Patents

Literature

1981results about "Liquid ingredients supply apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

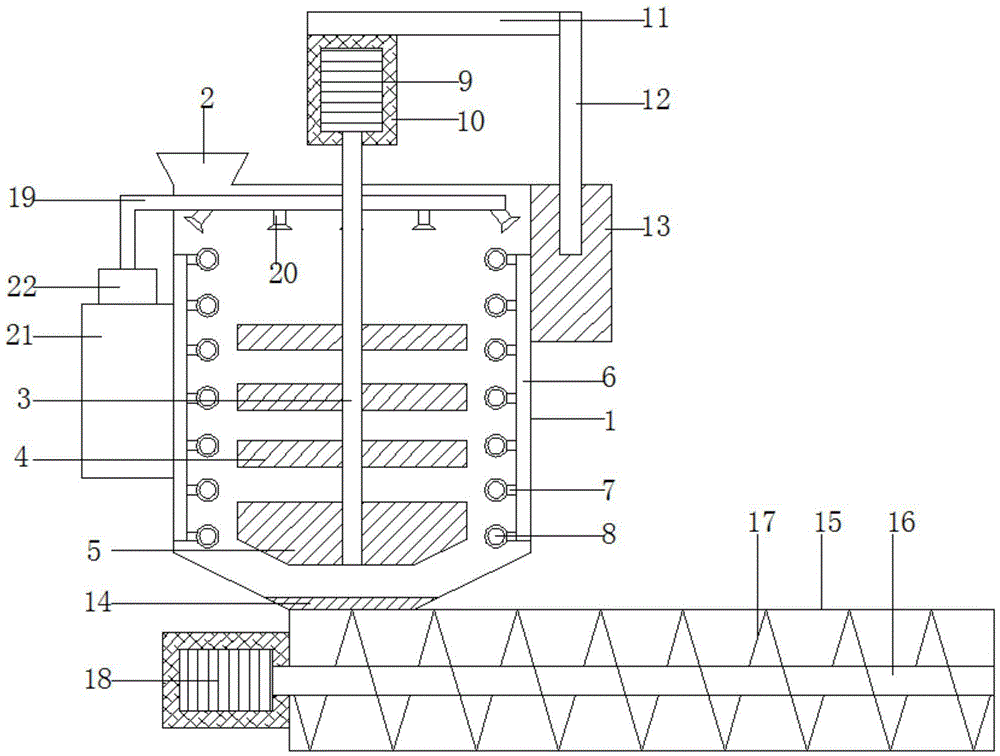

Efficient mixing system for well cementing operation

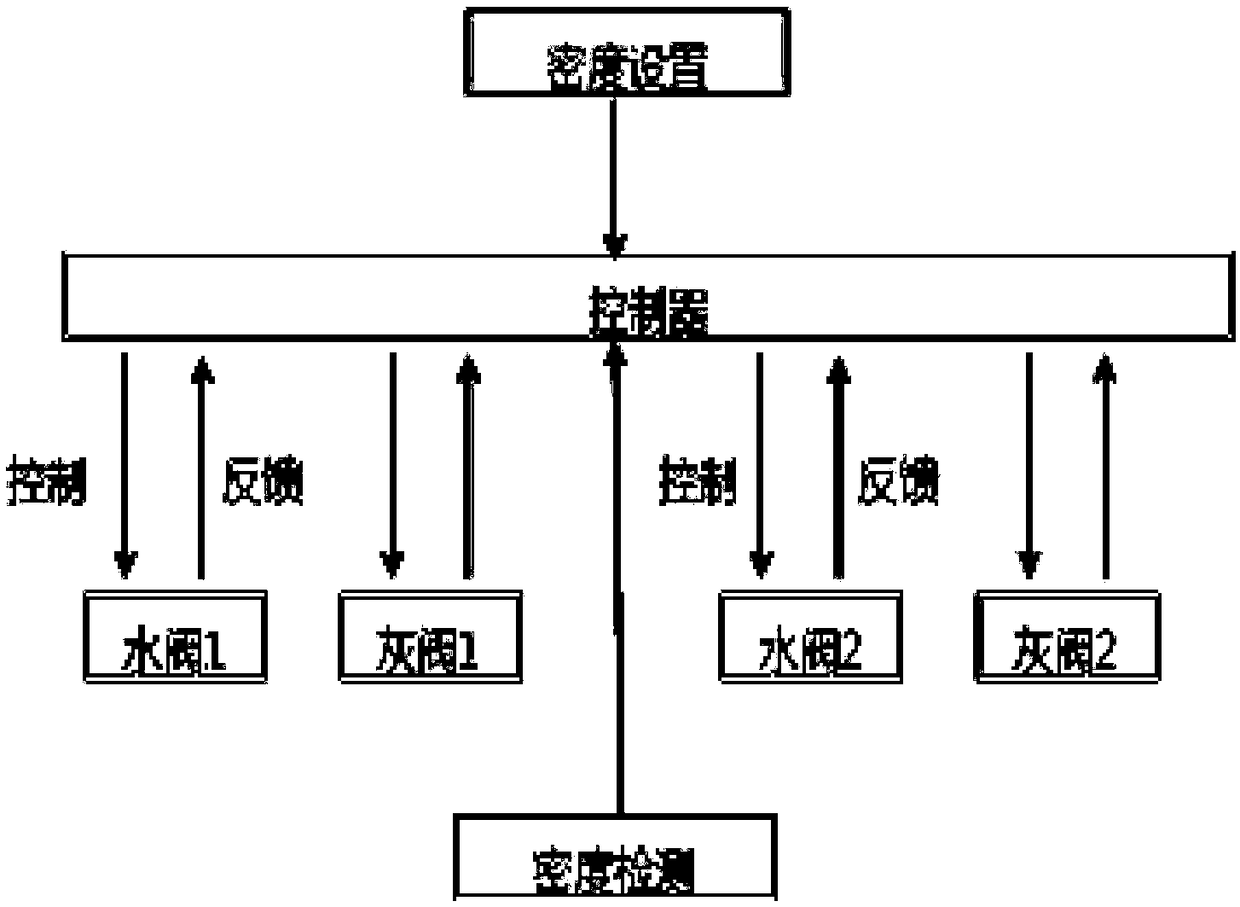

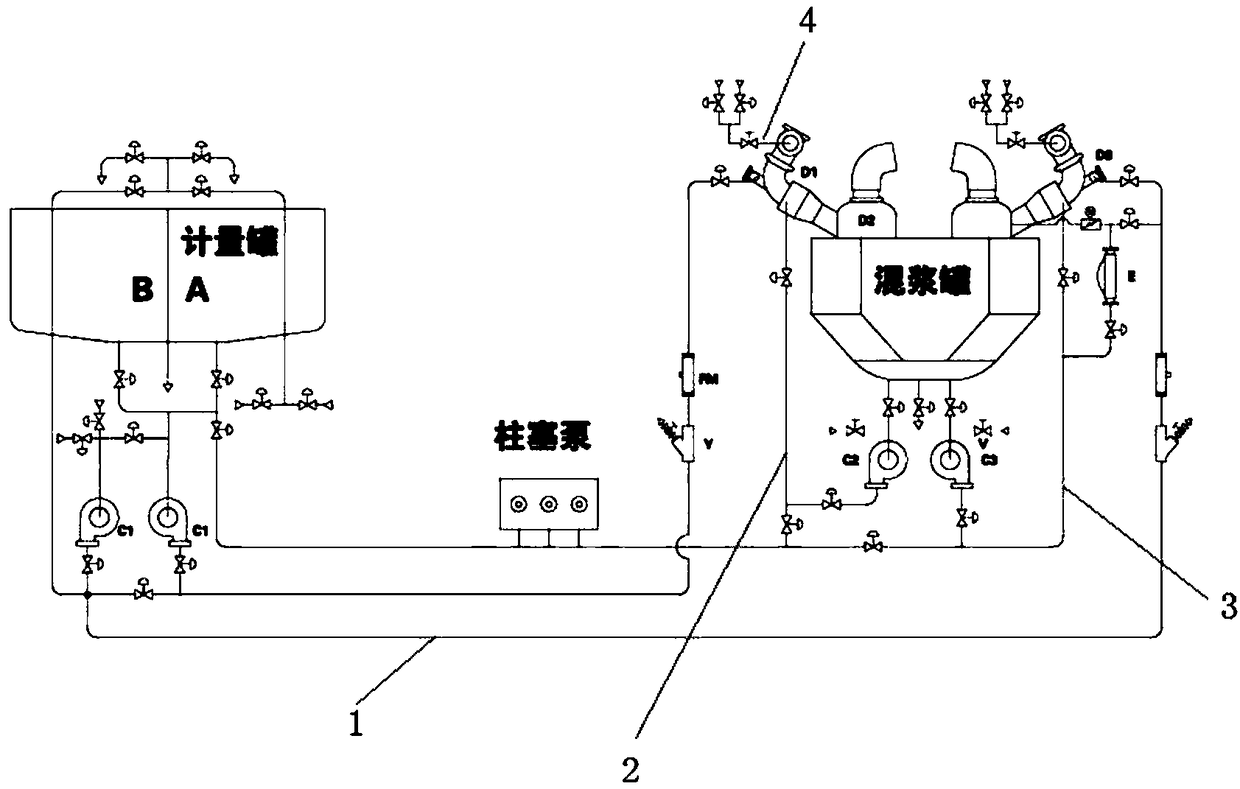

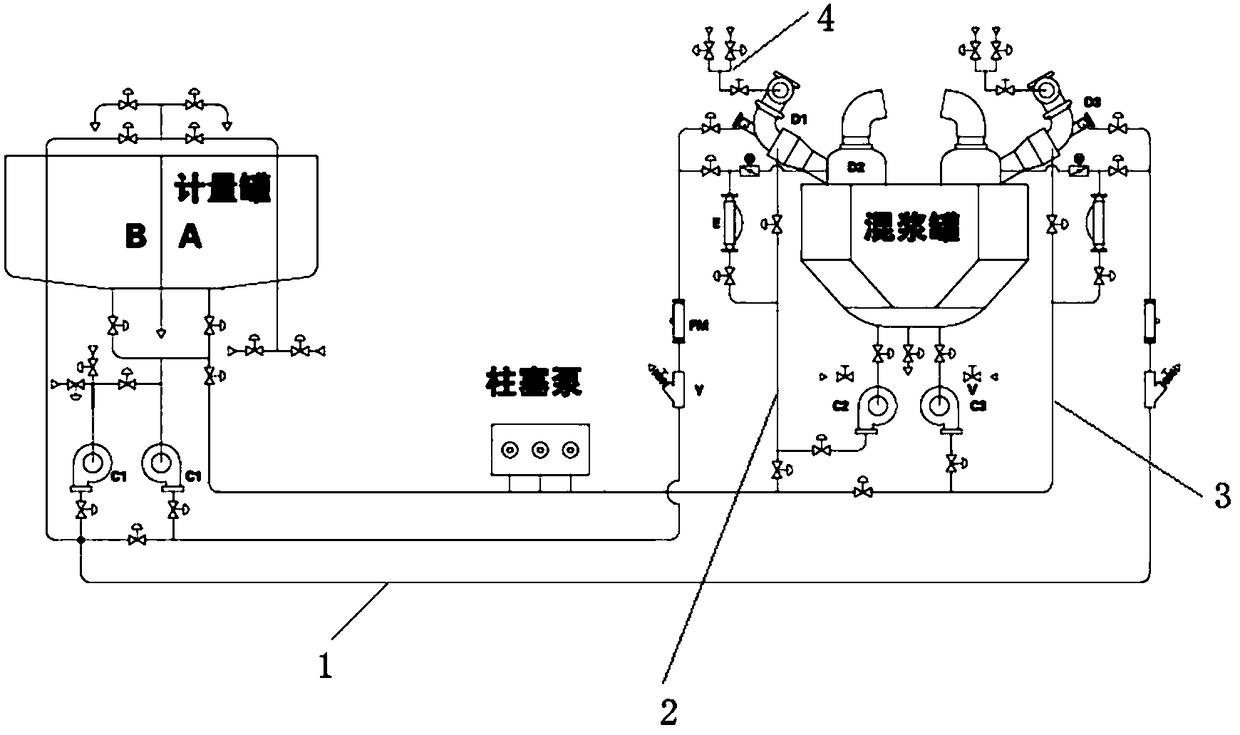

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

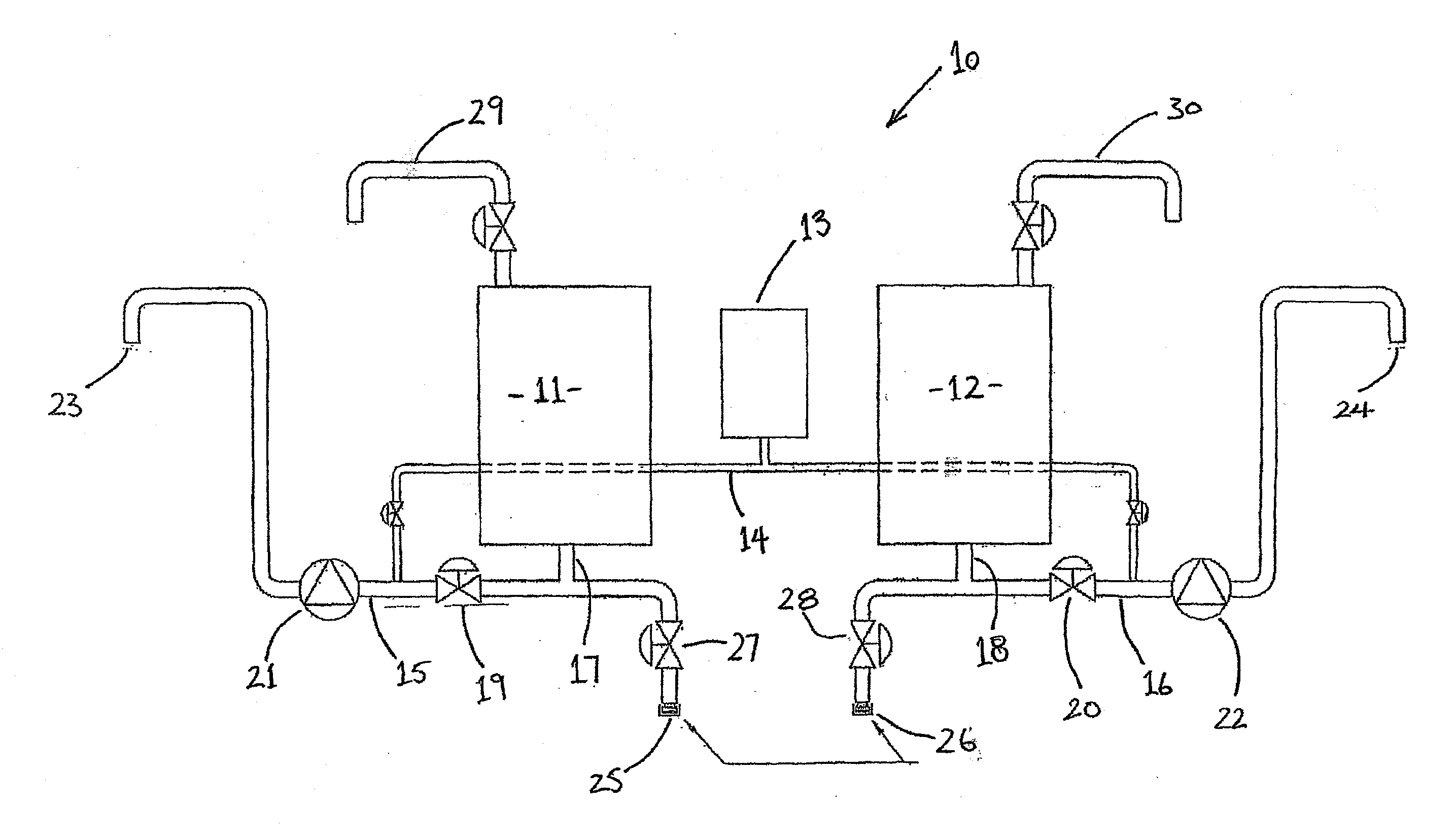

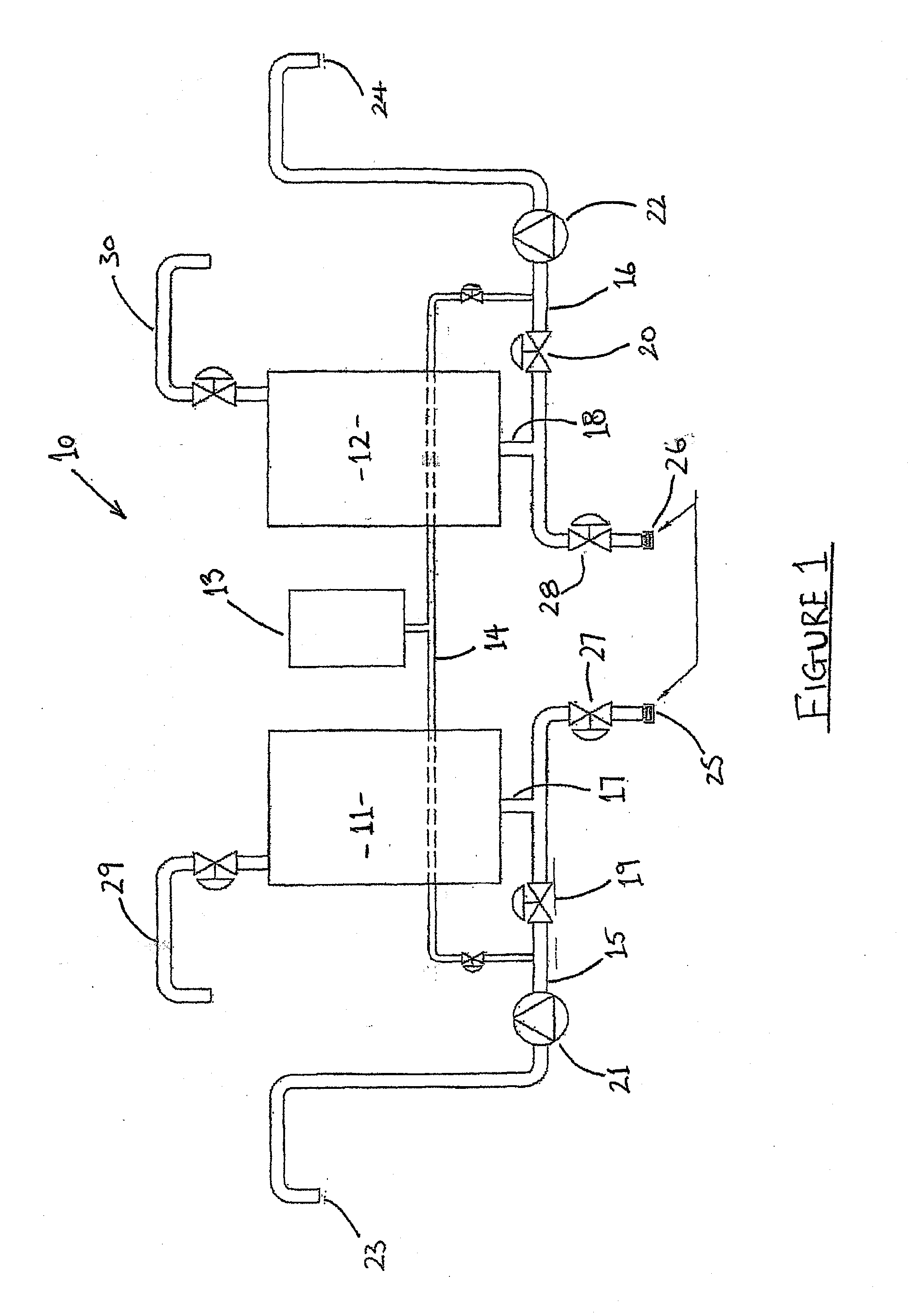

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

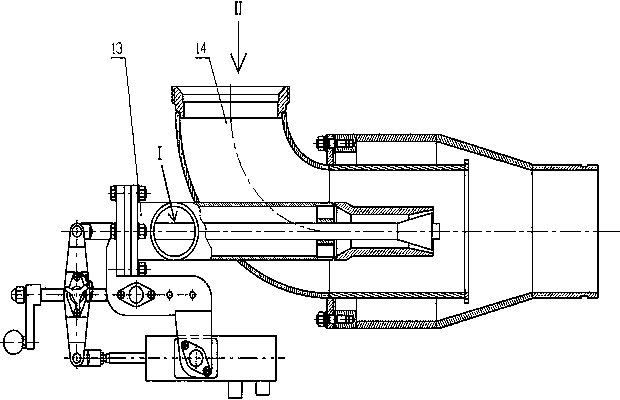

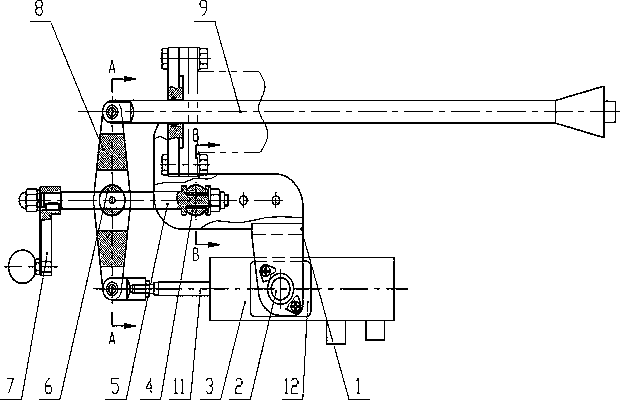

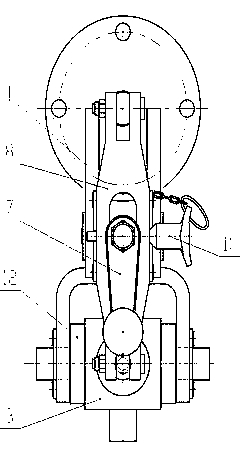

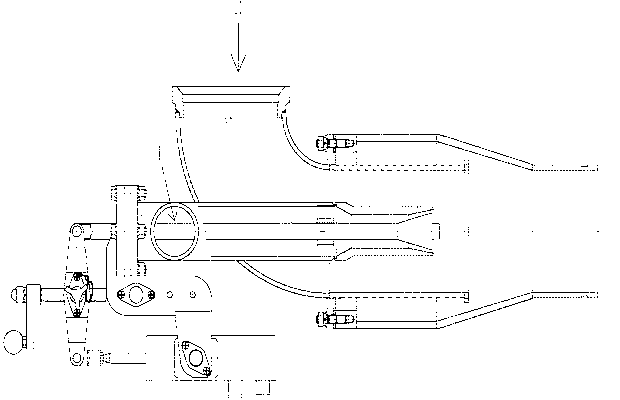

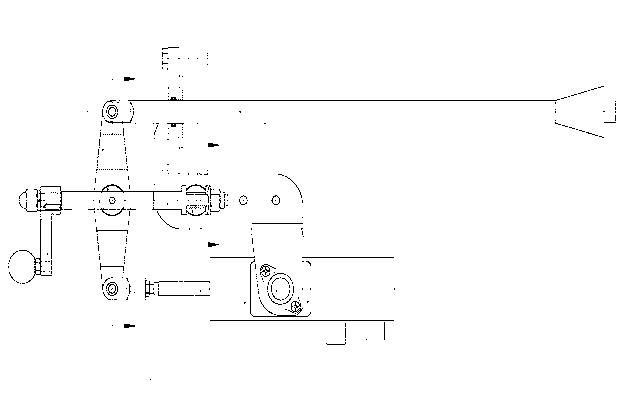

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335BControl openingAccurate opening controlFlow mixersTransportation and packagingHigh energyEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

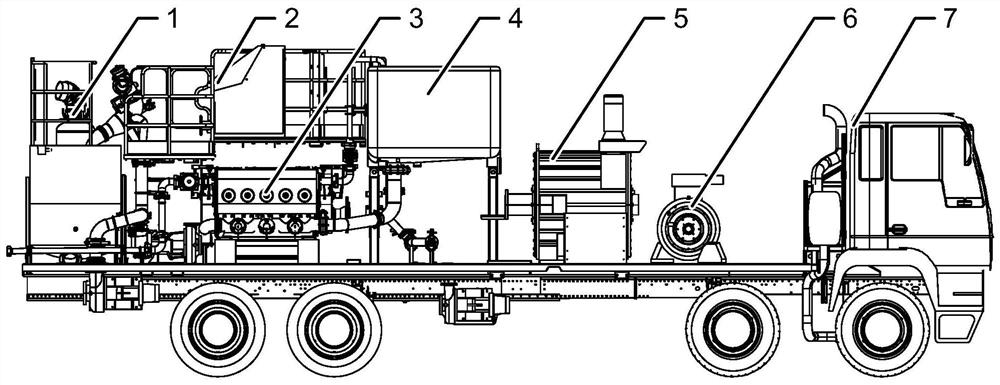

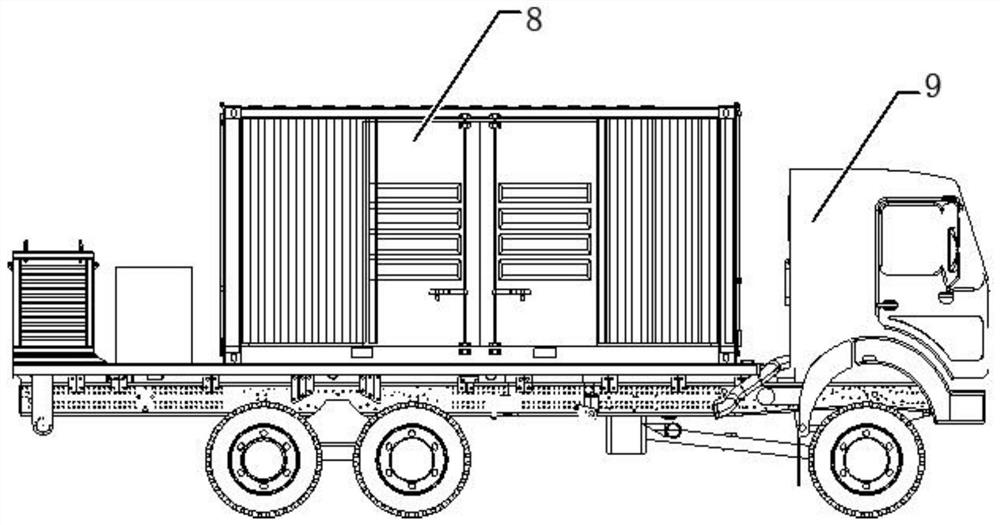

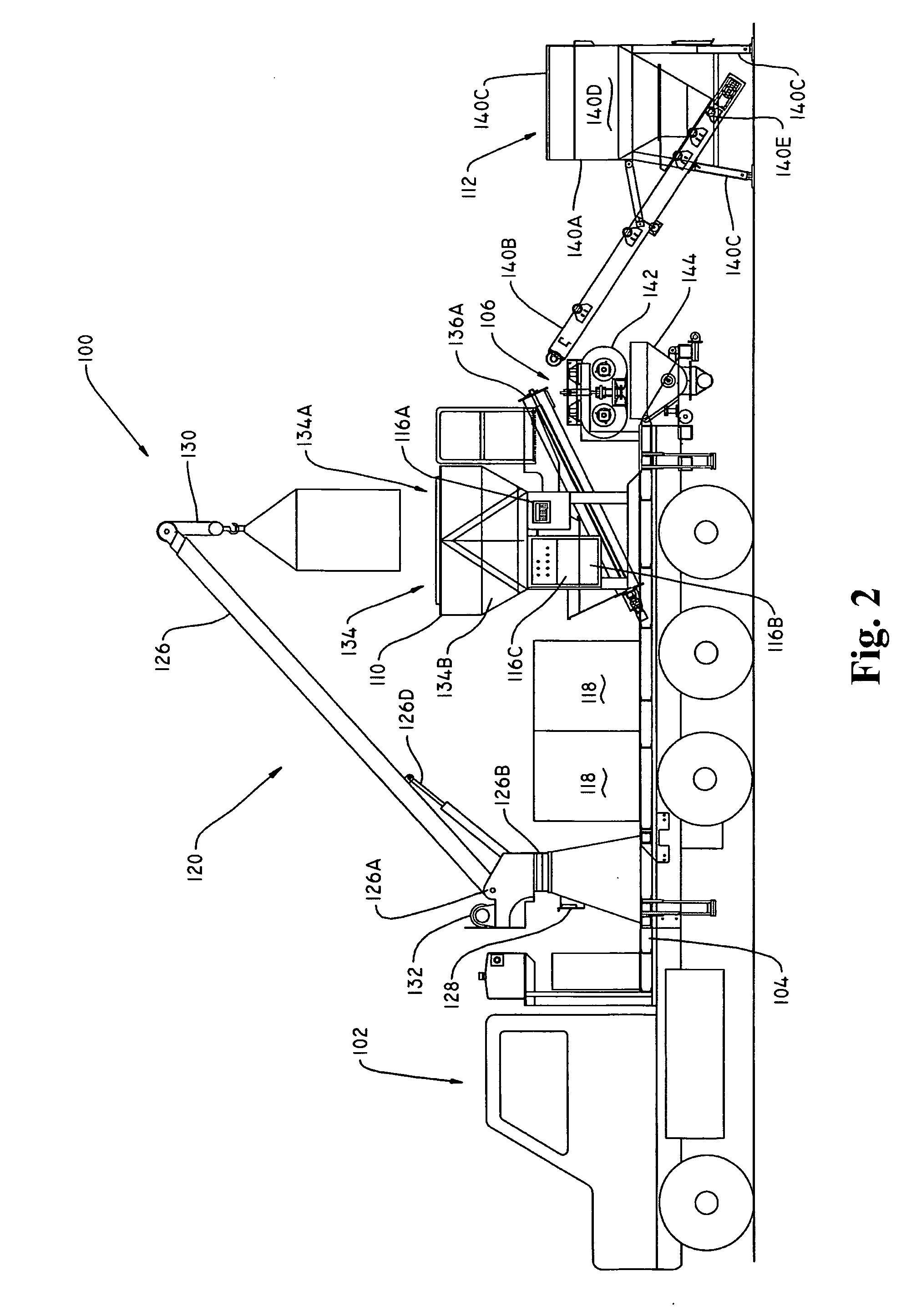

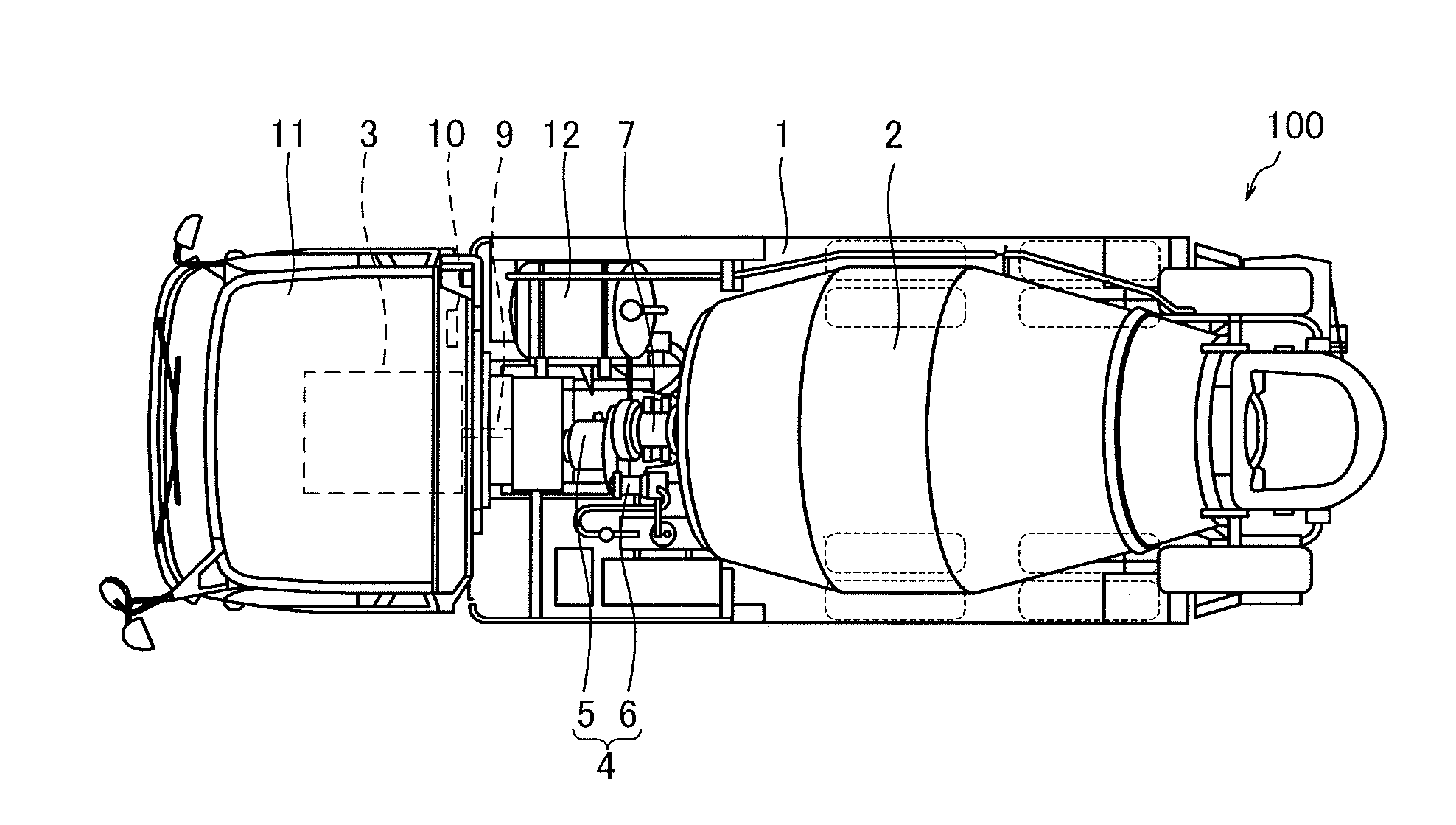

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335APrecise position controlGuaranteed nonlinear compensationFlow mixersMixing operation control apparatusHigh energyEngineering

