Patents

Literature

40results about How to "Avoid material accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

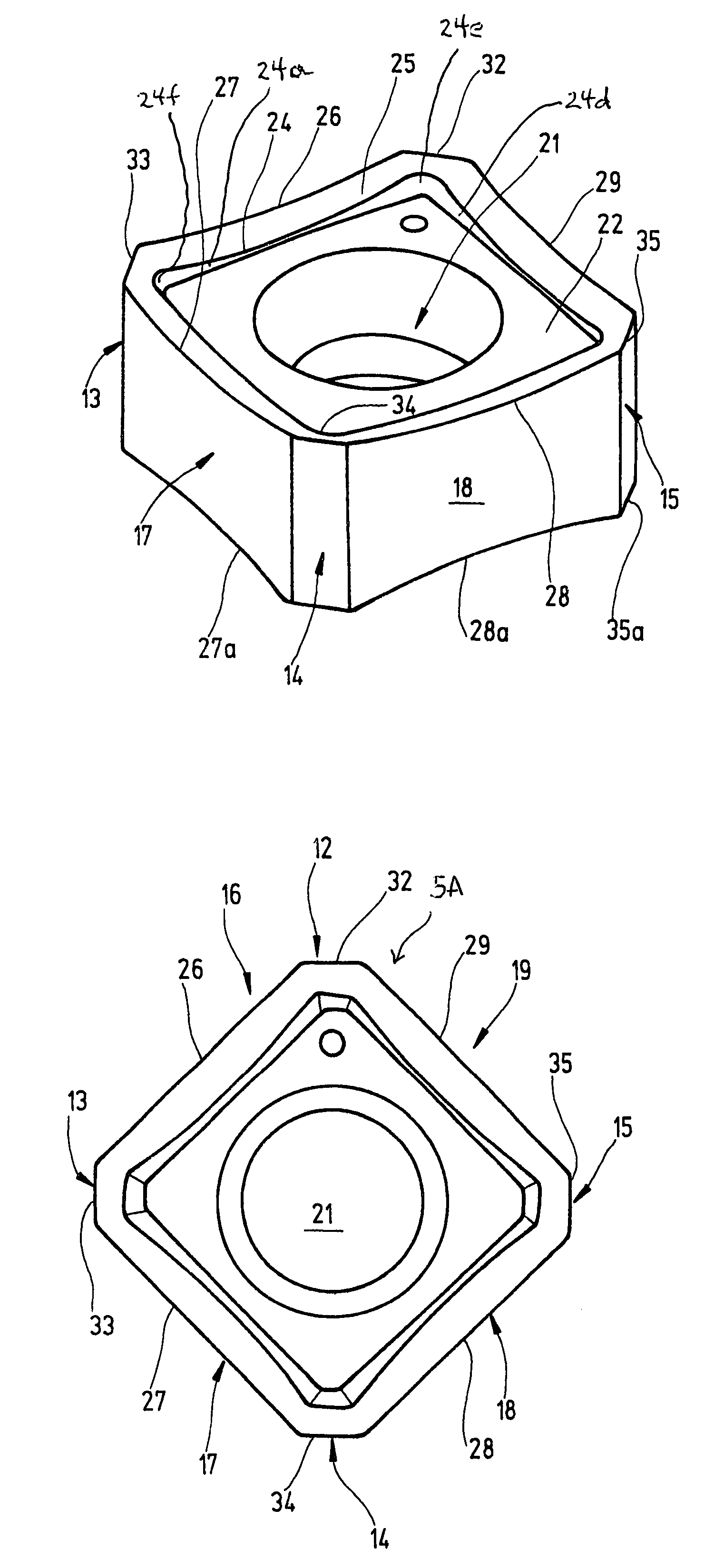

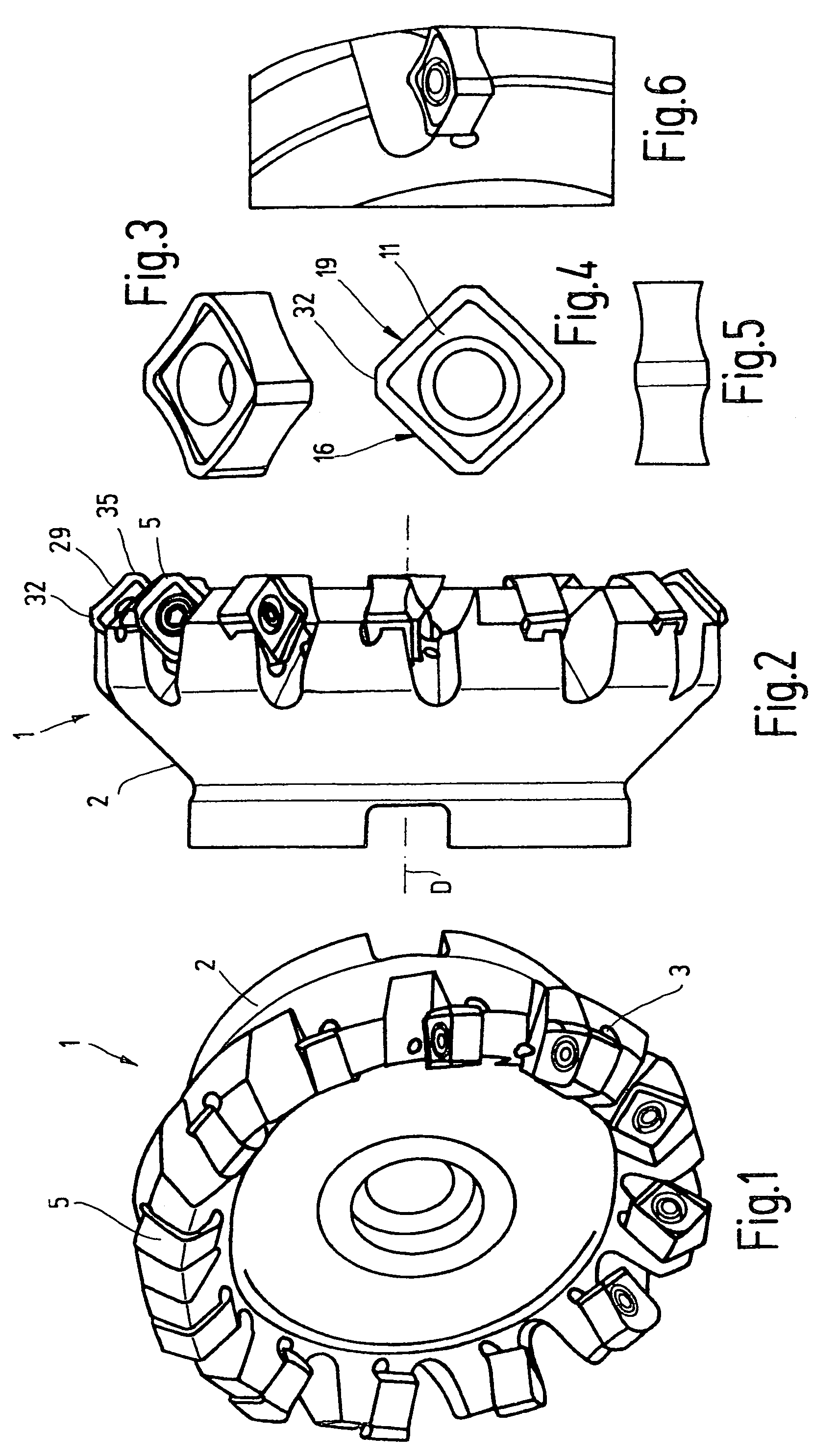

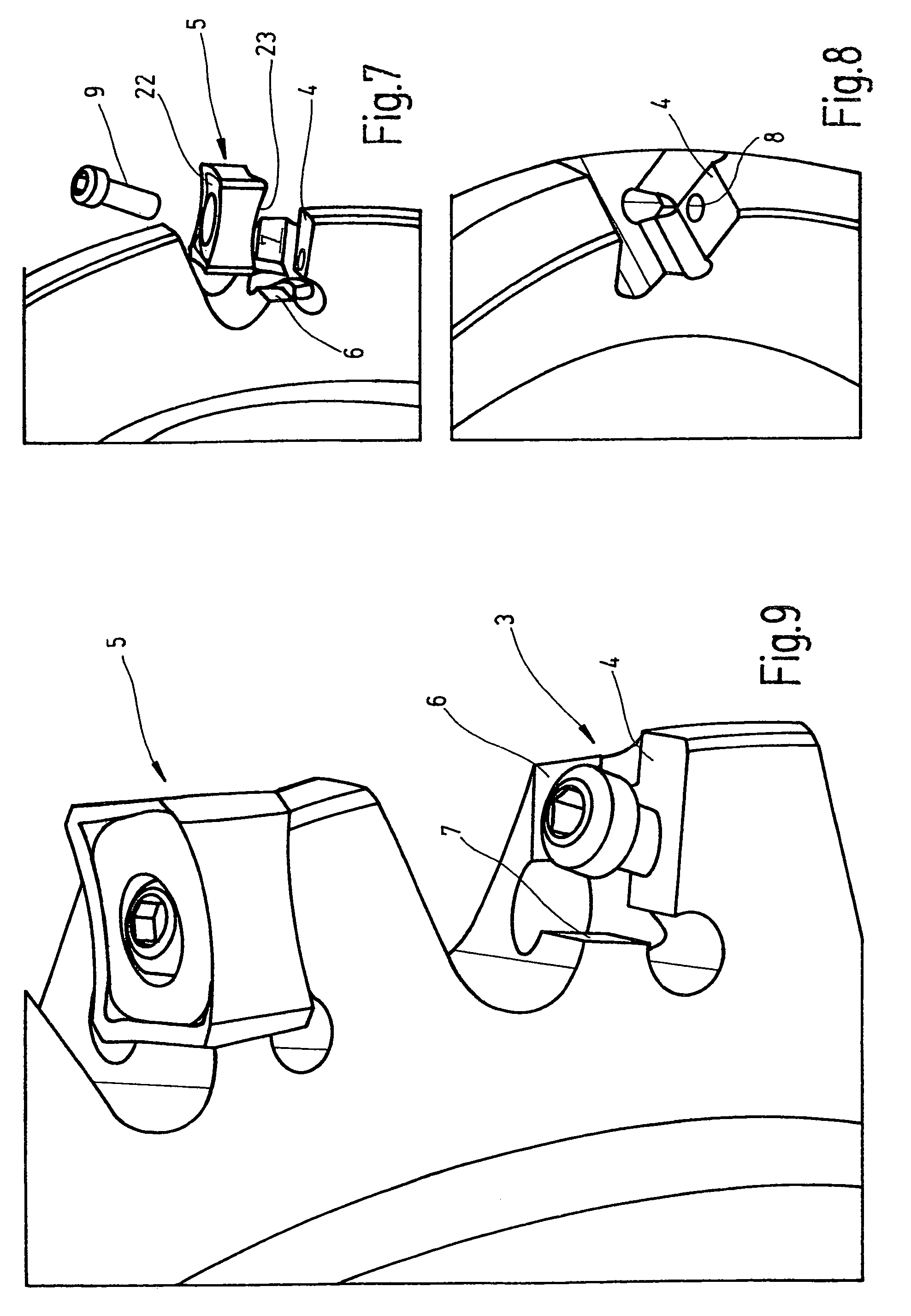

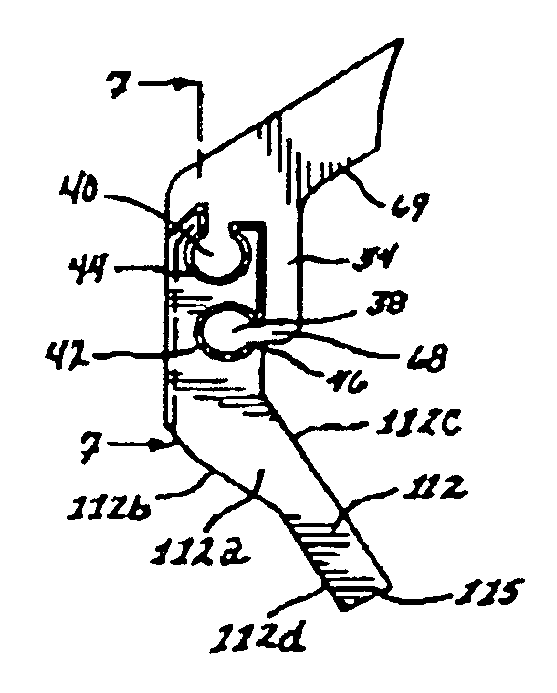

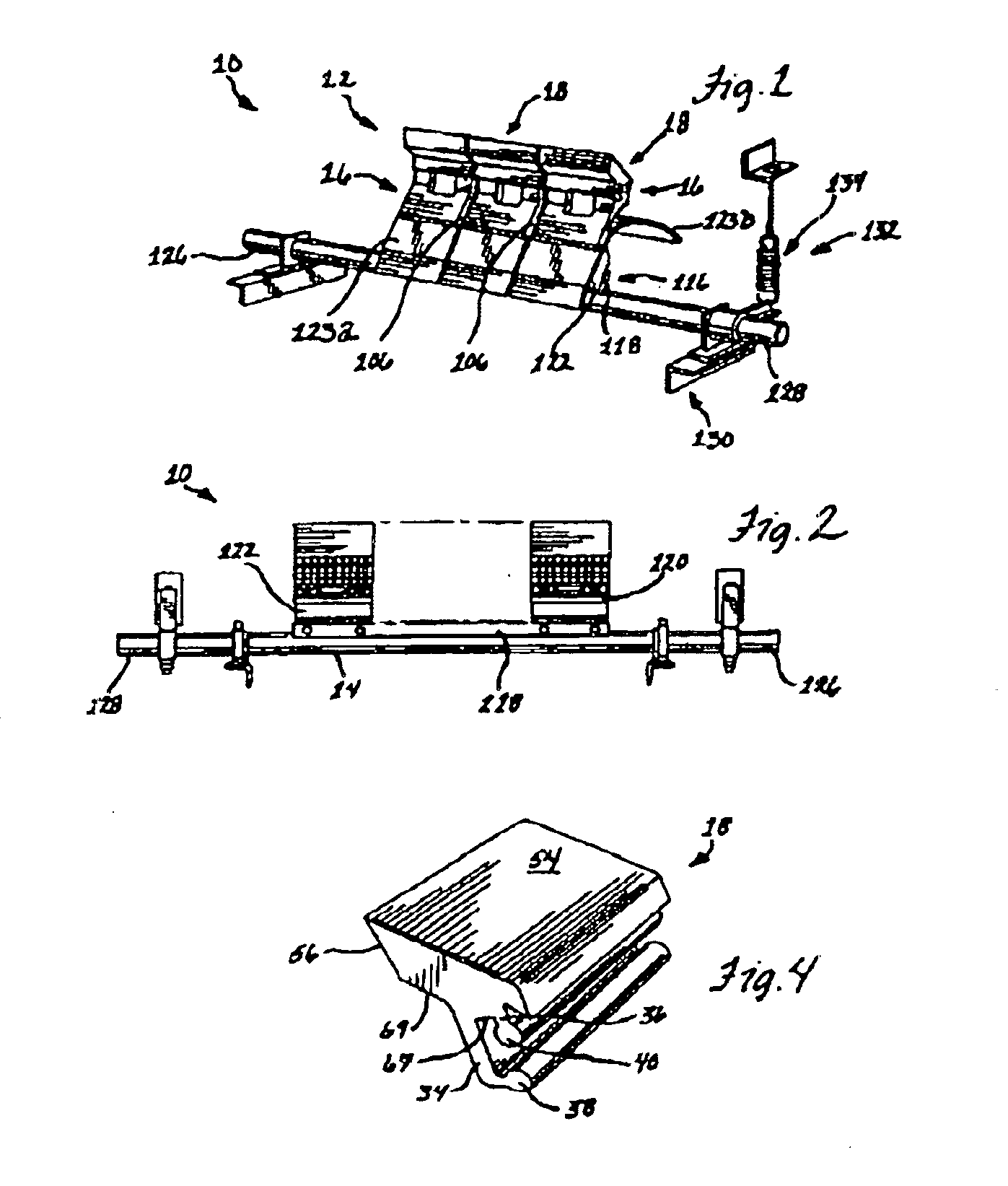

Cutting insert having a rake surface and a plateau surface separated by a step

ActiveUS7306409B2Convenient heightImprove protectionTransportation and packagingMilling cuttersMilling cutterPlateau

A cutting insert intended exemplarily for use in a face-milling cutter, has an all-around extending rake surface which changes into a plateau surface by an uninterrupted step. The step reaches its greatest height in the corner regions of the cutting insert. The rake surface defines a positive rake angle. The step prevents the produced chips from running onto the plateau surface. As a result of such a measure, a smear-on of material onto the plateau surface from a chip is prevented.

