Patents

Literature

85results about How to "Less occurrence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry powder which retains savor and flavor and method for producing the same

InactiveUS20050031769A1Avoid and reduce occurrenceLess occurrenceFruit and vegetables preservationFood shapingSolubilityProduct gas

In order to provide a spray dry method capable of producing a dry powder retaining the savor and flavor of a raw material and having solubility without any thermal deterioration, at a mass scale, a method for producing a dry powder keeping savor and flavor from a hydrous liquid material containing a savory and flavorful component and, preferably, a hygroscopic component by spray drying is disclosed, the method including spray drying the hydrous liquid material at the microfine liquid droplet state in gas atmosphere at the outlet temperature of a spray dryer at 20 to 90° C. and the outlet relative humidity of 1% RH to 40% RH, to prepare a dry powder of a mean particle size of 0.1 μm to 15 μm.

Owner:AJINOMOTO CO INC

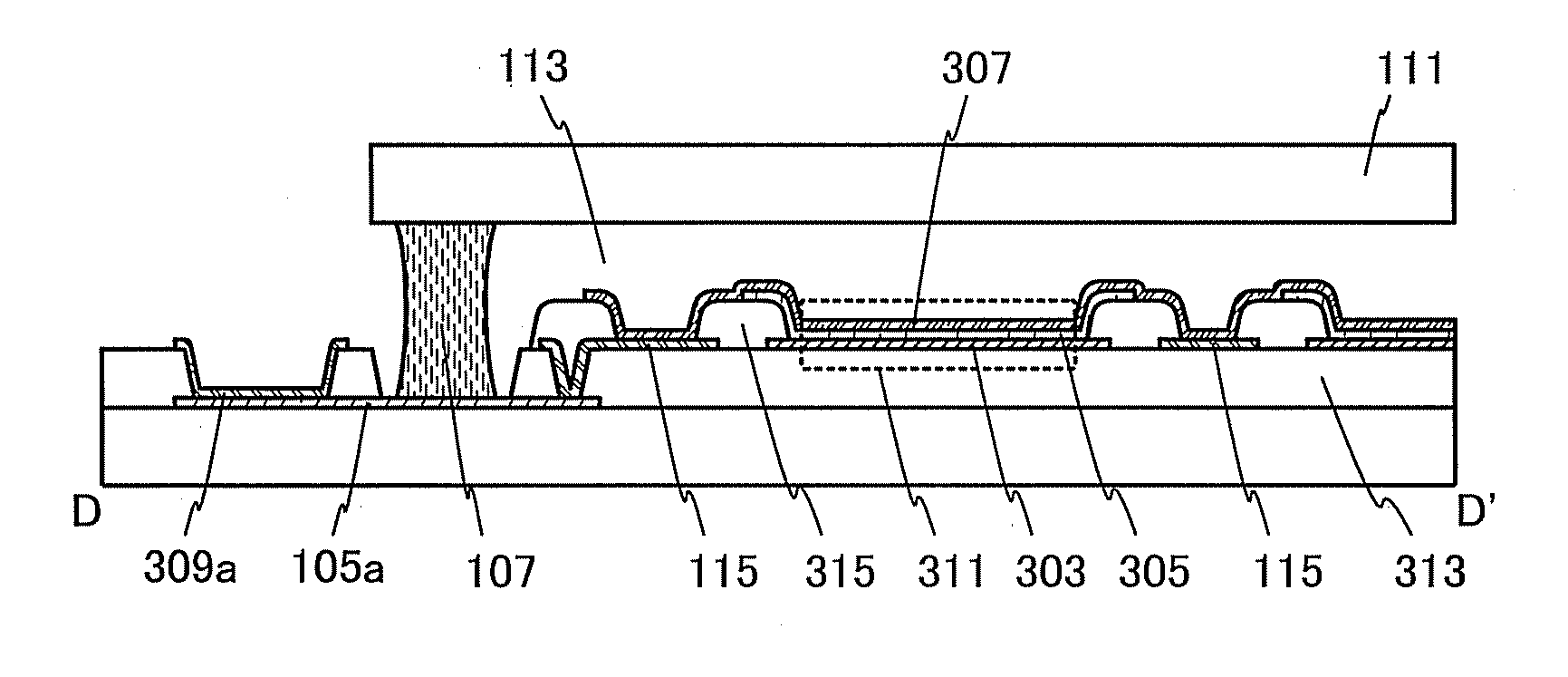

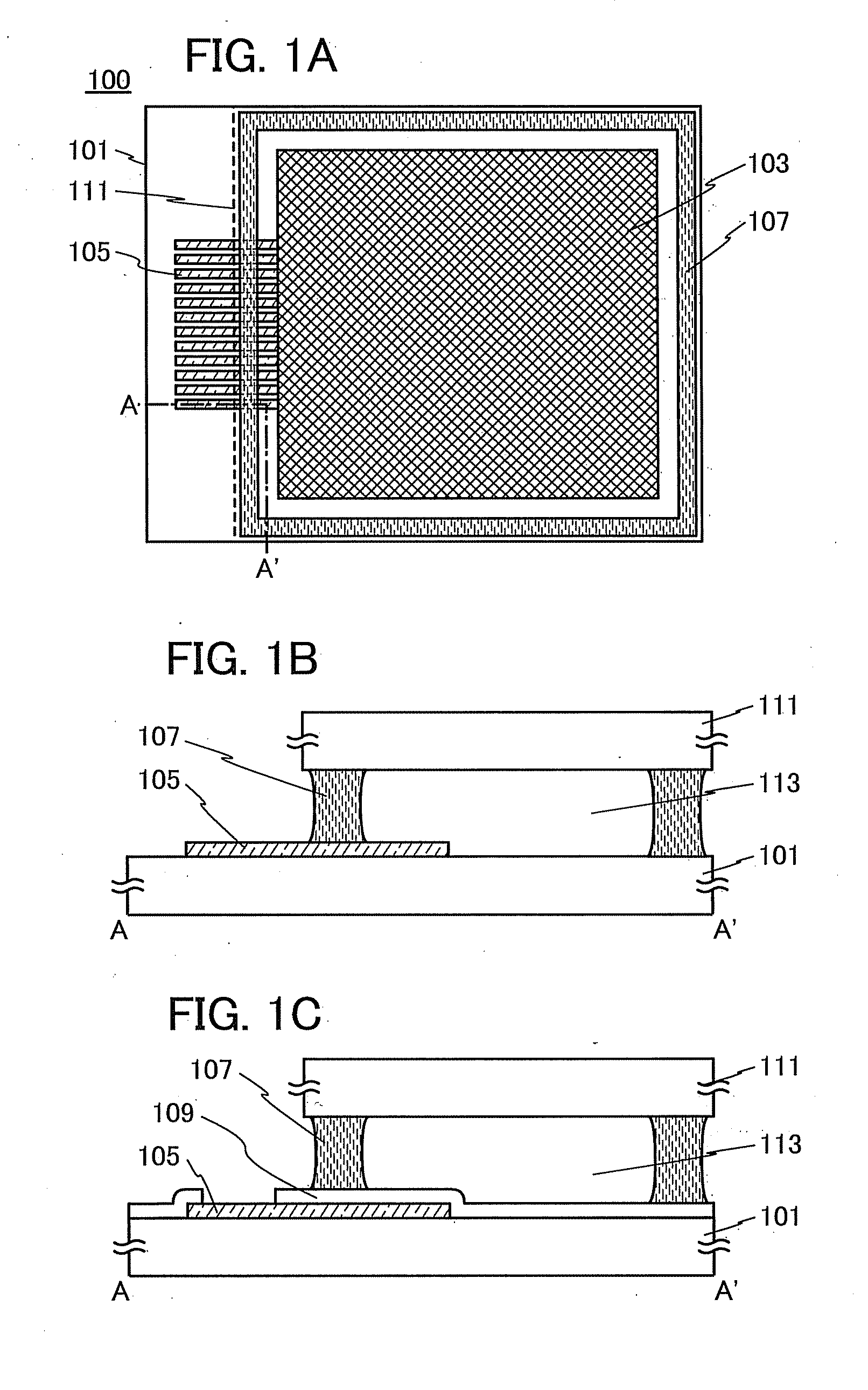

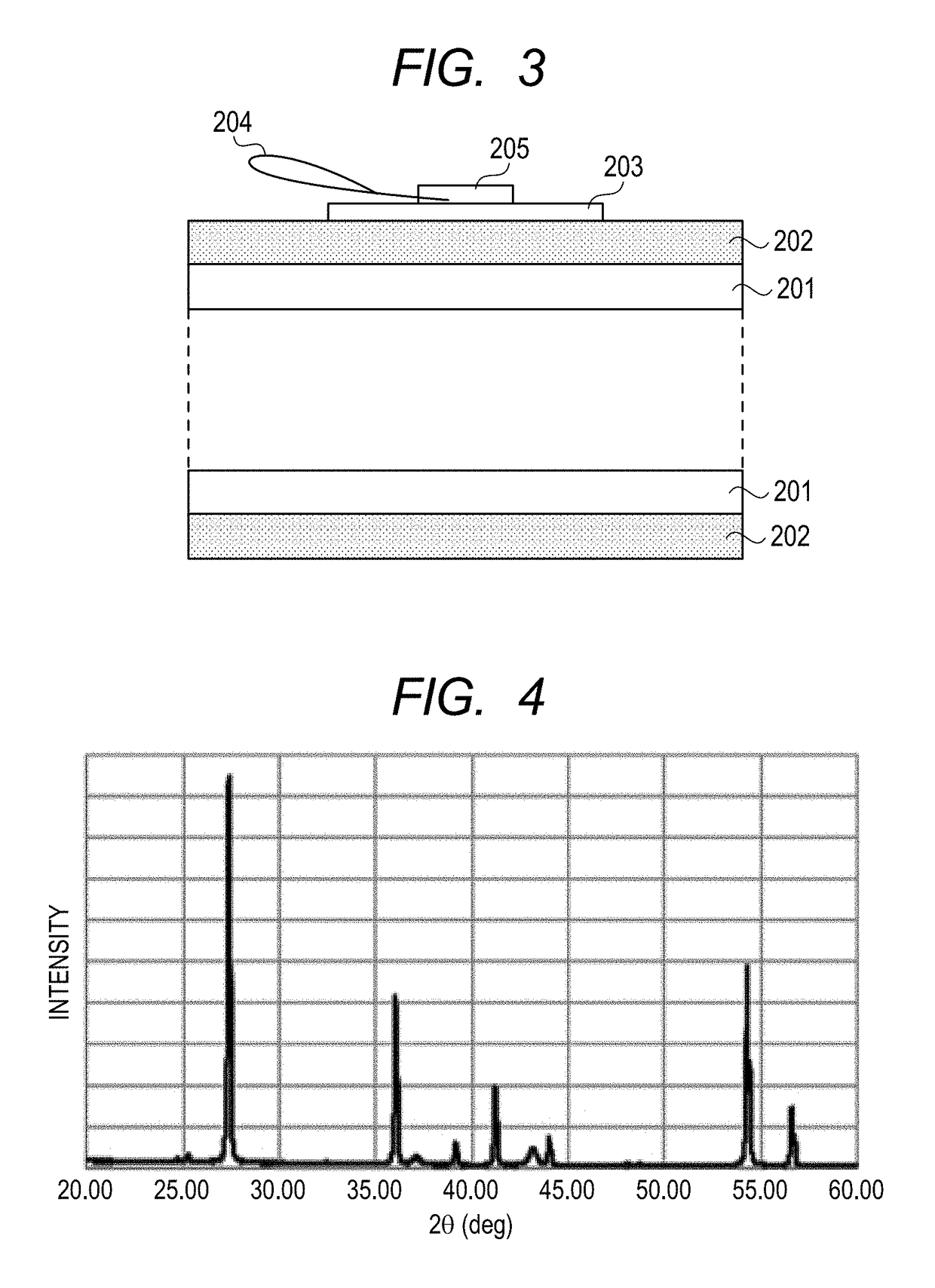

Light-Emitting Device

ActiveUS20130049062A1Less occurrenceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesFritThermal expansion

To provide a highly reliable light-emitting device with less occurrence of cracks in a sealant bonding two facing substrates together. In a light-emitting device, a first substrate including a light-emitting unit, and a second substrate are bonded to each other with glass frit. A wiring in the area overlapping with a sealing material formed by melting and solidifying glass frit may be formed of a conductive material having a linear thermal expansion coefficient close to that of a substrate material. More specifically, the difference in the linear thermal expansion coefficient between the conductive material and the substrate material is 5 ppm / K or less at a temperature of 0° C. to 500° C.

Owner:SEMICON ENERGY LAB CO LTD

Polymerization catalyst for polyesters, polyesters produced with the same and process for producing polyesters

InactiveUS20030045673A1Excellent in melt thermal stabilityLess occurrenceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationForeign matterPolyester

A novel polymerization catalyst for polyesters, which does not contain any germanium or antimony compound as the main component; polyesters produced with the catalyst; and a process for producing polyesters. This polymerization catalyst is excellent in catalytic activity, little causes thermal degradation of polyesters in melt molding even when neither deactivated nor removed, and can give thermally stable polyesters which little generate foreign matter and are excellent in transparency and color. The polymerization catalyst is one which contains as the first metal-containing component at least one member selected from the group consisting of aluminum and aluminum compounds and which gives polyethylene terephthalate (PET) having a thermal stability parameter (TS) satisfying the relationship: (1) TS<0.3

