Patents

Literature

140 results about "Single-cylinder engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

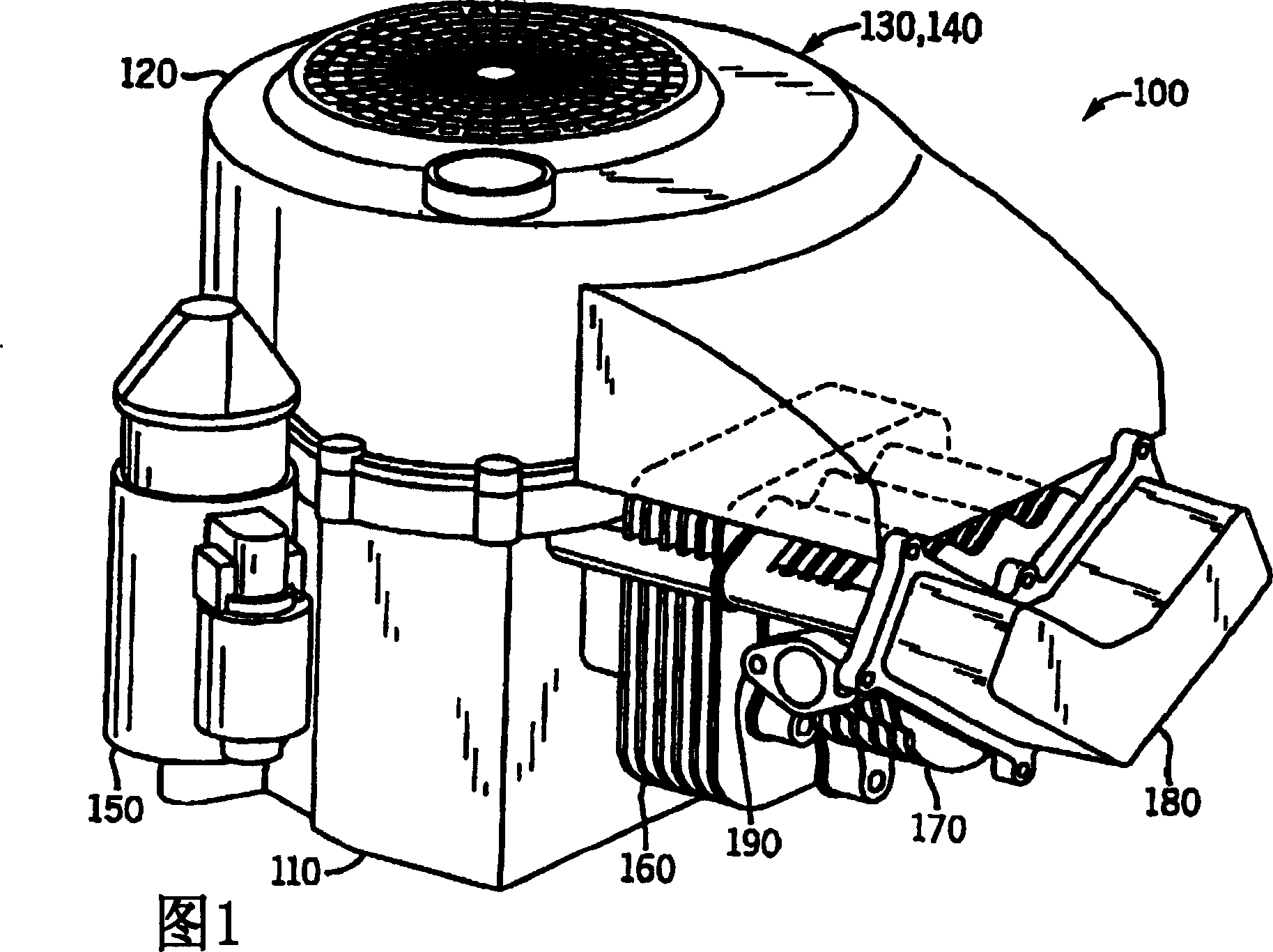

A single-cylinder engine is a piston engine with one cylinder. It is often used on motorcycles, scooters, go-karts, ATVs, radio-controlled vehicles, portable tools and garden machinery (such as lawnmowers, rototillers and string trimmers).

