Engine

A technology for engines and transmission shafts, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of low energy conversion efficiency of engines, low energy conversion efficiency, and cannot be further improved, and achieve simple structure, high energy conversion efficiency, and not easy flameout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

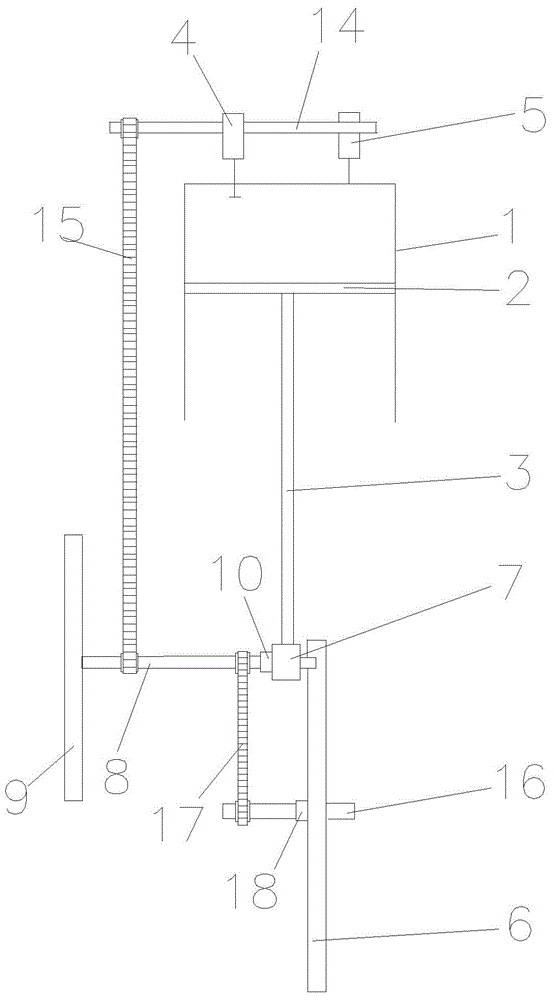

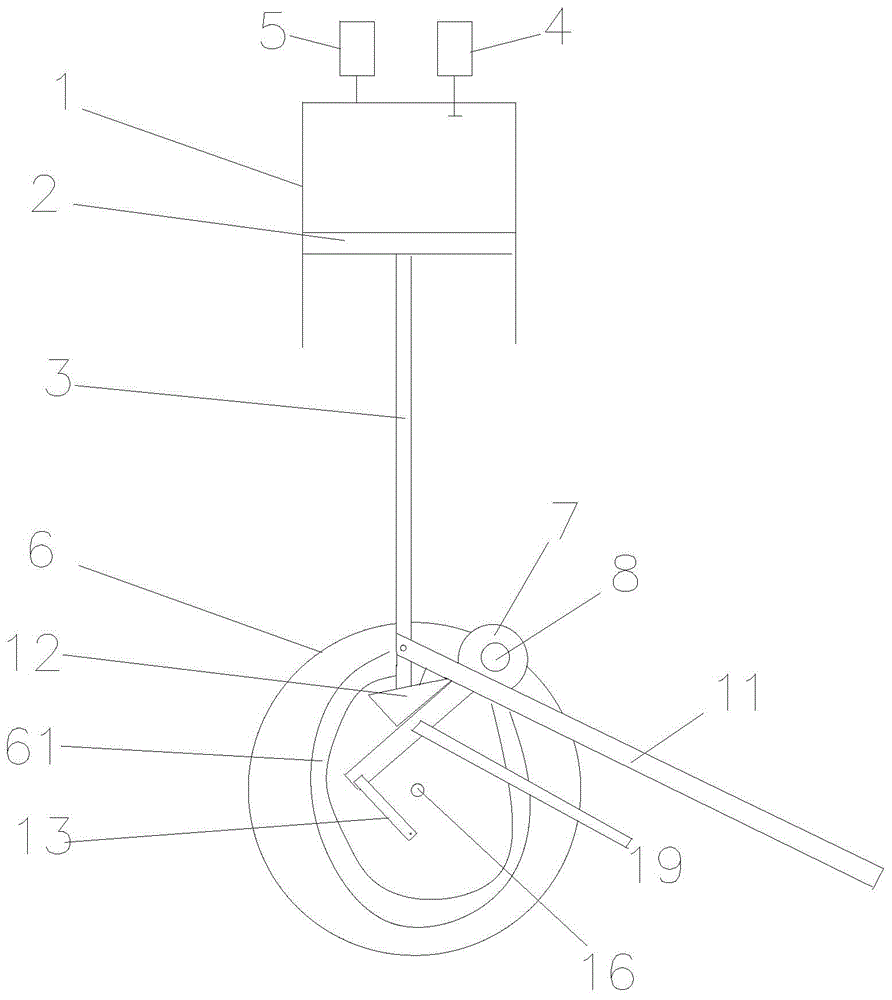

[0027] Such as Figure 1~3 As shown, the engine of the present invention mainly includes a cylinder 1, a piston 2 located in the cylinder 1, a connecting rod 3 connected to the piston 2, an intake device 4, an exhaust device 5, a track mechanism 6 and an elastic mechanism 7 . Among them, the cylinder 1 is provided with an intake valve matched with the intake device 4, and an exhaust valve matched with the exhaust device 5, the intake device 4 provides combustible gas for the cylinder 1, and the exhaust device 5 discharges the combustible gas in the cylinder 1. exhaust gas.

