Patents

Literature

521 results about "Cement rotary kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

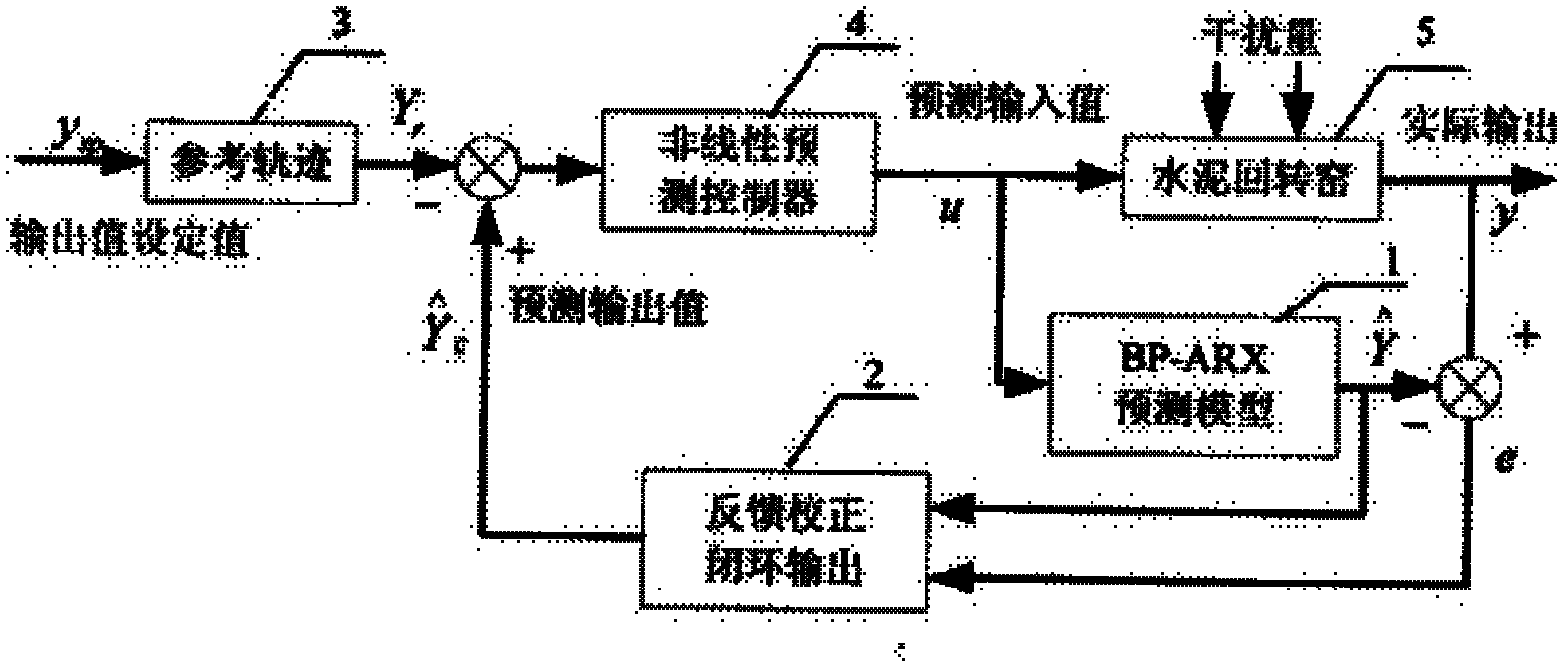

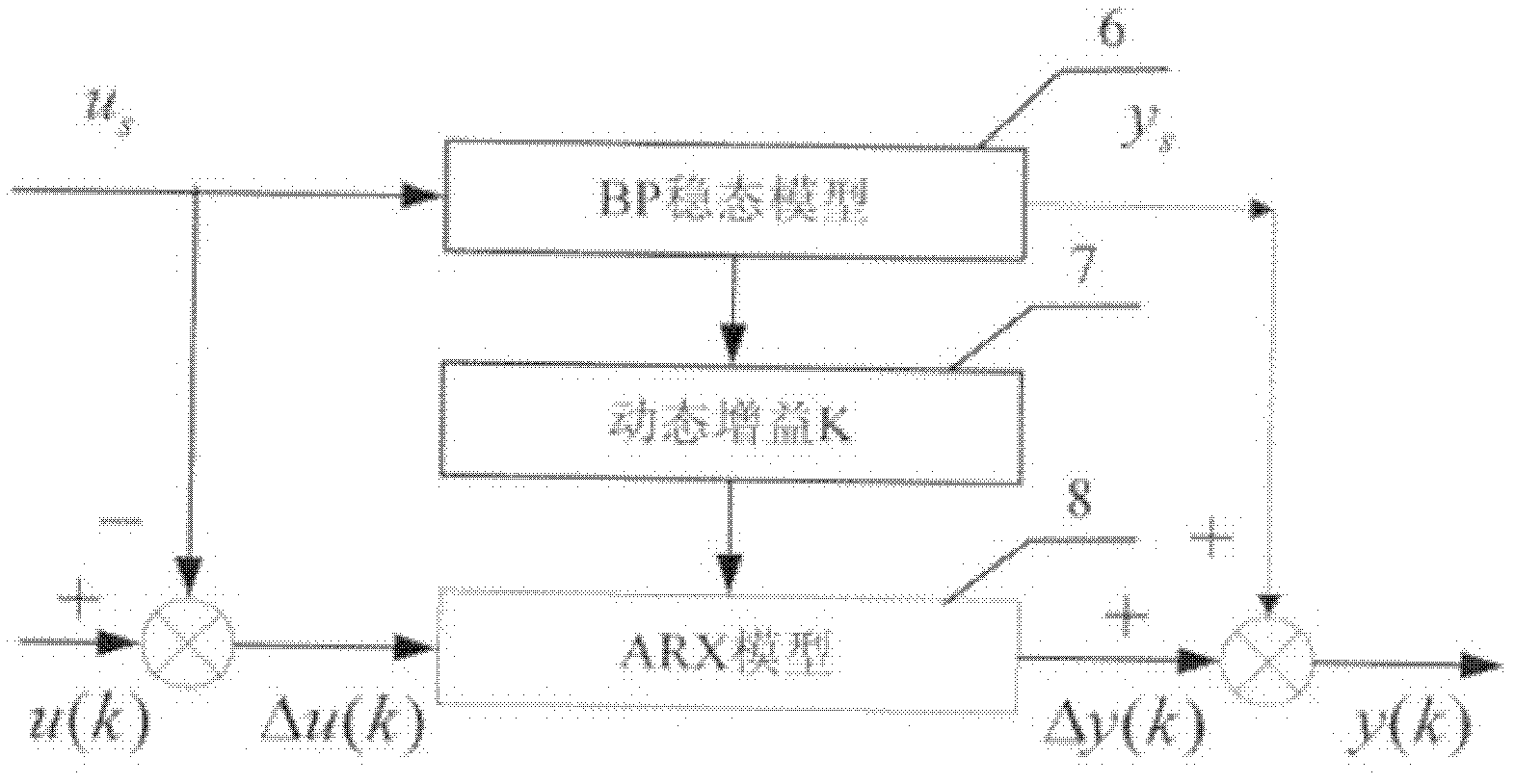

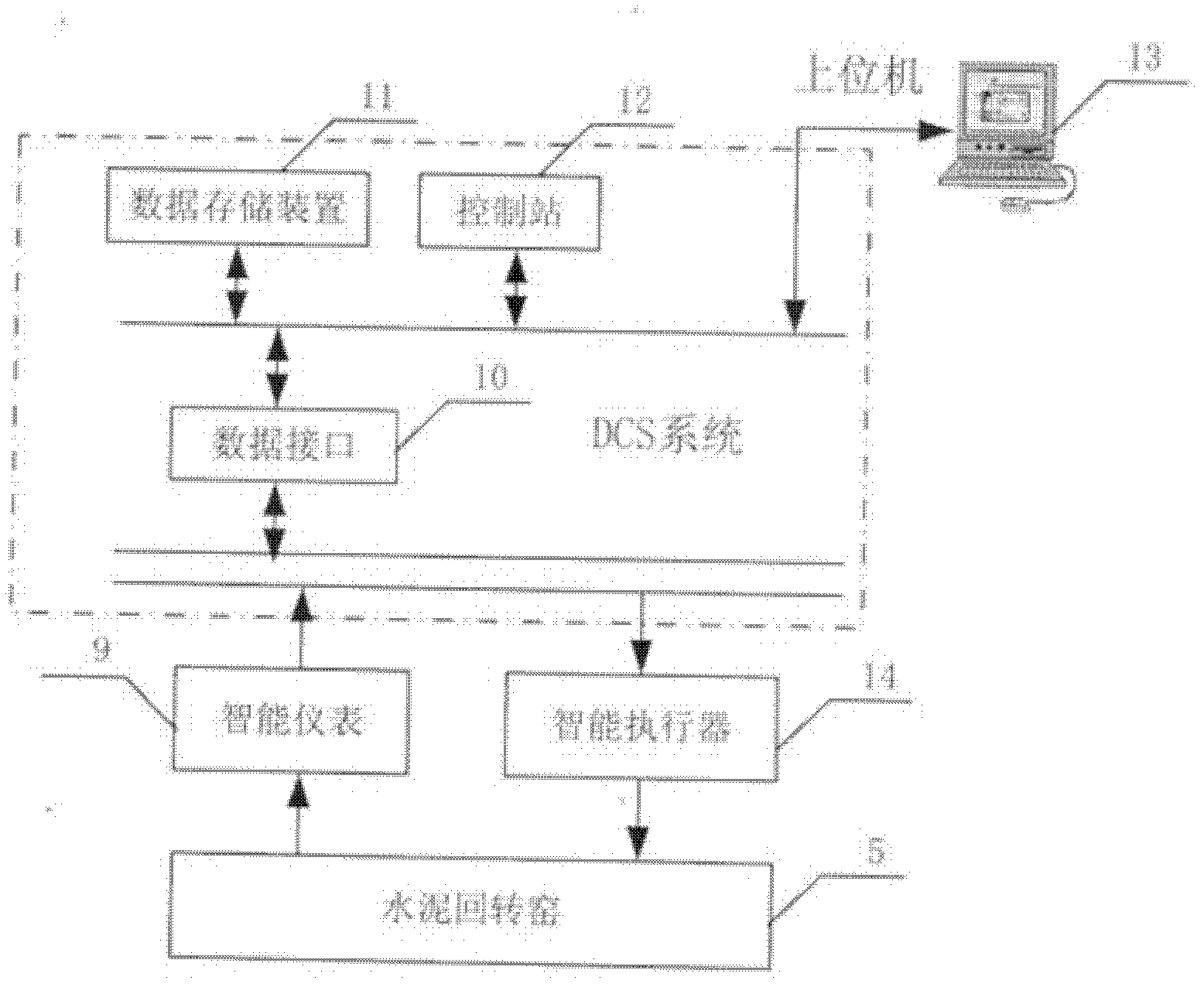

Calcination predictive control system and method for rotary cement kiln

InactiveCN102629104AStable temperatureTaking into account energy consumption per unit of productionRotary drum furnacesAdaptive controlData informationClosed loop

The invention relates to a calcination predictive control method and a calcination predictive control system for a rotary cement kiln. The method comprises the following steps of: (1) acquiring field data of the calcining process of the rotary cement kiln and classifying the field data; (2) respectively carrying out model identification on the data and organically combining the data to establish a prediction model; (3) carrying out prediction on historical and future data information on the calcining process by the prediction model to obtain an output of the calcining process and outputting error feedback correction by utilizing the model to obtain a closed-loop prediction output of the calcining process; and (4) according to the closed-loop prediction output and a reference output trace,constructing a non-linear target function and carrying out solution of a optimal solution on the target function by using a sequential quadratic programming method to obtain a predicted value of the calcination controlling quantity. The system comprises an intelligent detection instrument and an actuator which are connected with the rotary cement kiln, a data storage device and an upper computer,wherein a calcination predictive control algorithm is embedded in the upper computer. The calcination predictive control method and the calcination predictive control system for the rotary cement kiln can be suitable for the dynamism of the calcining process of the rotary cement kiln and the coupling, nonlinearity and obsoleteness between multiple variables, and obtain good control effect.

