Method for producing polyacrylic acid-based water-absorbing resin

A polyacrylic acid-based, manufacturing method technology, applied to the field of absorbent articles, can solve problems such as increased packaging and transportation costs, insufficient, impact resistance, liquid retention capacity, absorption capacity, etc., and deterioration of liquid absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

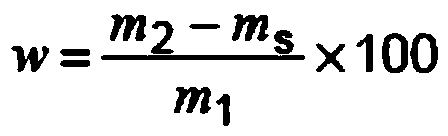

Method used

Image

Examples

manufacture example 1

[0148] The acrylic acid / sodium acrylate mixed monomer solution (the molar ratio of acrylic acid / sodium acrylate is 2.2 / 7.8) was transported through pipelines, the monomer concentration of acrylic acid / sodium acrylate was 44.0% by weight, and the flow rate of the monomer solution was 8689kg / h. The temperature of the monomer solution is 80-90°C. Polyethylene glycol diacrylate (molecular weight: 522) with a concentration of 11.3% by weight was transported at the branch of the monomer solution pipeline, and the flow rate was 72 kg / h. In addition, an aqueous sodium persulfate solution with a concentration of 4% by weight (flow rate: 60 kg / h) was delivered to the monomer through the branch of the monomer solution pipeline by a delivery pump to initiate a polymerization reaction. The reaction solution is sprayed onto the reaction bed to obtain a hydrogel polymer.

Embodiment 1

[0150] Get 5000g hydrogel-like polymer (water content: 50% by weight) in manufacturing example 1, add 1250g water on the surface of the gel, after the gel completely absorbs the water, use a meat grinder (the hole diameter of the orifice plate is 4.5 mm, with a porosity of 34.4%), it was broken twice to prepare a fine particle gel. Add 100g concentration of sucrose stearate (S-770, Mitsubishi Chemical) suspension on the fine particle gel surface atomization, after mixing uniformly, then use a meat grinder (orifice opening diameter is 4.5mm) mm, with a porosity of 34.4%) to break it into fine-grained gels. Spread the crushed gel particles on a wire mesh for drying at a drying temperature of 140° C. for 45 minutes to obtain a cross-linked polymer. The dried cross-linked polymer is finely granulated by using a crushing machine, and sieved to obtain water-absorbent resin particles 1 with a particle size of less than 150 microns and containing a surface modifier.

[0151] Get 500...

Embodiment 2

[0158] Change the drying temperature of the gel in Example 1 to 130°C for 60 minutes, and other operations are the same as in Example 1 to obtain a water-absorbent resin 2-1 with a particle size of 300-425 microns, a moisture content of 3.5% by weight, and a CRC It is 43.2g / g.

[0159] Then the water-absorbent resin 2-1 was subjected to the same surface cross-linking and additive process as in Example 1 to obtain a water-absorbing agent 2 with a CRC of 32.3g / g, a salt water absorption of 28.5g / g in one minute, and pure water in one minute. The amount was 130.2 g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com