Patents

Literature

1380results about How to "Burn completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

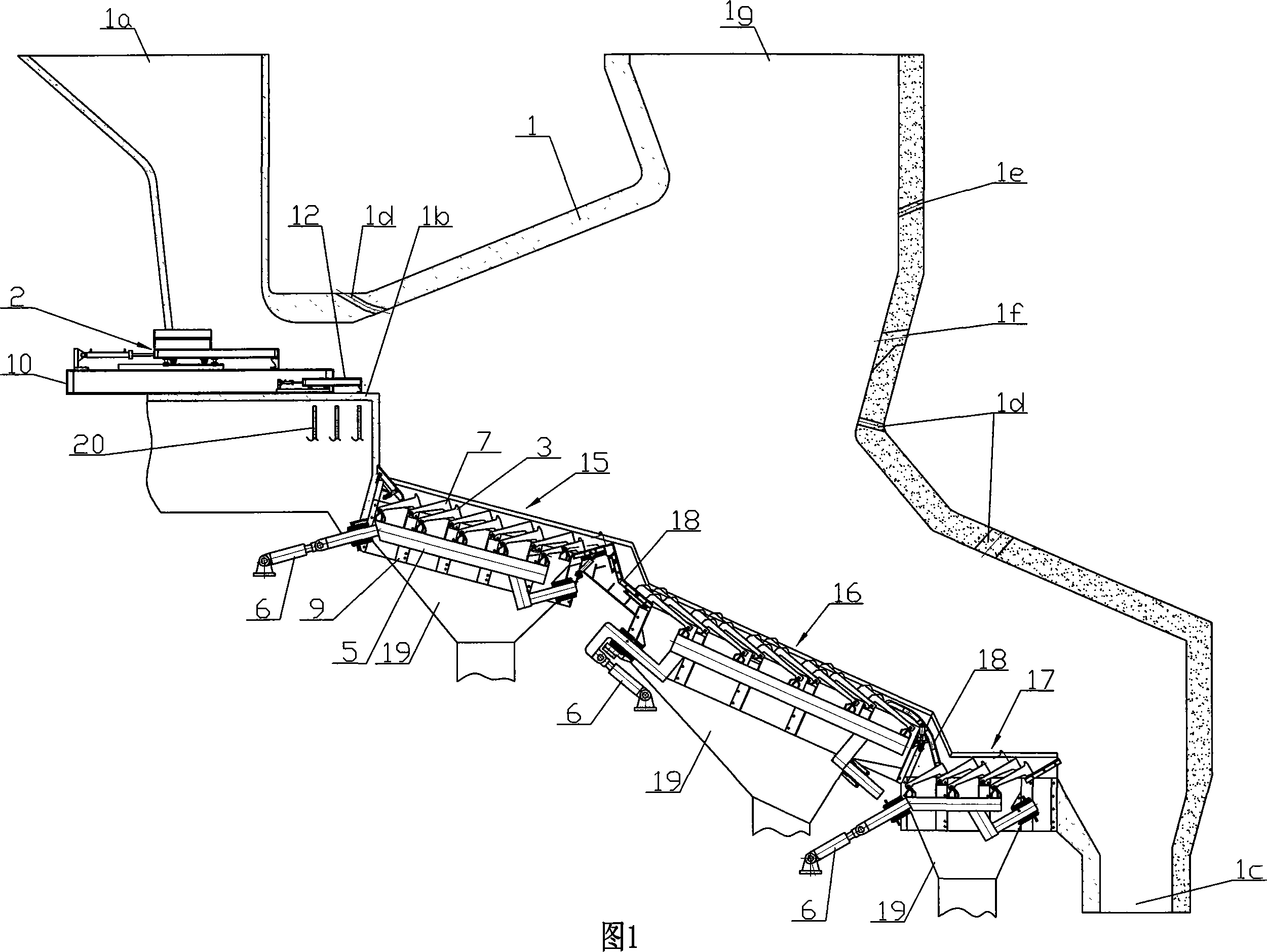

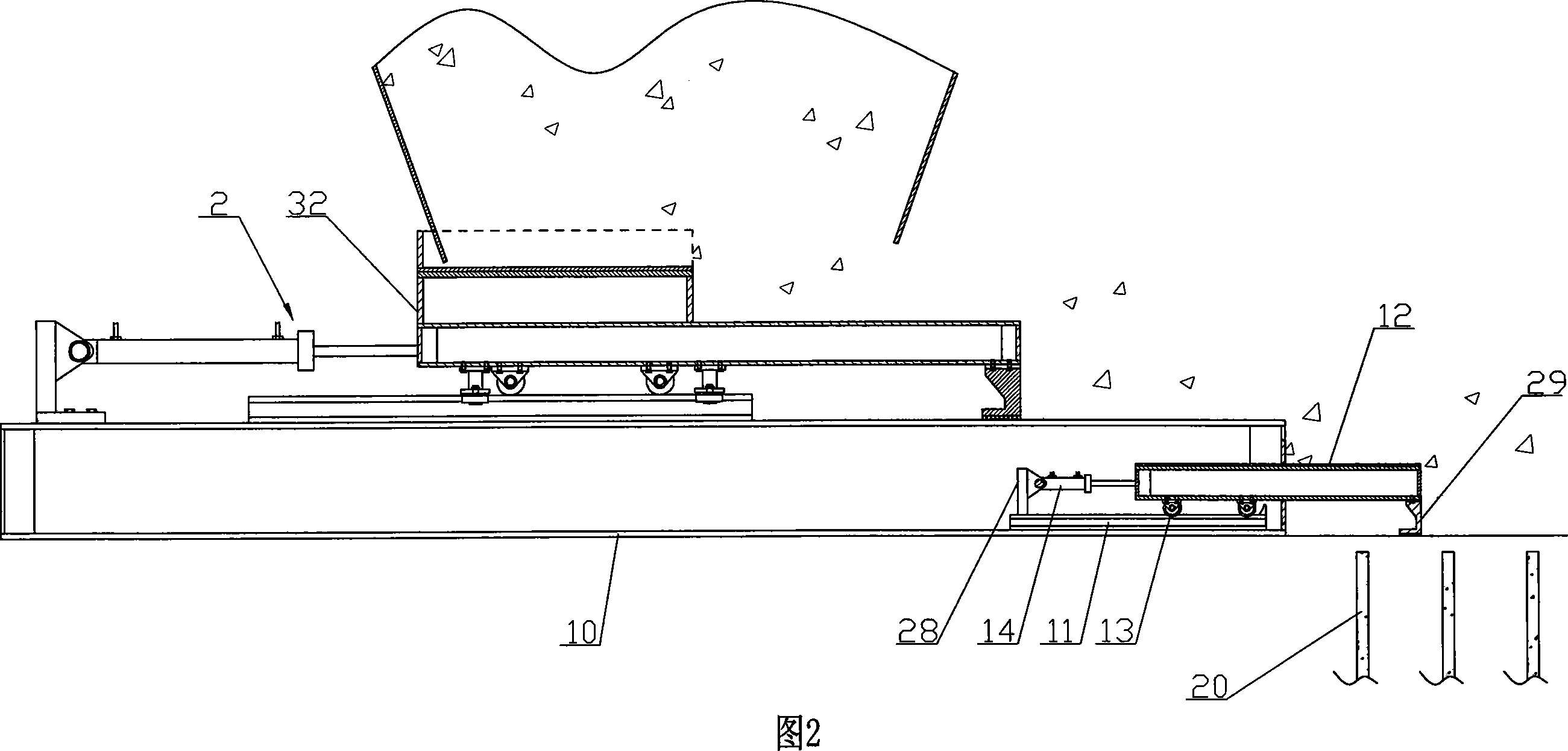

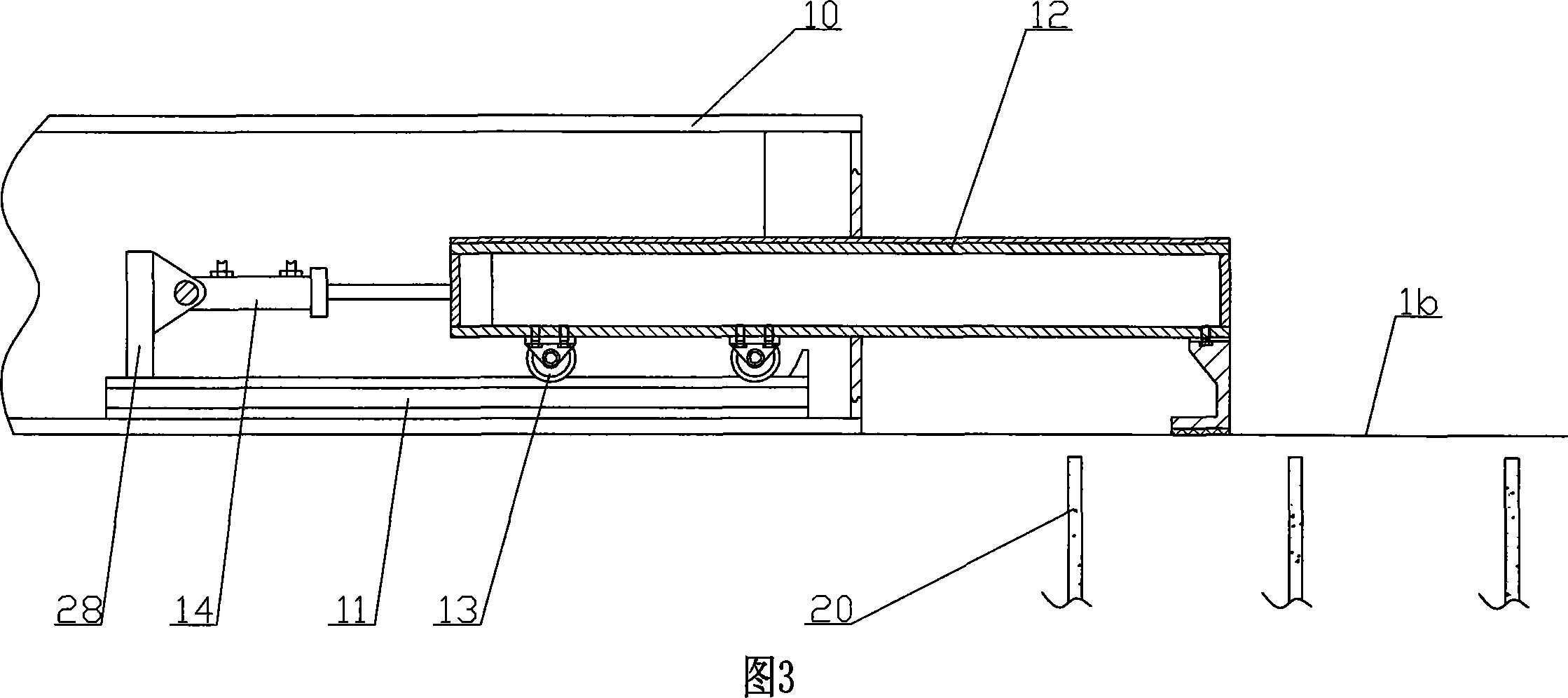

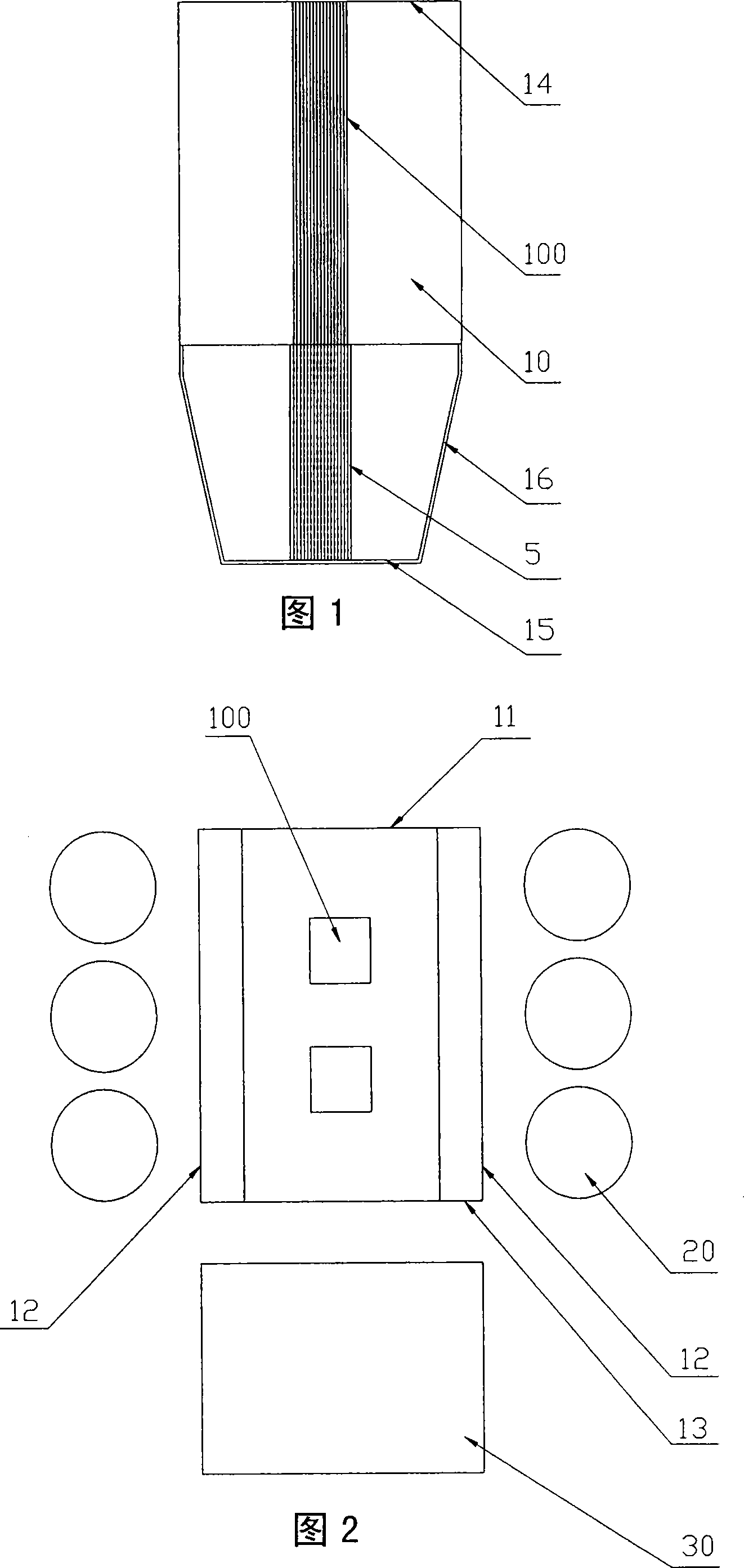

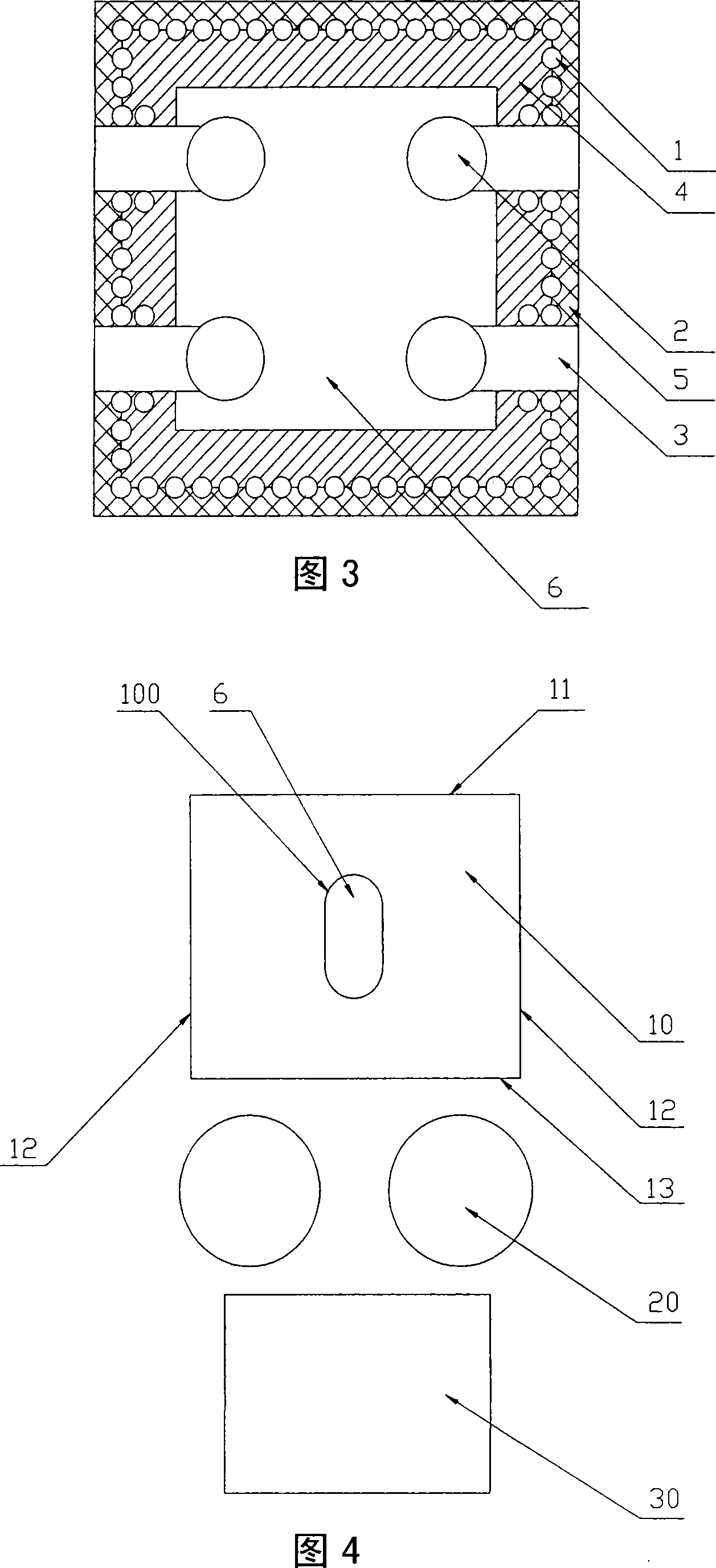

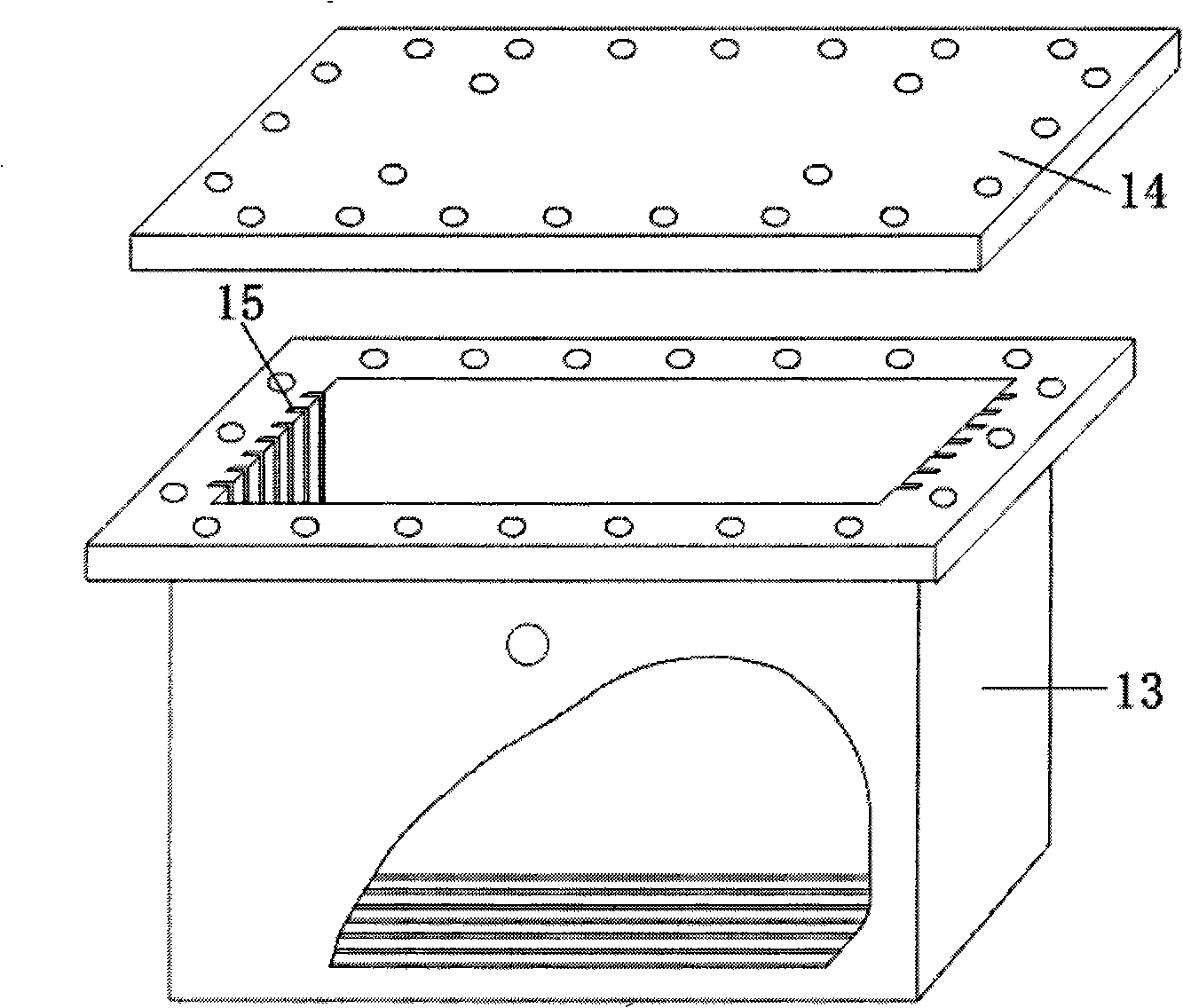

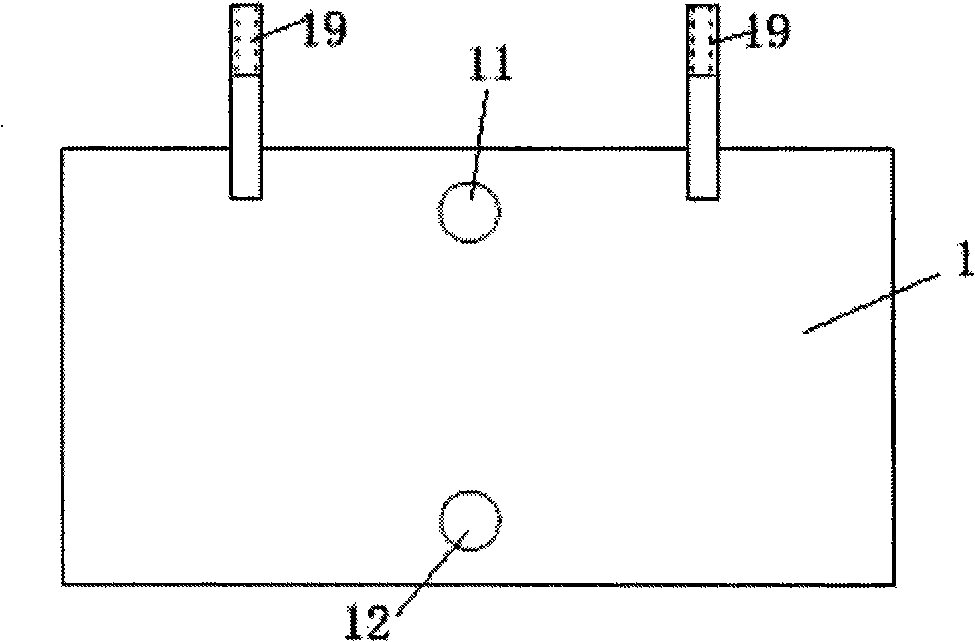

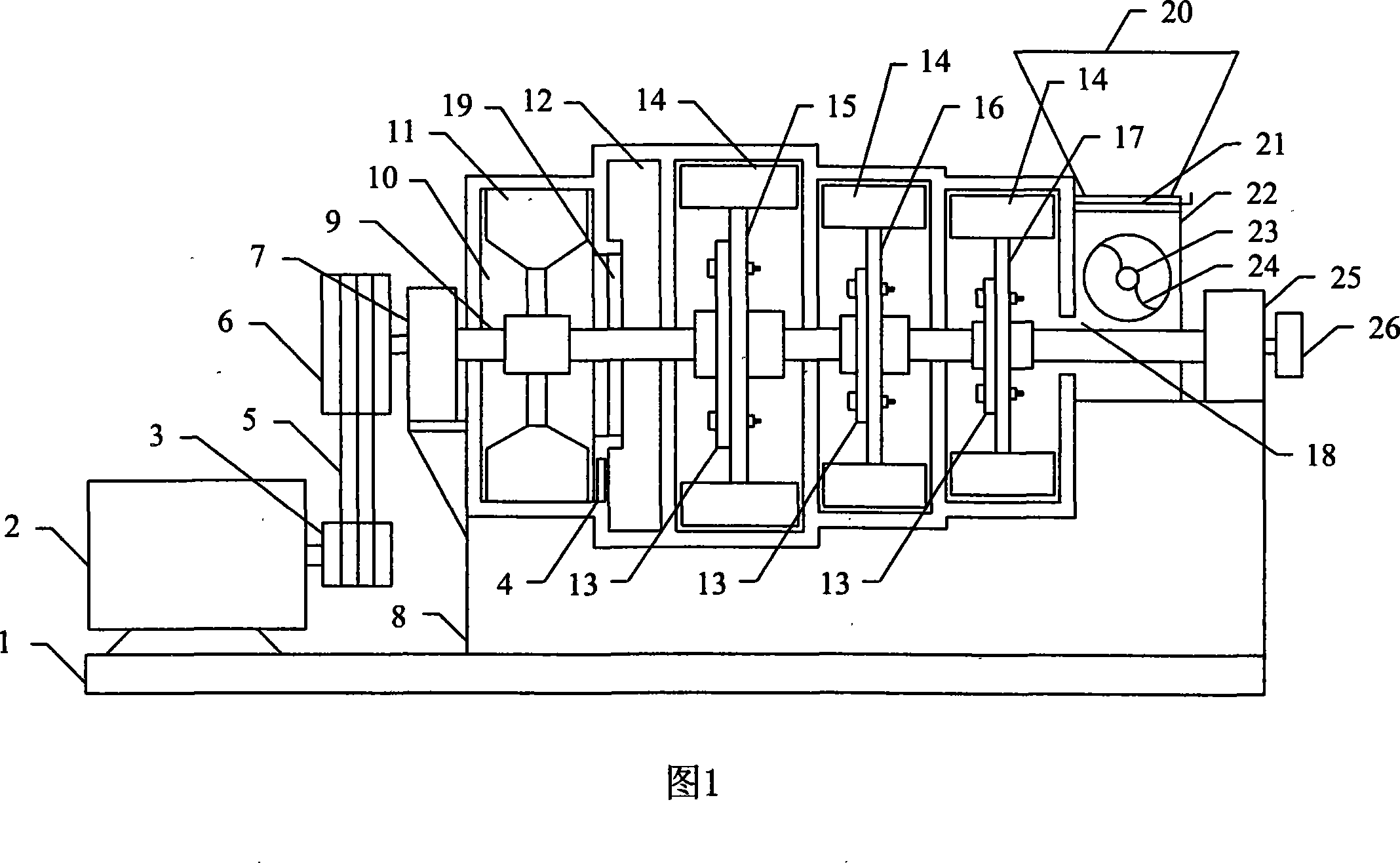

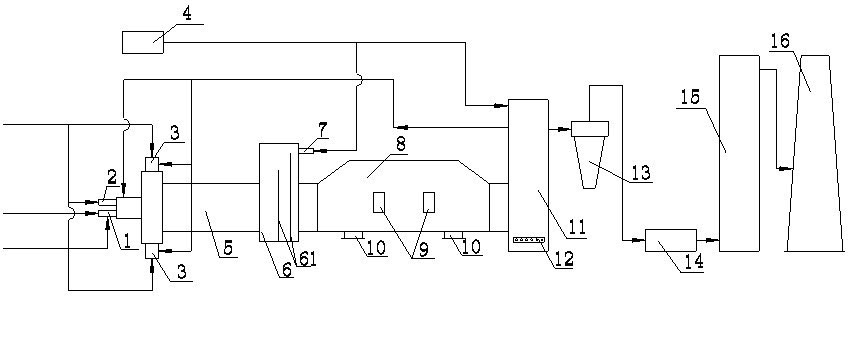

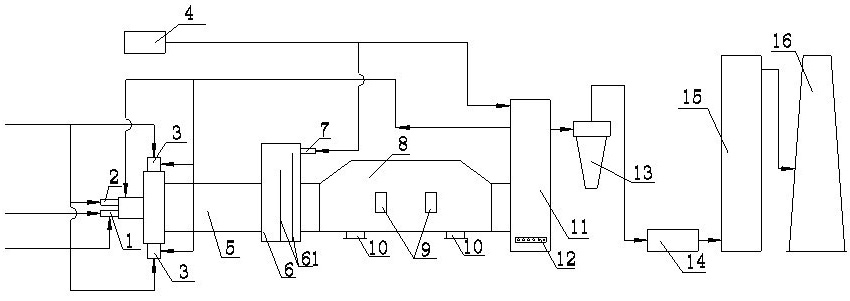

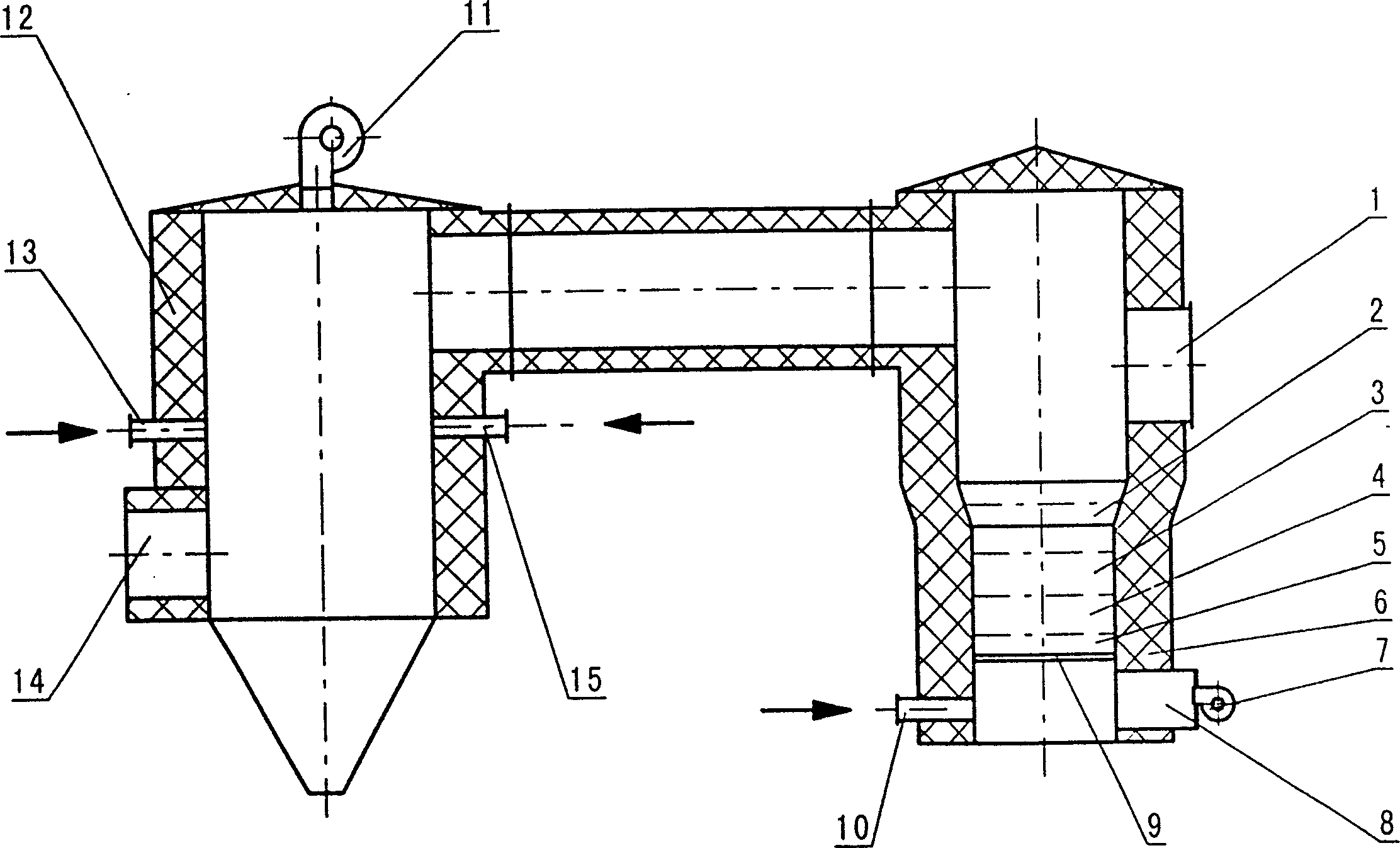

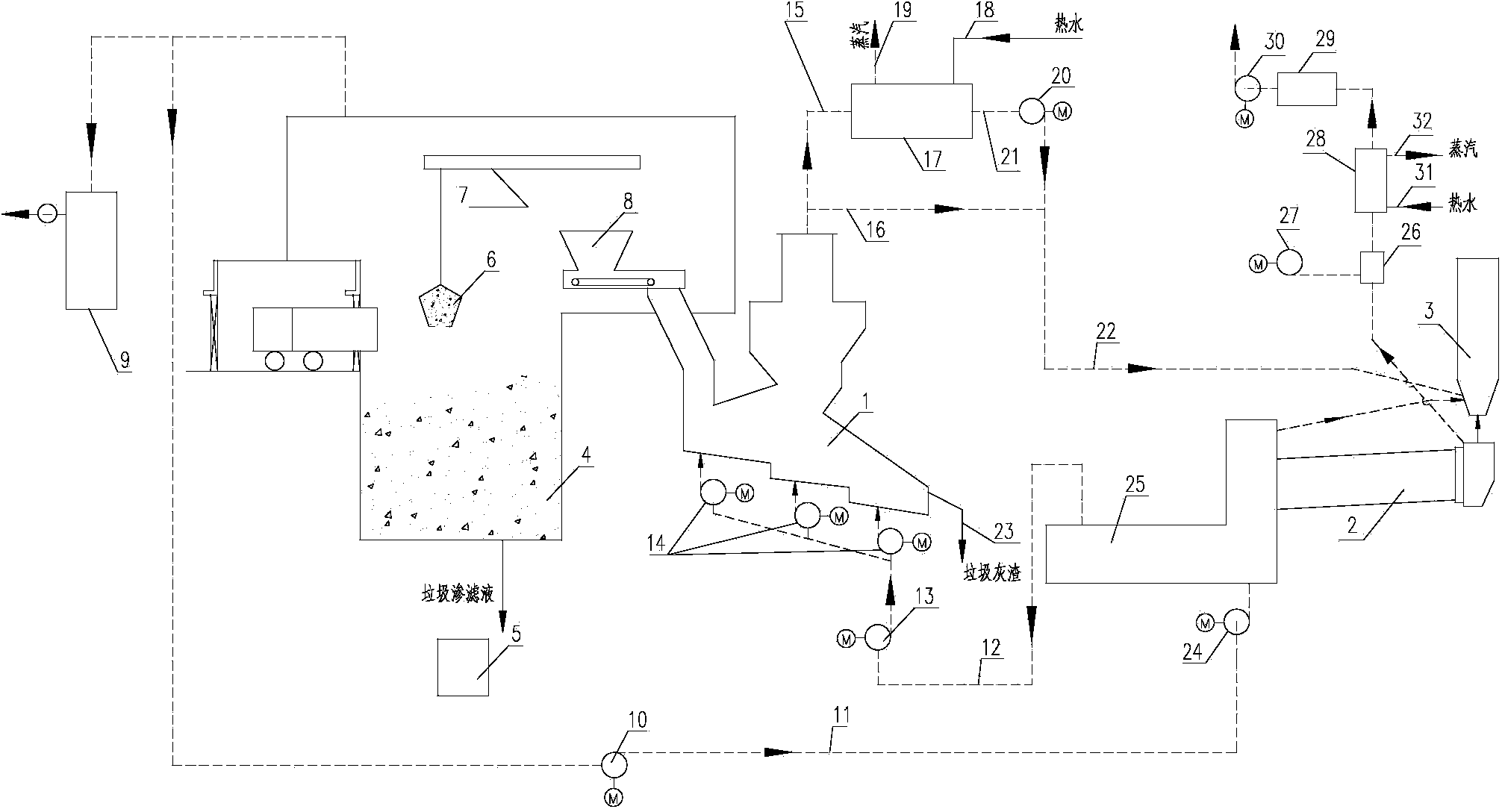

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

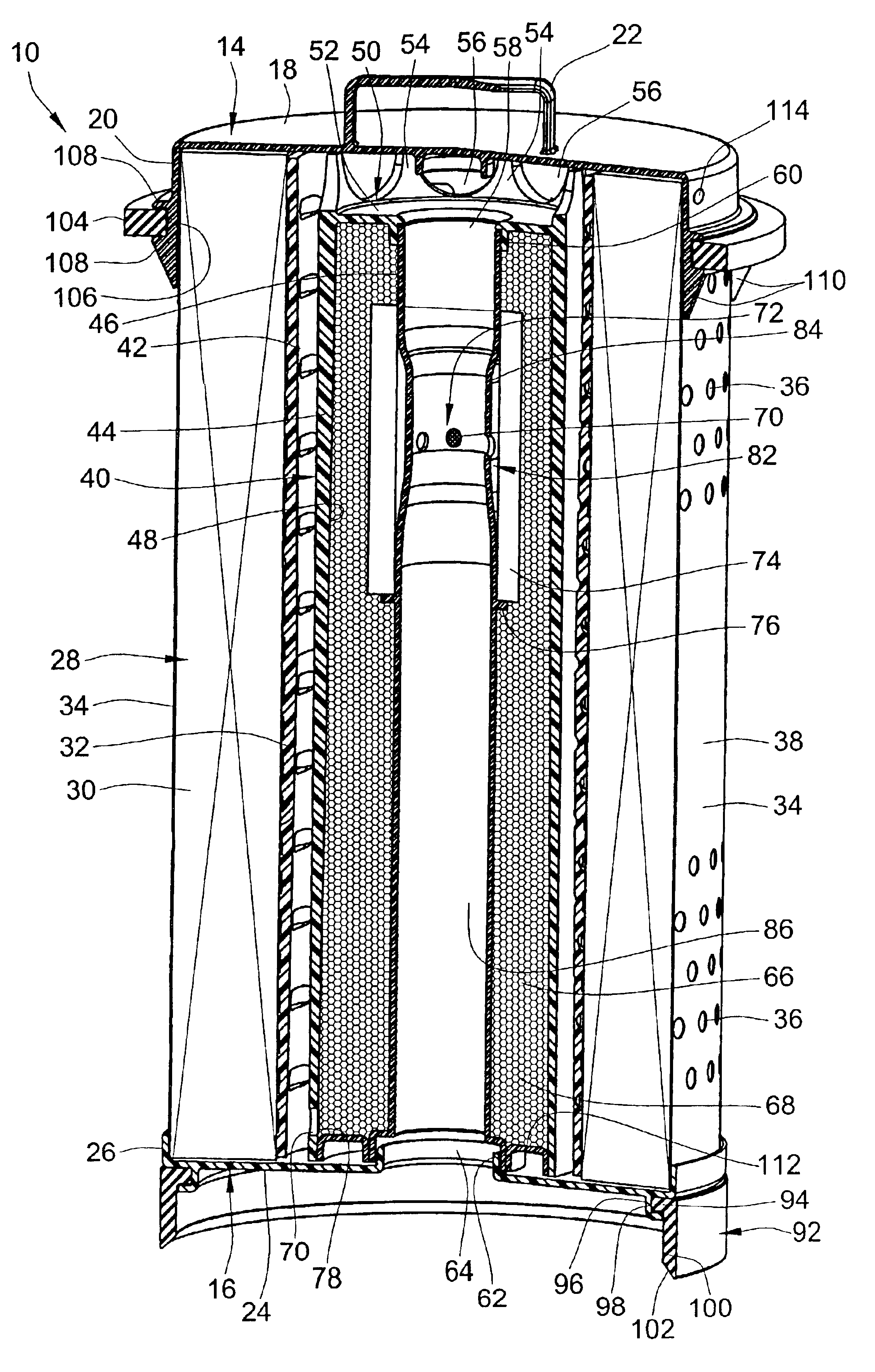

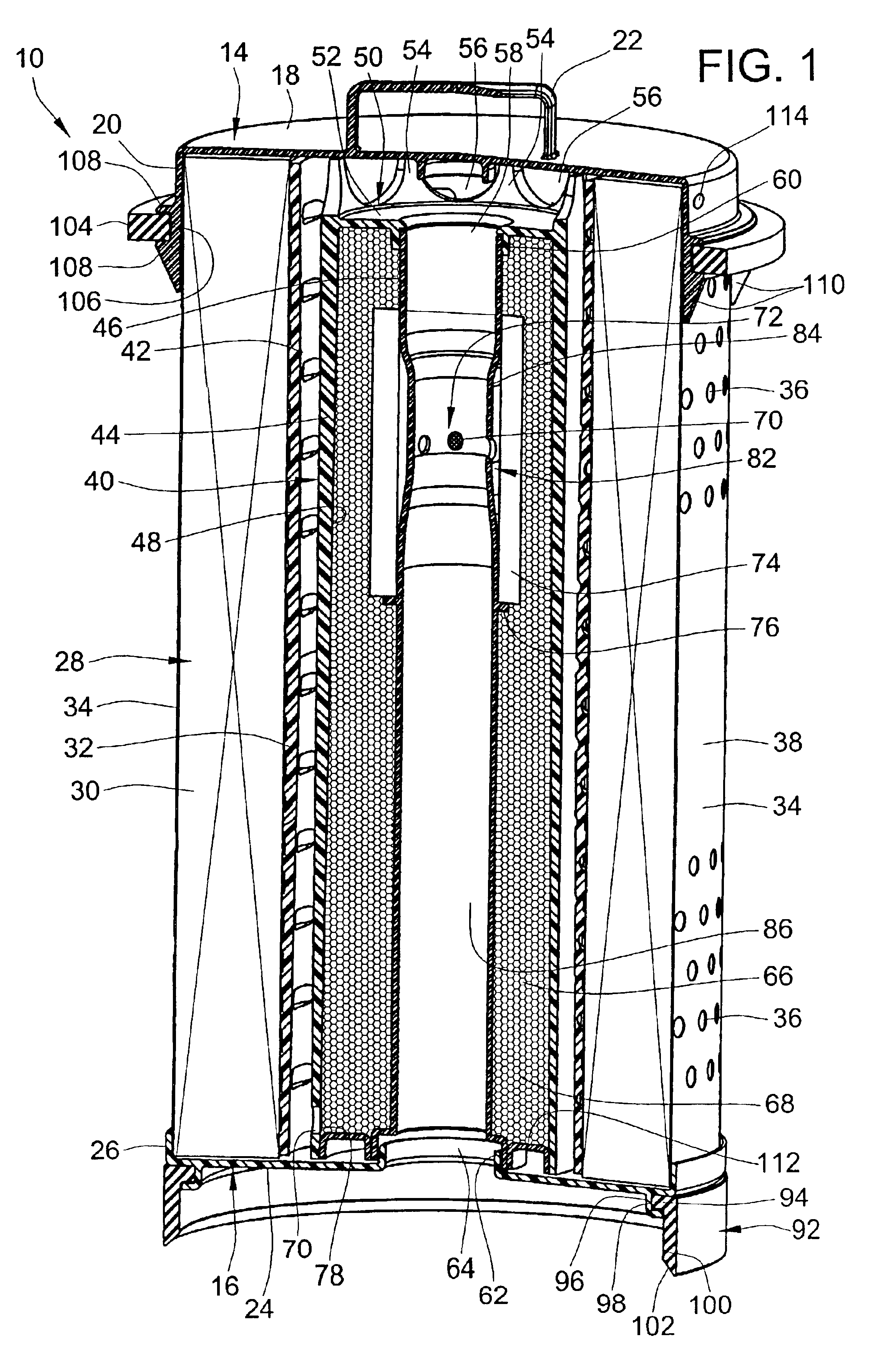

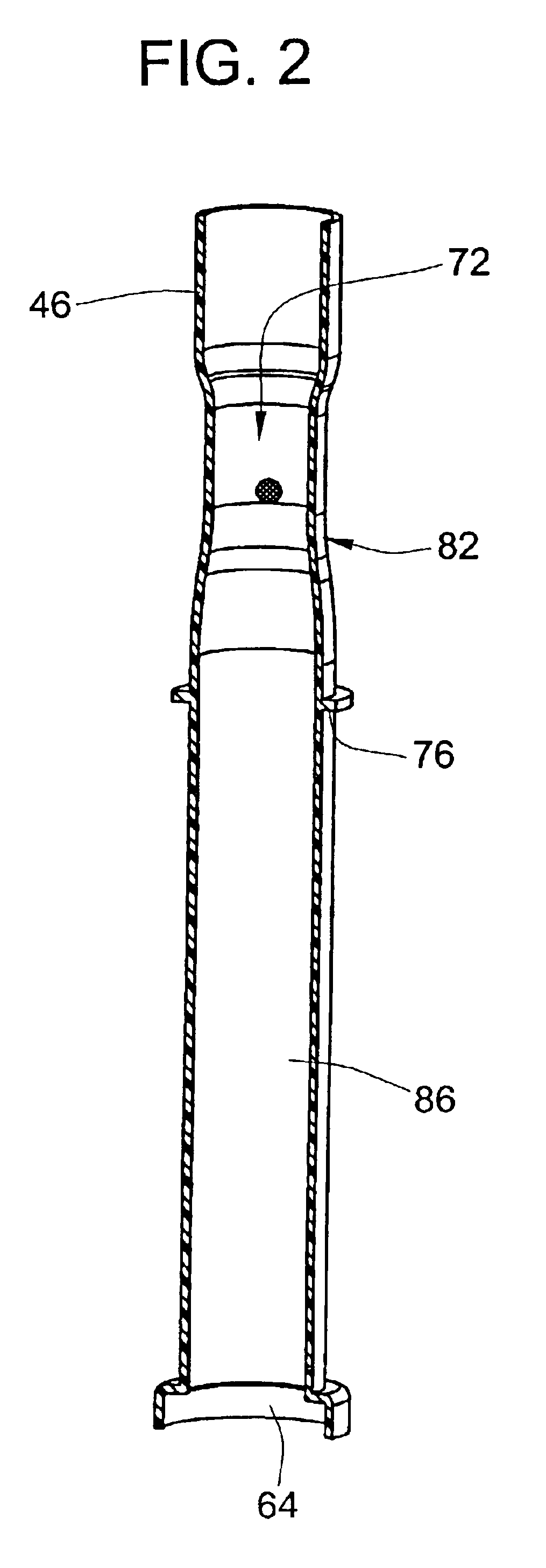

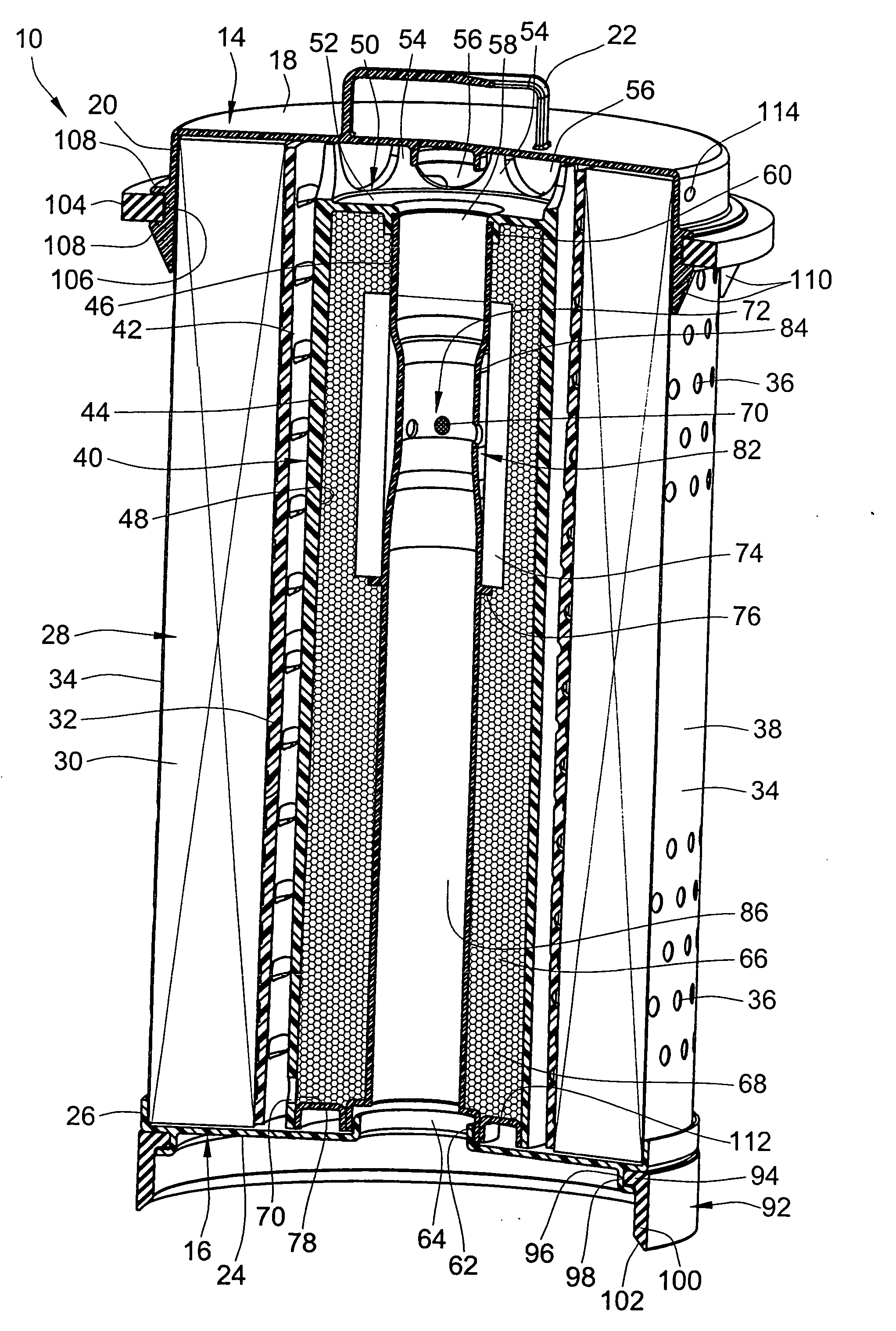

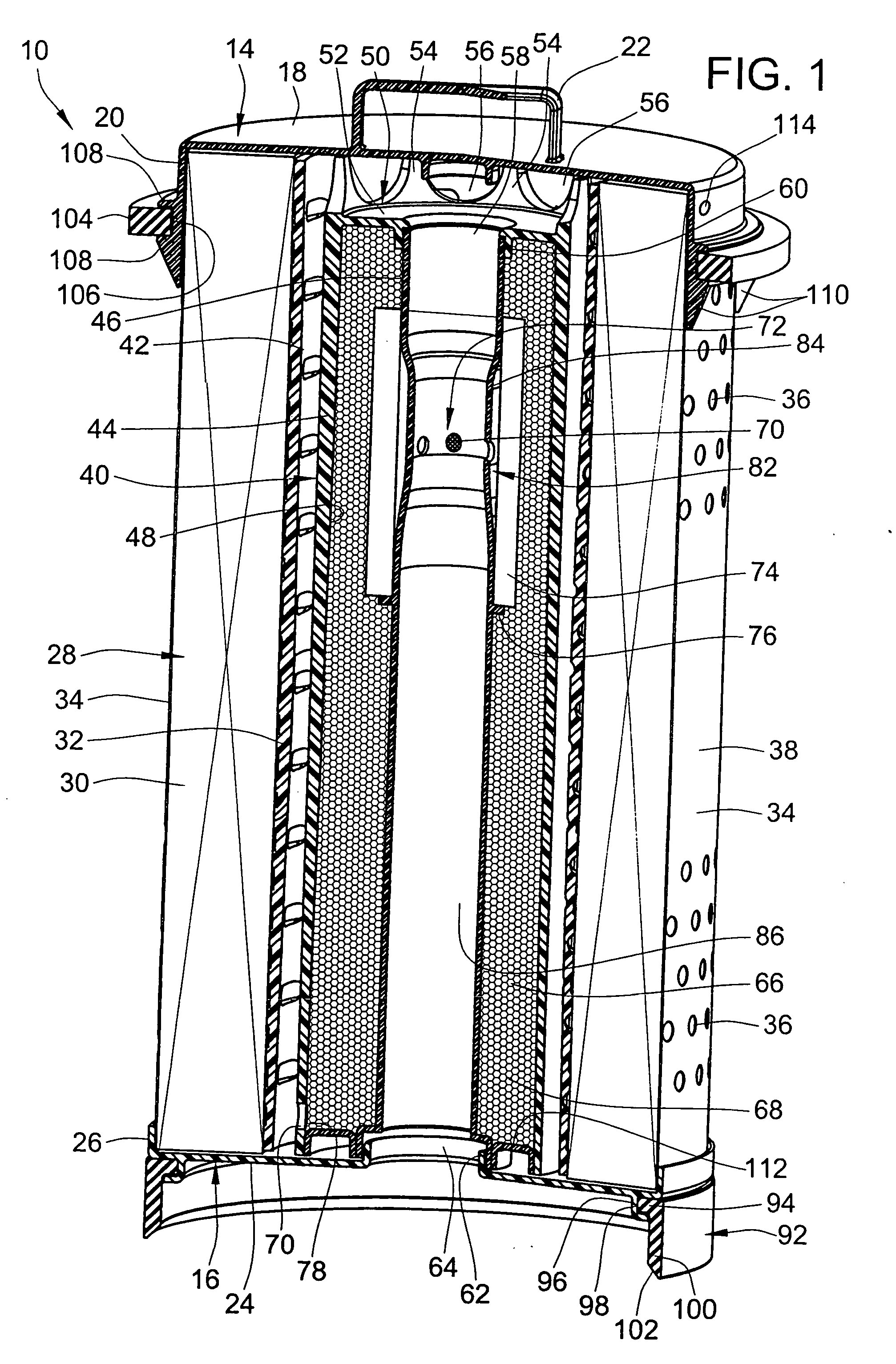

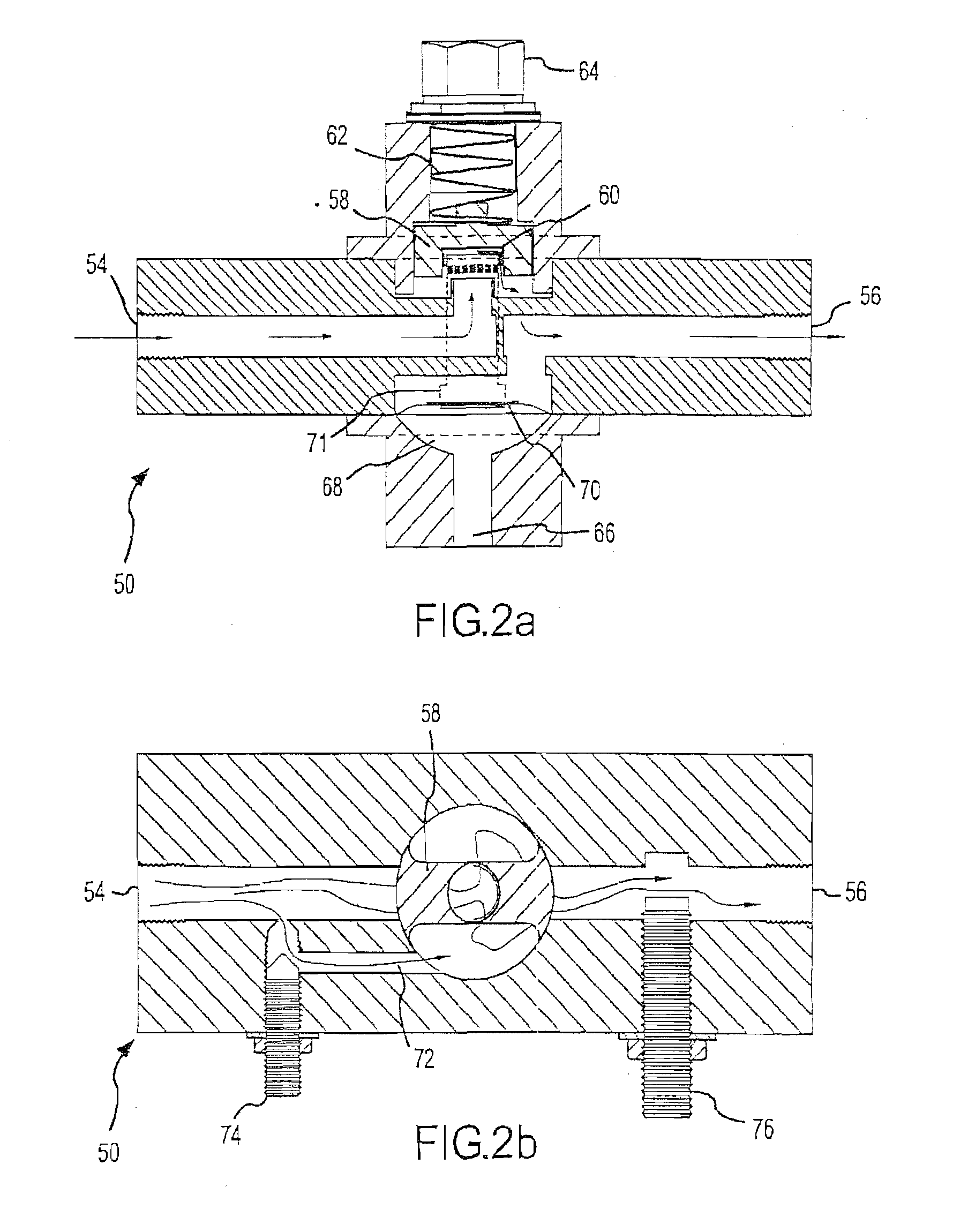

Environmentally friendly acid neutralizing full flow cartridge

InactiveUS6984319B2Burn completelyDispersed particle filtrationMachines/enginesParticulatesEngineering

An environmentally friendly acid neutralizing filter cartridge is adapted to be mounted in a cartridge mounting body of an engine oil circuit for filtering particulates and neutralizing acid in oil. The filter cartridge comprises a support housing that comprises substantially no metal parts such that the filter cartridge can be readily incinerated. A full flow particulate filter and a bypass particulate filter are arranged in the support housing. A bed of acid neutralizing particles is contained in the support housing. The housing is configured such that a predetermined primary flow path is defined through the filter cartridge that passes through the full flow particulate filter and bypassing the bed of acid neutralizing particles; and a predetermined bypass path is defined through the filter cartridge that passes, in sequence, through the bed of acid neutralizing particles and the bypass particulate filter.