Owner:TOYOBO CO LTD

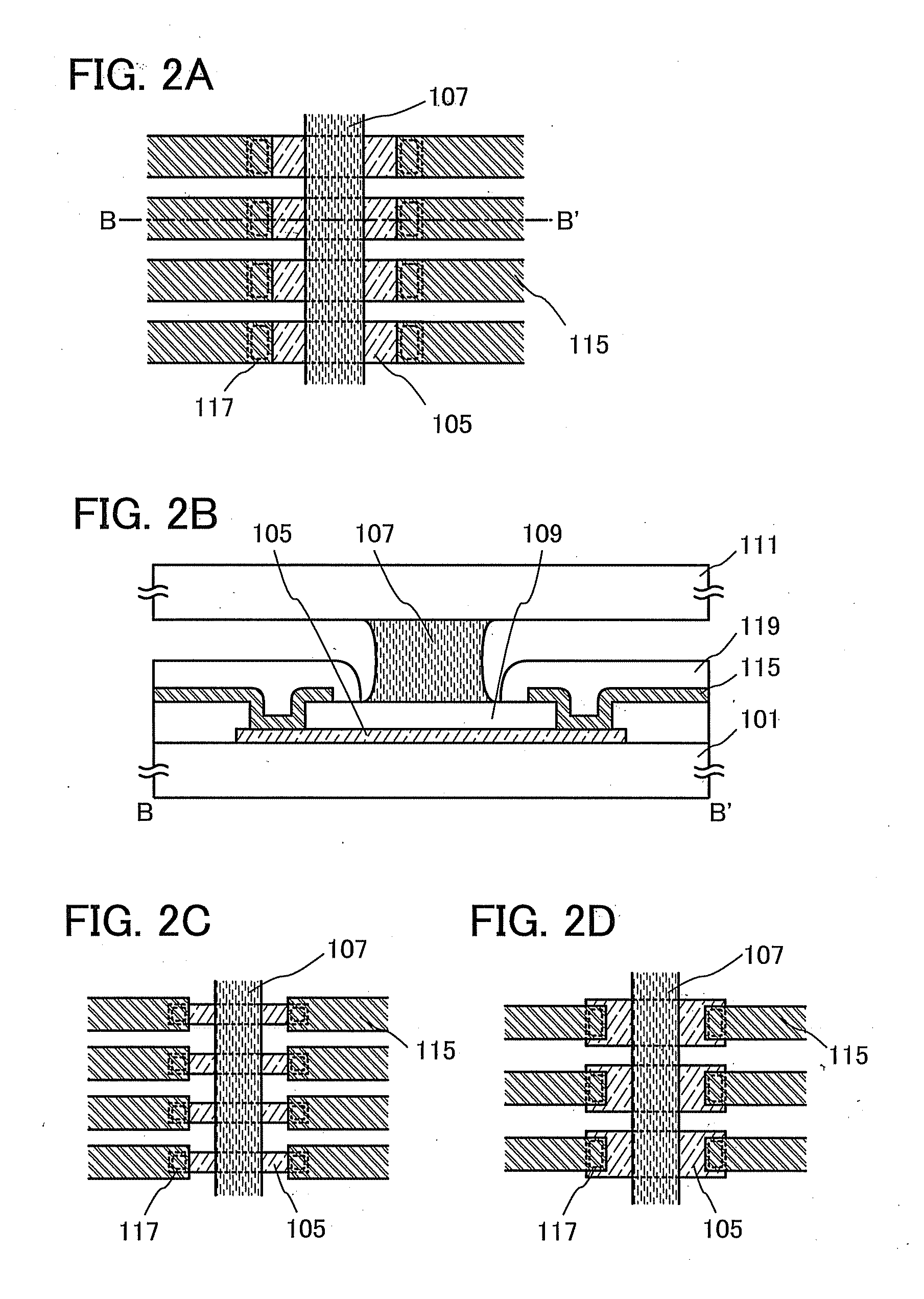

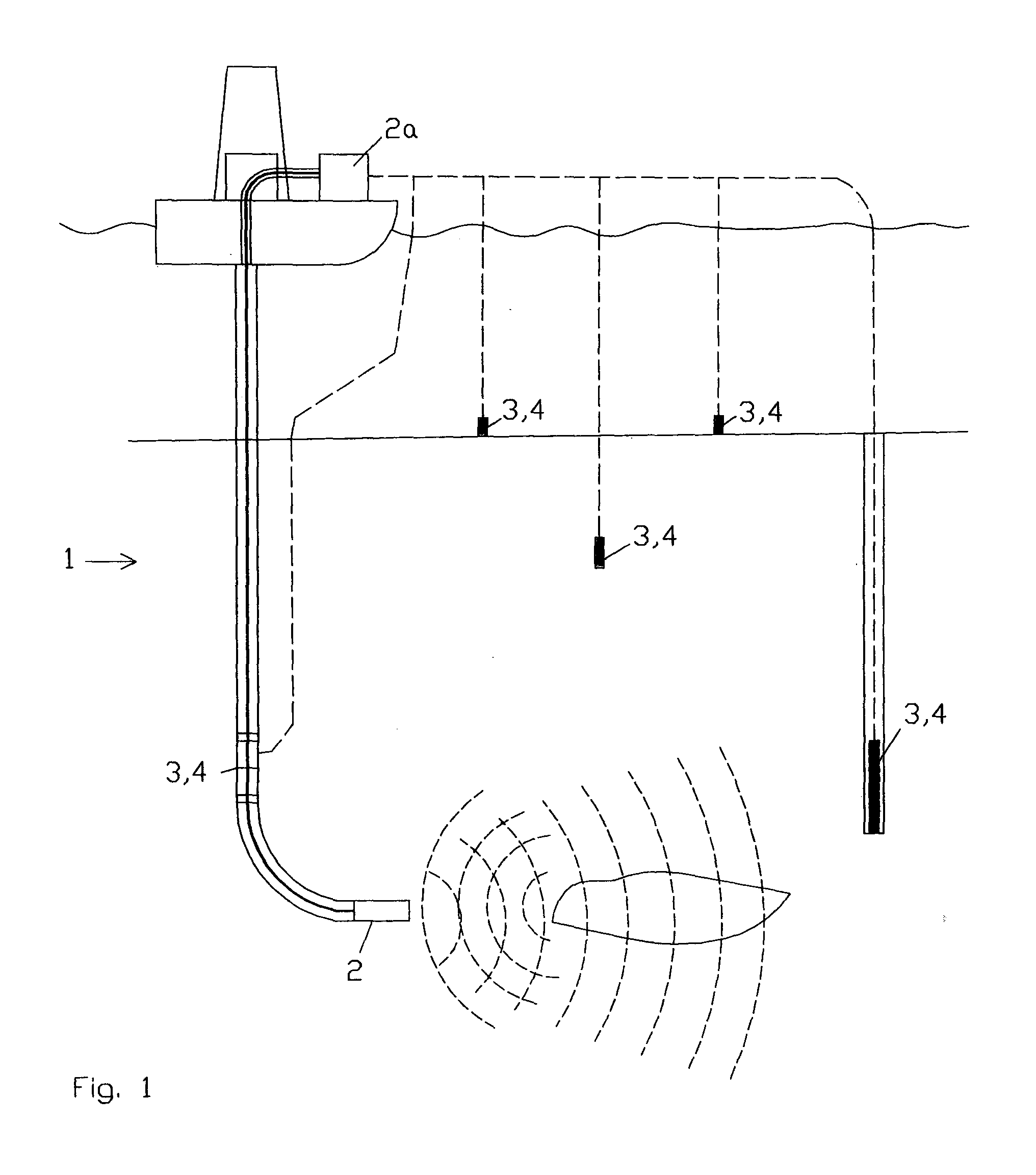

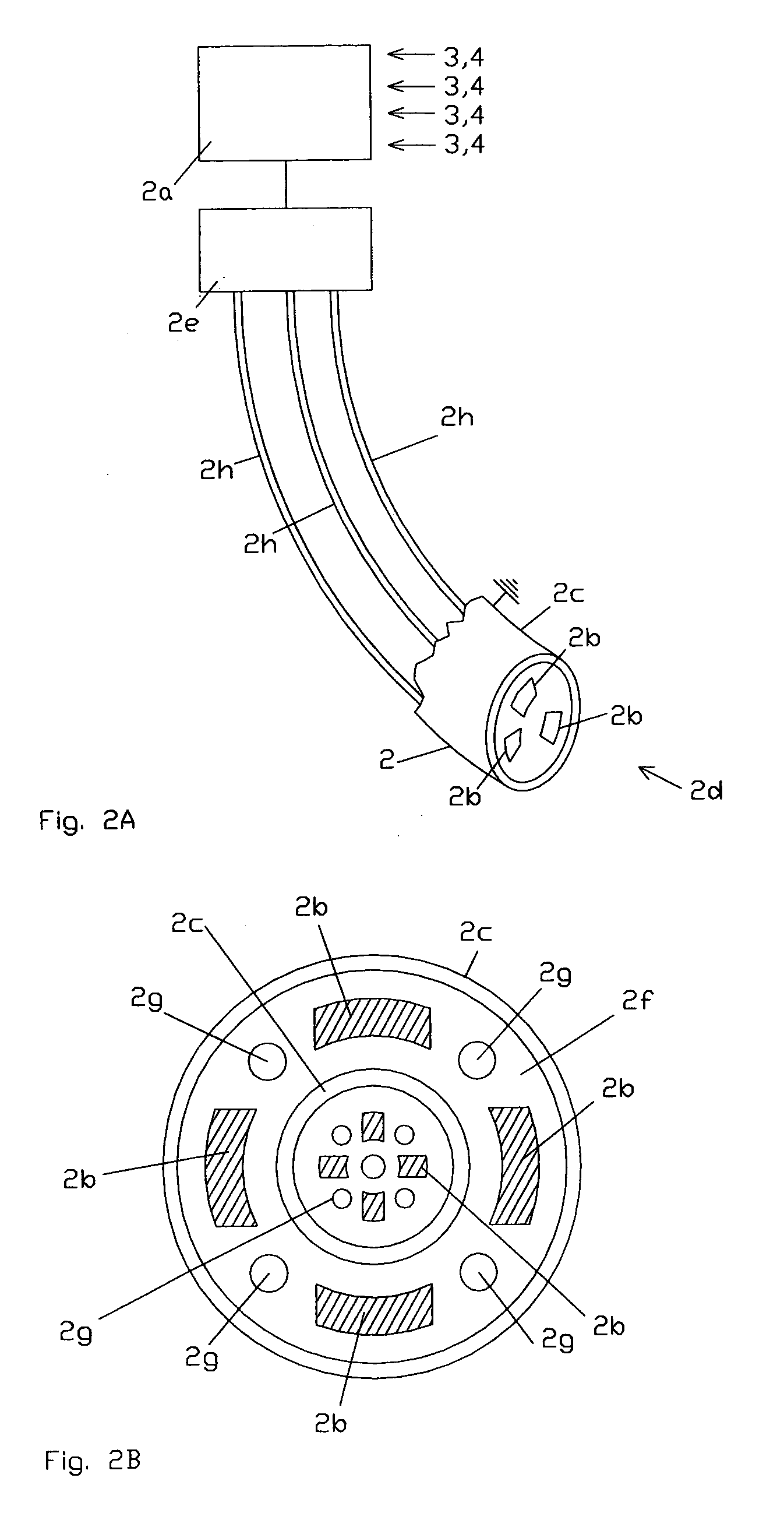

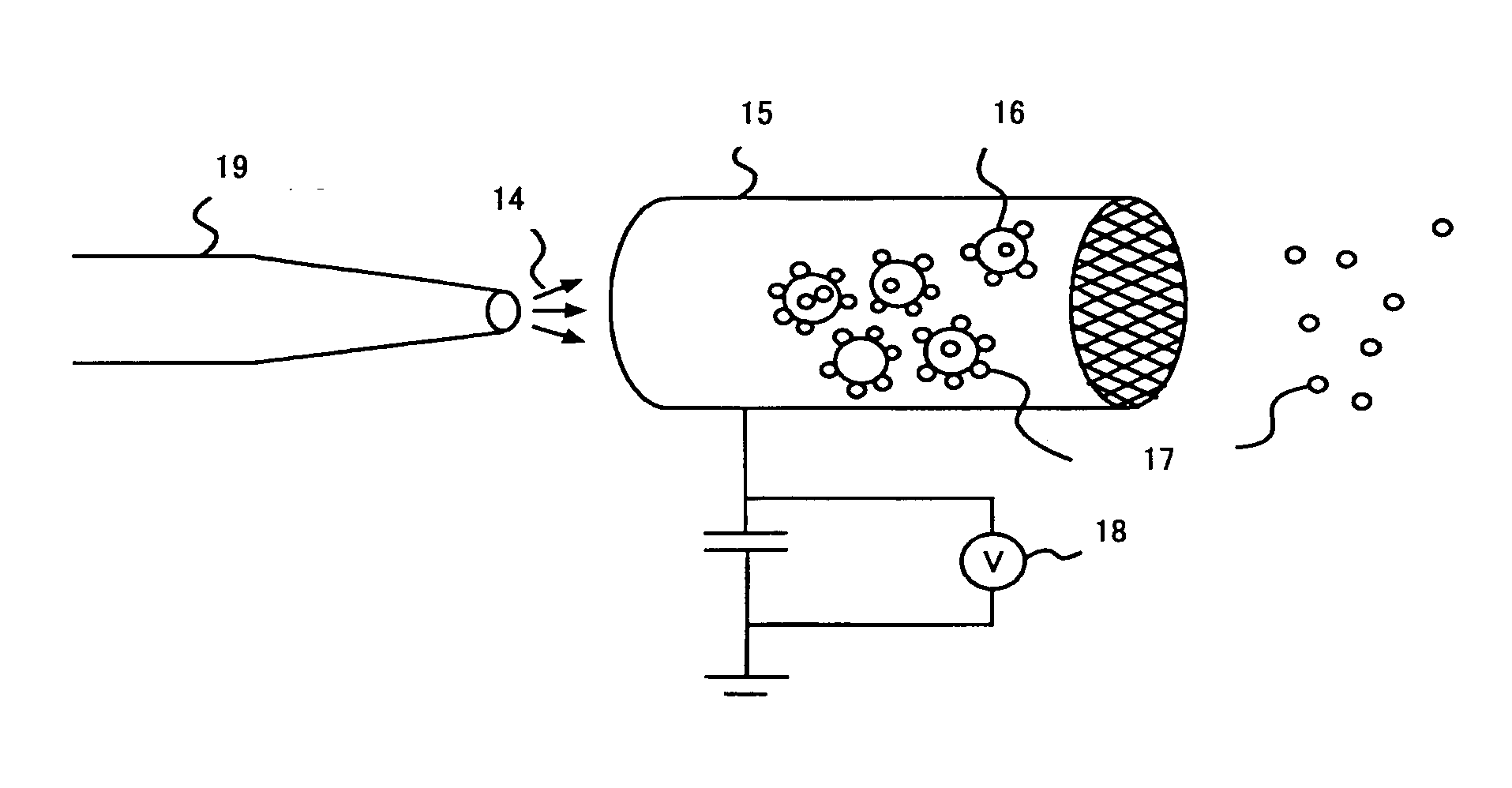

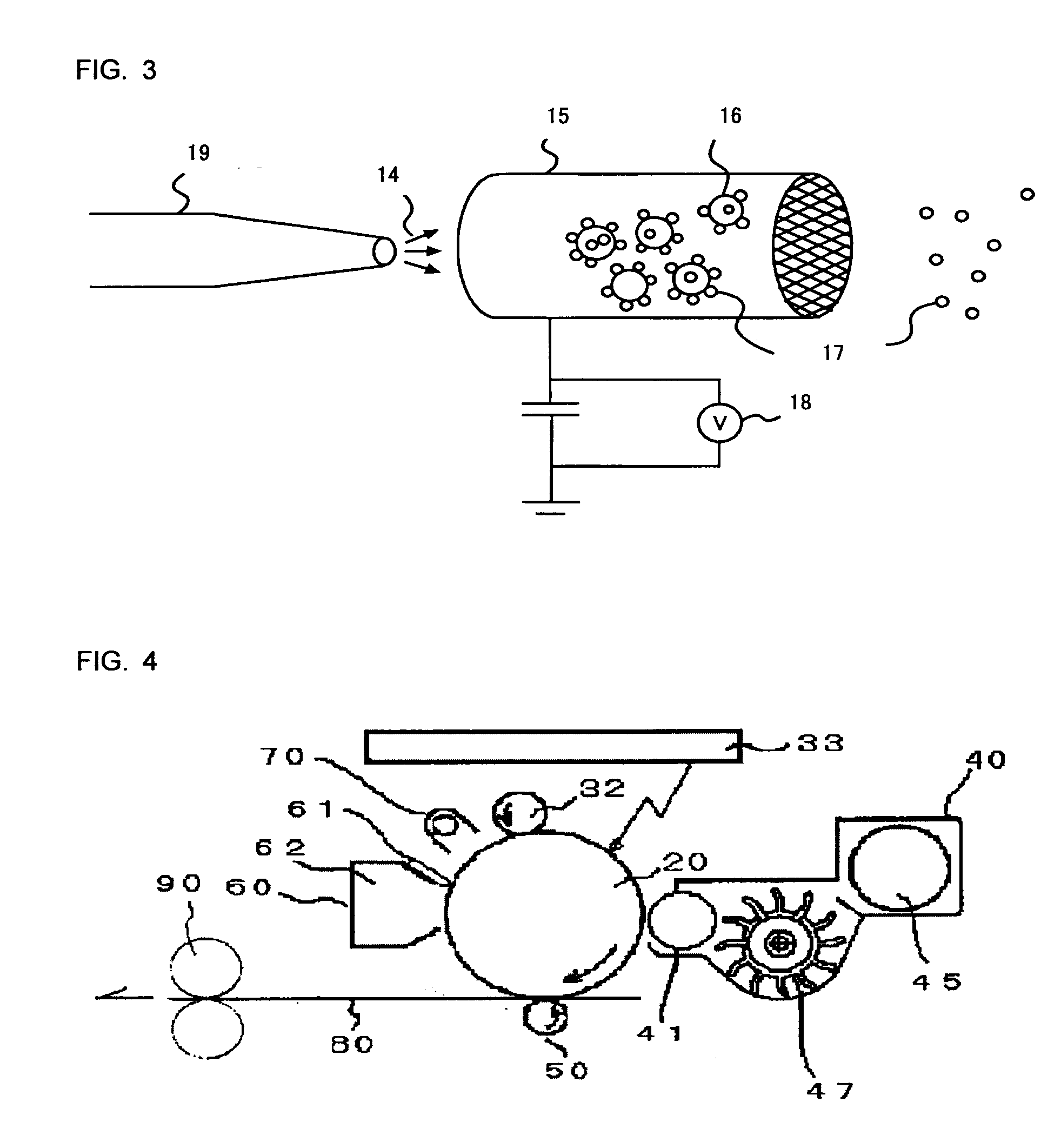

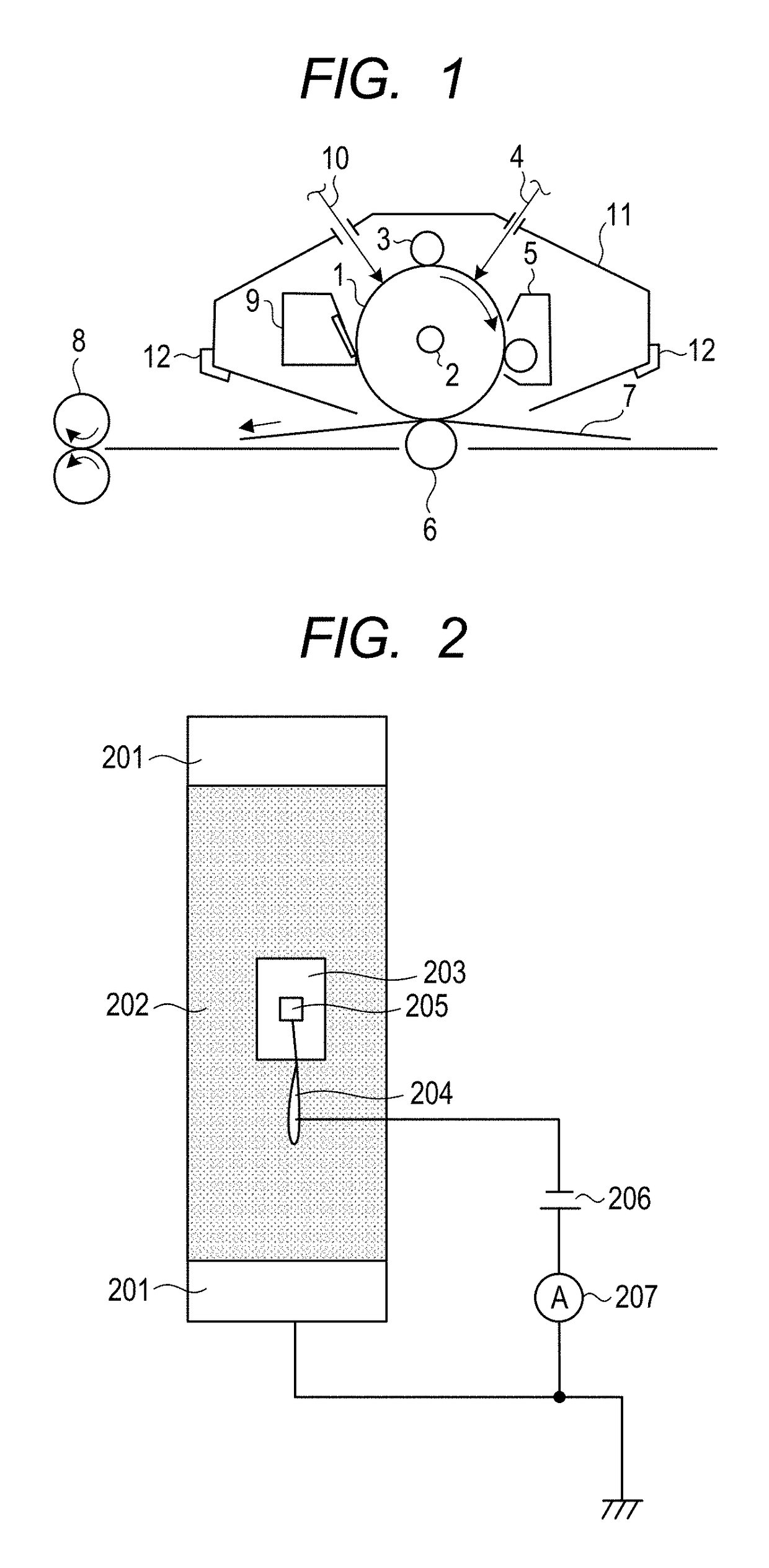

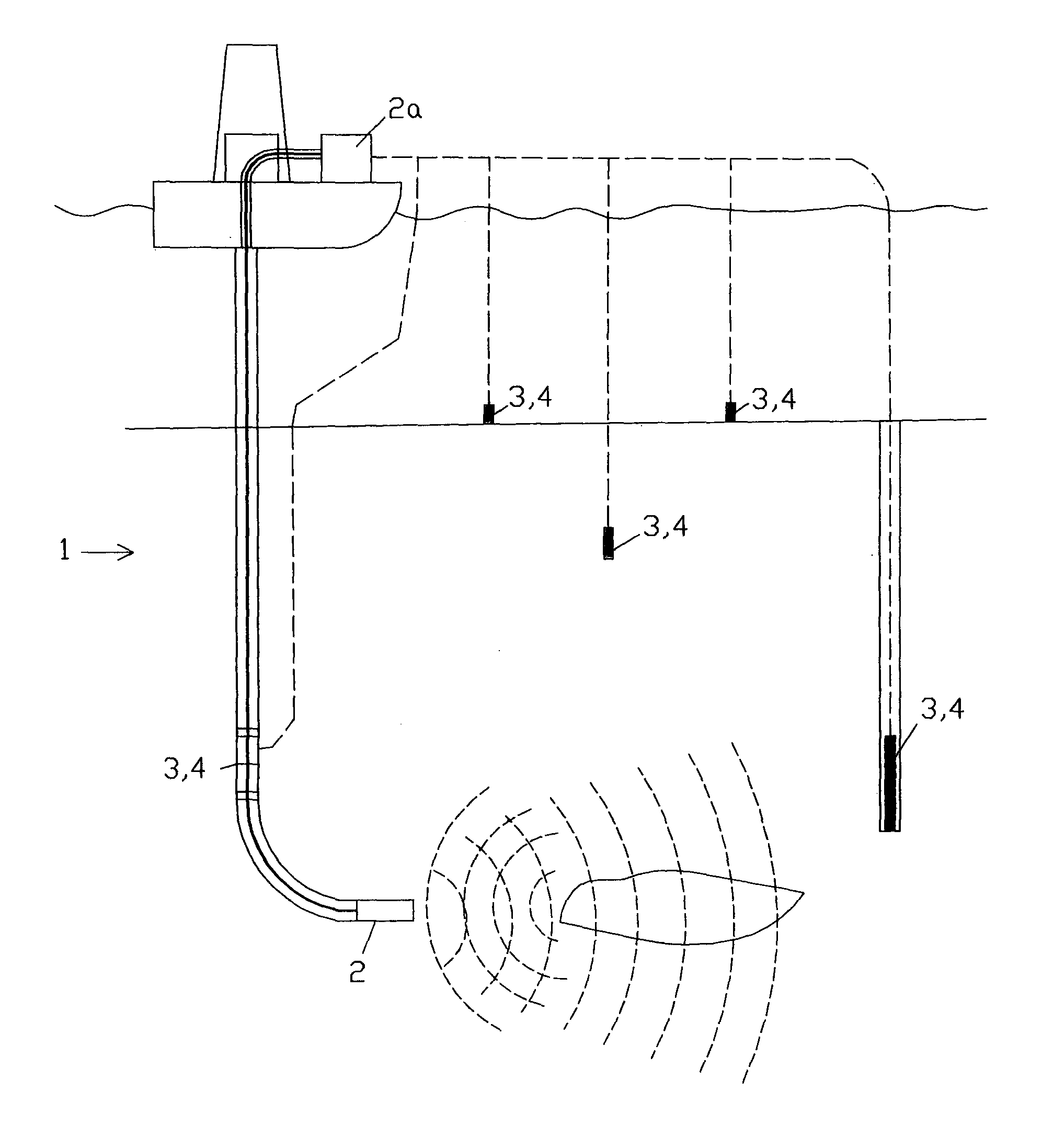

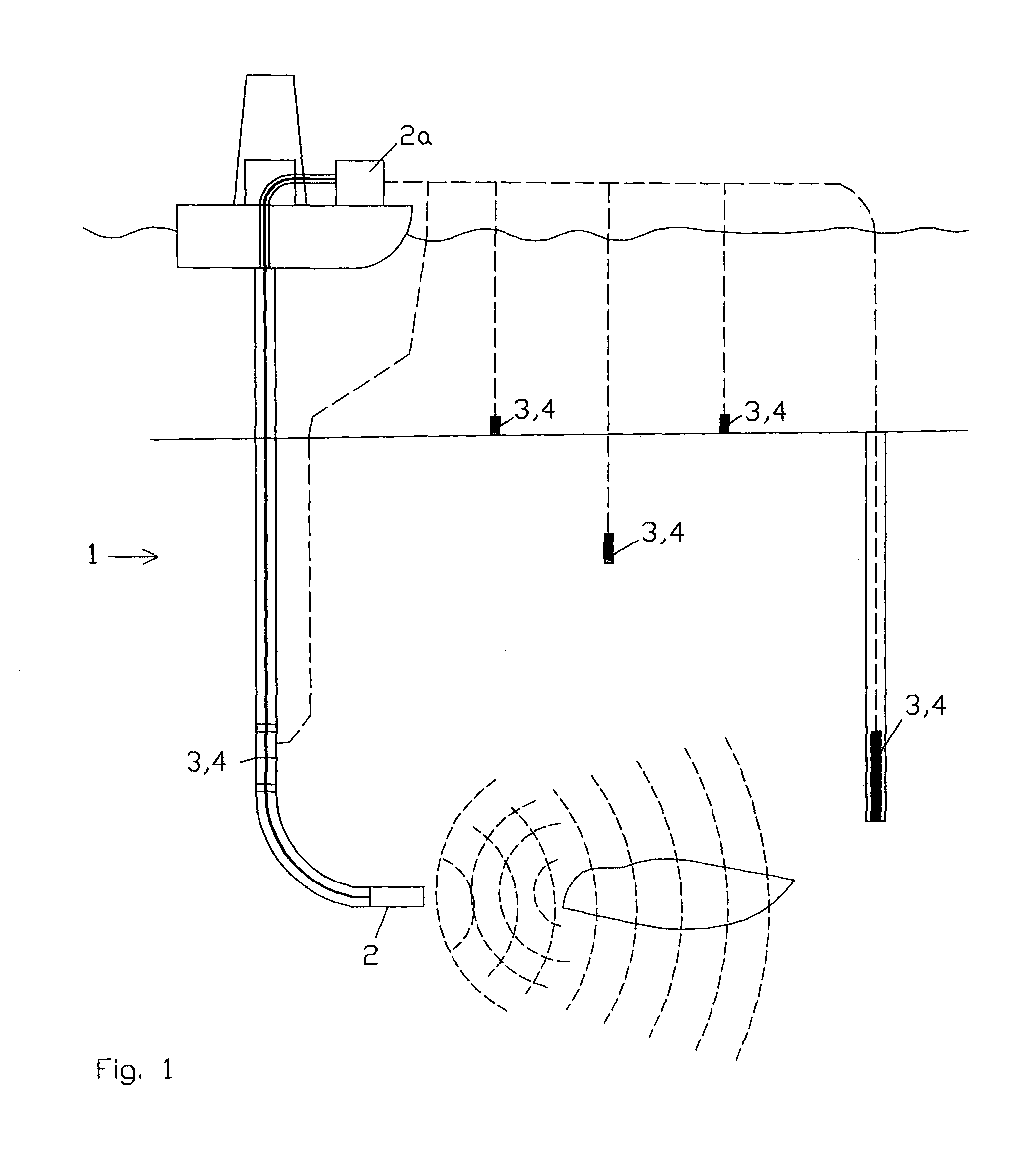

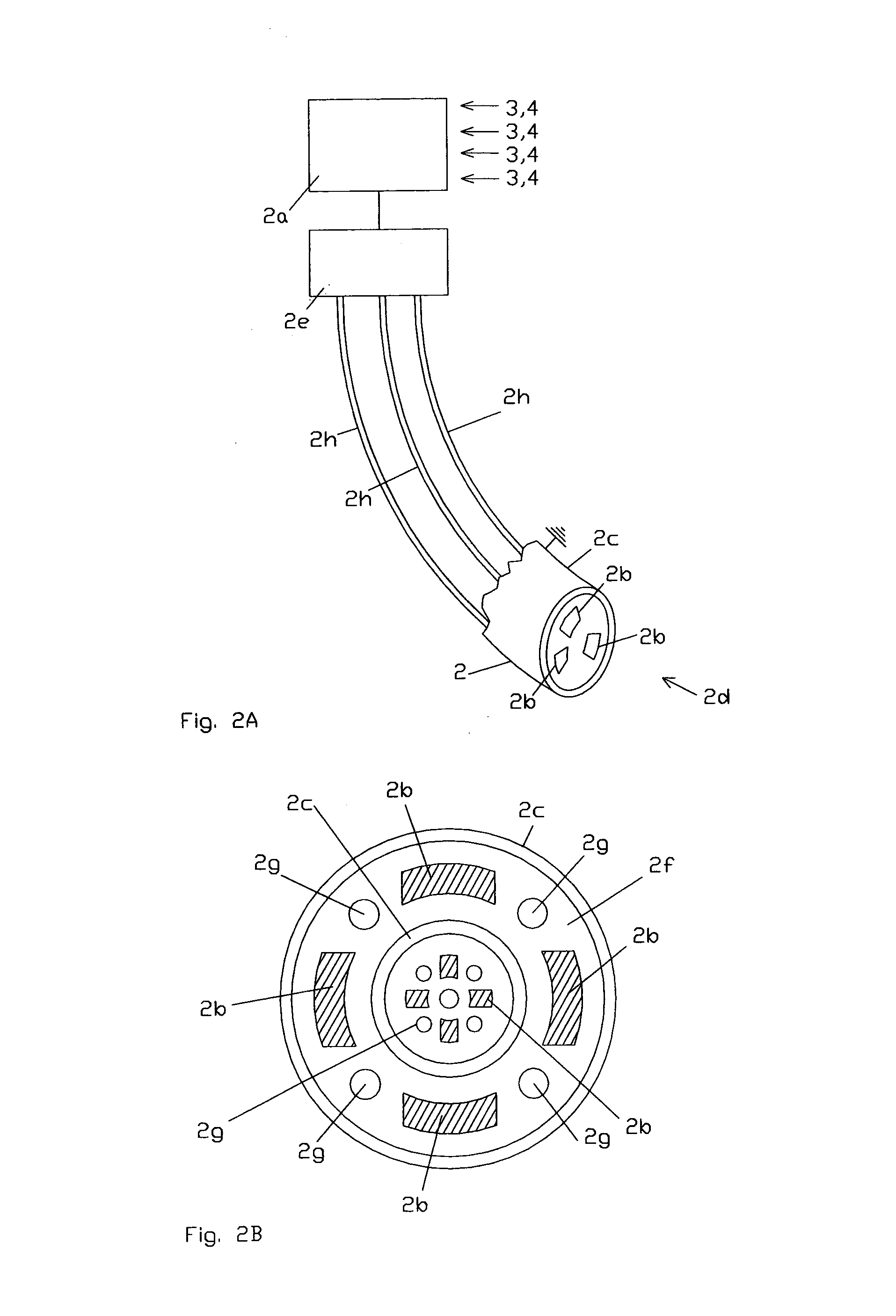

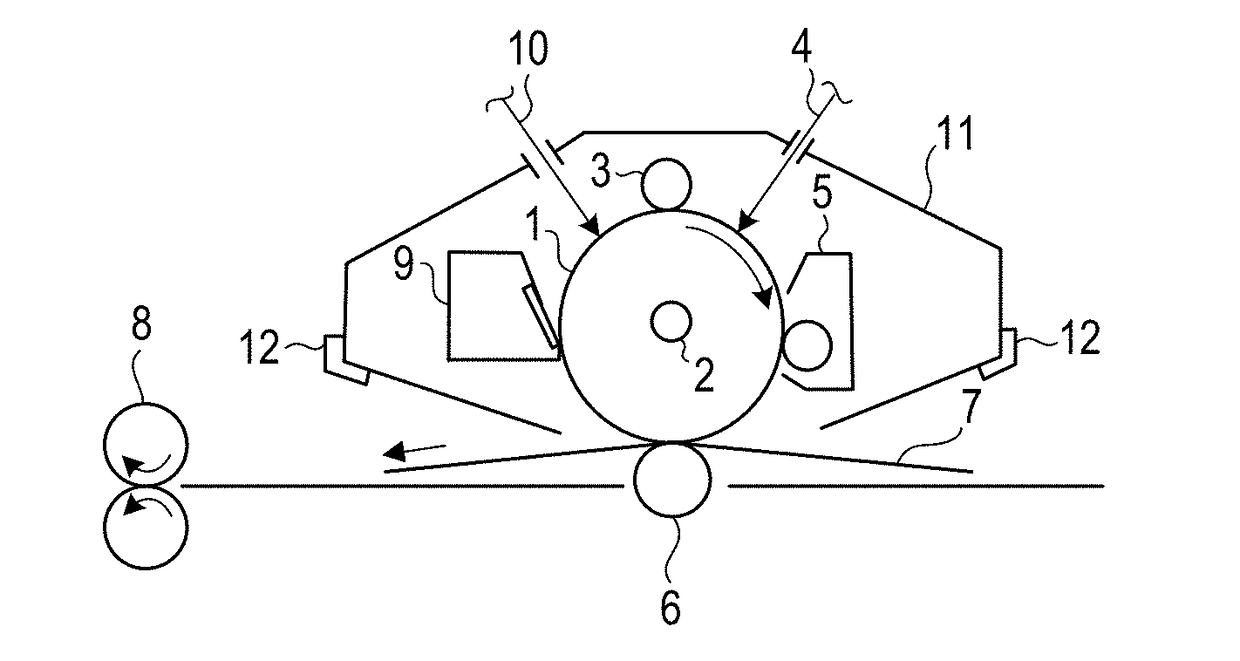

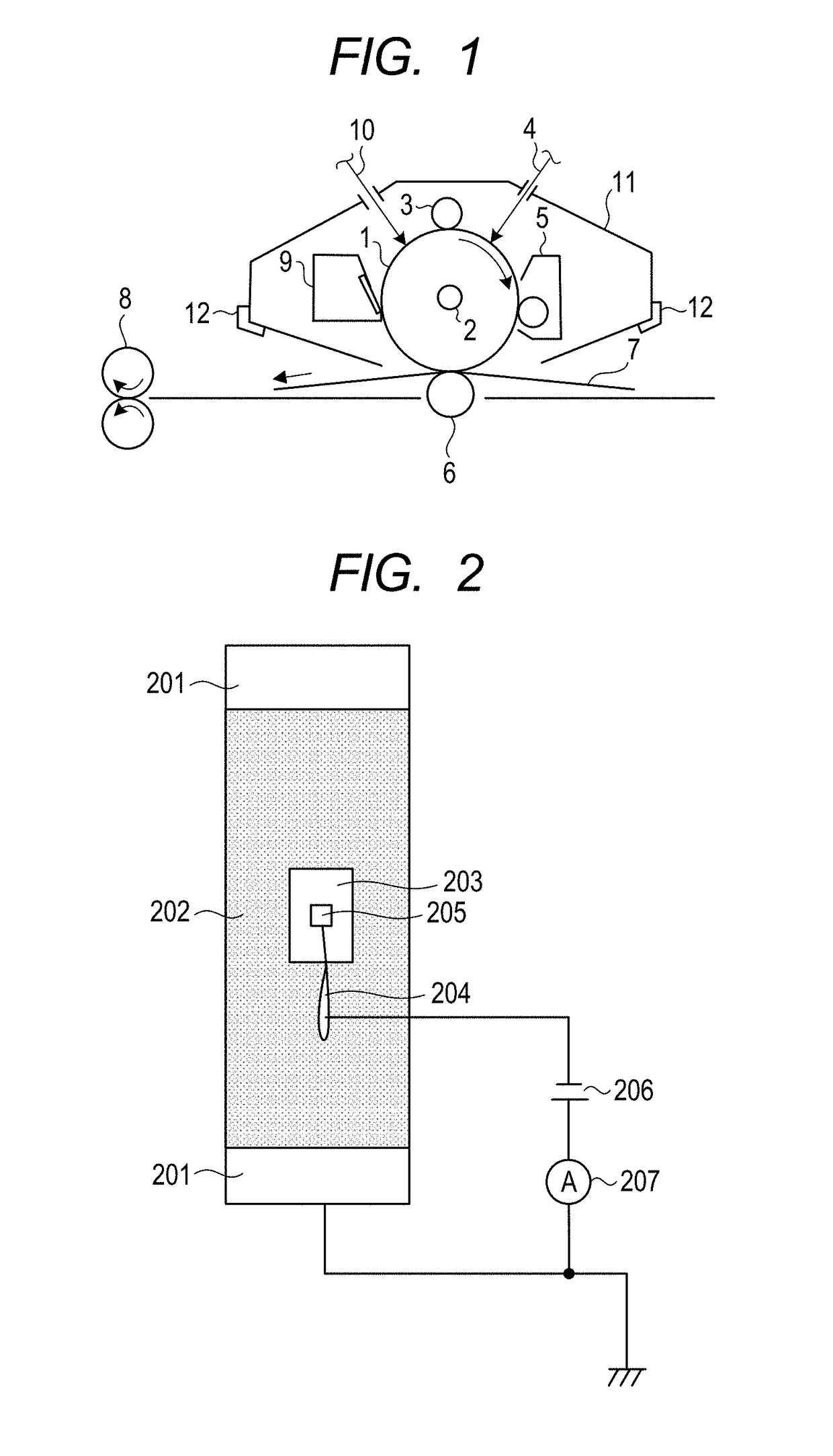

Assembly for drilling and logging, method for drilling and logging and device for electro pulse drilling

ActiveUS20100212962A1Easy to controlLess occurrenceSurveyDisloding machinesDrill holeBiomedical engineering

Assembly for drilling and logging, comprising a device for electro pulse drilling (EPD device), at least one device to receive acoustic signals generated by the EPD device, distinguished in that the assembly further comprises at least one device to receive electromagnetic signals generated by the EPD device. Method for drilling and logging, and device for electro pulse drilling.

