Patents

Literature

72results about How to "Reduce working space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

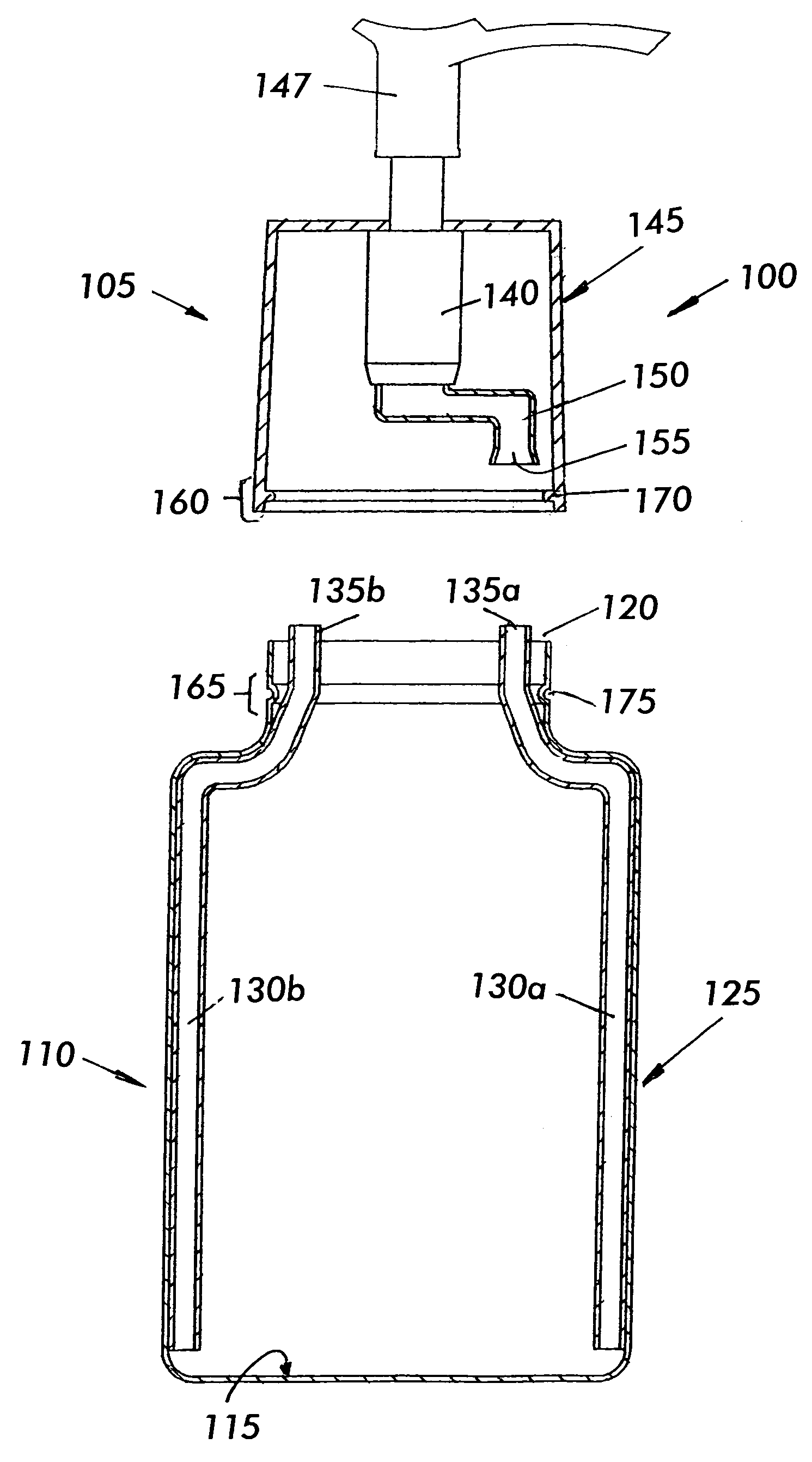

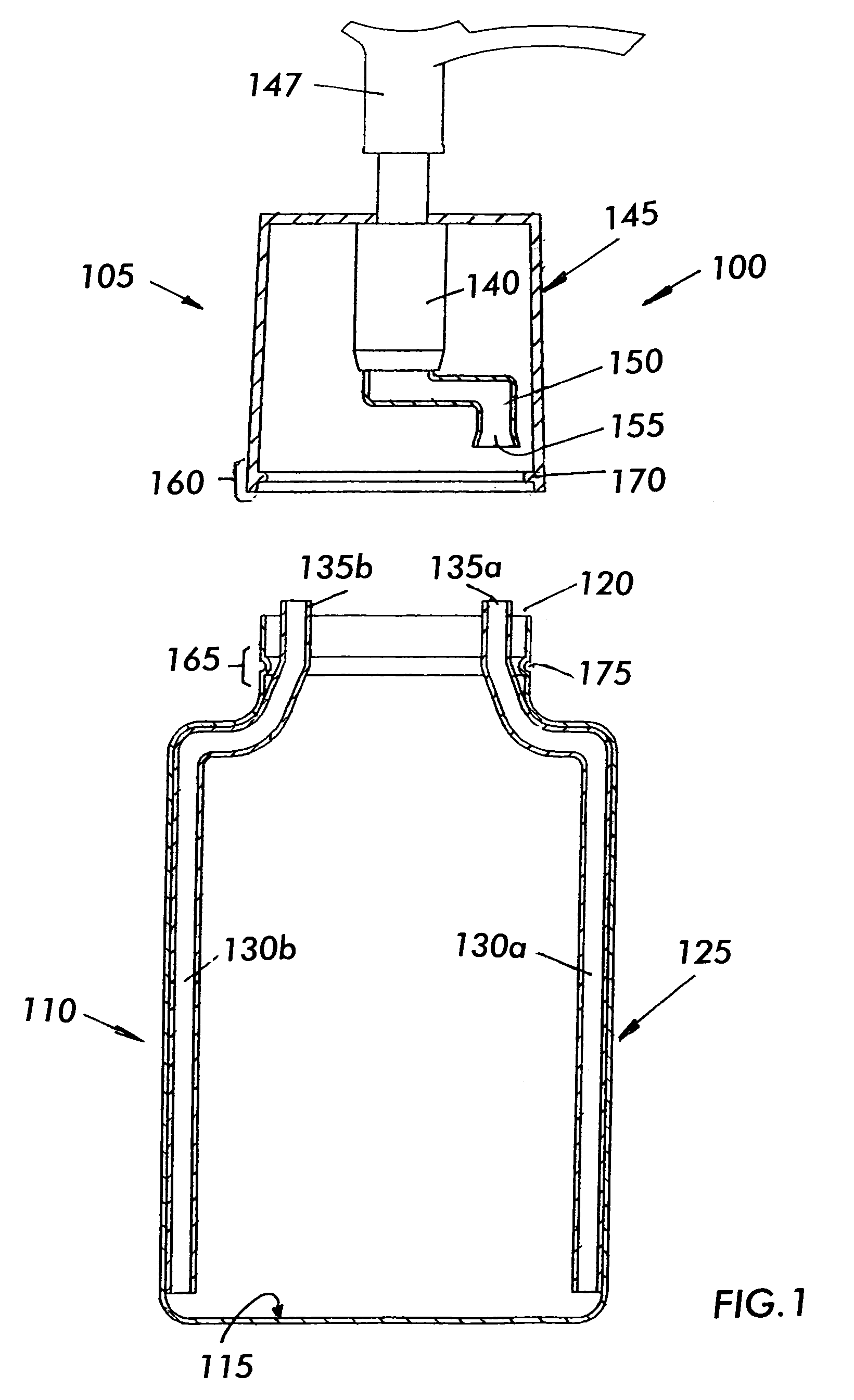

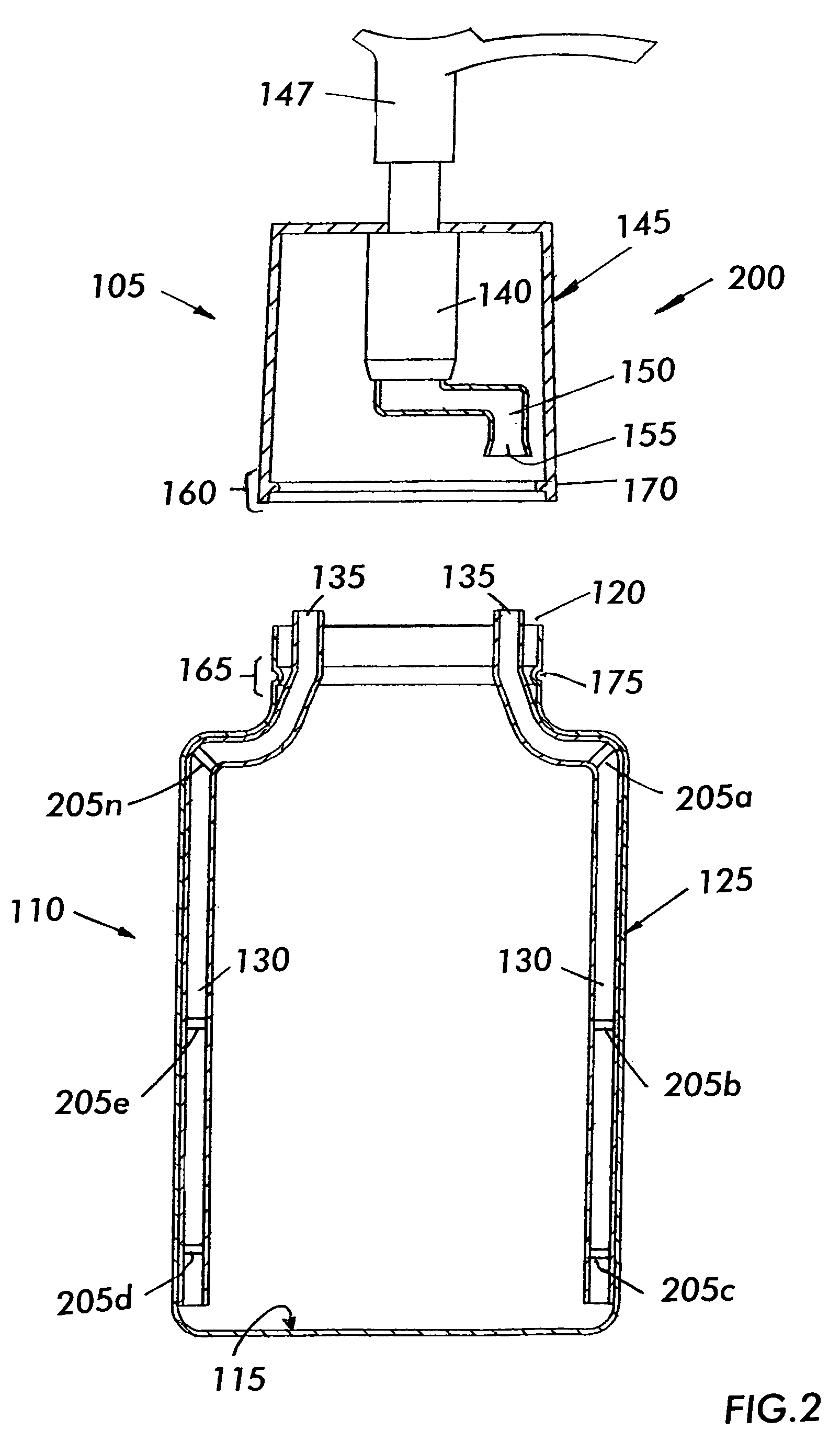

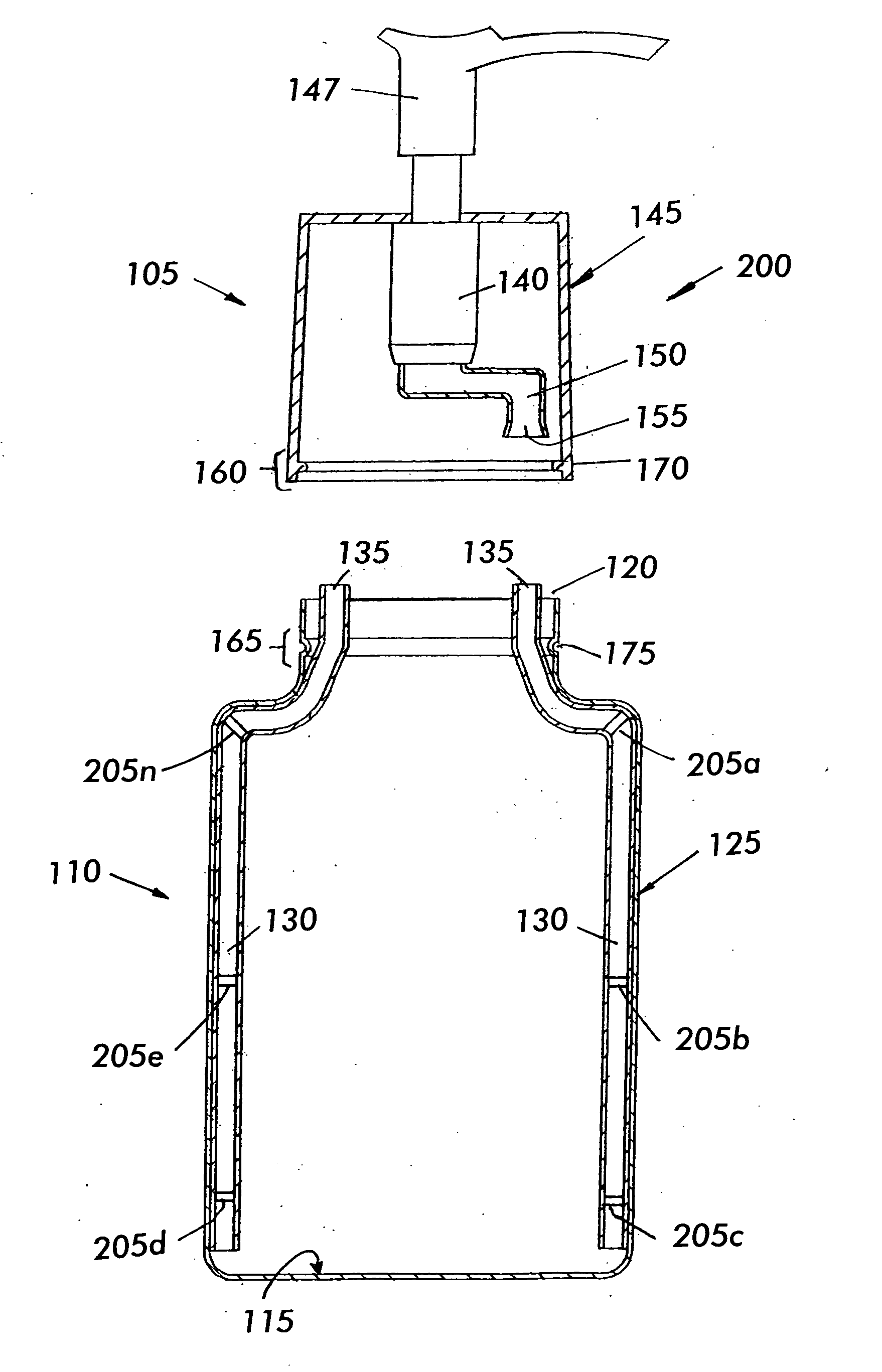

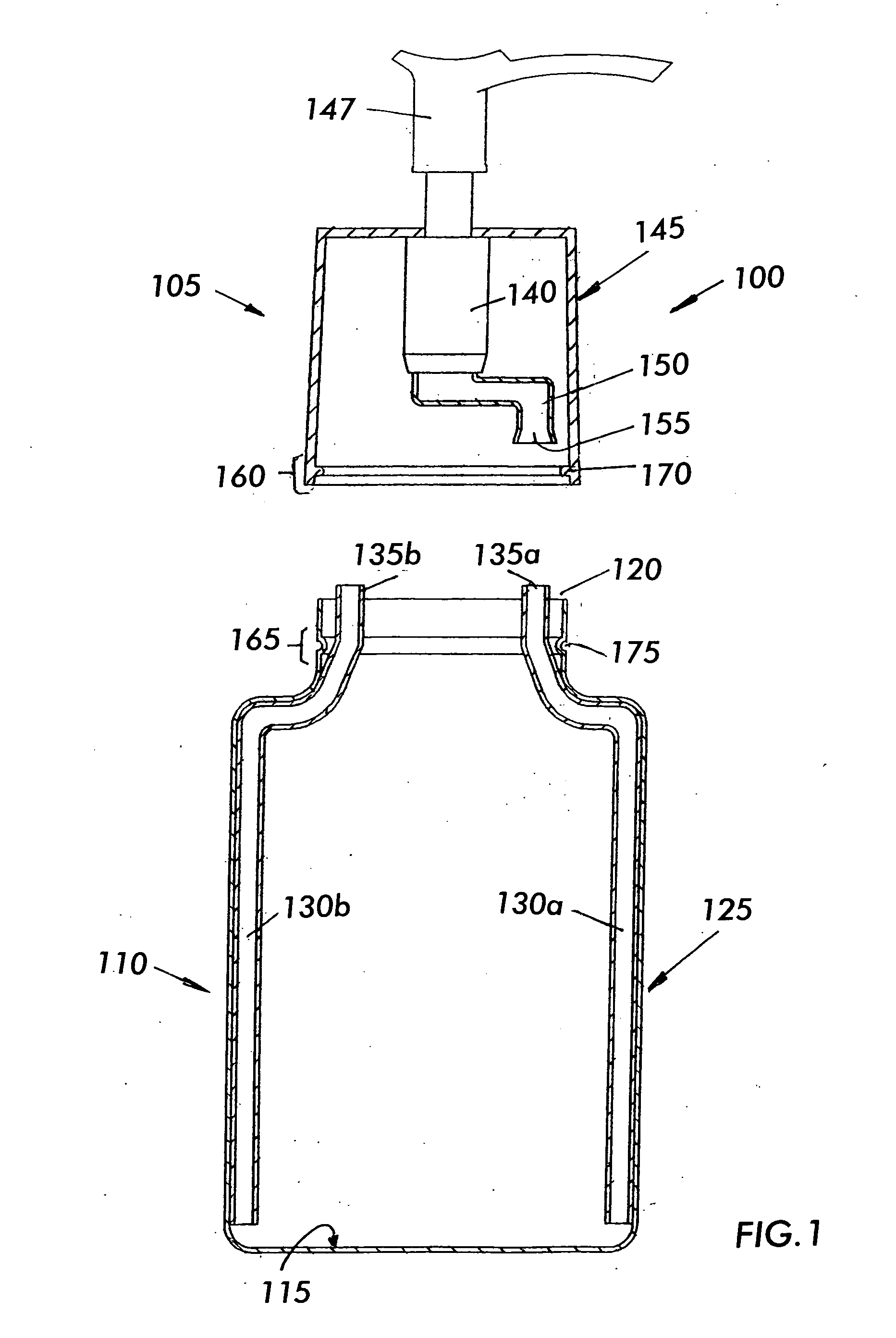

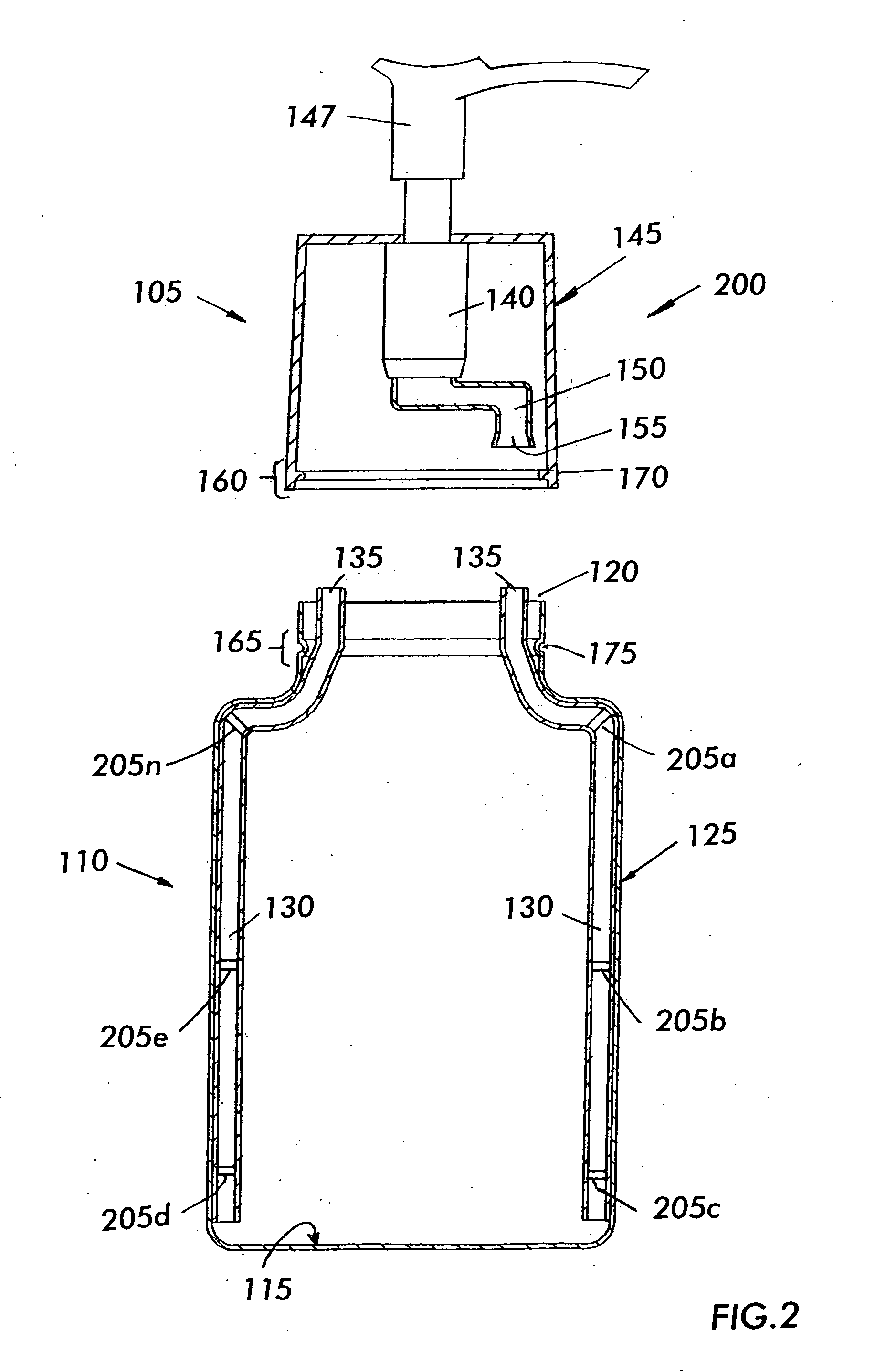

Dispenser assembly

ActiveUS7490743B2Easy to assembleReduce working spaceLarge containersLiquid transferring devicesCouplingEngineering

A dispenser assembly is provided. The dispenser assembly includes a container having a bottom, an open top and a side wall extending between the bottom and the open top, and a mating arrangement, the side wall having an inner surface; at least one container passageway mounted on the inner surface of the side wall and extending from the open top of the container to a position proximate to the bottom of the container; and a pump cap having a cap body, a pump mechanism arranged within the cap body, a pump cap passageway coupled to the pump mechanism, and a coupling arrangement arranged on the pump cap body and configured to detachably couple to the mating arrangement of the container such that the container passageway aligns with and sealingly engages the pump cap passageway in a fluid connection when the pump cap is mounted to the container. In this manner, the dispenser permits a fluid arranged within the container to flow through the container passageway and the pump cap passageway when the pump mechanism of the pump cap is activated.

