Patents

Literature

209results about How to "Strong hydrogen bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

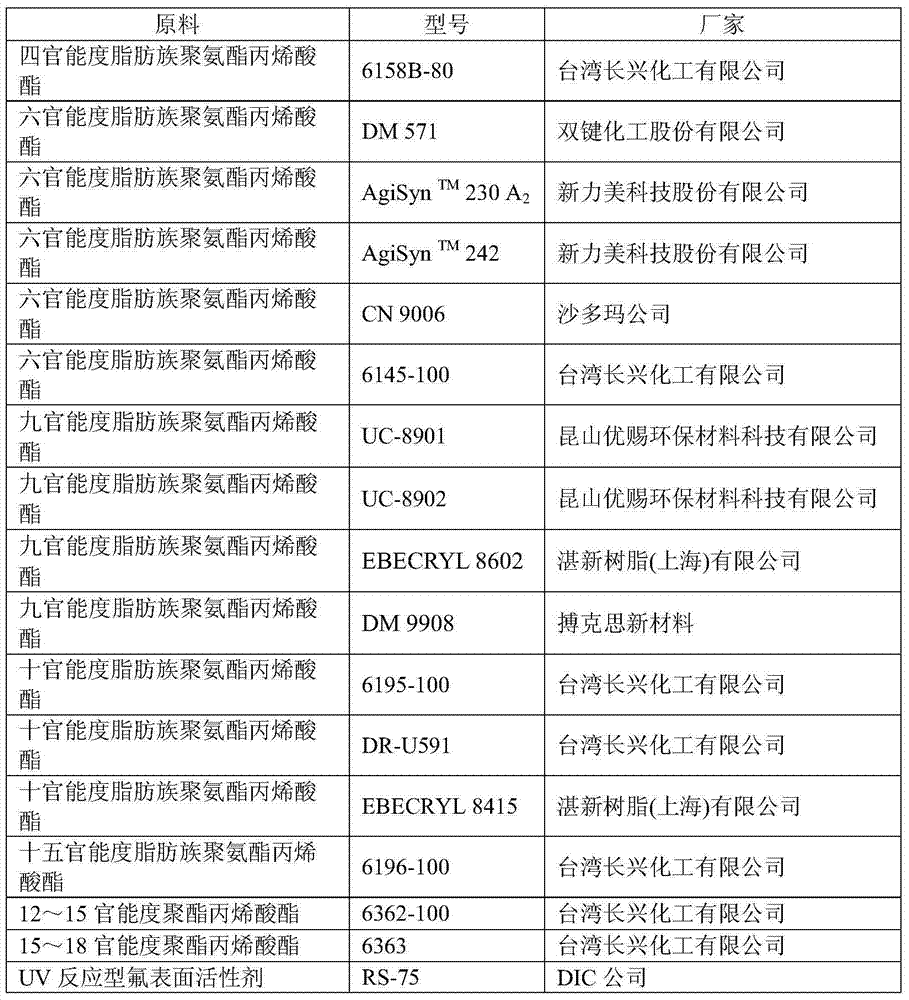

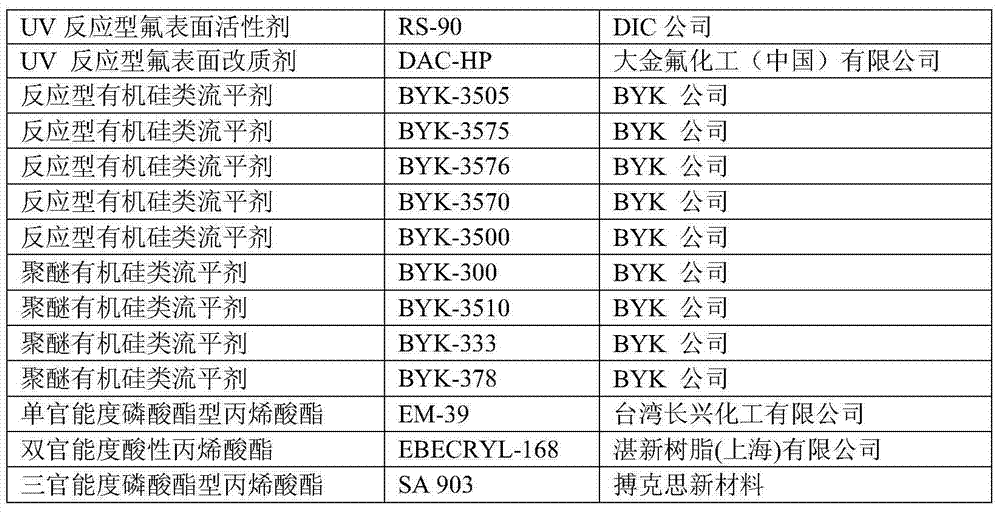

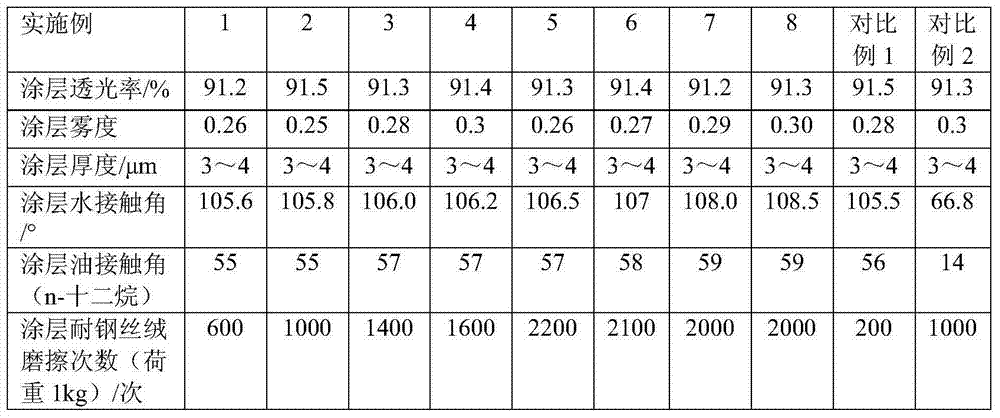

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

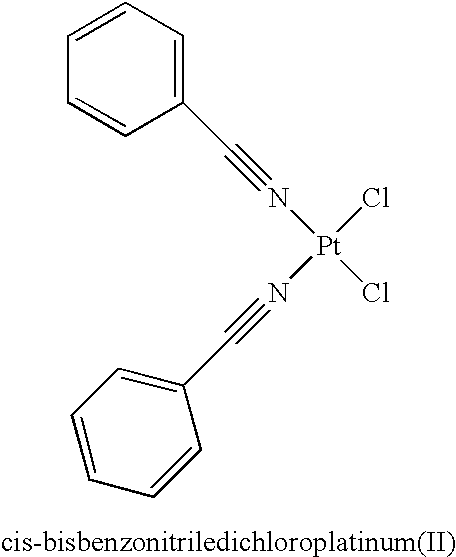

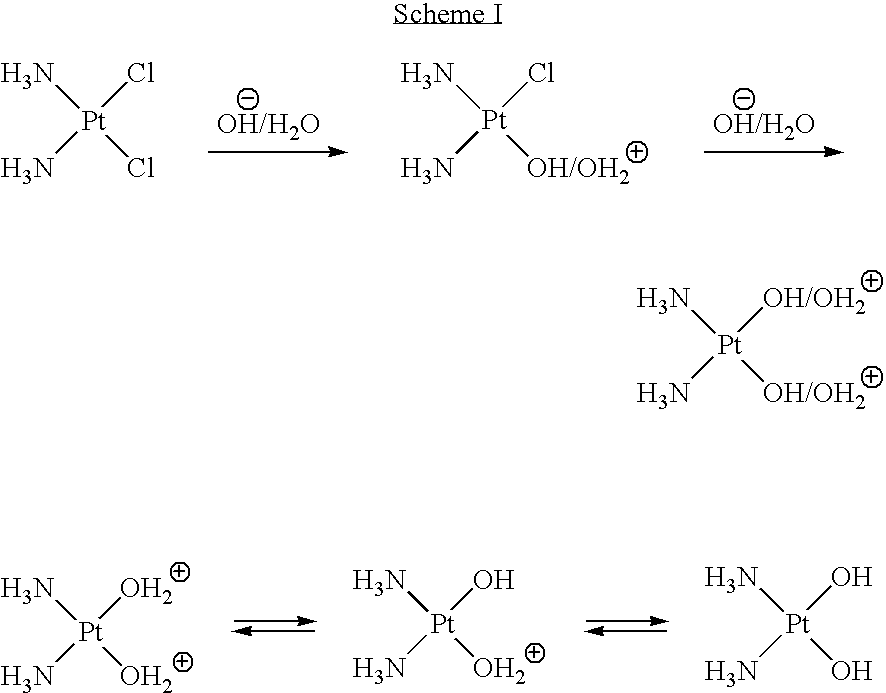

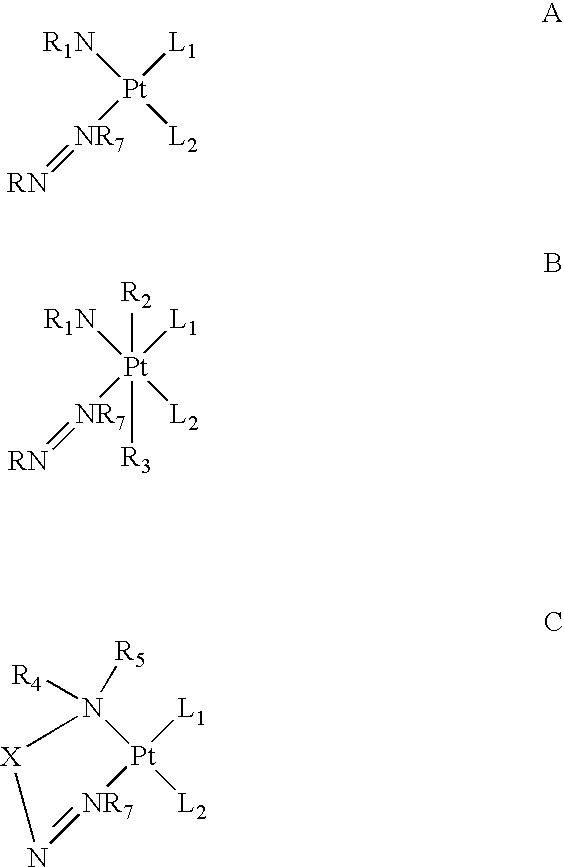

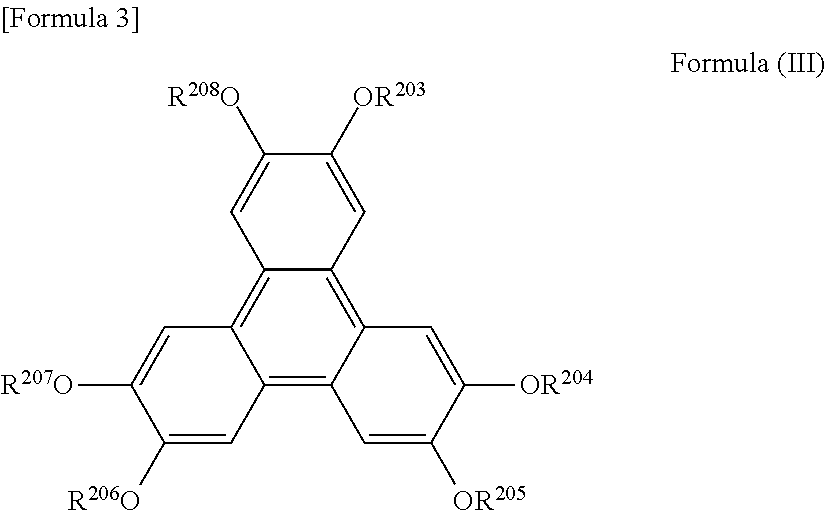

Monoazole ligand platinum analogs

InactiveUS7759488B2Easily transported into tumor cellStrong hydrogen bondingOrganic active ingredientsPlatinum organic compoundsPurinePt element

Disclosed herein are novel platinum-based analogs with a single substituted azole ligand: RN═NR7, wherein the RN═NR7 functional group is covalently bonded to the platinum through nitrogen of NR7. The analogs also have nitrogen donor ligands capable of forming hydrogen bonds with the bases in DNA or RNA, and one or more leaving groups which can be displaced by water, hydroxide ions or other nucleophiles, which is thought to form active species in vivo, and then, form cross-linked complexes between nucleic acid strands, principally between purines in DNA (or RNA), i.e., at the Guanine or Adenine bases, thereof. These platinum analogs may also be more easily transported into tumor cells, due to their increased lipophilicity and are likely to be useful as anti-neoplastic agents, and in modulating or interfering with the synthesis or replication or transcription of DNA or translation or function of RNA in vitro or in vivo, as they are potentially capable of forming a platinum coordinate complex with an intact or nascent DNA or RNA and thereby interfering with cellular synthesis, transcription or replication of nucleic acid polynucleotides.

