Piston for a two-stroke engine operating with advanced scavenging and a two-stroke engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

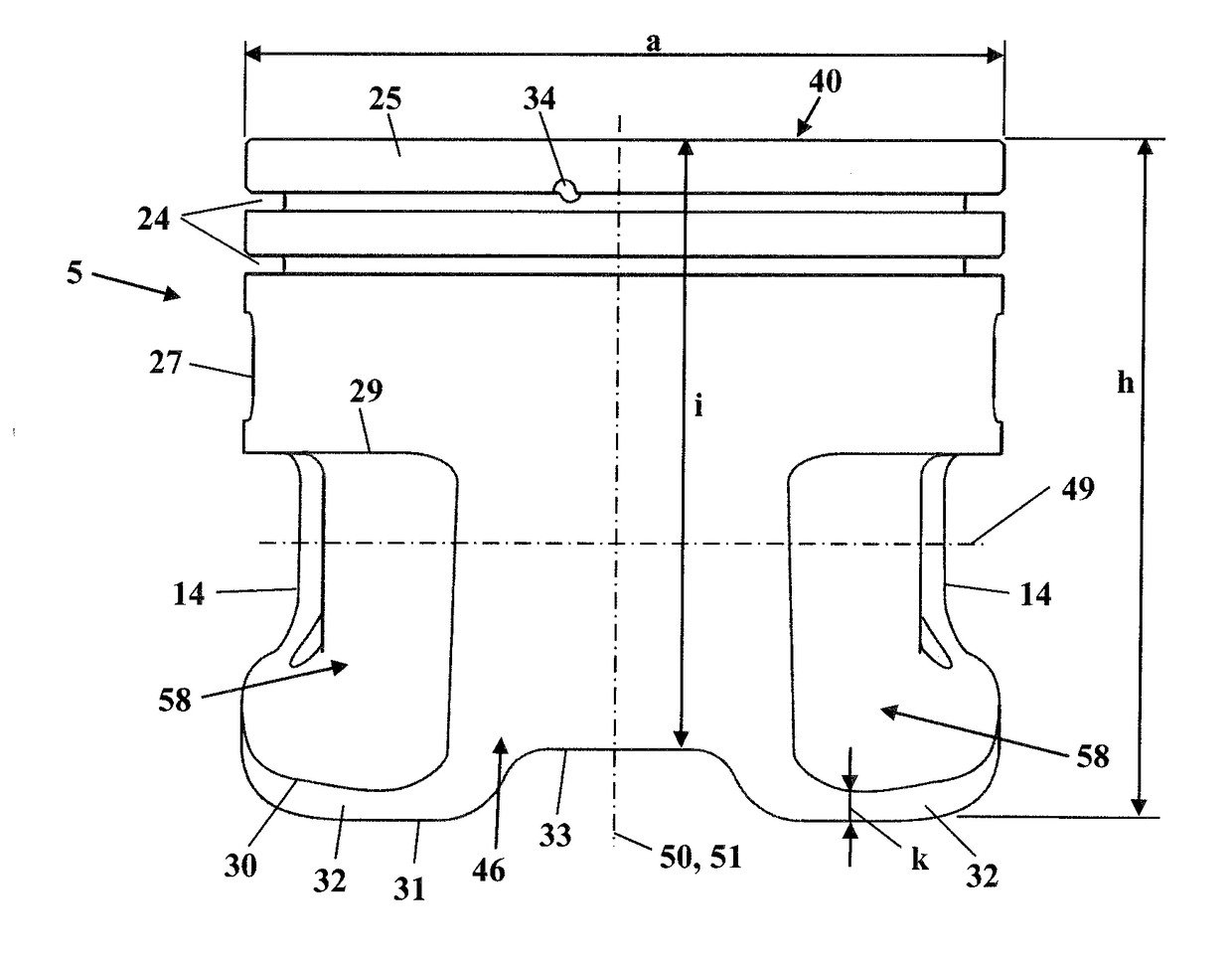

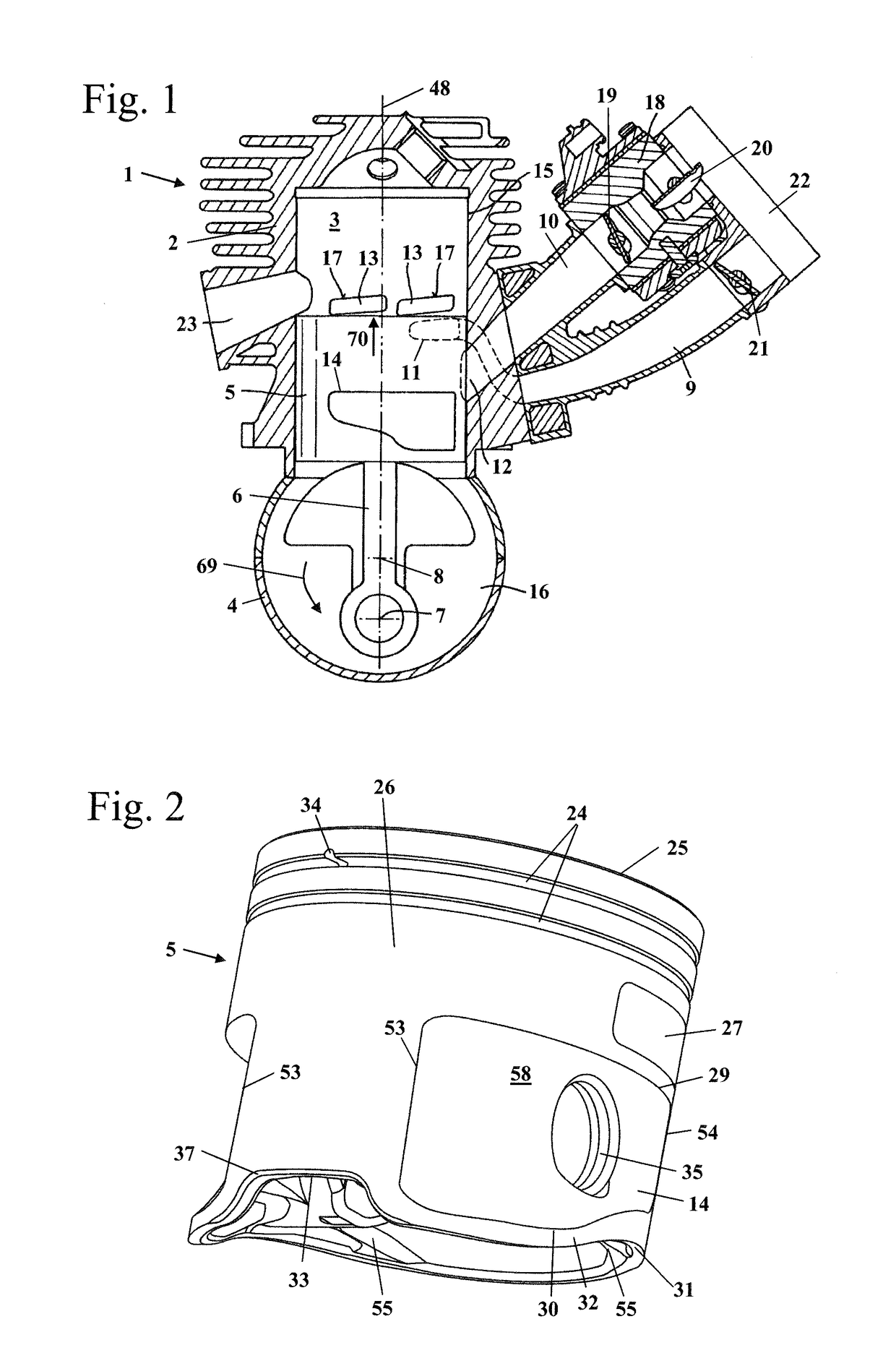

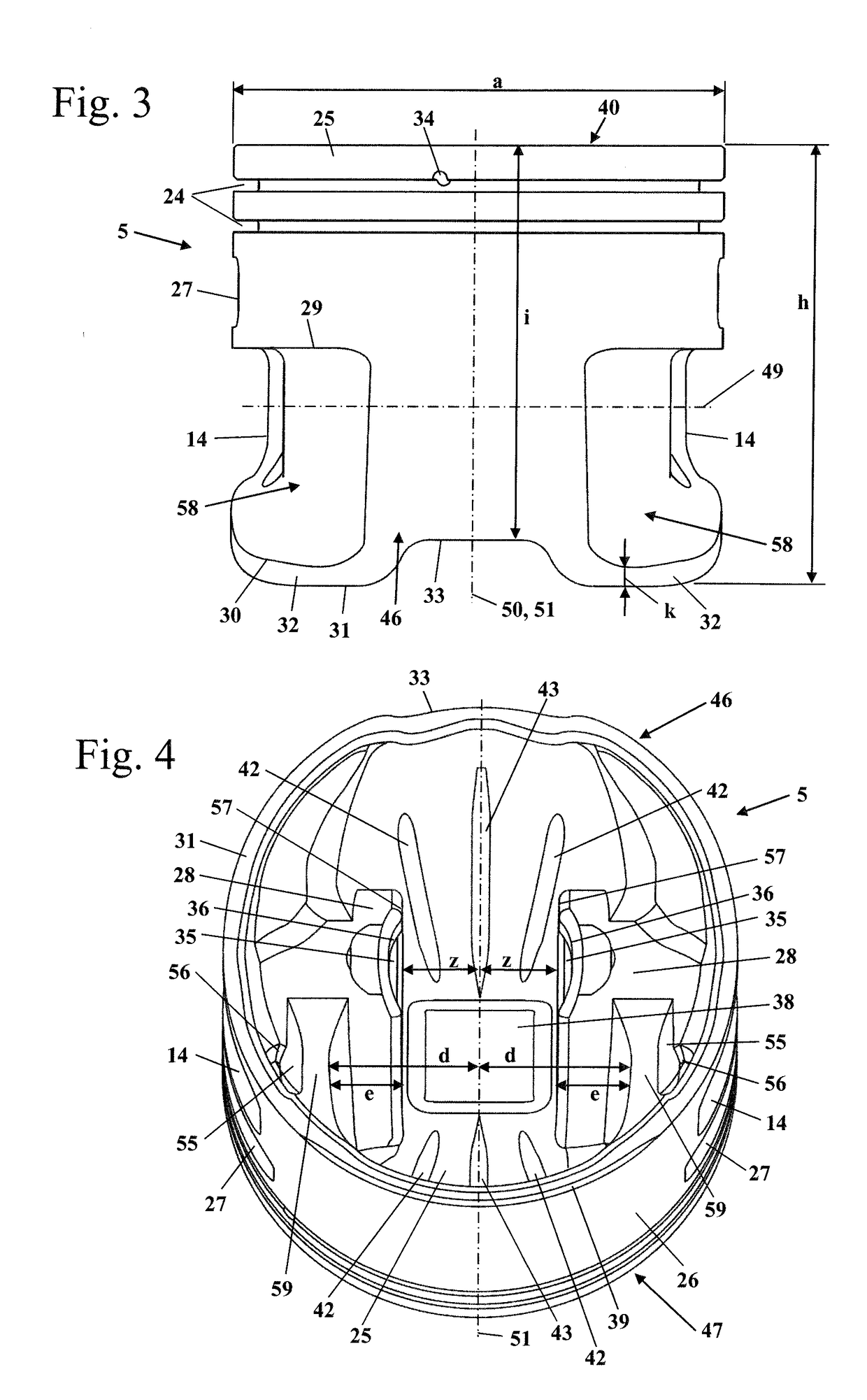

[0028]FIG. 1 diagrammatically shows one embodiment for a two stroke engine 1. The two stroke engine 1 is configured as a single cylinder engine and has a cylinder 2, in which a combustion chamber 3 is configured. The cylinder 2 has a cylinder longitudinal axis 48. The combustion chamber 3 is delimited by a piston 5 which is mounted so as to move to and fro in a cylinder bore 15 of the cylinder 2 in the direction of the cylinder longitudinal axis 48, in the direction of which the piston 5 moves during operation. FIG. 1 shows the piston 5 at its bottom dead center. The piston 5 drives a crankshaft 7 via a connecting rod 6. The crankshaft 7 is mounted in a crankcase interior 16 of a crankcase 4 such that it can be rotated about a rotational axis 8. During operation, the crankshaft 7 rotates in a rotational direction 69. The two stroke engine 1 can be, for example, the drive motor in a handheld work apparatus, such as a power saw, an angle grinder, a blower device or the like. The crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com