Patents

Literature

57results about How to "Excellent compression resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene multilayer microporous membrane, battery separator using same, and battery

InactiveCN101208198AImprove permeabilityExcellent mechanical propertiesSynthetic resin layered productsSecondary cellsVitrificationSurface layer

A multi-layer, microporous polyethylene membrane having at least three layers comprising (a) a first microporous layer amount of a polyethylene resin and constituting at least both surface layers, and (b) at least one second microporous layer made of a polyethylene resin, a heat-resistant resin having a melting point or glass transition temperature of 150°C or higher and a filler, and sandwiched by both surface layers.

Owner:东丽东燃机能膜合同会社

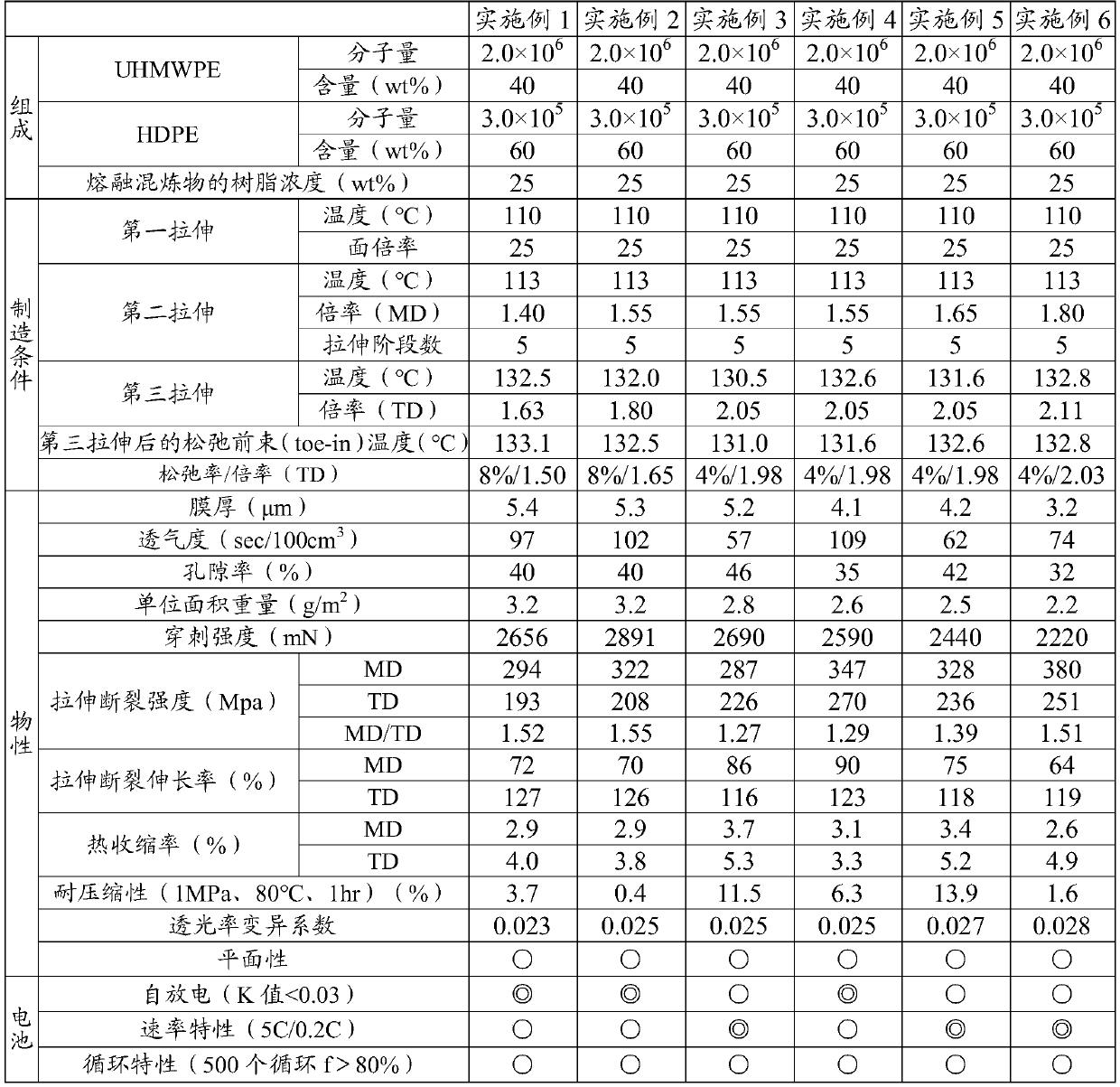

Polyethylene microporous membrane, process for production thereof, and battery separator

InactiveCN101233176AImprove breathabilityImprove featuresCell component detailsPolymer sciencePore diameter

PROBLEM TO BE SOLVED: To provide a microporous polyethylene membrane exhibiting little change in thickness and air permeability during compression and having a rapid electrolyte-absorption rate, and to provide its production method and a battery separator formed by such microporous polyethylene membrane.SOLUTION: The microporous polyethylene membrane is made of a polyethylene resin comprising ≤15 mass% of ultra-high molecular weight polyethylene having a mass-average molecular weight of ≥1 x 10<SP POS="POST">6< / SP>. The microporous polyethylene membrane is a single film that has a densely-structured layer comprising an average pore diameter of 0.01-0.05 μm and a coarsely-structured layer having an average pore diameter larger by 1.2-5.0 times than that of the densely-structured layer, both structured layers being adjacent to each other in a thickness direction, wherein a coarsely-structured layer is formed at least on one surface.

Owner:TONEN CHEM CORP

Process for producing microporous polyolefin film and microporous polyolefin film

ActiveCN101151308AStable manufacturingEfficient manufacturingSemi-permeable membranesMembranesPolymer sciencePolyolefin

A microporous polyolefin membrane having excellent compression resistance is obtained by stretching a gel molding comprising a polyolefin and a membrane-forming solvent, removing the membrane-forming solvent, and stretching the resultant membrane again at least uniaxially at a speed of 3% / second or more at a temperature equal to or lower than the crystal dispersion temperature +20°C.

Owner:TORAY IND INC

Method for producing polyolefin microporous membrane

InactiveCN101208379AExcellent mechanical propertiesImprove shutdown characteristicsSemi-permeable membranesMembranesPolyolefinSolvent

A method for producing a microporous polyolefin membrane by extruding a melt blend comprising a polyethylene resin, polypropylene having a mass-average molecular weight of 1 × 10 5 or more and an ethylene content of 5% by mass or less, and a membrane-forming solvent through a die, slowly cooling the resultant extrudate to form a gel-like sheet, stretching the gel-like sheet, and removing the above membrane-forming solvent, the slow-cooling speed of the extrudate being 30°C / second or less.

Owner:TONEN CHEM CORP

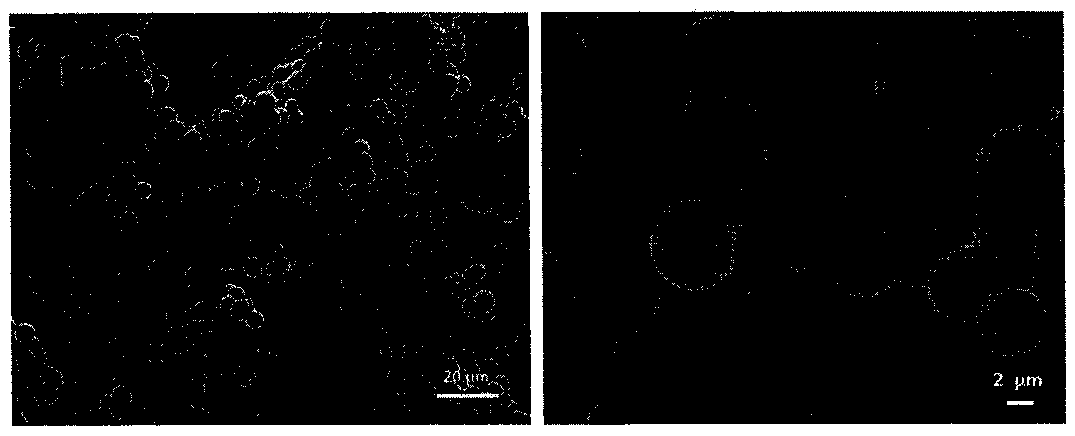

Preparation method and application of three-element siloxane sponge

ActiveCN104194028ALow densityExcellent compression resistanceFatty/oily/floating substances removal devicesLiquid separationSilanesHydrolysis

The invention relates to a preparation method and application of three-element siloxane sponge, belonging to the technical field of preparation and application of environmental functional materials. The method comprises the following steps: alkoxy silane hydrolysis, gelation, product washing and drying. Compared with the traditional two-element siloxane sponge, the three-element siloxane sponge contains abundant non-polar groups and higher roughness on the surface, and is endowed with the superhydrophobic and superoleophylic effects; the contact angle with water exceeds 160 degrees; and the material has excellent mechanical properties. The preparation method is simple to operate, has the advantages of cheap raw materials and the like, and can easily implement large-scale preparation. The three-element siloxane sponge has the advantages of low density, excellent compression resistance, high oil absorption speed, high oil absorption power and the like, has wide application prospects in the fields of organic chemical solvent treatment, oily wastewater treatment, oil spillage treatment and the like, and is a novel efficient oil-water separation material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Preparation method of biomimetic cartilage doped ordered magnetic nano-short fibers spliced double-layer hydrogel

InactiveCN109836595AHigh simulationImprove the shortcomings of weak mechanical propertiesProsthesisFiberCross-link

The invention discloses a preparation method of a biomimetic cartilage doped ordered magnetic nano-short fibers spliced double-layer hydrogel. According to the invention, nano-fibers containing magnetic particles are prepared by an electrospinning technology, and the nano-fibers are cut by a high-speed shear type homogenizer to obtain short fibers; the short fibers are mixed with a gel precursor and a cross-linking agent, and under the action of an external magnetic field, the magnetic short fibers are arranged orderly; by UV-irradiation, the gel precursor is cross-linked to obtain hydrogel doped with the ordered magnetic short fibers; two pieces of hydrogel are spliced in the way that the short fibers are perpendicular to each other, and spliced hydrogel is obtained relying on magnetic nanoparticles in the two pieces of hydrogel attracting each other; the spliced hydrogel is immersed in a sodium alginate solution, and a calcium chloride solution is added for gelatinization of the sodium alginate solution so as to obtain spiced double-layer hydrogel. The spiced double-layer hydrogel has a similar structure to cartilage tissue, good mechanical properties and magnetic properties, canpromote cell directed proliferation and differentiation, and is used for cartilage tissue repair.

Owner:BEIHANG UNIV

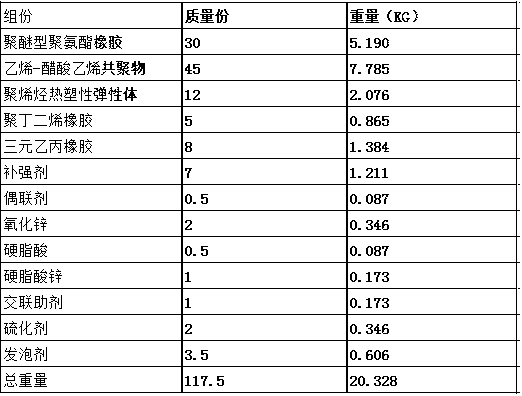

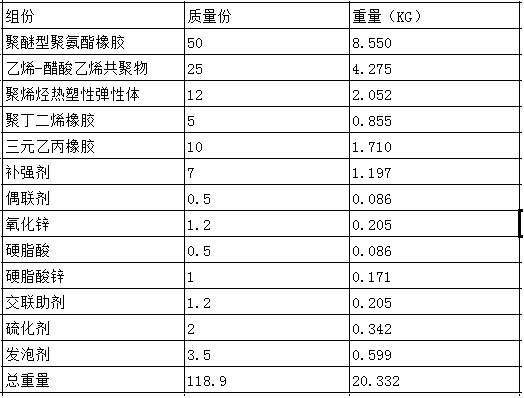

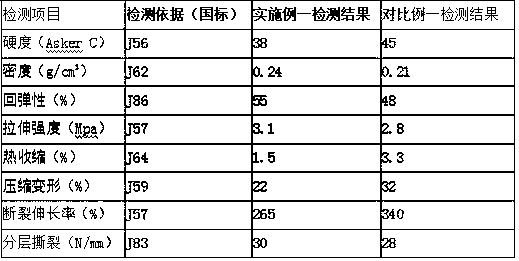

Composition and preparation method for preparing wear-resistant waterproof high-elasticity foaming materials

InactiveCN110256837AIdeal raw material function combinationIncrease elasticityPolymer sciencePolyolefin

The invention discloses a composition and a preparation method for high-elasticity wear-resistant foaming materials, wherein the composition comprises, by mass, 20-65 parts of a polyether type polyurethane rubber, 20-65 parts of an ethylene-vinyl acetate copolymer, 7-18 parts of a polyolefin thermoplastic elastomer, 3-8 parts of a polybutadiene rubber, 5-15 parts of ethylene propylene diene monomer, 5-10 parts of a reinforcing agent, 0.3-1 part of a coupling agent, 1.0-2.0 parts of zinc oxide, 0.5-1.0 part of stearic acid, 0.8-1.5 parts of zinc stearate, 0.5-1.5 parts of a cross-linking aid, 1.0-2.5 parts of a vulcanizing agent, and 1.5-3.5 parts of a foaming agent. The preparation method mainly comprises: two mixing, granulation, and foaming. According to the present invention, by adopting the technical scheme, the obtained foaming material product has advantages of small density, softness, wear resistance, excellent anti-cussion performance, good elasticity, compression resistance, small compression deformation and folding deformation resistance.

