Patents

Literature

429results about How to "Increase absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

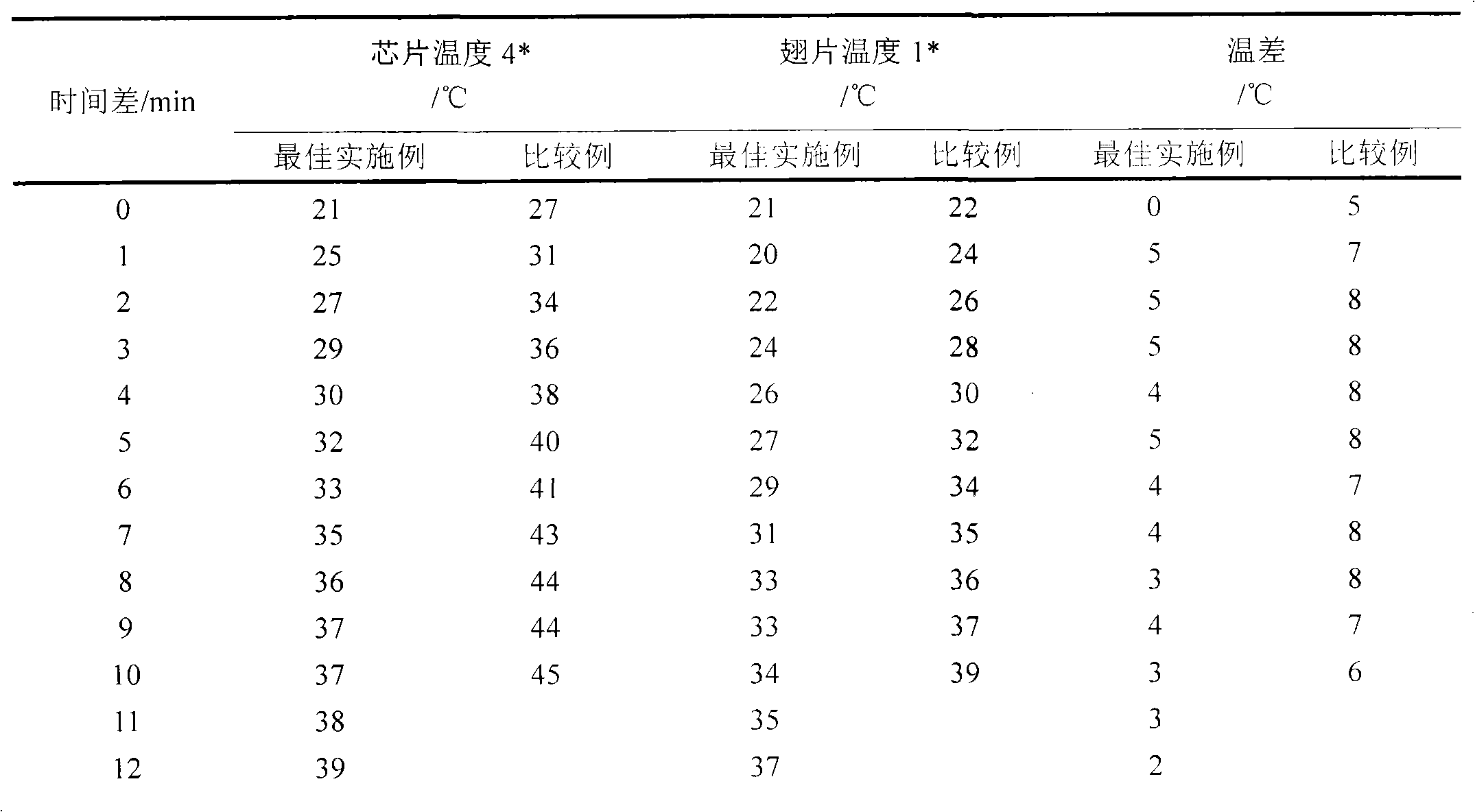

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

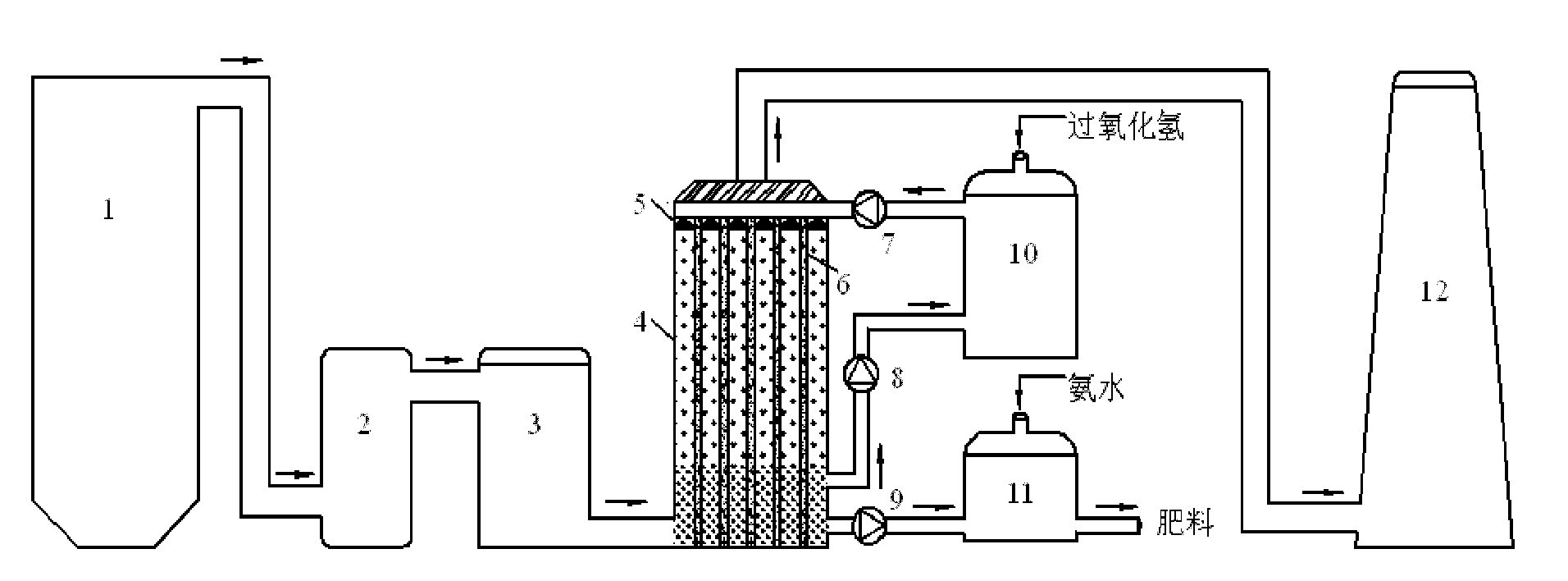

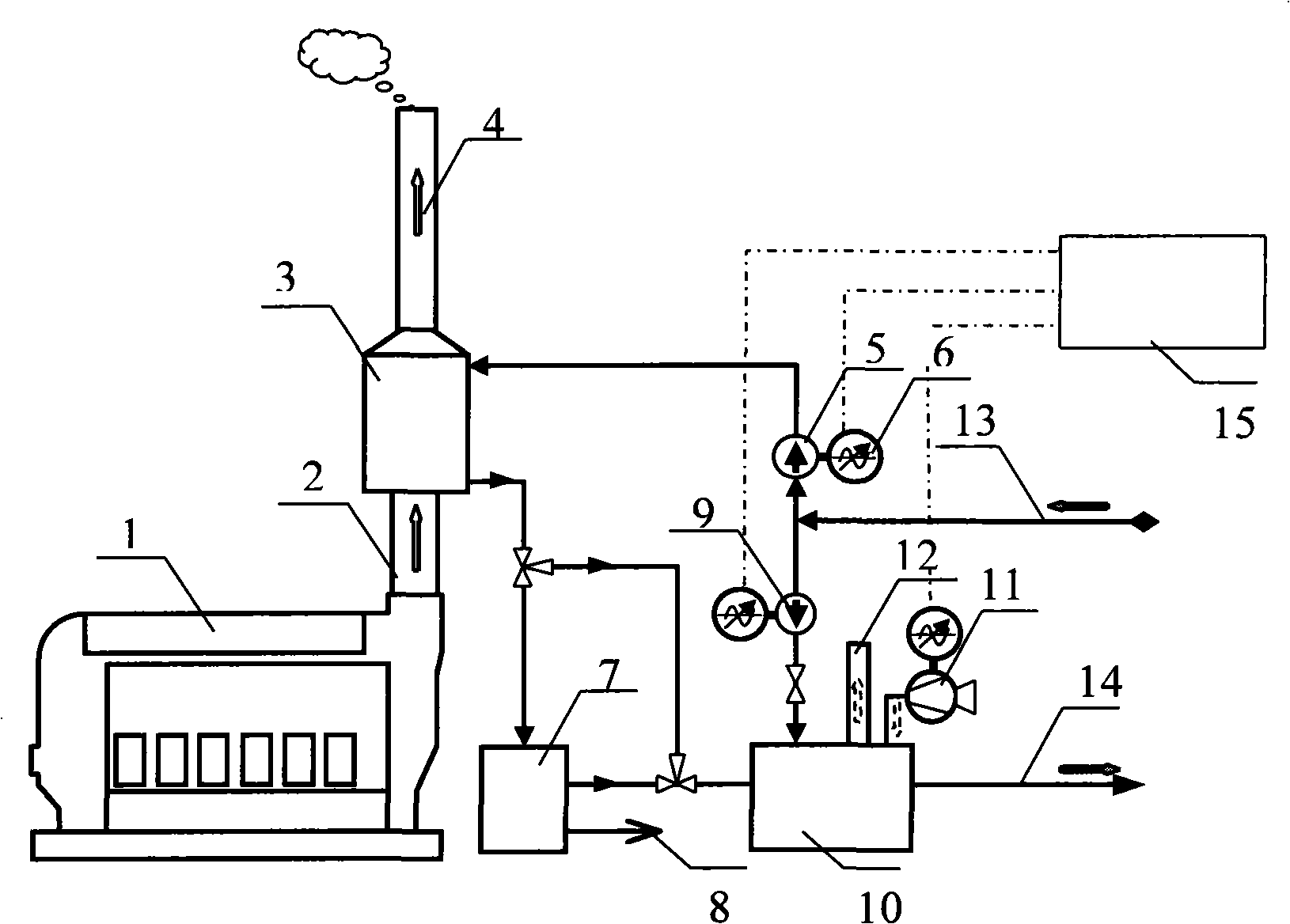

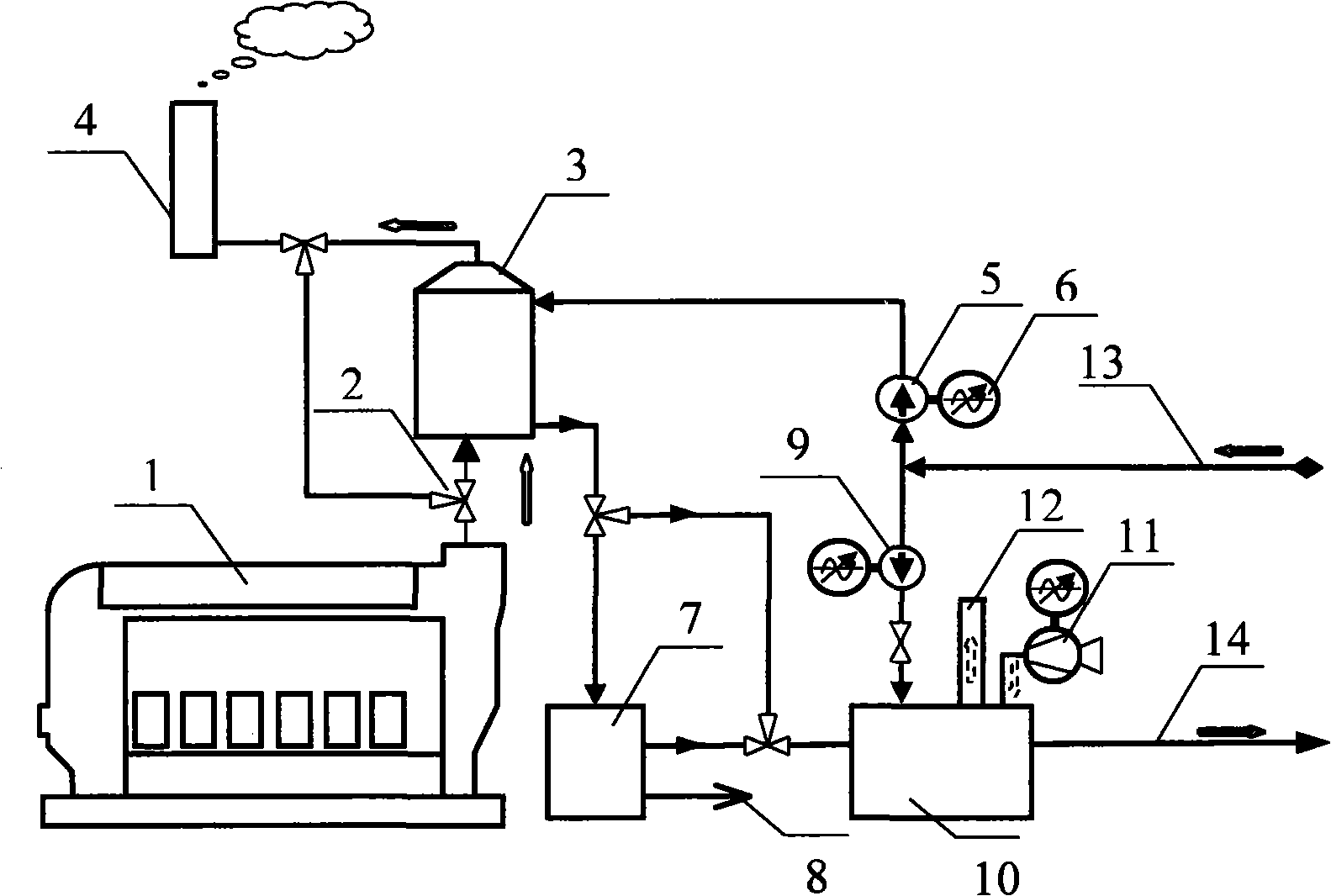

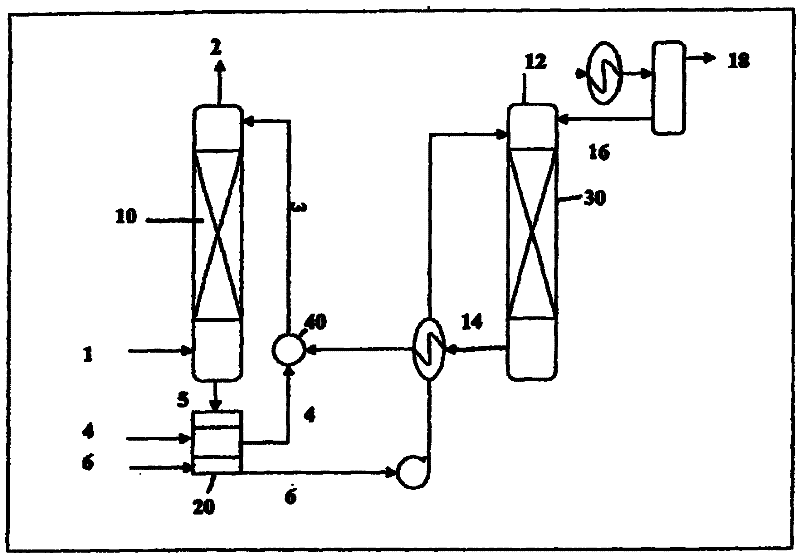

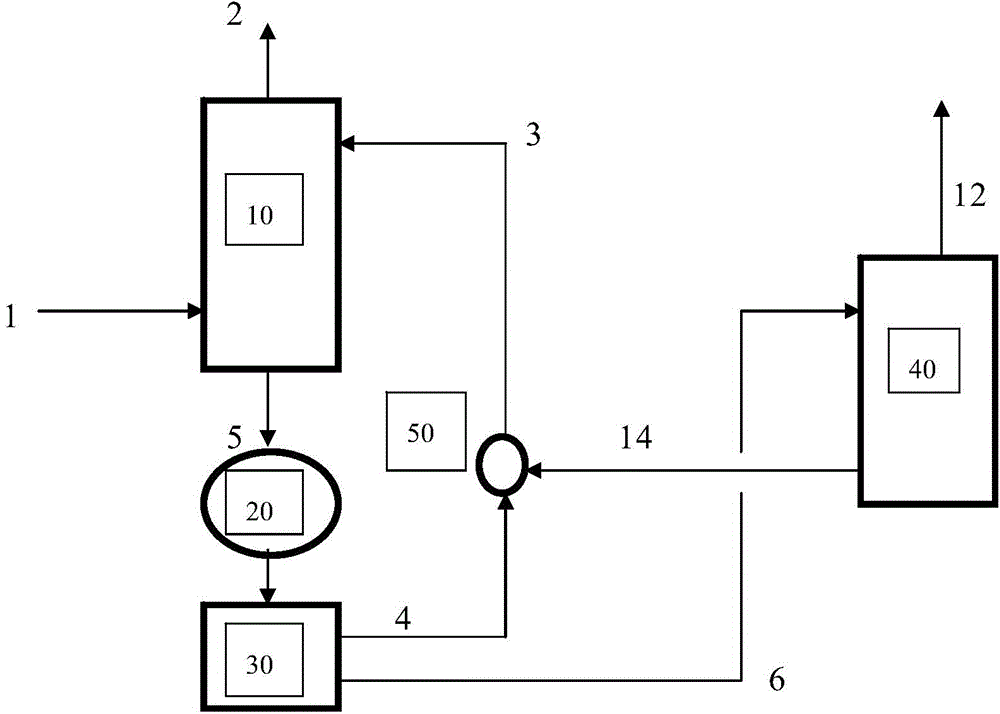

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

InactiveCN101940871AThe process is simple and reliableSmall footprintDispersed particle separationAir quality improvementFertilizerAmmonium sulfate

The invention discloses a photochemical advanced oxygenation-based simultaneous desulfuration and denitration system. The system is provided with a burning and exhausting system consisting of a burner, an electrostatic dust collector, a heat exchanger, a spray tower, a liquid adding tower and a chimney, wherein fume generated by the burner enters the electrostatic dust collector, fume particles are removed from the fume by the electrostatic dust collector, the fume enters the heat exchanger and is cooled by the heat exchanger, and then the fume enters the spray tower; an UV light tube is arranged in the spray tower; hydrogen peroxide solution from the liquid adding tower is pumped by a circulating pump, sprayed into the spray tower through an atomizing nozzle and is activated by ultraviolet light to decompose hydrogen peroxide and then generate hydroxyl radicals (.OH) with strong oxidizing property; after being contacted with the fume in the spray tower, the hydroxyl radicals undergoes a gas-liquid absorption reaction with the fume to oxidize and remove NOx and SO2 in the fume; the fume, after being absorbed and washed, enters the chimney from the top of the spray tower and is exhausted; and sulfuric acid solution and salpeter solution generated in the spray tower are pumped into the separating column by the circulating pump and are reacted with added ammonia water to generate agricultural fertilizers including ammonium sulfate and ammonium nitrate.

