Tape printer

A belt printer and print head technology, which is applied in typewriters, printing devices, printing, etc., can solve the problems of increasing costs, and achieve the effect of avoiding damage to printing belts and ribbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

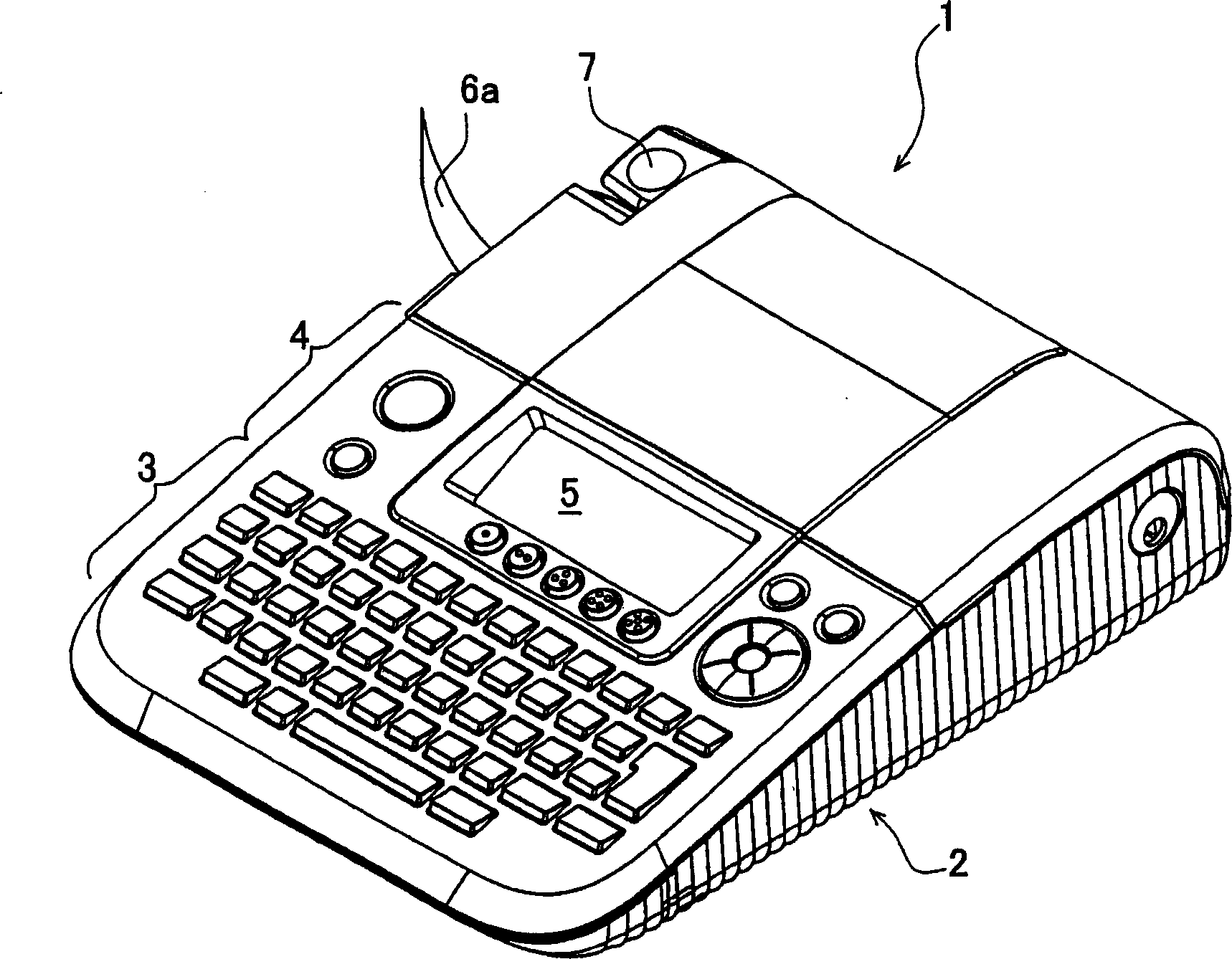

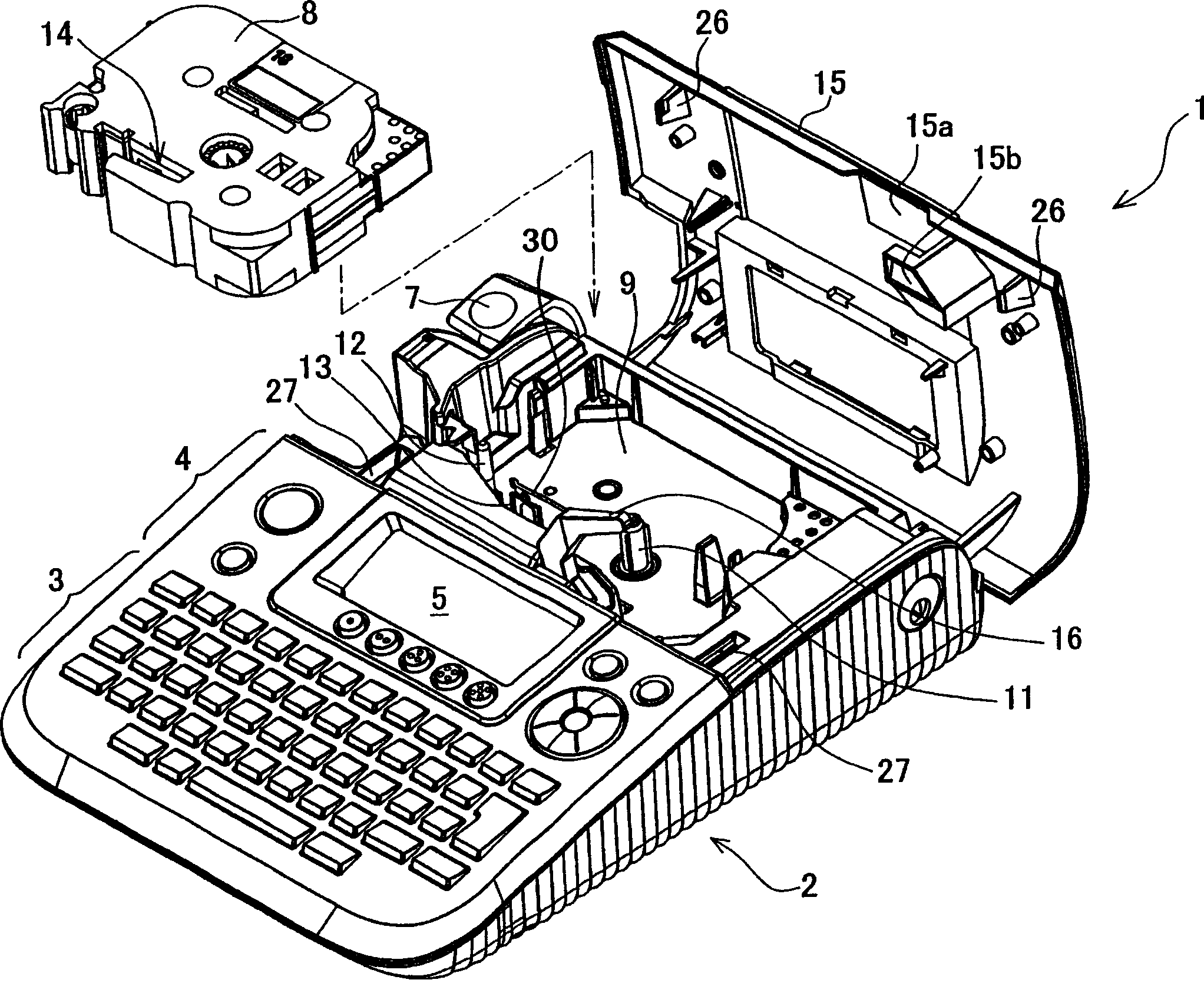

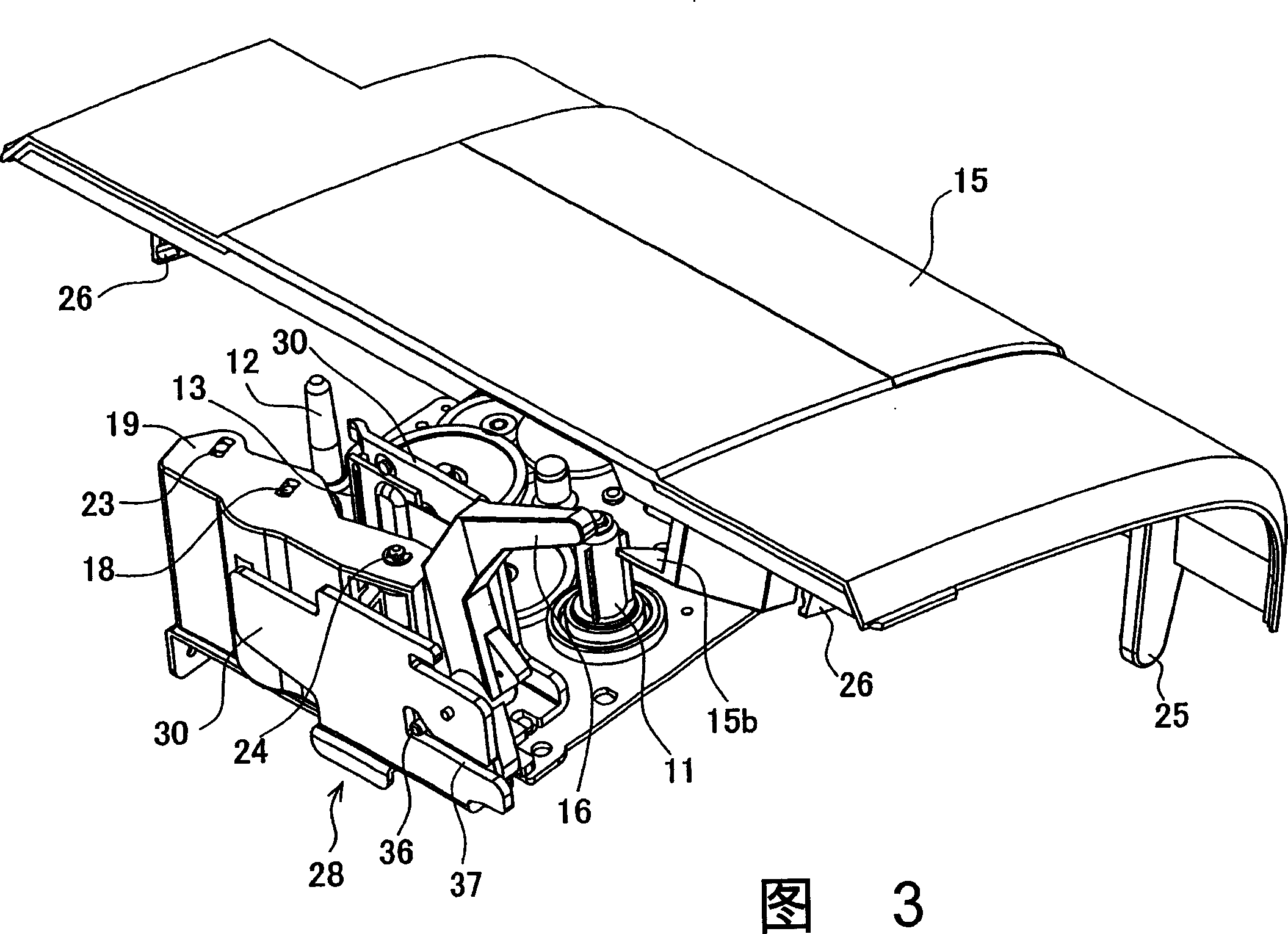

[0027] A first aspect embodying the tape printer of the present invention will now be described in detail with reference to the accompanying drawings. First, refer to Figures 1 to 4 A schematic structure of the tape printer of the first aspect is explained. figure 1 is an external view of the tape printer according to the first aspect of the present invention. figure 2 is a perspective view of a tape printer with an open cover element. Figure 3 is an enlarged perspective view of the cover member and a printing mechanism. Figure 4 is an explanatory diagram of the relationship between a cassette and a printing mechanism branch.

[0028] like figure 1 As shown, the tape printer 1 of the first aspect is provided with a keyboard 3 , function keys 4 , a liquid crystal display (hereinafter referred to as “LCD”) 5 and a knife lever 7 . A keyboard 3 for inputting various characters is provided on a top surface of a main body 2 . Above the keyboard 3, various function keys 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com