Owner:东莞华工佛塑新材料有限公司

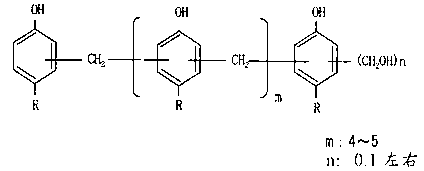

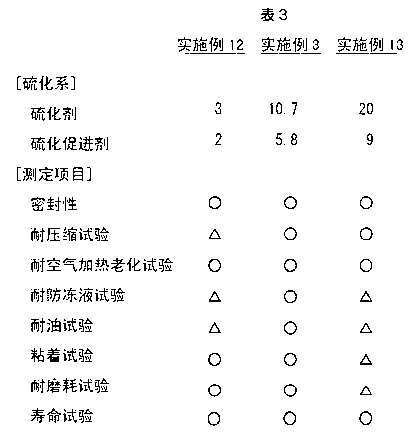

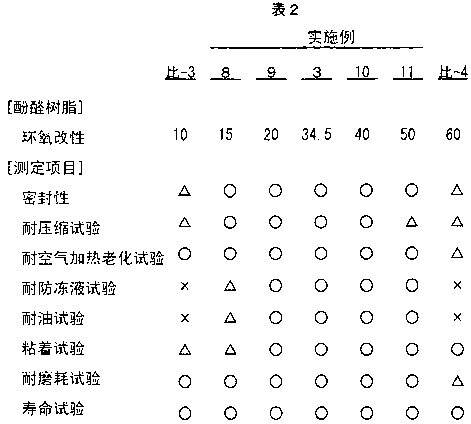

Fluororubber-metal laminate

ActiveCN102844177AShow resistance to compressionExcellent compression resistanceEngine sealsCoatingsPolymer scienceVulcanization

A fluororubber metal-laminate sheet, which comprises a metallic sheet and a vulcanized fluororubber layer provided on the metallic sheet by applying a composition comprising (A) 100 parts by weight of a polyol-vulcanizable fluororubber, (B) 10-50 parts by weight of an amorphous graphite, (C) 15-50 parts by weight of a phenol resin, (D) 2-9 parts by weight of an epoxy group- or (meth)acryloxy group-containing silane coupling agent, (E) 3-20 parts by weight of a polyol-based vulcanizing agent, and (F) 2-9 parts by weight of a vulcanization accelerator to the metallic sheet, followed by vulcanization of the fluororubber composition to form laminate. The fluororubber-metal laminate sheet achieves further improvement in sealability showing the surface smoothness of product, compression resistance showing rubber flowability, etc.

Owner:NOK CORP

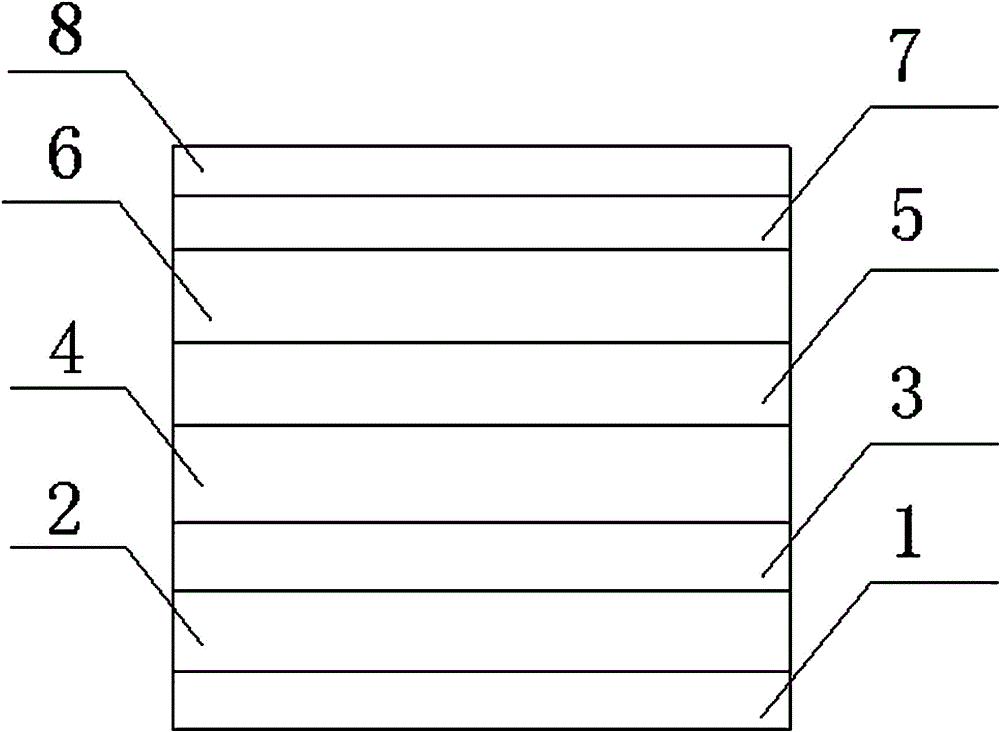

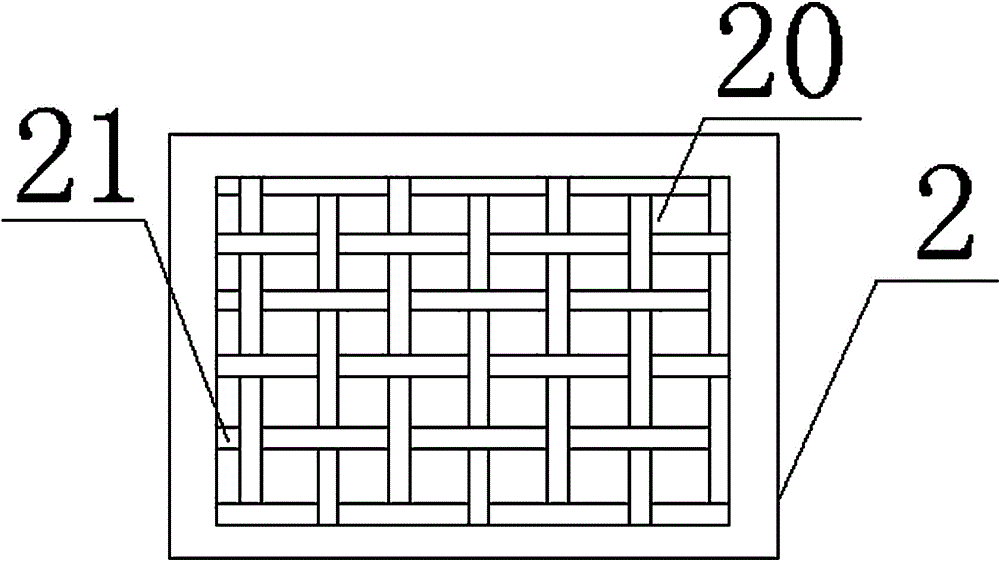

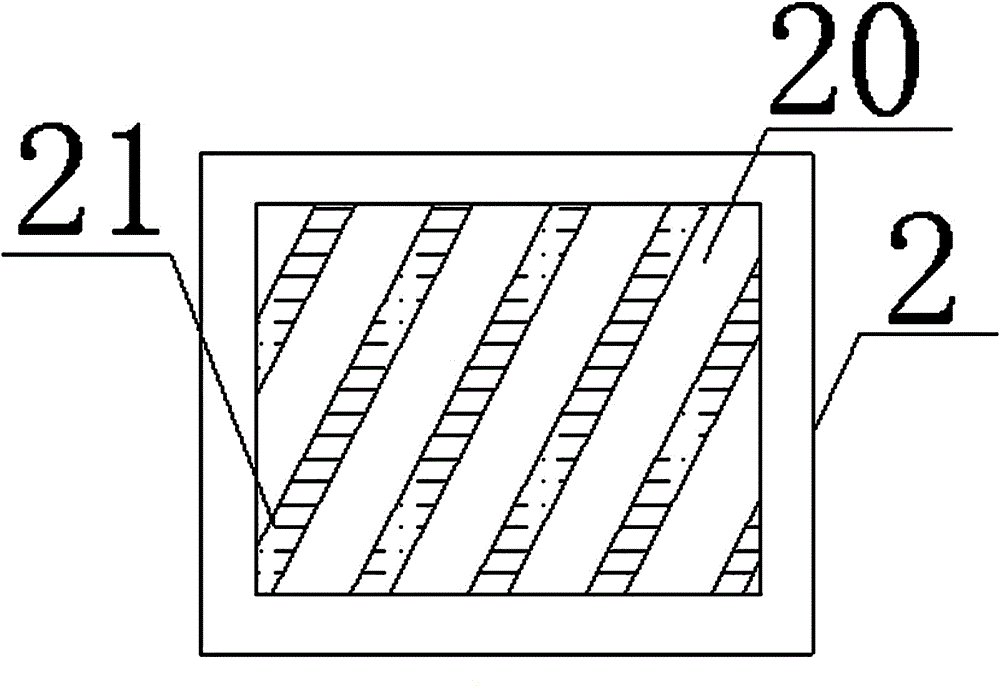

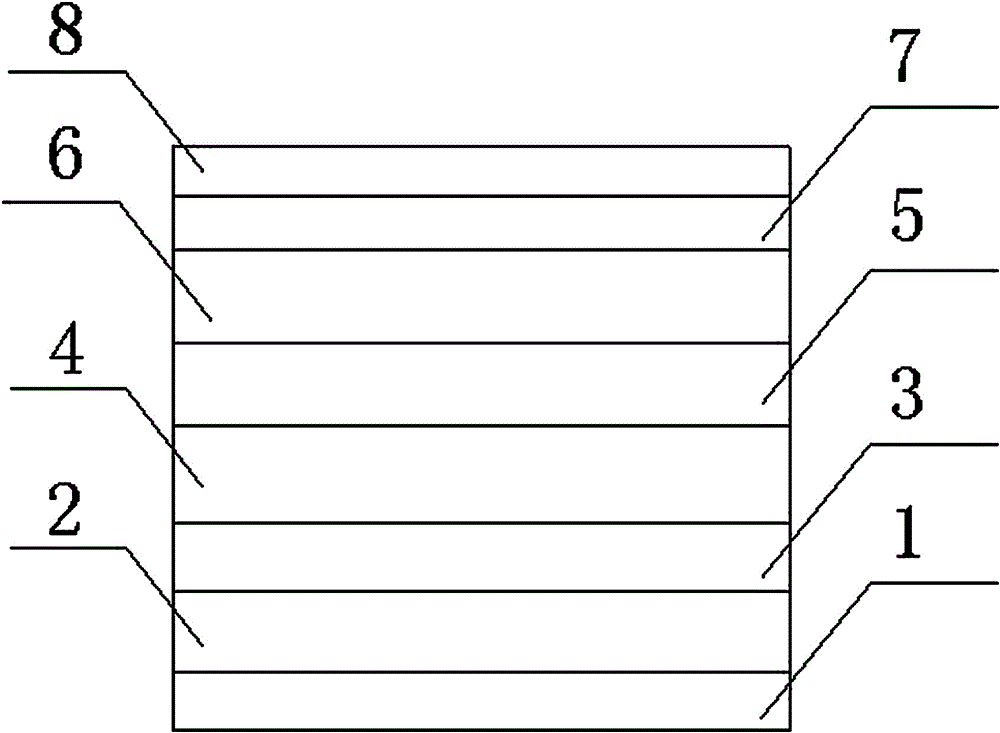

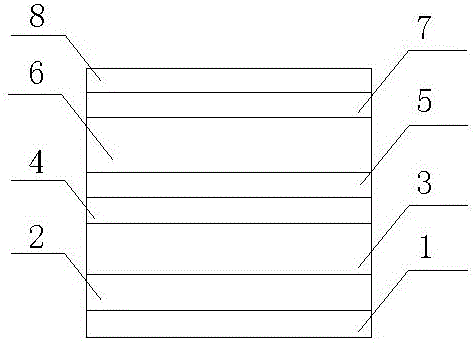

Fireproof insulation board

ActiveCN106013658AGood fire resistance and heat resistanceImprove toughnessCovering/liningsCoatingsEmulsionCoating

The invention discloses a fireproof insulation board. The fireproof insulation board comprises a base layer, a frame layer, a binding layer, a plastering mortar layer, an insulation layer, an emulsion layer, a decorative coating and an abrasion-resistant layer. The frame layer covers the base layer and is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form a filling cavity, and the filling cavity is filled with filler. The binding layer covers the frame layer. The plastering mortar layer covers the binding layer, the insulation layer covers the plastering mortar layer, the emulsion layer covers the insulation layer, the upper surface of the emulsion layer is coated with decorative paint to form the decorative coating, and the upper surface of the decorative coating is coated with transparent abrasion-resistant paint to form the abrasion-resistant layer.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