Owner:AUTO KAPS

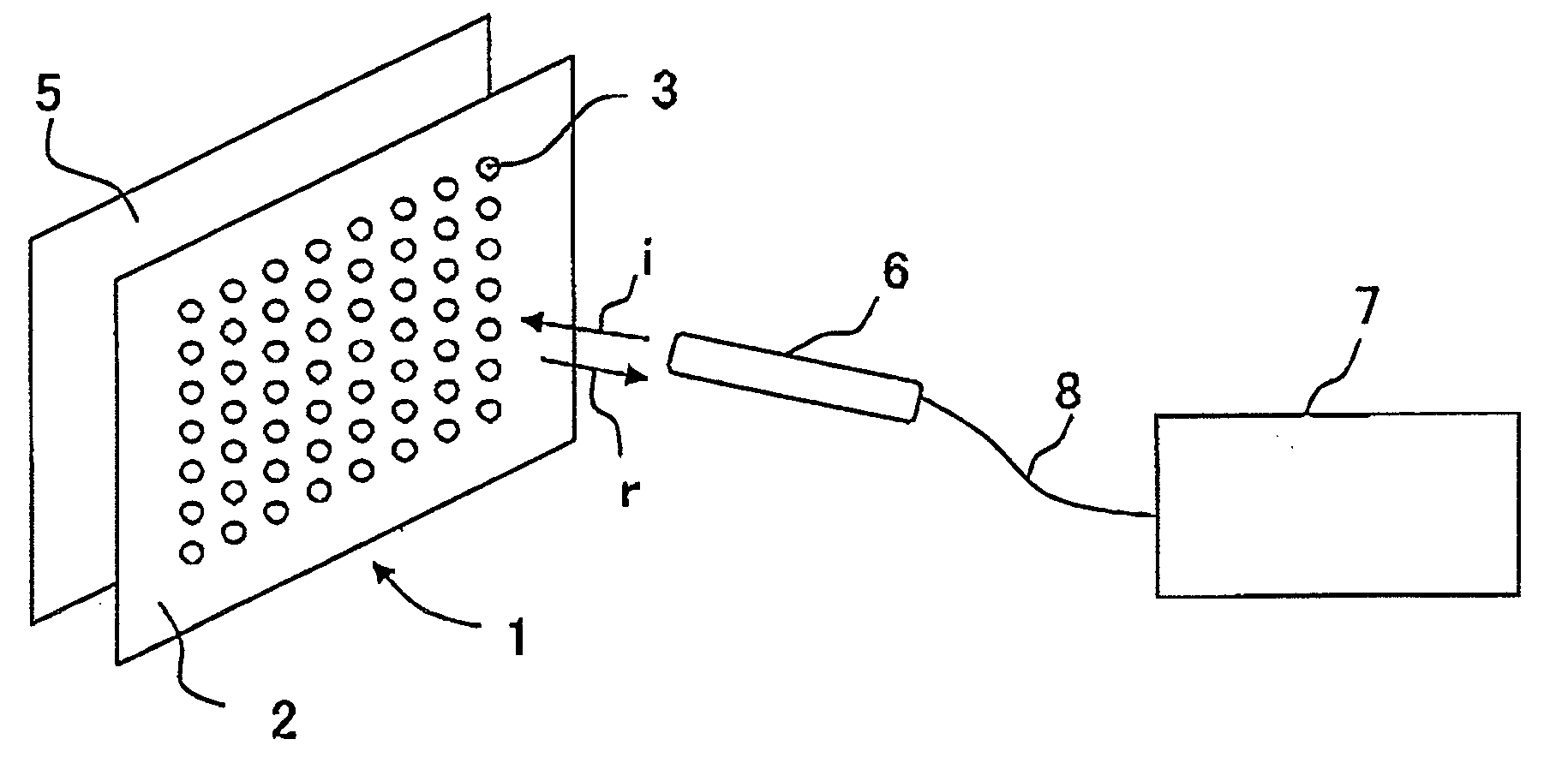

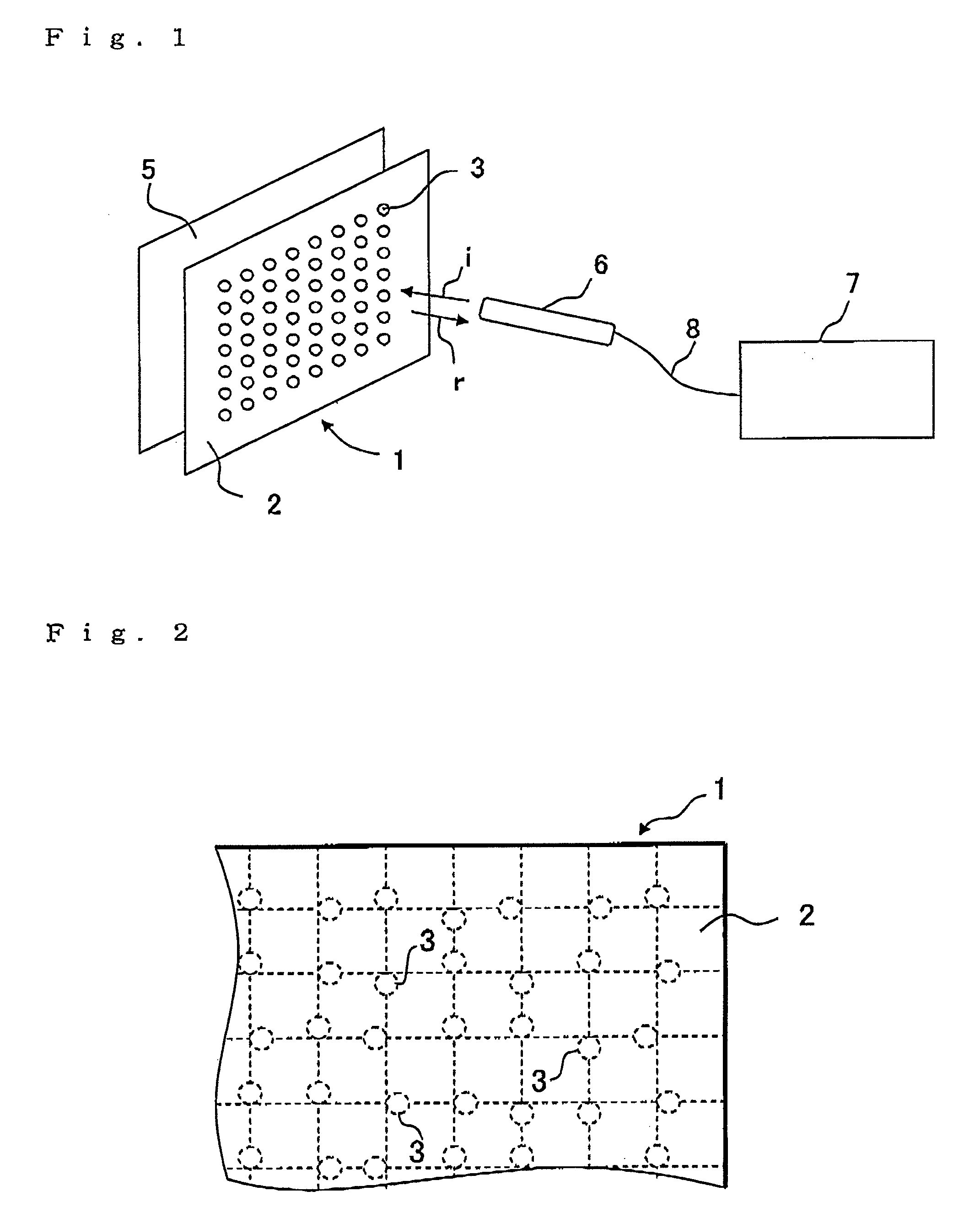

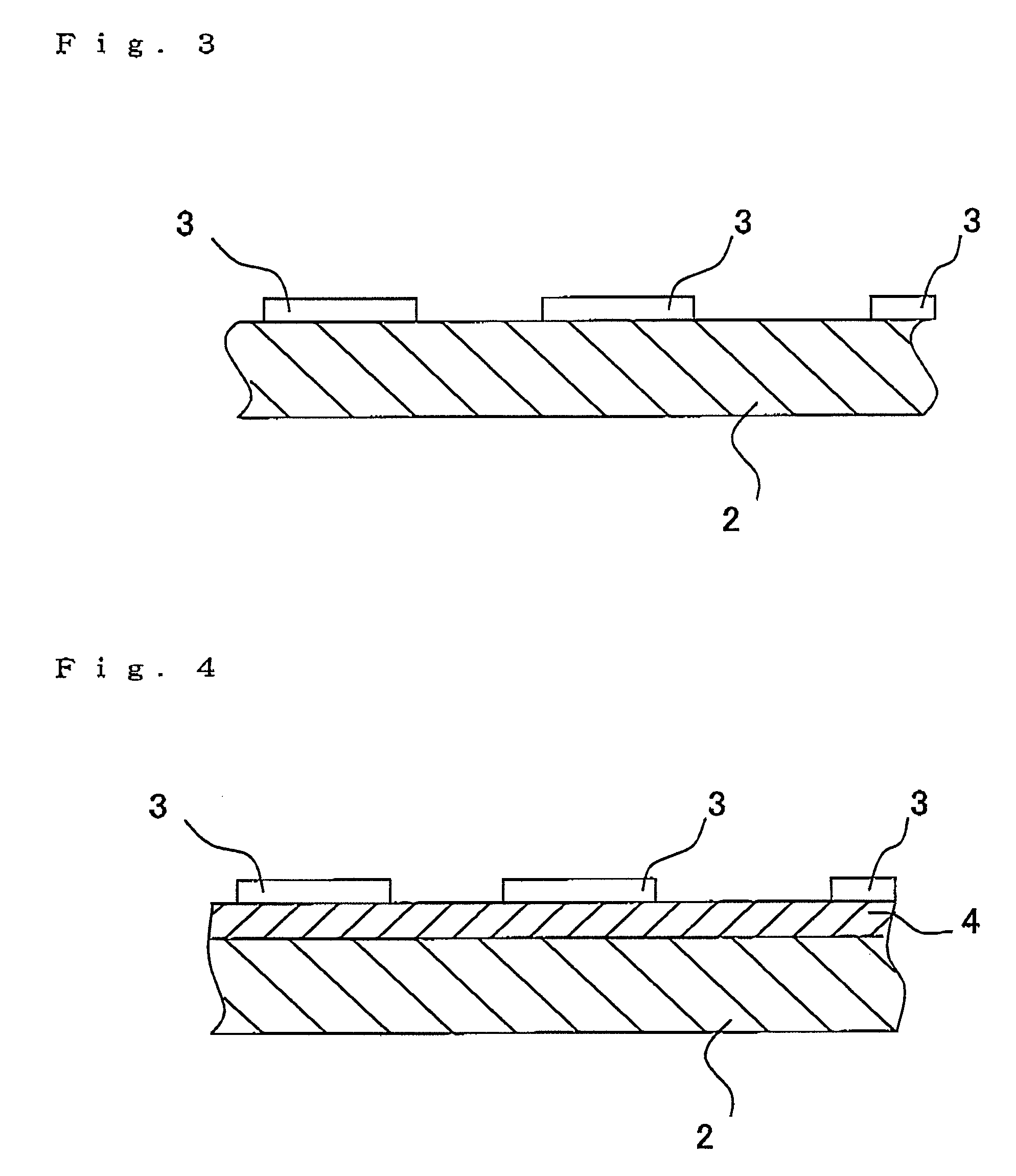

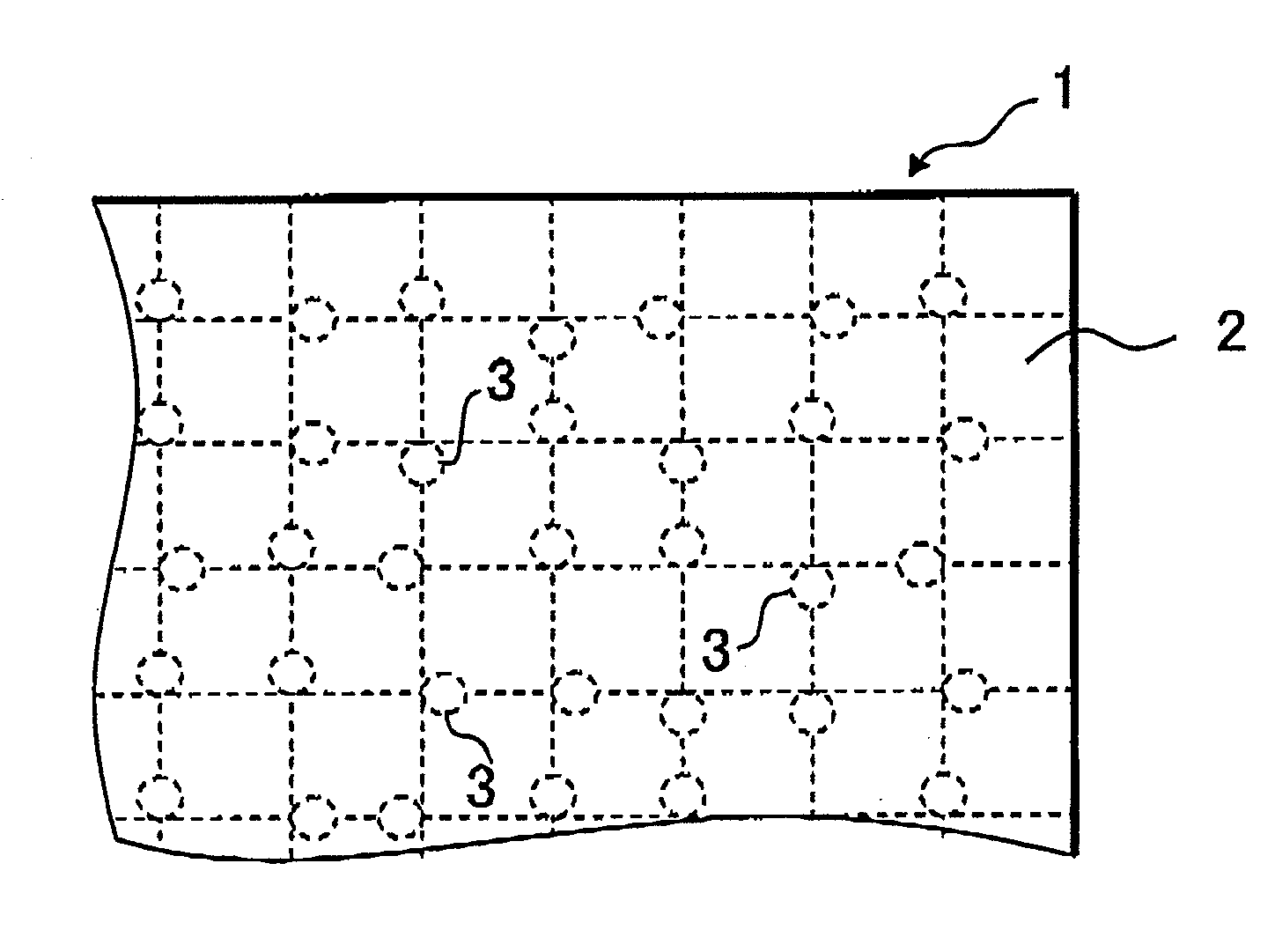

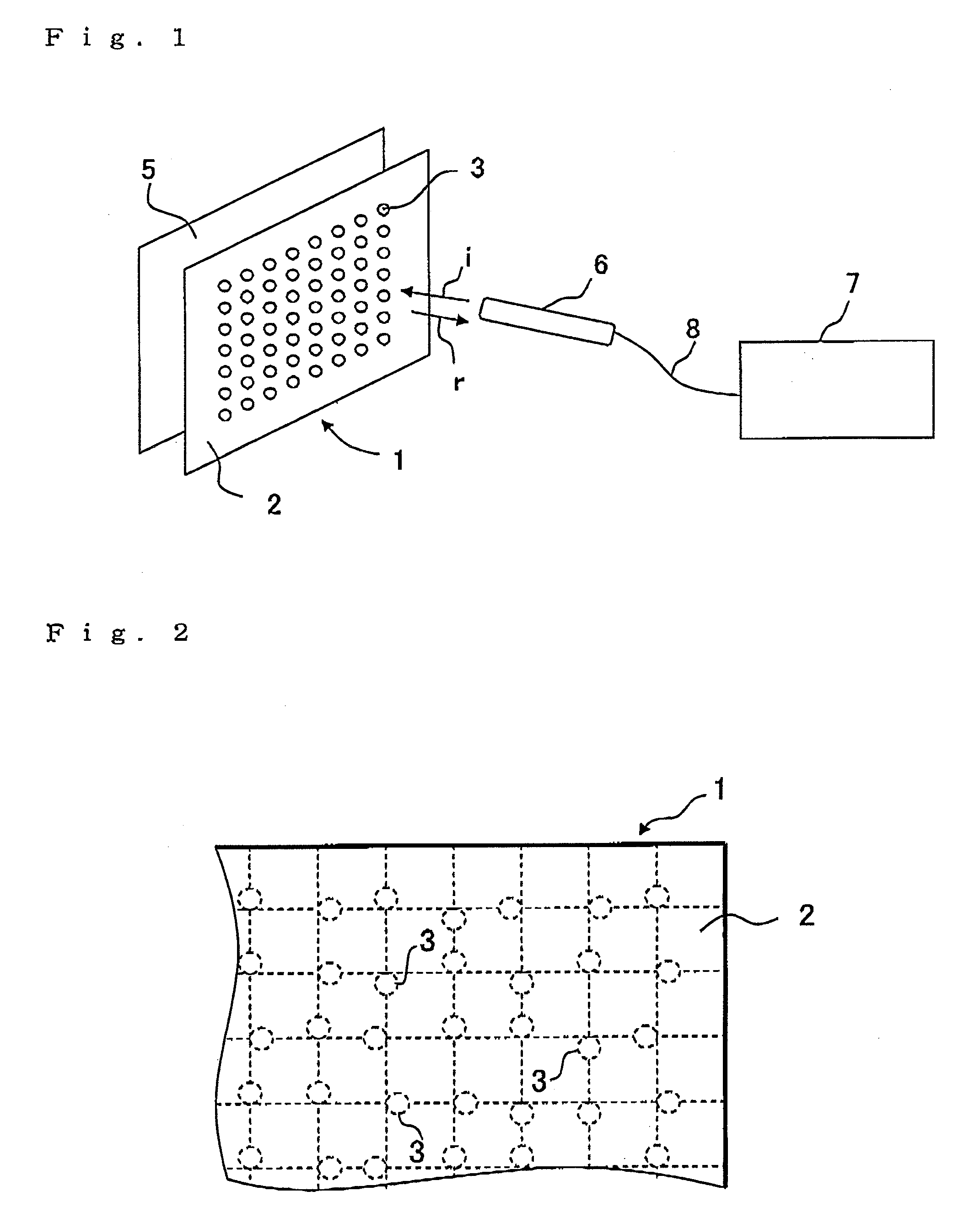

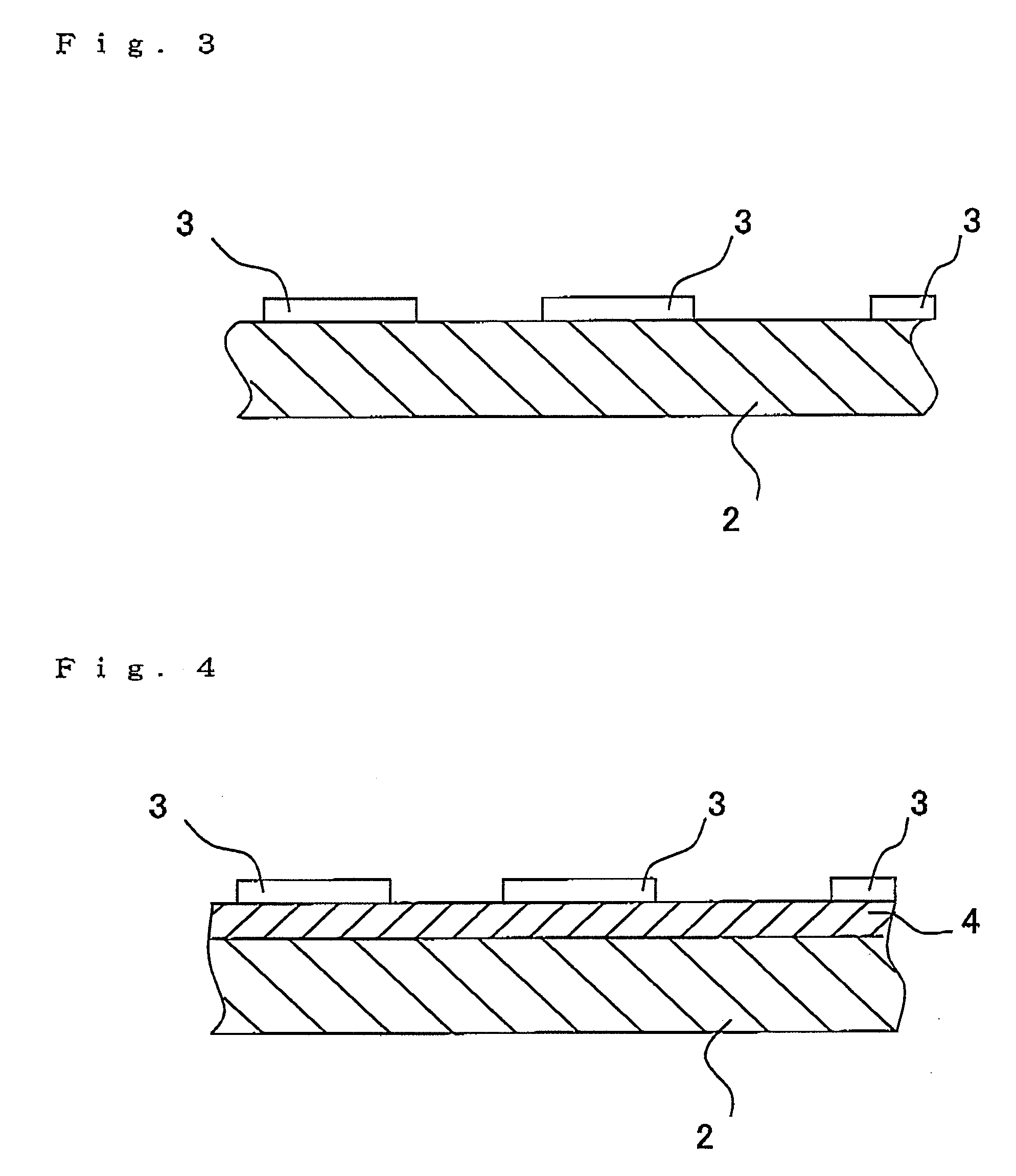

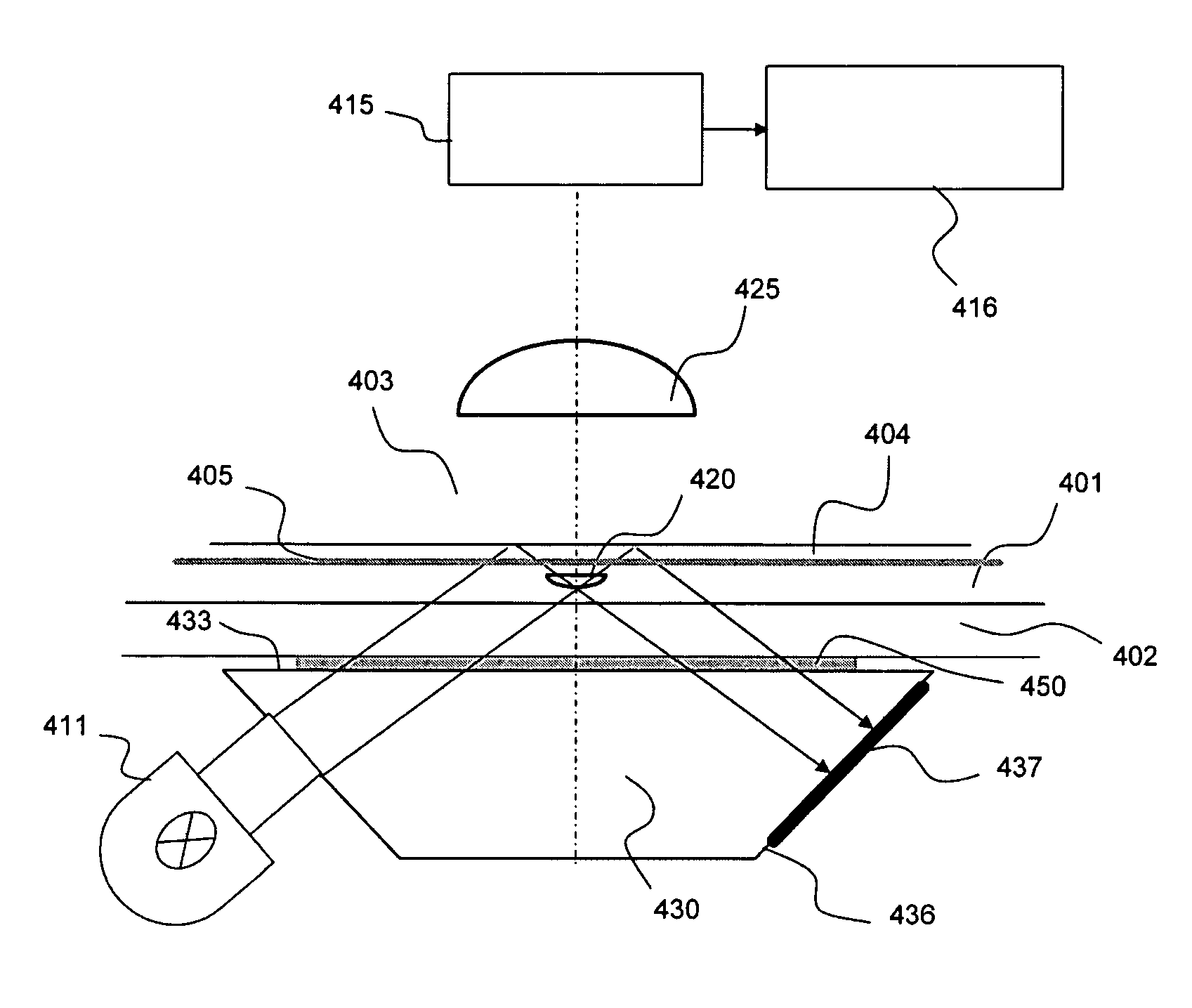

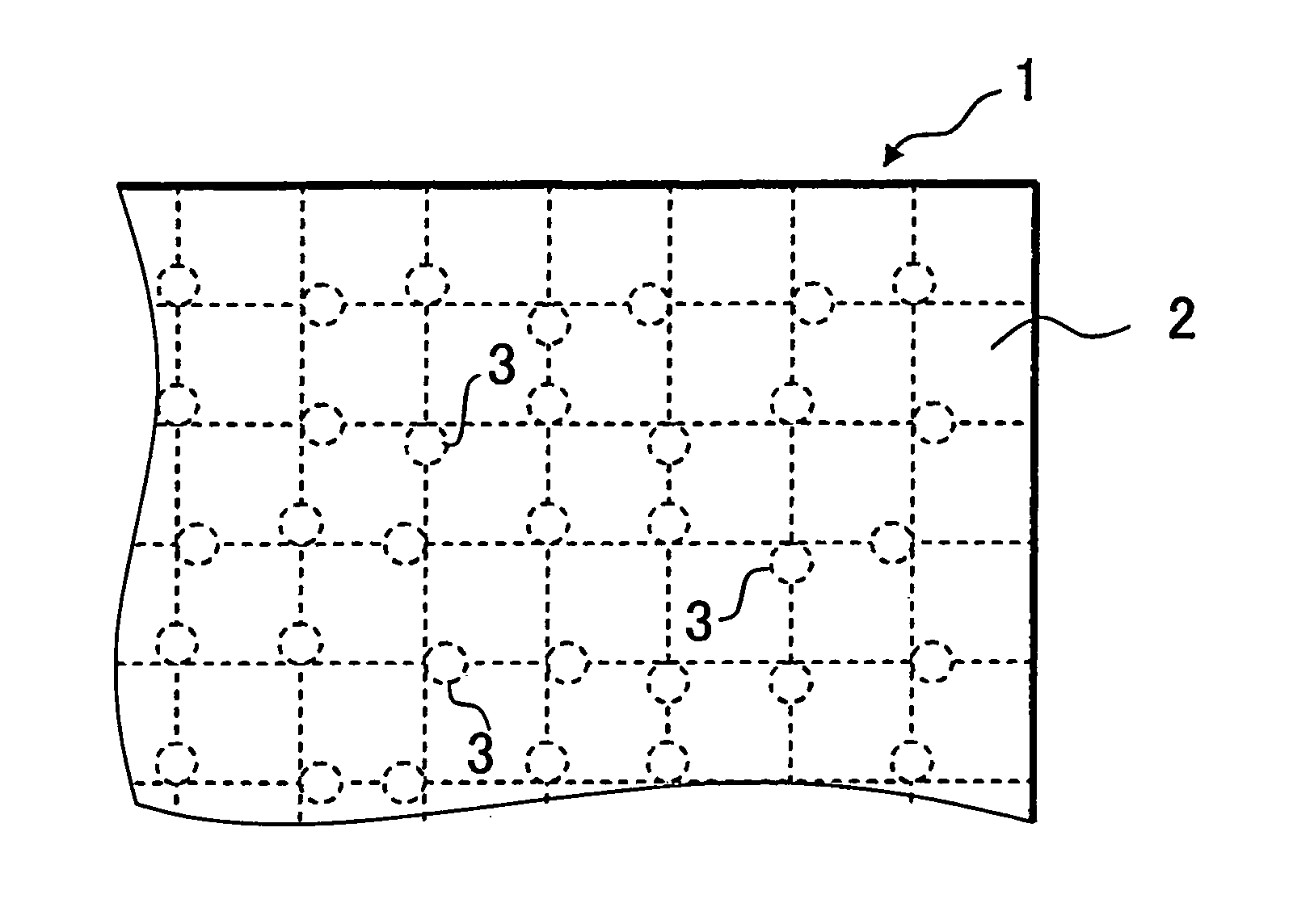

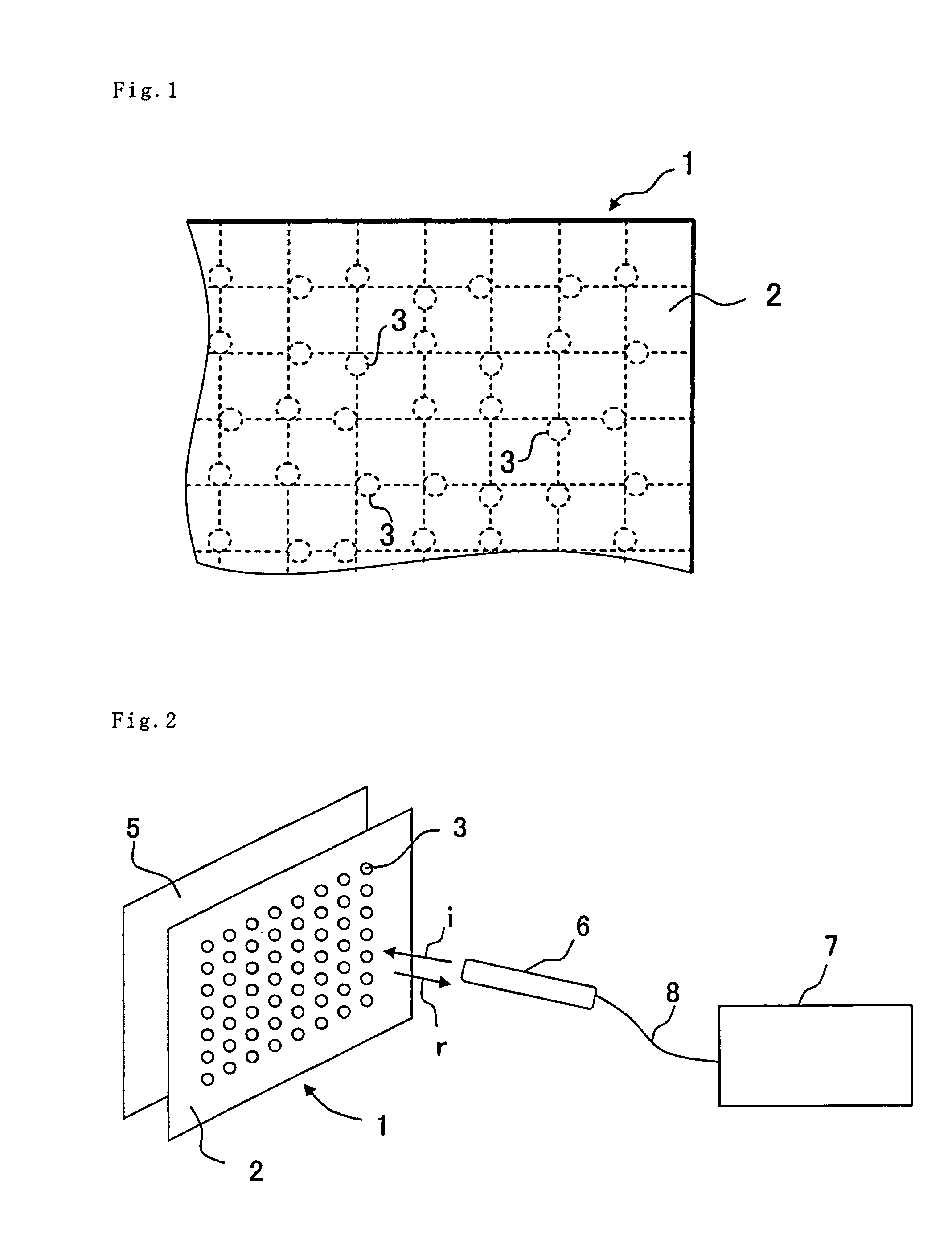

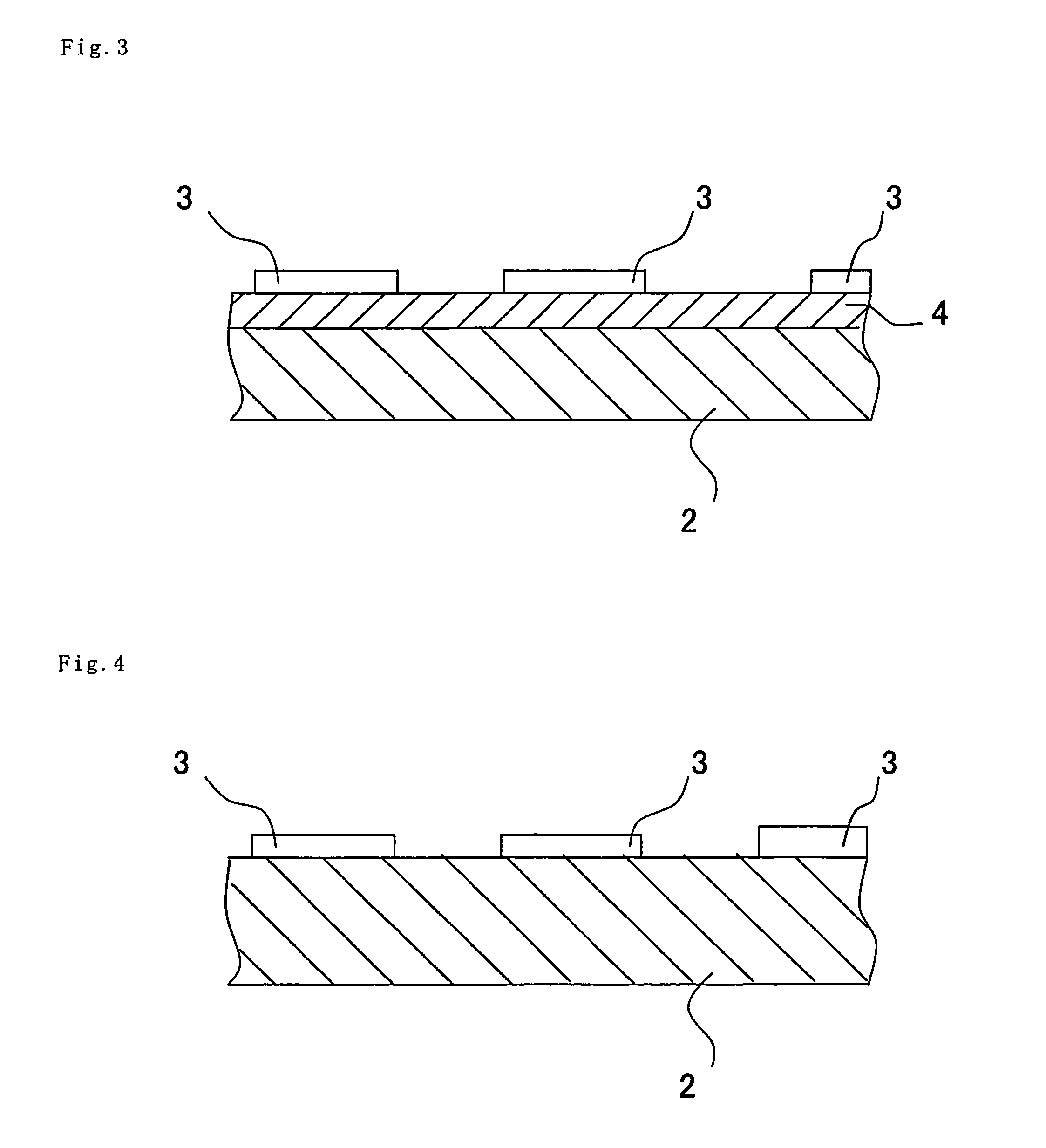

Pattern printed sheet

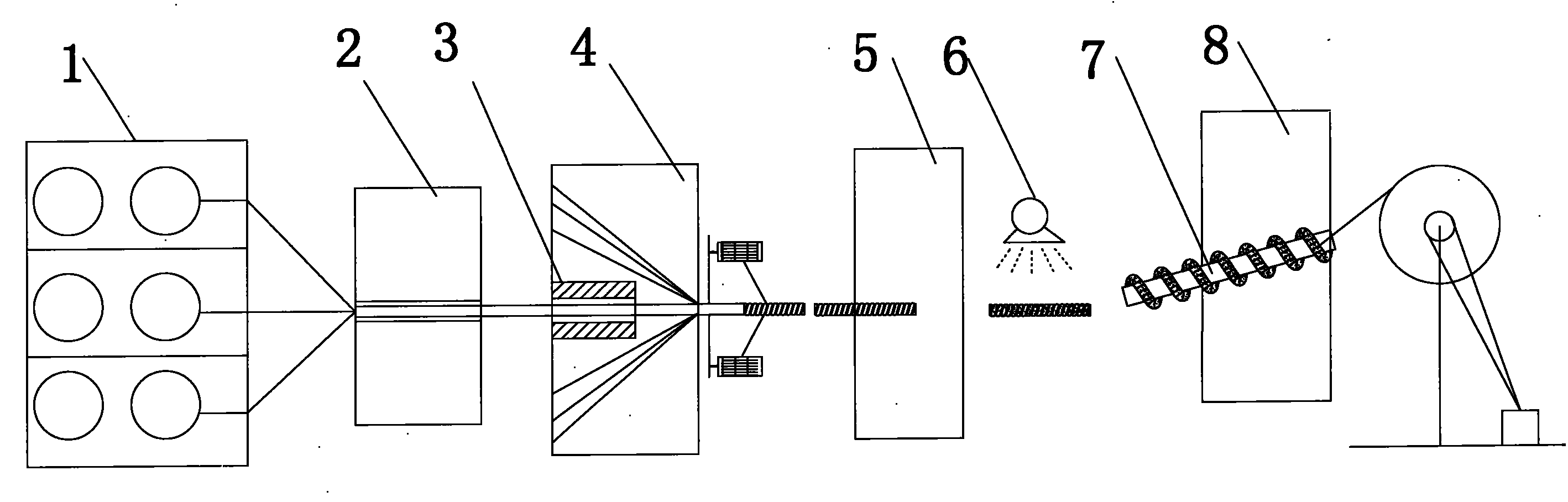

InactiveUS9213929B2Low priceReduce working spaceRecord carriers used with machinesNon-linear opticsMicroscopic observationDisplay device

The pattern printed sheet 1 of the present invention includes a substrate 2 and a non-visible light-reflective transparent pattern 3 printed on a surface of the substrate, wherein an ink for forming the transparent pattern 3 contains a non-visible light-reflective material capable of selectively reflecting a light having a wavelength in a non-visible light range, and the transparent pattern 3 printed on the surface of the substrate 2 has a multilayer structure in section which is repeated at predetermined intervals as observed by a scanning electron microscope, and reflects only a circular polarization component in a predetermined rotation direction relative to an incident light applied thereto. The pattern printed sheet is usable as a coordinate detecting means which is applicable a data input system of a type capable of directly hand-writing input data on an image screen of a display device, and has a reduced weight and a low price, and is readily obtained in the form of a large area sheet and can be mass-produced.

Owner:DAI NIPPON PRINTING CO LTD

Pattern printed sheet

InactiveUS20070290047A1Reduce working spaceReduce weightRecord carriers used with machinesNon-linear opticsMicroscopic observationDisplay device

The pattern printed sheet 1 of the present invention includes a substrate 2 and a non-visible light-reflective transparent pattern 3 printed on a surface of the substrate, wherein an ink for forming the transparent pattern 3 contains a non-visible light-reflective material capable of selectively reflecting a light having a wavelength in a non-visible light range, and the transparent pattern 3 printed on the surface of the substrate 2 has a multilayer structure in section which is repeated at predetermined intervals as observed by a scanning electron microscope, and reflects only a circular polarization component in a predetermined rotation direction relative to an incident light applied thereto. The pattern printed sheet is usable as a coordinate detecting means which is applicable a data input system of a type capable of directly hand-writing input data on an image screen of a display device, and has a reduced weight and a low price, and is readily obtained in the form of a large area sheet and can be mass-produced.

Owner:DAI NIPPON PRINTING CO LTD

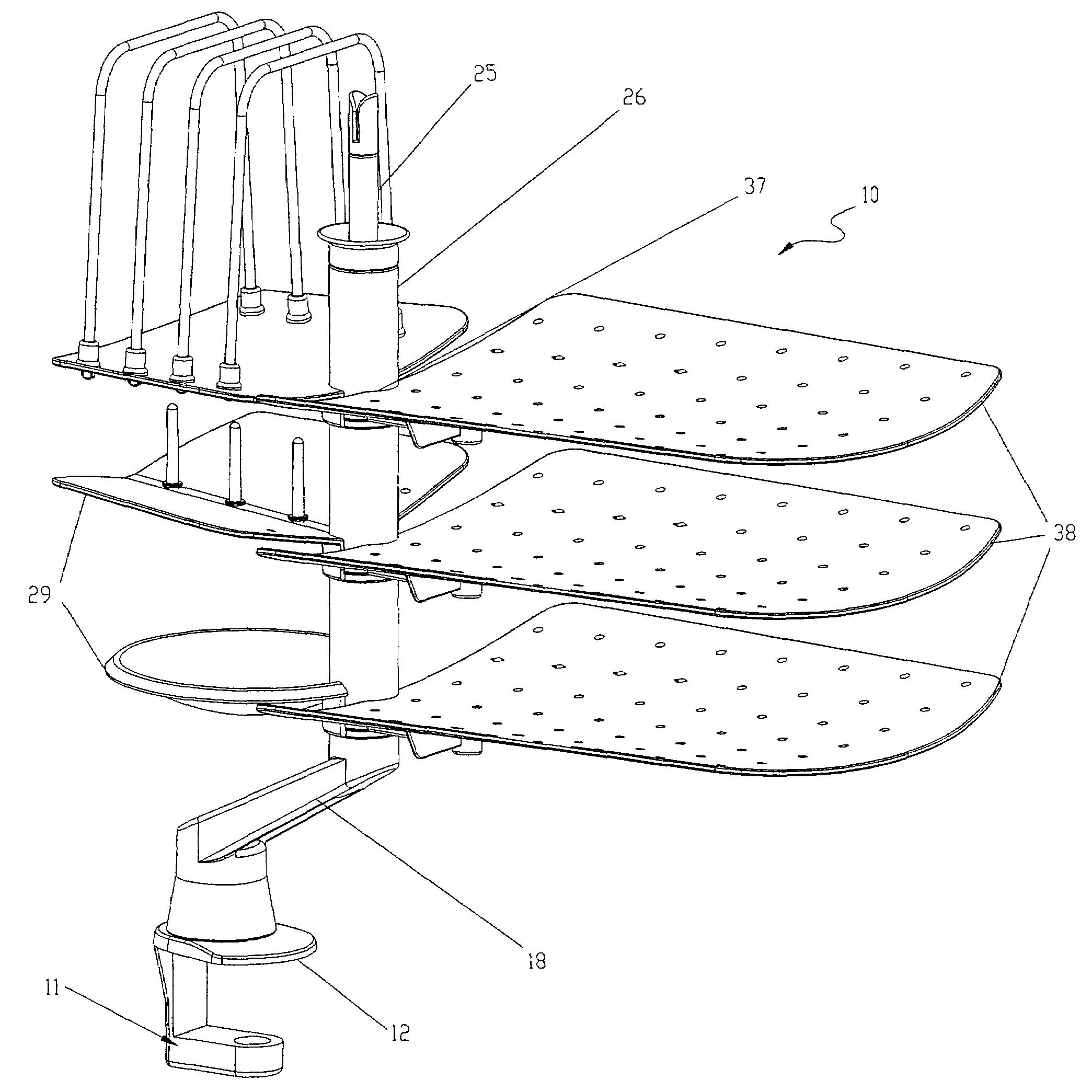

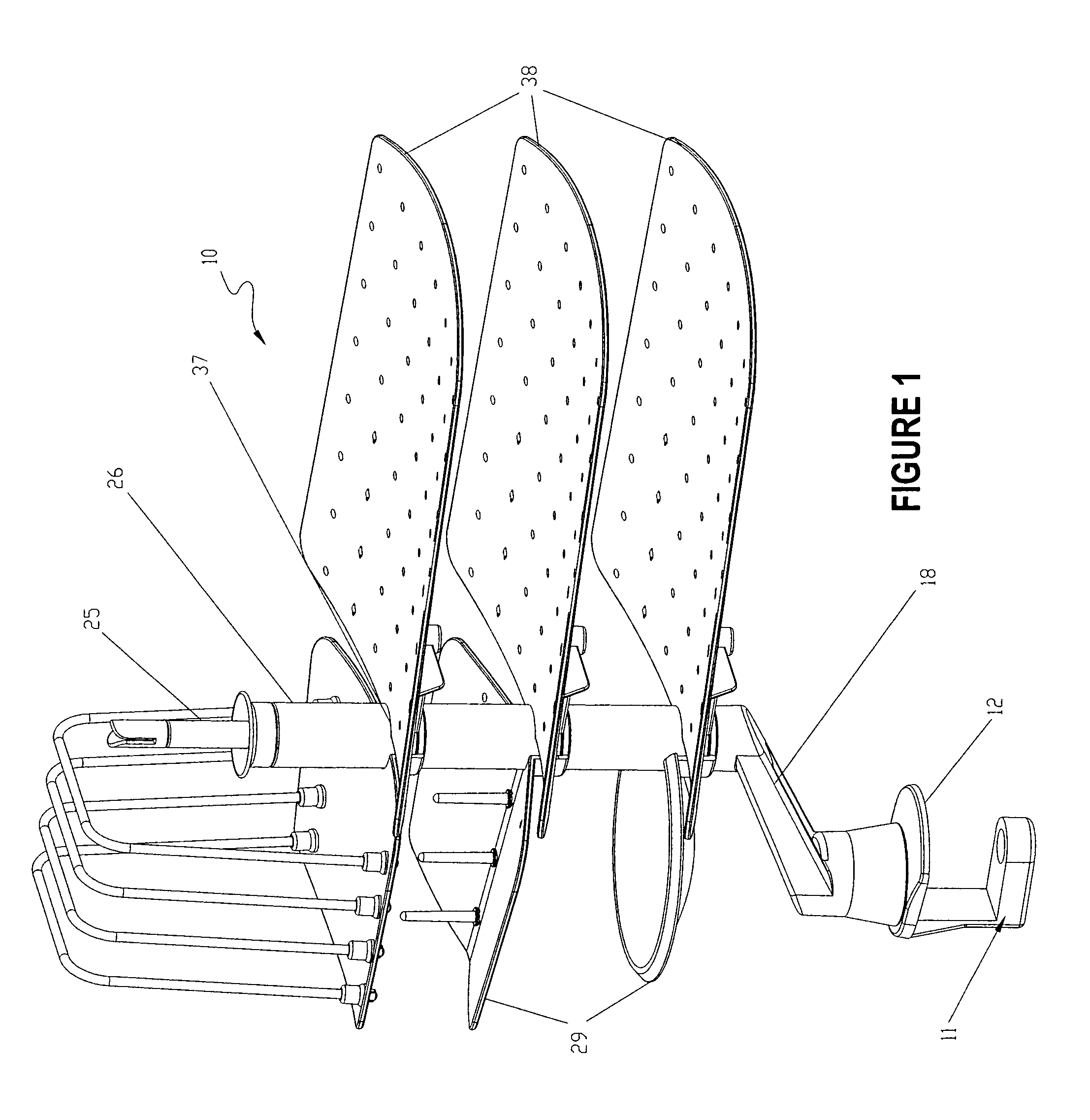

Multiple tray desk organizer

InactiveUS6968957B2Reduce working spaceEasy accessShow cabinetsCard-filingEngineeringSupport surface

A desk tray is mounted on a support surface with a support base. Extending vertically from the support base is an elongated rod carrying a spindle. The spindle and rod have several receptacles at different levels above the support surface. The spindle and rod are rotatably mounted on the support base.

Owner:CUSTOM PLASTICS +1

Dispenser assembly

ActiveUS20060086759A1Easy to assembleReduce working spaceLarge containersLiquid transferring devicesCouplingEngineering

A dispenser assembly is provided. The dispenser assembly includes a container having a bottom, an open top and a side wall extending between the bottom and the open top, and a mating arrangement, the side wall having an inner surface; at least one container passageway mounted on the inner surface of the side wall and extending from the open top of the container to a position proximate to the bottom of the container; and a pump cap having a cap body, a pump mechanism arranged within the cap body, a pump cap passageway coupled to the pump mechanism, and a coupling arrangement arranged on the pump cap body and configured to detachably couple to the mating arrangement of the container such that the container passageway aligns with and sealingly engages the pump cap passageway in a fluid connection when the pump cap is mounted to the container. In this manner, the dispenser permits a fluid arranged within the container to flow through the container passageway and the pump cap passageway when the pump mechanism of the pump cap is activated.

