Patents

Literature

33results about How to "Shorten the mixing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

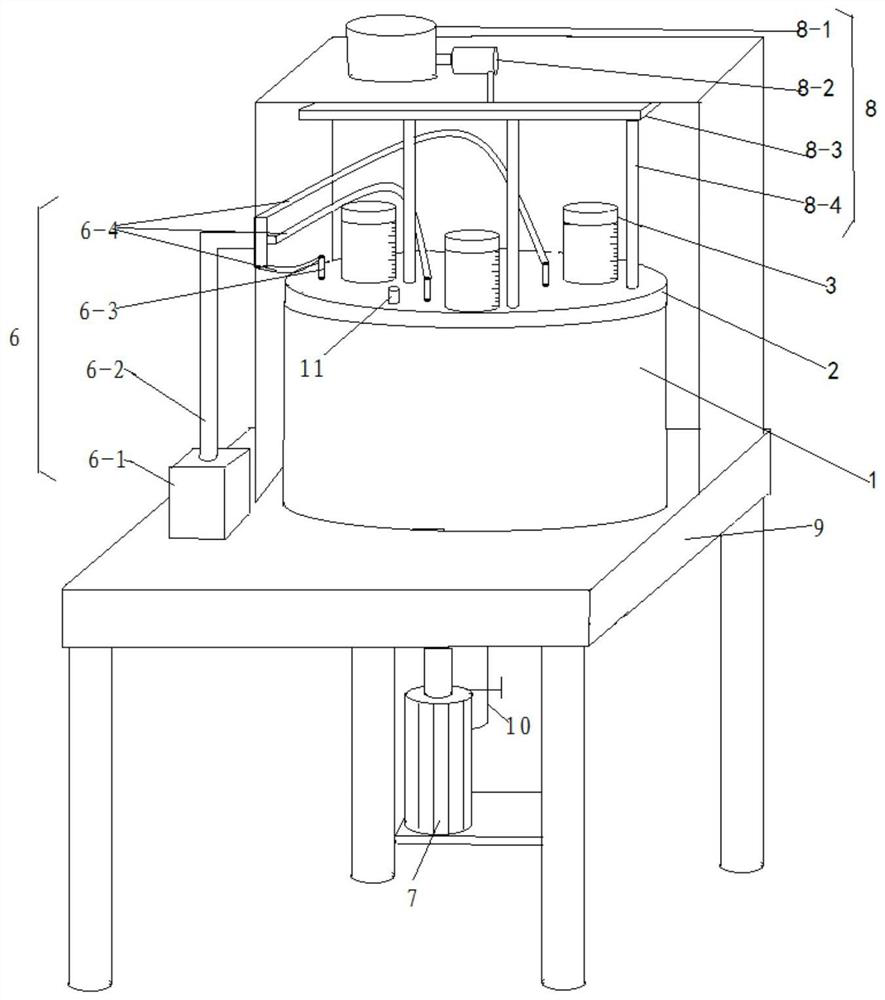

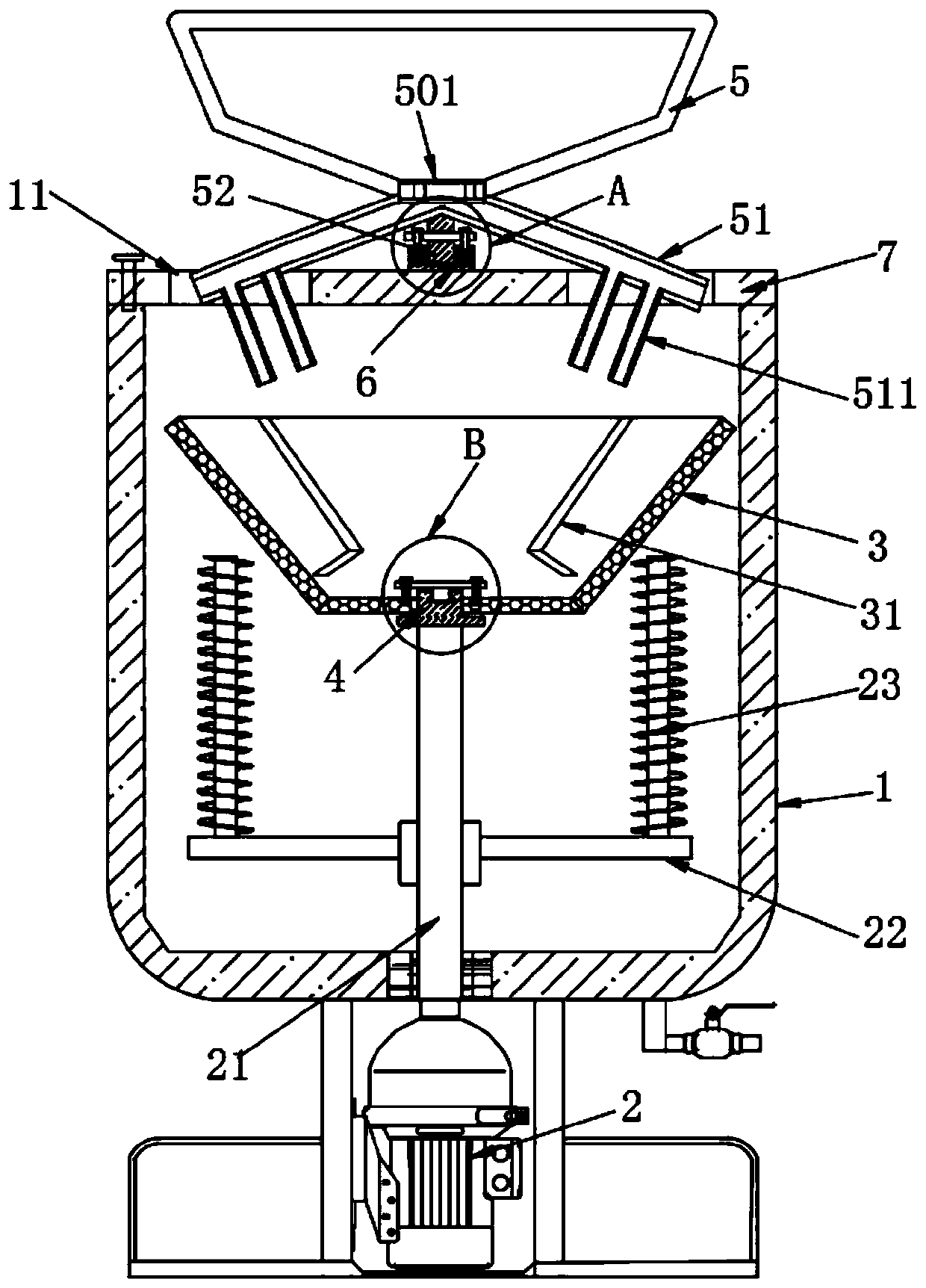

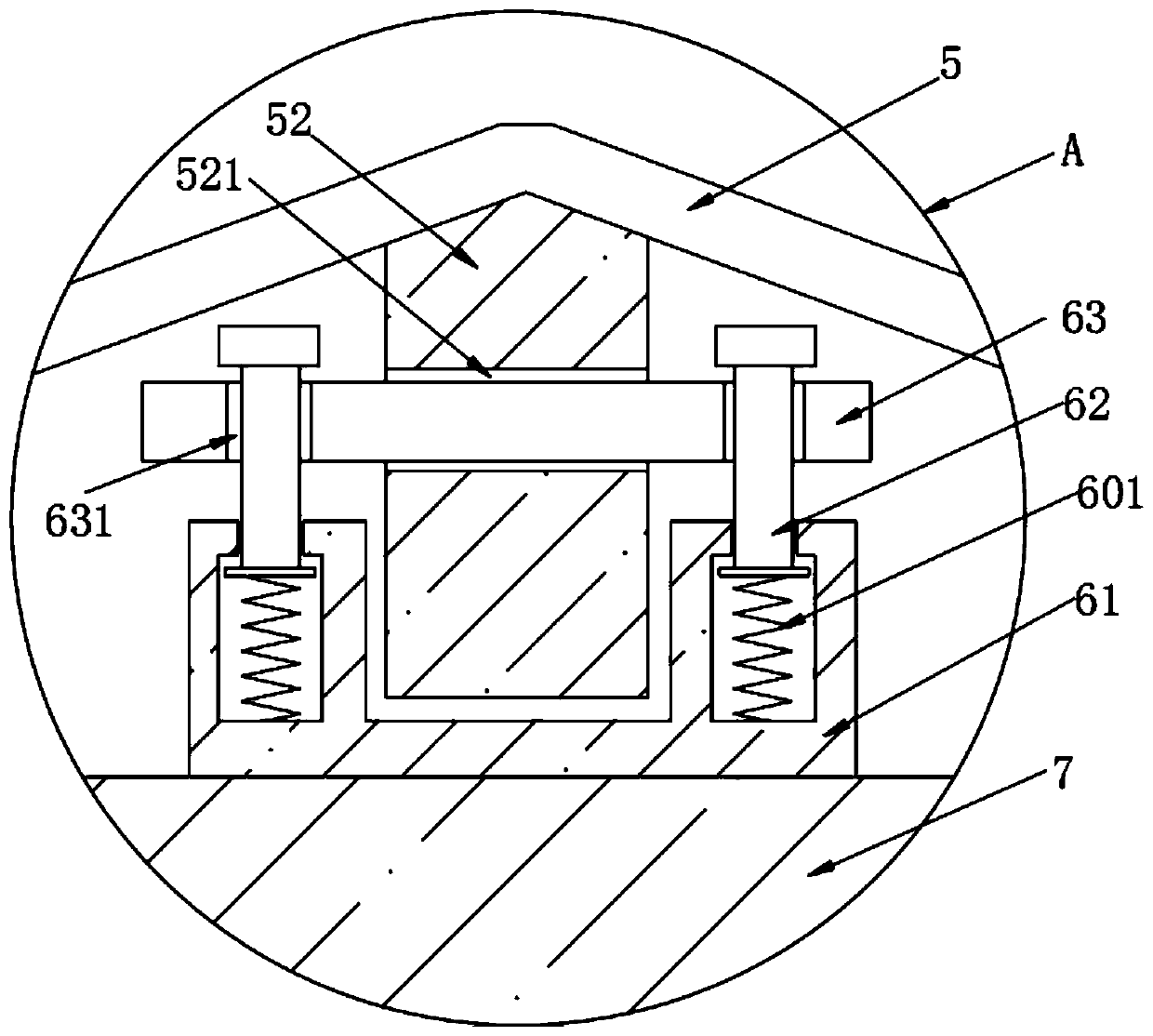

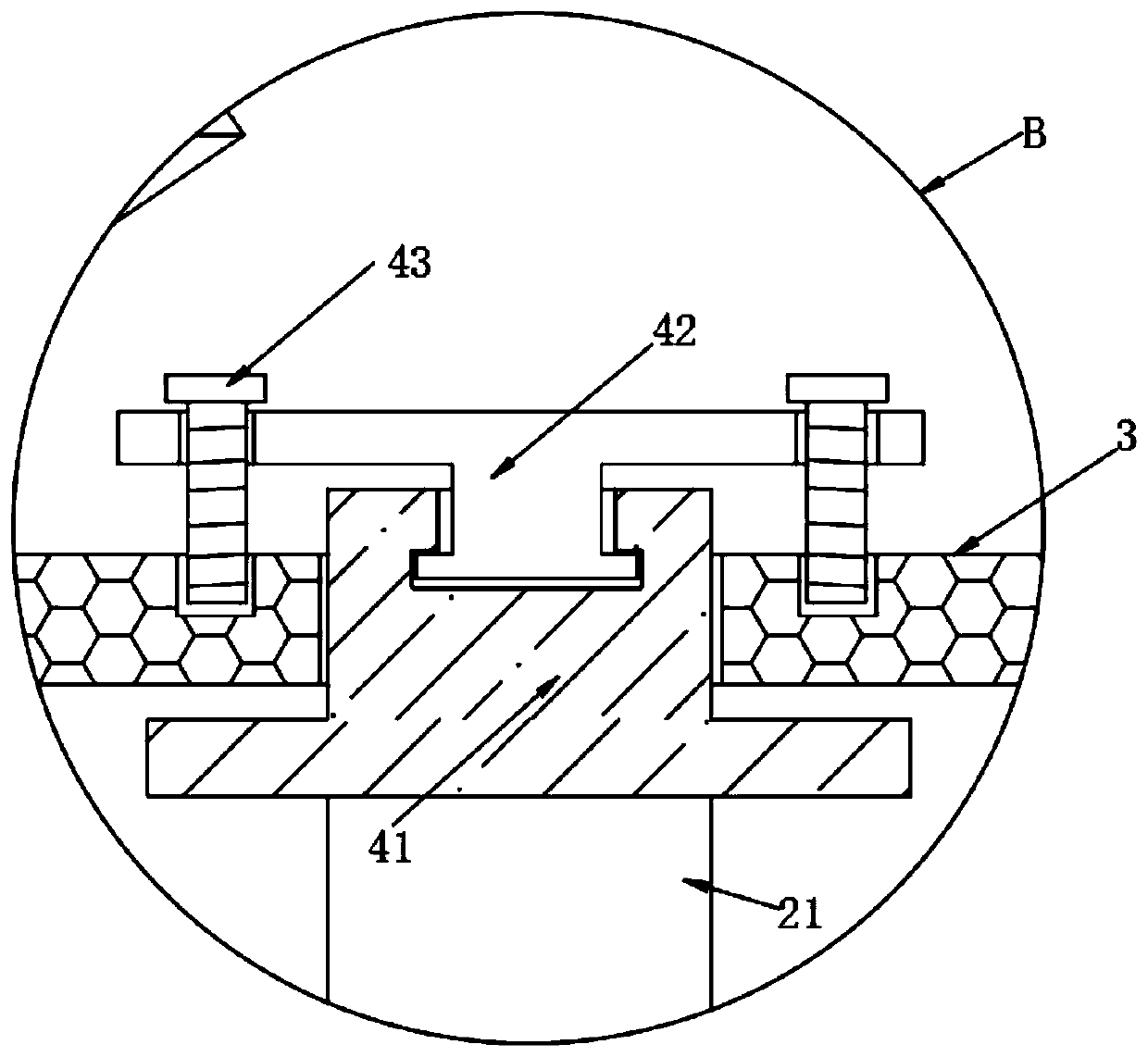

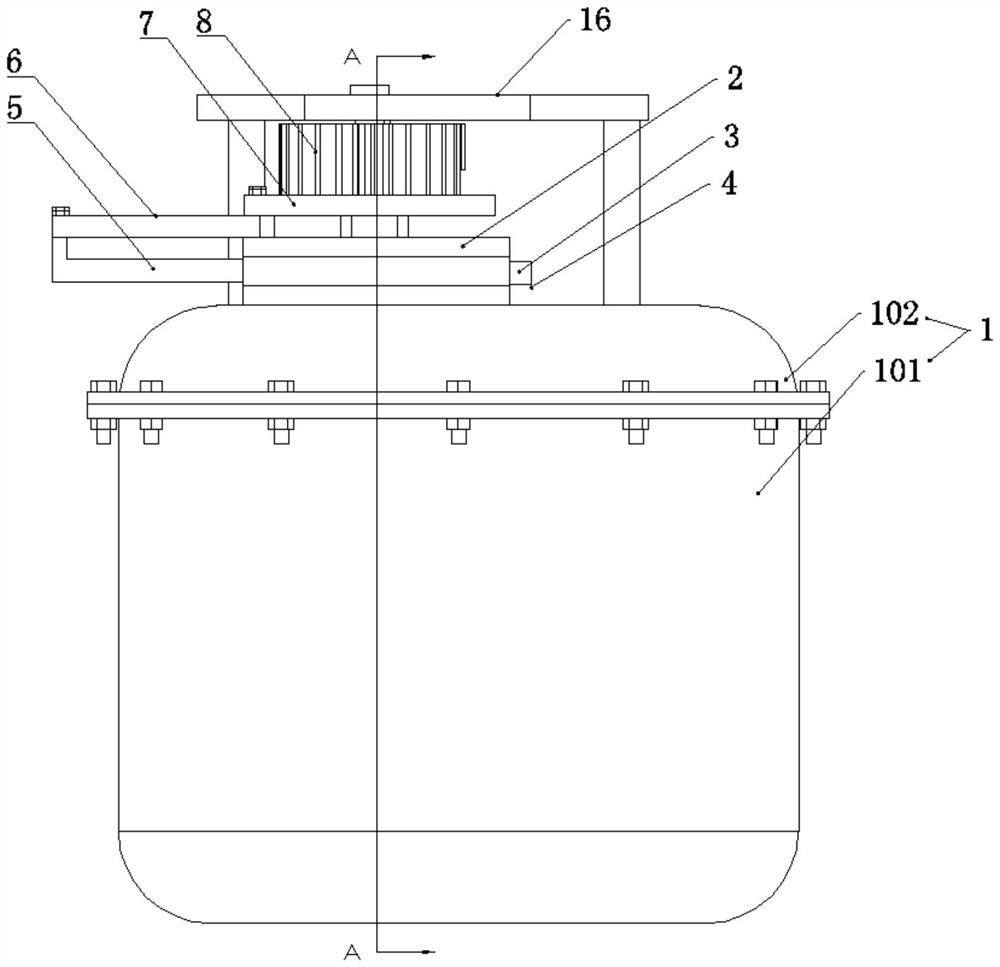

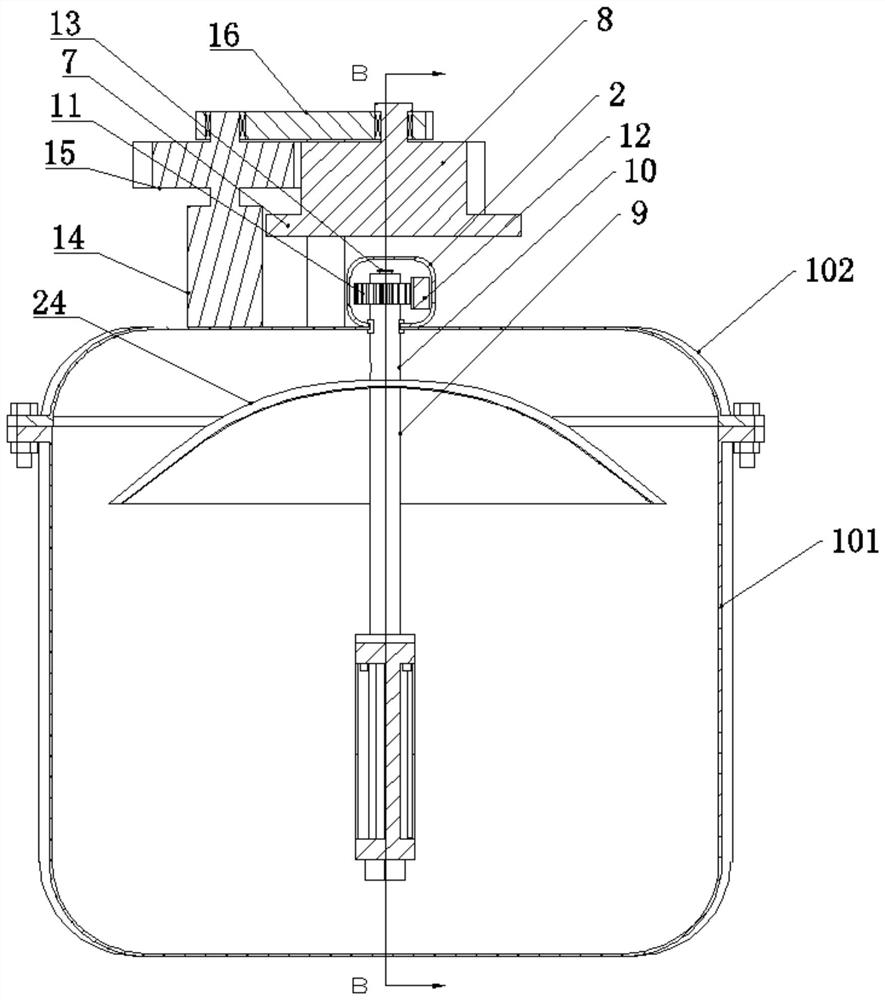

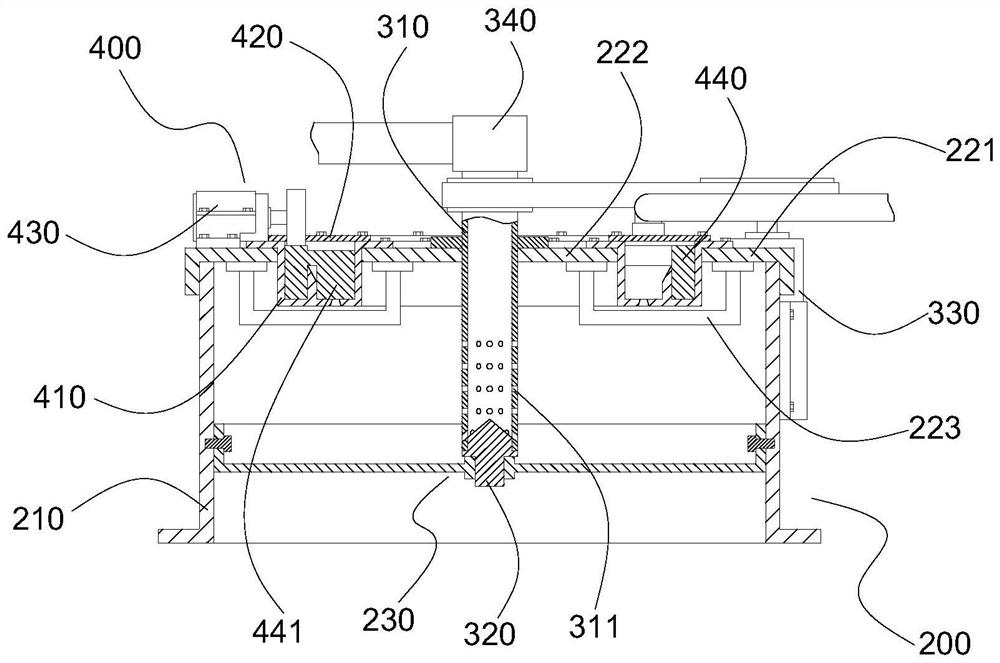

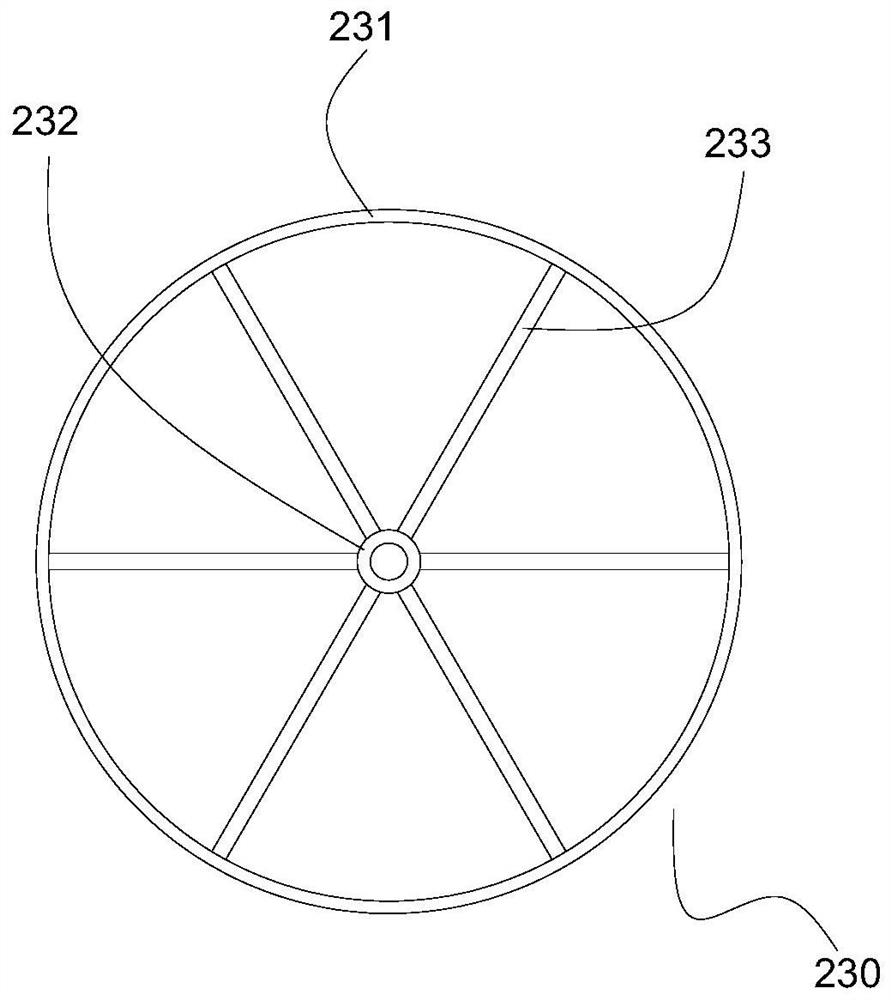

Automatic chemical cleaning liquid medicine stirring and preparing device for reverse osmosis membrane cleaning

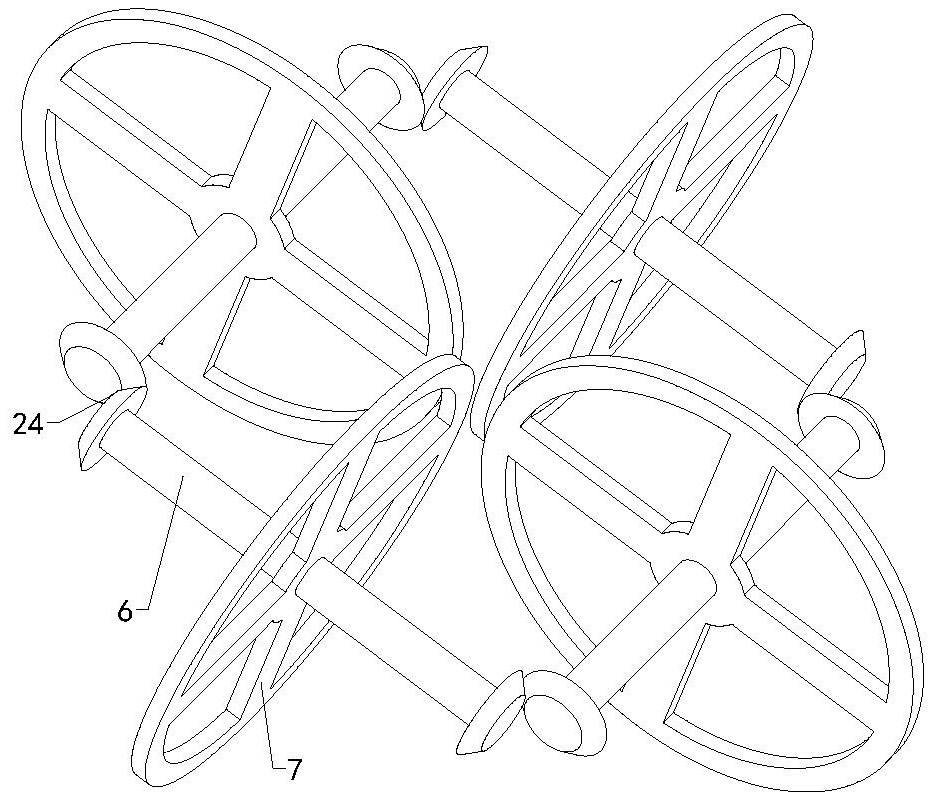

PendingCN112546903AImprove the mixing effectShorten the mixing timeFlow mixersRotary stirring mixersPhysical chemistryReverse osmosis

