Patents

Literature

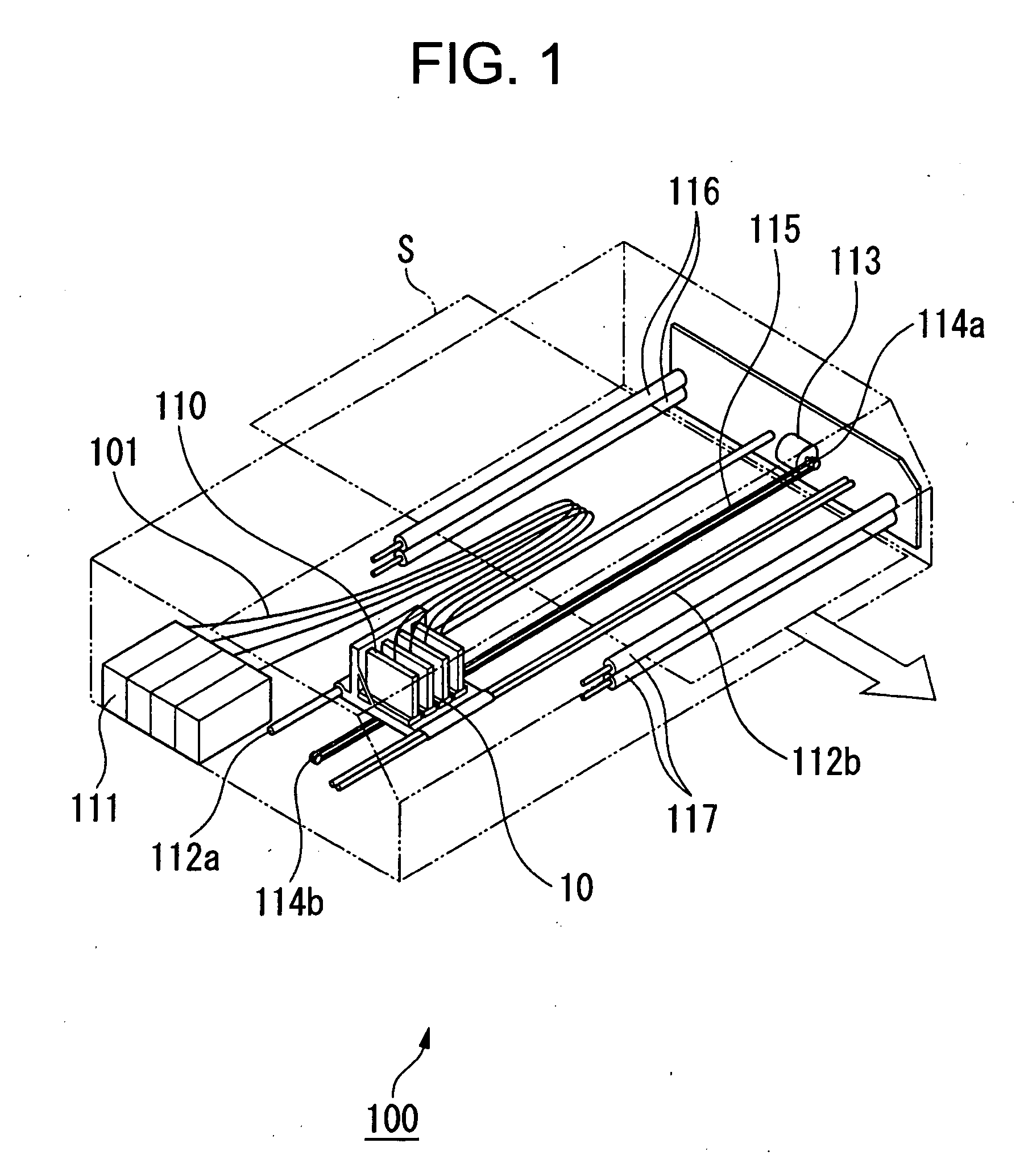

93results about How to "Efficient and stable preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for manufacturing microfibrillated cellulose fiber

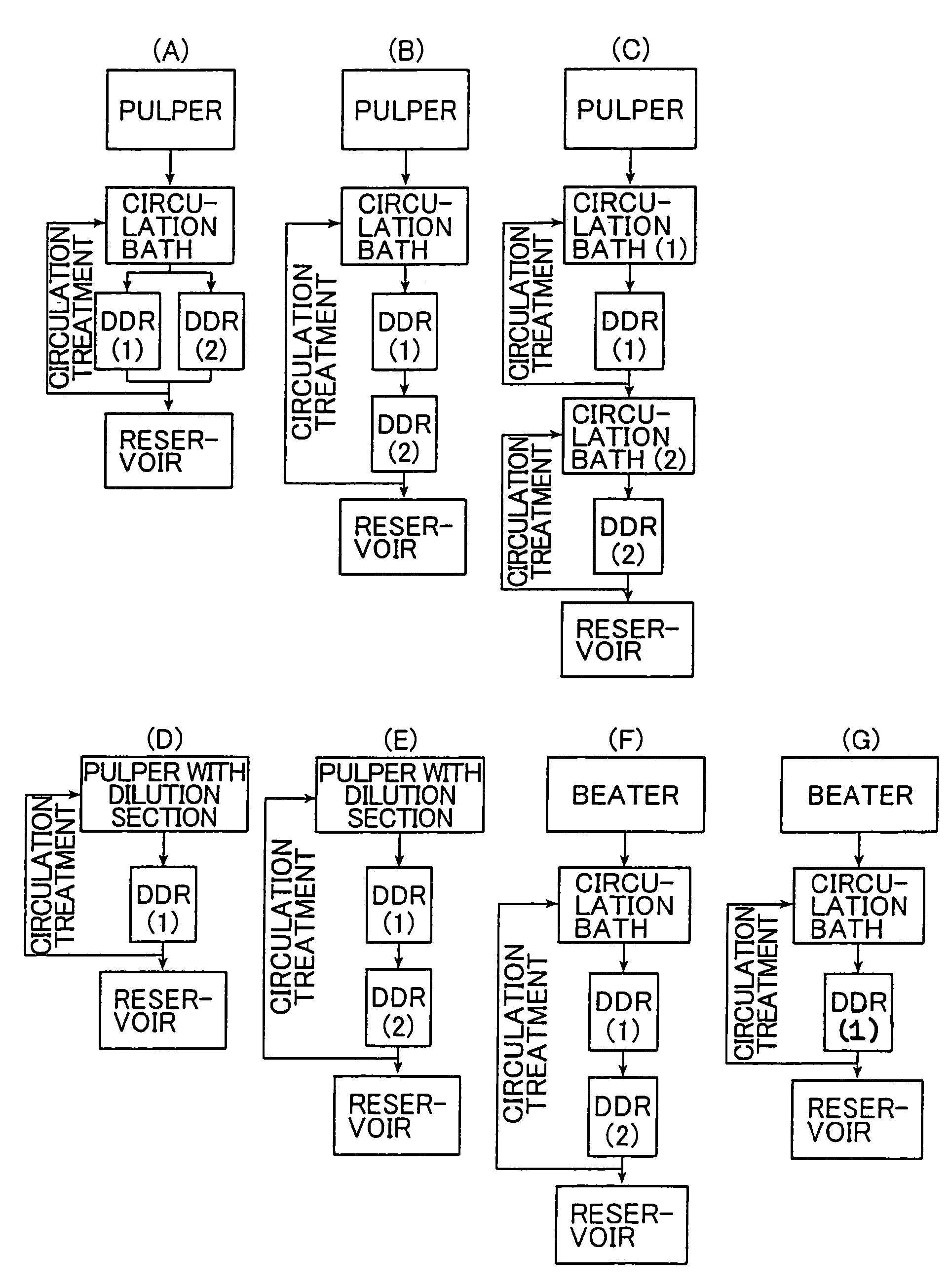

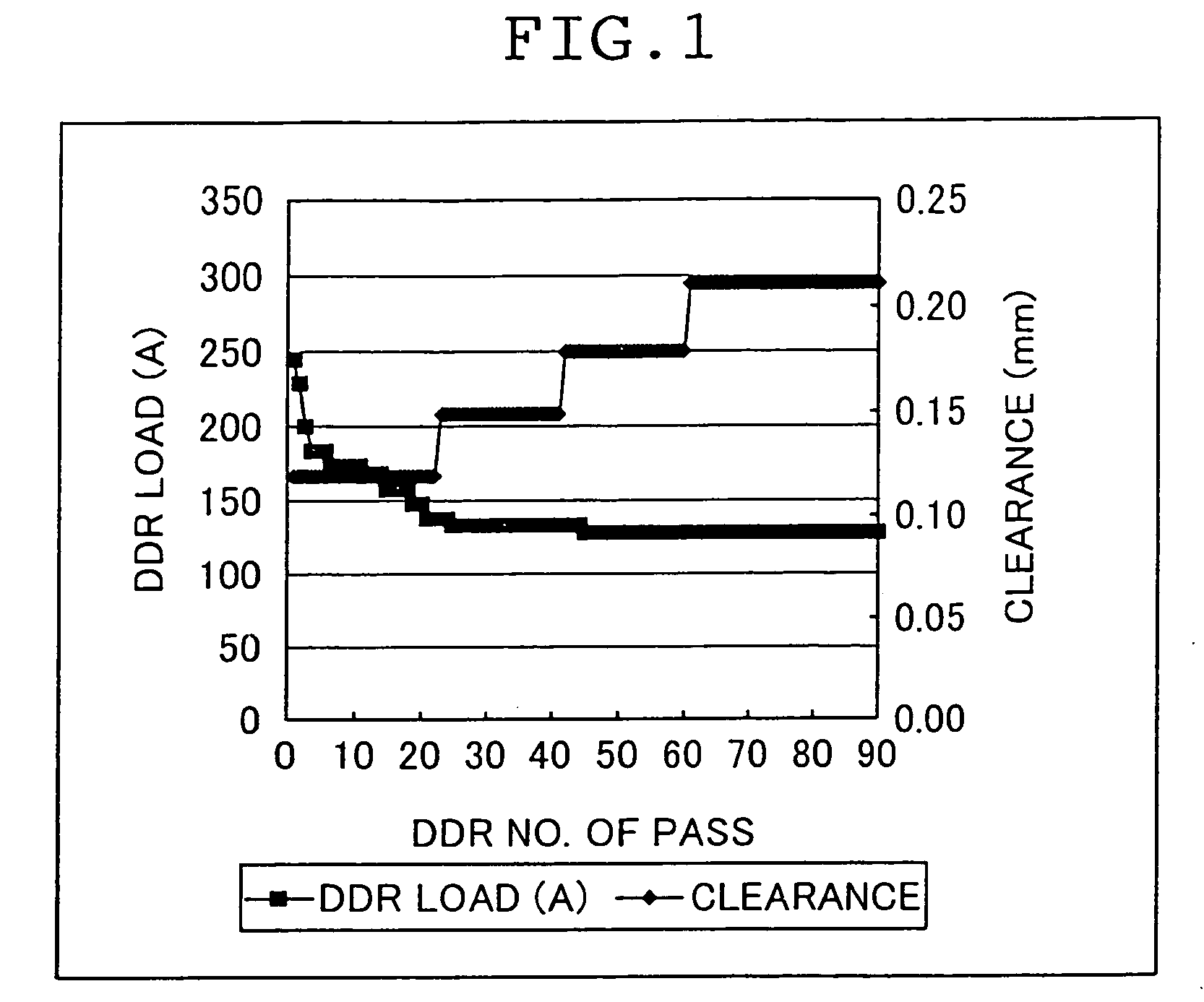

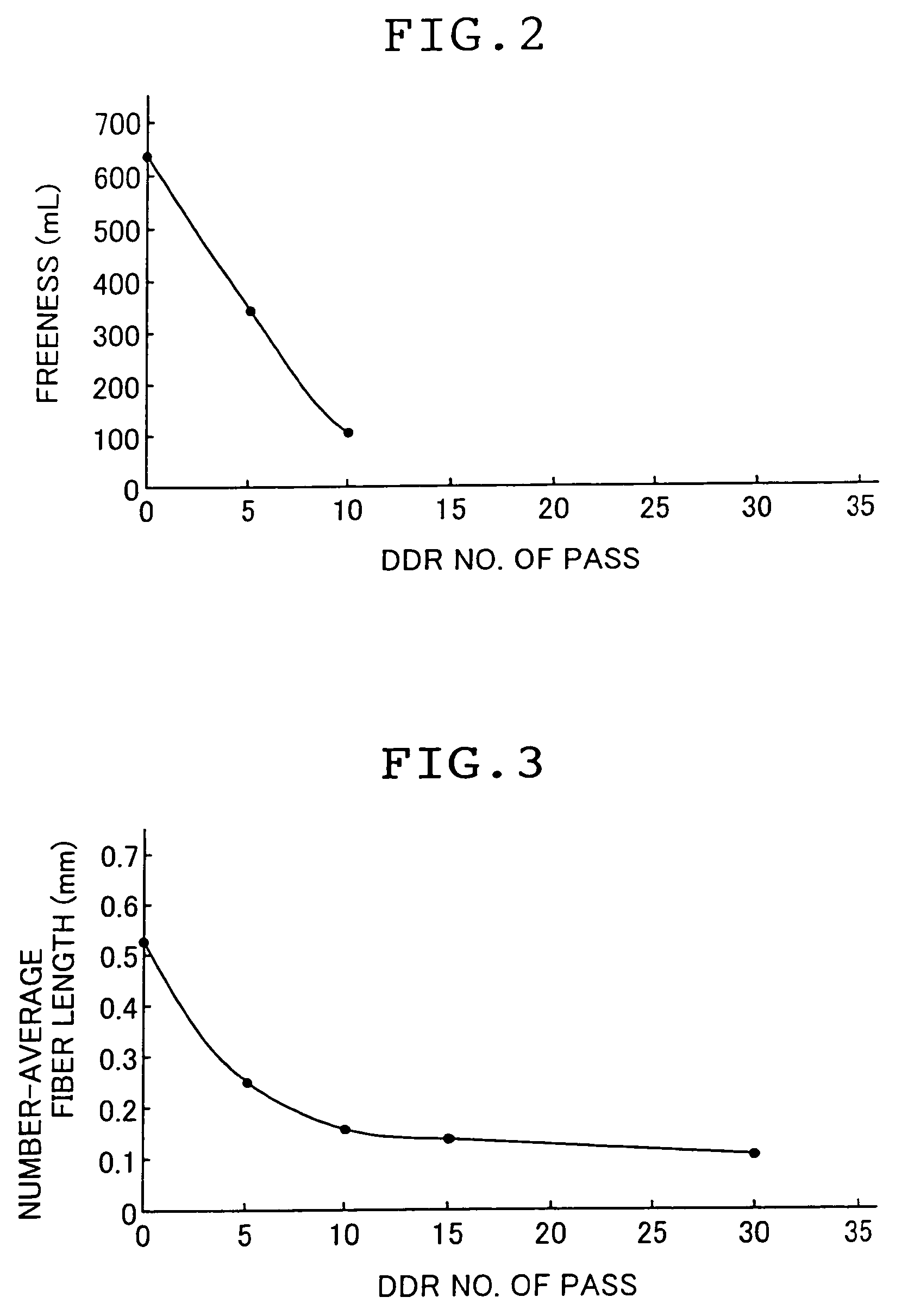

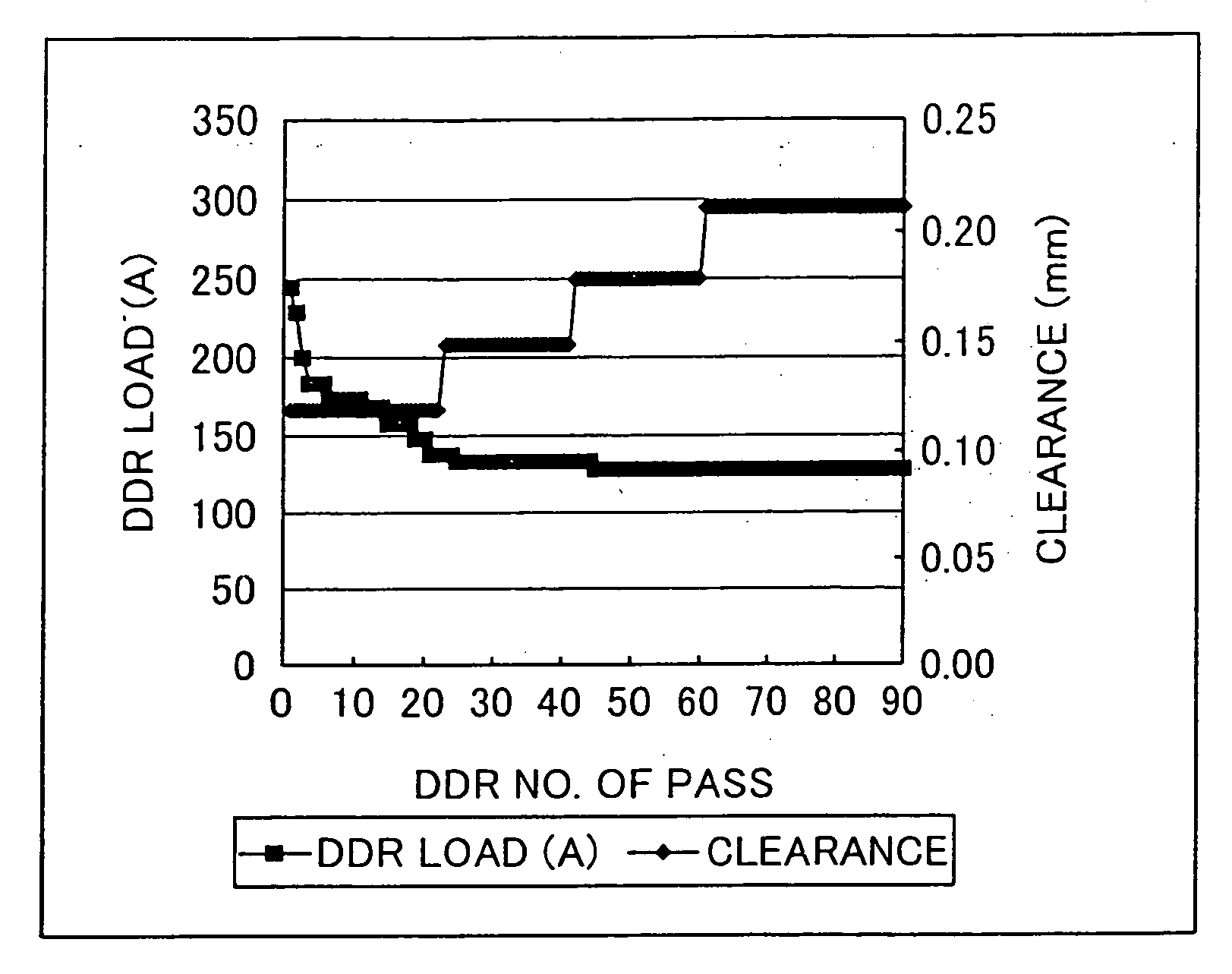

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

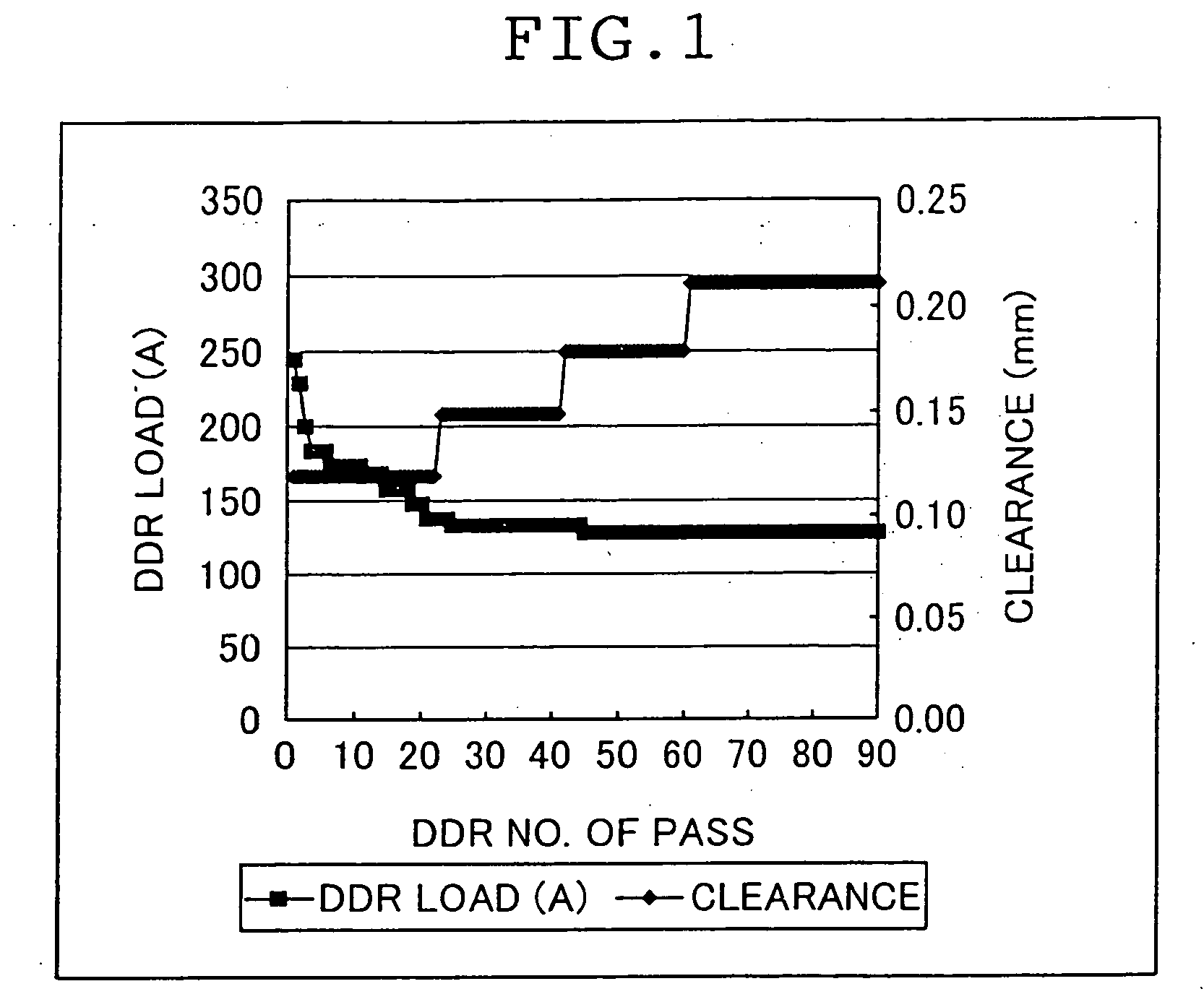

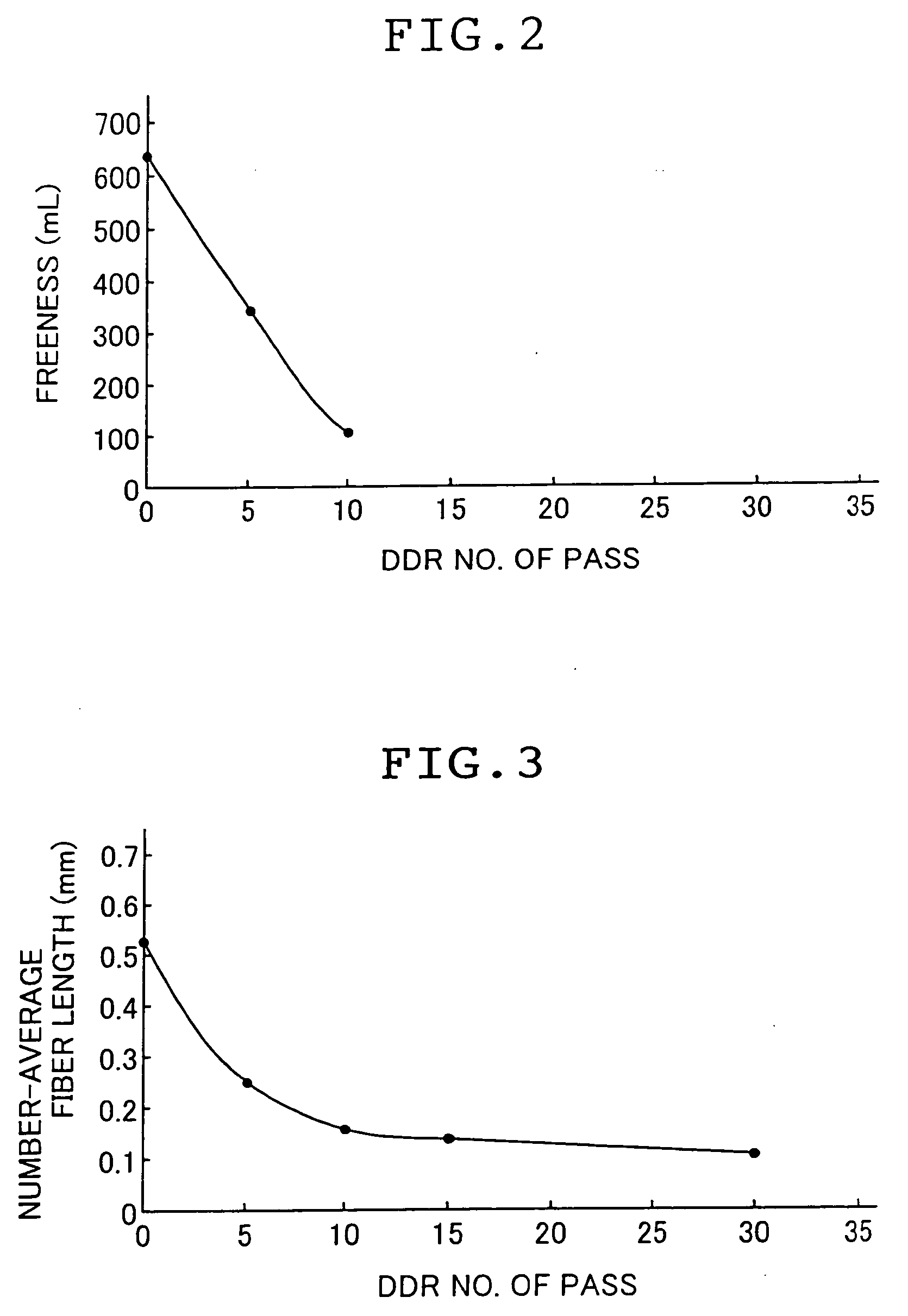

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS20050194477A1Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