Owner:BALDWIN FILTERS

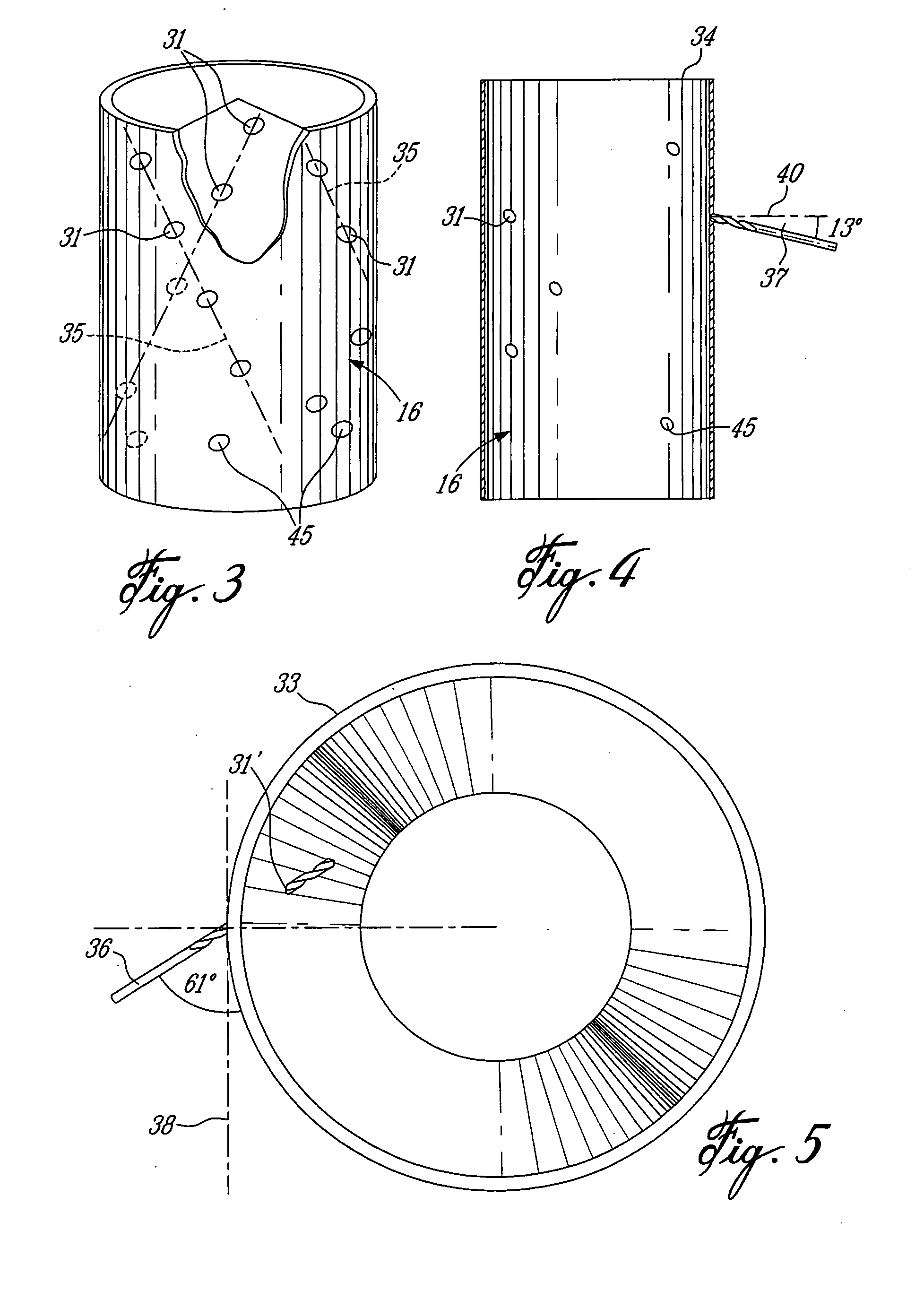

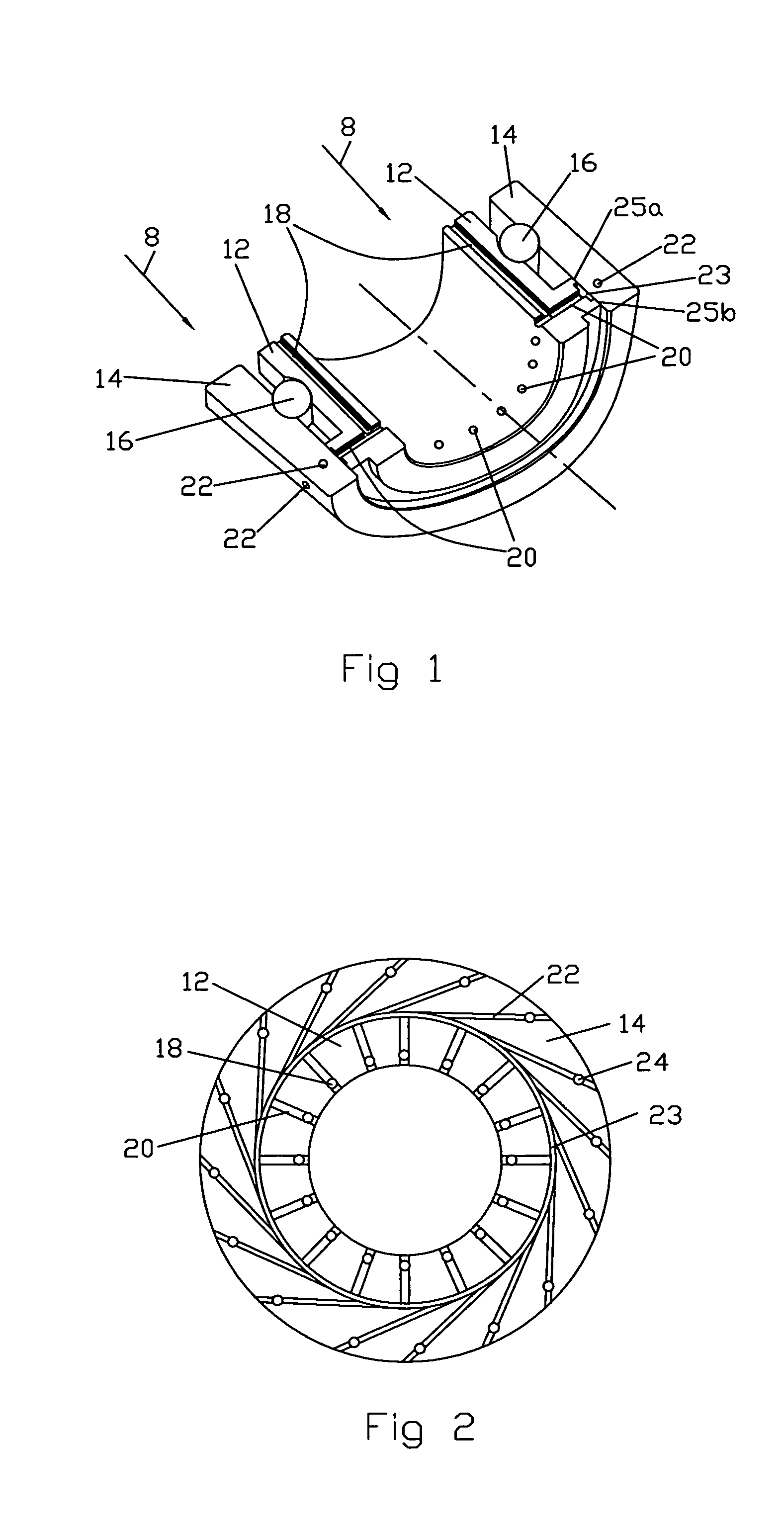

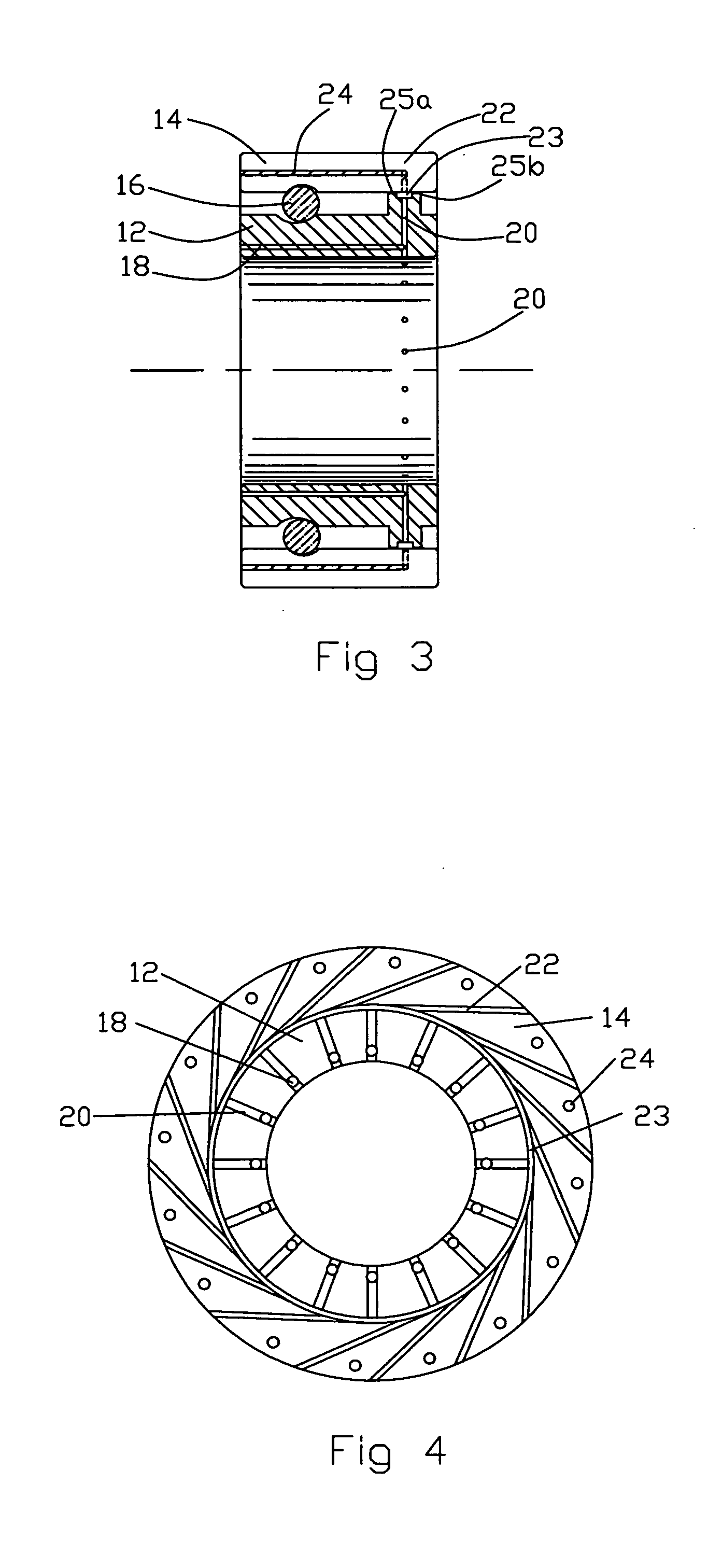

High efficiency cyclone gasifying combustion burner and method

InactiveUS20070137537A1Reduce pollutant emissionIncreased timeAir supply regulationDomestic stoves or rangesPyrolysisVertical angle

A cyclone gasifying combustion burner and its operation is described. An exemplary burner has an inner cylindrical wall with a contour chamber feeding combustion air into the inner cylindrical wall, with an open end and a solid fuel support end where a combustible material forms a fuel bed. The inner cylindrical wall has a series of inclined air jet holes of substantially predetermined diameter and disposed at substantially predetermined locations therein to create a unidirectional cyclone within a combustion zone defined within the inner cylindrical wall. The air jet holes are disposed at a tangential and vertical angle whereby the combustion air is drawn into the inner cylindrical wall and creates a cyclone flow to mix with the combustion gases released from the flaming pyrolysis fuel bed and causes the combustion gases to flow in a cyclone path within a reaction zone to increase the residency, mixing and turbulence time of the combustion gases and simultaneously precipitate suspended particles against an inner surface of the inner cylindrical wall whereby the particles are caused to gravitate to the fuel bed where they are removed in a controlled manner during the operation of the burner.