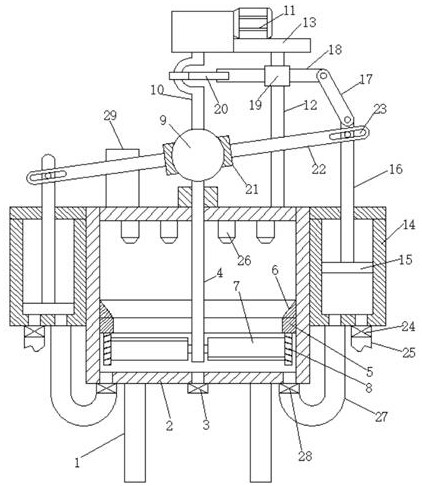

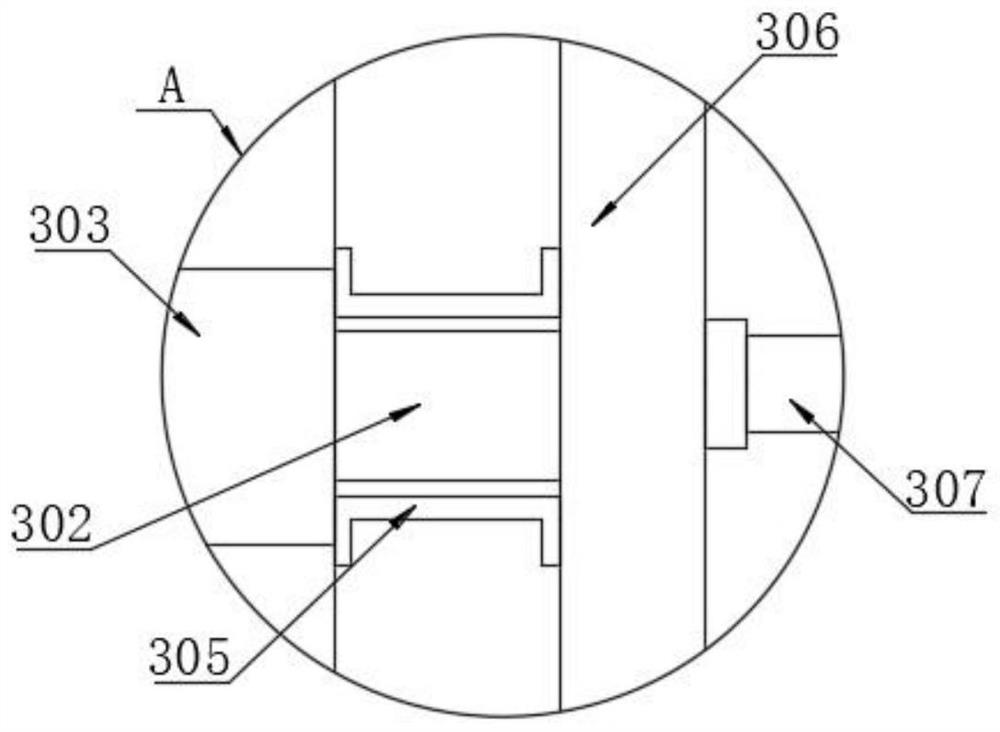

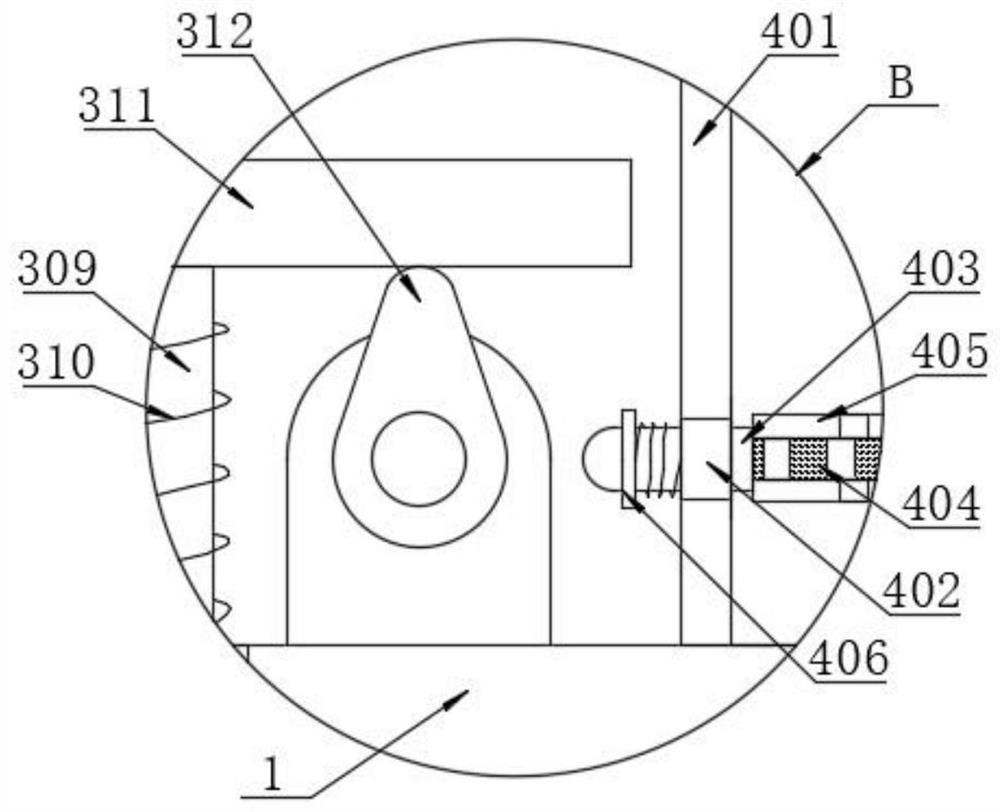

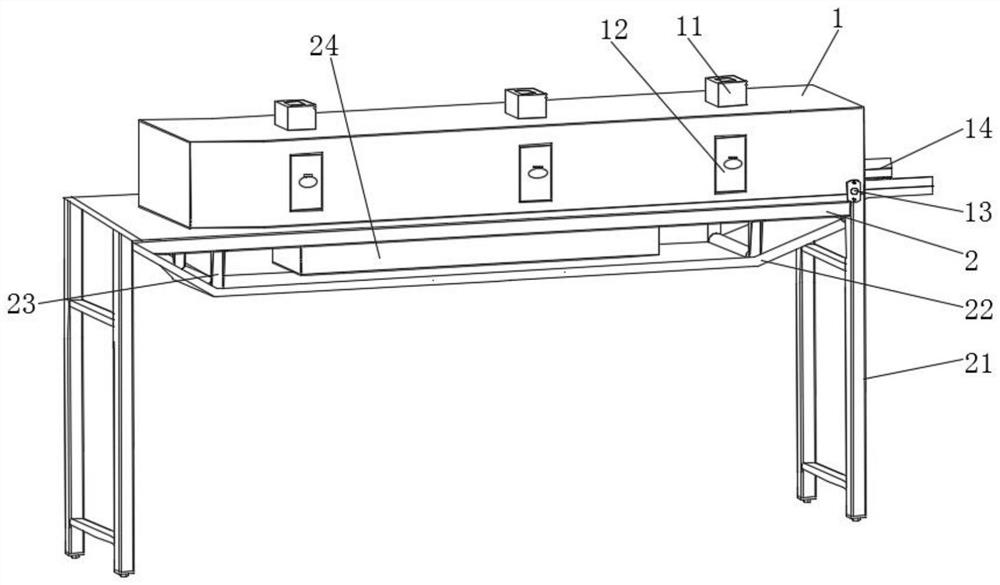

The invention relates to the field of filtering material treatment, in particular to an automatic chemical cleaning liquid medicine stirring and preparing device for reverse osmosis membrane cleaning,and the device comprises a mixing box fixed on a rack, a rotating shaft is rotationally connected to the center of an upper cover of the mixing box in a fixed-axis manner, and a plurality of blade plates for stirring chemical cleaning liquid medicine are rotationally connected to the lower end of the rotating shaft in a fixed-axis manner, pump cylinders are symmetrically and fixedly connected tothe two sides of the outer side wall of the mixing box, a driving mechanism is arranged on a box cover of the mixing box, the driving mechanism is in transmission connection with the rotating shaft, and the driving mechanism drives the pump cylinders to circularly mix chemical cleaning liquid medicine in the mixing box. According to the automatic chemical cleaning liquid medicine stirring and preparing device for reverse osmosis membrane cleaning, the stirring effect on chemical cleaning liquid medicine is improved, the stirring duration is shortened, the stirring efficiency is improved, the concentration of the liquid medicine is prepared more uniformly, and the reverse osmosis membrane cannot be damaged when the prepared chemical cleaning liquid medicine is used for cleaning a reverse osmosis membrane.

Owner:CHANGSHA MEDICAL UNIV

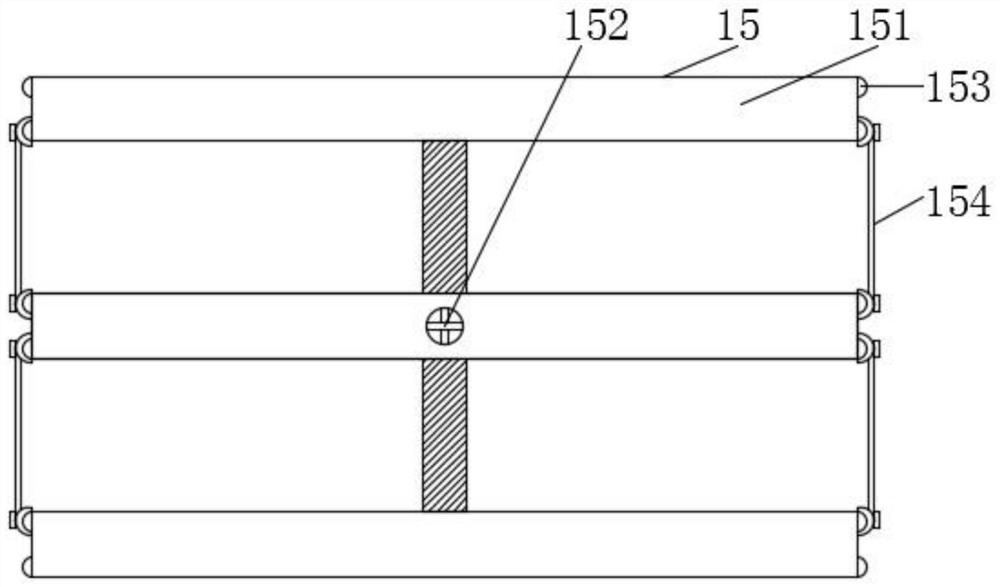

Wear-resistant, oil-resistant and ageing-resistant control cable

InactiveCN105602024AIncrease the rate of vulcanizationShorten the mixing timeRubber insulatorsInsulated cablesButadiene-styrene rubberOxide

The invention discloses a wear-resistant, oil-resistant and ageing-resistant control cable. The wear-resistant, oil-resistant and ageing-resistant control cable comprises a conductor. The conductor is wrapped by a polyvinyl chloride insulating layer, the polyvinyl chloride insulating layer is wrapped by a lining layer, the lining layer is wrapped by an armor layer, and the armor layer is wrapped by an outer sheath. The outer sheath is prepared from a modified natural rubber composite, and the modified natural rubber composite is prepared from natural rubber, butadiene styrene rubber, butadiene rubber, epoxidized natural rubber, modified composite filler, stearic acid, zinc oxide, sulphur, 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, an accelerant, an age resister, a scorch retarder, a resorcinol-hexamine complex and 2-ethylhexyl epoxystearate. The wear-resistant, oil-resistant and ageing-resistant control cable is high in strength, excellent in wear resistance and oil resistance, good in ageing resistance and long in service life.

Owner:ANHUI HAIYUAN SPECIAL CABLE

Reverse feeding one-step mixing preparation method of chloroprene mixing rubber

The invention discloses a chloroprene mixing rubber preparation method through a backward feed one-step mixing, and a formula and a preparation technology thereof. A technical scheme of one-step mixing is employed in the invention by simultaneously adding a vulcanizing agent, chloroprene rubber and other cooperative auxiliaries into an internal mixer for mixing, so as to overcome problems and insufficiencies of prior art, such as waste of time and labor, low efficiency, high costs and uneven quality. According to the chloroprene mixing rubber preparation method through the backward feed one-step mixing provided by the invention, purposes of reducing mixing time, increasing mixing efficiency, lowering man-hour cost and raising quality of mixing rubber in the mixing preparation of the chloroprene mixing rubber are realized through the backward feed one-step mixing.