Owner:YANSHAN UNIV

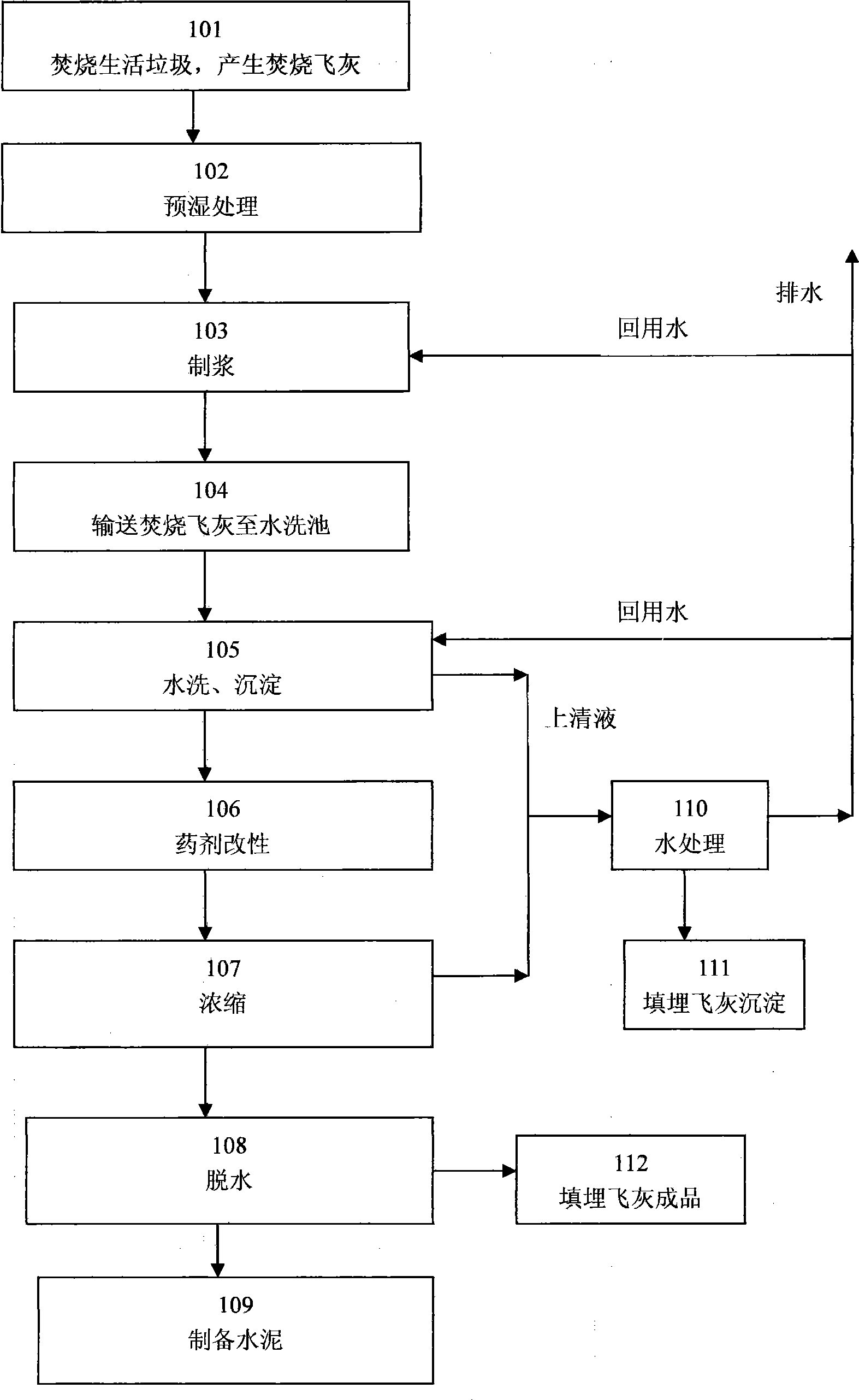

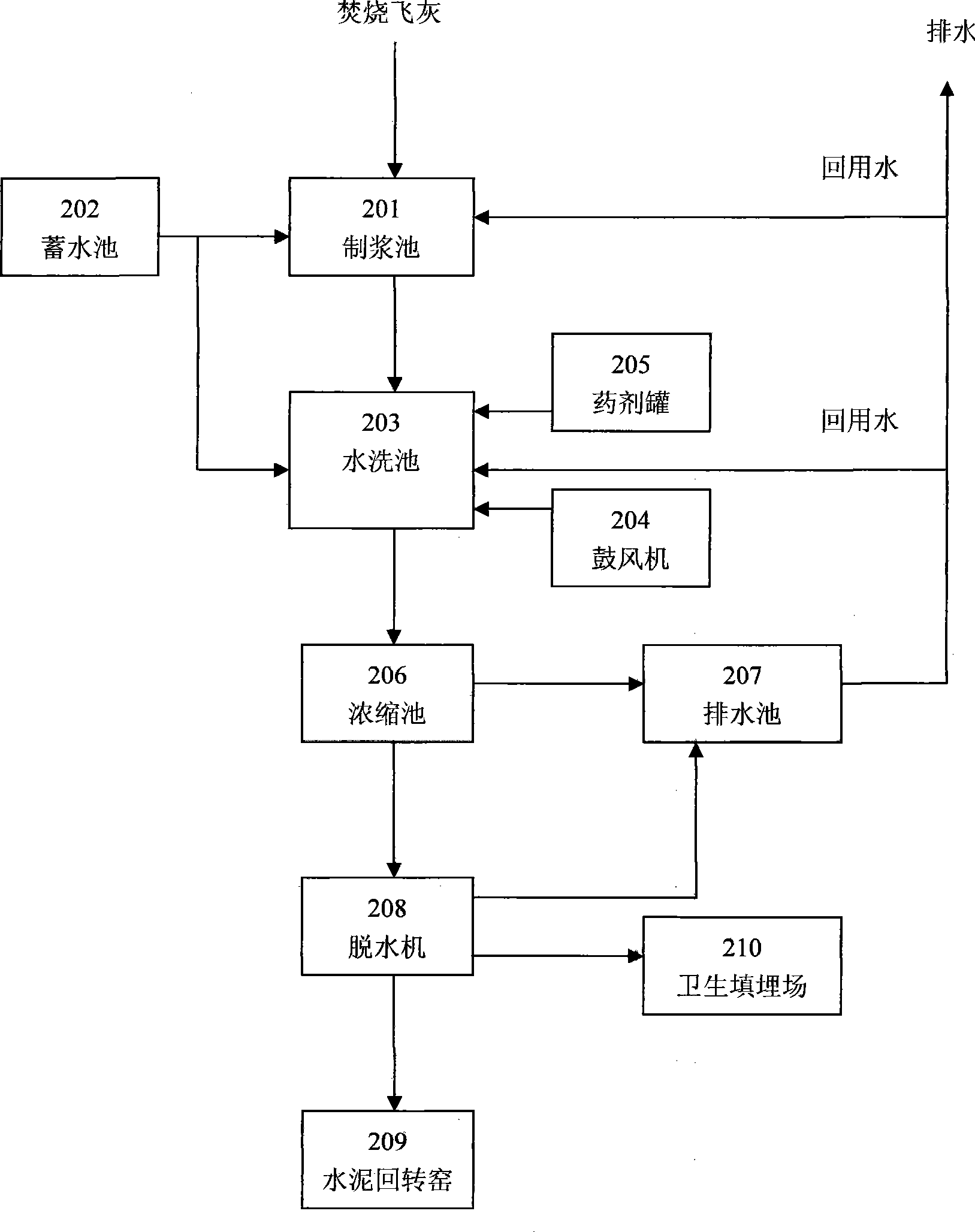

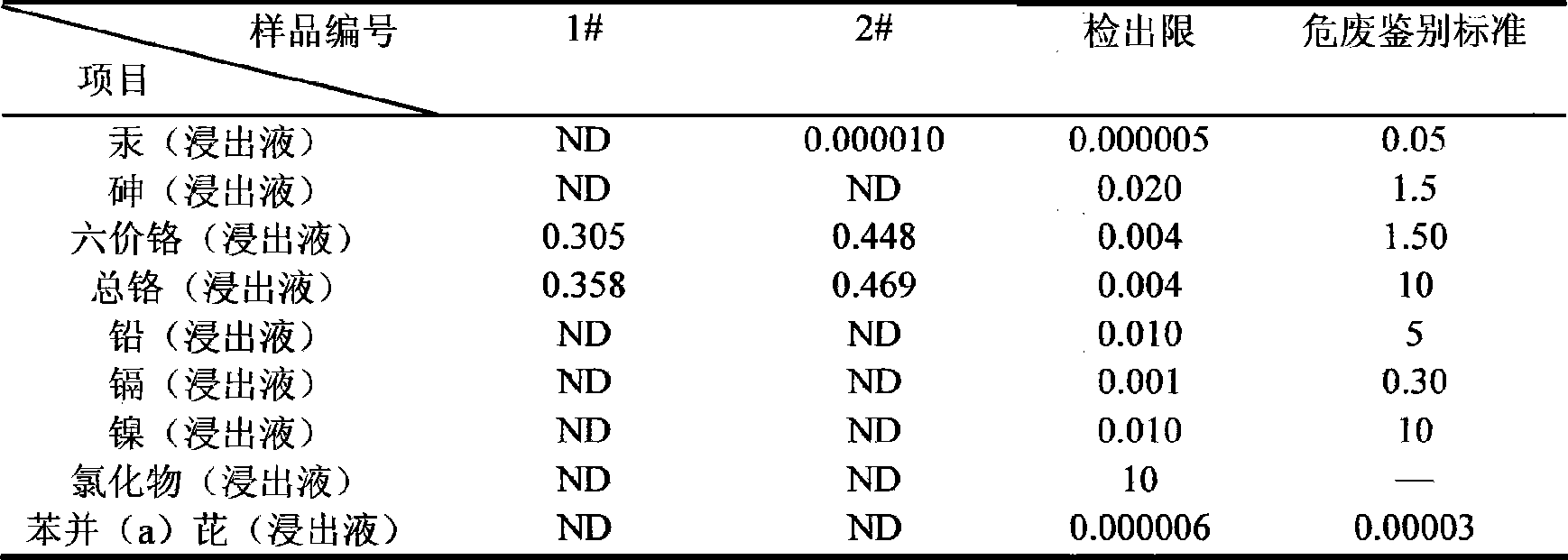

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

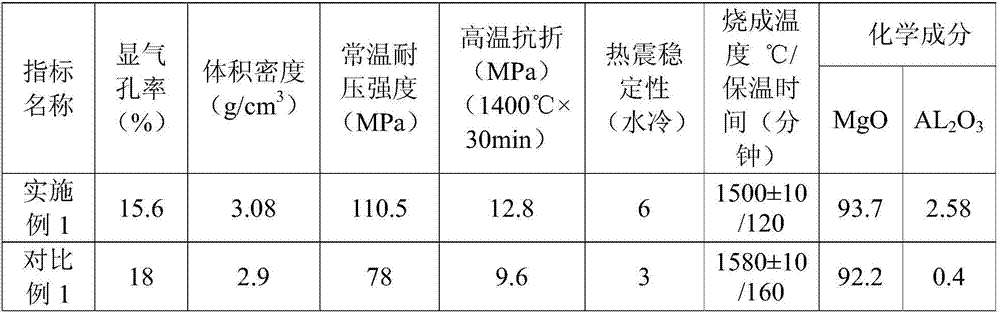

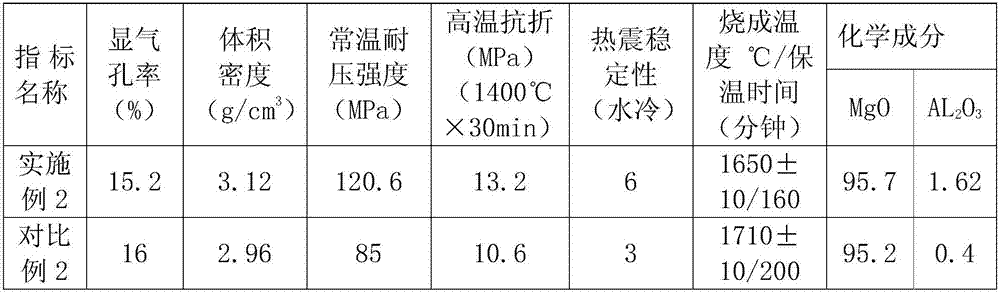

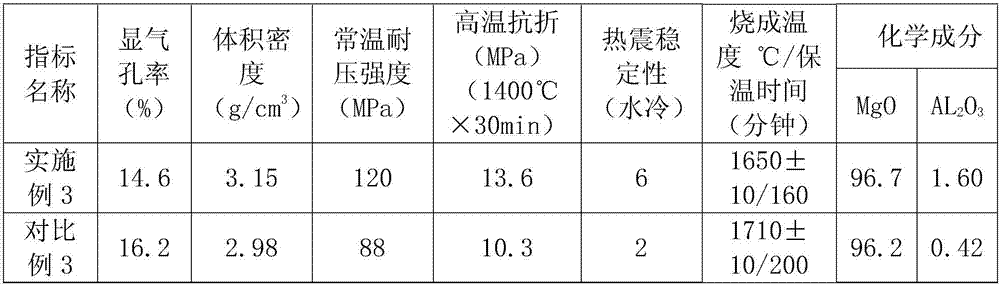

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

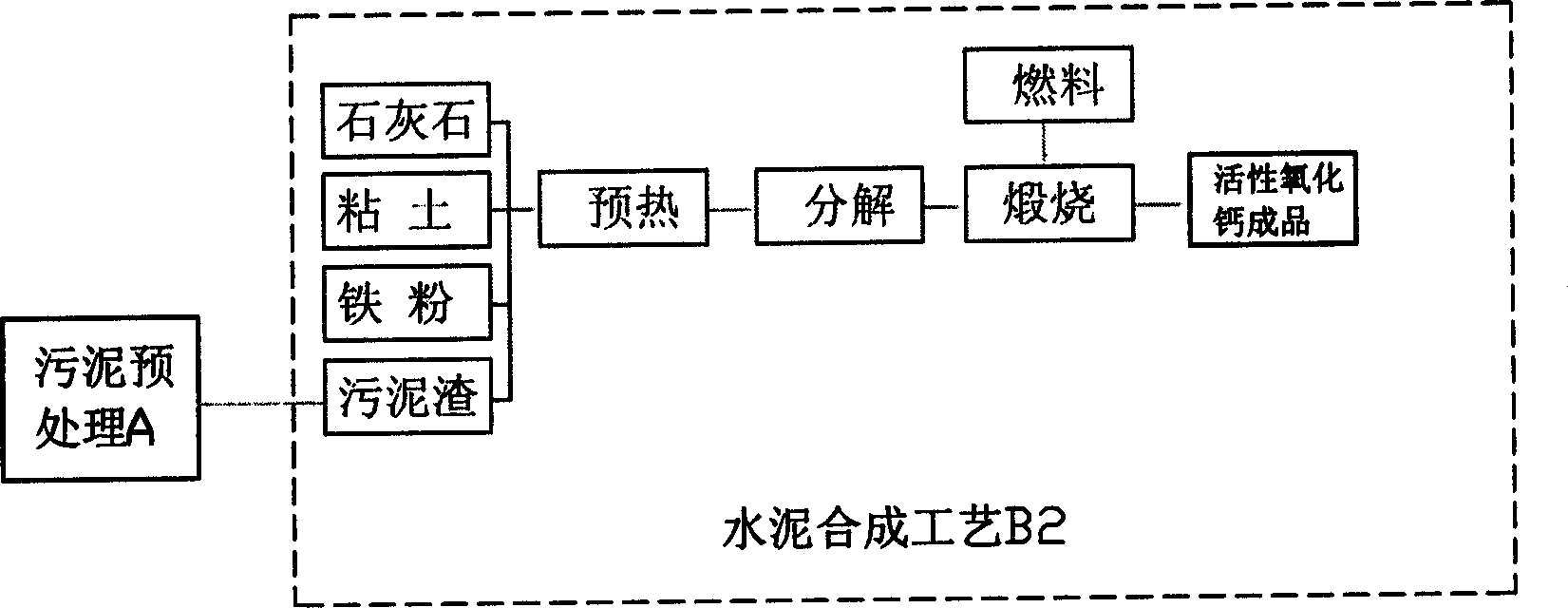

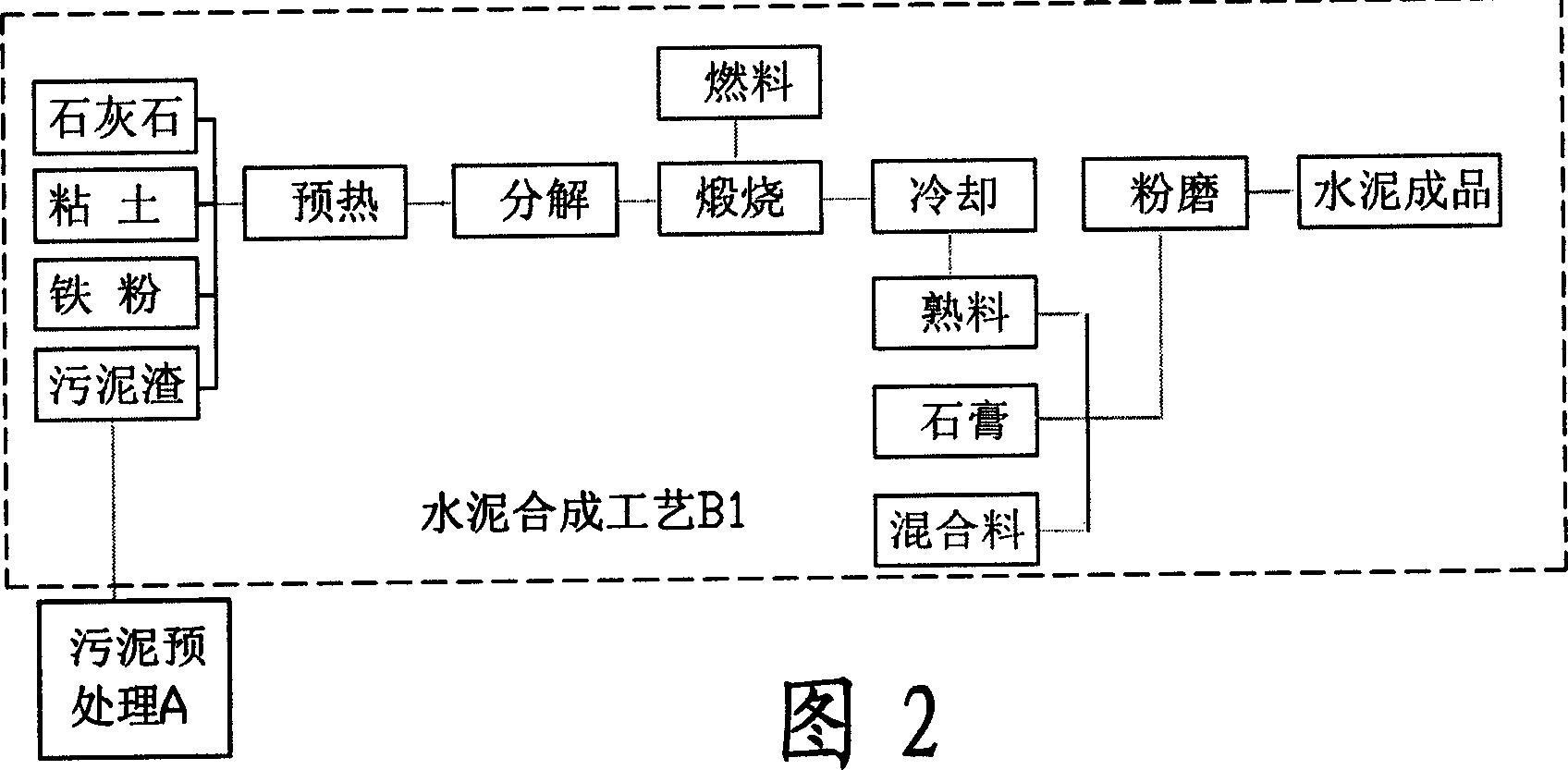

Method and device of treating urban mud by using cement rotary kiln

InactiveCN1861532AAvoid swappingAvoid lostAluminium compoundsSludge treatment by oxidationConvex structureCalcium hydroxide

A method for treating city sludge by the rotary kiln of preparing cement features that said sludge containing calcium hydroxide is calcined in said rotary kiln to become calcium oxide. Its apparatus is composed of a sludge pre-treating unit and new material synthesizing unit. The spiral blades of the screw stirring-delivering mechanism have the concave-convex structure on their edge, resulting in high stirring effect and strength.

Owner:北控东方(北京)环保技术有限公司

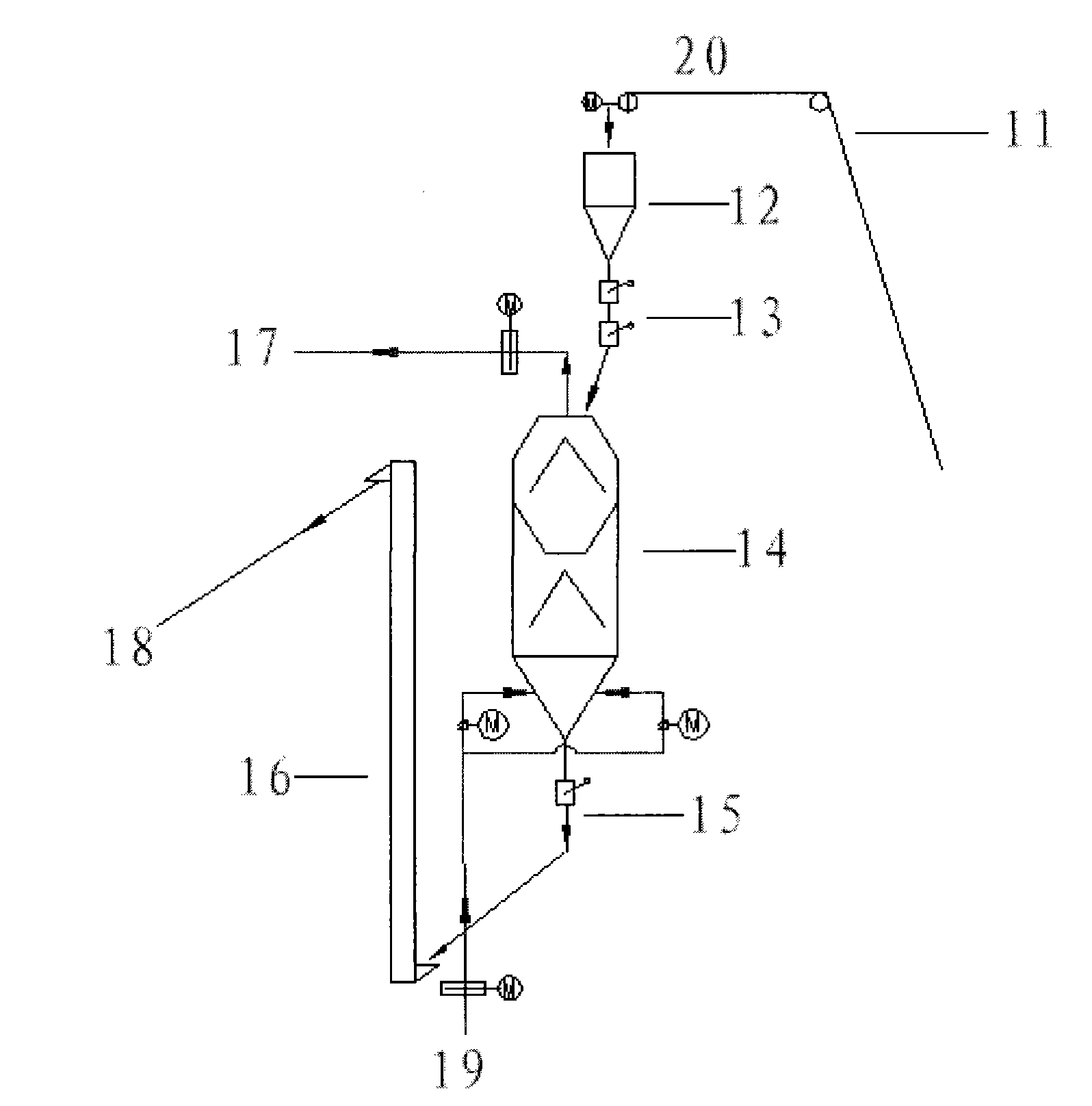

Cement rotary kiln and incinerator combined treatment system for urban domestic refuse

InactiveCN1844747AImprove heat utilizationReduce processing costsSolid waste managementRotary drum furnacesThermal energySlag

The invention discloses a system for using cement rotary kiln and incinerator to process life waste of city. It comprises a waste incinerator, a cement generator, a controller and several channels. It is characterized in that: said waste incinerator comprises rotary waste incinerator (7), waste feeder (6), waste tank (4), bag deduster (3) and wind discharger (2); said cement generator comprises a cement rotary kiln (15) whose head is connected to a material cooling device (21) and end is connected to a preheat device (12); said waste incinerator, cement generator and several channels form a closed system. The invention can be used to treat city life waste, while its heat and slag can be utilized, with lower pollution discharge and lower cost, without secondary treatment.

Owner:HEFEI CEMENT RES DESIGN INST

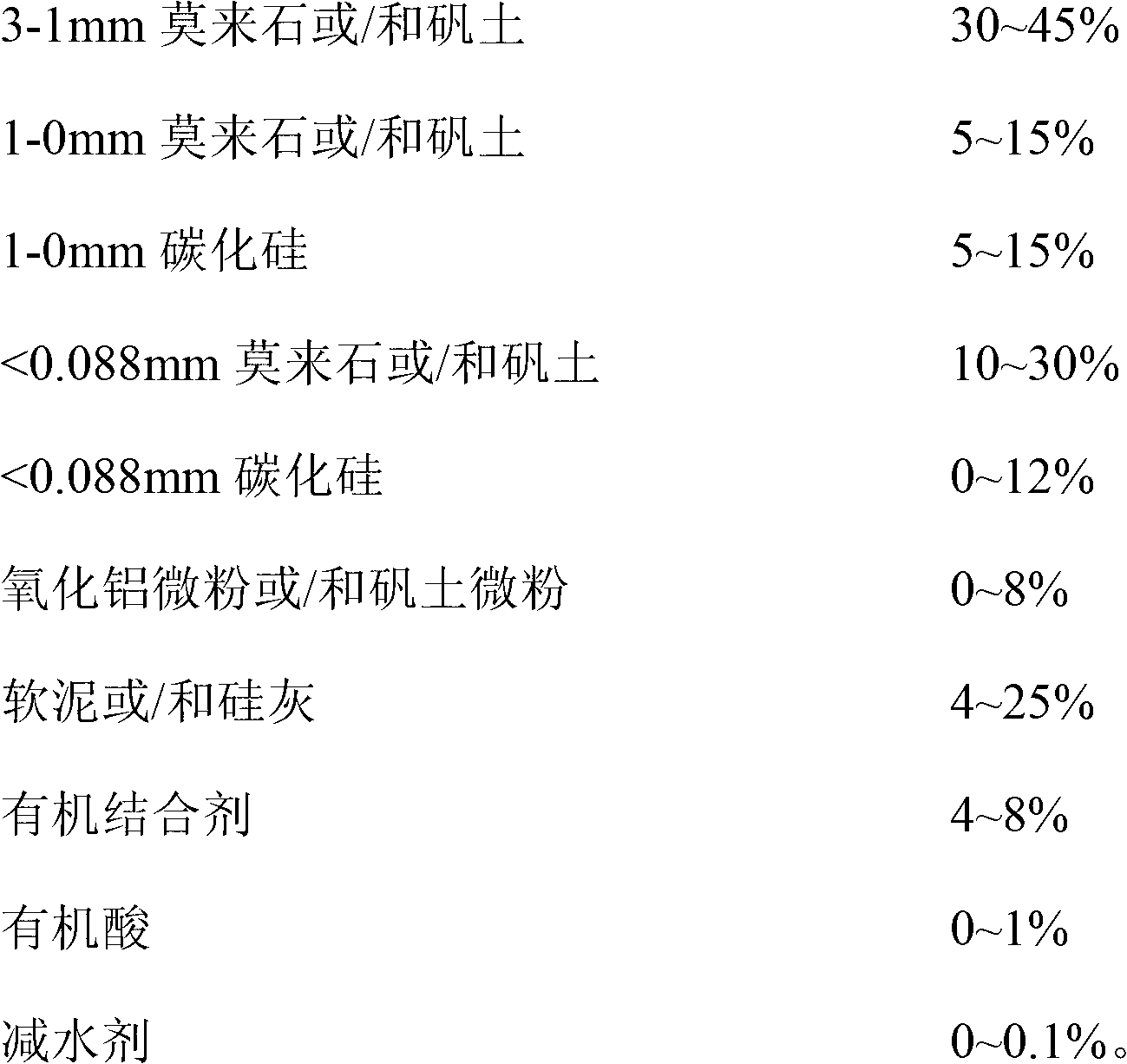

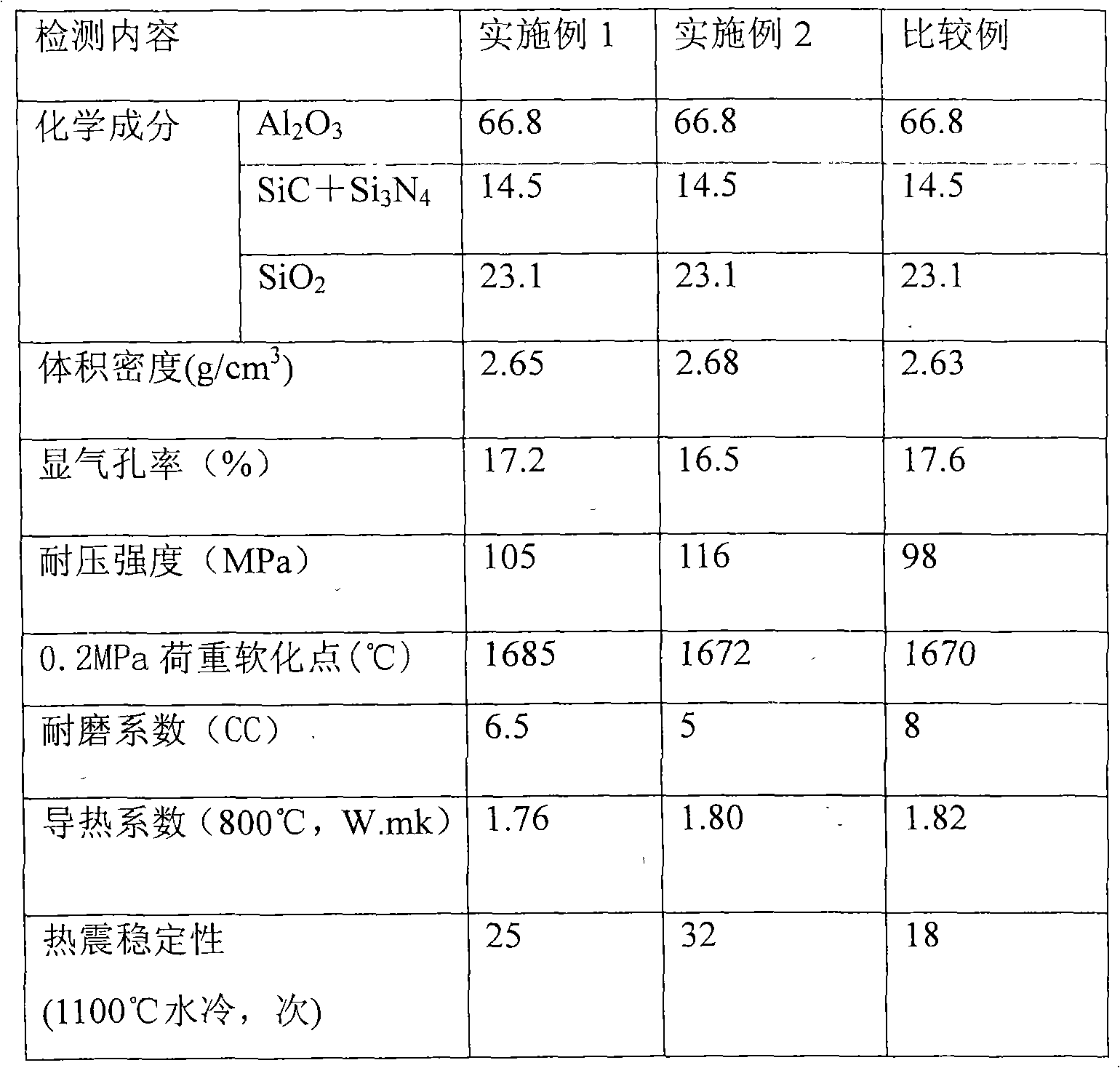

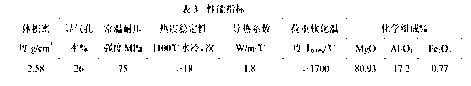

Sintered alumina-silica refractory material and preparation method thereof

The invention relates to a sintered alumina-silica refractory material. The alumina-silica refractory material comprises aggregate, powder and additive; the aggregate comprises mullite or / and alumina and silicon carbide; the powder comprises mud or / and siliceous dust; and the additive comprises an organic bonding agent. The invention also provides a preparation method for the refractory material. The content of alumina in the refractory material is 30 to 60 percent; and the refractory material is low in price, high in high temperature resistance, erosion resistance, thermal shock resistance and wear resistance, and low in heat-conducting property and used for the cold ends of a decomposition band and a transition band of a rotary cement kiln, and can replace the conventional anti-stripping high-alumina brick and the conventional anti-stripping silicon mullite brick; and the requirements of the cement kiln on low heat conduction and alkali eclipse resistance of the refractory material can be met, the radiation loss can be reduced, and the service life of the kiln is prolonged, and the economic benefit of the kiln is improved.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Technological process for preprocessing refuse burning fly-ash to be cement raw materials

InactiveCN101333084AReduce chlorine contentRealize resource utilizationSolid waste managementResource utilizationMaterials science

The invention provides a technique which makes the solid waste incineration fly ash into cement raw materials, comprising the following steps: washing, stirring, adding heavy metal stabilizer, separating liquid from solid waste incineration fly ash, mixing the solid waste incineration fly ash into the cement raw meal and sending the raw meal into a cement rotary kiln to calcine the raw meal so as to prepare the cement clinker. The invention also provides a method for treating the wastewater generated in the washing process. The solid waste incineration fly ash treated through the method disclosed in the invention can partially substitute for cement raw materials to prepare cement, while all the indicators of the cement can meet the relevant standards so as to effectively realize solid waste incineration fly ash resource utilization.