Owner:SOUTHEAST UNIV

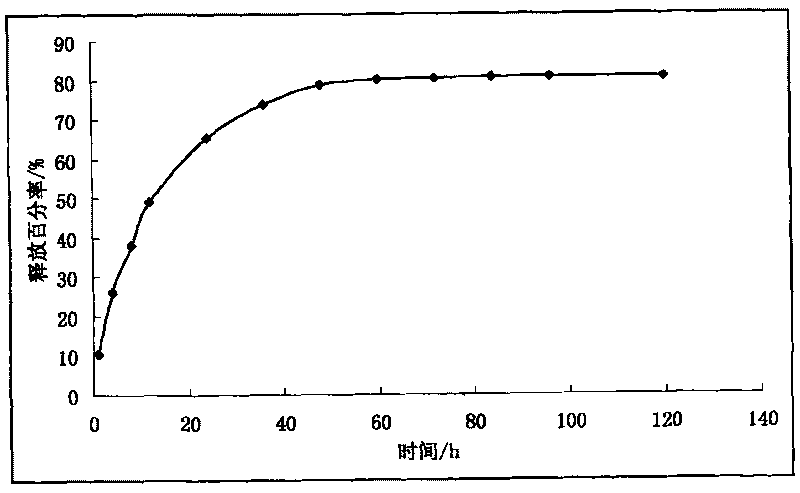

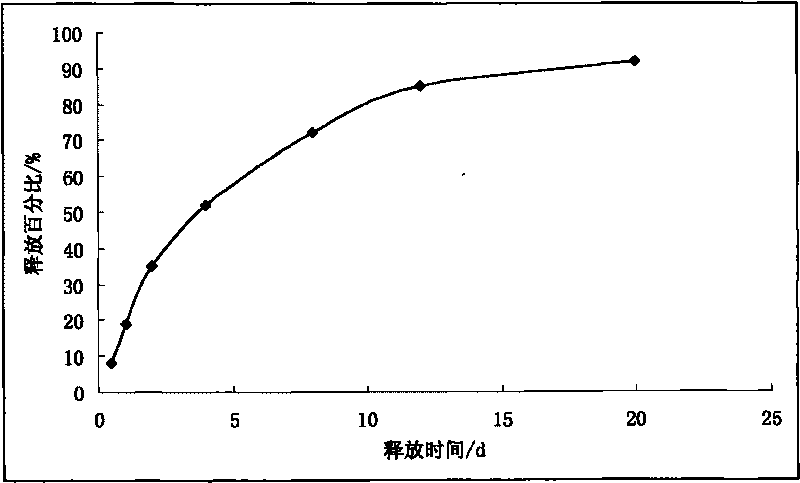

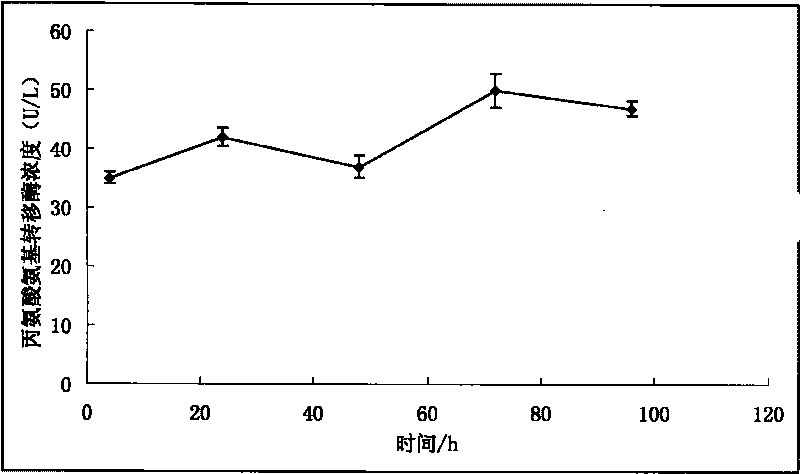

Method for preparing anti-infective agent long-acting injection

ActiveCN101703776AIncrease absorption rateGuaranteed effective concentrationSolution deliveryAntiinfectivesLong actingAbsorption rate

The invention provides a method for preparing anti-infective agent long-acting injection, and relates to an anti-infective agent long-acting injection. Each 1,000 mL of injection comprises the following components: 10 to 500 g of anti-infective agent, 100 to 900 g of cosolvent, 0 to 100 g of blocker, local anesthetic or stabilizer, and the balance of oil solvent. The method method for preparing the injection comprises: 1, dissolving 10 to 500 g of anti-infective agent in 100 to 900 g of cosolvent and mixing the two well; 2, adding 0 to 100 g of blocker and / or local anesthetic or stabilizer; and 3, adding the oil solvent till full volume and mixing thoroughly to form a uniform system. The method has antibacterial medicaments dissolved in the cosolvent first and then uniformly dispersed in the oil solvent capable of dissolving the antibacterial medicaments mutually so as to prolong the absorption rate of organisms to the medicaments, thereby maintaining the effective concentration of the medicaments in the organisms for a long time, achieving the long-acting effects and reducing the toxic effects of the medicaments.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE +1

Novel phase-change material composition

ActiveCN104726069AImprove thermal performanceGood dispersionHeat-exchange elementsParticulatesCarbon nanotube

The invention discloses a novel phase-change material composition. The novel phase-change material composition mainly comprises carbon nanotubes, graphene, fumed silica, metal or metal oxide particles and a phase-change material. The carbon nanotubes, graphene and metal or metal oxide particles can further accelerate heat transmission. The phase-change material is used for improving a hot end initial temperature absorption rate. The fumed silica has effects of precipitation prevention and thickening and can prevent graphene and particle aggregation settlement after heat absorption liquefaction of the phase-change material. The carbon nanotubes, graphene and metal or metal oxides can finally form a full 3D network comprising particles (metal or metal oxides), wires (carbon nanotubes) and planes (graphene) in the fluid (of phase-change material subjected to heat absorption melting). The novel phase-change material composition has high heat conductivity and low thermal resistance value, has high specific heat capacity, greatly improves phase-change material heat absorption, heat storage and heat radiation efficiency and has a high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

Method and apparatus for desulfurizing exhaust gas of seagoing vessel

InactiveCN101314106AGood technical effectImprove emission reduction efficiencyDispersed particle separationWater savingWater discharge

The invention relates to a method and a device for desulfurizing exhaust smoke of a sea-going ship, which uses sea water to reduce discharge of sulfur dioxide and other pollutants of the sea-going ship. The method comprises the following steps of: sea water scrubbing, acidic sea water transferring, acid separating treatment, water discharge and so on. The device comprises a scrubber and a water-saving acid separator, wherein, the upper part of the scrubber is provided with a scrubbing layer, and is communicated with a scrubbing sea water pump through a pipeline; the lower part of the scrubber is provided with a cooling layer; one end of the scrubber is communicated with a smoke exhaust pipe of a ship engine through a scrubbing inlet pipe, while the other end of the scrubber is connected with a scrubbing exhaust pipe; the lower part of the scrubber is communicated with the water-saving acid separator; and the water-saving acid separator is connected with a mixed sea water pump, a draught fan and a main discharge pipe for suitably discharging sea water which is subject to the acid separating treatment. The method and the device have the advantages of high desulfurizing efficiency, small sea water consumption, low equipment manufacturing cost and low running cost.