Owner:NINGBO JIEBAO GROUP CO LTD

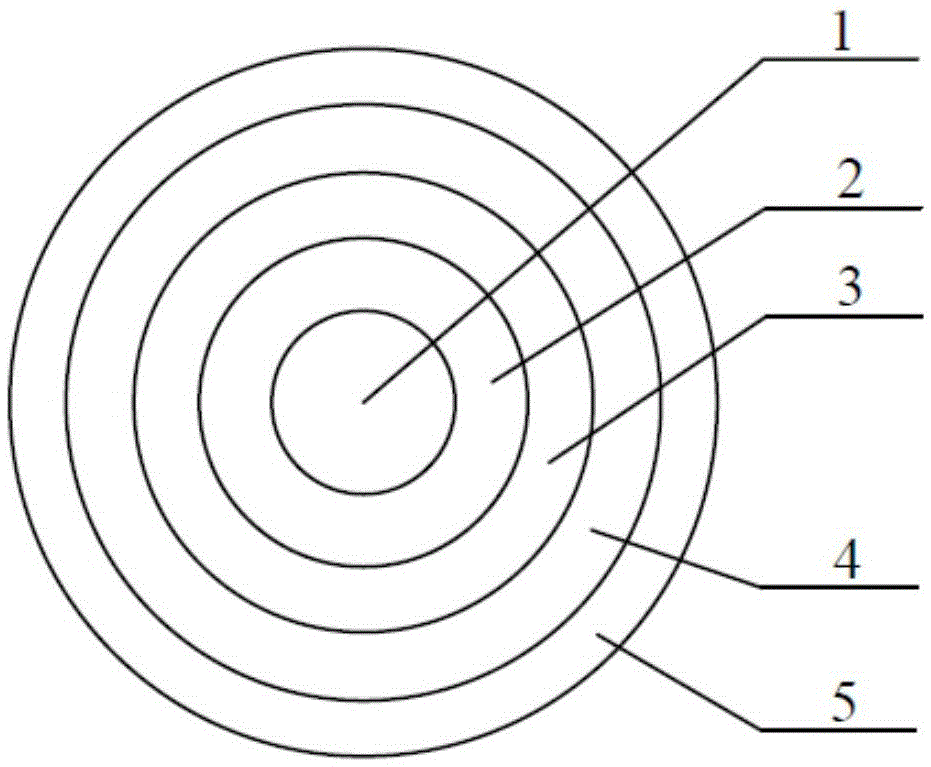

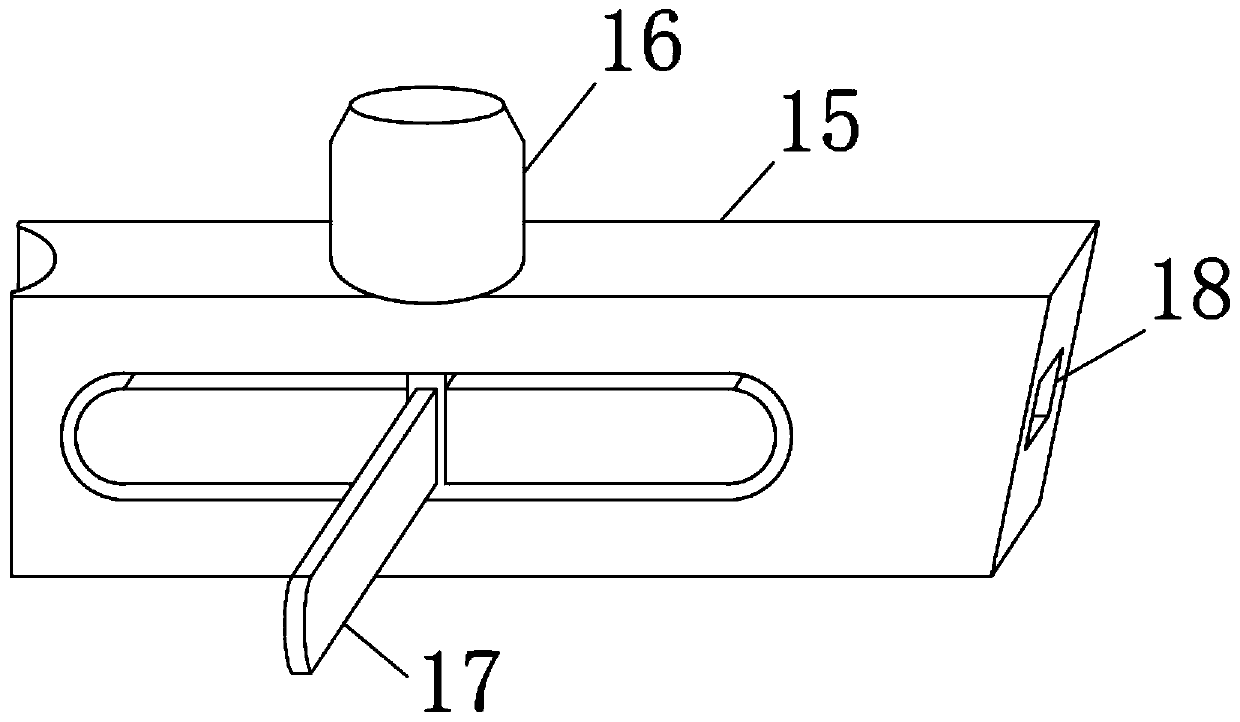

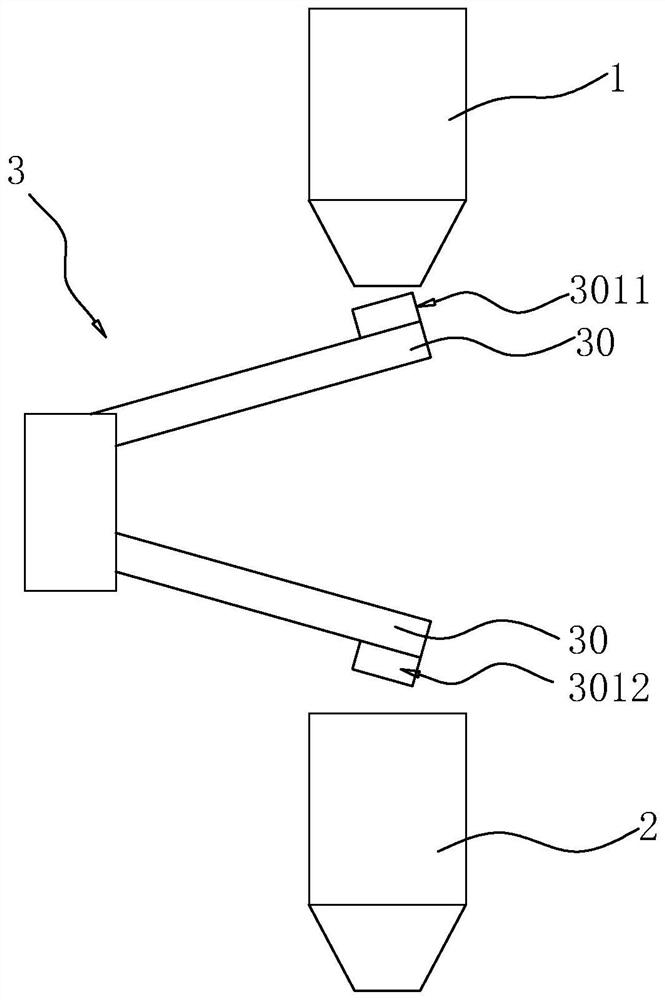

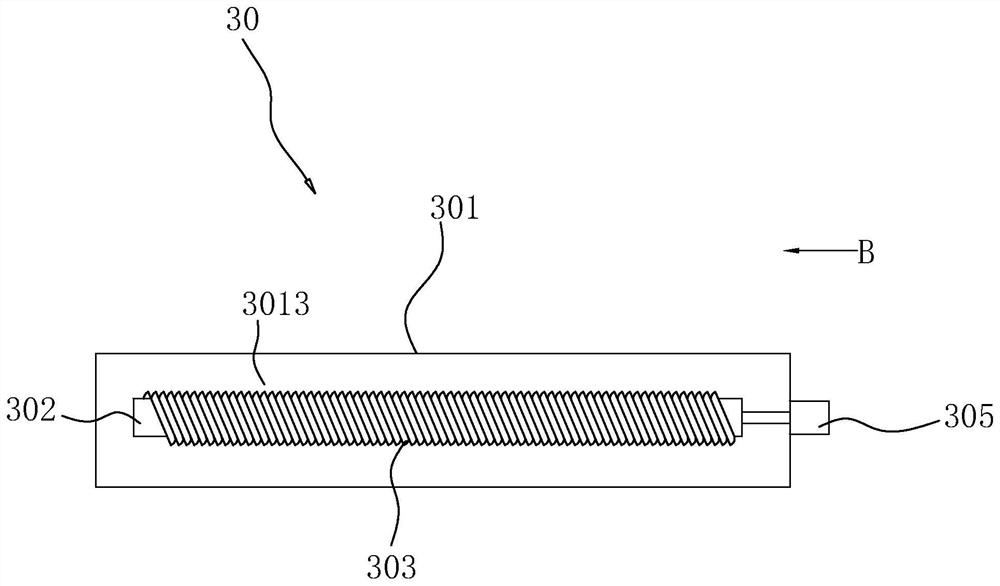

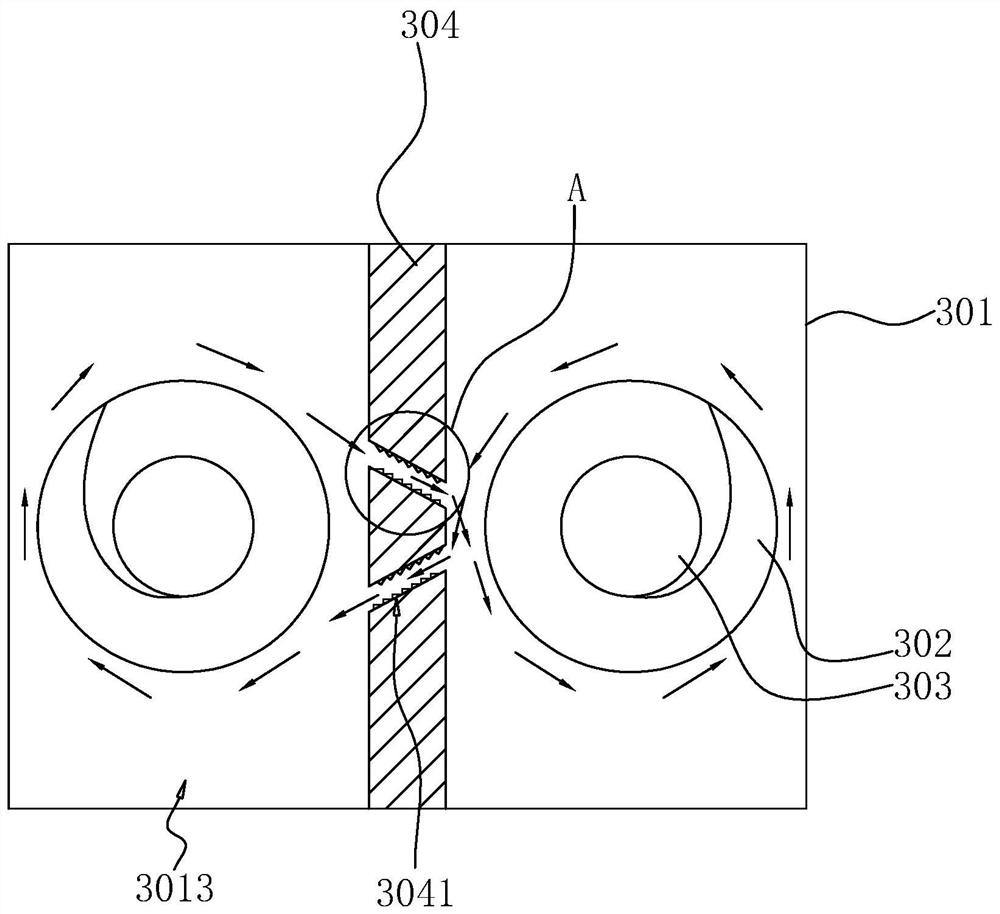

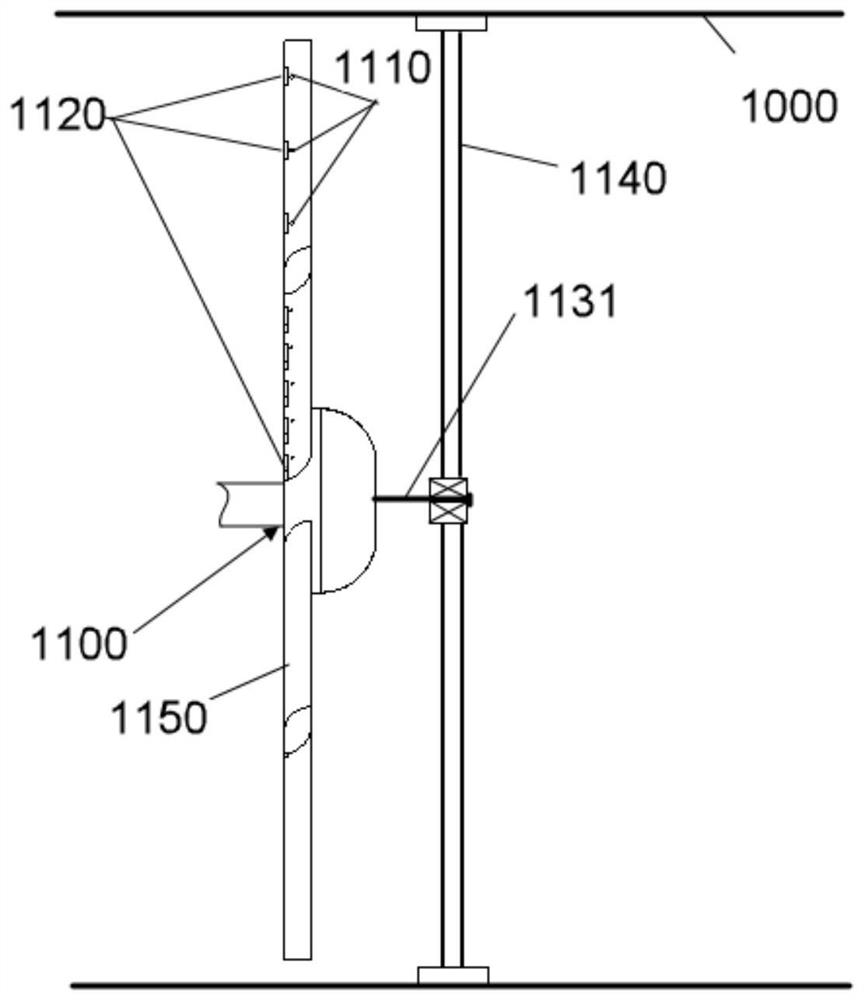

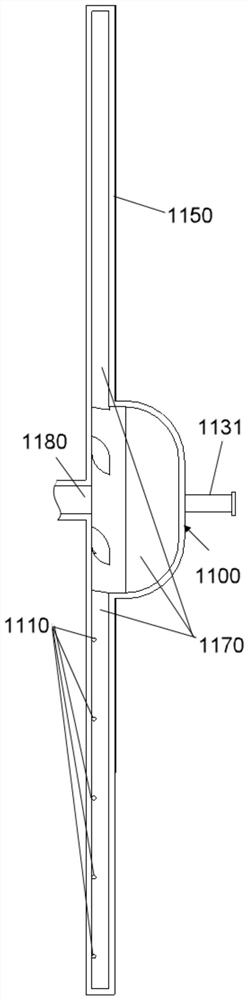

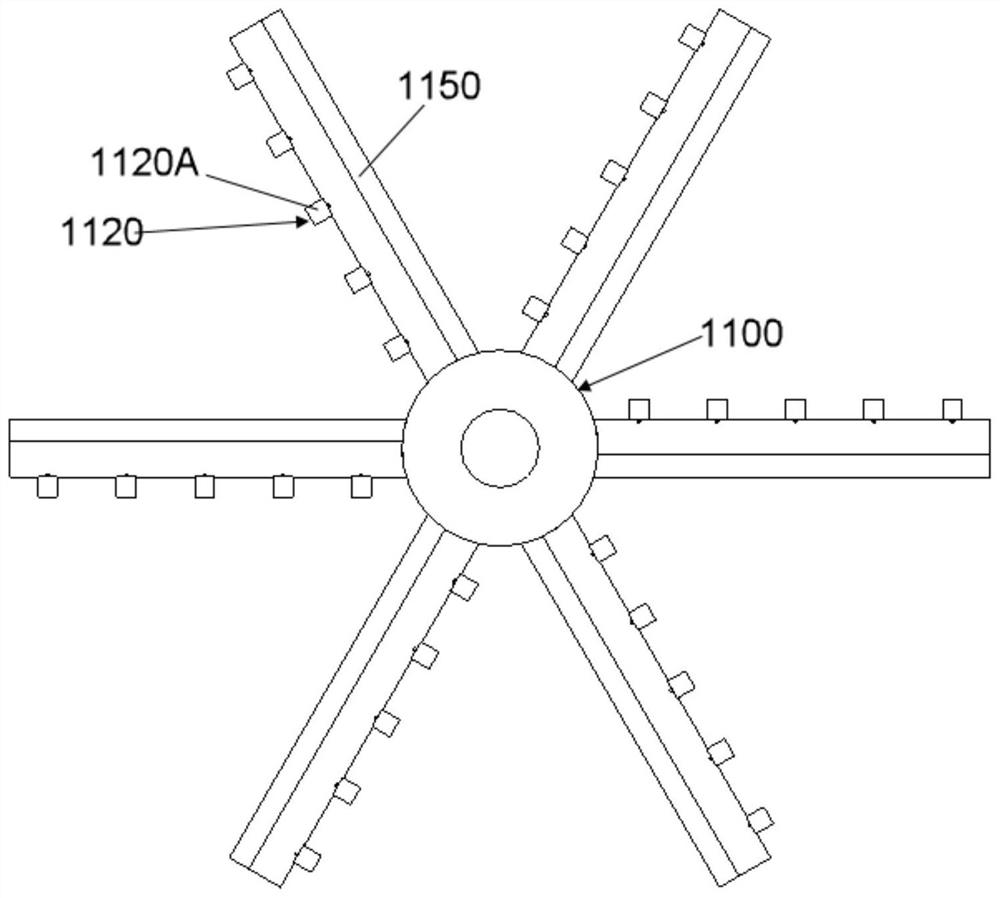

Distributor and clarification tank

ActiveCN109293113AShorten the mixing timeImprove efficiencyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentEngineeringDistributor

The invention relates to a distributor and a clarification tank. The distributor is arranged in a pipeline under the working condition. The inside of the distributor is provided with a hollow cavity for accommodating a liquid medicament, and the distributor is provided with several distribution holes used for letting the liquid medicament in the hollow cavity flow out. Baffle boards are arranged adjacent to at least part of the distribution holes, and the baffle boards are arranged according to the following mode: at least a part of the liquid medicament flowing out of the corresponding distribution holes is impacted by the liquid in the pipeline onto the baffle boards and is then reflected towards the place outside the area of the baffle boards under the action of the baffle boards so asto be mixed with the liquid in the pipeline by the utilization of the flowing liquid. By the flowing of the liquid during the pipeline transportation of the liquid, the liquid medicament and the liquid in the pipeline are mixed, and the liquid medicament flowing out of the distribution holes will be impacted by the liquid onto the baffle boards and reflected to the place outside the area of the baffle boards. Thereby, the liquid medicament is quickly dispersed under the reflection effect of the baffle boards, and the mixing effect is improved.

Owner:BGT GRP CO LTD

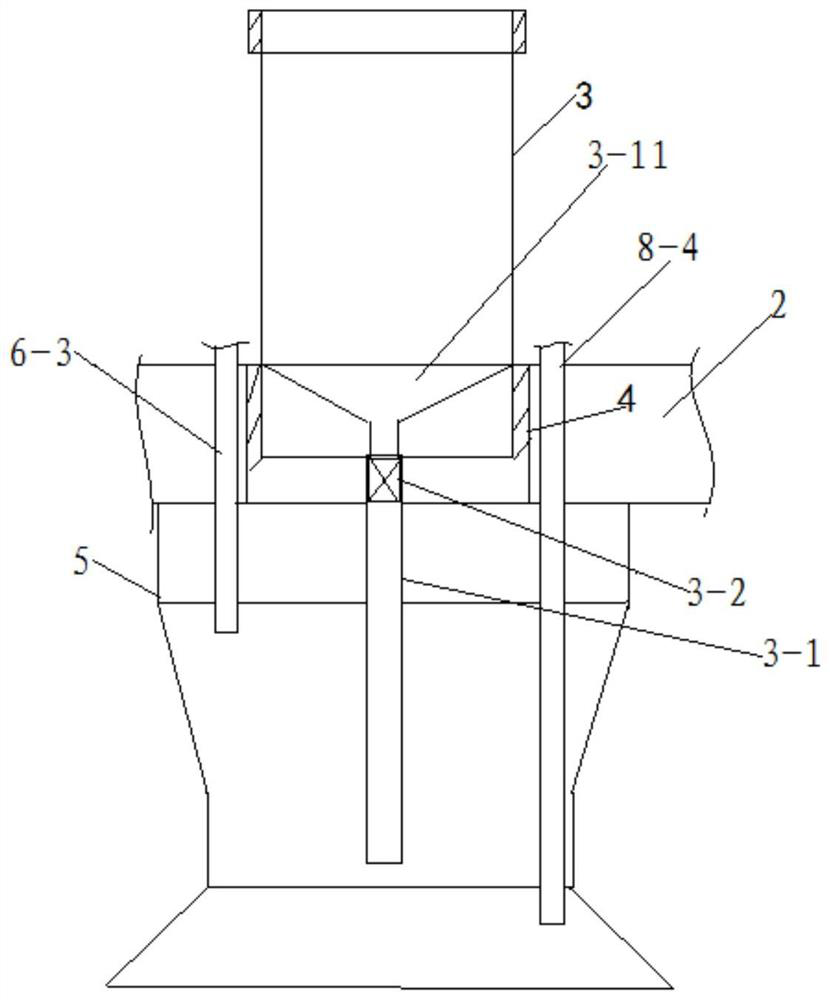

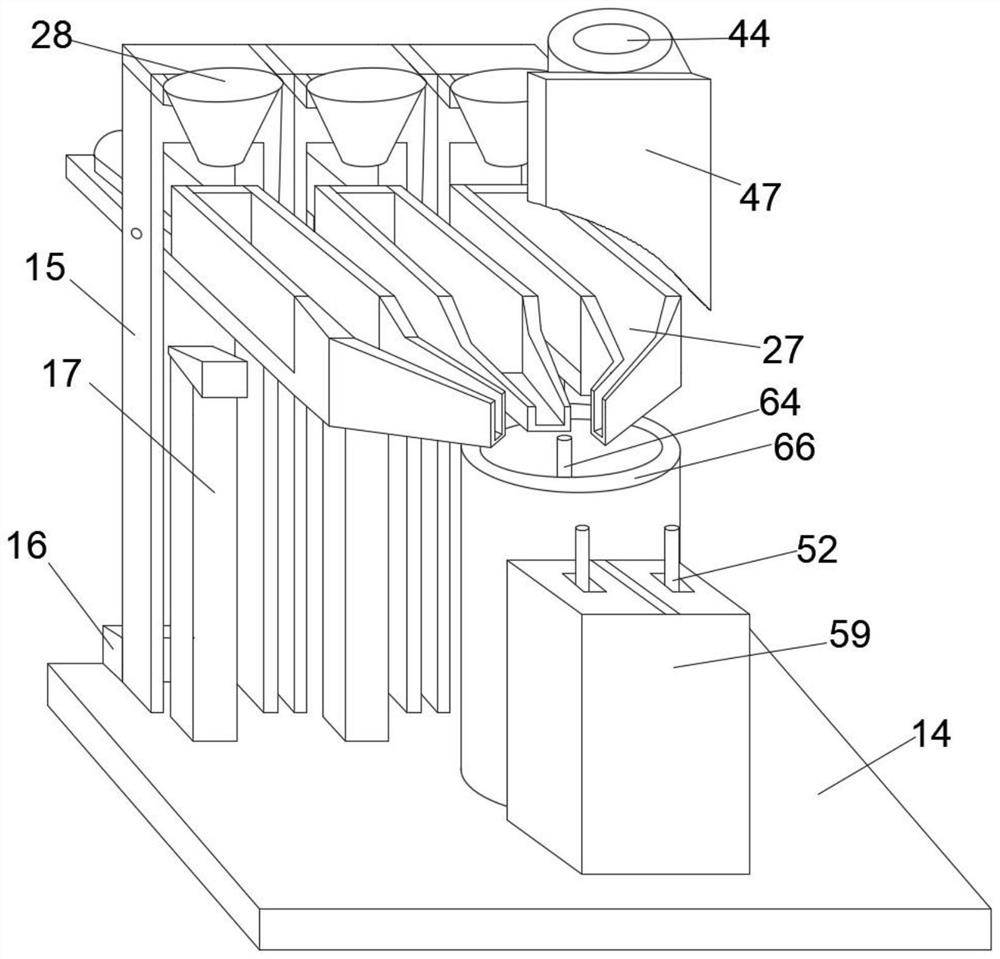

Pigment blending device for art pattern design

InactiveCN111845183ALow degree of reunionReduce the likelihood of reunionsFlow mixersRotary stirring mixersPolymer scienceGas supply

The invention discloses a pigment blending device for art pattern design. The pigment blending device comprises a pigment blending barrel, a barrel cover, quantitative pigment storage devices, Venturitubes, gas supply devices and conveying pipes; the barrel cover is arranged at the top of the pigment blending barrel, and three first through holes are formed in the barrel cover in the longitudinaldirection; the three quantitative pigment storage devices penetrate into the through holes from the upper end openings of the through holes in the longitudinal direction correspondingly and are connected with the through holes in a sealed mode, and openings for pigment to flow out are formed in the bottom walls of the quantitative pigment storage devices; the three Venturi tubes are correspondingly arranged on the bottom wall of the barrel cover on the peripheral walls of the lower ports of the through holes in the longitudinal direction, and the top ends of the Venturi tubes are connected with the bottom wall of the barrel cover in a sealing mode; the gas supply devices are correspondingly in communication with the Venturi tubes; and the top ends of the three conveying pipes are in communication with the openings correspondingly, the bottom ends of the conveying pipes penetrate through the corresponding through holes and enter the correspondingly Venturi tubes, and electromagnetic valves are further arranged on the conveying pipes. According to the pigment blending device for art pattern design, pigment can be dispersed in the Venturi tubes, agglomeration of the pigment in the pigment blending barrel is reduced, the stirring time can be shortened during blending, and therefore energy consumption is reduced.

Owner:HUAIHUA UNIV

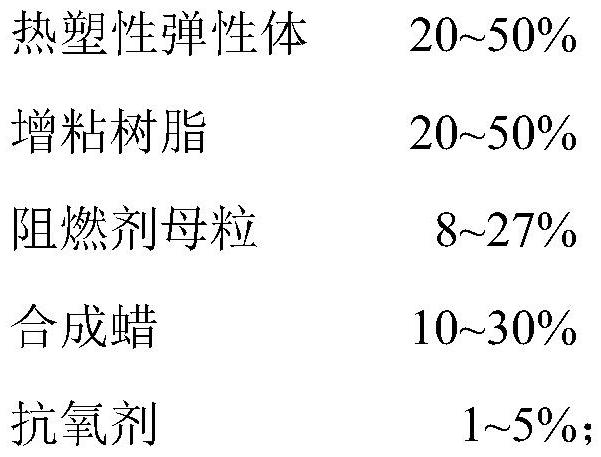

Flame-retardant hot melt adhesive and preparation method thereof

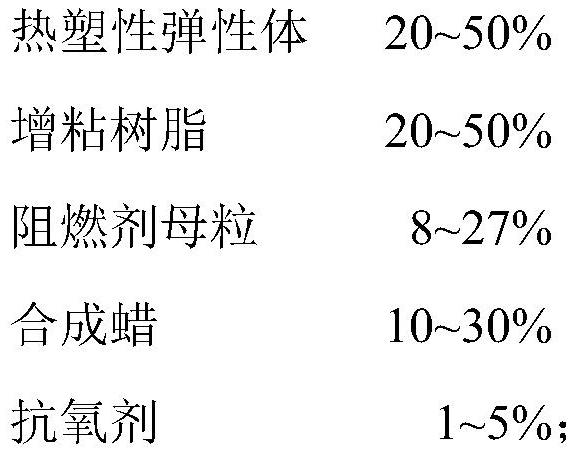

ActiveCN113621325AGuaranteed performanceFully dispersedNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerMasterbatch

The invention discloses a flame-retardant hot melt adhesive. The flame-retardant hot melt adhesive is prepared from the following components in percentage by mass: 20 to 50 percent of thermoplastic elastomer, 20 to 50 percent of tackifying resin, 8 to 27 percent of flame retardant master batch, 10 to 30 percent of synthetic wax and 1 to 5 percent of an antioxidant, wherein the flame retardant master batch comprises a nitrogen-phosphorus flame retardant and an EVA carrier. By designing the raw materials and the proportions thereof, the specific flame retardant master batch is selected to replace general flame retardant powder and has better compatibility with a hot melt adhesive formula, and the problem of non-uniform dispersion of the flame retardant does not exist. The invention discloses a preparation method of a flame-retardant hot melt adhesive. The preparation method comprises the following steps: uniformly mixing tackifying resin and a flame retardant master batch, adding a thermoplastic elastomer and synthetic wax, and carrying out mixing. Thus, the dispersion effect of the flame retardant master batch is further improved, the original performance of the hot melt adhesive is maintained, and flame-retardant performance also meets corresponding requirements.

Owner:中山诚泰化工科技有限公司

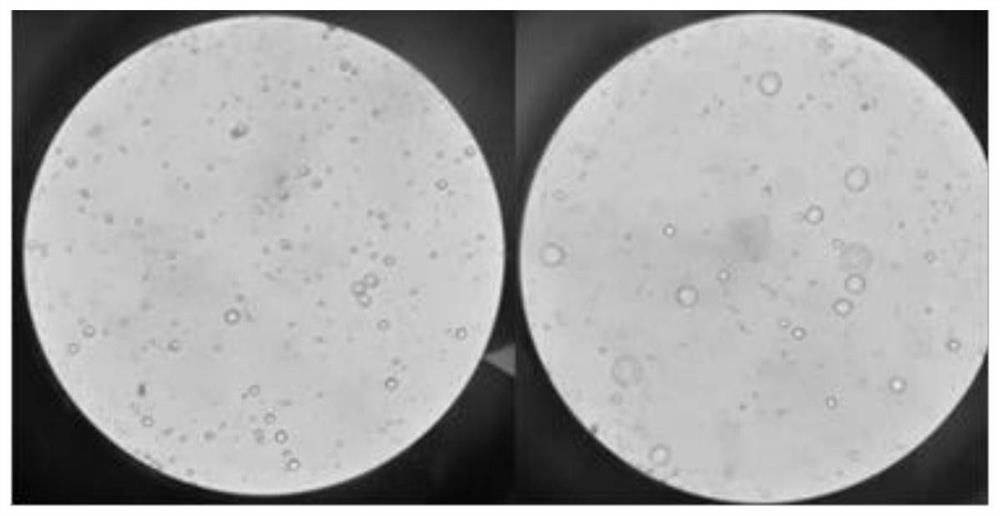

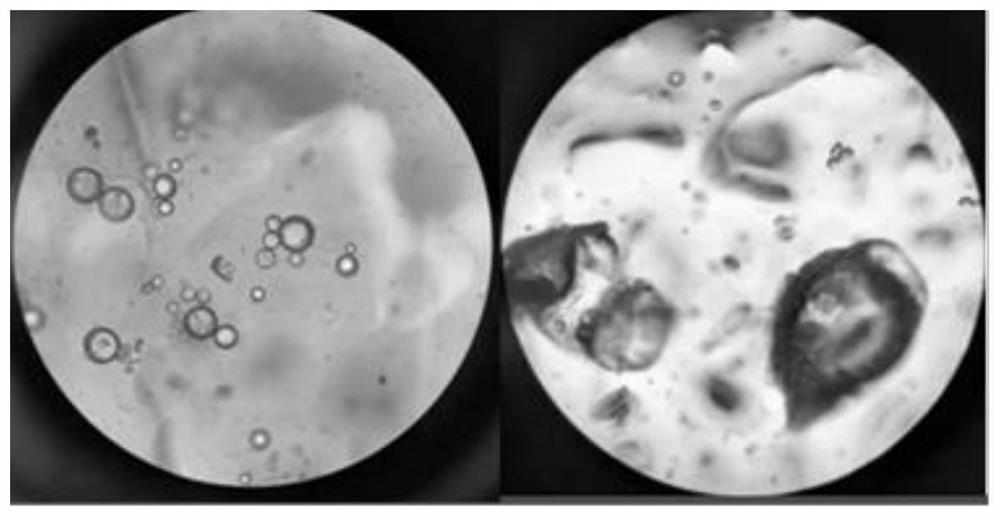

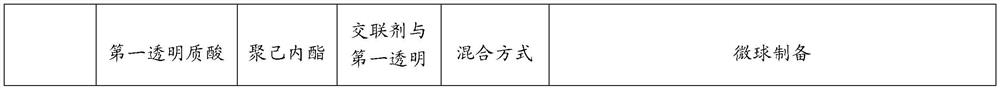

Preparation method of hyaluronic acid filling agent

The invention provides a preparation method of a hyaluronic acid filling agent. The preparation method comprises the following steps: uniformly mixing dried first hyaluronic acid or salt thereof with dried degradable polymer microspheres to obtain a starting raw material; carrying out a cross-linking reaction on the initial raw material by using a cross-linking agent, purifying and granulating to obtain hyaluronic acid gel containing microspheres; and purifying, filling and sterilizing the hyaluronic acid gel containing the microspheres to obtain the hyaluronic acid filling agent. The microspheres and the hyaluronic acid or the salt thereof are mixed in a dry powder state, so that materials can be uniformly mixed in a relatively short time, microsphere aggregation is effectively avoided, the uniform mixing time is shortened, deformation and fusion of the microspheres caused by aggregation and exposure in the sterilization and temperature rise process are avoided, Therefore, the occurrence rate of needle blockage in the injection process and postoperative adverse reaction is reduced.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