Owner:DEN NORSKE STATS OLJESELSKAP AS

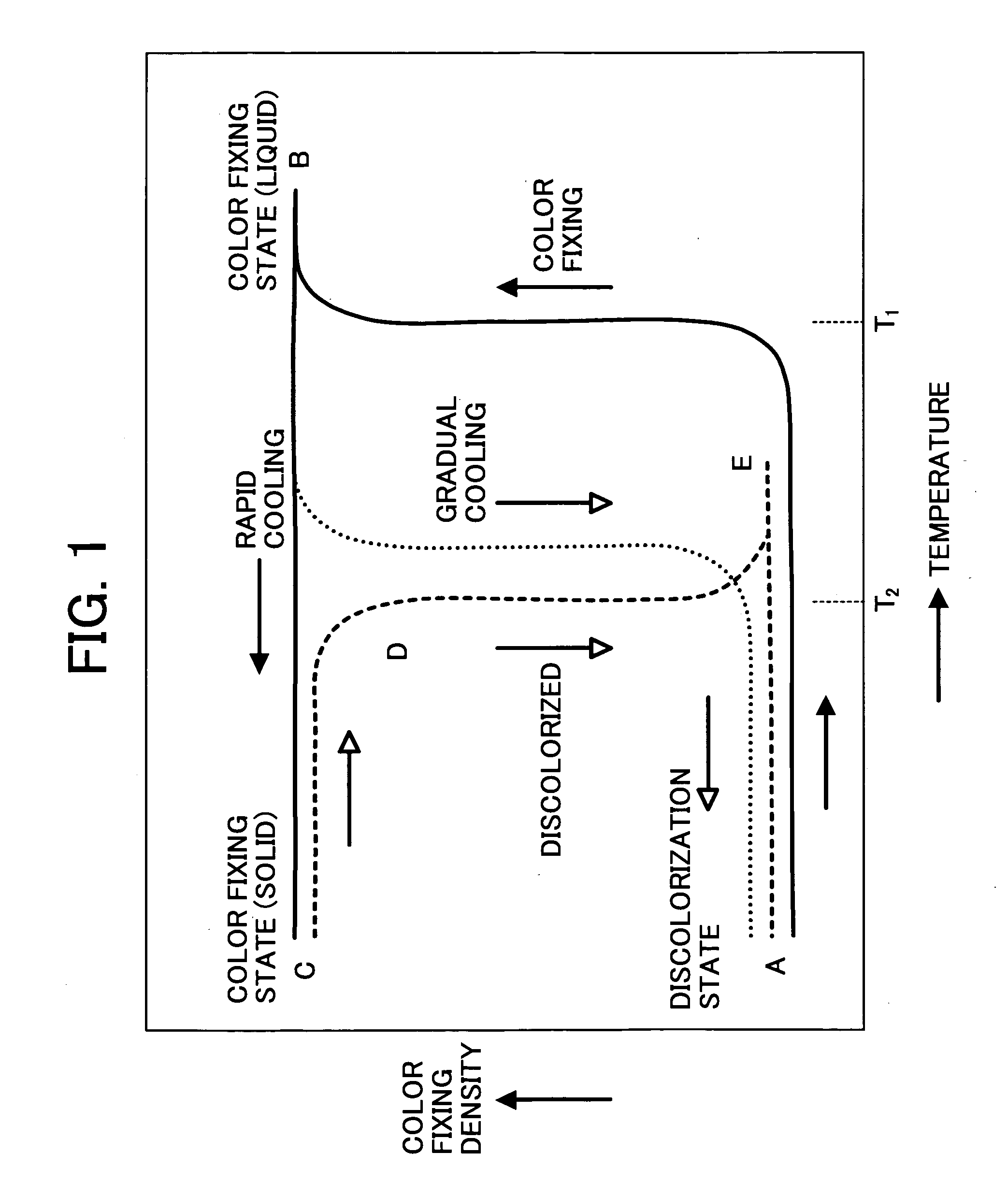

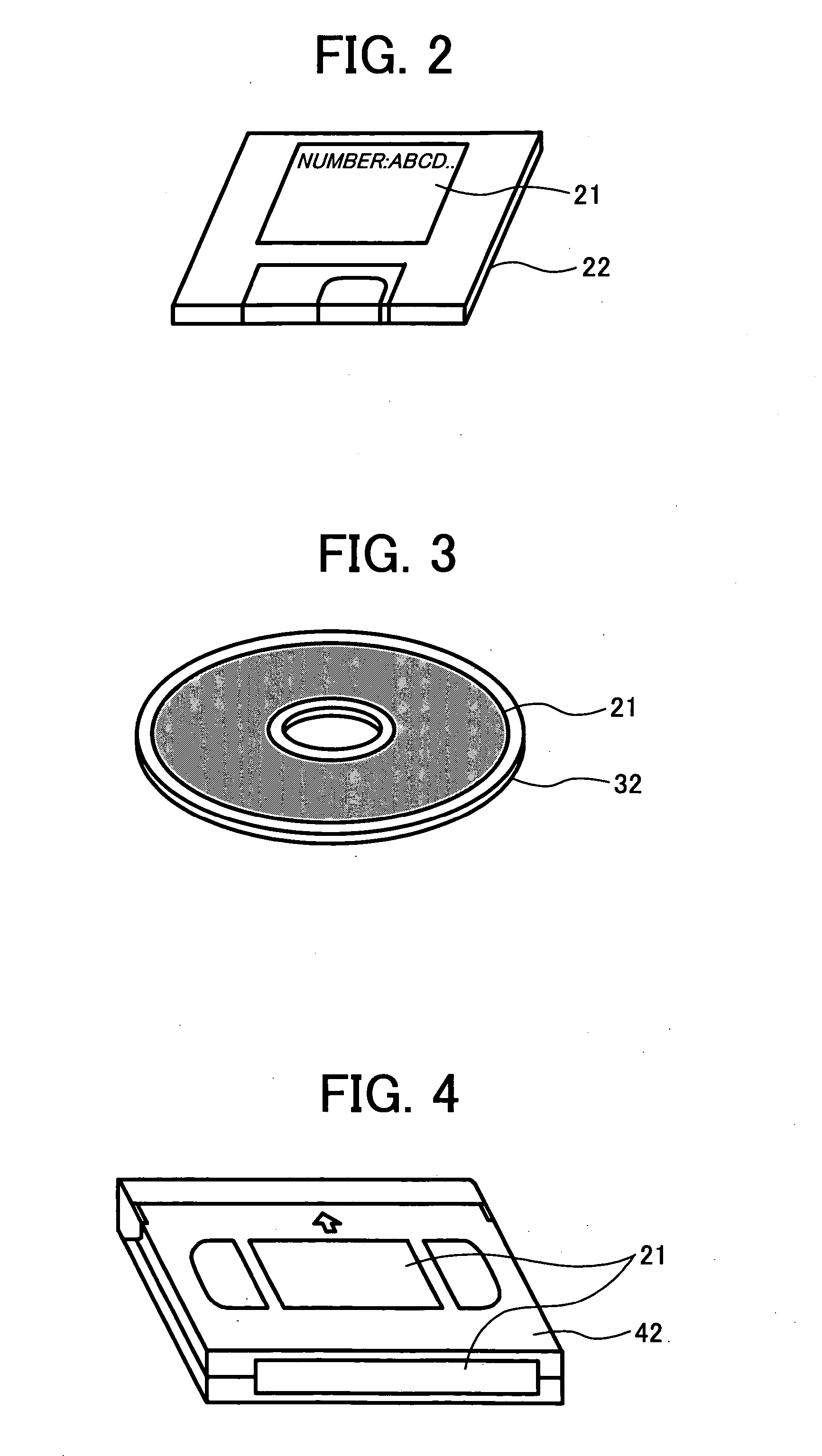

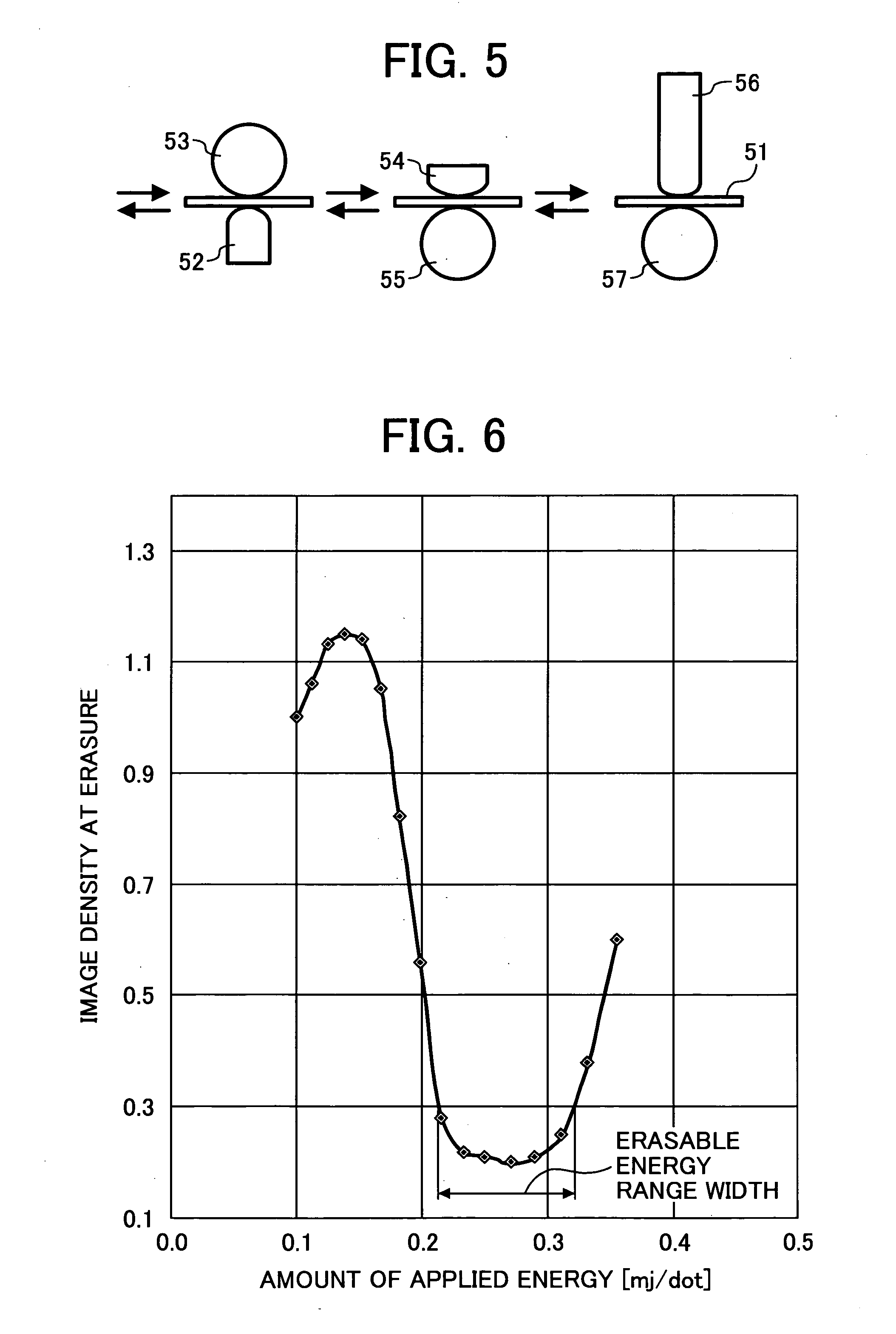

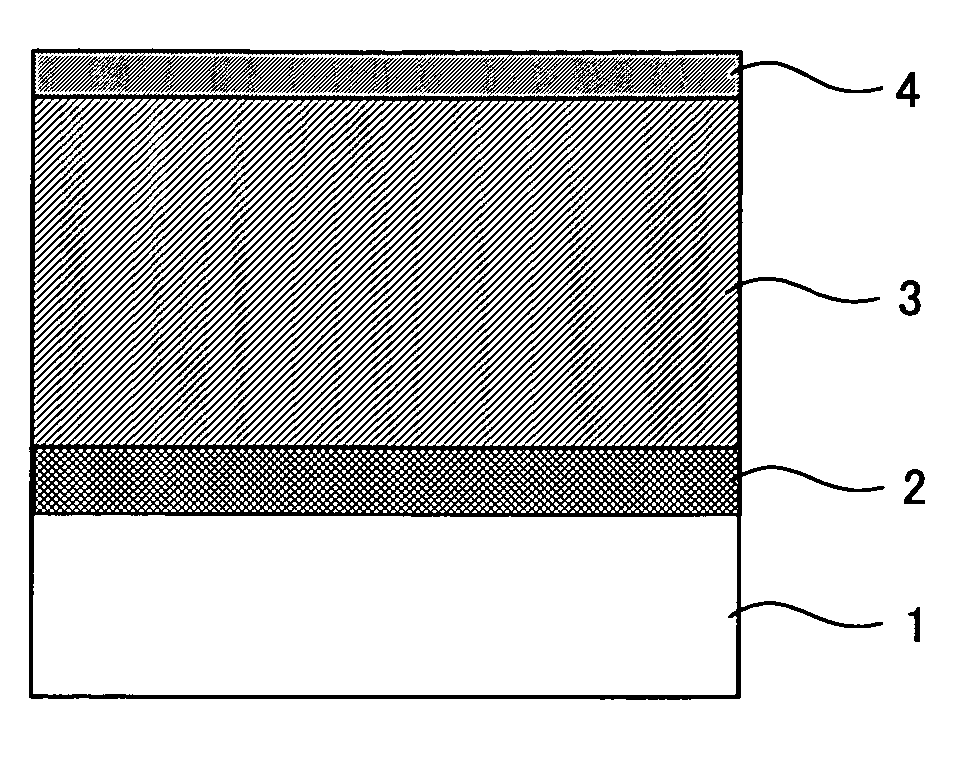

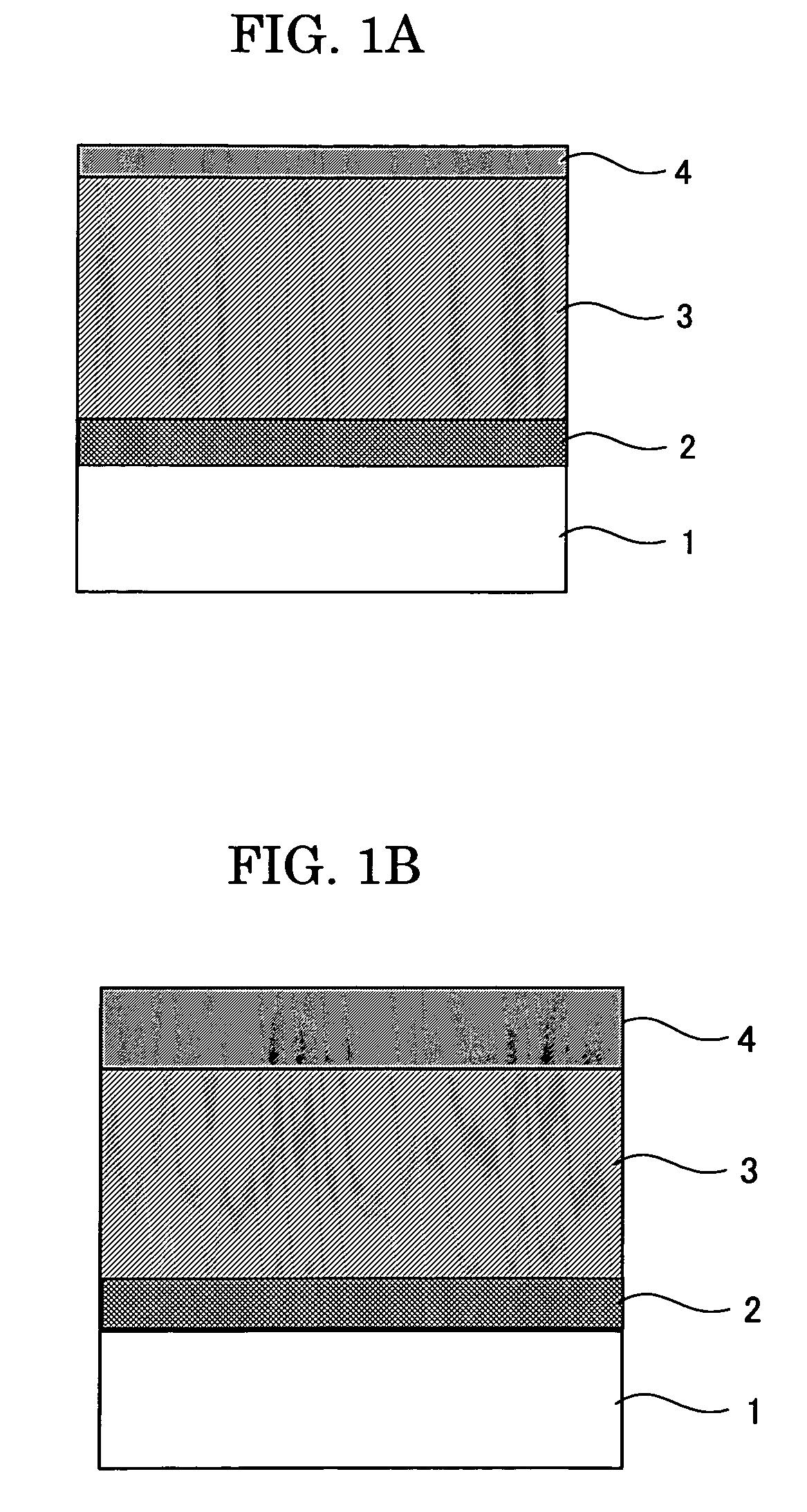

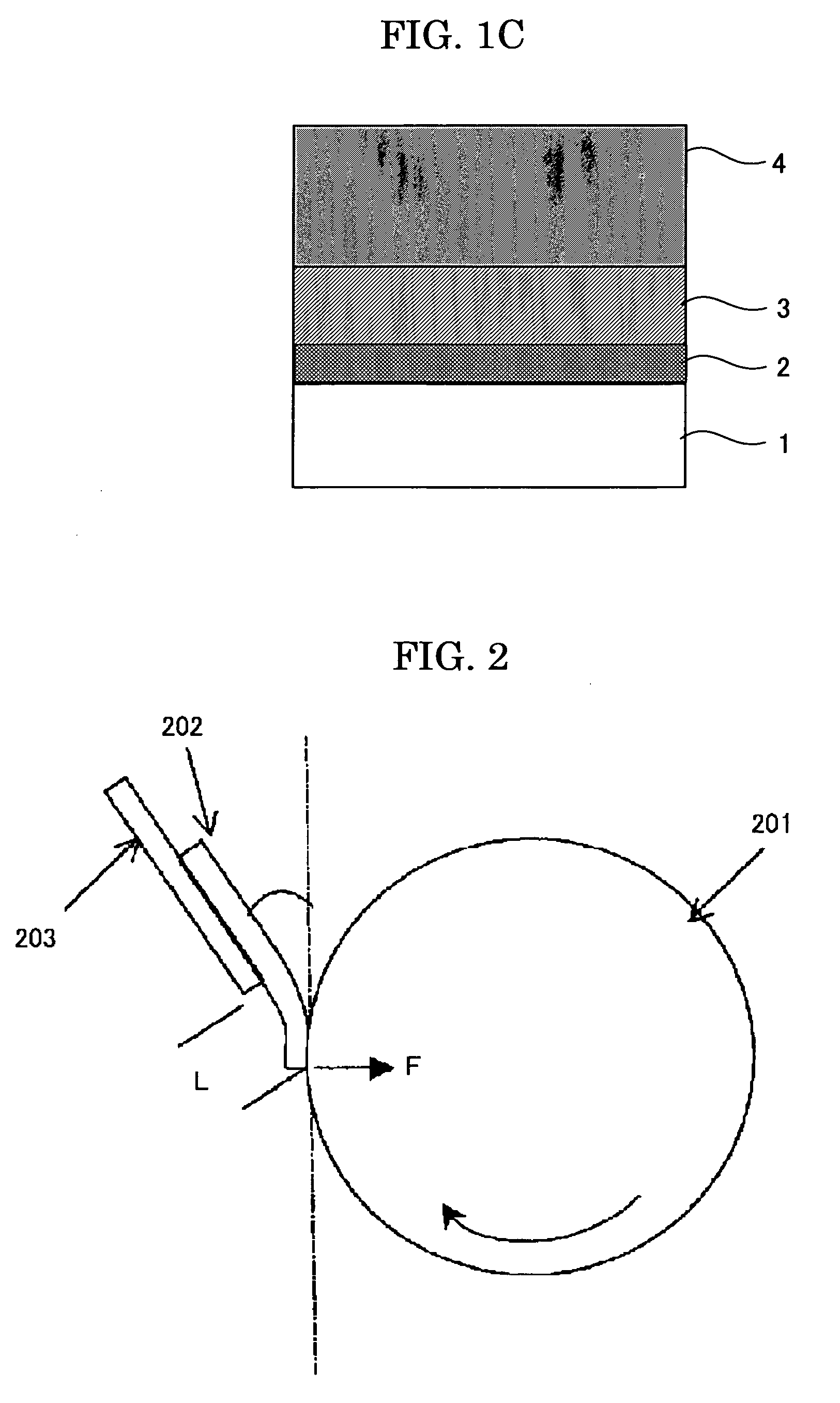

Reversible thermosensitive recording medium, information storage material, reversible thermosensitive recording label, image processing method and image processing device

ActiveUS20050137088A1High image densityLess occurrenceAblative recordingRecording measured valuesImaging processingRecording layer

A reversible thermosensitive recording medium including a substrate, a reversible thermosensitive recording layer and an intermediate layer. The reversible thermosensitive recording layer is configured to reversibly record and erase an image therein and disposed overlying the substrate and includes a binder resin and a reversible thermosenstive coloring composition. The reversible thermosenstive coloring composition includes an electron donating coloring compound and an electron accepting compound. The intermediate layer includes another binder resin and a content of hollow particles having a hollow ratio not less than 70% and a ratio of a maximum particle diameter thereof to a 50% cumulative particle diameter of from 2.0 to 3.0. The reversible thermosensitive recording layer achieves a colored state when heated to a temperature not lower than a melting point thereof, and achieves a discolorization state when heated to a temperature lower than the melting point. The reversible thermosensitive recording layer has an erasable energy range width of at least 0.1 mJ / dot when using a thermal head.

Owner:RICOH KK

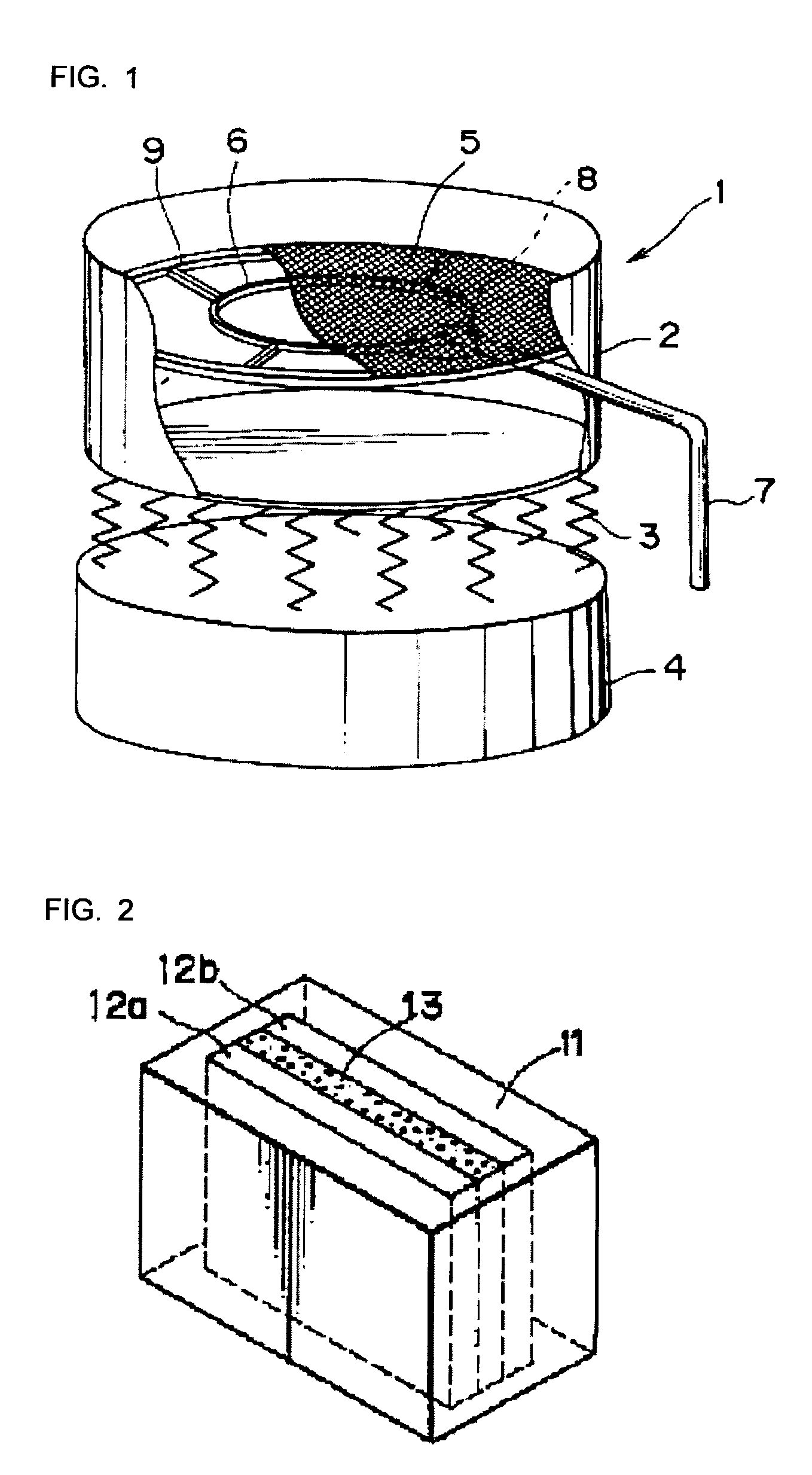

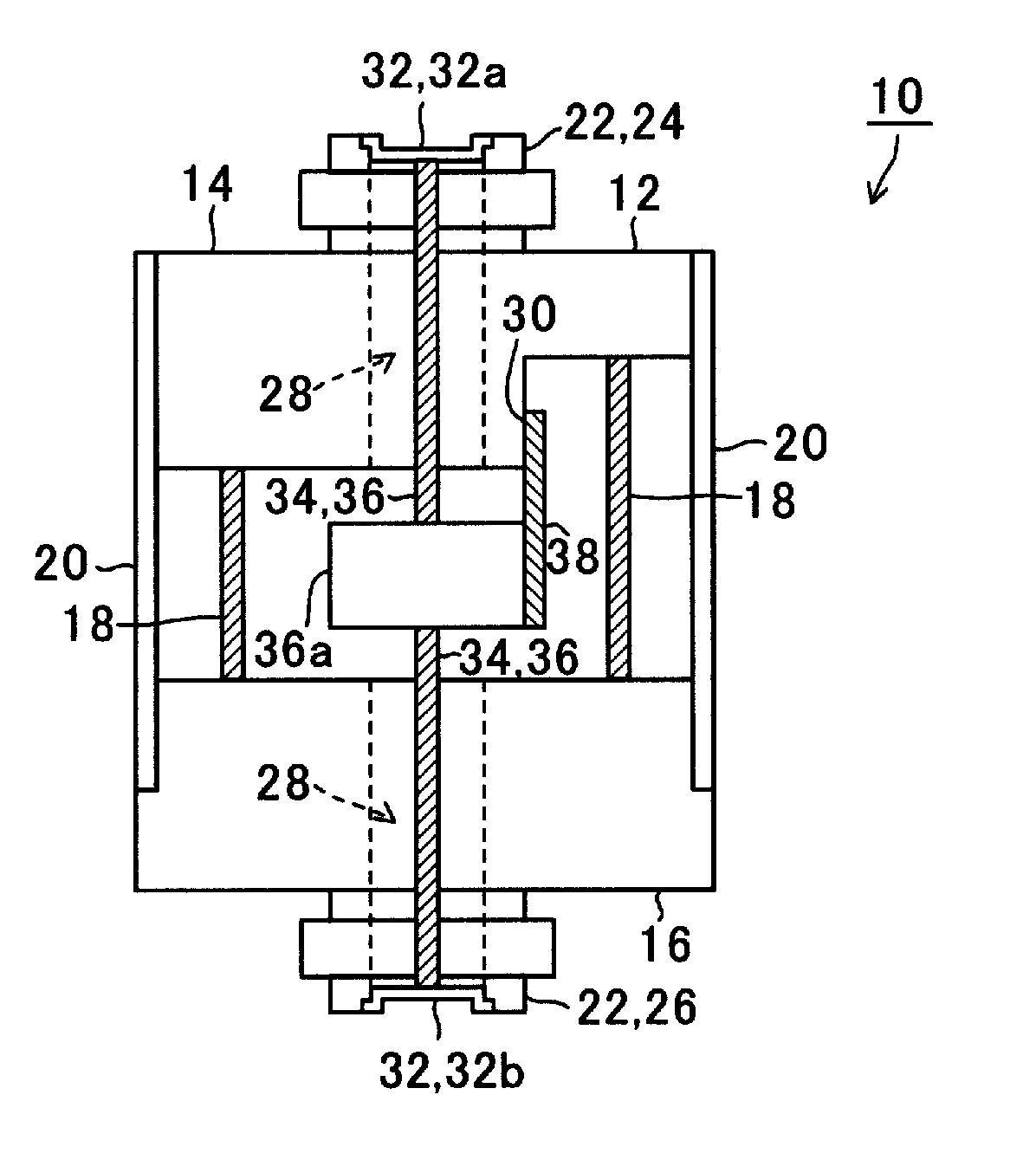

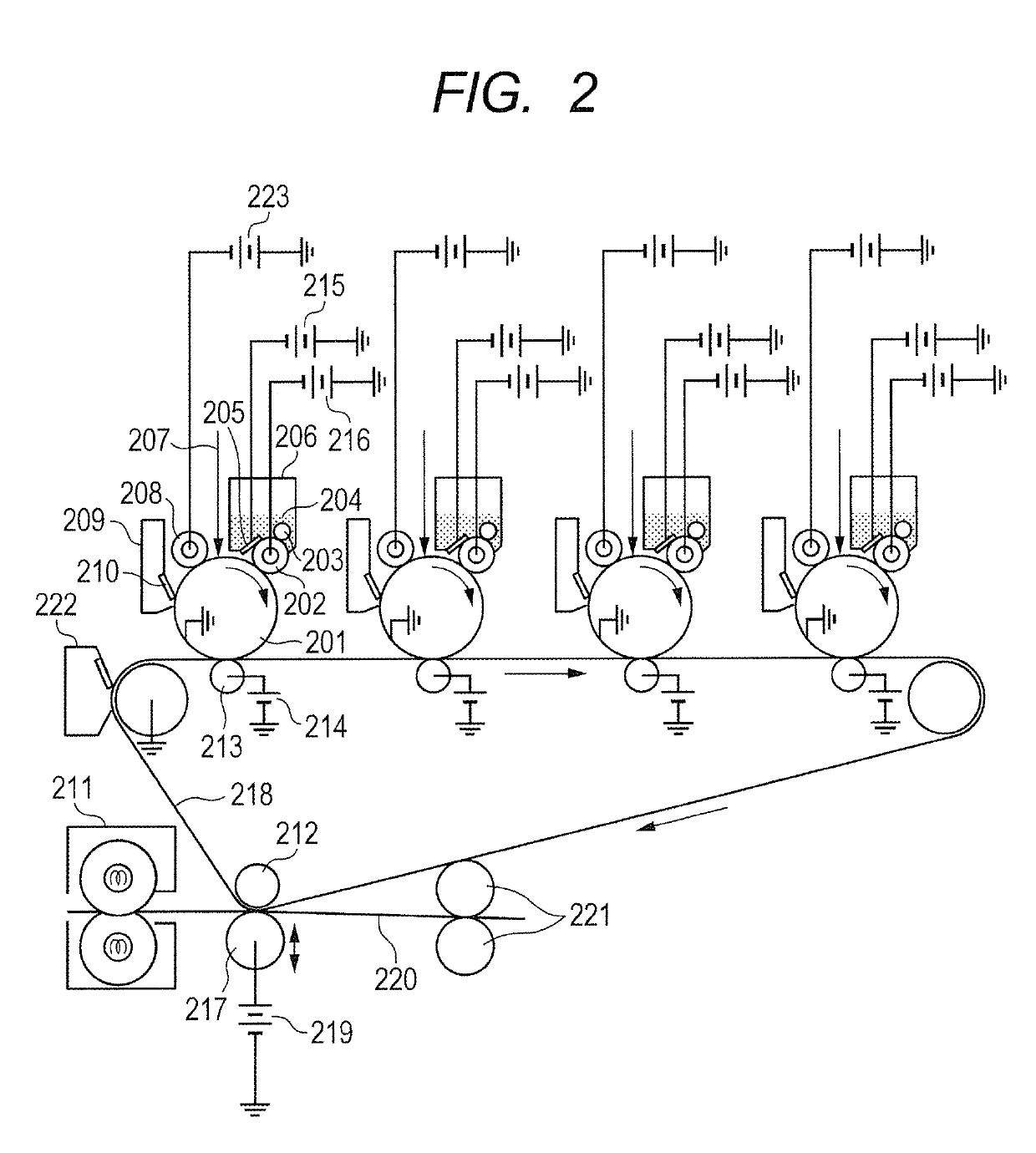

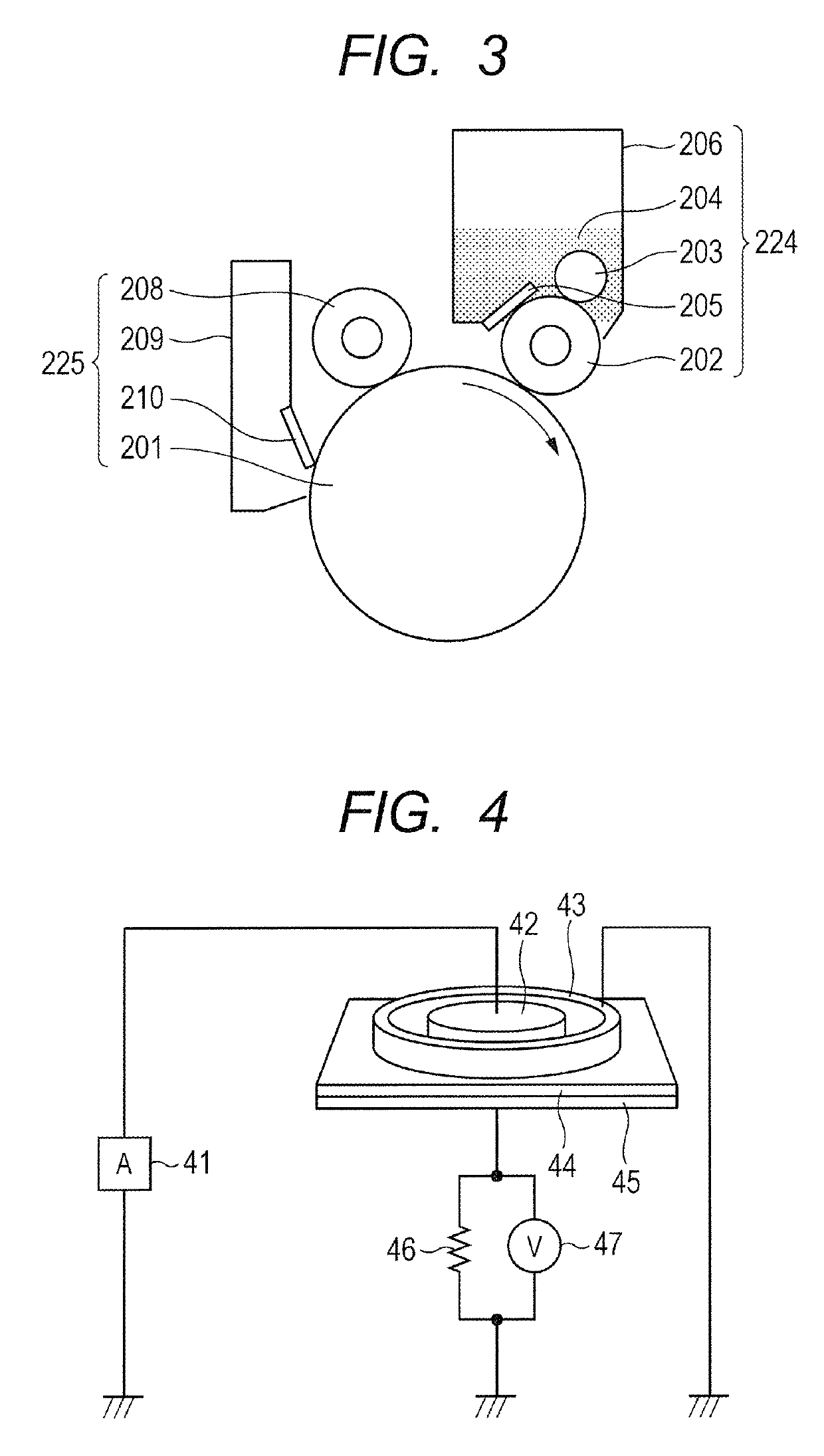

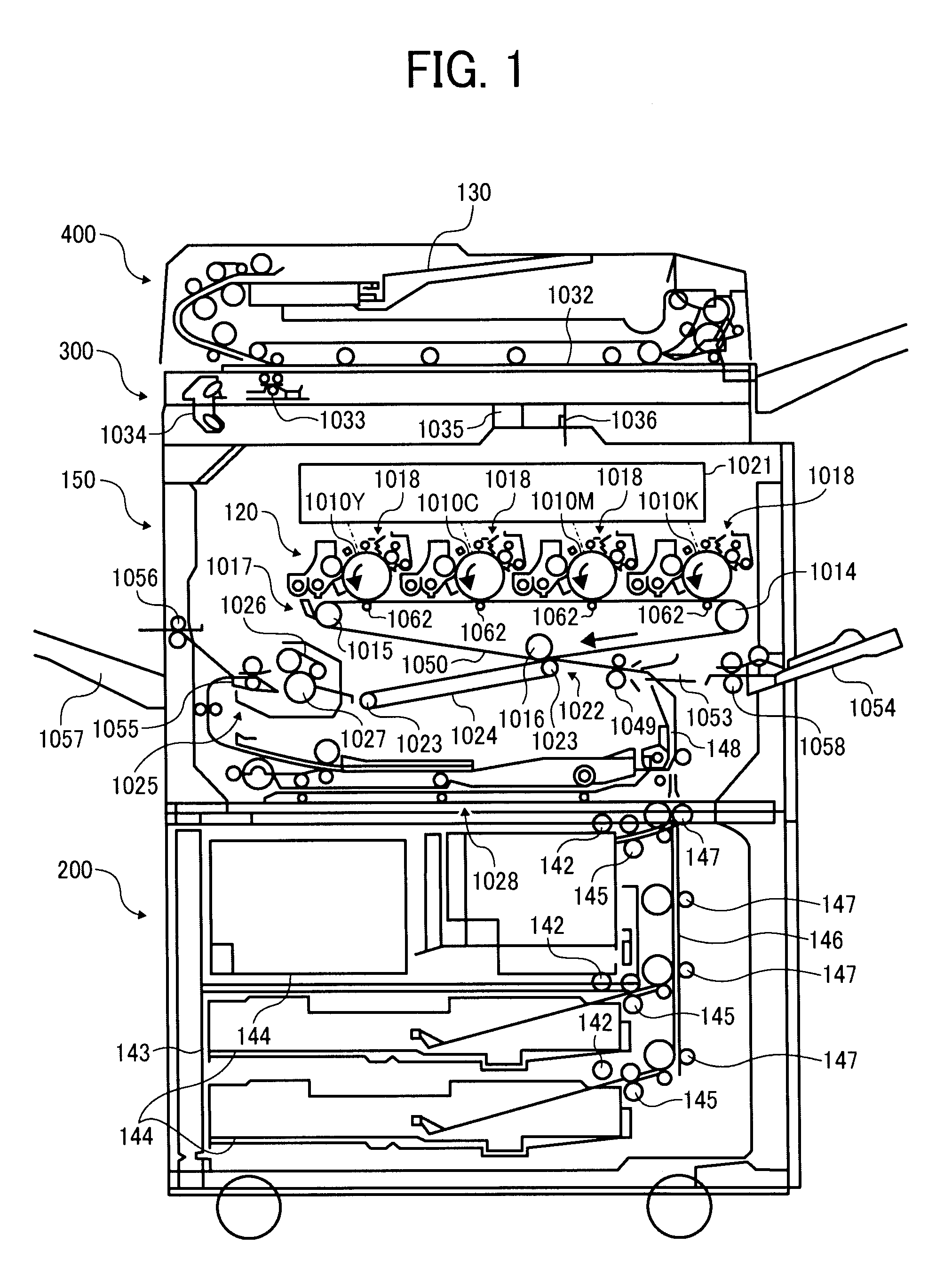

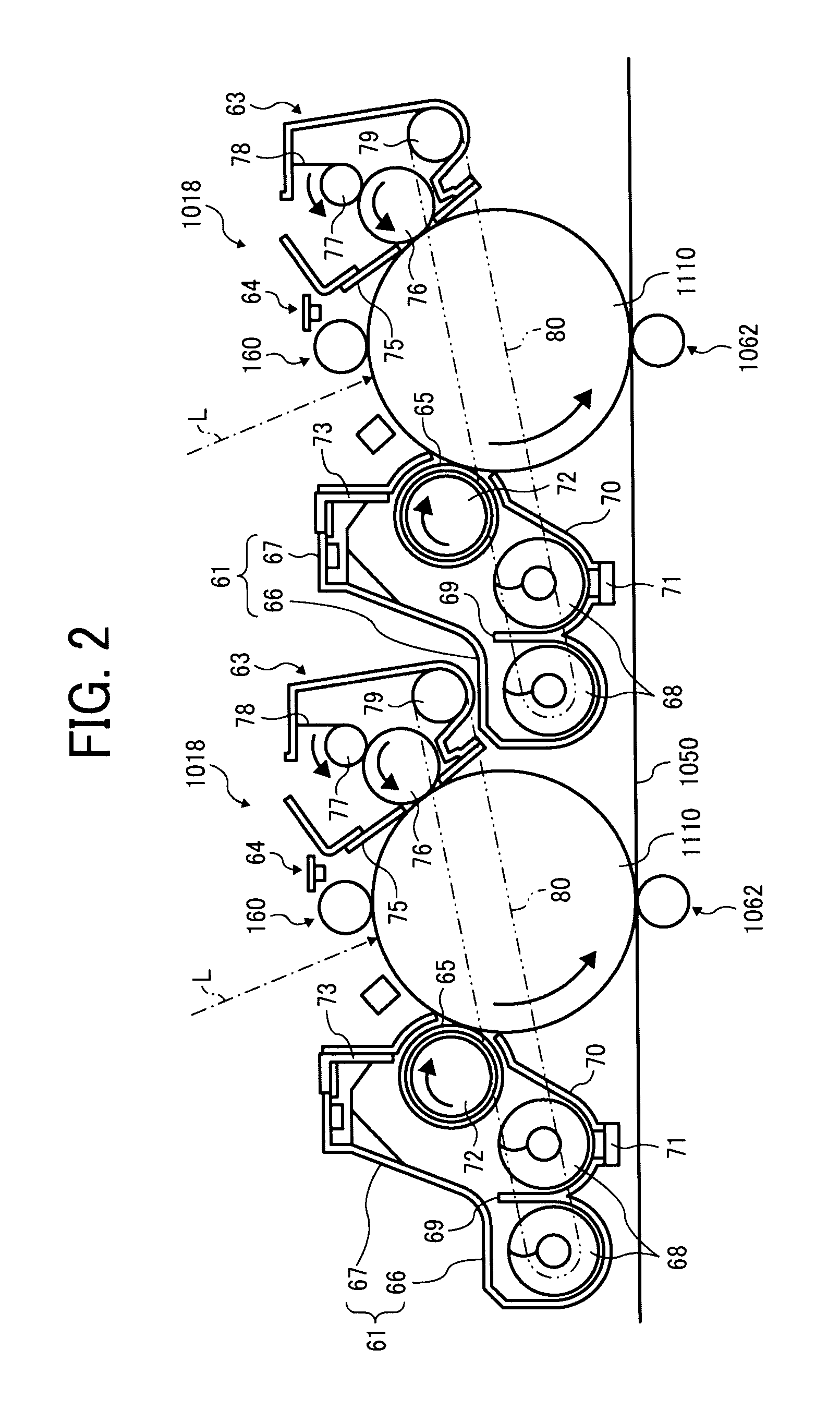

Image forming process, image forming apparatus, and process cartridge

InactiveUS20060068308A1High qualityIncrease durabilityDevelopersElectrographic process apparatusCompound (substance)Engineering

An image forming process is provided, which is consisting of forming step for forming a latent electrostatic image on a photoconductor, developing step, transferring step, and fixing step, wherein the photoconductor contains the crosslinked charge transporting layer containing a cured product formed from at least a radical polymerizable compound having three or more functionalities and no charge transport structure, and a radical polymerizable compound having one functionality and a charge transport structure, wherein the developer includes a toner and a carrier, the carrier has core particles and a coating layer for coating the core particles, the content of the core particles having a particle diameter of smaller than 44 μm in the carrier is 70% by mass or more, and the content of the core particles having a particle diameter of smaller than 22 μm in the carrier is 7% by mass or less, a mass average particle diameter of the carrier (Dw) is 25 μm to 45 μm, and a ratio (Dw / Dp) of Dw to a number average particle diameter (Dp) is 1 to 1.30.

Owner:RICOH KK

Electrophotographic developer and carrier therefor, core material particle for carrier for electrophotographic developer and production method thereof and image forming method

ActiveUS20070243482A1Minimize toner spentImprove image qualityElectrographic process apparatusDevelopersCost effectivenessEngineering

The present invention can provide small-diameter core material particles for electrophotographic carrier, the particles that can prevent occurrences of carrier adhesions and reduce toner spent, have excellent durability and cause little fluctuations in image density with a narrow particle diameter distribution, and an efficient, cost-effective production method thereof. That is, the core material particles for electrophotographic carrier are particles wherein the weight average particle diameter, Dw, is in the range of 22 μm to 32 μm, the ratio of Dw to the number average particle diameter, Dp, satisfies the condition, 1<Dw / Dp<1.20, the content of particles smaller than 20 μm in diameter is in the range of 0% by mass to 7% by mass and smaller than 36 μm is in the range of 90% by mass to 100% by mass, and the BET specific surface area is in the range of 300 cm2 / g to 900 cm2 / g.

Owner:RICOH KK

Diaphragm for pressure sensor and pressure sensor

InactiveUS20090308168A1Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

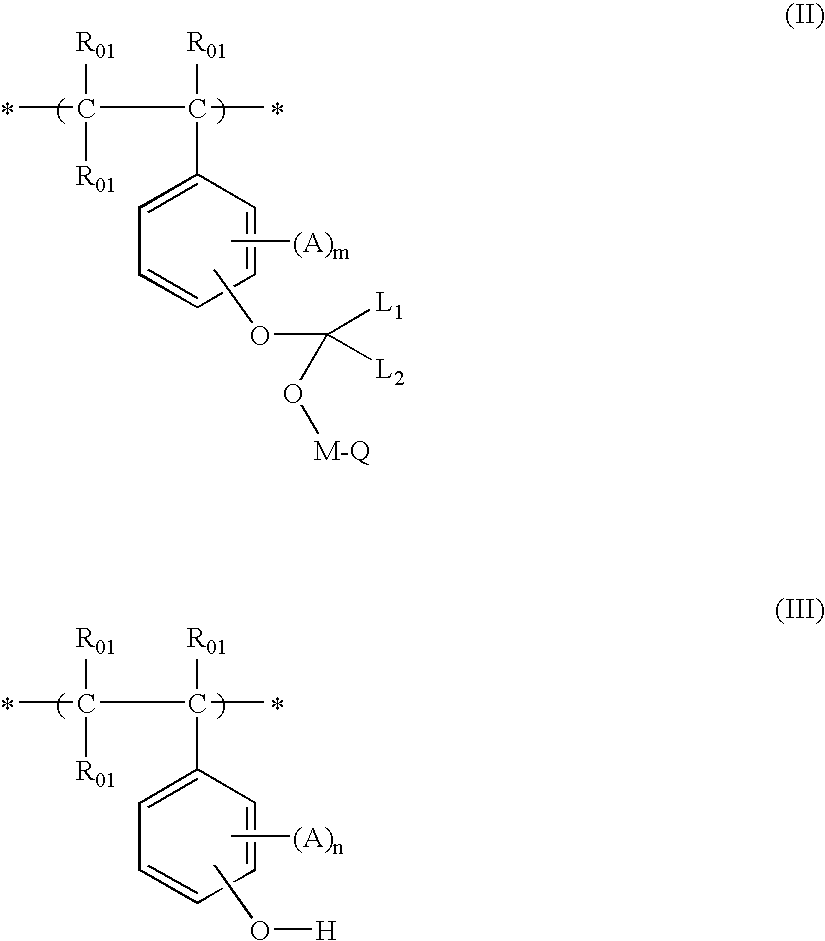

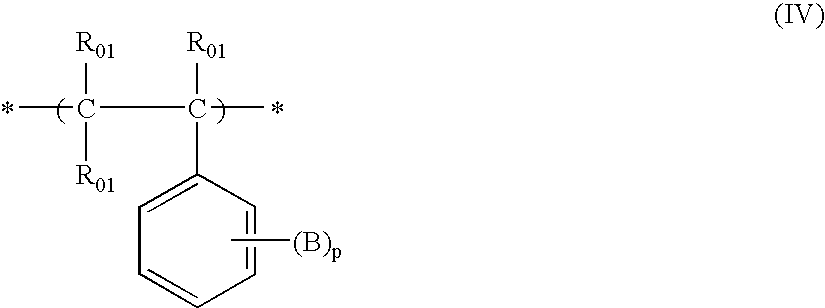

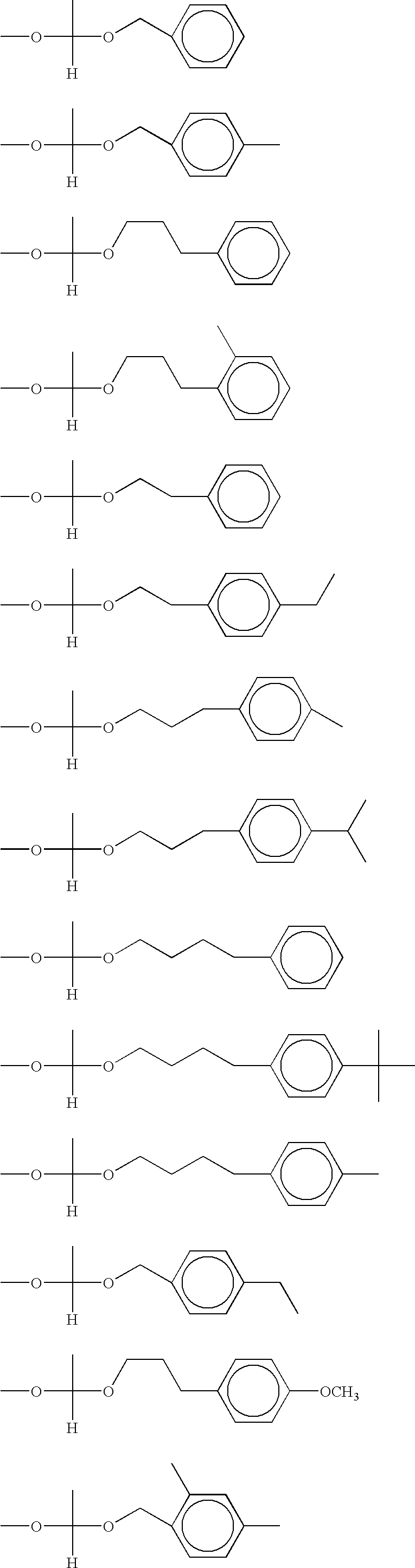

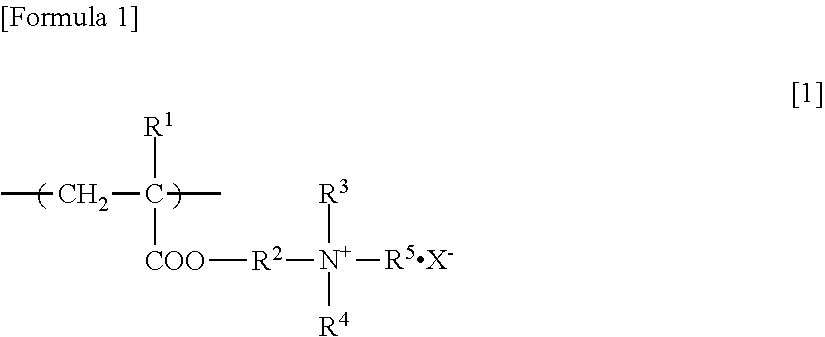

Electroconductive member for electrophotography and quaternary ammonium salt

ActiveUS10280148B2Reduction in electroconductivity through electrification are suppressedLess occurrenceOrganic chemistryElectrographic process apparatusPolymer scienceEngineering

Provided is an electroconductive member for electrophotography in which movement of a quaternary ammonium salt toward the surface of a binder resin is suppressed and which exhibits a less reduction in electroconductivity through electrification. The electroconductive member for electrophotography comprises an electroconductive shaft core and a resin layer, and the resin layer comprises a binder resin and at least one selected from quaternary ammonium salts having structures represented by the formulae (1) to (8).