The invention relates to cementing equipment and mixing equipment for oil and gas field and provides a clear water controlling device for a high-energy mixer and the high-energy mixer. The clear water controlling device comprises a soleplate, a linear actuator, a hinge shaft, a rocking arm, a leading screw, a manual rocking handle, a thread spindle and a valve rod, and is characterized in that the soleplate is hinged with a mounting base of the linear actuator; the hinge shaft is inserted in a central shaft hole of the soleplate; one end of the leading screw is fixed on the hinge shaft; the central portion of the leading screw forms a sleeve joint with the thread spindle, which is inserted in a central hole of the rocking arm; the upper end of the rocking arm is hinged with the valve rod; the lower end of the rocking arm is hinged with a push rod of the linear actuator; a through hole is arranged at the junction of the thread spindle and the leading screw; and a pin is disposed inside the trough hole. According to the invention, automatic and accurate control of the valve rod feed can be conveniently realized such that the slurry mixing effect of the high-energy mixer is more excellent than that in the prior art and the high-energy mixer can be used in both automatic and manual modes.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

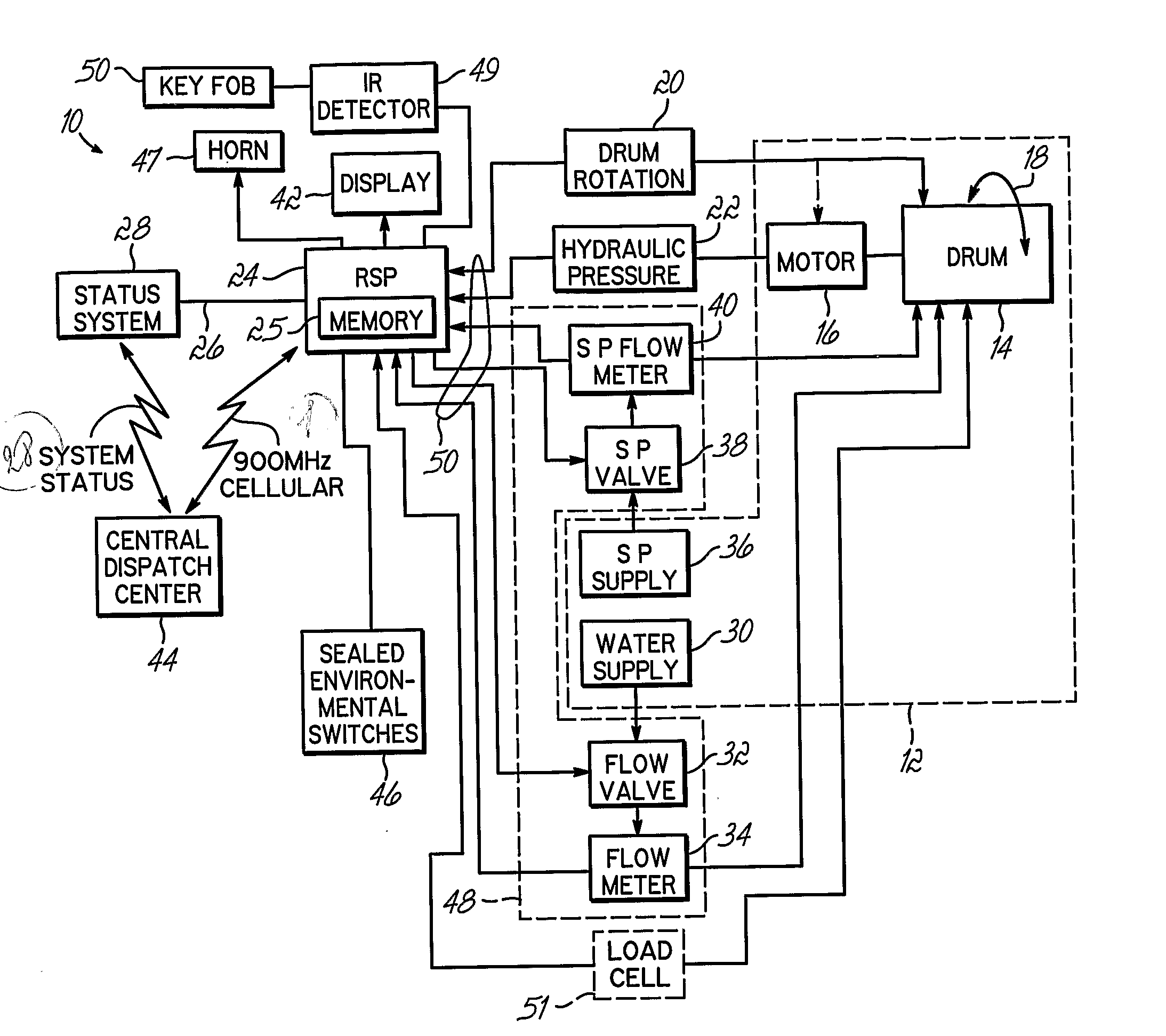

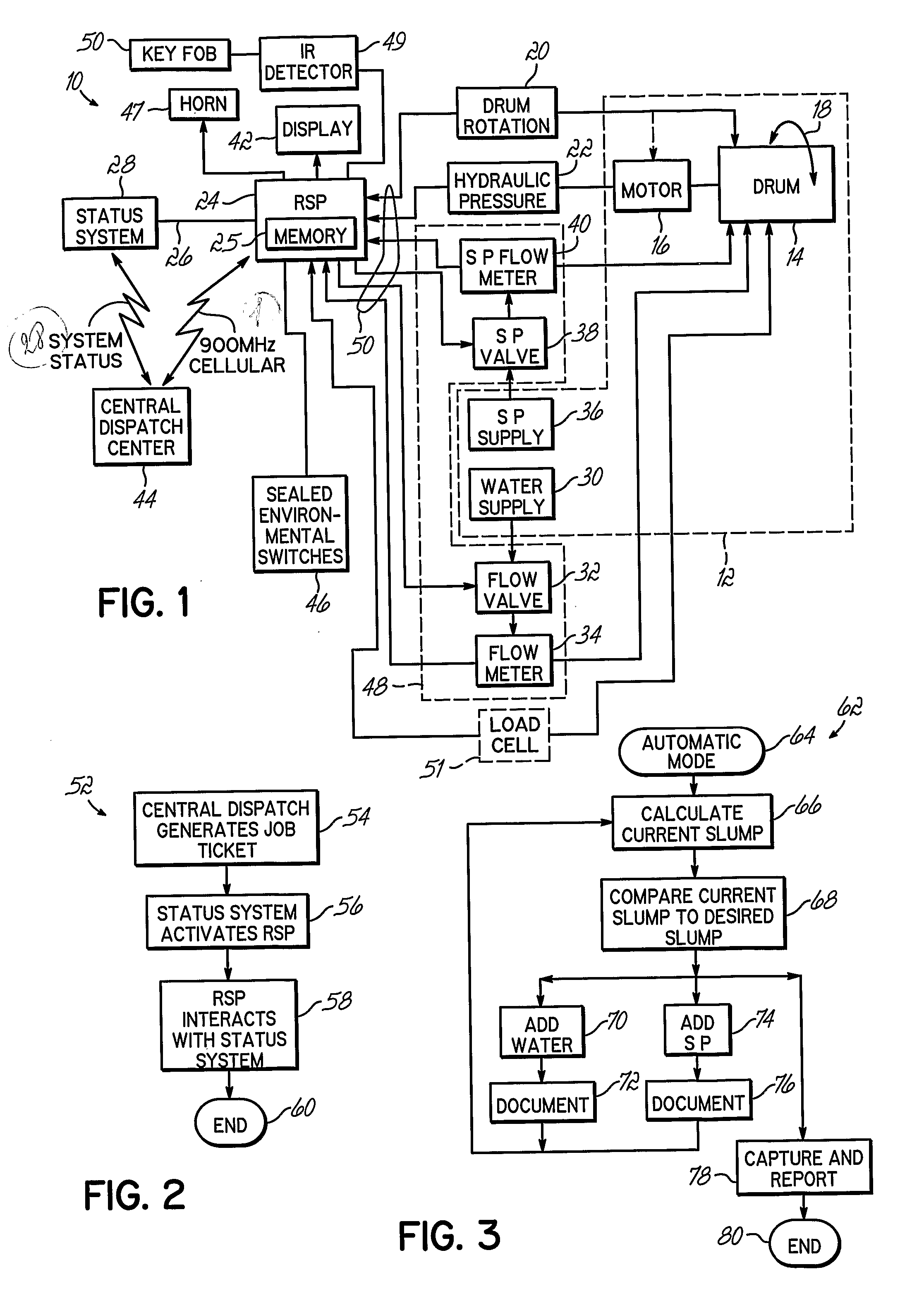

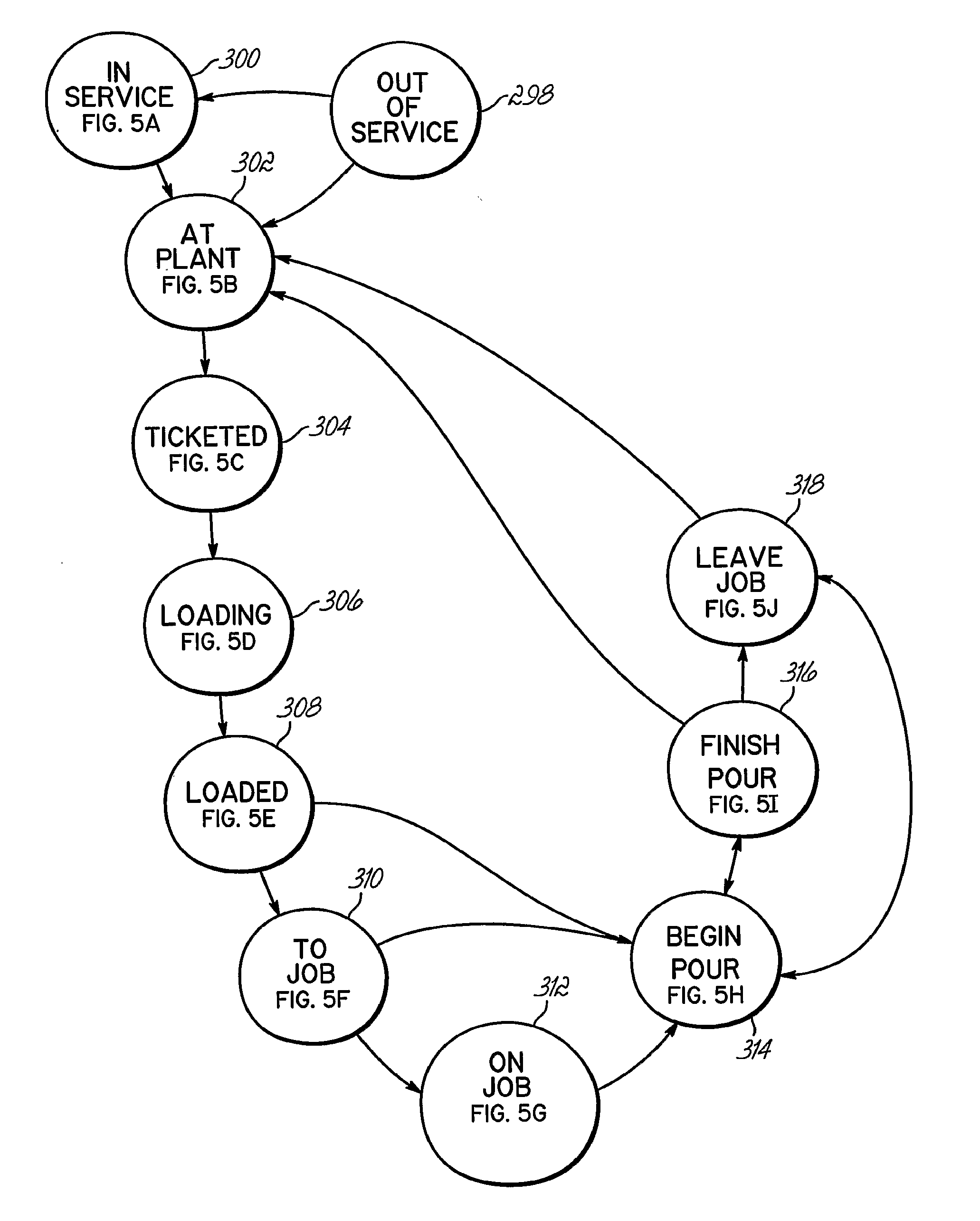

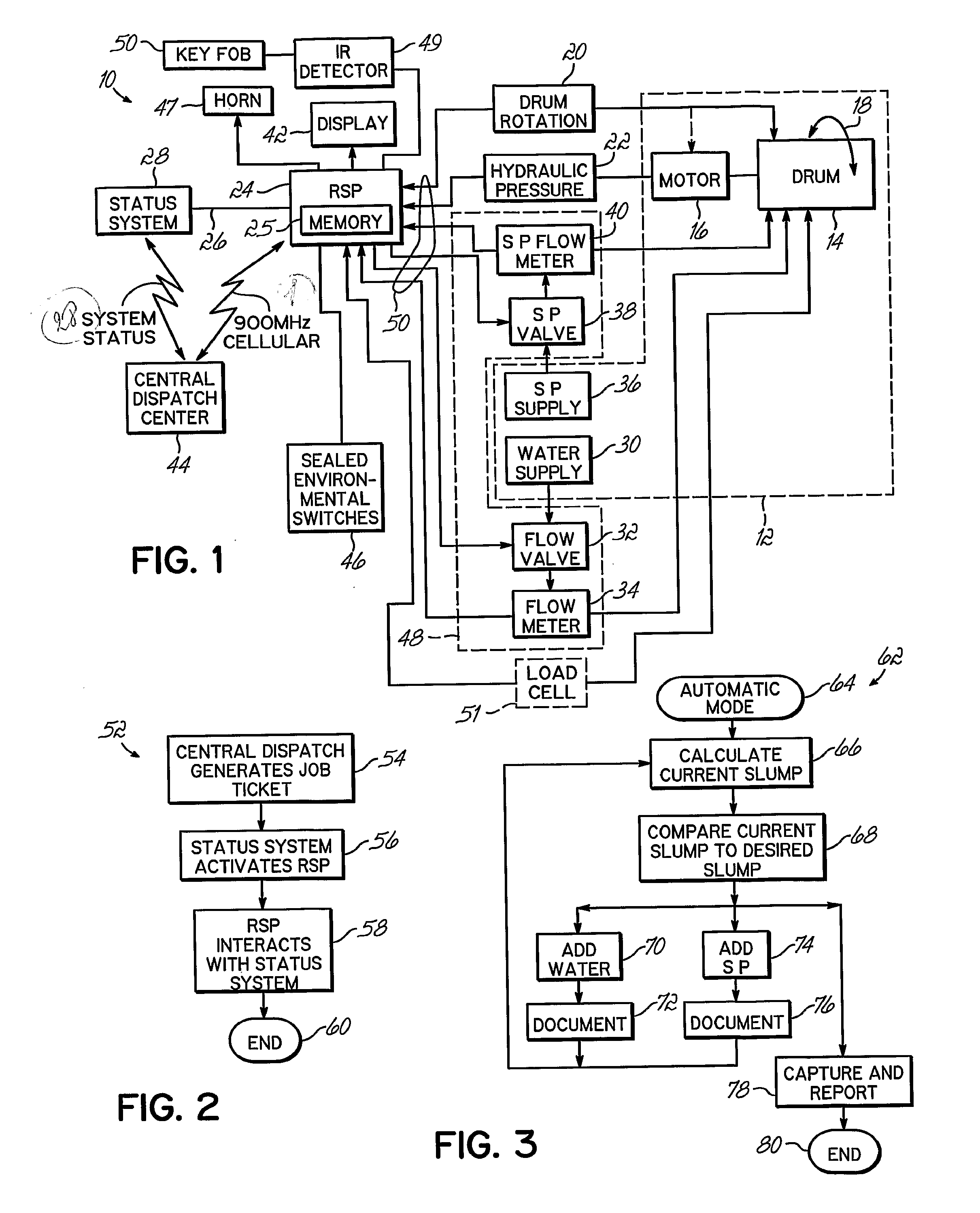

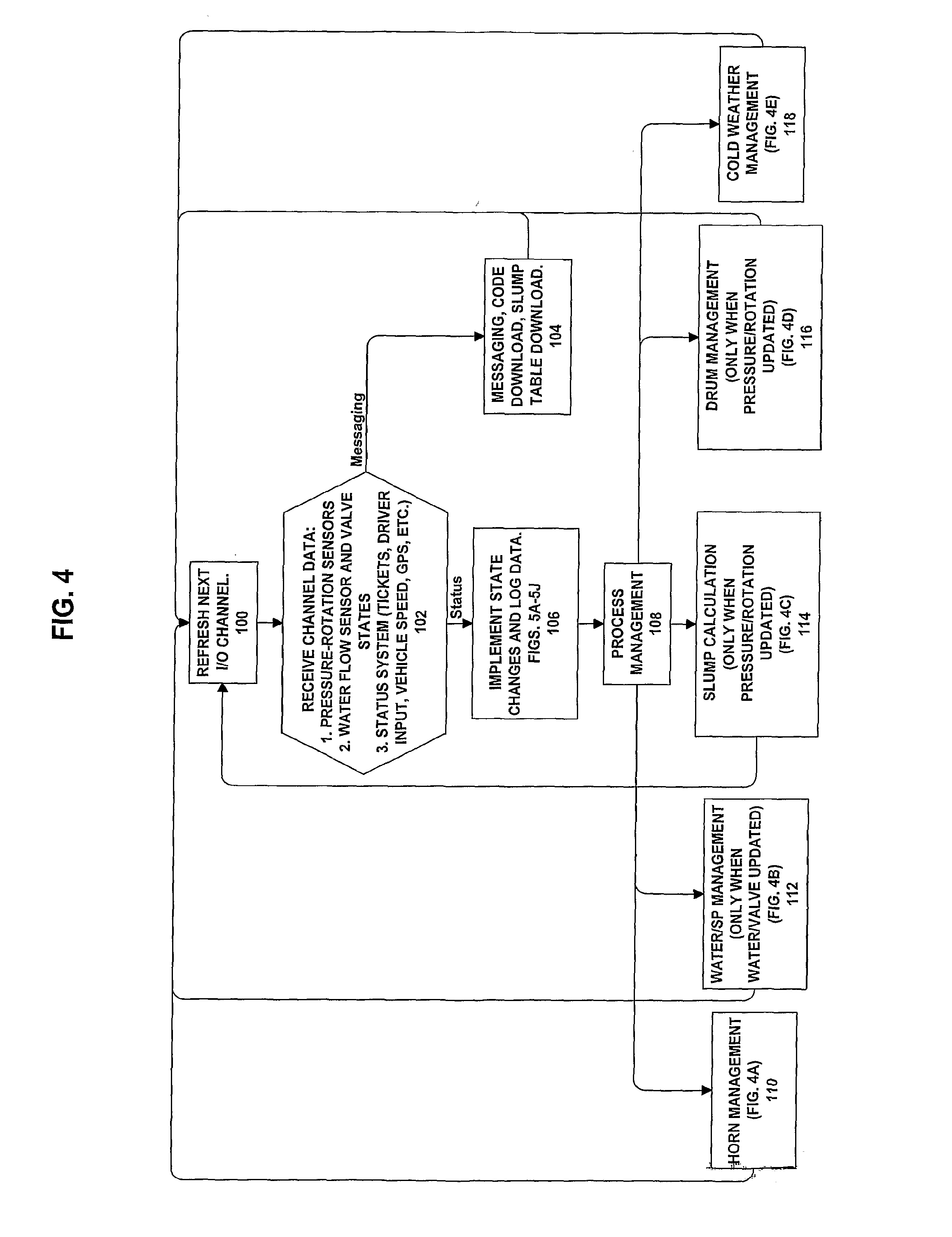

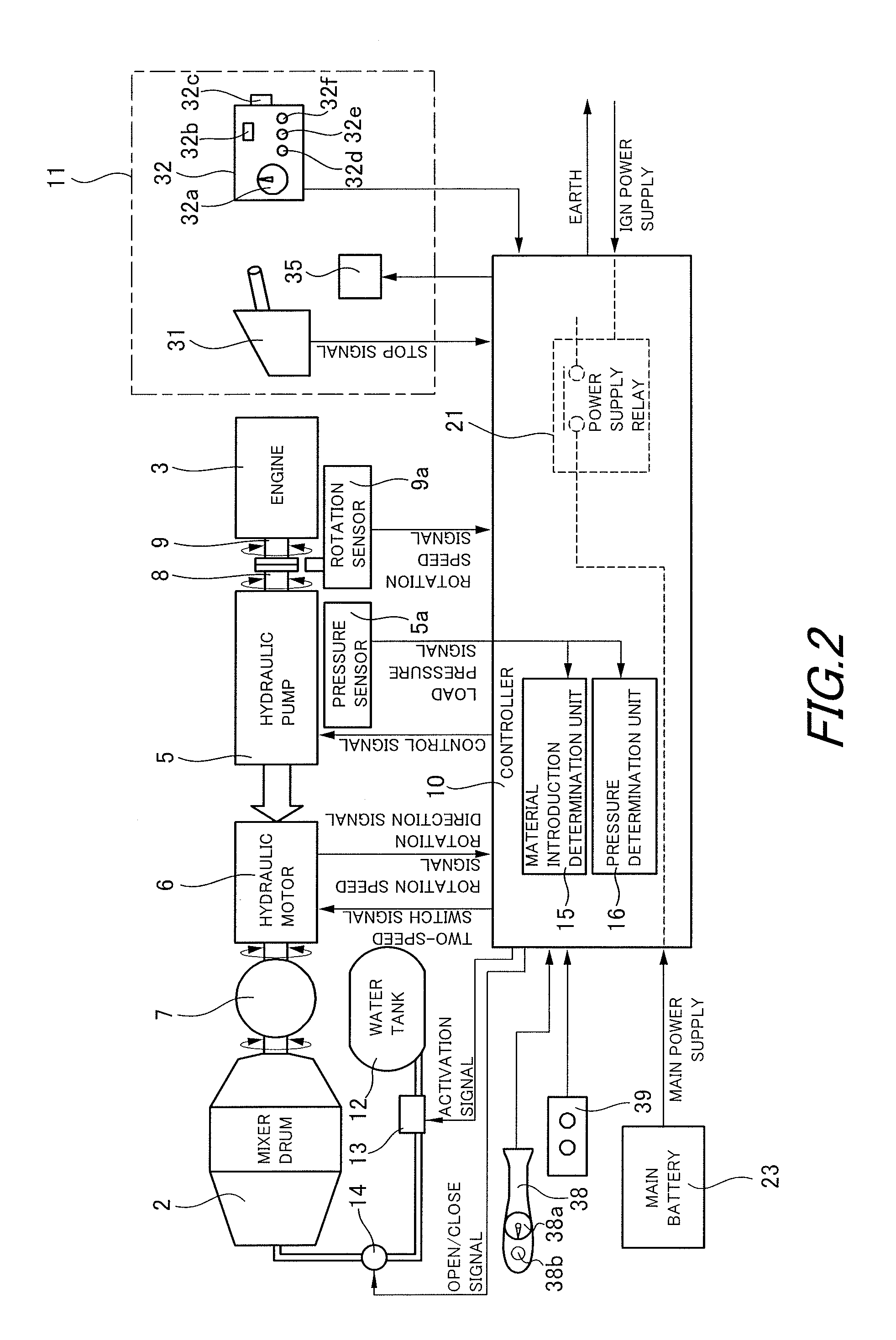

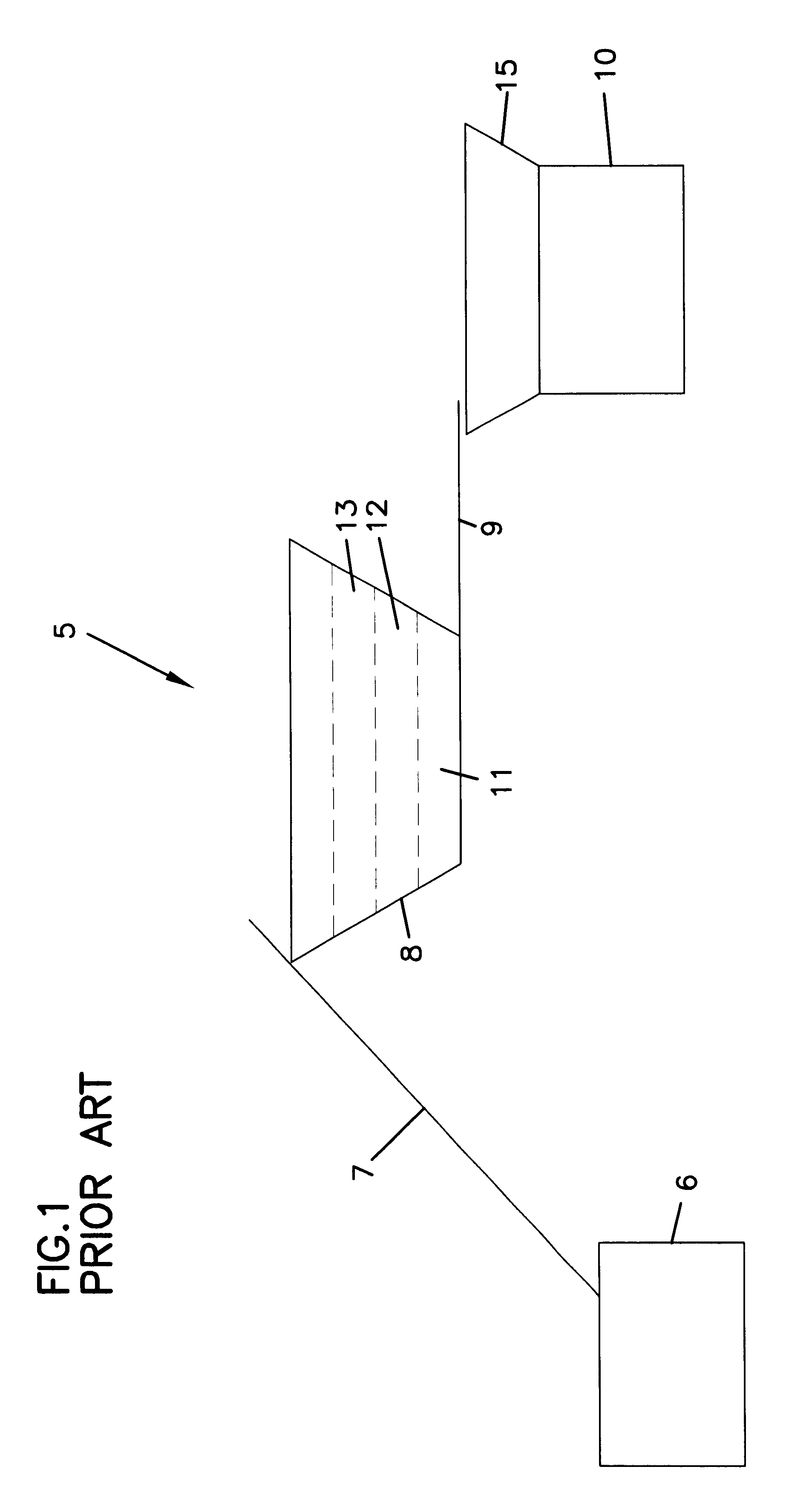

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS20070185636A1Amount be controlSampled-variable control systemsAnalogue computers for trafficDelivery vehicleControl theory

A system for calculating and reporting slump in a delivery vehicle having a mixing drum (14) and hydraulic drive (16) for rotating the mixing drum, including a rotational sensor (20) configured to sense a rotational speed of the mixing drum, a hydraulic sensor (22) coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, and a communications port (26) configured to communicate a slump calculation to a status system (28) commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum.

