Patents

Literature

1156 results about "Thermal Head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Head is a component of a metrological device created to aid in development of new CPUs and chipsets. The first Thermal Head was constructed in 1996 by James Kerner. It was initially designed to control a slot 1 Intel processor's temperature while making computations in a test platform. A Thermal Head attached to a CPU may also increase a CPU's performance during computation. Today it is used for test/validation of a processor in conjunction with a Thermal Management System consisting of a temperature controller attached to the Thermal Head by way of an electrical umbilical.

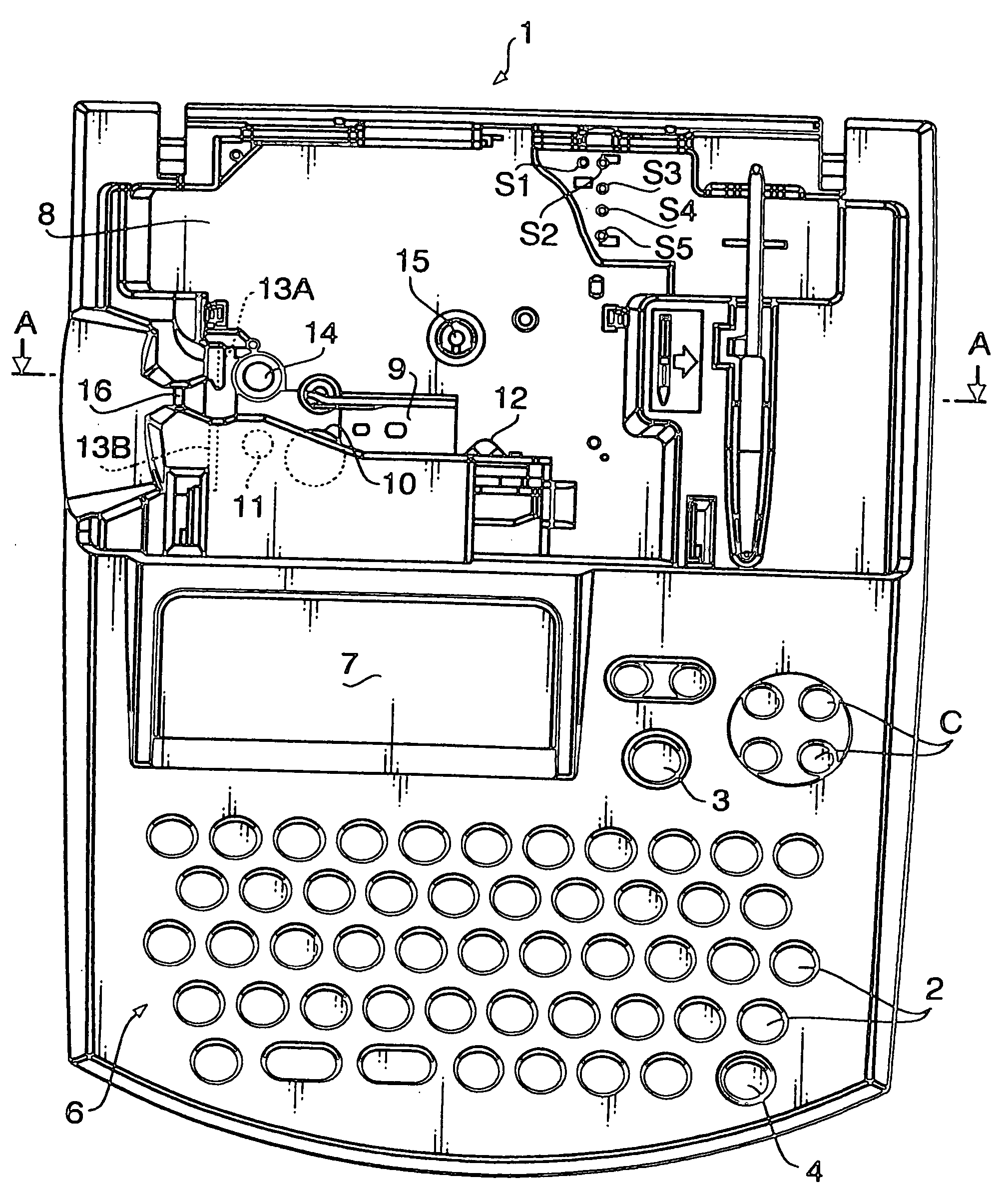

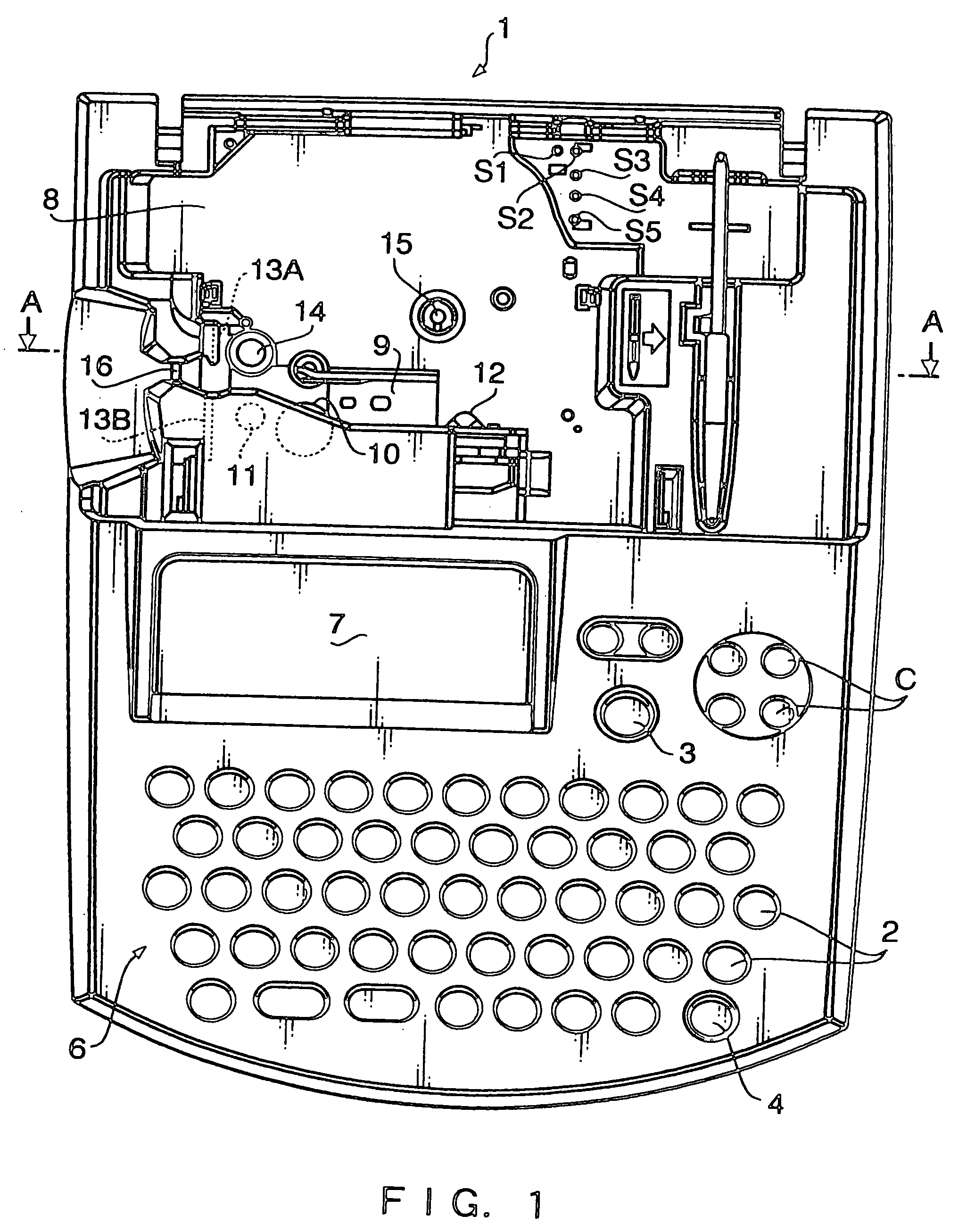

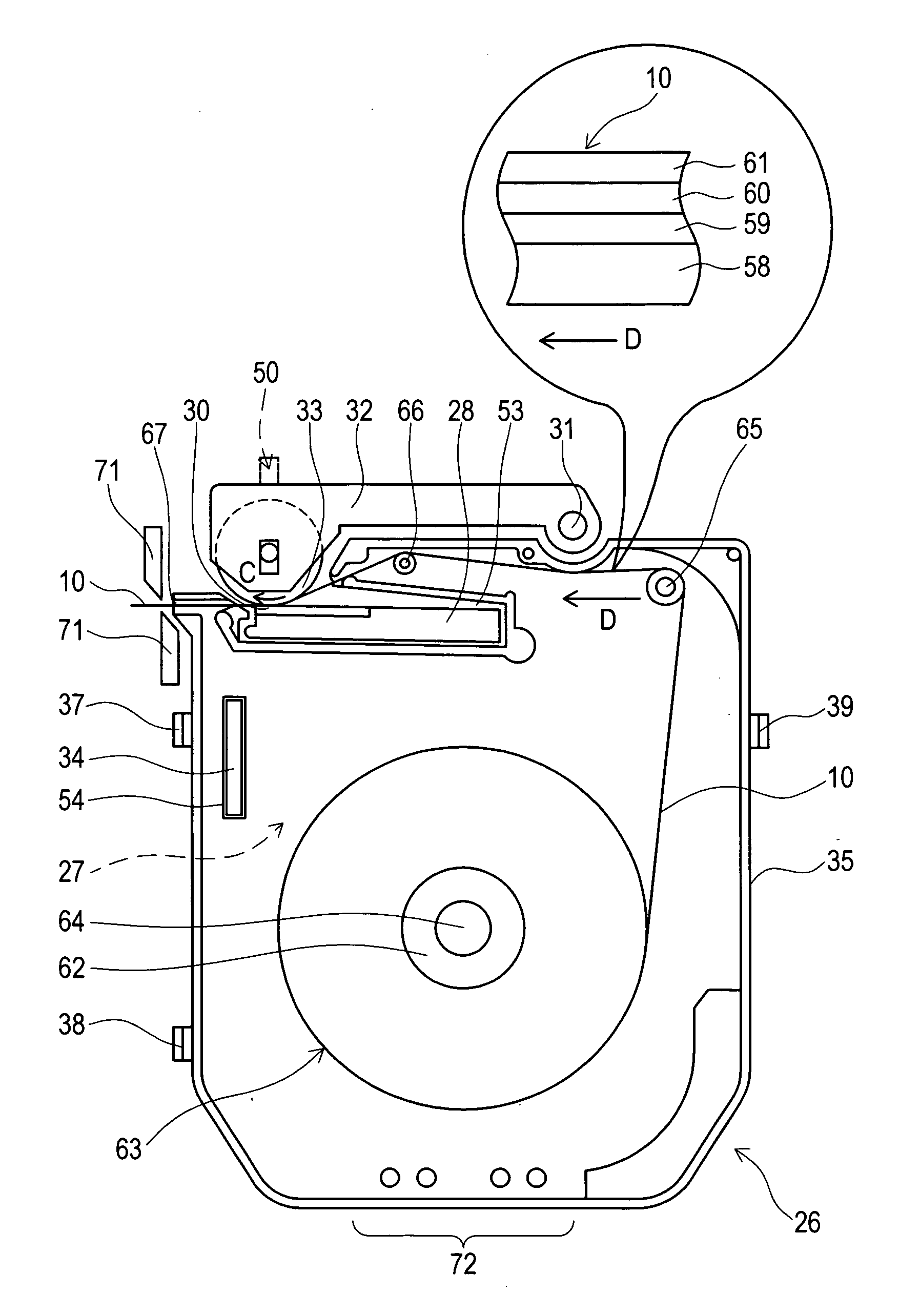

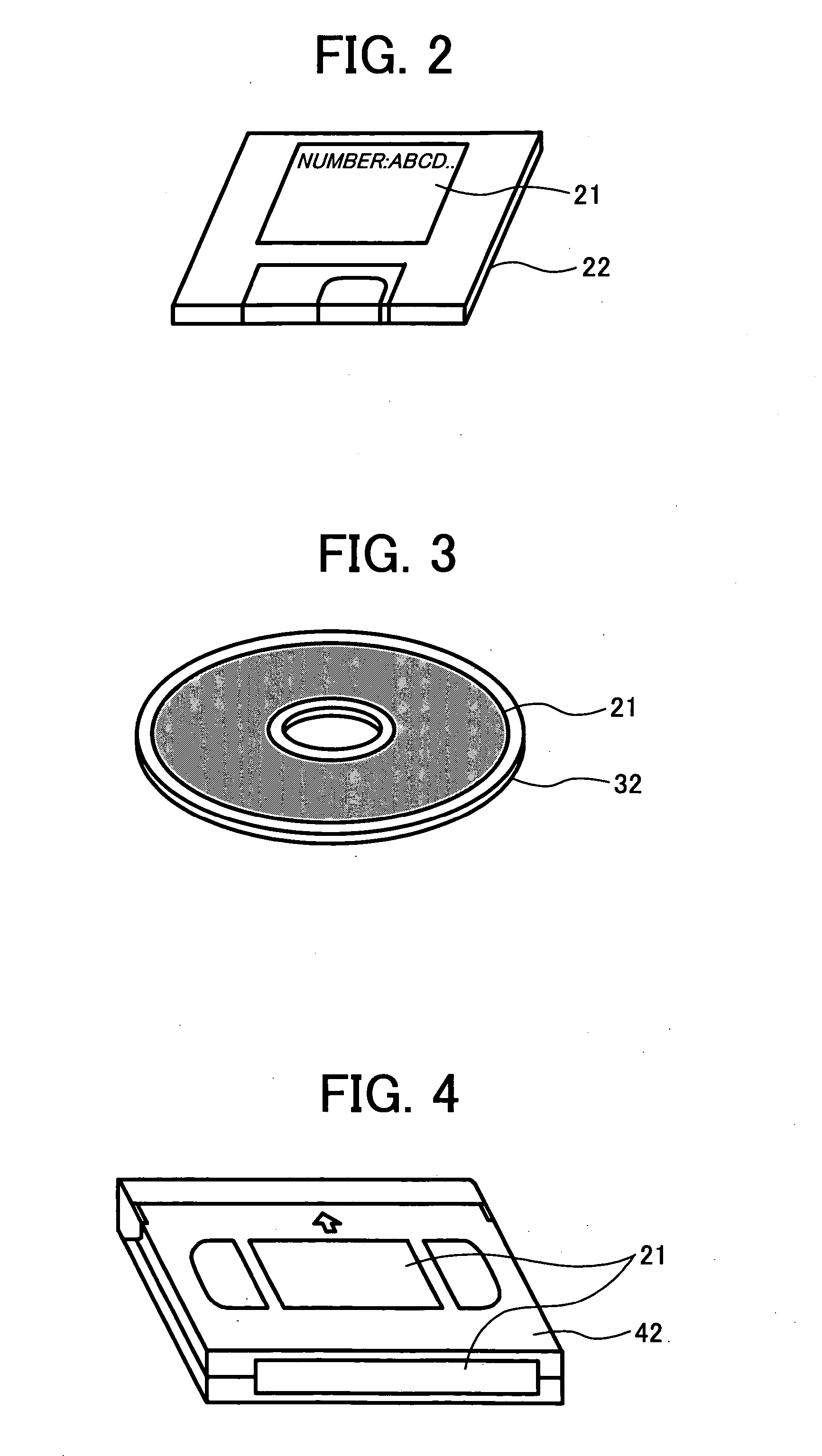

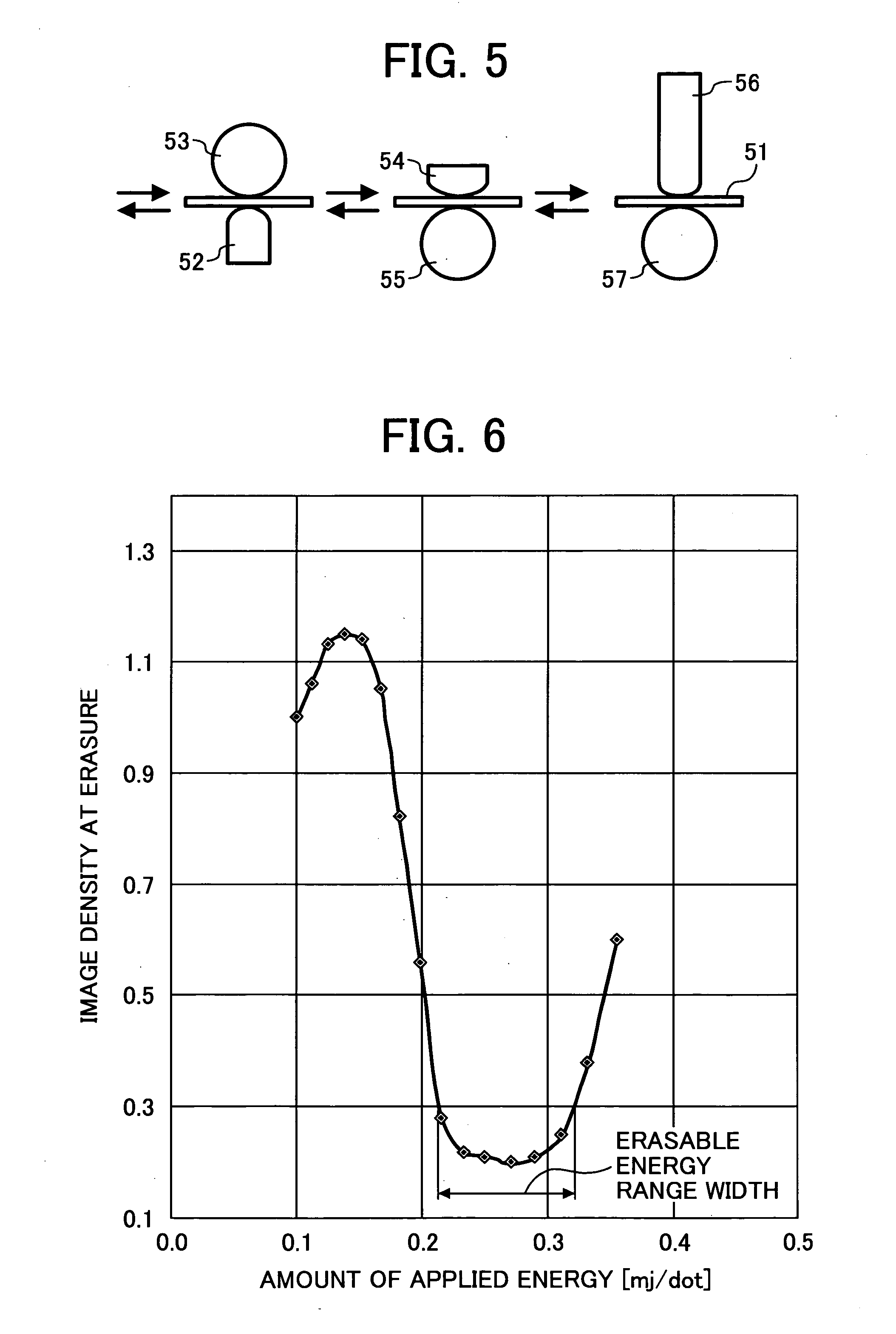

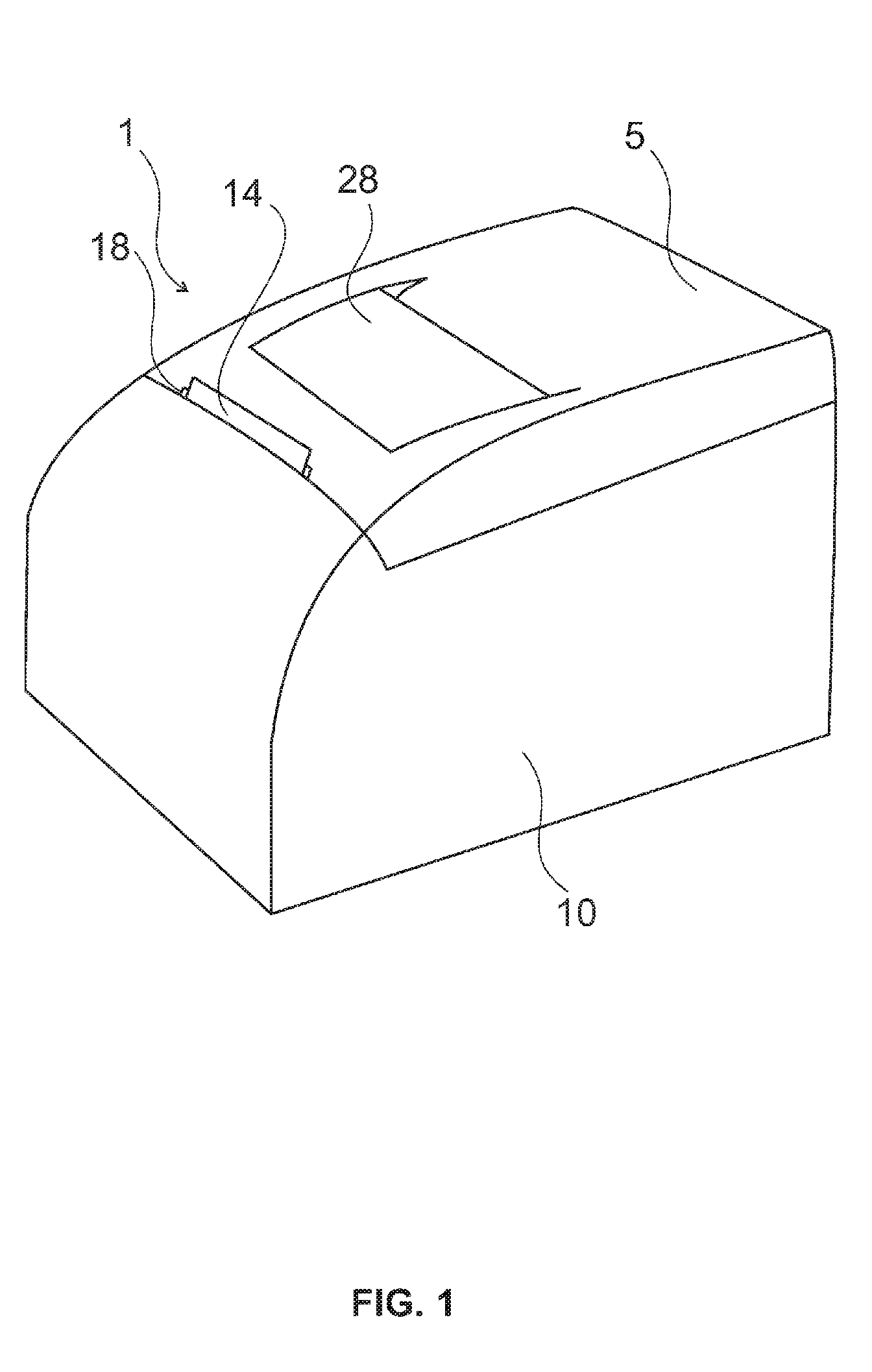

Cassette for holding ink ribbon and print paper therein and printer incorporating the cassette therein

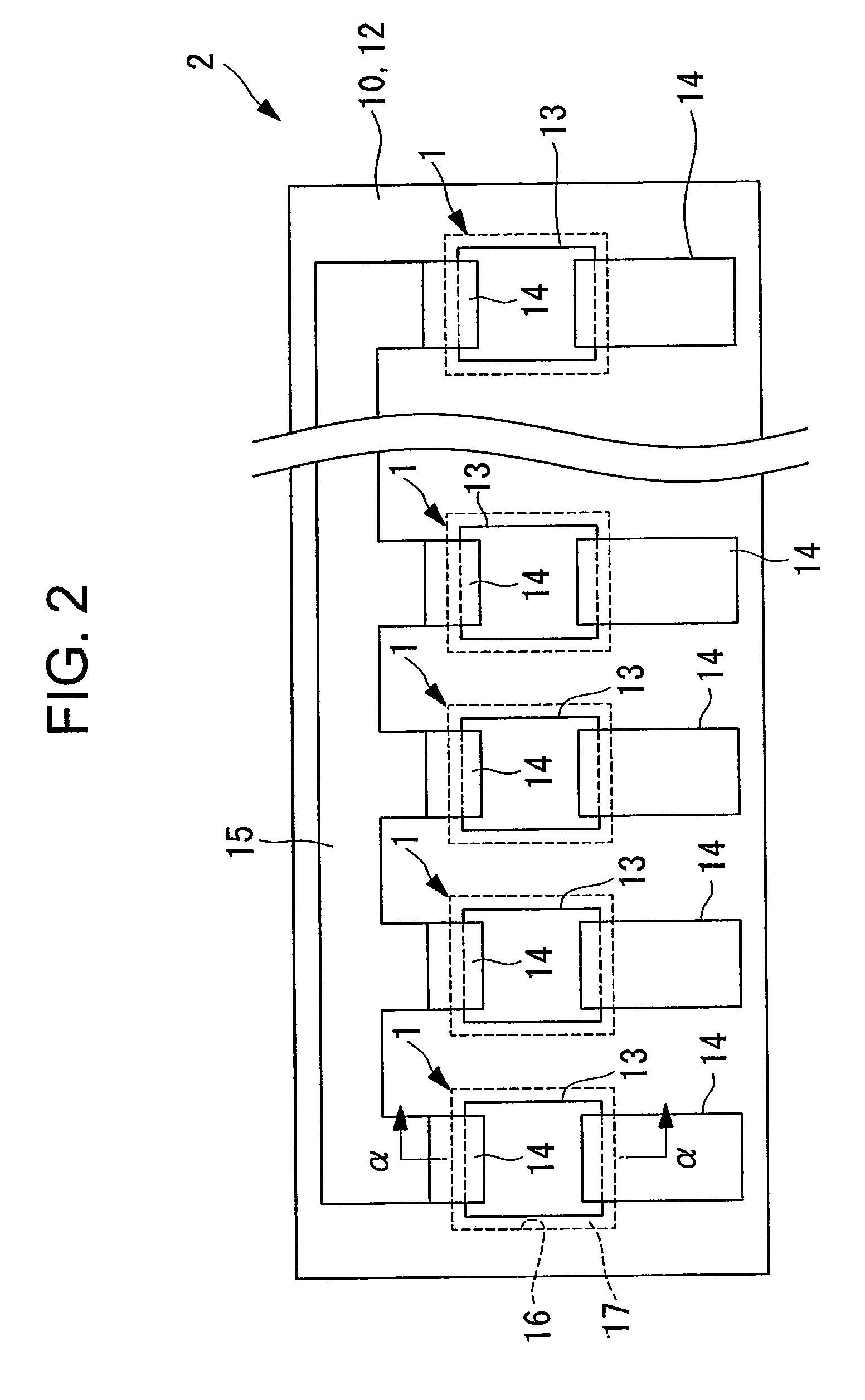

An ink ribbon-print paper cassette is used in a thermal printer. A paper tray accommodates a stack of single sheets of print paper. The paper tray has an opening through which the print paper is fed into a paper path on a sheet-by-sheet basis. An ink ribbon for thermal printing runs over a thermal head located adjacent the paper tray. A housing accommodates the paper tray, thermal head, and ink ribbon therein. When the cassette is loaded into the thermal printer, the outer surface of the cassette and an inner wall of the thermal printer cooperate to form a paper path therebetween through which each of the sheets of print paper is advanced from the paper tray to the thermal head.

Owner:OKI DATA CORP

Phase change memory devices, method for encoding, and methods for storing data

ActiveUS9093141B2Electrical apparatusVariable resistance carrier recordingThermal energyPhase-change memory

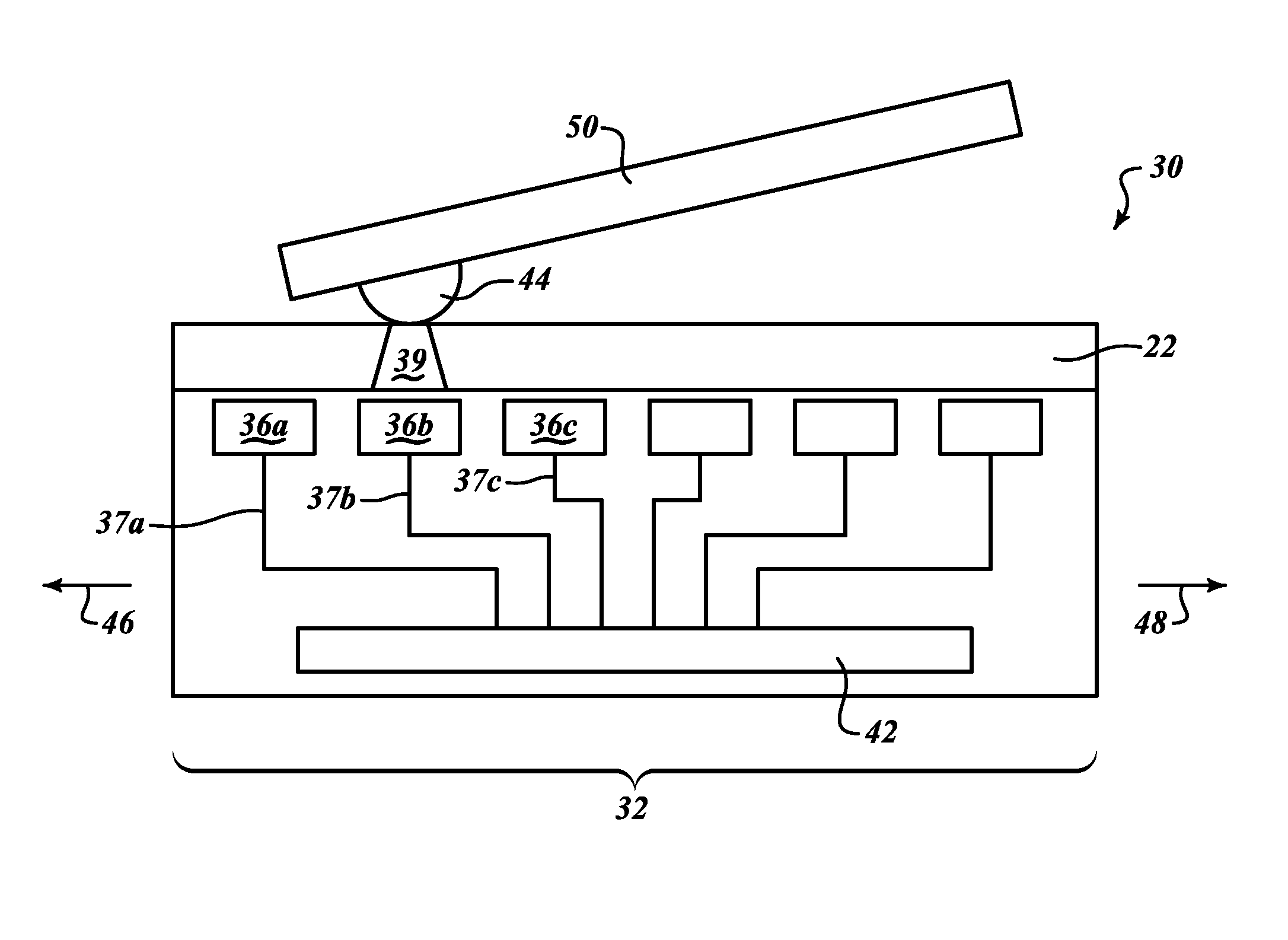

Phase change memory cells including a phase change media can be encoded using a source of energy that is not integral with the memory cell. External sources of energy include thermal heads, such as those used in direct thermal printing or thermal transfer printing and sources of electromagnetic radiation, such as lasers. Such types of phase change memory devices can be associated with substrates that include thermochromic materials or are suitable for thermal transfer printing so that the memory cells can be encoded and print media applied to the substrate using the same source of thermal energy.

Owner:INTERMEC IP CORP

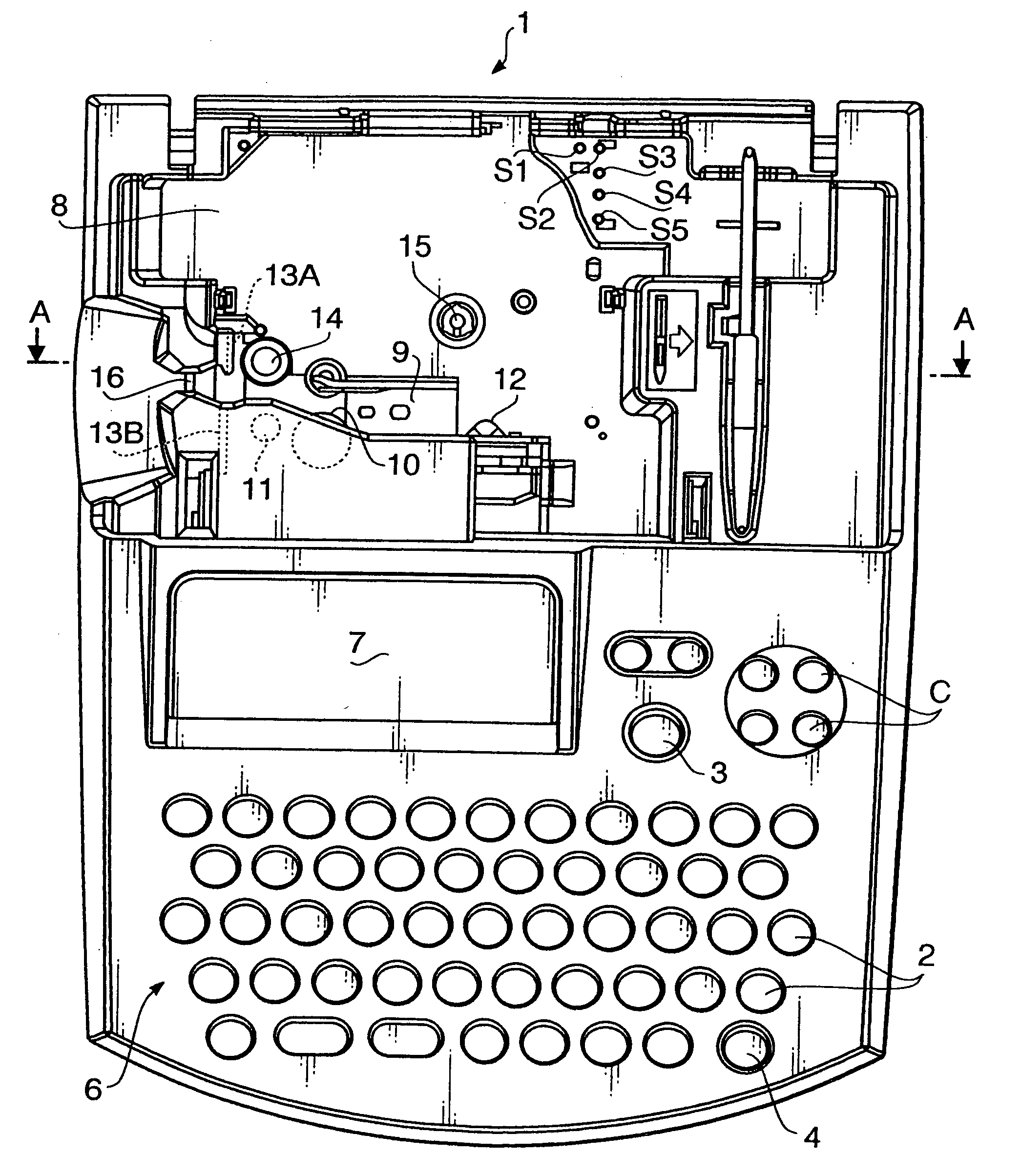

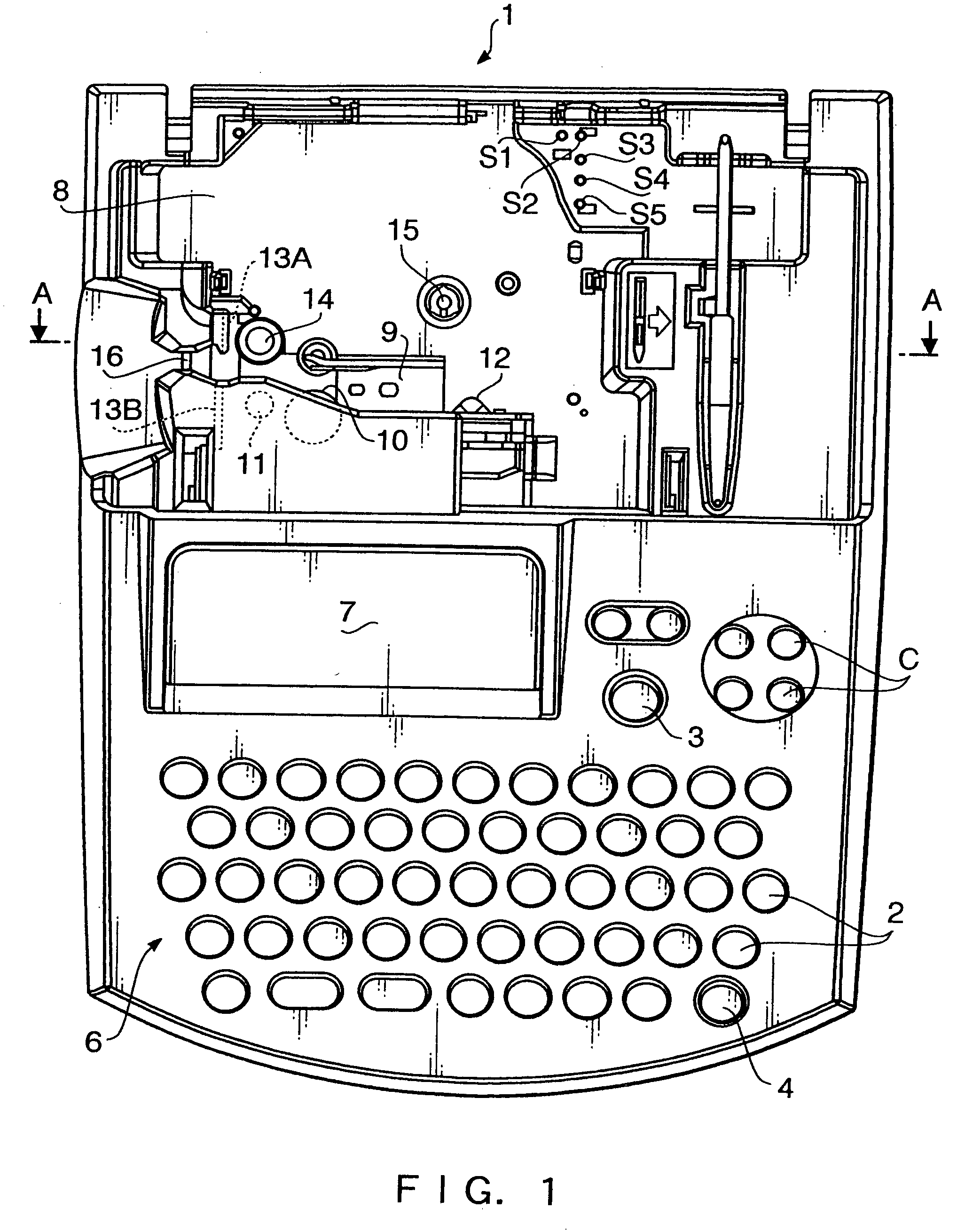

Placing printing elements and mark sensor at proper positions with respect to the cutter member

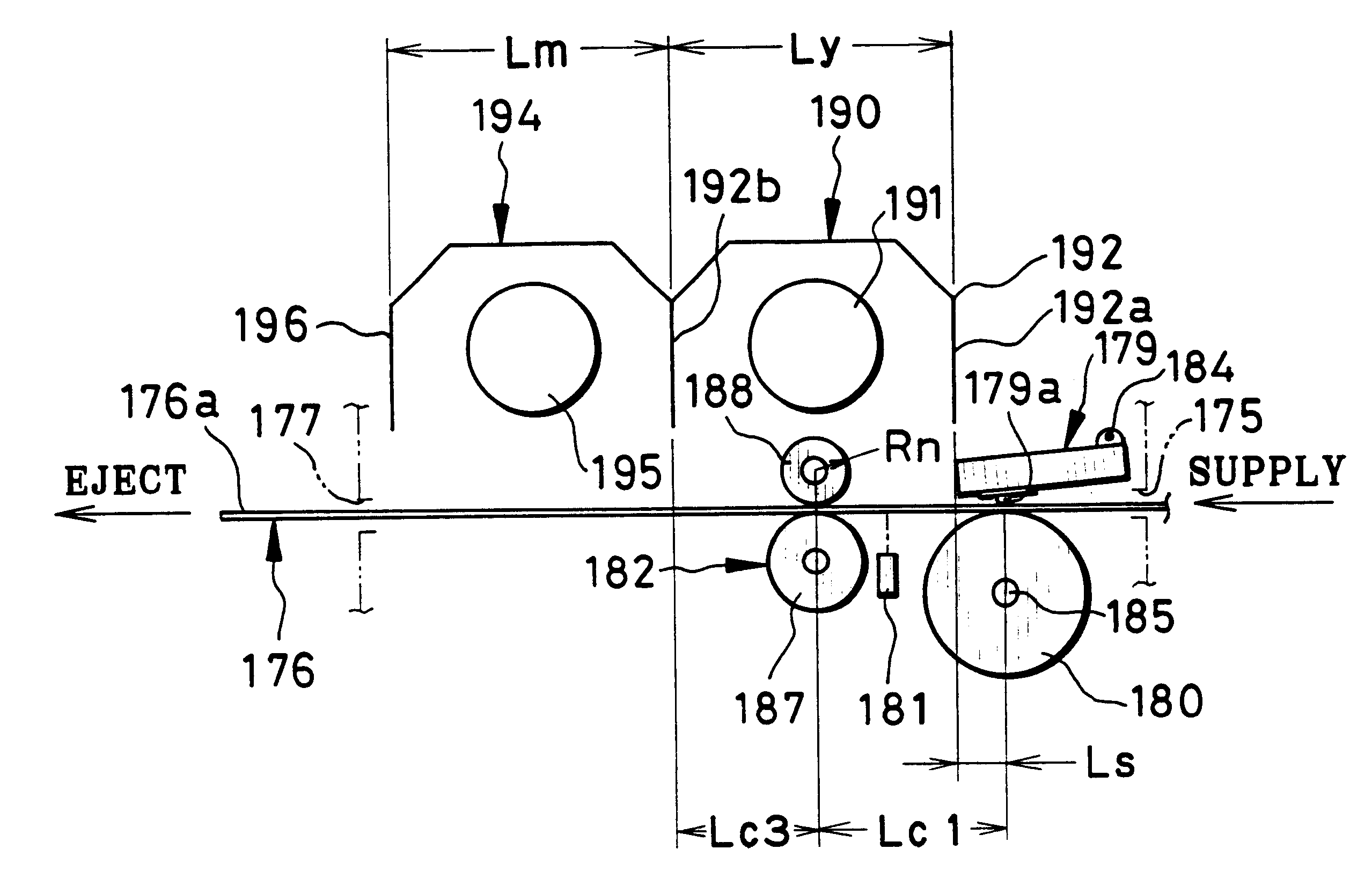

A tape printer, wherein when a label tape (36) is fed to a tape cutting position after the label (39) of the label tape (36) is printed out, the heating elements (R1 to Rn) of a thermal head (9) are disposed so as to be opposed to the position of a next printed label (39) slightly on the upstream side of a label head position on the downstream side of thereof in the feeding direction and to be opposed to the position of the next printed label (39) on the downstream side of the printing start position thereof (so that a<b can be established in FIG. 7), and a mark detection sensor (12)is disposed on the upstream side of the heating elements (R1 to Rn) so as to be opposed to the position slightly on the downstream side of the position opposed to a position detection mark (39B) (so that c<e can be established in FIG. 7).