Owner:WALTER AG

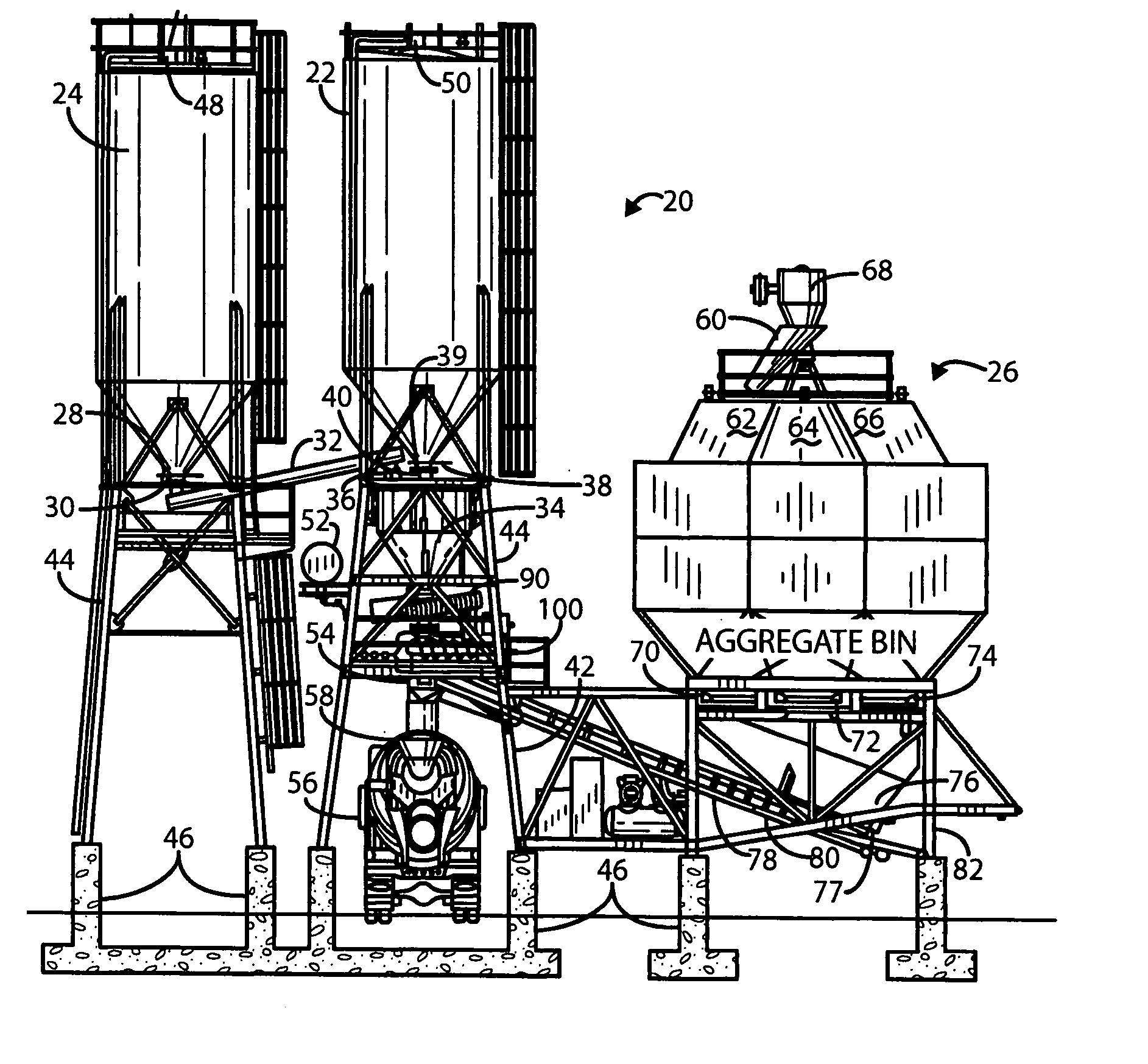

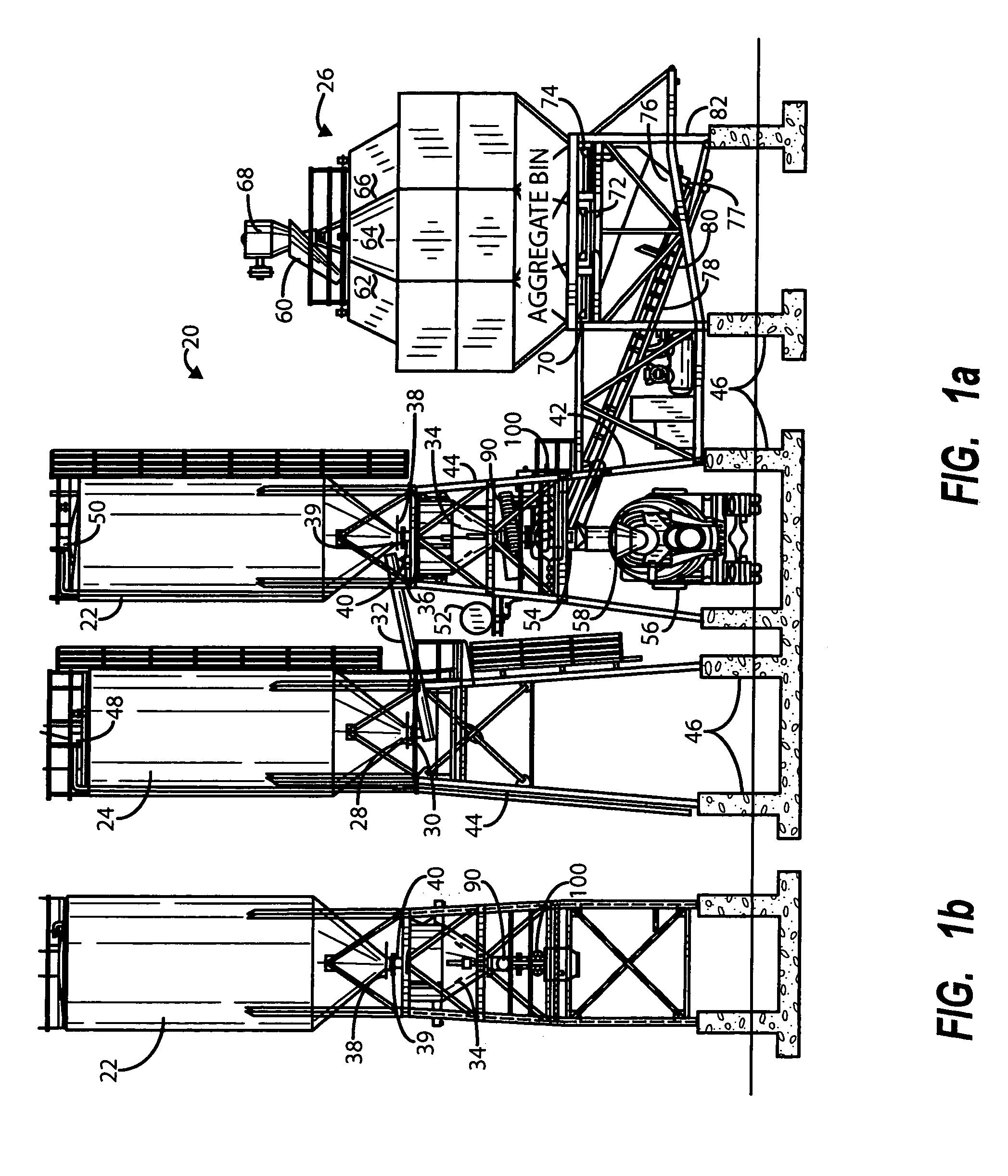

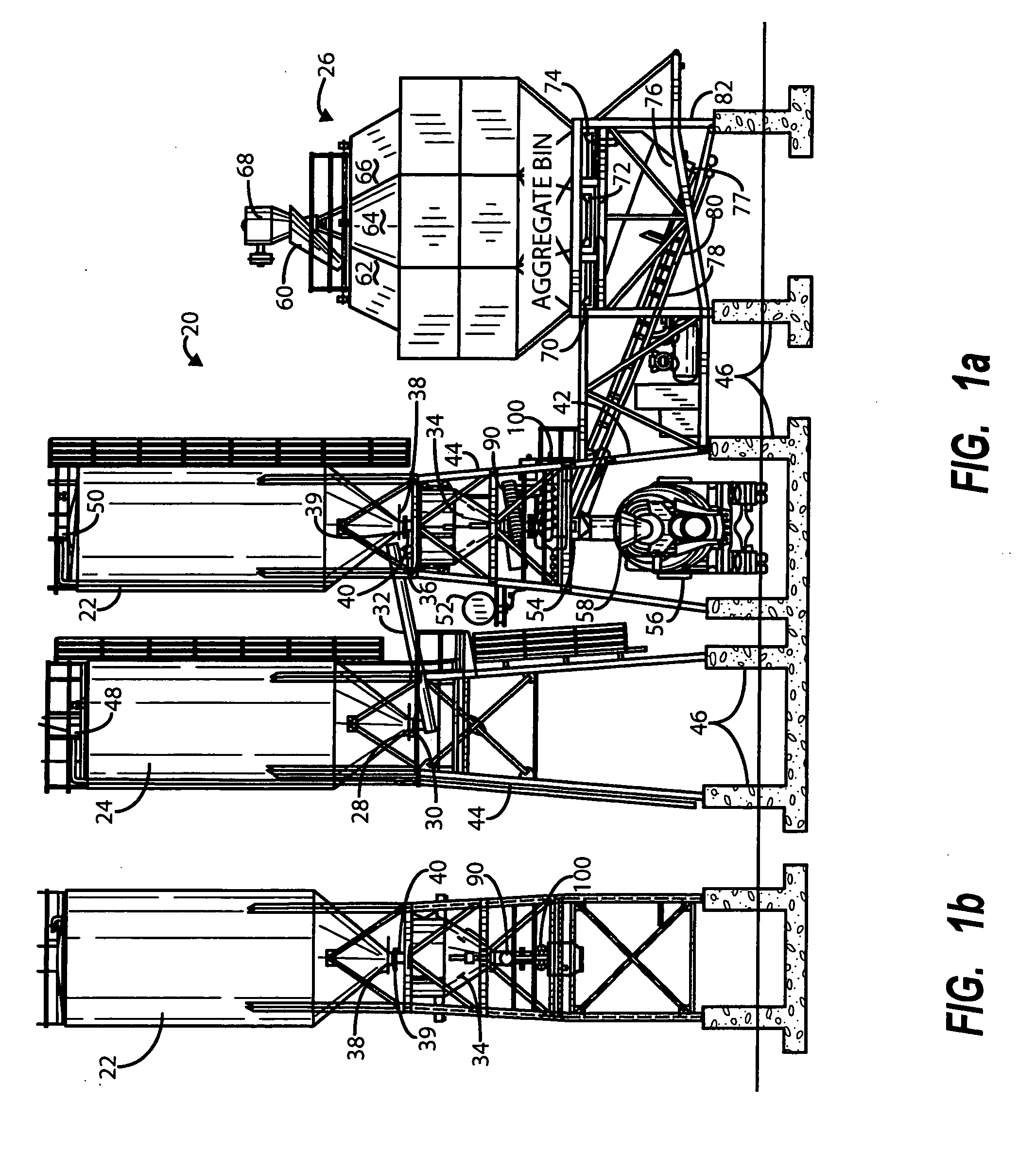

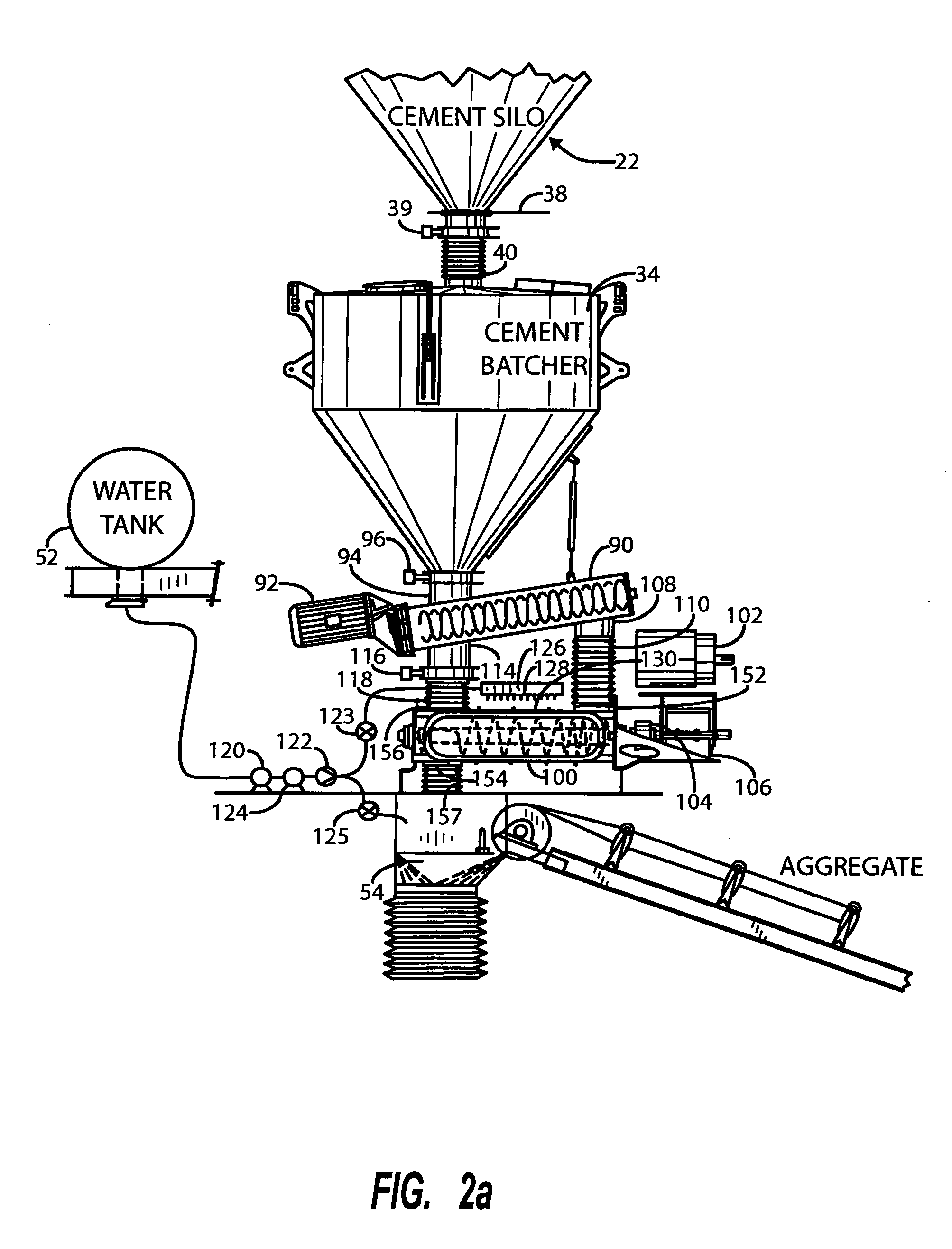

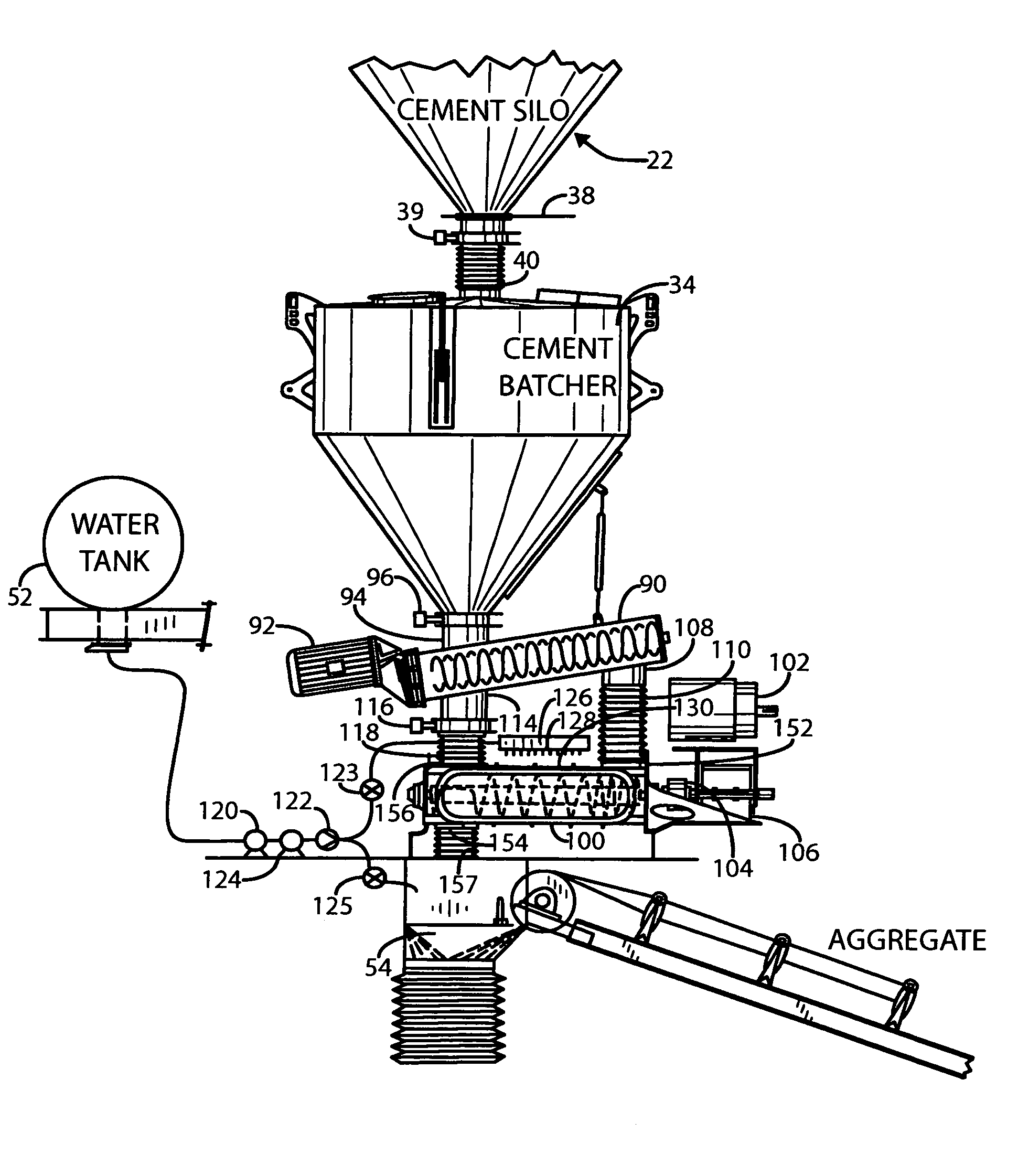

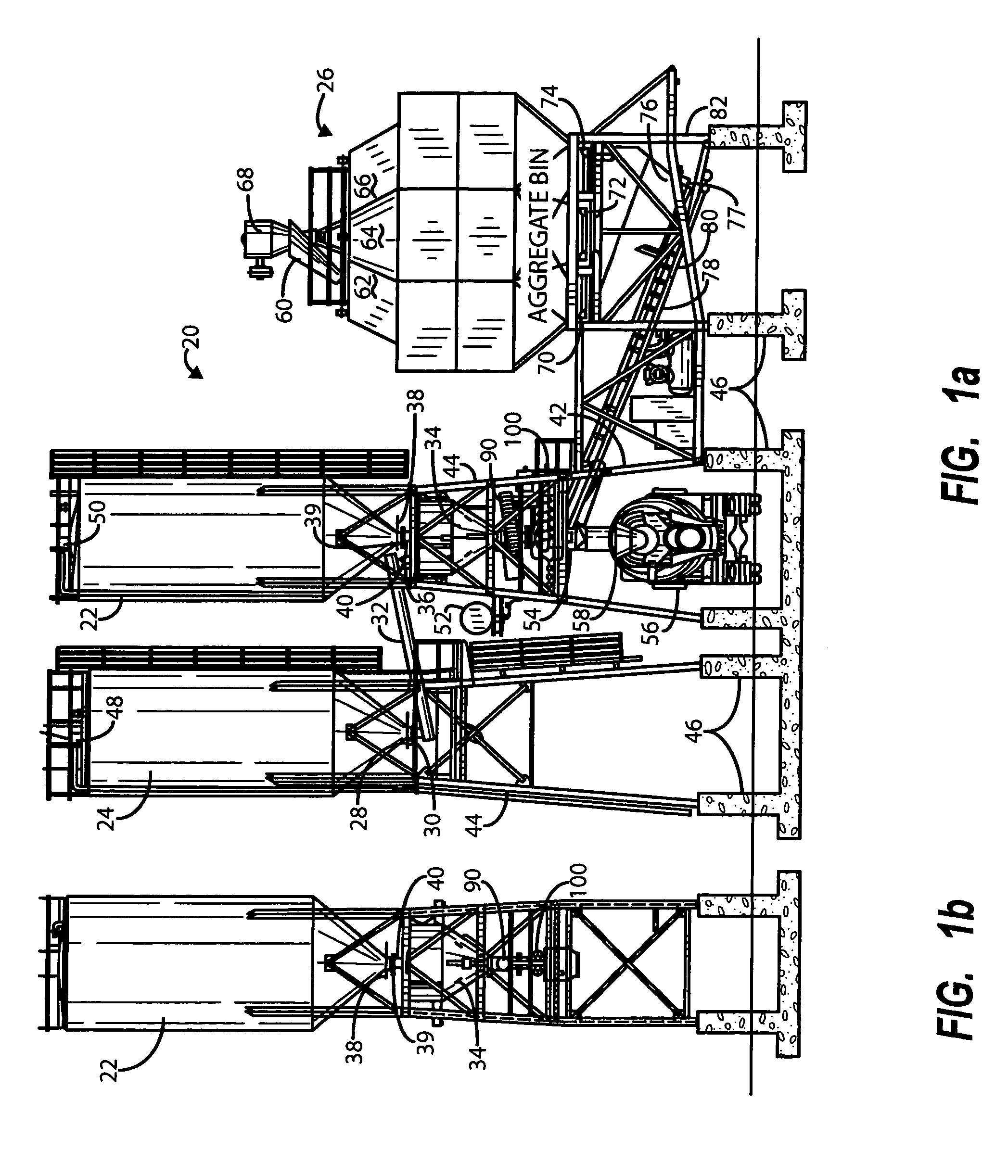

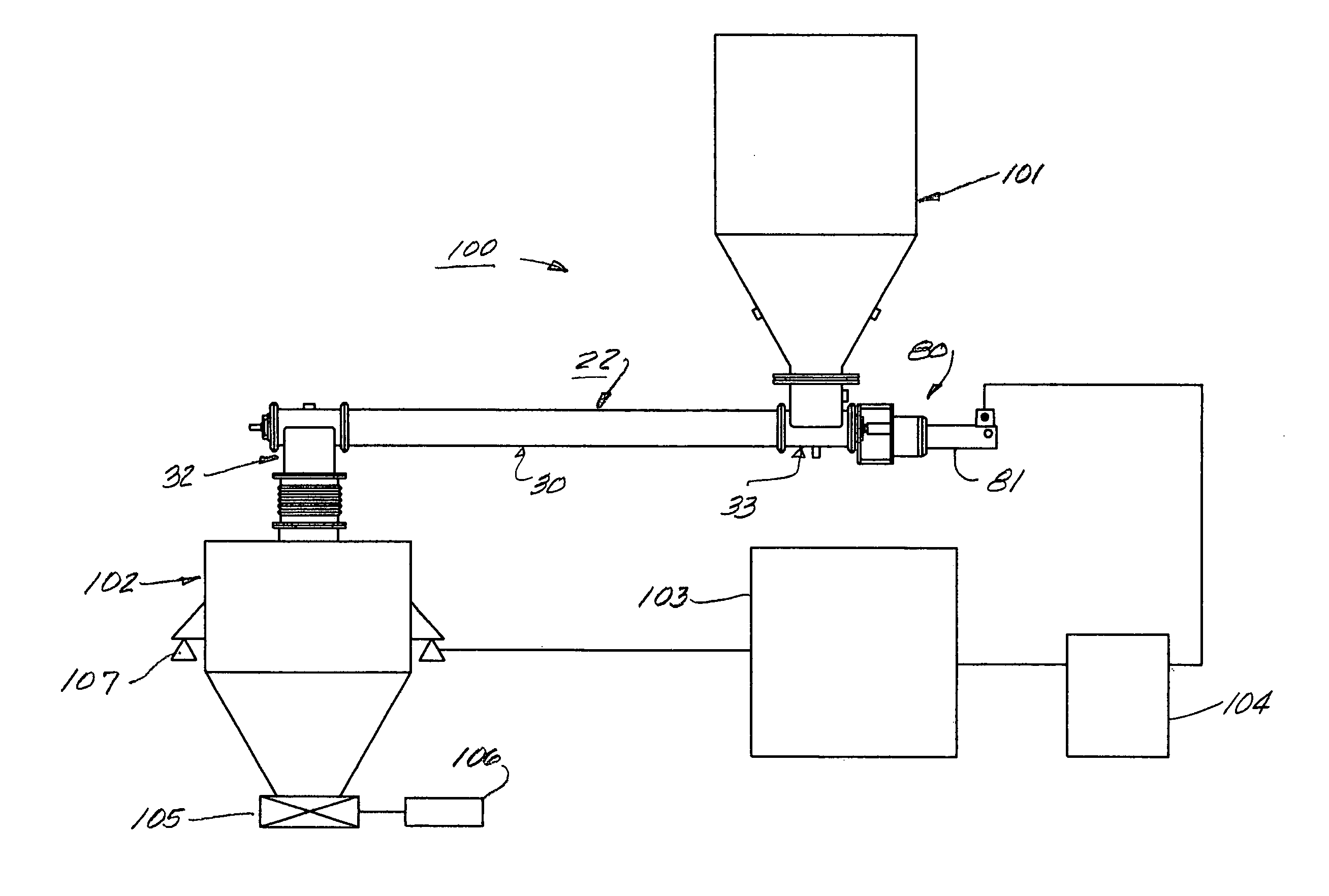

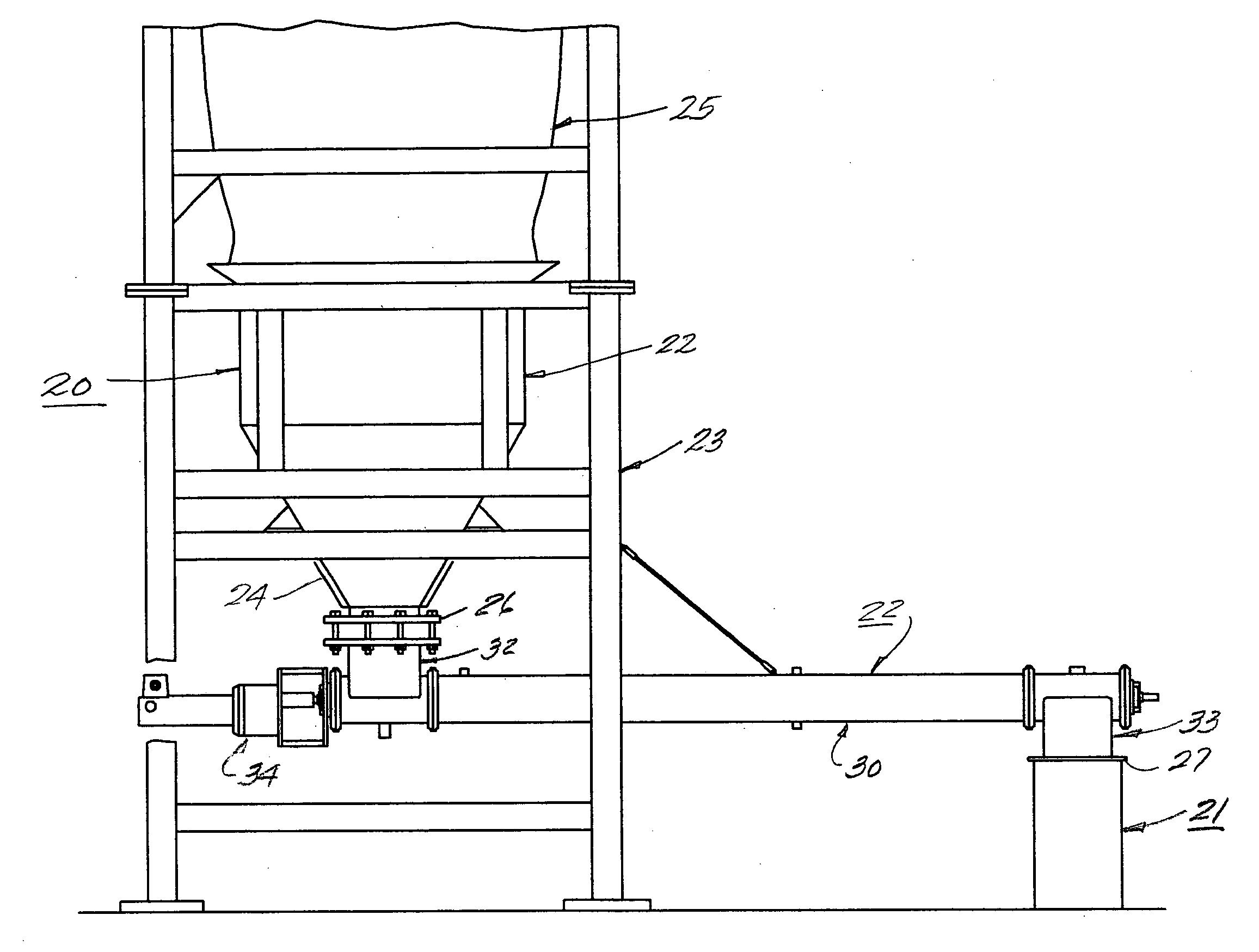

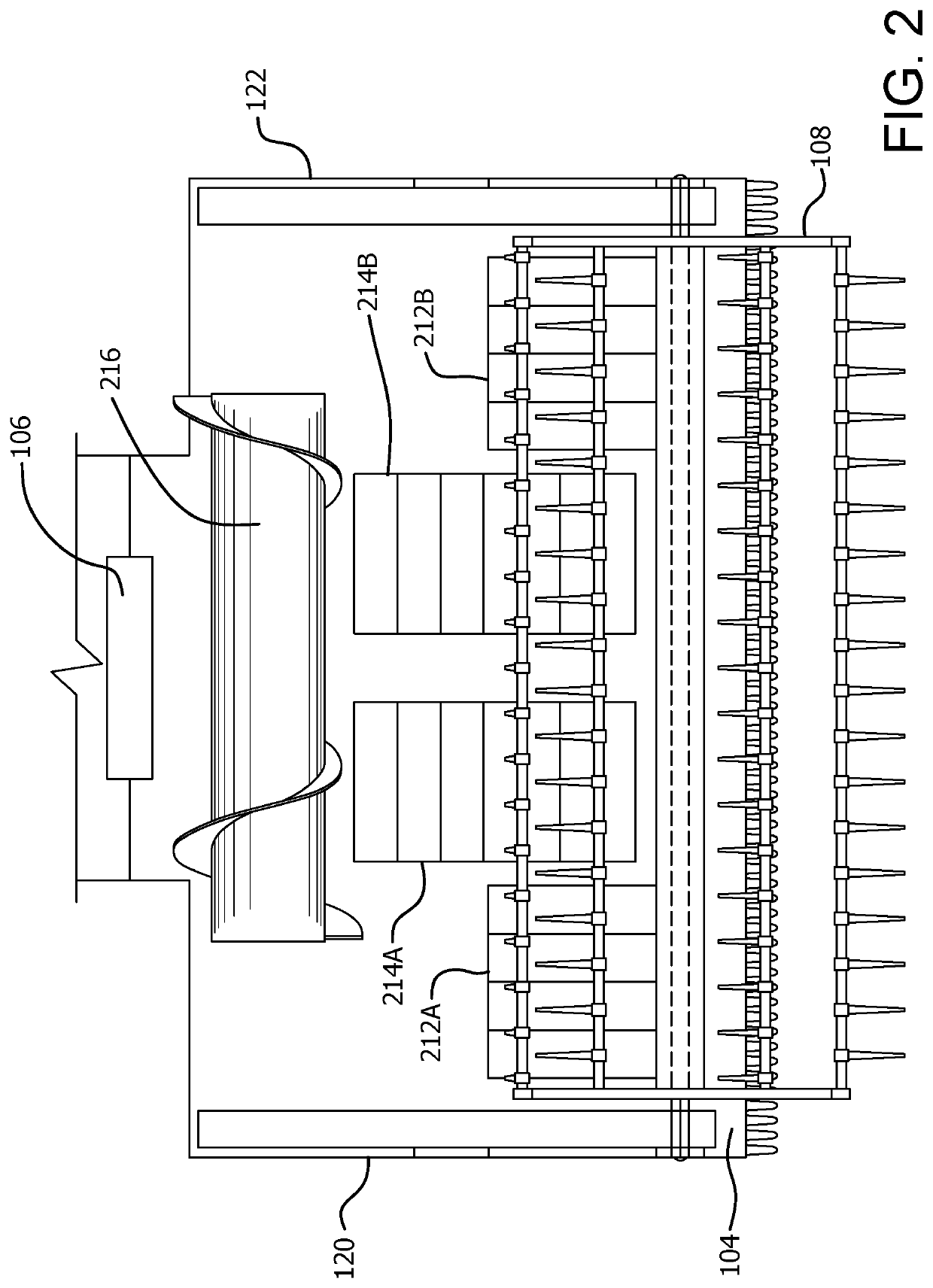

Concrete batching facility and method

ActiveUS20050219941A1Promote productionStrength optimizationDischarging apparatusRotary stirring mixersHybrid systemAdditive ingredient

A concrete batch mixing system and method are disclosed that enable the batch master to measure and control both the water and cementitious ingredient feeds in relation to each other so as to be able to blend the two ingredients in a known, selected, adjustable and repeatable manner, and to agglomerate these ingredients in a counter-rotating twin screw mixing apparatus for use in the preparation of batches of mixed concrete in a concrete batching process.