Owner:VERIFI

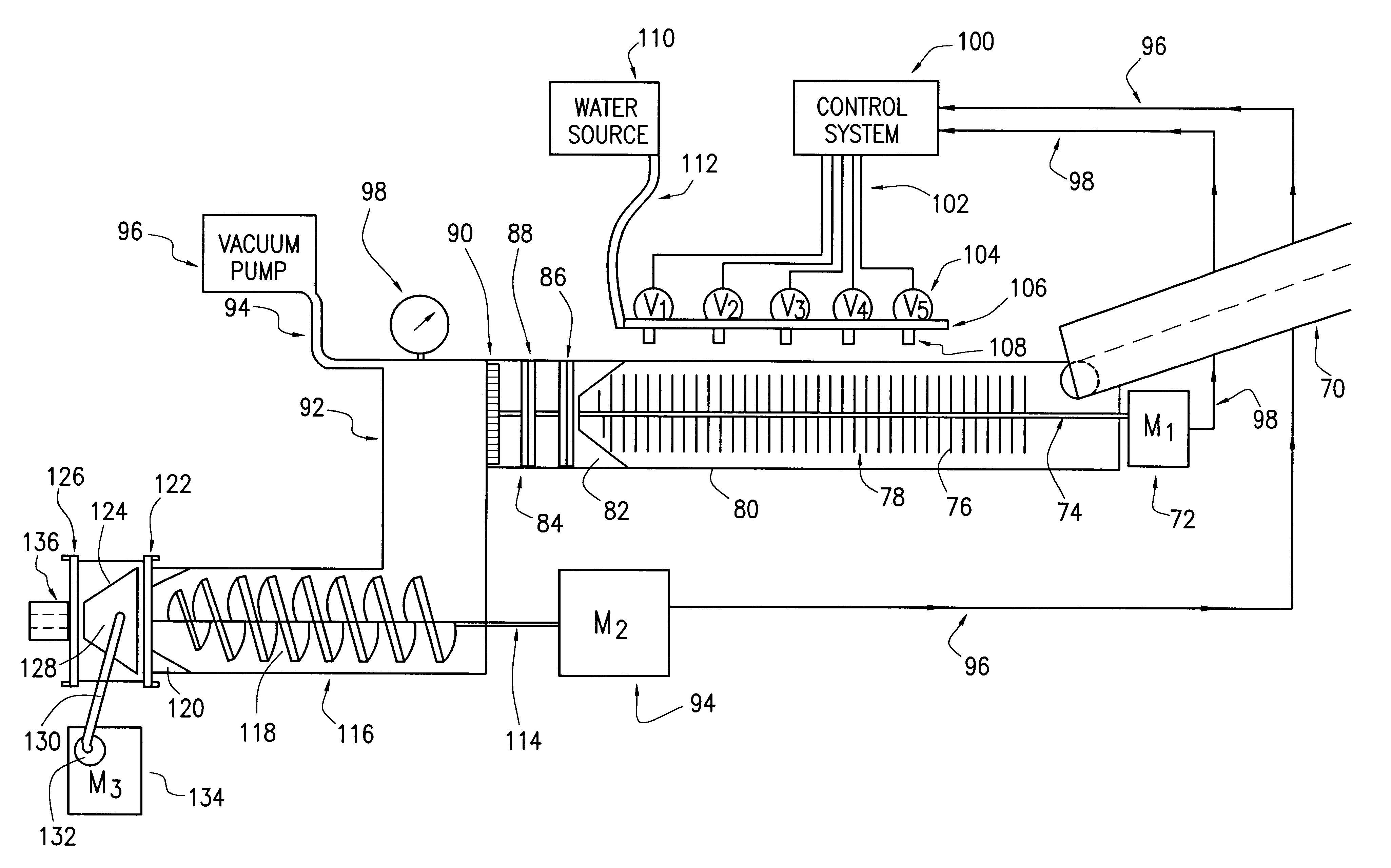

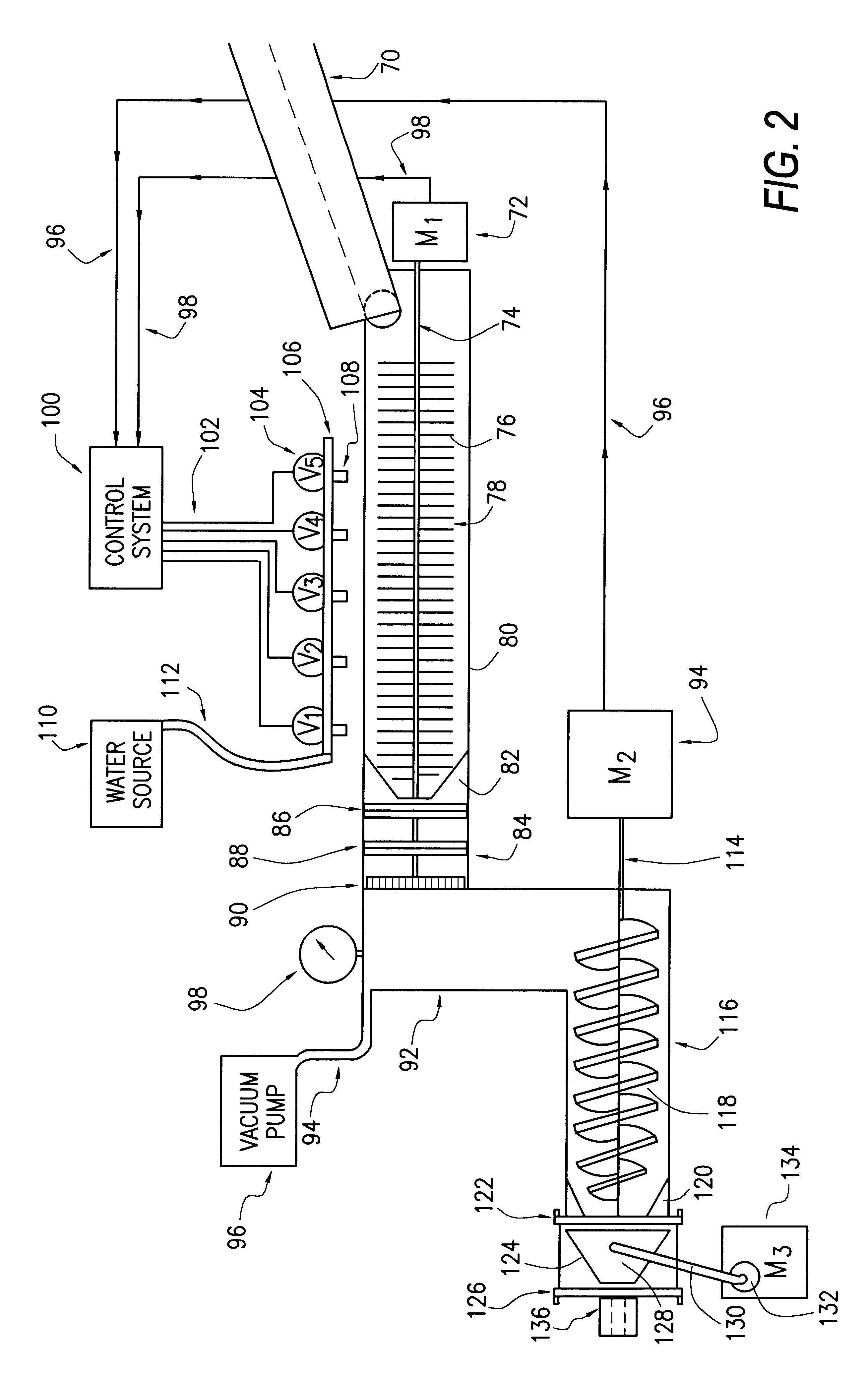

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

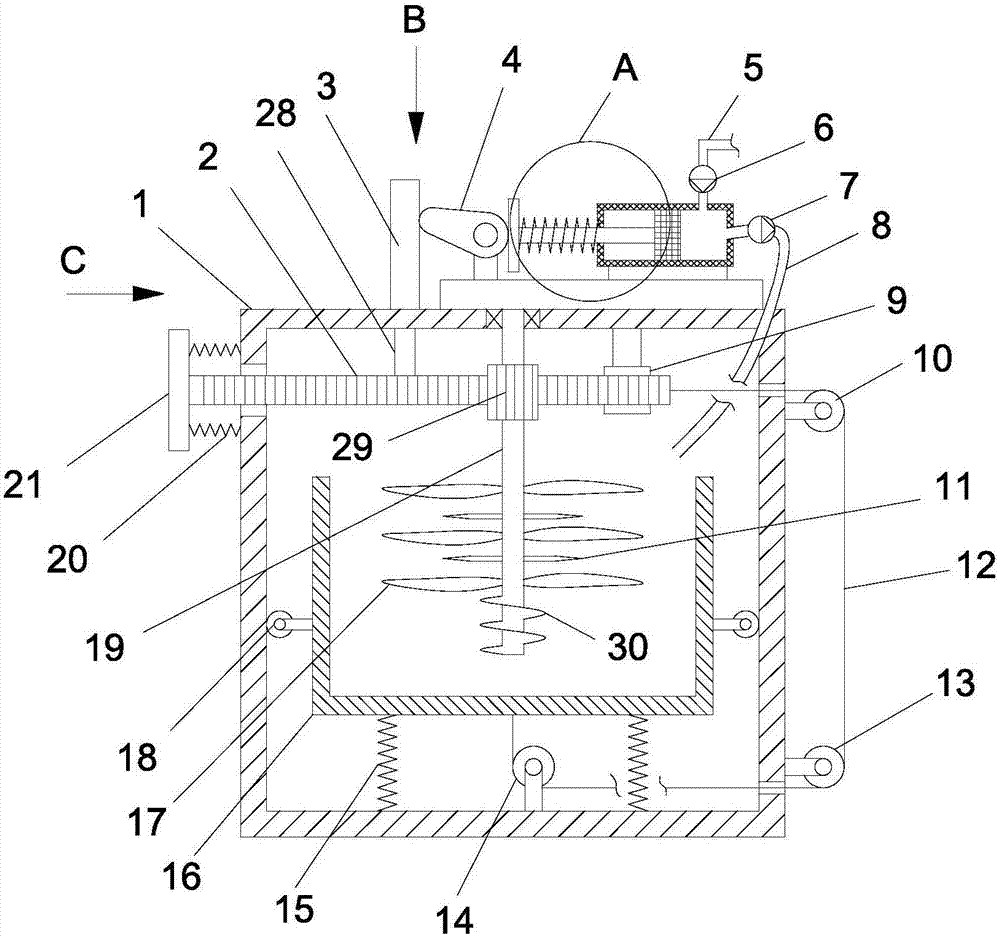

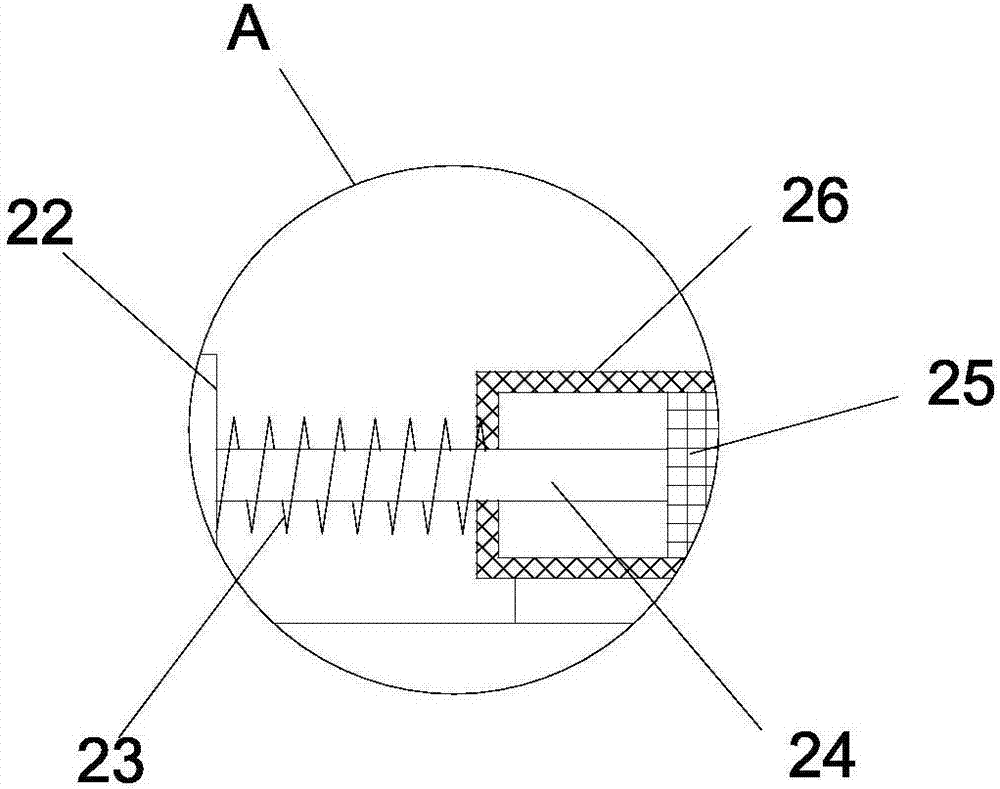

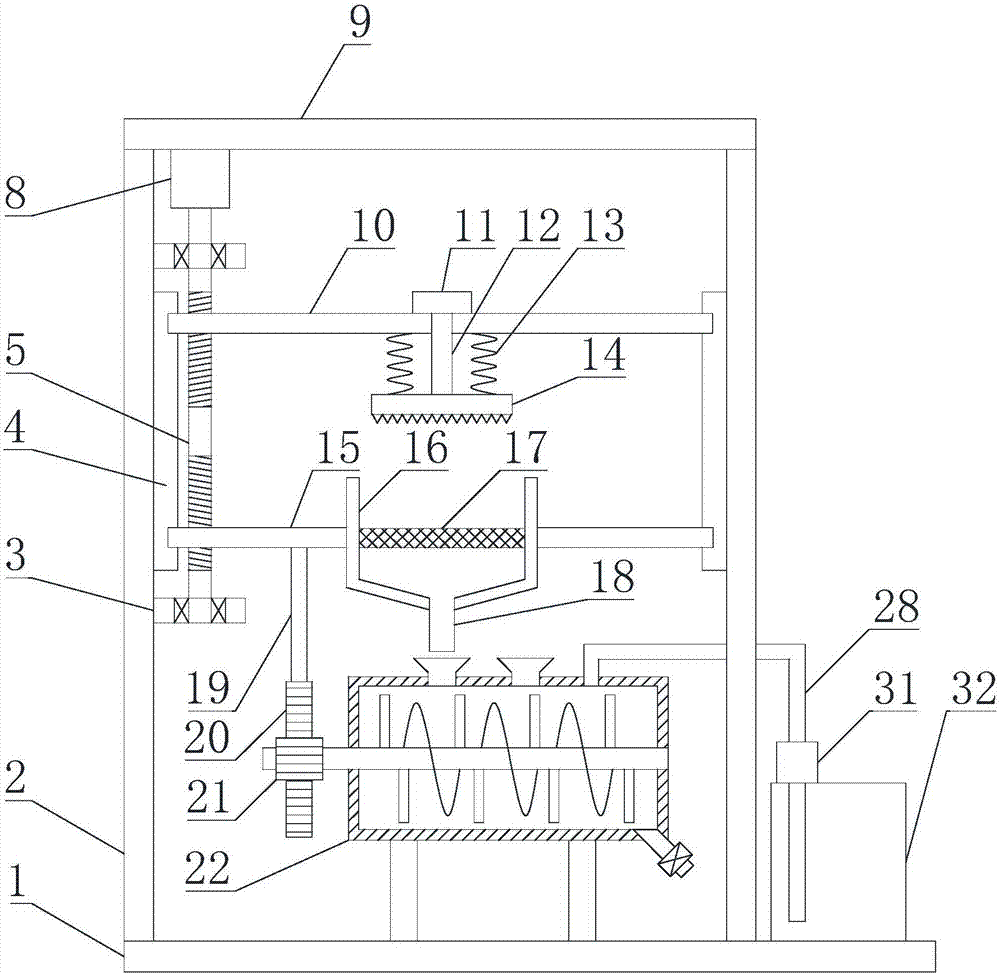

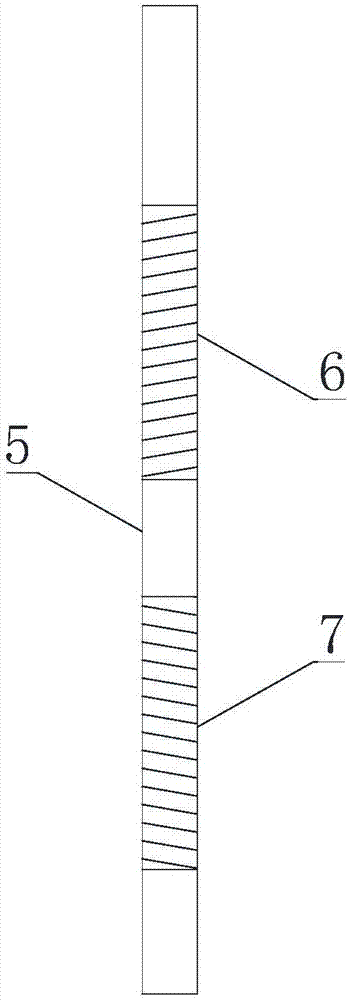

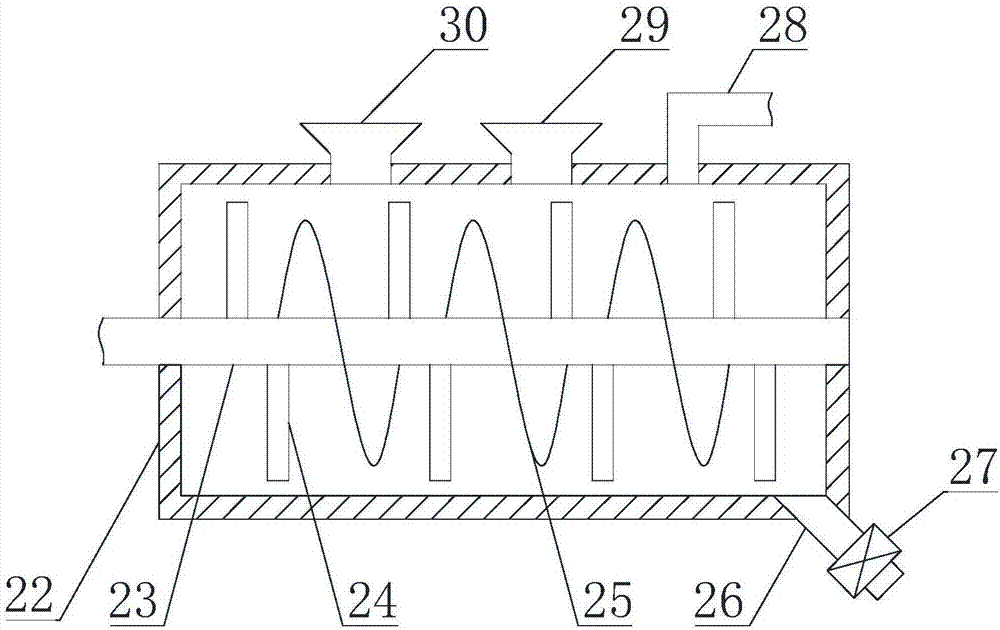

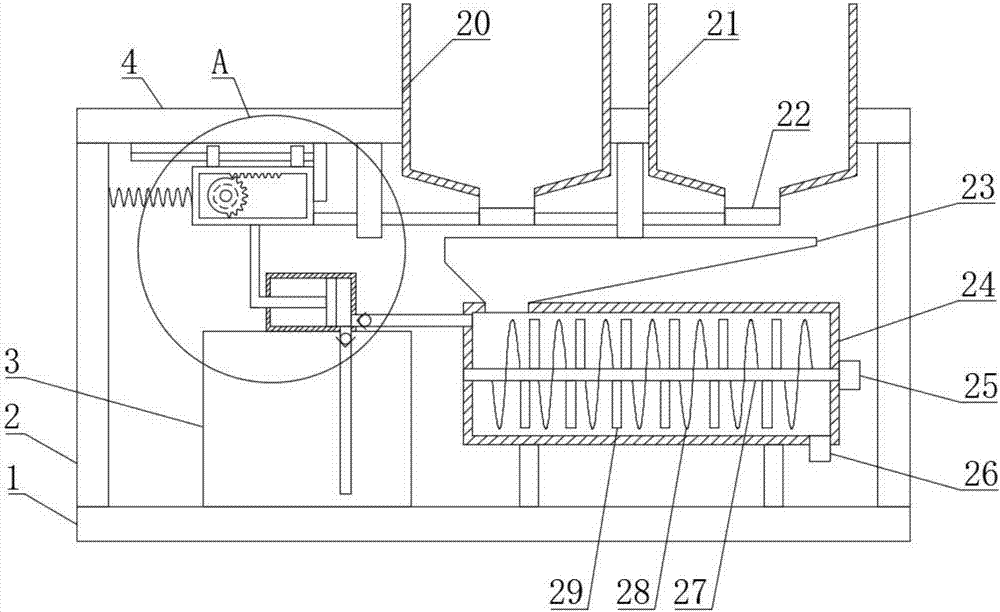

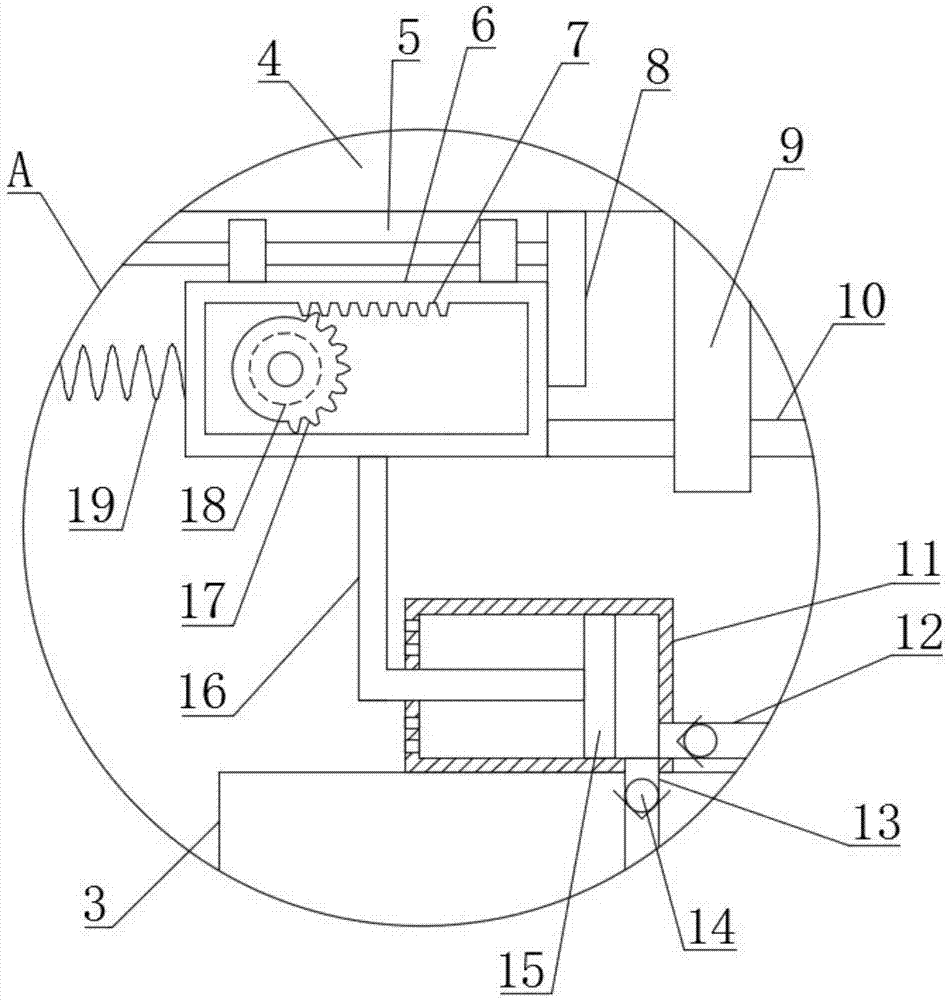

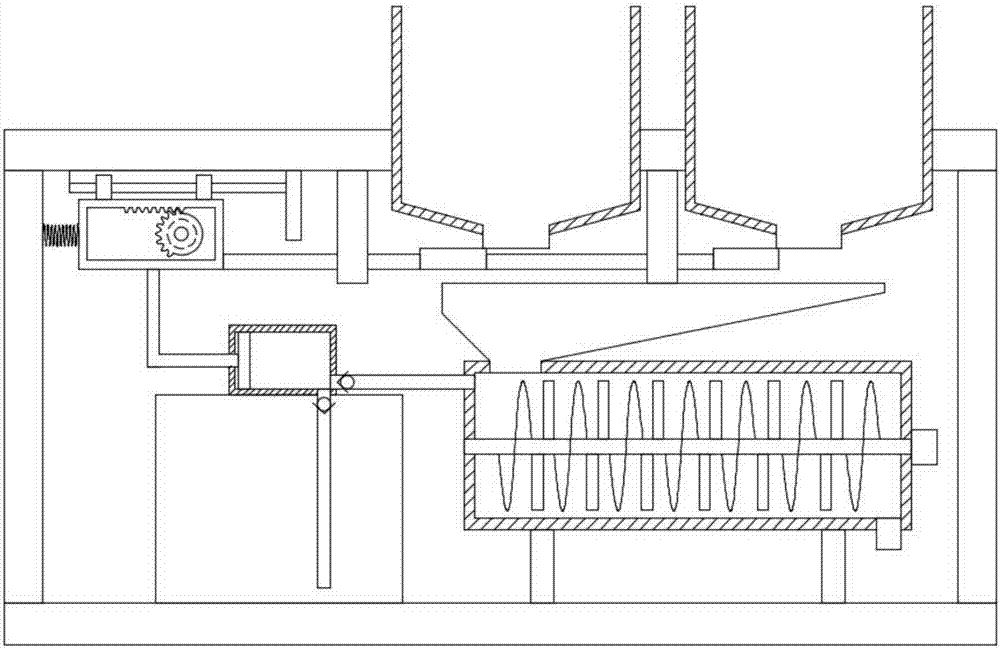

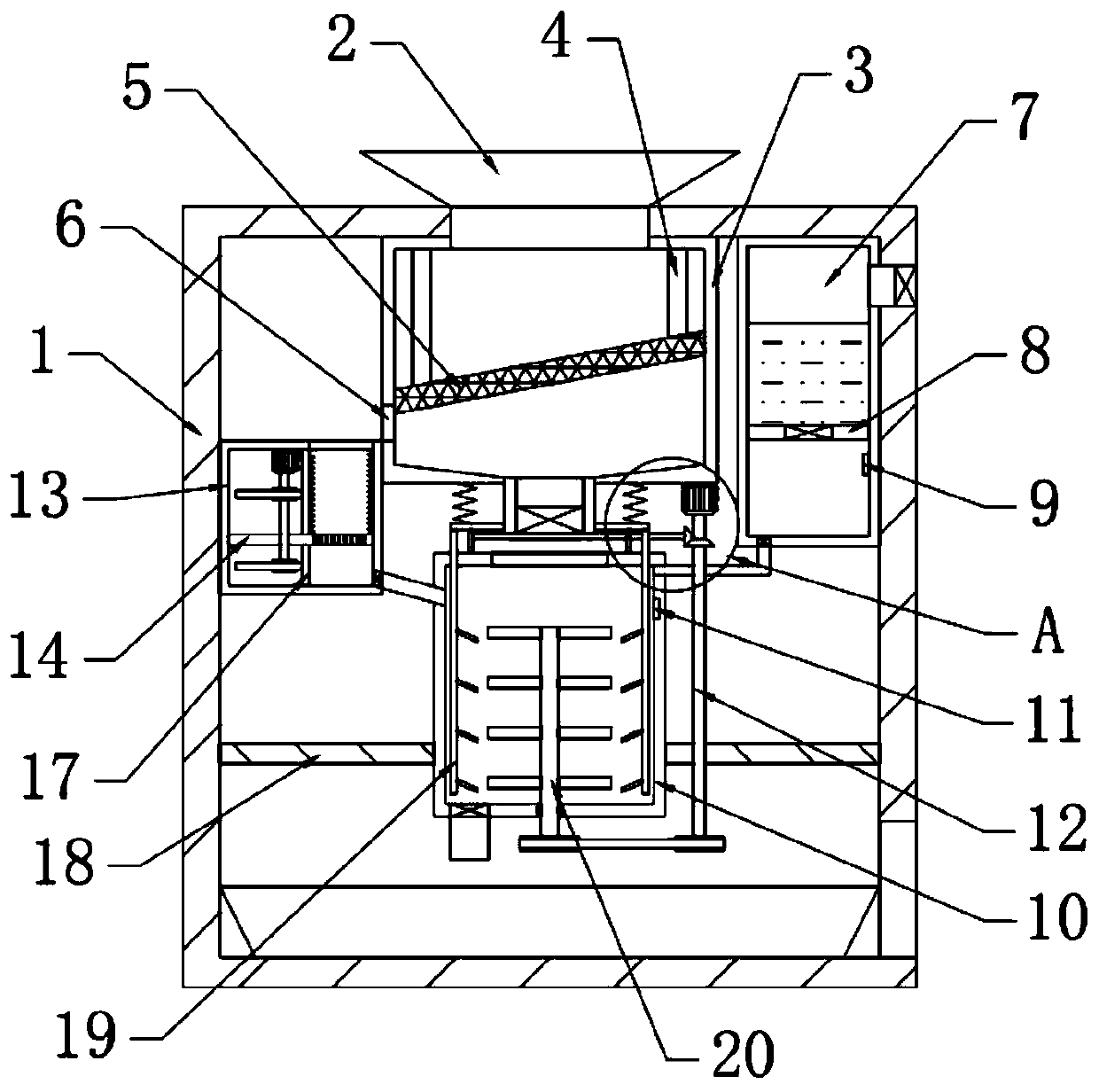

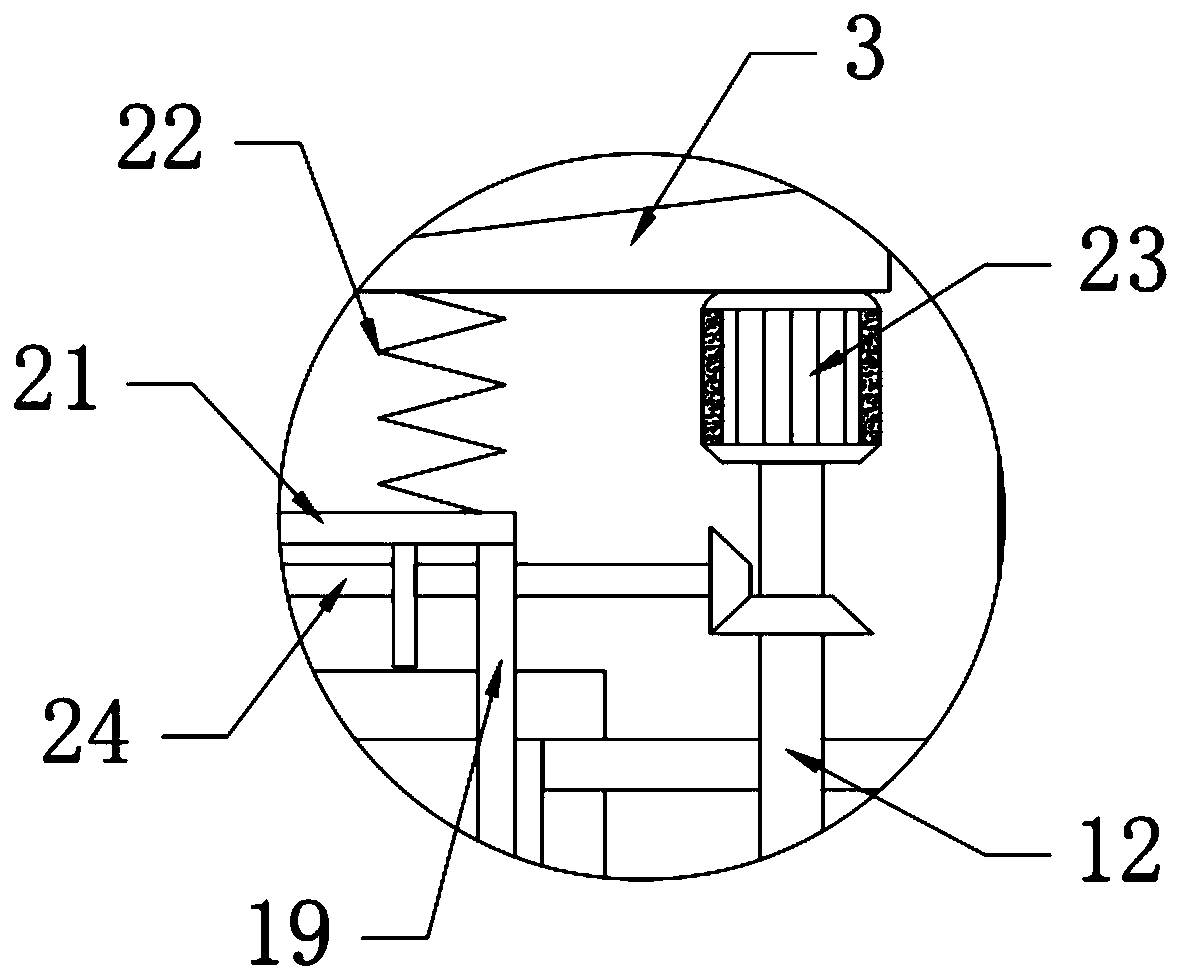

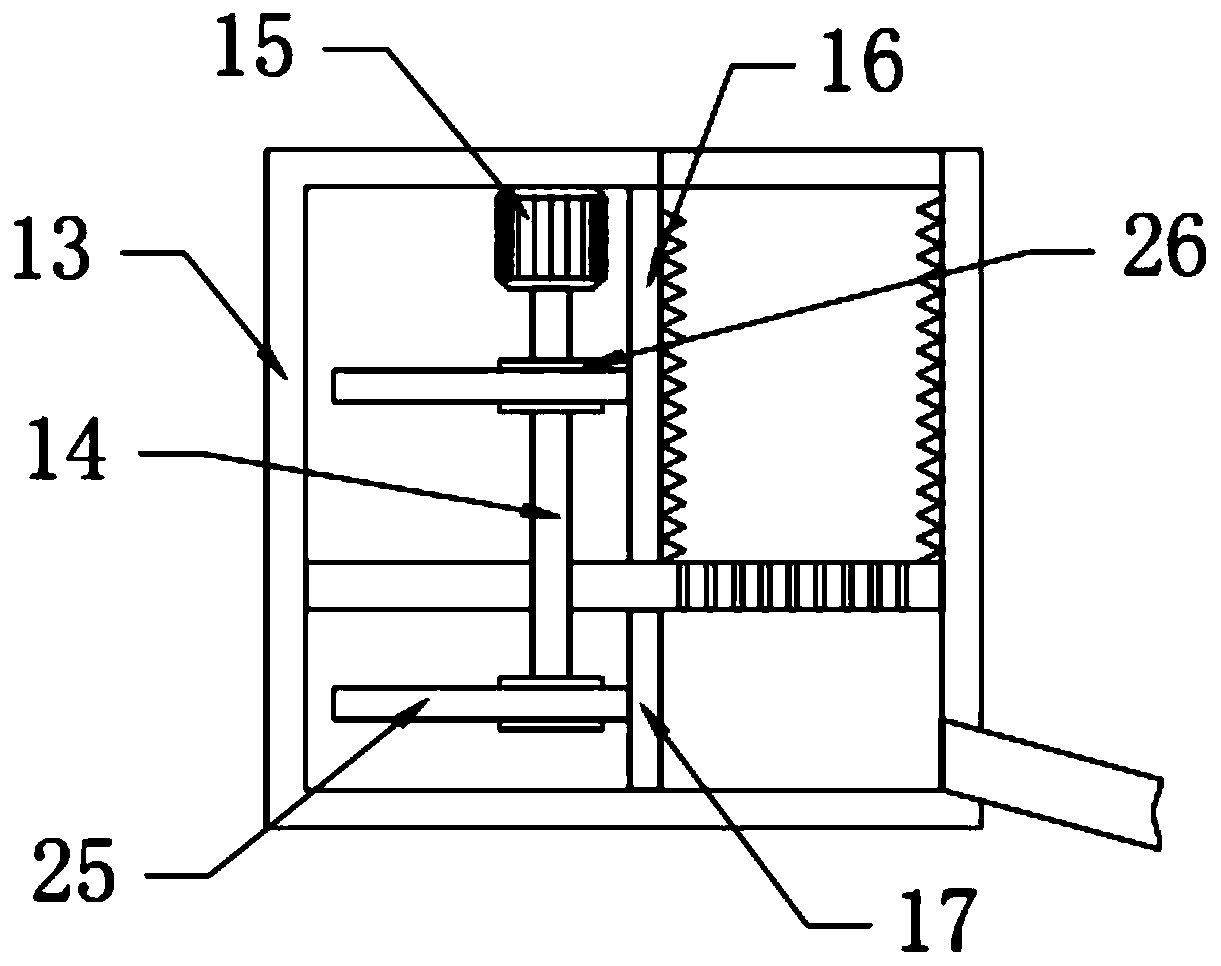

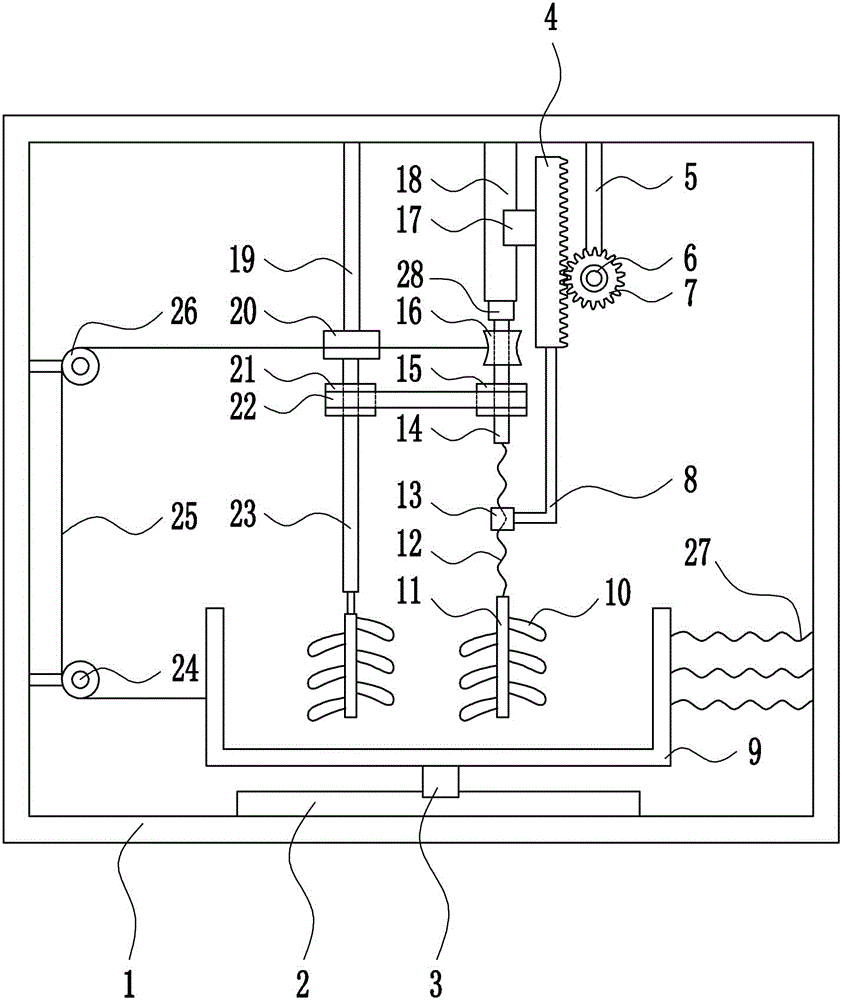

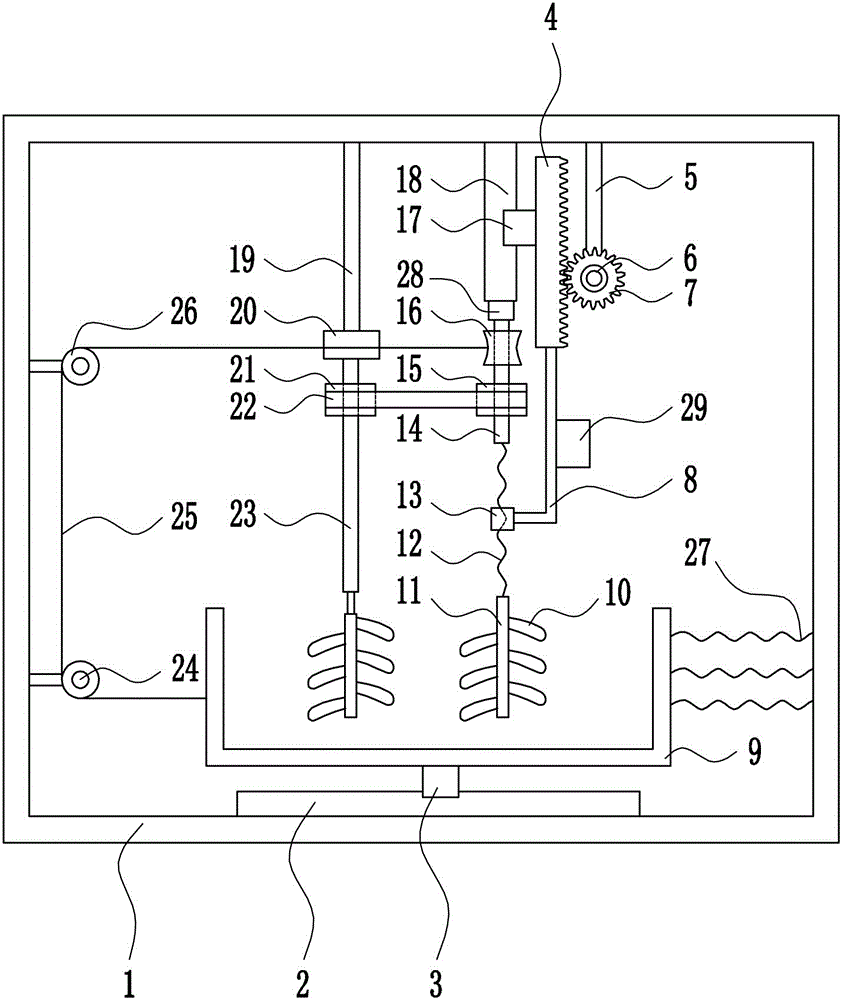

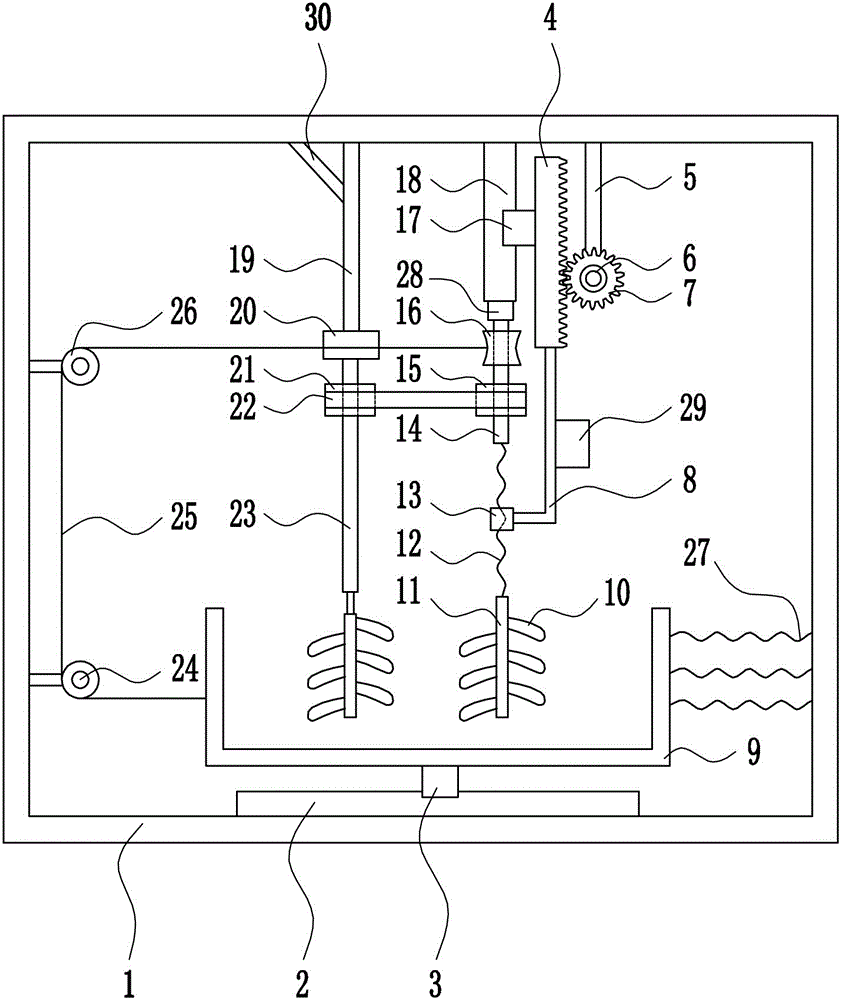

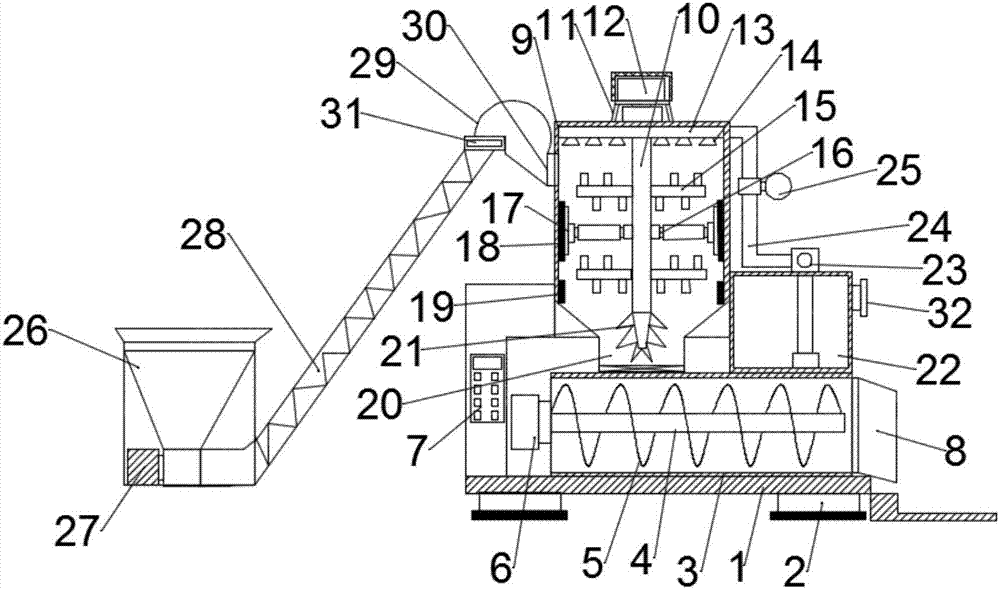

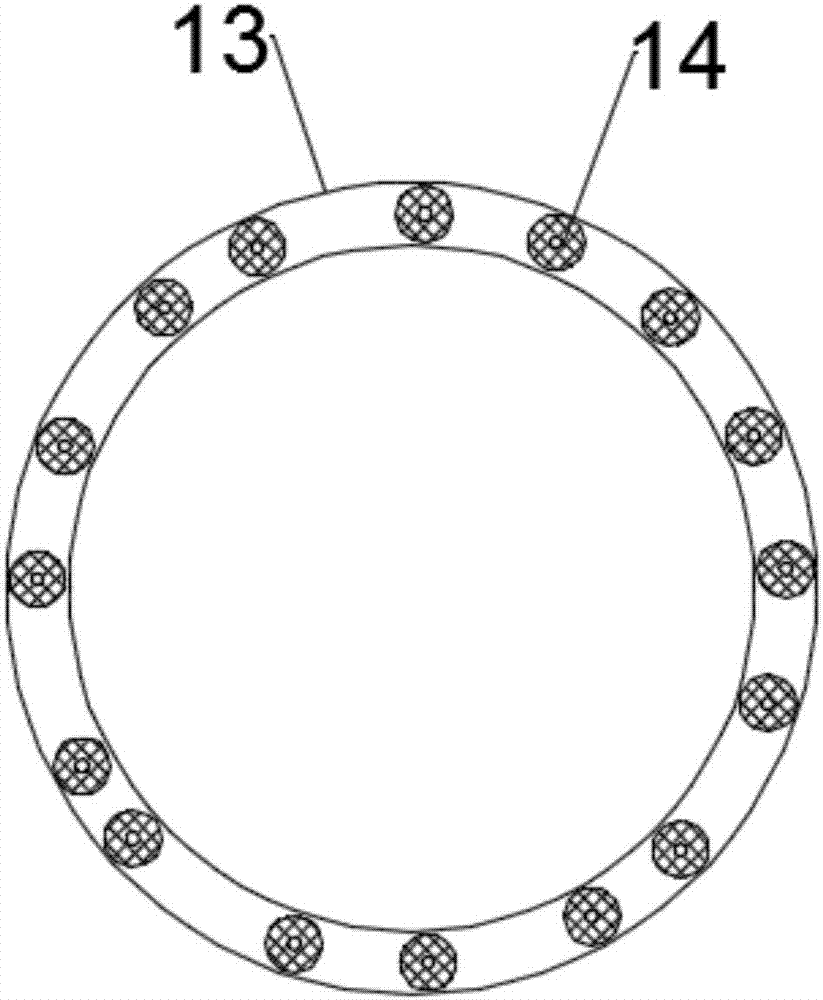

Concrete mortar stirring and mixing device for building construction

InactiveCN107053480AImprove the mixing effectImprove stirring efficiencyCement mixing apparatusLiquid ingredients supply apparatusHelical bladeArchitectural engineering

A concrete mortar mixing device for building construction, including a main body, a mixing bucket is arranged inside the main body, a limit spring is arranged between the mixing bucket and the main body, a number of auxiliary mixing blades and a number of auxiliary mixing blades and a number of Auxiliary cutting blade, the spur rack slides through the body, the left end of the spur rack is fixed with a limit plate, the limit plate is located outside the body, a first return spring is arranged between the limit plate and the body, and a piston is fixedly installed on the body The water-drawing sleeve, the left end of the piston rod is vertically fixed with a piston top plate, the cam is in contact with the right side of the transmission plate, and the cam is in contact with the left side of the piston top plate; the spiral blade arranged at the bottom of the stirring shaft in the present invention will move the bottom of the mixing tank The concrete mortar is turned upwards to make the mixing more complete. Driven by the wire rope, the mixing bucket vibrates up and down, making the concrete mortar shake up and down in the mixing bucket, which promotes the mixing effect of the concrete mortar.

Owner:长沙鼎成新材料科技有限公司

Dry Mix Cement Composition, Methods and Systems Involving Same

InactiveUS20090071374A1Modifies strengthEnhances polymerisationSolid waste managementAlkali metal silicate coatingsMulti phaseMaterials science

A dry mix cement composition including an alkaline multi-phase aluminosilicate material, wherein the alkaline multi-phase aluminosilicate material provides a source of alkaline and soluble silicate to the cement composition.