Owner:BROTHER KOGYO KK

Ink jet printer and ink jet printing method

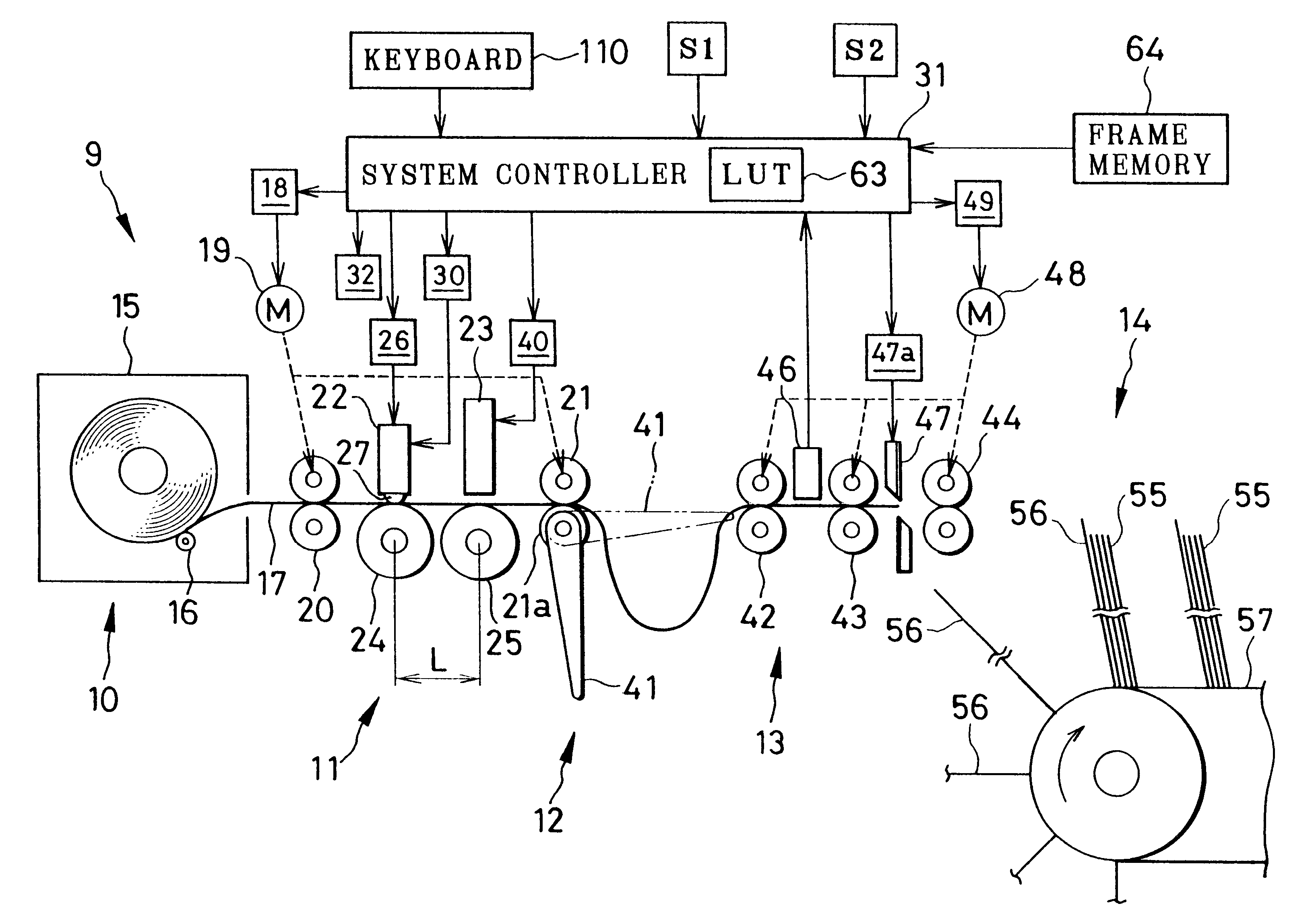

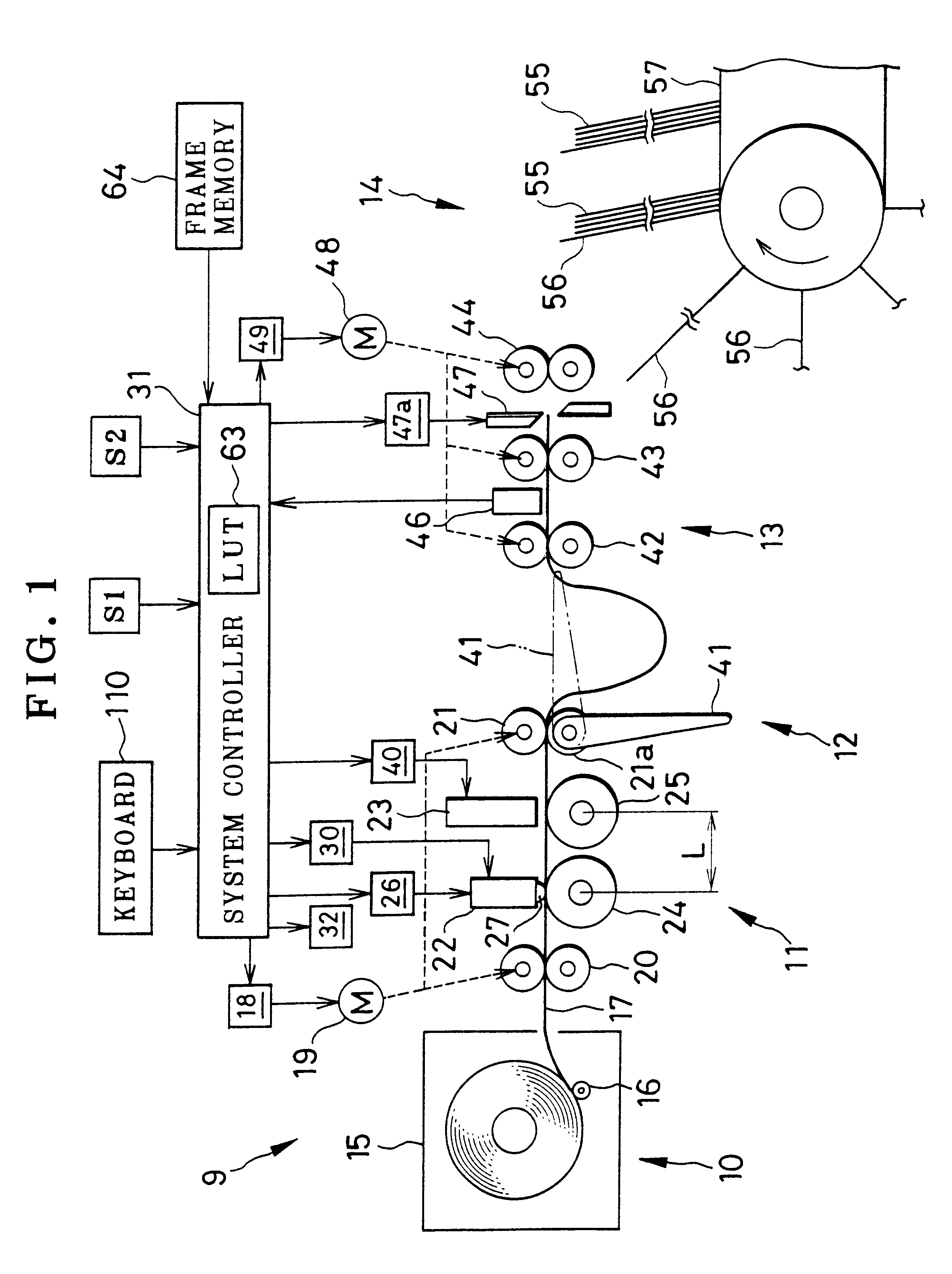

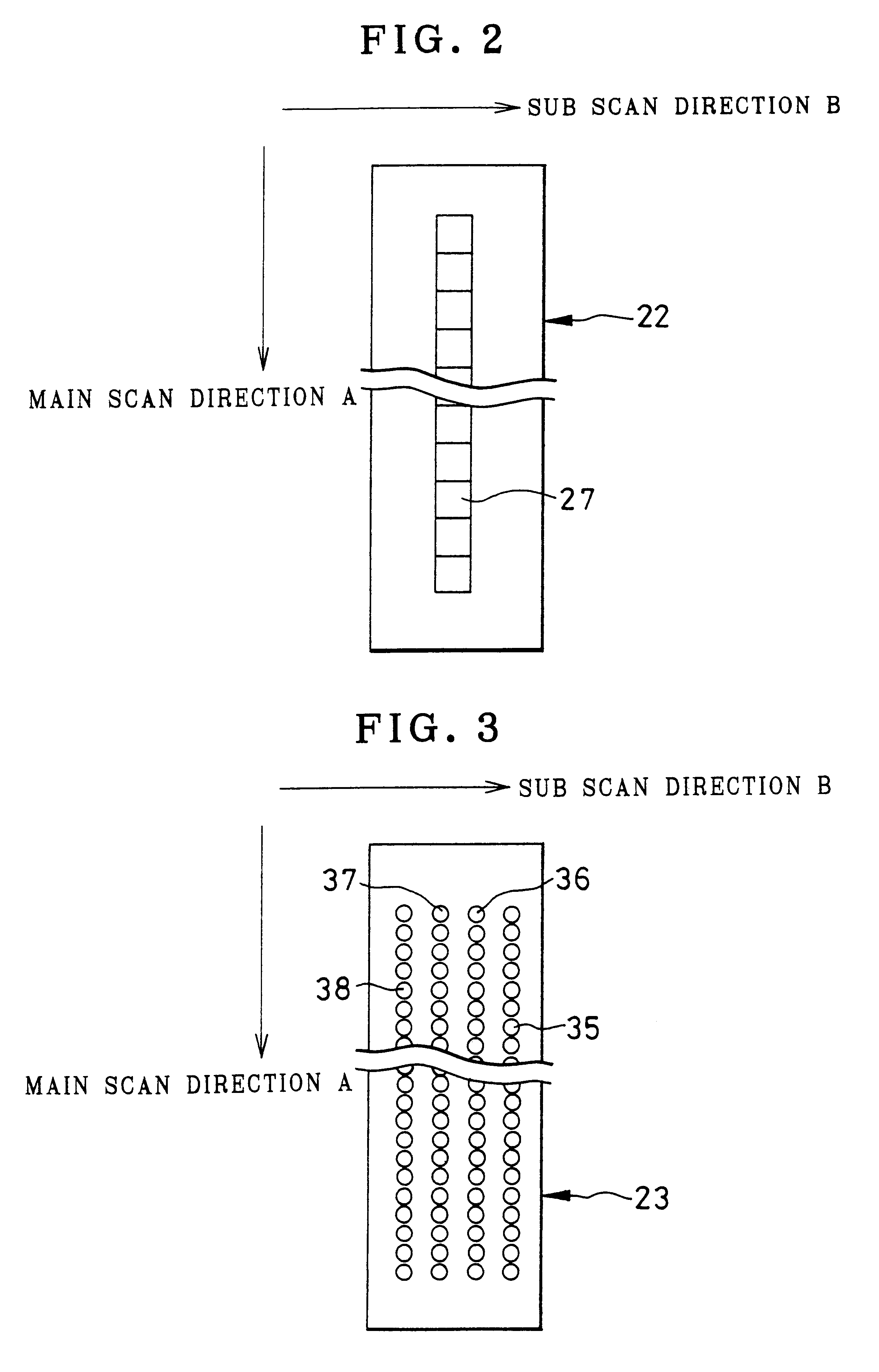

An ink jet printer comprises at least one ink jet head, in which plural nozzles are arranged in an array in a main scan direction, and eject a droplet of ink to recording material respectively at an ejected amount according to information of an image. Feeder rollers feed the recording material relative to the ink jet head in a sub scan direction, to print the image to the recording material two-dimensionally. A thermal head includes plural heating elements arranged in an array in the main scan direction, for applying heat to the recording material respectively in a heating region. A system controller sets drying heat energy according to the ejected amount, and drives the thermal head to apply the drying heat energy to the heating region, to promote drying of the droplet in the heating region.

Owner:FUJI FILM CO LTD +1

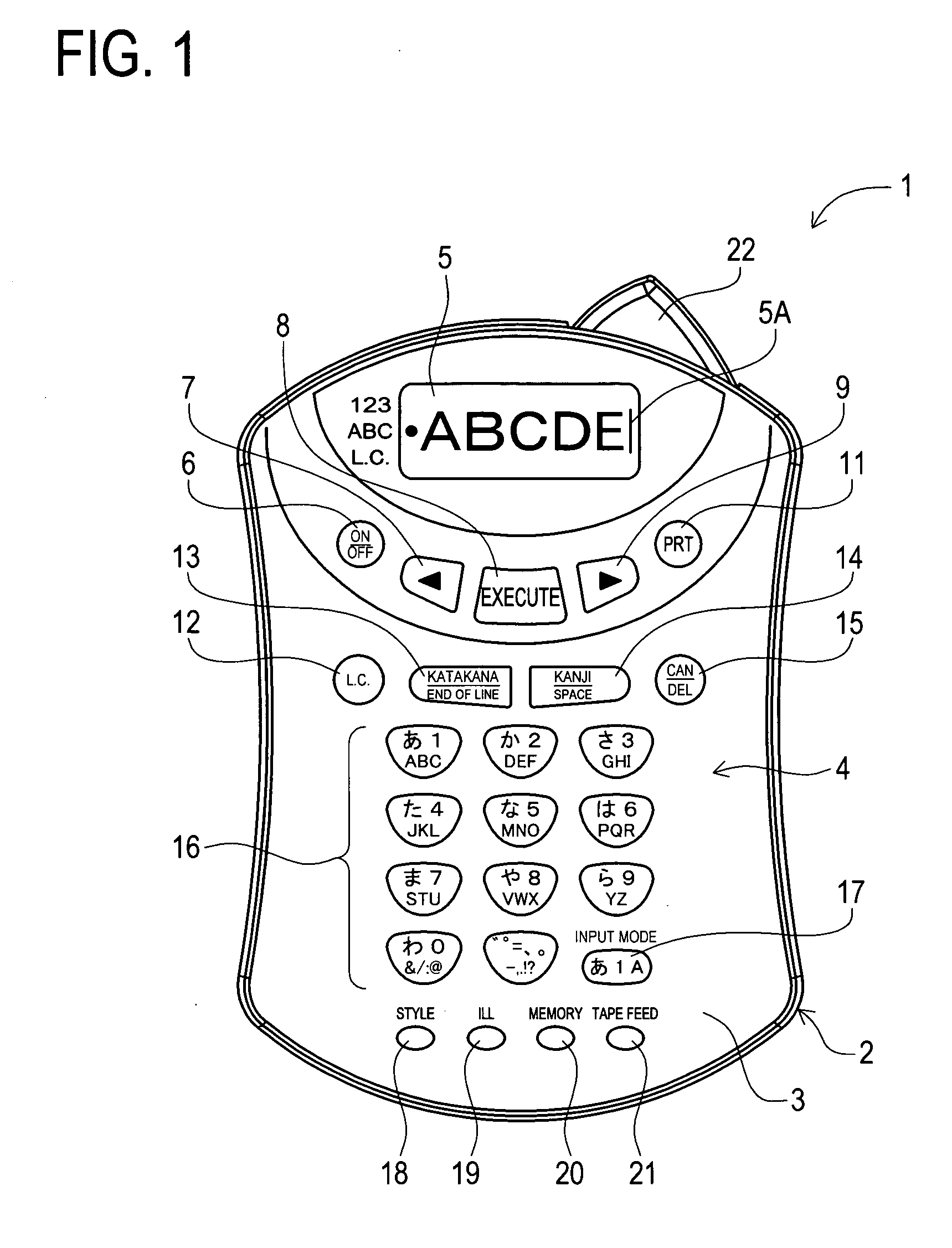

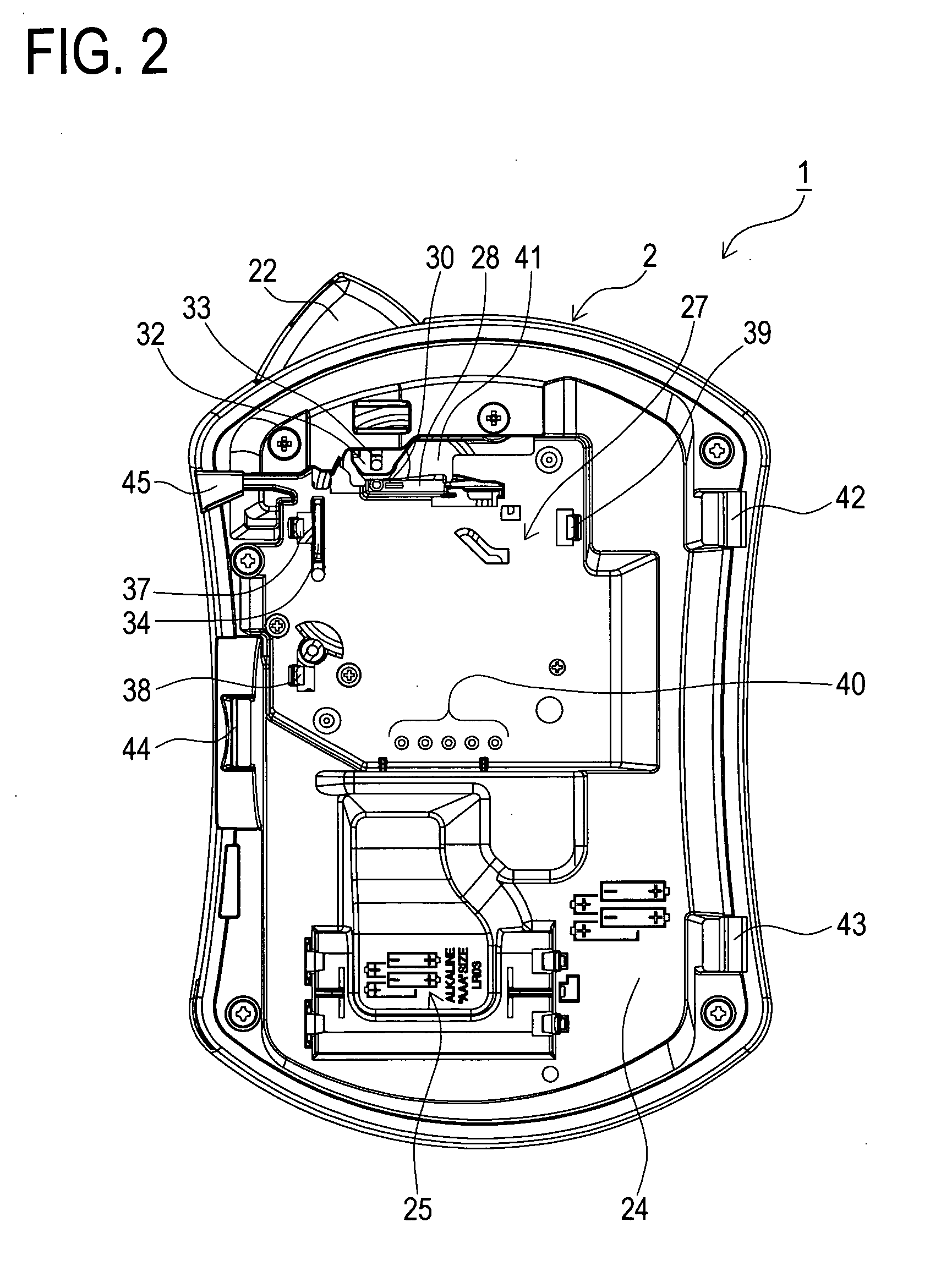

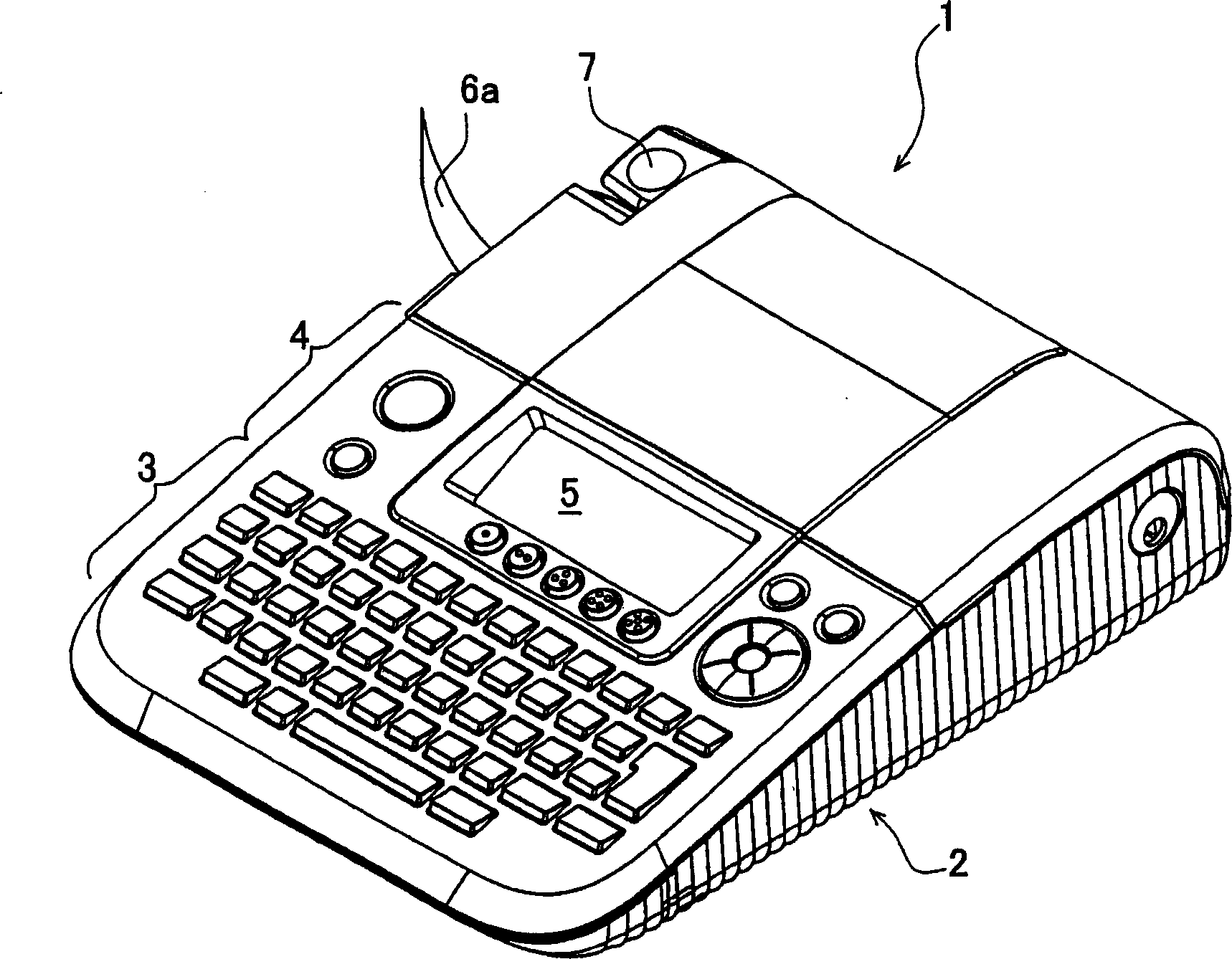

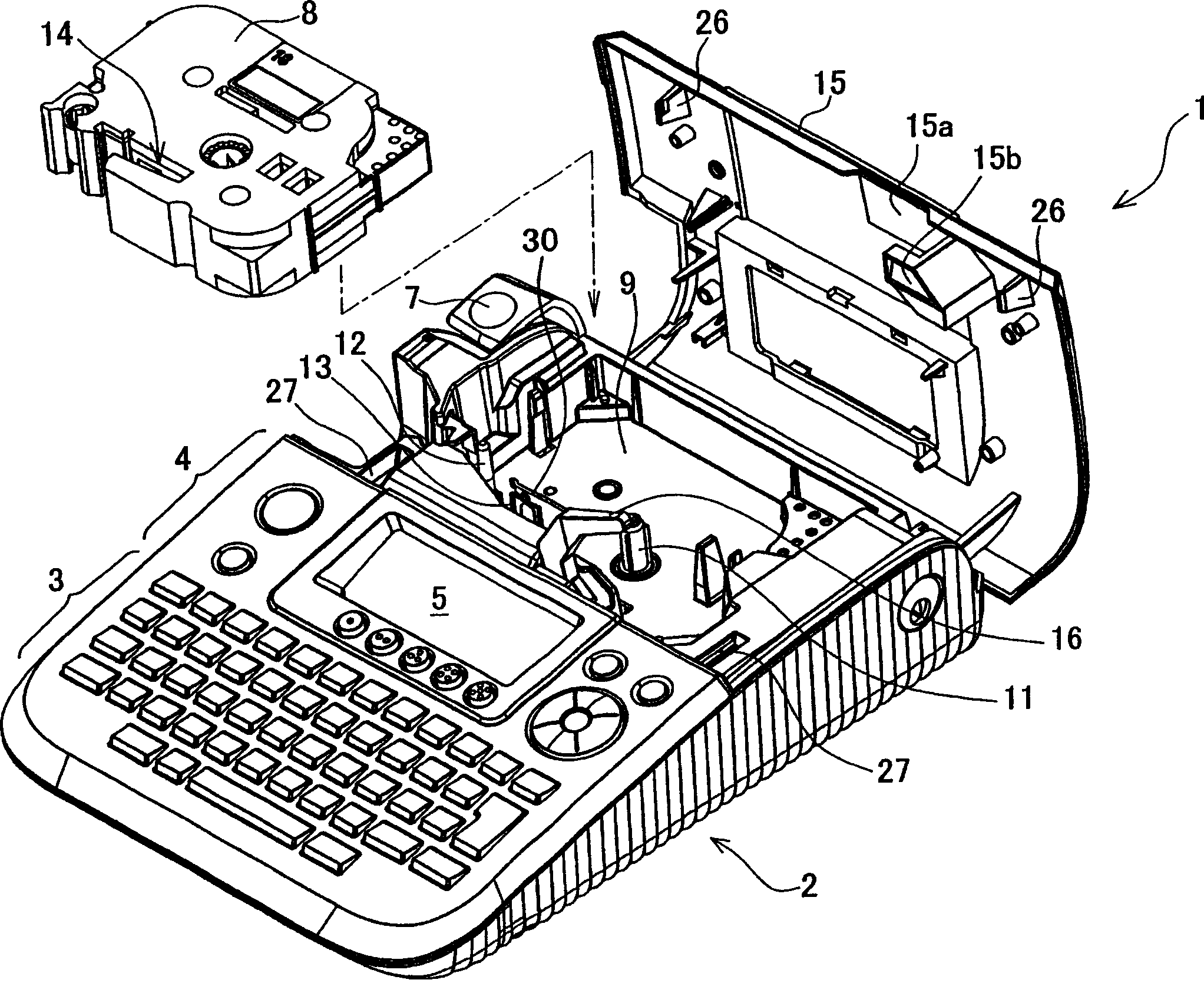

Tape printing device and tape cassette

InactiveUS20070009306A1Enabling detectionTypewritersOther printing apparatusMagnetic tapeThermal Head

When a label tape 36 after the printing on a label 39 has been fed to a tape cutting position, heating elements R1-Rn of a thermal head 9 is situated to face a position slightly on the upstream side of a label front end position (at the downstream end in the feeding direction) of the next label 39 which will be printed on next and to face a position on the downstream side of a print start position of the next label 39 (a<b in FIG. 7), and a mark sensor 12 is situated on the upstream side of the heating elements R1-Rn and to face a position slightly on the downstream side of a position indication mark 39B (c<e in FIG. 7).

Owner:BROTHER KOGYO KK

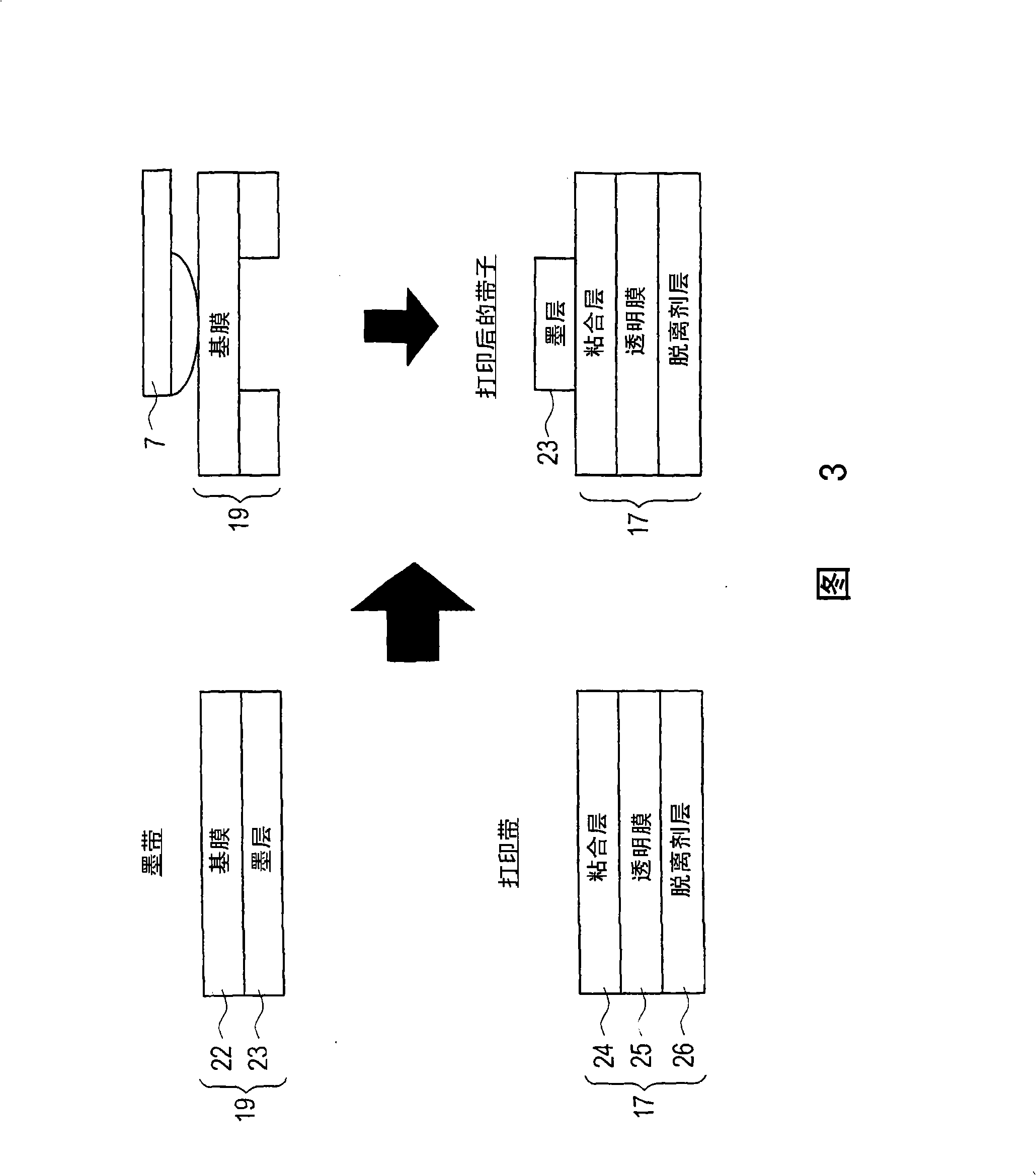

Lettering tape, tape cassette, tape printer

A lettering tape is formed having an integrated layered configuration in which a base layer, an ink layer, and an adhesive layer exhibiting adhesive properties when heated are sequentially stacked. When the lettering tape is selectively heated by a thermal head to form an image thereon, the heated portion of the ink layer onto which an image has been formed is adhered to the heated portion of the adhesive layer and simultaneously, the heated portion of the adhesive layer exhibits self-adhesive properties, thereby enabling transfer to the target transfer body.

Owner:BROTHER KOGYO KK

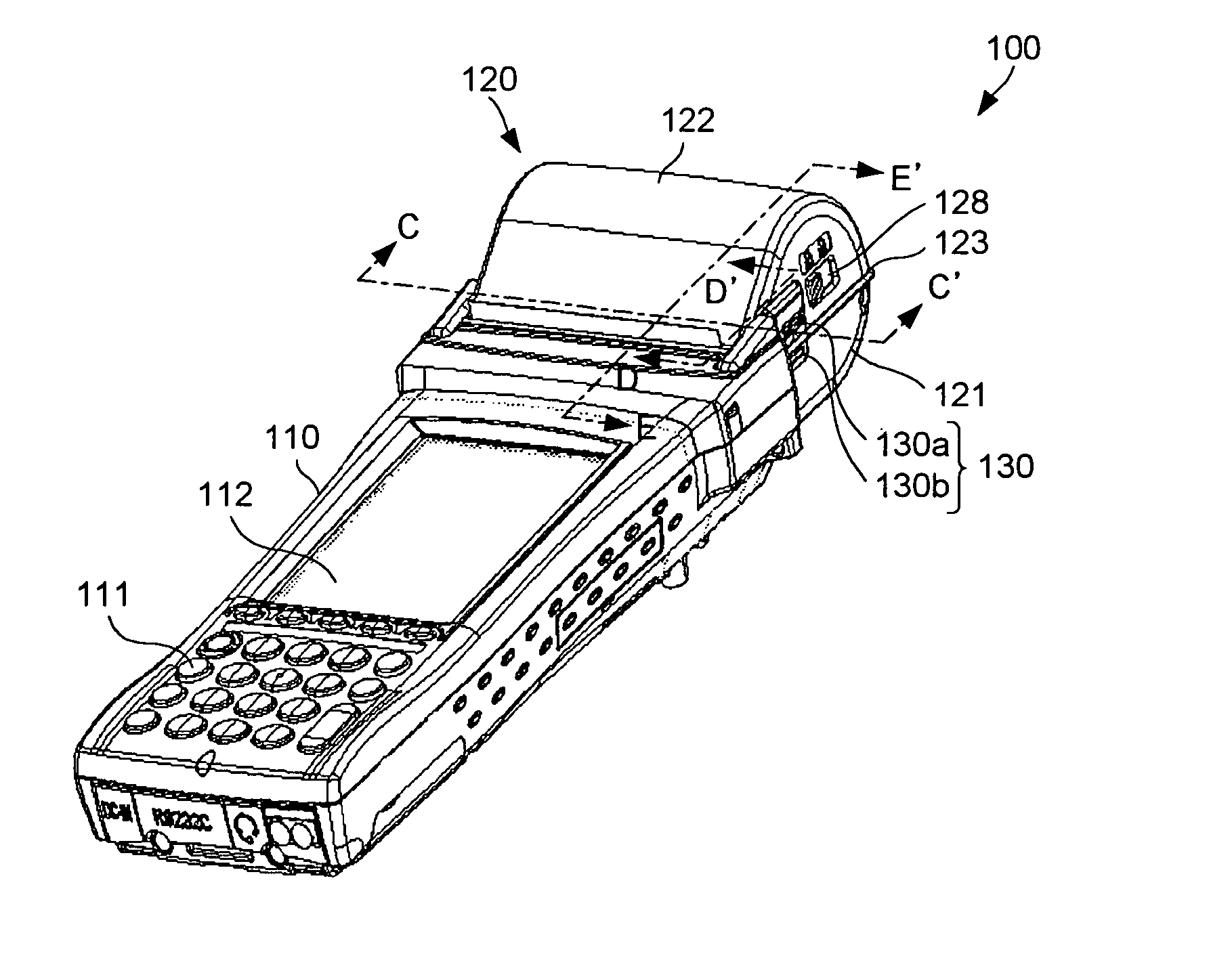

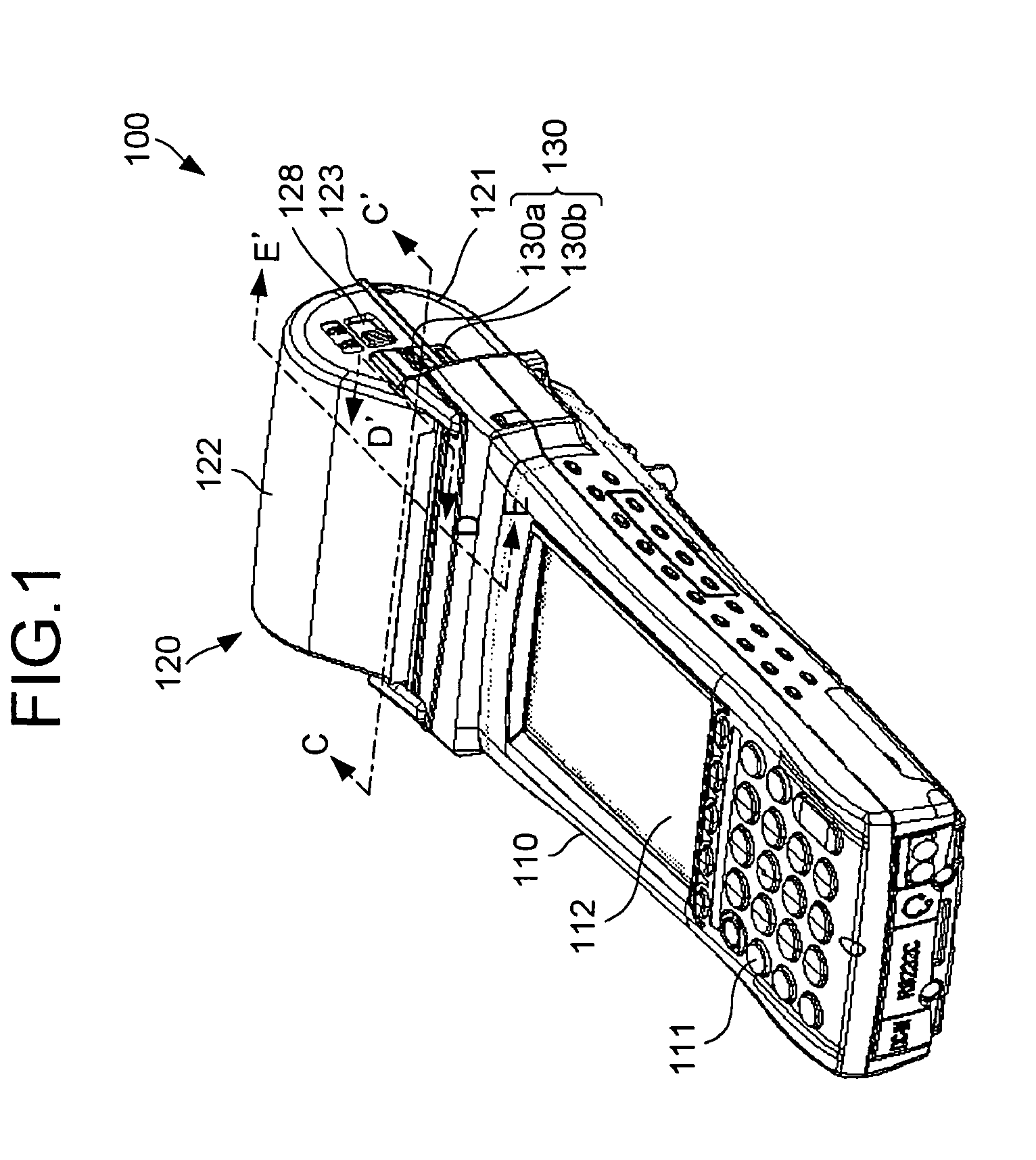

Handy thermal head printer

A printer has a main body and a printer unit that is fixed to the main body. The printer unit has an upper cover and a lower cover. The lower cover is attached to the main body and the upper cover is fixed to the lower cover. A hollow space is formed between the upper and lower covers and a printing paper is set in this space. A sensor is provided in the upper cover and it detects a mark on the non-printable surface of the printing paper. One protrusion is provided in each of the upper and lower covers such that the protrusions make an electrical contact when the upper and lower covers are closed. A control unit is provided in the main body and it is electrically connected to the mark detection unit through the protrusions on the upper and lower covers and it controls various operations of the printer.

Owner:FUJITSU FRONTECH LTD

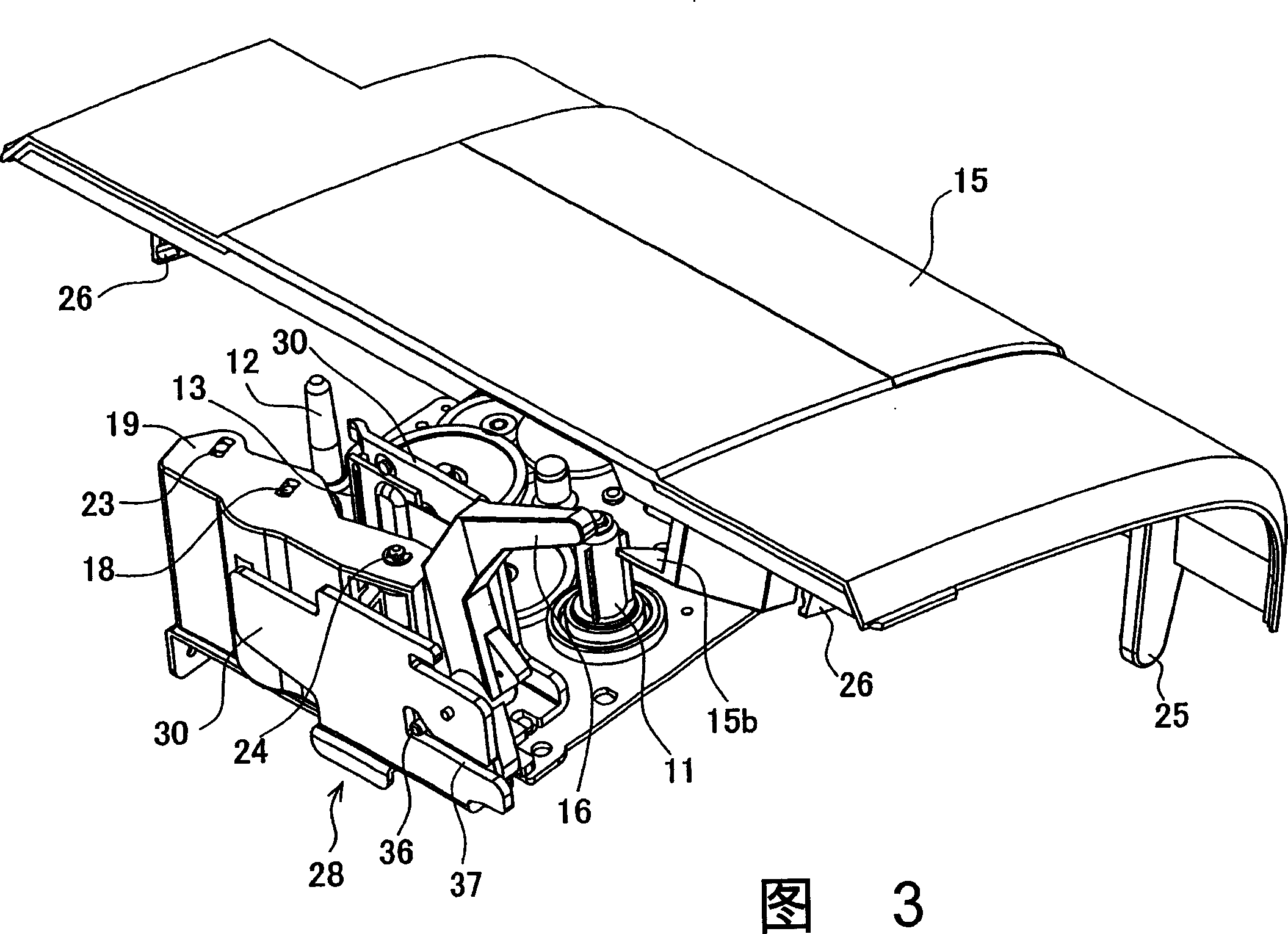

Tape printer

It is intended to provide a tape printer which enables to forcibly separate a platen roller and a print head along with an opening movement of a cover element in case the platen roller and the print head have adhered to each other because of a long-period storage of the tape printer with the platen roller and the print head being in contact. Accordingly, a cam pressing member and a cam receiver move a roller holder to a withdrawing position in which the platen roller and a thermal head are separated from each other when the cover element is opened, so that the cam pressing member and the cam receiver can be forcibly returned to the withdrawing position from a position in which the platen roller is in contact with the thermal head.