Owner:SHANGHAI UNIV

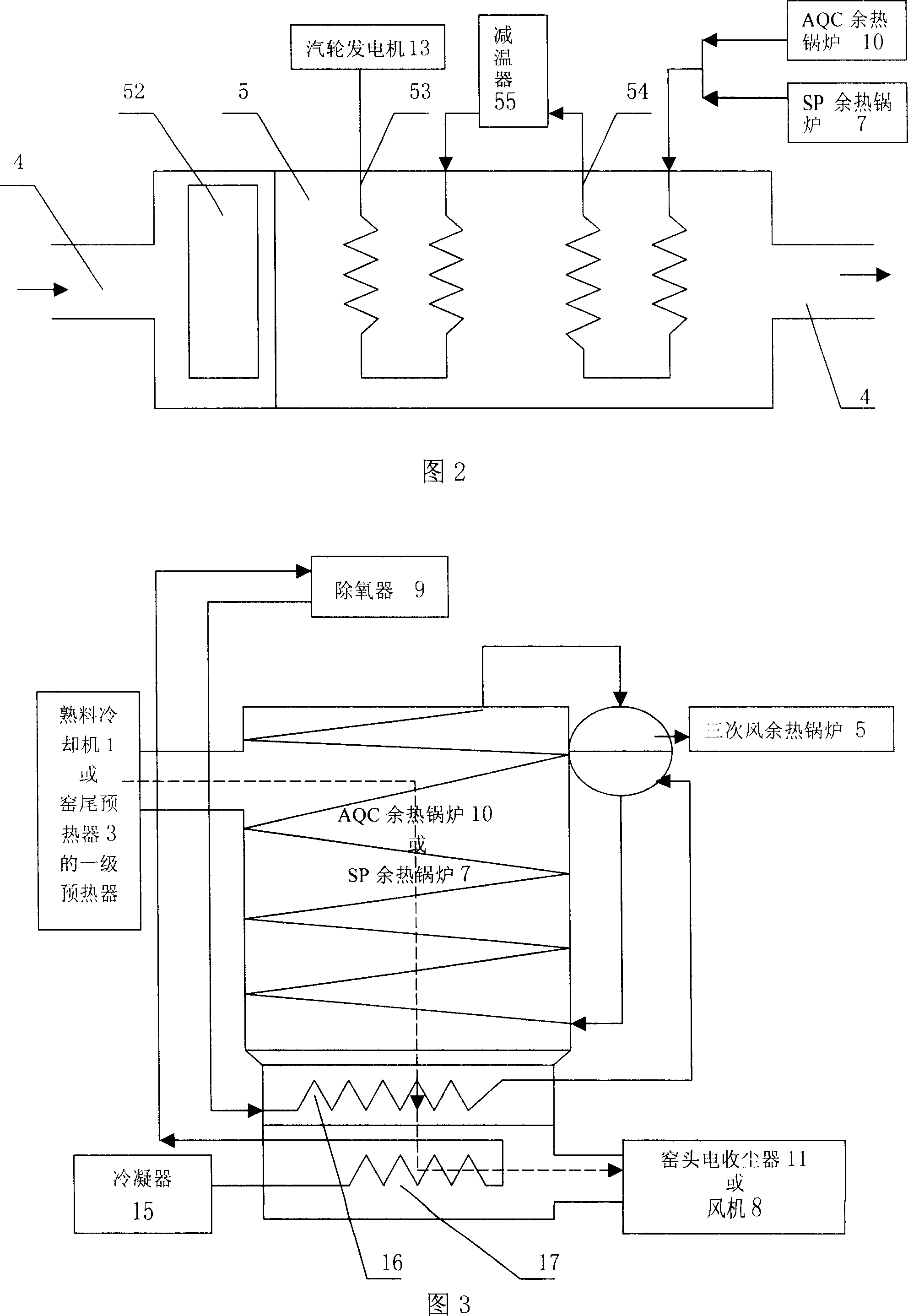

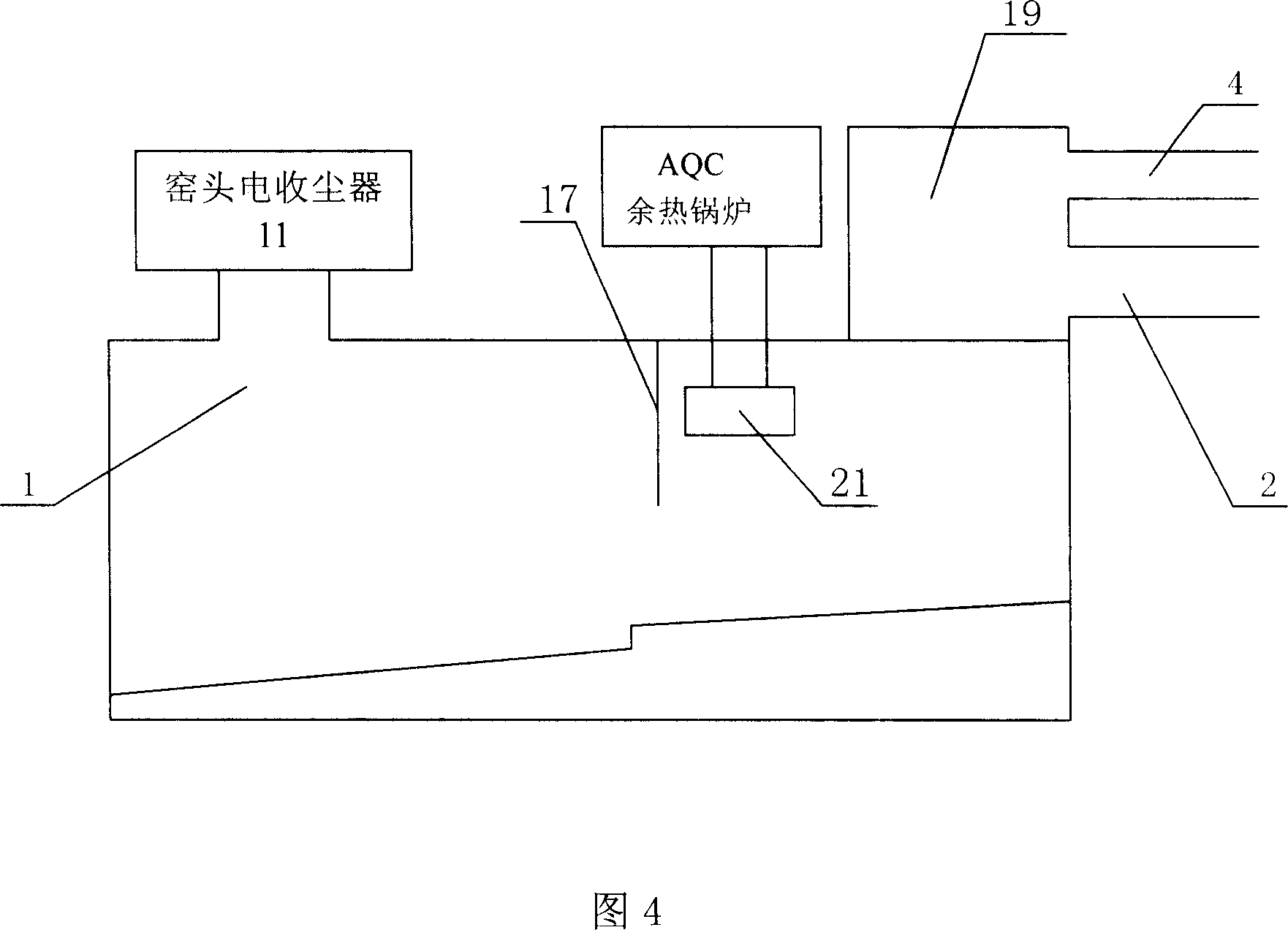

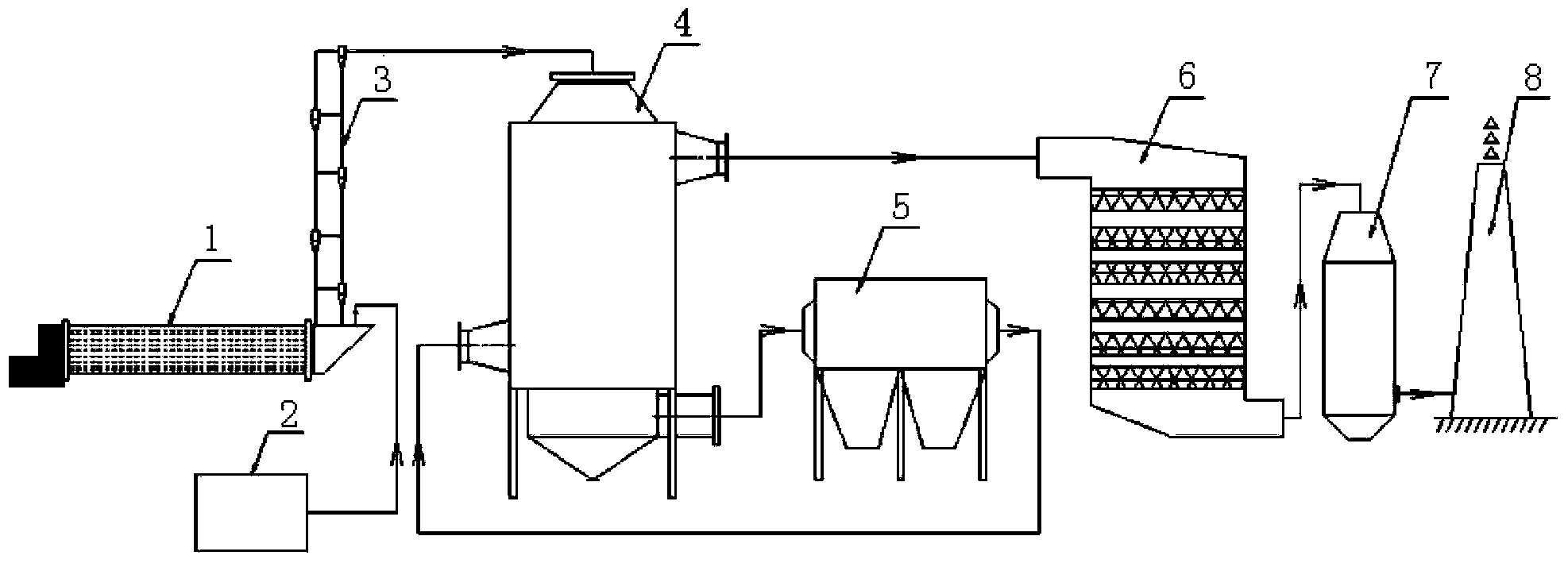

Residual heat generating system used for new type nonaqueous cement production line

ActiveCN101013002AMeet production needsIncrease profitIncreasing energy efficiencyClinker productionDeaeratorSuperheated steam

The invention discloses an abundant generating system used in dry cement product line, comprising a grog cooler, a AQC abundant heat boiler, a cement rotary furnace, a head frame of cement rotary furnace, a third-stage wind tube, a cement preheating device, a cement predissociation furnace, a SP abundant heat boiler, a fan, a deaerator, a condenser, and a generator of turbine. The third-stage wind tube is between the head frame and the predissociation furnace. The head frame is communicated with the grog cooler. The invention is characterized in that third-stage wind tube is arranged with a third-stage wind abundant-heat boiler with bypass wind channels; the medium inlet of the third-stage wind abundant-heat boiler via the tube is connected with the AQC abundant-heat boiler and the SP abundant-heat boiler, while the medium outlet is connected with the turbine generator. The invention can completely absorb the abundant heat of product line, to supply overheated steam to the generator, while the electricity generation is higher than 40kwh.

Owner:BEIJING LIULIHE CEMENT +1

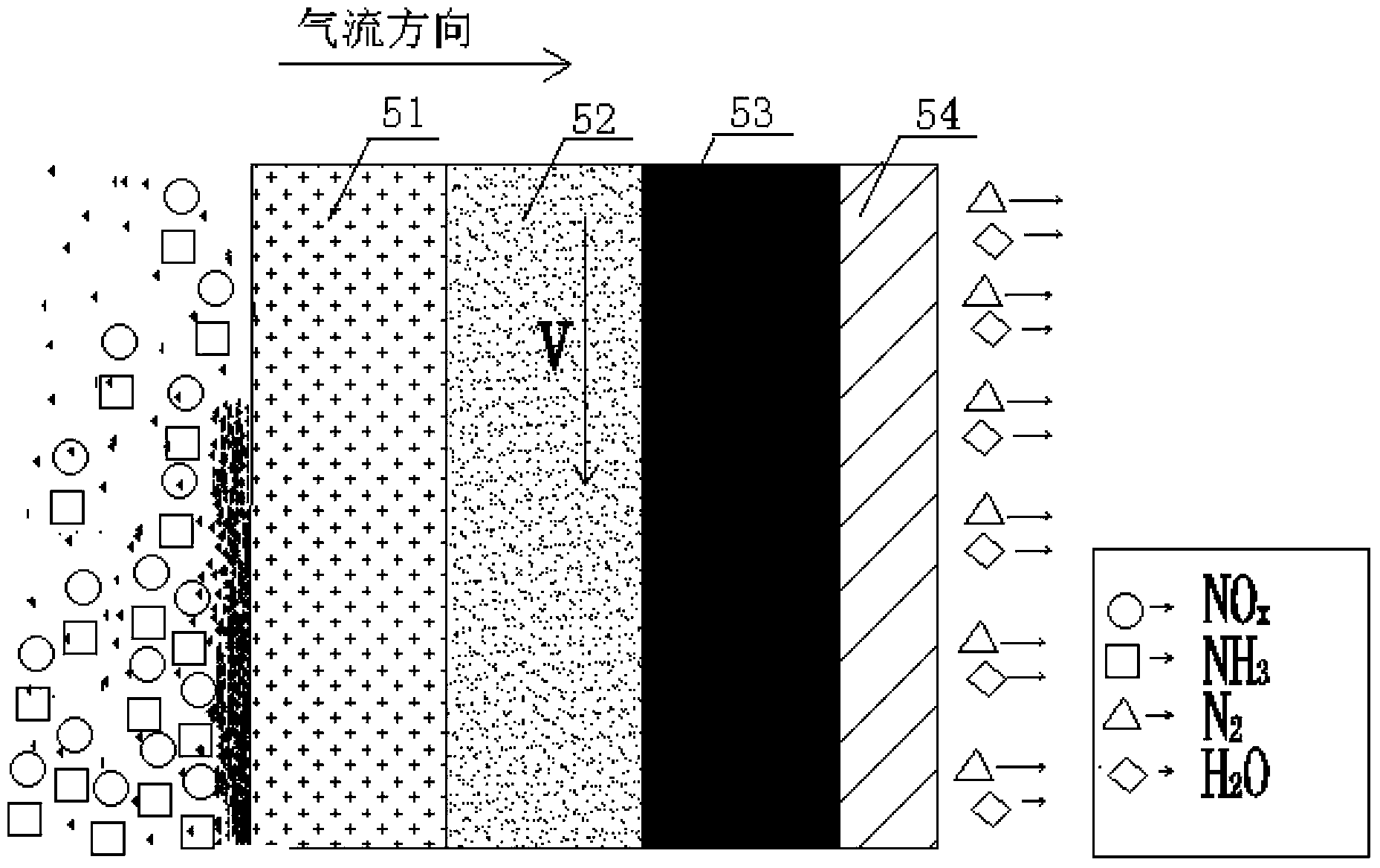

SCR (Selective Catalytic Reduction) denitration device for NOx control of rotary cement kiln

InactiveCN103406006AImprove denitrification efficiencyReduce wearCombination devicesLighting and heating apparatusFlue gasProcess engineering

The invention discloses an SCR (Selective Catalytic Reduction) denitration device for NOx control of a rotary cement kiln, wherein the rotary cement kiln is connected with a heat exchanger; a reducing agent injection system is arranged at the kiln tail part of the rotary cement kiln; the flue gas outlet of the rotary cement kiln is connected with the high-temperature flue gas inlet of the heat exchanger; the low-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of a bag type dust collector; the outlet of the bag type dust collector is connected to the low-temperature flue gas inlet of the heat exchanger; the high-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of an SCR reactor; the flue gas inlet of a desulfurizing tower is connected with the flue gas outlet of the SCR reactor. The three denitration technologies of SNCR (Selective Non-Catalytic Reduction), integrated dust collection and denitration and SCR are combined so that the flue gas of the rotary cement kiln is denitrated three times; specifically, firstly, NOx in the high-temperature flue gas has a selective non-catalytic reaction with a reducing agent at the tail of the kiln; secondly, the bag type dust collector provided with a denitration-functional catalytic filter bag is used for dust removal and secondary denitration; finally, the third time of denitration is performed in the SCR reactor; as a result, the denitration efficiency is greatly improved.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Novel abrasion resistant silicon-mullite-nitrogen brick for transition zones of rotary cement kiln

InactiveCN102115335AImprove work efficiencyReduce surface temperatureRotary drum furnacesBrickMullite

The invention relates to a refractory material forming product applied to transition zones of a rotary cement kiln, and the refractory material forming product provided by the invention is formed by molding through machine pressing and high-temperature calcination. In the invention, silicon nitride or ferro-silicon nitride is introduced into the traditional silicon-mullite brick or silicon-mullite red brick. The temperature at which silicon nitride starts oxidizing in an oxidizing atmosphere is 1300 DEG C, and the temperature at which silicon carbide starts oxidizing in the oxidizing atmosphere is 800 DEG C, thus the oxidation resistance of the silicon-mullite brick can be obviously improved. In addition, since silicon nitride has less coefficient of linear expansion, lower coefficient of heat conductivity and stronger alkali corrosion resistance as compared with silicon carbide, the manufactured novel silicon-mullite-nitrogen brick has lower coefficient of heat conductivity, less volume change and more excellent alkali corrosion resistance. The silicon-mullite brick manufactured by the method is used for the transition zones of the rotary cement kiln, the temperature of a kiln body can be significantly reduced, and the silicon-mullite brick has less possibility of being oxidized, therefore, the service life of the abrasion resistant material of the transition zones of the cement kiln is prolonged and is up to 1.5-2 years. The novel abrasion resistant silicon-mullite-nitrogen brick is especially suitable for the upper and lower transition zones of the rotary kiln with frequent changes of atmosphere in the kiln.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

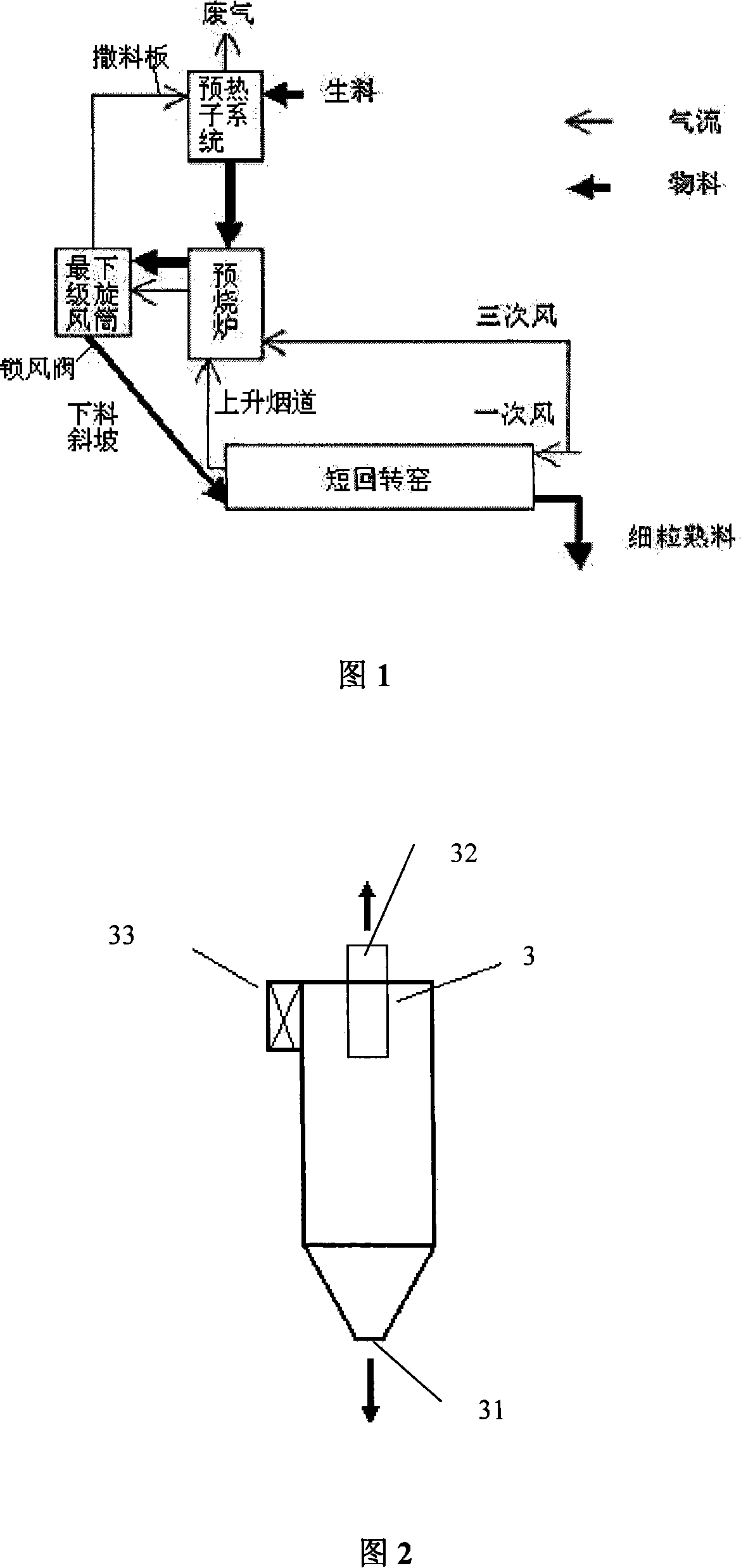

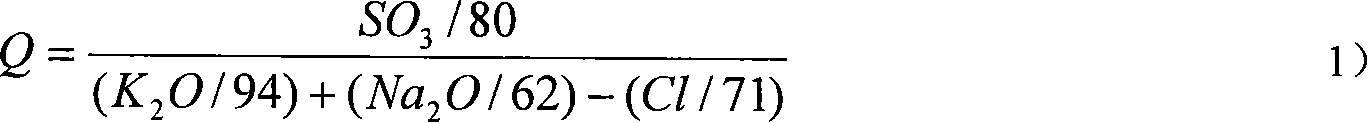

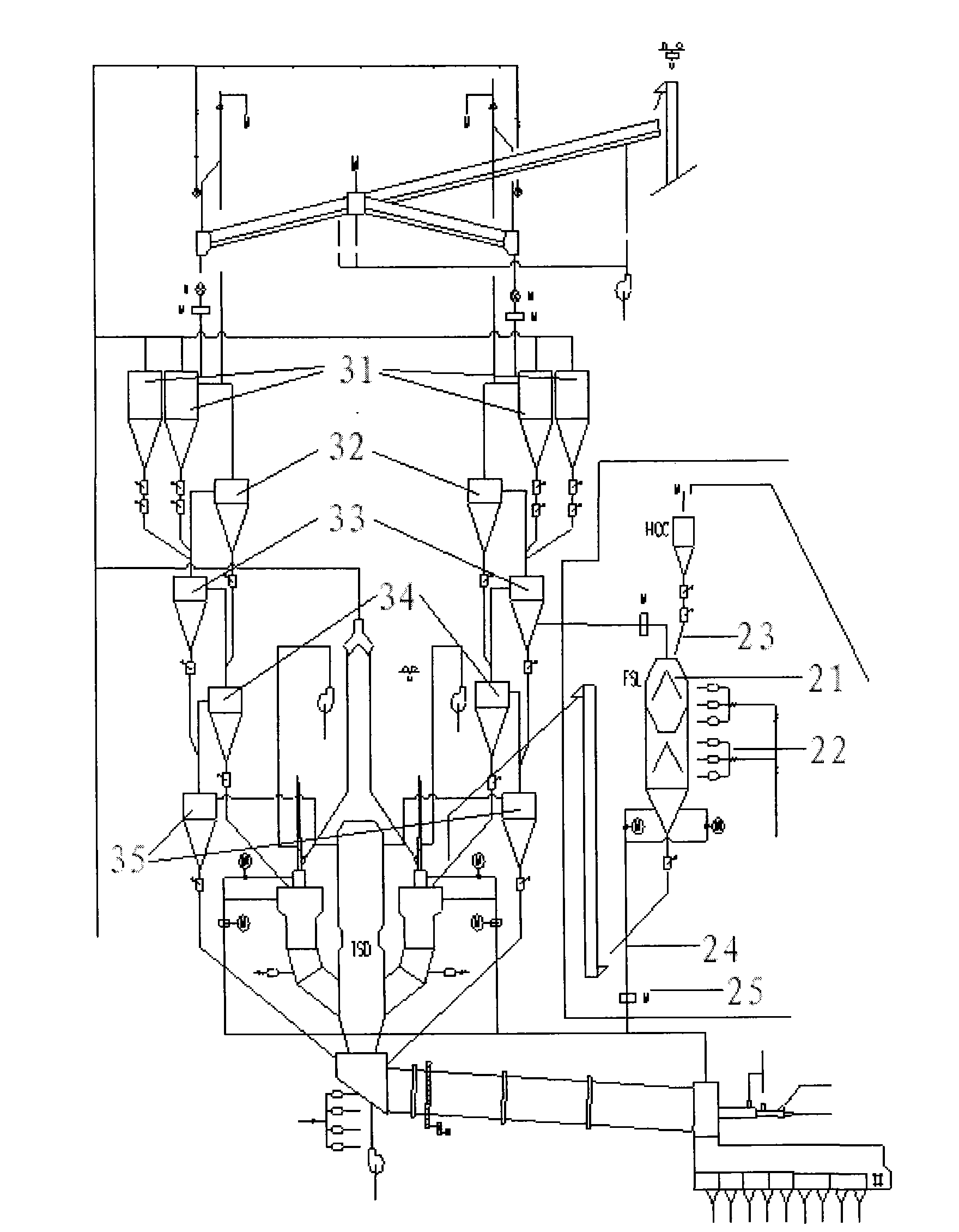

Cement presintering production method and system

ActiveCN101139175AIncrease productionQuality improvementRotary drum furnacesCharge manipulationElectricityBottle neck

The present invention relates to a new cement manufacturing technology. By enhancing the temperature of the kiln feed of a rotary kiln, the inefficient heat transfer process remaining in the cement rotary kiln is greatly reduced or eliminated and the thermal bottle-neck problem in the cement calcinations is solved so as to realize the fast firing of the fine particles and highly efficient cooling of the clinkers, and the anti-skinning materials, high temperature resistant materials and insulating materials are adopted and the aspect ratio, rotation speed and slope of the rotary kiln are changed so as to realize the present invention, thus generating the very obvious comprehensive effects of enhancing the output of the cements, lowering the burning heat consumption and the grinding pow consumption and enhancing the clinker quality.