Owner:AUTO KAPS

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

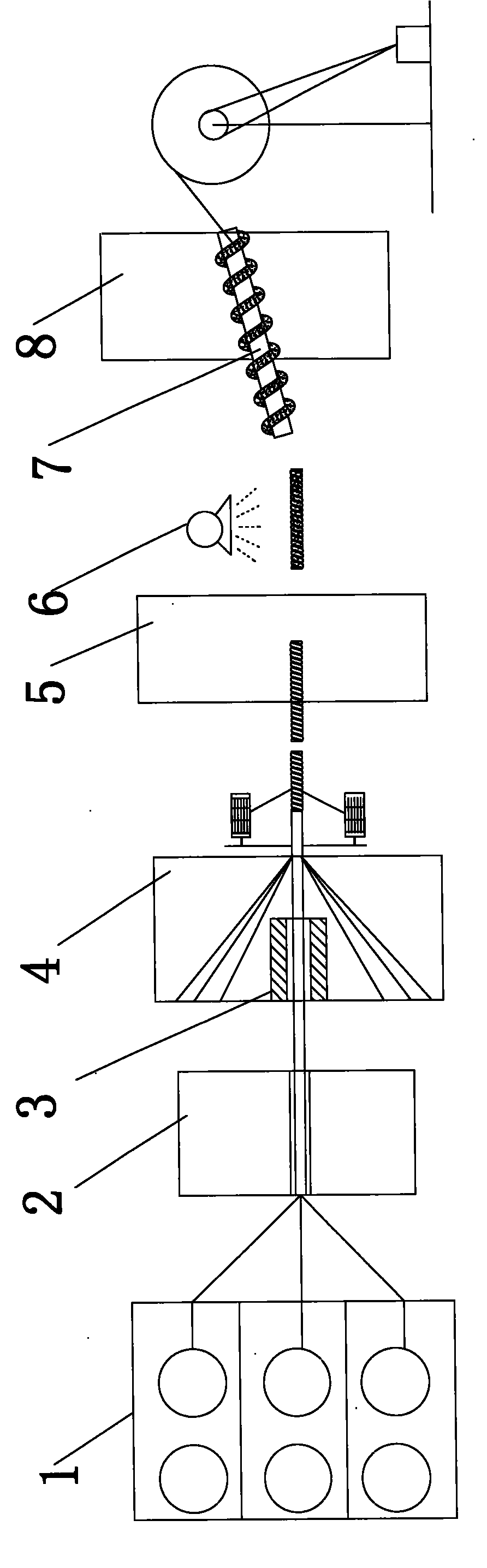

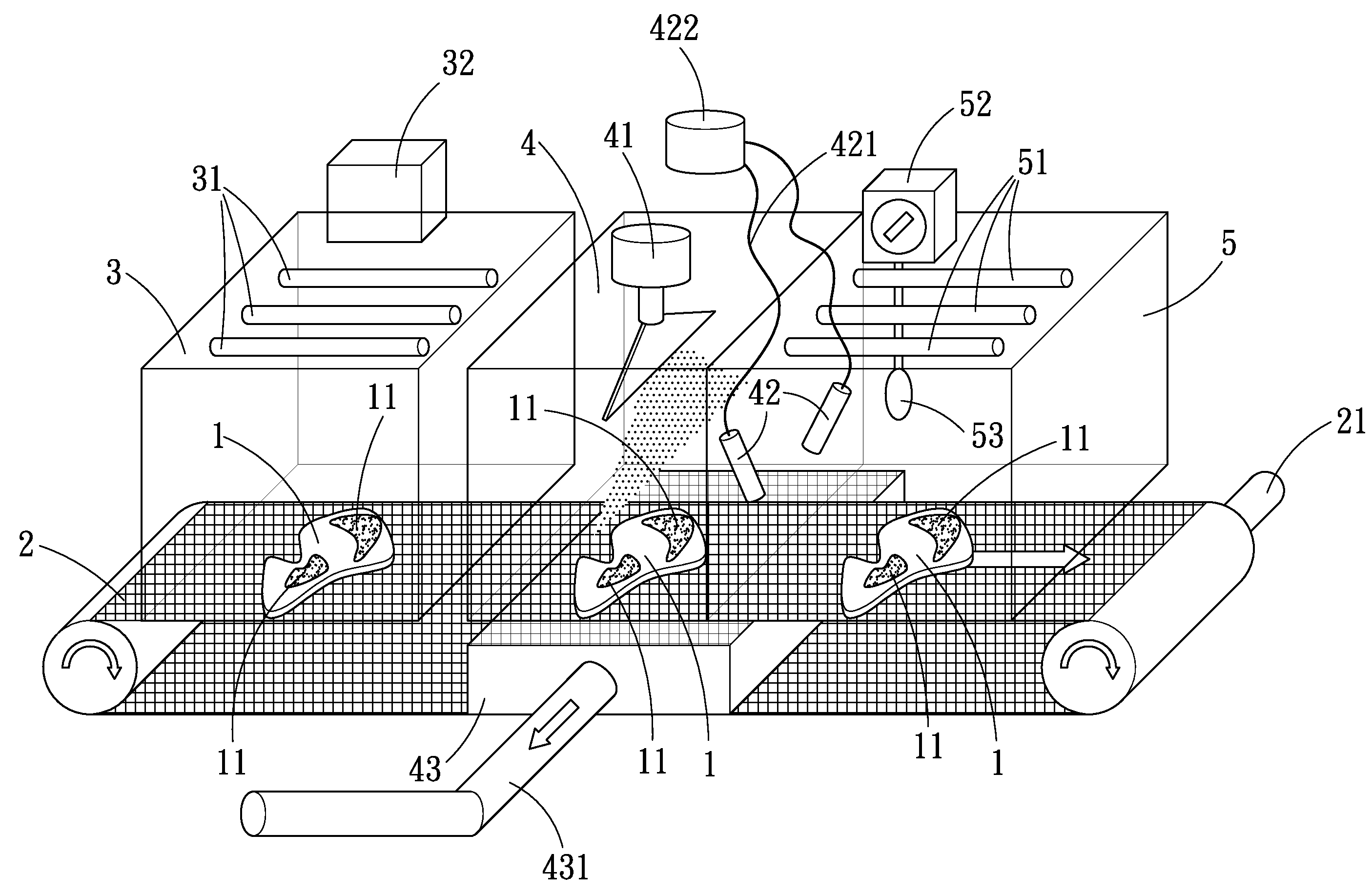

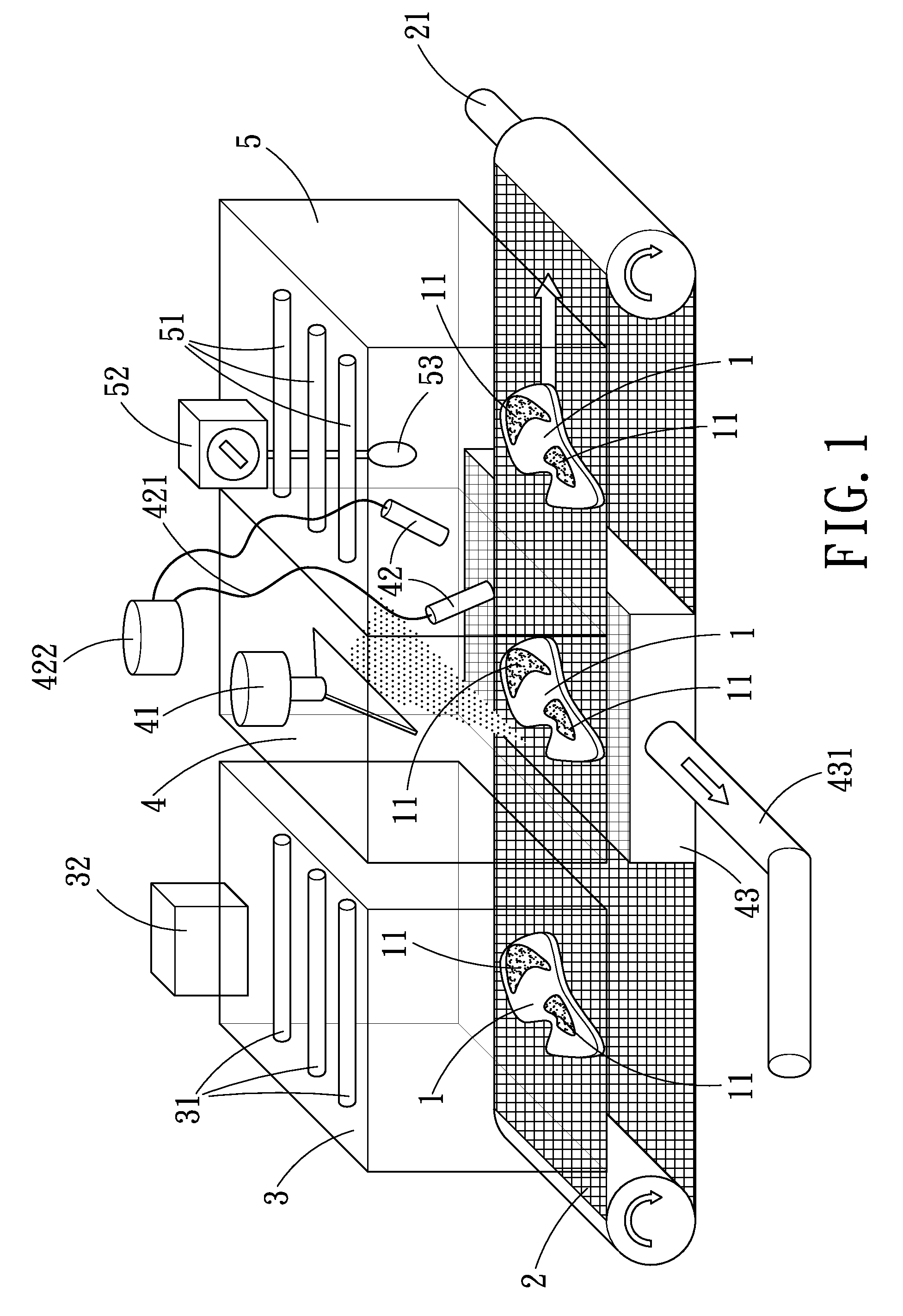

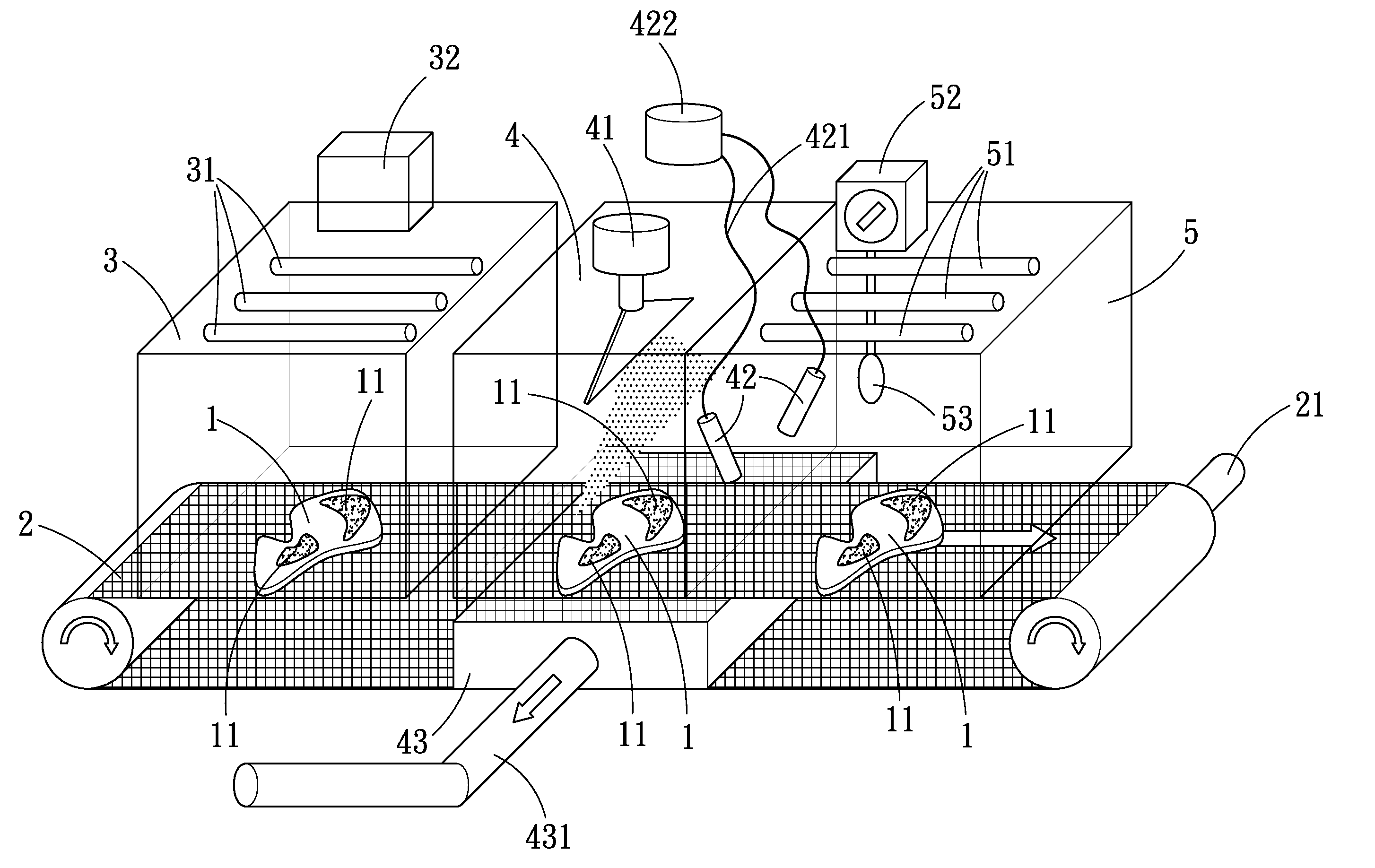

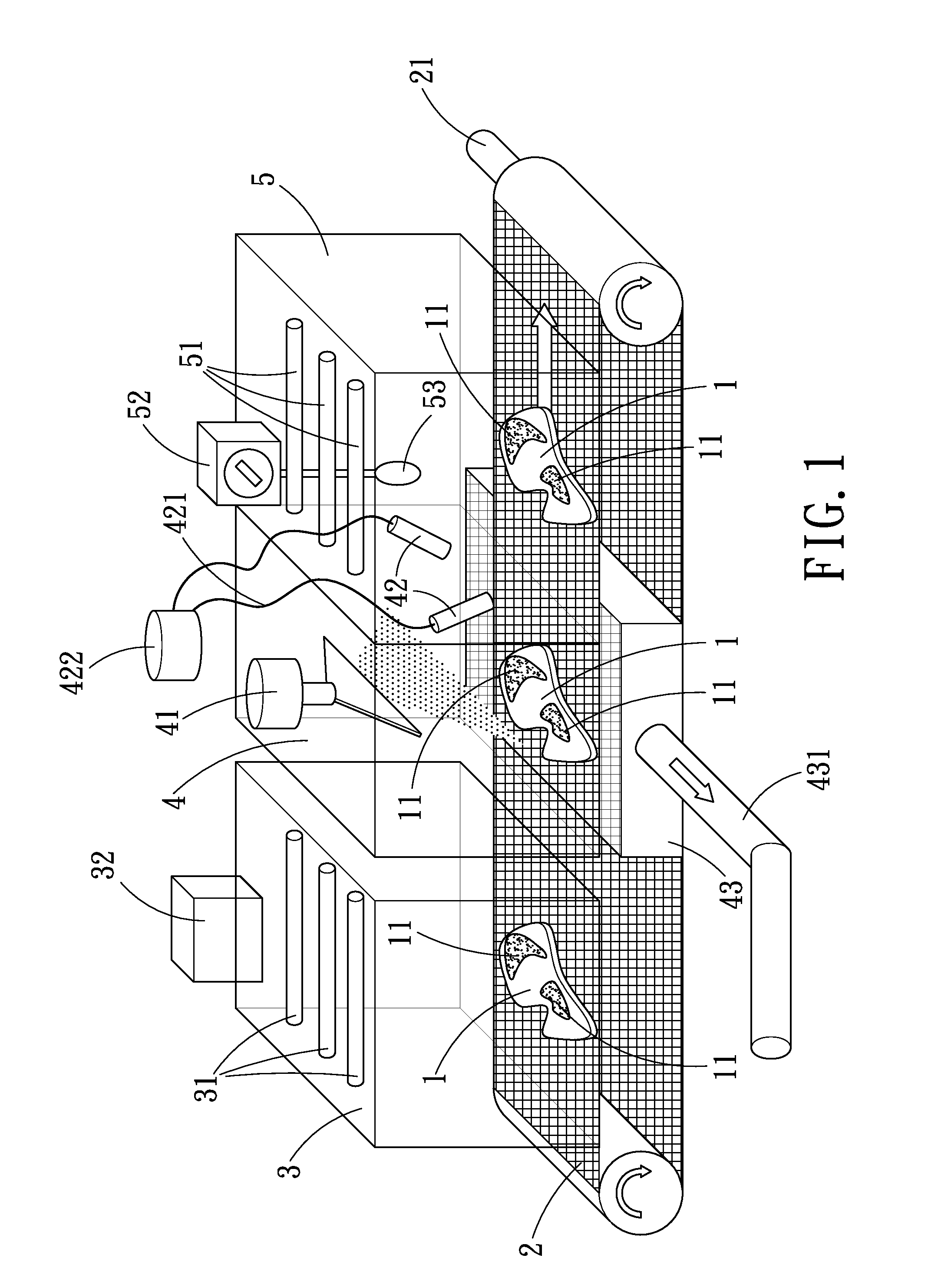

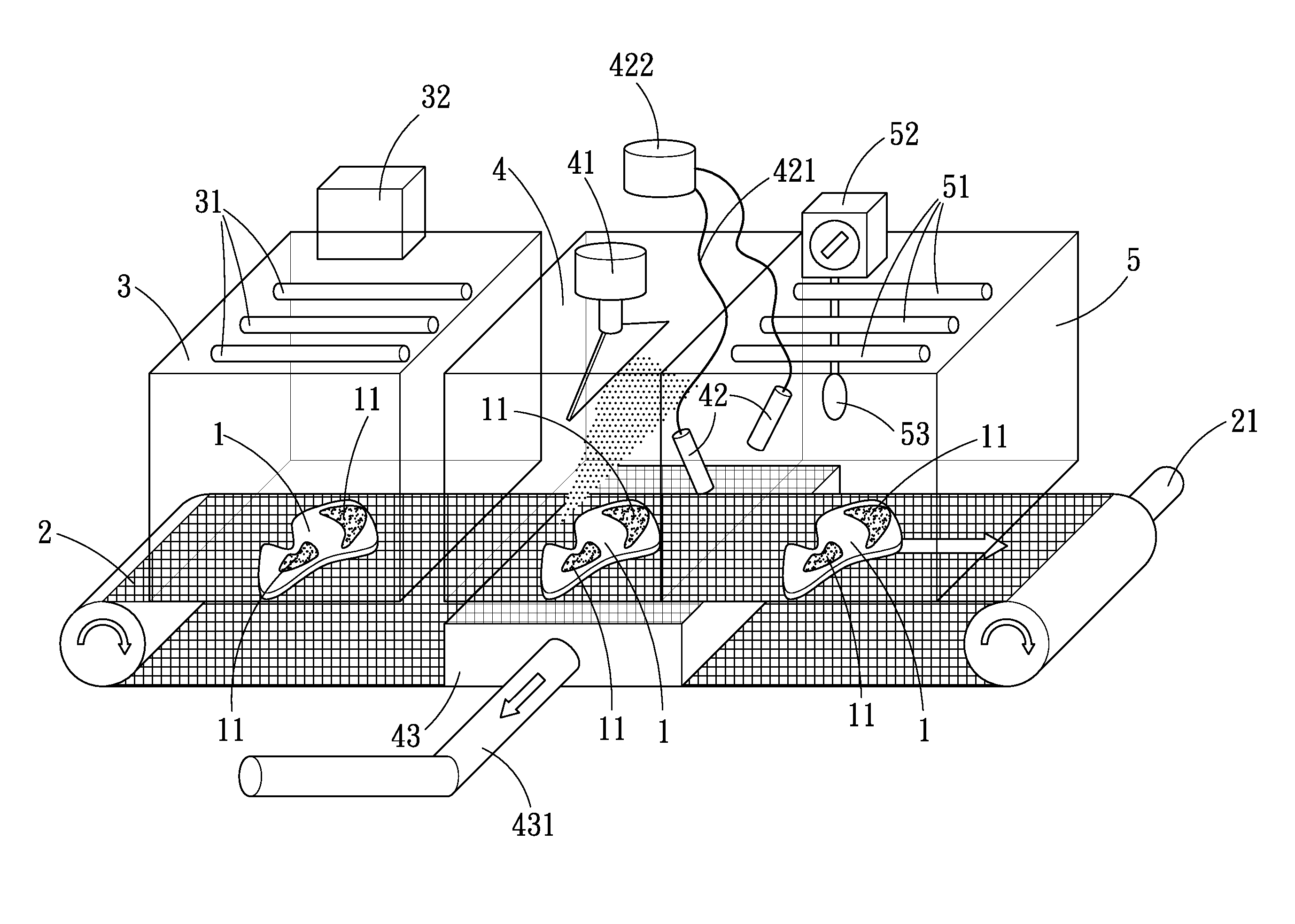

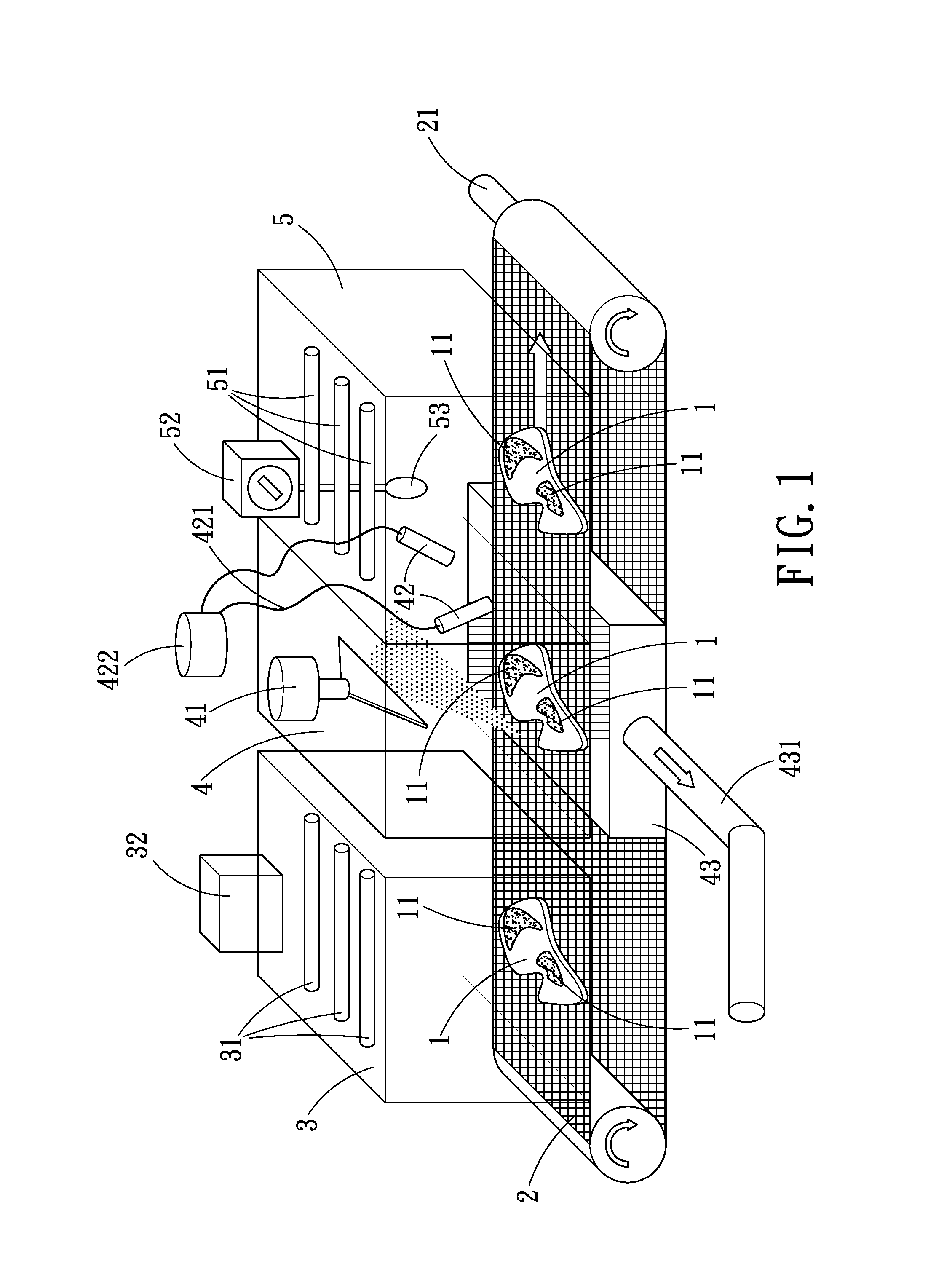

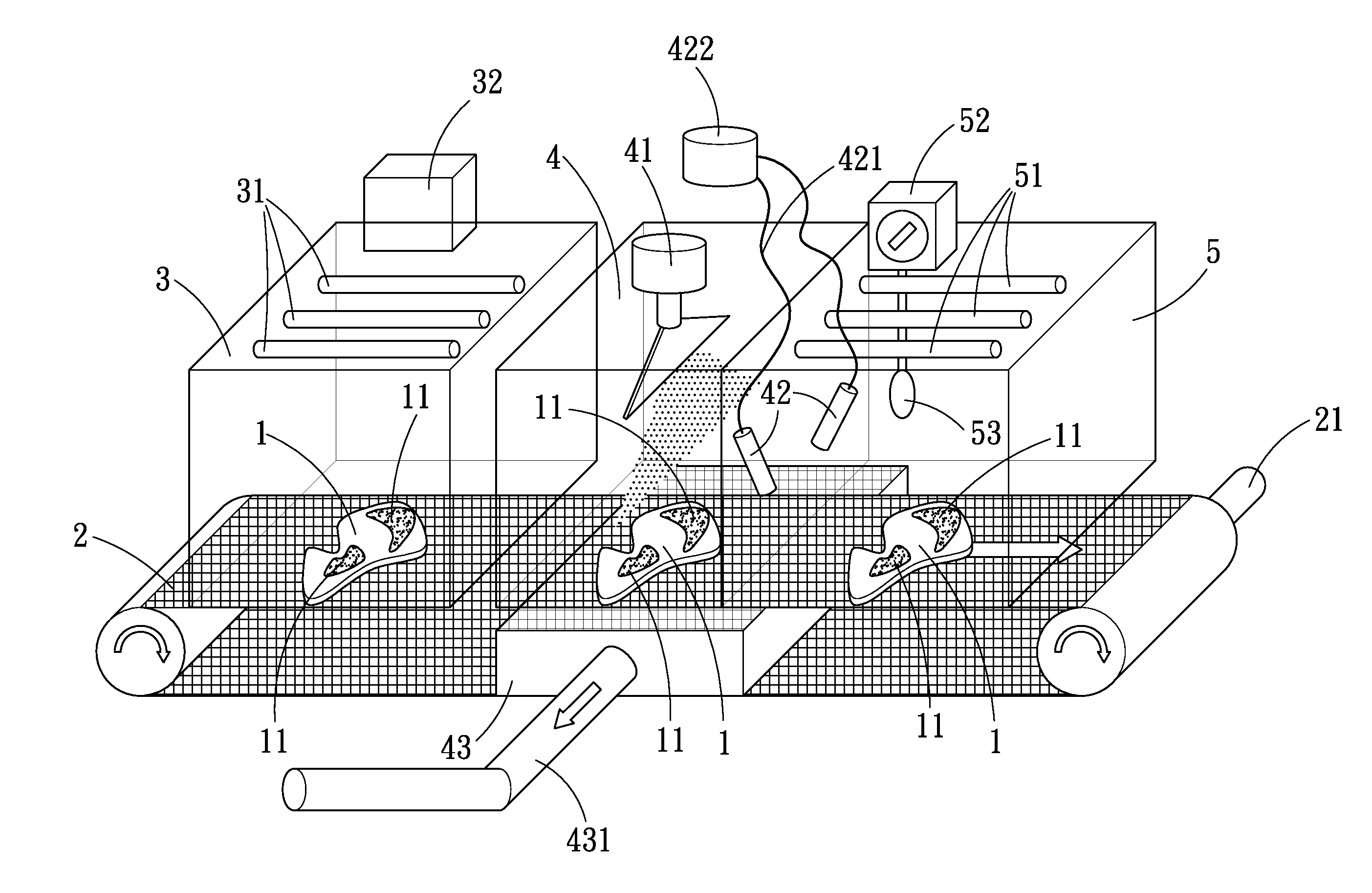

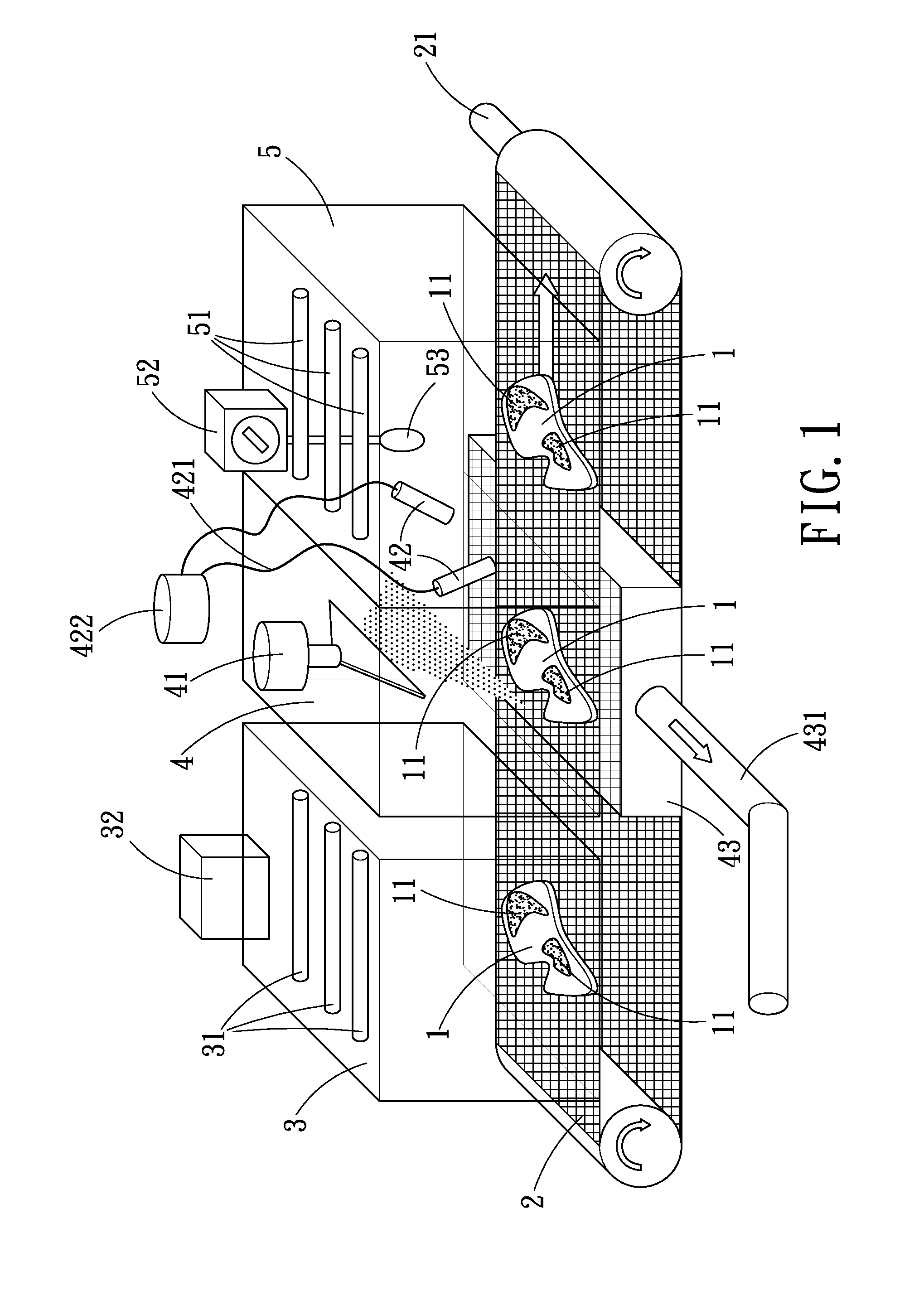

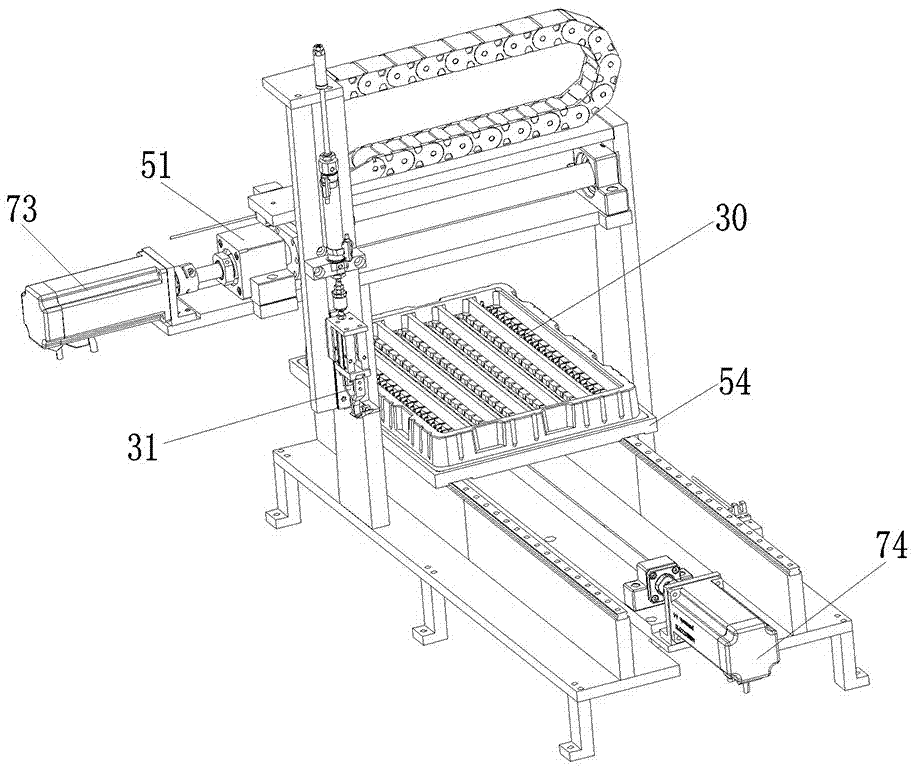

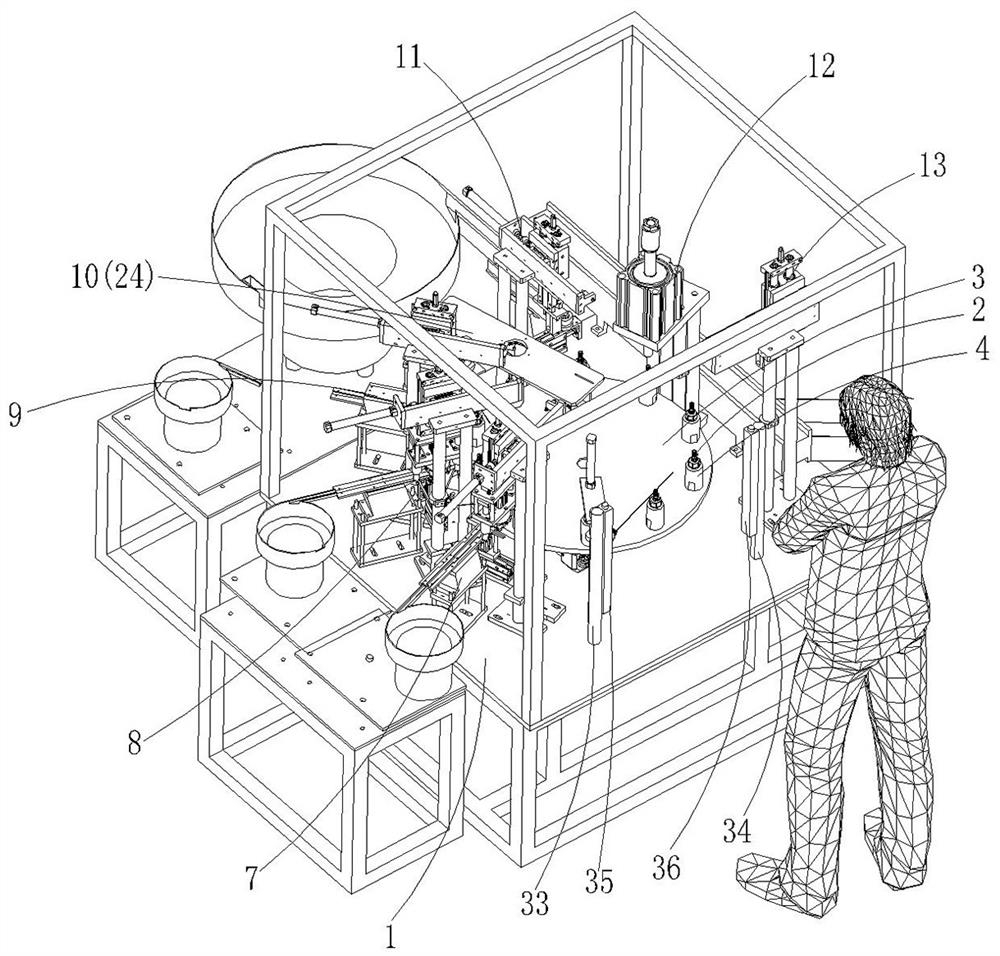

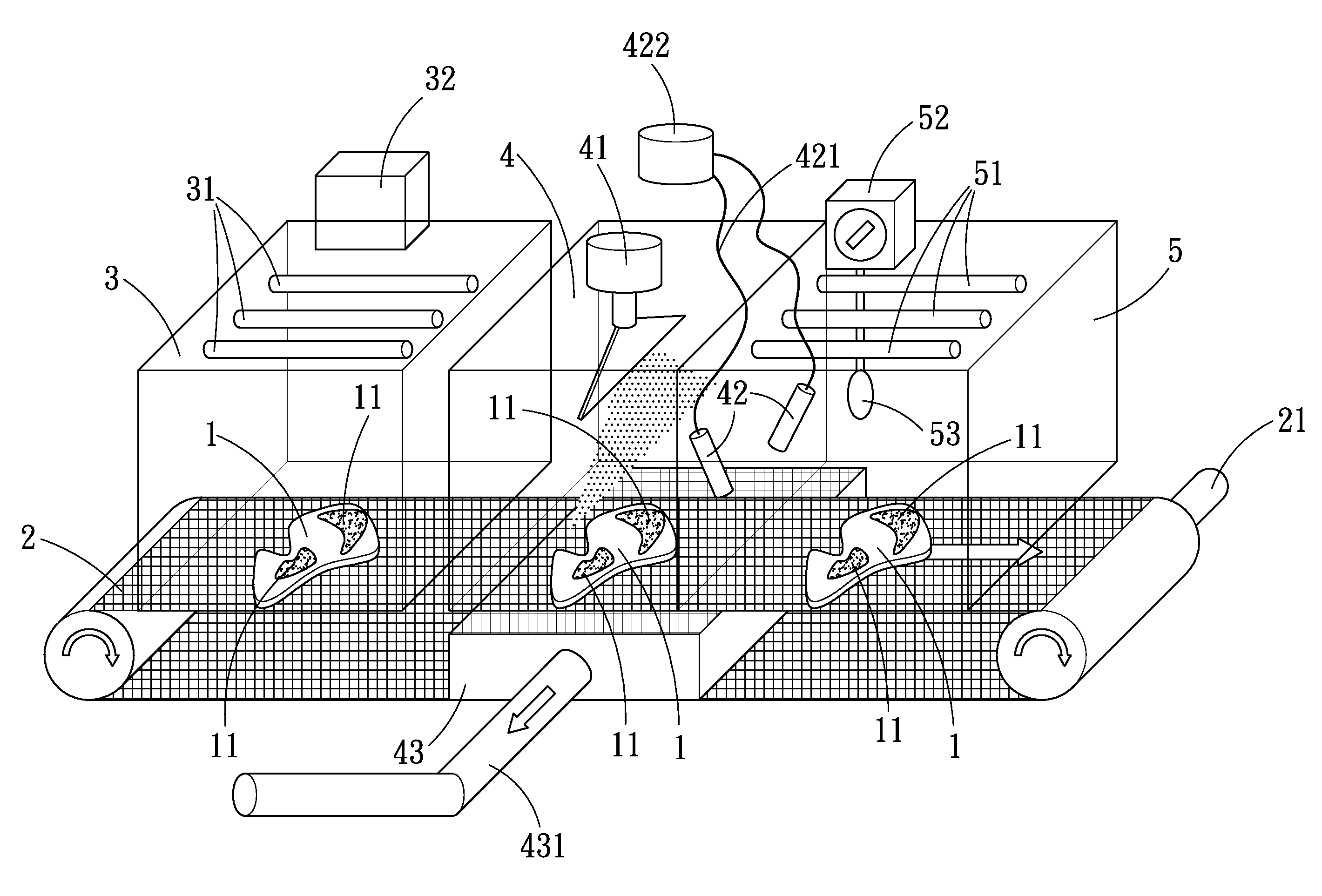

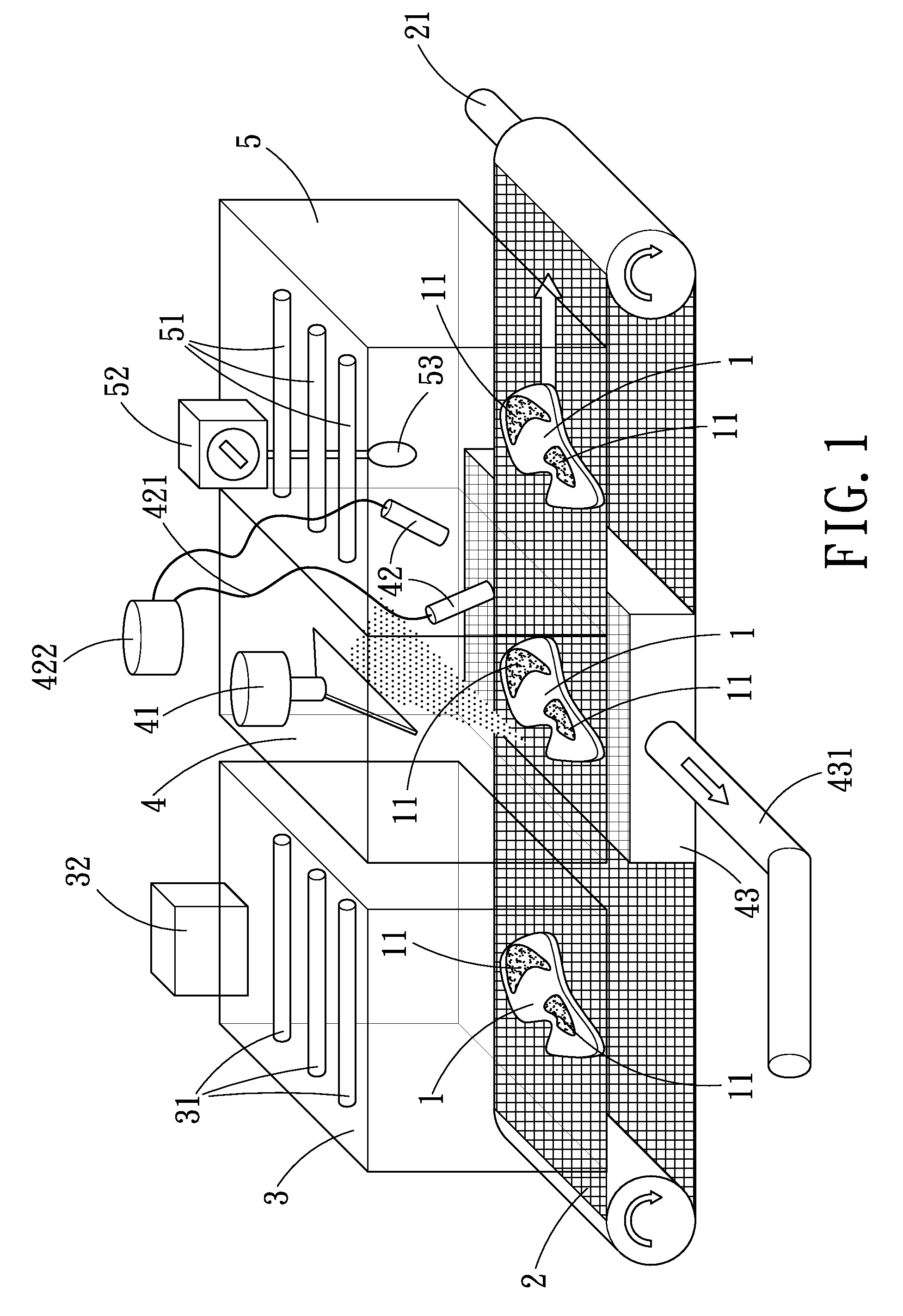

System for applying hot melt adhesive powder onto a non-metallic object surface

ActiveUS20120272899A1High degree of automationReduce labor intensityLiquid surface applicatorsElectrostatic heating/coolingUltravioletCleansing Agents

A system for applying hot melt adhesive powder onto a non-metallic object surface comprises a convey belt, a radiation chamber, a spraying chamber and a heating chamber. The convey belt is used to deliver a non-metallic object treated by a cleaning agent and a conductive liquid through the radiation chamber where the surface of the non-metallic objected is radiated by ultraviolet rays and ozone and then through the spraying chamber where the surface of the non-metallic object is sprayed with charged hot melt adhesive powder, and finally into the heating chamber where the hot melt adhesive powder attached onto the non-metallic object will be melted into a liquid adhesive film ready to be bonded.

Owner:ORISOL ASIA

Method and System for Applying Hot Melt Adhesive Powder onto a Non-Metallic Object Surface

InactiveUS20100021630A1High degree of automationReduce labor intensityAdhesive processes with surface pretreatmentPretreated surfacesUltravioletCleansing Agents

A method for applying hot melt adhesive powder onto a non-metallic object surface comprises the steps of applying a cleaning agent, applying a conductive liquid, radiating, spraying hot melt adhesive powder; and heating. A system for applying hot melt adhesive powder onto a non-metallic object surface comprises a convey belt, a radiation chamber, a spraying chamber and a heating chamber. The convey belt is used to deliver a non-metallic object treated by a cleaning agent and a conductive liquid through the radiation chamber where the surface of the non-metallic objected is radiated by ultraviolet rays and ozone and then through the spraying chamber where the surface of the non-metallic object is sprayed with charged hot melt adhesive powder, and finally into the heating chamber where the hot melt adhesive powder attached onto the non-metallic object will be melted into a liquid adhesive film ready to be bonded.