Owner:CANON KK

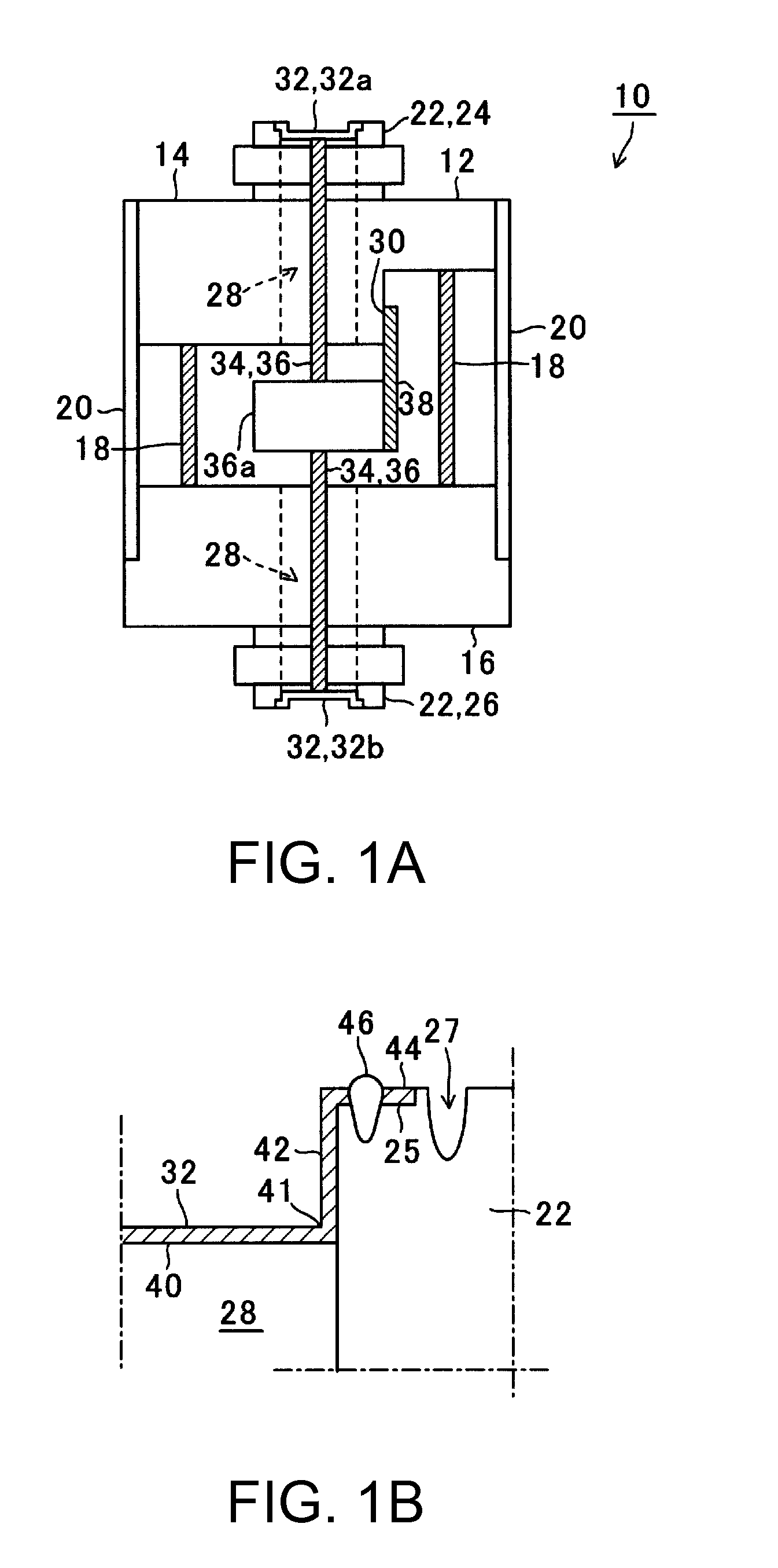

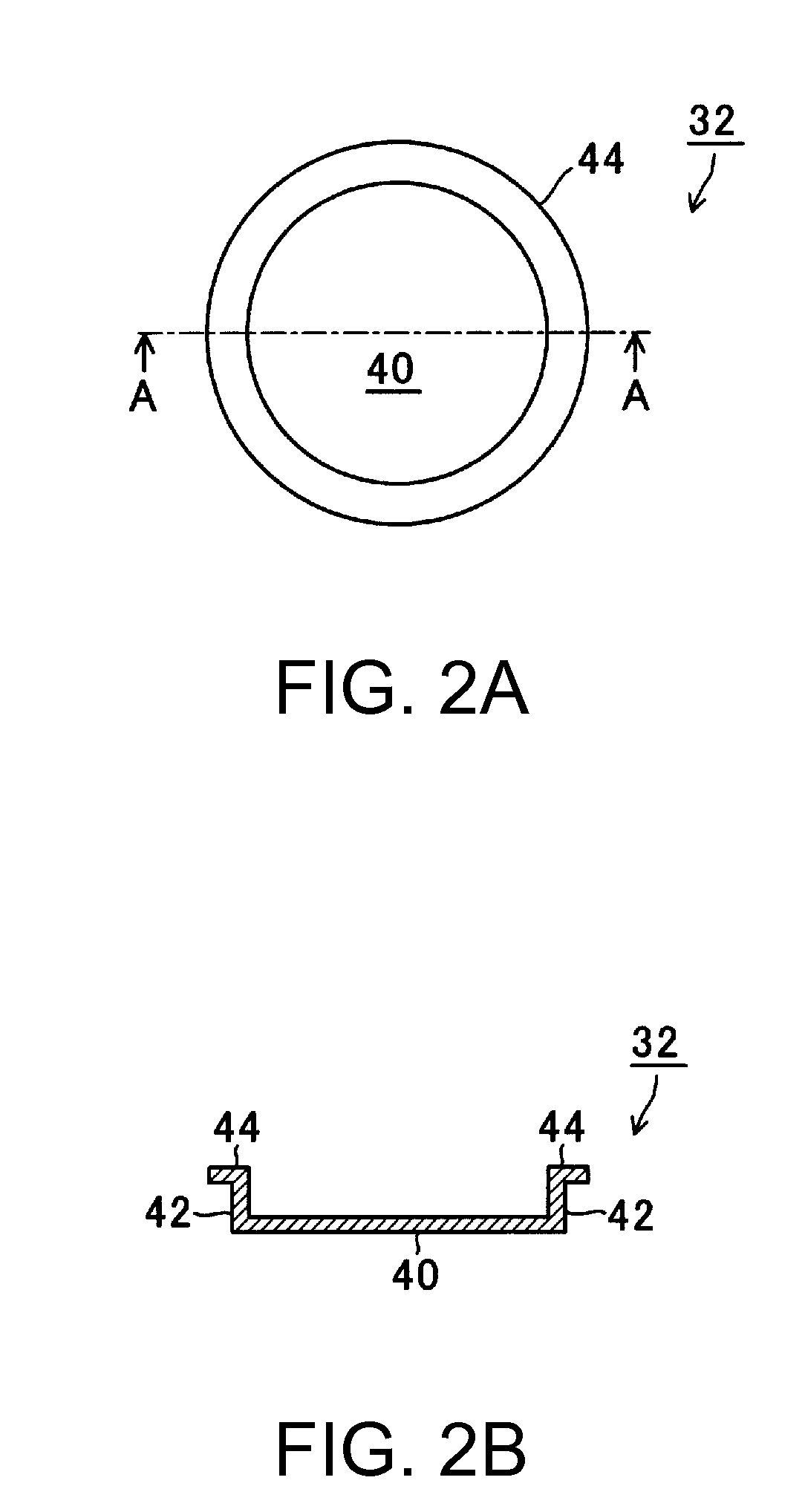

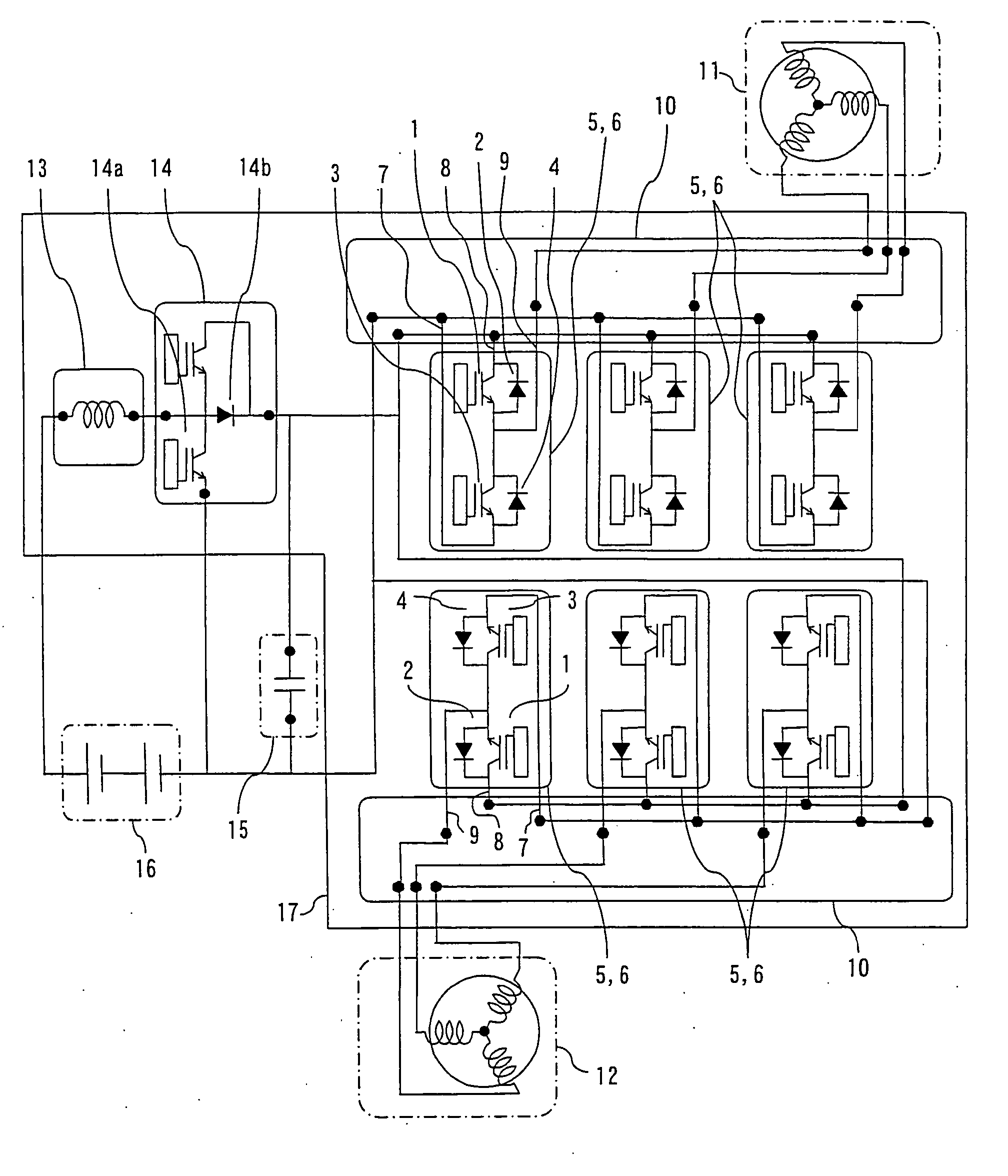

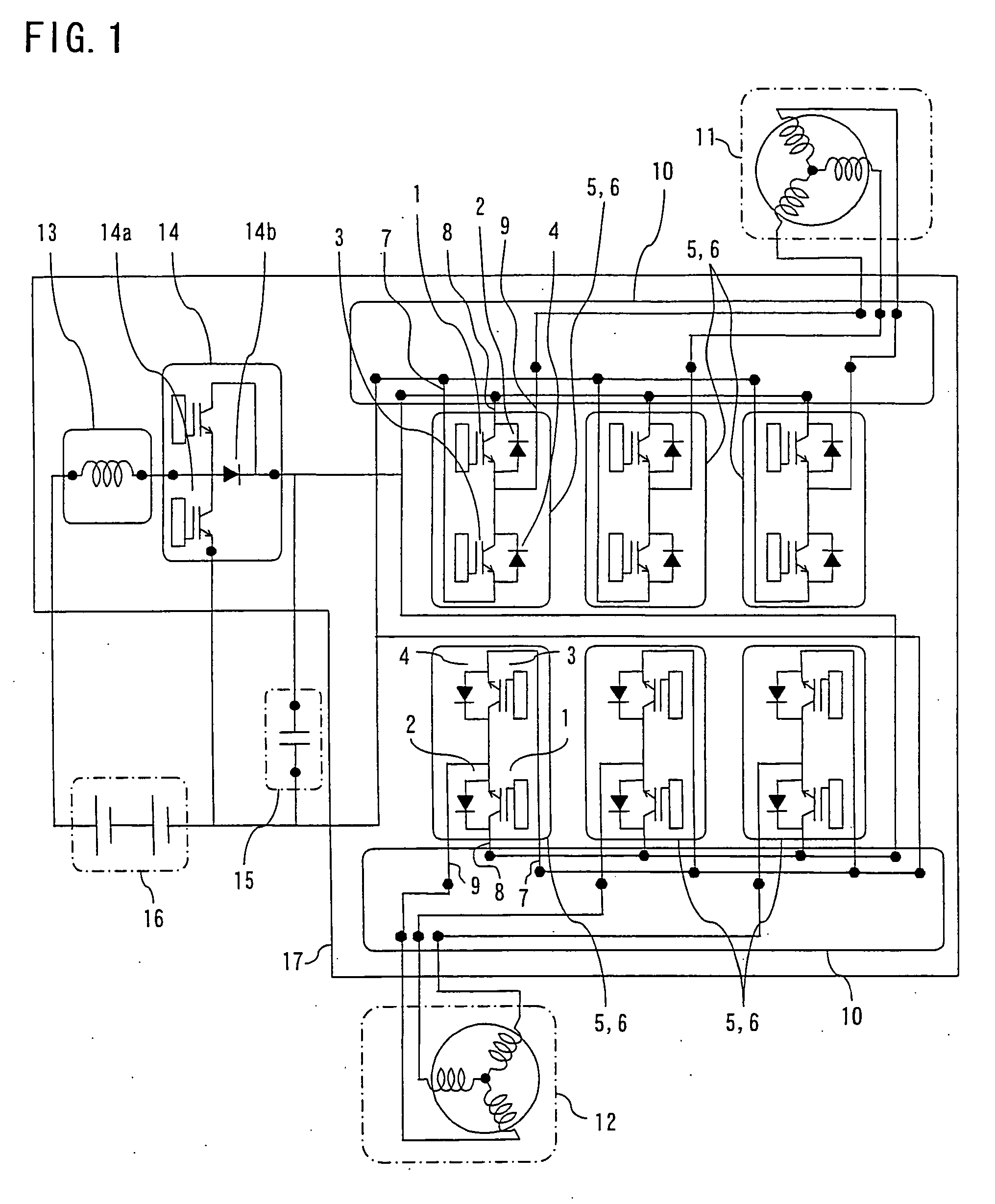

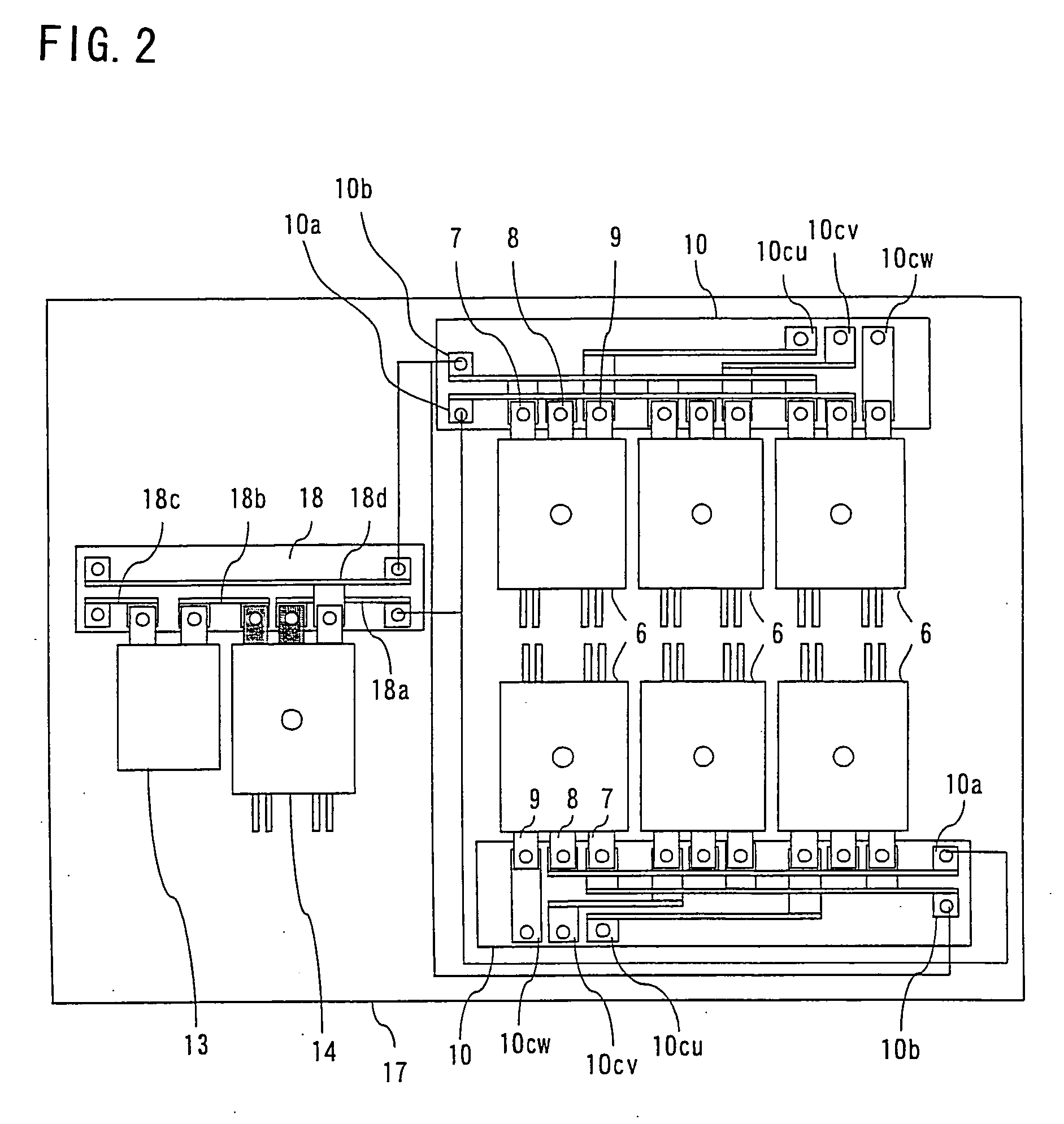

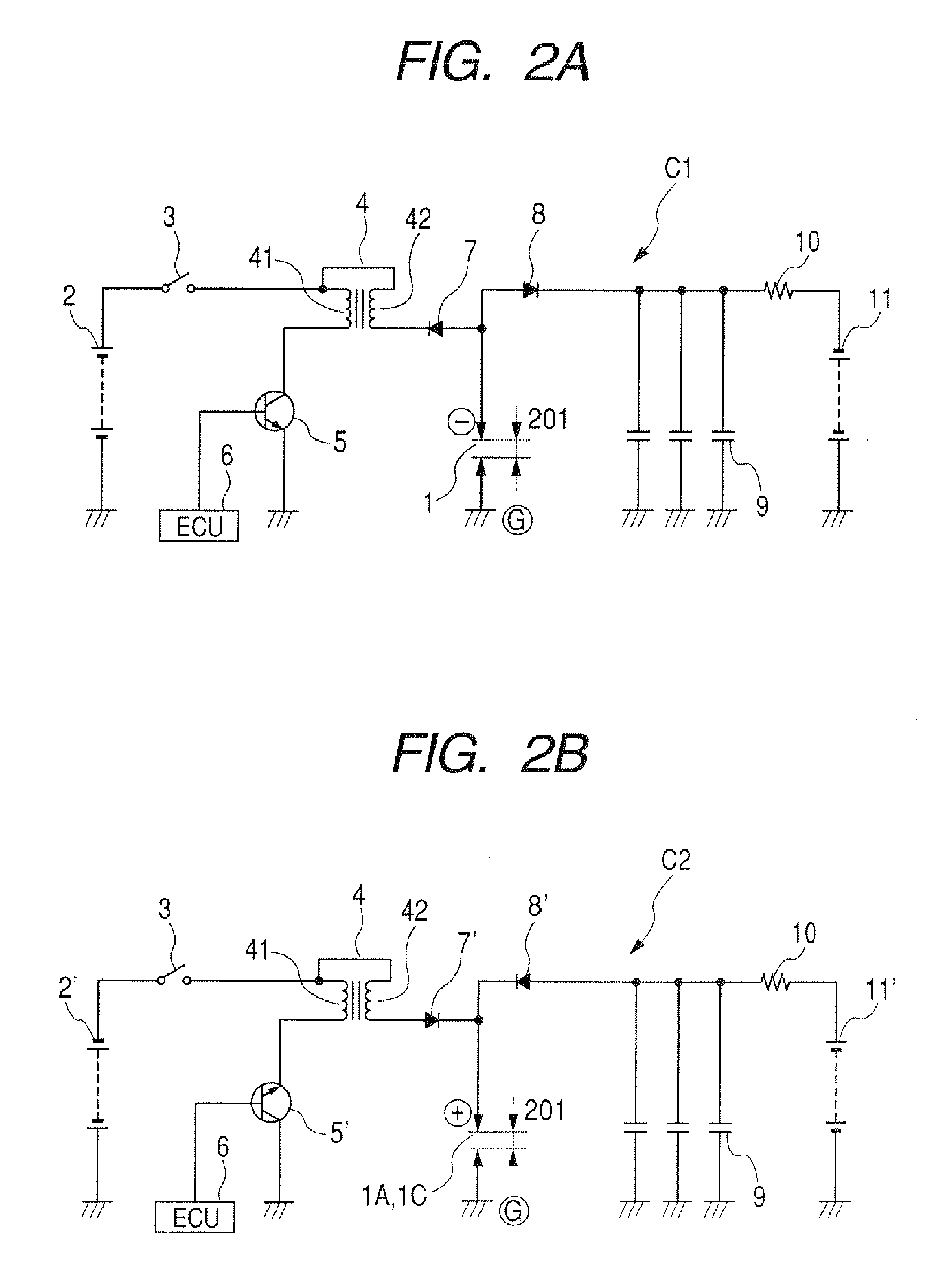

Power unit

ActiveUS20060273592A1Reduce in quantityImprove mechanical durabilityConversion constructional detailsSolid-state devicesSemiconductorElectric machine

A power unit includes a plurality of power modules for controlling individual phases of a pair of rotating electric machines and a heat sink on which the power modules are mounted. Each of the power modules includes a metal block, four power electronic semiconductor devices which are heat-generating elements mounted on the metal block with electrically conductive device bonding layers placed in between, and a plastic case. The plastic case is made of a plastic material sealing the power electronic semiconductor devices and the metal block in a single package with leads connected to top- and bottom-side electrodes of the power electronic semiconductor devices extending outward from the plastic case.

Owner:MITSUBISHI ELECTRIC CORP

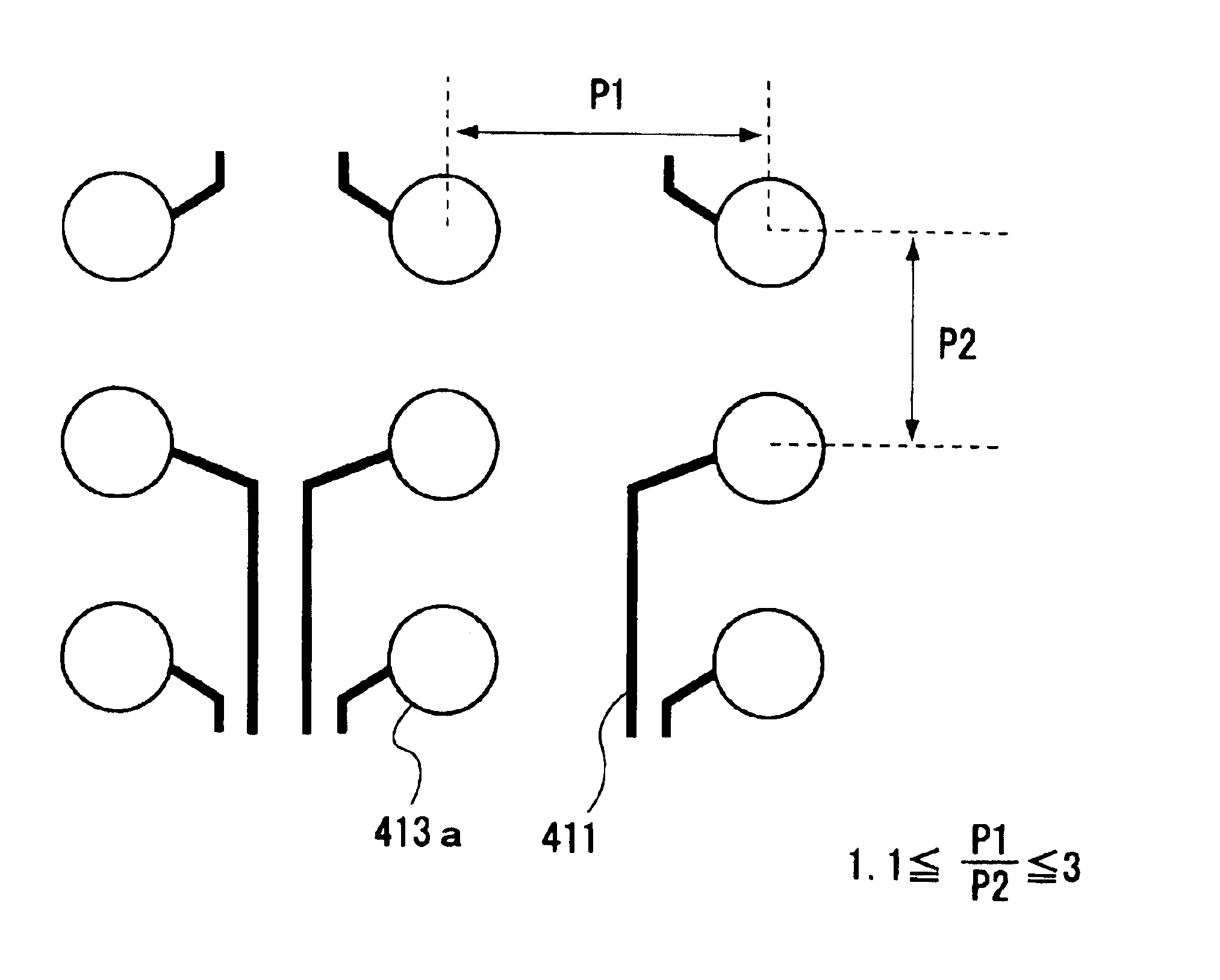

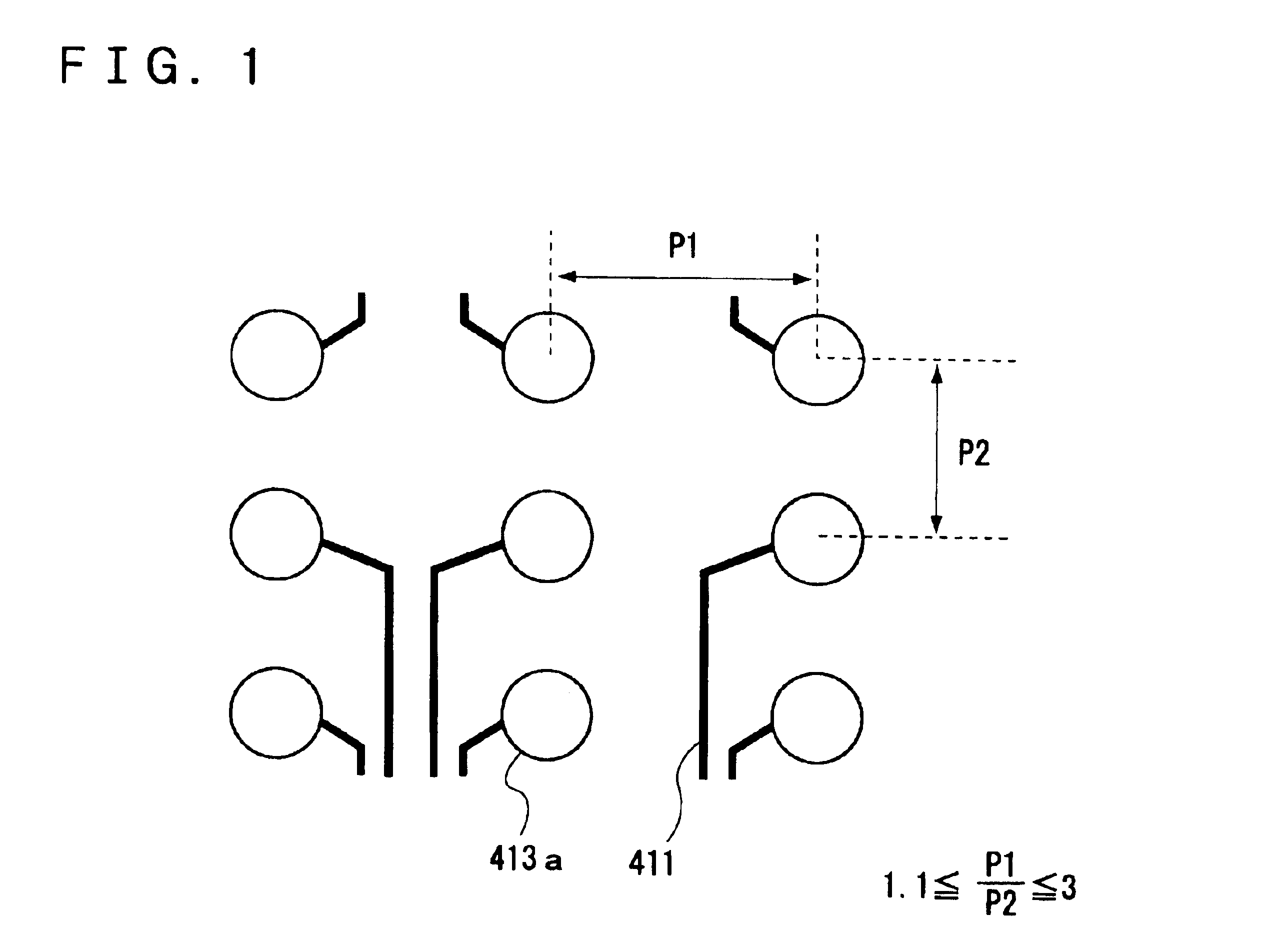

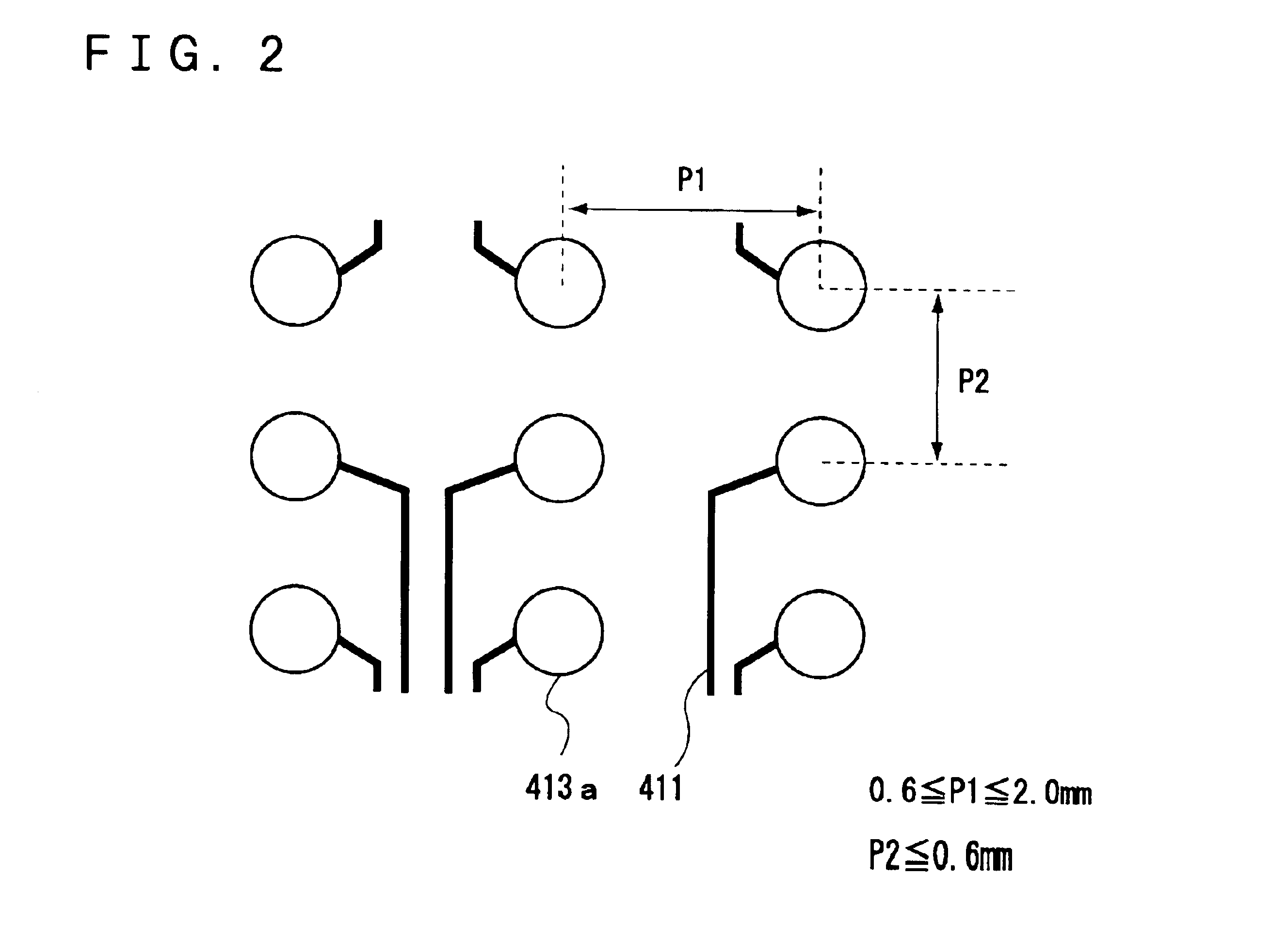

Circuit board, mounting structure for semiconductor device with bumps, and electro-optic device and electronic device