Owner:CHINA BUILDING MATERIALS ACAD

Formula of silicon carbide spray coating

The invention discloses a formula of silicon carbide spray coating, comprising the following components: silicon carbide, mullite, alumina micropowder, silica micropowder and compound additive composed of sodium tripolyphosphate and methylcellulose. The formula comprises the following components in percentage by weight: 10-40% of the silicon carbide, 40-60% of the mullite, 10-20% of the alumina micropowder, 0-15% of the silica micropowder and 0-2% of the compound additive. When the spray coating prepared by the formula of the invention is used for spraying a rotary cement kiln, a spraying layer has small possibility of falling and has good stability and long service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

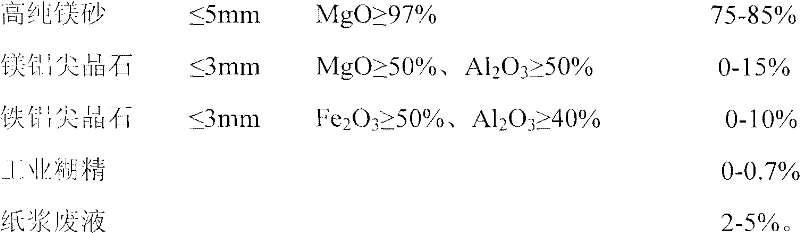

Magnesium-ferrum-aluminum composite spinel brick for large-scale cement kiln and preparation method thereof

The invention relates to a magnesium-ferrum-aluminum composite spinel brick for a large-scale cement kiln and a preparation method thereof, belonging to the field of refractory materials. The preparation method is characterized by comprising the following steps: by using high-purity magnesia, magnesia alumina spinel and hercynite as main raw materials and using pulp waste liquid and industrial dextrin as binders, mixing, pressing, drying, and firing at 1500-1700 DEG C to obtain the magnesium-ferrum-aluminum composite spinel brick. The product is applicable to firing zones and transition zones of cement kilns in all sizes, and can completely substitute magnesia-chromite bricks in the aspects of performance and cost, thereby implementing no chromium in the cement kiln refractory material. The product has obvious kiln skin adhesion effect, has the advantages of high heat and vibration stability, high temperature toughness and long running time (longer than 12 months), and performs very active functions on enhancing the running rate of the large-scale cement rotary kiln; and the fired magnesium-ferrum-aluminum composite spinel brick has the advantages of simple technique and low cost.

Owner:TONGDA REFRACTORY TECH CO LTD +1

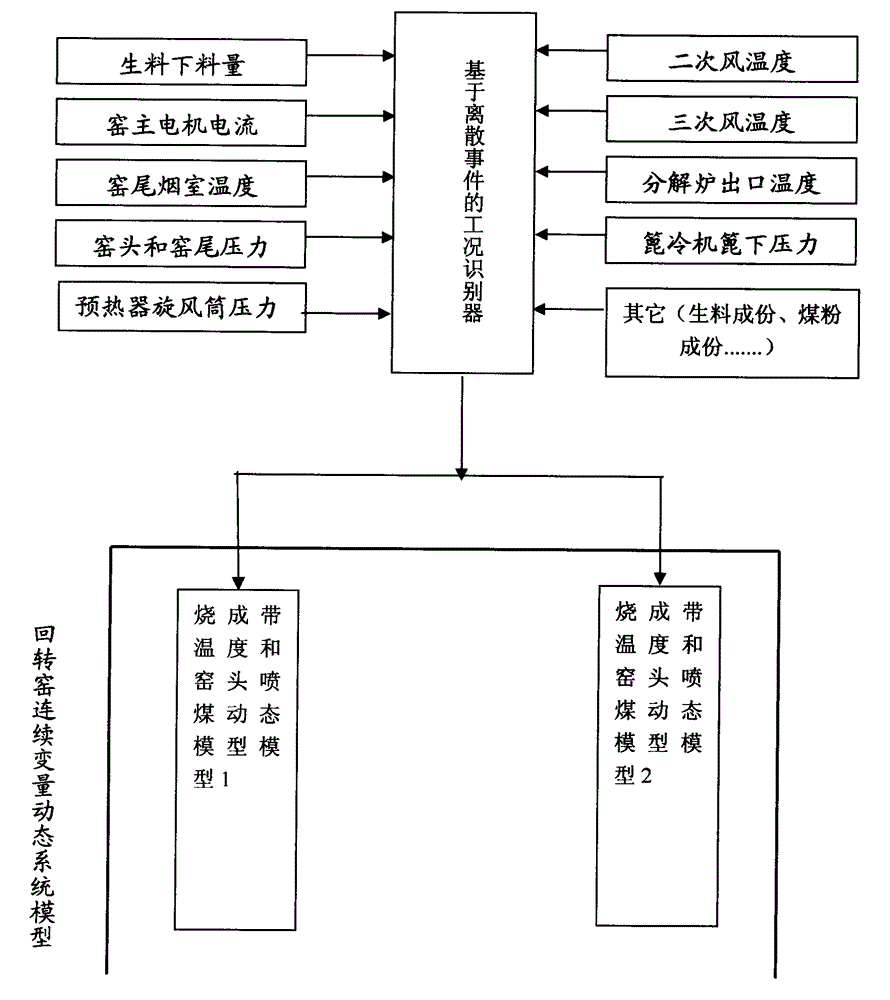

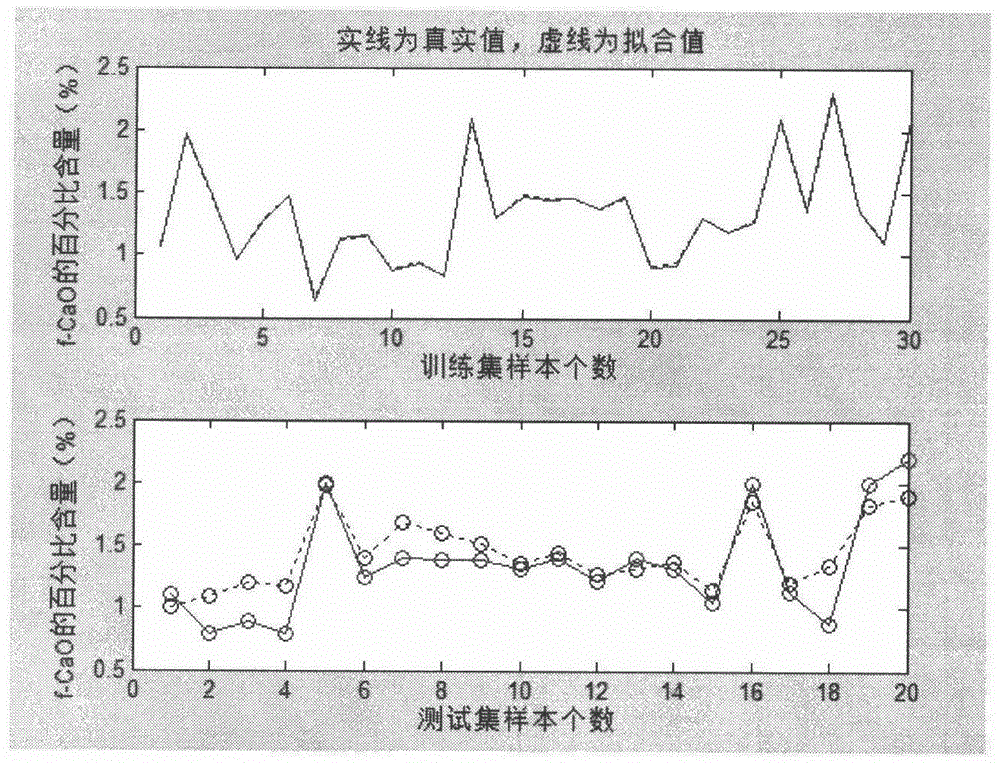

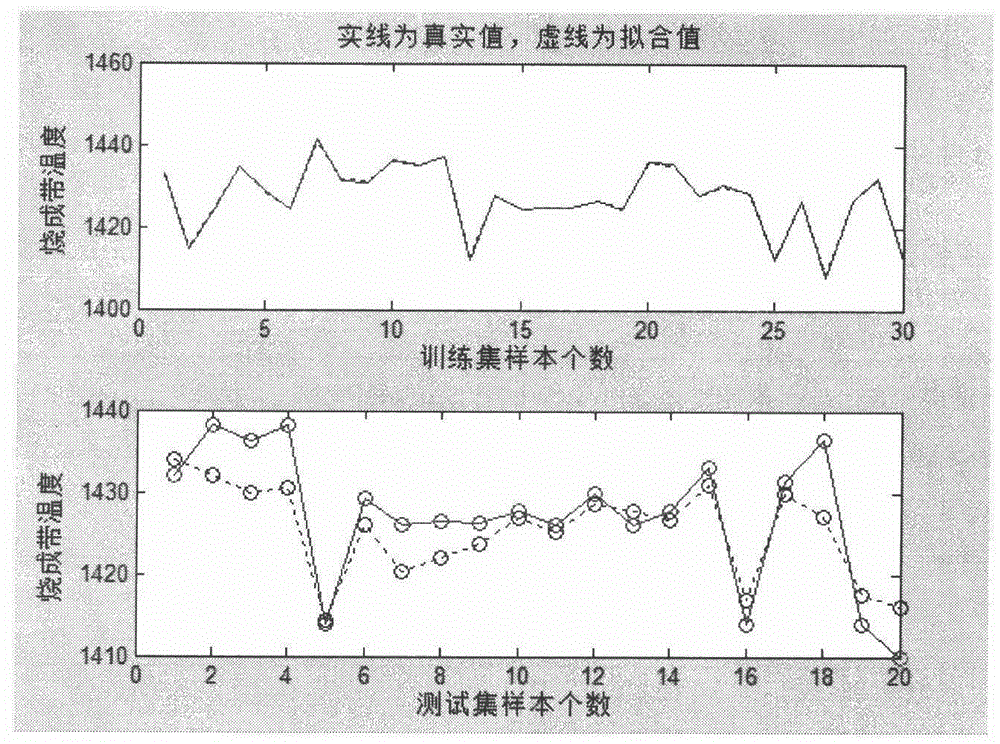

Hybrid modeling method for rotary cement kiln burning zone temperature based on LS_SVM soft measurement

InactiveCN104794263ASimulation is accurateImprove accuracyCharacter and pattern recognitionSpecial data processing applicationsProduction lineDiscrete event dynamic system

The invention discloses a hybrid modeling method for rotary cement kiln burning zone temperature based on LS_SVM soft measurement. The method comprises the steps that firstly, design data provided by a cement plant are analyzed and processed; by means of the LS_SVM method and the relation between free CaO content and burning zone temperature T, a virtual measurement model for the kiln hood temperature, kiln main machine current and smoke chamber temperature approaching to the burning zone temperature is built; on the basis of the correlation detection amount capable of being collected by a cement production line DCS, a working condition recognizer is used for recognizing two working stations, a DEDS model for the rotary cement kiln burning zone temperature is built, and CVDS models for the burning zone temperature and the coal injection quantity on various working conditions are built respectively. A hybrid model obtained through the hybrid modeling method can be used as a simulation platform to replace an actual rotary kiln for all kinds of control and research in the cement clinker burning process.

Owner:UNIV OF JINAN +1

Method for manufacturing silicon oxynitride-bonded high aluminum-silicon carbide prefabricated member

The invention relates to a method for manufacturing a silicon oxynitride-bonded high aluminum-silicon carbide prefabricated member. The method comprises the following steps: with high aluminum (alumina, mullite and andalusite) particles, silicon carbide particles and fine powder, alumina powder, corundum powder, alumina micro powder, pure calcium aluminate cement, silica powder and silicon powder as raw materials, adding a water reducer, adding water and agitating evenly to form pug; manufacturing a blank body by vibrating casting and molding; and manufacturing the silicon oxynitride-bonded high aluminum-silicon carbide prefabricated member through high-temperature in-situ reaction in a nitrogen atmosphere. The silicon oxynitride-bonded high aluminum-silicon carbide prefabricated member manufactured by the method has the characteristics of being good in peeling resistance, low in cost, long in service life and the like, and can replace high aluminum-silicon carbide castable for a kilneye and a coal-injection duct of a rotary cement kiln at present.

Owner:ZHENGZHOU UNIV

Silicon mullite red brick for large cement kiln and its producing method

The present invention is silicon mullite red brick for large cement kiln and belongs to the field of refractory material technology. The silicon mullite red brick is made with alum as aggregate, silicon carbide, electrocast white alundum powder, andalusite powder, clay, yellow dextrin, methyl cellulose and water, and through mixing, pressing and sintering. Practical application in large cement kiln shows that the silicon mullite red brick has high heat insulating effect and long service life.

Owner:江苏君耀耐磨耐火材料有限公司

High intensity low conductivity magnesium aluminate spinel brick

The invention relates to a high intensity low conductivity magnesium aluminate spinel brick. The high intensity low conductivity magnesium aluminate spinel brick comprises the following ingredients: 20-25% magnesium aluminate composite material with granularity of 5-3 mm, 20-25% magnesium aluminate composite material with granularity of 3-1 mm, 12-16% fused magnesite with granularity of 1-0 mm, 12-16% fused magnesite with granularity of 180 F, 10-12% magnesium aluminate composite material with granularity of 180 F, 4-8% fused magnesium aluminate spinel with granularity of 180 F, 2-5% Alpha-Al2O3 fine powder, and calcium lignosulphonate which accounts for 3.5-5 weight percentage of the raw material. The high intensity low conductivity magnesium aluminate spinel brick is suitable for cement rotary kiln, has good sintering performance, thermal shock resistance, erosion resistance and permeating resistance, and has good economic and social benefits.

Owner:TONGDA REFRACTORY TECH CO LTD +1

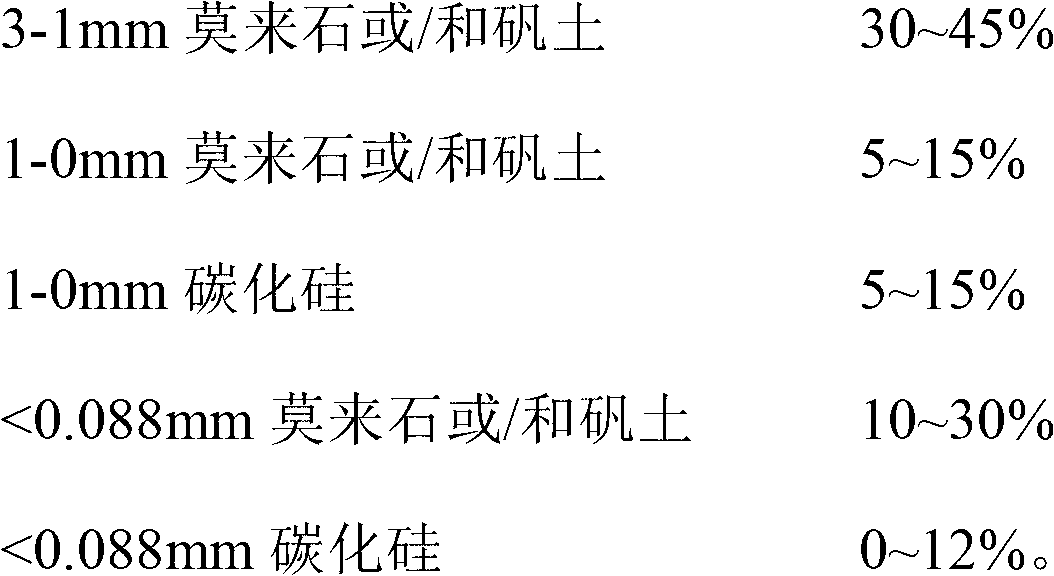

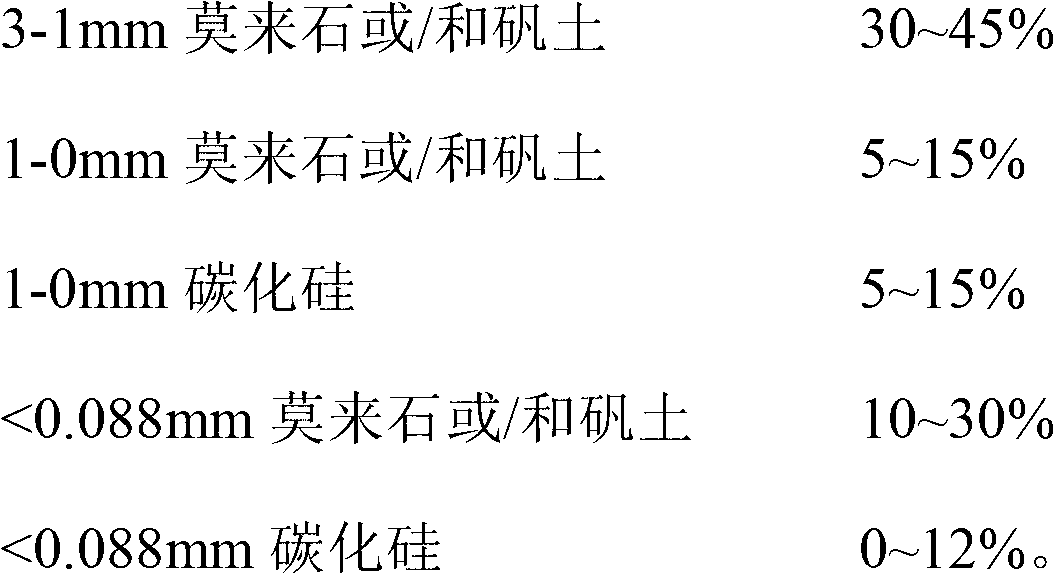

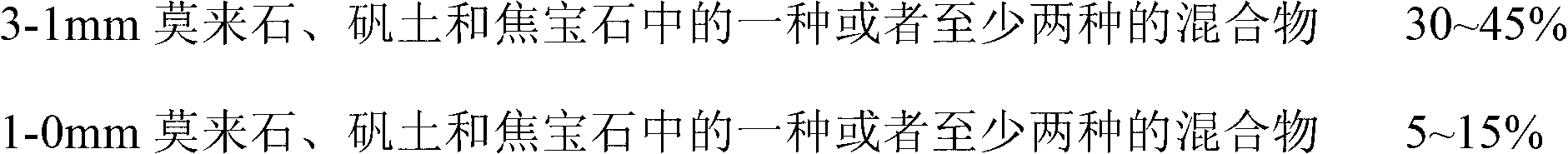

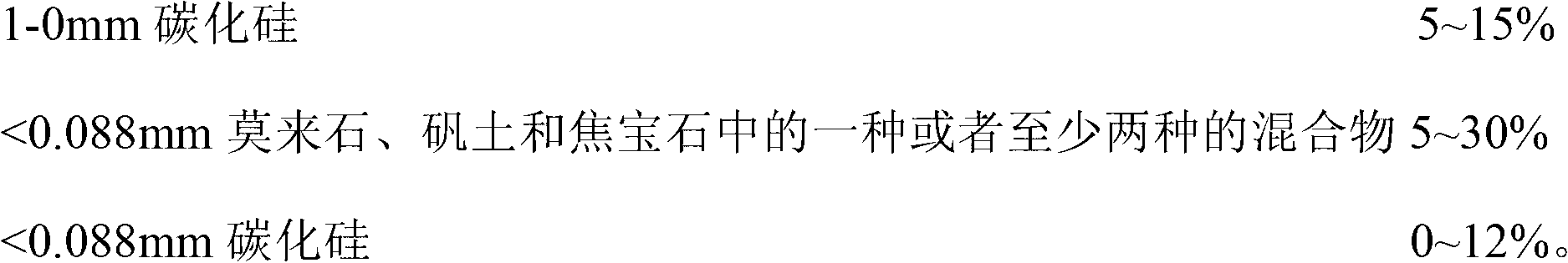

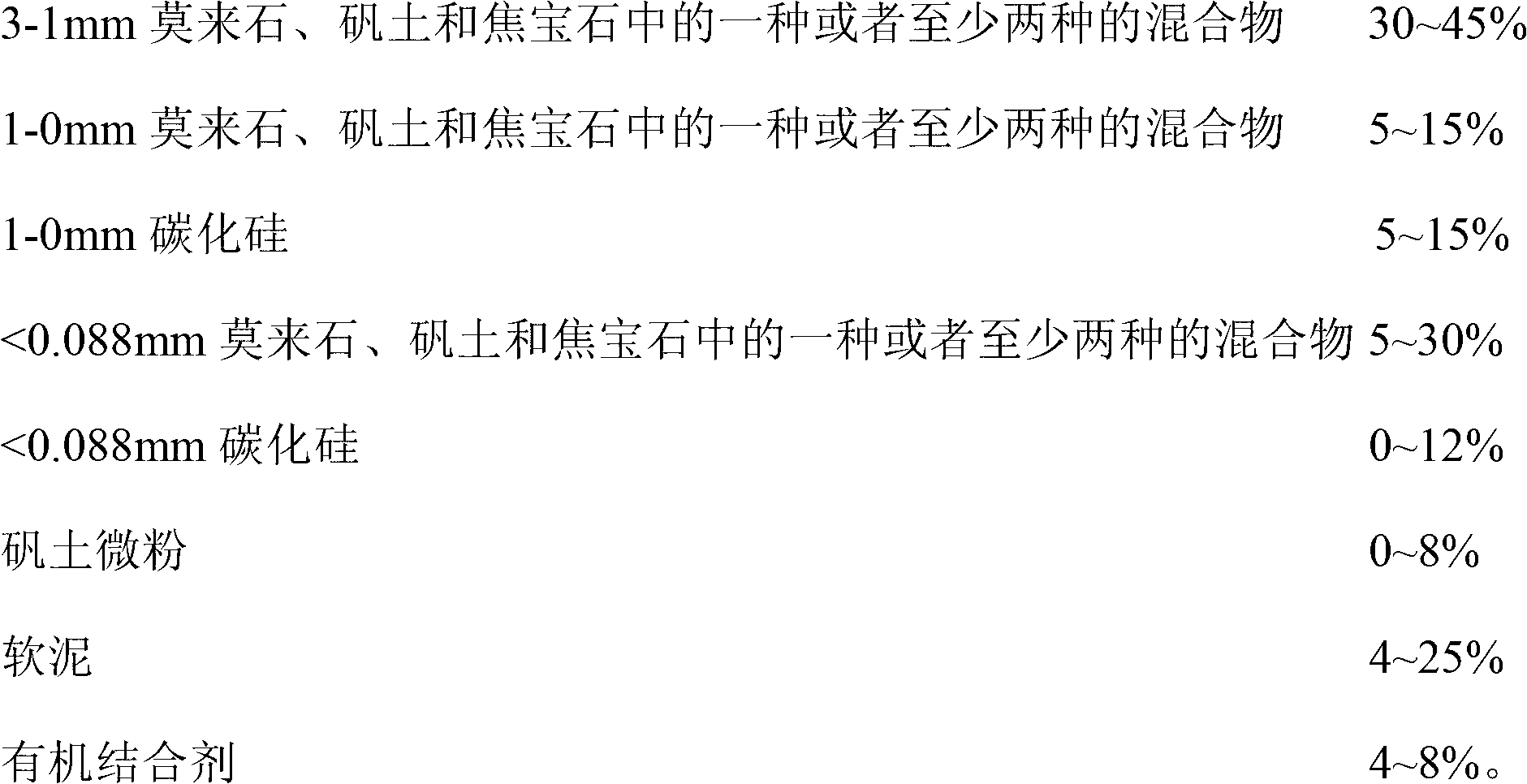

Low-aluminum sintered alumina-silica refractory material and preparation method thereof

The invention relates to a sintered alumina-silica refractory material. The sintered alumina-silica refractory material comprises aggregate, powder and additive; the aggregate comprises one or mixture of at least two of mullite, alumina and flint clay and silicon carbide; the powder comprises mud; and the additive comprises an organic bonding agent. The invention also provides the preparation method for the refractory material. The refractory material is low in price, and high in high temperature resistance, erosion resistance, thermal shock resistance and wear resistance and low in heat-conducting property and used for the cold ends of a decomposition band and a transition band of a rotary cement kiln, can replace the conventional anti-stripping high-alumina brick and the conventional anti-stripping silicon mullite brick; and the requirements of the cement kiln on low heat conduction and alkali eclipse resistance of the refractory material can be met, the radiation loss can be reduced, and the service life of the kiln is prolonged, and the economic benefit of the kiln is improved.