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

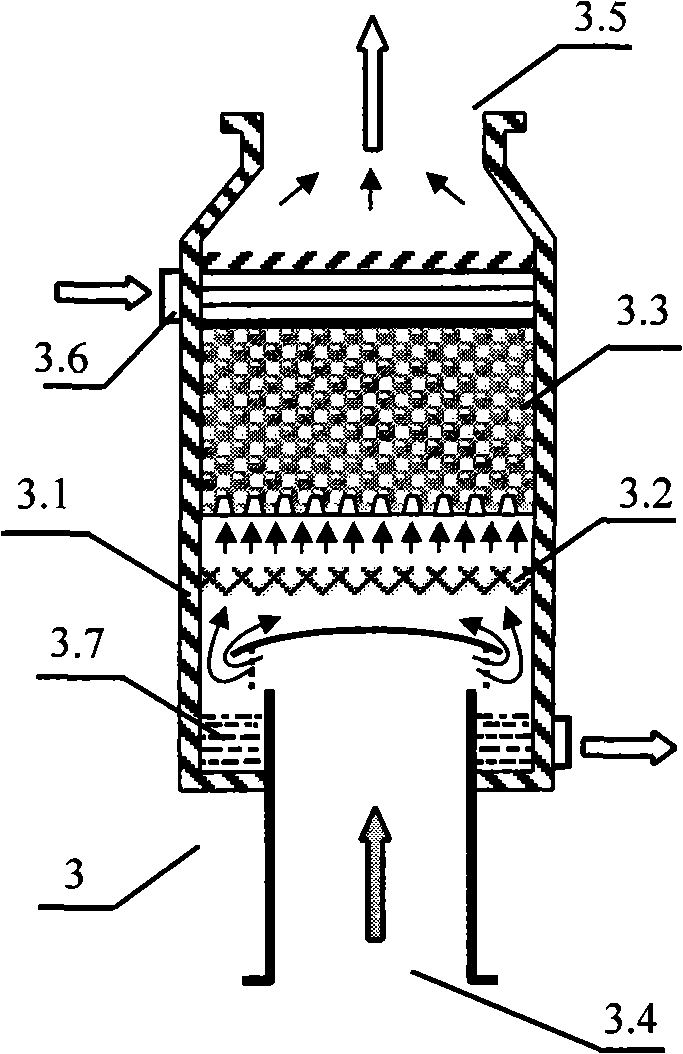

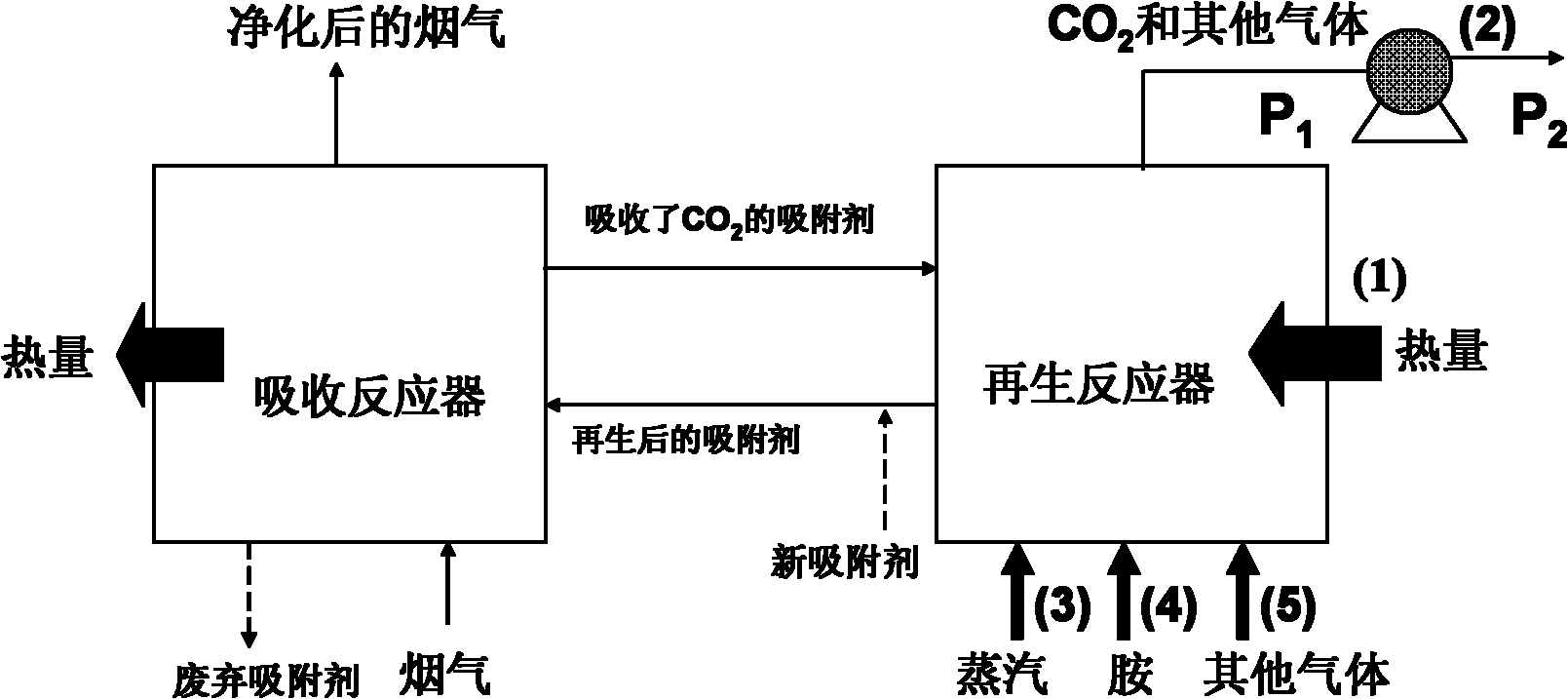

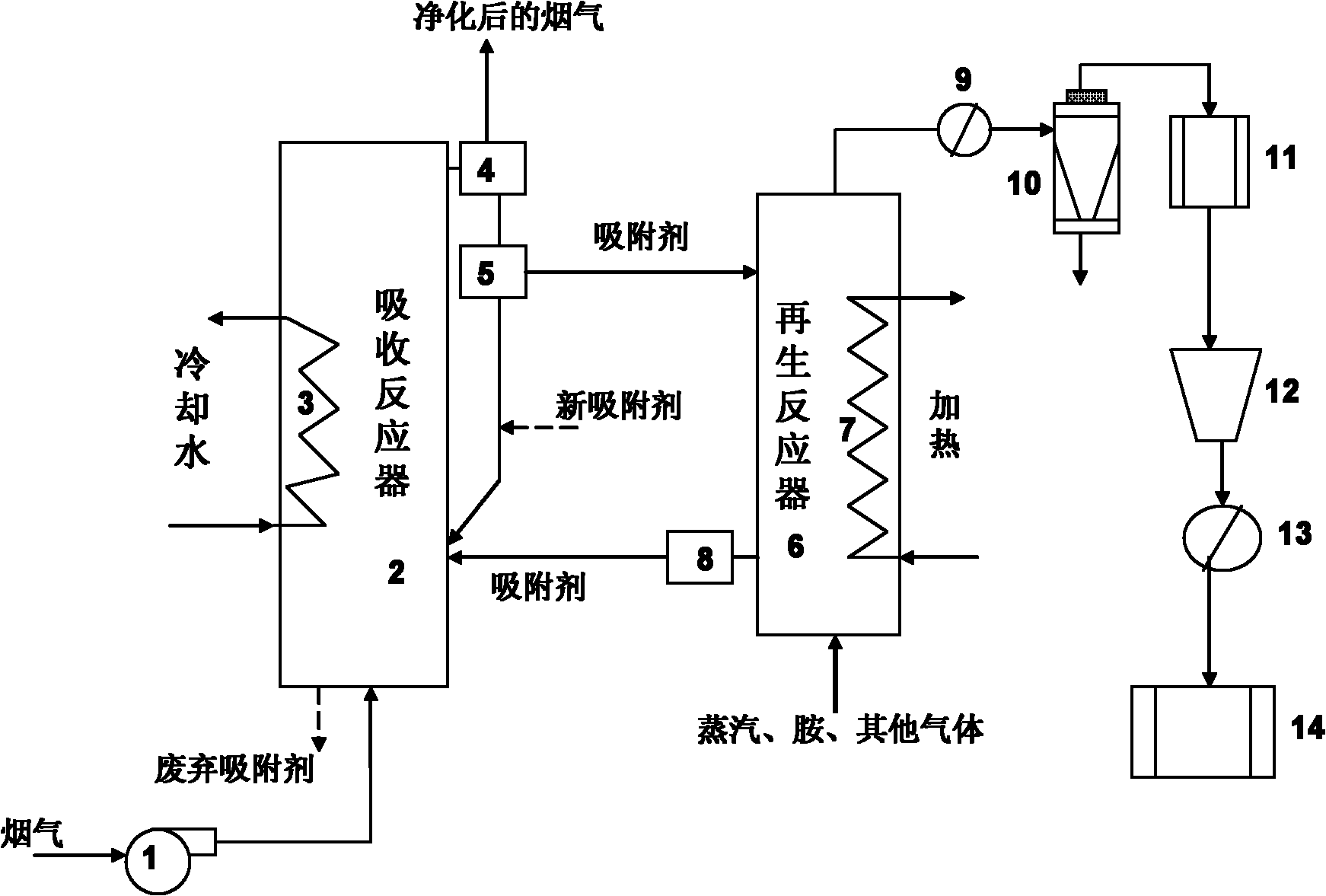

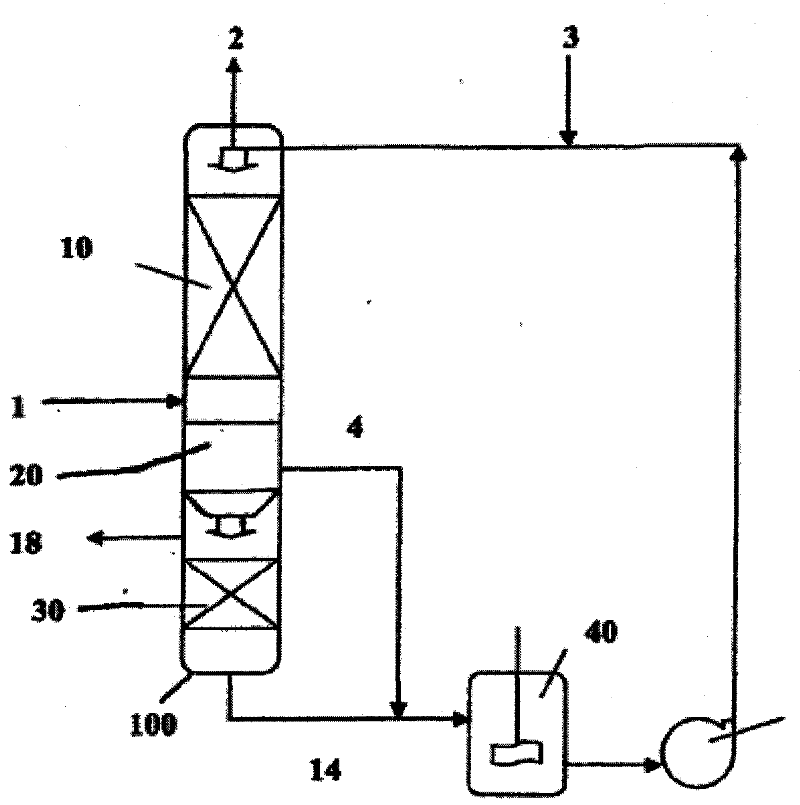

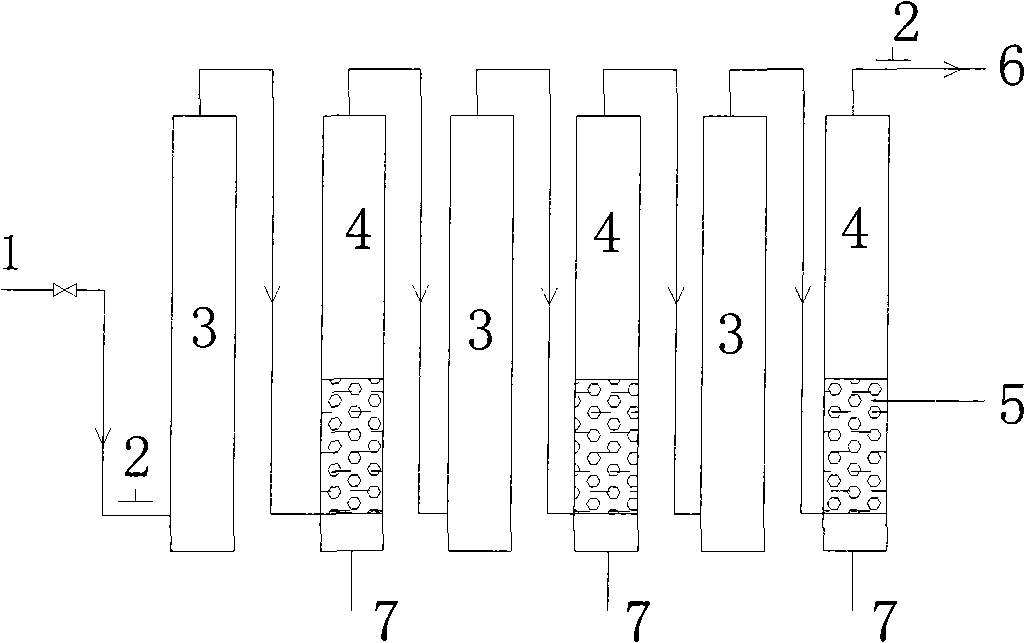

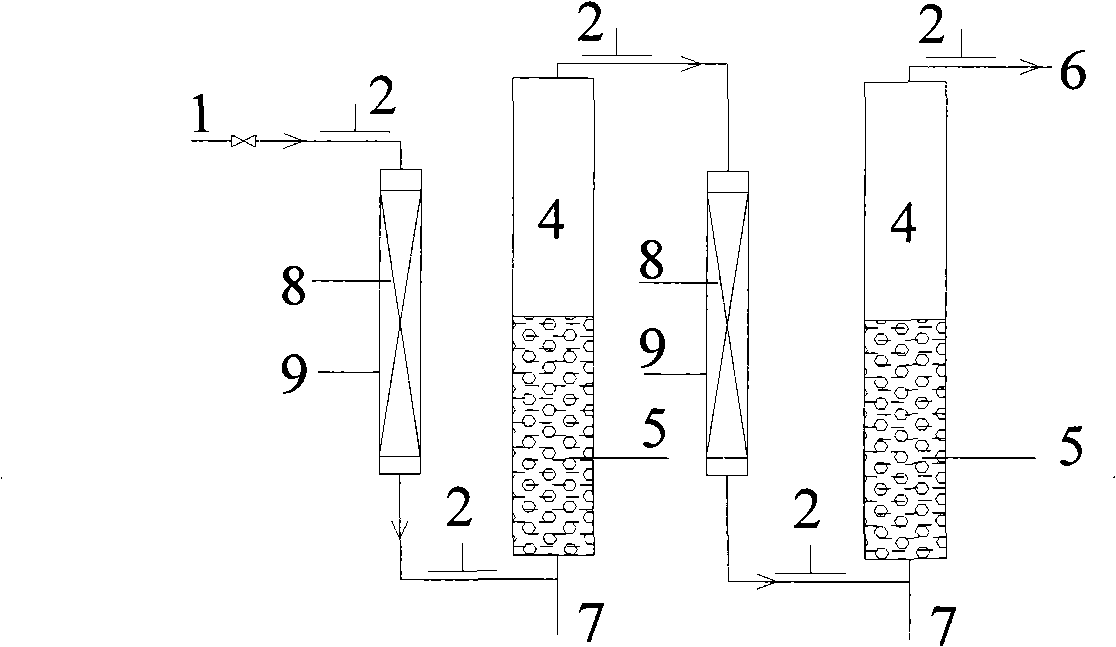

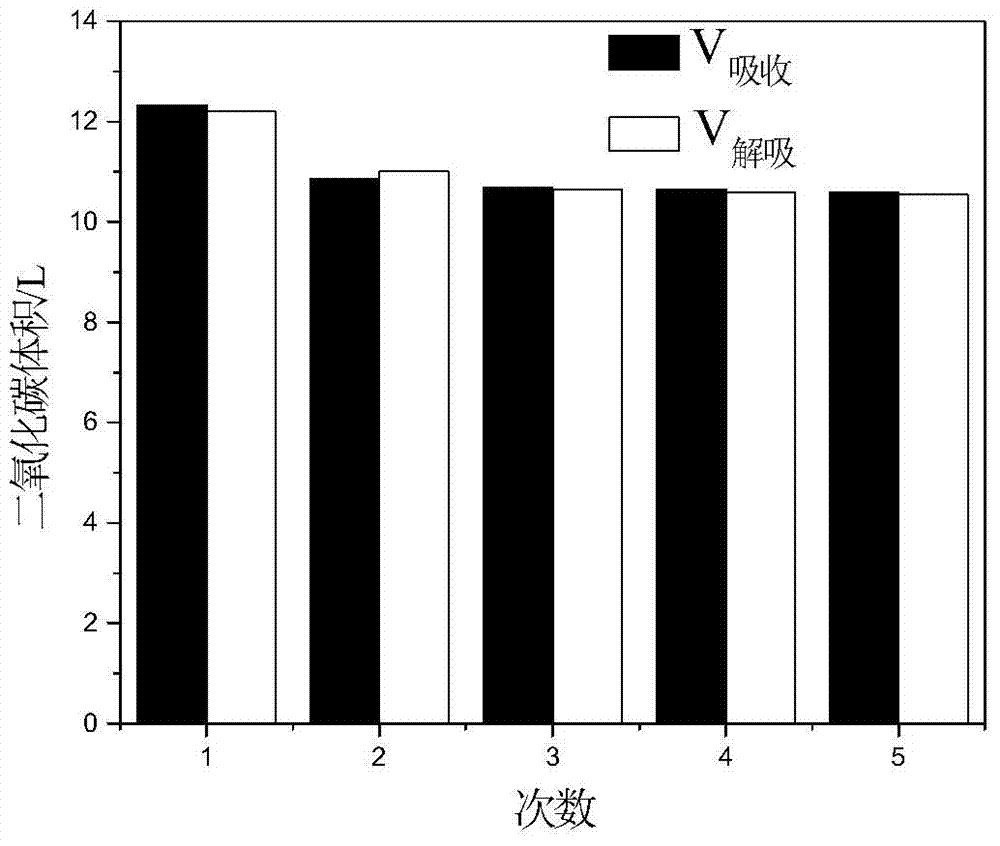

Process and equipment for removing CO2 in flue gas by utilizing amine solid adsorbent

InactiveCN102198360AHigh specific surface areaHigh porosityProductsMethane captureChemistryProduct gas

The invention belongs to the technical field of separation of CO2 in flue gas discharged during s combustion process, and in particular relates to a process and equipment for removing CO2 in flue gas by utilizing an amine solid adsorbent. In the process, the CO2 gas in the flue gas is fully contacted with the amine solid adsorbent so that CO2 gas molecules are rapidly diffused into pores of the solid adsorbent to react with amine liquids in the pores and then the CO2 is rapidly adsorbed by the adsorbent, and meanwhile the amine solid adsorbent adsorbed with the CO2 is regenerated by utilizing one or more regeneration methods such as thermal regeneration, vacuum regeneration, steam regeneration, amine steam regeneration and gas introduction regeneration. The adopted main equipment consists of a CO2 absorption reactor using the amine solid adsorbent, a regeneration reactor, a gas-solid separator, a gas-liquid separator and the like. The process and equipment provided by the invention have the advantages of simple and compact overall design, low investment and operating cost, stable and reliable operating performance and capability of efficiently separating the CO2 in the flue gas with low cost.

Owner:TSINGHUA UNIV

Acidic compositon for external use and agent for accelerating infiltration of cosmetic preparation, hair-growing agent, and preparation for external use each containing the composition into skin or the like

InactiveUS20050074421A1Reduce mixingIncrease absorption rateCosmetic preparationsHair cosmeticsOtic AgentsTreatment effect

An acidic composition for external use which contains an acidic polysaccharide and water as essential ingredients, and an agent for accelerating the penetration into skin or the like of a cosmetic preparation, hair-growing agent or preparation for external use, each containing the composition. The composition is easy to manufacture, and shows a stronger cosmetic or therapeutic effects than conventional compositions.

Owner:NEOCHEMIR INC

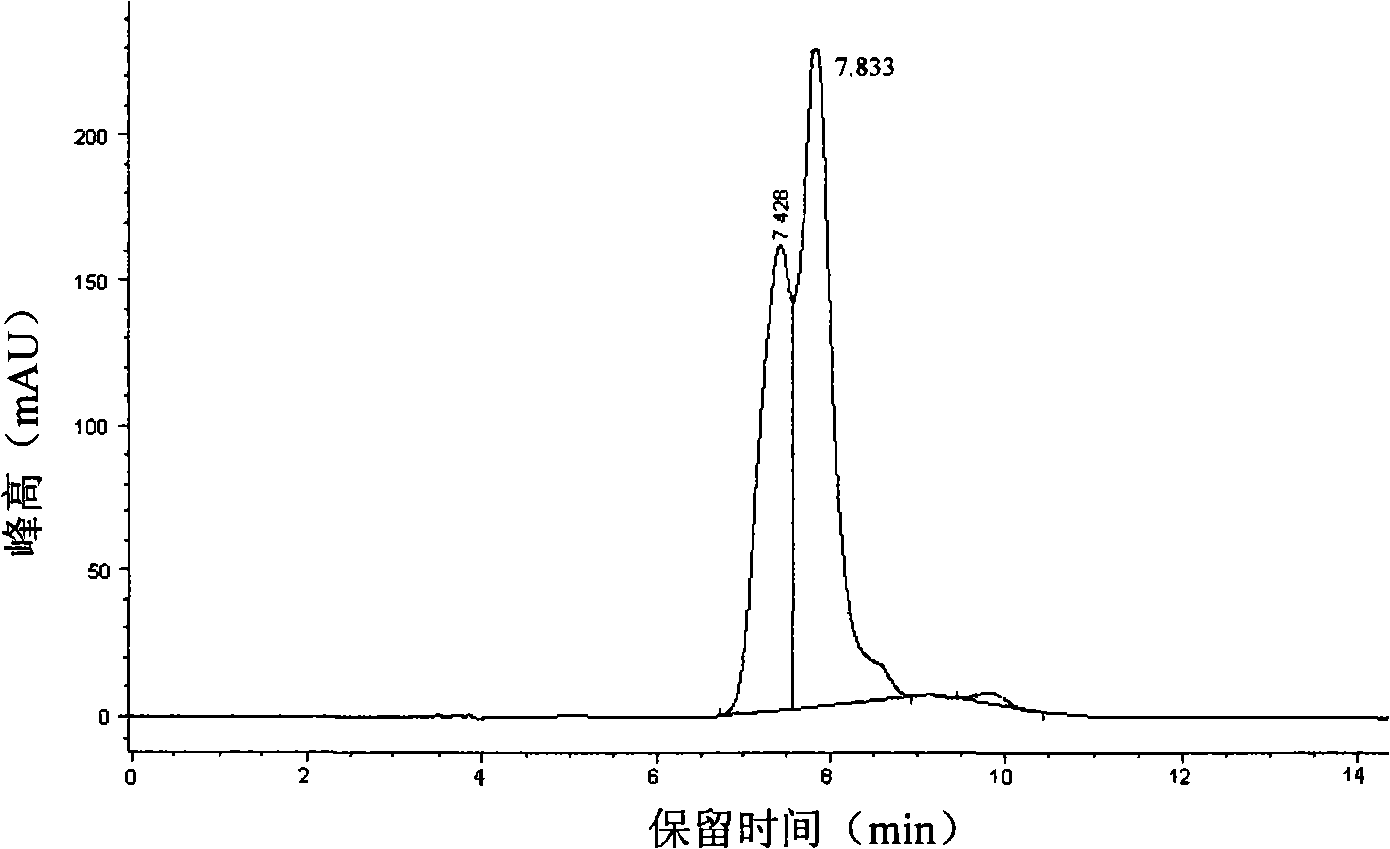

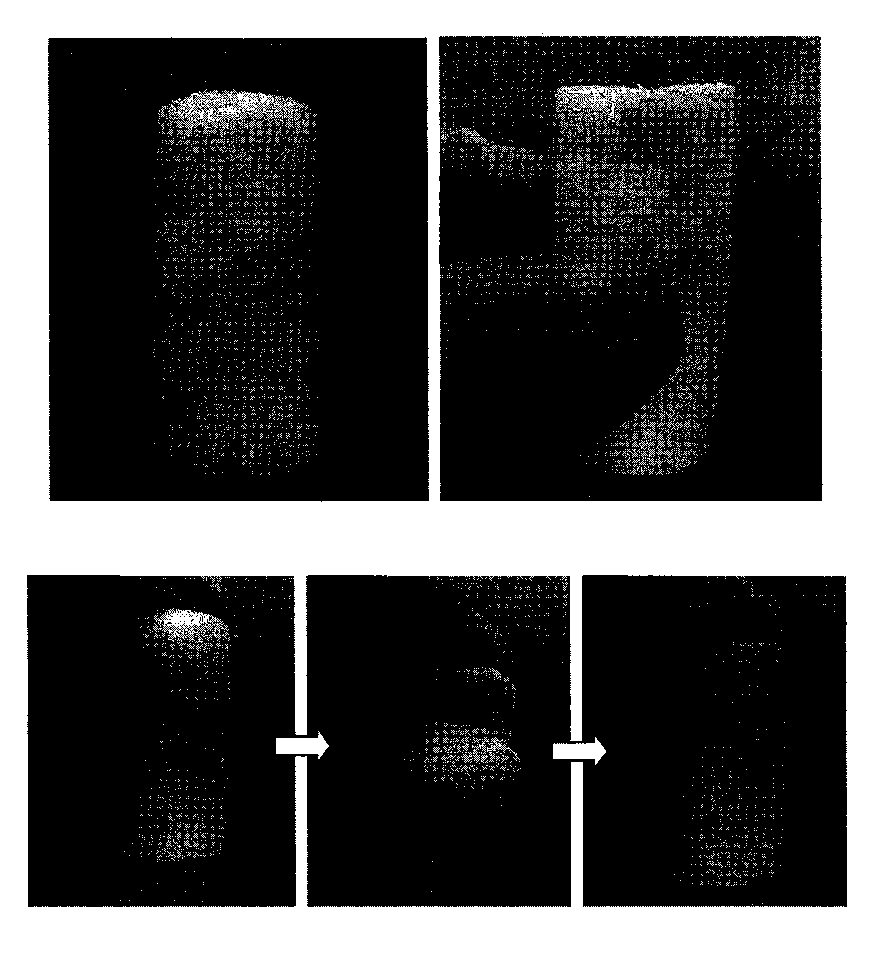

Method for preparing water absorption polymer with high liquid absorption speed, dispersity and dried degree

The invention discloses a preparation method of absorbent polymer which is characterized in high speed rate of liquid absorption, good dispersibility and high dry-touch degree. Acrylic acid is added into sodium hydroxide aqueous solution, which is uniformly mixed with acrylamide and then crosslinking agent, and foam stabilizer aqueous solution is added; while being aerated with nitrogen gas, the solution is ordinally added with polymerization initiator azodi (2-amidinopropane hydrochloride) aqueous solution, ammonium persulphate aqueous solution, sodium bisulfite aqueous solution and uniformly mixed; the aeration of nitrogen gas is stopped, and when the temperature of the solution is raised to 35 to 45 DEG C, the solution is added with foamer aqueous solution and uniformly mixed, so that porous gel is obtained; when the temperature is raised to 100 DEG C to 110 DEG C, the porous gel is put in the temperature environment of 80 to 90 DEG C for two the three hours; after being cooled down, the porous gel is taken out of a container, scissored into pieces, dried, crumbled and filtered, and grains are collected; crosslinking treatment agent is sprayed on the surface of grains, and after stirring and heating, the absorbent polymer is obtained. In three minutes, the volume of saline absorbed by the product prepared by the invention can reach 70 ml / gSAP.