Owner:ZEOBOND RES

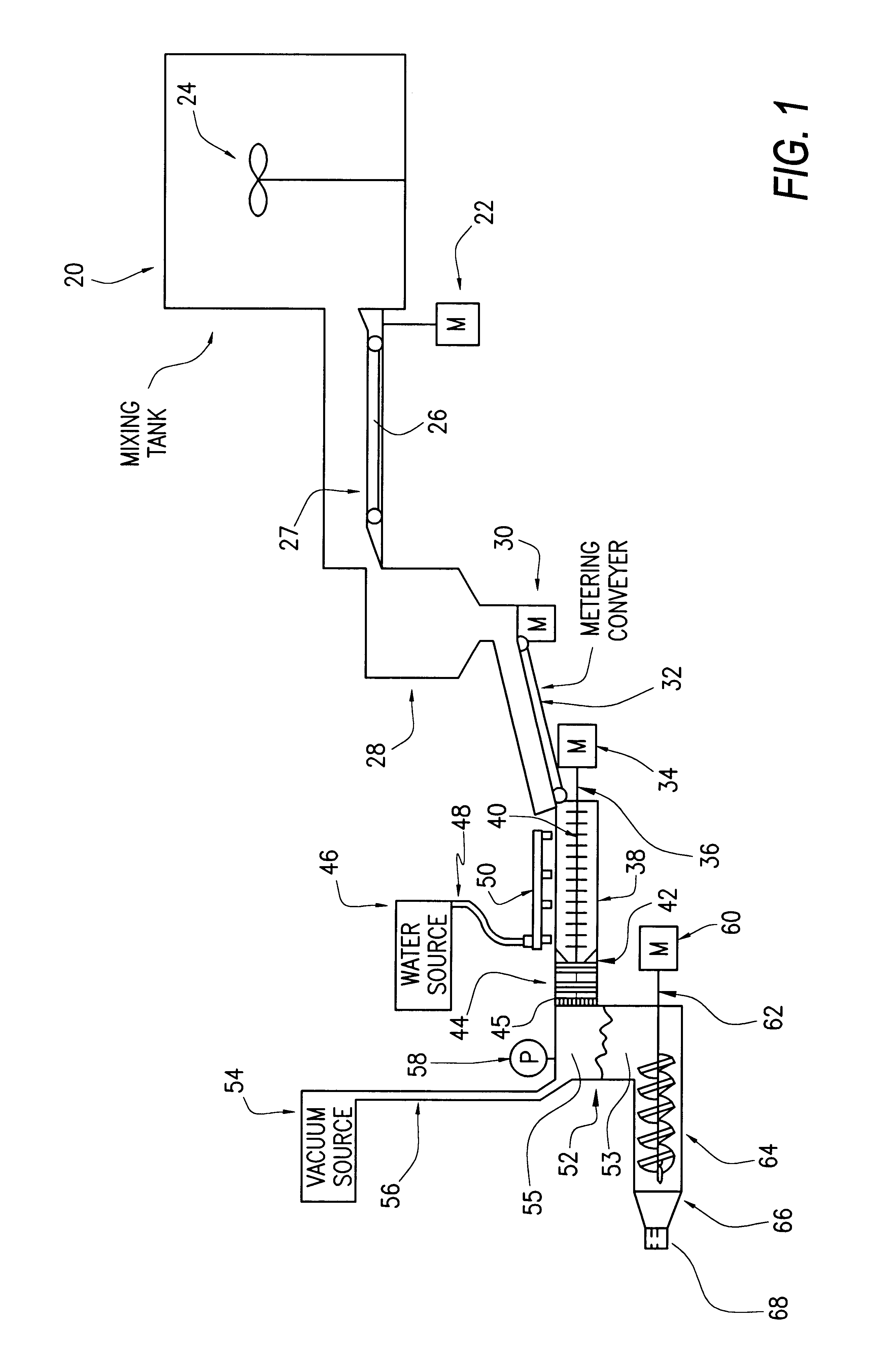

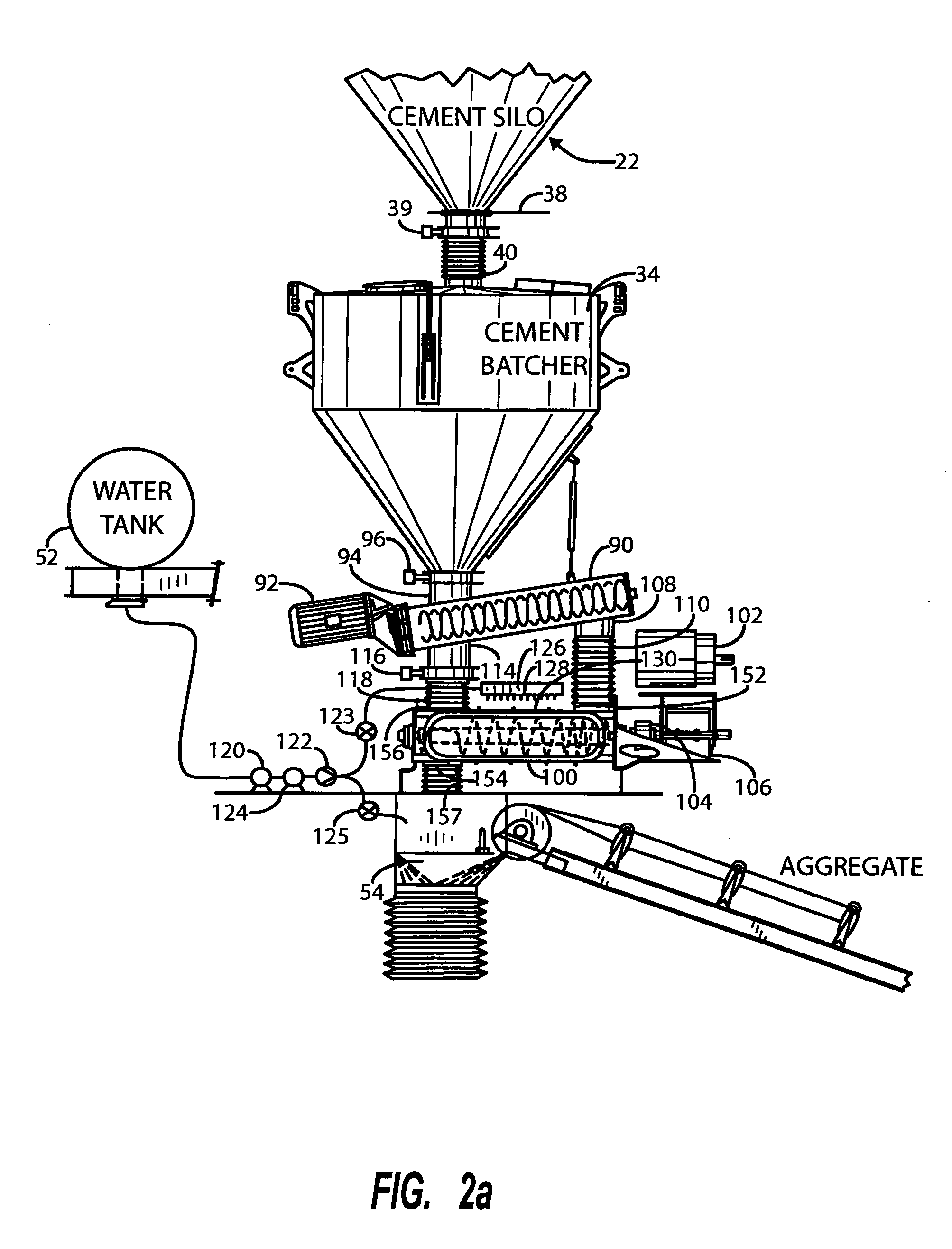

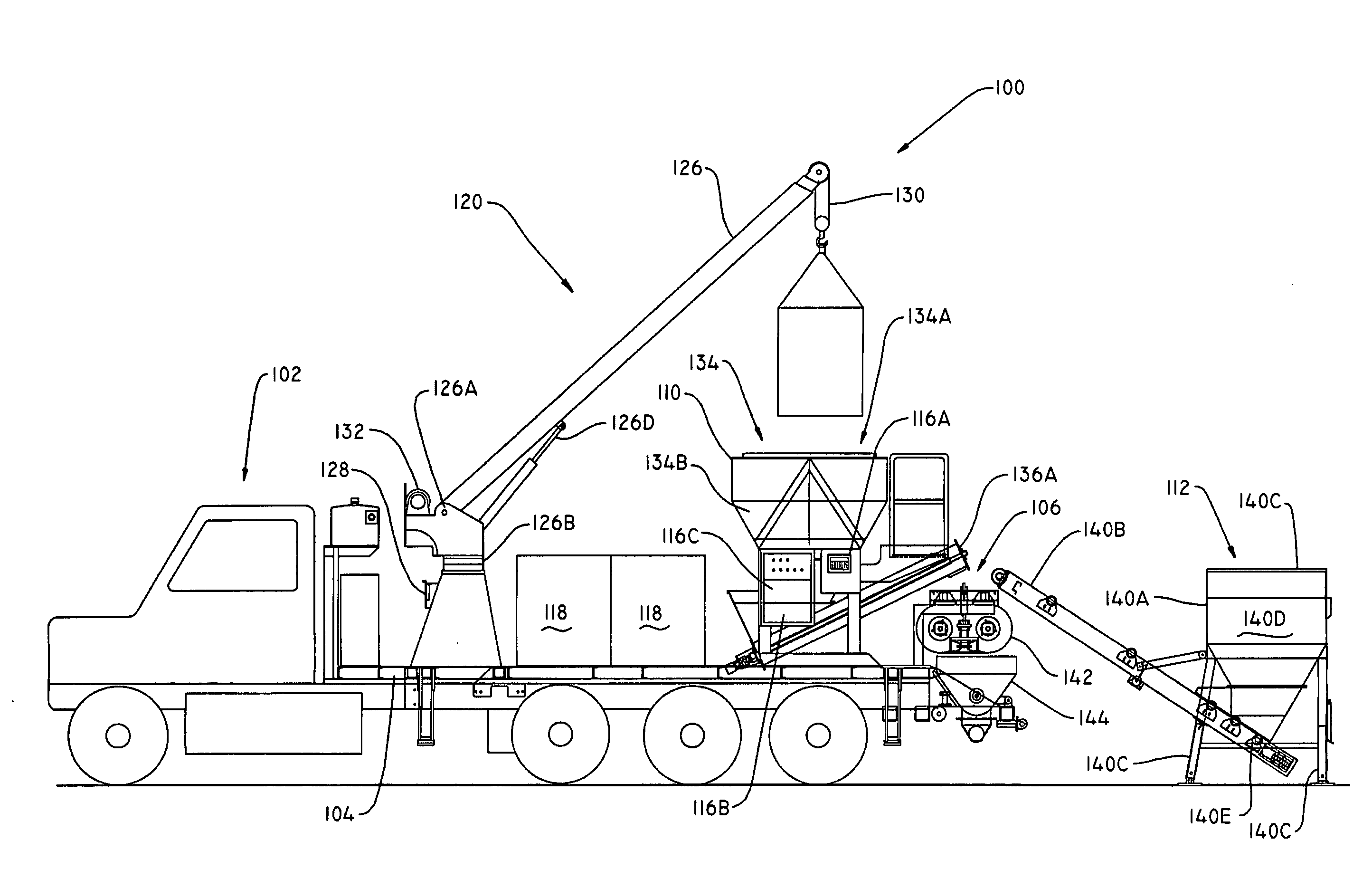

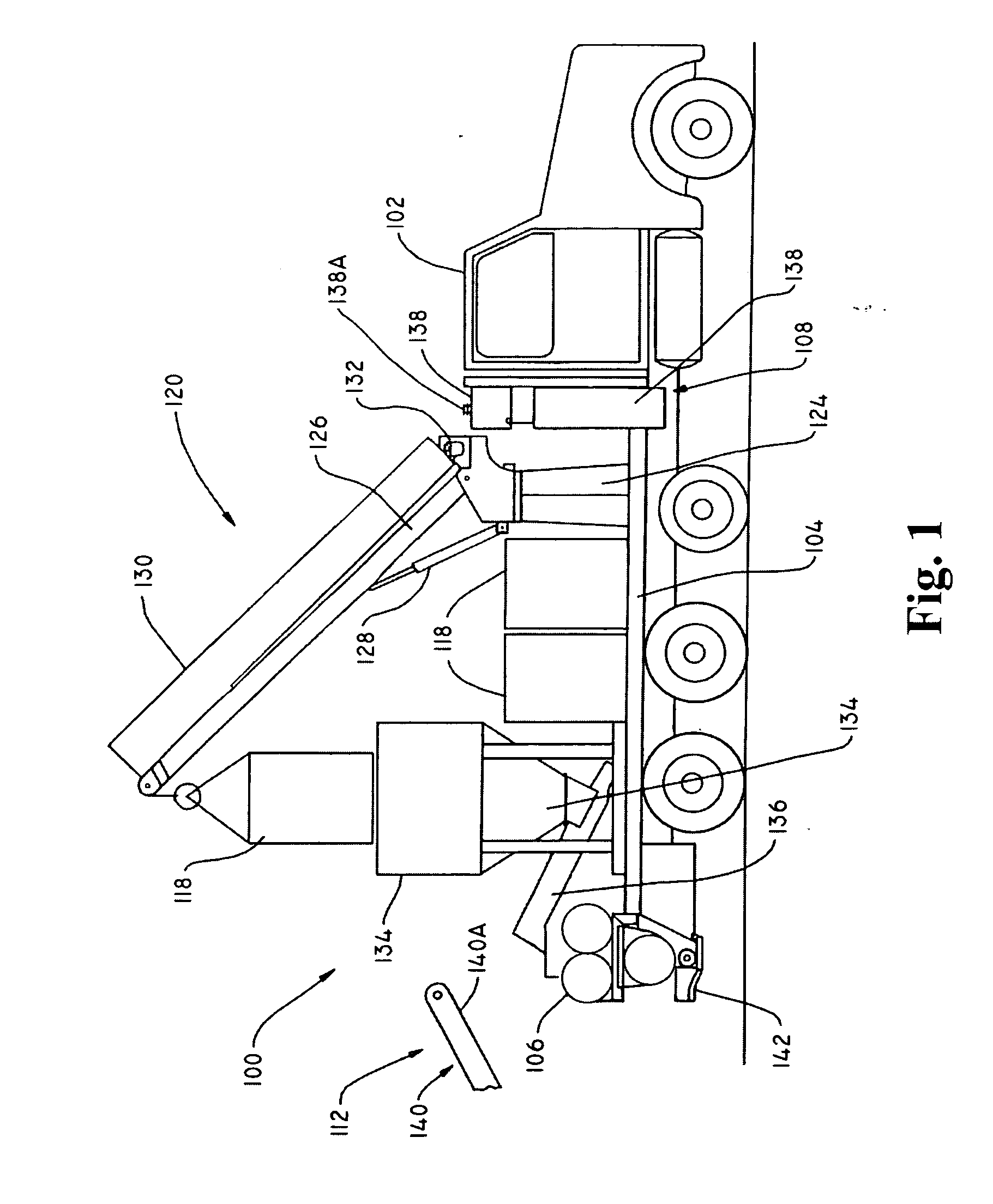

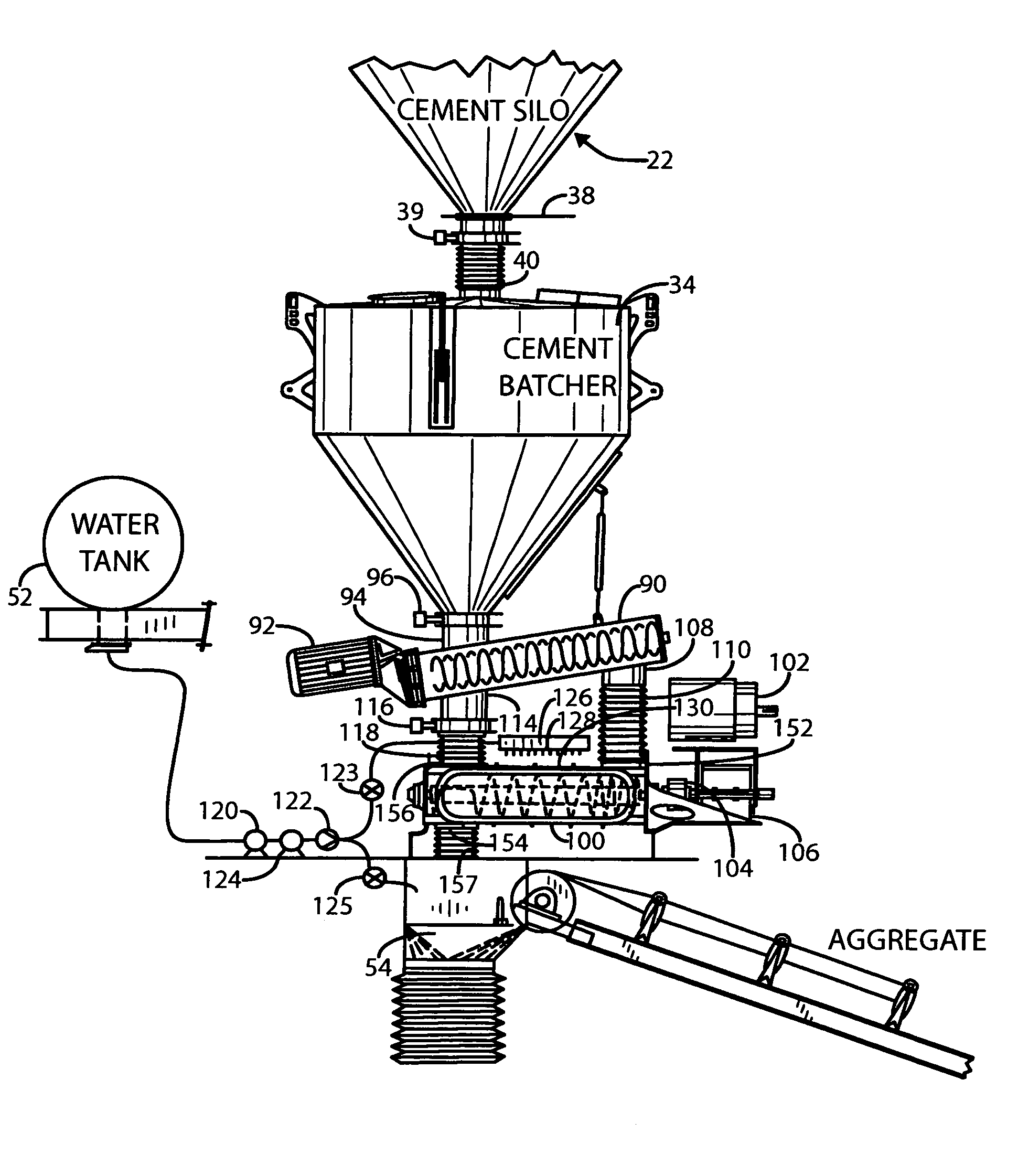

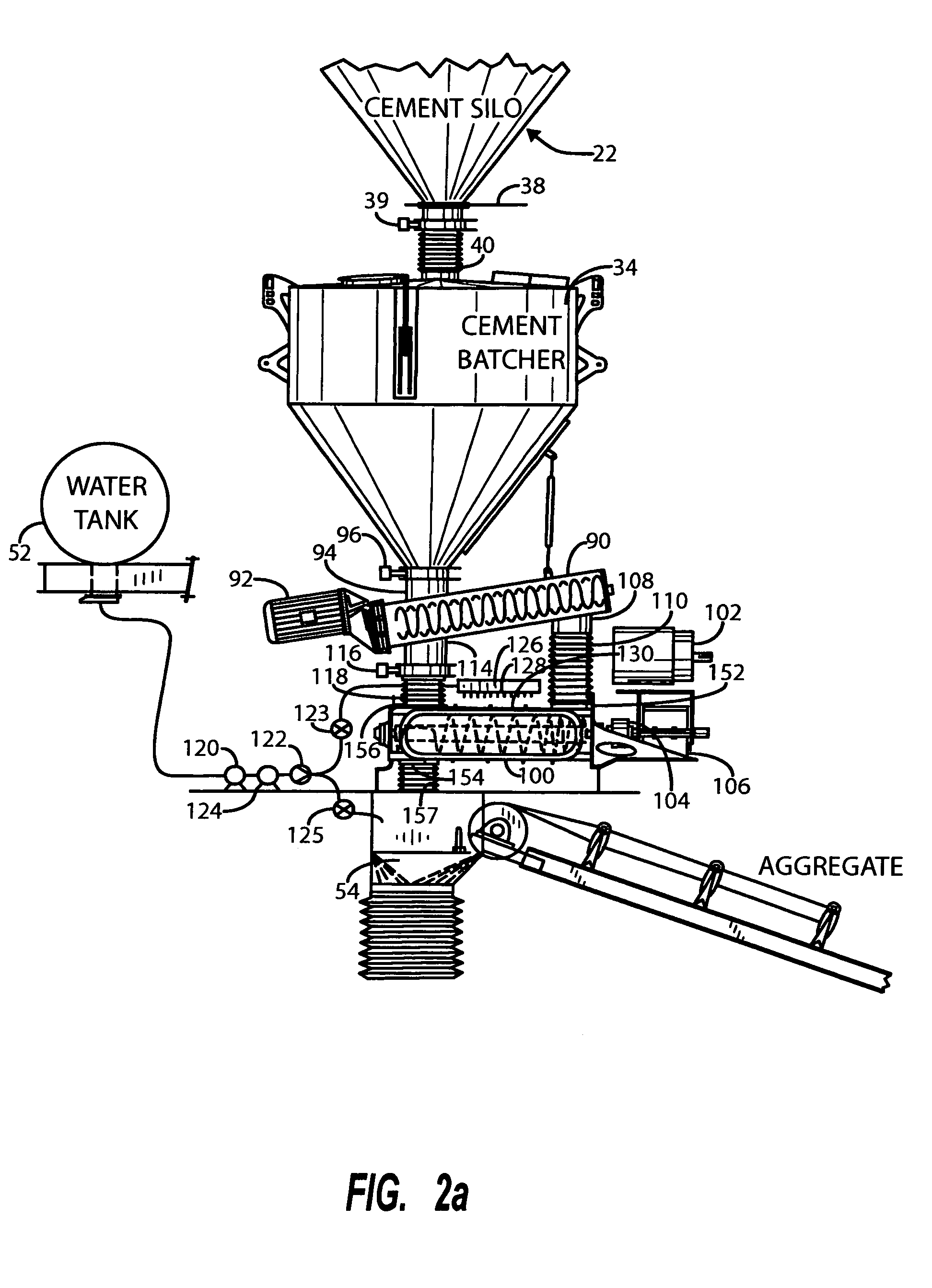

Concrete batching pre-mixer and method

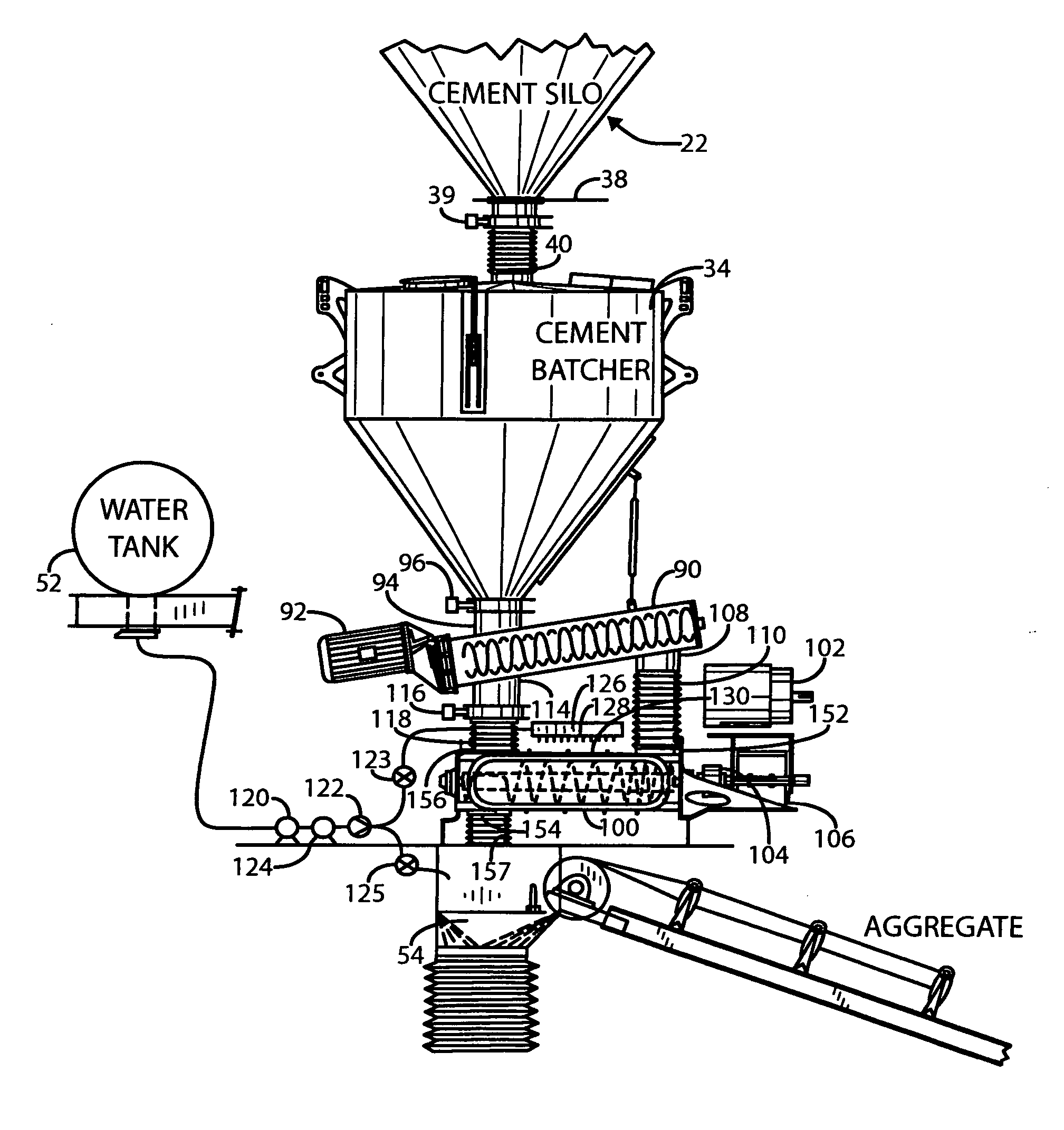

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

Efficient concrete mixer with water capable of being added automatically

InactiveCN104924462AQuality assuranceReduce noiseDischarging apparatusCement mixing apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete mixer with water capable of being added automatically. The efficient concrete mixer comprises a mixing drum, a screw conveying drum and spray heads. A feeding funnel is arranged at the left end of the upper side of the mixing drum, a stirring rotating shaft is vertically arranged at the axis of the inside of the mixing drum, stirring blades are arranged on the outer wall of the middle section of the stirring rotating shaft in a left-right symmetrical mode, and the bottom of the stirring rotating shaft is connected with a stirring plate. According to the concrete mixer with water capable of being added automatically, the stirring blades, the stirring plate and stirring wheels are used for stirring concrete in the horizontal direction and the vertical direction at the same time, a hydraulic cylinder is used for driving a mixing mechanism to move up and down for stirring, hence, the stirring effect and working efficiency of the mixer are greatly improved, and the concrete quality is guaranteed; moreover, automatic discharging is achieved through a screw conveying mechanism, the concrete can be stirred continuously in the discharging process, and the working efficiency of the mixer is improved; in addition, noise of the mixer in the working process is small, and automatic water adding and cleaning can be achieved.

Owner:苏晓玲

Portable cement mixing apparatus

InactiveUS20090177313A1Sampled-variable control systemsDigital data processing detailsAdditive ingredientEngineering

A portable cement mixing system uses ingredients such as cement, water and sand in predetermined quantities. A digital controller coordinates all of the operating elements of the apparatus for the entire mixing process and stores mixing programs relative to the mixing process for a variety of cements which includes the various ingredient quantities. Separate storage containers each coupled to a conveyors from the container extend to a mixer to transfer that quantity to the mixer for each cement ingredient. The conveyors are operated in sequence by the controller to load the mixer with a predetermined quantity of each of the required ingredients prior to mixing. The mixer and its contents are weighed before and during the transfer of each ingredient to precisely determine and transfer the required amount of each ingredient. After the mixer is loaded with all of the ingredients, the mixer is operated for a predetermined length of time.

Owner:SMART BATCH SYST

Construction refuse crushing recycling device

InactiveCN107234724AQuality assurancePlay a buffering effectSolid waste managementCement mixing apparatusArchitectural engineeringHigh pressure

The invention discloses a construction refuse crushing recycling device which comprises a base, a support and a top plate. The support is arranged on the base, and the top plate is arranged at the top of the support. A motor is arranged at the left side of the bottom of the top plate and is further connected with a lifting screw rod. The support is provided with sliding rails, and the sliding rails are connected with a first supporting plate and a second supporting plate in a sliding mode. The first supporting plate is provided with a through hole, and the through hole is connected with a first connecting rod in a sliding mode. The bottom end of the first connecting rod is fixedly connected with a pressing plate, and a high-pressure spring is arranged between the pressing plate and the first supporting plate. The second supporting plate is fixedly provided with a material crushing box, and a filtering plate is arranged inside the material crushing box. The bottom of the material crushing box is further connected with a discharging pipe. According to the construction refuse crushing recycling device, the lifting screw rod rotates to drive the pressing plate and the filtering plate inside the material crushing box to be drawn together in the middle, and thus construction refuse can be squeezed and crushed; and the crushed construction refuse is filtered through the filtering plate so as to be squeezed and crushed to be in a fine state continuously, and the phenomenon that the construction refuse is too large and thus later-period recycling cannot be facilitated is prevented.