Owner:ORISOL ASIA

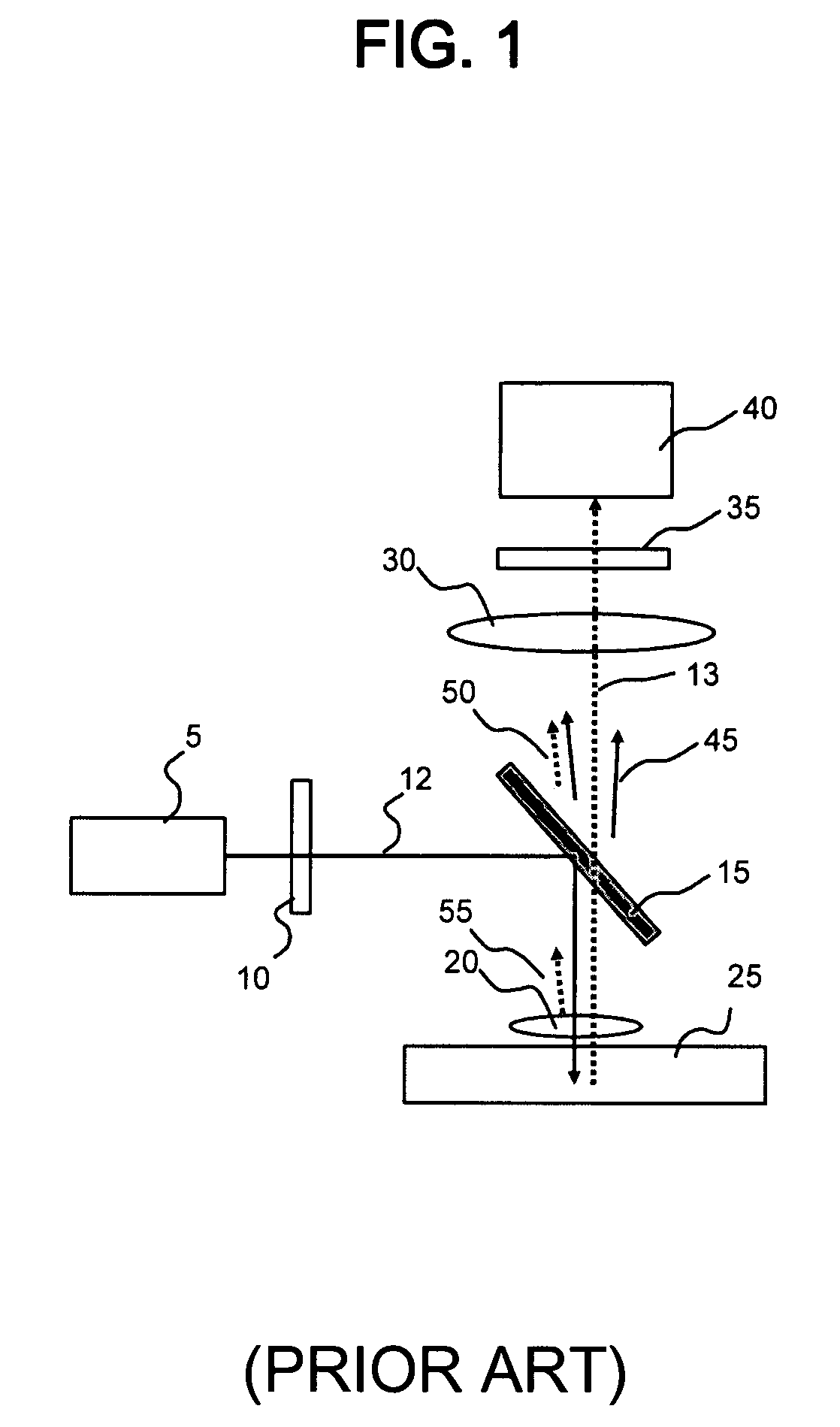

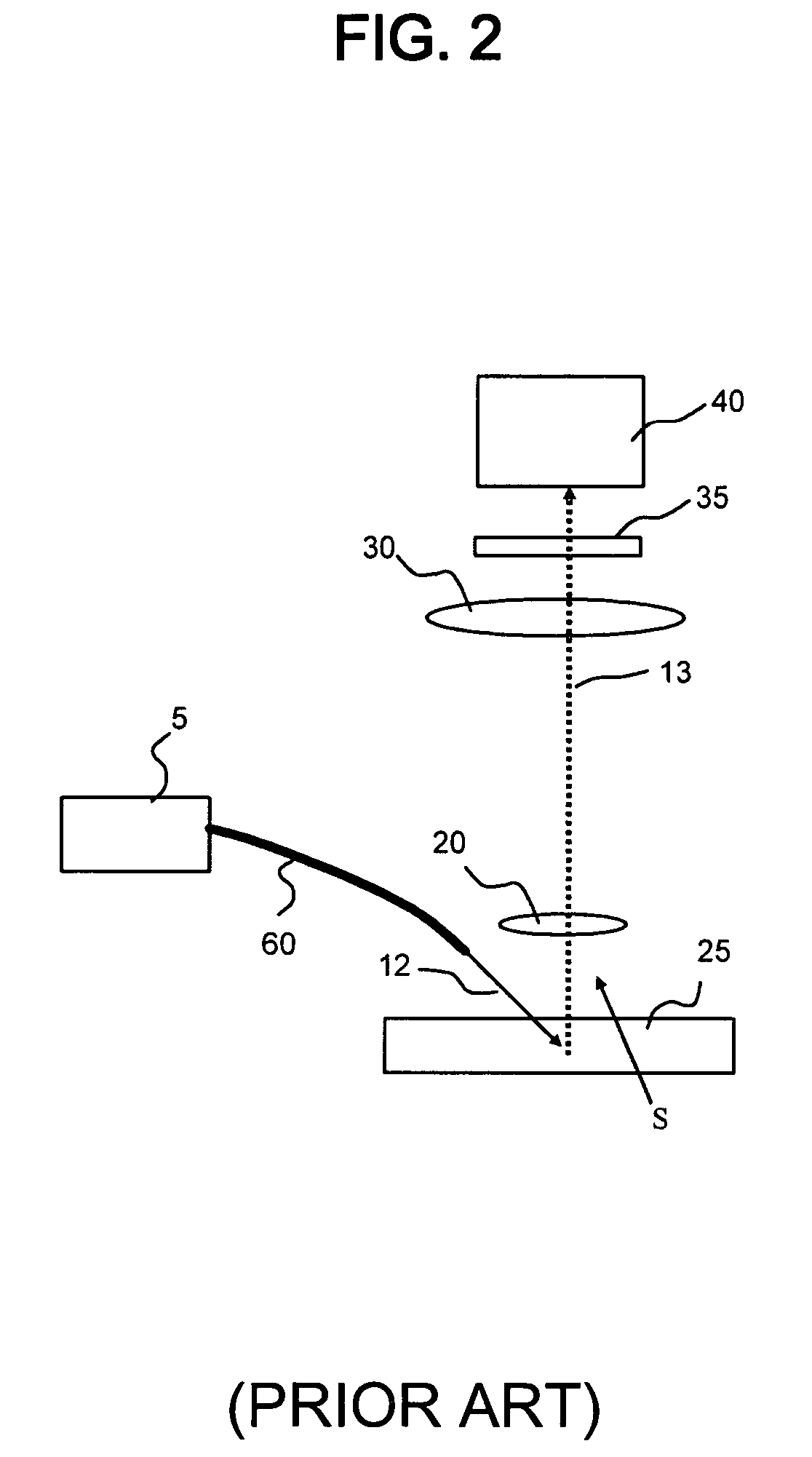

Fluorescence microscope and observation method using the same

ActiveUS7297961B2Easy to getReduce Optical NoisePhotometryPhase-affecting property measurementsMicroscopic observationRefractive index

The present invention relates, in general, to a fluorescence microscope and method of observing samples using the microscope and, more particularly, to a fluorescence microscope and method of observing samples using the microscope, which can reduce optical noise and obtain images with higher sensitivity, thus obtaining precise information about the density, quantity, location, etc. of a fluorophore, and which can simultaneously process separate images even when a plurality of fluorophores having different excitation and fluorescent wavelength ranges is distributed, thus easily obtaining information about the fluorophores. The fluorescence microscope of the present invention includes an objective lens, and first and third medium units. The first medium unit has a refractive index of n1 to accommodate one or more micro-objects including fluorophores and provide a path of excitation light to excite the fluorophores. The third medium unit has a refractive index of n3, and is placed between the first medium unit and the objective lens to totally reflect the excitation light incident through the first medium unit at an interface of the third medium unit coming into contact with the first medium unit. The refractive indices of the third and first medium units satisfy a relationship of n1>n3.

Owner:KOREA ELECTROTECH RES INST

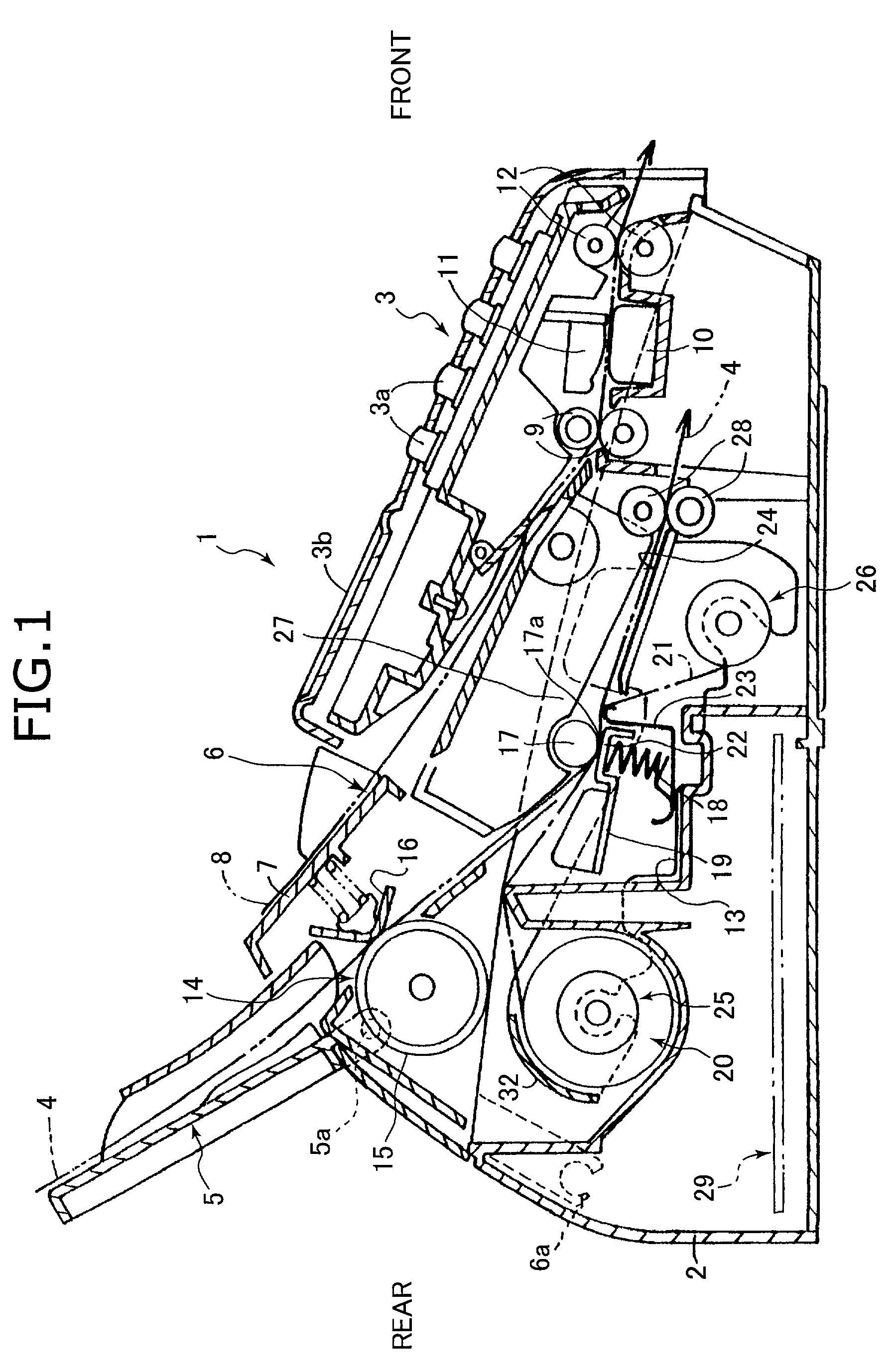

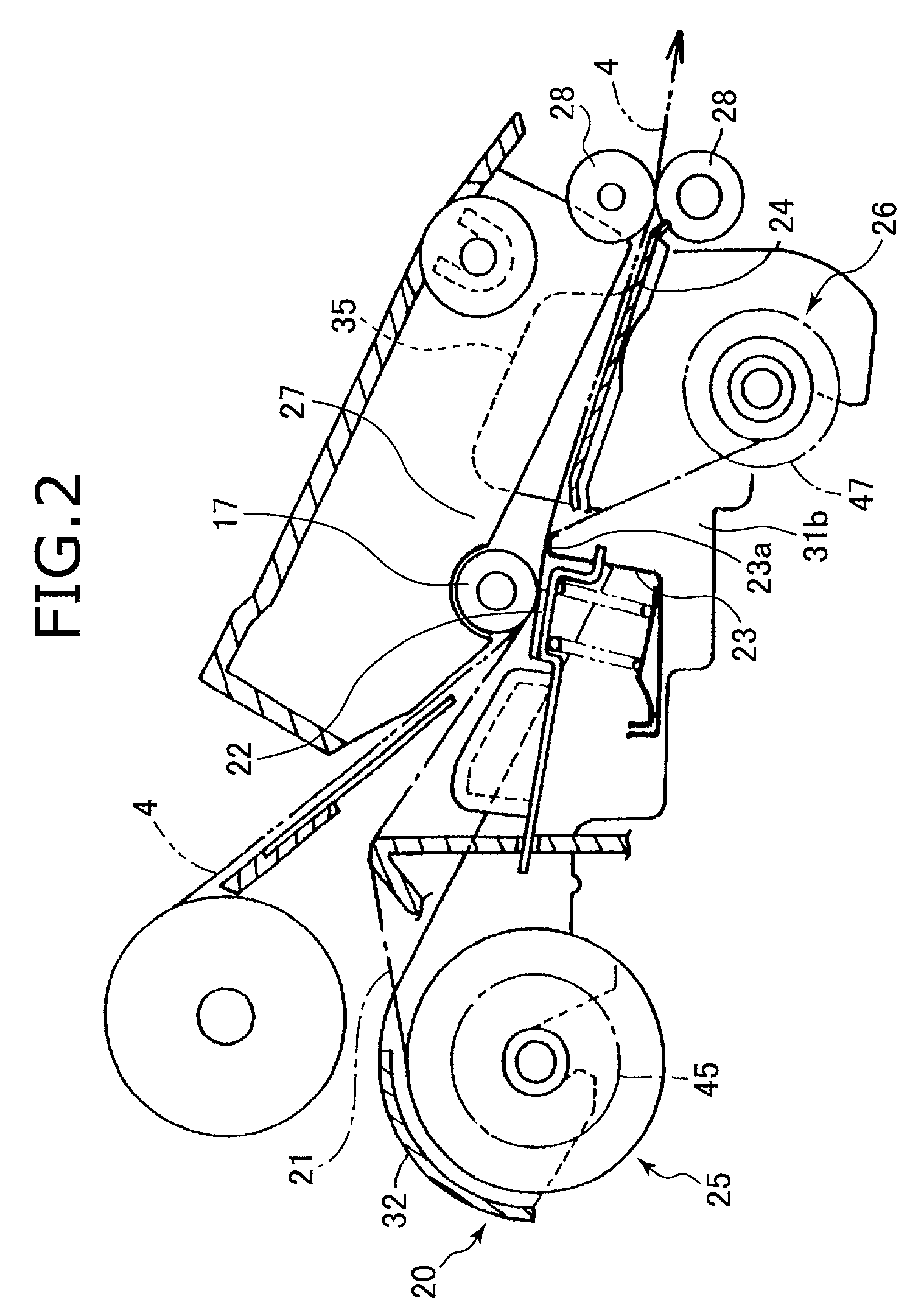

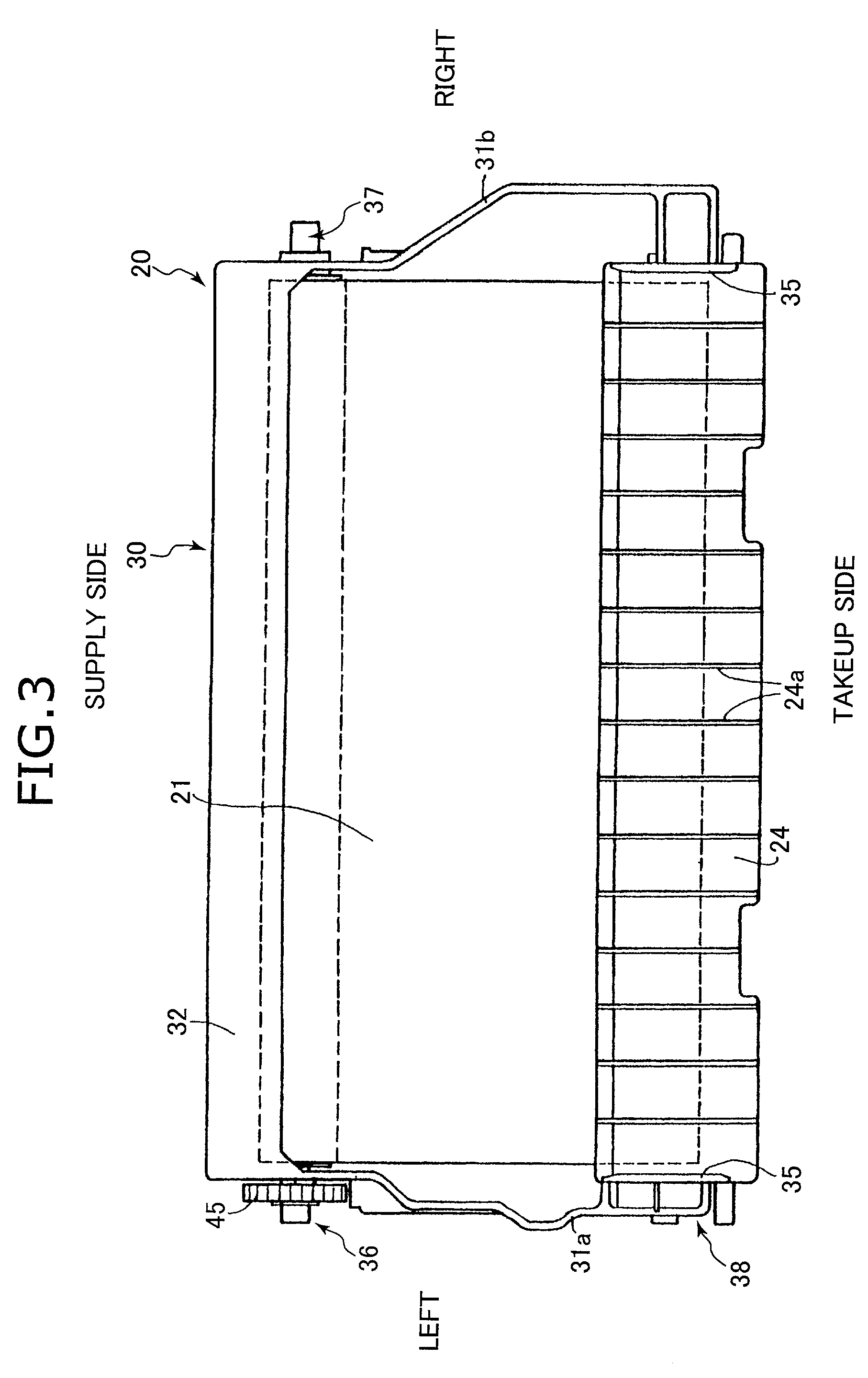

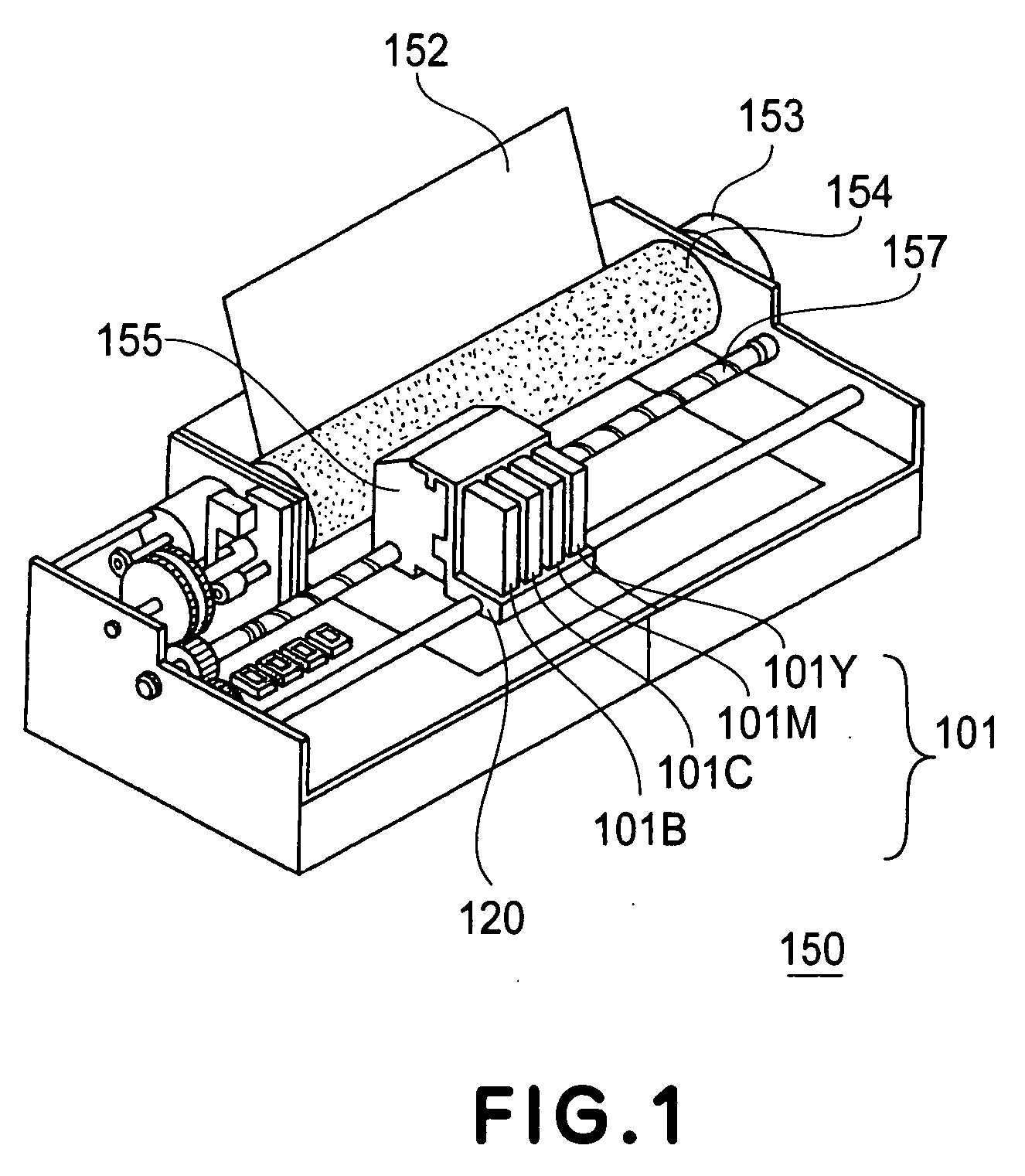

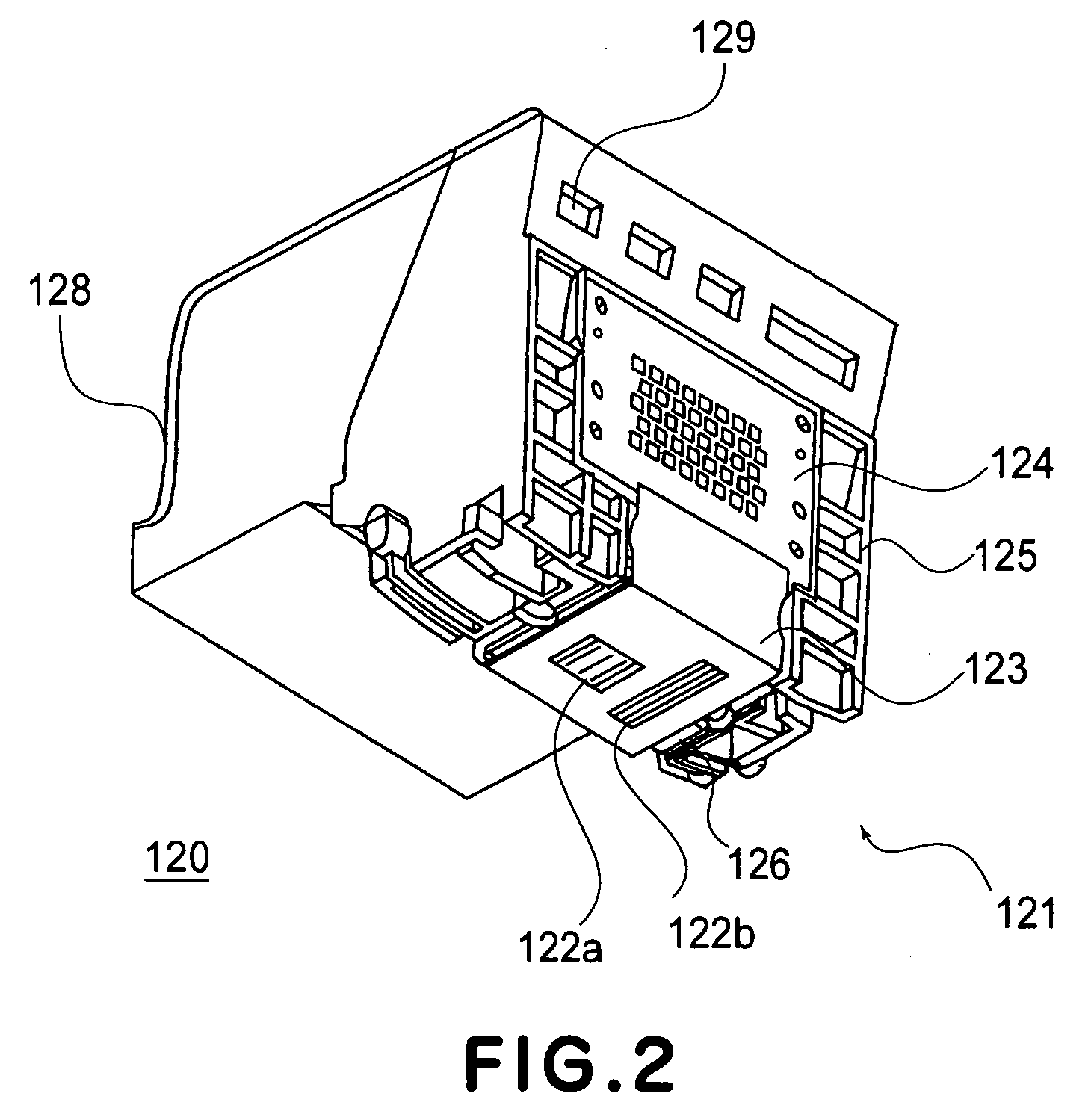

Image forming device and ink sheet cartridge mounted on the image forming device

InactiveUS20010046399A1Reduce working spaceInk ribbon cartridgesRecording apparatusImage formationEngineering

An ink sheet cartridge 20 includes a cartridge body 30. The cartridge body 30 has a pair of side plates 31a, 31b, a partitioning plate 24, and a cover segment 32 together defining a flame shape with an central open space. When the ink sheet cartridge 20 is accommodated to a facsimile device 1, a thermal head 22 and a platen 17 are positioned at the central open space. Also, the partitioning plate 21 serves as a lower transport chute defining a transport path with an upper chute members 27, so that a recording sheet 4 is transported along the transport path.

