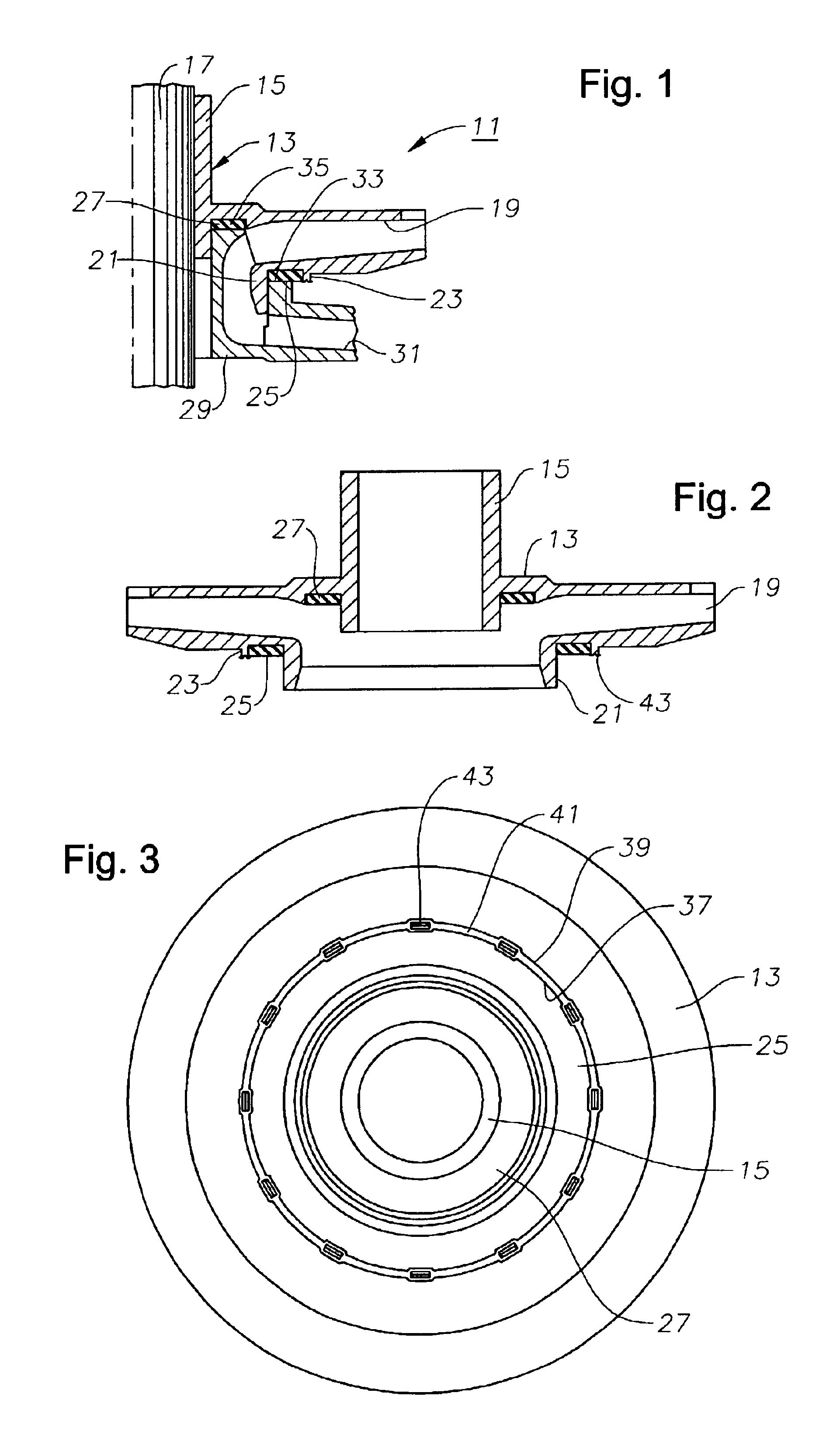

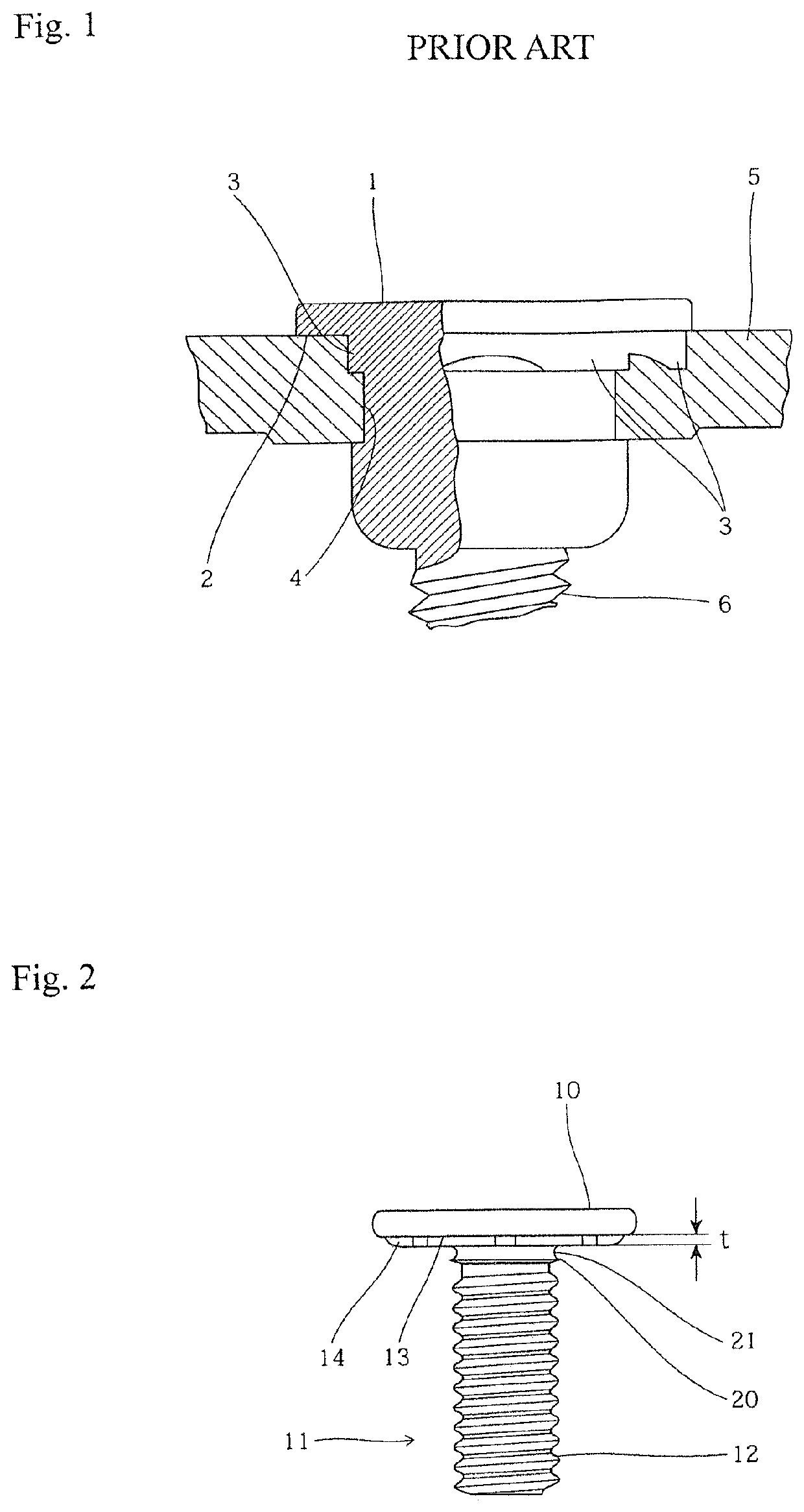

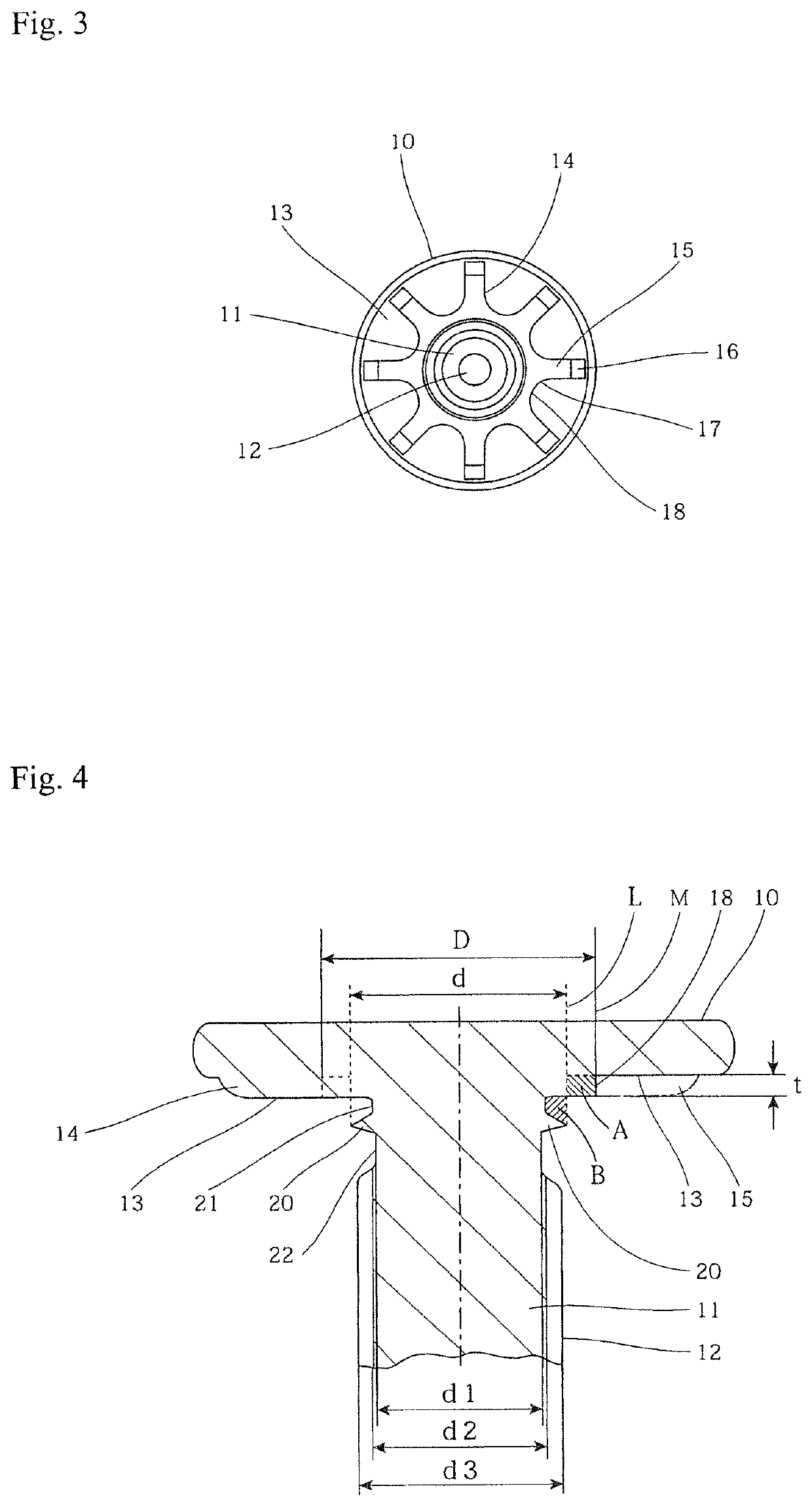

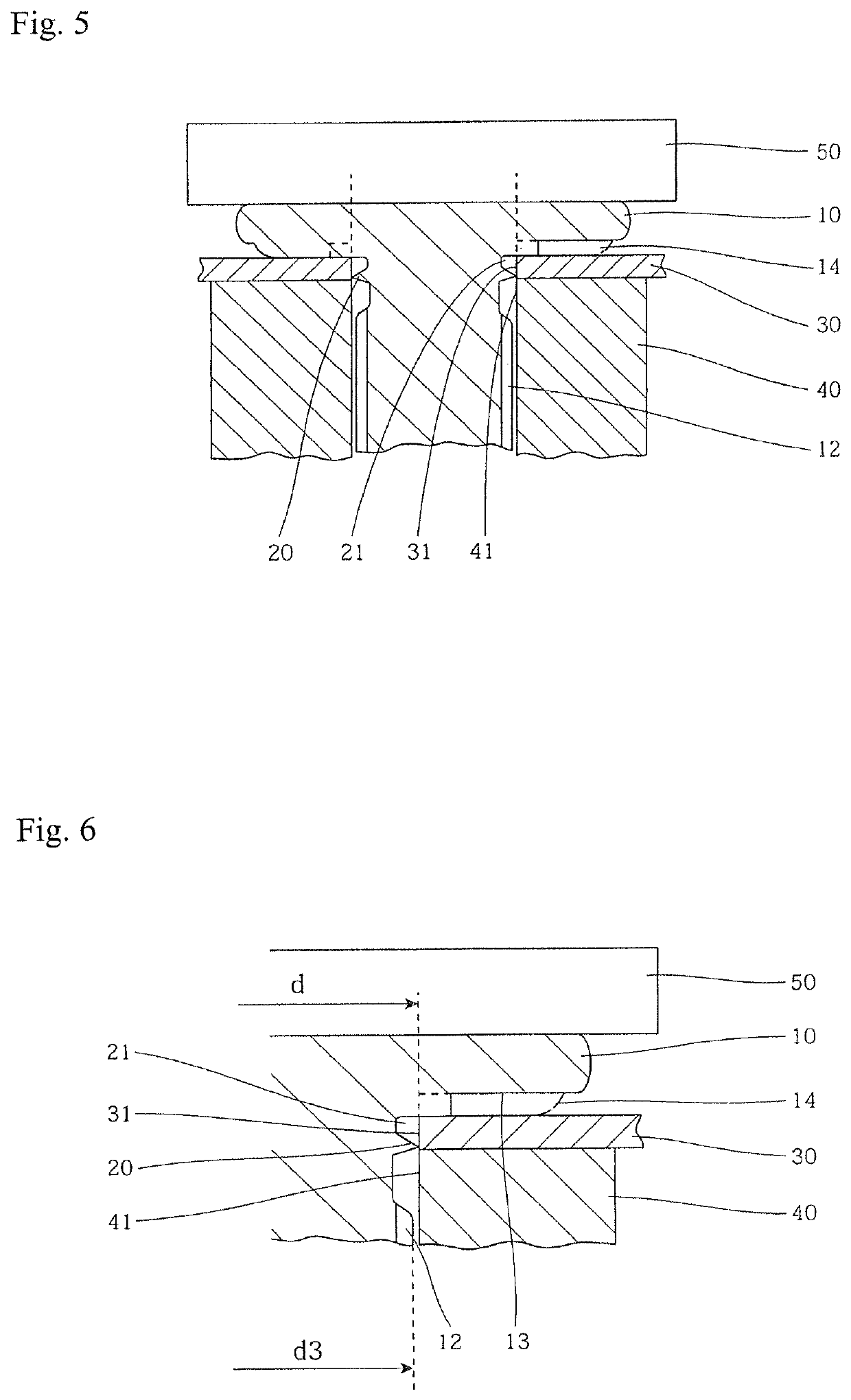

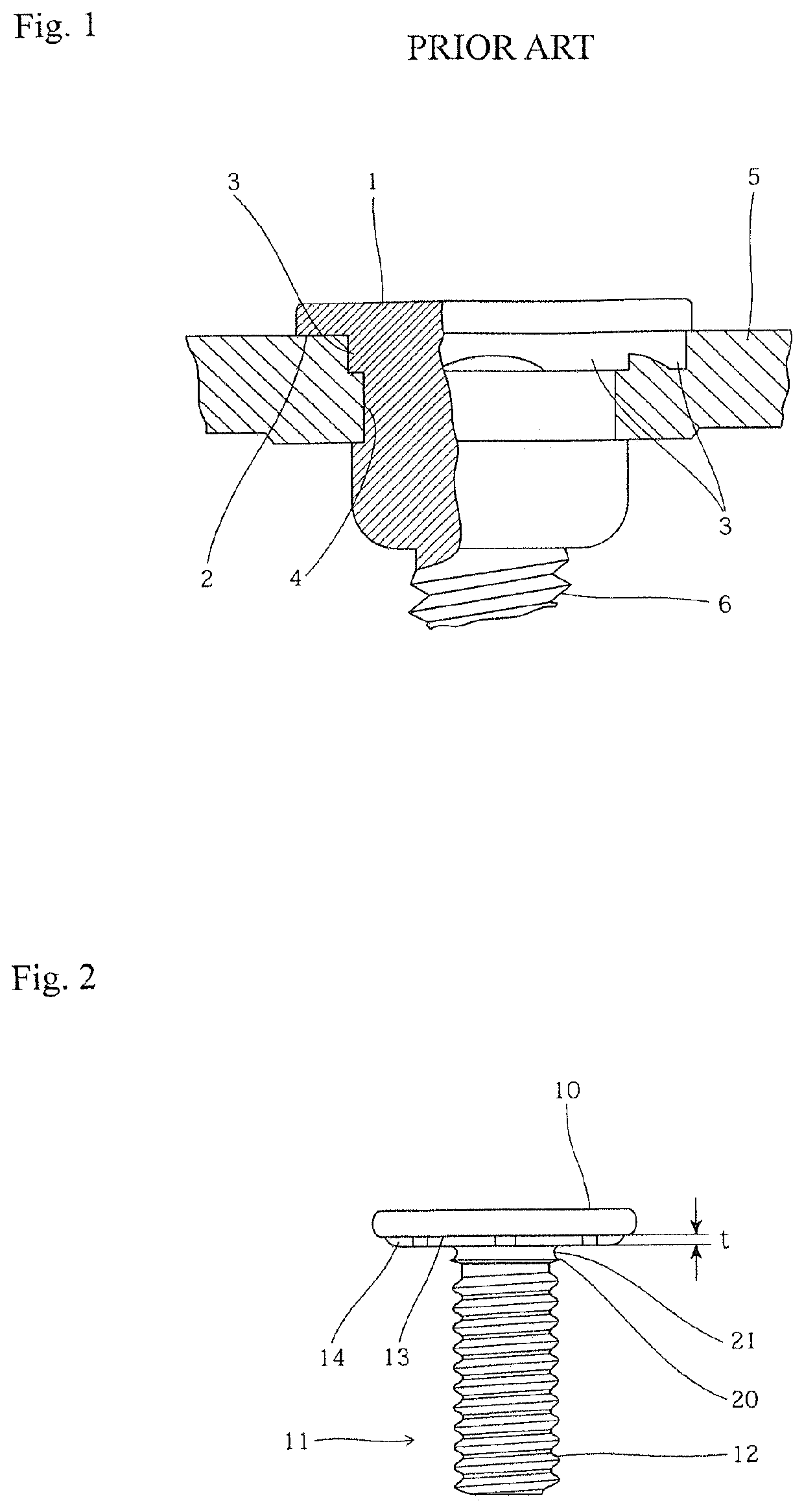

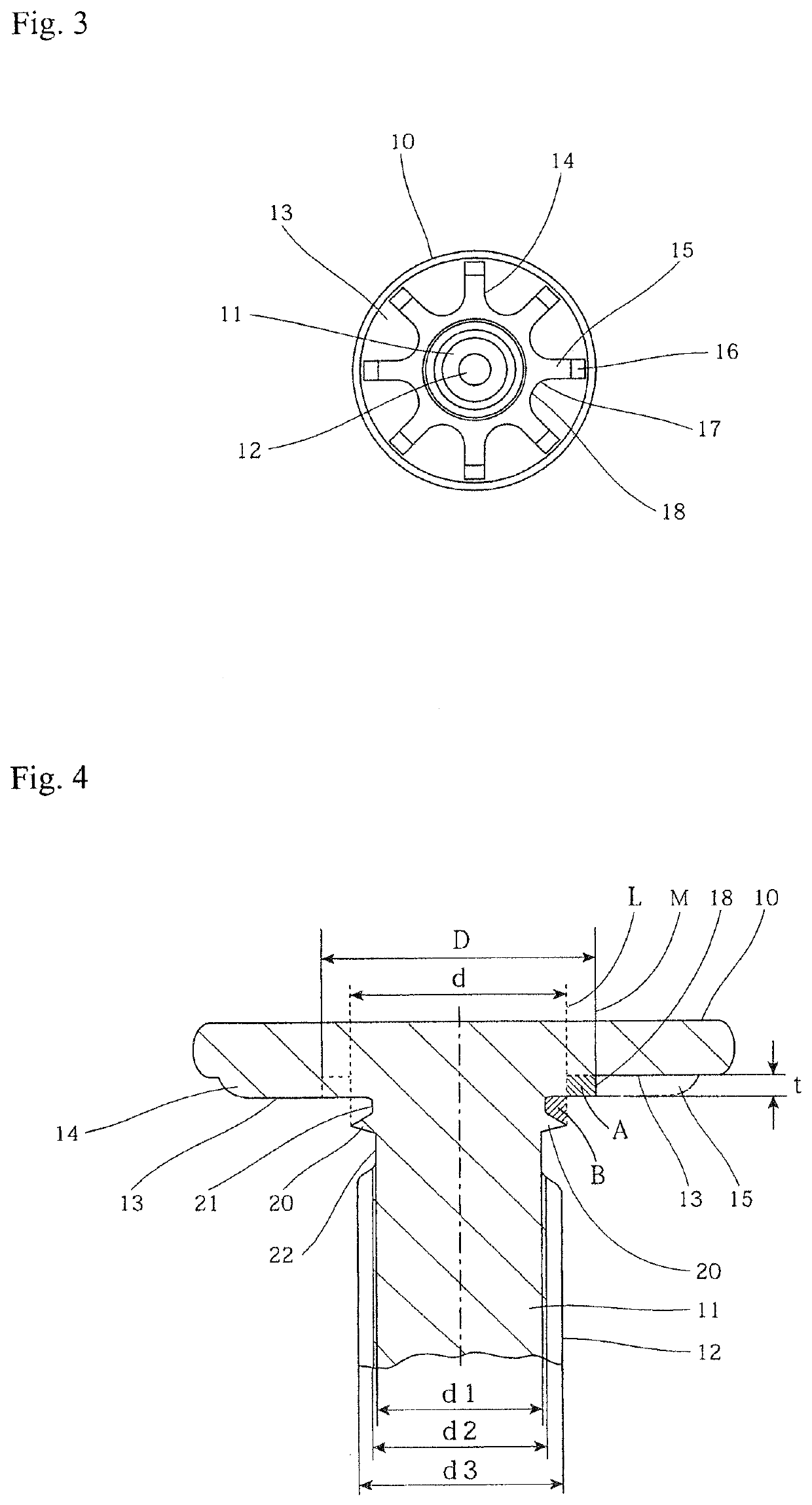

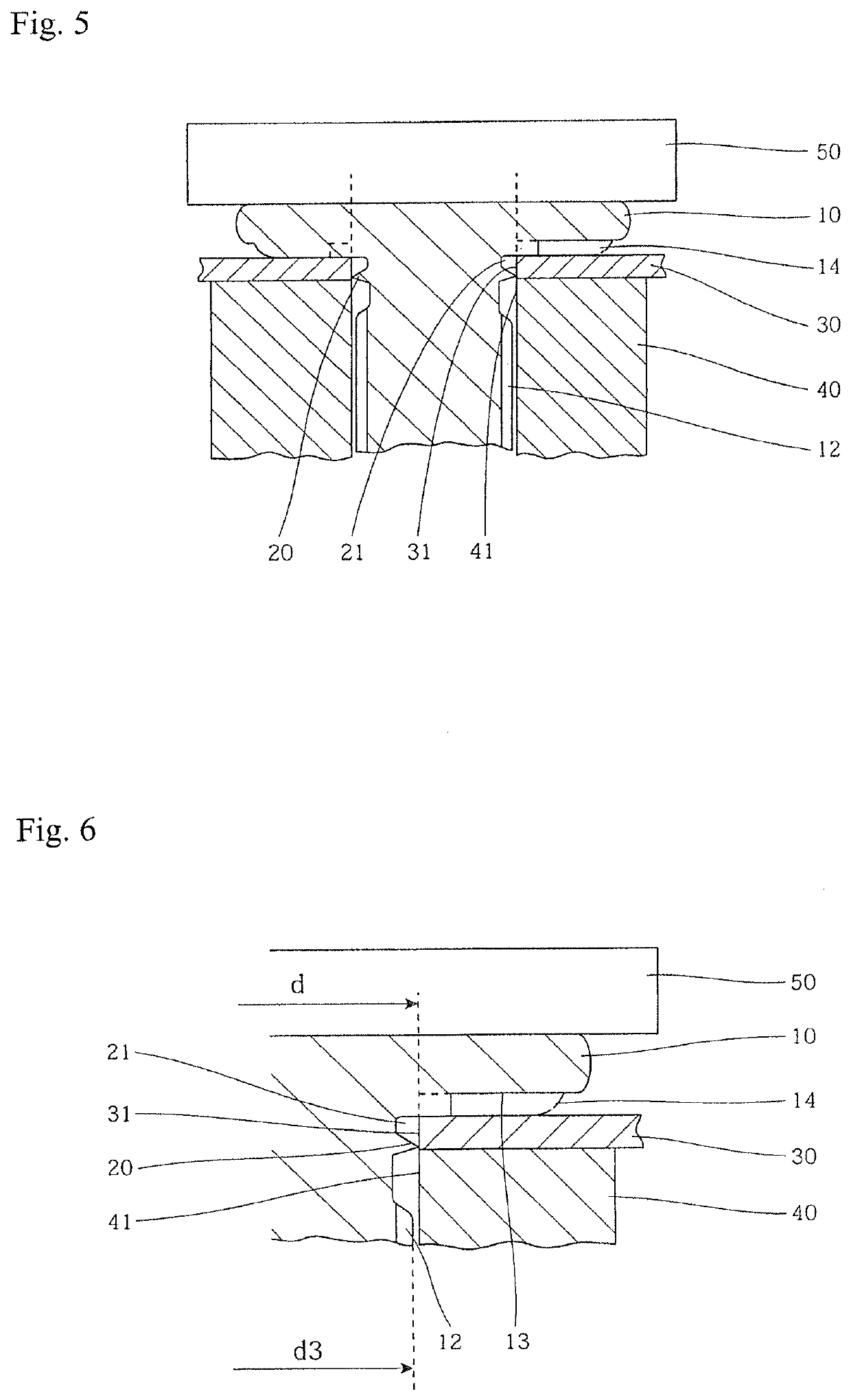

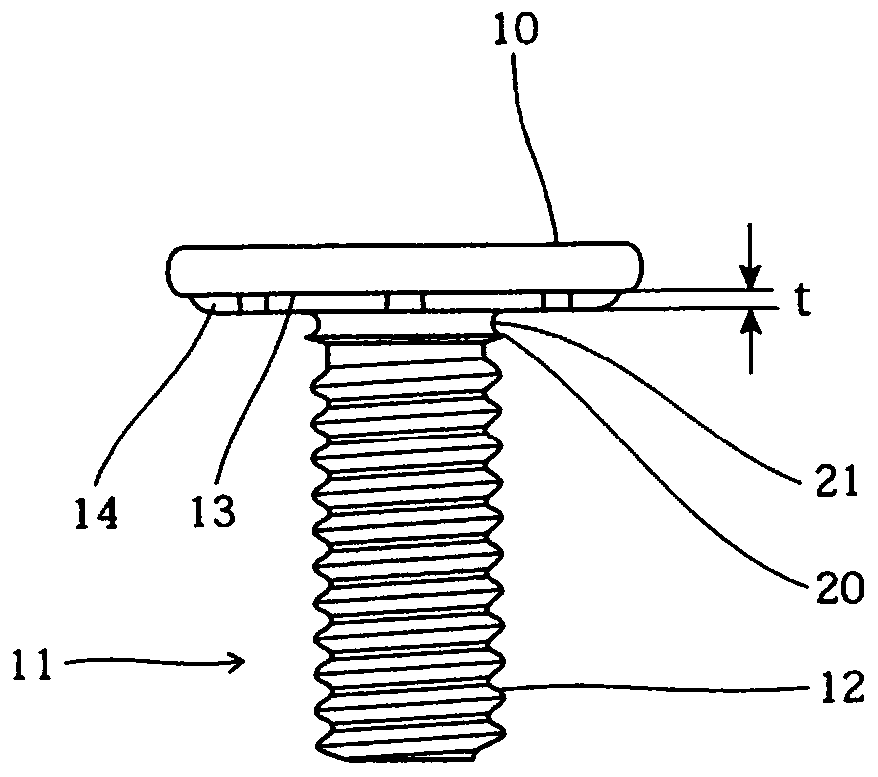

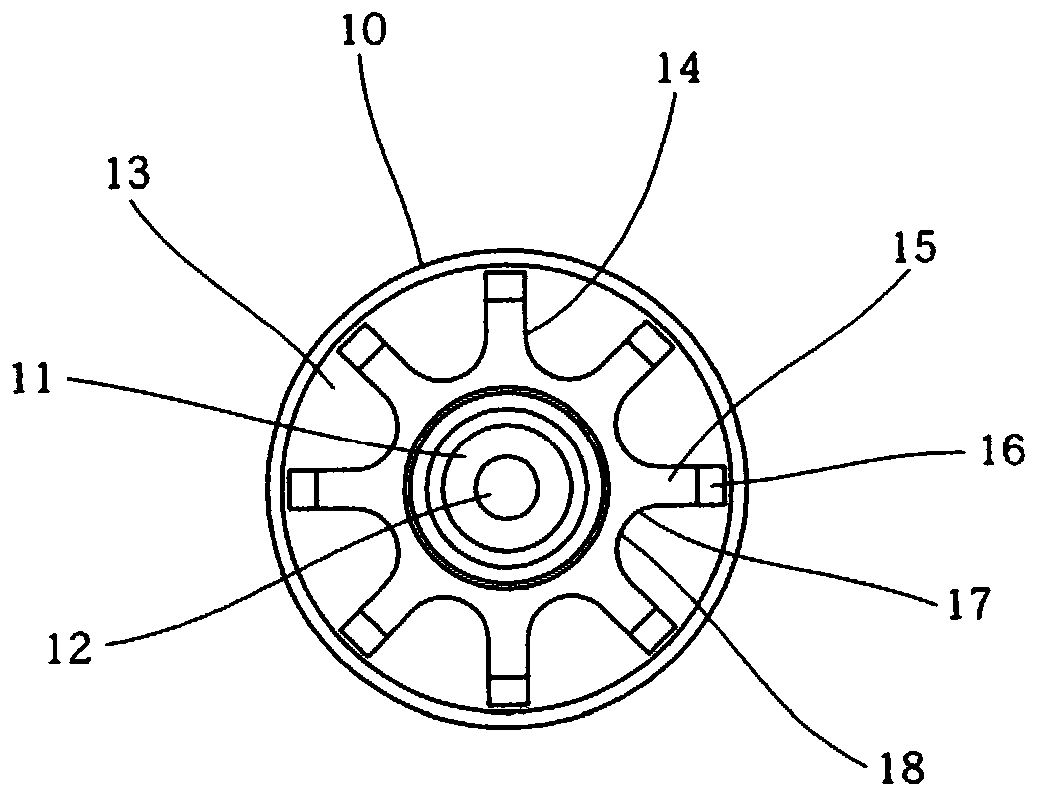

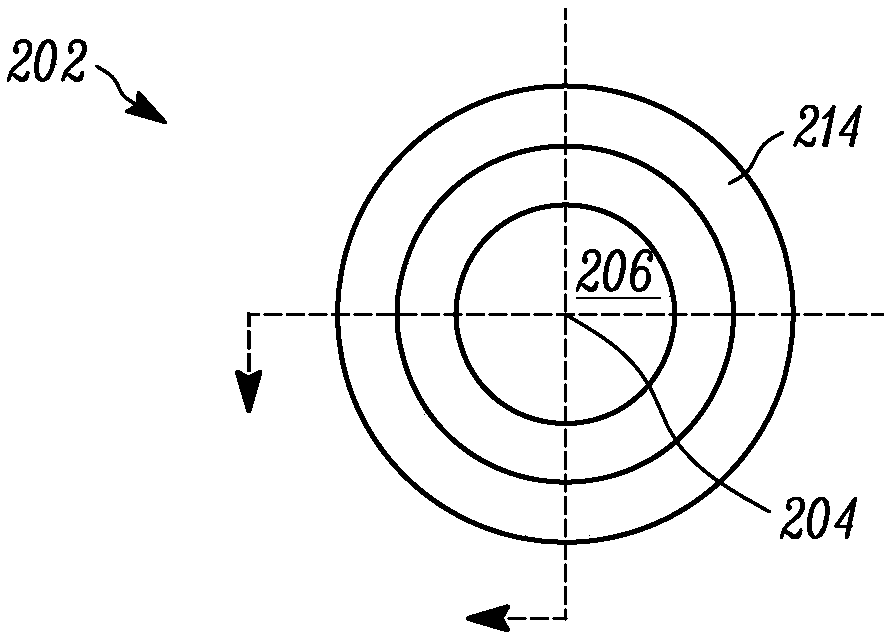

Staking bolt

The staking bolt of the present invention includes a head 10 and a shank 11 having an external thread 12. At the upper end of the shank 11, a ring-shaped protrusion 20 and a ring groove 21 located closer to the head relative to the ring-shaped protrusion 20 are formed. The head 10 is flat, and on the bearing face 13, a whirl-stop protrusion 14 having a plurality of radially extending arms 15 protrudes with a thickness of t. The minimum diameter D between respective arms 15 is larger than the outer diameter d of the ring-shaped protrusion 20, and t×(D−d) / 2 which is the longitudinal cross-sectional area A of the minimum diameter portion of the whirl-stop protrusion 14 is equal to or greater than the longitudinal cross-sectional area of the ring groove 21.