Owner:ANHUI RUITAI NEW MATERIALS TECH

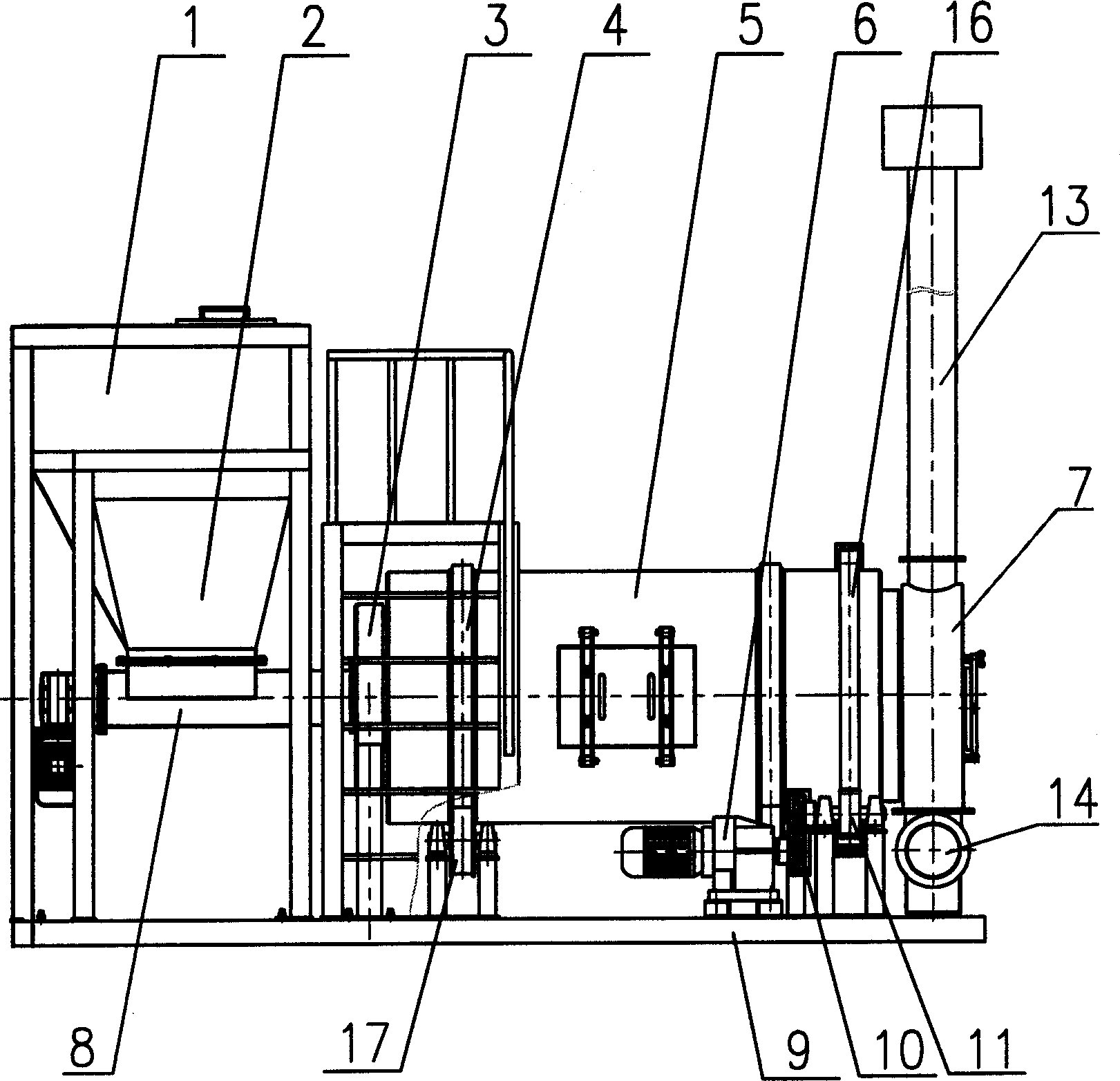

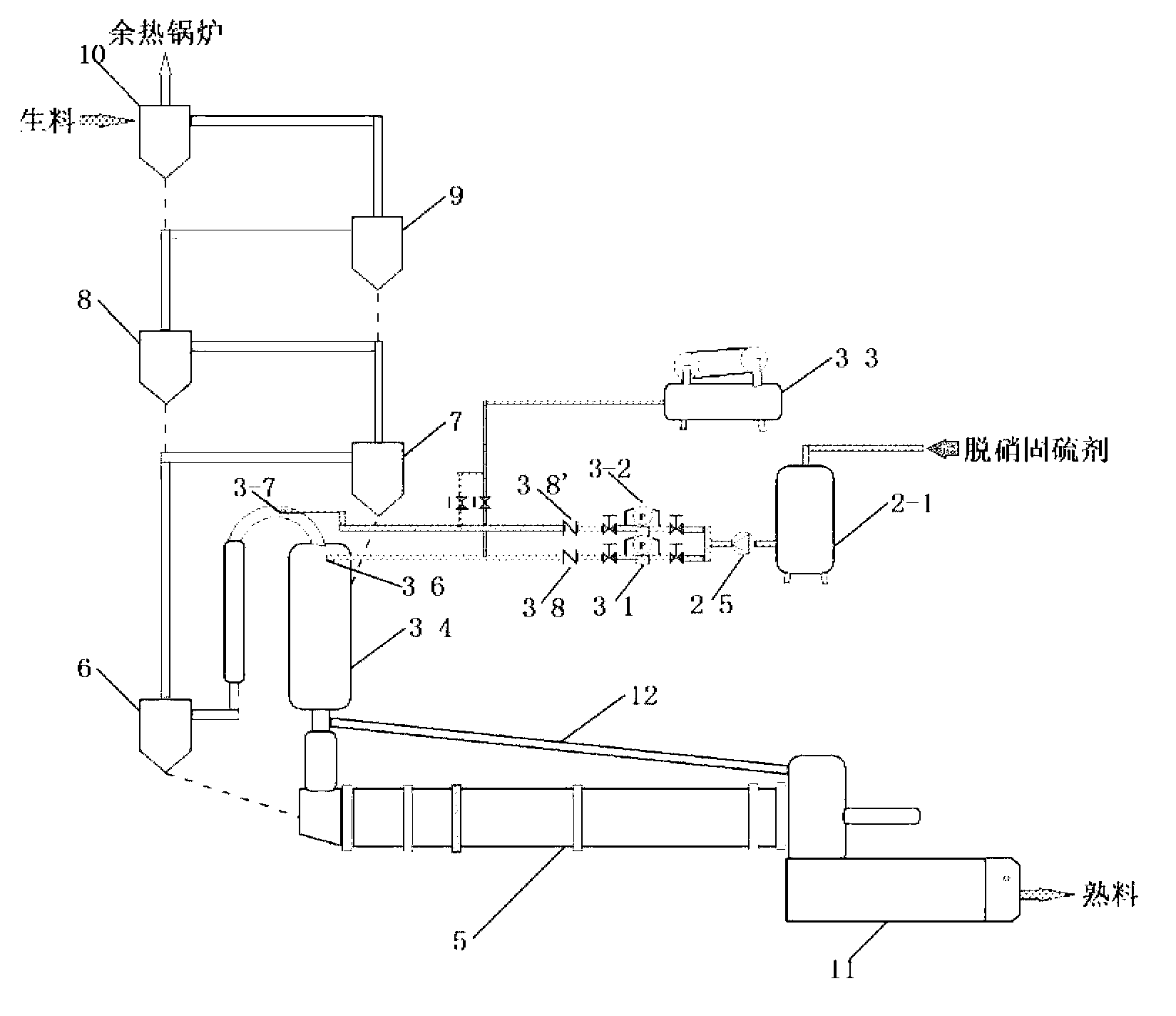

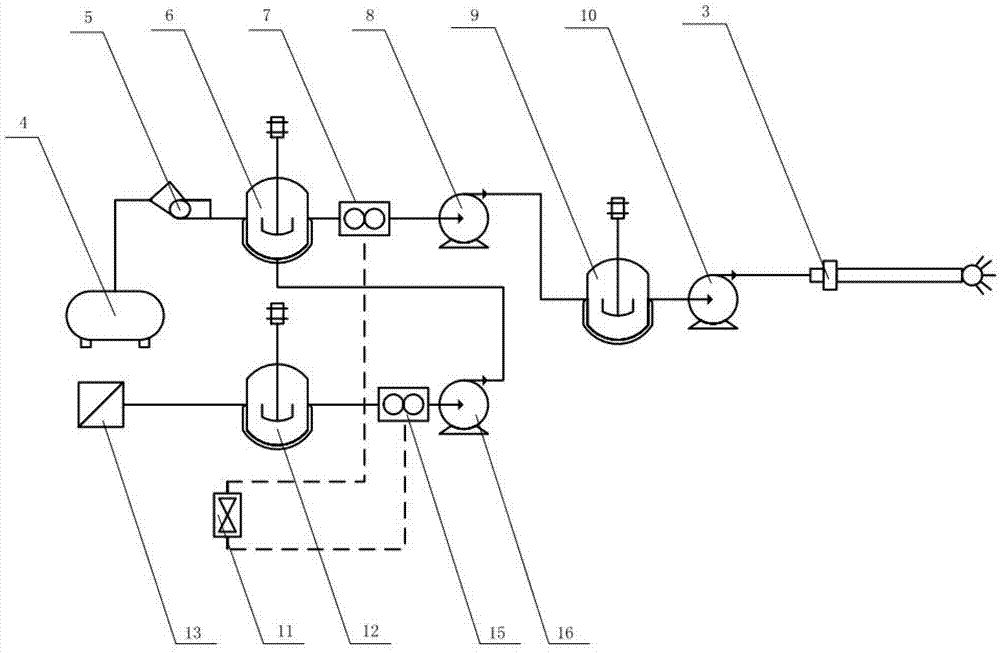

Method and apparatus for cement rotary kiln flue gas denitration and desulfurization

ActiveCN102974207ACost-effectiveSolve the problem of excessive emissionsDispersed particle separationAutomatic controlFlue gas

The present invention discloses a denitration sulphur-fixing agent used for cement rotary kiln flue gas denitration and desulfurization, and a method and an apparatus for cement rotary kiln flue gas denitration and desulfurization using the agent. The denitration sulphur-fixing agent includes a reducing agent with a mass percent concentration of15-25% and a sulphur-fixing agent with a mass percent concentration of 30-55%. The apparatus includes a denitration sulphur-fixing agent preparation system, a denitration sulphur-fixing agent storage system, a denitration sulphur-fixing agent injection system and an automatic control system, wherein the denitration sulphur-fixing agent preparation system, the denitration sulphur-fixing agent storage system and the denitration sulphur-fixing agent injection system are successively connected; and the automatic control system is respectively connected with the denitration sulphur-fixing agent preparation system and the injection system. The unique denitration sulphur-fixing agent provided by the present invention is injected into the nozzle of the cement rotary kiln in two routes. Compared with the conventional technologies of SCR denitration and wet desulfurization, the original production process is unchanged, the method and the apparatus have the characteristics of simple manipulation and economy and high-efficiency.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

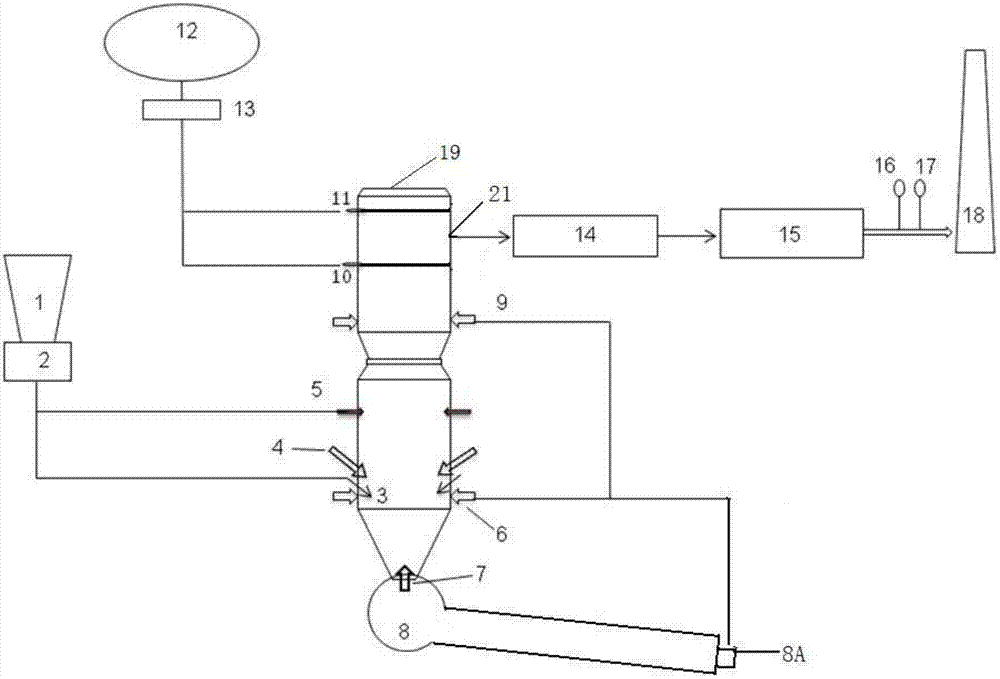

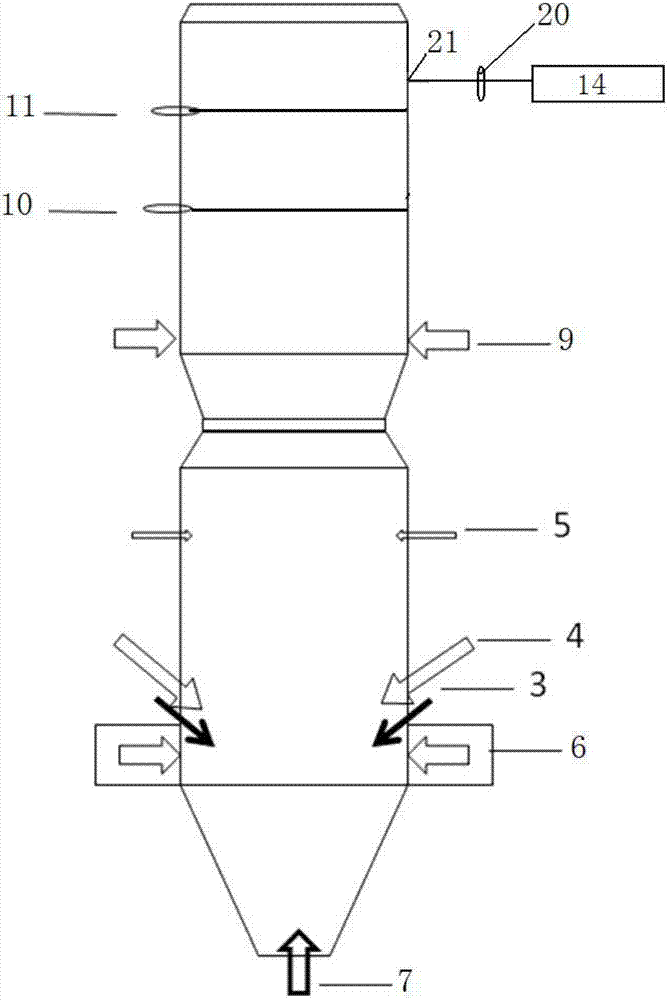

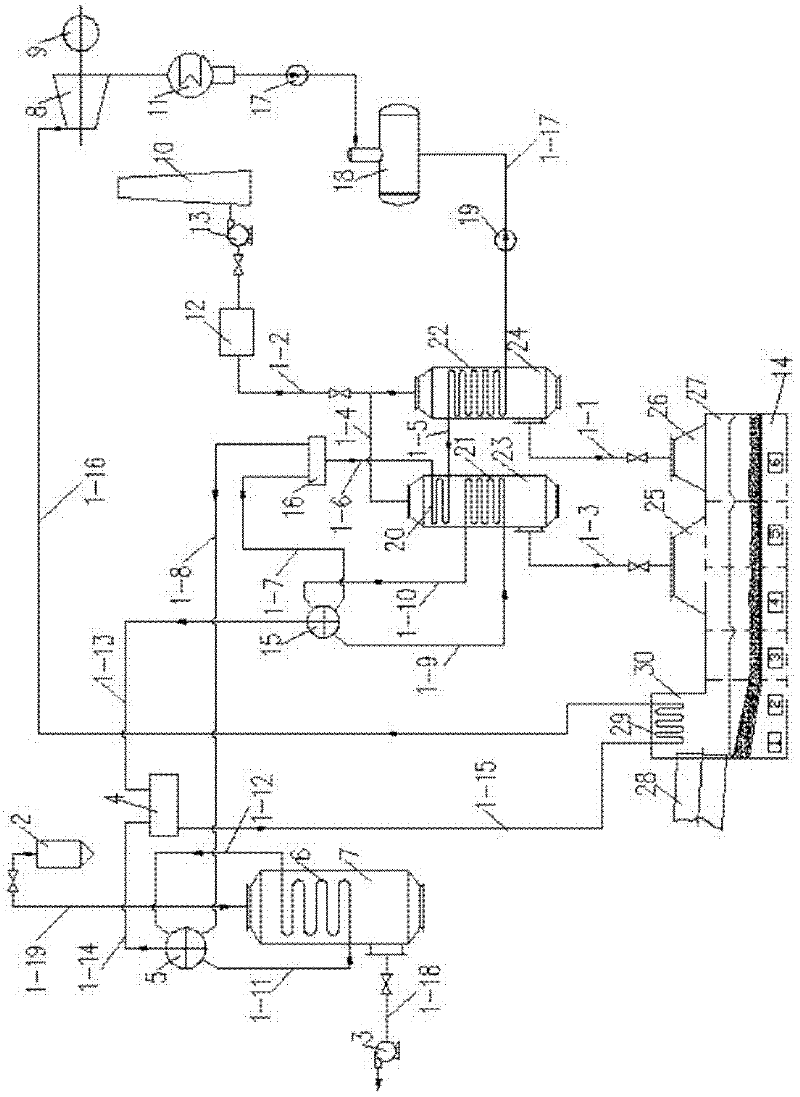

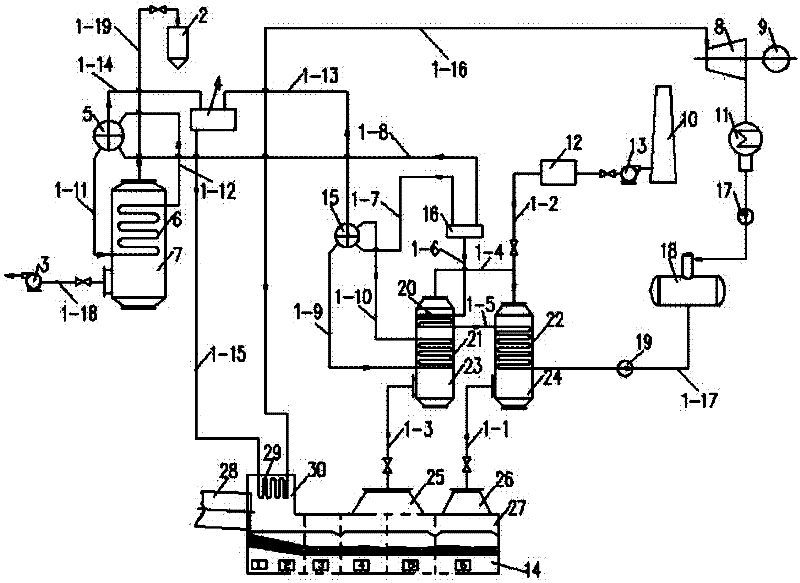

Efficient reburning denitrification device and technical method

ActiveCN103206865AImprove removal efficiencyMeet emission standardsIncreasing energy efficiencyWaste heat treatmentWater storage tankEngineering

The invention discloses an efficient reburning denitrification device which comprises a decomposing furnace. The bottom of the decomposing furnace is provided with a secondary air inlet and is connected with a rotary cement kiln. The decomposing furnace comprises a main low-nitrogen burner and a reburning burner on the lower portion from bottom to top, and a raw material inlet is arranged at the position of the main low-nitrogen burner. Coal powder in a coal powder bunker enters the decomposing furnace from the main low-nitrogen burner and the reburning burner. A tertiary air inlet is arranged below the raw material inlet and connected with a cooler of the rotary cement kiln. The decomposing furnace comprises an overfire air inlet and an SNCR (selective non-catalytic reduction) spray gun on the upper portion from bottom to top. The overfire air inlet is connected with the tertiary air inlet and the cooler of the rotary cement kiln. The SNCR spray gun is connected with a centrifugal pump and an ammonia water storage tank device. A smoke outlet is arranged at the upper section of the decomposing furnace and connected with a cyclone preheater, an electric dust collector and a chimney. The invention further provides a technical reburning denitrification method by the efficient reburning denitrification device. By the efficient reburning denitrification device and the technical reburning denitrification method, NOx removal efficiency can be improved, sprayed ammonia water is reduced, and denitrification cost of cement enterprises is lowered.

Owner:上海三融环保工程有限公司

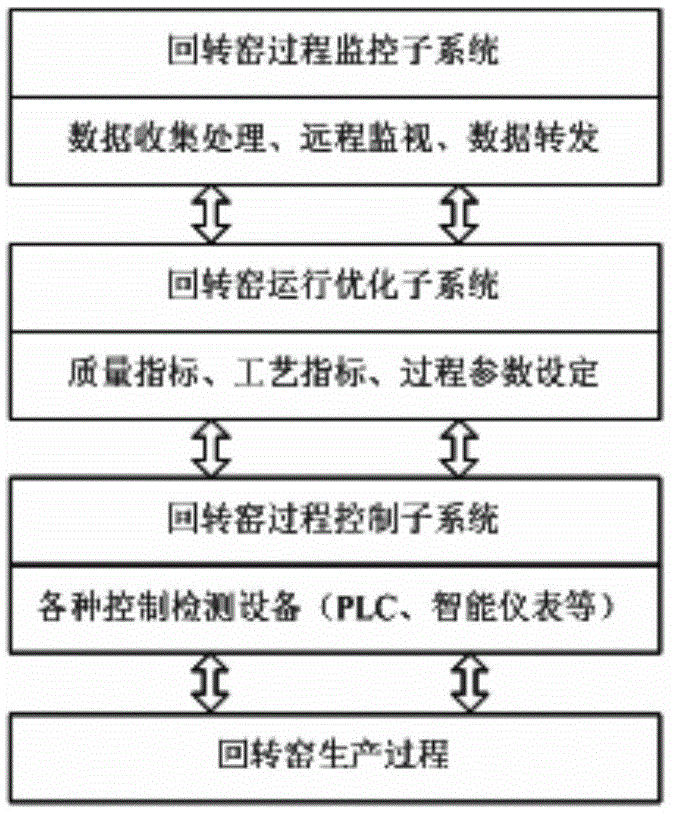

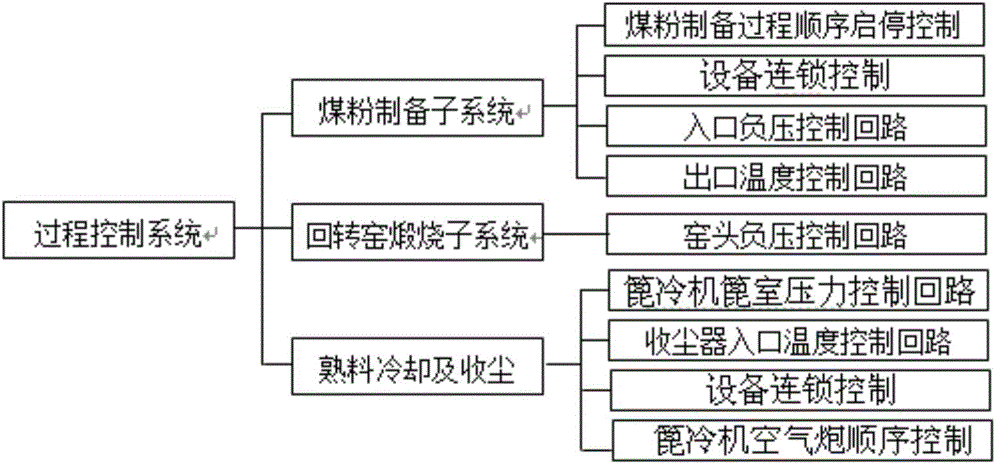

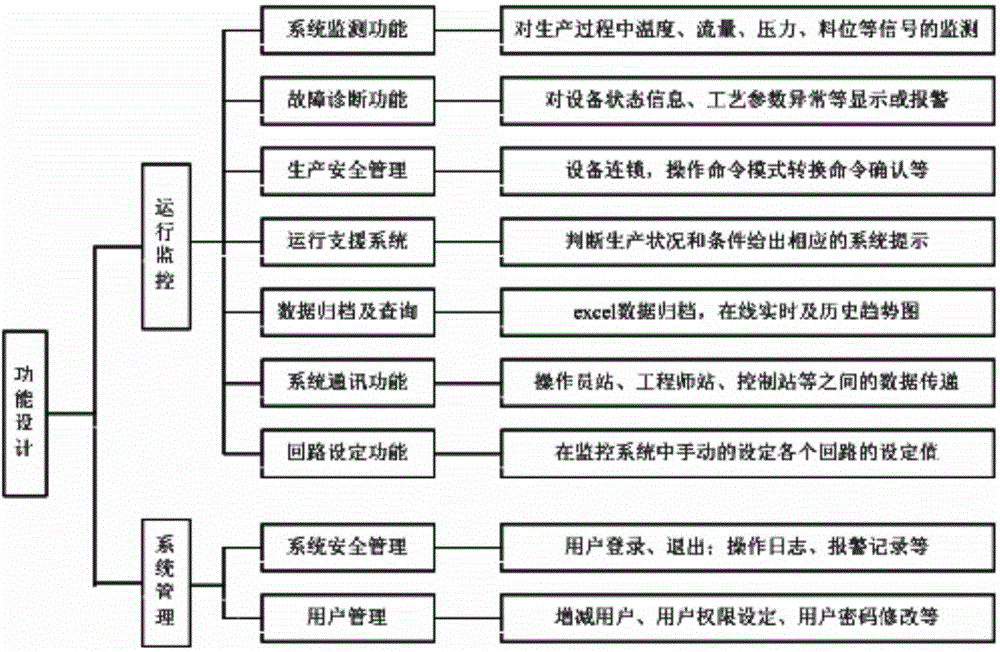

Cement rotary kiln intelligent optimization control system

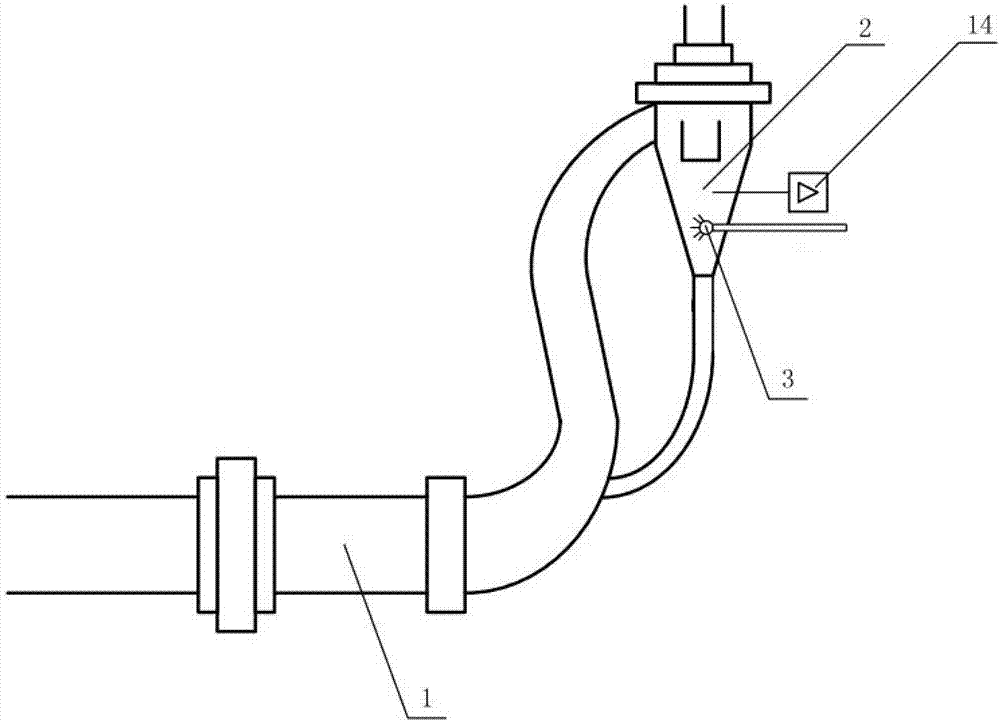

The invention discloses a cement rotary kiln intelligent optimization control system. The system structurally comprises (1) a process control subsystem composed of a rotary kiln head negative pressure control circuit, a grate cooler grate chamber pressure control circuit, the inlet temperature control circuit of a kiln head exhaust gas dust collector, the inlet negative pressure control circuit of a coal dust preparing system and the bowl mill outlet temperature control circuit of the coal dust preparing system; (2) an operation optimization subsystem composed of an operation quality index setting module, a key technological parameter control circuit optimization setting module and a circuit intelligent control module; and (3) a process monitoring subsystem having system monitoring, fault diagnosis, equipment management and safety guaranteeing functions. The system can adapt to a cement rotary kiln calcining process characterized by strong non-linearity, strong coupling, great inertia and large lag to improve the clinker unit weight qualified rate and reduce energy consumption.