Owner:BROTHER KOGYO KK

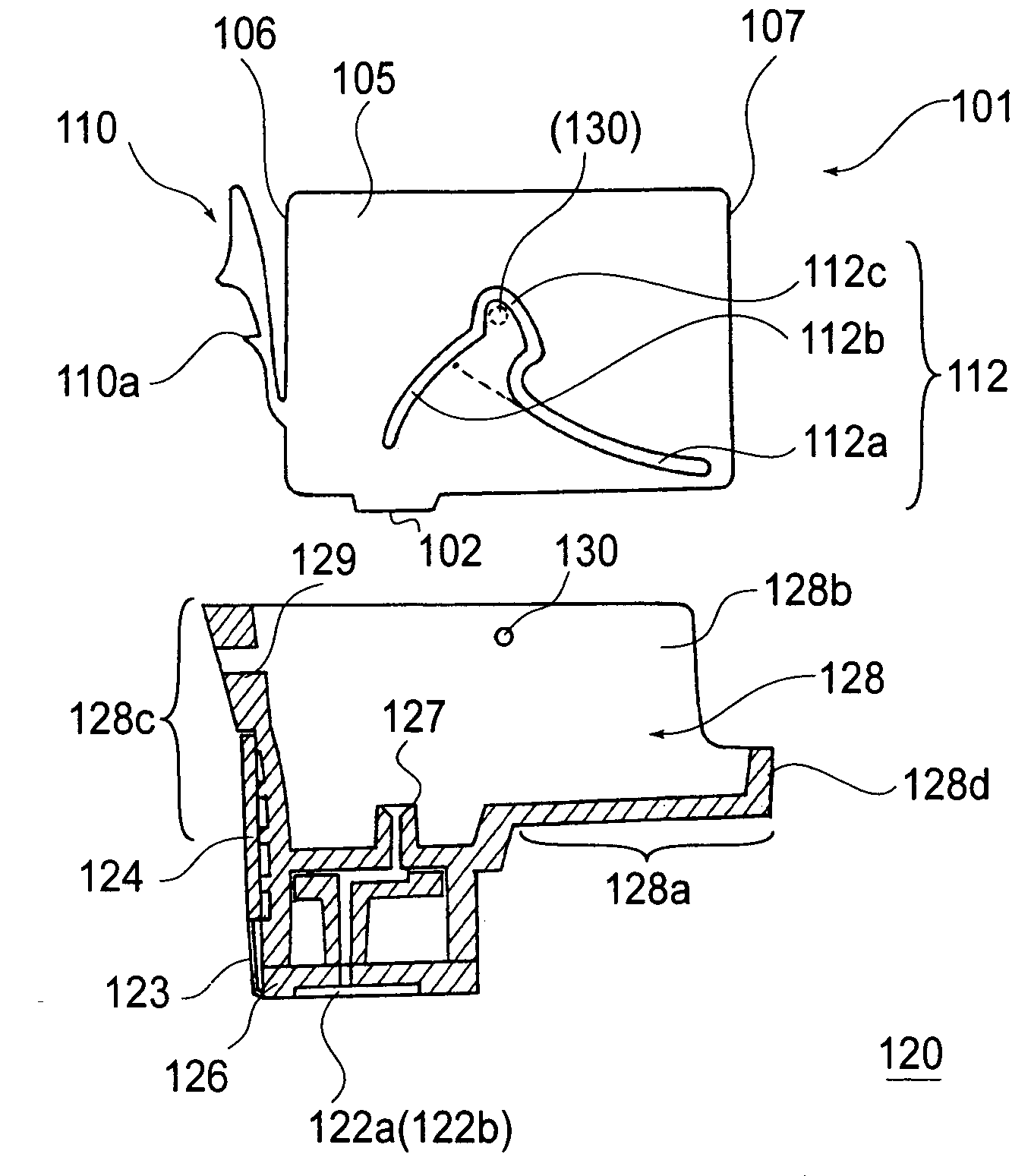

Ink container and mounting method of the ink container

An ink container capable of being simply mounted in a holder with a small working space includes a rib-like guide portion for determining a mounting path during mounting of the ink container in a head cartridge at a side surface. The head cartridge includes a holder portion provided with a sliding projection which slides in contact with the guide portion. When the ink container is mounted, a user moves the ink container so that a first inclined portion first contacts the sliding projection and thereafter the ink contained is moved in an obliquely below direction toward the head cartridge while sliding the sliding projection along the first inclined portion.

Owner:CANON KK

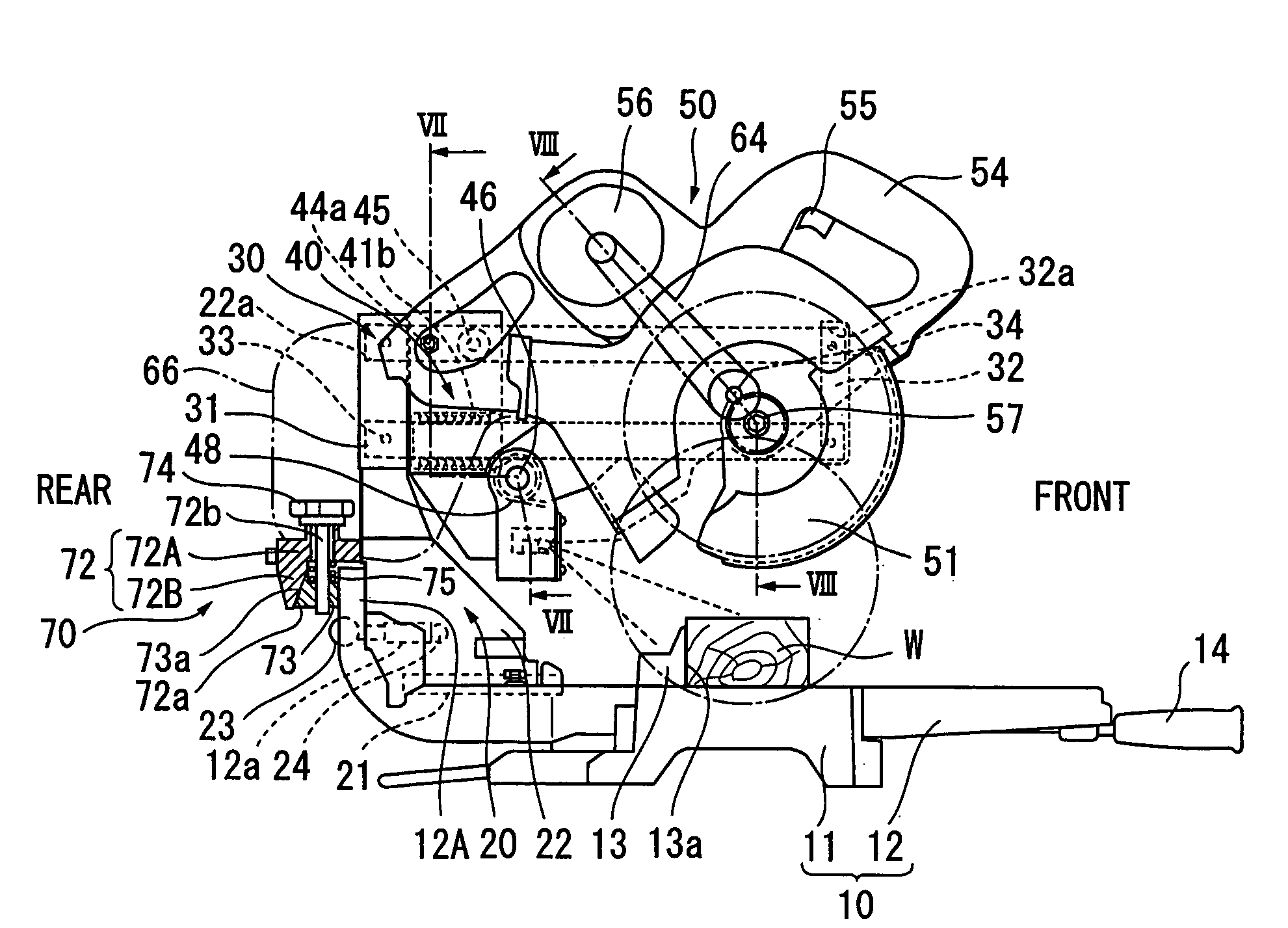

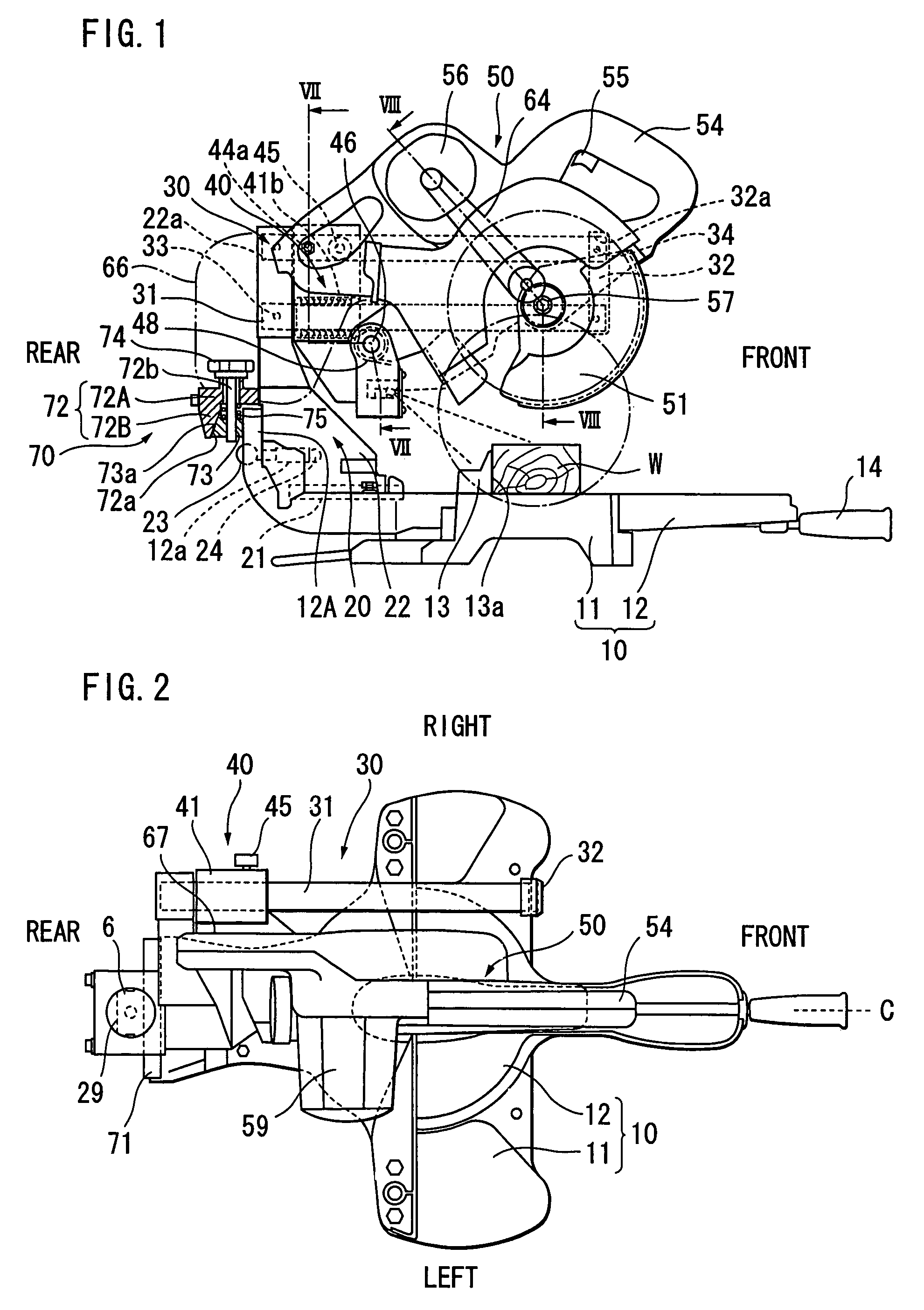

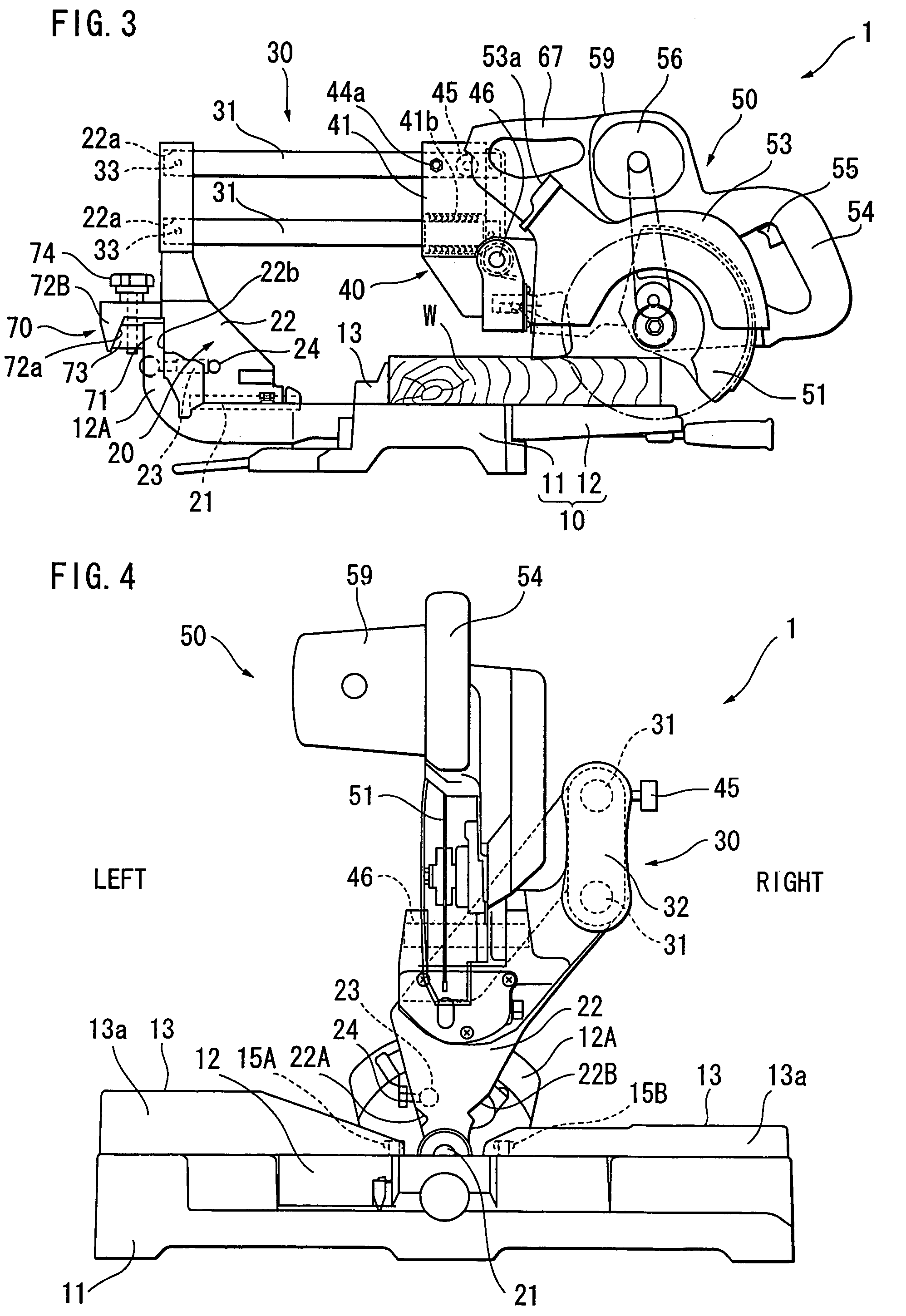

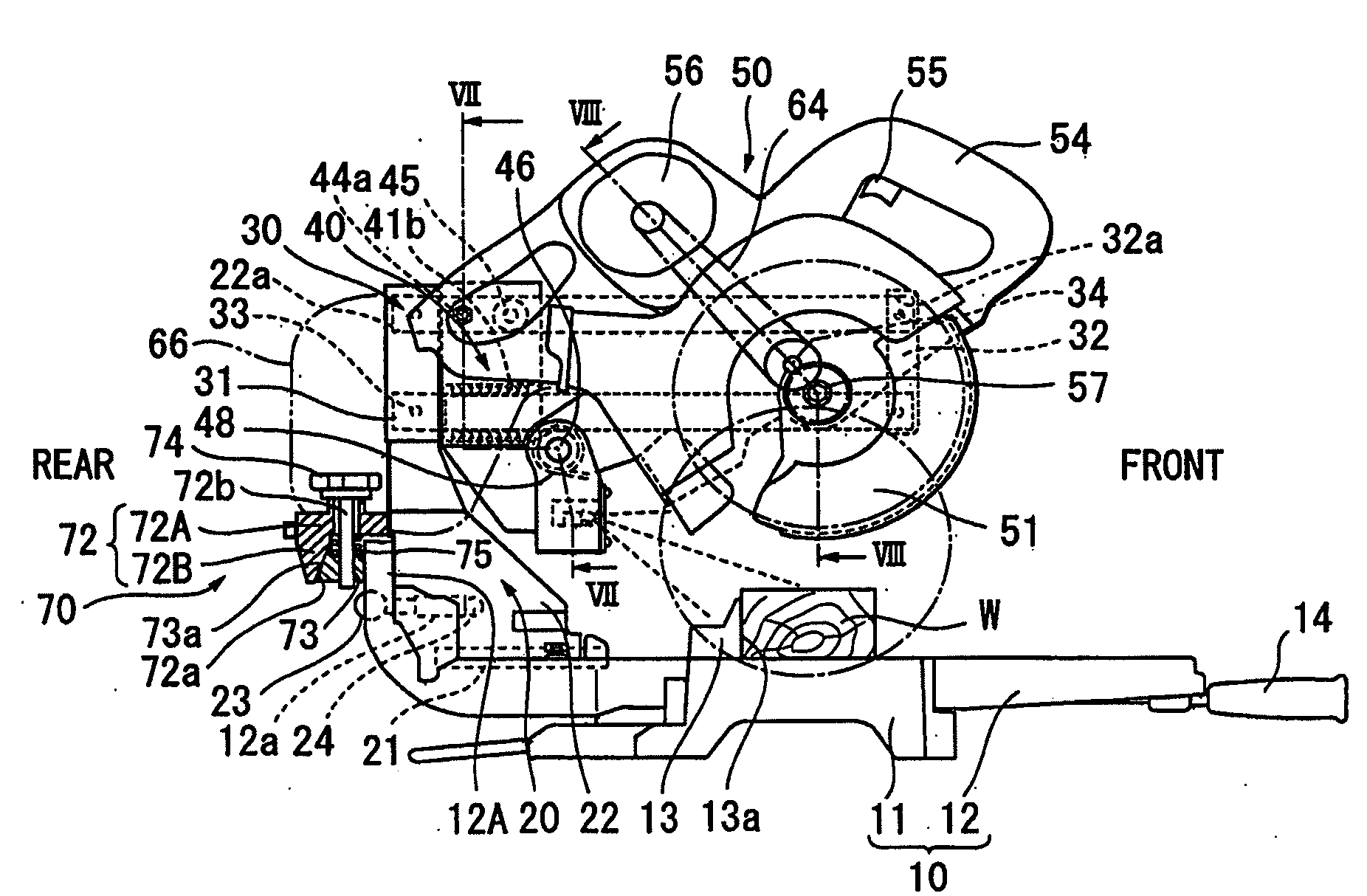

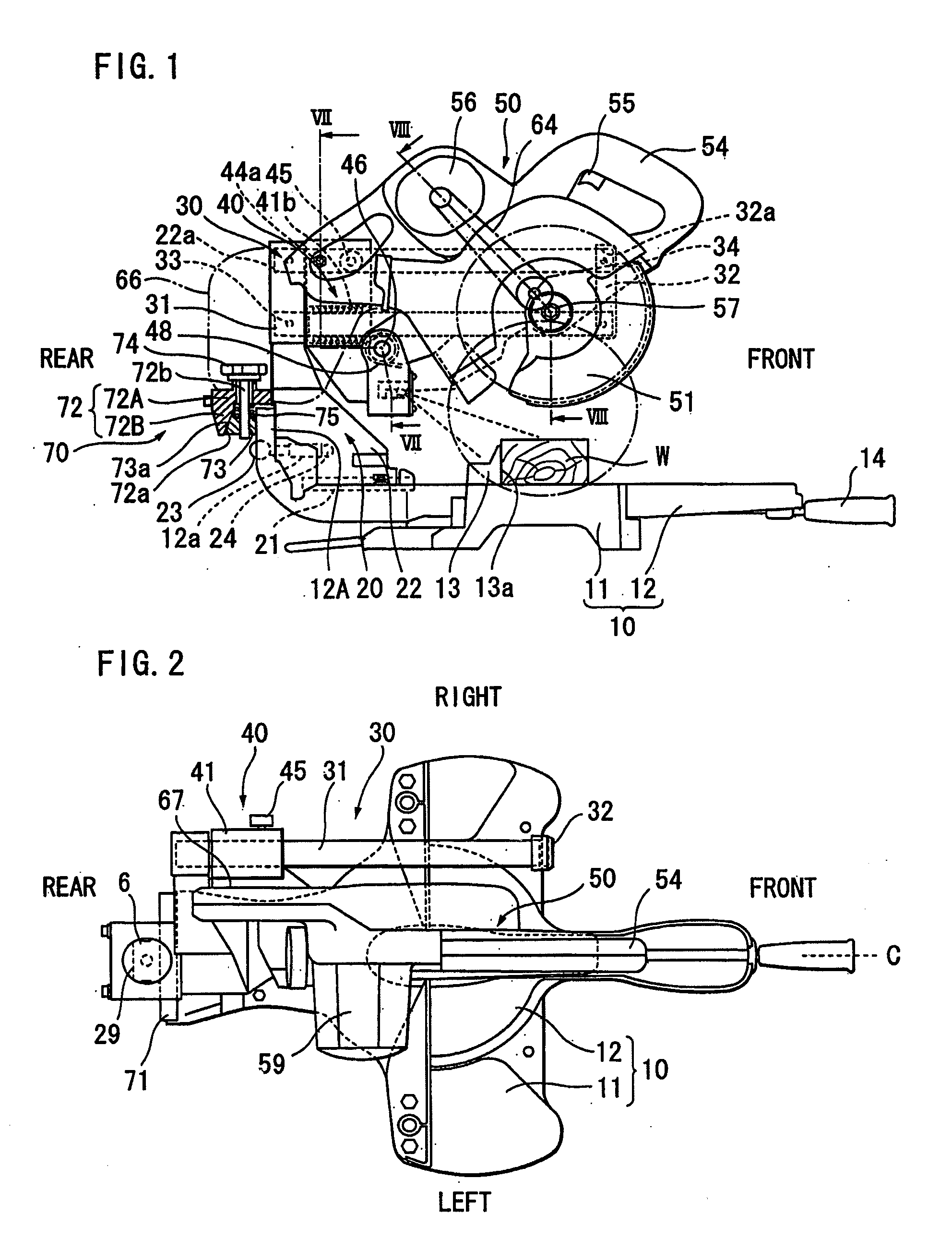

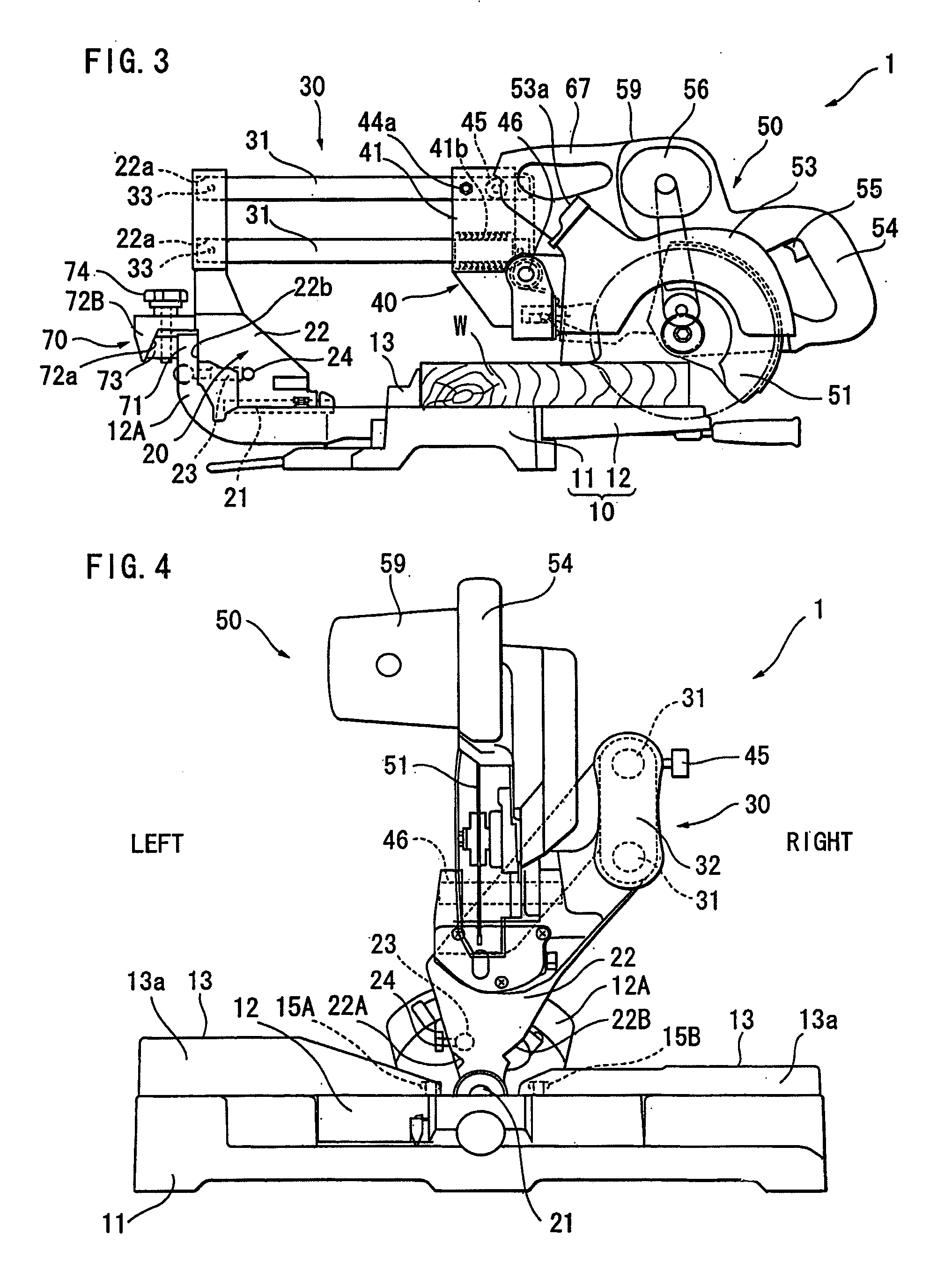

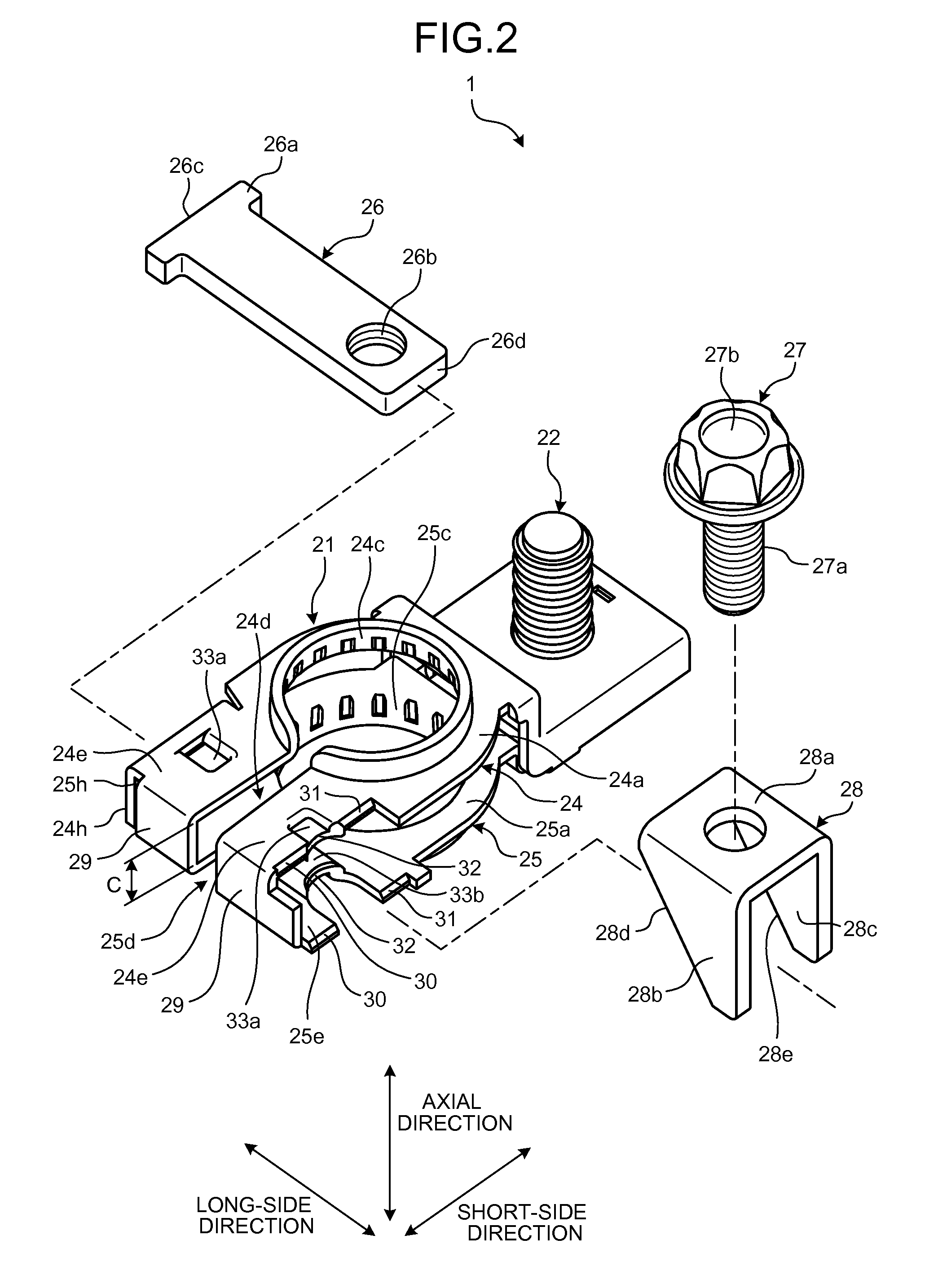

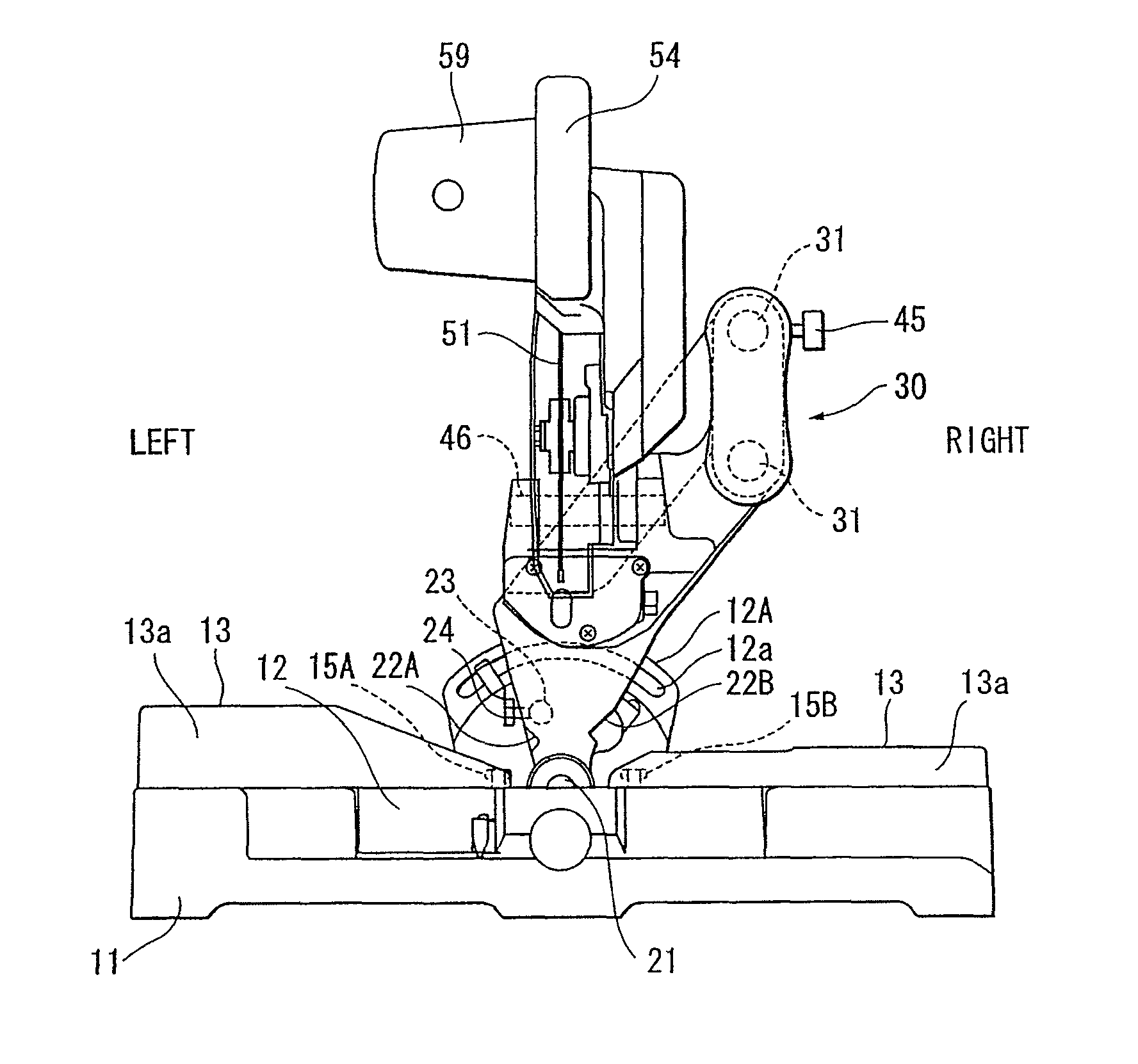

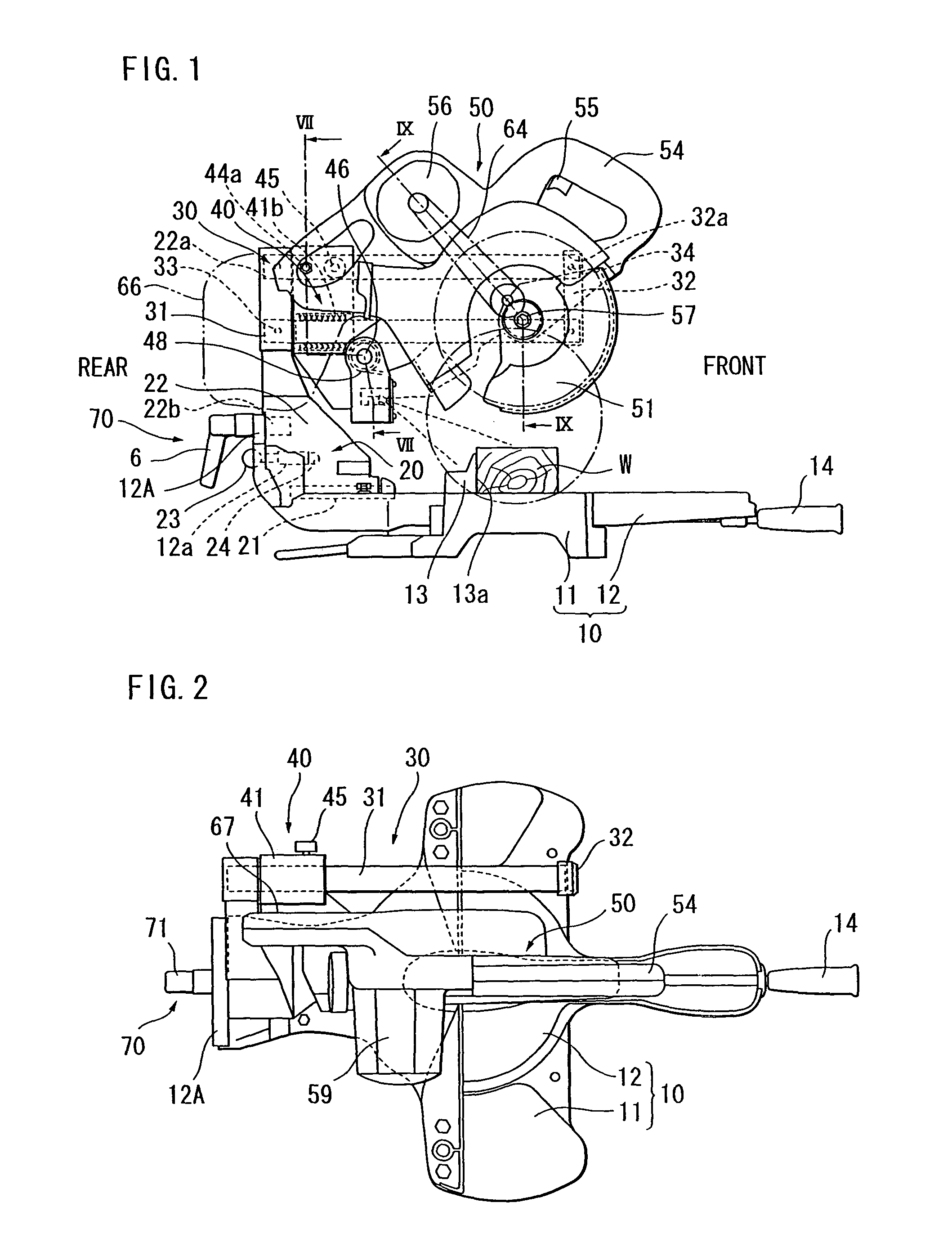

Miter saw having holder fixing mechanism

A miter saw having a holder fixing mechanism for fixing a pivot posture of a holder. The holder supports a support section on which a saw blade section is pivotally movably supported. The holder is laterally pivotally movable about a holder shaft to change angle of a side surface of a circular saw blade relative to an upper surface of a base. The holder fixing mechanism includes a clamp bolt whose axis is directed perpendicular to the holder shaft and in parallel with the side surface of the circular saw blade. By the rotation of the clamp bolt about its axis, a fixing relationship between the holder and the base section is established.

