Patents

Literature

1273results about How to "Improve lipophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of synthesis and use

InactiveUS6235886B1Increase the number ofGood curative effectSugar derivativesMicrobiological testing/measurementNucleotideOrganic chemistry

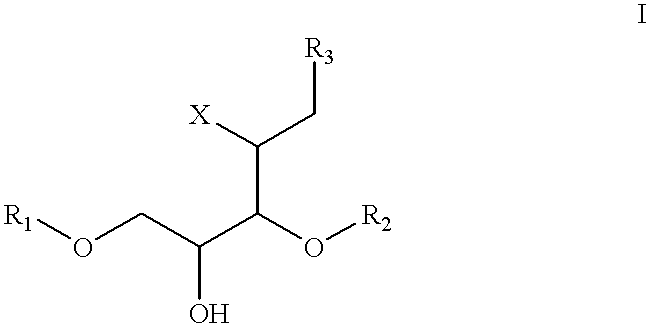

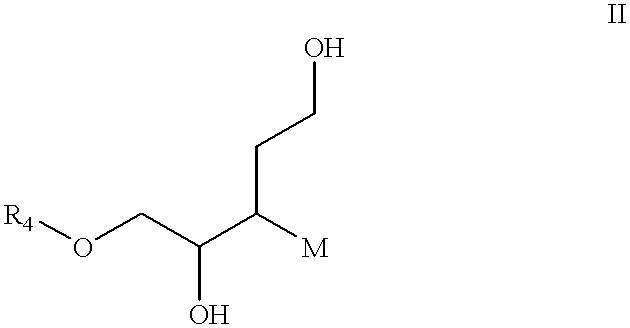

Oligonucleotide and nucleotide amine analogs and methods of preparing and using these compounds are provided by the present invention.

Owner:IONIS PHARMA INC

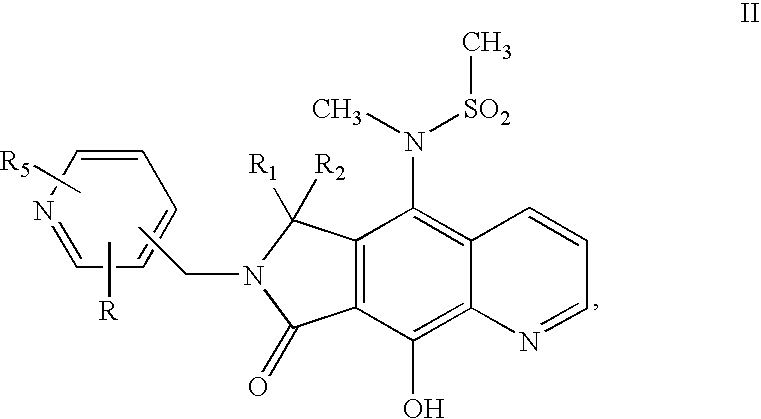

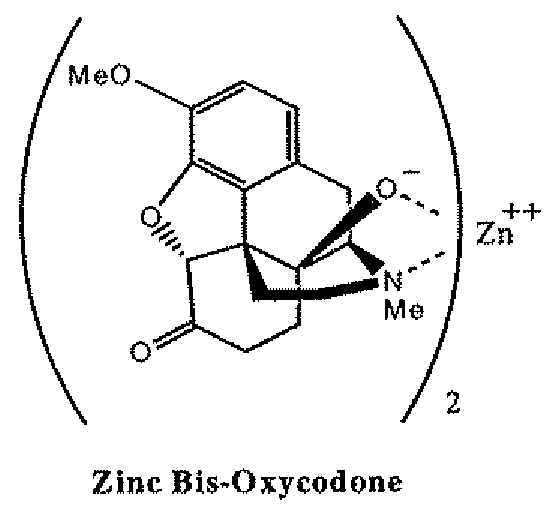

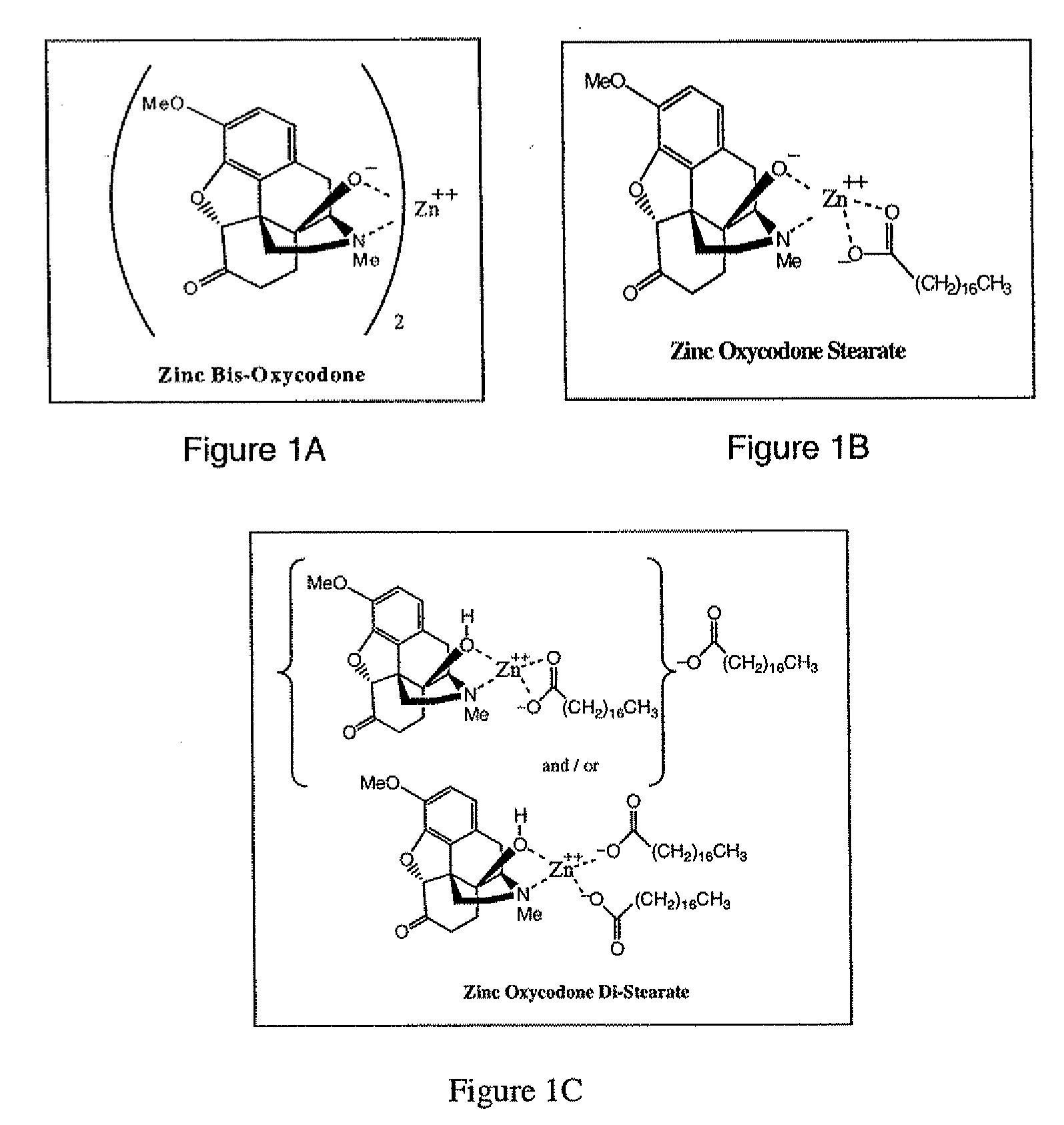

Abuse-deterrent pharmaceutical compositions of opioids and other drugs

ActiveUS7399488B2Good treatment effectSmall dosePowder deliveryNervous disorderAdditive ingredientWater insoluble

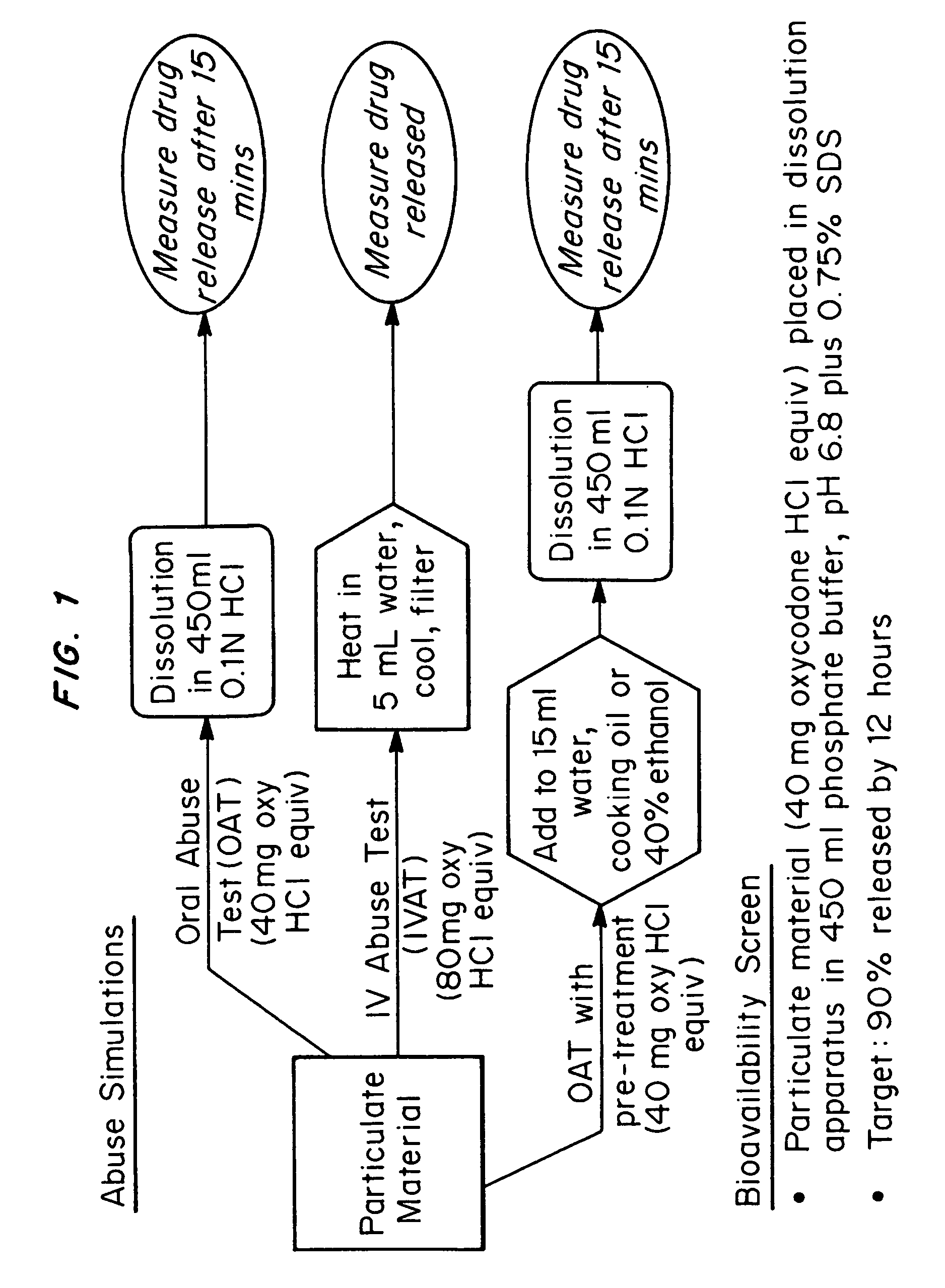

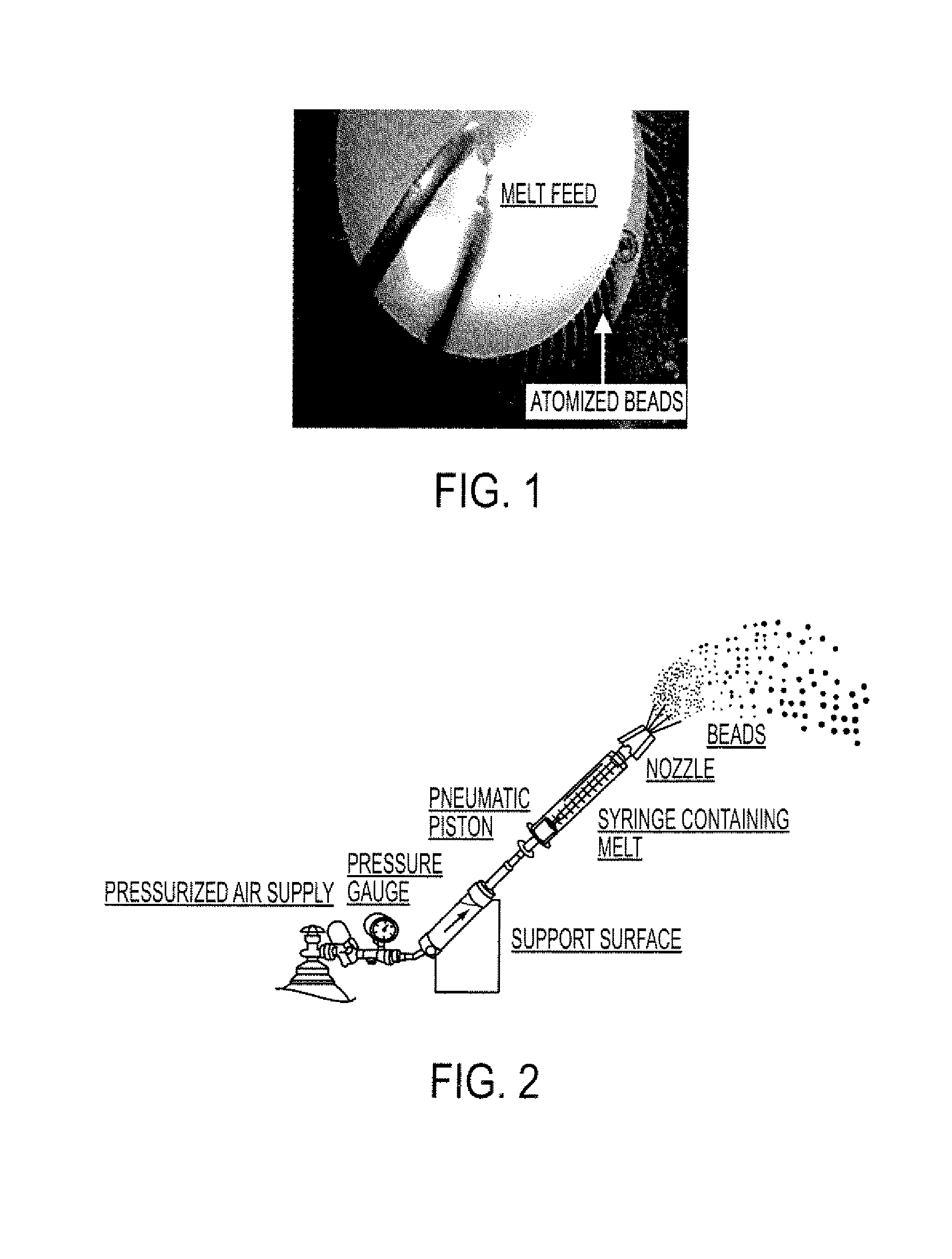

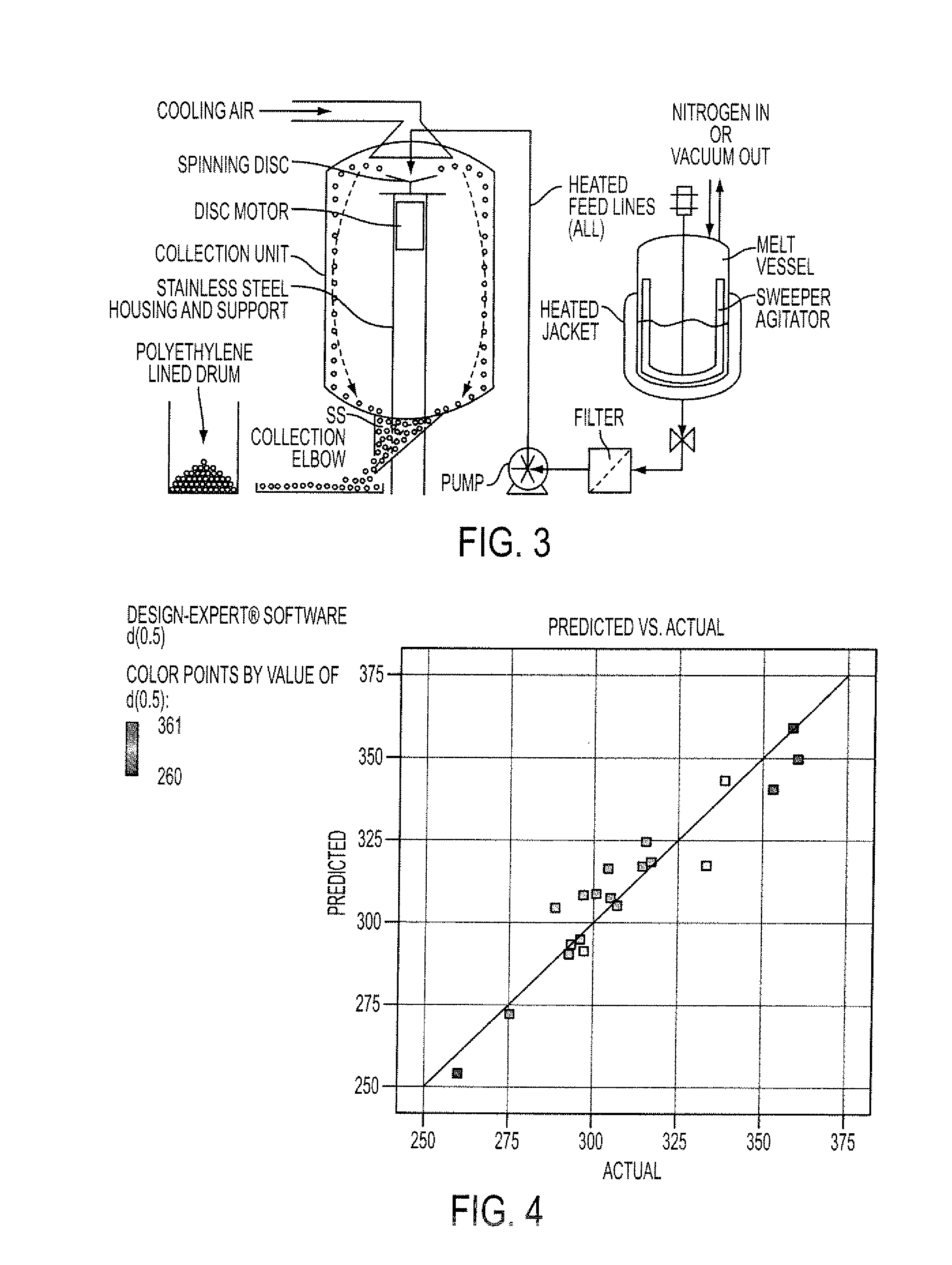

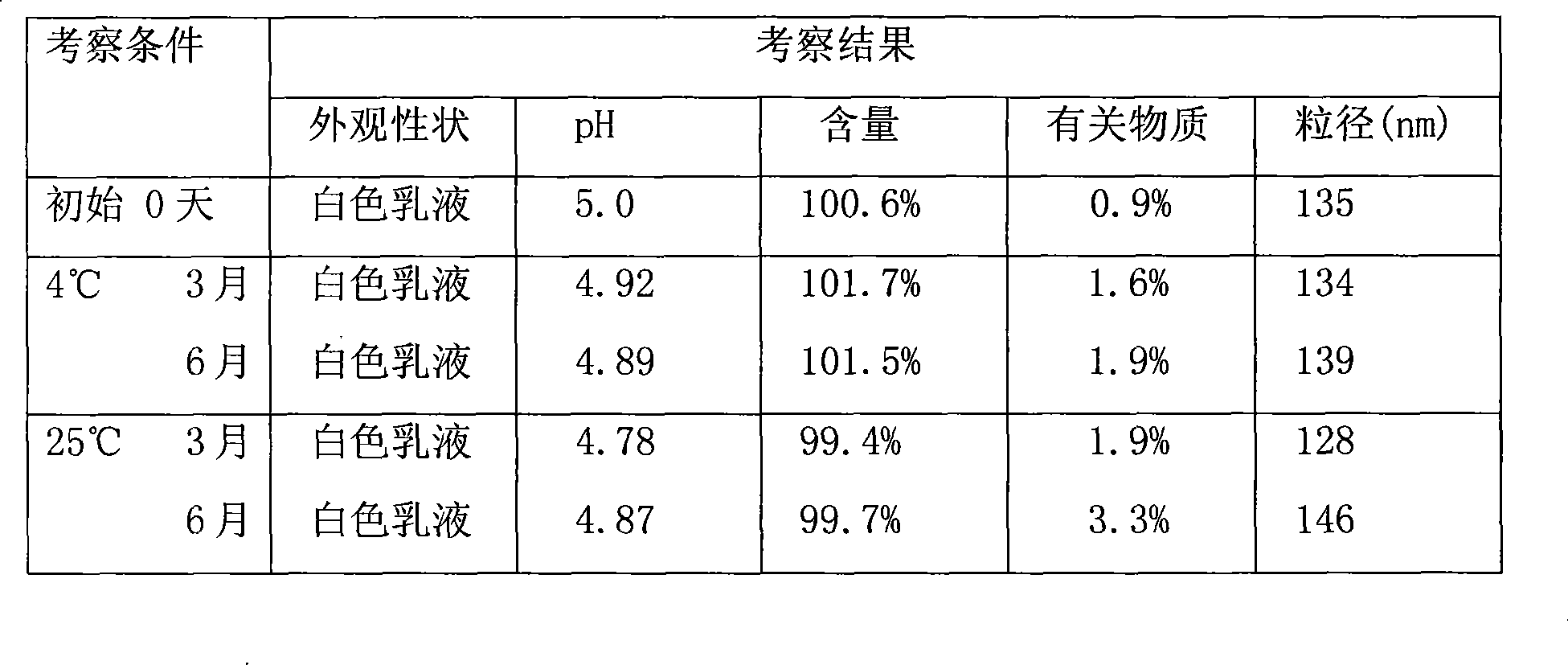

An abuse-deterrent pharmaceutical composition has been developed to reduce the likelihood of improper administration of drugs, especially drugs such as opiods. In the preferred embodiment, a drug is modified to increase its lipophilicity. In preferred embodiments the modified drug is homogeneously dispersed within microparticles composed of a material that is either slowly soluble or not soluble in water. In some embodiments the drug containing microparticles or drug particles are coated with one or more coating layers, where at least one coating is water insoluble and preferably organic solvent insoluble, but enzymatically degradable by enzymes present in the human gastrointestinal tract. The abuse-deterrent composition retards the release of drug, even if the physical integrity of the formulation is compromised (for example, by chopping with a blade or crushing) and the resulting material is placed in water, snorted, or swallowed. However, when administered as directed, the drug is slowly released from the composition as the composition is broken down or dissolved gradually within the GI tract by a combination of enzymatic degradation, surfactant action of bile acids, and mechanical erosion.