Owner:DRISDELLE MARK +1

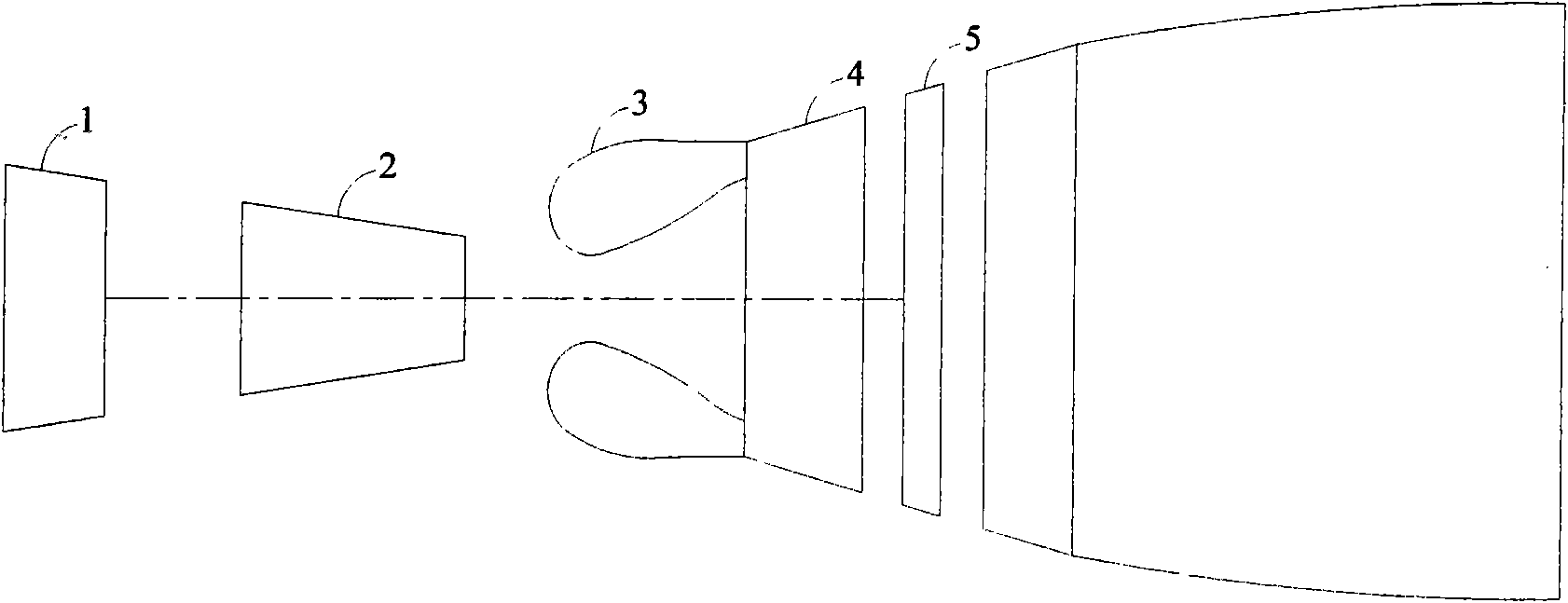

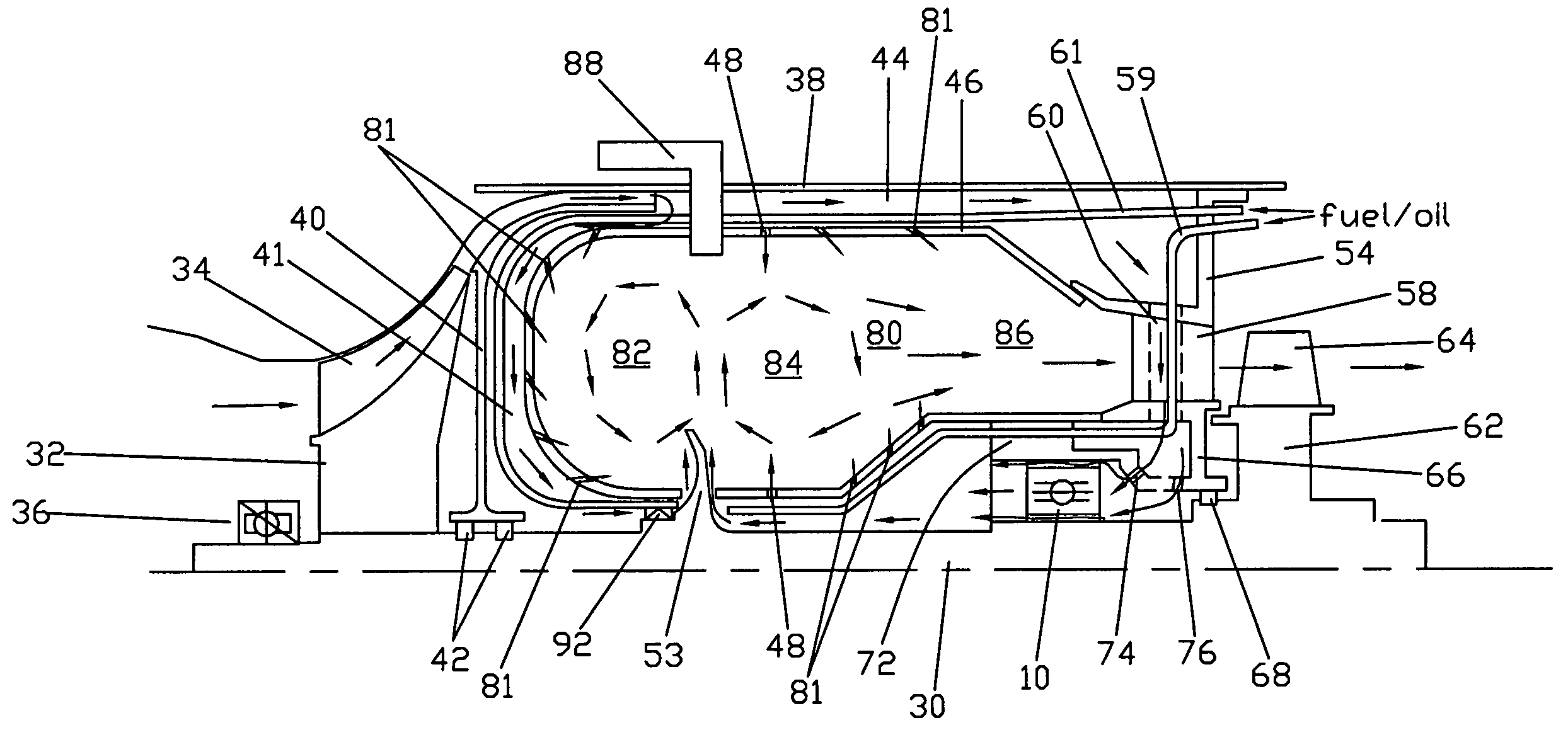

Low-pollution combustion chamber provided with premixing and pre-evaporating ring pipe

ActiveCN101788157AReduce pollutionFast evaporation blendingContinuous combustion chamberCombustion chamberCombustible gas

The invention relates to a low-pollution combustion chamber provided with a premixing and pre-evaporating ring pipe, which adopts a single-ring cavity structure and consists of a combustion chamber outer casing, a combustion chamber inner casing, an outer flame tube, an inner flame tube and a combustion chamber head part, wherein air used for combustion completely enters into the flame tubes from the combustion chamber head part; the scheme of fractional combustion can be adopted, and pre-combustion stage and a main-combustion stage are divided; the main-combustion stage comprises the premixing and pre-evaporating ring pipe, a main-combustion stage nozzle and a main-combustion stage swirler; fuel oil is evaporated and mixed inside the premixing and pre-evaporating ring pipe and then enters into the flame tubes after forming even mixed combustible gas, belonging to premixed combustion; a fuel nozzle is used for supplying the fuel oil for the pre-combustion stage and the main-combustion stage; the stable working range of the combustion chamber is mainly controlled by the pre-combustion stage, so that the stable combustion can be ensured to be carried out in the combustion chamber within wider working range, and a stable ignition source can be provided for the main-combustion stage; the pollution emission is mainly controlled by the main-combustion stage, and the equivalent weight ration of the premixed gas of the main-combustion stage can be controlled within the low-pollution combustion range, so that the pollution emission of the whole combustion chamber cam be ensured to be greatly reduced. The premixing and pre-evaporating structure has small size, simple structure and modularized characteristic, can reduce the pollution emission of the combustion chamber of an aircraft engine, and ensures good combustion stability.

Owner:BEIHANG UNIV

Environmentally friendly acid neutralizing full flow cartridge

InactiveUS20060113233A1Burn completelyDispersed particle filtrationMembrane filtersParticulatesEngineering

An environmentally friendly acid neutralizing filter cartridge is adapted to be mounted in a cartridge mounting body of an engine oil circuit for filtering particulates and neutralizing acid in oil. The filter cartridge comprises a support housing that comprises substantially no metal parts such that the filter cartridge can be readily incinerated. A full flow particulate filter and a bypass particulate filter are arranged in the support housing. A bed of acid neutralizing particles is contained in the support housing. The housing is configured such that a predetermined primary flow path is defined through the filter cartridge that passes through the full flow particulate filter and bypassing the bed of acid neutralizing particles; and a predetermined bypass path is defined through the filter cartridge that passes, in sequence, through the bed of acid neutralizing particles and the bypass particulate filter.

Owner:BALDWIN FILTERS

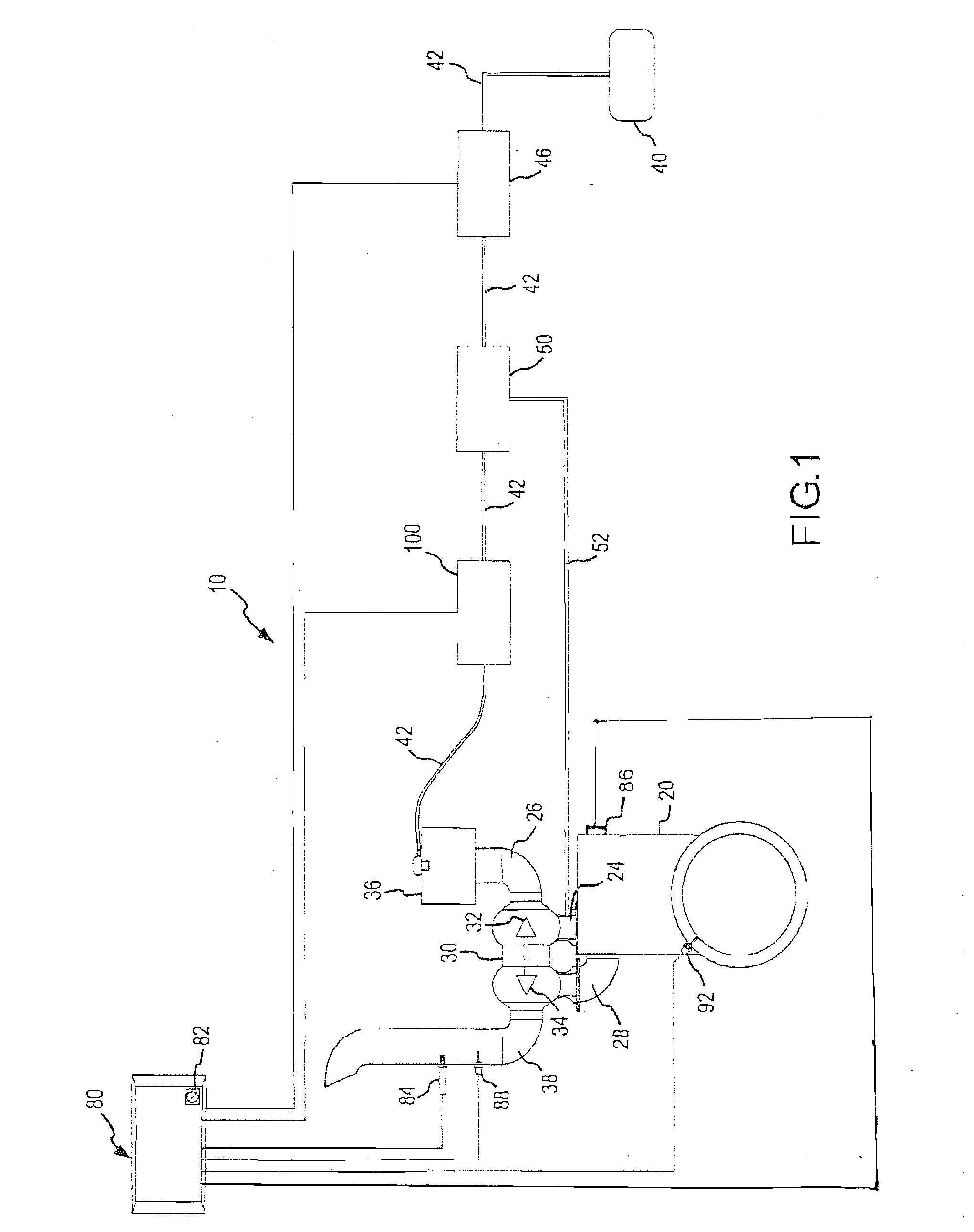

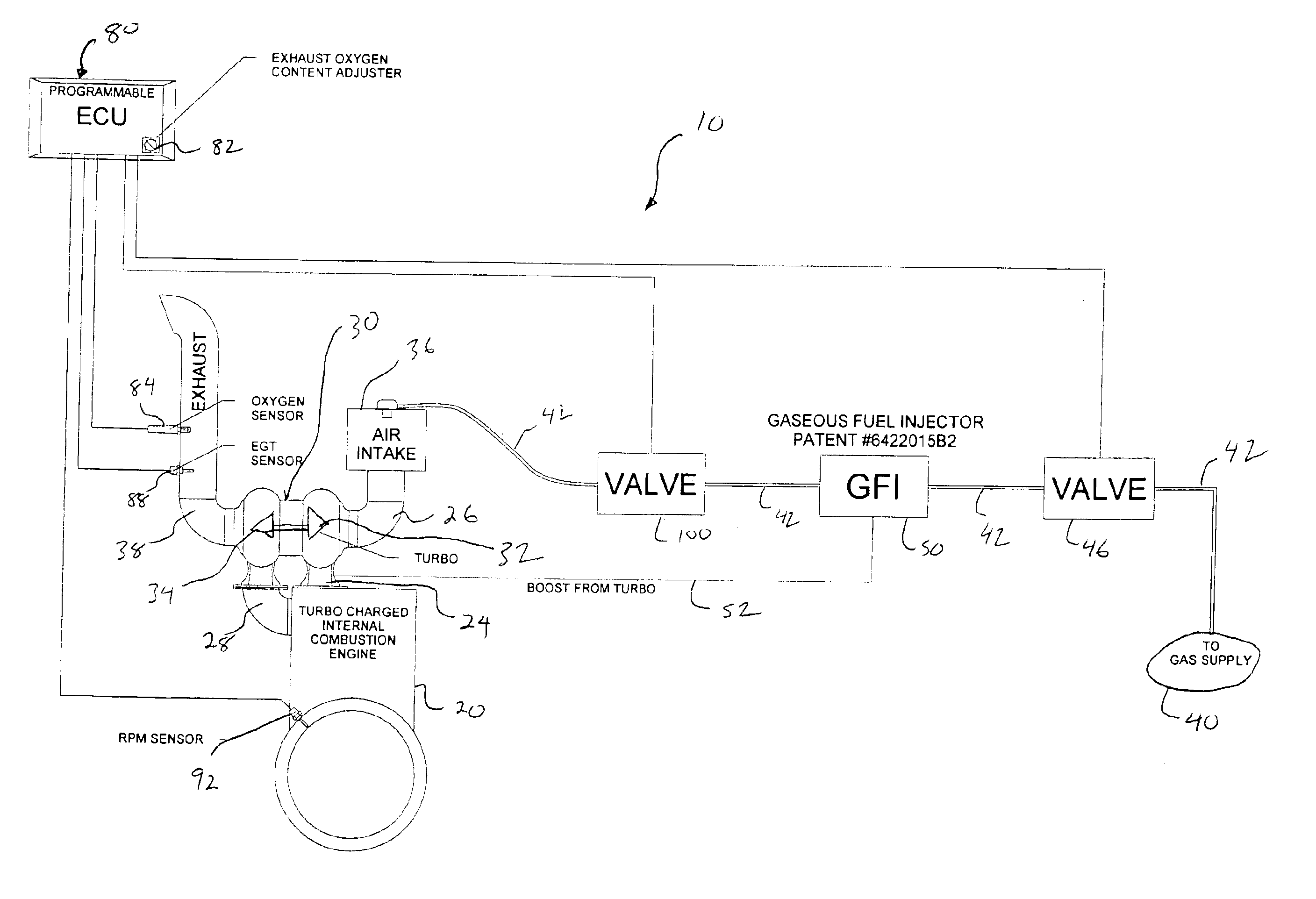

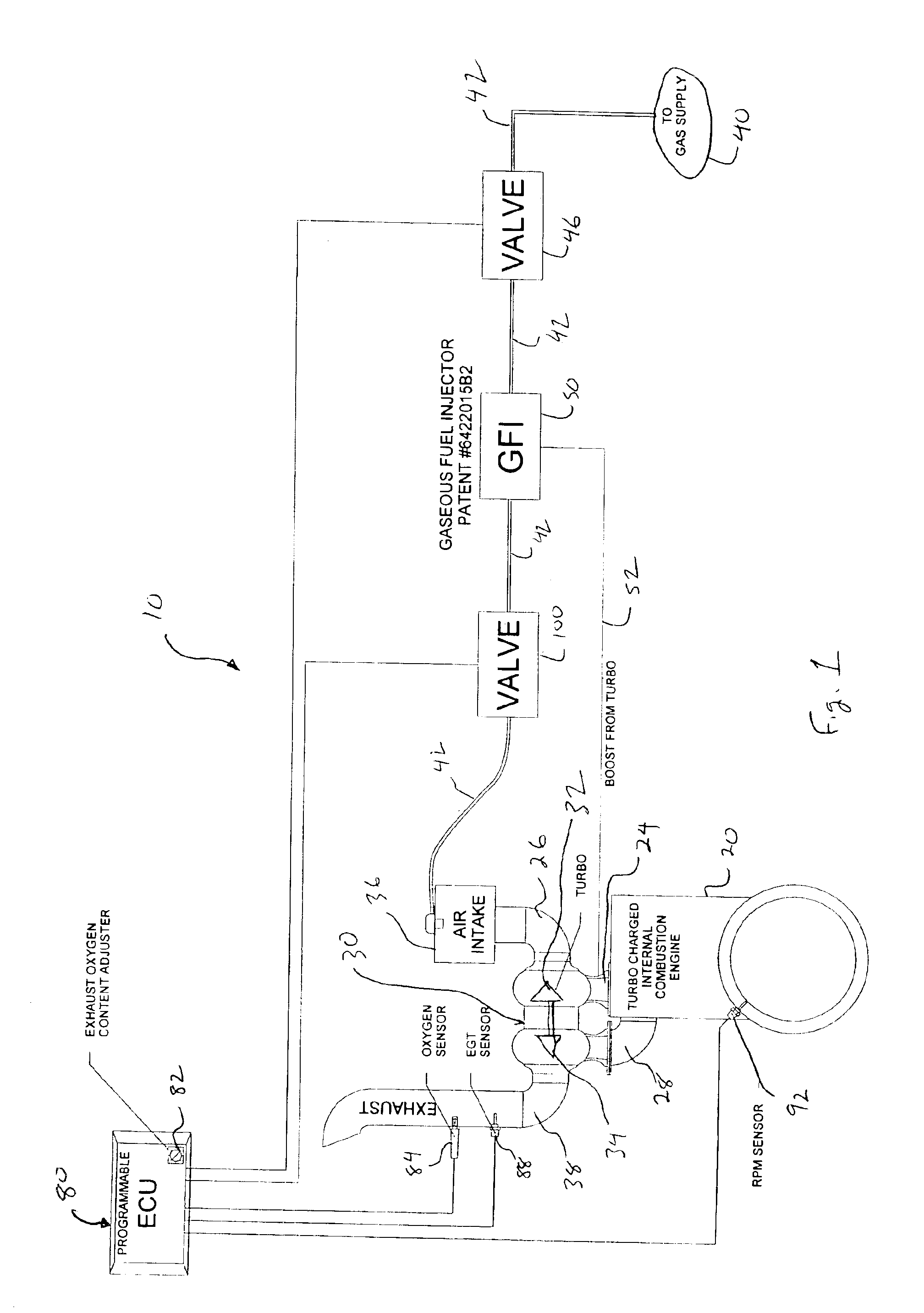

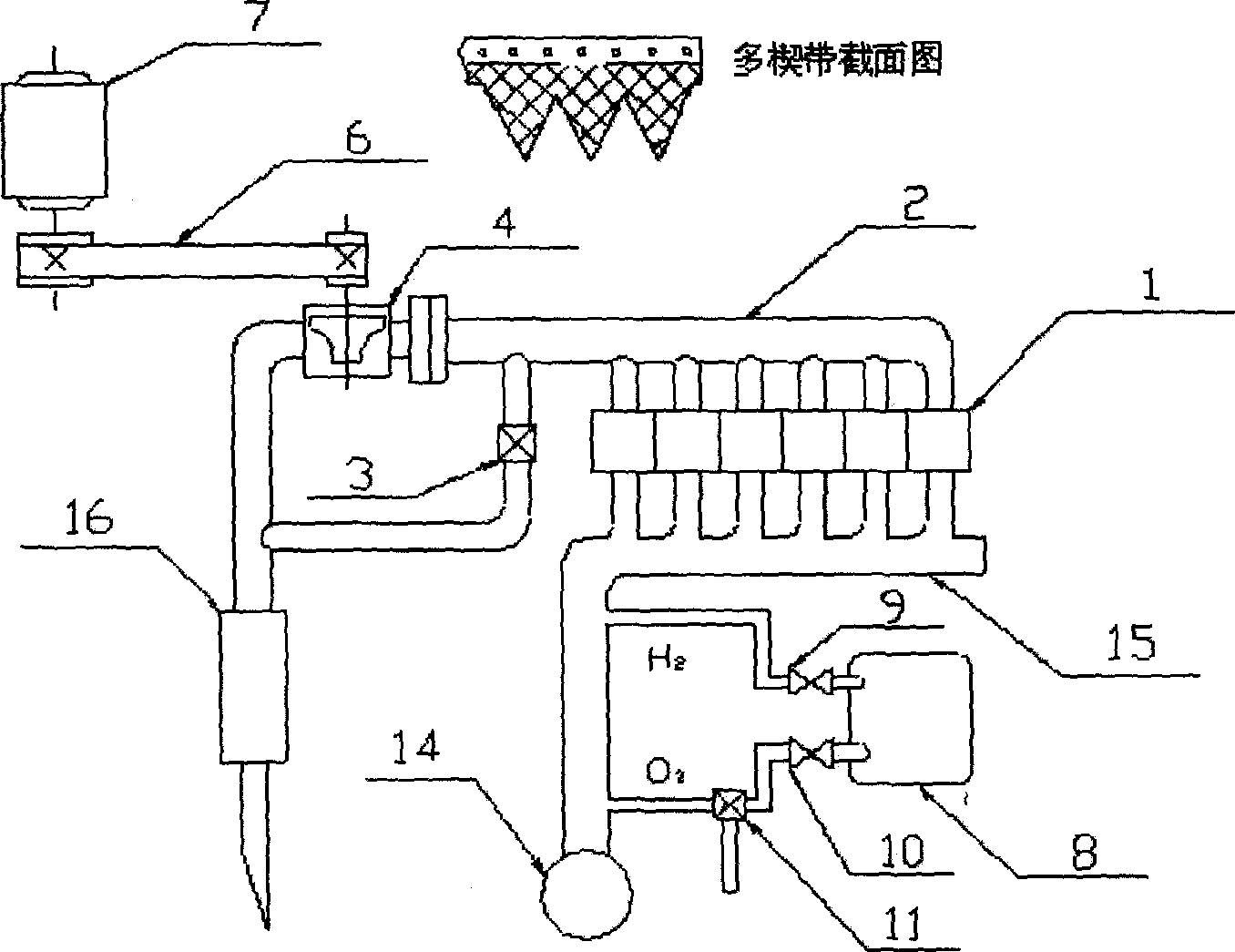

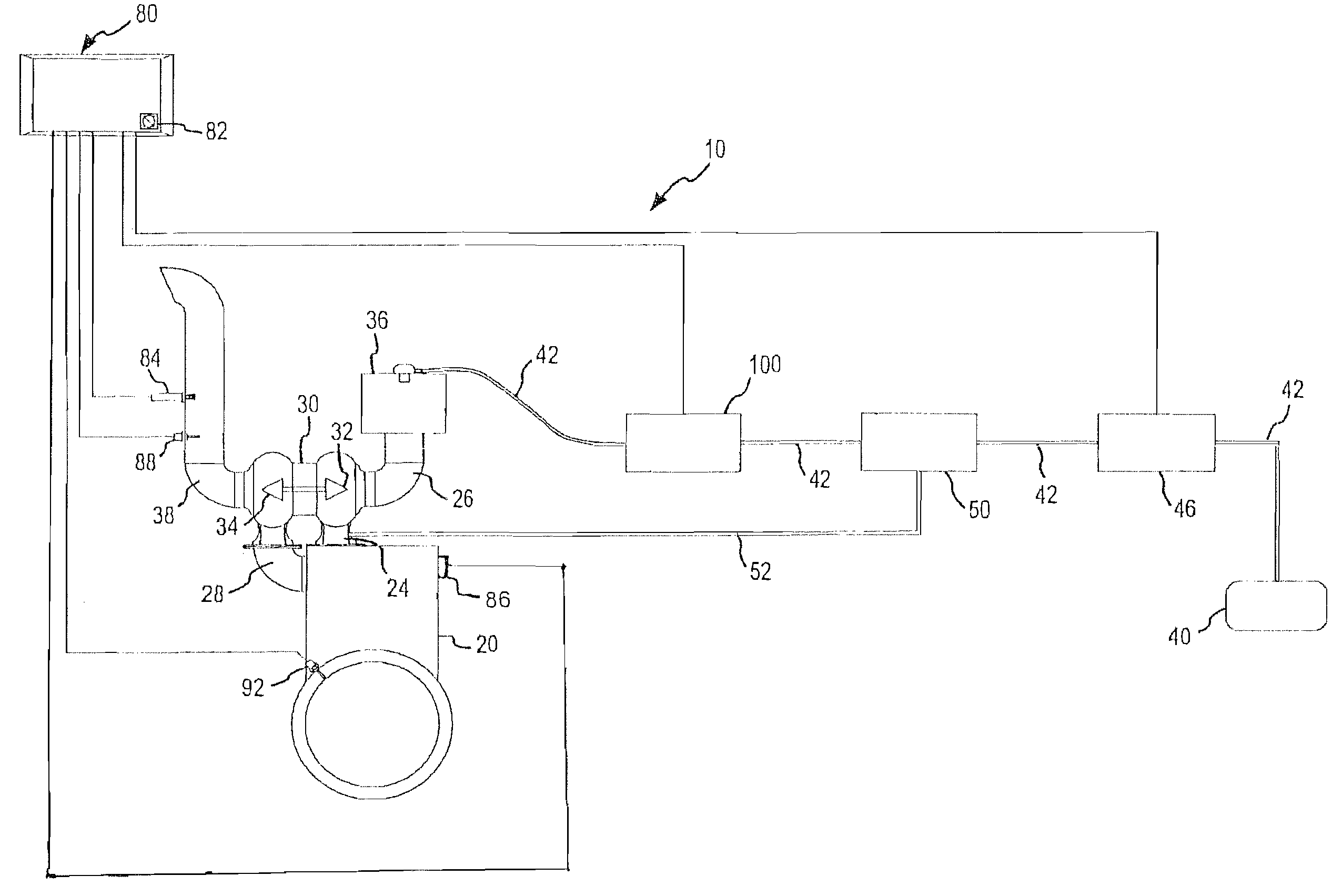

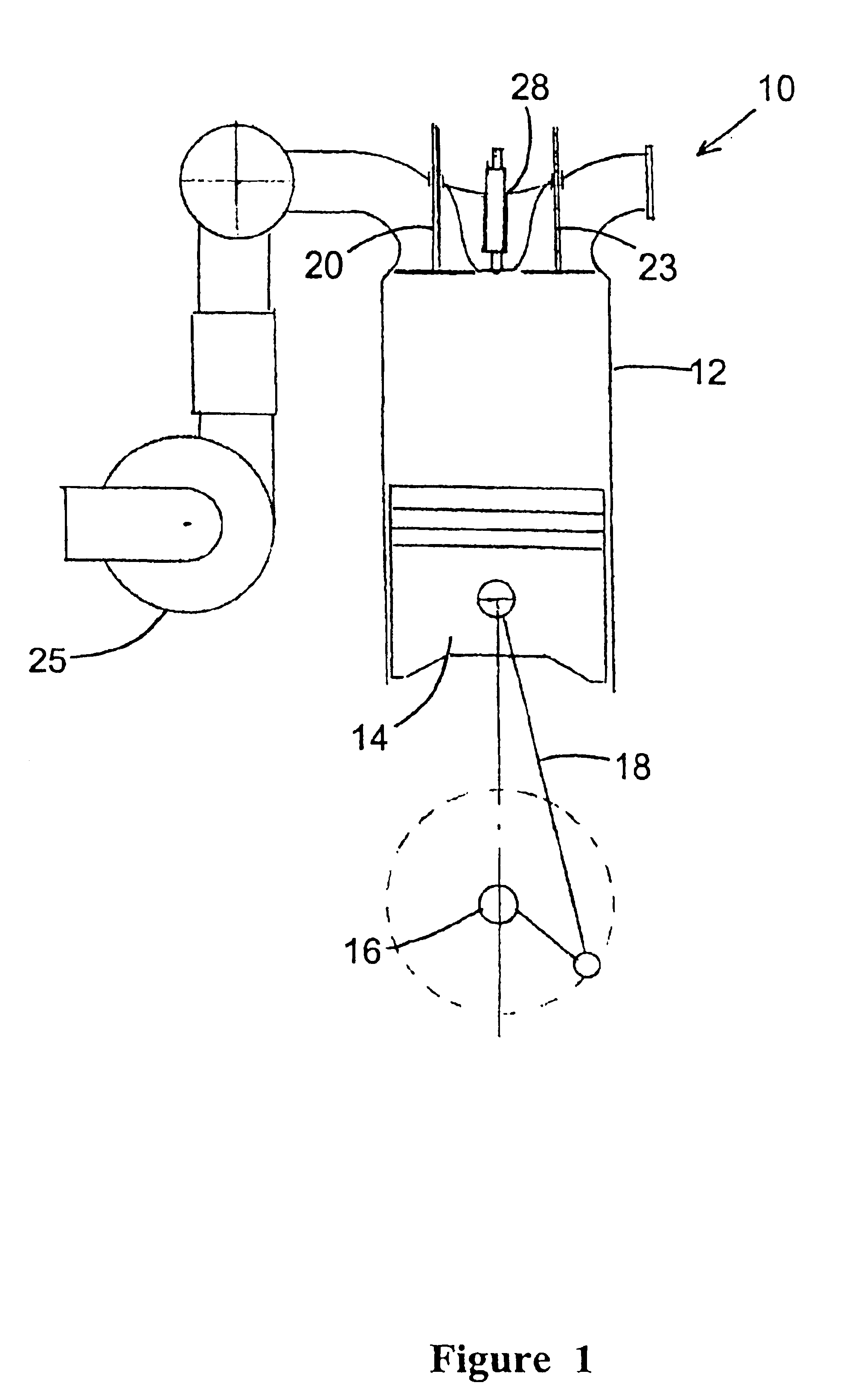

Process for use with dual-fuel systems

InactiveUS20070157912A1Avoid power outagesHigh outputElectrical controlInternal combustion piston enginesStream flowInlet pressure

A system and method is provided for use with a duel-fuel fumigation system. The system injects a gaseous-fuel flow into the air intake stream of a diesel engine. As presented, the system is operative to meter the gaseous-fuel flow into the diesel engine based on one or more engine parameters such as, for example, exhaust gas temperature, exhaust oxygen levels, engine speed, engine load and / or engine inlet pressure. Monitoring one or more engine parameters allows fine-tuning the flow of gaseous fuel into the engine and thereby prevents loss of engine power at high-end loads while maintaining favorable emission outputs over substantially the entire operating range of the engine.