High-temperature-resistant and fire-proof external wallboard

InactiveCN105713506AImprove lipophilicityEnhanced heat and compression resistanceFireproof paintsCovering/liningsPalygorskitePolypropylene

The invention discloses a high-temperature-resistant and fire-resistant exterior wall panel, which comprises a base layer, a fire-resistant insulation layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer arranged sequentially from the inside to the outside; Parts include: 27-30 parts of hydroquinone, 11-14 parts of hexachlorocyclotriphosphazene, 18-22 parts of polyoxypropylene glycol, 65-70 parts of isophorone diisocyanate, trimethylpentanediol 50-60 parts, 3-4 parts of glucose, 0.3-0.6 parts of organic bismuth catalyst DY-20, 25-35 parts of foaming agent, 9-12 parts of foaming aid, 19-22 parts of palygorskite, 13 parts of dolomite ~16 parts, diatomite 6-9 parts, glass fiber 5-8 parts, straw silk 12-15 parts, magnesium hydroxide 16-19 parts, anti-aging agent 2-3 parts. The high-temperature-resistant fire-proof exterior wall panel proposed by the invention has excellent high-temperature resistance and fire-proof performance, excellent water resistance, high hardness and good compression resistance.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Heat-preservation building outer wallboard

InactiveCN105968703AGood fire resistance and heat resistanceHigh hardnessWallsFire proofingSodium BentonitePolyvinyl alcohol

The invention discloses a thermal insulation building exterior wall panel, comprising a base layer, a bonding layer, a thermal insulation layer, a plastering mortar layer, a fireproof layer, a waterproof layer, a latex layer, a decorative coating and a wear-resistant layer sequentially arranged from the inside to the outside; The raw materials of the fireproof layer include by weight: 115-118 parts of modified phenolic resin, 18-21 parts of urea-formaldehyde resin, 15-18 parts of polyvinyl butyral, 20-23 parts of acrylate rubber, 0.9 parts of silane coupling agent ~1.2 parts, nylon fiber 17-20 parts, soybean fiber 12-15 parts, bentonite 21-24 parts, calcined kaolin 25-28 parts, foaming agent 17-20 parts, foaming aid 3-6 parts, microcapsules 16-19 parts of red phosphorus, 2-3 parts of antioxidant. The preparation method of the modified phenolic resin is as follows: after reacting hydroquinone and diphenyl chlorophosphate, lauraldehyde is added for the reaction to obtain the second material; and the second material is reacted with boric acid to obtain the modified phenolic resin.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Fireproof high-temperature-resistant building outer wall board

InactiveCN105907036AGood fire resistance and heat resistanceImprove fire resistance and heat resistanceBuilding componentsInsulation layerWear resistant

The invention discloses a fireproof high-temperature-resistant building outer wall board, which comprises a base layer, a heat insulation layer, a surface mortar layer, a fireproof high-temperature-resistant layer, a waterproof layer and a decoration wear-resistant coating in sequential arrangement from inside to outside, wherein the fireproof high-temperature-resistant layer is prepared from the following raw materials in parts by weight: 109 to 112 parts of modified phenolic resin, 25 to 28 parts of alkyd resin, 22 to 25 parts of ethylene-ethylic acid ethylene copolymer, 13 to 16 parts of polyether sulfone, 0.7 to 1.0 part of silane coupling agents, 18 to 21 parts of polyacrylonitrile fiber, 22 to 25 parts of ramie, 22 to 25 parts of kieselguhr, 14 to 17 parts of nanosilicon dioxide, 33 to 36 parts of ground limestone, 16 to 19 parts of melamine pyrophosphate and 2 to 3 parts of anti-aging agents. A preparation method of the modified phenolic resin comprises the following steps that hydroquinone and diphenyl chlorophosphate take a reaction; then, p-nitrobenzaldehyde is added for reaction; boracic acid and acidized ammonium molybdate are added for reaction to obtain modified phenolic resin.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

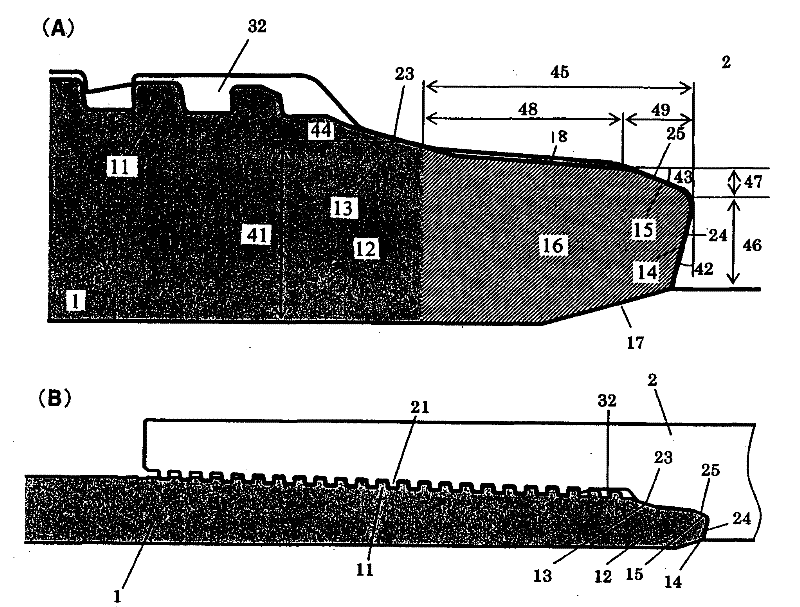

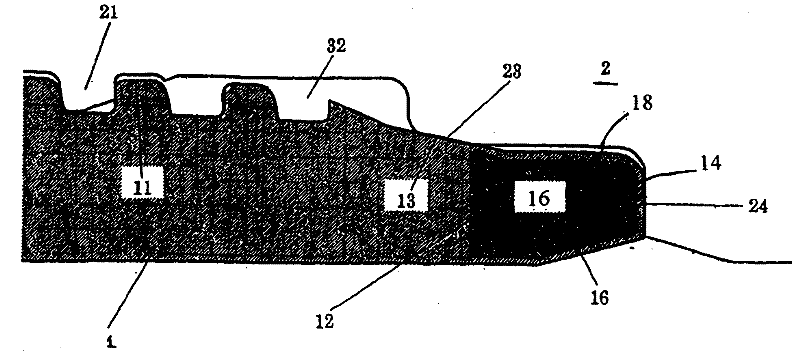

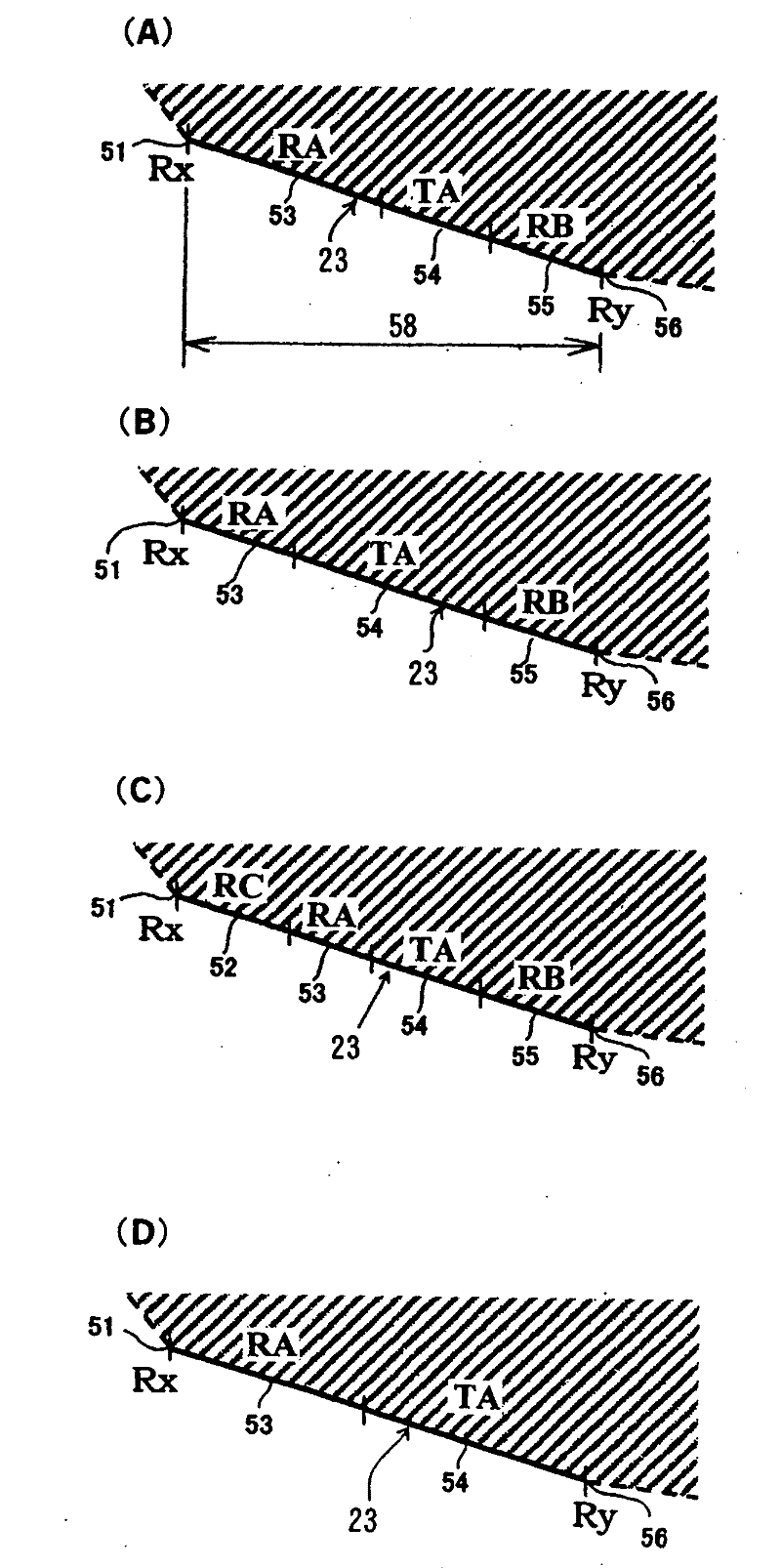

Threaded joint for steel pipes

ActiveCN102187139AReduce microwearExcellent compression resistanceDrilling rodsDrilling casingsEngineeringShoulder surface

In a threaded joint for steel pipes comprising a pin (1) and a box (2), each having a threaded portion (11 or 21), a sealing surface (13 or 23), and a shoulder surface (14, 15 or 24, 25), the sealing surface (13) of the pin (1) is formed by a tapered surface, and the sealing surface (23) of the box (2) is formed by a first curved surface portion with a large radius of curvature in the range of 15- 120 mm, a tapered surface portion, and a second curved surface portion with a large radius of curvature again in the range of 15 - 120 mm.