Toner, method for preparing the toner, and developer including the toner

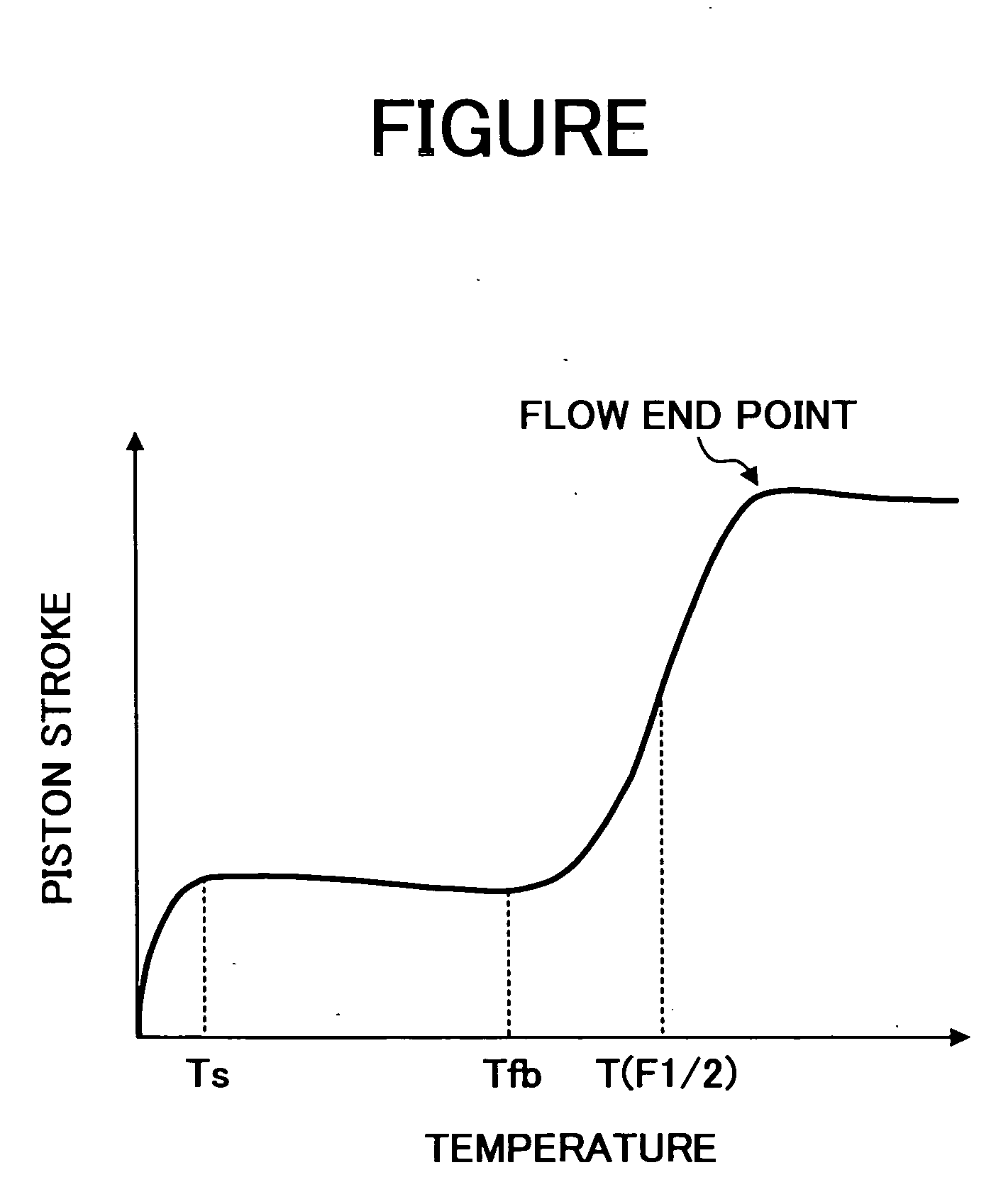

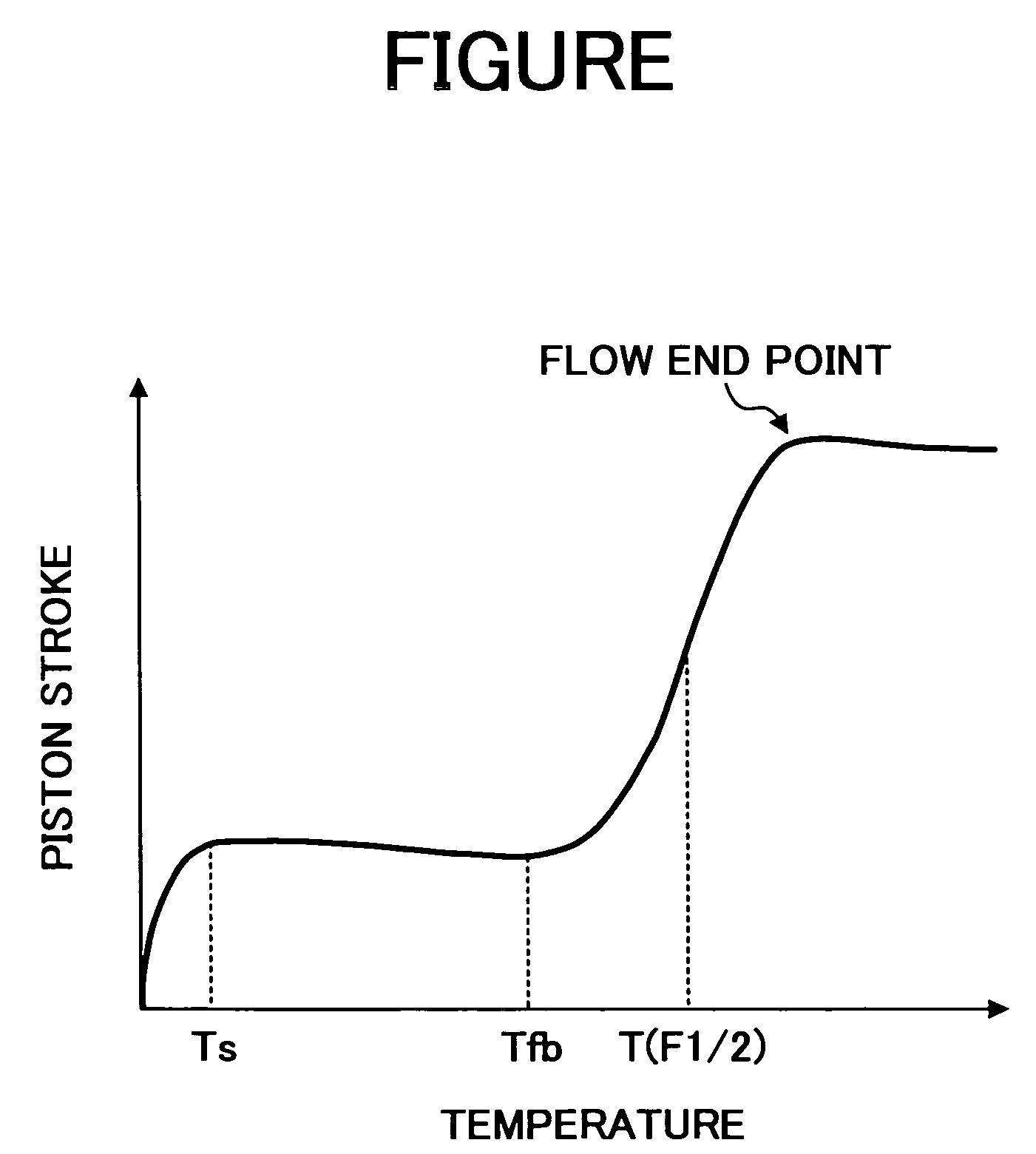

A toner including a binder resin comprising a polyester resin in an amount of from 50 to 100% by weight, wherein the polyester resin includes an unsaturated polyester resin which is preferably a crystalline polyester resin; a colorant; and a fatty acid metal salt which is preferably microencapsulated. A method for preparing a toner including forming particles of a toner composition including at least a binder resin including a polyester resin in an amount of from 50 to 100% by weight and a colorant, in an aqueous medium to prepare a dispersion of a particulate material, wherein the polyester resin includes an unsaturated polyester resin; drying the particulate material; and mixing a fatty acid metal salt with the particulate material to subject double bonds of the unsaturated polyester resin to oxidation polymerization.

Owner:RICOH KK

Toner containing unsaturated polyester in binder resin, method for preparing the toner, and developer including the toner

A toner including a binder resin comprising a polyester resin in an amount of from 50 to 100% by weight, wherein the polyester resin includes an unsaturated polyester resin which is preferably a crystalline polyester resin; a colorant; and a fatty acid metal salt which is preferably microencapsulated. A method for preparing a toner including forming particles of a toner composition including at least a binder resin including a polyester resin in an amount of from 50 to 100% by weight and a colorant, in an aqueous medium to prepare a dispersion of a particulate material, wherein the polyester resin includes an unsaturated polyester resin; drying the particulate material; and mixing a fatty acid metal salt with the particulate material to subject double bonds of the unsaturated polyester resin to oxidation polymerization.

Owner:RICOH KK

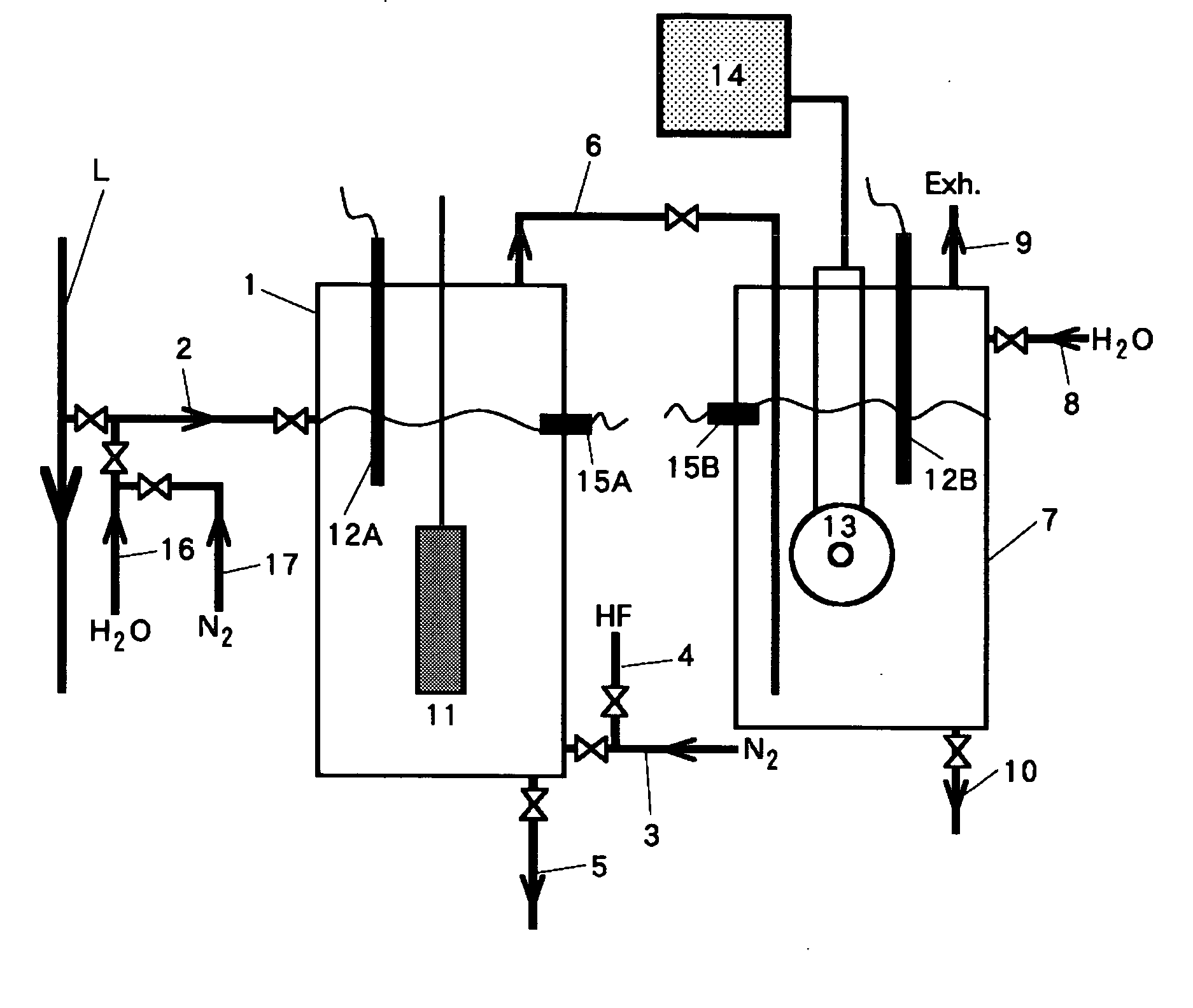

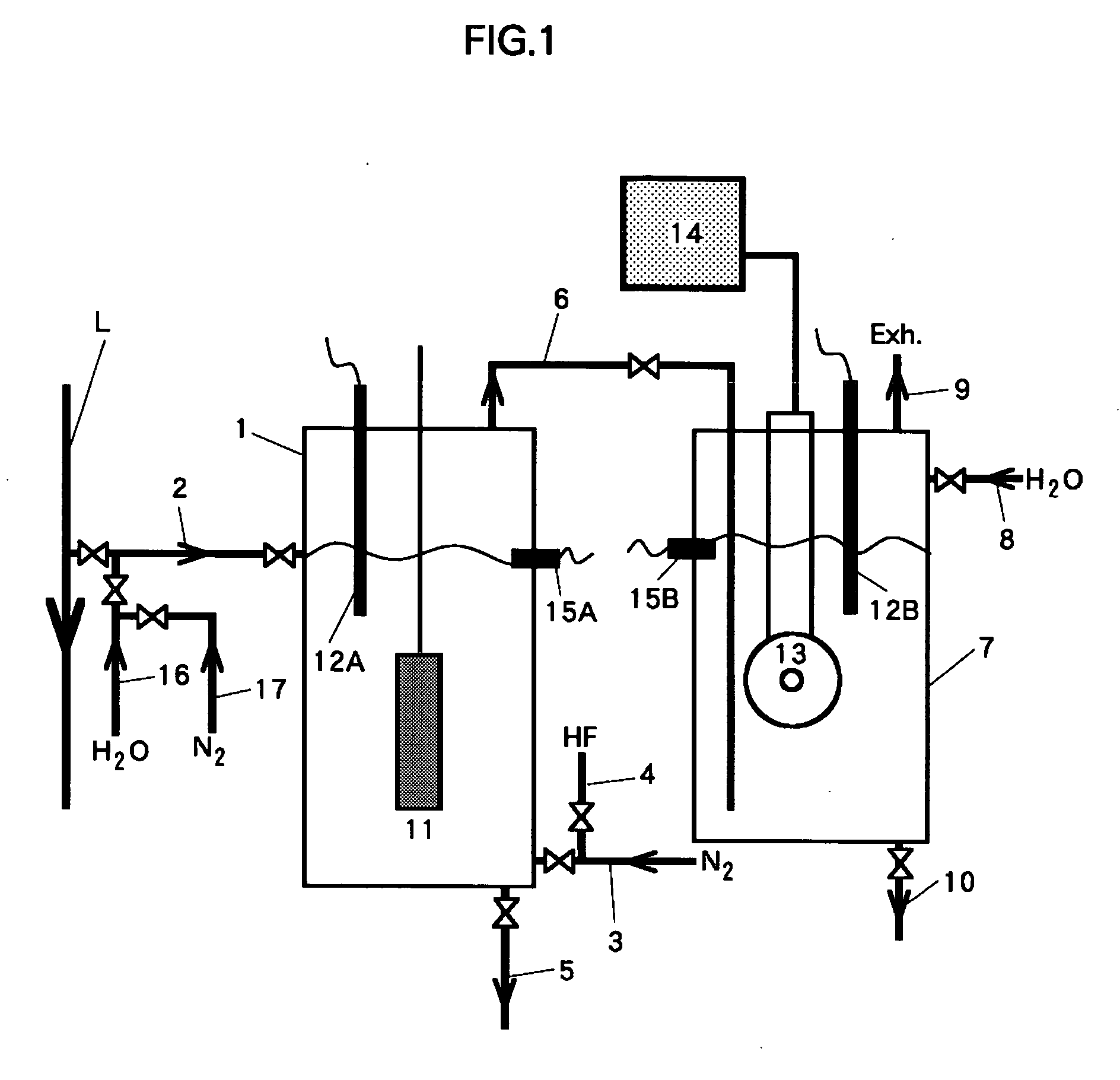

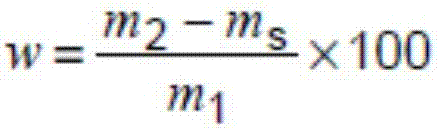

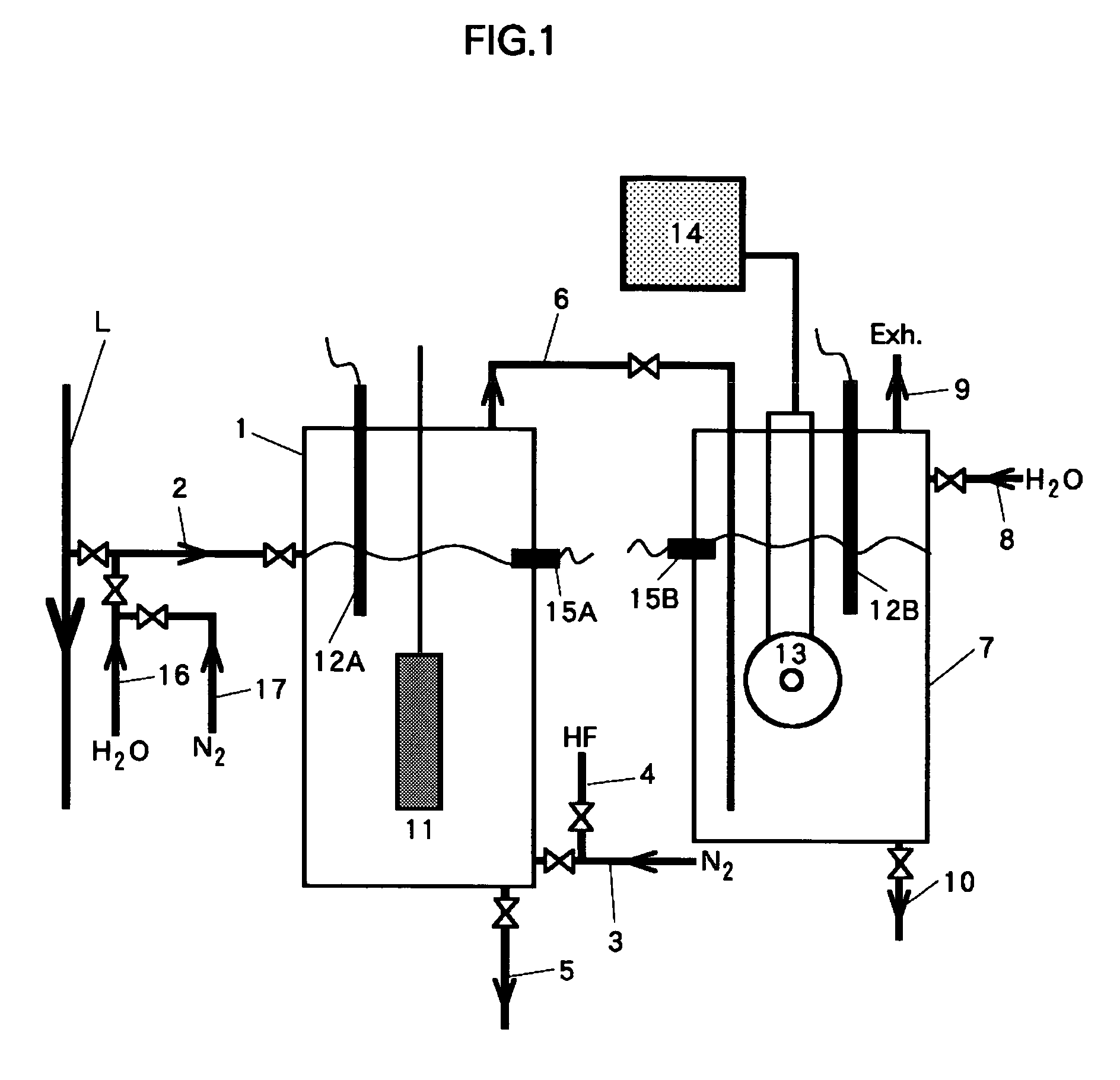

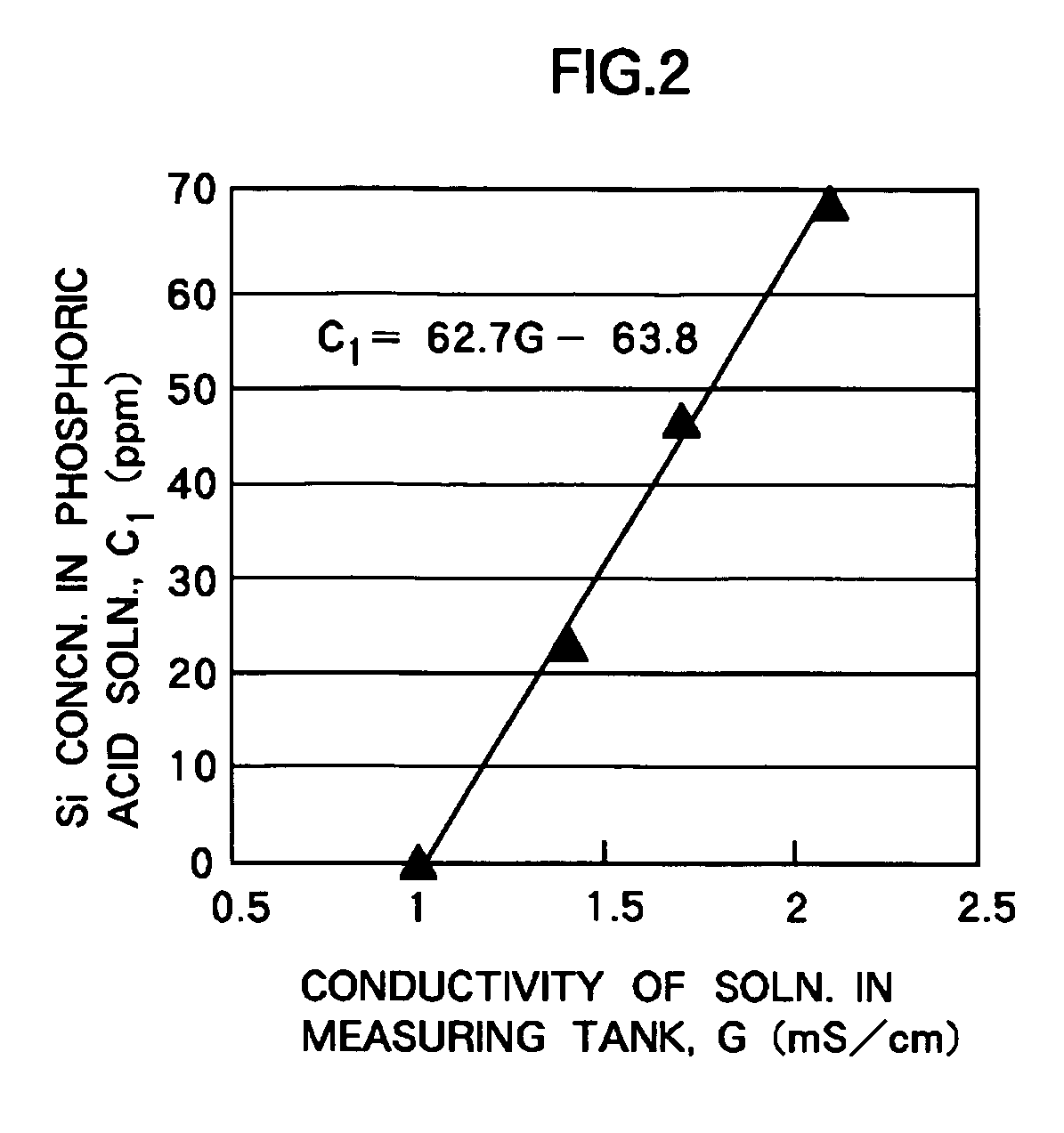

Equipment and method for measuring silicon concentration in phosphoric acid solution

ActiveUS20060263251A1Improve processing performanceReduce amountSemiconductor/solid-state device testing/measurementDecorative surface effectsIonCompound (substance)

Disclosed is equipment for measuring a silicon concentration in a phosphoric acid solution under use as an etching solution during operation of a semiconductor substrate processing system. The equipment is provided with at least a reaction tank and a concentration-measuring tank. The reaction tank includes a reaction unit for adding hydrofluoric acid to a predetermined constant amount of the phosphoric acid solution drawn out of the semiconductor substrate processing system to form a silicon fluoride compound and then causing the silicon fluoride compound to evaporate. The concentration-measuring tank comprises a hydrolysis unit for bubbling the silicon fluoride compound, which has evaporated from the reaction tank, through deionized water to hydrolyze the silicon fluoride compound and a measurement unit for determining a change rate of silicon concentration in the deionized water subsequent to the bubbling. Also disclosed is a method for measuring a silicon concentration in a phosphoric acid solution under recirculation and use as an etching solution in a semiconductor substrate processing system in operation.