Owner:MCNEILUS TRUCK & MFG INC

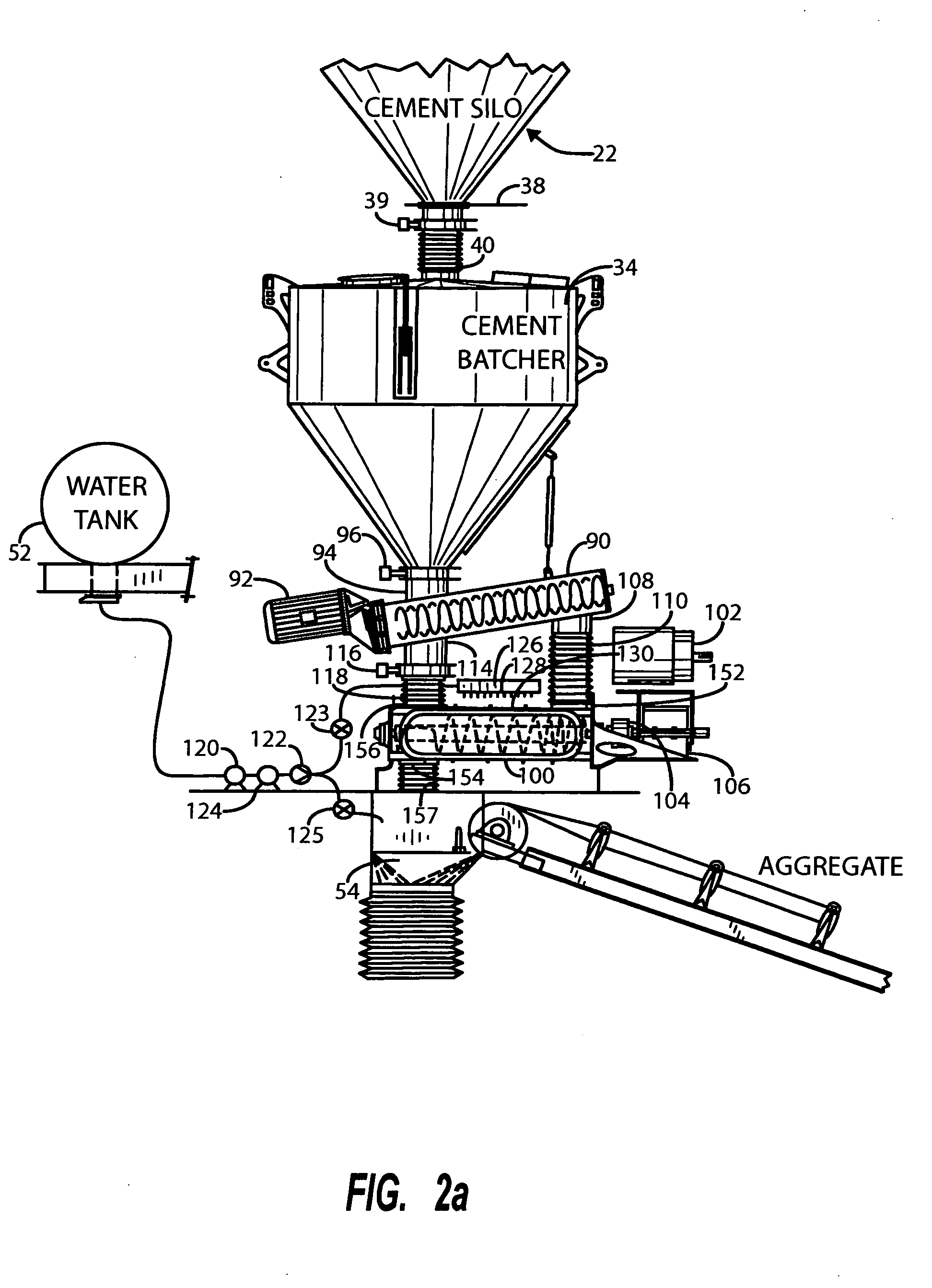

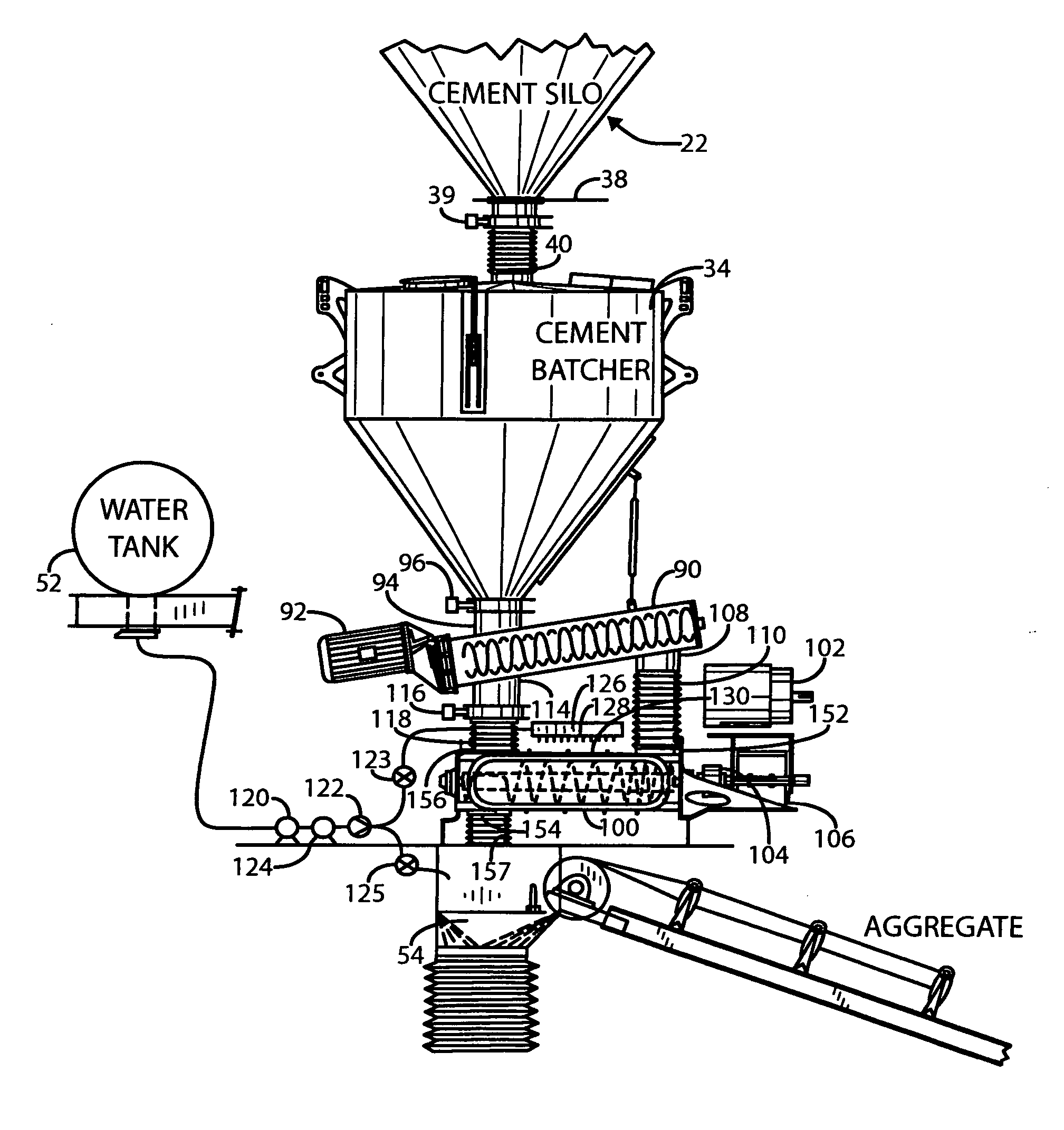

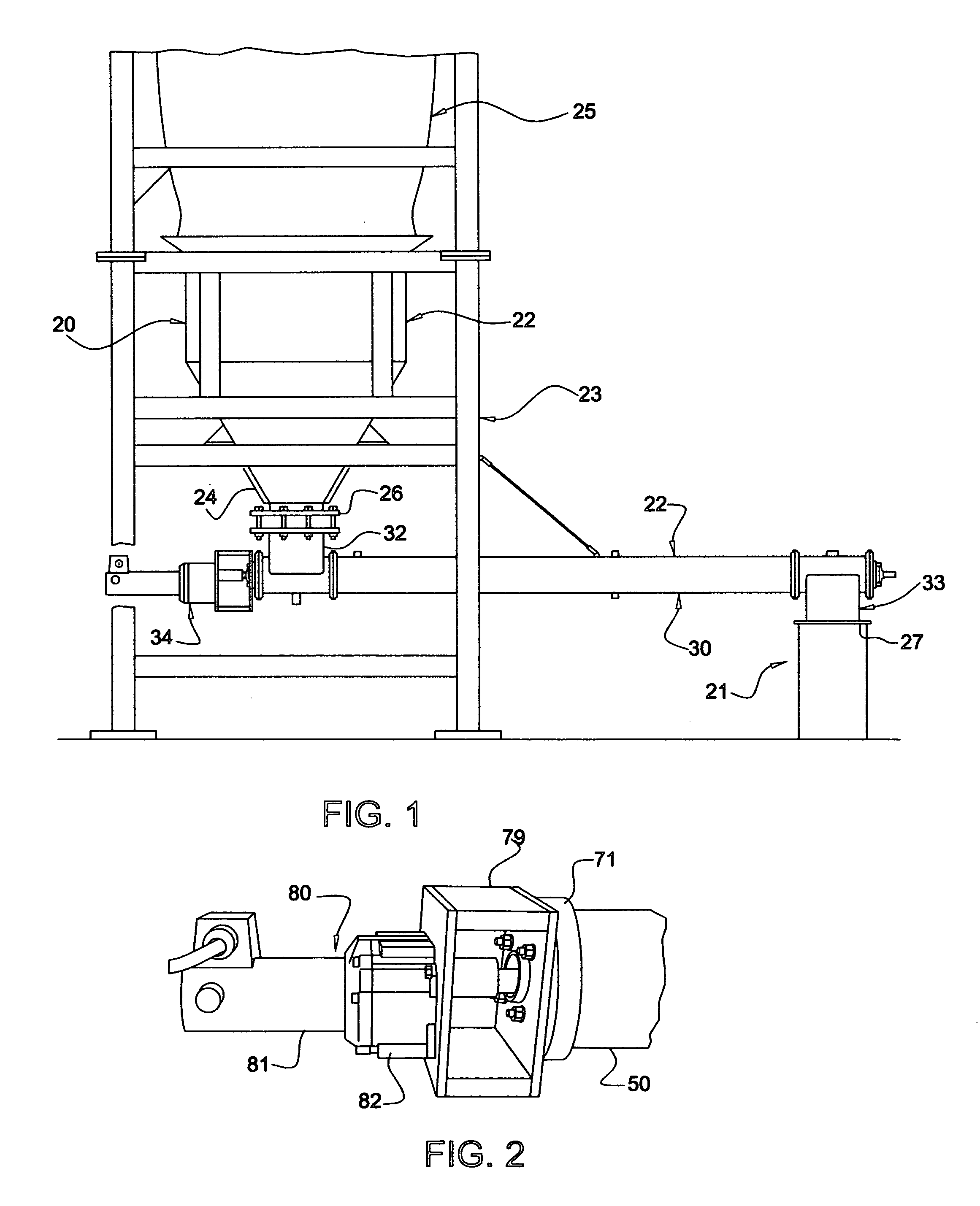

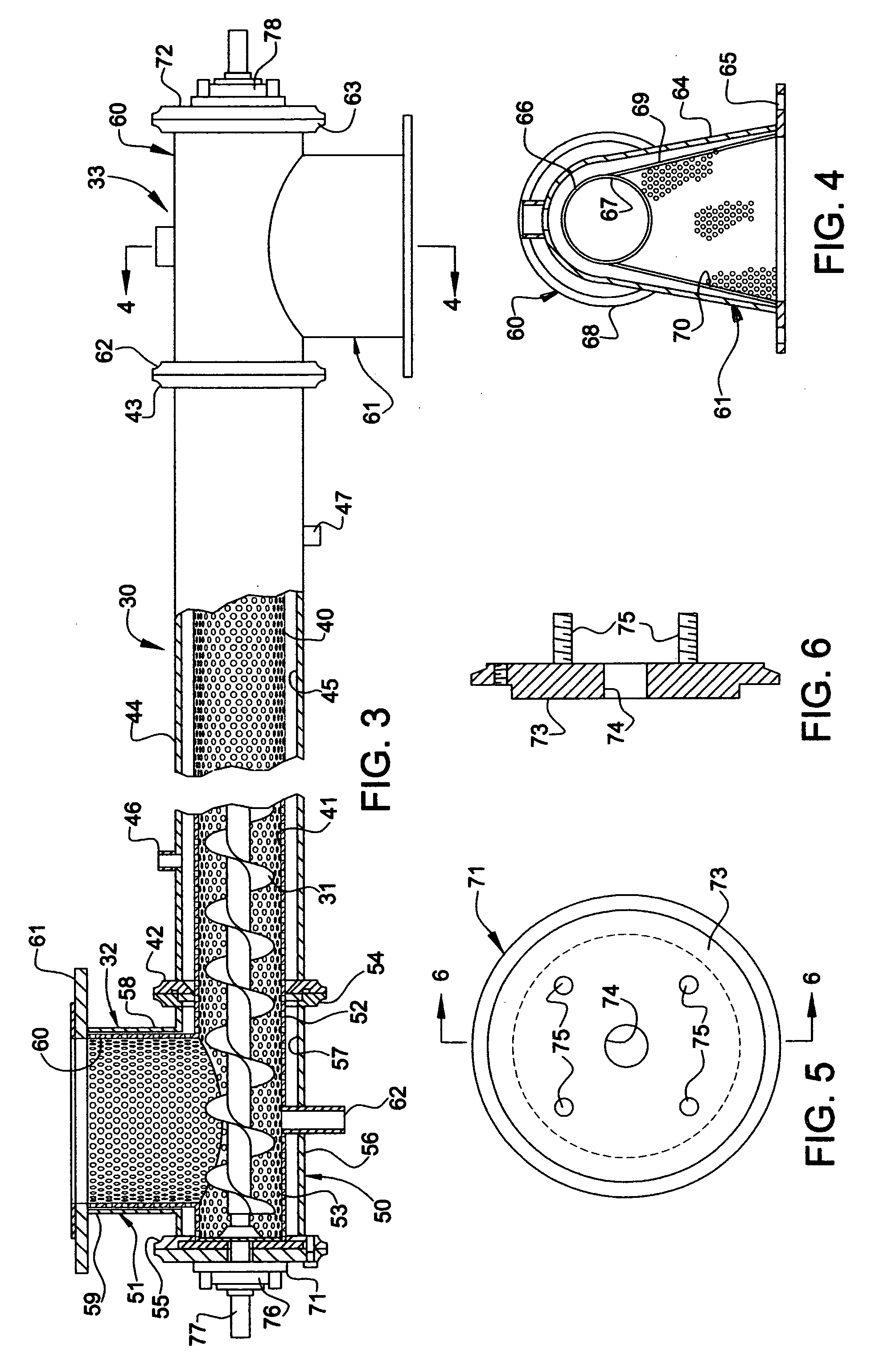

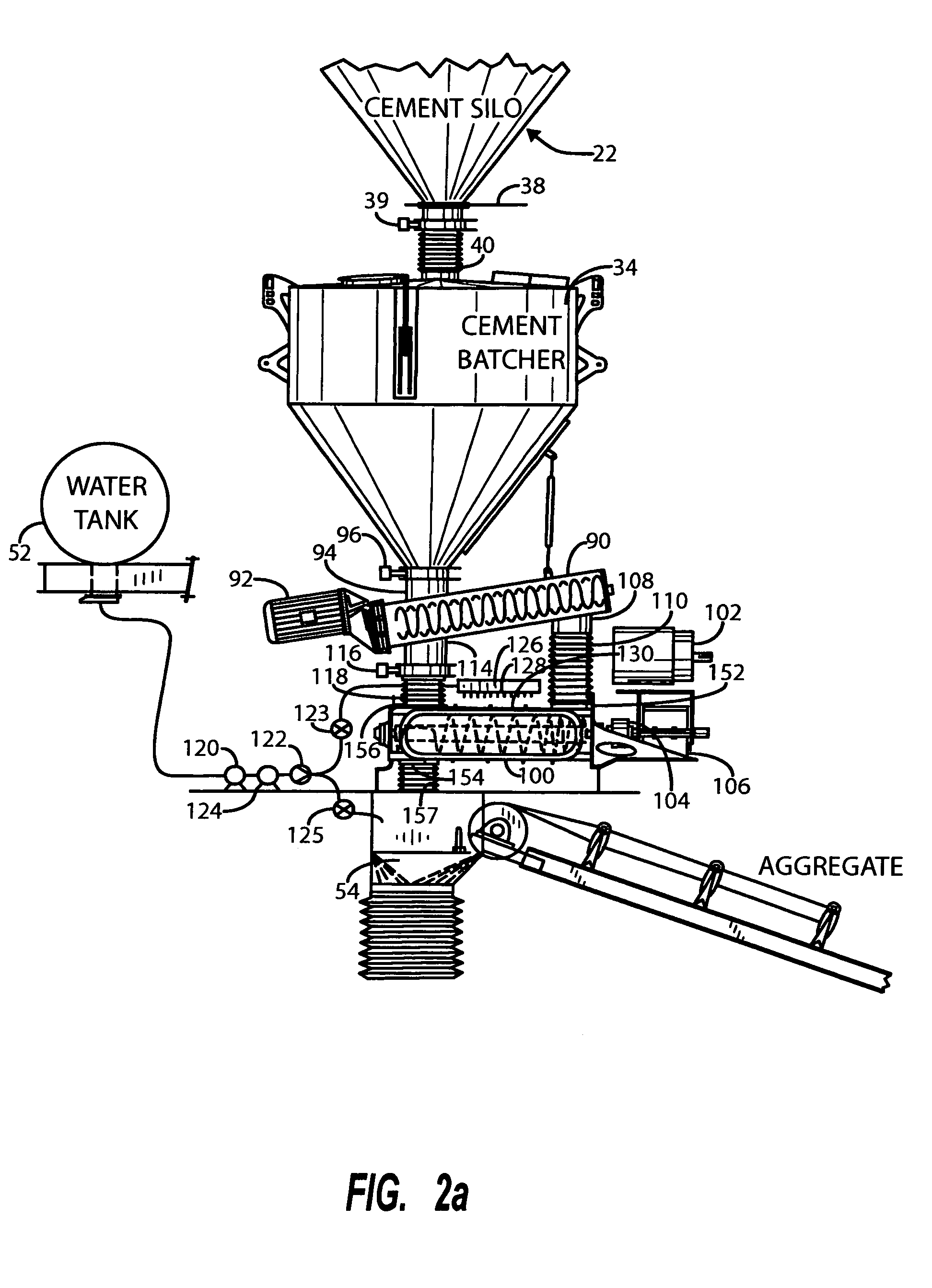

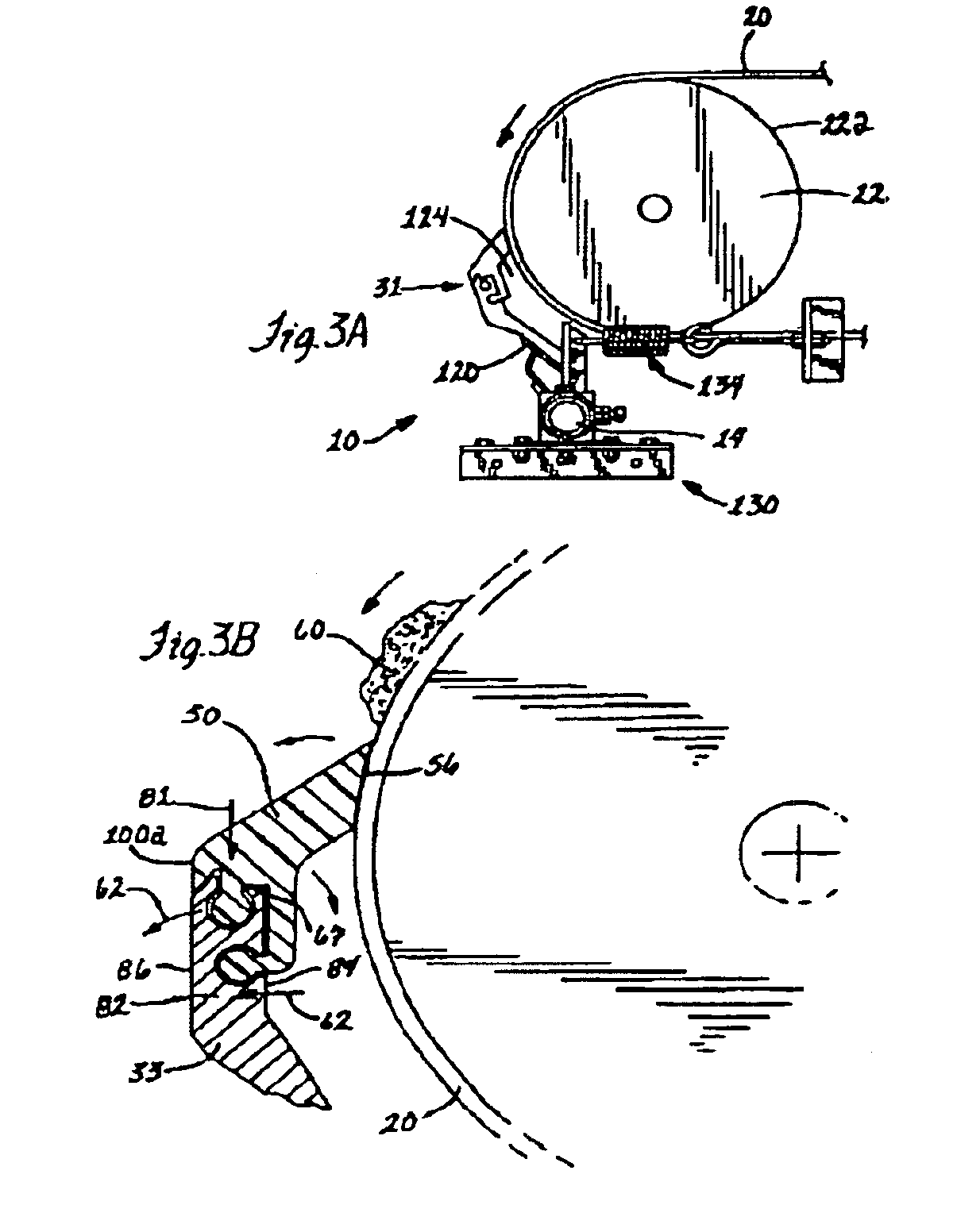

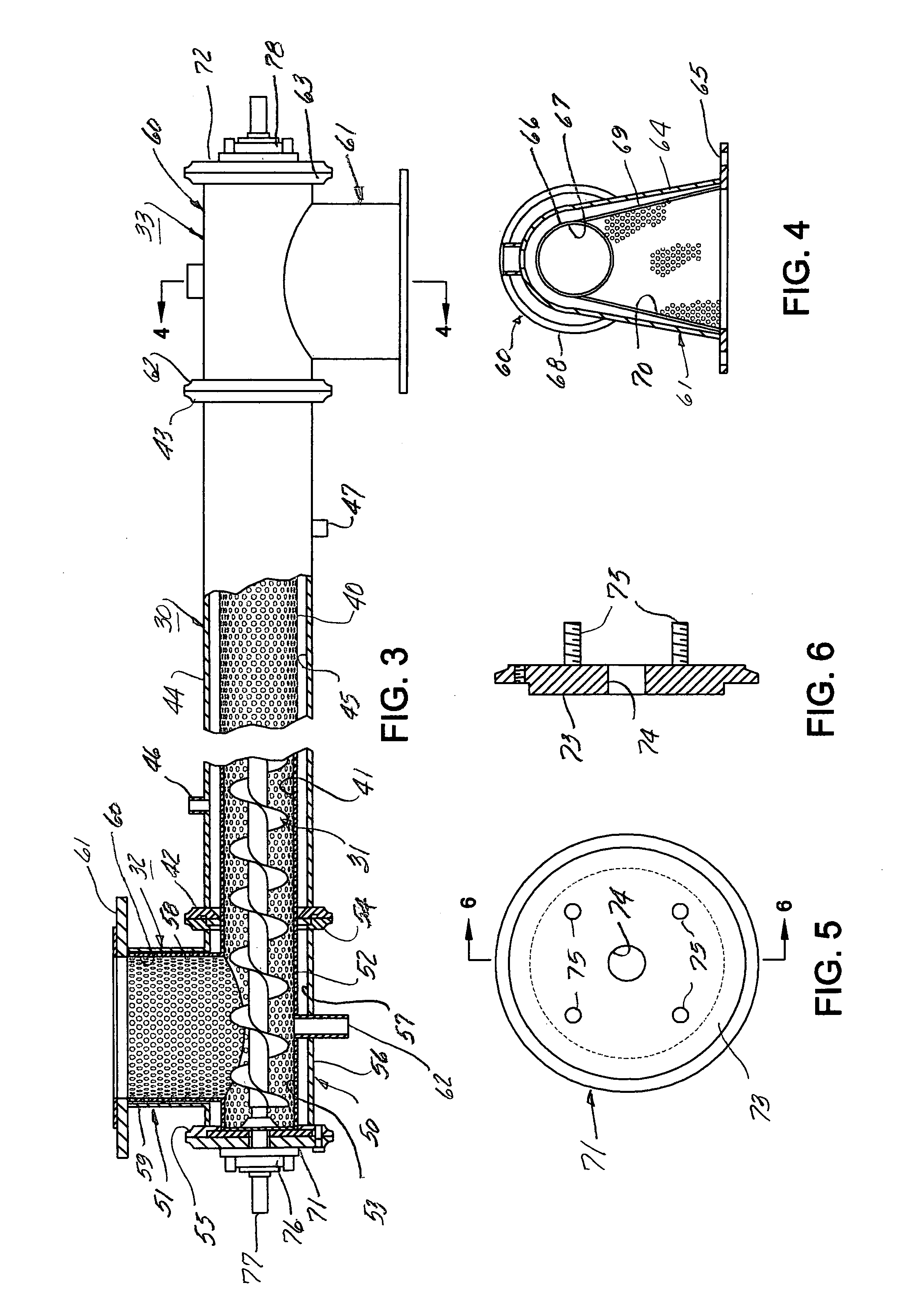

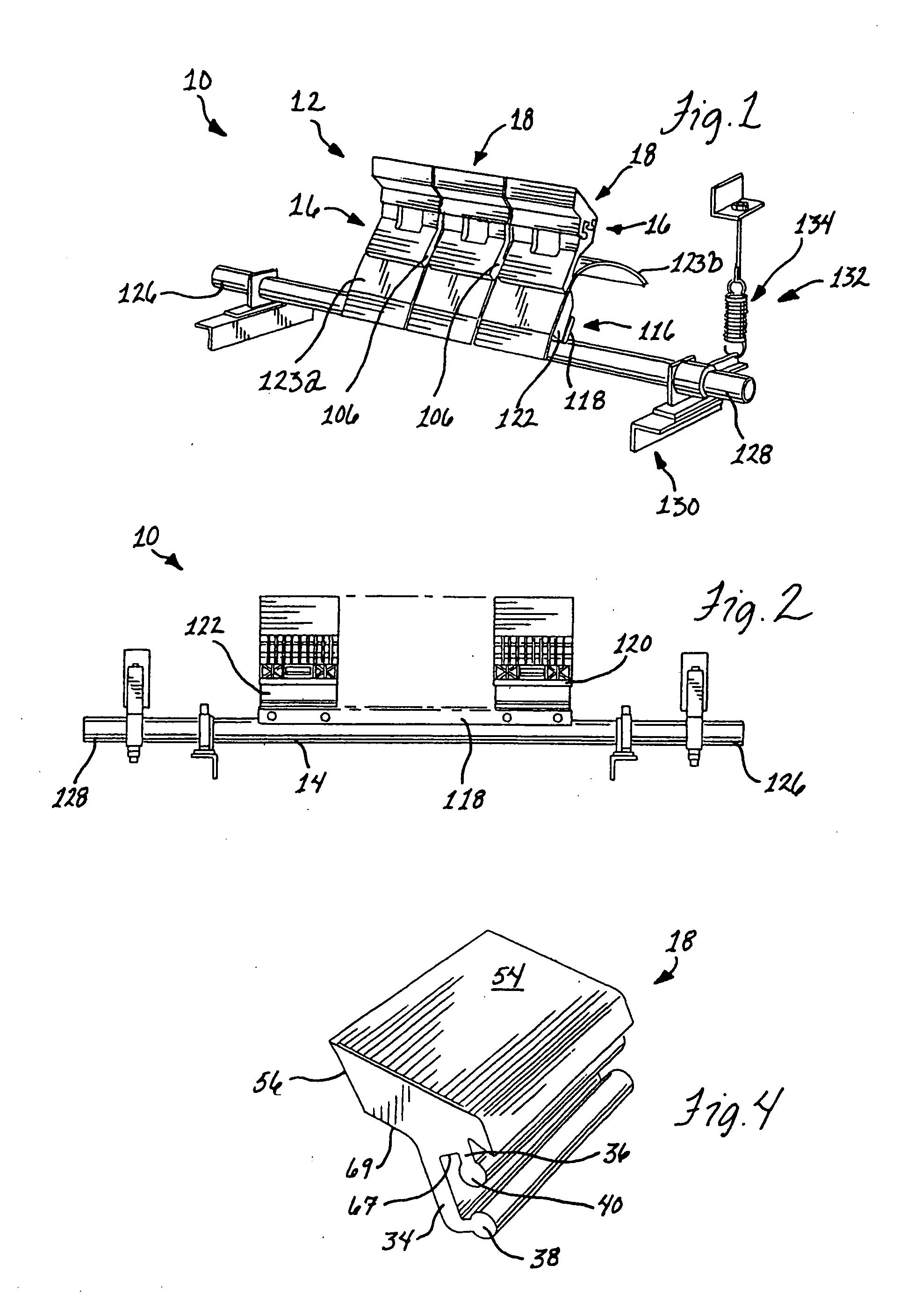

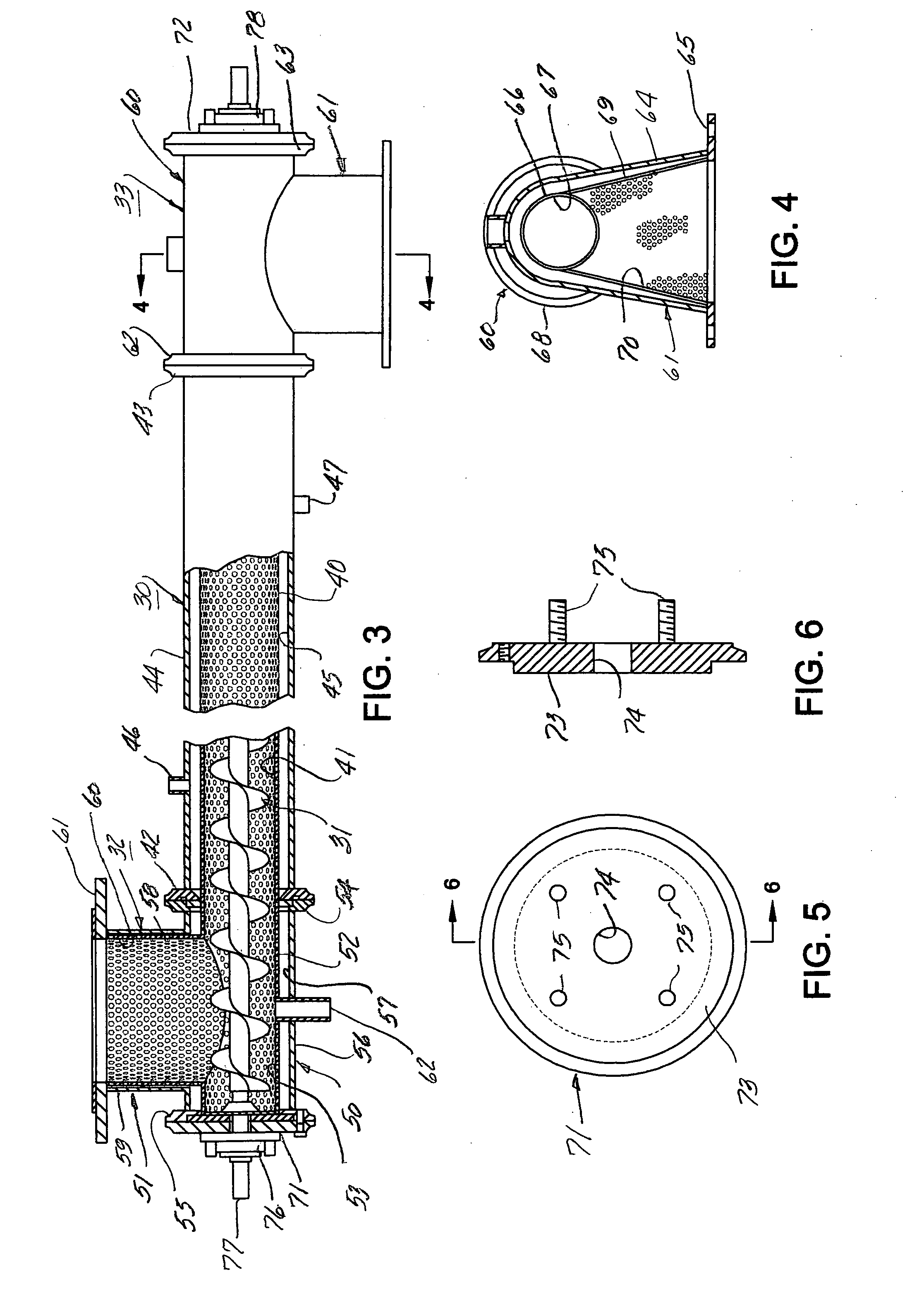

Concrete batching pre-mixer and method

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

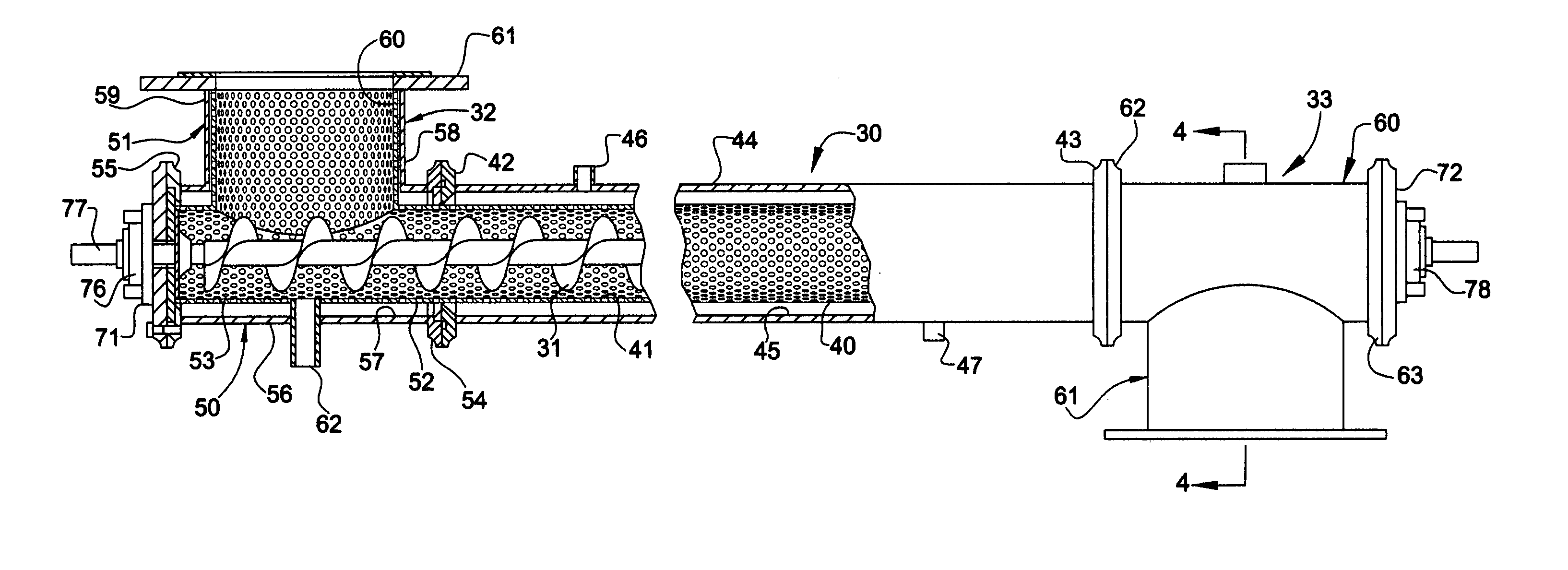

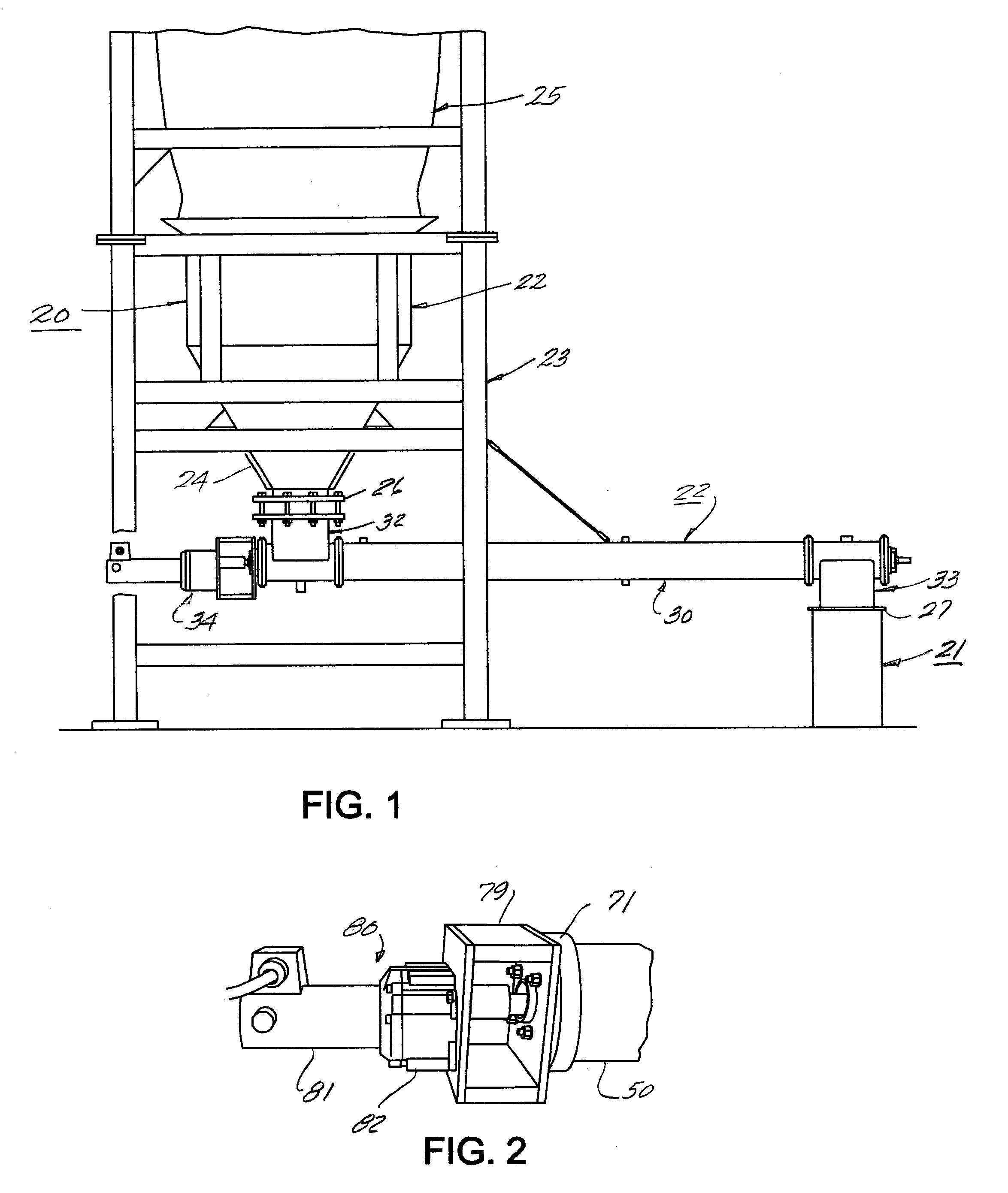

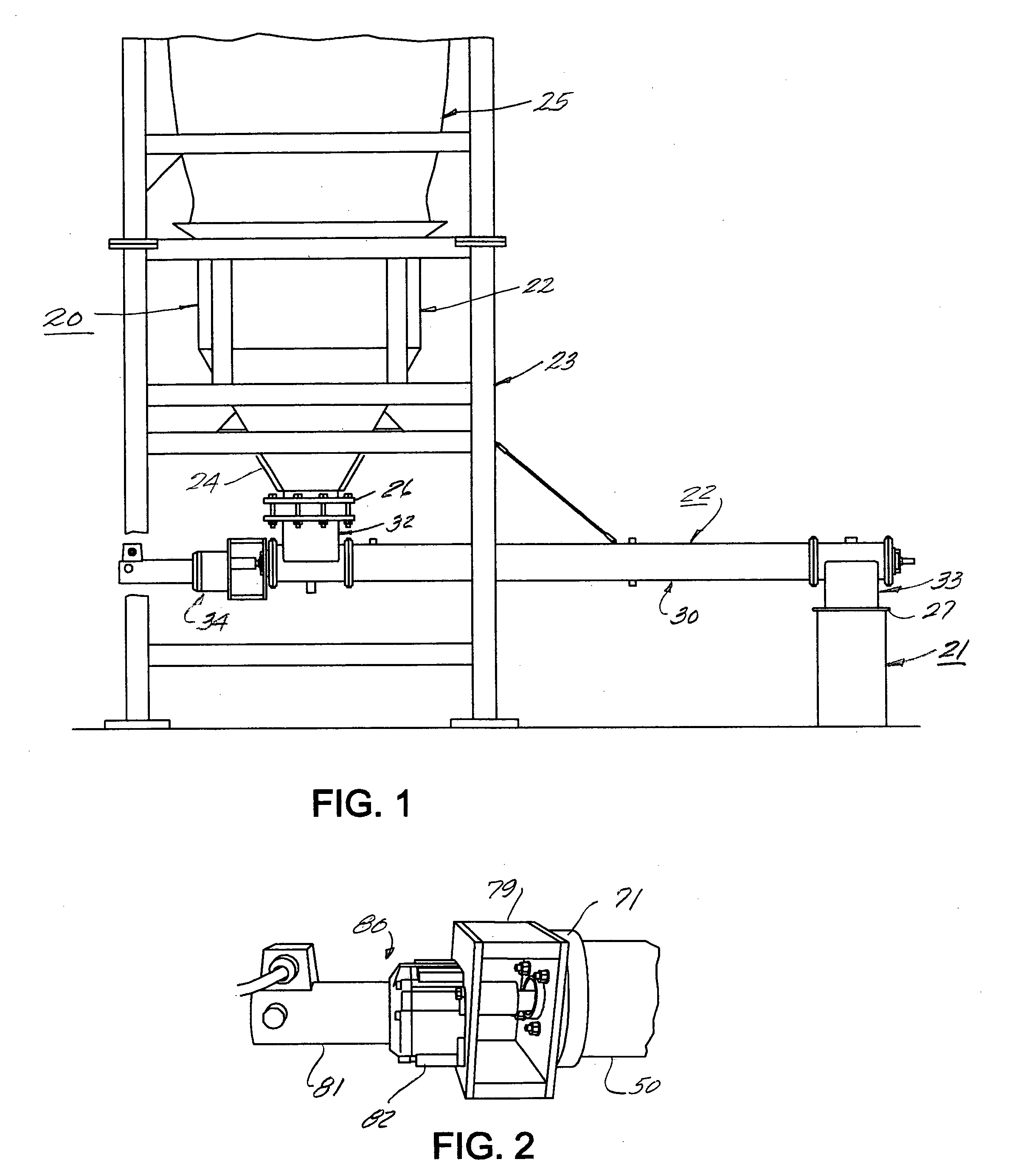

System and method for handling bulk materials

ActiveUS7137759B1Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsGuide tubeBulk material handling

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

Concrete batching facility and method

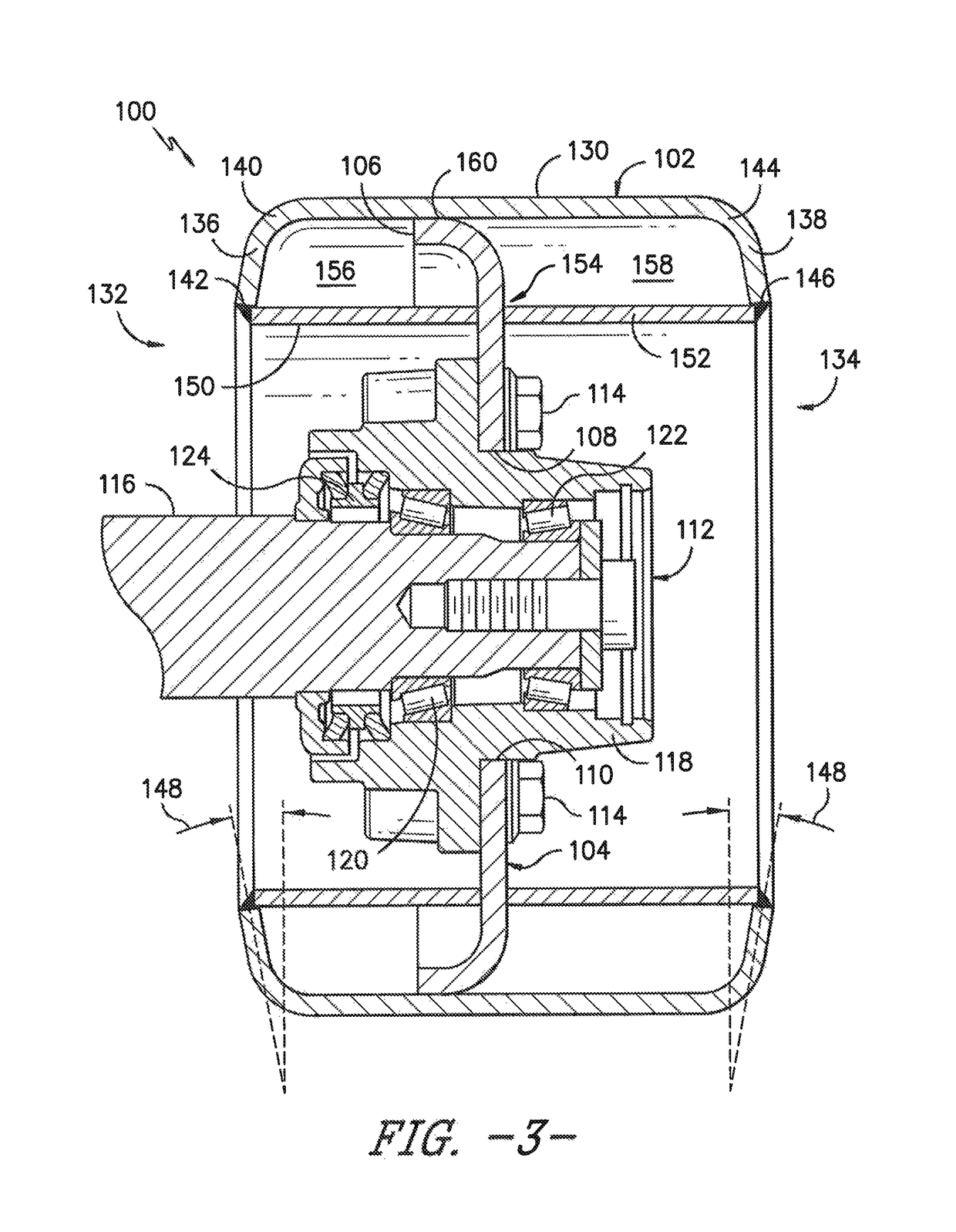

ActiveUS7320539B2Optimizes production and strengthAvoid material accumulationDischarging apparatusMixing operation control apparatusHybrid systemAdditive ingredient

A concrete batch mixing system and method are disclosed that enable the batch master to measure and control both the water and cementitious ingredient feeds in relation to each other so as to be able to blend the two ingredients in a known, selected, adjustable and repeatable manner, and to agglomerate these ingredients in a counter-rotating twin screw mixing apparatus for use in the preparation of batches of mixed concrete in a concrete batching process.

Owner:MCNEILUS TRUCK & MFG INC

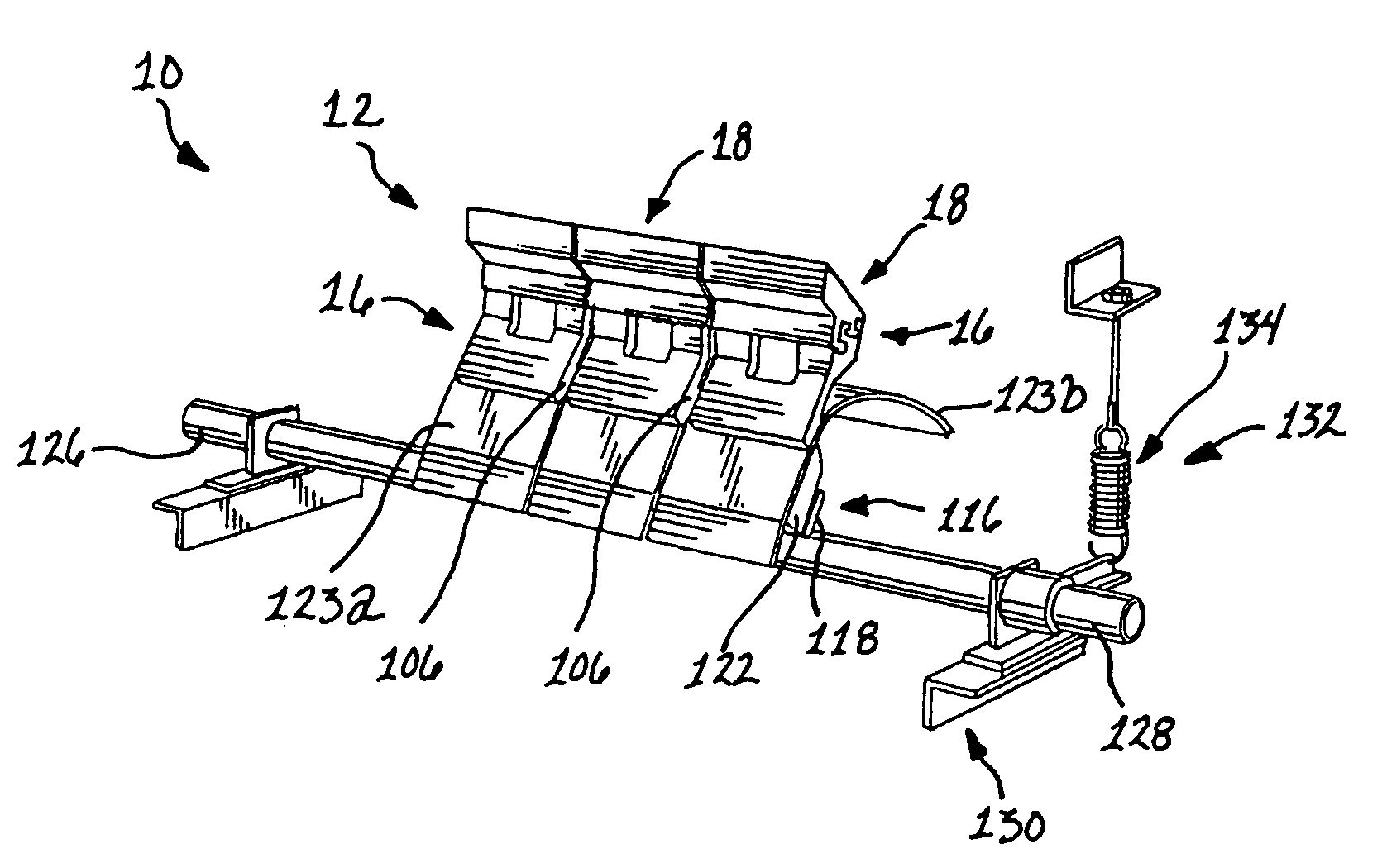

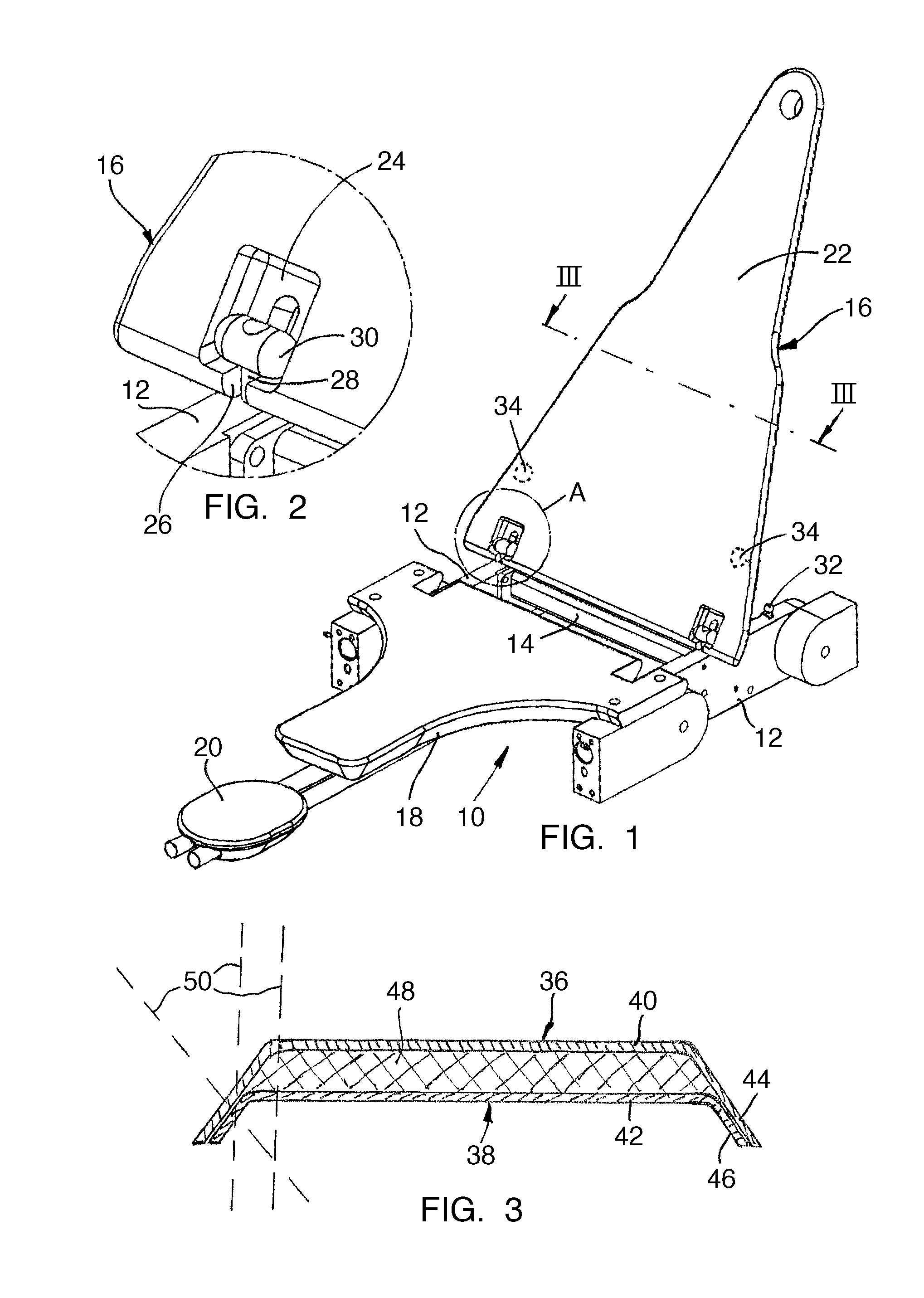

Scraper blade for conveyor belts

ActiveUS6926133B2Abrasion resistance is improvedImprove wear lifeConveyorsCleaningEngineeringMechanical engineering

A two piece scraper blade is provided that includes a scraper member that is releasably connected to a base member. The scraper member can be of a different material than the base member to provide various advantages including with respect to its wear resistance. Further, a toolless interconnection is provided for ease in attaching the scraper member to the base member. When worn, the scraper member can be replaced with a new scraper member in an easy and quick fashion.

Owner:FLEXIBLE STEEL LACING

System and method for handling bulk materials

ActiveUS7320561B2Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsHandling systemGuide tube

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

Scraper blade for conveyor belts

A two piece scraper blade is provided that includes a scraper member that is releasably connected to a base member. The scraper member can be of a different material than the base member to provide various advantages including with respect to its wear resistance. Further, in one form, a toolless interconnection is provided for ease in attaching the scraper member to the base member. In another form, the scraper member and base member are provided with engaging surfaces with one of the surfaces including teeth for gripping into the other surface when the scraper member is connected to the base member. In this form, the forces for inserting and removing the scraper member from the base member are greater than the form in which a toolless interconnection is provided, and thus a more robust connection between the scraper and base members is provided thereby.

