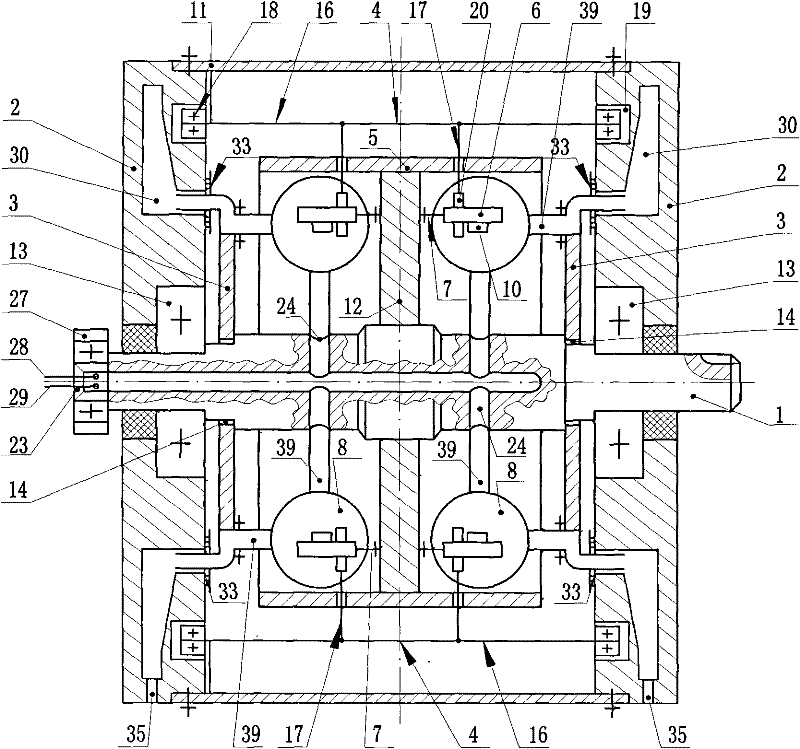

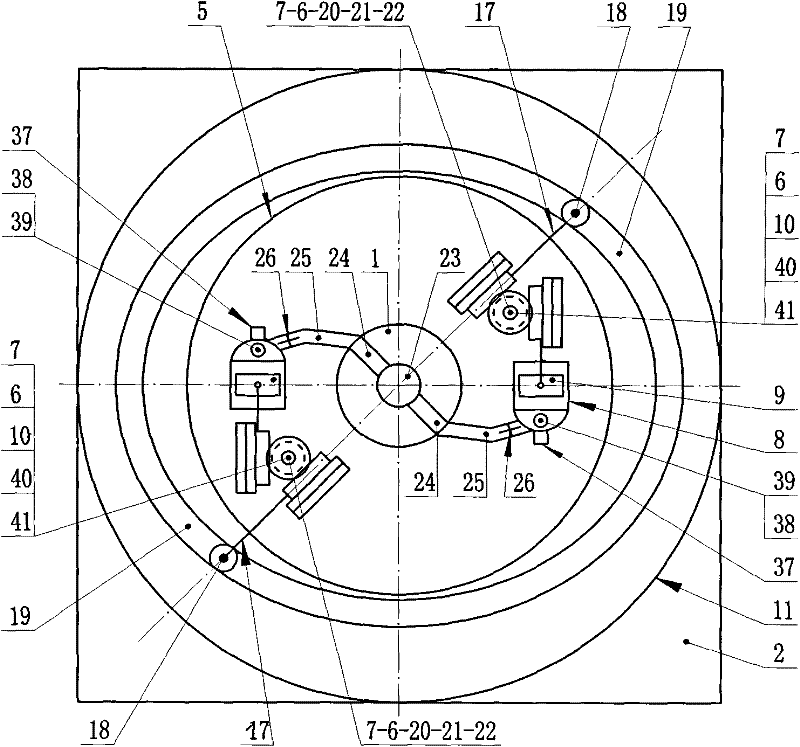

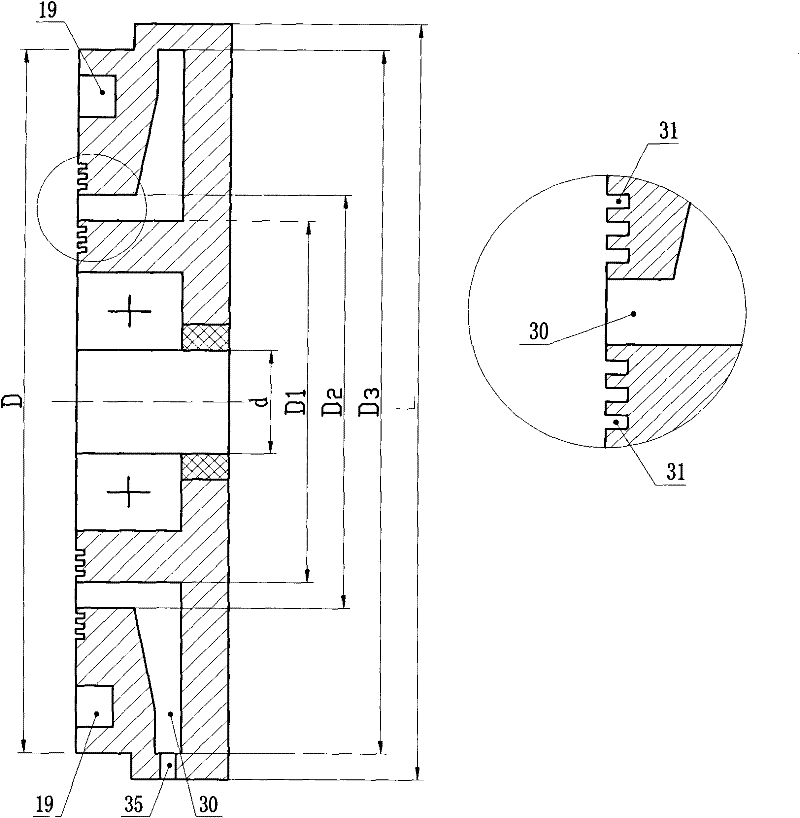

Rotary engine with double rows of pistons

A rotary engine and piston-type technology, applied in the field of power machinery, can solve problems such as high manufacturing cost, reduced air chamber sealing, pollution, etc., and achieve the effects of increasing work reliability, eliminating mechanical vibration, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Because this model is a double-row symmetrical structure, the crank-connecting rod piston type single-cylinder engine head (8) and its corresponding supporting parts are fixedly installed on the two sides of the head tray (12) and are in one-to-one correspondence with each other. Back-to-back, the two parallel vertical bars (17) of the double T-shaped rolling link (3) are respectively connected with the transmission parts on both sides at the same time, and the two vertical bars (17) are connected to the double T-shaped rolling link (3). Driven by it, its movement is synchronous and its direction is exactly the same. For ease of description, simple and clear, only one side of the pallet (12) is described below for the single-row head movement and work process, and the model is further described in detail below in conjunction with the description of the drawings and specific implementation methods: design elliptical track groove (major axis- Minor axis)÷2=piston stroke S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com