Owner:TATSUMO KK

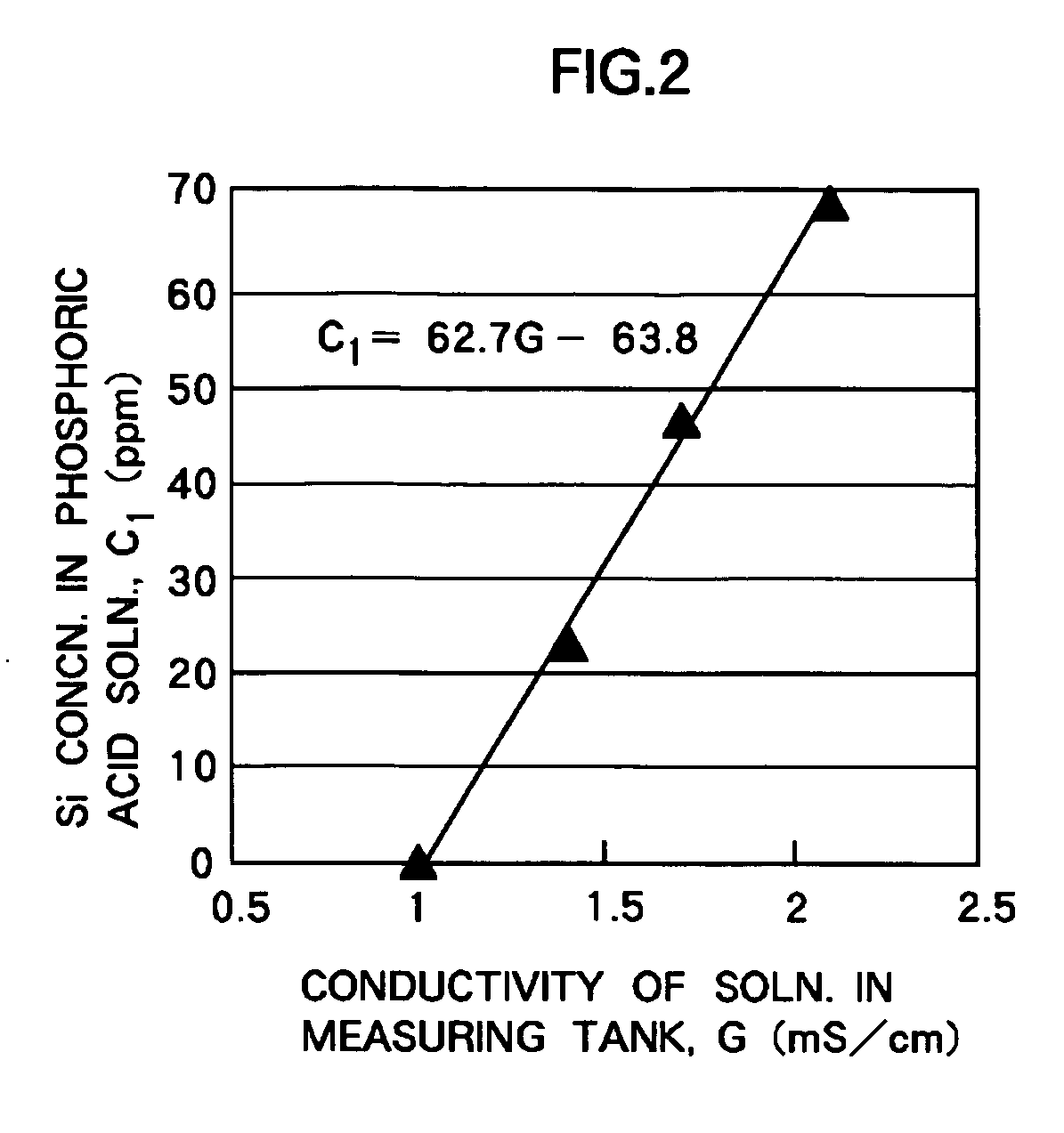

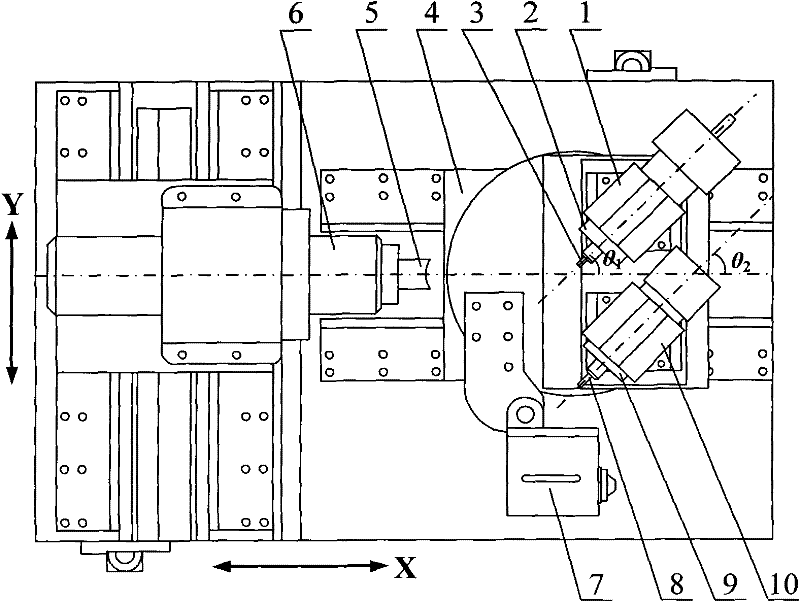

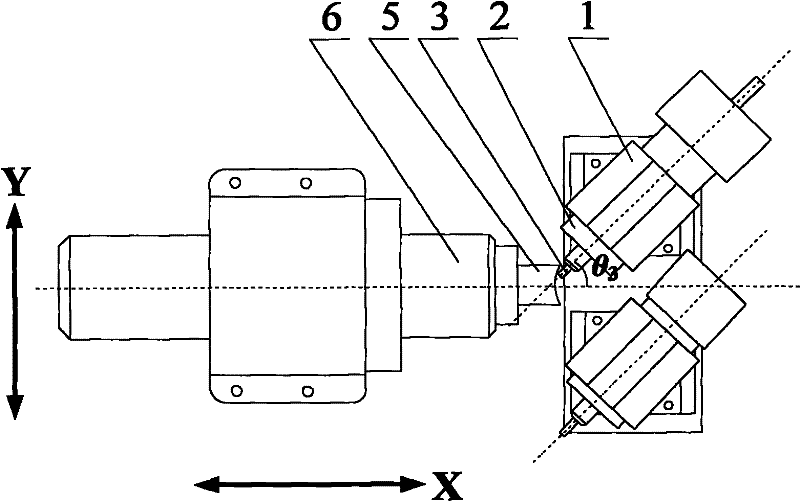

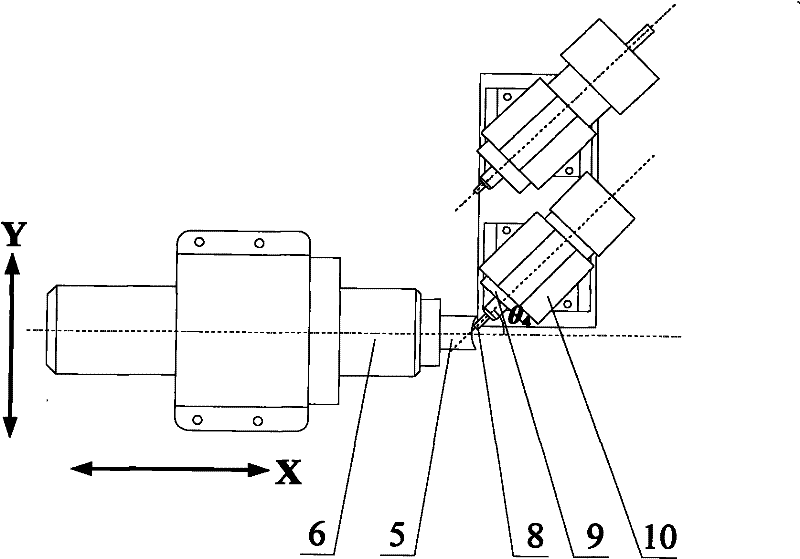

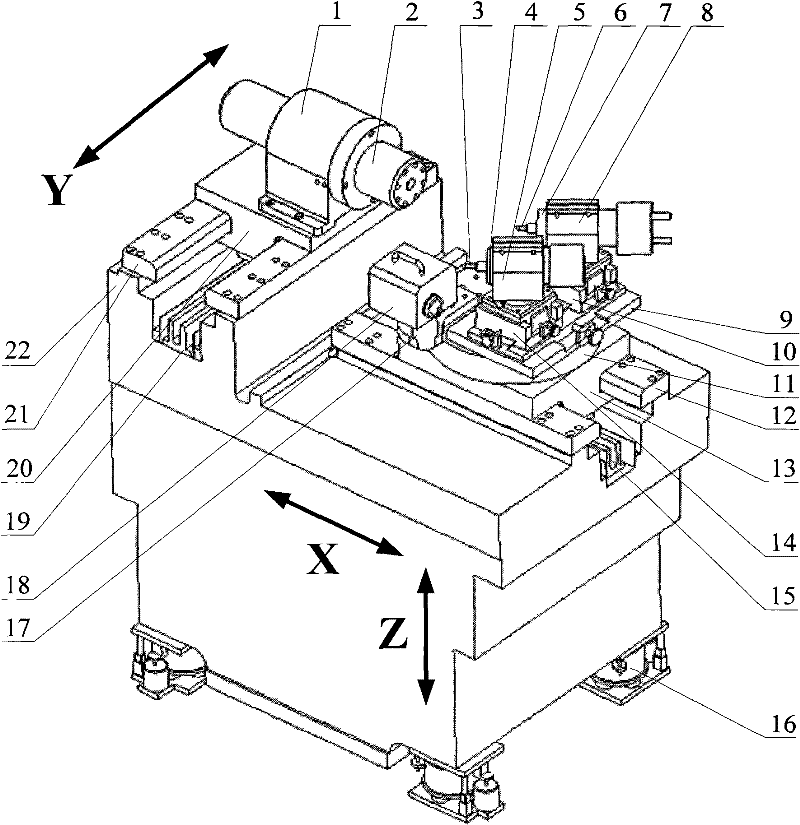

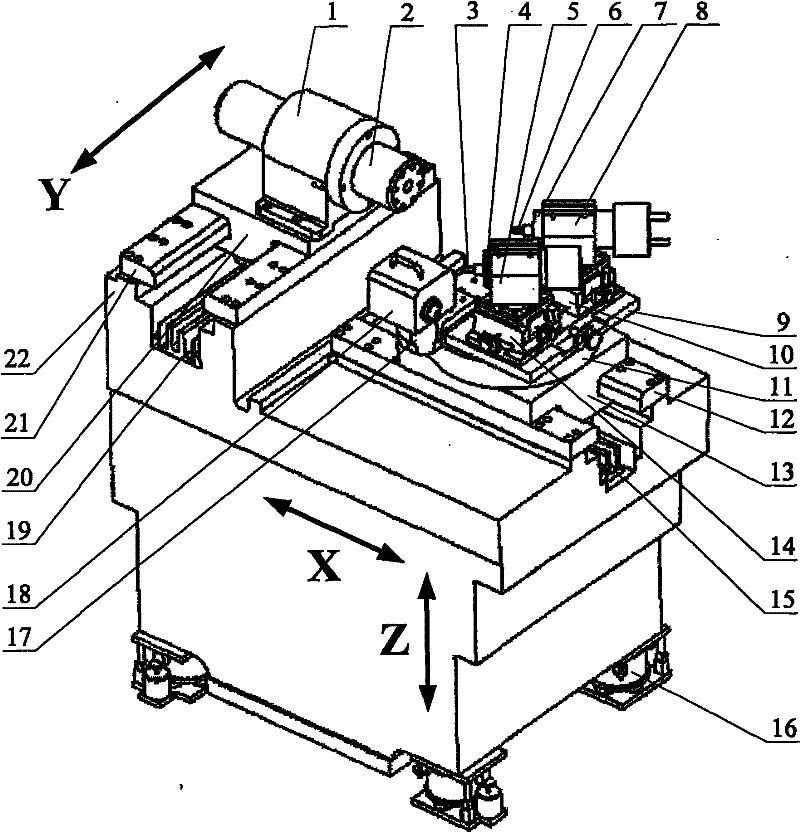

Small-caliber aspherical composite precise processing method

InactiveCN102161169AReduce installation errorsReduce tool setting errorsInterference phenomenonEngineering

The invention relates to a small-caliber aspherical composite precise processing method. The method comprises the following steps of: 1. clamping a workpiece (5) on a precise machine tool, wherein axes of a grinding wheel spindle (2) and a grinding head spindle (9) are parallel, separated from a sliding table (4) and intersected with the axis of a workpiece spindle (6); and grinding and processing an inclined shaft of the workpiece (5) by a micropowder grinding wheel (3); 2. carrying out in-place measurement on the workpiece (5) by using a detecting device (7) to generate a compensation processing track, and then processing along the track by the mocropowder grinding wheel (3); and 3. using a grinding head (8) to grind and polish the workpiece (5) to finally obtain a finished product. In the small-caliber aspherical composite precise processing method, precise inclined axis mirror grinding and inclined axis magnetorheological polishing and grinding are integrated into a single machine tool, so that the installation and the tool setting errors are reduced, the working hours are also reduced, the accuracy and the efficiency are improved, the interference phenomenon is prevented, the controllability is good, and continuous processing can be achieved.

Owner:HUNAN UNIV

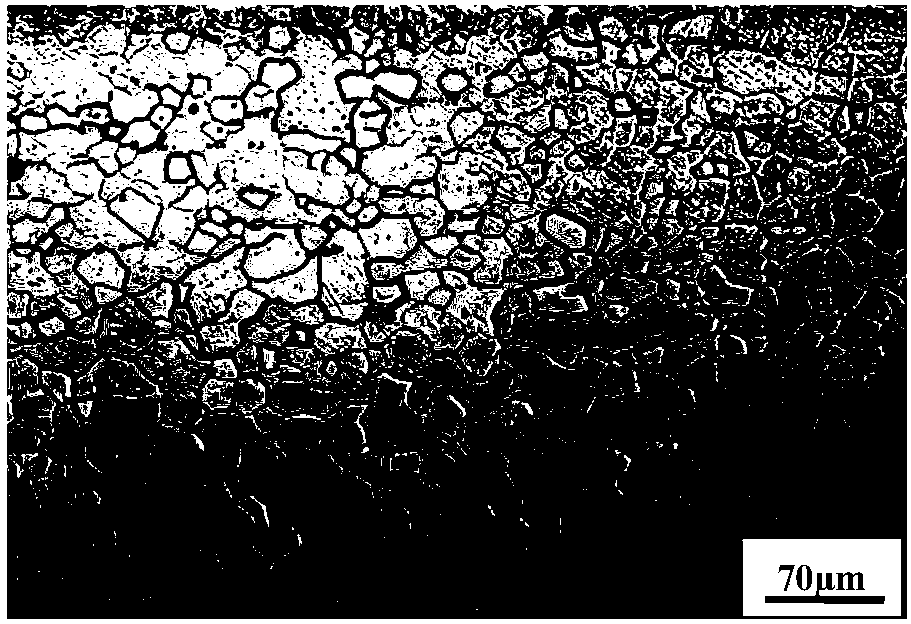

Preparation method of Ti2AlNb-based alloy large-size uniform fine-grain bar

The invention belongs to the technical field of Ti-Al intermetallic compound material processing and relates to a preparation method of a Ti2AlNb-based alloy large-size uniform fine-grain bar. The method is characterized by comprising the following steps: performing homogenization treatment on the components; performing cogging and forging; forging below the beta transformation temperature; testing the beta transformation temperature T(beta) of the forging stock; forging above the beta transformation temperature; forging below the beta transformation temperature; and rolling for shaping. The invention provides a preparation method of a Ti2AlNb-based alloy large-size uniform fine-grain bar, and the problems of a Ti2AlNb-based alloy ingot including high deformation resistance, insufficient processing plasticity, low structure uniformity after forging, easy cracking in forging and low yield are overcome.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

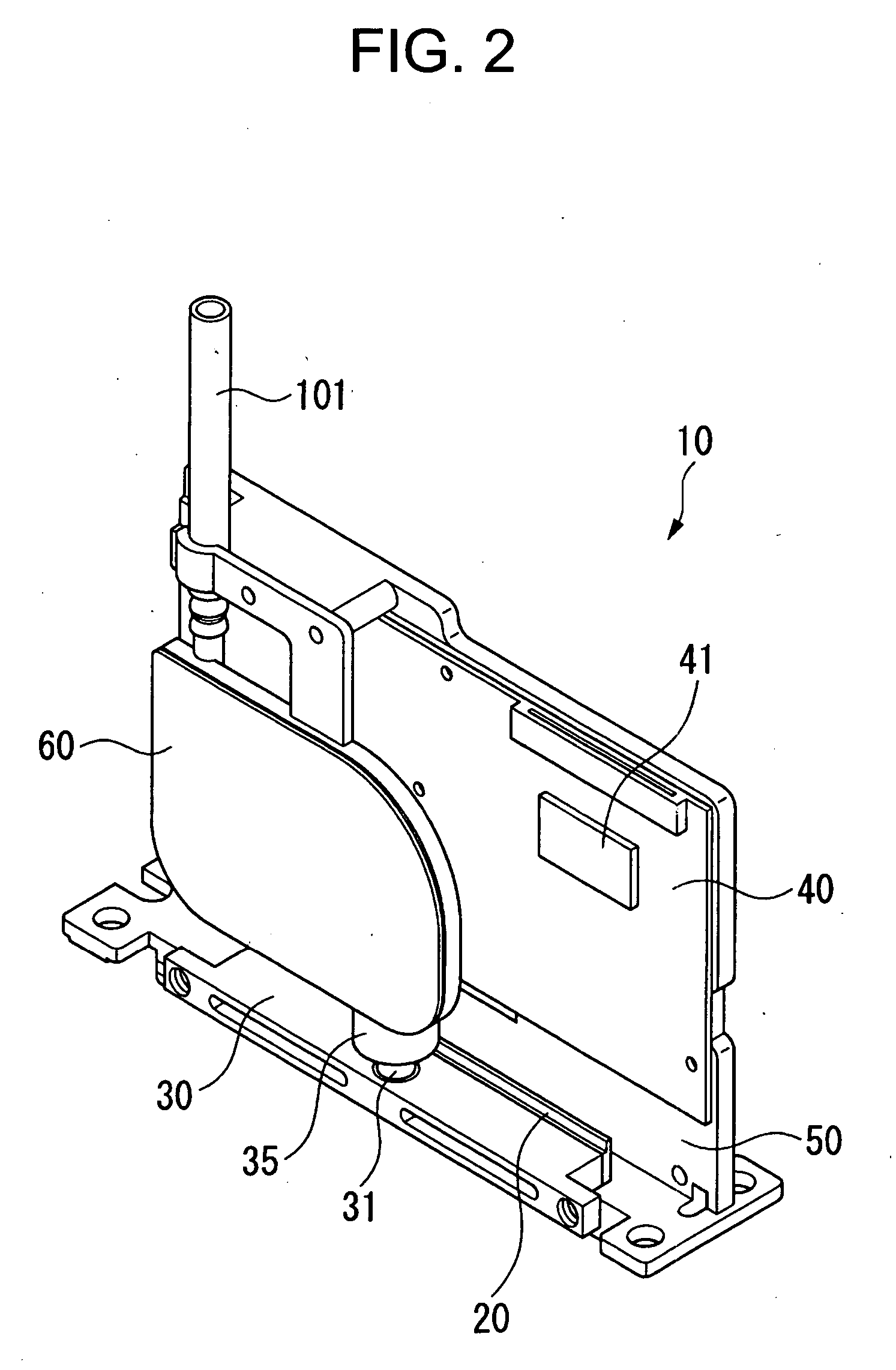

Small-caliber aspherical composite precise processing machine tool

InactiveCN102161168AReduce installation errorsReduce tool setting errorsControllabilitySmall caliber

The invention relates to a small-caliber aspherical composite precise processing machine tool, comprising a tool body (22) with a shock absorber (16), wherein the tool body (22) is provided with a first sliding table (20) which is provided with a spindle bracket (1); a second sliding table (13) is arranged correspondingly to the first sliding table (20) and is provided with a rotating bracket (17) and a supporting plate (9); the rotating bracket (17) is provided with a detecting device (18); and an inclined axis mirror grinding device (10) with a triaxial fine-tuning frame and an inclined axis magnetorheological grinding and polishing device (14) are arranged in parallel on the supporting plate (9). In the small-caliber aspherical composite precise processing machine tool, the precise inclined axis mirror grinding device and the inclined axis magnetorheological grinding and polishing device are integrated on a single tool body; through the combination of the two techniques of the precise inclined axis mirror grinding and the inclined axis magnetorheological grinding and polishing, the good controllability of the processing path is achieved, and the phenomenon of the interference is effectively prevented; and by in-place measurement of the shape of a workpiece, the error compensation processing of the workpiece is realized, and the accuracy of the shape of the workpiece is improved.