Owner:BROTHER KOGYO KK

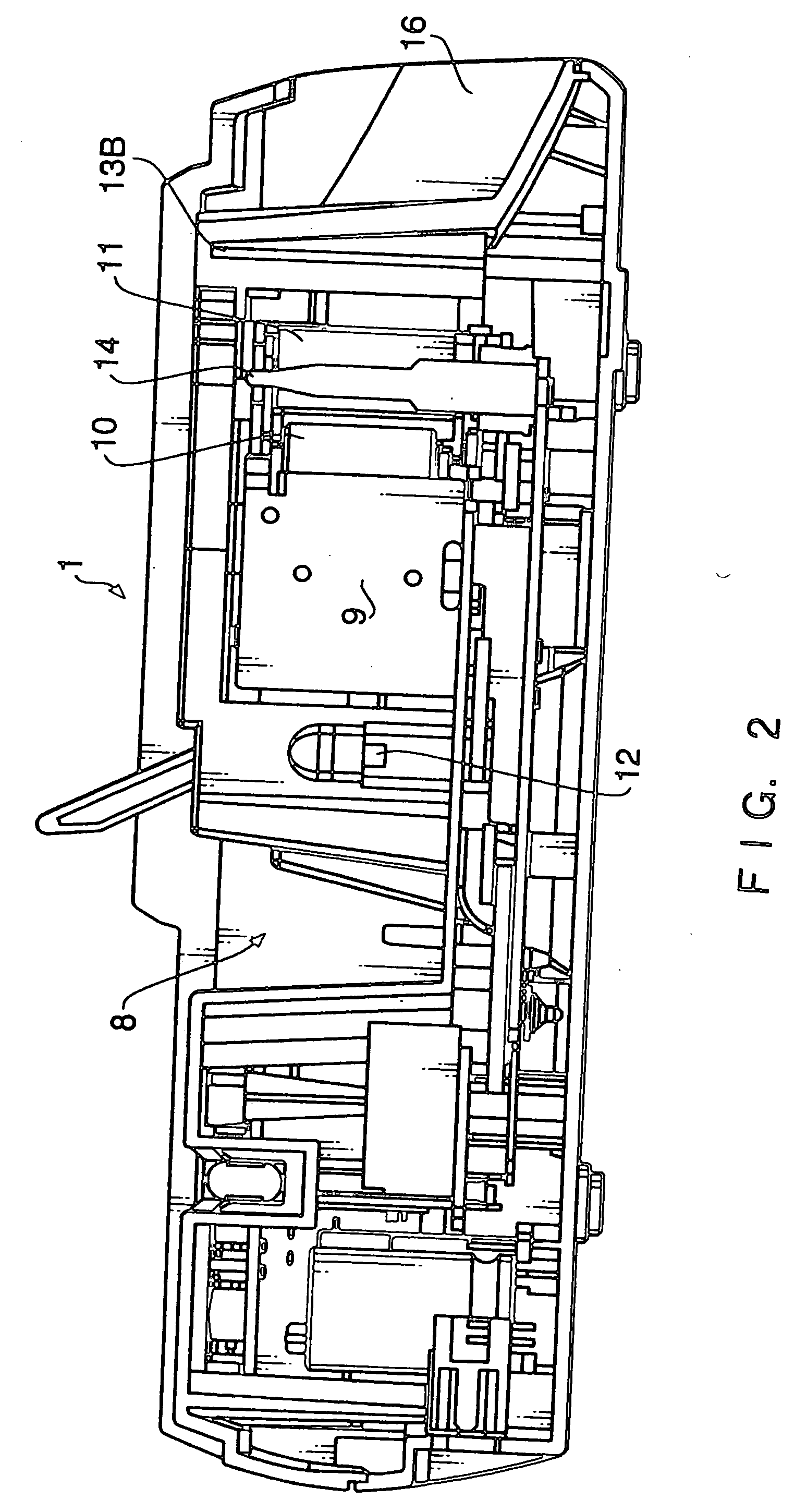

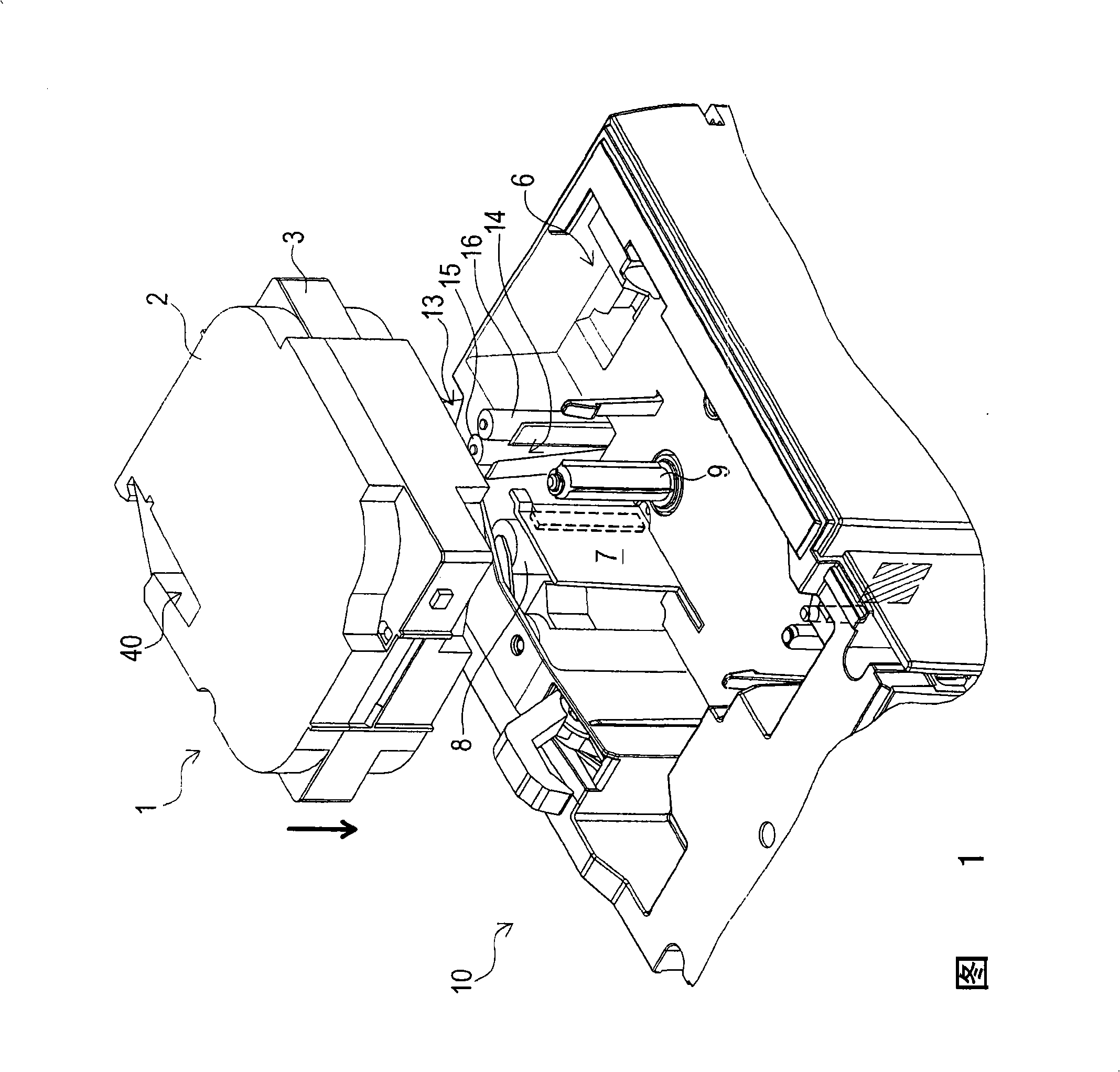

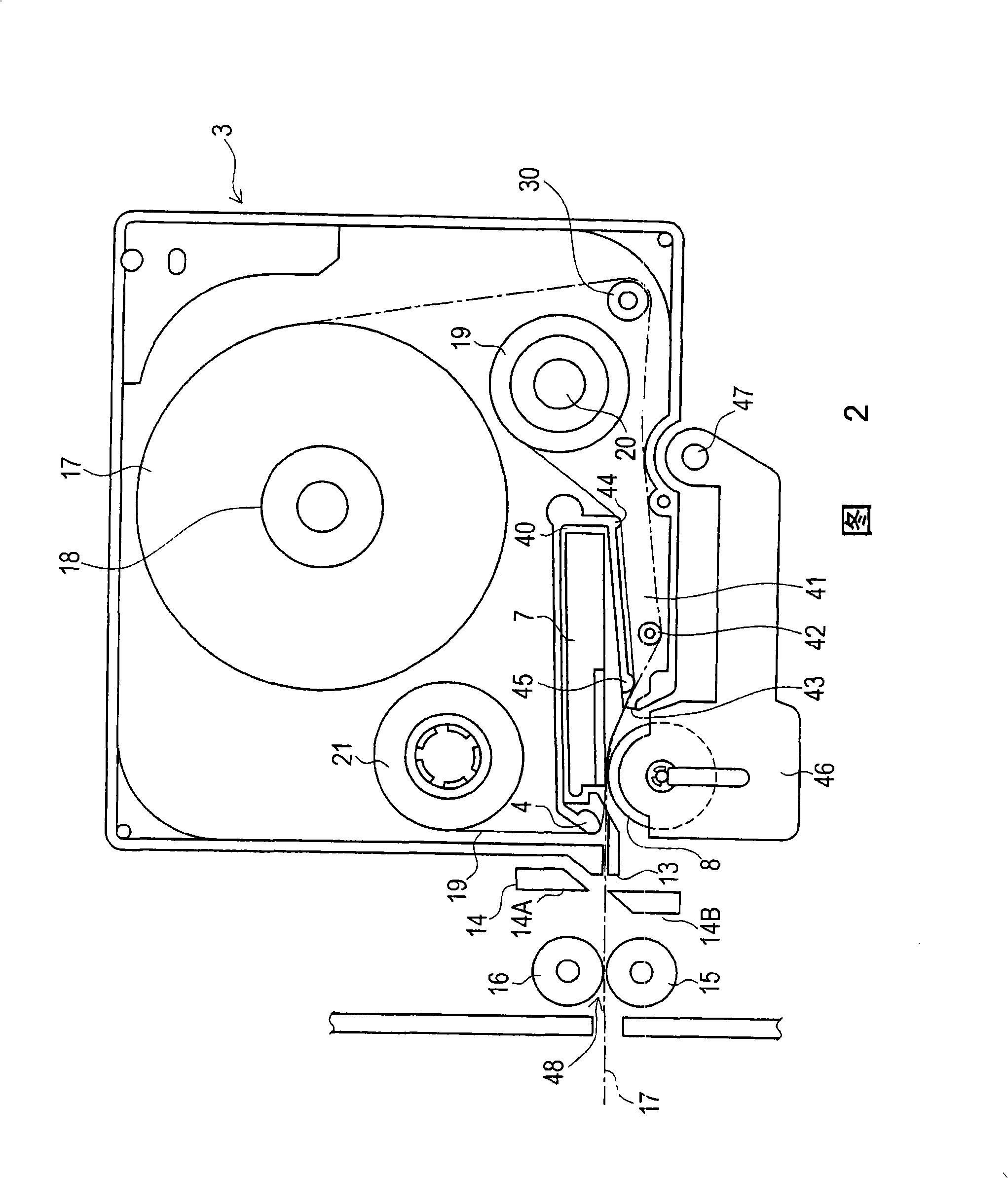

Tape cassette and tape printer

A tape cassette includes an ink ribbon provided with a base film coated with an ink layer thereon and a film tape provided with a transparent film with an adhesive layer formed on one surface thereof. When an adhesive layer of the film tape and the ink layer of the ink ribbon of the tape cassette into contact at a print position, the ink layer is adhered onto the adhesive layer on condition that the adhesive layer is heated to exhibit self-adhesive properties, and characters and the like are printed on the film tape. At a tape printing apparatus with the tape cassette mounted thereon, by arranging a cutter unit immediately downstream the thermal head, a post-printing tape is cut promptly after printing.

Owner:BROTHER KOGYO KK

Printer

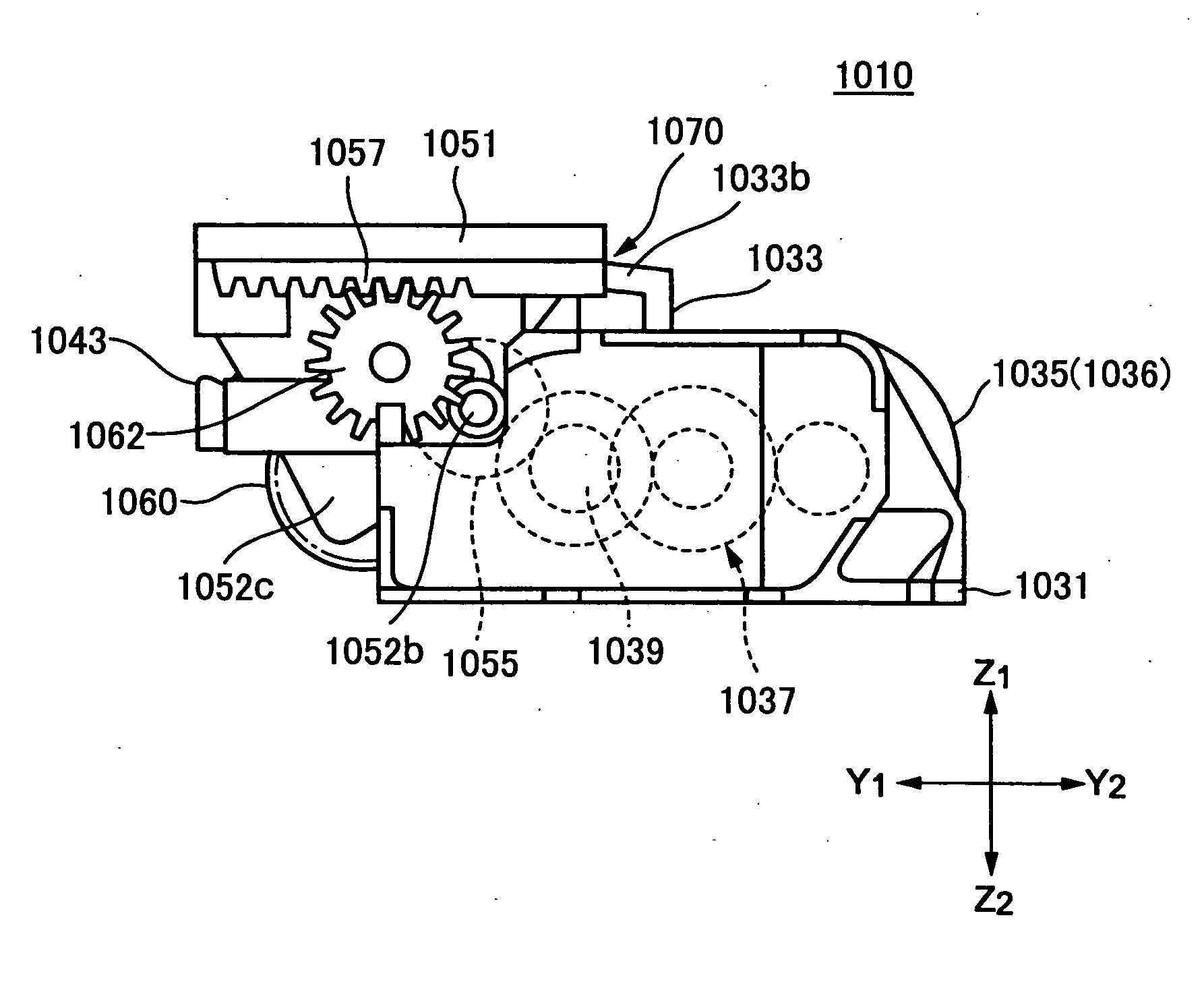

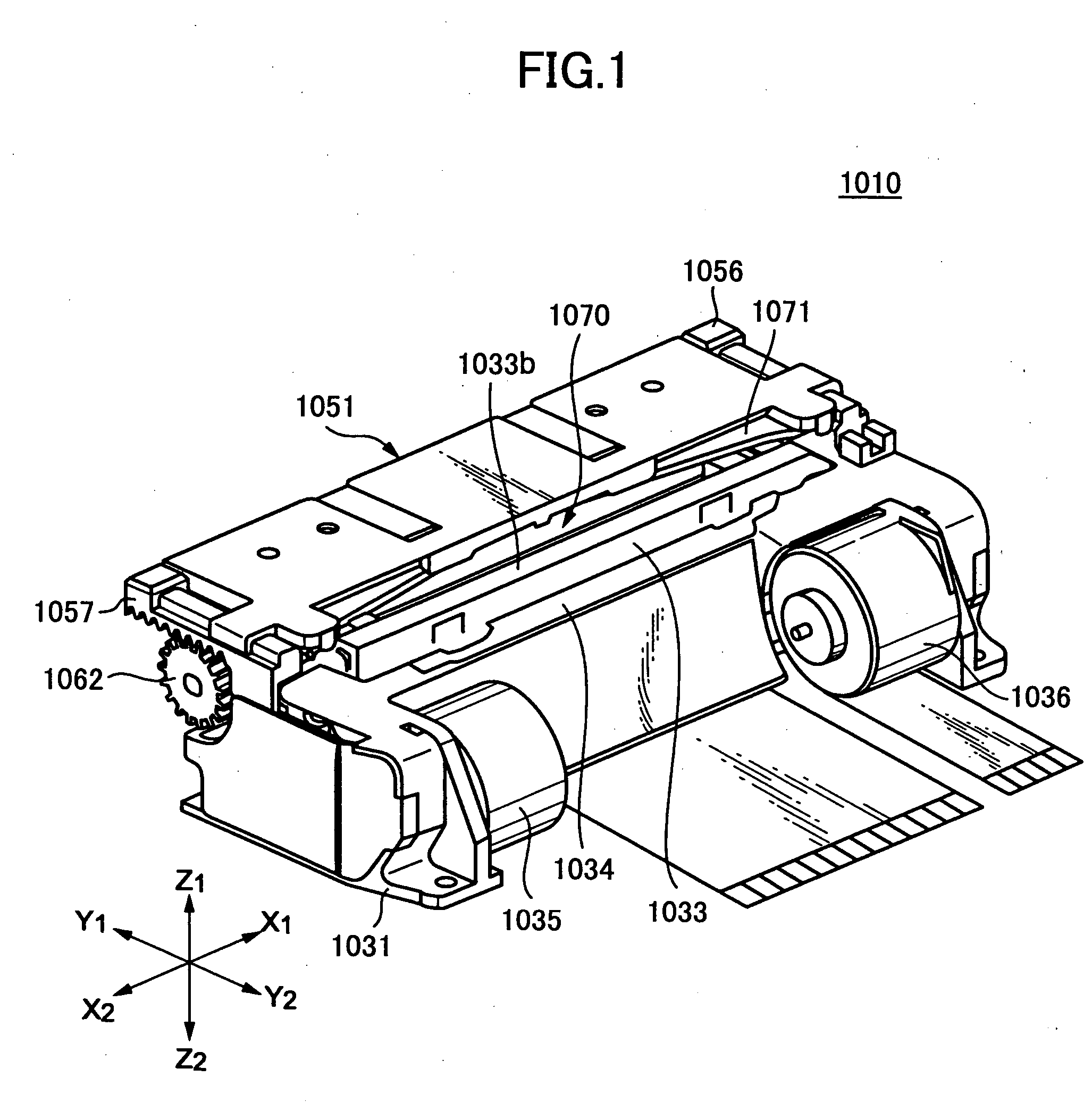

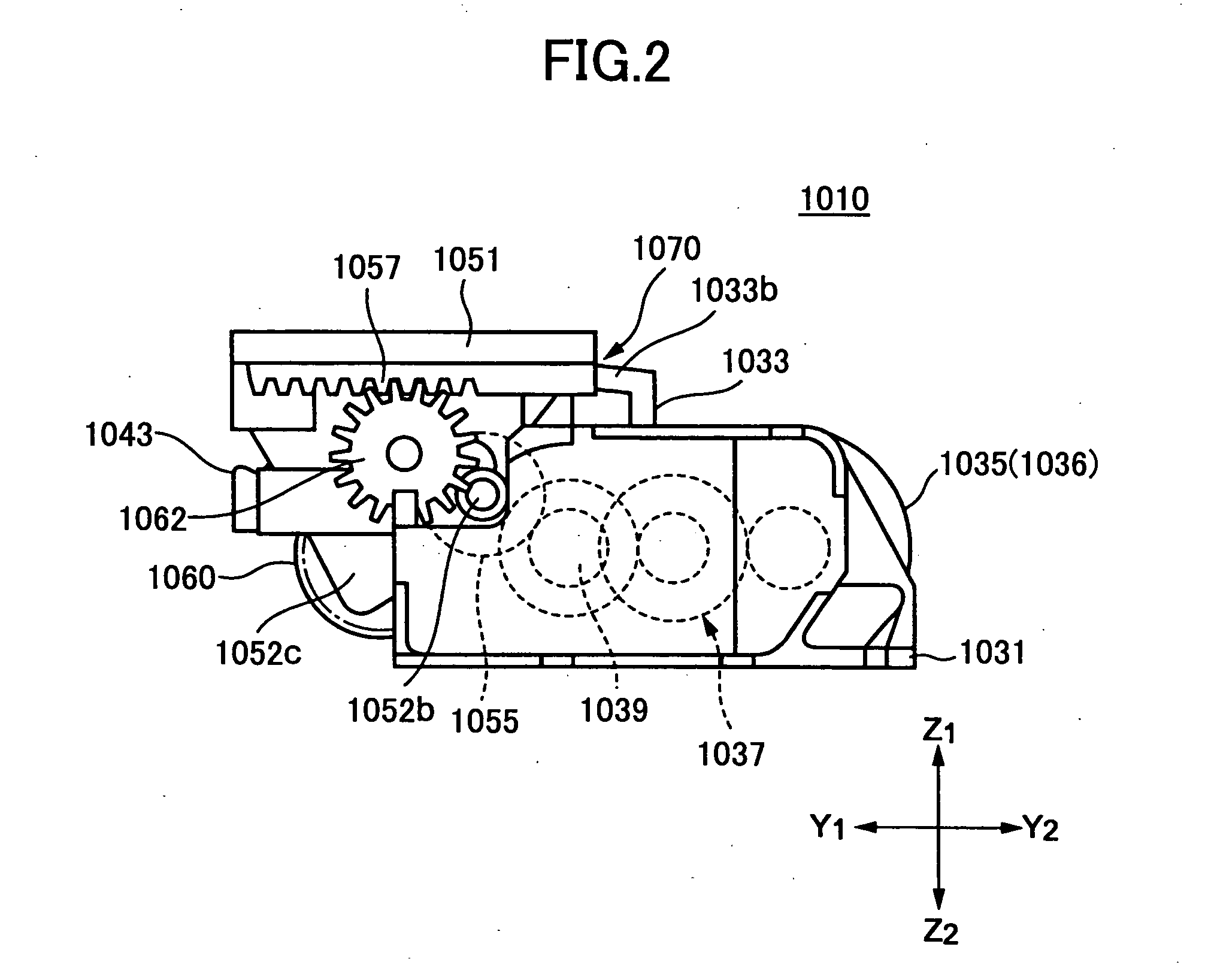

ActiveUS20080056793A1Small sizeEffectively availableRecording apparatusInk ribbonsColor imageEngineering