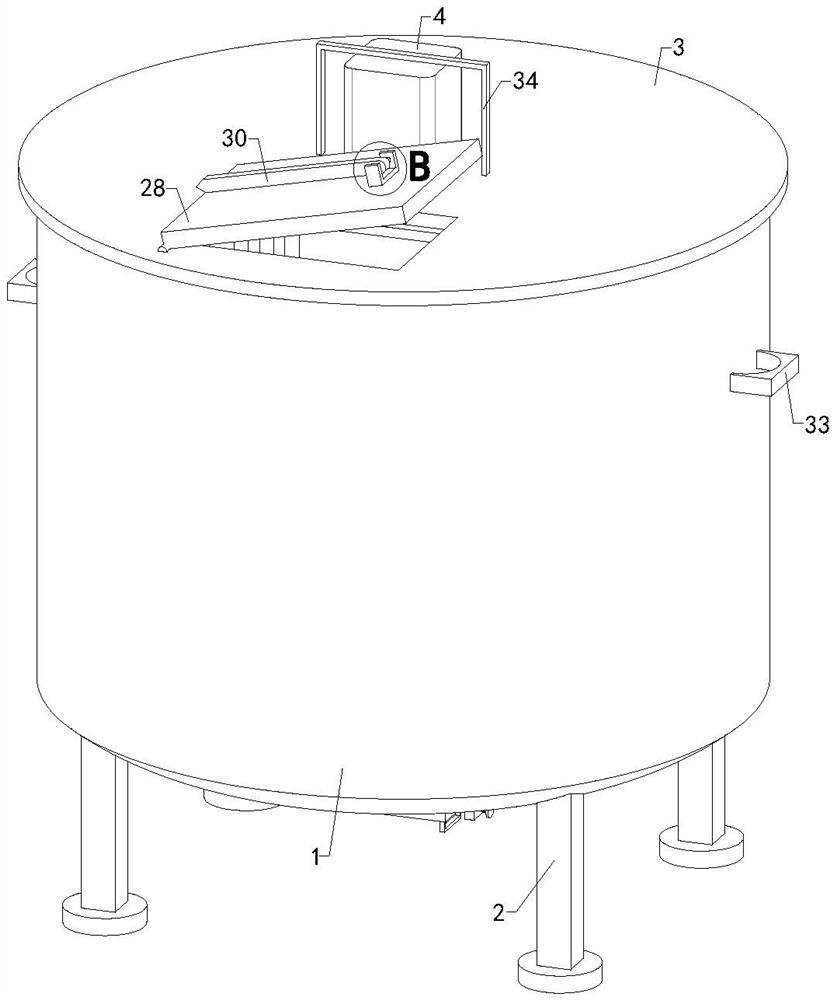

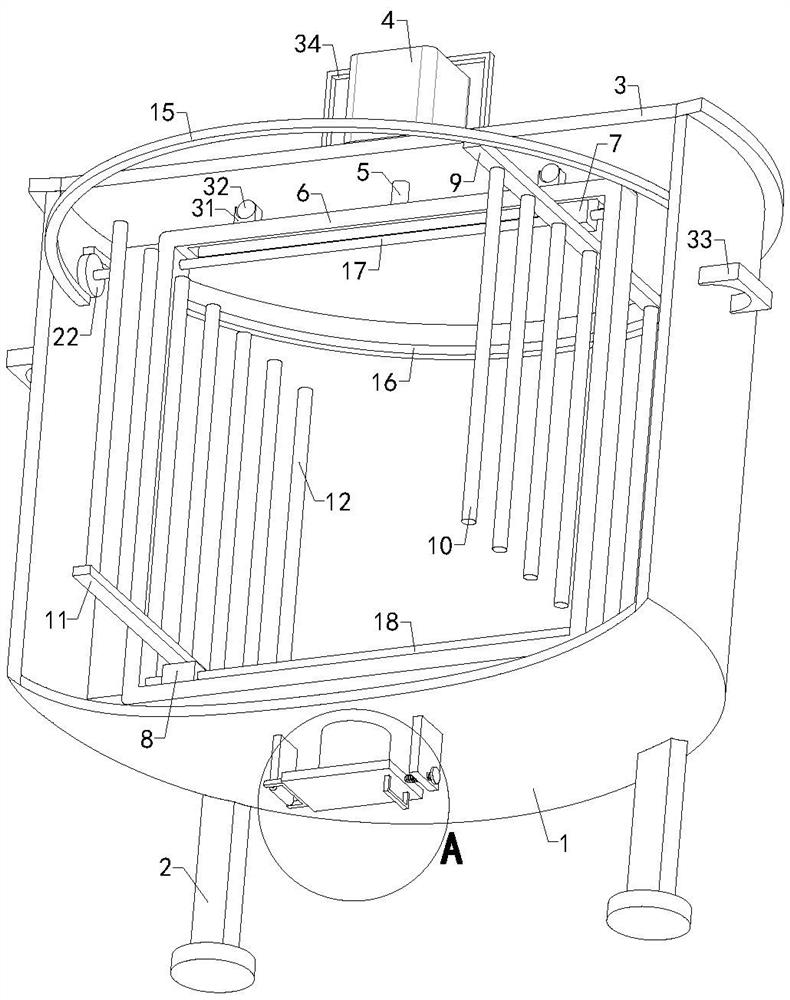

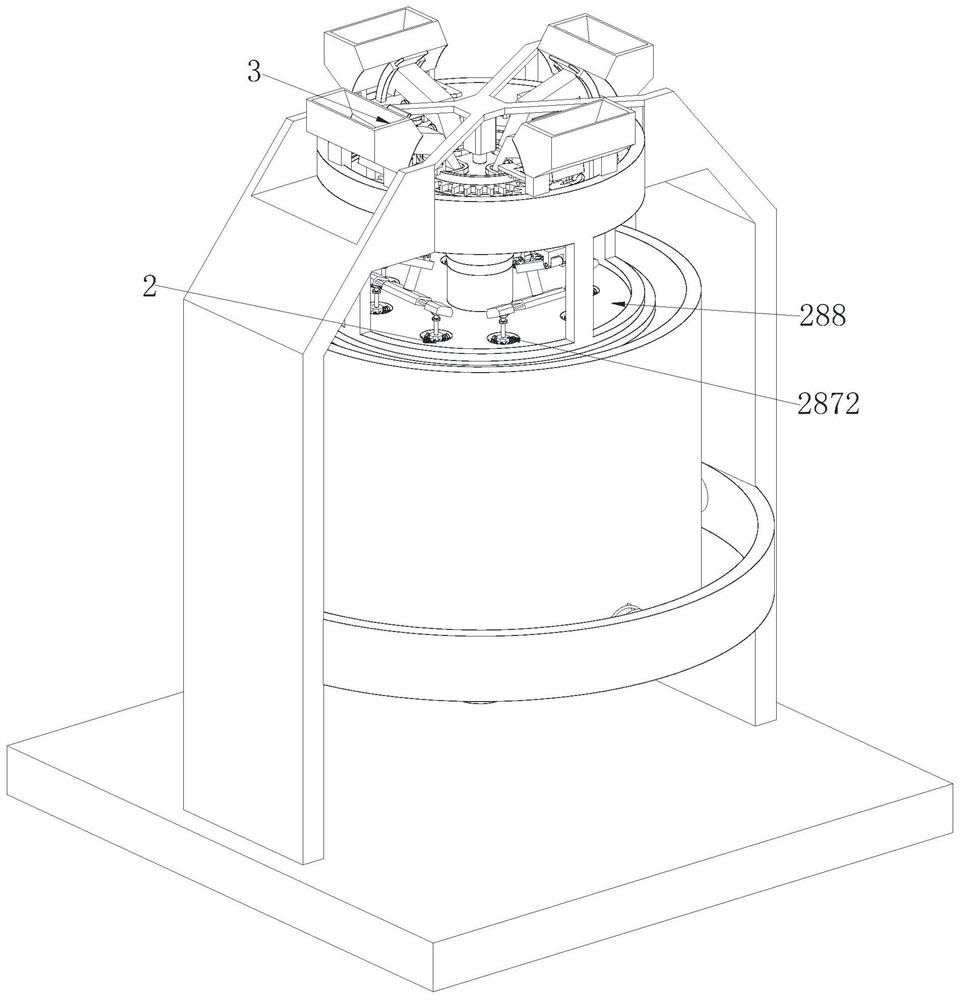

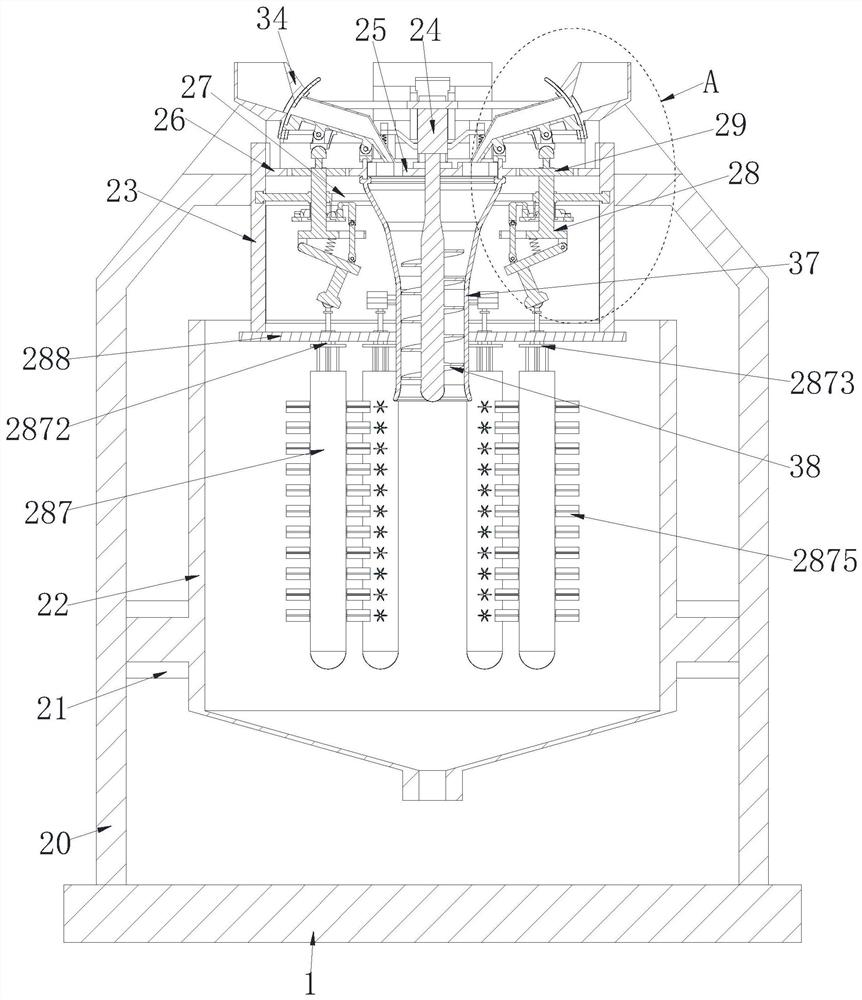

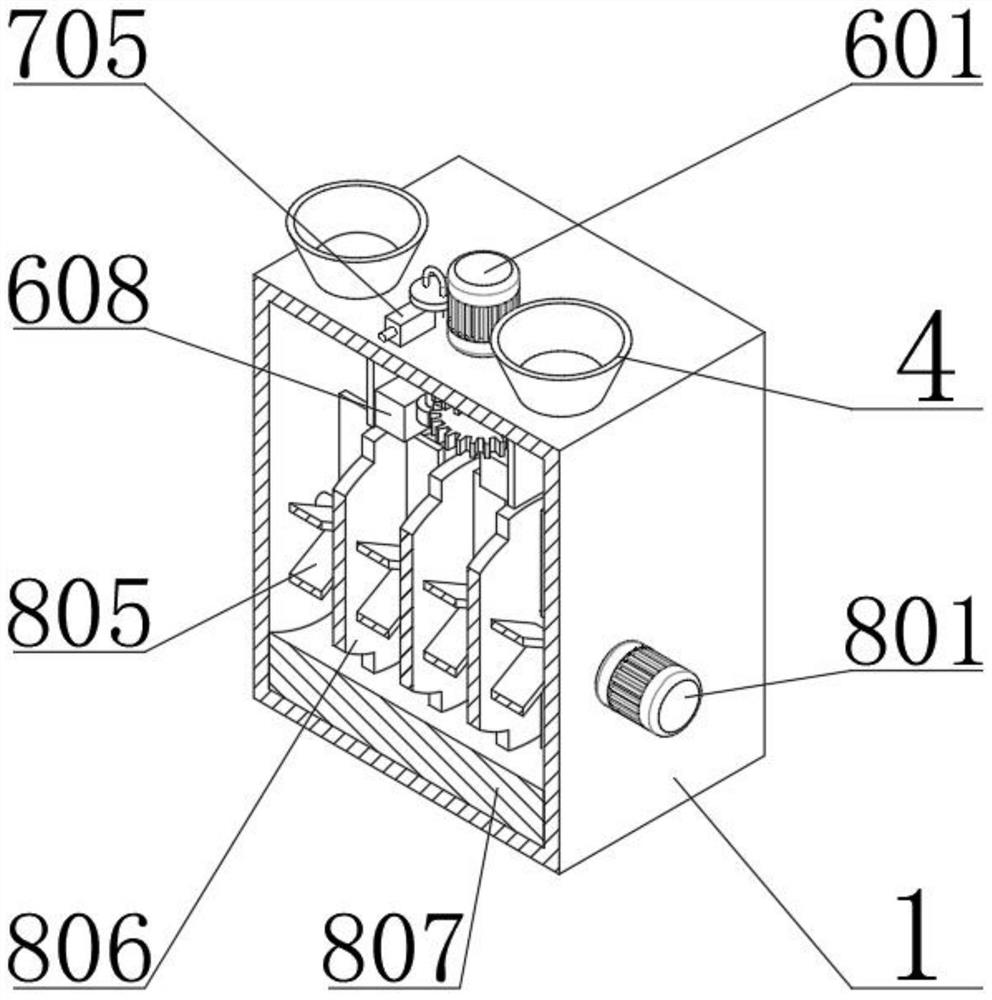

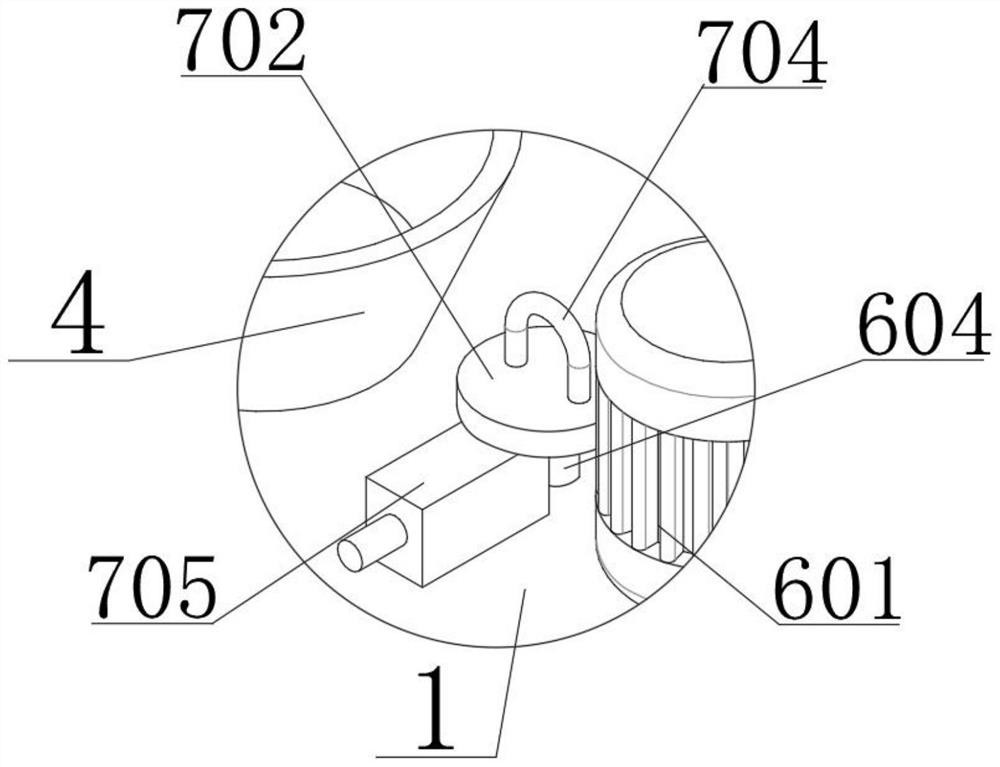

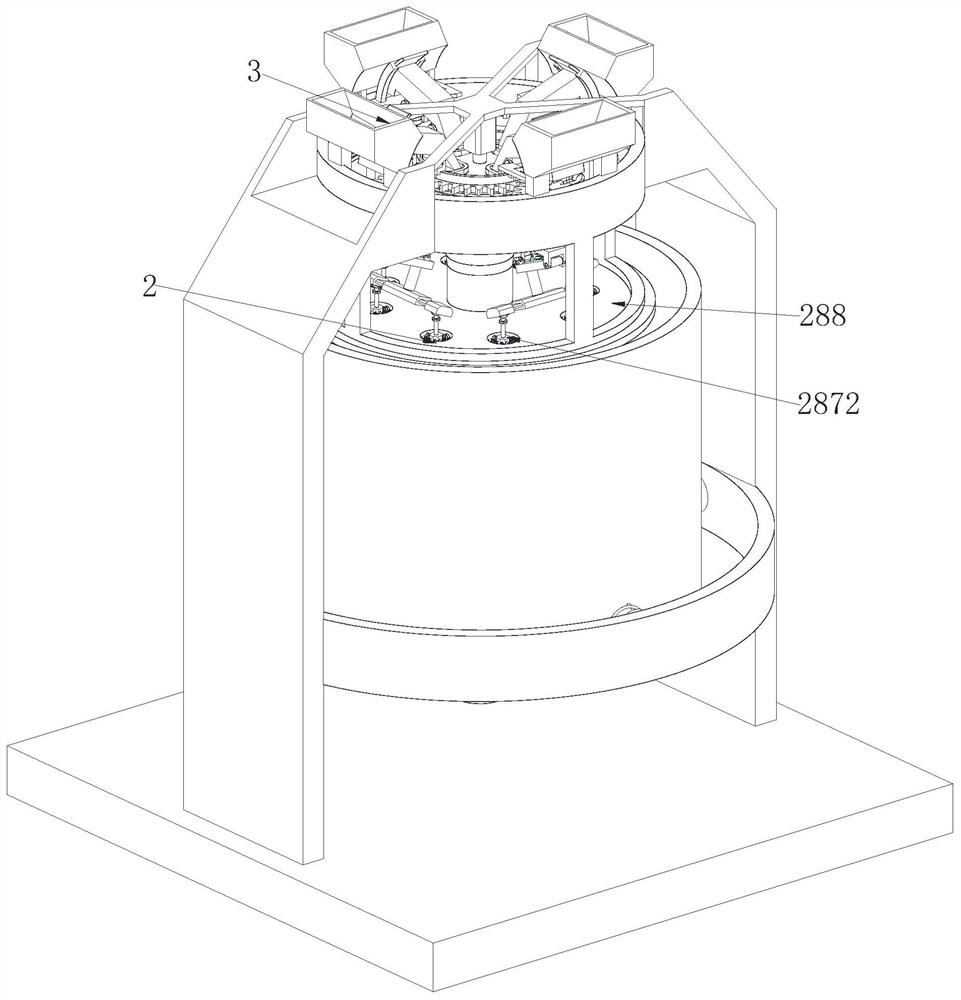

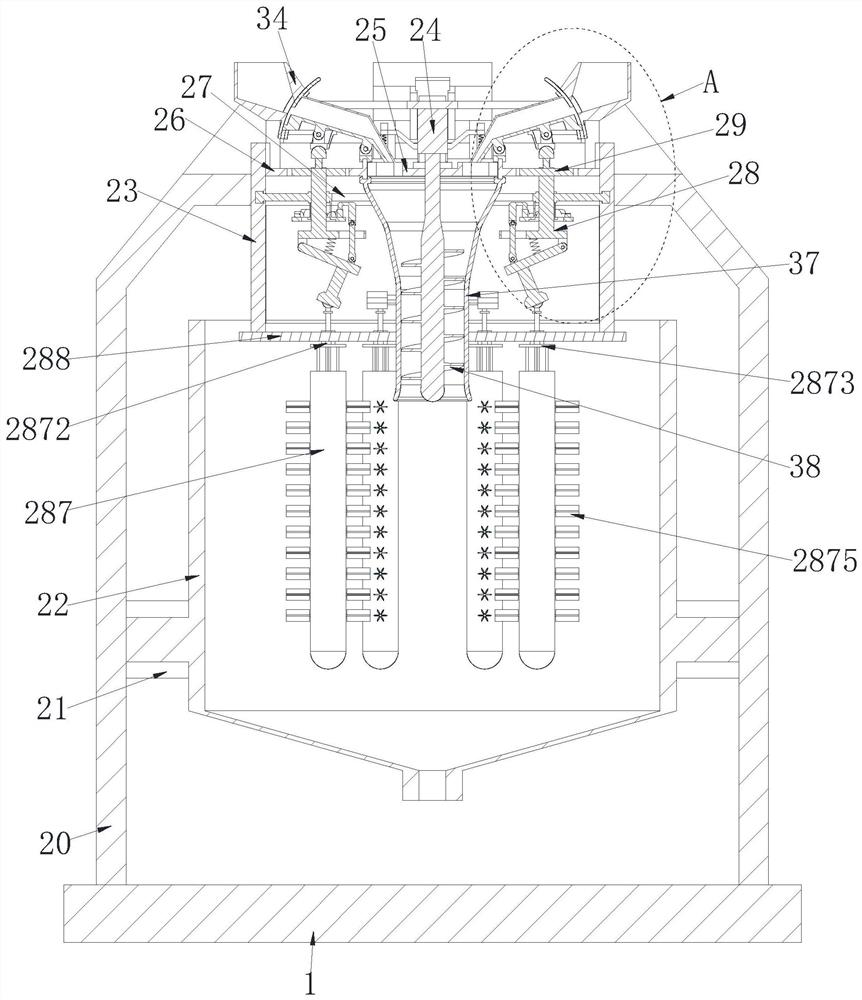

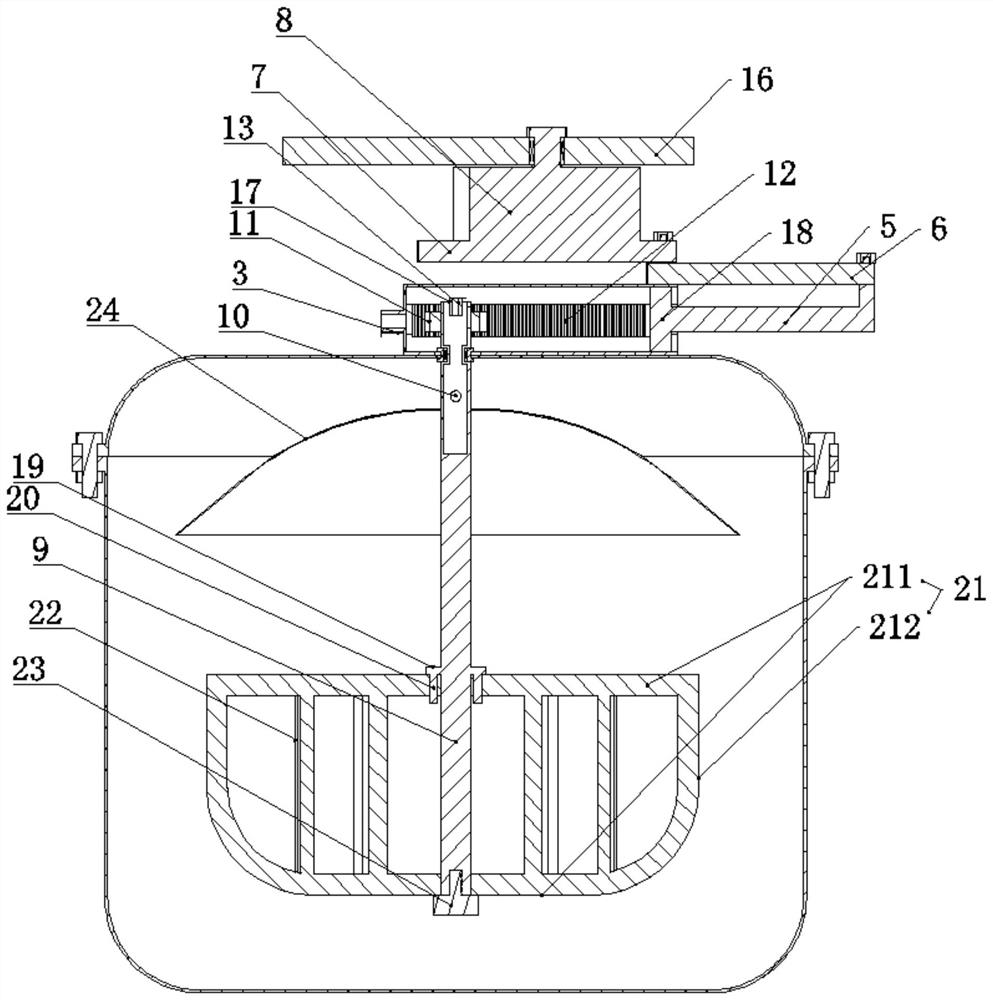

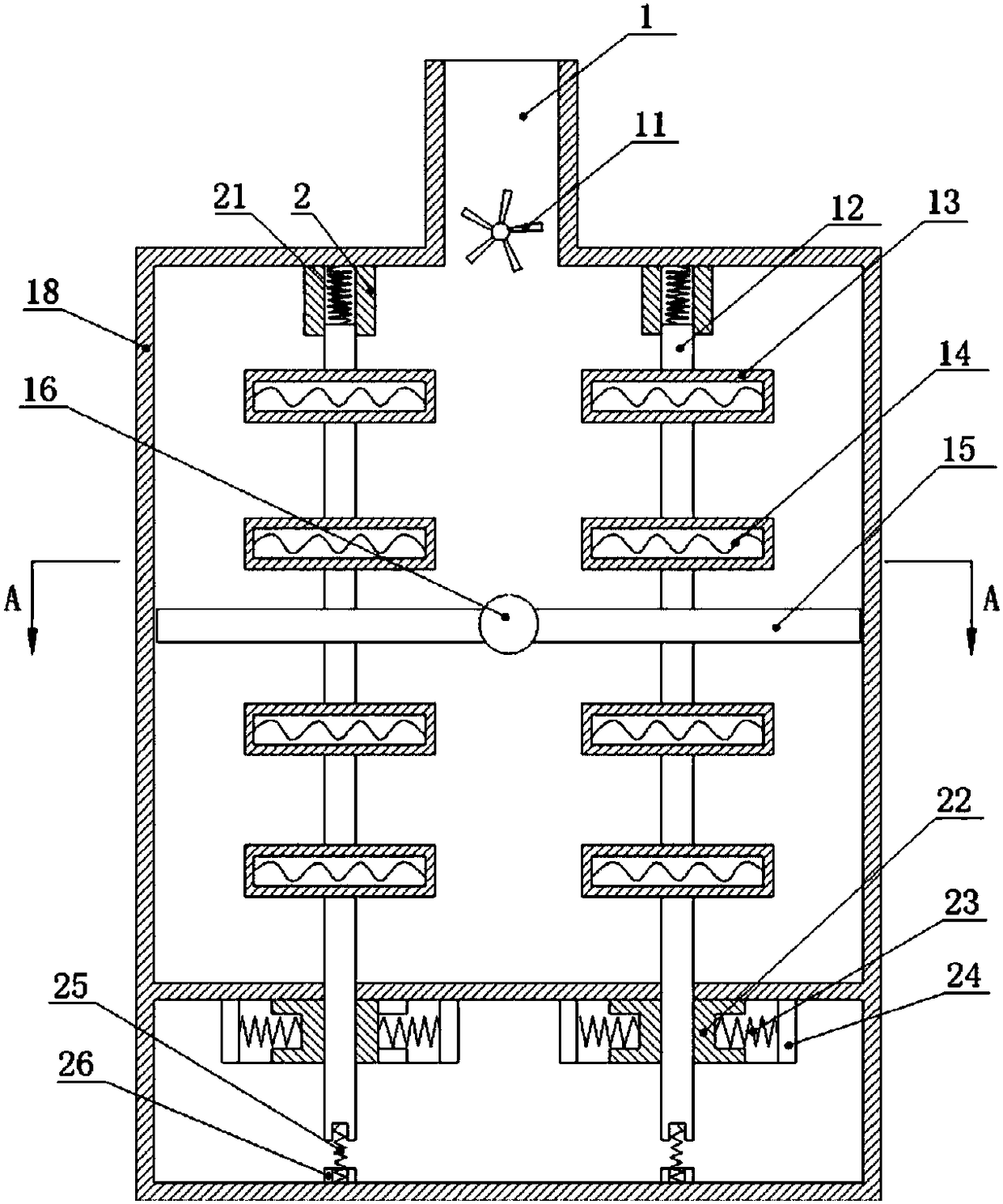

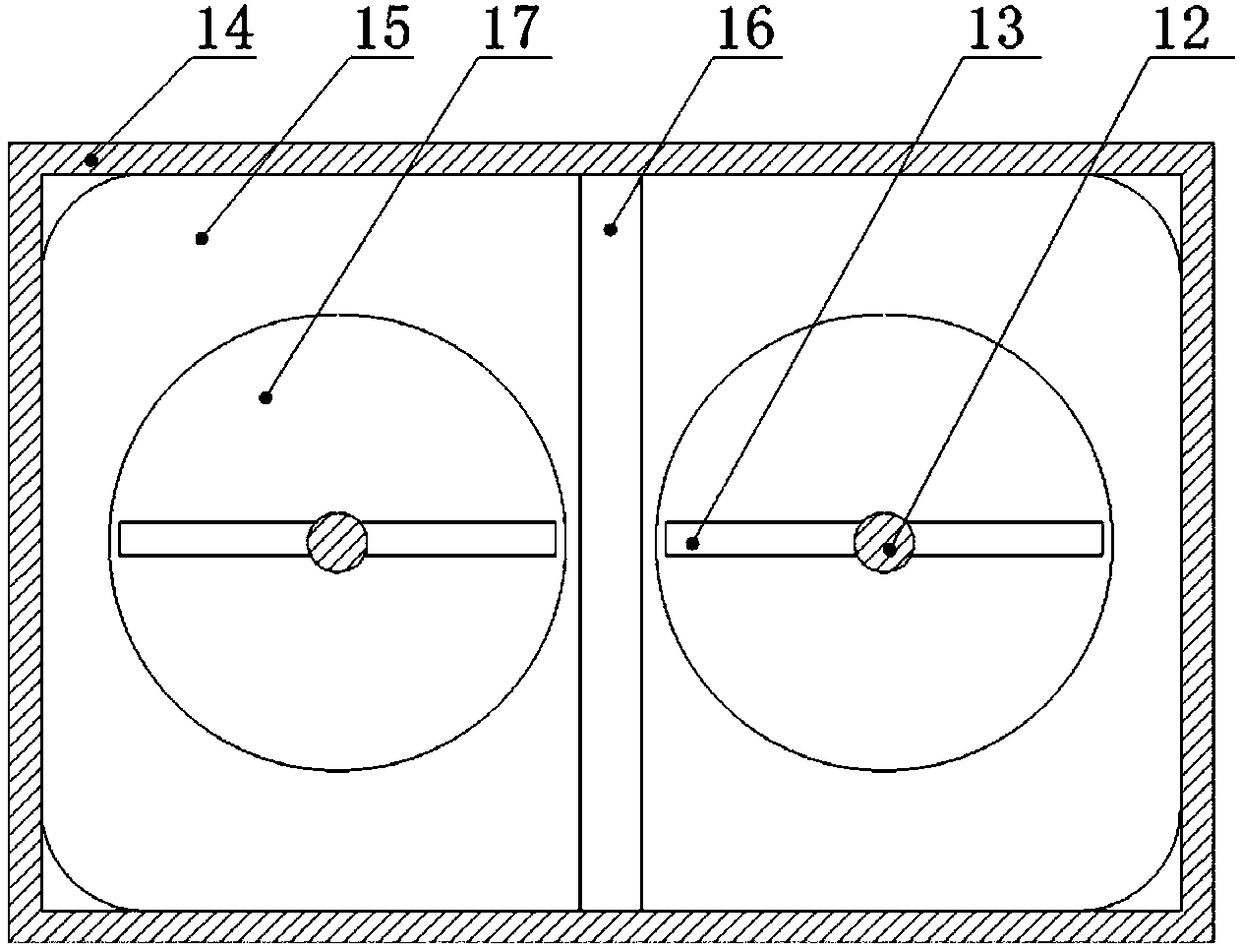

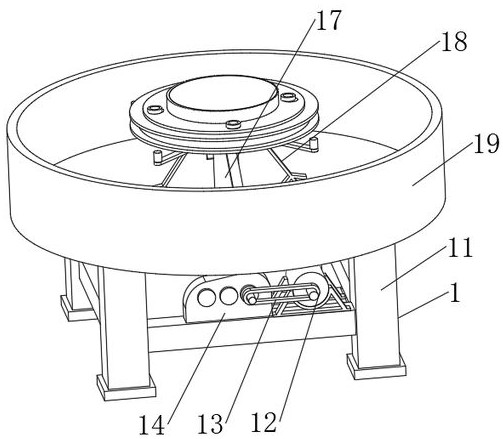

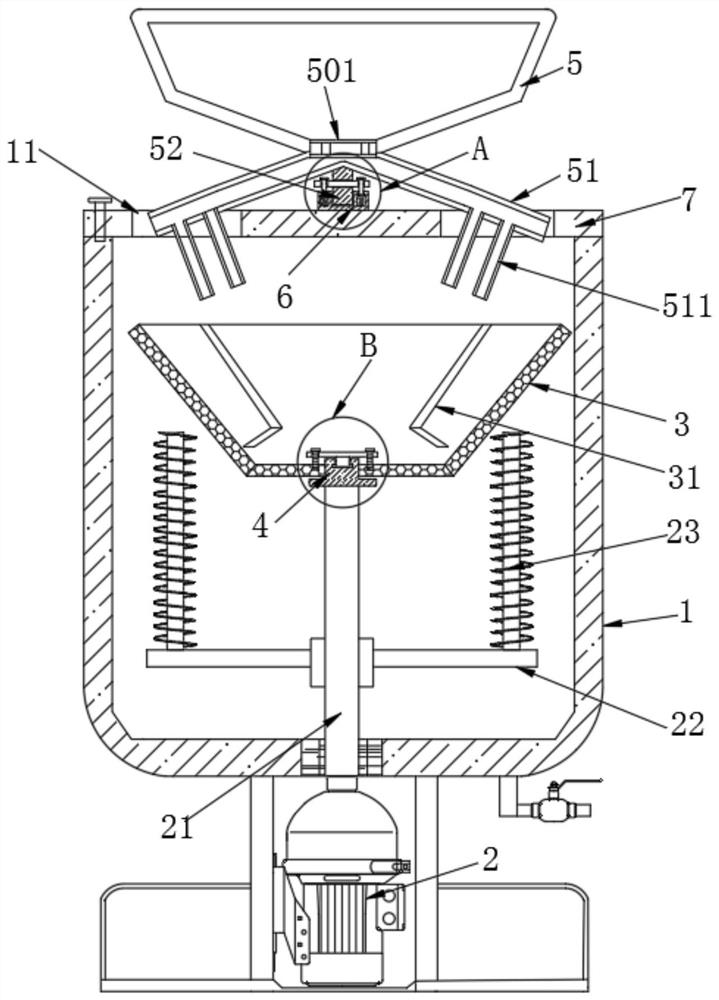

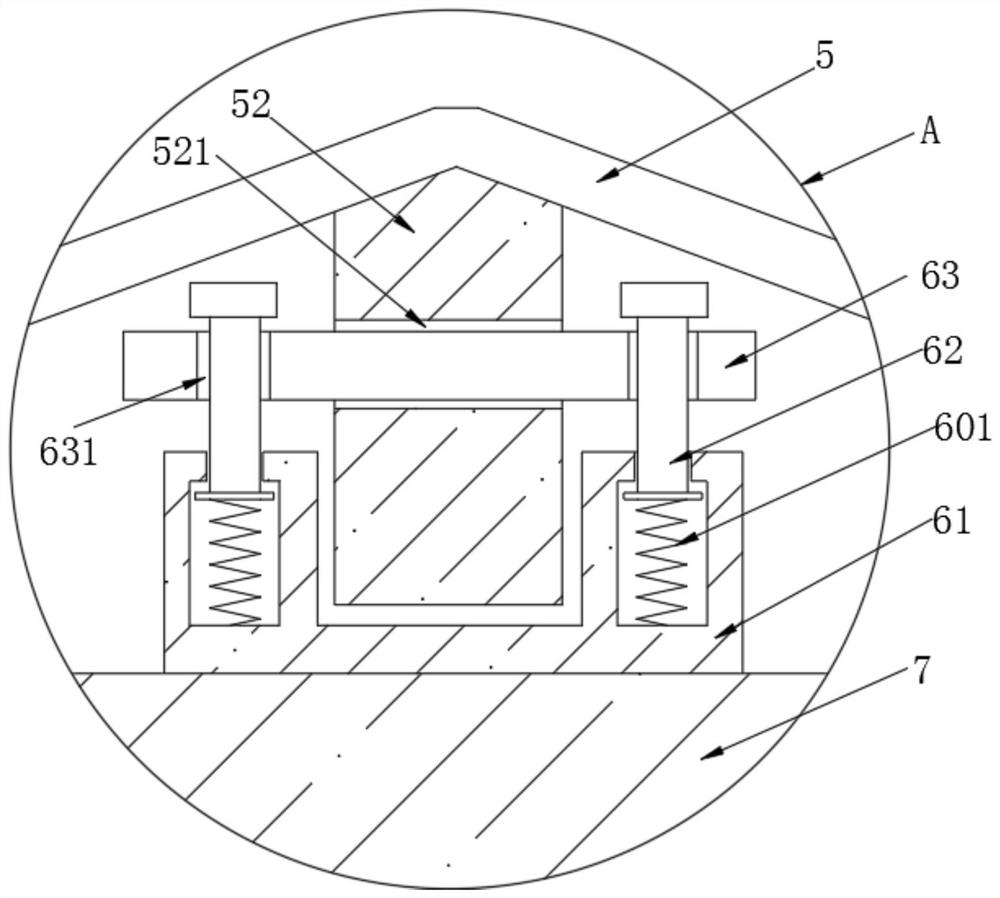

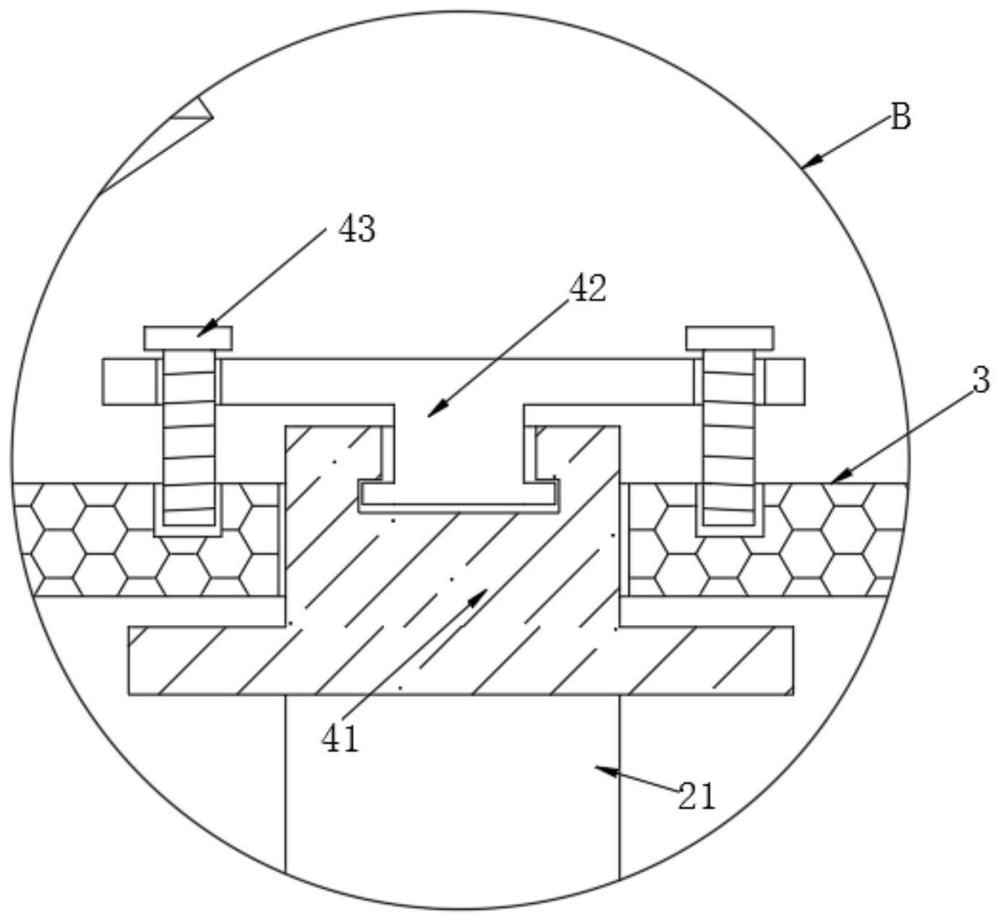

A kind of hydrogel dressing production equipment

ActiveCN113952862BImprove stirring and mixing effectShorten the mixing timeTransportation and packagingRotary stirring mixersBLENDER/MIXERMedical product

Owner:苏州汇涵医用科技发展有限公司

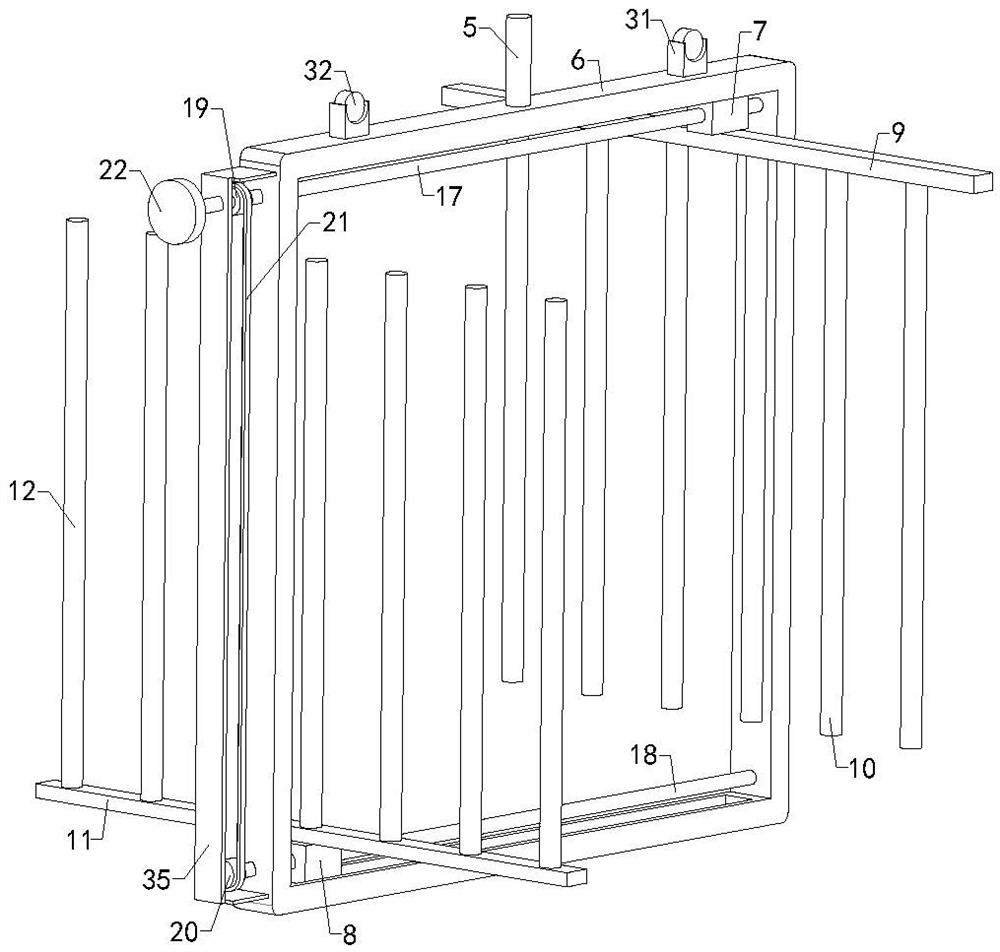

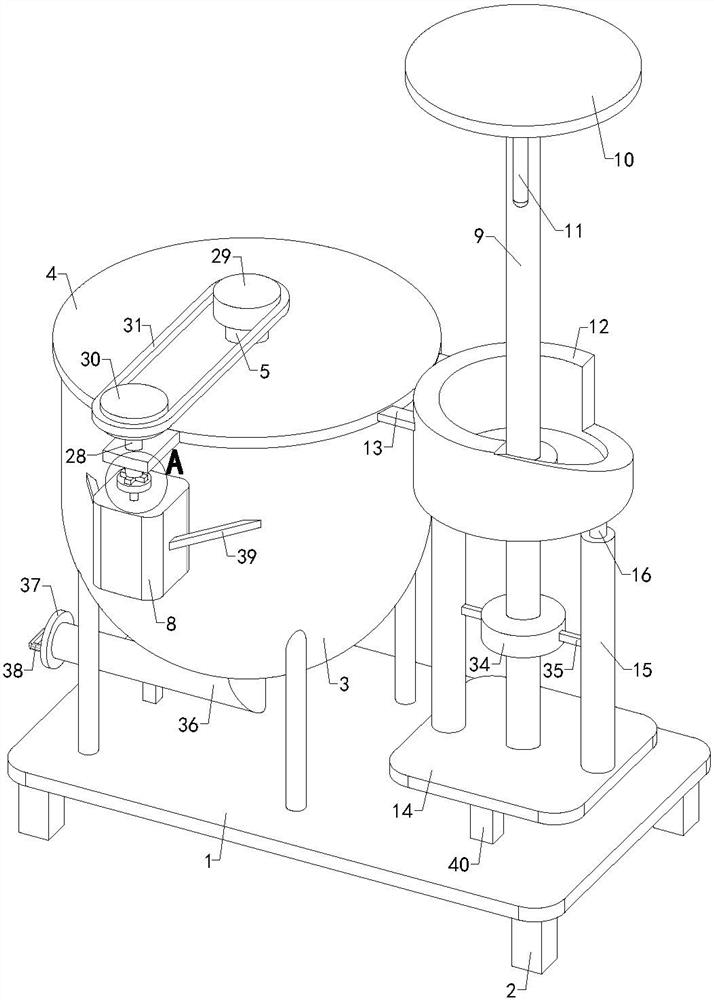

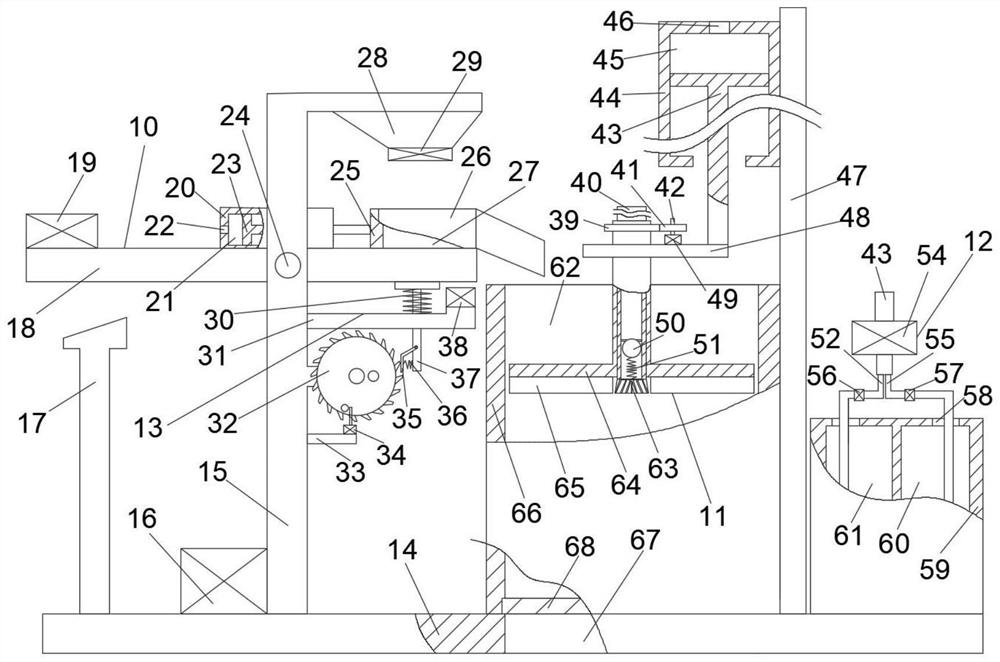

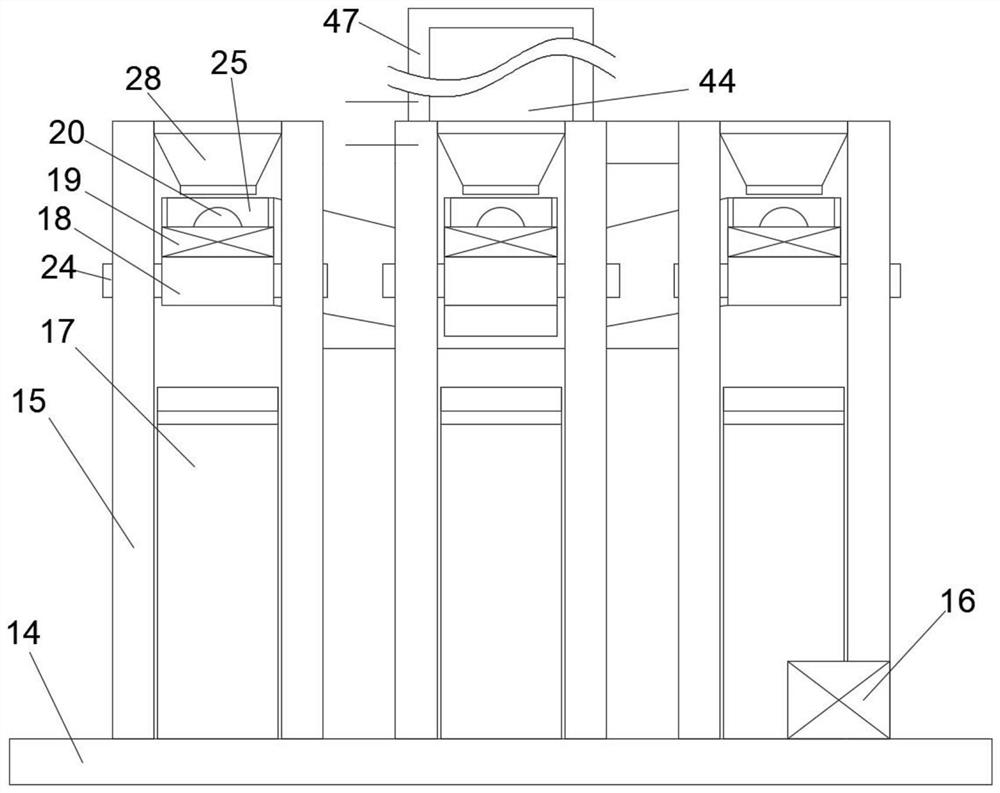

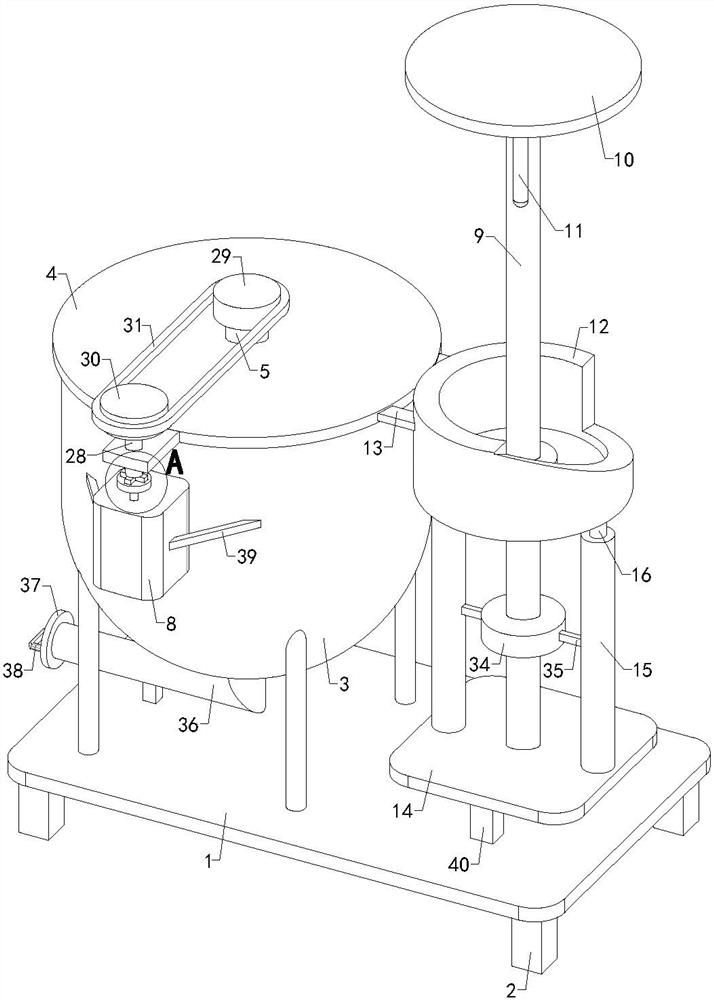

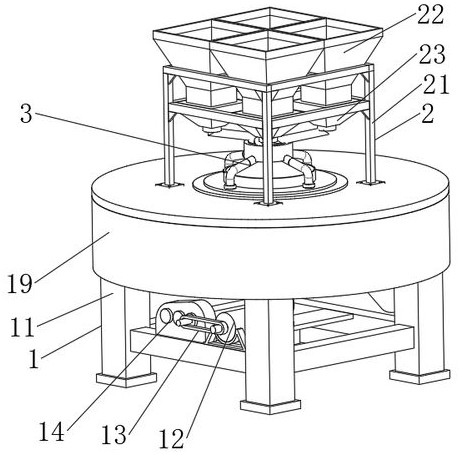

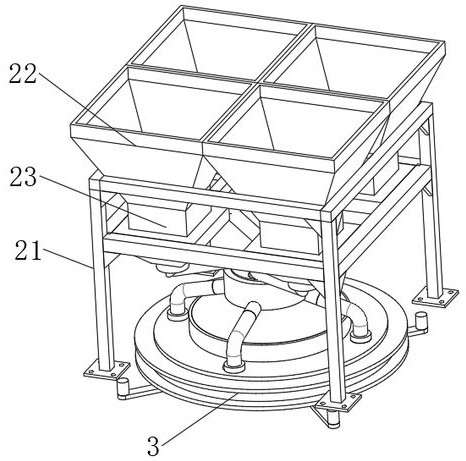

Preparation method of polymer cement waterproof mortar

ActiveCN112919857AStir wellLow efficiencySolid waste managementCement mixing apparatusPolymer sciencePolymer chemistry

The invention relates to a preparation method of polymer cement waterproof mortar, which applies preparation equipment of the polymer cement waterproof mortar.The preparation equipment of the polymer cement waterproof mortar comprises a base, a stirring device and a feeding device, wherein the stirring device is arranged on the upper surface of the base, and the feeding device is arranged above the stirring device. The invention can solve the following problems in the prior art: raw materials of mortar are put into existing stirring equipment in proportion for stirring, the stirring equipment needs longer time to uniformly stir the raw materials of the mortar in the stirring equipment due to the large input amount of the raw materials in the stirring process of the raw materials of the mortar, the use efficiency of the mortar is reduced, and the construction period is prolonged; and the stirring treatment mode of mortar raw materials is too simple, all the raw materials of the mortar are difficult to fully and uniformly mix, the prepared mortar is common in quality and low in use value, and the safety of buildings is influenced.