Owner:NORTHEASTERN UNIV +1

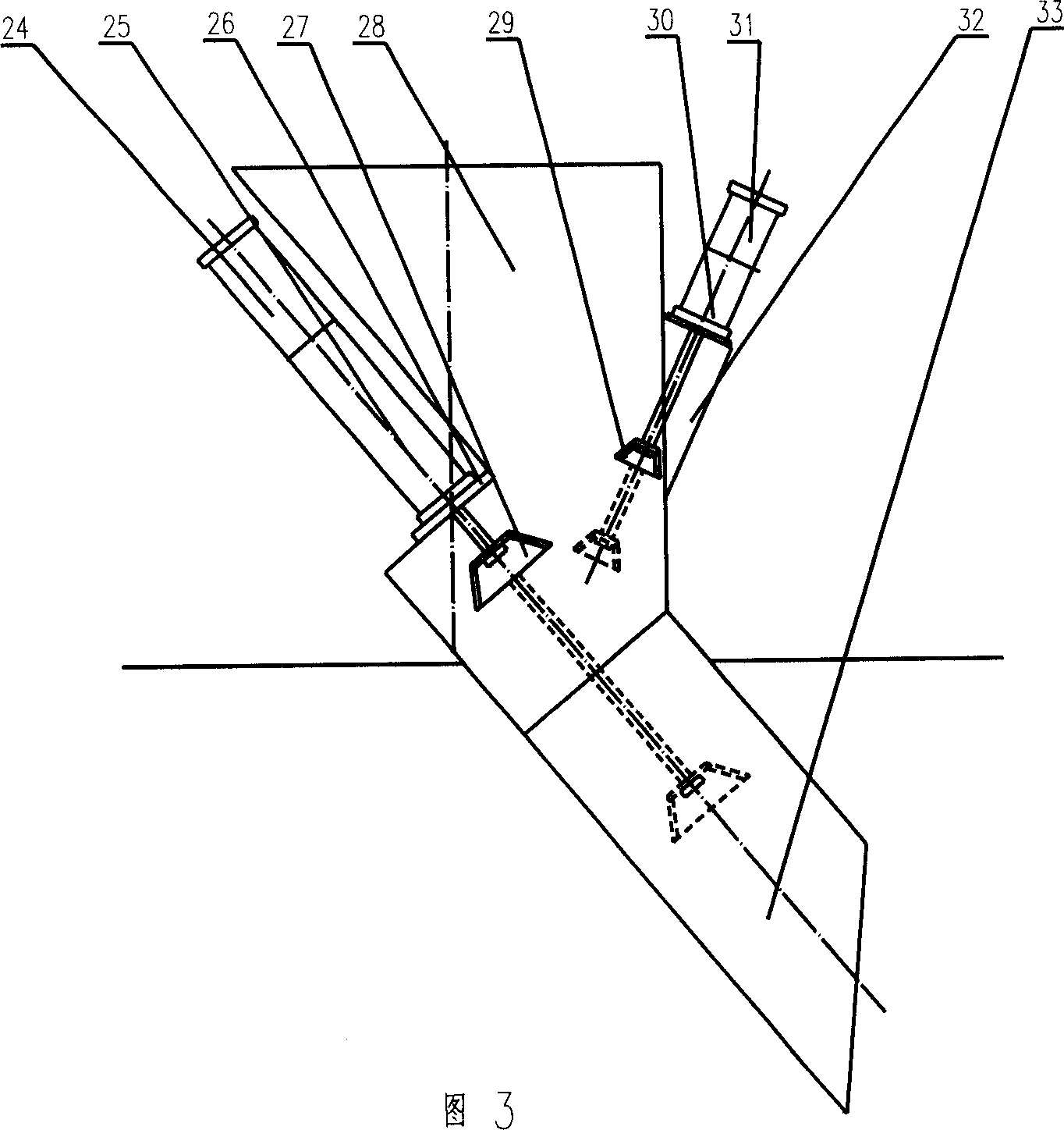

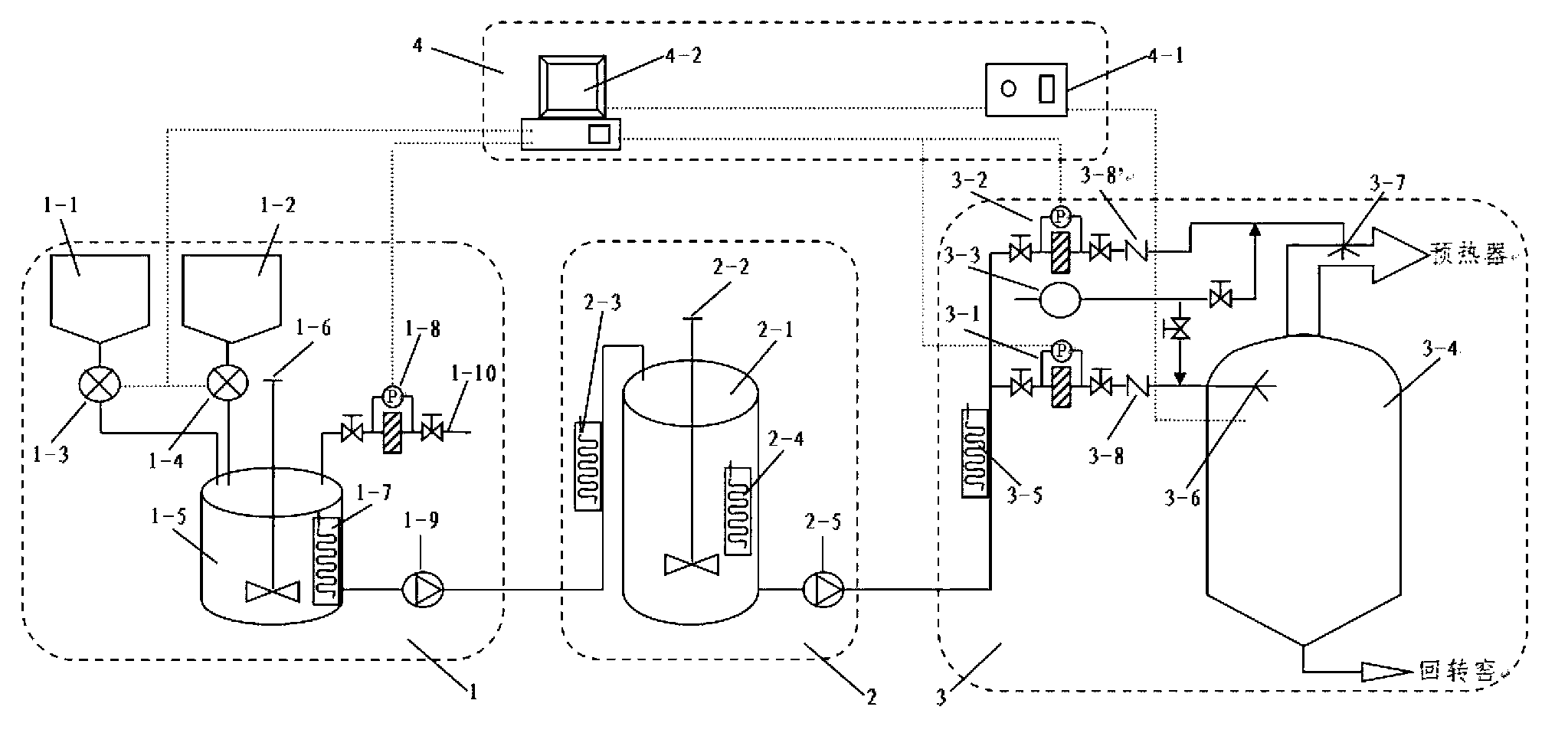

SNCR (selective non-catalytic reduction) denitration device and method for rotary cement kiln nitrogen oxide control

ActiveCN102806002AImprove denitrification activityImprove denitrification performanceDispersed particle separationEnvironmental resistanceBucket elevator

The invention discloses an SNCR (selective non-catalytic reduction) denitration device and an SNCR denitration method for rotary cement kiln nitrogen oxide control and belongs to the technical field of rotary cement kiln pollutant control. The device comprises a reducing agent preparation and storage system, a reducing agent spraying system and a control system, wherein the reducing agent preparation and storage system comprises a urea storage chamber, a bucket elevator, a urea dissolving tank, an additive storage tank, two conveying pumps, a metering device and a modified reducing agent storage tank, the reducing agent spraying system comprises a booster pump and a spray gun, the control system comprises two flow meters and two flow meter controllers, and in addition, a NOx on-line detection instrument is arranged at the outlet part of a decomposing furnace. The method is realized by using the device, Na2CO3 or H2O2 is used as additives, the additives are added into urea solution with the mass fraction being 20 to 60 percent according to a mole ratio of the additives to the urea being 1:3-15, and then, the mixed solution is sprayed into the decomposing furnace in an atomized state. The SNCR denitration device and the SNCR denitration method have the advantages that economy and environment protection are realized, and the denitration performance is high.

Owner:TSINGHUA UNIV

Treatment method of organochlorine pesticide polluted soil

ActiveCN102775080ACause secondary pollutionEfficient use ofSoil lifting machinesCement productionDecompositionBiology

The invention discloses a treatment method of organochlorine pesticide polluted soil, which comprises the following steps: (1) pretreatment: detecting and analyzing organochlorine pesticide polluted soil; digging out the organochlorine pesticide polluted soil, and mechanically and manually screening to remove impurities; adding quicklime, stirring, piling, and carrying out thermal desorption to remove volatile organic pollutants, thereby obtaining pretreated organochlorine pesticide polluted soil; and (2) cement rotary kiln treatment: after metering the pretreated organochlorine pesticide polluted soil, grinding with clay, iron powder and limestone to obtain cement raw meal, homogenizing the cement raw meal, sending into a preheater to carry out preheating, sending into a decomposition furnace to carry out decomposition, sending into a cement rotary kiln, calcining to obtain cement clinker, cooling the cement clinker, and grinding to obtain cement. The treatment method disclosed by the invention has the advantages of no toxicity, low cost and no secondary pollution on the environment, can change wastes into valuable substances, and effectively utilizes the resources.

Owner:江苏常环环境科技有限公司

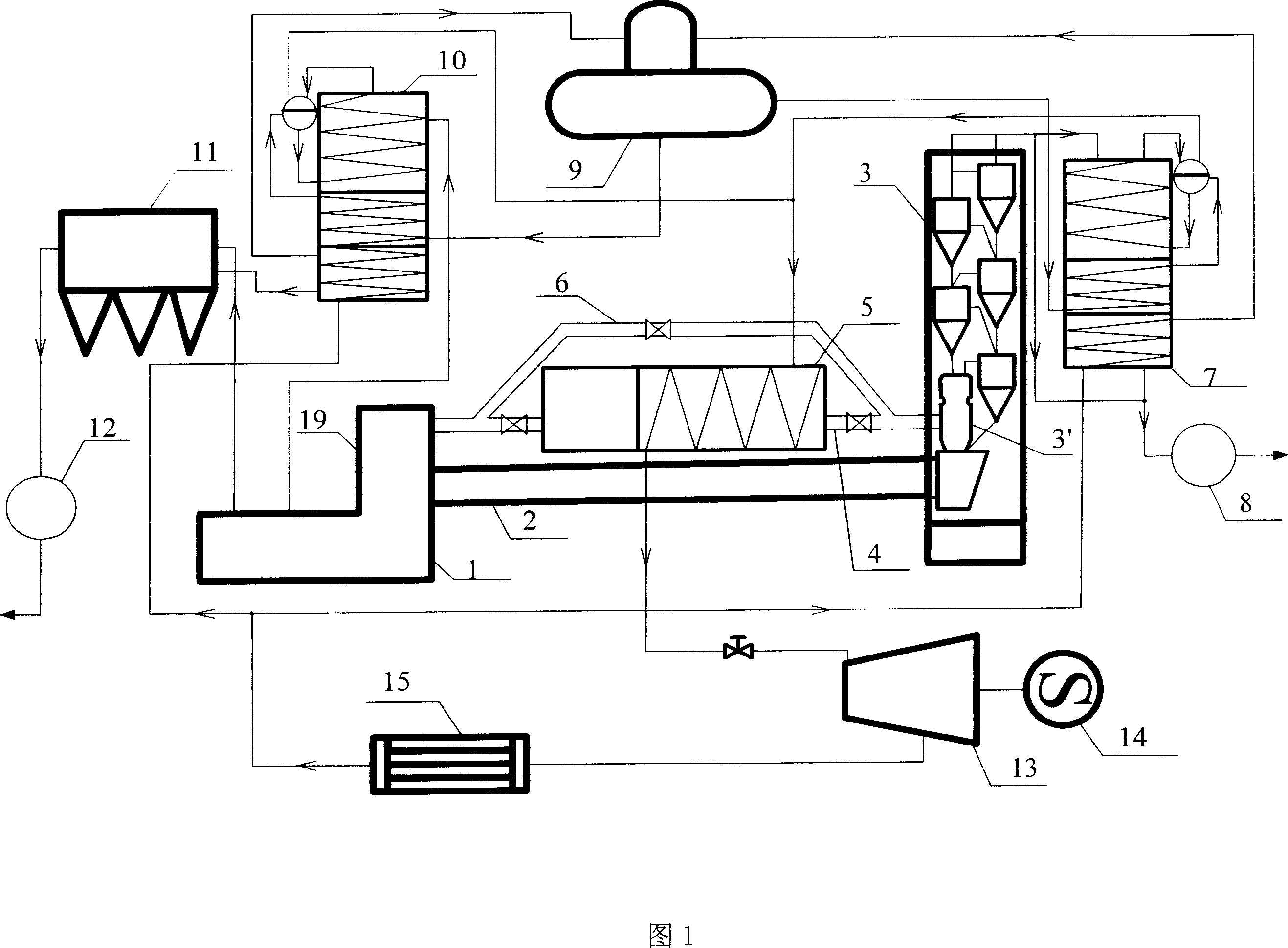

Cement kiln waste heat comprehensive utilization power generation system and method

InactiveCN102506588AImprove the efficiency of waste heat recovery and utilizationIncrease power generationIncreasing energy efficiencyClinker productionEngineeringRecuperator

The invention provides a cement kiln waste heat comprehensive utilization power generation system which comprises a rotary cement kiln, a grate cooler, an AQC (air quenching cooler) waste heat boiler, an SP waste heat boiler, a steam turbine and a power generator, wherein the AQC waste heat boiler comprises a first heat exchanger, a second heat exchanger and a first boiler barrel, the first heat exchanger is internally provided with a first economizer, the second heat exchanger is internally provided with a second economizer and a first evaporator; the SP waste heat boiler comprises a third heat exchanger and a second boiler barrel, the third heat exchanger is internally provided with a second evaporator; water in the first economizer is heated and then flows into the second economizer and continuously flows to a water supply collection tank and respectively flows into the first boiler barrel and the second boiler barrel; and water in the first boiler barrel is heated circularly in the first evaporator, water in the second boiler barrel is circularly heated in the second evaporator, and heat steam is collected to a steam collection tank, and enters into a fourth evaporator for being continuously heated, and finally enters into the steam turbine to drive the power generator to generate electricity. According to the invention, the recycling efficiency of waste heat of the cementkiln is increased and electric energy production is increased.