Owner:BIONUMERIK PHARMA INC

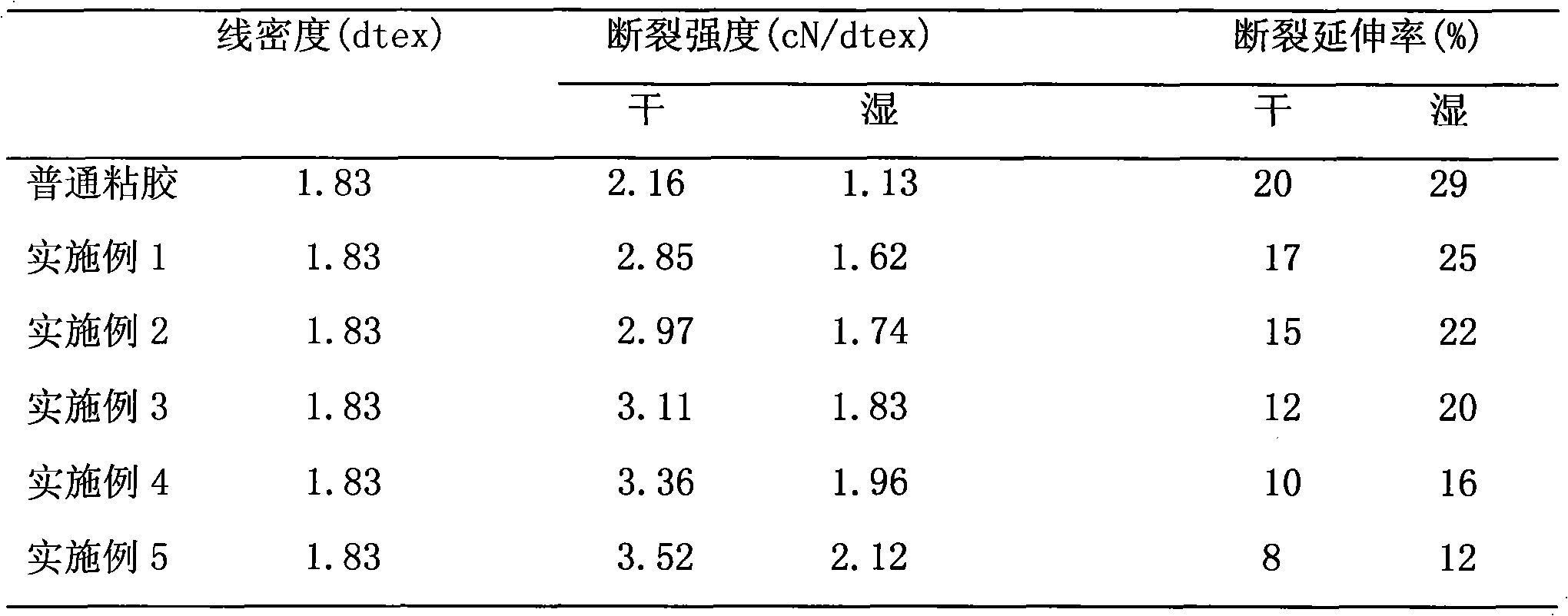

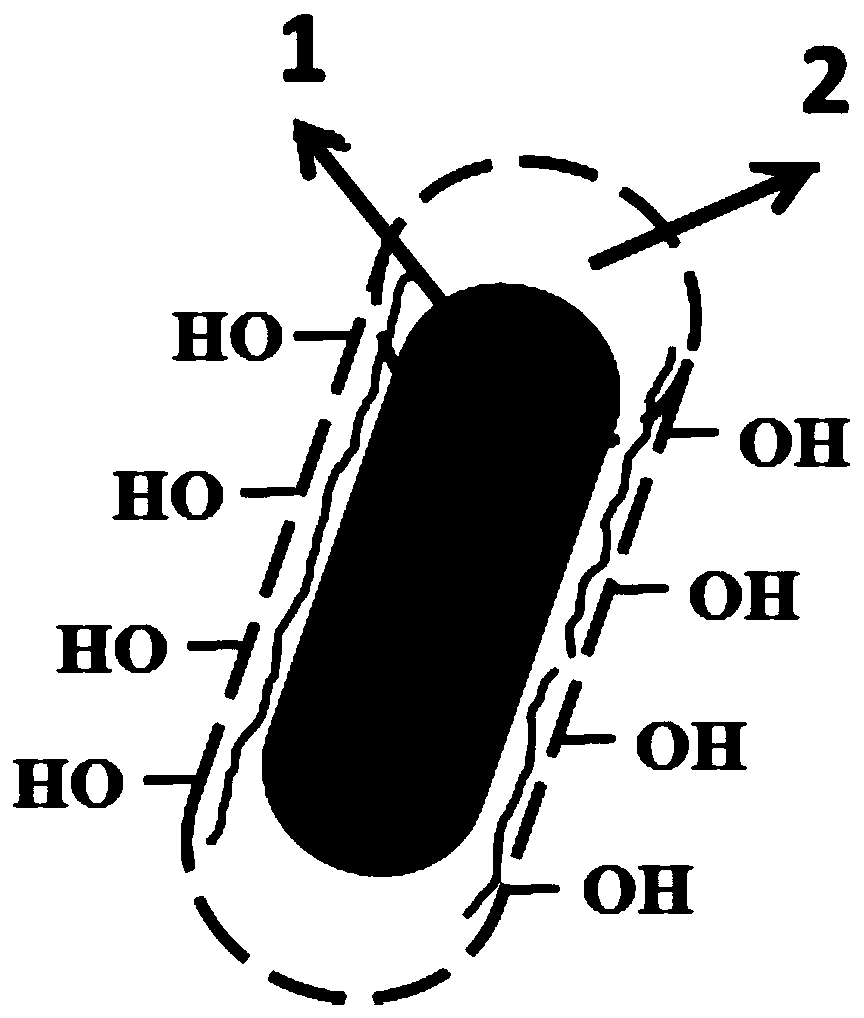

High-strength viscose fiber and production method thereof

ActiveCN101775671ARealize industrial productionHigh crystallinityConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseMicro nanoHigh intensity

The invention discloses a high-strength viscose fiber and a production method thereof, which are characterized in that the viscose fiber is formed by mixing bacterial cellulose and viscose spinning solution, wherein the content of the bacterial cellulose in the viscose fiber is 1 to 10 percent. The production method comprises the following steps: the flake bacterial cellulose is pre-processed, and then the flake bacterial cellulose after the preprocessing is smashed with a ball milling method to obtain a micro nano-grade bacterial cellulose powder; the bacterial cellulose powder is added into the viscose spinning solution to be uniformly scattered and defoamed to obtain a spinning solution; and the spinning solution is made into a high-strength viscose fiber. The content of the bacterial cellulose in the viscose fiber is 1 to 10 percent. The viscose fiber which is prepared with the production method has high strength, small shrinkage and good elasticity, can be blended and interwoven with cotton, wool and other synthesized fibers to be used for the fields such as top-grade costume fabric and industrial textiles, and the like.

Owner:QINGDAO TIANYI GROUP

Ultraviolet cured paint for electric product surface coating

InactiveCN101358048AImprove wear resistanceHigh efficiency and speed of curingCoatingsSolventFunctional monomer

The invention relates to a UV-curable coating used in surface coating for electronic products, which is prepared by the components with the following weight percentage: 10 to 30wt percent of dual-functional polyurethane acrylate, 5 to 40wt percent of multi-functional nuclear hybrid acrylate monomer, 5 to 30wt percent of ethoxylated or propoxylated multi-functional acrylate monomer, 0 to 15wt percent of single-functional monomer, 1 to 6wt percent of photoinitiator, 0 to 5wt percent of modified nano material, 0.1 to 2wt percent of flatting agent, and 10 to 50wt percent of solvent. The UV-curable coating of the invention is widely applicable to the surface coating of electronic products, such as mobile phones, MP3, MP4 and digital cameras, etc, and has the advantages of high wear resistance, high transparency, strong adhesion, high gloss, etc.

Owner:SOUTH CHINA UNIV OF TECH

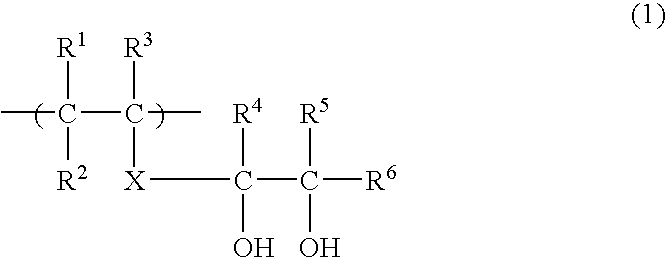

Water-soluble polyvinyl alcohol resin filament and nonwoven fabric made by using the same

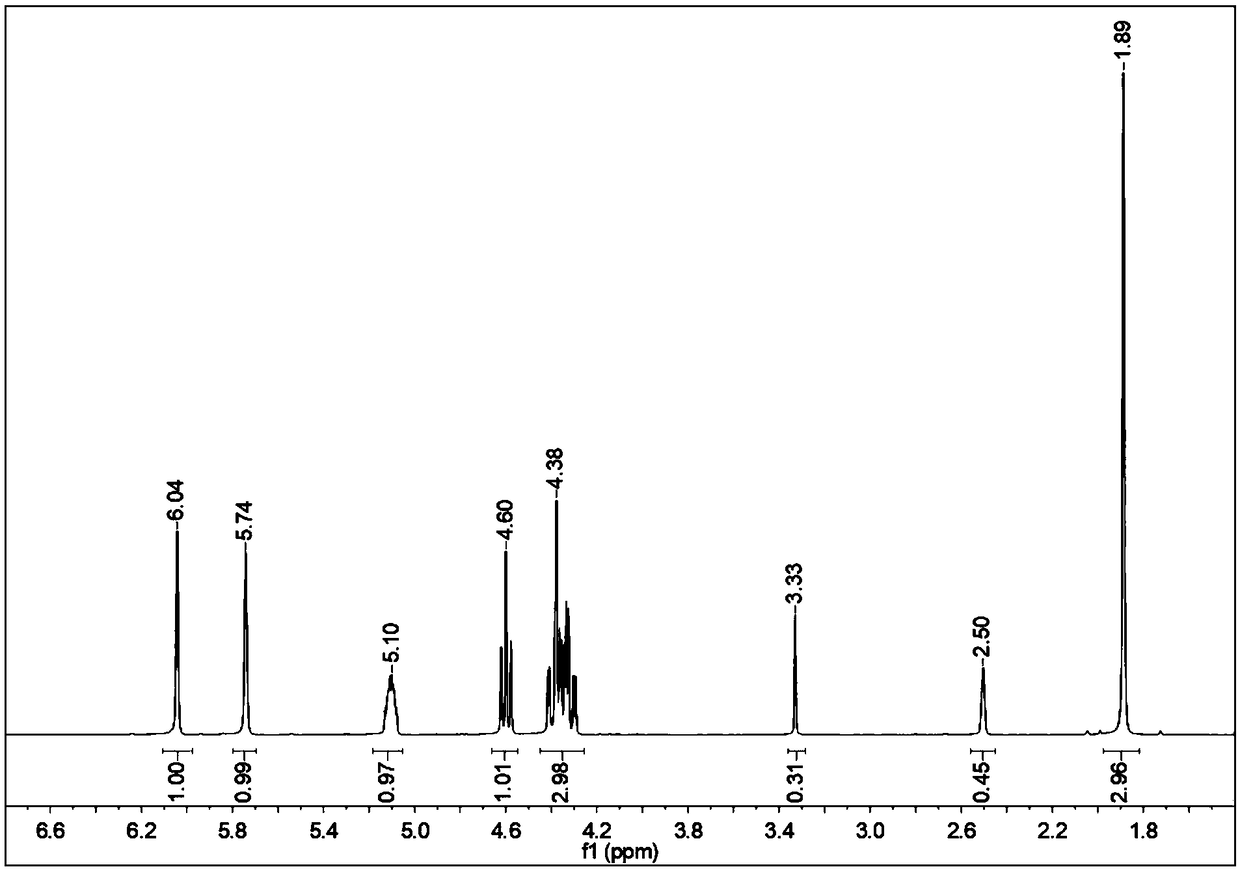

InactiveUS20090061719A1Good water solubilityRadiation suppressionLayered productsMonocomponent synthetic polymer artificial filamentSolubilityDissolution