Internal combustion engine

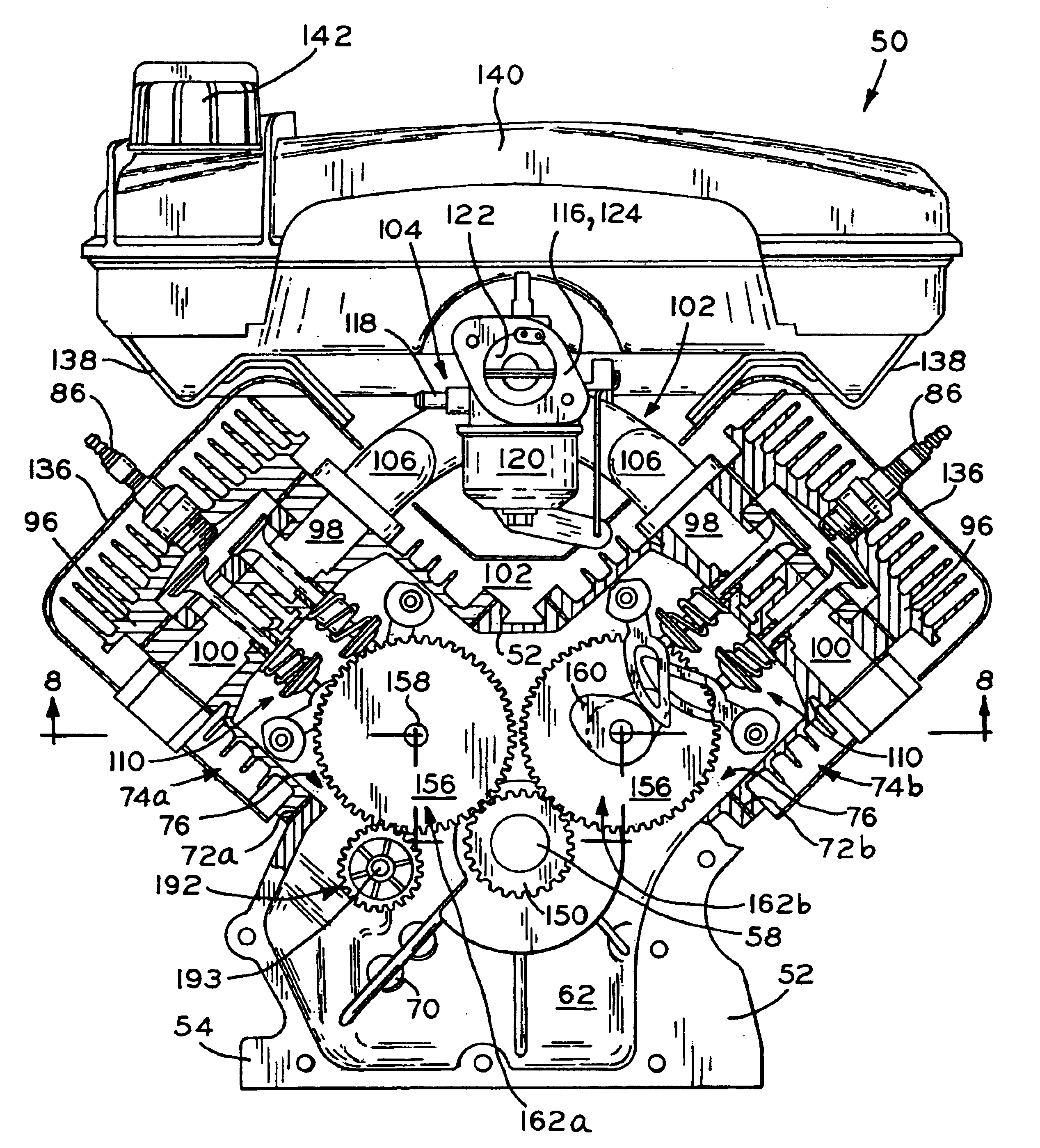

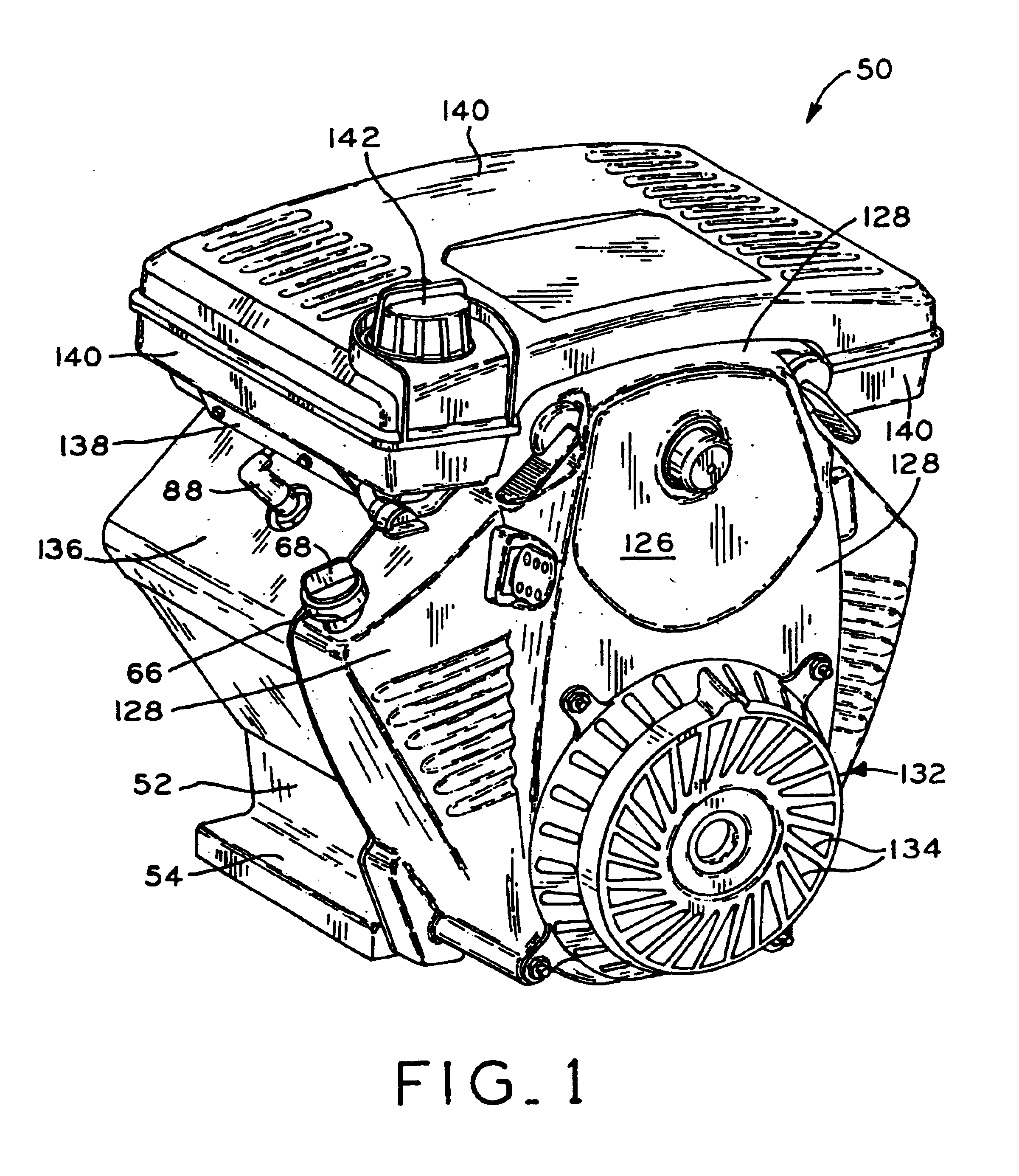

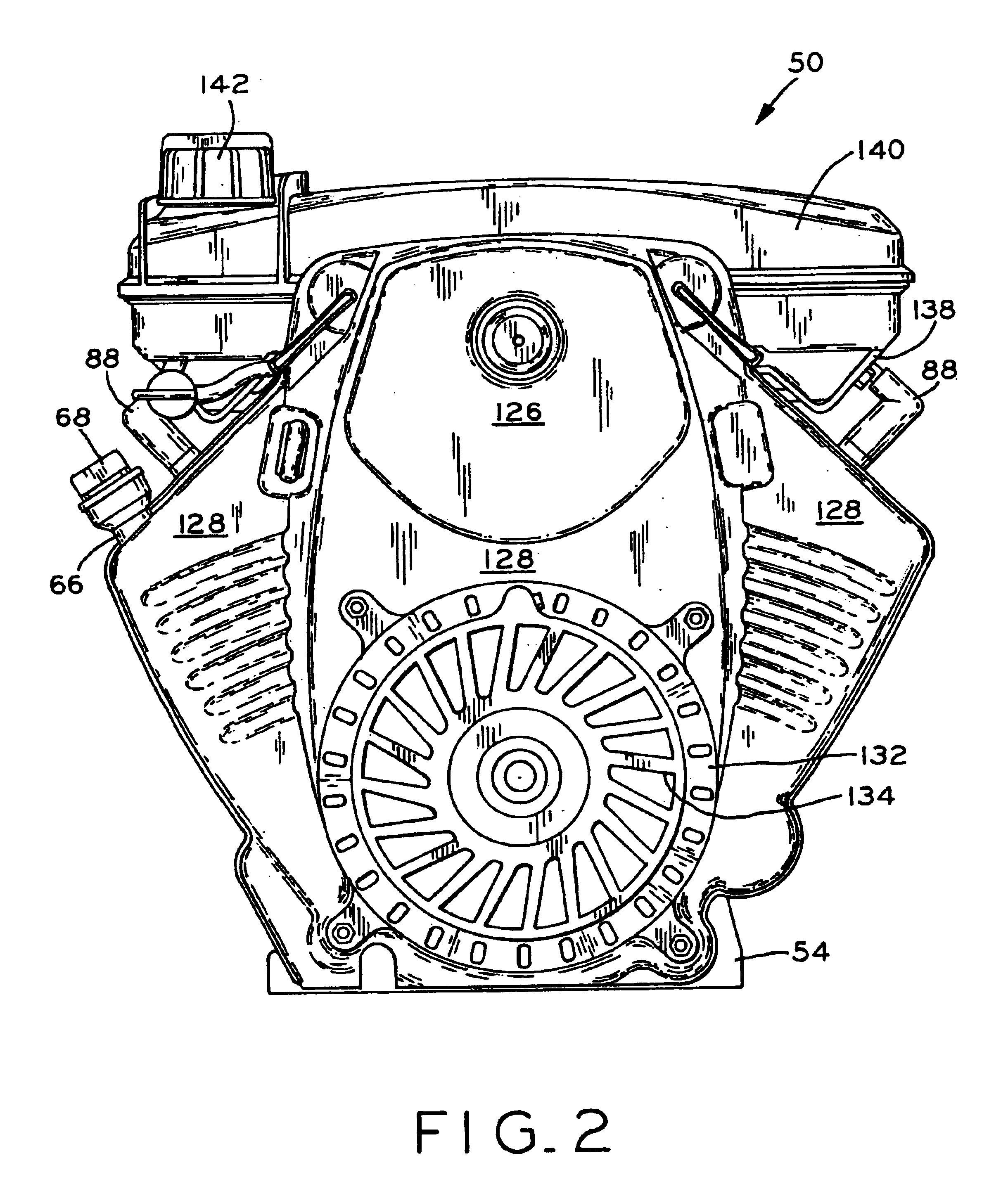

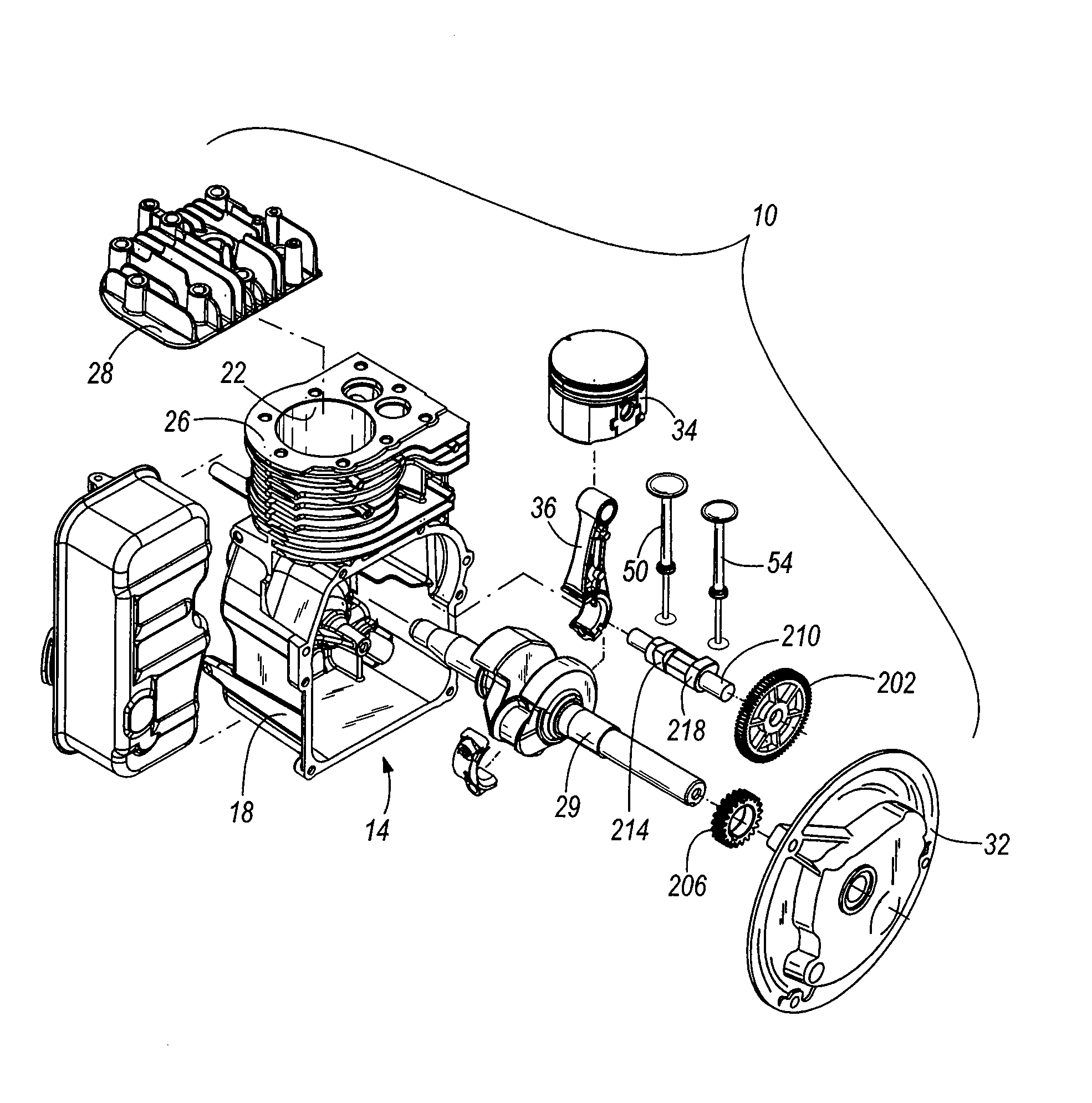

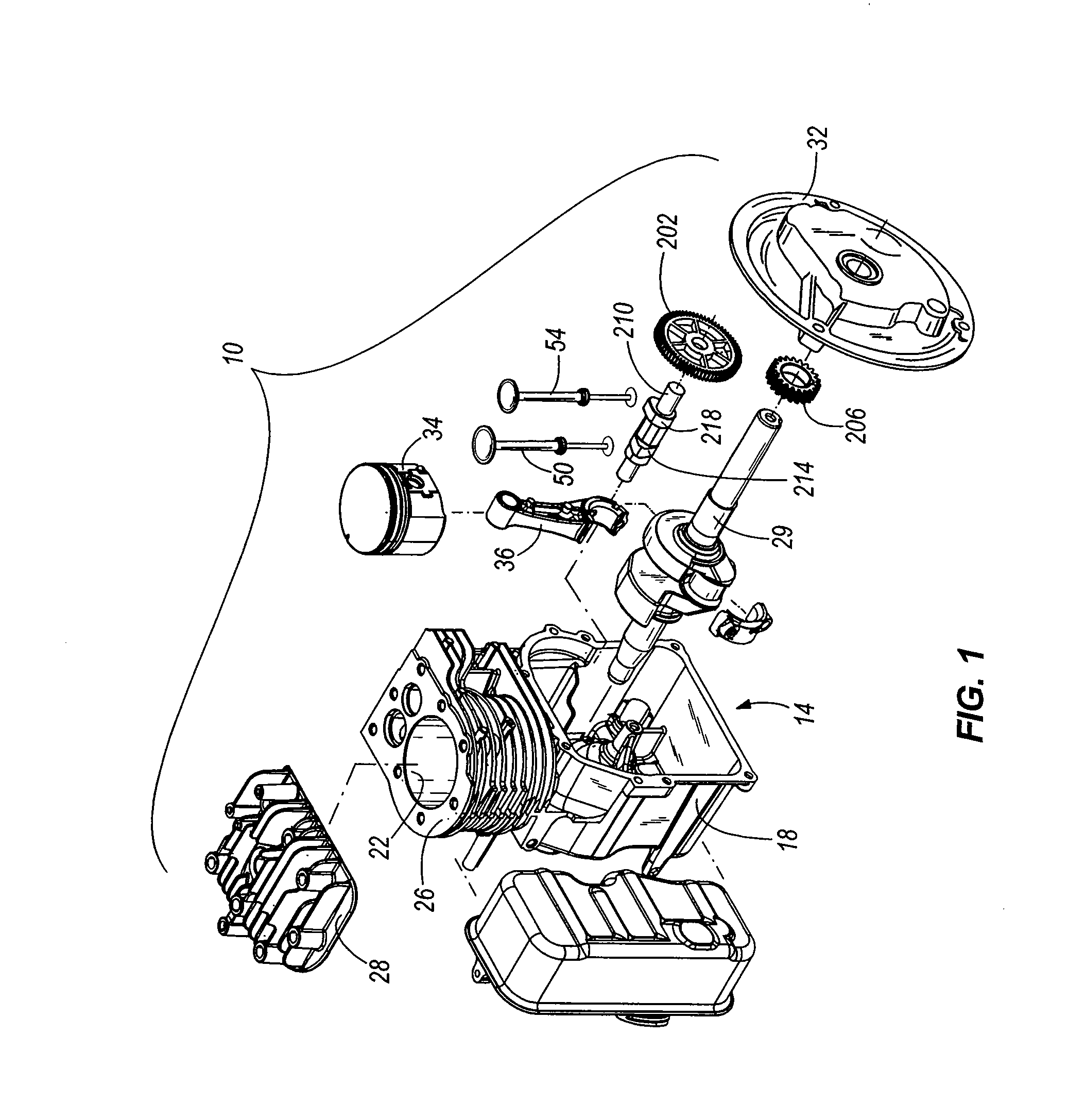

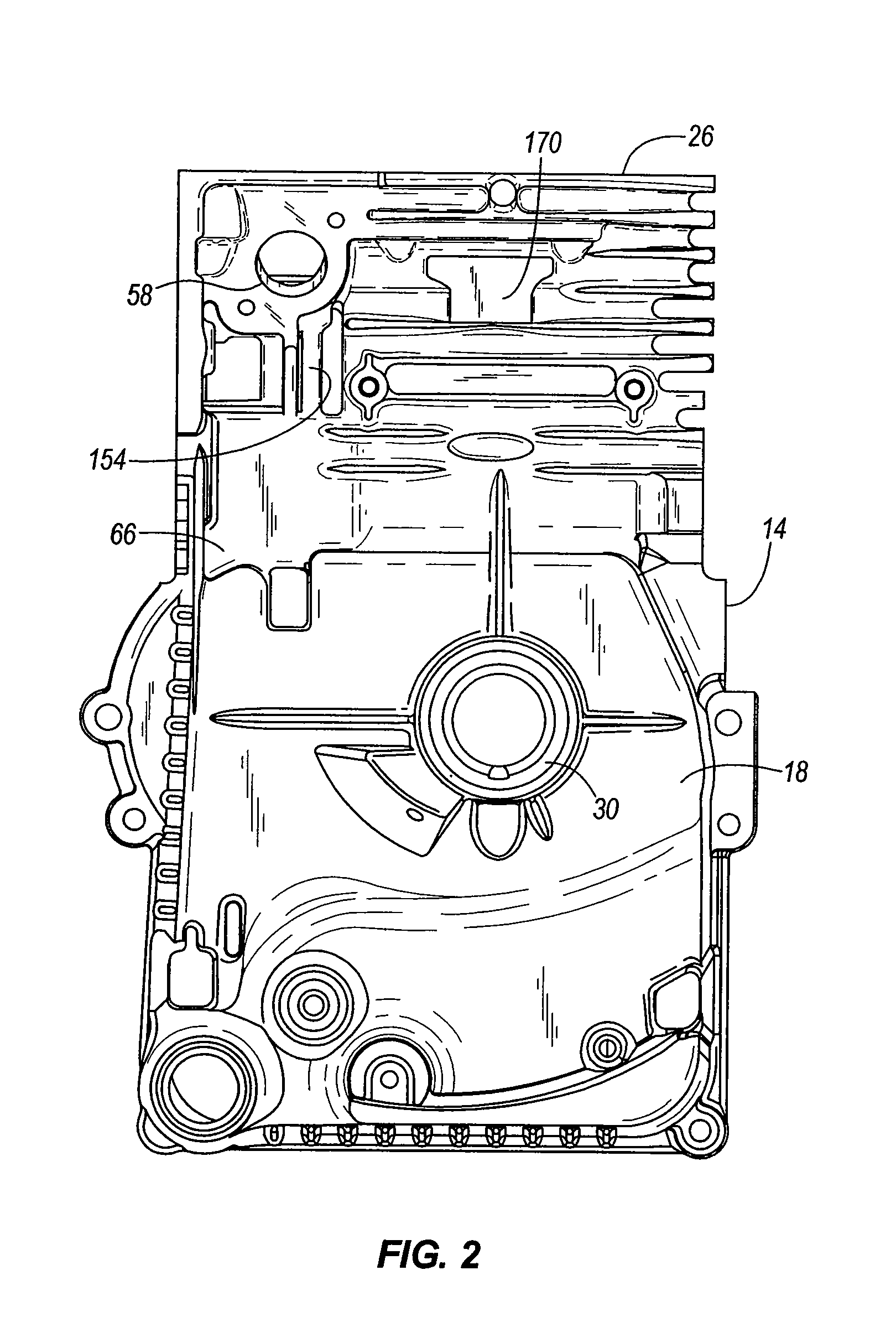

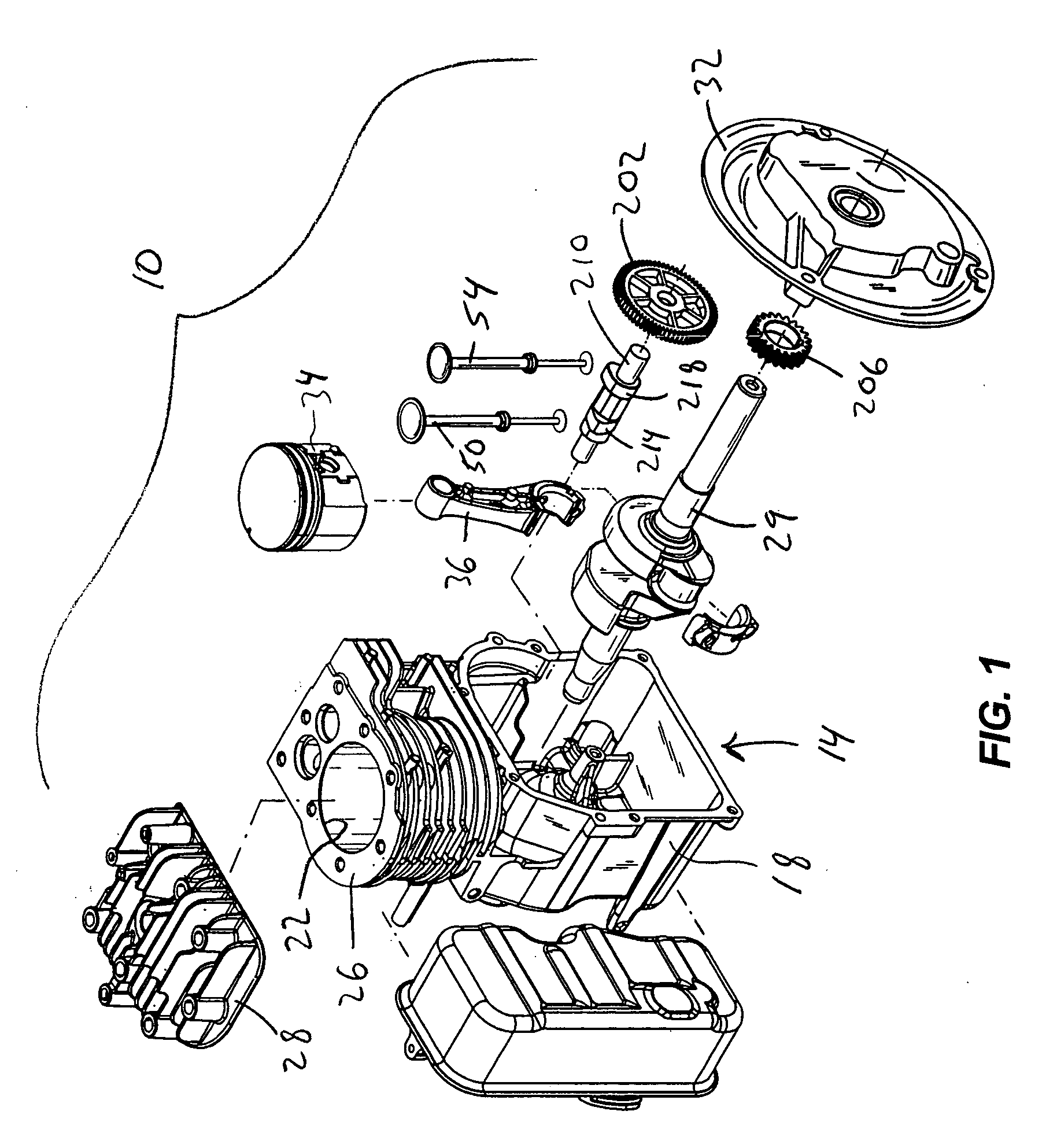

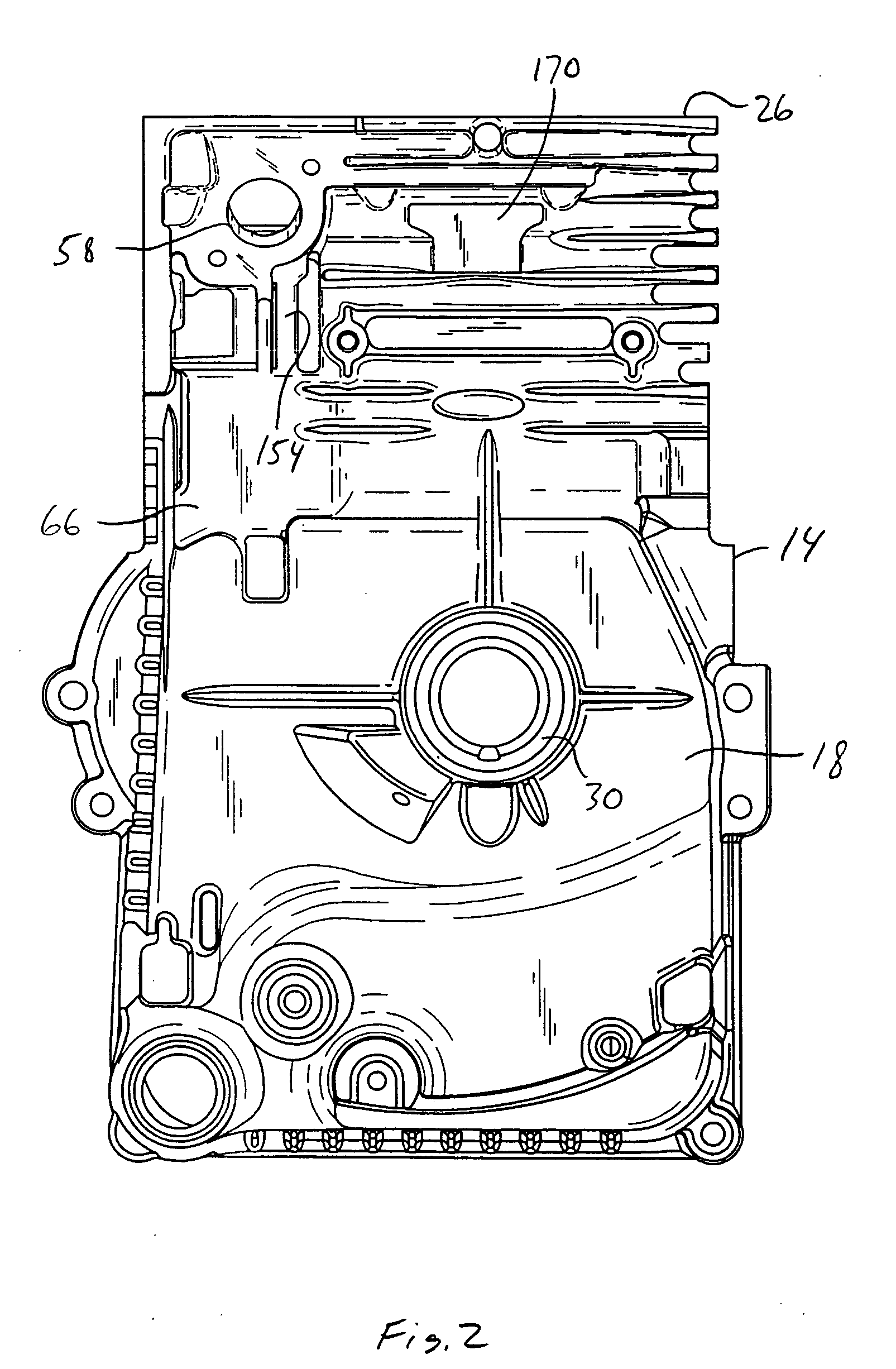

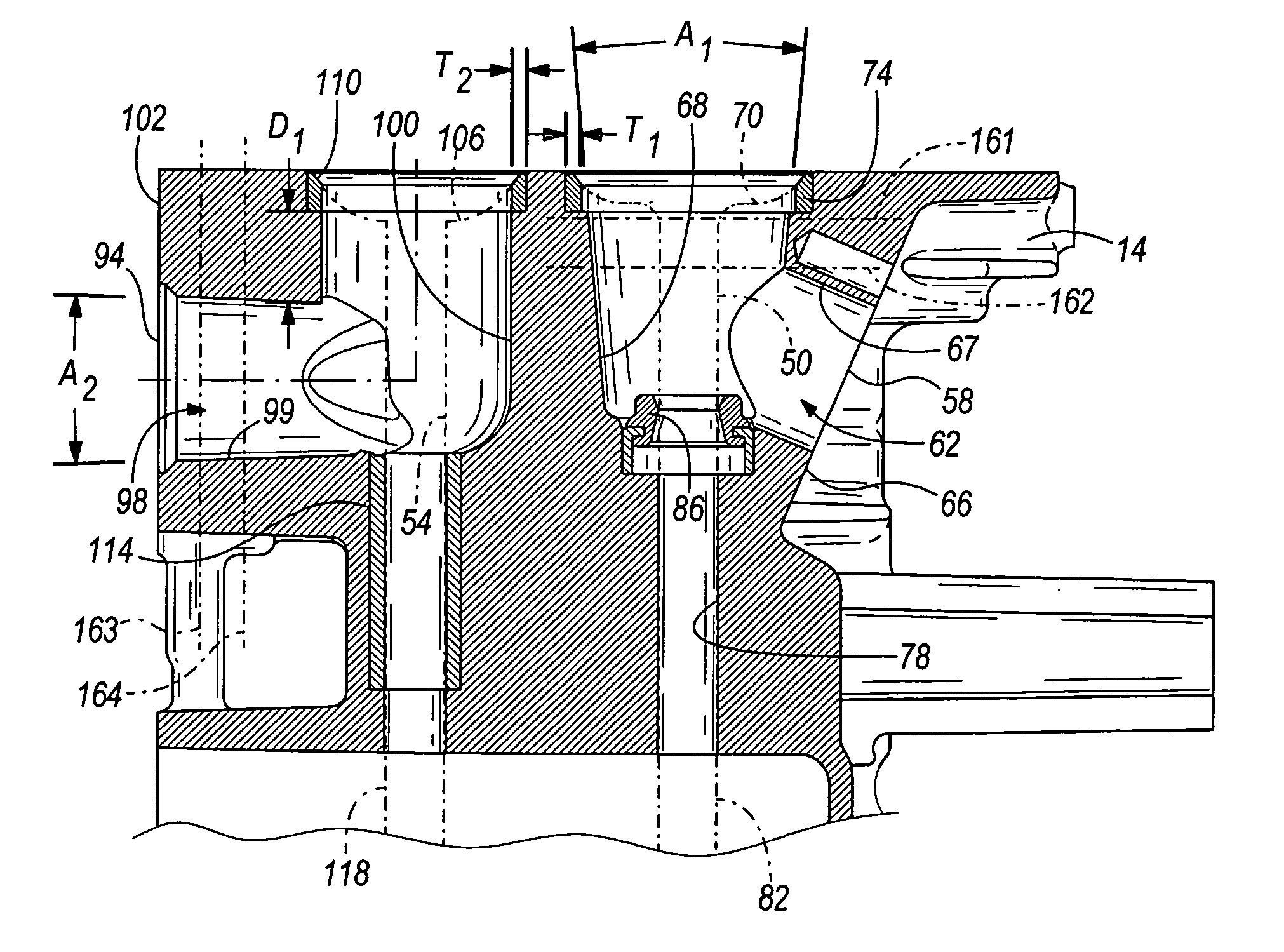

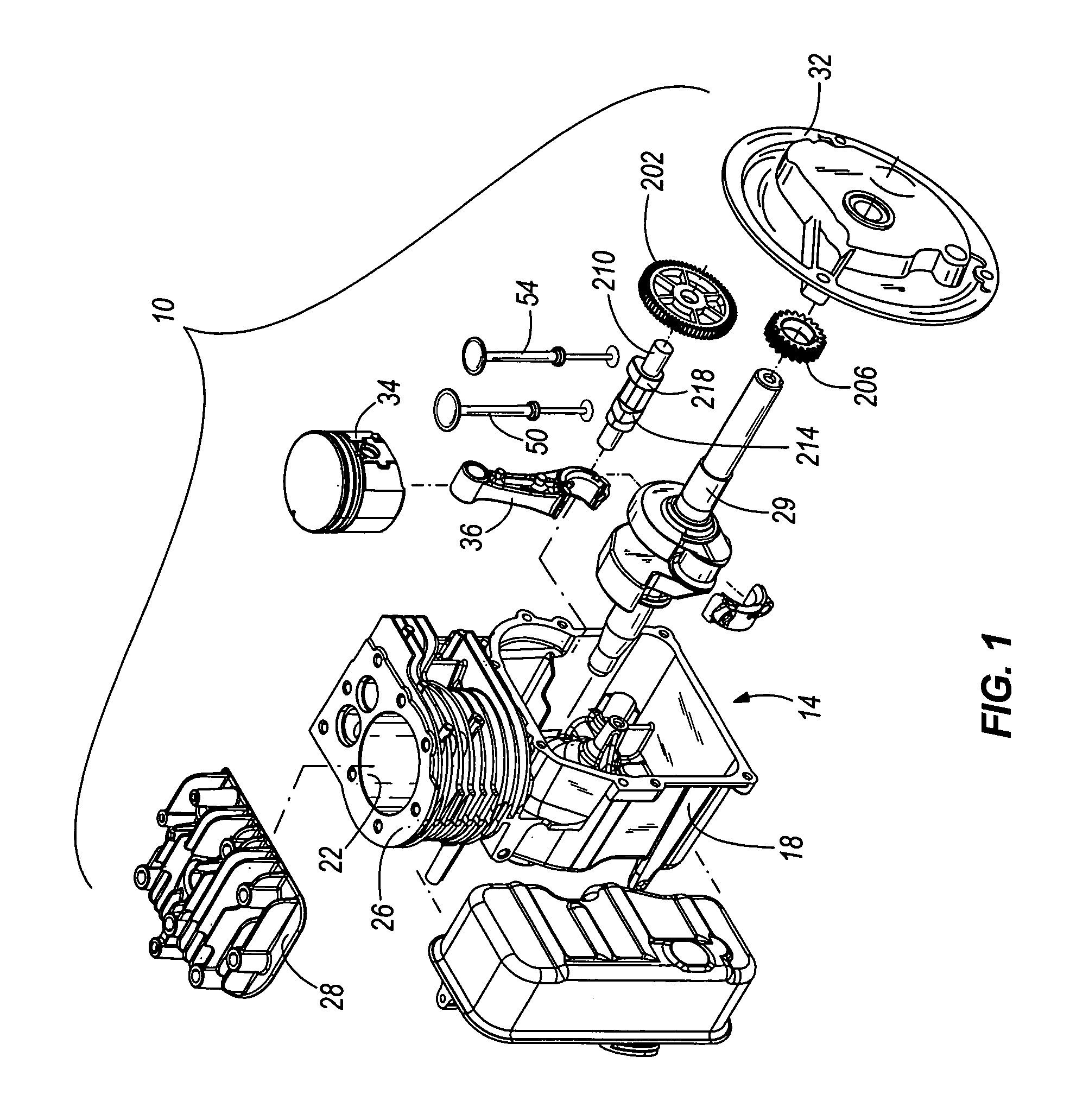

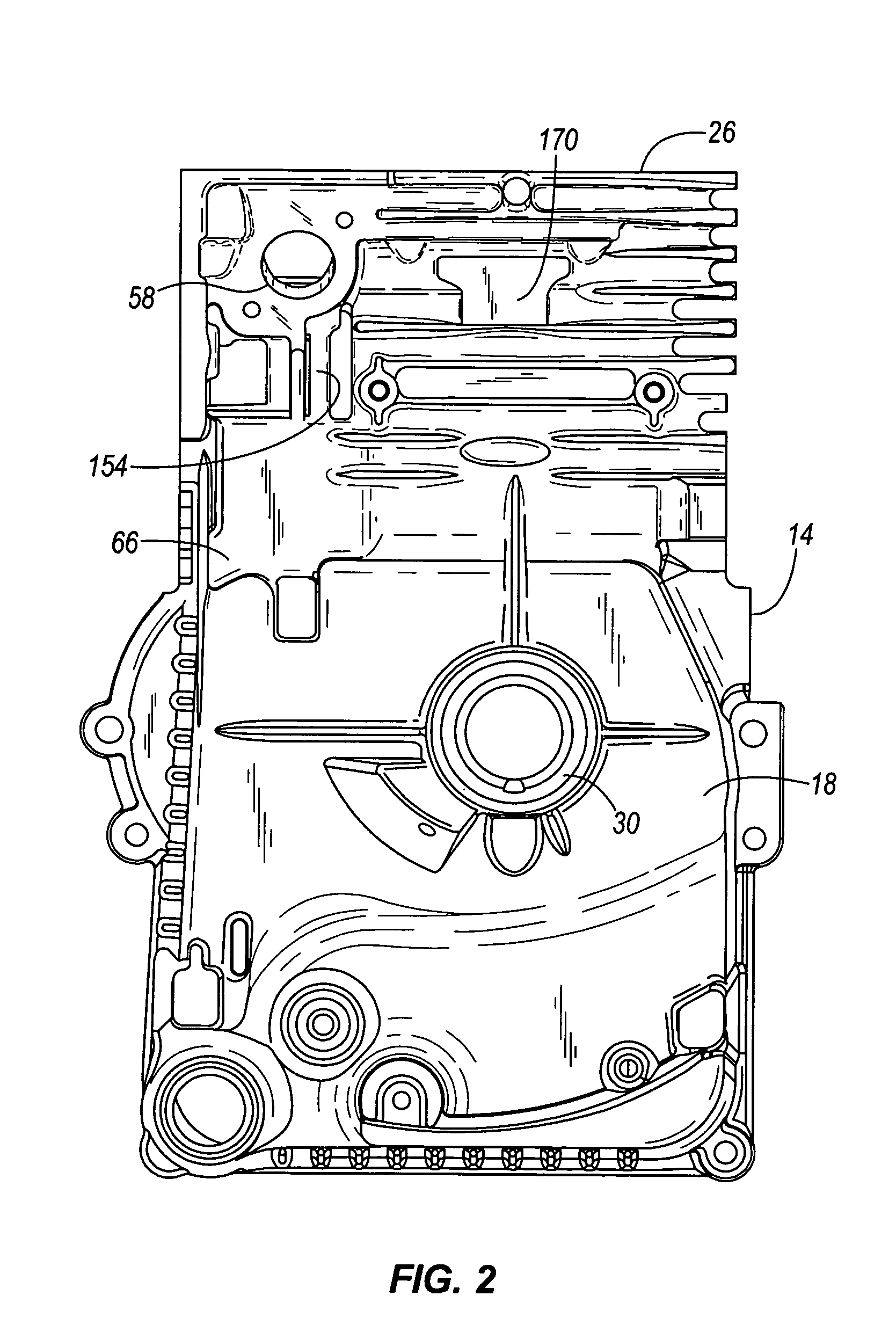

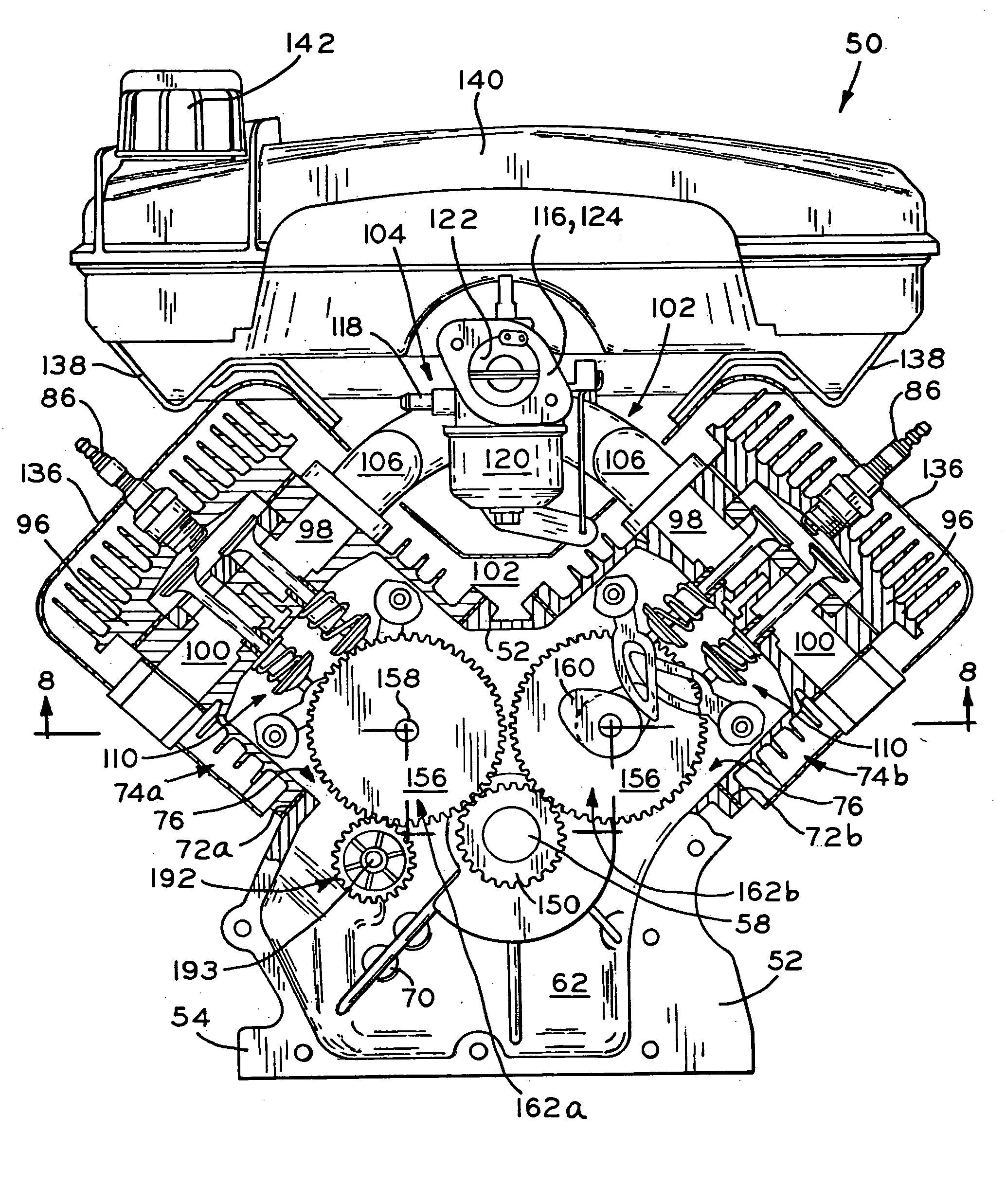

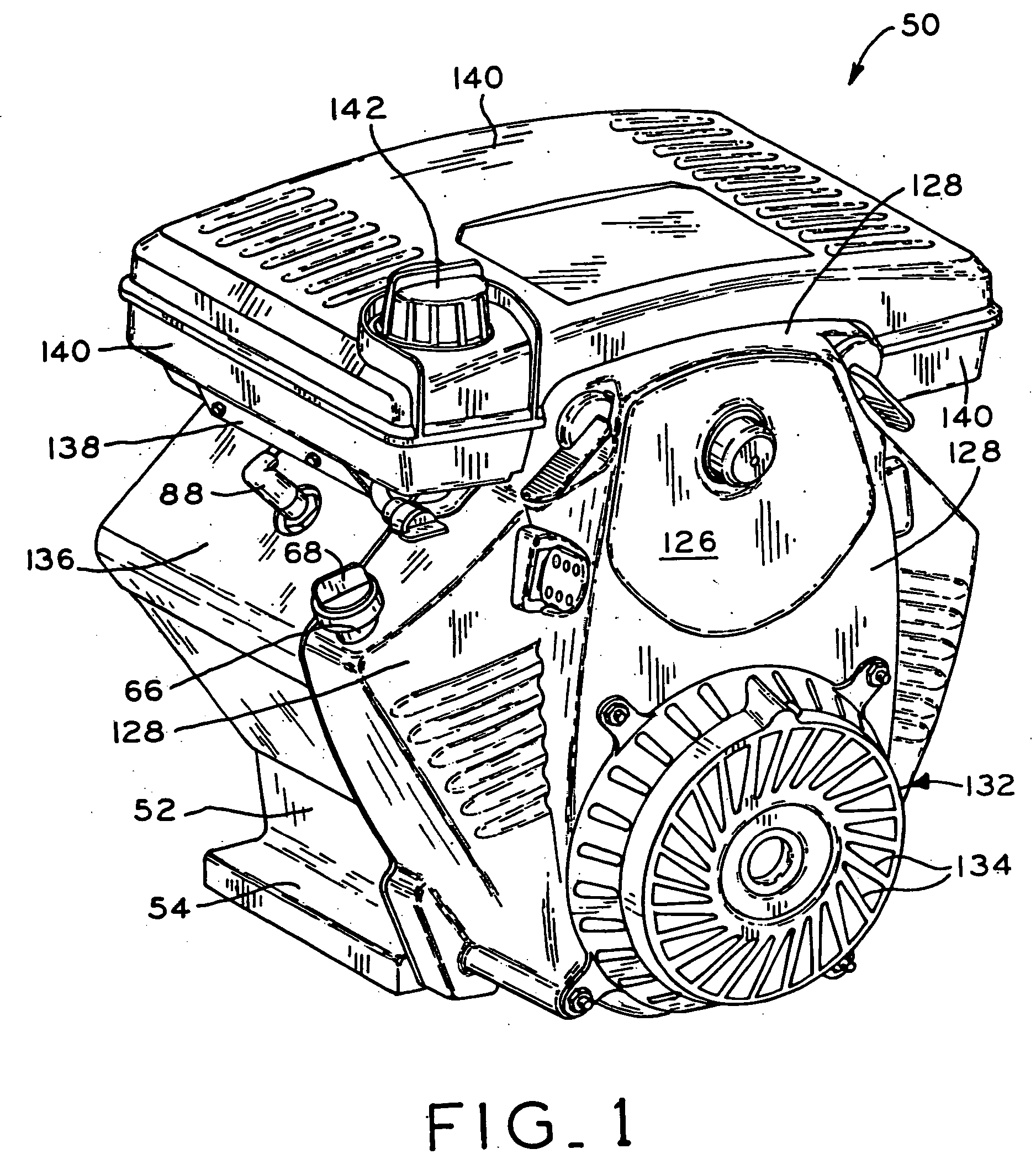

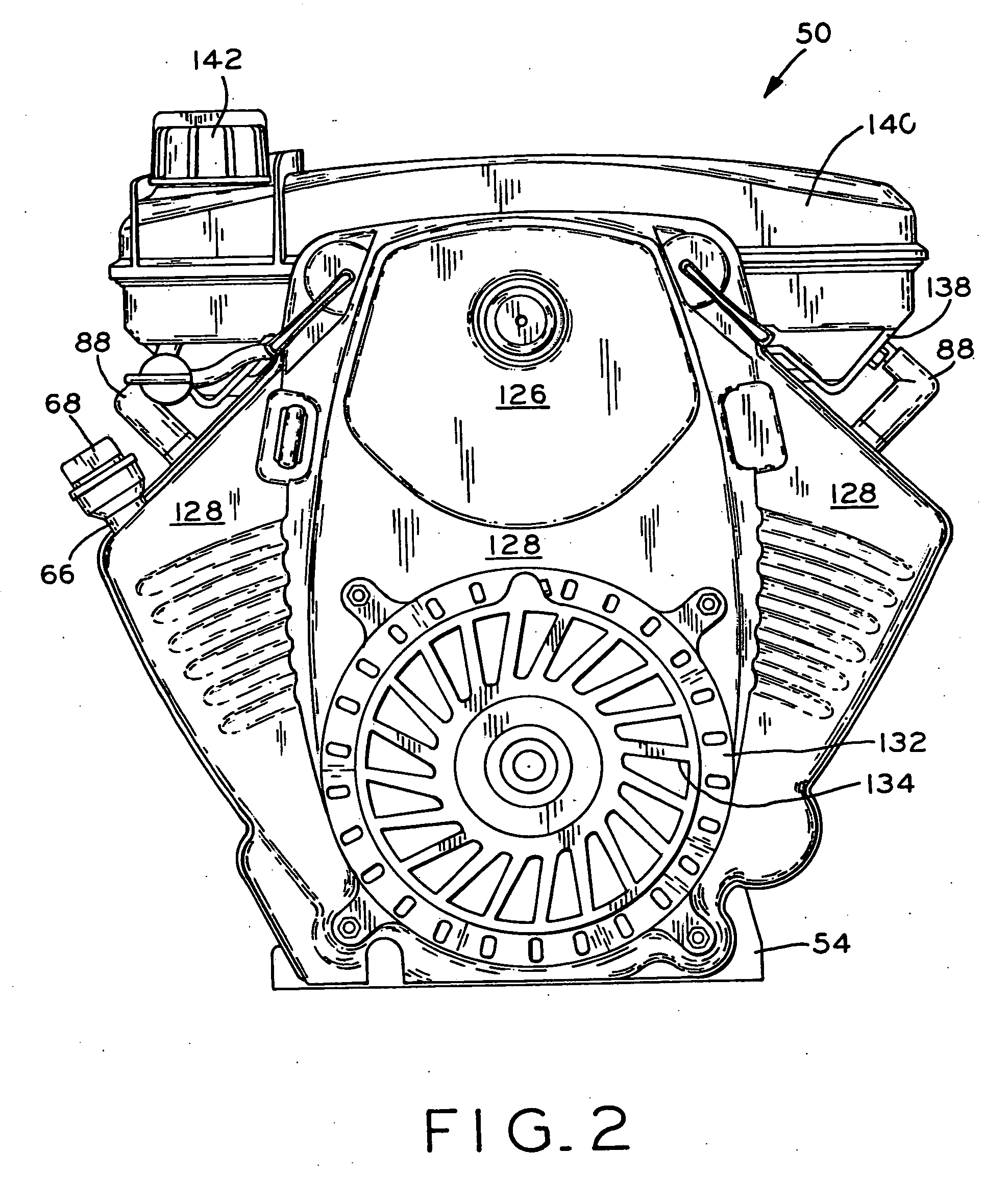

A twin cylinder engine, includes a pair of cylinder members mounted to mounting surfaces of a crankcase, and cylinder heads mounted to the cylinder members. The cylinder members are modular components, which may be pre-assembled with components of the valve train as packaged units before the cylinder members are attached to the crankcase. Each cylinder member rotatably supports a cam gear which extends into the crankcase for driving engagement with the crankshaft. The cylinder members may be configured for either side valve-type (“L-head”), or overhead valve-type (“OHV”) engines, and the cylinder members may also be used in single cylinder engines.

Owner:TECUMSEH POWER

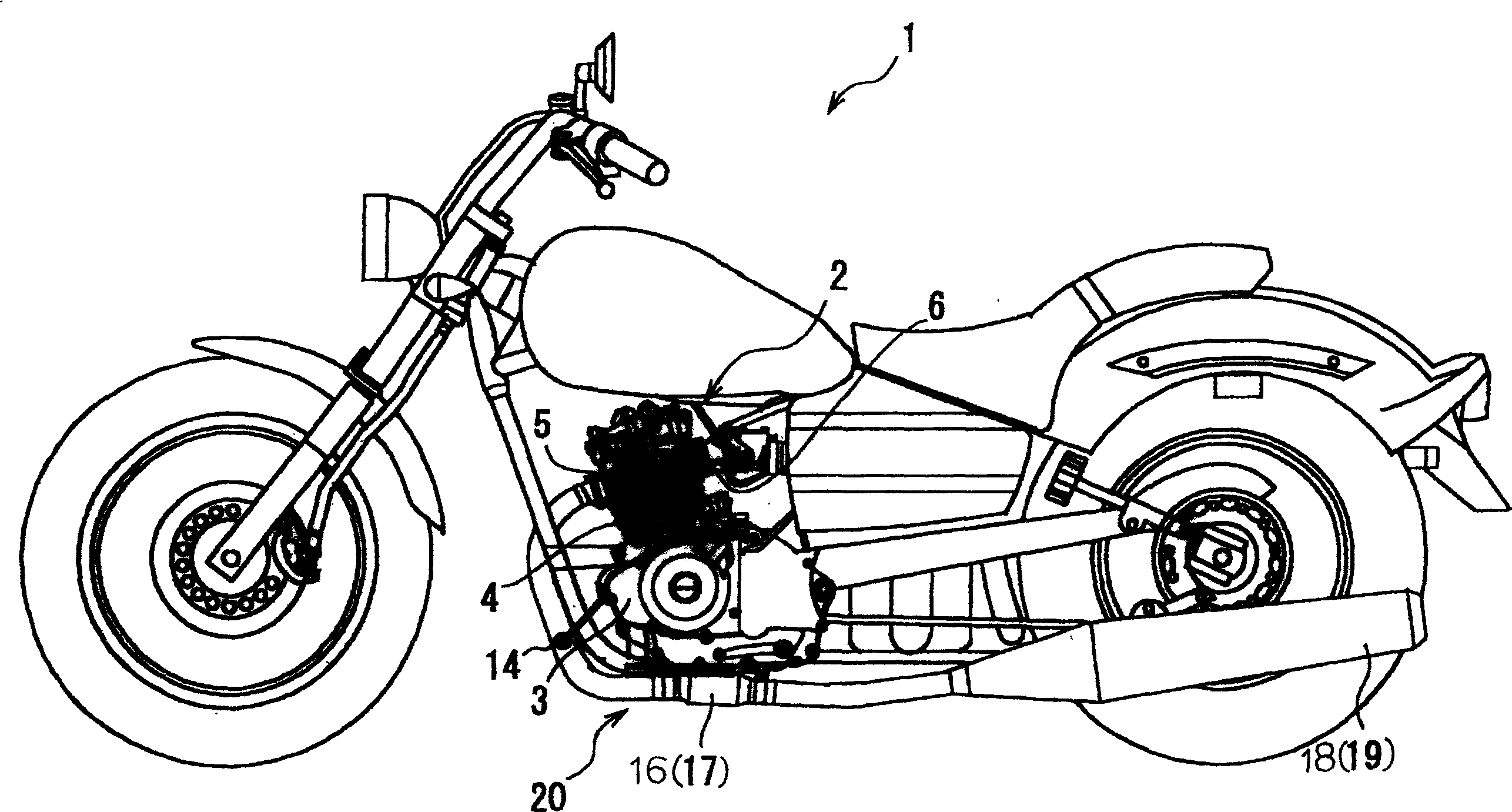

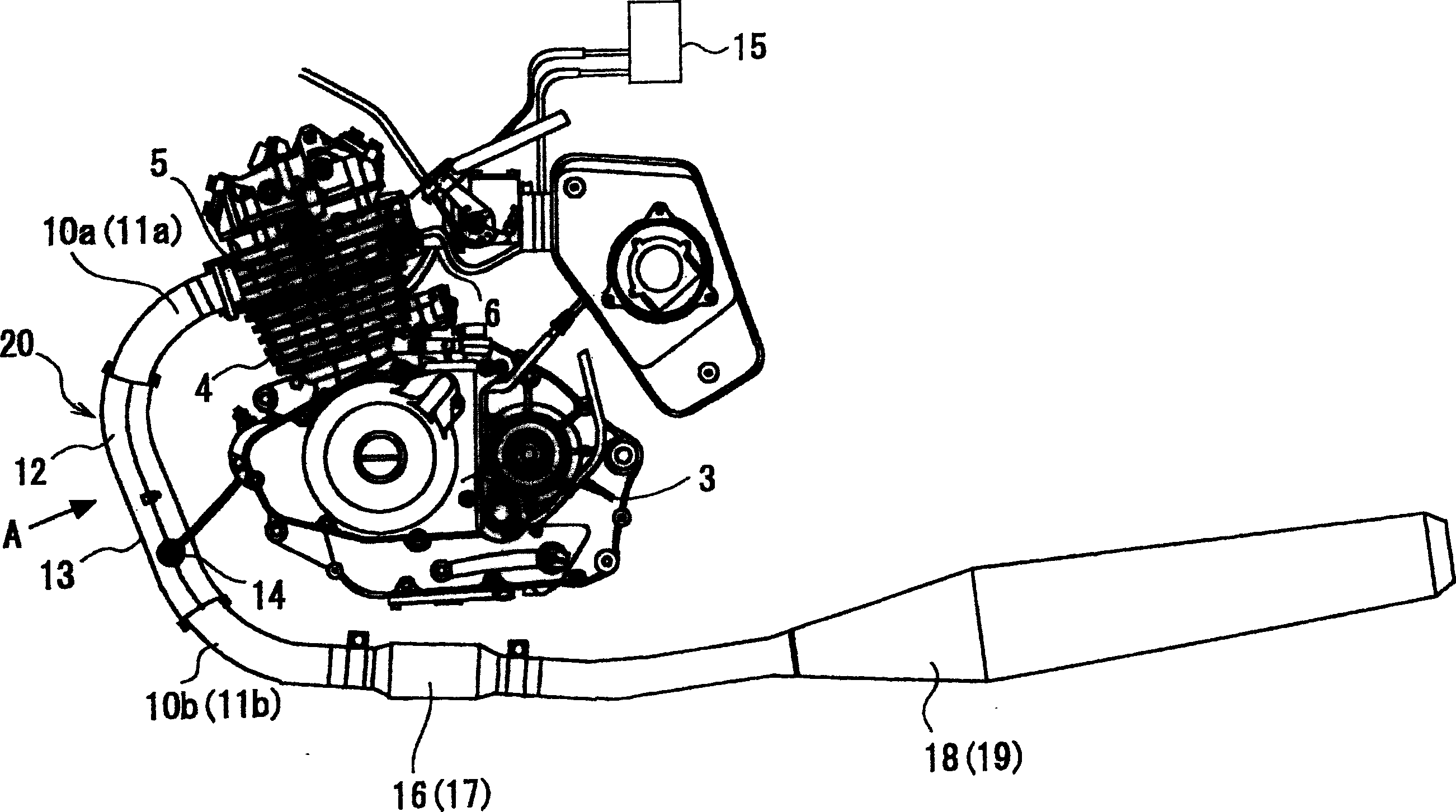

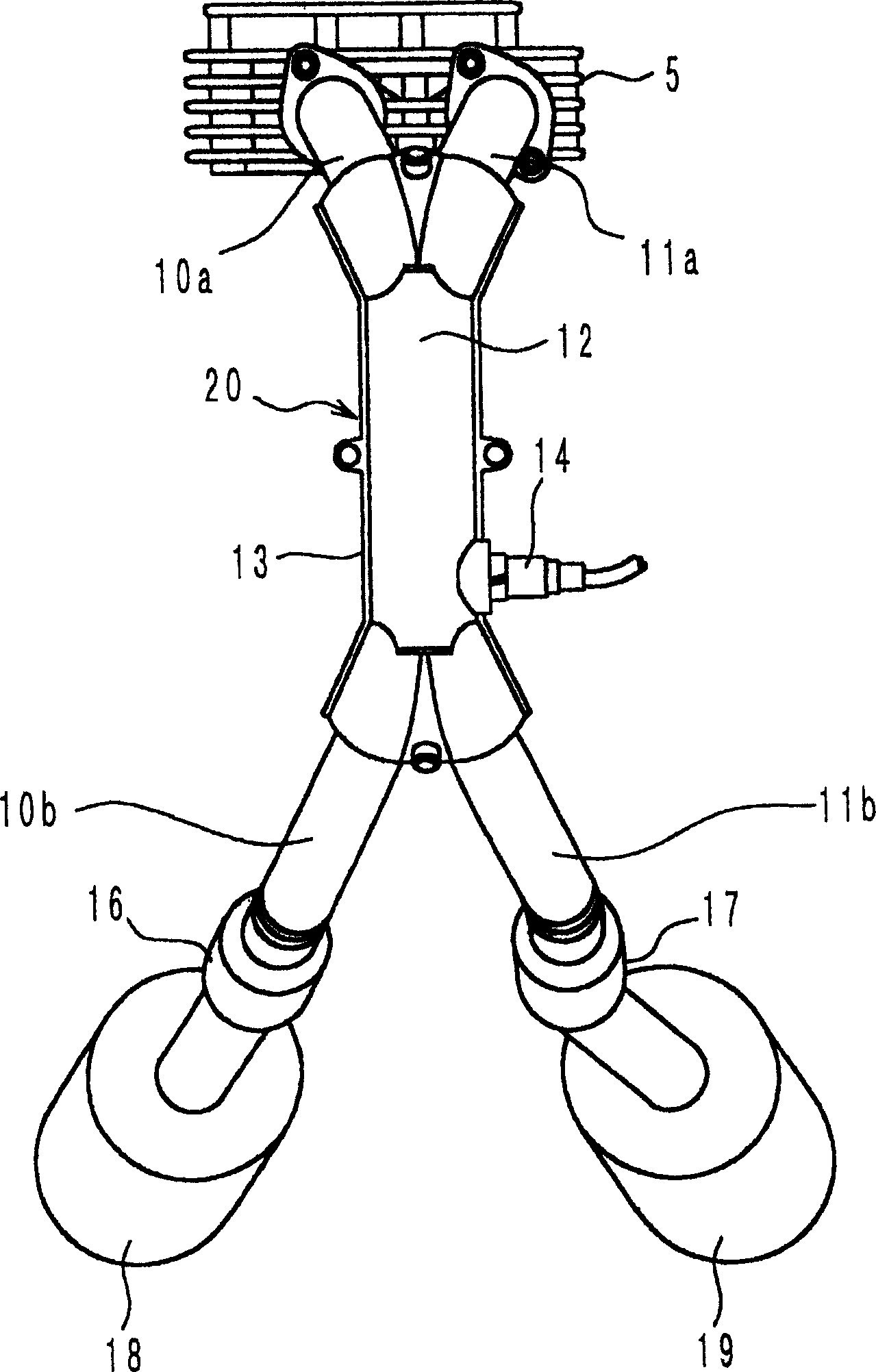

Exhaust pipe structure of automatic two wheel vehicle

InactiveCN1782337AStrong activationIncrease temperatureExhaust apparatusCylinder headsCylinder headOxygen

PROBLEM TO BE SOLVED: To provide an exhaust pipe structure capable of accurately controlling an air-fuel ratio in a motorcycle having two mufflers in its exhaust system while mounting a single cylinder engine thereon. SOLUTION: In this motorcycle, the single cylinder engine is mounted and two mufflers 18 and 19 are installed in the exhaust system of the single cylinder engine. The exhaust system comprises exhaust outlet pipes 10a and 11a connected to the cylinder head 5 of a single cylinder, a main exhaust pipe 12 for flowing, therein, all exhaust gas in the single cylinder continuously connected to the exhaust outlet pipes 10a and 11a, two branched exhaust pipes 10b and 11b continuously connected to the downstream side of the main exhaust pipe 12, and the mufflers 18 and 19 installed at the end part of the branched exhaust pipes 10b and 11b. An O<SB>2< / SB>sensor 14 detecting the concentration of oxygen in the exhaust gas is installed in the main exhaust pipe 12, and catalysts 16 and 17 are installed in the branched exhaust pipes 10b and 11b. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:AISAN IND CO LTD

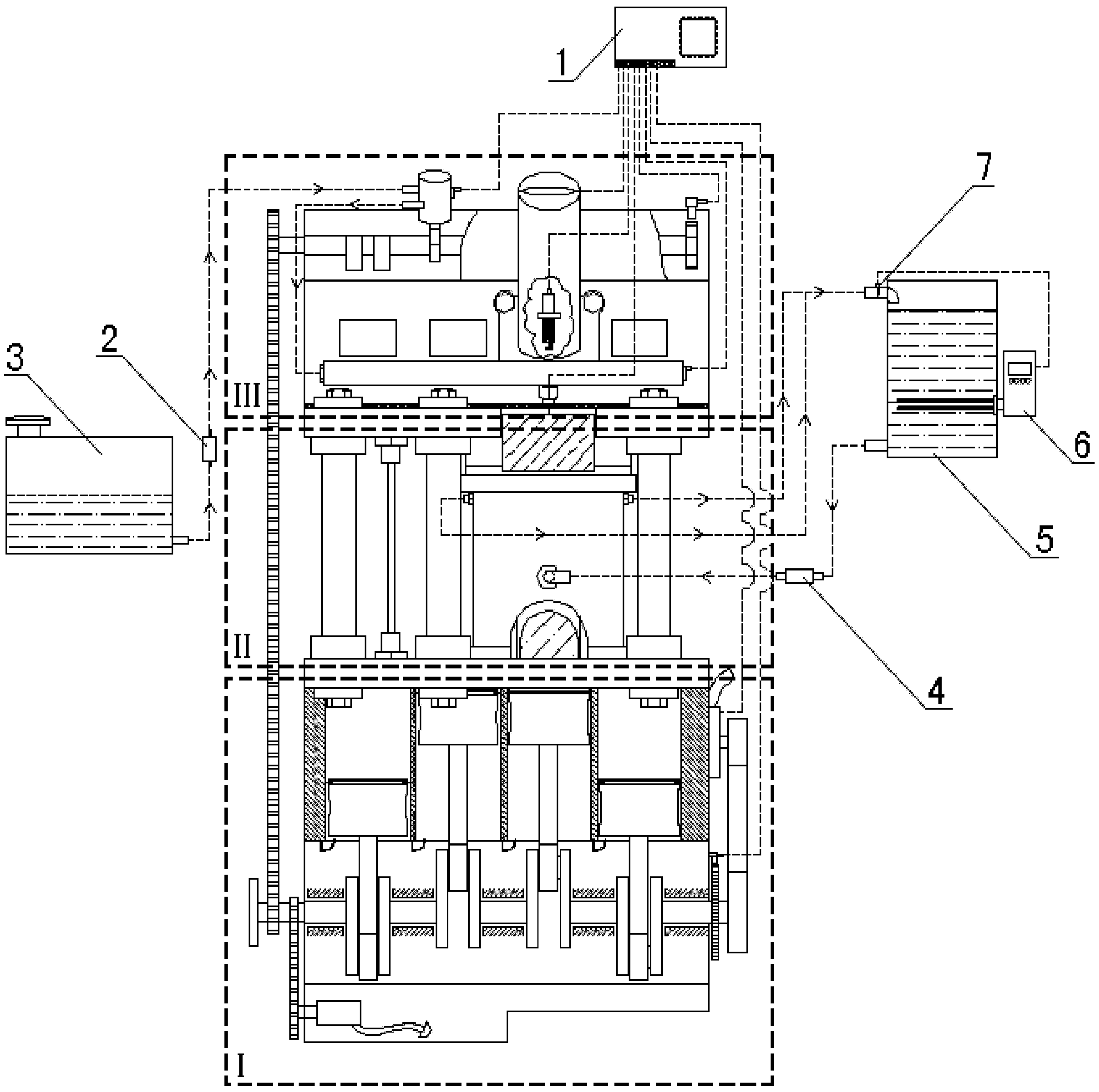

Visual direct-injection gasoline engine

InactiveCN103541813AEasy to control temperatureInjection pressure adjustableLiquid coolingValve arrangementsRail pressureFuel tank

The invention discloses a visual direct-injection gasoline engine, and belongs to the technical field of engines. According to the visual direct-injection gasoline engine, the upper portion and the lower portion of a lengthened visual part are fixedly connected with a cylinder cover part of the engine and a cylinder body part of the engine respectively, and a control unit is respectively connected with a fuel pressure adjusting valve, a throttle valve, a sparking plug, a fuel injector, a cam shaft phase sensor, a rail pressure sensor, a mechanical supercharger and a rotating speed sensor; a low pressure oil pump is in serial connection with a fuel tank and a high pressure oil pump; a water outlet of a water tank is connected with a water inlet of a base, and a water pump is in serial connection with the water tank and a water inlet pipeline of a base of a water jacket; a digital display heating pipe is installed in the water tank and connected with a temperature sensor of cooling liquid; the temperature sensor of the cooling liquid is fixedly connected to a water return port of the water tank. The visual direct-injection gasoline engine can solve the problems that in the prior art, when an optical engine and an actual gasoline engine are refitted by a single-cylinder engine, assimilating performance is poor, and the single-cylinder engine is difficult to refit and balance, the visual direct-injection gasoline engine is applicable to optical research in a supercharging small-displacement cylinder, and the visual direct-injection gasoline engine is low in operating noise, long in service life and low in cost.