Owner:NIPPON STEEL CORP +1

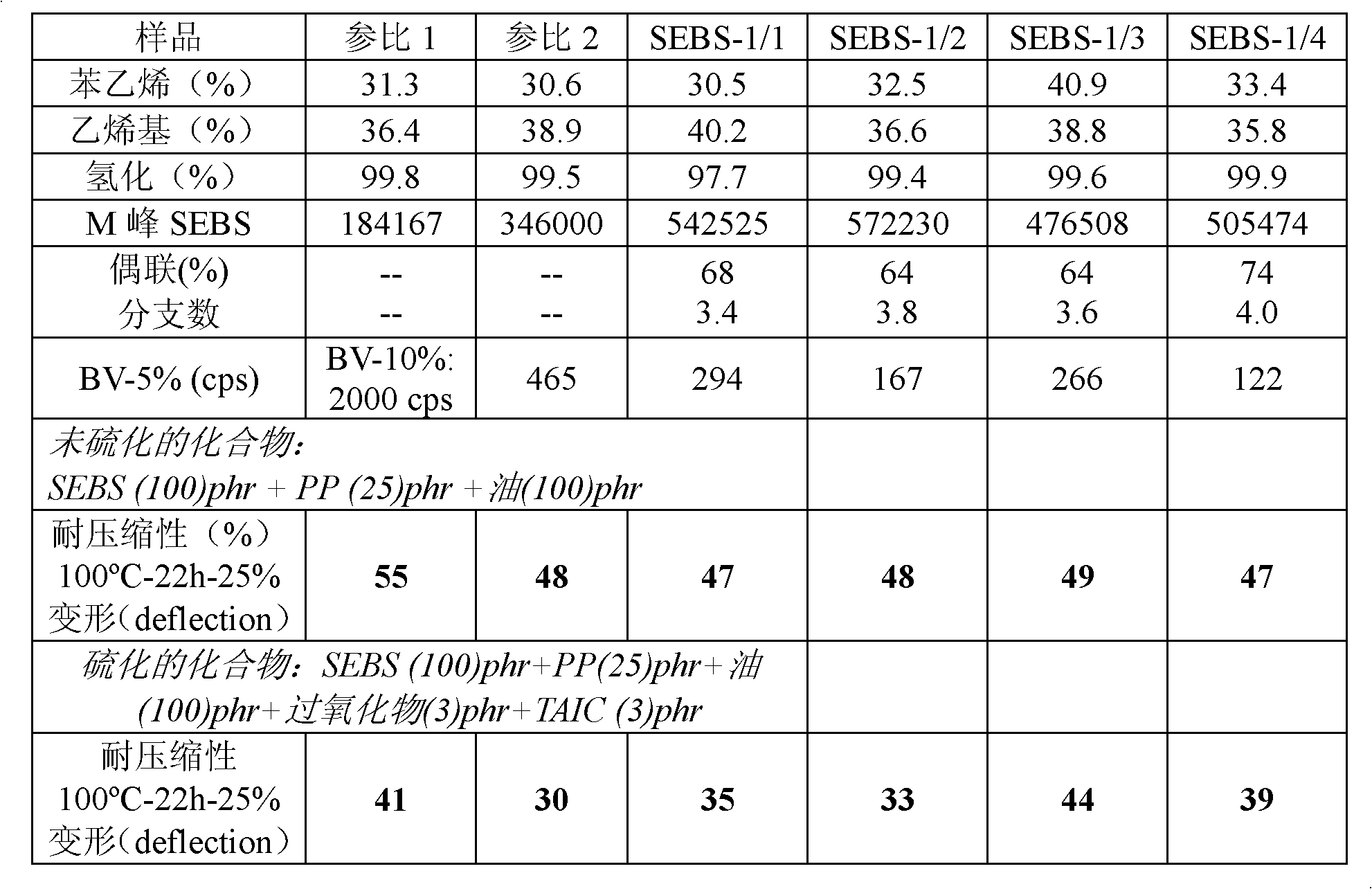

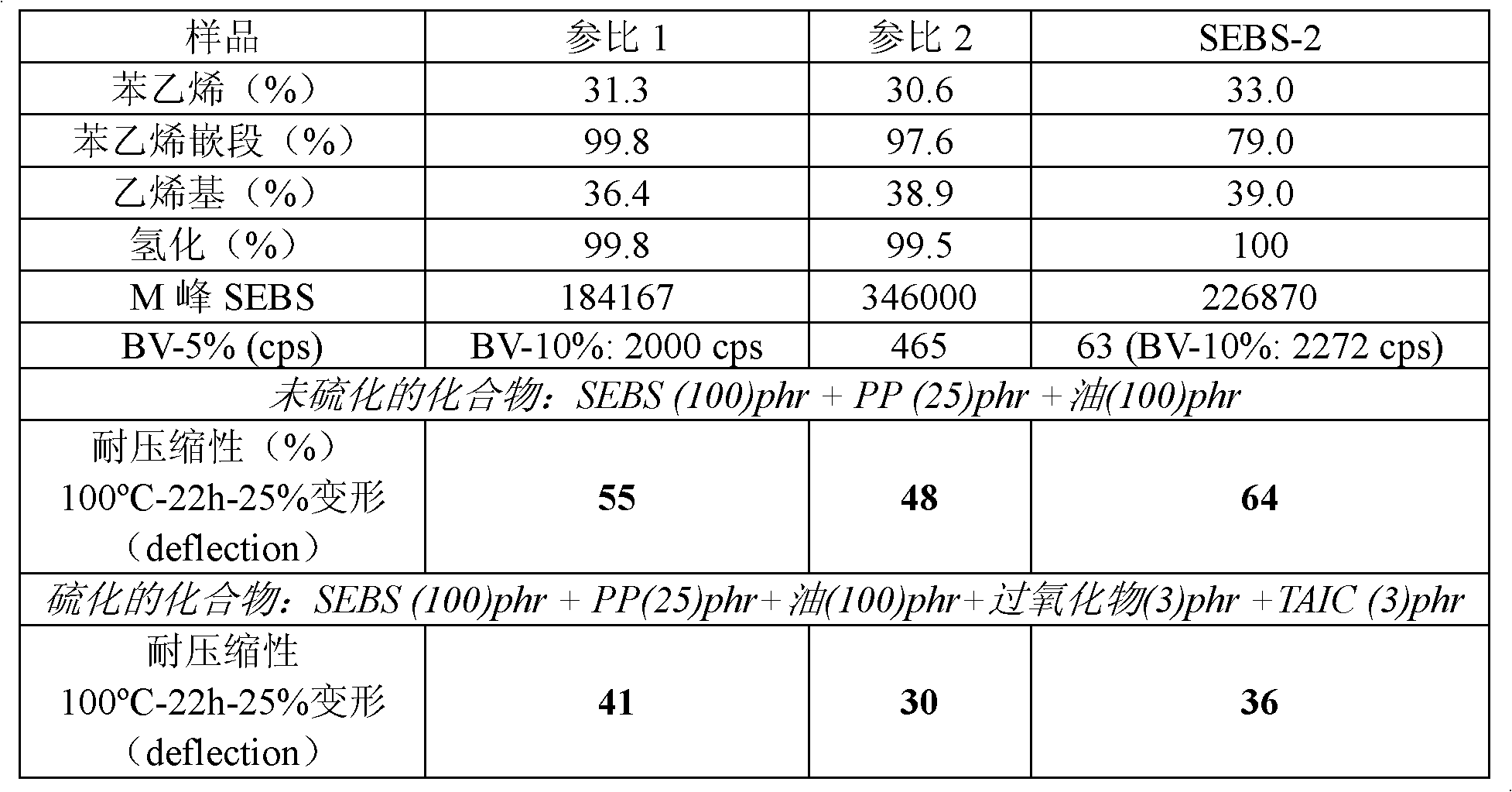

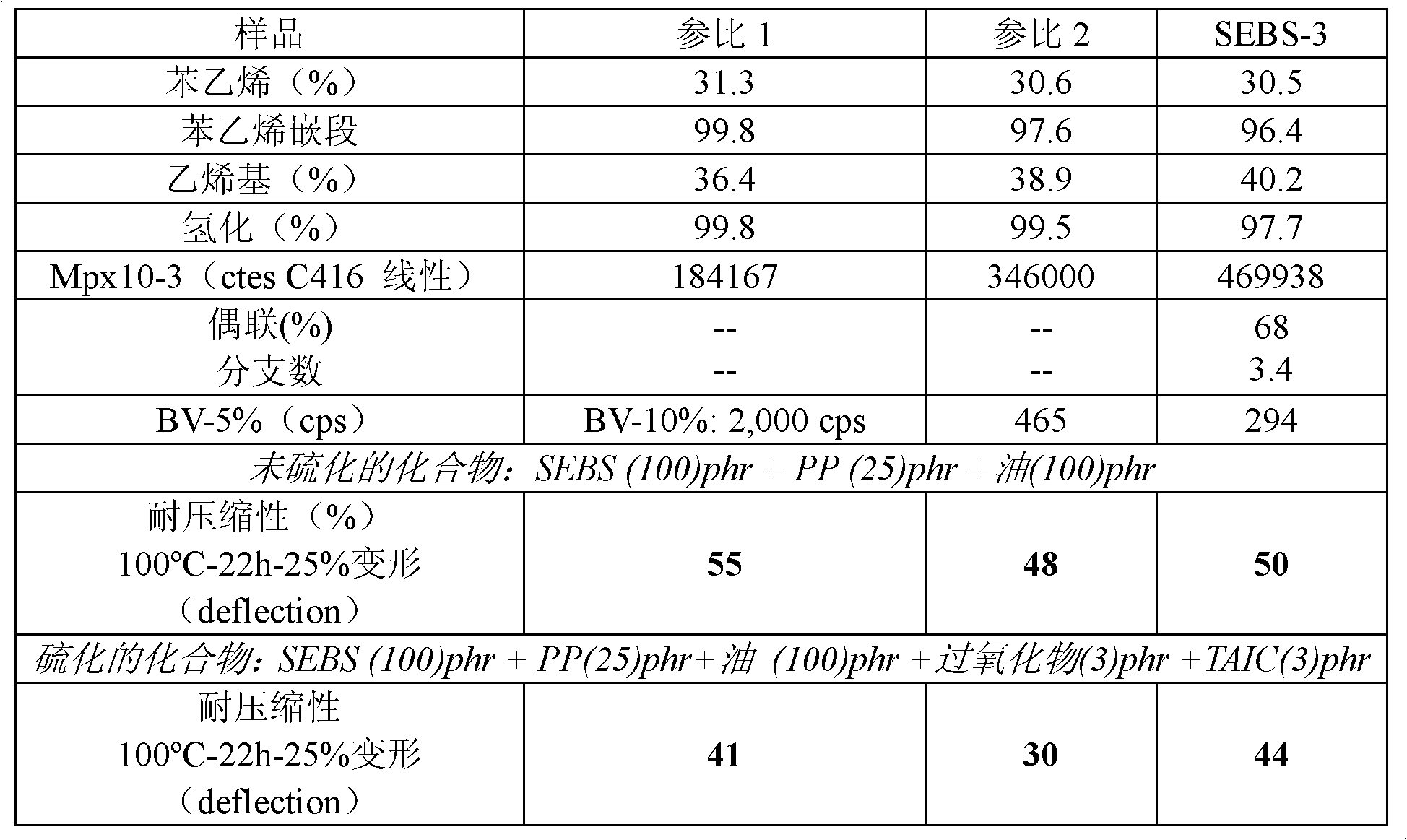

Hydrogenated rubber with improved high-temperature properties

The invention relates to a thermoplastic elastomer composition characterised in that it has a resistance to compression at temperatures of between 20 and 100 C, comprising hydrogenated styrene-butadiene block copolymers, and to the copolymers that form said composition. In addition, the invention relates to a product obtained by means of moulding or extrusion of the aforementioned composition.

Owner:丹拿索尔合成橡胶公司

External wall penal with excellent silencing and fireproof performances

InactiveCN105838231AImprove lipophilicityPromote softeningFireproof paintsCovering/liningsAntioxidantPotassium hydroxide

The invention discloses an exterior wall panel with excellent sound-absorbing and fire-proof performance, which comprises a base layer, a sound-absorbing fireproof layer, a plastering mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer; the preparation method of the sound-absorbing fireproof layer is as follows: hydroquinone, Potassium hydroxide and toluene are mixed evenly, and then a toluene solution containing hexachlorocyclotriphosphazene is added dropwise, heated up, kept warm, washed with an alkali solution to obtain an organic phase, then the organic phase is distilled under reduced pressure, dried in vacuum, and recrystallized to obtain material a ; Mix material a and polytetrahydrofuran ether glycol evenly, then add trimethyl-1,6-hexamethylene diisocyanate, fill with dry nitrogen for protection, heat up, keep warm, and cool down to obtain material b; Add trimethylpentanediol, glycerin, bismuth neodecanoate, foaming agent, foaming aid, expanded perlite, palygorskite, diatomaceous earth, glass fiber, flax fiber, zinc borate hydrate, anti-aging agent and Acetone is mixed evenly, coated on the surface of the base layer, then heated up, and kept warm to obtain a sound-absorbing and fire-proof layer.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