A water-soluble polyvinyl alcohol resin filament is provided, which is formed by melt-spinning a material consisting essentially of a water-soluble polyvinyl alcohol resin having a 1,2-diol structural unit represented by the following general formula (1). A nonwoven fabric is also provided, which is produced by using the water-soluble polyvinyl alcohol resin filament. Therefore, the nonwoven fabric is excellent in water solubility at a lower temperature, and substantially free from bubbling during dissolution thereof in water. In addition, a fully saponified PVA can be used for melt-forming. This suppresses emanation of acetic acid odor, thereby improving the working environment.wherein R1, R2, R3, R4, R5 and R6, which may be the same or different, are each a hydrogen atom or a monovalent organic group, and X is a single bond or a connecting chain.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

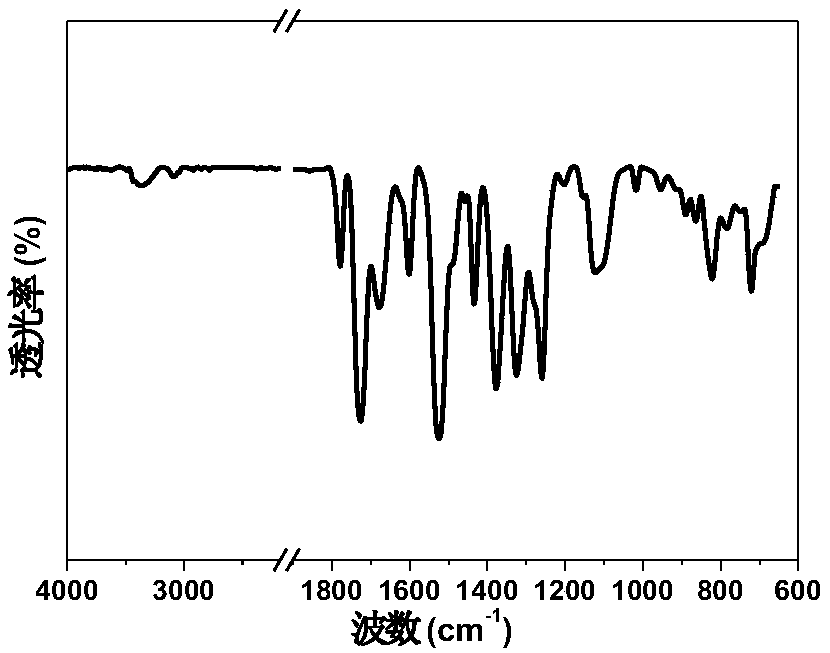

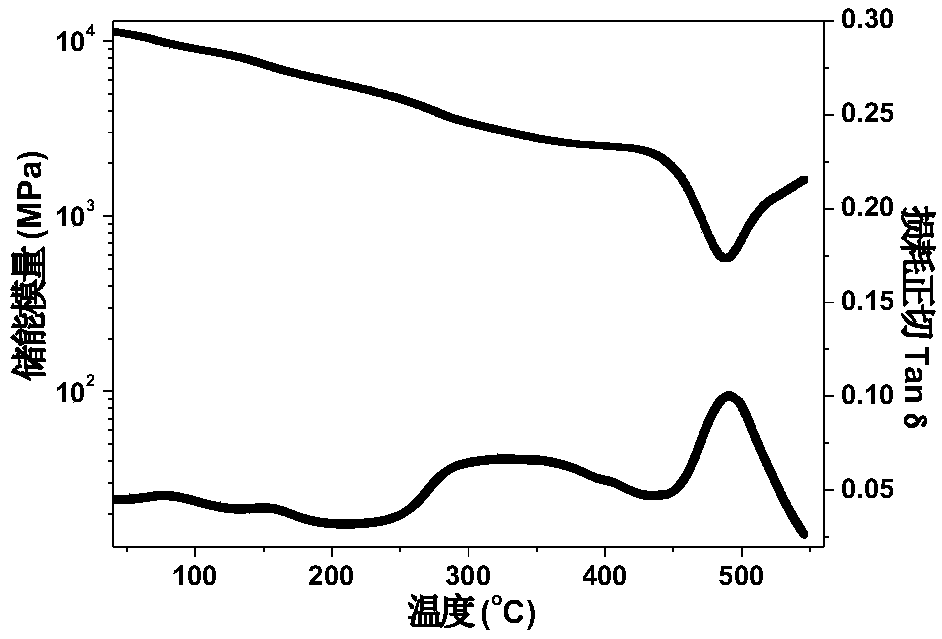

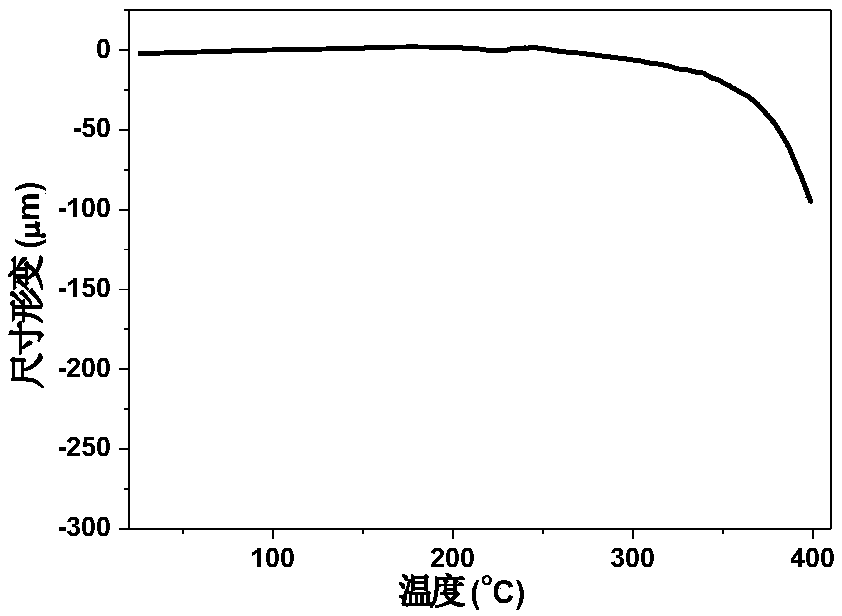

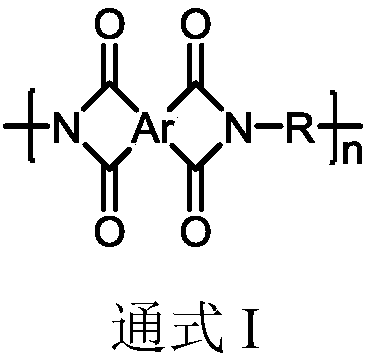

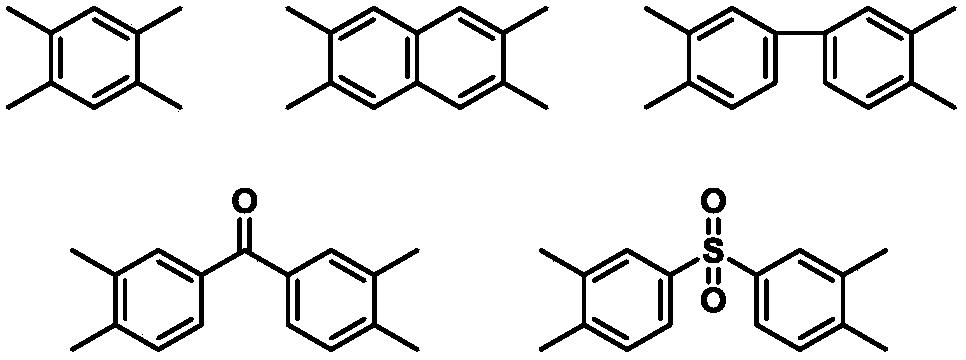

Ultra-low-expansion fluorine-containing polyimide thin film and preparation method and application thereof

The invention relates to an ultra-low-expansion fluorine-containing polyimide thin film and a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that in the prior art, a linear thermal expansion coefficient of a polyimide thin film in a wide temperature range is not low enough and when the linear thermal expansion coefficient is reduced,other performances of the polyimide thin film are difficult to obtain concurrently. According to the ultra-low-expansion fluorine-containing polyimide thin film, a molecule main chain structure of polyimide comprises a linear rigid unit, a polar amide group and a fluorine-containing group; preparation raw materials comprise aromatic dianhydride and diamine with the amide group and the fluorine-containing group. The preparation method comprises dissolving the aromatic diamine with the amide group and the fluorine-containing group, and adding the aromatic dianhydride to obtain polyamic acid homogeneous solution; carrying out film coating, curing, stripping and drying; tiling the product on a substrate, and carrying out fixing and annealing processing to obtain the polyimide thin film. The ultra-low-expansion fluorine-containing polyimide thin film and the preparation method and the application thereof implement wide application in the field of electronic and flexible display.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for preparing vinyl chloride by hydrochlorinating acetylene through using quaternary phosphonium long-chain ionic liquid as medium

ActiveCN104109076AAvoid local overheatingAvoid catalytic carbon depositionPreparation by halogen halide additionPhosphoniumHydrogen chloride

The invention discloses a method for preparing vinyl chloride by hydrochlorinating acetylene through using a quaternary phosphonium long-chain ionic liquid as a medium. The method comprises the following steps: dissolving a catalyst in a quaternary phosphonium long-chain anion functional ionic liquid medium to prepare a catalysis system, activating the catalysis system by introducing hydrogen chloride in advance, and introducing acetylene and hydrogen chloride to carry out a reaction. The method using the ionic liquid as the reaction medium and a mercury-free compound as the catalyst realizes the green and environmentally-friendly liquid phase reaction of acetylene hydrochlorination, has a very good catalysis efficiency, and makes the acetylene conversion rate reach 80-98% and the vinyl chloride selectivity reach above 99.5%.

Owner:ZHEJIANG UNIV

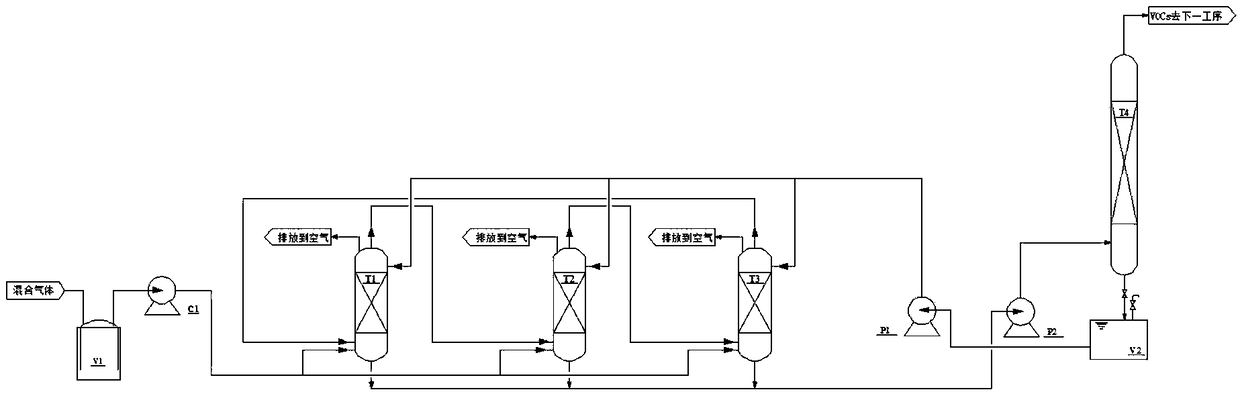

VOCs absorbent and application thereof

ActiveCN108786383AOptimal Intake ConcentrationLow mass transfer efficiencyGas treatmentDispersed particle separationSolubilityBiodiesel

The invention provides a VOCs absorbent and application thereof. The absorbent uses ionic liquid as a polarity phase, a small amount of ion liquid is evenly dispersed in a large amount of water or biodiesel to obtain a microemulsion under the effects of a non-ionic surface active agent and a cosurfactant. The microemulsion has very high VOCs solubleness, and the problems of inorganized VOCs discharge treatment and VOCs recycle of sewage treatment plants are solved.