Owner:HUNAN UNIV

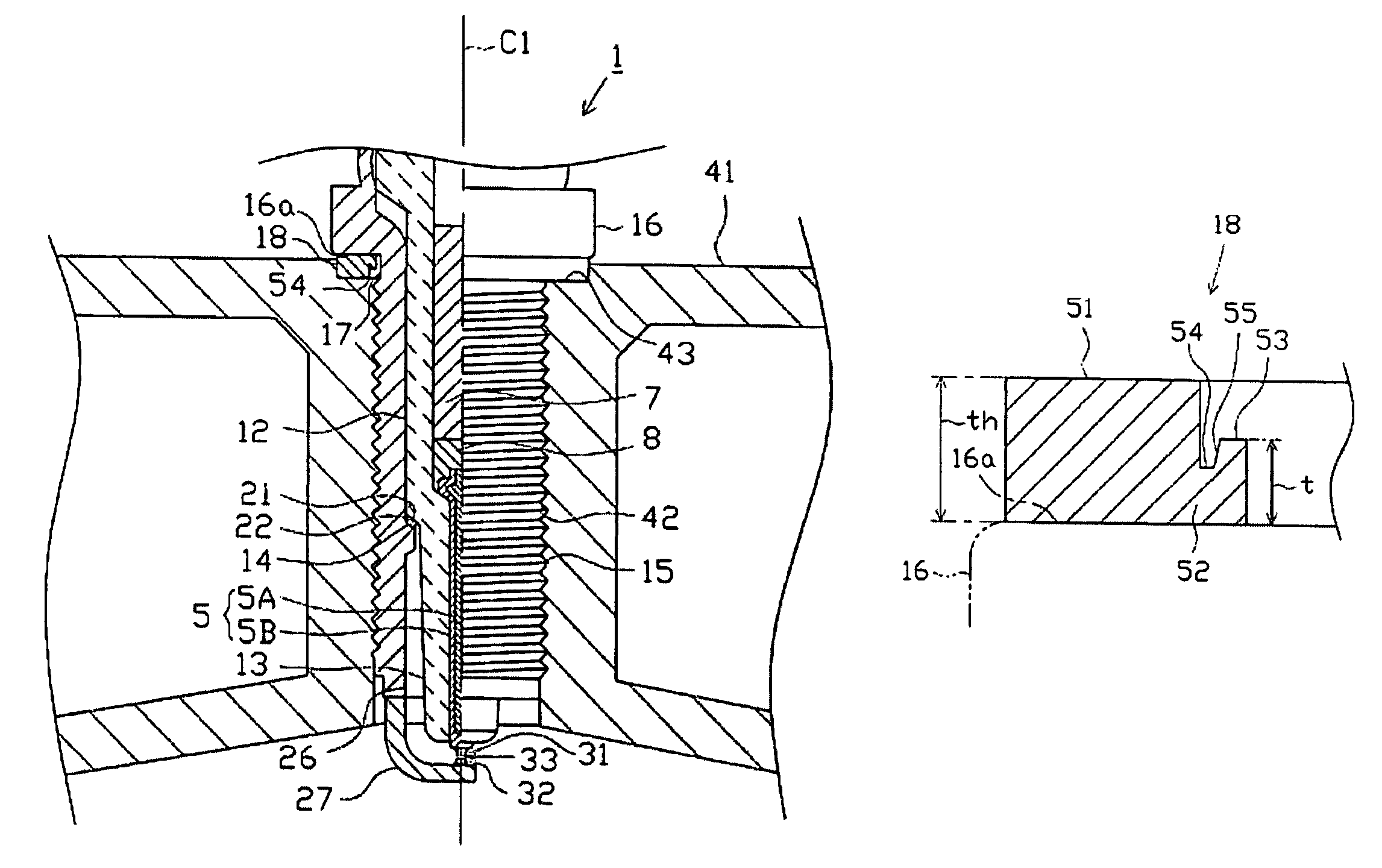

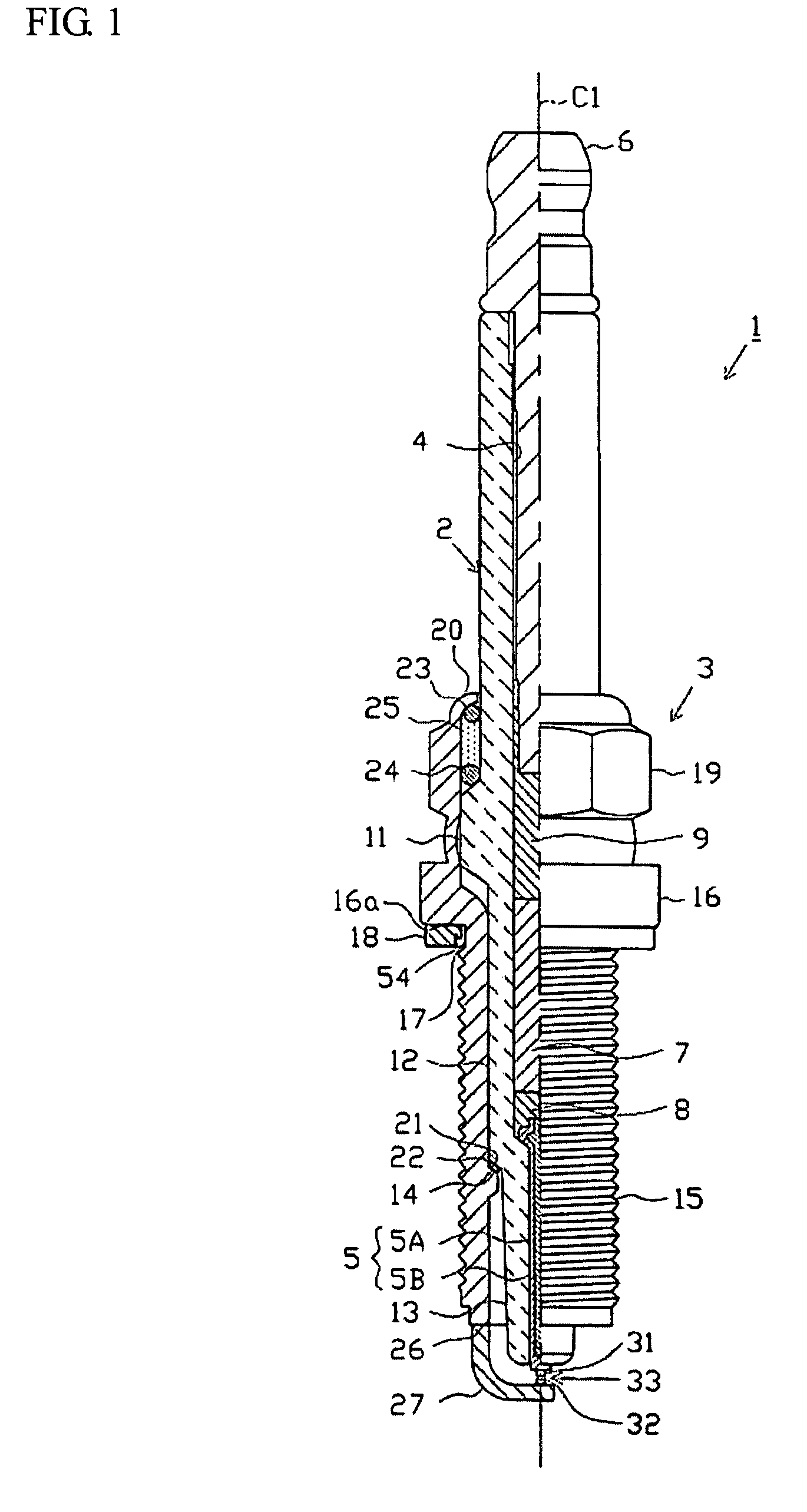

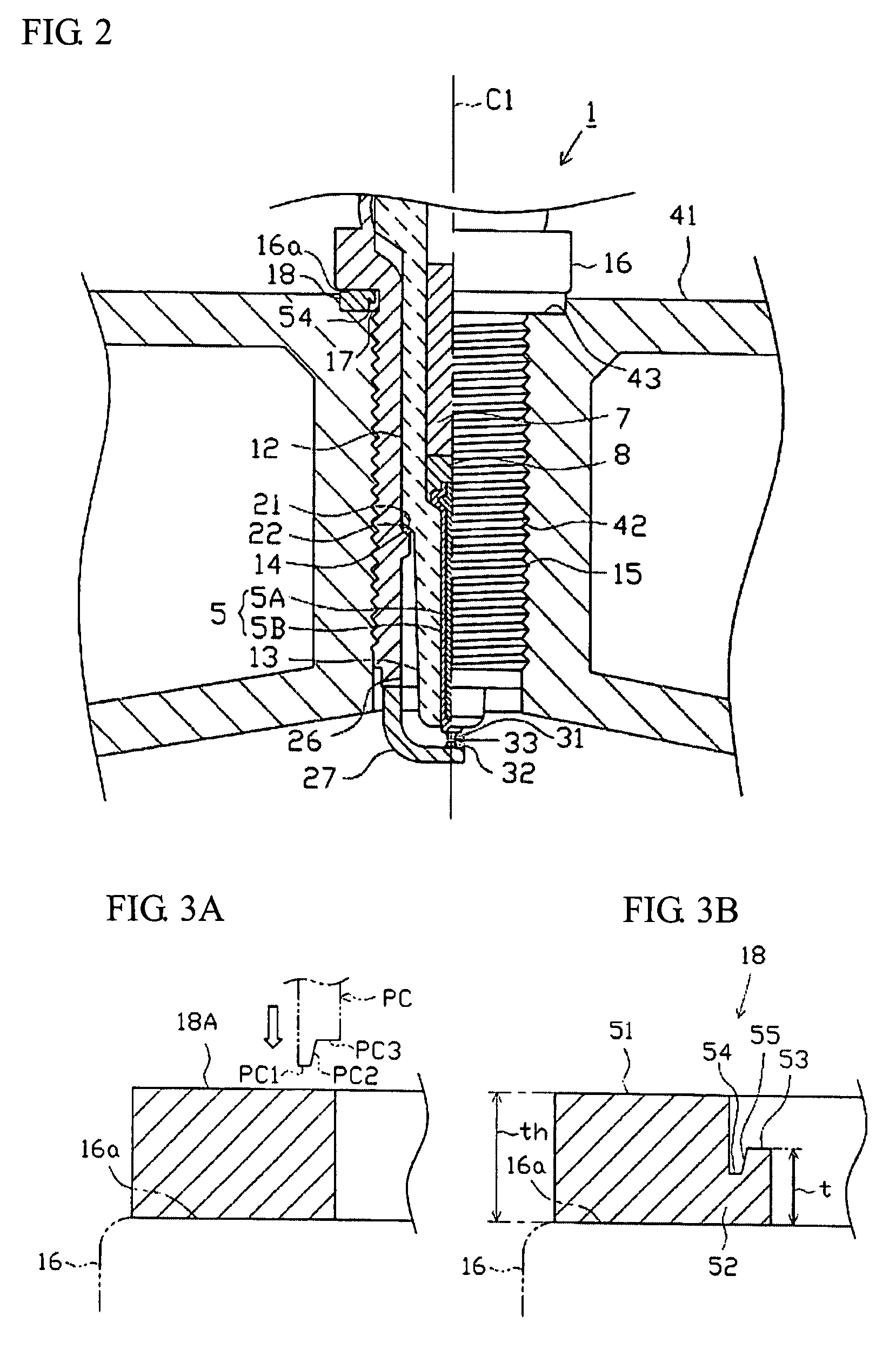

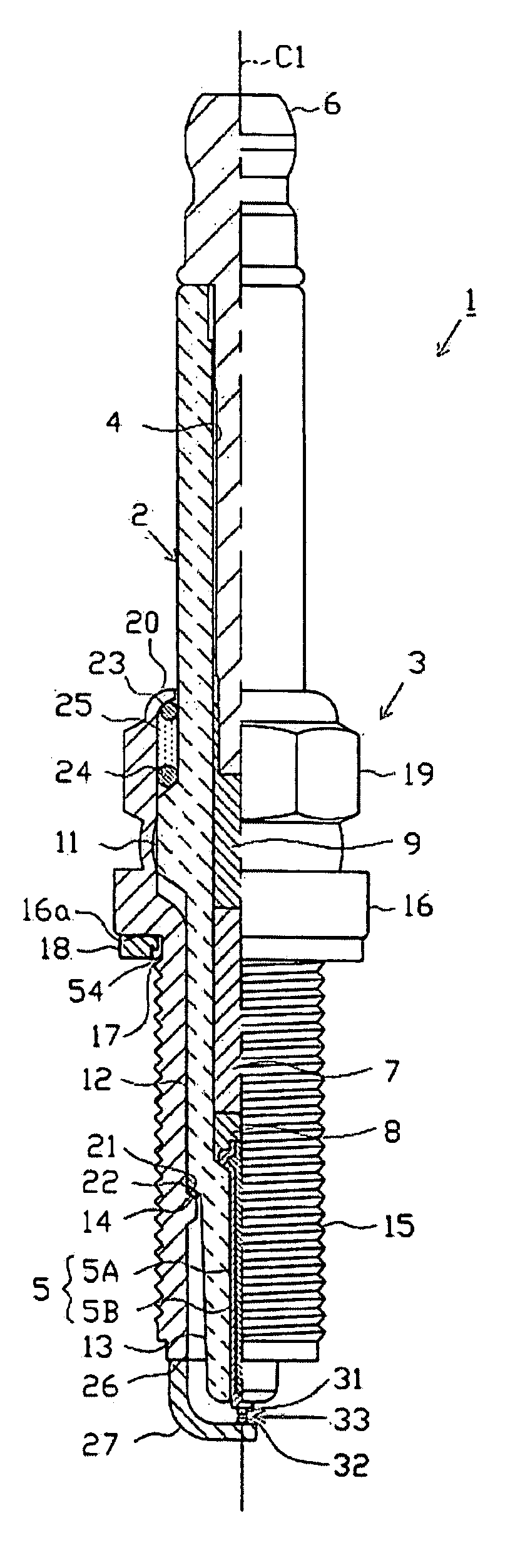

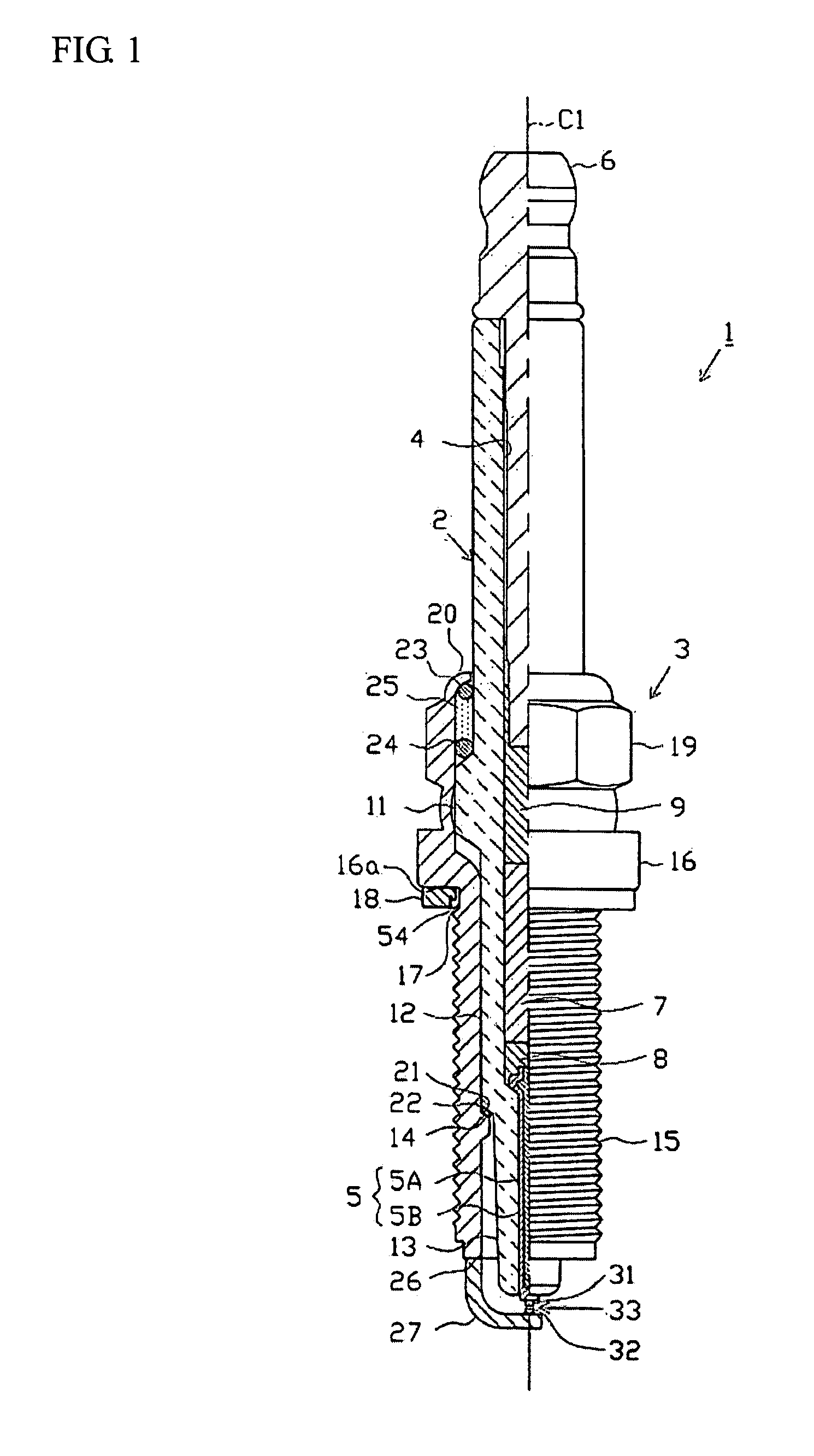

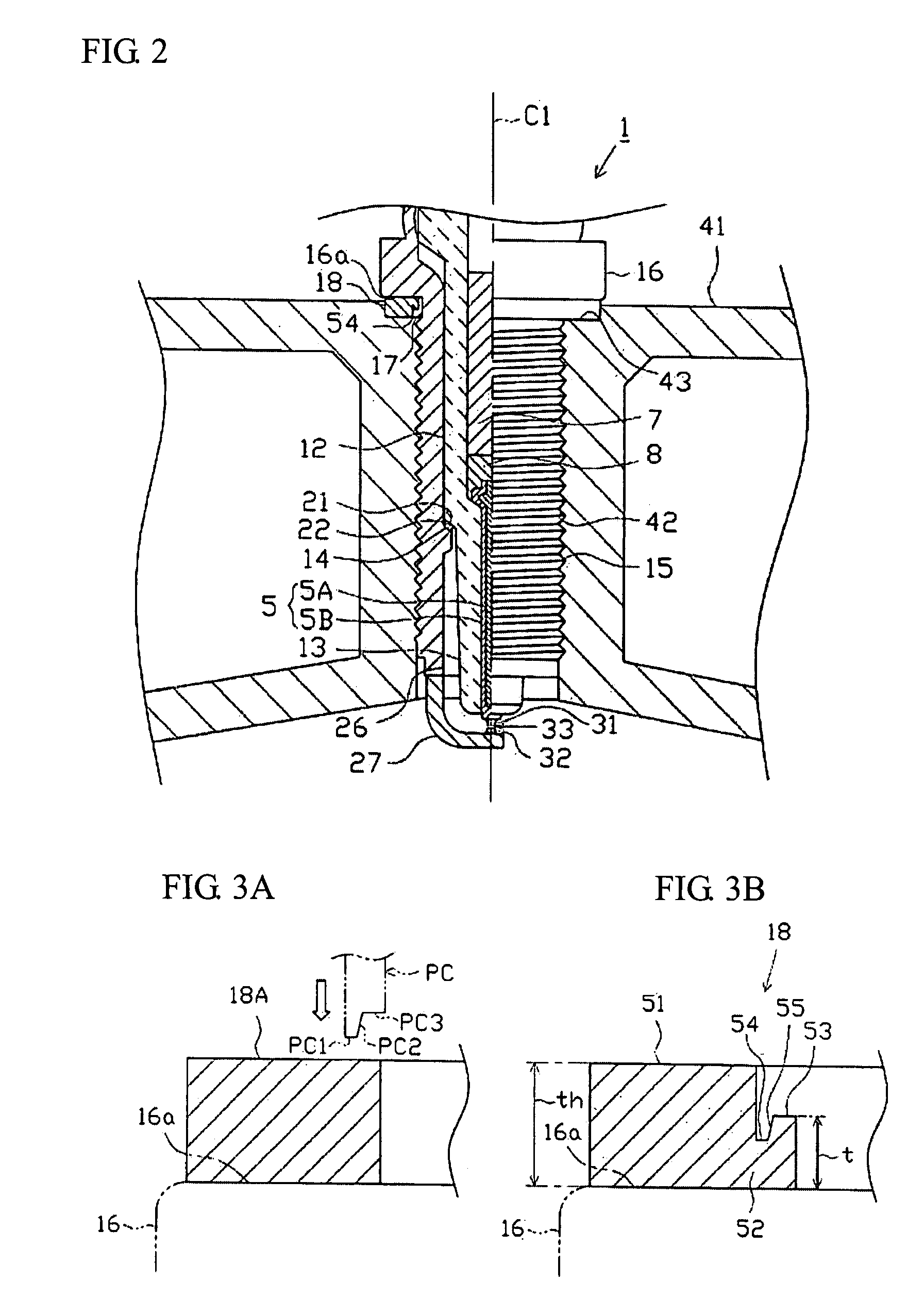

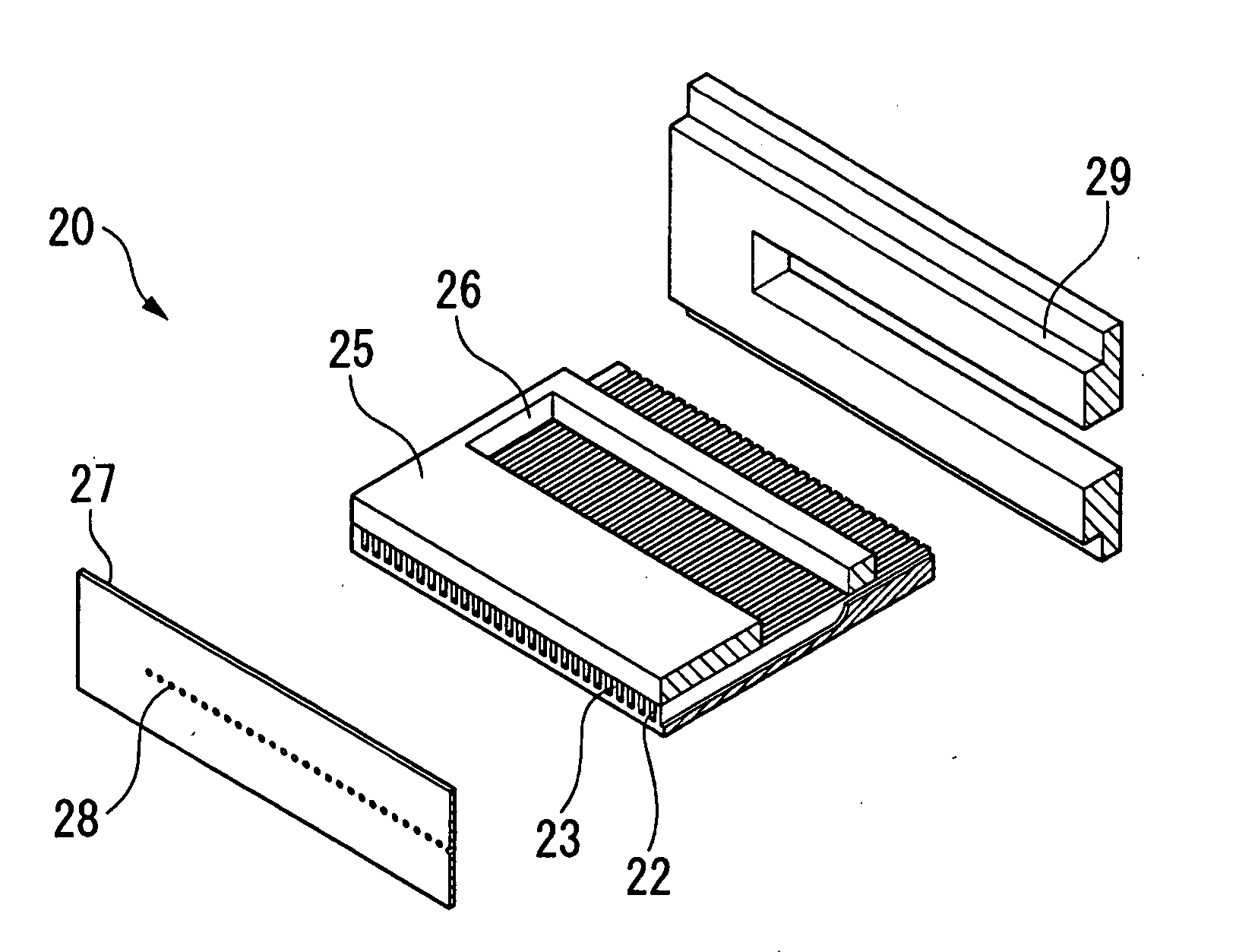

Spark plug for internal combustion engine and method of manufacturing the same

ActiveUS7477006B2Suppress mutationAvoid problemsSpark gapsEngine sealsExternal combustion engineInternal combustion engine

A spark plug for an internal combustion engine includes: a cylindrical insulator as defined herein; a center electrode as defined herein; a cylindrical metal shell as defined herein; and a ground electrode as defined herein, an annular gasket receiving portion projecting radially outward being provided on a rear end side of the externally threaded portion of the metal shell, and a metallic gasket capable of abutting against the gasket receiving portion being provided on the outer periphery of the metal shell, wherein the gasket has a solid annular shape, an inside diameter of the gasket is smaller than an outside diameter of the externally threaded portion, and a groove portion whose depth coincides with the direction of the axis is provided over an entire circumference of the gasket.

Owner:NGK SPARK PLUG CO LTD

Spark plug for internal combustion engine and method of manufacturing the same

ActiveUS20080098974A1Avoid productivityEfficient and stable preparationSpark gapsEngine sealsEngineeringInternal combustion engine

A spark plug for an internal combustion engine includes: a cylindrical insulator as defined herein; a center electrode as defined herein; a cylindrical metal shell as defined herein; and a ground electrode as defined herein, an annular gasket receiving portion projecting radially outward being provided on a rear end side of the externally threaded portion of the metal shell, and a metallic gasket capable of abutting against the gasket receiving portion being provided on the outer periphery of the metal shell, wherein the gasket has a solid annular shape, an inside diameter of the gasket is smaller than an outside diameter of the externally threaded portion, and a groove portion whose depth coincides with the direction of the axis is provided over an entire circumference of the gasket.

Owner:NGK SPARK PLUG CO LTD

Anode material for lithium secondary battery, manufacturing method of the same, lithium secondary battery anode using the same, and lithium secondary battery

ActiveCN1918730AImprove discharge capacityImprove efficiencyGraphiteNegative electrodesDischarge efficiencyElectrical battery

The invention provides an excellent graphite negative electrode material for lithium secondary batteries which enables to obtain a lithium secondary battery which has high discharge capacity, high charge / discharge efficiency, and excellent load characteristics when used at a high electrode density and also has small electrode expansion at charging. The graphite negative electrode material contains a graphite composite mixed powder (C) composed of a graphite composite powder (A), wherein a graphite (D) having an aspect ratio of not less than 1.2 and not more than 4.0 and a graphite (E) having an orientation different from that of the graphite (D) are composited, and an artificial graphite powder (B).

Owner:MITSUBISHI RAYON CO LTD

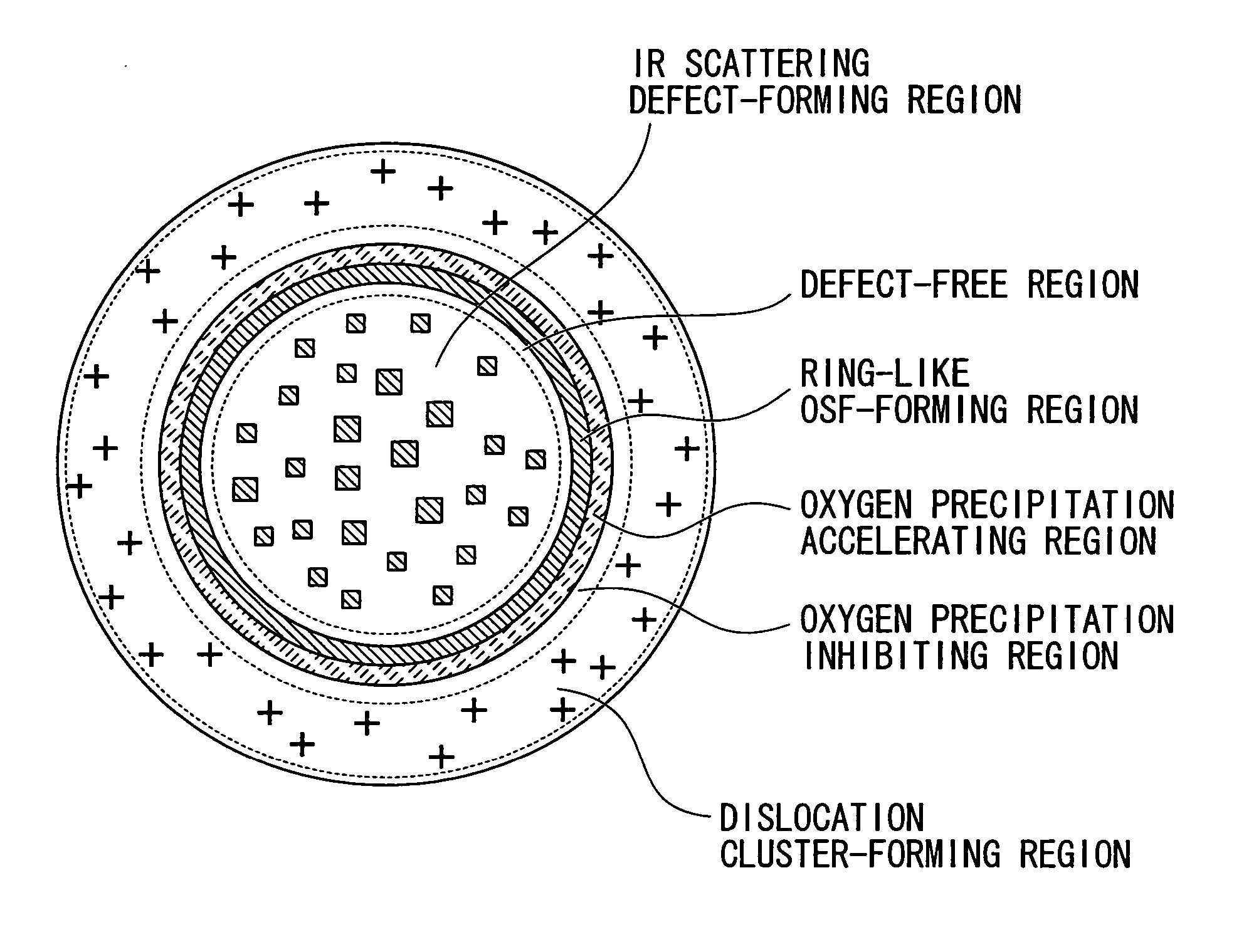

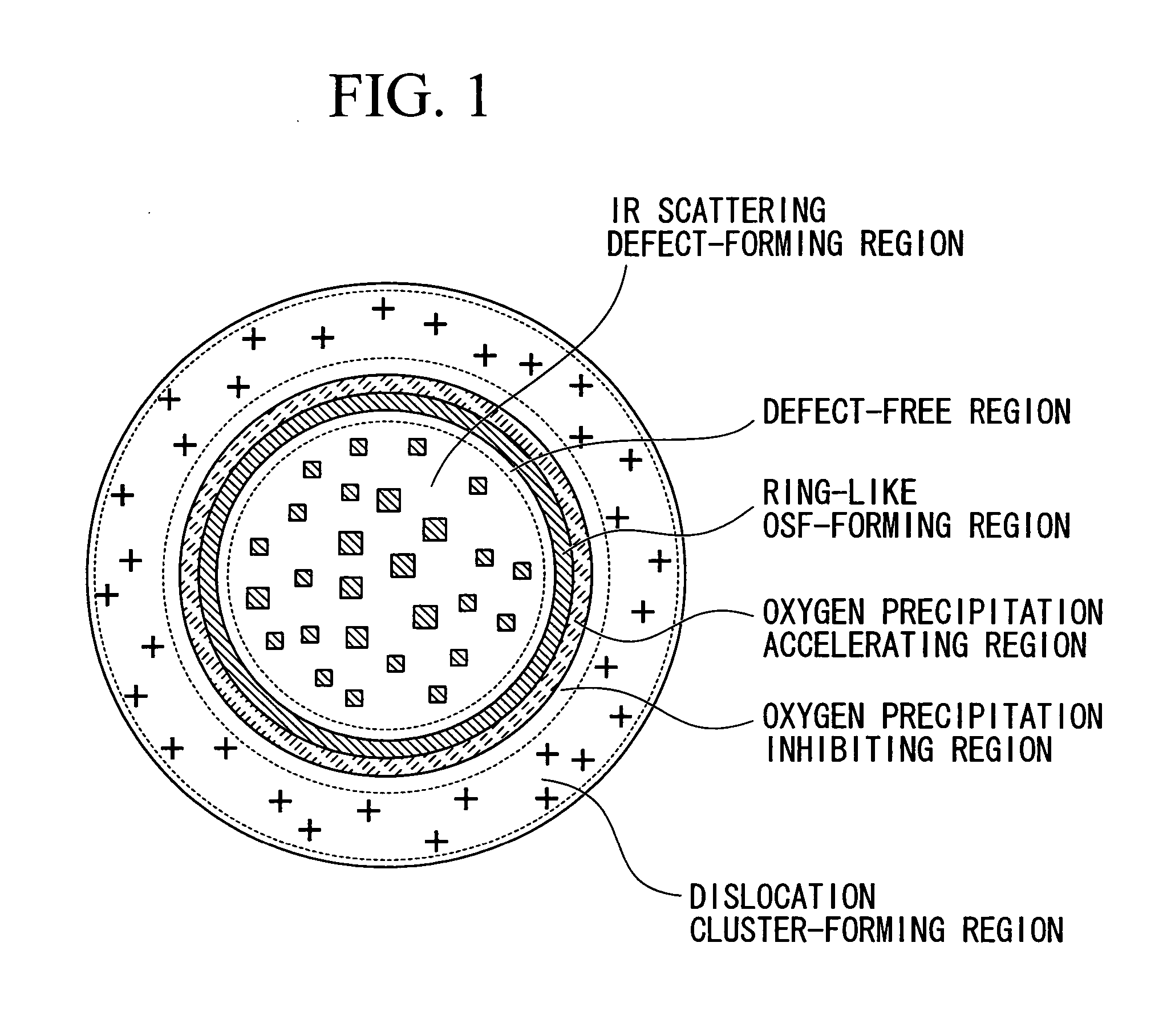

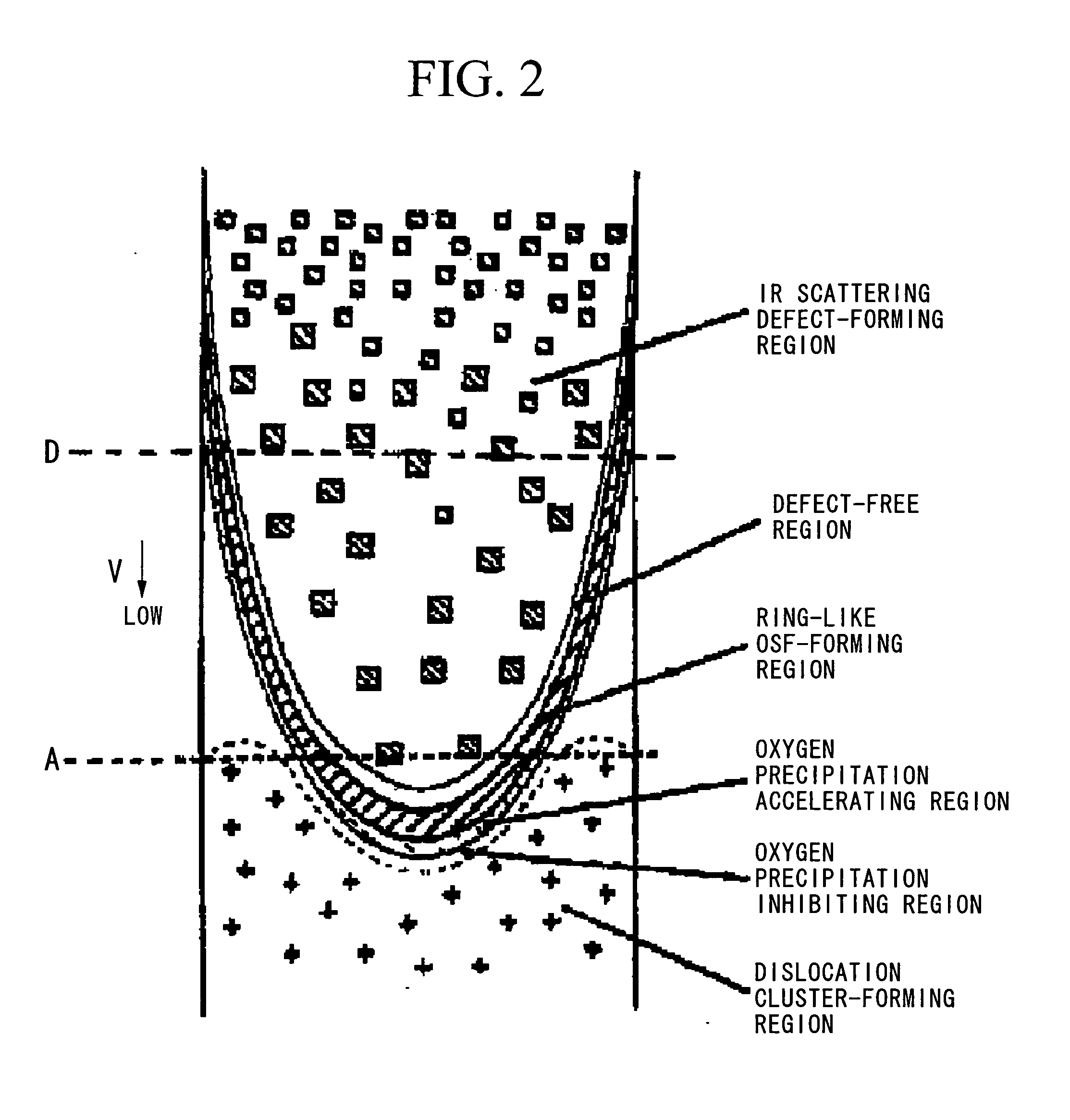

Silicon wafer, method for manufacturing the same and method for growing silicon single crystals