Owner:西安陕鼓工程技术有限公司

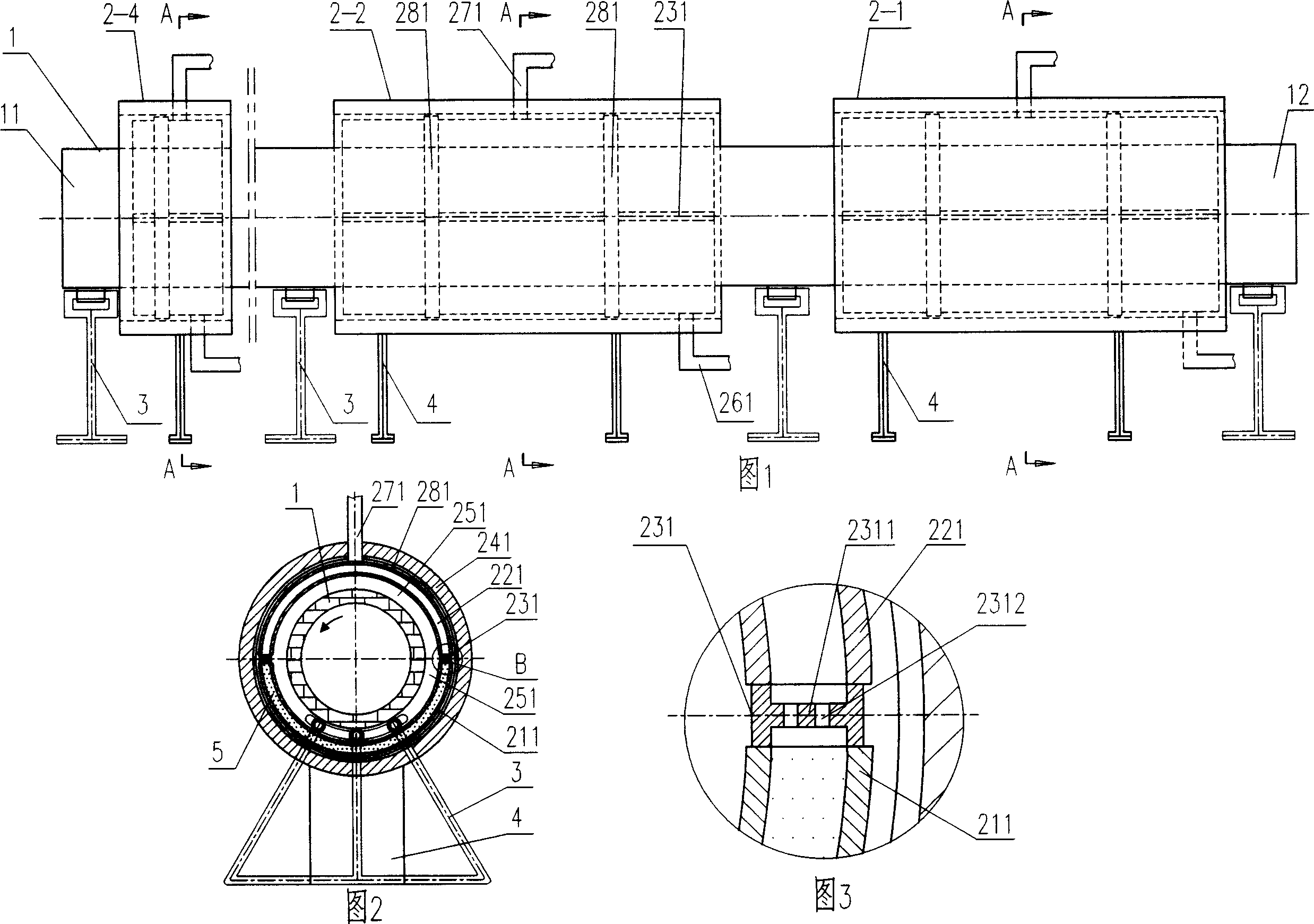

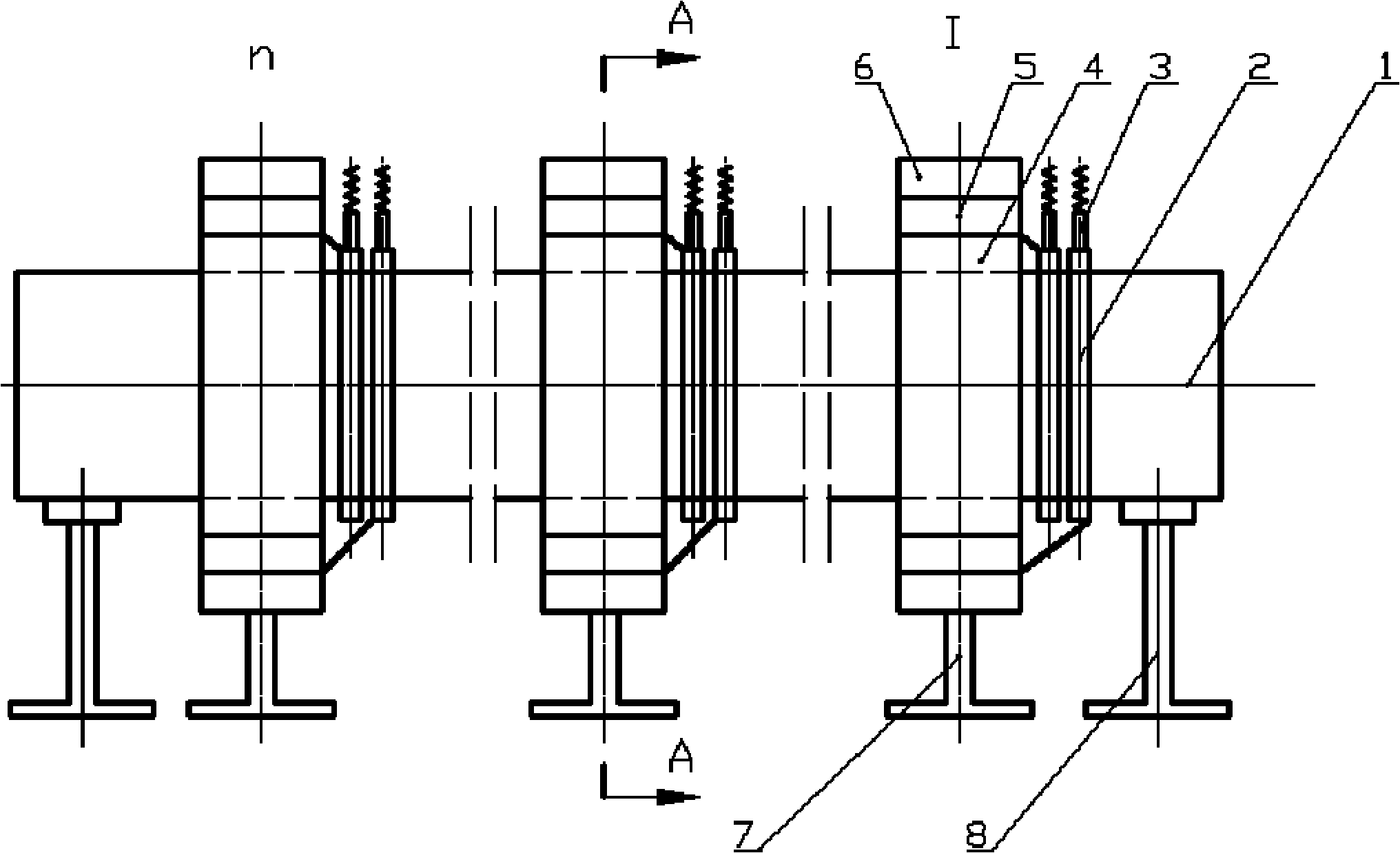

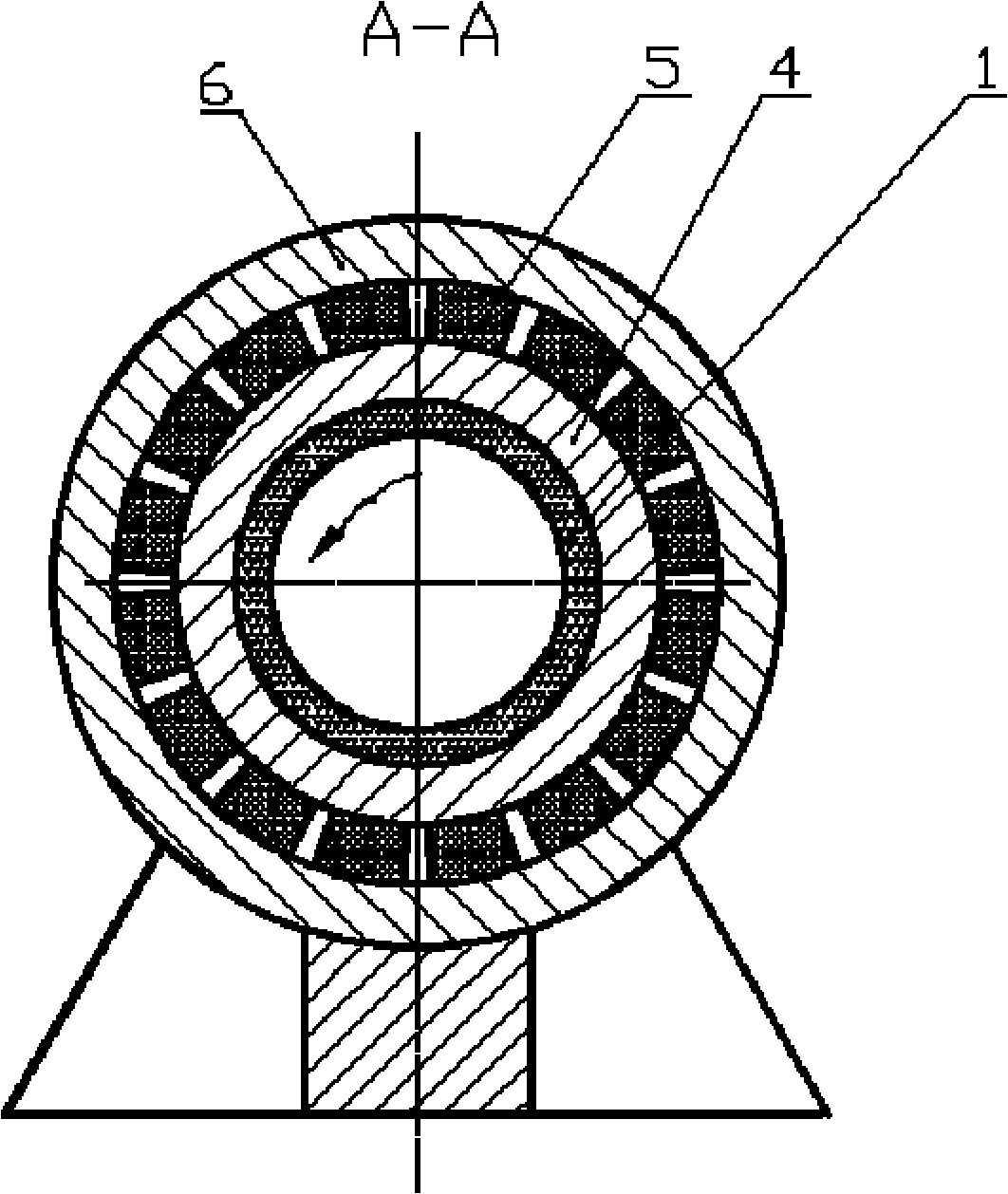

Dry method cement rotary kiln surface waste-heat utilization method and device

InactiveCN1967120ADoes not affect the production processFunction increaseRotary drum furnacesClinker productionThermal energyInsulation layer

It relates to a cement rotary kiln surface residual heat utilization with the said surface with heating device and heat drawing device from the low pressure vapor in production, transmitting the heat of the rotary kiln to the heat drawing device through radiation and convection, introducing the vapor generated from the heat drawing device to the steam turbine, driving the generator, steam engine or other places for reutilization of the residue heat. It is formed by n heat drawing devices of sealing hollow housings around the rotary kiln and evaporator, 1<=n<=60, leaving a small clearance between the sealing hollow housing and the rotary kiln housing, with each heat drawing device having a bottom intake for water or gas, a top exhaust, and an insulation layer outside the seal housing. It is reasonable, simple, practical and low in cost.

Owner:周玉芬

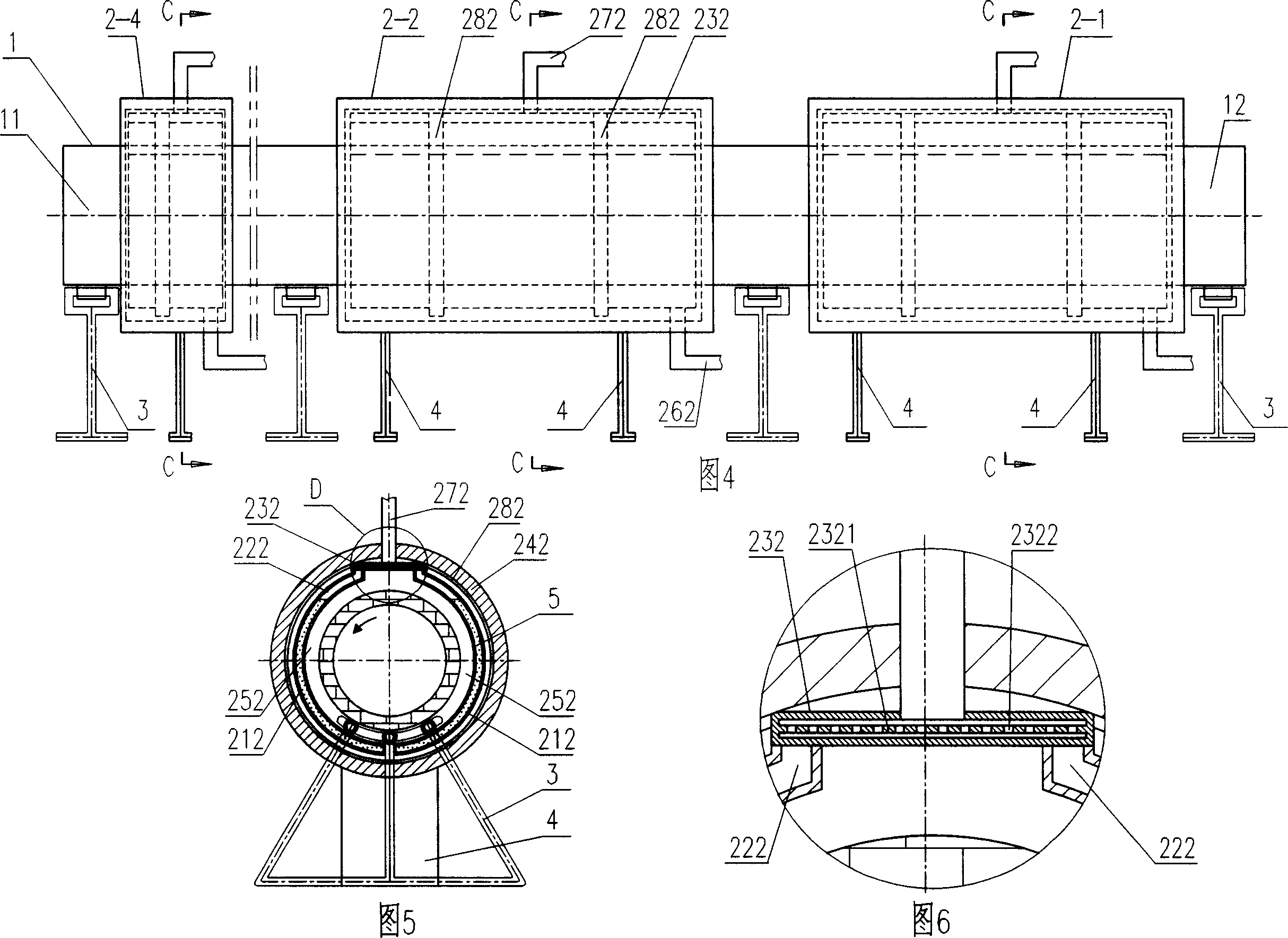

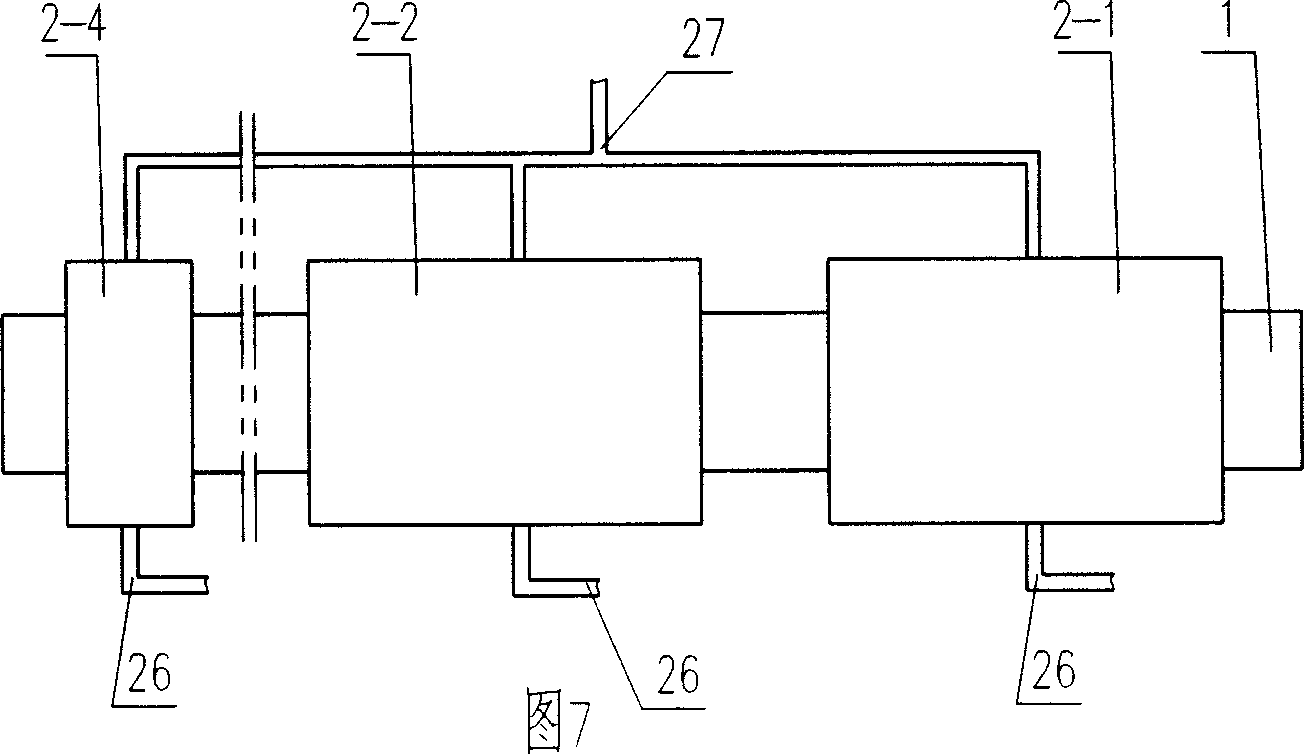

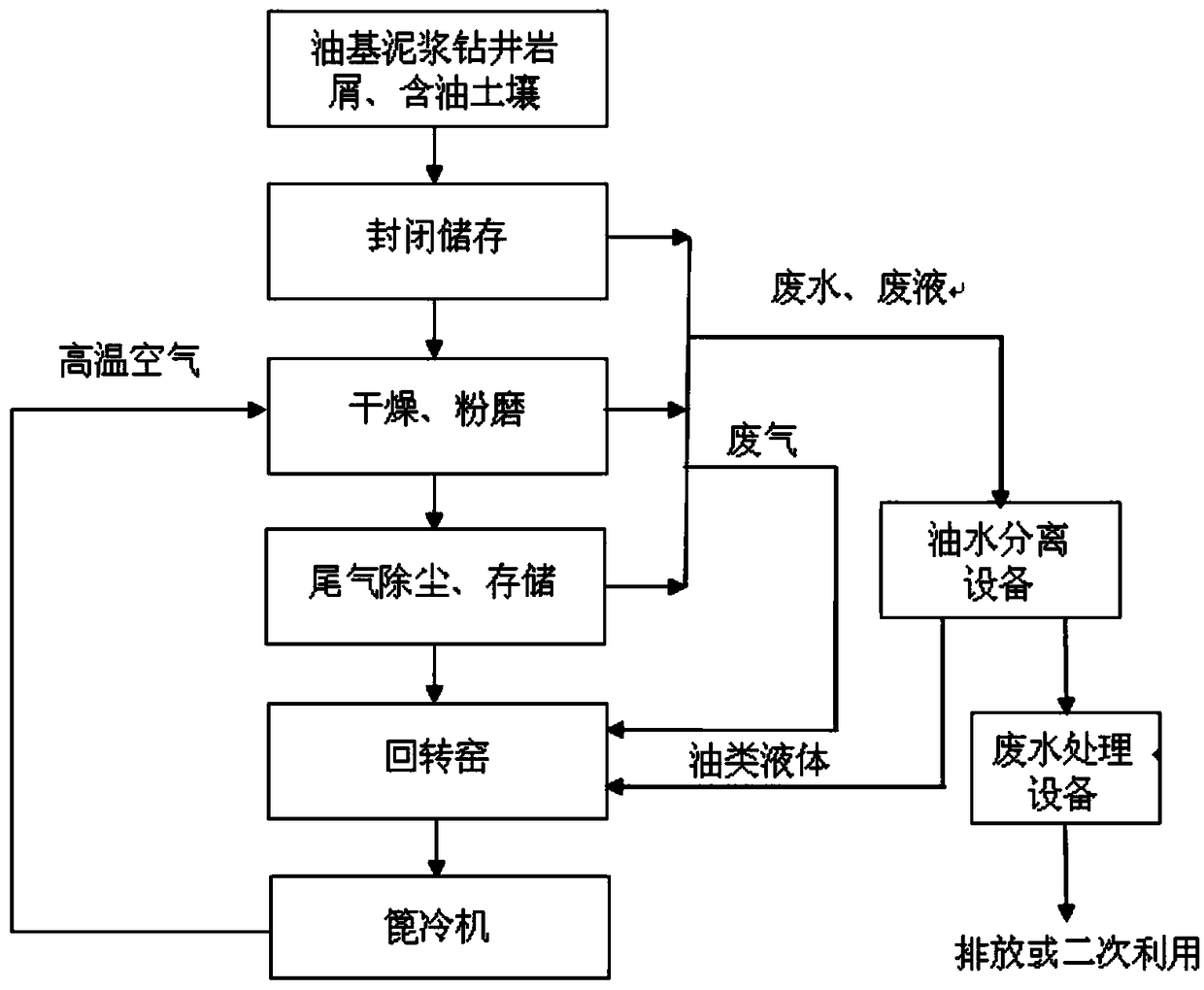

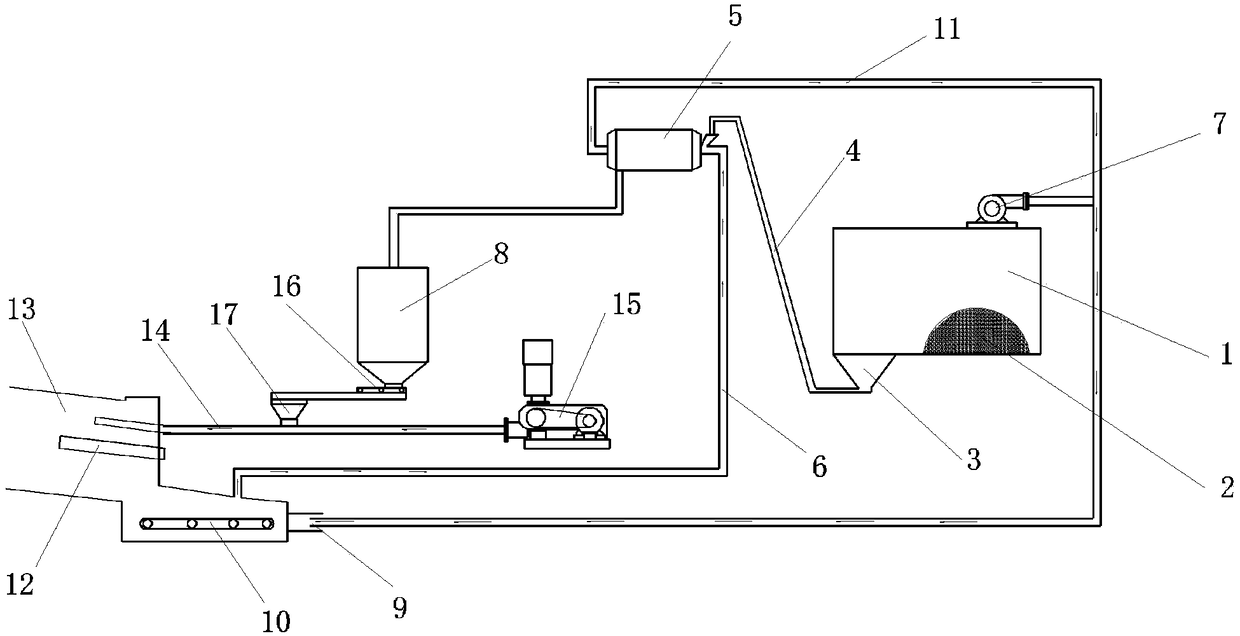

Equipment and method for cooperative treatment of drilling solid waste by using cement kiln

PendingCN109265028AReduce consumptionEasy to handleCement productionIncinerator apparatusCement kilnPollution

The invention discloses equipment and method for cooperative treatment of drilling solid waste by using a cement kiln. The equipment comprises the cement rotary kiln, a drilling waste storage and treatment closed system, a waste gas collecting and sealing treatment system and a waste water and waste liquid collecting and treatment system. The drilling waste is oil-based mud drilling rock debris oroil-containing soil, and the systems are fully closed. According to the equipment and method, the cement kiln is used for cooperative treatment of the oil-based mud drilling rock debris and the oil-containing soil, people only need to conduct adaptive reconstruction on an existing cement production line and pollution control facilities of the existing cement production line, the oil-based mud drilling rock debris and the oil-containing soil can serve as full-substitute materials, waste oil substances can serve as part of fuel to replace coal powder, and the consumption of fire coal and silicon materials of ton products can be reduced. Besides, emission of the pollutants can not be increased, hazardous solid waste of the similar kind can be effectively treated, and the purposes of recycling, reduction and harmless treatment of the hazardous solid waste are achieved.

Owner:乐山华宇欣和石油科技有限公司

Whisker composite high performance magnesia brick and manufacturing method thereof

The invention relates to the technical field of refractory materials, particularly relates to the technical field of refractory materials for a refractory furnace permanent lining, an alloy metallurgical smelting furnace, a glass kiln regenerative chamber and a cement rotary kiln and particularly relates to a whisker composite high performance magnesia brick and a manufacturing method thereof. The whisker composite high performance magnesia brick comprises, by weight, 5-10% of fused magnesite of 5-8mm, 10-20% of fused magnesite of 3-5mm, 10-20% of fused magnesite of 3-0.074mm, 5-10% of fused magnesite of less than 0.074mm, 5-10% of high purity magnesite of 5-8mm, 5-15% of high purity magnesite of 3-5mm, 0-10% of high purity magnesite of 3-0.074mm, 5-10% of high purity magnesite of less than 0.074mm, 5-15% of recycled waste magnesium brick of 3-5mm, 5-15% of recycled waste magnesium brick of 0-3mm, 5-15% of magnesium oxide whiskers, 1-15% of magnesium borate whiskers, 2-5% of nano-magnesium aluminate adhesive dry powder and 2-5% of paper pulp.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