Owner:HEBEI UNIV OF TECH

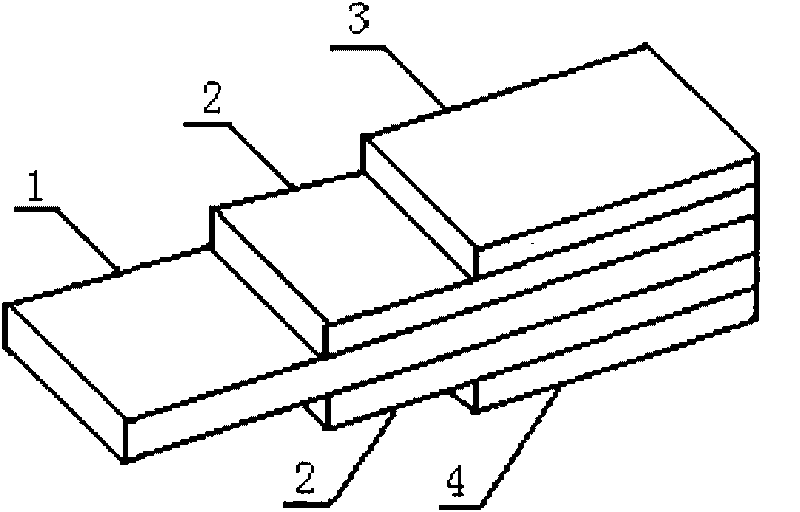

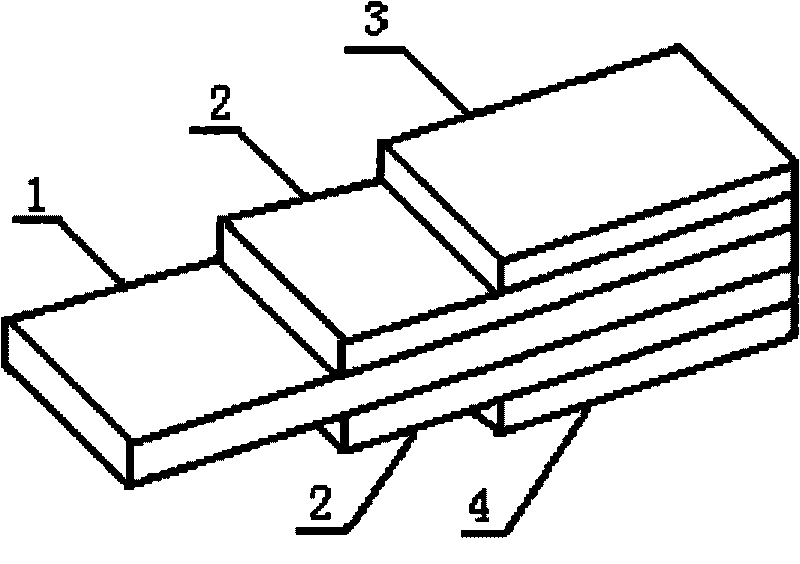

Carbonized bacterial cellulose/carbon nanotube film material and preparation method thereof

The invention discloses a carbonized bacterial cellulose / carbon nanotube film material and a preparation method thereof. The preparation method comprises the followings: 1) preparing a carboxylated carbon nanotube nano dispersion solution; 2) preparing bacterial cellulose / carboxylated carbon nanotube aerogel; 3) carrying out carbonization treatment to prepare a carbonized bacterial cellulose / carbon nanotube film. According to the carbonized bacterial cellulose / carbon nanotube film material and the preparation method thereof, the integrity and good mechanical properties of the carbonized bacterial cellulose / carbon nanotube film are ensured and the carbonized bacterial cellulose / carbon nanotube film has high electrical conductivity; a preparation technology is simple, green and environmentally friendly and is suitable for batch production.

Owner:NANJING FORESTRY UNIV

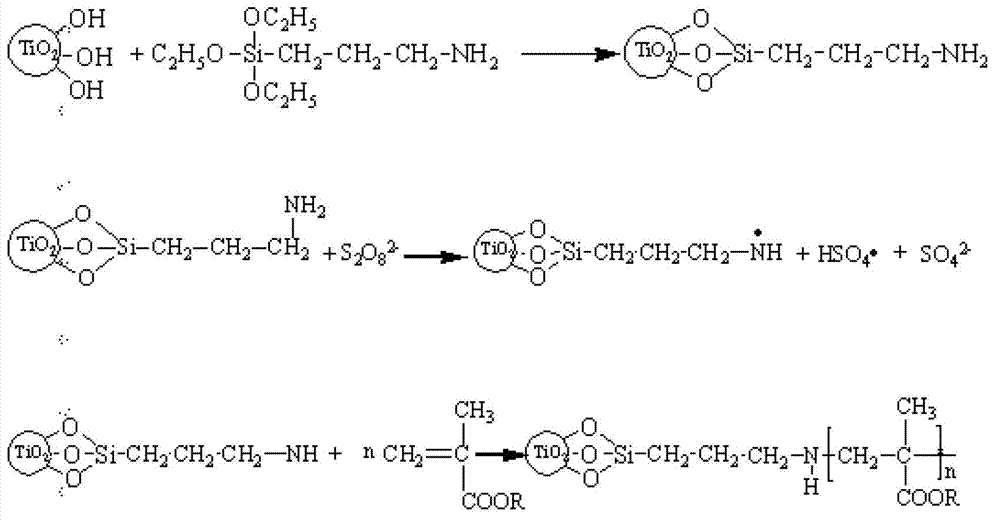

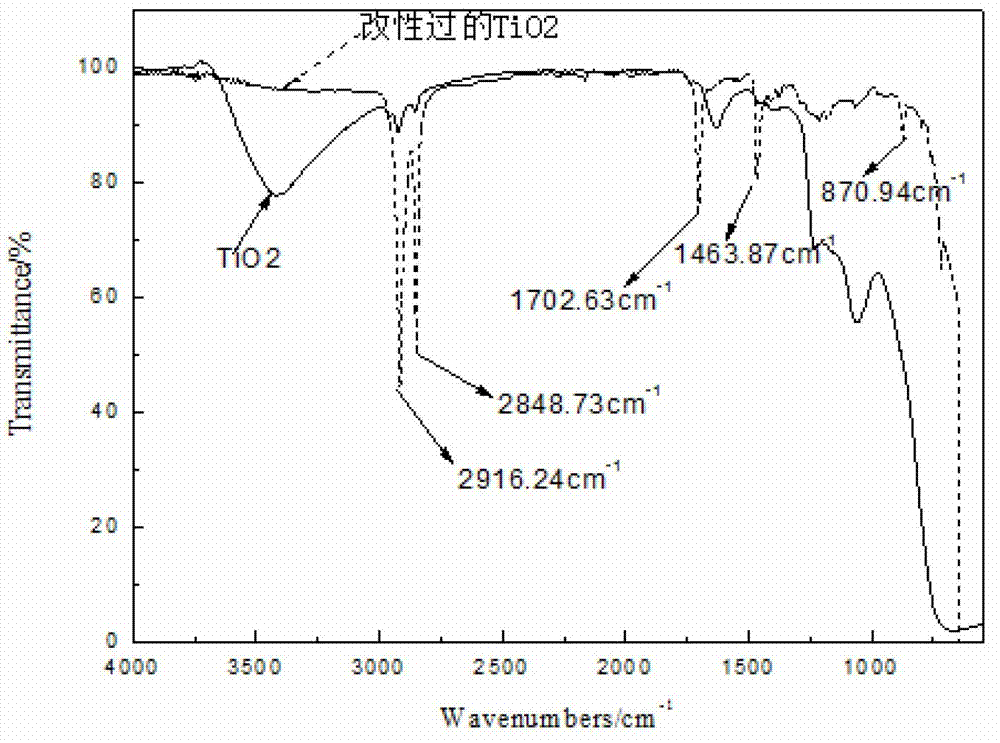

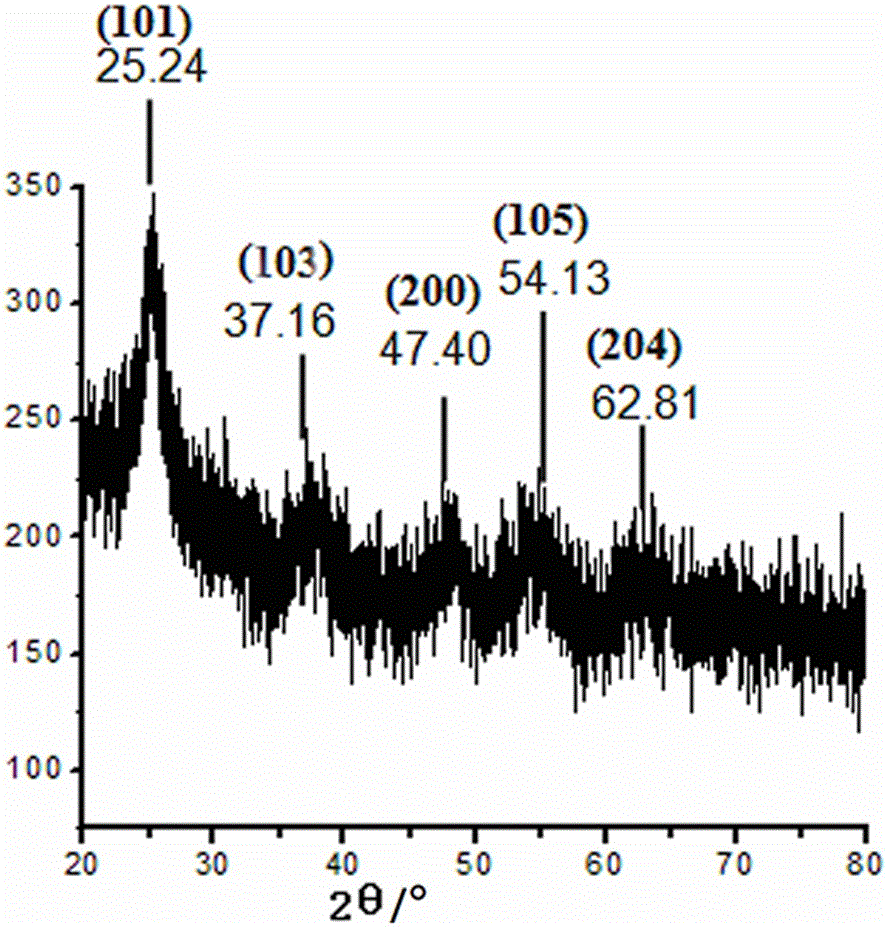

PVDF (polyvinylidene fluoride) film modified with nano-titanium dioxide and preparation method for PVDA film

The invention provides a PVDF (polyvinylidene fluoride) film modified with nano-titanium dioxide and a preparation method for the PVDA film. Fluorinated polyacrylate is grafted on the surface of the nano-titanium dioxide in the film, compatibility of TiO2 in PVDF is greatly improved due to the existence of a graft monomer, and when the PVDF film is used for solar cell back films, bonding force between the PVDF film and other dorsal plate base materials is greatly enhanced. The preparation method includes: firstly grating the fluorinated polyacrylate on the surface of TiO2, weighing graft copolymer and the PVDF according to a part ratio for mixing in a mechanical stirring manner, using an extruder for extrusion and strip formation after uniformly mixed, placing into a drying oven to dry moisture after being cut into granules, squeezing out by a single screw for tape casting, and obtaining the modified PVDF film.