Owner:AOYAMA SEISAKUSHO CO LTD

Staking bolt

The staking bolt of the present invention includes a head 10 and a shank 11 having an external thread 12. At the upper end of the shank 11, a ring-shaped protrusion 20 and a ring groove 21 located closer to the head relative to the ring-shaped protrusion 20 are formed. The head 10 is flat, and on the bearing face 13, a whirl-stop protrusion 14 having a plurality of radially extending arms 15 protrudes with a thickness oft. The minimum diameter D between respective arms 15 is larger than the outer diameter d of the ring-shaped protrusion 20, and t×(D−d) / 2 which is the longitudinal cross-sectional area A of the minimum diameter portion of the whirl-stop protrusion 14 is equal to or greater than the longitudinal cross-sectional area of the ring groove 21.

Owner:AOYAMA SEISAKUSHO CO LTD

Staking bolt

Owner:AOYAMA SEISAKUSHO CO LTD

Replaceable staking insert assembly and method

A rotor assembly. The rotor assembly may include a rotor, at least one axial slot positioned about the rim of the rotor having a first staking recess positioned therein, a blade positioned within each of the axial slots having a second staking recess positioned therein, a staking insert having a base portion and a projection extending therefrom with the base portion being disposed within the first staking recess and the projection being disposed within the second staking recess, and a shim positioned within the first staking recess adjacent to the base portion, opposite the projection, of the staking insert. The first staking recess retains the staking insert while the projection of the staking insert retains the blade in both the aft and forward directions.

Owner:GENERAL ELECTRIC CO

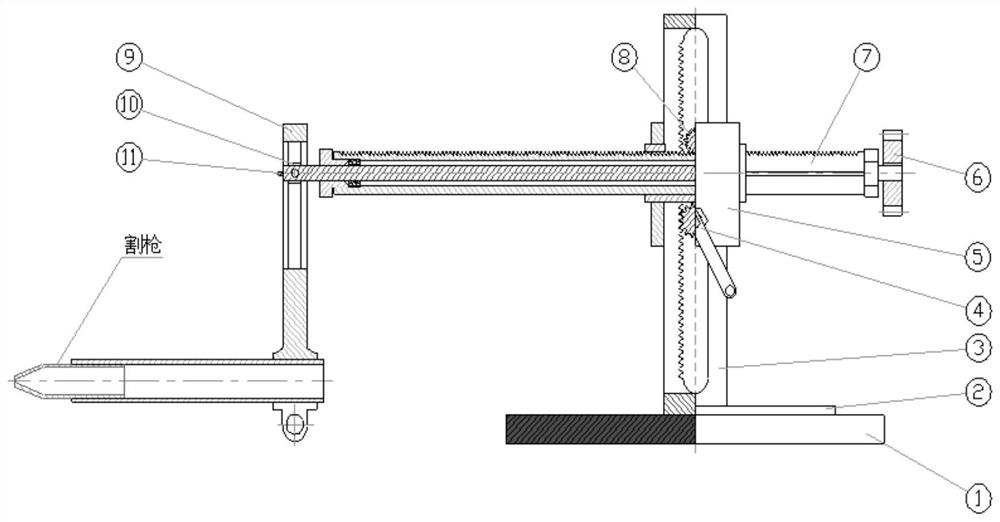

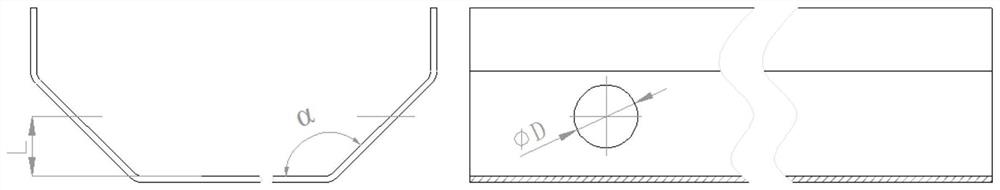

A tool for opening holes in the bent bottom plate of the lower section of the bell-type transformer oil tank

InactiveCN110640332BEliminate the stake out processImprove quality and efficiencyLaser beam welding apparatusGear wheelControl system

The invention discloses a bell jar type transformer oil tank lower section bending bottom plate opening tooling, comprising an electromagnet base, an electrical control system, a Y-direction moving guide rail, a Y-direction driving gear set, a slider A, and a driving gear rotating around the X-direction , X-direction moving and rotating structure group, X-direction driving gear group, torch clamping device, fixing bolt group and laser pointer, the electromagnet base fixes the device as a whole on the plane of the bottom plate of the lower section, and the electrical control system It is electrically connected with the torch, the Y-direction moving guide rail is provided with a high-precision scale, and the slider A is set on the outside of the Y-direction moving guide rail. The present invention has the advantages of compact overall structure, convenient maintenance, simple and flexible operation. Its own size and positioning size are unified, which greatly improves the quality of opening the installation hole of the pipe joint and the working efficiency.

Owner:SHANDONG MINGRUN POWER STATION EQUIP +1

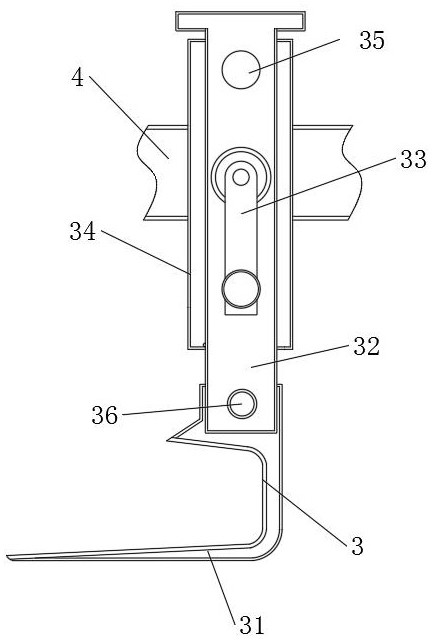

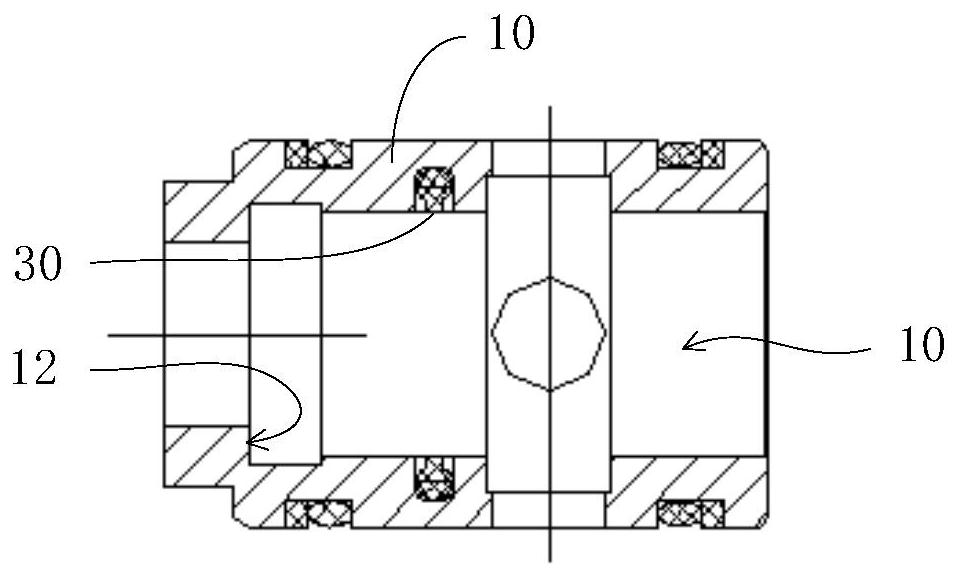

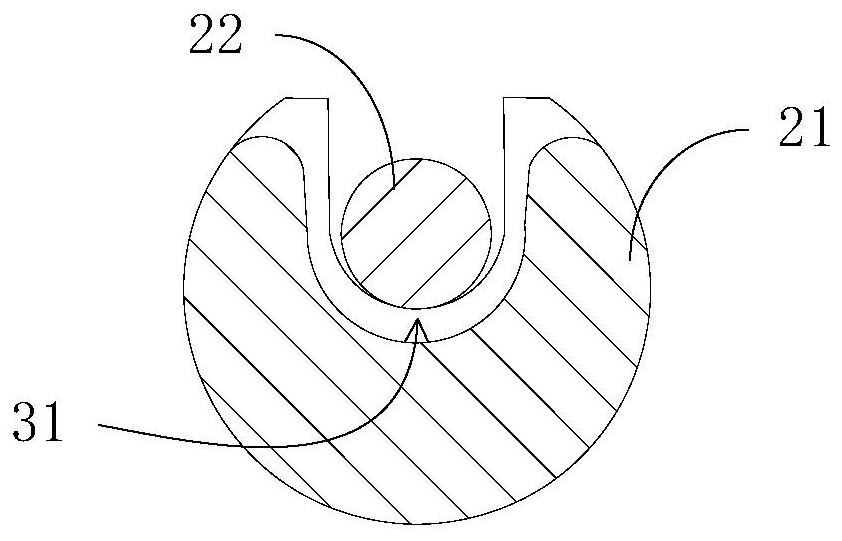

An assembly tooling and assembly method for a small-sized composite seal

ActiveCN109397171BCause lifespan problemsGood for deformation controlMetal working apparatusMetal-working hand toolsStructural engineeringMechanics

The invention discloses an assembling tool and an assembling method of a small-size combined sealing part. The assembling tool comprises a ring staking column, a compression rod and a positioning andshaping rod, wherein the ring staking column is used for allowing one combined sealing part or above to be arranged on the ring staking column in a sleeved mode, the compression rod is matched with the ring staking column and is used for arranging the combined sealing part into a heart shape, the outer peripheral size of the combined sealing part is enabled to be reduced, and is suitable for beinginserted into an inner cavity of a workpiece; the positioning and shaping rod is arranged in an inner cavity which is working, is used for carrying out axial positioning on the ring staking column, and shaping is carried out on the released combined sealing part. According to the assembling tool and the assembling method, the combined sealing part is arranged into the heart shape, the deformationis controllable, so that the problems of poor sealing performance and the service life of sealing rings caused by disordered deformation of the combined sealing part during manual assembling are avoided, the assembling quality is guaranteed, and the working efficiency is improved.

Owner:HEFEI CHANGYUAN HYDRAULICS

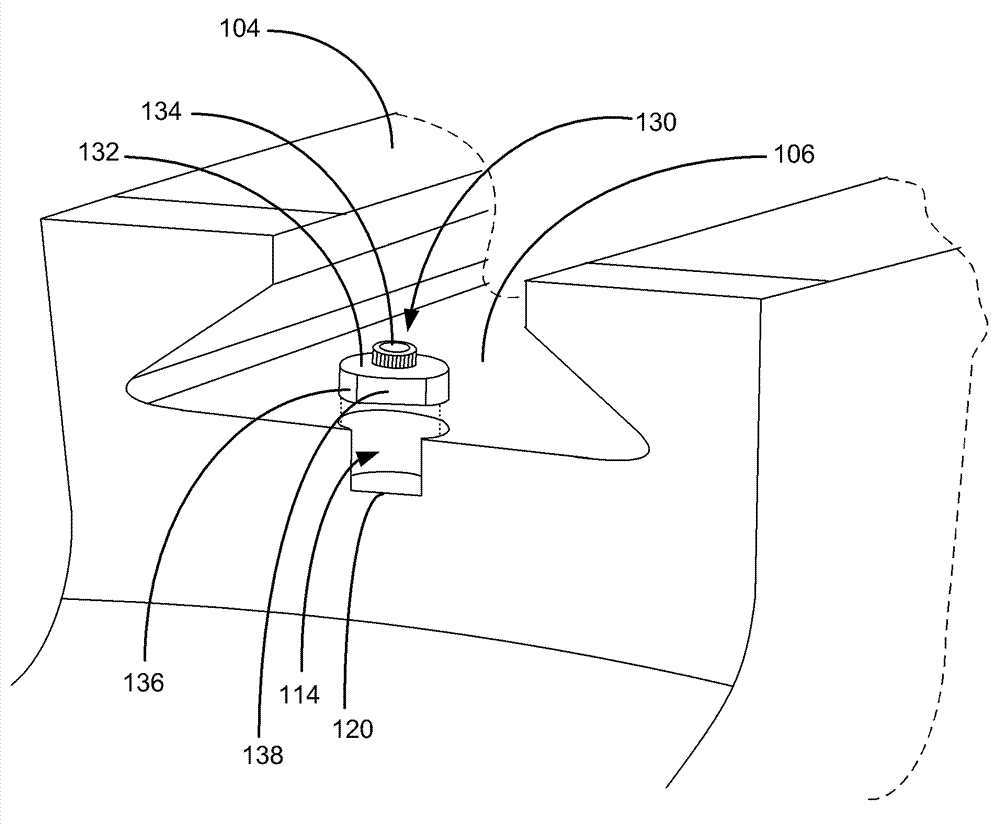

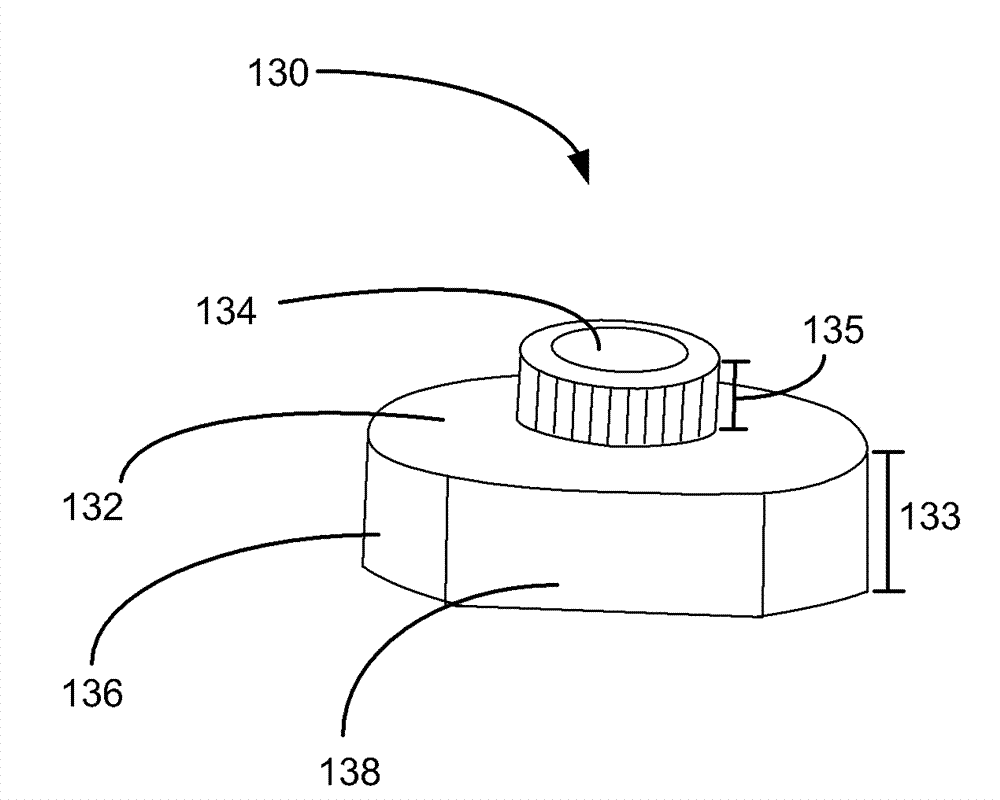

Staking tool and method of using the same

A staking tool is provided that is coupled to an axle of a vehicle and that includes a collar and a striker. The collar includes a guide notch defined on an interior surface. The striker includes a shaft and a handle. The shaft includes an angled tip at a first end of the striker and the handle includes a striking surface at a second end of the striker. The shaft is configured to slide longitudinally within the guide notch. A method for staking a spindle nut is also provided that includes positioning a collar over the spindle nut fastened on an axle of a vehicle, aligning a guide notch on the collar with a staking notch on the axle, inserting a striker into the guide notch, and striking the striker with a hammer.