Owner:JILIN UNIV

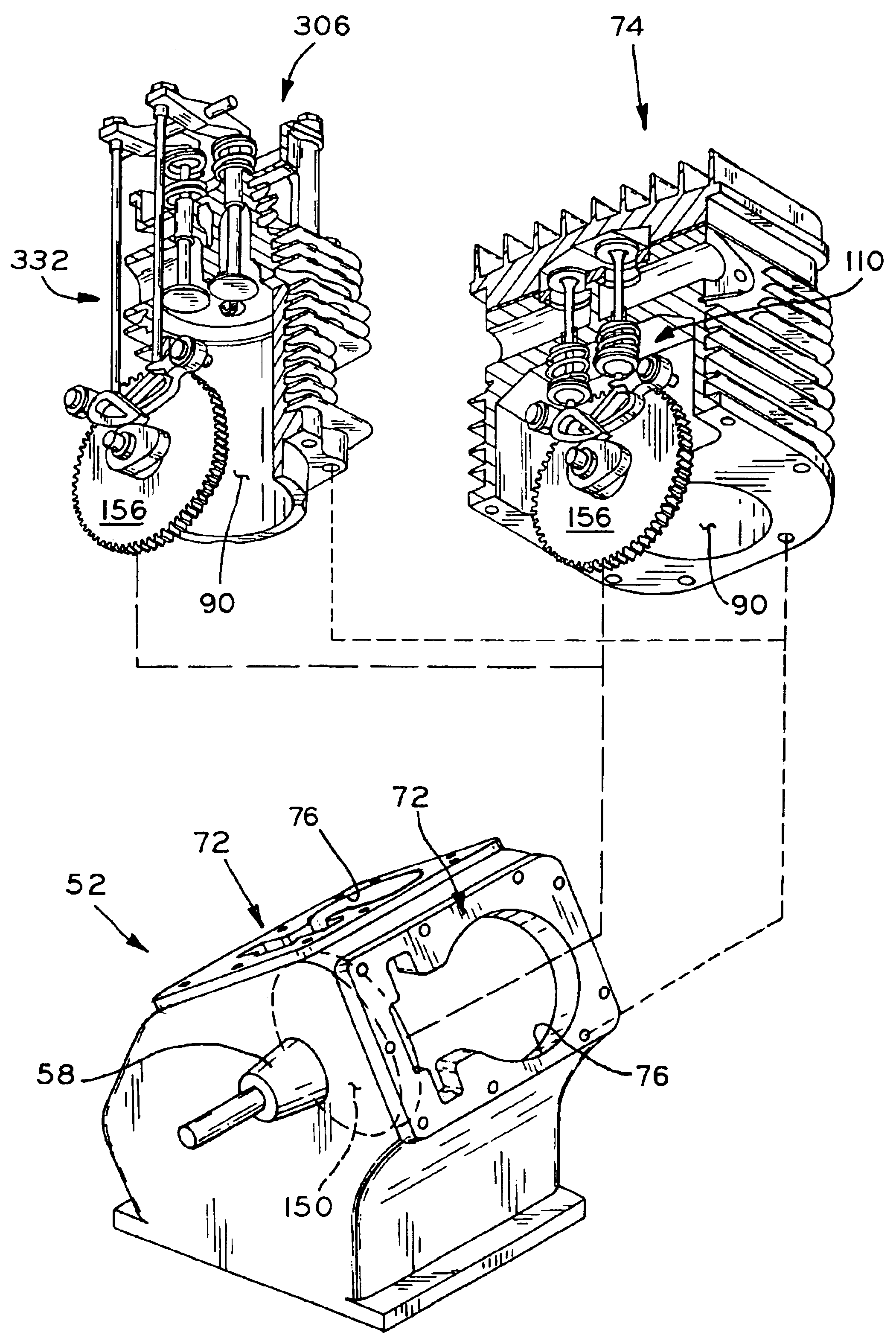

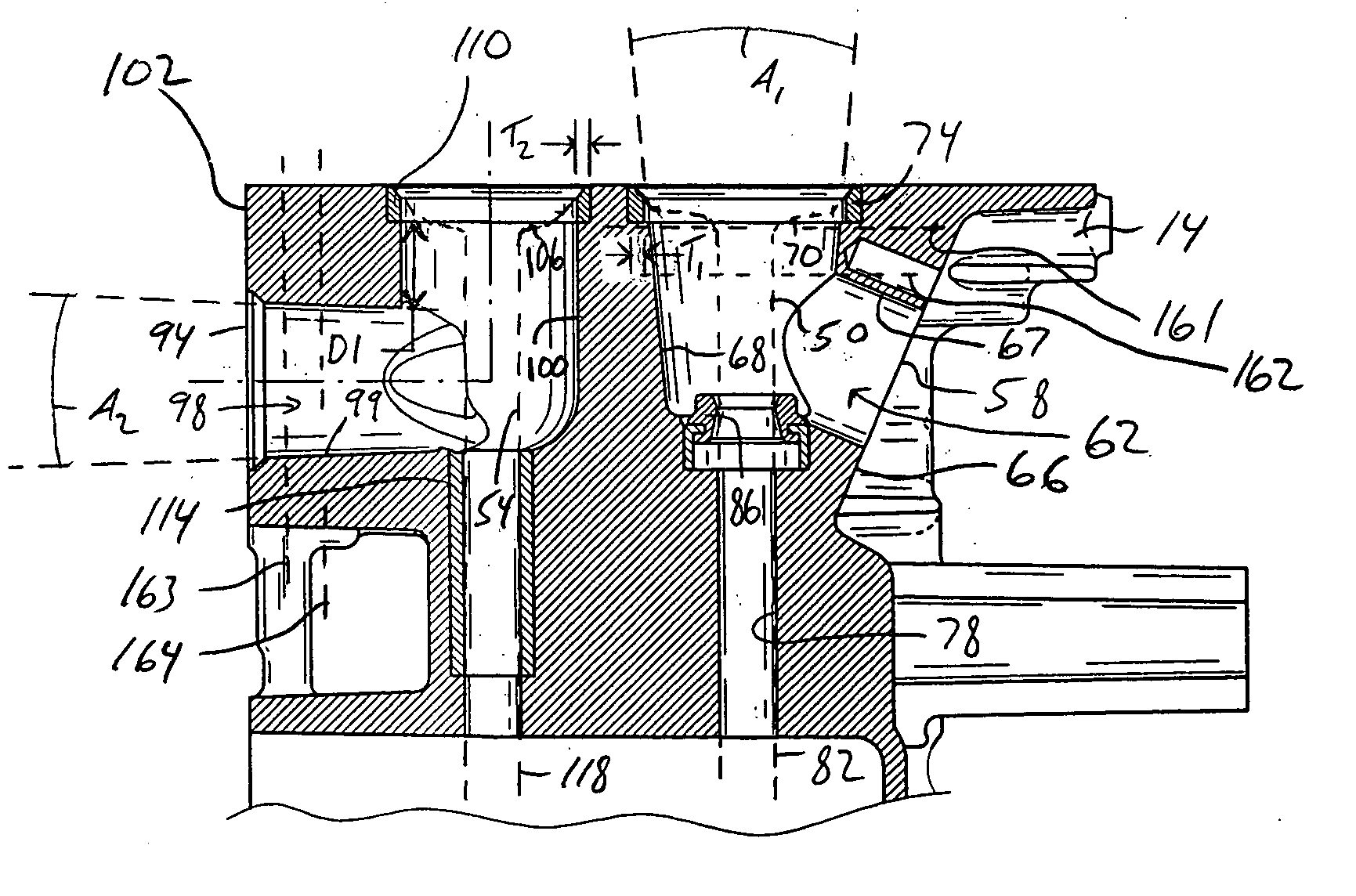

Modular internal combustion engines

A line of small internal combustion engines, including twin cylinder engines and single cylinder engines. The engines each include a crankcase, and one or more cylinder members attached to the crankcase, the cylinder members being separate components from the crankcase. A number of different crankcases are provided for various types of single and two cylinder engines, the crankcases having common mounting structure to which the cylinder members may be attached. Thus, the manner in which the cylinder members are attached to the crankcases is the same for each of the different types of crankcases. Two different types of cylinder members are provided, one having a side valve or “L-head” valve train, and the other having an overhead cam (“OHV”) valve train. The cylinder members are therefore modular components which may be selectively used in a variety of different types of engines.

Owner:TECUMSEH POWER

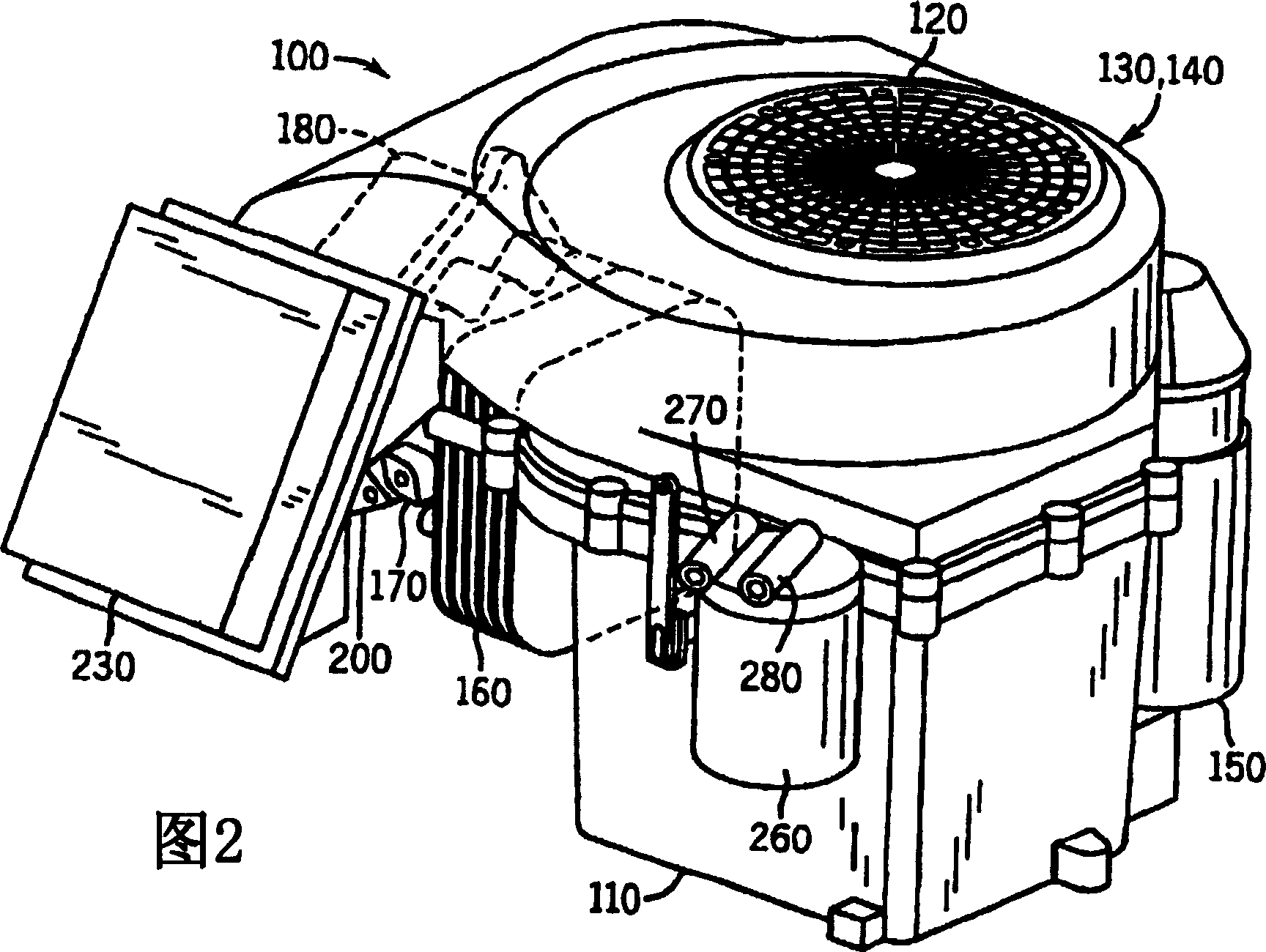

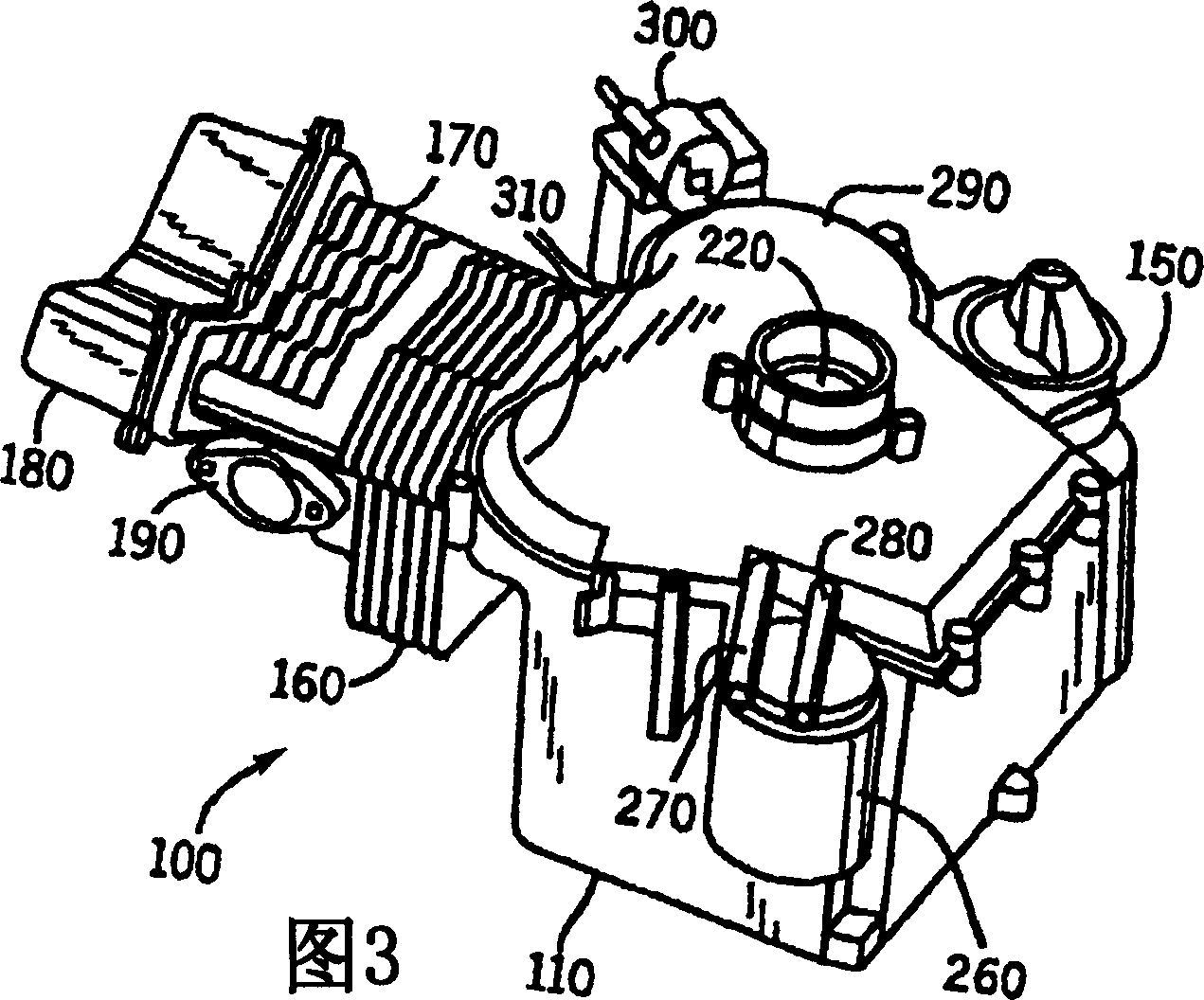

Reduced-emission single cylinder engine

InactiveUS20080202483A1Reduce the amount requiredCasingsCombustion enginesBreatherReciprocating motion

Owner:BRIGGS & STRATTON

Modular electronic-controlled engine model

ActiveCN103714740AImprove interchangeabilityEasy to assembleEducational modelsMicrocontrollerExhaust valve

The invention discloses a modular electronic-controlled engine model. The modular electronic-controlled engine model comprises a mechanical portion and a control circuit portion. In the mechanical portion, a piston, a connecting rod, a crank, a cylinder, a cylinder cover and a crankcase are assembled into a single-cylinder engine model, and then multiple single-cylinder engine models are assembled into a in-line type V-shaped opposite-type multicylinder engine model. The control portion is composed of a single chip microcomputer, a position sensor, LED lamps and a power source. The position sensor is located at the upper dead center of the cylinder, and used as the input single of the single chip microcomputer to control the operation of the LED lamps. The lighting of the yellow LED lamp indicates the ignition working condition. The lighting of the red LED lamp indicates the inlet valve opening condition. The lighting of the greed LED lamp indicates the exhaust valve opening condition. By observing the LEDs and the movement of the piston, the multicylinder engine successful ignition time and the inlet valve and exhaust valve opening and closing time can be obtained. The modular electronic-controlled engine model of the invention can be used in the engine teaching practices in universities to help students to understand the working sequence and valve opening and closing time of different types of engines having different cylinder number.

Owner:GUANGXI UNIV

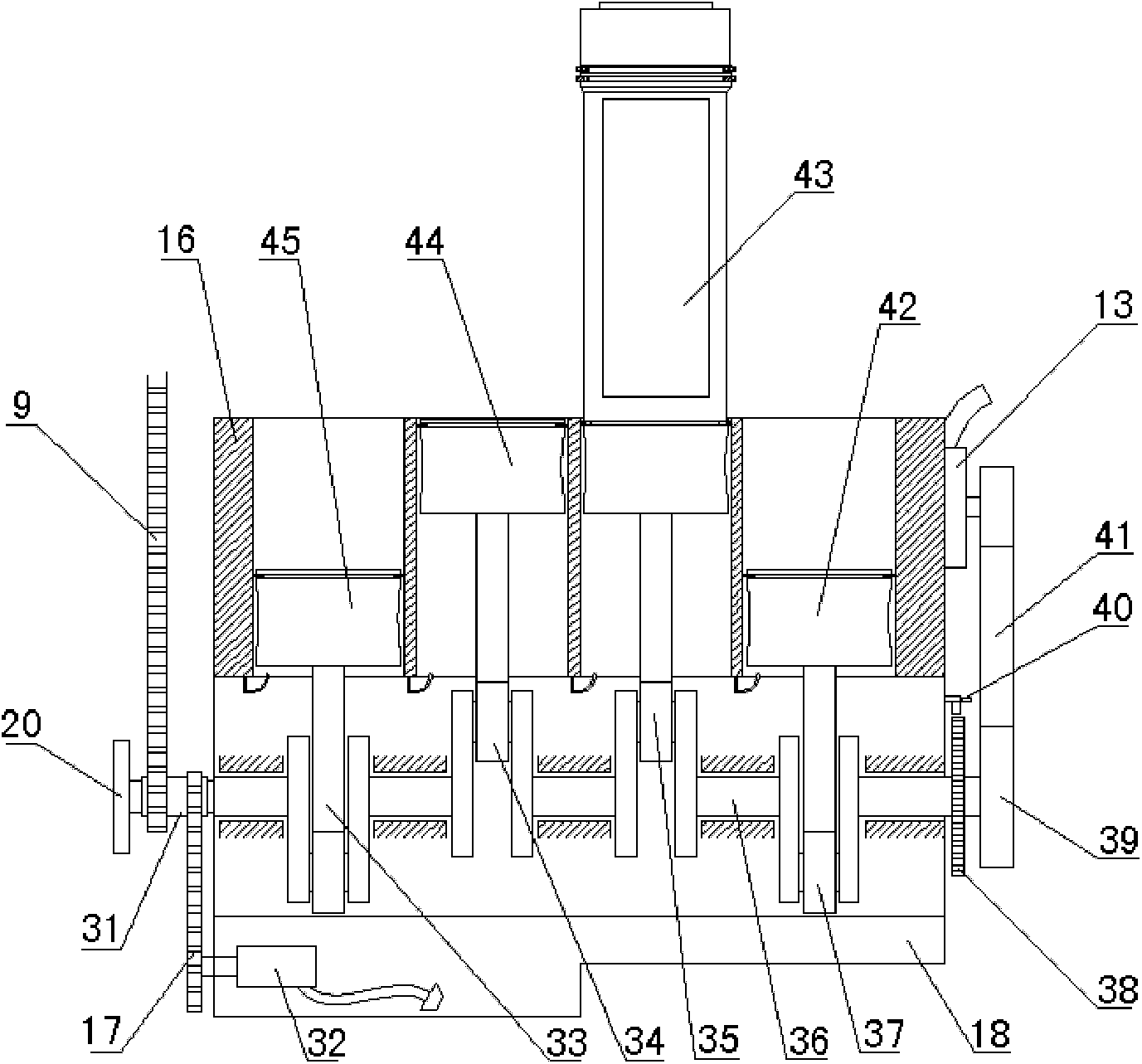

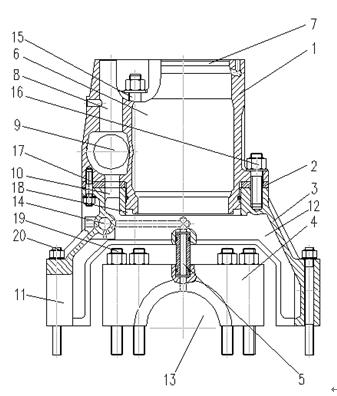

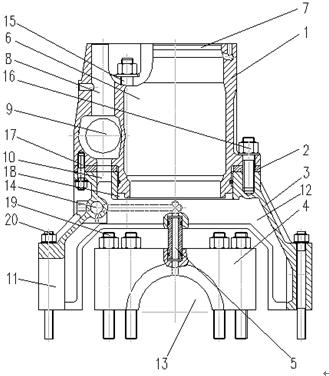

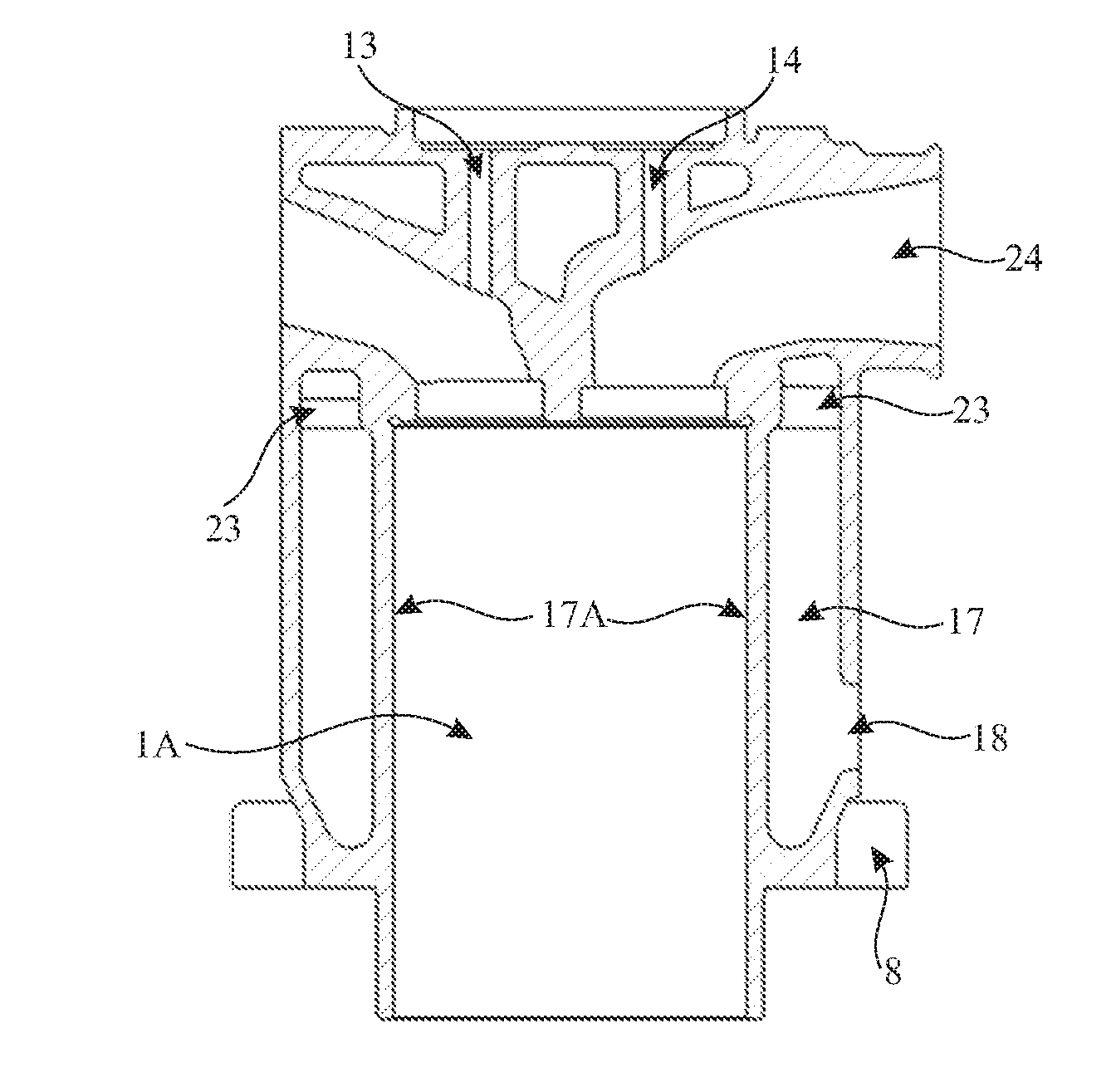

Adjustable single cylinder engine body structure

The invention relates to an adjustable single cylinder engine body structure. A cylinder hole (6) is arranged in a cylinder body (1), a cylinder sleeve support (7) is arranged inside the cylinder hole (6), the left side of the cylinder body (1) is provided with an air distribution tappet hole (8), a cam shaft supporting hole (9) and an air distribution oil return hole (10). A crankcase (3) is arranged at the lower portion of the cylinder body (1), an adjusting plate (2) is arranged between the cylinder body (1) and the crankcase (3), a positioning mouth opening (18) is positioned on the adjusting plate (2, the lower portion of the crankcase (3) is provided with a connecting rod dismounting hole (11), and the left wall of the crankcase (3) is provided with a longitudinal main oil way (14). A first arched partition plate (12), a second arched partition plate (12) and a third arched partition plate (12) are longitudinally arranged on the crankcase (3), correspond to a top-arranged bearing cover (4) and are connected with the top-arranged bearing cover (4) through an engine oil transition device (5), an installing hole of the engine oil transition device (5) is arranged at the upper portion of the top-arranged bearing cover (4), and a main bearing hole (13) is arranged at the lower portion of the top-arranged bearing cover (4). By means of the adjustable single cylinder engine body structure, the economic investment for engine study is reduced, and the utilization ratio is improved.