Owner:CHANGZHOU UNIV +1

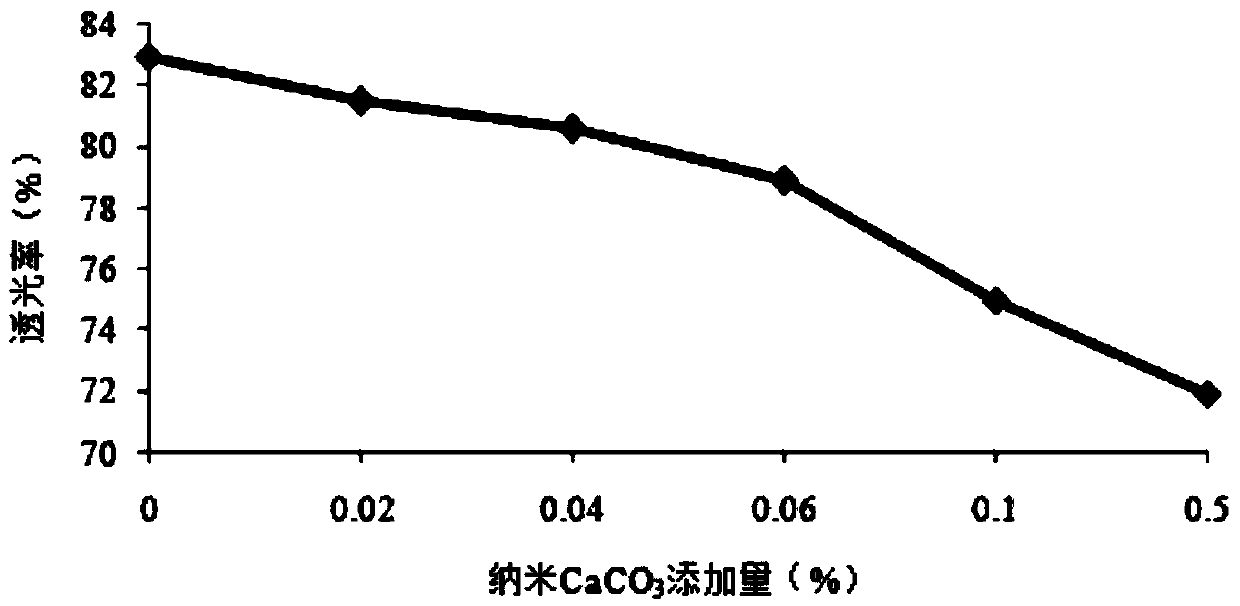

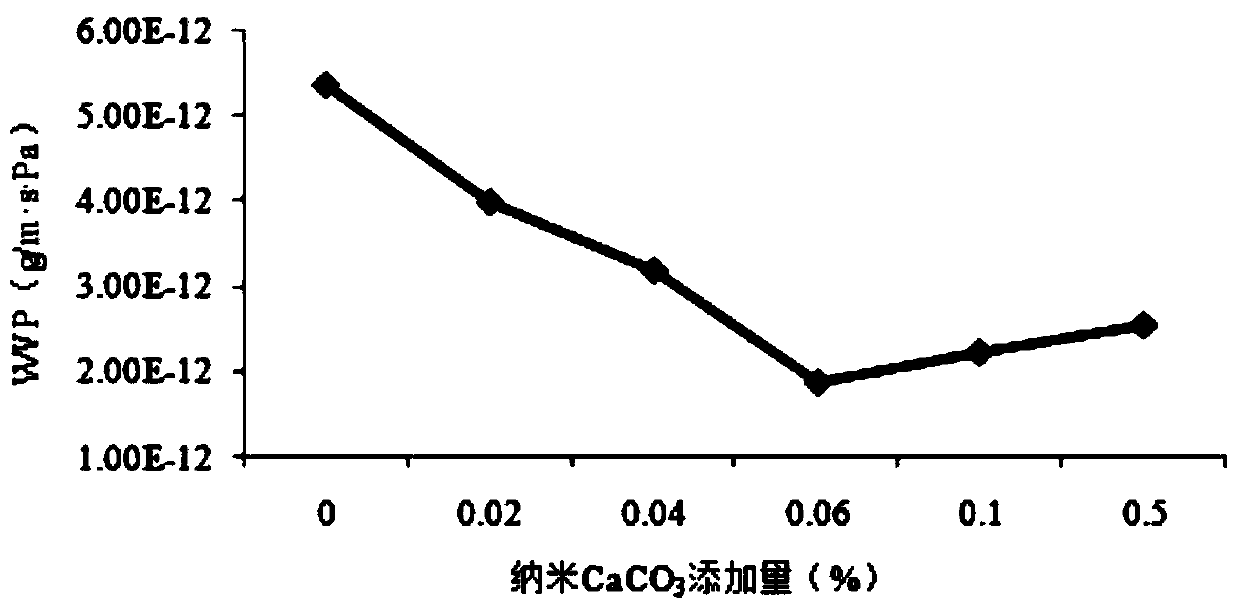

Corn starch composite membrane as well as preparation method and applications thereof

ActiveCN104194064AReduce light transmittanceLow moisture permeabilityFlexible coversWrappersWaxy cornNanoparticle

The invention discloses a corn starch composite membrane as well as a preparation method and applications thereof. The corn starch composite membrane comprises corn starch, glycerol and an enhancer, wherein the enhancer is nano CaCO3, waxy corn starch nanoparticles or chitosan, the mass ratio of the corn starch to glycerol is equal to (6.5-8.0):(1.5-3.0), when the enhancer is nano CaCO3 and waxy corn starch nanoparticles, the masses of the enhancer / corn starch are respectively 0.02-0.5, and 1-25; when the enhancer is nano CaCO3 or chitosan, the mass ratio of nano CaCO3 and corn starch is 0.06, and the mass ratio of chitosan and corn starch is 10-50; the size of the nano CaCO3 ranges from 30nm to 50nm; and the size of the waxy corn starch nanoparticles is 70-120nm. The mechanical performance of the composite membrane is obviously improved; the light transmittance and moisture penetrability of the membrane can be reduced; the thermal characteristic is better; the thermal stability of the composite membrane is higher than that of the corn starch membrane; and the corn starch and the nano CaCO3 particles have better compatibility.

Owner:QINGDAO AGRI UNIV

Highly heat-resistant ultralow-expansion polyimide film and preparation method and application thereof

The invention relates to a highly heat-resistant ultralow-expansion polyimide film and a preparation method and application thereof, which belong to the technical field of polyimide and solve the problem that the polyimide film in the prior art can not have both low thermal expansion coefficient and good heat resistance, particularly the problem that the polyimide film in the prior art can not have both high heat resistance and ultralow expansion coefficient within a wide temperature range. According to the highly heat-resistant ultralow-expansion polyimide film, a linear rigid unit and a polar amide group are contained in the molecular main chain structure of polyimide; and preparation raw materials include aromatic dianhydride and diamine with an amide structure. According to the preparation method, aromatic diamine is dissolved in organic solvent, aromatic dianhydride is added, and thereby a homogeneous phase polyamic acid solution is obtained; the homogeneous phase polyamic acid solution is coated, solidified, stripped, dried and annealed, and thereby the polyimide film is obtained. The highly heat-resistant ultralow-expansion polyimide film and the preparation method and application thereof realize application in the fields of electronics, microelectronics, optical display, optical communication and the like, particularly wide application in the field of flexible photoelectronics.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Melamine fumiture surface paper coated with ultrasonic violet curing coating and preparation method

InactiveCN101748654ASolve the problem of recoatabilitySolve Adhesion ProblemsPaper coatingPhysical paper treatmentMelamineMaterials science

The invention belongs to the field of building decoration material, in particular to melamine fumiture surface paper coated with an ultrasonic violet curing coating which is formed by applying the ultrasonic violet curing coating on the surface, and a preparation method thereof. A common paper substrate is dipped into melamine for once and then taken out and dried; and then a layer of ultrasonic violet curing coating is applied on one surface of the common paper dipped with the melamine, and is radiated and cured by ultrasonic violet; and the a layer of melamine is applied on the other surface of the common paper dipped with the melamine and dried, to obtain the melamine fumiture surface paper coated with the ultrasonic violet curing coating. After being coated at high temperature, the melamine fumiture surface paper coated with the ultrasonic violet curing coating obtained through the invention of the invention has the advantages of good adhesion of the surface ultrasonic violet curing coating and the melamine layer and good recoatability of the ultrasonic violet curing coating surface, and has better recoatability than the prior commonly used melamine fumiture surface paper.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Method for preparing waterproofing agent of saponin-free cation paraffin emulsion artificial board

InactiveCN101649224AHigh molecular weightImprove hydrophobicityOther chemical processesWax physical treatmentParaffin waxFiber

The invention discloses a method for preparing a waterproofing agent of a saponin-free cation paraffin emulsion artificial board. The method comprises the following steps: under the function of a cosolvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, a cation monomer, acrylamide and a derivative thereof and the like, as a copolymerization monomer and preparing a saponin-free benzene polymer with strong cation charges by a saponin-free emulsion polymerization method; taking the saponin-free benzene polymer as a high molecular emulsifying agent of solid paraffin, emulsifying and dispersing the paraffin and preparing the waterproofing agent of the saponin-free cation paraffin emulsion artificial board with favorable stability by homogenizing at high pressure. The invention overcomes the defects of poor waterproof effect, poor stability, easy bubbling of emulsion and the like due to the addition of a small molecular emulsifyingagent in the traditional paraffin emulsion; the product adopts the saponin-free benzene polymer with strong cation charges as the high molecular emulsifying agent of the solid paraffin, and the high molecular emulsifying agent which can generate a very strong hydrogen bond function with fibre in the artificial board not only enhances the water resistance of a board material but also can enhance the physical strength of the artificial board.

Owner:SHAANXI UNIV OF SCI & TECH

Activated plant fiber, preparation method thereof and application of activated plant fiber in polylactic acid composite material

ActiveCN110130094ASmall range of activitiesIncrease mobilityVegetal fibresBulk chemical productionFiberLactide

The invention relates to activated plant fiber, a preparation method thereof and an application of the activated plant fiber in a polylactic acid composite material. The preparation method comprises steps as follows: the plant fiber is pretreated by a solvent, the surface of the plant fiber is dissolved, and then the solvent is reserved; the activated plant fiber mainly comprises a plant fiber body and a wrapping layer which are connected through physical bonds and chemical bonds, and the wrapping layer is a polymer solution. The application is as follows: after the activated plant fiber is prepared, the activated plant fiber, lactide and a catalyst are mixed and subjected to a synchronous reaction on the premise that the anhydrous solvent is retained and a plant fiber / polylactic acid composite material is prepared, or the activated plant fiber, lactide and the catalyst are mixed and subjected to in-situ ring-opening polymerization, a plant fiber / polylactic acid grafted polymer is prepared, then the plant fiber / polylactic acid grafted polymer and polylactic acid are subjected to melt blending, and the plant fiber / polylactic acid composite material is prepared. The method is simple,the activated plant fiber has higher activity, and the finally prepared polylactic acid composite material has excellent performance.

Owner:北京朗净汇明生物科技有限公司 +1

Collagen/chitosan composite sponge biological dressing and preparation method thereof

ActiveCN105031711AImprove antibacterial propertiesGood biocompatibilityAbsorbent padsBandagesWound dressingBiological dressing

The invention provides a collagen / chitosan composite sponge biological dressing, and belongs to the field of medical polymer materials. The biological dressing is compounded by collagen, chitosan and nano-titanium dioxide; the nano-titanium dioxide accounts for 1-5% of the total weight of the collagen and the chitosan; and weight percentage of the collagen is 50-70%, and the weight percentage of the chitosan is 30-50%. The wound dressing has good mechanical property; toxin residues caused by utilization of cross-linking agents and structure collapse caused by secondary freeze-drying are avoided; the problem of bacterial infection in a wound healing process can be solved effectively; and a sterile environment can be provided in a wound healing process.

Owner:ZHENGZHOU UNIV

Nanofiber membrane with heavy metal adsorbing function and preparation method of nanofiber membrane

InactiveCN104587981ASimple processLow costOther chemical processesWater contaminantsSorbentNanofiber

The invention relates to a nanofiber membrane with a heavy metal adsorbing function and a preparation method of the nanofiber membrane. The nanofiber membrane comprises a matrix and macromolecules self-assembled on the surface of the matrix. The preparation method comprises the following step: self-assembling the macromolecules carrying amino groups on a thermoplastic nanofiber membrane by virtue of a chemical oxidative polymerization method to obtain the nanofiber membrane. The nanofiber membrane is simple in preparation process and low in cost, and is capable of efficiently adsorbing heavy metal ions; the defect that a conventional heavy metal ion adsorbing agent requires to be separated for the second time is avoided; the effective removal of hexavalent chromium ions is realized by using a principle of first adsorption and then reduction; meanwhile, the macromolecules have a strong hydrogen bond function among hydrophilic nanofiber membranes, cannot drop from the membranes, and can be recycled.