Owner:HONDA MOTOR CO LTD

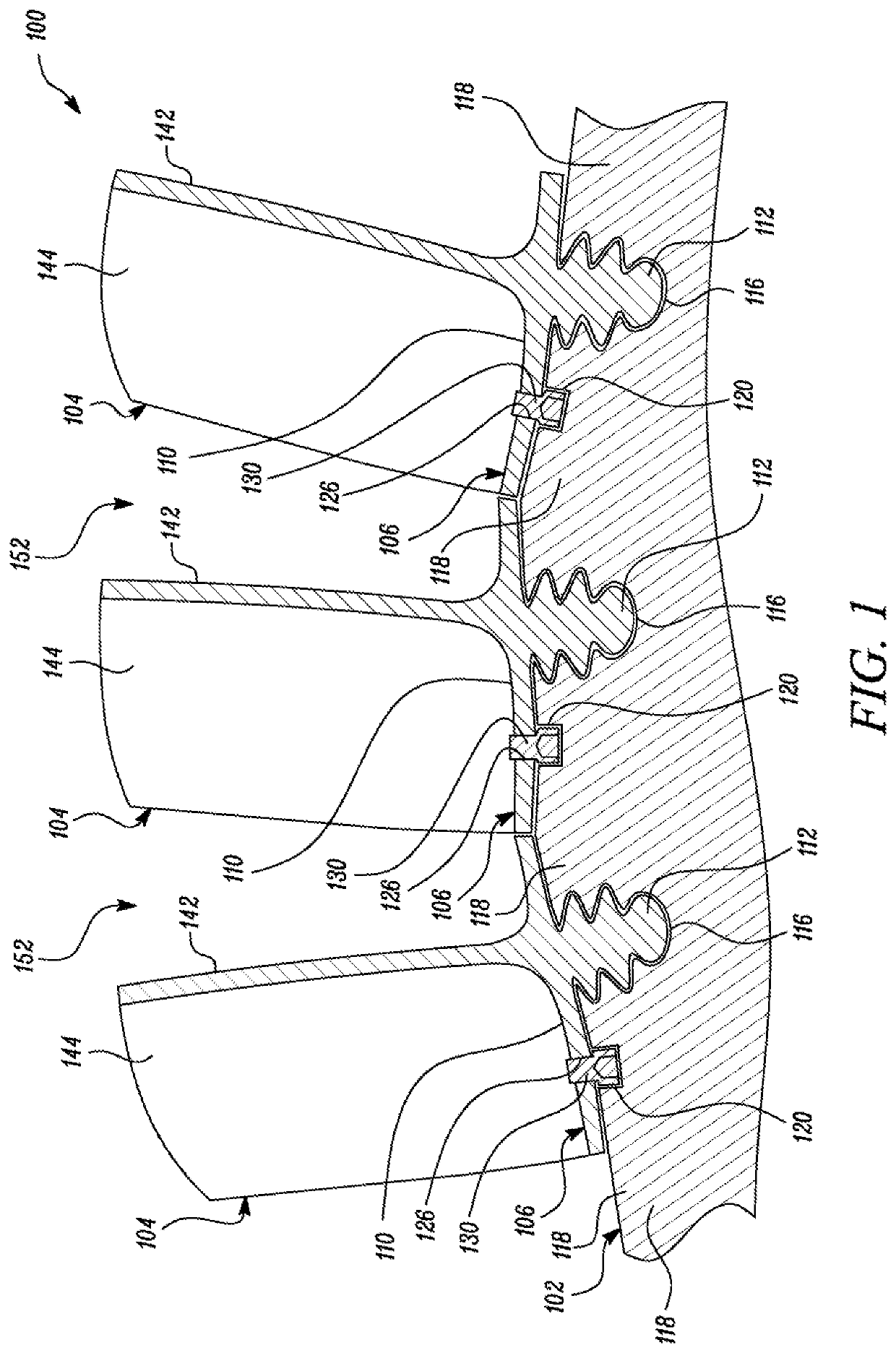

Staking tool assembly

A staking tool assembly for staking a pin coupling a turbine blade with a turbine disk is disclosed. The staking tool assembly includes a guide block configured to be positioned between a space defined between two consecutive turbine blades mounted on the turbine disk. The guide block includes a bottom surface configured to abut a blade root of the turbine blade. The guide block further includes a groove extending from the bottom surface through the guide block. The groove is configured to receive a portion of the pin extending outwardly from the blade root to facilitate a staking of the pin.

Owner:SOLAR TURBINES

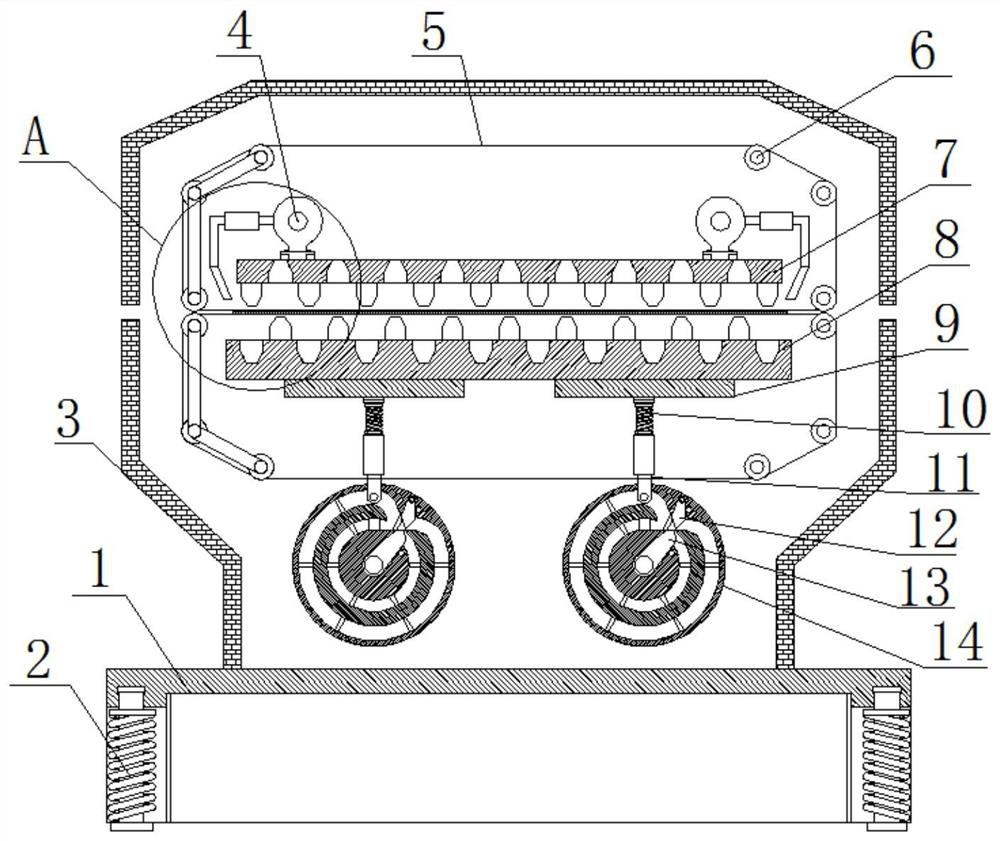

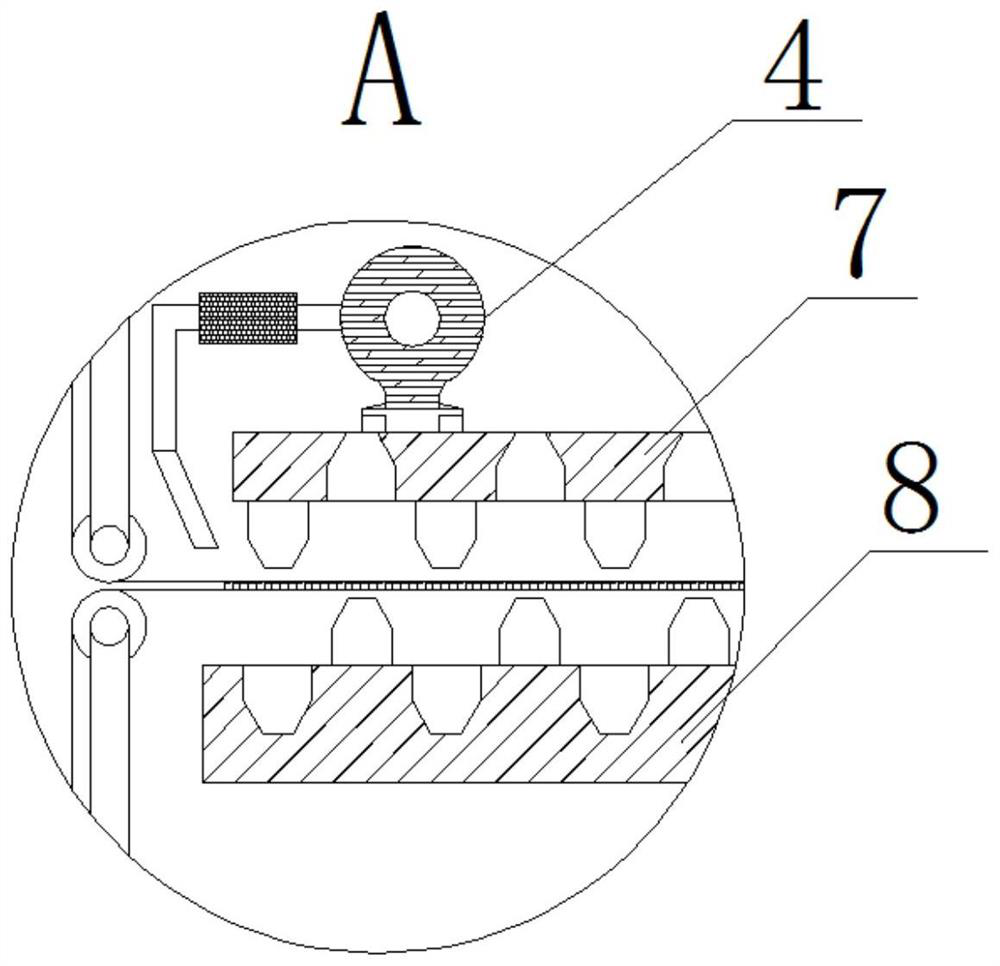

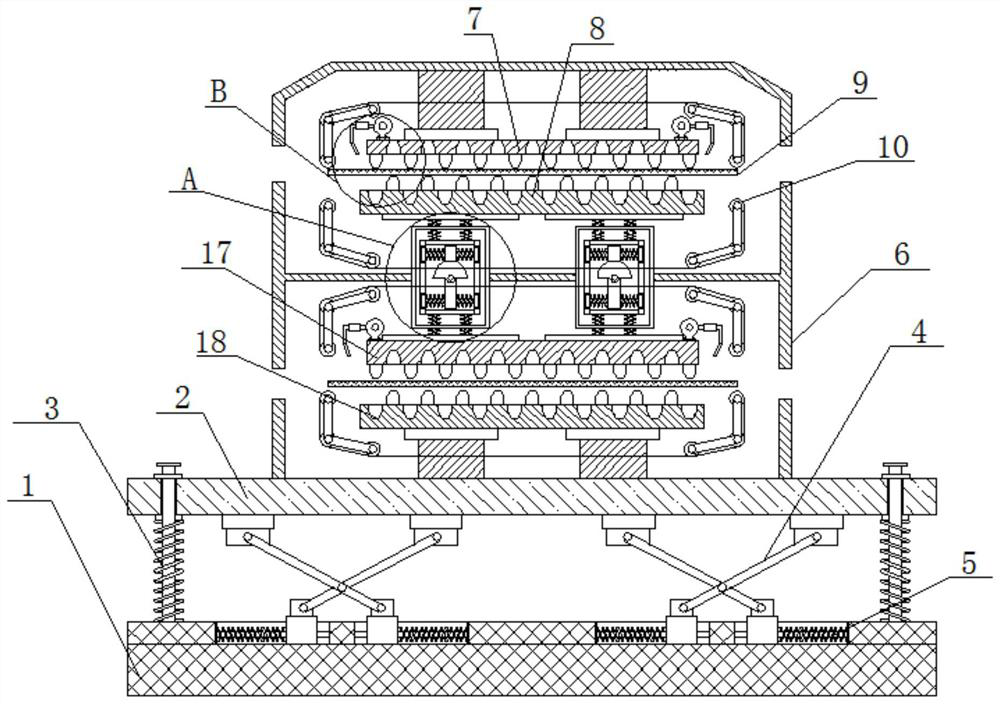

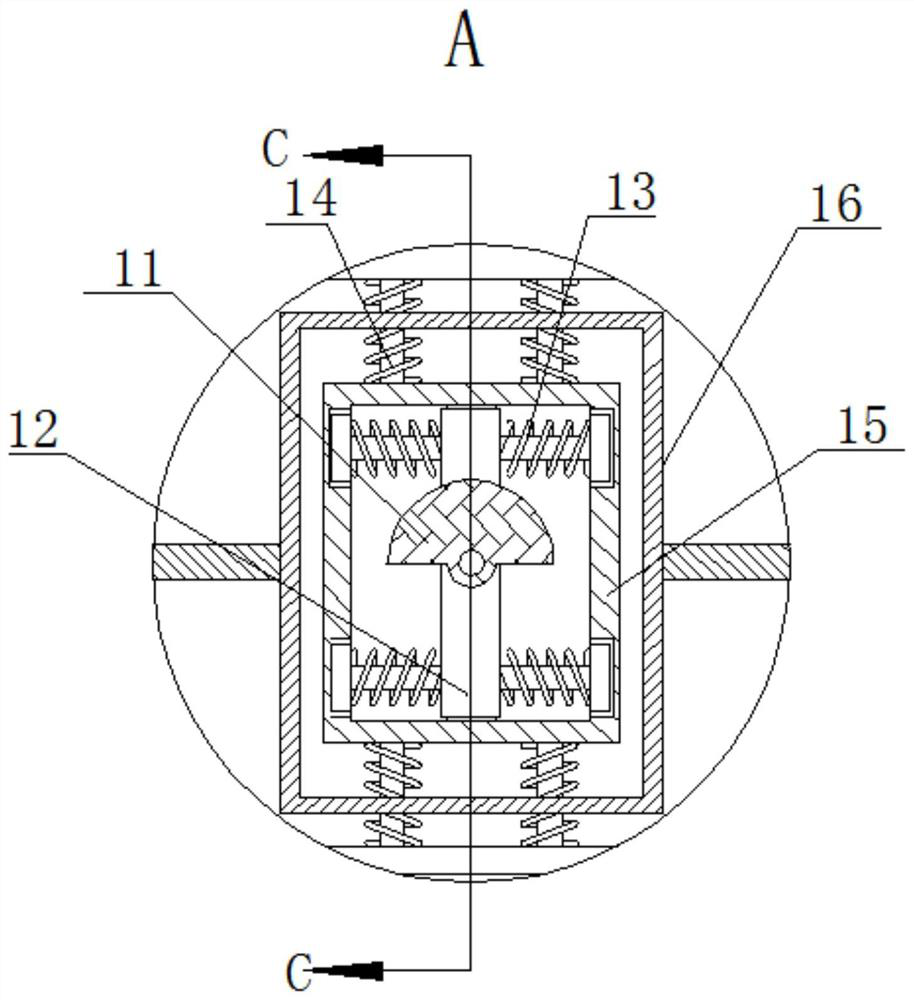

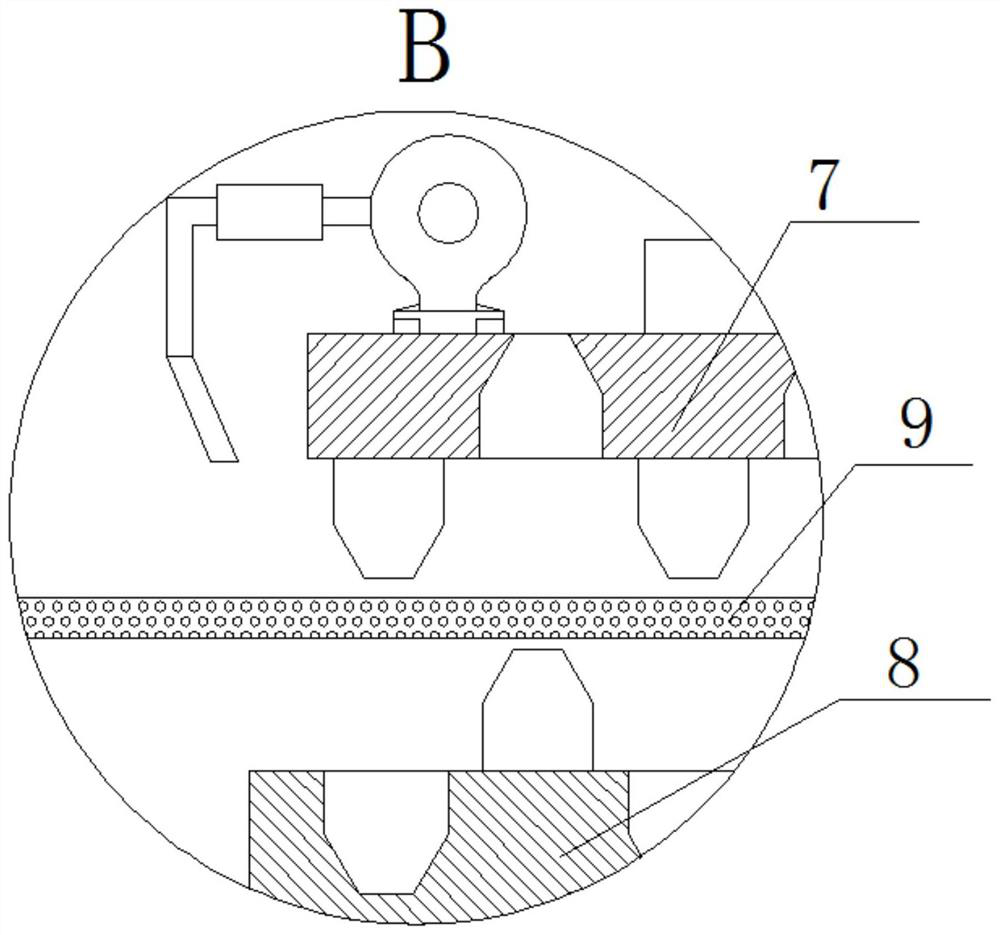

Leather vibration staking machine

The invention relates to the technical field of leather processing, and discloses a leather vibration staking machine. The machine comprises a base, shock absorbers are movably connected to the two sides of the base, a rack is fixedly connected to the top of the base, an upper die plate is movably connected to the interior of the rack, protrusions and grooves in the upper die plate and a lower dieplate are arranged at intervals, and the axis of each protrusion is collinear with the axis of the corresponding groove. According to the machine, leather can be softened under the action of repeatedmeshing, jacking, stretching, bending and rubbing in the conveying process from left to right, a balance spring on the outer side of a push rod can provide certain supporting force, and especially atthe moment of starting and stopping the machine, when the push rod moves up and down, the lower die plate can move up and down along with the push rod and cannot incline left and right, so that the metal fatigue of the machine is reduced, and the service life is prolonged; dust collection fans can absorb fluff fibers generated by leather vibration, so that the fluff fibers are prevented from falling into the machine to damage the machine; and the dampers on the two sides of the base can reduce noise in the operation process of the machine, so that a good working environment is provided.