Owner:段梦麟

Chinese medicine volatoile oil self-mciro emulsifying nano composition and preparing method

InactiveCN1748777ALess irritatingLow toxicityEmulsion deliveryPlant ingredientsIrritationCurative effect

The Chinese medicine volatile oil self micro emulsifying nanometer composition consists of Chinese medicine volatile oil 0.2-40 wt%, surfactant 0.4-80 wt%, co-surfactant 0-40 wt%, and water 0-99.40 wt%. The present invention applies self micro emulsifying technology in Chinese medicine volatile oil to make medicine, such as soft capsule and oral liquid, self micro emulsified in body to nanometer size, or make medicine, such as injection and inhalant, existing in bacteria-free solution. The prepared self micro emulsifying nanometer composition has reduced irritation and toxicity, raised absorption rate and mucous membrane penetrating capacity, raised bioavailability, raised curative effect and improved patientí»s compliance.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

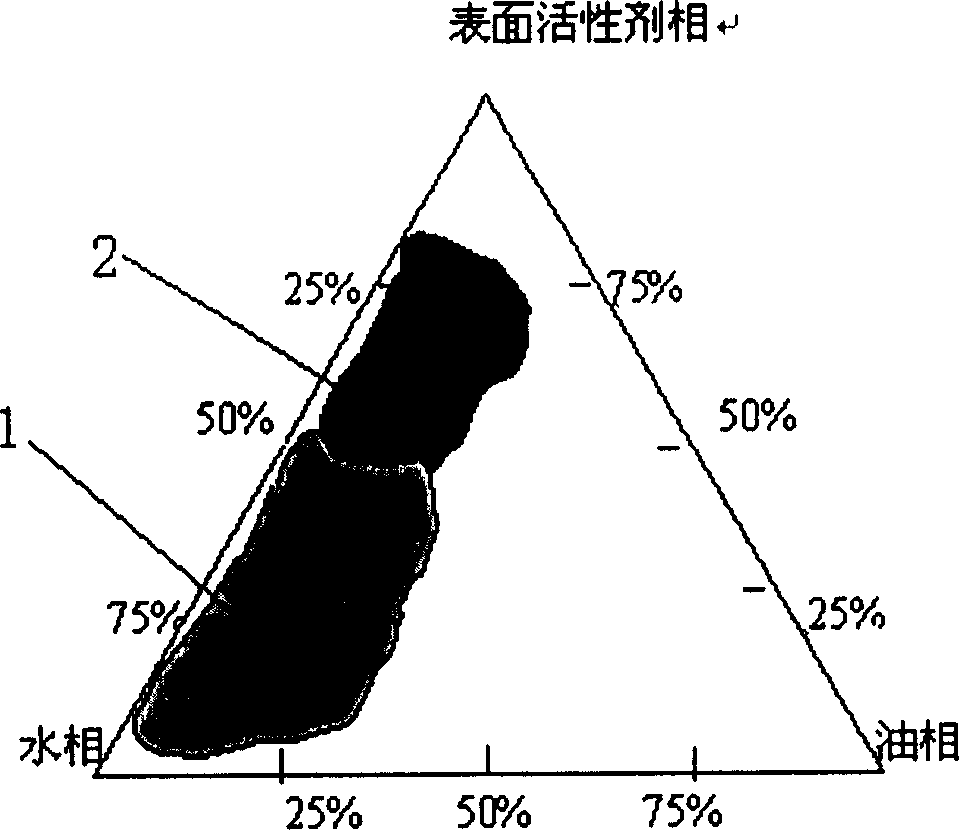

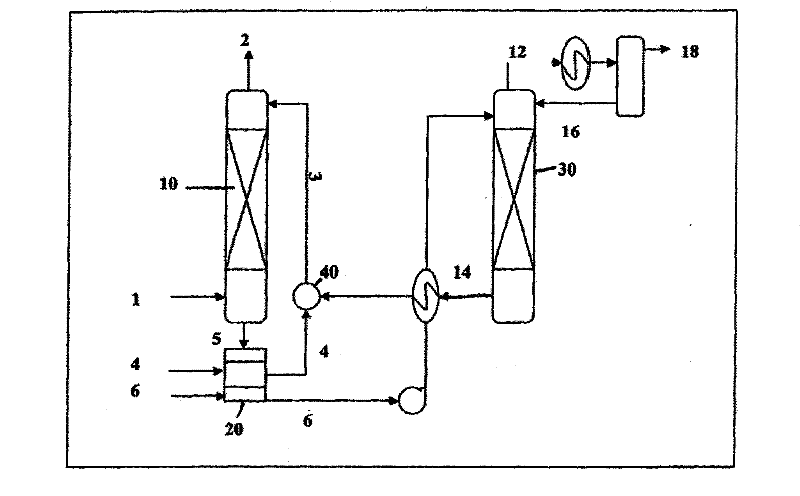

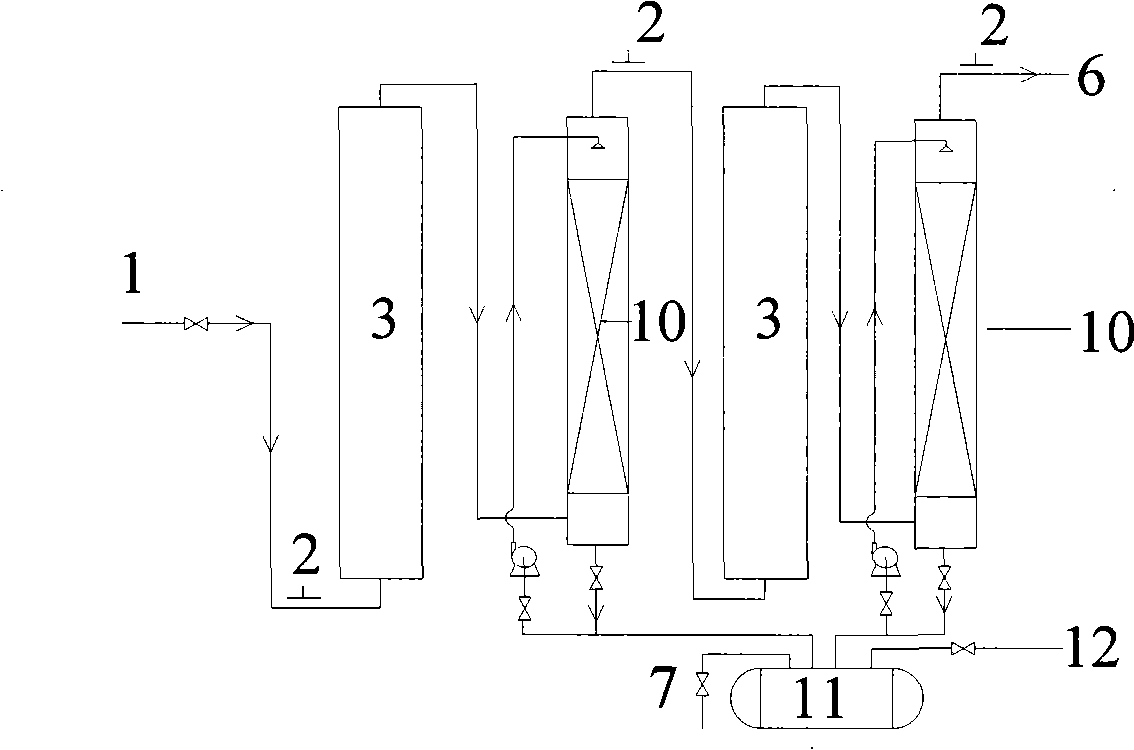

Methods and systems for deacidizing gaseous mixtures

InactiveCN102186559AReduce energy consumptionIncrease absorption rateGas treatmentCarbon compoundsDecreased energyGas phase

The invention provides a process for deacidizing a gaseous mixture. The method comprises absorbent is used to contact with the gaseous mixture in an absorbing unit, and the absorbent contains organic phase and load phase which do not mix with each other; the organic phase absorbs acid gas and transforms the acid gas into the absorptive acid gas so as to transform the absorbent into rich acid gas absorbent and transform the gaseous mixture into purified gaseous mixture; the absorbed acid gas is delivered to the load phase so that first poor acid gas phase and rich acid gas phase are formed in the rich acid gas absorbent to provide the rich acid gas phase to a separating unit to separate the first poor acid gas phase and rich acid gas phase; the separated first poor acid gas phase is recycled into the absorbing unit; the separated rich acid gas phase is provided to a regenerating unit to gain acid gas and second poor acid gas phase; and the second poor acid gas phase is recycled into the absorbing unit. The deacidizing process, compared with the prior art, decreases energy consumption to the minimum and increases the absorbing efficiency to the maximum.

