Patents

Literature

238results about How to "Reduce chlorine content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

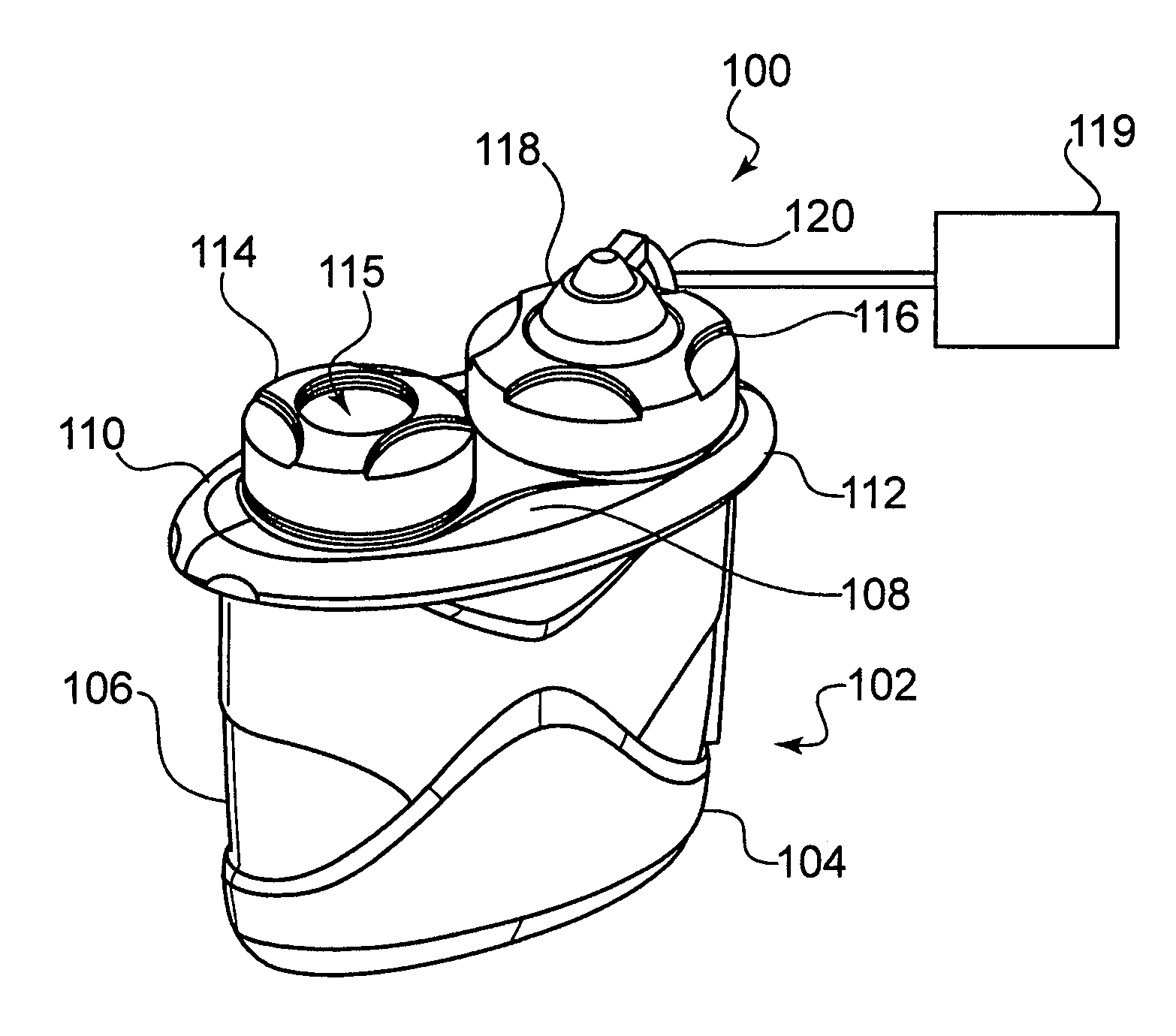

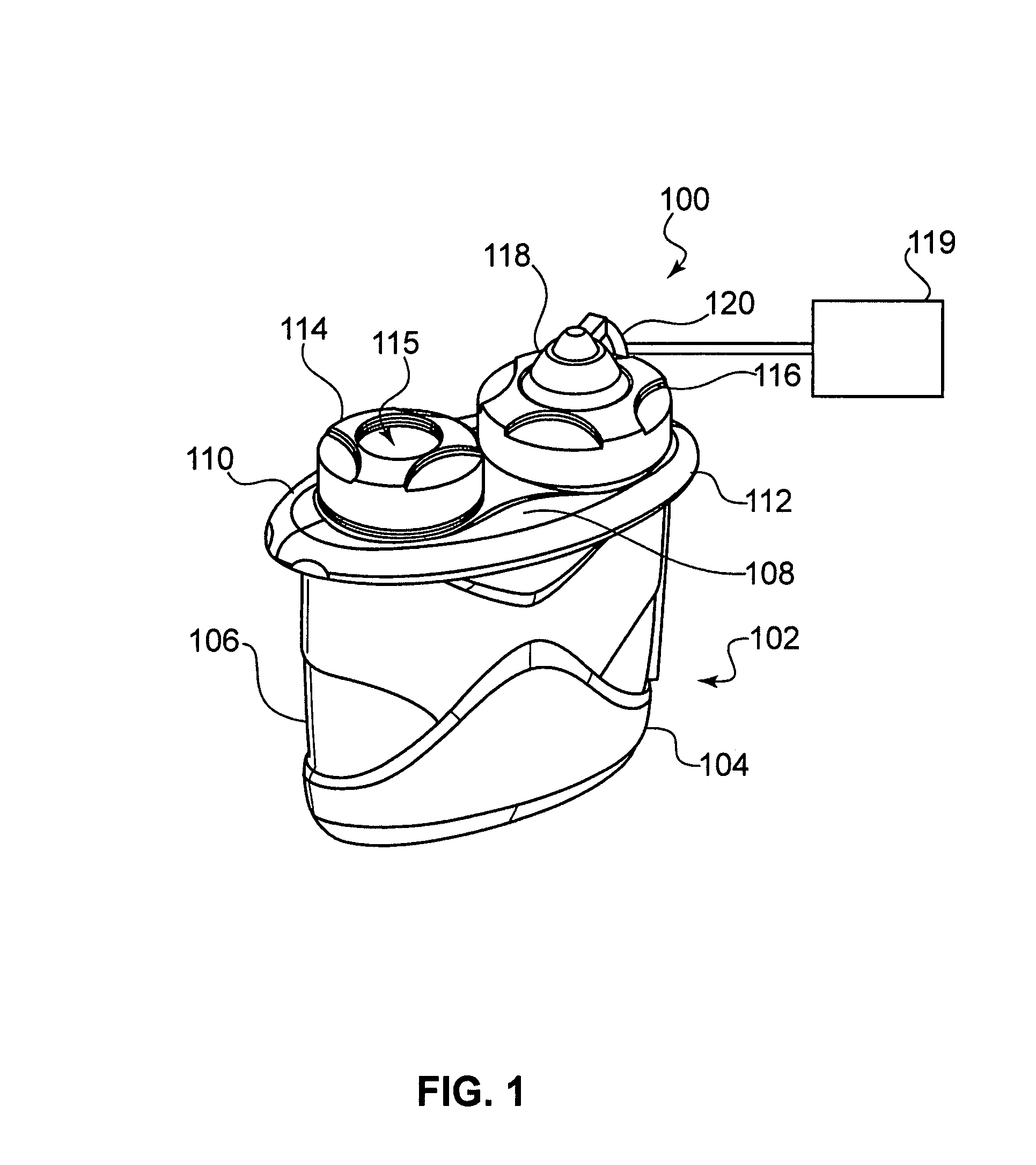

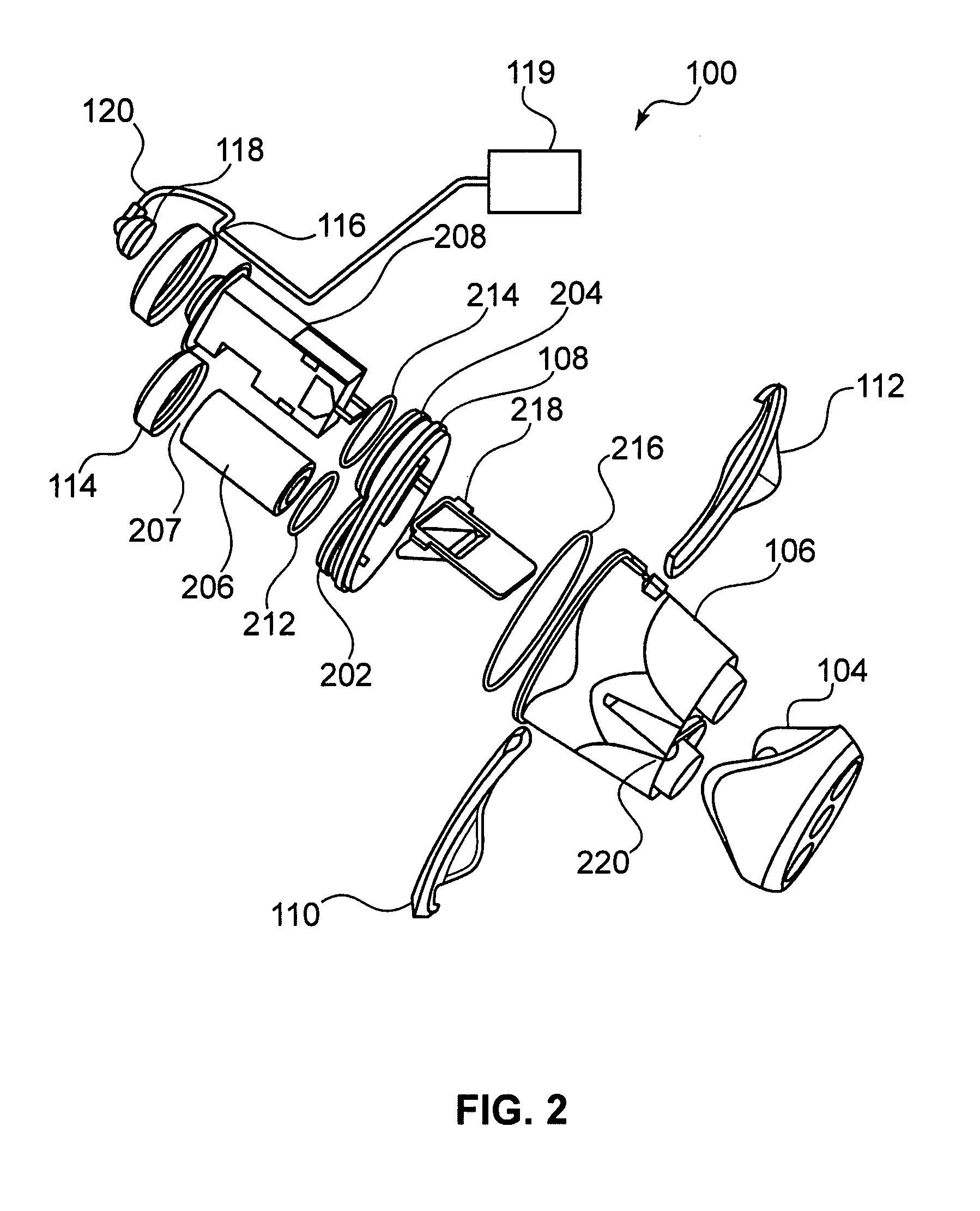

Apparatus for purifying water

InactiveUS7238278B2Reduce concomitant disadvantageEconomical purification processLiquid solutions solvent extractionLoose filtering material filtersHypohaliteMetal salts

The invention relates to a method for purifying water by forming in an electrolytic cell molecular halogen, hypohalic acid, hypohalite ions or combinations thereof, from halide ions dissolved in the water; and dissolving one or more soluble metal salts in the water to provide corresponding metal ions. The invention also relates to a system for purifying water, having an electrolytic cell comprising a plurality of electrodes sufficient to electrolytically convert halide ion in the water into molecular halogen, hypohalic acid, or hypohalite ions, or combinations thereof; and a metal generator, which provides concentrations of one or more metals to the water.