Owner:TGI

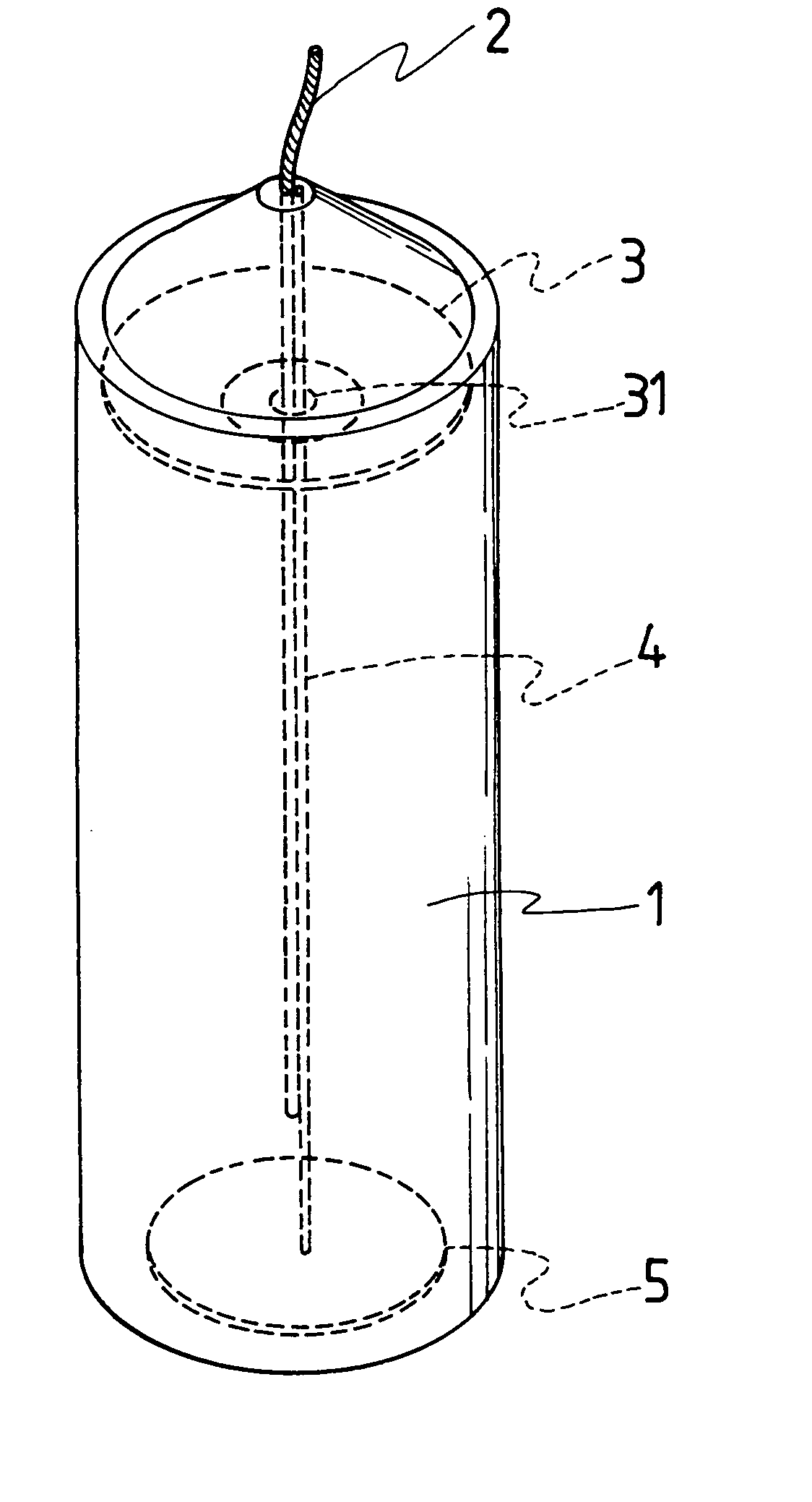

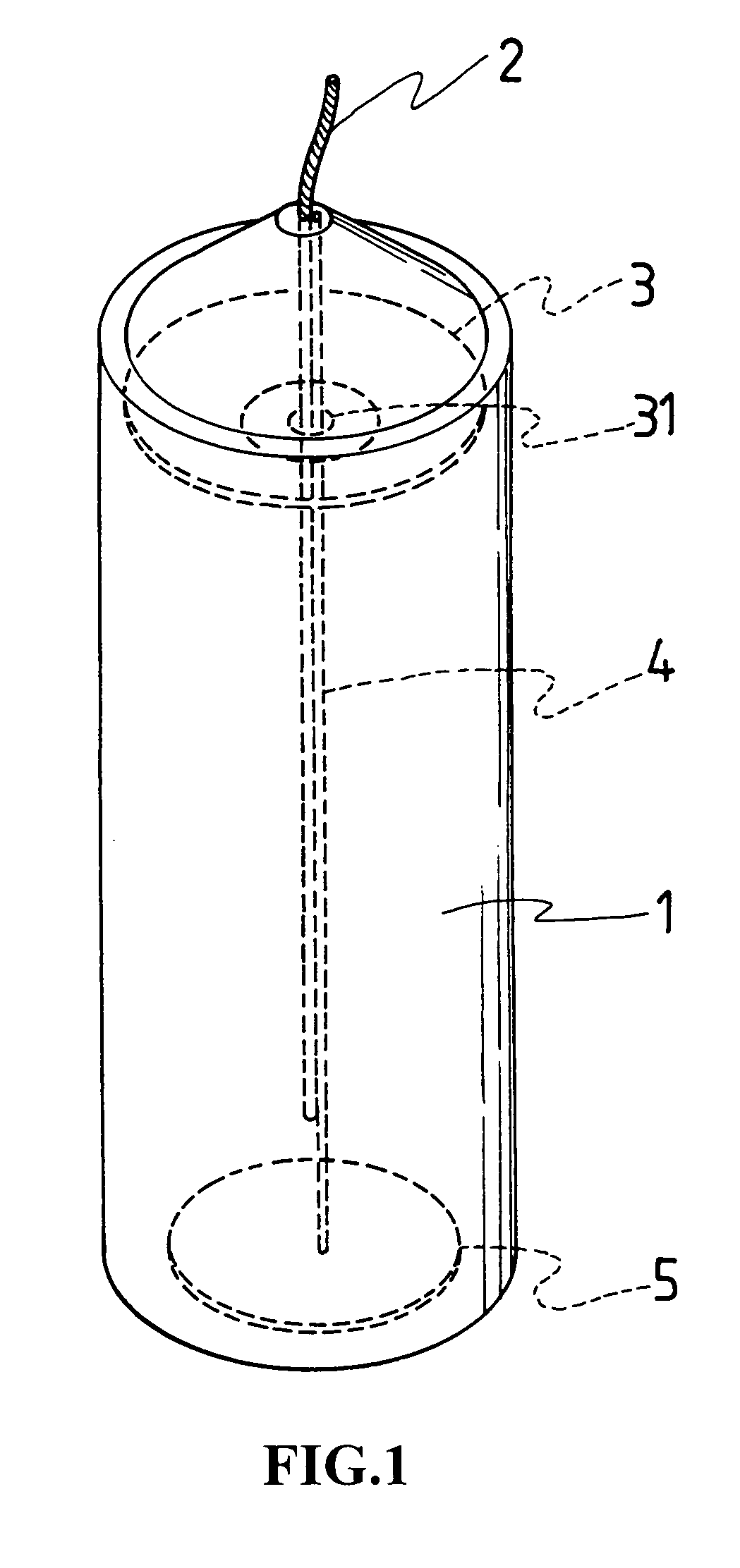

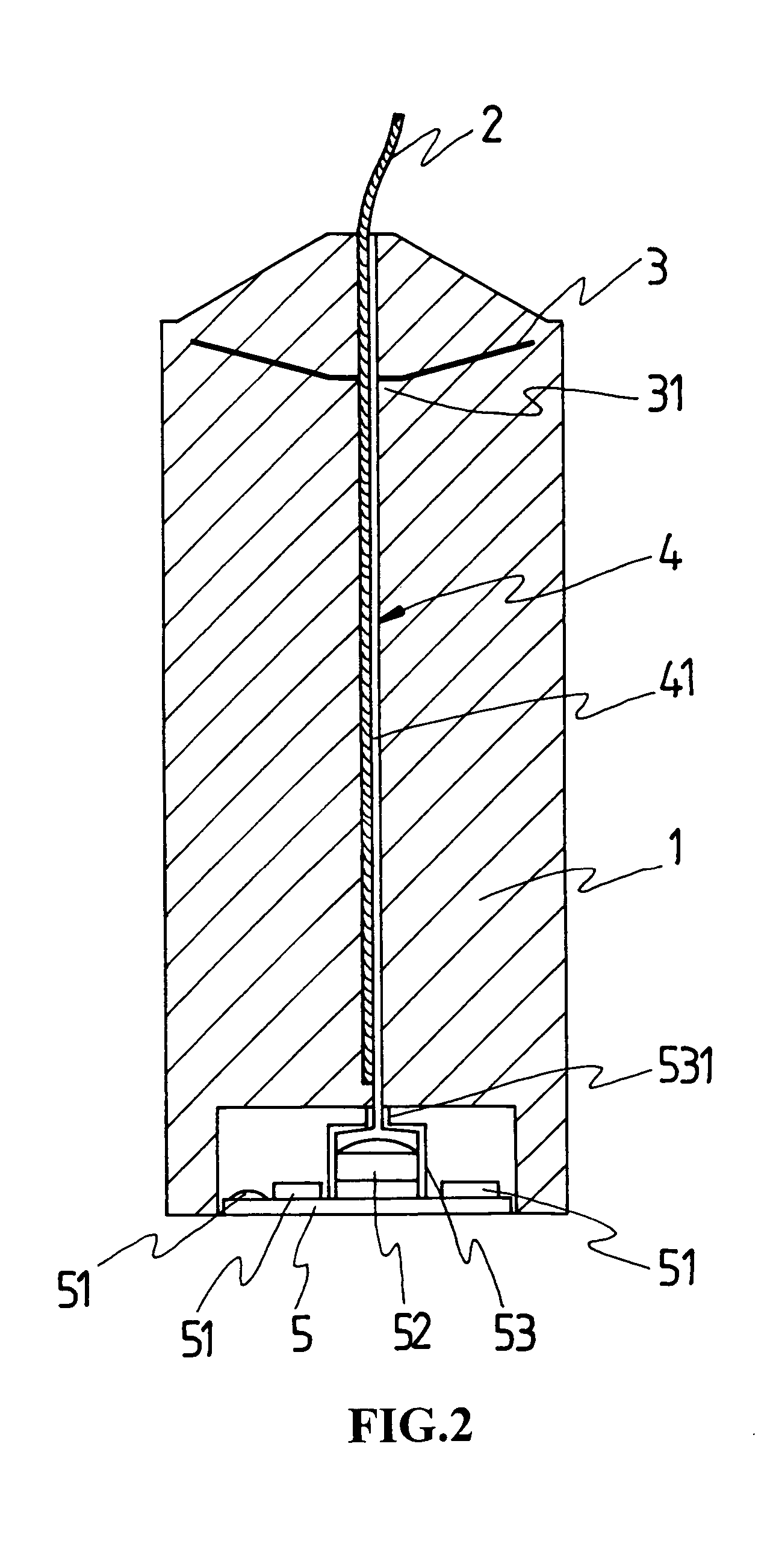

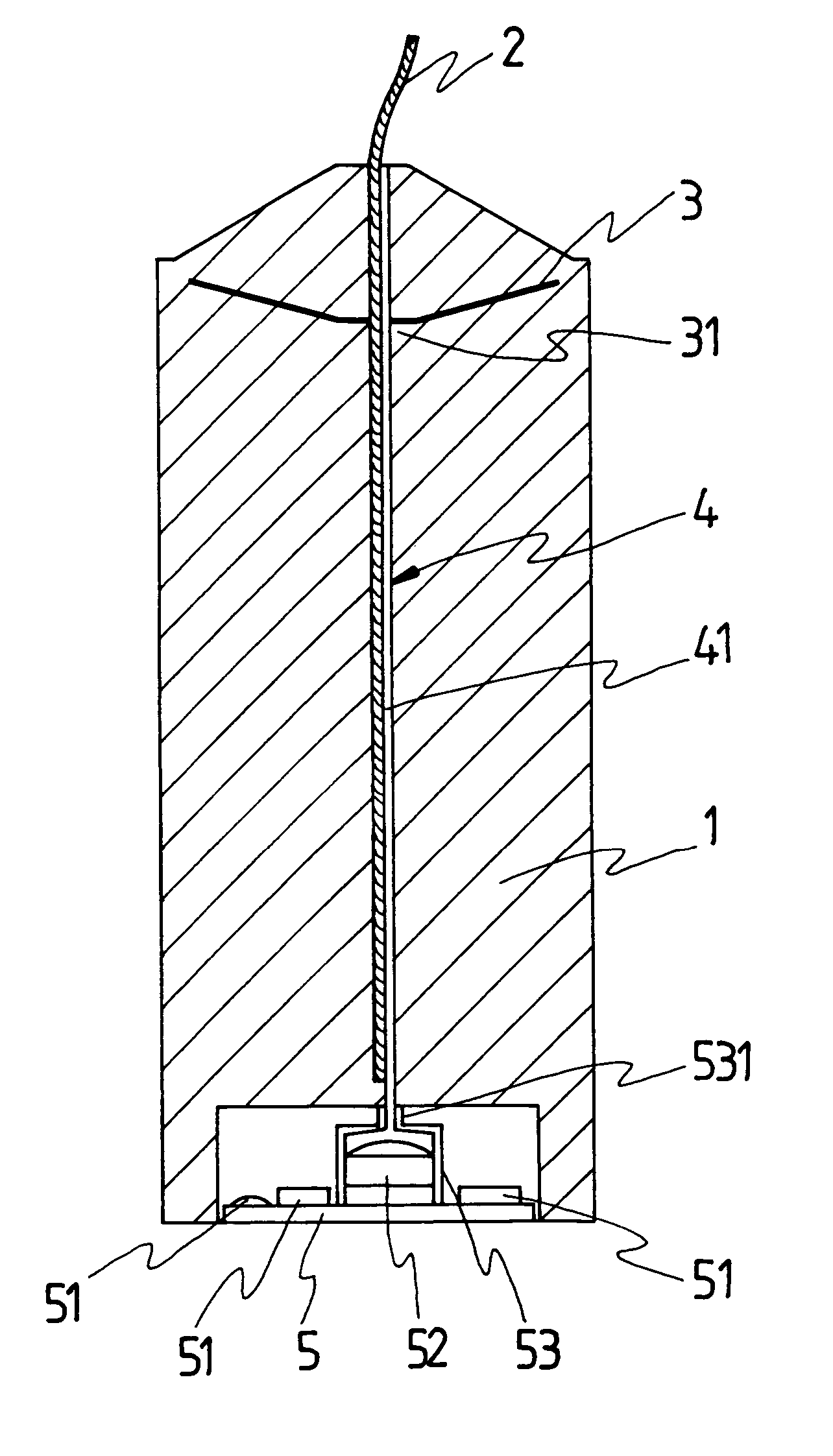

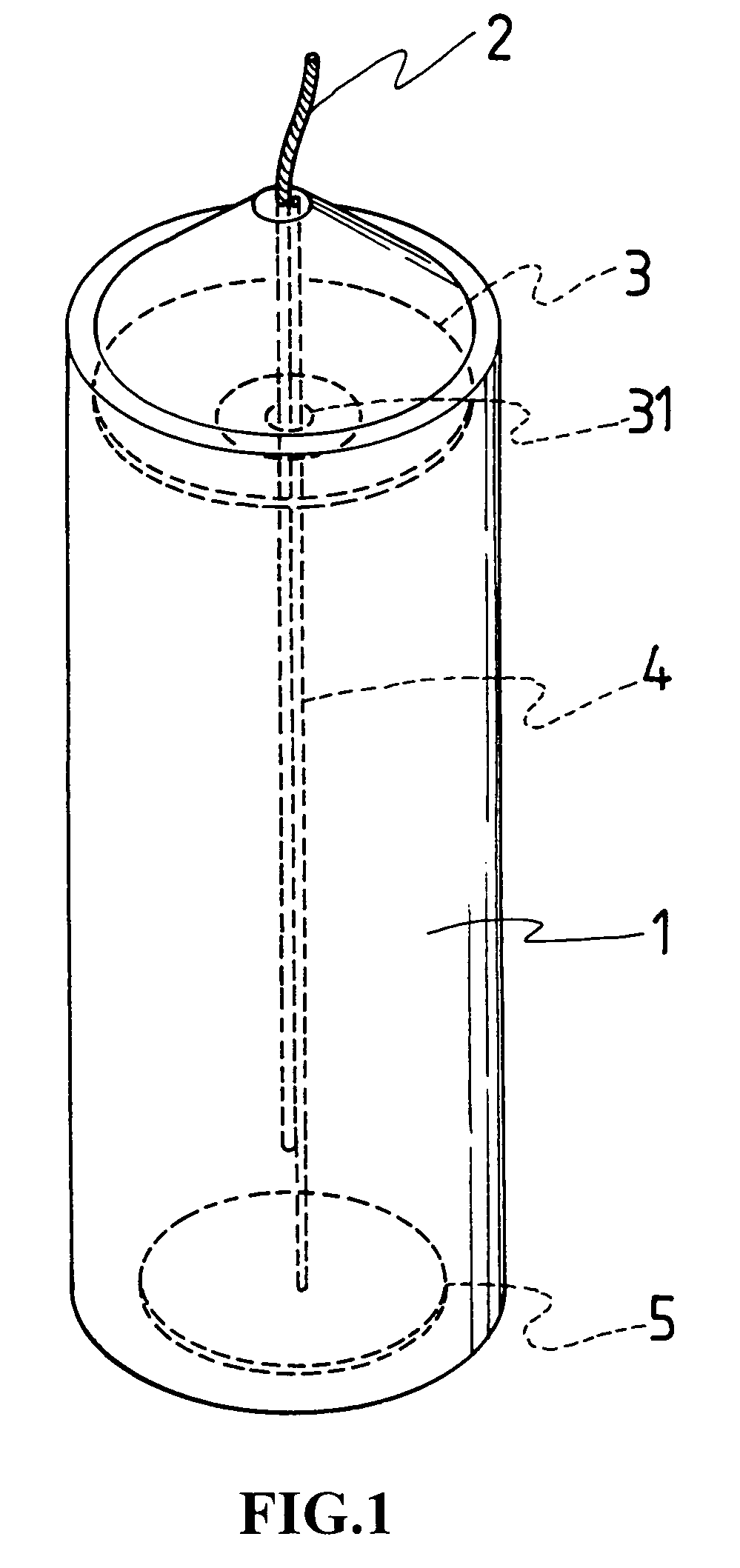

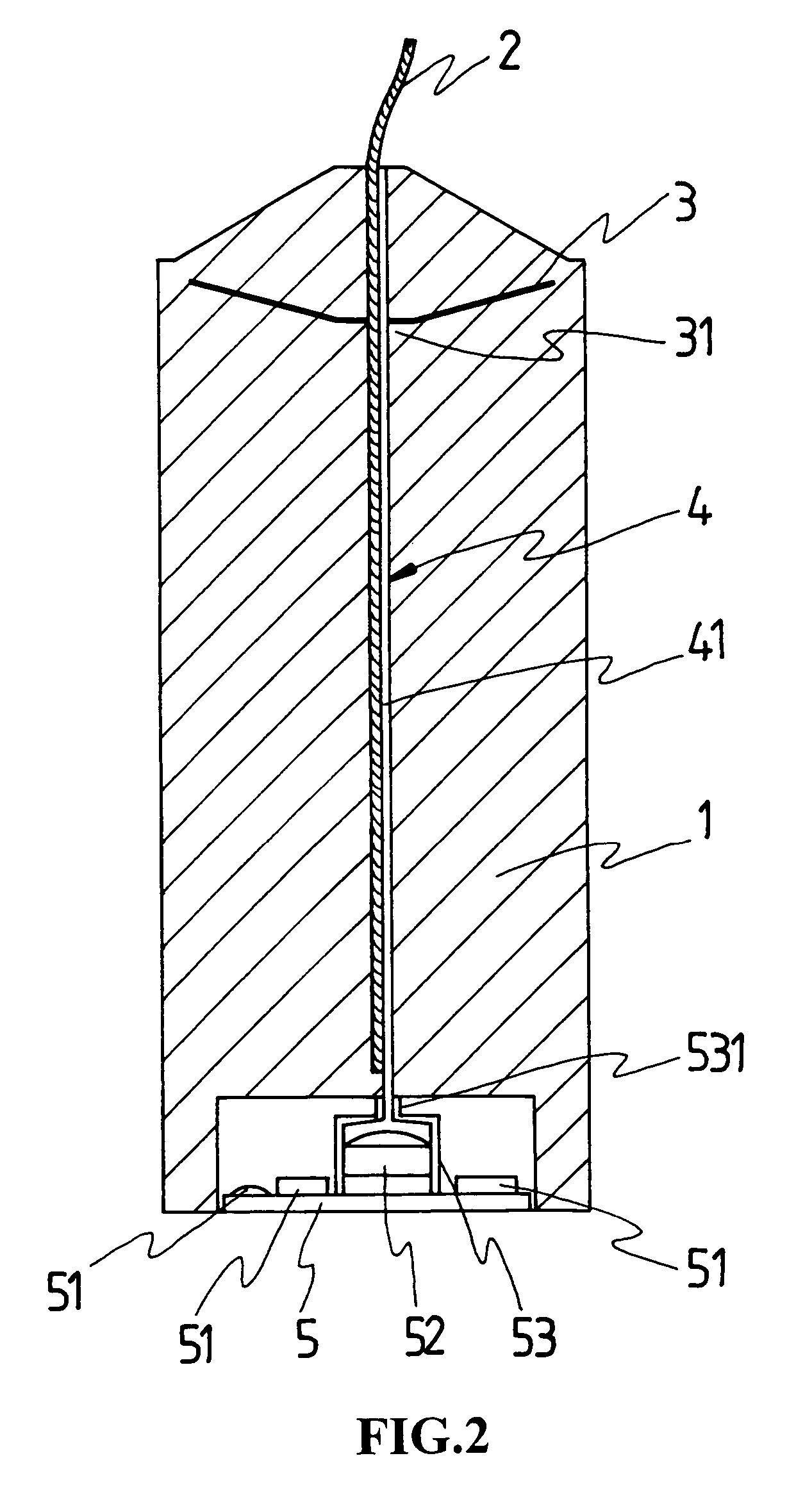

Electronic switch for drop-free candle

An electronic switch for a drop-free candle is comprised of a candle, a wick, a metal disk, a conductor and a circuit board; the metal disk being buried in the candle; the conductor being provided in the form of an optical fiber or a magnet twisted pair cable; the conductor being provided along the wick to control the operation of the circuit board provided at the bottom of the candle to realize the function of an electronic switch while preventing drops of the fatting substance of the candle.