Owner:FLEXIBLE STEEL LACING

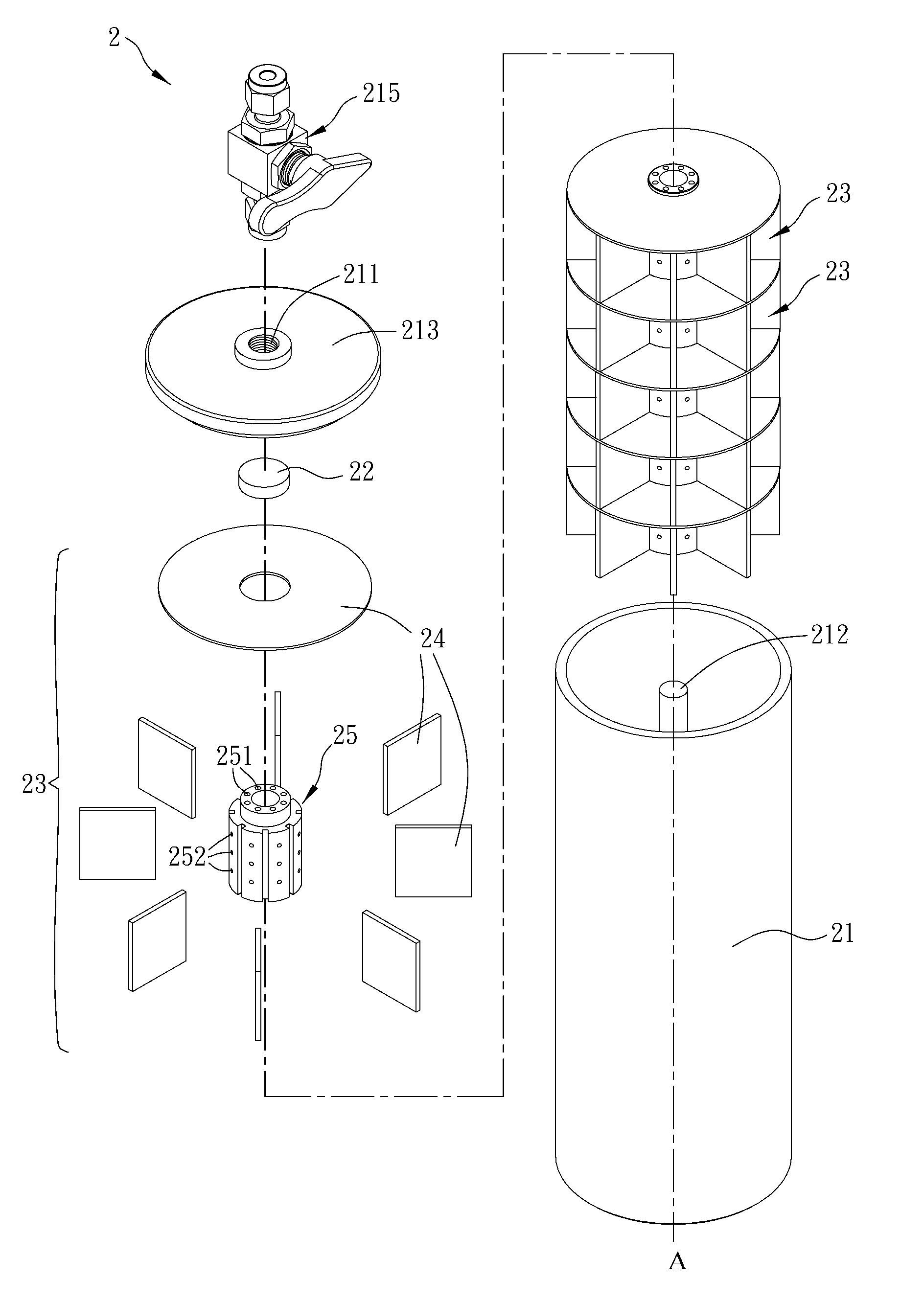

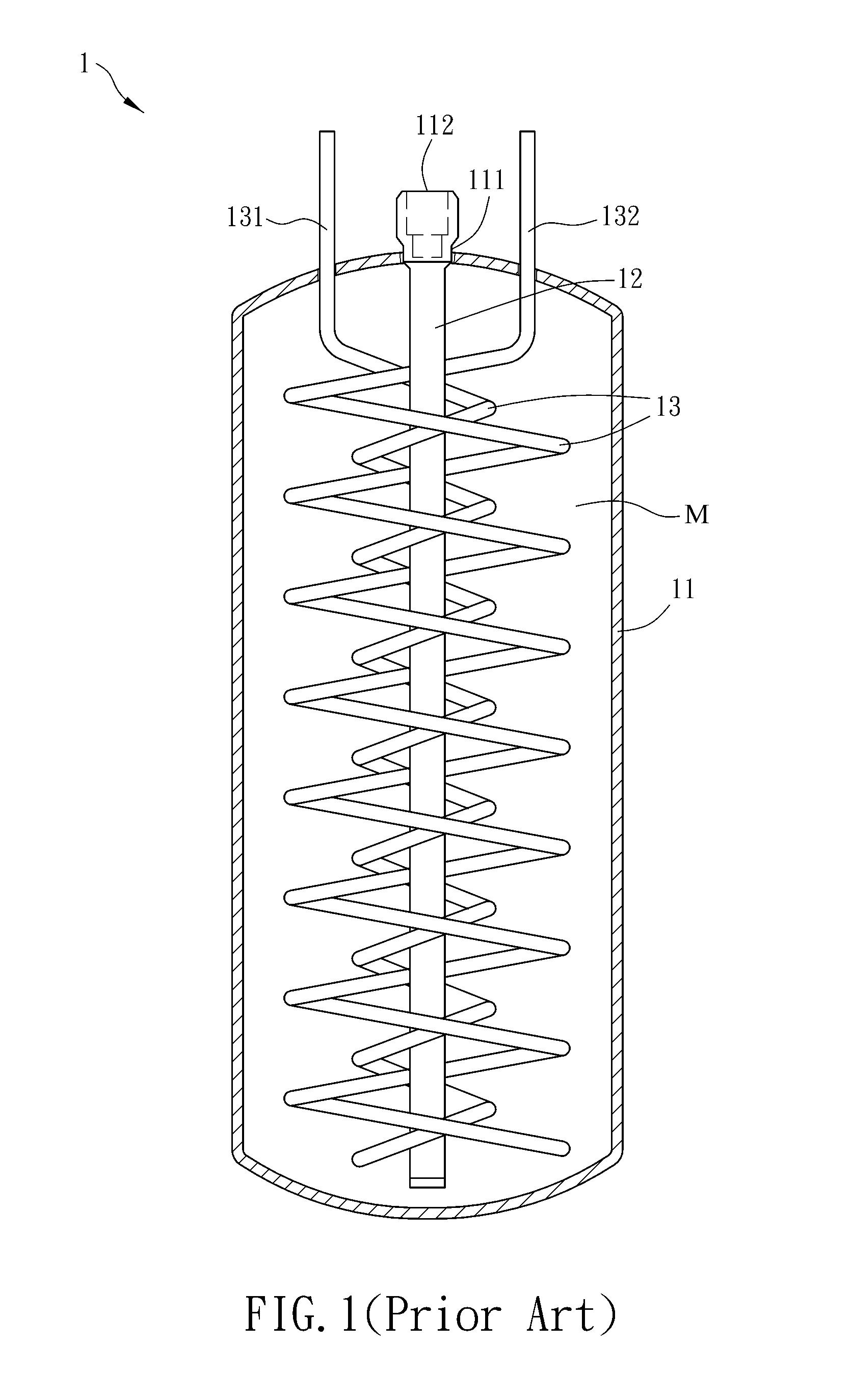

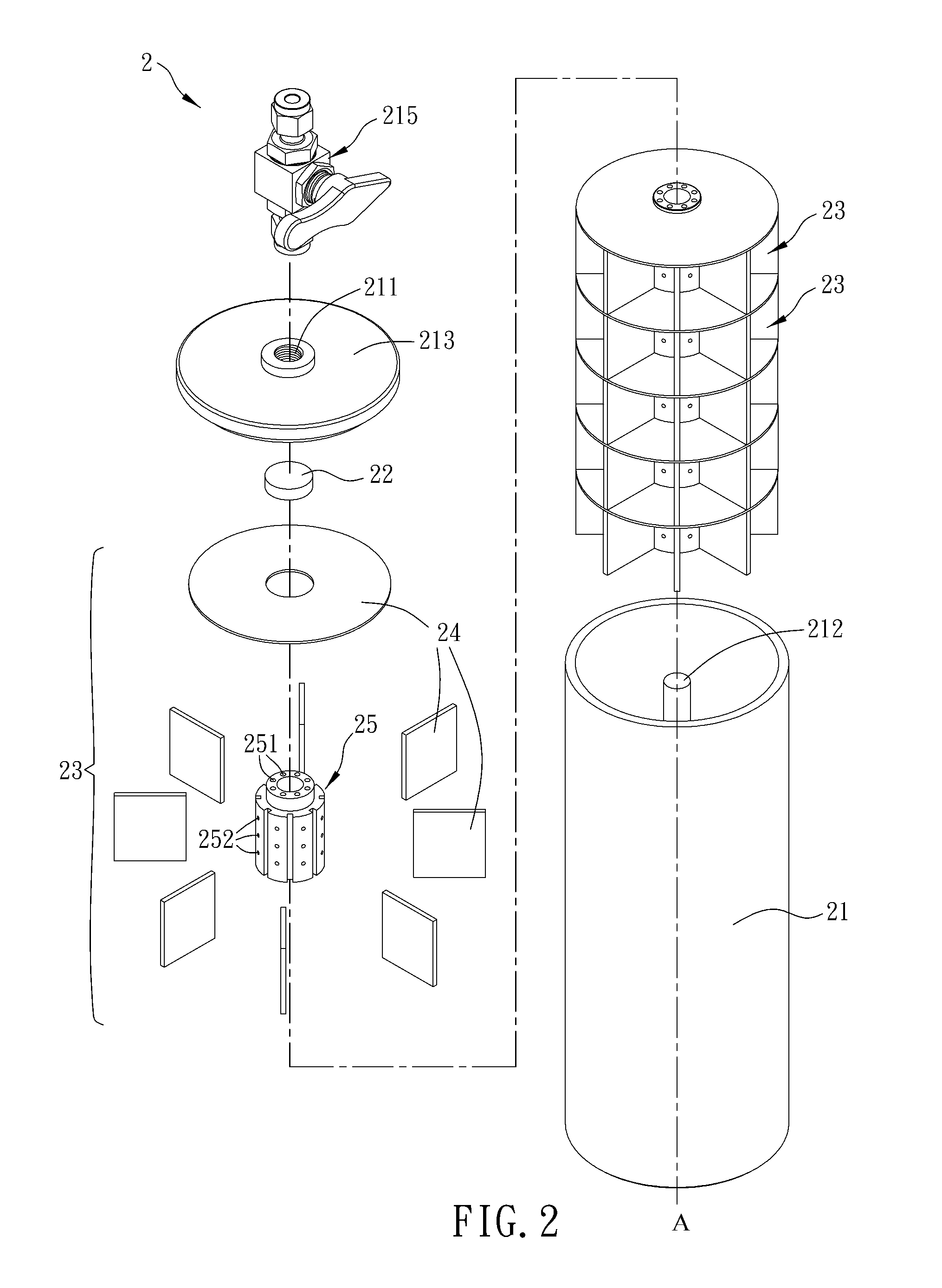

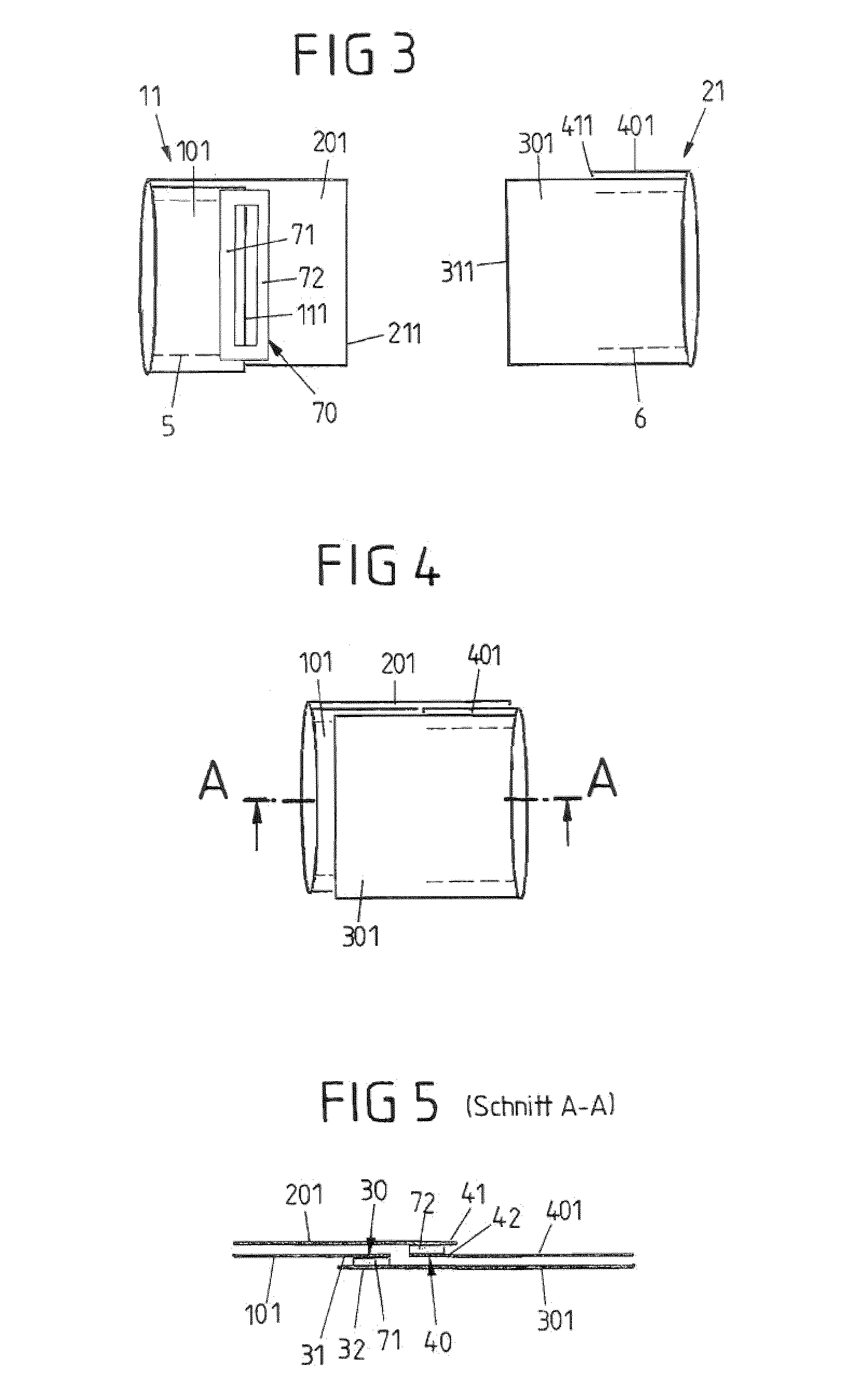

Hydrogen storage apparatus

InactiveUS20120211376A1Material be accumulate be easeEase phenomenonFixed capacity gas holdersLiquid materialEngineeringMechanical engineering

A hydrogen storage apparatus includes a canister, a first filter element and at least one hydrogen storage unit. The canister has an opening and a rod. The first filter element is disposed in the opening. The hydrogen storage unit is accommodated in the canister. The hydrogen storage unit includes a compartment structure and a hydrogen channel element. The compartment structure divides a space inside the canister, and the hydrogen channel element is pierced by the rod and connected with the compartment structure. The hydrogen channel element includes a plurality of axial channels and a plurality of radial channels. The axial channels are connected with the opening and the radial channels. The radial channels are connected with the space inside the canister.

Owner:NAT CENT UNIV

Scraper blade for conveyor belts

A two piece scraper blade is provided that includes a scraper member that is releasably connected to a base member. The scraper member can be of a different material than the base member to provide various advantages including with respect to its wear resistance. Further, in one form, a toolless interconnection is provided for ease in attaching the scraper member to the base member. In another form, the scraper member and base member are provided with engaging surfaces with one of the surfaces including teeth for gripping into the other surface when the scraper member is connected to the base member. In this form, the forces for inserting and removing the scraper member from the base member are greater than the form in which a toolless interconnection is provided, and thus a more robust connection between the scraper and base members is provided thereby.

Owner:FLEXIBLE STEEL LACING

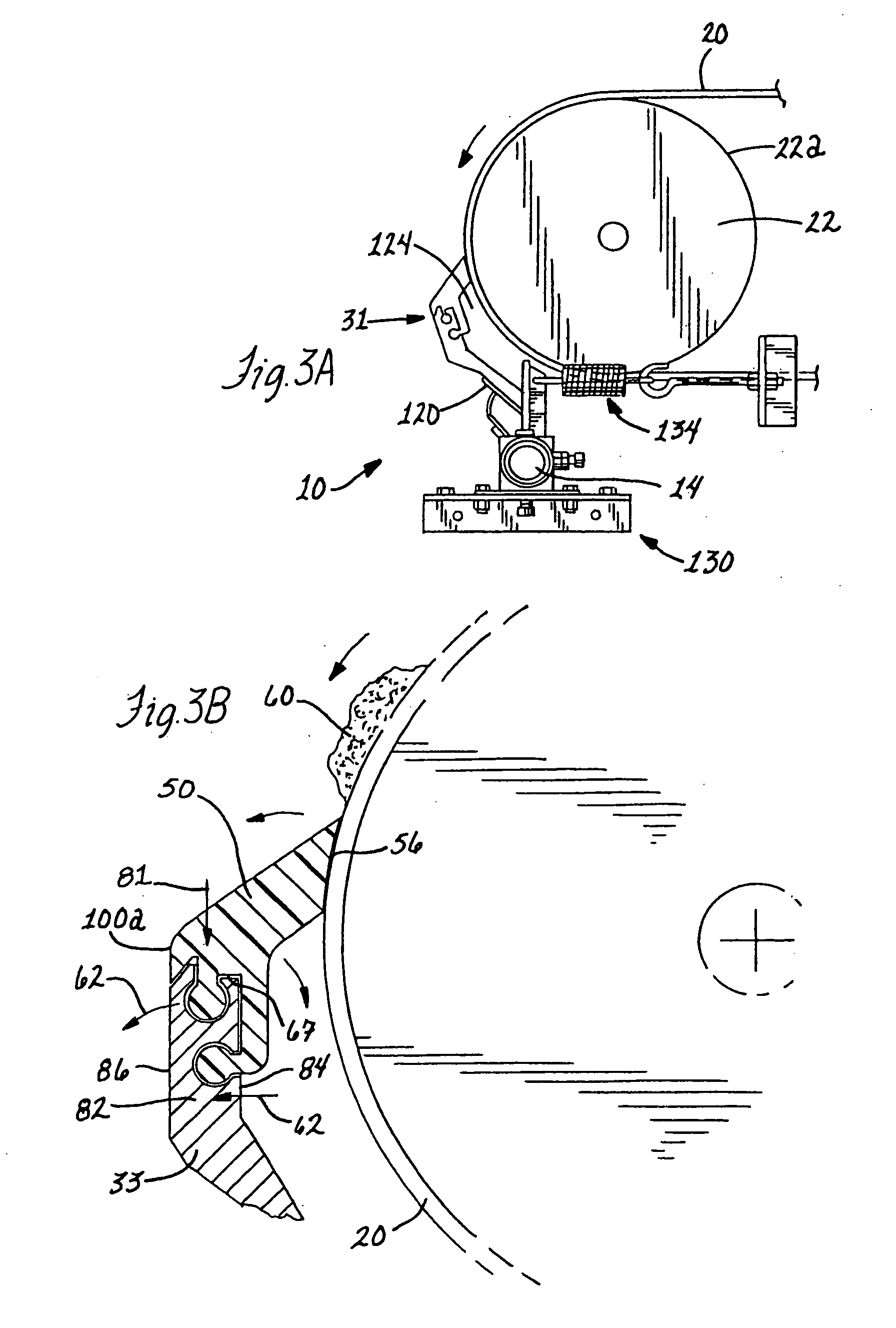

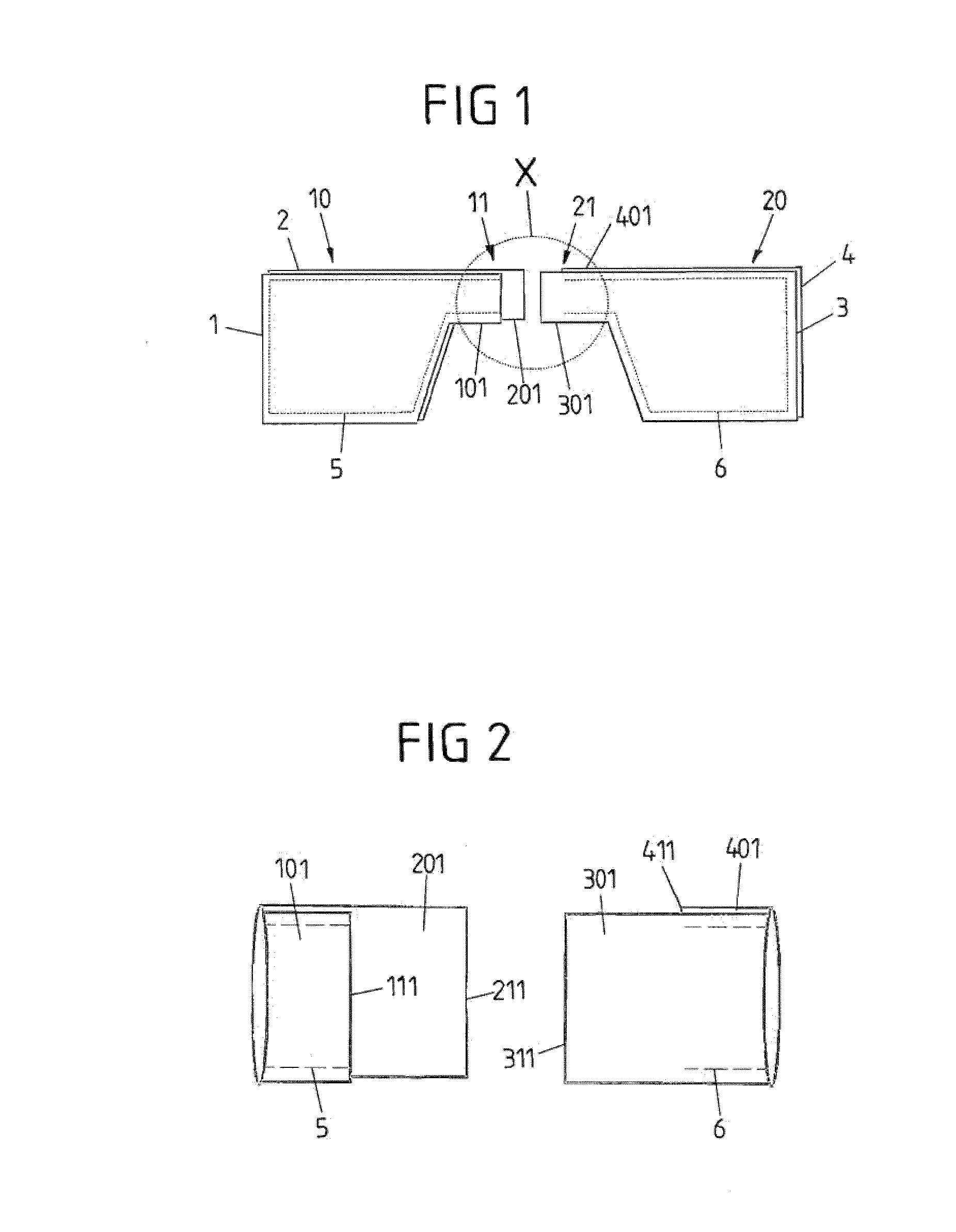

X-rayable patient positioning plate

InactiveUS20120204351A1Easy interchangeEasy to replaceOperating tablesSofasFilling materialsEngineering

In an X-rayable patient positioning plate with an outer shell, enclosing a hollow space filled with filler material, the shell consists of a tub-like upper part (36) and a tub-like lower part (38), each having a tub floor (40, 42) forming the plate top side and the plate bottom side, respectively, which forms with the tub margin (44, 46) an inner angle of more than 90°, while the top part (36) and the bottom part (38) are dimensioned and fitted into each other such that the tub margins (44, 46) of the two parts (36, 38) lie flat against each other and their tub floors (40, 42) bound the hollow space of the shell between them.