Owner:COLLEGIUM PHARMA INC

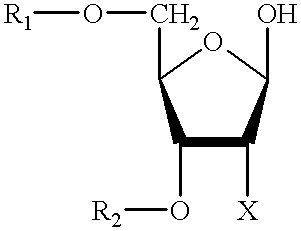

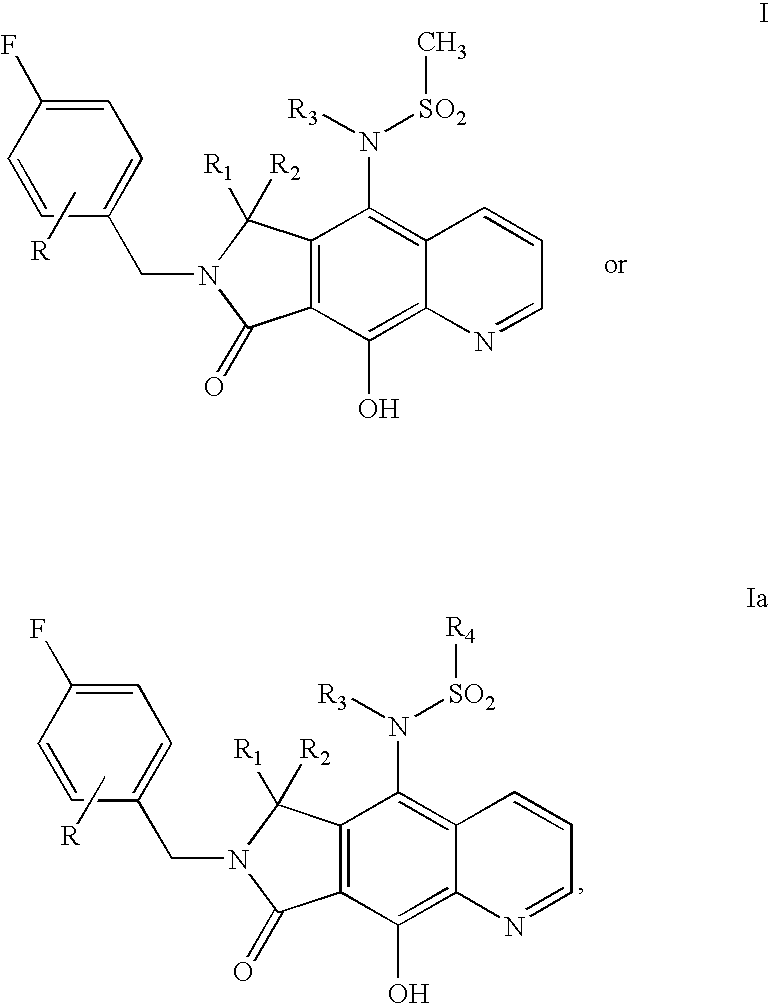

Integrase inhibitor compounds

InactiveUS20070072831A1Increasing cellular accumulationImprove bioavailabilityBiocideAntiviralsBiochemistryIntegrase inhibitor

Owner:GILEAD SCI INC

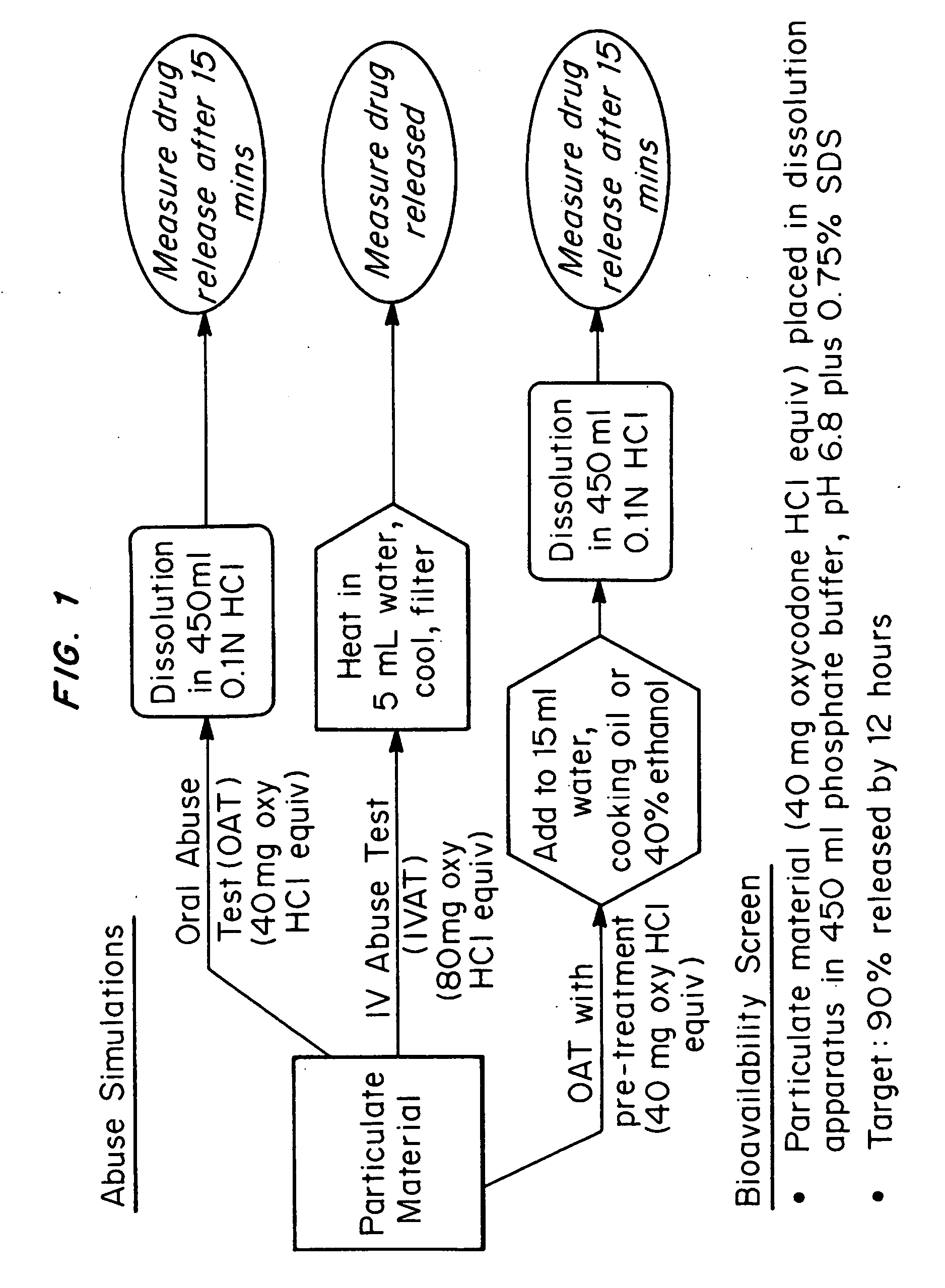

Abuse-deterrent drug formulations

ActiveUS20050281748A1Reduce the possibilityImprove lipophilicityTelevision system detailsPowder deliveryImmediate releaseActive agent

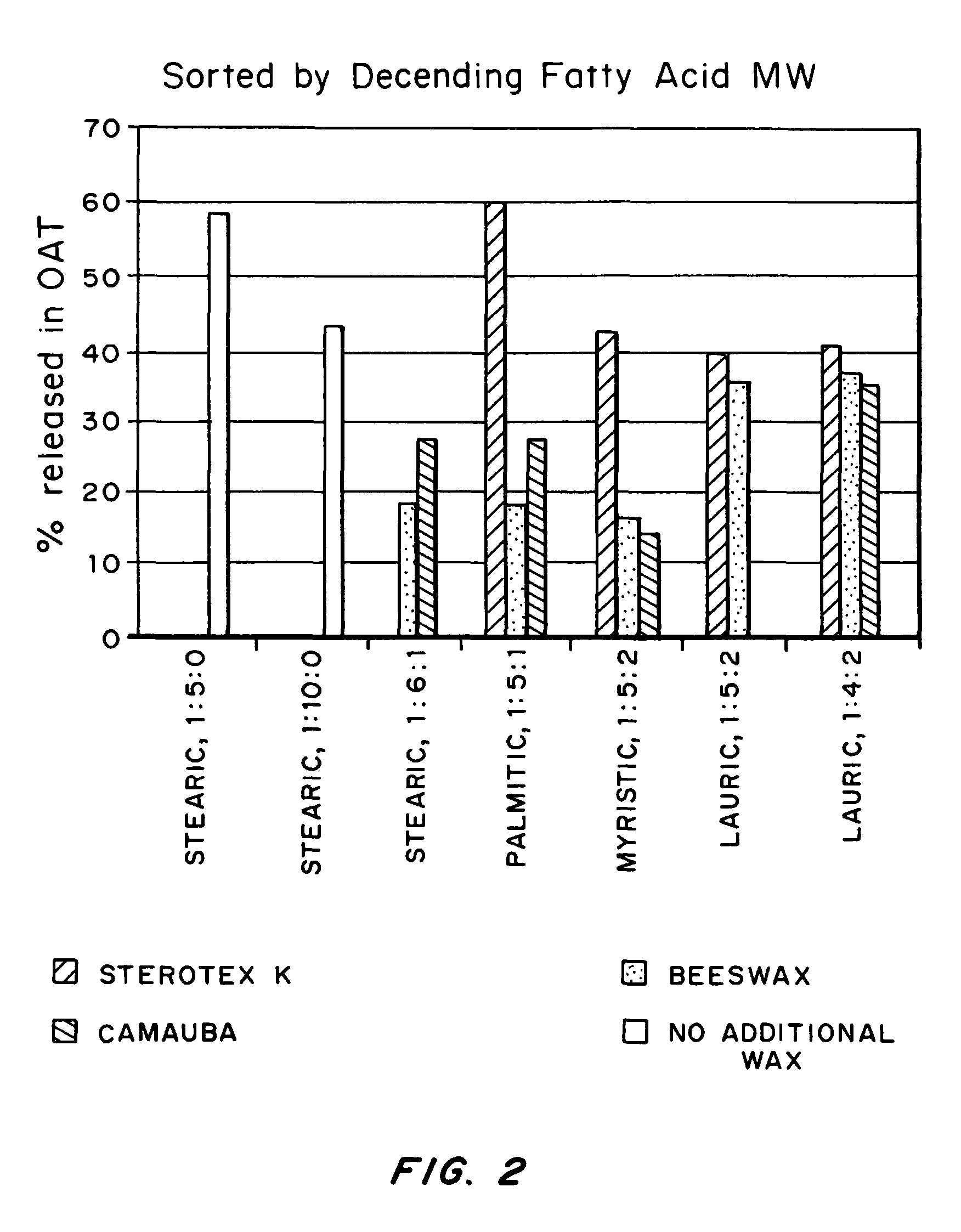

An abuse-deterrent pharmaceutical composition has been developed to reduce the likelihood of improper administration of drugs, especially drugs such as opiods. In the preferred embodiment, the drug is modified to increase its lipophilicity by forming a salt between the drug and one or more fatty acids wherein the concentration of the one or more fatty acids is one to 15 times the molar amount of the active agent, preferably two to ten times the molar amount of the active agent. In one embodiment the modified drug is homogeneously dispersed within microparticles composed of a material that is either slowly soluble or not soluble in water. In some embodiments the drug containing microparticles or drug particles are coated with one or more coating layers, where at least one coating is water insoluble and preferably organic solvent insoluble. The abuse-deterrent composition prevents the immediate release of a substantial portion of drug, even if the physical integrity of the formulation is compromised (for example, by chopping with a blade or crushing) and the resulting material is placed in water, snorted, or swallowed. However, when administered as directed, the drug is slowly released from the composition as the composition is broken down or dissolved gradually within the GI tract by a combination of enzymatic degradation, surfactant action of bile acids, and mechanical erosion.

Owner:COLLEGIUM PHARMA INC

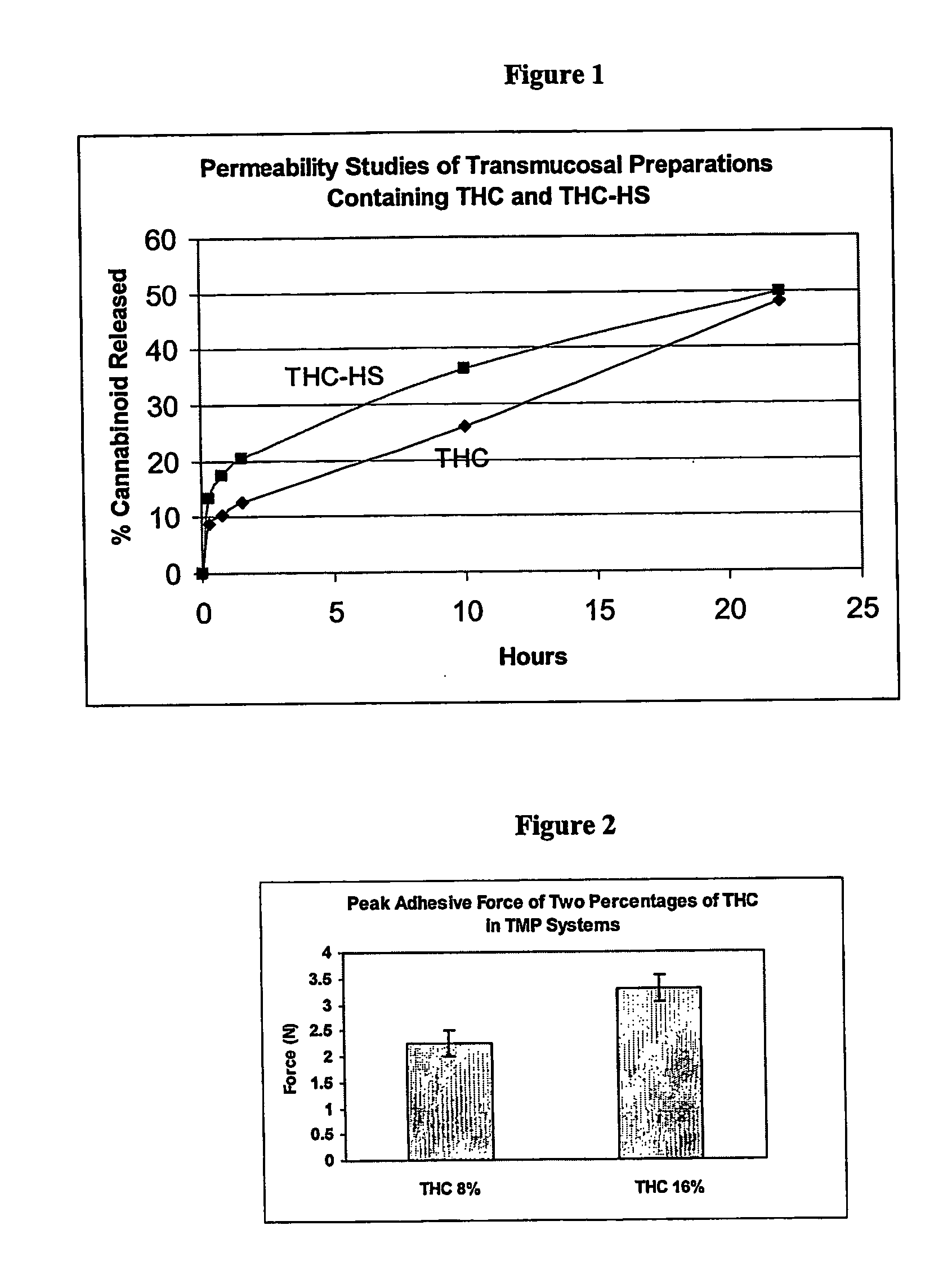

Transmucosal delivery of cannabinoids

InactiveUS20060257463A1Strong tendencyReduced bioavailabilityBiocidePharmaceutical non-active ingredientsCannabisCannabinoid

A method of transmucosally delivering a cannabinoid to a subject in need of such treatment comprising the steps of: administering to the subject a transmucosal preparation containing the cannabinoid wherein said transmucosal preparation is made by incorporating an effective amount of the cannabinoid via hot-melt extrusion technology, hot-melt molding, admixing or a solvent cast technique into a film matrix or a reservoir containing the cannabinoid, and attaching said transmucosal preparation to the mucosa of the subject.

Owner:UNIVERSITY OF MISSISSIPPI

Abuse-deterrent pharmaceutical compositions of opioids and other drugs

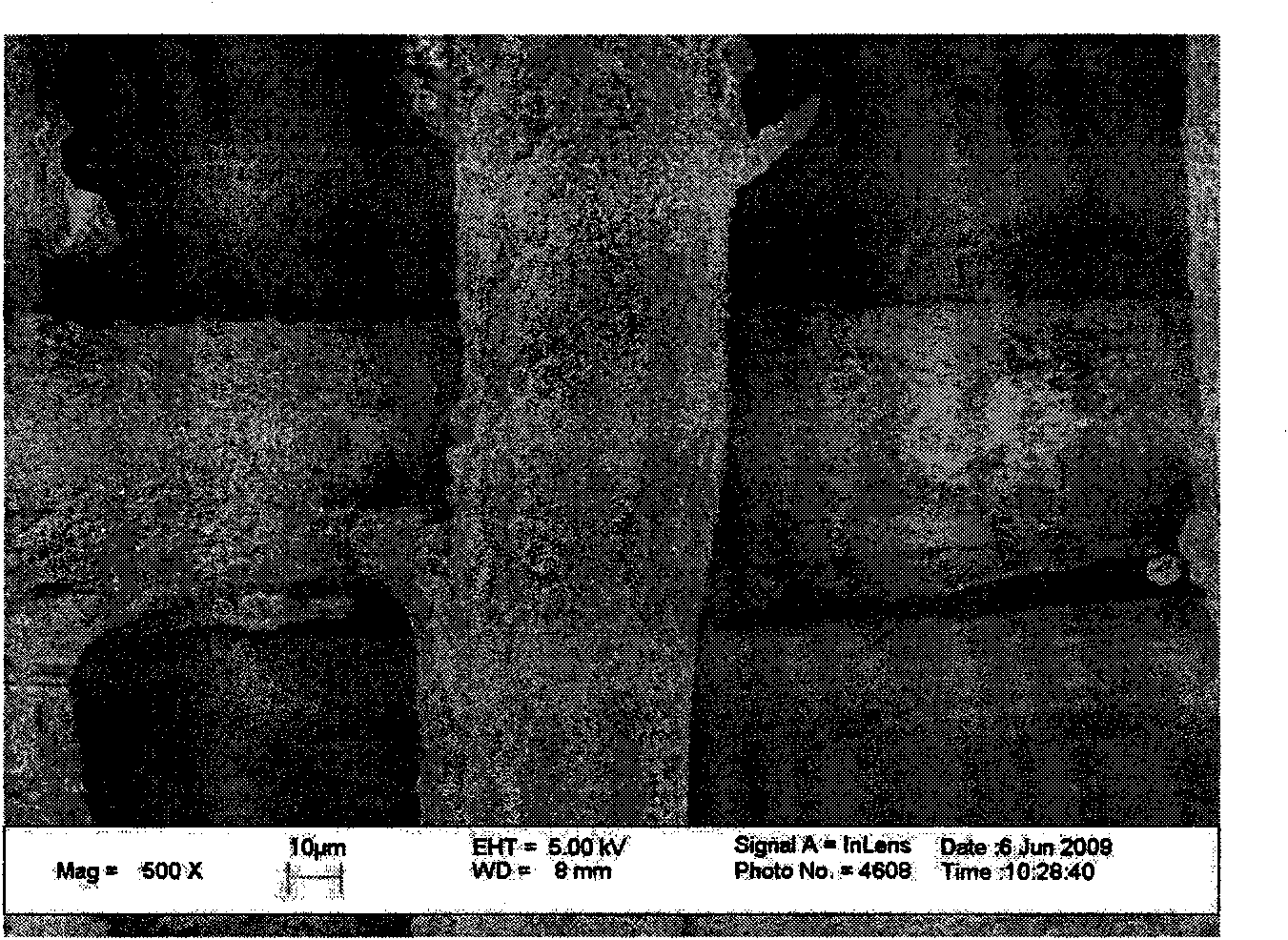

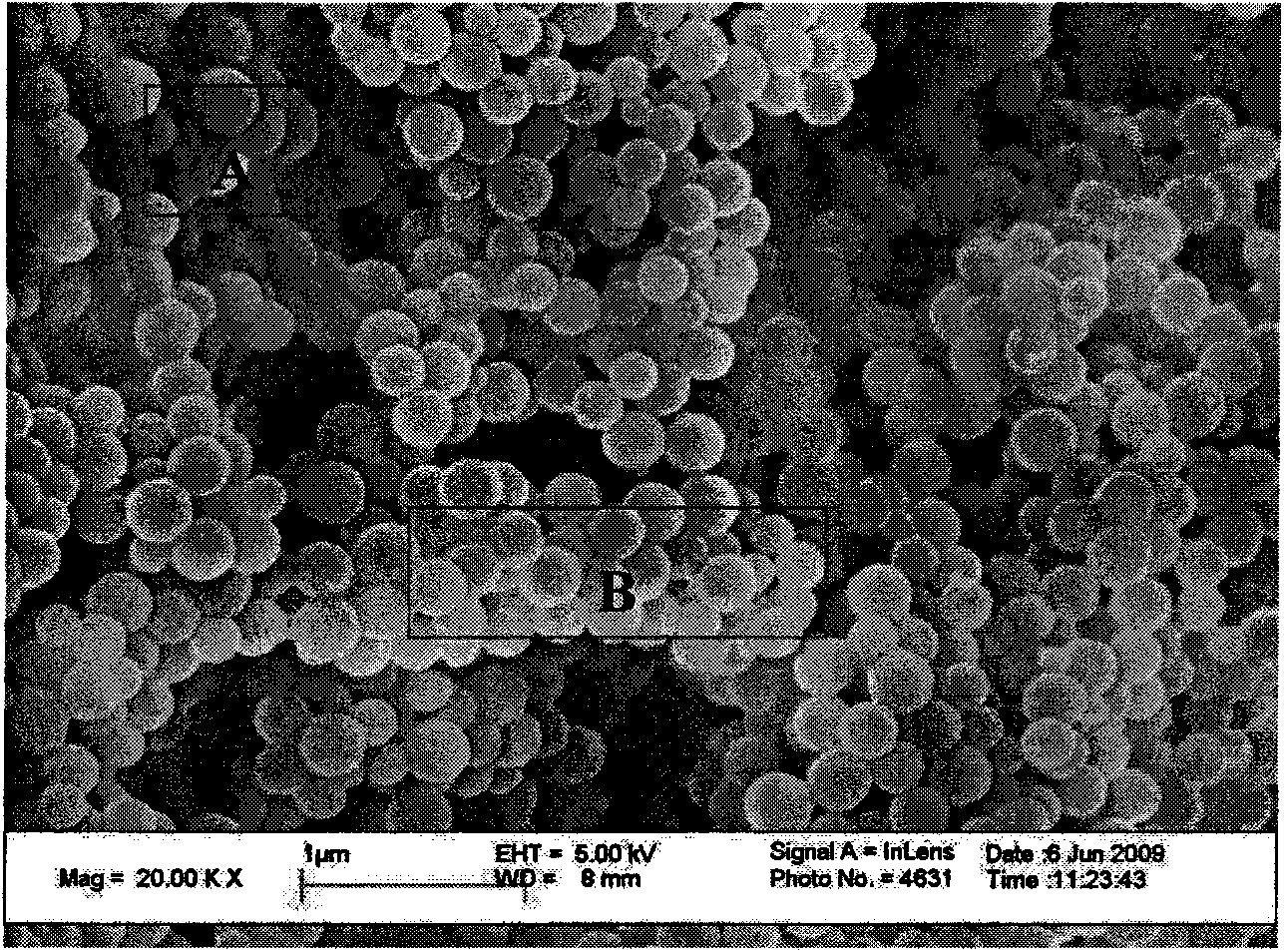

ActiveUS20090297617A1Reduce the possibilityImprove lipophilicityBiocidePowder deliveryAs DirectedOrganic solvent

An abuse-deterrent pharmaceutical composition has been developed to reduce the likelihood of improper administration of drugs, especially drugs such as opioids. In a preferred embodiment, a drug is modified to increase its lipophilicity. In some embodiments the modified drug is homogeneously dispersed within spherical microparticles composed of a material that is either slowly soluble or not soluble in water. In some embodiments the drug containing microparticles or drug particles are coated with one or more coating layers, where at least one coating is water insoluble and / or organic solvent insoluble. The abuse-deterrent composition retards the release of drug, even if the physical integrity of the formulation is compromised (for example, by chopping with a blade or crushing) and the resulting material is placed in water, snorted, or swallowed. However, when administered as directed, the drug is slowly released from the composition as the composition is passes through the GI tract.