Owner:KOKI HLDG CO LTD

Method For Applying Hot Melt Adhesive Powder Onto A Shoe Or Sole Part

InactiveUS20130089677A1Save energyReduce labor intensityRadiation applicationsPretreated surfacesWorking environmentCleansing Agents

A method for applying hot melt adhesive powder onto a sole or shoe part includes the steps of applying a cleaning agent, irradiating, applying a conductive liquid which has a conductivity at least 100 times higher than water, spraying hot melt adhesive powder; and heating. The method can save energy, reduce the working space, reduce the labor intensity and improve the working environment by making the spraying and the melting operation of the hot melt adhesive carry out automatically.

Owner:ORISOL ASIA

Method for Applying Hot Melt Adhesive Powder onto a Shoe or Sole Part

ActiveUS20140093655A1Save energyReduce labor intensityPretreated surfacesDomestic articlesWorking environmentCleansing Agents

A method for applying hot melt adhesive powder onto a sole or shoe part includes the steps of applying a cleaning agent, irradiating, applying a conductive liquid which has a conductivity at least 100 times higher than purified water which has a conductivity of 5.5.10−6 S / m, spraying hot melt adhesive powder; and heating. The method can save energy, reduce the working space, reduce the labor intensity and improve the working environment by making the spraying and the melting operation of the hot melt adhesive carry out automatically.

Owner:ORISOL ASIA

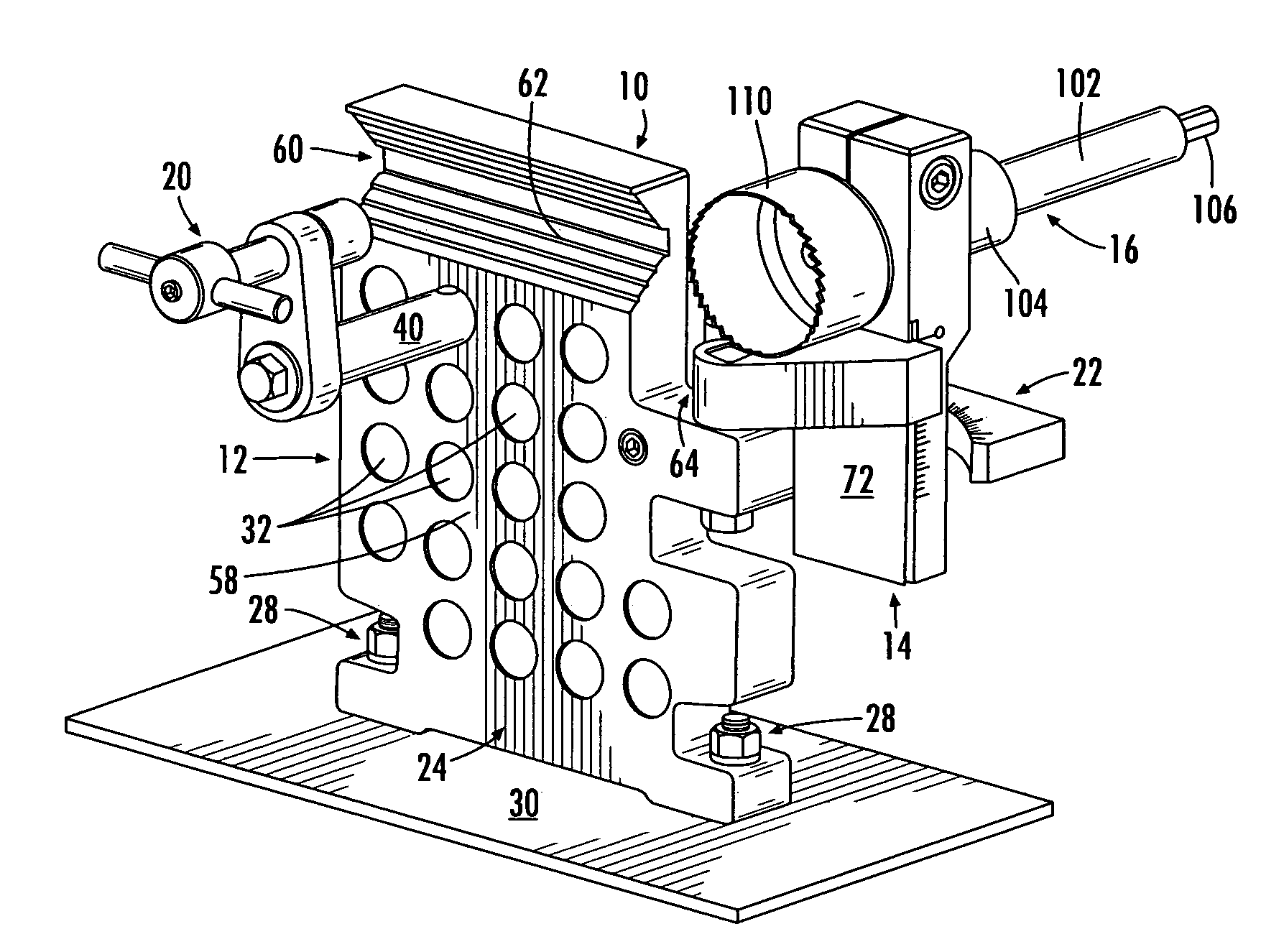

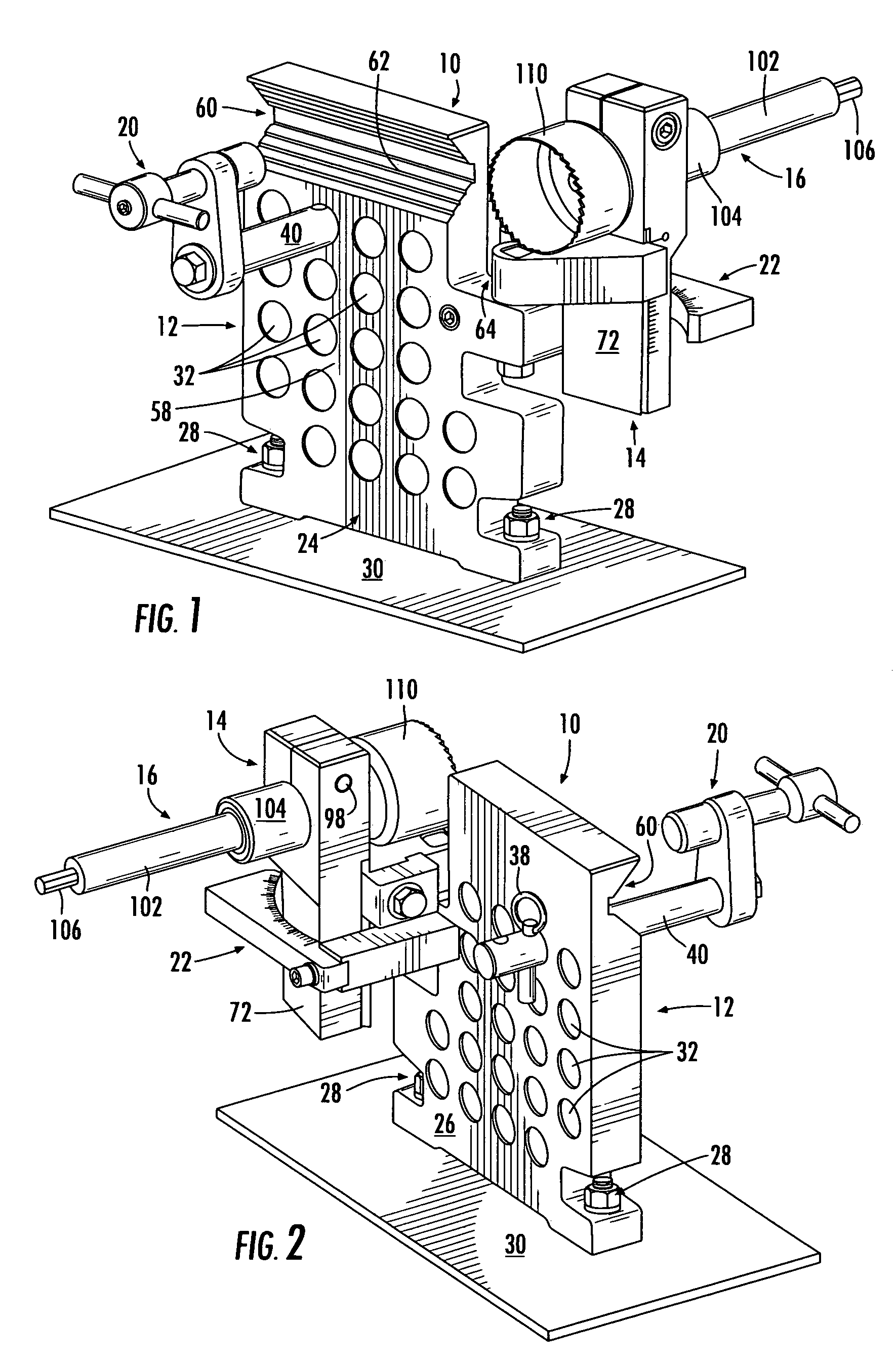

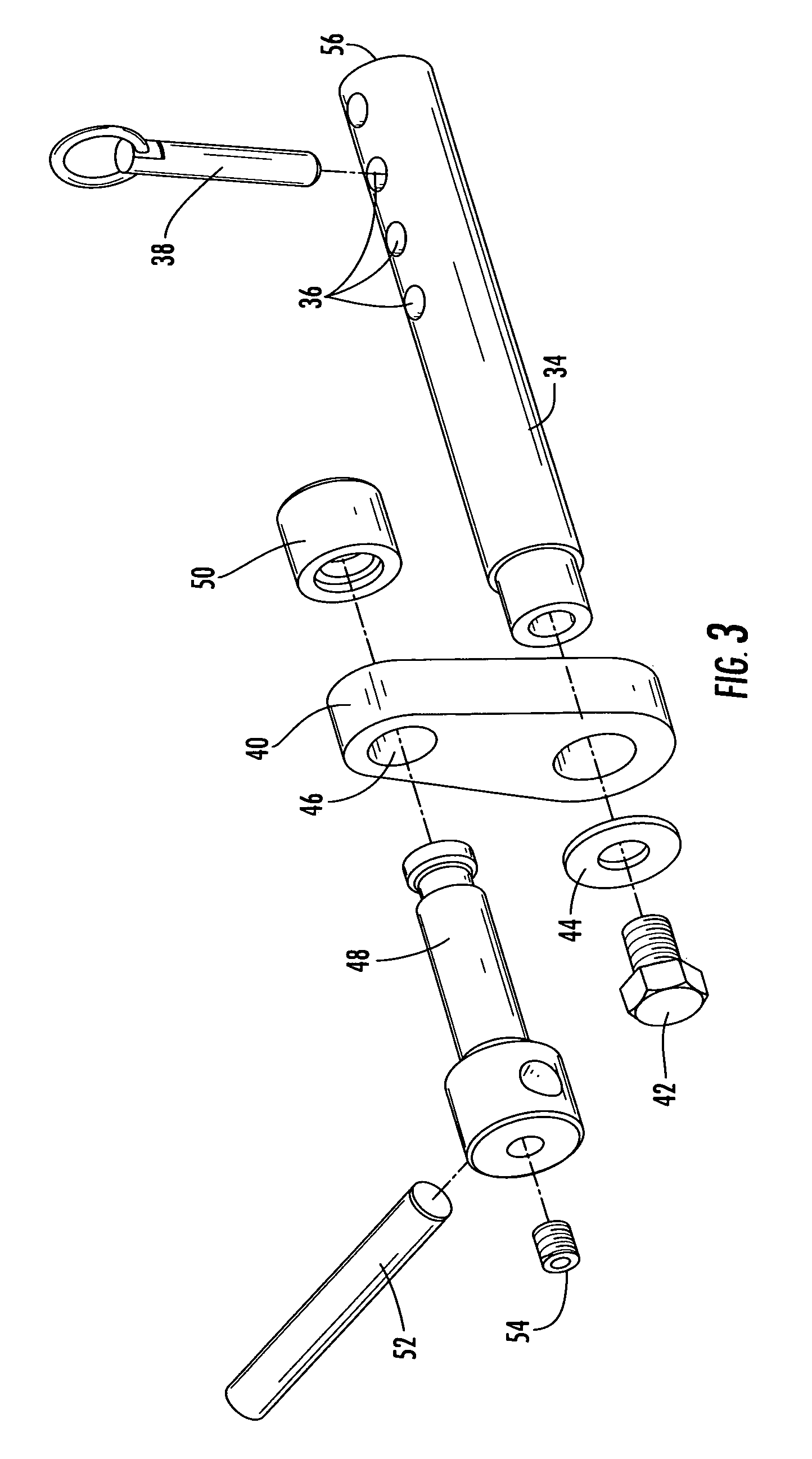

Rotary tube notching apparatus

InactiveUS7607870B2Reduce working spaceLocated very closeDrilling/boring measurement devicesTurning machine accessoriesSurface mountingEngineering

A rotary tube notching apparatus capable of operable attachment to a powered rotational drive device such as a drill, is comprised of a surface mountable tube support assembly capable of alternately receiving straight or bent tubing; a height adjustable carriage assembly pivotally mounted to the tube support assembly to enable offset notching, and a shaft assembly rotatably mounted to said carriage assembly for receiving a cutting tool.

Owner:HUGHES JR ROBERT K

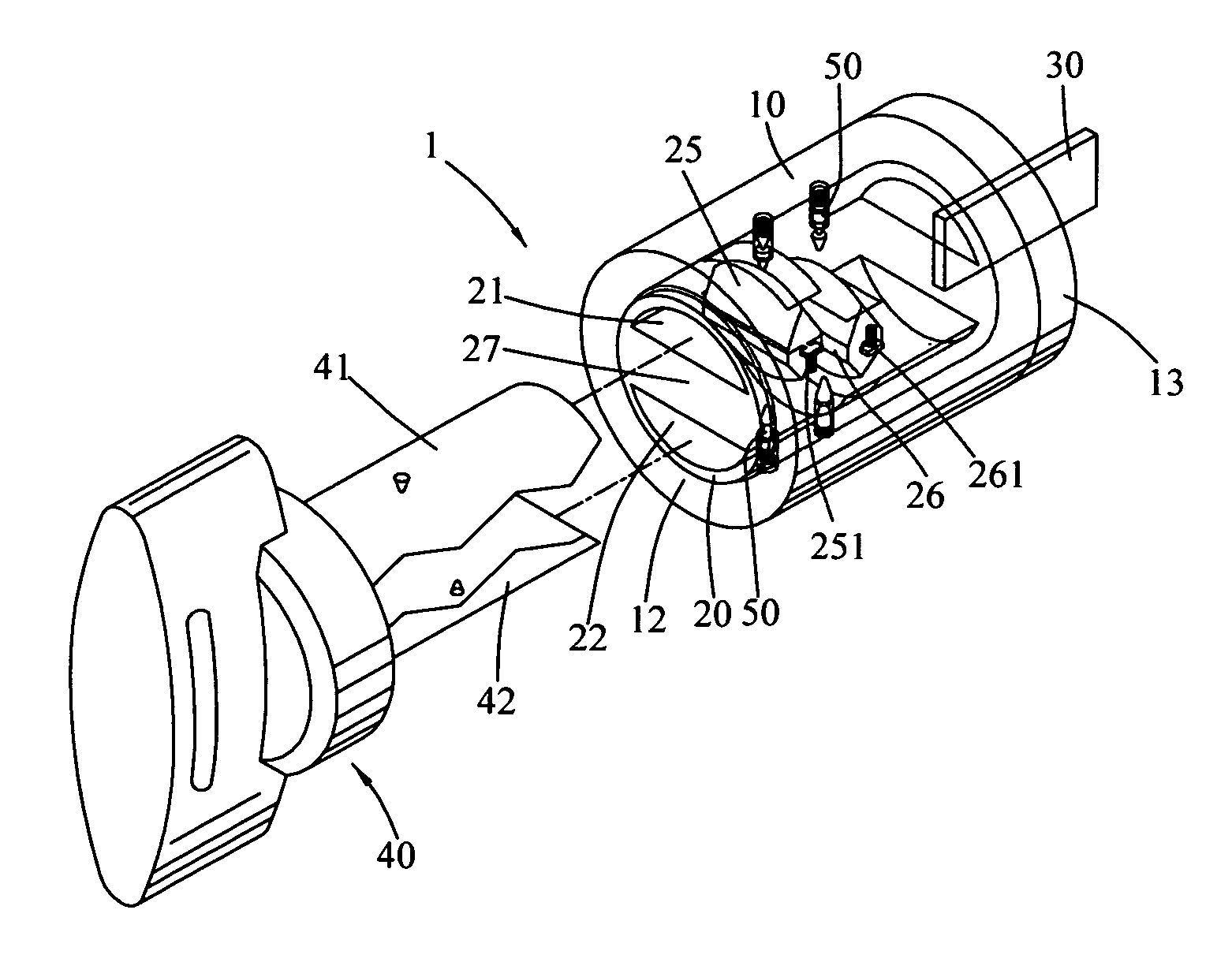

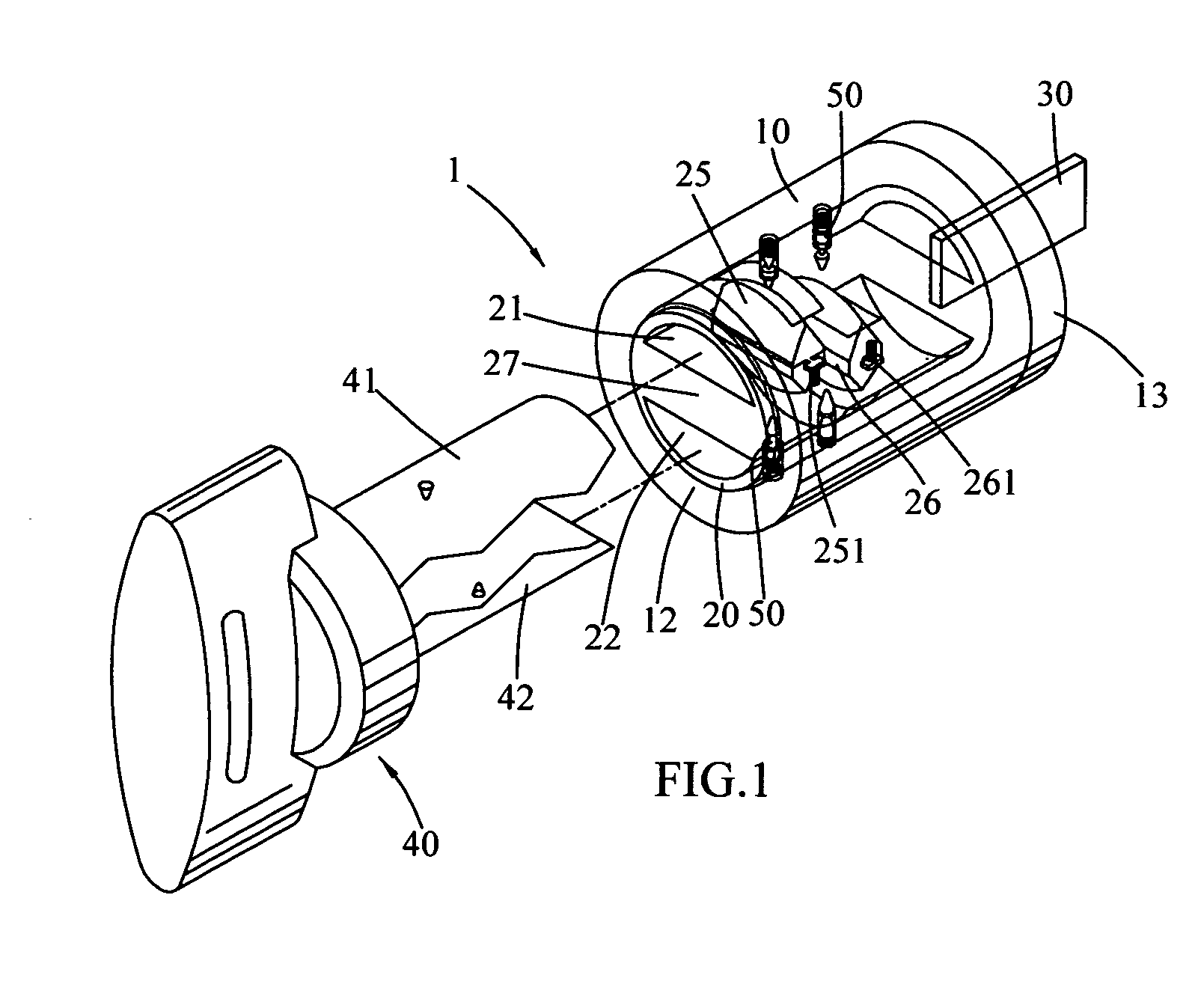

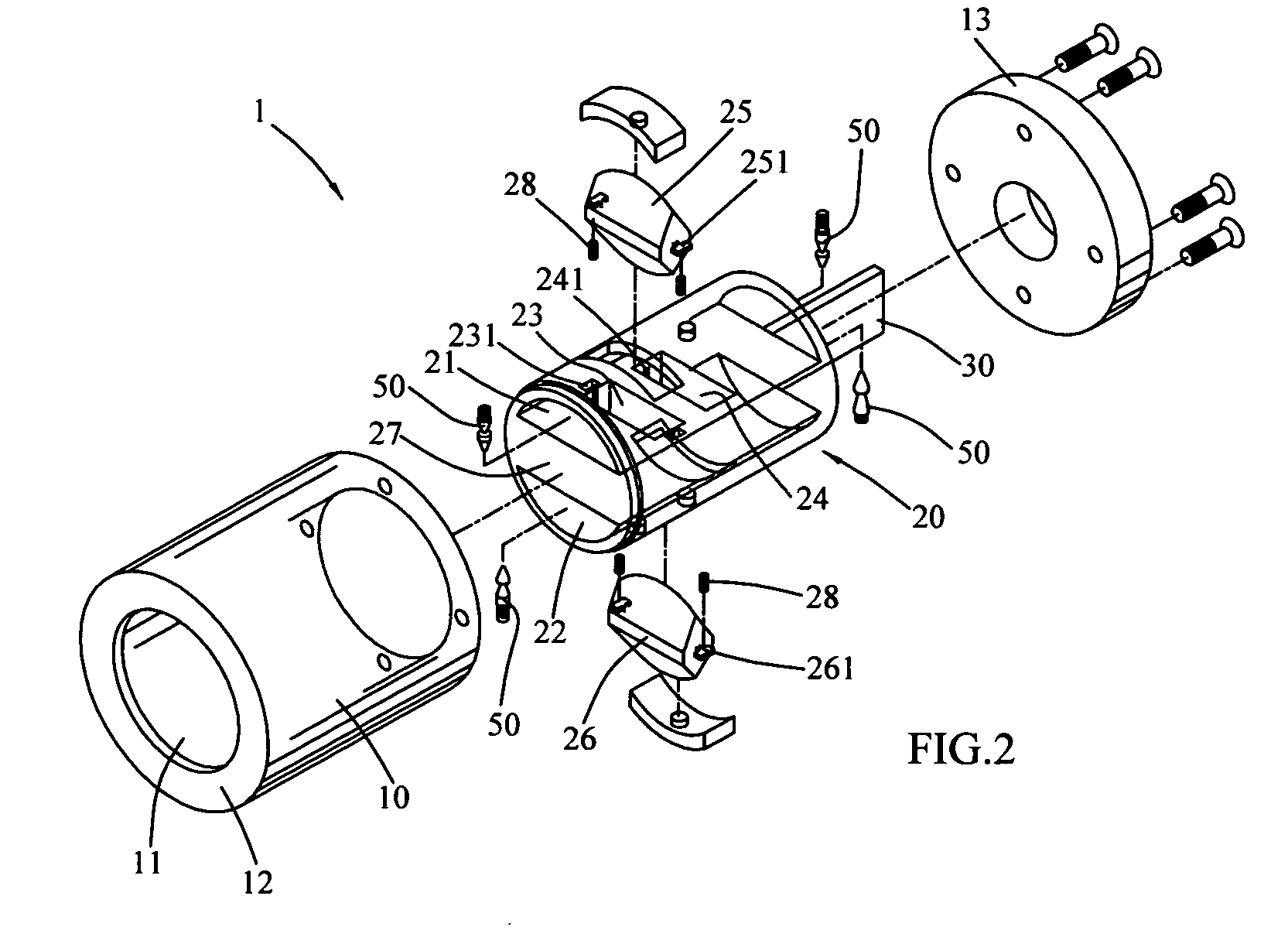

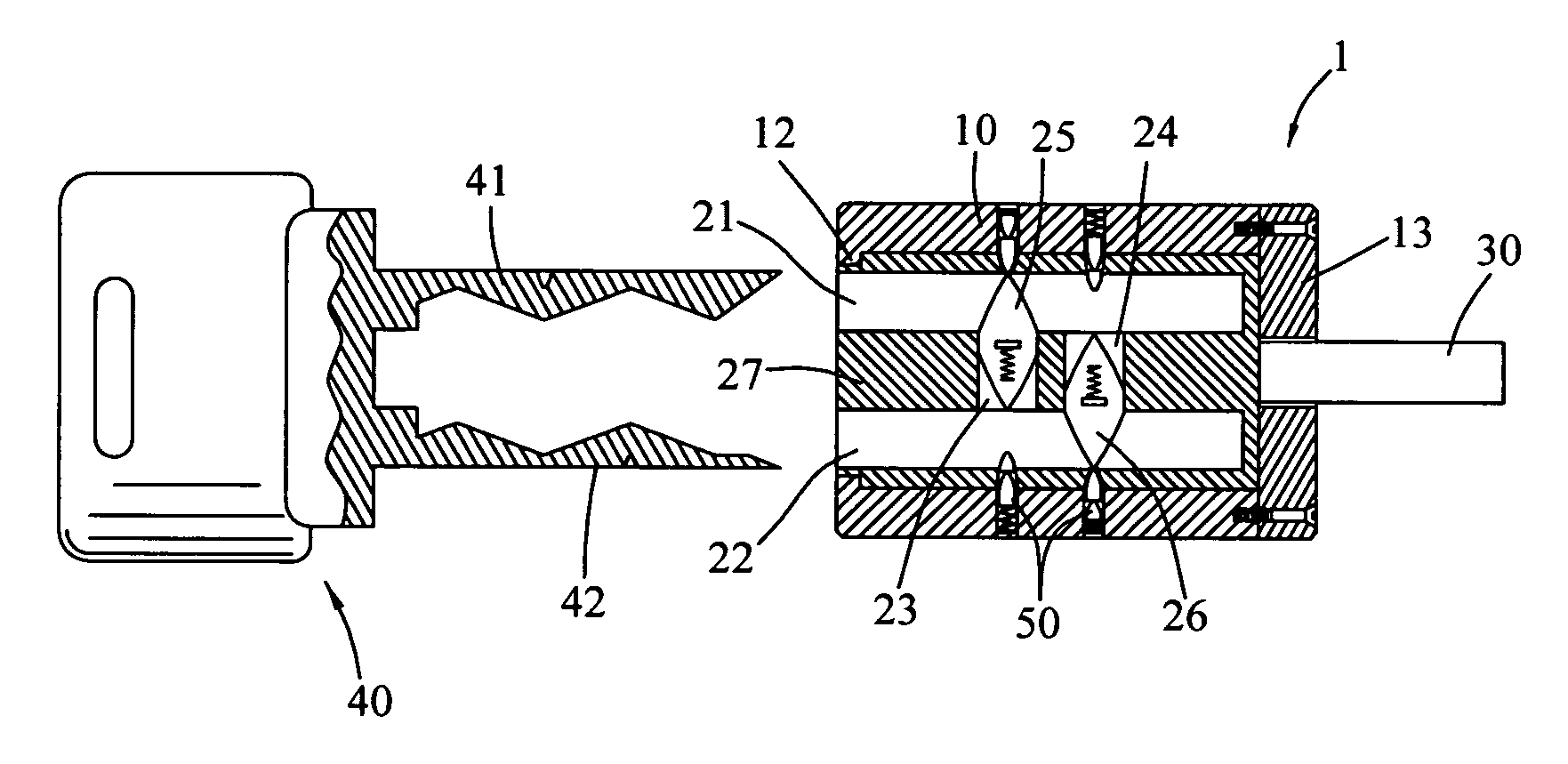

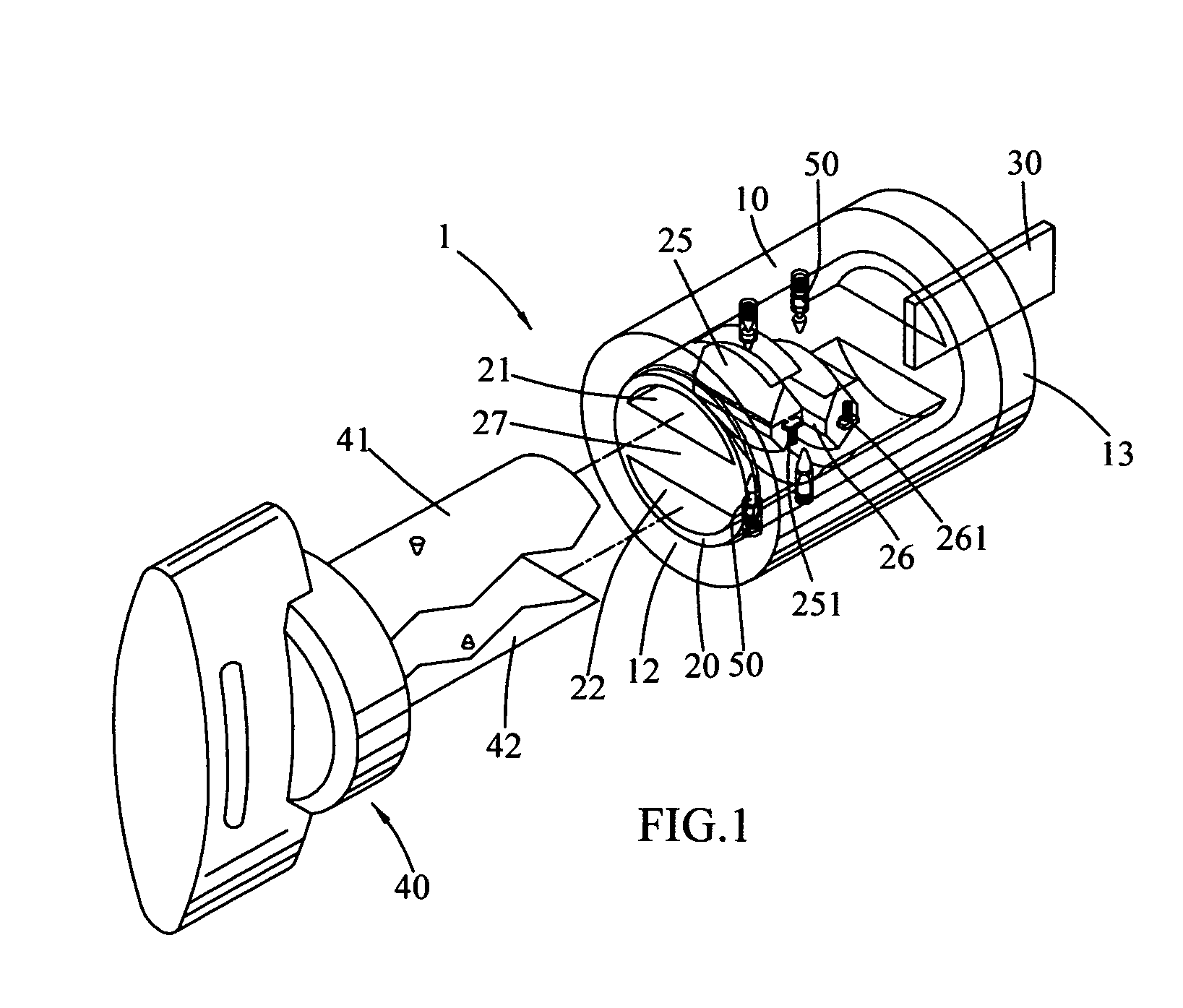

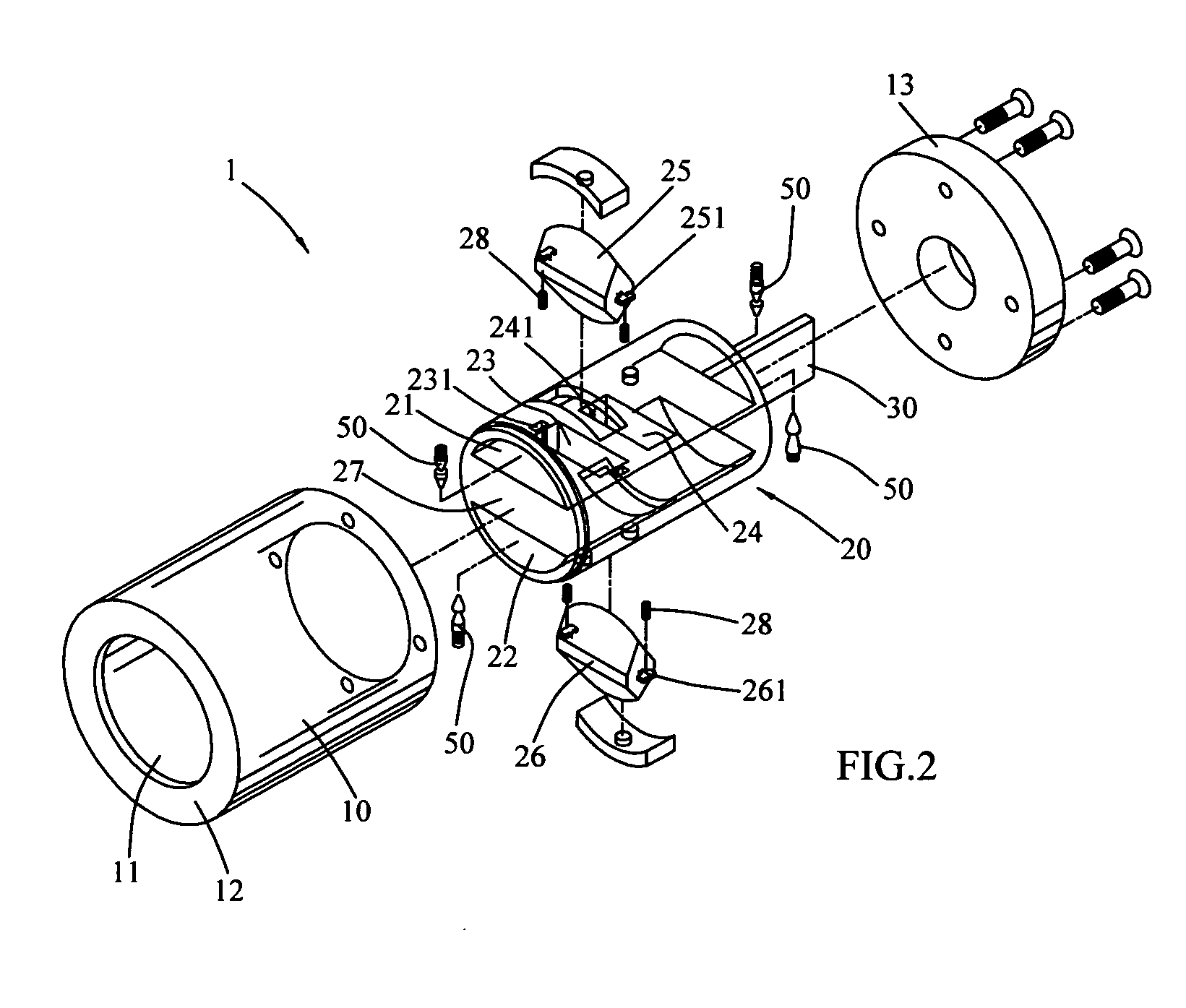

Lock barrel and a driving part for the same

InactiveUS20080066508A1Prevent problemIncrease the difficultyKeysCylinder locksMoving partsEngineering

A lock barrel and a driving part for the same comprises a plurality of key channels for the insertion o the driving part (key) and a plurality of transverse gateways for housing movable parts, which will bulge into the key channels for making the channels effectively small and therefore shielding them from illegally intruded tools.

Owner:CHAO SHENG HO +1

Miter saw having holder fixing mechanism

ActiveUS20090071308A1Reduce working spaceEasy to operateMetal sawing devicesGuide fencesCircular sawEngineering

A miter saw includes a base section on which a workpiece is mounted, a saw blade section supporting a circular saw blade having a rotation axis extending in a lateral direction, a holder shaft extending in a direction perpendicular to the rotation axis, a holder tiltable about the holder shaft, two parallel guide bars disposed slidable with respect to the holder and extending toward the rotation axis, a support segment fixed to the guide bars and supporting the saw blade section, a pivot shaft disposed between the saw blade section and the support segment and extending in parallel with the rotation axis so that the saw blade section is pivotable about the pivot shaft, and a holder fixing mechanism that fixes a tilting posture of the holder and includes an operation member supported to the holder and having a rotatable shaft passing through a space between the two guide bars.