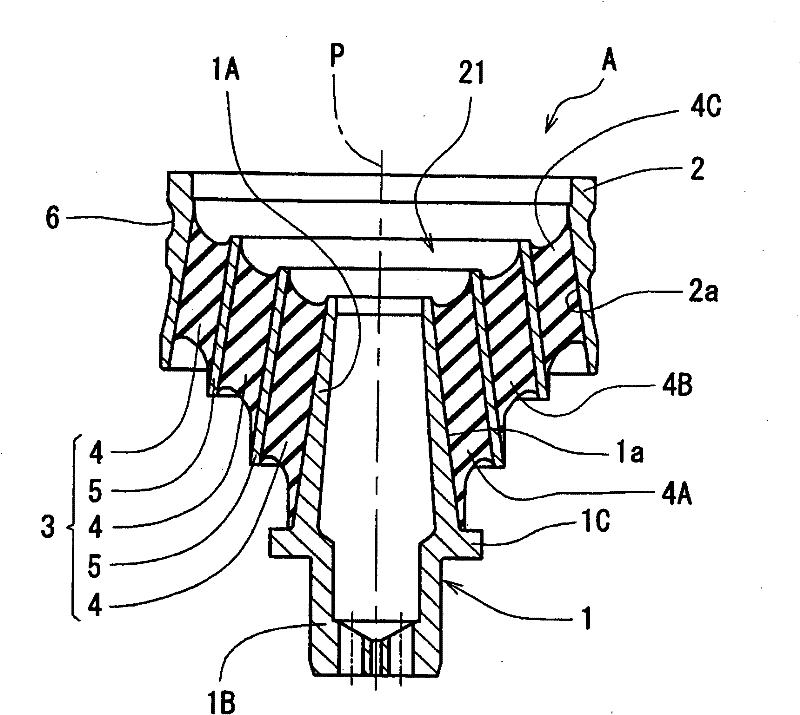

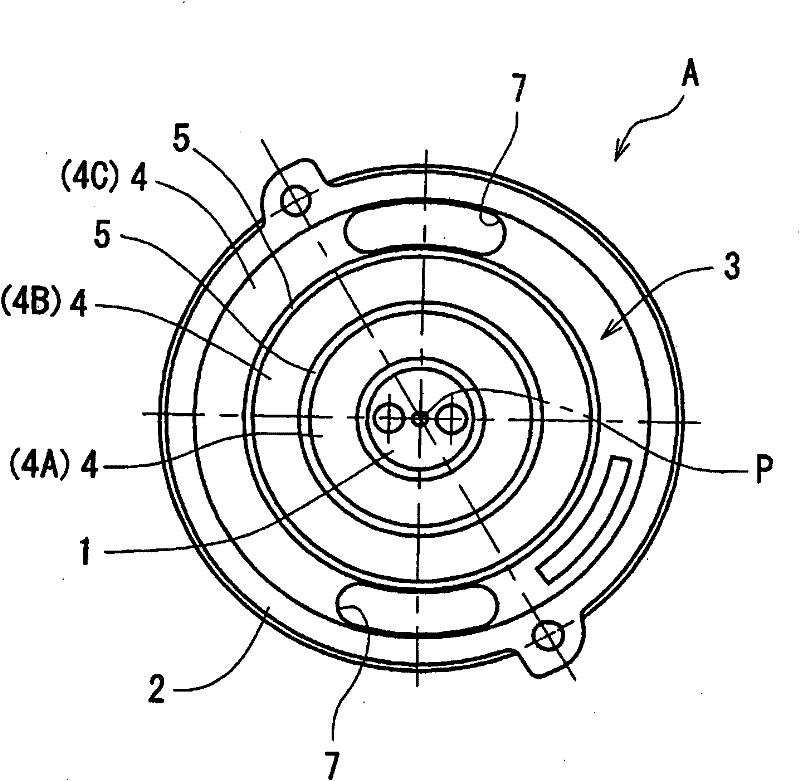

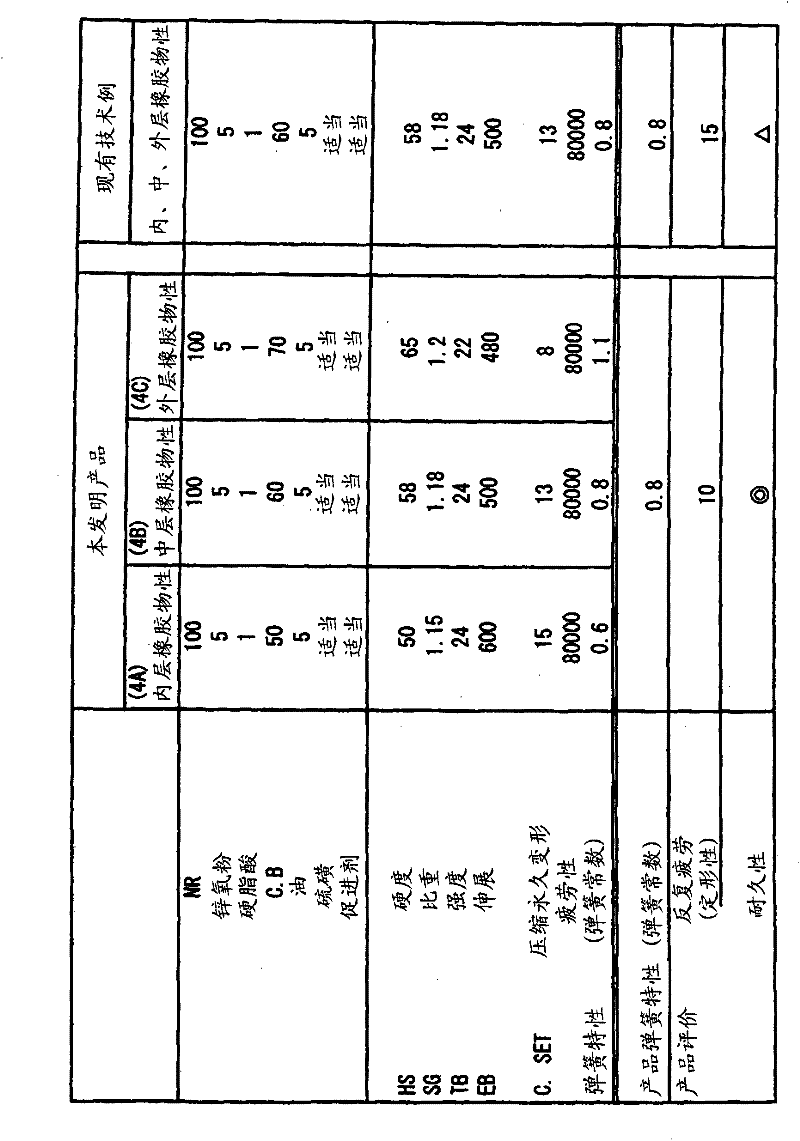

Shaft spring of railway vehicle

ActiveCN102094925AImprove torsion resistanceExcellent compression resistanceGas based dampersRubber materialEngineering

The invention provides a shaft spring of a railway vehicle which is improved through research and development, will not trigger the deterioration of riding comfortableness, and can improve endurance. An elastic part (3) of a lamination rubber structure is clamped between a main shaft (1) and an outer cylinder (2) having an axle center (P) equal or approximately equal to the main shaft, forming the shaft spring for the railway vehicle. The elastic part (3) is alternately laminated with a plurality of rubber layers (4A, 4B, 4C) and one or over one hard bulkheads (5) in internal and external radial directions under the state that the elastic part (3) is or is approximately concentric to the axle center (P). In the plurality of rubber layers (4A, 4B, 4C), an external side rubber layer (4C) is made from rubber materials with high spring constant, a middle rubber layer (4B) is made from rubber materials of moderate spring constant, and an internal side rubber layer (4A) is made from rubber materials of low spring constant.

Owner:NITTA CHEM IND PROD CO LTD

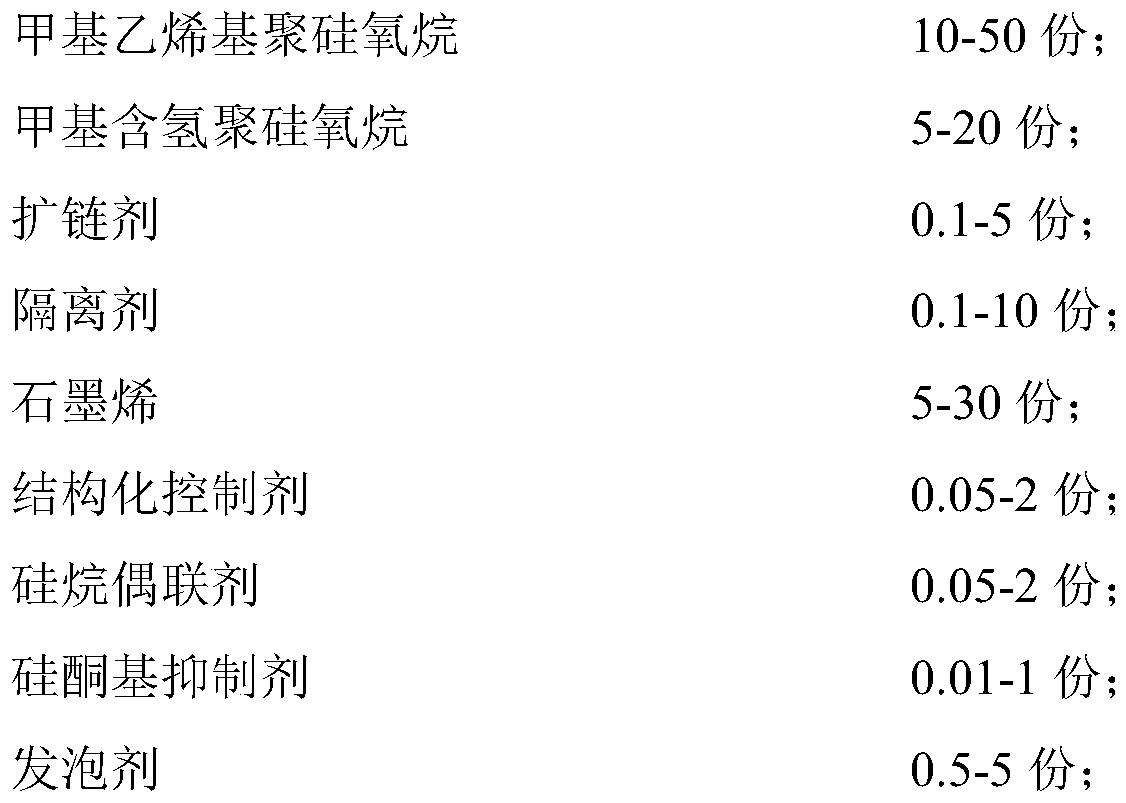

Graphene-based organosilicon porous nanometer material and preparation method thereof

InactiveCN111138861ALight viscoelasticFine and uniform cross-section cellsPolymer sciencePtru catalyst

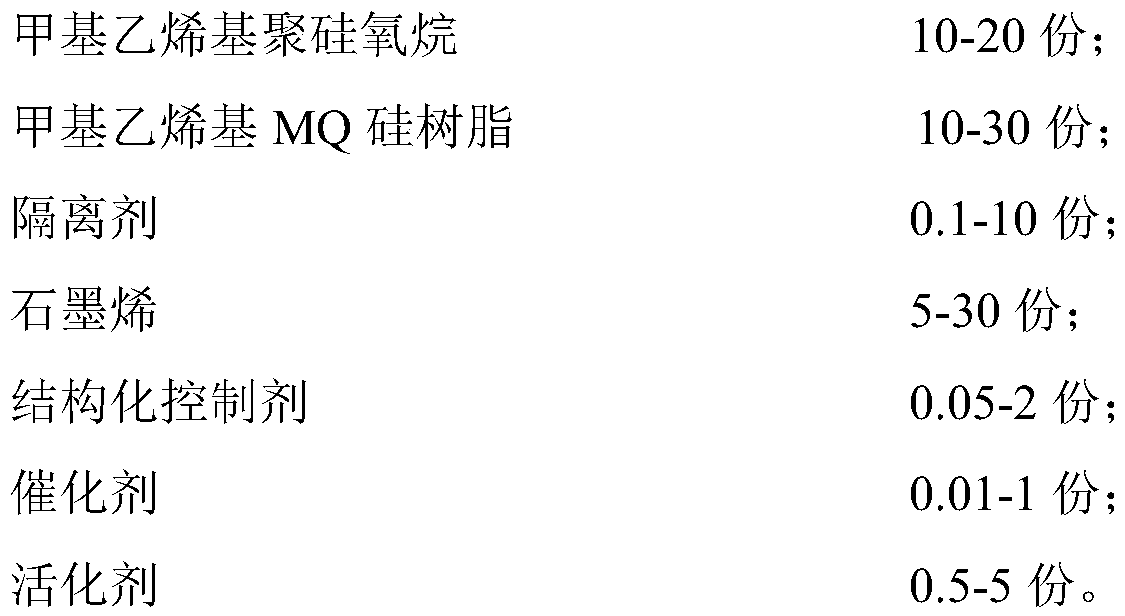

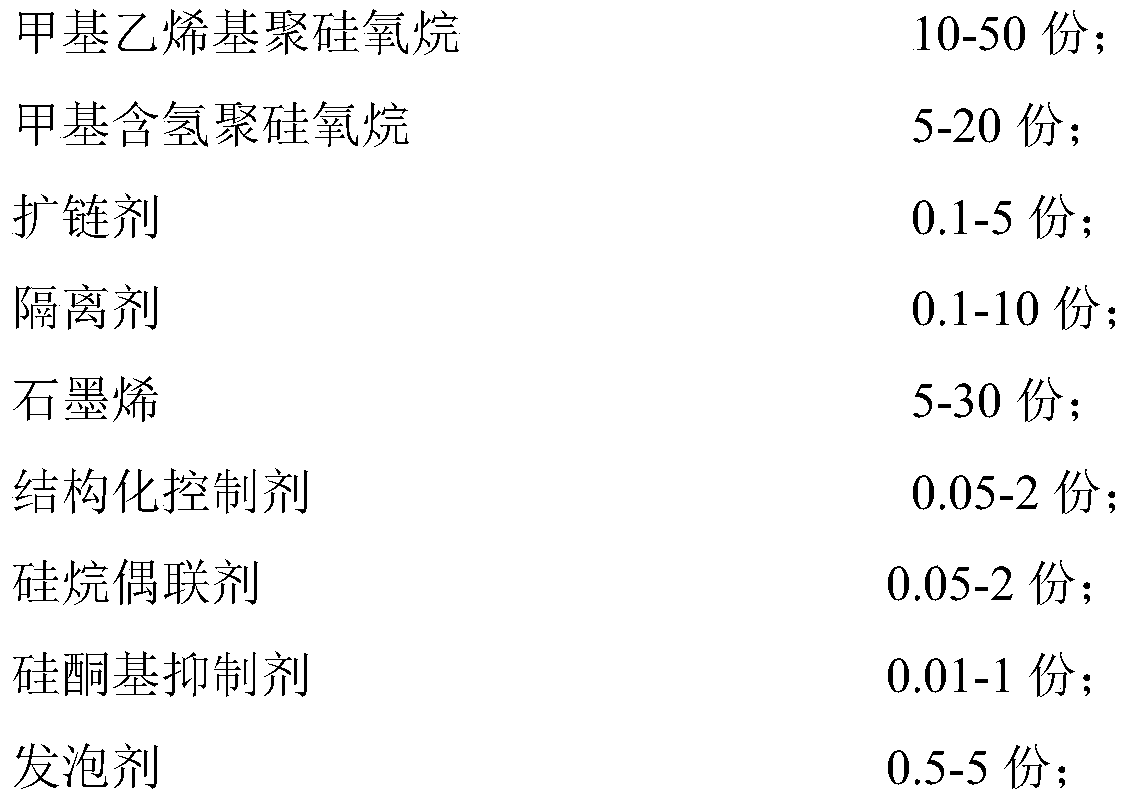

The invention relates to a graphene-based organosilicon porous nanometer material and a preparation method thereof. The graphene-based organosilicon porous nanometer material is composed of a component A and a component B according to a weight ratio of (1-2): 1, wherein the component A comprises the following raw materials in parts by weight: 10 to 50 parts of methyl vinyl polysiloxane, 5 to 20 parts of methyl hydrogen-containing polysiloxane, 0.1 to 5 parts of a chain extender, 0.1 to 10 parts of a separant, 5 to 30 parts of graphene, 0.05 to 2 parts of a structured control agent, 0.05 to 2 parts of a silane coupling agent, 0.01 to 1 part of a silicone-based inhibitor and 0.5-5 parts of a foaming agent; and the component B comprises the following raw materials in parts by weight: 10 to 20parts of methyl vinyl polysiloxane, 10 to 30 parts of methyl vinyl MQ silicon resin, 0.1 to 10 parts of a separant, 5 to 30 parts of graphene, 0.05 to 2 parts of a structured control agent, 0.01 to 1part of a catalyst and 0.5-5 parts of an activator. The graphene-based organosilicon porous nanometer material is light in weight, viscoelastic, fine and uniform in cross section foam pores, firm inbonding a base material due to interaction of a graphene nanometer film and an organosilicon material base body, excellent in compression resistance, impact resistance and thermal stability, and is applicable to light-weight application scenes like sealed shock absorption, microwave absorption, electromagnetic shielding and heat dissipation protection.