Owner:MAQUET GMBH

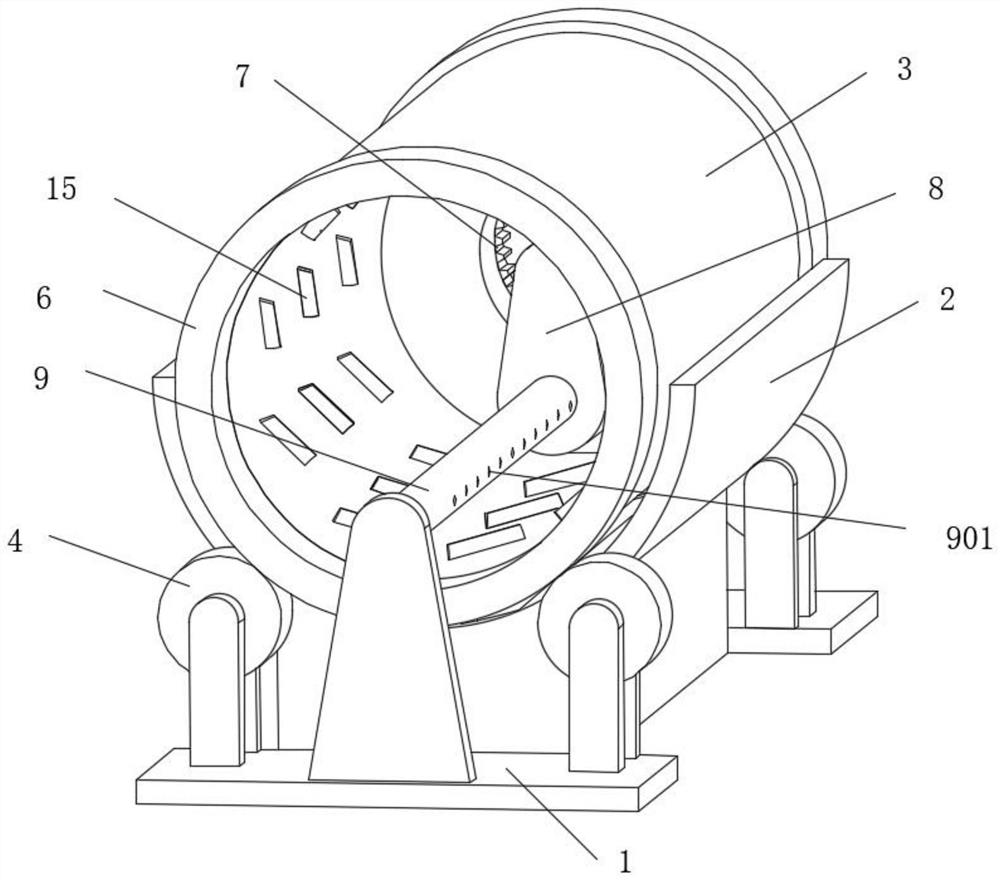

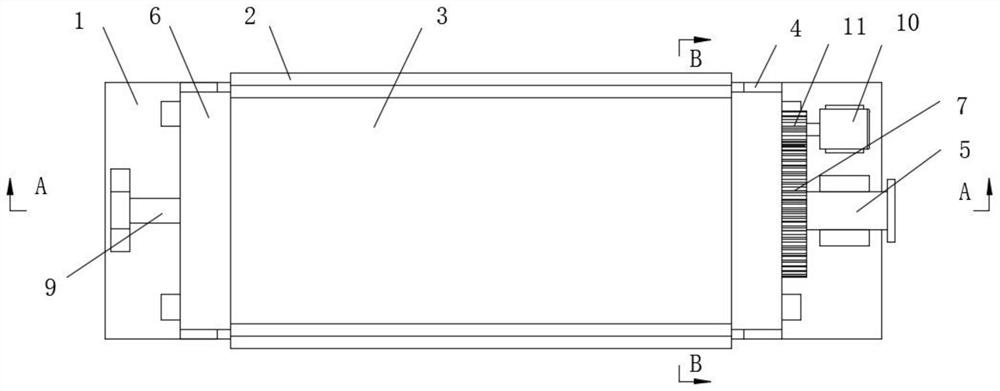

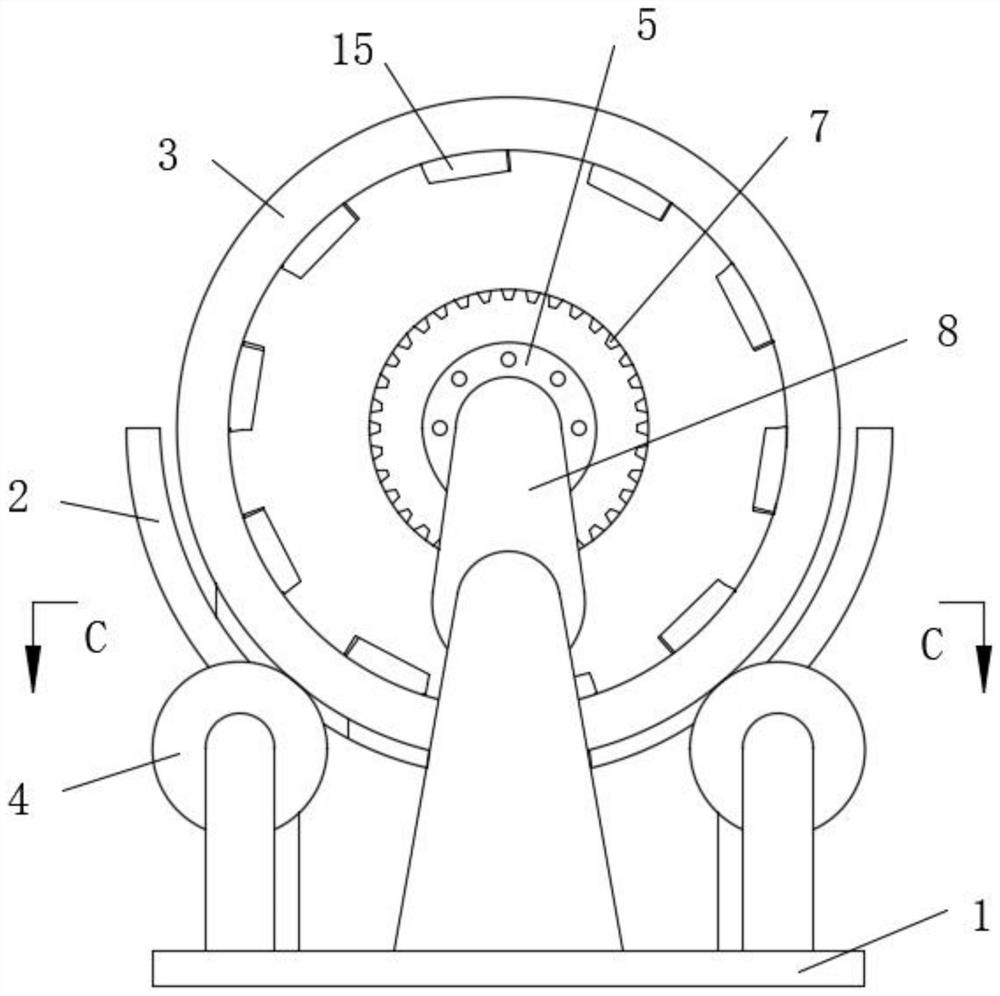

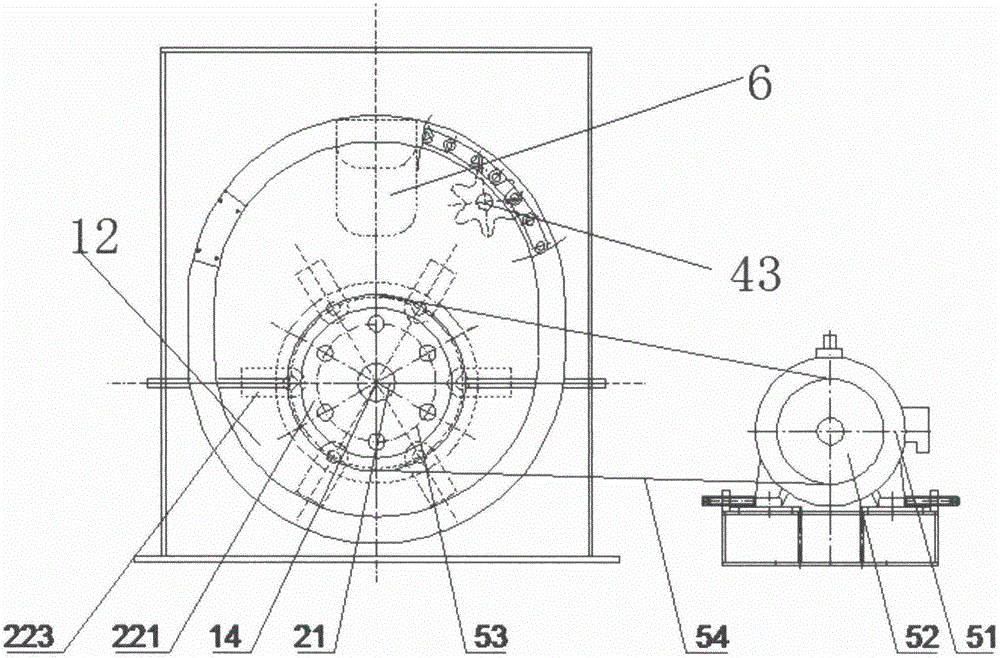

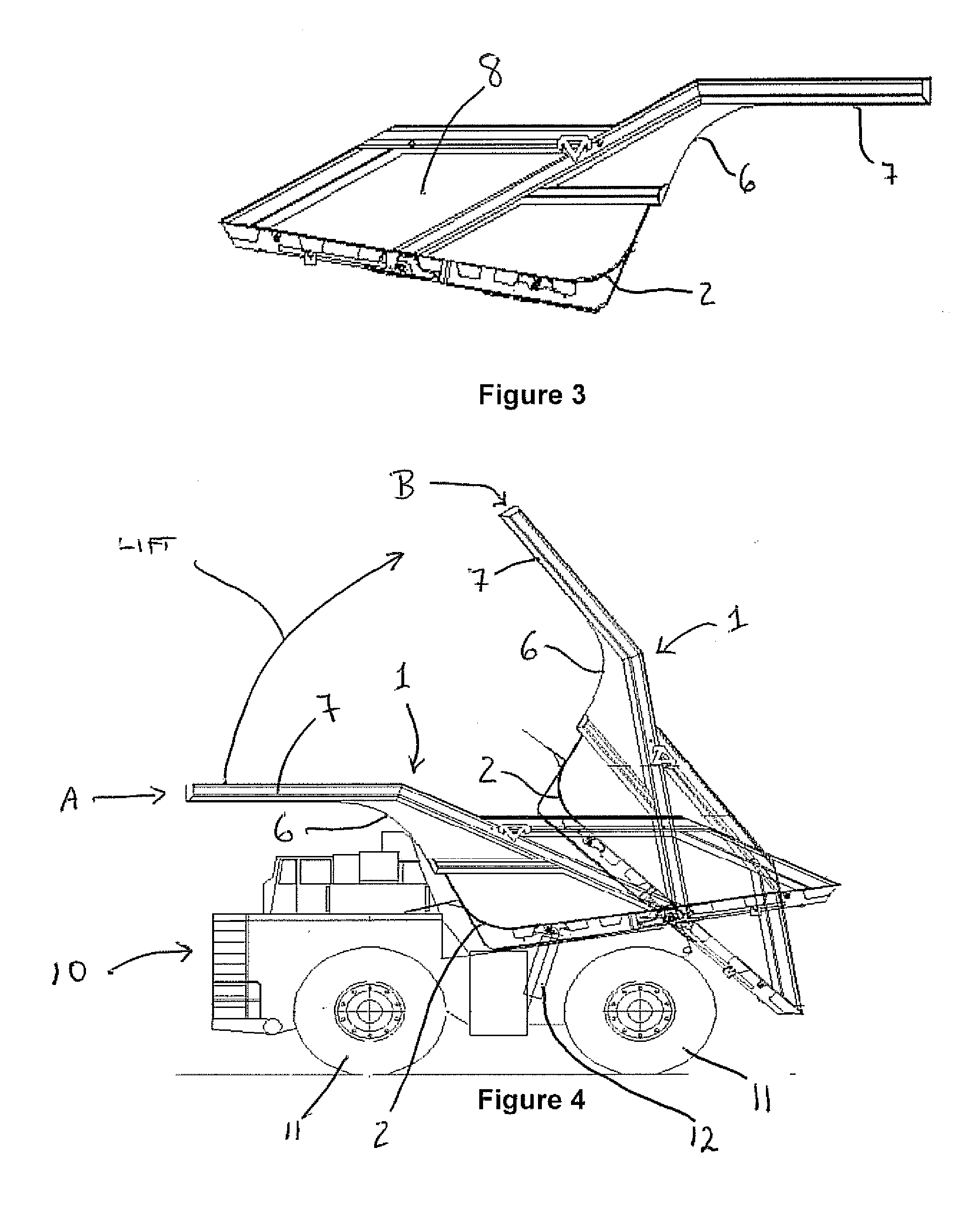

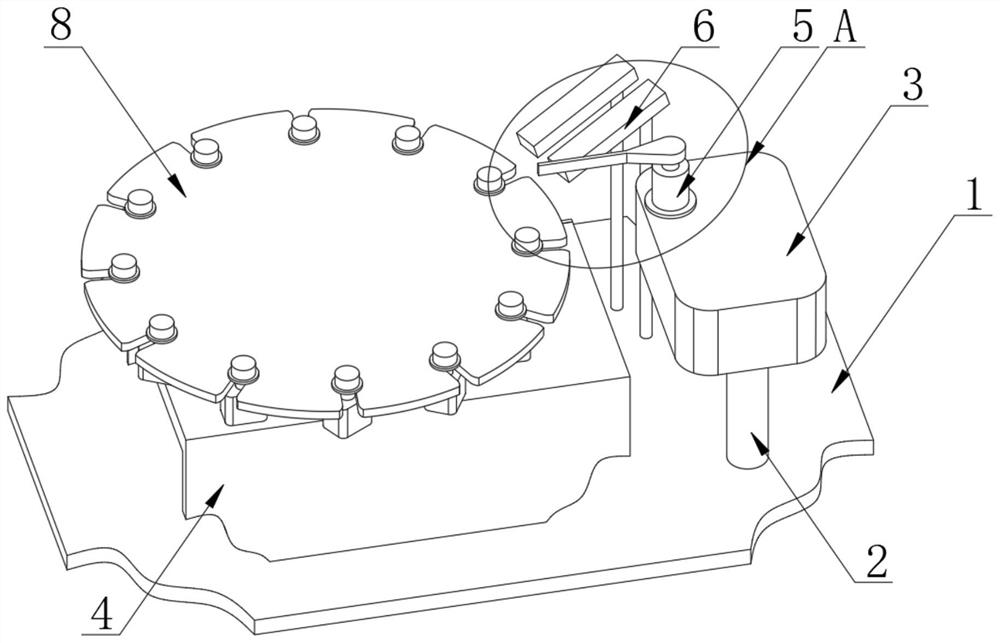

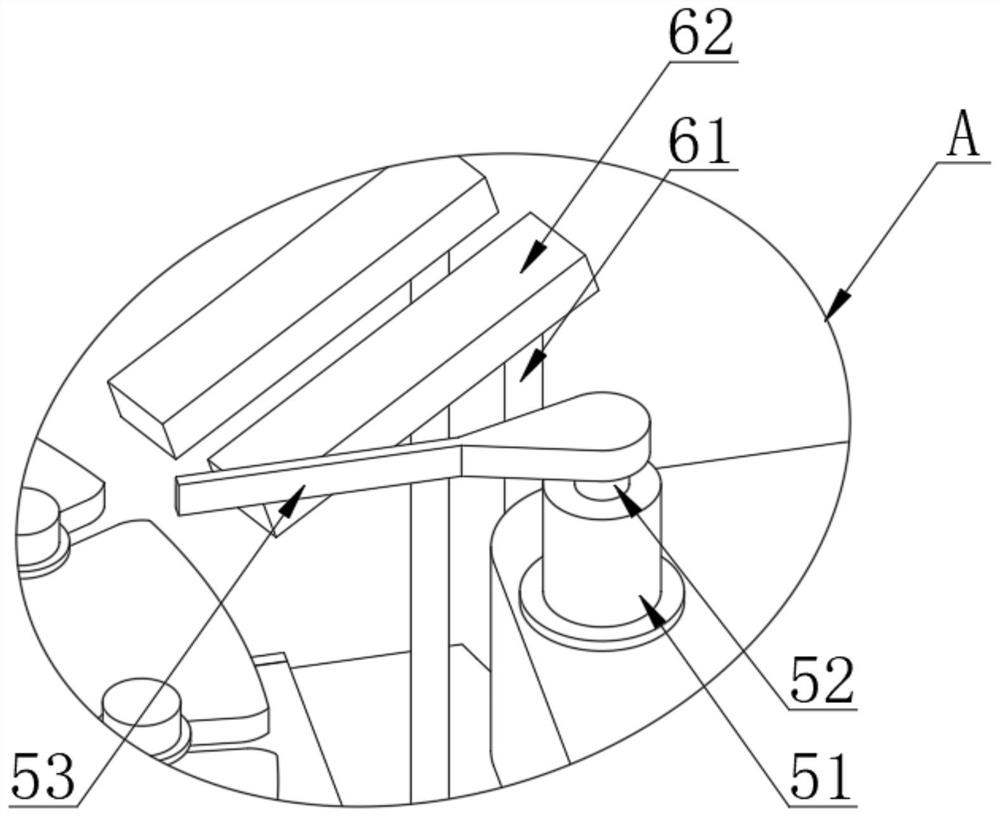

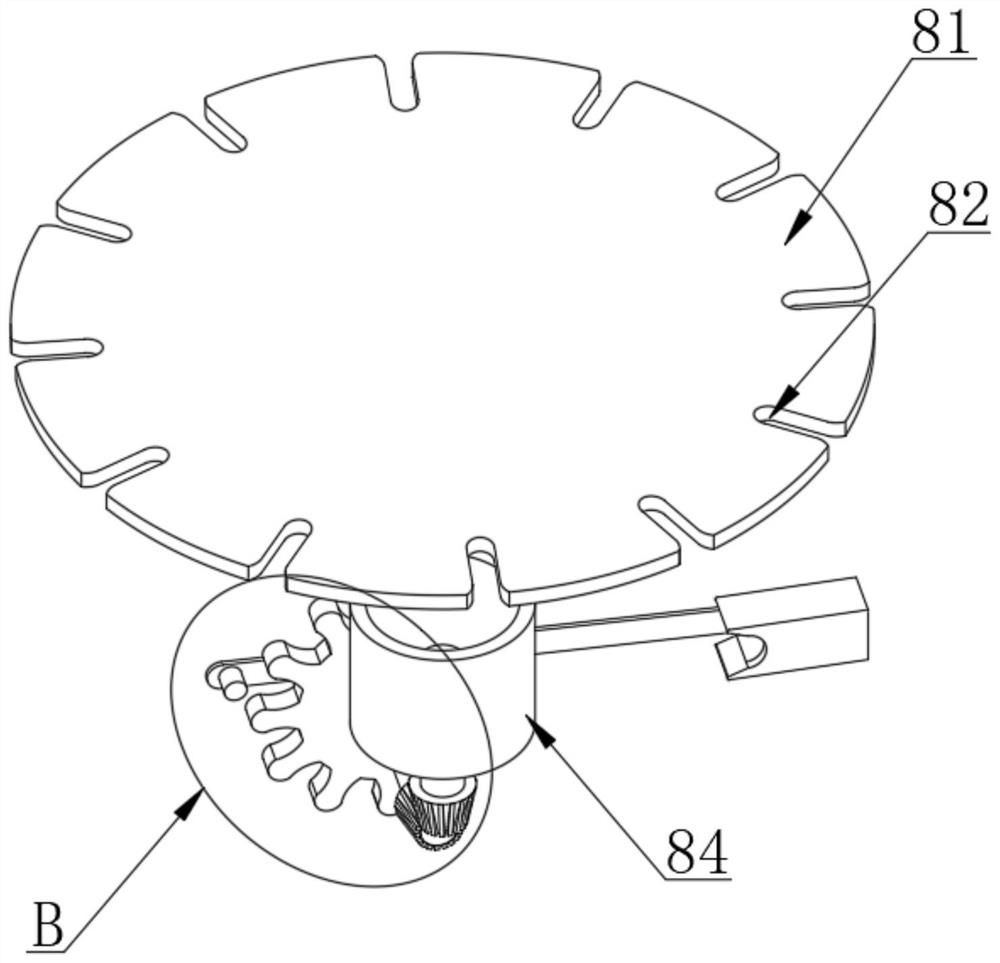

Solid-liquid separation microstrainer

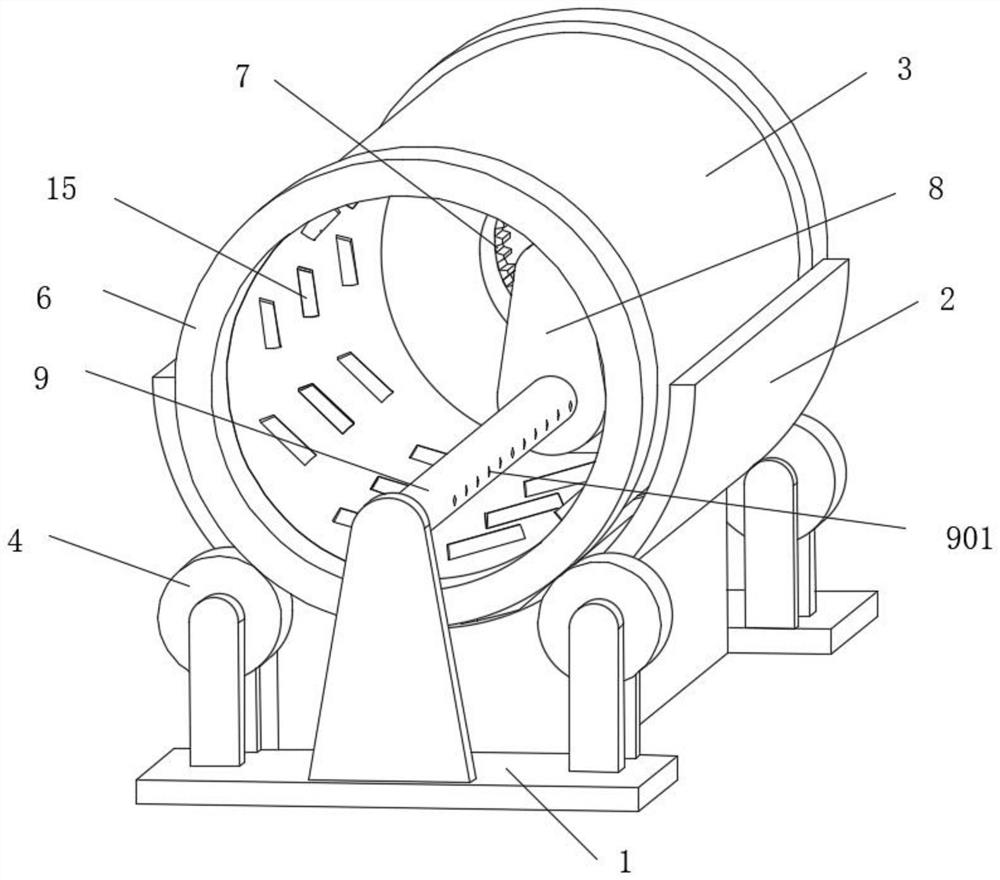

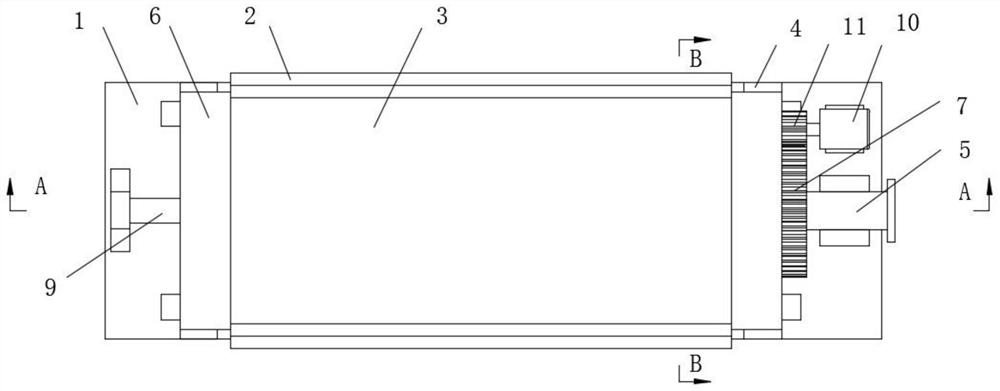

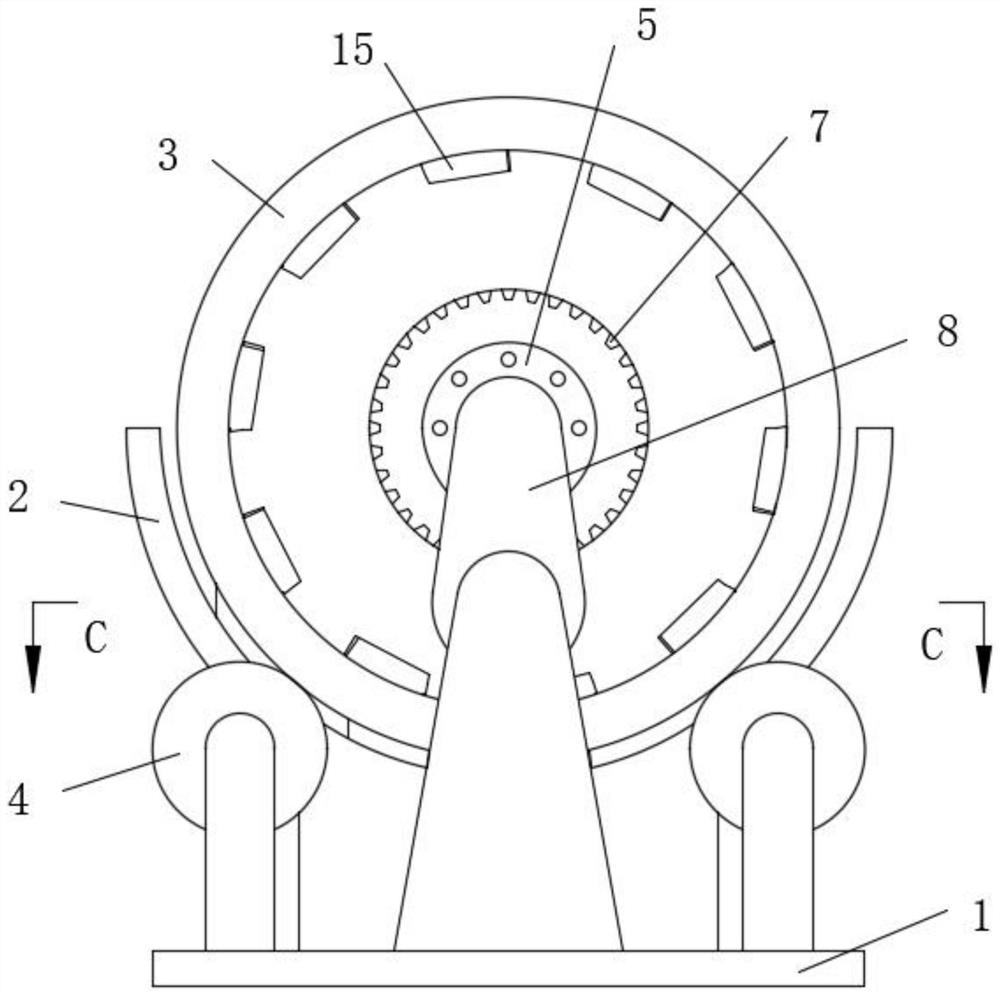

ActiveCN112426787AIncrease profitGood effectMoving filtering element filtersGear wheelElectric machinery

The invention relates to the technical field of environmental protection equipment, and discloses a solid-liquid separation microstrainer which comprises a base. A waterproof plate is fixedly mountedat the top of the middle of the base, a water tank is formed in the bottom of the waterproof plate, supporting wheels are movably mounted at the tops of the two ends of the base, and filter cartridgesare fixedly mounted at the tops of the supporting wheels. Rotating rings matched with the supporting wheels are fixedly installed at the two ends of the filter cartridge, a feeding pipe extending into the filter cartridge is arranged in the middle of the back face of the filter cartridge, a large gear ring is fixedly installed on the back face of the filter cartridge, a motor is fixedly installedat the top of the back face of the base, and the output end of the motor is fixedly connected with a small gear meshed with the large gear ring. A discharging box is fixedly installed on the front face of the feeding pipe, a supporting shaft is fixedly connected to the front face of the discharging box, a discharging rotating wheel is installed in the discharging box and driven by a transmissiongear to rotate, a rotating shaft is arranged to rotate along with the discharging rotating wheel, the filtering efficiency can be improved, and the service life of a filter cartridge can be prolonged.

Owner:深圳市树立水处理设备有限公司

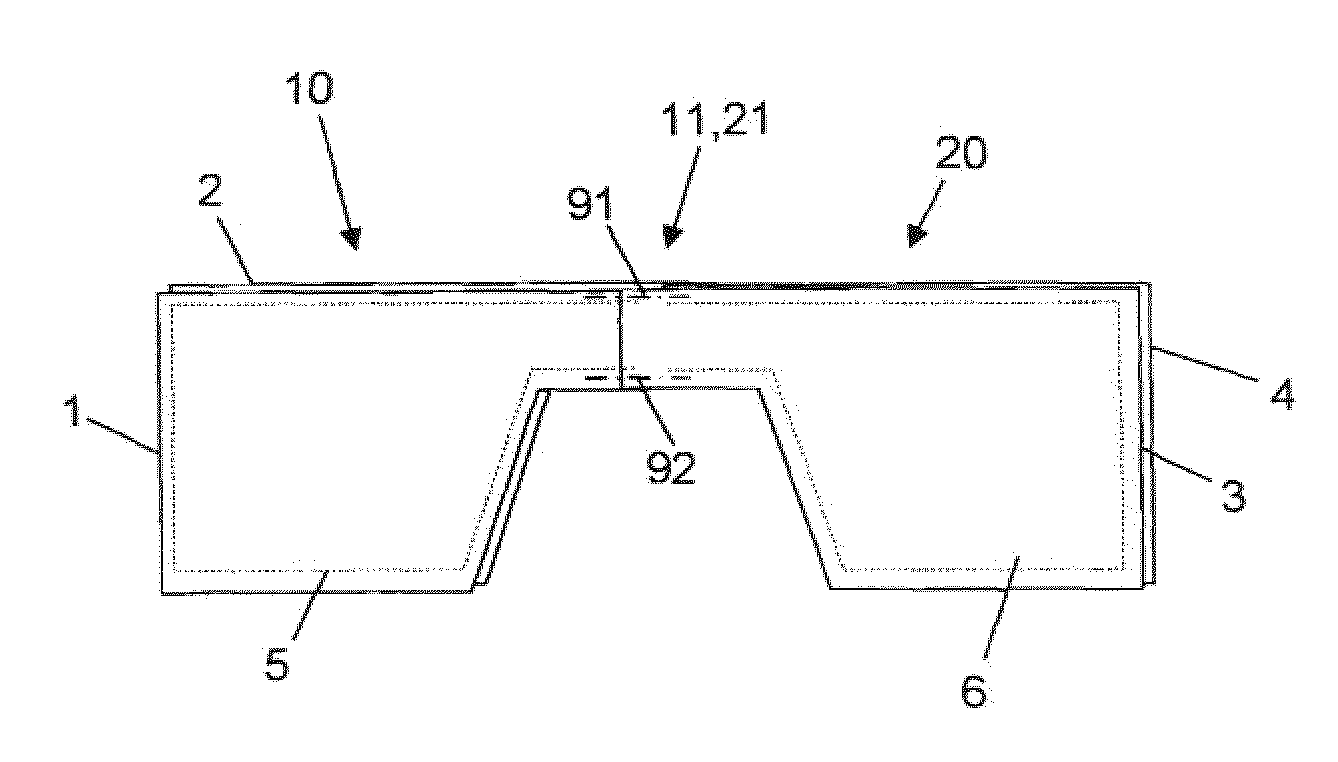

Airbag for a vehicle passenger-protecting system and a method for producing the same

InactiveUS20120306186A1Avoid material accumulationRaise the possibilityLamination ancillary operationsPedestrian/occupant safety arrangementEngineeringElectrical and Electronics engineering

An airbag device for a vehicle passenger-protecting system. According to one variant, the airbag device comprises a first airbag segment, which has at least two material blanks and a second airbag segment which has at least two material blanks, wherein the material blanks of the first airbag segment and the material blanks of the second airbag segment are connected to one another at the respective circumferential edge in a gas-tight manner. The first airbag segment has a first transitional section and the second airbag segment has a second transitional section, wherein the transitional sections form a transitional region in which the two airbag segments are connected to one another in a gas-tight manner. An opening can be formed in each of the two transitional sections.

Owner:TAKATA CORPORATION

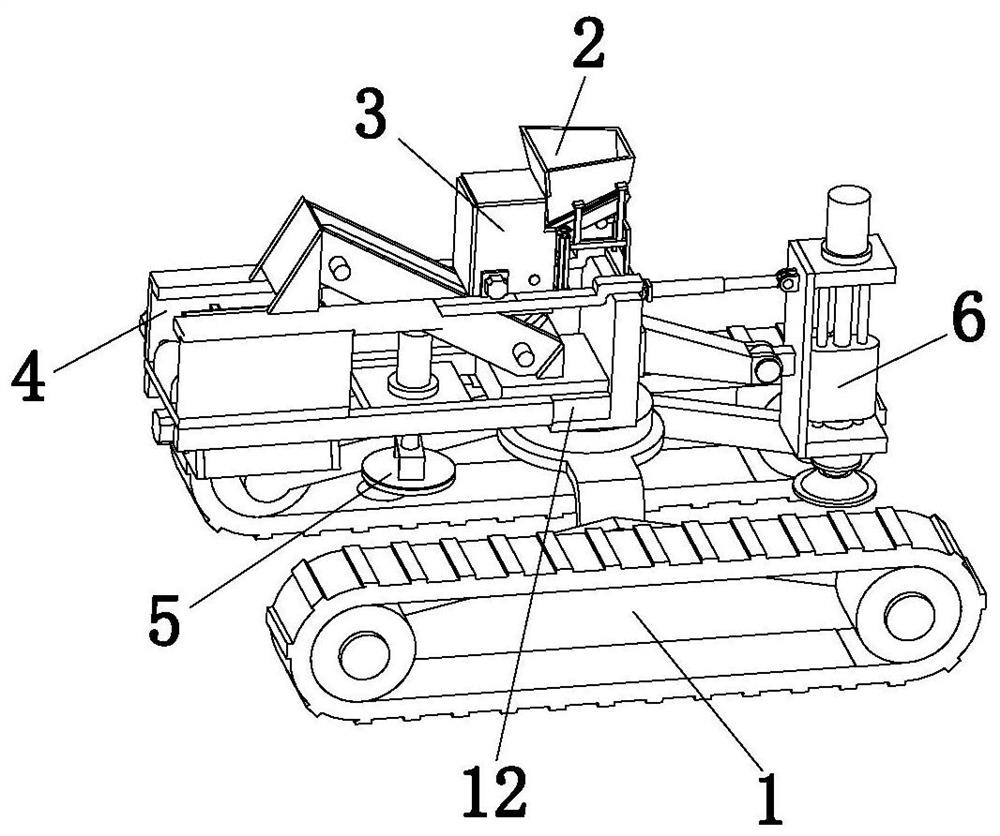

Landfilling system for mining area restoration and landfilling process of system

InactiveCN112554940AAvoid stickingAvoid stuckMaterial fill-upGrain treatmentsMining engineeringMechanical engineering

The invention discloses a landfilling system for mining area renovation and a landfilling process of the system, and belongs to the technical field of coal mine pit backfilling. The landfilling systemcomprises an advancing system, a vibration feeding system, a crushing and conveying system, a screening and distributing system, a grinding system and a tamping system; and the advancing system is arranged on the pit face of a mine pit, the vibration feeding system is arranged in the middle of the top of the advancing system, the crushing and conveying system is arranged at the discharging end ofthe vibration feeding system, the screening and distributing system is installed on the lower portion of the discharging end of the crushing and conveying system, the grinding system is arranged between the crushing and conveying system and the screening and distributing system, and the tamping system is arranged at the end, away from the grinding system, of the advancing system. By means of allthe arranged systems, vibration feeding, crushing, screening and distributing, paving and tamping operation can be conducted on backfill materials, the materials can be backfilled into the mine pit more tightly and compactly, and the serious consequence that filling materials in a backfill area are too loose, and consequently land subsidence is caused is prevented.

Owner:王常浩

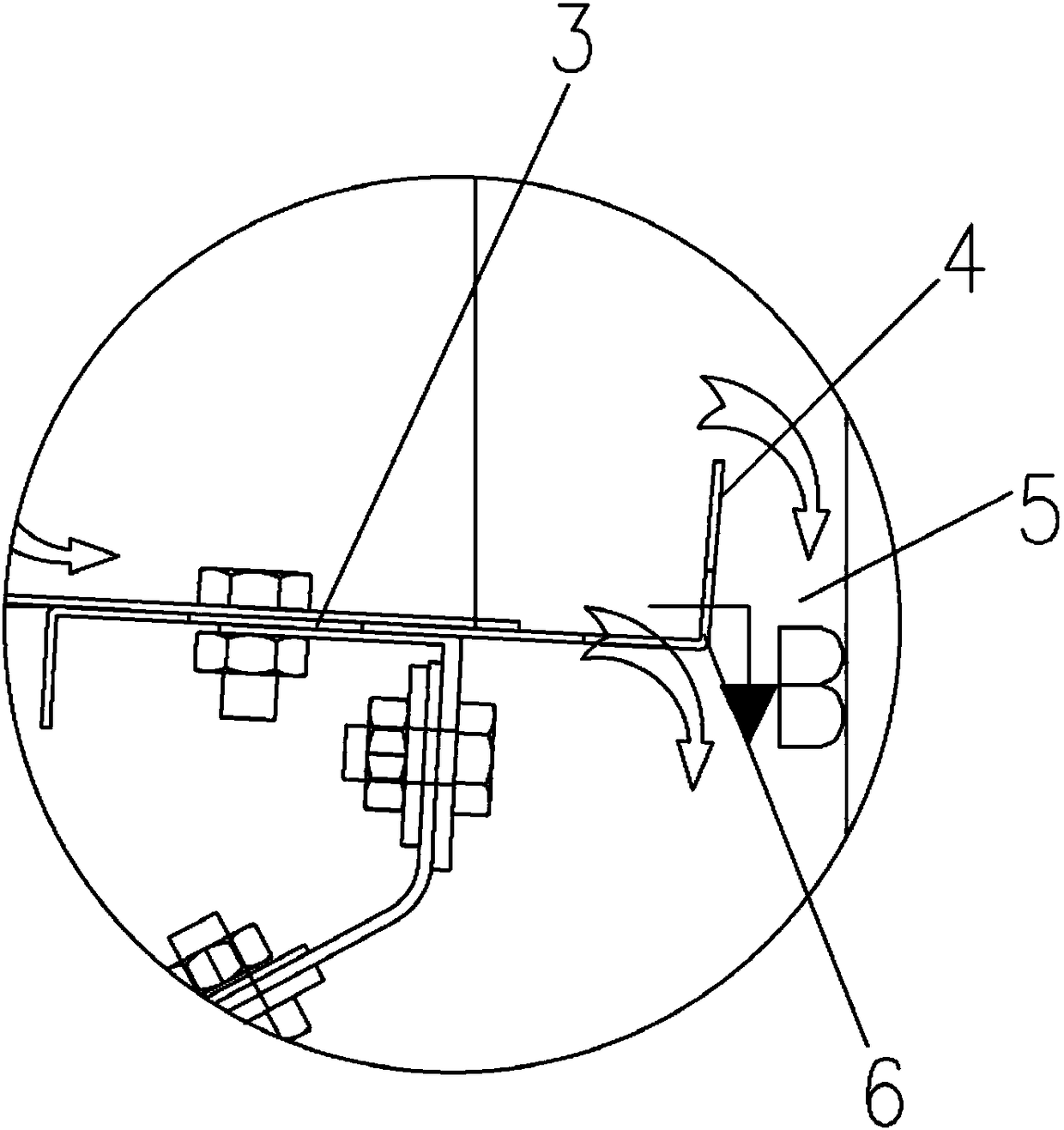

Screen strip rotation hammer type crusher

The invention discloses a screen strip rotation hammer type crusher. The screen strip rotation hammer type crusher comprises a machine shell, a heavy hammer device, a screen strip device, a first drive device and a second drive device. The screen strip device comprises a screen strip assembly. The screen strip assembly is of an annular or U-shaped structure formed by multiple screen strips arranged in parallel. The screen strip assembly wraps the outer portion of the heavy hammer device. The first drive device and the screen strip assembly are connected to drive the screen strip assembly to rotate. In the screen strip rotation hammer type crusher, when sticky materials with the high water content are encountered and the materials are beaten to screen strips, some materials can be bonded to the surfaces of the screen strips, due to rotation of the screen strips, the materials bonded to the screen strips can disengage during screen strip moving or can be beaten away by materials when the angles of the screen strips change, finally the screen strips rotate to extrusion cavities and are extruded and ground through hammer heads to be cleaned thoroughly, and therefore material accumulation can be effectively avoided, and the blockage situation is eradicated.

Owner:陈爱广

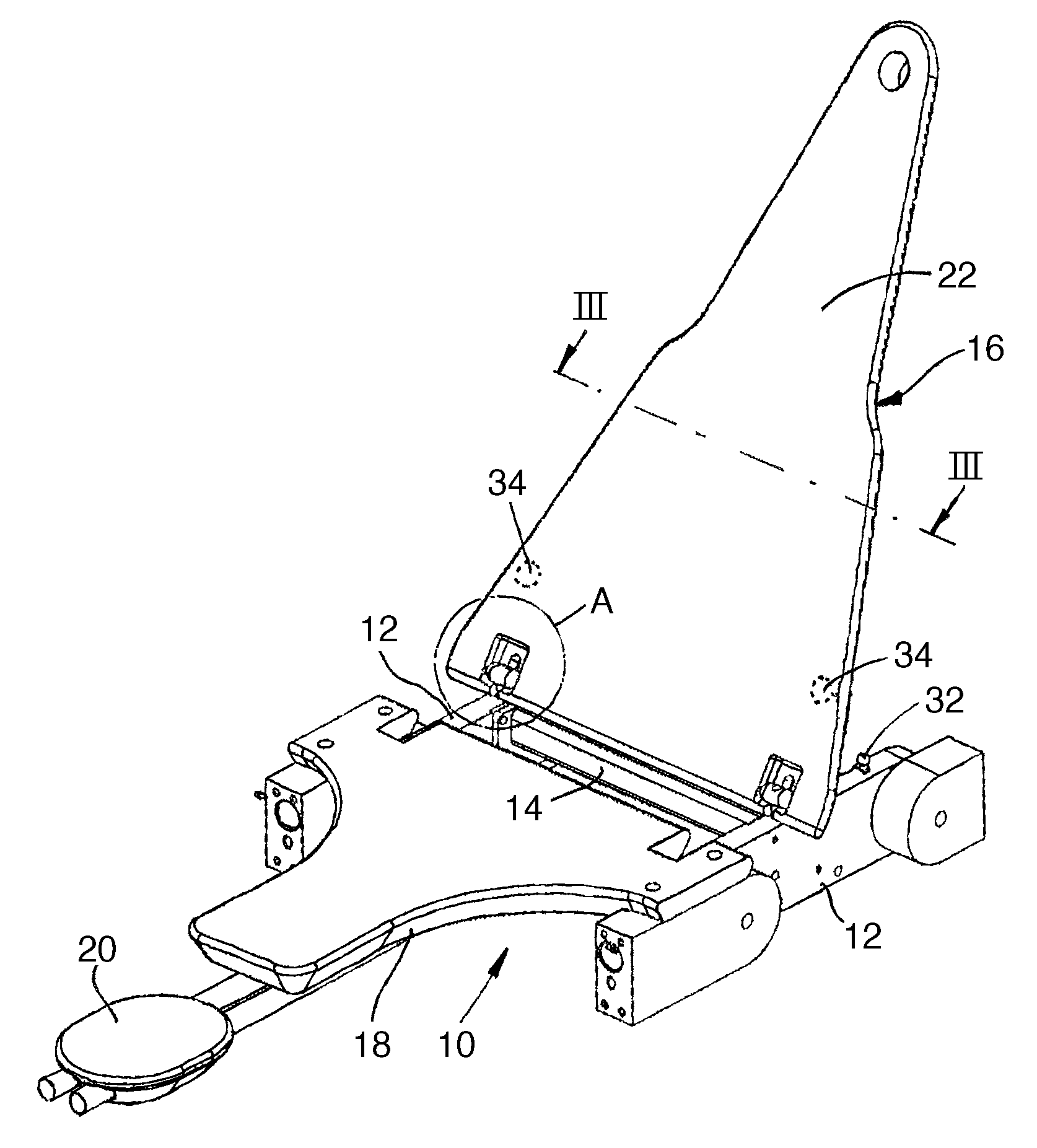

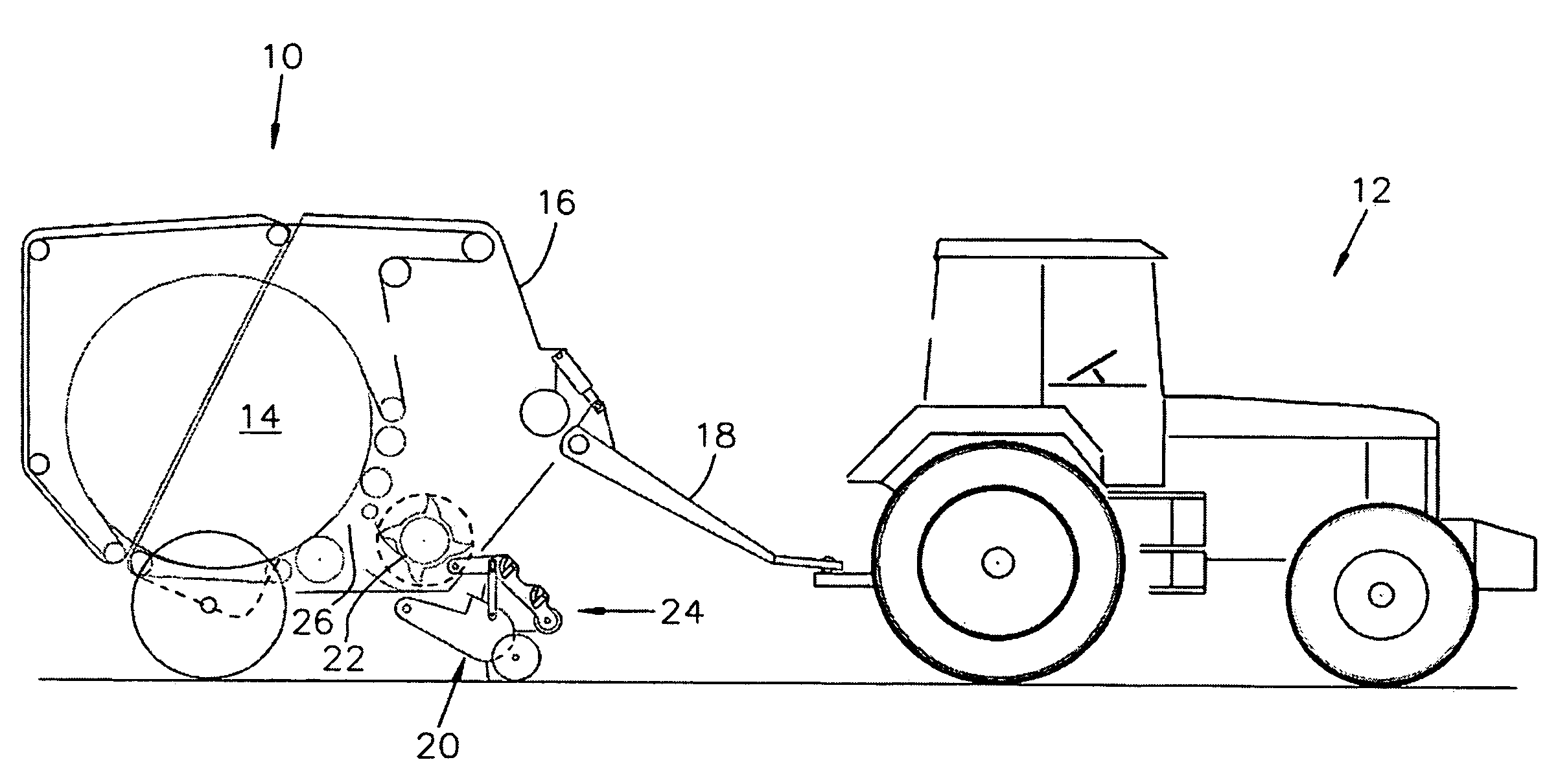

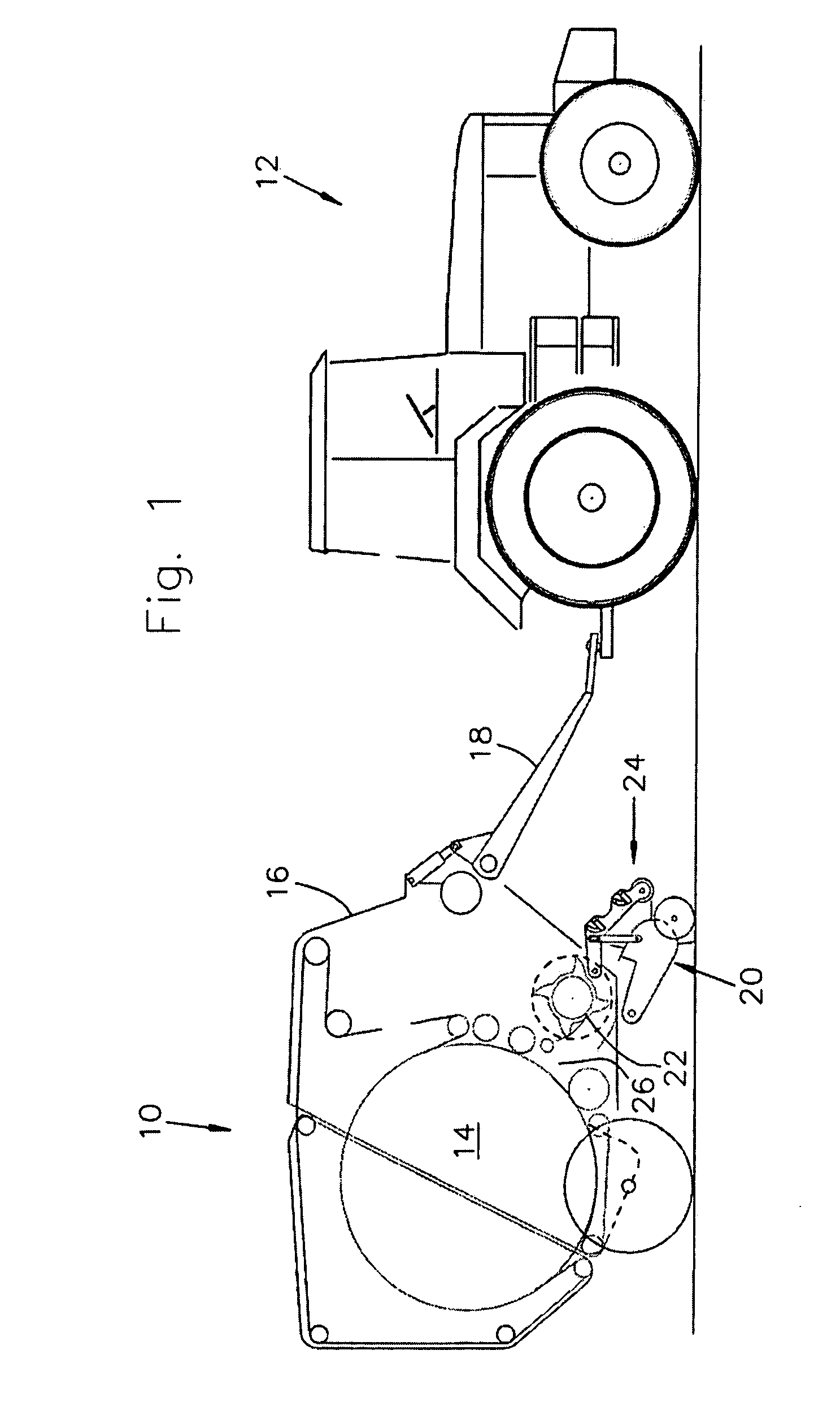

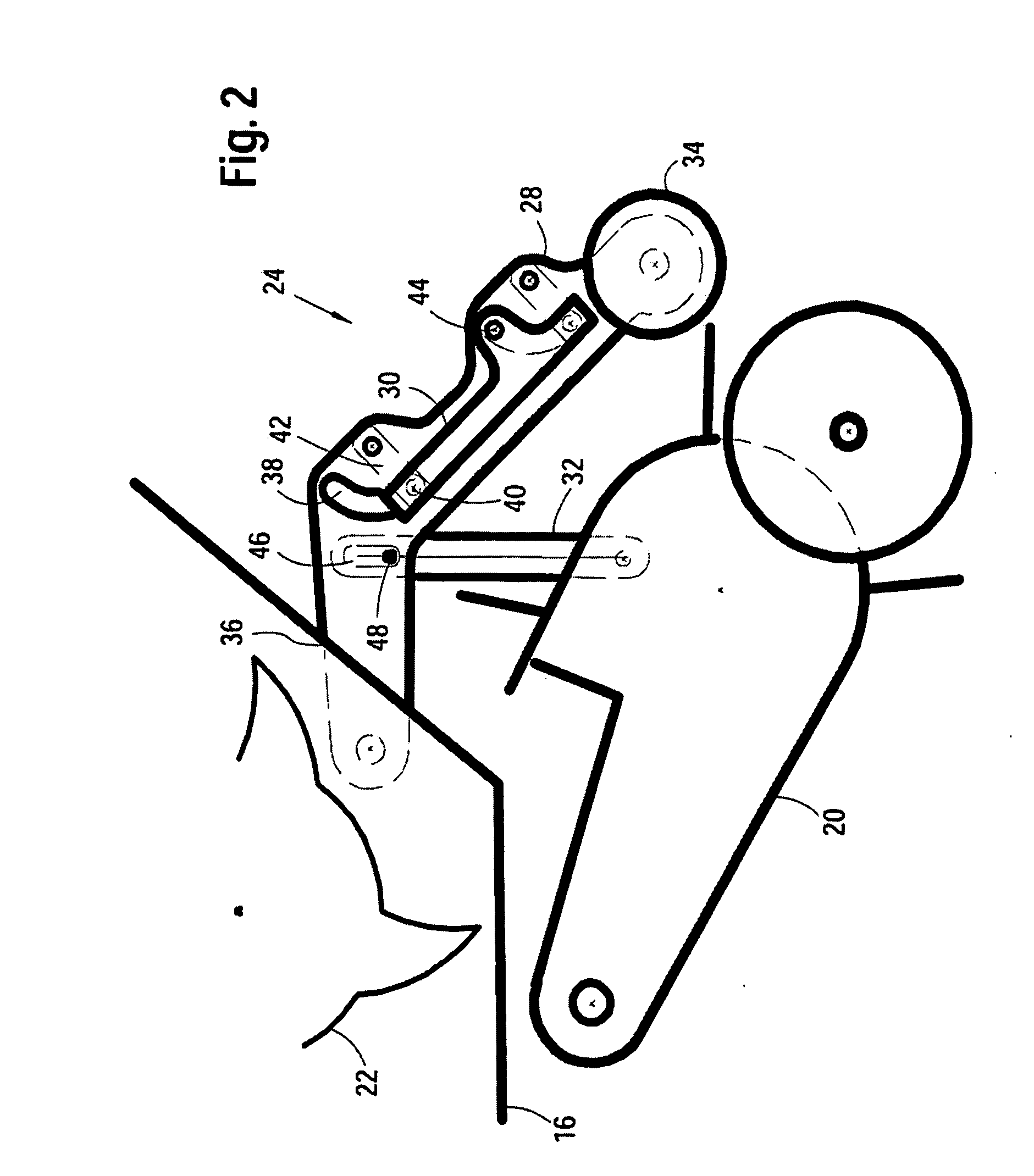

Agricultural Press

ActiveUS20080141642A1The implementation process is simpleEasy to transportLoadersMowersEngineeringRange of movement

An agricultural press has material receiver for picking up a swath of crop material from the ground and delivering it to the press chamber. A material hold-down device extends over the material receiver and is mounted for vertical movement relative to the material receiver. During normal operation the hold-down device moves over a first range of movement in response to changing swath thicknesses. If a material jam should nevertheless arise, the material hold-down device can be moved in total or in part, either mechanically or manually, over an second range of movement in addition to the first range of movement in order to be able to liberate the wedged material.