Owner:胡亮

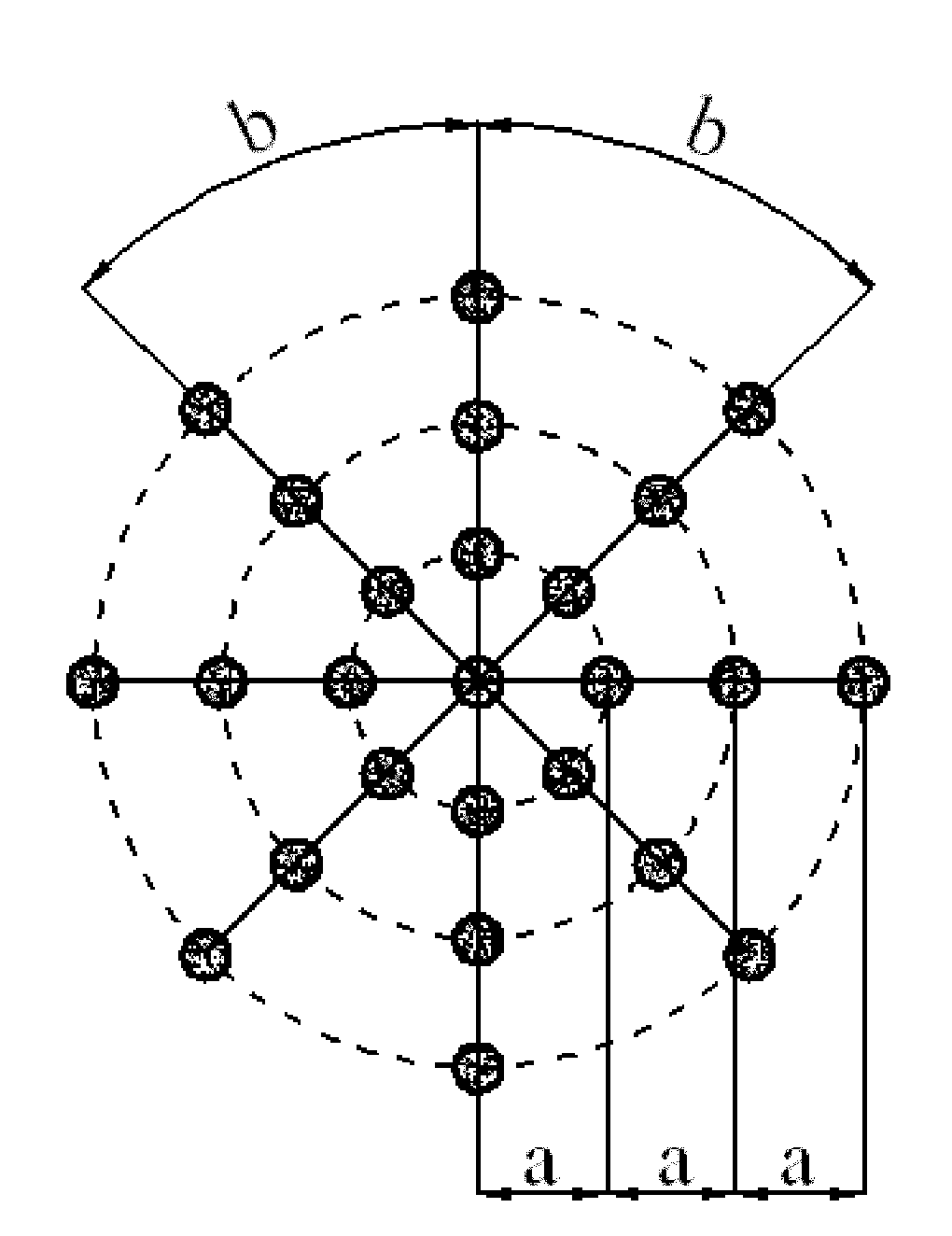

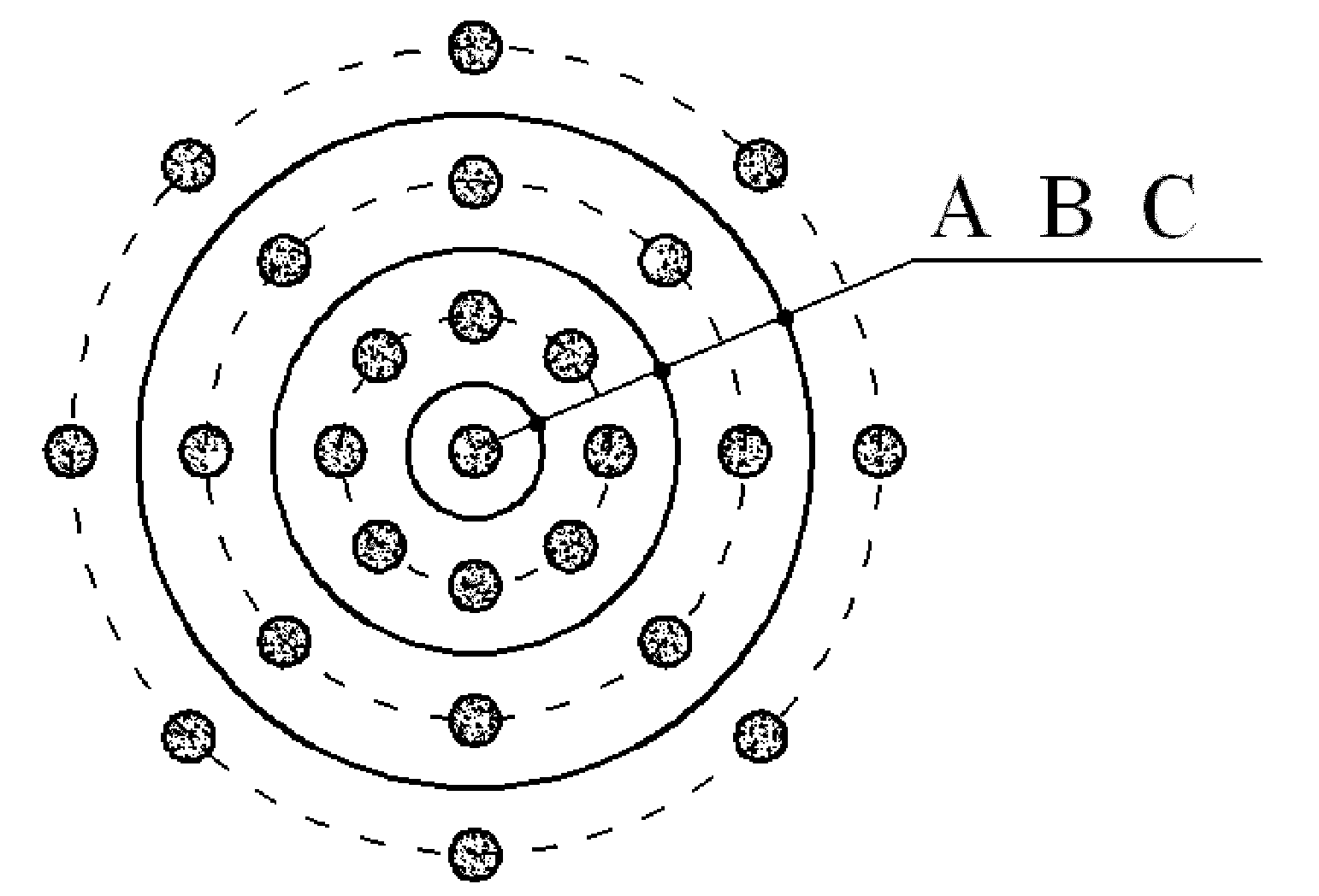

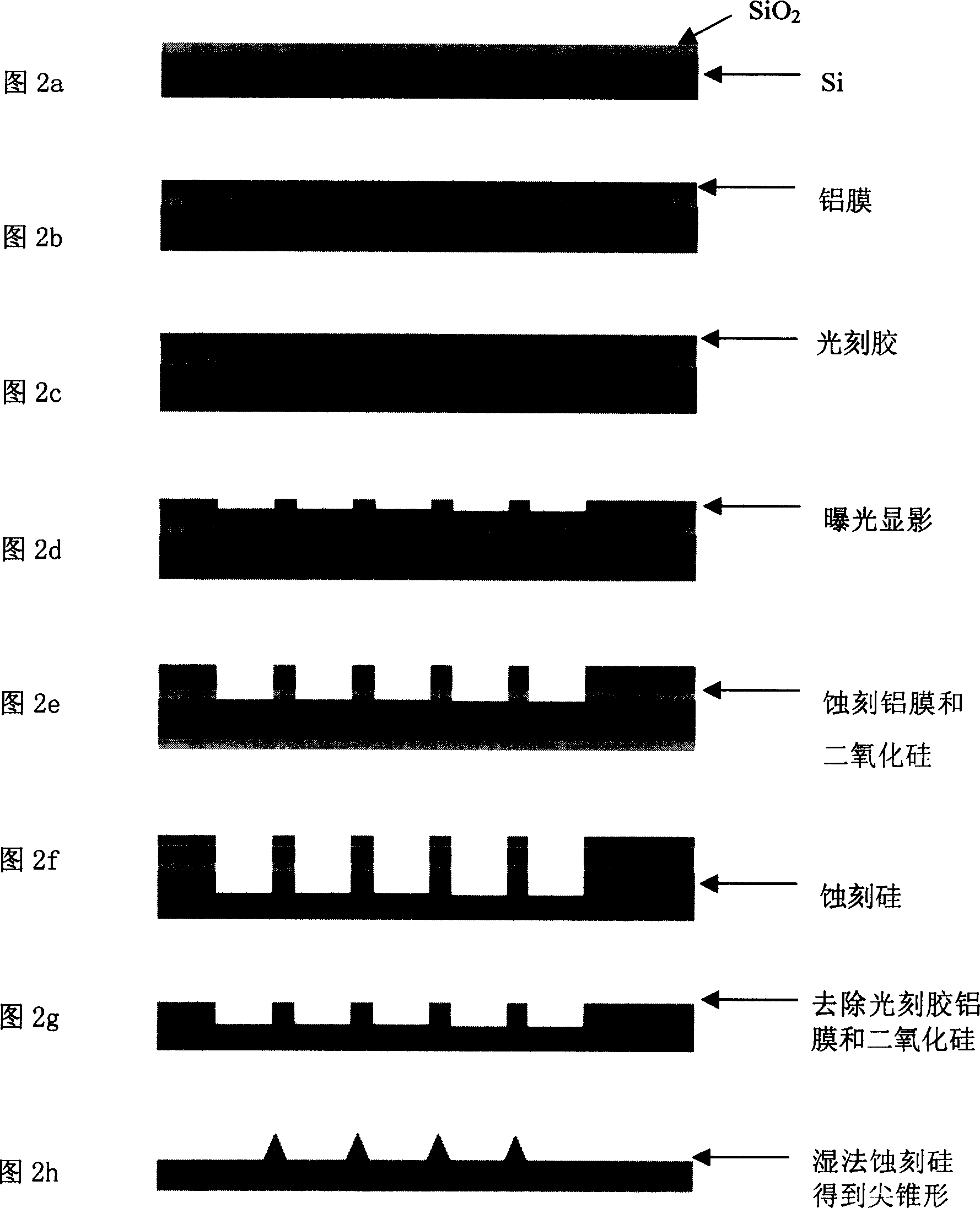

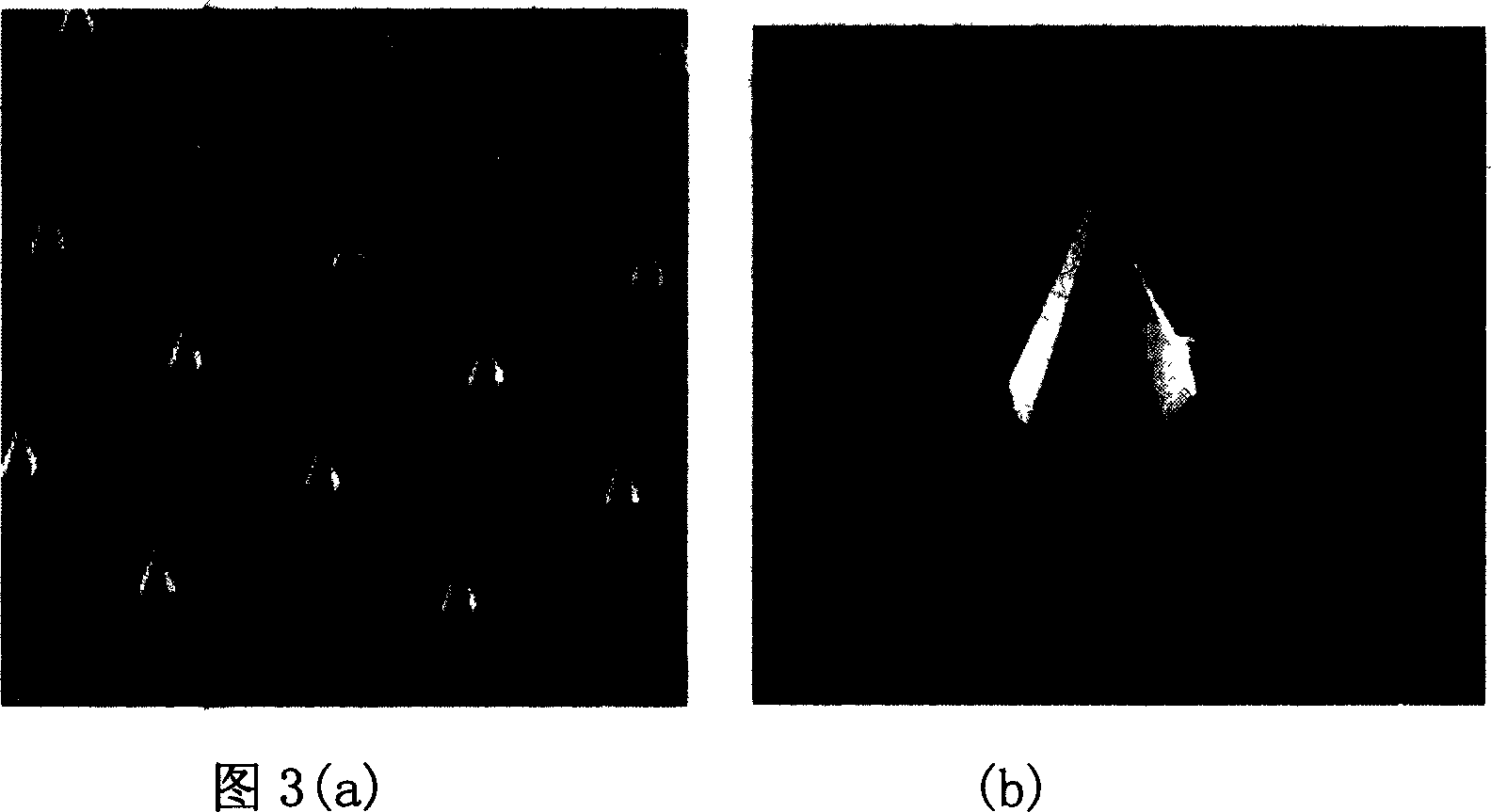

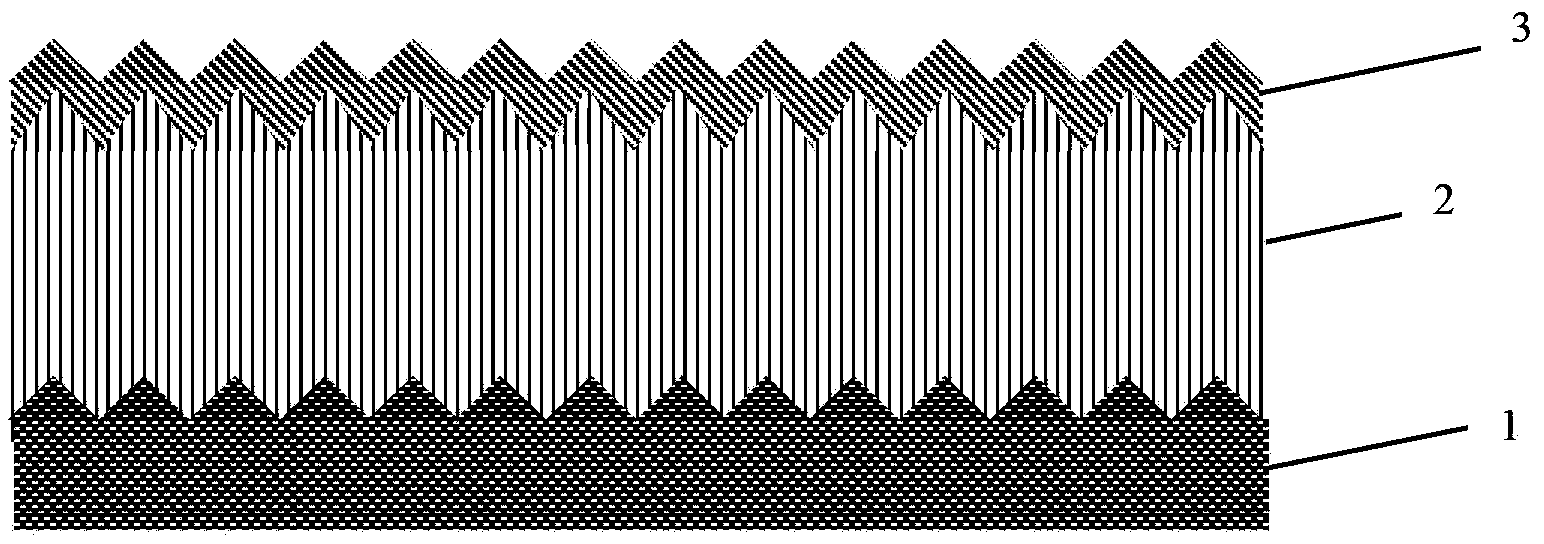

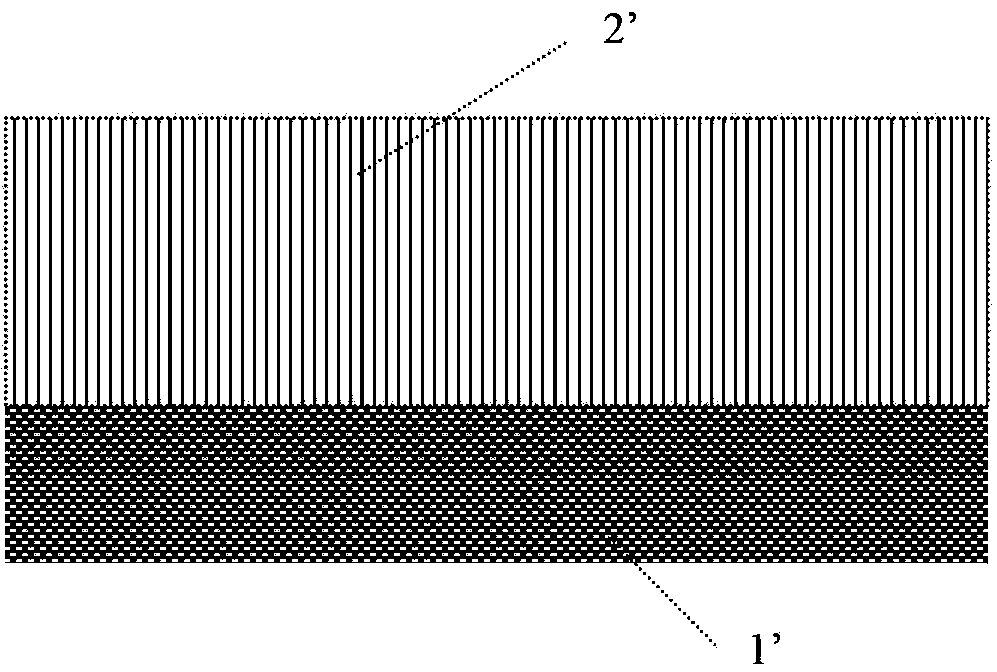

Minisize solid silicon needle array chip and its preparation method and use

ActiveCN1569271AIncrease absorption rateHigh mechanical strengthMicroneedlesMedical devicesMicroelectromechanical systemsDrug release

The invention belongs to a transdermal drug releasing device field. It relates in particular to a preparing method and usage of the minitype solid silicon pin array chip by monocrystalline silicon and Microelectromechanical systems(MEMS) technology. The minitype solid silicon pin array chip is processed by the adoption of photoengraving, wet etching, plasma dry etching, filming and other MEMS technologies. A side groove opens on the side of the mini pins, one or a plurality of drug storage pool being manufactured on the back of the solid mini pins by the combined utilization of double face alignment light photo technology, the drug dosage can be increased by the connection of the drug storage pool and the solid mini pin surface. The present invention has simple process and durable solid mini pins, being suitable for transdermal drug release of bio drug with macromolecules in particular.

Owner:SUZHOU NANOMED BIOMED CO LTD

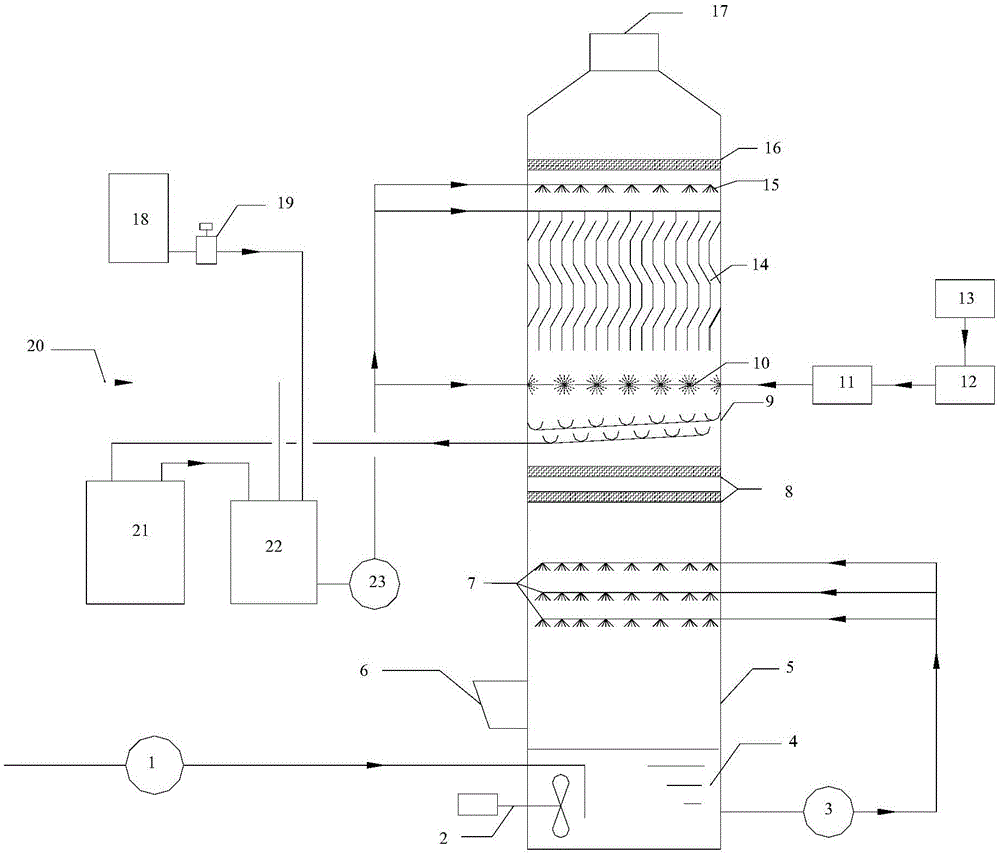

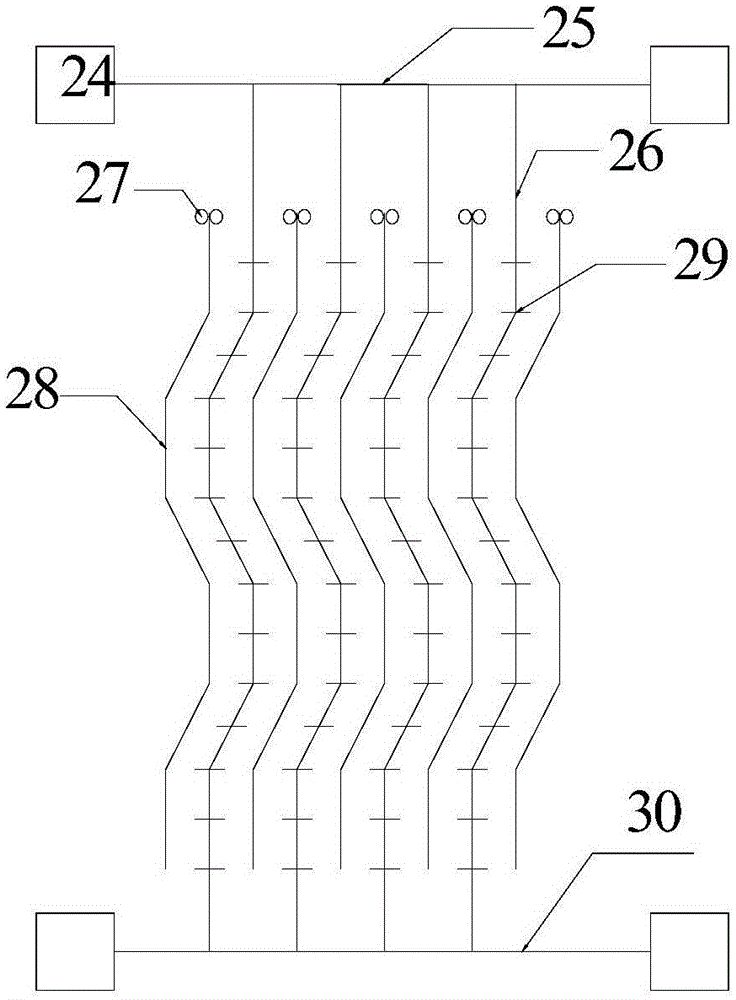

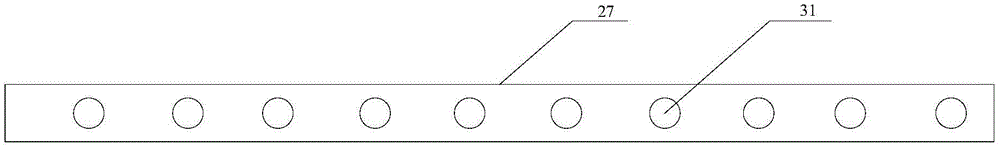

Super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas

ActiveCN105080311AWell mixedIncrease profitCombination devicesExternal electric electrostatic seperatorElectricitySlurry

The invention discloses a super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas. The treating technology includes the steps that the exhaust gas is fed into an absorption tower through an exhaust gas inlet of the absorption tower and upwards flows, desulfurization spraying and primary demisting are sequentially carried out, ozone oxidation, alkali liquor atomization mixing denitration and wet-type electric precipitation are carried out at the same time, secondary demisting is finally carried out, and then the exhaust gas is exhausted through an exhaust gas outlet in the top of the absorption tower; ozone and denitration absorption liquor are fed into an oxidation and denitration section through an air way and a liquor way respectively and mixed through double-fluid denitration spraying guns to be atomized and sprayed into the exhaust gas; slurry generated by desulfurization spraying falls into a slurry pond, and air is introduced into the slurry pond for oxidation; atomization alkaline liquor is captured through wet-type electric precipitation, and washing water generated in the wet-type electric precipitation process and washing water generated after wet-type electric precipitation are collected through a liquid collecting tank and temporarily stored and filtered outside the absorption tower to be reused as washing water. By means of the super-clean exhausting integral tower and treating technology, the desulfurization efficiency of the absorption tower is improved; meanwhile, denitration, dust removing and demisting can be achieved, and therefore the coal-fired exhaust gas can meet the stricter exhausting standard.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Gas phase oxidation-liquid phase reduction method for absorbing and removing nitrous oxides in exhaust air

InactiveCN101279185AAchieve emission standardsSimple processDispersed particle separationGas phaseEmission standard

The invention provides a gas-phase oxidation / liquid-phase reduction method for absorbing and removing NOx. The method utilizes O2 in waste gases as an oxidizer; after be processed by non-catalyst oxidization or catalyzed oxidation by modified active carbon materials, NOx waste gas with low oxidization degree reacts with an alkaline reducing solution fully to remove NOx. After going through multi-grade oxidization, reduction and absorption, the NOx in waste gases can fully meet the emission standard. The method of the invention has the advantages of being able to realize up-to-standard emission of NOx waste gas with low oxidization degree, simple technique, small cost and high removing efficiency.

Owner:ZHEJIANG UNIV OF TECH

Liquid absorbent for removing hydrogen sulfide in oil gas

The invention provides liquid absorbent for removing hydrogen sulfide in oil gas. The liquid absorbent comprises two types of substance, one is six-hydrogen triazine compounds, and the other one is pbo alkanes compounds. Both the six-hydrogen triazine compounds and the pbo alkanes compounds have absorptive action on hydrogen sulfide, present a homogenous phase after being mixed according to a certain proportion and has extremely water solubility; compared with an existing product, the rate of absorption is increased, and absorption efficiency is improved. By means of the hydrogen sulfide absorbent, corrosion, caused by hydrogen sulfide, to metal equipment and pipes can be relieved, working personnel is protected against harm of hydrogen sulfide poisonous gas, and the situation that the environment is polluted by hydrogen sulfide is prevented.