Owner:浙江天造环保科技有限公司

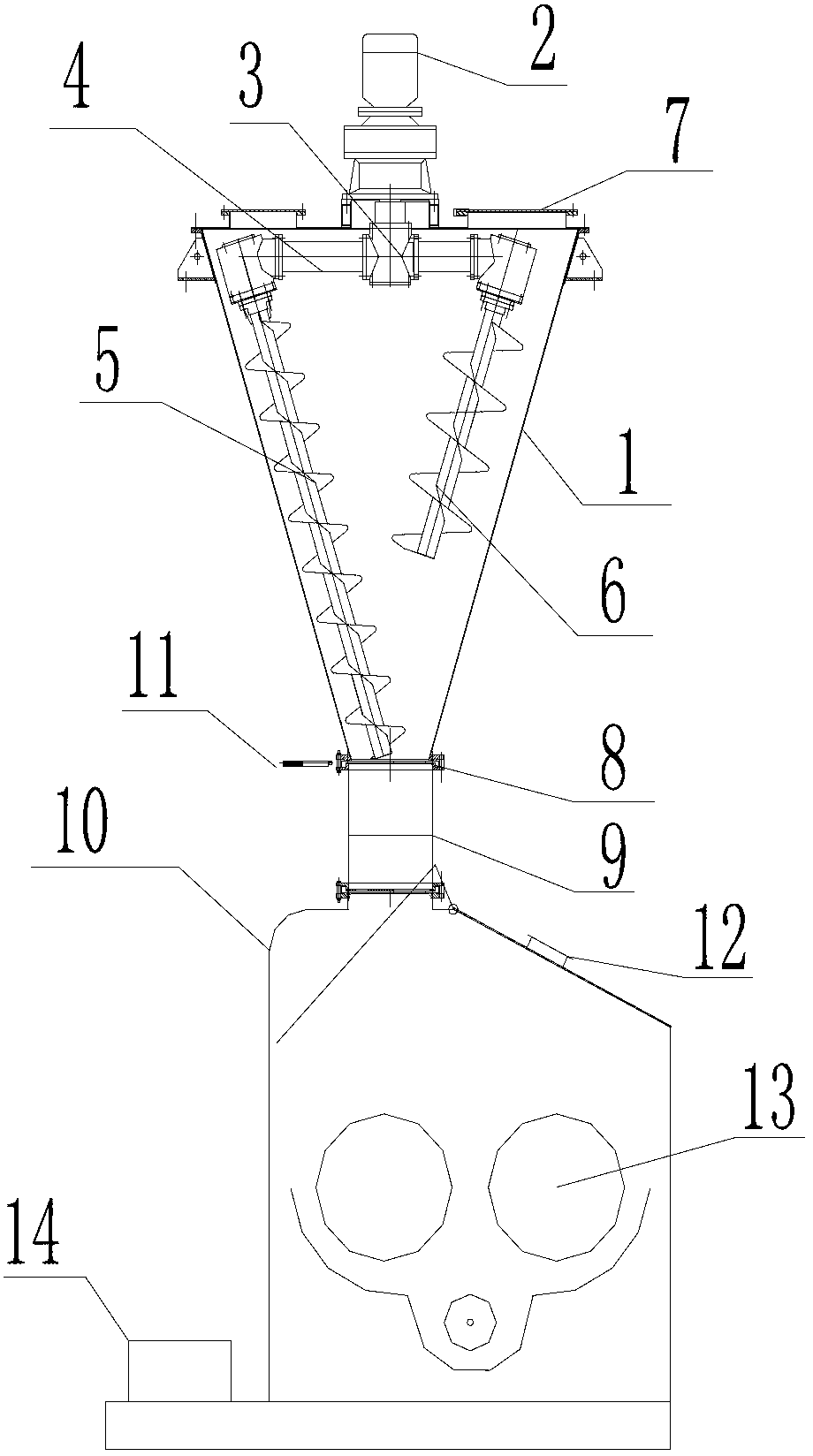

Raw material premixing device for manufacturing denitrification catalysts

InactiveCN102989341ASimple device structureShorten the mixing timeRotary stirring mixersCatalyst activation/preparationMotor shaftEngineering

The invention relates to a raw material premixing device for manufacturing denitrification catalysts. The raw material premixing device comprises a cone, wherein a motor is arranged in the middle of the upper part of the cone and is provided with a motor shaft, the motor shaft is connected with a metal rod, a long threaded rod and a short threaded rod are welded at the two ends of the metal rod, the upper part of the cone is further provided with a feeding port, the bottom of the cone is provided with a discharge port, a metal sleeve is arranged under the discharge port, and the cone is connected with a mixing mill by the metal sleeve. The raw material premixing device can uniformly mix raw materials, efficiently improve a mixing effect, and enhance production efficiency.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

Device and method for preparing digestion-free protein with active protein and soybean protein as raw materials

PendingCN111772031AEvenly mixedShorten the mixing timeRotary stirring mixersTransportation and packagingFree proteinActive protein

The invention relates to the technical field of health-care food, in particular to a device and method for preparing digestion-free protein with active protein and soybean protein as raw materials. The device comprises a box body, a discharging hopper and a box door, wherein the box door is installed on the front side of the box body, and the discharging hopper arranged in a bilateral symmetry mode is installed on the top end face of the box door; a uniform discharging device is installed in the center of the top end of the box body; a speed regulation control device is installed on the innerside of the uniform discharging device; and a stirring device is installed on the inner side of the bottom end of the box body. By virtue of the uniform discharging device, the active protein and thesoybean protein can be discharged uniformly, therefore, the mixing uniformity is ensured, the stirring time is shortened, and a relatively good production effect is ensured.

Owner:讷河市笙得利农业科技发展有限公司

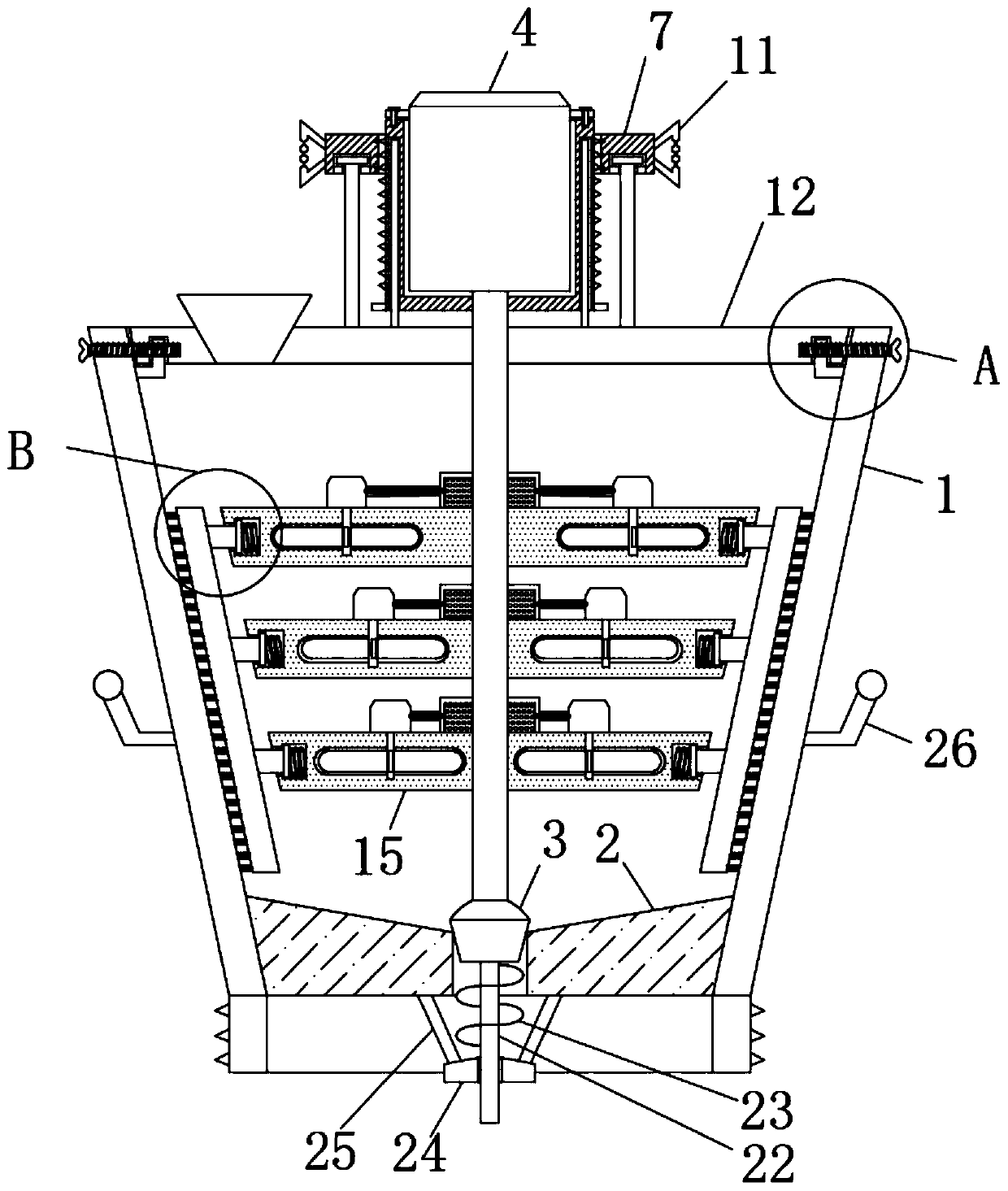

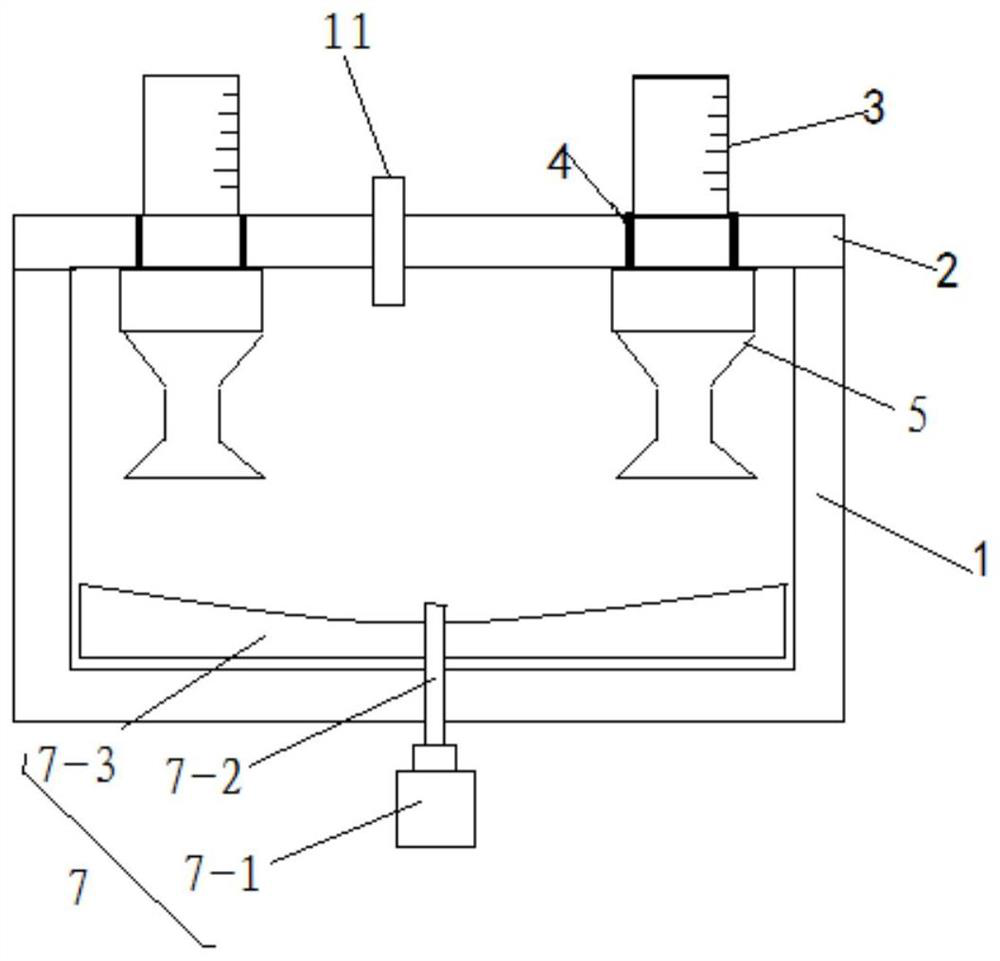

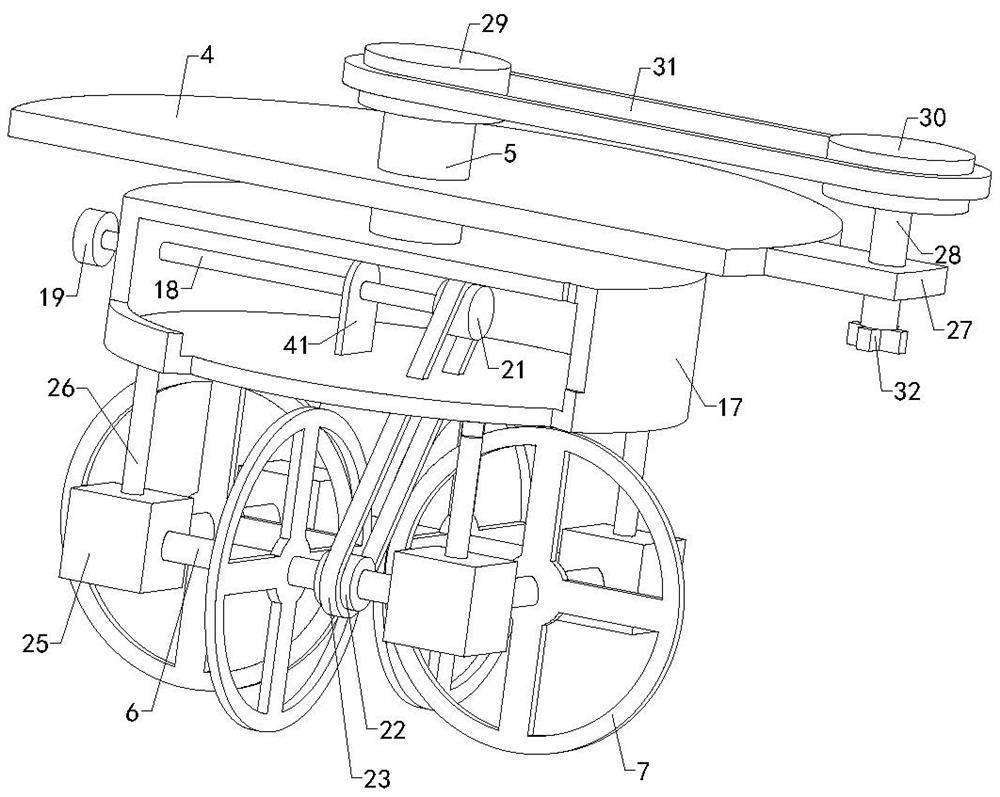

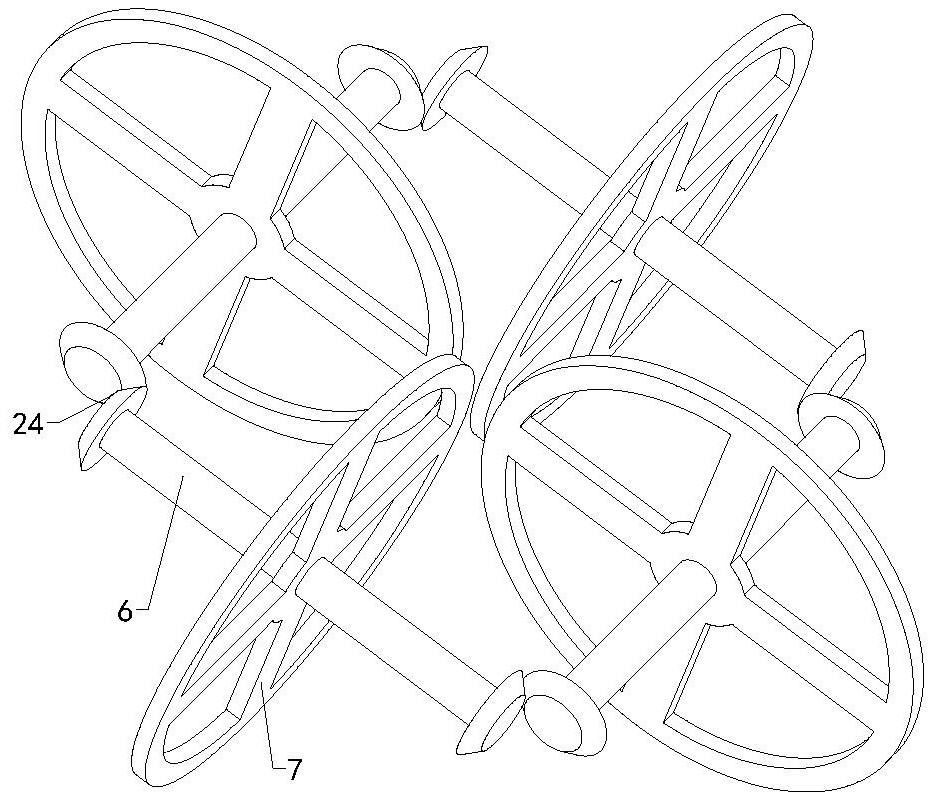

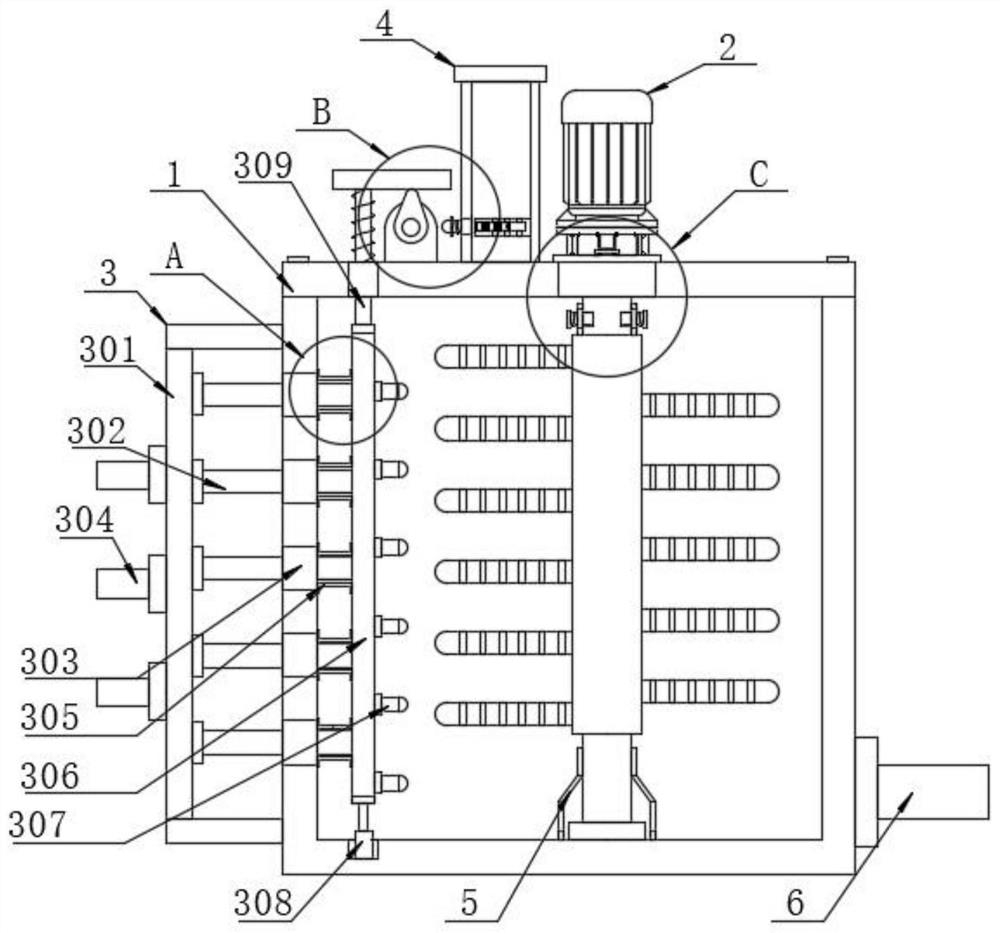

Efficient porous cellulose fermentation culture equipment

ActiveCN113426321AEasy to sampleEasy to observeRotary stirring mixersMixer accessoriesCelluloseElectric machinery

The invention relates to the technical field of fermentation equipment accessory devices, in particular to efficient porous cellulose fermentation culture equipment. The equipment comprises a horizontally-arranged bottom plate. A box opening is formed in the top end of a box body, and a box cover arranged at the box opening. A connecting shaft longitudinally and rotatably arranged in the middle of the box cover, and a stirring mechanism arranged at the bottom end of the connecting shaft. The stirring mechanism comprises four supporting shafts horizontally arranged in the positive direction, and each supporting shaft is fixedly sleeved with a stirring wheel. A driving mechanism is arranged at the top end of the connecting shaft and comprises a motor. A fixing column is arranged on the bottom plate, a top plate is arranged at the top end of the fixing column, and a guide column is arranged at the bottom end of the top plate. A groove plate is slidably arranged in the middle of the fixing column, and an arc-shaped inclined face is arranged on the side wall of the groove plate. Two connecting rods are arranged on the box cover. A supporting plate is rotationally arranged on the lower portion of the fixing column, and two air cylinders are symmetrically arranged on the supporting plate. Raw materials are stirred in multiple dimensions, the stirring time is shortened, cleaning is convenient, and the working efficiency is improved.

Owner:苏州汇涵医用科技发展有限公司

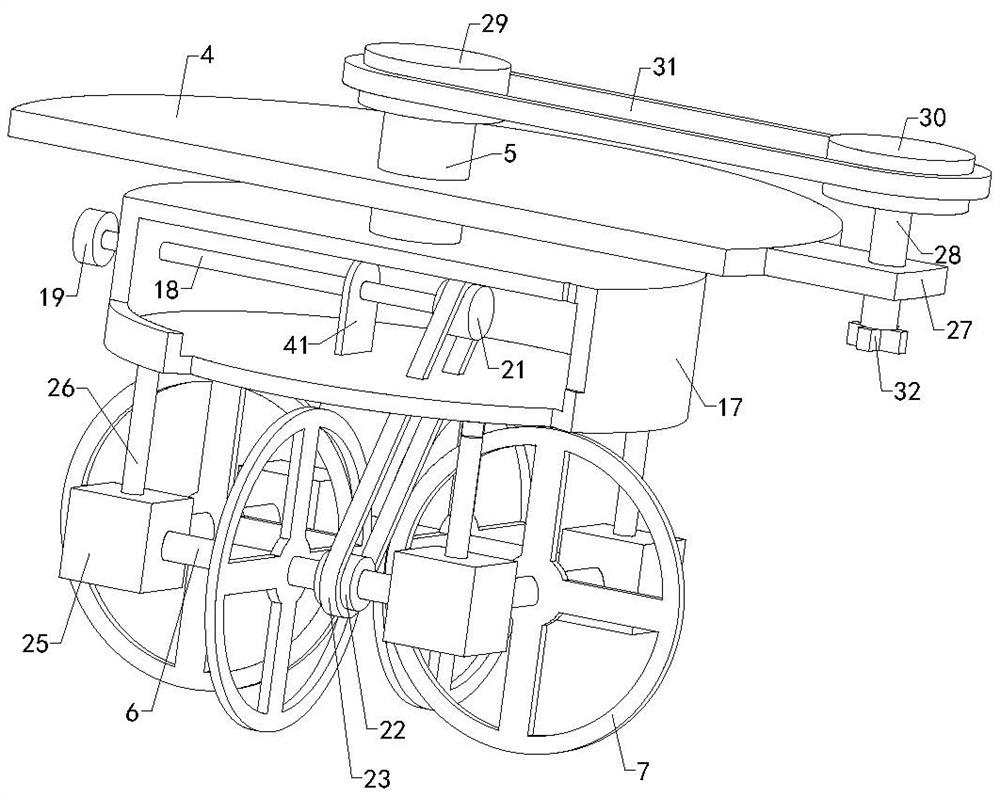

Raw material mixing equipment for 3D printing material production

ActiveCN111015989AImprove mobilityShorten the mixing timeAdditive manufacturing apparatus3D object support structuresProcess engineering3D printing

The invention belongs to the technical field of mixing equipment, and particularly relates to raw material mixing equipment for 3D printing material production. The raw material mixing equipment comprises a machine body screwed and fixed with an upper cover, the bottom of the machine body is fixedly connected with a motor, the motor is electrically connected with an external power supply, and theoutput end of the motor is fixedly connected with a connecting rod; various raw materials dispersedly flow downwards through a two-way pipe due to the influence of gravity; when the raw materials reach the position of the material distributing pipe, one part of the raw materials is dispersed and directly flow downwards; the two-way pipe and the material distributing pipe play a role in increasingthe flowing path of the raw materials; various raw materials are gradually mixed during flowing and falling; the raw materials are divided into two strands through the two-way pipe and the material distributing pipe to flow into a material mixing filter cone, the two strands of raw materials make contact with each other when making contact with two guide plates, the mixing degree is further increased till the raw materials penetrate through the material mixing filter cone and flow into the machine body, preliminary mixing is achieved, and therefore the mixing time of subsequent mixing work canbe shortened.

Owner:佛山市广科产业技术研究院有限公司

Hopper of concrete mixing plant

InactiveCN114311314AShorten the mixing timeImprove production efficiencyMixing operation control apparatusLiquid ingredients supply apparatusRotational axisHydraulic pump

The concrete mixing plant hopper comprises a base, the upper end face of the base is fixedly connected with a hydraulic pump, a mixing main plate, a water tank and a mixing barrel, the upper end face of the base is fixedly connected with three limiting frames which are evenly distributed front and back, a discharging port is formed in the base, the upper end face of the base is fixedly connected with a telescopic air pump, and the telescopic air pump is fixedly connected with a telescopic sleeve. The upper end of the batching main plate is fixedly connected with a batching rotating shaft, the batching rotating shaft is rotationally connected with a batching mechanism, the right end face of the batching main plate is fixedly connected with a proportion adjusting mechanism, and the left end face of the modulation main plate is fixedly connected with a modulation mechanism. A water supply mechanism is arranged above a water tank fixedly connected with the upper end face of the base. The device can replace most functions of a weighing system of a mixing station, water and other concrete raw materials are uniformly mixed in a layered manner, the occurrence of raw material clusters which are not uniformly mixed with the water is reduced, the mixing time of a concrete mixer is shortened, and the concrete preparation efficiency and quality are improved.

Owner:王巧

Capsule type 90% super-concentrated clothing cleaning care agent and environment-friendly preparation process

InactiveCN112410136AAvoid it happening againAuxiliary AntifreezeNon-ionic surface-active compoundsDetergent dyesActive agentCleansing Agents

The invention discloses a capsule type 90% hyperconcentrated clothing cleaning care agent and an environment-friendly preparation process, and belongs to the technical field of cleaning agents. The cleaning agent is composed of the following raw materials in percentage by weight: 0-35% of anionic surfactant, 55-90% of nonionic surfactant, 0-5% of dirt suspension dispersant, 0-5% of humectant, 0-3%of neutralizer, 0-0.5% of preservative, 0-2.0% of essence, pigment and the balance of deionized water. According to the invention, the effective concentration reaches 90%, which is several times of that of common products in the market, so that a large amount of packing materials can be saved. The product has the advantages of low carbon, environmental protection, high concentration efficiency, greenness, energy conservation, less moisture, and water resource saving; wherein bacteria growth of the product is not easily caused by reduction of deionized water, and the antibacterial ability is further improved by filling the PVA water-soluble plastic film capsule with the product, and external water vapor immersion can be reduced; therefore, the storage life is prolonged, and the packaging difficulty is reduced.

Owner:钦州威优威科技开发有限公司

Preparation process of novel polymer material for coating preparation

PendingCN114437587AHigh resistance to salt sprayGood weather resistanceRotating receptacle mixersAntifouling/underwater paintsWeather resistanceLow temperature curing

The invention discloses a preparation process of a novel polymer material for coating preparation. The preparation process comprises the following steps: S11, weighing the following raw materials in parts by weight: 50-70 parts of a polymer mixed base material, 3-4 parts of an antibacterial agent, 4-5 parts of graphene, 1.6-2 parts of a coupling agent, 5-6 parts of a curing agent and 1-1.2 parts of a flatting agent; s12, adding the weighed polymer mixed base material, graphene and coupling agent into stirring equipment together, stirring for the first time under the condition that the temperature is 25-40 DEG C, naturally cooling to 0-5 DEG C, then adding the flatting agent, antibacterial agent and curing agent into the stirring equipment together, and stirring for the second time, thereby obtaining the coating after the second-time stirring is completed; the high polymer material product meets the low-temperature curing condition, the water resistance, weather resistance and mechanical performance of the coating can be improved, it is guaranteed that the coating has good fluidity in the curing process, and the coating has good appearance and mechanical performance.