Owner:ZODIAC POOL SYST LLC

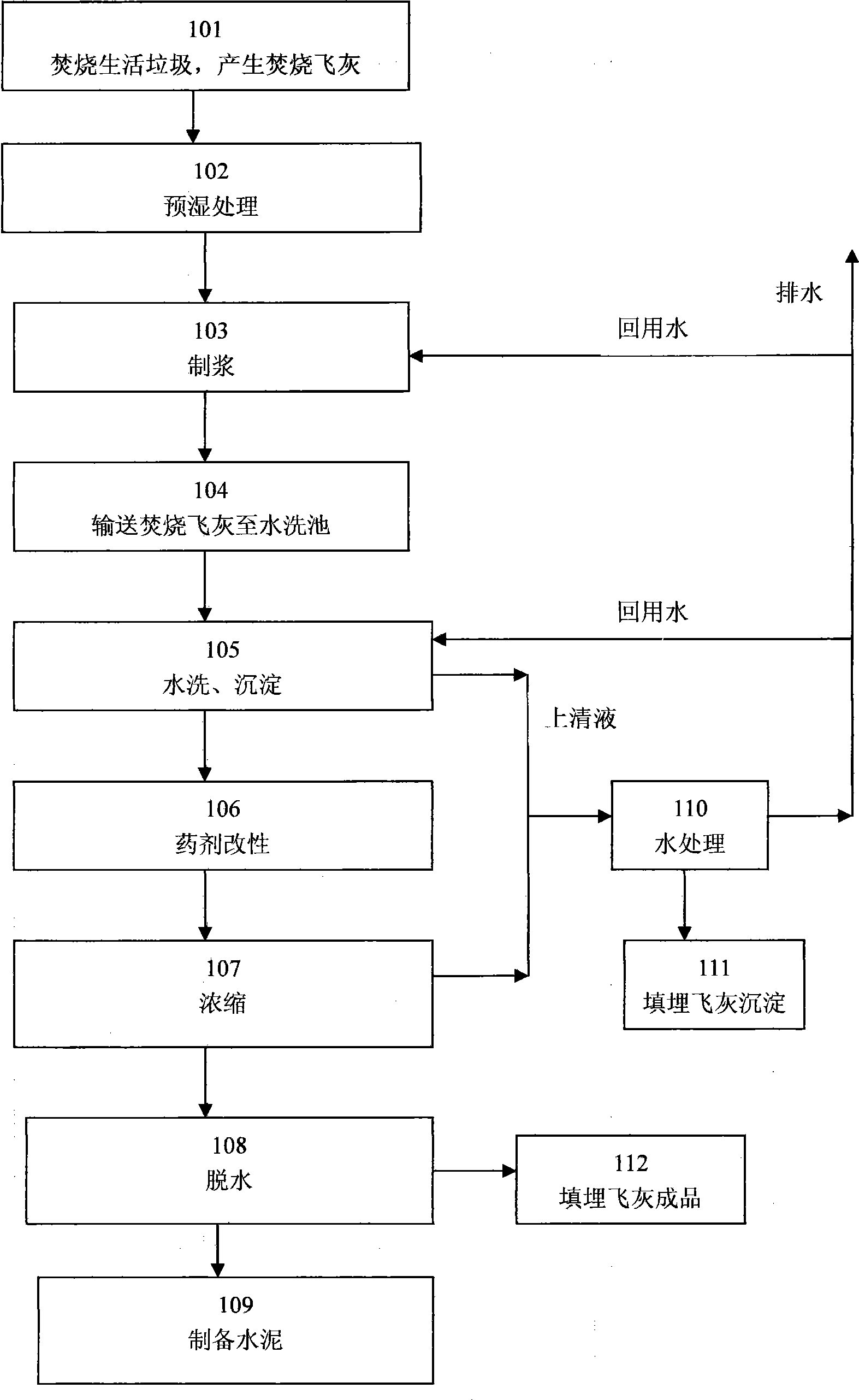

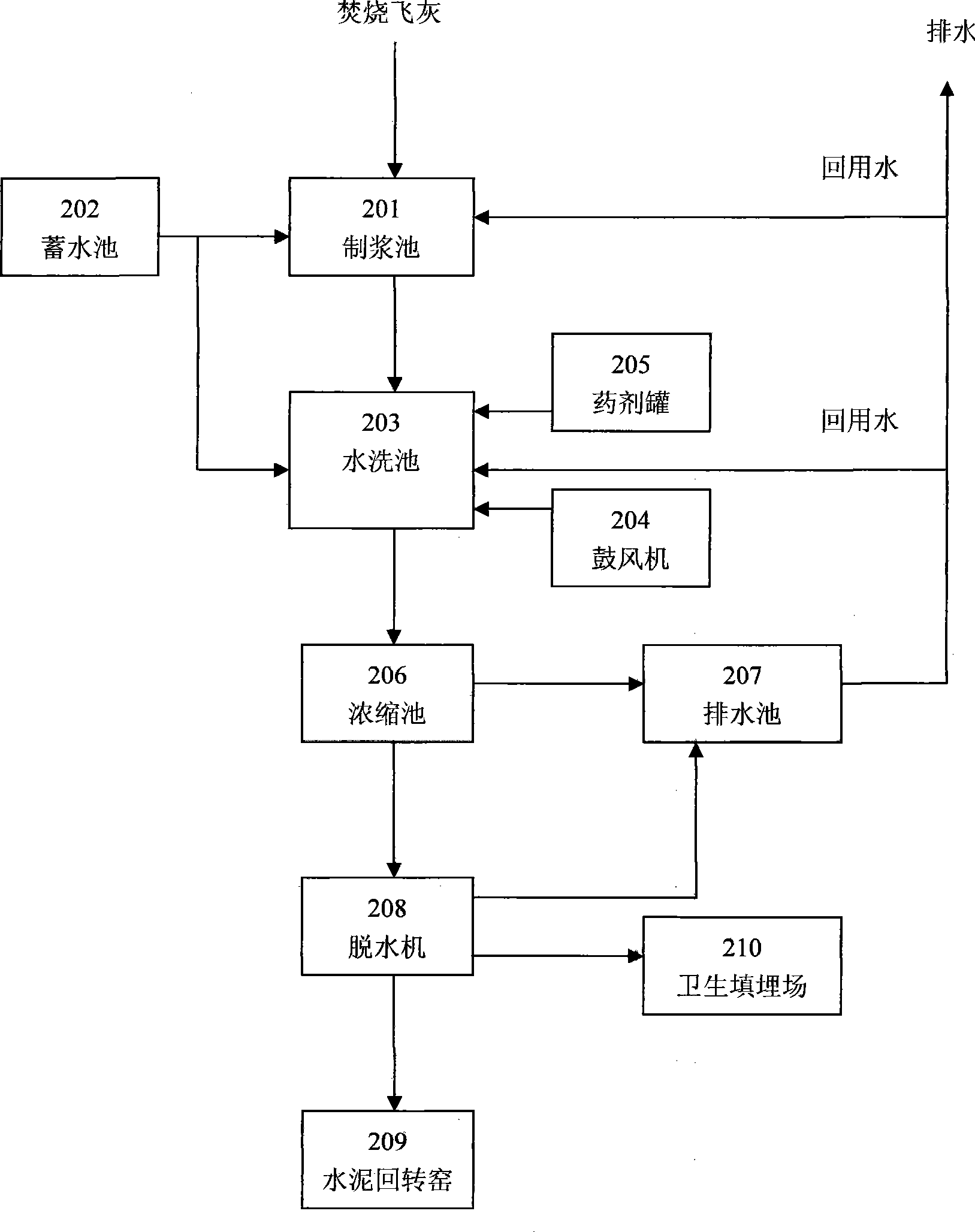

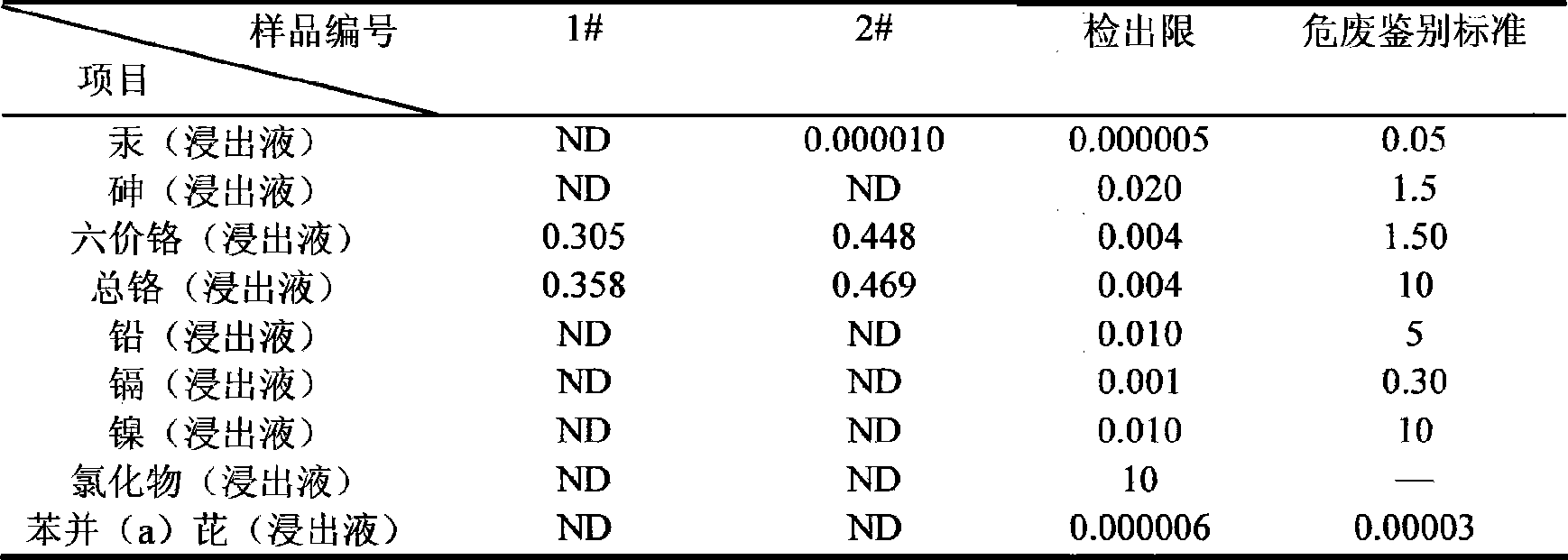

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