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

Noise-reducing and fireproof external wall panel

InactiveCN105713505AImprove lipophilicityIncrease contact angleFireproof paintsPolyurea/polyurethane coatingsAttapulgus clayMagnesium

The invention discloses a noise-reducing and fireproof external wall panel. The external wall panel comprises a base layer, a noise-reducing and fireproof layer, a flow guide plate layer, an abrasion-resistant layer and a decoration coating which are arranged sequentially from inside to outside; a preparation method of the noise-reducing and fireproof layer comprises steps as follows: a phosphonitrilic chloride trimer is heated, kept at the temperature, cooled to the room temperature and washed, and polydichlorophosphazene is obtained; polydichlorophosphazene is added to tetrahydrofuran, hydroquinone is dropwise added, then reflux heating, distillation, washing and vacuum drying are performed, and a material a is obtained; after the material a and poly-1,4-butylene adipate glycol are evenly mixed, 1,6-hexamethylene diisocyanate is added, dry nitrogen is introduced for protection, and a material b is obtained through heating, temperature keeping and cooling; diethylene glycol, pentaerythritol, bismuth laurate, a foaming agent, a blowing promoter, bentonite, palygorskite, expanded perlite, glass fibers, jute fibers, magnesium hydroxide, an anti-aging agent and acetone are evenly mixed, the surface of the base layer is coated with the mixture, and then the noise-reducing and fireproof layer is obtained through heating and temperature keeping.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Compression-resistant polyurethane foam and preparation method thereof

ActiveCN113292764ADoes not change the macrostructureEasy to compressPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

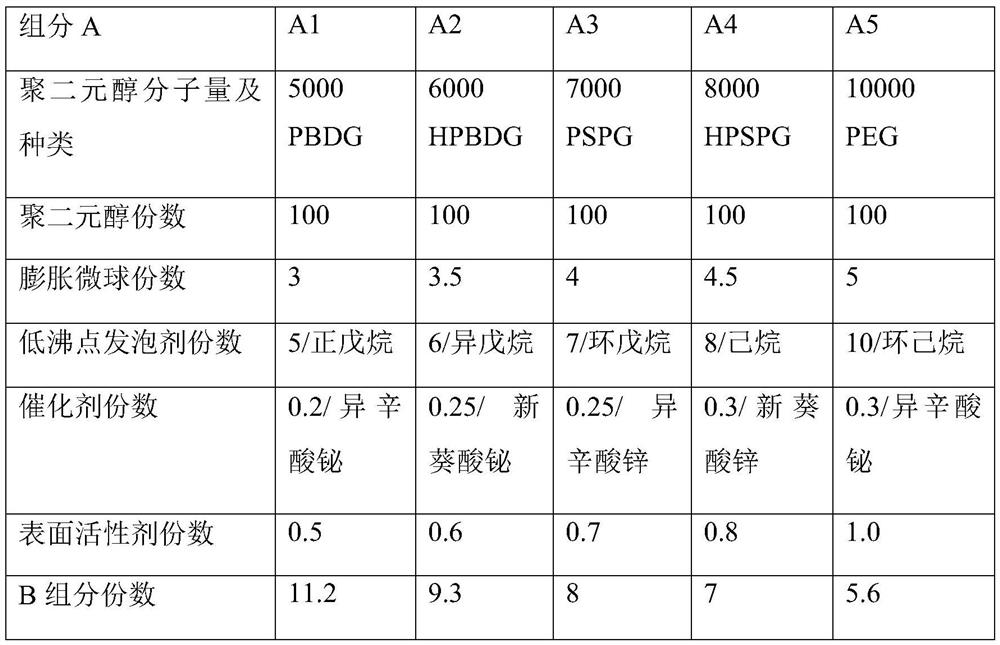

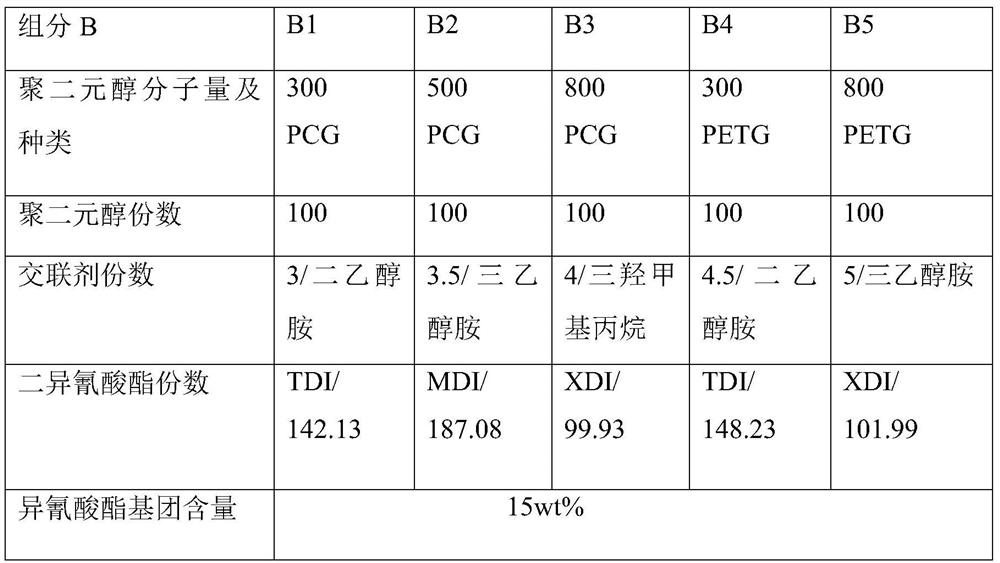

The invention discloses compression-resistant polyurethane foam. The compression-resistant polyurethane foam comprises a component A and a component B, wherein the component A comprises polydihydric alcohol of which the molecular chain does not contain F, O and N elements, and expanded microspheres, a low-boiling-point foaming agent, a catalyst and a surfactant; the component B comprises diisocyanate, a chain extender, a cross-linking agent and polydihydric alcohol, wherein the diisocyanate is excessive; the component A and the component B are mixed and then coated on the surface of a high polymer material or metal material film, and the polyurethane foam is obtained after curing molding. The invention also discloses a preparation method of the compression-resistant polyurethane foam. The final polyurethane molecular blocks are arranged in order, and the polyurethane foam has a three-stage compression-damping structure at a microscopic level so that the polyurethane foam has good compression resistance, has long service time under a compression condition, and can better adapt to a service environment and protect devices.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

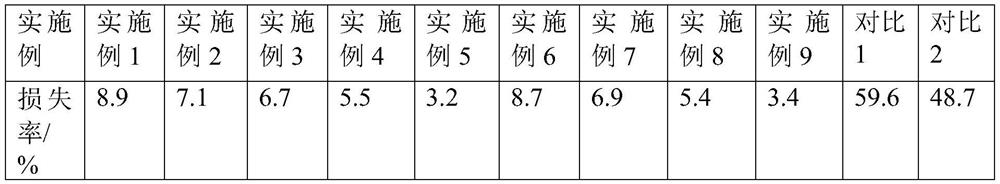

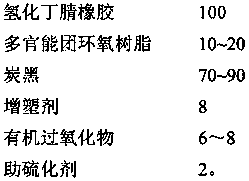

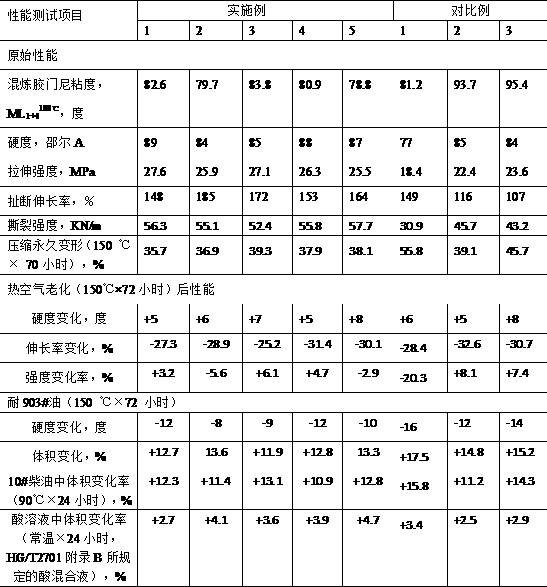

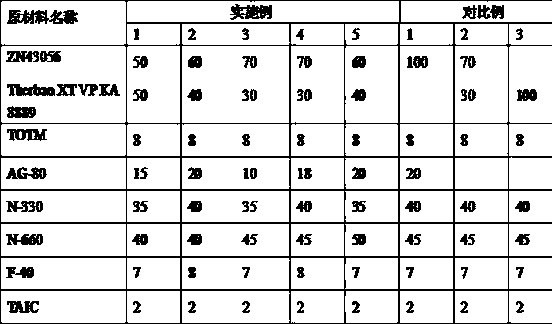

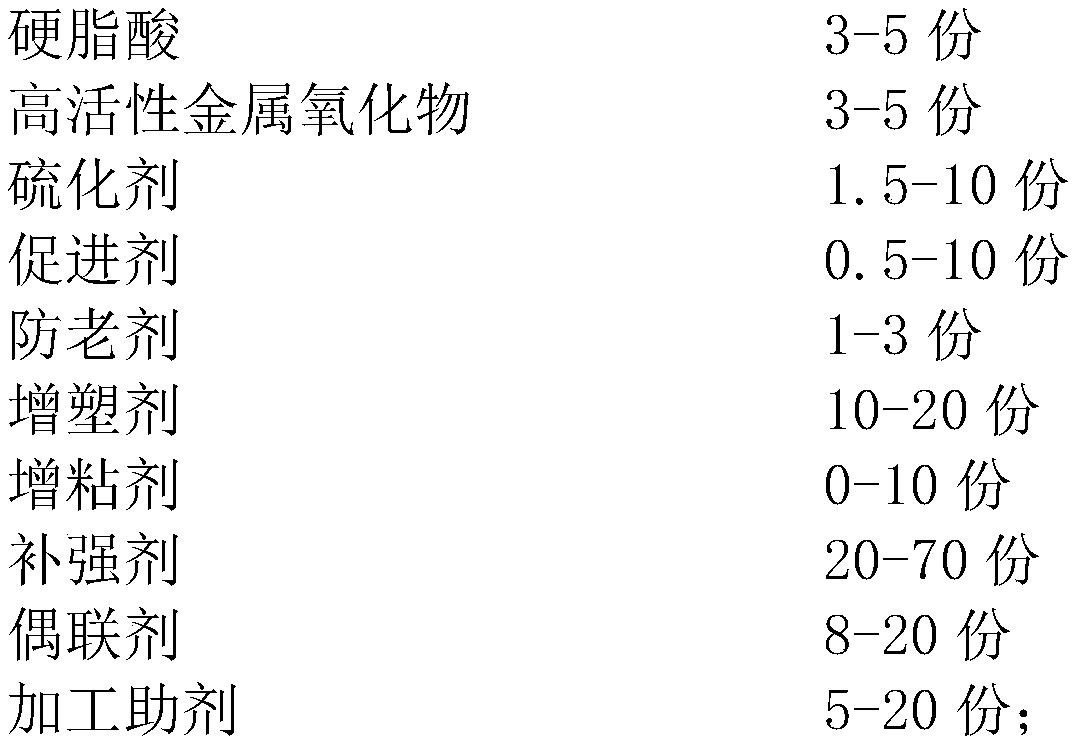

High-performance hydrogenated butadiene-acrylonitrile rubber compound and preparation method thereof

The invention relates to a high-performance hydrogenated butadiene-acrylonitrile rubber compound and a preparation method thereof. The high-performance hydrogenated butadiene-acrylonitrile rubber compound comprises high-saturation hydrogenated butadiene-acrylonitrile rubber, carboxyl hydrogenated butadiene-acrylonitrile rubber and multifunctional epoxy resin. The hydrogenated butadiene-acrylonitrile rubber is cross-linked in the function of an organic peroxide, and at the same time, carboxyl hydrogenated butadiene-acrylonitrile rubber and multifunctional epoxy resin are self-crosslinked, so that a diversified polymer crosslinking system is formed and meets the requirement of features, such as oil resistance, heat resistance, hydrogen sulfide resistance, high hardness and good compression resistance, of rubber sealing products used in an oil field. Meanwhile, liquid multifunctional epoxy resin is taken as a rubber reactive temporary plasticizer, allows a rubber compound to be relativelylow in Mooney viscosity, and improves the compounding, molding and vulcanization processing property. During preparation, conventional mixing technology can be used, an open mill or an internal mixercan be used for mixing, and the rubber compound adapts to mould pressing or injection molding vulcanization process. Compared with a rubber compound in the prior art, the rubber compound is excellentin performance, simple in preparation method, low in cost, and suitable for industrial production.