Owner:ANHUI YIQI SOFTWARE TECH

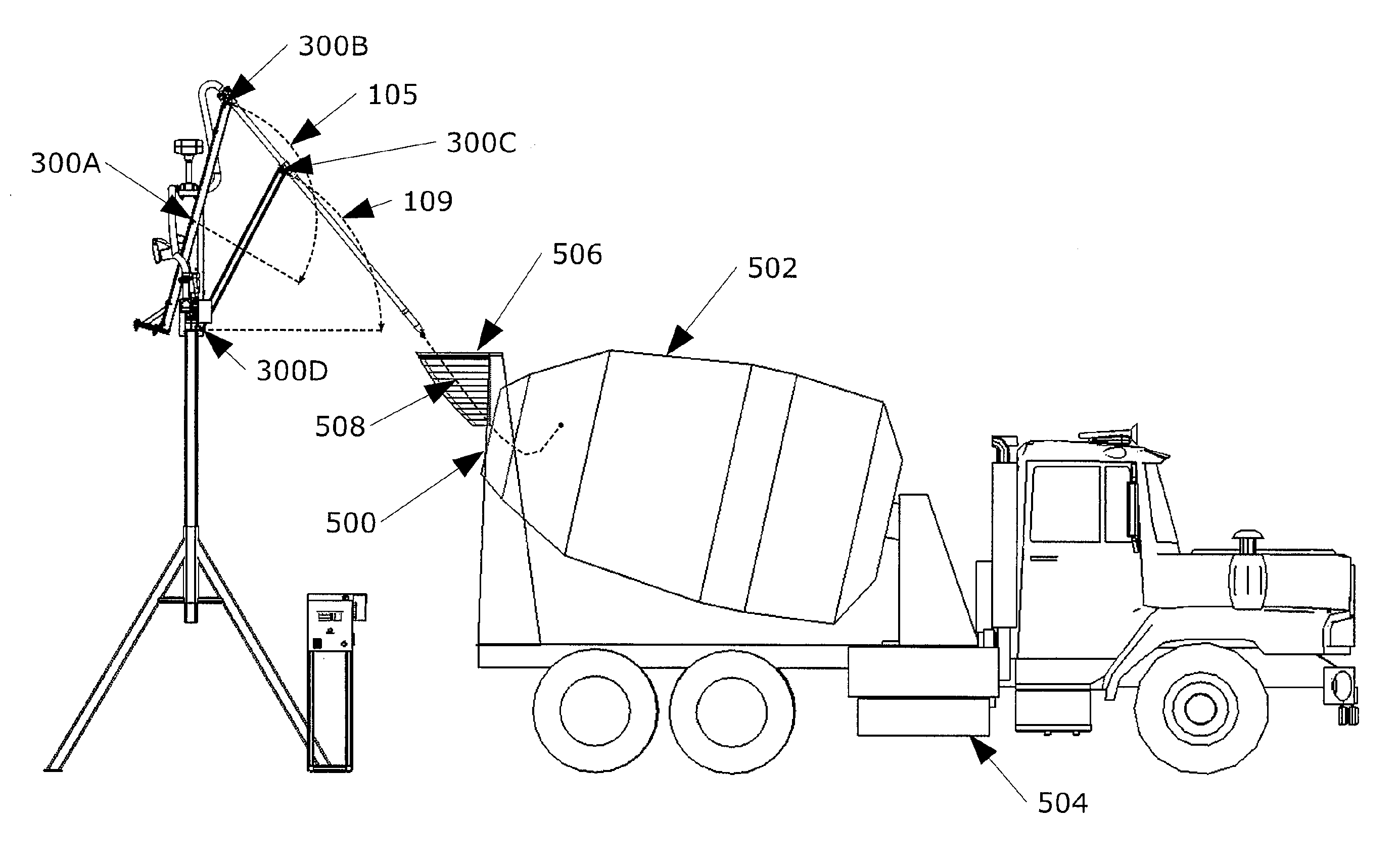

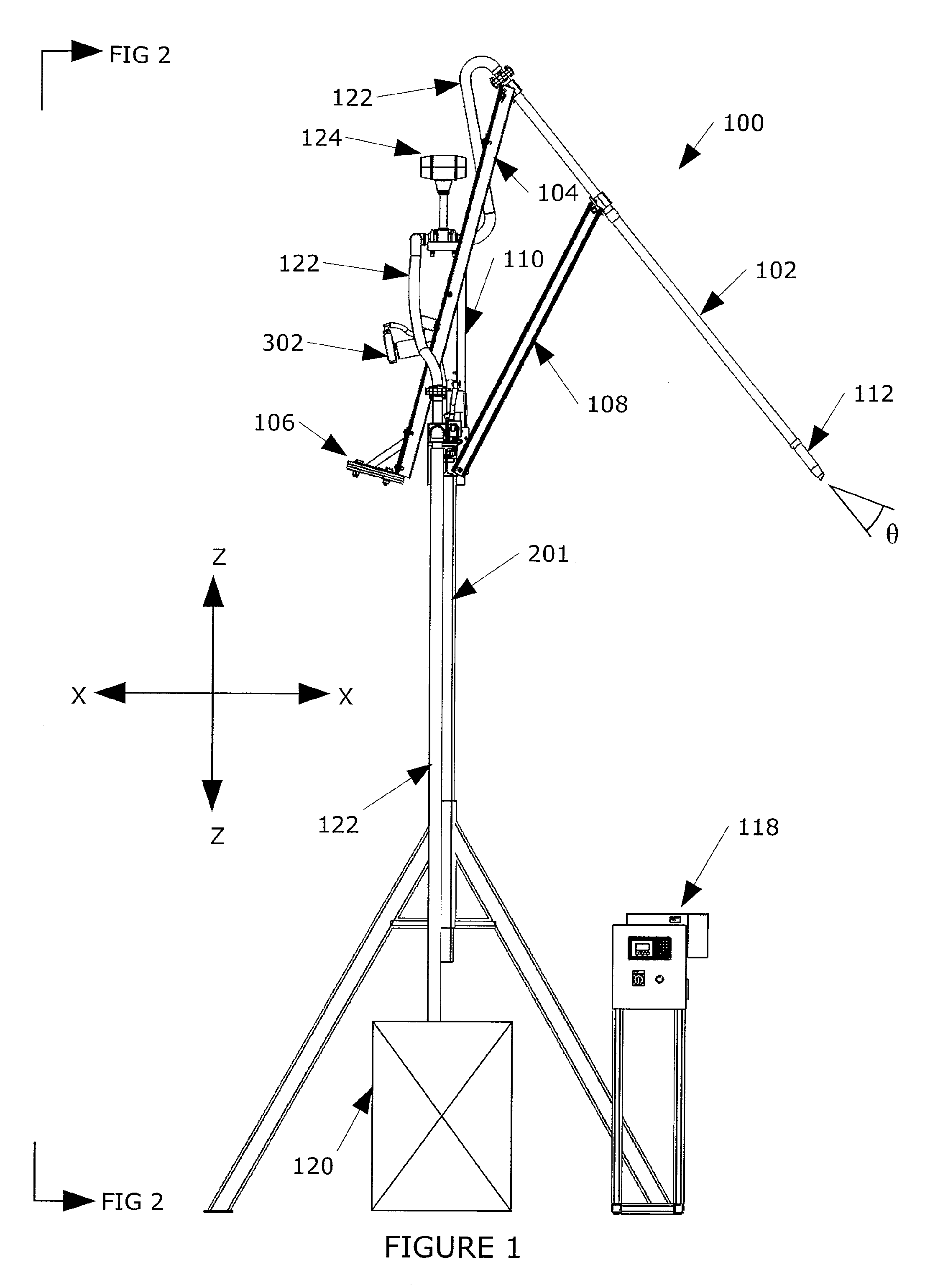

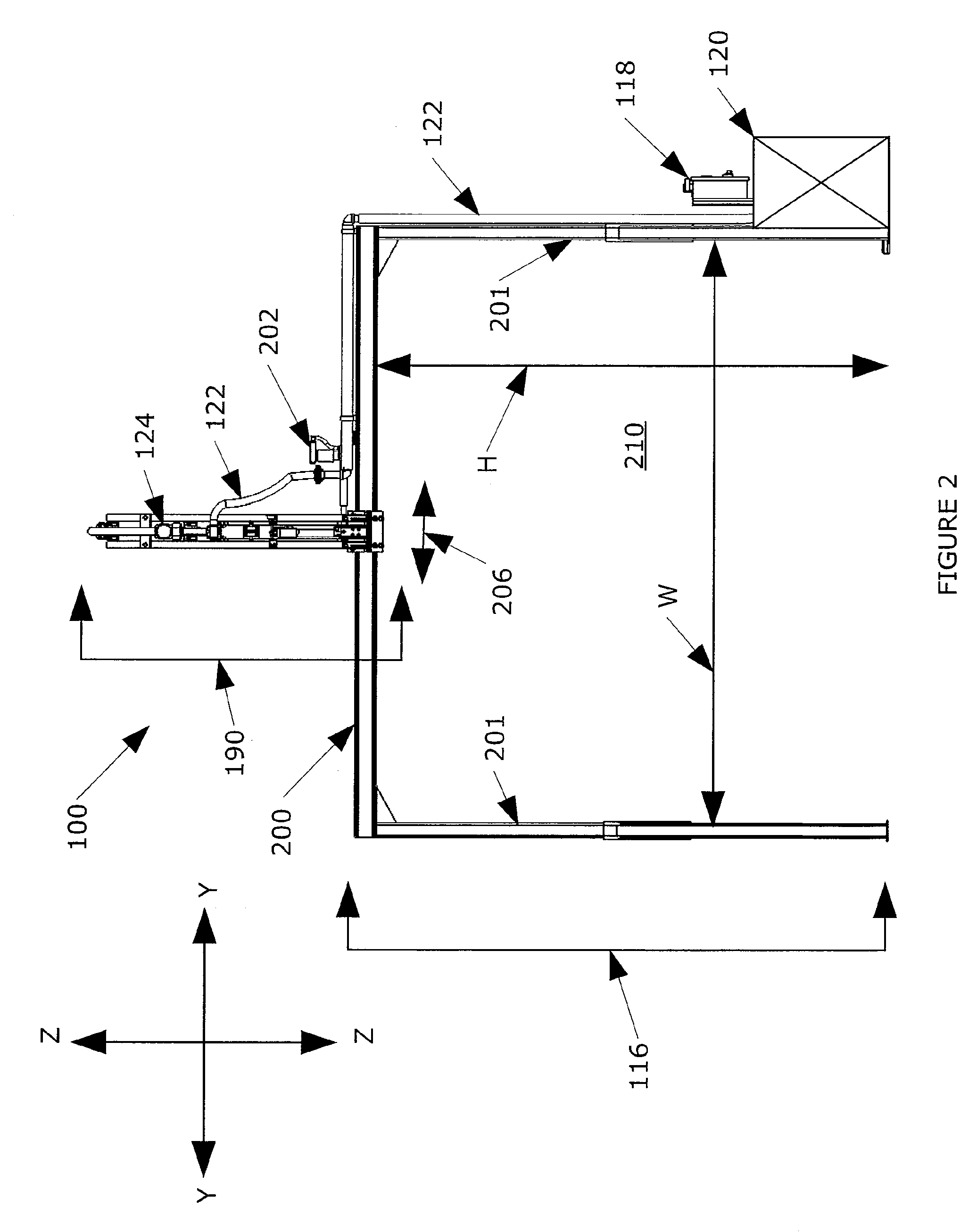

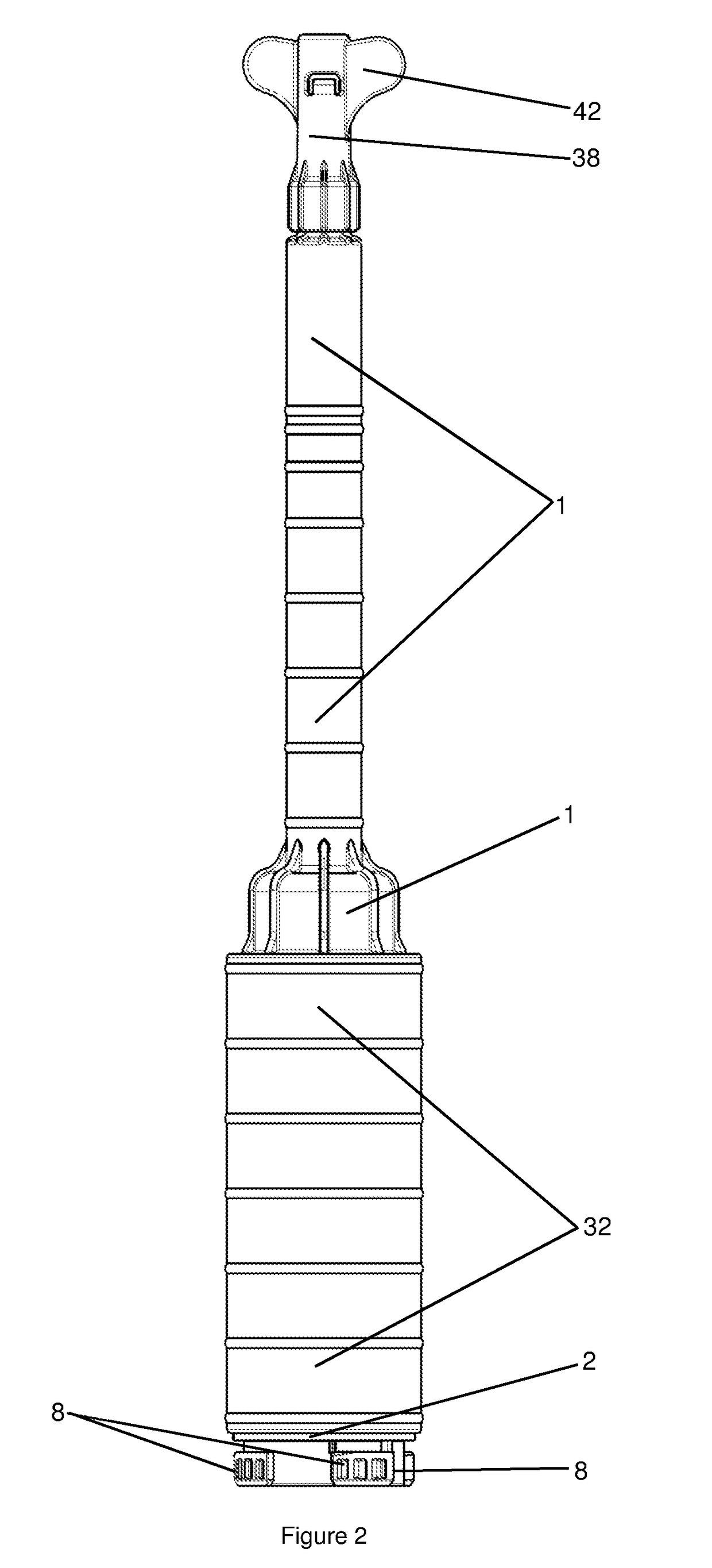

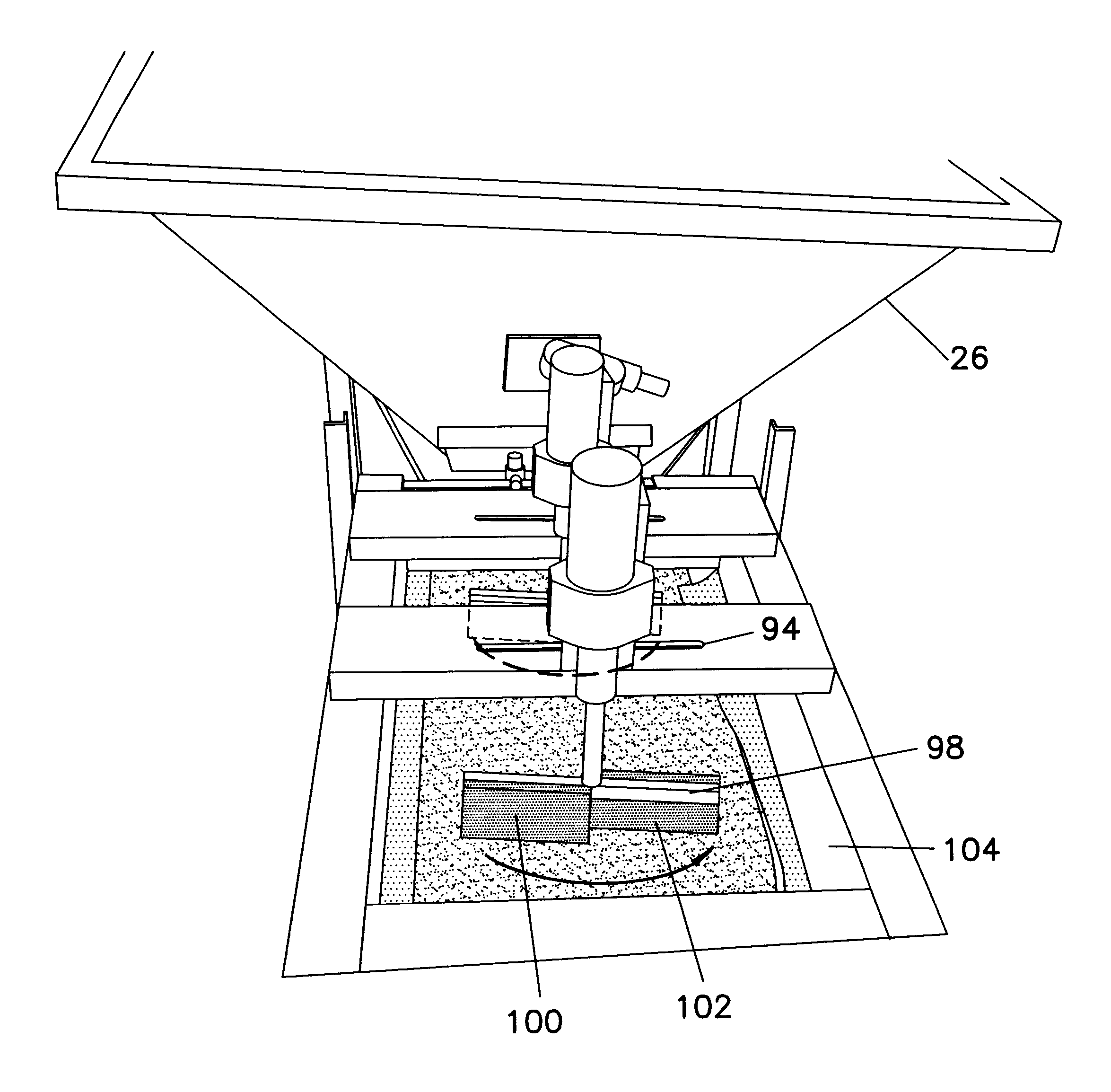

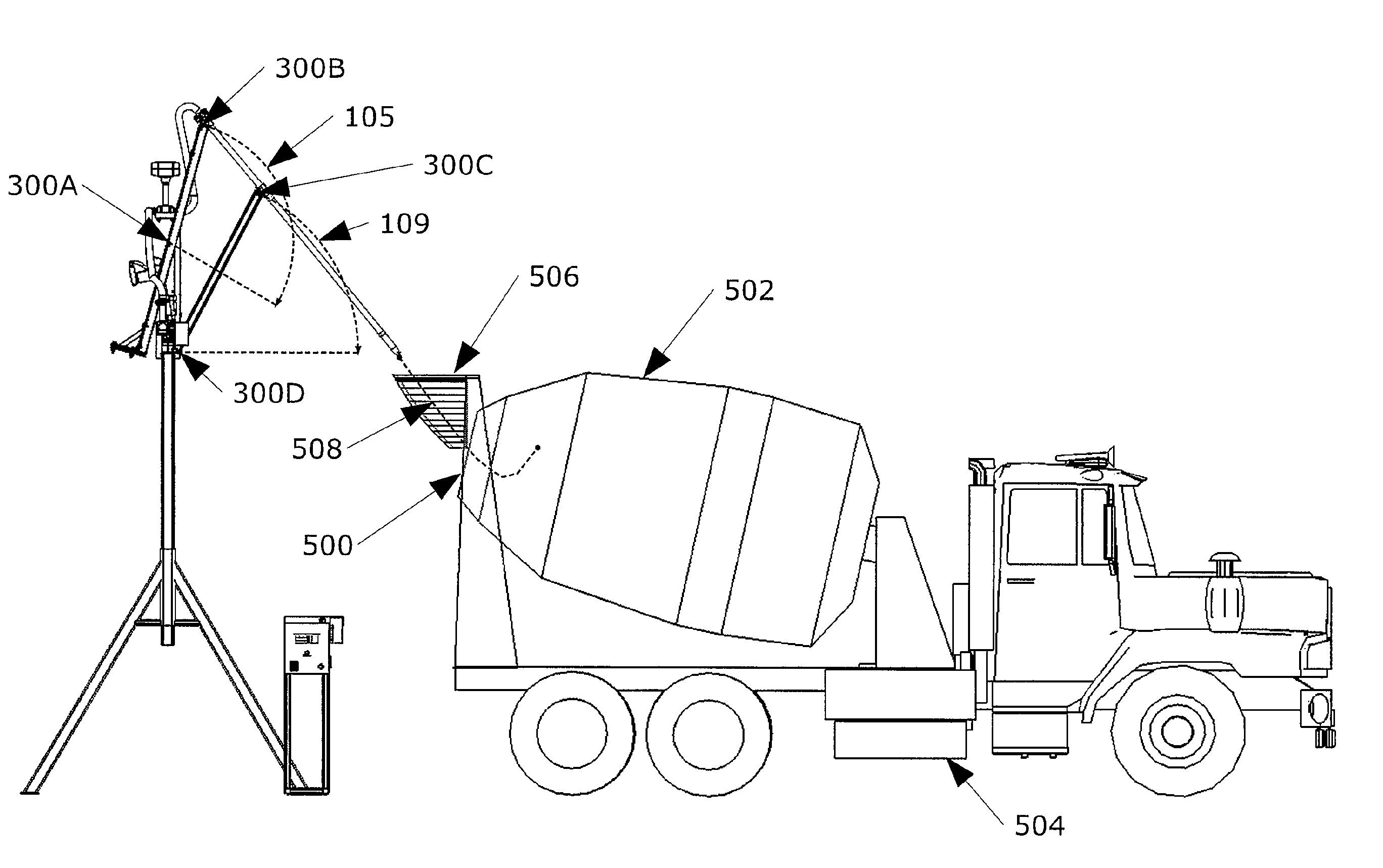

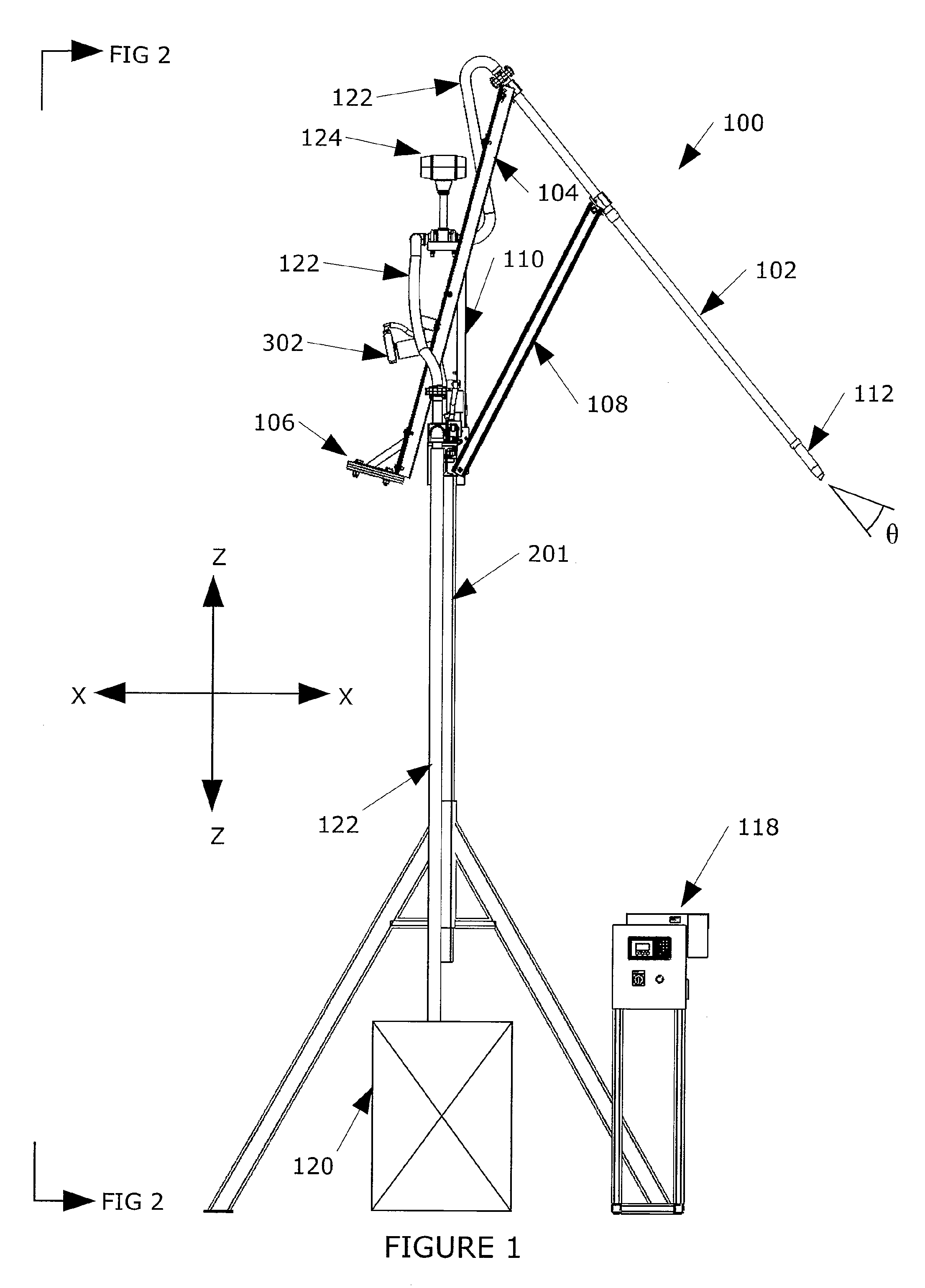

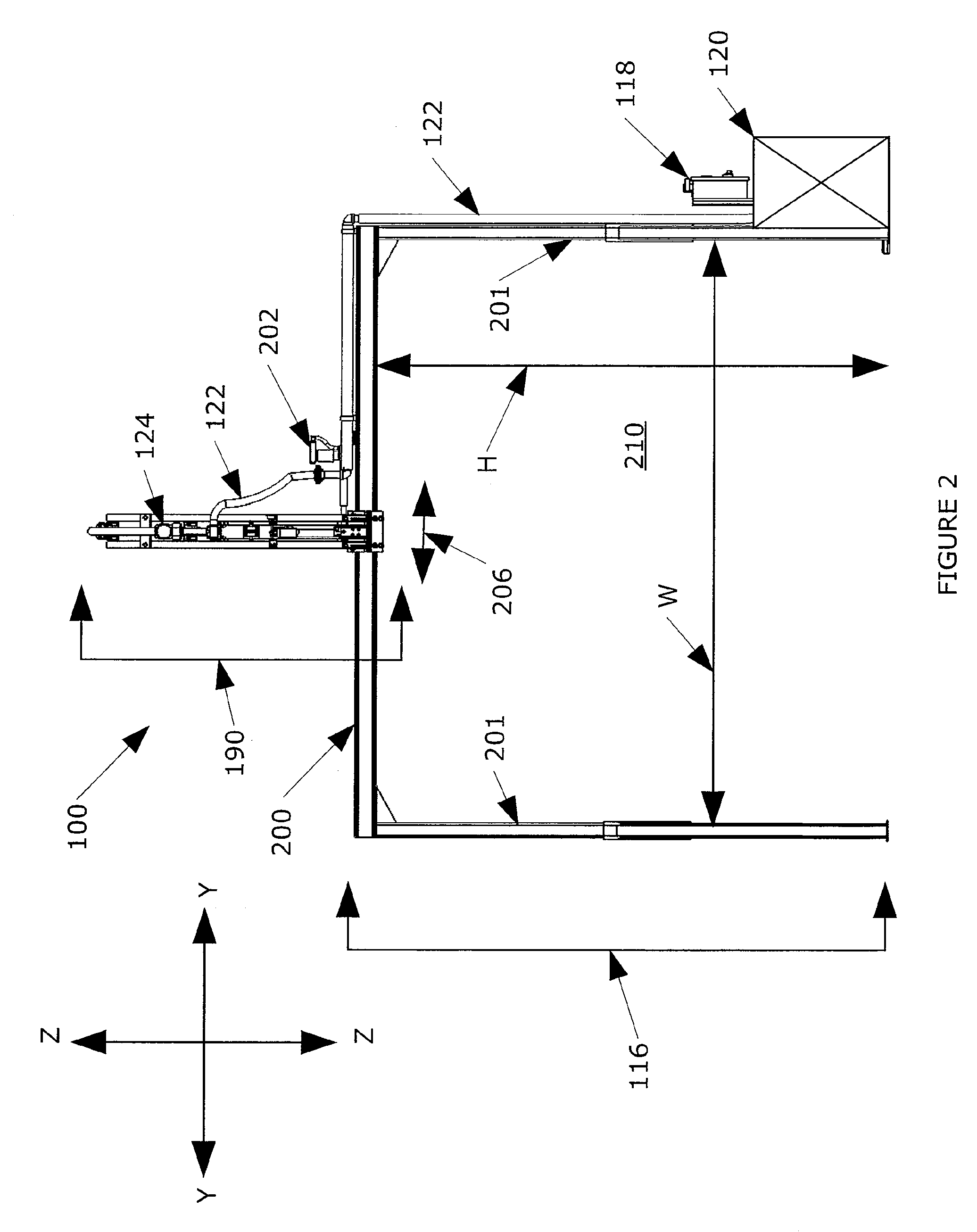

System and Process for Introducing a Rigid Lance into a Concrete Mixing Truck Using an Articulated Arm

ActiveUS20090103392A1Reduce chanceCement mixing apparatusLiquid ingredients supply apparatusLinear motionNonlinear motion

A present invention provides for a system (100) for injecting cooling fluid into a concrete mixing container (502), the system (100) comprising a support structure (116) having a leg assembly with two or more supporting legs (201) and a cross member beam (200) supported between said two or more legs (201), the two or more legs (201) and the cross member beam (200) being positioned with respect to one another in such a manner as to define a passageway (210) of sufficient height (H) and width (W) between the two or more legs (201) and beneath the cross member beam (200) to allow passage of a concrete mixer truck (504) through the passageway (210) and a lance device (190) positioned on the cross member beam (200) of the support structure (116), the lance device (190) comprising an articulated arm that includes a rigid lance (102) which allows for the flow of a cooling fluid there through; and a means for acting on the articulated arm to cause pivotal movement of the articulated arm in a non-linear motion thereby controlling the angle of the rigid lance (102) while at the same time controlling the insertion and retraction movement of the rigid lance (102) into the concrete mixing container (502) for fluid injection of the cooling fluid into the concrete mixing container (502). The present invention further comprises a process for injecting cooling fluid into a concrete mixing container (502).

Owner:AIR LIQUIDE IND US LP

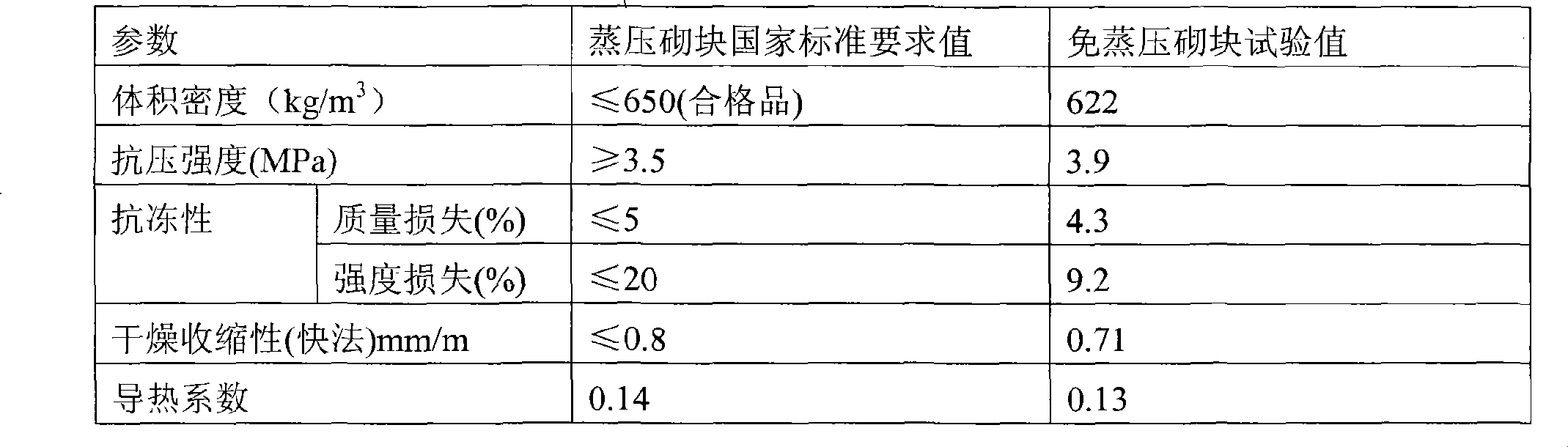

Preparation of 06 grade gypsum based autoclave-free aerated concrete building blocks

InactiveCN101439955AIncrease profitLess investmentSolid waste managementCeramic shaping apparatusThermal insulationSlurry

The invention relates to a method for preparing an aerated concrete block, in particular to the method for preparing a 06-grade gypsum based vapor pressure free aerated concrete block, which is characterized in that that the method comprises the following steps: 1) preparing raw materials; 2) selecting the raw materials; 3) preparing composite gelled materials; 4) dissolving retarder sodium citrate in water which accounts for 1 / 5 to 2 / 5 of the total amount, stirring the mixture and immediately adding the mixture to the composite gelled material, and stirring the mixture for 2 minutes to obtain liquid slurry; 5) adding a mixture of air-entraining agent aluminum powder and degreaser honeylocust fruit powder to the remaining water to be stirred into a suspension which is then immediately added to the liquid slurry, and stirring the mixture for 3 minutes to obtain mixed slurry; 6) pouring the mixed slurry into a test mold, and performing cutting and demolding after 6 to 8 hours of natural curing to obtain a blank body; and 7) performing damp heat curing on the blank body for 24 hours, and then drying and dehydrating the blank body naturally to obtain the finished product. The method has the advantages of simple process, low cost and high utilization rate of desulfurization construction gypsum; and the finished product has the characteristics of light weight, thermal insulation, sound absorption and insulation, vibration resistance and fire prevention, conditioning treatment, good water resistance, small dry-wet shrinkage, and stable performance.

Owner:中博建设工程集团有限公司 +1

Efficient concrete quantified stirring device

InactiveCN107139328AStir wellNo manual controlDischarging apparatusCement mixing apparatusGear wheelArchitectural engineering

The invention discloses a high-efficiency concrete component mixing device, which comprises a base, a support plate is fixedly arranged at the left and right ends of the base through a support rod, a cement tank and a gravel tank are fixedly arranged on the support plate; a slide rail is arranged on the left side of the bottom of the support plate , the lower part of the slide rail is slidingly connected with the moving frame through the slider, the left end of the moving frame is connected with the left support rod through the spring, the right end of the moving frame is connected with the first moving rod, and two cover plates are arranged on the first moving rod, inside the moving frame A rack is arranged on the top, and a first motor is fixedly arranged on the top of the support plate through a bracket. The motor shaft at the top of the first motor is connected with a gear, and the gear meshes with the rack; the right side of the base is also fixed with a mixing bucket through a bracket. The invention drives the moving frame to move left and right through the cooperation of incomplete gears and springs, so that the cover plate is intermittently opened and closed, and the amount of cement and sandstone is basically the same each time, and the component stirring is carried out. The amount of stirring at one time is not much, and the stirring more fully.

Owner:童红妃

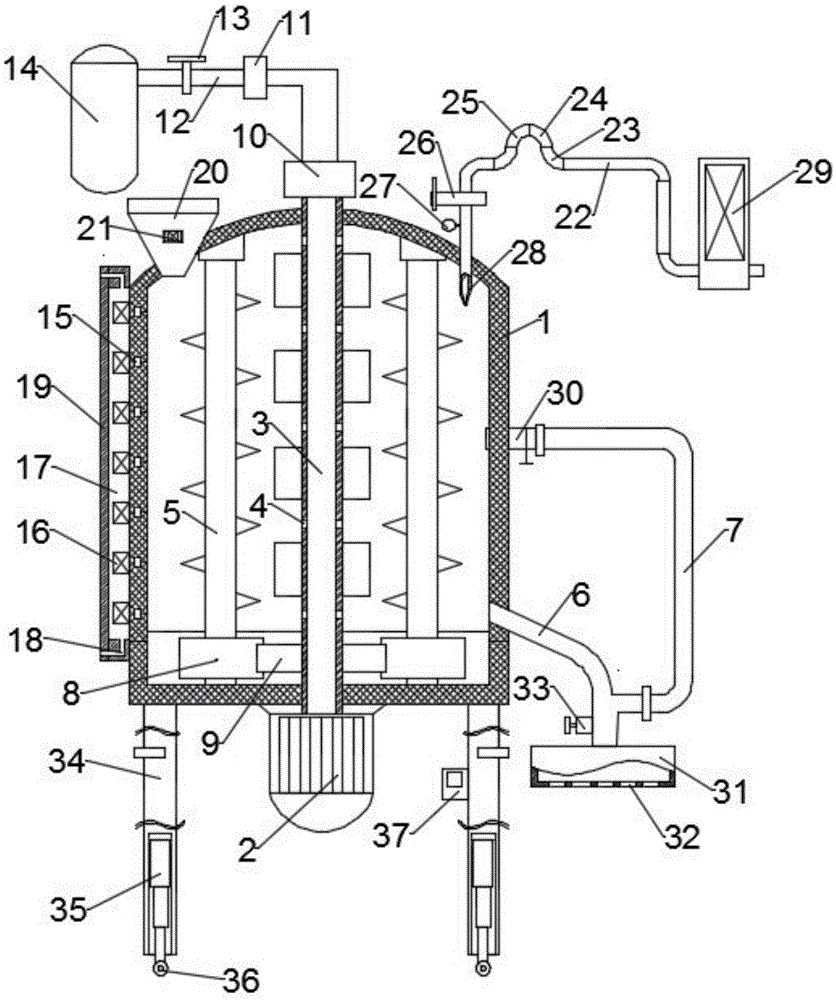

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

Method and System for Calculating and Reporting Slump in Delivery Vehicles

InactiveUS20100312438A1Analogue computers for trafficComputations using stochastic pulse trainsDelivery vehicleControl theory