Owner:凯霆(广州)贸易有限公司

Efficient double-layer leather oscillation staking machine

InactiveCN112011652AAvoid multiple pulling and softening operationsImprove work efficiencySkins/hides/leather/fur manufacturing apparatusLeather softeningWorking environmentStructural engineering

The invention relates to the technical field of leather treatment processes, and discloses an efficient double-layer leather oscillation staking machine. The machine comprises a base; damping springsare movably connected with the upper portion of the base; spring shafts are movably connected with the upper portion of the base; inclined rods are hinged to the upper parts of the spring shafts; anda fixing plate is hinged to the upper portions of the inclined rods. A vertical shaft driven by a rotating wheel is in one reciprocating stroke; upper and lower groups of leather can be subjected to staking operation at the same time; and the leather is repeatedly engaged, jacked, stretched, bent and rubbed in the staking process, and formed at once, so that repeated staking operation is avoided,and the working efficiency is greatly improved. Through the combined damping effect of two sets of damping devices, vibration and noise generated when the machine works are reduced, so that the metalfatigue of the machine is reduced, the service life is prolonged, and a better working environment is provided. Dust particles and fluff generated after vibration are absorbed through dust collectingdraught fans on the two sides, so that the product surface quality is improved, and the environment is protected.

Owner:广州景铄服饰有限公司

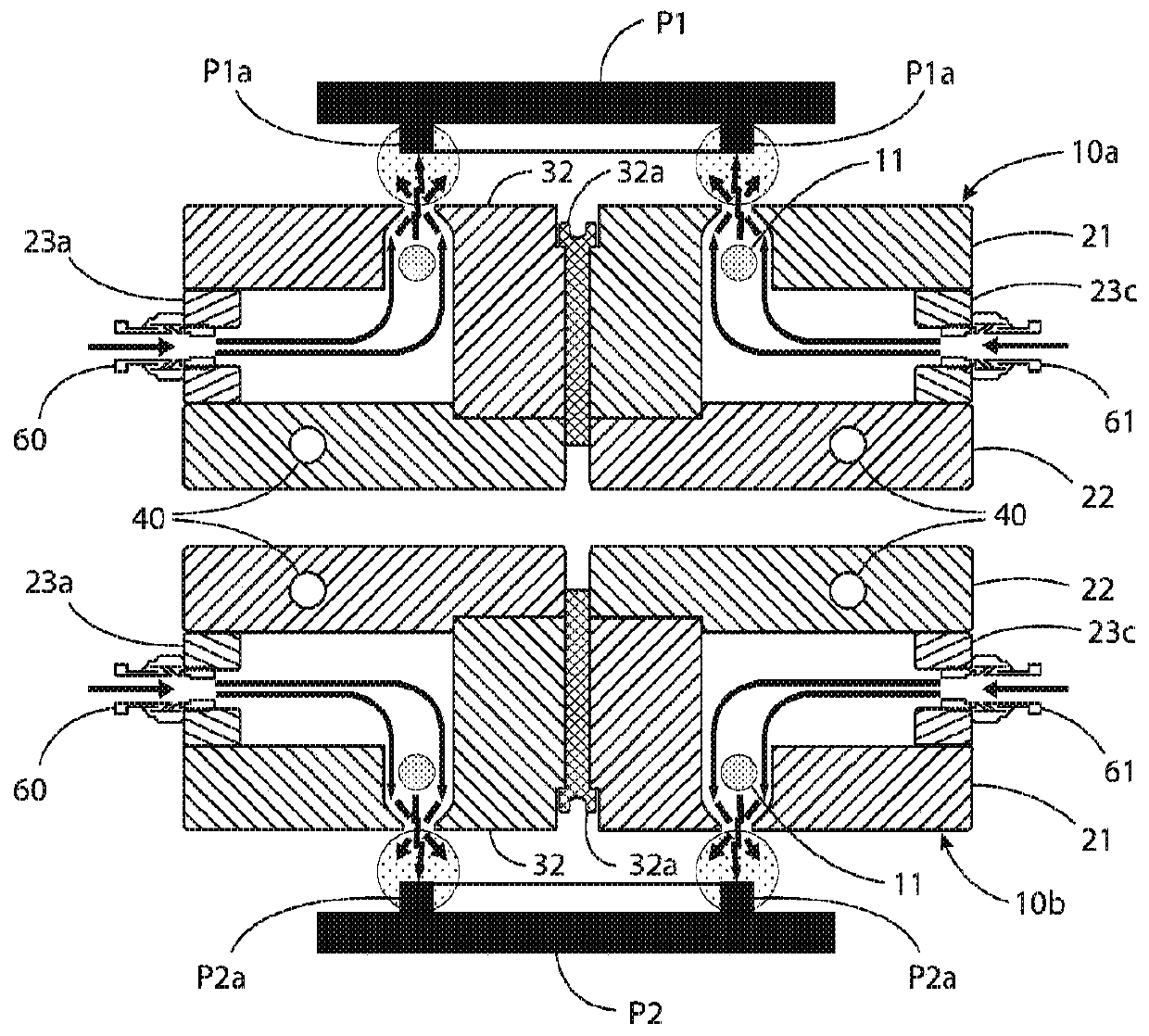

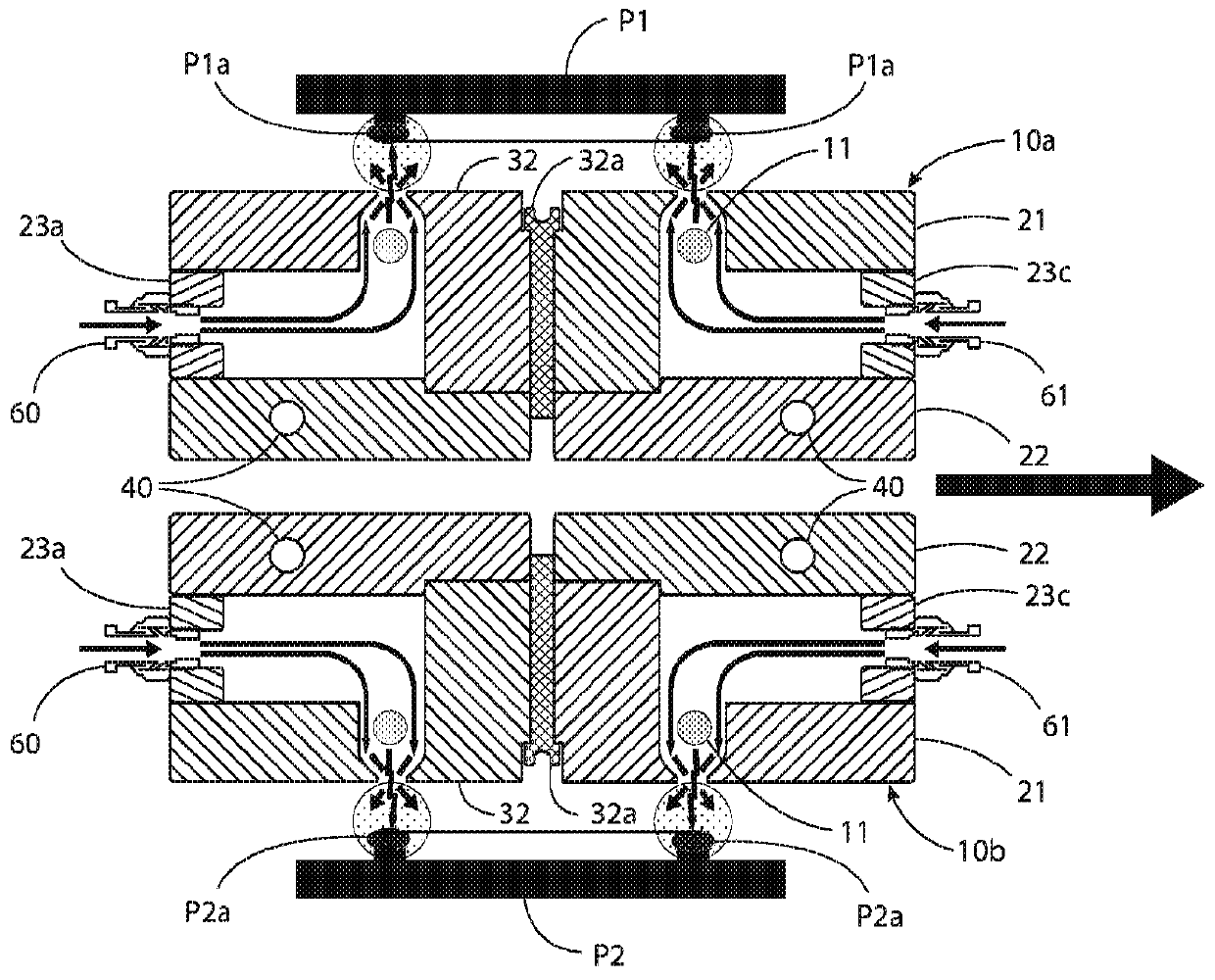

Gas-shielded infrared welding and staking system

An infrared welding system for joining two parts (PI, P2) made of thermoplastic material comprises a pair of infrared heaters (11, 11) for heating the two parts (PI, P2) while spaced from each other;and energizing the infrared heaters (11, 11) to emit infrared heat and directing the emitted infrared heat onto selected portions (Pla, P2a) of the opposed surfaces of the parts (PI, P2) to melt at least portions of the opposed surfaces, while directing an inert gas onto the selected portions to prevent ignition of the melted thermoplastic material. The two parts (PI, P2) are clamped together by moving at least one of the parts toward the other part to press the melted surfaces of the parts (PI, P2) into contact with each other. The parts (PI, P2) are cooled while they remain clamped togetherto solidify the molten thermoplastic material and thus weld the two parts (PI, P2) together.