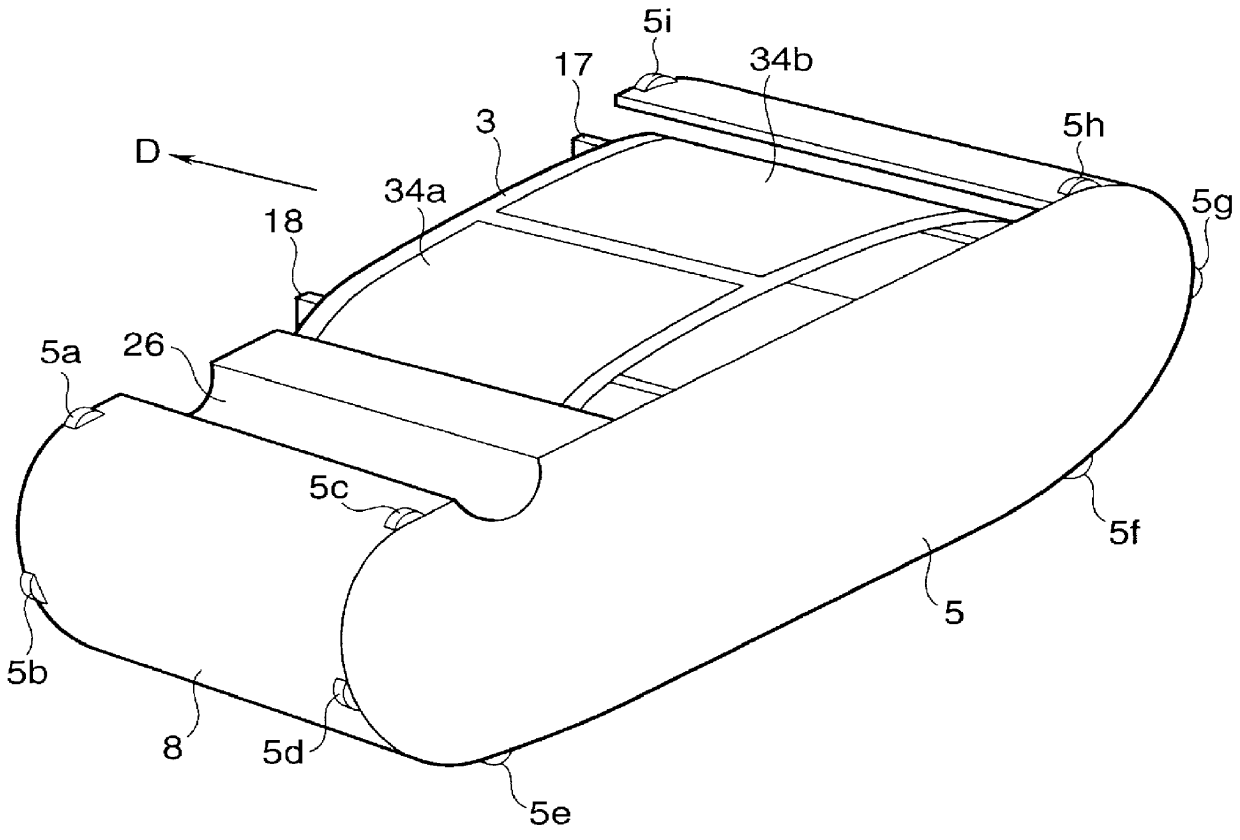

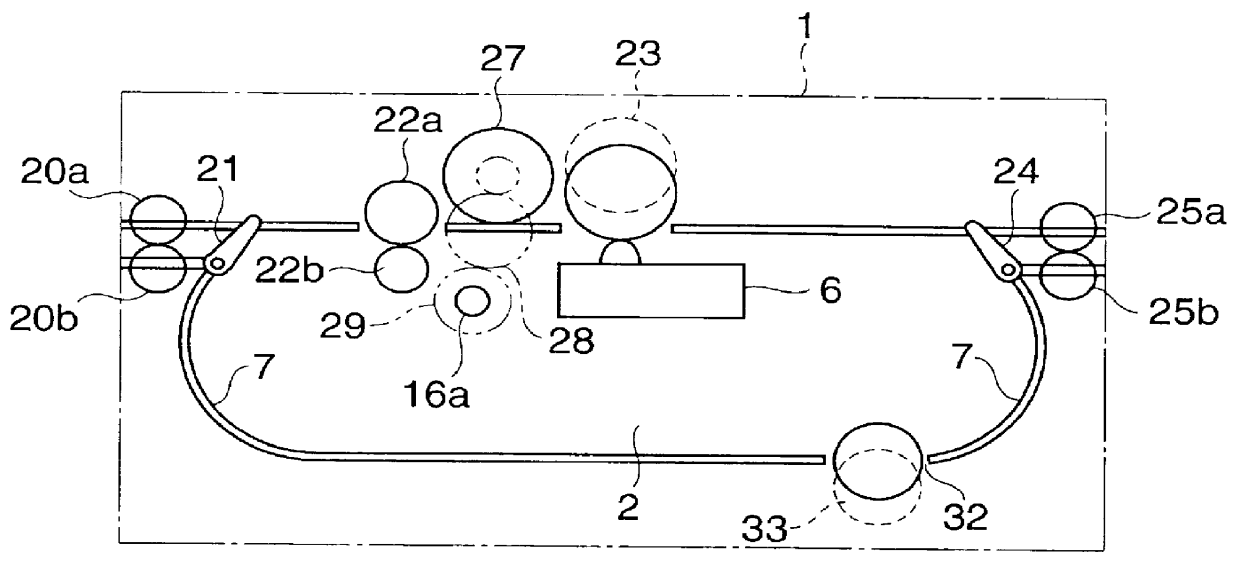

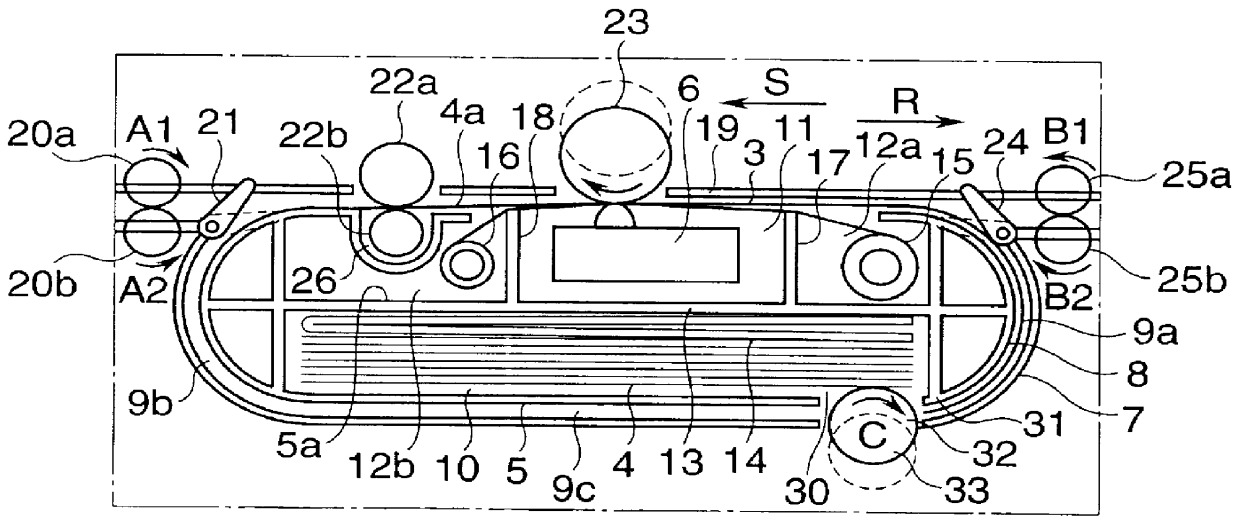

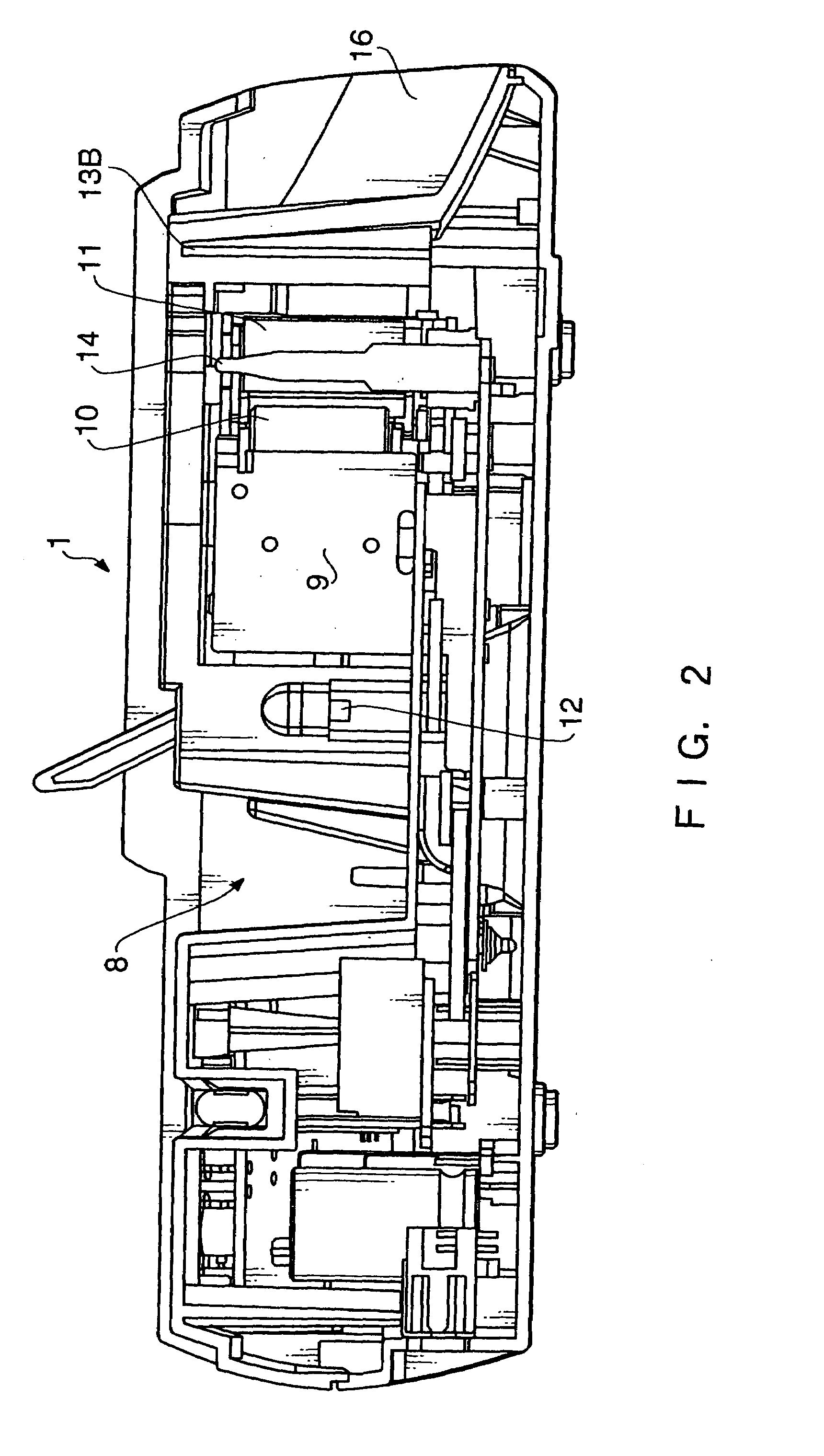

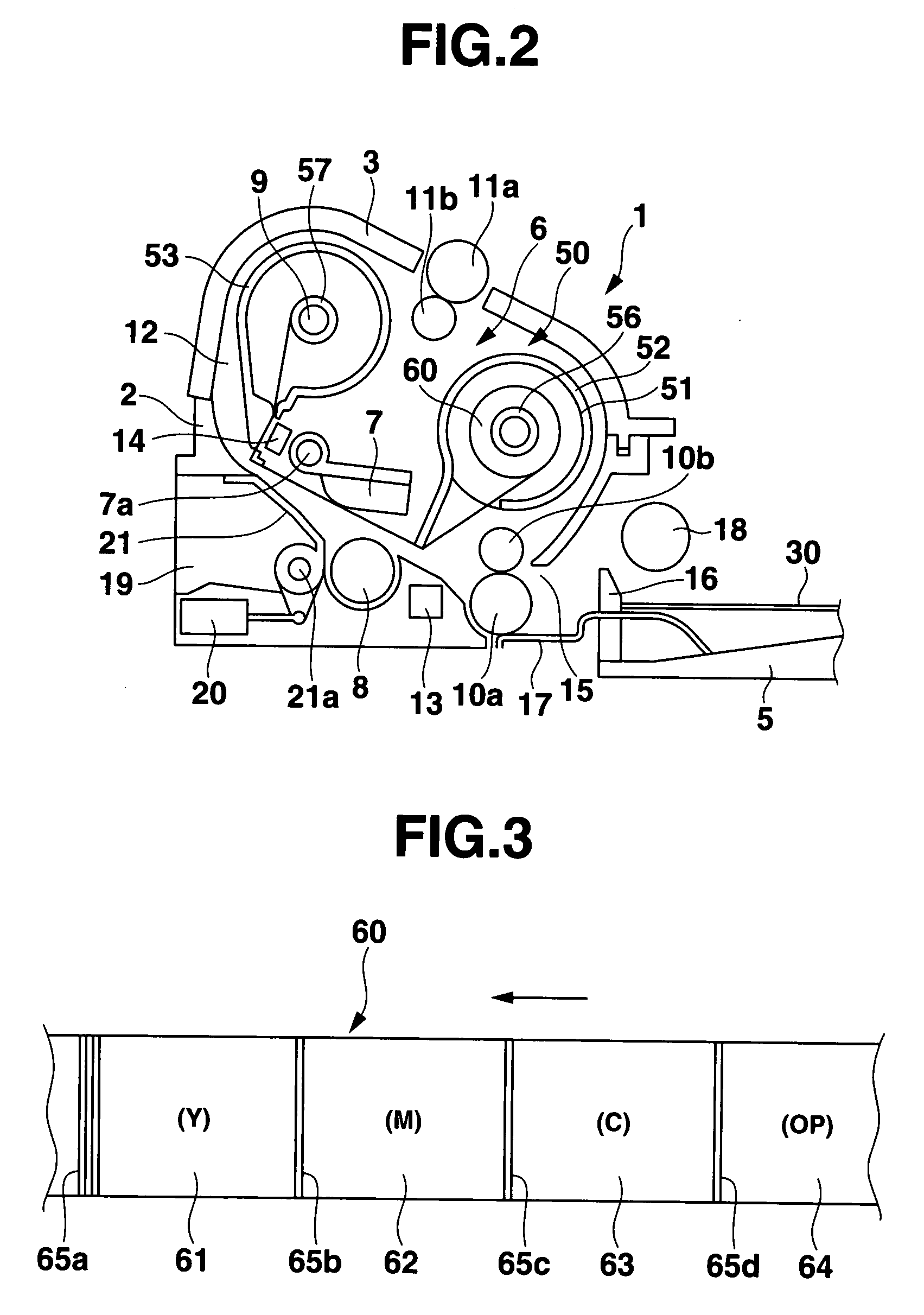

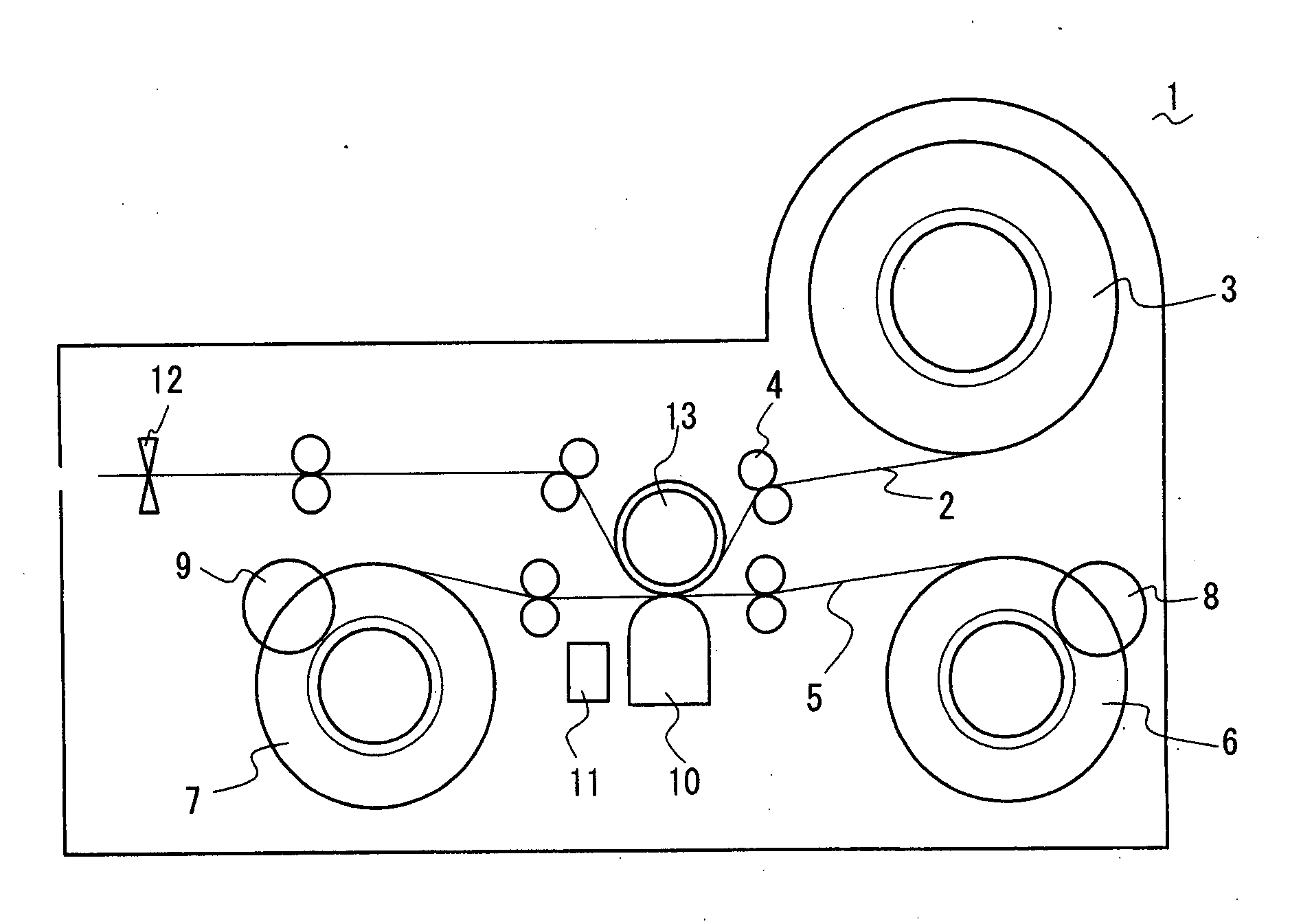

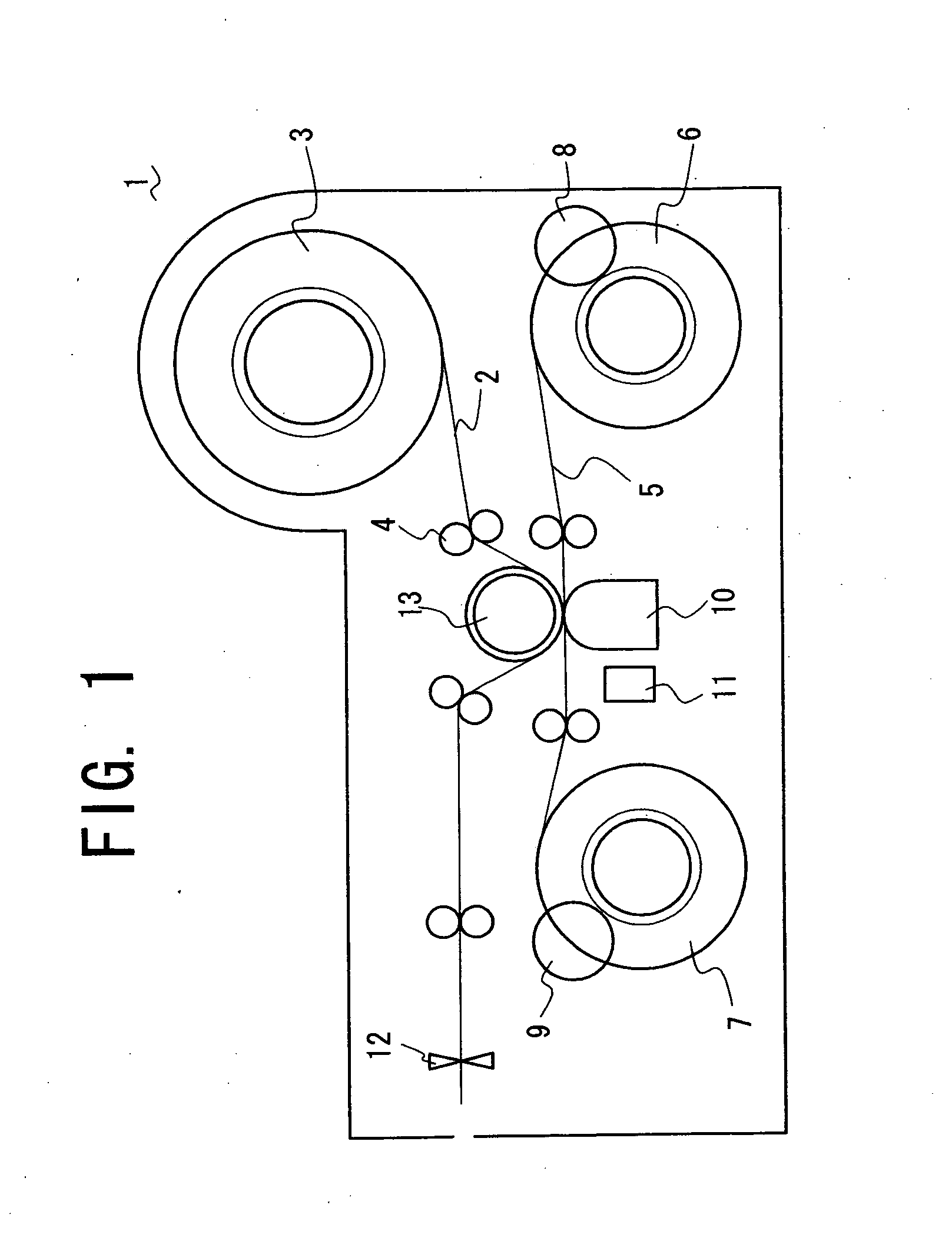

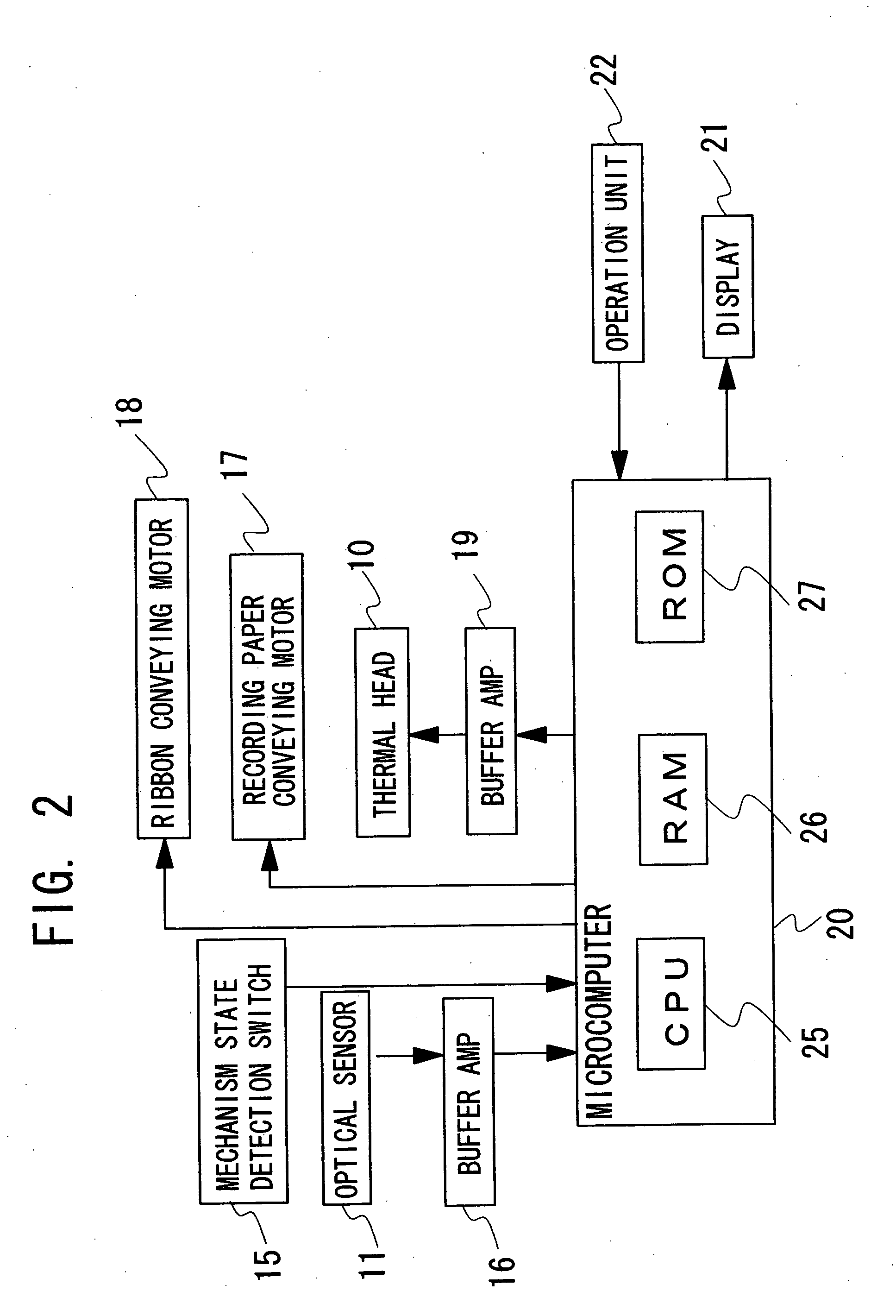

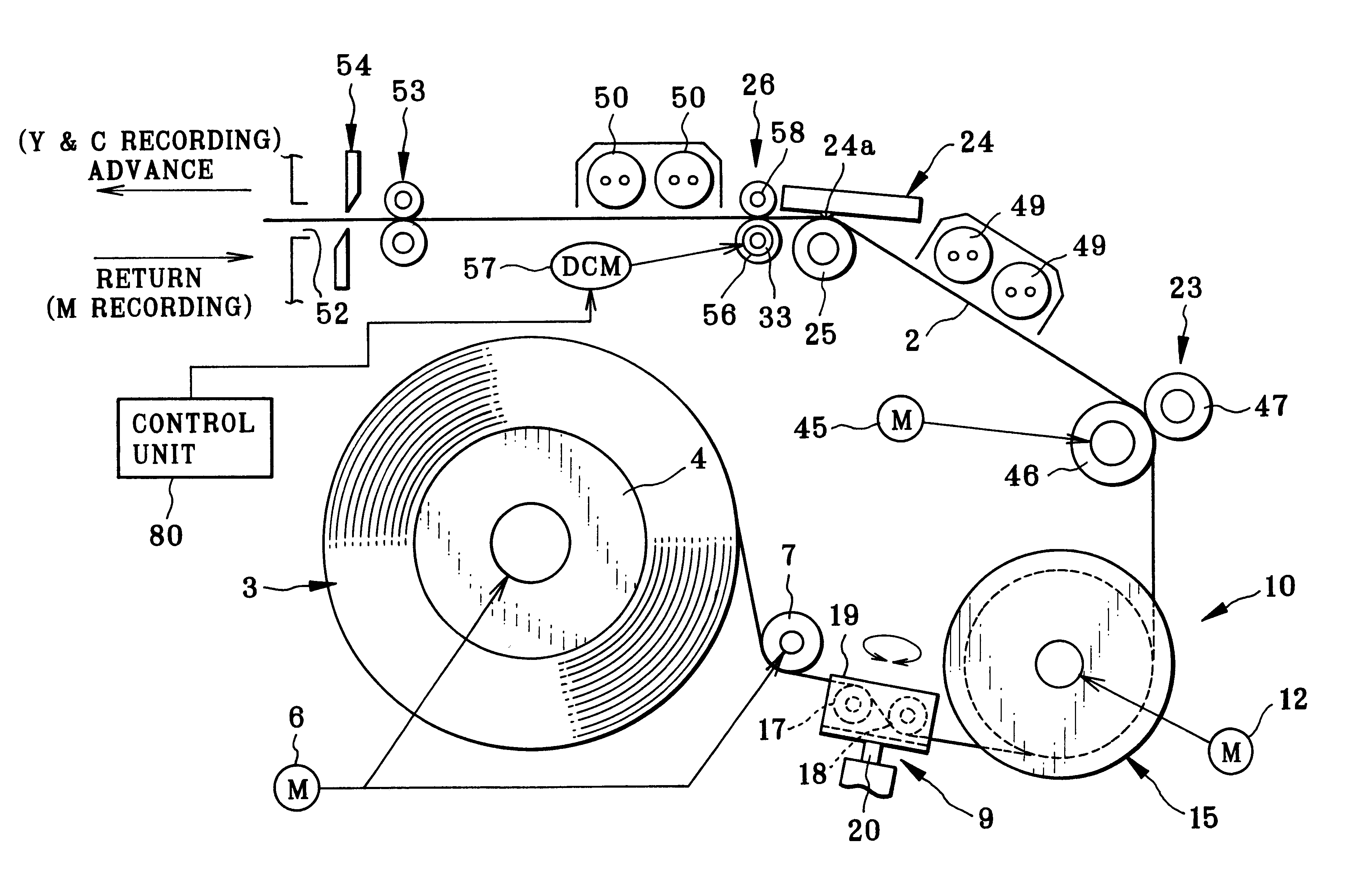

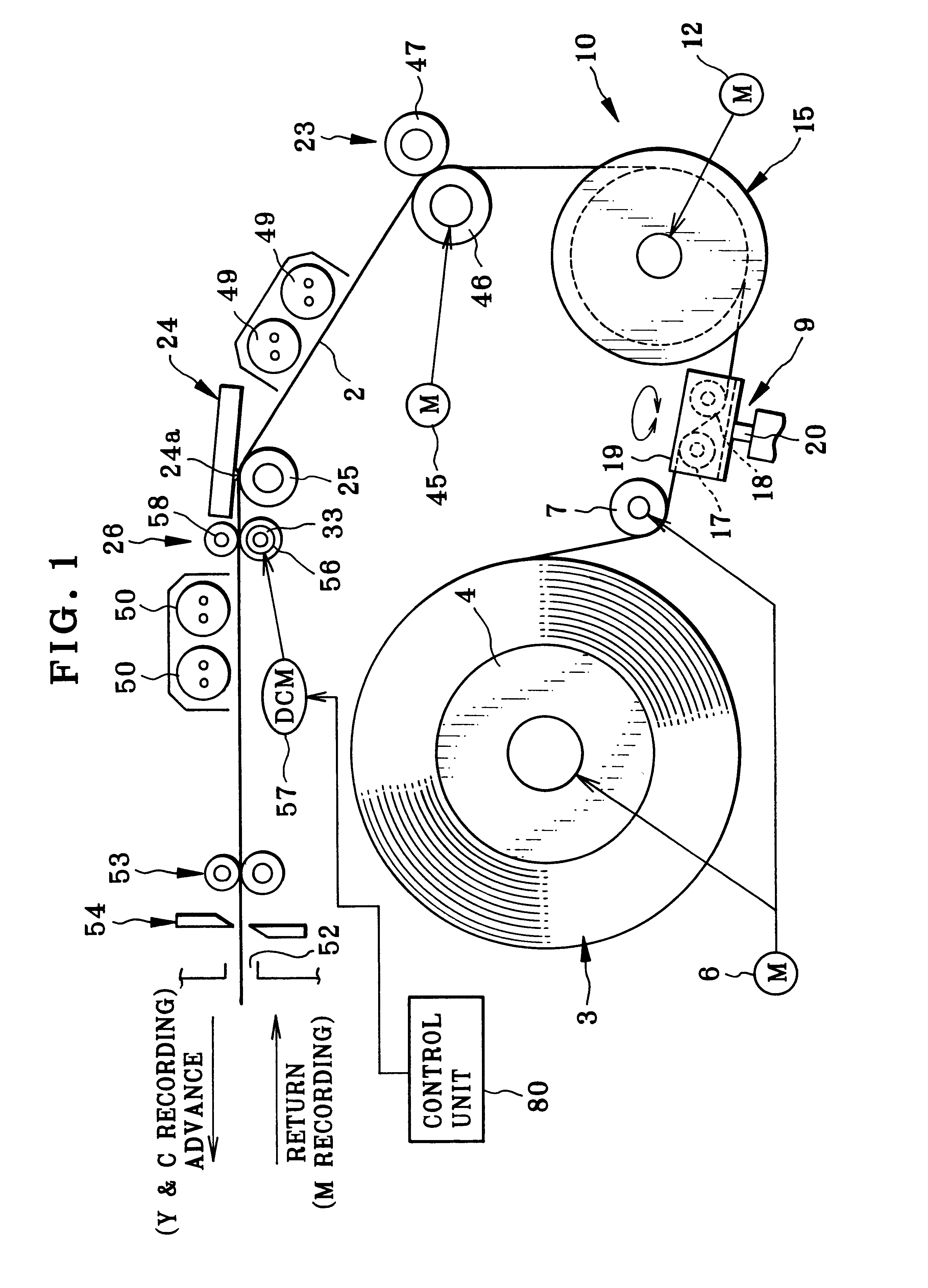

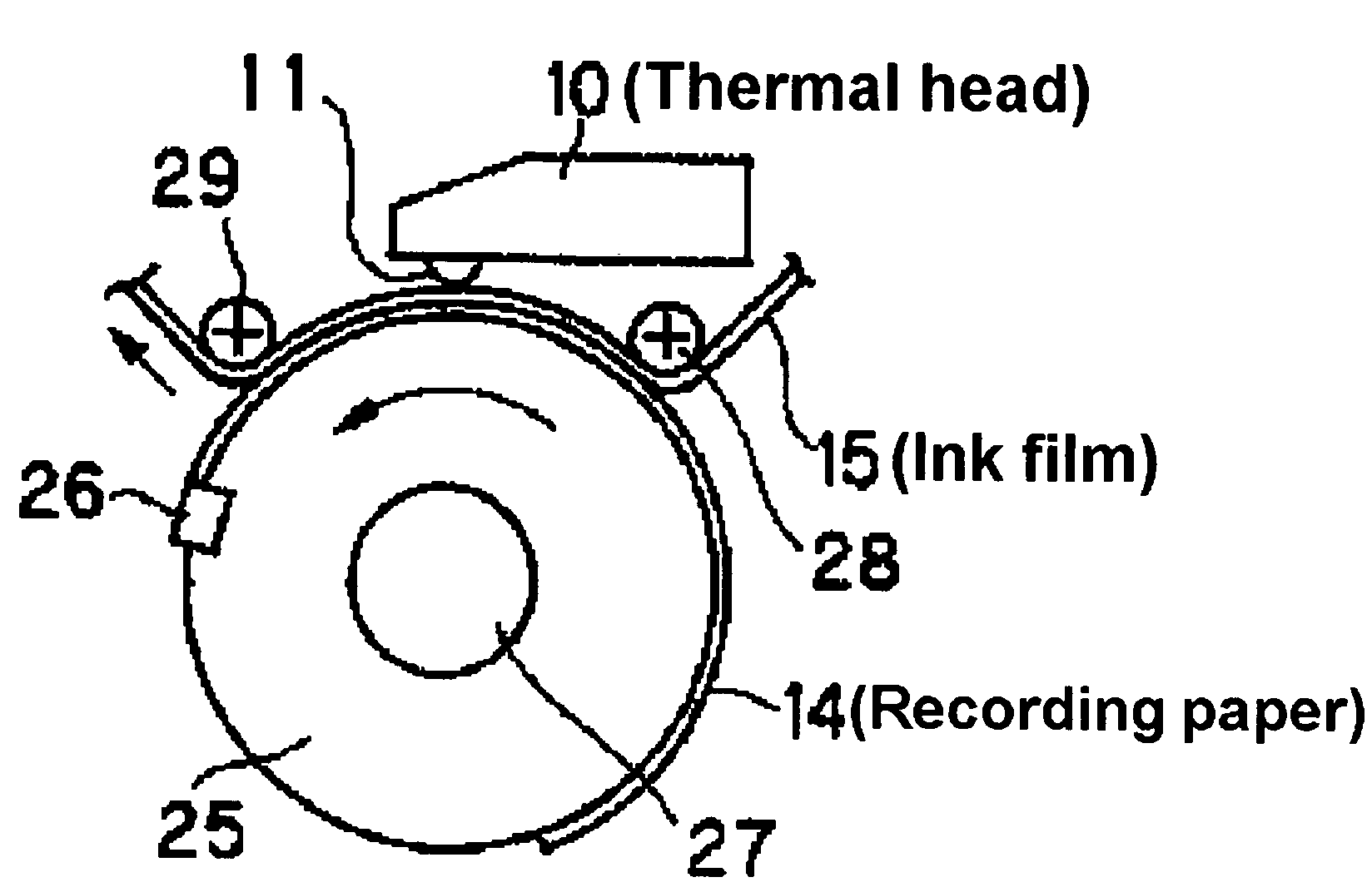

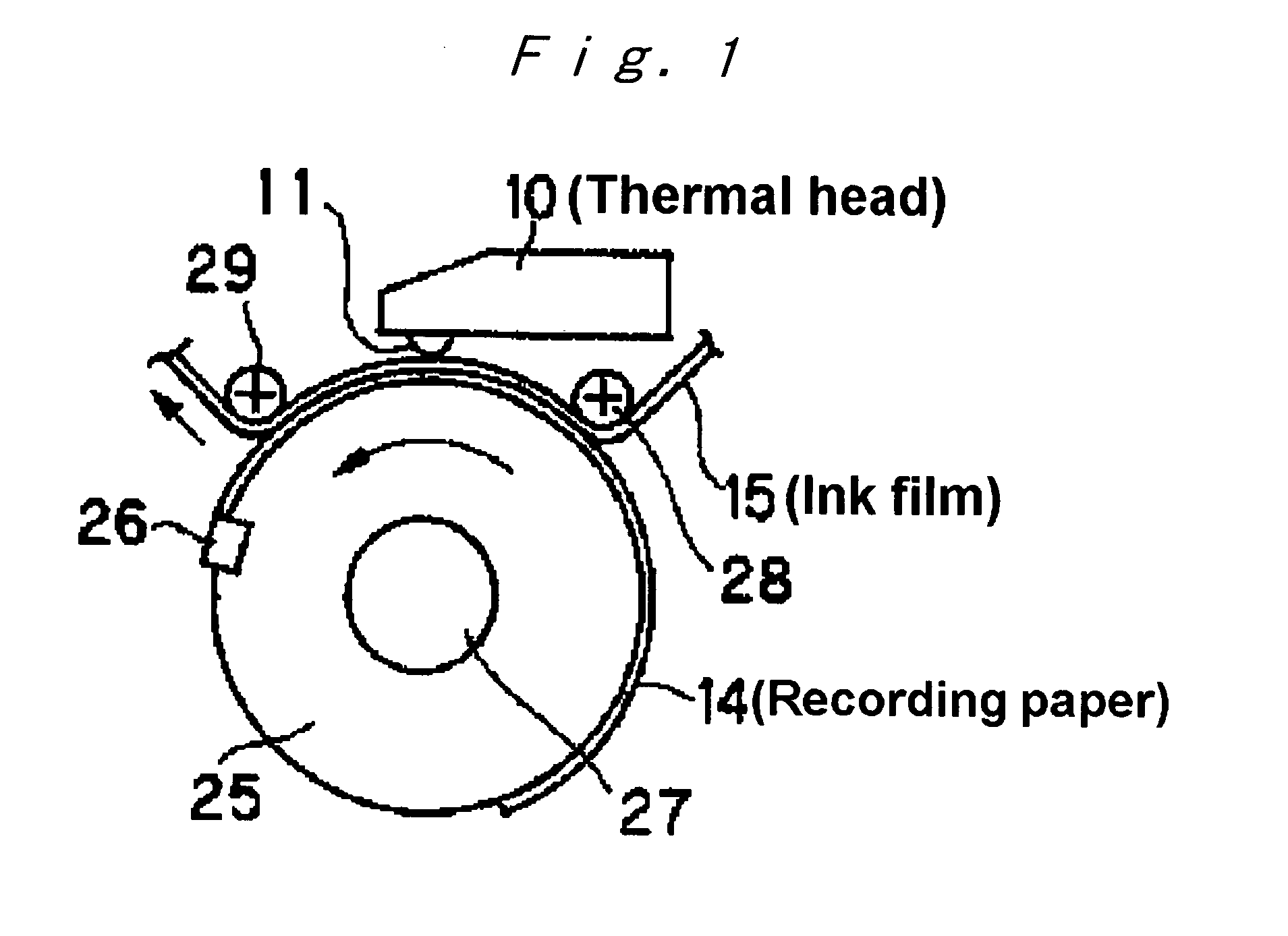

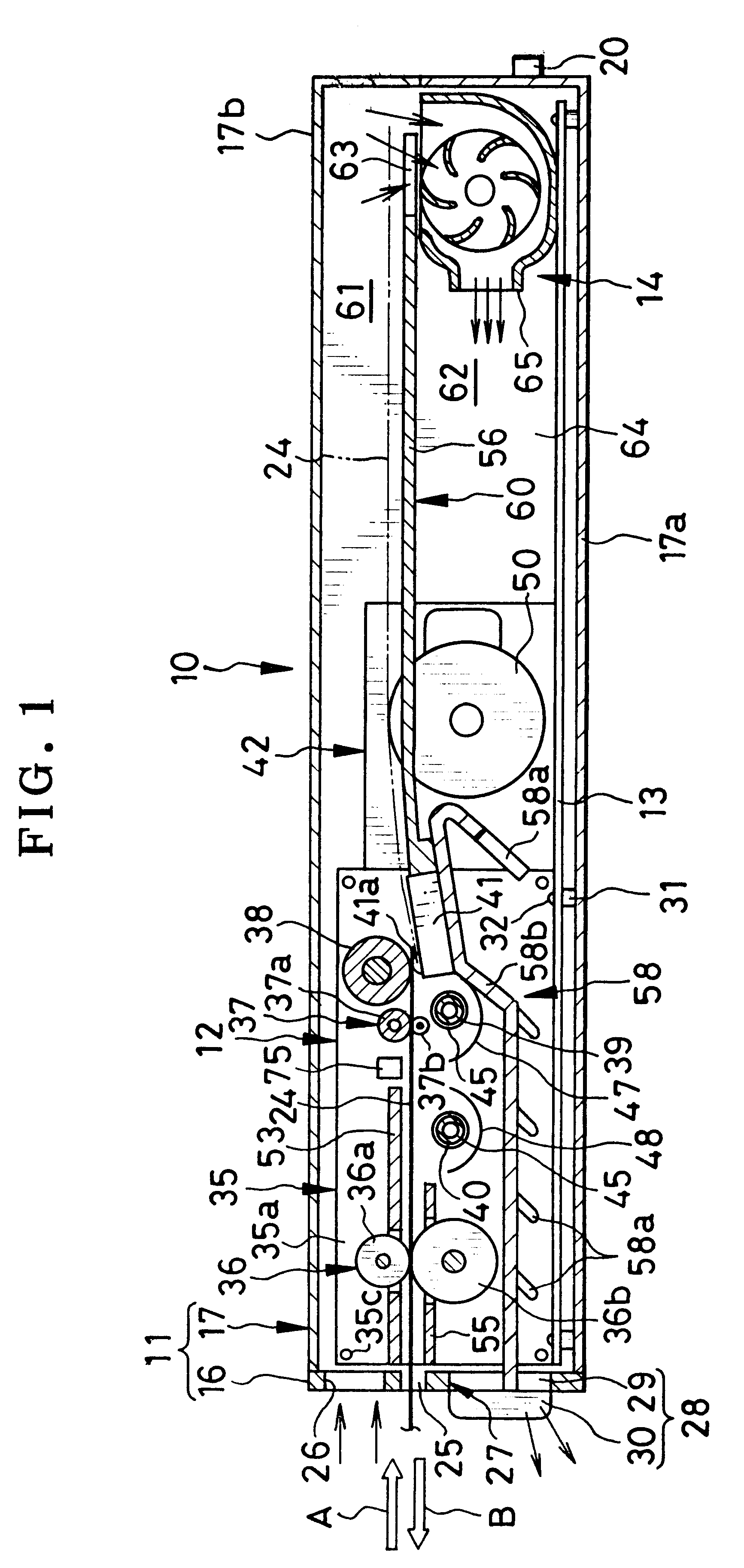

A size-reduced printer that conveys a recording sheet in a circulating manner along a ring-like conveyance path while printing a plurality of images on the recording sheet in different colors sequentially in a superimposed manner, thereby forming a full color image. When a ribbon cassette that contains a multi-color ink ribbon is loaded at a predetermined position within a printer housing, a ring-like conveyance path is formed between the ribbon cassette and the printer housing. While the thermal head is driven and the recording sheet is conveyed once in a circulating manner along the conveyance path, a one-color image is printed on a previous printed one-color image in a superimposed manner in a corresponding one of the different color inks of the multi-color ink ribbon, thereby forming a full color image fully.