Owner:COLLEGIUM PHARMA INC

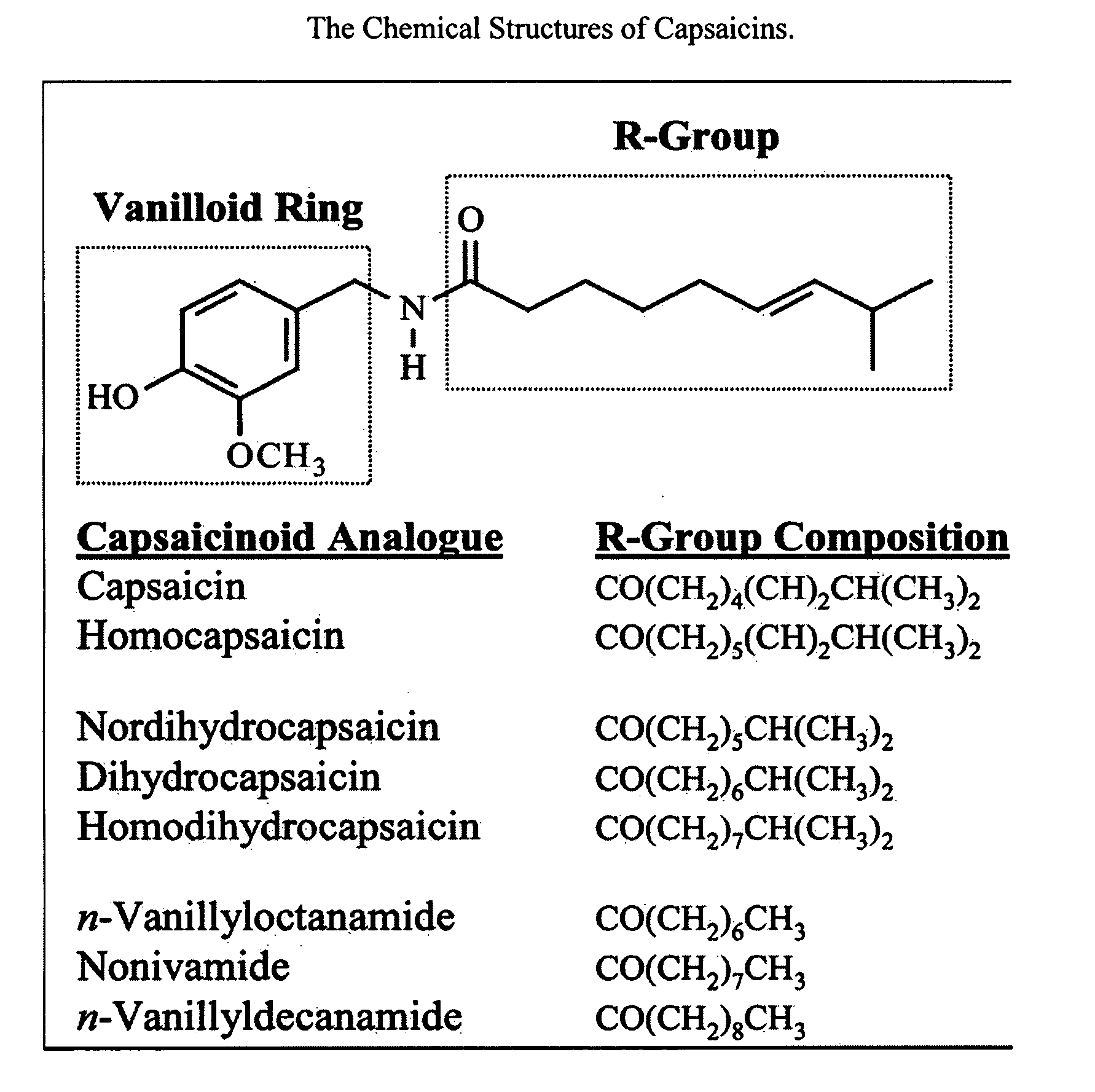

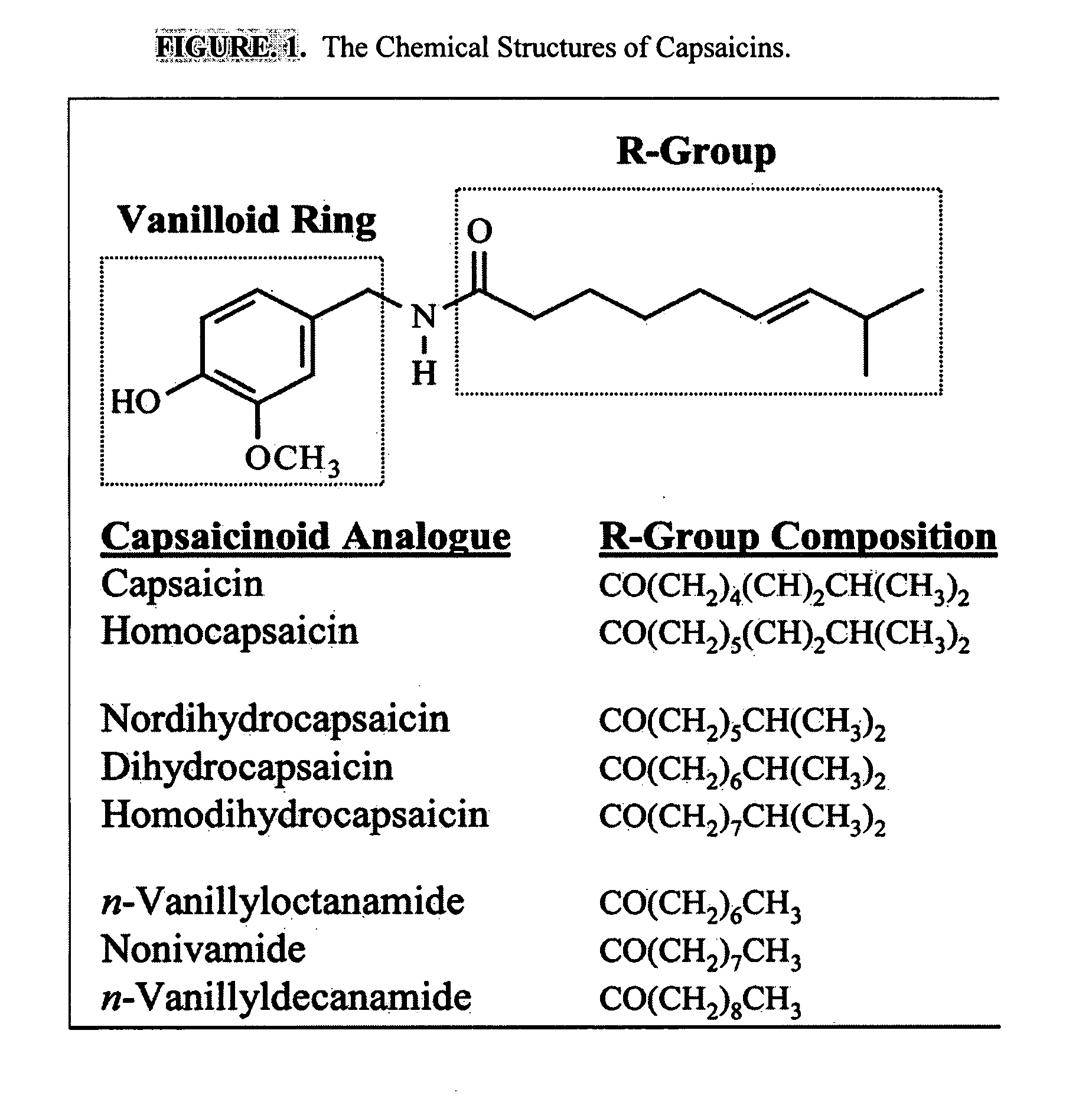

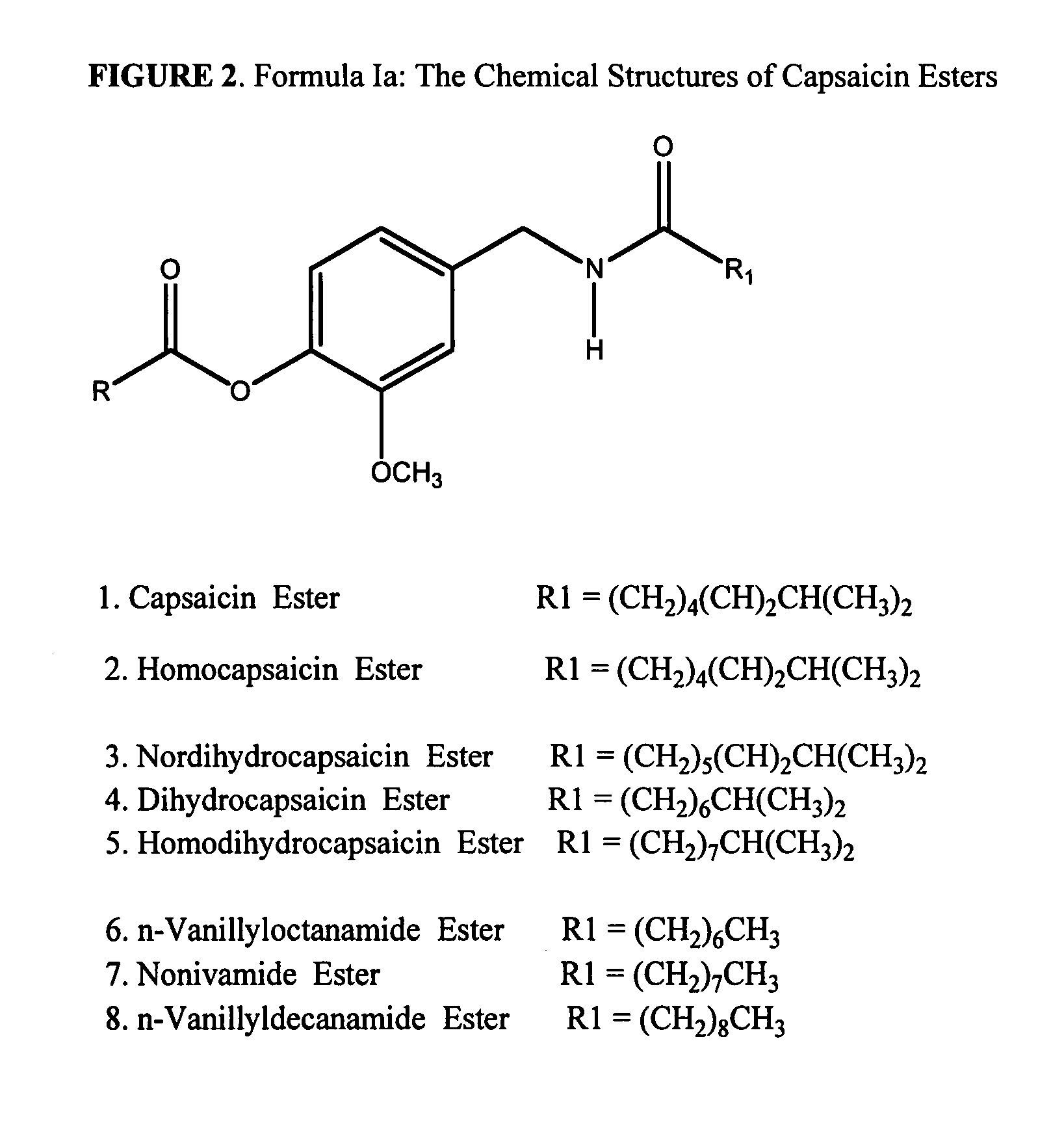

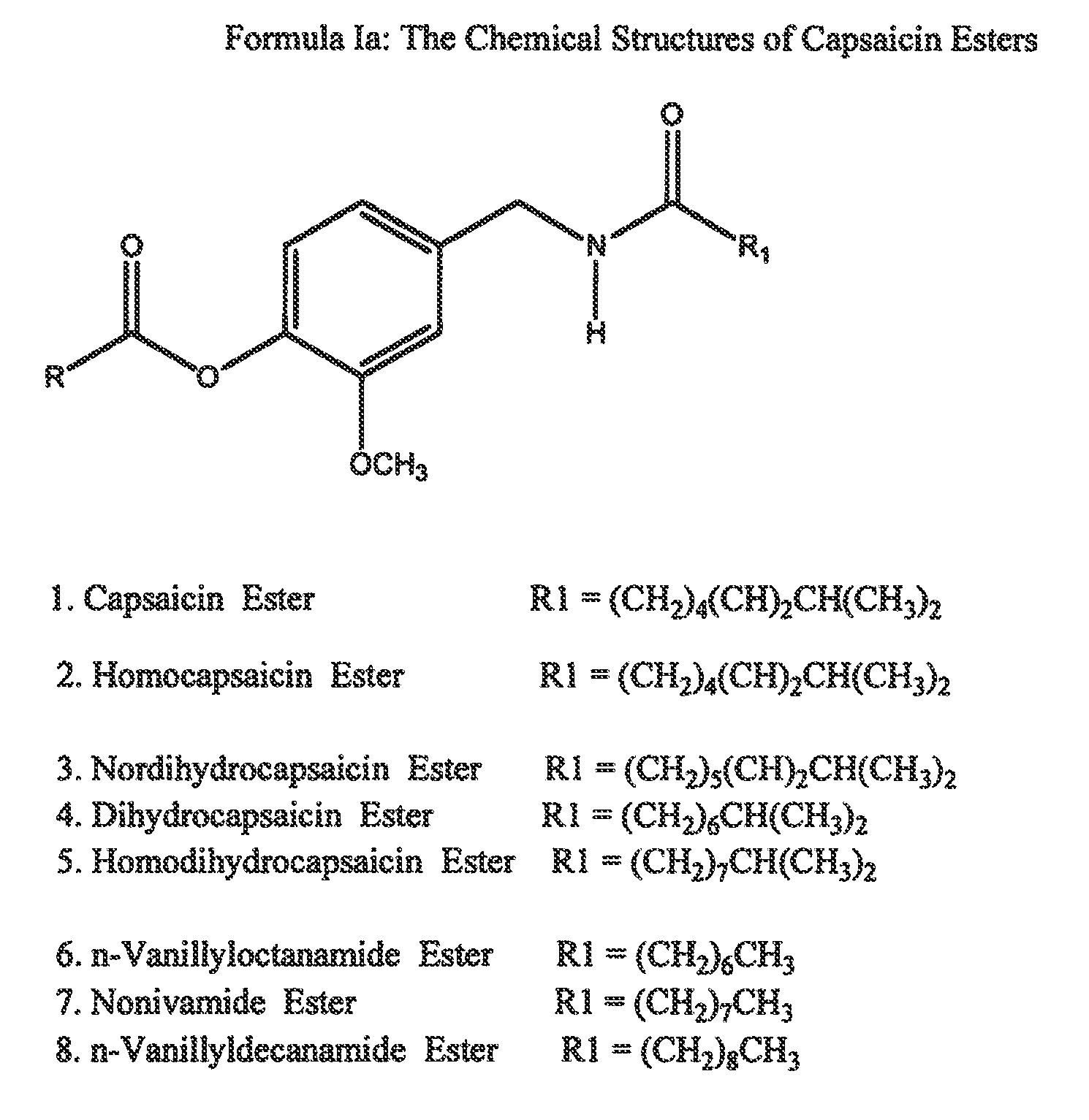

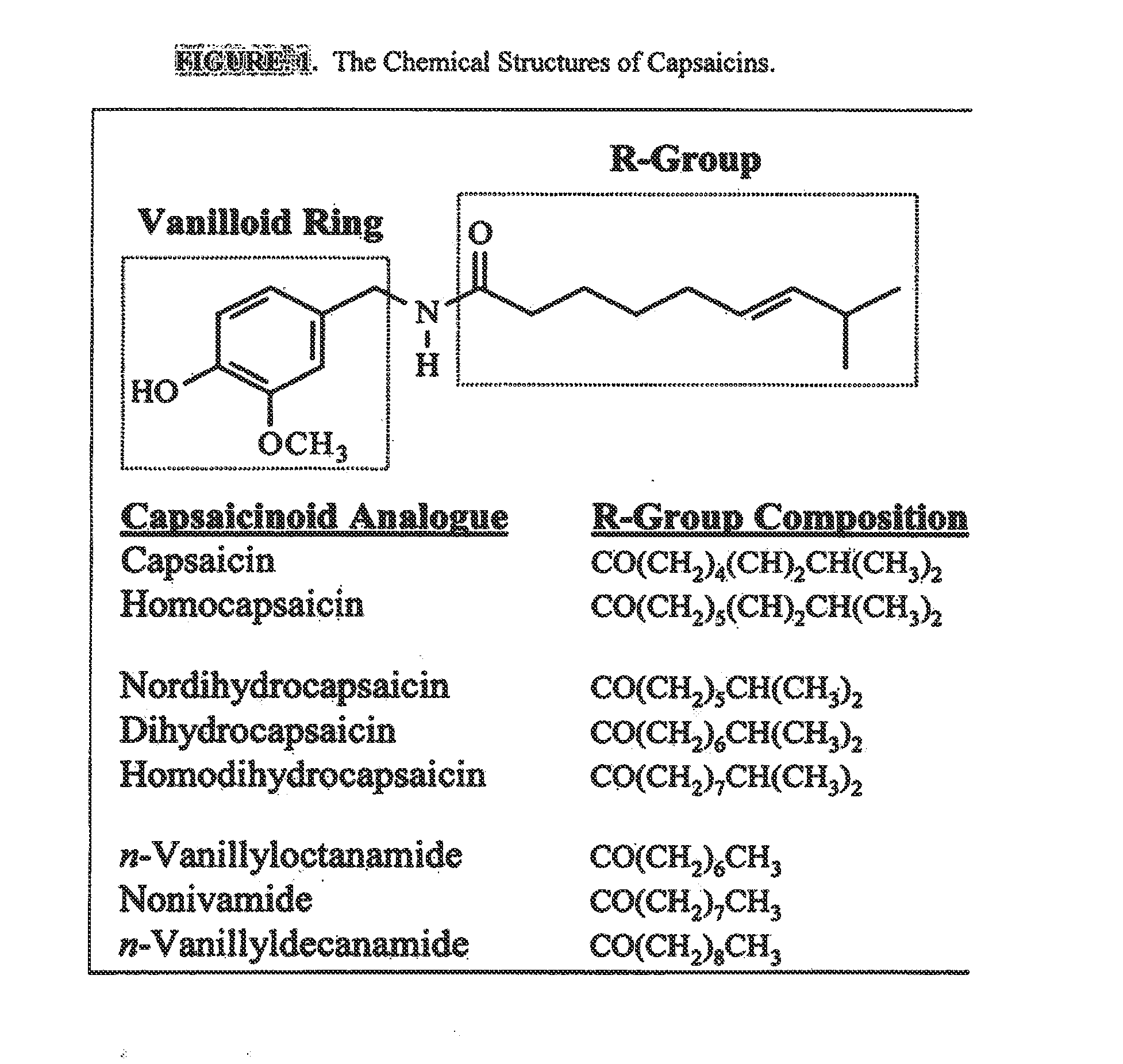

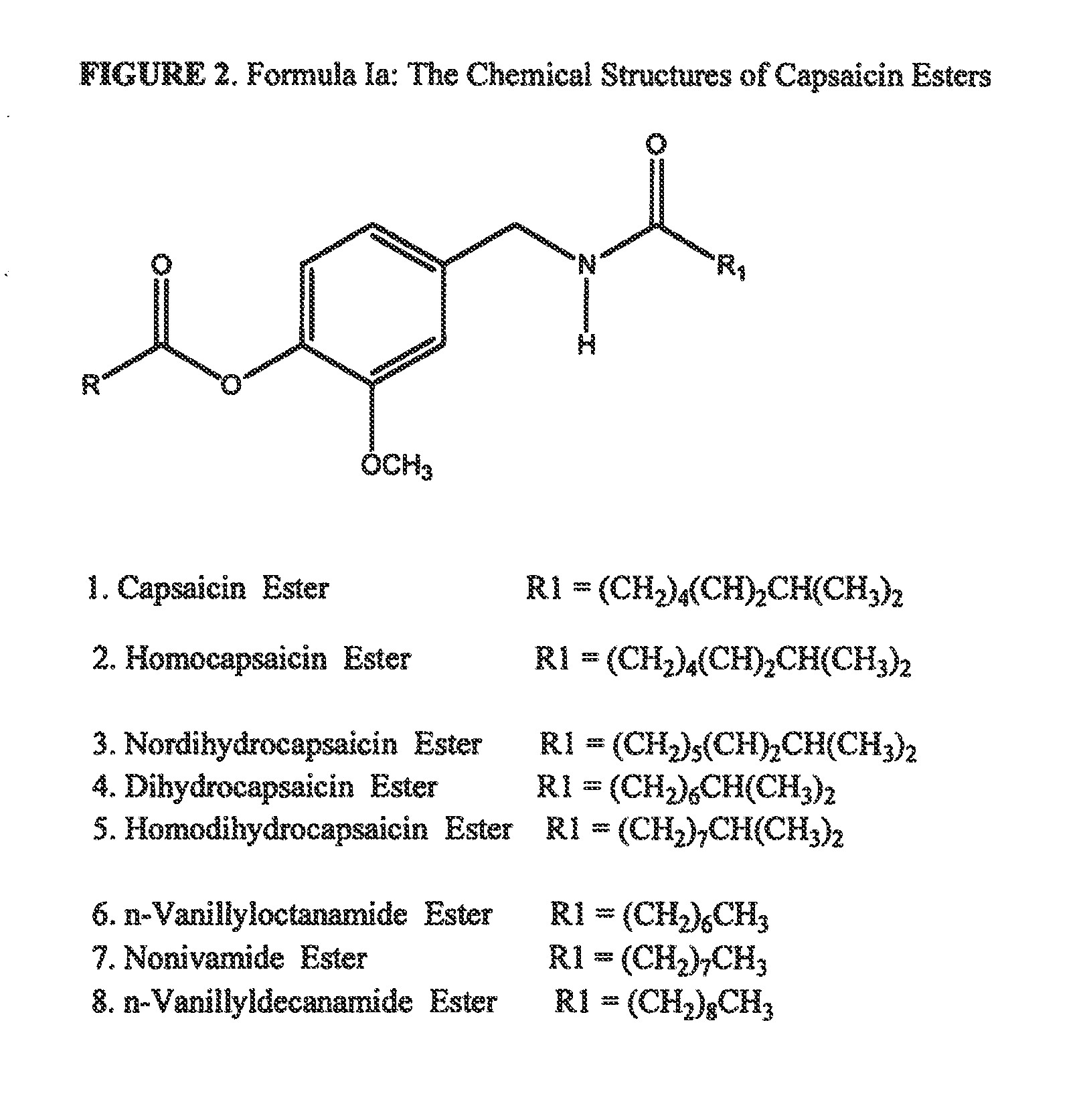

Esters of capsaicin for treating pain

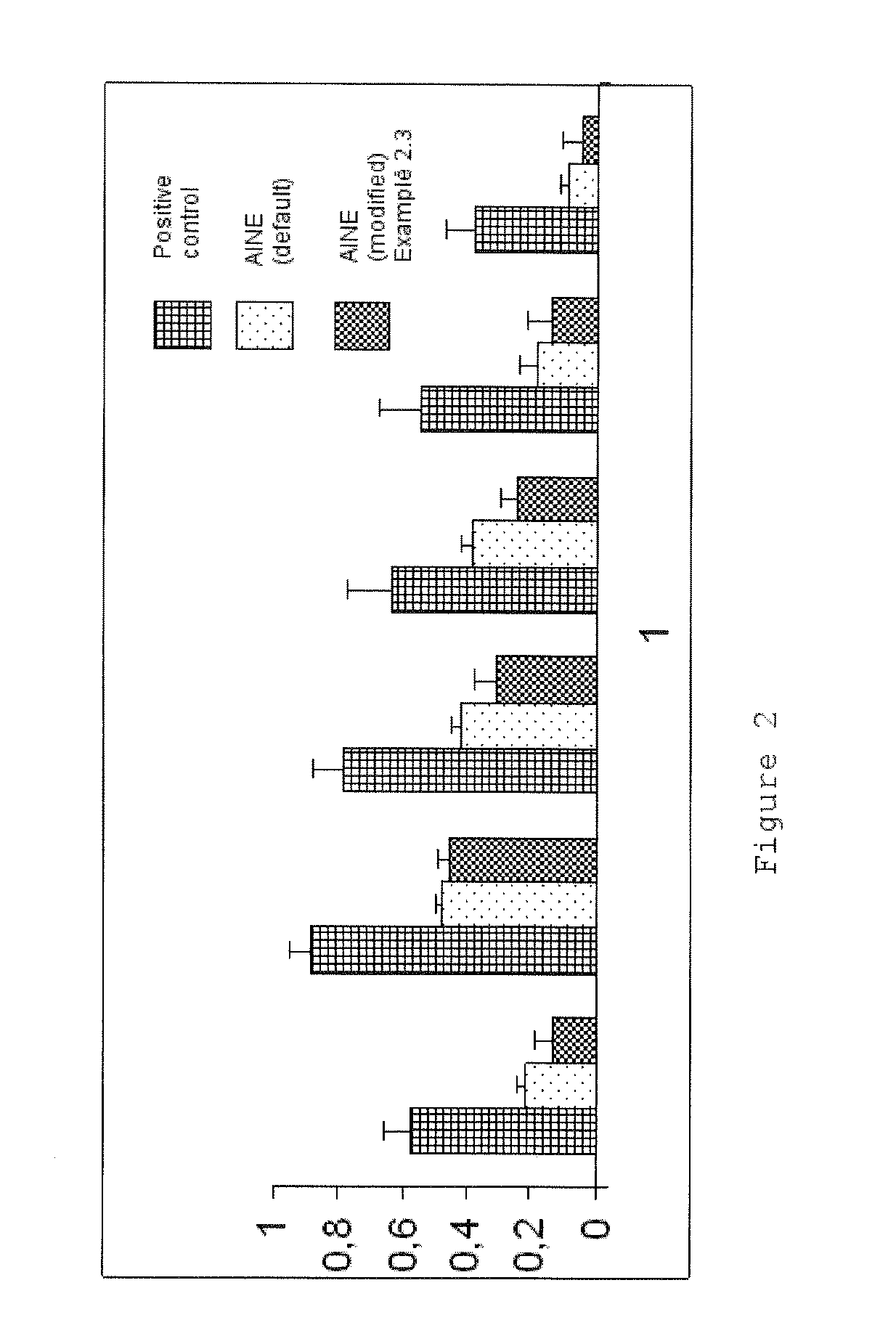

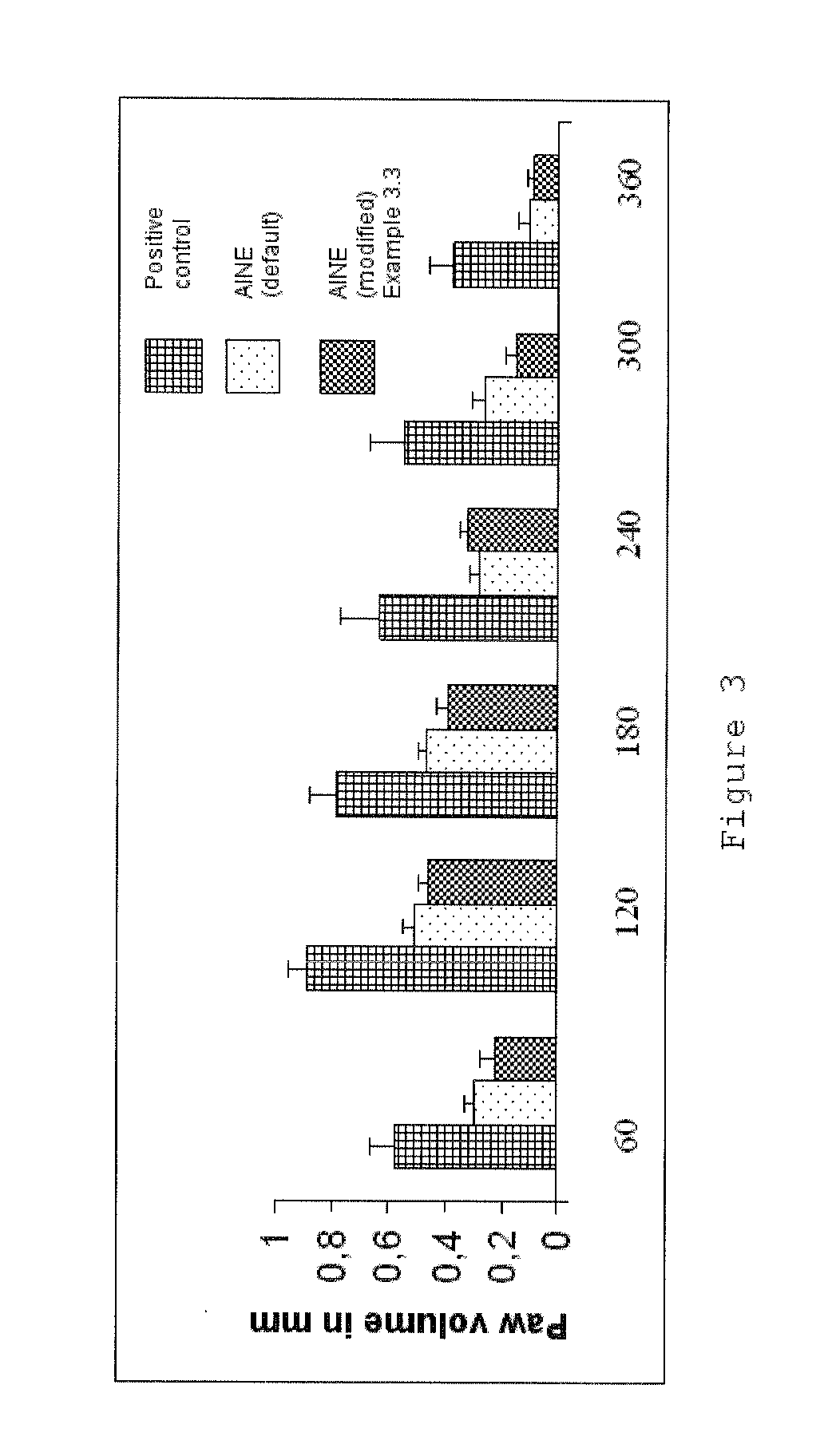

ActiveUS20080020996A1Reduce generationImprove lipophilicityAntibacterial agentsBiocideSolubilityIrritation

The present invention relates to the formulations of ester derivatives of capsaicin and ester derivatives of myristoleic acid. These derivatives are capable of reverting to the active parent compound following enzymatic or chemical hydrolysis. These derivatives have a higher lipophilicity, lipid solubility and less irritation to the skin than the parent compound, and hence are better able to be incorporated into certain pharmaceutical formulations, including cream and ointment pharmaceutical formulations. The pharmaceutical compositions of the present invention contain a compound of following formula (Ia):R—CO-CAP (Ia)wherein CAP refers to collectively the capsaicins represented in FIG. 1 and a compound of formula (Ib):MCO-O—R (Ib)wherein MCO refers to myristoleic acid.In formulae Ia and Ib, R is selected from alkyl groups of up to about 18 carbon atoms and aryl groups of up to about 18 carbon atoms and alkylene group of up to about 18 carbon atoms and an arylene group of up to about 18 carbon atoms. The alkyl, aryl and alkylene groups may be substituted or un-substituted, branched or straight chains. In addition, R may contain heteroatoms and may be straight chained or branched.The pharmaceutical compositions containing compounds of formulae Ia and Ib are useful for pain management in mammals in vivo and have been contemplated to be used in the treatment of various pains in humans.

Owner:TRINITY LAB INC

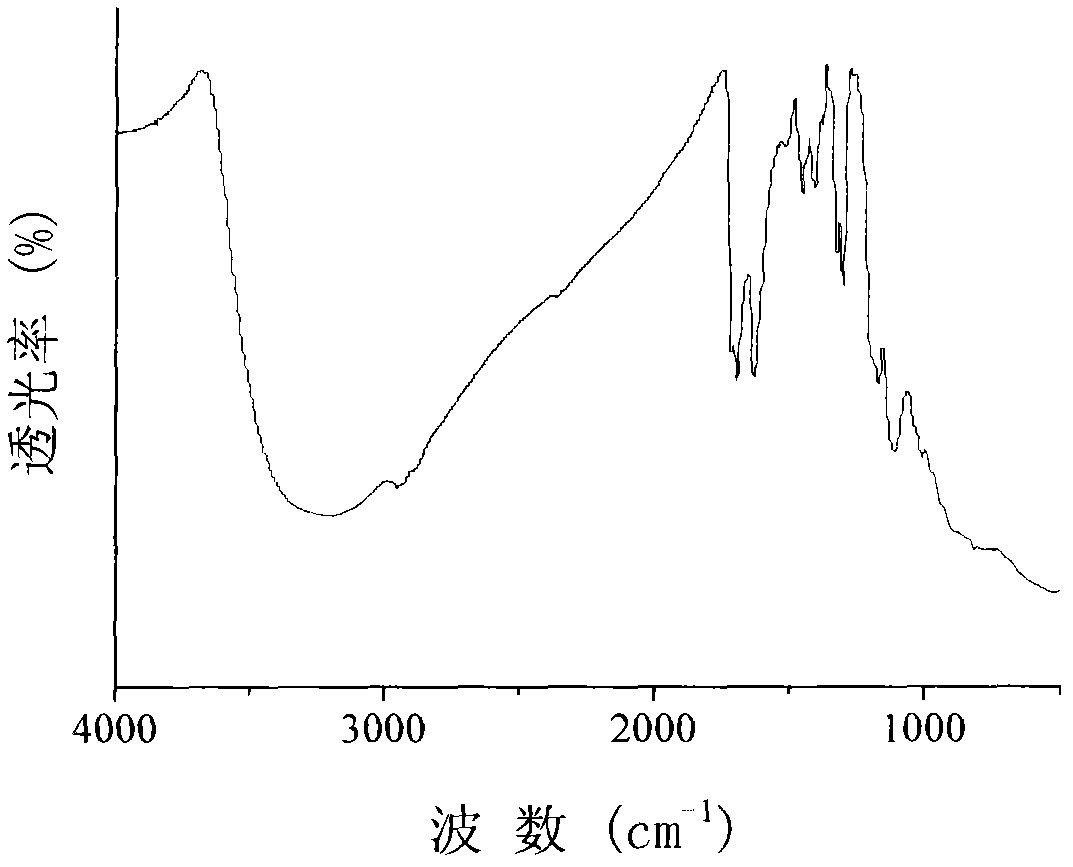

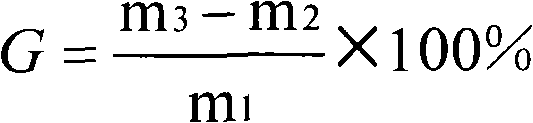

Carbon nanofiber aerogel as well as preparation method and application thereof

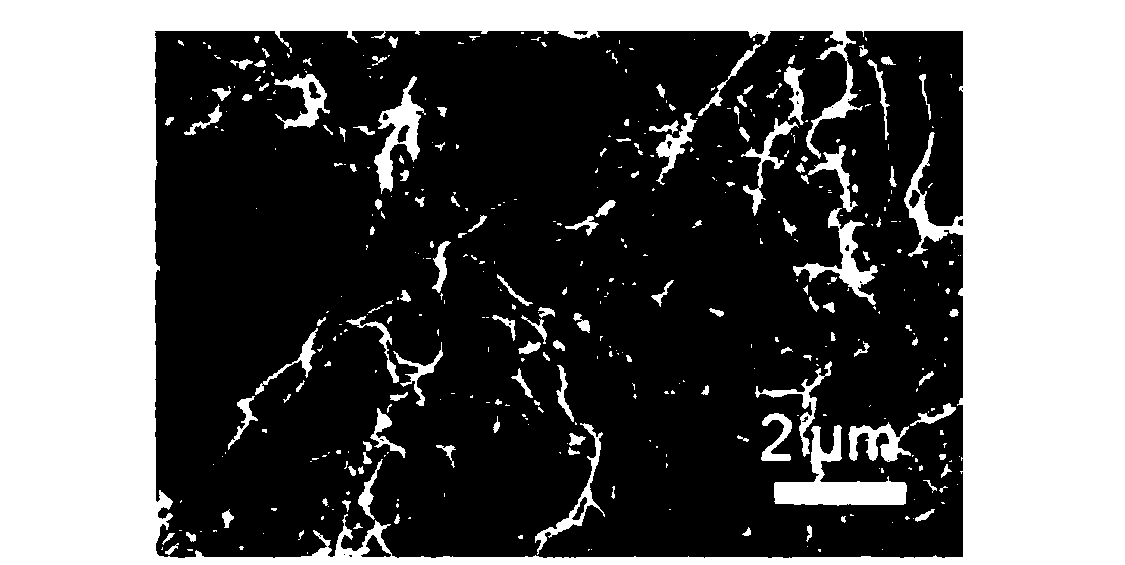

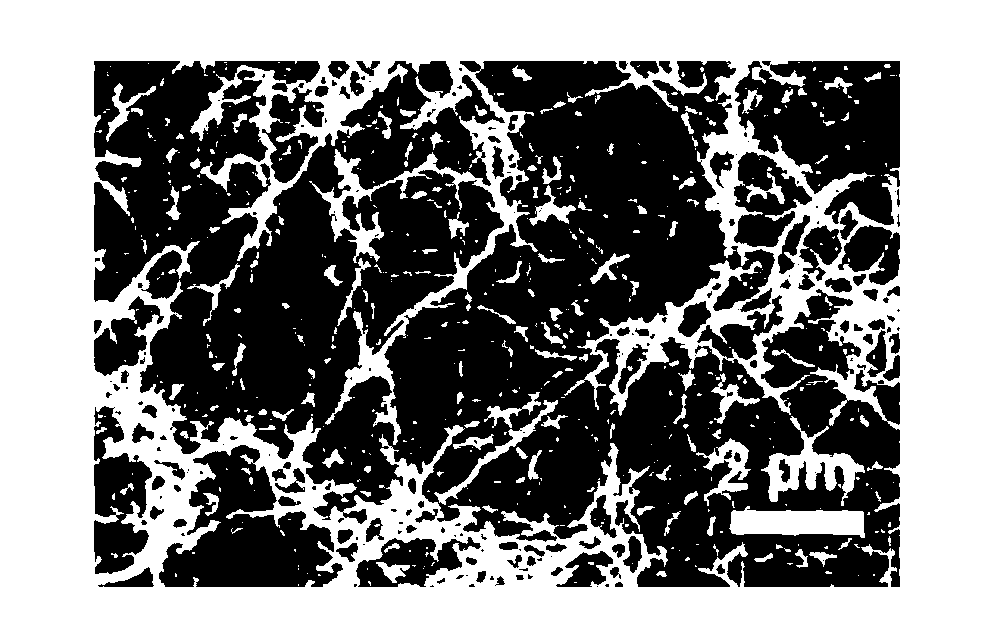