Owner:KOKI HLDG CO LTD

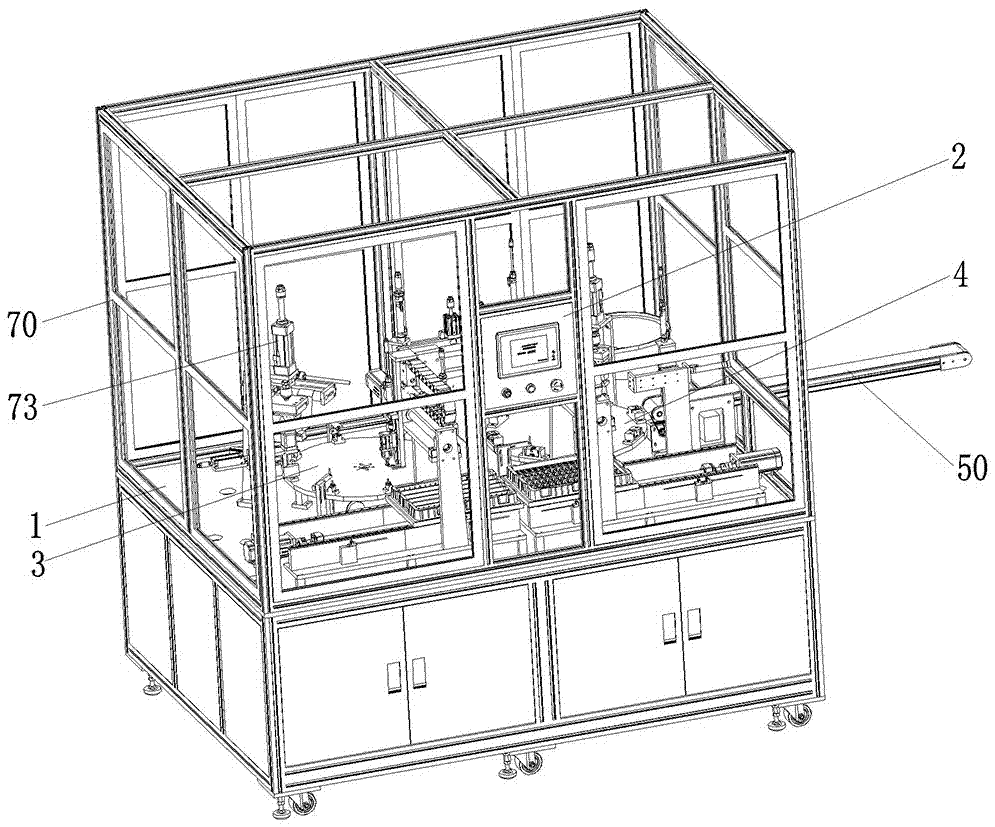

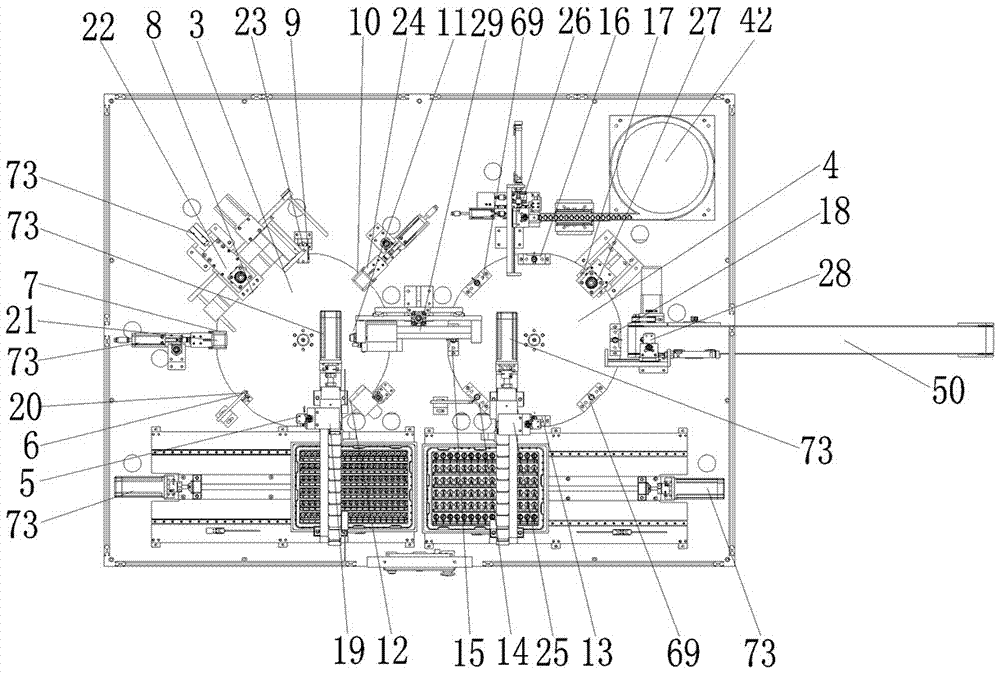

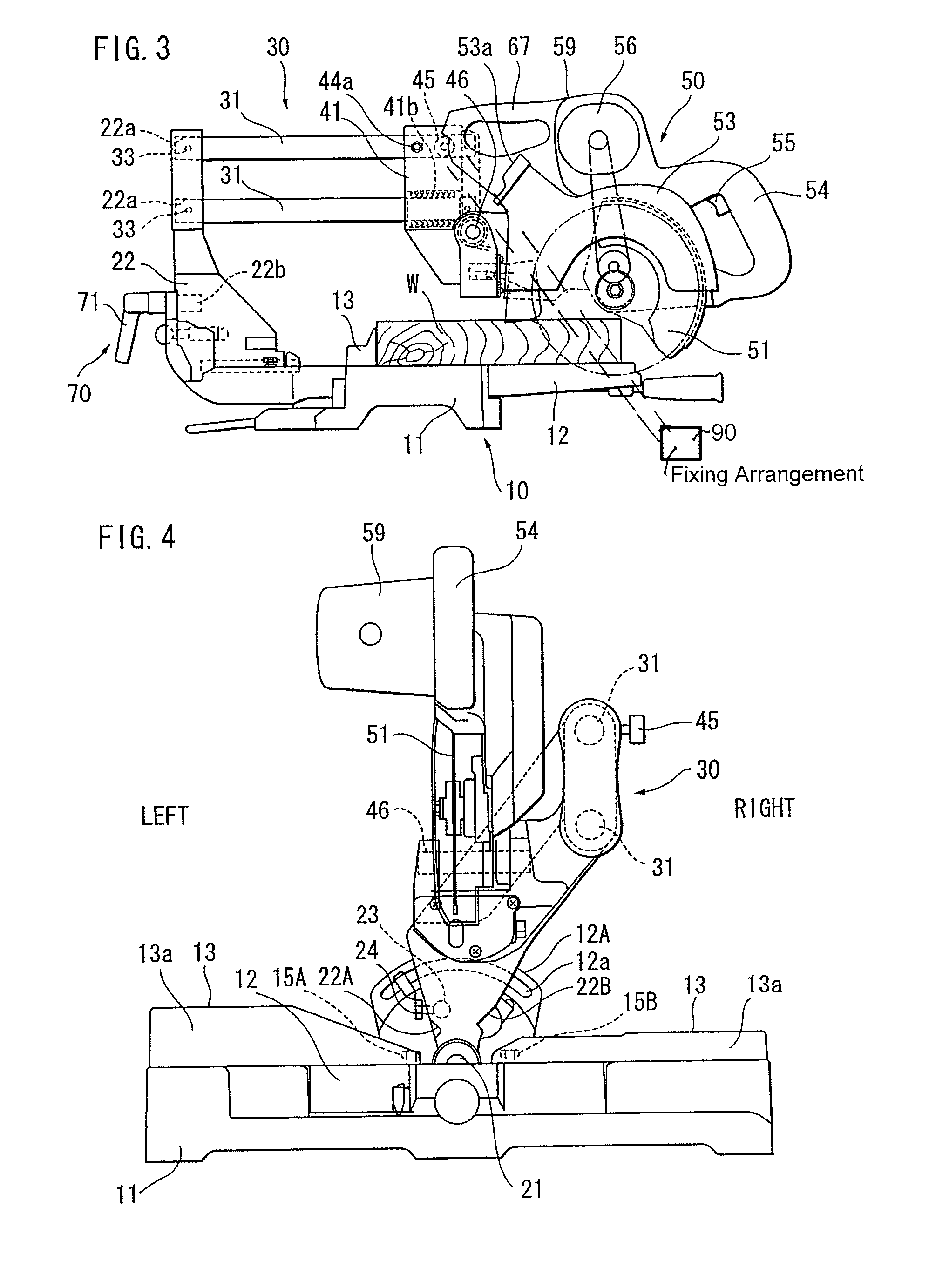

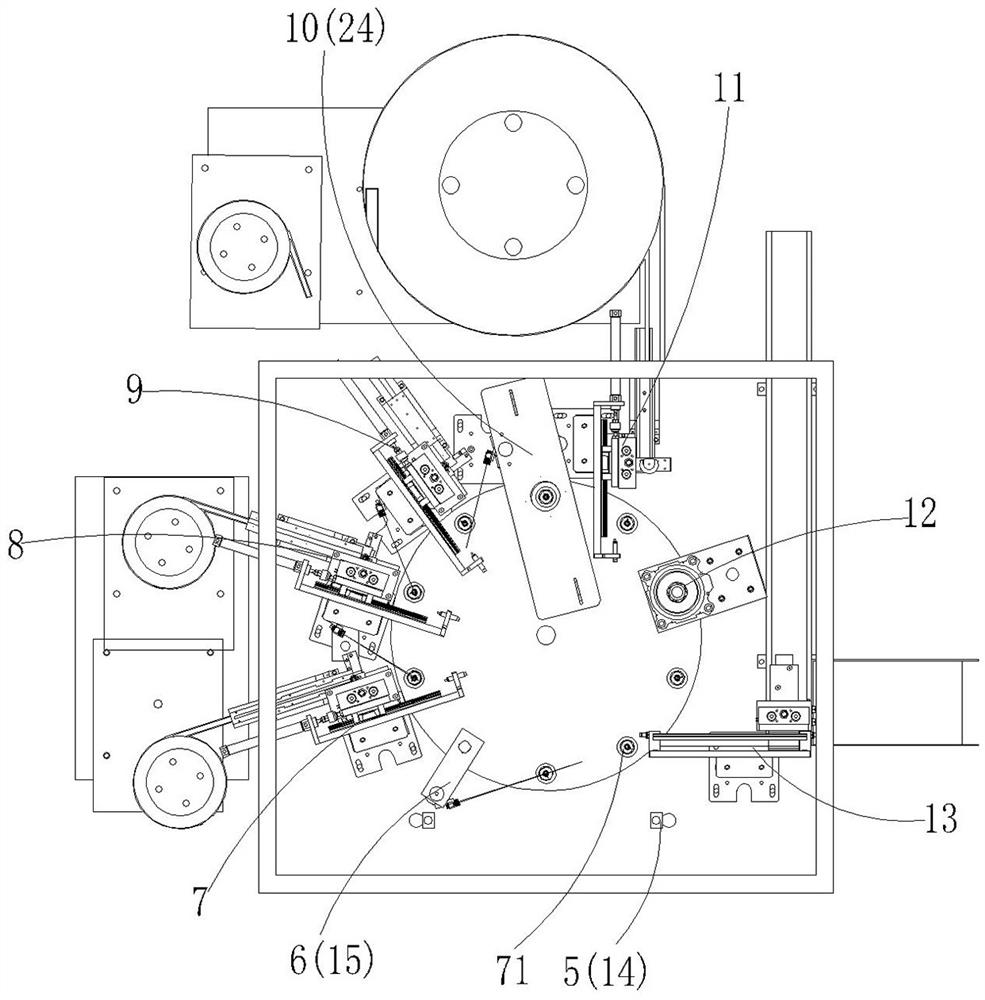

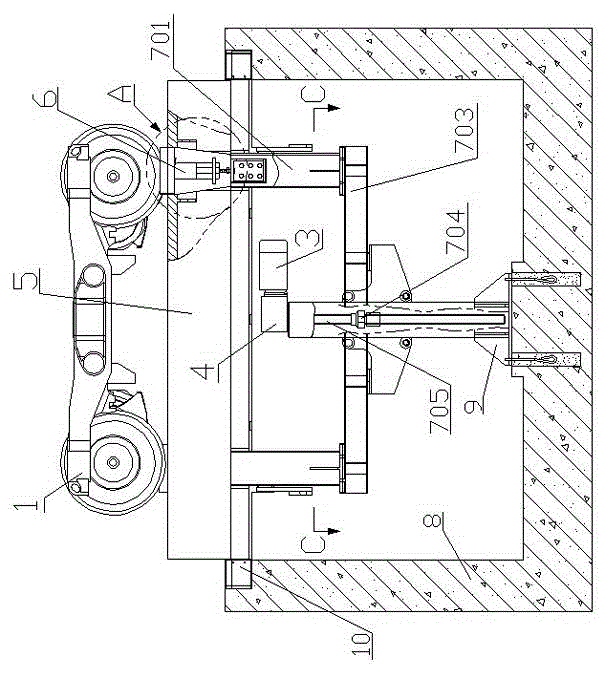

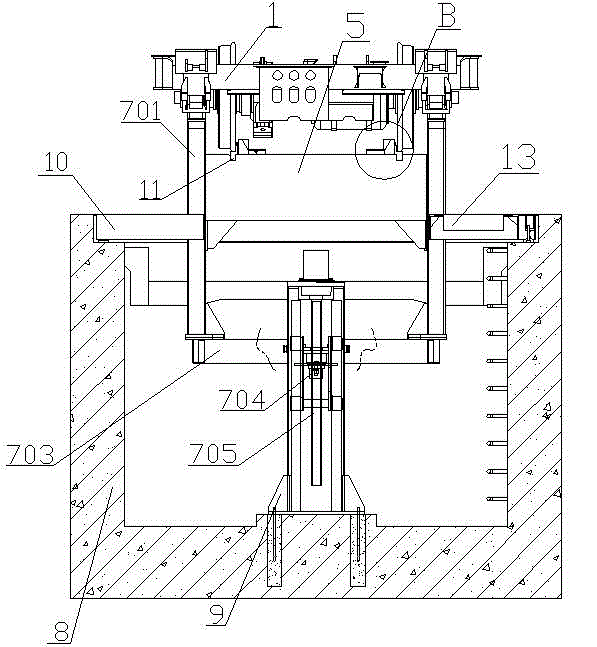

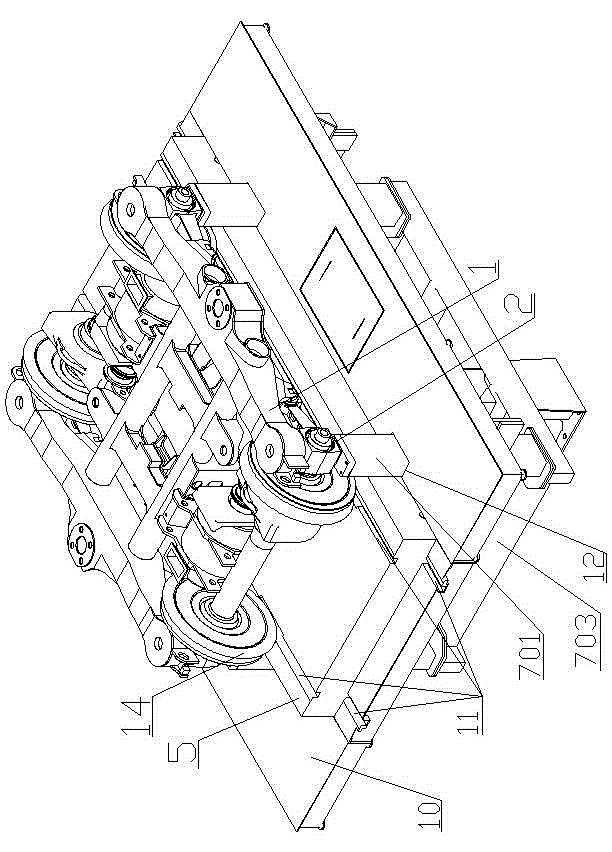

Full-automatic pointer assembling machine

PendingCN107984218AEasy to adjust the rotation speedReduce working spaceAssembly machinesMetal working apparatusTransfer mechanismComputer science

The invention discloses a full-automatic pointer assembling machine. The machine comprises a workbench and a control device for controlling the full-automatic pointer assembling machine; and an eight-station rotating disk, a six-station rotating disk as well as a transfer mechanism arranged between the eight-station rotating disk and the six-station rotating disk are arranged on the workbench. According to the machine, functions of assembling, thermal transfer printing, hot riveting and the like of pointers are realized through automatic machinery, the operation field is reduced, a lot of manpower and production costs are saved, and the productivity is greatly increased.

Owner:NINGBO JINHUI POINTER

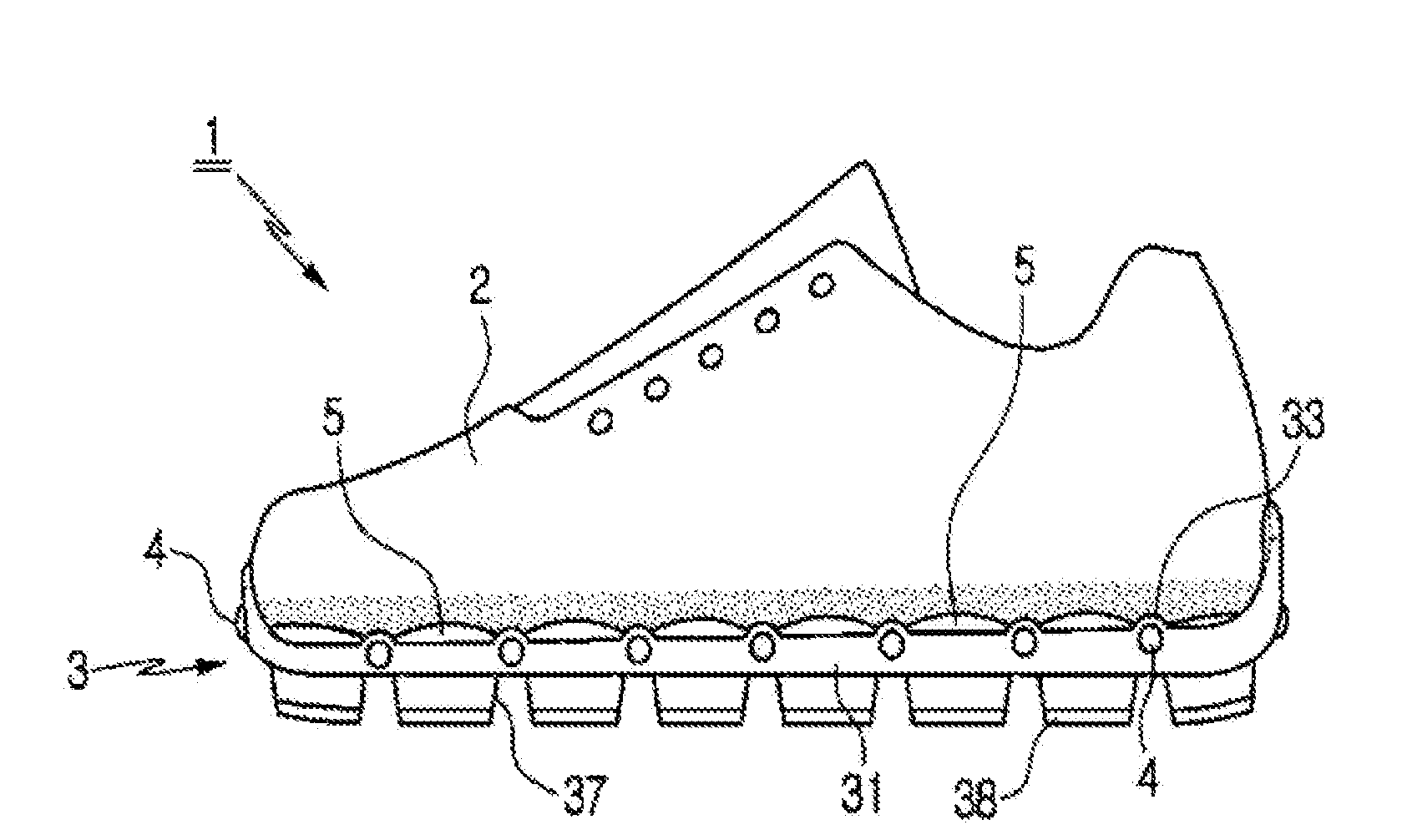

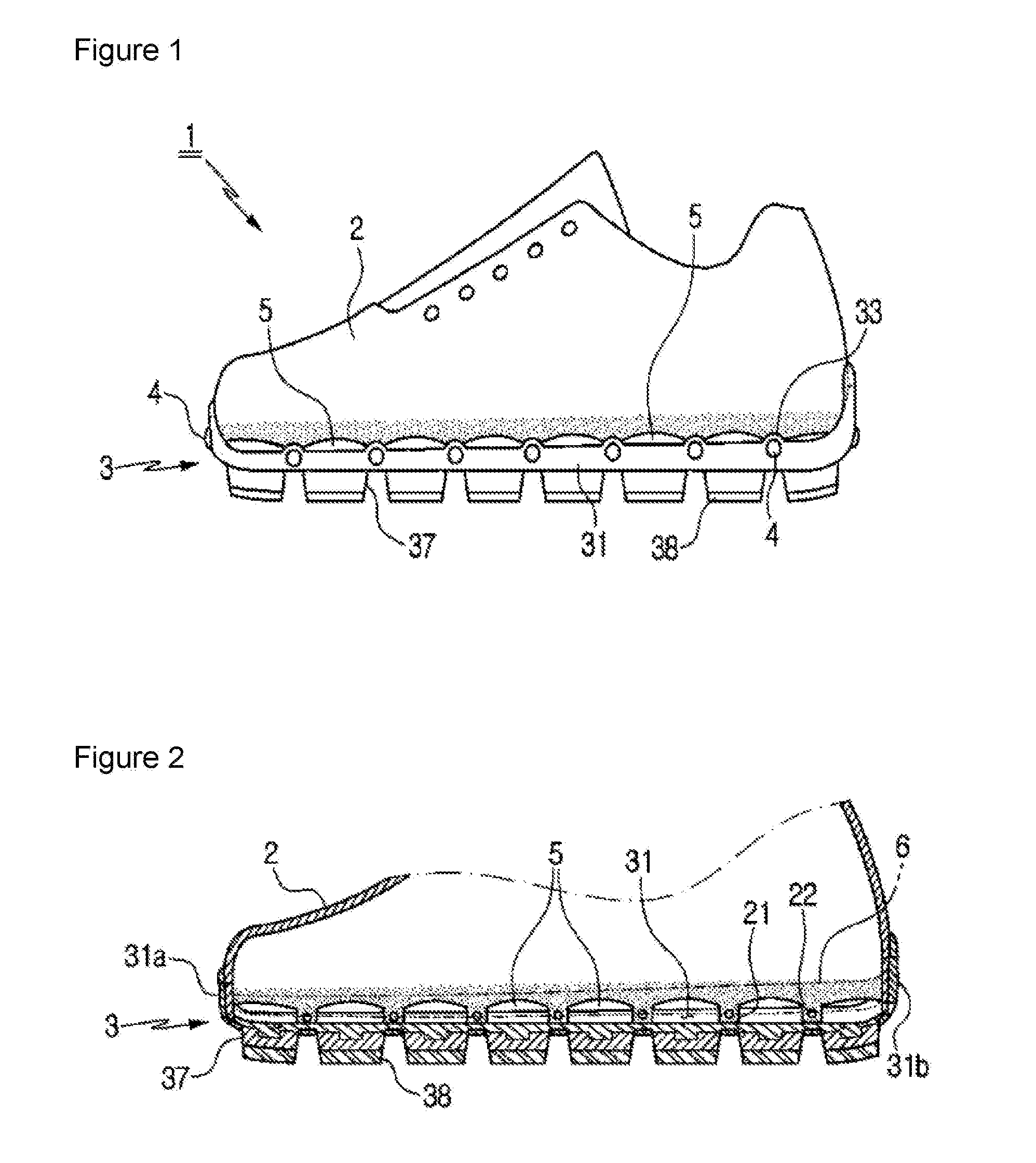

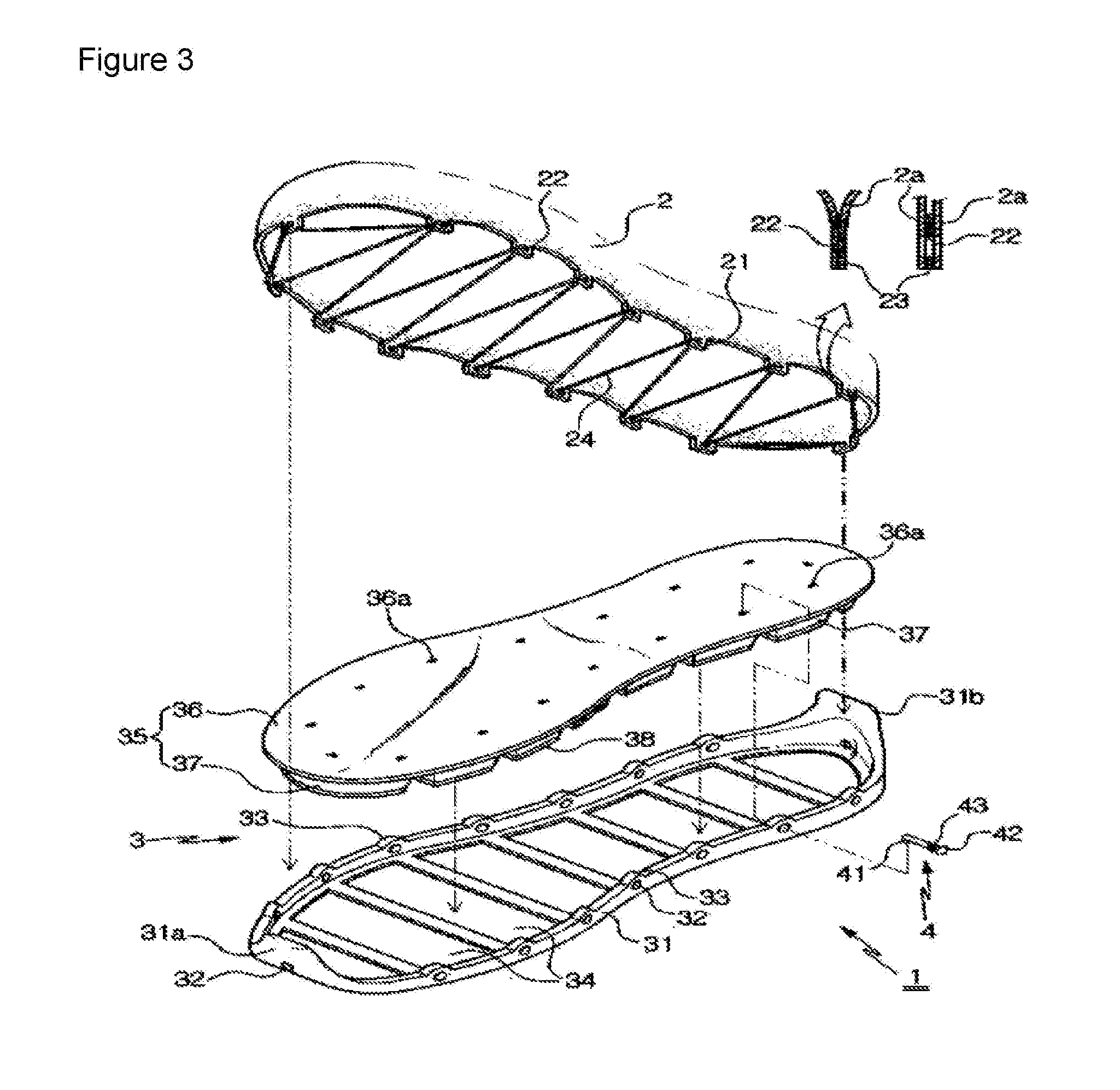

Gluing-free shoe and method for manufacturing same

A gluing-free shoe provides a gluing-free shoe comprising an upper leather and a sole coupled to each other without using glue, wherein the upper leather has an upper leather fixing piece formed on the lower end thereof, a fixing hole extending through the upper leather fixing piece, a reinforcing core material having high strength and durability is embedded on the lower end of the upper leather and inside the fixing piece; the sole comprises a frame, which is fixed to the upper leather, and an outsole fitted to the frame, the frame is injection-molded using a hard synthetic resin or molded using a rubber molding material, a frame fixing piece is formed on the upper side of the periphery of the frame to be positioned outside the upper leather fixing piece formed on the upper leather, a pin coupling hole being formed in the frame fixing piece.

Owner:KIM NAM GUK

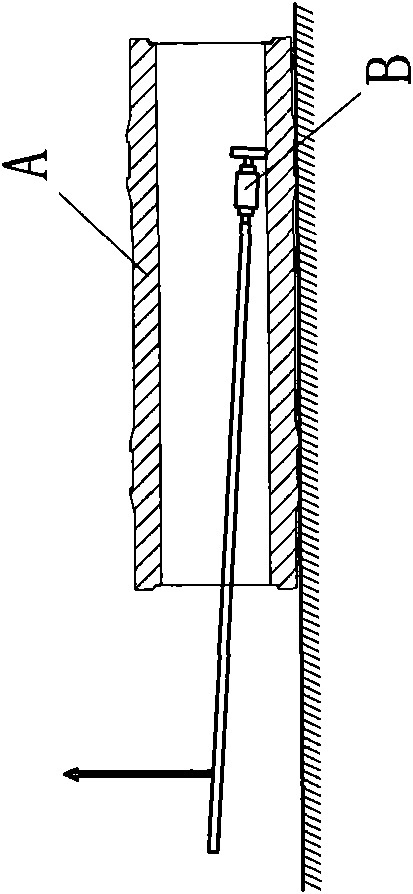

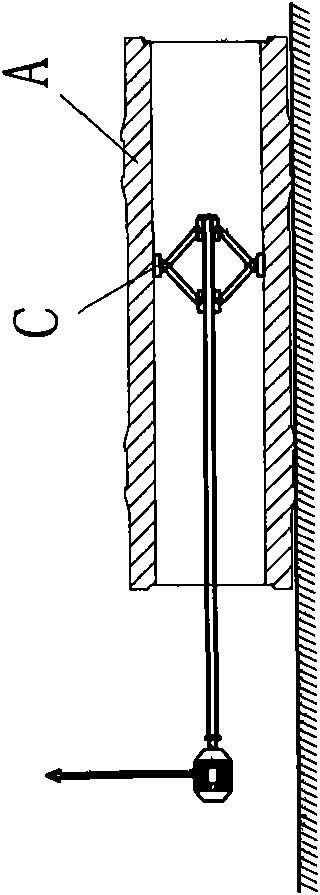

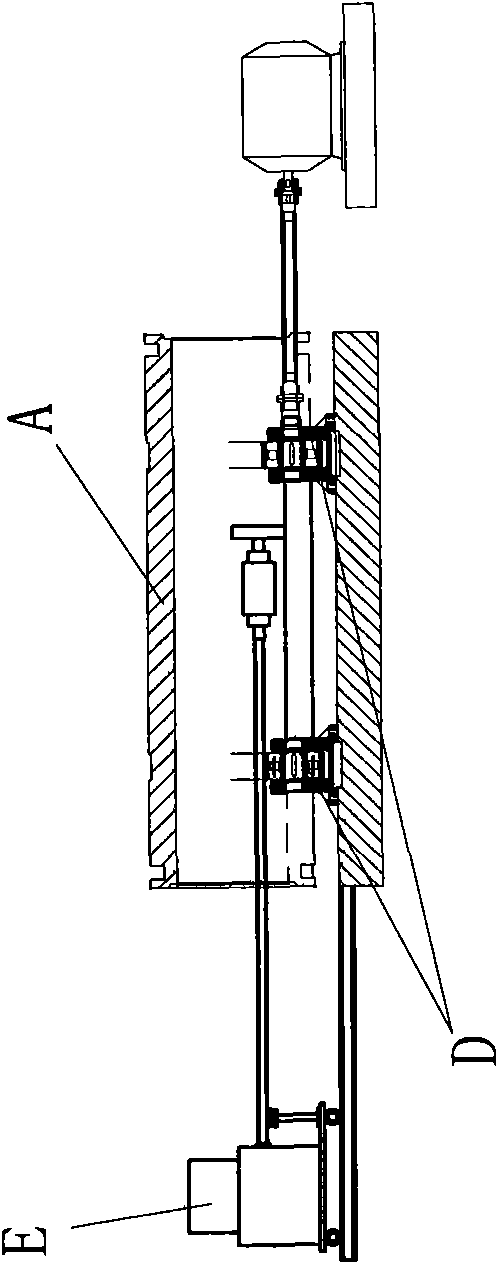

Cold-mould vertical spraying and cleaning system

The invention relates to a cold-mould vertical spraying and cleaning system comprising a ground pit, a hollow rotating bracket, a dust remover, an operating vehicle, a hollow guide rod and an actuating mechanism, wherein the ground pit can contain a cold mould which is placed vertically; the hollow rotating bracket is arranged on the bottom of the ground pit and used for fixing and supporting thebottom end of the cold mould and driving the cold mould to rotate around the vertical shaft of the hollow rotating bracket; the dust remover is arranged below the hollow rotating bracket; the operating vehicle is arranged on the top of the ground pit and capable of moving along the ground pit; the hollow guide rod is vertically arranged on the operation vehicle and capable of moving up and down; and the actuating mechanism is arranged on the lower end port of the hollow guide rod. In the invention, the casting mould for spraying or cleaning is vertically arranged instead of being horizontallyarranged in a traditional way, and therefore, the occupation area of the casting mould is reduced by about 50% as compared with the traditional horizontal way. By adopting direct-current variable-speed hoisting equipment, the invention can automatically control according to different thickness requirements for the paints of the cold mould in different positions. The system has the advantages of simpler structure and more convenient operation; the system adopts the hollow rotating bracket to organically combine the rotation and the support of the cold mould and enhance the bearing capacity; andsince a passage is formed at the center of the hollow rotating bracket, the system can remove dust, thereby being beneficial to environmental protection.