Owner:DEERE & CO

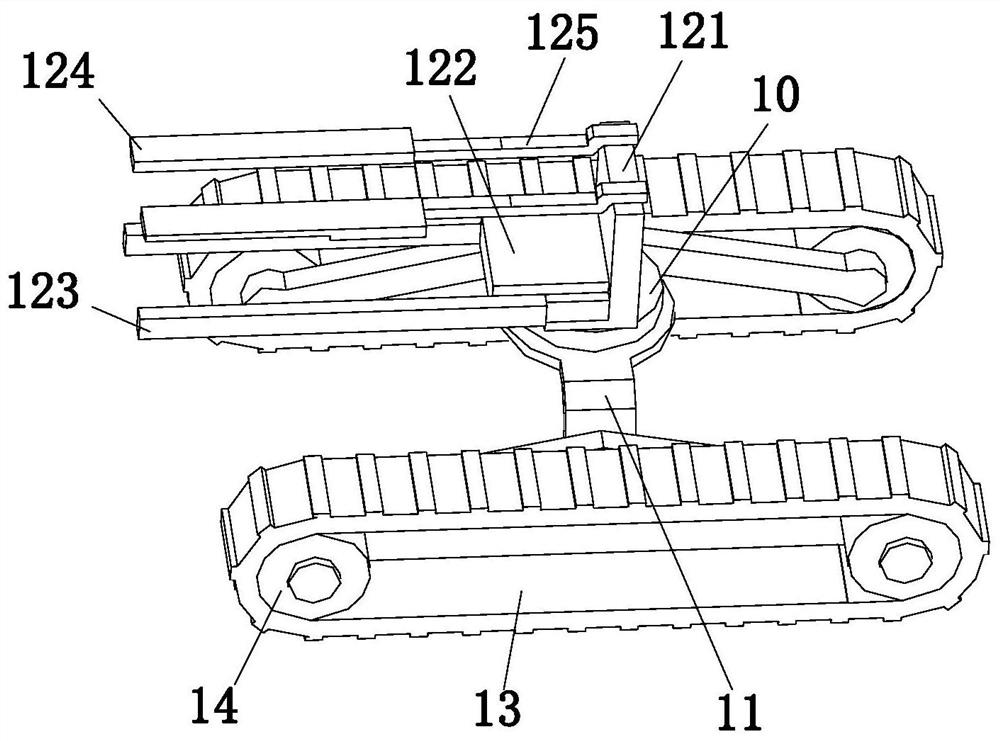

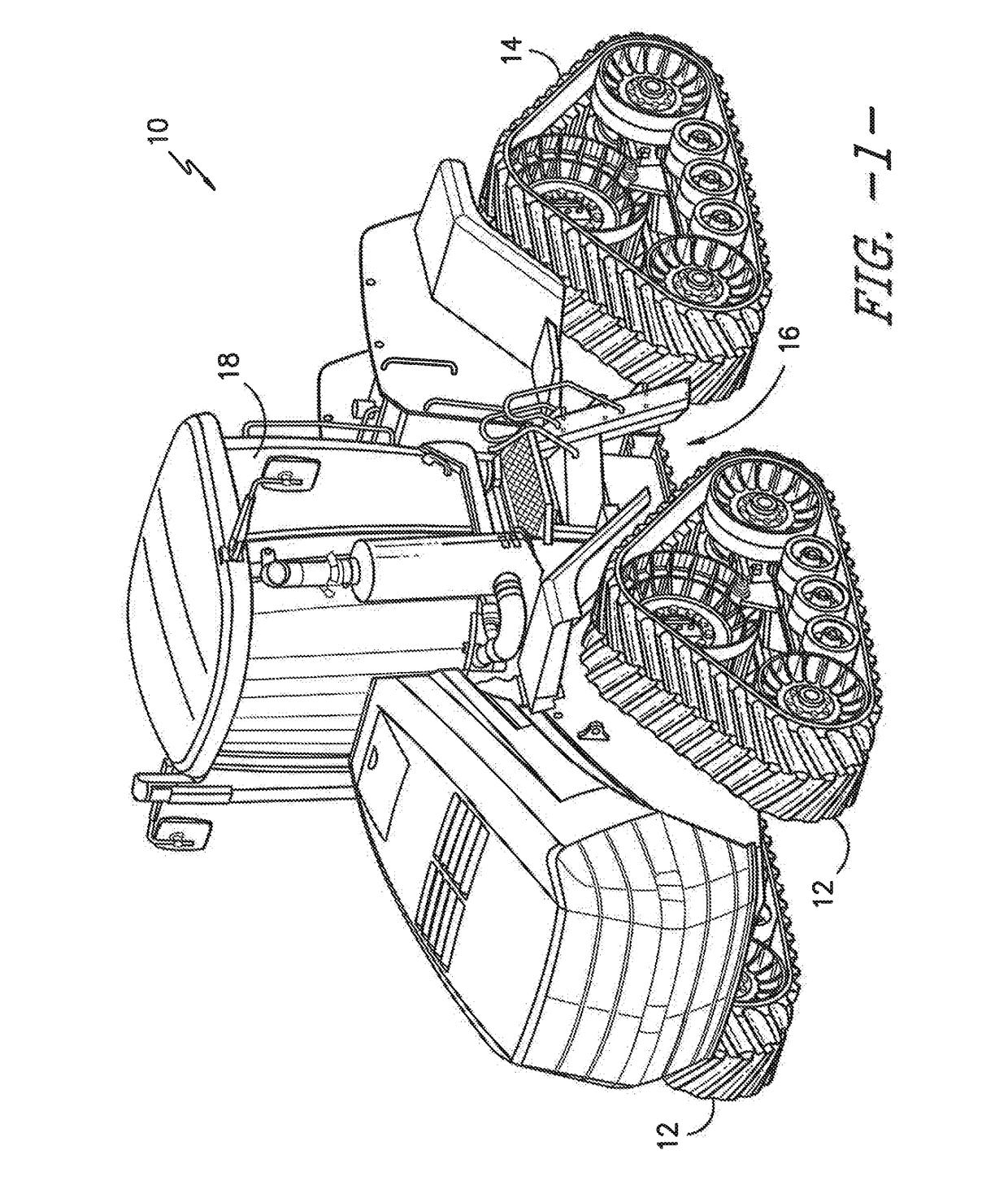

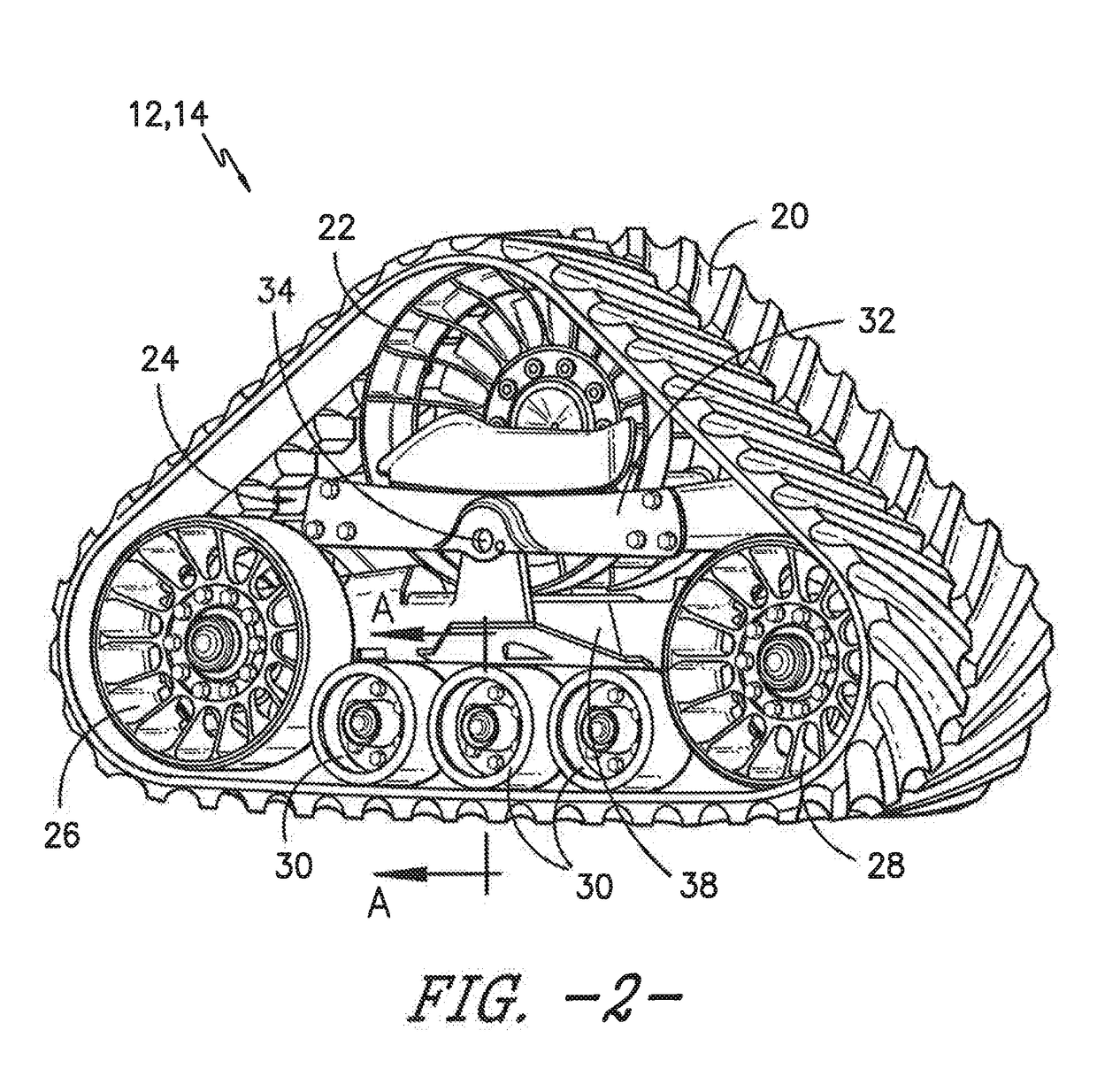

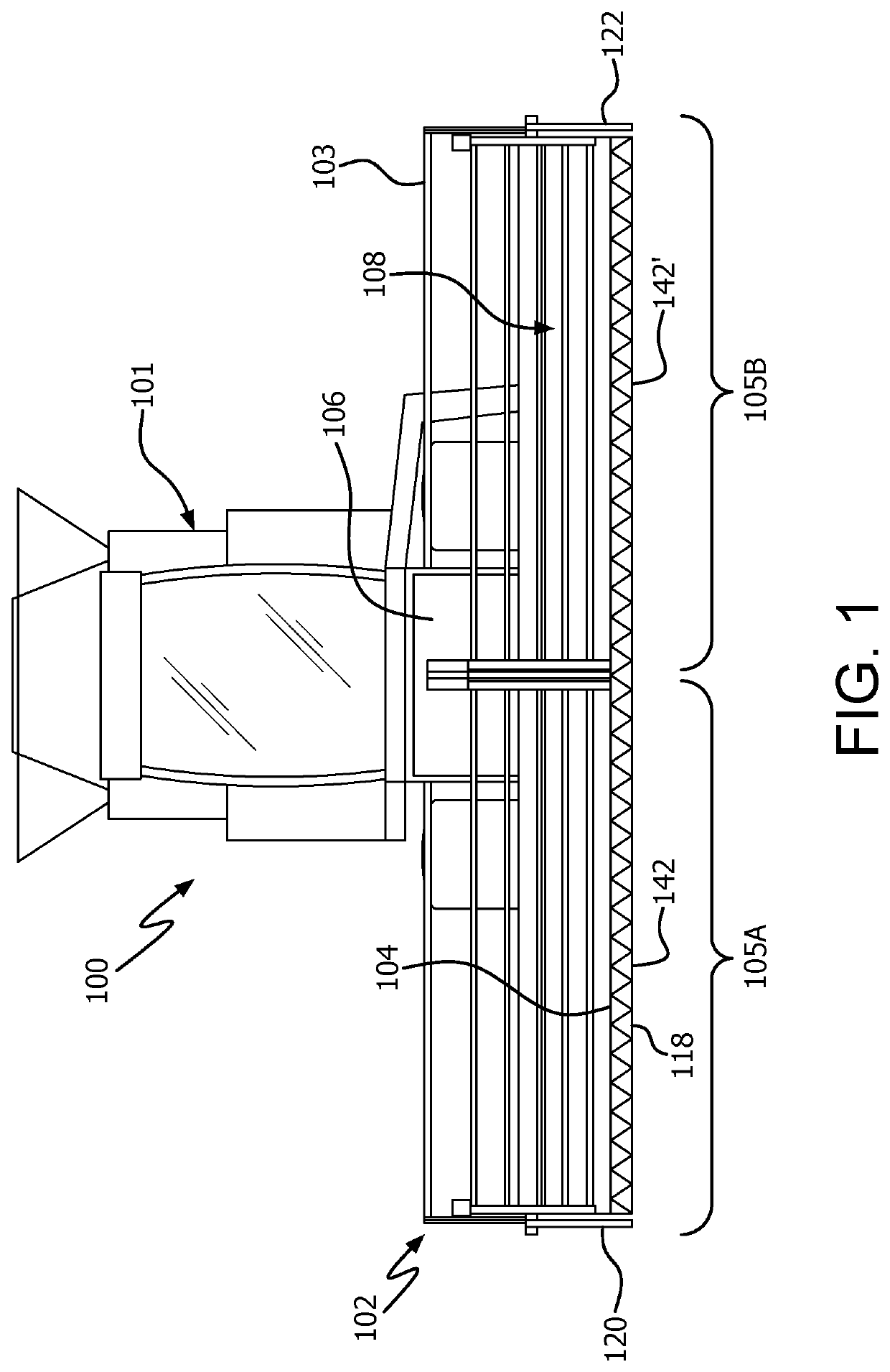

Wheel designs for use within a track assembly of a work vehicle

Owner:BLUE LEAF I P INC

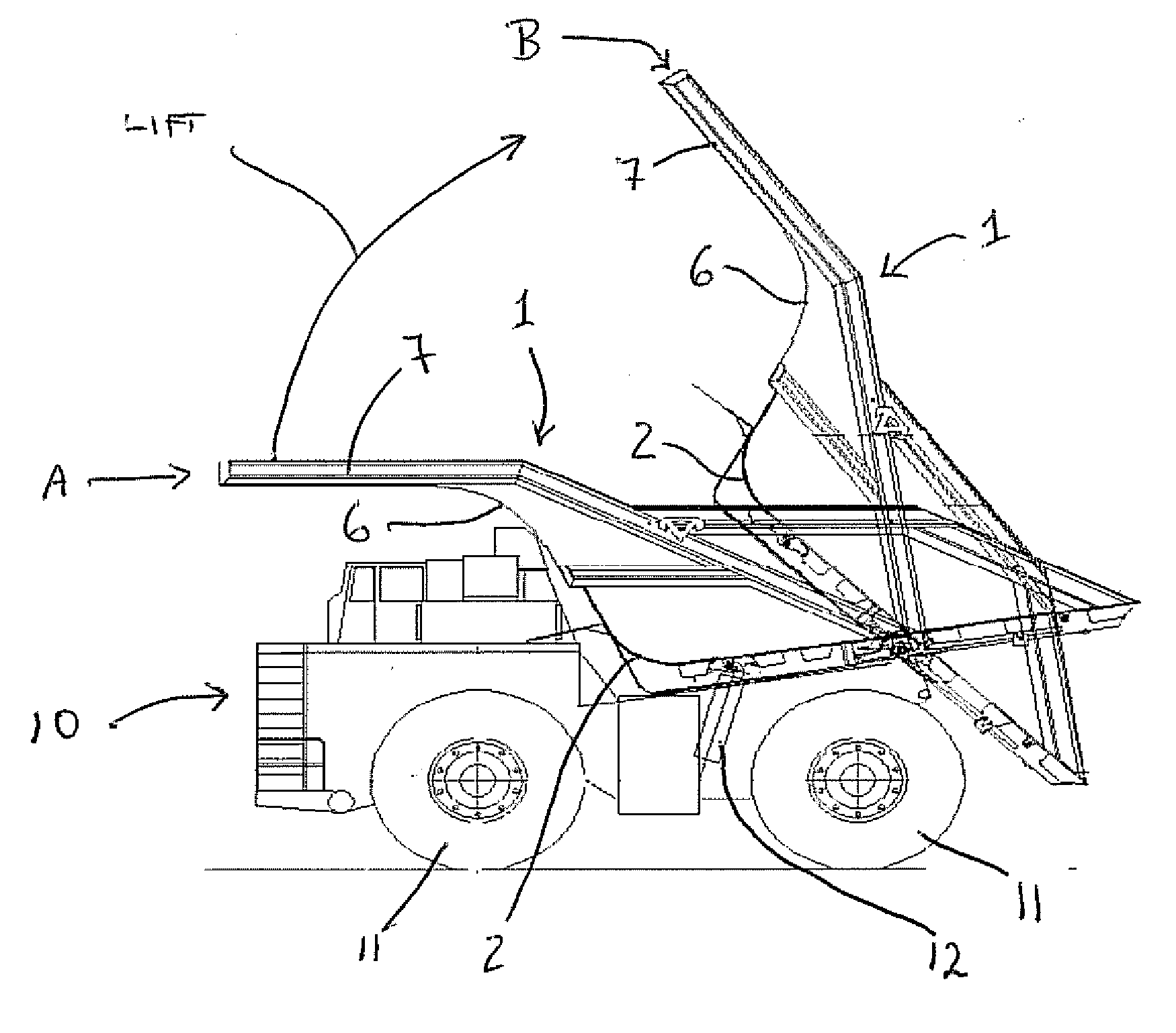

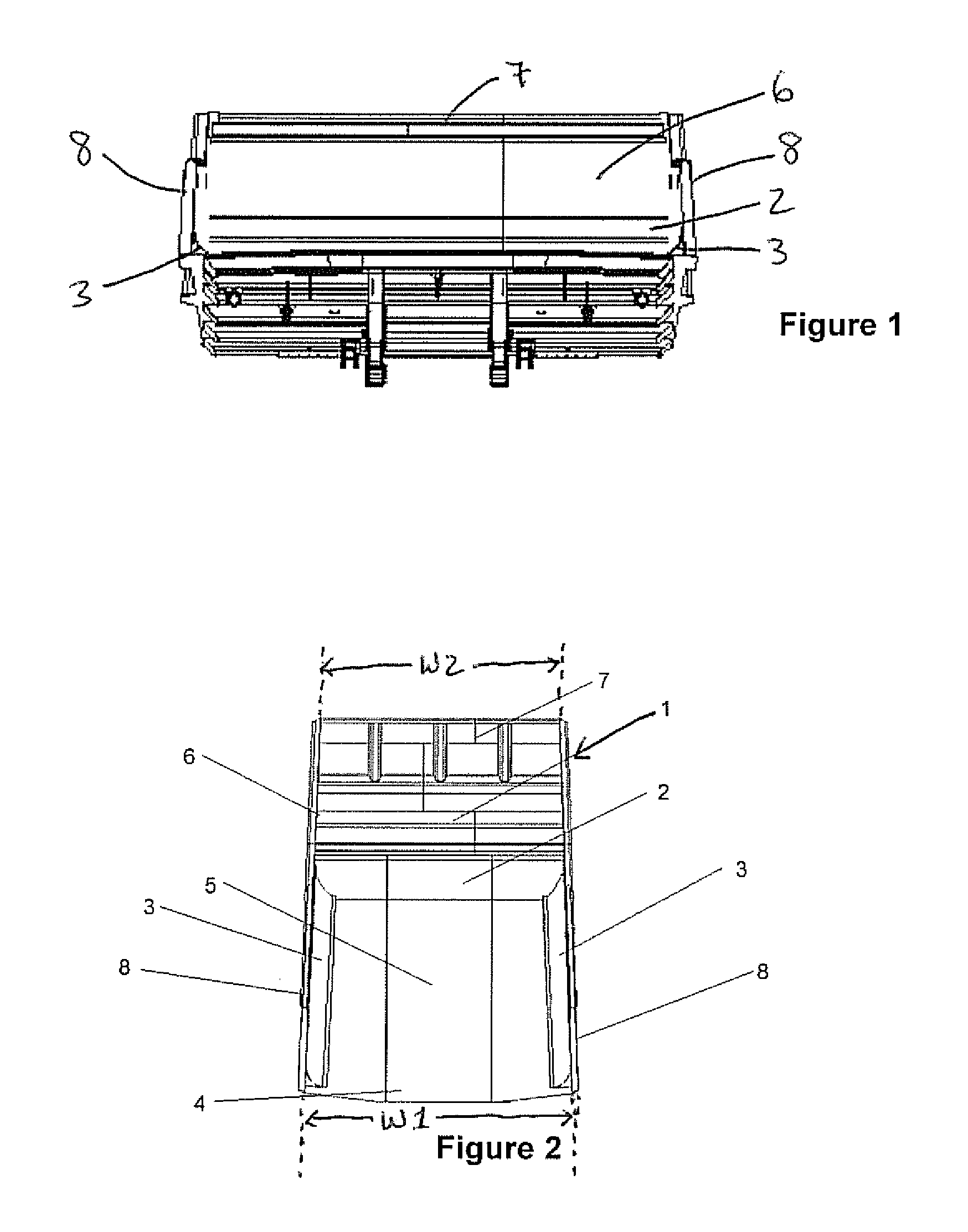

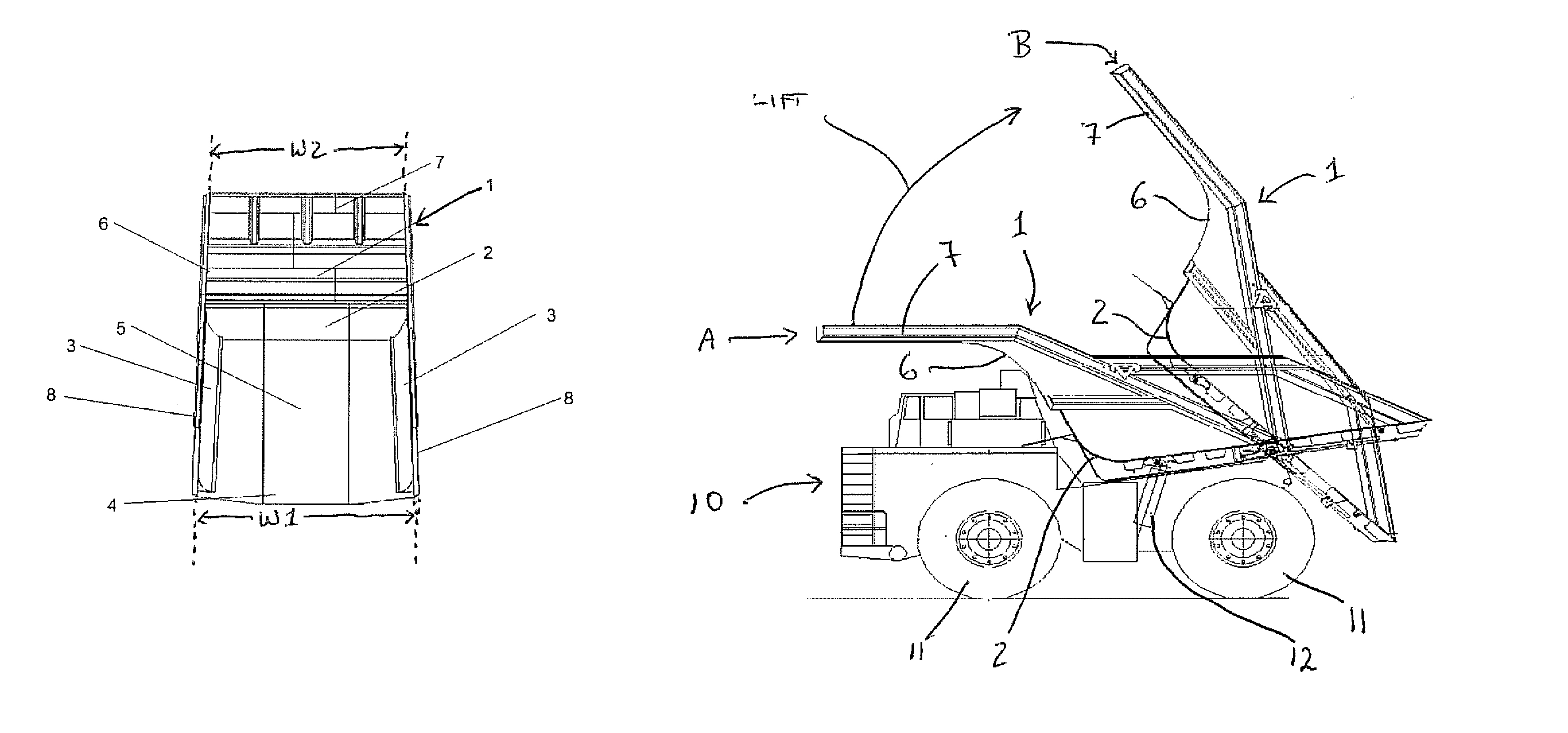

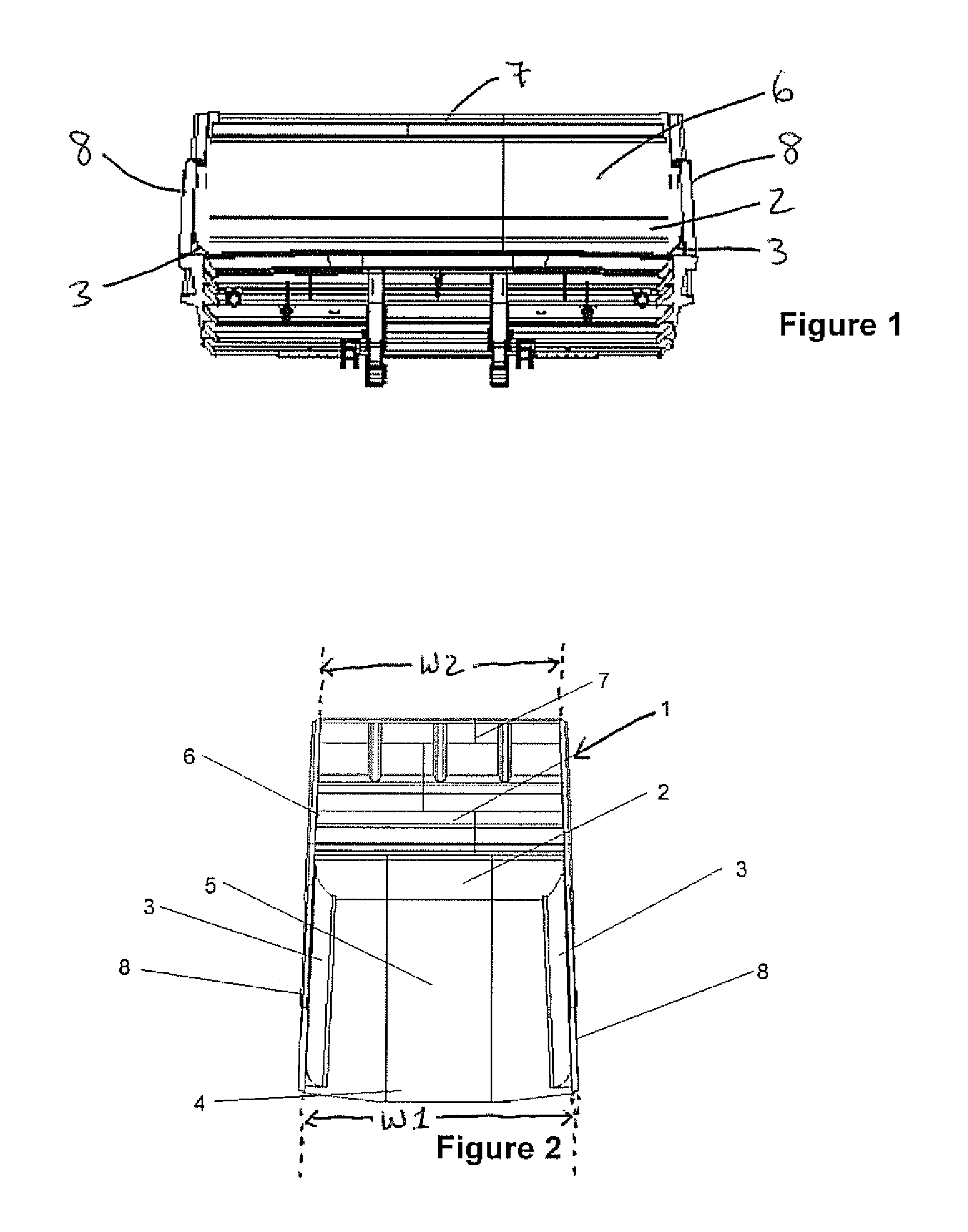

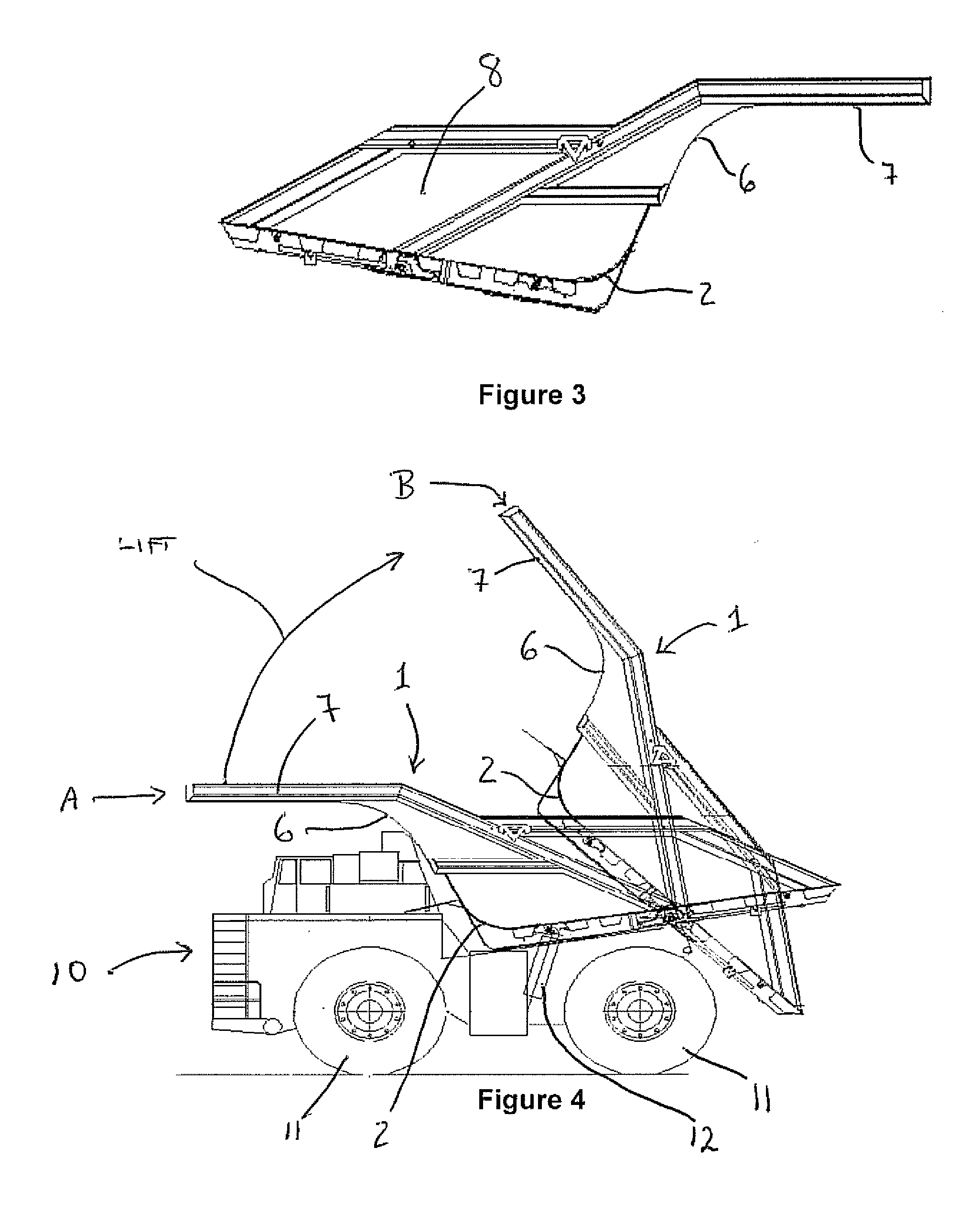

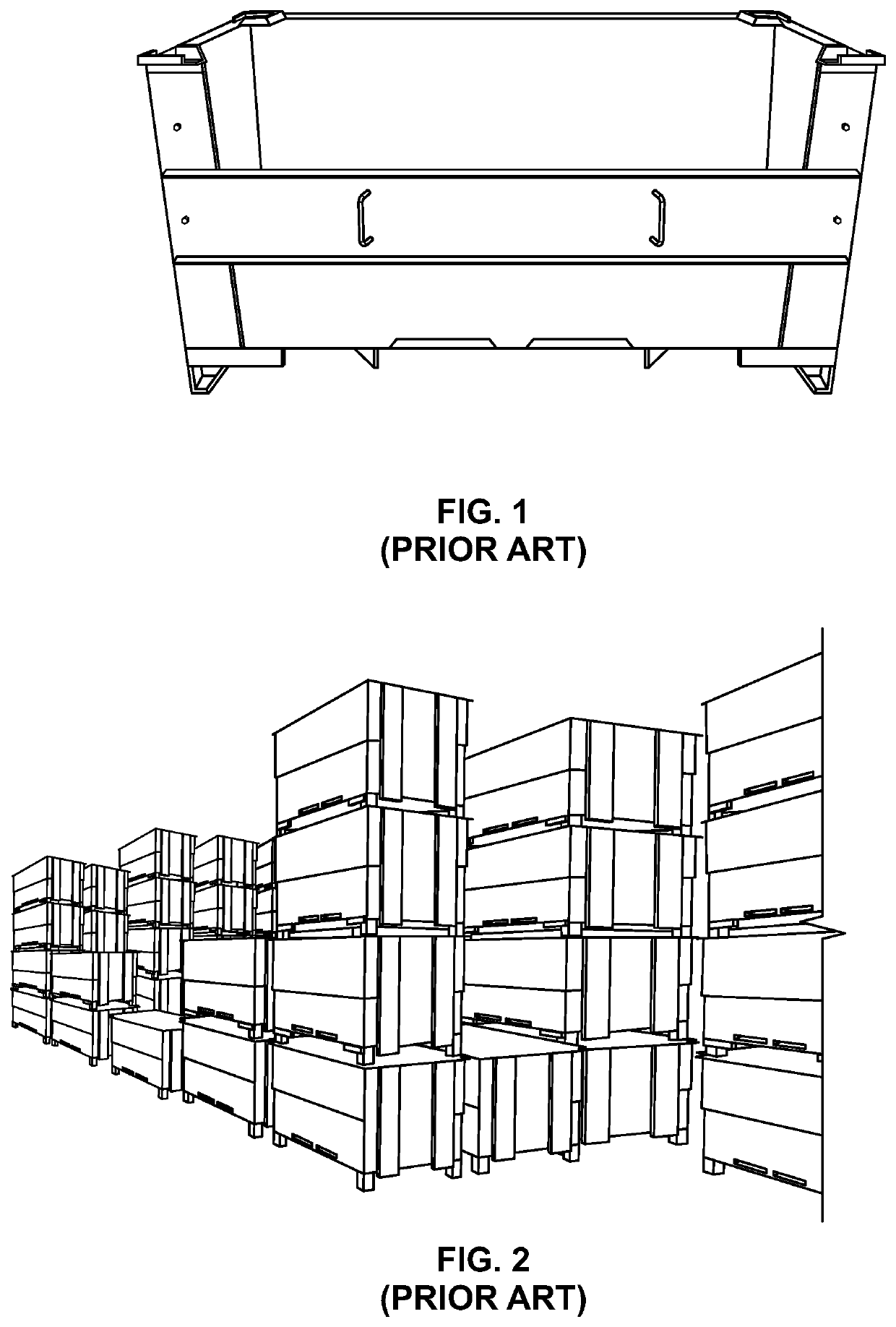

Hopper for transportation of mineral or aggregates

ActiveUS20130094904A1Reduce weightReduce appearance problemsLarge containersItem transportation vehiclesEngineeringMechanical engineering

A hopper for transportation of mineral or aggregates which prevents the material from falling off due to movements or slope, and which improves load performance and facilitates the download. In the joining areas between the front and the floor and between the sides and the floor there are folded or cylindered pieces giving curvature to such joining points, thus adding anti-adherent features to this hopper. The front is folded with a wide radius, also achieving an anti-adherent feature. There are also folds in the front and the shield to avoid beams in those areas of the hopper, thus decreasing the total weight of such hopper and reducing the appearance of cracks and lessening the amount of welding. Additionally, the area of release is wider than the front and shield portions to allow for a better sliding of the material during unloading.