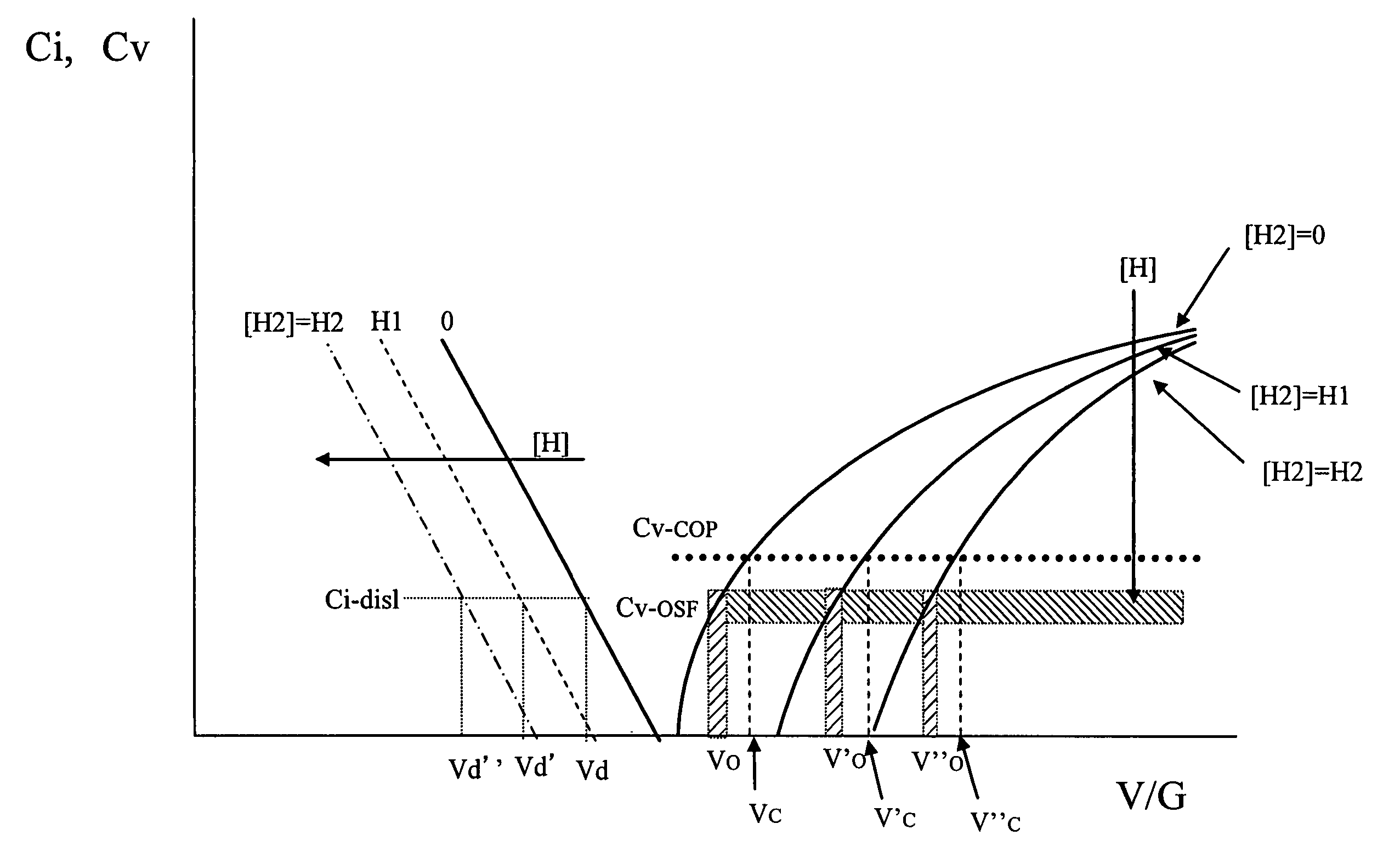

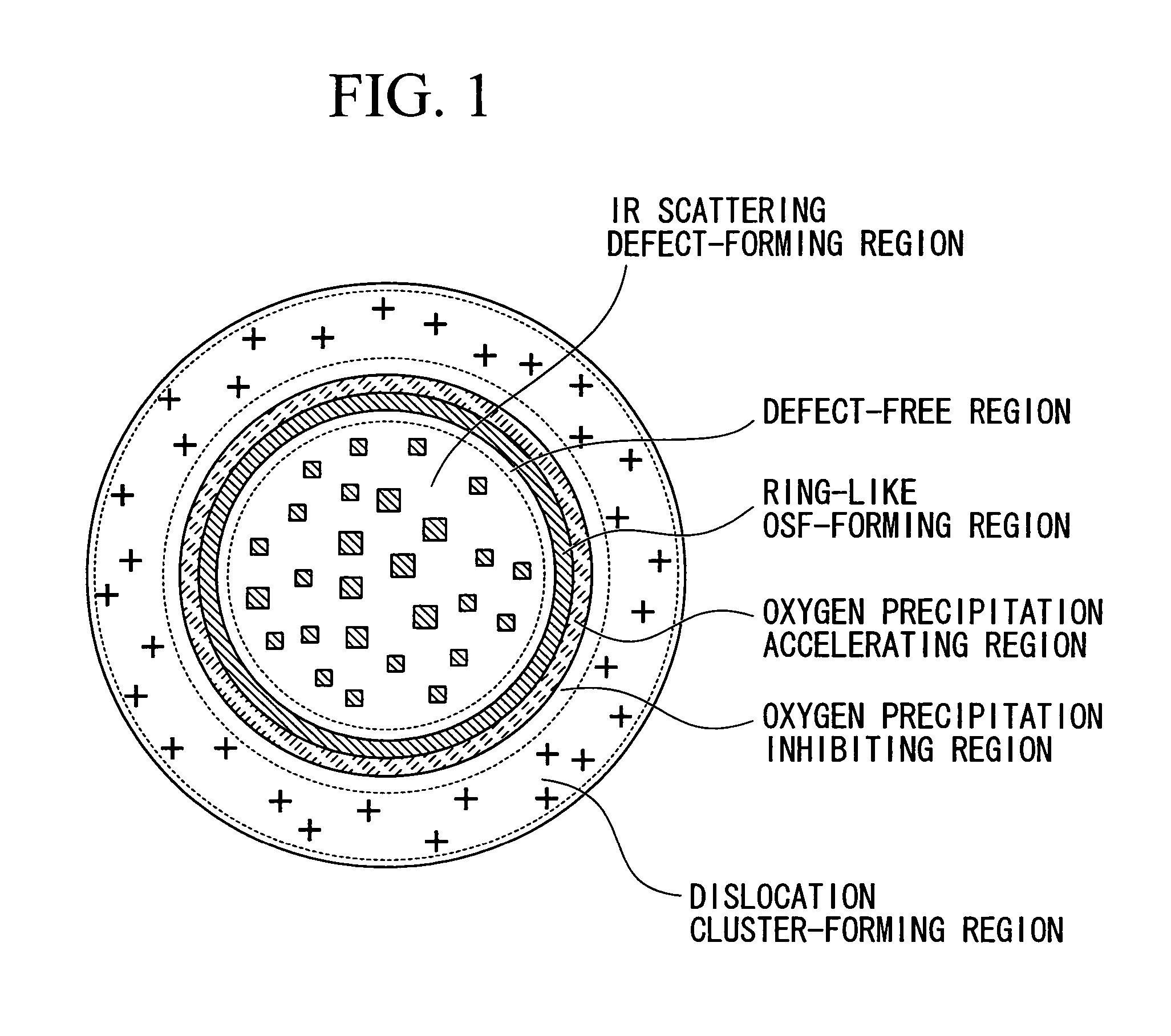

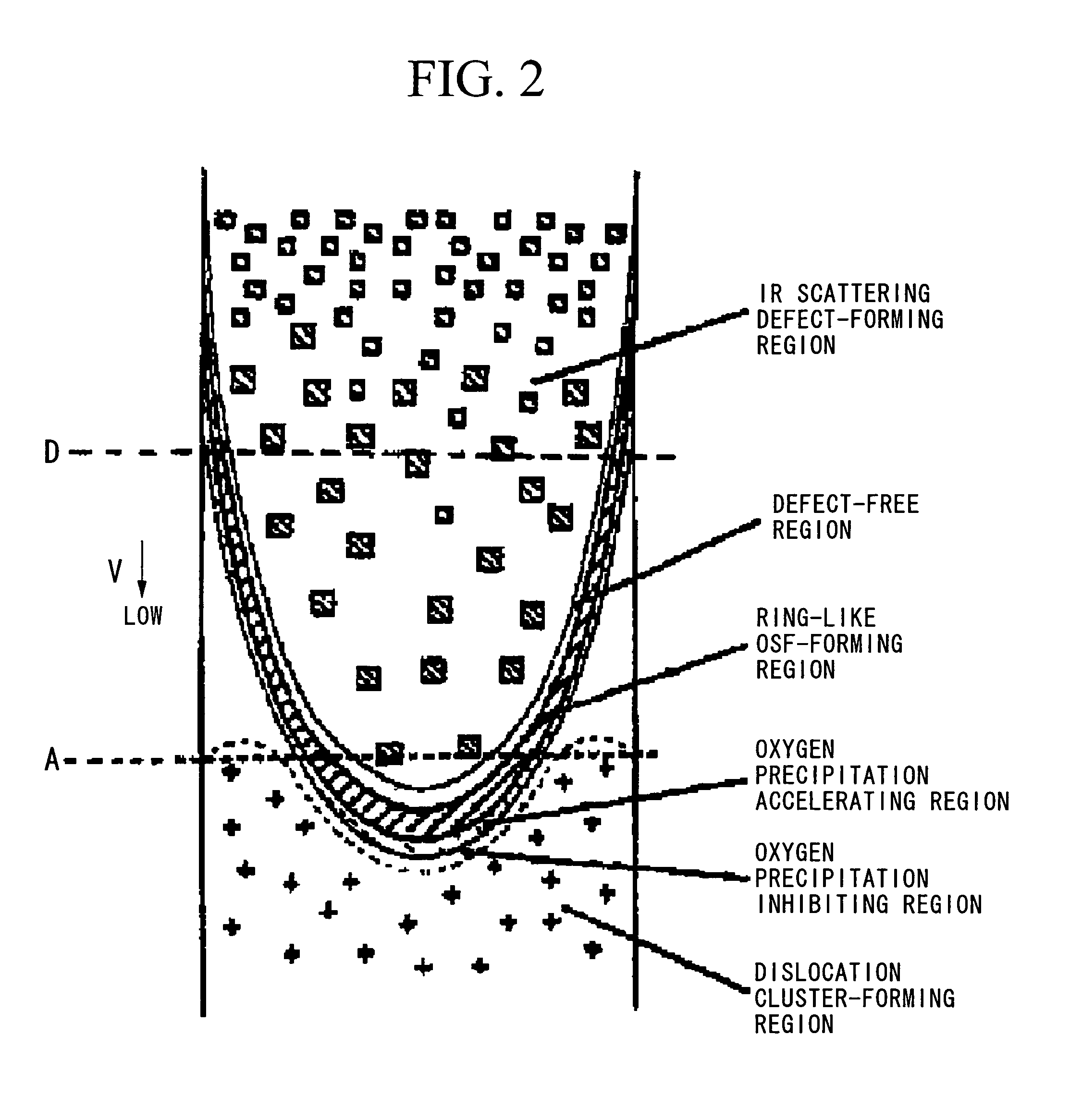

ActiveUS7364618B2Efficient and stable preparationPolycrystalline material growthAluminium silicatesHydrogenSingle crystal

This silicon wafer is obtained from a silicon single crystal grown by the CZ method in a hydrogen-containing inert gas atmosphere, and is a completely grown-in defect-free wafer containing no COPs or dislocation clusters throughout the wafer in the thickness and radial directions thereof, and all the portions consist essentially of an interstitial rich region. This method for growing silicon single crystals includes pulling a silicon single crystal in a hydrogen-containing inert gas atmosphere so as to expand the range of the pull rate for the PI region, wherein the pulling of the silicon single crystal is conducted at a pull rate within this expanded range of the pull rate for the PI region so as to grow a body portion that is an interstitial rich region.