Owner:DONGHUA UNIV

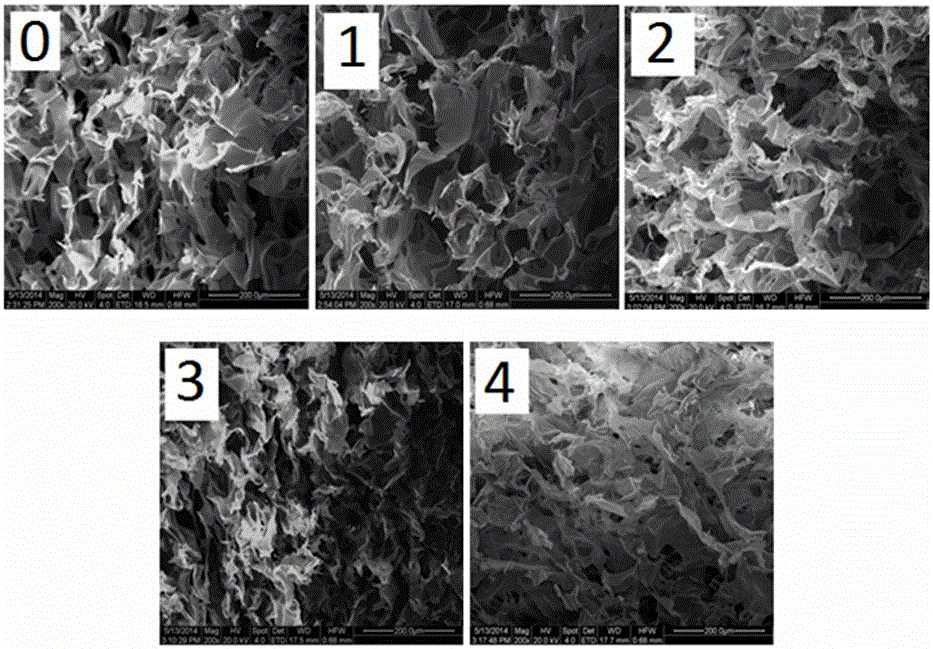

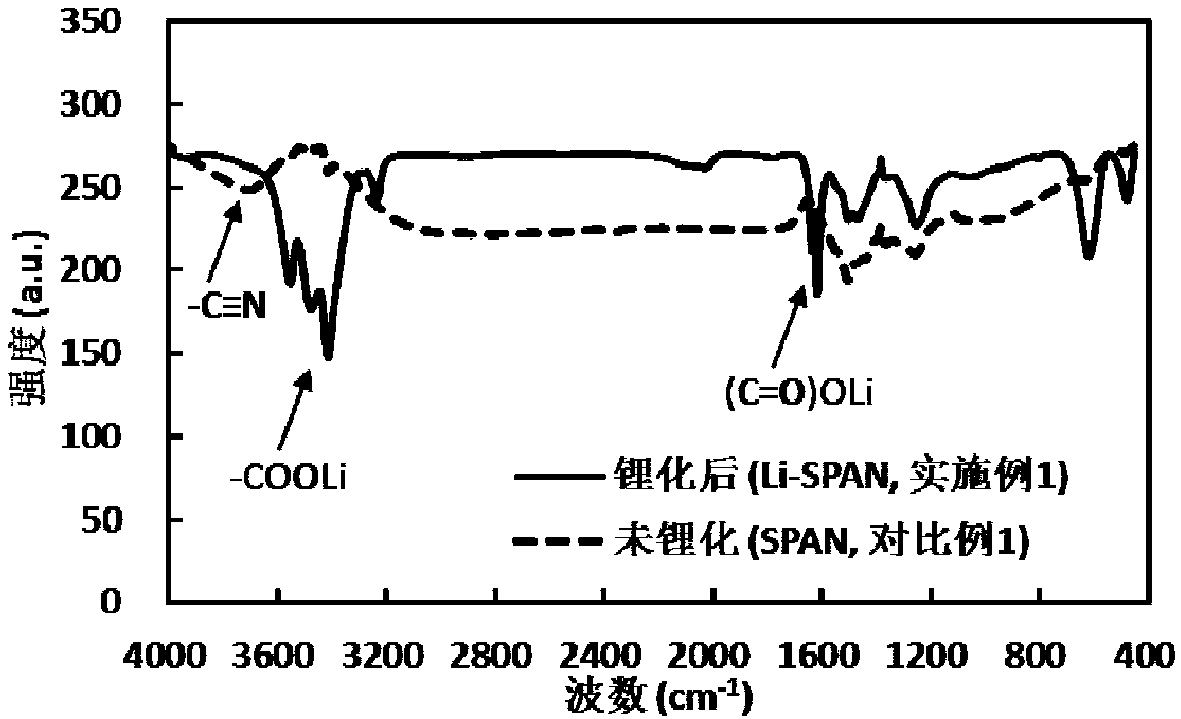

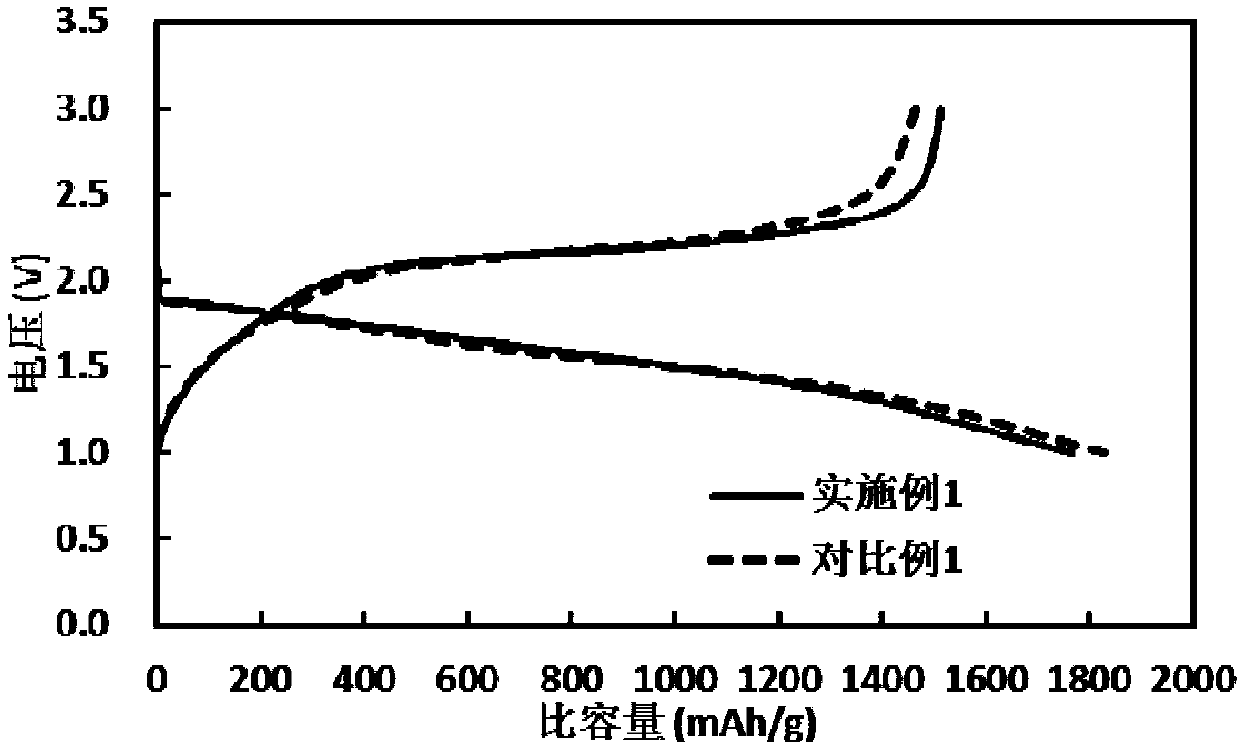

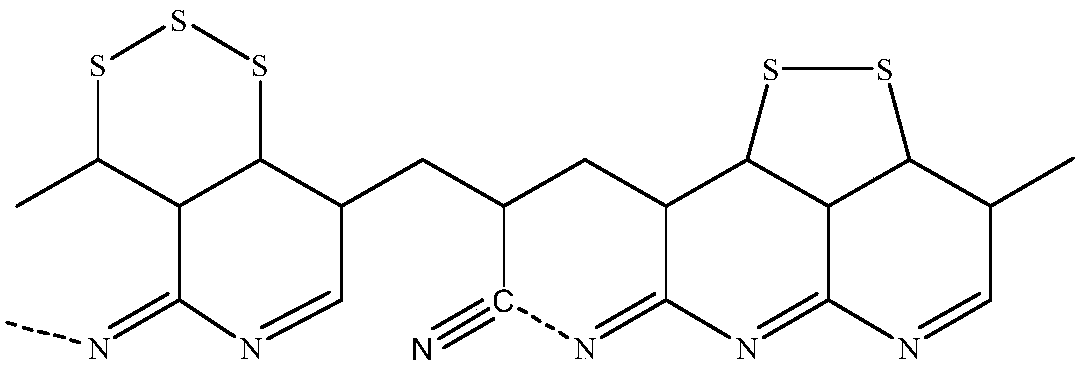

Lithiated vulcanized polyacrylonitrile, preparation method thereof, positive pole plate and lithium-sulfur secondary battery

ActiveCN110416487AIncrease loadIncrease the areaSecondary cellsNon-aqueous electrolyte accumulator electrodesIonEngineering

The invention relates to the technical field of lithium-sulfur secondary batteries, and mainly relates to lithiated vulcanized polyacrylonitrile used as a lithium-sulfur secondary battery positive electrode active material and a positive pole plate and lithium-sulfur secondary battery comprising the active material. The lithiated vulcanized polyacrylonitrile is prepared by lithiation of vulcanizedpolyacrylonitrile. By lithiation of the vulcanized polyacrylonitrile, the vulcanized polyacrylonitrile active material generates hydrophilic carboxylate ions, a hydrogen bond with a relatively high acting force is favorably formed in a system when the vulcanized polyacrylonitrile active material is combined with a conductive binding agent, and the sulfur-loading quantity and the unit area capacity of a positive electrode are favorably improved.

Owner:CONTEMPORARY AMPEREX TECH CO

High-surface-energy long-carbon-chain polyamide transparent film, as well as preparation method and application thereof

ActiveCN107163572ASimple preparation processPolarity hasFlat articlesCoatingsPolyamideBackbone chain

The invention belongs to the technical field of packaging materials, and particularly relates to a high-surface-energy long-carbon-chain polyamide transparent film, as well as a preparation method and an application thereof. The high-surface-energy long-carbon-chain polyamide transparent film is prepared from raw materials including long-carbon-chain polyamide material, wherein the long-carbon-chain polyamide is polyamide having the number of methylene between adjacent amide groups on the main chain being more than or equal to 10, and the surface tension of the high-surface-energy long-carbon-chain polyamide transparent film is 32-45mN / m; and the long-carbon-chain polyamide material is one or more of long-carbon-chain polyamide, additive-containing long-carbon-chain polyamide, long-carbon-chain polyamide alloy or long-carbon-chain polyamide nano-composite material. The high-surface-energy long-carbon-chain polyamide transparent film has the advantages of excellent mechanical performance, good size stability, good oil resistance and good gas barrier property, shows good printing performance under the condition that corona and other surface treatment means are not adopted, has excellent transparent property, and has a wide market prospect in packaging and printing technical fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Highly-hydrophilic adsorbent as well as preparation and application to absorption of rubidium ions or lithium ions

ActiveCN108435143AFix instabilityGood quid pro quoOther chemical processesWater contaminantsRubidiumDesorption

The invention discloses a highly-hydrophilic adsorbent as well as preparation and application to absorption of rubidium ions or lithium ions. The preparation method of the highly-hydrophilic adsorbentis characterized in that a lithium ion sieve or a rubidium ion exchanger is added in an aqueous solution of a hydrophilic polymer, is fully stirred and mixed and drops in a phase conversion agent ina form of droplets; and after a primary ecological adsorbent in a form of a sphere is formed by solution phase transformation, the chemical cross-linking reaction is performed in an oil phase solutionof diisocyanate to obtain the highly-hydrophilic adsorbent. The adsorbent disclosed by the invention has the benefits that the ion exchange conditions of a lithium ion and rubidium ion adsorbent areensured due to high hydrophilic capacity, and the problem of solution loss of the adsorbent in the repeated use is solved; the preparation method is simple, and the preparation and the regulation aremild; the adsorbent prepared by the preparation method disclosed by the invention is higher in absorption and desorption speed.

Owner:西安金藏膜环保科技有限公司

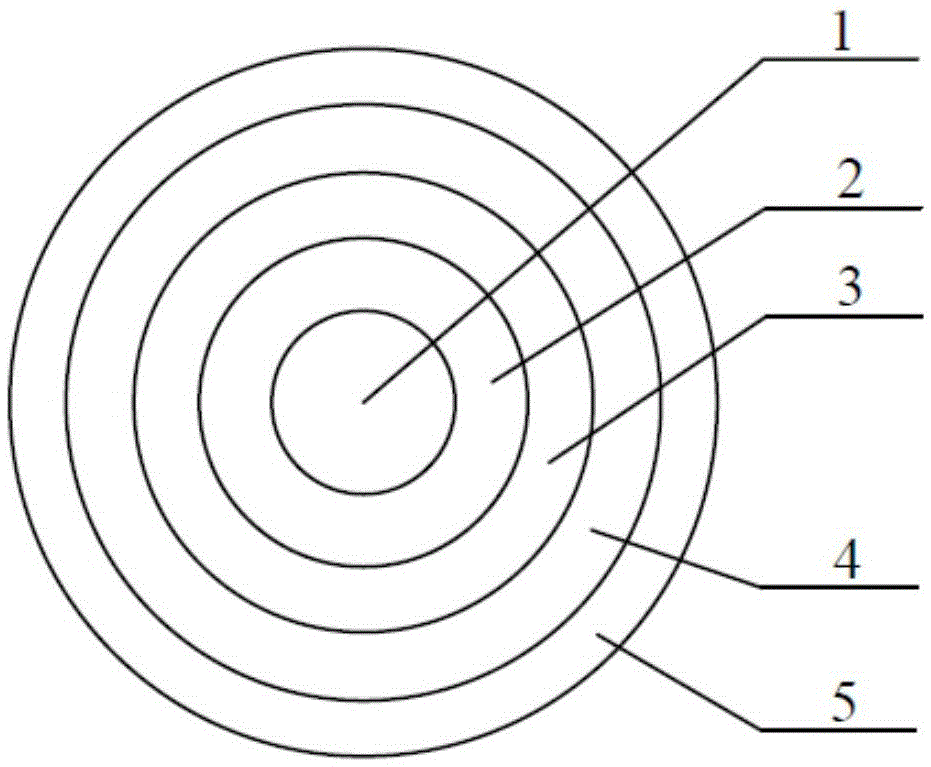

Silicone oil removing water base detergent

ActiveCN102358873AEasily biodegradableEfficient removalOrganic detergent compounding agentsSurface-active detergent compositionsWater basedPoly(ethylene glycol) dimethyl ether

The invention discloses a silicone oil removing water base detergent, comprising a mixed liquor of water and polyoxyethylene octylphenol ether, sorbide ester, glycol monoether and polyethylene glycol dimethyl ether, wherein the polyoxyethylene octylphenol ether accounts for 0.01-0.5wt% of the mixed liquor, and the sorbide ester accounts for 0.005-0.1wt% of the mixed liquor, and the glycol monoether accounts for 0.1-1.0wt% of the mixed liquor, and the polyethylene glycol dimethyl ether accounts for 0.01-0.5wt% of the mixed liquor. Aiming at problems that dust free chamber consumptions have standard exceeded silicone oil content and are not easily cleaned, and exisiting silicone oil removing detergent is not suitable for processing of dust free chamber consumptions, the invention provides a water base detergent, which is suitable for cleaning dust free chamber consumptions, and has simple formula, low costs, good silicone oil removing effect and good biodegradability.