Owner:DUKANE CORP

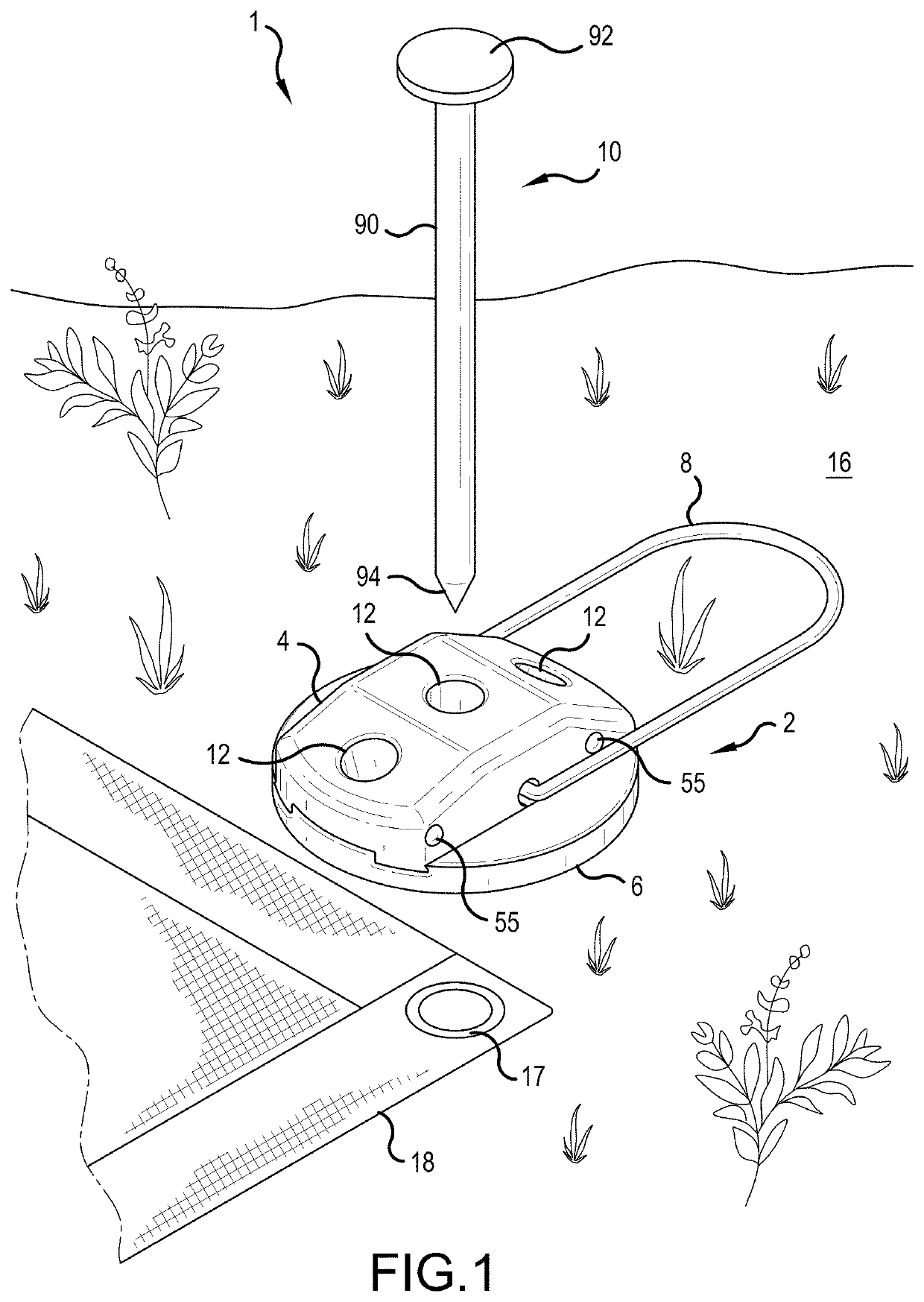

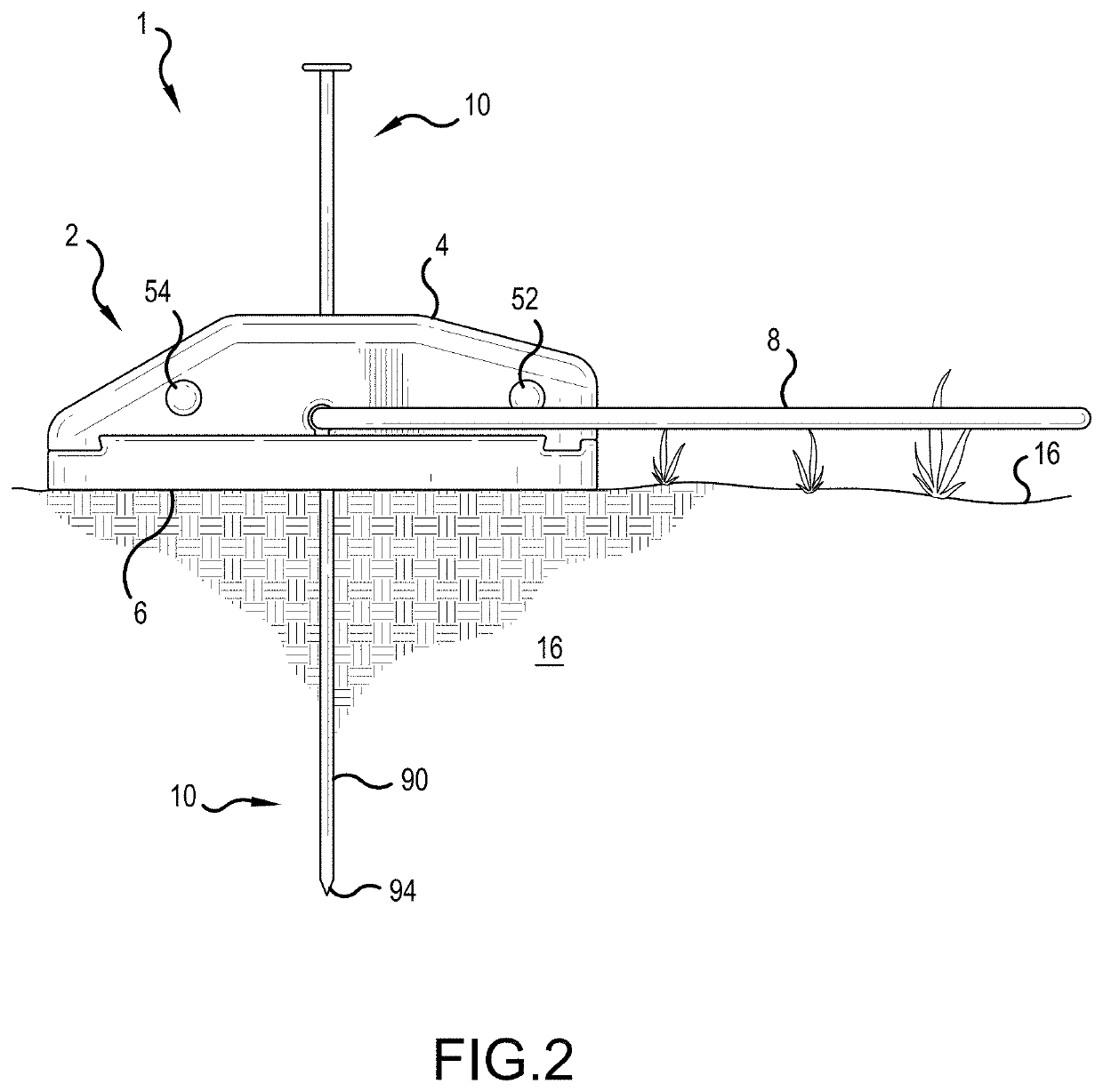

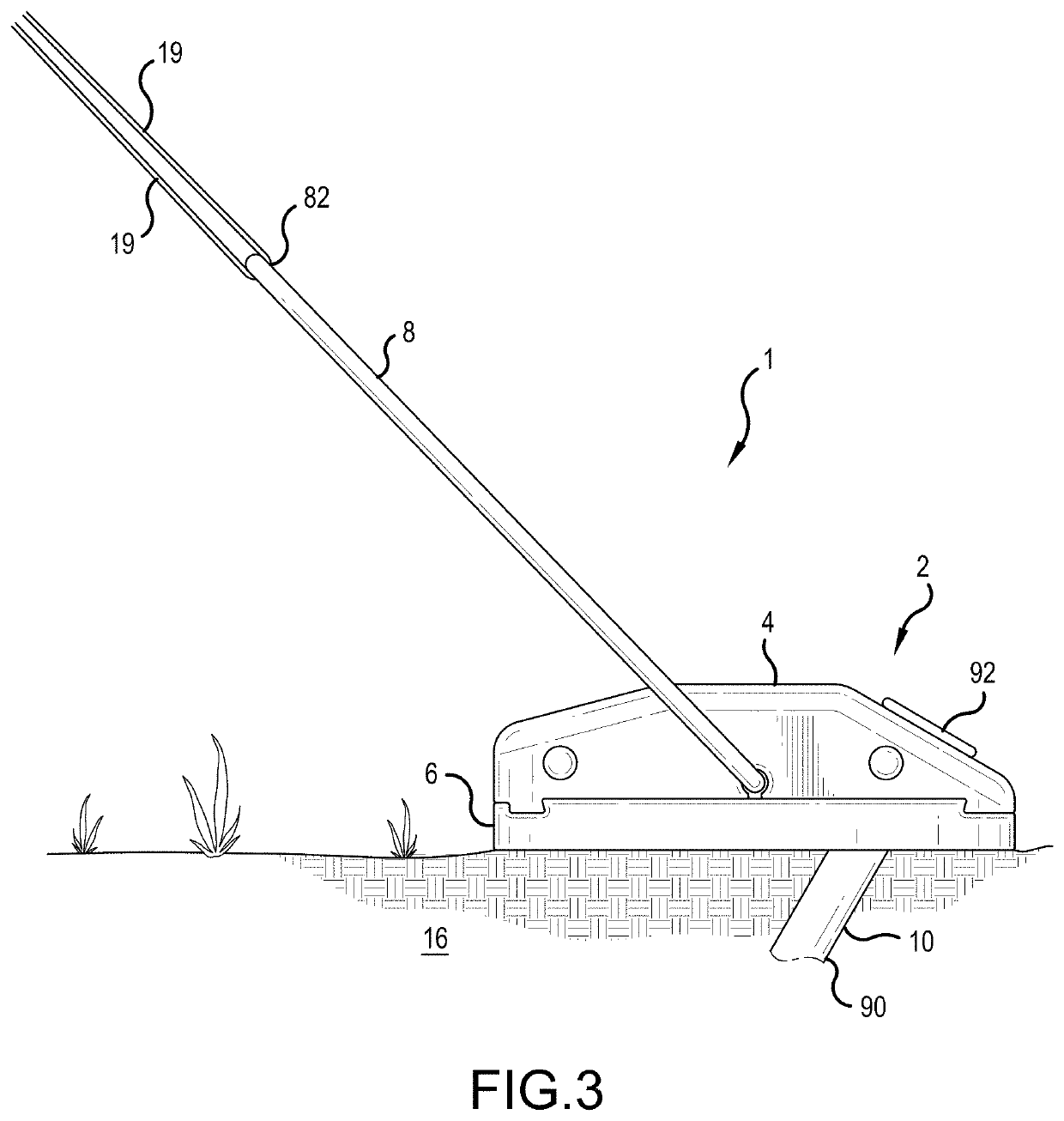

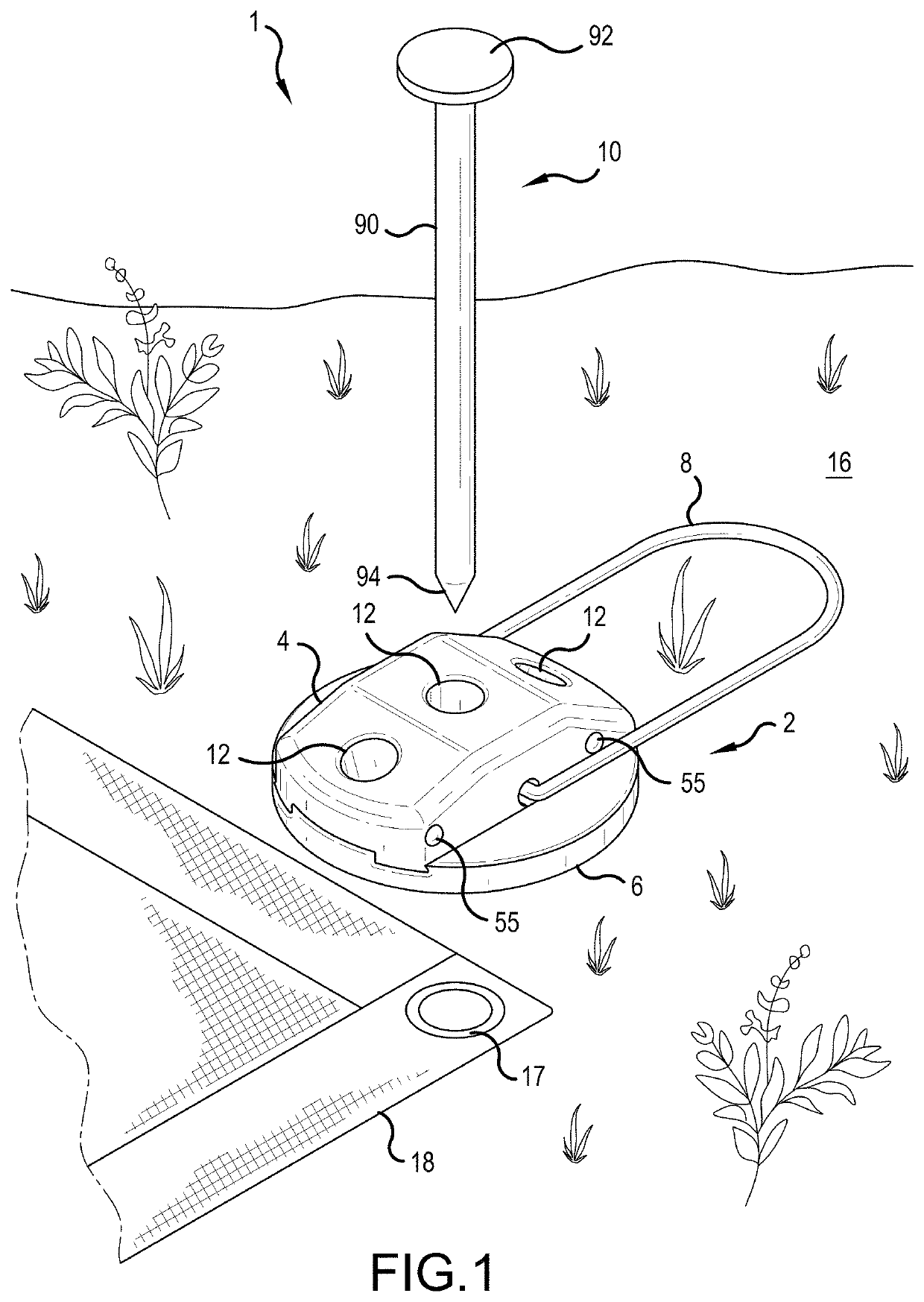

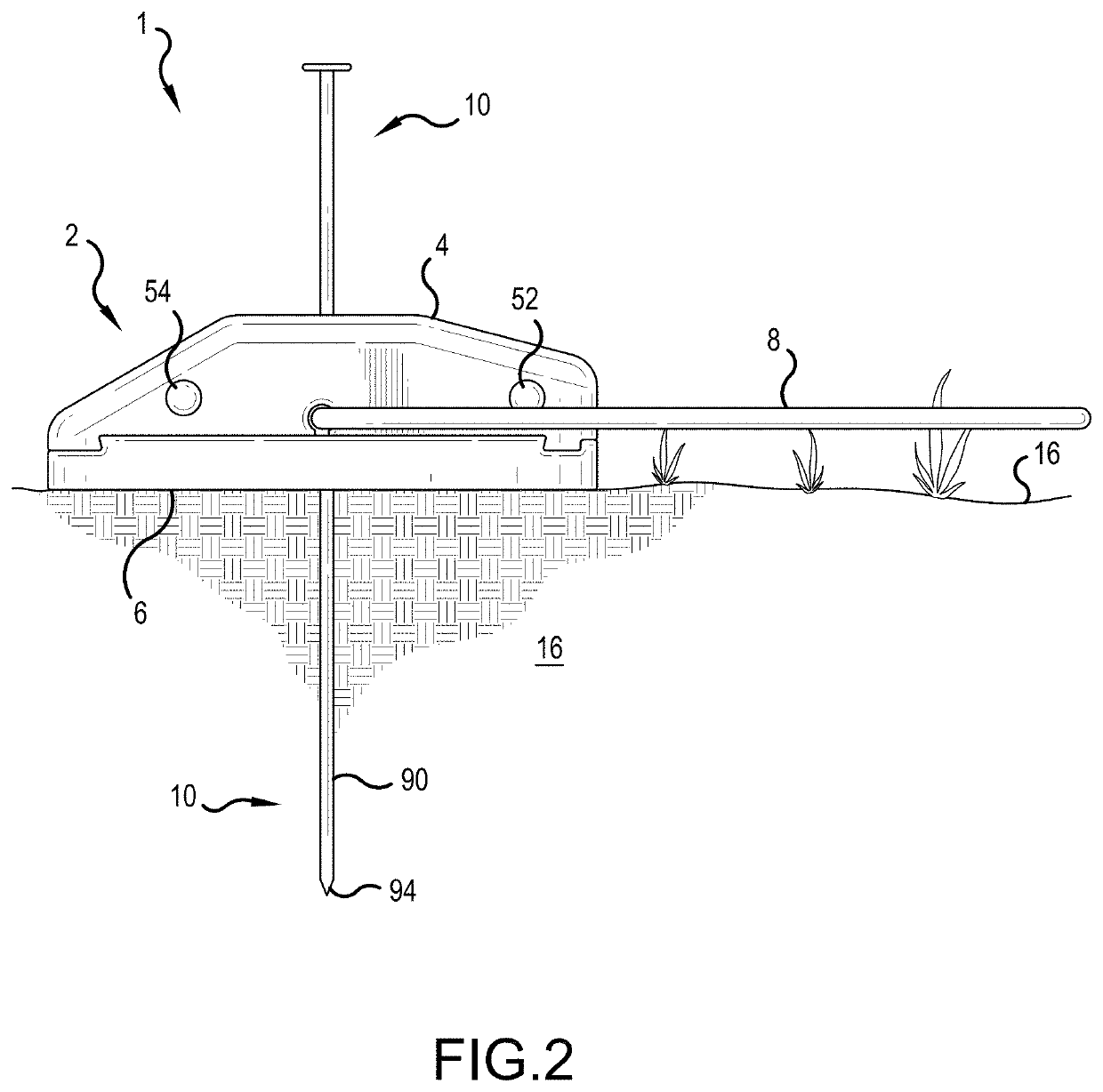

Bail-actuated multi-faceted staking system and method

A staking system includes a multifaceted support, each of the faces including a separate aperture to allow a stake to mount therethrough at varying angles. The support may be made of two separable elements. A bail is hingedly mounted in the support and set between various positions over the top of the support. A puller can be used to cause lever-action removal of the stake from the ground, and the pullet may be adjected to various distances. The support may be rotated along the ground surface to provide better attack angles for the lever-actuated removal.