Owner:SUMCO CORP

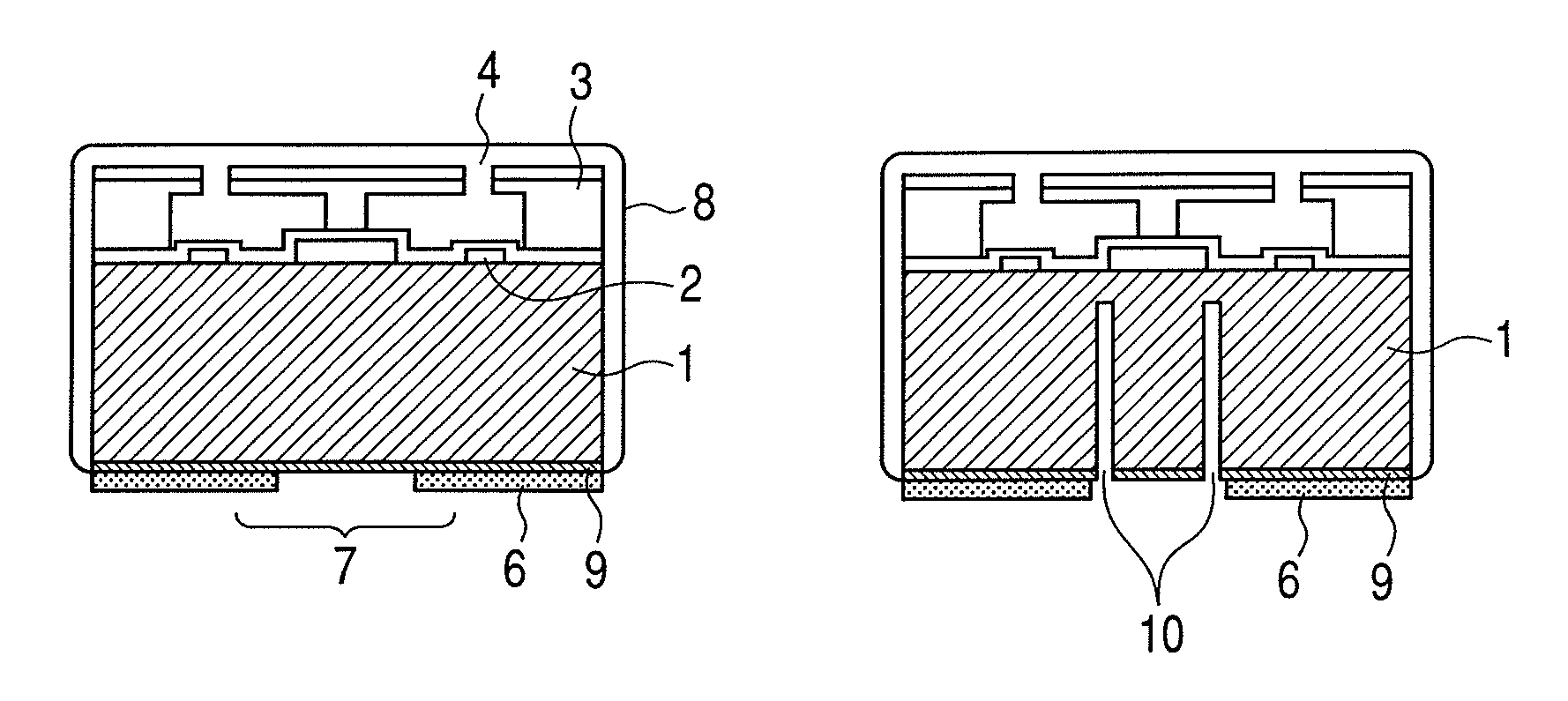

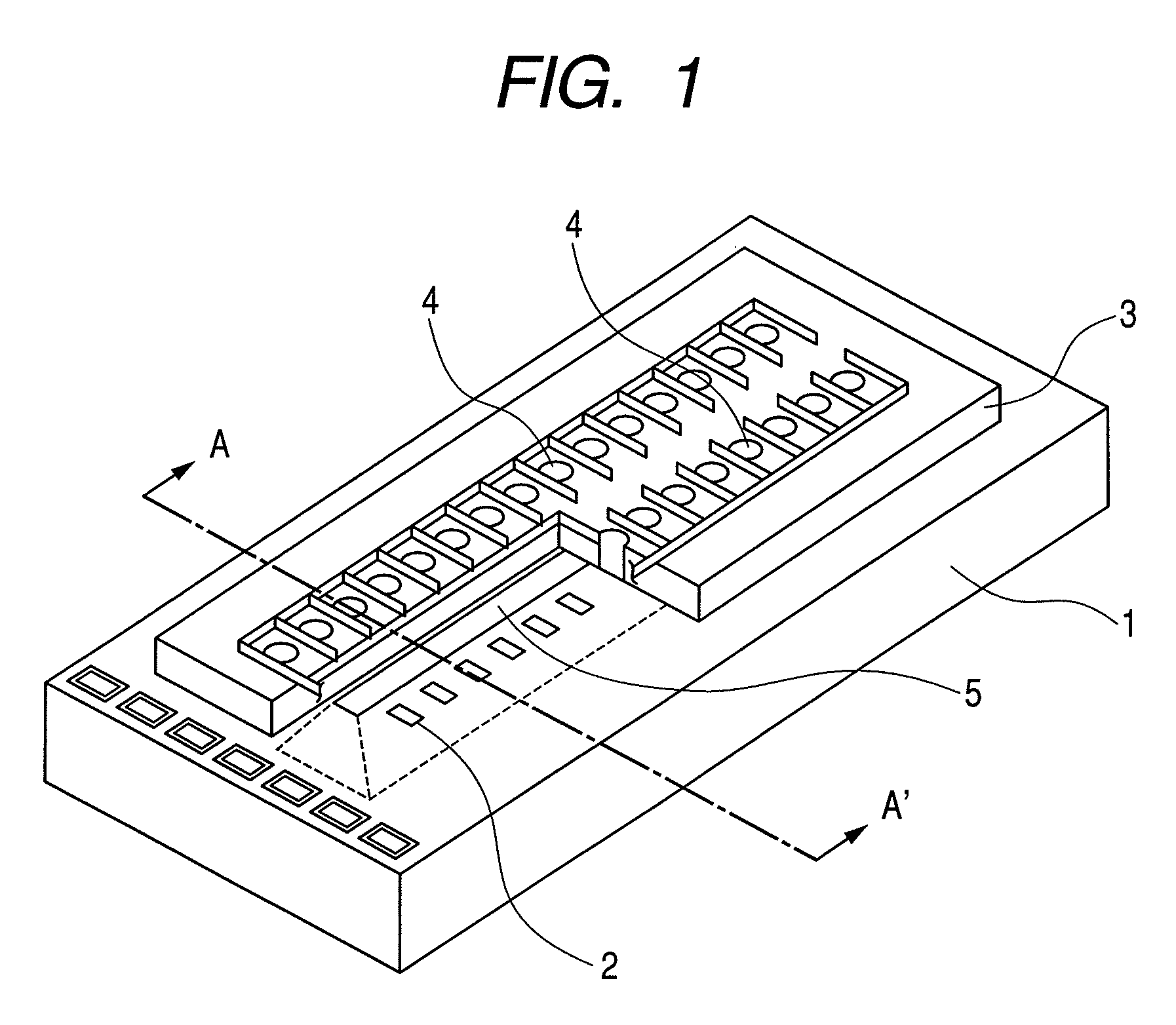

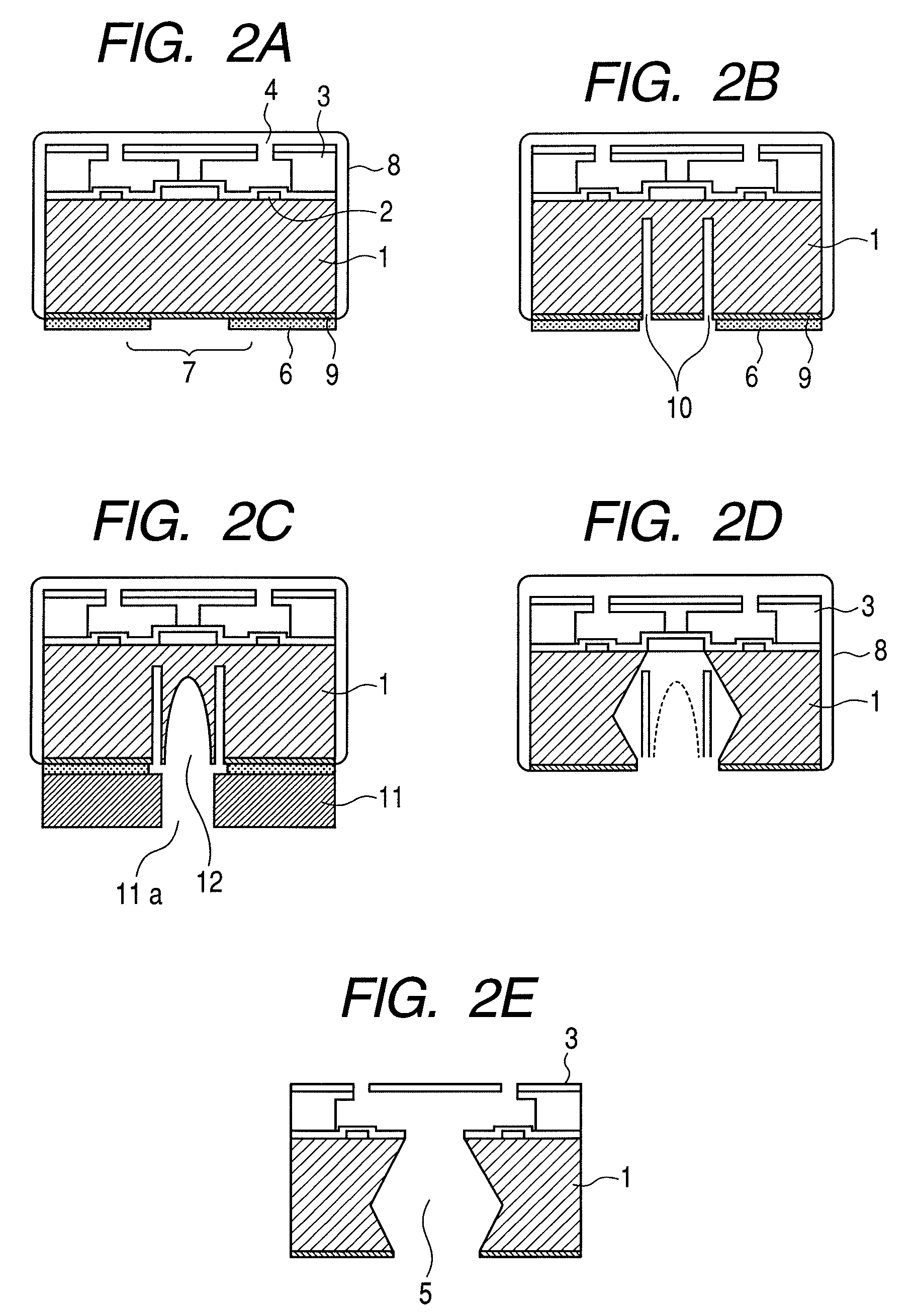

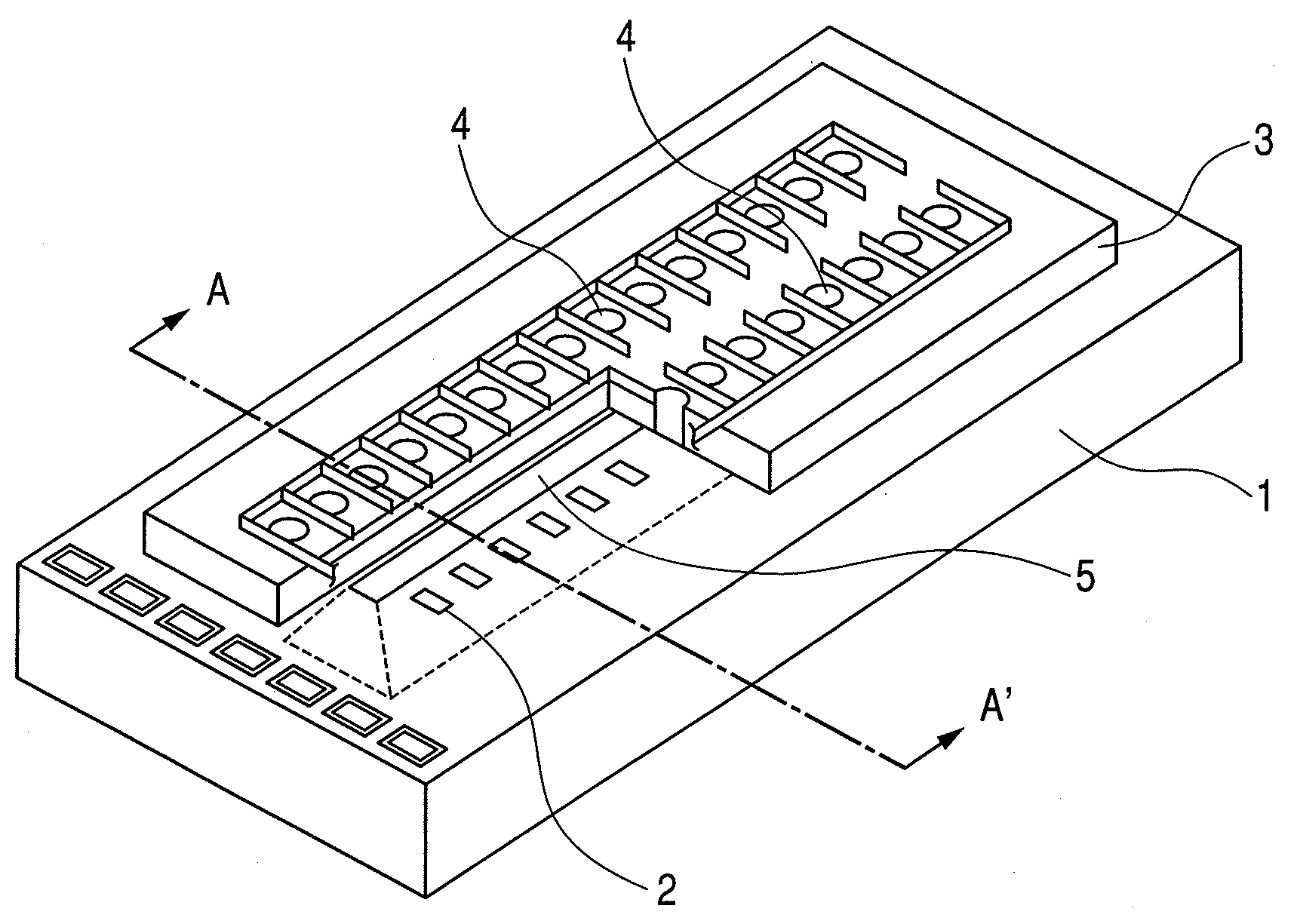

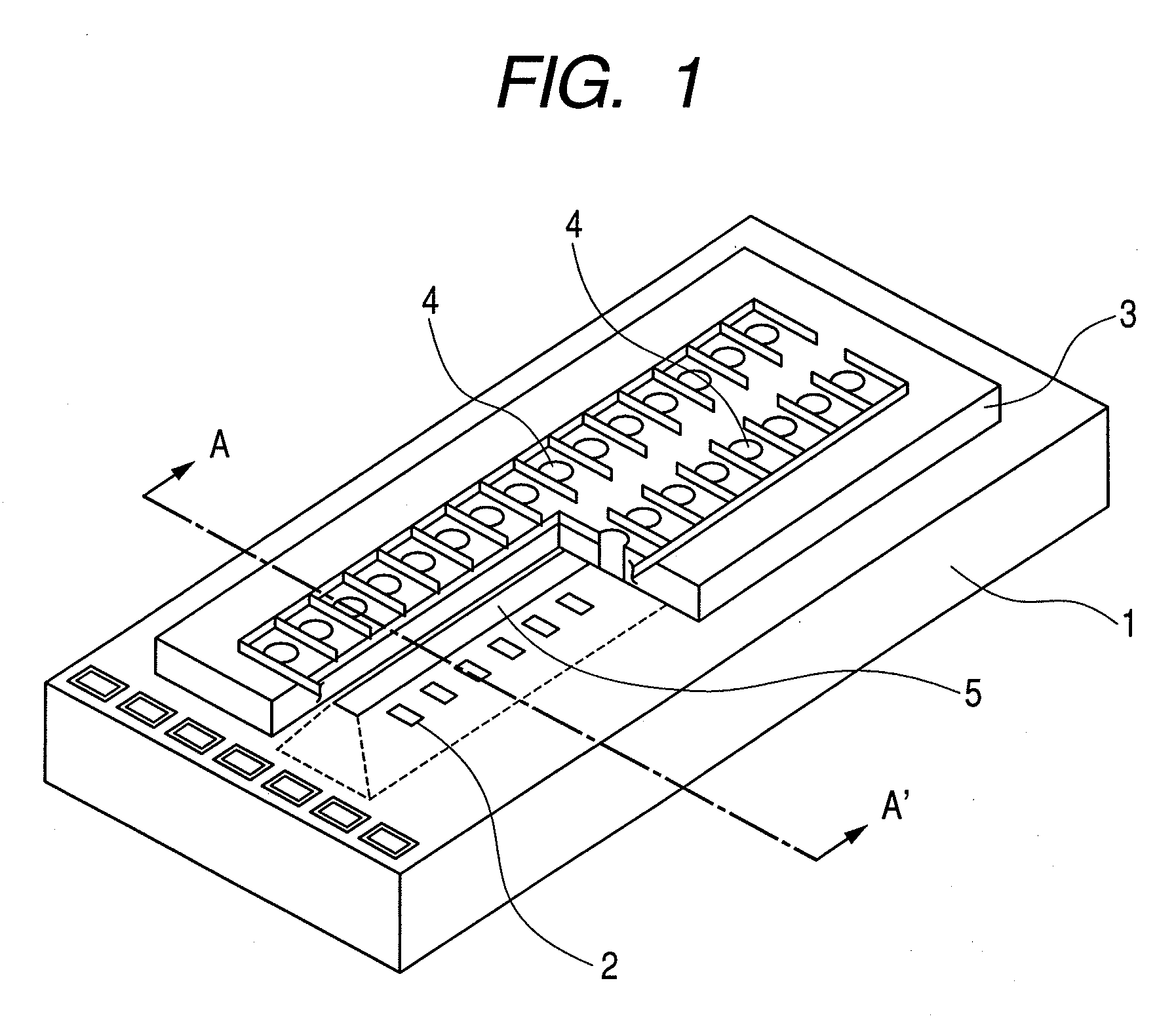

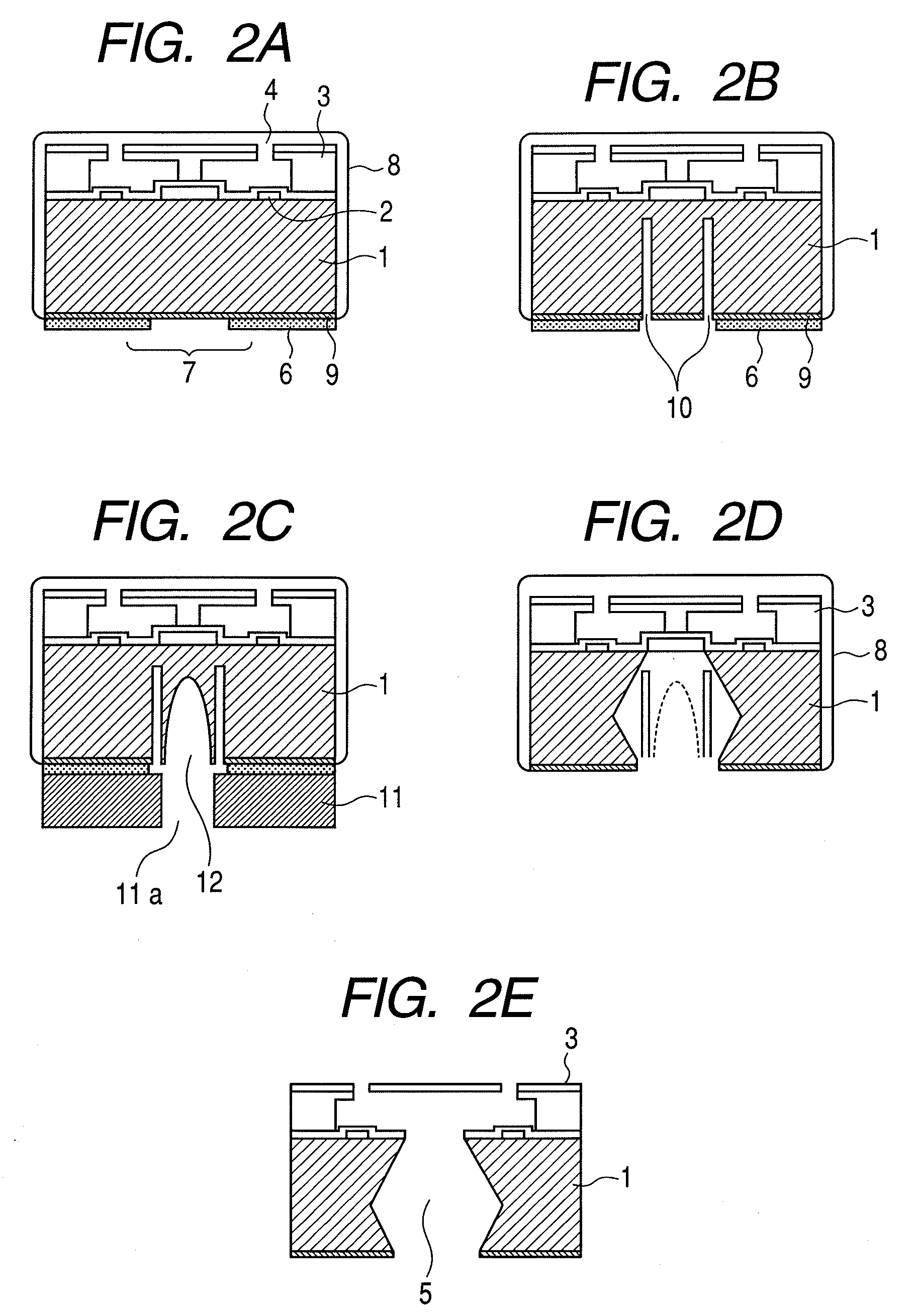

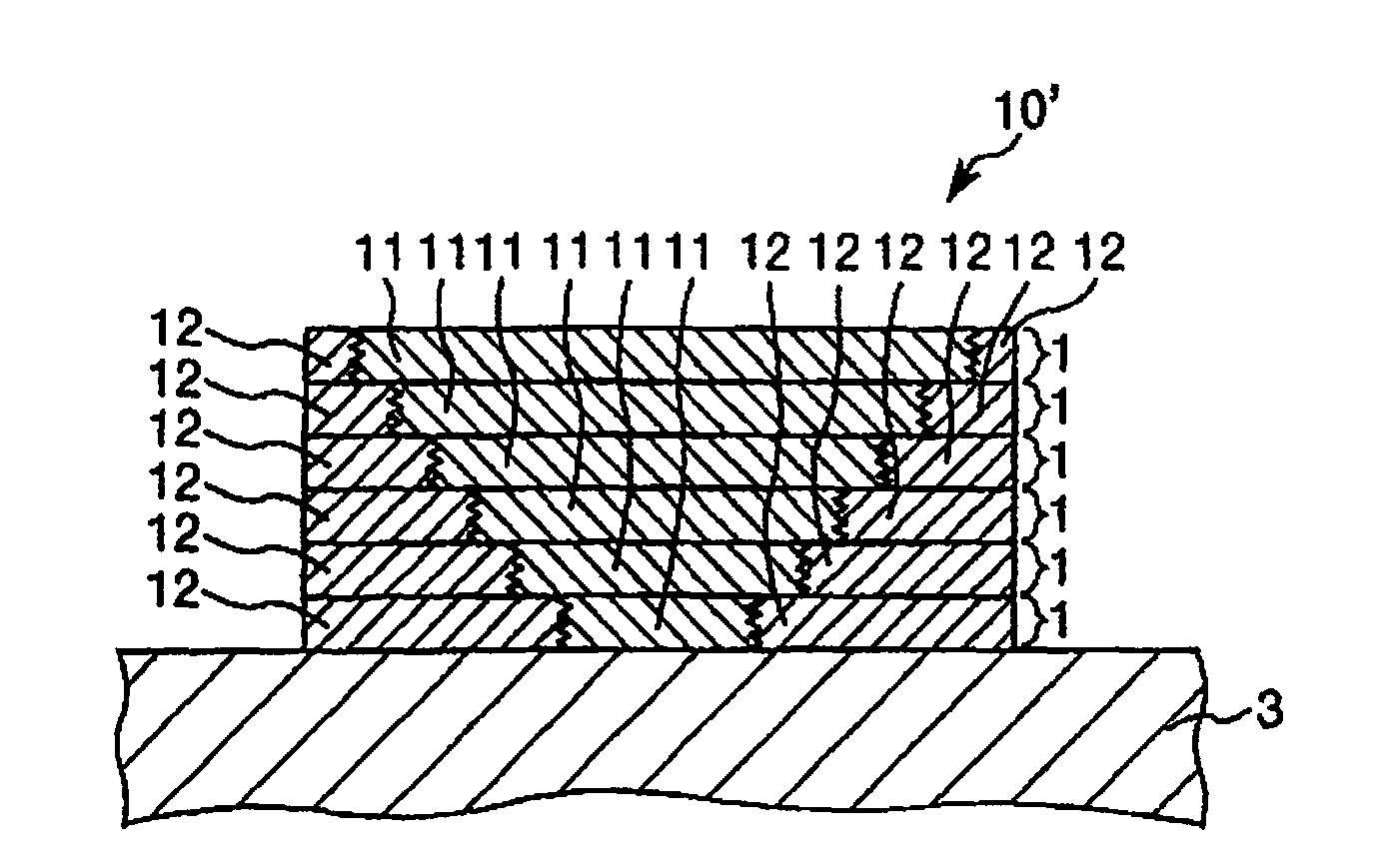

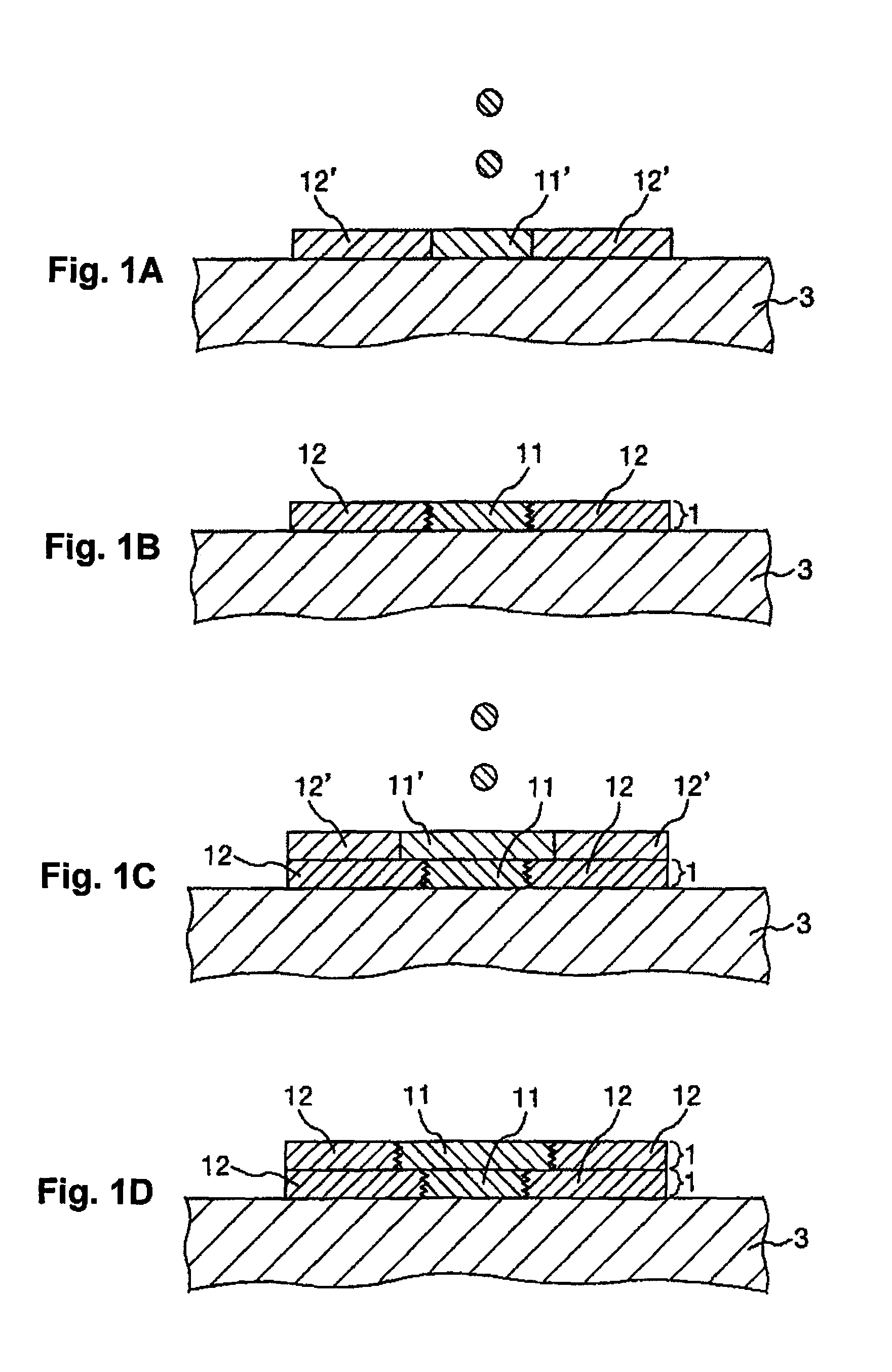

Manufacturing method for liquid discharge head substrate

InactiveUS8091234B2Efficient and stable preparationIncrease supplyRecording apparatusWriting implementsEngineeringAnisotropic etching

A manufacturing method, for a liquid discharge head that includes a silicon substrate in which a supply port is formed for supplying a liquid, includes the steps of providing the silicon substrate, a mask layer provided with an opening that corresponds to the supply port being provided on one face of the silicon substrate; forming a groove in the silicon substrate along the shape of the opening in the mask layer; removing, via sandblasting, silicon of the silicon substrate inward of the groove in the silicon substrate; and performing, from the one face, anisotropic etching of the silicon substrate that has been sandblasted, and forming the supply port.

Owner:CANON KK

Manufacturing method for liquid discharge head substrate

InactiveUS20090065473A1Efficient and stable preparationIncrease supplyRecording apparatusWriting implementsEngineeringAnisotropic etching

To provide a manufacturing method, for a liquid discharge head that includes a silicon substrate in which a supply port is formed for supplying a liquid, includes the steps of: providing the silicon substrate, a mask layer provided with an opening that corresponds to the supply port being provided on one face of the silicon substrate; forming a groove in the silicon substrate along the shape of the opening in the mask layer; removing, using sandblasting, silicon of the silicon substrate from the inner wall of the groove in the silicon substrate; and performing, from the one face, anisotropic etching of the silicon substrate that has been sandblasted, and forming the supply port.

Owner:CANON KK

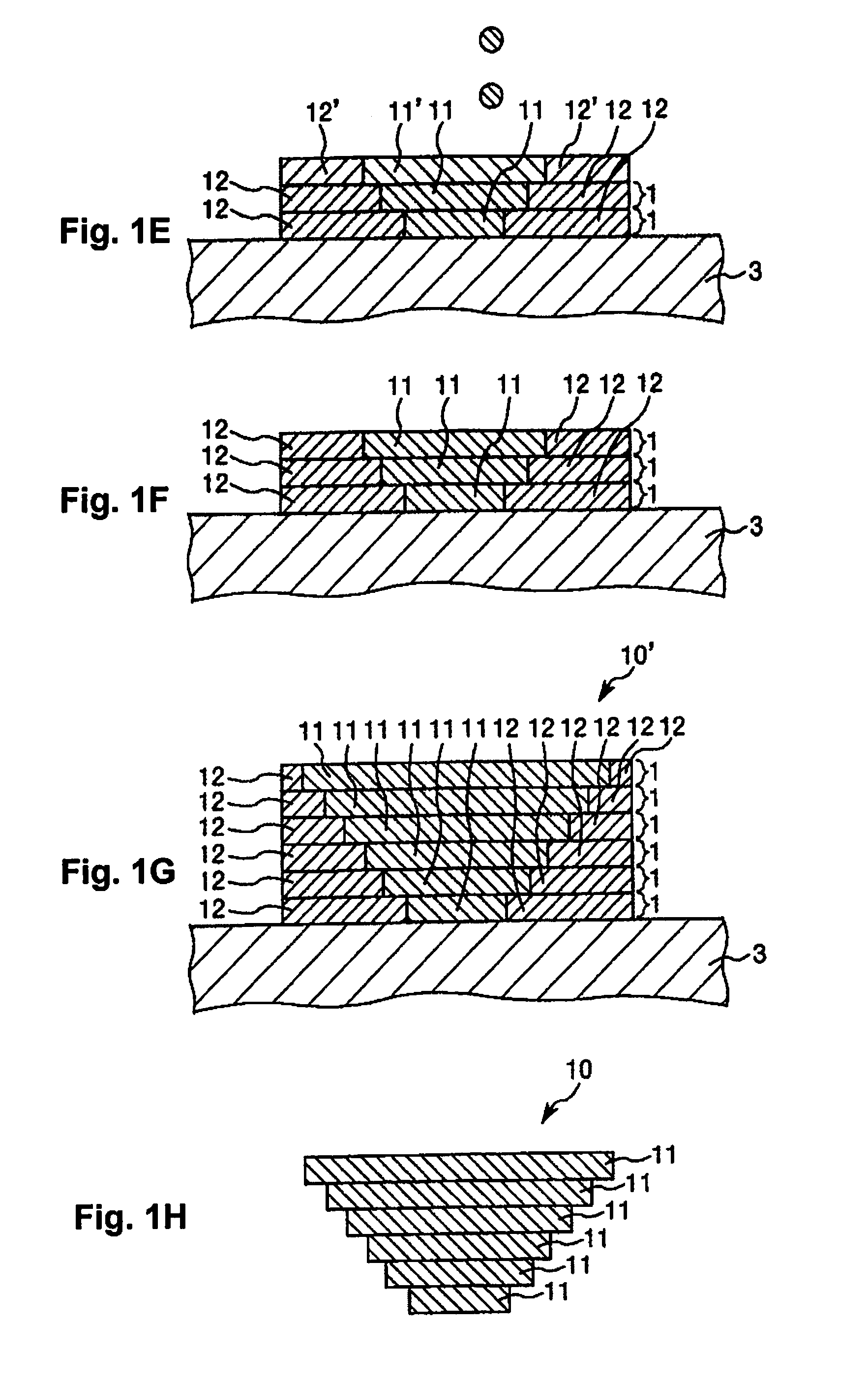

Three-dimensional shaped article manufacturing method

ActiveUS9481162B2Efficient and stable preparationEfficient preparationManufacturing heating elementsInksThree dimensional shapeViscoelasticity

A three-dimensional shaped article manufacturing method with which a three-dimensional shaped article having a glossy texture can be manufactured stably and efficiently is provided. A three-dimensional shaped article manufacturing method for manufacturing a three-dimensional shaped article by laminating layers formed by discharging and curing inks including a curable resin, the method including: applying a substantive section-forming ink to a region that forms the three-dimensional shaped article, and applying a sacrificial layer-forming ink for forming a sacrificial layer to a region that is adjacent to a region that forms an outermost layer of the three-dimensional shaped article and on a surface side of the outermost layer, a viscoelasticity of the sacrificial layer-forming ink during curing of the substantive section-forming ink being not less than a viscoelasticity of the substantive section-forming ink during curing of the substantive section-forming ink.

Owner:SEIKO EPSON CORP

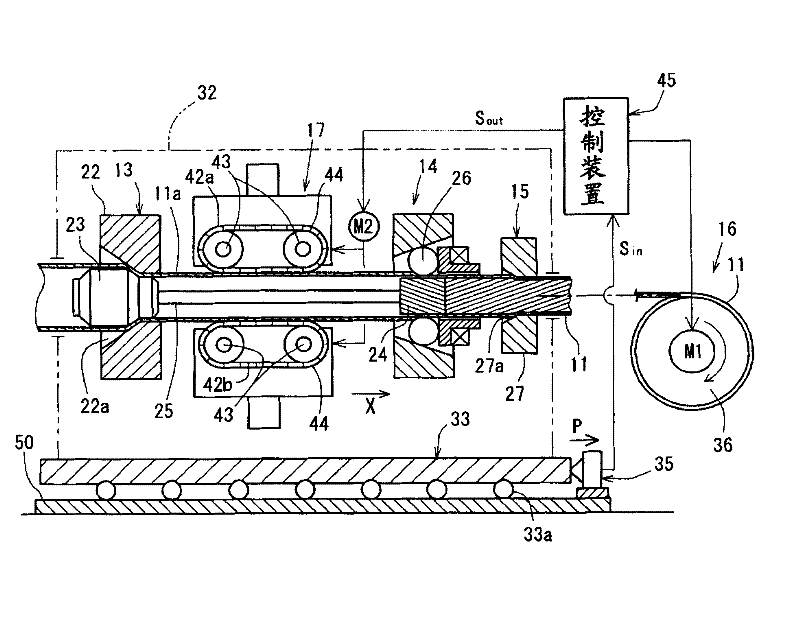

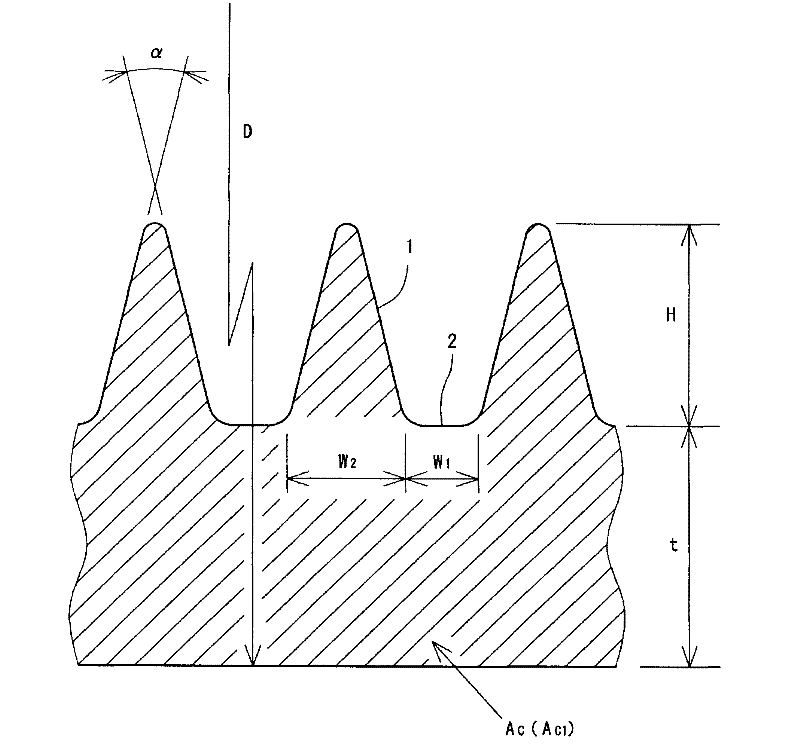

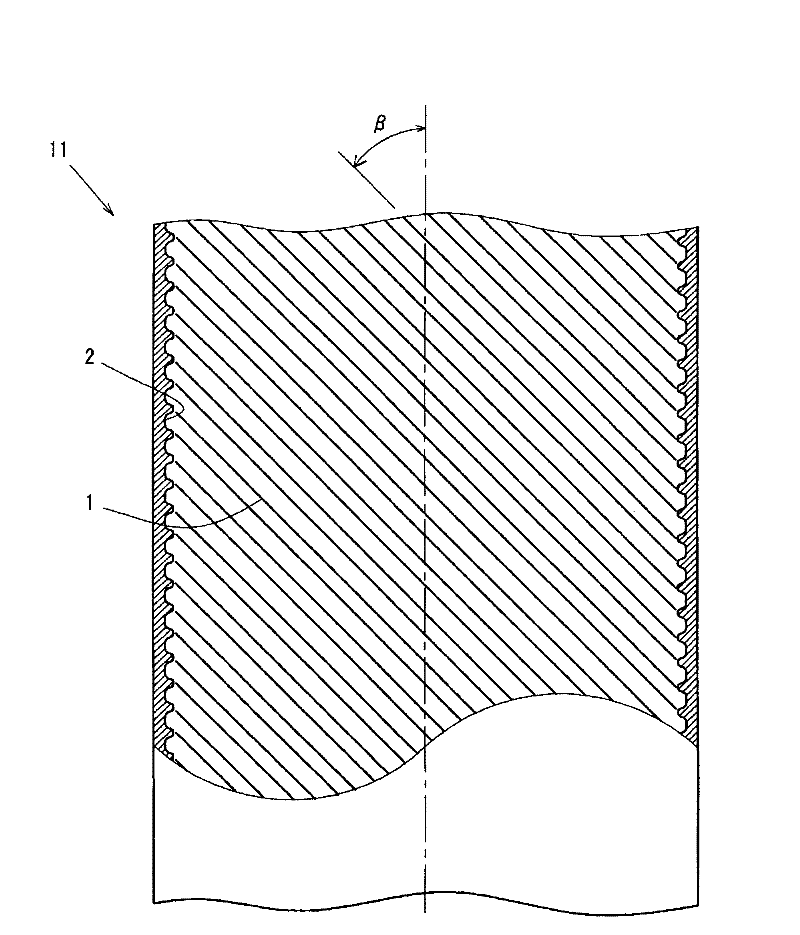

Pipe having grooved inner surface, apparatus for producing the same and method for producing the same

InactiveCN102245323AEasy broken tube detectionReliable identificationDrawing mandrelsDrawing diesCENBOLEngineering

Provided is a pipe having a grooved inner surface, which has excellent thermal conduction properties, can be made compact and lightweight, and allows resources to be conserved. Also provided are a method and apparatus for producing this pipe having a grooved inner surface, which allow efficient and stable production thereof. The apparatus which is used for producing the pipe having a grooved inner surface is provided with: diameter-reducing means for drawing a base pipe in order to reduce the diameter thereof, and groove-forming means for forming a large number of grooves on the inner surface of the base pipe. If, for example, the angle of twist of a groove with respect to the centre axis of the pipe is beta (DEG) and the apex angle of a fin which is formed between adjacent grooves is alpha (DEG), then beta is between 30 and 60 and alpha is between 5 and 20. If the outer diameter is D (mm), the groove depth is H (mm), and the cross-sectional area with respect to the axial direction of the pipe is Ac (mm<2>), then D is no greater than 6, H is at least 0.07, and Ac is less than 0.8*D.