InactiveUS6853092B2Increase distanceReduce generationPrinted circuit assemblingFinal product manufactureDevice materialEngineering

Owner:BOE TECH GRP CO LTD

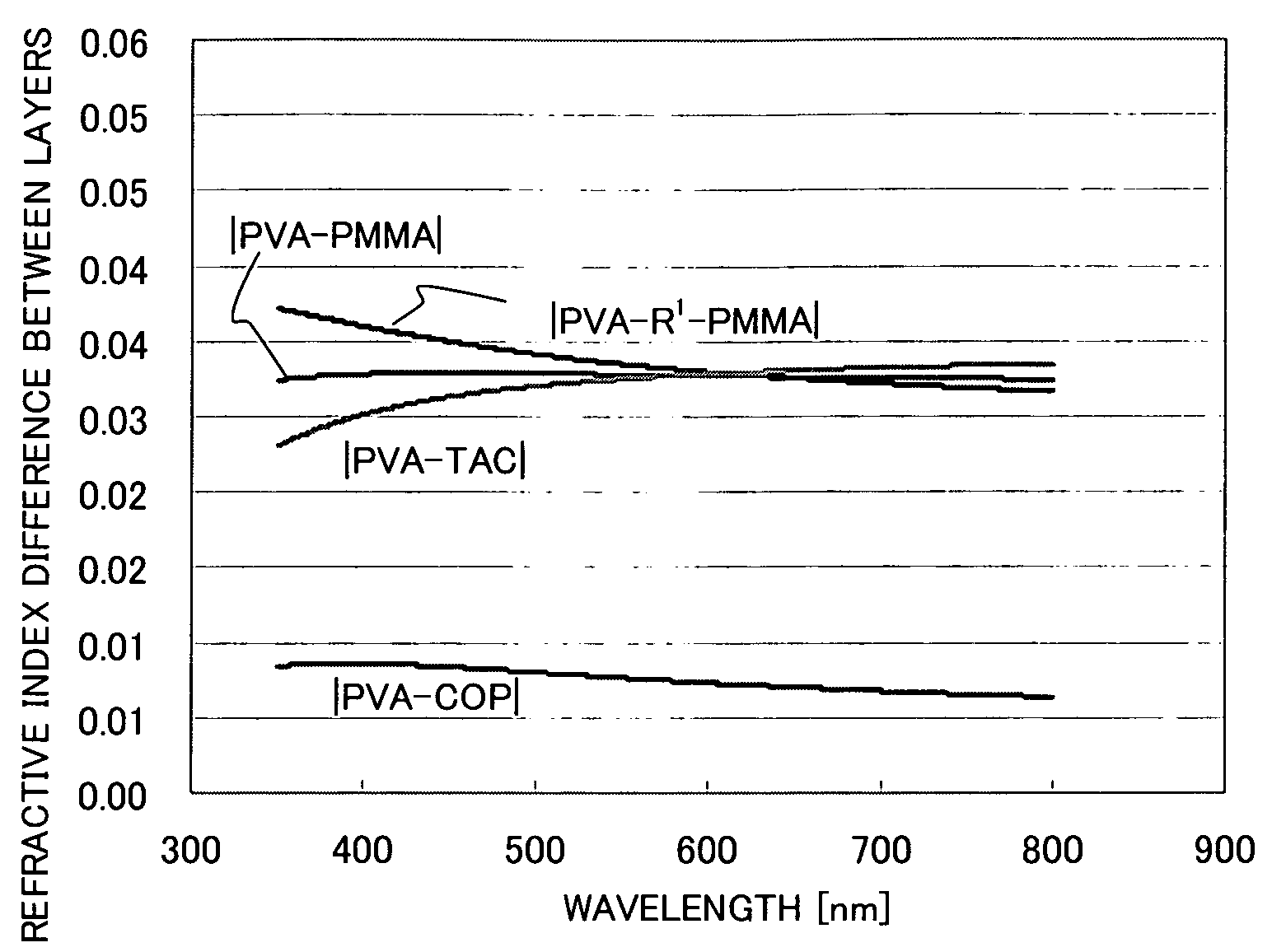

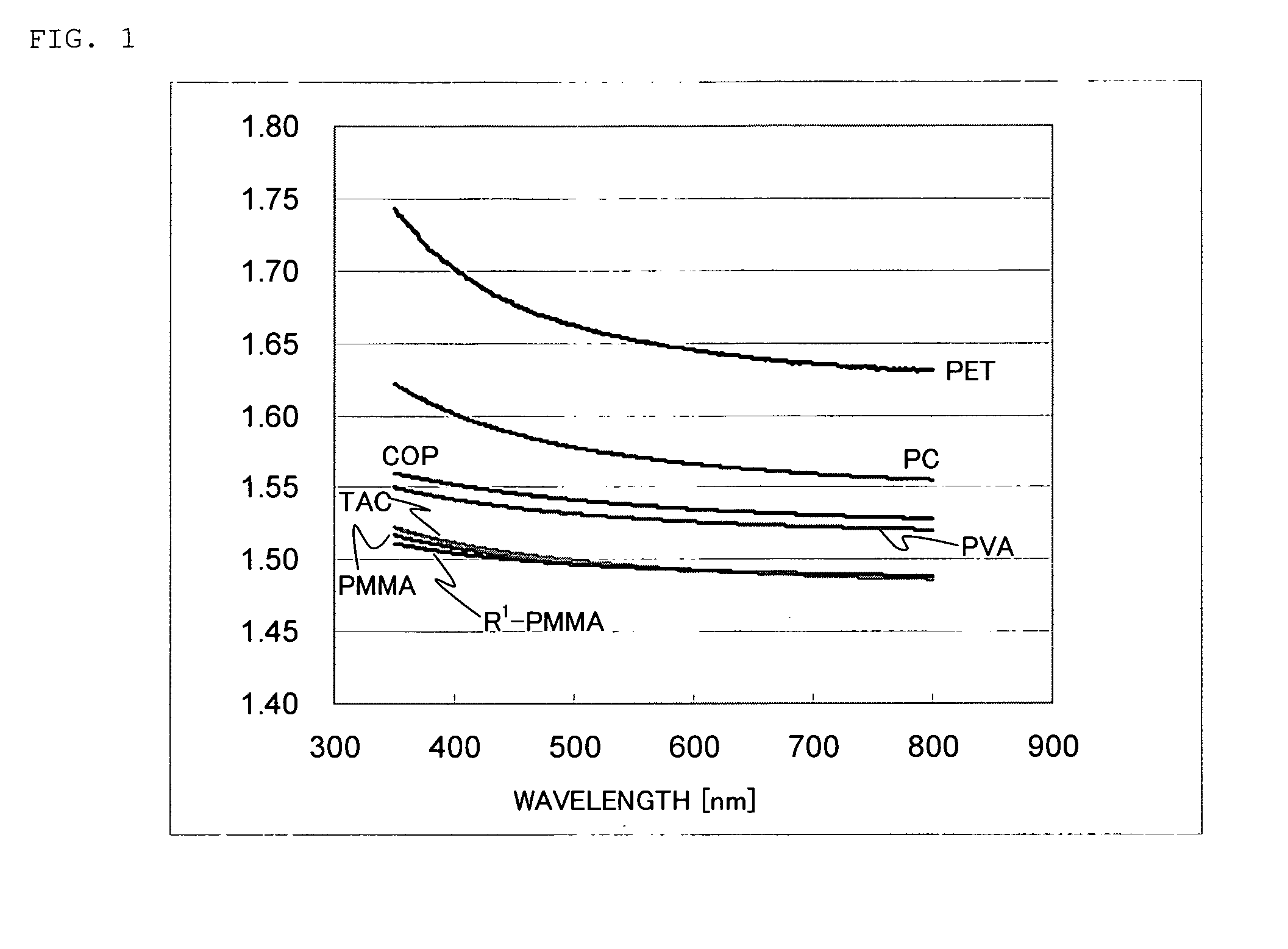

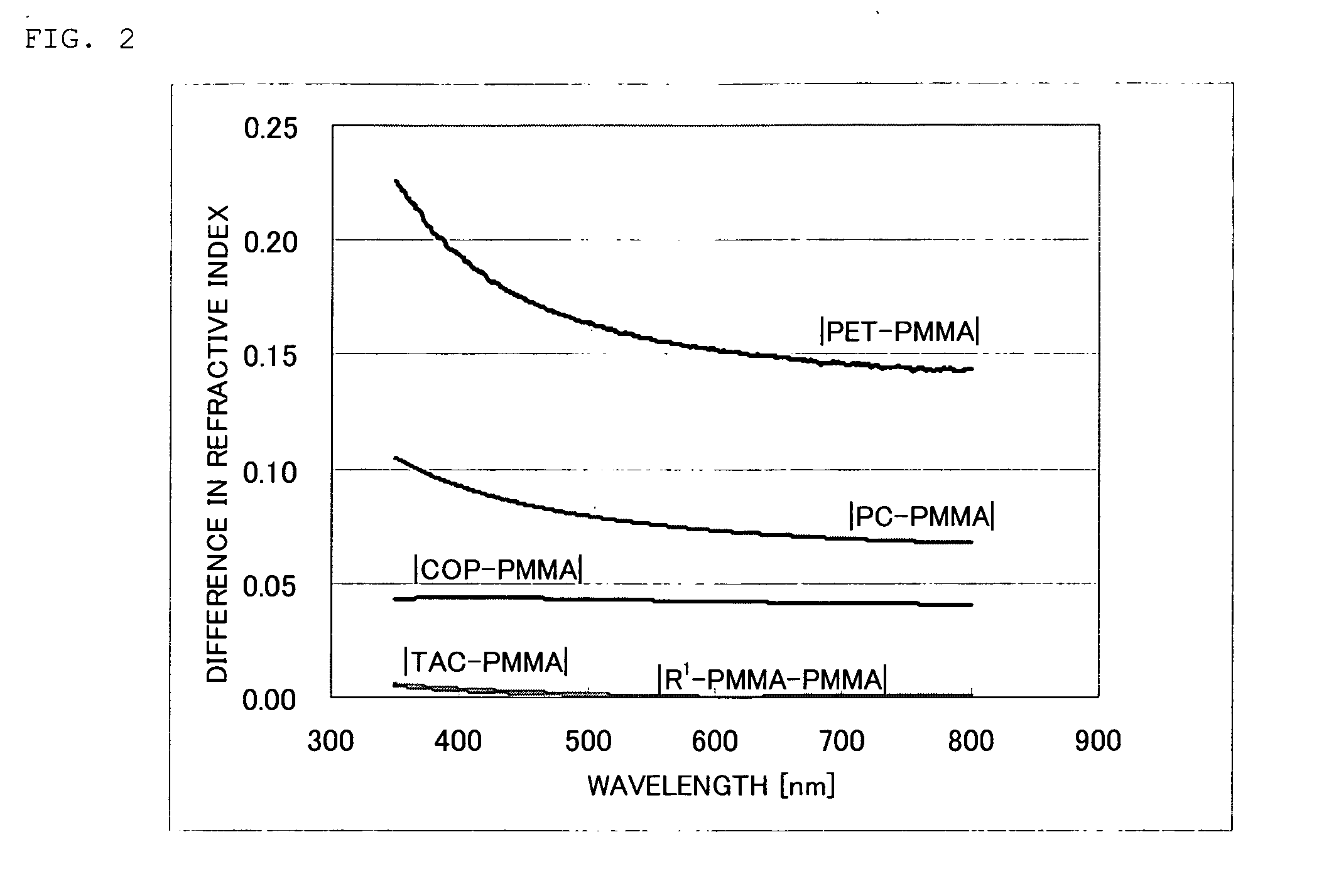

Protective Film for Polarizing Plate

ActiveUS20090086320A1High color reproductionLess occurrenceLiquid crystal compositionsPrismsTectorial membraneLiquid-crystal display

A protective film for polarizing plate comprising k layers (k is an integer of 2 or more) of thermoplastic resin layer laminated, whereina refractive index ni(380) at a wavelength of 380 nm and a refractive index ni(780) at a wavelength of 780 nm in the i th thermoplastic resin layer as well as a refractive index ni+1(380) at a wavelength of 380 nm and a refractive index ni+1(780) at a wavelength of 780 nm in the i+1 th thermoplastic resin layer have a relationship in∥ni(380)−ni+1(380)|−|ni(780)−ni+1(780)∥≦0.02(where, i is an integer of 1 to k−1). A polarizing plate is obtained by bonding the protective film for the polarizing plate and a polarizer. And a liquid crystal display comprising the polarizing plate and a liquid crystal panel.

Owner:ZEON CORP

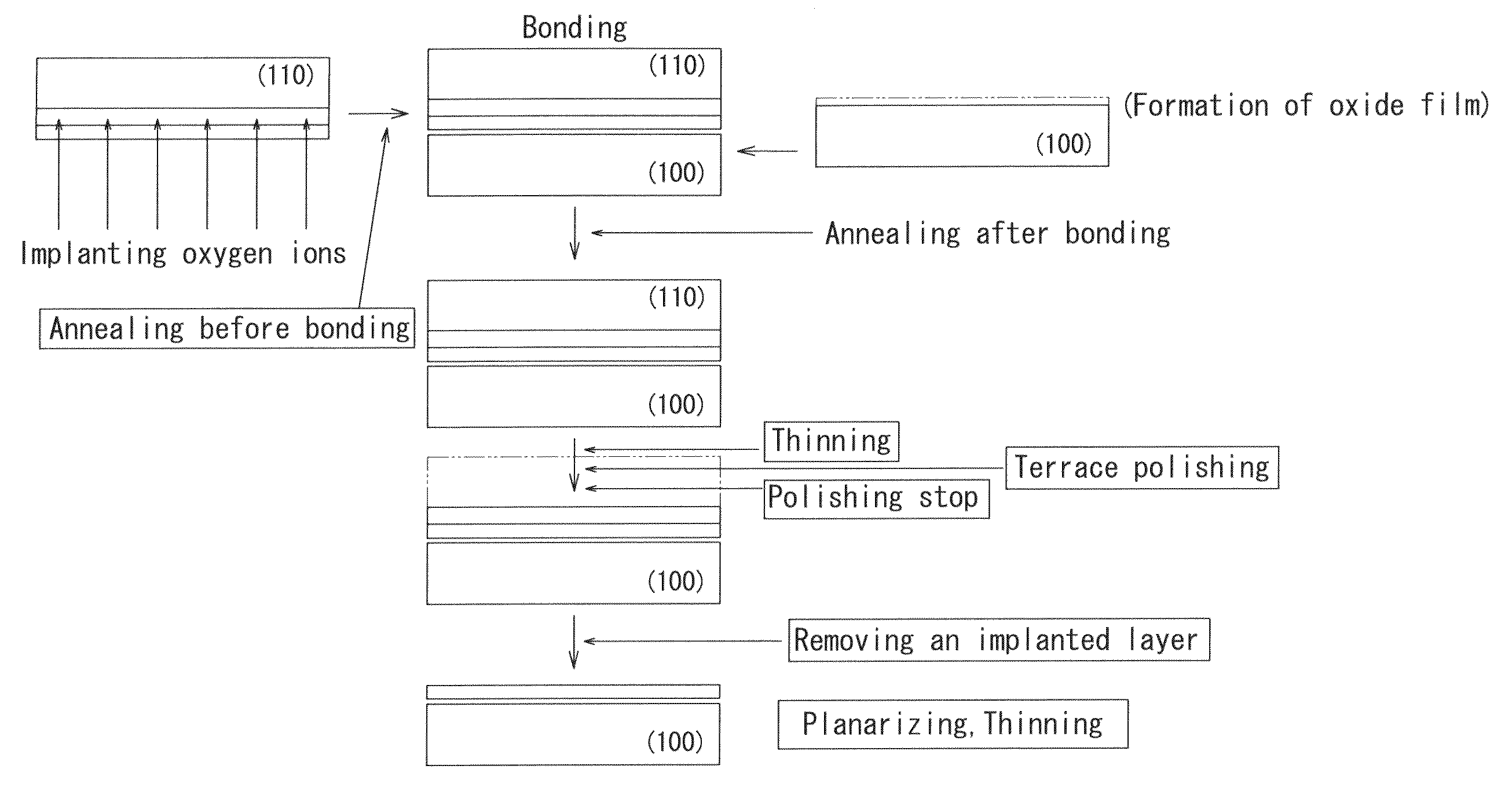

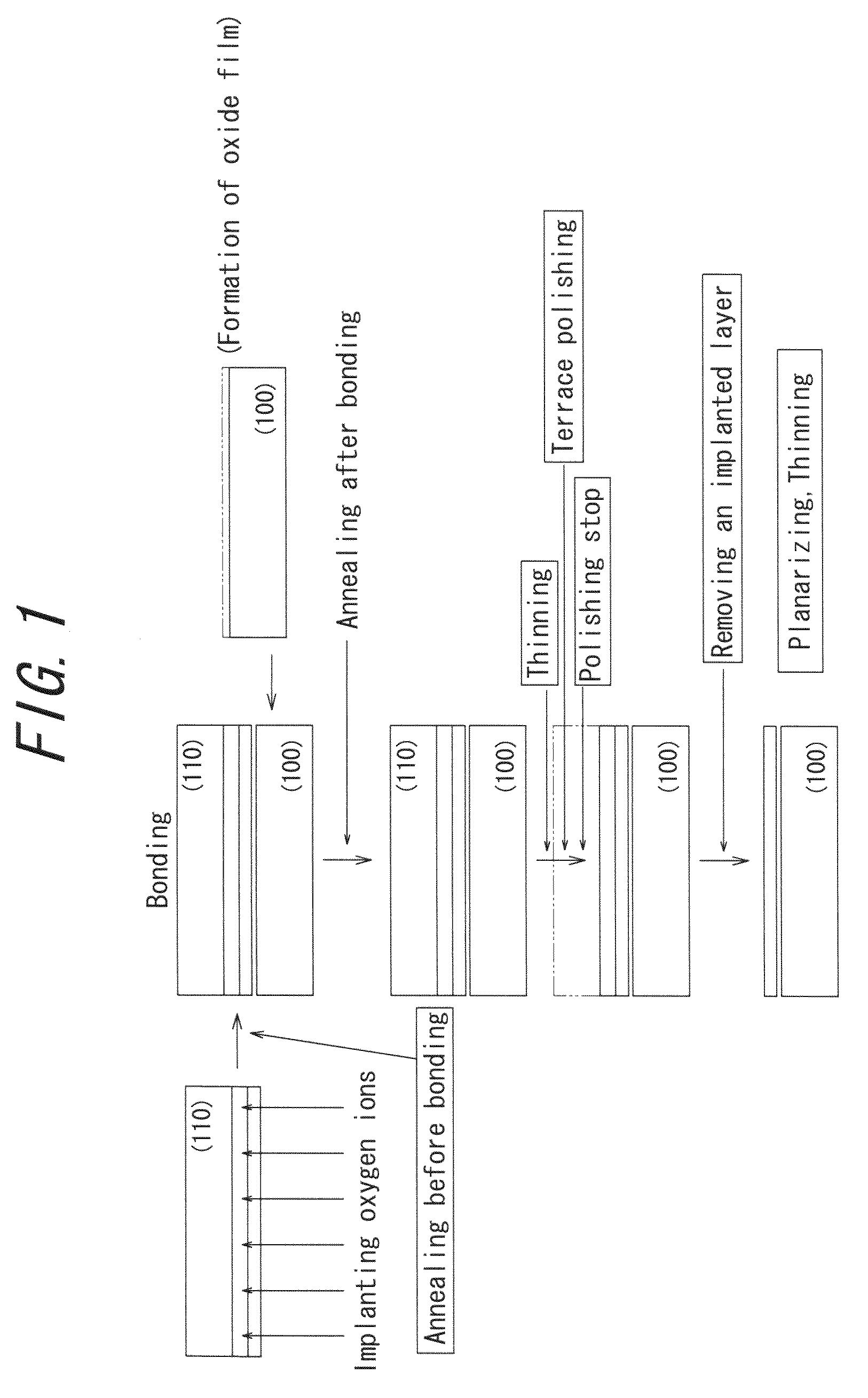

Method for producing bonded wafer

InactiveUS20090186464A1Improve thickness uniformityImprove surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

In the method for producing a bonded wafer by bonding a wafer for active layer to a wafer for support layer and then thinning the wafer for active layer, when oxygen ions are implanted into the wafer for active layer, the implantation step is divided into two stages conducted under specified conditions.

Owner:SUMCO CORP

Method of manufacturing toner and toner

InactiveUS20090280421A1Efficient and stable preparationSmall facilityDevelopersOrganic solventOil phase

A method of manufacturing a toner including dispersing a binder resin, a coloring agent and a releasing agent in an organic solvent to obtain an oil phase; dispersing the oil phase in an aqueous medium with a shearing force to obtain a dispersion emulsion; wherein the shearing force is made by a screen or vessel that is situated around a rotor, the screen spinning in a direction opposite to the direction that the rotor spins. Toner produced. Method of using the toner.

Owner:RICOH KK

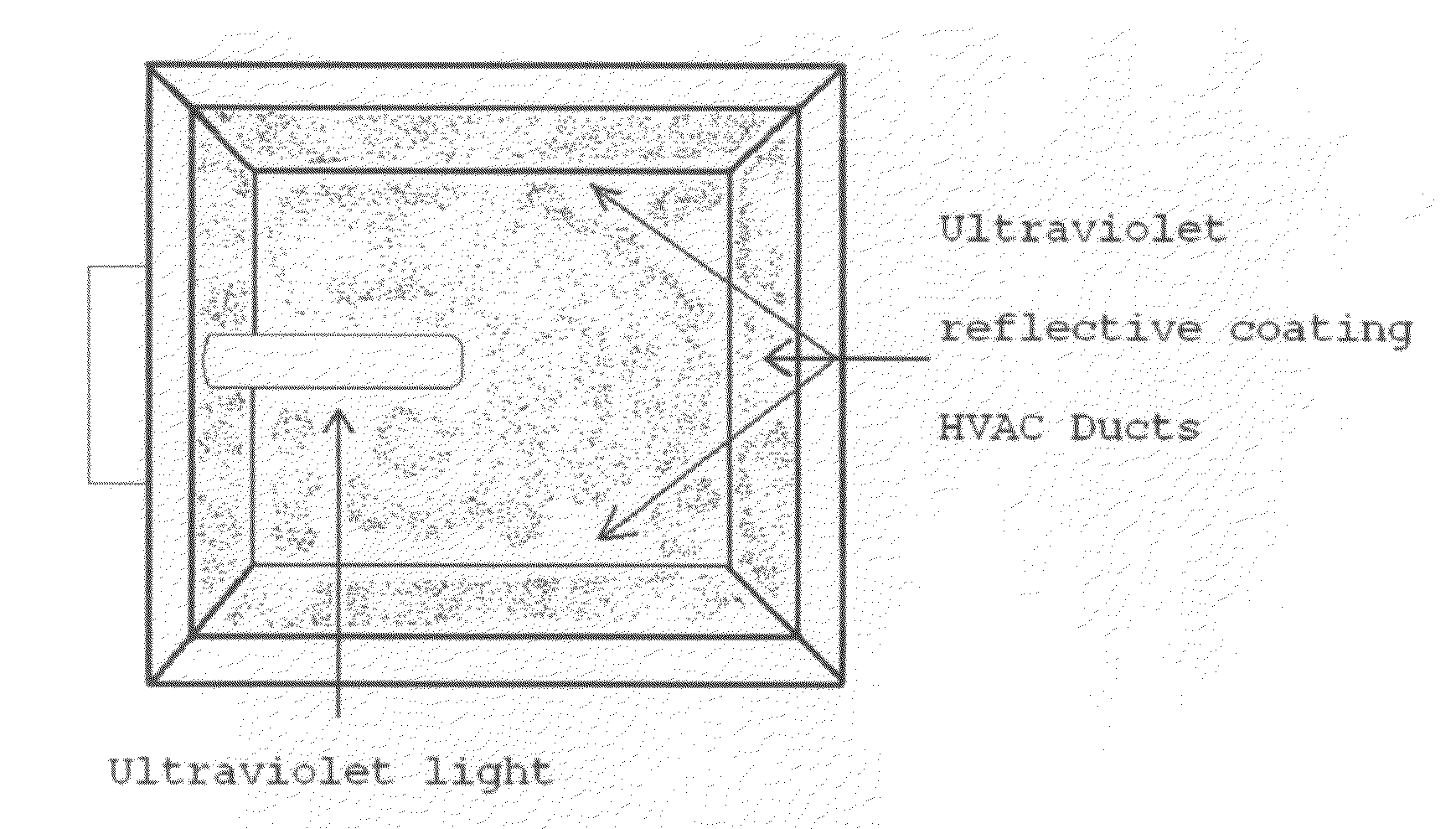

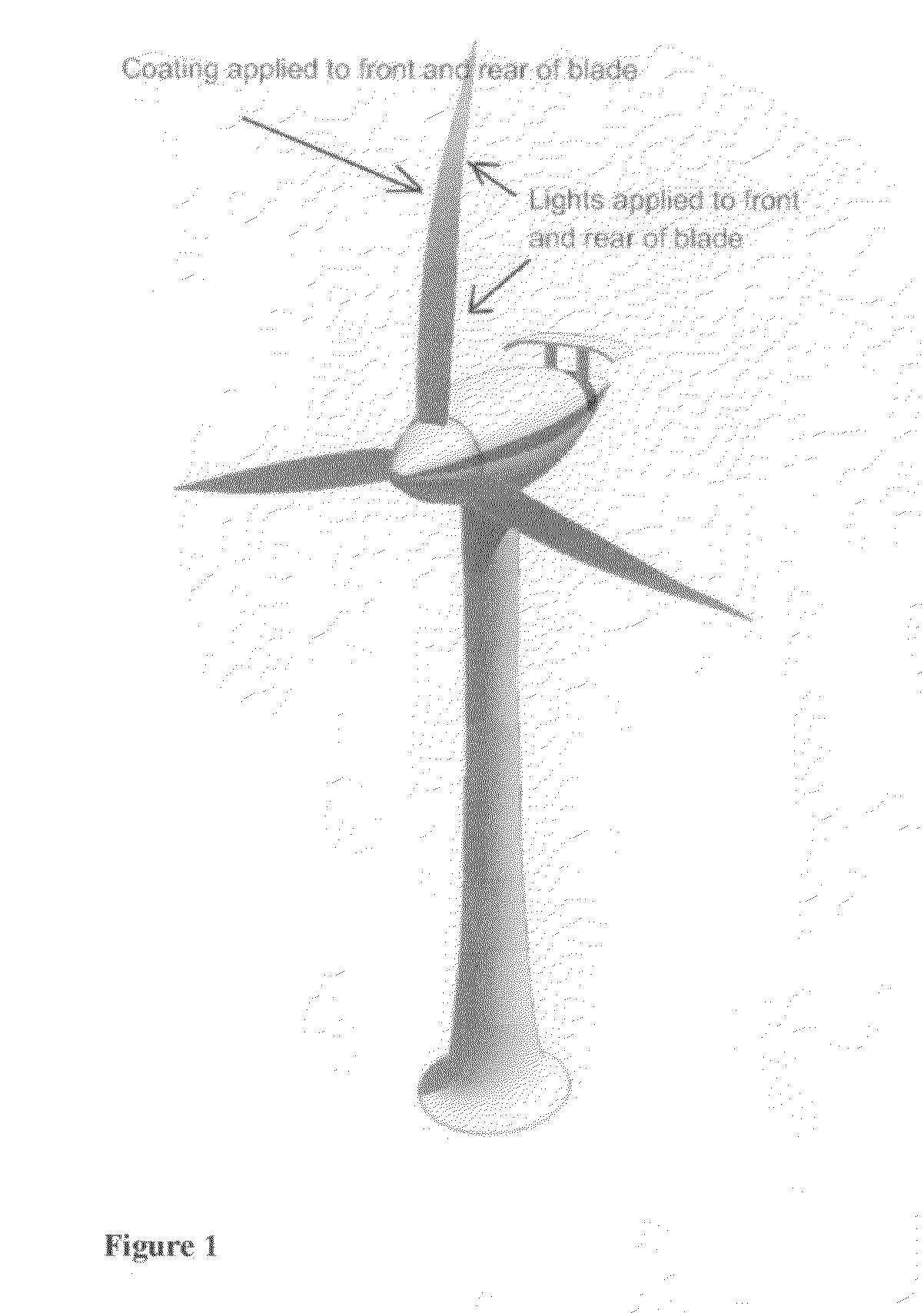

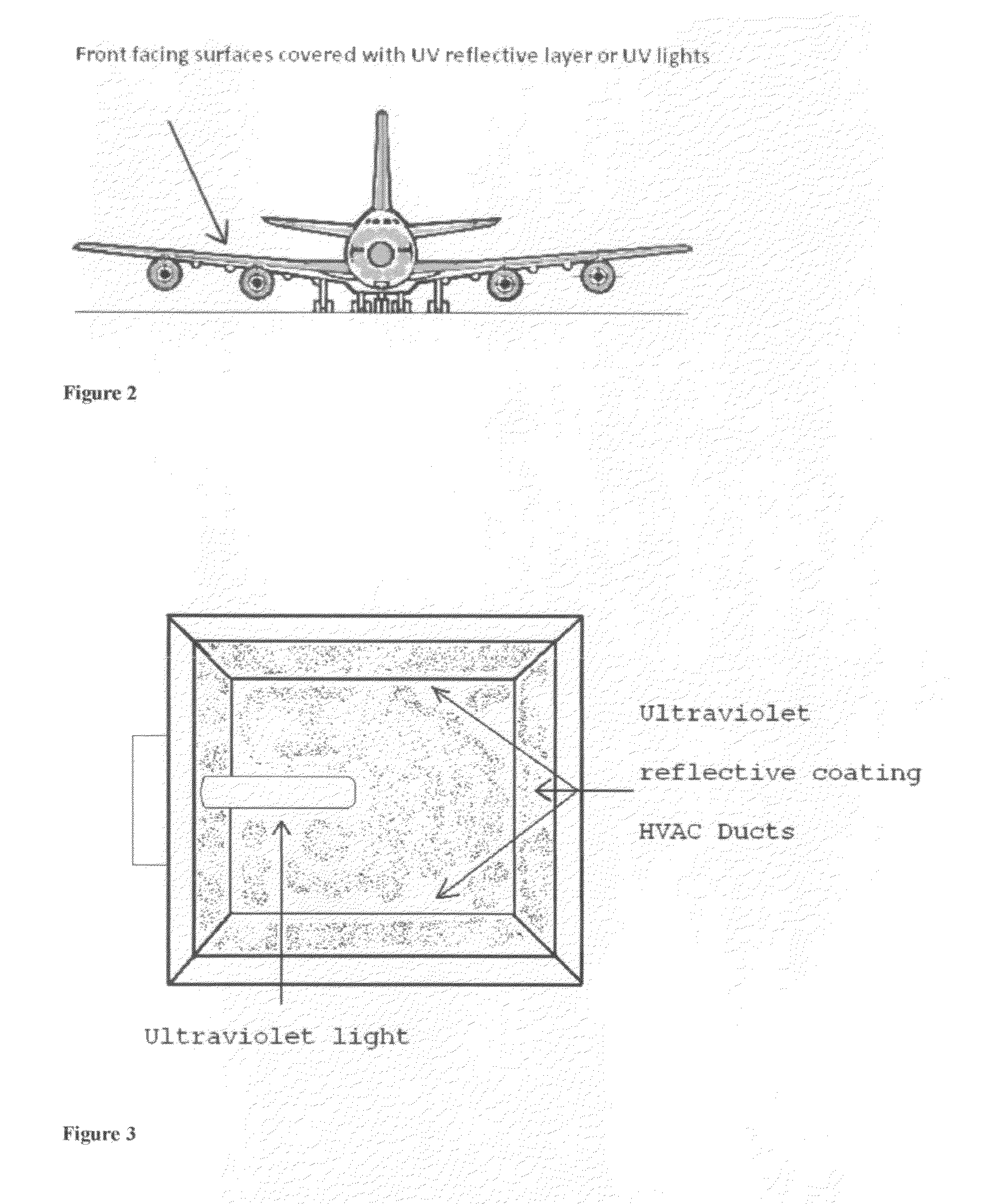

Application of ultraviolet reflective materials to surfaces to enhance avian and human safety

InactiveUS20100098844A1Save million of dollarAvoid deathMachines/enginesAnimal repellantsUltraviolet lightsAir conditioning

The purpose of this invention, what is being patented, is the application of ultraviolet lights or reflective paint, coating or other material to serve as a means of creating a reflective surface for ultraviolet light. The advantages are many including use on any object that is subject to bird impact—solid or transparent—moving or non-moving, This invention is also valuable when applied to interior surfaces of sanitation equipment (like air conditioning ducts, ultraviolet air cleaners, ultraviolet water purifiers) which are then struck by ultraviolet light to reflect (or bounce) the light and enhance the area of coverage and effectiveness.