Owner:PREST O FIT MFG

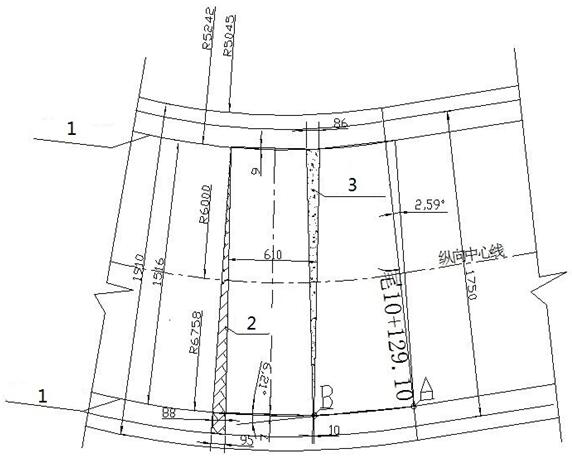

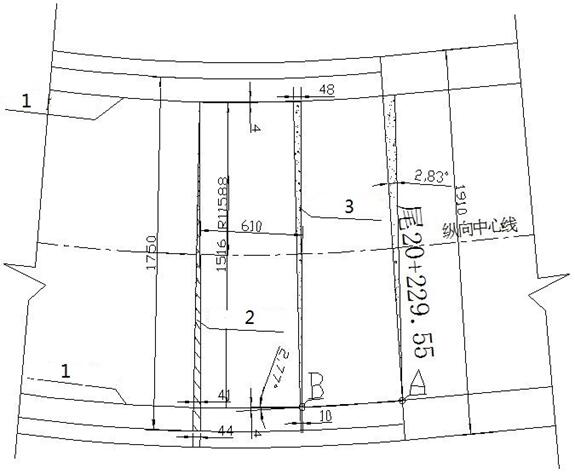

A Construction Method for Concrete Lining of Steel Formwork Pallet in Bend Pipe Section of Tailgate Tunnel

ActiveCN109736316BRealize curved layoutSmooth connectionFoundation engineeringSteering wheelDrive wheel

The invention relates to a tailrace tunnel bent pipe section steel mould trolley concrete lining construction method which comprises the steps that in a tailrace tunnel lining process, arc line arrangement is carried out for the travelling track of a steel bar installation trolley and a steel mould lining trolley, measurement and staking-out are carried out, and then track installation and bendingfixation are carried out; two driving wheels running in front of a linear steel bar trolley are transformed into steering wheels from directional wheels; bottom arch lining of the steel mould liningtrolley adopts a mode of additionally arranging a wedge-shaped steel panel on an original long hydraulic needle beam type steel mould trolley for lining; and for side top arch lining, a long hydraulicself-propelled track type steel mould trolley for original linear section lining is disassembled into two parts, namely two long hydraulic self-propelled track type steel mould trolleys, and then wedge-shaped steel panels are additionally arranged on the two trolleys for lining. The invention aims to provide the tailrace tunnel bent pipe section steel mould trolley concrete lining construction method in which a shaping steel mould trolley, a trolley track and a steel bar trolley are consistent with the design of a bent pipe section with a small curvature radius in a lining process.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

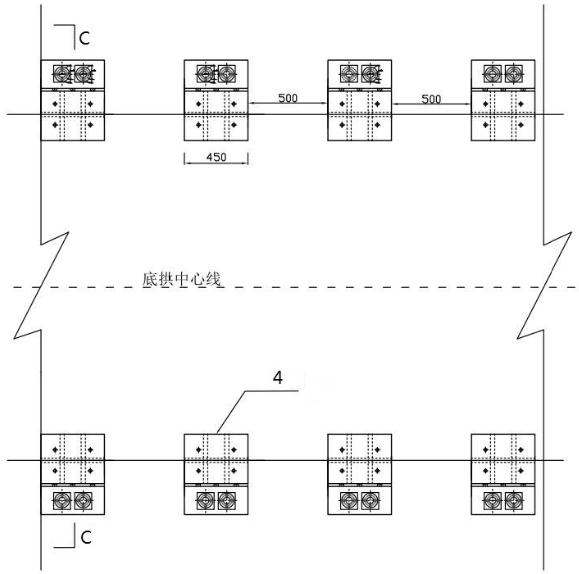

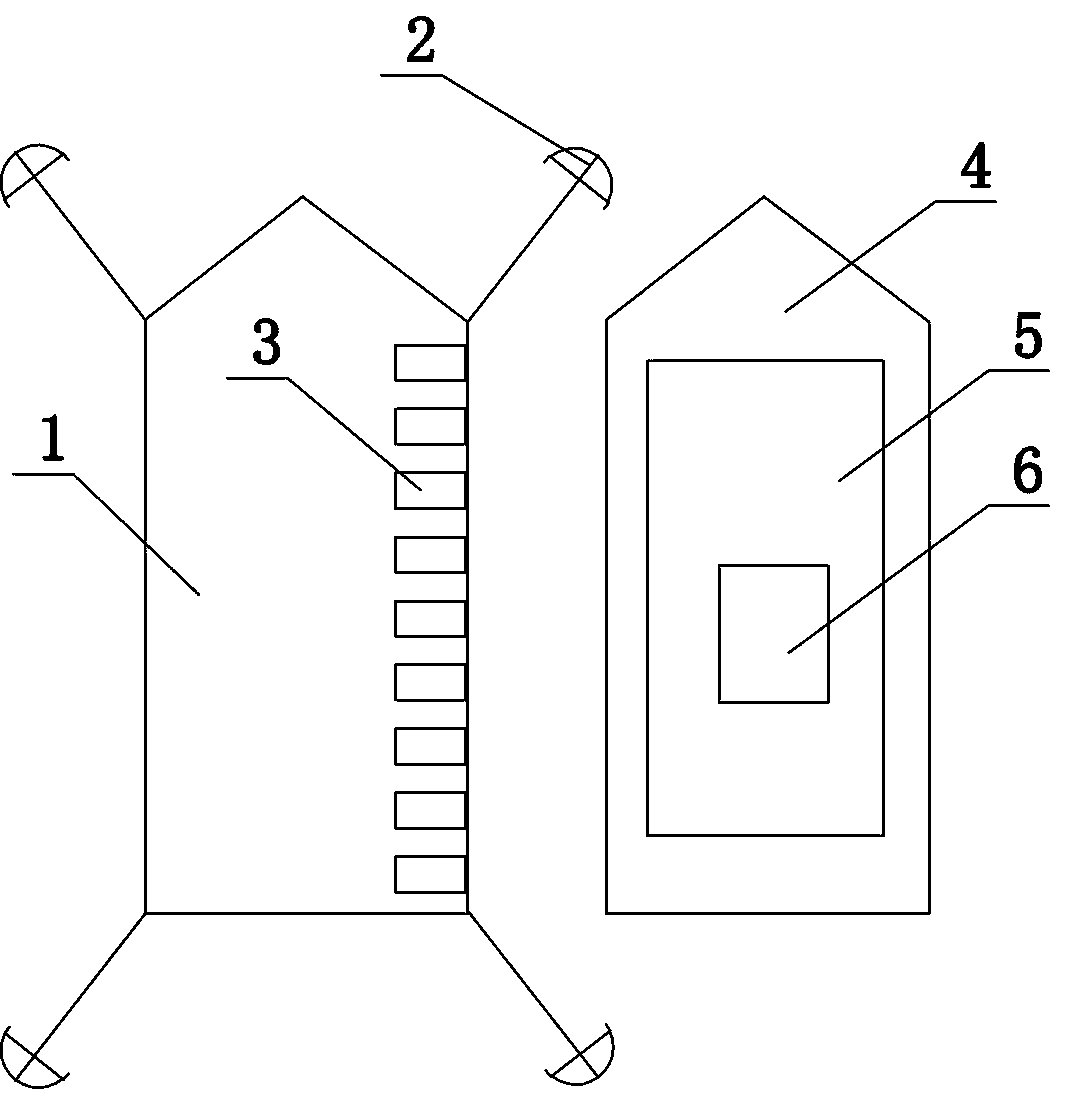

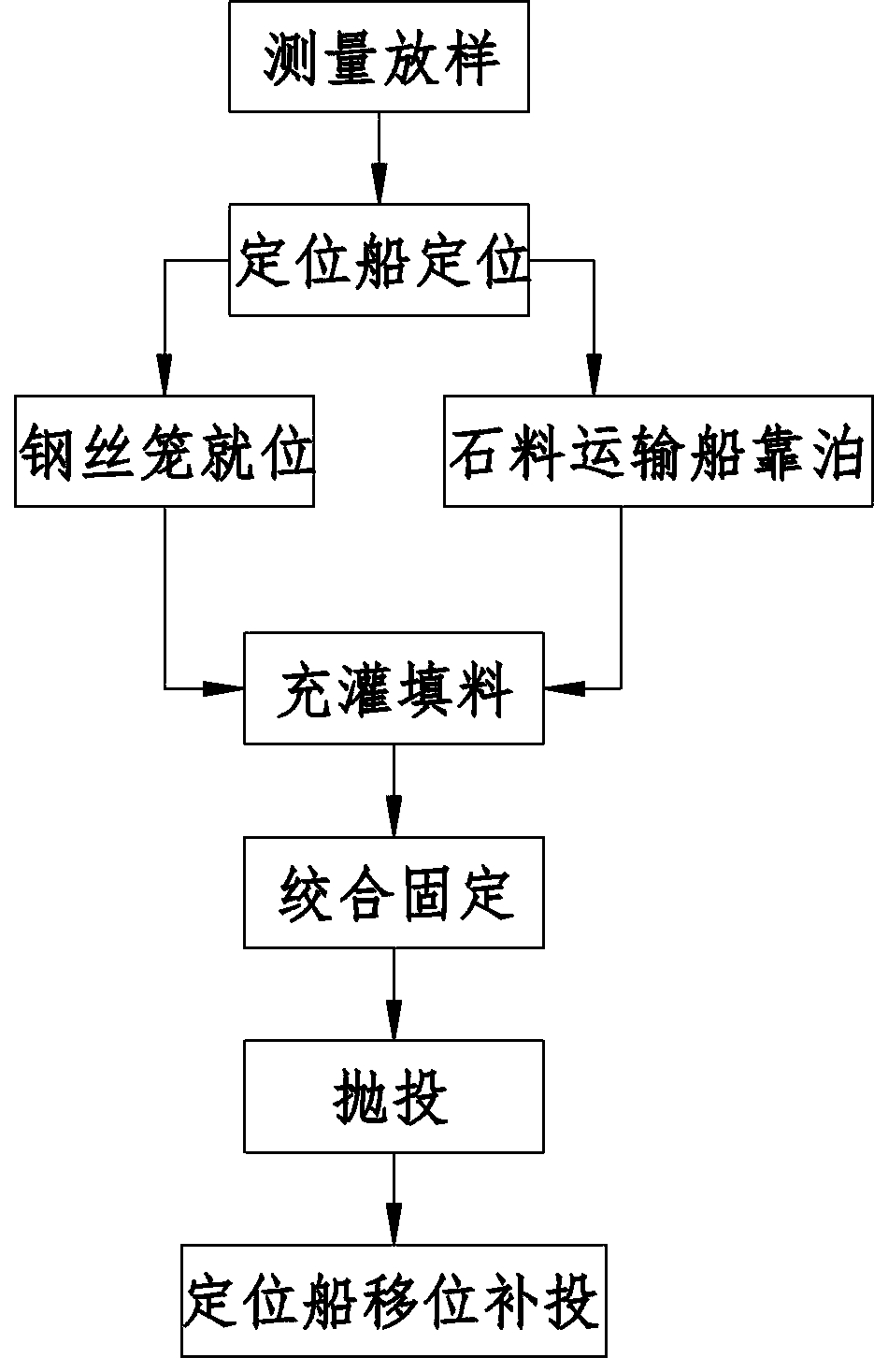

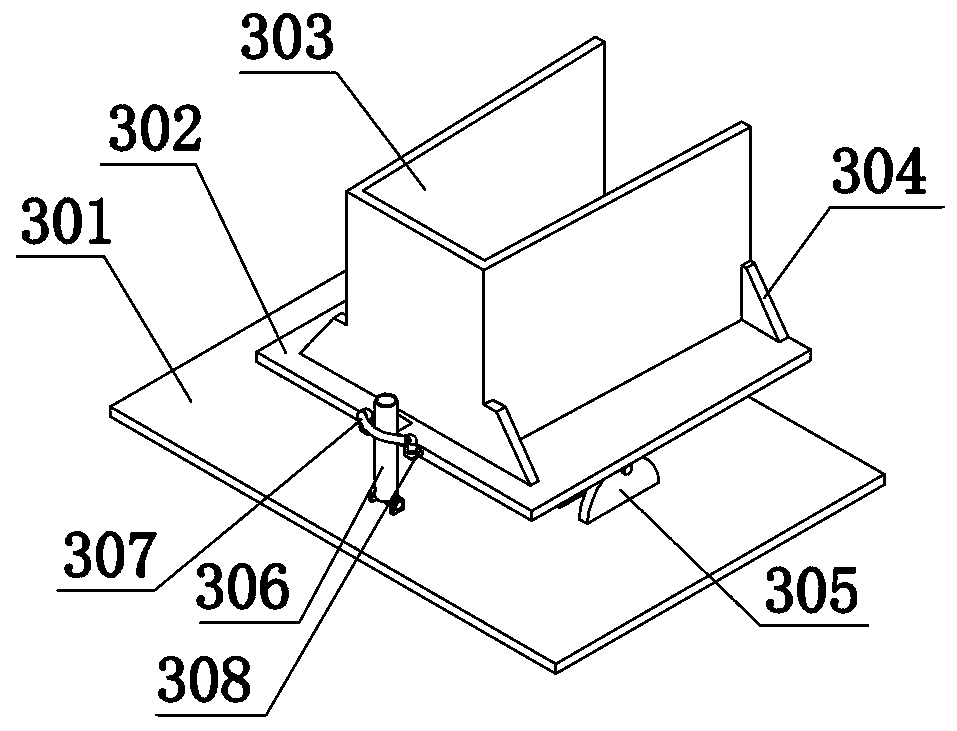

A construction method for placing an underwater steel wire gabion

InactiveCN108643187BReduce working spaceImprove construction efficiencyFoundation engineeringMarine engineeringGabion

The invention relates to the field of channel improvement and maintenance construction, in particular to a construction method for placing an underwater steel wire stone cage. The construction methodcomprises the steps of: 1)staking out in survey, 2) positioning by a positioning ship, 3) placement of a steel wire cage in place, 4) filler charging, 5) twisting fixation, 6) throwing, and 7) displacement feeding by the positioning ship. The construction method greatly improves the construction efficiency, is more precise in feed positioning, and improves the construction quality.