Owner:SHENGLI OILFIELD SHENGLI CHEM +1

Zr-Co-Re thin film getter provided with protection layer, and preparation method thereof

InactiveCN103849835AIncrease speedIncrease inspiratory capacityVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

The invention relates to a Zr-Co-Re thin film getter provided with a protection layer, and a preparation method thereof. The Zr-Co-Re thin film getter is composed of a getter layer and the protection layer; main components of the getter layer are Zr, Co, and one or more selected form rare earth elements La, Ce, Pr, and Nd; and main component of the protection layer is Ni. Pulsed laser deposition film plating is adopted, and deposition of the double-layer structured thin film getter containing the protection layer and the getter layer on texture monocrystalline silicon is carried out. The texture substrate is capable of increasing effective area of the getter thin film, and so that inspiratory flow rate and inspiratory capacity are increased. The surface of the getter layer is plated with a Ni protection layer; Ni is capable of realizing dissociation of hydrogen, and increasing absorption amount of hydrogen; and the Ni protection layer is capable of inhibiting absorption of oxygen and reducing activation temperature. Activation of the Zr-Co-Re thin film getter can be realized in roasting processes at a temperature of 180 to 350 DEG C; after roasting, the Zr-Co-Re thin film getter possesses excellent inspiration performance at room temperature, can be used for internal gas residue removing of high vacuum microelectronic devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

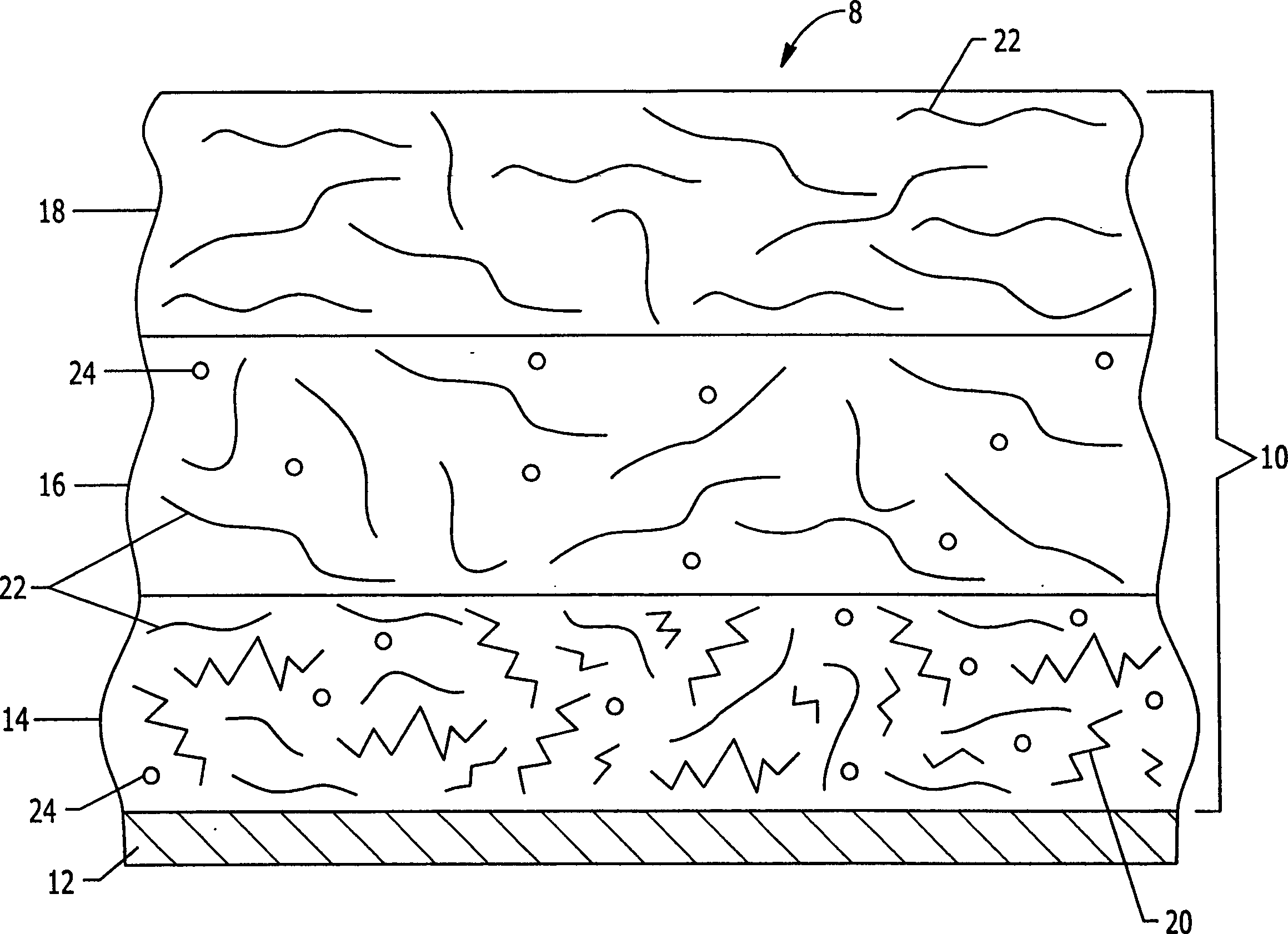

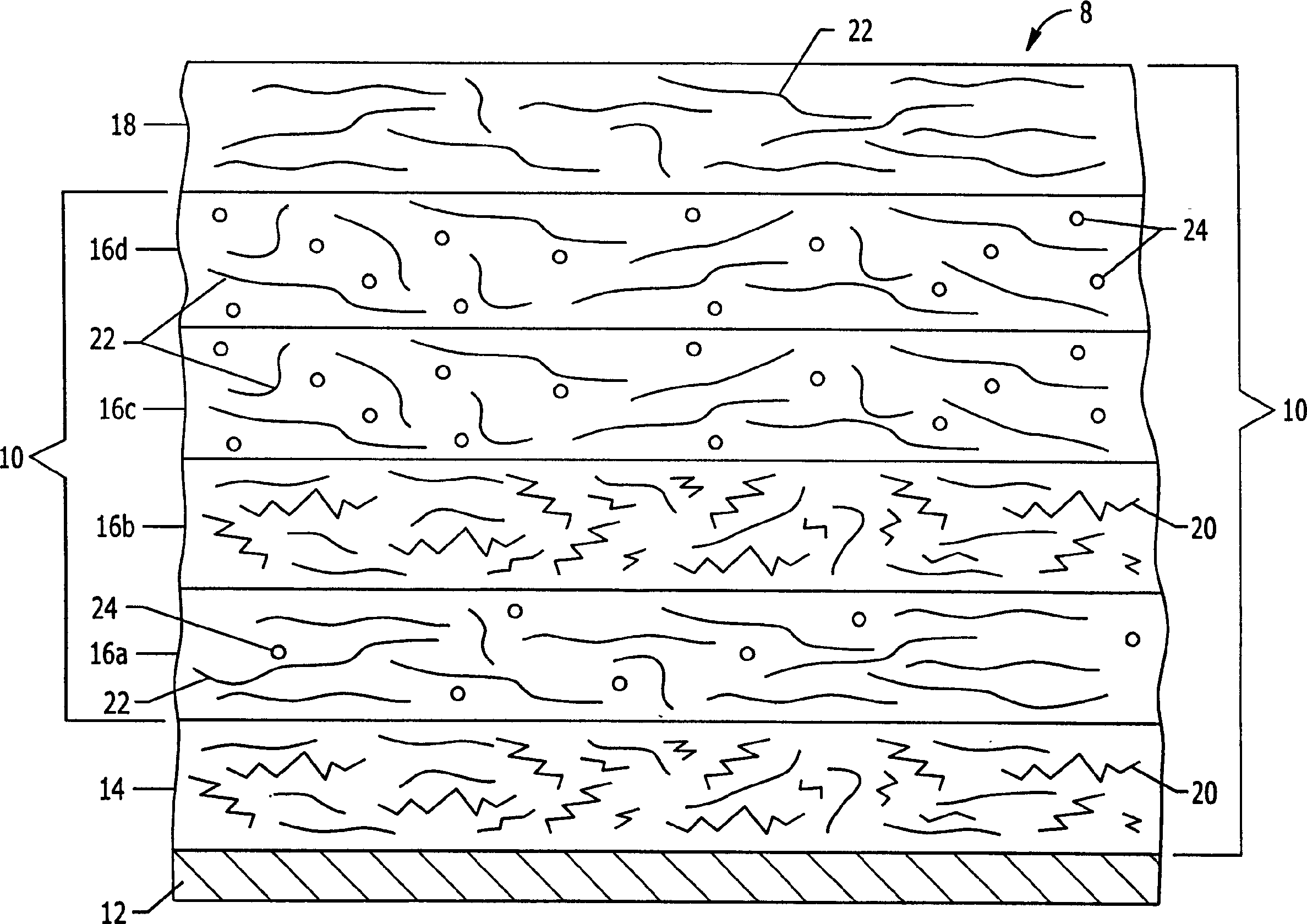

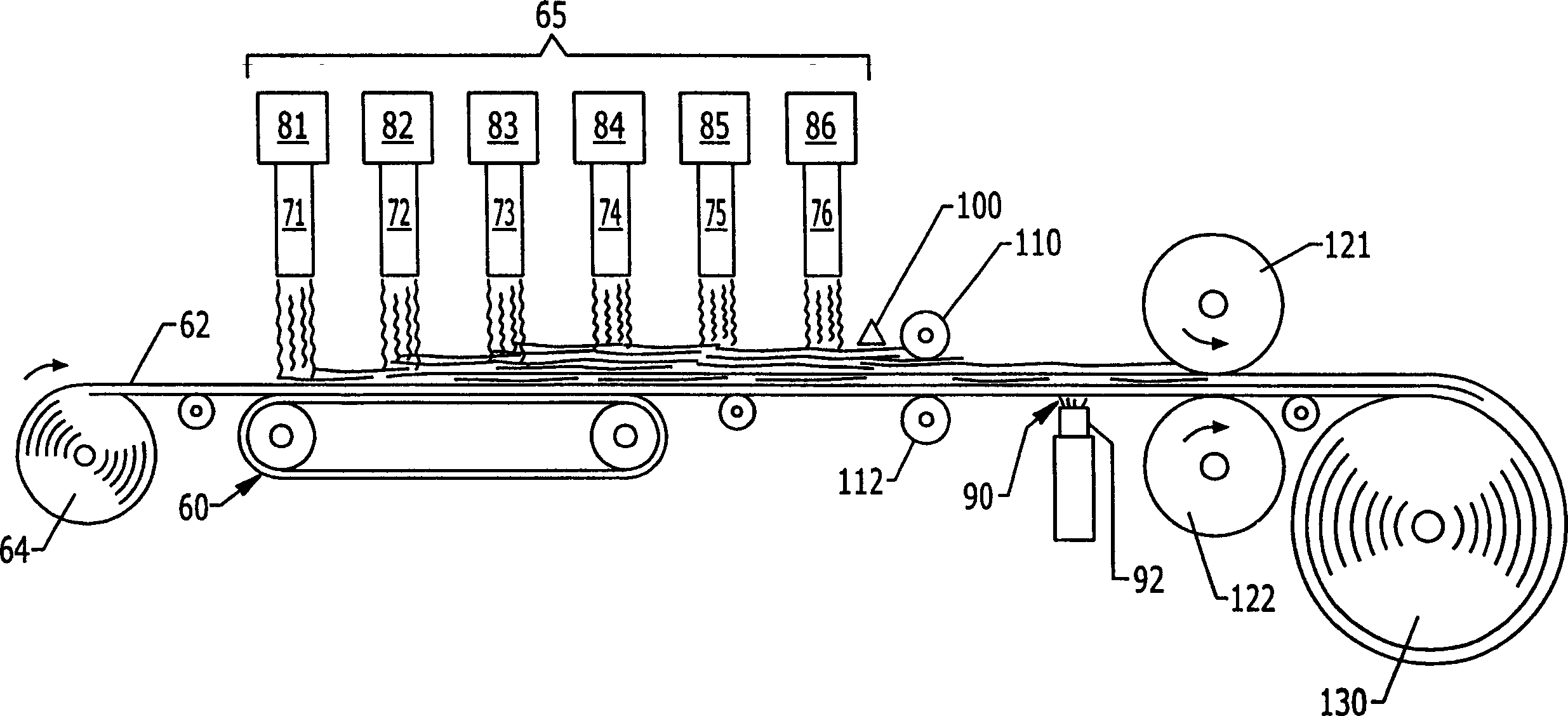

Absorbent cores with improved intake performance

InactiveCN1658810AImprove transmission performanceImproves liquid transfer propertiesAbsorbent padsBaby linensFeminine Hygiene ProductsBiomedical engineering

Multilayered absorbent cores are provided that include synthetic fiber to improve the liquid transport properties of the resulting absorbent articles. The synthetic fiber, which may be found in either the innermost and / or intermediate layers of the absorbent core, particularly improve the rewet performance of the absorbent article. The absorbent cores may be incorporated into a number of absorbent articles, including diapers, feminine hygiene products and incontinence pads.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

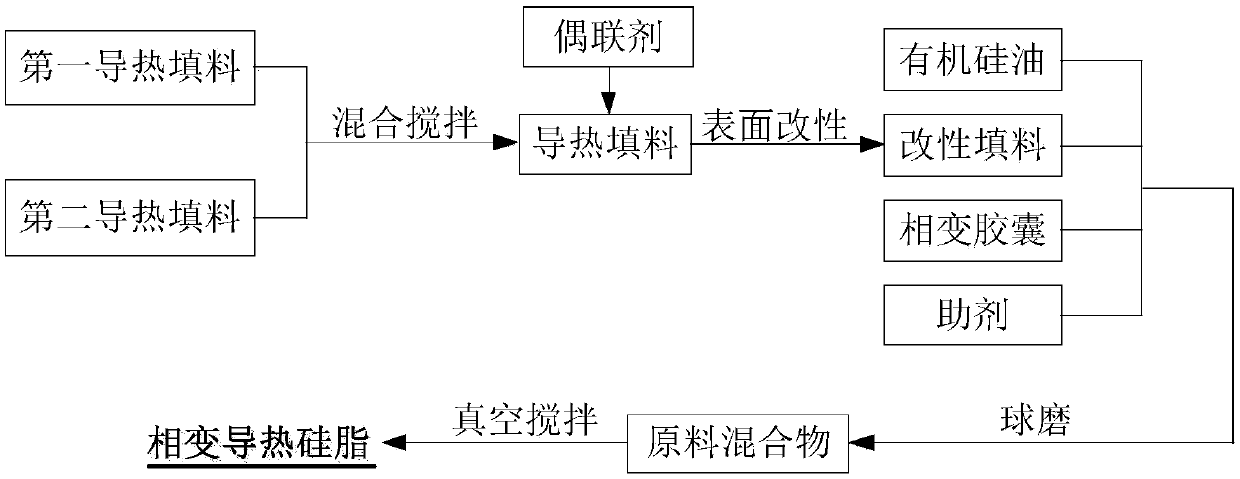

Phase-change heat-conducting silicone grease and preparation method thereof

PendingCN108047722AHigh thermal conductivityLarge specific surface areaHeat-exchange elementsHeat conductingPhase change

The invention provides phase-change heat-conducting silicone grease and a preparation method thereof. The phase-change heat-conducting silicone grease is prepared from organic silicone oil, phase-change capsules, heat-conducting filler and an assistant. The invention also provides the preparation method of the phase-change heat-conducting silicone grease. The preparation method comprises the following steps: preparation of modified heat-conducting filler, preparation of a raw-material mixture, vacuum stirring treatment and the like. The phase-change heat-conducting silicone grease prepared bythe method has the beneficial effects that the fluidity and the wettability are good, the service life is long, the compatibility between the heat-conducting filler and the silicone oil is good, the heat-storage function is achieved, the interfacial thermal contact resistance of nodes and a radiating device of a high-power electrical appliance can be effectively reduced, and the heat transfer canbe accelerated; the preparation process is simple, the cost performance is high, and the application is wide.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

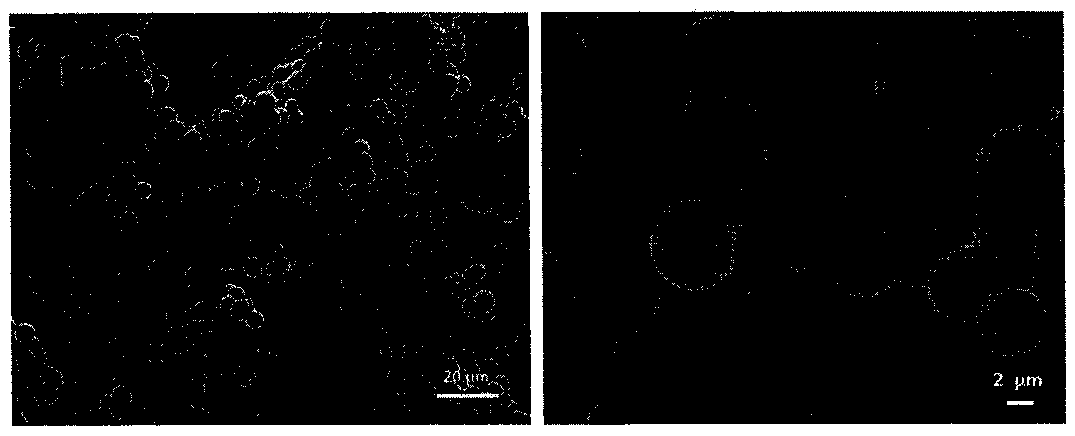

High liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use

ActiveCN106279494AHigh specific surface areaStrong foaming abilityCoatingsAbsorption rateStorage material

The invention provides high liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use. The high liquid absorption rate acrylic acid water-absorbent resin is prepared from acrylic acid, an alkali, water, a cross-linking agent, a high temperature-resistant foaming agent, a copolymerization monomer, a reducer and an initiator. A mass ratio of the acrylic acid, alkali to water is (25-45): (7-22): (33-68) and based on the acrylic acid mass, a use ratio of the cross-linking agent is in a range of 0.001-1wt%, a use ratio of the high temperature-resistant foaming agent is in a range of 0.01-2wt%, a use ratio of the copolymerization monomer is in a range of 0-10wt%, a use ratio of the reducer is in a range of 30-500ppm and a use ratio of the initiator is in a range of 0.001-1wt%. A high liquid absorption rate of the acrylic acid water-absorbent resin is 15-40s. The acrylic acid water-absorbent resin can be used as a liquid absorption material in fields of paper diapers, baby diapers and sanitary napkins in the health care industry and can also be used as a water absorption and storage material in industries of desert treatment, water blockage in an oil field and agricultural and forestall water retention.

Owner:WANHUA CHEM GRP CO LTD

Synthetic method for instant-absorption type super absorbent resin

InactiveCN103408689AImprove gel barrier phenomenonThe effect of absorption ratio is smallCross-linkOil phase

The invention relates to a synthetic method for a high-speed instant-absorption type super absorbent resin. The synthetic method comprises the following steps: 1) adding a copolymerization water-soluble monomer, a cross-linking agent and an initiator into a mixed aqueous solution of acrylic acid and sodium hydroxide, placing an obtained mixture in a glass container and carrying out stirring so as to prepare a water phase solution; 2) with a dispersant as a continuous phase of inverse emulsion polymerization, adding the dispersant into a reaction flask and then adding an emulsifier and a copolymerization hydrophobic monomer to prepare an oil phase solution; and 3) adding the water phase solution into the oil phase solution drop by drop, carrying out mixing and high speed stirring for emulsification, allowing a temperature to gradually rise after uniform stirring of a system, wherein time for a later-period polymerization reaction is 2.5 to 3.5 h, cooling to room temperature after completion of the reaction and successively carrying out filtering, washing and vacuum drying so as to obtain the white powdery water-absorption resin. The invention has the following beneficial effects: since synthesis conditions are simple, the imbibition rate of the resin can be improved while high water absorbency is maintained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Water-absorbent material mainly used for diaper or pad and production method thereof

InactiveCN101491685AMaintain antibacterial and deodorizing abilityIncrease absorption rateAbsorbent padsNon-woven fabricsMedical productChitin formation

The invention provides a water absorbing material mainly used for napkin and diaper and a production method thereof. The water absorbing material mainly comprises the following compositions in portion by mass: 10 to 45 portions of water-absorption modified polyacrylonitrile fiber, and 55 to 90 portions of a bamboo carbon fiber. 1 to 35 portions of chitin antibacterial moisture-conductive acrylic fiber can be mixed into the compositions. The water absorbing material is processed into non-woven fabric by the water-absorption modified polyacrylonitrile fiber and the bamboo carbon fiber through mixing, opening, carding, spreading, needling, shaping and other steps, overcomes the deficiency of single fiber, has comprehensive performance higher than other materials mixed with other fibers and the water-absorption modified polyacrylonitrile fiber, is applicable to napkin and diaper, or other water absorbing living or medical products, and has the advantages of simple and practical process and low cost.

