Innocent treatment method and apparatus for refuse burning flyash

A waste incineration fly ash and harmless treatment technology, applied in the field of environmental engineering, can solve the problems of dioxin volatilization, damage to cement quality, air pollution, etc., achieve good environmental benefits, avoid clogging problems, and reduce heavy metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further understand the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the protection scope of the present invention.

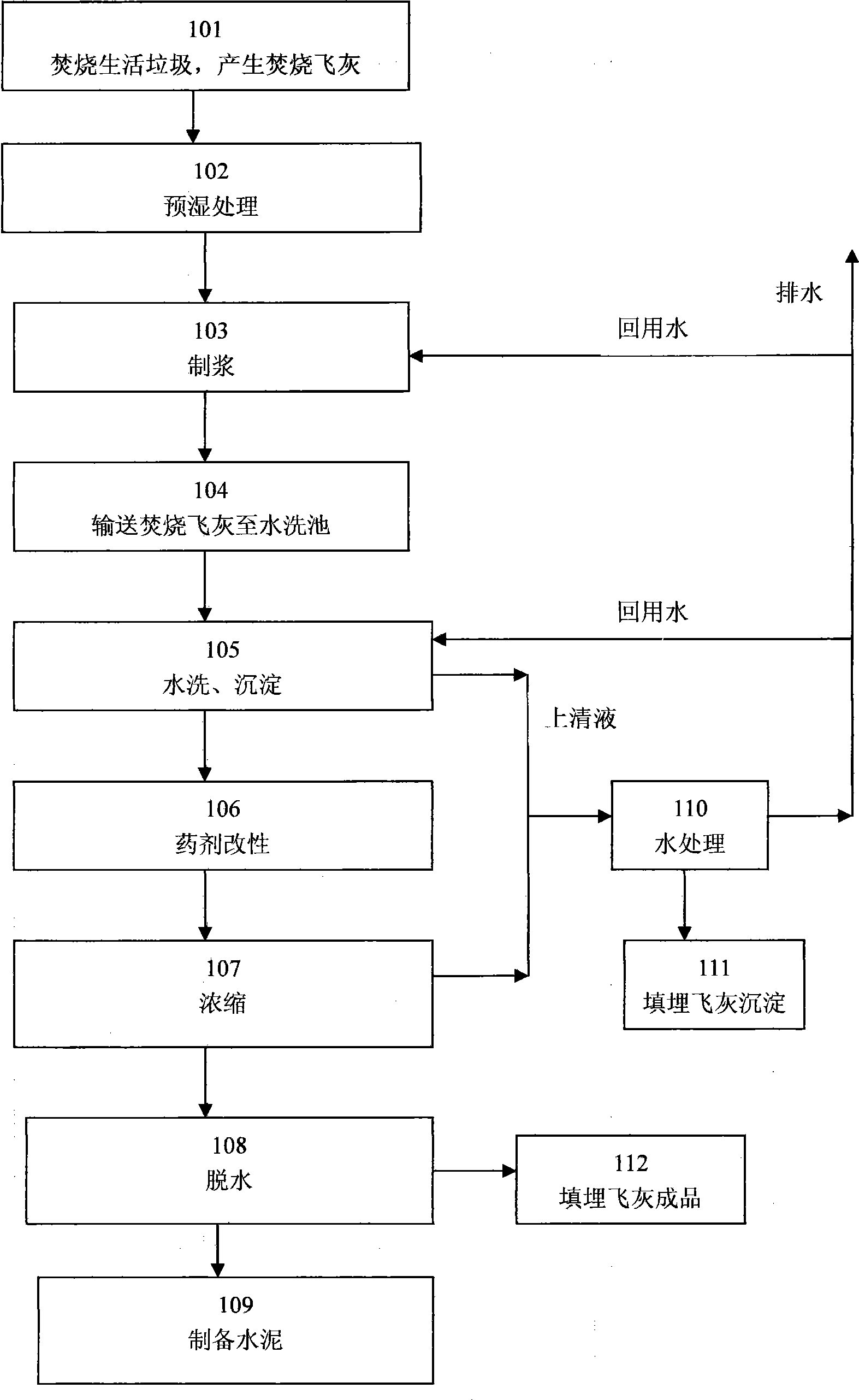

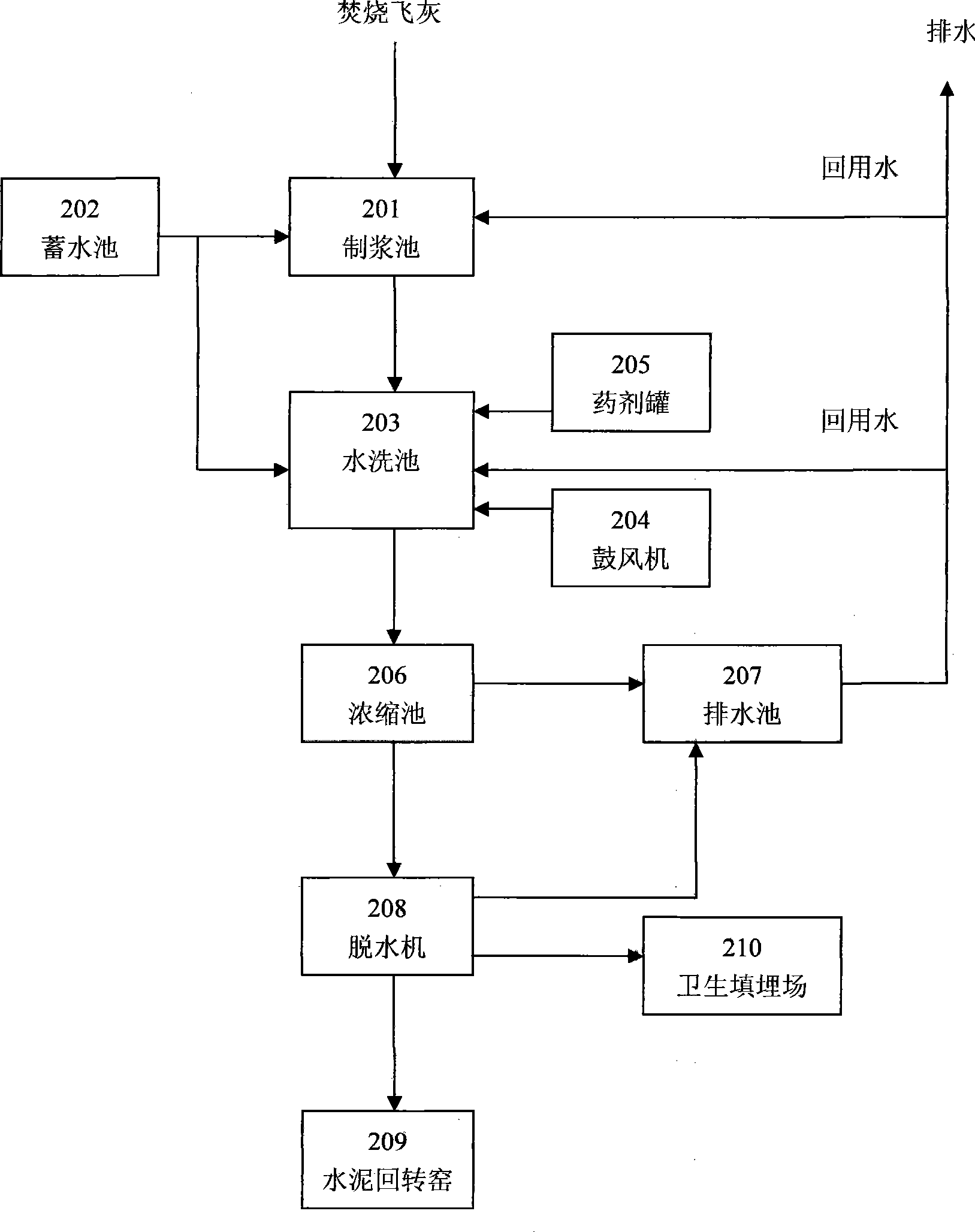

[0054] Such as figure 1 Shown is a schematic diagram of the method for harmless treatment of waste incineration fly ash according to the present invention. 101 Incineration of domestic waste to produce incineration fly ash. First, 102 pre-wet treatment is performed on the incineration fly ash, and water and heavy metal stabilizers are added to control dust and prevent heavy metal ions from being separated into the atmosphere. The pre-wet incineration fly ash is transported to the pulping tank for 103 pulping; the pulping method is: mix the incineration fly ash with tap water or recycled water at a ratio of 1:2 to 1:20, and use a blade with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com