Owner:CASIO COMPUTER CO LTD

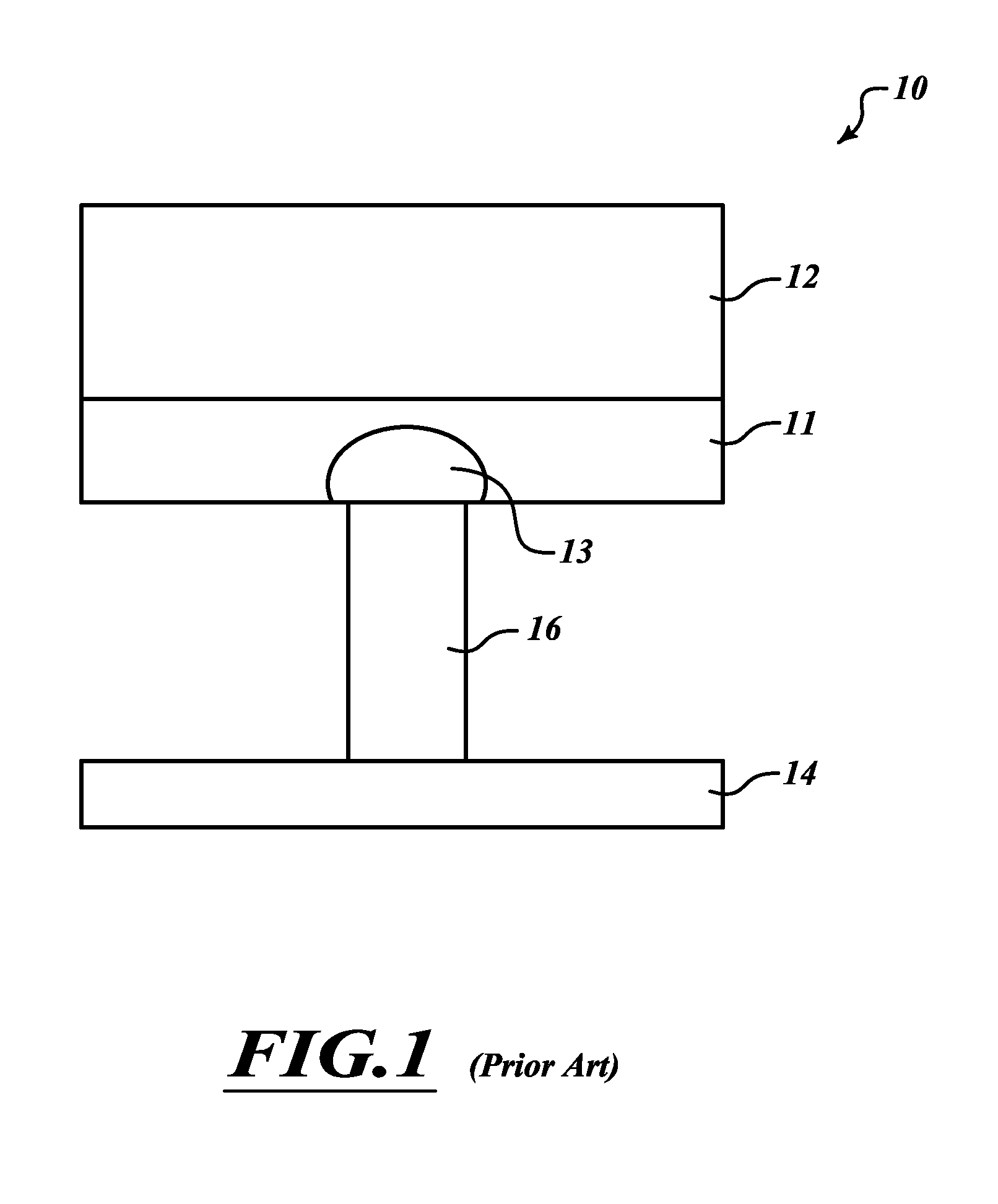

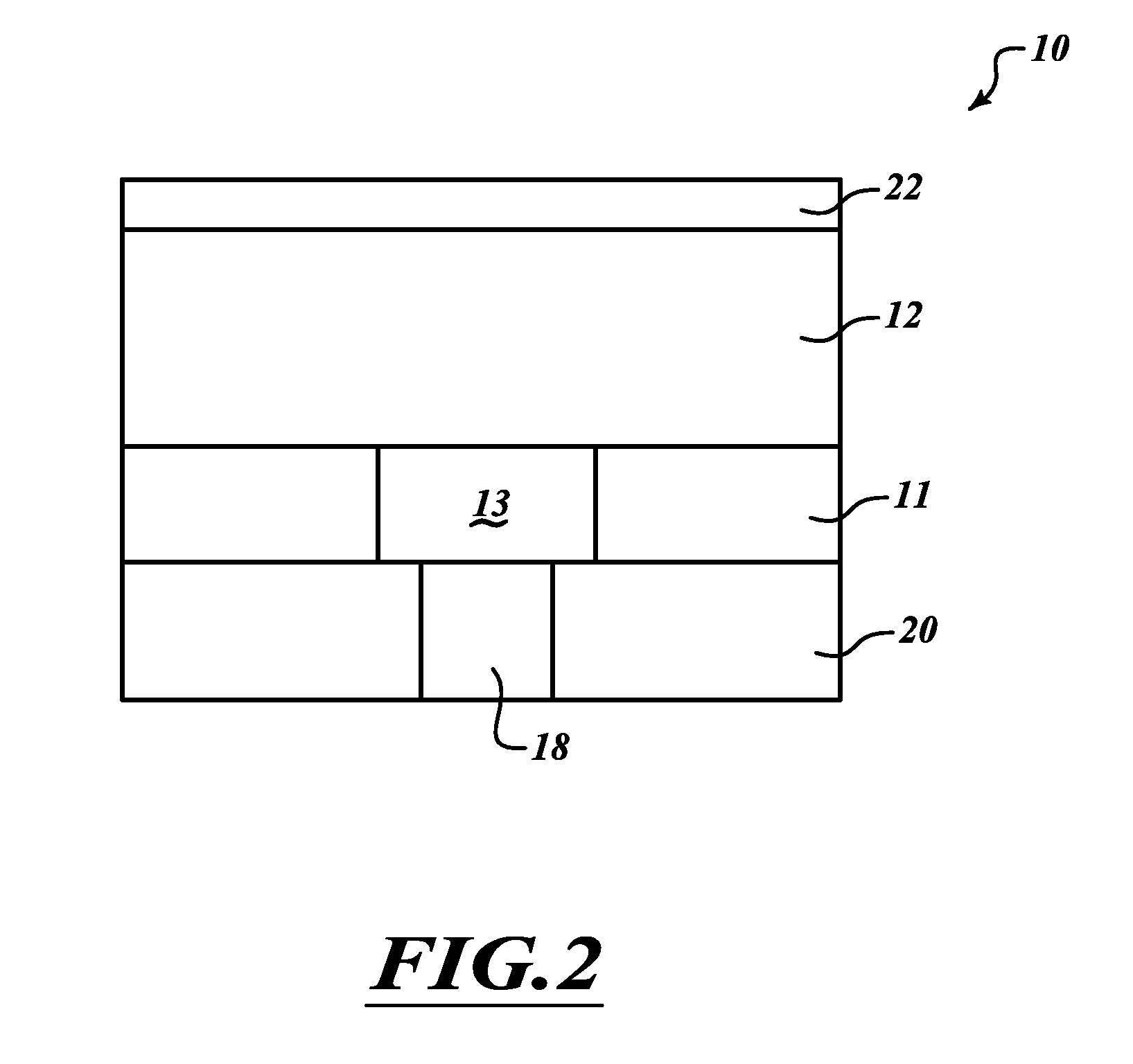

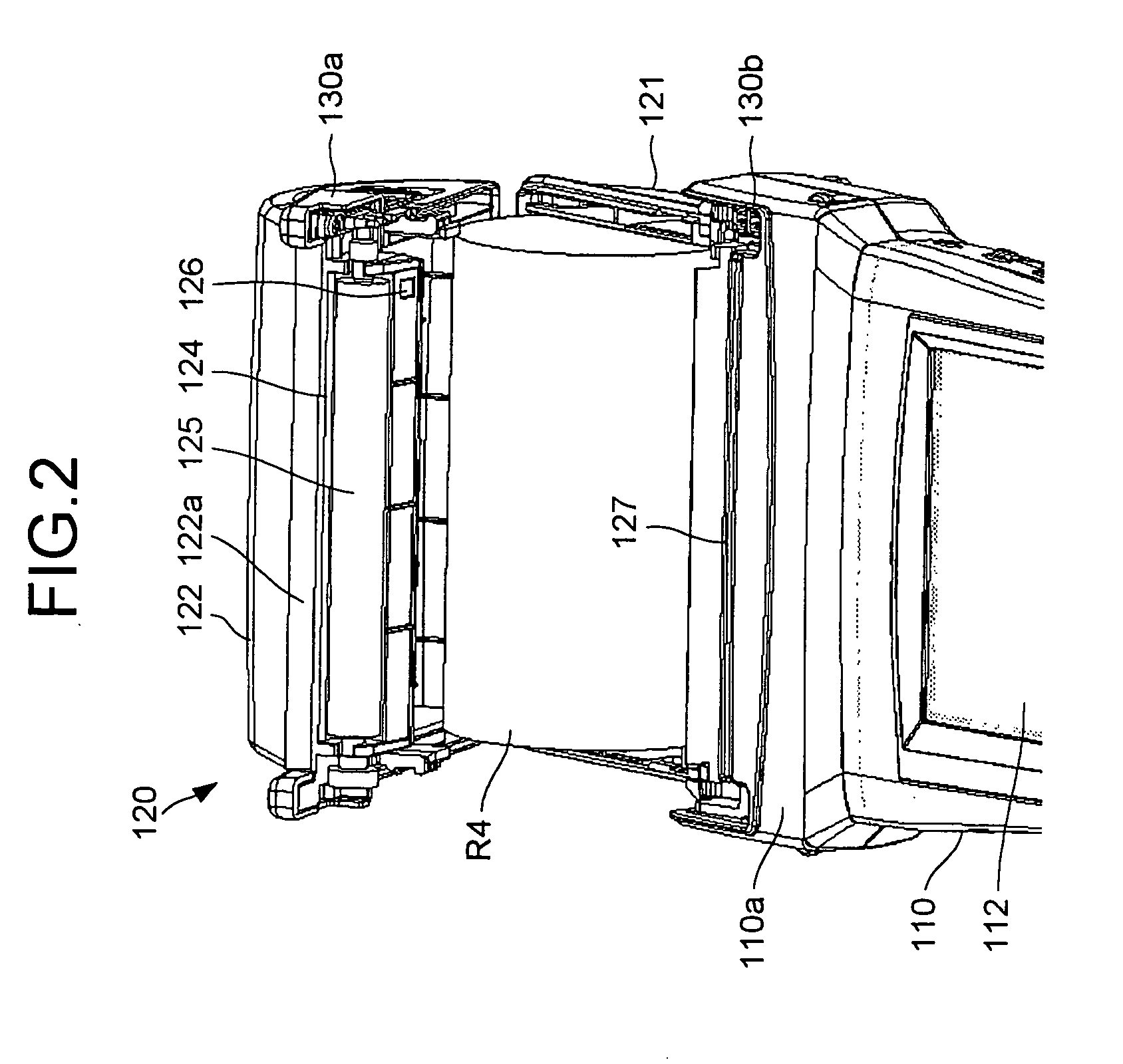

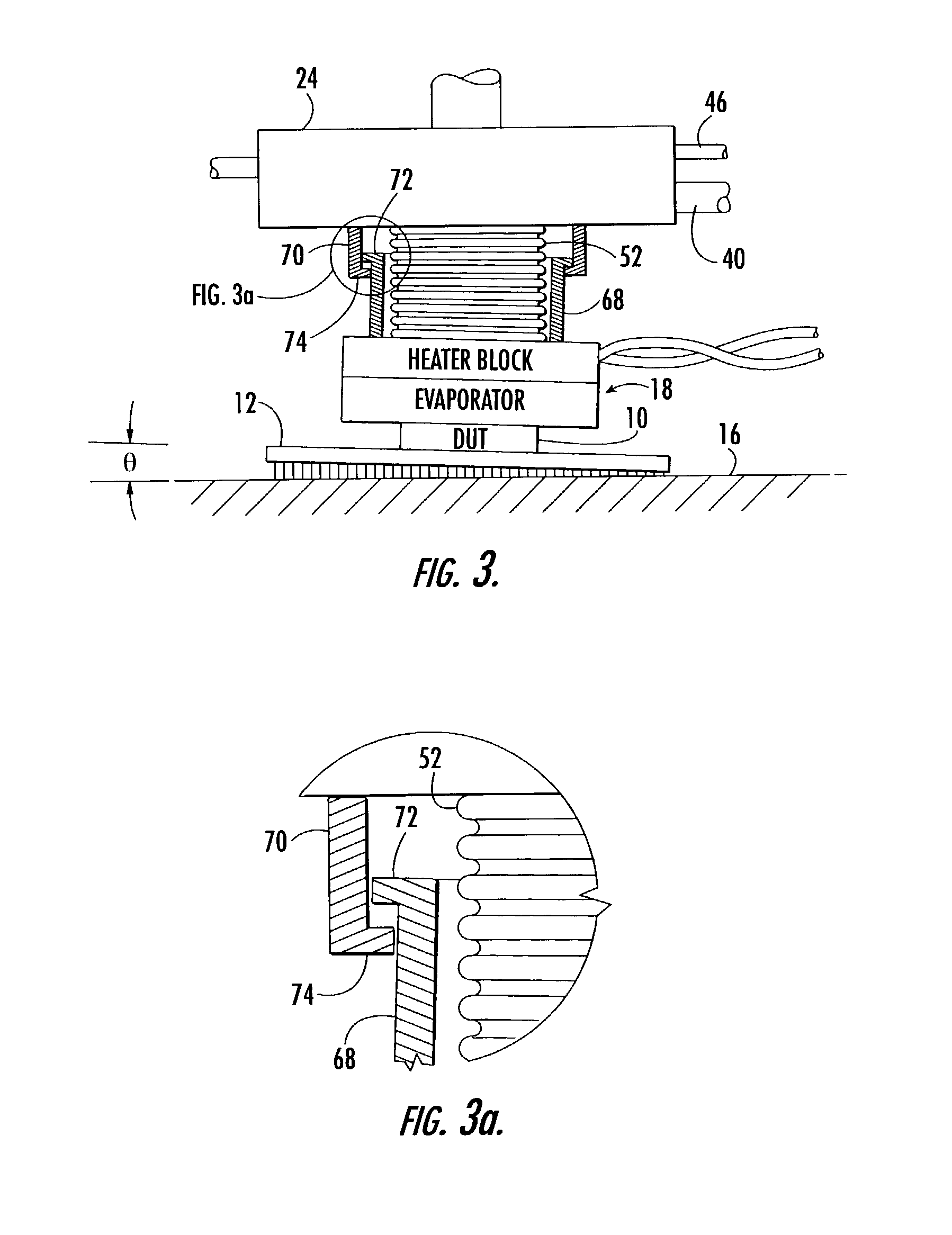

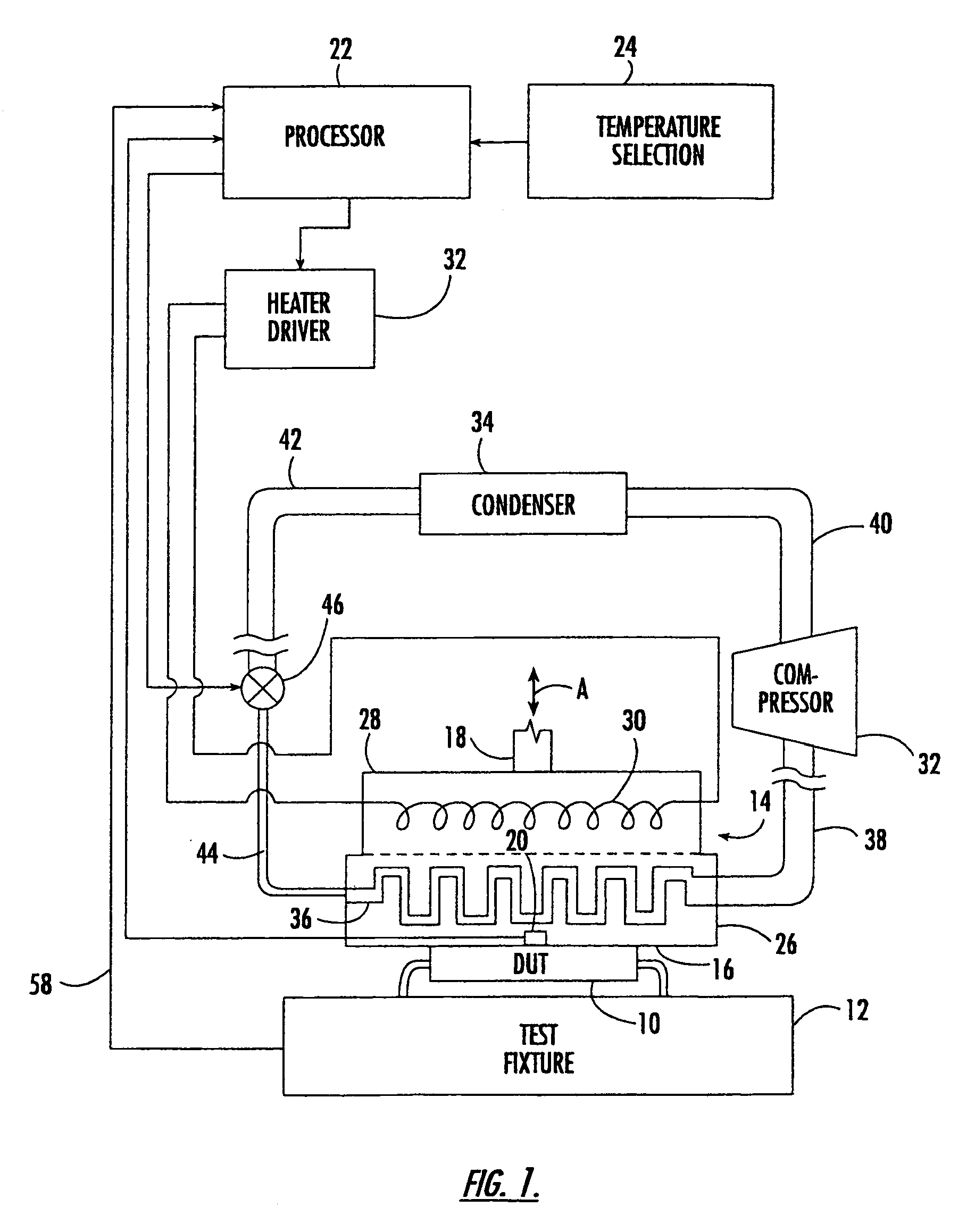

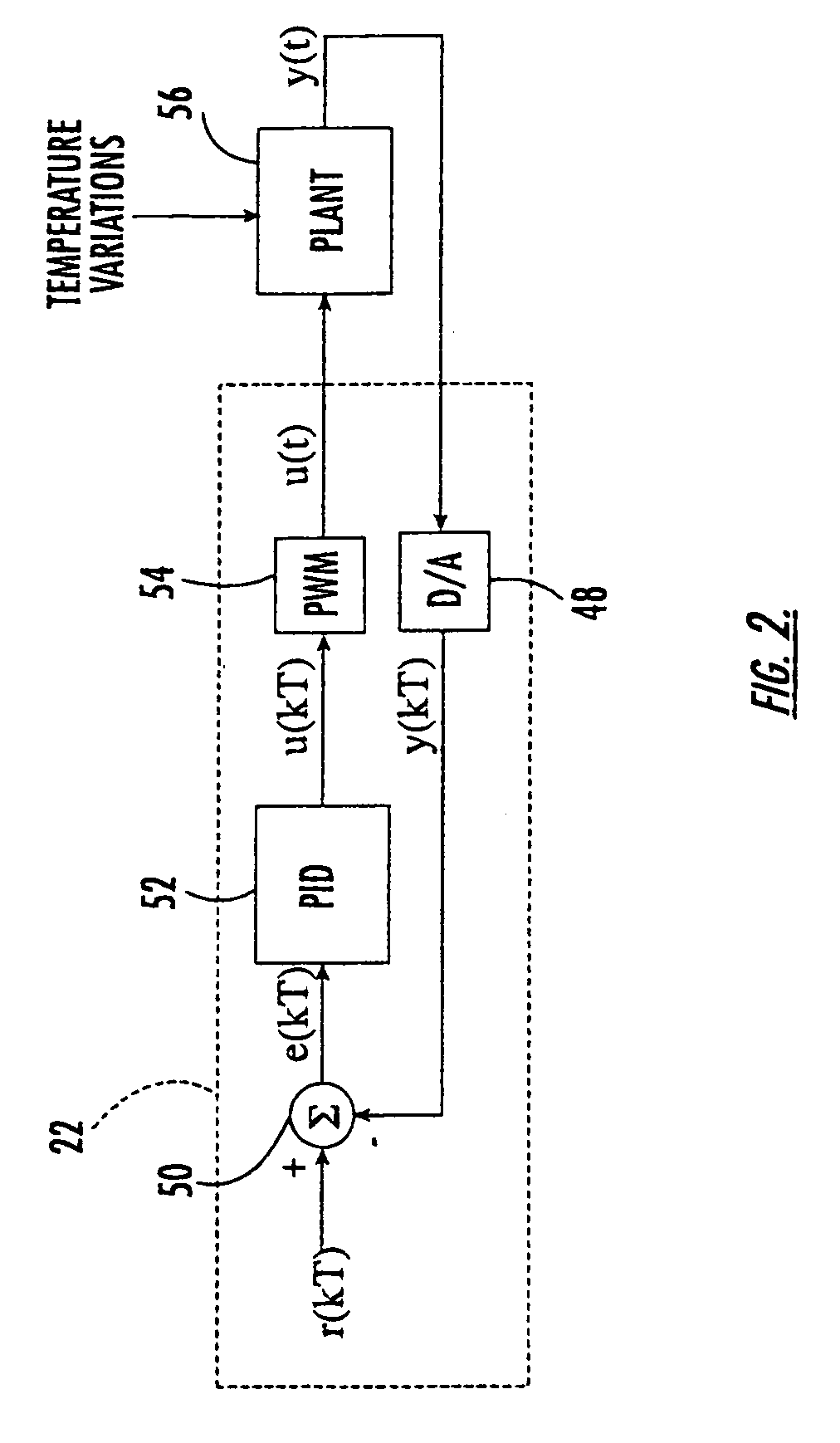

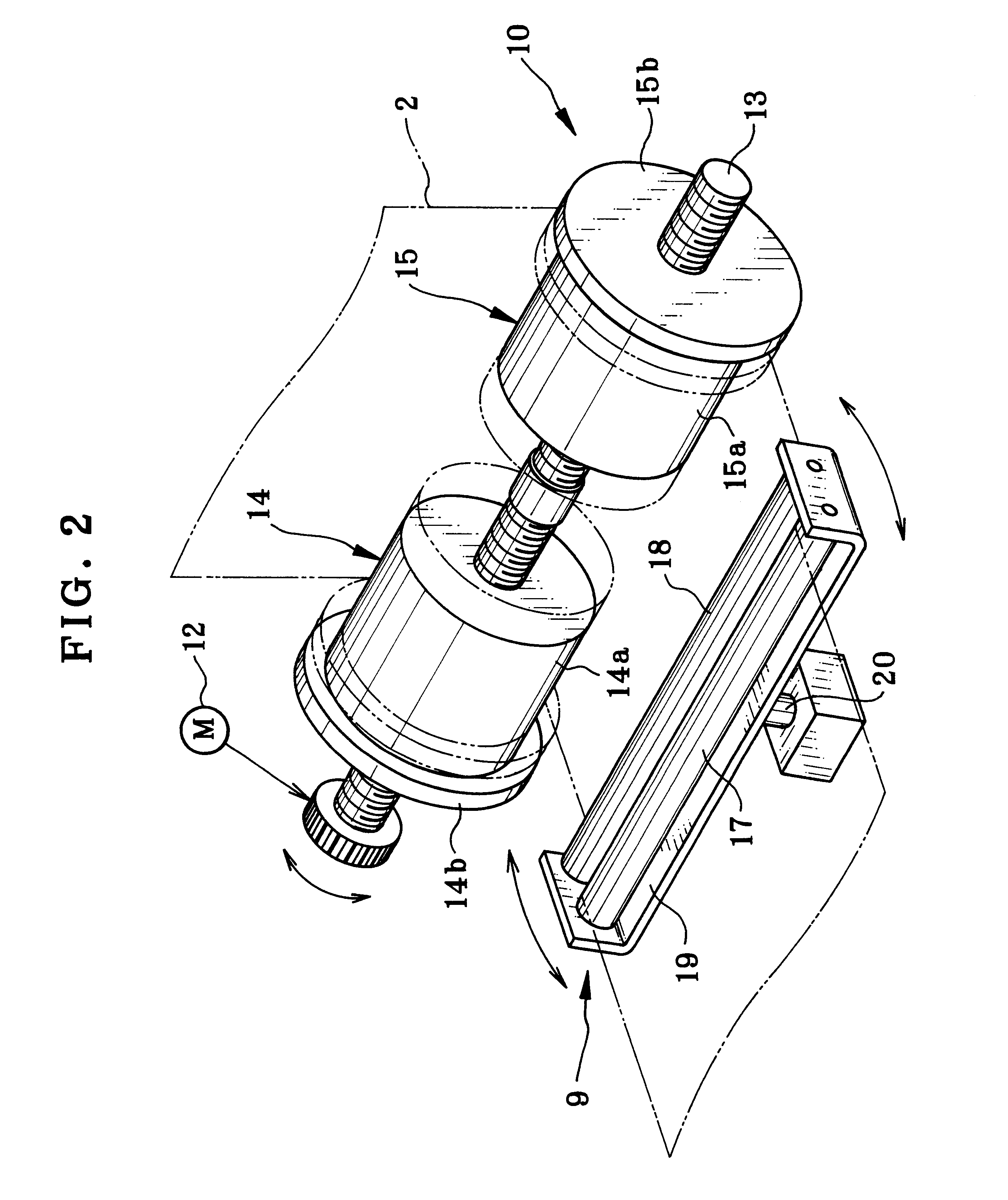

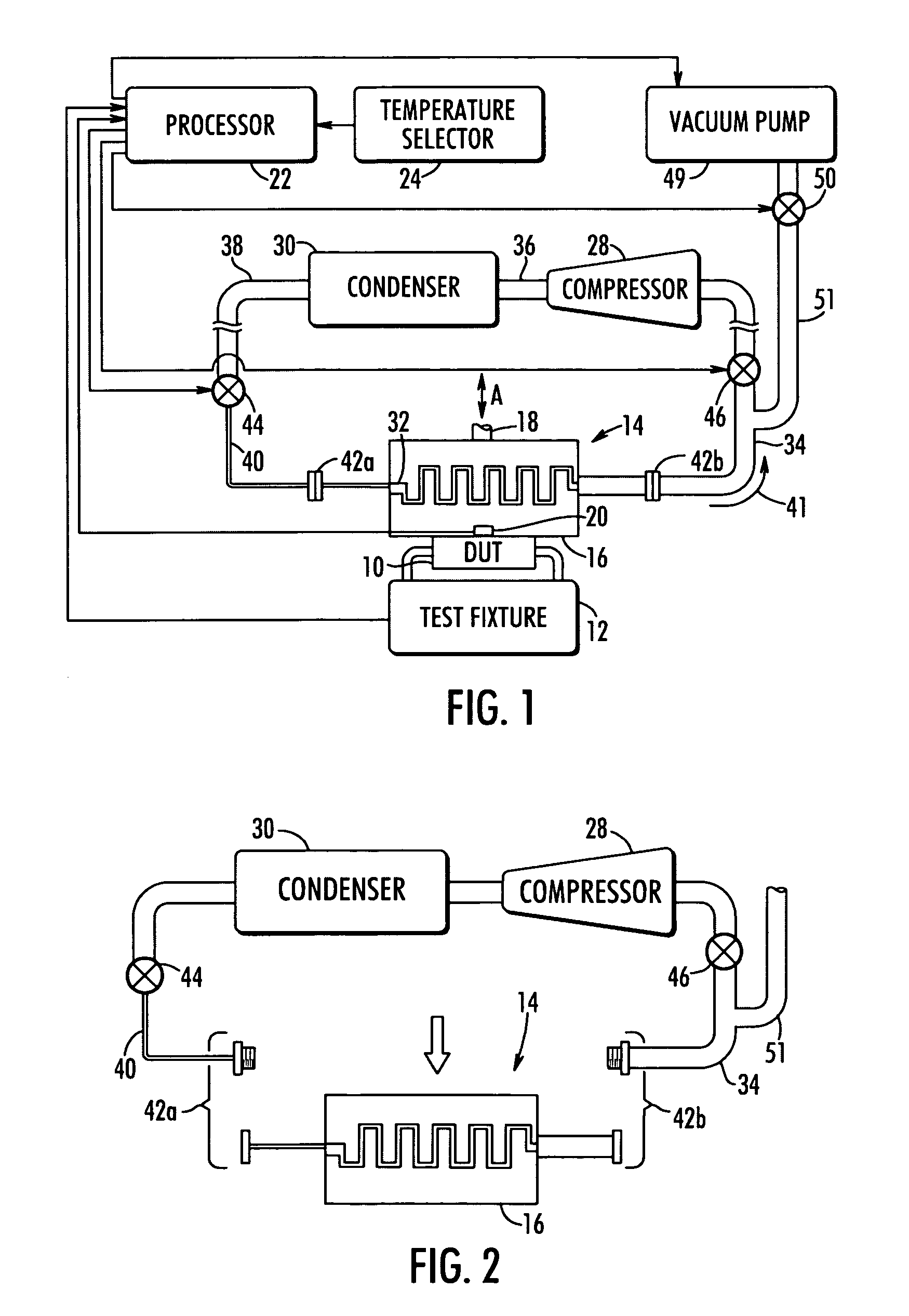

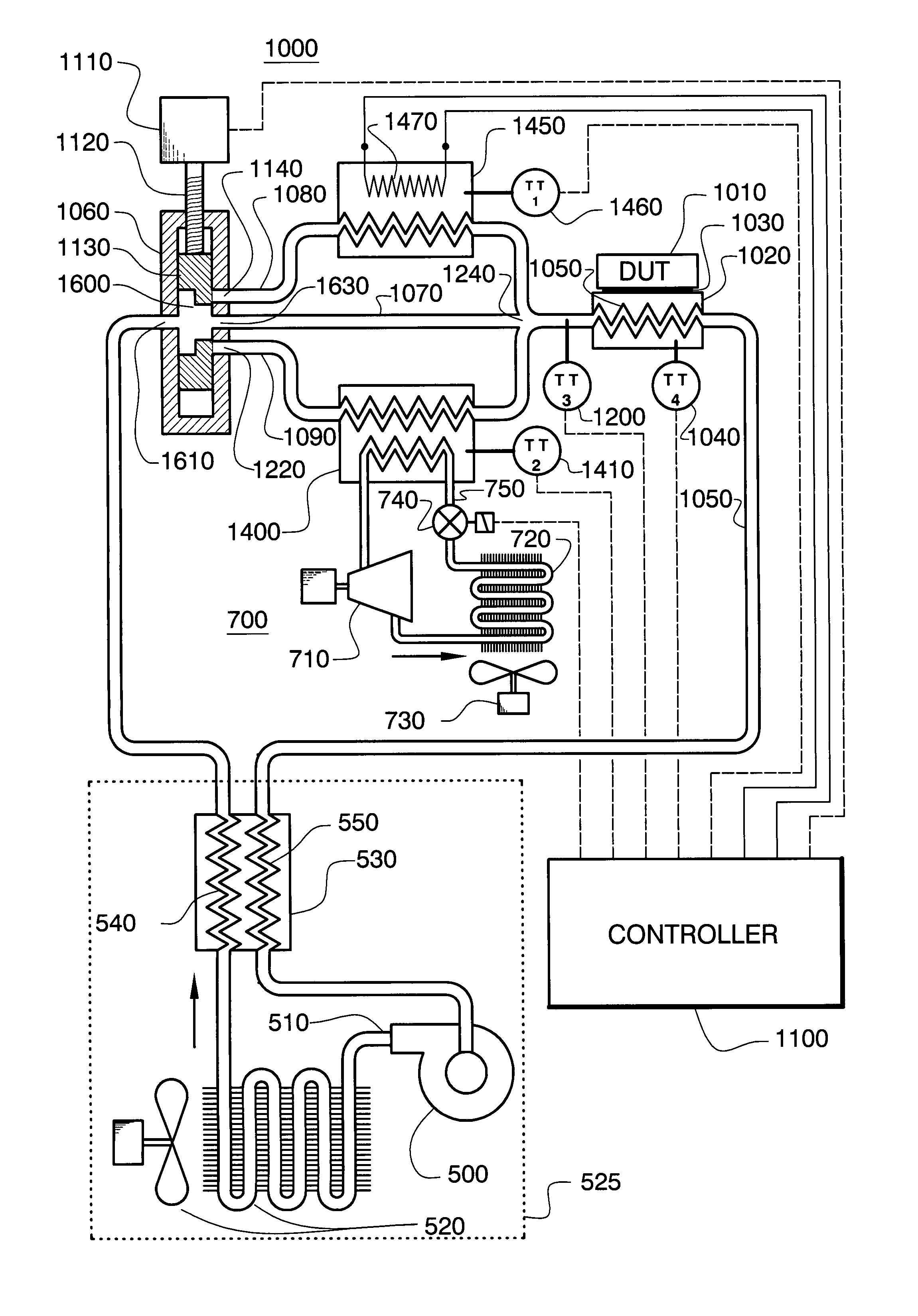

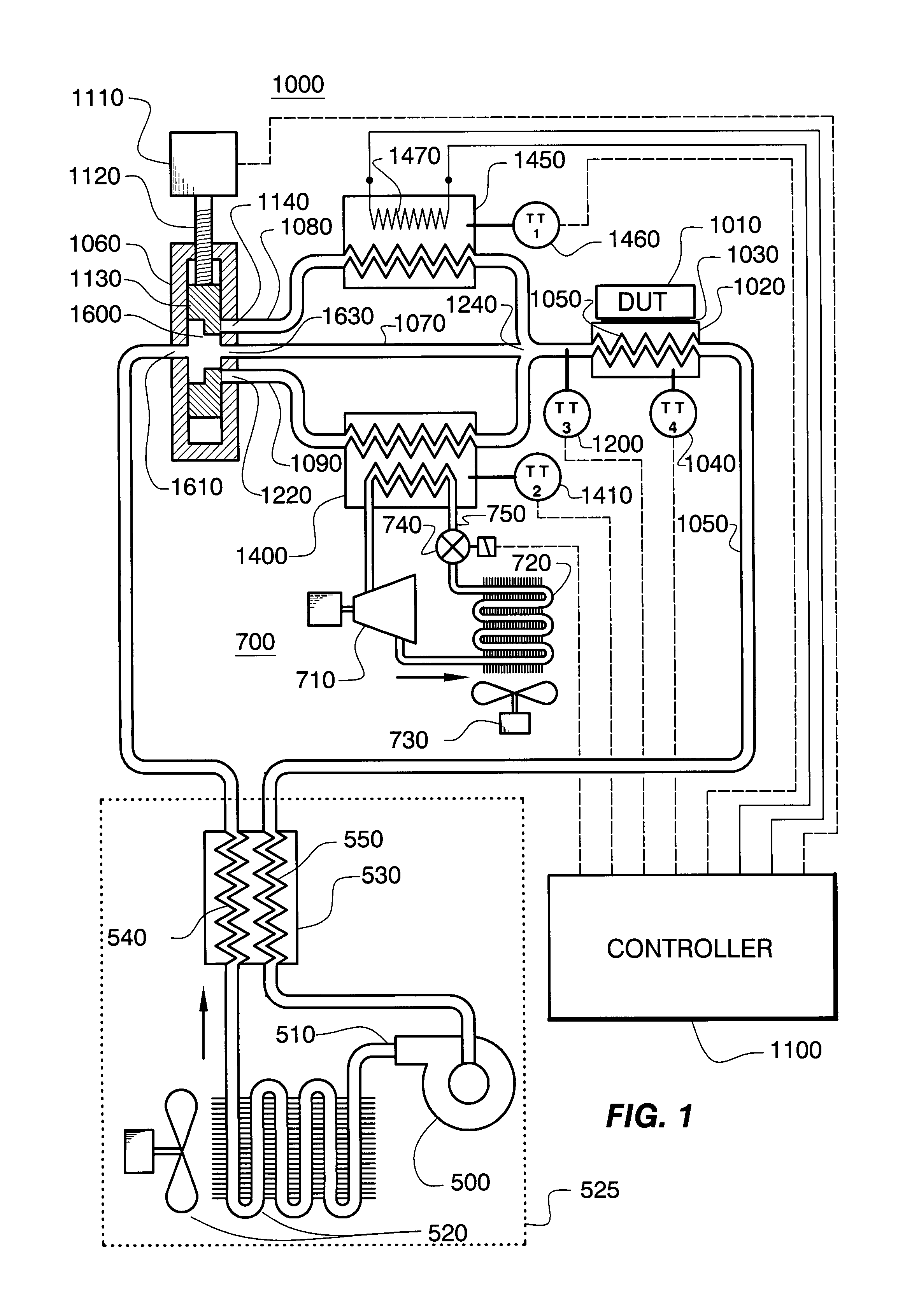

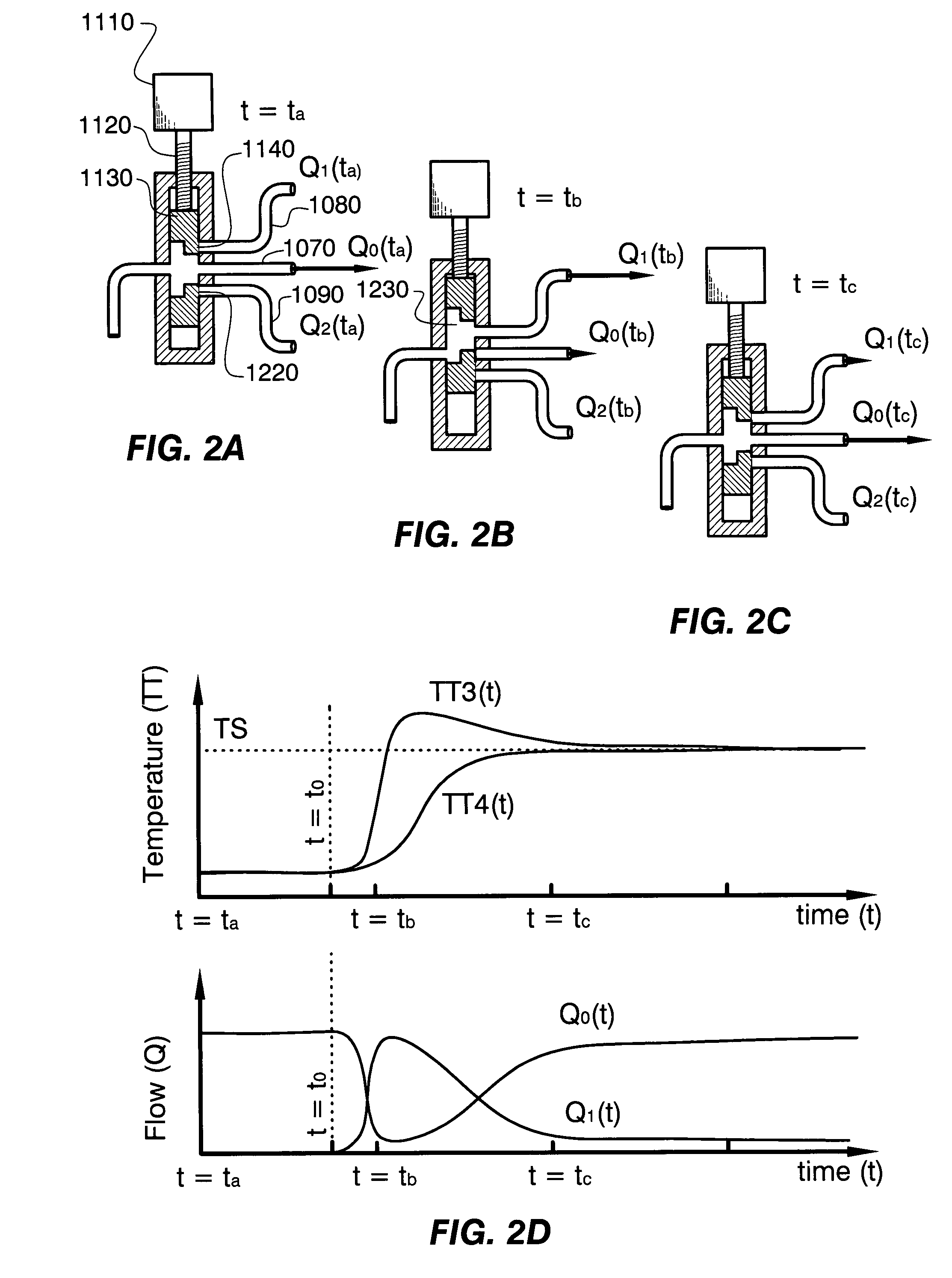

Apparatus and method having mechanical isolation arrangement for controlling the temperature of an electronic device under test

InactiveUS7100389B1Good electrical contactMechanical apparatusElectronic circuit testingEngineeringRefrigeration

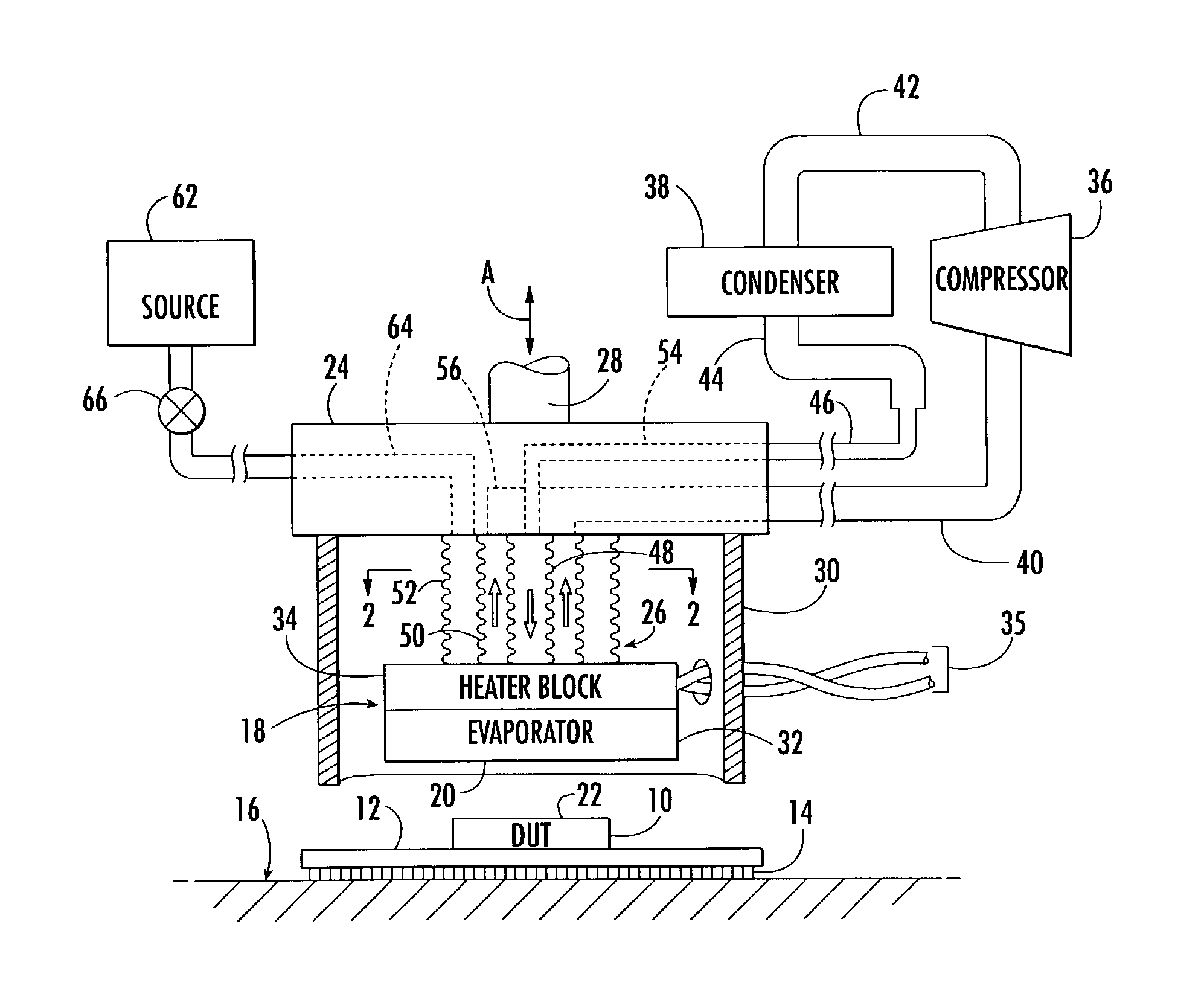

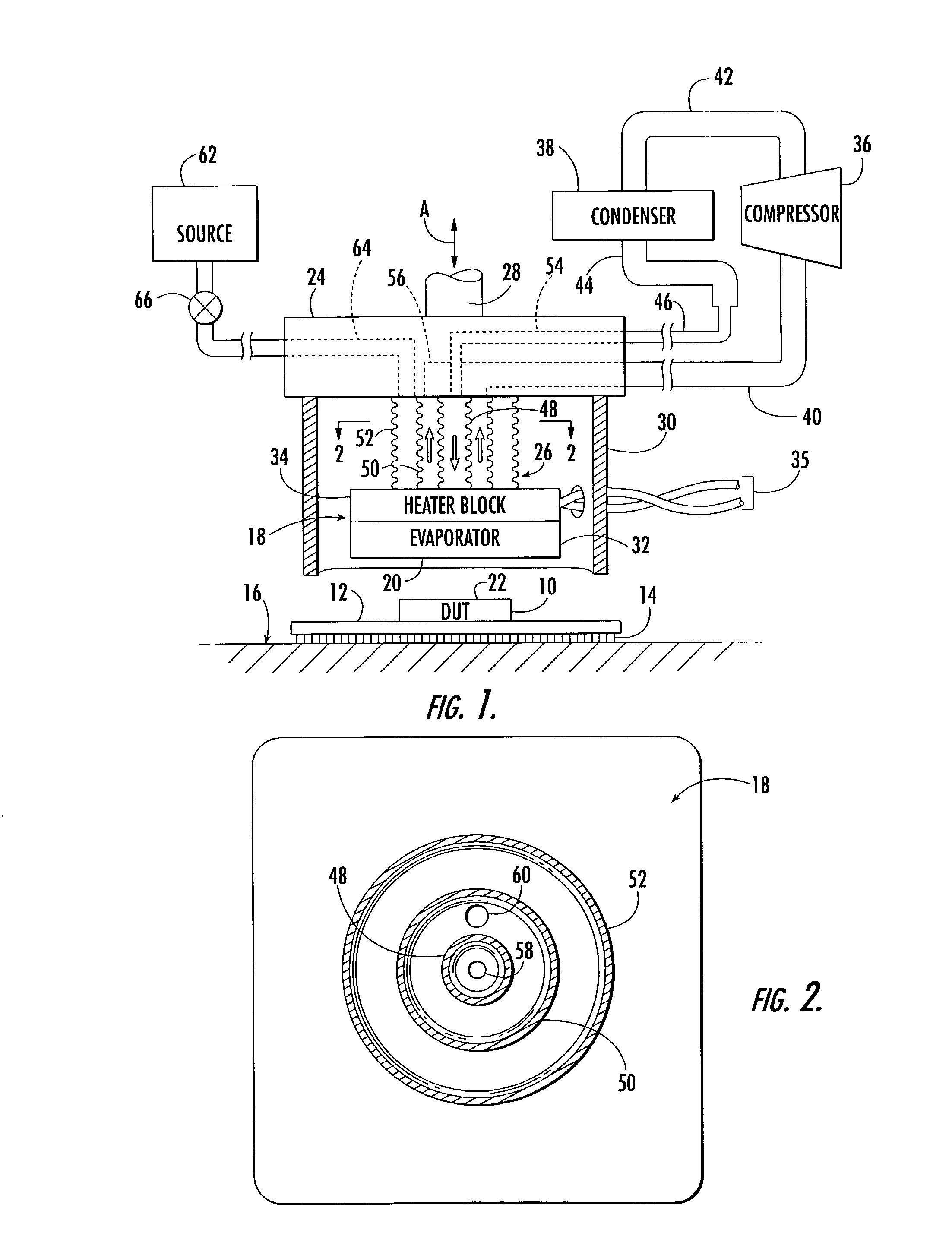

An apparatus and method for controlling the temperature of an electronic device under test utilizes a thermal head spaced apart from a movable support structure by a mechanical isolation assembly. The support structure has a manifold configured to route refrigerant fluid between the evaporator head and components of a refrigeration system. The mechanical isolation assembly is configured to compensate for variations in the planar orientation of the device under test. Moreover, the mechanical isolation assembly preferably includes bellows through which the refrigerant fluid is conducted.

Owner:ADVANTEST CORP +1

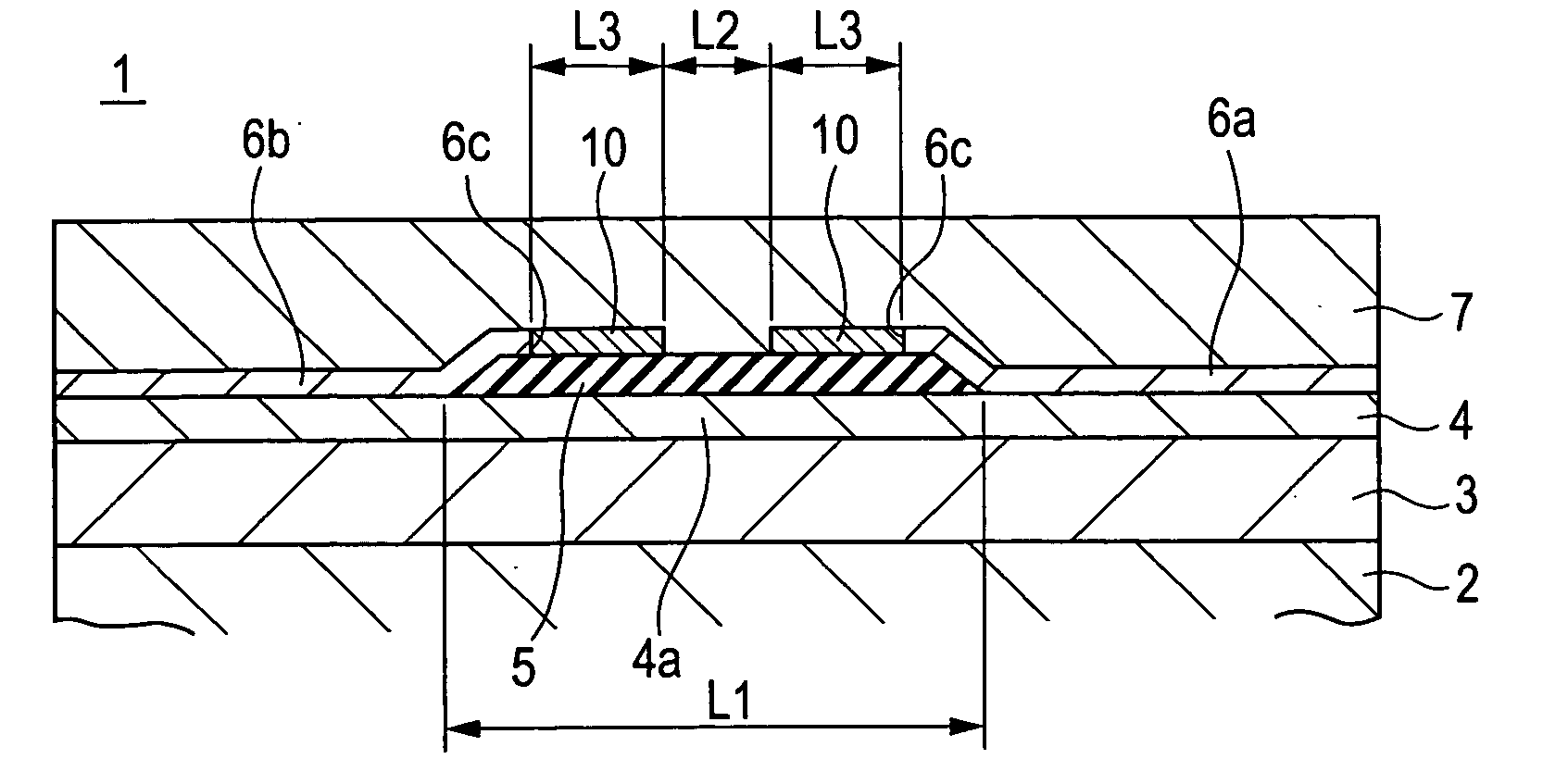

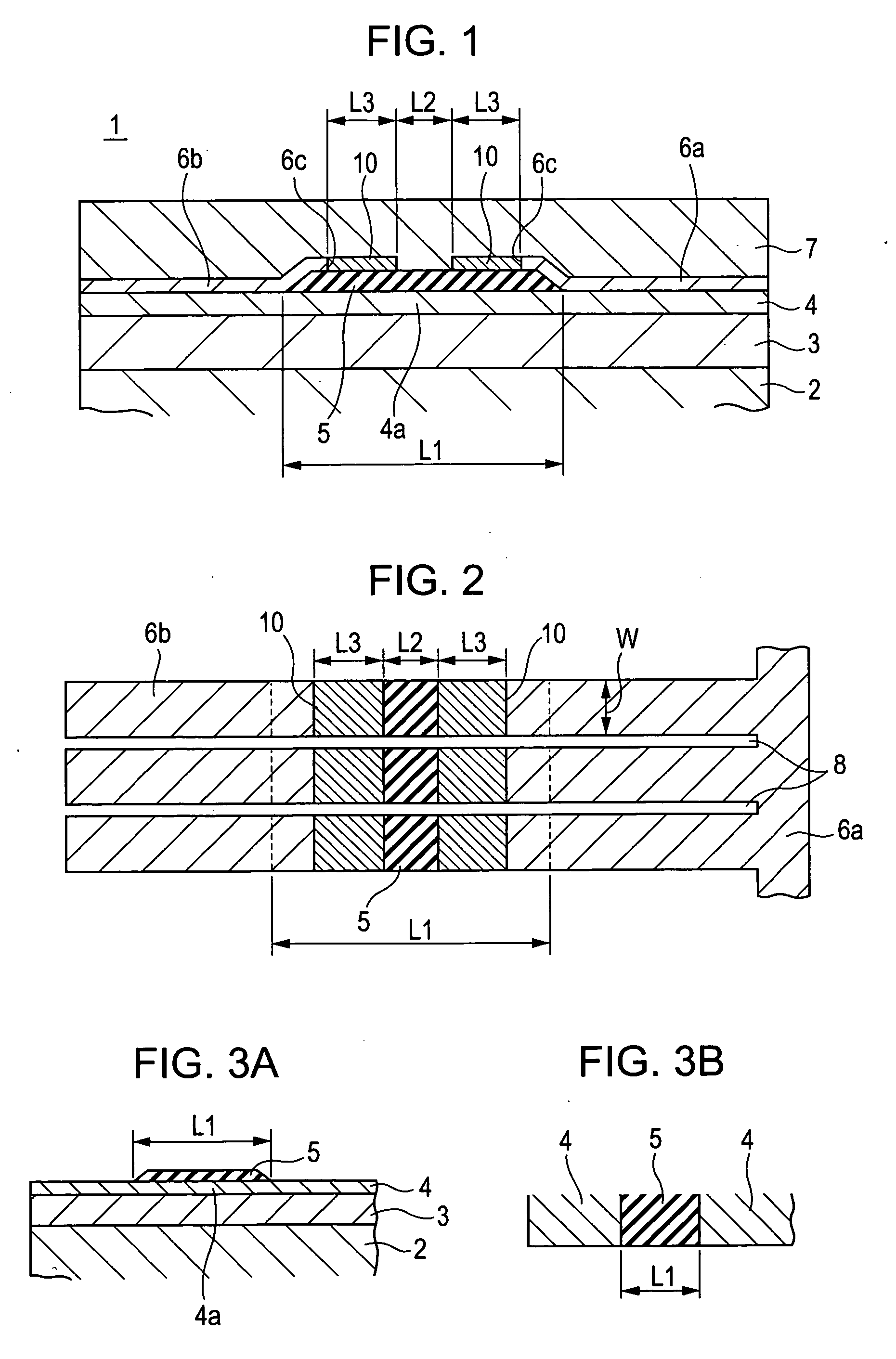

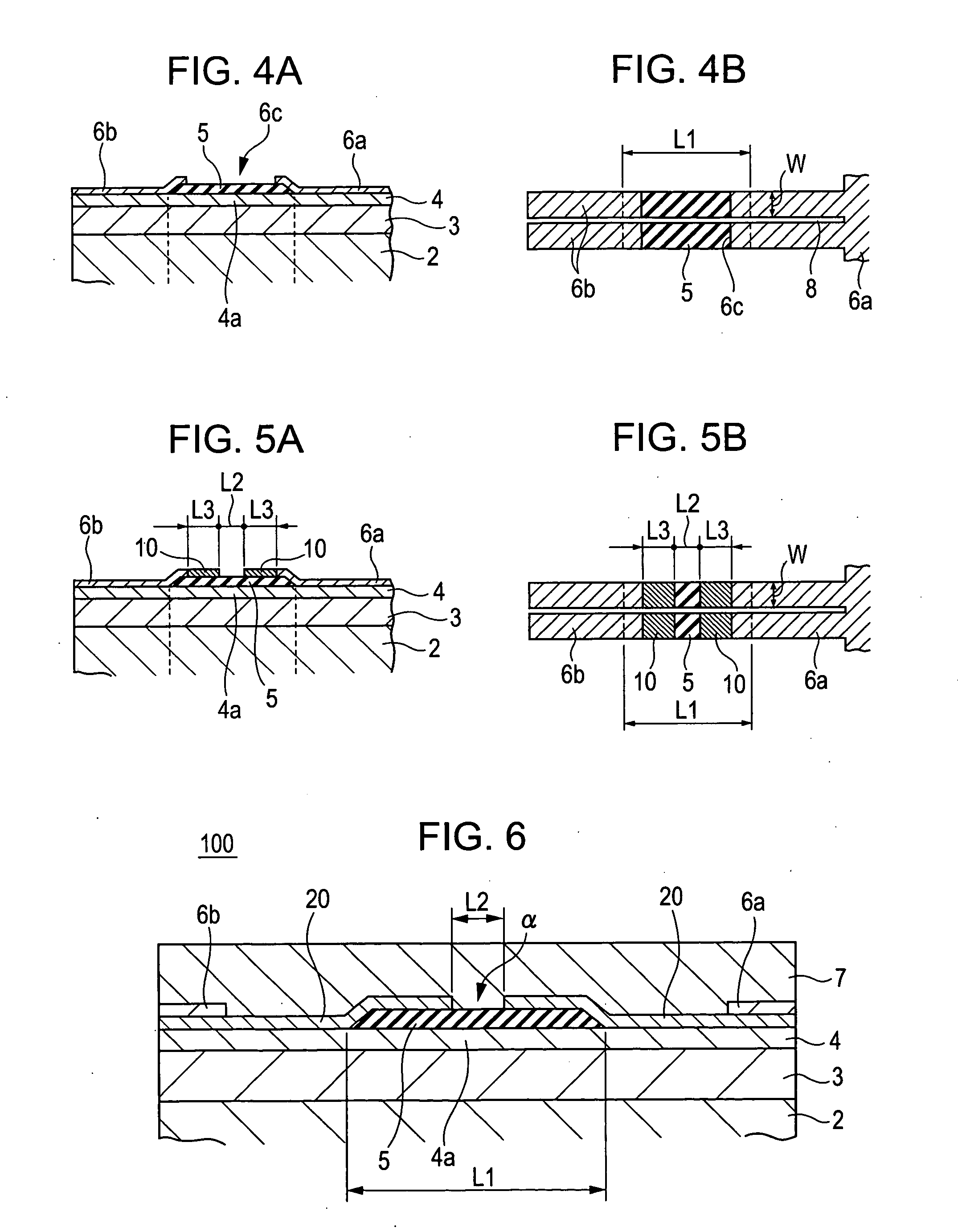

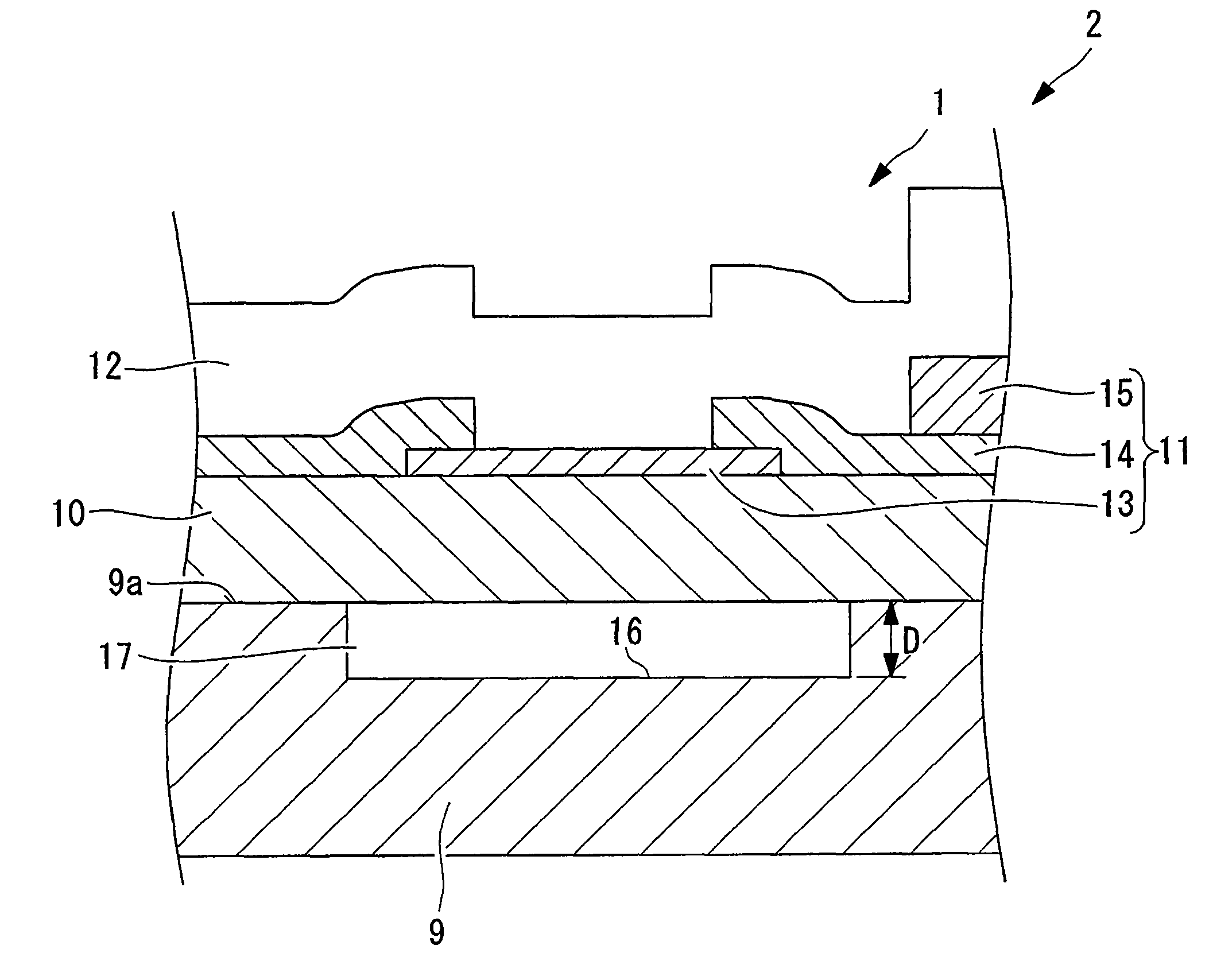

Thermal head, method for manufacturing the same, and method for adjusting dot aspect ratio of thermal head

In a thermal head provided with a resistance layer having a plurality of heating element portions which generate heat by energization, an insulating barrier layer which determines the two-dimensional size of each heating element portion by covering each heating element portion, and electrode layers electrically connected to two end portions of each of the plural heating element portions, in the length direction of the resistance, a heat transfer layer is disposed on at least the insulating barrier layer to determine the two-dimensional surface exposure area of the insulating barrier layer by covering part of the insulating barrier layer and to dissipate the heat generated from the plural heating element portions, and surface exposure regions of the insulating barrier layer are specified as effective heating regions of the plural heating element portions by adjusting the two-dimensional size of the heat transfer layer.