Owner:FURUKAWA ELECTRIC CO LTD

Silicon wafer, method for manufacturing the same and method for growing silicon single crystals

ActiveUS20070157870A1Efficient and stable preparationPolycrystalline material growthAluminium silicatesHydrogenWafering

This silicon wafer is obtained from a silicon single crystal grown by the CZ method in a hydrogen-containing inert gas atmosphere, and is a completely grown-in defect-free wafer containing no COPs or dislocation clusters throughout the wafer in the thickness and radial directions thereof, and all the portions consist essentially of an interstitial rich region. This method for growing silicon single crystals includes pulling a silicon single crystal in a hydrogen-containing inert gas atmosphere so as to expand the range of the pull rate for the PI region, wherein the pulling of the silicon single crystal is conducted at a pull rate within this expanded range of the pull rate for the PI region so as to grow a body portion that is an interstitial rich region.

Owner:SUMCO CORP

Three-dimensional shaped article manufacturing method

ActiveUS9463614B2Efficient and stable preparationEfficient preparationAdditive manufacturing apparatusInksThree dimensional shapeViscoelasticity

A three-dimensional shaped article manufacturing method with which a three-dimensional shaped article having a matte-toned texture can be manufactured stably and efficiently is provided. A three-dimensional shaped article manufacturing method of the present invention is a method for manufacturing a three-dimensional shaped article by laminating layers formed by discharging and curing inks including a curable resin, the method including applying a substantive section-forming ink to a region that forms the three-dimensional shaped article, and applying a sacrificial layer-forming ink for forming a sacrificial layer to a region that is adjacent to a region that forms an outermost layer of the three-dimensional shaped article and on a surface side of the outermost layer, a viscoelasticity of the sacrificial layer-forming ink during curing of the substantive section-forming ink being less than a viscoelasticity of the substantive section-forming ink during curing of the substantive section-forming ink.

Owner:SEIKO EPSON CORP

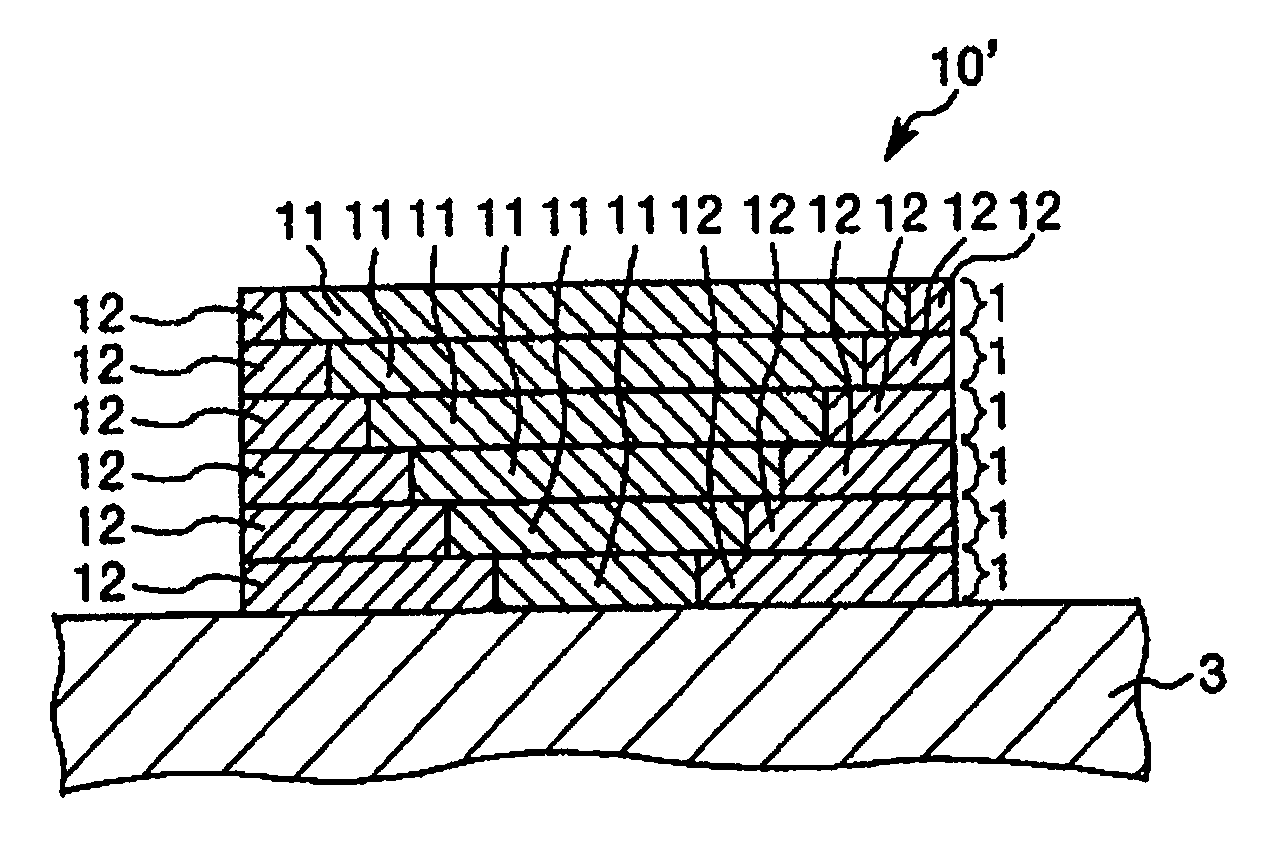

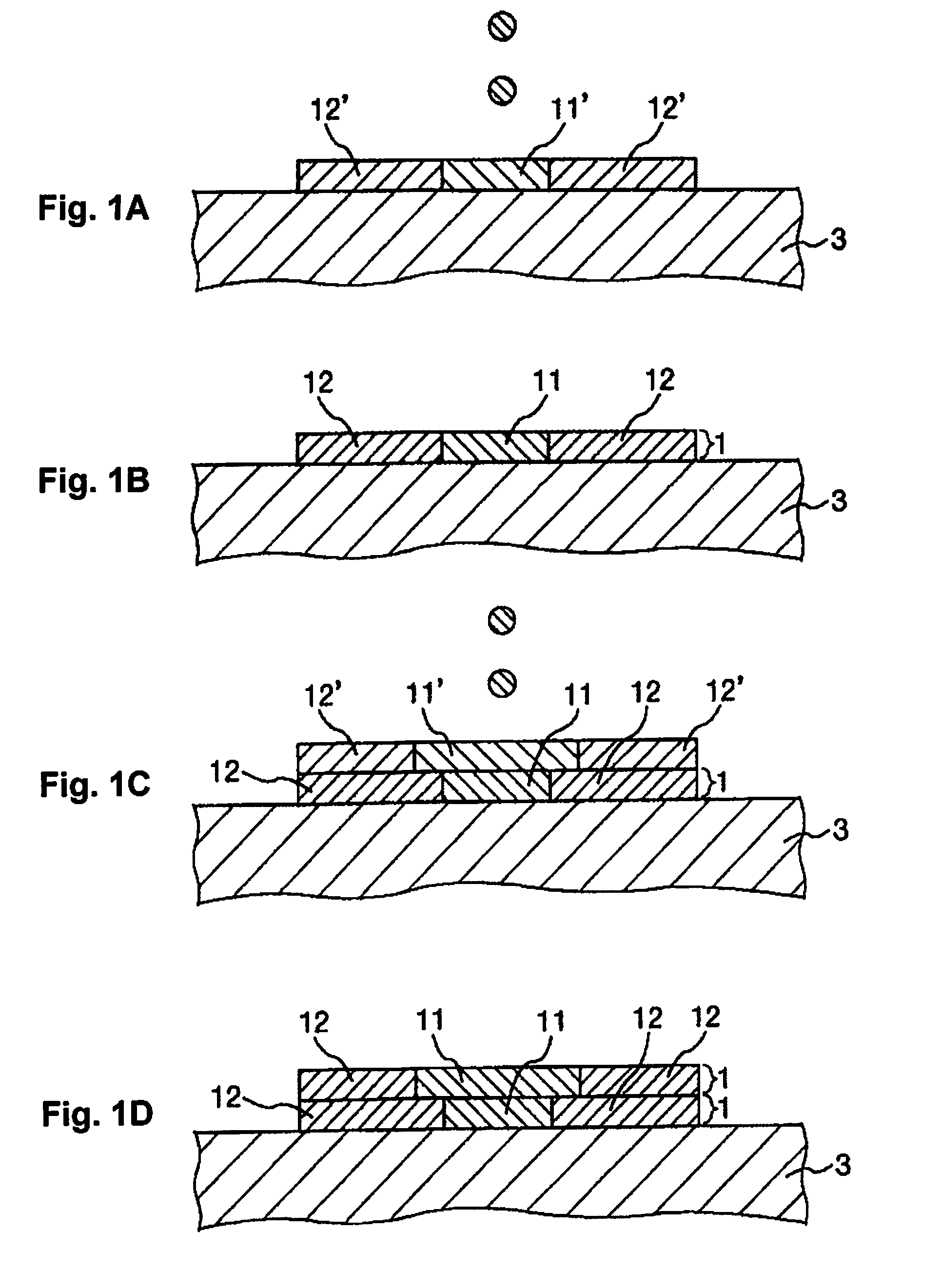

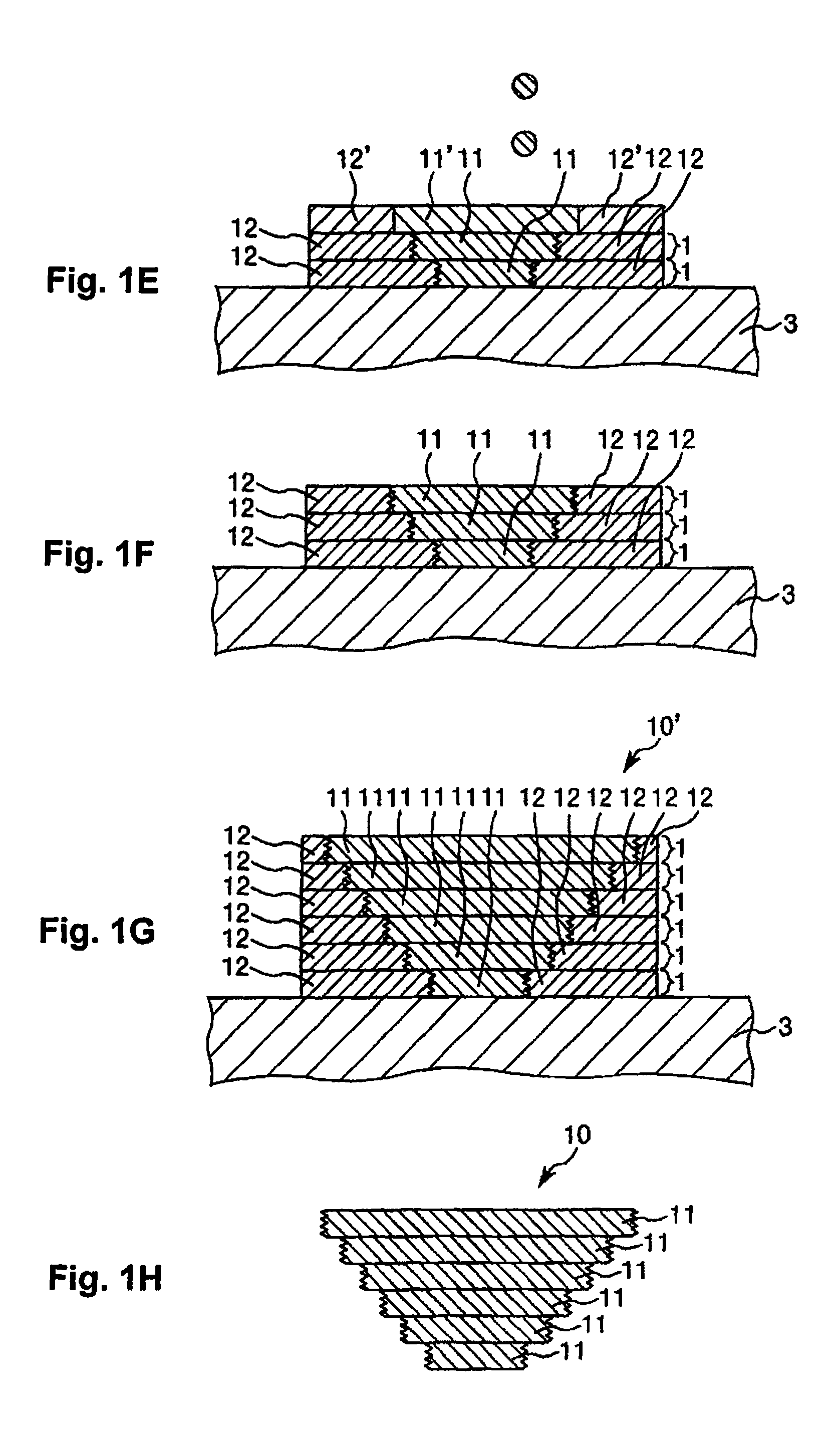

Ink jet head nozzle plate manufacturing method, Ink jet head nozzle plate manufacturing apparatus, Ink jet head nozzle plate, Ink jet head, and Ink jet recording apparatus

ActiveUS20070064049A1Improve image qualityQuality improvementPrintingLaser beam welding apparatusMicrolensLaser beams

A method for efficiently and stably manufacturing a nozzle plate wherein nozzle openings are accurately formed. According to an ink jet head nozzle plate manufacturing method for emitting a laser beam through lenses onto the face of a nozzle plate to form a plurality of nozzle openings, these lenses are a plurality of micro lenses arranged on the same plane, and the pitch for arranging the micro lenses that are adjacent in the direction in which the nozzle openings are formed in the nozzle plate is defined as an integer multiple of the pitch for arranging adjacent nozzle openings.

Owner:SII PRINTEK

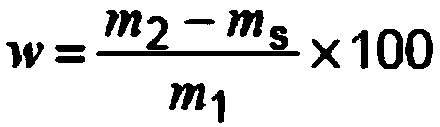

Manufacturing method of water absorption resin with high liquid absorption rate

The invention relates to a manufacturing method of water absorption resin with high liquid absorption rate. The manufacturing method comprises the following steps: acquiring a monomer containing unsaturated acrylic acid and a cross-linking agent aqueous solution; polymerizing the monomer containing the unsaturated acrylic acid and the cross-linking agent aqueous solution monomer to obtain a hydrogel-like cross-linked polymer; granulating and crushing the hydrogel-like cross-linked polymer in the polymerization process or after the polymerization by virtue of a high shearing and / or extrusion acting force to form gel particles, drying, crushing, and screening. The manufacturing method has the beneficial effects that a method using no additives such as a foaming agent, and a surfactant and capable of efficiently producing the water absorption resin with high liquid absorption rate is provided, and the water absorption resin with high liquid absorption rate is obtained.

Owner:宜兴丹森科技有限公司

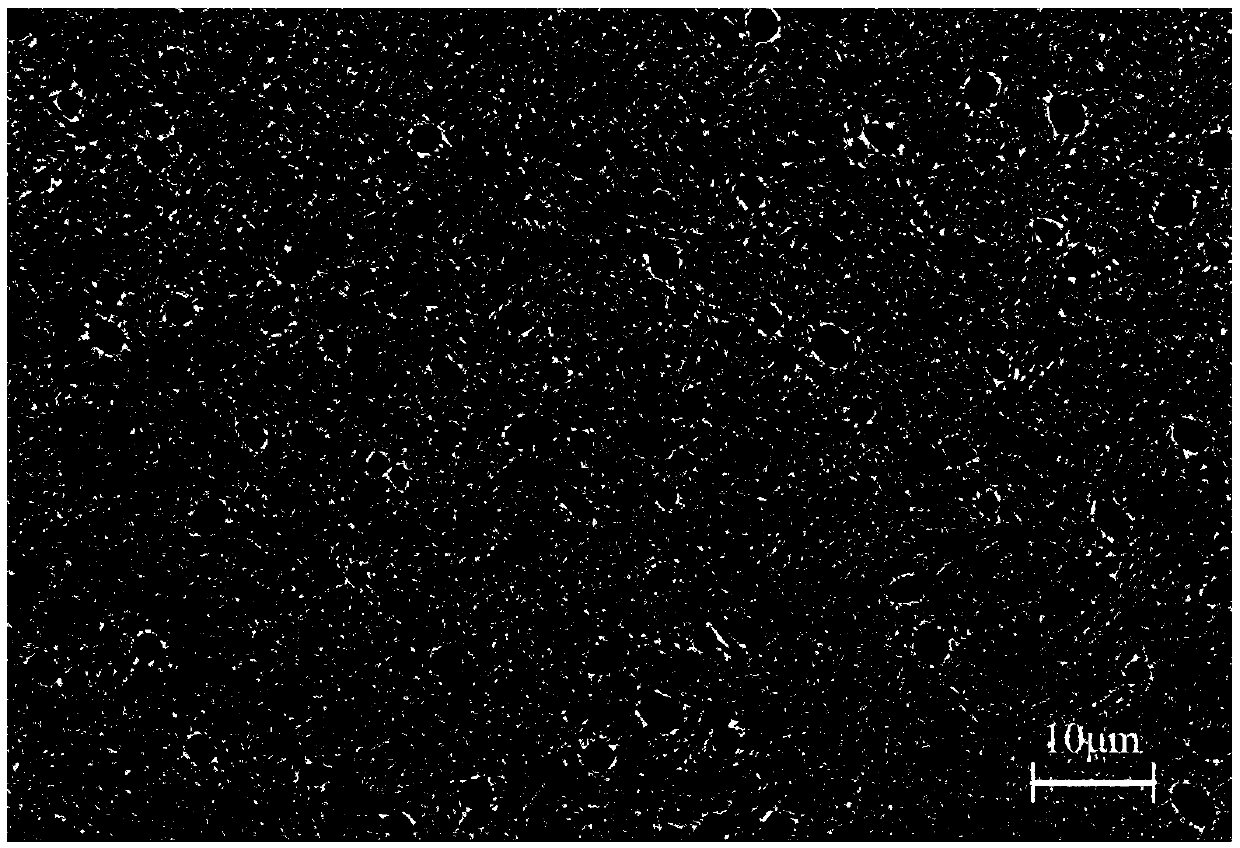

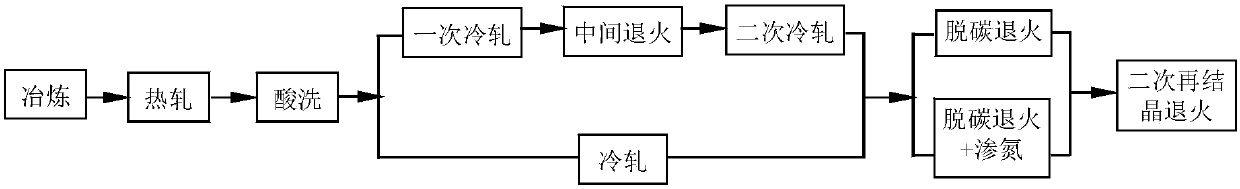

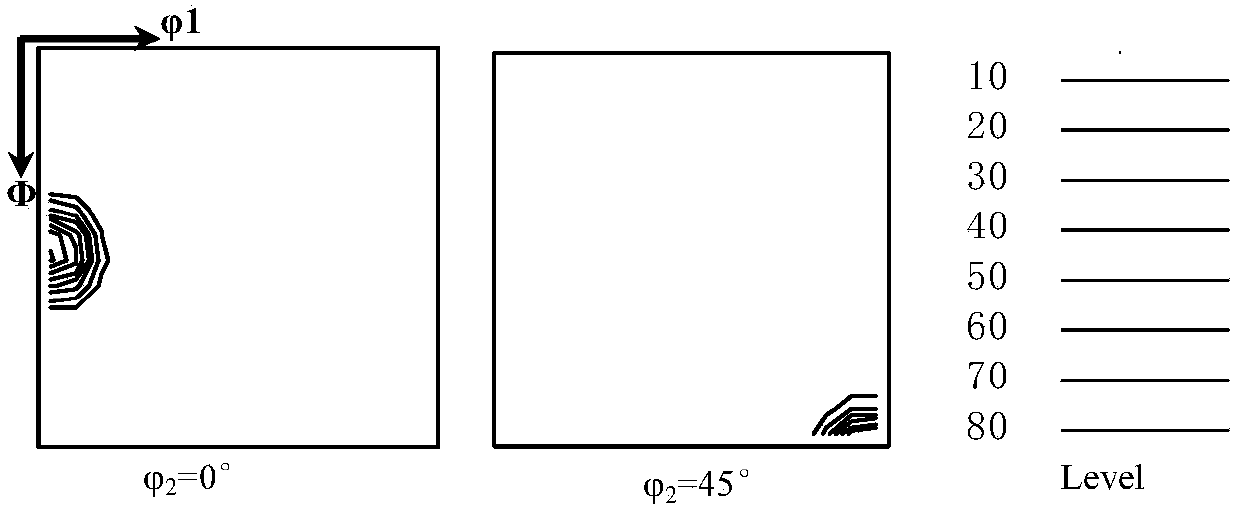

High magnetostriction coefficient Fe-Ga based thin strip and preparation method thereof

ActiveCN108251753ASimple and efficient scale preparationEfficient and stable preparationMagnetostrictive device manufacture/assemblySolid state diffusion coatingThin slabDie casting

The invention relates to a high magnetostriction coefficient Fe-Ga based thin strip and a preparation method thereof. According to the high magnetostriction coefficient Fe-Ga based thin strip and thepreparation method thereof, slabs of die casting, slab continuous casting, thin slab continuous casting and thin strip continuous casting are adopted, and simple and efficient scale production can berealized by using traditional rolling and annealing processes; an inhibitor system of low temperature intrinsic inhibitors and nitriding is established, and heat treatment and the rolling process arecontrolled to precipitate fine Cu2S, Nb(C,N) and V(C,N) or composite precipitates thereof as main intrinsic inhibitors; when the intrinsic inhibition is insufficient, nitriding is used for supplementing and forming nitrides such as AIN or BN before the secondary recrystallization annealing to achieve flexible control of the inhibition; cold rolling parameters are fine controlled to ensure primaryrecrystallization to obtain fine and uniform organizations and favorable textures, the coordinated matching of the organizations, the textures and the inhibitors before secondary recrystallization isachieved, and perfect and sharp secondary recrystallization of texture Goss ({110}(001)) is obtained. The magnetostriction coefficient (3 / 2) lambda s of a Fe-Ga based thin strip finished product is ashigh as 220-370ppm.