Owner:NO 70 INST OF CHINA NORTH IND GRP

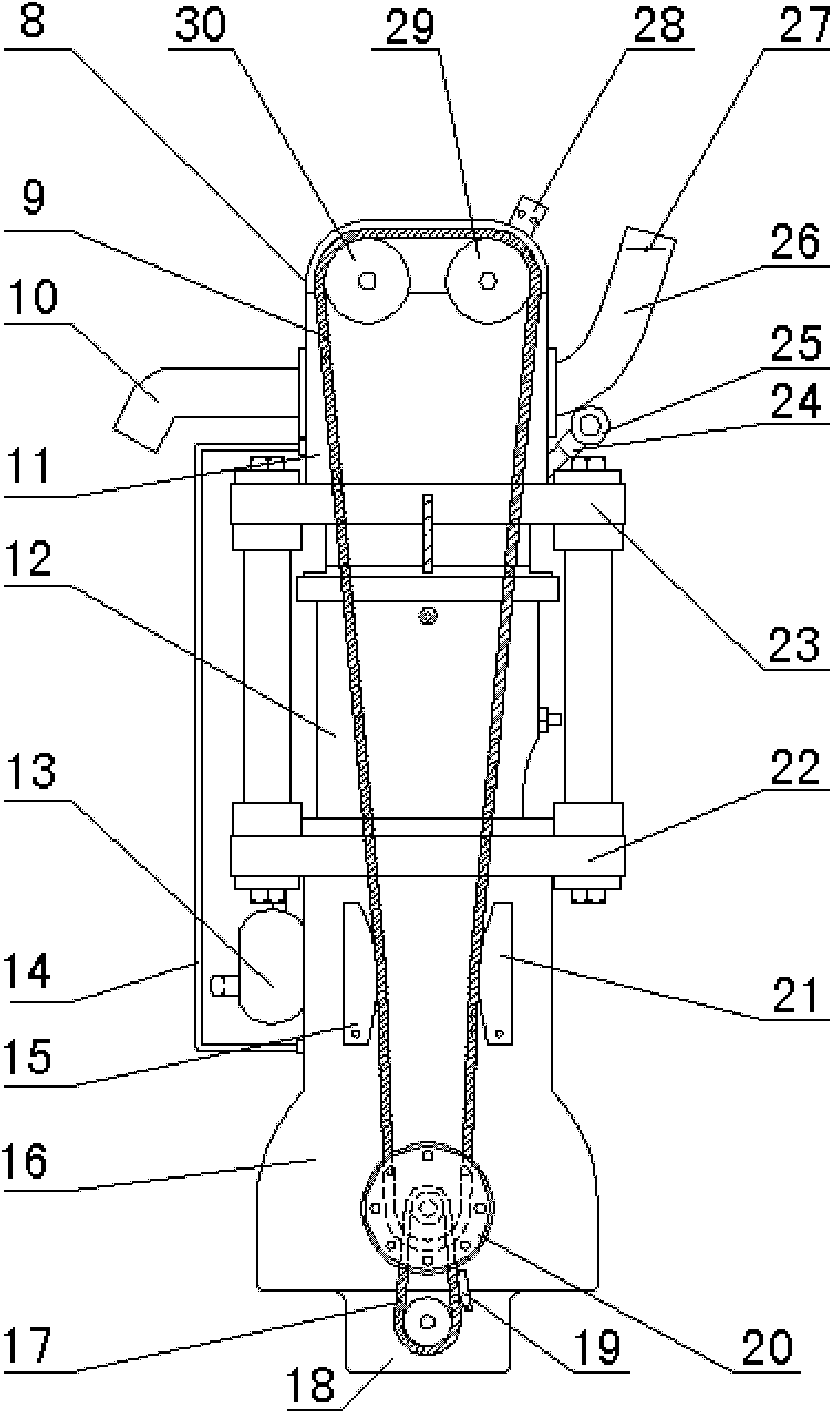

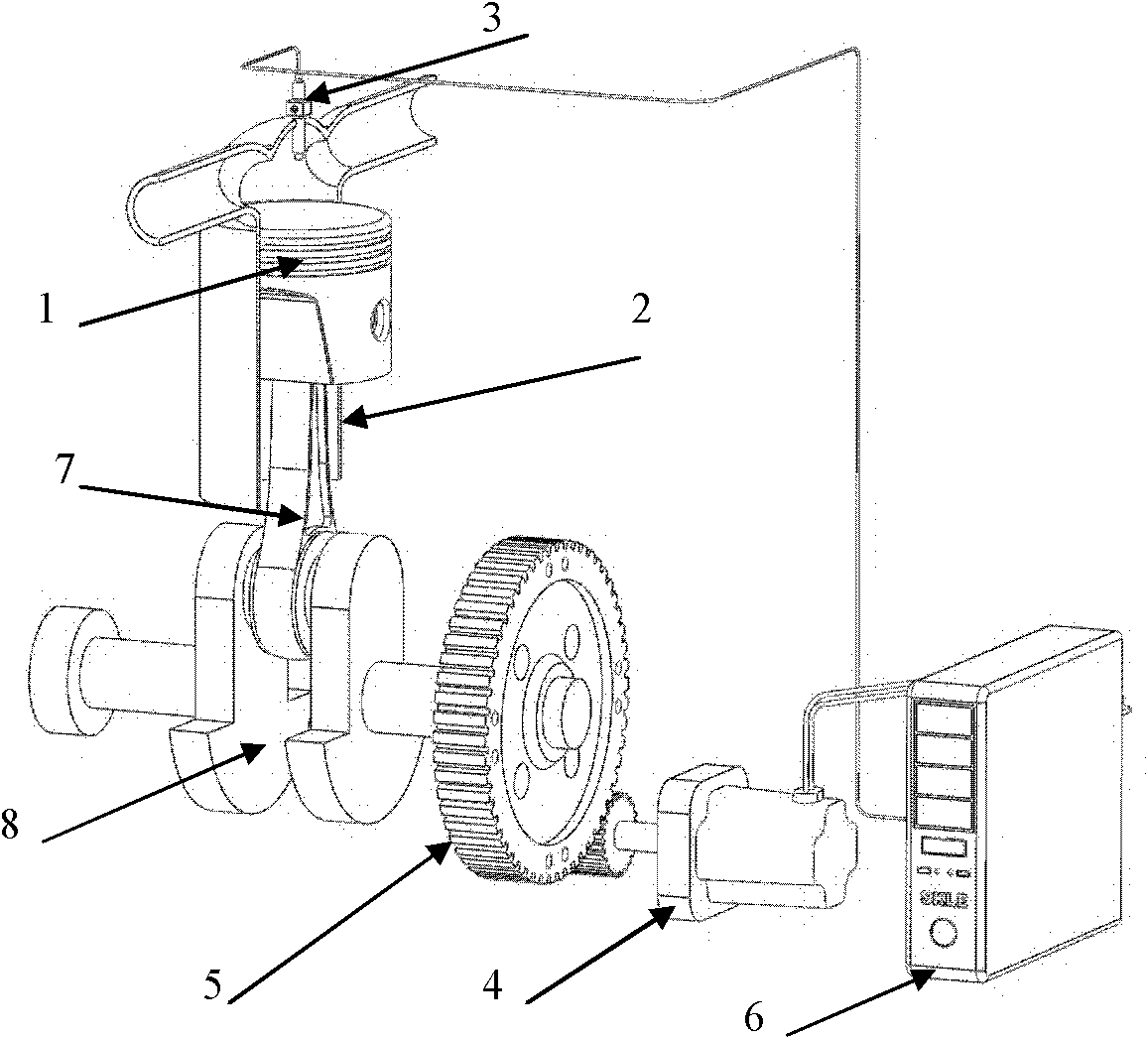

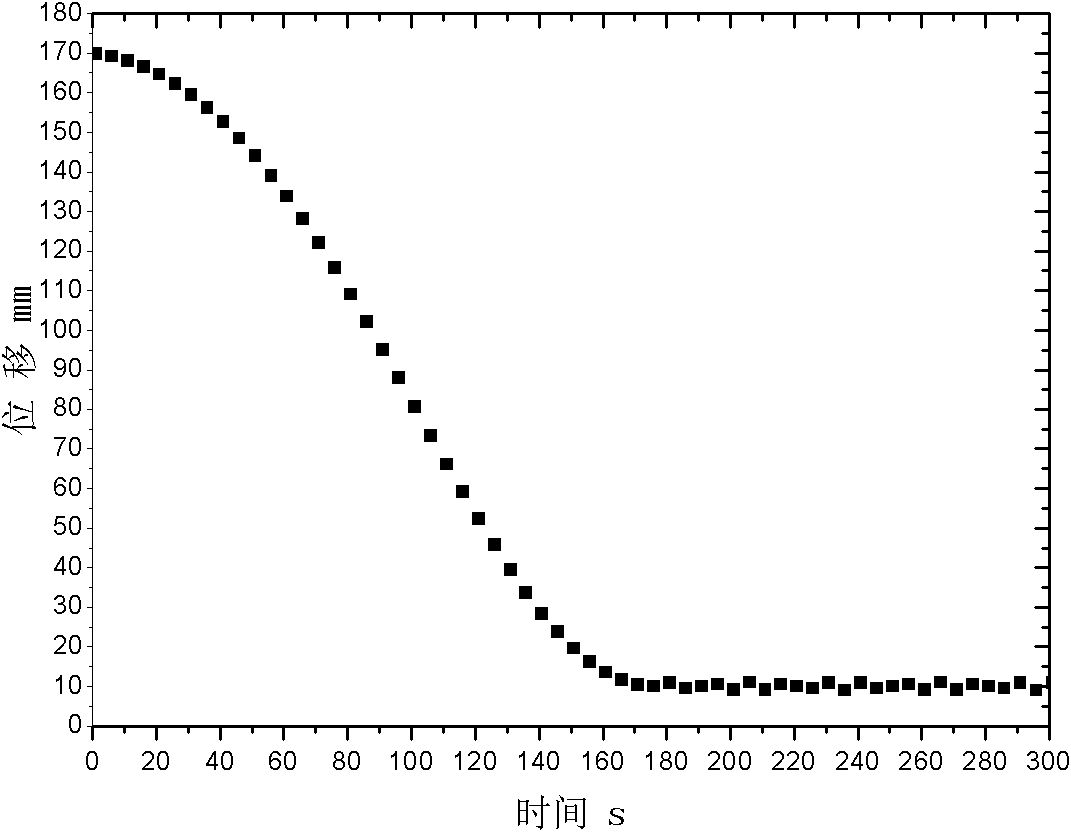

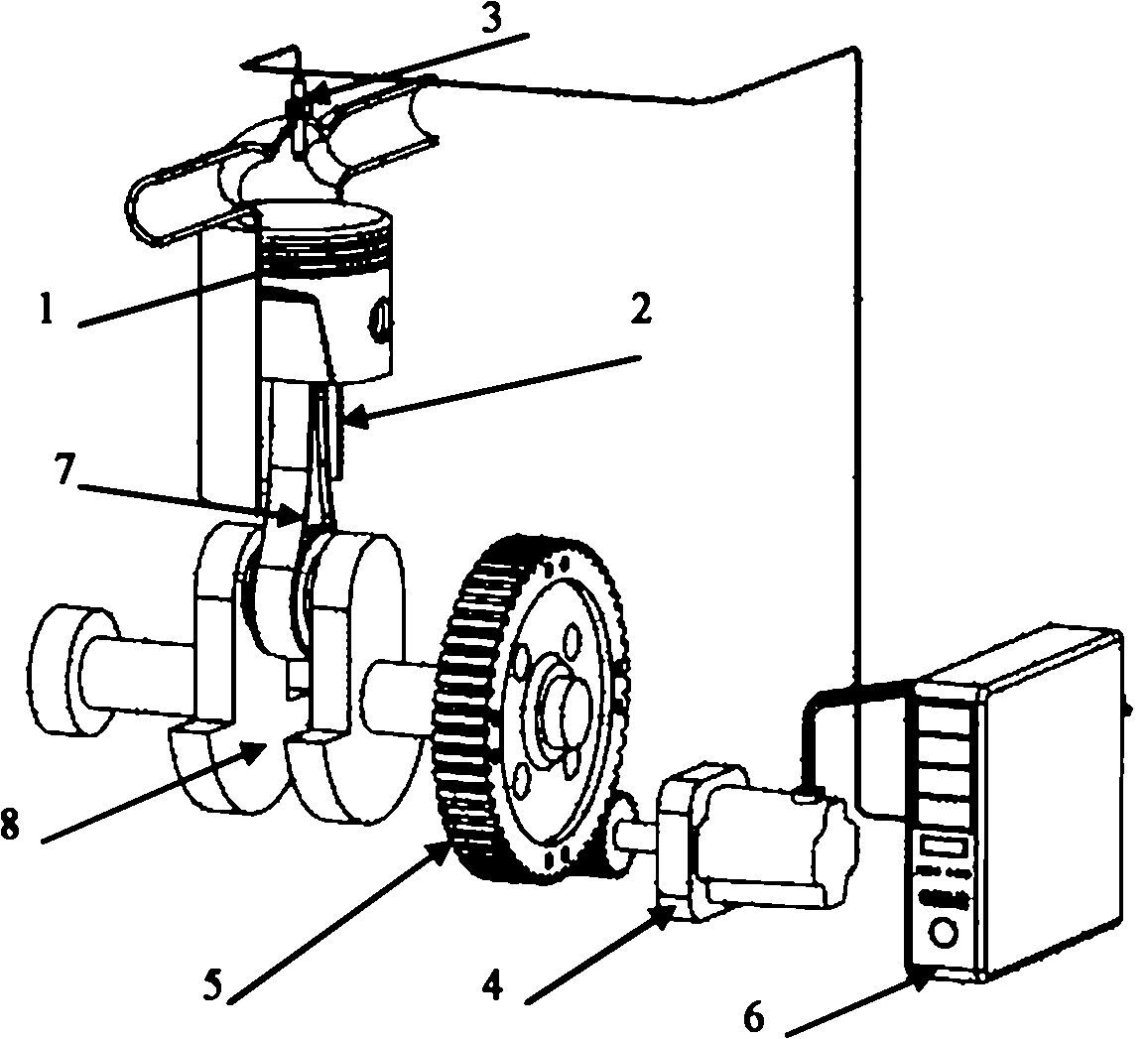

Piston top dead center automatic detecting and positioning device of reciprocating machinery

InactiveCN102243071AImprove accuracySimple structureMeasurement devicesVisual observationTop dead center

The invention discloses a piston top dead center automatic detecting and positioning device of reciprocating machinery. The device is characterized in that a displacement sensor is arranged at the position of an oil nozzle in a cylinder sleeve above a piston; the gear of a step motor is engaged with a flywheel ring gear of an engine; the signal output of the displacement sensor is connected to the input end of a controller; and a drive power wire of the step motor is connected to the output end of the controller. The system has a simple structure, and has the advantages of accurate positioning and short response time as compared with a visual observation method, so that the piston top dead center position of the reciprocating machinery is accurately positioned in a visual and digitized way. Single cylinder engine tests prove that the device can effectively improve the position accuracy of the piston top dead center, and the debugging process cannot influence the assembling process. The device is also suitable for piston positioning of other reciprocating machinery.

Owner:TIANJIN UNIV

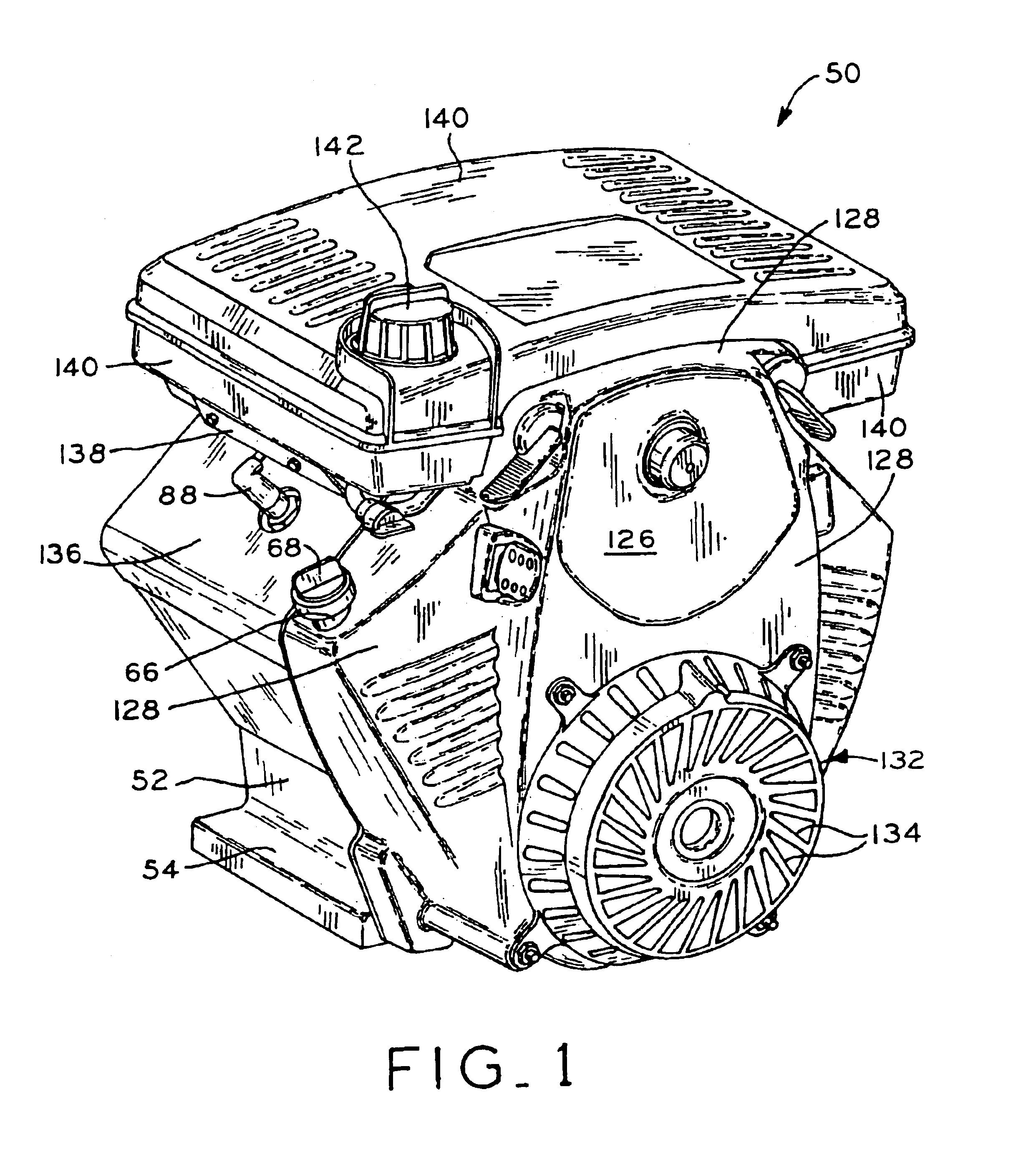

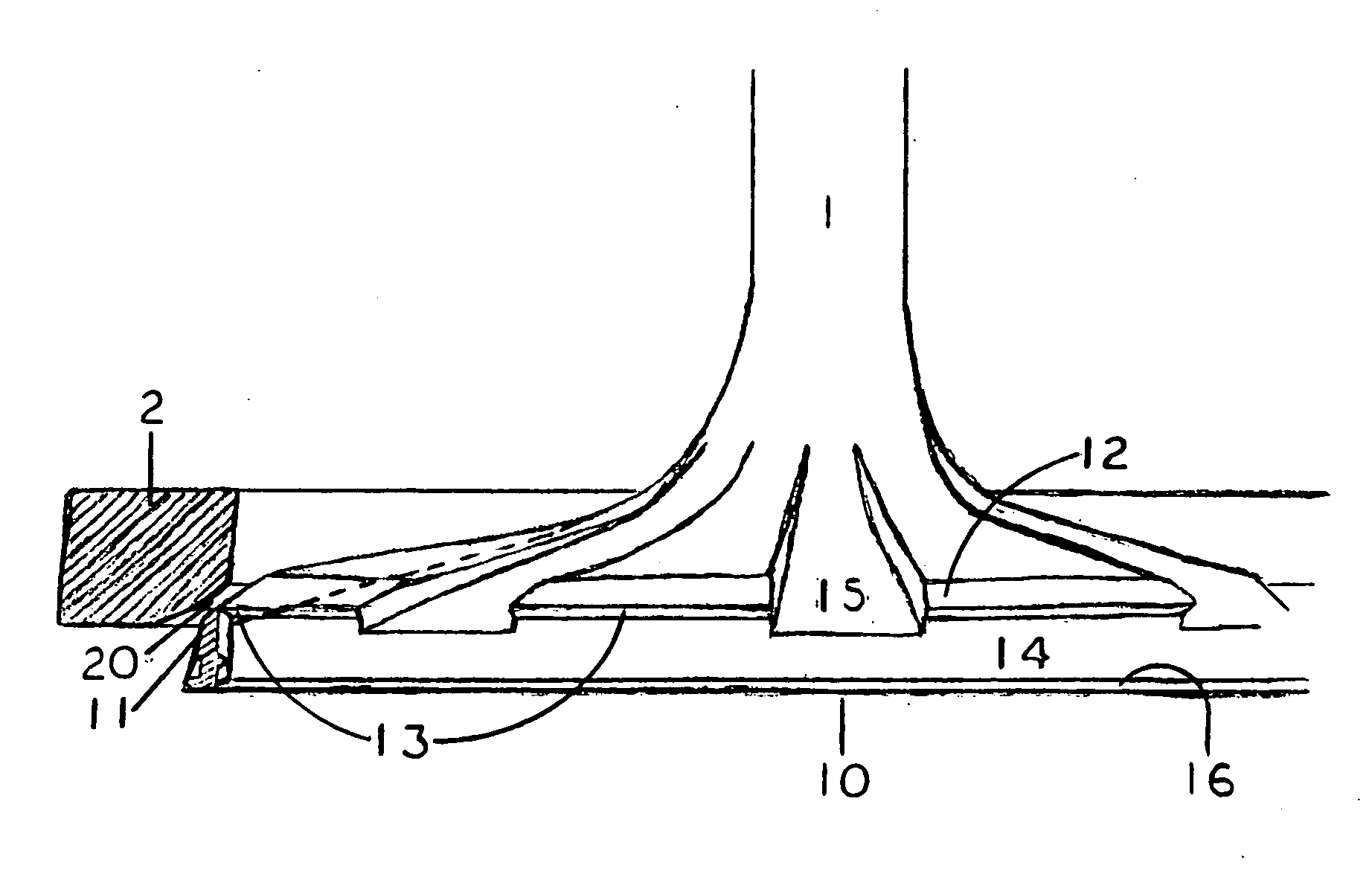

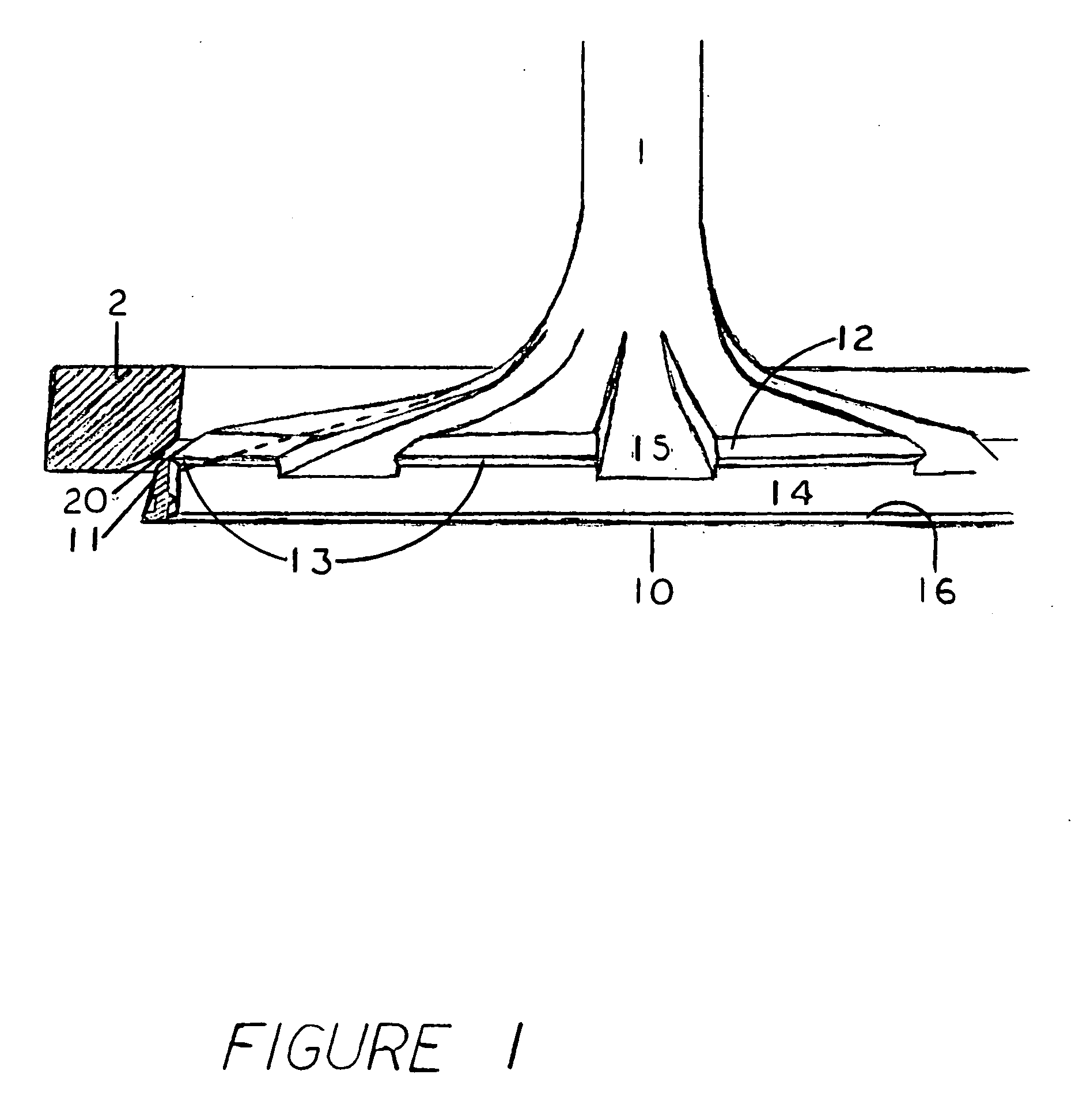

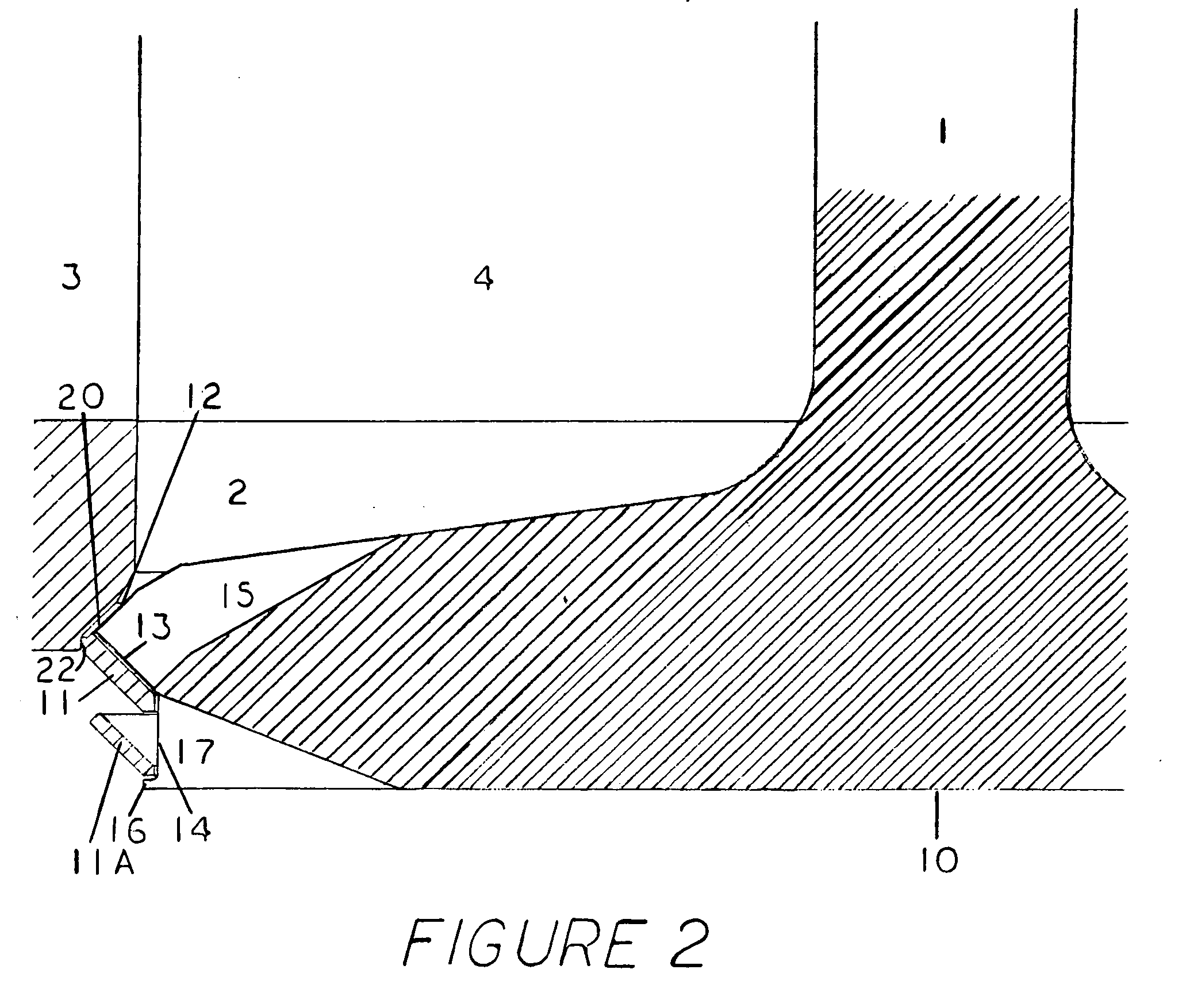

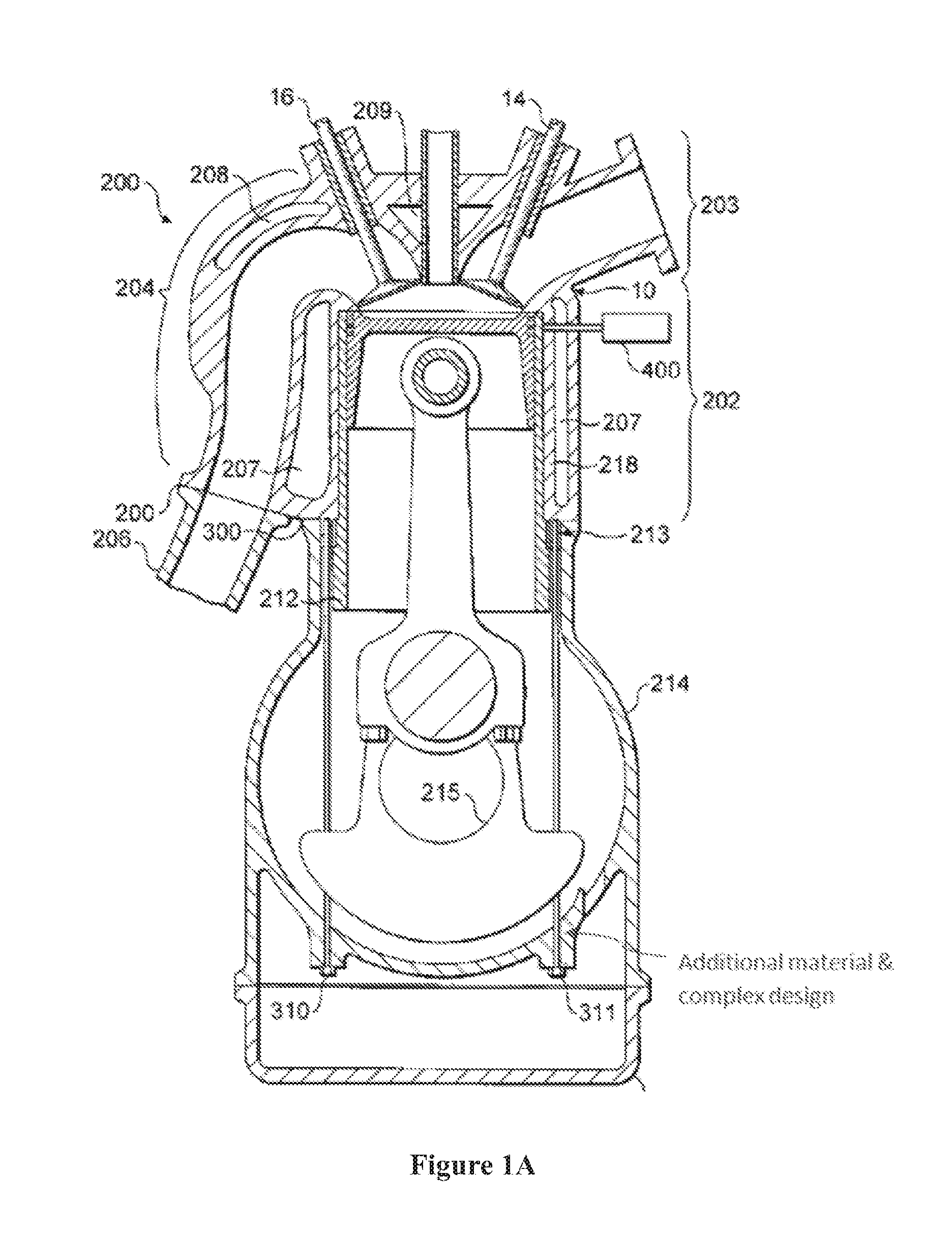

Air flow arrangement for a reduced-emission single cylinder engine

InactiveUS20060037577A1Improves air-fuel mixingAccurate CalibrationCylinder headsCylindersSingle-cylinder engineAirflow

The present invention provides a reduced emission, single cylinder engine incorporating an air flow arrangement for improving flow efficiency of the intake air drawn into the engine and the exhaust discharged from the engine.

Owner:BRIGGS & STRATTON

Hybrid valve for internal combustion engines

InactiveUS20100192892A1Improve performanceImprove efficiencyInternal combustion piston enginesSlide valveJet flowVariable valve timing

A next generation hybrid valve concept for enhanced induction cycle function for internal combustion engines. Said hybrid valve effectively combining automatic pressure activated check valve function with traditional poppet valve function to create an effective low cost self regulating variable valve timing (VVT) system. Said hybrid valve consisting of a free floating annular ring seal which is affixed concentrically around a modified poppet valve seat or within an engine head seat insert configured with releasably sealable jet flow passage ways.The concept can provide an effective range of late opening and early closing times to control reversion as well as a very broad range of early opening and late closing times. In addition, the actuation of the free floating ring seal is variable, automatic and controlled and timed very precisely by cycle exchange functions allowing for effective variable valve function in four (4) dimensions within single cylinder engines and five (5) dimensions within multi-cylinder engines.