Owner:中国冶金科工股份有限公司

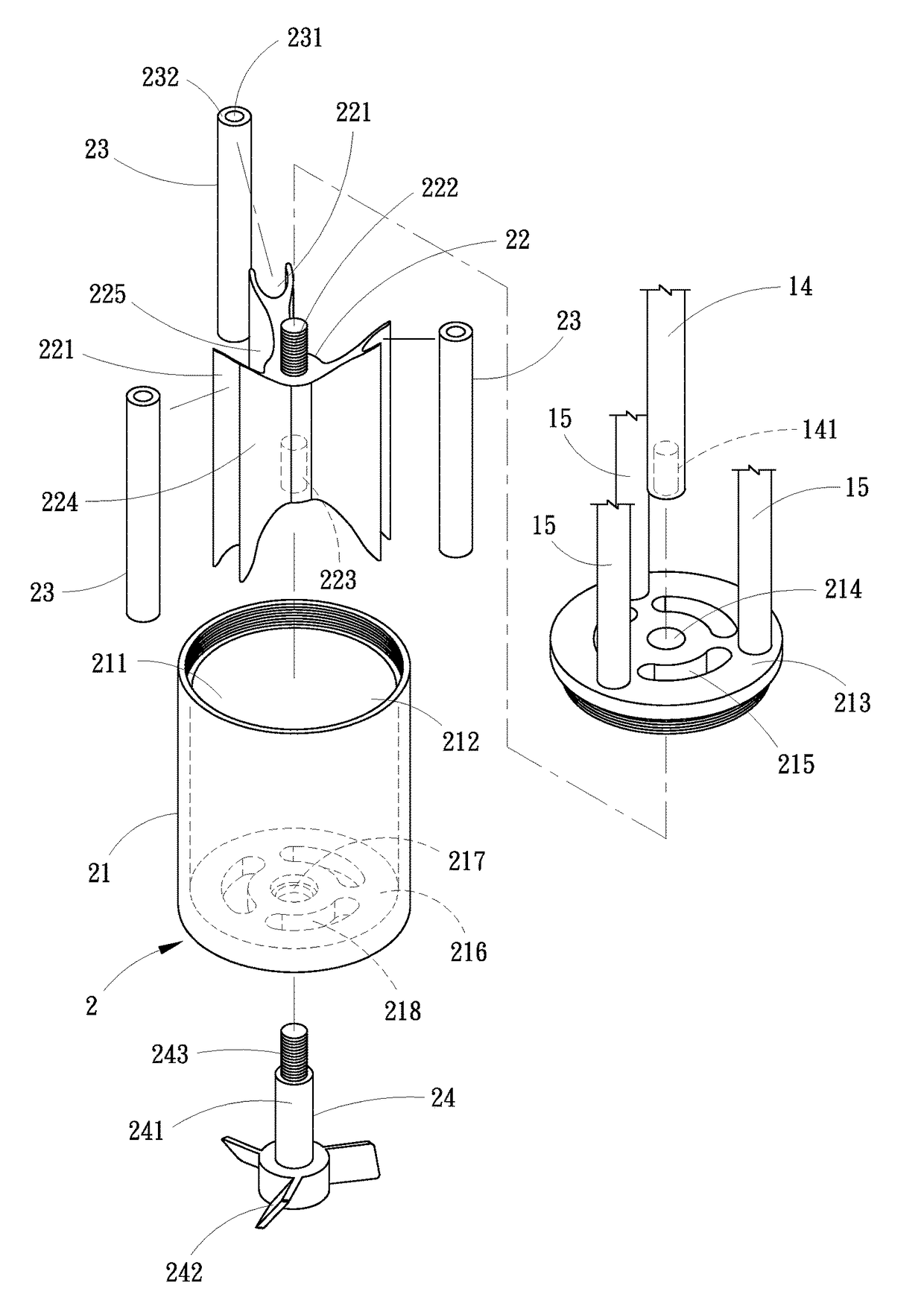

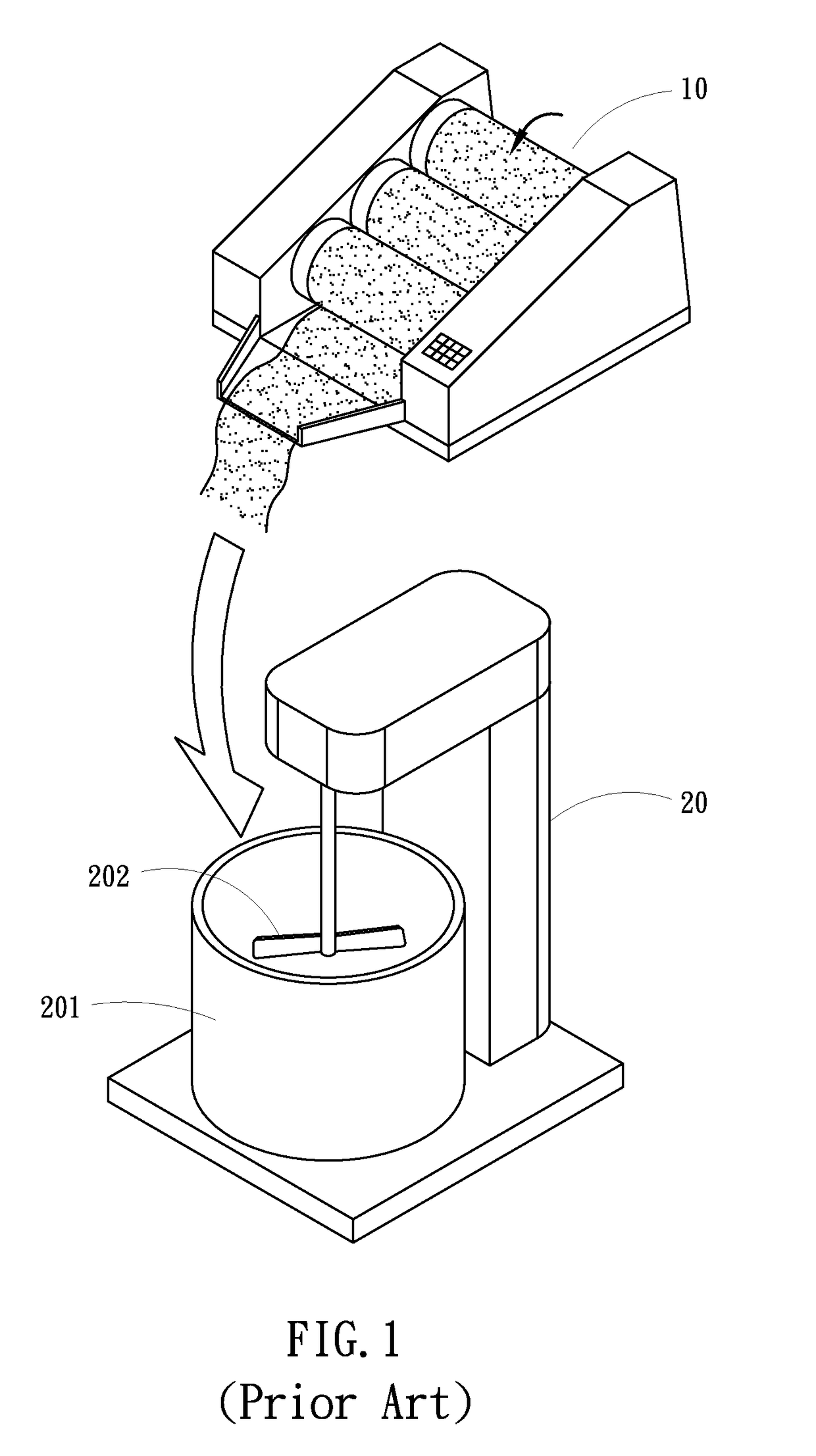

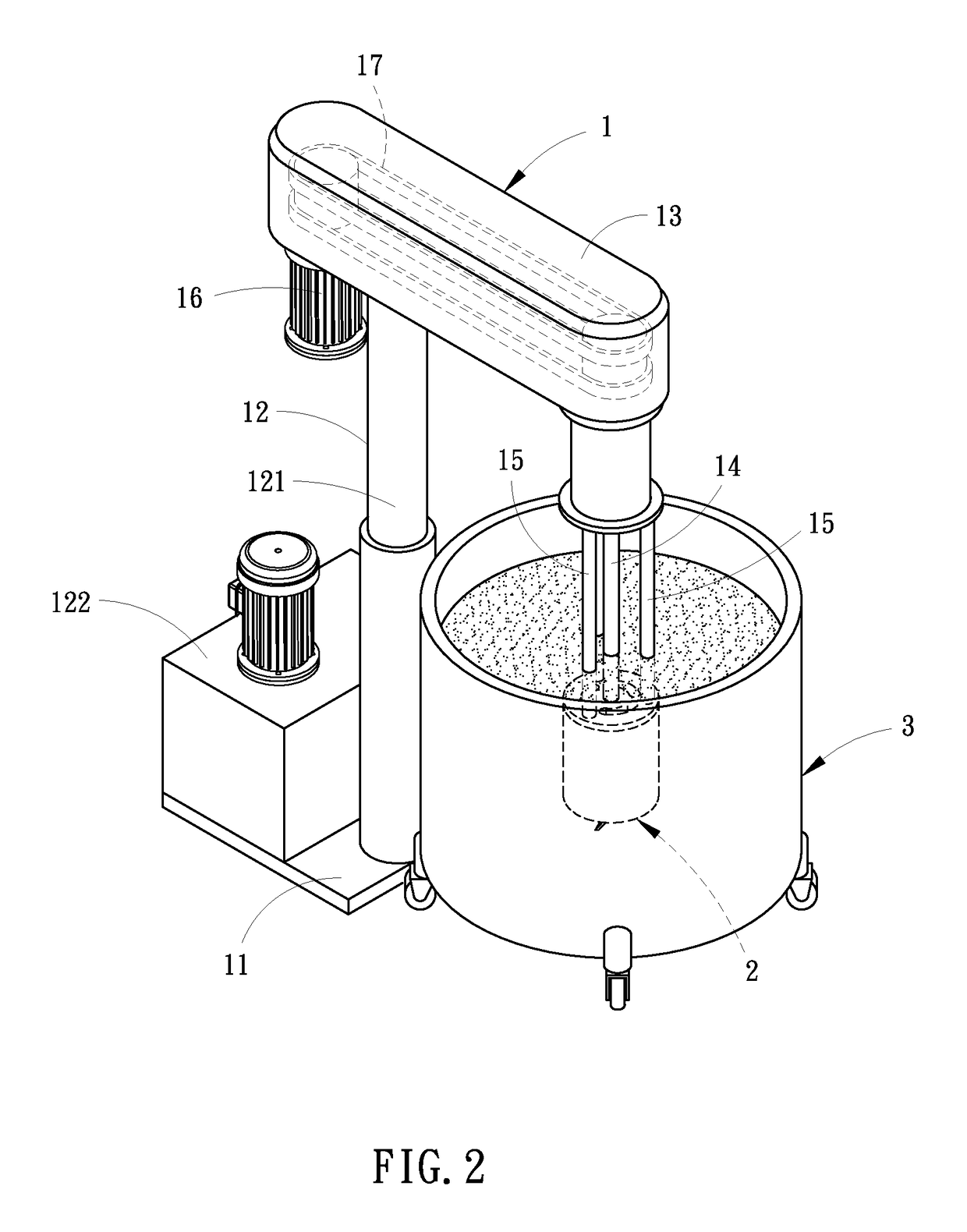

Mixing and grinding mechanism and mixer grinder using the same

ActiveUS9764295B2Low costReduce working spaceRotary stirring mixersTransportation and packagingEngineeringSlurry

A grinding and mixing mechanism for mixing and grinding fluid paint or fluid slurry includes a barrel, a rotor rotatably mounted in the barrel, grinding rolls rotatably mounted in the outer perimeter of the rotor and rotatably kept in contact with the inner barrel wall of the barrel for grinding a fluid paint or slurry, and a stirrer connected to the rotor for synchronous rotation with the rotor to mix the fluid paint or slurry circulated through the barrel. The invention also provides a mixer grinder using the grinding and mixing mechanism.

Owner:CATHAY COATING MFG

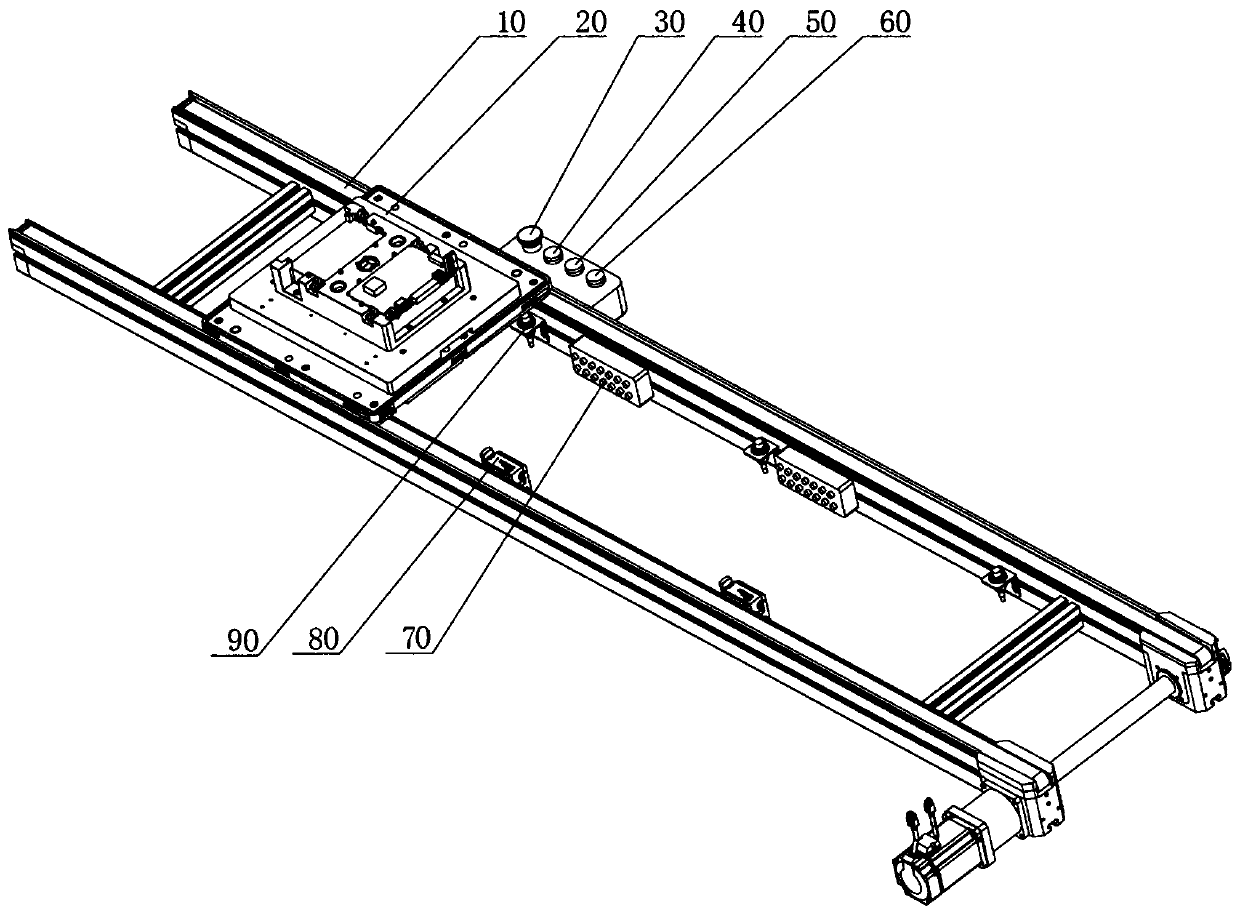

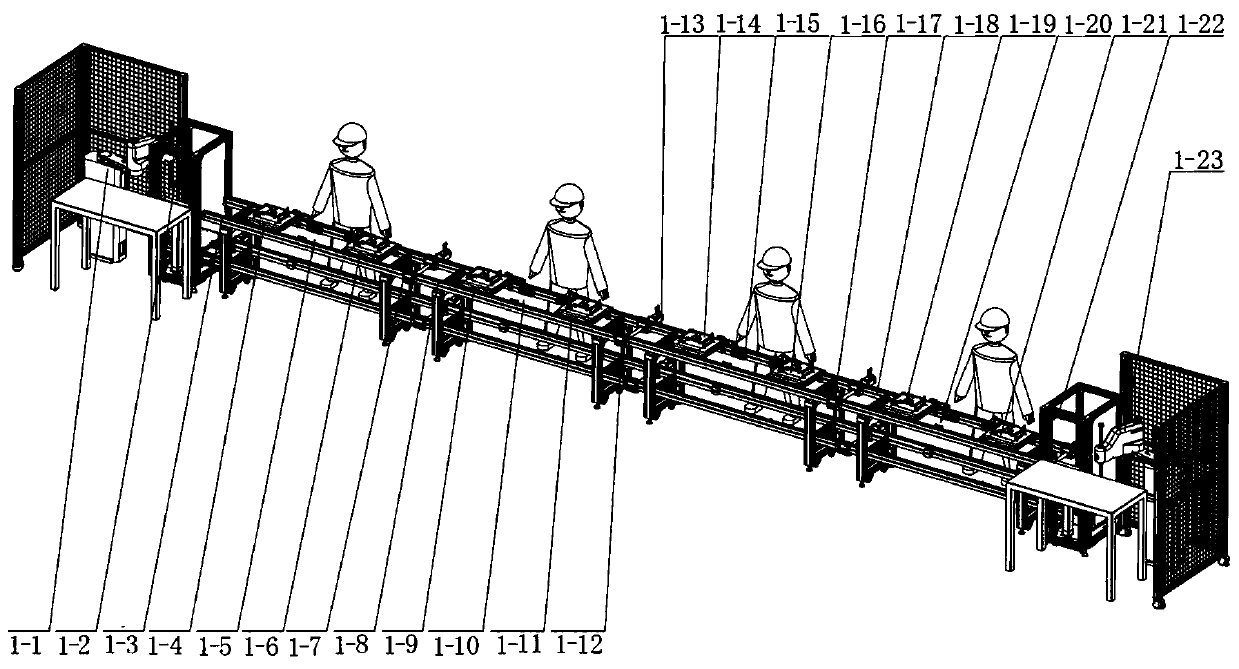

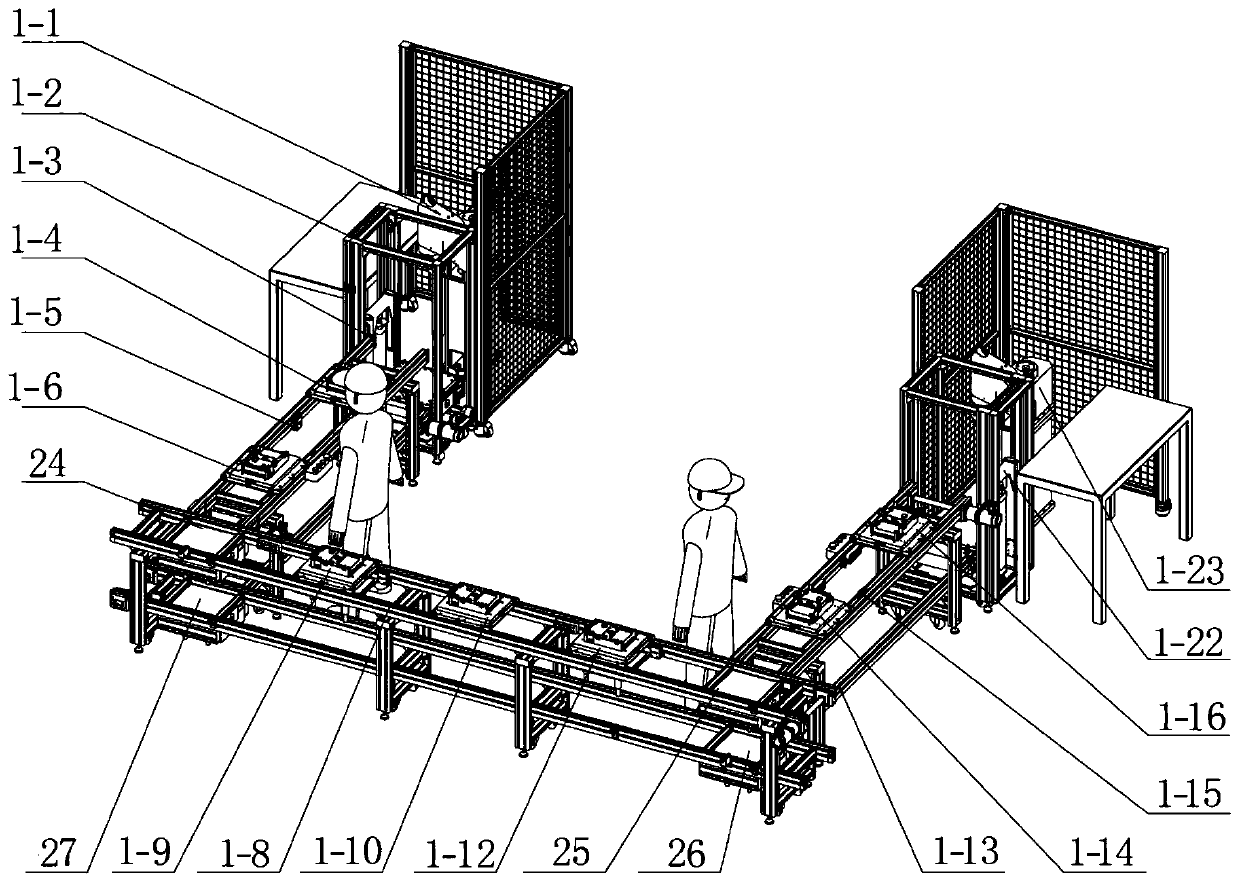

Automatic feeding and blanking production line and control method thereof

The invention discloses an automatic feeding and blanking production line and a control method thereof. The automatic feeding and blanking production line contains two structure modes, namely, a U-shaped line layout and a line type line layout. A production line body is formed by basic units and meets the requirement of a modular assembly technology; each basic unit is divided into an upper layerand a lower layer, so that modular splicing can be realized, and multiple layout forms are realized; and in addition, a tray backflow function can be realized. The production line is further providedwith a tray and tool conveying mechanism for supporting quick changeover, a tray conveying control system, a single-station manual / automatic real-time switching control system, a production line conveyor line body transfer real-time control mechanism, a production line work-in-process temporary storage station design, and flexible and changeable production line arrangement forms. On the basis of the idea of lean production, the problems of high stock level, circulation difficulty, high manufacturing cost, low product quality, waste in space, time, manpower and tool, and the like existing actually are solved.

Owner:西安精雕精密机械工程有限公司

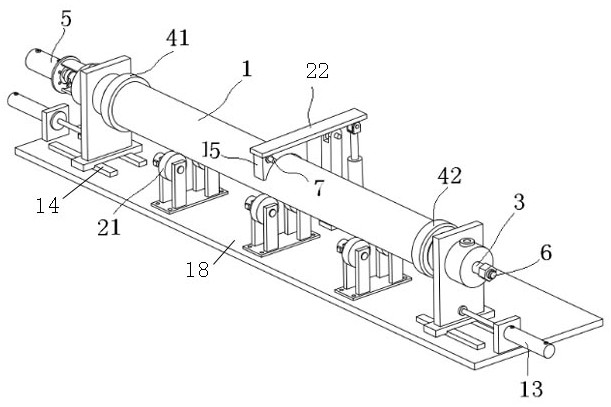

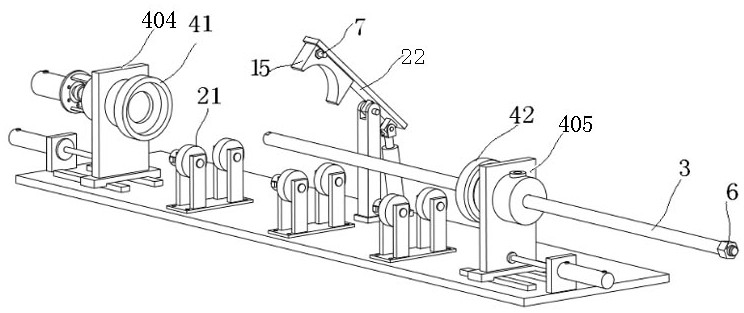

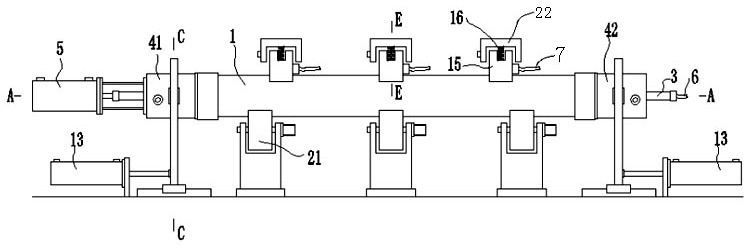

Metal pipe inner surface electrodeposition device and method

PendingCN111826699AAvoid scatterReduce wasteCellsSealing devicesWater storage tankLiquid storage tank

The invention discloses a metal pipe inner surface electrodeposition device, and relates to the technical field of metal pipe inner surface treatment. The device comprises a base, an anode, a carbon brush, composite joints, a reciprocating driving part and a plurality of liquid storage tanks. The base is provided with a plurality of supporting rollers used for horizontally supporting a metal pipeand driving the metal pipe to rotate in the circumferential direction, and two ends of the base are respectively provided with a first sliding seat and a second sliding seat; a swing frame is furtherarranged in the middle of the base; two ends of the metal pipe are respectively provided with the composite joints; and a deoiling cleaning liquid storage tank, a deionized water storage tank and a surface activating liquid storage tank are respectively connected with liquid conveying ports of the composite joints arranged at the front end and the rear end of the metal pipe through different conveying pipes, the processes of deoiling, washing, acidifying, activating, electrodepositing and the like on the inner wall of the metal pipe are automatically completed under the control of a liquid flow switch valve, the work of replacing and resealing the composite joints is not needed during the process, and the work efficiency is improved, and the scattering phenomenon of a working site and treatment liquid is reduced.

Owner:SHENGLI OIL FIELD HIGHLAND GASOLINEEUM EQUIP

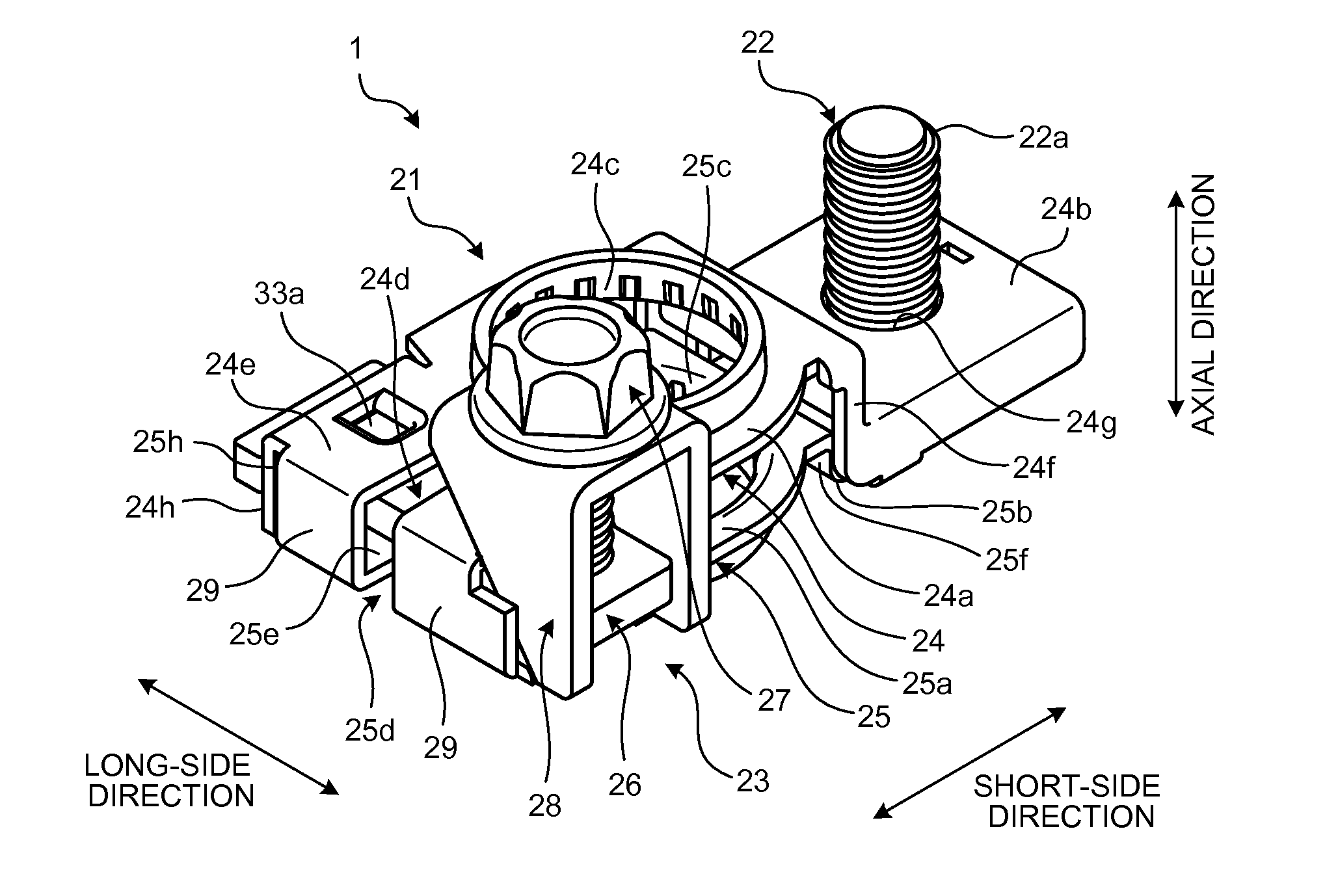

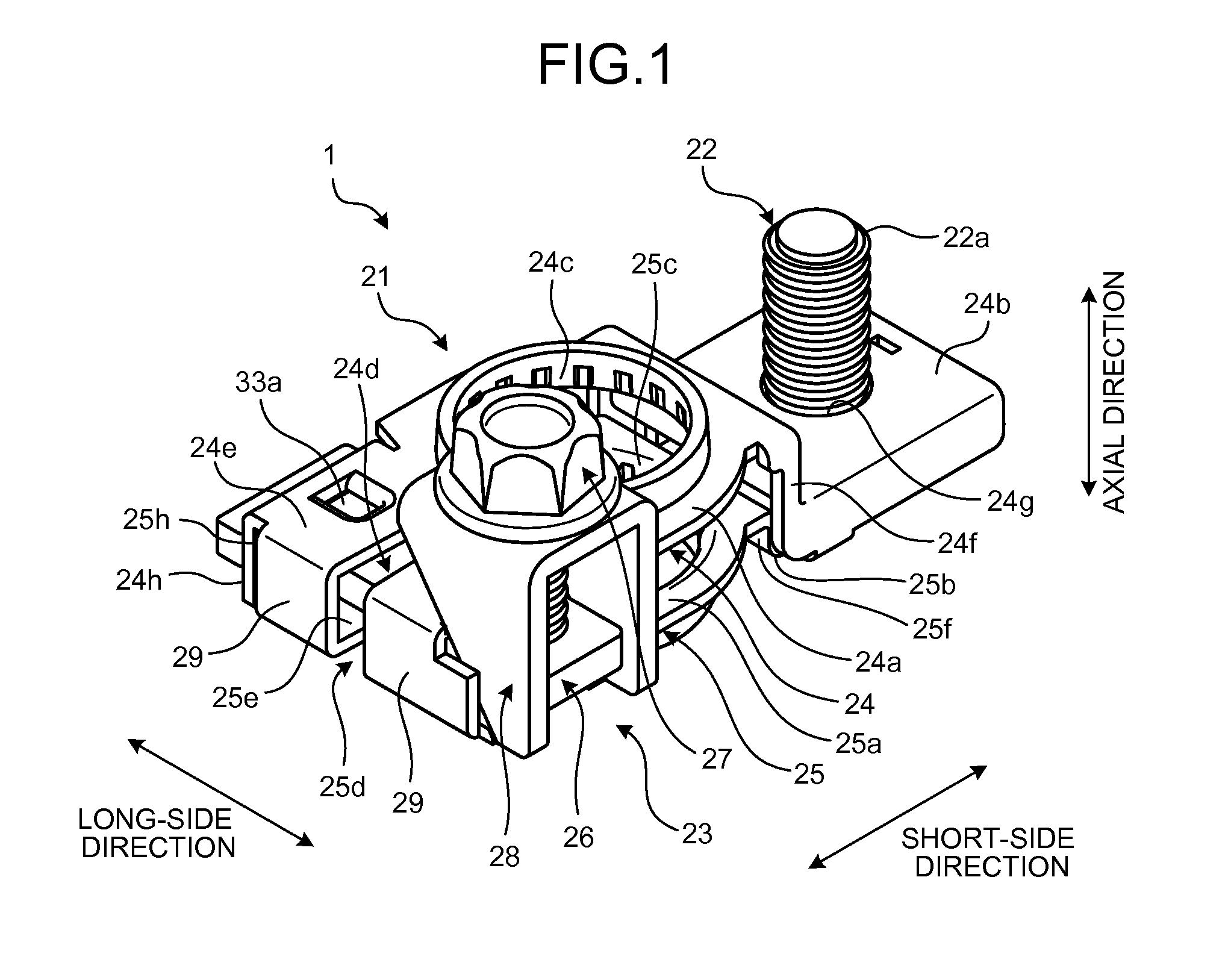

Battery terminal

ActiveUS20160126530A1Reduce working spaceImprove fastnessCurrent conducting connectionsSmall-sized cells cases/jacketsEngineeringMechanical engineering

A battery terminal includes a penetration plate arranged to penetrate from one end portions of annular portions to the other end portions interposing slits, a fastening bolt supported to be rotatable around an axial direction by a threaded hole provided on the other end portion of the penetration plate, and a spacer arranged in contact with the annular portions from the other end portion side of the penetration plate and converting a tightening force in the axial direction arising along with the rotation of the fastening bolt around the axial direction into a pressing force that presses the annular portions from a long-side direction. The penetration plate is arranged to penetrate a clearance of the pair of annular portions. The pair of annular portions includes projecting portions as a clearance reduction portion that reduces the clearance in at least a part of the penetration area of the penetration plate.

Owner:YAZAKI CORP

Miter saw having circular saw blade section pivotally movable upward and downward and tiltable leftward and rightward

ActiveUS8061250B2Reduce working spaceEasy to operateMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A miter saw includes a base section having a front side and a rear side defining a first direction, and having a right side and a left side those defining a second direction. A holder is movably supported to the rear side of the base section and pivotable in the second direction. A fixing mechanism fixes a pivot position of the holder relative to the base section. A guide bar section includes two guide bars supported to the holder and extending in the first direction. A saw blade support section is disposed slidable with respect to the guide bars and selectively position-fixable with respect to the guide bars. A saw blade section which is pivotably supported accommodates a motor and rotatably supports a circular saw blade driven by the motor.

Owner:KOKI HLDG CO LTD

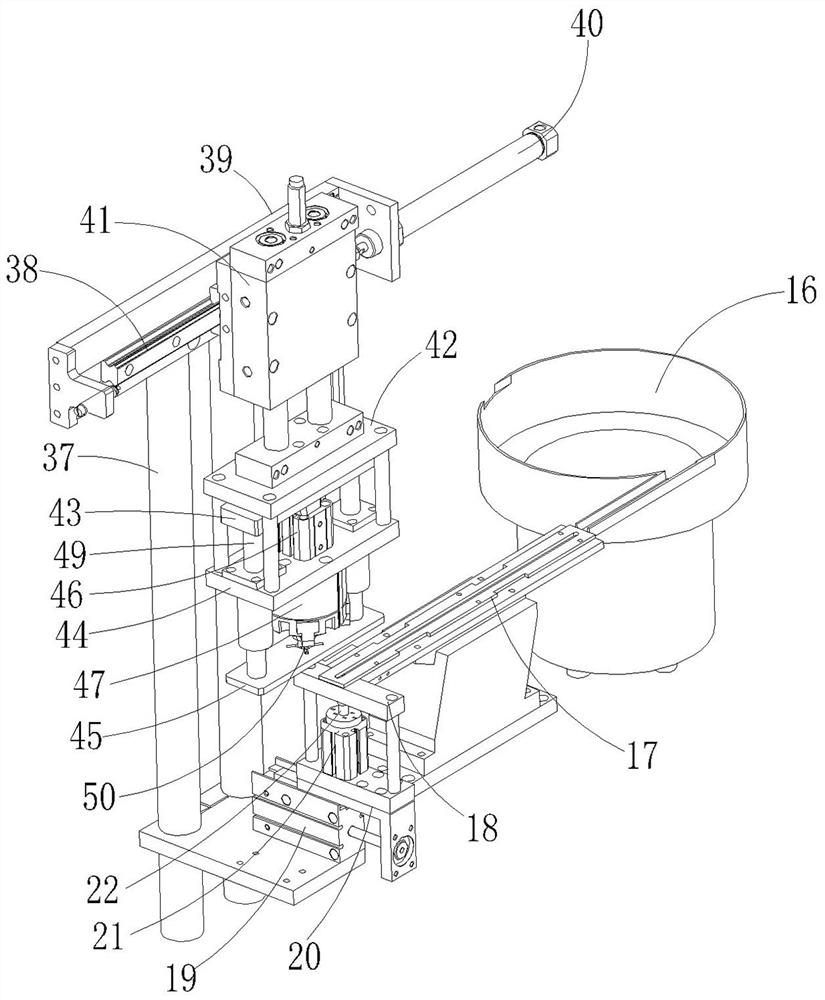

Automatic assembling detection equipment for pipe connector sealing rings and assembling detection method

ActiveCN112621216AAccurate removalEnsure physical safetyAssembly machinesSortingSonarElectric machinery

The invention relates to automatic assembling detection equipment for pipe connector sealing rings and an assembling detection method. The automatic assembling detection equipment comprises a workbench and a control device for controlling the automatic assembling detection equipment for the pipe connector sealing rings, and the workbench is provided with a circular station rotary disc driven by a rotary disc motor; and a manual safety feeding mechanism, an infrared detection mechanism, a first sealing ring assembling mechanism, a second sealing ring assembling mechanism, a third sealing ring assembling mechanism, a visual detection mechanism, a steel sleeve assembling mechanism, a sonar detection mechanism and a discharging mechanism are sequentially and annularly arranged around the circular station rotary disc. According to the automatic assembling detection equipment for the pipe connector sealing rings and the assembling detection method, the functions of assembling and detecting a pipe connecting part, the multiple sealing rings and a steel sleeve and the like are achieved through an automatic machine, the operation field is reduced, a large amount of labor and production cost is saved, the productivity is greatly improved, and the consistency and the percent of pass of products are effectively improved; and the detection mode is diversified, detection is more in place, unqualified products can be effectively removed, and meanwhile the body safety of staff can be guaranteed.

Owner:宁波友谊铜业有限公司

Lock barrel and a driving part for the same

InactiveUS7353675B1Increase the difficultyReduce working spaceKeysCylinder locksMoving partsElectrical and Electronics engineering

Owner:CHAO SHENG HO +1

System for applying hot melt adhesive powder onto a non-metallic object surface

ActiveUS8505477B2Save energyReduce working spaceLiquid surface applicatorsElectrostatic heating/coolingUltravioletCleansing Agents

A system for applying hot melt adhesive powder onto a non-metallic object surface comprises a convey belt, a radiation chamber, a spraying chamber and a heating chamber. The convey belt is used to deliver a non-metallic object treated by a cleaning agent and a conductive liquid through the radiation chamber where the surface of the non-metallic objected is irradiated by ultraviolet rays and ozone and then through the spraying chamber where the surface of the non-metallic object is sprayed with charged hot melt adhesive powder, and finally into the heating chamber where the hot melt adhesive powder attached onto the non-metallic object will be melted into a liquid adhesive film ready to be bonded.

Owner:ORISOL ASIA

Transparent sheet having a pattern for infrared reflection

ActiveUS8993100B2Low costEasy to liftLamination ancillary operationsLayered product treatmentHandwritingDisplay device

An infrared ray reflection pattern-printed transparent sheet is provided which can be applied to a data input system of a type of handwriting directly on a screen of a display device and provides a coordinate detect means and which is lightweight, low in a cost, readily increased in an area, possible in mass production and excellent in a read performance. It is an infrared ray reflection pattern-printed transparent sheet in which infrared ray reflective transparent patterns are printed on a surface of a transparent substrate and which is disposed oppositely to a front face of a display device. A cross section obtained by cutting the infrared ray reflective transparent patterns printed on the above transparent substrate in a face orthogonal to the above transparent substrate is formed so that it assumes a multilayer structure comprising a fixed repeating cycle when observed under a scanning electron microscope.

Owner:DAI NIPPON PRINTING CO LTD

Device for measuring and adjusting bogie size of motor train unit

The invention relates to an adjusting device for motor train unit overhauling, in particular to a device for measuring and adjusting the bogie size of a motor train unit. The device for measuring and adjusting the bogie size of the motor train unit comprises a power mechanism, a transmission mechanism, a fixed platform, a measuring platform and a lifting mechanism, wherein the fixed platform is of a hollow structure, the measuring platform is embedded into the hollow structure of the fixed platform and in slide fit with the fixed platform, the fixed platform and the measuring platform are respectively provided with two parallel rails, a lifting column in the lifting mechanism is in slide fit with a positioning hole in the fixed platform, the bottom end of the lifting column is connected with a lifting supporting frame, a wheel positioning mechanism is arranged on the lifting column, and the lifting supporting frame is connected with the transmission mechanism. Compared with the prior art, the device for measuring and adjusting the bogie size of the motor train unit has the advantages that wheel positioning, positioning rotating arm supporting and measuring platform lifting can be sequentially achieved through the lifting mechanism, and the operation field can be saved.

Owner:TANGSHAN BAICHUAN INTELLIGENT MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com