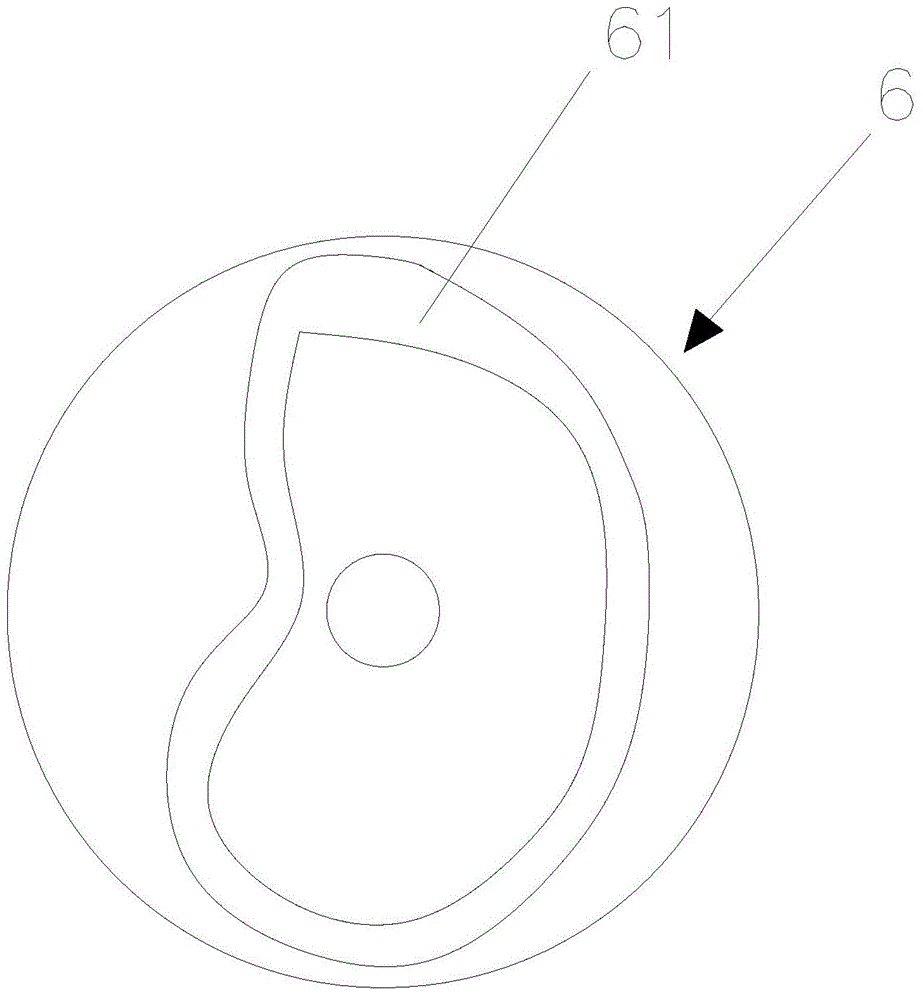

[0028] The track mechanism 6 is in the shape of a turntable, and one side thereof is provided with a closed track 61, and the lower end of the connecting rod 3 is closely matched with the closed track 61. The shape and size of the closed track 61 need to meet the following conditions: the lower end of the connecting rod 3 slides in the closed track 61 for a week to complete the four strokes of air intake...

Embodiment 2

[0036] The track mechanism 6 replaces the turntable shape with a cylindrical shape, and the closed track 61 is arranged on the outer wall of the cylinder, and the cylinder is fixed with a support to make it rotate. Other structural settings are the same as in Embodiment 1.

[0037] Working process of the present invention:

[0038] Intake stroke: the track mechanism 6 drives the connecting rod 3 to move from the top dead center to the bottom dead center, the intake valve opens, the combustible gas is sucked into the cylinder 1, and the intake stroke ends when the piston 2 reaches the bottom dead center. In this process, the switch protrusion 13 locks the elastic mechanism 7, and there is no power output.

[0039]Compression stroke: the track mechanism 6 drives the connecting rod 3 to move from the bottom dead center to the top dead center, the intake valve and the exhaust valve are closed, the combustible gas is compressed, the pressure and temperature rise, until the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com