The invention provides a carbon nanofiber aerogel as well as a preparation method and the application of the carbon nanofiber aerogel. The method comprises the following steps: a), obtaining neutral bacterial cellulose blocks by soaking bacterial cellulose blocks into deionized water for deacidification; b), using liquid nitrogen to refrigerate the neutral bacterial cellulose blocks and drying in a freeze dryer to obtain a bacterial cellulose aerogel; and c), warming the bacterial cellulose aerogel and performing high-temperature pyrolysis to obtain the carbon nanofiber aerogel. The preparation method for the carbon nanofiber aerogel, provided by the invention, is simple, feasible and good in repeatability, and the raw material is cheap and easy to obtain, so that large-scale preparation can be realized easily; the carbon nanofiber aerogel prepared by the invention has good lipophilicity and facilitates adsorbing raw oil and chemical reagent during raw oil pollution and chemical reagent leakage; and in addition, as the carbon nanofiber aerogel has electrical conductivity and elasticity, the carbon nanofiber aerogel can be further used for preparing a pressure sensor.

Owner:UNIV OF SCI & TECH OF CHINA

Abuse-deterrent drug formulations

ActiveUS7771707B2Reduce the possibilityImprove lipophilicityPowder deliveryTelevision system detailsActive agentWater insoluble

An abuse-deterrent pharmaceutical composition has been developed to reduce the likelihood of improper administration of drugs, especially drugs such as opiods. In the preferred embodiment, the drug is modified to increase its lipophilicity by forming a salt between the drug and one or more fatty acids wherein the concentration of the one or more fatty acids is one to 15 times the molar amount of the active agent, preferably two to ten times the molar amount of the active agent. In one embodiment the modified drug is homogeneously dispersed within microparticles composed of a material that is either slowly soluble or not soluble in water. In some embodiments the drug containing microparticles or drug particles are coated with one or more coating layers, where at least one coating is water insoluble and preferably organic solvent insoluble. The abuse-deterrent composition prevents the immediate release of a substantial portion of drug, even if the physical integrity of the formulation is compromised (for example, by chopping with a blade or crushing) and the resulting material is placed in water, snorted, or swallowed. However, when administered as directed, the drug is slowly released from the composition as the composition is broken down or dissolved gradually within the GI tract by a combination of enzymatic degradation, surfactant action of bile acids, and mechanical erosion.