Nanosized silica sphere/polypiperazine-amide nano composite nanofiltration membrane and preparation method thereof

InactiveCN104841296AEvenly dispersedStrong hydrogen bondingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationMembrane surface

The invention belongs to the technical field of water treatment membranes, and discloses a nanosized silica sphere / polypiperazine-amide nano composite nanofiltration membrane and a preparation method thereof. The nanosized silica sphere / polypiperazine-amide nano composite nanofiltration membrane is prepared by forming a polypiperazine-amide macromolecule functional separation layer embedded with nanosized silica spheres on an ultrafiltration support membrane. The nanosized silica spheres can be effectively introduced into the polypiperazine-amide macromolecule layer, so that the nano composite nanofiltration membrane with excellent properties can be prepared. Relatively strong oxygen bands are arranged between nanosized silica and polypiperazine-amide macromolecules of the nano composite nanofiltration membrane disclosed by the invention, so that the nanosized silica spheres can be uniformly and stably dispersed in the polypiperazine-amide macromolecule functional separation layer, the water flux of the nano composite nanofiltration membrane can be remarkably improved, good separation stability and membrane surface hydrophilicity are achieved, and meanwhile the nanosized silica sphere / polypiperazine-amide nano composite nanofiltration membrane is simple in preparation method, high in operability, low in production cost and good in industrial application prospect.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Paper improver

InactiveUS7547376B2Increase distanceImprove adsorption capacityNatural cellulose pulp/paperSpecial paperPolymer scienceOptical property

The invention provides a paper quality improver for papermaking that allows improvement in the bulky value and the optical properties such as brightness and opacity as well as in the paper strength of a sheet obtained by papermaking a pulp material. The paper quality improver for papermaking is a paper quality improver for papermaking containing a copolymer (A) having a constituent unit derived from at least one nonionic monomer having a solubility parameter of 20.5 (MPa)1 / 2 or less and a constituent unit derived from at least one anionic or cationic monomer and a surfactant (B) at a certain ratio, the quality improver providing at least one paper quality improving effect of: (i) standard improved bulky value: 0.02 g / cm or more; (ii) standard improved opacity: 1.0 point or more; and (iii) standard improved brightness: 0.5 point or more.

Owner:KAO CORP

Wear-resistant, oil-resistant and ageing-resistant control cable

InactiveCN105602024AIncrease the rate of vulcanizationShorten the mixing timeRubber insulatorsInsulated cablesButadiene-styrene rubberOxide

The invention discloses a wear-resistant, oil-resistant and ageing-resistant control cable. The wear-resistant, oil-resistant and ageing-resistant control cable comprises a conductor. The conductor is wrapped by a polyvinyl chloride insulating layer, the polyvinyl chloride insulating layer is wrapped by a lining layer, the lining layer is wrapped by an armor layer, and the armor layer is wrapped by an outer sheath. The outer sheath is prepared from a modified natural rubber composite, and the modified natural rubber composite is prepared from natural rubber, butadiene styrene rubber, butadiene rubber, epoxidized natural rubber, modified composite filler, stearic acid, zinc oxide, sulphur, 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, an accelerant, an age resister, a scorch retarder, a resorcinol-hexamine complex and 2-ethylhexyl epoxystearate. The wear-resistant, oil-resistant and ageing-resistant control cable is high in strength, excellent in wear resistance and oil resistance, good in ageing resistance and long in service life.

Owner:ANHUI HAIYUAN SPECIAL CABLE

Light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer and preparation method thereof

ActiveCN103554429ALow shrinkageReduced flexibilityFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceMacromonomer

The invention discloses a light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer and a preparation method thereof. The preparation method for the light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer comprises the following steps: heating 10 to 90 parts by weight of a polyurethane macromonomer and 10 to 90 parts by weight of a (methyl)acrylate macromonomer to a temperature of 60 to 75 DEG C under the action of a catalyst B and carrying out a reaction for 4 to 5 h so as to obtain the light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer. The structure of the light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer combines the advantages of polyurethane and poly(methyl) acrylate into one; meanwhile, an introduced ethoxy structure improves fluidity of the polymer and reduces shrinkage, which is beneficial for uniform coating of the polymer during production of a pressure-sensitive adhesive, and low shrinkage can guarantee stability of the pressure-sensitive adhesive and prolongs the service life of the pressure-sensitive adhesive.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