Owner:HUFF REGGIE DWAYNE

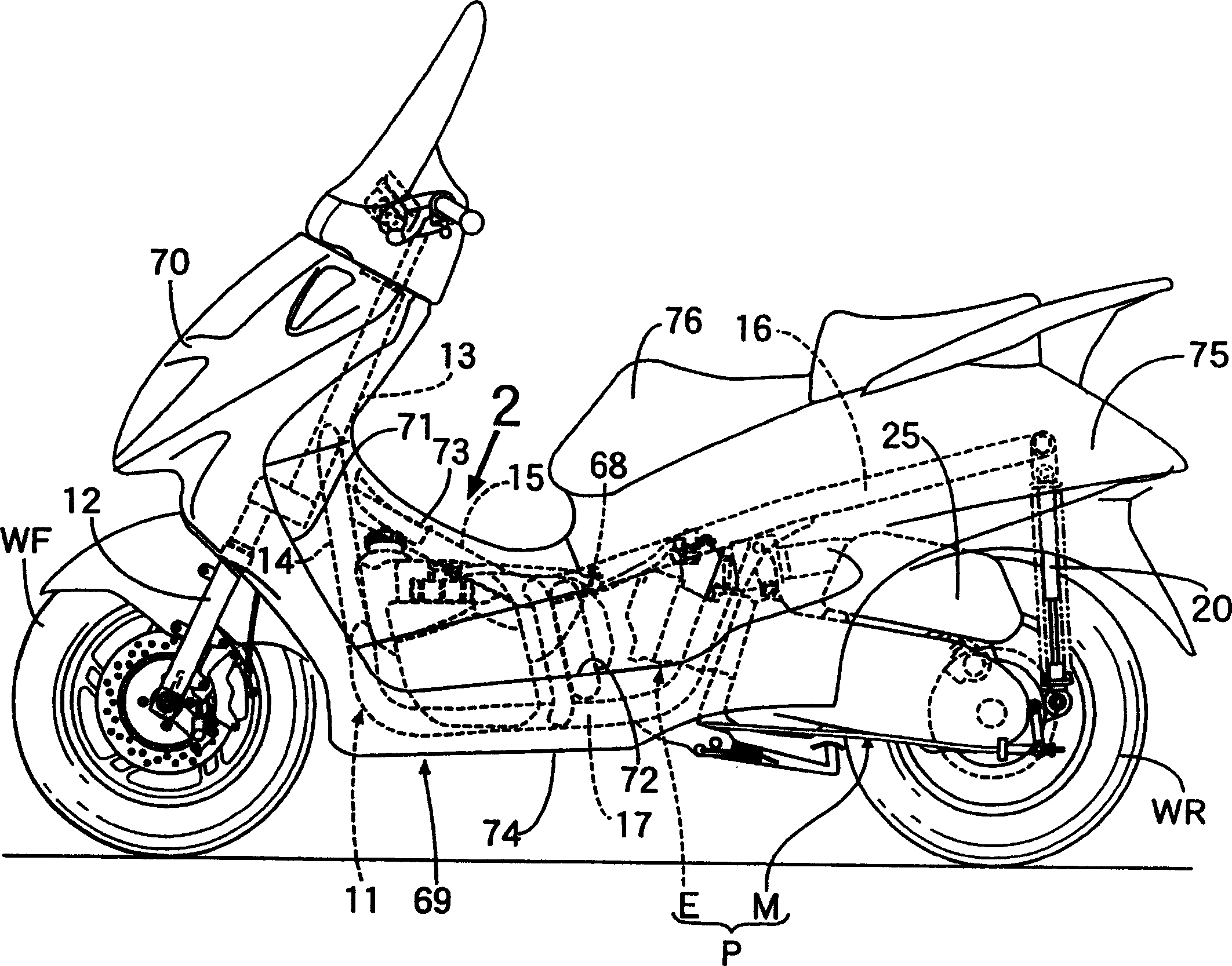

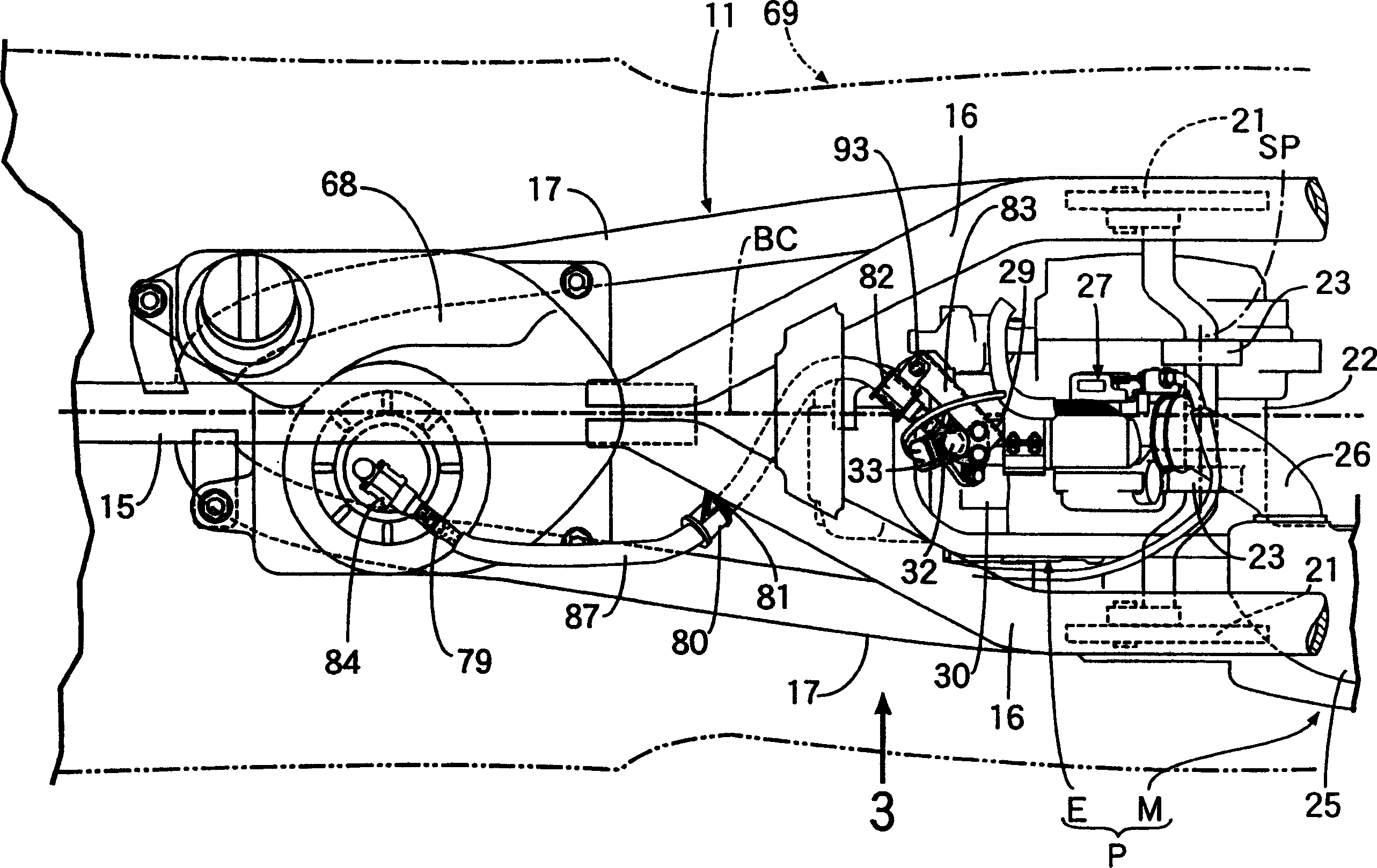

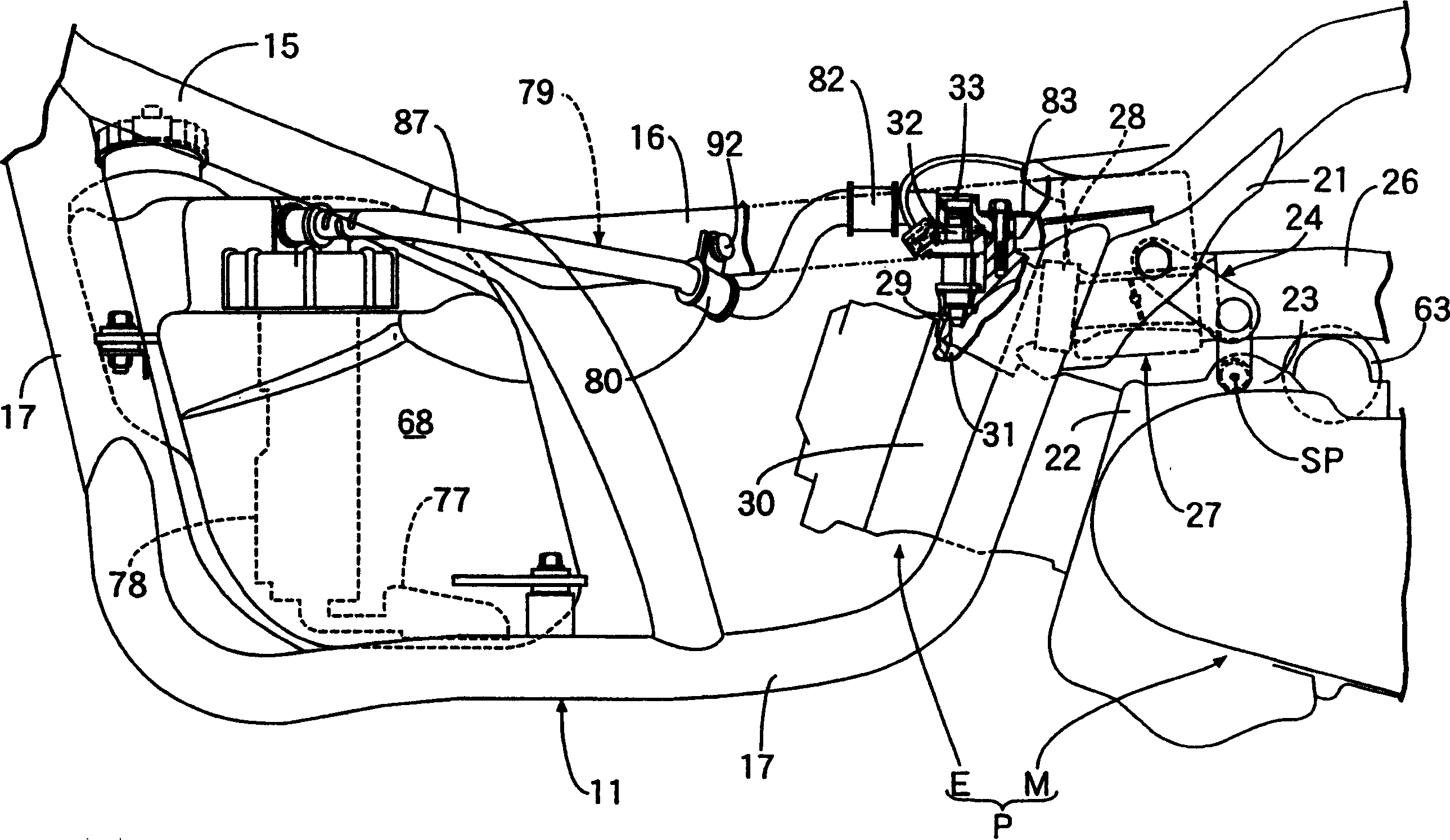

Fue supply structure for small vehicle engine

In a small sized vehicle in which, to a cylinder head of an engine, an intake pipe which is communicated with an intake port of the cylinder head is connected and, to the intake pipe or the cylinder head, a fuel injection valve which injects fuel toward the intake port is mounted, the reliability of mounting of the fuel injection valve and a fuel hose can be enhanced when the fuel is supplied to a single cylinder engine or when fuel is independently supplied to respective cylinders of a multi-cylinder engine. A fuel joint 33 having a connecting pipe portion 33a to which a fuel hose 79 for introducing fuel to a fuel injection valve 32 is connected is hermitically fitted on a head of the fuel injection valve 32 while setting a circumferential position of the fuel injection valve 32 to the connecting pipe portion 33a to a fixed position and, at the same time, the fuel joint 33 is fastened to the intake pipe 29 such that the fuel joint 33 is sandwiched between the fuel injection valve 32 and the intake pipe 29 while setting the position of the fuel injection valve 32 with respect to the intake port 31 to a fixed position.

Owner:HONDA MOTOR CO LTD

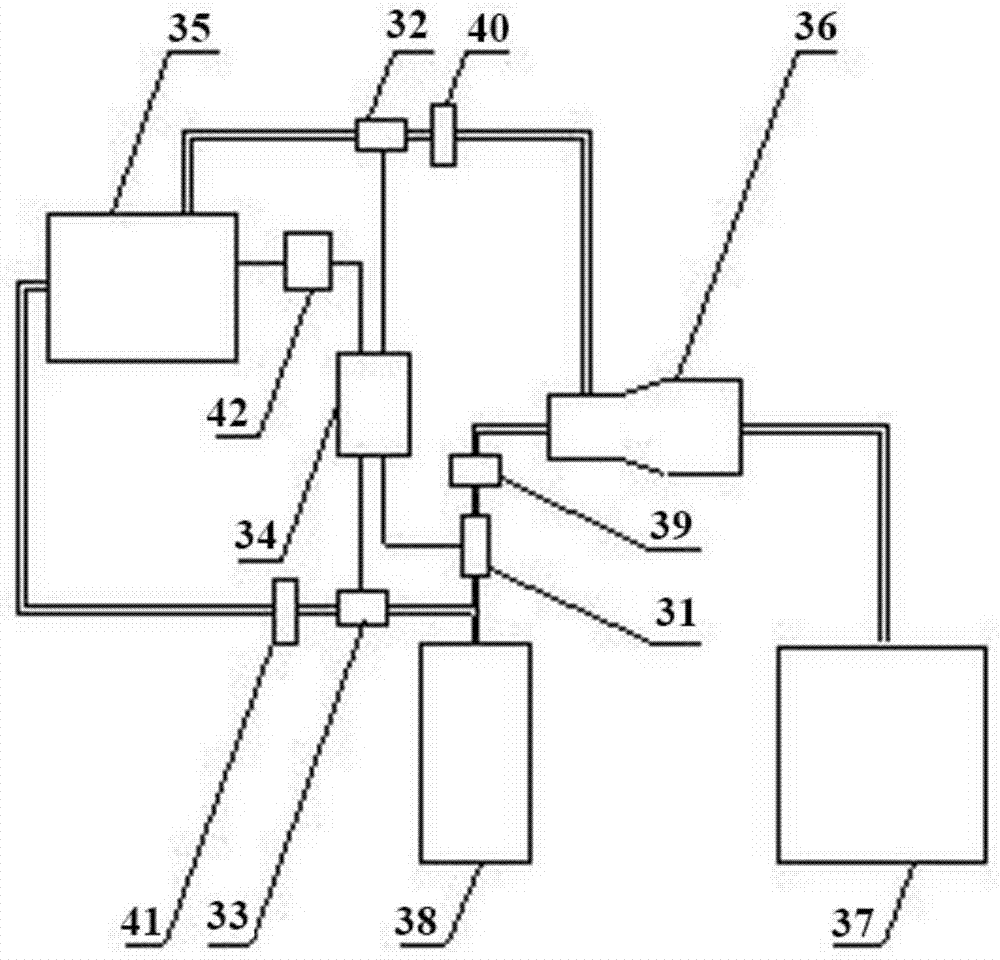

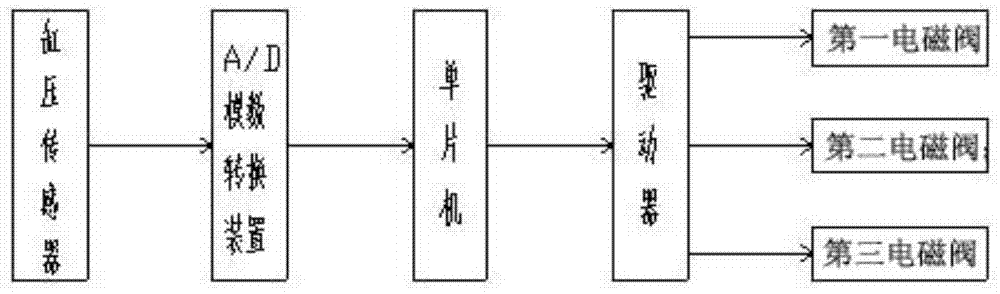

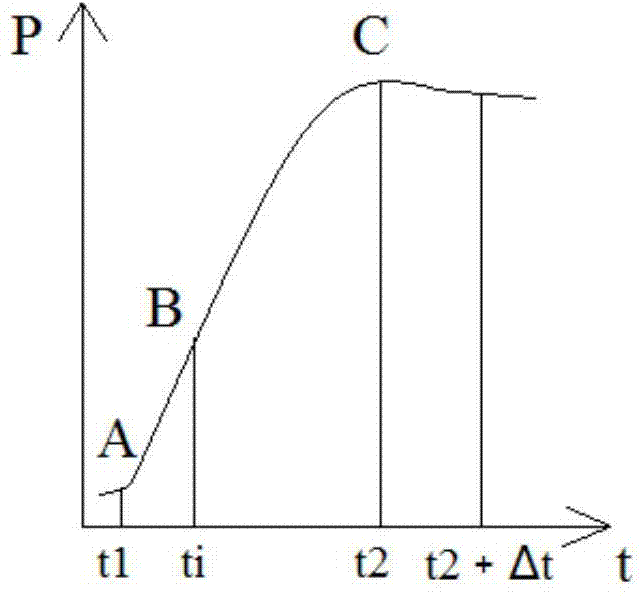

System and method for collecting combustion products of constant volume combustion bomb

InactiveCN104730199APrecise control of thermodynamic parametersAccurate reproduction of combustionChemical analysis using combustionWithdrawing sample devicesGas cylinderControl system

The invention relates to a system and a method for collecting the combustion products of a constant volume combustion bomb, aiming at overcoming the defects of a single-cylinder engine all-cylinder sampling system and the traditional gas collecting device and method. The system for collecting the combustion products of the constant volume combustion bomb comprises a constant volume combustion bomb, a quenching device, a first electromagnetic valve, a first flow metering valve, a second electromagnetic valve, a second flow metering valve, a third electromagnetic valve, a third flow metering valve, a gas bag or gas cylinder, a nitrogen steel cylinder, a synchronous data acquisition system and a singlechip control system. The system and the method have the advantages and the beneficial effects that multiple thermodynamic parameters can be accurately controlled by the constant volume combustion bomb, so that the combustion under various conditions can be accurately reproduced, and the influence of actual cyclical variation of an engine to sampling can be eliminated.

Owner:TIANJIN UNIV

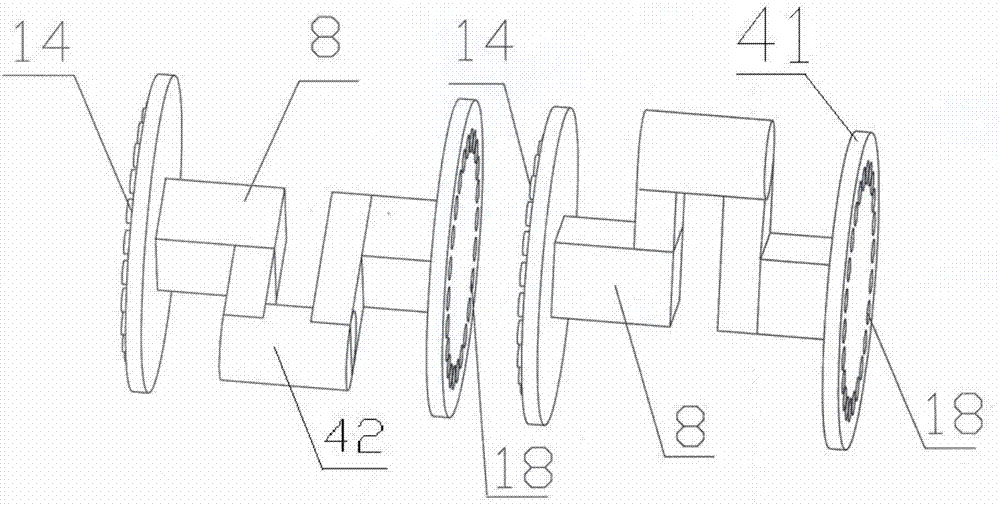

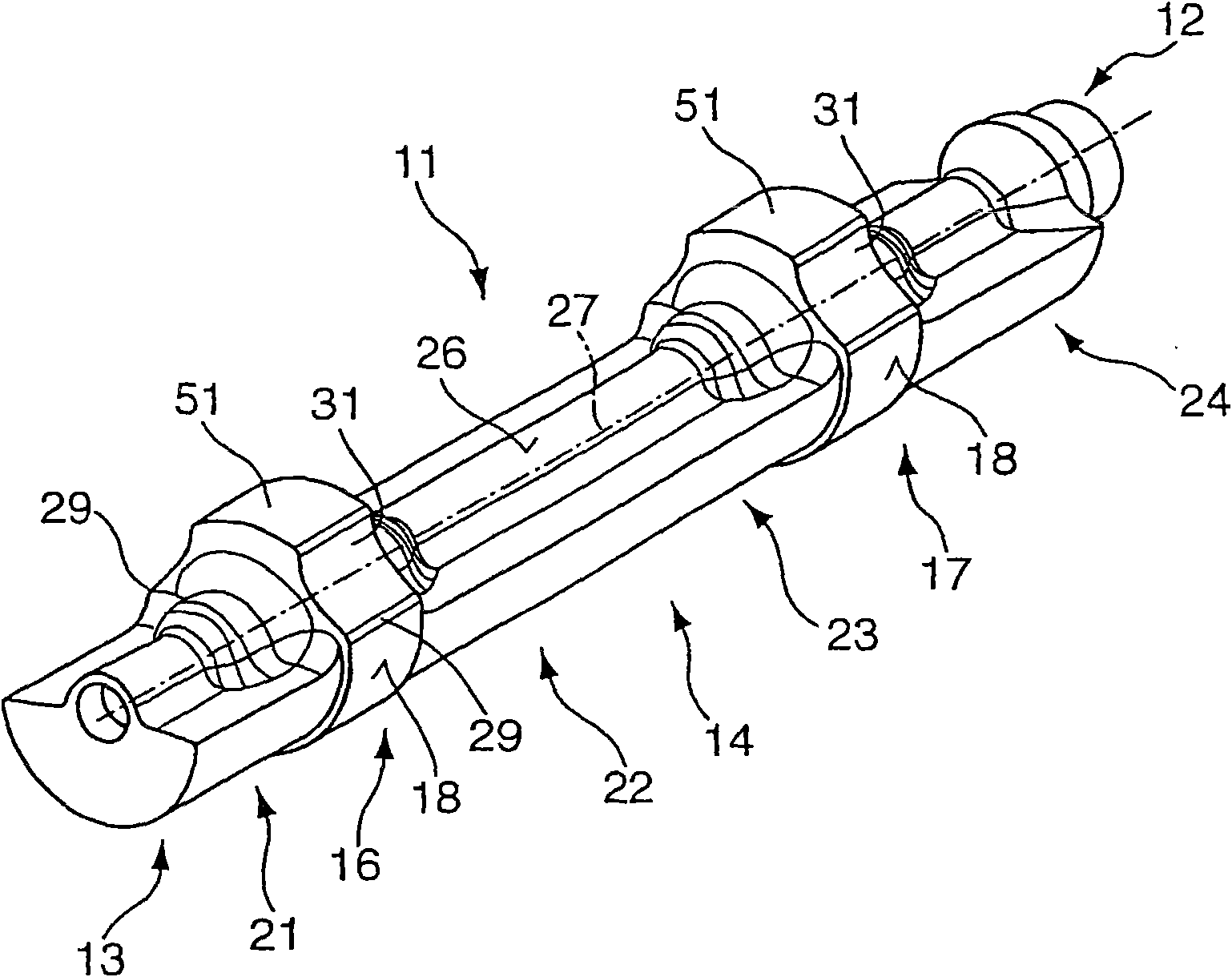

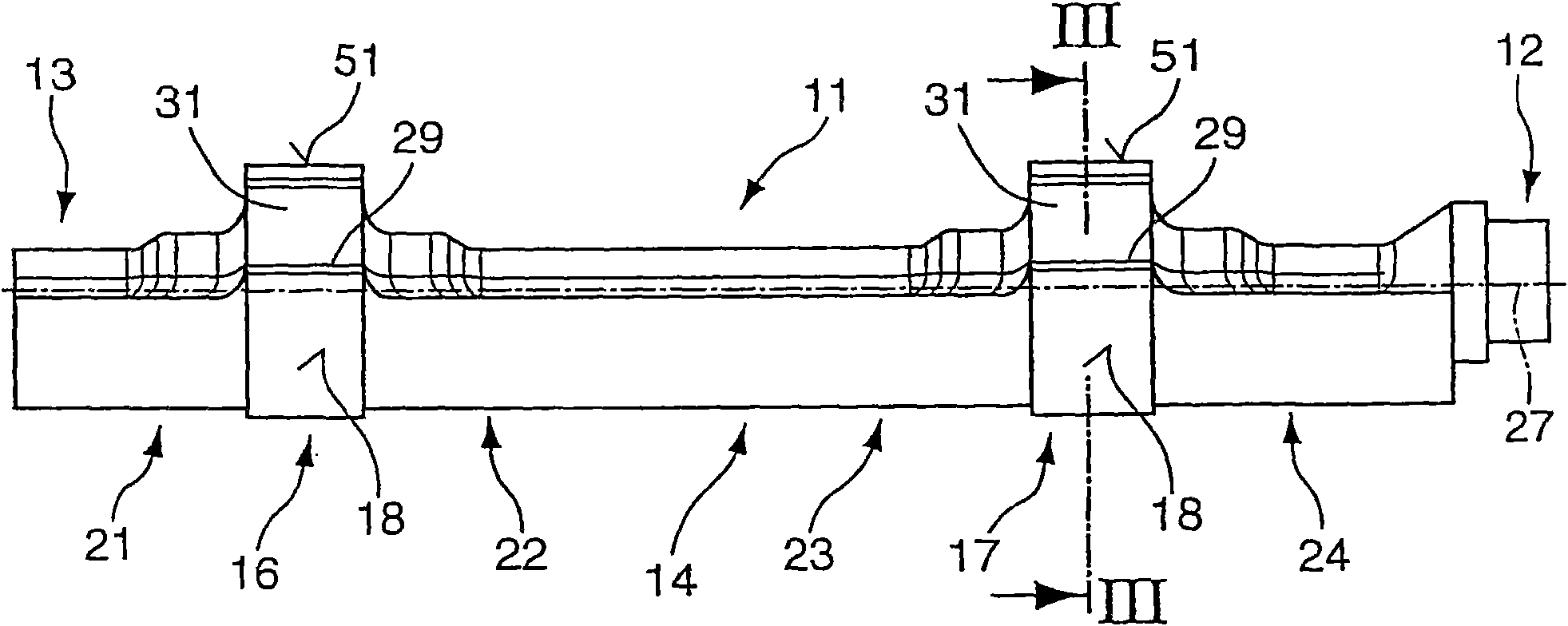

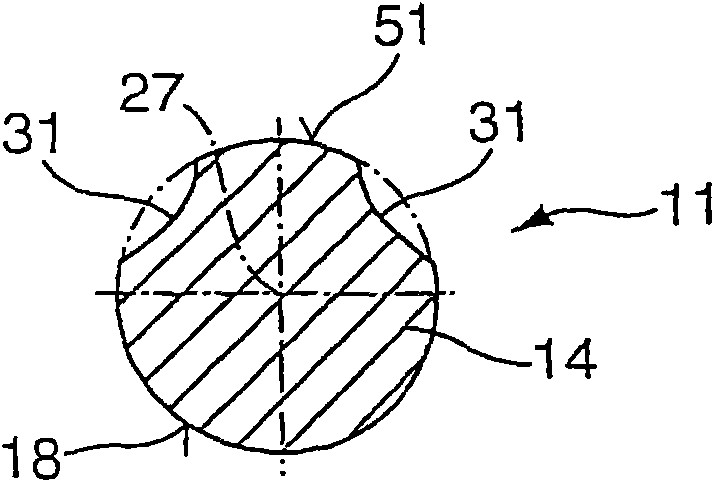

Balancing shaft

ActiveCN101680507ACheap manufacturingLow costInertia force compensationShaftsEngineeringSingle-cylinder engine

The invention relates to a balancing shaft for a single- or multi-cylinder motor having at least one unbalanced weight section (21, 22; 23, 24) and at least one bearing point (16, 17), wherein the at least one unbalanced weight section (21, 22; 23, 24) is allocated to the bearing point (16, 17) and the bearing point has a radial contact surface (18) that extends only partially over a circumference of the bearing point (16, 17) and a centrifugal force resulting from the rotation of the balancing shaft (11) lies inside a region of the bearing point (16, 17) formed by the contact surface (18) extending partially over the circumference of the bearing point (16, 17), wherein at least one support surface (51) is provided that is provided partially over the circumference of the bearing point (16, 17) and separately from the contact surface (18).

Owner:HERZOG INTERTEC GMBH

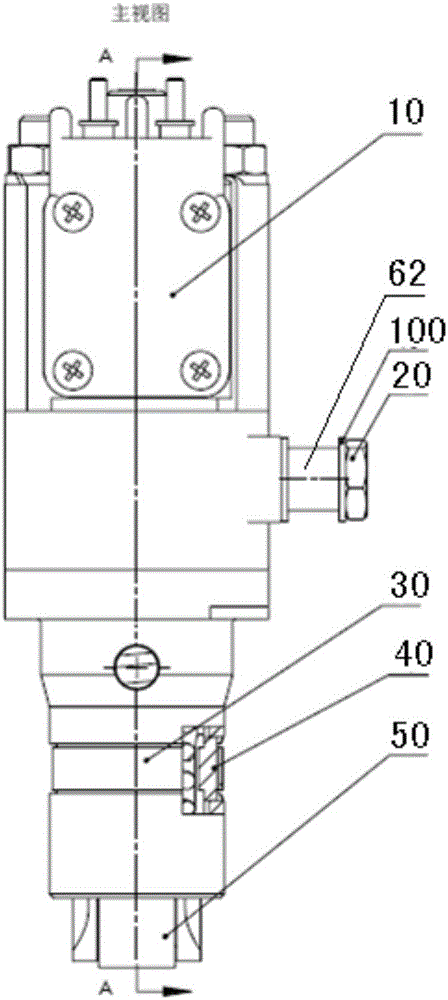

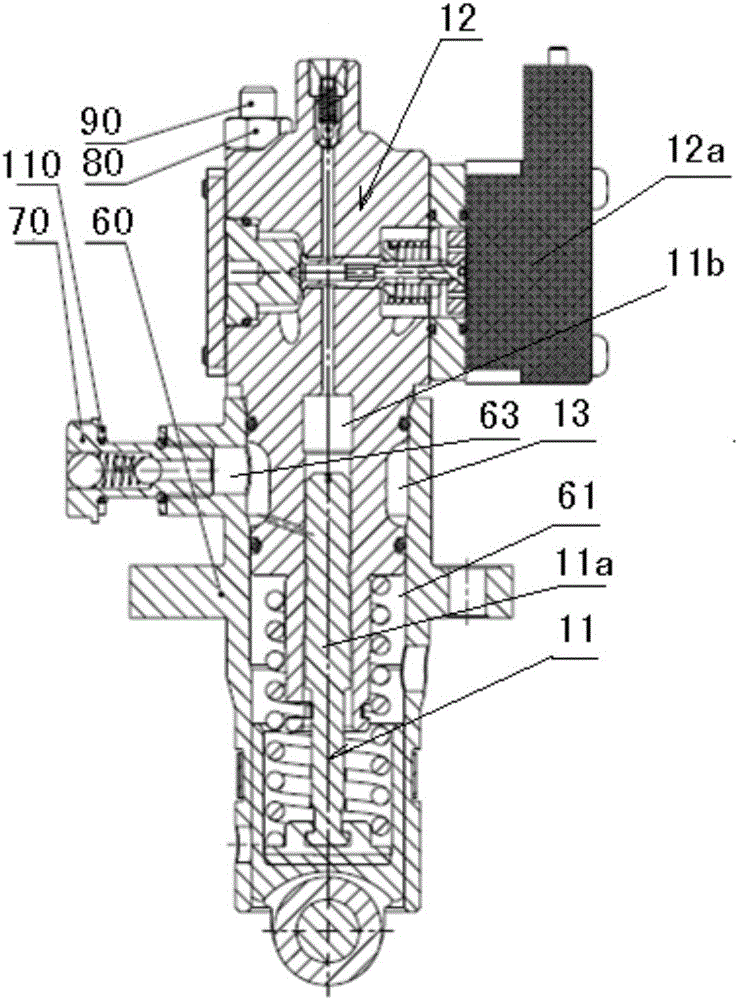

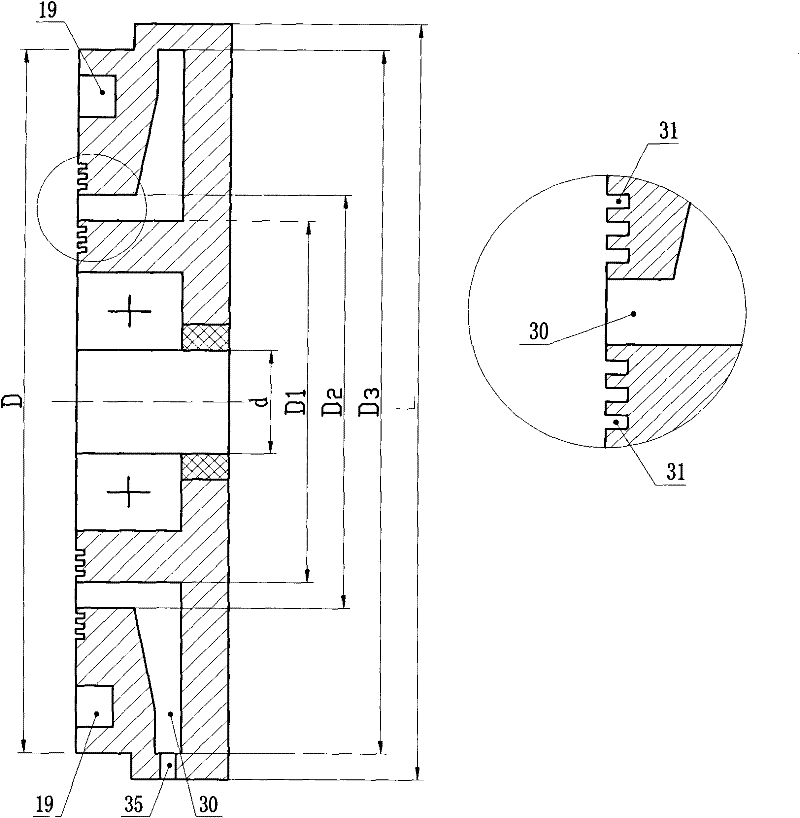

Fuel injecting electronic unit pump of single-cylinder diesel engine

ActiveCN105156244AImprove economyEasy to operateFuel injection apparatusMachines/enginesNational standardCylinder block

The invention discloses a fuel injecting electronic unit pump of a single-cylinder diesel engine. The fuel injecting electronic unit pump comprises a guiding sleeve and an electronic control pump part. An axial electronic control pump part installing hole is formed in the guiding sleeve, a fuel feeding hole and a pressure stabilizing hole are formed in the sleeve wall of the guiding sleeve, and the lower portion of the guiding sleeve is connected with a holding body part through an elastic clamp ring and a guiding block. A plunger valve of the electronic control pump part is partly inserted into the electronic control pump part installing hole and fixedly connected with the guiding sleeve through a fastener. An annular fuel feeding groove in the electronic control pump part is aligned with the fuel feeding hole and the pressure stabilizing hole. A fuel feeding screw installed in the fuel feeding hole is connected with a fuel feeding pipe of the diesel engine, and a pressure stabilizing valve part installed in the pressure stabilizing hole is connected with a fuel returning pipe of the diesel engine. The fuel injecting electronic unit pump is directly installed on a gear chamber cover of a cylinder body of the single-cylinder engine and driven by a camshaft of a fuel pump to feed fuel, and under the condition that the engine is not greatly modified, it is achieved that the emission level of an existing diesel engine with a mechanical in-line pump is upgraded from the level of the non-road second-stage national standard to the level of the non-road third-stage national standard or the level of a higher standard.

Owner:NANYUE FUEL INJECTION SYST CO LTD

Monoblock Engine

InactiveUS20150053154A1Simplify cylinderSimplify manifold designCylinder headsSealing arrangements for enginesExhaust valveCrankcase

The present invention discloses a monoblock engine in which the head and the block of the engine are cast integrally. The engine incorporates a cylinder and water coolant jackets, intake manifold and an exhaust manifold, vertical intake and exhaust valves, core removal holes, and a push-fit type cylinder liner which is secured in place so that leakage of fuel from the cylinder is eliminated. The water coolant jackets for the head and the block are connected using four water jacket gateways or connectors. The monoblock is fitted with the crankcase using a leak proof & robust flange-joint and mechanical fastening system which is easy to install. The invention is embodied for a single cylinder engine as well as multi-cylinder engines. By integrating cylinder head and manifolds with block, the critical joint between head and block and head and intake Manifold will be eliminated. At the same time, gasket and mechanical fasteners for tightening also can be eliminated. The water jacket design is communized & optimized for both head and block for better performance.