Owner:安徽捷翁新材料科技有限公司

A kind of preparation method of polymer cement waterproof mortar

ActiveCN112919857BStir wellLow efficiencySolid waste managementCement mixing apparatusPolymer sciencePolymer

The invention relates to a preparation method of polymer cement waterproof mortar, which uses a polymer cement waterproof mortar preparation equipment. The polymer cement waterproof mortar preparation equipment comprises a base, a stirring device and a feeding device, and a stirring device is arranged on the upper surface of the base. A feeding device is arranged above the stirring device. The present invention can solve the following problems at present: the raw materials of the mortar are put into the existing stirring equipment for stirring in proportion, so that the raw materials of the mortar are stirred in the stirring equipment due to the large input amount of the raw materials, resulting in the stirring equipment. It takes a longer time to mix these mortar raw materials evenly, which will reduce the use efficiency of the mortar and prolong the construction period; the mixing method of the mortar raw materials is too simple, and it is difficult to fully mix the raw materials of all parts of the mortar. The quality of the mortar is average and the use value is low, which affects the safety of the building.

Owner:浙江天造环保科技有限公司

A kind of environmental protection aerated brick short-cycle production line and its production process

ActiveCN112606193BImprove the mixing effectWell mixedDischarging apparatusCeramic shaping plantsBrickAluminium powder

This application relates to the field of green building materials, and in particular to a short-cycle production line of environmentally friendly aerated bricks and its production process. A short-cycle production line of environmentally friendly aerated bricks includes a first mixing zone for the first step of slurry Stirring once; the second stirring zone is used to stir the slurry for the second time; the transfer zone is used to transfer the slurry from the first stirring zone to the second stirring zone, and the transfer zone is provided with a feed inlet And a discharge port, the feed port is facing the discharge end of the first stirring zone, and the discharge port is facing the feeding end of the second stirring zone. The present application also provides a short-cycle production process for environmentally friendly aerated bricks, using the aforementioned short-cycle production line for environmentally friendly aerated bricks. The application has the following effects: while ensuring that the added auxiliary materials are mixed evenly with the slurry, the stirring time is reduced, and auxiliary materials such as aluminum powder are added to the aerated bricks of the application, so that the aerated bricks have fire resistance, noise reduction and degaussing Sex is better.

Owner:惠州市亚巴郎新型建材有限公司

Air exhaust, defoaming and stirring device for finishing agent

PendingCN114405340AImprove stirring efficiencyIncrease the mixing areaLiquid degasificationRotary stirring mixersReciprocating motionProcess engineering

The invention relates to the technical field of textile production, and discloses a finishing agent air exhaust defoaming stirring device which comprises a tank body and a stirring mechanism, the stirring mechanism comprises a rotating shaft and stirring blades, an automatic air exhaust mechanism is arranged on the upper end face of the tank body, and the automatic air exhaust mechanism comprises an air cylinder and a piston moving in the air cylinder in a sealed mode. Reciprocating movement of the piston is controlled by a driving mechanism, the upper end of the rotating shaft extends into the air cylinder and is in sealing running fit with the air cylinder and the tank body, an air suction hole is formed in the rotating shaft and located above the interior of the tank body, and an exhaust hole communicated with the air suction hole is formed in the rotating shaft and located in the air cylinder. A first one-way valve for discharging air in the tank body in a one-way mode is arranged in the exhaust hole, an exhaust pipe is arranged at one end of the air cylinder, a second one-way valve for discharging air in the air cylinder in a one-way mode is arranged in the exhaust pipe, and a linkage mechanism for driving the rotating shaft to rotate along with reciprocating motion of the piston is arranged between the rotating shaft and the piston. The stirring device can obviously improve the production efficiency of the finishing liquid and effectively reduce the equipment cost.

Owner:SHAOXING KEQIAO DEMEI FINE CHEM CO LTD

A high-efficiency porous cellulose fermentation and cultivation equipment

ActiveCN113426321BEasy to sampleEasy to observeRotary stirring mixersMixer accessoriesCelluloseElectric machinery

The invention relates to the technical field of auxiliary devices of fermentation equipment, in particular to a high-efficiency porous cellulose fermentation and cultivation equipment, comprising a horizontally arranged bottom plate, a box opening at the top of the box body, and a box cover at the box opening. A connecting shaft is arranged longitudinally in the middle, and a stirring mechanism is arranged at the bottom end of the connecting shaft. The stirring mechanism includes four supporting shafts arranged horizontally in a positive direction. Each supporting shaft is fixedly sleeved with a stirring wheel, and the top of the connecting shaft is provided with a drive The driving mechanism includes a motor, the bottom plate is provided with a fixed column, the top of the fixed column is provided with a top plate, the bottom end of the top plate is provided with a guide column, the middle of the fixed column is slidably provided with a groove plate, and the side wall of the groove plate is provided with an arc-shaped inclined surface The box cover is provided with two connecting rods, the lower part of the fixed column is rotatably provided with a supporting plate, and two cylinders are symmetrically arranged on the supporting plate. In the present invention, the raw materials are stirred in multiple dimensions, the stirring time is shortened, the cleaning is convenient, and the work efficiency is improved.

Owner:苏州汇涵医用科技发展有限公司

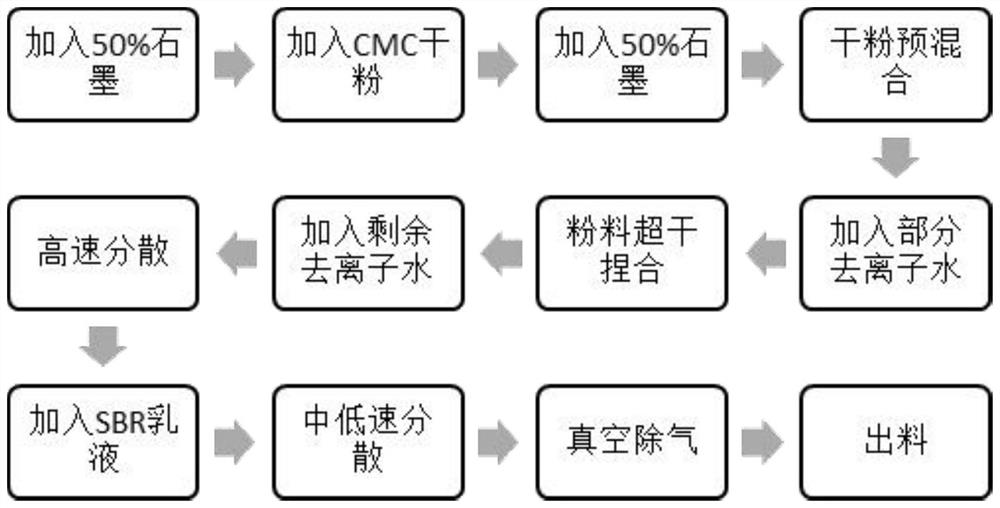

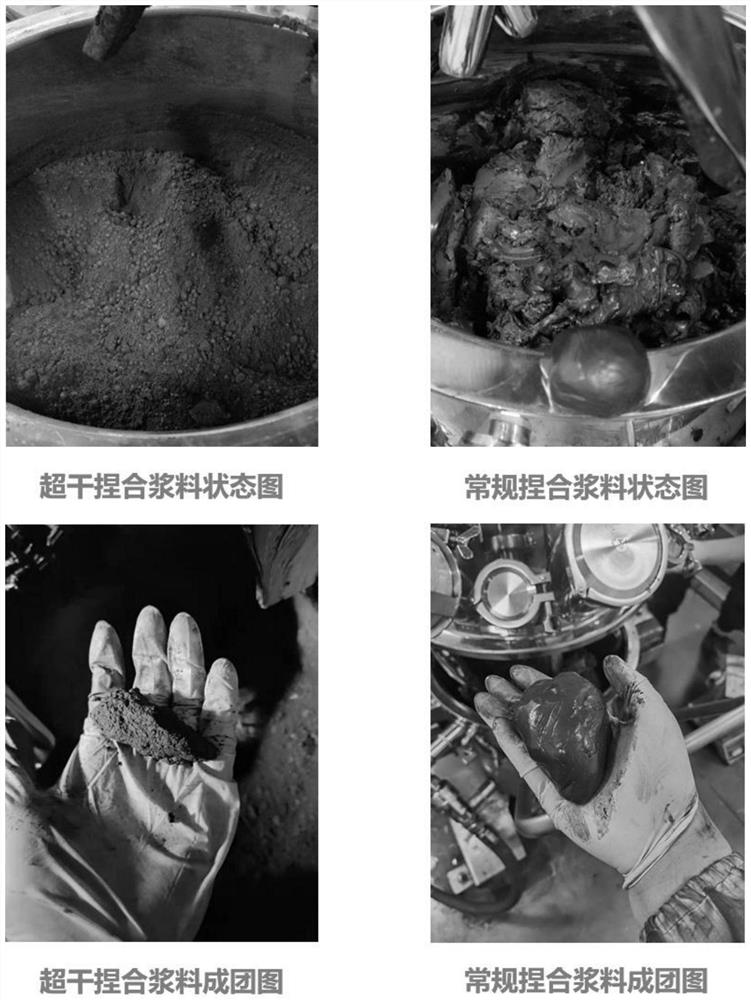

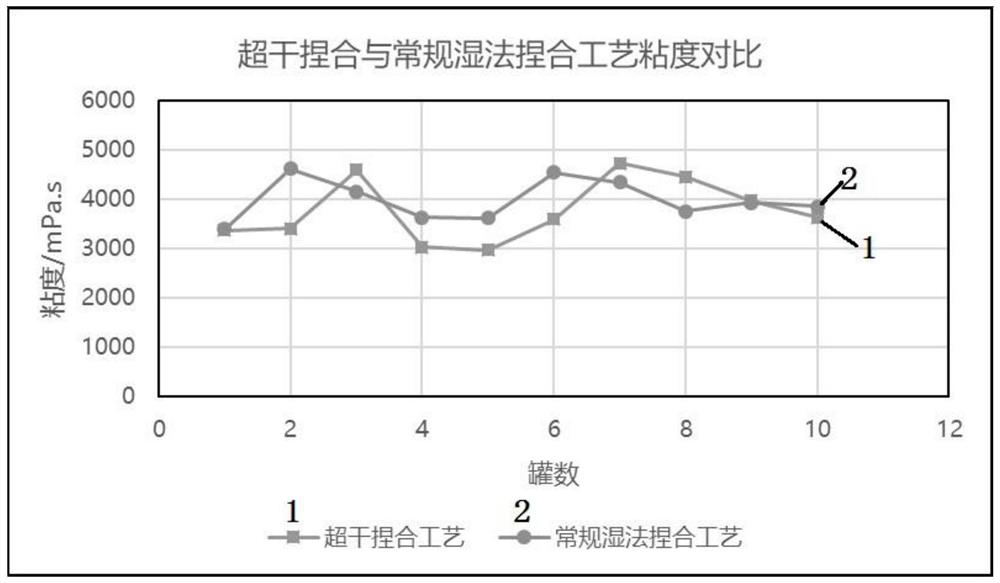

Negative electrode slurry dry-type preparation method

PendingCN113991106ASmall finenessFully coveredCell electrodesSecondary cellsElectrical batterySlurry

The invention belongs to the technical field of battery slurry preparation, and particularly relates to a negative electrode slurry dry-type preparation method which comprises the following steps: S1, mixing and stirring a negative electrode active material and a thickening agent to obtain a first premix; s2, adding part of the solvent into the first premix, stirring, and performing dry kneading to obtain a second premix; s3, adding the residual solvent into the second premix, and stirring and dispersing to obtain a third premix; and S4, adding a binder into the third premix, and stirring and dispersing to obtain the negative electrode slurry. According to the dry-type preparation method of the negative electrode slurry, a conduction agent is not used, the step of preparing a glue solution is omitted, the dry mixing time is shortened, meanwhile, dry-type kneading can crush large-particle negative electrode active substances, the fineness of the slurry is reduced, and the stability and uniformity of the negative electrode slurry are guaranteed.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

A distributor and clarifier

ActiveCN109293113BShorten the mixing timeImprove efficiencyFlow mixersWater/sewage treatment by ion-exchangeLiquid stateEngineering

The invention relates to a distributor and a clarification tank. The distributor is arranged in a pipeline under the working condition. The inside of the distributor is provided with a hollow cavity for accommodating a liquid medicament, and the distributor is provided with several distribution holes used for letting the liquid medicament in the hollow cavity flow out. Baffle boards are arranged adjacent to at least part of the distribution holes, and the baffle boards are arranged according to the following mode: at least a part of the liquid medicament flowing out of the corresponding distribution holes is impacted by the liquid in the pipeline onto the baffle boards and is then reflected towards the place outside the area of the baffle boards under the action of the baffle boards so asto be mixed with the liquid in the pipeline by the utilization of the flowing liquid. By the flowing of the liquid during the pipeline transportation of the liquid, the liquid medicament and the liquid in the pipeline are mixed, and the liquid medicament flowing out of the distribution holes will be impacted by the liquid onto the baffle boards and reflected to the place outside the area of the baffle boards. Thereby, the liquid medicament is quickly dispersed under the reflection effect of the baffle boards, and the mixing effect is improved.

Owner:BGT GRP CO LTD

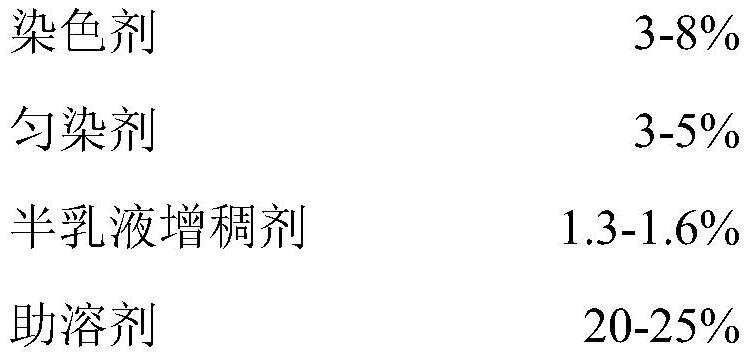

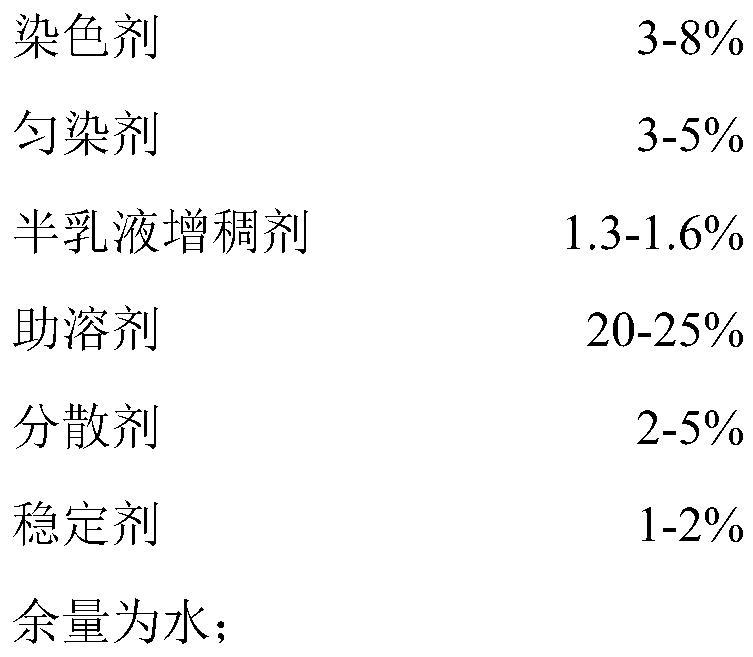

Organic dye for fabric dyeing and preparation method thereof

The invention relates to an organic dye for fabric dyeing and a preparation method thereof. The organic dye is prepared from the following components in percentage by weight: 3-8% of a dyeing agent, 3-5% of a leveling agent, 1.3-1.6% of a semi-emulsion thickening agent, 20-25% of a cosolvent, 2-5% of a dispersing agent, 1-2% of a stabilizer and the balance of water, the coloring agent is organic dye; the leveling agent is an isocyanate compound; the semi-emulsion thickening agent is prepared from a thickening agent and an emulsifying agent according to the weight ratio of 50: (2-3); the cosolvent is an organic solvent; the dispersing agent is an anionic dispersing agent or an amphoteric dispersing agent. The preparation method comprises the following steps: S1, preparing a semi-emulsion thickening agent; s2, dye grinding; s3, preparing the organic dye. The dye has the advantages of being wide in application range, long in storage time and good in stability.

Owner:晋江市维盛织造漂染有限公司

Paclitaxel liposome dissolution stirring mechanism

InactiveCN108499420AAchieving stirringImprove uniformityShaking/oscillating/vibrating mixersRotary stirring mixersBiochemical engineeringDissolution

The invention relates to the technical field of life science and medicine, in particular to a paclitaxel liposome dissolution stirring mechanism. The paclitaxel liposome dissolution stirring mechanismcomprises a stirring barrel, wherein a first stirring shaft is arranged in the stirring barrel; the top of the stirring barrel is provided with a slide sleeve; the first stirring shaft is glidingly arranged in the slide sleeve; a tension spring is arranged in the slide sleeve; one end of the tension spring is fixedly connected with the stirring barrel; the other end of the tension spring is rotationally connected onto the first stirring shaft; the bottom of the stirring barrel is provided with a slide groove; an electromagnet is arranged at the end part of the slide groove; iron semicircle buckle plates are oppositely arranged in the slide groove; the semicircle buckle plates are in slide arrangement and can be buckled to form a sleeve; the sleeve and the first stirring shaft form a pairof threaded pairs; springs are connected between the semicircle buckle plates and the electromagnet; the bottom end of the first stirring shaft is provided with a first wafer; an annular second waferin contact with the first wafer is arranged on the bottom wall of the stirring barrel; a pressure spring is connected between the bottom end of the first stirring shaft and the bottom wall of the stirring barrel. The paclitaxel liposome dissolution stirring mechanism solves the problem of nonuniform liposome stirring in the prior art.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