Owner:YU SHUNG LUN

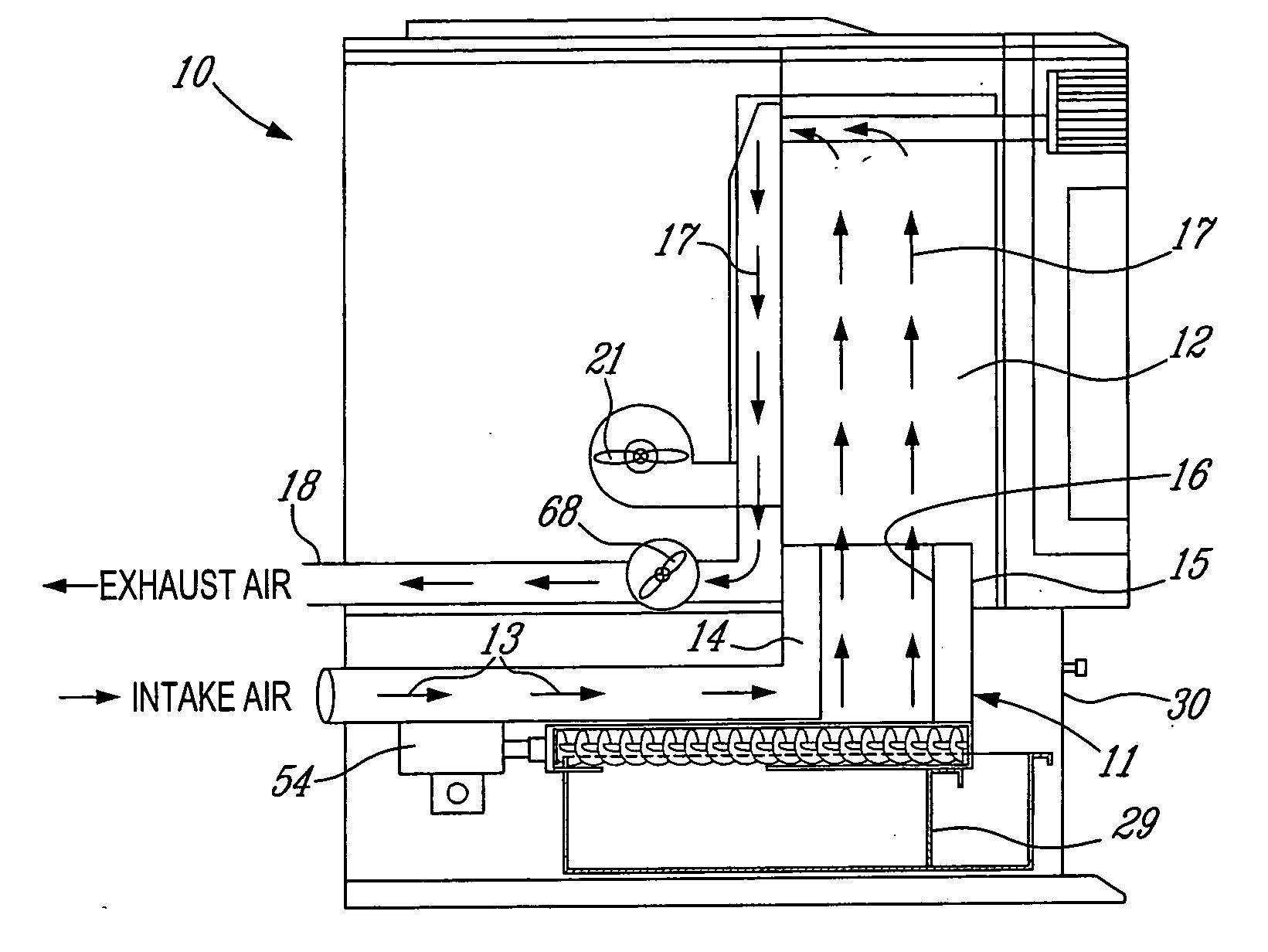

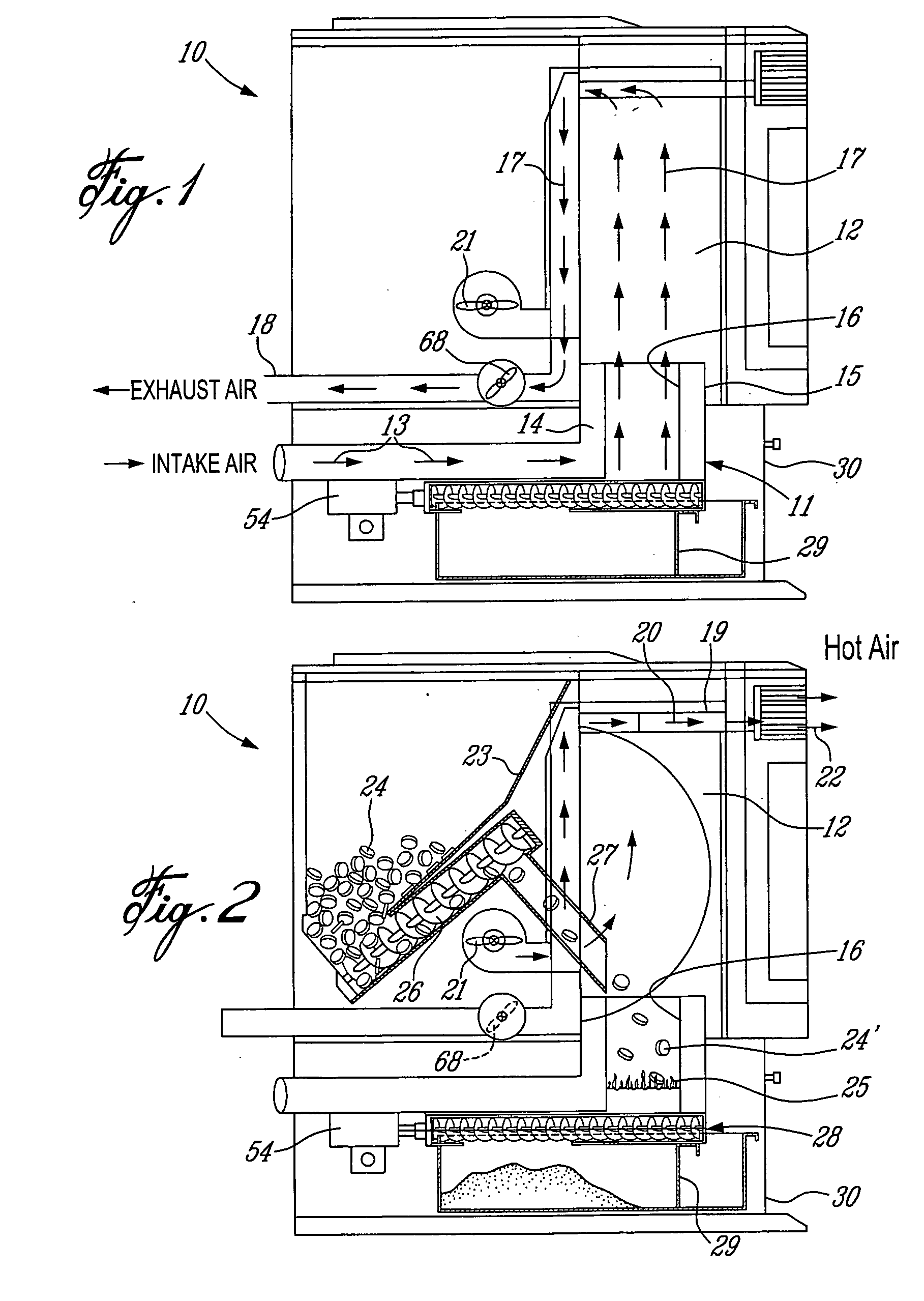

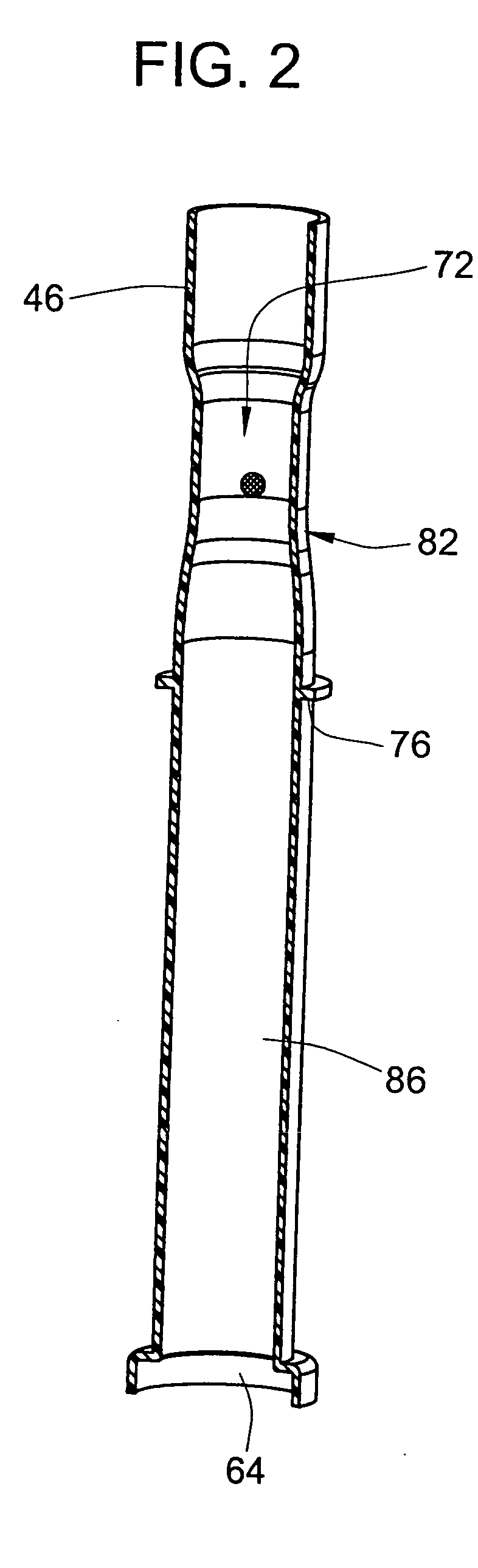

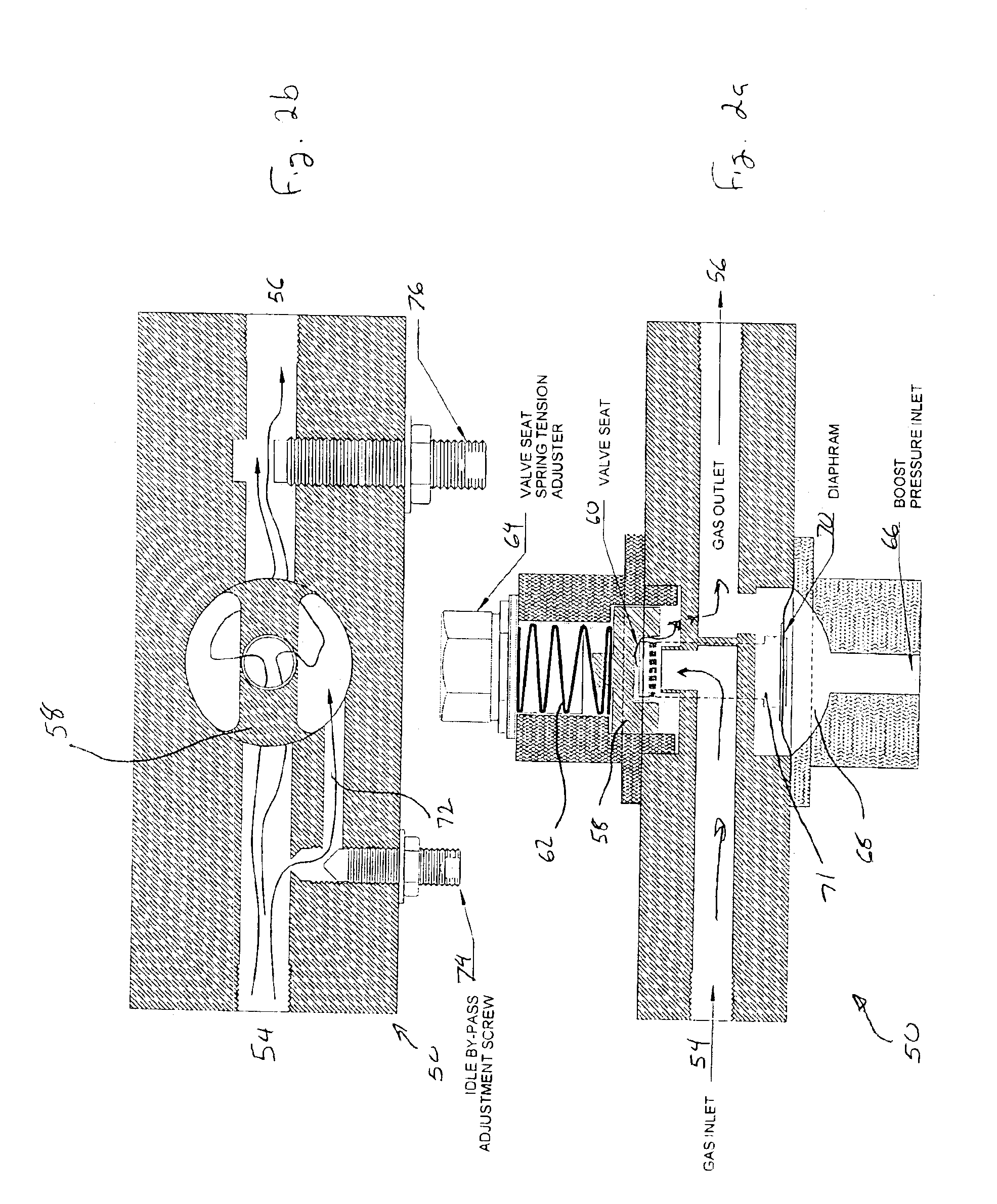

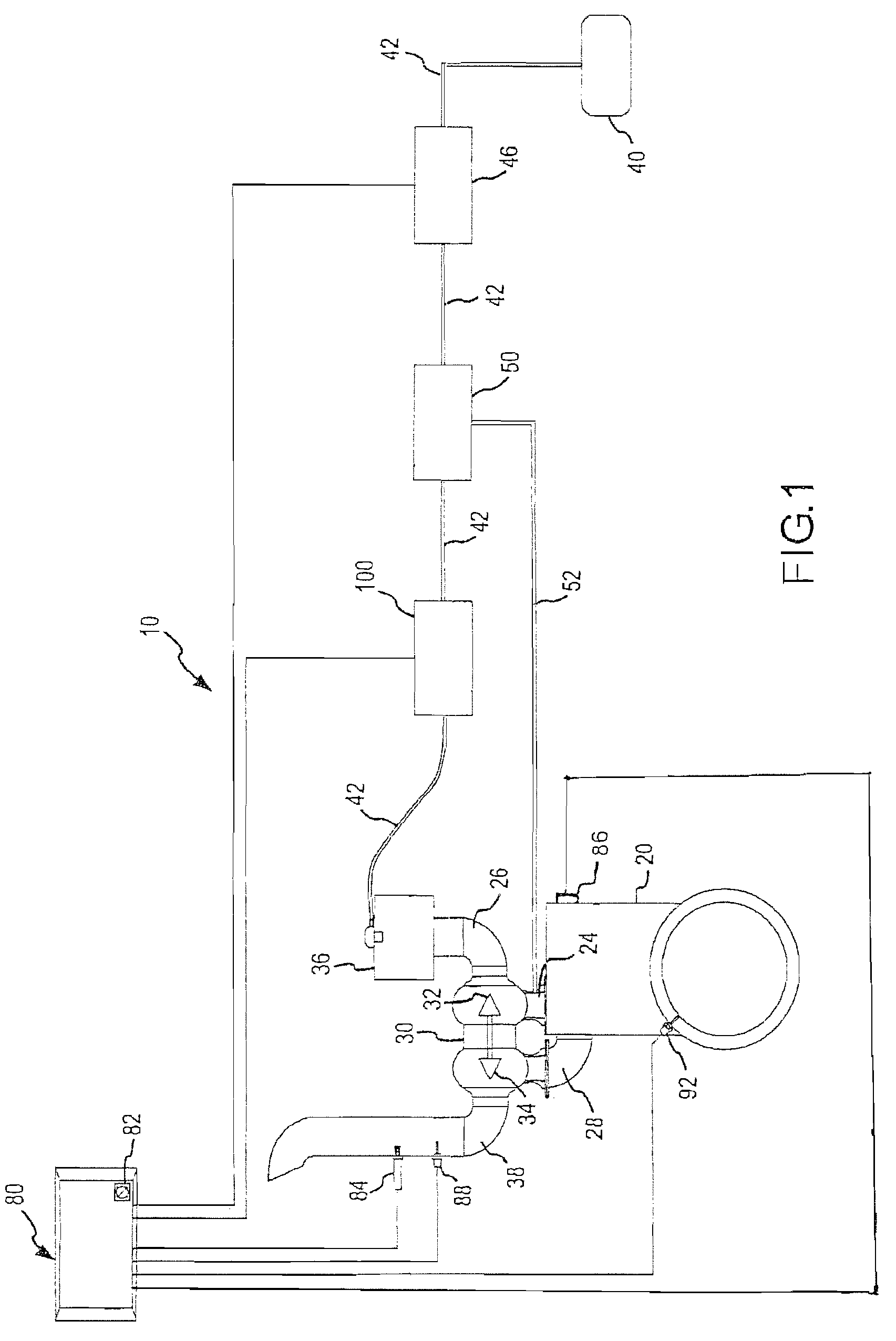

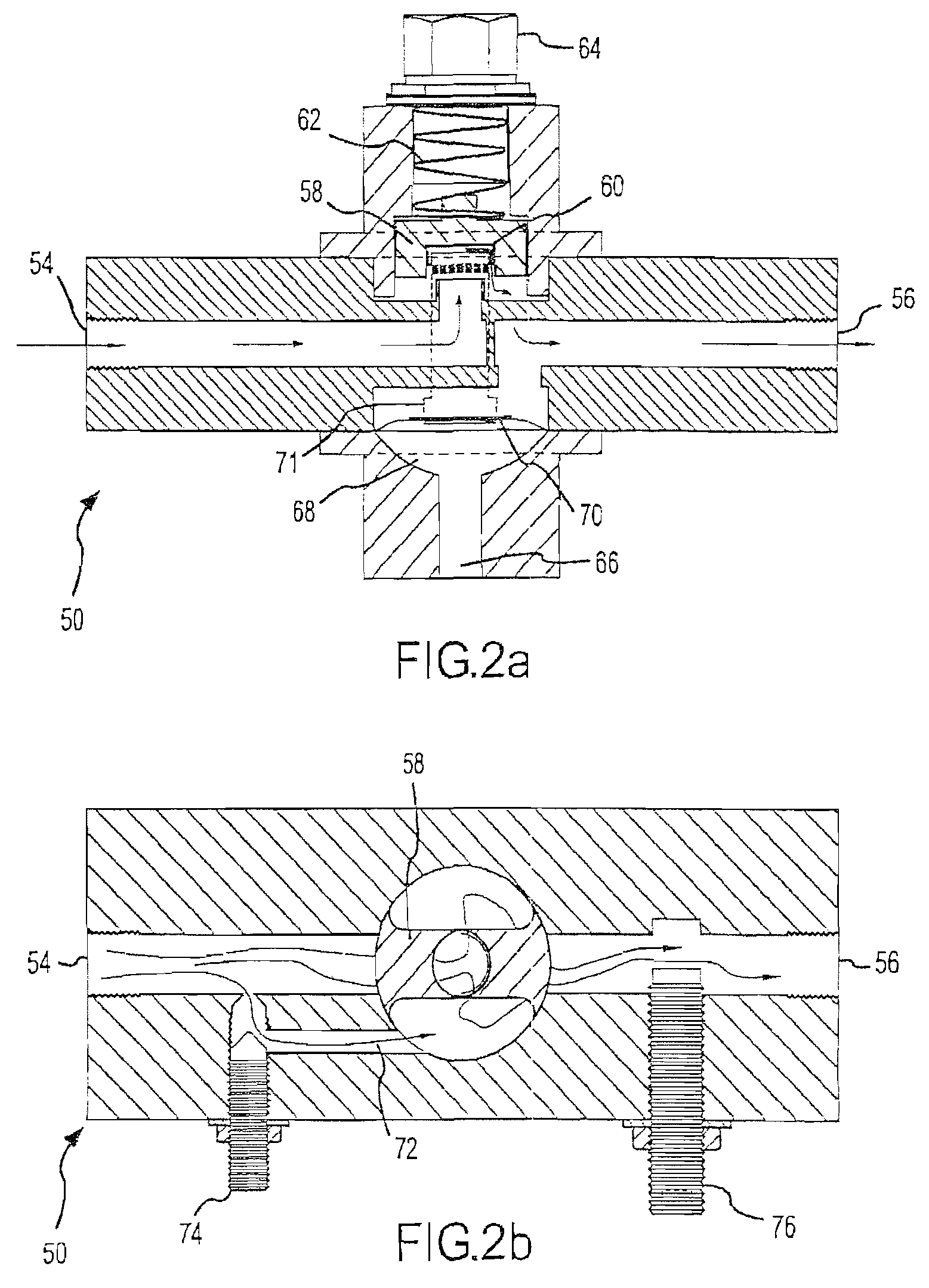

Fumigation system for a diesel engine

ActiveUS6901889B1Avoid damageReduce supplyElectrical controlInternal combustion piston enginesParticulatesCombustion

A system and method is provided to reduce particulate and NOx emissions from diesel engines through the use of a duel-fuel fumigation system. The system injects a gaseous-fuel flow into the air intake stream of a diesel engine. This results in more complete combustion within the engine as well as reduced diesel fuel usage, which each work to reduce emission outputs of the engine. As presented, the system is operative to meter the gaseous-fuel flow into the diesel engine based on one or more engine parameters such as, for example, exhaust gas temperature, exhaust oxygen levels, engine speed and / or engine load. Monitoring one or more engine parameters allows fine-tuning the flow of gaseous fuel into the engine and thereby prevents loss of engine power at high-end loads while maintaining favorable emission outputs over substantially the entire operating range of the engine.

Owner:TGI

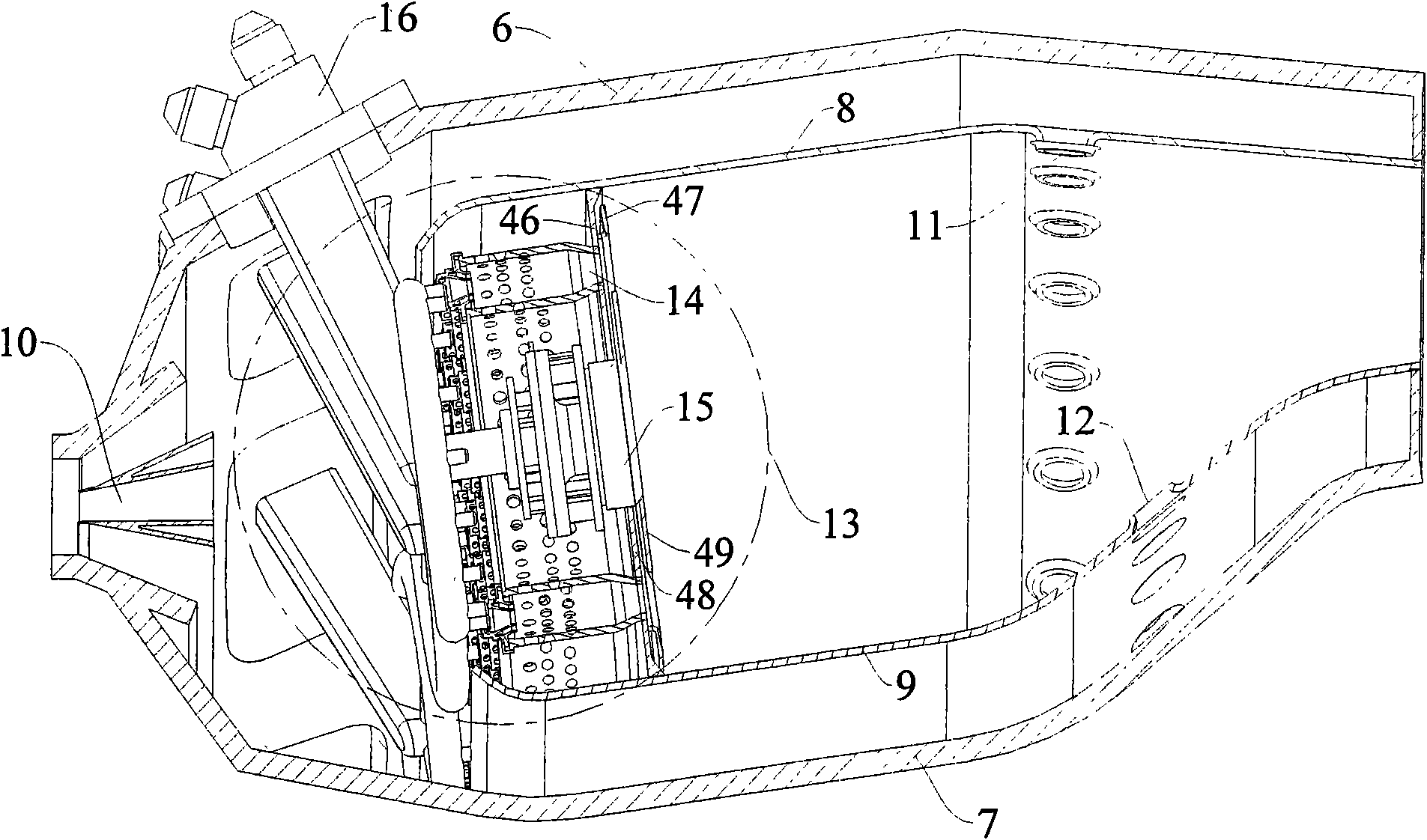

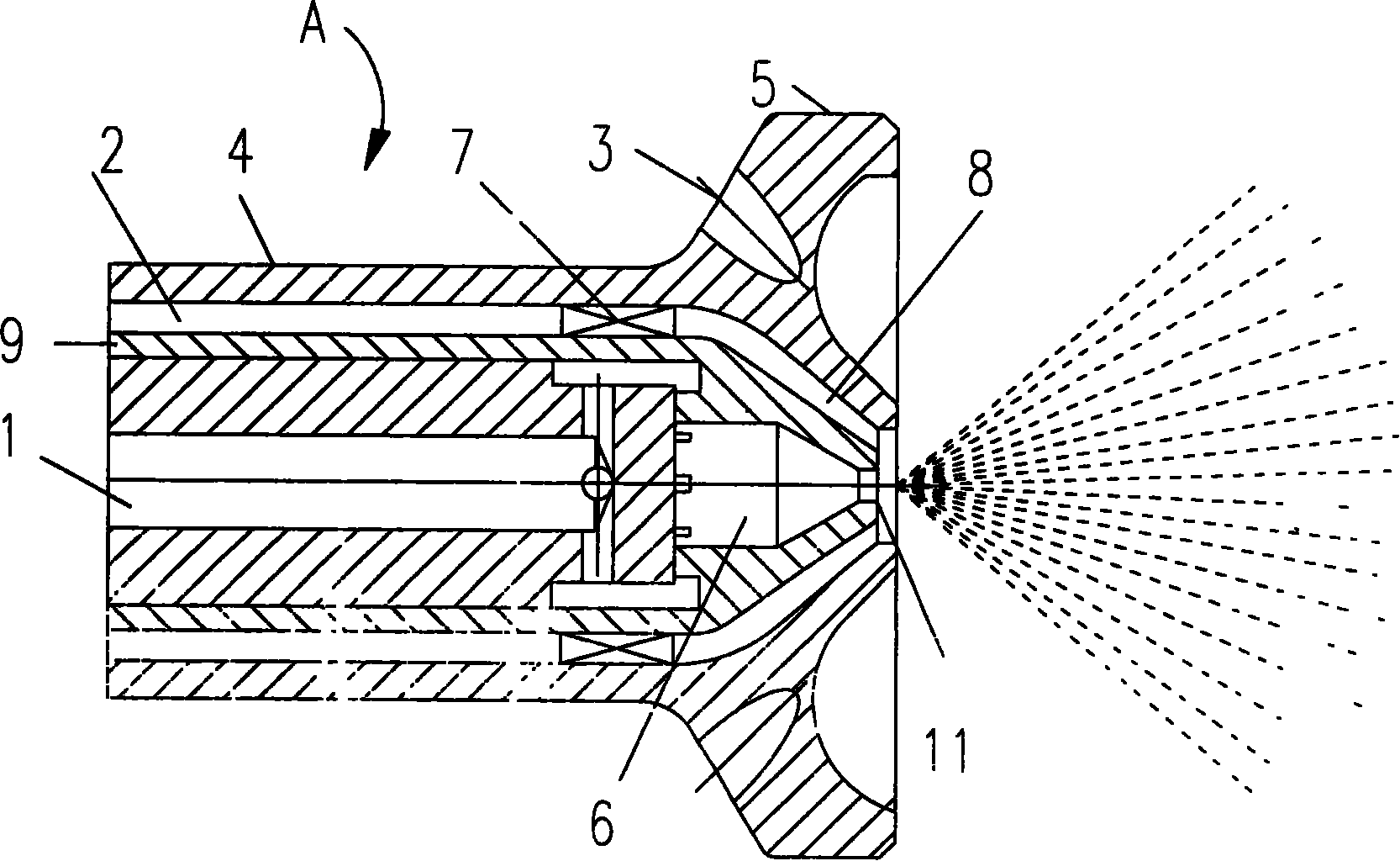

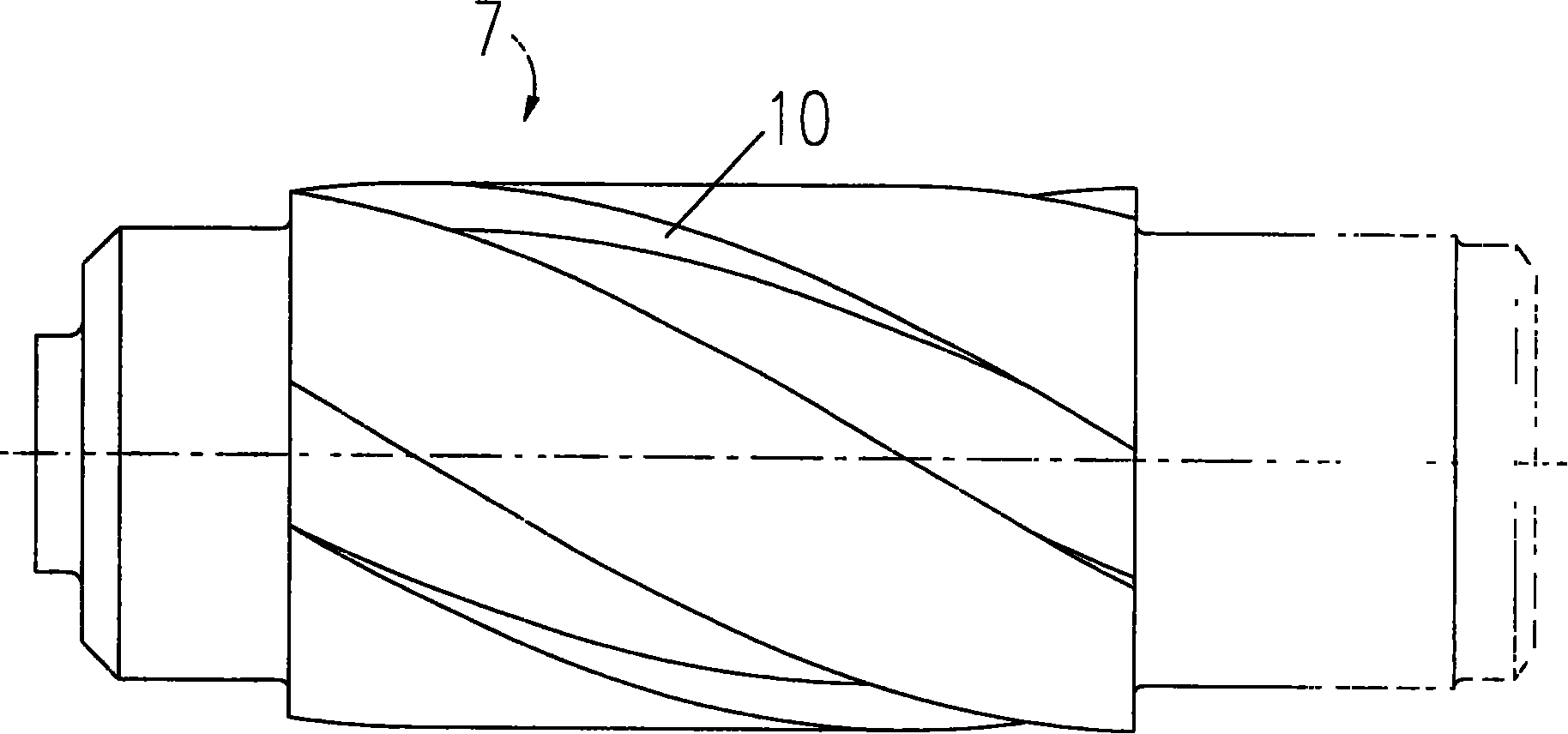

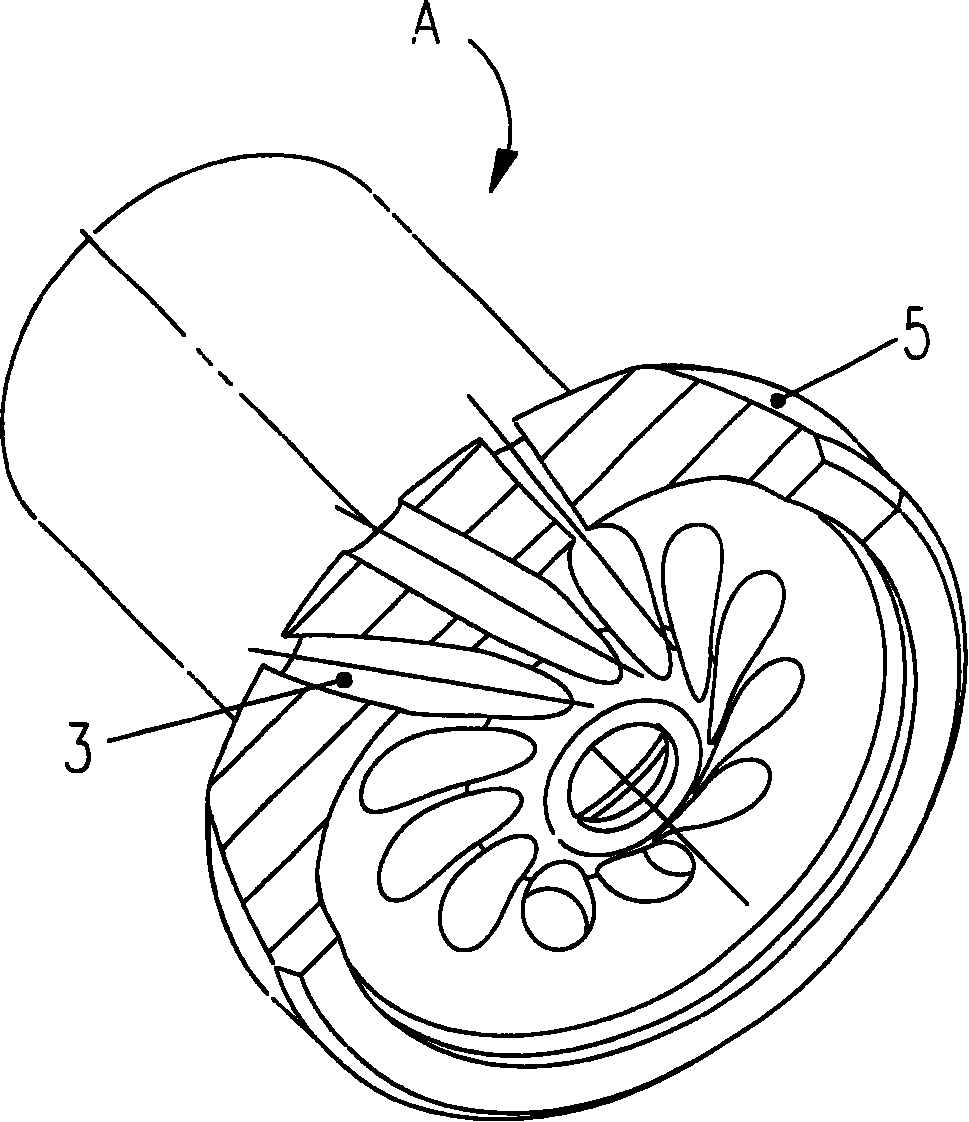

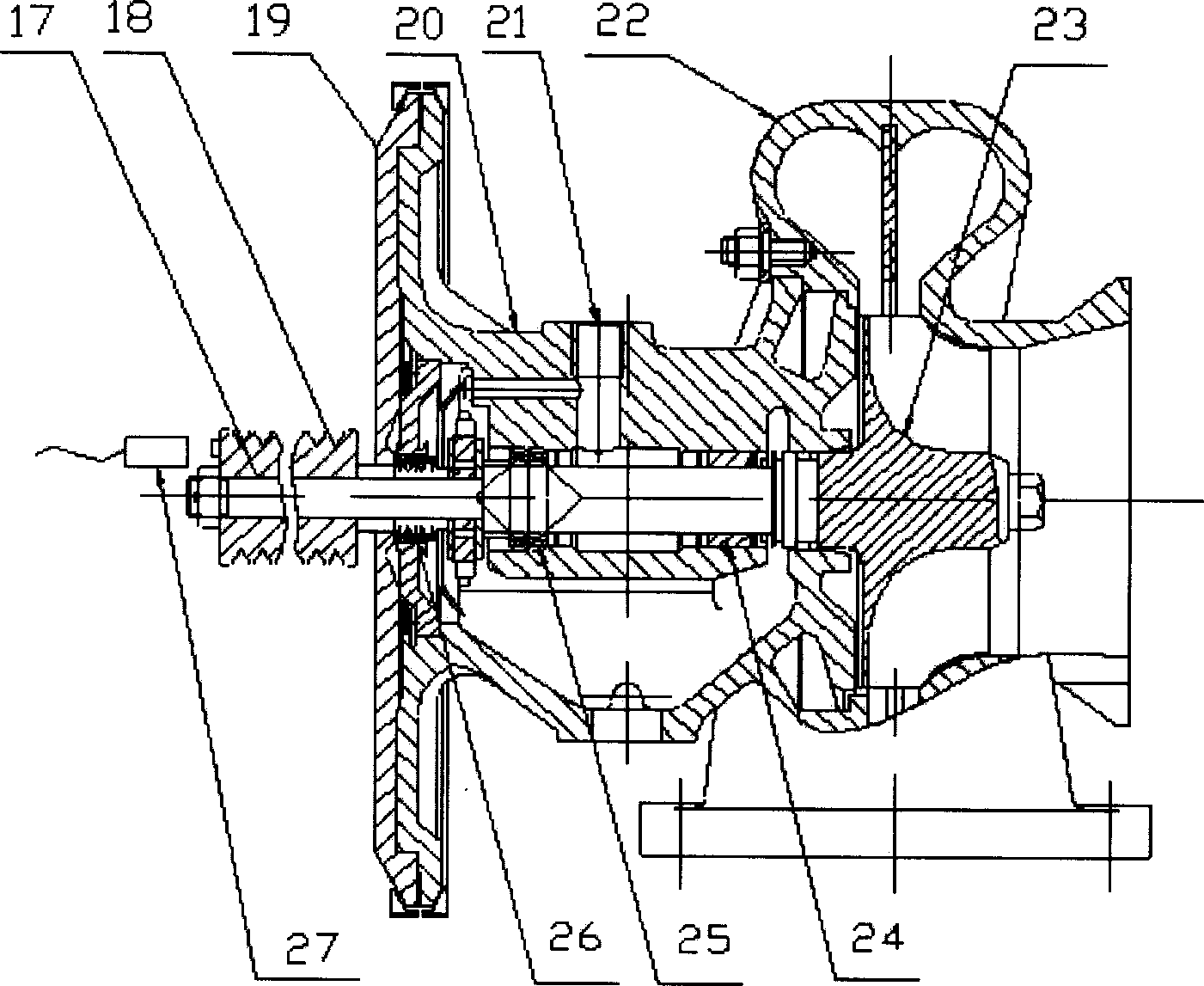

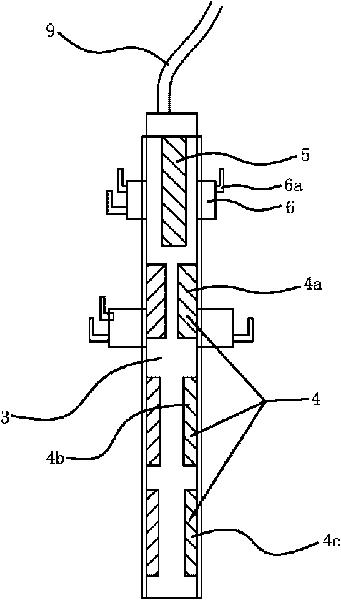

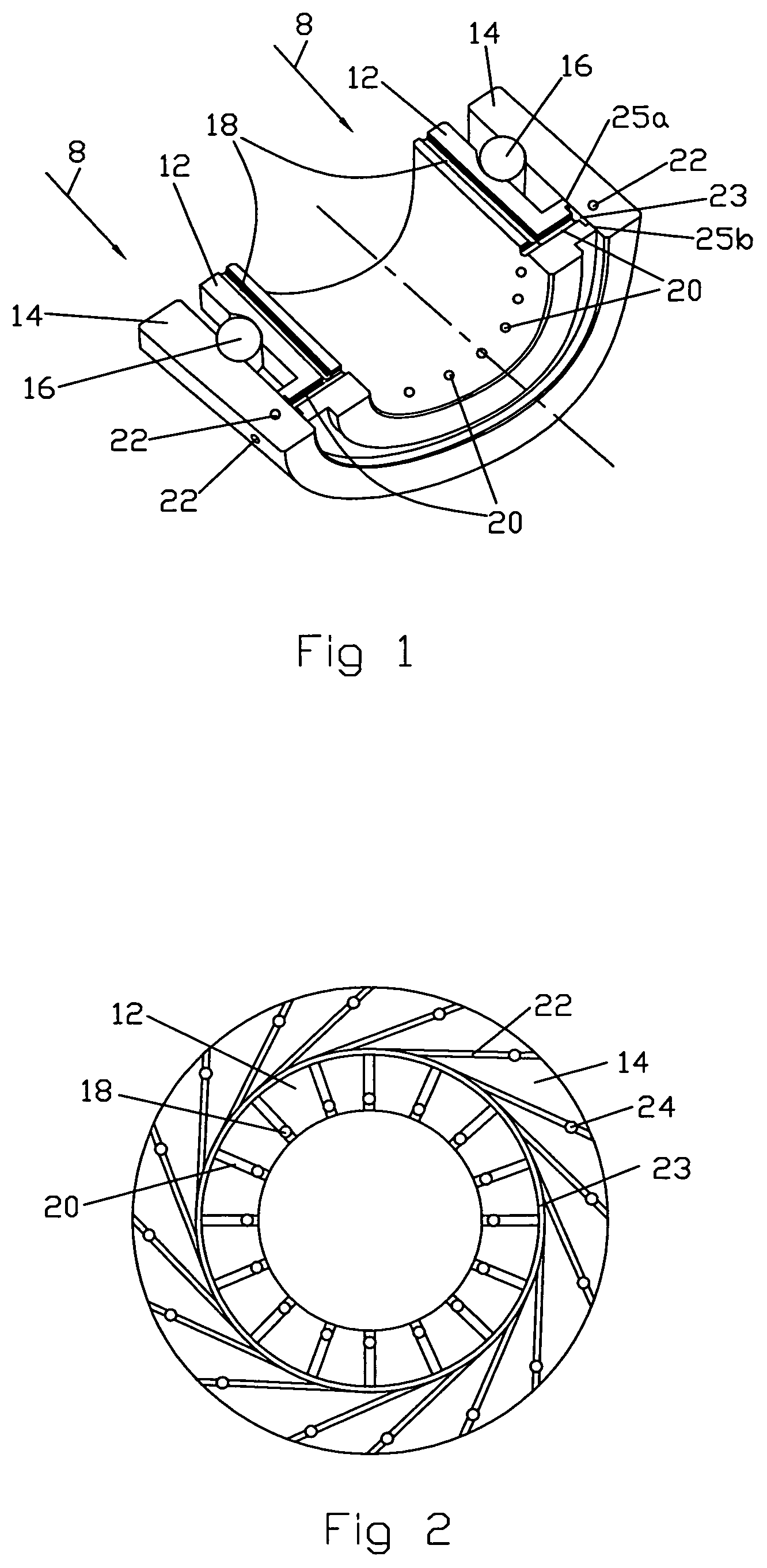

Nozzle for minisize gas-turbine combustor

ActiveCN101206029ACompact structureGood atomization qualityBurnersContinuous combustion chamberPollutantCombustion chamber

The invention discloses a nozzle of a combustion chamber of a miniature gas turbine, relates to the gas turbine technology, and in particular to a small size fluid fuel nozzle used in a combustion chamber of a 100 kW level miniature gas turbine. The nozzle consists of three parts which are a fuel oil passage, a fuel air passage and an air channel at the root of a burner, comprehensively utilizes the advantages of pneumatic nebulization and pressure atomization, and is a combined type high performance pneumatic atomizing nozzle. The nozzle of the invention has the characteristics that: the nozzle adopts a conventional processing method to realize excellent atomization of the fuel in small scale space, so as to meet the requirement for the quality of fuel atomization under a quite wide burden of the combustion chamber of the miniature gas turbine; the nozzle can avoid burnout and overcomes the defect of nozzle blockage caused by high temperature coking of the fuel; meanwhile, the nozzle can make the fuel in the combustion chamber to be combusted more fully and reduce discharge of pollutants such as smoke black and so on.