Owner:MAHINDRA & MAHINDRA LTD

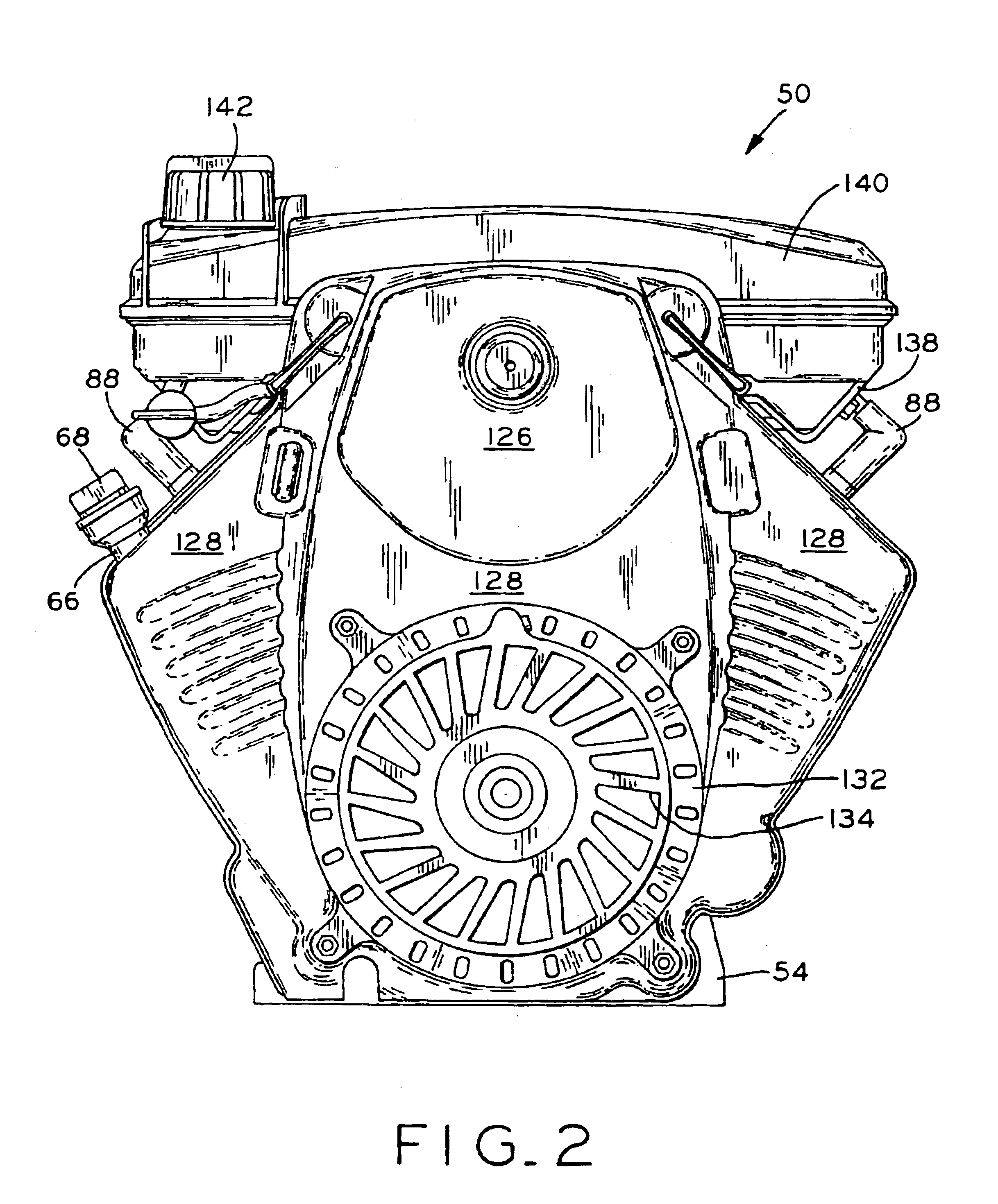

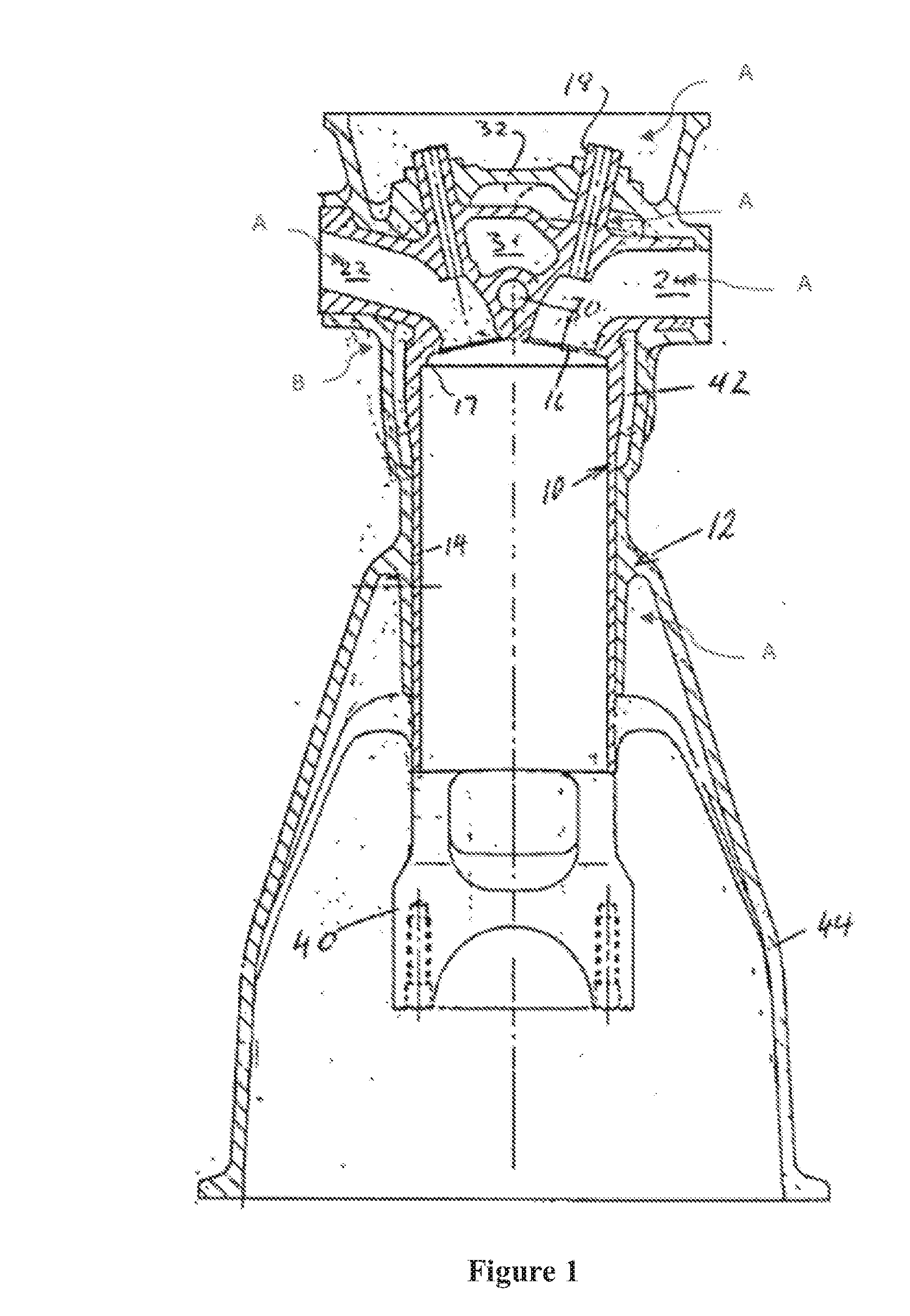

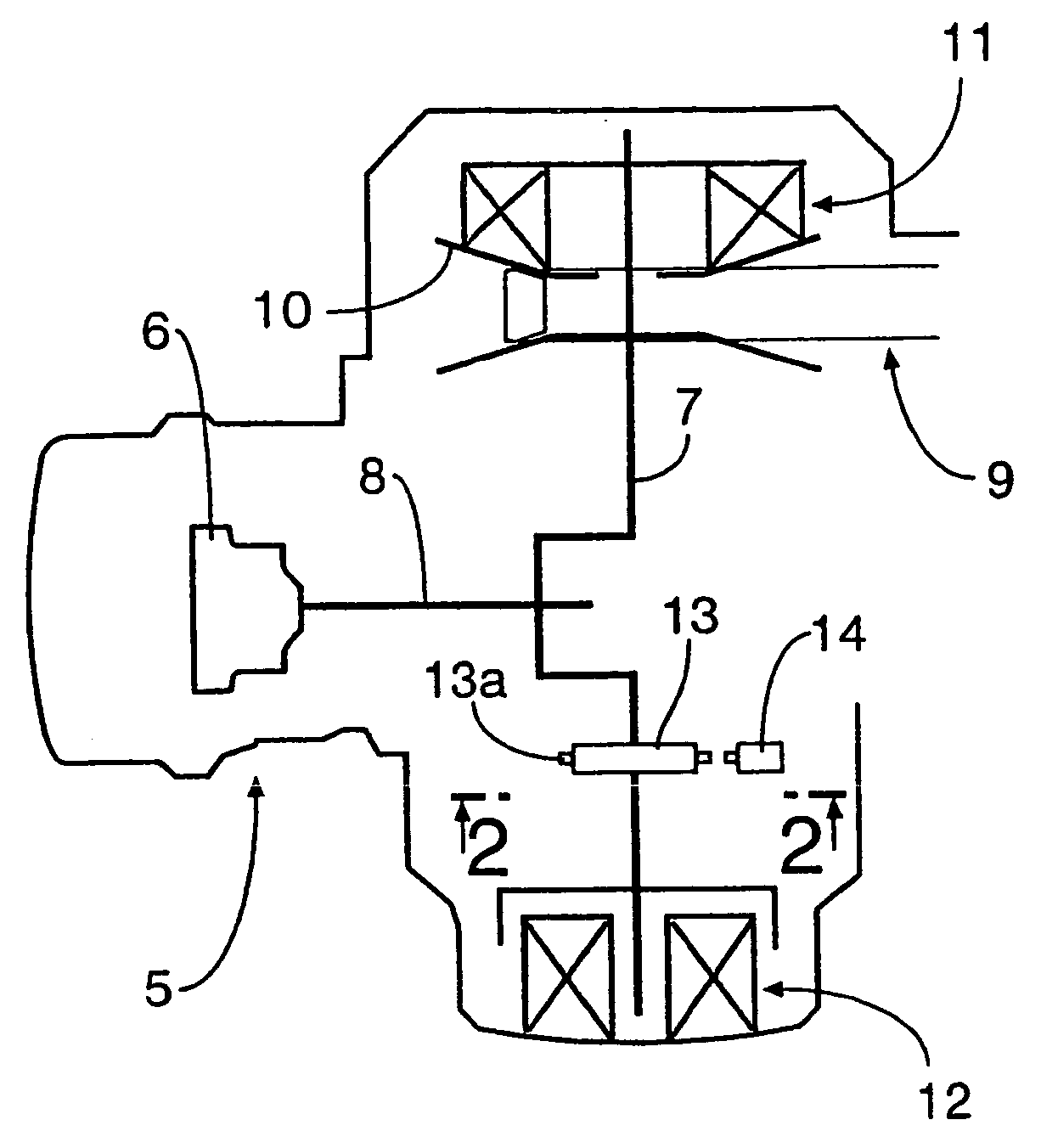

Balance system for single cylinder engine

InactiveCN1617977AReduce vibrationReduce wearInertia force compensationCounterweightsCouplingEngineering

A balancing system (500) and method for balancing piston forces of a single cylinder internal combustion engine (100) are disclosed. The balance system (500) includes a crankshaft (220), a balance assembly (445) and a groove (610). The crankshaft (220) includes a crankshaft portion (510), a crank (530), a crank pin (520), and an eccentric flange (550) adjacent the crank (530). The balance assembly (445) has a balance mass portion (570) and a coupling arm (580) secured to each other, and a pin (600) protruding from the side of the balance mass portion (570). Eccentric flange (550) supports coupling arm (580). The groove (610) can accommodate the pin (600) and the pin (600) can slide along the groove (610) and also rotate within the groove (610) so that the balance assembly (445) moves towards and away from the crankshaft ( 220) can be rotated.

Owner:KOHLER CO

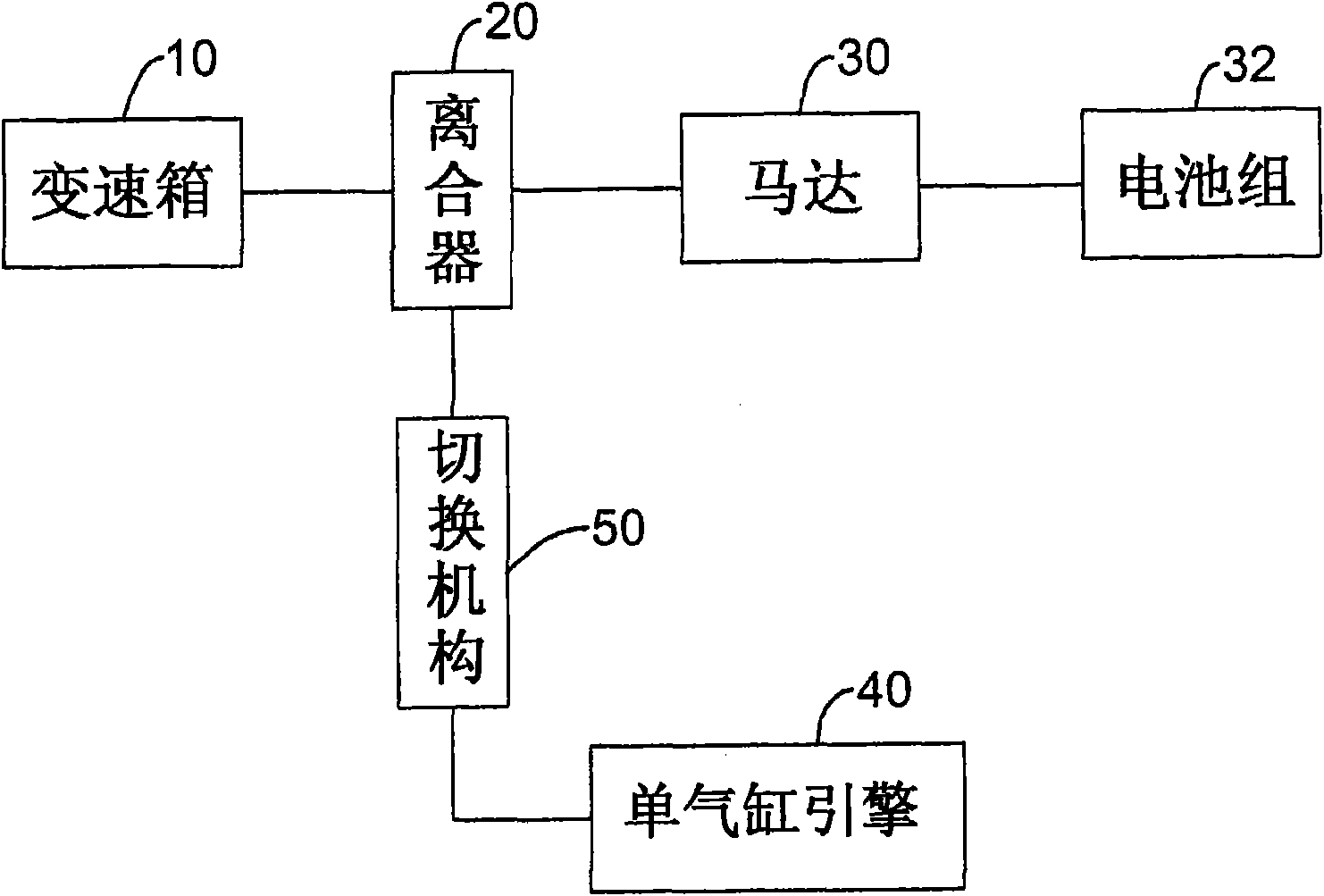

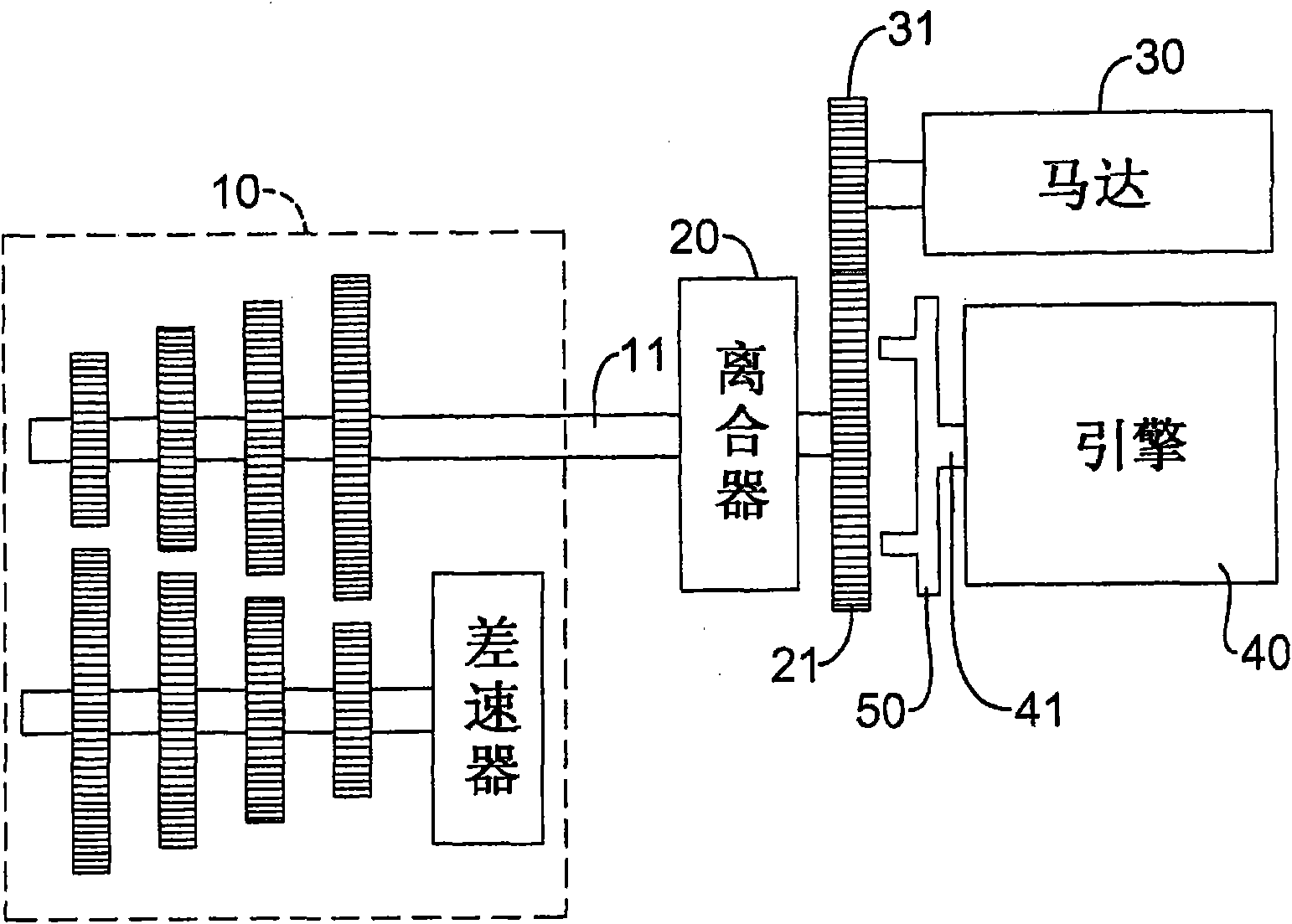

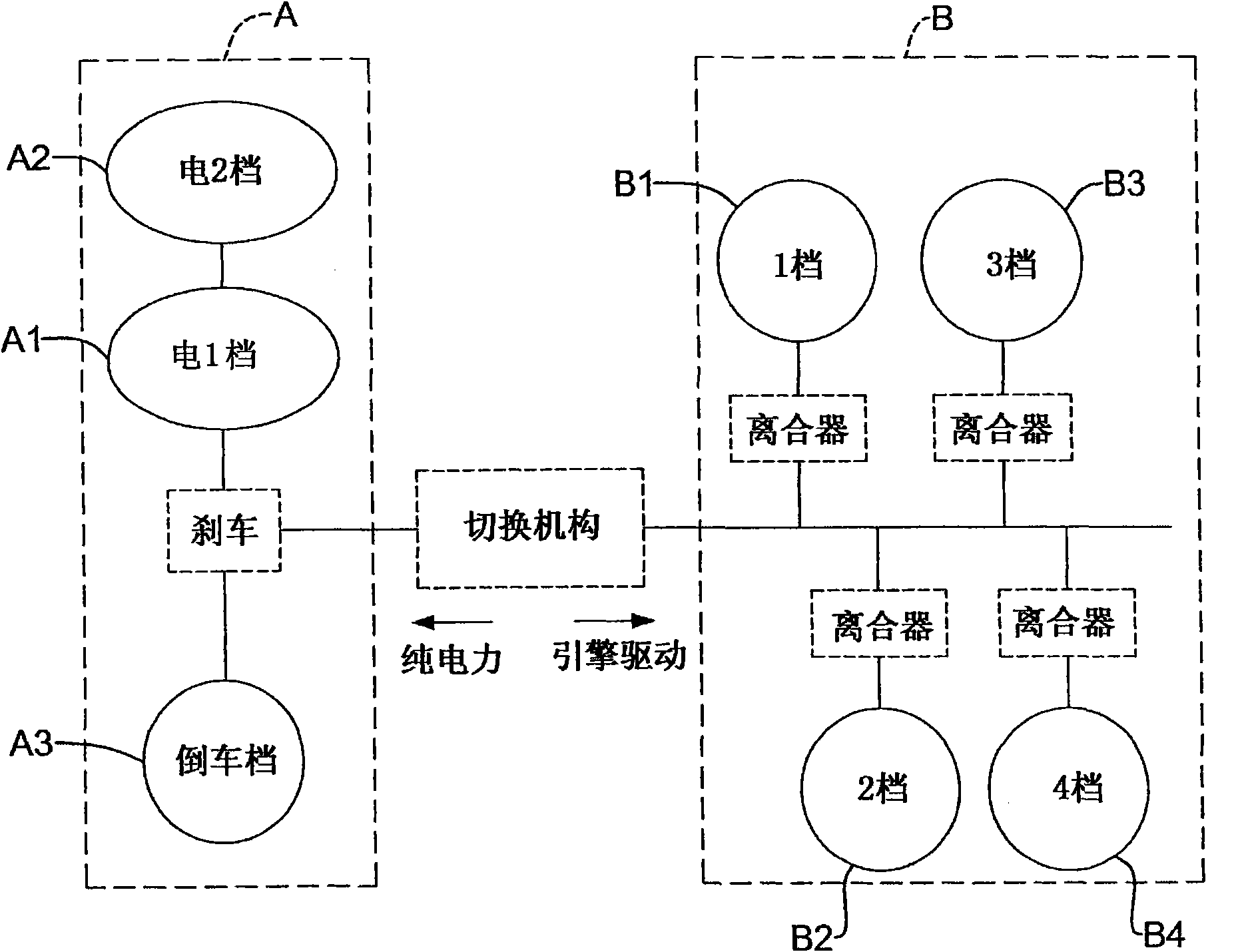

Hybrid power system for automobile

InactiveCN101823420AReduce the number of partsLow costHybrid vehiclesInertia force compensationEngineeringSingle-cylinder engine

The invention discloses a hybrid power system for an automobile, mainly comprising a manual gear box, a clutch, a motor and a single-cylinder engine. The clutch is connected with the manual gear box; the motor is connected with the clutch; one end of the single-cylinder engine is provided with a switching mechanism and is selectively connected with the clutch through the switching mechanism; and the switching mechanism is driven by a gear shift lever for the automobile so as to control the separation and the combination of the single-cylinder engine and the clutch. When shifting the gear with the gear shift lever according to the need of the driving speed, the user can control the manual gear box so that the power is transmitted to the manual gear box only by the motor or the motor and the single-cylinder engine. Because the automobile can be driven to run by using the electric power, the oil consumption is saved. Because the single-cylinder engine is adopted, the automobile manufacturing cost is greatly reduced.

Owner:朱心平

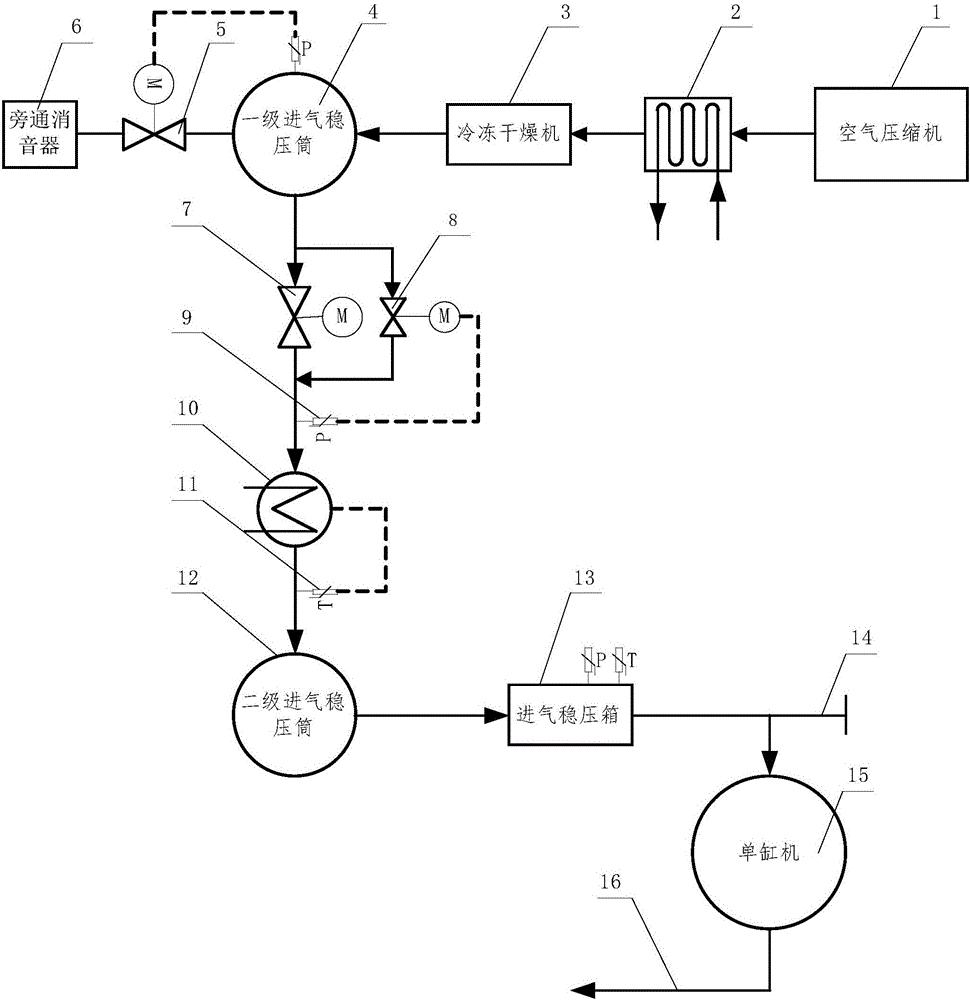

Air inlet boundary control apparatus of single-cylinder engine and method thereof

PendingCN106525440AAccurate predictionAccurately predict emissionsEngine testingPredicting performanceEngineering

The invention relates to an air inlet boundary control apparatus of a single-cylinder engine. The air inlet boundary control apparatus comprises an air compressor, a plate-type heat exchanger, a freezer dryer, an air inlet heater and other components. Under different environment conditions and different operation conditions, the single-cylinder engine acquires a same air inlet temperature with the air inlet temperature of a whole machine. Compared to an existing single-cylinder engine air inlet system, by using the air inlet boundary control apparatus of the single-cylinder engine of the invention, an air inlet temperature adjusting range is large so that the single-cylinder engine can accurately simulate an air inlet boundary condition of the whole machine under the different environment conditions and the different operation conditions, which is good for accurately predicting performance and discharge of the whole machine. In addition, the invention also provides an air inlet boundary control method of the single-cylinder engine.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

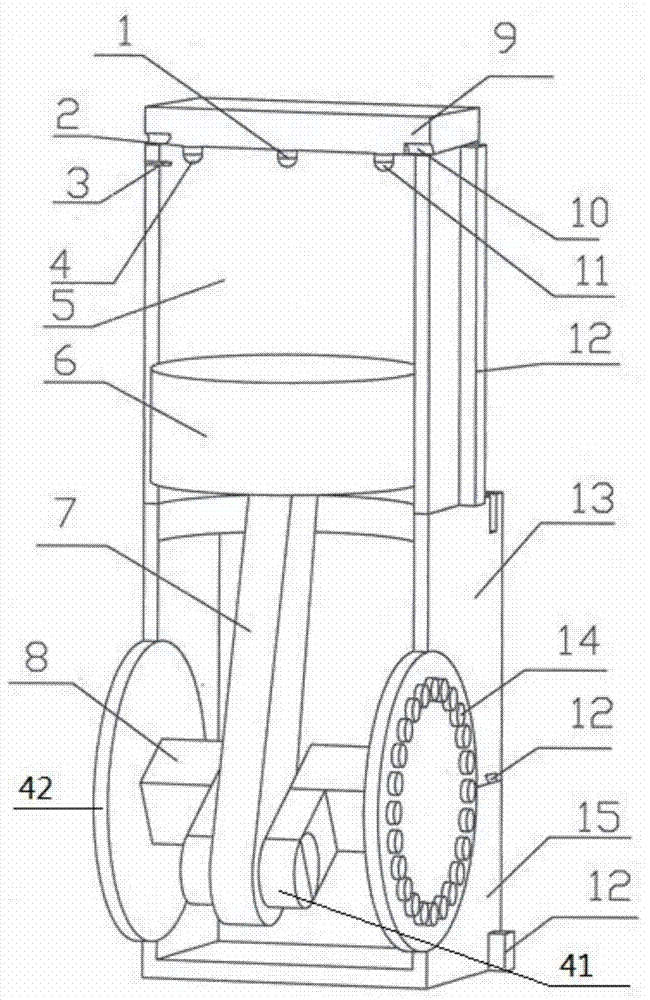

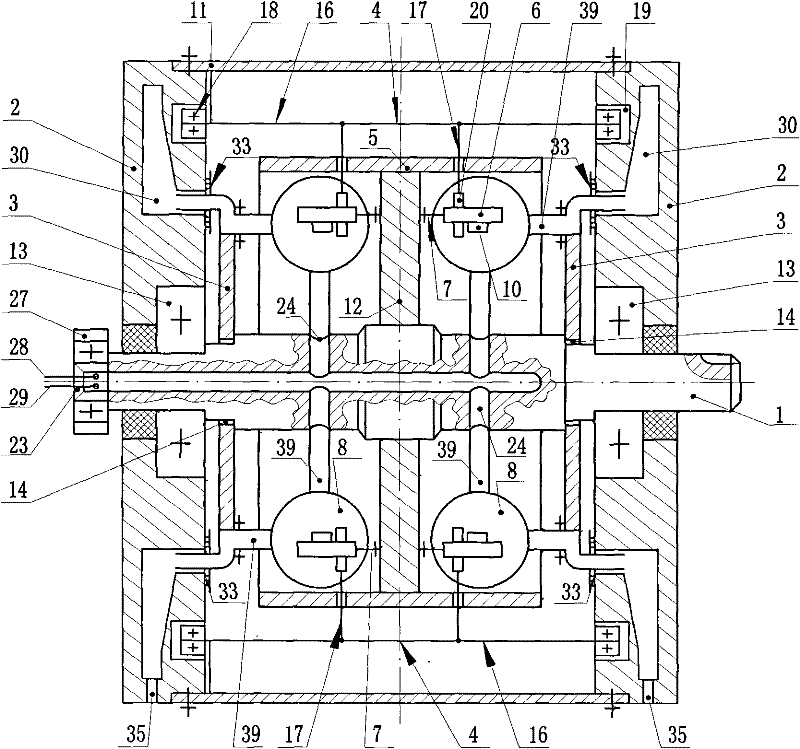

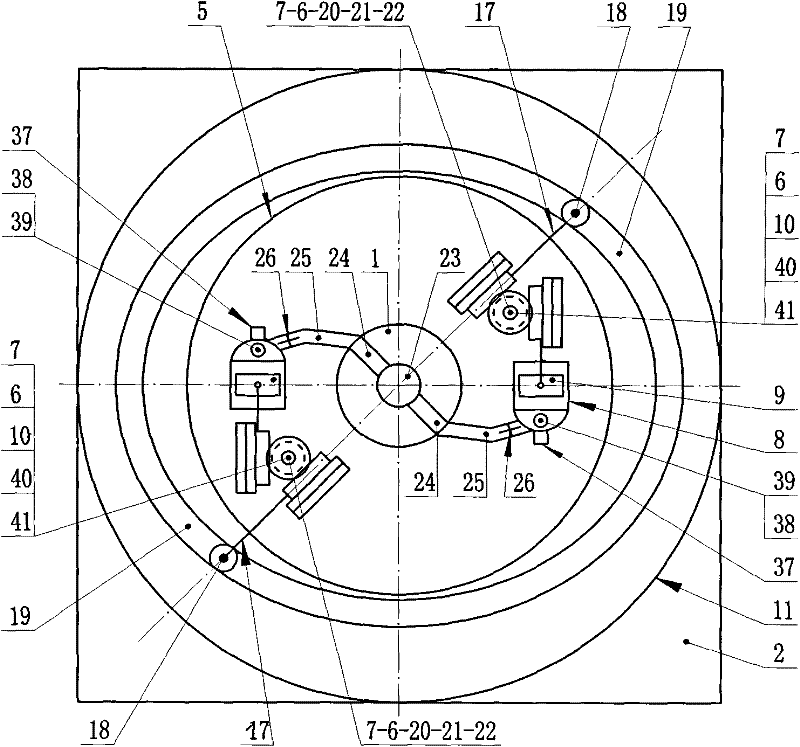

Rotary engine with double rows of pistons

InactiveCN102536446AEasy to achieve static and dynamic balanceQuality improvementInternal combustion piston enginesRotary engineGasoline

A rotary engine with double rows of pistons belongs to the field of power machinery and consists of a spindle (1), two symmetrical opposite elliptical track groove discs (2), two symmetrical air exhaust double-layered sleeves (3), double-T-shaped rolling connecting rods (4), a bidirectional cylindrical rotating cylinder (5), turning gears (6), gear shafts (7), crank connecting rod piston type single-cylinder engine heads (8), pistons (9), piston rod racks (10), a cylindrical shell (11) and the like. Two or four or a plurality of even-number engine heads (8) are respectively symmetrically mounted on two side surfaces of an engine head tray (12) around centers of the two side surfaces, so that a rotary engine head assembly with double rows of pistons is formed; two rolling connecting rod bearings (18) are inserted into two symmetrical opposite elliptical track grooves (19); and the two piston rod racks (10) and two vertical rod racks (20) are respectively meshed with the two turning gears. The rotary engine is simple and compact in structure, long in service life, stable in running and low in vibration and noise, is high-efficiency, energy-saving and emission-reduction, not only can be made into a gasoline engine, but also can be made into a diesel engine, and is applicable to various types of fuels.

Owner:方保林

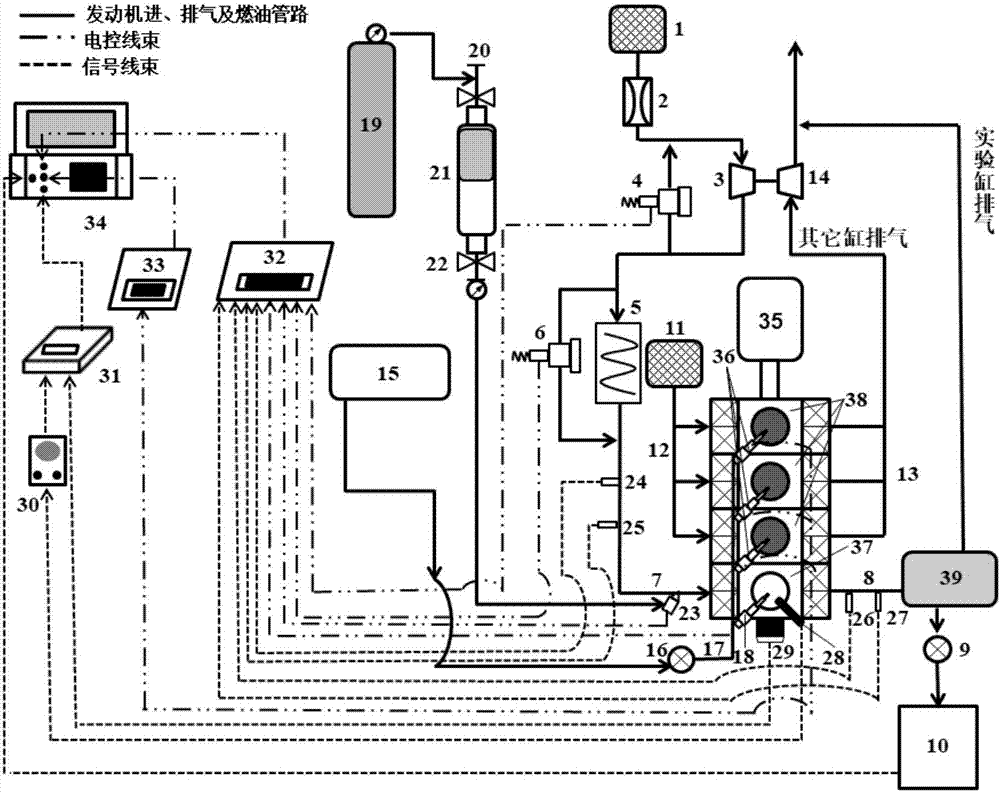

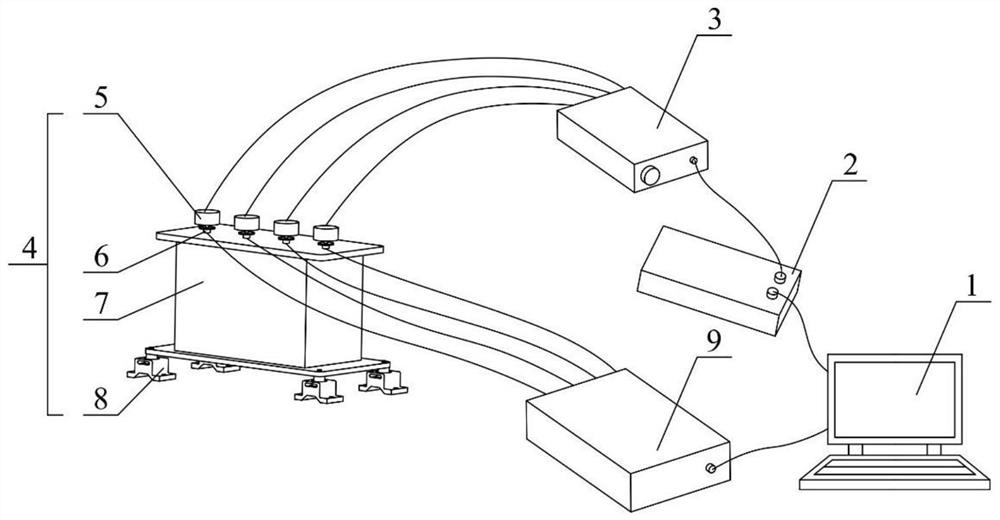

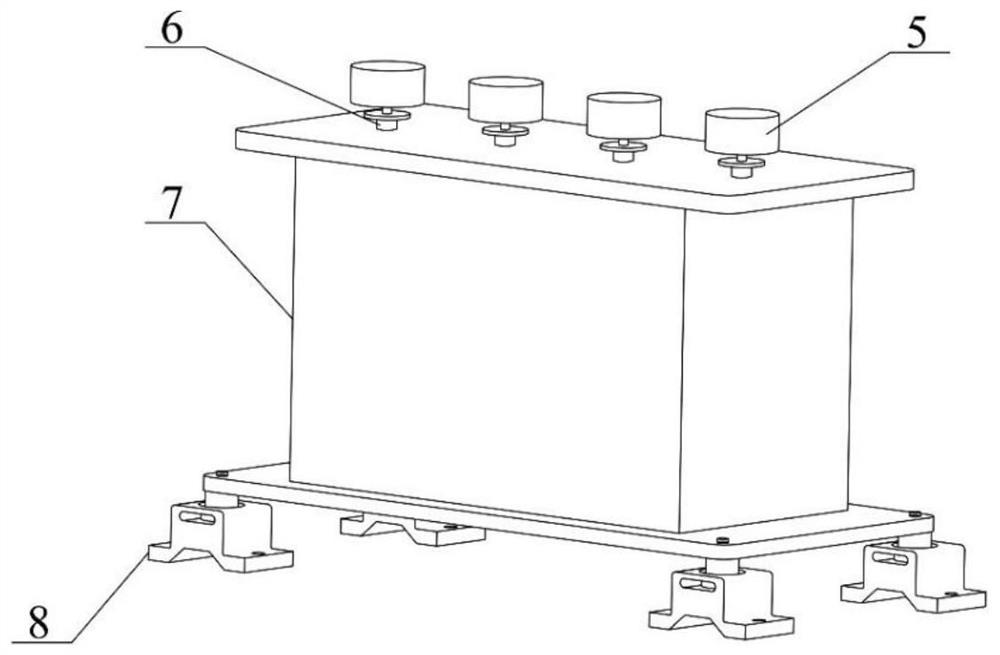

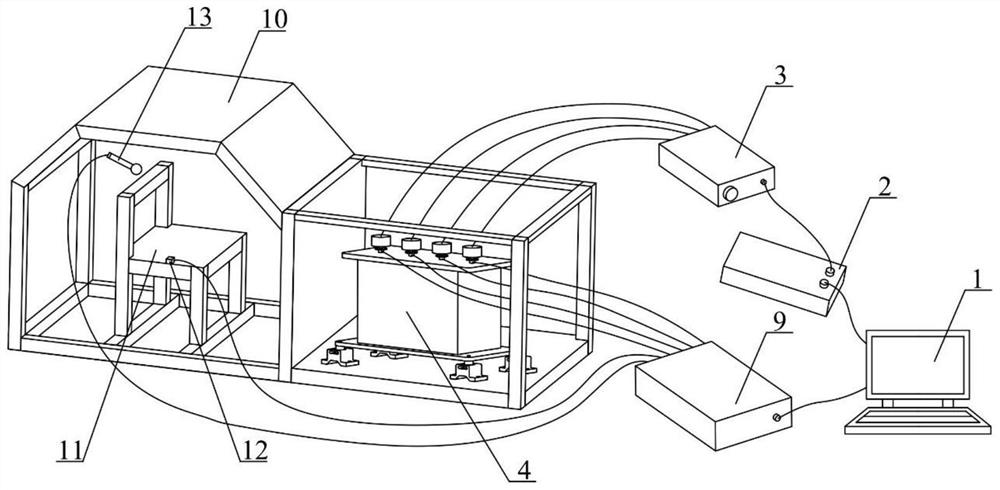

Single-cylinder engine bench experiment system with reverse towing function, and control method of single-cylinder engine bench experiment system

ActiveCN107884199ASimple requirementsLower requirementInternal-combustion engine testingInternal combustion piston enginesEngineeringDynamometer

The invention discloses a single-cylinder engine bench experiment system with the reverse towing function, and a control method of the single-cylinder engine bench experiment system. The system comprises a dynamometer, a signal acquisition system, an experiment cylinder and other cylinders both isolated from a multi-cylinder engine. The experiment cylinder is provided with an experiment cylinder air inlet system, an experiment cylinder air exhaust system and an experiment cylinder air inlet channel oil injection system. Other cylinders are provided with other cylinder air inlet systems and other cylinder air exhaust systems. The experiment cylinder and other cylinders simultaneously have an in-cylinder direct injection oil spraying system. According to the invention, a method for achievinga preset rotating speed of the experiment cylinder is realized through the reverse towing of other cylinders. Therefore, the requirement of an experiment bench on the dynamometer is simplified. The air inlet pressure, the air inlet temperature and the rotating speed of the experiment cylinder are maintained at constant values through intelligently controlling the experiment cylinder after the adoption of different oil spraying strategies by the experiment cylinder. Compared with a method for calculating the indicating power of the experiment cylinder according to the instantaneous pressure inthe cylinder, the above calculation method for calculating the indicating power of the experiment cylinder is more accurate.