Owner:NORTHEASTERN UNIV

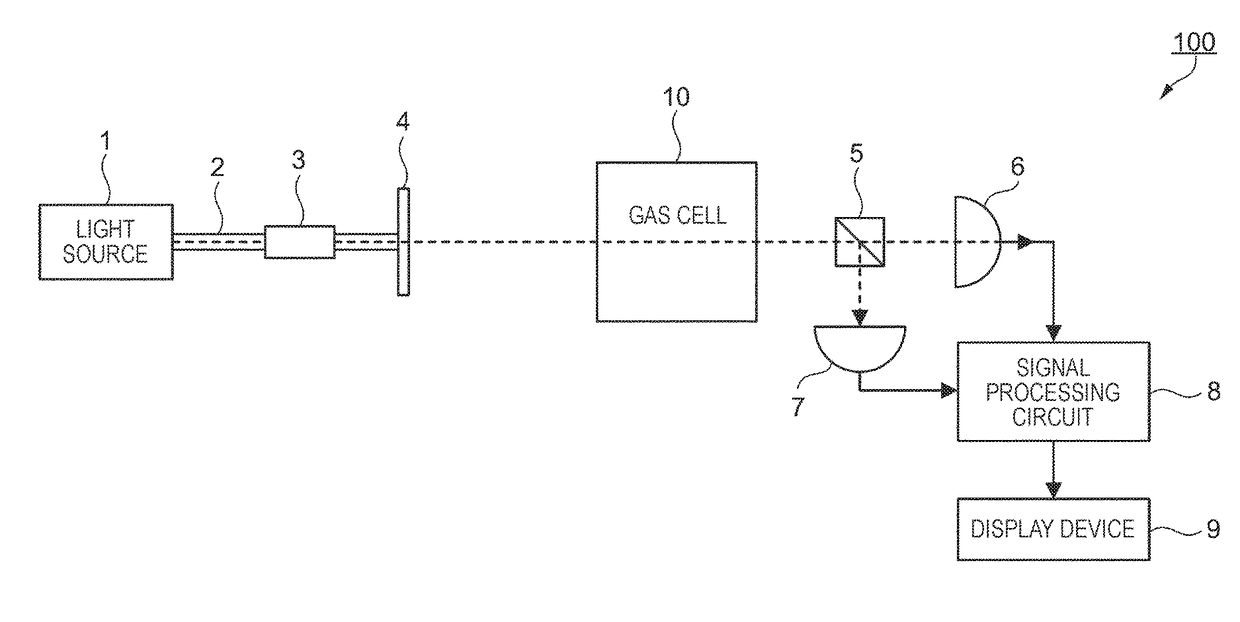

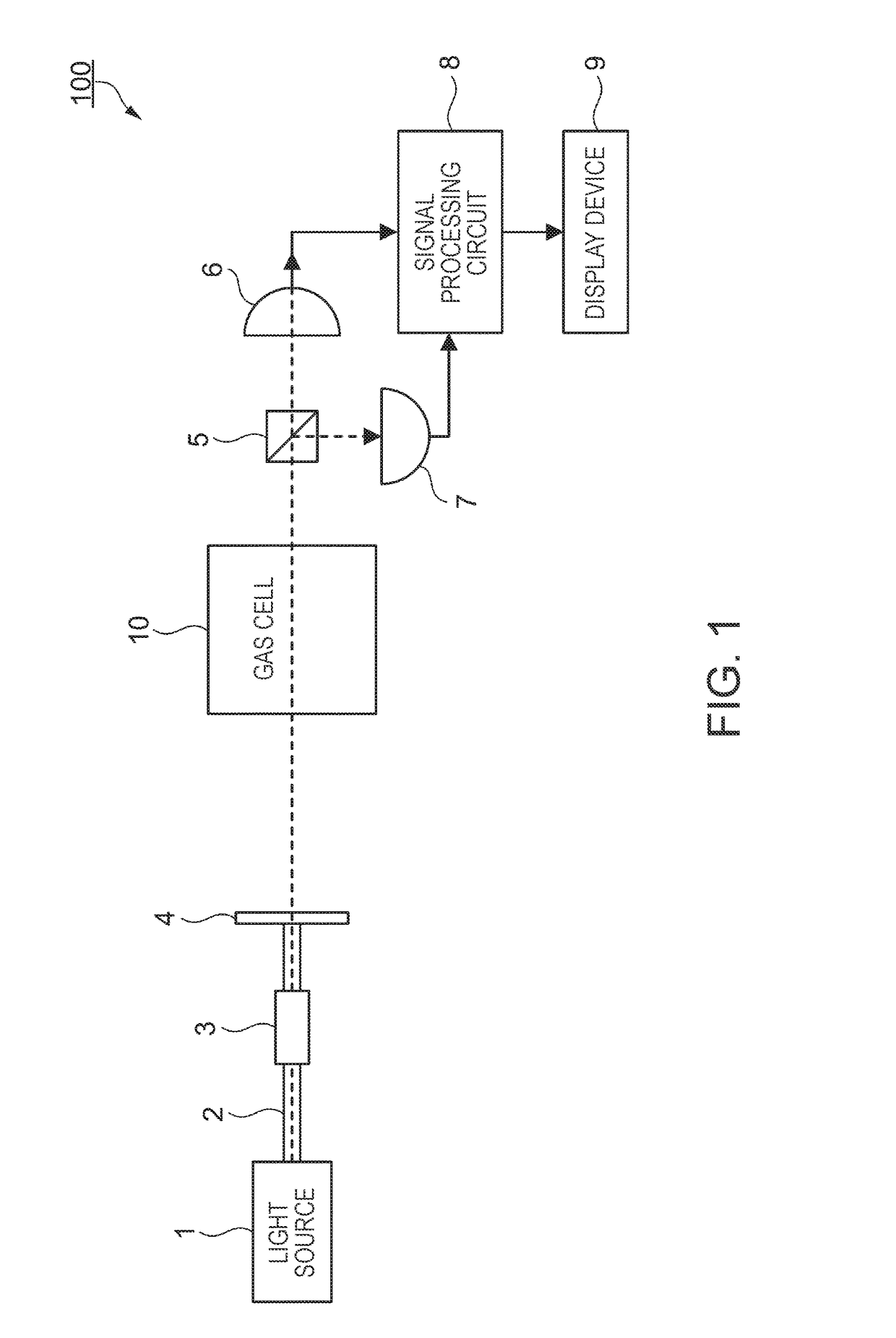

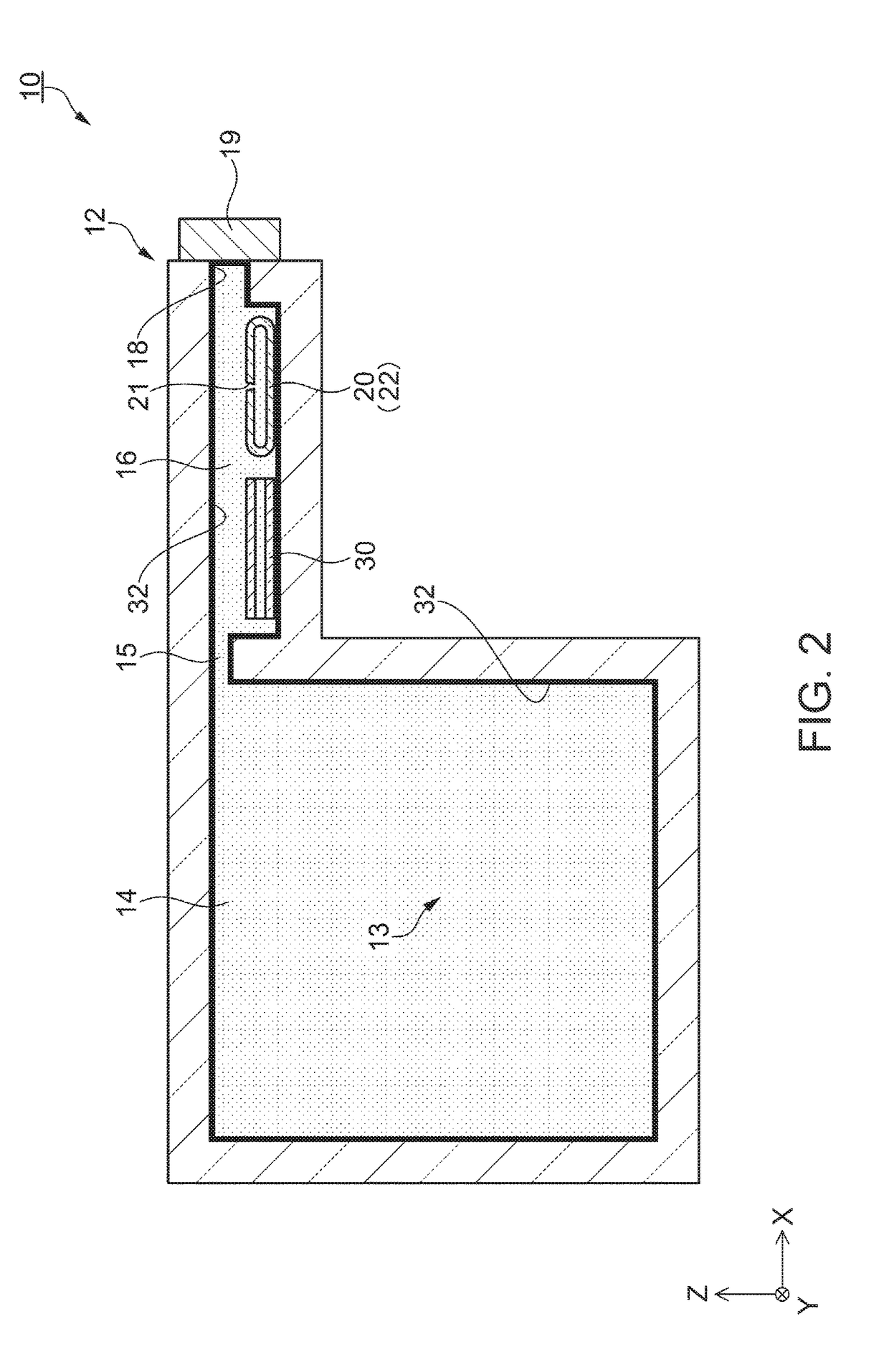

Manufacturing method for gas cell, manufacturing method for magnetic field measurement apparatus, and gas cell

ActiveUS20180003778A1Reduce the amount of variationStable formWax coatingsApparatus using atomic clocksElectrical batteryEngineering

A manufacturing method for a gas cell includes disposing a holding member including a coating material in a reservoir of a cell having a main chamber, the reservoir communicating with the main chamber, and an opening provided in the reservoir, sealing the cell, heating the holding member so as to generate a vapor of the coating material in the cell, and cooling the cell so as to form a film of the coating material on an inner wall of the cell.

Owner:SEIKO EPSON CORP

Microporous film

InactiveUS20010005563A1High mechanical strengthSolve the lack of resistanceCell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte cellsElectrolyteMaterials science

A microporous film which is excellent in permeability and mechanical strength and has breakage resistance at high temperatures; a separator for a nonaqueous-electrolyte battery which comprises the microporous film; and a nonaqueous-electrolyte battery employing the separator. The microporous film has a gel content of from 20 to 90% as determined through 3-hour immersion in boiling xylene.

Owner:NITTO DENKO CORP

Preparation method of polyacrylic acid series water-absorbent resin

The invention relates to a method for producing polyacrylic water-absorbing resin, which comprises obtaining an aqueous solution containing unsaturated acrylic monomers and a crosslinking agent; mixing the azo compound solution with the initiator solution, and then preparing a polyacrylic acid-based water-absorbing resin that is simultaneously used as an initiator and a foaming agent Initiator-foaming agent particle dispersion liquid, described azo compound solution is the compound solution that contains primary ammonia, secondary ammonia, tertiary ammonia or quaternary ammonium salt group, and described initiator solution is the solution that contains persulfate compound, The mass ratio of the azo compound component to the persulfate component is 100:1 to 1:100, and in the initiator-foaming agent particle dispersion, the number average particle size of the initiator-foaming agent particle The diameter is 0.1 to 900 microns; the initiator-foaming agent particle dispersion is mixed with the unsaturated acrylic monomer and the crosslinking agent aqueous solution to polymerize to prepare a hydrogel polymer, and the polymer is granulated and dried , crushing, sieving and surface crosslinking. A water-absorbent resin having a high liquid absorption rate and a composition thereof are obtained.

Owner:宜兴丹森科技有限公司

Equipment and method for measuring silicon concentration in phosphoric acid solution

ActiveUS7713478B2Easily and economically measureEfficient and stable preparationSemiconductor/solid-state device testing/measurementDecorative surface effectsHydrofluoric acidPhysical chemistry

Disclosed is equipment for measuring a silicon concentration in a phosphoric acid solution under use as an etching solution during operation of a semiconductor substrate processing system. The equipment is provided with at least a reaction tank and a concentration-measuring tank. The reaction tank includes a reaction unit for adding hydrofluoric acid to a predetermined constant amount of the phosphoric acid solution drawn out of the semiconductor substrate processing system to form a silicon fluoride compound and then causing the silicon fluoride compound to evaporate. The concentration-measuring tank comprises a hydrolysis unit for bubbling the silicon fluoride compound, which has evaporated from the reaction tank, through deionized water to hydrolyze the silicon fluoride compound and a measurement unit for determining a change rate of silicon concentration in the deionized water subsequent to the bubbling. Also disclosed is a method for measuring a silicon concentration in a phosphoric acid solution under recirculation and use as an etching solution in a semiconductor substrate processing system in operation.

Owner:TATSUMO KK

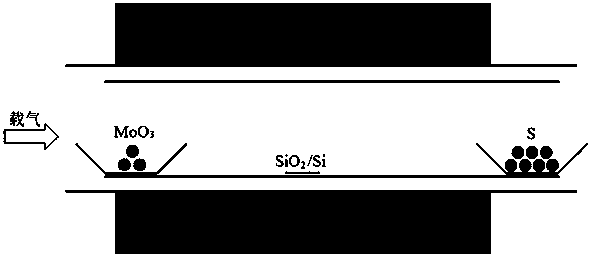

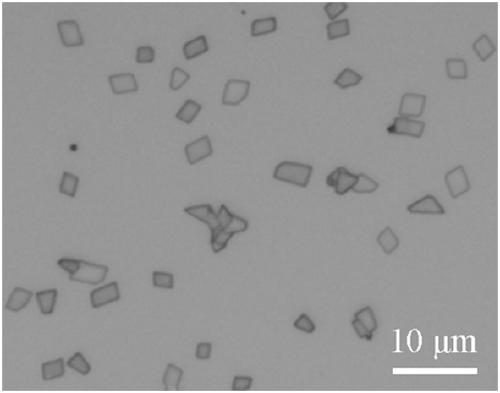

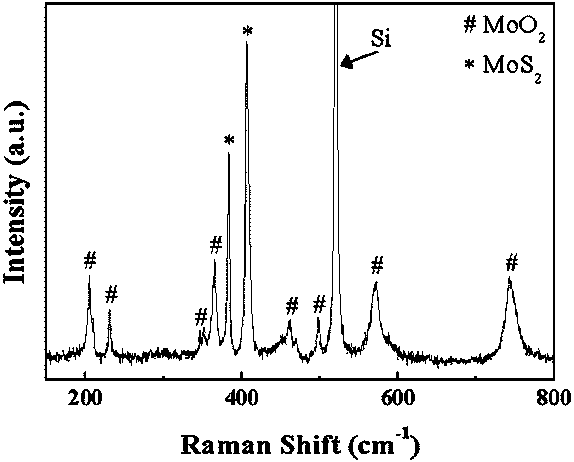

Preparation method of MoS2/MoO2 heterojunction

InactiveCN109207957AThe reaction process is simpleEfficient and stable preparationChemical vapor deposition coatingChemistryOptoelectronic materials

The invention relates to a preparation method of an MoS2 / MoO2 heterojunction, and belongs to the technical field of nano-optoelectronic material preparation. The problems that existing heterojunctionpreparation methods are prone to introducing impurities and poor in repeatability can be solved. A solid S and MoO3 are used as a precursor, and the MoS2 / MoO2 heterojunction is synthesized on a targetsubstrate after a chemical gas-phase reaction, wherein the concentration of S vapor in a tubular furnace temperature area can be adjusted through the magnitude of carrier gas flow. Compared with a positioning mechanical transfer method, according to the preparation method of the MoS2 / MoO2 heterojunction, the large-area MoS2 / MoO2 heterojunction can be prepared stably and efficiently, and the preparation method can extend to preparation of a Van der Waals heterojunction based on two-dimensional transition metal chalcogenide. The obtained MoS2 / MoO2 heterojunction can be used for scientific research and making nano-optoelectronic devices.

Owner:TAIYUAN UNIV OF TECH

Manufacturing method of polyacrylic acid-series water-absorbent resin

InactiveCN108192013AIncrease absorption rateEfficient and stable preparationCross-linkPolymer science

The invention discloses a manufacturing method of polyacrylic acid-series water-absorbent resin. The manufacturing method comprises the following steps: obtaining an aqueous solution which contains unsaturated acrylic monomers and a cross-linking agent; mixing foaming agent particles and / or a foaming agent solution, unsaturated acrylic monomers and a cross-linking agent aqueous solution; polymerizing a monomer water solution to form a porous gel-like cross-linked polymer; crushing the porous gel-like cross-linked polymer into gel particles through shearing and / or extruding acting force in a polymerizing process or after polymerizing, wherein the number average particle size of the gel particles is 0.5 to 20 mm, the weight percentage of the gel particles with the particle size of greater than 2 mm is 10 to 100 percent, and the porous structure destruction rate of the gel particles is 0 to 70 percent after the porous gel-like cross-linked polymer is subjected to the shearing and / or extruding acting force; further drying, fining and screening the manufactured gel particles. The liquid absorption characteristic of the water-absorbent resin is not influenced; the water-absorbent resin with high-speed liquid absorption rate and low monomer residue amount can be produced and obtained highly effectively.

Owner:宜兴丹森科技有限公司

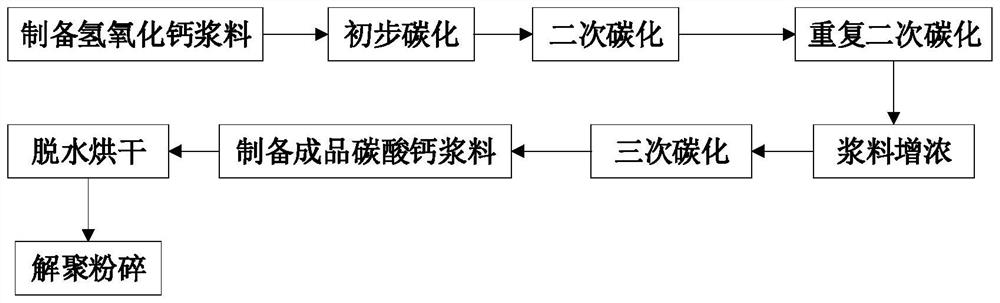

Preparation method of large-particle calcium carbonate

ActiveCN111874935AIncrease concentrationMeet the requirements of large particle calcium carbonateCalcium/strontium/barium carbonatesProductsCalcium hydroxideCarbonization

The invention discloses a preparation method of large-particle calcium carbonate. The method comprises the following steps: preparing calcium hydroxide slurry, carrying out primary carbonization, carrying out secondary carbonization, repeating the secondary carbonization, thickening the slurry, carrying out tertiary carbonization, preparing finished calcium carbonate slurry, carrying out centrifugal dehydration, drying the mixture, and performing de-aggregation and pulverization. According to the method, calcium hydroxide raw pulp is fully and completely prepared into primary calcium carbonateslurry in a repeated secondary carbonization mode, then the concentration of the slurry is increased in a partial slurry thickening mode, so that crystal nucleuses are separated out, and the slurry with the crystal nucleuses separated out is fed back to a carbonization tank to be further carbonized; therefore, the particle size of the finally prepared calcium carbonate powder can reach more than30 microns, and the requirements of related fields on large-particle calcium carbonate are met. The method has the advantage in preparation of the large-particle calcium carbonate.

Owner:浙江省建德市正发药业有限公司

Method for producing polyacrylic acid-based water-absorbing resin

InactiveCN111116947AIncrease absorption rateEfficient and stable preparationPolymer scienceCross linker

A method for producing a polyacrylic acid-based water-absorbent resin comprises the steps of: obtaining an aqueous solution containing an acrylic monomer and a crosslinking agent; carrying out polymerization reaction on an aqueous solution containing an acrylic monomer and a cross-linking agent to obtain a gel-like cross-linked polymer of which the water content is 30-80 wt%;mixing a water-containing gel-like cross-linked polymer with polyacrylic acid water-absorbent resin particles with the number-average particle size of 1-200 microns in a polymerization reaction process or after the polymerization reaction is finished, and crushing the mixture into gel particles with the number-average particle size of 50-1mm; heating and drying the crushed gel particles by adopting a heating medium with the temperature of 80-170 DEG C to obtain a cross-linked polymer with the water content of 0.1-10wt%; and carrying out fine granulation on the dried cross-linked polymer, and screening the granulesto prepare the water-absorbent resin particles. According to the present invention, a method for efficiently producing a water-absorbent resin having a low liquid reflux amount and a high liquid absorption rate can be provided, and a water-absorbent resin having a high liquid absorption rate can be obtained.

Owner:宜兴丹森科技有限公司

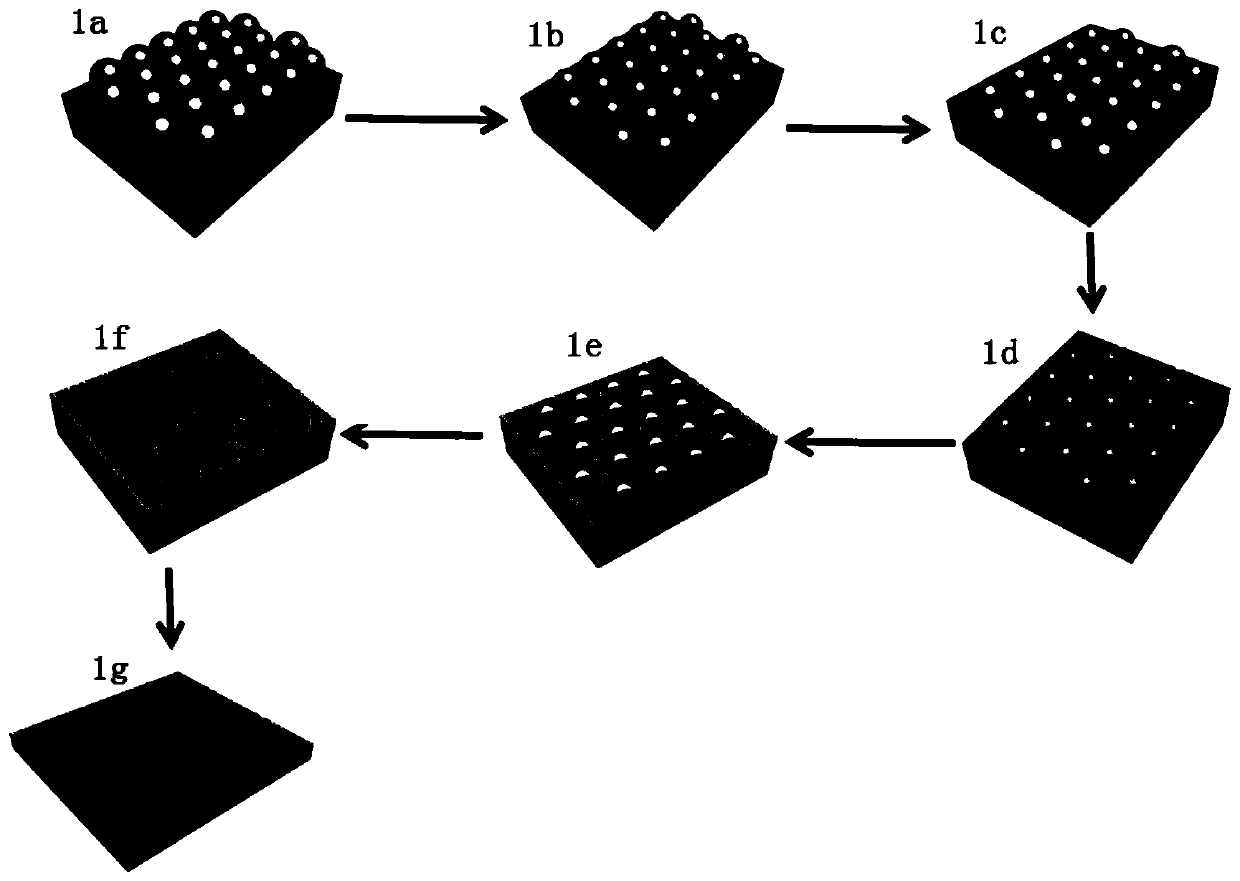

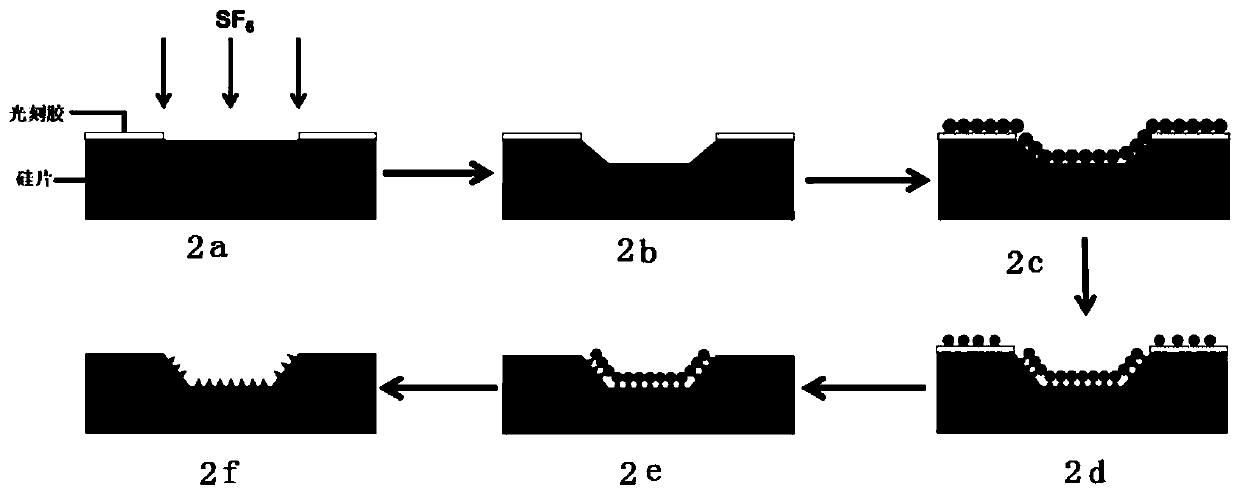

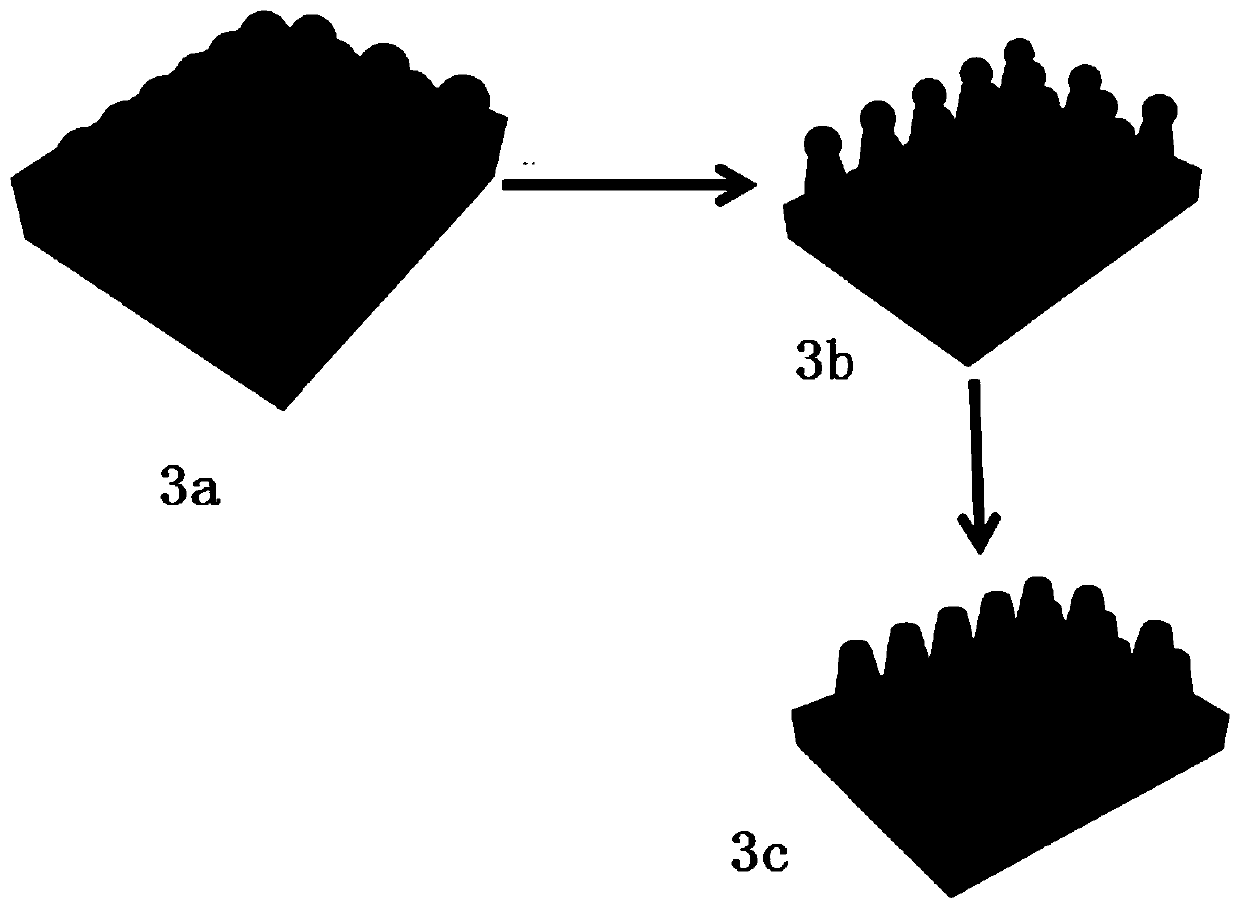

Groove composite multi-bulge structure and preparation process thereof

ActiveCN111039253ANovel structureHas the ability to gather lightDecorative surface effectsRaman scatteringCrystallographySquare Millimeter

The invention discloses a groove composite multi-bulge structure and a preparation process thereof. The groove composite multi-bulge structure provided by the invention comprises a substrate, the semiconductor device further comprises a plurality of grooves arranged on the substrate, wherein the substrate is provided with a groove, the protrusions are compounded on the surface of the groove, the transverse size of the top of the groove is smaller than or equal to 1 micrometer, at least 1*105 grooves are formed in the substrate per square millimeter, the number of the protrusions compounded onthe surface of each groove is larger than or equal to 40, and the transverse size of the end, close to the surface of the groove, of each protrusion is larger than or equal to 60 nanometers. The SERSsubstrate is very novel in structure, and has high light absorption capacity and high SERS activity.

Owner:JIANGSU HINOVAIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com