Owner:江苏中国科学院能源动力研究中心 +1

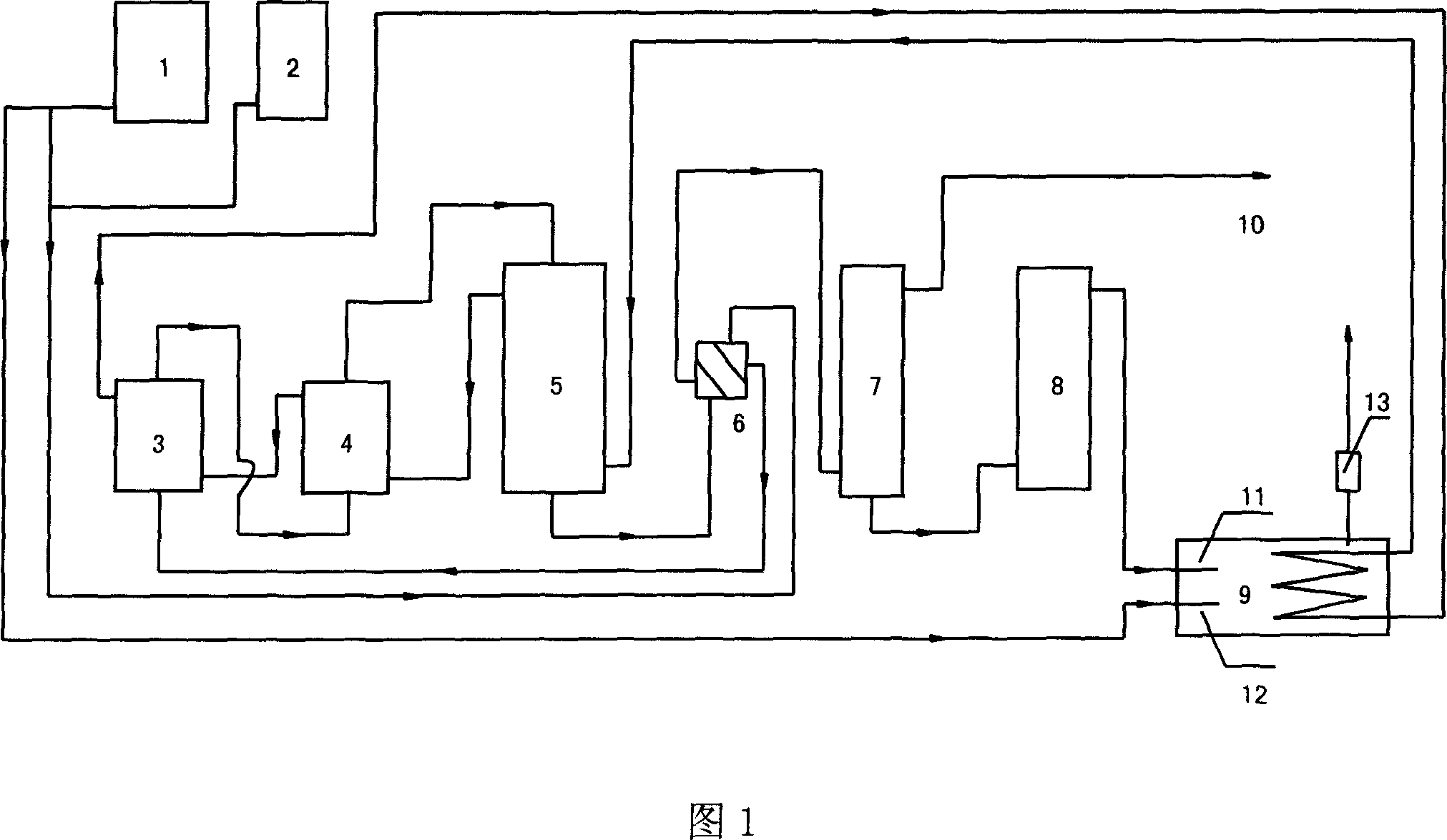

Method of preparing hydrogen by reforming methanol-water steam

This invention discloses a method for reforming methyl alcohol vapour to prepare hydrogen including: preheating, vapouring to 230-280deg.C raw materials of methyl alcohol and water in the mol ratio of 1 :1-1.6, then carrying out catalyzing and reforming reaction in a reactor to be mixed and puried characterizing that : a, when starting, the method utilizes methyl alcohol as the heat-supply material and utilizes the discharge gas in reforming and puring alcohol and its vapour after starting up, b, the alcohol and its discharge gas supply heat by independent burning sprayers of alcohol and discharge gas in a heating furnace, c, waste gas after combustion is discharged after adsorption and purification, which replaces traditional coal and oil as the heat supply fuel.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

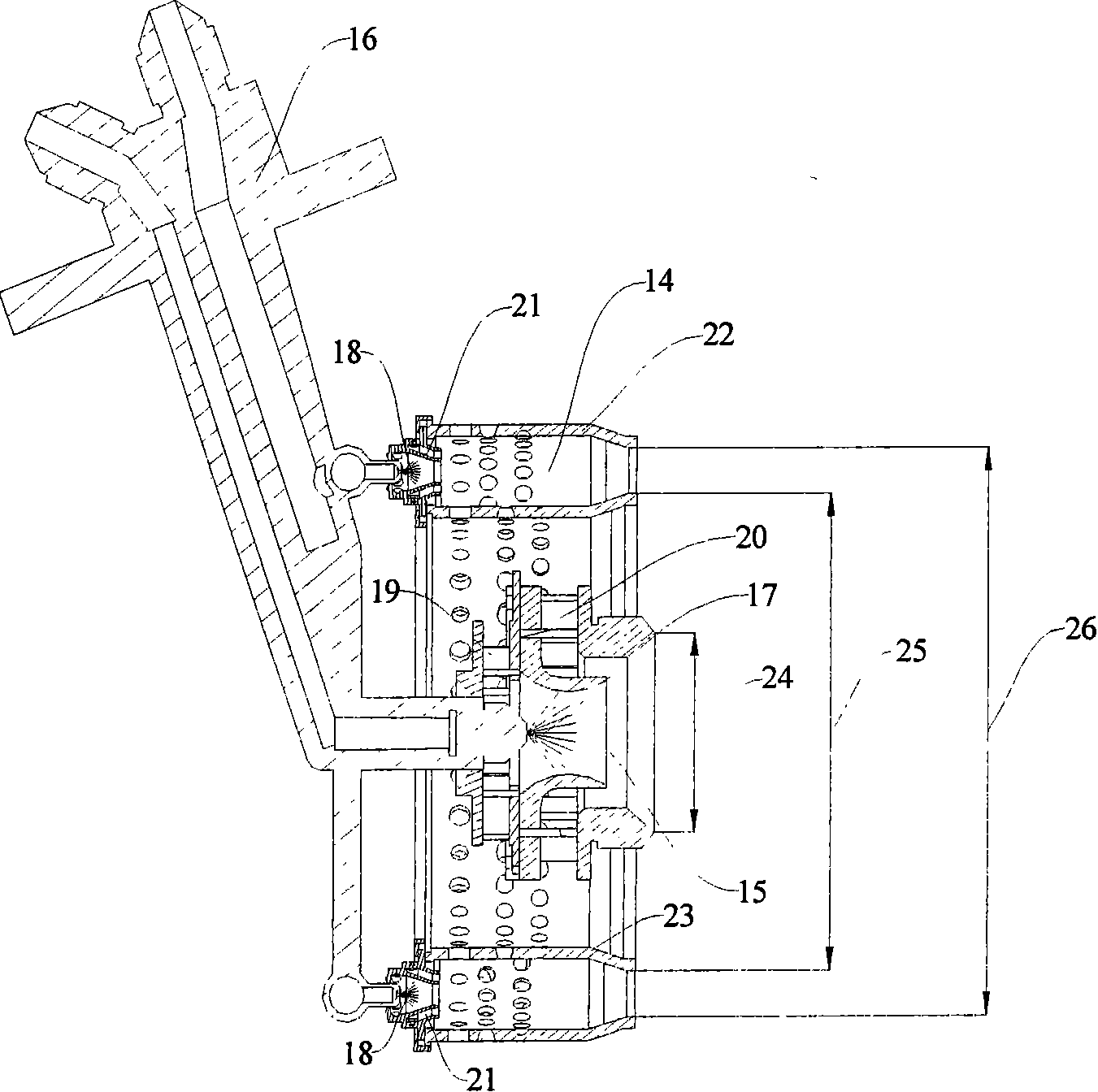

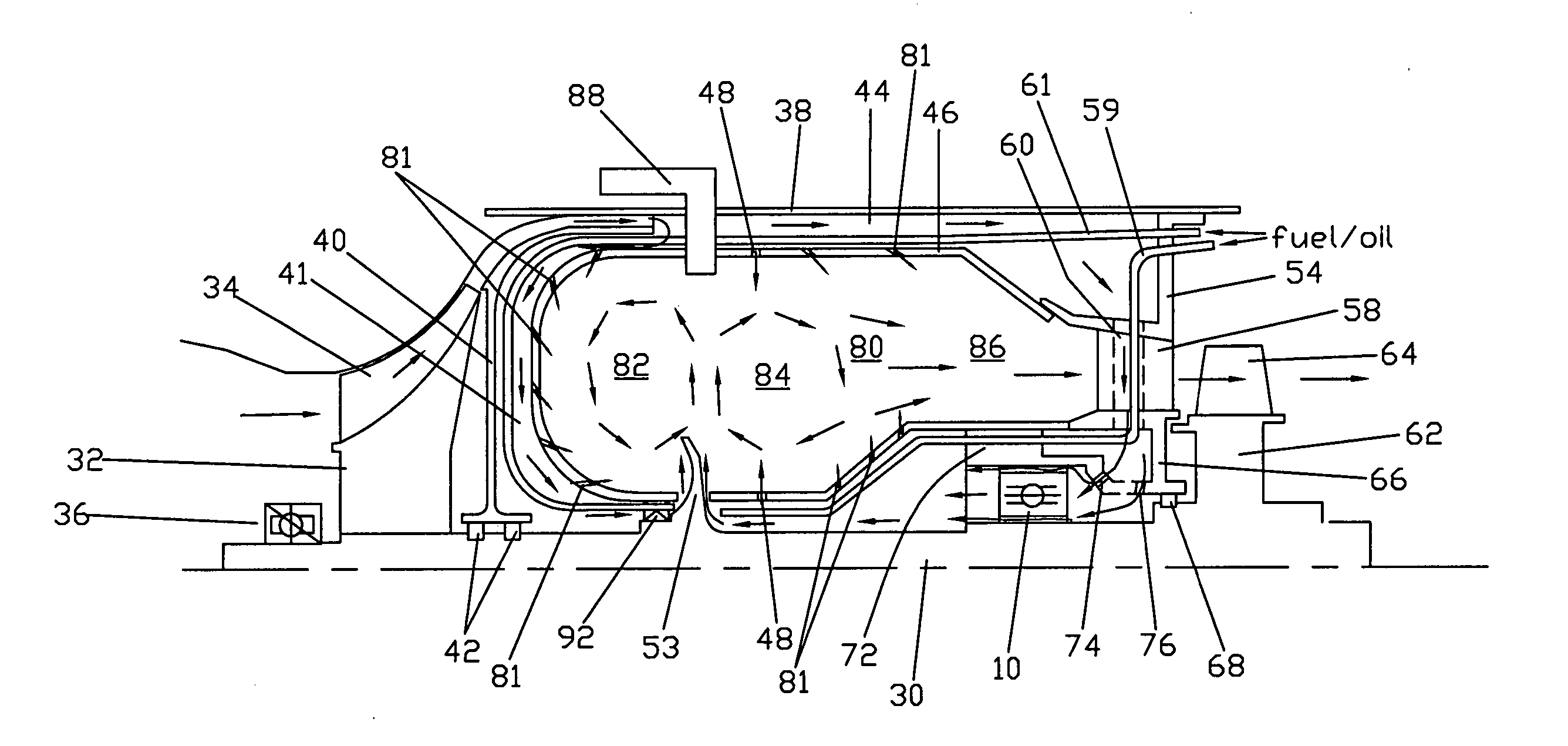

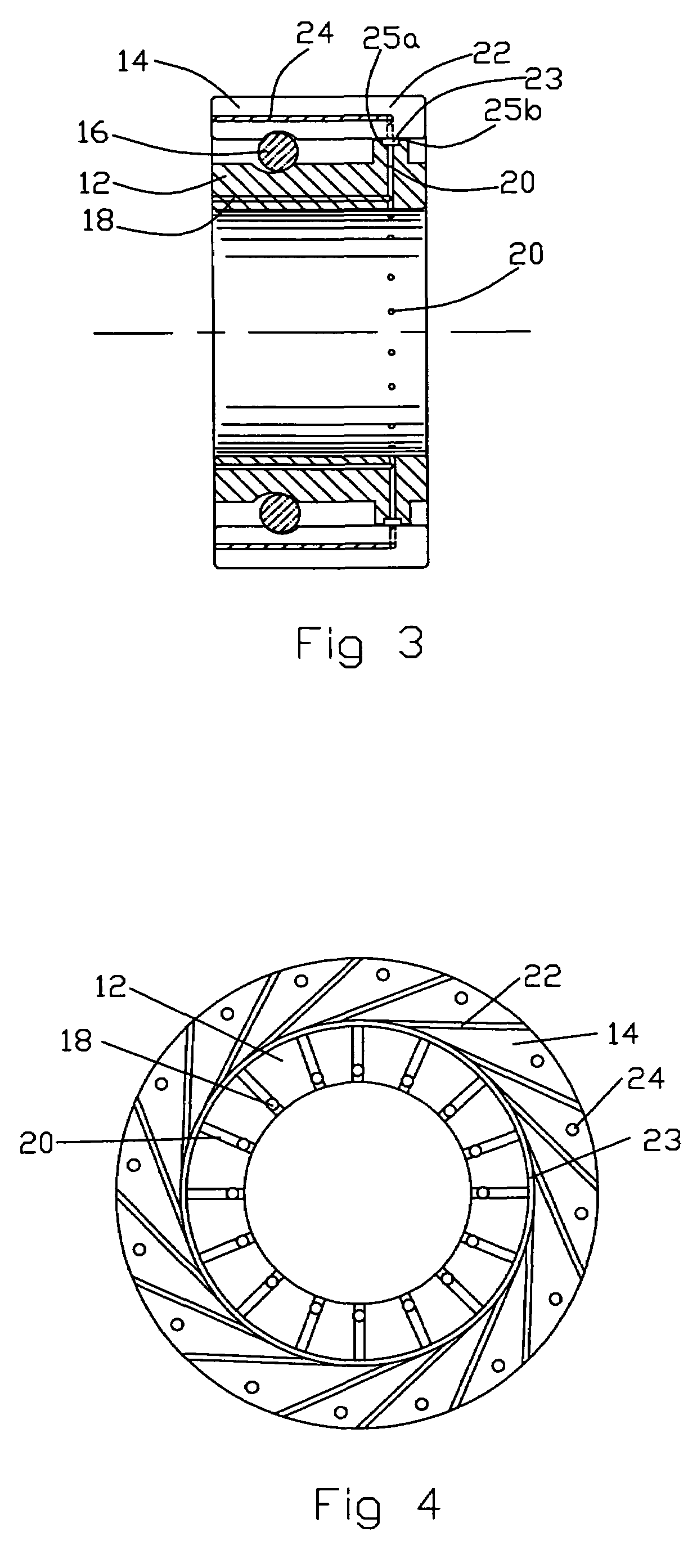

Small gas turbine engine with multiple burn zones

InactiveUS20070234733A1Most efficientImprove stabilityTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorTurbine

A small gas turbine engine for use in an UAV such as a cruise missile, the gas turbine having a combustor forming a primary burn zone and a secondary burn zone, and in which fuel is injected into both the primary and the secondary burn zones by either a rotary cup injector or a plurality of fuel injector nozzles. The secondary burn zone with separate fuel injection allows for the diameter of the engine to be reduced in size but still allow for adequate power and efficiency to be reached for powering the vehicle. Air flow from the compressor is used to cool the combustor walls before being injected into the combustor, and to pass through and cool the guide nozzles and a main bearing located near the hot section of the combustor prior to being introduced into the combustor.

Owner:FLORIDA TURBINE TECH

Boiler furnace of circulating fluidized bed with water-cooled column

ActiveCN101196297AEvenly heatedIncreased hydrodynamic safetyFluidized bed combustionApparatus for fluidised bed combustionBoiler furnaceCirculating fluidized bed boiler

The invention relates to a circulating fluid bed boiler furnace with water-cooled posts, which is characterized in that: the water-cooled posts arranged in the boiler furnace are able to provide enough heating area; meanwhile, enough space is left between posts for mixing materials at lower section of the boiler furnace, so as to ensure the concentration, temperature and the evenness of heat transfer; the heating status of the heat face of the water-cooled posts and the wall around the boiler furnace are similar, which is particularly beneficial for enhancing the hydrodynamic force safety of supercritical circulating fluidized bed boiler furnace. The water-cooled posts are able to be internally provided with dusts being able to through with secondary winds at the central area of the boiler furnace. The invention arranges the vertical water-cooled posts encircled by film walls between boiler furnace grid plate and a ceiling and working substance are provided from up to down in the film wall pipe; the external side of the water-cooled post faces to the burning space of the boiler furnace.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

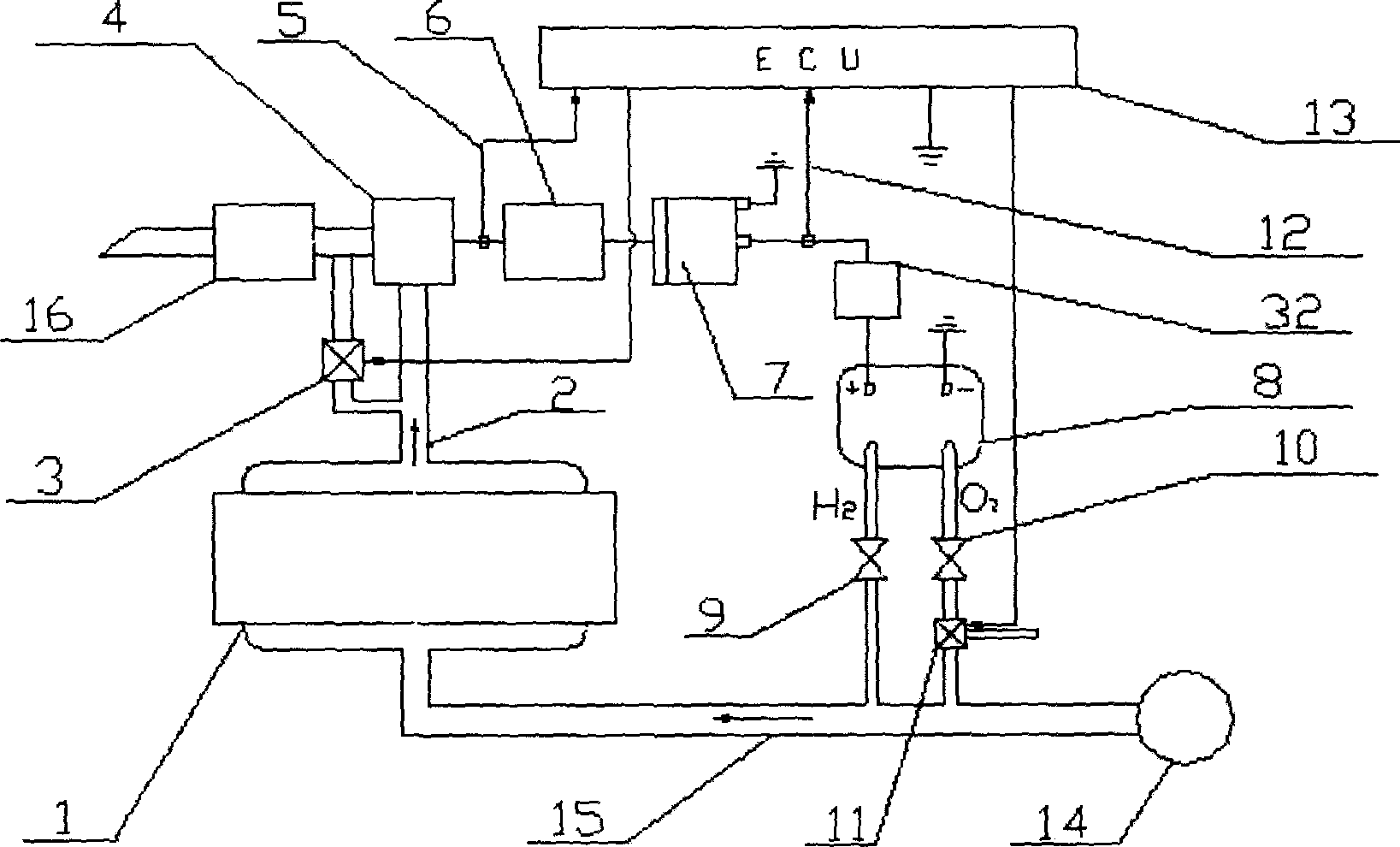

Power generating and hydrogen producing method and unit utilizing waste gas of internal combustion engine

InactiveCN1388308AAvoid storage hazardsSolve the problem of high cost of hydrogen productionElectrolysis componentsInternal combustion piston enginesExternal combustion engineMechanical energy

The present invention relates to the method and unit to utilize the energy of waste gas of internal combustion engine to generate hydrogen and oxygen and to improve burning state of internal combustion engine. The electricity generating and hydrogen generating unit consists of waste gas turbine converting the energy in waste gas into mechanical energy, electricity generator converting the mechanical energy into electrical energy, water electrolyzer utilizing the electrical energy to electrolyze water into hydrogen and oxygen and electric controller. The hydrogen and oxygen are fed to the internal combustion engine for catalyzing hydrocarbon fuel inside the internal combustion engine to improve burning, increase power output and reduce exhaust.

Owner:姜伟

Process for use with dual-fuel systems

InactiveUS7533634B2Avoid power outagesHigh outputElectrical controlInternal combustion piston enginesInlet pressureEngine power

Owner:TGI

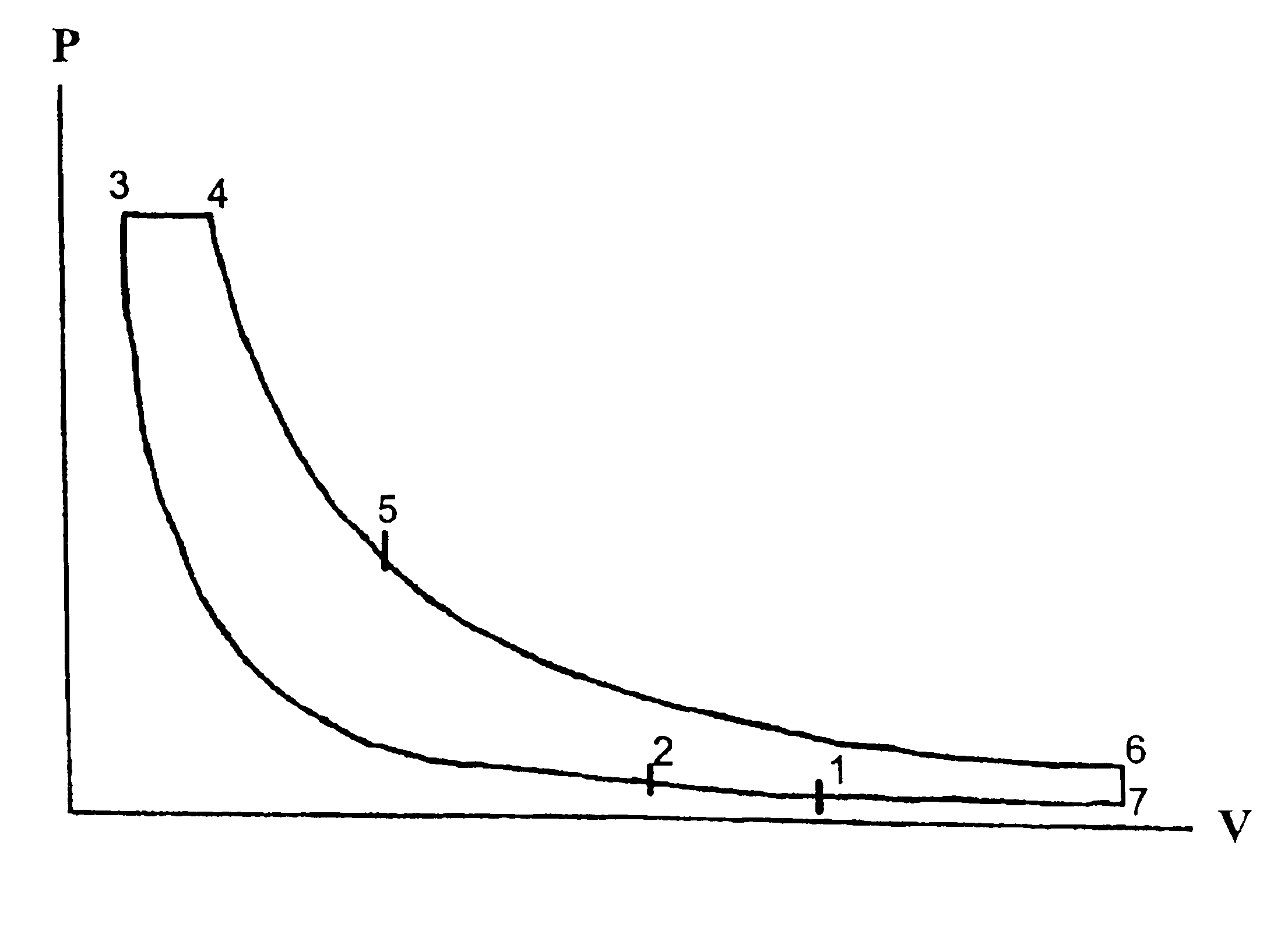

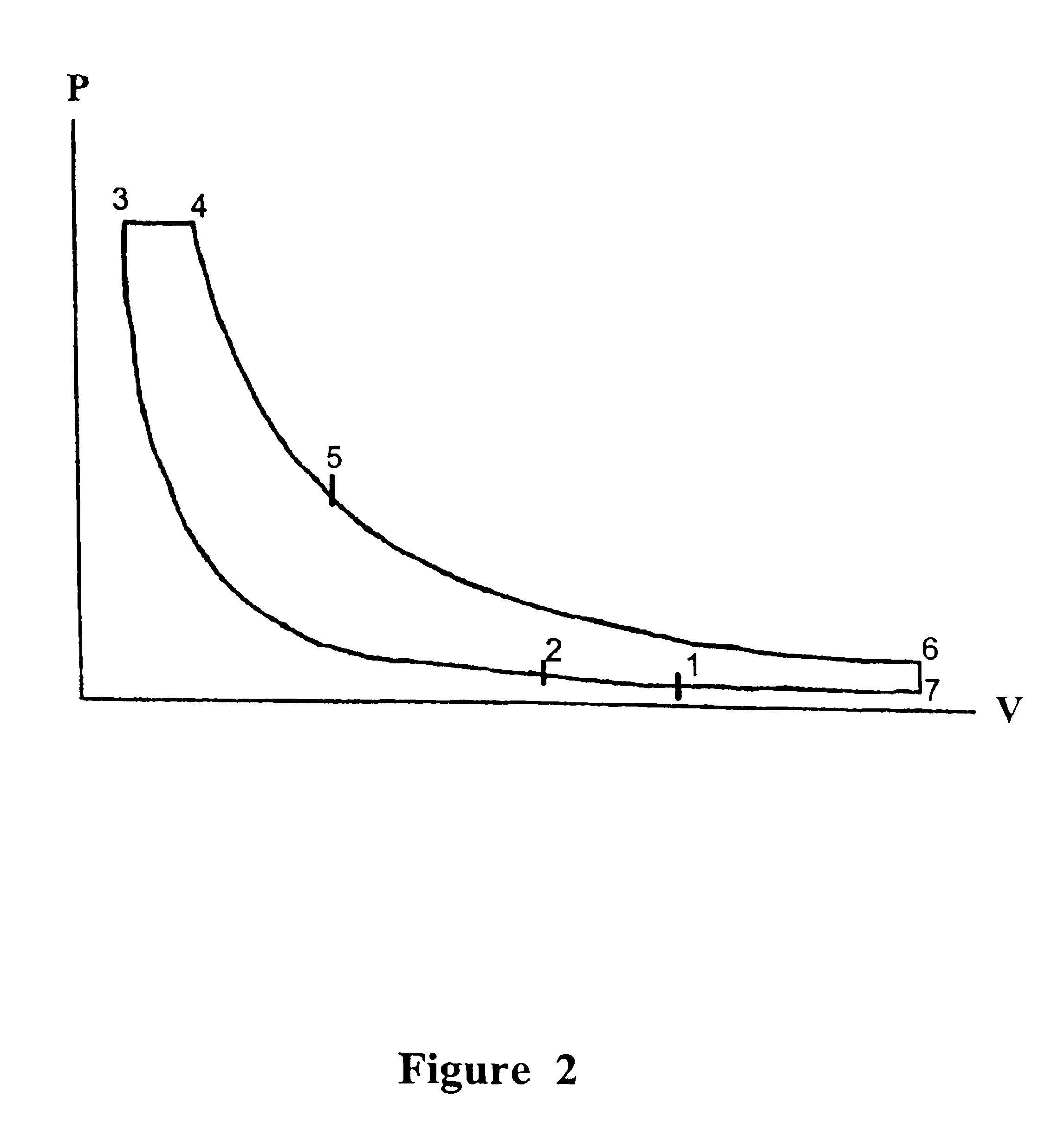

Over expanded limited-temperature cycle two-stroke engines

InactiveUS6848416B1Reduce NOx levelReducing post-combustion temperatureElectrical controlCombustion enginesPressure decreaseFour-stroke engine

A method for combusting fuel in an engine involving decreasing a first volume of gas to a second volume, in two stages, while increasing the pressure and temperature of that volume of gas (a compression process having a chosen compression ratio), then increasing the second volume to a third volume at constant pressure while adding heat until a predetermined temperature is obtained, increasing the third volume of gas to a fourth volume, in two stages while decreasing the pressure at the predetermined temperature (an expansion process having a chosen expansion ratio much greater than the compression ratio), decreasing the pressure to atmospheric pressure while removing heat under constant volume, and finally decreasing the volume of gas to the first volume while removing heat under constant pressure to complete an over expanded, limited-temperature cycle. Also disclosed is an engine employing said over expanded, limited-temperature cycle.

Owner:PIEN PAO C

Electronic switch for drop-free candle

InactiveUS6960076B2Eliminate dropImprove securityFuel lightersCapillary burnersElectrical conductorElectronic switch

An electronic switch for a drop-free candle is comprised of a candle, a wick, a metal disk, a conductor and a circuit board; the metal disk being buried in the candle; the conductor being provided in the form of an optical fiber or a magnet twisted pair cable; the conductor being provided along the wick to control the operation of the circuit board provided at the bottom of the candle to realize the function of an electronic switch while preventing drops of the fatting substance of the candle.

Owner:YU SHUNG LUN

Oil resistance foamable end cap sealing material and preparation method thereof

InactiveCN101649180AEmission reductionBurn completelyOther chemical processesVulcanizationNitrile rubber

The invention discloses an oil resistance foamable end cap sealing material and a preparation method thereof. The method comprises the following steps: using butadiene-nitrile rubber, butadiene-nitrile hydride rubber, carboxylic butadiene-nitrile rubber or chloroprene rubber to plastify with an open mill, a internal mixer or a screw masticator and prepare plasticated rubber, then using plasticatedrubber, vulcanizer, foaming agent, anti-aging agent, softening oil, reinforcing agent and the like to mix with an open mill, a internal mixer or a screw masticator and prepare mixed rubber, then adopting the mixed rubber to prepare rubber sheets of the oil resistance foamable end cap sealing material through extruding, rolling and the like; using the rubber sheets and paper cores to perform vulcanization foaming and forming in heated moulds and demoulding to obtain integrated environmental filter element without end cap which can be used in the air, fuel oil or engine oil filter of the automobile engine. Compared with the widely used filter element with an end cap, the filter element without end cap can bear heat and oil and is lighter, and when the filter element without end cap reachesthe service life to be discarded, the filter element can be fully burned and does not cause environmental pollution.