Owner:ALPS ALPINE CO LTD

Thermal transfer printer

InactiveUS20060007295A1Accurate graspAccurate quantityRecording apparatusPrinting mechanismsEngineeringHeat sensitive

Owner:FUNAI ELECTRIC CO LTD

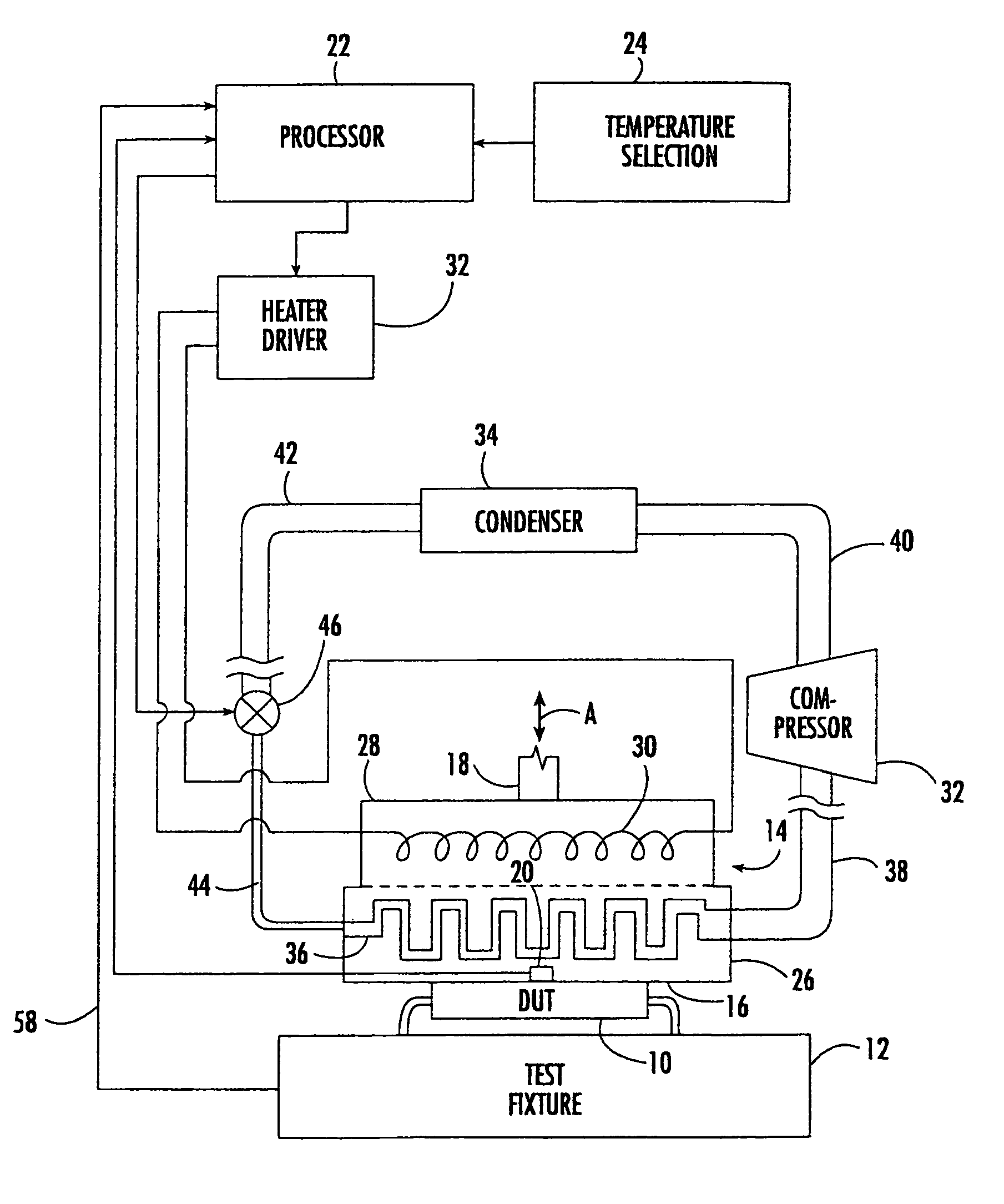

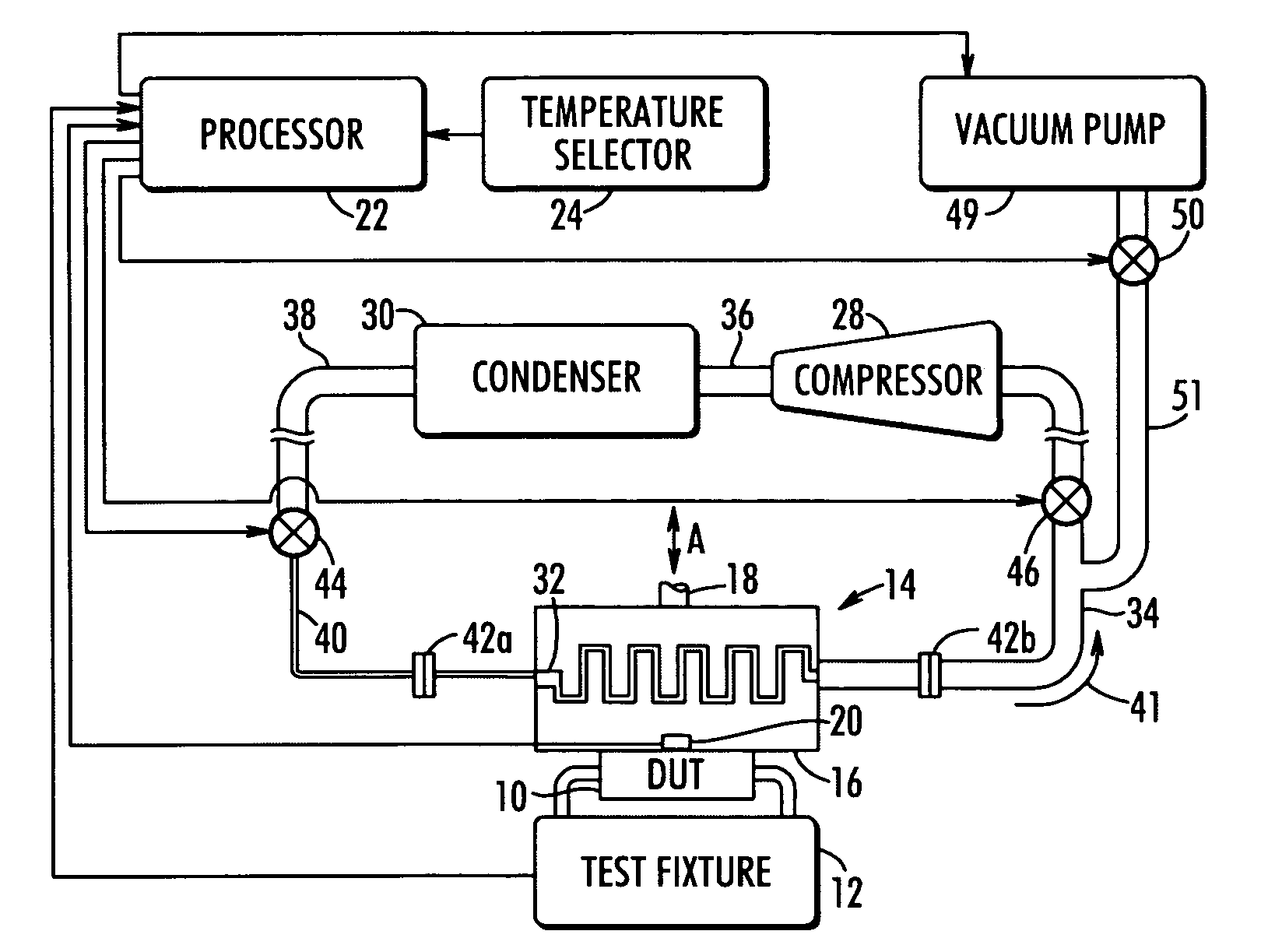

Apparatus and method for controlling the temperature of an electronic device under test

InactiveUS6993922B2Mechanical apparatusHeating or cooling apparatusTemperature controlThermal energy

An apparatus for controlling the temperature of an electronic device under test includes a thermal head having a temperature controlled surface for making thermal contact with the electronic device. The thermal head defines a flow channel for passage of a refrigerant fluid so as to cause transfer of thermal energy between the electronic device and the thermal head. A refrigeration system is connected in fluid communication with the flow channel of the thermal head to supply refrigerant fluid thereto. The refrigeration system includes a metering valve operative to regulate introduction of the refrigerant fluid into the thermal head. A controller is operative to control the metering valve for maintaining a predetermined temperature at the temperature controlled surface.

Owner:DELTA DESIGN

Thermal printing

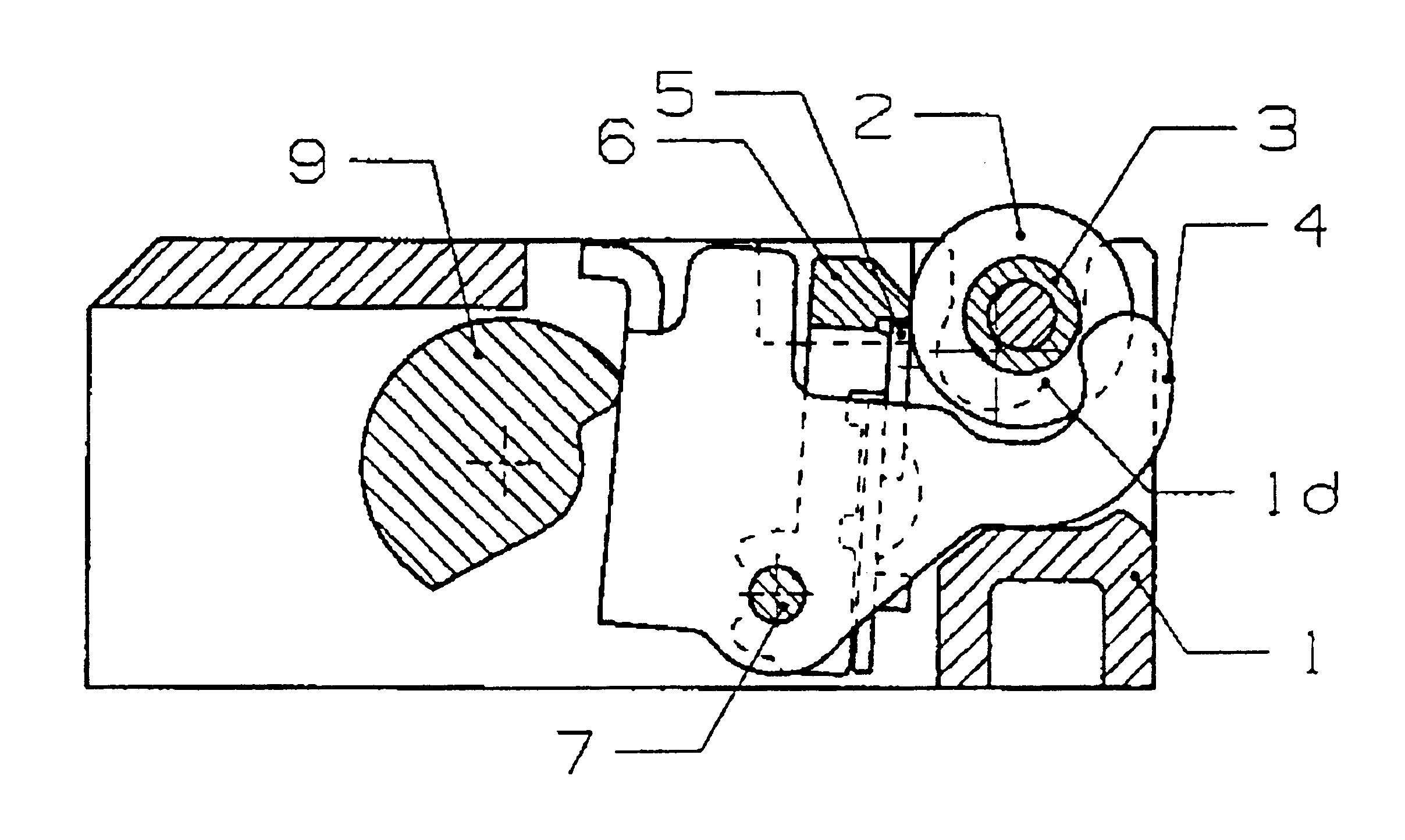

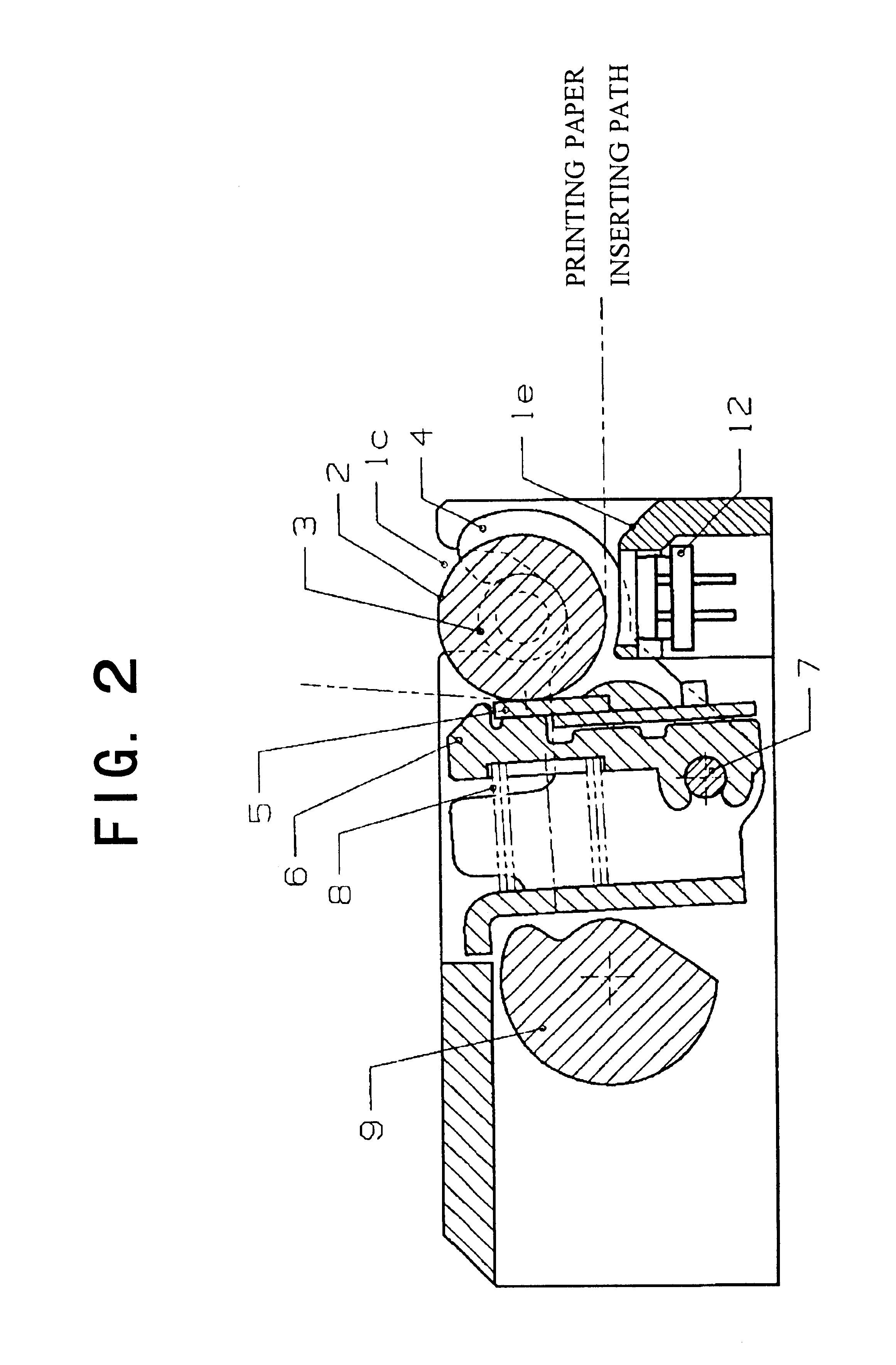

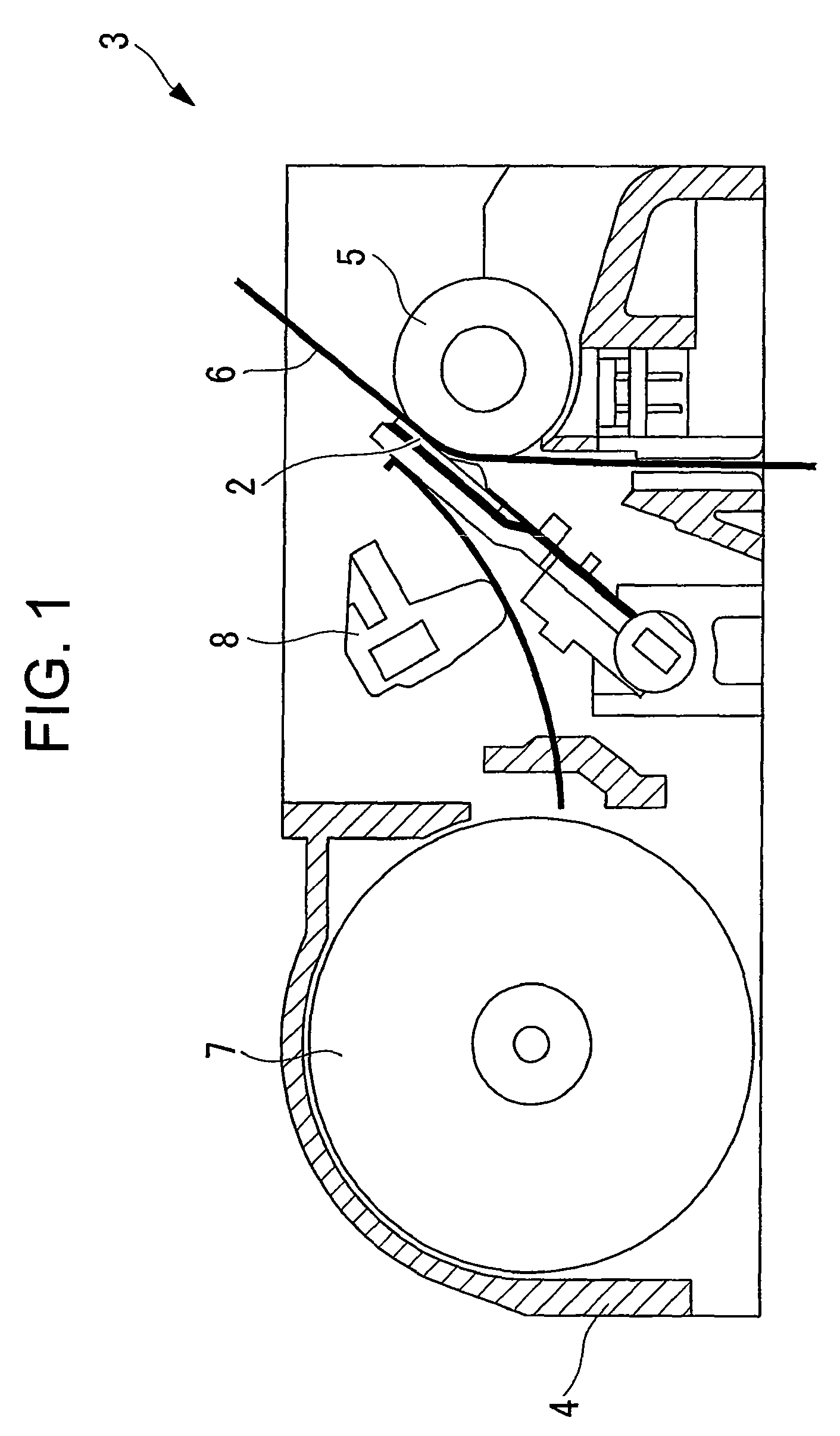

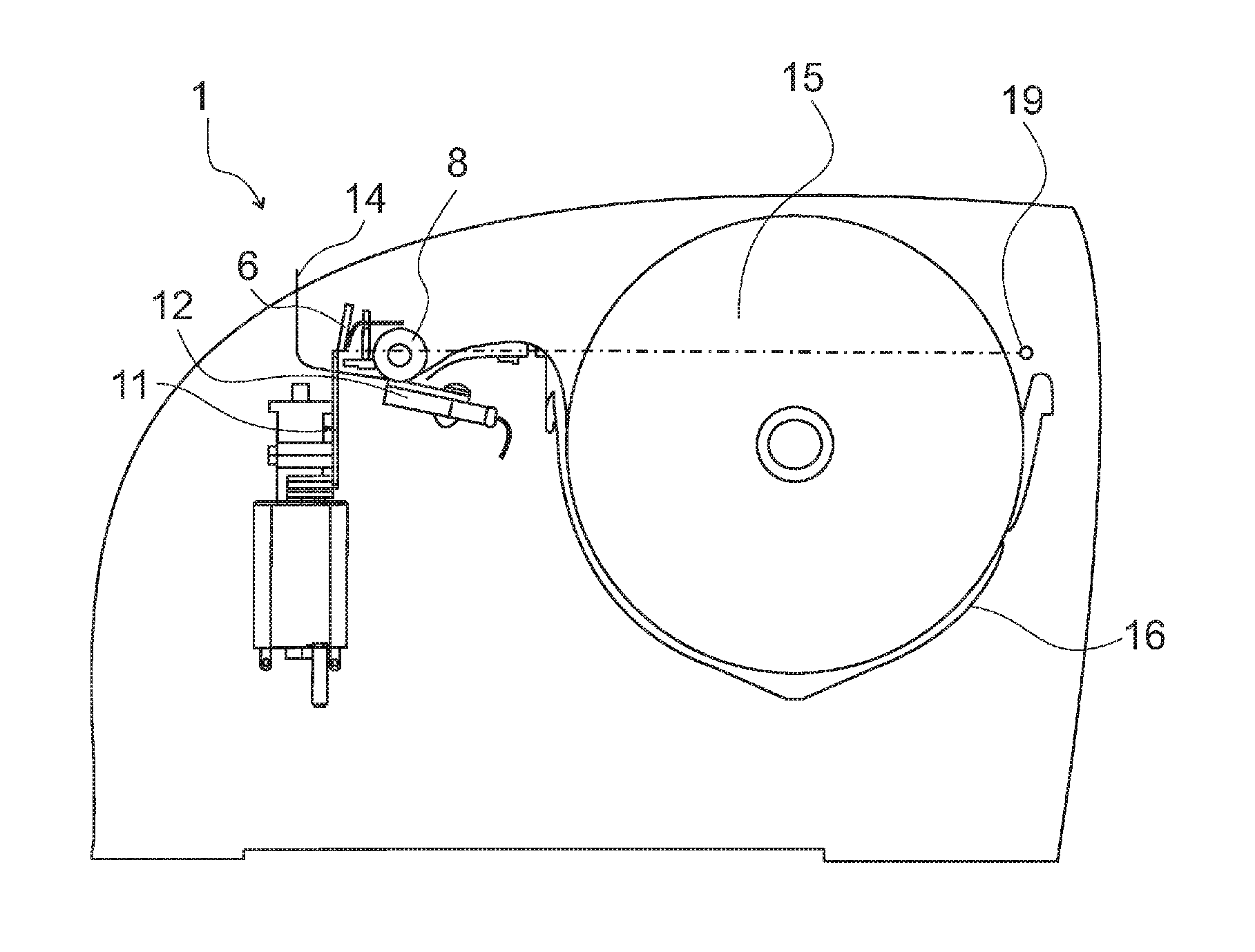

A conventional thermal printer has had a structure in which a platen roller cannot be removed from a frame. Therefore, it has been necessary to insert a printing paper between a thermal head and the platen roller. Thus, it has been hard to load the printing paper. In order to solve the problem, there has been devised means for engaging the platen roller with the frame by the biasing force of the thermal head pressing the platen roller to forcibly lift up the platen roller, thereby removing the platen roller. However, there have been problems in that great operating force is required for the removal and the precision in a platen roller support position is low. A frame is provided with a slit (1c) having such a shape as to guide a bearing of a platen roller (2), and the bearing of a platen roller (2) is pushed against the slit by a lock arm using the biasing force of a pressure spring (8) for causing a thermal head (5) to come in press-contact with the platen roller (2). Consequently, the platen roller (2) is supported.

Owner:SEIKO INSTR INC

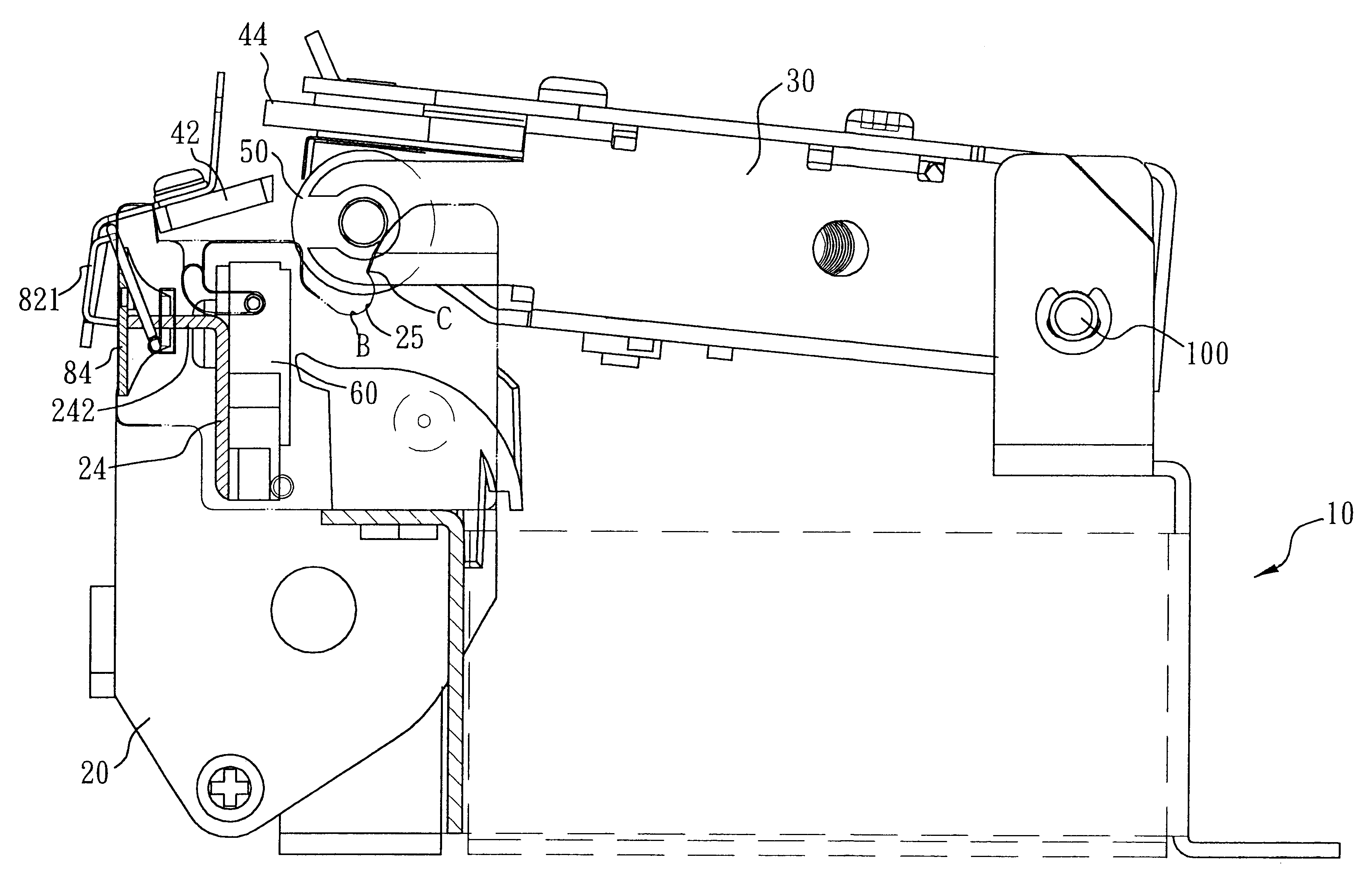

Restraining module for a cutter of a printer

InactiveUS6447187B1Damage preventionPrinting mechanismsOther printing apparatusPulp and paper industryKnife blades

Disclosed is a printer having: a fixed chassis mounted thereon; a moving chassis being engageable with the fixed chassis between an open position and a closed position; a cutter including a fixed blade and a moving blade; a paper drive roll; a thermal head; and driving means driving the paper drive roll to subject paper rolling along a paper path formed between the thermal head and the paper drive roll, and the fixed blade and moving blade; wherein the thermal head is in a path of the paper drive roll and wherein the moving blade urges the fixed blade towards the fixed chassis when the moving chassis is at the closed position, and a restraining module for maintaining an appropriate gap between the fixed blade and the moving blade when the moving chassis is engaging the fixed chassis.

Owner:XAC AUTOMATION

Color thermal printer having tension roller

A color thermal printer has a feed roller set, a thermal head, and a tension roller set that are serially arranged along a transporting path. The feed roller set and the tension roller set are rotated by respectively a stepping motor and a DC motor. The stepping motor rotates forwards. Simultaneously, the DC motor rotates the tension roller set forwards, to apply a first transporting force to the continuous recording sheet at a level higher than a predetermined transporting force of the feed roller set. Also, the stepping motor rotates backwards. Simultaneously, the DC motor rotates the tension roller set backwards, to apply a second transporting force to the continuous recording sheet at a level lower than the predetermined transporting force. A torque limiter applies load to the tension roller set relative to an output shaft of the DC motor, to keep the tension roller set rotated at a speed according to the predetermined transporting force simultaneously with application of the first or second transporting force to the continuous recording sheet. Thus, transport of the continuous recording sheet is stabilized according to a difference between the predetermined transporting force and the first or second transporting force.

Owner:FUJIFILM HLDG CORP +1

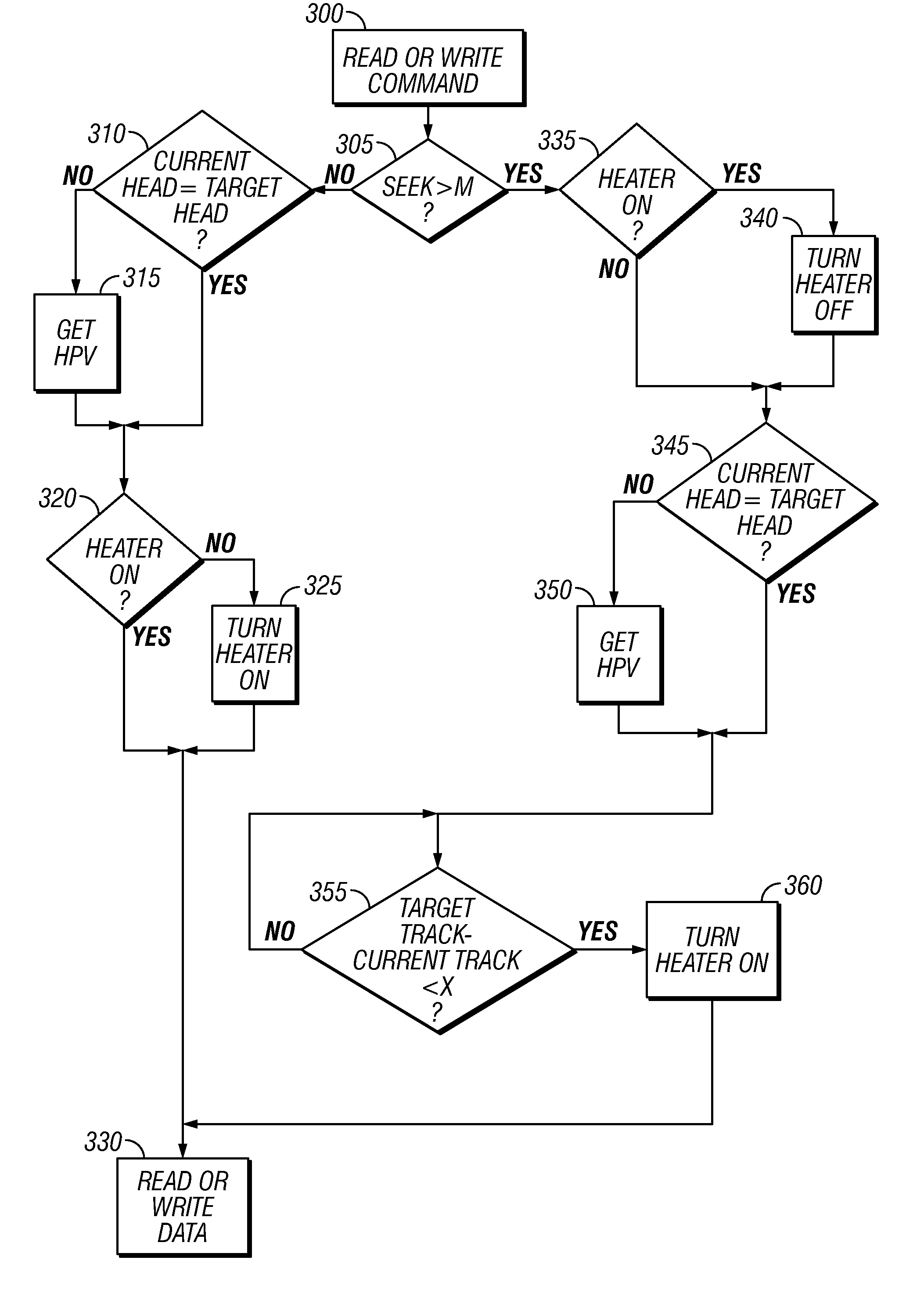

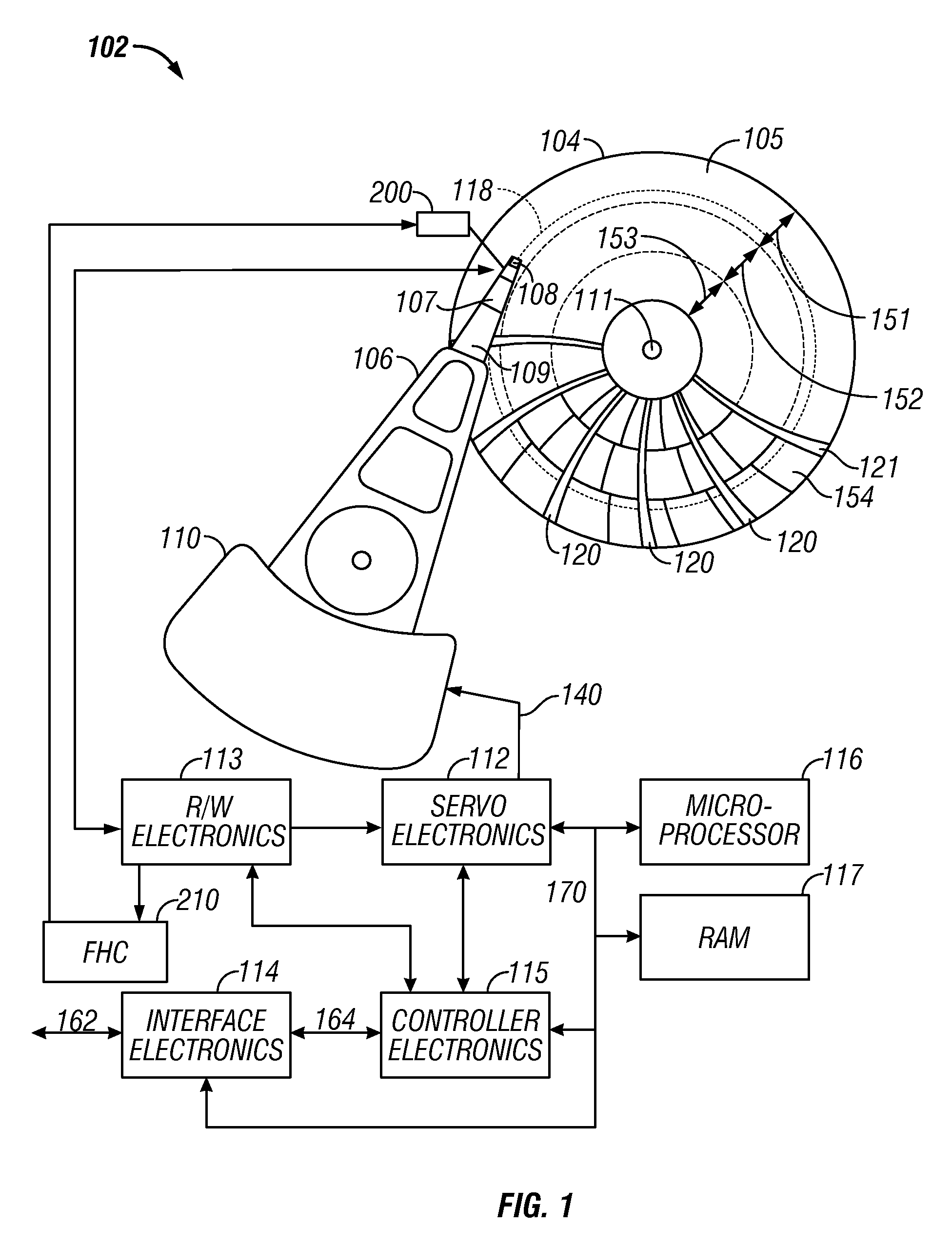

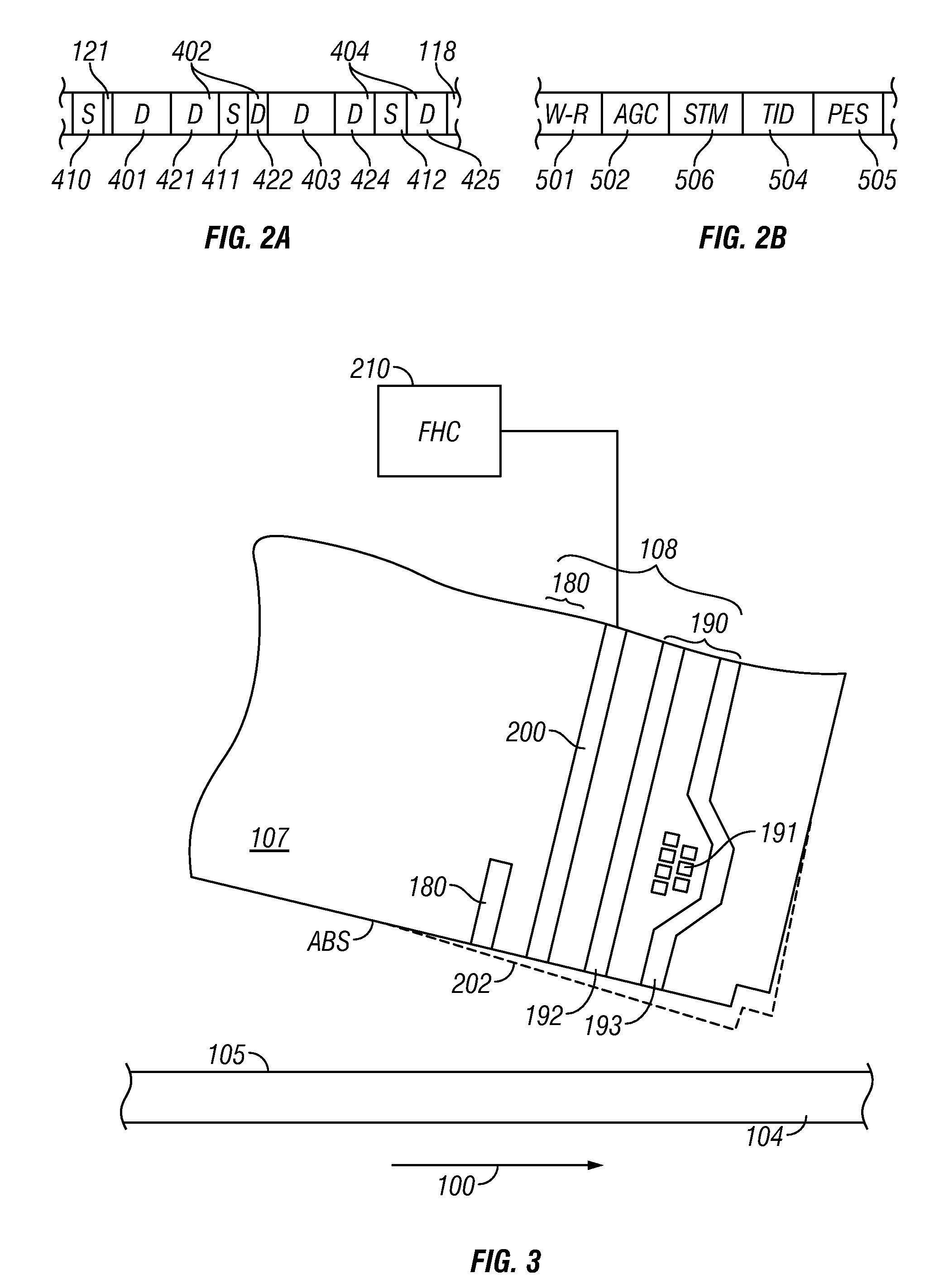

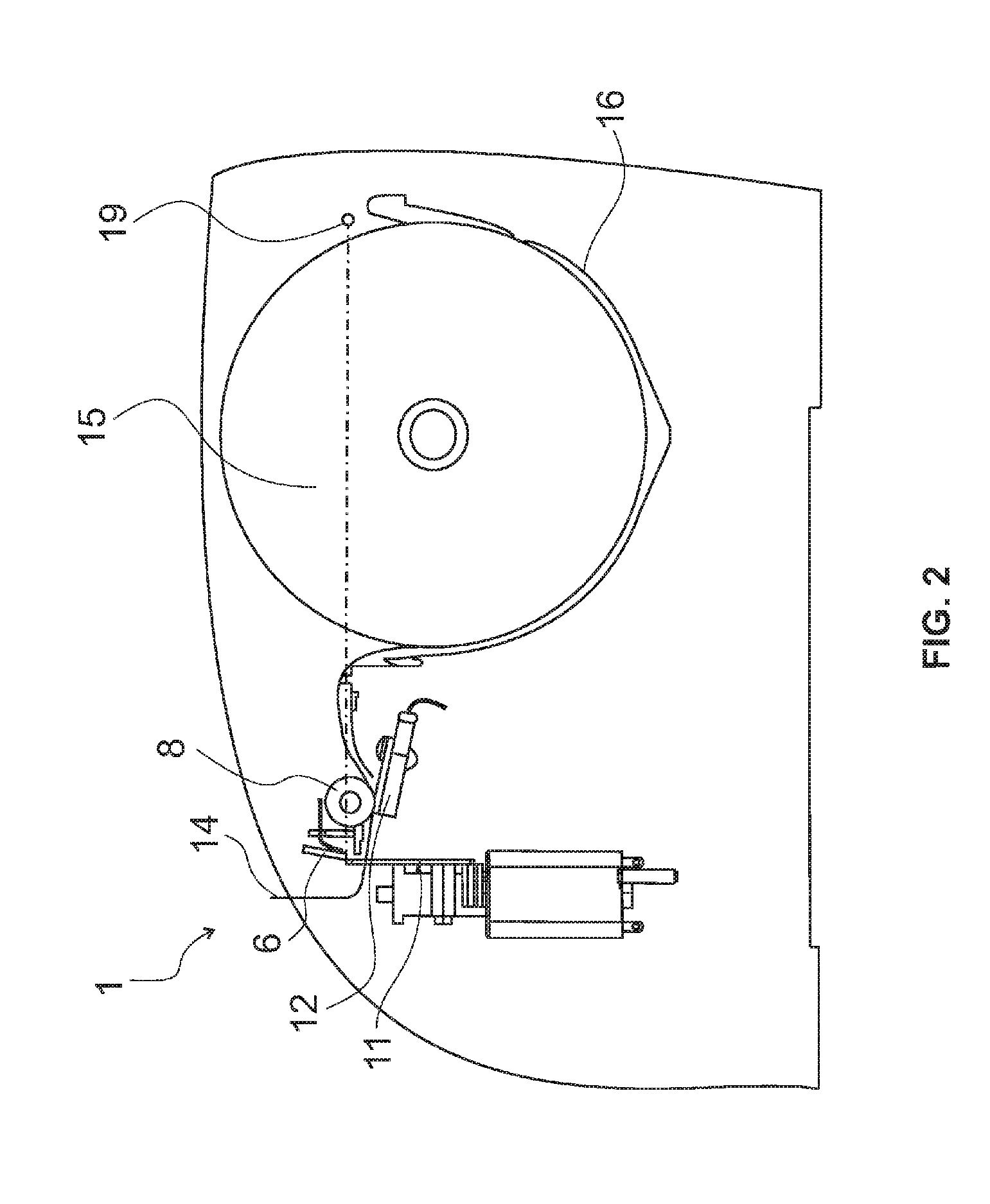

Disk drive with improved method for operating a thermal head fly-height actuator

ActiveUS7375914B1Risk minimizationOptimal head-disk spacingDriving/moving recording headsRecord information storageHeat sensitiveEngineering

A disk drive has a resistive heater located near the read / write head as a thermal fly-height actuator and uses an improved method for operating the fly-height actuator. As part of the method, the heater may be deactivated during a seek to minimize the risk of head-disk contacts. When a write command is received, a level of heater power is applied to pre-heat the write head prior to writing the initial data sectors. This pre-heating heater power level may be higher than the power level used for writing. Then when writing commences, the lower power level is applied to the heater so the write head has the optimal head-disk spacing during the writing of all the data sectors, including the initial data sectors. Even though the heater may be deactivated during the seek the controller can initiate pre-heating during the last portion of the seek before the write head has reached the target track.