Owner:PETTINGER FR EMEST

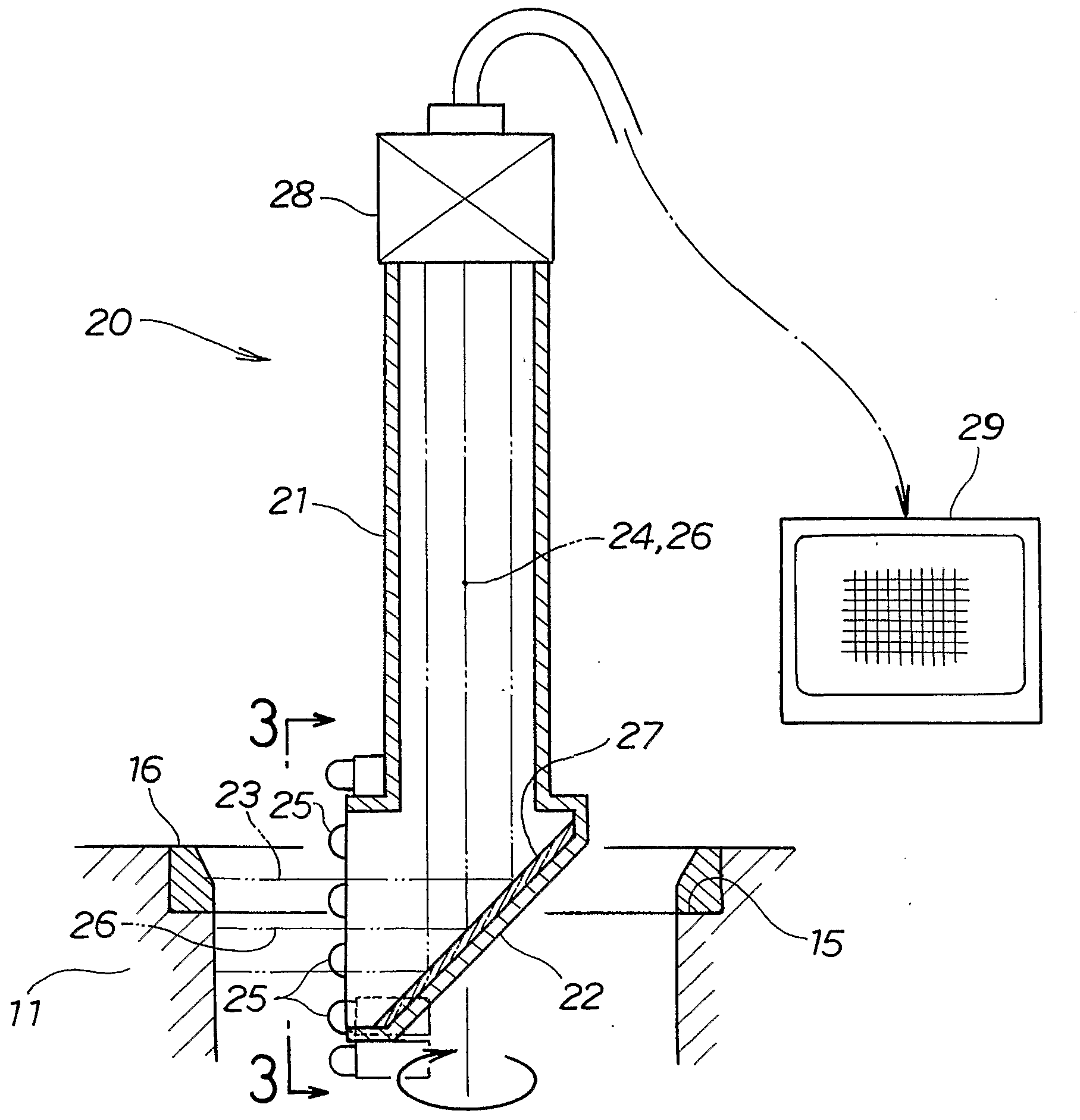

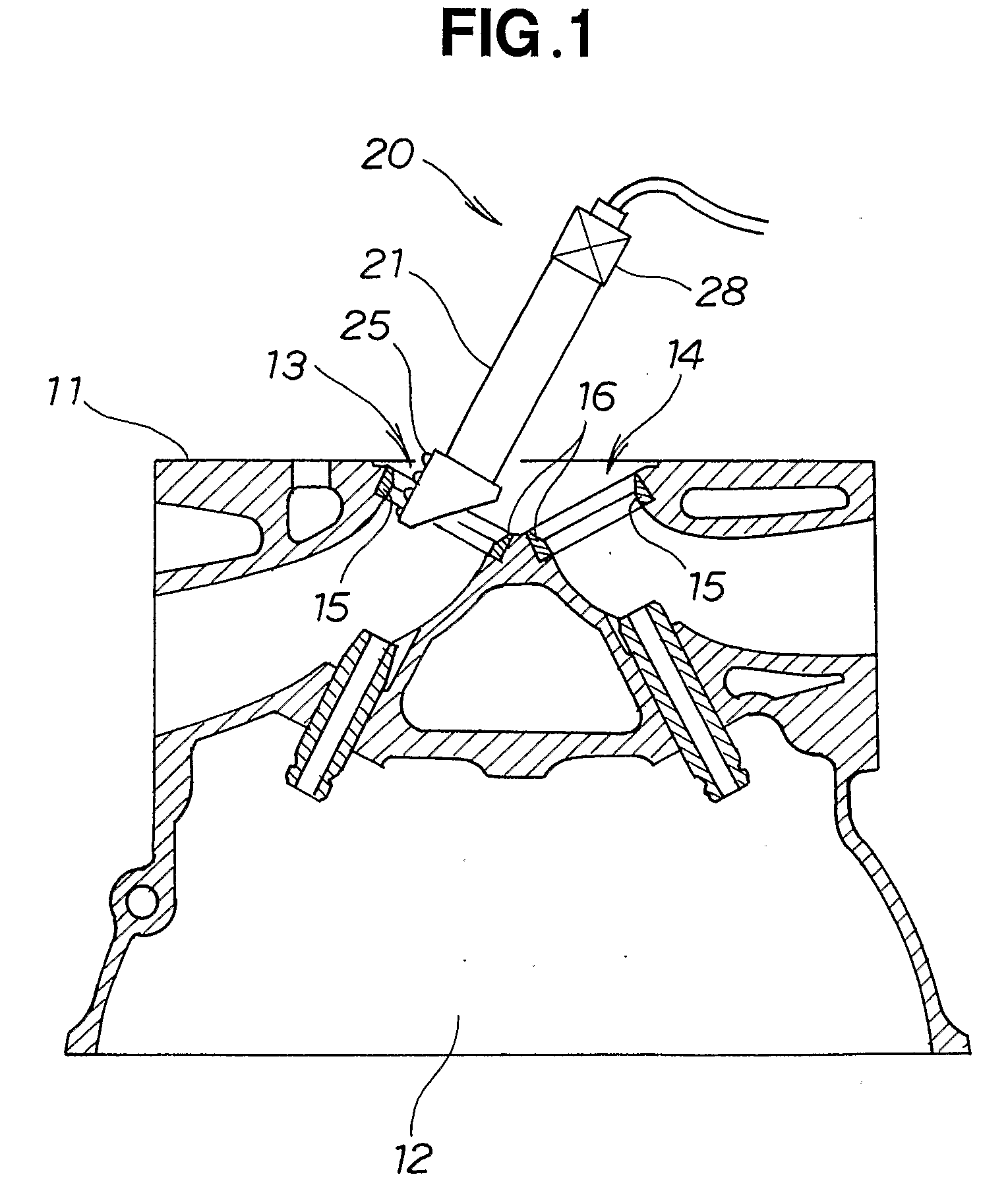

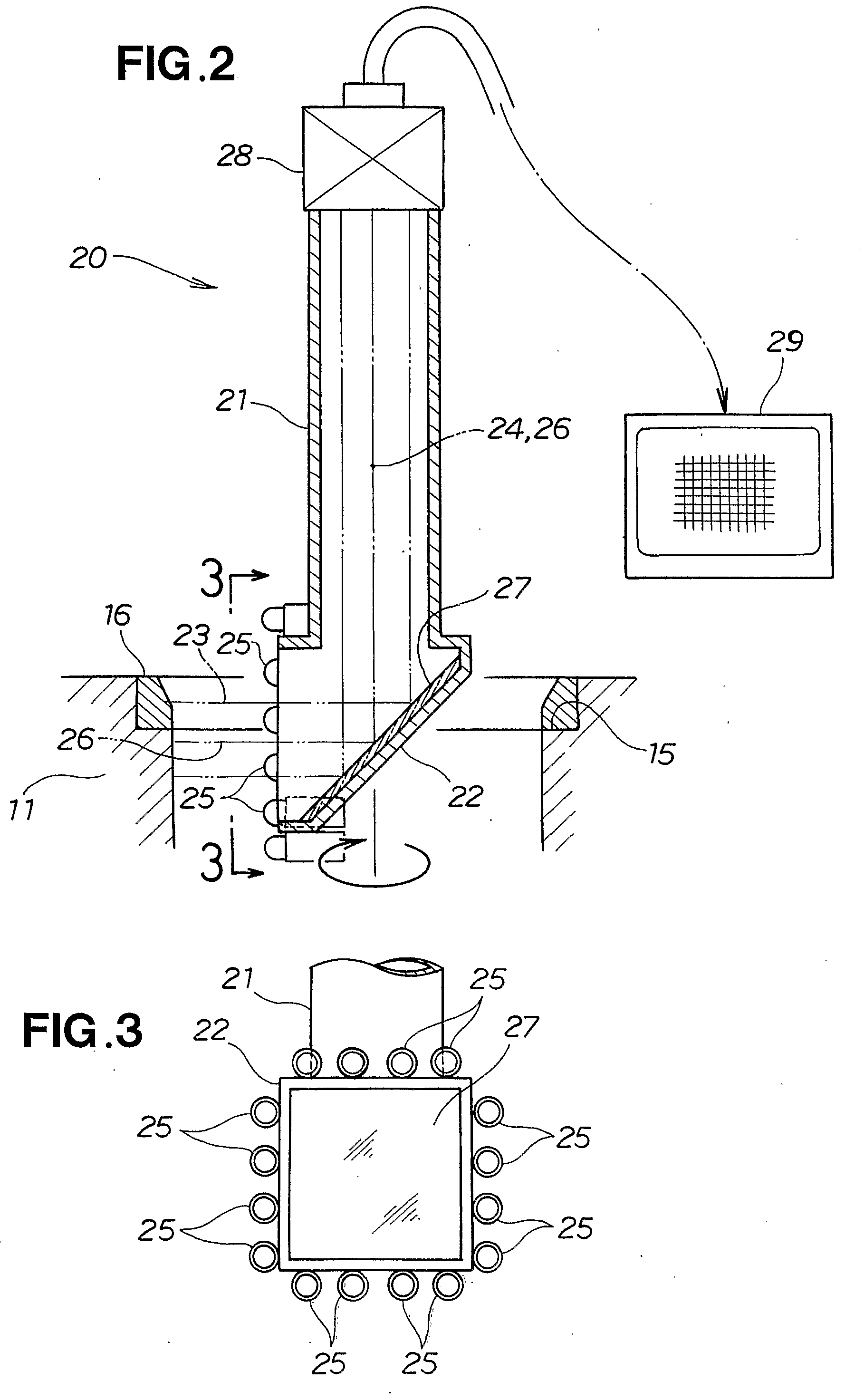

Measurement of gaps between valve seats and attachment parts

InactiveUS20090123032A1Precise measurementLess occurrenceCharacter and pattern recognitionMachines/enginesCcd cameraColor image processing

An apparatus for measuring gaps that form between attachment parts (15) in exhaust ports. of an engine, and valve seats (16) provided to the attachment parts. This apparatus comprises, at one end of a cylinder (21), white light-emitting diodes (25) for emitting light orthogonal to a longitudinal axis (24) of the cylinder. An optical axis (26) from the light-emitting diodes is bent by 90° by a mirror (27). Color images obtained by a CCD camera (28) provided at the other end of the cylinder are binarized by a color image processor (29) with a range of hue, a range of chroma, and a range of brightness.

Owner:HONDA MOTOR CO LTD

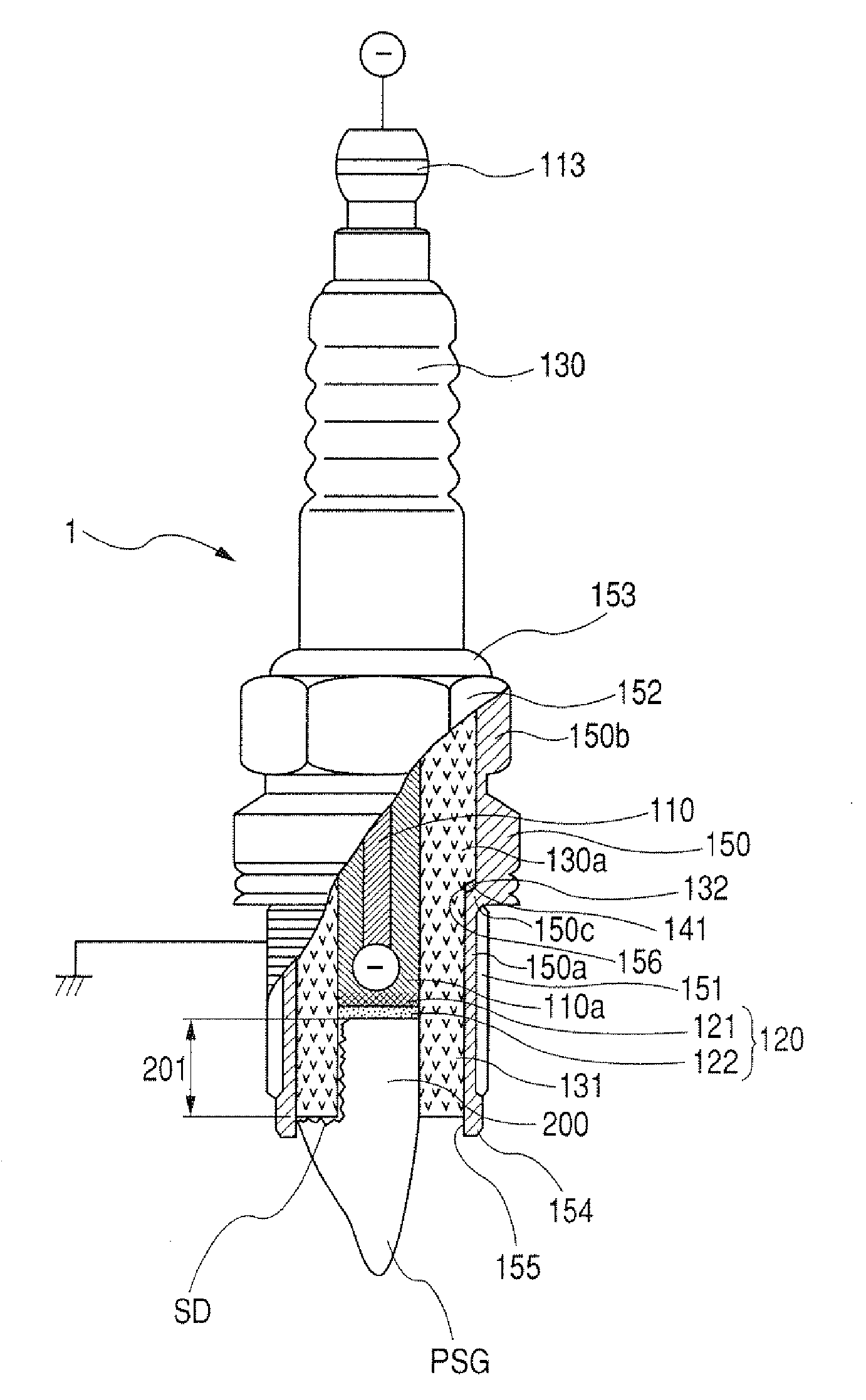

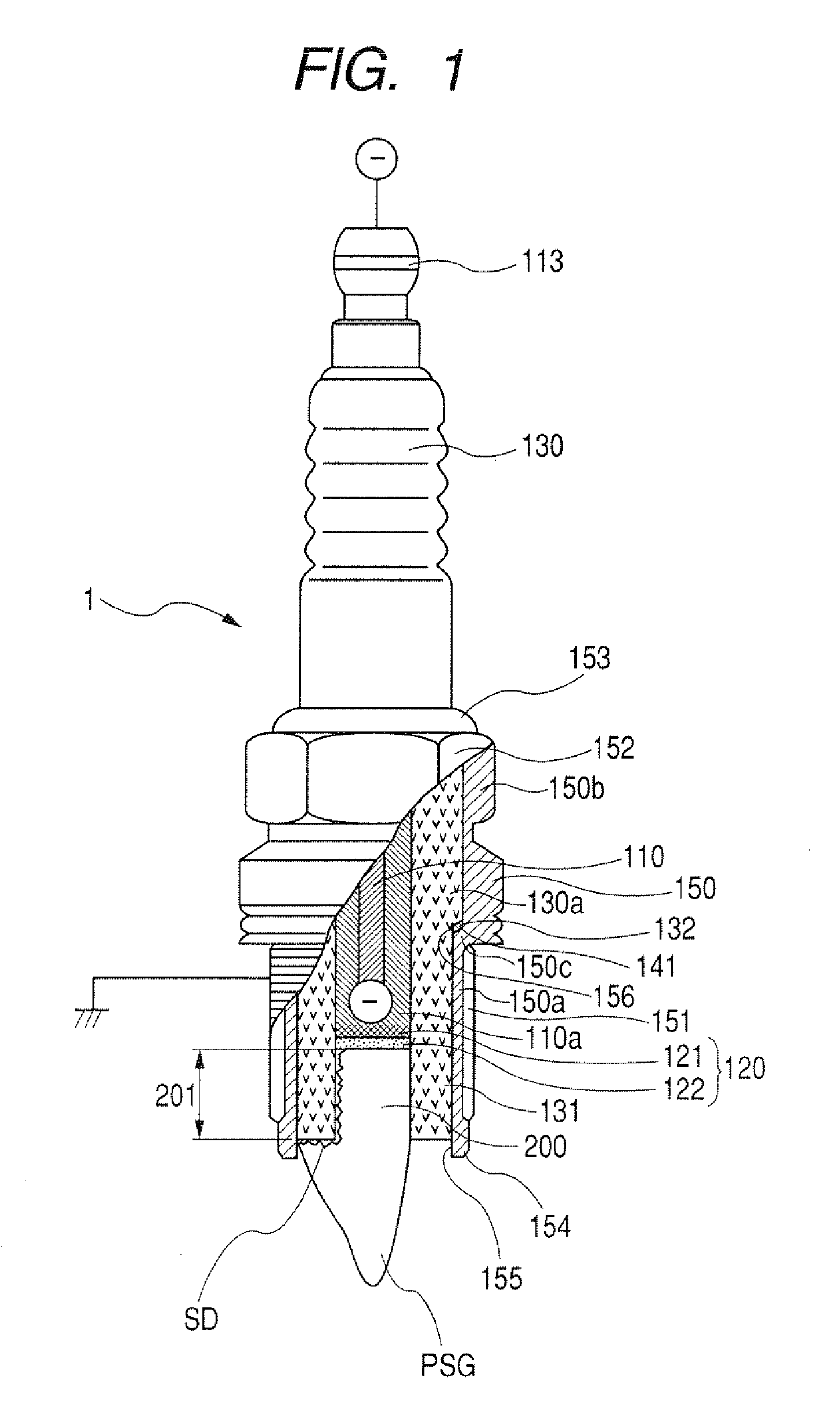

Plasma type ignition plug

InactiveUS20080121200A1Avoid excessive wearLess occurrenceSparking plugsCombustion enginesEngineeringInternal combustion engine

A plasma type ignition plug for igniting an internal combustion engine is disclosed having a negative electrode, a positive electrode, and a discharging distance fixing member, which includes an electrically conductive material replenishing section, made of an electrically conductive material available to melt when subjected to a heat of gas in plasma state, and an electrically conductive material replenished section to which the electrically conductive material is replenished. The discharging distance fixing member is covered on a surface of the negative electrode for initiating the spark discharge between a surface of the discharging distance fixing member and the positive electrode so as to avoid a fluctuation in a spark discharge distance caused by a wear of the negative electrode due to a collision of gas in the plasma state.

Owner:DENSO CORP

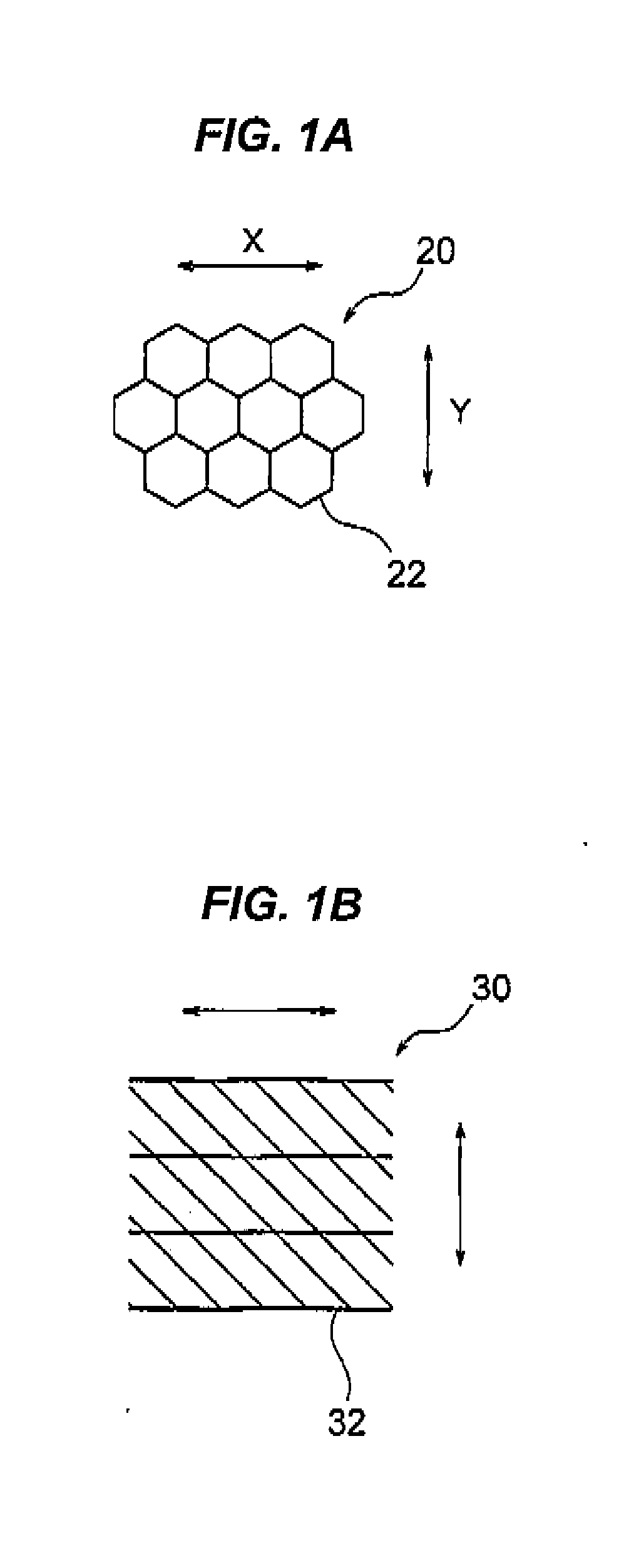

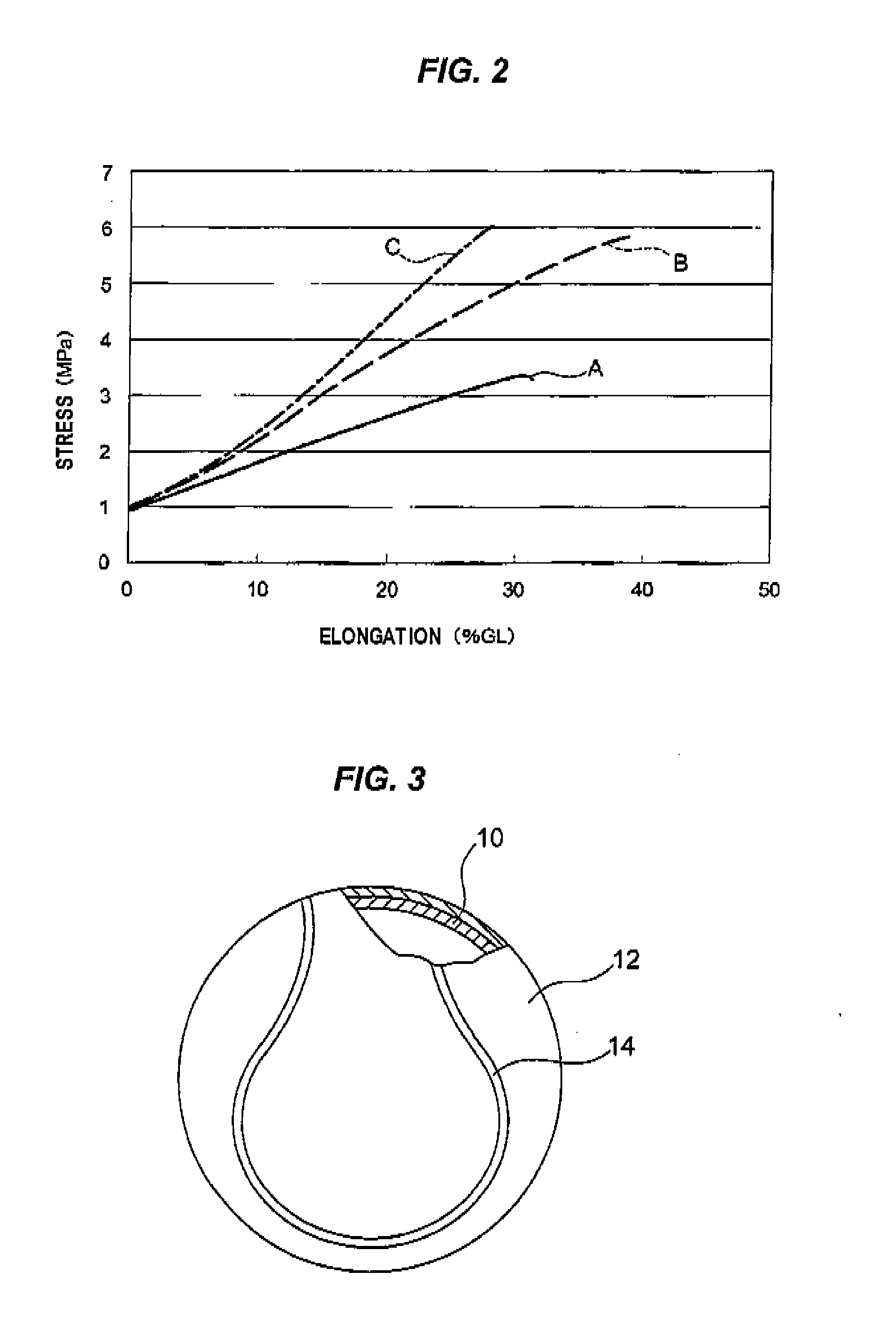

Block copolymer composition

InactiveUS6939906B2Less occurrenceExcellent impact resistanceFilm/foil adhesivesSpecial tyresIsoprenePolystyrene

Disclosed is a block copolymer composition comprising a block copolymer (I) comprising at least two polymer blocks (each polymer block (S) comprising vinyl aromatic hydrocarbon monomer units) and at least one polymer block (B) comprising isoprene monomer units and 1,3-butadiene monomer units, and a polystyrene resin (II), wherein, in the block copolymer (I), the amount of the vinyl aromatic hydrocarbon monomer units, the total amount of the isoprene monomer units and the 1,3-butadiene monomer units, and the isoprene monomer unit / 1,3-butadiene monomer unit weight ratio are within specific range, wherein the block copolymer (I) has a vinyl aromatic hydrocarbon block ratio (BL) within a specific range, and wherein the block copolymer (I) and the polystyrene resin (II) satisfy a relationship represented by the following formula (1):15+0.25BL≦Wa≦35+0.25BL (1)wherein BL represents the block ratio of the copolymer (I), and Wa represents the weight percentage, based on the total weight of the copolymer (I) and the resin (II), of the copolymer (I).

Owner:ASAHI KASEI KOGYO KK

Polymerization catalyst for polyesters, polyesters produced with the same and process for producing polyesters

InactiveUS7199212B2Excellent in melt thermal stabilityLess occurrenceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationForeign matterPolyester

A novel polymerization catalyst for polyesters, which does not contain any germanium or antimony compound as the main component; polyesters produced with the catalyst; and a process for producing polyesters. This polymerization catalyst is excellent in catalytic activity, little causes thermal degradation of polyesters in melt molding even when neither deactivated nor removed, and can give thermally stable polyesters which little generate foreign matter and are excellent in transparency and color. The polymerization catalyst is one which contains as the first metal-containing component at least one member selected from the group consisting of aluminum and aluminum compounds and which gives polyethylene terephthalate (PET) having a thermal stability parameter (TS) satisfying the relationship: (1) TS<0.3.

Owner:TOYOBO CO LTD

Resist composition and pattern forming method using the same

ActiveUS20080081282A1High resolutionHigh sensitivityPhotosensitive materialsRadiation applicationsResistSolubility

A resist composition containing: a polymer having a group capable of decomposing under an action of an acid and having a weight average molecular weight of from 1,000 to 5,000, of which solubility in an alkali developer increases under an action of an acid; and a compound capable of generating a compound having a structure represented by the following formula (A-I) upon irradiation with actinic rays or radiation: Q1-X1—NH—X2-Q2 (A-I) wherein Q1 and Q2 each independently represents a monovalent organic group, provided that either one of Q1 and Q2 has a proton acceptor functional group, Q1 and Q2 may be combined with each other to form a ring and the ring formed may have a proton acceptor functional group; and X1 and X2 each independently represents —CO— or —SO2—.