Owner:ZHEJIANG ZANSHENG NEW MATERIALS CO LTD

Modified fluororubber sealing gasket material and preparation method thereof

The invention discloses a modified fluororubber sealing gasket material which is characterized by being prepared from the following raw materials in parts by weight: 65-70 parts of fluororubber, 3-4 parts of graphite, 10-12 parts of phenolic resin, 2-3 parts of silane coupling agent KH-550, 4-6 parts of dibutyl phthalate, 2-3 parts of polyisobutene, 2-5 parts of diethylene glycol benzoate, 2-3 parts of magnesium oxide, 2-3 parts of zinc oxide, 1-2 parts of anti-aging agent ODA, 1-2 parts of accelerant CZ, 1-2 parts of monobutyl tin oxide, 1-2 parts of sulfur, 30-35 parts of N550 carbon black, 10-12 parts of calcium carbonate powder, 15-18 parts of nano clay and 10-12 parts of modified attapulgite clay. Due to the added modified attapulgite clay, the process performance of the size is improved, and the toxic and side effects and environmental pollution are reduced by using an environment-friendly compounding agent. The modified fluororubber sealing gasket material has high sealing property, compression resistance, ageing resistance, oil resistance and friction resistance.

Owner:马鞍山市中澜橡塑制品有限公司

External wall panel with excellent fireproof performance

InactiveCN105860814AEnhanced heat and compression resistanceImprove flame retardant performanceCovering/liningsCellulose coatingsPerliteDibutyl tin dilaurate

The invention discloses an external wall panel with excellent fireproof performance. The external wall panel comprises a base layer, a heat-insulation fireproof layer, a finishing mortar layer, a waterproof layer, a decorative coating and a wear-resistant layer which are arranged sequentially from inside to outside, wherein the heat-insulation fireproof layer is prepared from the raw materials in parts by weight: 27-30 parts of hydroquinone, 11-14 parts of hexachlorocyclotriphosphazene, 18-22 parts of poly (1,6-hexamethylene adipate) diol, 65-70 parts of diphenylmethane diisocyanate, 50-60 parts of ethylene glycol, 0.8-1.2 parts of pentaerythritol, 0.3-0.6 part of dibutyl tin dilaurate, 25-35 parts of foaming agent, 9-12 parts of foaming auxiliaries, 19-22 parts of expanded perlite, 13-16 parts of bentonite, 6-9 parts of diatomite, 5-8 parts of glass fibers, 12-15 parts of cotton fibers, 16-19 parts of magnesium hydroxide and 2-3 parts of anti-aging agent. According to the external wall panel, the high-temperature resistance and fireproof performance are excellent, the water resistance is excellent, the hardness is high, and the compression resistance is good.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

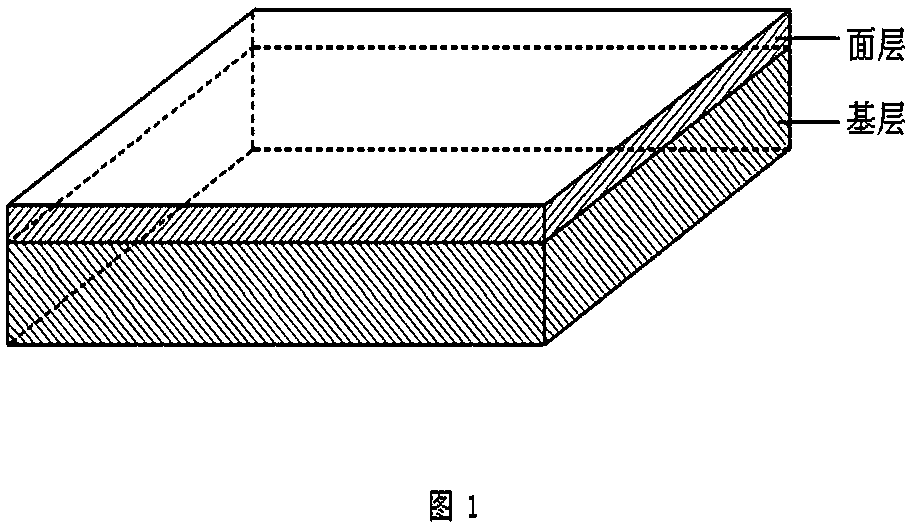

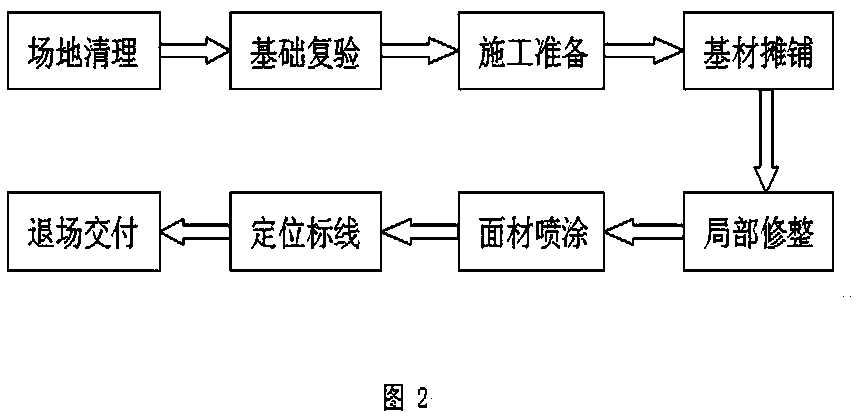

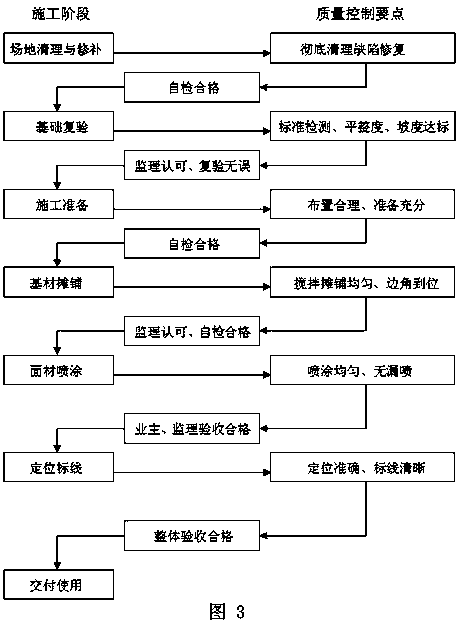

All-plastic plastic runway

The invention discloses a full polyurethane type all-weather running track, which relates to the technology field of all-weather running track. The full polyurethane type all-weather running track comprises a base layer and a surface layer, wherein the surface layer is sprayed on the surface of the base layer. The proportioning of materials for laying the base layer of one square meter running track comprises 0.2 kg of base coatings, 2.5 kg of environment-friendly glues and 12.5 kg of EPDM particles. The base layer is 10 mm thick by the use of mechanical spreading. The proportioning of materials for laying the surface layer of one square meter running track comprises 0.5 kg of polyurethane pigment paste, 1.5 kg of EPDM particles and 1.5 kg of environment-friendly glues. The polyurethane pigment paste, the EPDM particles and the environment-friendly glues are mixed uniformly in proportion to be sprayed on the surface layer by the use of mechanical spraying and to be sprayed for three times in a forward direction, a reverse direction and a forward direction; each time the surface layer is sprayed with thickness being 1.0 mm, and the thickness of the surface layer is 3 mm. The full polyurethane type all-weather running track has the advantages of ultraviolet resistance, strong light exposure resistance, color fastness, excellent performance of nail resistance, wear resistance, compression resistance and durability, longer service life, short construction period and less manpower.

Owner:上海天路弹性材料集团股份有限公司

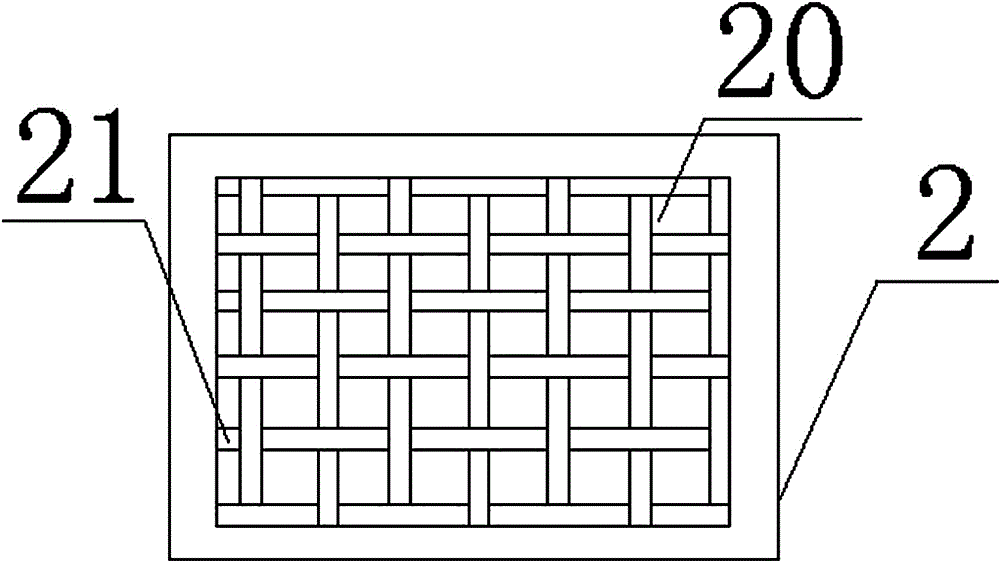

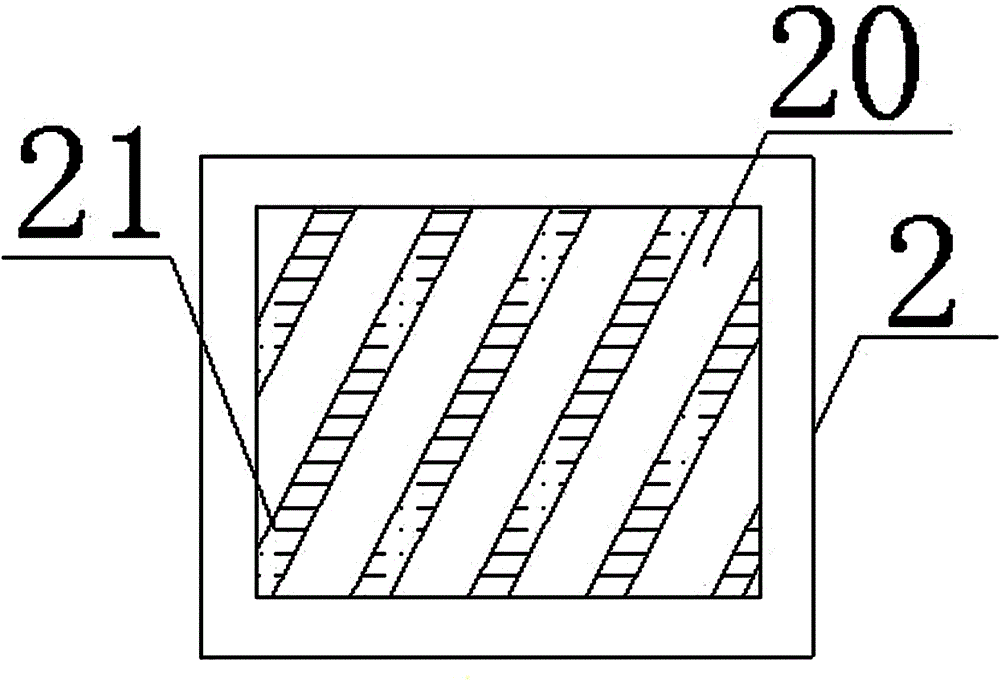

Elastic fireproof wallboard

ActiveCN106049786ALarge specific surface areaIncrease the areaCovering/liningsCeramicwareInsulation layerEngineering

The invention discloses an elastic fireproof wallboard which comprises a base layer, a frame layer, an adhesive layer, a plastering mortar layer, an insulation layer, a latex layer, a decorative coating and an abrasion-resistant layer. The base layer is covered by the frame layer. The frame layer is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form filling cavities. The filling cavities are filled with filler. The frame layer is covered by the adhesive layer. The adhesive layer is covered by the plastering mortar layer. The plastering mortar layer is covered by the insulation layer. The insulation layer is covered by the latex layer. The upper surface of the latex layer is coated with the decorative coating made of decorative paint. The upper surface of the decorative coating is coated with the abrasion-resistant layer made of transparent abrasion-resistant paint.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

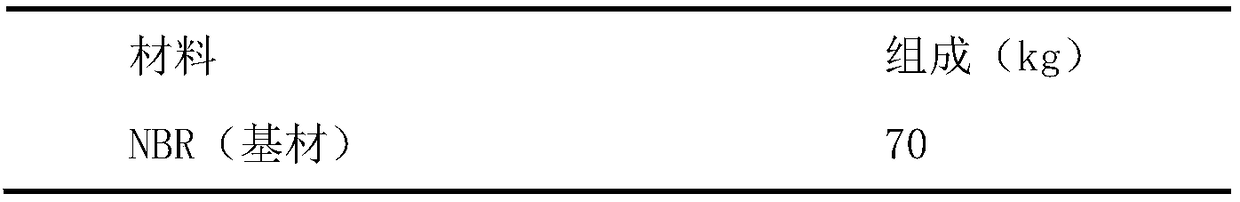

Magnetic rubber seal composite material with high pressure resistance and preparation method of magnetic rubber seal composite material

The invention relates to the field of functional magnetic seal composite materials, in particular to a magnetic rubber seal composite material with high pressure denaturation and a preparation methodof the magnetic rubber seal composite material. The magnetic rubber seal composite material is mainly characterized by forming by nitrile rubber, neoprene, magnetic powder and a reinforcement, vulcanization and protection system, mixing with an internal mixer and shaping and vulcanizing with a vulcanizing machine. The magnetic rubber seal composite material has the advantages of good dynamic sealing and static sealing and solvent resistance, high pressure denaturation, good thermal stability, magnetic stability and the like.