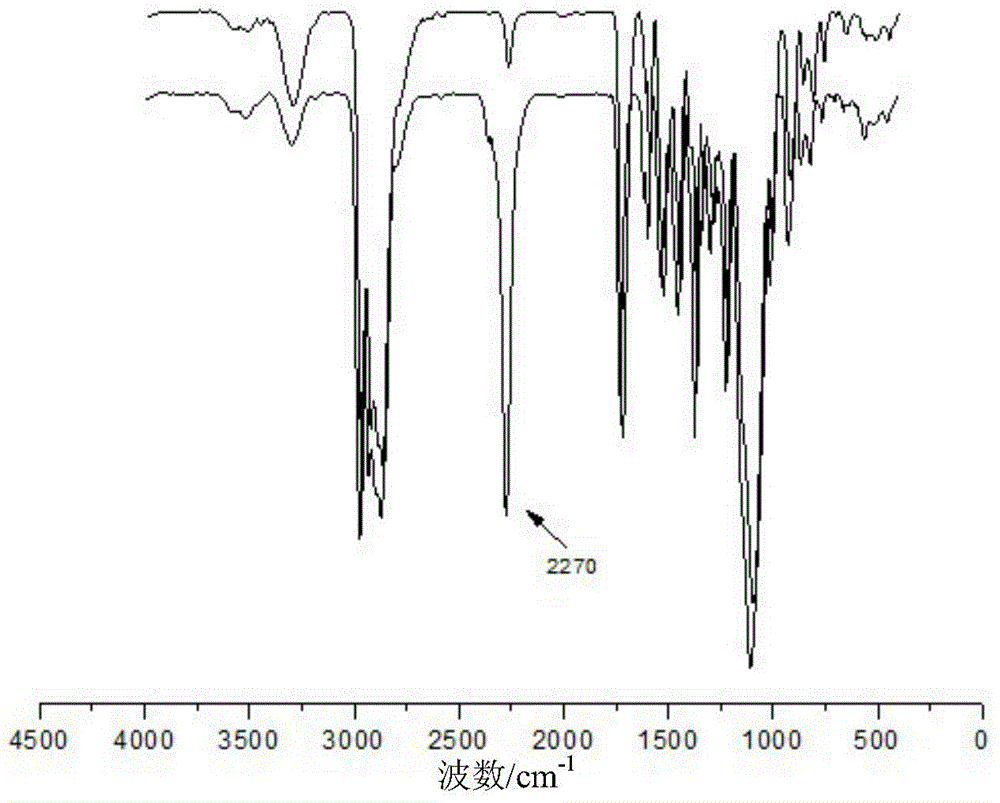

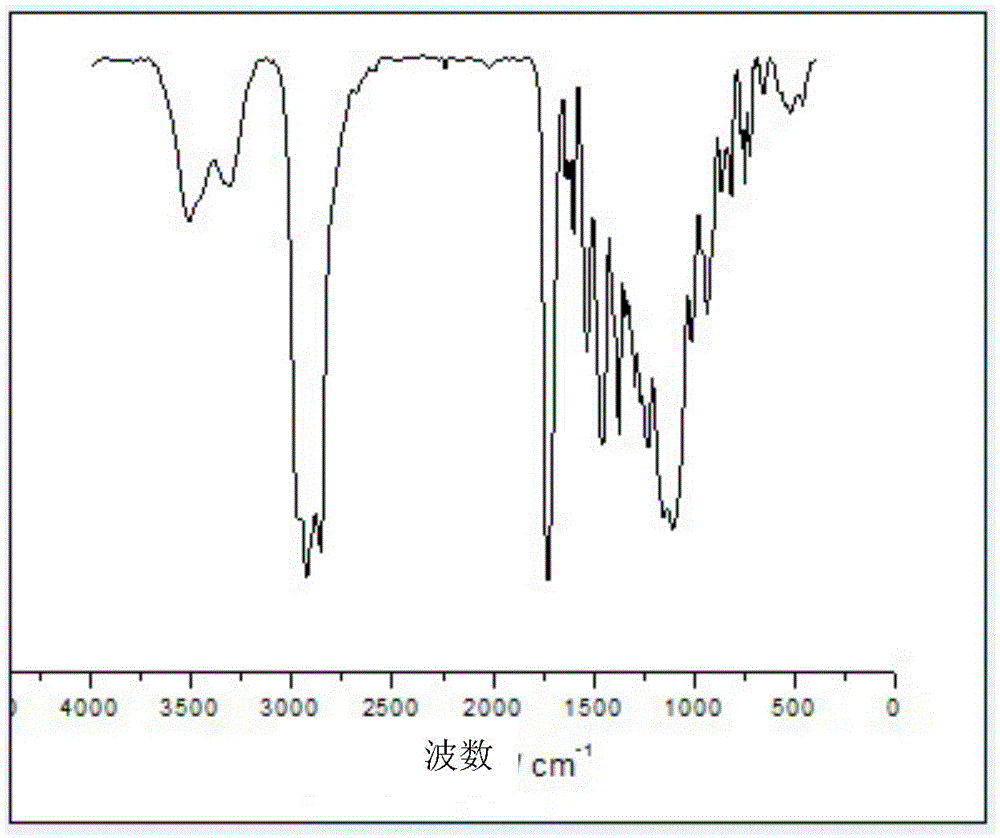

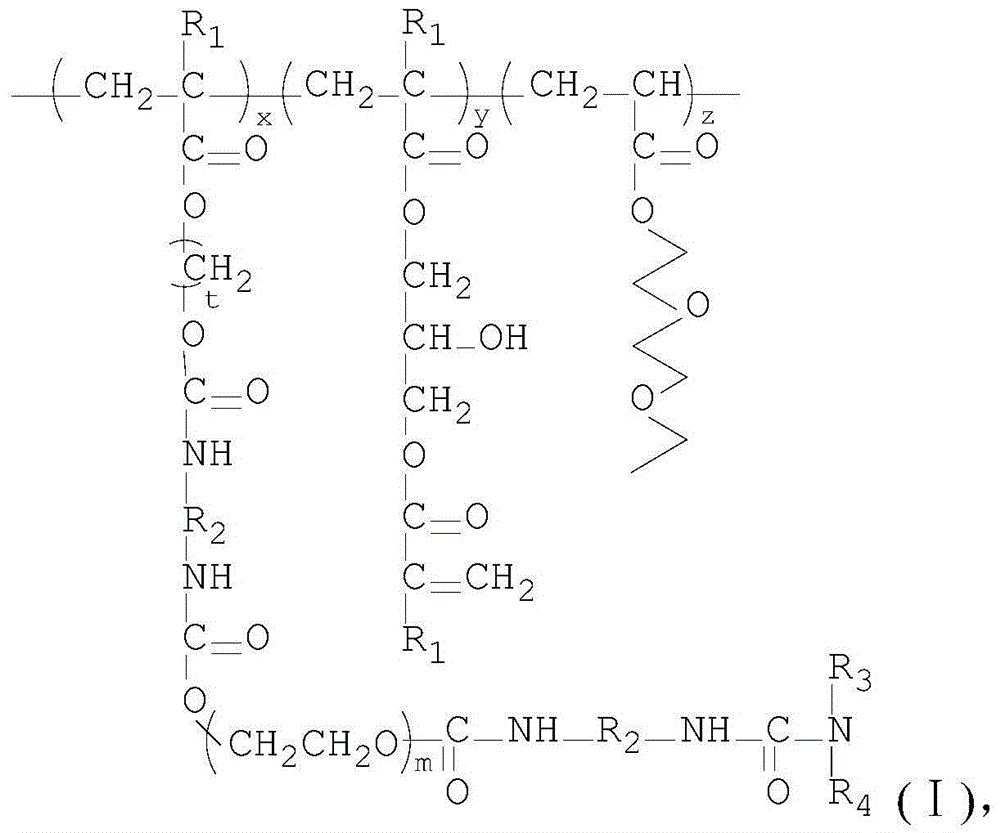

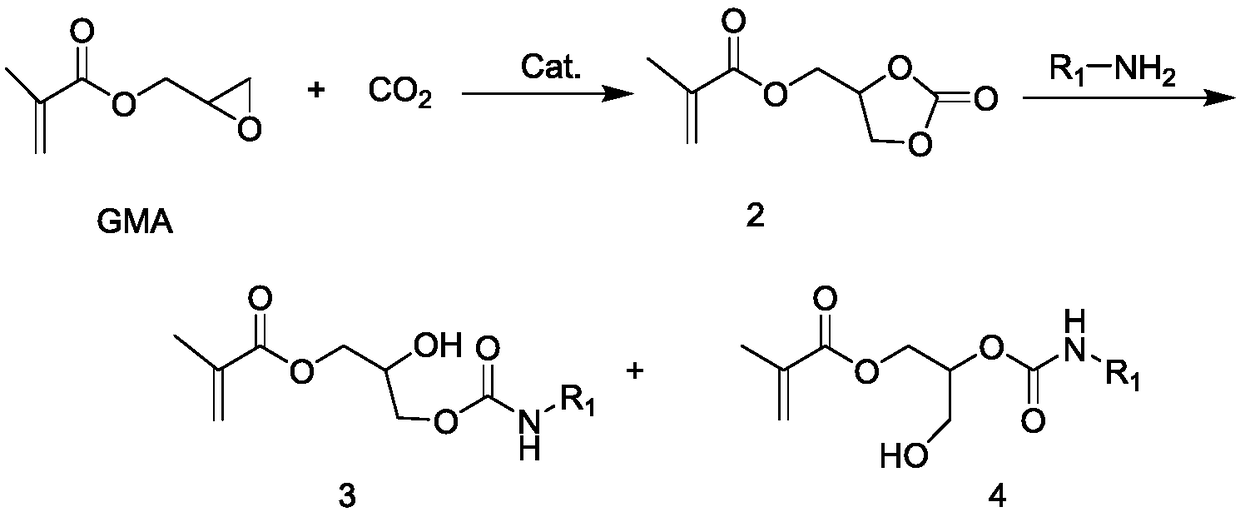

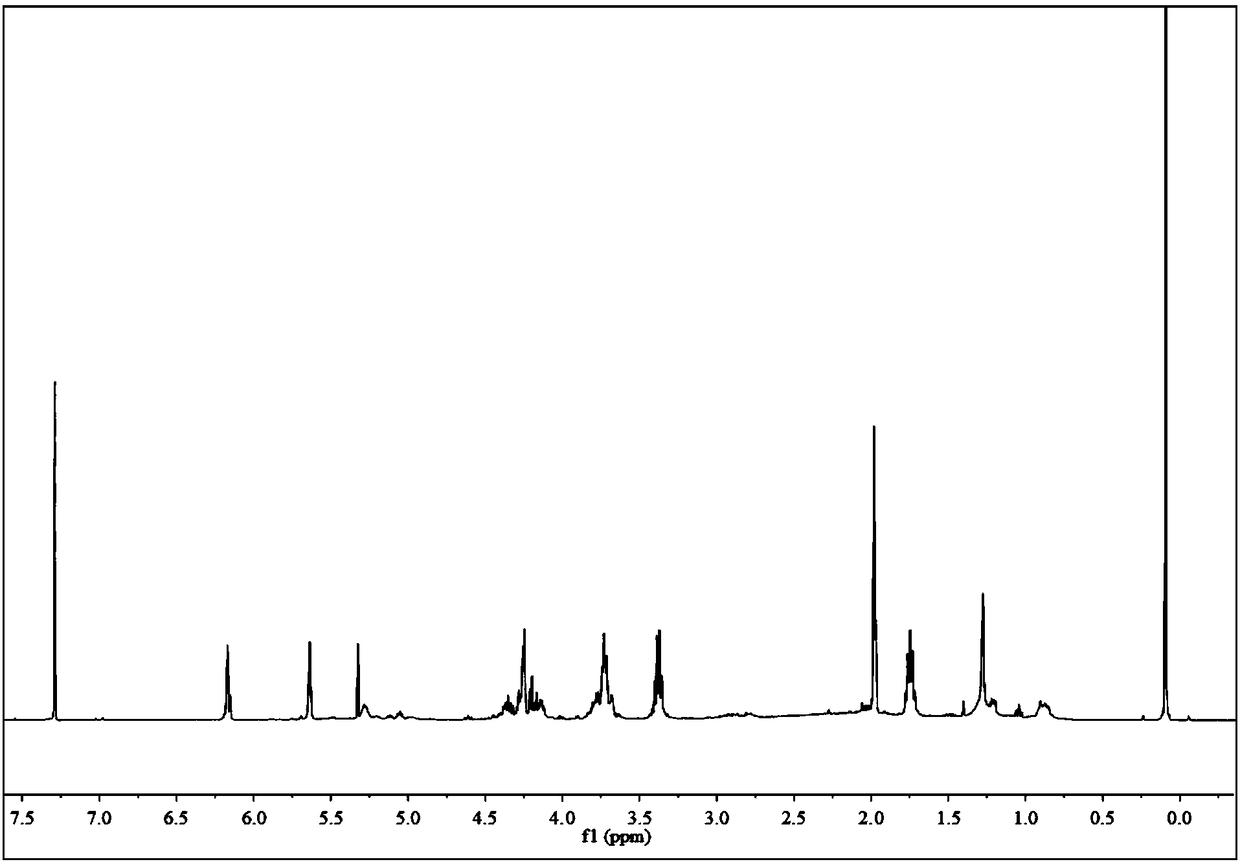

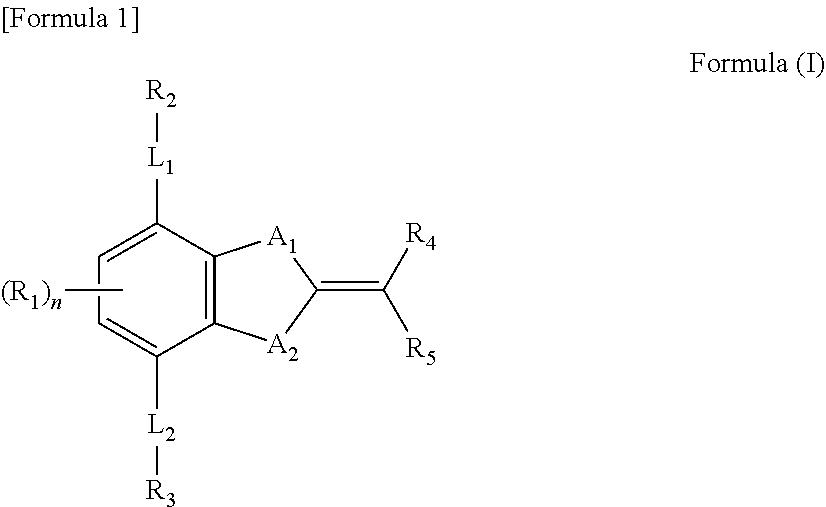

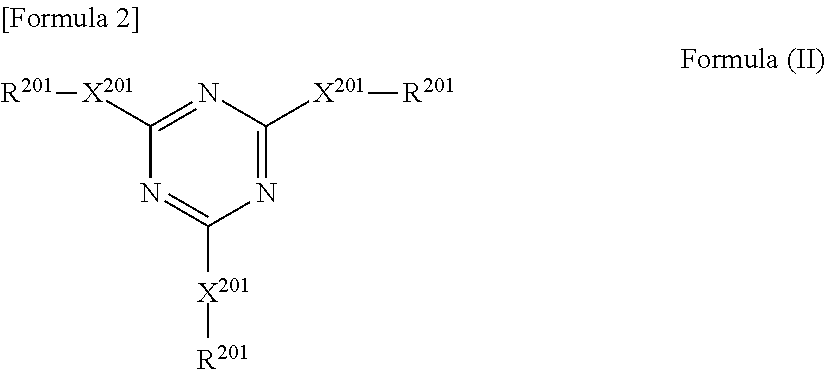

Urethane compound and synthesis and application thereof

ActiveCN108084059AEasy to prepareSuitable for mass productionCarbamic acid derivatives preparationOrganic compound preparationGlycidyl methacrylateSynthesis methods

The invention discloses a urethane compound and synthesis and application thereof. The urethane compound adopts the structure shown as a formula (1) or a formula (II); a synthesis method thereof comprises the following steps: synthesizing a cyclic carbonate intermediate from glycidyl methacrylate and CO2 as raw materials, and then performing a ring-opening reaction on the cyclic carbonate intermediate and a monoamino compound to obtain the urethane compound. Through improvement on a key molecular structure thereof, the overall process design of the synthesis method, and parameters and conditions of each step, the method is simple, the yield is high, the prepared urethane compound can be effectively applied to reinforcing and toughening modification of polypropylene carbonate, and the problems of unsatisfactory mechanical properties of the modified polypropylene carbonate and the like can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of coated sustained-release fertilizer

The invention discloses a preparation method of a coated sustained-release fertilizer. The method comprises the following steps: vegetable fat and starch are mixed under a temperature of 80-100 DEG C, such that vegetable fat plasticized starch is obtained; vegetable fat and diisocyanate are mixed by stirring under a temperature of 15-60 DEG C, such that a vegetable fat polyurethane prepolymer is obtained; the vegetable fat plasticized starch and the vegetable fat polyurethane prepolymer are mixed in a solvent, such that a modified starch solution is obtained; the modified starch solution is coated on the surface of fertilizer particles, and is dried, such that a modified starch coated sustained-release fertilizer is obtained. During the preparation process of the vegetable fat polyurethane prepolymer, a molar ratio of isocyanate to hydroxyl is 2-4. The modified starch prepared with vegetable fat is green and environment-friendly. The method has the advantages of simple production process, low production cost, and the like. The method provided by the invention is a novel application of vegetable fat in the fields of modified starch preparation and in sustained-release coating materials.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method of preparing retardation film, polarizing plate, and liquid crystal display

InactiveUS20150114257A1Superior retardation characteristicImprove moisture resistanceOptical articlesOrganic non-macromolecular adhesiveAcetic acidPolymer science

A method of preparing a retardation film includes cellulose acetate having an average degree of acetylation of 2.0 to 2.5 and having a moisture content of 1.0 mass % or less, where the retardation film includes a compound having a Van der Waals volume of 450 to 1000 Å3. The retardation film is prepared by a dope preparing step of dissolving cellulose acetate having an average degree of acetylation within the range of 2.0 to 2.5 to prepare a dope; a film product forming step of casting the dope onto a metal belt to form a film product; a film product peeling step of peeling off the film product from the metal belt; a drawing step of drawing the peeled film product; and a drying step at a drying temperature of 140° C. or more.

Owner:KONICA MINOLTA INC

Toughening type benzoxazine composite and preparation method thereof

The invention discloses a toughening type benzoxazine composite and a preparation method thereof. The toughening type benzoxazine composite is prepared by solidifying 75-96 parts of benzoxazine monomers, 3-20 parts of nylon 12 microspheres and 0.1-5 parts of benzoxazine monomer modified graphene oxide at the temperature of 160-200 DEG C. Benzoxazine monomer modified graphene oxide can effectively assist nylon 12 microspheres in uniformly dispersing in a benzoxazine resin matrix and thereby playing a role in synergistic toughening. The toughening type benzoxazine composite has high breaking tenacity, high Young modulus and high tensile strength. The toughening type benzoxazine composite can be widely applied to occasions with high requirements for the material toughness.

Owner:四川天策聚材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com