Owner:FUJIFILM CORP

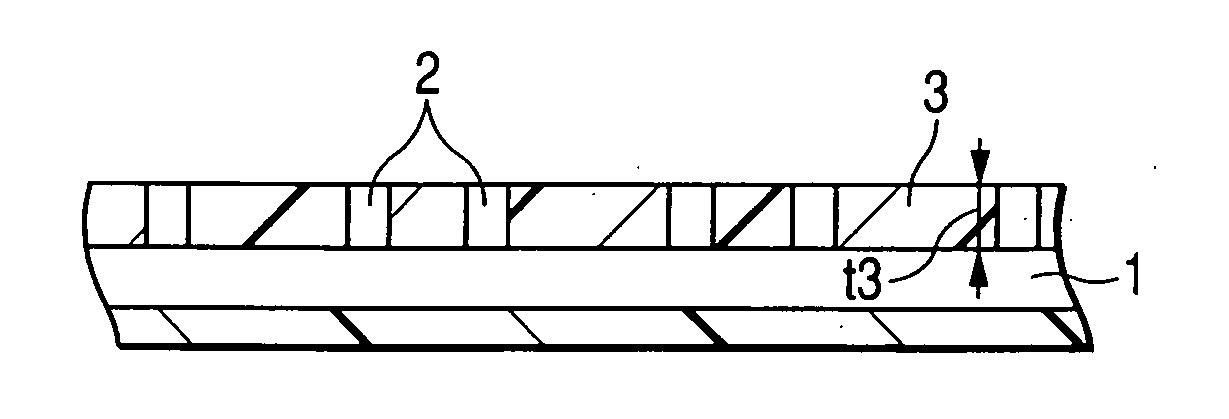

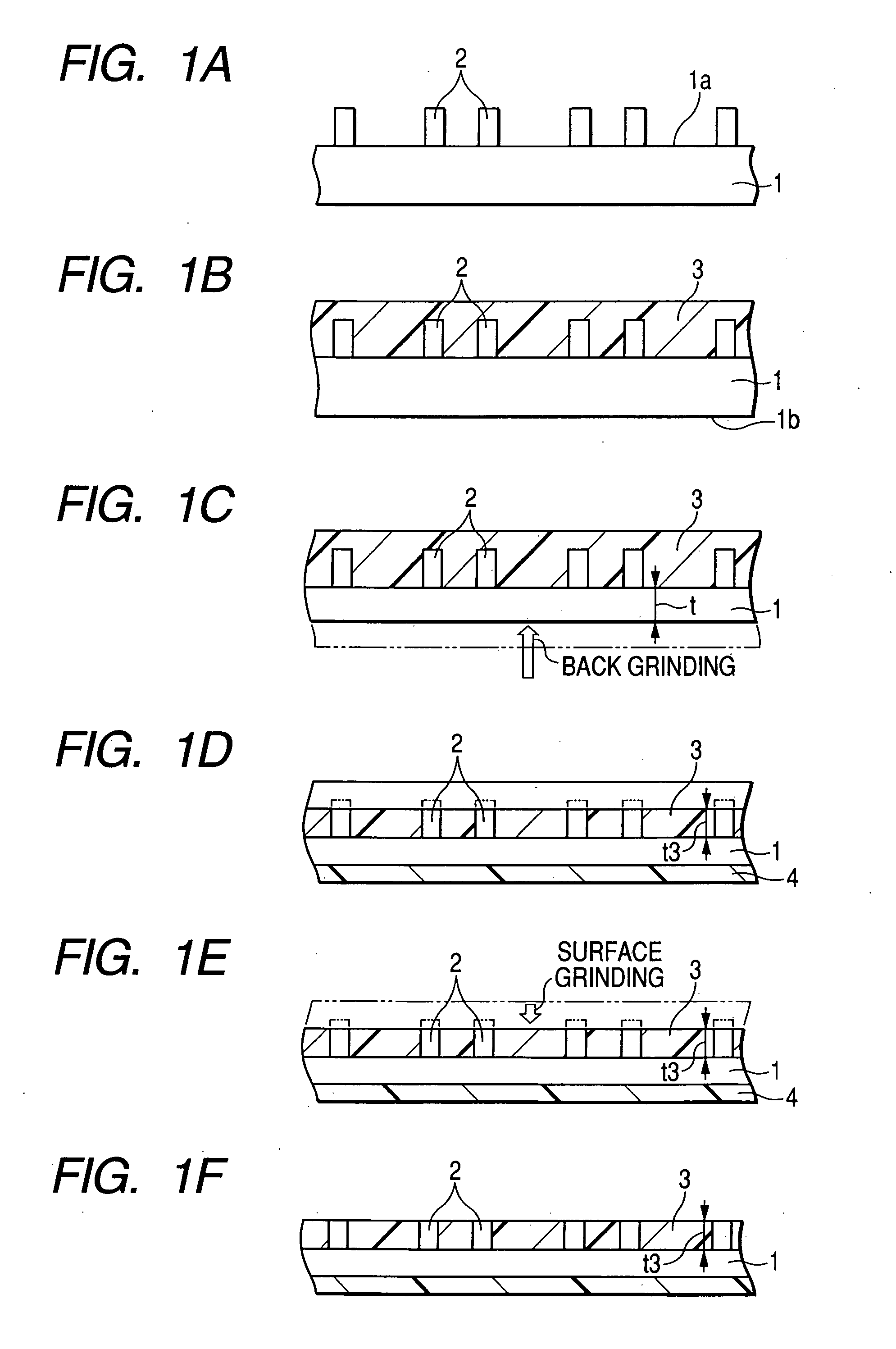

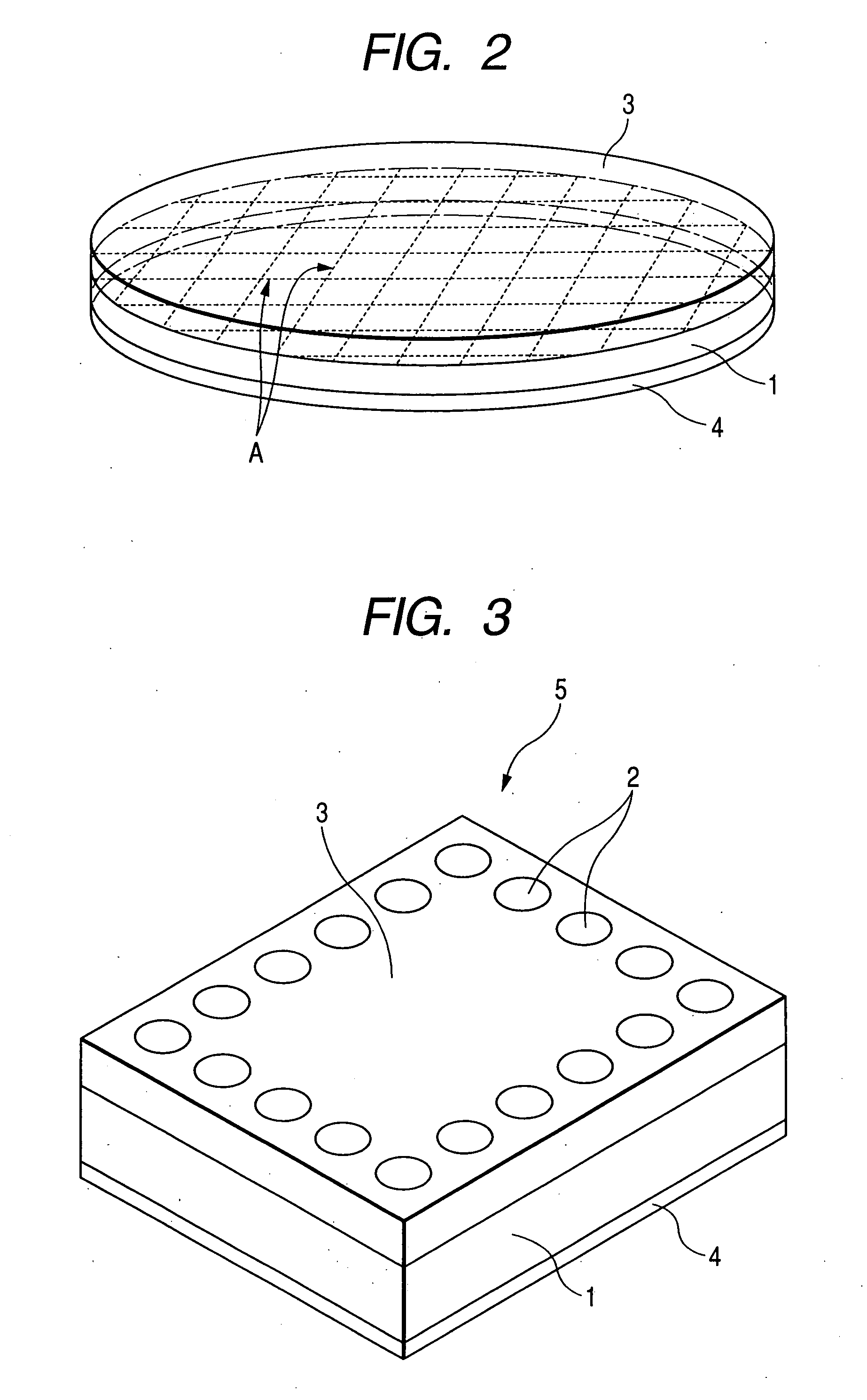

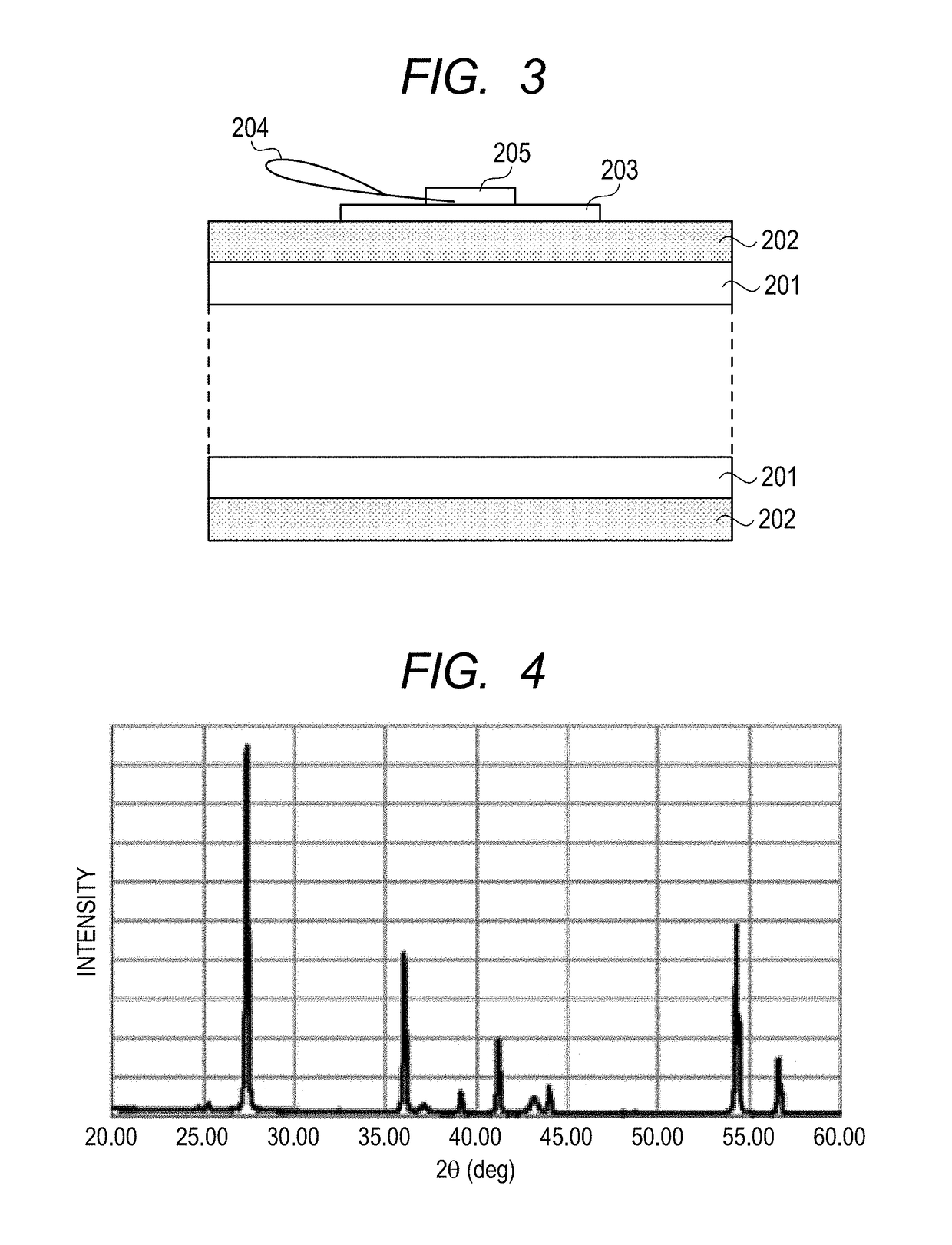

Semiconductor device and manufacturing method for the same

InactiveUS20080014719A1Reduce thicknessReduce breakageSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device has a semiconductor substrate having first and second surface, a first resin film formed on the first surface of the semiconductor substrate and a second resin film formed on the second surface of the semiconductor substrate. A projection electrode or an interconnection is formed on the first surface of the semiconductor substrate, the second resin film is made of low elastic resin which is capable of absorbing an impact applied to the second surface of the semiconductor substrate and the second resin film is thinner than the semiconductor substrate.

Owner:ROHM CO LTD

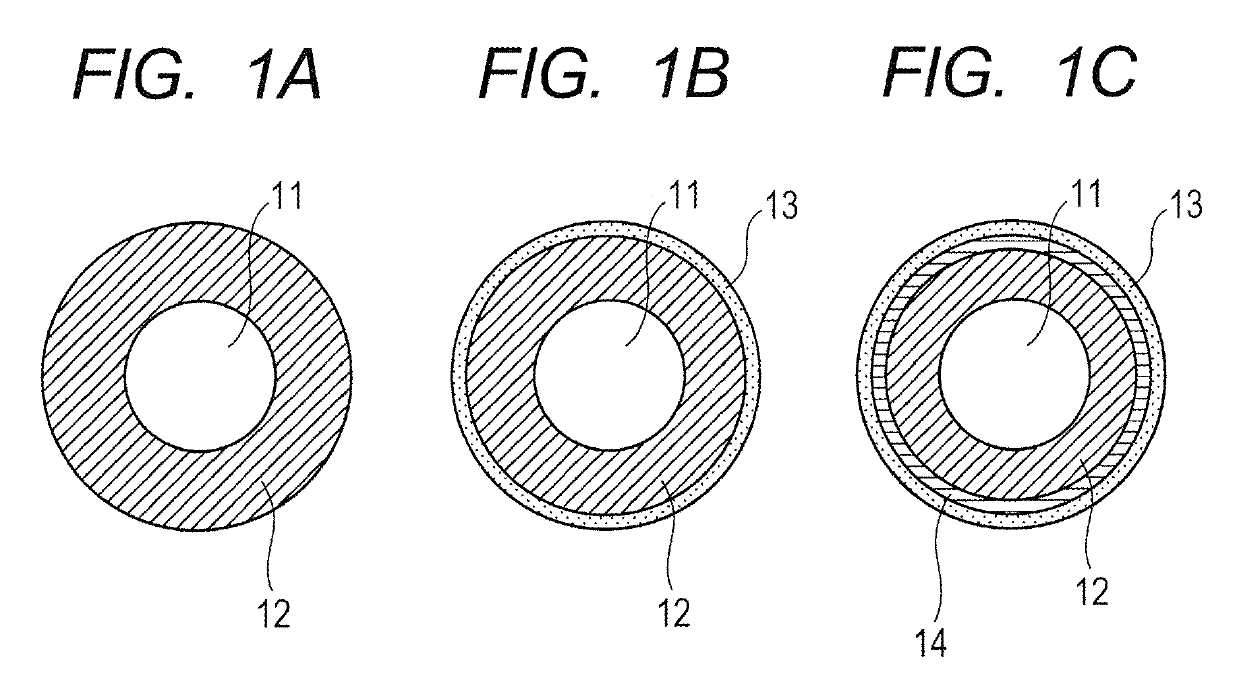

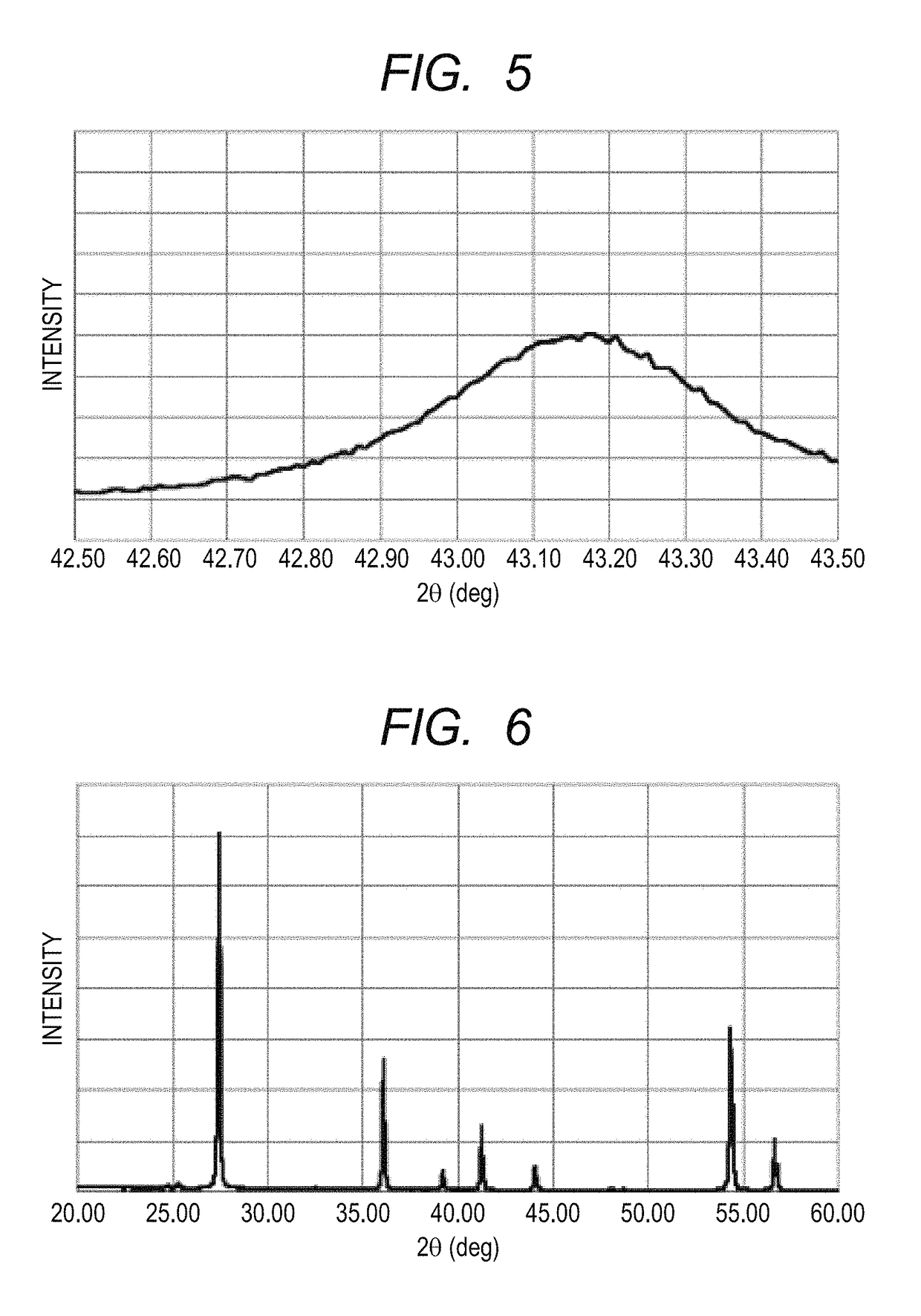

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

Provided is an electrophotographic photosensitive member which can simultaneously achieve less occurrence of leakage and the definition of an output image even when being an electrophotographic photosensitive member where a layer containing a metal oxide particle is adopted as an electroconductive layer, and which includes a support, an electroconductive layer and a photosensitive layer in this order, wherein the electroconductive layer contains a binder material and a particle represented by general formula (1):TiO2.00−XNY (1)wherein Ti represents a titanium atom, O represents an oxygen atom, N represents a nitrogen atom and 0.00<Y<X≤0.60 is satisfied.

Owner:CANON KK

Assembly for drilling and logging, method for drilling and logging and device for electro pulse drilling

ActiveUS8479841B2Easy to controlLess occurrenceSurveyConstructionsBiomedical engineeringElectromagnetic signal

An assembly for drilling and logging includes a device for electro pulse drilling (EPD device), at least one device to receive acoustic signals generated by the EPD device, distinguished in that the assembly further includes at least one device to receive electromagnetic signals generated by the EPD device. A method for drilling and logging, and device for electro pulse drilling.

Owner:DEN NORSKE STATS OLJESELSKAP AS

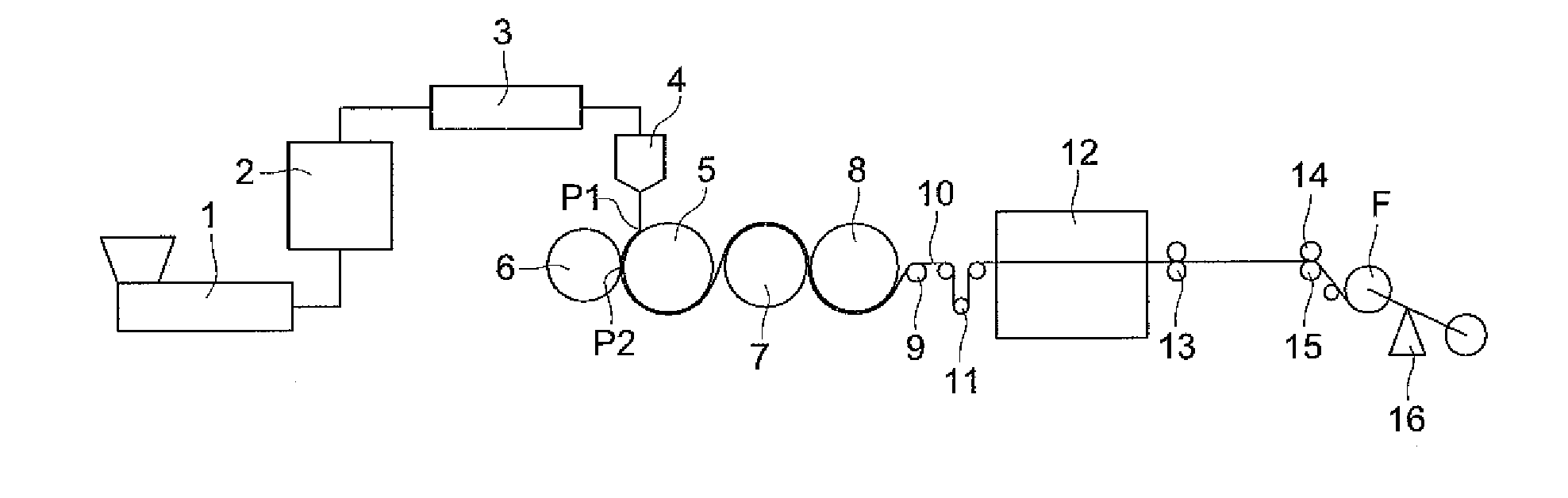

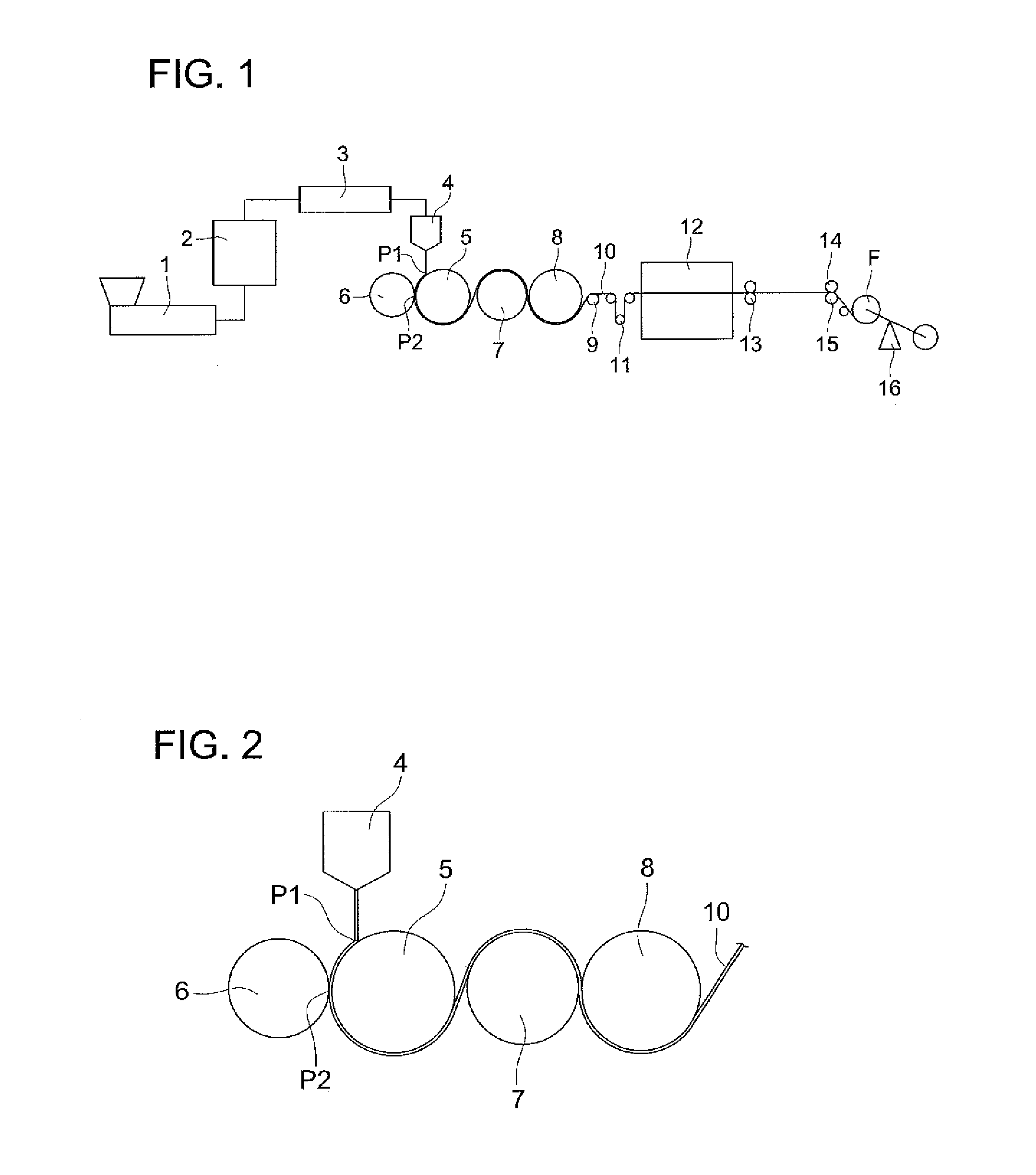

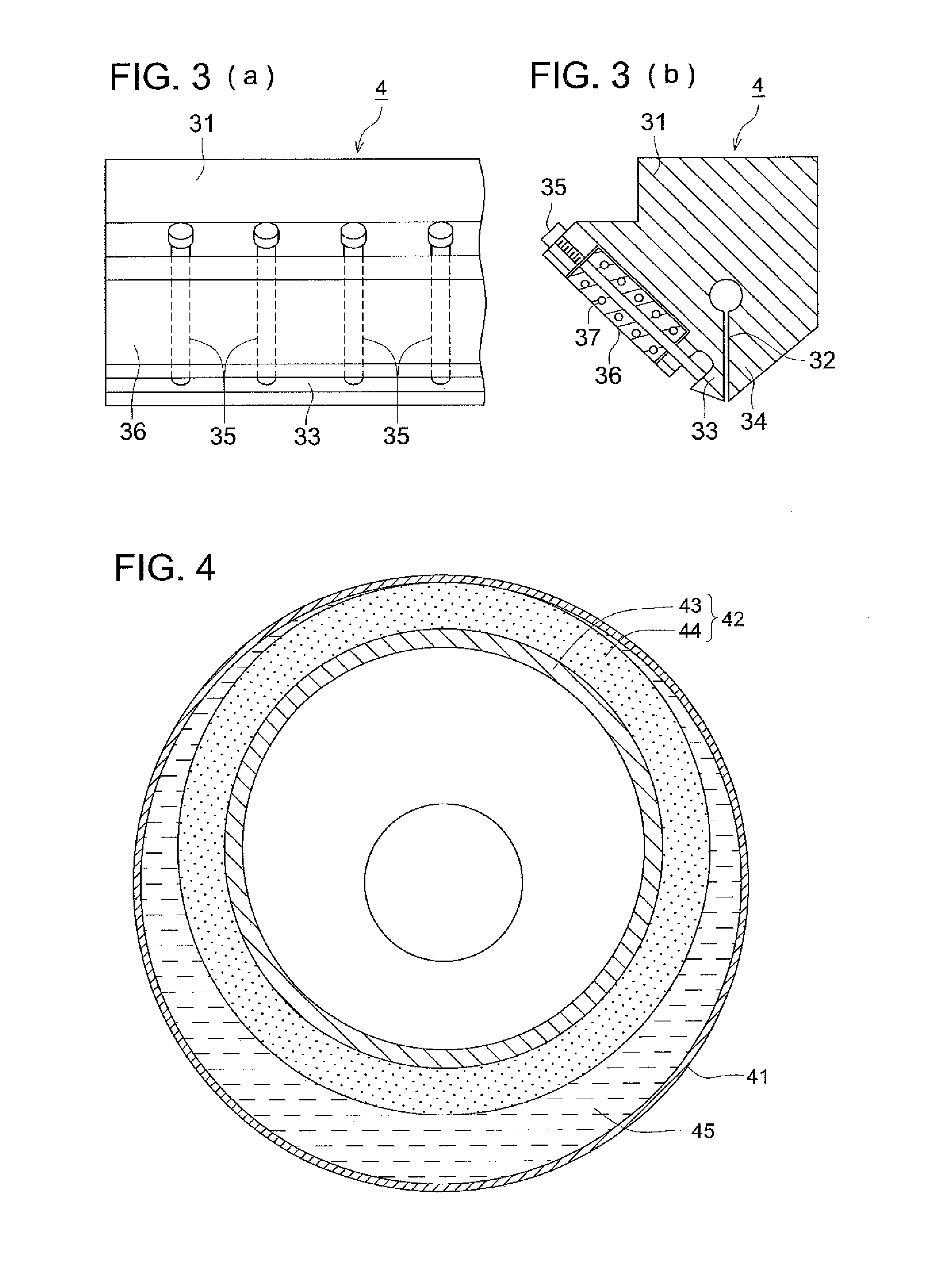

Method of producing cellulose ester film, cellulose ester film, polarizing plate and liquid crystal display

InactiveUS8246880B2Improve flatnessLow moisture permeabilityLiquid crystal compositionsCeramic shaping apparatusCellulosePolyester

Owner:KONICA MINOLTA OPTO

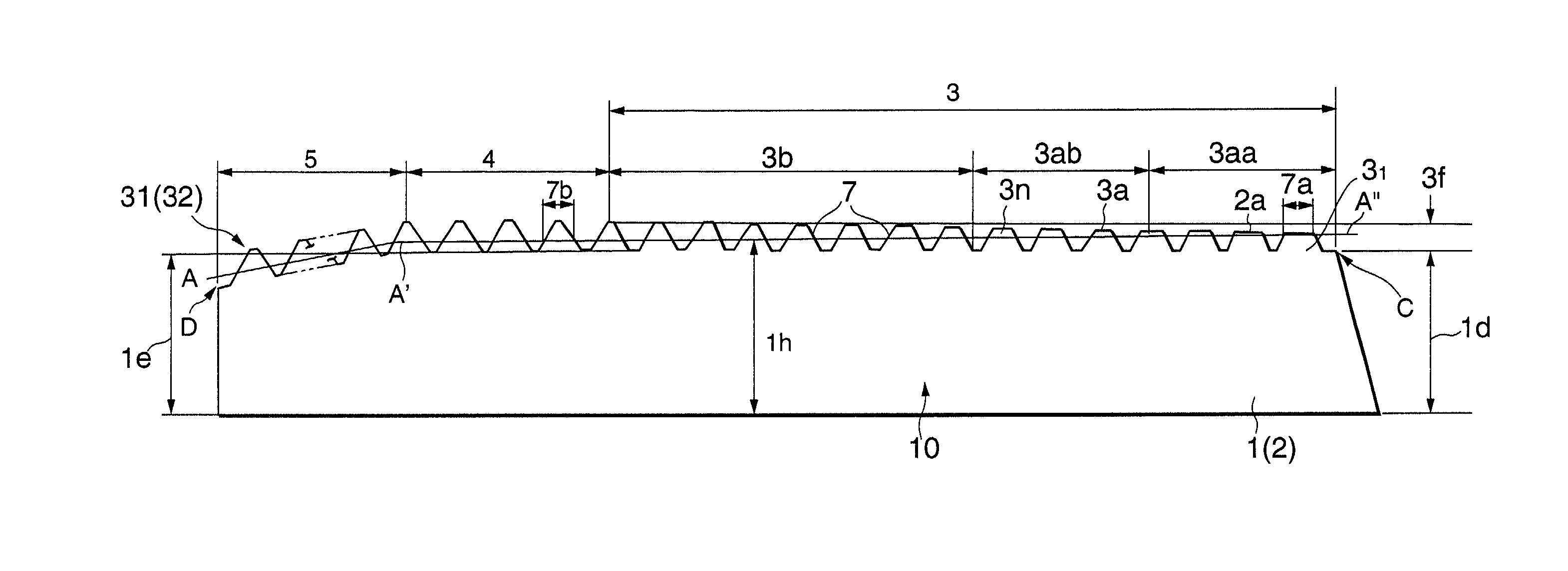

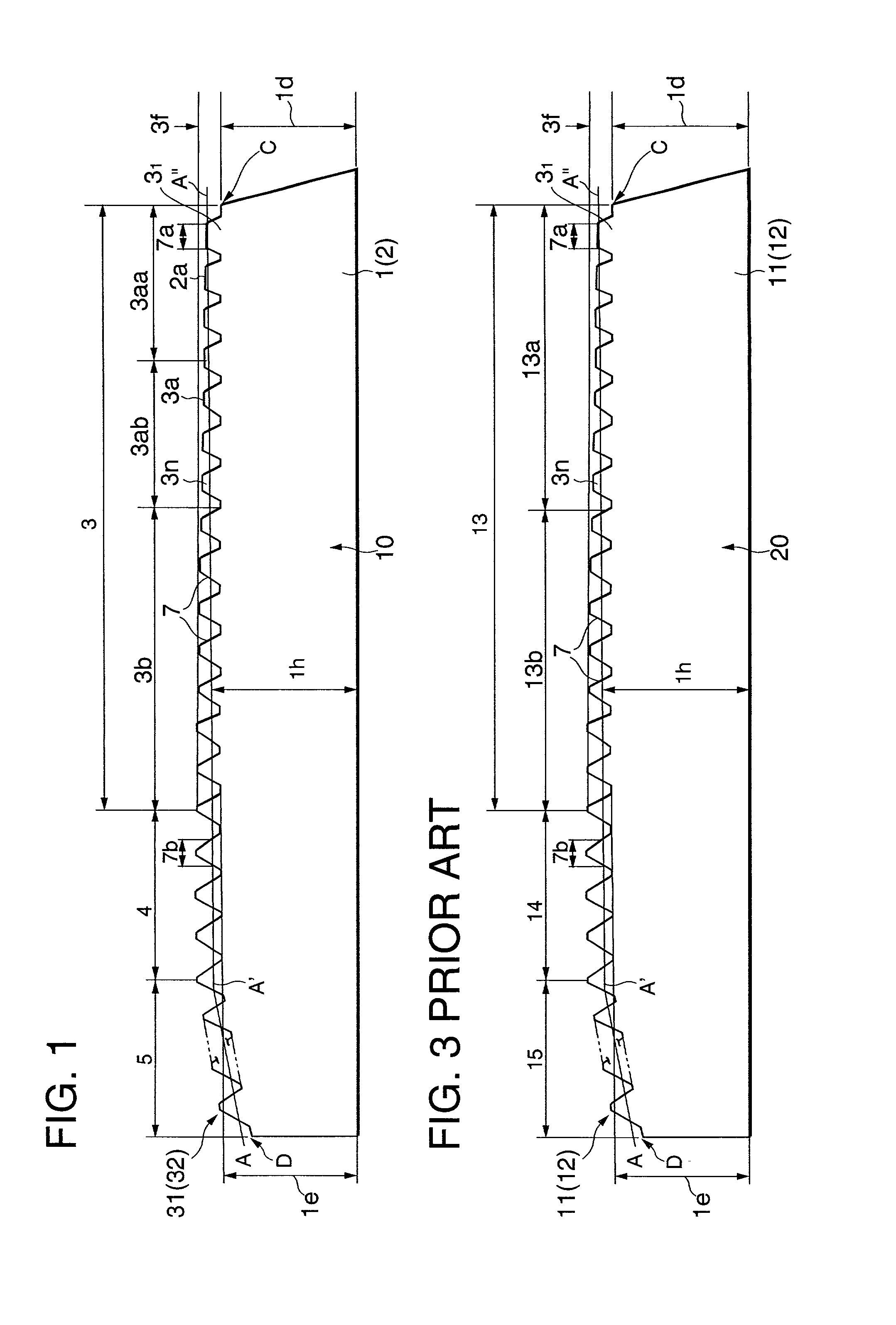

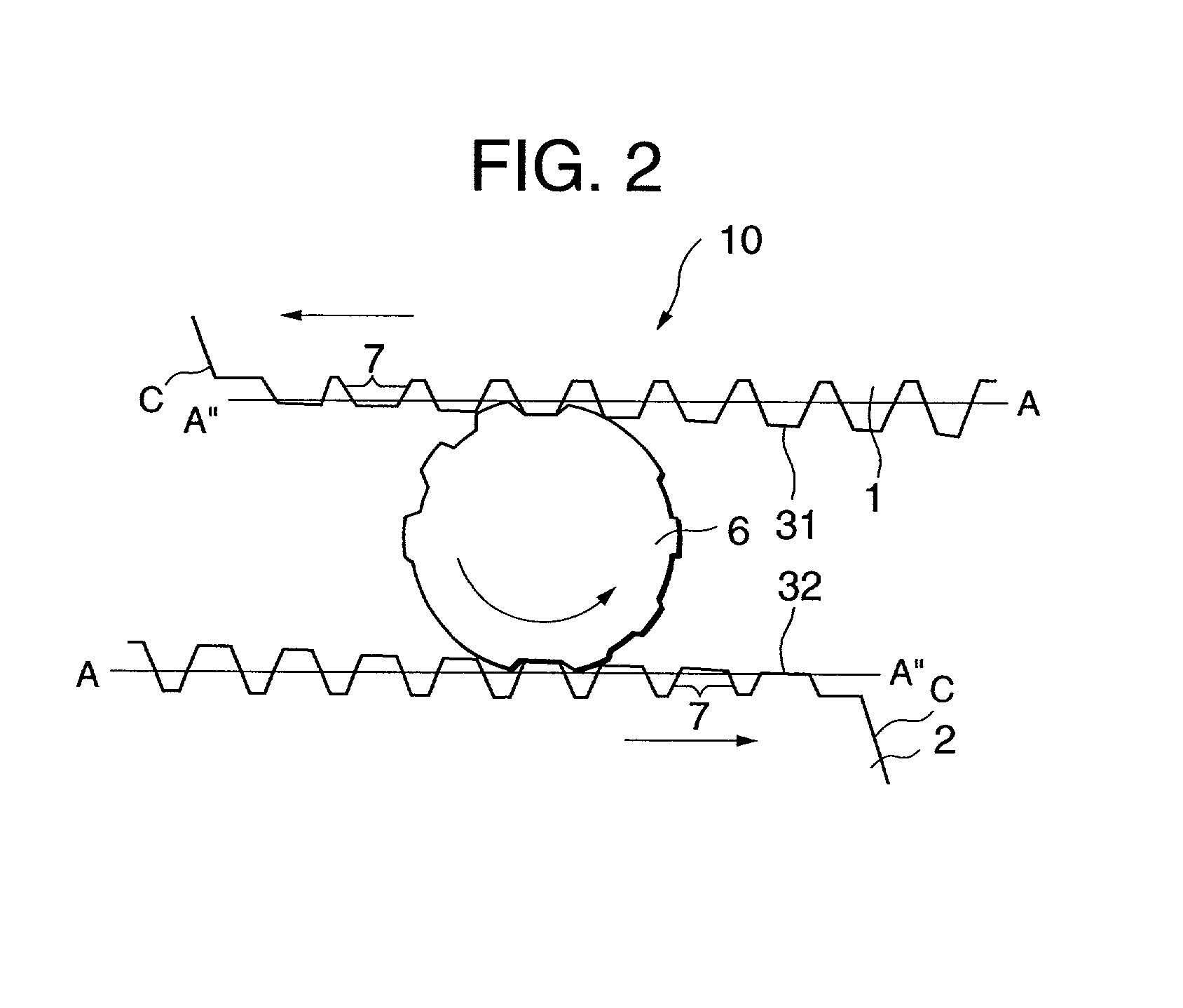

Tooth rolling flat dies and method for forming teeth

InactiveUS20020043094A1Reduce stress concentrationRelieve pressureGear wheelsScrew-threads articlesHobbingSurface roughness

A tooth rolling flat die and a method for forming a tooth are provided. The die has the same service life as those of the conventional tooth rolling flat dies using oil coolant even if conducted by semi-dry forming. Wherein the die comprises the surface roughness Rz of the first substantially quarter length portion of the leading teeth section wherein heights of the tops of the teeth are gradually increasing, ranging 20 to 35 mum, and that Rz of the second substantially quarter length portion of the leading teeth section, ranging 5 to 20 mum. The die is adapted for semi-dry forming the tooth.