Owner:QINGDAO UNIV OF SCI & TECH +2

High flame retardant heat preservation wallboard

ActiveCN106084731AGood fire resistance and heat resistanceImprove toughnessCovering/liningsFlooringFiberC-Met

The invention discloses a high flame retardant heat preservation wallboard which comprises a base layer, an inner fiberboard layer attached to the upper portion of the base layer, a heat preservation layer attached to the upper portion of the inner fiberboard layer, a vacuum layer attached to the upper portion of the heat preservation layer, a protective layer attached to the upper portion of the vacuum layer, an outer fiberboard attached to the upper portion of the protective layer, a light reflective layer attached to the upper portion of the outer fiberboard, and a waterproof layer attached to the upper portion of the light reflective layer. The thickness of the outer fiberboard is a, the light reflective layer is b, the thickness of the vacuum layer is c, and a, b and c meet the relation that a+c=b / 2.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

A kind of thermal insulation firewall board

ActiveCN106013594BGood fire resistance and heat resistanceImprove toughnessBuilding componentsInsulation layerEngineering

The invention discloses a heat insulation fireproof wallboard which comprises a base layer, an inner fiber board layer attached to the base layer, a heat insulation layer attached to the inner fiber board layer, a vacuum layer attached to the heat insulation layer, a protective layer attached to the vacuum layer, an outer fiber layer attached to the protective layer, a waterproof layer attached to the outer fiber board, and a reflective layer attached to the waterproof layer. The heat insulation fireproof wallboard has the excellent fireproof performance, is extinguished right after being deviated from fire, and is high in toughness and strength and excellent in heat insulation effect.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Fireproof building external wall panel

InactiveCN105968704AGood fire resistance and heat resistanceHigh hardnessCovering/liningsFlooringKetoneMelamine formaldehyde resin

The invention discloses a fireproof building exterior wall panel, which comprises a base layer, a fireproof layer and a wear-resistant decorative layer arranged sequentially from inside to outside; wherein the raw materials of the fireproof layer include: 97-100 parts of modified phenolic resin, melamine 22-25 parts of formaldehyde resin, 9-12 parts of liquid nitrile rubber, 14-17 parts of polyphenylene ether ketone, 0.9-1.2 parts of silane coupling agent, 13-16 parts of jute fiber, 5-8 parts of potassium titanate fiber, 23-26 parts of white carbon black, 21-24 parts of montmorillonite, 15-18 parts of foaming agent, 3-6 parts of foaming aid, 24-26 parts of hydrated zinc borate, 2-3 parts of anti-aging agent. The preparation method of the modified phenolic resin is as follows: react hydroquinone with diphenyl chlorophosphate to obtain the first material; react the first material with lauryl aldehyde to obtain the second material; Ammonium molybdate is reacted to obtain modified phenolic resin.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

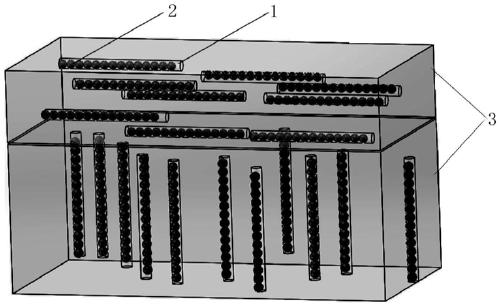

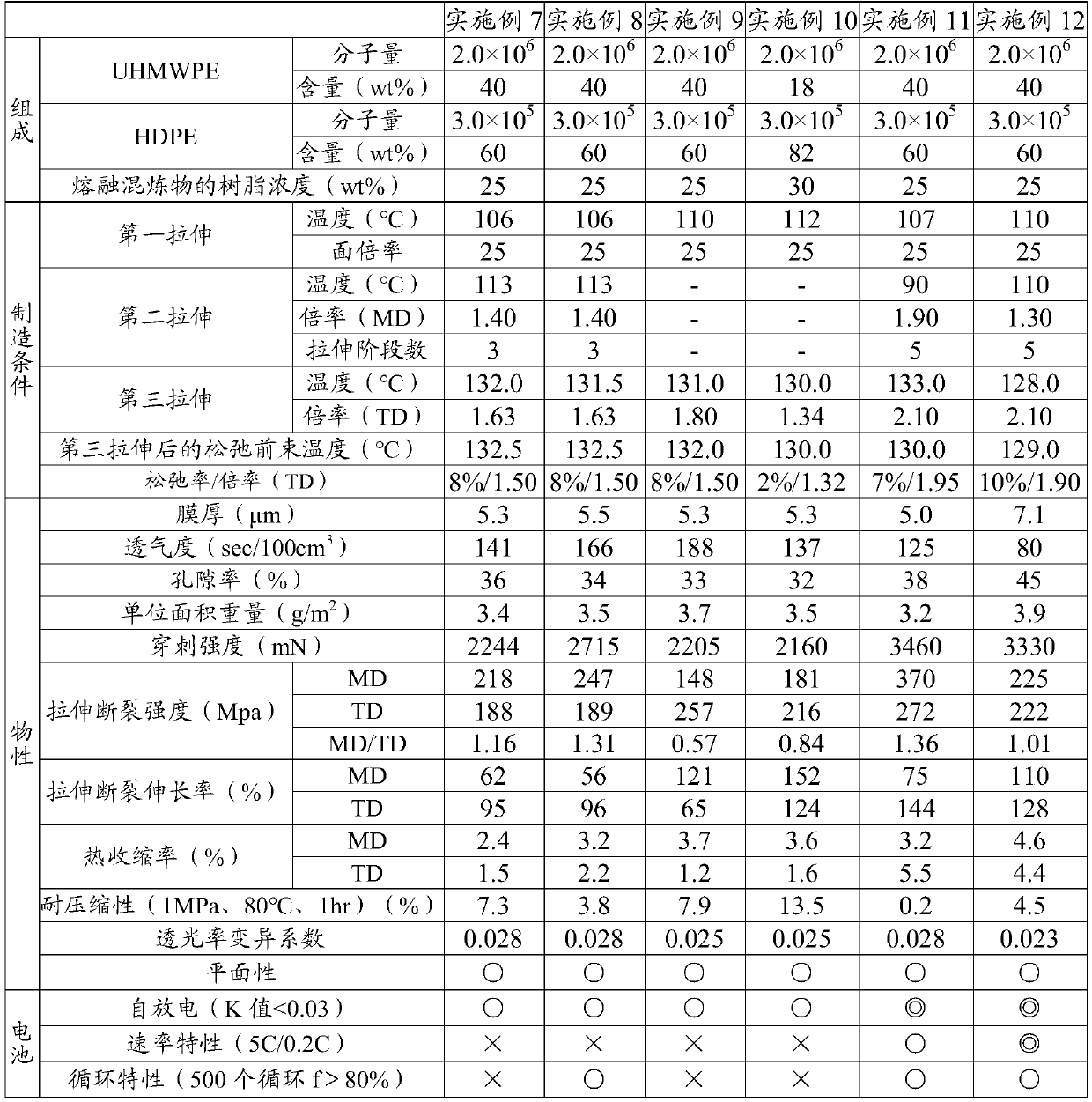

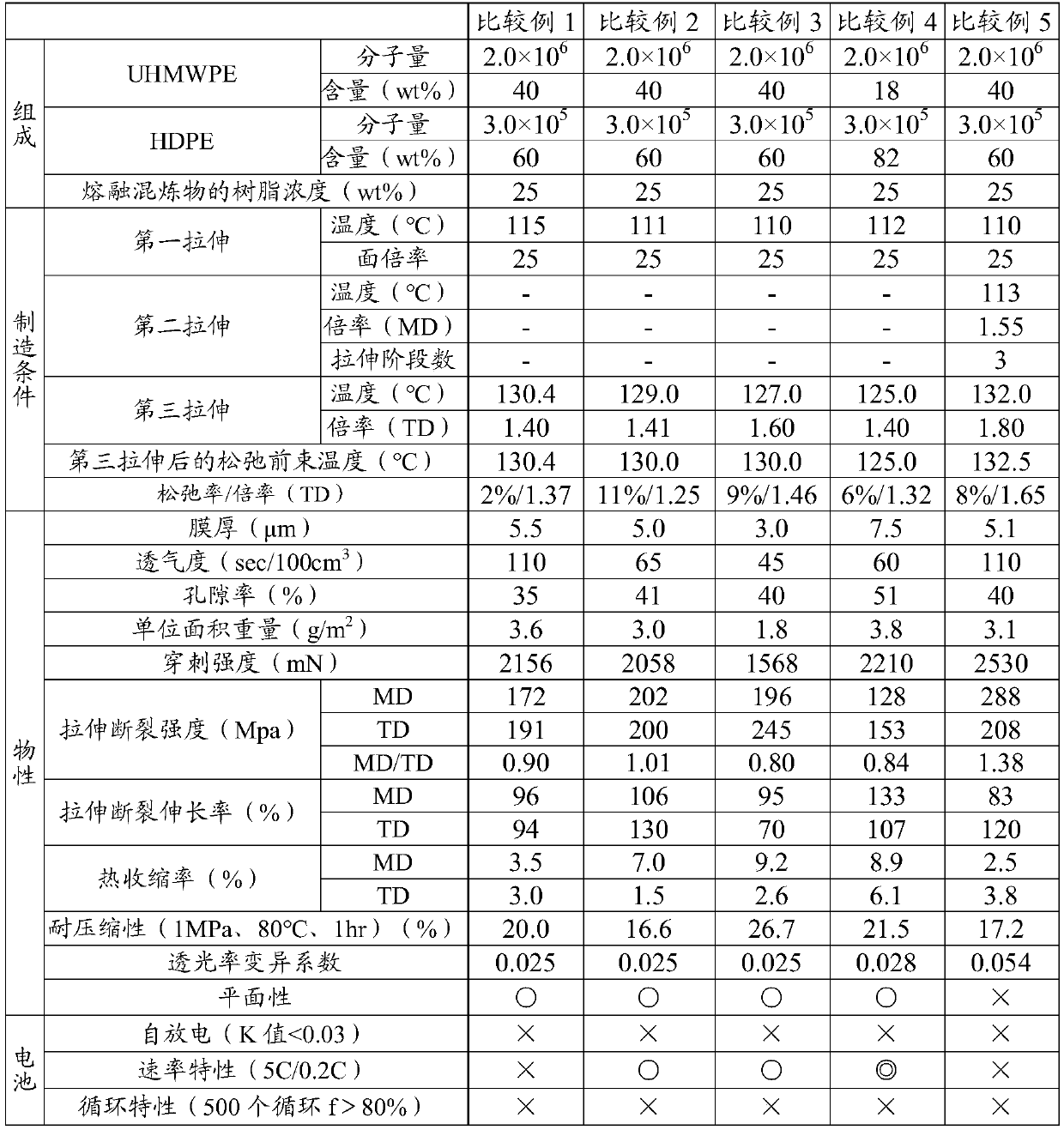

Polyolefin microporous film

InactiveCN110114397AExcellent compression resistanceExcellent self-discharge characteristicsCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolymer sciencePolyolefin

The present invention addresses the problem of providing a polyolefin microporous film having exceptional self-discharge characteristics when incorporated into a cell as a separator. The present invention solves the above-mentioned problem by a polyolefin microporous film in which the percentage change in film thickness when heated and compressed for 60 minutes at a temperature of 80 DEG C and a pressure of 1 MPa is 0-15% relative to a film thickness of 100% of the polyolefin microporous film prior to heating and compression.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com