Owner:SHANGHAI HUA HUA RUBBER CO LTD

Methanol gasoline heat value agent

InactiveCN101619250ASolve cold start difficultiesEasy to startLiquid carbonaceous fuelsAlcoholCombustion

The invention relates to a methanol gasoline heat value agent, belonging to the field of alcohol gasoline alternative fuel additives, and comprising the following components by weight percent: 2 percent to 4 percent of combustion catalyst, 2 percent to 4 percent of eduction agent, 83 percent to 90 percent of methanol heat value agent and 5 percent o 9 percent of gasoline heat value agent. The invention has the advantages of simple preparation, low cost, wide sources and the like, emphasizes on solving the problem that power of an engine is influenced by the descending of the heat value of methanol gasoline, and changes the difficulty of cold start of the methanol gasoline. Through a bench and road test, the use performance of the methanol gasoline after adding the heat value agent is close to burning commercial gasoline, is superior to the methanol gasoline of the same grade without adding the heat value agent, and the methanol gasoline after adding the heat value agent has equal oil consumption and power of agent with the burning commercial gasoline, better cold starting performance and acceleration quality than the commercial gasoline and lower pollution discharge than the commercial gasoline. The heat value agent has obvious effects on enhancing the heat value of the methanol gasoline and the power of the engine and easy cold start, and opens up a new path for all-round popularization with high ratio and large area of the methanol gasoline.

Owner:占小玲

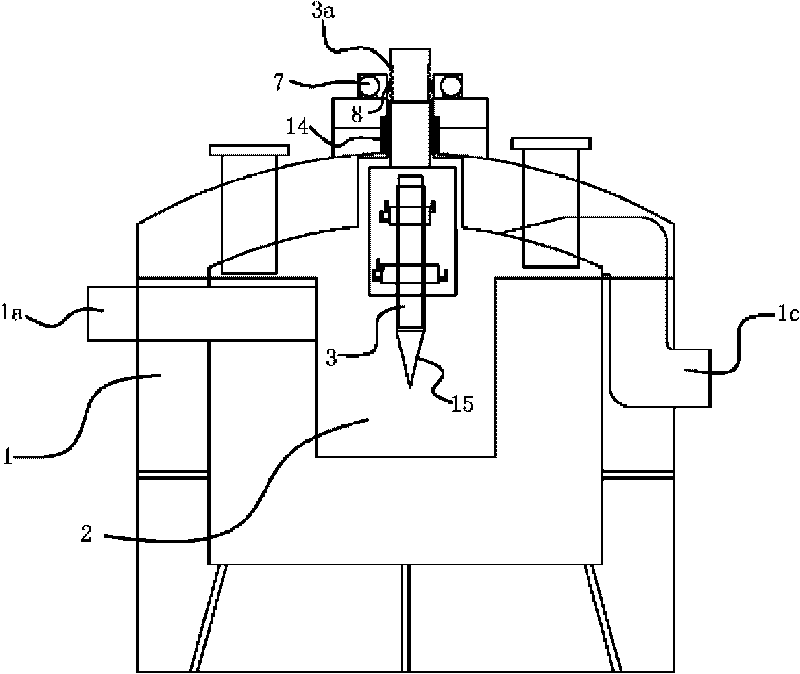

Plasma melting cracking treating equipment

ActiveCN101737786ABurn completelyImprove incineration effectIncinerator apparatusPlasma flameIncineration

The invention provides plasma melting cracking treating equipment belonging to the technical field of machines and solving the technical problems of low incineration temperature, poor incineration effect, insufficient incineration and the like of a traditional incineration furnace. The plasma melting cracking treating equipment comprises a furnace body with a charging port and a discharging port, wherein the furnace body is internally provided with an incineration cavity communicated with the charging port and the discharging port; the furnace body is also provided with a gas outlet communicated with the incineration cavity; the top of the furnace body is also provided with a plasma torch generator capable of generating plasma flames; one end of the plasma torch generator penetrates into the incineration cavity; and the other end penetrates out of the furnace body and is connected with a lifting mechanism capable of driving the plasma torch generator to lift upwards and downwards. The treating equipment has the advantages of higher flame temperature, more sufficient incineration, higher incineration efficiency and the like.

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

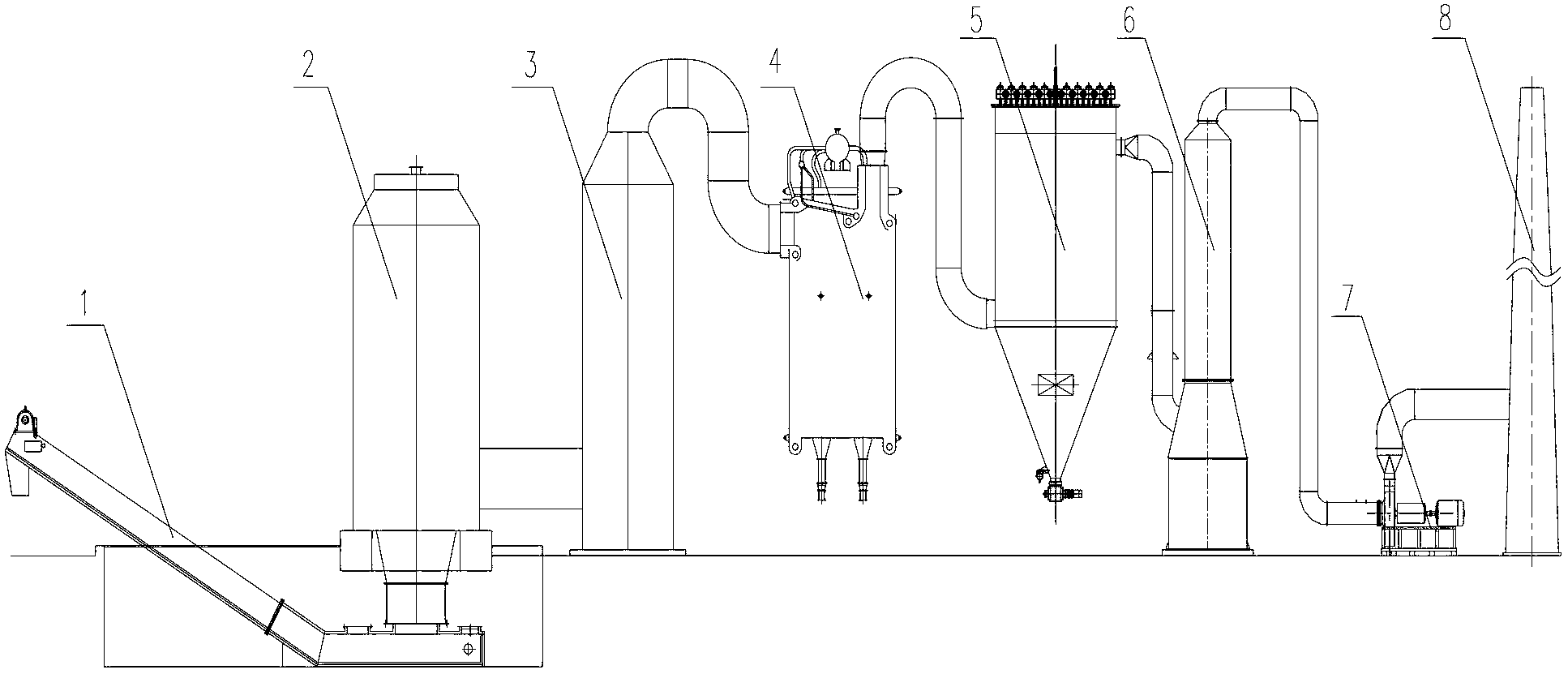

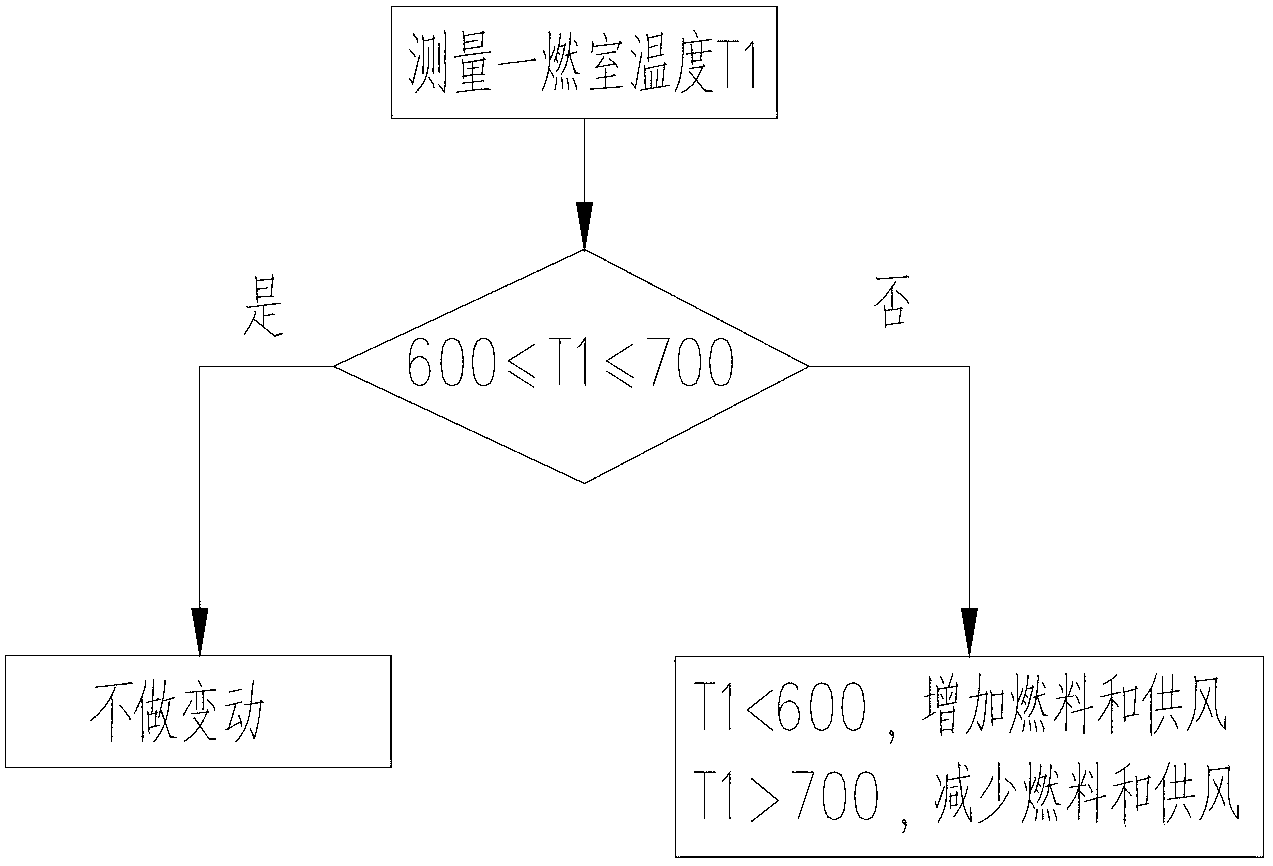

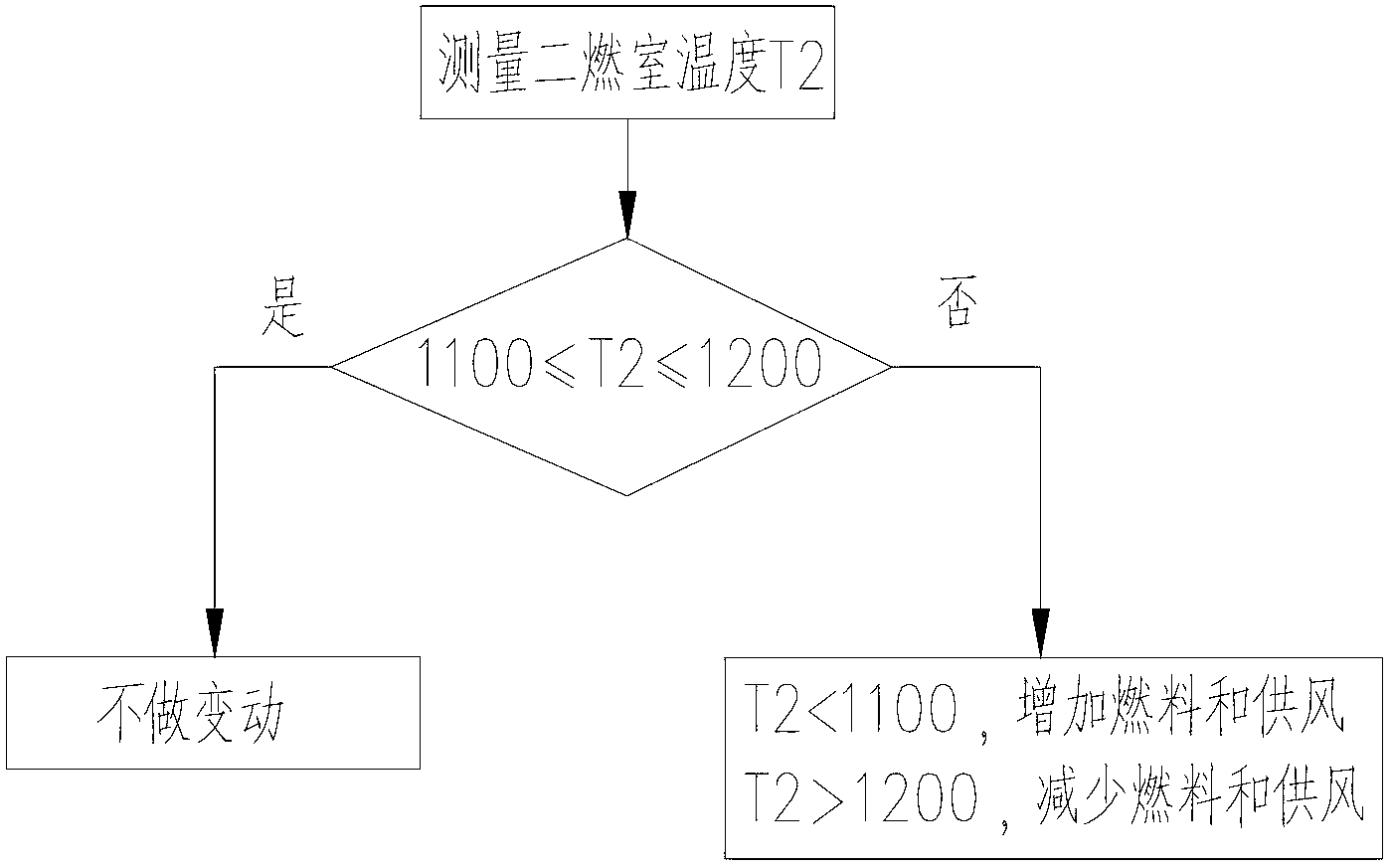

Incineration disposal method for high-salinity wastewater

InactiveCN103017177AAvoid redissolutionReduce salt contentIncinerator apparatusSteam generation using hot heat carriersComing outFurnace temperature

The invention discloses an incineration disposal method for high-salinity wastewater. The high-salinity wastewater is sprayed into a combustion chamber I after being atomized by utilizing a waste liquid spray gun through compressed air. In the combustion chamber I, the consumption of auxiliary fuel and air supply volume are controlled through temperature feedback to keep furnace temperature at 600-700 DEG C. Smoke generated in the combustion chamber I enters a combustion chamber II under the action of an induced draft fan; in the combustion chamber II, the consumption of the auxiliary fuel and the air supply volume are controlled through the temperature feedback to keep the furnace temperature at 1100-1200 DEG C, and moreover, the standing time of the smoke is longer than 2 seconds. Smoke coming out from the combustion chamber II enters a waste heat boiler, and the heat of the smoke is recycled through heat exchange. Smoke coming out from the waste heat boiler is respectively dedusted and deacidified through a bag type dust collector and a smoke deacidification unit, and then, is discharged on the standard. According to the incineration disposal method for the high-salinity wastewater, not only can saline matter in the high-salinity wastewater be separated out through the evaporation of water without coking but also hazardous organic matters in the smoke can be fully destroyed by fire.

Owner:BMEI

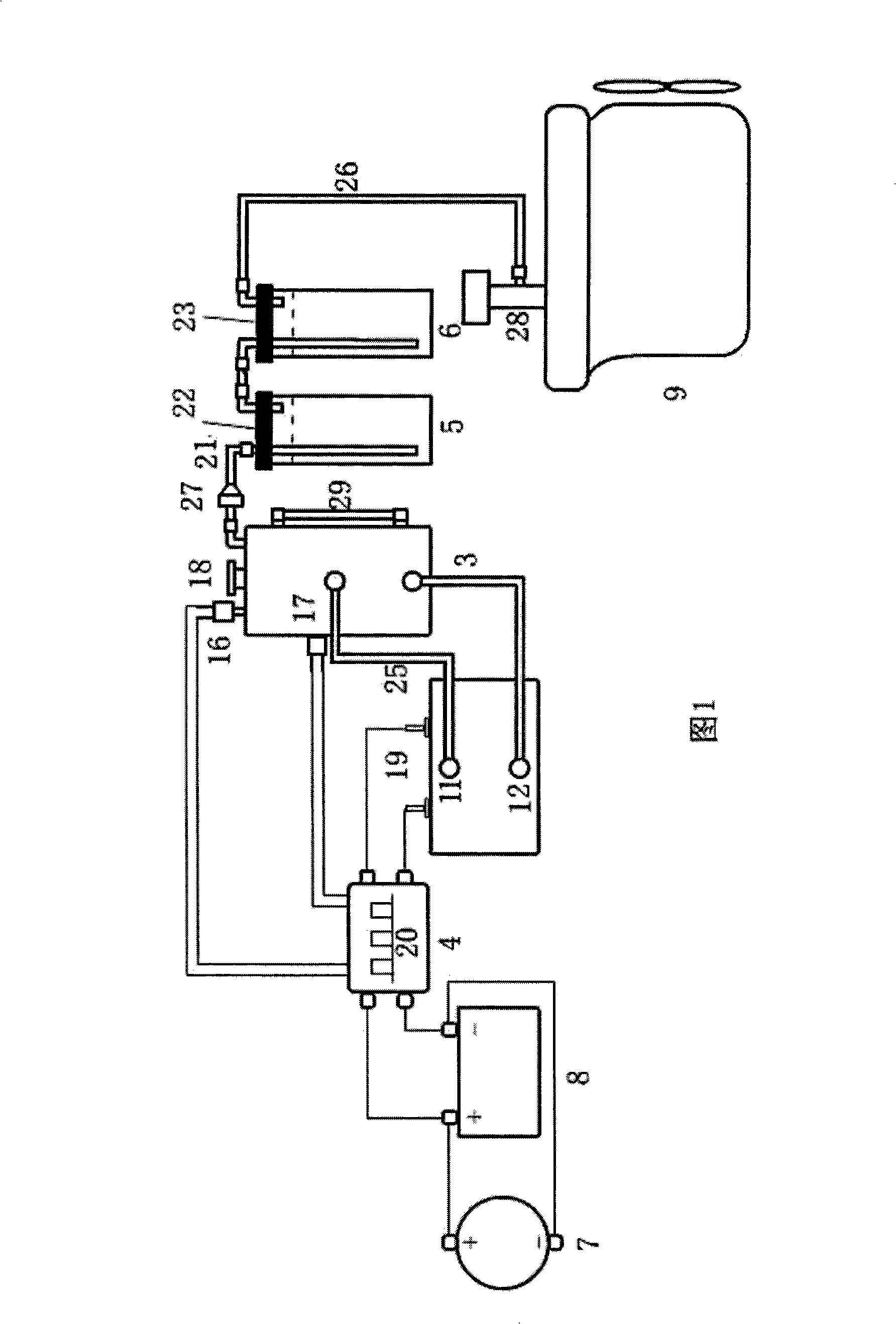

Micro-hydrogen injection energy-saving exhaust-reduction device of internal combustion engine

ActiveCN101403354ASuitability for useSuitable for maintenanceInternal combustion piston enginesNon-fuel substance addition to fuelElectrolysisExternal combustion engine

The invention relates to an energy conservation and emission reduction device for internal-combustion engine micro-hydrogen jet, which comprises an oxyhydrogen electrolysis pool, an electrolyte reservoir, a current pulse width modulation volume control and safety protection circuit, a gas washing tank, a water seal anti-backfire pot, a generator and a multiple-connected battery; the current pulse width modulation volume control and safety protection circuit and the positive and negative electrodes of a conductive electrode plate of the oxyhydrogen electrolysis pool are connected into a loop; the case of the oxyhydrogen electrolysis pool is provided with two holes, and pipelines led out of the two holes of the oxyhydrogen electrolysis pool are sequentially connected with the electrolyte reservoir, the gas washing tank, the water seal anti-backfire tank and an internal-combustion engine. The device injects the mixed oxyhydrogen gas after water electrolysis into a combustion chamber of the internal-combustion engine to accelerate fuel oil or fuel gas combustion and realizes the full combustion of the fuel oil or fuel gas, thus improving the thermal efficiency, reducing the consumption of the fuel oil or fuel gas, and reducing the emissions of greenhouse gases, harmful gases and solid particles. The device is used for various vehicles, ships, generator sets and the like which take the internal-combustion engine as power.

Owner:WUHAN MICRO HYDROGEN NEW ENERGY CO LTD

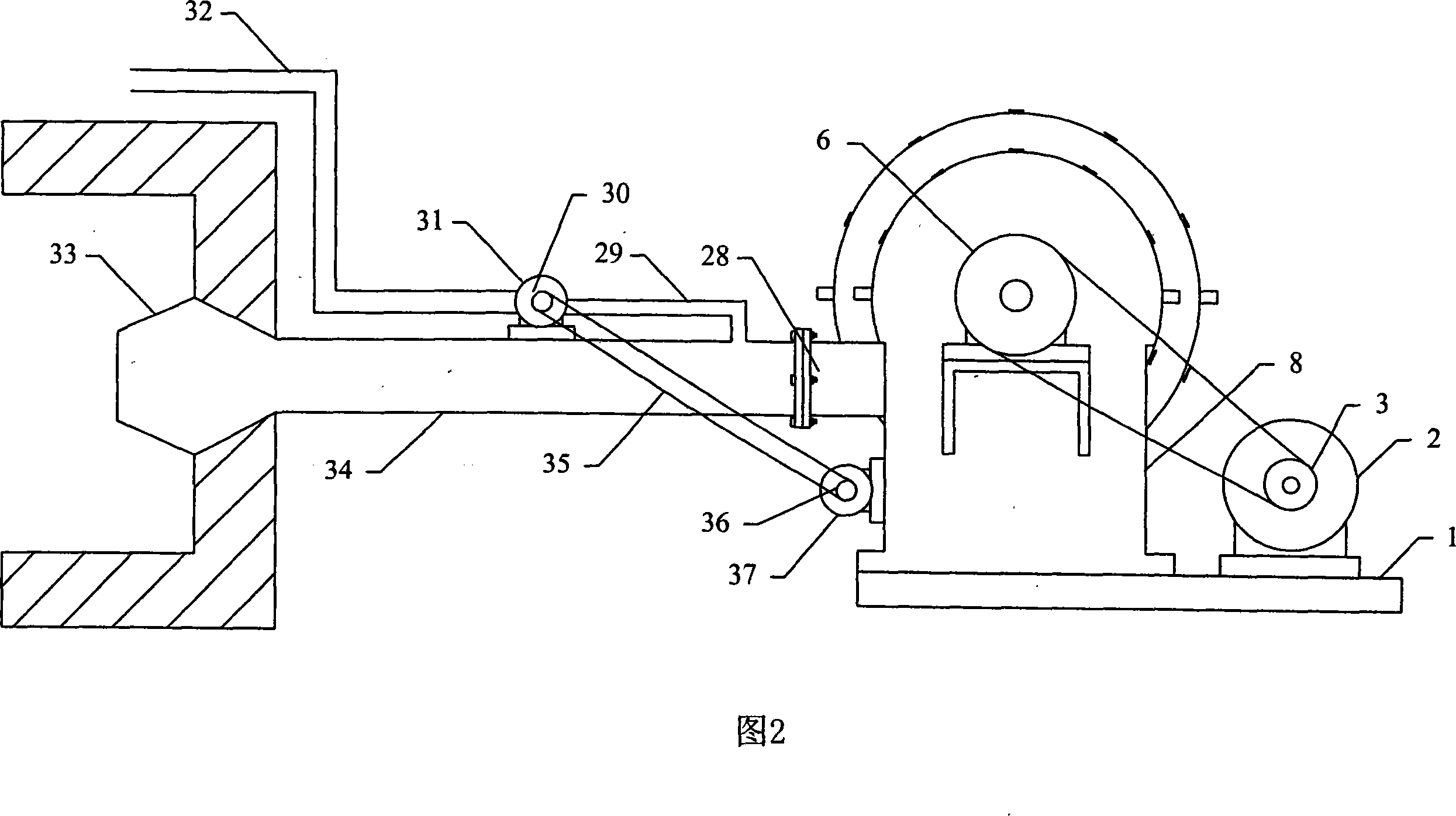

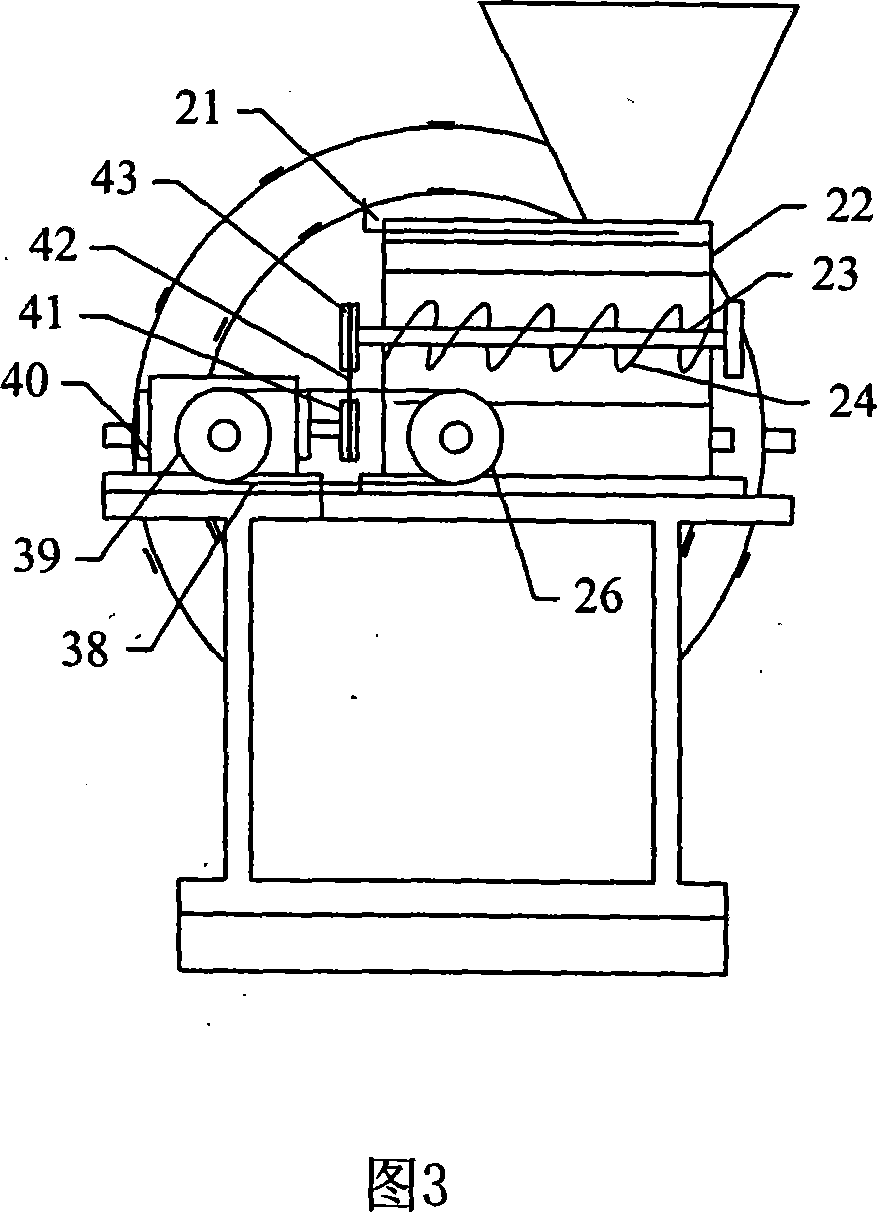

Centrifugal type composite coal-grinding and powder-spraying machine

InactiveCN101085428ABurn completelyReduce pollutionGrain treatmentsLump/pulverulent fuel feeder/distributionEngineeringGrind

The centrifugal compound grind coal powder machine has a main shaft at the base of the body, three sets of flying hammer of various diameters from the center of the shaft, linking as an integral with the vane by the bolt fastened tightly on the flange plate of the main shaft. Fan cabin set at the front of the machine, with wind introduction fan inside the fan cabin, with powder outlet at the left, and powder spraying barrel at the outlet. Rear of the machine sets spiral feeder whose left installs a worm decelerator, top of the feeder having the feeding hopper. It can be used together with the regeneration energy saving smelting-furnace, spraying coal powder into the furnace, reducing burning cost to over 66%. It is reduced in energy consumption, alleviated in contamination and increased in effect. It will be an ideal new generation product.