Owner:NACHI-FUJIKOSHI

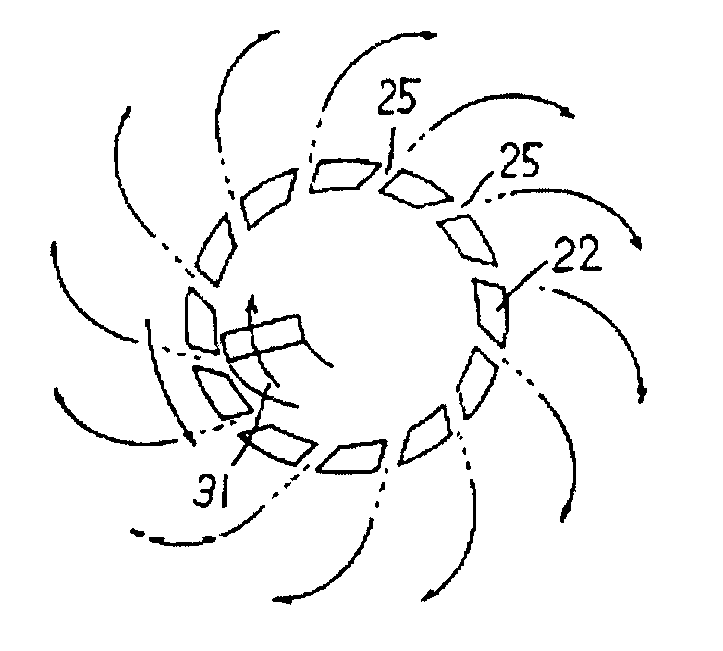

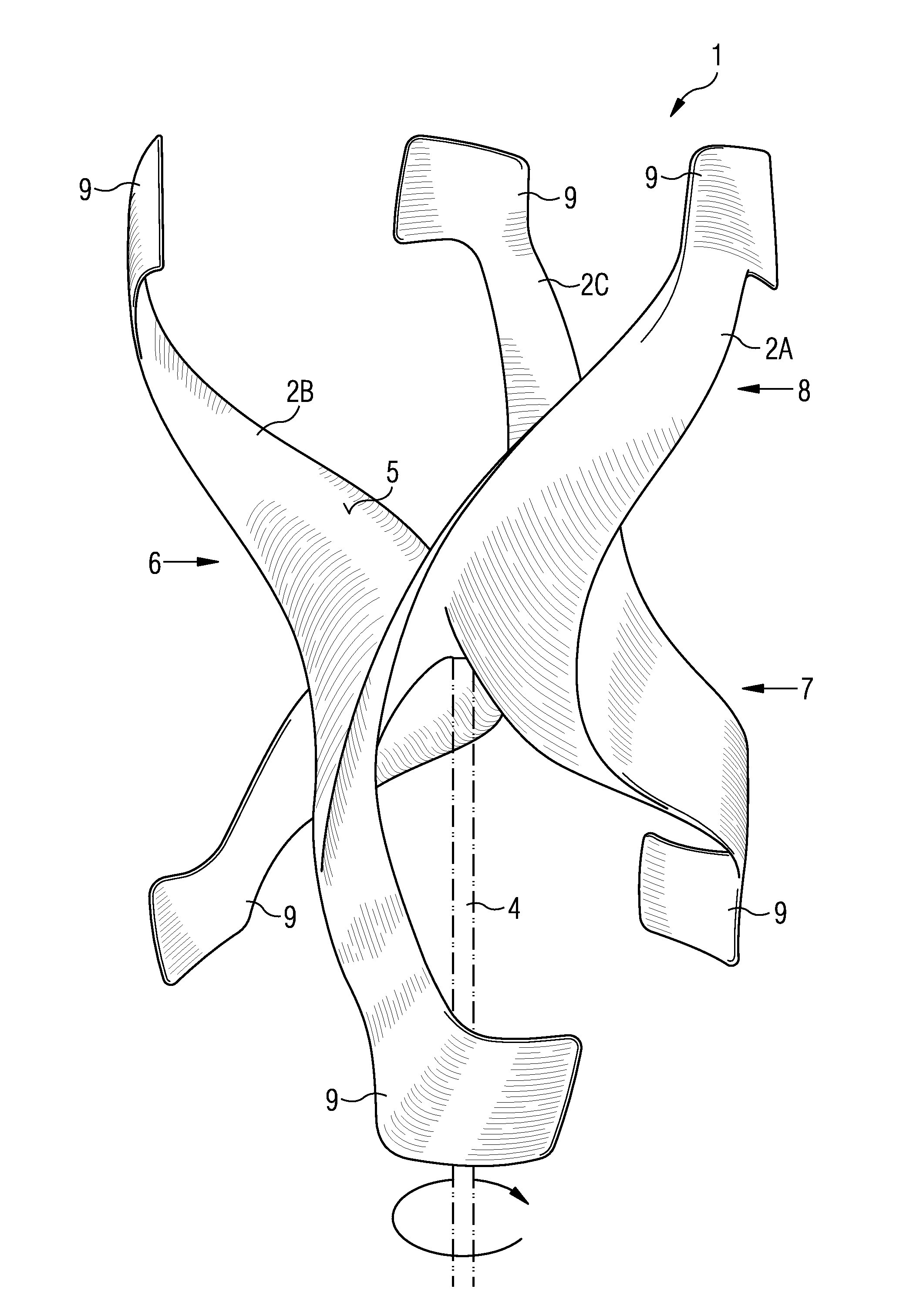

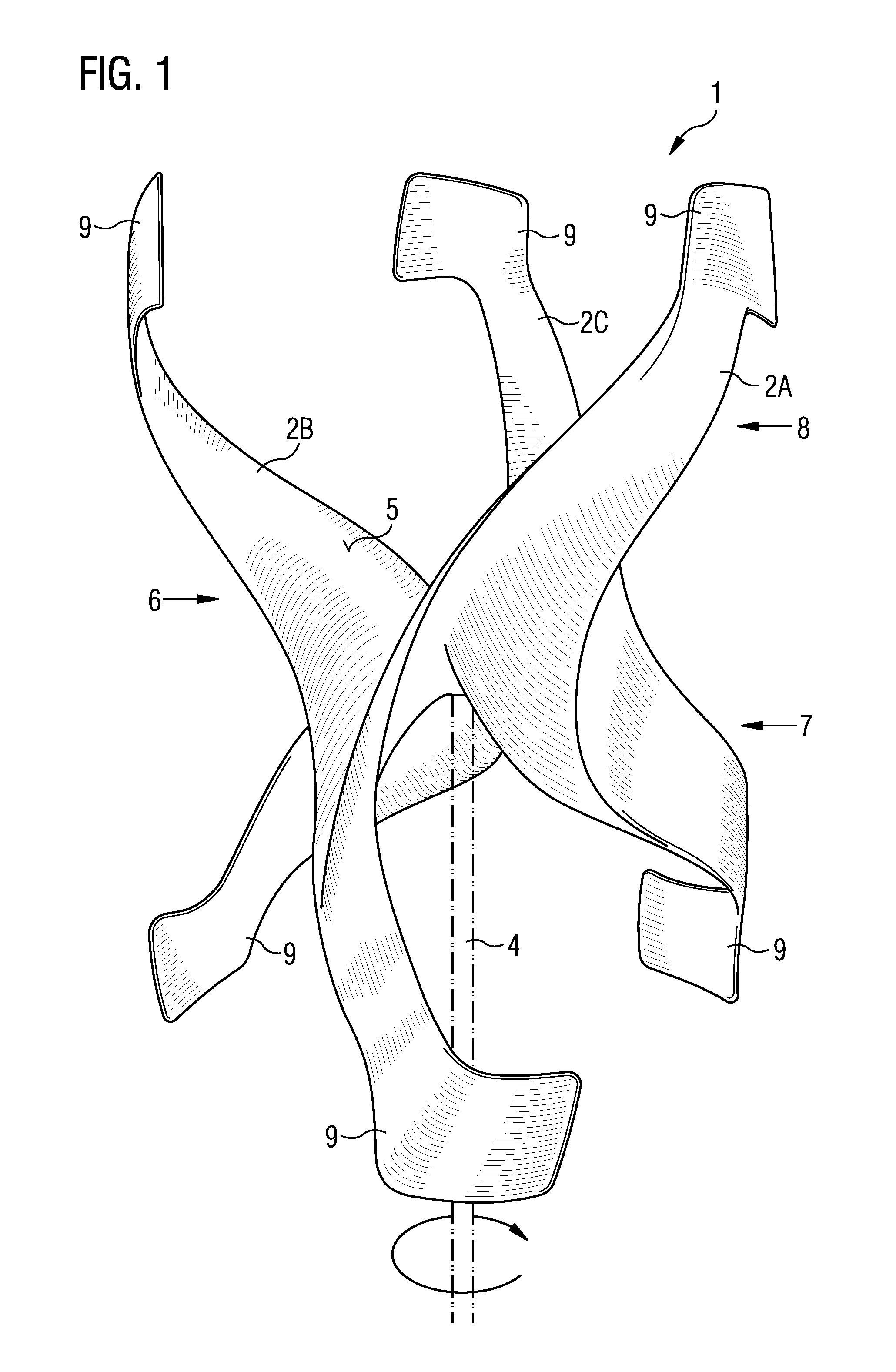

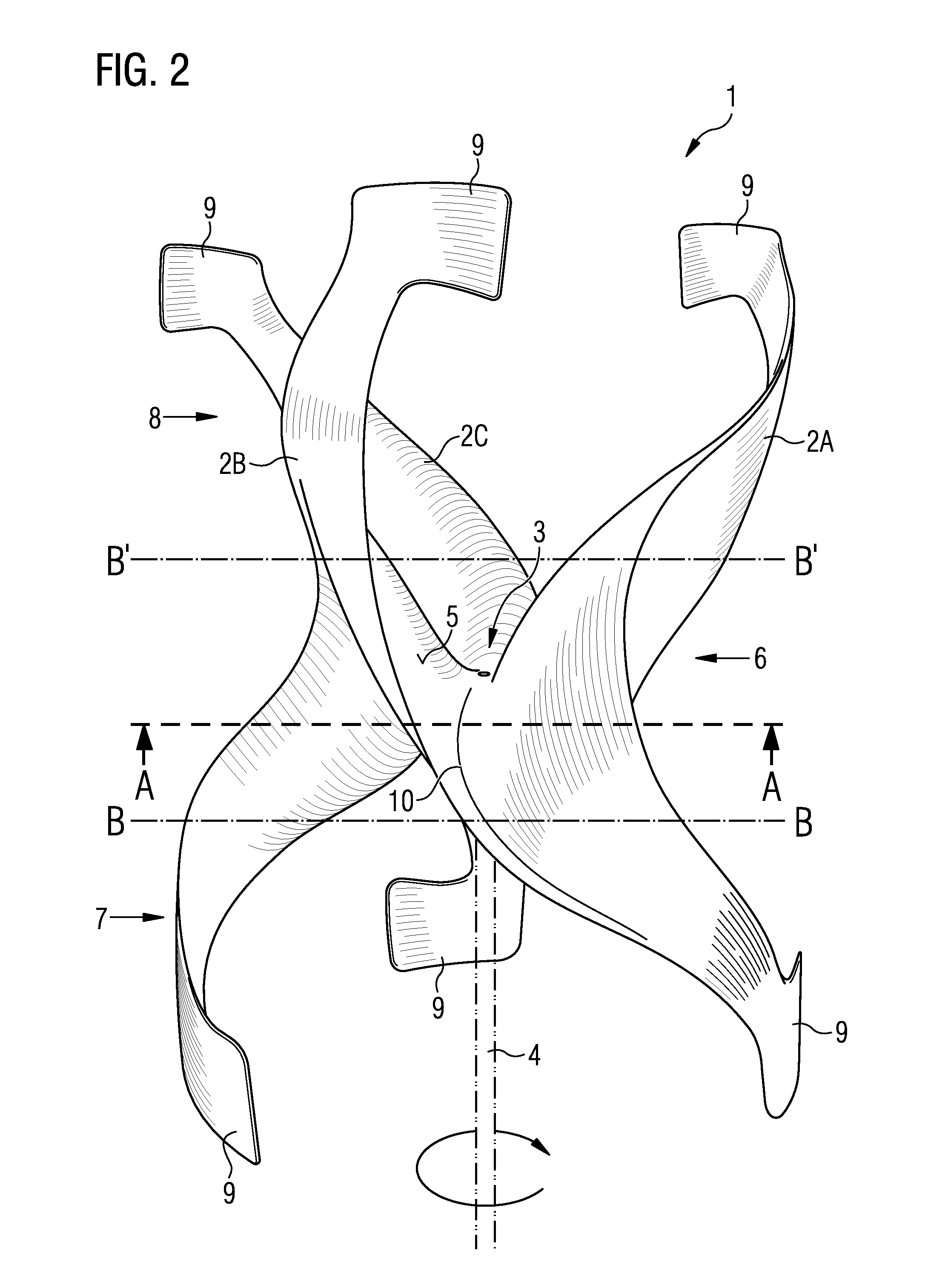

Rotor for Vertical Wind Power Station

InactiveUS20130224039A1Good lifting effectIncrease profitPropellersRotary propellersEngineeringMechanical engineering

The present invention relates to a rotor for a vertical wind power station comprising a plurality of planar rotor elements (2A, 2B, 2C) that are arranged around a hub region (3), wherein the rotor elements (2A, 2B, 2C) have a helical axis which is parallel or inclined relative to an axis of rotation (4) of the rotor (1) and around which the rotor elements (2A, 2B, 2C) are twisted in a spiraling manner, the rotor elements (2A, 2B, 2C) having concave and convex surface regions smoothly merging into each other and having different radii of curvature along the helical axis.

Owner:MOSER JOSEF

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveUS20180246425A1Improve leakageLess occurrenceElectrographic process apparatusNitrogenMaterials science

Provided is an electrophotographic photosensitive member which can simultaneously achieve less occurrence of leakage and the definition of an output image even when being an electrophotographic photosensitive member where a layer containing a metal oxide particle is adopted as an electroconductive layer, and which includes a support, an electroconductive layer and a photosensitive layer in this order, wherein the electroconductive layer contains a binder material and a particle represented by general formula (1):TiO2.00−XNY (1)wherein Ti represents a titanium atom, O represents an oxygen atom, N represents a nitrogen atom and 0.00<Y<X≤0.60 is satisfied.

Owner:CANON KK

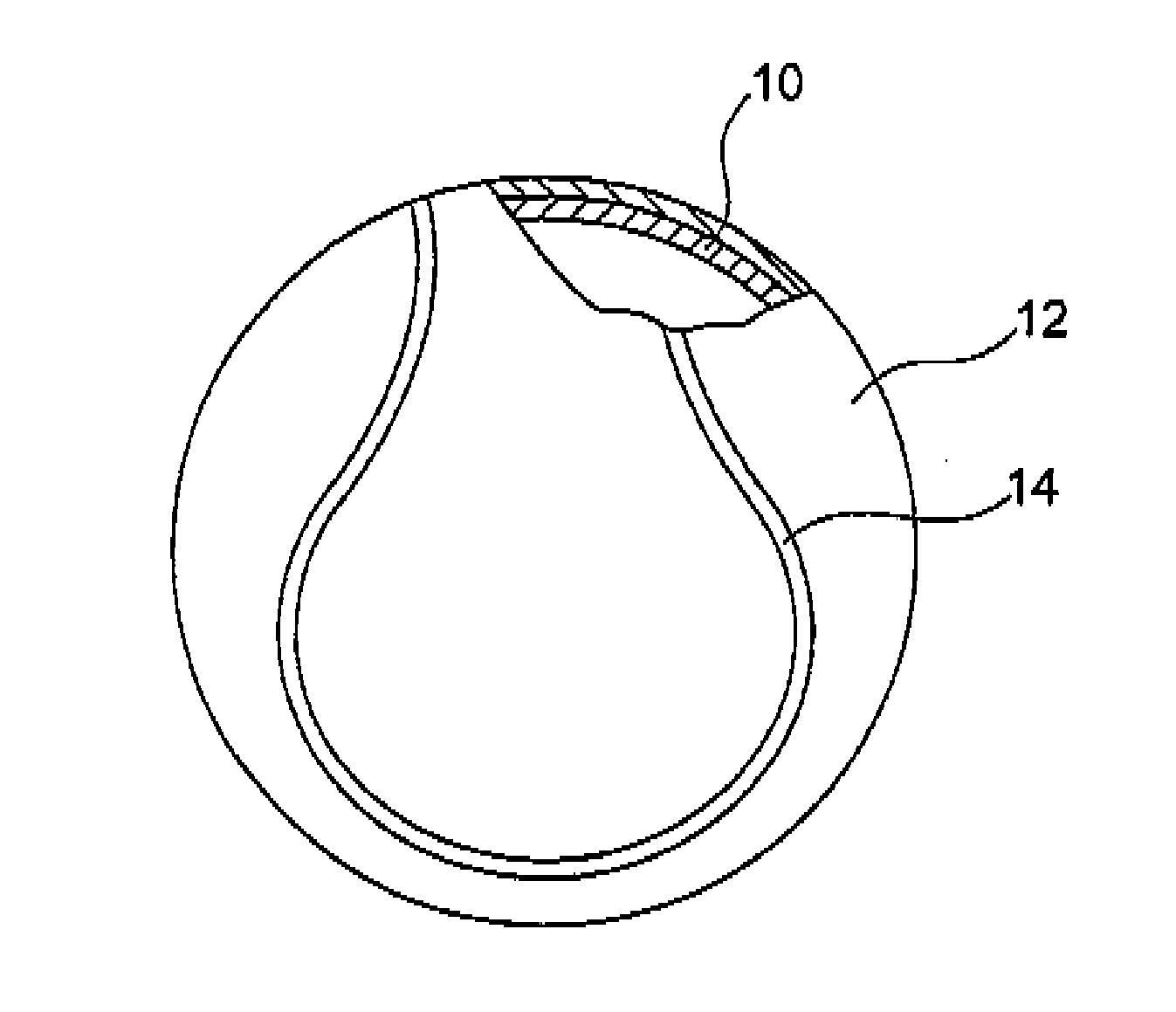

Tennis ball felt and tennis ball

InactiveUS20120165143A1Avoid creasesLess occurrenceHollow inflatable ballsHollow non-inflatable ballsFiberEngineering

To provide a tennis ball felt which has less occurrence of creases at the time of forming a tennis ball. According to one embodiment, a tennis bass felt, which is covered on a core of a tennis ball, includes: a base fabric formed of stretchy material; and fibers fixed with the base fabric.

Owner:BRIDGESTONE SPORTS

Toner

Provided is a toner that is excellent in heat-resistant shelf stability and low-temperature fixability, has durability, and causes less occurrence of fogging in high temperature and high humidity environments.The toner comprising at least a binder resin, a colorant, a release agent, a retention aid and a charge control resin. The binder resin is a copolymer containing a styrene-based monomer unit 67 to 78% by mass and a (meth)acrylic acid alkyl monomer unit 22 to 33% by mass. The content of the retention aid is 1 to 4 parts by mass with respect to 100 parts by mass of the binder resin, and the content of the charge control resin is 0.1 to 20 parts by mass with respect to 100 parts by mass of the binder resin.

Owner:ZEON CORP

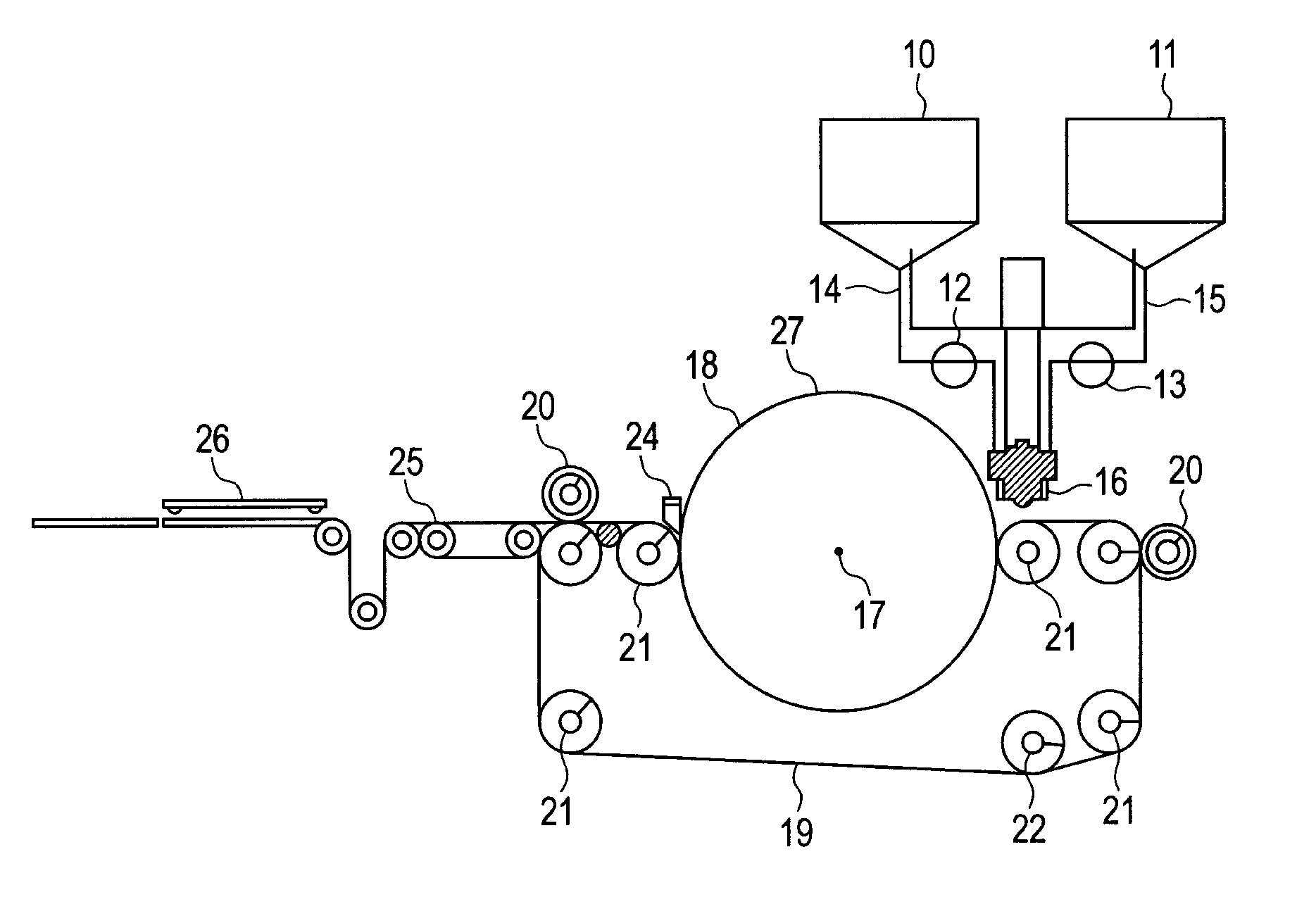

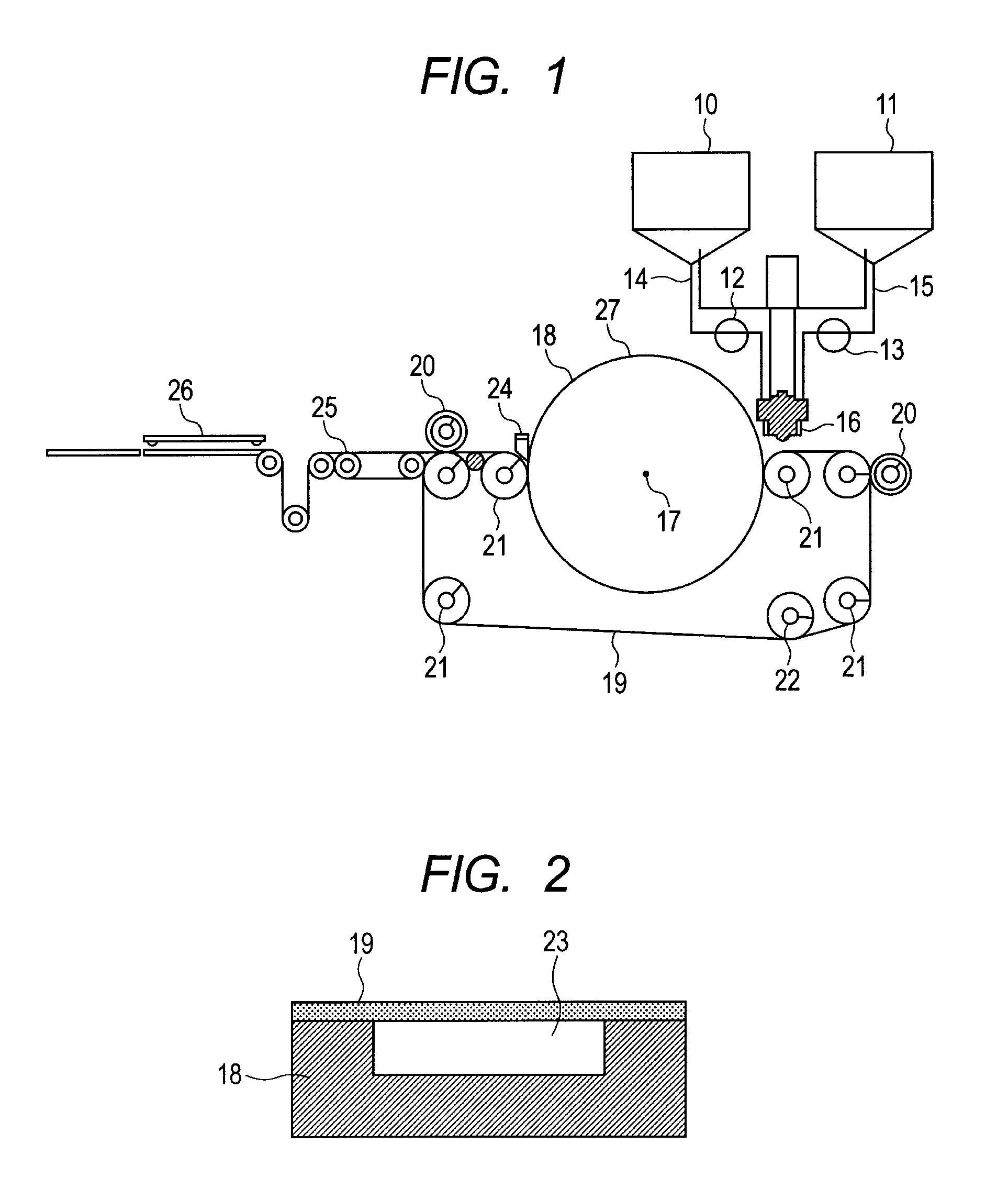

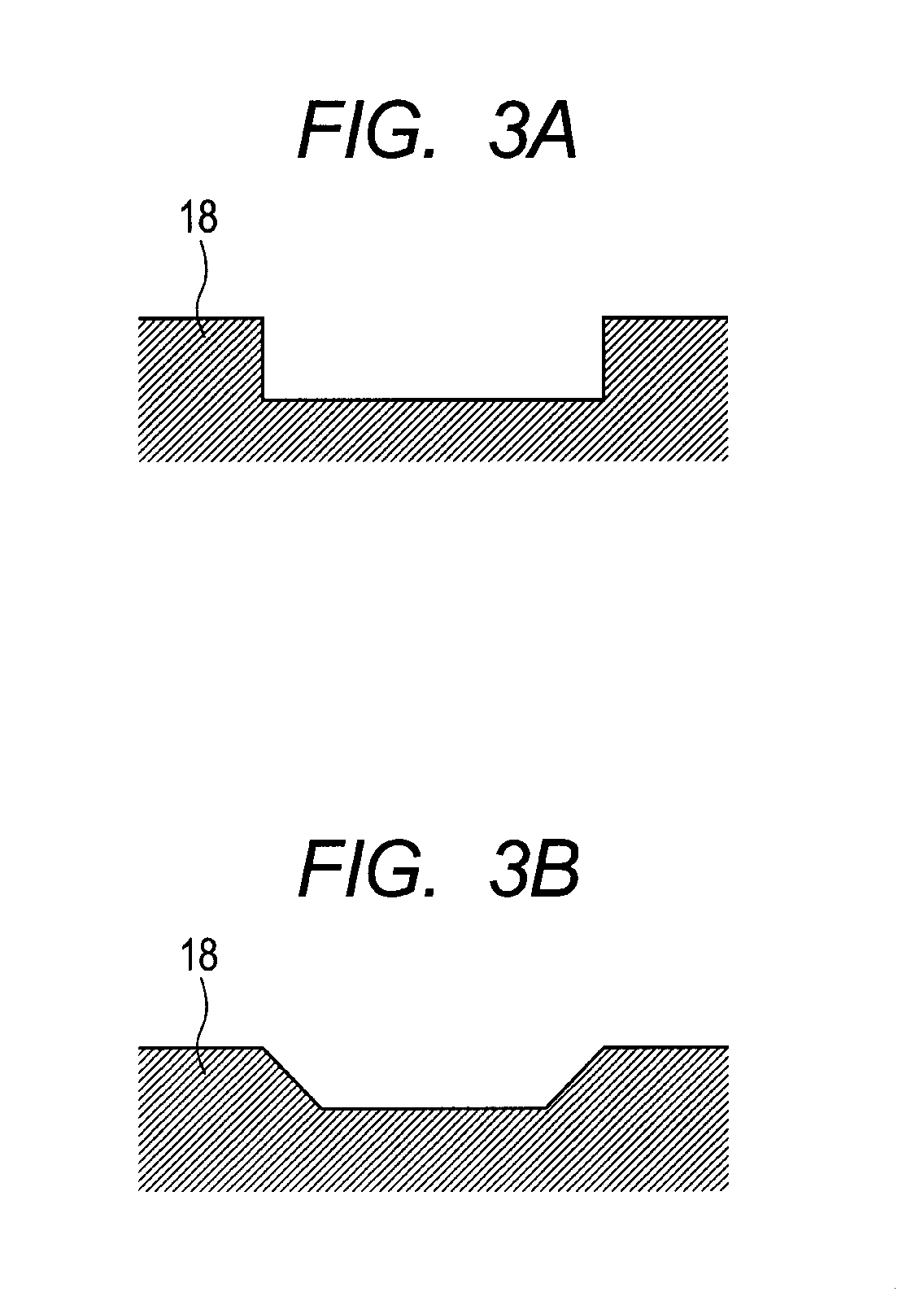

Method and apparatus for producing an electrophotographic blade member

ActiveUS20110233813A1Less irregularityLess occurrenceCeramic shaping apparatusElectrographic process apparatusPolyesterPolyol

A method of producing an electrophotographic blade member includes a continuous molding groove in an peripheral surface and an endless belt, in which the blade member includes a polyurethane resin cured a polyurethane composition having a viscosity of 500-3,000 mPa·s and including A)-D), and a position at which the composition is injected is set, on the belt, opposing to the groove, the position being away from a portion at which the molding drum and the belt are first contacted on an upstream for a moving direction of the belt: A) polyisocyanate; B) adipate-based polyester polyol having a number average molecular weight of 1,000-4,000; C) chain extender having a molecular weight of 200 or less; D) isocyanurate-forming catalyst at 20 to 500 ppm and a urethane-forming catalyst at 200-1,500 ppm.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com