Owner:WESTERN DIGITAL TECH INC

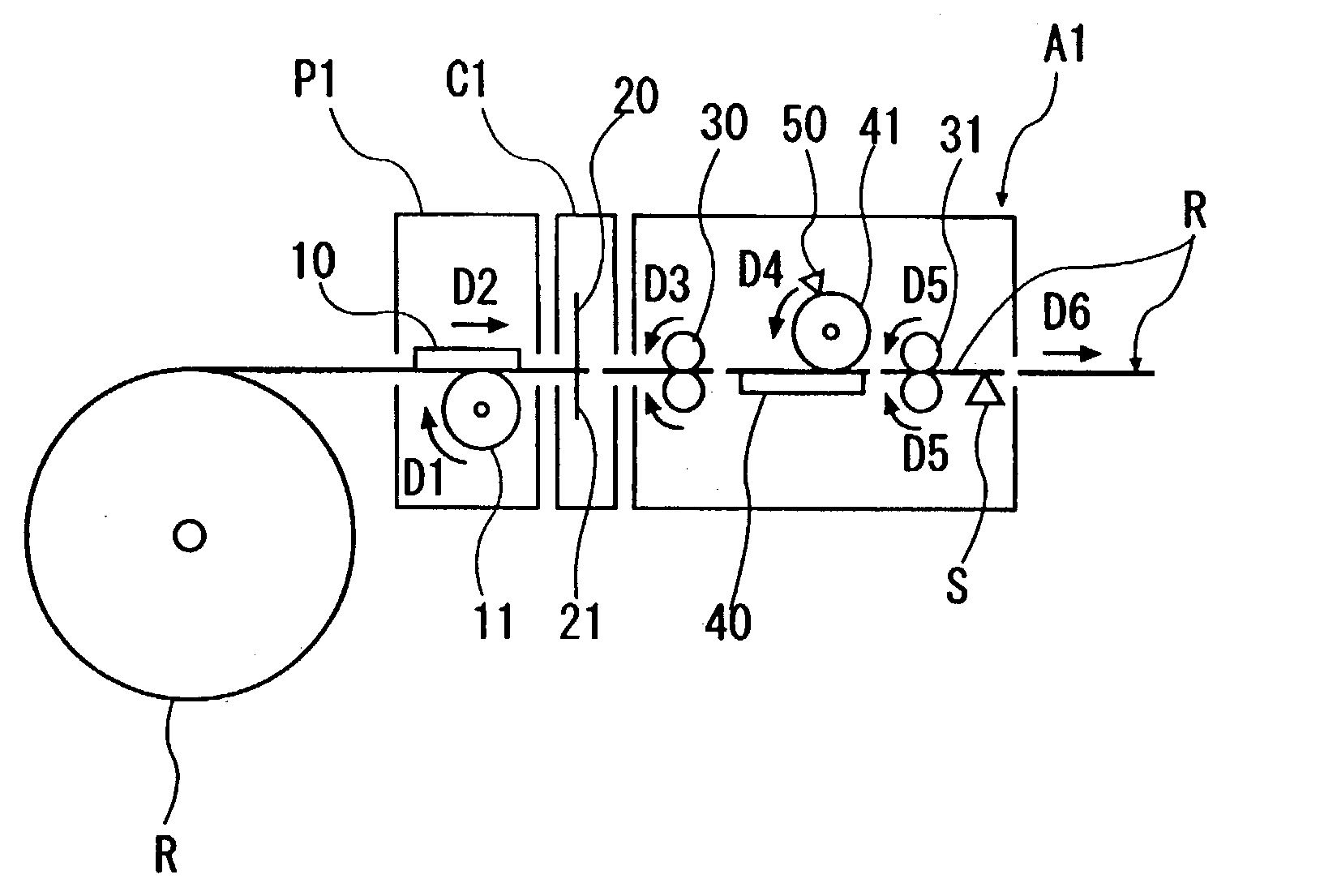

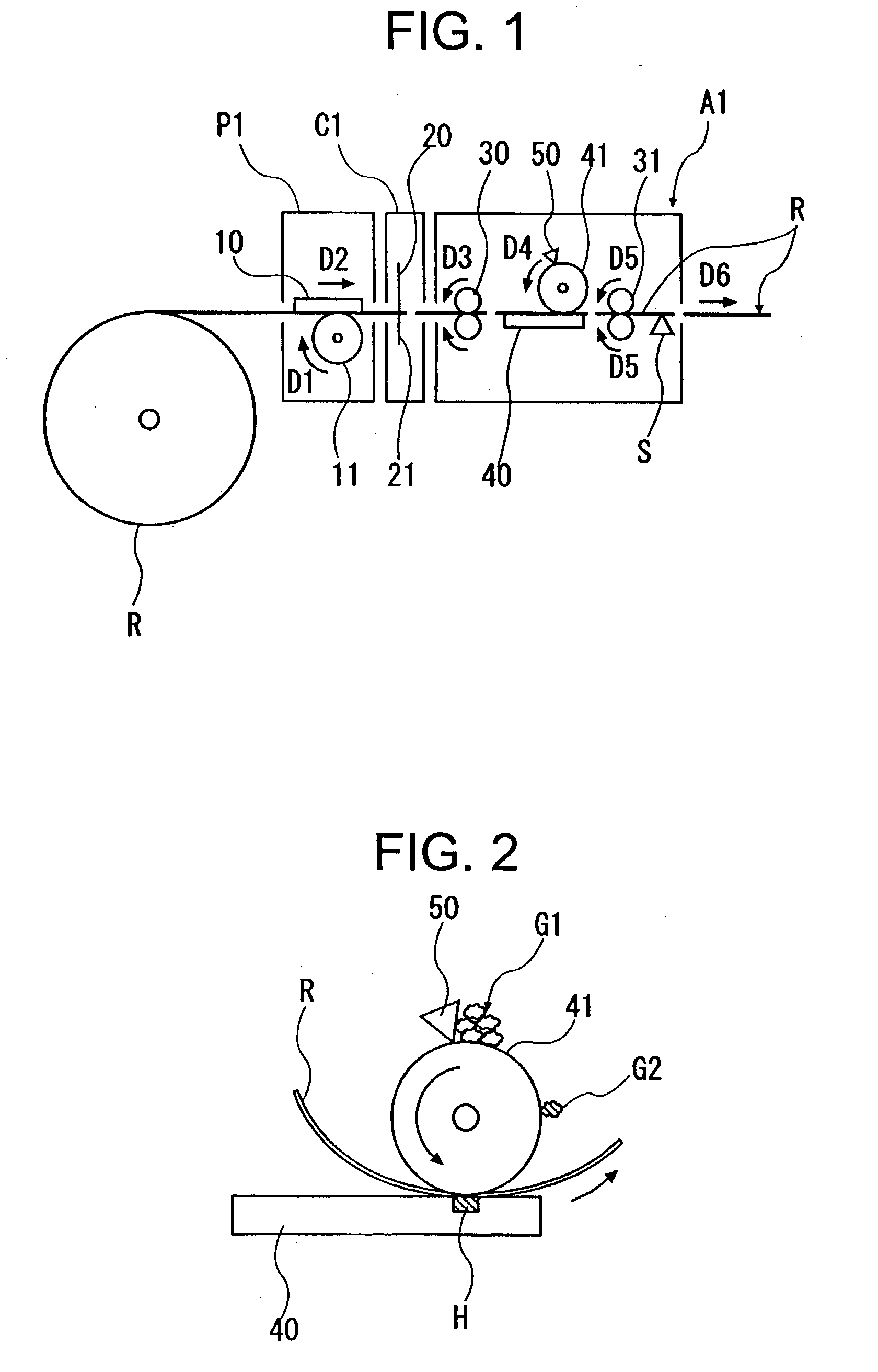

Thermal activator for heat sensitive adhesive sheet and printer apparatus utilizing the thermal activator

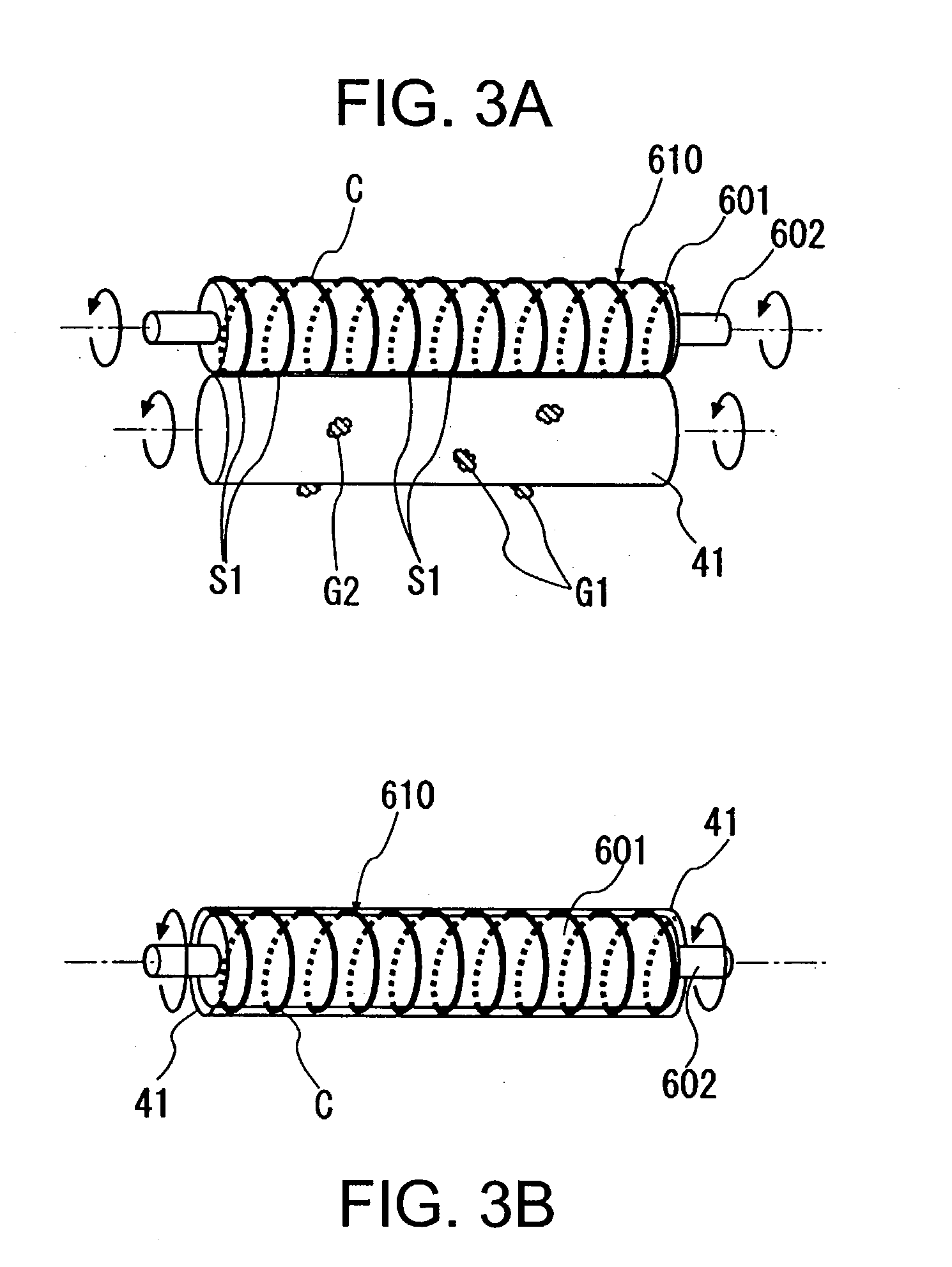

There is provided a thermal activator for a heat sensitive adhesive sheet capable of preventing or removing the heat sensitive adhesive and a product of denaturation of the heat sensitive adhesive from adhering to means for transporting the heat sensitive adhesive sheet and a printer apparatus utilizing the thermal activator. In a thermal activator for a heat sensitive adhesive sheet having at least heating means for activation (a thermal head 40 for thermal activation and a heating element H) for heating and activating a heat sensitive adhesive layer of a heat sensitive adhesive sheet (a heat sensitive adhesive label R) constituted of a printable surface (a thermal coat layer 501 and a color printing layer 502) and the heat sensitive adhesive layer (K) formed on one and another side of a base material (base paper 500) respectively and transport means (a platen roller 41 for thermal activation and the like) for transporting the heat sensitive adhesive sheet in a predetermined direction, there is provided anti-adhesion means (sheet materials 81 and 600 for cleaning) for preventing the heat sensitive adhesive or a product of denaturation of the heat sensitive adhesive from adhering to the transport means or removal means (a scraper 50, a rotary body 610 having a spiral groove or protrusion, a cylindrical rotary body 700 having a spiral blade, wires W, scraping tools 900 and 1100 in the form of a cutter blade, a transfer material 60, a cleaning roller 70, or the like) for removing the heat sensitive adhesive and the product of denaturation of the heat sensitive adhesive that have adhered to the transport means.

Owner:SAMBONGI NORIMITSU +5

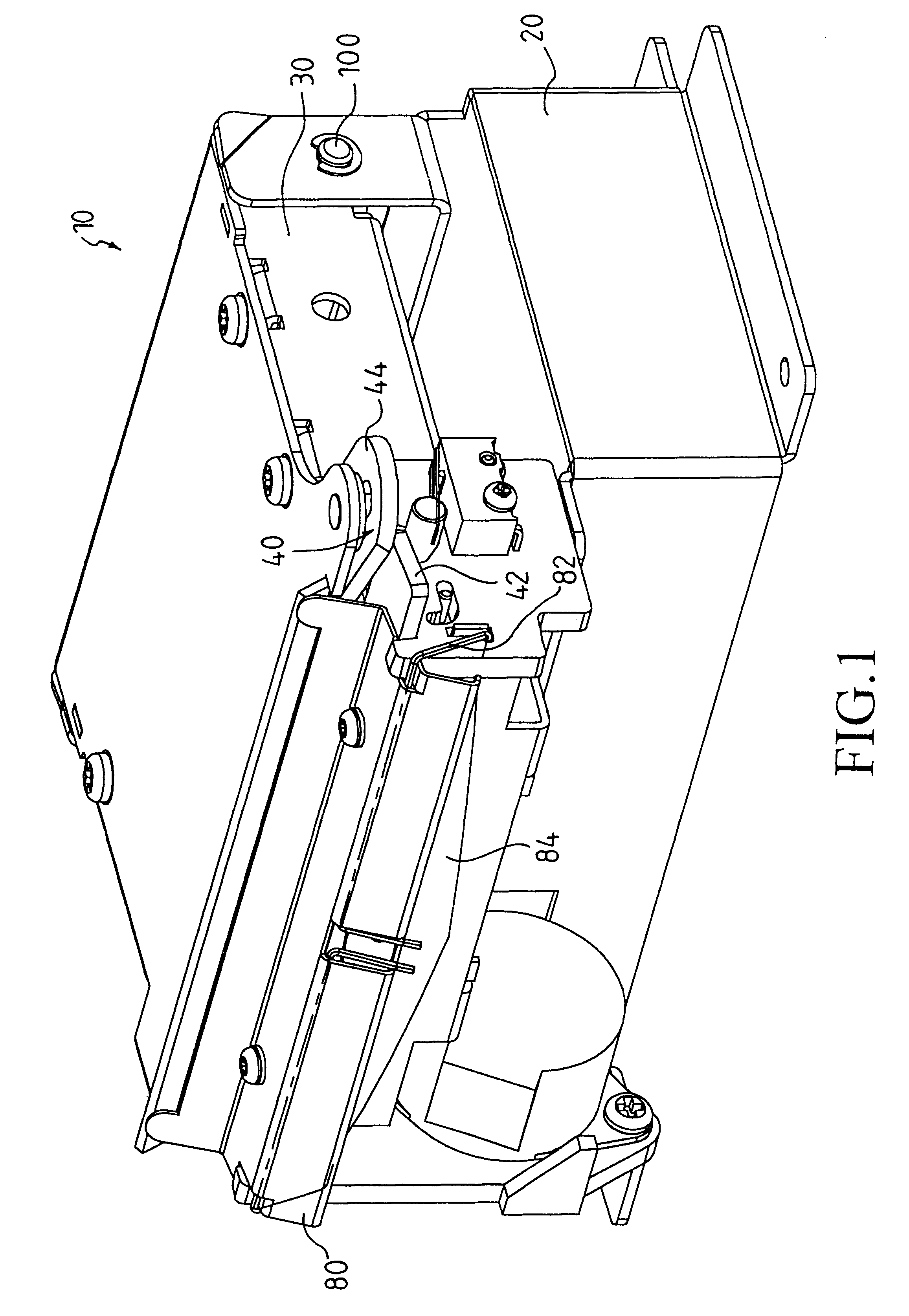

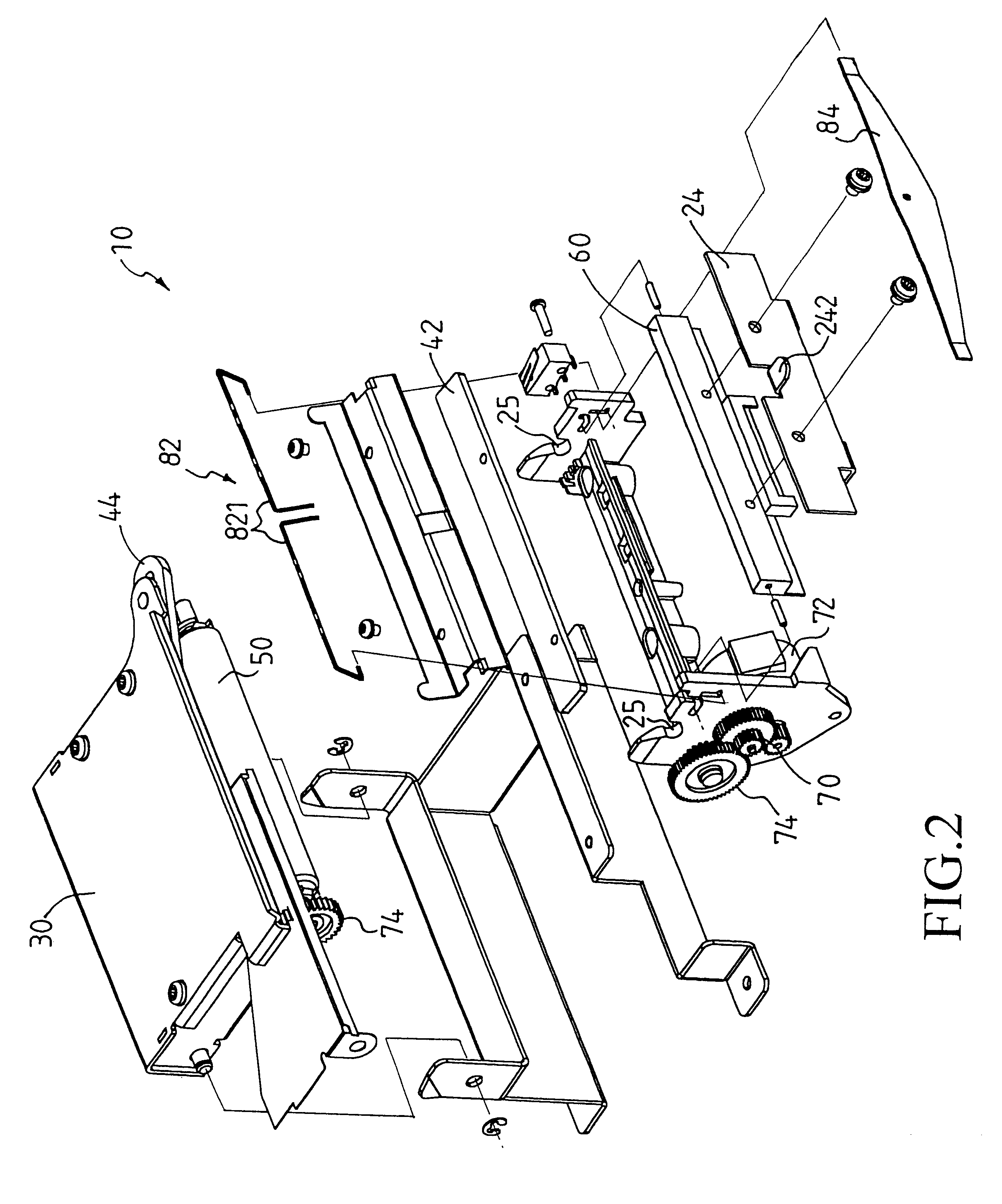

Thermal printer and cutter

InactiveUS20050036820A1Reduce weightGuaranteed uptimePrinting mechanismsRotary pressesEngineeringKnife blades

A thermal printer includes a first module having a motor and a thermal head support member to fix a thermal head, the thermal head support member having a fixed blade part working as a blade and an a second module being detachably coupled with the first module, the second module having a platen roller, a movable blade member and a movable blade member movement mechanism to move the movable blade member, wherein the movable blade member is disposed to face the fixed blade part and driving force of the motor is conveyed to the movable blade member movement mechanism, and thereby a cutter part is formed.

Owner:FUJITSU COMPONENENT LTD

Image-forming method using heat-sensitive transfer system

An image-forming method, containing the steps of: superposing a heat-sensitive transfer sheet on a heat-sensitive transfer image-receiving sheet so that the following at least one receptor layer of the heat-sensitive transfer image-receiving sheet can be contacted with the following thermal transfer layer of the heat-sensitive transfer sheet; and providing thermal energy given by a thermal head in accordance with image signals, thereby to form an image; wherein the heat-sensitive transfer image-receiving sheet is transported at a speed of 125 mm / s or more during the image formation, and wherein the heat-sensitive transfer image-receiving sheet contains, on a support, at least one receptor layer containing a polymer latex, and at least one heat insulation layer containing hollow polymer particles but free of any resins having poor resistance to an organic solvent except for the hollow polymer particles, and the heat-sensitive transfer sheet contains, on a support, a thermal transfer layer.

Owner:FUJIFILM CORP

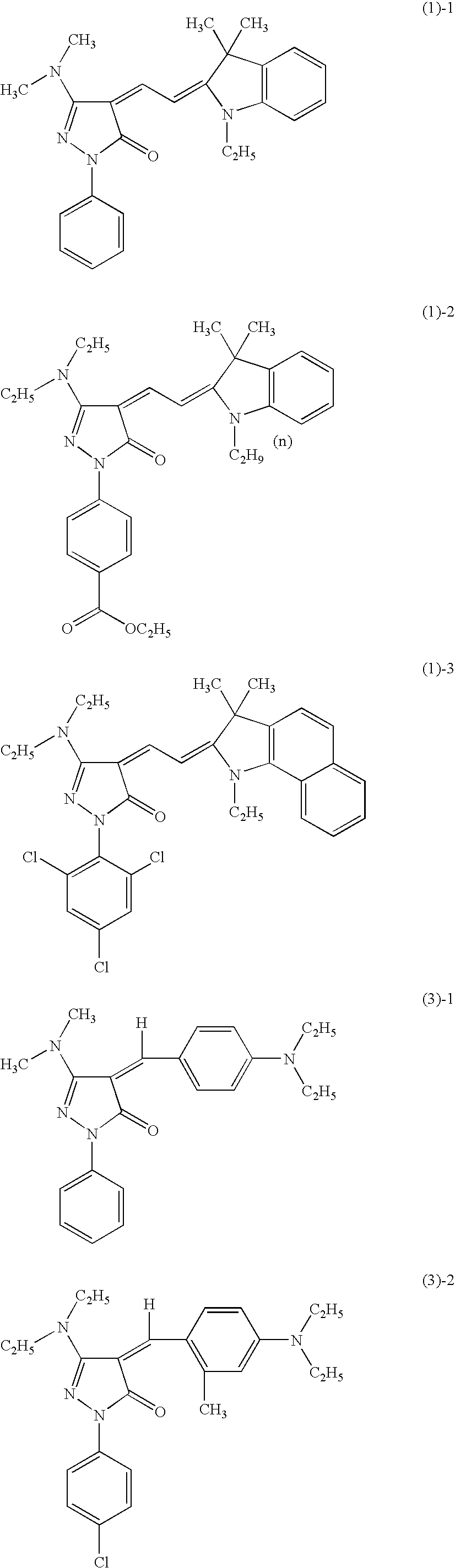

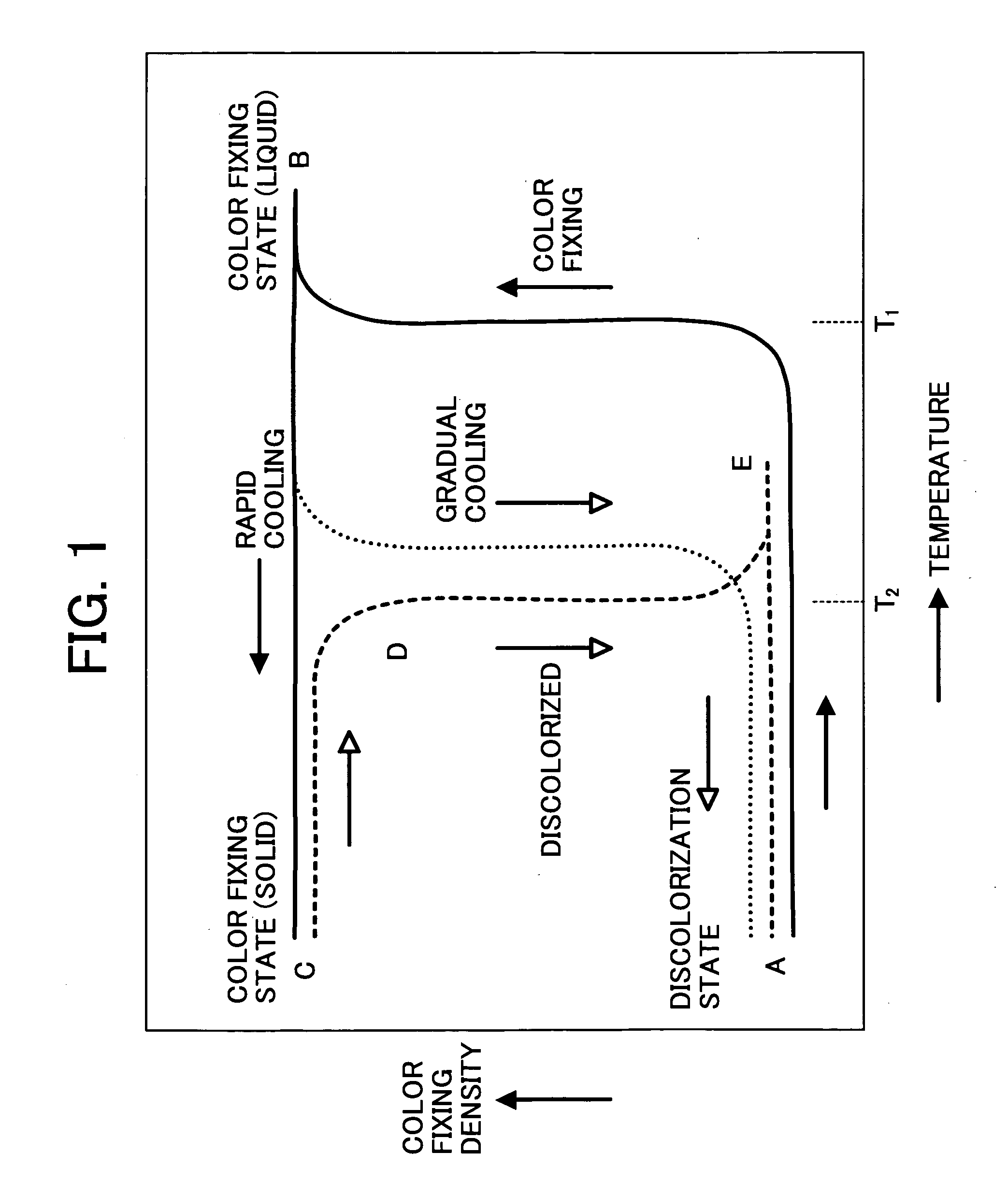

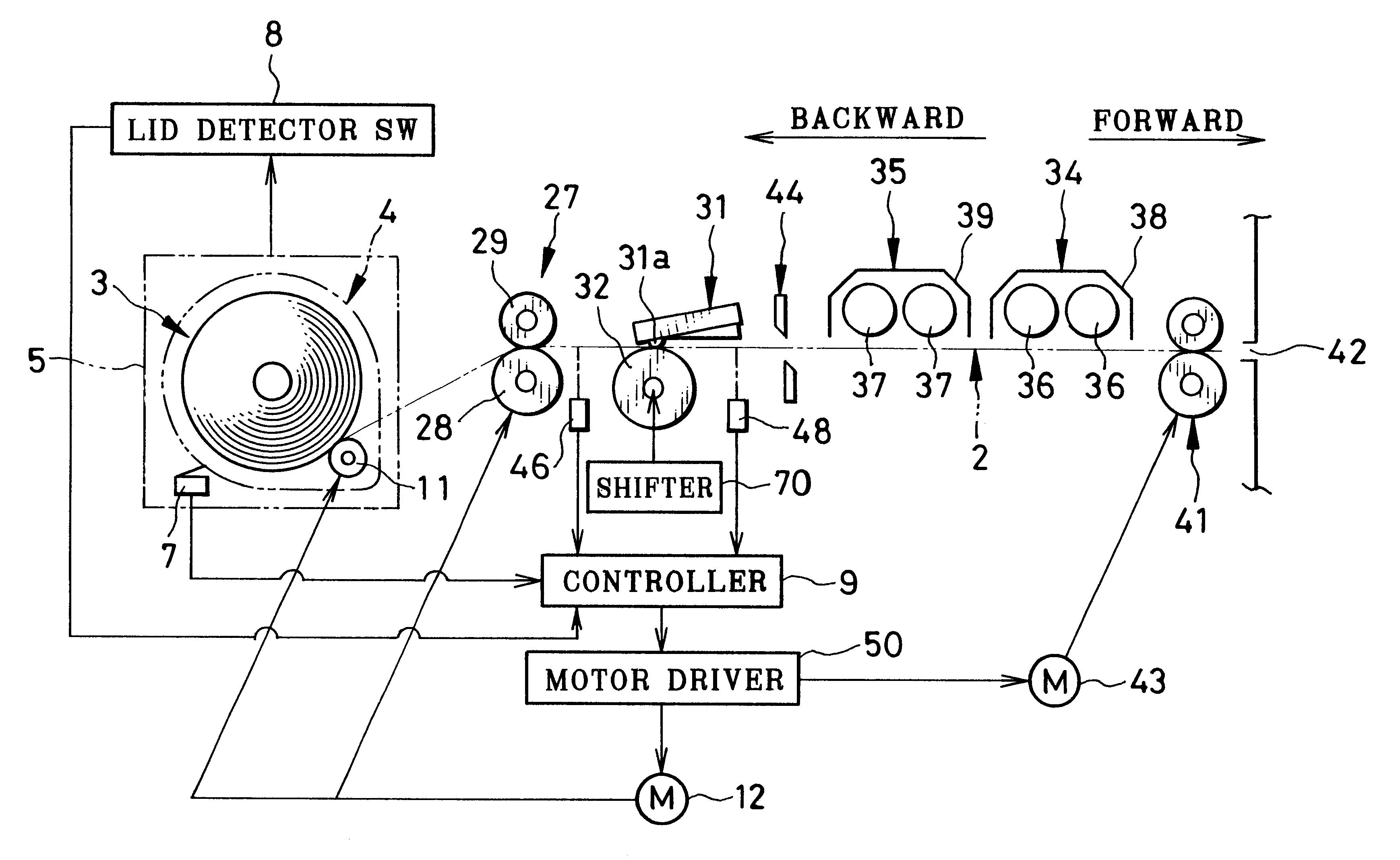

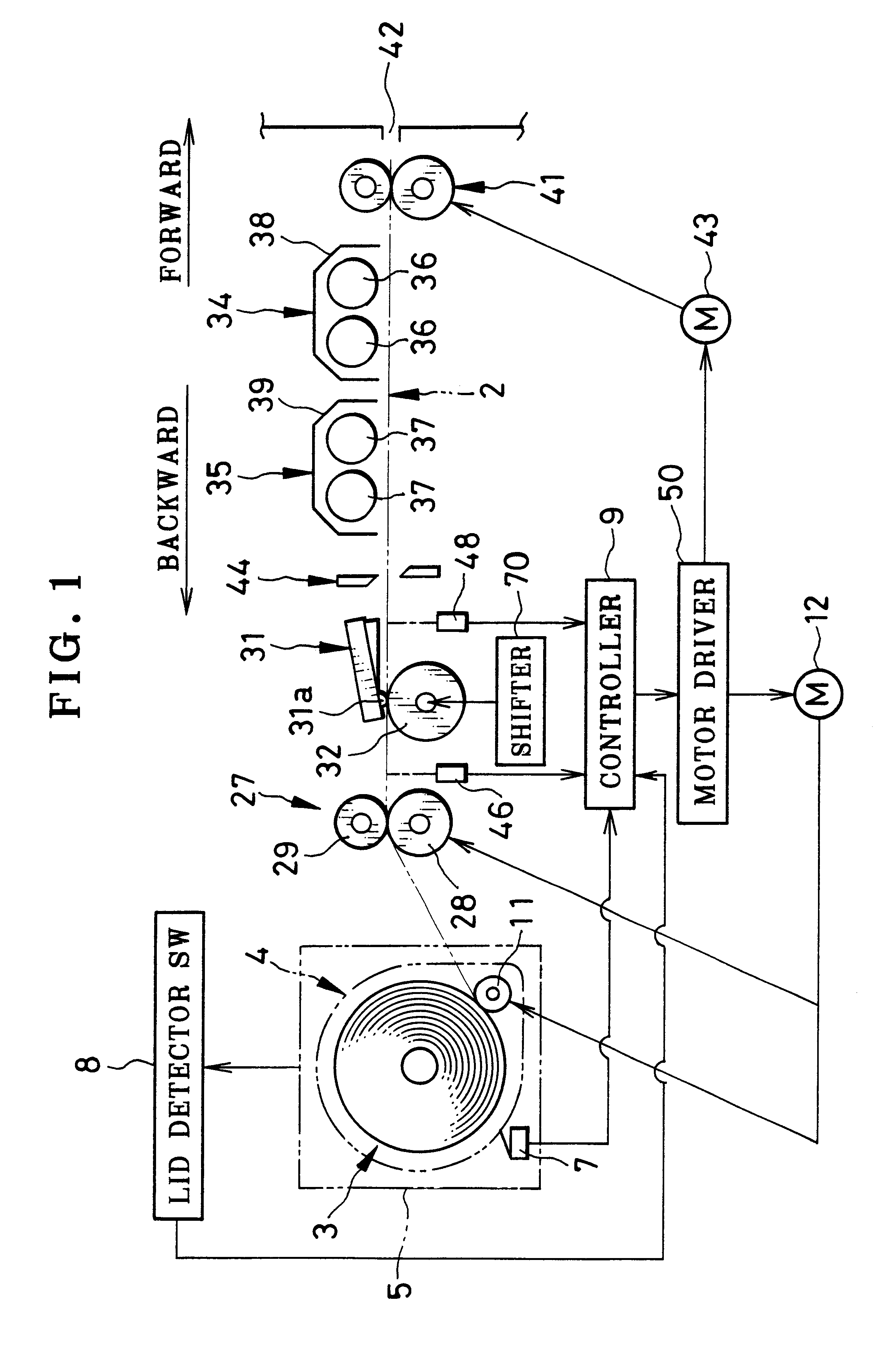

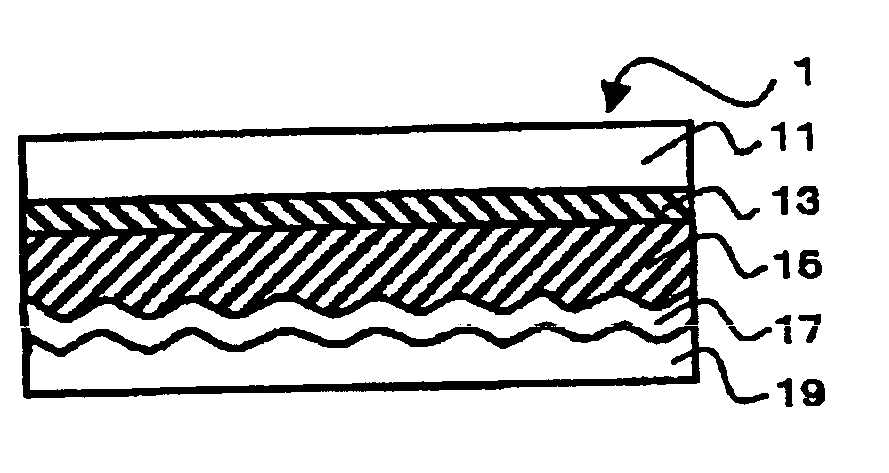

Reversible thermosensitive recording medium, information storage material, reversible thermosensitive recording label, image processing method and image processing device

ActiveUS20050137088A1High image densityLess occurrenceAblative recordingRecording measured valuesImaging processingRecording layer

A reversible thermosensitive recording medium including a substrate, a reversible thermosensitive recording layer and an intermediate layer. The reversible thermosensitive recording layer is configured to reversibly record and erase an image therein and disposed overlying the substrate and includes a binder resin and a reversible thermosenstive coloring composition. The reversible thermosenstive coloring composition includes an electron donating coloring compound and an electron accepting compound. The intermediate layer includes another binder resin and a content of hollow particles having a hollow ratio not less than 70% and a ratio of a maximum particle diameter thereof to a 50% cumulative particle diameter of from 2.0 to 3.0. The reversible thermosensitive recording layer achieves a colored state when heated to a temperature not lower than a melting point thereof, and achieves a discolorization state when heated to a temperature lower than the melting point. The reversible thermosensitive recording layer has an erasable energy range width of at least 0.1 mJ / dot when using a thermal head.

Owner:RICOH KK

Head cleaning method and device for thermal printer, and recording sheet roll for the same

A thermal printer includes a capstan roller and pinch roller, which feed a continuous color thermosensitive recording sheet from a recording sheet roll. A thermal head operates for image recording to the continuous recording sheet. A roll loading chamber is loaded with one of the recording sheet roll and a cleaning sheet roll. The cleaning sheet roll includes a continuous cleaning sheet wound in a roll form, and discernment indicia provided in a predetermined position. An information reading photoelectric sensor reads the discernment indicia. A controller causes the capstan roller and pinch roller to feed the continuous cleaning sheet when the discernment indicia is read, to wipe and clean the thermal head with the continuous cleaning sheet. In a preferred embodiment, a cutter precuts the continuous recording sheet in a precutting position distant by a predetermined length from a front edge of the continuous recording sheet, to remove a front edge portion.

Owner:FUJIFILM HLDG CORP +1

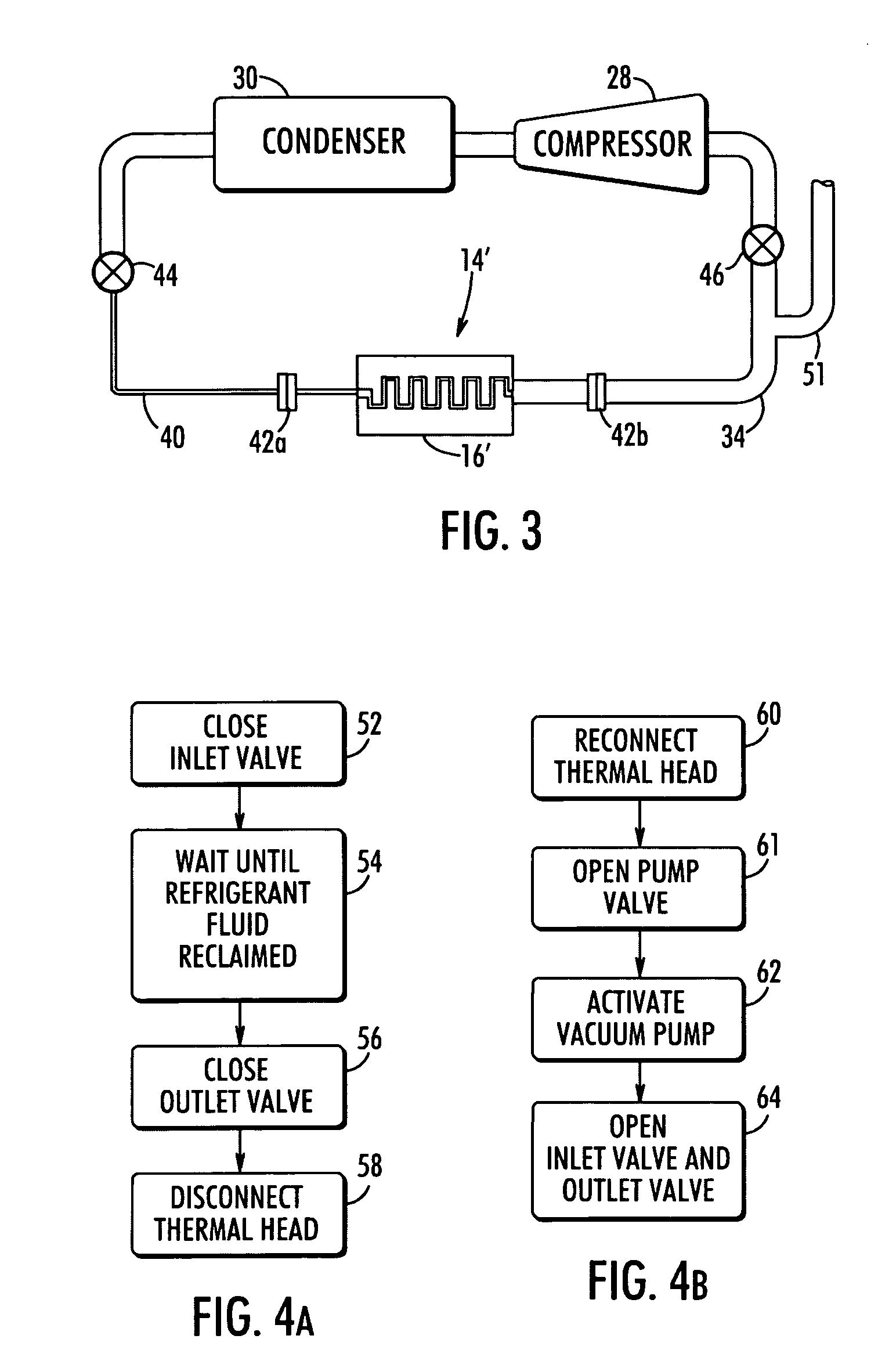

Apparatus and method for controlling the temperature of an electronic device

InactiveUS7017358B2Compression machines with non-reversible cycleRefrigeration devicesInlet valveEngineering

An apparatus for controlling the temperature of an electronic device under test includes a thermal head. The thermal head defines a flow channel for passage of a refrigerant fluid so as to cause transfer of thermal energy between the electronic device and the thermal head. A refrigeration system is connected in fluid communication with the flow channel of the thermal head to supply refrigerant fluid thereto. An inlet valve and outlet valve are provided to facilitate disconnection of the thermal head from the refrigeration system. The valves are sequentially closed with the refrigeration system continuing to operate during the interim period so as to reclaim the refrigerant fluid. Accordingly, thermal head may be disconnected from refrigeration system and removed.