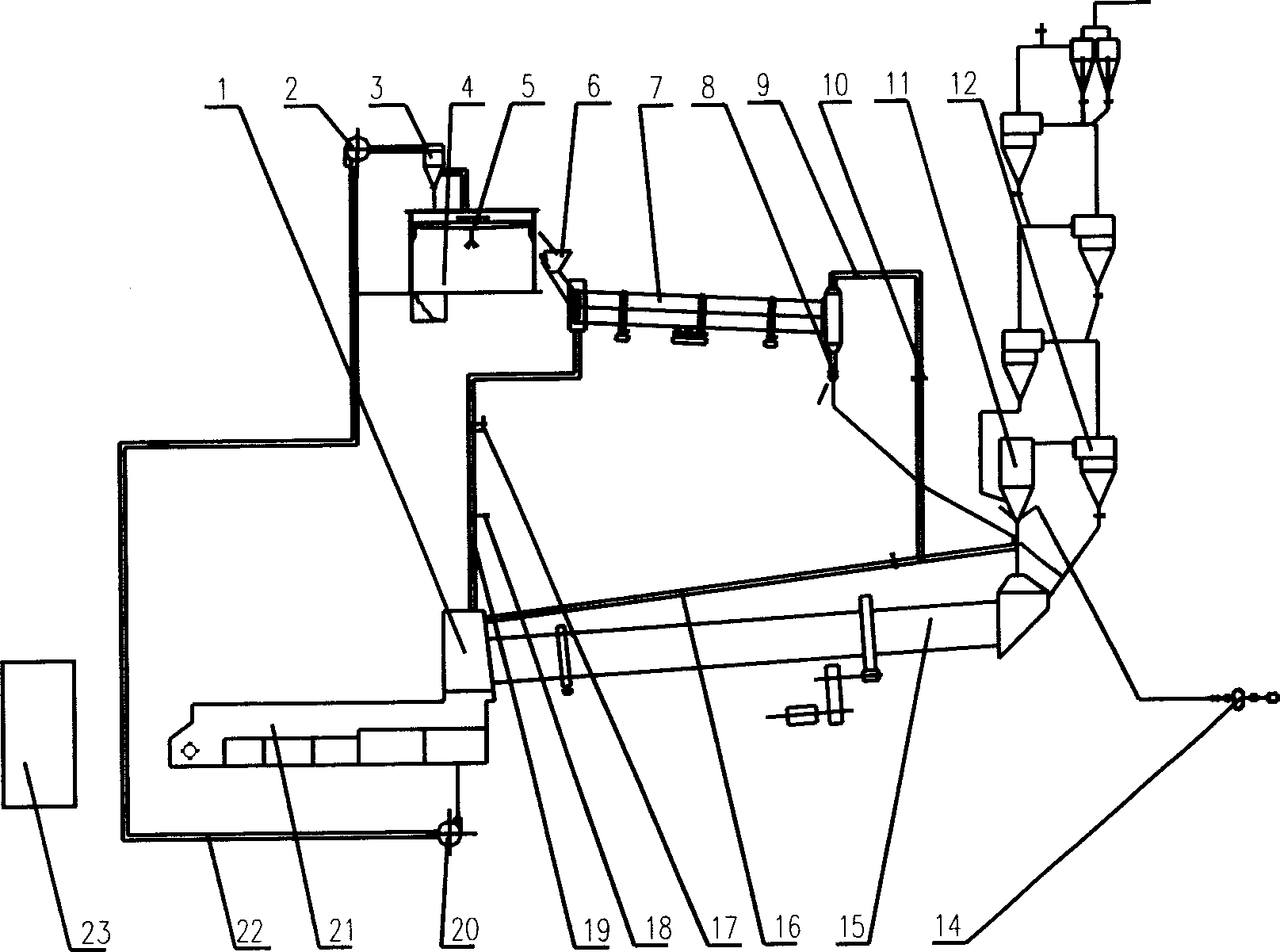

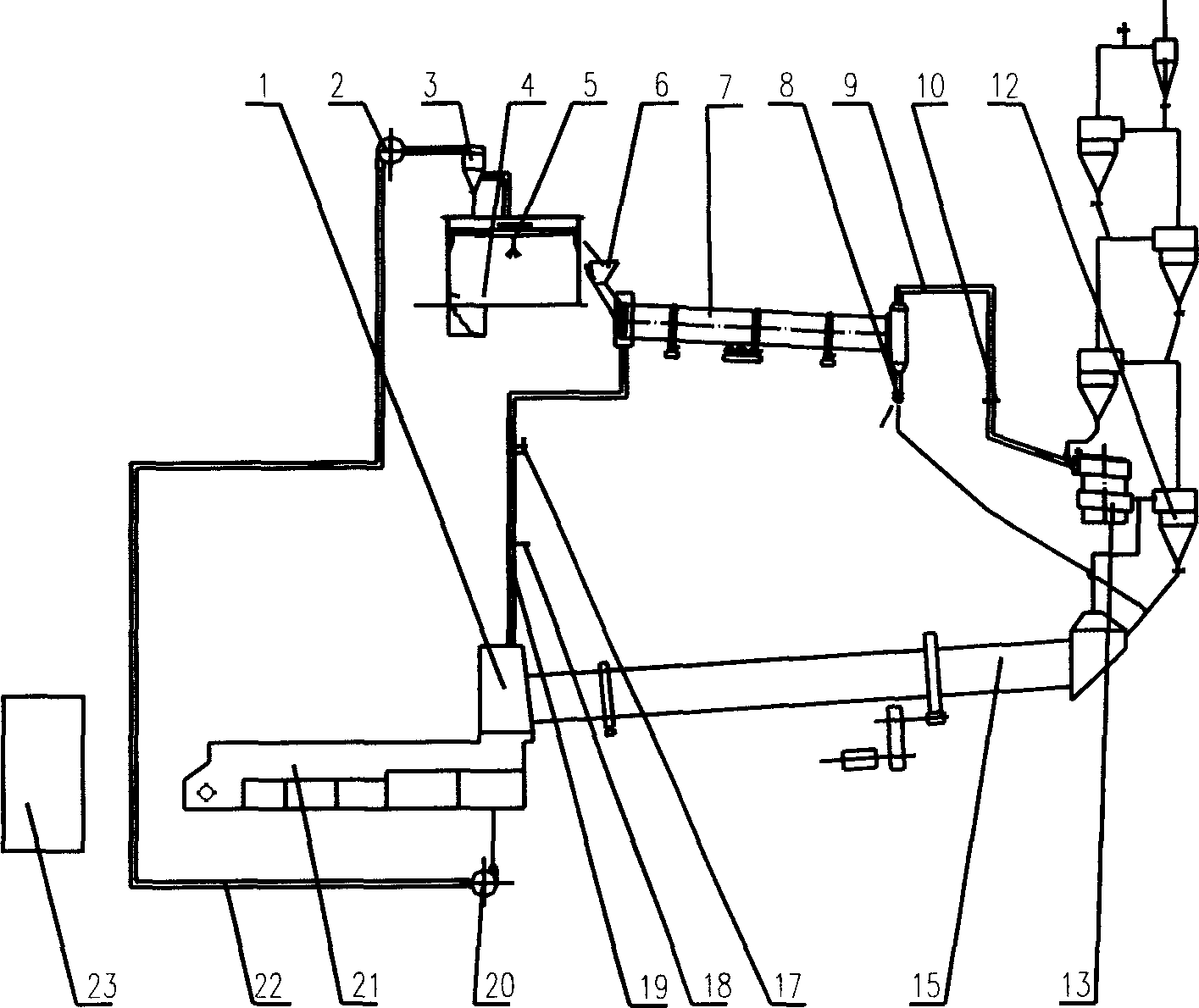

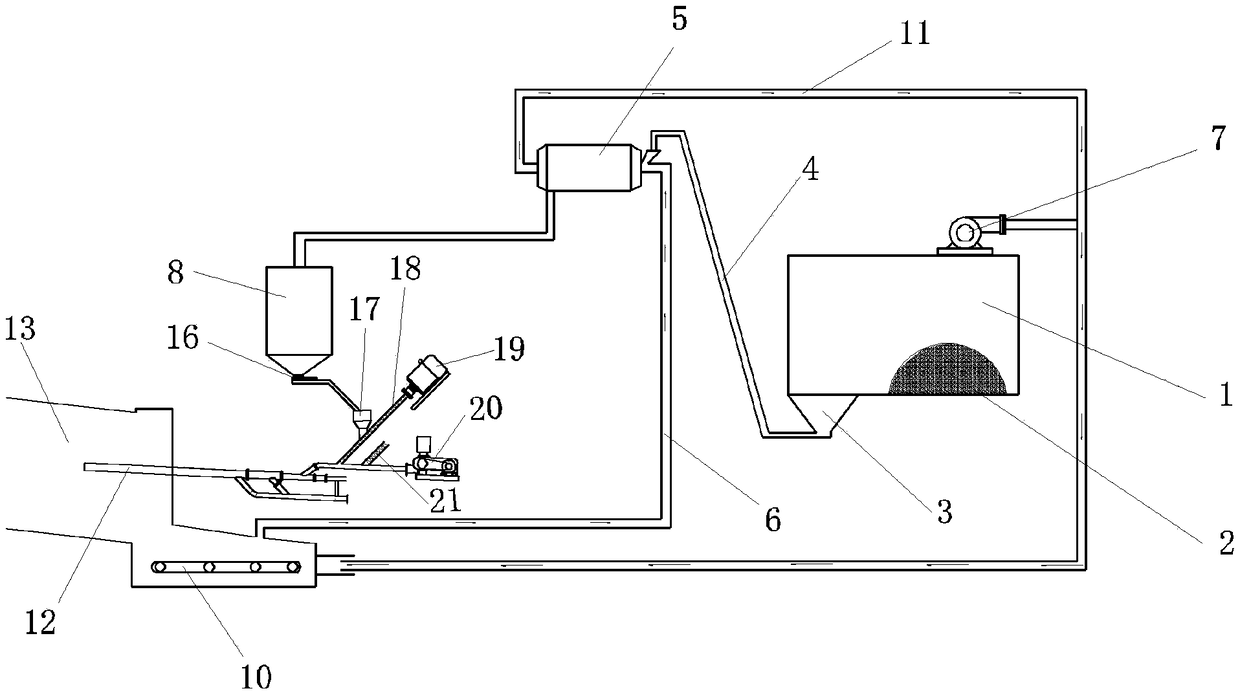

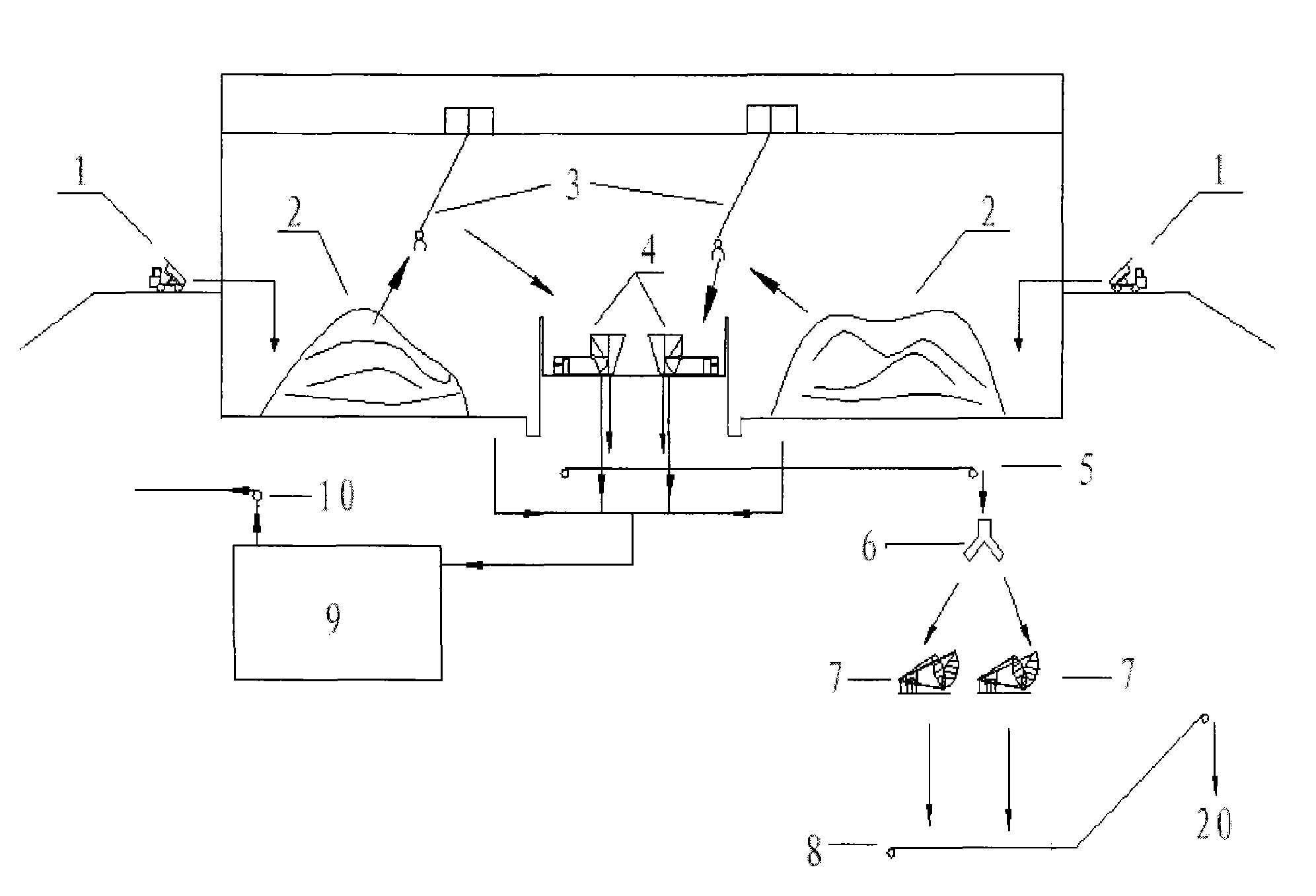

Process system for processing municipal domestic waste by cement rotary kiln

InactiveCN101618954ANo need to increase consumptionRealize "harmlessCement productionProcess systemsProcessing cost

The invention relates to a process system for processing municipal domestic waste by a cement rotary kiln. The domestic waste is processed by the following steps: manually separating, pre-dewatering and shattering the domestic waste; drying and burning the shattered domestic waste by an auxiliary burning furnace; enabling generated waste gas and released heat to enter a preheat decomposing system of the cement rotary kiln; and finishing the drying, preheating and partial burning functions of cement raw material, wherein burning ash enters the cement rotary kiln by a cement-decomposing kiln as a raw material to produce cement clinker. The invention fully utilizes facilities and places of the prior cement plants to save investments, processes harmful gas, does not need fuel consumption and has low processing cost and great handling capacity because of a high heat value of organic matter in the waste, solves the problem of secondary pollution, saves natural resources and non-renewable energy and reduces the influence of the waste on a burning system to the minimum.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

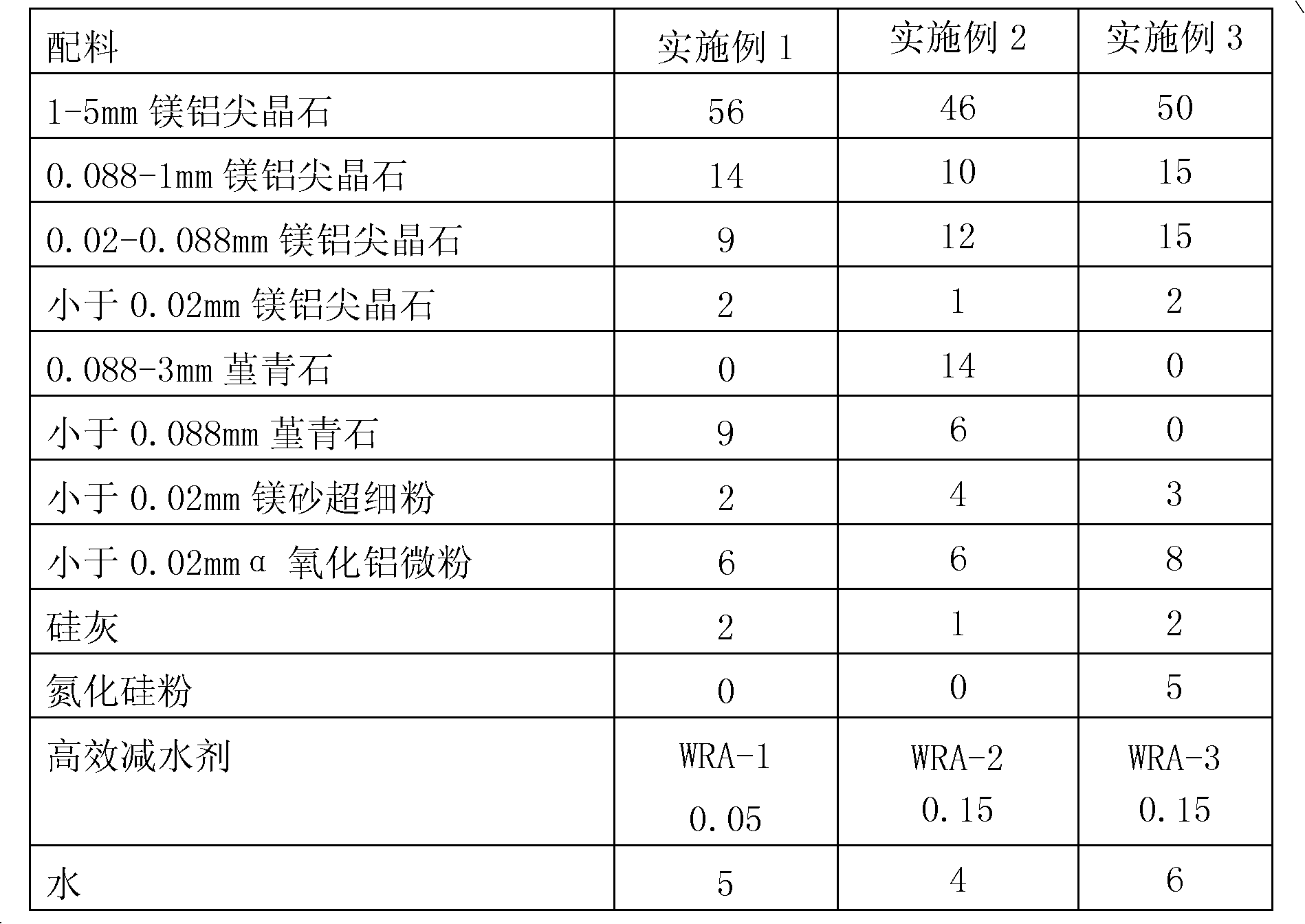

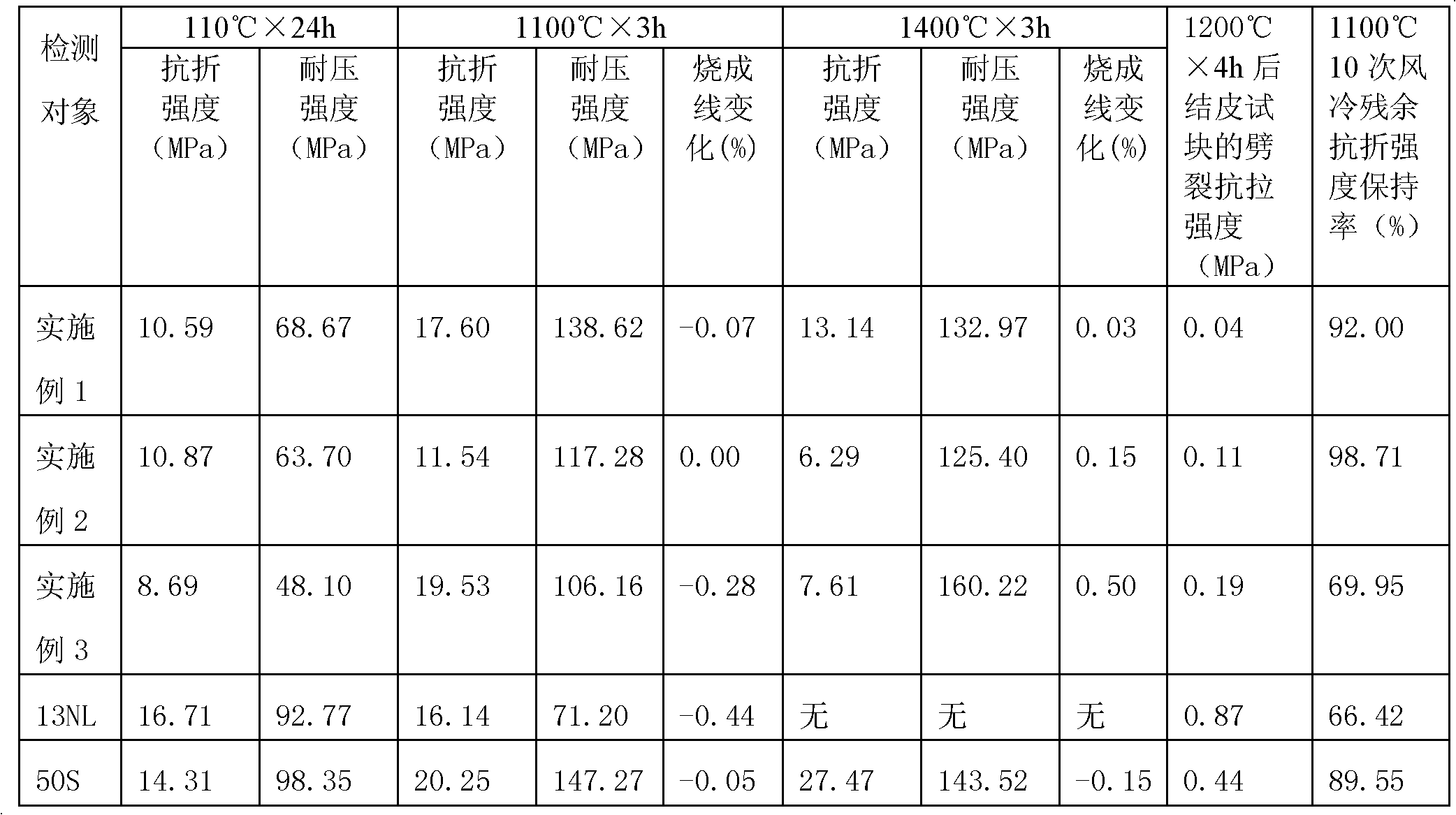

Anti-skinning unshaped refractory material made of magnesium aluminate spinel used for cement kiln and preparation method and application of anti-skinning unshaped refractory material

The invention discloses an anti-skinning unshaped refractory material made of magnesium aluminate spinel used for a cement kiln and a preparation method and application of the anti-skinning unshaped refractory material. The anti-skinning unshaped refractory material comprises raw materials as follows: quaternary mixed magnesium aluminate spinel with the particle diameter below 5mm, secondary mixed cordierite with the particle diameter below 3mm, superfine magnesia powder with the particle diameter smaller than 0.02mm, alpha-alumina micropowder with the particle diameter smaller than 0.02mm, silicon micropowder, silicon nitride powder, a high-efficiency water-reducing agent and water. According to the anti-skinning unshaped refractory material disclosed by the invention, with the magnesium aluminate spinel as the main crystalline phase and a superfine magnesia powder-silicon micropowder-silicon nitride powder-water system to substitute a pure calcium aluminate cement bonding agent, a complex-phase structure with the magnesium aluminate spinel as the main crystalline phase and the cordierite as the secondary crystalline phase is formed under high temperature, so that the refractory material has certain high-temperature resistance and good anti-skinning and anti-heat shock performances, can be used as the anti-skinning unshaped refractory material for a novel dry-process cement rotary kiln and a cement presintering production process, and has broad application prospect.

Owner:CHINA BUILDING MATERIALS ACAD +1

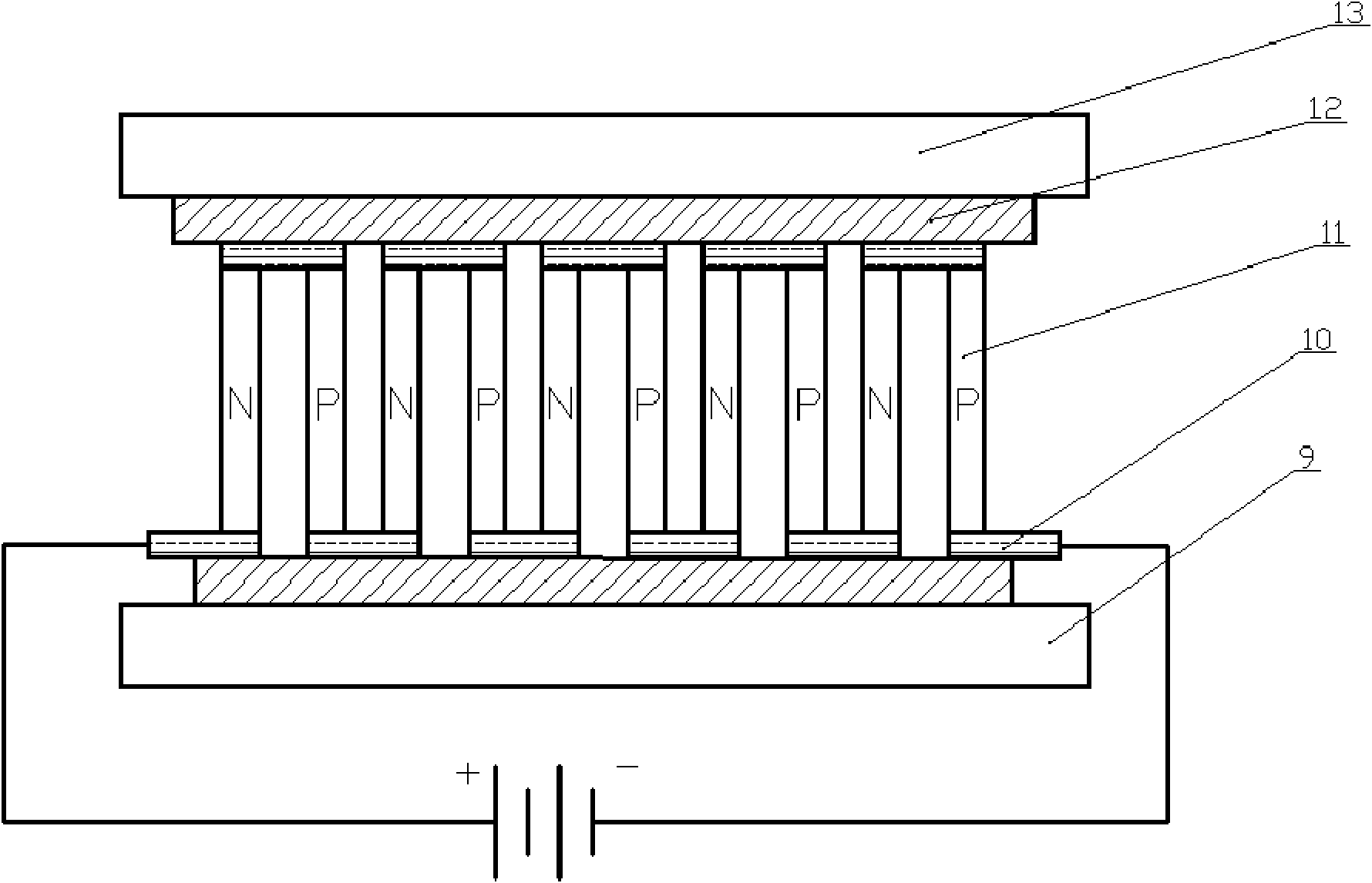

Generating system using surface residual heat of dry cement rotary kiln

InactiveCN102072641ASolve the problem of comprehensive utilizationEnergy savingRotary drum furnacesGenerators/motorsElectromotive forceMaterials science

The invention discloses a generating set which can rotate along with a cement rotary kiln and generate power by using residual heat of a dry cement rotary kiln. In the generating set, residual heat on the surface of the rotary kiln is collected, heat is transferred to the hot end of a semiconductor temperature difference generating module, a radiator is arranged at the cold end of the temperature difference generating module, a temperature difference is generated between the hot end and the cold end of the temperature difference generating module, and electromotive force is generated under the action of Seebeck effect, output through a slip ring or an electric brush or applied to an electrical appliance load which needs direct current power supply, so that power generation by using surface residual heat of the cement rotary kiln is realized. A system comprises components such as the temperature difference generating module, a heat collector, the radiator, the slip ring, the electric brush and the like. A generating component is fixed with the cement rotary kiln and rotates along with the cement rotary kiln, so that the originally wasted surface residual heat of the rotary kiln is directly converted into electric energy and a low-grade efficient residual heat utilization mode is realized. The system has the advantages of energy conservation, simple structure and long service life, is firm, durable and clean, and is free from leakage and noise, and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com