Owner:长江武汉航道局武汉航道管理处

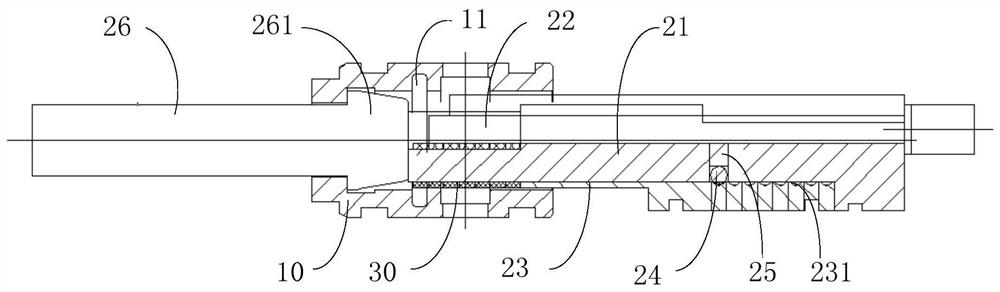

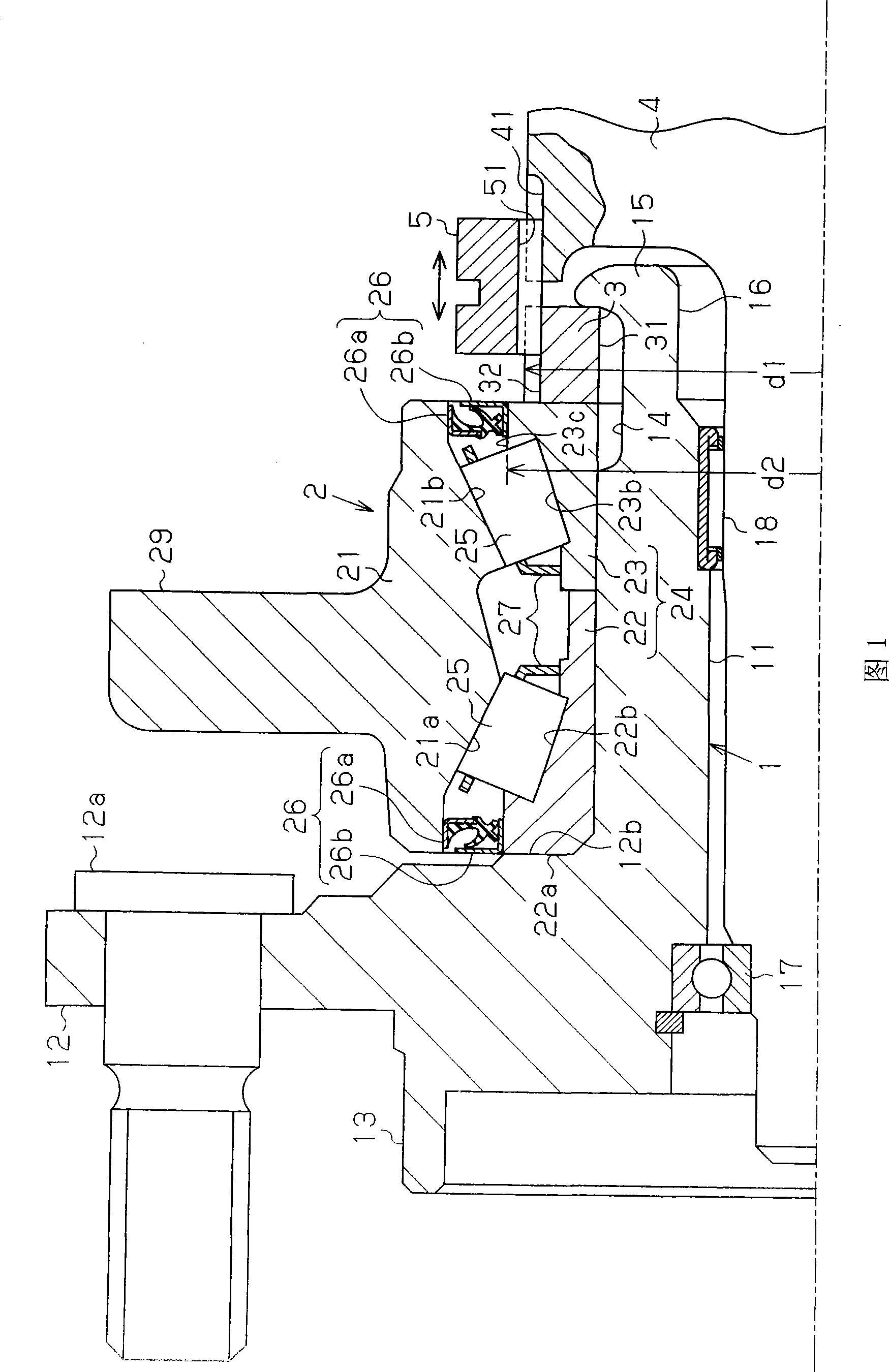

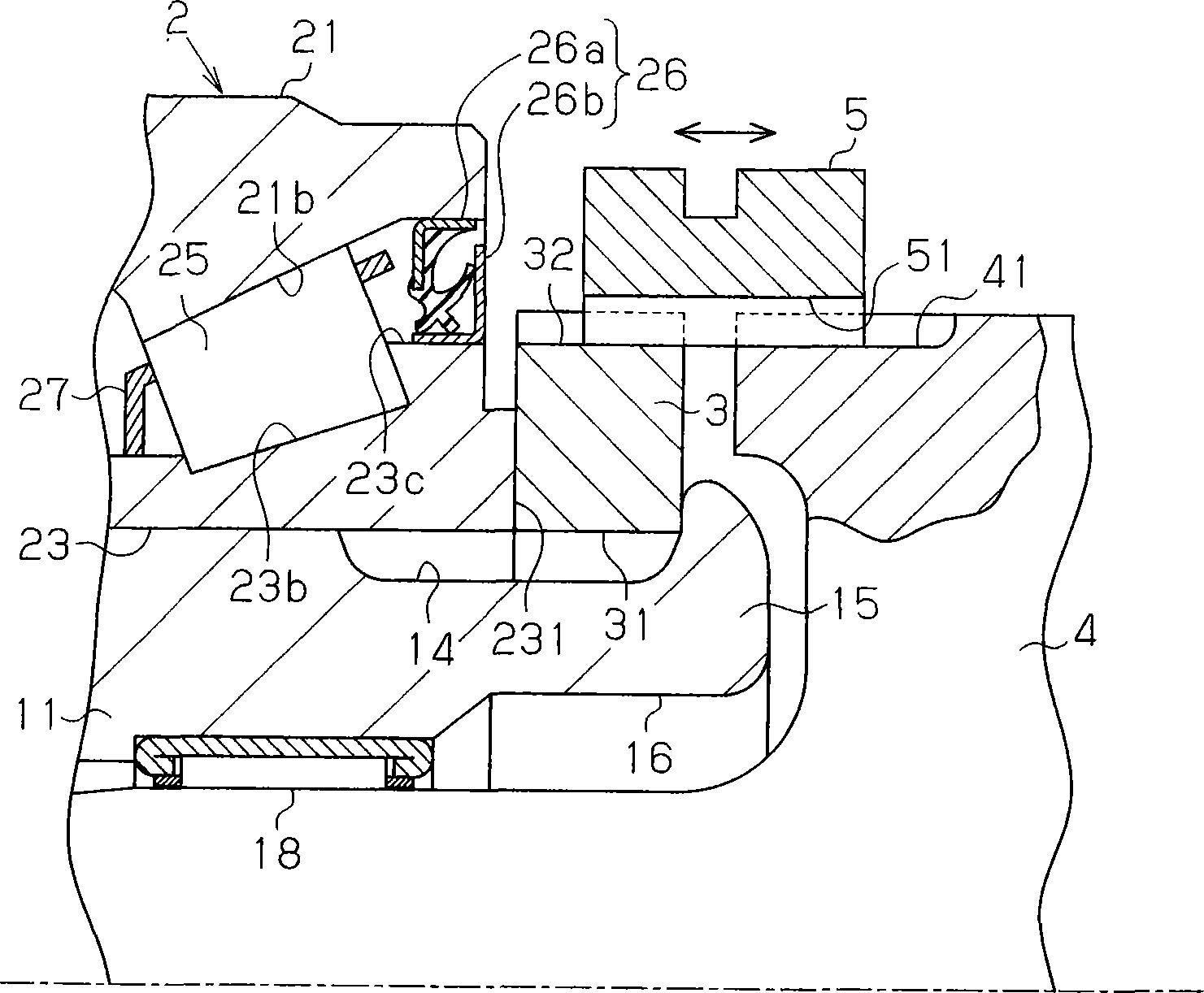

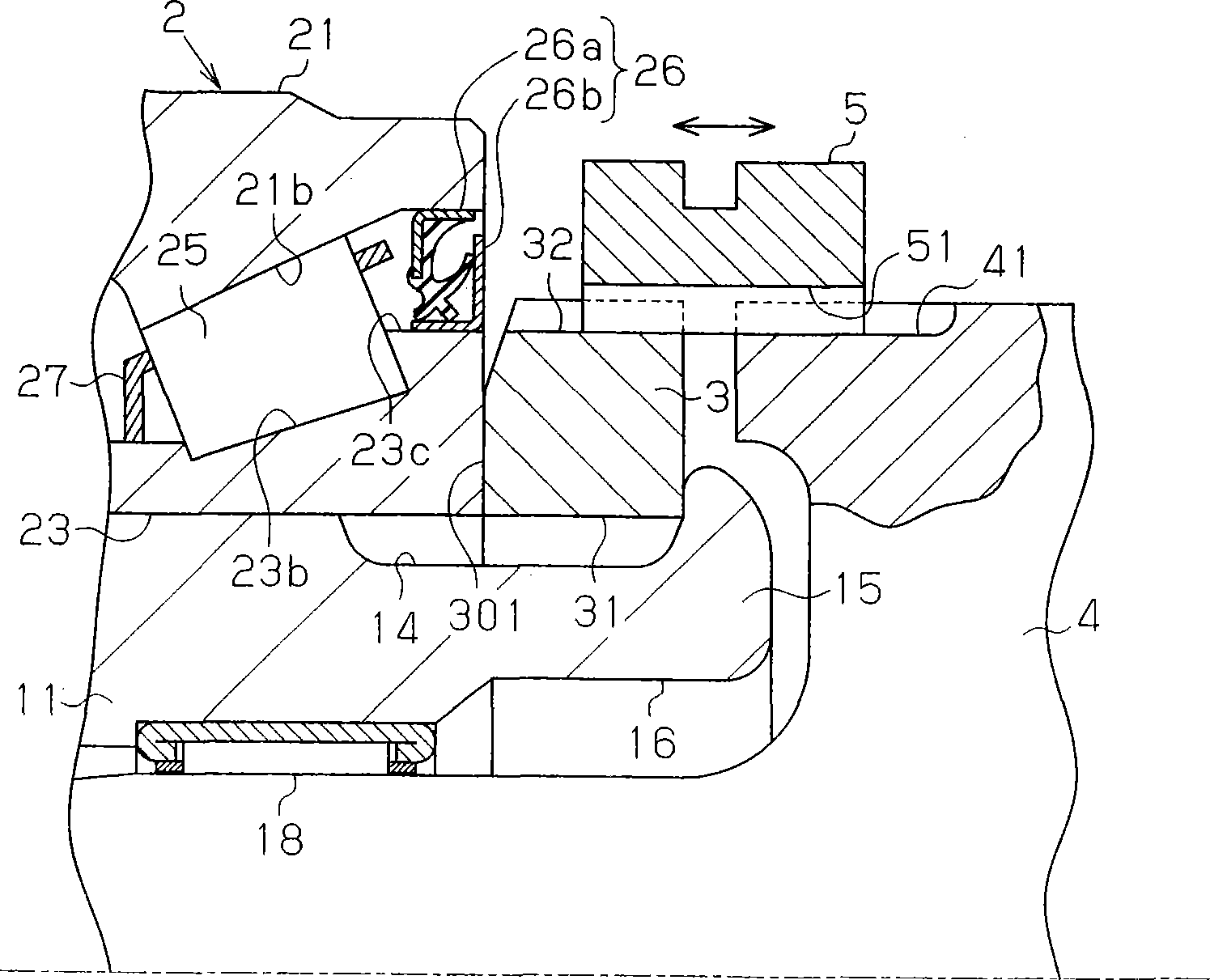

Bearing device for wheel

InactiveCN101356064BAvoid interferenceAvoid deformationRoller bearingsBearing assemblyRolling-element bearingCoupling

The present invention provides a bearing device for a wheel which has a rolling bearing (2); an inner shaft (1), on the outer periphery of which an inner ring (24) of the rolling bearing (2) is installed; a coupler ring (3) fitted to an end of the inner shaft (1); and a staking part (15) formed at the end of the inner shaft (1) to fix the coupler ring (3) and the rolling bearing (2) to the inner shaft (1) in such a way that they cannot move in the axial direction of the inner shaft (1). The outer diameter dl of the coupler ring (3) is set smaller than the diameter d2 of the shoulder part (23c) of the inner ring (24). Alternatively, projection parts (231, 301) are formed on either of mutually facing end faces of both the coupler ring (3) and the inner ring (24), which causes the coupler ring (3) to be disposed away from a seal member (26). Consequently, interference between the coupler ring (3) and the seal member (26) is prevented.

Owner:JTEKT CORP

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including displacement/vibration welded or heat staked laminates

ActiveUS20180272685A1High rateSolve the slow construction speedLamination ancillary operationsLaminationSurface finishEngineering

A system and method are provided for implementing relatively low temperature joining processes, including displacement / vibration welding techniques and / or heat staking techniques, in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components in additive material (AM) manufacturing systems. A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through comparatively low temperature welding or other mechanical joining (including displacement / vibration welding or heat staking); and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

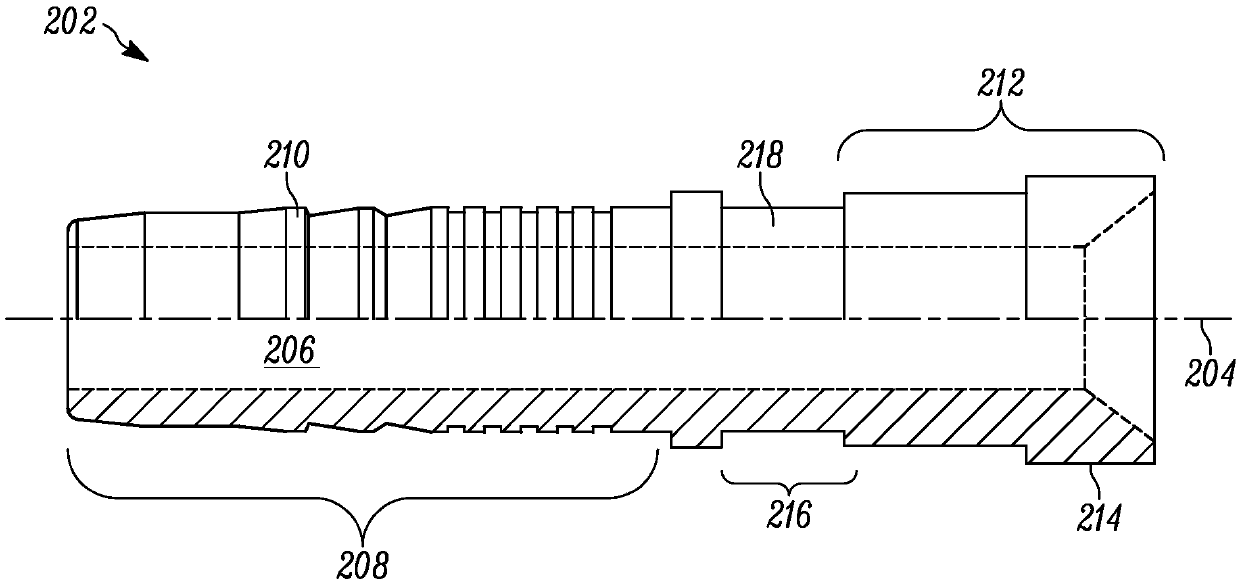

Eight sided forged ferrule staking crimped fitting and method of manufacture thereof

Methods of making hose fittings include providing a stem having a fluid conduit, a first end, a second end with a raised shoulder, and a crimp region disposed between the first end and the second end.A swivel tube nut is placed over the stem, and the swivel tube nut is retained on the stem by the raised shoulder. A ferrule is thereafter placed over the first end of the stem, and the ferrule comprises a partially or fully formed octagonal wrench surface, formed prior to. The ferrule is then crimped, at the octagonal wrench surface, onto the crimp region of the stem.

Owner:CONTITECH USA INC

Industrial floor construction joint processing method

The invention discloses a industrial floor construction joint processing method. The method comprises the following steps of S1, grinding an industrial floor surface; S2, performing shot blasting andriveting operation on the industrial floor surface; S3, performing grooving operation on two sides of a construction joint to form two main staking grooves parallel to the construction joint; S4, pouring anticorrosive resin paint into the main staking grooves and the construction joint until the main staking grooves and the construction joint are completely filled with the anticorrosive resin paint; and S5, performing surface coating on the industrial floor surface. According to the method, the main staking grooves are additionally arranged on two sides of the construction joint, an auxiliaryreinforcement groove and an auxiliary staking groove are additionally arranged on the of the industrial floor surface, after the anticorrosive resin paint is simultaneously poured into the construction joint, the main staking grooves, the auxiliary reinforcement groove and the auxiliary staking groove, a T-shaped pull riveting structure is formed at node positions formed by the construction joint,the auxiliary reinforcement groove and the auxiliary staking groove and the main staking grooves, the auxiliary reinforcement groove and the auxiliary staking groove, concrete can be effectively strengthened.

Owner:苏州铭涂新材料科技发展有限公司

Bail-actuated multi-faceted staking system and method

A staking system includes a multifaceted support, each of the faces including a separate aperture to allow a stake to mount therethrough at varying angles. The support may be made of two separable elements. A bail is hingedly mounted in the support and set between various positions over the top of the support. A puller can be used to cause lever-action removal of the stake from the ground, and the pullet may be adjected to various distances. The support may be rotated along the ground surface to provide better attack angles for the lever-actuated removal.

Owner:PREST O FIT MFG

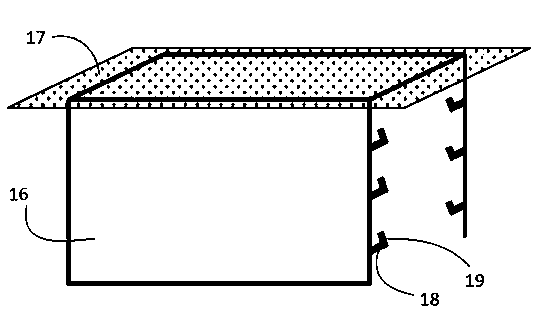

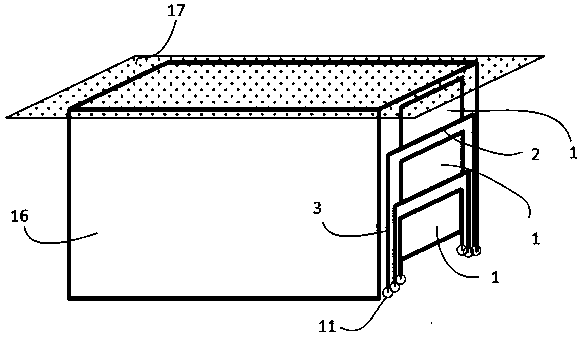

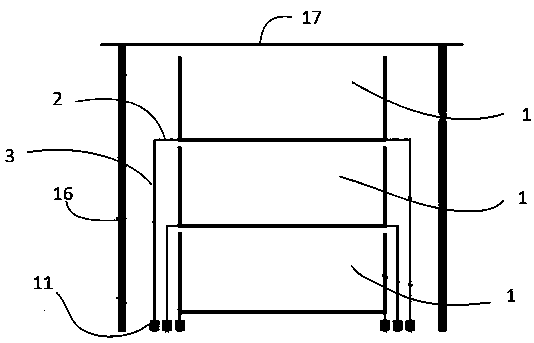

Single-box multi-layer steel bar classification storage method

InactiveCN111361839AReduce the chance of getting caught in the rainQuality improvementLoading/unloadingExternal fittingsEngineeringRebar

The invention discloses a single-box multi-layer steel bar classification storage method. The single-box multi-layer steel bar classification storage method is characterized by including the followingsteps that A, a site where steel bars are stacked is hardened; B, processing is carried out to form a single-box multi-layer steel bar classification storage structure which includes a box body, steel bar storage grooves and a rainproof shed, a plurality of supporting structures are arranged on the inner side of the box body, the two ends of the supporting structures extend to the edges of the two ends of the side plates of the box body correspondingly, the steel bar storage grooves are located on the supporting structures and are slidably connected to the supporting structures in a matched mode, the rainproof shed is arranged above the box body, and the periphery of the rainproof shed extends out of the box body; and C, the steel bars entering the site for the first time are stacked in steel bar staking grooves at a lower layer, and the steel bars entering the site for the second and third times are stacked in the steel bar staking grooves at middle and upper layers correspondingly.The multi-layer of steel bar stacking grooves are formed in a single box, the steel bar stacking and using can be realized by reasonably using a vertical space in a limited field, and the possibilityof the steel bars being exposed to rain due to worker errors can be reduced by arranging the rainproof shed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com