Owner:COLLEGIUM PHARMA INC

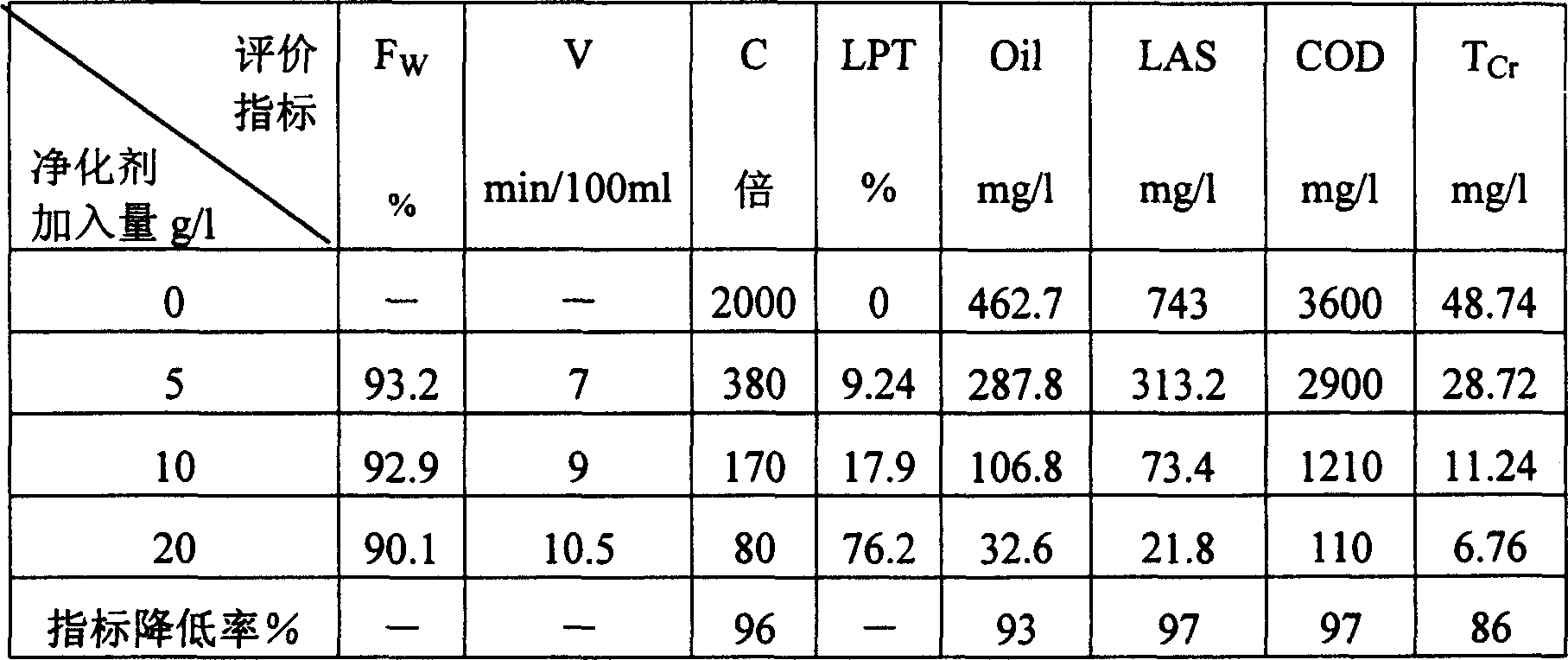

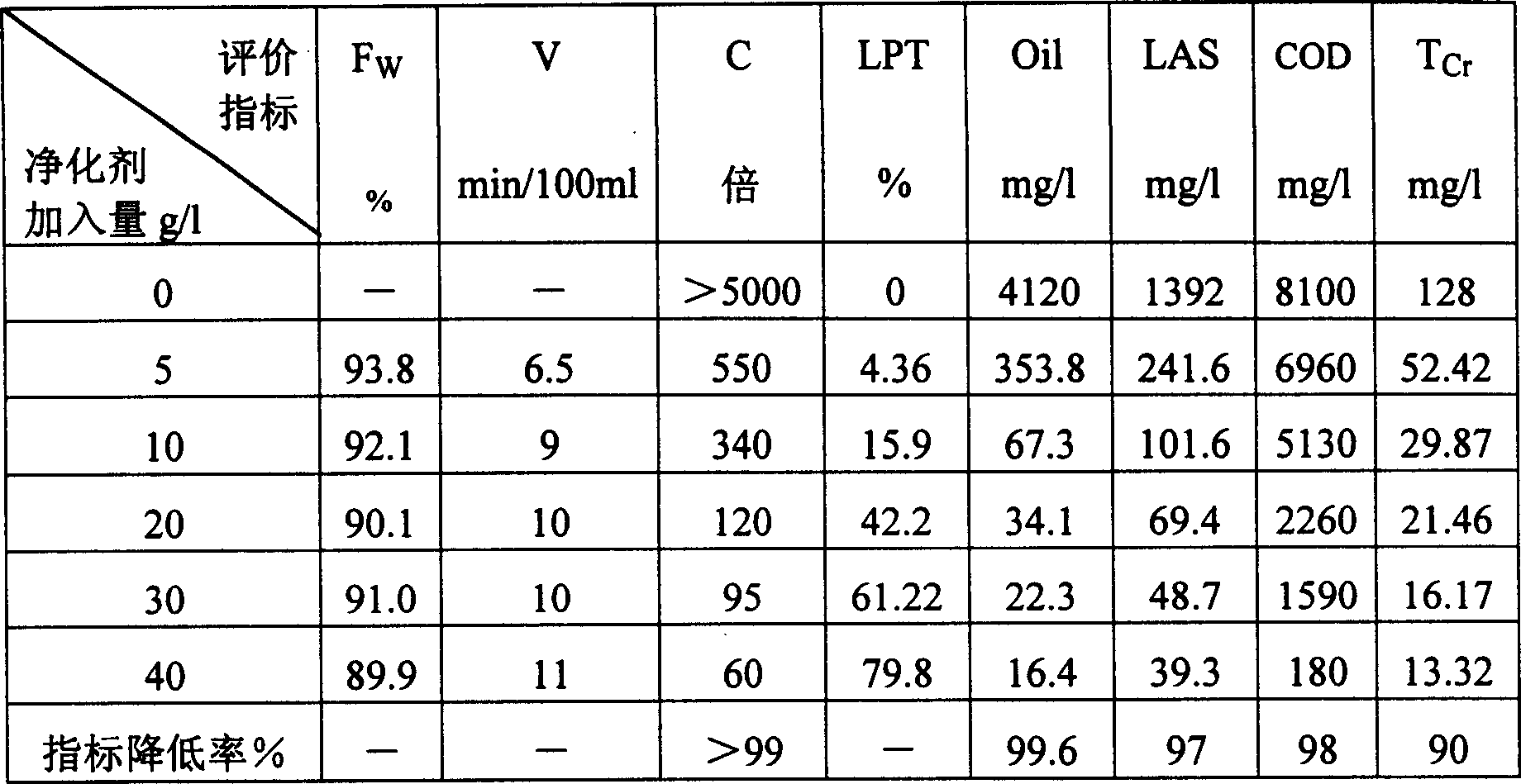

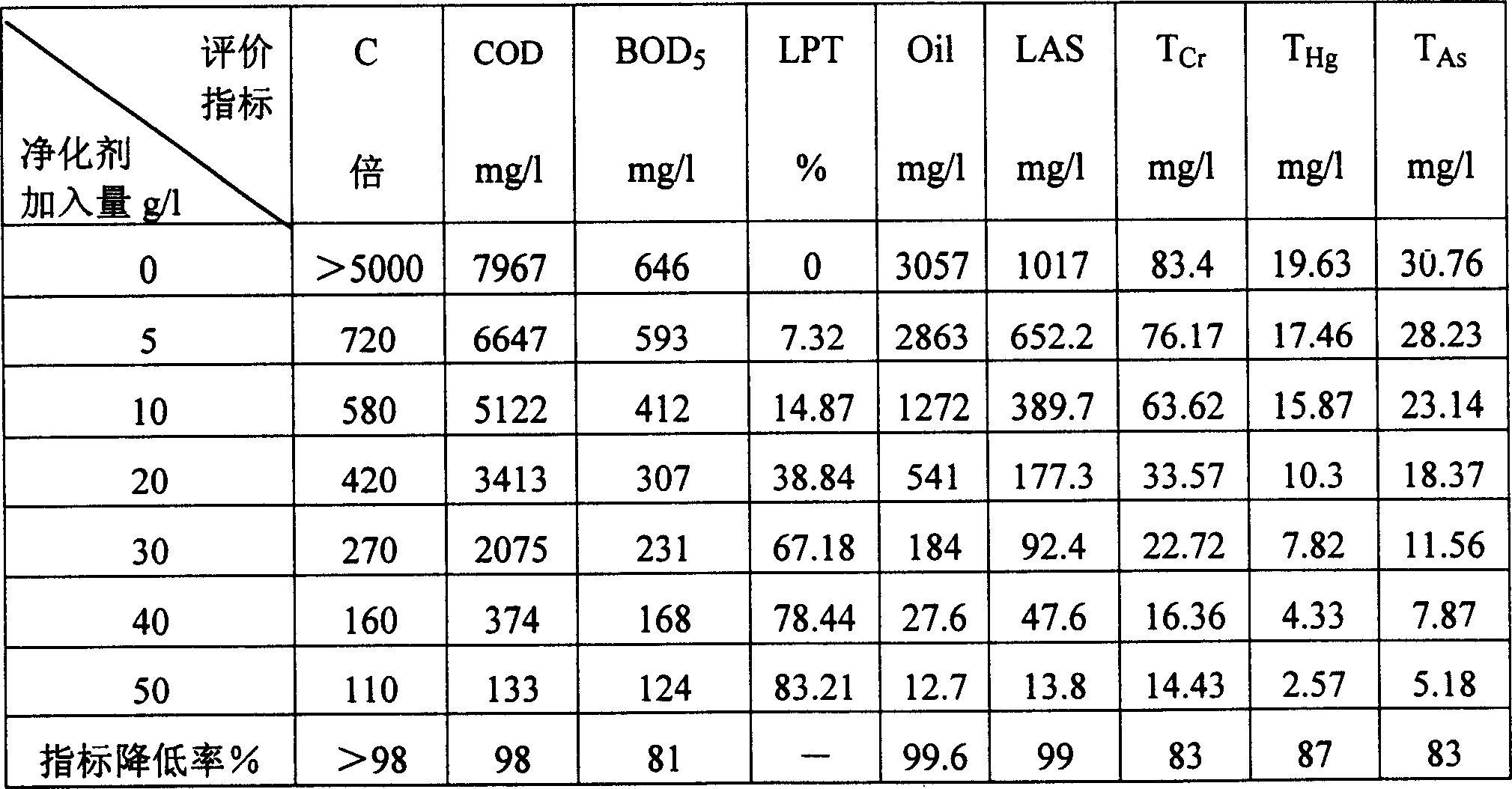

Waste water purifying agent, and its preparing method and use

ActiveCN1611450AStrong adsorptionImprove lipophilicityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionChemistryCompound (substance)

The invention relates to a kind of wastewater depurator and its manufacturing method and application, which involves in sewage disposal environment. The wastewater depurator contains blend concave-convex stick soil, inorganic filling containing silicon dioxide, acidifying high-chemical valence metal salt and so on. After acidifying to PH 1-3, high-chemical valence metal salt solution evenly mixes with other components and dries, then it can be acquired. The wastewater depurator can make condensation and absorption function in a whole, and can make treating effictiveness basically not influenced by factors such as water-body condition, pollution extent, wastewater category and so on. And also it has stable treating effictiveness, wide scope of application, especially adapts to preliminary purifying treatment for industrial wastewater with bad pollution. The manufacturing method and the industrial art for water treatment are simple so that it is easy for operation, and in a result, it has wider extending application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phthalimide derivatives of non-steroidal Anti-inflammatory compounds and/or tnf-alpha modulators, method for producing same, pharmaceutical compositions containing same and uses thereof for the treatment of inflammatory diseases

InactiveUS20120115817A1Inhibit inflammationMinimizing major limitation and complicationBiocideMonoazo dyesNon steroidal anti inflammatoryRheumatoid arthritis

The present invention relates to phthalimide derivatives of non-steroidal and / or TNF-α modulating anti-inflammatory compounds as well as the process of obtaining the so-called derivatives, pharmaceutical compositions containing such derivatives and their uses, including use in the treatment of inflammatory diseases, especially those related to chronic inflammatory processes, such as rheumatoid arthritis and intestinal inflammatory diseases (for instance, Chron's disease) and the use of the referred to pharmaceutical compositions as antipyretic, analgesic and platelet antiaggregating medications.

Owner:EMS +1

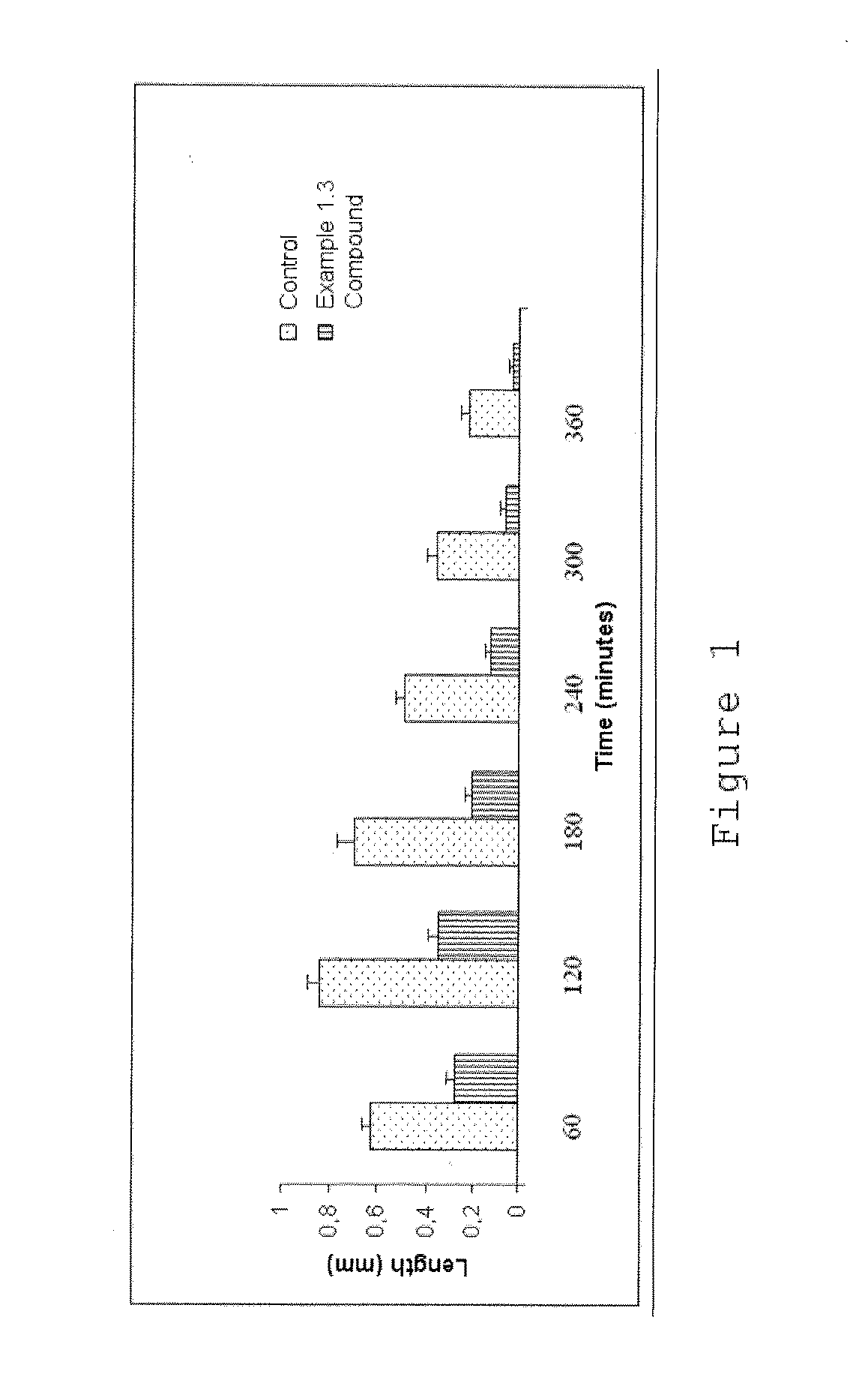

Esters of Capsaicin for Treating Pain

InactiveUS20110218180A1Improve lipophilicityNon-irritation to skinAntibacterial agentsBiocideSolubilityIrritation

The present invention relates to the formulations of ester derivatives of capsaicin and ester derivatives of myristoleic acid. These derivatives are capable of reverting to the active parent compound following enzymatic or chemical hydrolysis. These derivatives have a higher lipophilicity, lipid solubility and less irritation to the skin than the parent compound, and hence are better able to be incorporated into certain pharmaceutical formulations, including cream and ointment pharmaceutical formulations. The pharmaceutical compositions of the present invention contain a compound of following formula (Ia):R—CO—CAP (Ia)wherein CAP refers to collectively the capsaicins represented in FIG. 1 and a compound of formula (Ib):MCO—O—R (Ib)wherein MCO refers to myristoleic acid.In formulae Ia and Ib, R is selected from alkyl groups of up to about 18 carbon atoms and aryl groups of up to about 18 carbon atoms and alkylene group of up to about 18 carbon atoms and an arylene group of up to about 18 carbon atoms. The alkyl, aryl and alkylene groups may be substituted or un-substituted, branched or straight chains. In addition, R may contain heteroatoms and may be straight chained or branched.The pharmaceutical compositions containing compounds of formulae Ia and Ib are useful for pain management in mammals in vivo and have been contemplated to be used in the treatment of various pains in humans.

Owner:TRINITY LAB INC

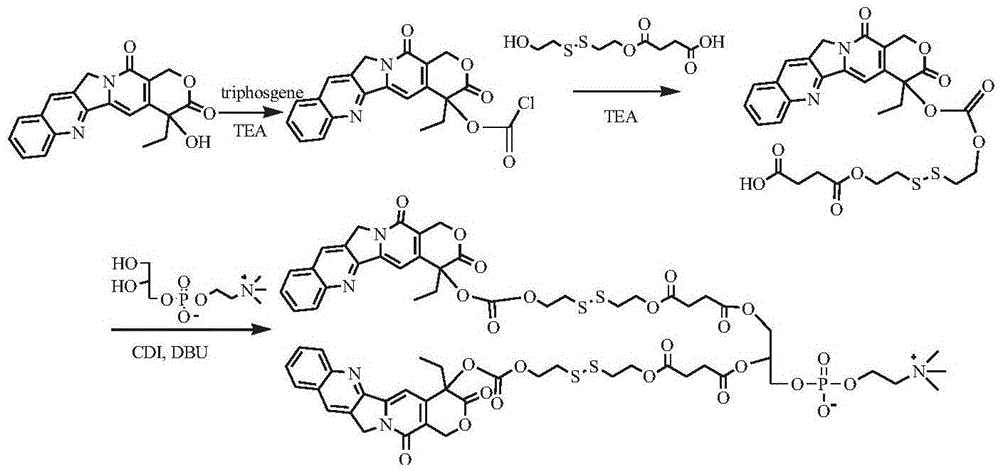

Quick release type medicine phosphatide compound and medicine composition thereof

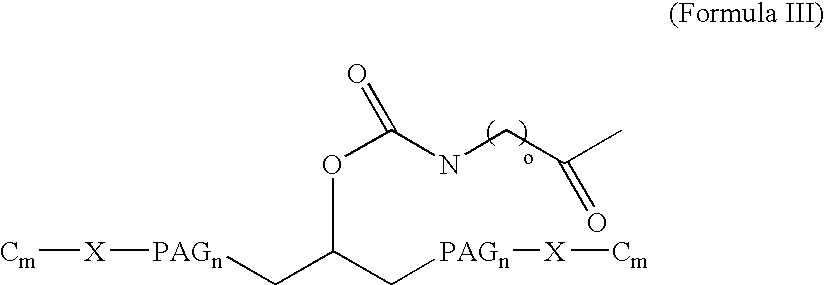

InactiveCN105457038AEnhance hydrophobic lipophilic effectImprove hydrophobicityHeavy metal active ingredientsDipeptide ingredientsPharmacodynamic StudyHydrophobic effect

The invention discloses a quick release type medicine phosphatide compound and a medicine composition thereof. In the compound, a medicine Y1 and a medicine Y2 are connected with a quick release type hydrophobic spacer arm and an enhancement type hydrophobic spacer arm through chemical bonds, the two spacer arms are cooperated to enhance the hydrophobic effect to form hydrophobic lipotropy chains, the two hydrophobic chains are connected with a phospholipid hydrophilic head to form an amphipathic molecule. The medicine composition is the quick release type medicine phosphatide compound or a combined medicine composition of the compound and a carrier acceptable in pharmacodynamics. The quick release type medicine phosphatide compound and lipidosome nano particles thereof can be used as a liquid preparation, a solid preparation, a semi-solid preparation, a sterilization preparation and a sterile preparation, are low in toxicity and can be used for efficiently treating various tumor diseases.