Owner:XIHUA UNIV

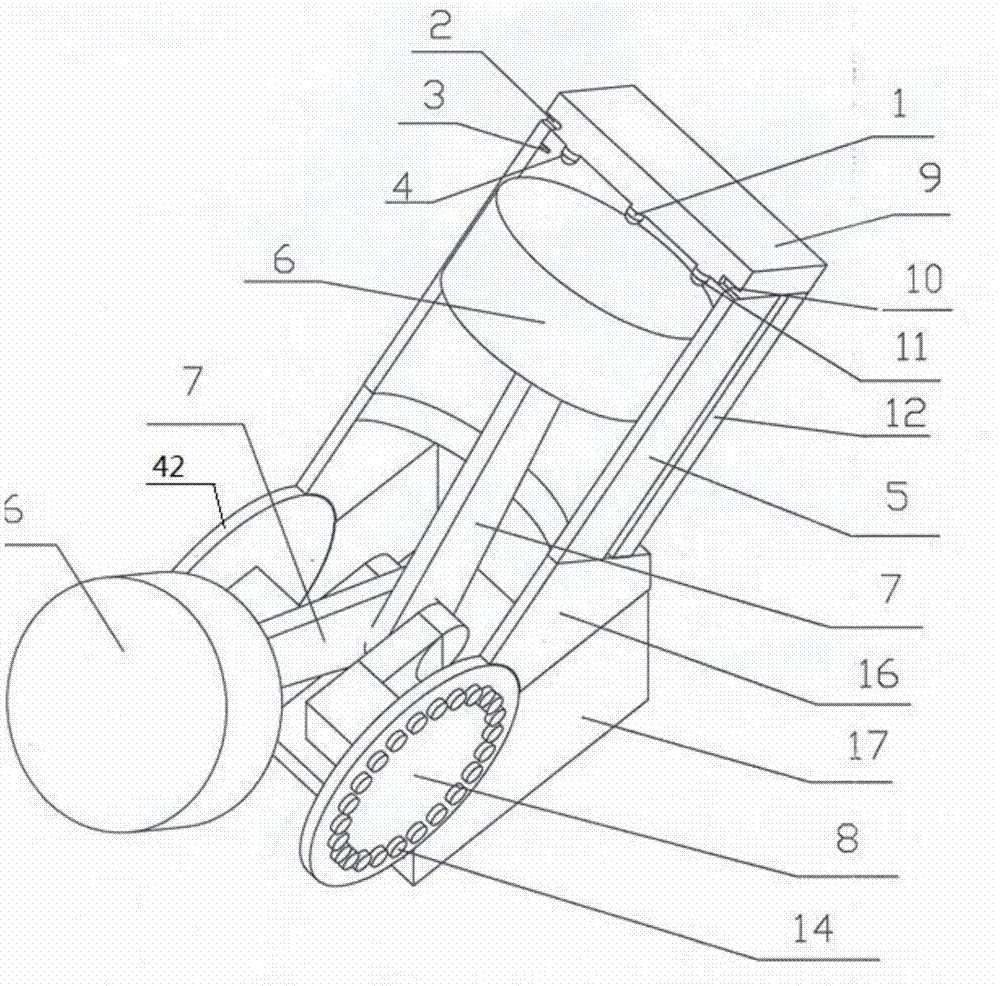

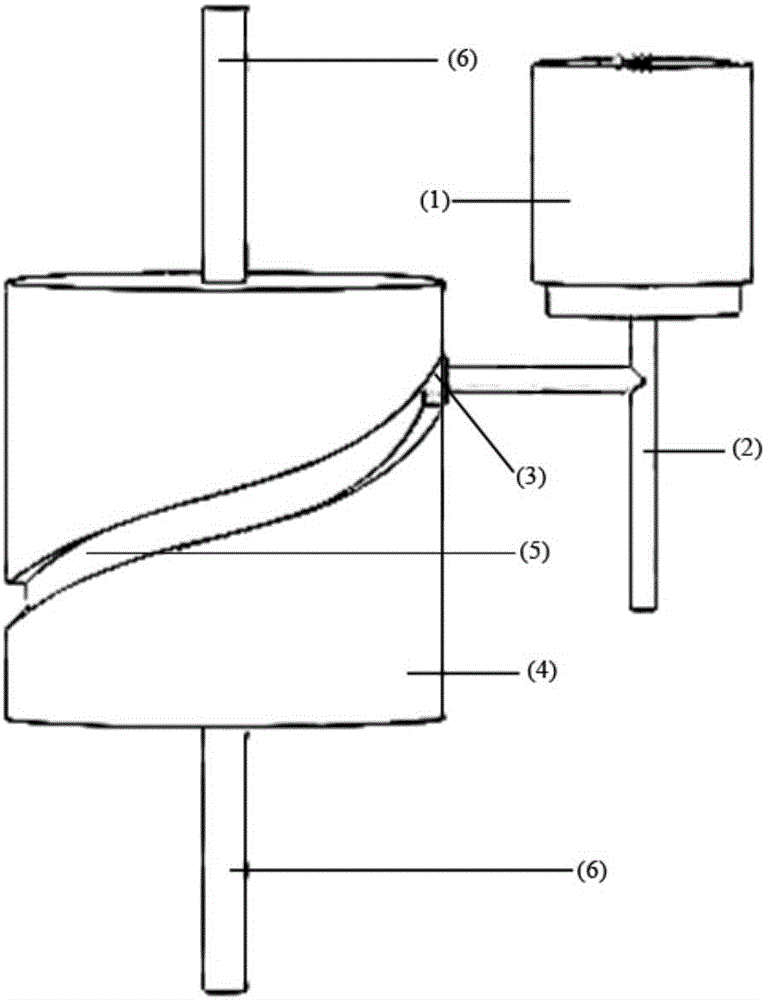

Roller side movement cylindrical cam single-cylinder engine

The invention relates to internal combustion engine devices, in particular to a roller side movement cylindrical cam single-cylinder engine. The roller side movement cylindrical cam single-cylinder engine comprises a piston connected with a push rod and further comprises a cylindrical cam. A power shaft is fixed to the cylindrical cam. A cam sliding groove is formed in the outer side of the cylindrical cam. A side rod is arranged on one side of the push rod of the piston, and a roller is arranged at the top end of the side rod. The roller moves in the cam sliding groove, and linear back-and-forth movement of the push rod of the piston is converted into rotation movement through the cylindrical cam. Continuous changes of a roller acceleration curve are achieved through the cam outline, that is, sudden change impact does not occur when the roller is in the upper dead center and the lower dead center. A cam rotor can be used as a flywheel of a traditional internal combustion engine, so that a flywheel structure is omitted, and the size of the engine is reduced. The push rod of the piston is always kept on the side portion of the cam, and the position is unchanged relatively, so that loads borne by the piston are not alternating side pressure. Accordingly, the service life of the piston and the push rod is greatly prolonged.

Owner:ZHEJIANG UNIV

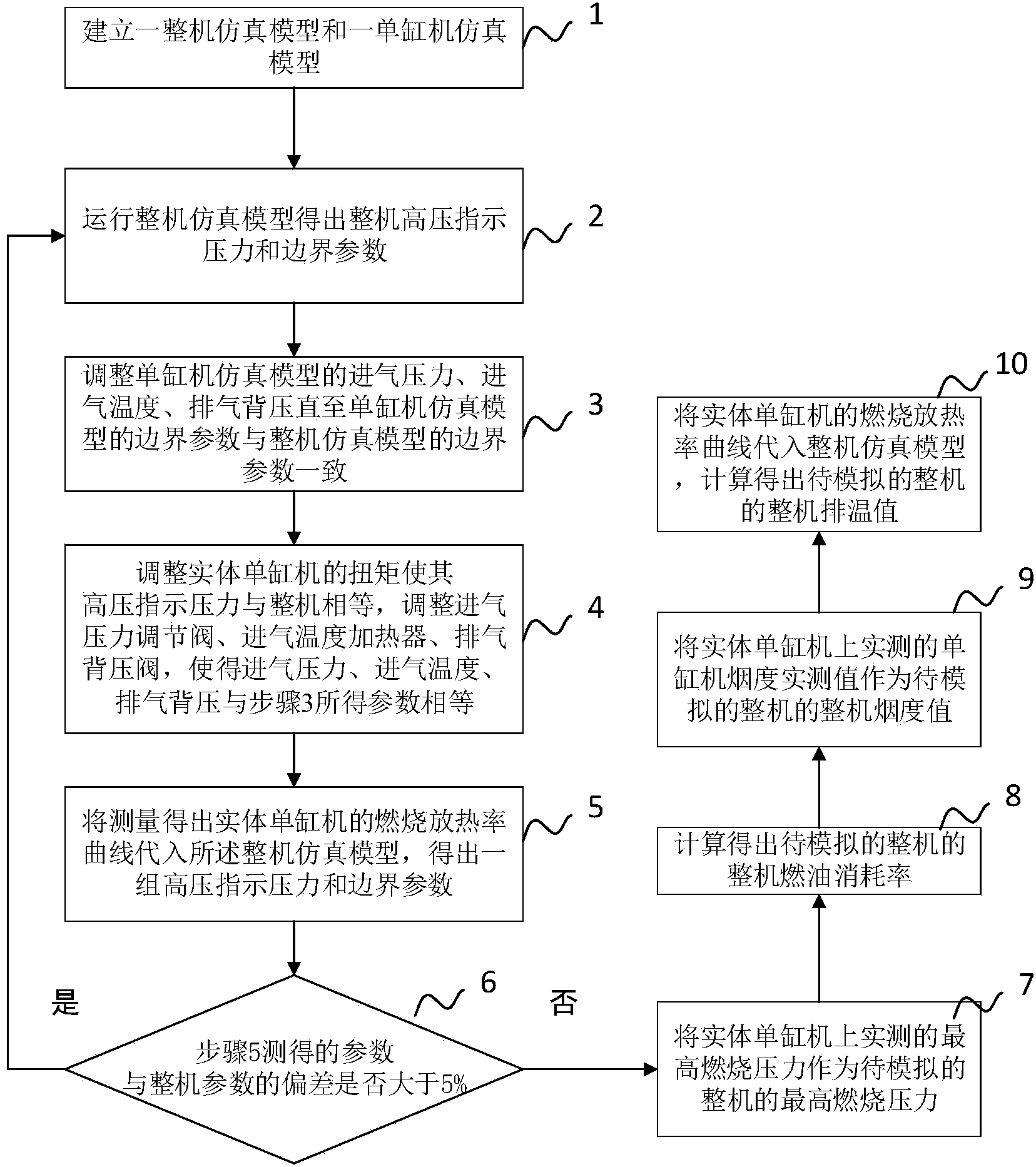

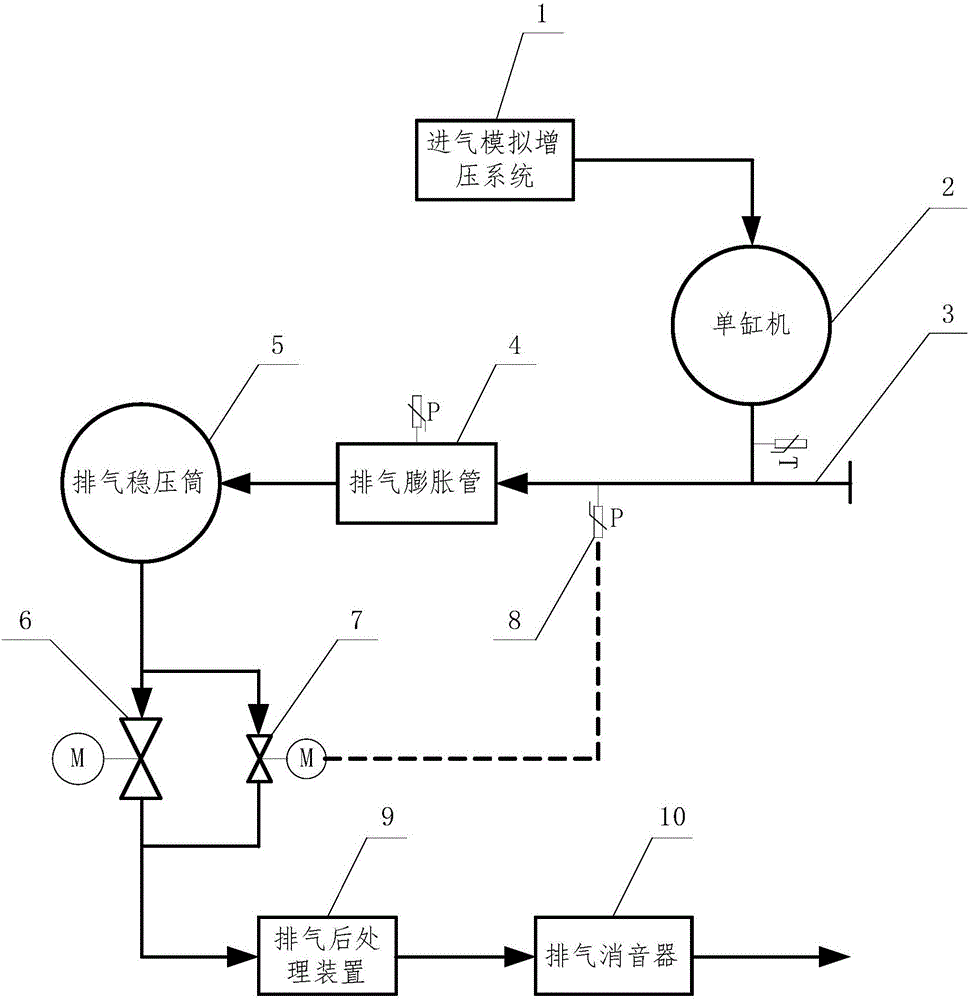

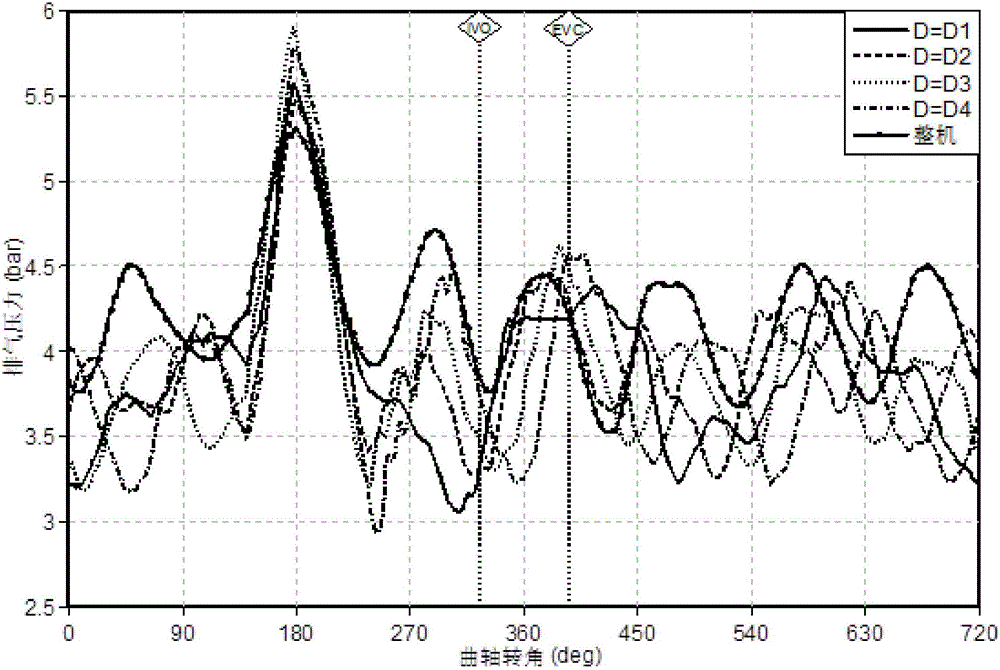

Testing method and device of single cylinder engine simulation complete machine

ActiveCN104344959AHigh precisionImprove R&D efficiencyInternal-combustion engine testingInlet pressureRate curve

The invention discloses a testing method and device of a single cylinder engine simulation complete machine. The testing method comprises the following steps: S1 establishing simulation models; S2 operating a complete machine simulation model to obtain complete machine high-pressure indicated pressure and boundary parameters; S3 operating a single cylinder engine simulation model, and adjusting the high-pressure indicated pressure and the boundary parameters of the single cylinder engine simulation model to be equal to those of the complete machine; S4 operating a solid single cylinder engine to be detected and adjusting the high-pressure indicated pressure to be equal to that of the complete machine; adjusting an air inlet pressure adjusting valve, an air inlet temperature heater and an air discharging back pressure valve to be equal to records in the step S3; S5 substituting a combustion heat releasing rate curve of the solid single cylinder engine into the complete machine simulation model; S6 judging whether an error is greater than a preset ratio or not; S7 processing parameters of the solid single cylinder engine. The complete machine simulation model and the single cylinder engine simulation model are established, and air inlet pressure, air inlet temperature and air discharging back pressure are repeatedly debugged on the solid single cylinder engine to obtain reasonable parameters of the complete machine to be simulated, so that the precision of single cylinder engine simulation complete machines including diesel engines and the like is improved.

Owner:中国船舶集团有限公司第七一一研究所

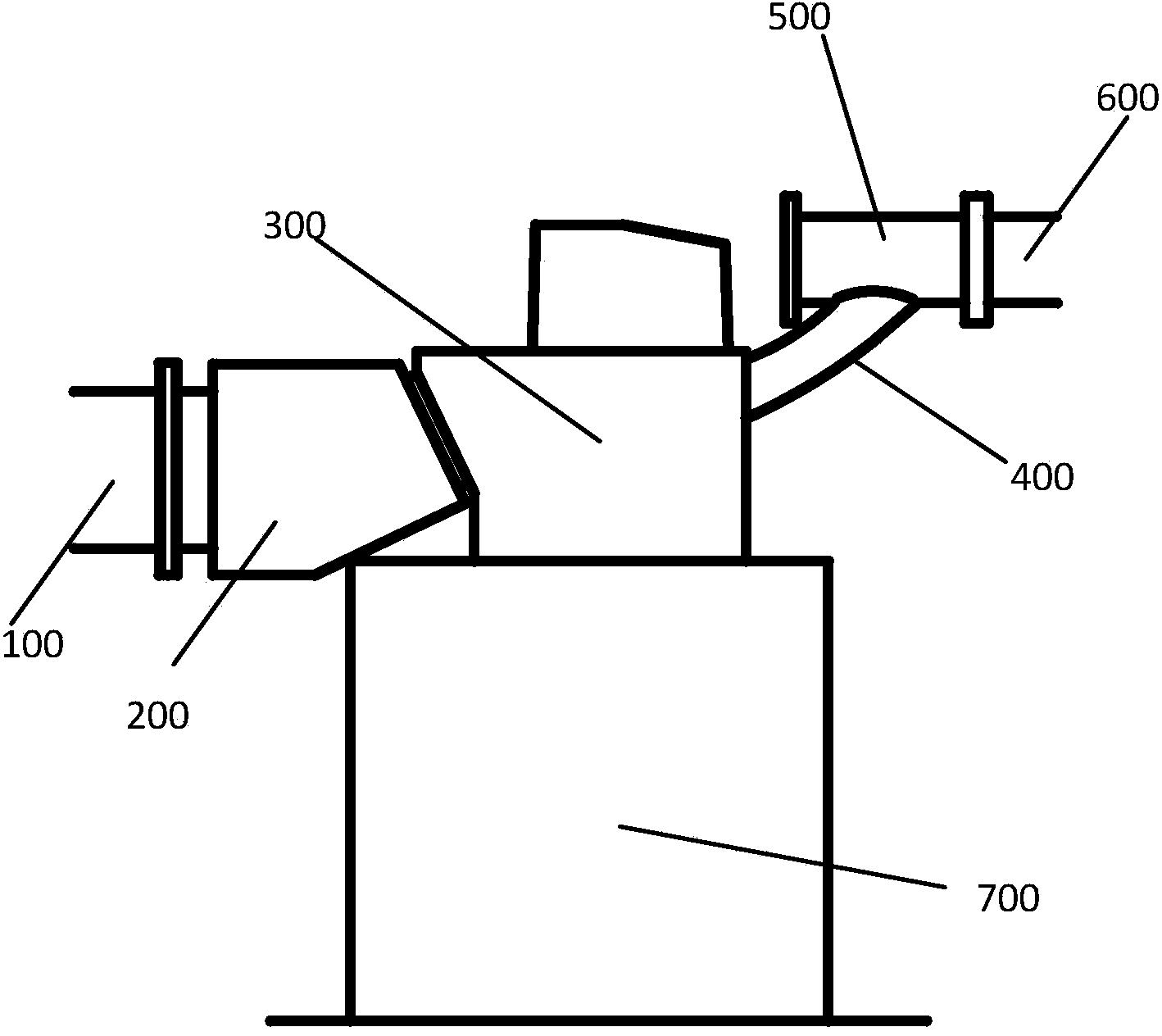

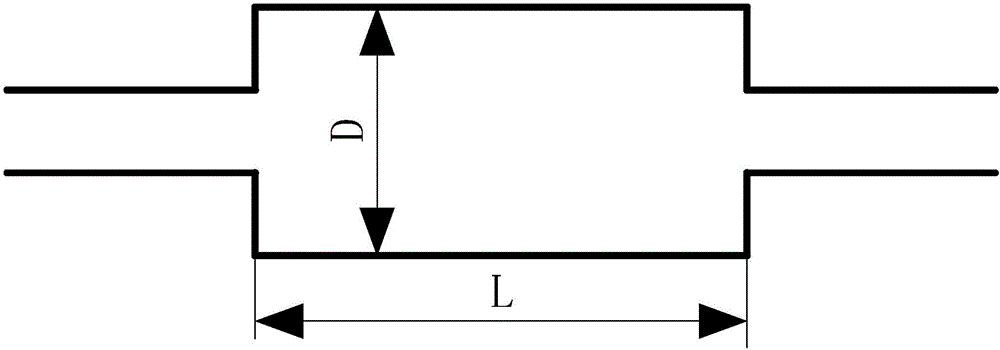

Exhaust boundary control device of single-cylinder engine

InactiveCN106545396ASimulation is accuratePredictive performanceInternal-combustion engine testingExhaust apparatusEngineeringSingle-cylinder engine

The invention relates to an exhaust boundary control device of a single-cylinder engine. The exhaust boundary control device comprises an exhaust expansion pipe, an exhaust pressure stabilizing cylinder, an exhaust pressure rough adjusting valve and an exhaust pressure fine adjusting valve, and the exhaust pressure rough adjusting valve and the exhaust pressure fine adjusting valve are arranged in parallel; according to the exhaust boundary control device, the single-cylinder engine obtains the steady-state exhaust pressure and / or exhaust pressure waves basically consistent with the whole device at the scavenging stage; therefore, the exhaust boundary of a whole multi-cylinder machine can be precisely simulated in the single-cylinder engine, and therefore the scavenging process of the whole multi-cylinder machine can be accurately simulated so as to more accurately predict the performance of the whole multi-cylinder machine.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

System and method of simulating engine energization

ActiveCN112710473ASimple structureTo achieve the purpose of motivating simulationInternal-combustion engine testingSustainable transportationTransfer path analysisClassical mechanics

The invention discloses a system and a method for simulating engine excitation. A master control computer controls a signal generator to output a cylinder pressure signal when a real engine runs, and a power amplifier drives an engine excitation source generating device to simulate the excitation of the real engine. The engine excitation source generating device receives the cylinder pressure signal and generates excitation force to simulate vibration and sound excited by the engine. A 'source-path-response 'model is established, a force vibration transfer function and a force sound transfer function corresponding to the structure are acquired, and an engine transfer path analysis test is performed. On the premise of guaranteeing stable output of excitation source signals required by a test, the structure is greatly simplified, the requirement that the excitation source is convenient to disassemble and assemble is met, excitation simulation of the engine under different working conditions can be achieved, and excitation simulation of other multi-cylinder engines or single-cylinder engines can also be achieved. And partial NVH tests related to the engine can be carried out in a laboratory range.

Owner:WUHAN UNIV OF TECH

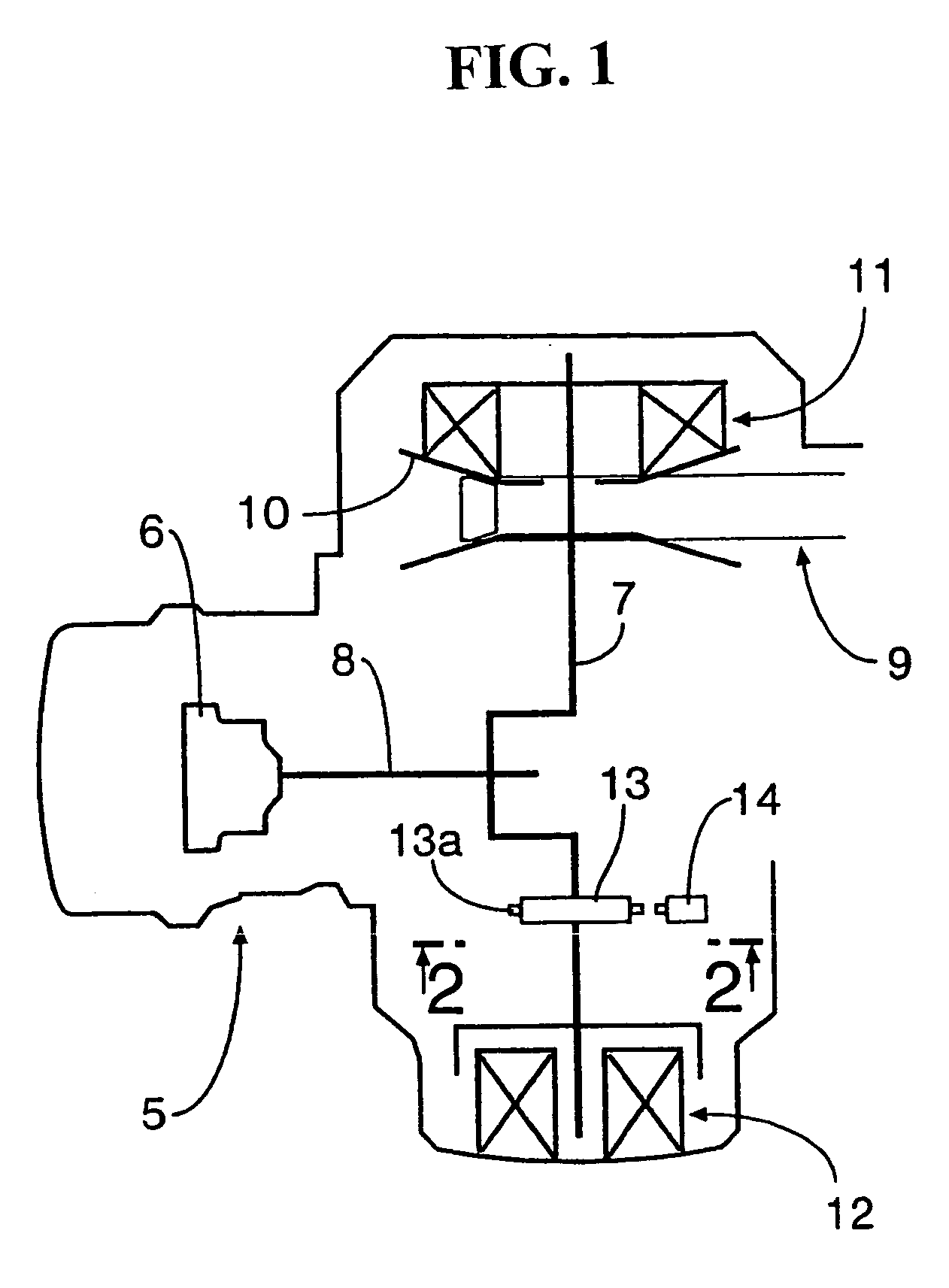

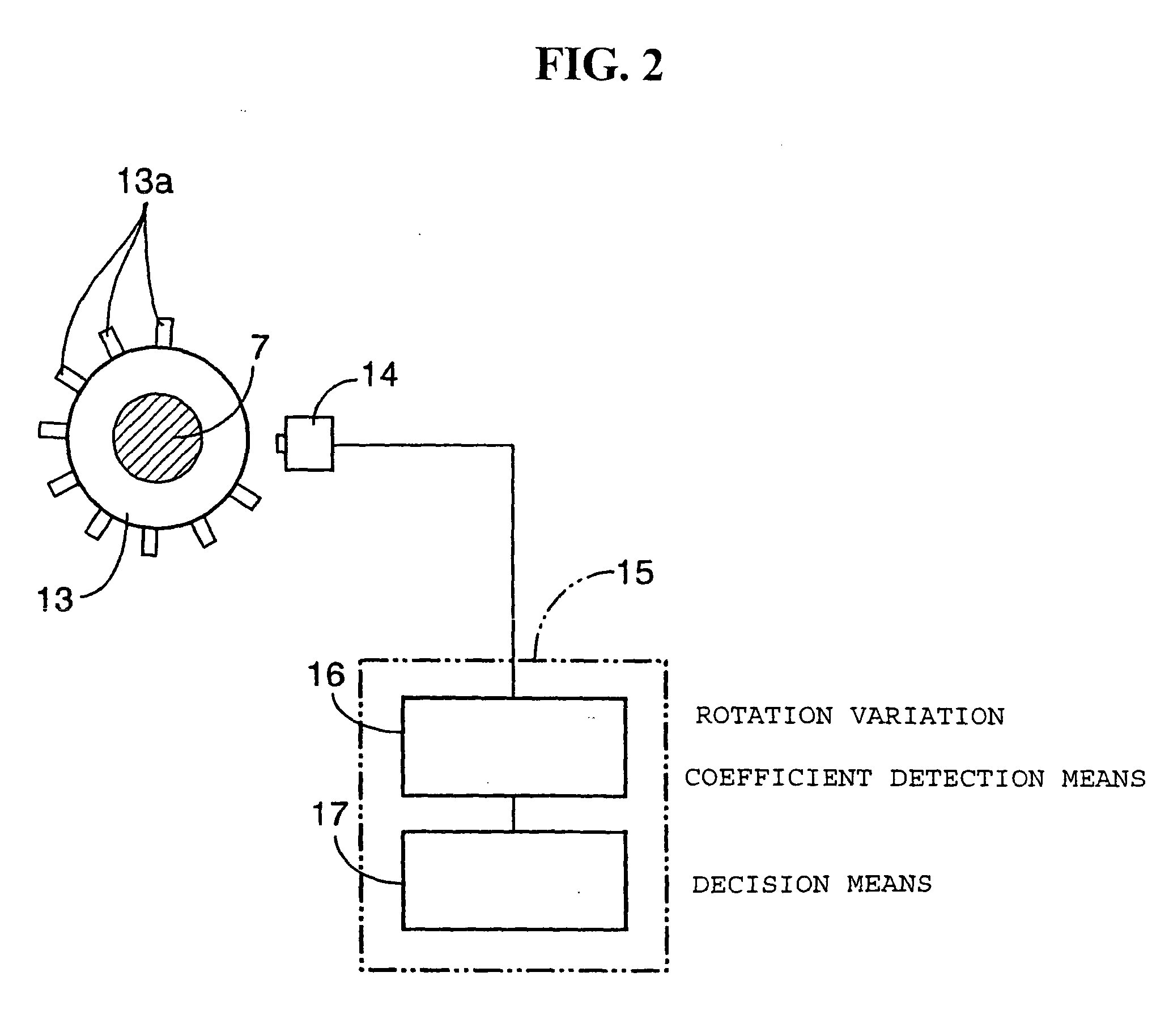

Clutch connection/disconnection detection system for single-cylinder engine

InactiveUS20050020407A1Accurate detectionAnalogue computers for vehiclesElectrical controlEngineeringSingle-cylinder engine

To detect with high accuracy the connection / disconnection of a clutch intermediately provided between a crankshaft of a single-cylinder engine and a power transmission means for transmitting the output of the crankshaft. The rotation variation coefficient of a crankshaft is detected by a rotation variation coefficient detection means and a decision means decides the connection / disconnection of a clutch by comparing the rotation variation coefficient detected by the rotation variation detection means with a preliminarily determined threshold.