Owner:MINETEC

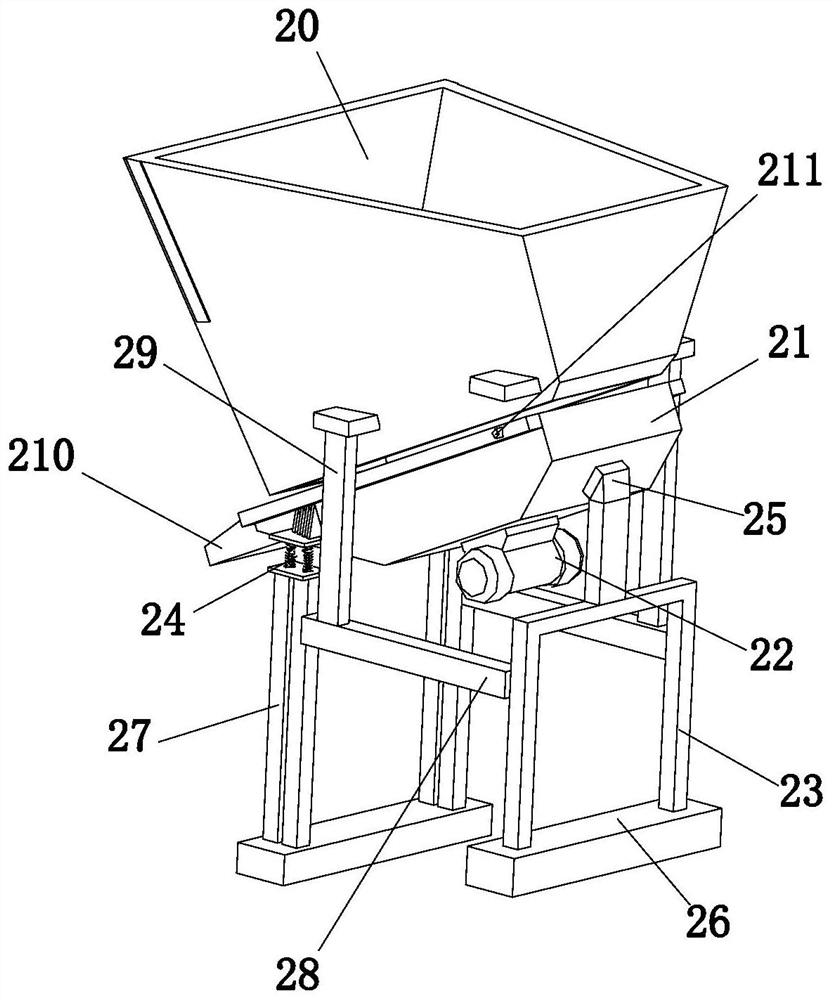

Granulator for producing pig feed

InactiveCN107373730AReduce falling speedAvoid material accumulationFeeding-stuffMotor shaftEngineering

The invention discloses a granulator for producing pig feed. The granulator comprises a stirring tank. An opening is formed in the upper end of the stirring tank, an upper cover is fastened at the opening in the upper end of the stirring tank, a motor base is welded on the upper cover, and a motor is fixed onto the motor base by the aid of screws; a center hole is formed in the center of the upper cover, and a motor shaft of the motor is vertically downwardly arranged. The granulator has the advantages that granules which fall from a granulating mold head can fall into a material groove in an oblique pipe, granular materials can be gradually heated by hot air via air holes in the oblique pipe, the integral oblique pipe slowly rotates under the effect of the motor at the moment, the materials can fall onto a material plate from the inside of the material groove after the oblique pipe rotates by a circle, and then can be dried again, accordingly, the purpose of reducing the falling speeds of the granular materials by the aid of the integral oblique pipe can be achieved, the problem of material accumulation due to existing excessively fast material plates can be solved, and outstanding integral drying and granulating effects can be realized.

Owner:黄贤飞

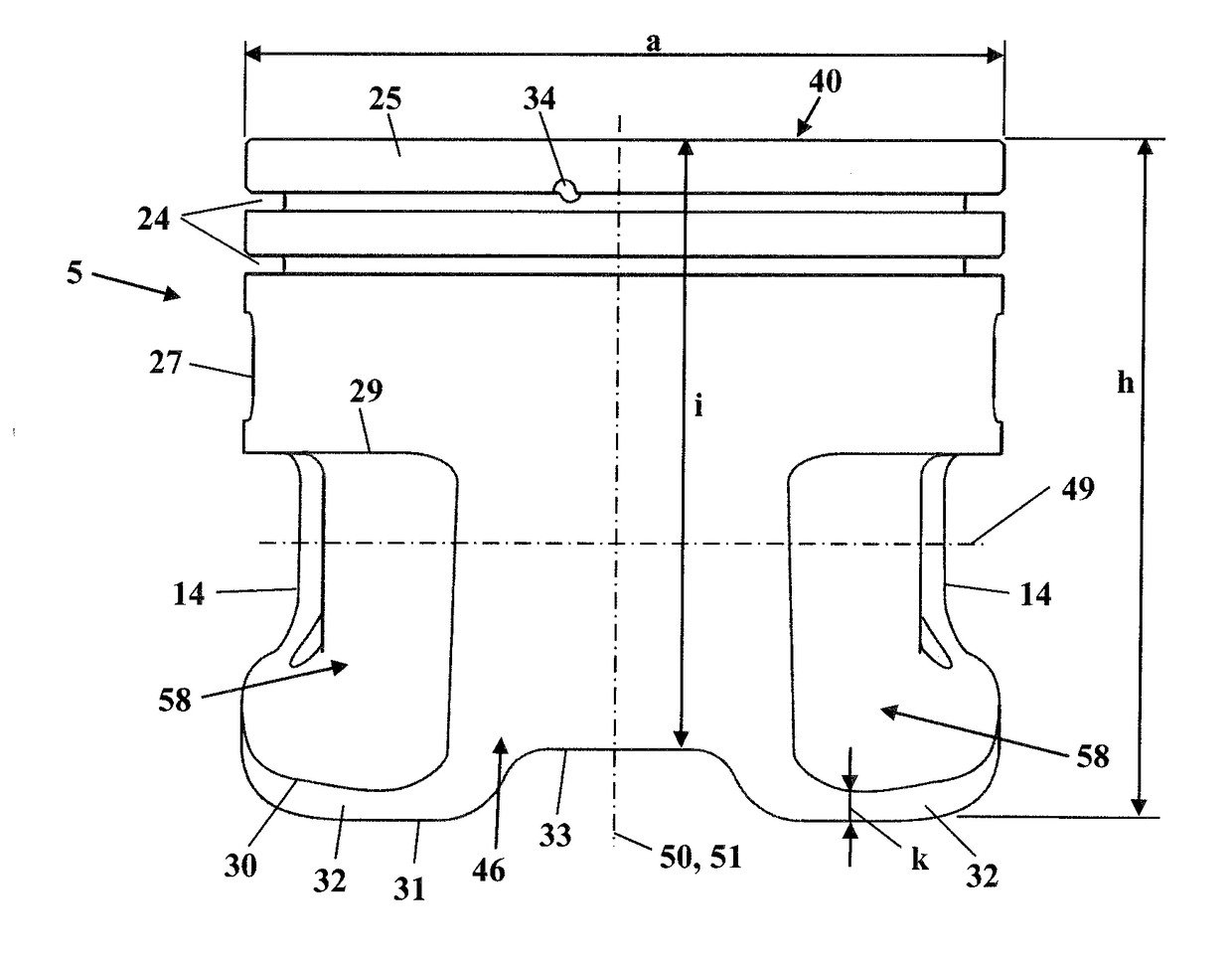

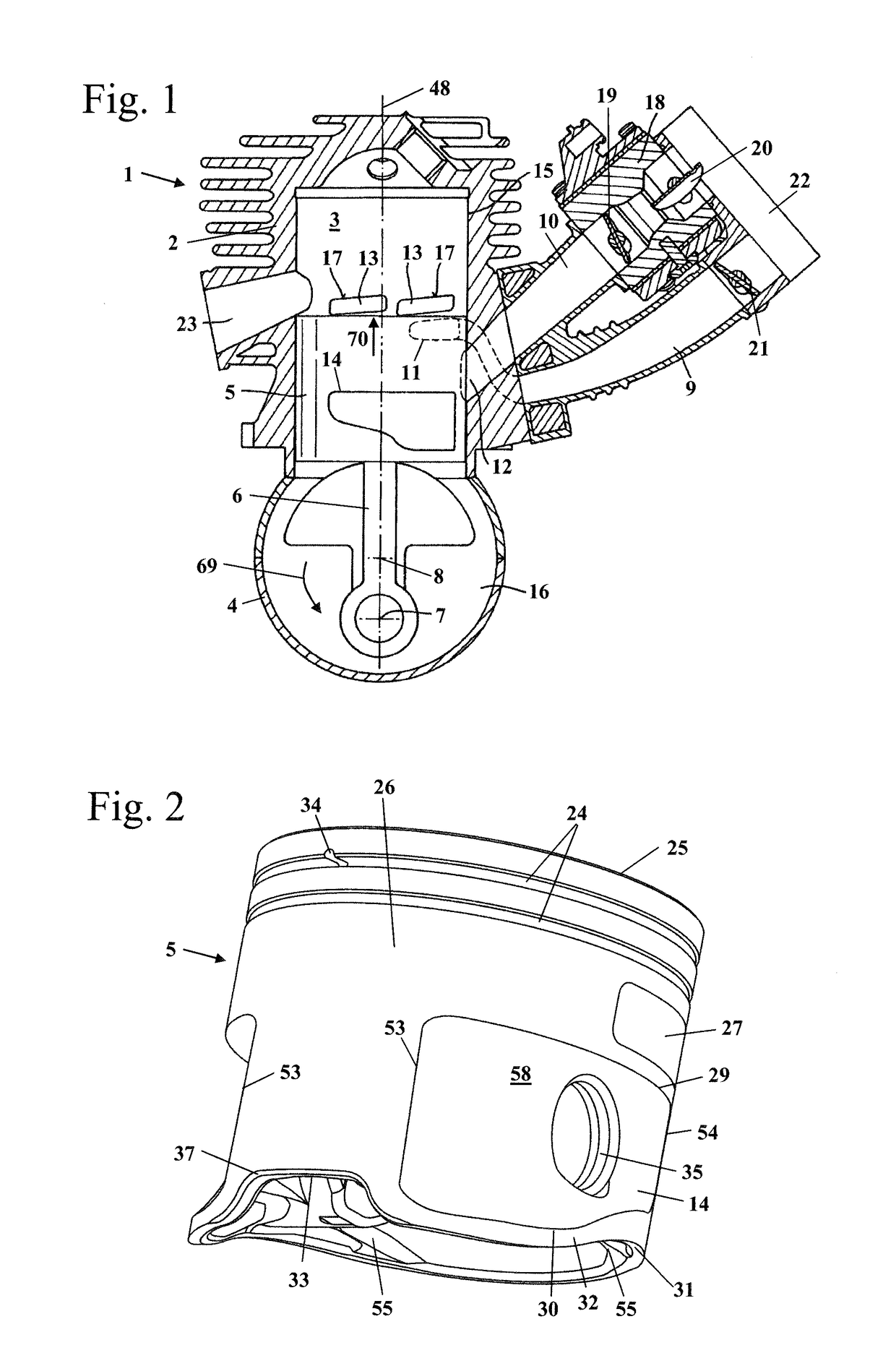

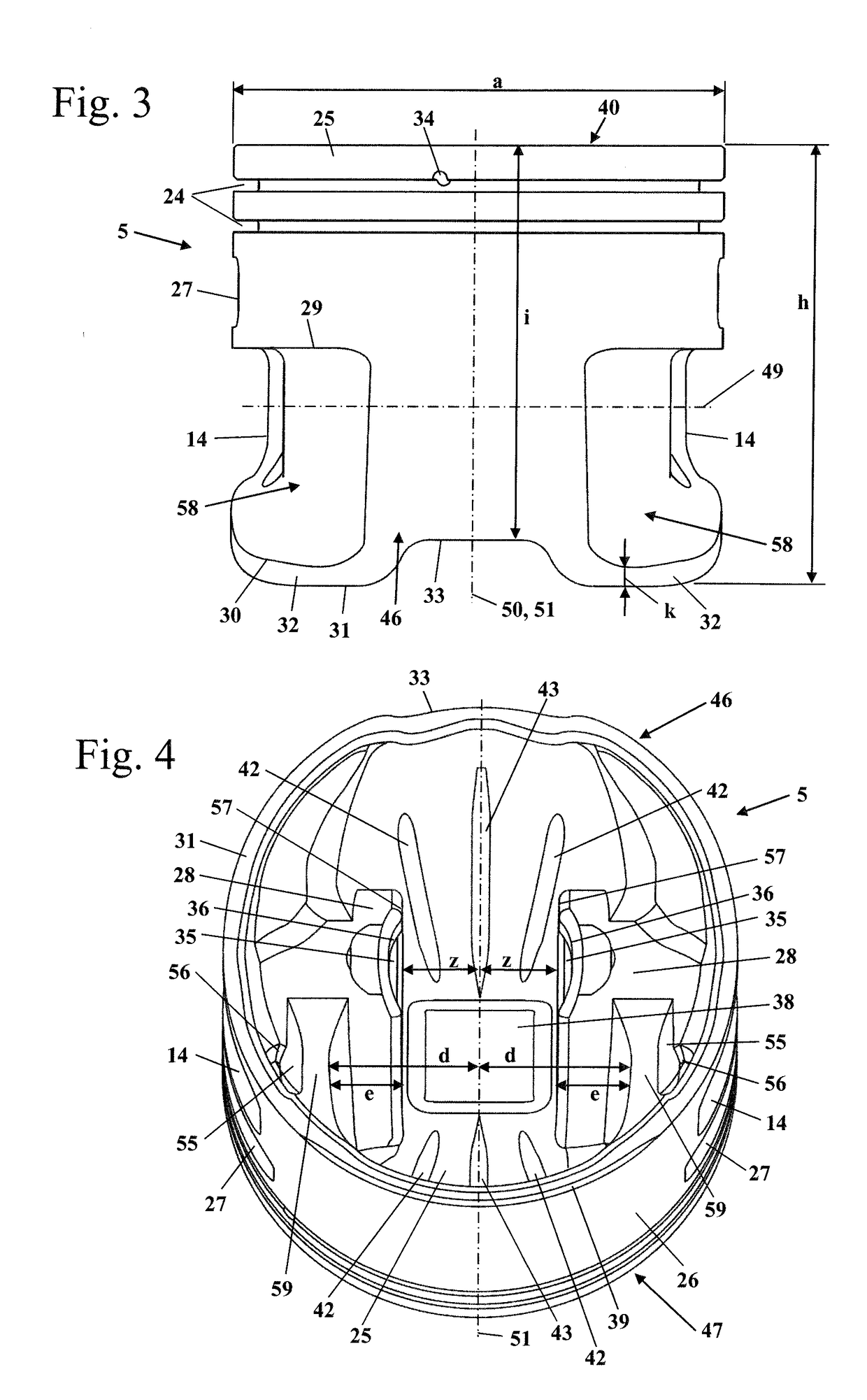

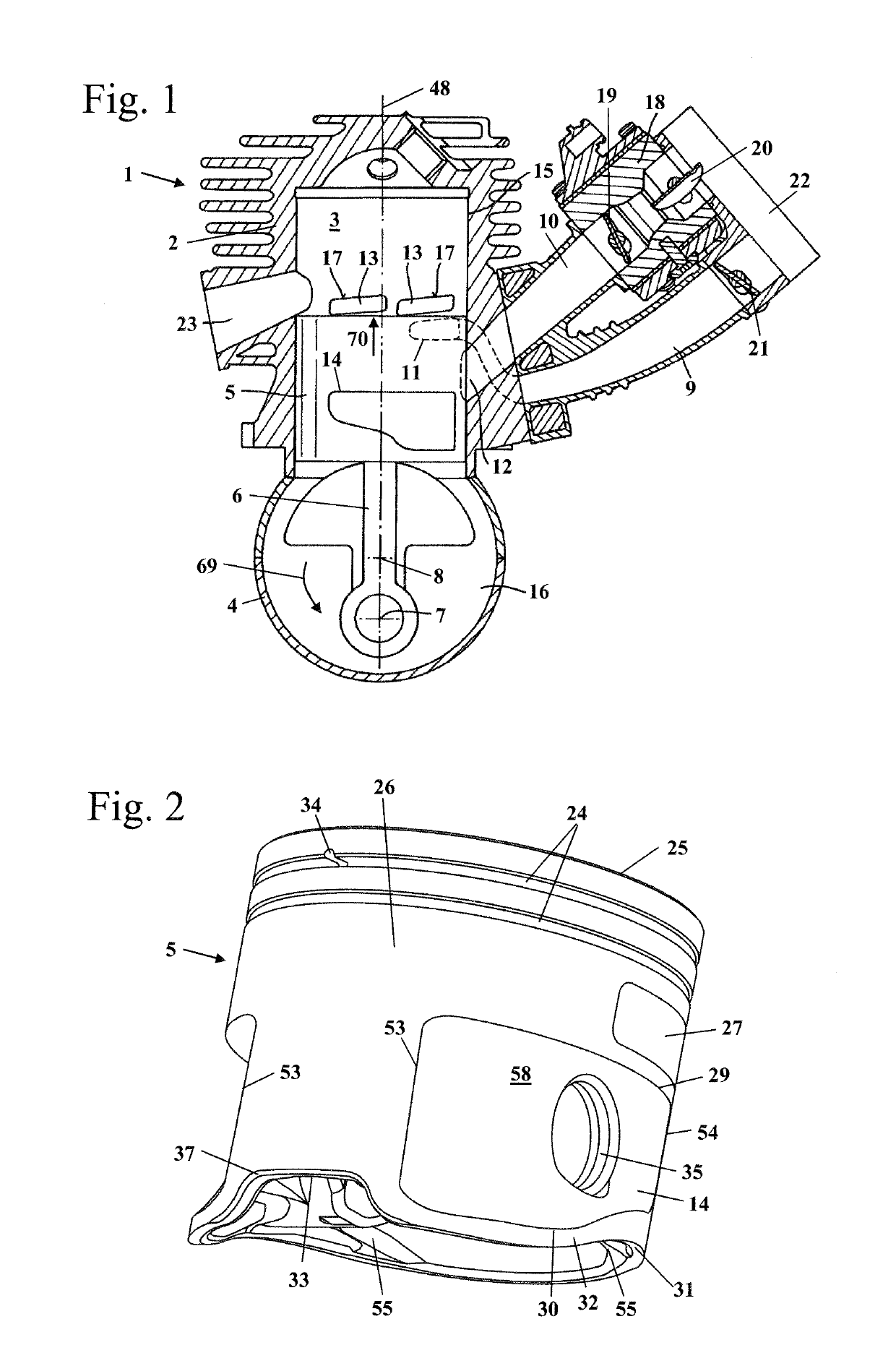

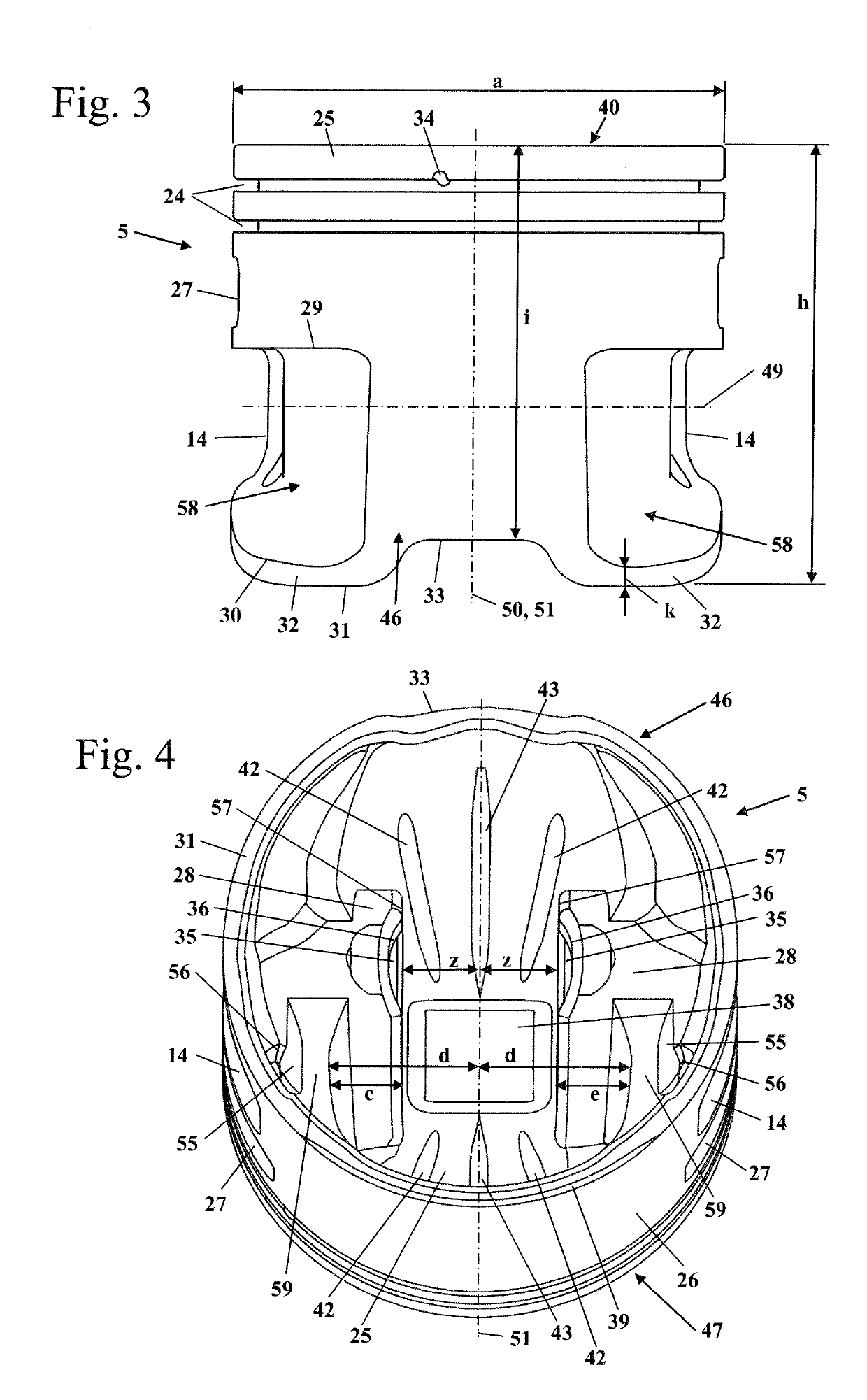

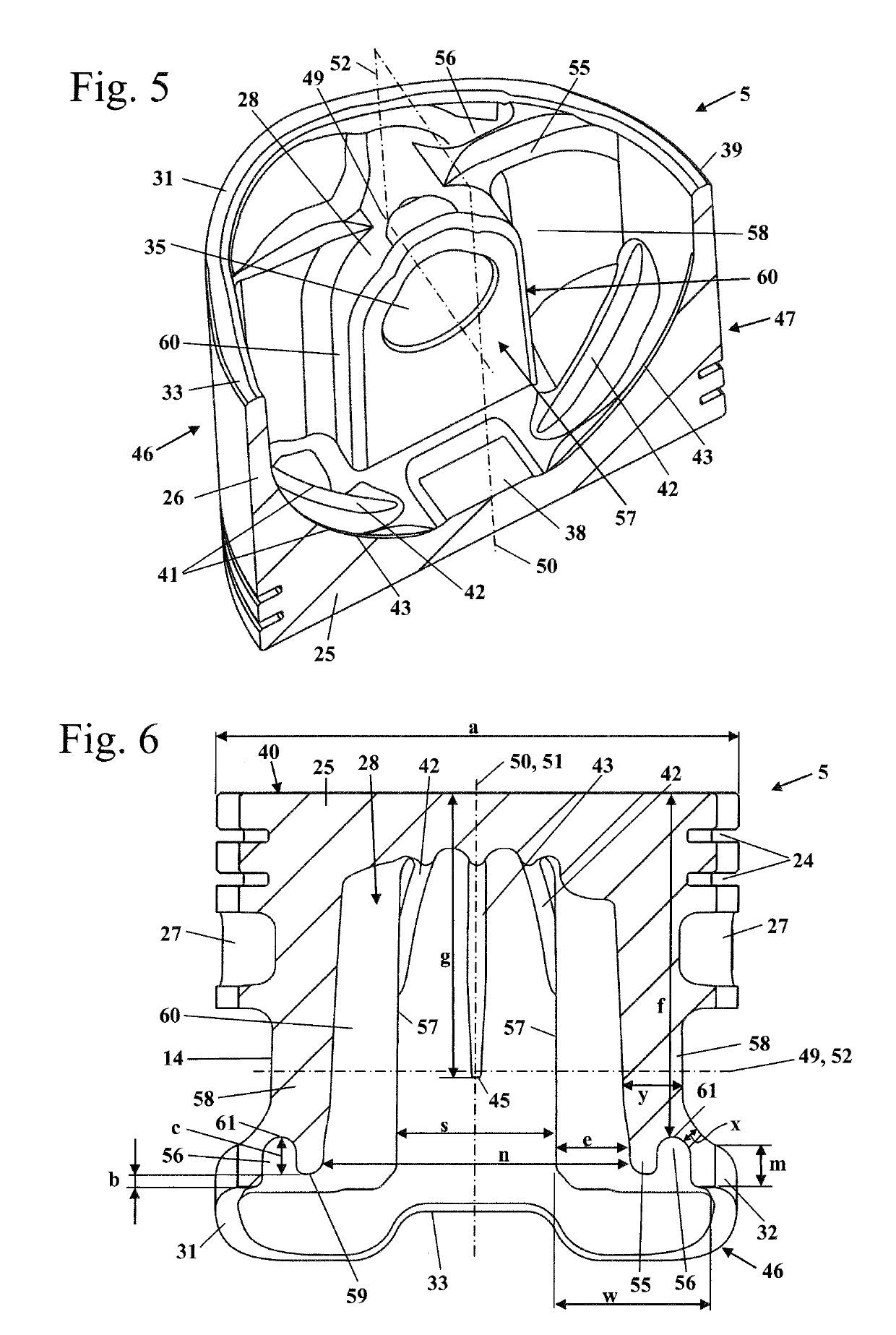

Piston for a two-stroke engine operating with advanced scavenging and a two-stroke engine

ActiveUS20180051649A1High stabilityImprove stabilityMachines/enginesPistonsTransverse axisFour-stroke engine

A piston for a two stroke engine which operates with advanced scavenging has a piston base and a piston skirt. The center axis of the piston skirt forms a longitudinal center axis of the piston. The piston has two piston pin eyes, in which piston pin receptacles are configured. The center axis of the piston pin receptacles forms a transverse axis of the piston. The piston has at least one piston pocket. At least one piston pin eye is connected via at least one connecting rib to the piston skirt. Here, the connecting rib runs on that side of the piston pocket which faces away from the piston base.

Owner:ANDREAS STIHL AG & CO KG

System and method for handling bulk materials

ActiveUS20070154271A1Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsEngineeringGuide tube

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

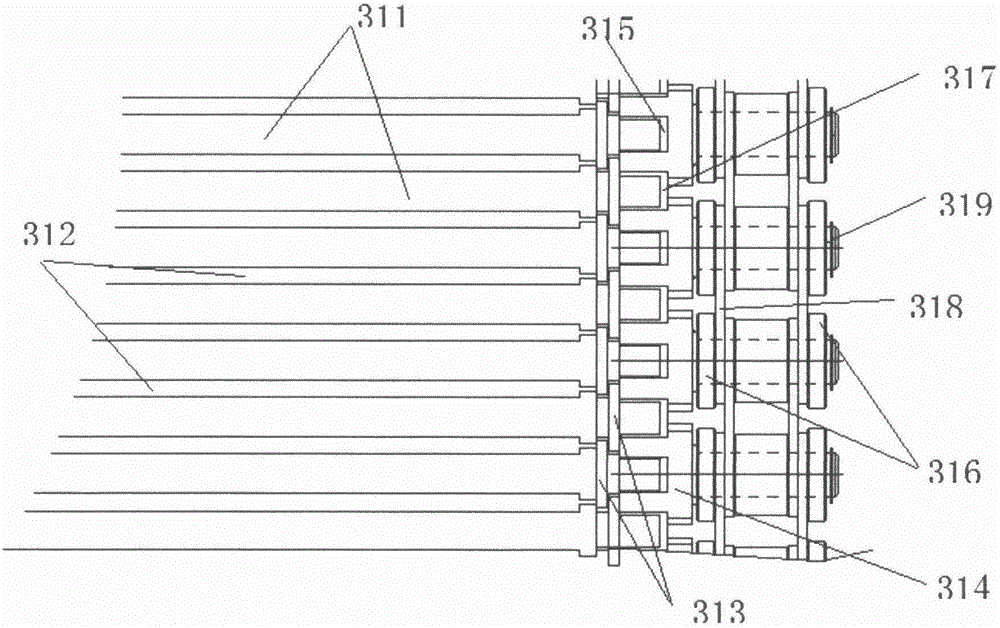

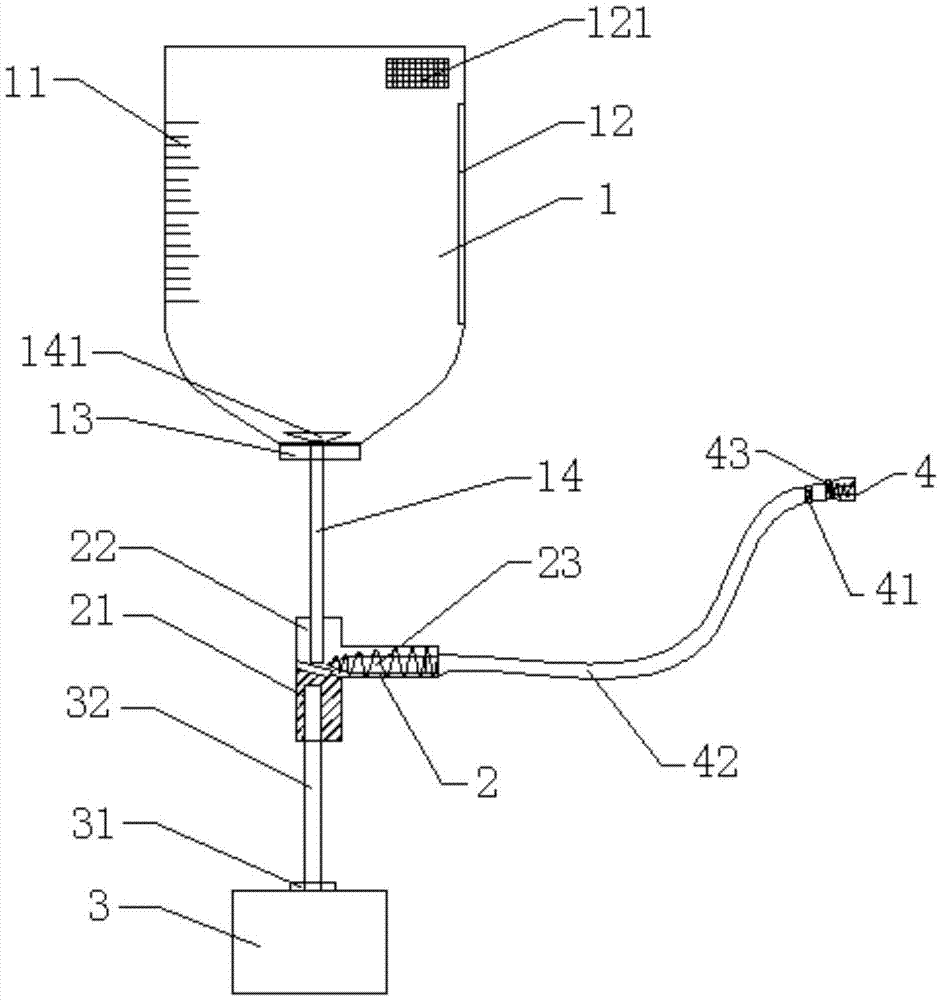

Air pressure type fertilizer application and agent application apparatus

InactiveCN106912242AAvoid material accumulationSimple structurePressurised distribution of liquid fertiliserInsect catchers and killersFertilizerSpray nozzle

The present invention discloses an air pressure type fertilizer application and agent application apparatus, which comprises a material box, a mixing material conveying device, a gas cylinder and a spraying nozzle, wherein the material box is provided with scales, the bottom portion of the material box is provided with a material outlet, the material outlet is connected to a material outlet pipe, the side edge of the gas cylinder is provided with a gas outlet, the gas outlet is connected to a gas conveying pipe, the mixing material conveying device is respectively communicated and connected to the other end of the material outlet pipe and the other end of the gas conveying pipe, a negative pressure chamber and a material inlet channel are formed in the mixing material conveying device through the material outlet pipe and the gas conveying pipe, the outlet position of the material inlet channel is connected to a screw material conveying rod, the output end of the mixing material conveying device is connected to a material spraying soft pipe, the spraying nozzle is spirally connected to the other end of the material spraying soft pipe, and the connection position of the spraying nozzle and the material spraying soft pipe is provided with a pressurization device and a screw adjustment button. The air pressure type fertilizer application and agent application apparatus of the present invention has characteristics of simple structure, low cost, and high use reliability.