Owner:SOUTHEAST UNIV

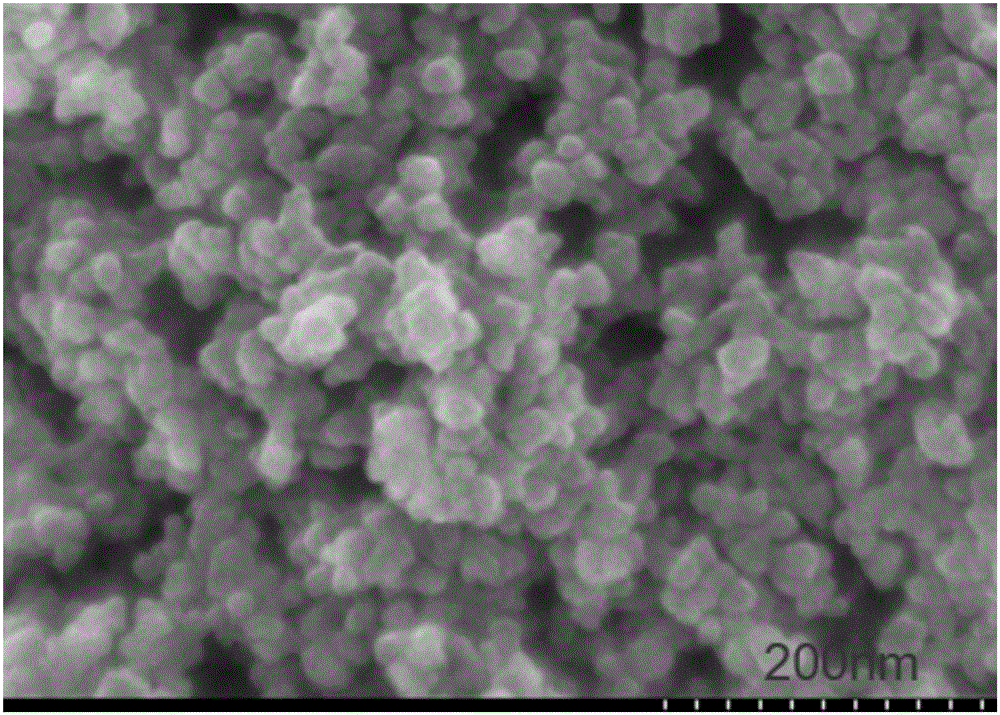

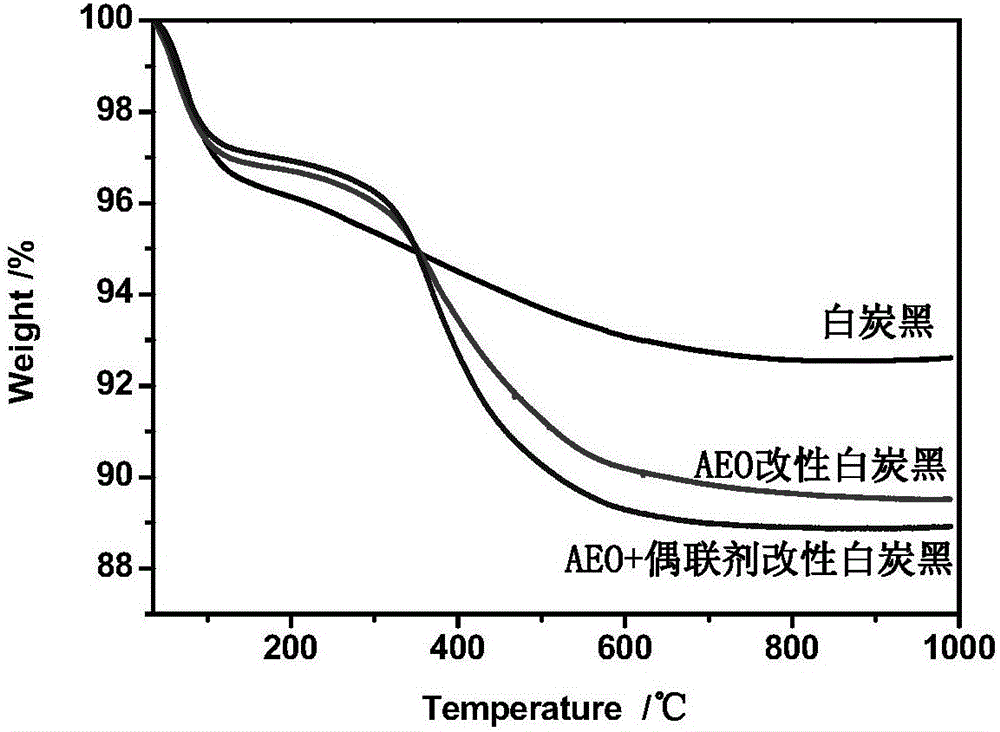

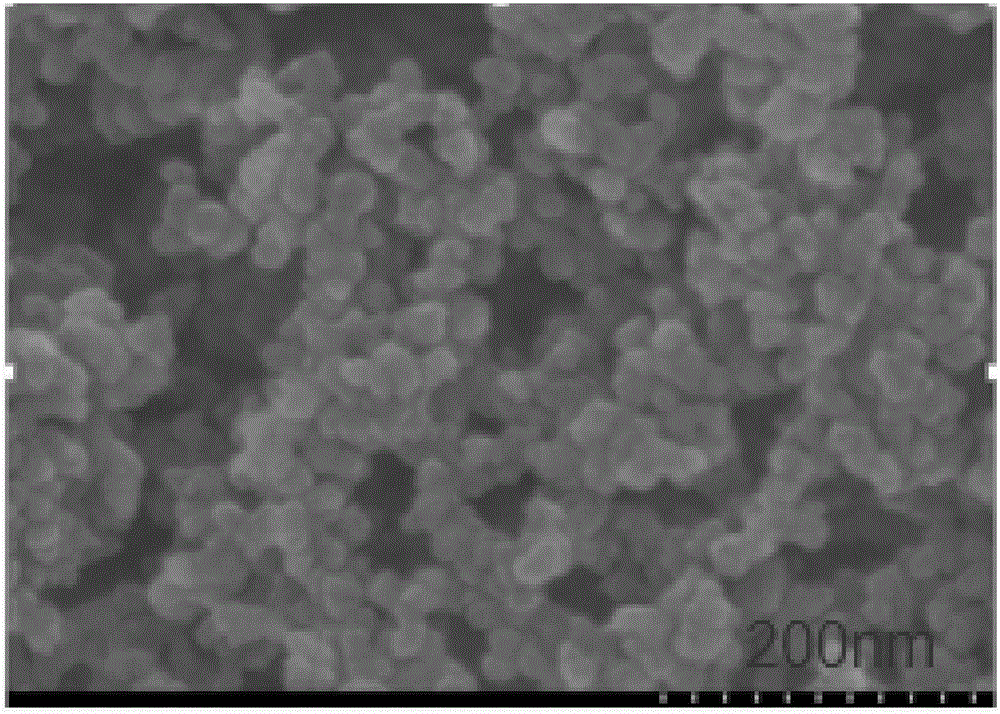

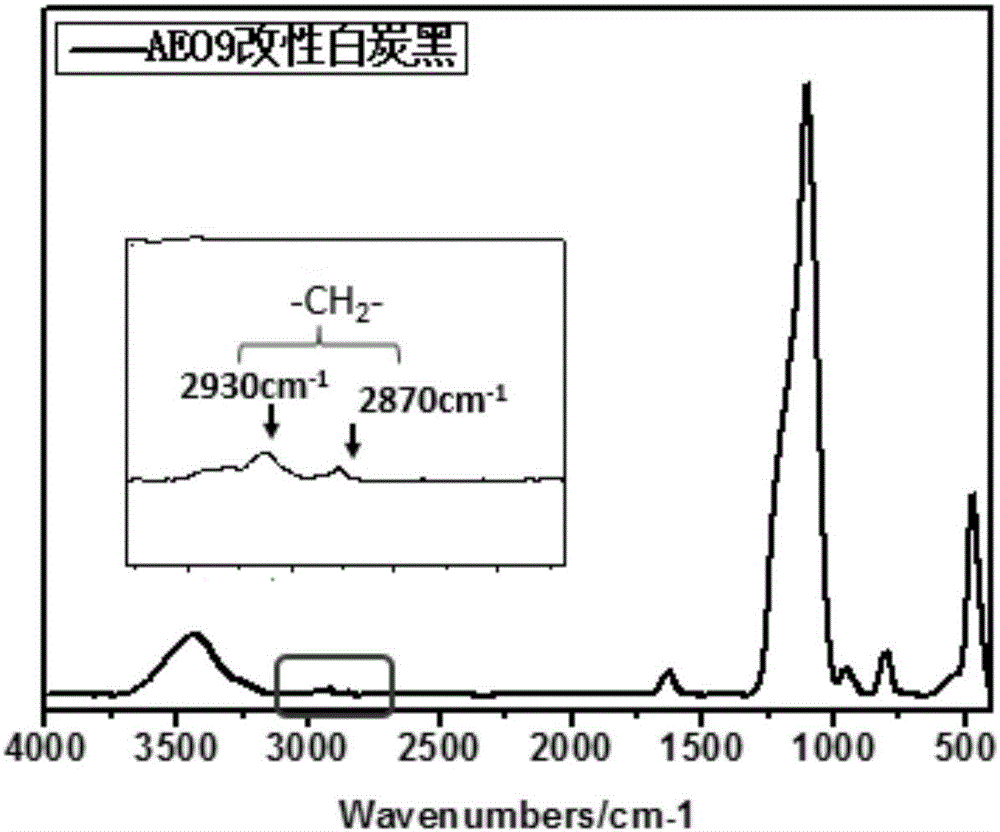

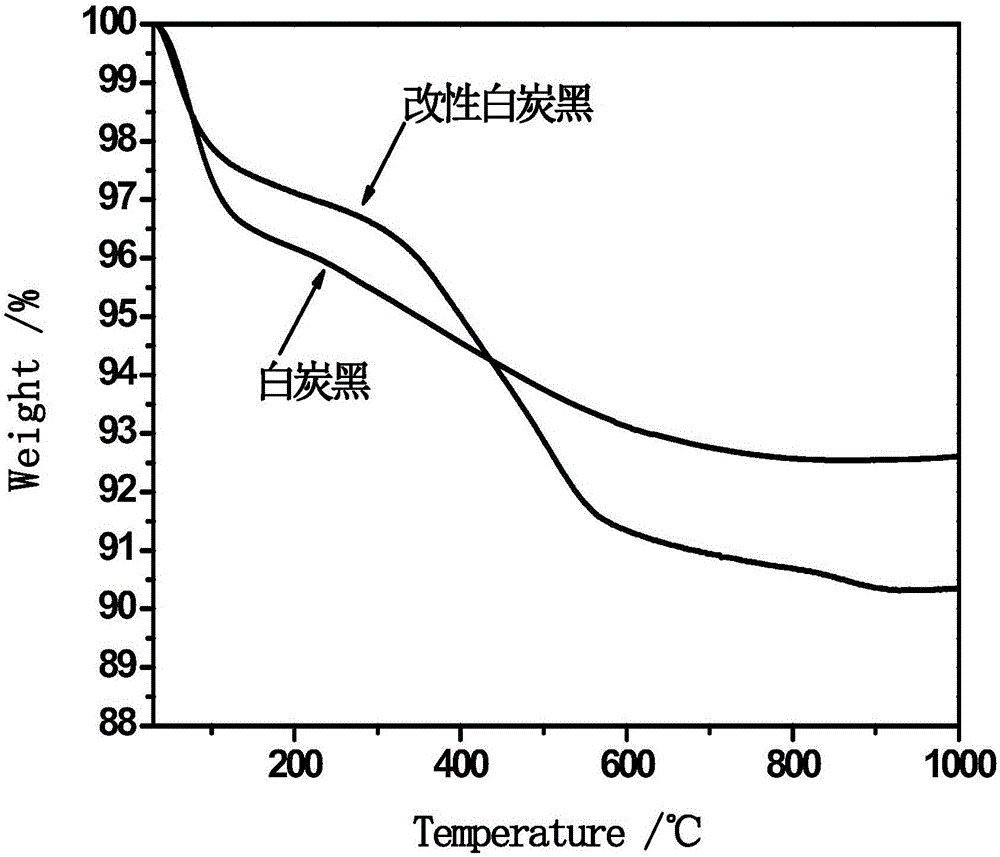

Modification of white carbon black by co-using AEO and silane coupling agent, and method for compounding modified white carbon black and rubber

The invention provides modification of white carbon black by co-using AEO and a silane coupling agent, and a method for compounding the modified white carbon black and a rubber, and relates to the field of applications of AEO (aliphatic polyoxyethylene ether) in wet modification of white carbon black by matching with a silane coupling agent. According to the present invention, the direct modification of white carbon black in a water phase by using an insoluble silane coupling agent can be achieved by using the amphiphilicity of AEO and the grafting property of AEO to white carbon black; compared to the traditional method for modifying the white carbon black in the water phase by using the silane coupling agent, the method of the present invention has the following characteristics that the use of a large amount of organic solvents is avoided, the white carbon black modification cost is saved, the VOC emission generated during the modification process is significantly reduced, and the environmental protection is easily achieved; the modification method is characterized in that AEO accounting for 1-100% of the mass of the white carbon black and the silane coupling agent accounting for 1-100% of the mass of the white carbon black are introduced to modify the white carbon black; and the modified white carbon black and the rubber can be compounded through a variety of methods, the white carbon black in the prepared composite material has the uniform distribution, and the dynamic mechanical property and the strength are significantly improved compared to the existing wet modified white carbon black / rubber composite material.

Owner:BEIJING UNIV OF CHEM TECH

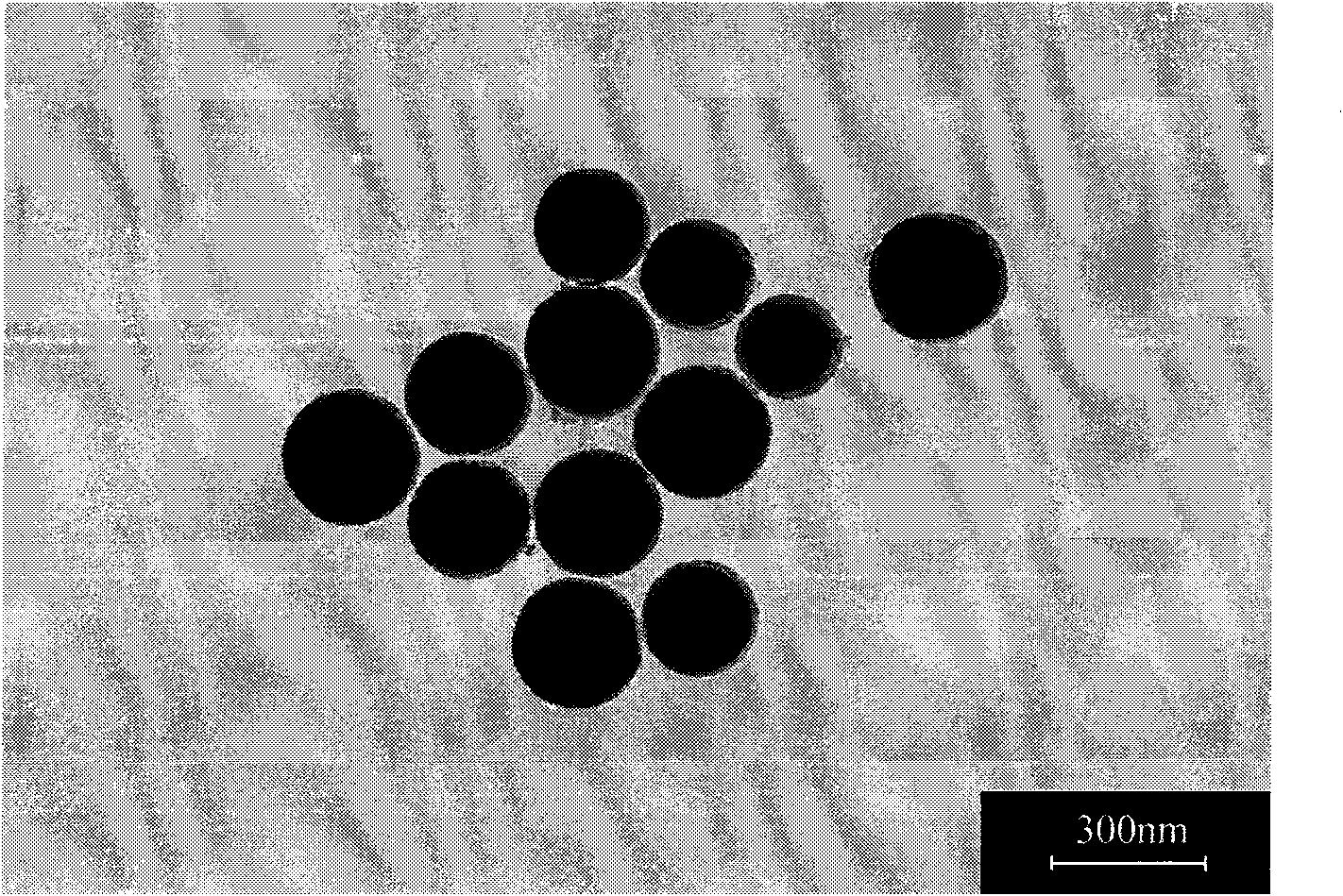

Lyophobic and oleophylic micro nano-coatings applied to of oil filtering dehydration and preparation method thereof

InactiveCN101601940AImprove hydrophobicityAvoid oleophobic effectDewatering/demulsification with mechanical meansFiltration separationMicro nanoFiltration

The invention discloses Lyophobic and oleophylic micro nano-coatings applied to oil filtering dehydration and a preparation method thereof. Base material of the coatings is metal mesh grid with 50-1800 meshes, the surface of the metal mesh grid is coated with a layer of dense micro nano-coating which is dense thin film composed of nano silica global particles with partical size ranging from 90nm to 500nm.In the method of the invention, the sol-gel method is adopted, tetraethyl ester serves as the precursor, ammonia water serves as the catalyst, ethanol serves as the solvent, alkyl oxosilane serves as lyophobic modifier, the method of hydrolytie polycondensation is adopted to obtain lyophobic nano silica sol, the process of impregnation or spraying is adopted to coat the gel on the metal mesh grid with 50-1800 meshes, after thermal treatment, oil-water separation net with lyophobic and oleophylic properties is obtained. The method of the invention features simple process, no harm to the environment, no need of fluorine material, wide application to coalescing separator as a separation filter element and the function of filtration and dehydration of oil.

Owner:SOUTH CHINA UNIV OF TECH

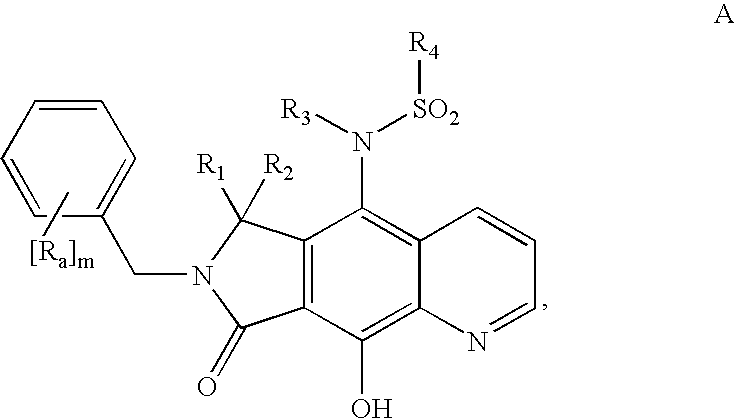

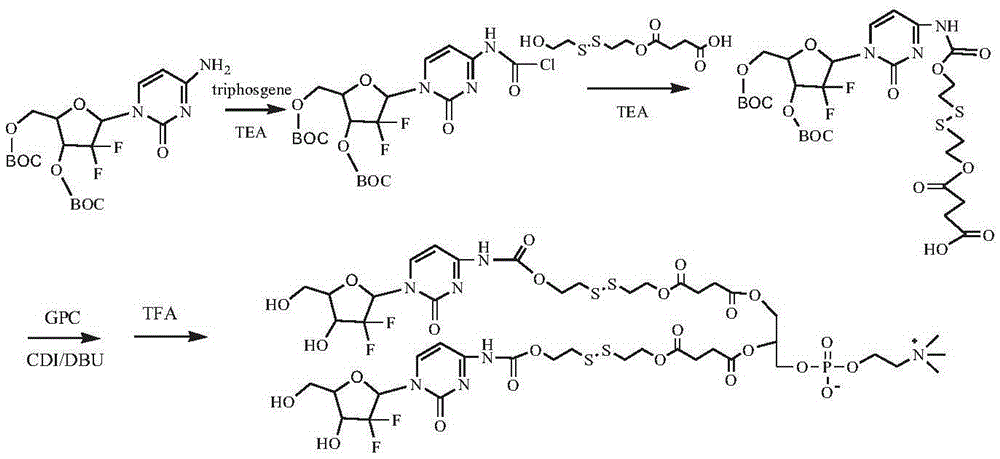

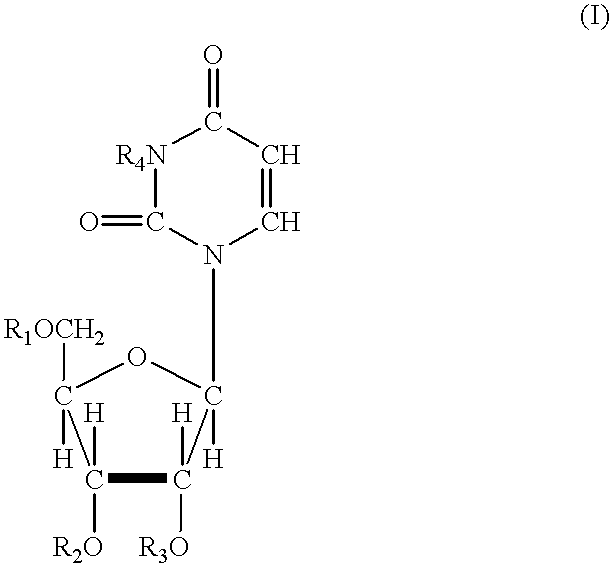

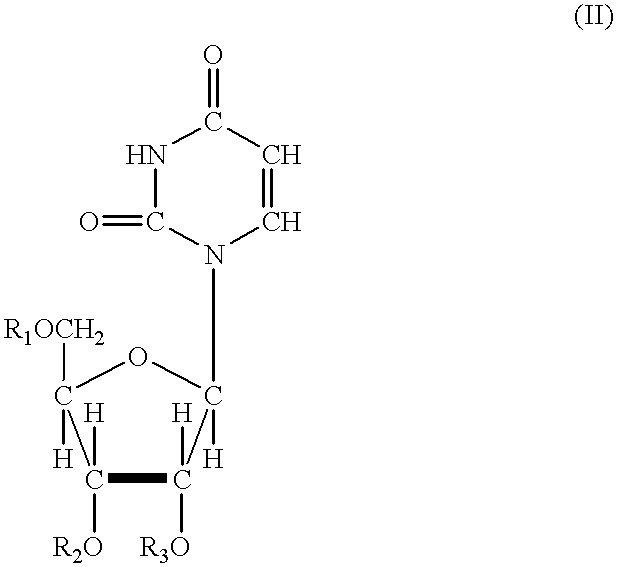

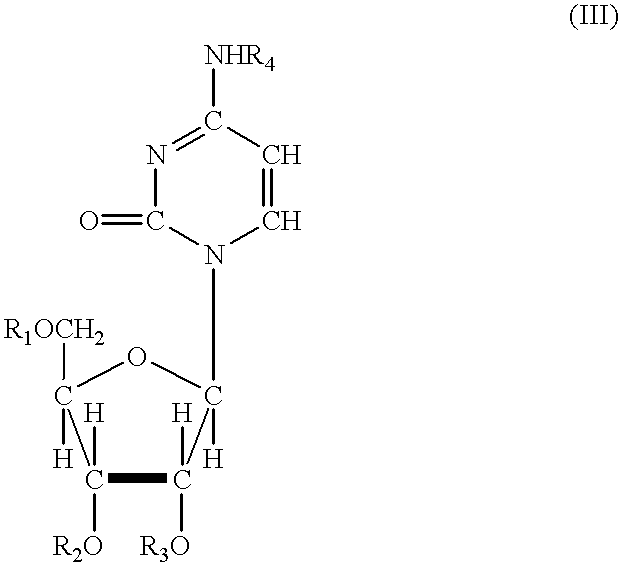

Acylated uridine and cytidine and uses thereof

ActiveUS6258795B1No untoward pharmaceutical effectEfficient managementBiocideSugar derivativesDiseaseDiabetes mellitus

The invention relates to compositions comprising acyl derivatives of cytidine and uridine. The invention also relates to methods of treating hepatopathies, diabetes, heart disease, cerebrovascular disorders, Parkinson's disease, infant respiratory distress syndrome and for enhancement of phospholipid biosynthesis comprising administering the acyl derivatives of the invention to an animal.

Owner:WELLSTAT THERAPEUTICS

Method for modifying white carbon black by adopting aliphatic polyoxyethylene ether and compounding white carbon black with rubber

The invention provides a method for modifying white carbon black by adopting aliphatic polyoxyethylene ether and compounding the white carbon black with rubber and relates to the field of application of the aliphatic polyoxyethylene ether to white carbon black modification, hoping to achieve the aims of modifying the white carbon black under the condition of no VOC emission by adopting a cheap and available modifying agent and enabling the modified white carbon black to be well dispersed as filler in a rubber matrix. The modification method is characterized in that chemical bonding and physical adsorption effect are utilized for bonding the white carbon black with 1-100% by mass of the aliphatic polyoxyethylene ether, so that the modified white carbon black is prepared. Preparation steps are as follows: white carbon black suspension is prepared, temperature of the suspension is adjusted, the white carbon black is modified, and the modified white carbon black is dried. The modified white carbon black has the advantages that particle size is reduced and hydrophobicity is obviously improved. Meanwhile, the modified white carbon black can be compounded with multiple rubbers in multiple ways, the white carbon black is uniformly distributed in the prepared rubber / modified white carbon black composite material, and all the performances of the composite material can be obviously improved compared with rubber / unmodified white carbon black.

Owner:BEIJING UNIV OF CHEM TECH

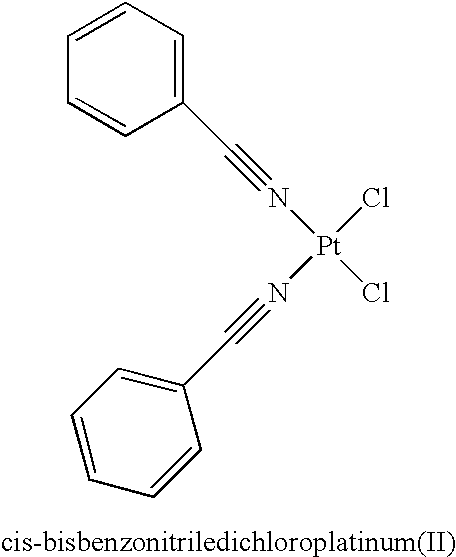

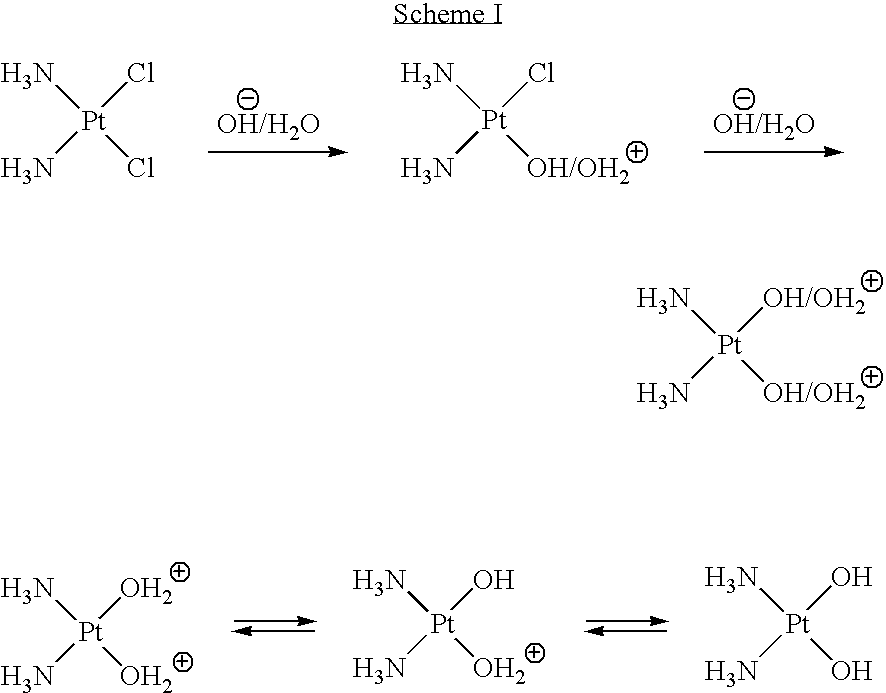

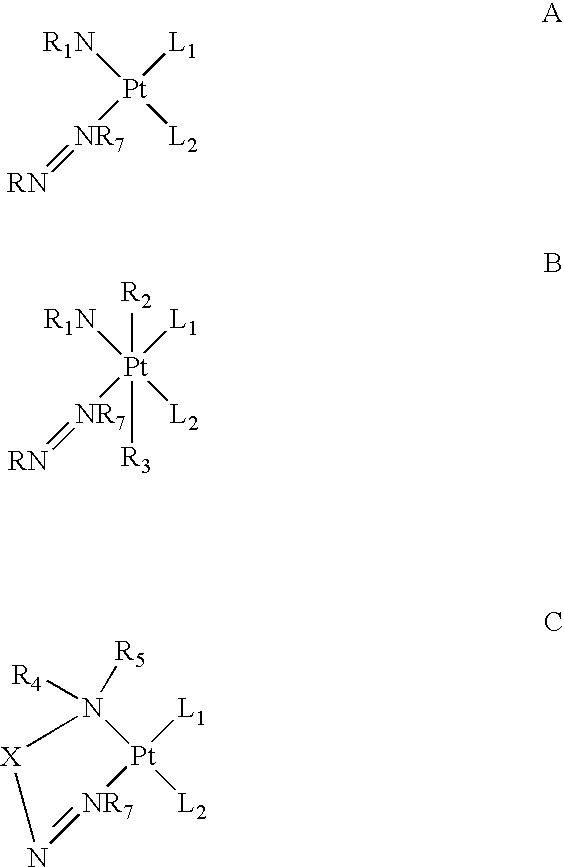

Monoazole ligand platinum analogs

InactiveUS7759488B2Easily transported into tumor cellStrong hydrogen bondingOrganic active ingredientsPlatinum organic compoundsPurinePt element

Disclosed herein are novel platinum-based analogs with a single substituted azole ligand: RN═NR7, wherein the RN═NR7 functional group is covalently bonded to the platinum through nitrogen of NR7. The analogs also have nitrogen donor ligands capable of forming hydrogen bonds with the bases in DNA or RNA, and one or more leaving groups which can be displaced by water, hydroxide ions or other nucleophiles, which is thought to form active species in vivo, and then, form cross-linked complexes between nucleic acid strands, principally between purines in DNA (or RNA), i.e., at the Guanine or Adenine bases, thereof. These platinum analogs may also be more easily transported into tumor cells, due to their increased lipophilicity and are likely to be useful as anti-neoplastic agents, and in modulating or interfering with the synthesis or replication or transcription of DNA or translation or function of RNA in vitro or in vivo, as they are potentially capable of forming a platinum coordinate complex with an intact or nascent DNA or RNA and thereby interfering with cellular synthesis, transcription or replication of nucleic acid polynucleotides.

