System of cement kiln for co-treatment of household garbage

A technology for co-processing and domestic waste, which is applied in cement production, solid waste removal, joint combustion mitigation, etc. It can solve the problems of polluted environment, high harmful components, low temperature, etc., and achieve the effect of high moisture and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

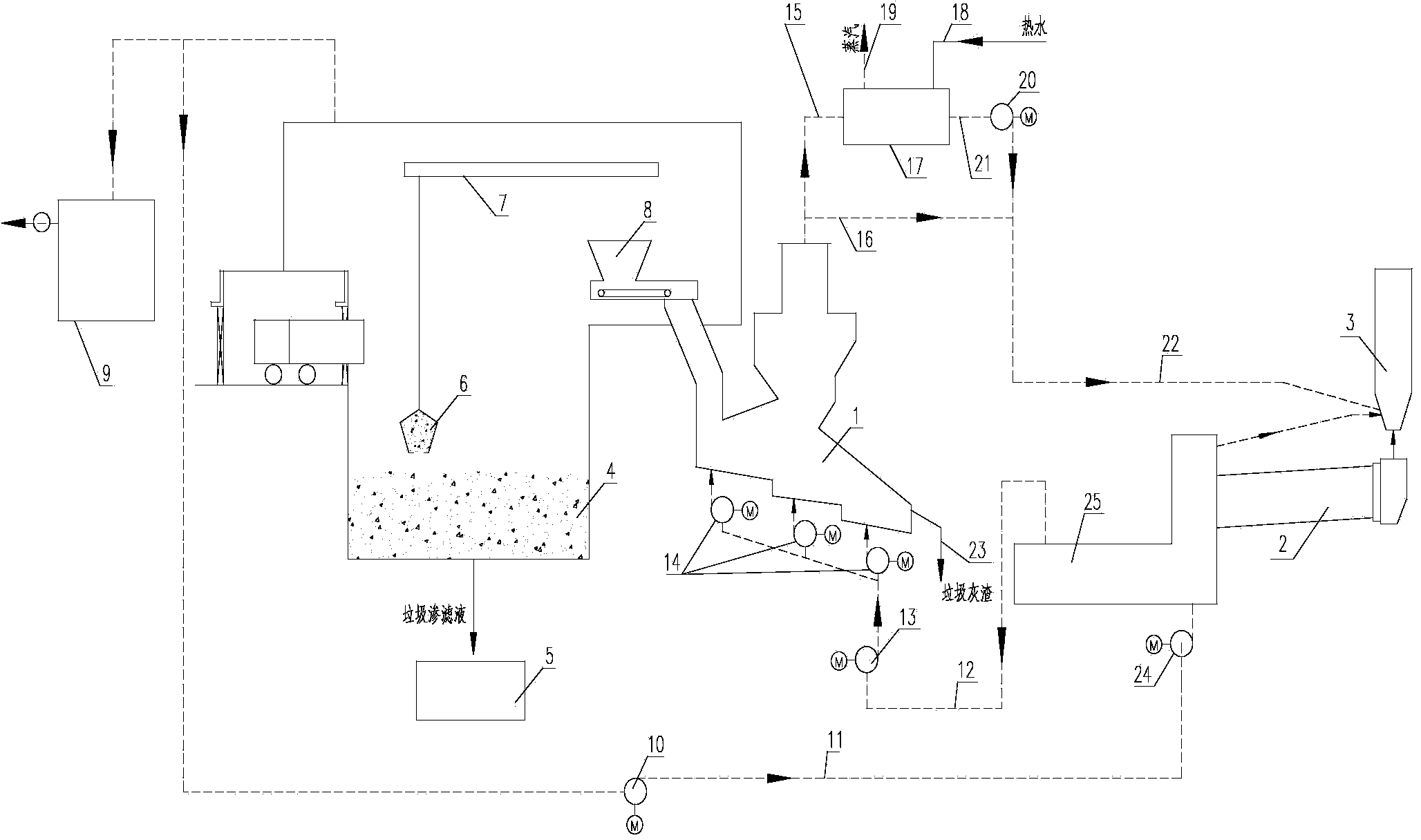

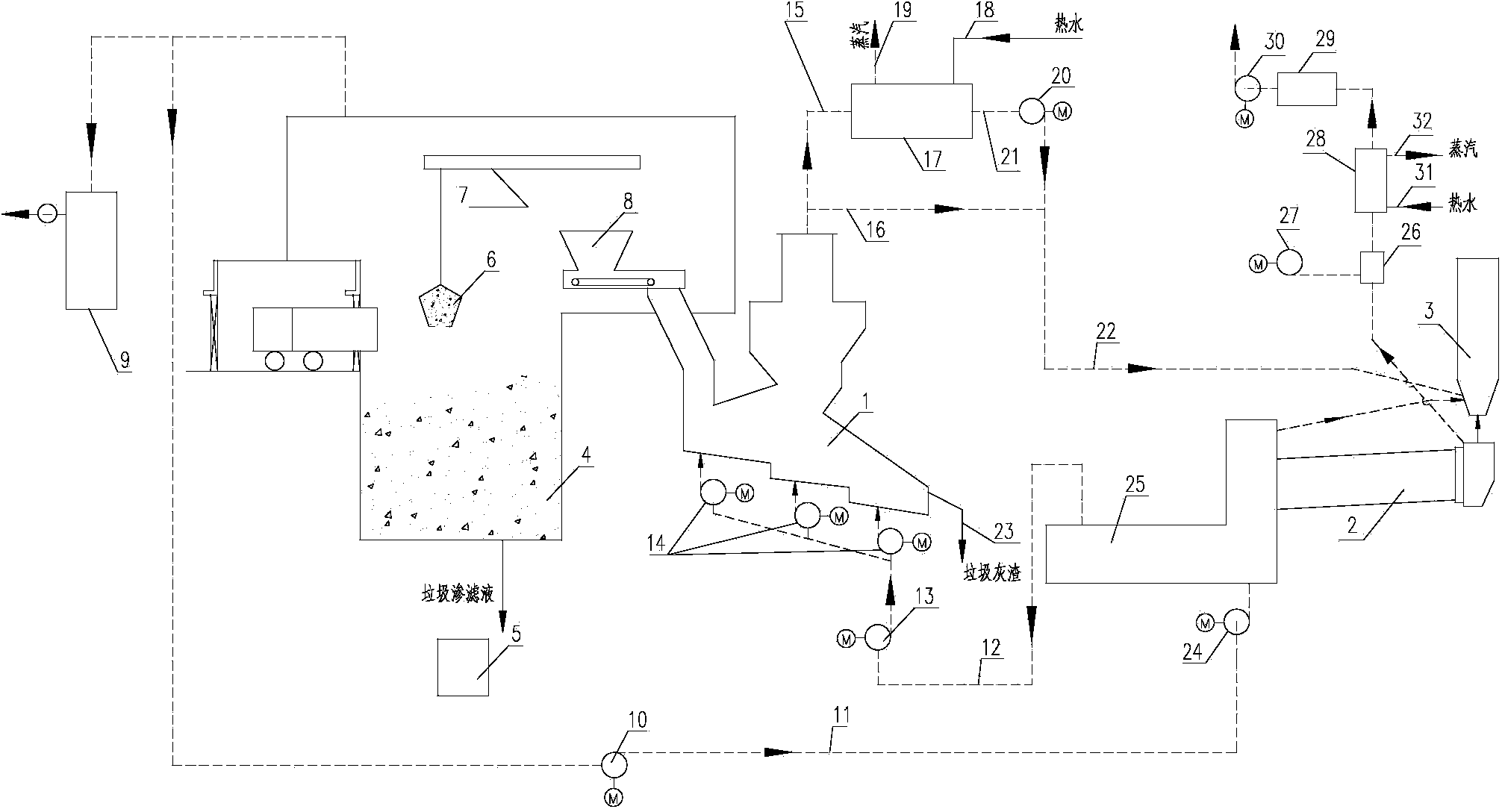

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

[0045] Such as figure 1 , 2 As shown, the present invention provides a system for the co-processing of domestic waste in cement kilns, including a waste incinerator 1, a cement rotary kiln 2, a decomposition furnace 3, a waste storage pit 4, a landfill leachate treatment system 5, a grab bucket 6, and a driving 7. Feeding system 8, deodorizing system 9, odor fan 10, induced draft fan 13, primary fan 14, steam boiler 17, high temperature fan 20, cooling fan 24, cooling machine 25;

[0046] figure 1 The middle rotary kiln 2, the calciner 3, the cooling machine 25, the cooling fan 24 and their connections all belong to the cement clinker production line system, and all others belong to the waste incineration system. The waste incineration system is connected to the cement clinker burning system through the mixed flue gas 22 pipeline and the high-temperature hot air 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com