Owner:VERIFI INC

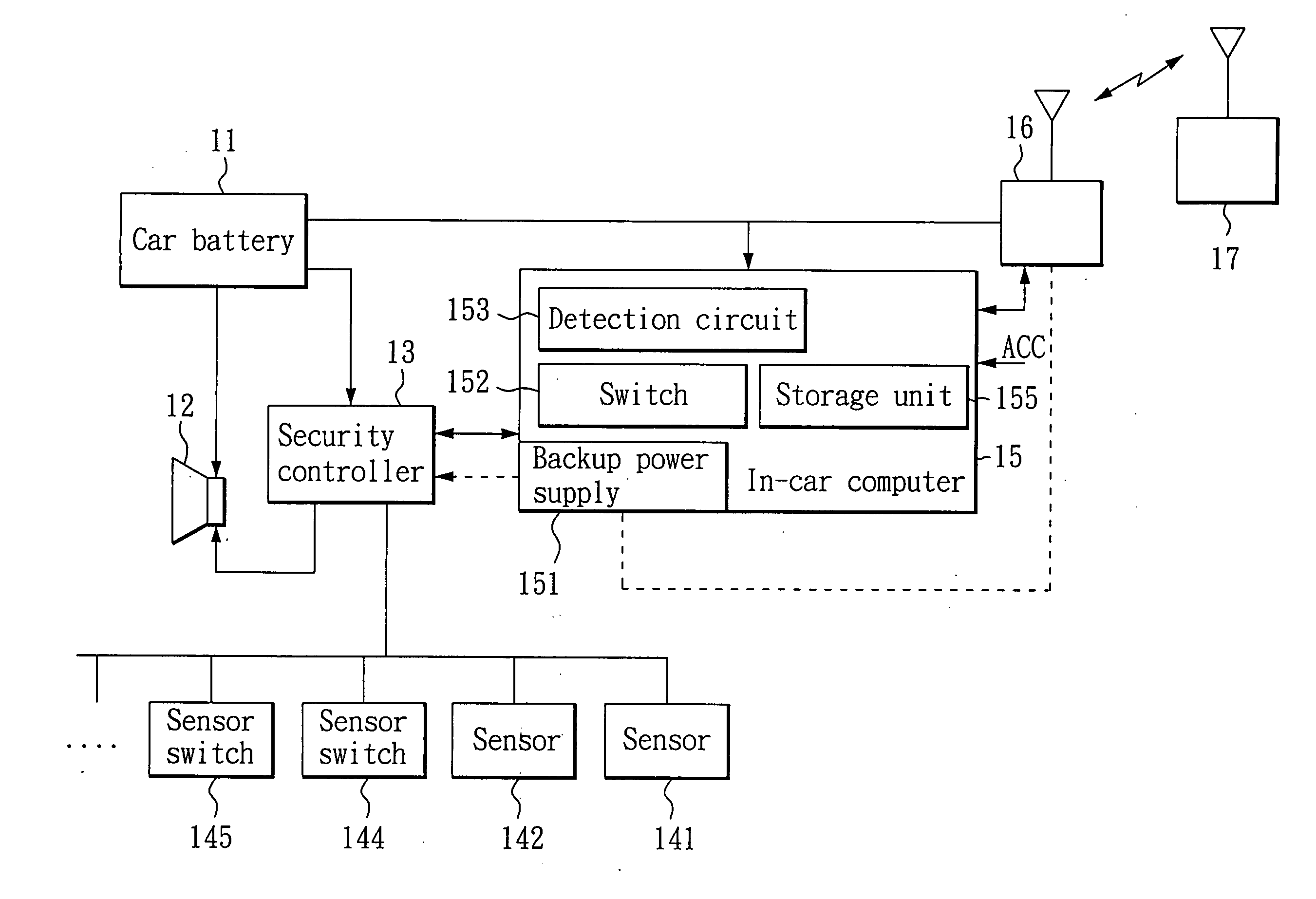

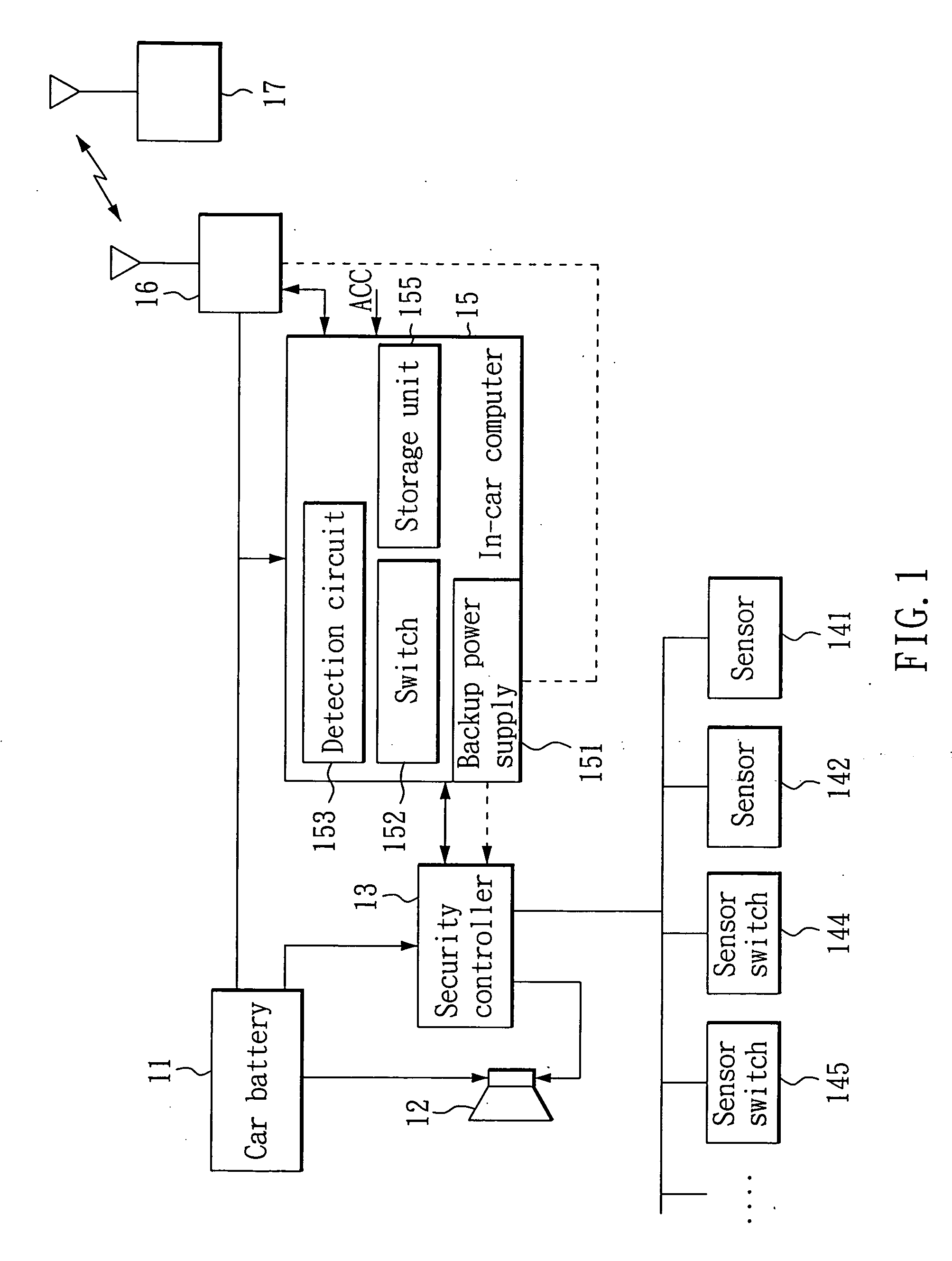

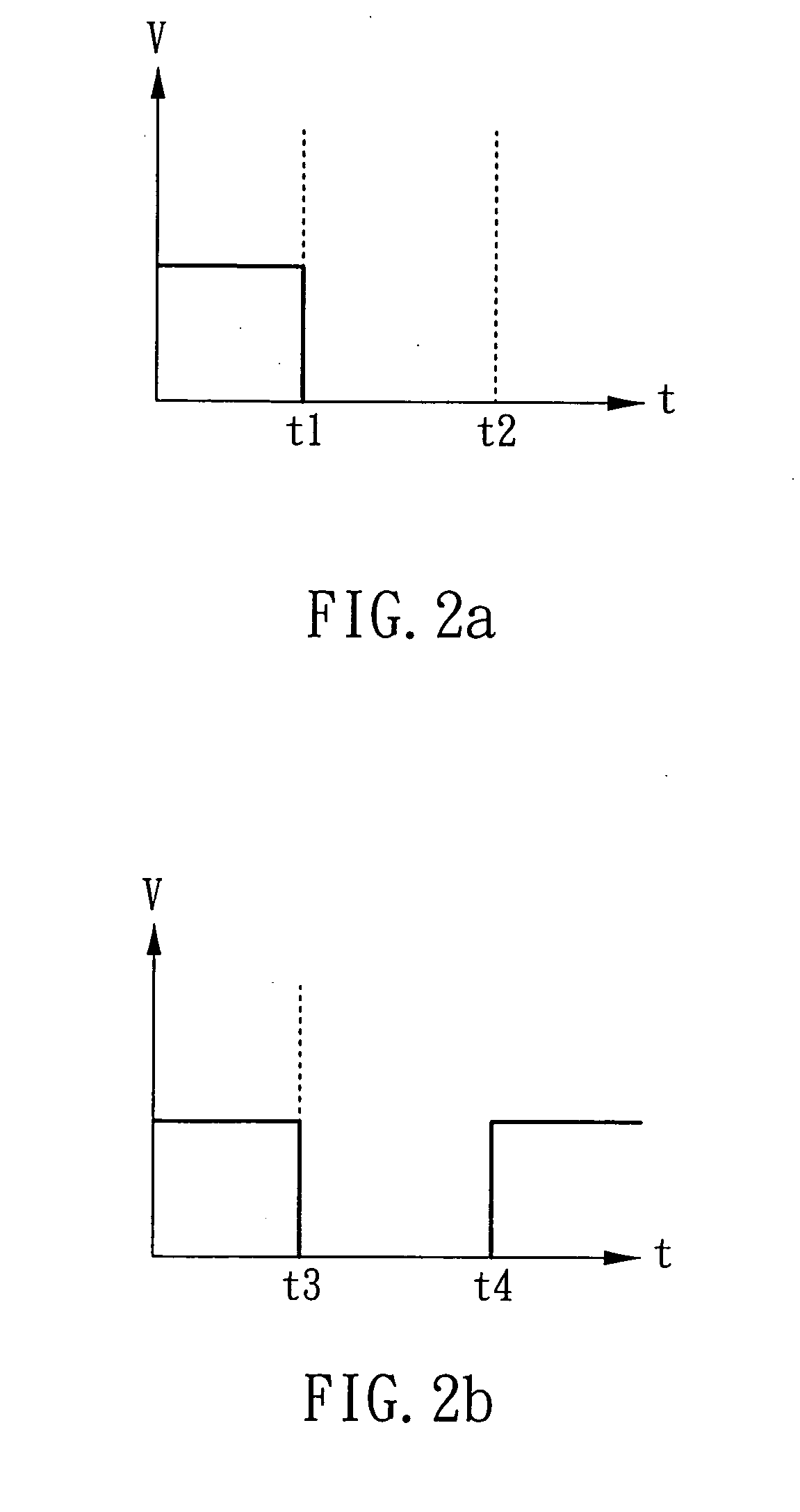

Vehicle security system

Disclosed is a vehicle security system, which uses a detection circuit to detect the supply of electric power from the car battery to the in-car computer and the status of the car ignition switch, and to start a backup power supply for the in-car computer, and drives the in-car computer to send an informing message to a remote receiver via a wireless communication module when the supply of electric power from the car battery to the in-car computer is terminated or when the car ignition switch is switched on during the alert mode of the vehicle security system.

Owner:XINGYI SCI & TECH

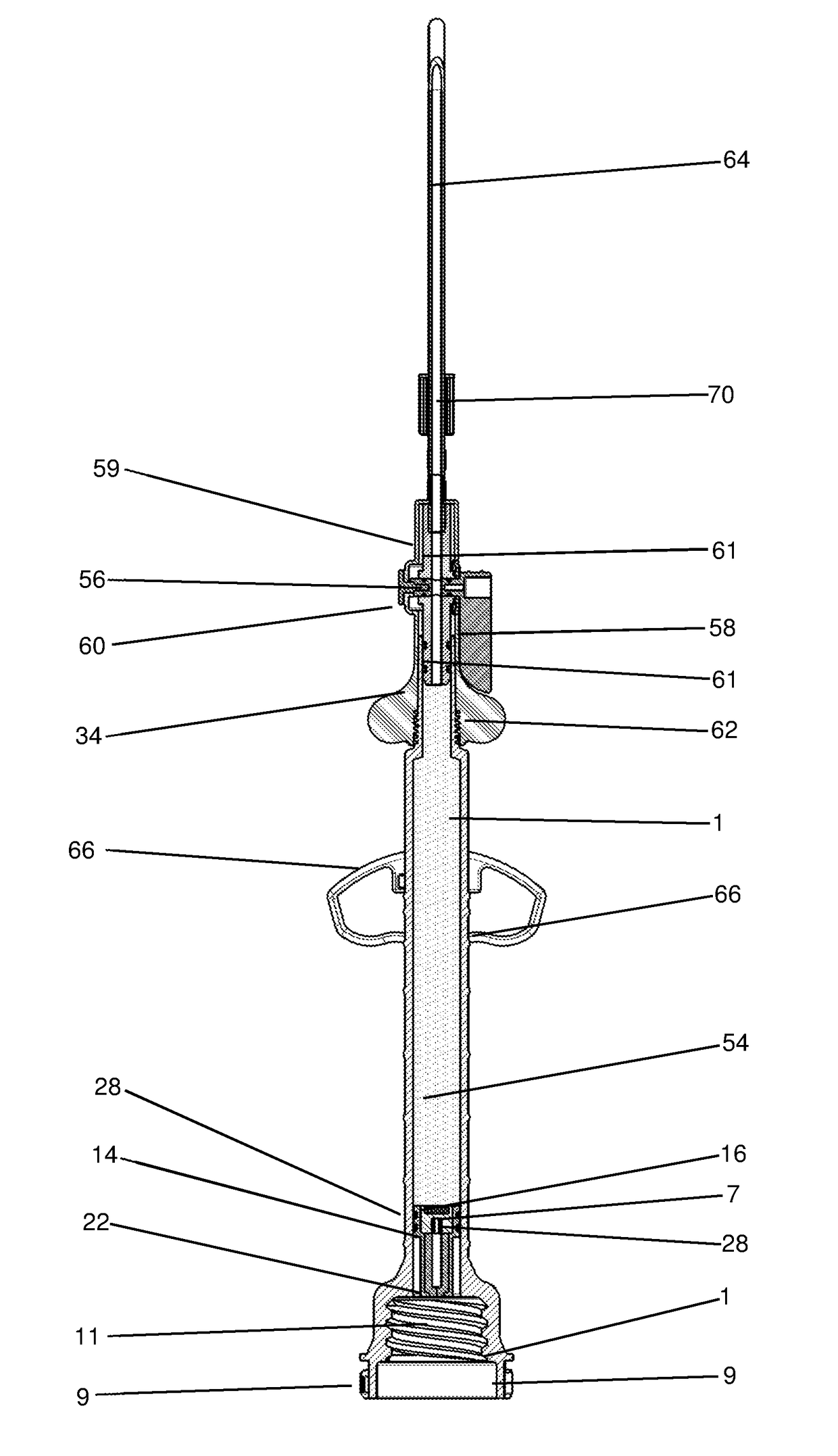

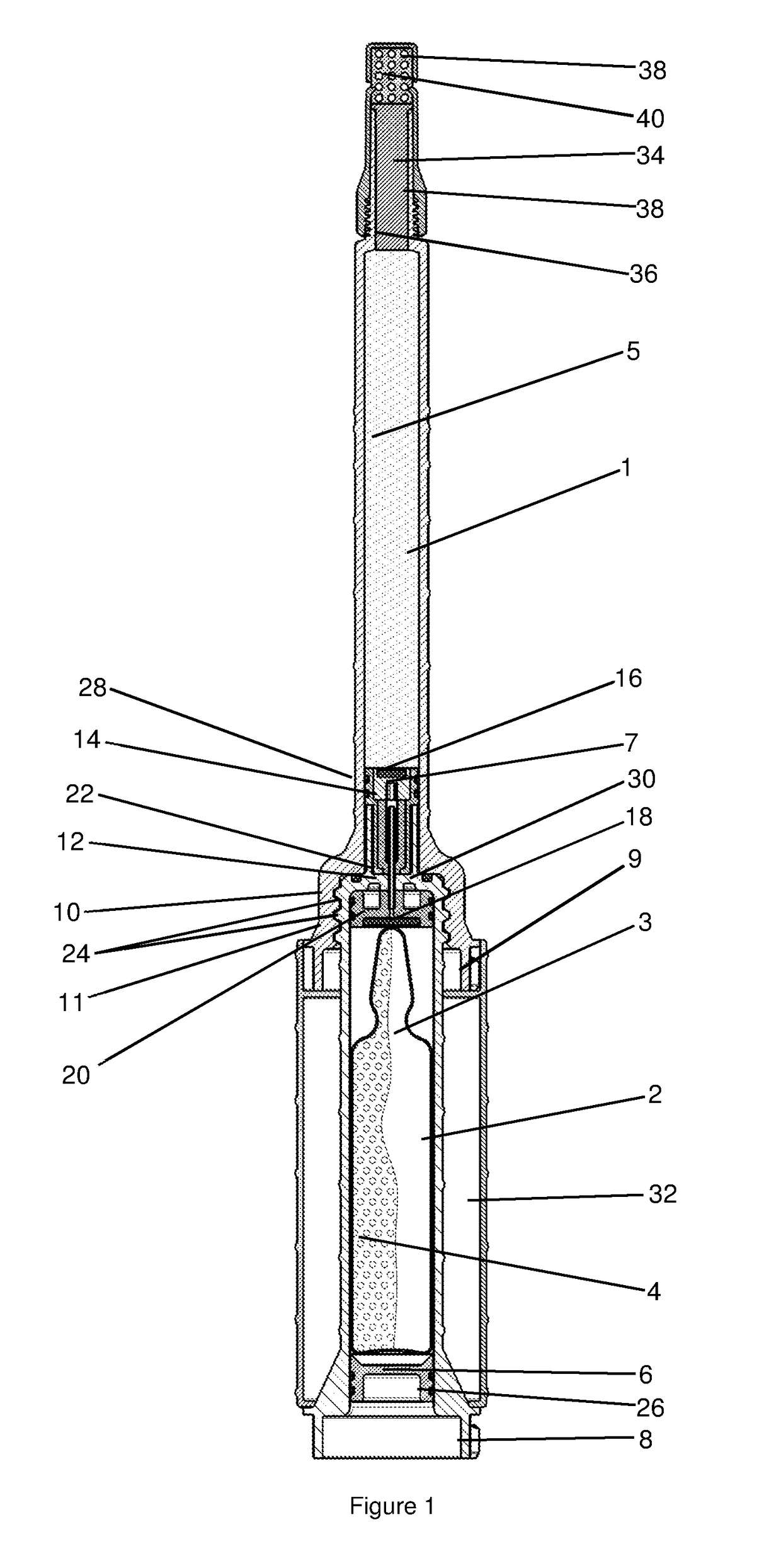

Two-part storage and mixing device for the production of a bone cement, and pertinent method

Owner:HERAEUS MEDICAL

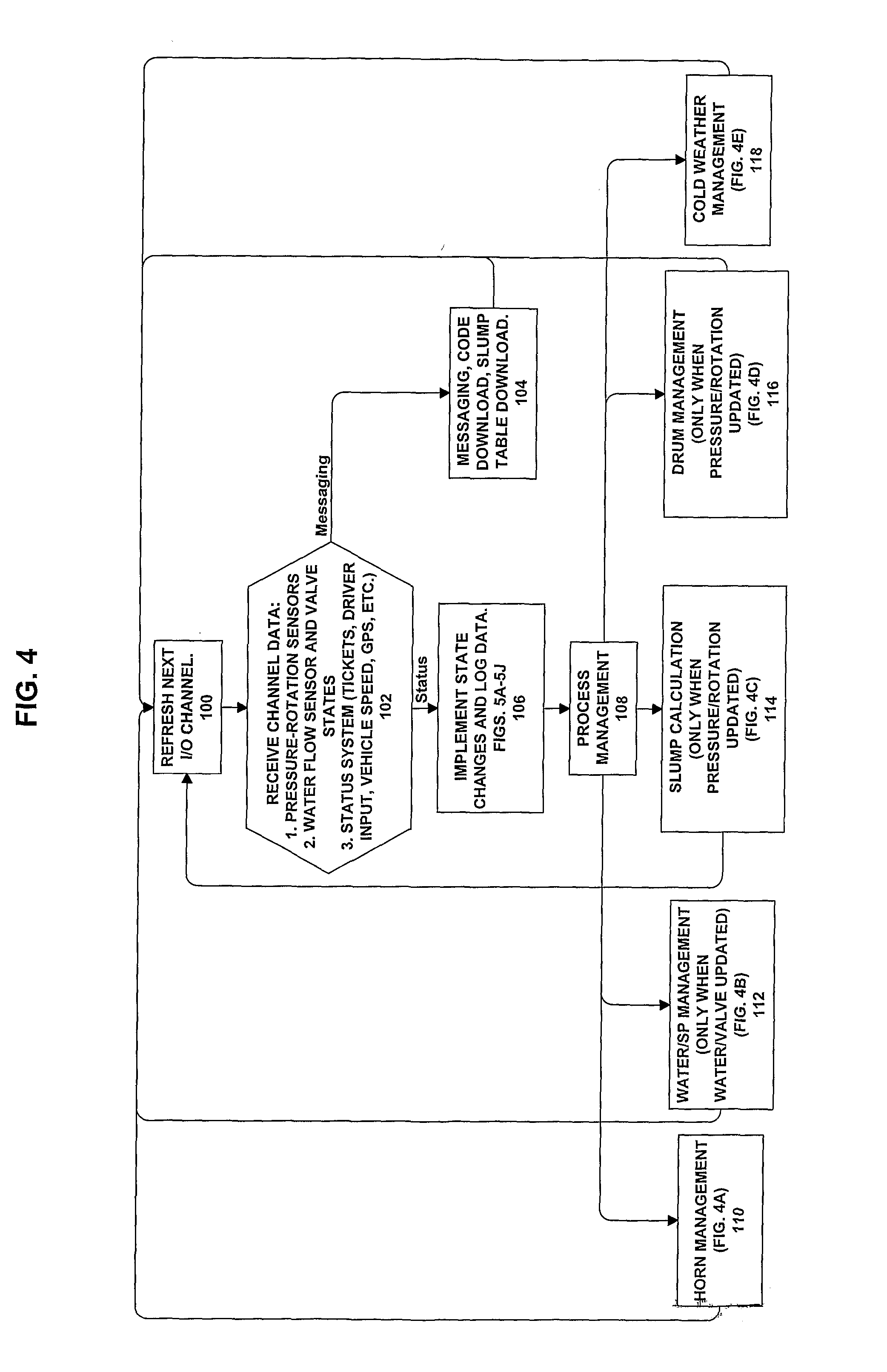

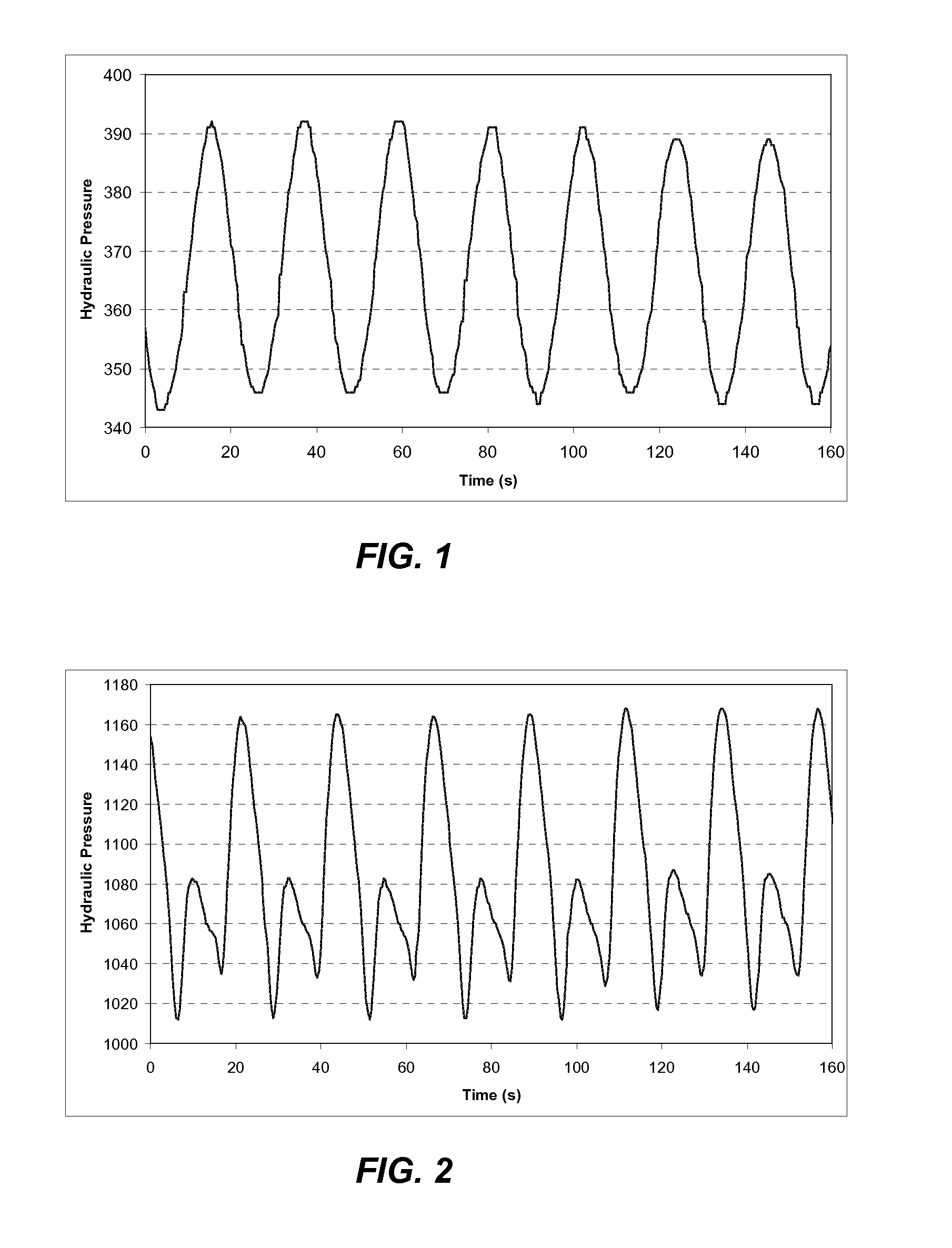

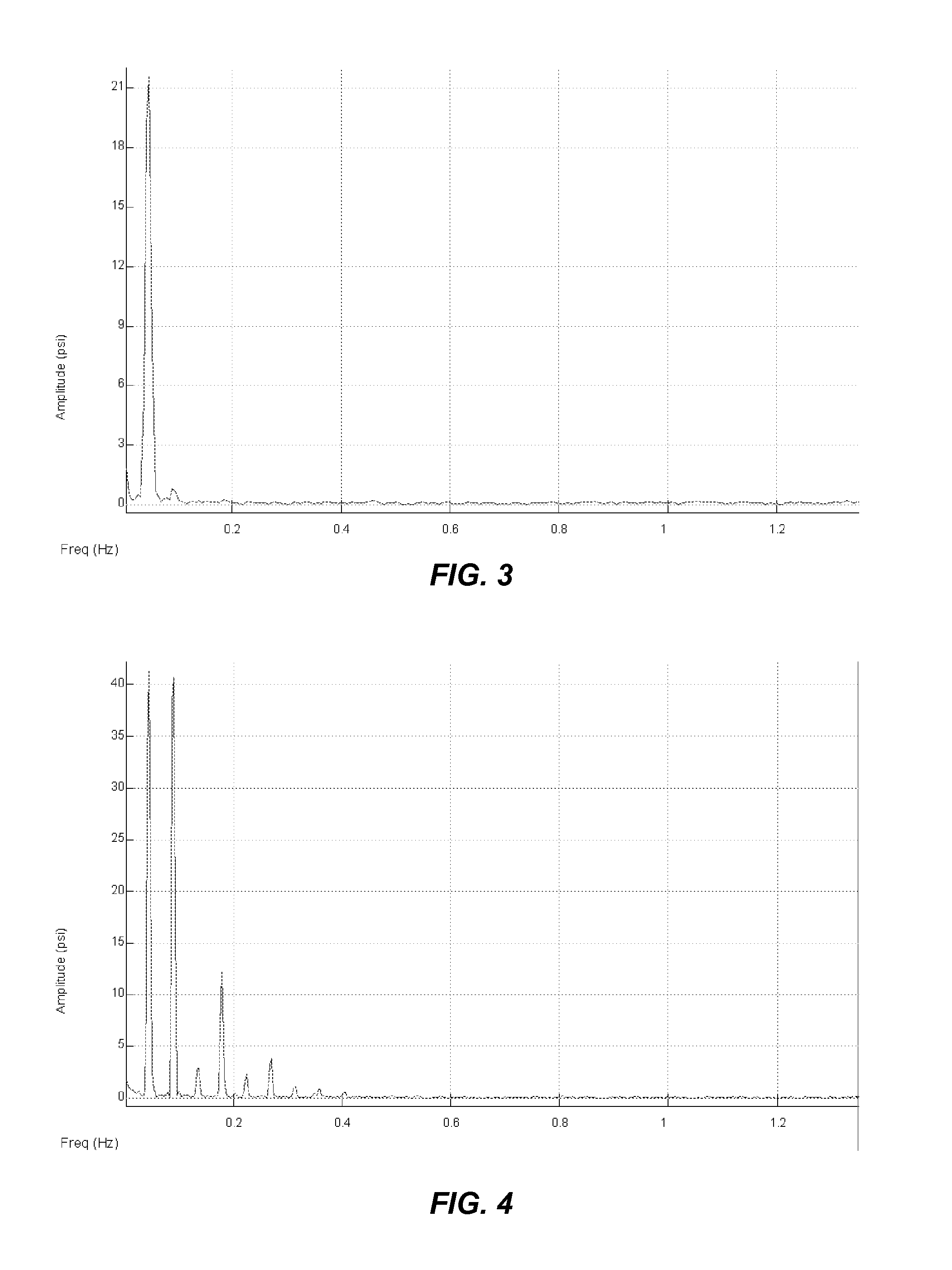

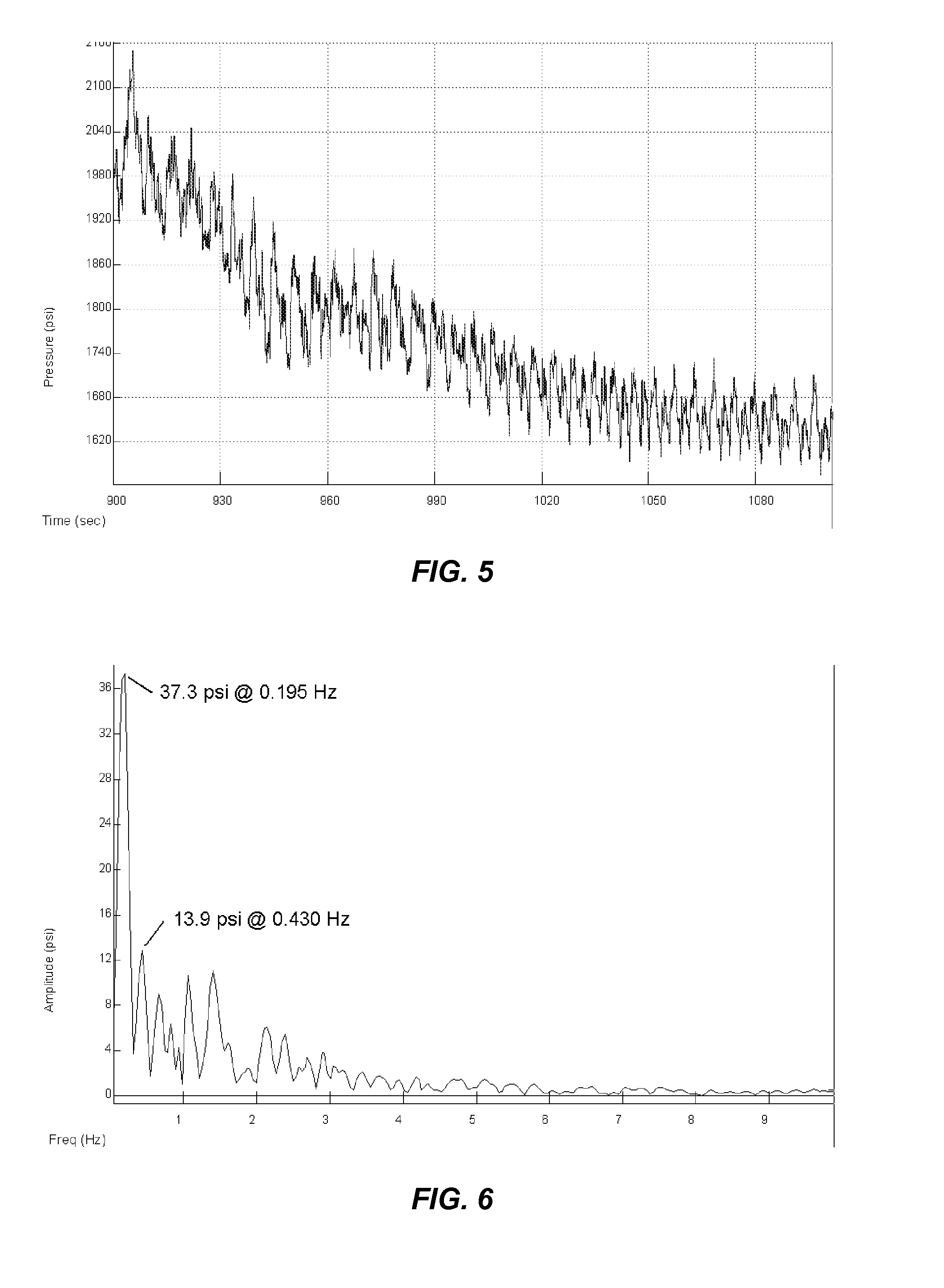

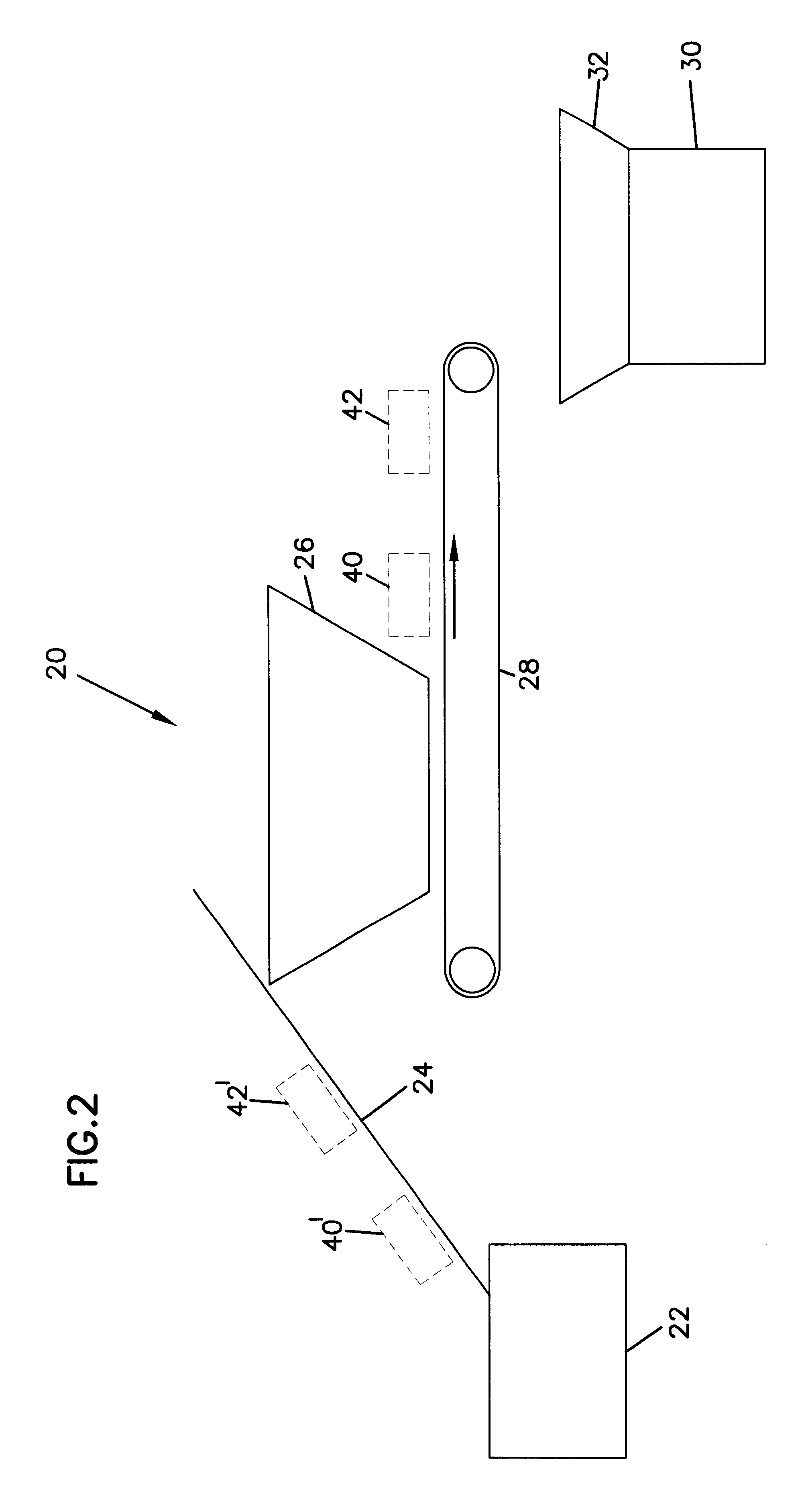

Mixer waveform analysis for monitoring and controlling concrete

ActiveUS20120020180A1Quick fixEasy to adjustSampled-variable control systemsMixing operation control apparatusWaveform analysisTime domain