Owner:BIONUMERIK PHARMA INC

Tamper-resistant pharmaceutical compositions of opiods and other drugs

InactiveUS20110142943A1Reduce the possibilityImprove lipophilicityBiocidePowder deliveryAs DirectedOpioid

Tamper-resistant pharmaceutical compositions have been developed to reduce the likelihood of improper administration of drugs, especially drugs such as opioids. The tamper-resistant compositions retard the release of drug, even if the physical integrity of the formulation is compromised (for example, by chopping with a blade or crushing) and the resulting material is placed in water, snorted, or swallowed. However, when administered as directed, the drug is slowly released from the composition as the composition is passes through the GI tract.

Owner:COLLEGIUM PHARMA INC

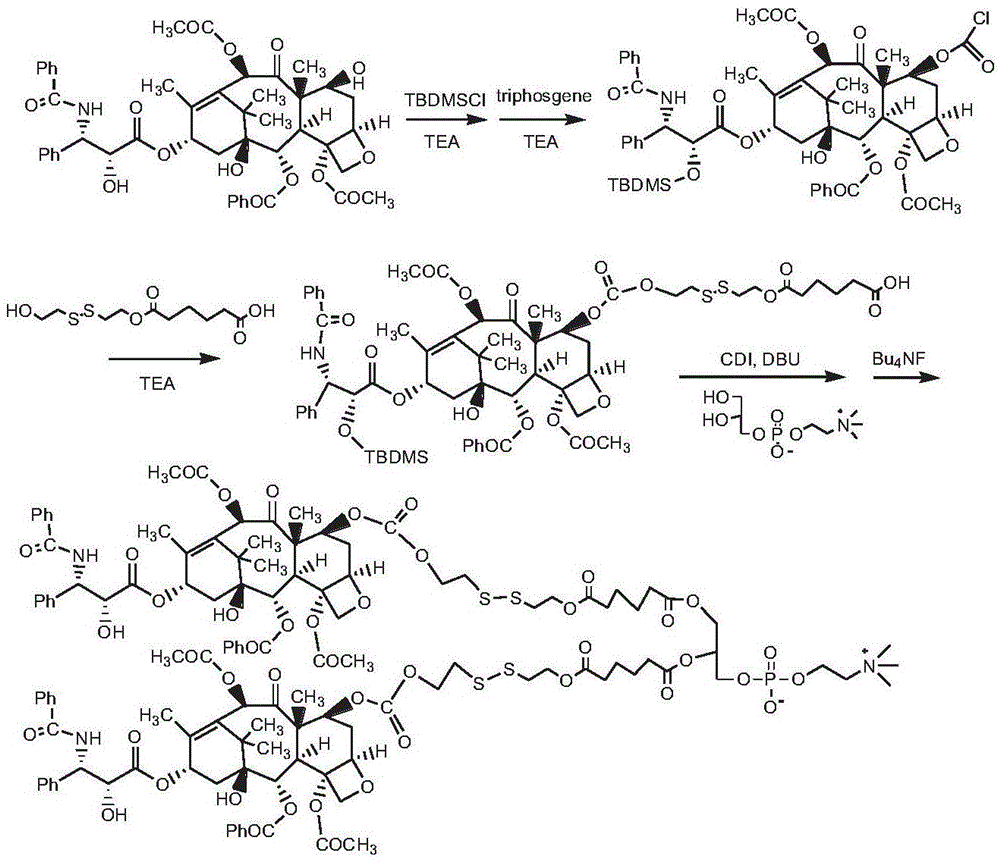

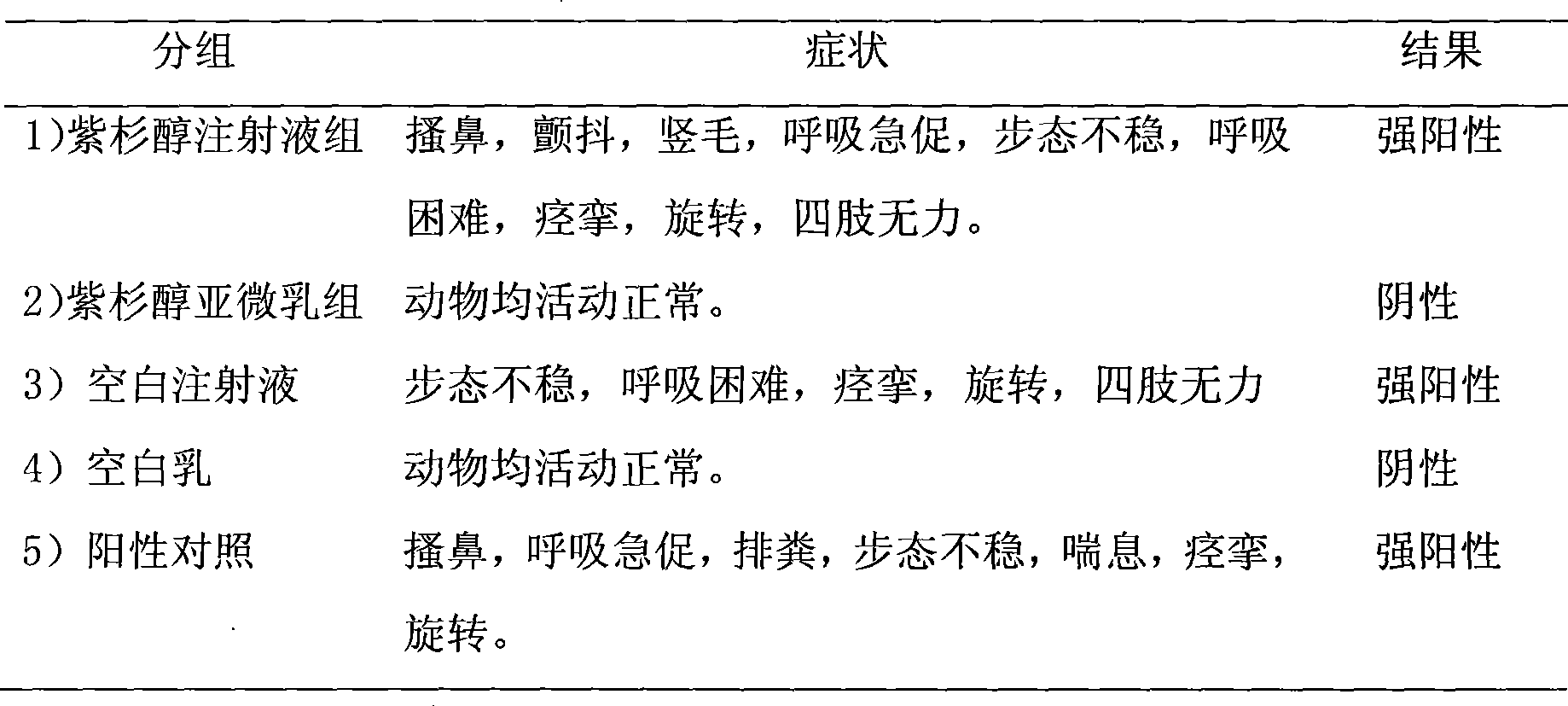

Paclitaxel lipid composite

ActiveCN101396346AImprove solubilityGood dispersionOrganic active ingredientsPharmaceutical non-active ingredientsEmulsionDrug loading dose

The invention discloses a paclitaxel lipid complex. The paclitaxel lipid complex consists of paclitaxel and lipid material. The weight proportion of the paclitaxel and the lipid material is 1 to 1 - 19, the preferential proportion is 1 to 2 - 10, and the more preferential proportion is 1 to 3 - 6. The lipid material is selected from natural lipid and synthetic lipid or the mixture thereof. The paclitaxel lipid complex can also contain antioxidation stabilizer. The invention also discloses a preparation method of the paclitaxel lipid complex and the application in the preparation of injection submicron emulsion and dry emulsion. The paclitaxel lipid complex has high solubility in oil, and the prepared submicron emulsion has the advantages of high drug loading quantity, high stability, high safety and low irritability.

Owner:BEIJING WEHAND BIO PHARMA CO LTD

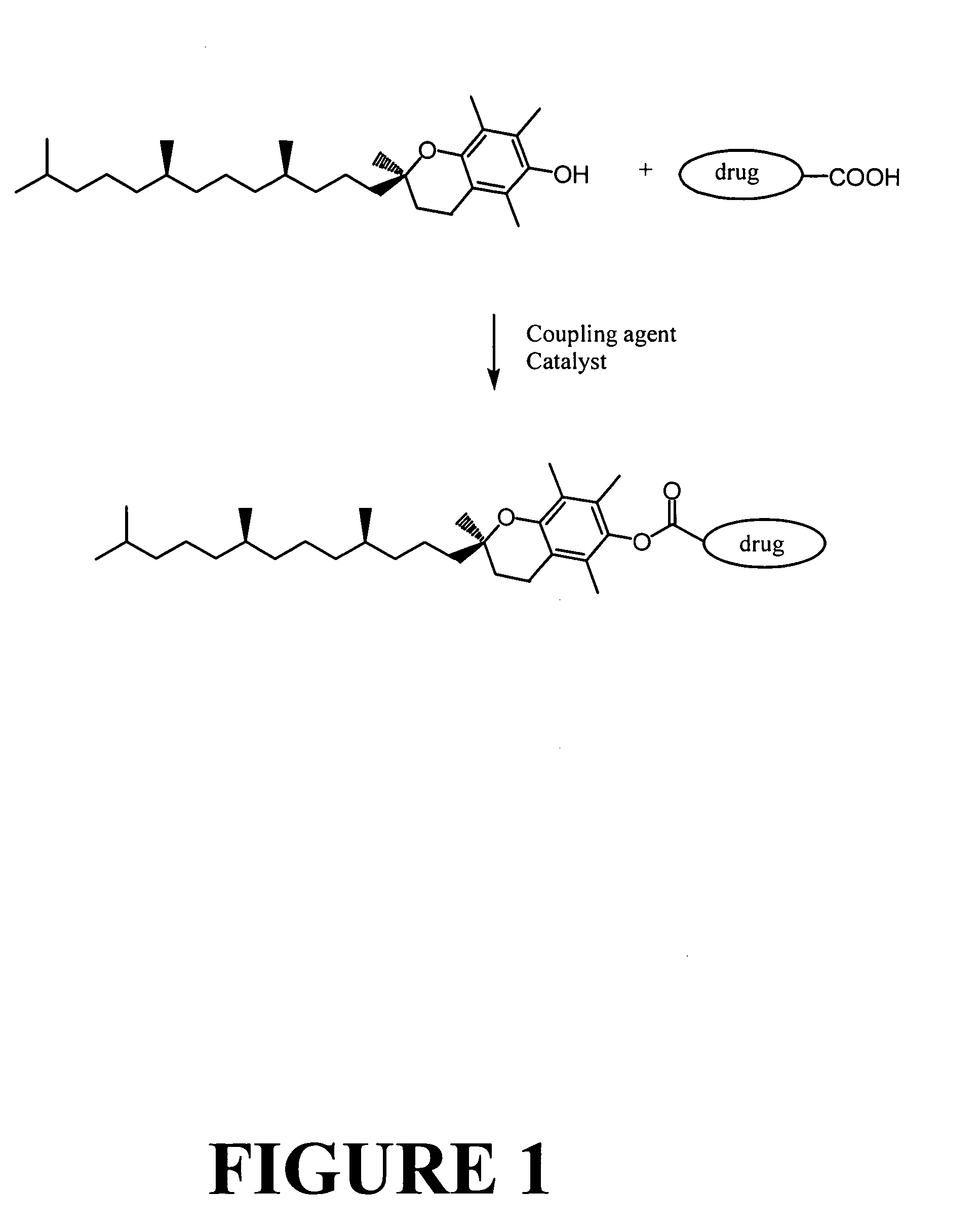

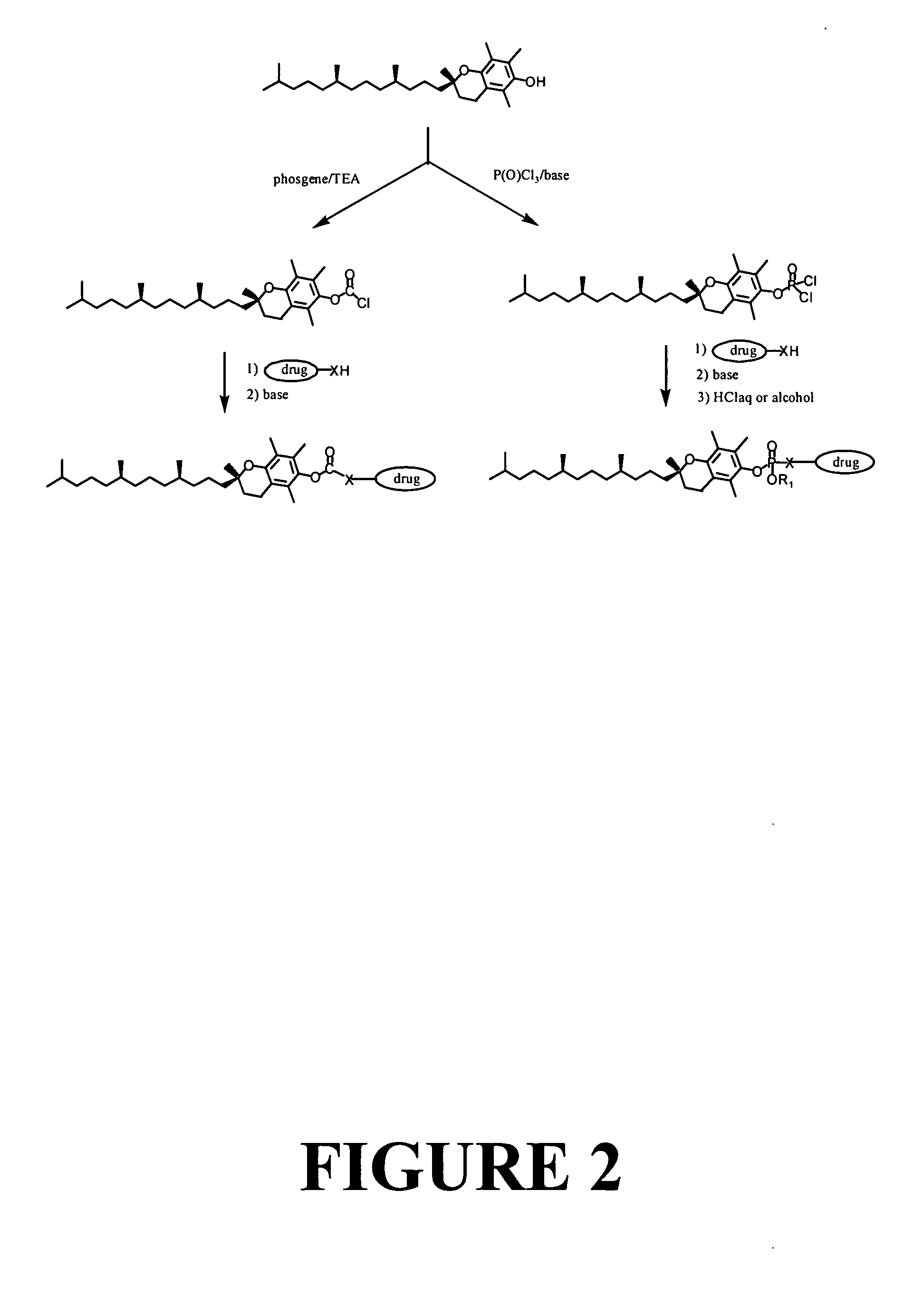

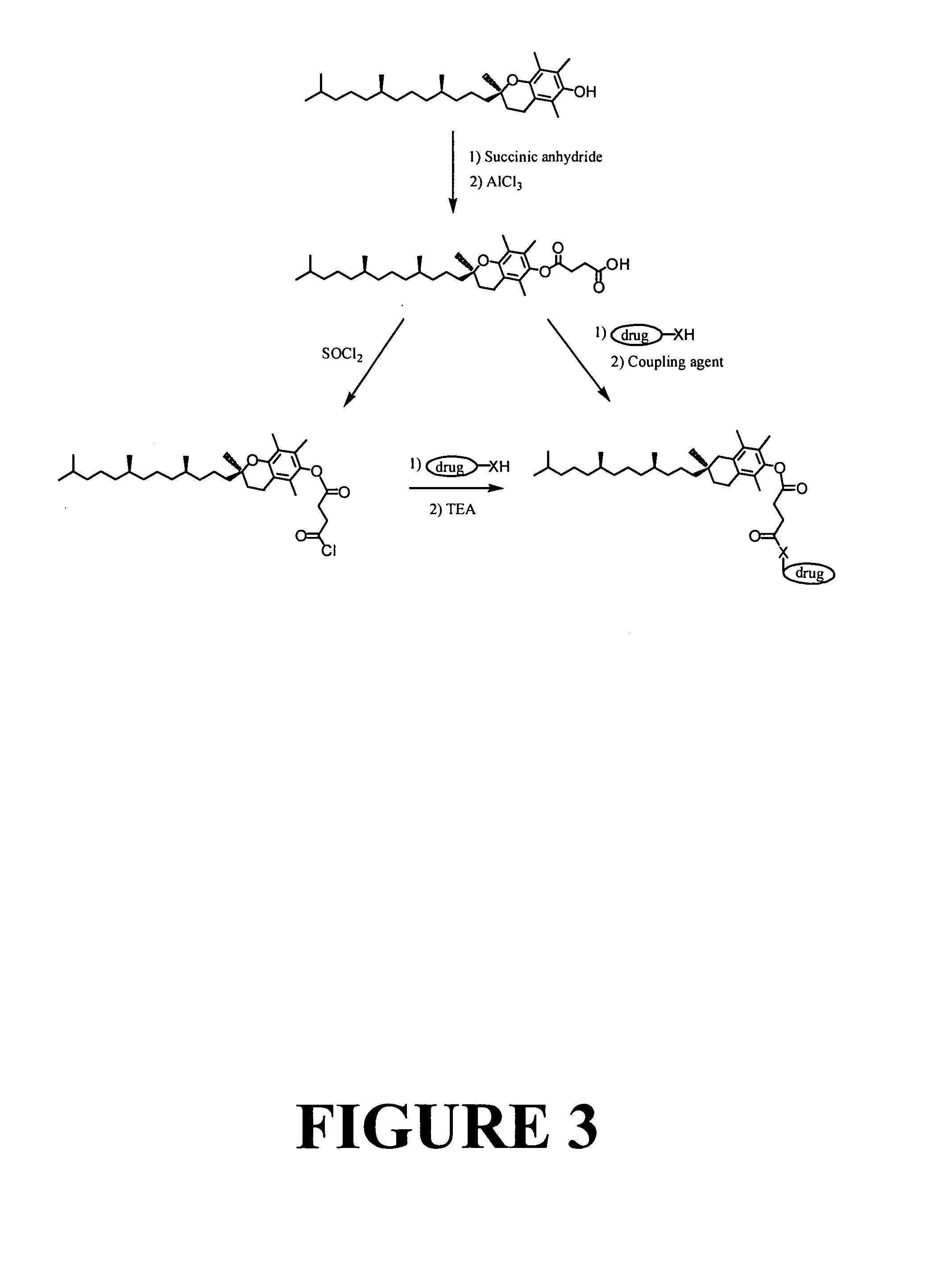

Tocopherol-modified therapeutic drug compounds

Tocopherol-modified therapeutic drug compounds; emulsion, microemulsion, and micelle formulations that include the compounds; methods for making the compounds and formulations; methods for administering the compounds and formulations; and methods for treating conditions using the compounds and formulations.