Owner:严哲文

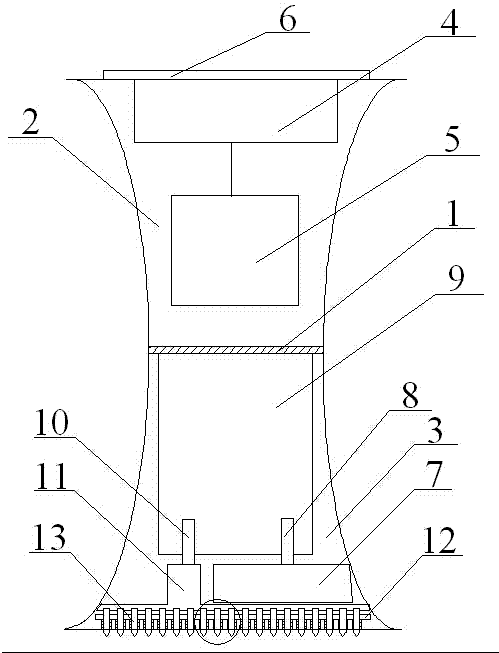

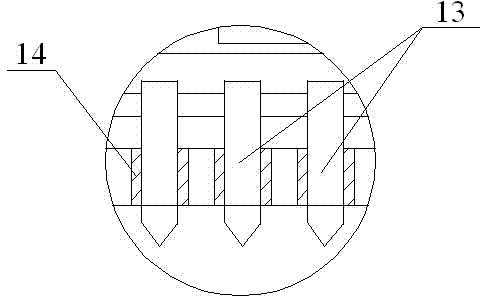

Ultrasound micro-needle composite transdermal drug delivery device

InactiveCN104117138AAdjust the applicable lengthIncrease contact areaMicroneedlesMedical devicesPeristaltic pumpDrug Storage

The invention relates to an ultrasound micro-needle composite transdermal drug delivery device which comprises an ultrasound transdermal drug delivery system and a porous micro-needle transdermal drug delivery system. The ultrasound transdermal drug delivery system comprises an ultrasonator, a control mechanism and an ultrasonic wave transmission dielectric layer arranged on the outer side of an end plate of a shell; the porous micro-needle transdermal drug delivery system comprises a drug storage pool, a liquid inlet pipe, a miniature peristaltic pump, a liquid outlet pipe, a drug inlet pool and poly-p-xylylene thin film, a plurality of micro needles are arranged on the poly-p-xylylene thin film, one end of each micro needle is communicated with the drug inlet pool, and the other end of each micro needle is used for being in contact with the skin for drug delivery. The ultrasound micro-needle composite transdermal drug delivery device solves the technical problems that irritabilities of patients are prone to being caused by an existing transdermal drug delivery device, the existing transdermal drug delivery device is low in drug delivery speed and poor in drug delivery effect, and the lengths of the micro needles cannot be adjusted when the existing transdermal drug delivery device acts on different parts of the human body so that the existing transdermal drug delivery device is limited in application range; the ultrasound micro-needle composite transdermal drug delivery device is high in drug delivery speed, good in drug delivery effect and suitable for application and popularization.

Owner:HENAN UNIV OF SCI & TECH

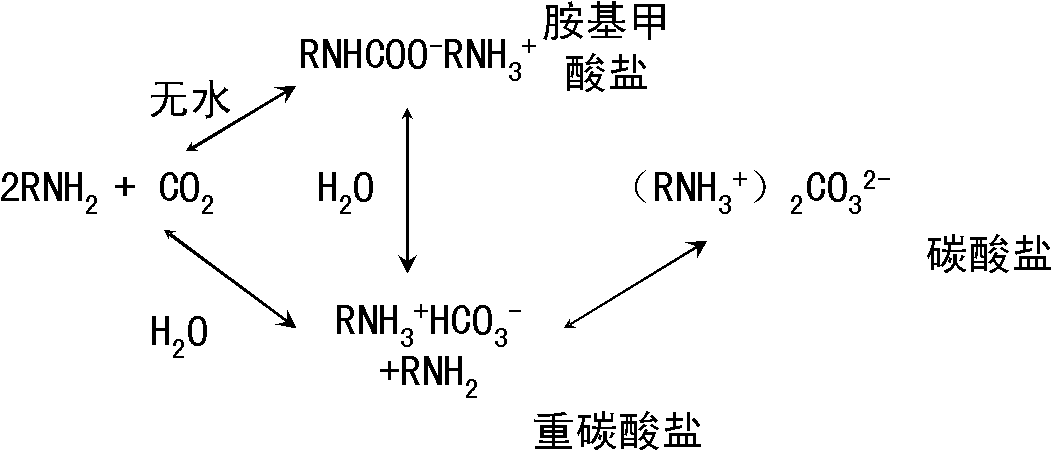

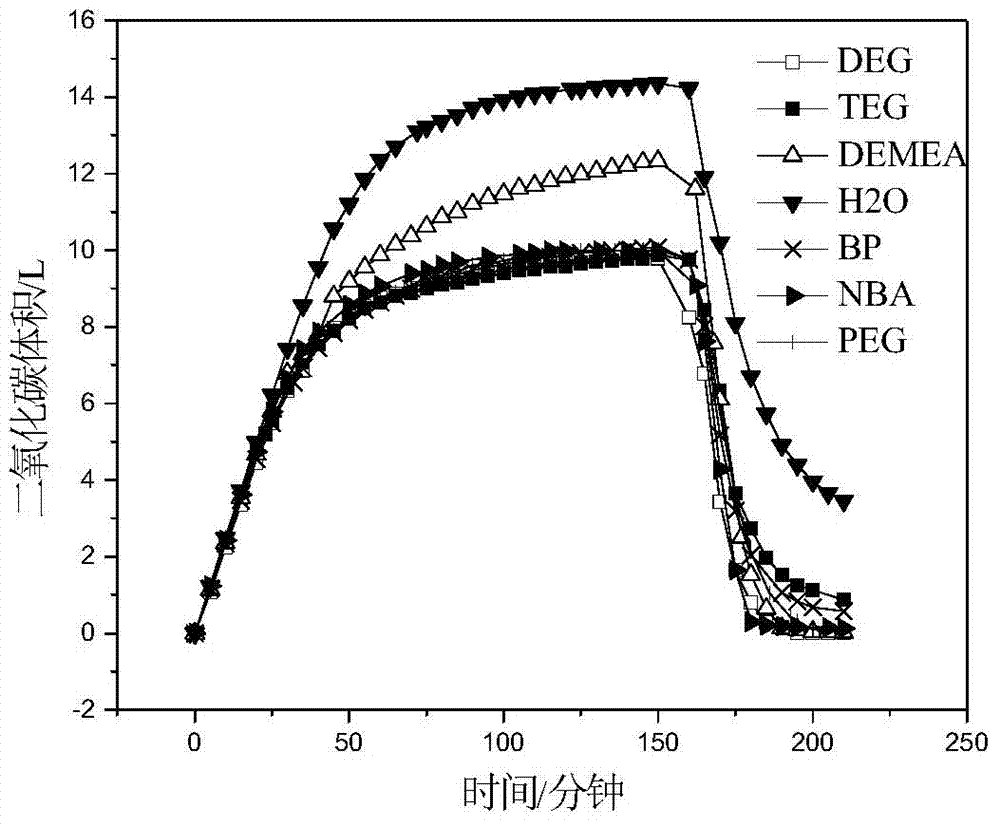

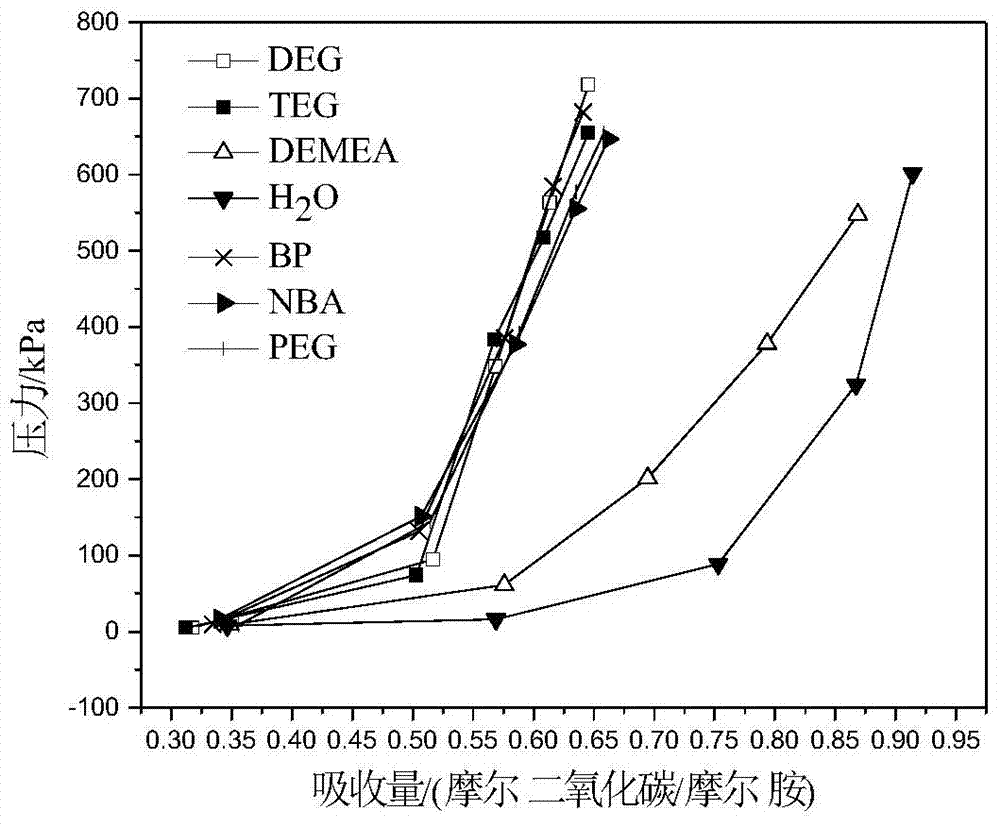

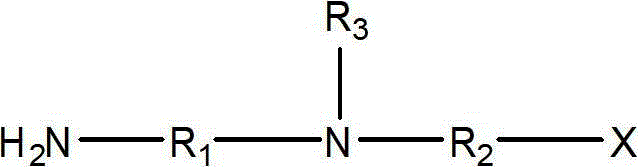

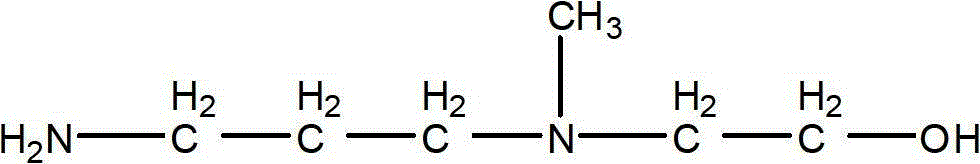

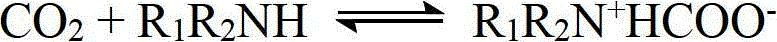

Non-aqueous decarburization solution for capturing carbon dioxide in mixed gas and application thereof

ActiveCN104492226AImprove corrosion resistanceLow regeneration energy consumptionDispersed particle separationAir quality improvementChemical reactionAbsorption capacity

The invention provides non-aqueous decarburization solution for capturing carbon dioxide in a mixed gas, and belongs to the technical field of capturing of carbon dioxide gas. The invention relates to a non-aqueous decarburization solution, wherein a main absorption component is N-ethyldiethanolamine, and a solvent is N,N-diethylethanolamine. Because the non-aqueous decarburization solution has a high boiling point and low viscosity, uses tertiary amine capable of participating in CO2 absorption as the solvent, and uses secondary amine with a fast absorption speed and a high absorption amount, and easy to regenerate as the main absorption solvent, the absorption capacity, purification degree and desorption speed for carbon dioxide are increased, the temperature range of the reaction is expanded, the volume of a regeneration tower is reduced, the energy consumption of the regeneration is greatly reduced, and the equipment investment and operation cost are reduced. The non-aqueous decarburization solution provided by the invention is mainly used for capturing carbon dioxide in the tail gases of multiple chemical reactions, the tail gases of steel plants and cement plants, ore decomposition gas, combustion flue gas, natural gas, city gas and marsh gas, and has wide application prospect.

Owner:DALIAN UNIV OF TECH

Novel absorbent for capturing and separating carbon dioxide

ActiveCN102974203AReduce heat of reactionImprove stabilityDispersed particle separationBy chemical separationAbsorption capacityDesorption

The invention belongs to the technical field of gas separation and purification and relates to a novel absorbent for capturing and separating CO2 in mixed gas. An active amine compound aqueous solution with a special structure is used as an absorbent; two functional groups, namely a primary amine functional group and a tertiary amine functional group, are contained in the active amine molecules; primary amine is mainly used for improving the absorption rate, and tertiary amine is mainly used for increasing the absorption amount and reducing the desorption temperature; and the two types of amine can promote activation. The active amine compound aqueous solution comes into contact with treated gas to purify gas; and the concentration of the absorbent is 5-80wt%. The absorbent provided by the invention is wide in amine concentration range, high in CO2 absorption rate, large in absorption capacity and low in desorption temperature and causes little corrosion to equipment. The novel absorbent can be widely applied to separation and purification of CO2 in natural gas, transformation gas, flue gas and synthesized gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Anion type polymer containing tetramethylguanidine cation and its preparation method and uses

InactiveCN1884315ASimple preparation processMild conditionsDispersed particle separationPolymer scienceCarboxylic acid

The invention discloses a cross-linked anion polymer containing tetramethylguanidine cation and it's preparing method and usage. The anion in anionic construction unit is carboxylate anion, contra-ion is 1, 1, 3, and 3- tetramethylguanidine cation (tetramethylguanidine cation for abbreviation). The polymer is prepared through polymerization of ionic vinyl monomer which is got through neutralization of vinyl monomer containing carboxy group with 1, 1, 3, and 3- tetramethylguanidine (tetramethylguanidine for abbreviation). Said polymer is porous particle, and can be used as desulfurizer to absorb sulfur dioxide, the absorption is characterized by high selectivity, large absorption capacity and rapid speed; said polymer can be reused for several times. The method is characterized by simple process, soft condition, short reacting time and high productivity.

Owner:ZHEJIANG UNIV

Astaxanthin self-emulsifying soft capsule preparation and preparation thereof

InactiveCN101301282APrevent oxidationImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismVegetable oilMass ratio

The invention discloses an astaxanthin self-emulsifying soft capsule preparation and a method for preparing the same, which relates to an astaxanthin preparation, in particular to the astaxanthin self-emulsifying soft capsule preparation capable of self-emulsifying in a body after oral administration as well as the method for preparing the same. The invention provides the astaxanthin self-emulsifying soft capsule preparation which has high bioavailability and good oxidation resistance and can self-emulsify in the body after the oral administration. The compositions of the astaxanthin self-emulsifying soft capsule preparation and the content by mass ratio are as follows: astaxanthin raw material: oil phase: emulsifier: coemulsifier is equal to 1: 20-60: 10-70: 0-30, wherein, an oil phase adopts natural vegetable oil or fatty acid ester, the emulsifier adopts nonionic emulsifier, and the coemulsifier adopts chain alcohol or short chain alcohol. The astaxanthin raw material, the oil phase, the emulsifier and the coemulsifier are added into a container, N2 is aerated into the container, and astaxanthin self-emulsifier is obtained by ultrasonic vibration; and the astaxanthin self-emulsifier is cooled to be the room temperature and is pressed to obtain the astaxanthin self-emulsifying soft capsule preparation.