Owner:ANHUI HUAXIN LEAD IND GROUP

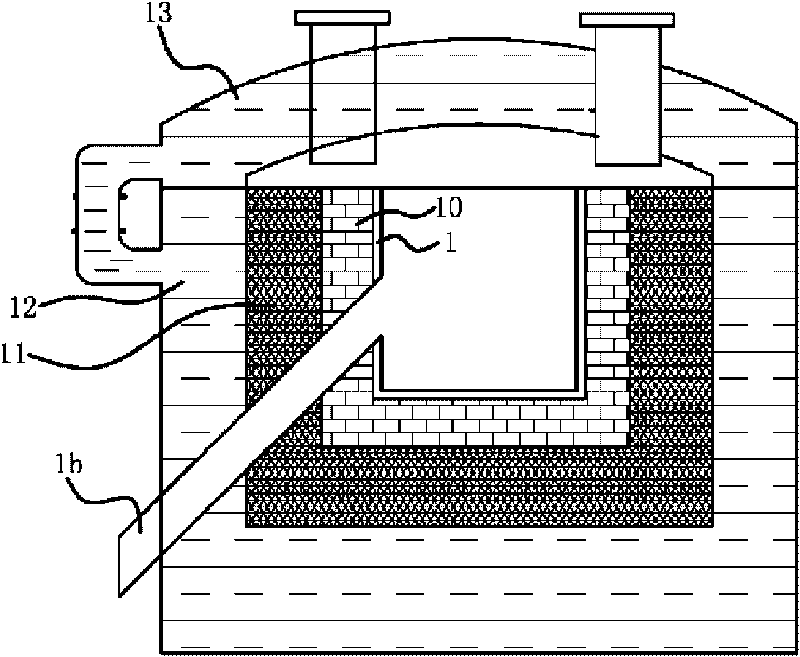

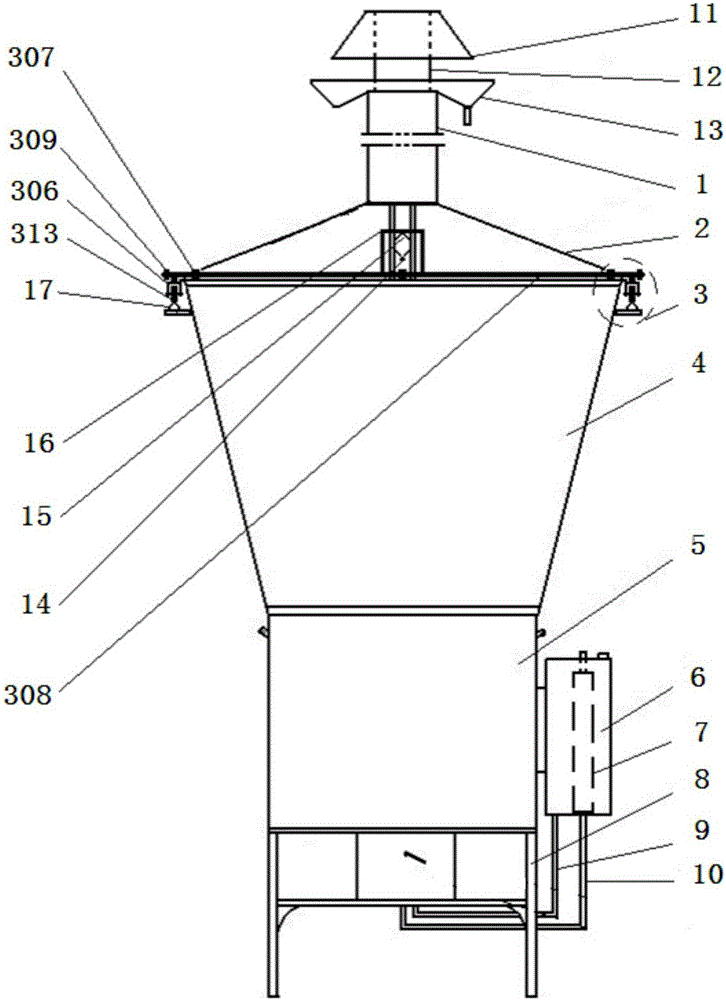

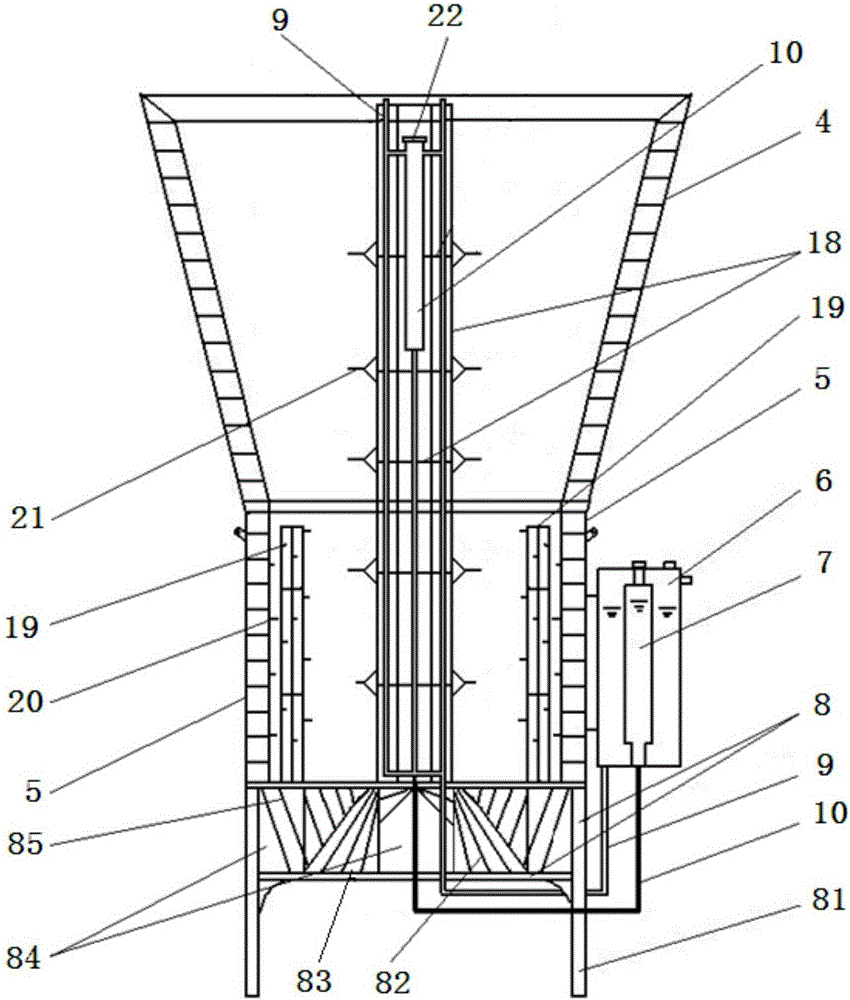

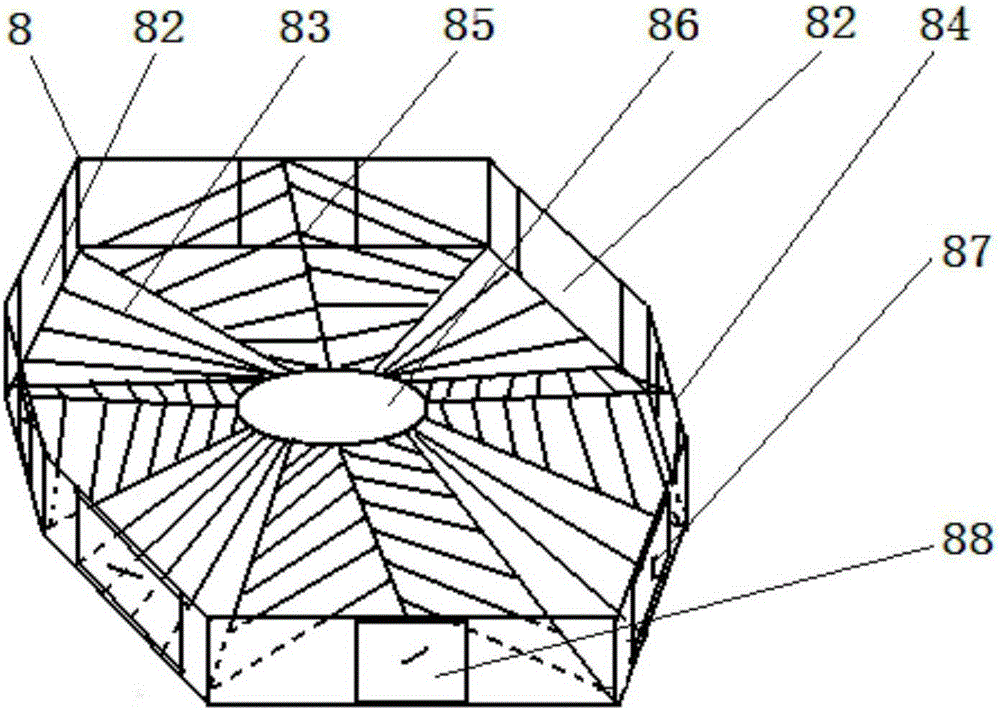

Environment-friendly efficient waste incinerator

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

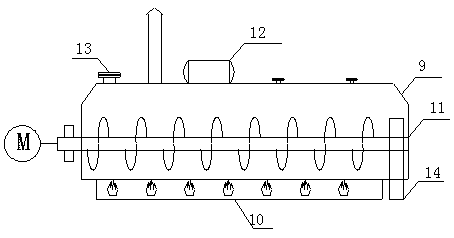

High-concentration saliferous organic waste liquid incinerator and incineration technique

ActiveCN102168857AEfficient combustionStable combustionIncinerator apparatusAir preheaterThermal energy

The invention discloses a high-concentration saliferous organic waste liquid incinerator and an incineration technique, which belongs to the processing field of organic waste liquid. The high-concentration saliferous organic waste liquid incinerator comprises a horizontal furnace, a vertical furnace, an afterheat boiler, and a draught fan. The furnace end of the horizontal furnace is provided with a waste liquid burner, a coaxial burner, and a tangential burner. The furnace end of the horizontal furnace is also provided with a cyclone separator, an air preheater and the like. A retaining walland a cooling air system are arranged in the vertical furnace; the stability and pressure of each stage are controlled by the incineration technique; a low-heating value liquid carrier atomizing burning technology is used by the high-concentration saliferous organic waste liquid incinerator and incineration technique, and has excellent processing effects for high-concentration saliferous organic waste liquid, high-concentration saliferous organic waste water, waste oil and the like. The processing capacity is more than 2.0 tons per hour; the waste liquids can be completely burnt; the continuous running period is more than 30 days; the consumption of natural gas is less than 60 cubic meters for each ton of waste liquid; and the heat recycling volume of each ton of waste liquid is more than2.5 tons; therefore, the resources are effectively and circularly utilized.

Owner:中昊黑元化工研究设计院有限公司

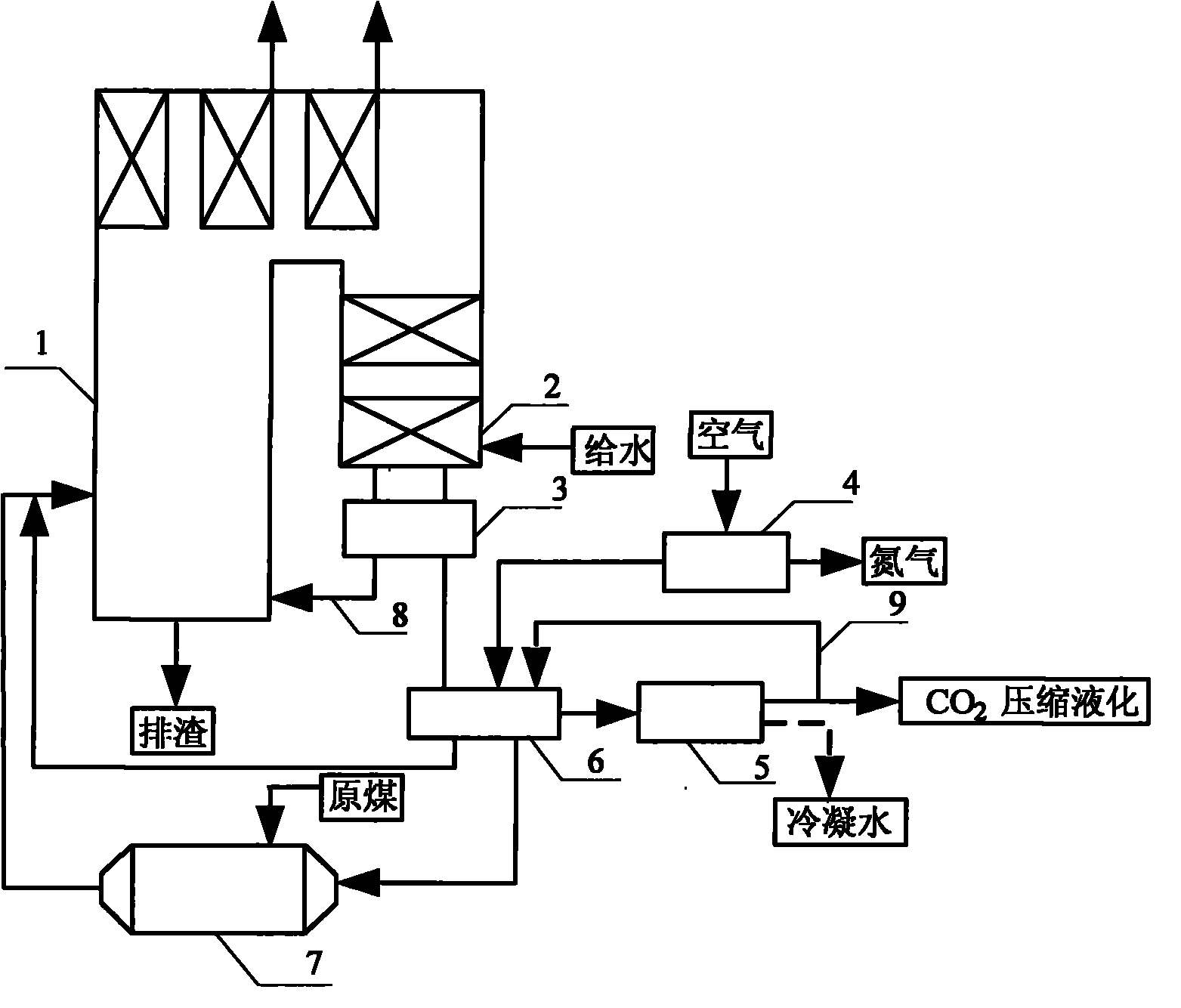

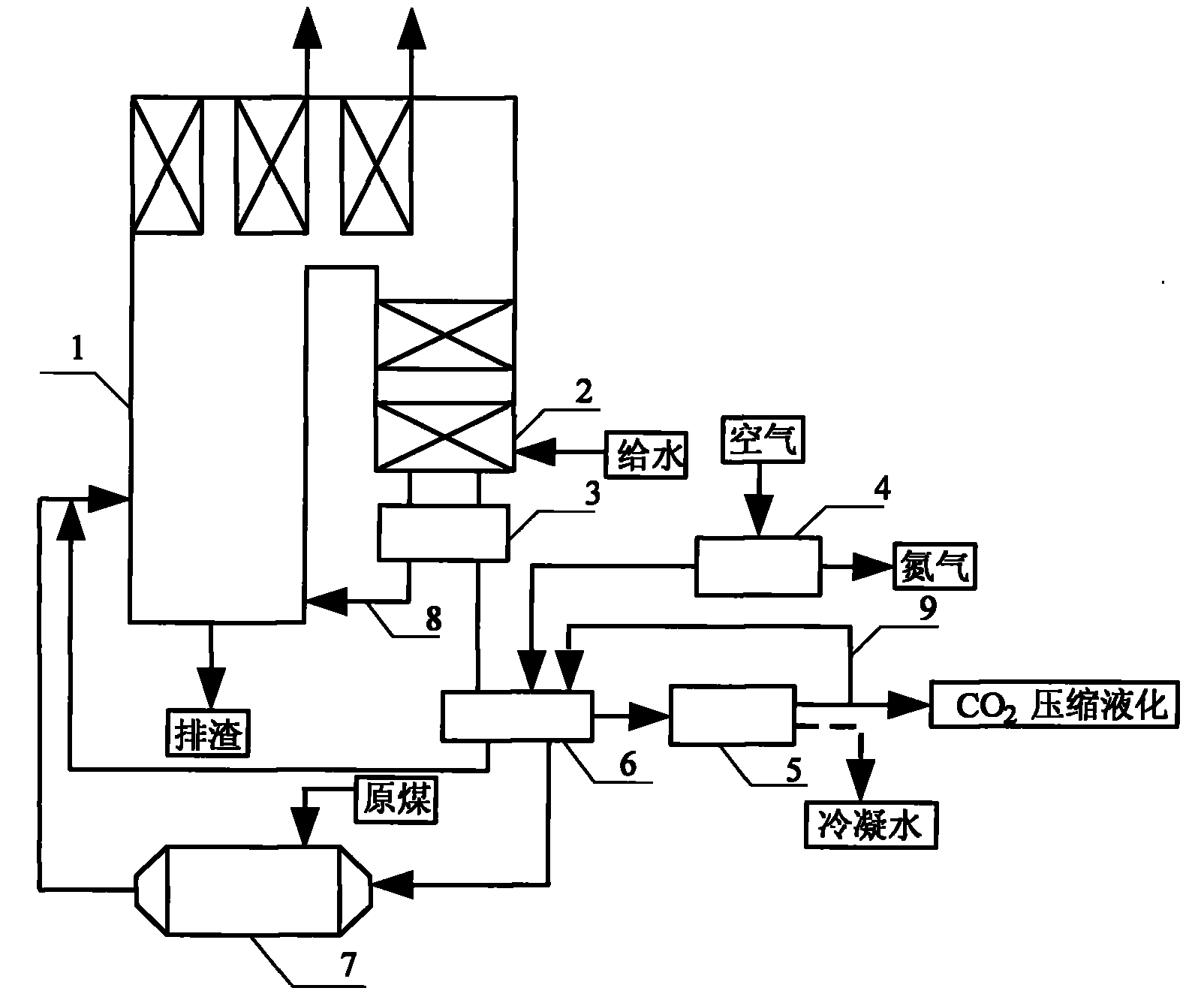

System adopting high concentration CO2 flue gas as coal dust drying medium in boiler

InactiveCN101893370AInitial temperature adjustmentIncrease working temperatureDrying gas arrangementsHigh concentrationCoal dust

The invention relates to a system adopting a high concentration CO2 flue gas as a coal dust drying medium in a boiler and belongs to the technical field of energy technology application and CO2 capture. The flue gas which is dehydrated and heated to a certain temperature and contains over 95 percent of CO2 is used as the drying medium for coal dust pulverizing. The drying medium is an inert gas with low oxygen content so as to solve the problem of easy explosion of a coal pulverizing system when hot air is used as the drying medium and improve the operational safety of the coal pulverizing system. Meanwhile, compared with the temperature of the hot air, the initial temperature of the drying medium can be greatly improved so as to reduce the power consumption of a coal mill, improve the fineness of coal dust, improve combustion efficiency, reduce the exhaust gas temperature and improve the heat efficiency of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

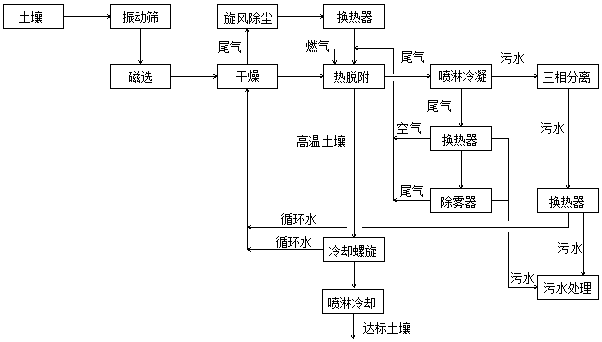

Low-energy-consumption organic contaminated soil heterotopic thermal desorption process

ActiveCN108237143AEasy to handleDecompose thoroughlyContaminated soil reclamationIncinerator apparatusPollution soilSewage

The invention discloses a low-energy-consumption organic contaminated soil heterotopic thermal desorption process. The heat of high-temperature soil treated through indirect heterotopic thermal desorption equipment is recycled to generate high-temperature water, and heat of thermal desorption tail gas spraying sewage is recycled to generate high-temperature water. A belt type drier is arranged infront of the thermal desorption equipment, the high-temperature water serves as a heat source to dry the soil, the water content of the soil entering the thermal desorption equipment is lowered, the energy utilization efficiency is improved, the operation cost is lowered, and the treatment capacity of the thermal desorption equipment is improved. As the drier is used for carrying out drying pretreatment on the soil, the pretreatment efficiency of the soil is improved, and the occupied area of the pretreatment process is reduced. Meanwhile, a burning method is used for carrying out final treatment on dry tail gas and thermal desorption tail gas, and pollutants are thoroughly decomposed.

Owner:鸿灌环境技术有限公司

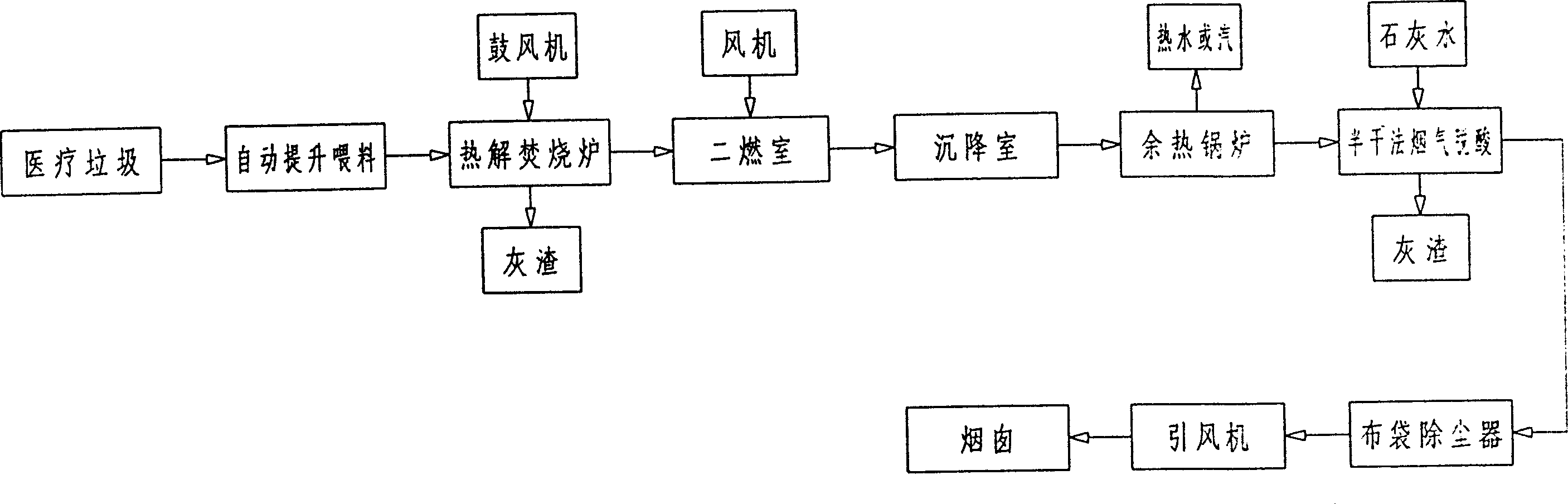

Process for burning medical refuse

ActiveCN1667315AReduce investment and operating costsBurn completelyIncinerator apparatusProduct gasEngineering

The invention relates to a medicine garbage burning technology. The medicine garbage is transferred to the material casting entrance by sealed special transport vehicle and casting equally, quantificatioally into the burning furnace by automatic lifting material feeding device. And the process of dehydration and drying, pyrolysis and gasification, burning, second burning, smoke sedimentation, waste heat recovery and smoke dealing with would be taken. Thus, the content reduce quantity would reach 99%. The invention can effectively avoid the produce of poisonous substance.

Owner:ZHENGCHANG GROUP JIANGSU

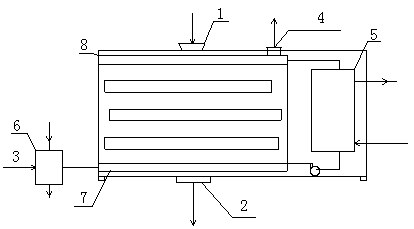

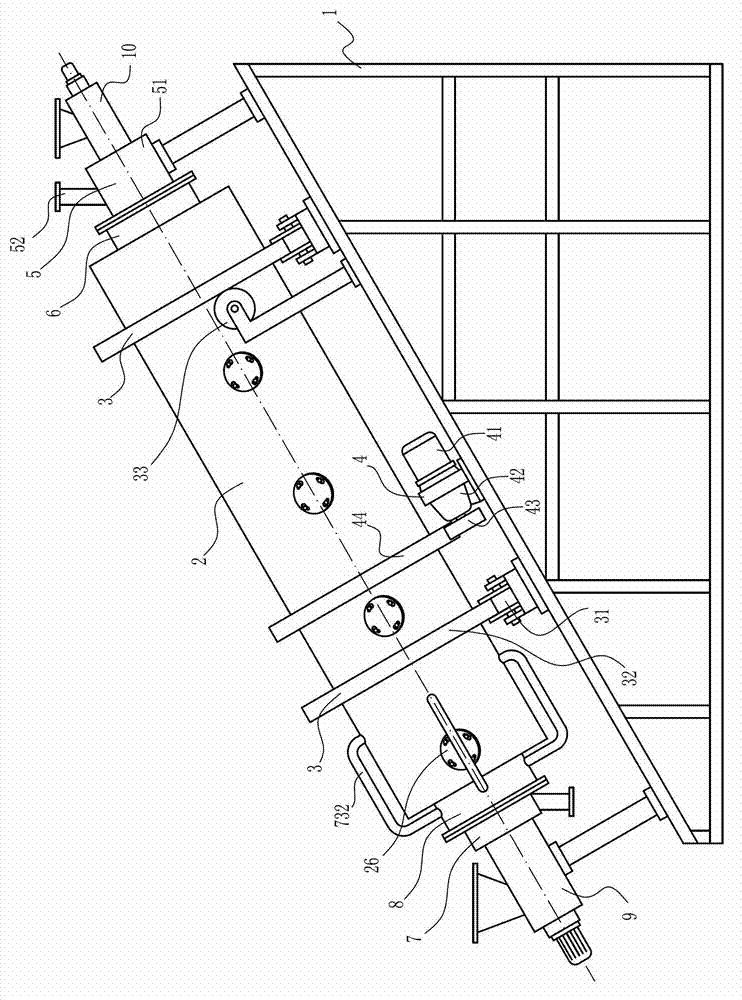

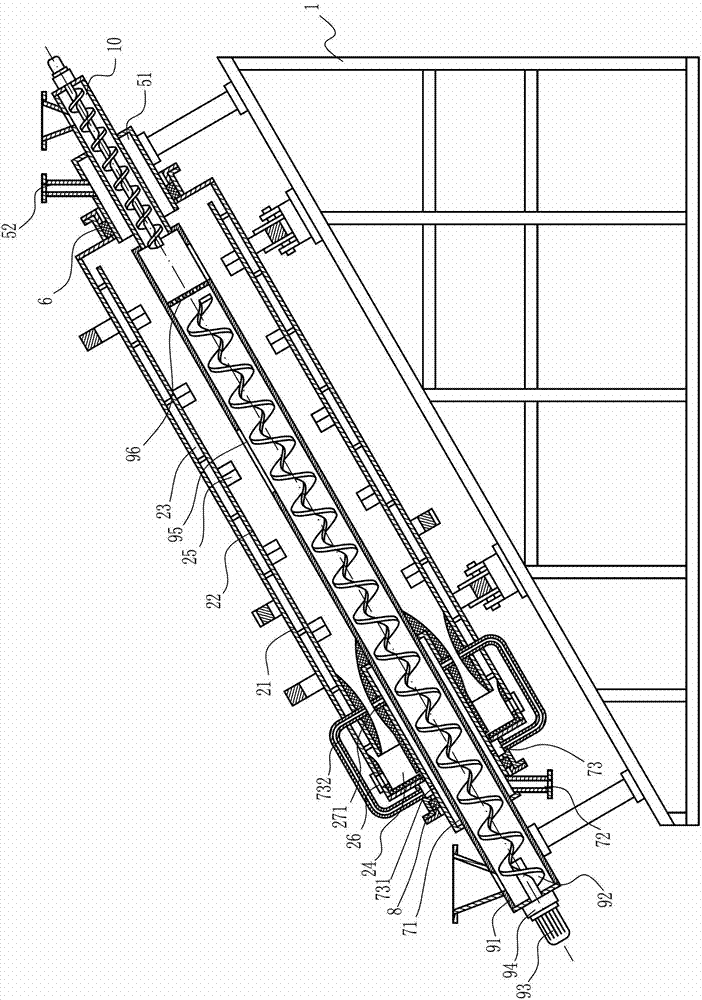

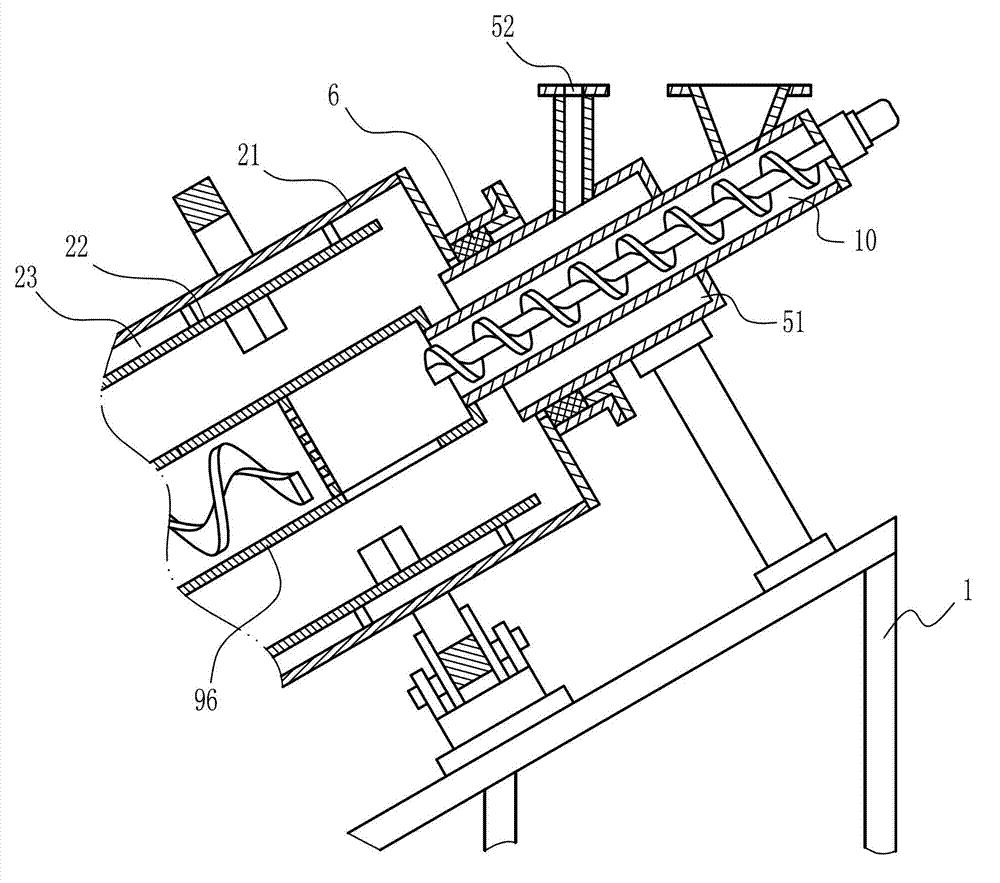

Wet sewage sludge combustion furnace

ActiveCN102889599AAchieve combustionConcentrated and dried with high efficiencyIncinerator apparatusSocial benefitsCombustion

The invention discloses a wet sewage sludge combustion furnace which comprises a machine frame, wherein the machine frame is provided with a barrel type furnace body in an inclining manner, and a riding wheel device and a furnace body revolution driving device are arranged between the barrel type furnace body and the machine frame; the machine frame is fixedly provided with a sludge granulation spiral conveyer, and a discharge end of the sludge granulation spiral conveyer stretches into the upper part of the interior of the barrel type furnace body; and the upper end of the sludge granulation spiral conveyer is provided with a steam exhausting device and a granulation discharge hole. The wet sewage sludge combustion furnace provided by the invention can concentrate the sludge in a sludge transport process, the subarid sludge is extruded and granulated through the granulation discharge hole, the sludge grains are driven by the revolving barrel type furnace body to continually roll and dry so as to move to a hearth position, and turn into flammable grains at the heart position, and the combustion of the sludgy is realized. The wet sewage sludge combustion furnace provided by the invention has the advantages that the structure is compact, the sludge concentration drying efficiency is high, an energy source is not wasted, the sludge incineration is thorough, the technical bottle neck of sludge incineration is fully solved, and the wet sewage sludge combustion furnace has great economic and social benefits and popularization and application values.

Owner:刘振亮

Small gas turbine engine with multiple burn zones

InactiveUS7568343B2Most efficientImprove stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCruise missile

A small gas turbine engine for use in an UAV such as a cruise missile, the gas turbine having a combustor forming a primary burn zone and a secondary burn zone, and in which fuel is injected into both the primary and the secondary burn zones by either a rotary cup injector or a plurality of fuel injector nozzles. The secondary burn zone with separate fuel injection allows for the diameter of the engine to be reduced in size but still allow for adequate power and efficiency to be reached for powering the vehicle. Air flow from the compressor is used to cool the combustor walls before being injected into the combustor, and to pass through and cool the guide nozzles and a main bearing located near the hot section of the combustor prior to being introduced into the combustor.

Owner:FLORIDA TURBINE TECH

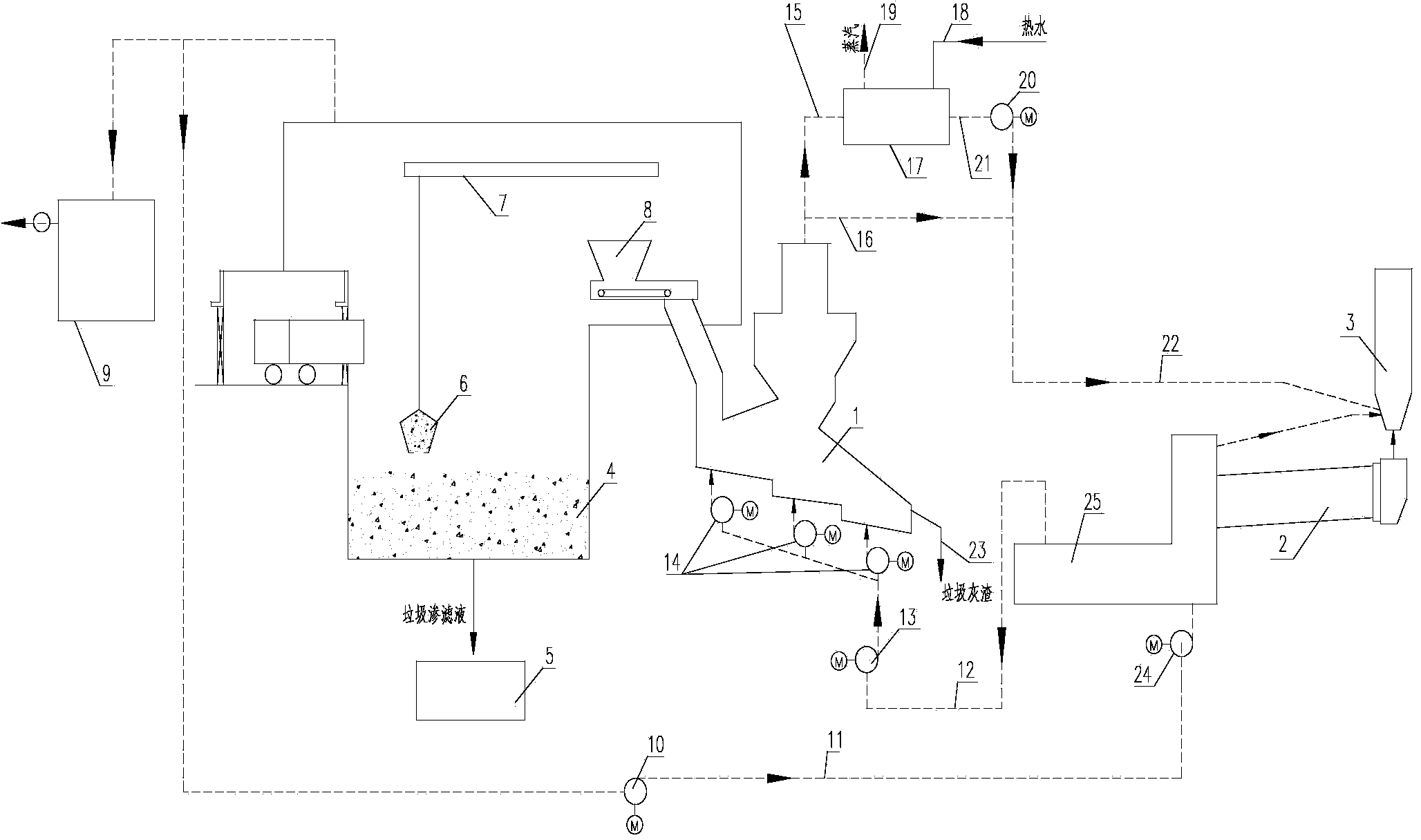

System of cement kiln for co-treatment of household garbage

ActiveCN104058614ALow calorific valueIncrease moistureSolid waste disposalCement productionVolume reductionFlue gas

The invention relates to a system of a cement kiln for co-treatment of household garbage. The system comprises a garbage incineration and flue gas treatment system, a combustion air system, a peculiar smell gas treatment system, a steam boiler system, a garbage leachate treatment system, and a garbage ash residue and flying ash treatment system. According to the system of the cement kiln for co-treatment of the household garbage, a garbage incinerator and a cement clinker production line are better combined together, the characteristics of high temperature, high stability, high-concentration alkaline materials, long standing time and the like of a cement firing system are utilized, dioxin-like harmful ingredients, garbage ash residues in garbage incineration flue gas, harmful elements and garbage leachate in flying ash and peculiar smell inside a garbage storage pit are perfectly and completely treated in a harmless mode, the environmental impact can completely meet the requirement of national standards, and the aims of harmlessness, volume reduction, recycling and environmental protection of household garbage treatment can be truly achieved. The system for the treatment of the household garbage is simple in flow path, easy and convenient to operate, stable in running, small in investment and ideal.

Owner:NANJING KISEN INT ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com