Owner:SONUS PHARM INC

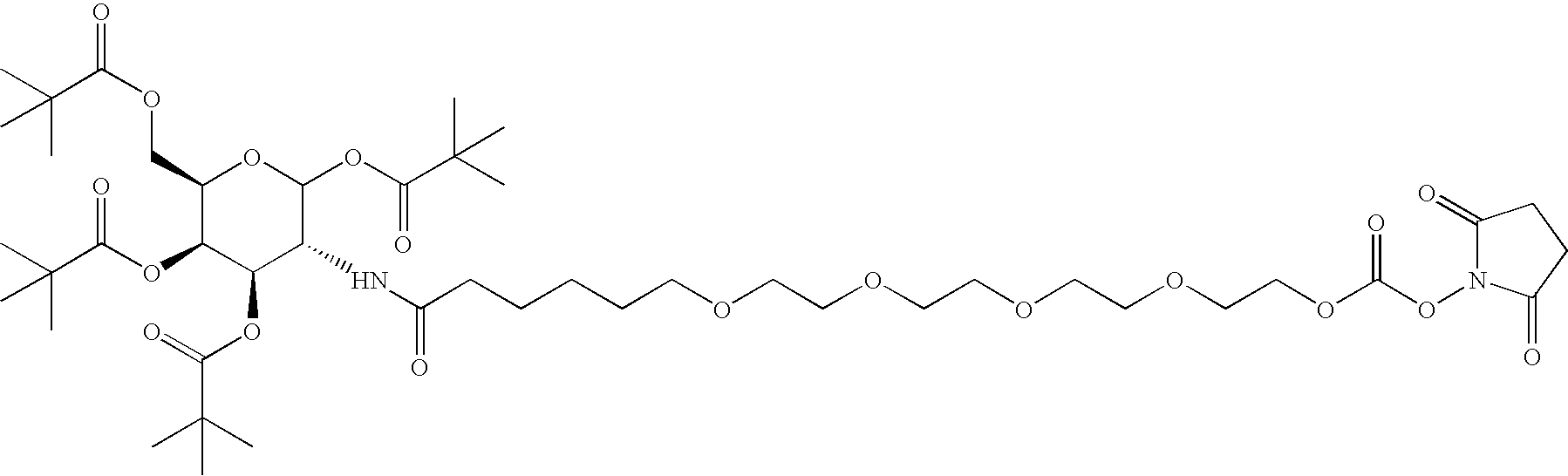

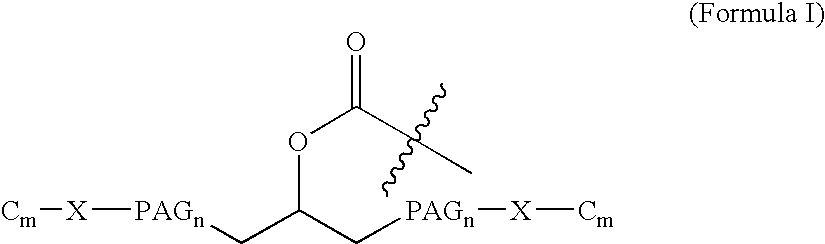

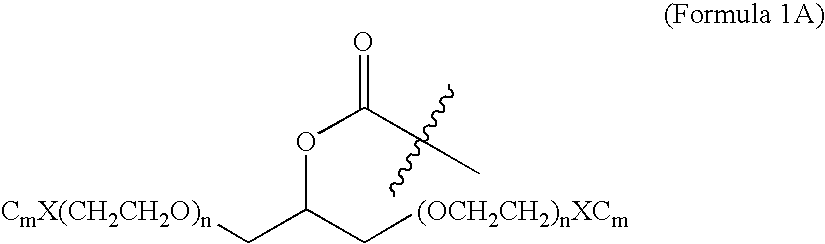

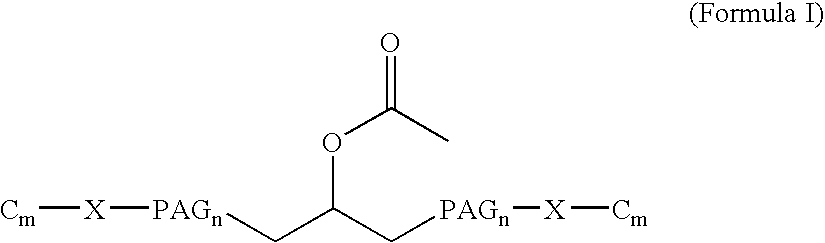

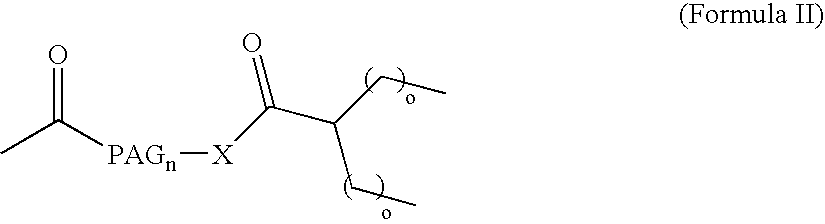

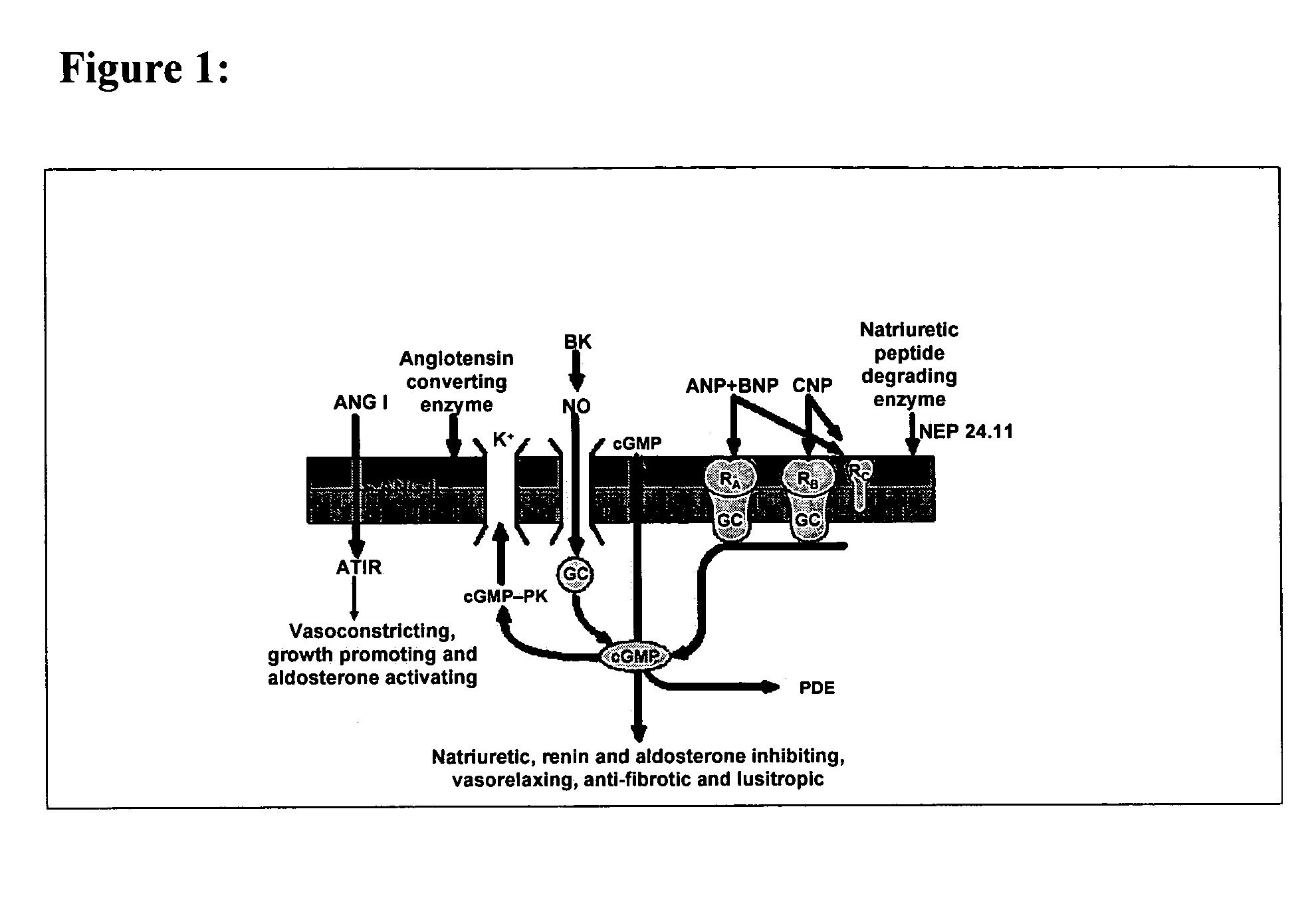

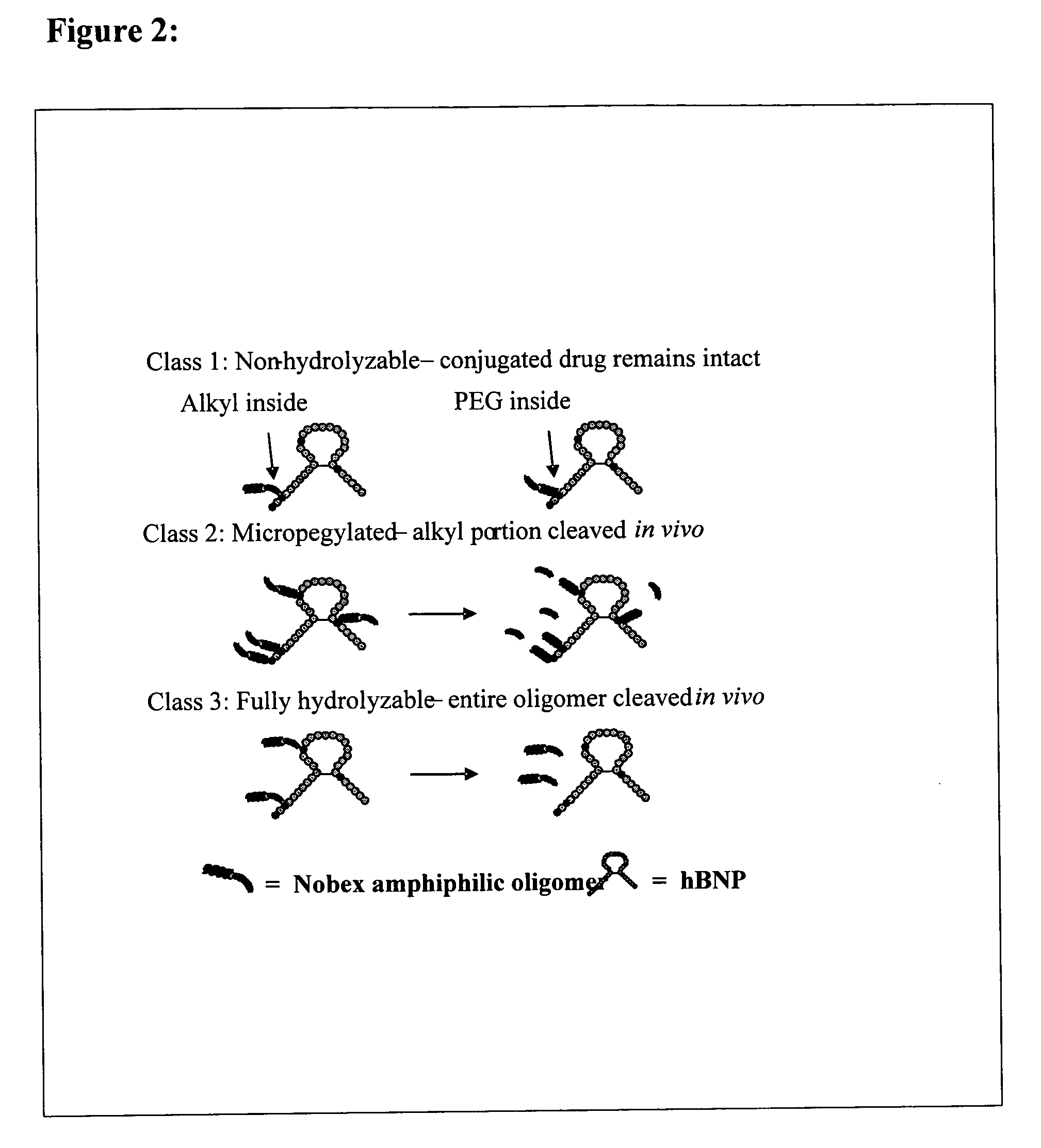

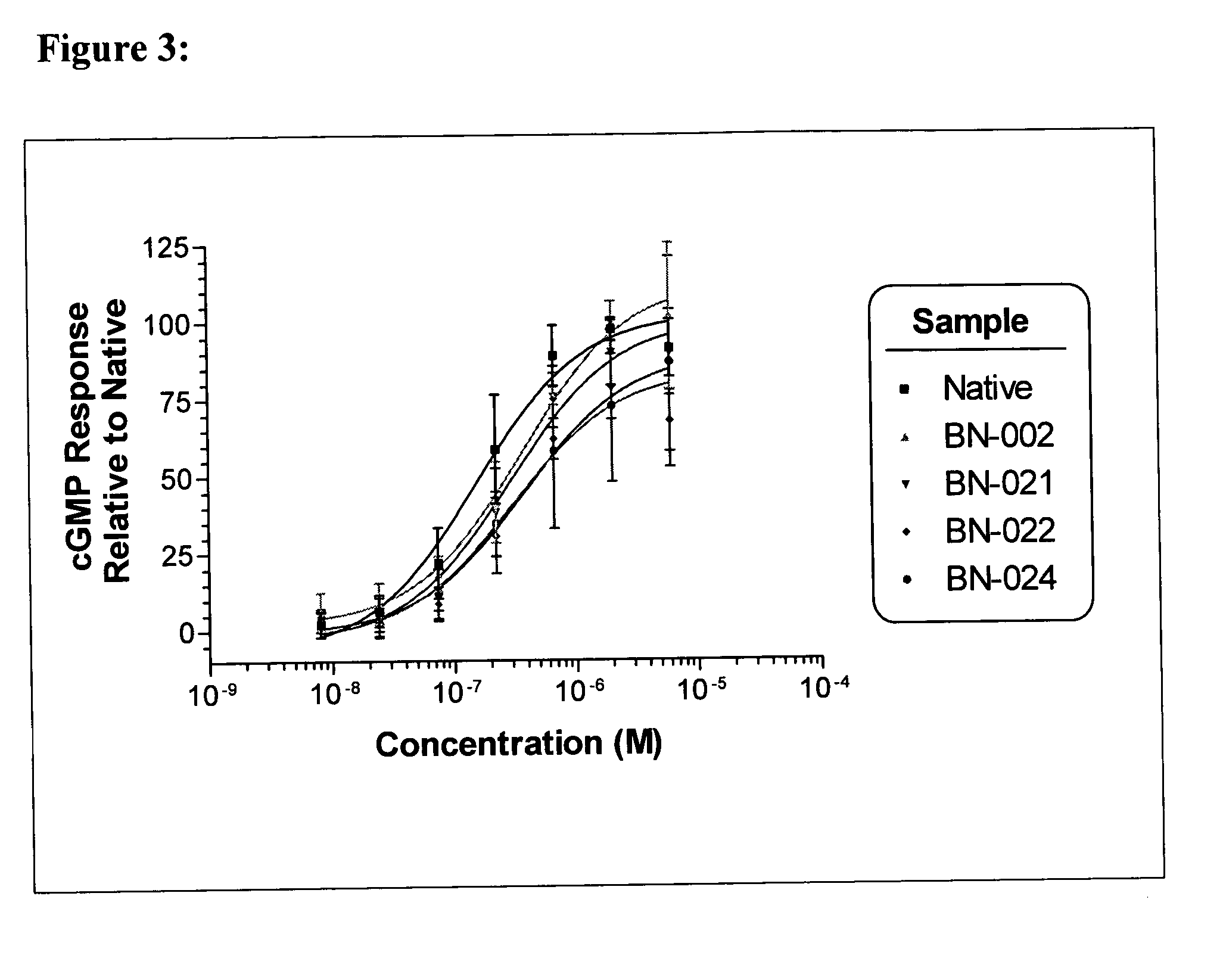

Natriuretic compounds, conjugates, and uses thereof

InactiveUS20060074009A1Improve the immunityExtended durationPeptide/protein ingredientsReceptors for hormonesHalf-lifeCongestive heart failure chf

Modified natriuretic compounds and conjugates thereof are disclosed in the present invention. In particular, conjugated forms of hBNP are provided that include at least one modifying moiety attached thereto. The modified natriuretic compound conjugates retain activity for stimulating cGMP production, binding to NPR-A receptor, and in some embodiments an improved half-life in circulation as compared to unmodified counterpart natriuretic compounds. Oral, parenteral, enteral, subcutaneous, pulmonary, and intravenous forms of the compounds and conjugates may be prepared as treatments and / or therapies for heart conditions particularly congestive heart failure. Modifying moieties comprising oligomeric structures having a variety of lengths and configurations are also disclosed. Analogs of the natriuretic compound are also disclosed, having an amino acid sequence that is other than the native sequence.

Owner:BIOCON LTD

Natriuretic compounds, conjugates, and uses thereof

InactiveUS20040203081A1Improve the situationAvoid delayPeptide/protein ingredientsReceptors for hormonesHalf-lifeCongestive heart failure chf

Modified n atriuretic compounds and conjugates thereof are disclosed in the present invention. In particular, conjugated forms of hBNP are provided that include at least one modifying moiety attached thereto. The modified natriuretic compound conjugates retain activity for stimulating cGMP production, binding to NPR-A receptor, and in some embodiments an improved half-life in circulation as compared to unmodified counterpart natriuretic compounds. Oral, parenteral, subcutaneous, and intravenous forms of the compounds and conjugates may be prepared as treatments and / or therapies for heart conditions particularly congestive heart failure. Modifying moieties comprising oligomeric structures having a variety of lengths and configurations are also disclosed. Analogs of the n atriuretic compound are also disclosed, having an amino acid sequence that is other than the native sequence.

Owner:BIOCON LTD

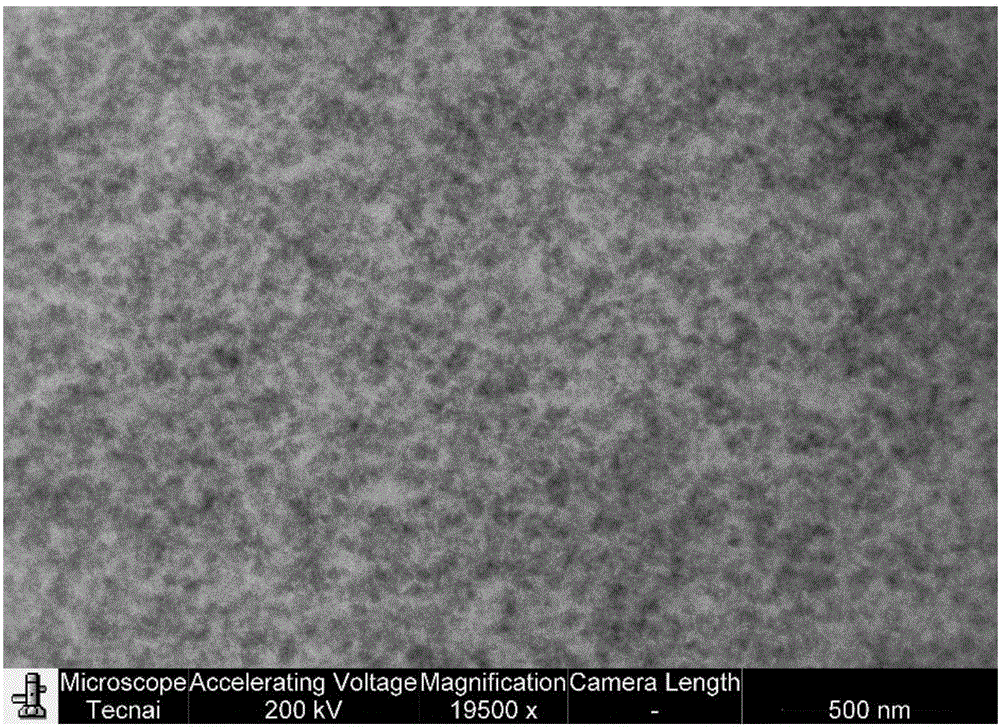

Method for modifying nano titanium dioxide sol by utilizing silane coupling agent

InactiveCN102031022ASimple processMild reaction conditionsPigment treatment with organosilicon compoundsSilanesPollution

The invention discloses a method for modifying nano titanium dioxide sol by utilizing a silane coupling agent. The method comprises: mixing 20-70 parts by weight of absolute ethyl alcohol, 10-25 parts by weight of deionized water and 5-25 parts by weight of hydrochloric acid at room temperature; adding the mixture to the mixed liquor of 100 parts by weight of butyl titanate and 20-70 parts by weight of absolute ethyl alcohol at the addition speed controlled at 0.4-0.6g / min; stirring the mixture for 0.5-1.5 hours, then adding 1-20 parts by weight of silane coupling agent, and stirring the mixture for 0-24 hours; and heating the mixture to 70-85 DEG C and stirring the mixture to react for 0.5-2.0 hour, thus preparing the nano titanium dioxide sol modified by the silane coupling agent, wherein the silane coupling agent is gamma-methacryloxy propyl trimethoxy silane, ethenyl trimethoxy silane or ethenyl triethoxy silane. The method has the characteristics of simple process, mild reaction conditions, no pollution, wider application prospect and the like.

Owner:SOUTH CHINA UNIV OF TECH

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Preparation method of high dispersed white carbon black

ActiveCN102229758AIncreased dispersionReduce forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsDispersityFiltration

The invention discloses a preparation method of high dispersed white carbon black. According to a new method and technology, a synthesis reaction of liquid soluble glass and concentrated sulfuric acid is carried out in two steps by first preparing fine seeds, and then carrying out a synthesis reaction, wherein the synthesis reaction is a precipitation reaction carried out under effects of an organic surfactant SDS and a composite silane coupling agent. The high dispersed precipitated white carbon black specially used in high-performance tyres is obtained through particle surface cladding, modification treatment, press filtration, washing, pulping and pressure drying. The method improves a traditional white carbon black production technology of a precipitation method by optimizing technological parameters and using an optimized auxiliary agent to meet a requirement of enhanced product dispersiveness; besides the method overcomes defects of an ordinary precipitation method, such as crude particles, wide distribution, strong hydrophilism and weak mixing dispersion. A prepared product has characteristics of fine primary particles, low surface hydroxyl content, increased lipophilicity,high bonding force with rubber high molecules and high wettability, and is an ideal reinforcing filling material specially used in high-performance tyres.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

Process for preparing nano silicon dioxide-acrylate composite emulsion

The preparation process of nanometer composite silica-acrylate emulsion includes the following steps: mixing small molecular alcohol, silane as coupling agent, deionized water and acid solution through stirring; adding the hydrolyzed product of nanometer silica and silane as coupling agent into benzene derivative solvent under the protection of inert gas via stirring; centrifugal separation, flushing with alcohol or acetone and vacuum drying to obtain modified nanometer silica; dispersing acrylate monomer into fine emulsion; mixing the modified silica, anionic or non-ionic emulsifier, stabilizer and water, emulsifying and adding soluble persulfate or liposoluble peroxide; and adding the fine emulsion into the mixed solution to obtain the nanometer composite silica-acrylate emulsion. The present invention has less environmental pollution and is suitable for industrial application.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Breviscapine-phosphotide compound and its preparing process

InactiveCN1359682AImprove absorption rateImprove absorptionOrganic active ingredientsUnknown materialsRefluxYolk

A breviscapine-phosphotide composition in the form of oral preparation or injection is prepared from breviscapine and soybean (or egg yolk, or synthetic) lecithine in a wt ratio of 1:(0.5-50) through heating, reflux, washing and drying. Its advantages are high stability and durability, and quickly taking its curative effect.

Owner:SHENYANG PHARMA UNIVERSITY

Abuse-deterrent pharmaceutical compositions of opioids and other drugs

InactiveUS20080199530A1Reduce the possibilityImprove lipophilicityPowder deliveryNervous disorderAdditive ingredientWater insoluble

Owner:COLLEGIUM PHARMA INC

Natriuretic compounds, conjugates, and uses thereof

InactiveUS7662773B2Extended durationImprove the immunityCosmetic preparationsPeptide/protein ingredientsHalf-lifeCongestive heart failure chf

Modified natriuretic compounds and conjugates thereof are disclosed in the present invention. In particular, conjugated forms of hBNP are provided that include at least one modifying moiety attached thereto. The modified natriuretic compound conjugates retain activity for stimulating cGMP production, binding to NPR-A receptor, and in some embodiments an improved half-life in circulation as compared to unmodified counterpart natriuretic compounds. Oral, parenteral, subcutaneous, and intravenous forms of the compounds and conjugates may be prepared as treatments and / or therapies for heart conditions particularly congestive heart failure. Modifying moieties comprising oligomeric structures having a variety of lengths and configurations are also disclosed. Analogs of the natriuretic compound are also disclosed, having an amino acid sequence that is other than the native sequence.

Owner:BIOCON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com