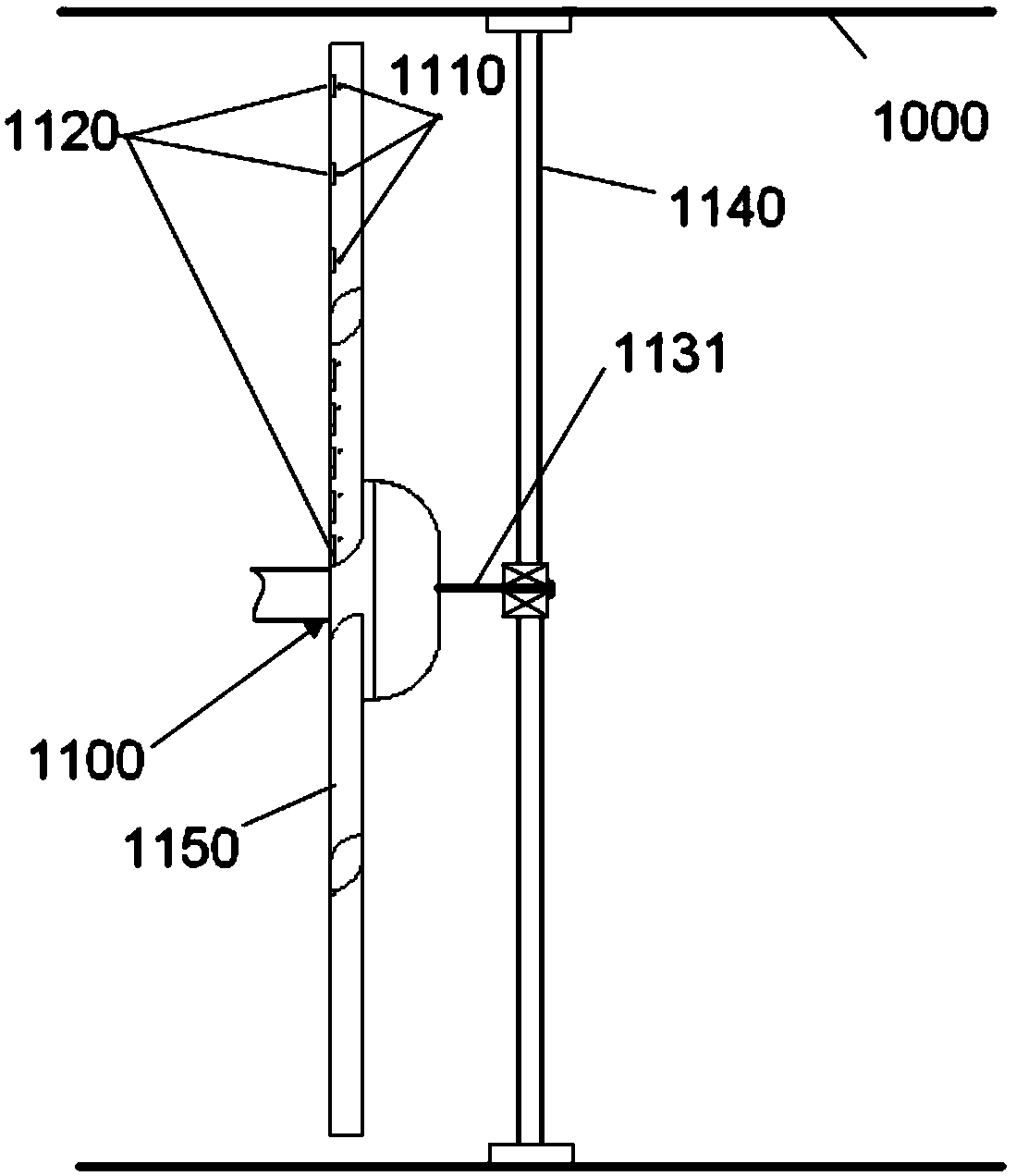

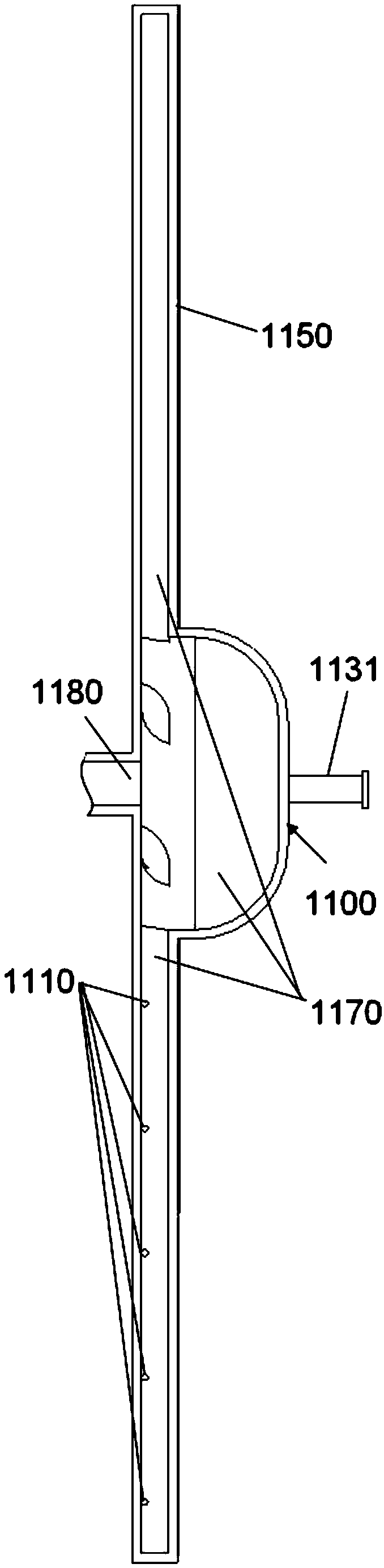

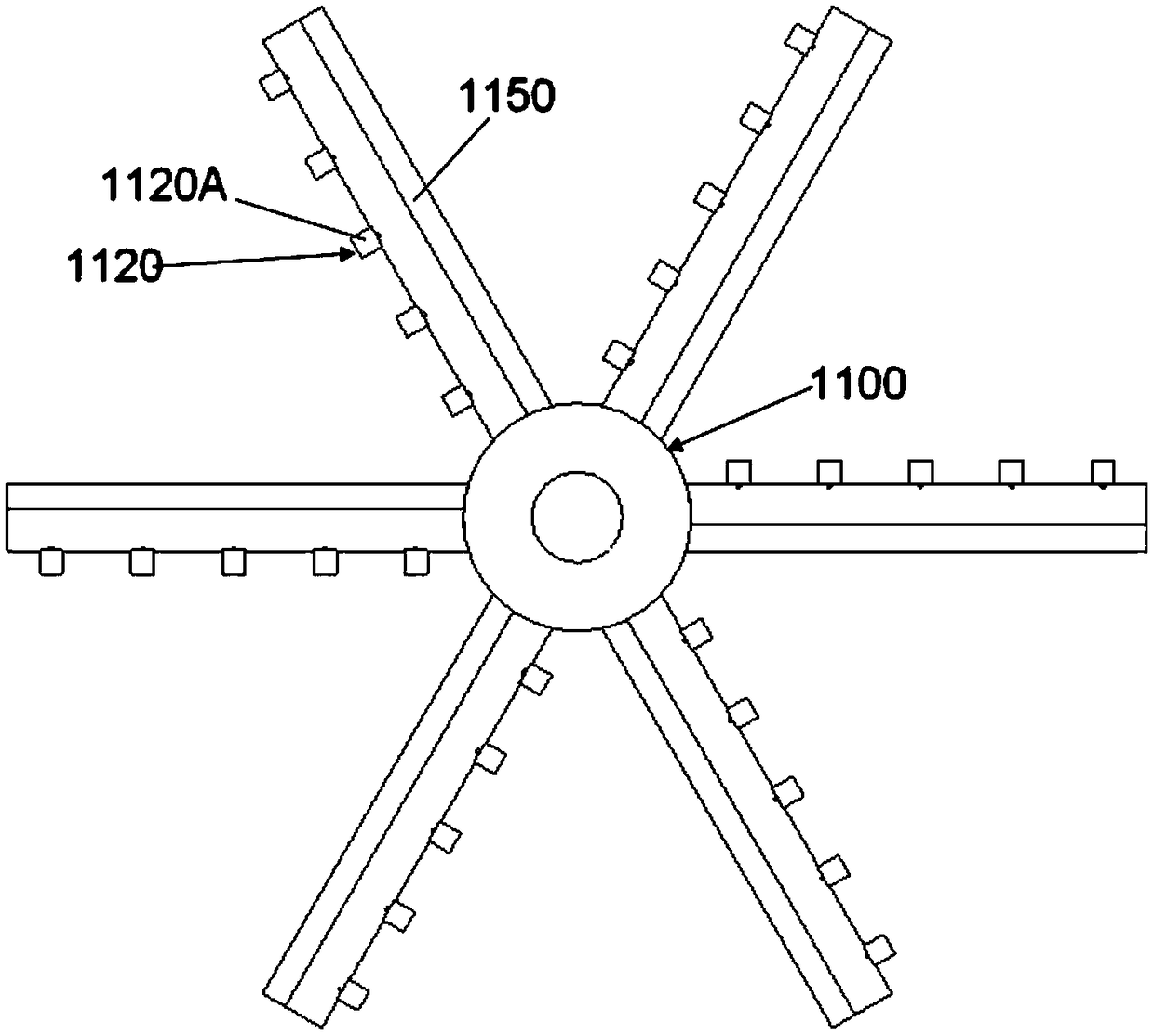

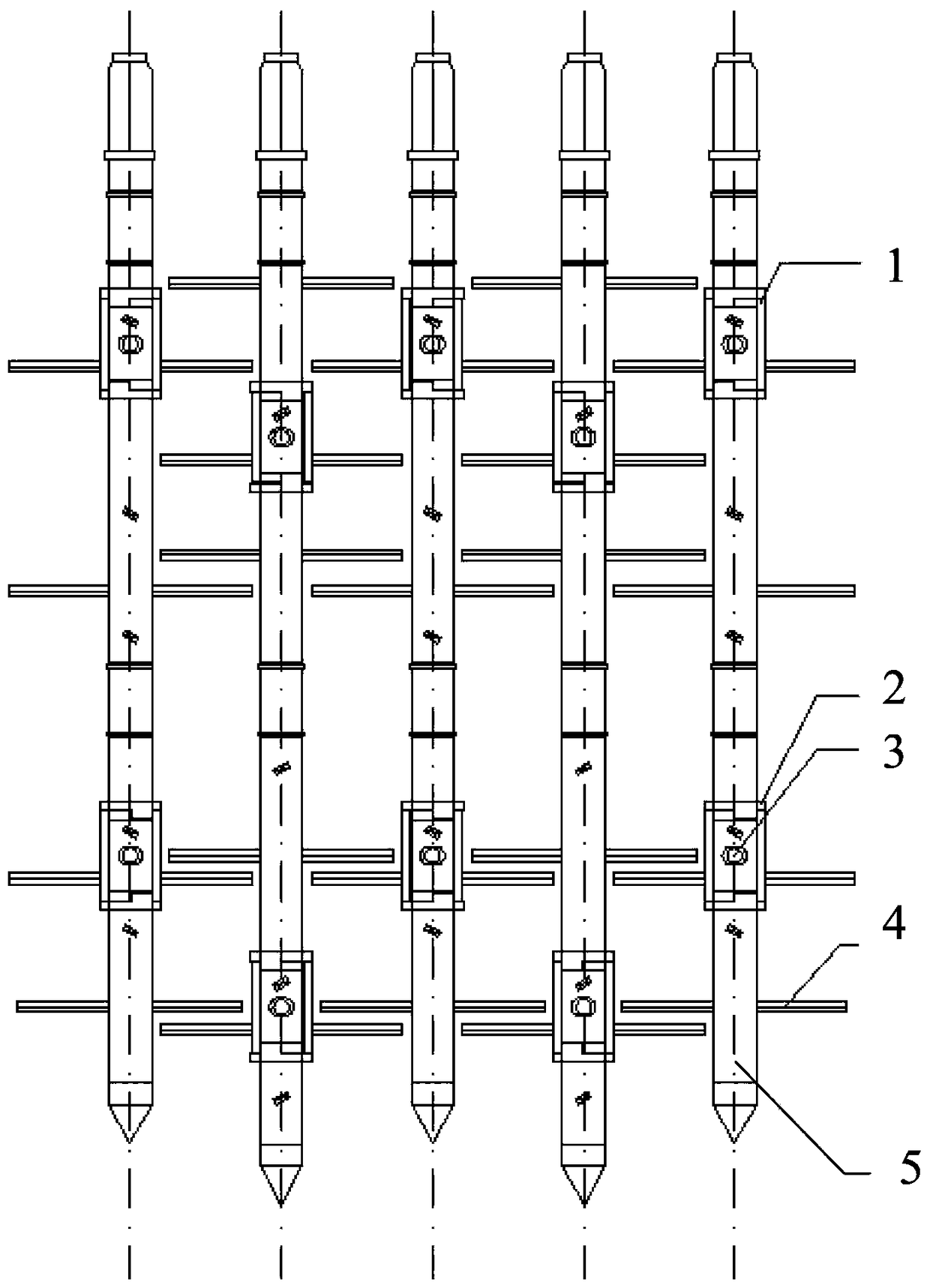

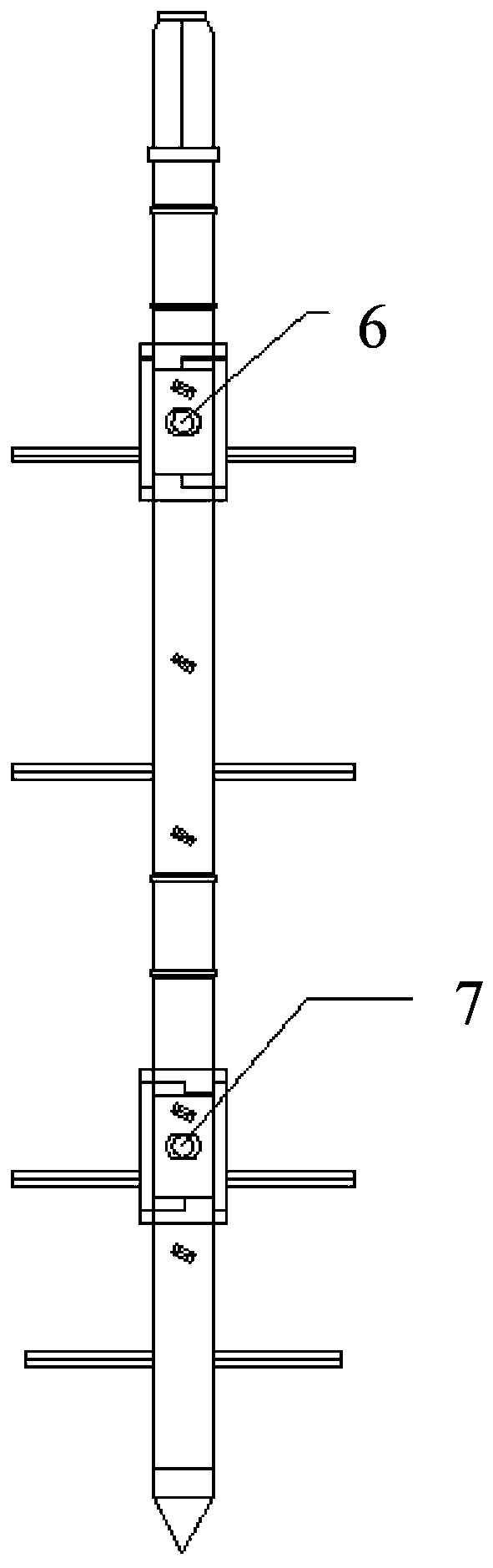

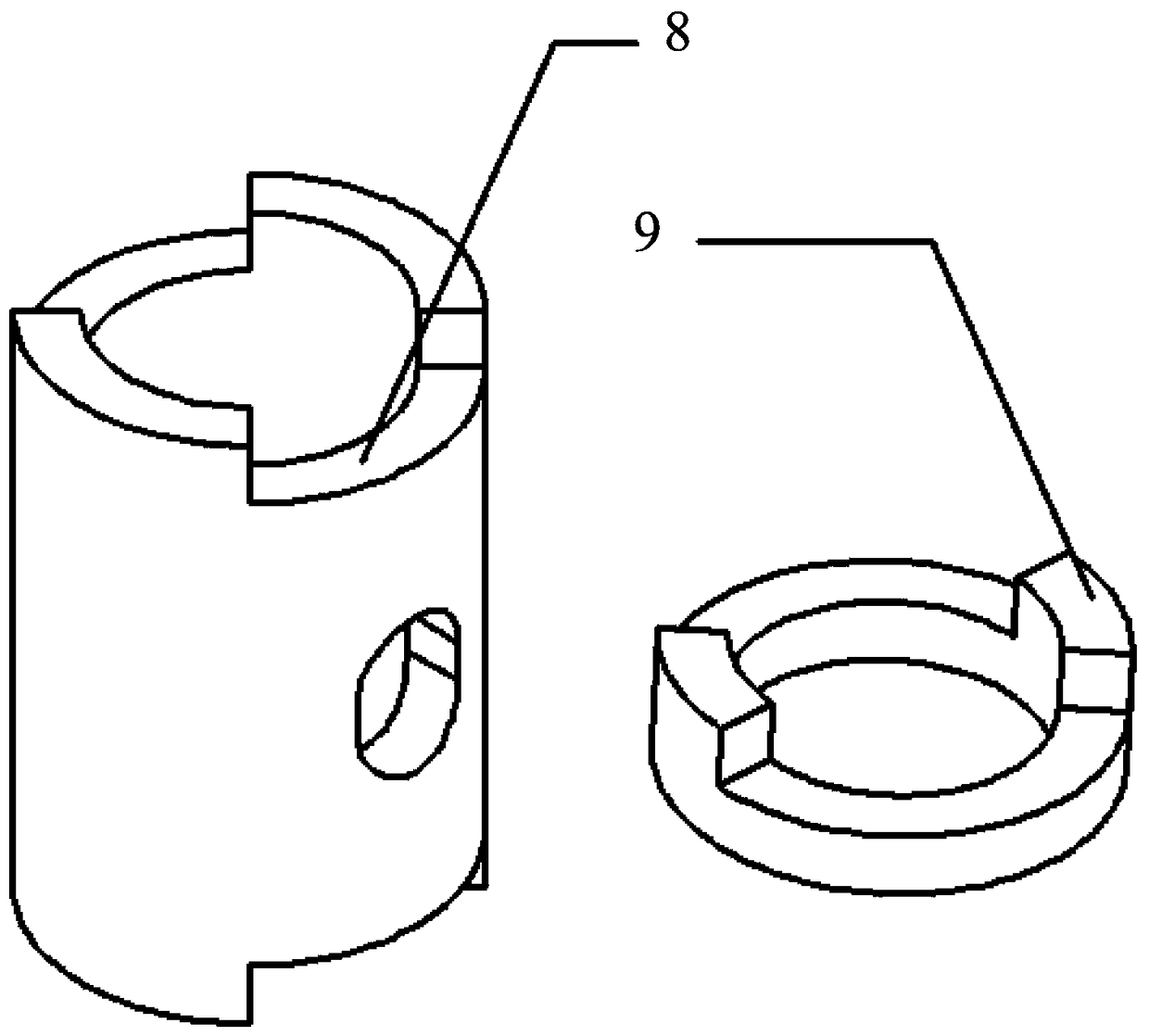

A cement-soil mixing pile device that can convert up and down to spray grout

ActiveCN104032733BSolve the phenomenon of uneven mixingShorten the mixing timeDrilling rodsDrilling casingsSoil mixingSlurry

The invention relates to a cement soil mixing pile device capable of switching up and down to spray slurry and a construction method. The device is improved and optimized on the basis of an original cement soil mixing pile machine. The device comprises movable hoop vanes, fixing sleeves, mixing vanes, a drill rod and slurry spraying opening groups. Upper and lower slurry spraying openings are automatically closed or opened under the action of the mechanical force of the movable hoop vanes according to different mixing directions, the lower slurry spraying opening sprays slurry when the drill rod drills downwards, and the upper slurry spraying opening sprays slurry when the drill rod is lifted. Compared with cement soil mixing pile devices and construction methods in the prior art, the cement soil mixing pile device capable of switching up and down to spray slurry and the construction method have the advantages that the mixing is uniform, the mixing efficiency is high, costs are low, the efficiency is high, the construction period is shortened, and the like.

Owner:SHANGHAI CHENGDI CONSTR +1

Concrete proportioning device with quantitative output mechanism

ActiveCN113561332ARealize the delivery mixing ratioWell mixedMixing operation control apparatusIngredients weighing apparatusIndustrial engineeringSupport plane

The invention relates to the technical field of concrete proportioning and mixing equipment, in particular to a concrete proportioning device with a quantitative output mechanism. The concrete proportioning device comprises a stirring assembly and a conveying assembly, wherein a feeding assembly is arranged above the stirring assembly, the feeding assembly comprises a support frame, a storage hopper is fixedly connected above the support frame, a metering hopper is fixedly connected below the storage hopper, the conveying assembly is arranged between the stirring assembly and the metering hopper, the conveying assembly comprises a rotating ring, a feeding plate is fixedly connected to the interior of the rotating ring, and a driving assembly is arranged below the feeding plate. According to the concrete proportioning device, conveying, mixing and proportioning of various materials can be effectively achieved, and the materials can be sequentially stacked through rotary feeding while the various materials are conveyed, so that the materials are fully mixed, the proportioning efficiency is higher, the subsequent working time is greatly shortened, and the overall working efficiency is improved.

Owner:高碑店市长盛商砼混凝土有限公司

A raw material mixing equipment for 3D printing material production

ActiveCN111015989BImprove mobilityShorten the mixing timeAdditive manufacturing apparatus3D object support structuresElectric machineryProcess engineering

Owner:佛山市广科产业技术研究院有限公司

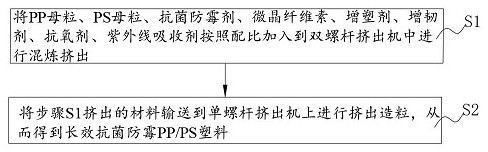

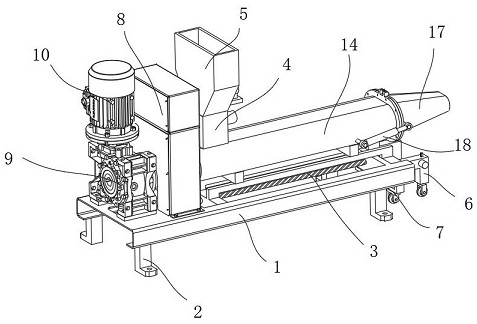

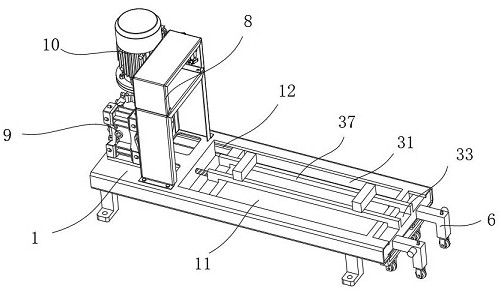

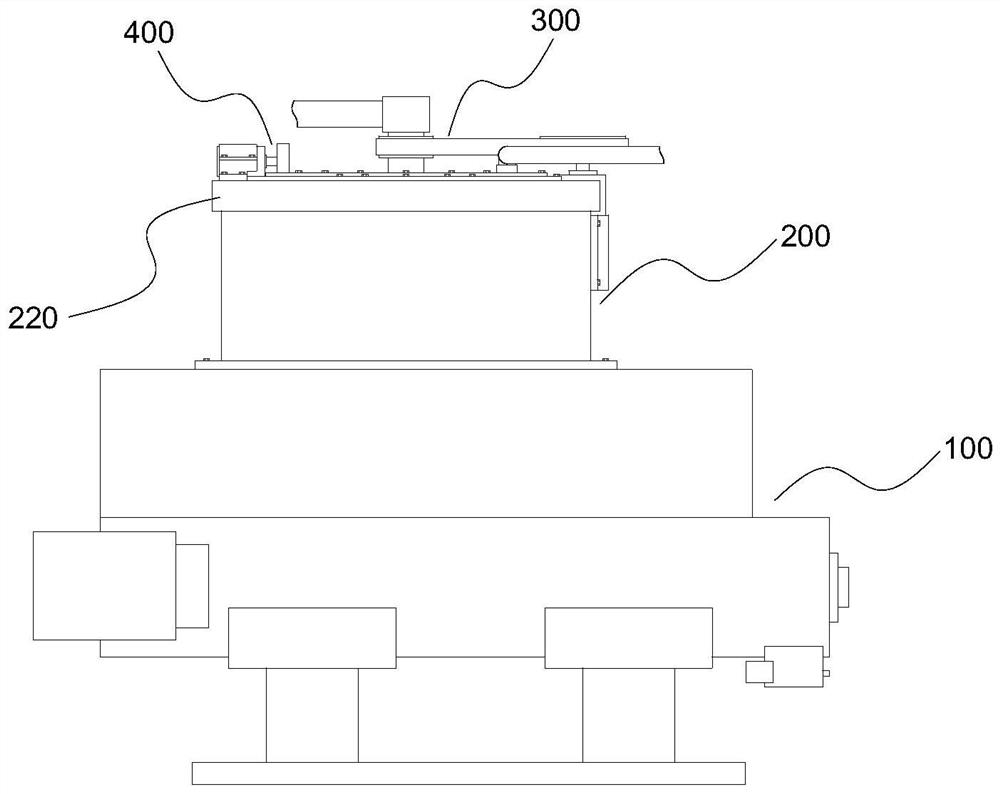

Long-acting antibacterial and mildew-proof PP/PS plastic and preparation method thereof

The invention provides long-acting antibacterial and mildew-proof PP / PS plastic and a preparation method thereof. The long-acting antibacterial and mildew-proof PP / PS plastic is prepared from following raw materials in parts by weight: 120-165 parts of PP master batch, 170-240 parts of PS master batch, 6-13 parts of an antibacterial and mildew-proof agent, 6-9 parts of microcrystalline cellulose, 2-4 parts of a plasticizer, 1-5 parts of a toughening agent, 1-5 parts of an antioxidant and 1-3 parts of an ultraviolet light absorber. The preparation method comprises the following steps: S1, adding the raw materials into a double-screw extruder according to the proportion, and mixing and extruding; and S2, conveying the materials extruded in the step S1 to a single-screw extruder, and granulating to obtain a finished product. The long-acting antibacterial and mildew-proof PP / PS plastic is prepared from the PP master batch, the PS master batch, the antibacterial and mildew-proof agent, the microcrystalline cellulose, the plasticizer, the toughening agent, the antioxidant and the ultraviolet light absorber, and the raw materials are premixed before entering a shell of the extruder, so that the mixing uniformity is improved, and the mixing time in an extrusion screw is shortened.

Owner:余姚市谐丰模塑有限公司

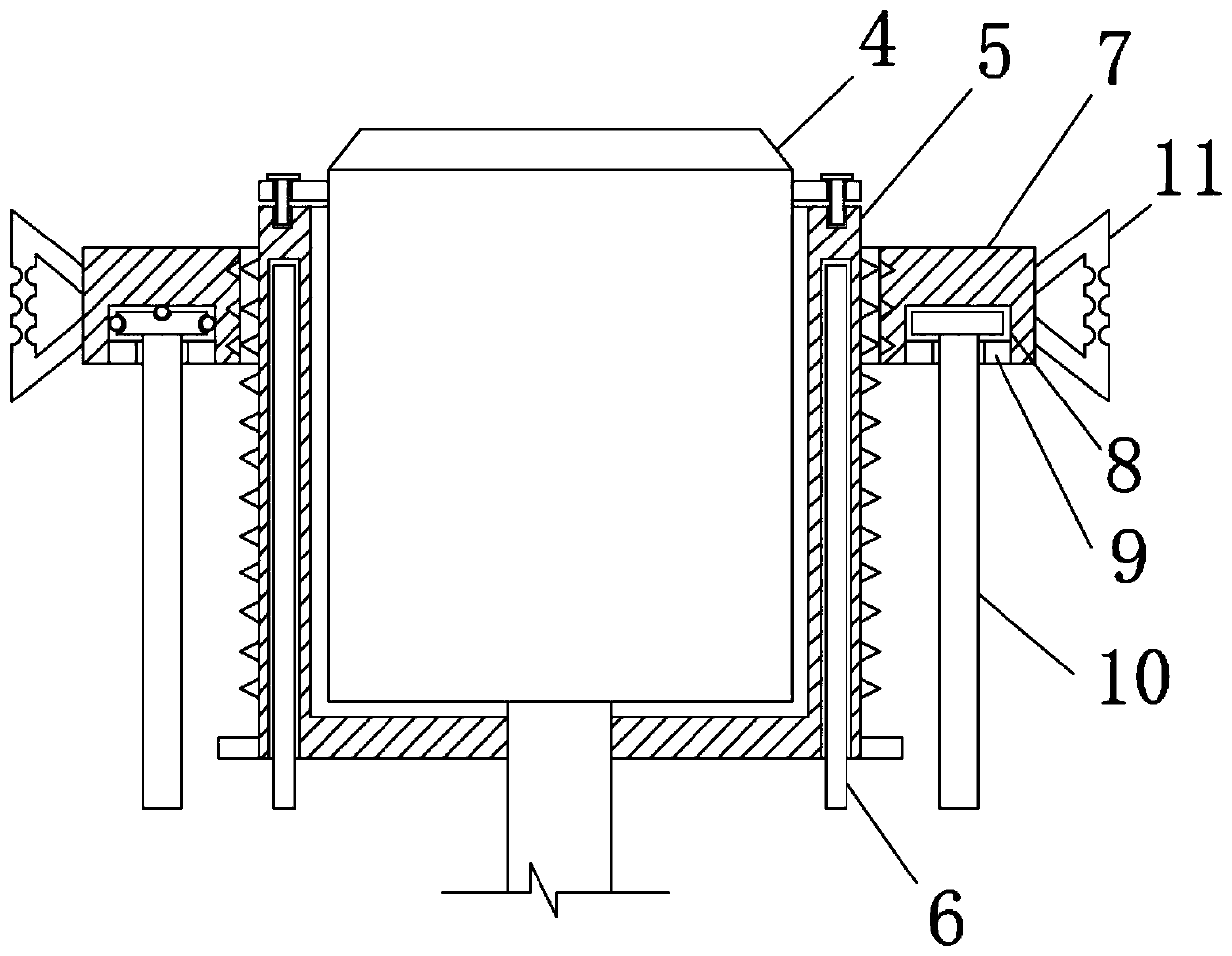

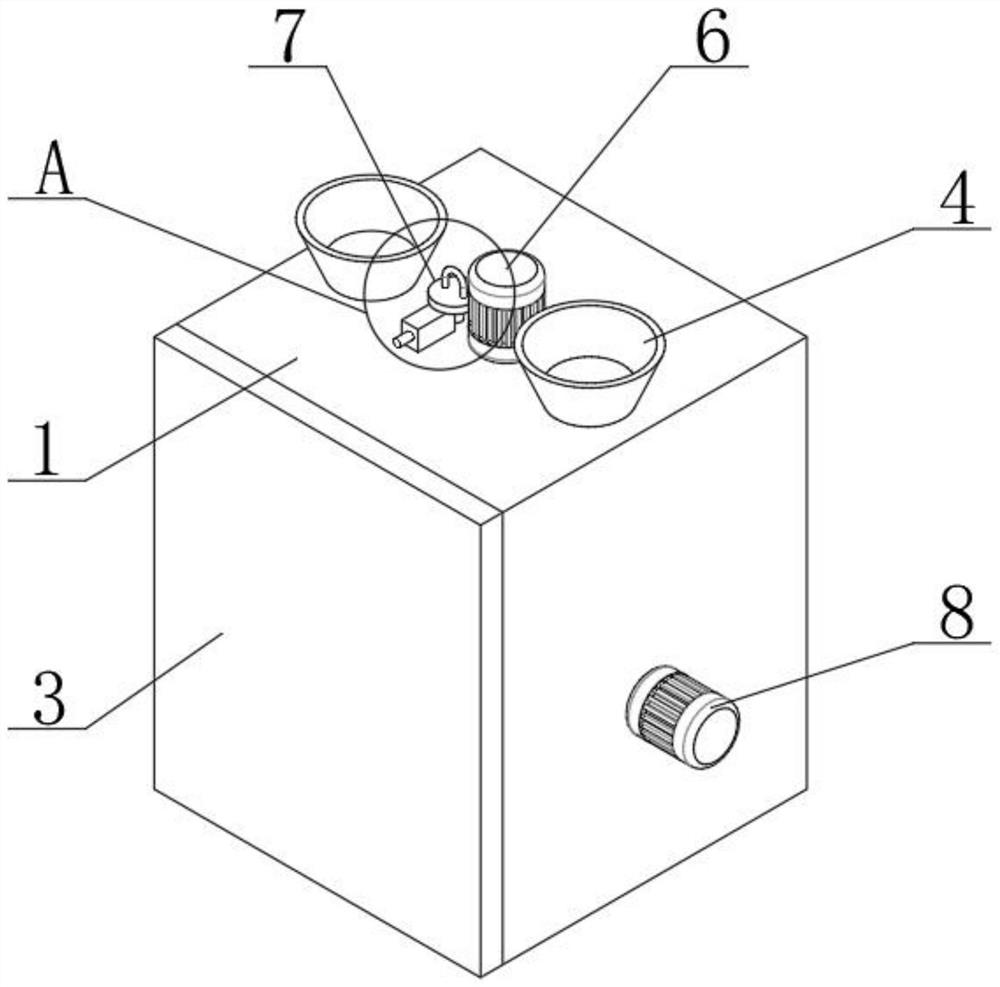

Stirring equipment with premixing function for battery production

PendingCN114653235ANovel structureShorten mixing timeElectrode manufacturing processesTransportation and packagingProcess engineeringEngineering

The invention provides battery production stirring equipment with a premixing function. The battery production stirring equipment comprises a screw stirrer body and a premixing device mounted at the top of the screw stirrer body, and the premixing device comprises a liquid supply mechanism and a powder feeding mechanism; the liquid supply mechanism comprises a liquid spraying pipe, the liquid spraying pipe is arranged in the middle of the powder feeding mechanism in a penetrating mode, and the liquid spraying pipe can spray liquid to the periphery of the outer side of the bottom; the powder feeding mechanism can feed powder downwards, a feeding area is in a circular-ring-shaped outline, and the fed powder makes contact with liquid diffusing towards the periphery to be premixed. The device is novel in structure, can preliminarily mix fed liquid and powder, and is also convenient for uniformly distributing and feeding subsequently added materials, so that the subsequent stirring and mixing time is shortened, and the working efficiency is improved.

Owner:GUANGDONG ORRITT NEW ENERGY EQUIP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com