Owner:CHONGQING TONGNAN YUNFENG AGRI DEV CO LTD

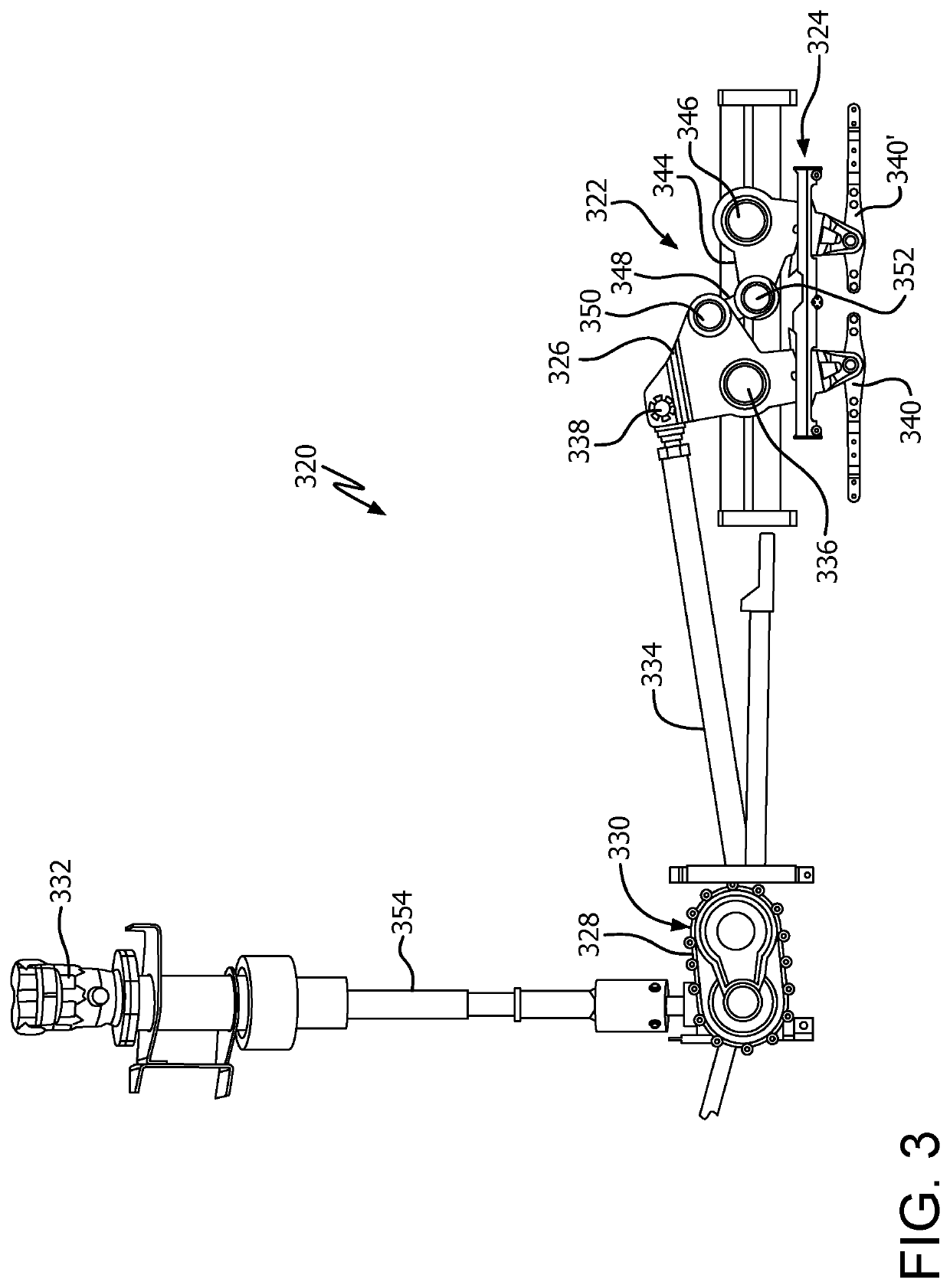

Center link knife drive for a header of an agricultural harvester

A knife head drive assembly for a header of an agricultural harvester including a knife head assembly for attachment to a forward end of the header. A first pivot arm and a second pivot arm are carried by the knife head assembly and are pivotably connected by a linkage. A rotating crank is operatively connected to and extending substantially transverse to the knife head assembly for engagement with a drive. A reciprocating shaft is connected to the rotating crank and either of the pivot arms or the linkage. Operation of the knife head drive assembly results in substantially linear, opposed oscillating motion of cutter bars carried by the knife head assembly.

Owner:BLUE LEAF I P INC

Piston for a two-stroke engine operating with advanced scavenging and a two-stroke engine

A piston for a two stroke engine which operates with advanced scavenging has a piston base and a piston skirt. The center axis of the piston skirt forms a longitudinal center axis of the piston. The piston has two piston pin eyes, in which piston pin receptacles are configured. The center axis of the piston pin receptacles forms a transverse axis of the piston. The piston has at least one piston pocket. At least one piston pin eye is connected via at least one connecting rib to the piston skirt. Here, the connecting rib runs on that side of the piston pocket which faces away from the piston base.

Owner:ANDREAS STIHL AG & CO KG

Hopper for transportation of mineral or aggregates

ActiveUS8714658B2Reduce weightReduce appearance problemsLarge containersHopper carsEngineeringMechanical engineering

A hopper for transportation of mineral or aggregates which prevents the material from falling off due to movements or slope, and which improves load performance and facilitates the download. In the joining areas between the front and the floor and between the sides and the floor there are folded or cylindered pieces giving curvature to such joining points, thus adding anti-adherent features to this hopper. The front is folded with a wide radius, also achieving an anti-adherent feature. There are also folds in the front and the shield to avoid beams in those areas of the hopper, thus decreasing the total weight of such hopper and reducing the appearance of cracks and lessening the amount of welding. Additionally, the area of release is wider than the front and shield portions to allow for a better sliding of the material during unloading.

Owner:MINETEC

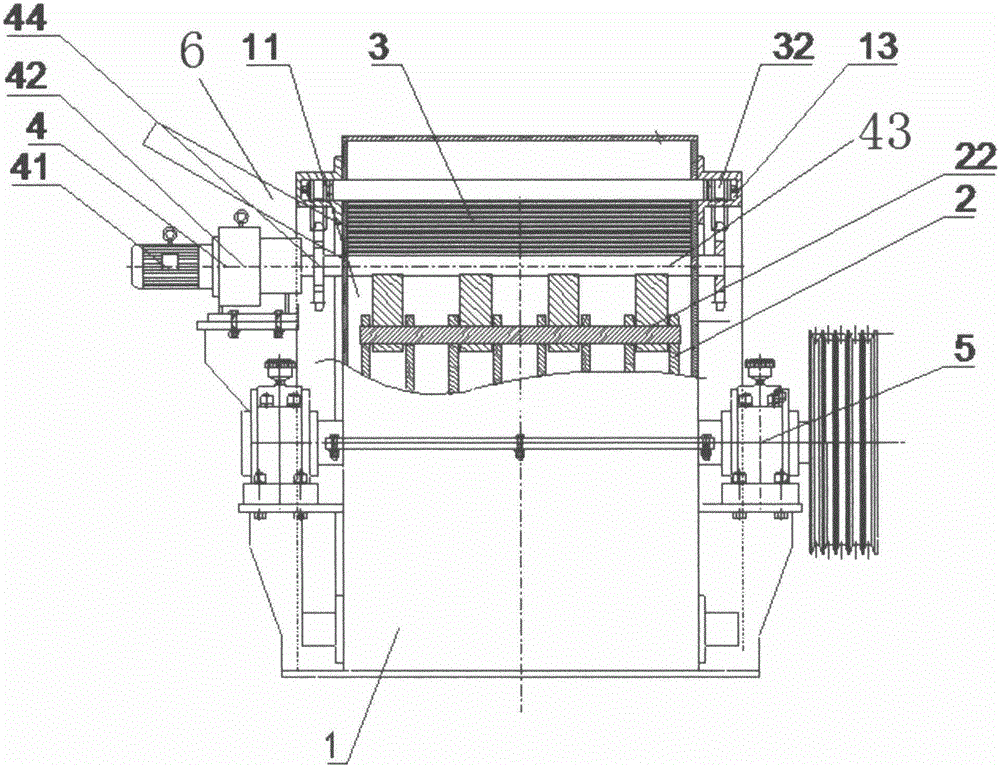

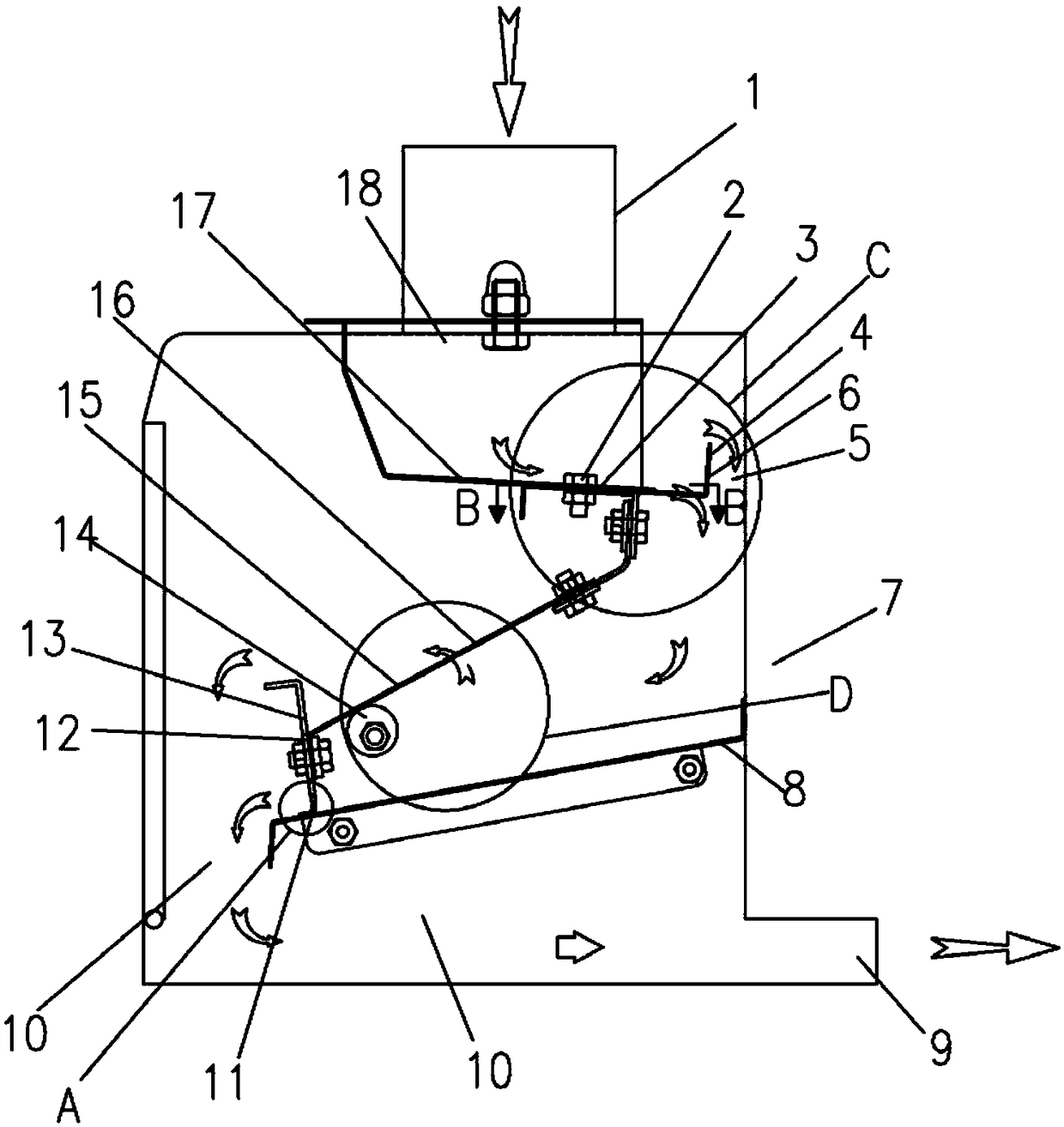

Material feeding and uniformizing device for flour cleaning machine

PendingCN108296175AAvoid material accumulationImprove the leveling effectSievingGas current separationEngineeringMechanical engineering

The invention discloses a material feeding and uniformizing device for a flour cleaning machine in the technical field of grain processing machinery. The material feeding and uniformizing device comprises a material feeding box, and a material feeding inlet is formed in the top of the material feeding box. A material receiving supporting plate is arranged on the lower side of the material feedinginlet and comprises a side wall and a bottom wall. The side wall is arranged on one side of the material feeding inlet, and the bottom wall guides materials to the other side of the material feeding inlet. An adjusting valve plate is arranged at the end of the bottom wall, and a circulating gap for material passing is reserved between the adjusting valve plate and the inner wall of the material feeding box. The adjusting valve plate comprises a flat plate connected with the bottom wall, and a cocked vertical plate. A plurality of valve plate overflowing holes are uniformly distributed in the break angle between the vertical plate and the flat plate along the arris of the break angle. An inclined material laying dripping plate is arranged on the lower side of the material receiving supporting plate, and a movable pressing plate is connected between the material receiving supporting plate and the material laying dripping plate. A uniform distribution plate is vertically arranged betweenthe lower end of the movable pressing plate and the lower end of the material laying dripping plate, and a bent L-shaped material distributing plate is hinged to the uniform distribution plate. According to the material feeding and uniformizing device, through two-time material uniformizing, it is ensured that the materials are uniform and flat.

Owner:扬州正大机械制造有限公司

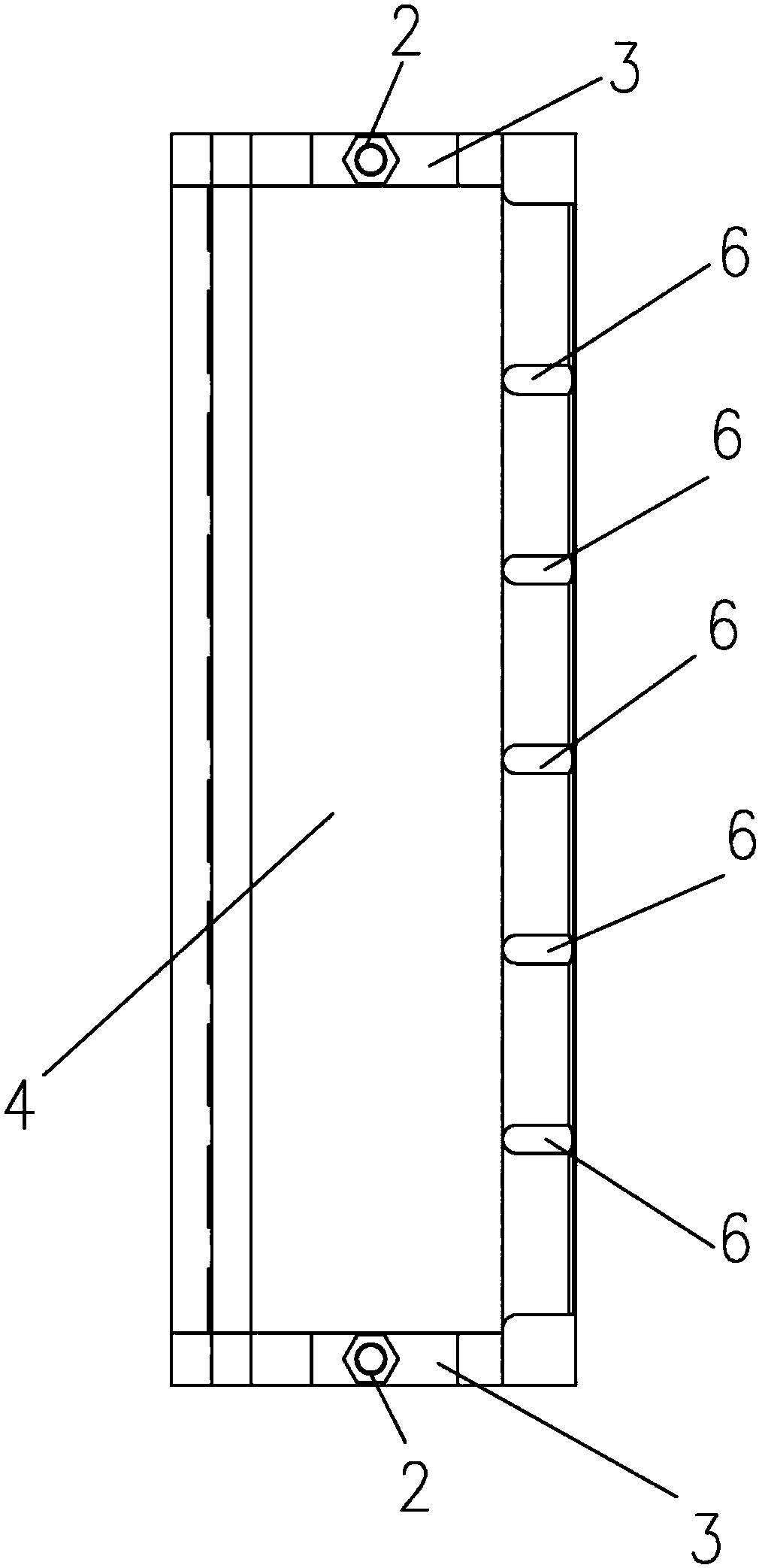

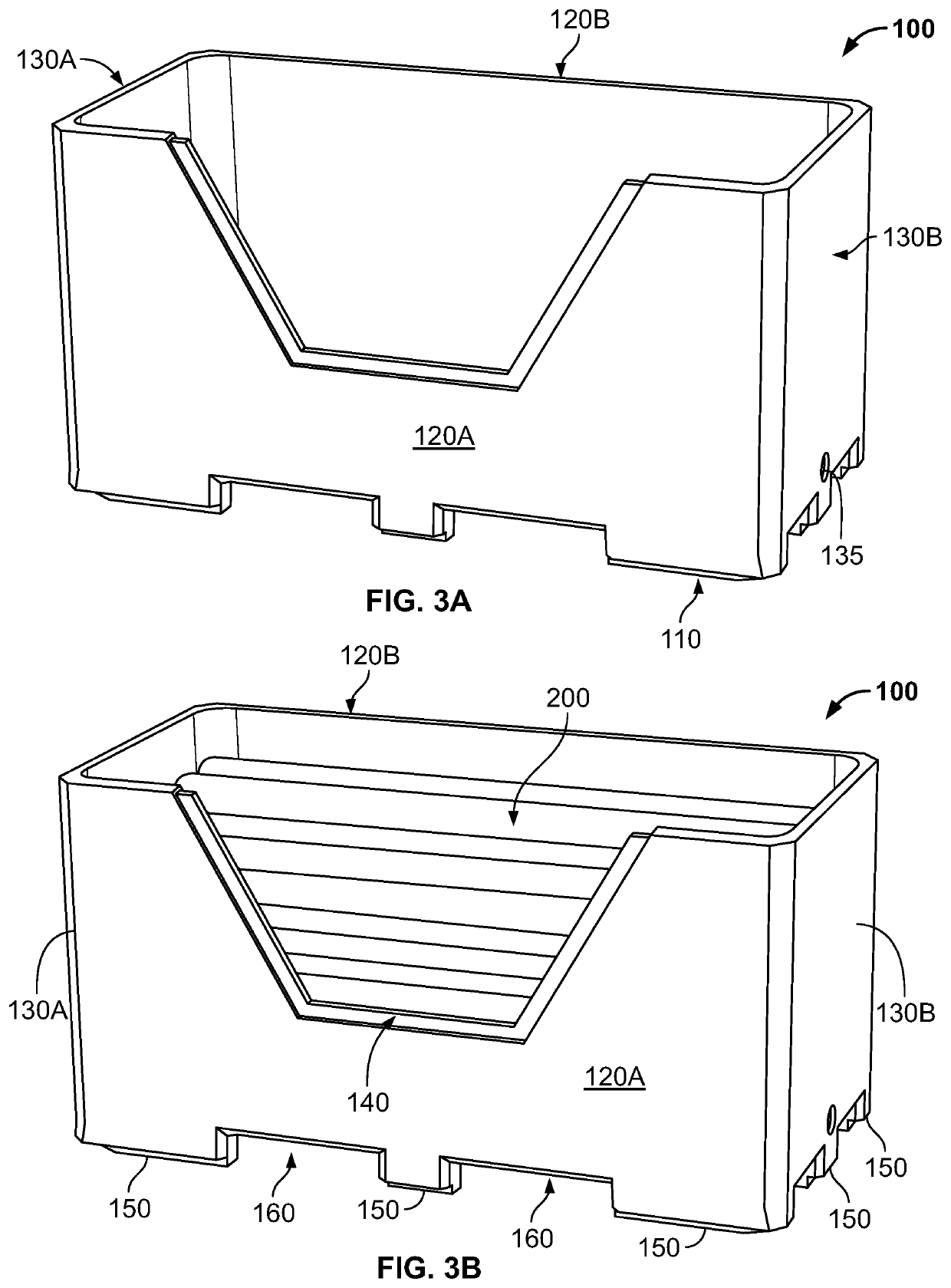

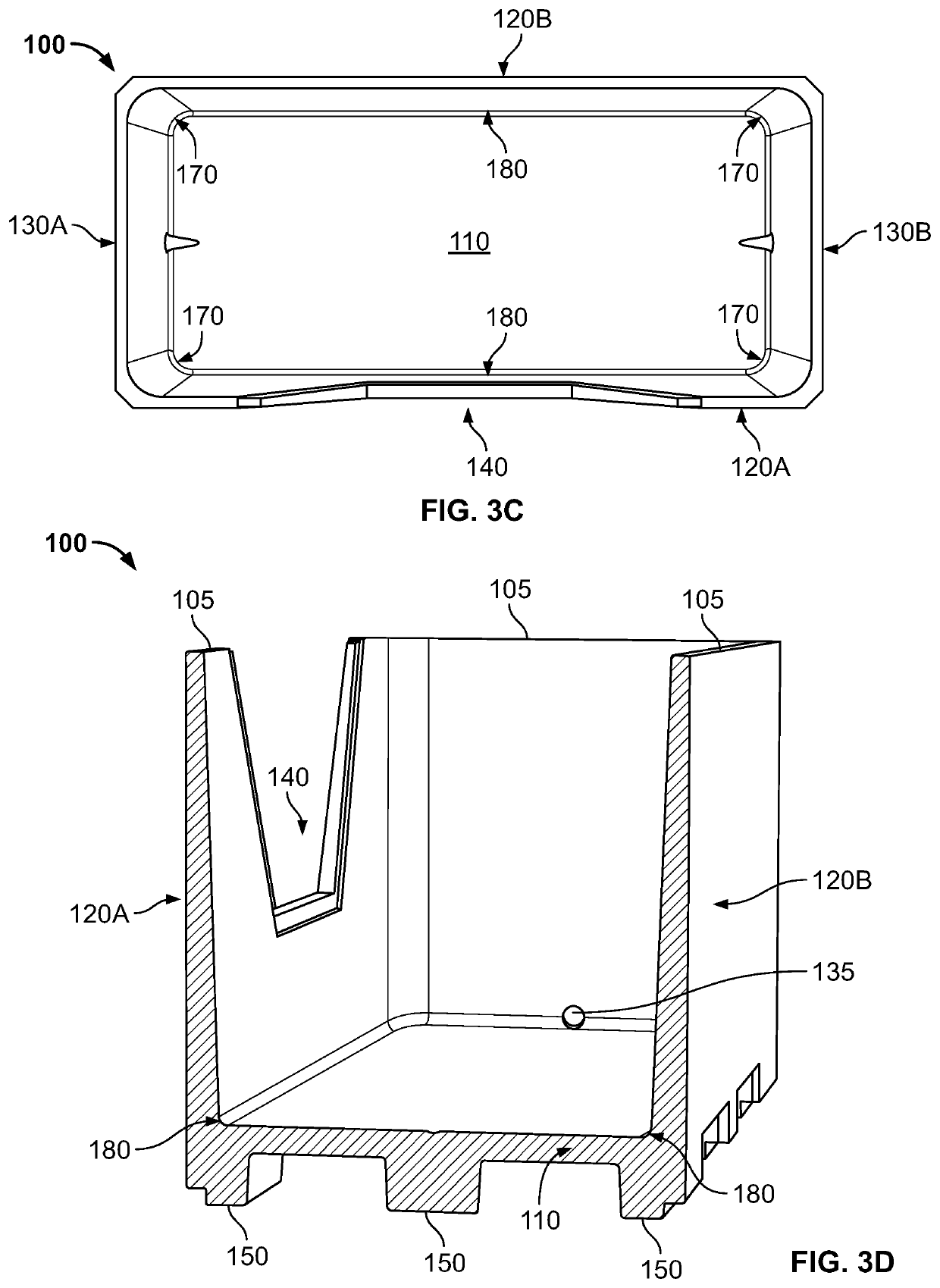

Reuseable shipping container for perishable food products

ActiveUS10766692B2Avoid material accumulationImprove hygienePackage recyclingRemovable lids/coversPerishable foodStructural engineering

Owner:SAEPLAST AMERICAS INC

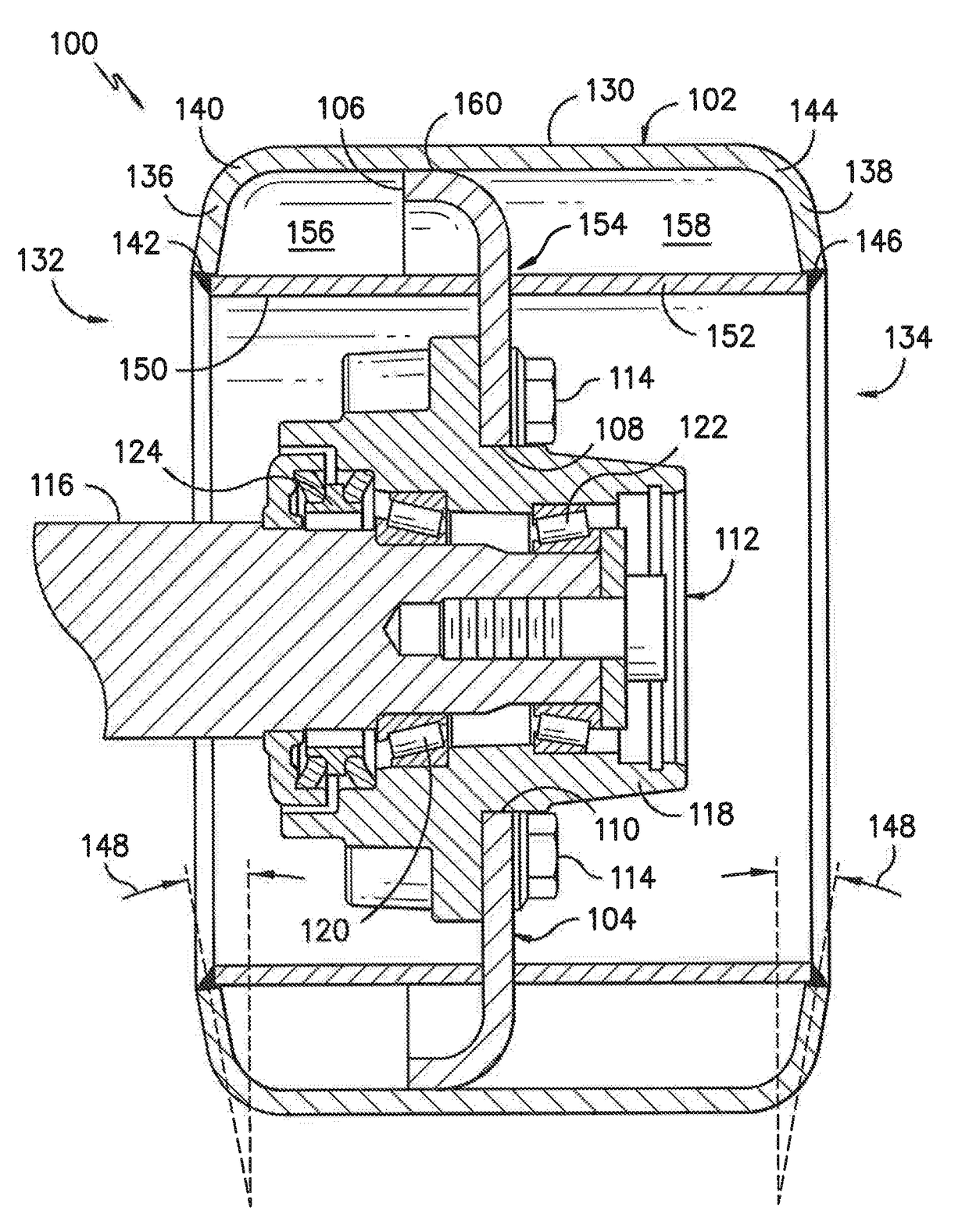

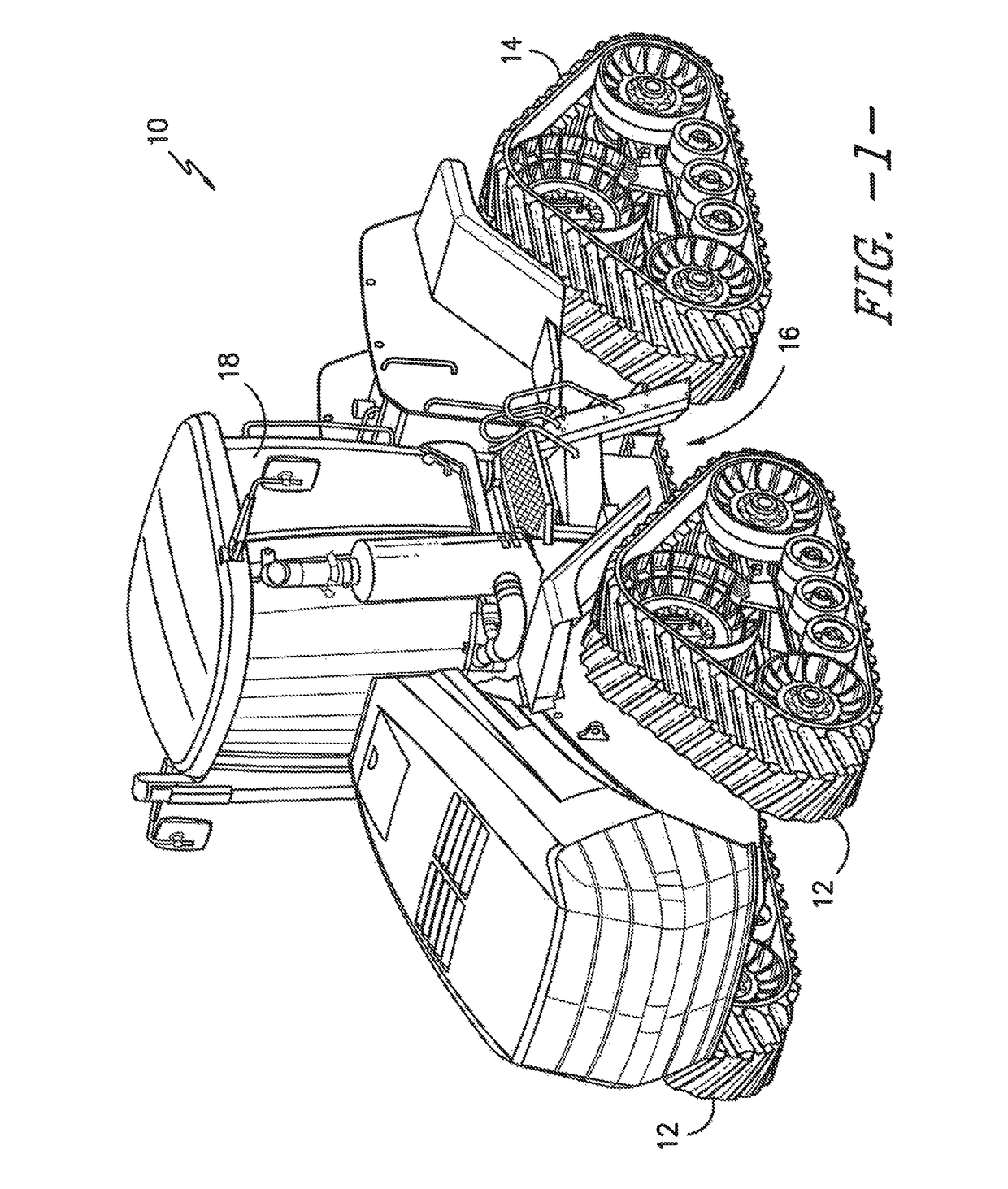

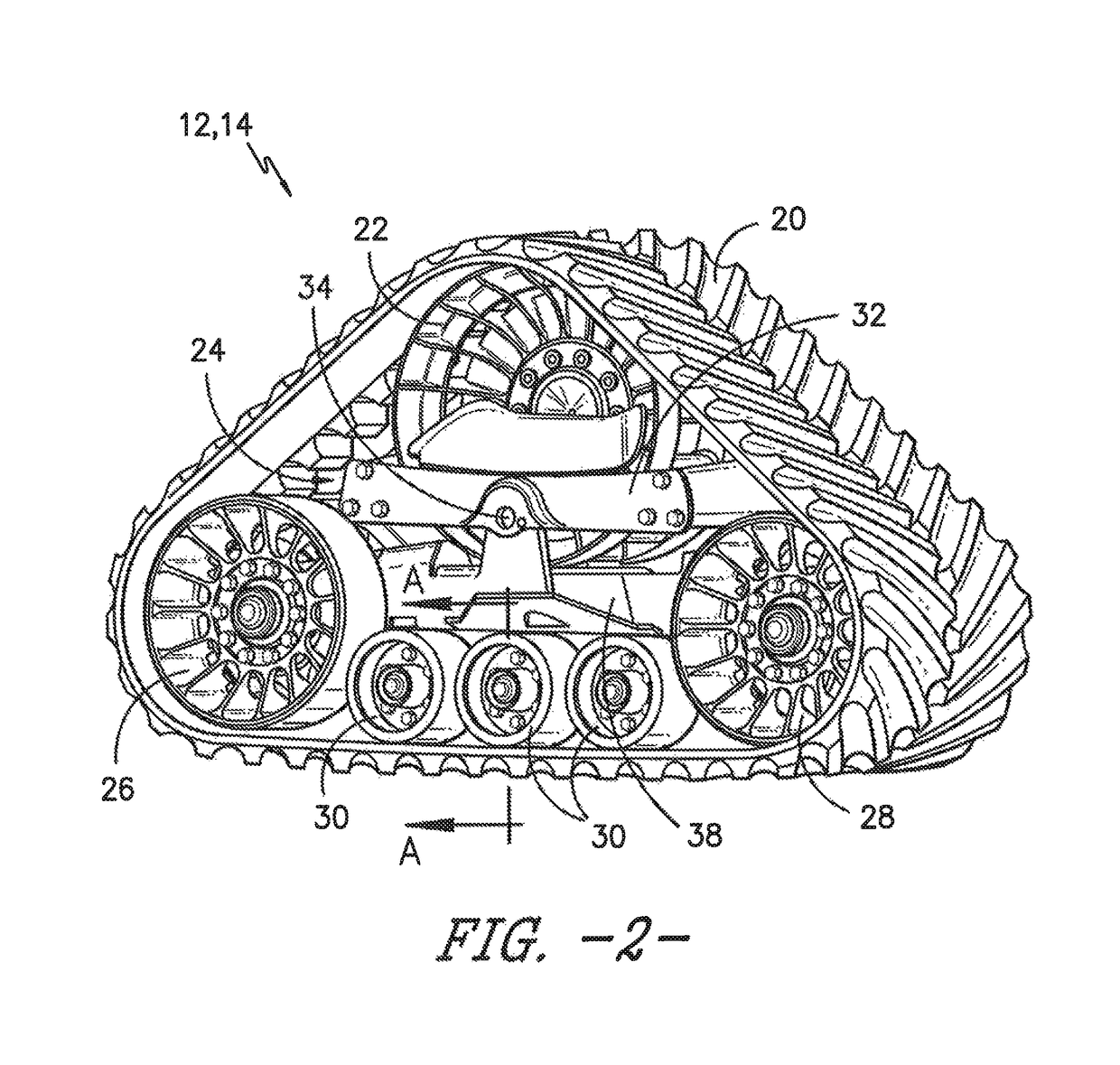

Wheel designs for use within a track assembly of a work vehicle

ActiveUS10227100B2Avoid material accumulationEndless track vehiclesEngineeringMechanical engineering

Owner:BLUE LEAF I P INC

A microfilter for solid-liquid separation

The invention relates to the technical field of environmental protection equipment, and discloses a microfiltration machine for solid-liquid separation, which includes a base, a waterproof board is fixedly installed on the top of the middle part of the base, a water tank is provided at the bottom of the waterproof board, and brackets are movable on the top of both ends of the base. The top of the supporting wheel is fixedly equipped with a filter cartridge, and the two ends of the filter cartridge are fixedly installed with rotating rings suitable for the supporting wheel. The middle part of the back of the filter cartridge is provided with a feeding pipe extending into it. The back of the filter cartridge A large ring gear is fixedly installed, and a motor is fixedly installed on the top of the back of the base. The output end of the motor is fixedly connected with a pinion gear meshed with the large ring gear. The front of the box is fixedly connected with a support shaft, and the feeding runner is installed inside the feeding box and driven to rotate through the transmission gear, and the rotating shaft is set to rotate with the feeding runner, which can improve the filtration efficiency and the service life of the filter cartridge .

Owner:深圳市树立水处理设备有限公司

Finished product conveying equipment for cosmetic production

PendingCN112875293AEasy to sortConvenient for storage and transshipmentConveyorsConveyor partsMechanical engineeringIndustrial engineering

The invention discloses finished product conveying equipment for cosmetic production. The finished product conveying equipment comprises a device bottom plate, wherein a supporting cylinder is fixedly arranged on the surface of the top end of the device bottom plate, and a control box is detachably arranged at the top end of the supporting cylinder; a supporting plate is detachably arranged at the top end of the device bottom plate, and a material blocking assembly is detachably arranged at the top end of the control box; a material conveying assembly is fixedly arranged at the top end of the device bottom plate; a transmission assembly is detachably arranged on the surface of the supporting plate, and a material dividing and clamping structure is attached to the other end of the transmission assembly; and the material blocking assembly comprises a fixed sleeve. According to the finished product conveying equipment, the material blocking assembly, the material conveying assembly, the transmission assembly and the material dividing and clamping structure are arranged, cosmetic bottles of the same batch are hung through mutual cooperation of the four parts, and then the cosmetic bottles can be conveniently sorted and stored and transferred in the later period through existing equipment; and thus, the working efficiency and the practical value of the equipment are further improved.

Owner:杨宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com