Owner:XIAMEN UNIV

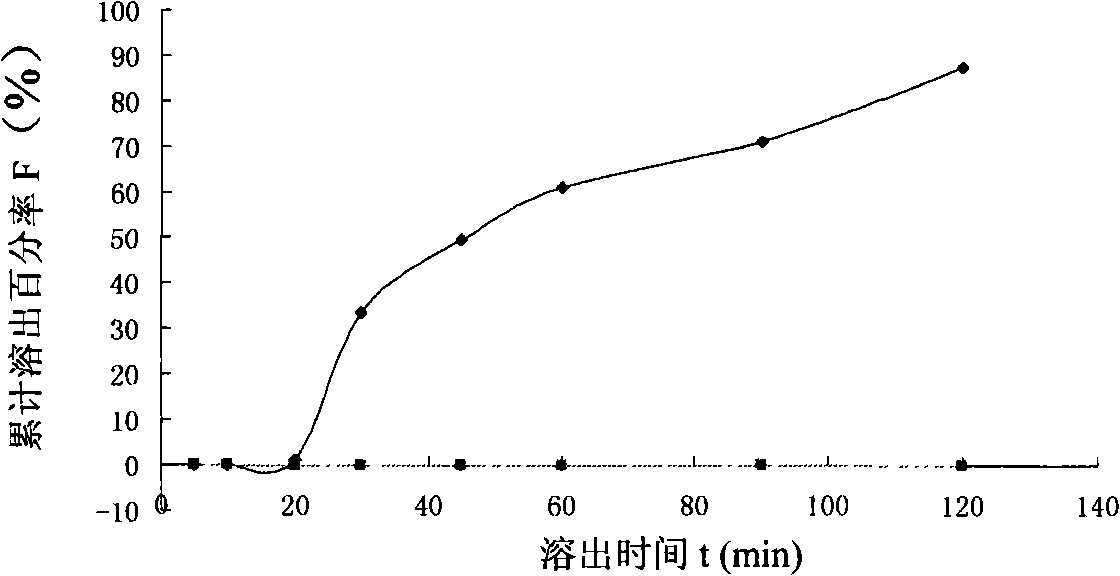

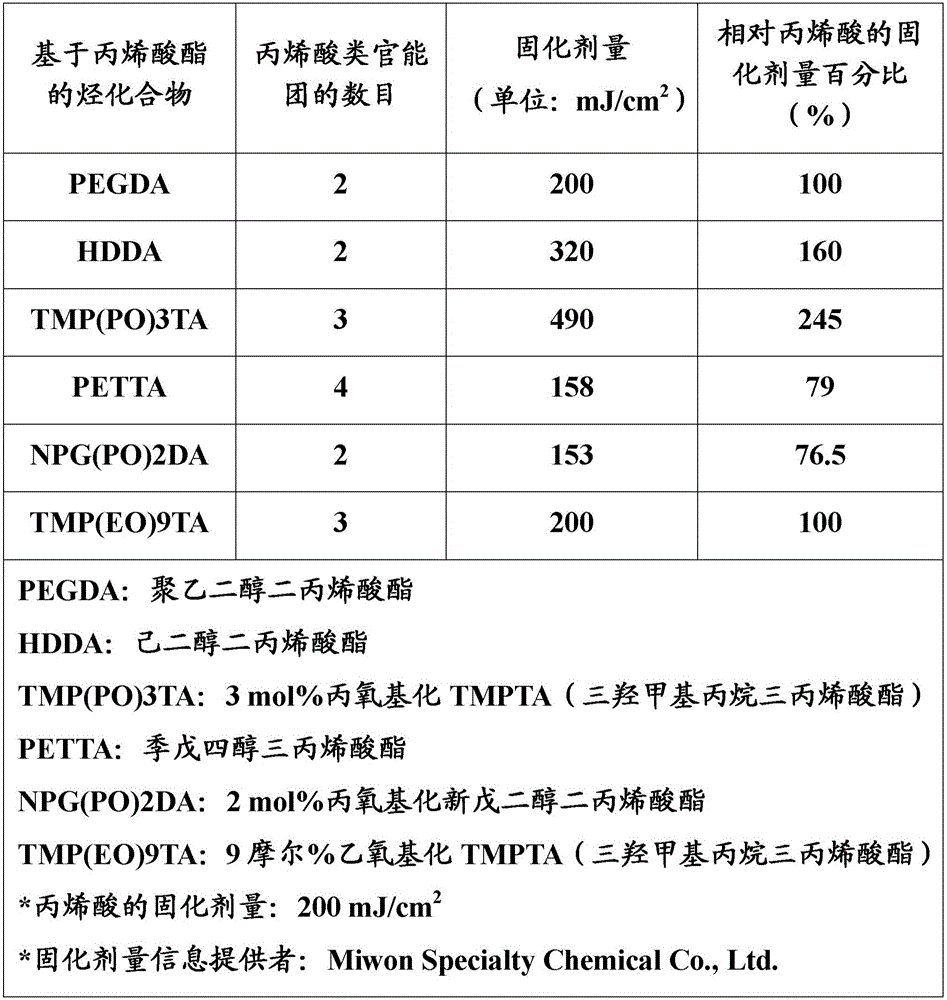

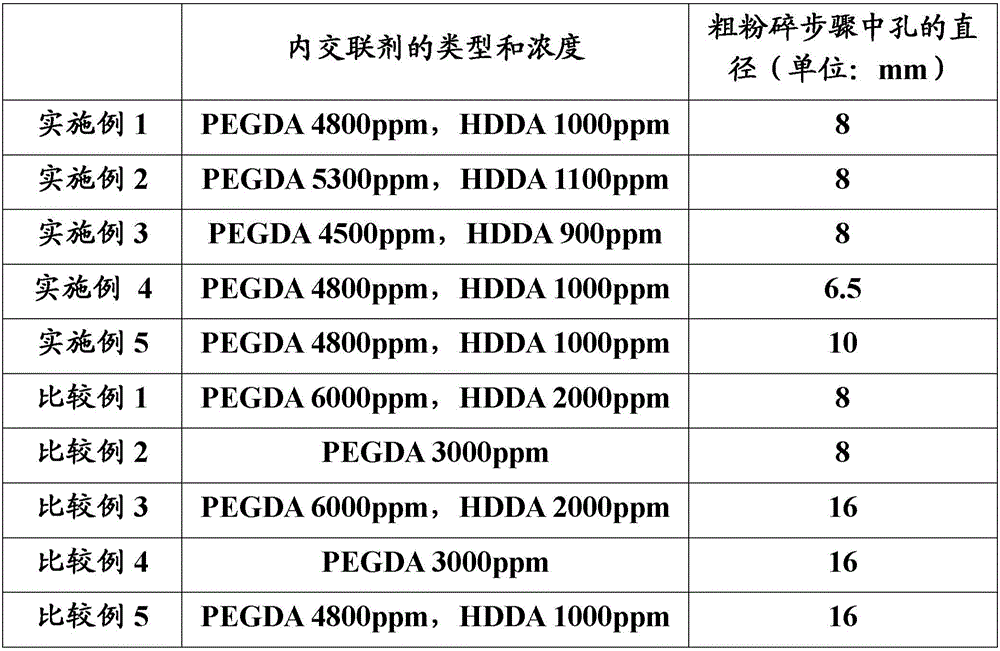

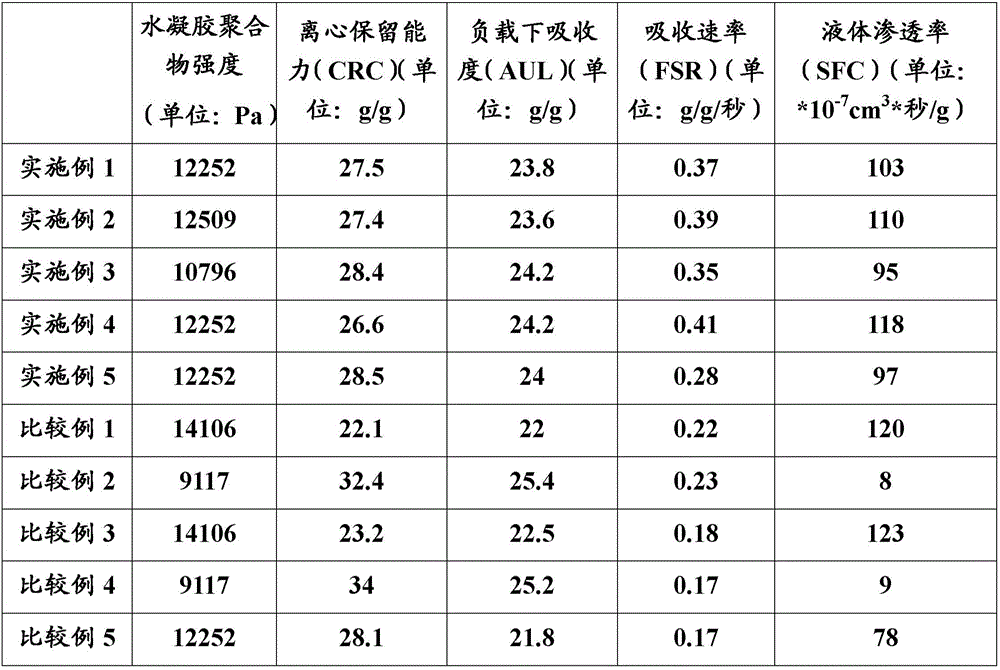

Method for preparing super-absorbent resin

ActiveCN105814088AIncrease absorption rateImprove permeabilityAbsorbent padsProsthesisSuper absorbentAbsorption rate

The present invention relates to a method for preparing a super-absorbent resin. According to the method for preparing a super-absorbent resin, a super-absorbent resin which has an improved absorption rate and solution permeability, no deterioration in water retaining capacity or pressurized absorptive capacity, and improved physical properties can be provided.

Owner:LG CHEM LTD

Deacidification process and system for gas mixtures containing acid gases

InactiveCN104548874AIncrease absorption rateReduce the totalDispersed particle separationAbsorption rateChemistry

The invention relates to a deacidification process for gas mixtures containing acid gases. The acid gases are separated from the gas mixtures through absorption of the acid gases by the aid of an absorbent and concentration. The invention further relates to a deacidification system for the gas mixtures containing the acid gases. The system comprises an absorption unit, a concentration unit, a separation unit and a regeneration unit. With the adoption of the process and the system, the absorption rate for separation of the acid gases from the gas mixtures can be increased, and the total energy consumption of the deacidification operation can be reduced.

Owner:胡亮

Preparation method and application of three-element siloxane sponge

ActiveCN104194028ALow densityExcellent compression resistanceFatty/oily/floating substances removal devicesLiquid separationSilanesHydrolysis

The invention relates to a preparation method and application of three-element siloxane sponge, belonging to the technical field of preparation and application of environmental functional materials. The method comprises the following steps: alkoxy silane hydrolysis, gelation, product washing and drying. Compared with the traditional two-element siloxane sponge, the three-element siloxane sponge contains abundant non-polar groups and higher roughness on the surface, and is endowed with the superhydrophobic and superoleophylic effects; the contact angle with water exceeds 160 degrees; and the material has excellent mechanical properties. The preparation method is simple to operate, has the advantages of cheap raw materials and the like, and can easily implement large-scale preparation. The three-element siloxane sponge has the advantages of low density, excellent compression resistance, high oil absorption speed, high oil absorption power and the like, has wide application prospects in the fields of organic chemical solvent treatment, oily wastewater treatment, oil spillage treatment and the like, and is a novel efficient oil-water separation material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Vegetation concrete and preparation method thereof

InactiveCN103283573APromote growthPromote absorptionCultivating equipmentsSoilless cultivationVegetationArbuscular mycorrhizal fungi

The invention relates to vegetation concrete, and belongs to the field of ecological restoration engineering. The vegetation concrete comprises base concrete located at the bottom and surface concrete located at the top, the base concrete is sprayed by vegetation concrete matrix materials, the surface concrete is sprayed by the vegetation concrete matrix material mixed with grass seeds, and the vegetation concrete matrix materials comprise, by mass, 75-85% of raw planting soil, 6-12% of cement, 2-5% of organic matters, 2-5% of concrete greening additives and 2-5% of arbuscular mycorrhizal fungi inoculant which are compatible. The problems that vegetation growth is stressed by matrix materials, and vegetation is easy to degrade in a maintenance process on existing vegetation concrete technical conditions are solved, and pollutant intercepting capacity when a vegetation concrete technology is applied to a buffer zone is enhanced.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION

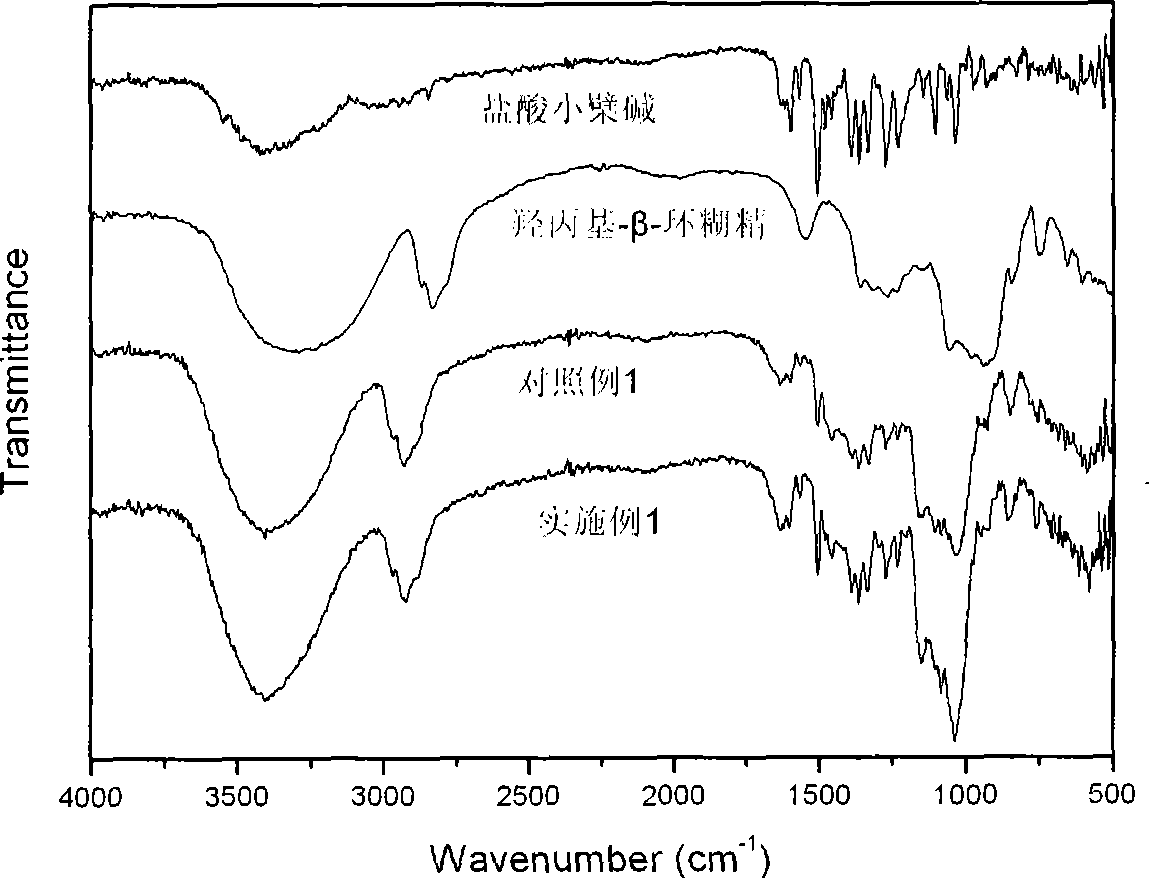

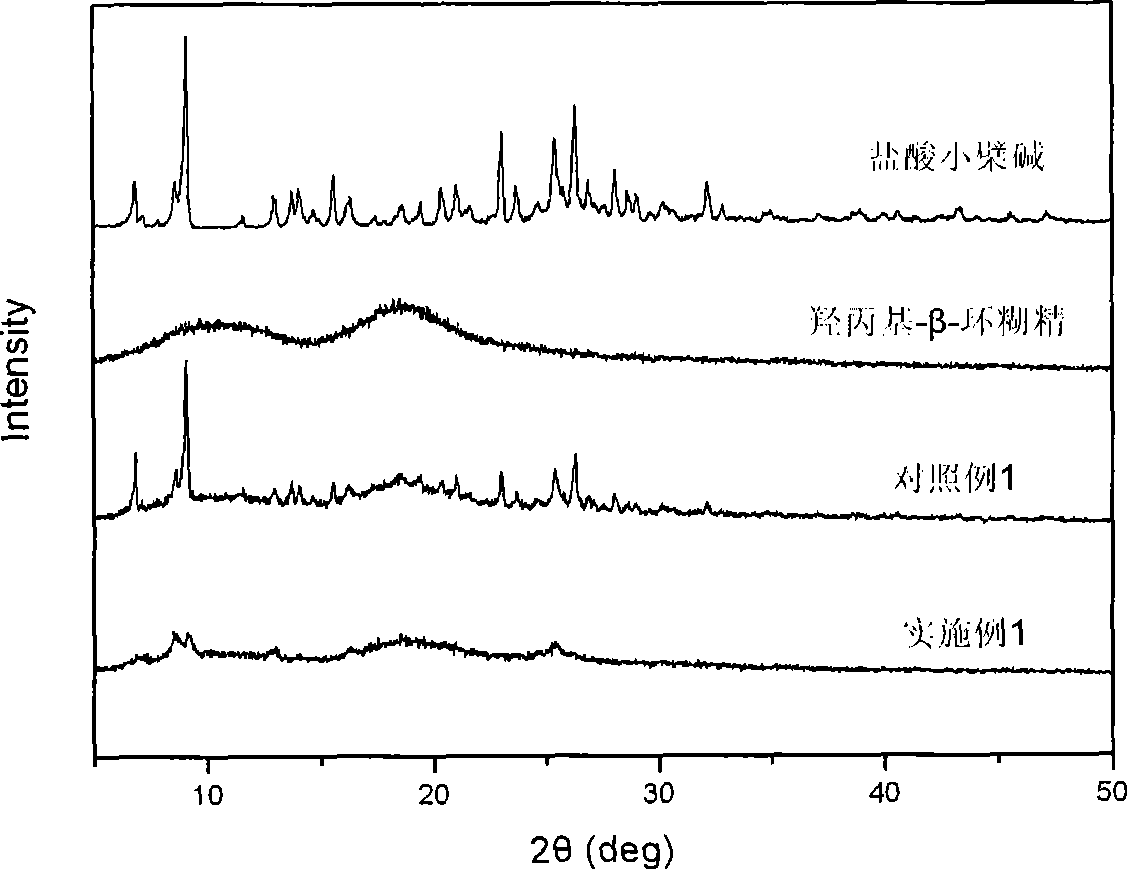

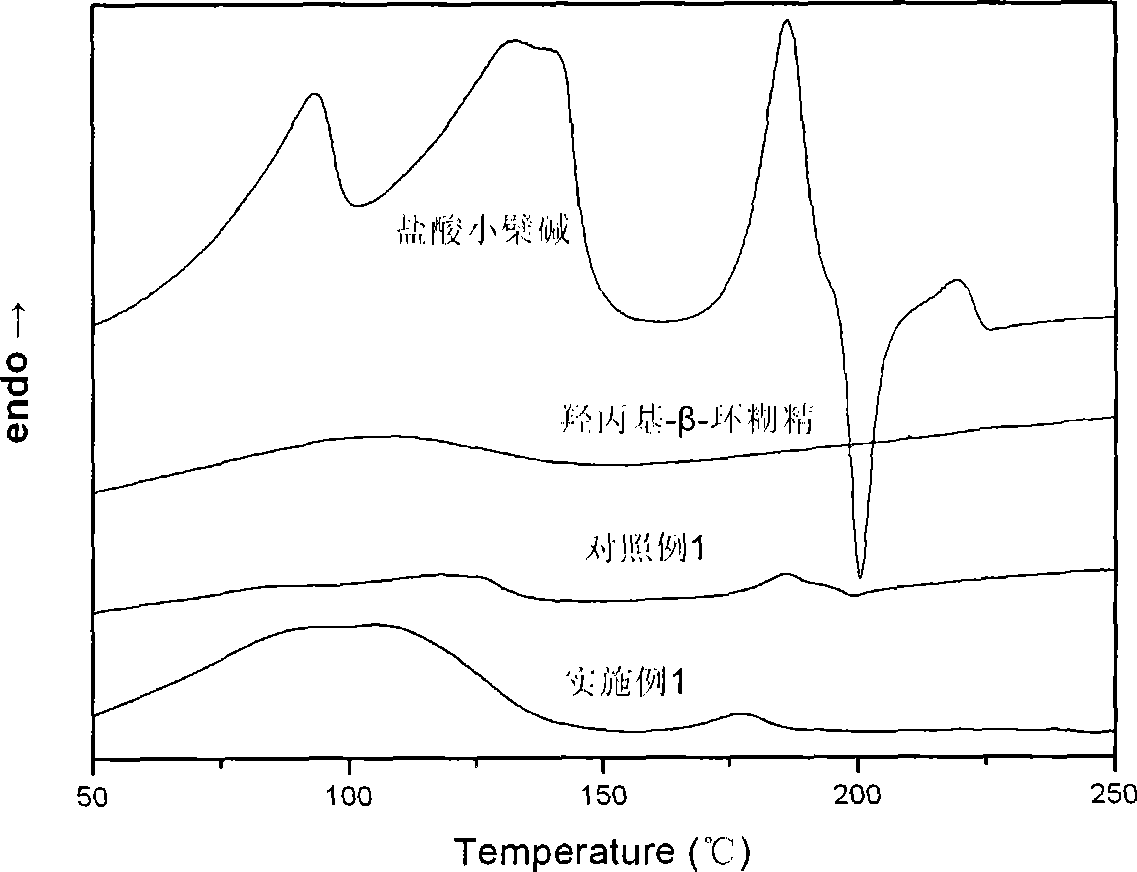

Berberine cyclodextrin inclusion compound, preparation thereof and preparation method

InactiveCN101461949AGood water solubilityHigh encapsulation efficiencyAntibacterial agentsOrganic active ingredientsSolubilityBerberine

The invention relates to a hydrochloric acid berberine / hydroxide propyl-beta-cyclodextrin clathrate, a preparation thereof and a method for preparing the same. By a gradient temperature reduction sealing method, the hydrochloric acid berberine and the hydroxide propyl-beta-cyclodextrin between which the mol ratio is 1:0.2-10 are sealed so as to improve the water solubility and biological availability of the hydrochloric acid berberine; the clathrate has the advantages of high sealing rate, large medicine loading capability and high purity; and the clathrate can be prepared into a clinically acceptable formulation with quick curative effect. The invention also clarifies the pharmacological functions of the clathrate.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com