Owner:HONDA MOTOR CO LTD

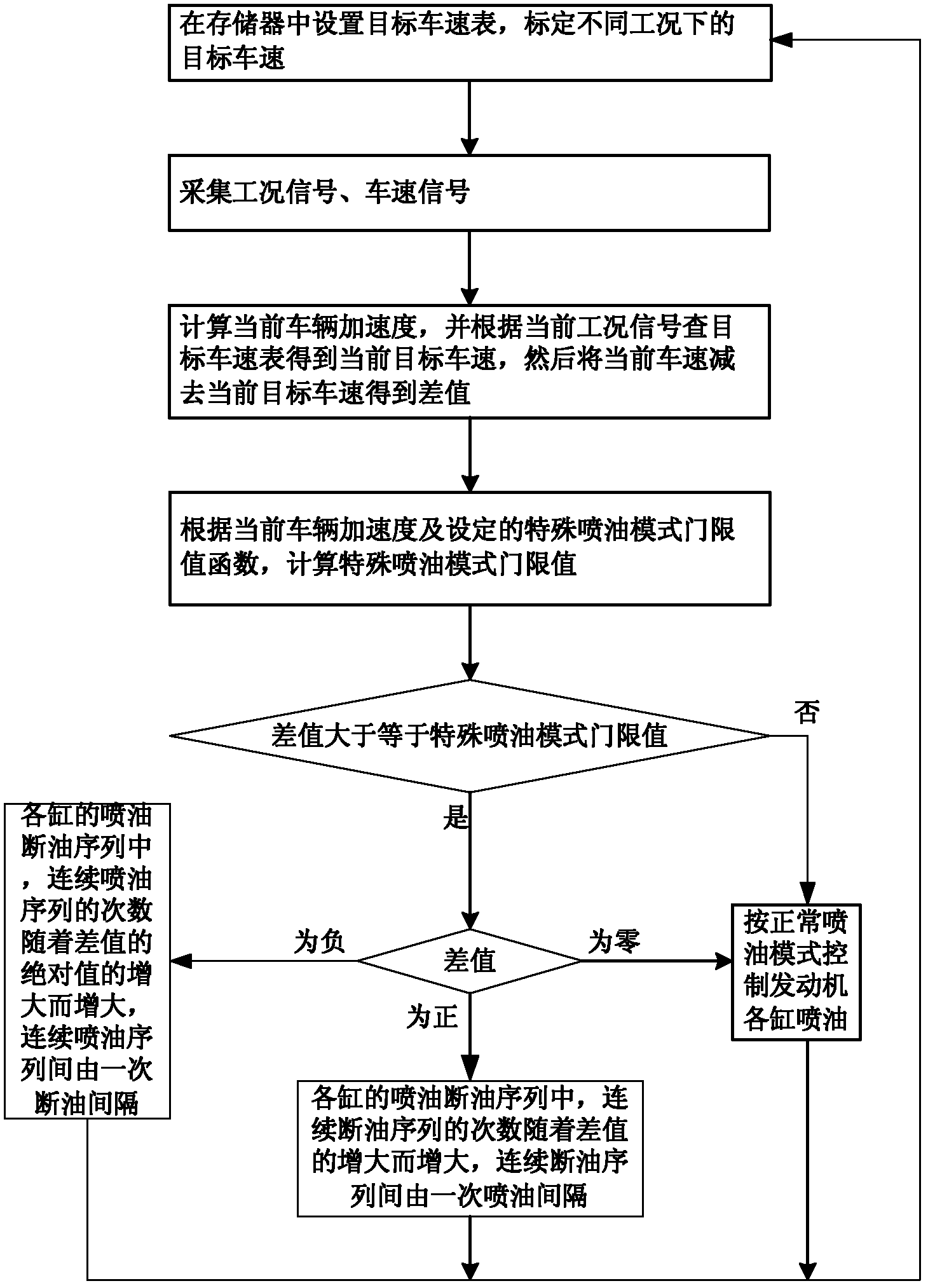

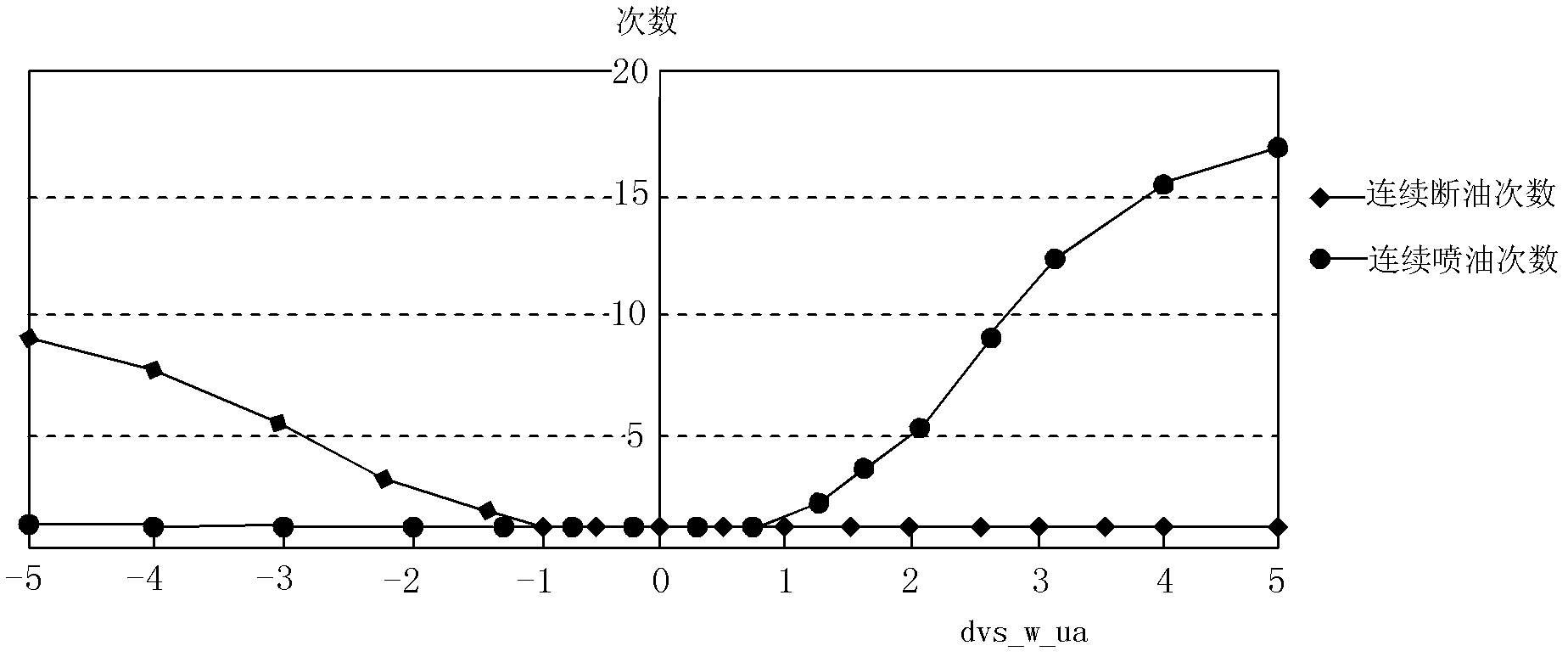

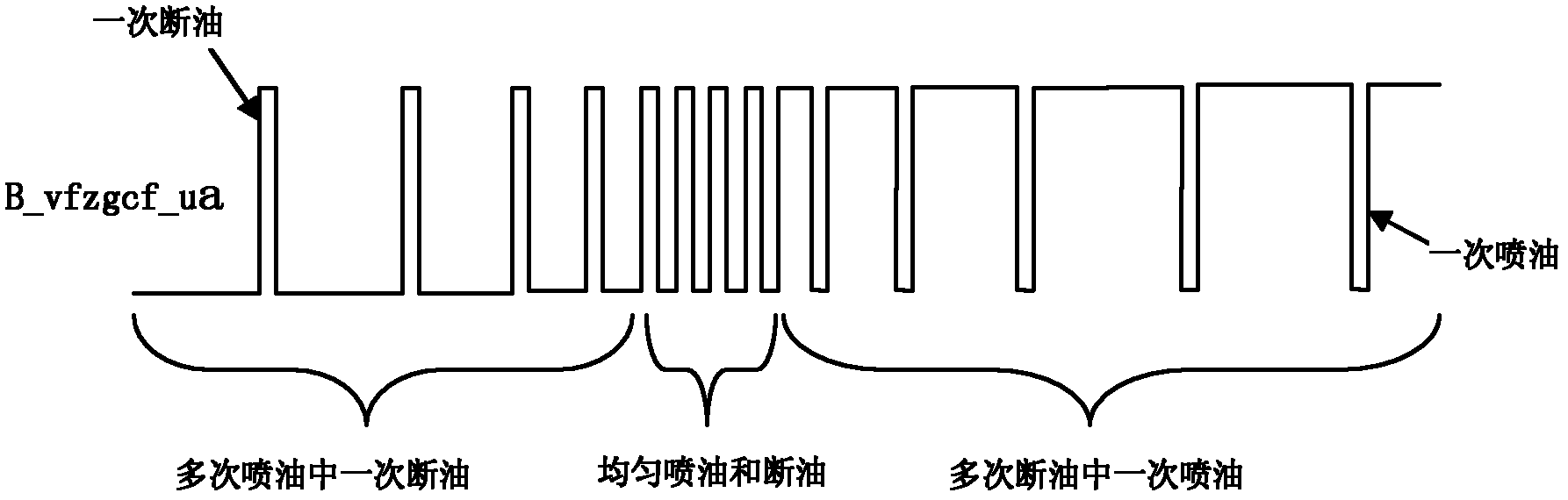

Automobile speed control method for electronic fuel injection automobile

ActiveCN102434301AGuaranteed smooth progressRealize vehicle speed controlElectrical controlMachines/enginesSingle-cylinder engineCutting sequence

The invention discloses an automobile speed control method for an electronic fuel injection automobile, which can calculate automobile accelerated speed based on automobile speed signals, achieve current objective automobile speed according to current work condition, obtain a differential value by using the current automobile speed to subtract the current objective automobile speed, and calculate a special fuel injection mode threshold value according to current automobile acceleration speed. When the differential value is larger than or equal to the special fuel injection mode threshold value and the differential value is minus, number of times of continuous fuel injection sequence in fuel injection fuel cut sequence of each cylinder increases with enlargement of the absolute value of the differential value, and the continuous fuel injection sequence is separated by one fuel cut. When the differential value is zero, the fuel injection fuel cut sequence of each cylinder is in normal fuel injection mode. When the differential value is positive, number of times of continuous fuel cut sequence in fuel injection fuel cut sequence of each cylinder increases with enlargement of the differential value, and the continuous fuel cut sequence is separated by one fuel injection. The automobile speed control method for the electronic fuel injection automobile can effectively limit automobile of the electronic fuel injection automobile with a single cylinder engine or a multiple cylinder engine, and the automobile speed is small in fluctuation.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

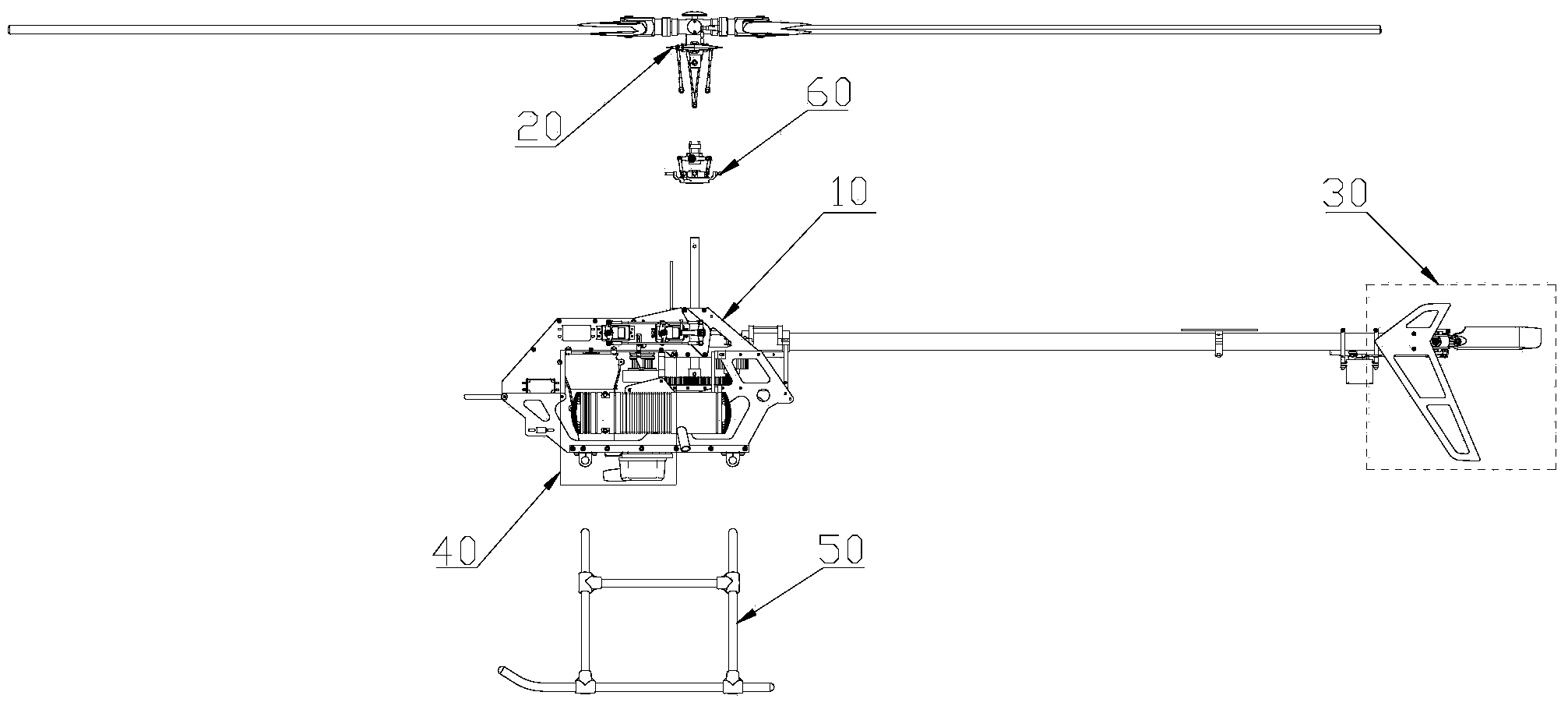

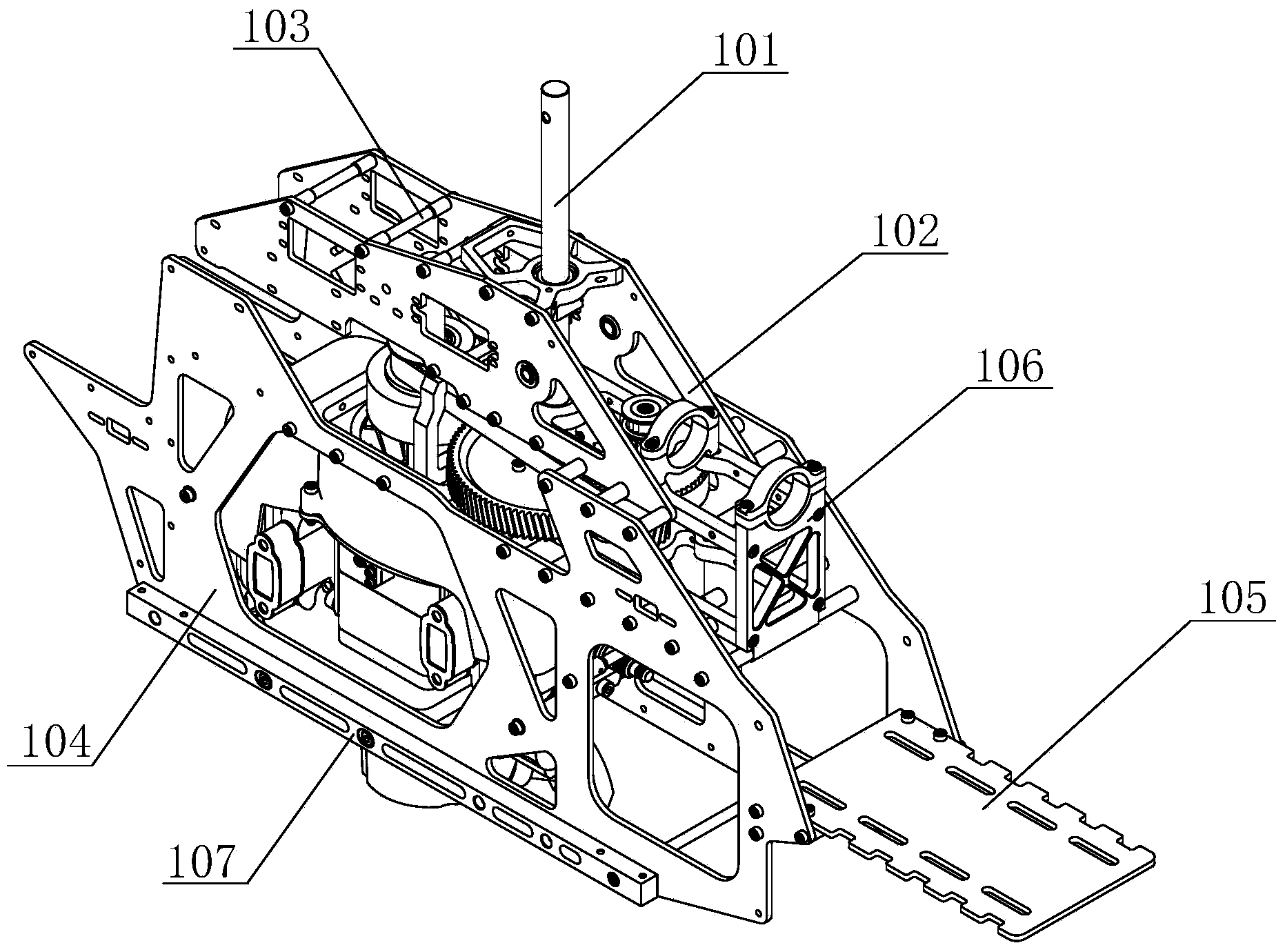

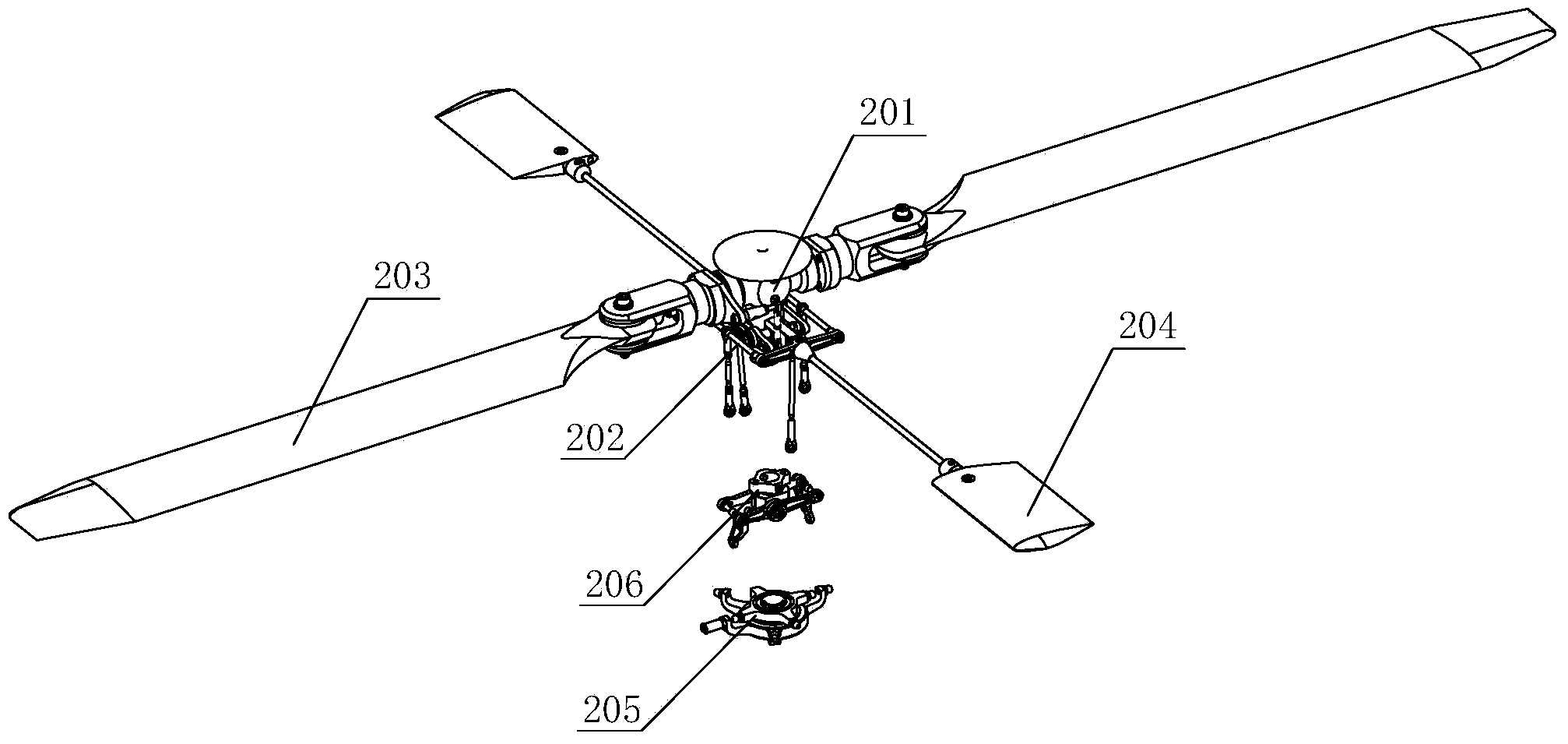

Vertical take-off and landing rotary wing type unmanned aerial vehicle

ActiveCN103803081AOperational securityAchieve vertical takeoffVertical landing/take-off aircraftsRotocraftFlight vehicleSingle-cylinder engine

The invention relates to the field of unmanned aerial vehicles, and in particular discloses a vertical take-off and landing rotary wing type unmanned aerial vehicle. The vertical take-off and landing rotary wing type unmanned aerial vehicle comprises a main frame assembly, an engine unit, a rotary wing assembly, a tail drive assembly and a total distance sliding block group, wherein the main frame assembly comprises a main shaft and two upper side plates oppositely arranged at two sides of the main shaft, the two upper side plates are fixedly connected with two lower side plates, a facility frame is connected with the two lower side plates and is provided with a drive unit, and the main shaft is vertically connected with the drive unit; the engine unit comprises an engine and a silencer connected with the engine, and the engine is a single-cylinder engine with displacement of 26CC. The vertical take-off and landing rotary wing type unmanned aerial vehicle disclosed by the invention has the advantages that the effective load of the aerial vehicle can achieve 5KG, the aerial vehicle is capable of vertically taking off and landing, has low requirements on floor space and has no requirement on special take-off / landing field or runway, the flying speed and height can be freely controlled, the manufacturing cost is low, the flexibility and the universality are high, and the operation of pilots is safe.

Owner:甘肃神龙航空科技有限公司

Air flow arrangement for a reduced-emission single cylinder engine

InactiveUS7086367B2Improves air-fuel mixingAccurate CalibrationCasingsCylinder headsSingle-cylinder engineAirflow

The present invention provides a reduced emission, single cylinder engine incorporating an air flow arrangement for improving flow efficiency of the intake air drawn into the engine and the exhaust discharged from the engine.

Owner:BRIGGS & STRATTON

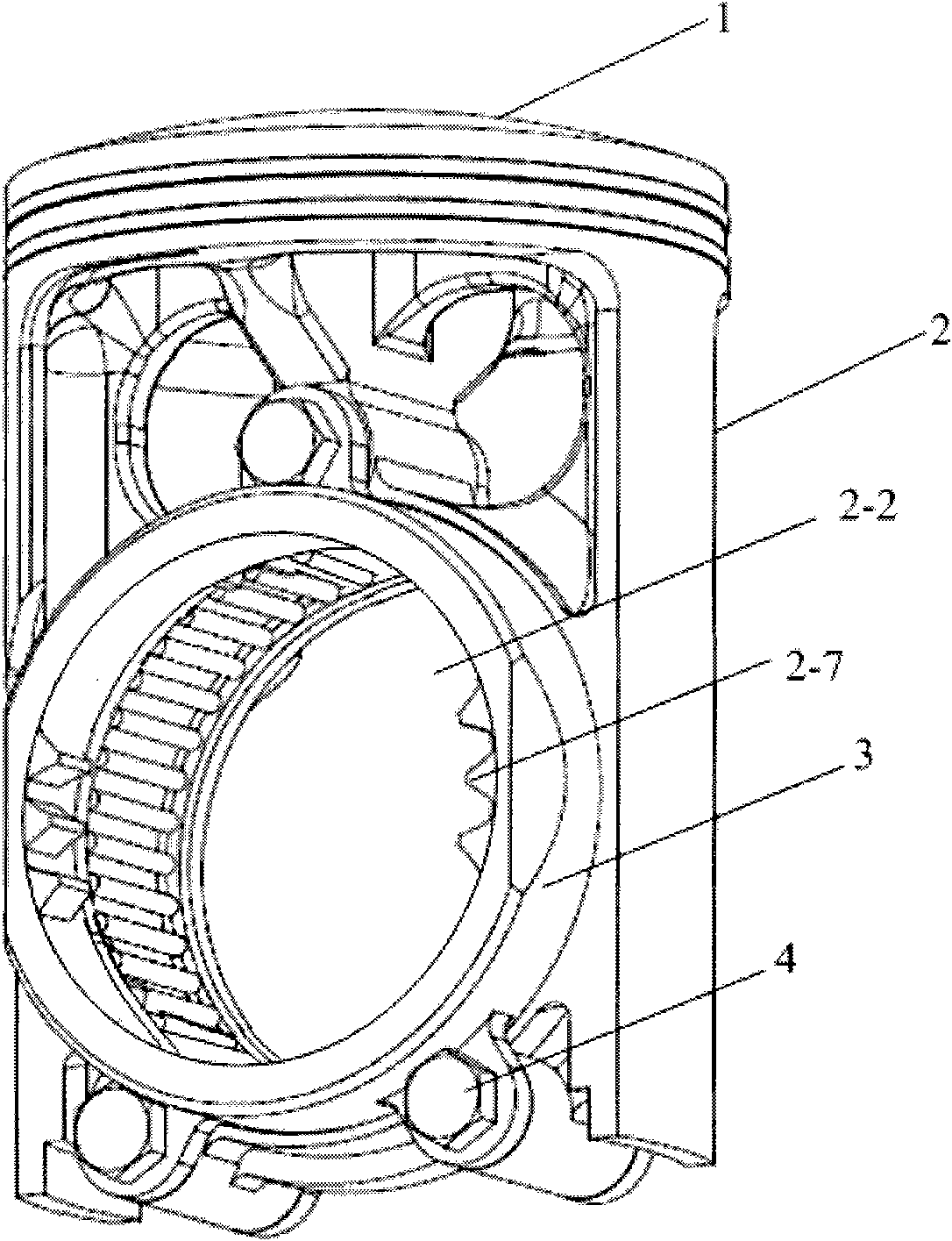

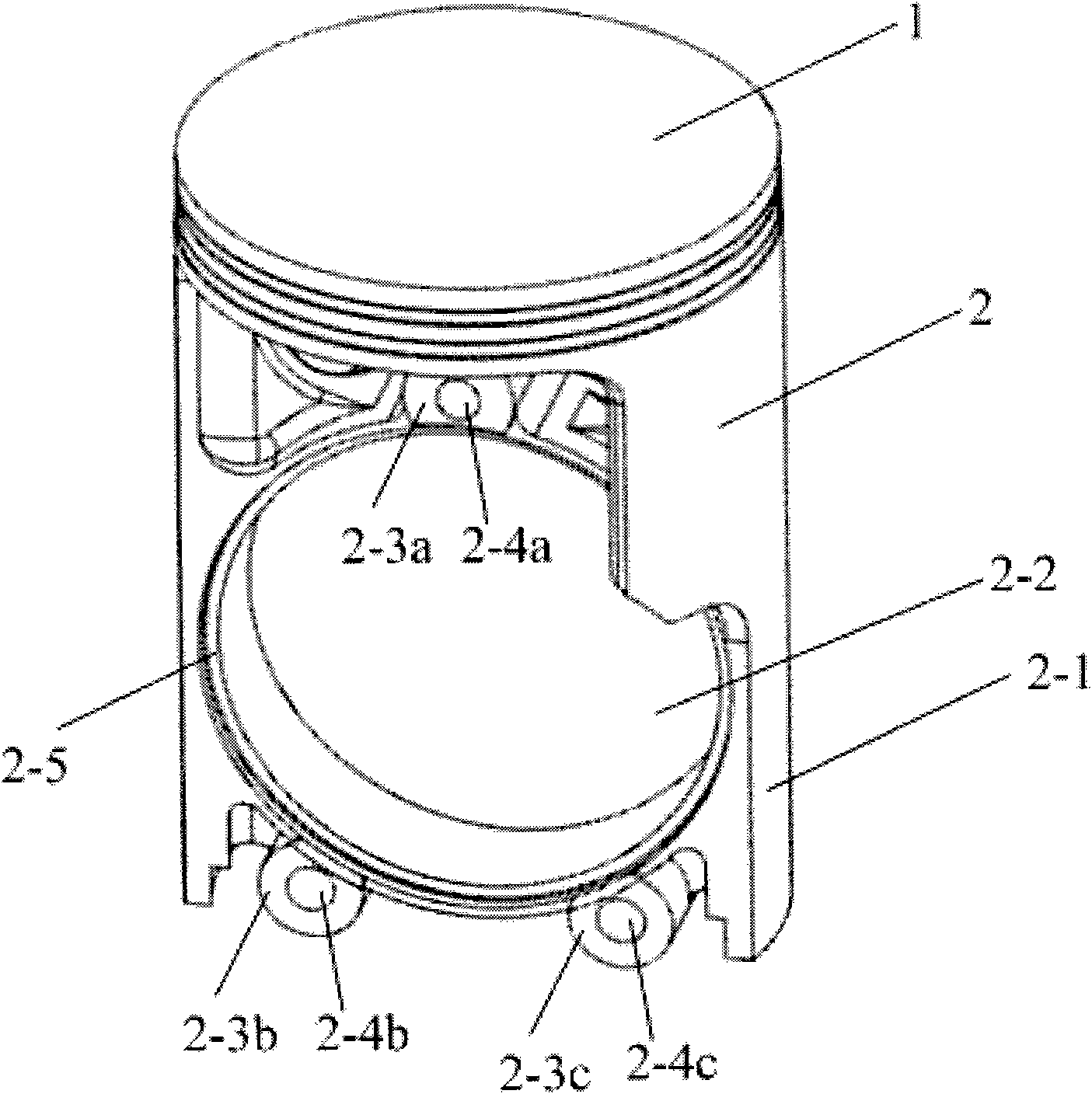

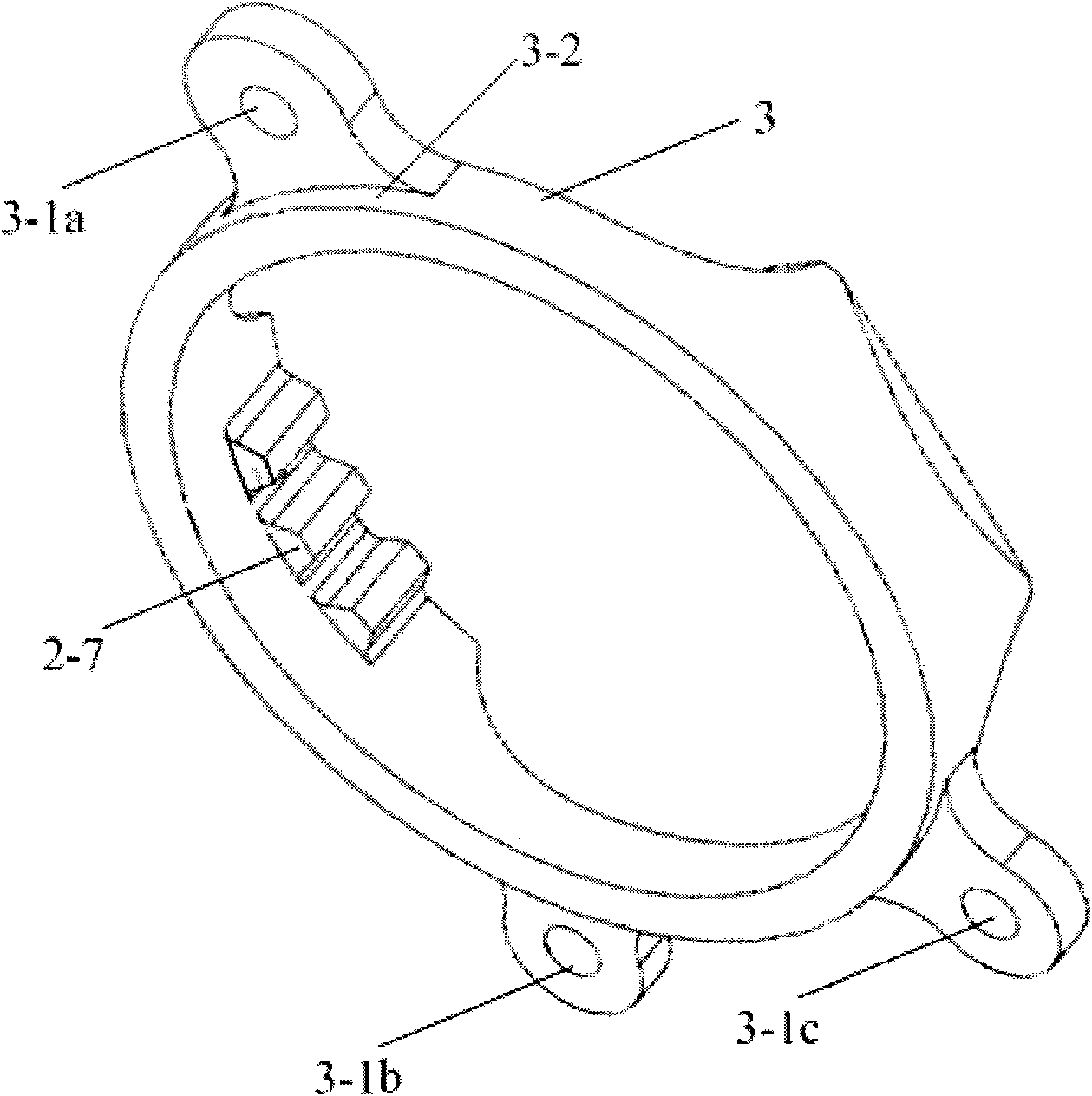

Piston, internal combustion engine and compressor of circular slider-crank mechanism of single cylinder engine

InactiveCN101644204ADirection of rotation is clearSmooth conversionPositive displacement pump componentsPlungersExternal combustion engineEngineering

The invention discloses a piston of a circular slider-crank mechanism of a single cylinder engine, comprising a piston seat and a crown arranged at the end of the piston seat, wherein, a circular slider containing hole is arranged on the piston seat. The piston is characterized in that piston separation blades are arranged on the end face edges of the circular slider containing hole and in the zone passing through the waist of the piston seat and are assembled on the piston seat in a demountable way; internal teeth segments are arranged on the piston separation blades on at least one end faceedge of the circular slider containing hole and in the zone passing through the waist of the piston seat. Being used, the piston of the invention can ensure smooth conversion from reciprocating motionto rotary motion and increase the strength of the waist of the piston seat. The invention also provides an internal combustion engine and a compressor.

Owner:BEIJING SINOCEP ENGINE TECH

Internal combustion engine

InactiveUS20050150474A1Reduce component countEasy to assembleValve drivesCylinder headsGear wheelCylinder head

A twin cylinder engine, includes a pair of cylinder members mounted to mounting surfaces of a crankcase, and cylinder heads mounted to the cylinder members. The cylinder members are modular components, which may be pre-assembled with components of the valve train as packaged units before the cylinder members are attached to the crankcase. Each cylinder member rotatably supports a cam gear which extends into the crankcase for driving engagement with the crankshaft. The cylinder members may be configured for either side valve-type (“L-head”), or overhead valve-type (“OHV”) engines, and the cylinder members may also be used in single cylinder engines.

Owner:TECUMSEH POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com