Method and system for motoring and obtaining information about quantity and characteristics of cementitious material In a rotating mixing drum. The present invention involves analysis of a sequence of values corresponding to a waveform reflecting the hydraulic pressure required to turn a concrete mixing drum at successive instances during rotation. Preferred embodiments involve the conversion of this time-domain data into the frequency-domain. Behavior of multiple harmonics can be examined in real time and further information obtained regarding physical properties of the concrete. Rheology or other properties can be adjusted by introducing a liquid into the concrete, based on a comparison between time-domain and / or frequency-domain values derived from a sample concrete in the drum and previously stored time-domain and / or frequency-domain values, which are preferably correlated with physical characteristics of concrete, such as slump, slump flow, load weight, and other factors.

Owner:VERIFI

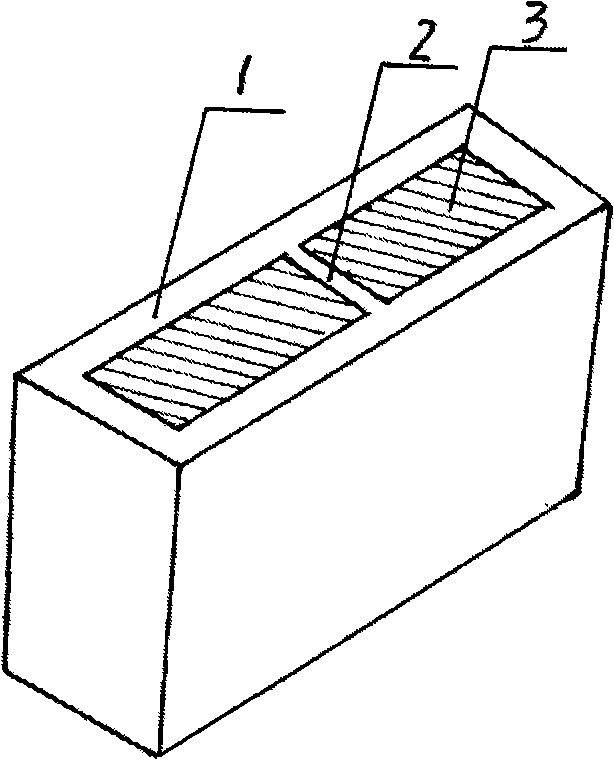

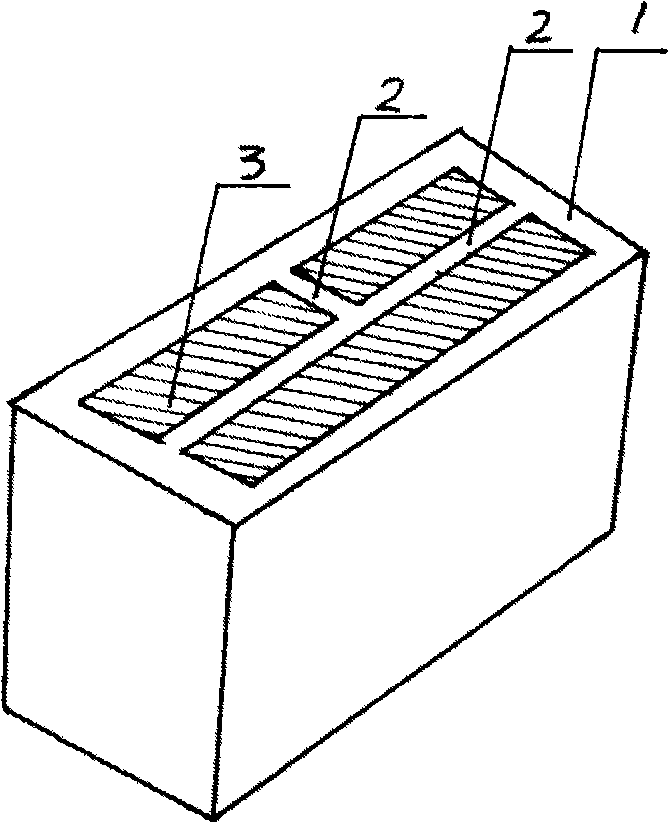

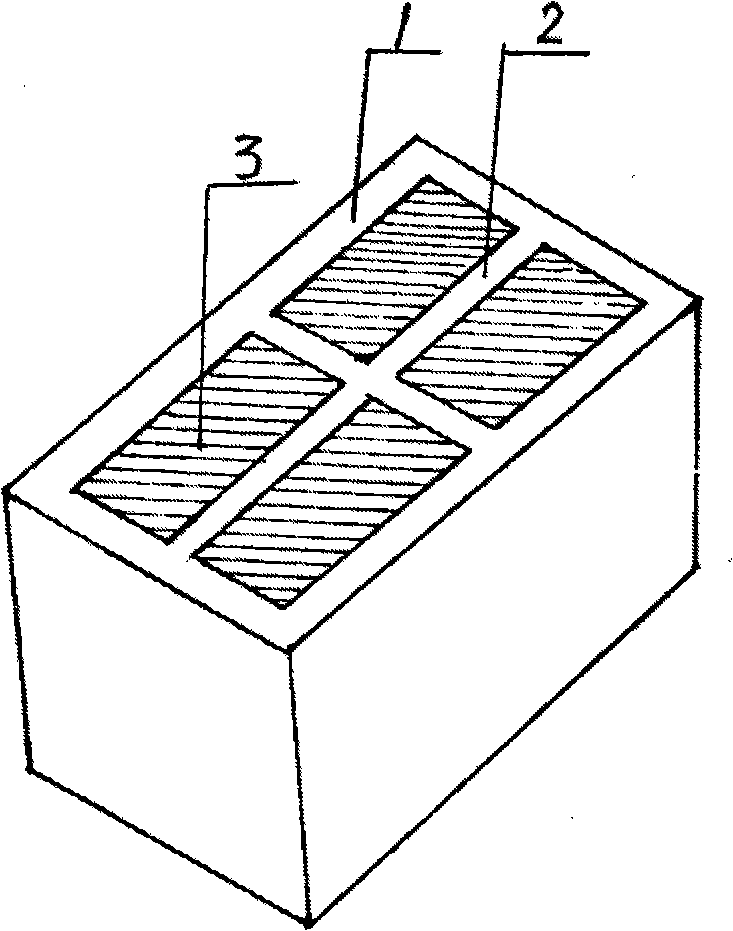

Steam pressurized concrete composite heat insulation building blocks and its production process

InactiveCN101265737AImprove thermal insulation performanceLight weightConstruction materialSolid waste managementSlurryAutoclaved aerated concrete

The invention discloses an autoclaved aerated concrete composite heat preservation building block and a production method thereof. The building block external wall and the building block are made of the autoclaved aerated concrete, the hole formed by the building block external wall and the building block rib is filled with heat preservation and insulation fillers for a second time. The building block adopts the autoclaved aerated concrete as the raw material and the preset mould core structure. The mould core is extracted after the slurry is poured so as to form a hollow structure in the building block body in the molding process, the void ratio of the hollow structure reaches 30%-70%. The light heat preservation and insulation material is filled for the second time after autoclaved curing the hollow structure block body, which reduces the production volume weight, improves the heat preservation and insulation performance of the material and facilitates the construction. Based on the application requirement, the absolute dry volume weight is adjustable in a range of 300-600kg / m<3>, the heat transfer coefficient amounts to less than 0.5W / m<2>.K, the method has a remarkable effect of energy saving, the single wall body material reaches 65% of the national building energy saving requirement, the energy-saving effect is obvious. The building block is widely applicable to industrial and civil building wall bodies.

Owner:ZHANGYE QINGTIAN BUILDING MATERIALS

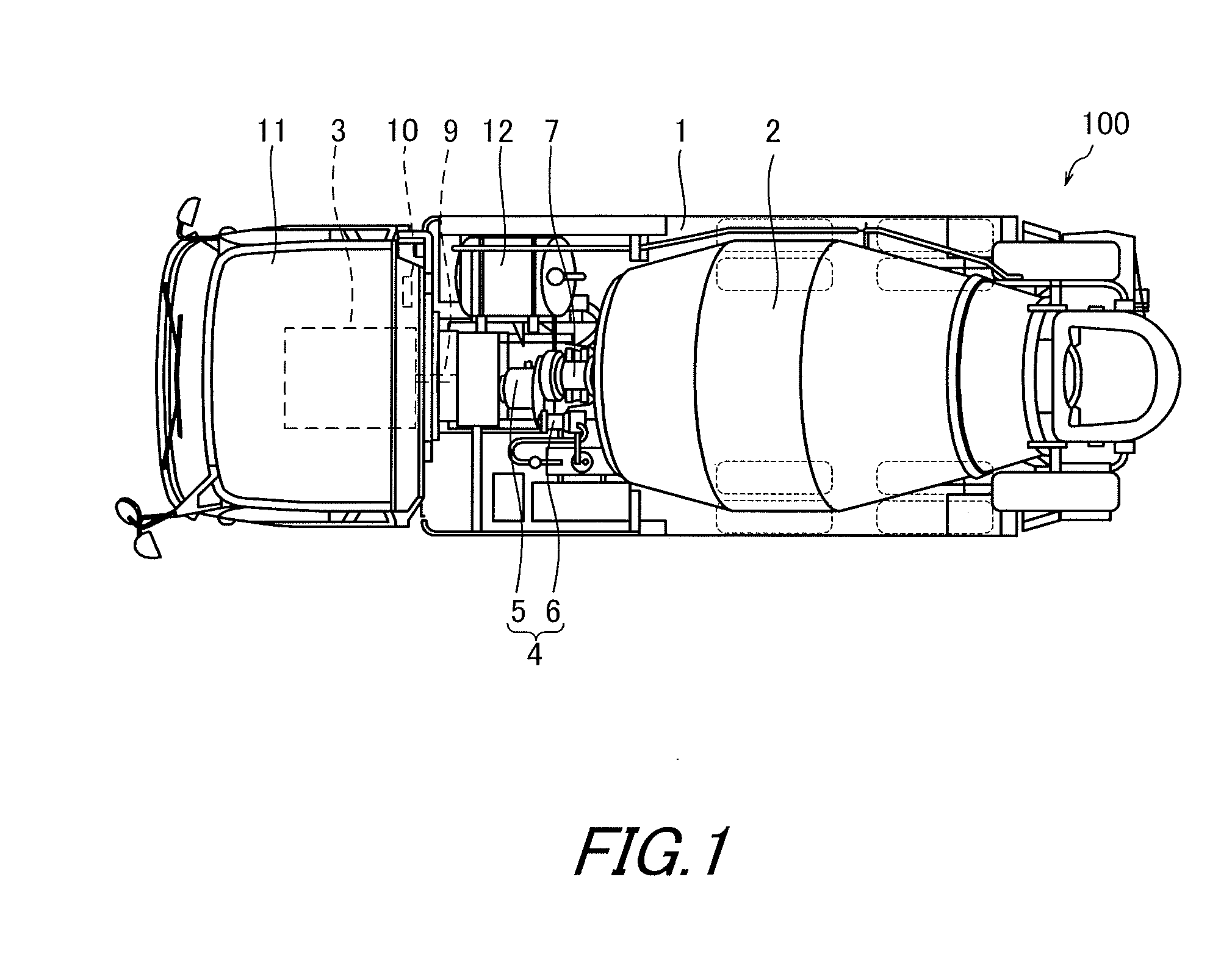

Concrete mixer truck

InactiveUS20130021867A1Mixing operation control apparatusCement mixing apparatusWorking fluidEngineering

Owner:KYB CORP

Concrete processing equipment

The invention relates to the technical field of construction, in particular to concrete processing equipment. The concrete processing equipment comprises a housing; the top of the housing is providedwith a feed hopper; the lower side of the feed hopper is provided with a screening box; the left side of the screening box is provided with a gravel processing mechanism; the lower side of the screening box is provided with a fixed plate which is fixedly connected with the housing; the fixed plate is fixedly connected with a stirring bucket; a water tank is arranged at the right side of the screening box; and a storage box is arranged at the lower side of the stirring bucket. According to the concrete processing equipment, the screening box is used for screening impurities such as gravel existing in a raw material so that the raw material falling into the stirring bucket is finer sand, the quality of the prepared concrete is beneficially improved; by arranging the gravel processing mechanism, the screened stone pieces can be crushed so that the stone pieces can be reutilized; by arranging a partition plate, a liquid level sensor and an infrared sensor, the amount of water and raw material added into the stirring bucket can be accurately controlled; and thus the ratio of the raw material to water is effectively controlled.

Owner:郭倩

Process and equipment for producing concrete products having blended colors

InactiveUS6910796B2Easy to changeResulting appearance of the visible surfaces of the concrete products can be readily alteredFrozen sweetsConfectioneryBrickRetaining wall

A process and equipment for producing multi-color concrete products, including architectural concrete blocks, concrete bricks, modular concrete products that are suitable for use in landscaping applications, such as retaining wall blocks, concrete pavers, and concrete slabs. The invention includes a spray mechanism that sprays liquid pigment onto concrete discharged from a hopper. The concrete then proceeds to a blending mechanism which blends the pigment into the concrete to produce a multi-color concrete blend. The concrete blend is then used to produce multi-colored concrete products.

Owner:ANCHOR WALL SYST

High-efficiency cement mixing device for construction sites

InactiveCN106142348ASave human effortLow costCement mixing apparatusLiquid ingredients supply apparatusLeft wallMaterials science

The invention relates to a mixing device, and particularly relates to a high-efficiency cement mixing device for construction sites. The technical problem to be solved is to provide the high-efficiency cement mixing device for construction sites with the high mixing efficiency. In order to solve the technical problem, the high-efficiency cement mixing device for construction sites comprises a tank, a first sliding rail, a first sliding block, a gear rack, a second connecting rod, a rotating motor, a gear, a supporting rod, a placing groove, blades, mixing rods, a lead screw and the like, wherein the first sliding block is arranged on the first sliding rail; the placing groove is formed in the top of the first sliding block; a spring is arranged on the right wall of the placing groove; the right end of the spring is connected to the inner right wall of the tank; and a second fixed pulley and a first fixed pulley are arranged on the inner left wall of the tank. The high-efficiency cement mixing device achieves the effect of high-efficiency cement mixing.

Owner:陈雯娣

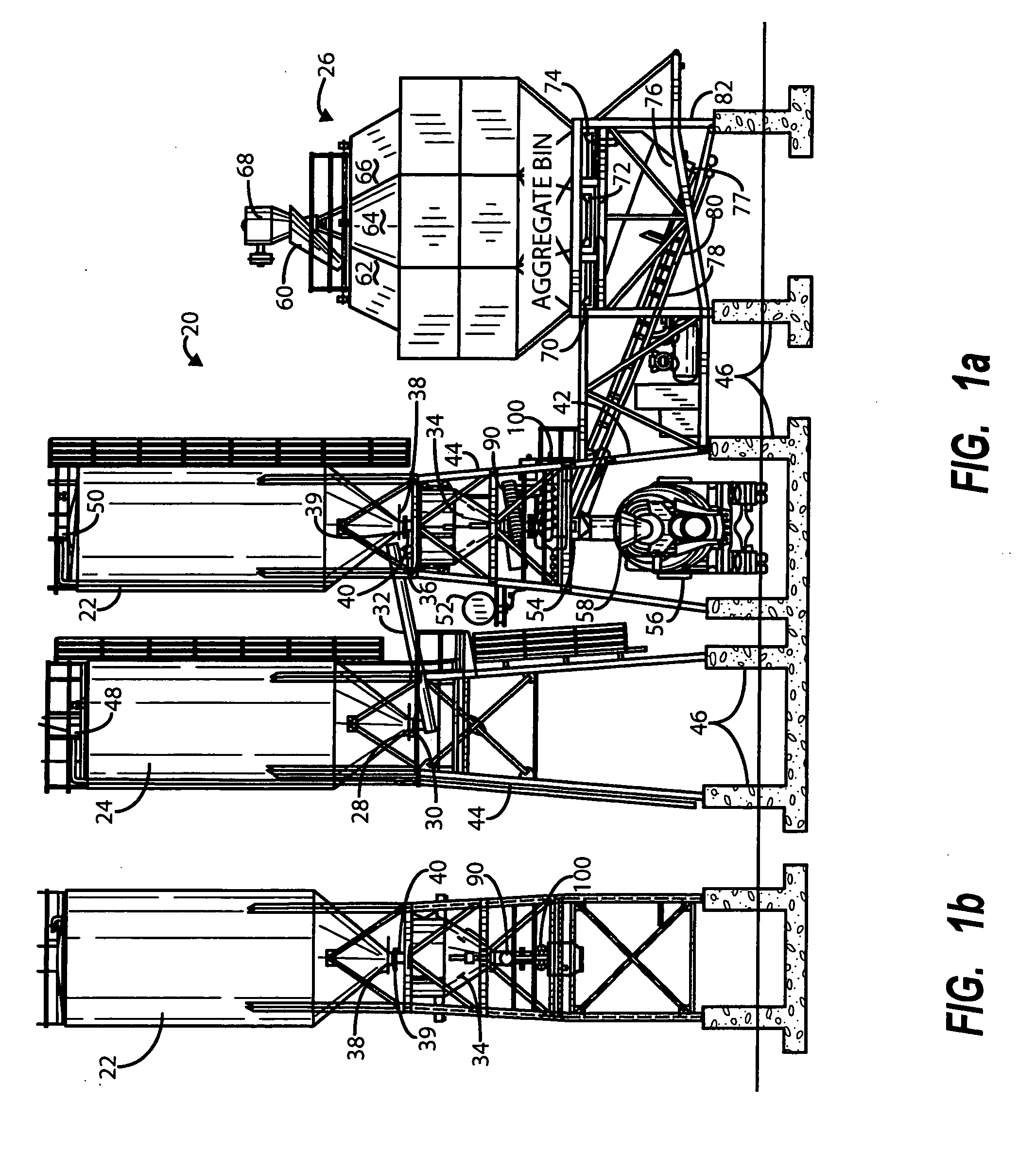

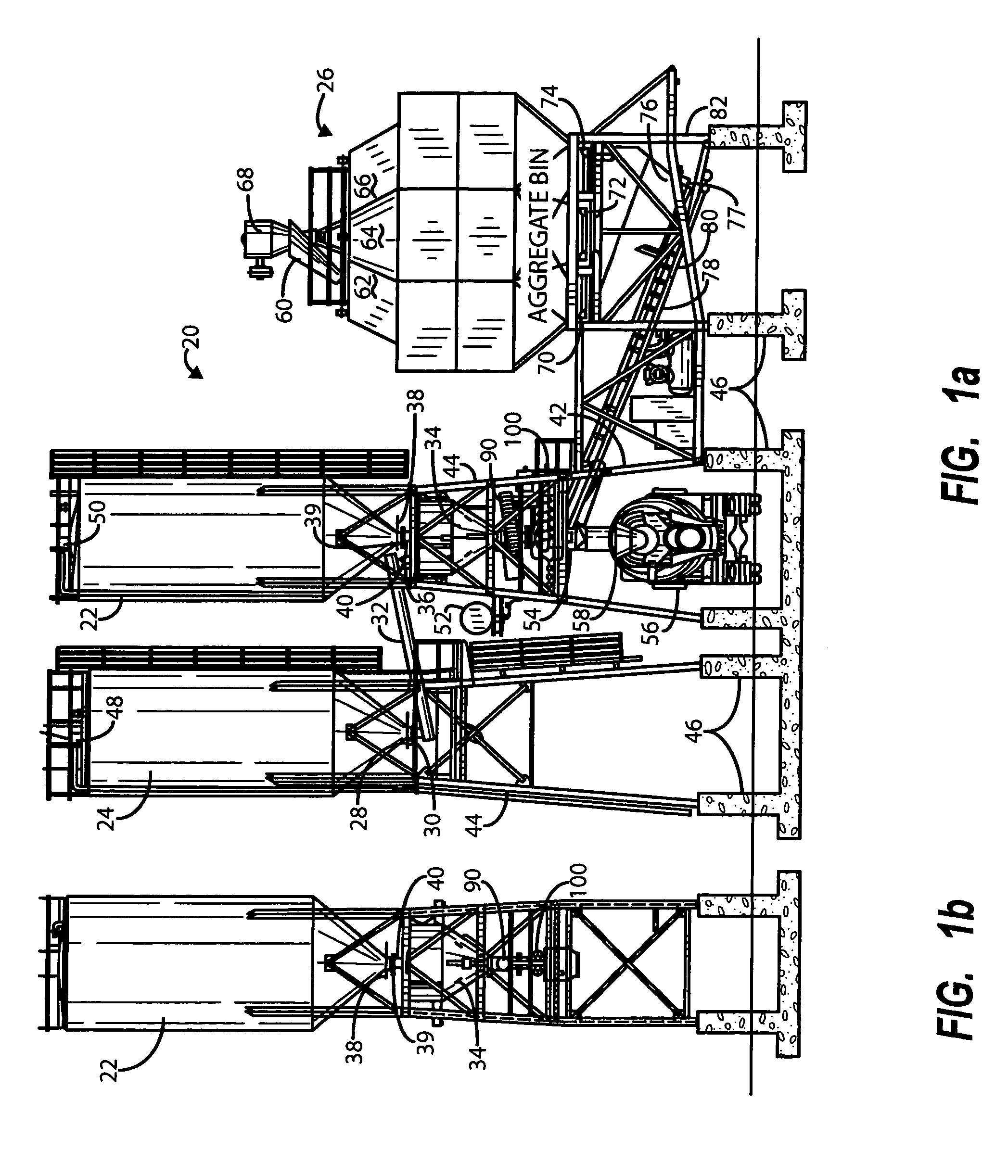

Concrete batching facility and method

ActiveUS7320539B2Optimizes production and strengthAvoid material accumulationDischarging apparatusMixing operation control apparatusHybrid systemAdditive ingredient

A concrete batch mixing system and method are disclosed that enable the batch master to measure and control both the water and cementitious ingredient feeds in relation to each other so as to be able to blend the two ingredients in a known, selected, adjustable and repeatable manner, and to agglomerate these ingredients in a counter-rotating twin screw mixing apparatus for use in the preparation of batches of mixed concrete in a concrete batching process.

Owner:MCNEILUS TRUCK & MFG INC

Hyaloclastite pozzolan, hyaloclastite based cement, hyaloclastite based concrete and method of making and using same

ActiveUS9828289B1Improve propertiesWater demandLiquid ingredients supply apparatusPolymer chemistryPozzolan

The invention comprises a composition comprising hyaloclastite having a volume-based mean particle size of less than or equal to 40 μm. The invention also comprises a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm. The invention further comprises a cementitious-based material comprising aggregate, a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm and water sufficient to hydrate the cementitious material. A method of using the composition of the present invention is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Hyaloclastite pozzolan, hyaloclastite based cement, hyaloclastite based concrete and method of making and using same

ActiveUS9822037B1Improved propertyWater demandLiquid ingredients supply apparatusVolcanoPolymer chemistry

The invention comprises a composition comprising hyaloclastite having a volume-based mean particle size of less than or equal to 40 μm. The invention also comprises a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm. The invention further comprises a cementitious-based material comprising aggregate, a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm and water sufficient to hydrate the cementitious material. A method of using the composition of the present invention is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

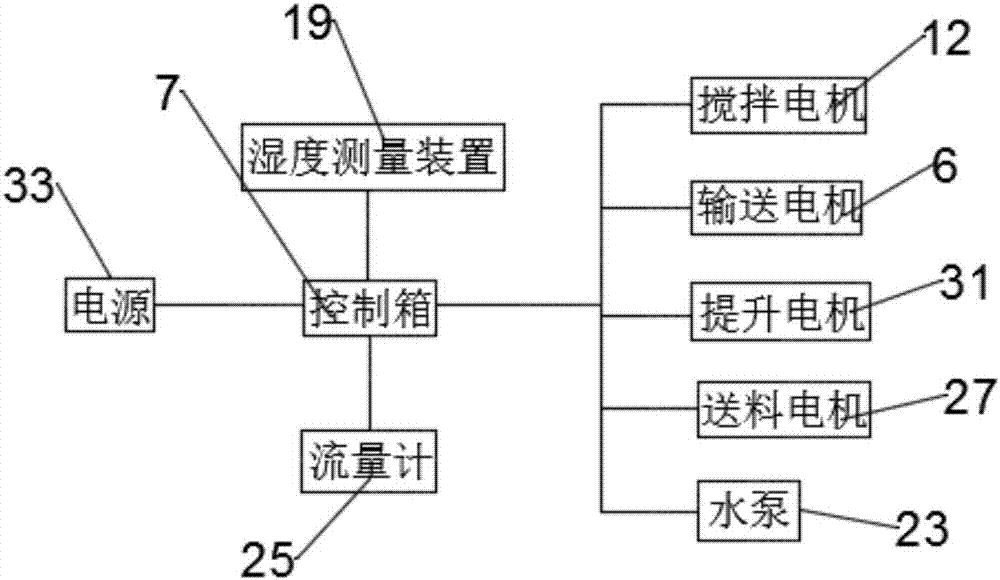

Efficient concrete stirring device capable of achieving convenient feeding and discharging for buildings

InactiveCN107225682AImprove uniformityQuality improvementDischarging apparatusCement mixing apparatusAutomatic controlTime efficient

The invention discloses an efficient concrete stirring device capable of achieving convenient feeding and discharging for buildings. The efficient concrete stirring device comprises a supporting frame, a conveying roller and a stirring case, the stirring case is connected with the conveying roller through a feeding pipe, a first rotating shaft is arranged in the conveying roller, a spiral conveying mechanism is arranged on the first rotating shaft, a fixing frame is arranged at the upper end of the stirring case, a stirring motor is arranged on the fixing frame, and the stirring motor is fixedly connected with a second rotating shaft. The efficient concrete stirring device is used for stirring of concrete, in the working process, automatic control over the device is conducted through a control case, the labor intensity of workers can be reduced, and improving of working efficiency is promoted; a feeding motor and a lifting motor are controlled to feed raw materials into the stirring case by means of a lifting device, operation is convenient and rapid, and time and labor are saved; and the concrete is conveyed to a discharge outlet through the spiral conveying mechanism under the action of a conveying motor, discharging is convenient and rapid, time and labor are saved, and the working efficiency is greatly improved.

Owner:张峰

System and process for introducing a rigid lance into a concrete mixing truck using an articulated arm

Owner:AIR LIQUIDE IND US LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com