Owner:DELTA DESIGN

Method and apparatus for controlling temperature

Apparatus to control a temperature of a device that includes: a thermal head adapted to be thermally contacted to the device; a combined path to the thermal head; a first path maintained at a first temperature and connected to the combined path; a second path maintained at a second temperature different from the first temperature and connected to the combined path; a third path connected to the combined path; a pump assembly operable to circulate thermal transfer fluid: from the thermal head, through each of the first, second and third paths, from each of the first, second and third paths, through the combined path, and from the combined path, to and through the thermal head; and a valve assembly operable to control amounts of thermal transfer fluid that flow into the first and second paths, thereby controlling the temperature.

Owner:CENTIPEDE SYST

Heating resistor element, manufacturing method for the same, thermal head, and printer

InactiveUS7768541B2Avoid deformationImprove printing qualityElectrographic process apparatusPrintingEngineeringHeat sensitive

Owner:SEIKO INSTR INC

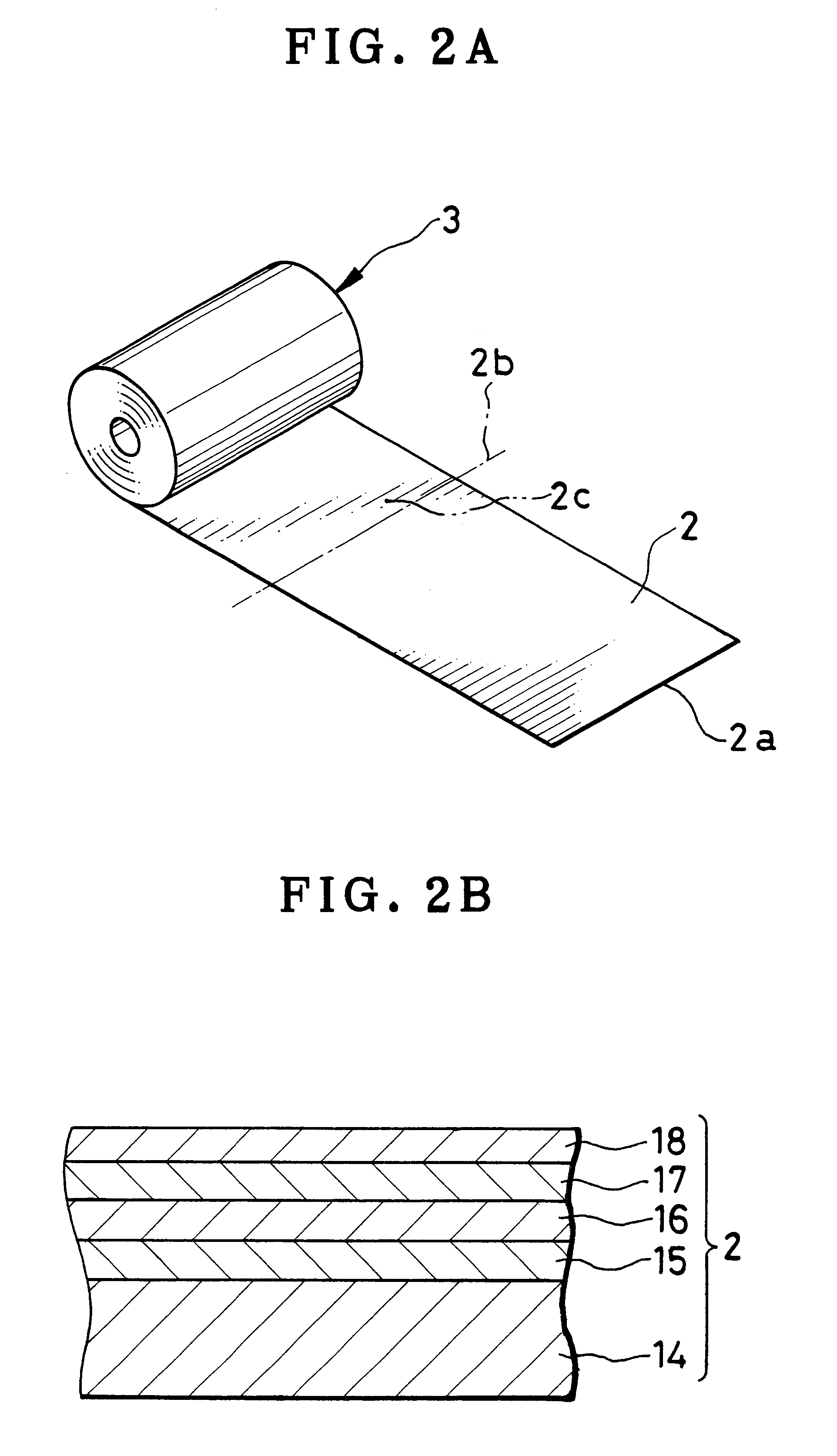

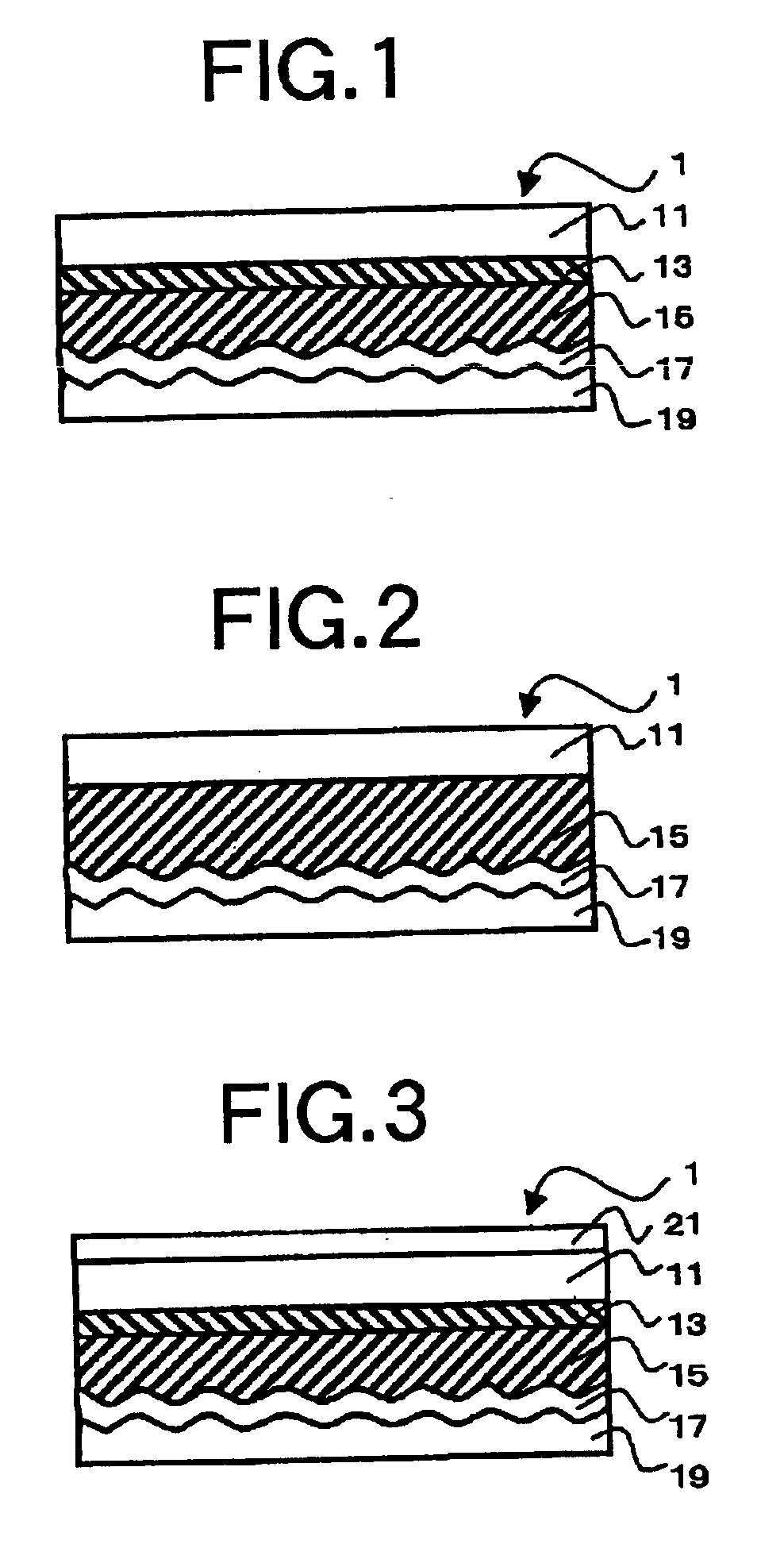

Transfer ribbon, image expressing medium and method for production of them

ActiveUS6909444B2Quality improvementHigh-quality designRecording apparatusInk ribbonsComputer scienceThermal Head

The invention provides a transfer ribbon having a layered structure in which a substrate, a relief layer and a reflection layer are laminated in this order, wherein the relief layer comprises an ionizing radiation-cured resin. The transfer ribbon can precisely transfer fine dots and / and dots placed close to each other with a low energy and at a high speed without any of burrs, chippings or lacks by means of a thermal head. Also, the invention provides an image expressing medium, which can be produced using the transfer ribbon described above, and comprises a support, a color layer and plural dots of relief hologram and / or diffraction grating. In the medium: the color layer and the dots are disposed on the same surface of the support; and the each dot has an area in a range from 0.0001 to 0.09 mm2; the each dots has a diffraction direction different from that of at least one of adjacent dots, or the dot has two or more sections each of which has a diffraction direction different from each other. The image expressing medium exhibits specially decorative effects such as a lame-like effect.

Owner:DAI NIPPON PRINTING CO LTD

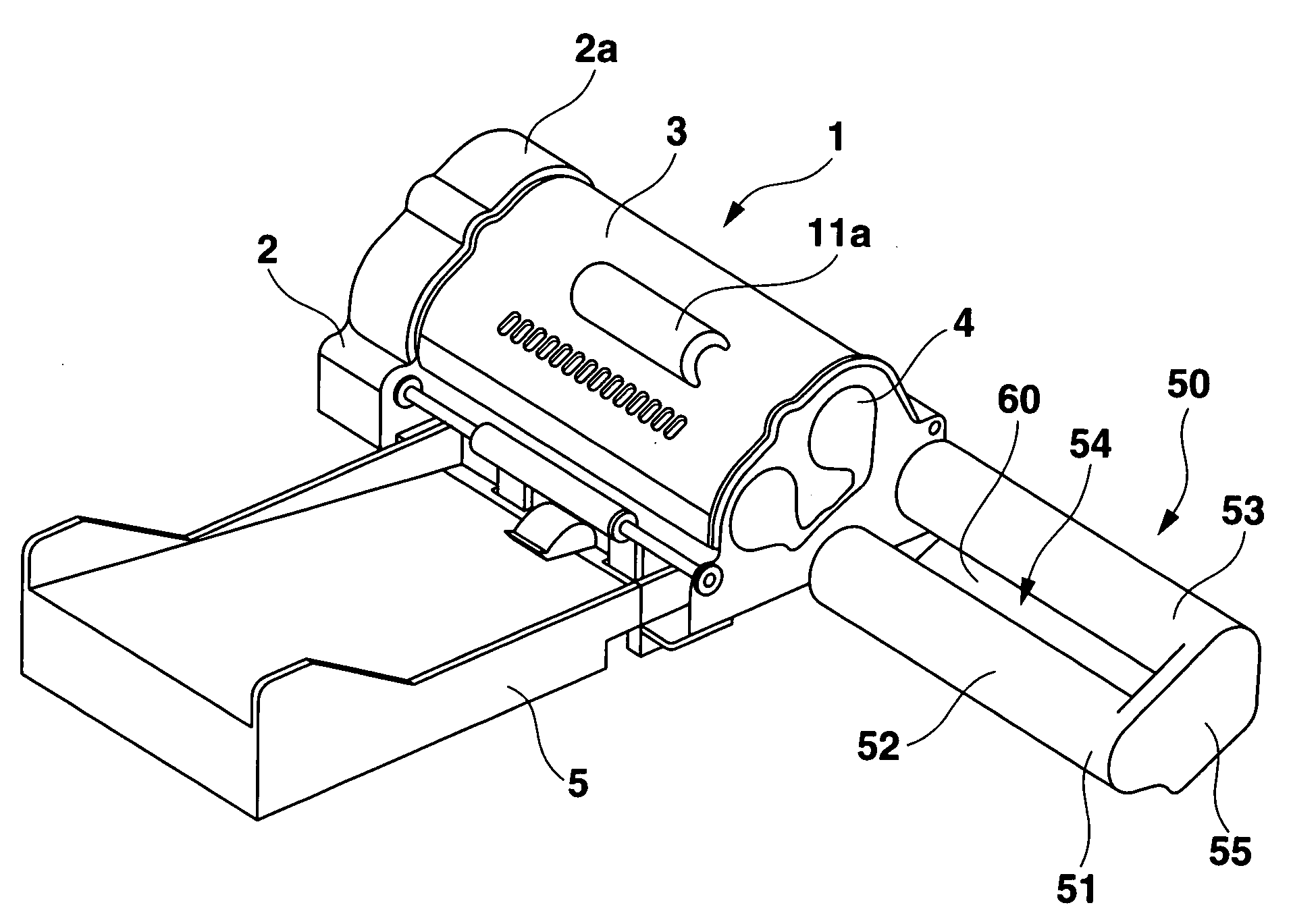

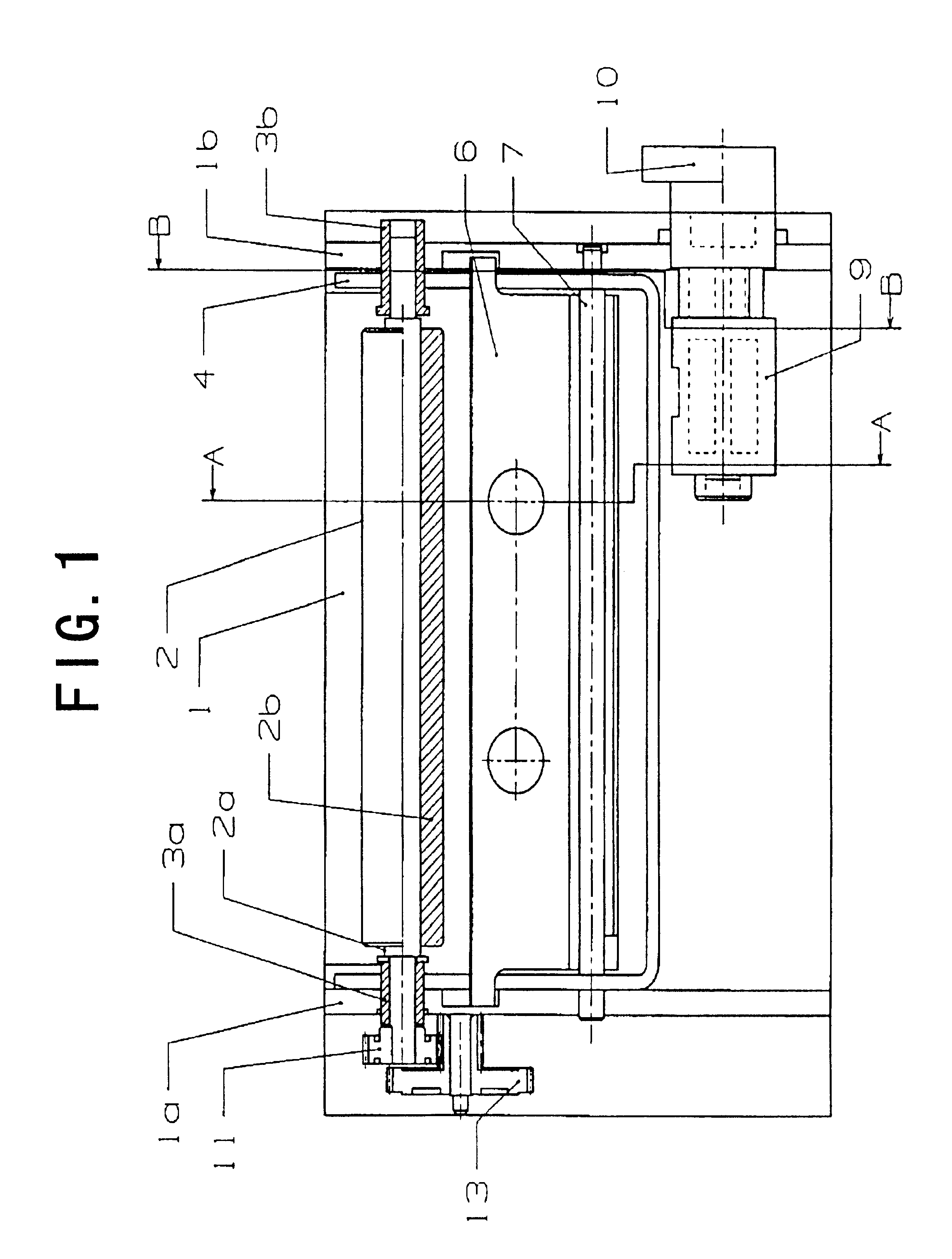

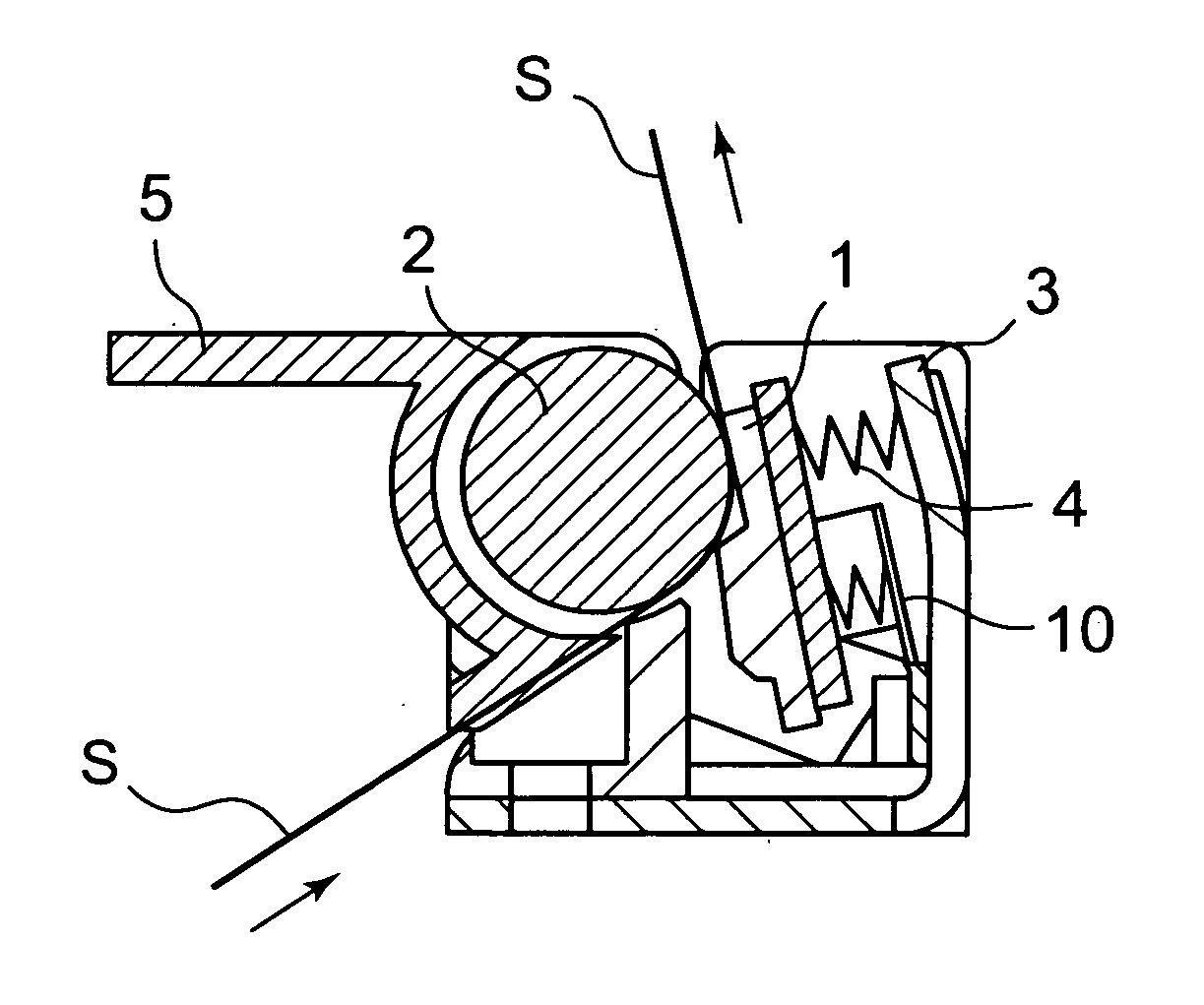

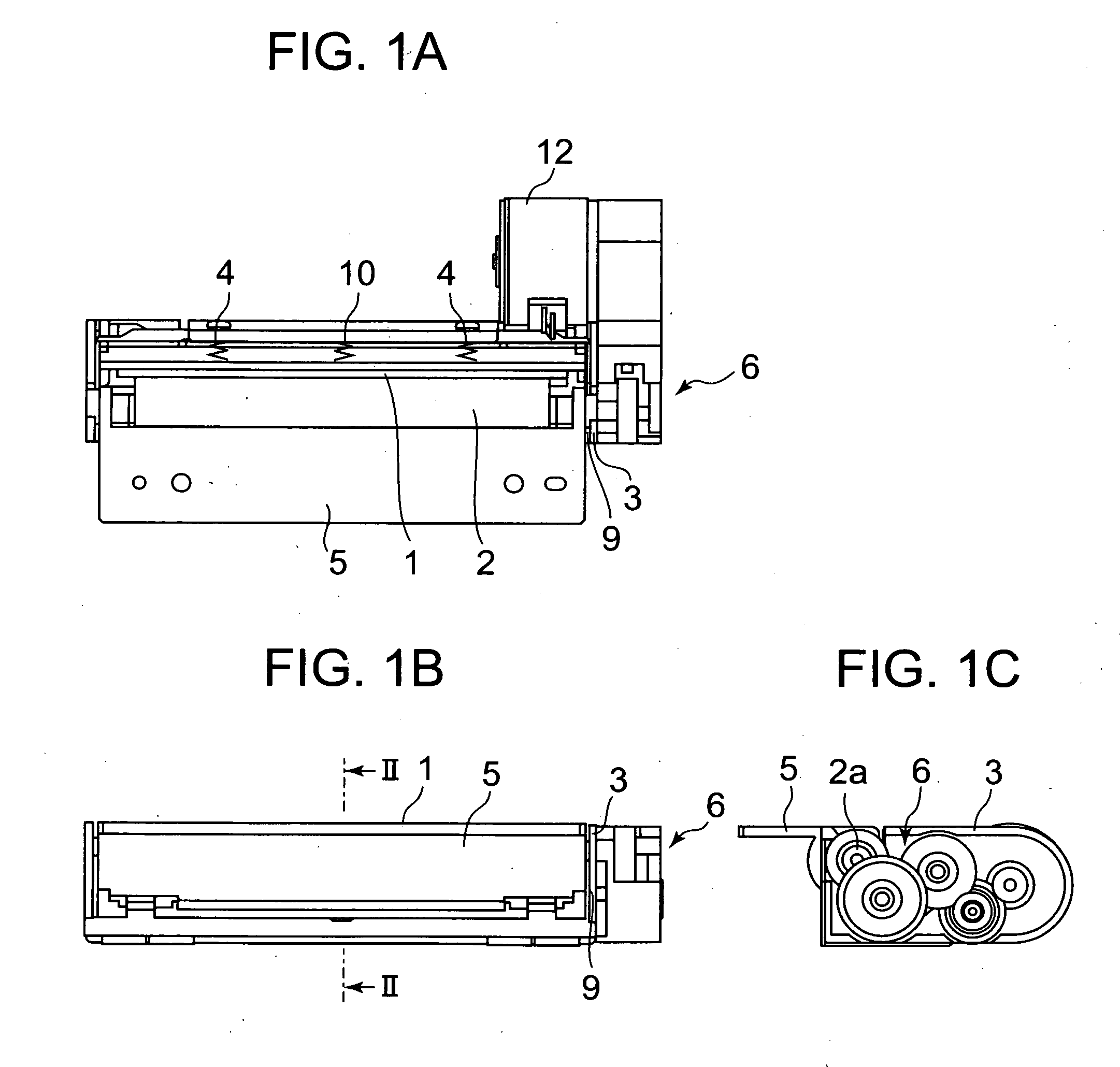

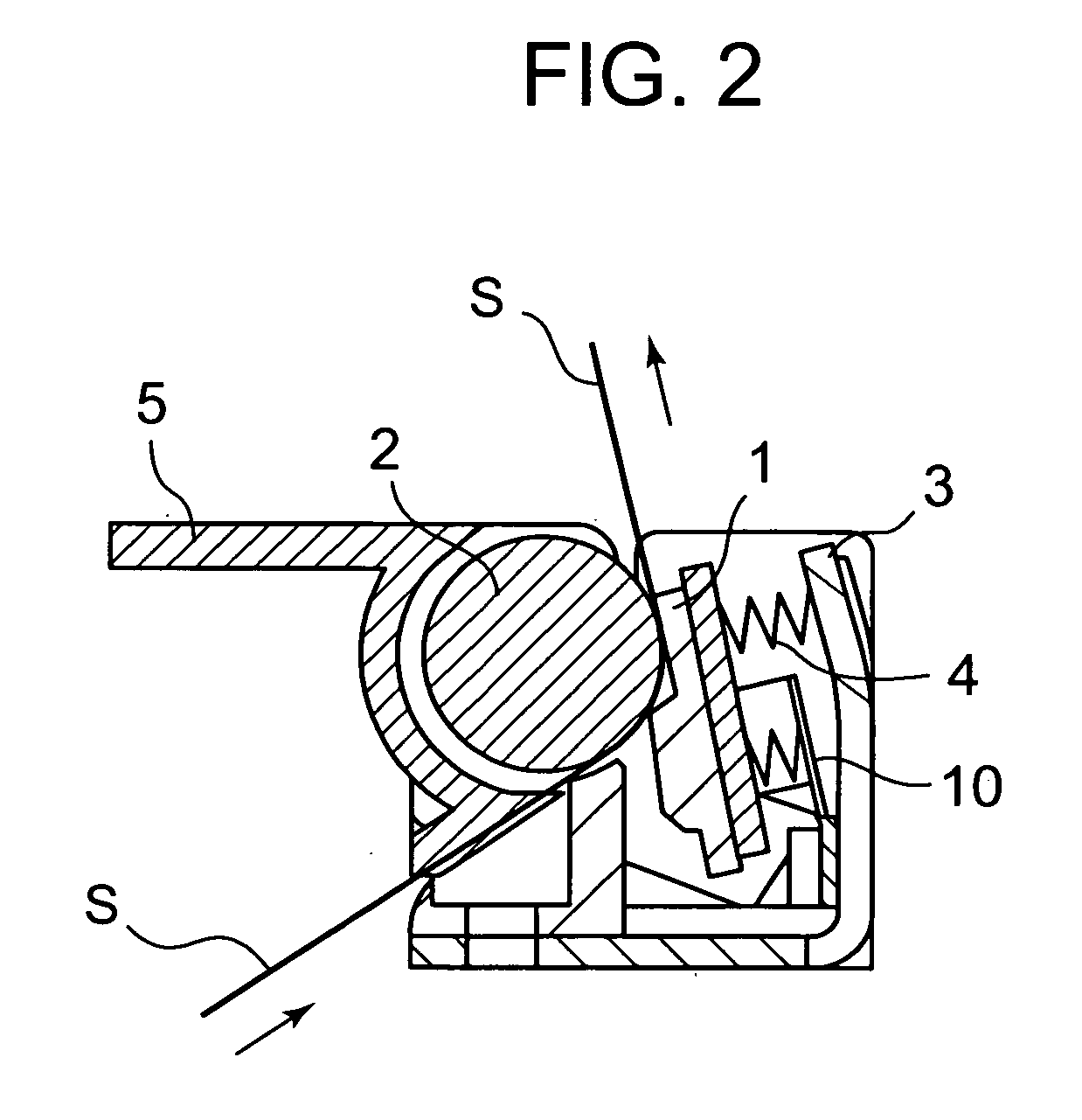

Platen retaining structure and recording unit

InactiveUS20080180468A1Unnecessary to provideRecording apparatusInking apparatusSpring forceEngineering

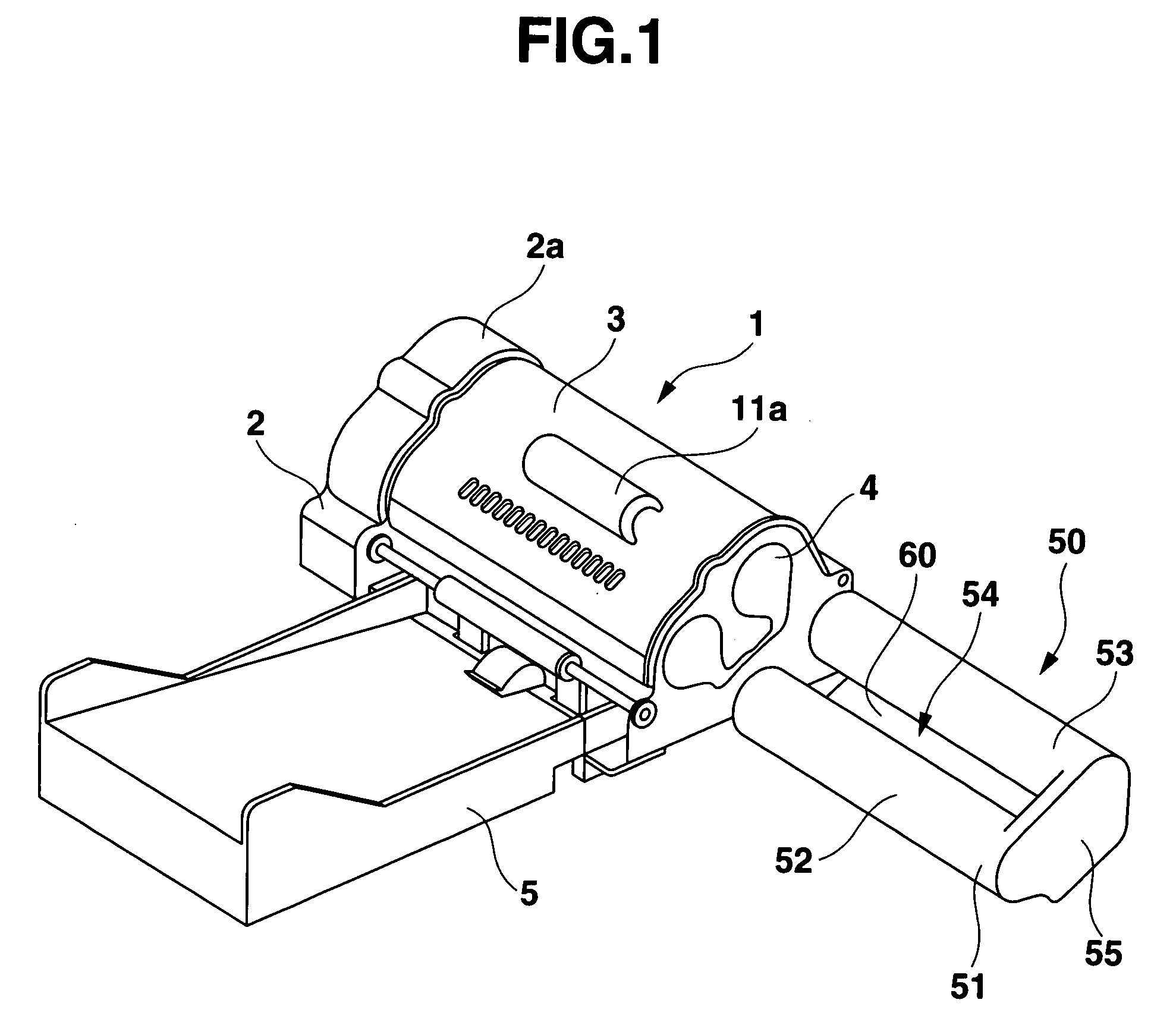

A shaft portion 2a of a platen roller 2 is inserted into an elongated hole-like recess 5a of a platen frame 5 so as to be movable therein. A release arm 9 having an engagement portion 9b engaged with a shaft portion 2a is swingably provided and is urged by a spring member 10. A switch 11 has an intercept 11a which can be contacted / separated to / from the release arm 9. When a thermal head 1 is moved against a spring force of a spring member 4, the release arm 9 follows the thermal head 1 to be allowed to swing by the spring member 10, thereby moving the shaft portion 2a in the recess 5a. When the switch 1 detects movement of the release arm 9, it is determined that recording is impossible since the thermal head 1 and the platen roller 2 are spaced apart from each other.

Owner:SEIKO INSTR INC

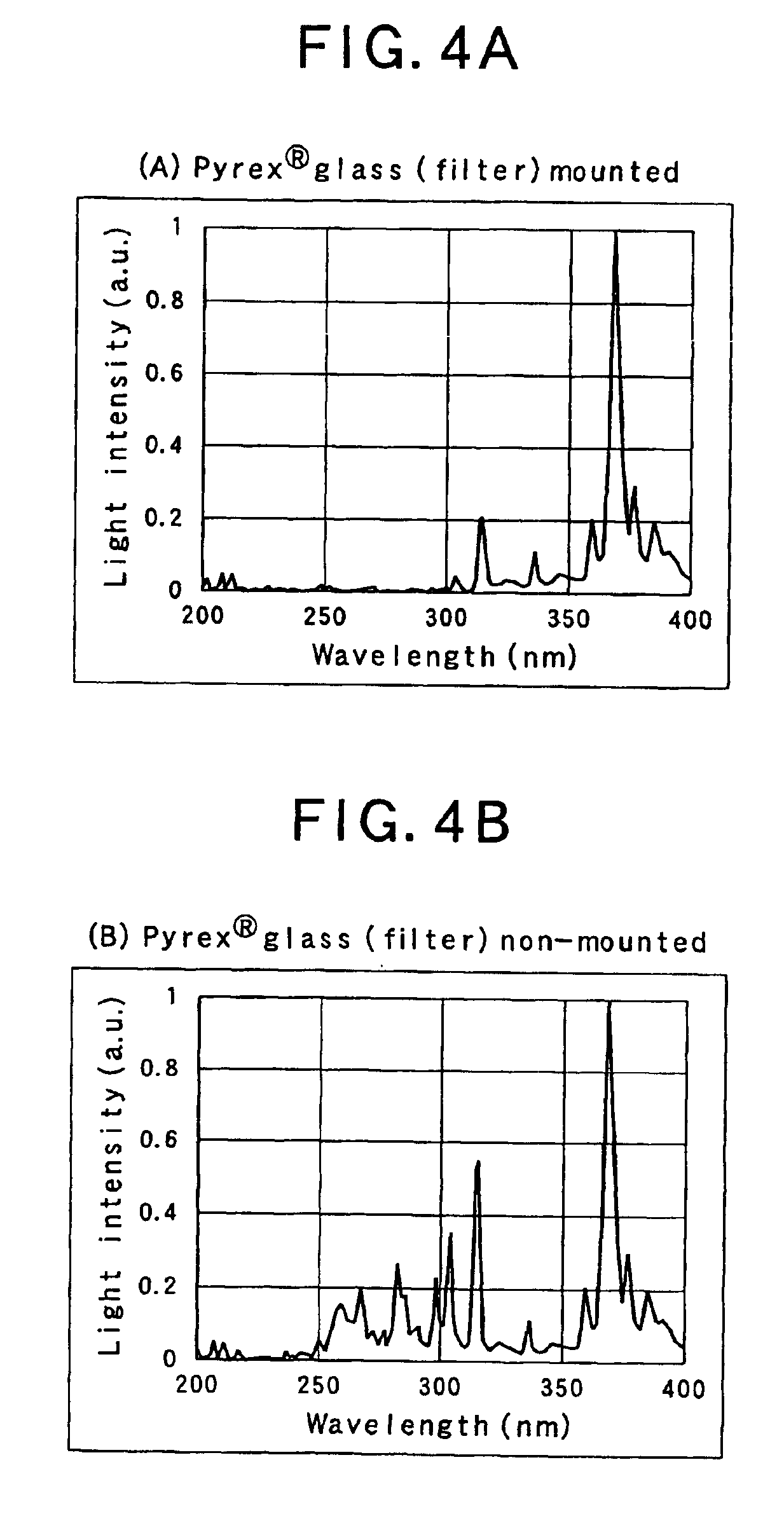

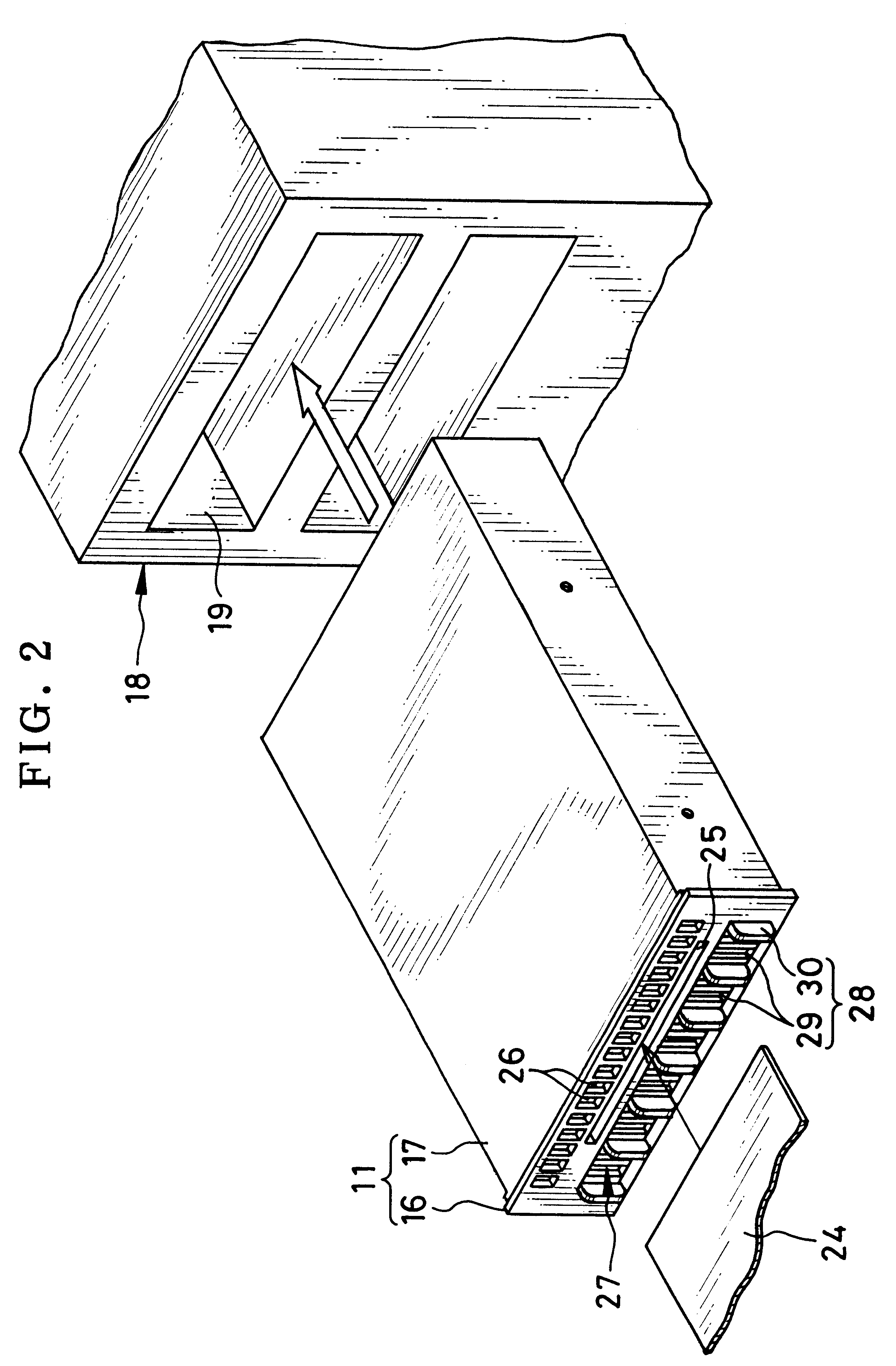

Thermal printer, thermal printing method and conveyor for recording material

A color thermal printer a conveyor for conveying a color thermosensitive recording sheet along a conveying path. A thermal head thermally records a full-color image to the recording sheet being conveyed. A fixer lamp applies ultraviolet rays of a predetermined range of wavelength to the recording sheet being conveyed, for optically fixing the recording sheet. In the thermal printer, a printer casing has a small height, and includes a front panel oriented vertically. An insertion opening in the front panel is adapted to insertion of the recording sheet before the recording, and ejection of the recording sheet after the recording. An air inlet and an air outlet are formed in the front panel. The insertion opening is disposed between the air inlet and the air outlet. An air passageway is disposed in the printer casing, and communicates from the air inlet to the air outlet via at least a portion of the conveying path. A fan unit is disposed in the air passageway, and causes air from the air inlet to flow along the air passageway, to cause heat generated in the printer casing to exit from the air outlet.

Owner:FUJIFILM CORP

Thermal printer

InactiveUS20090219375A1Easy for use printerReduce the possibility of damageRecording apparatusPower drive mechanismsHeat sensitiveThermal printing

THERMAL PRINTER comprised by two chassis, first chassis (3) having movable blade (11) from cutting mechanism (7), thermal head (12) from thermal printing mechanism (9), automatic activation mechanism from movable blade and tracking mechanism from platen roller (8), and second chassis (4) wherein fixed blade of the cutting mechanism, and platen roller of the thermal printing mechanism are positioned. Thermal head is horizontally placed allowing paper direction to frontal part from printer, and platen roller is placed right above thermal head. On frontal part, there is a vertical cutting mechanism with slightly inclination so that mobile blade movement direction in perpendicular to line formed between cover rotation axis and the contract point between both blades.

Owner:ELGIN SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com