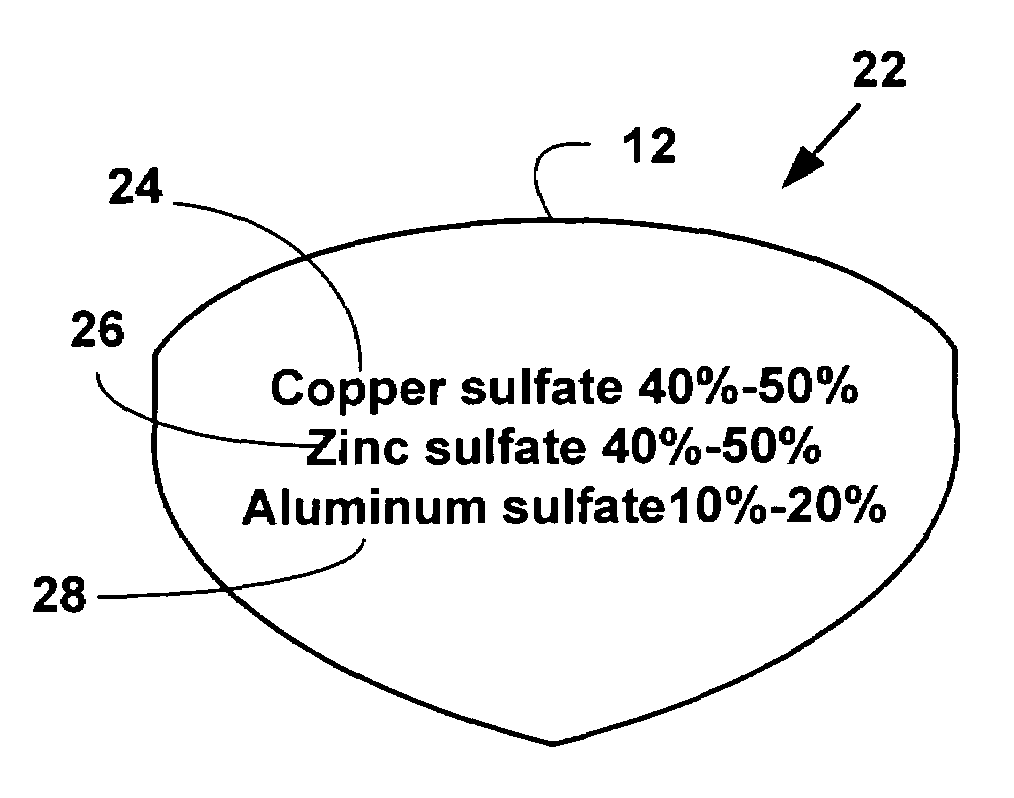

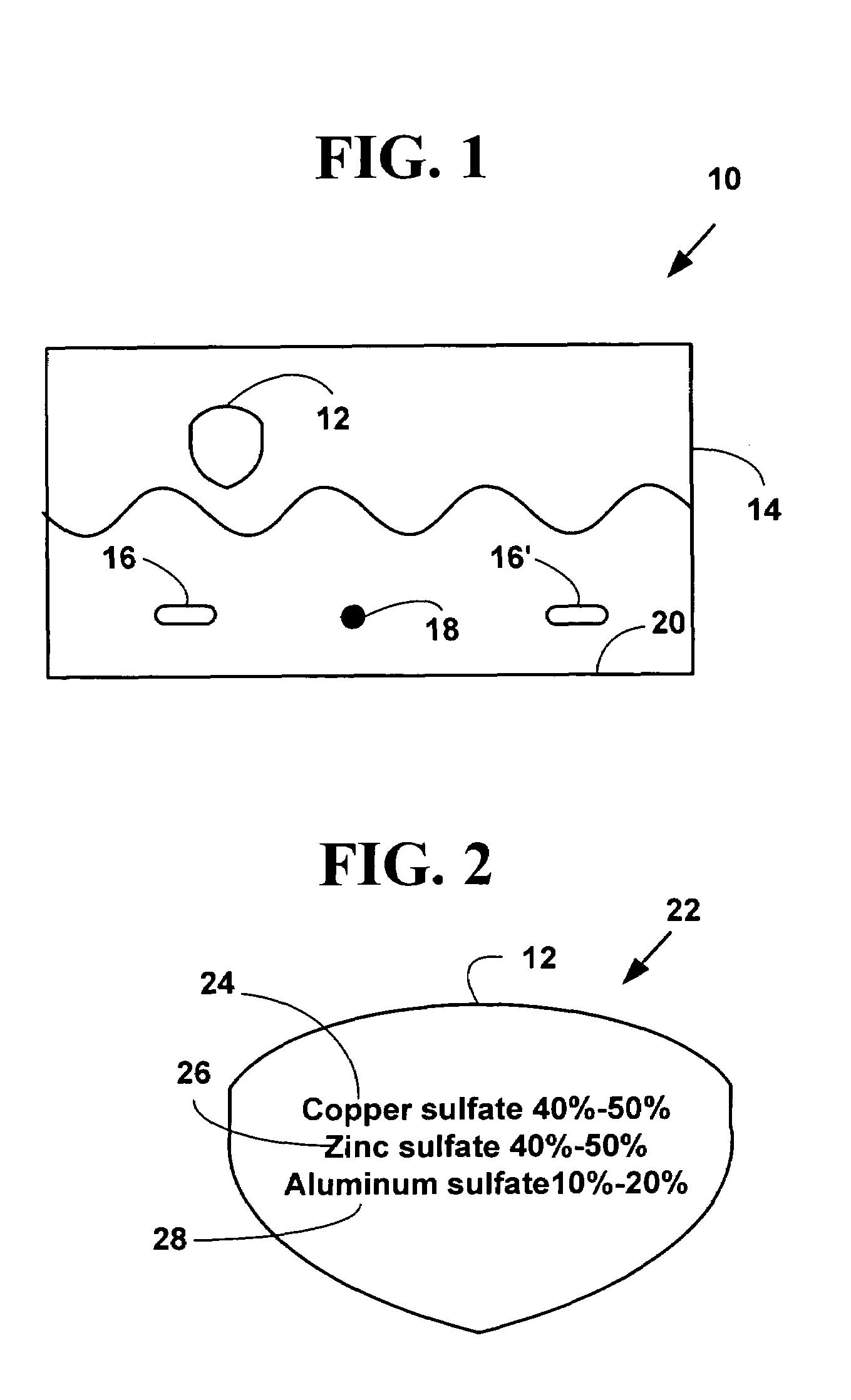

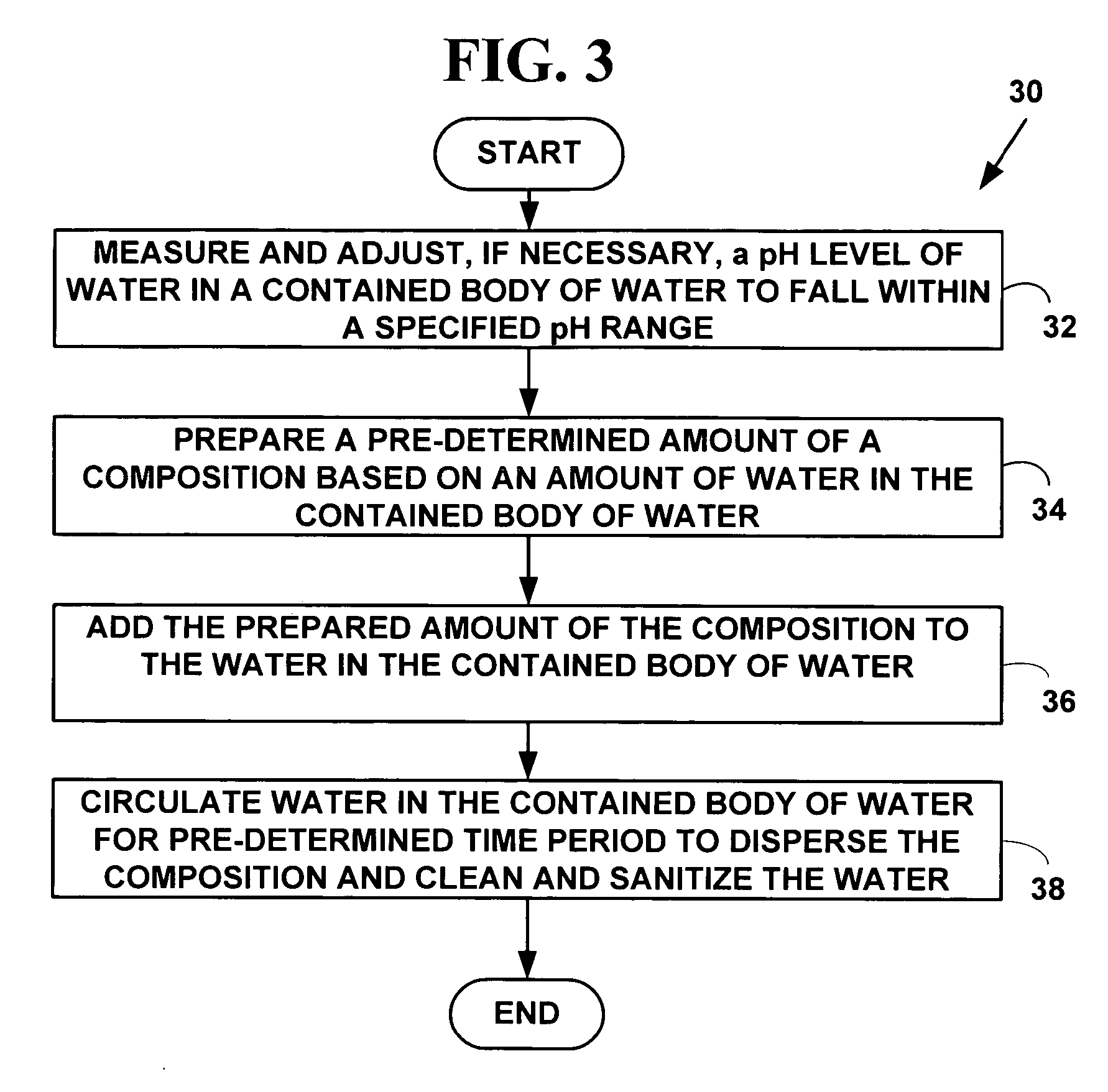

Composition for cleaning contained bodies of water

InactiveUS7252843B2Reduce the amount requiredReduce chlorine contentBiocideWater softeningAluminium sulfateZinc

A composition and method for cleaning, sanitizing and maintaining contained bodies of water such as swimming pools, wading pools, fountains, ornamental ponds, etc. The composition includes pre-determined percentages of copper sulfate, zinc sulfate, and aluminum sulfate by weight. The composition and method reduce amounts of chlorine and an amount of labor associated with the cleaning, sanitization and maintenance of contained bodies of water.

Owner:MOORE DAVID J +1

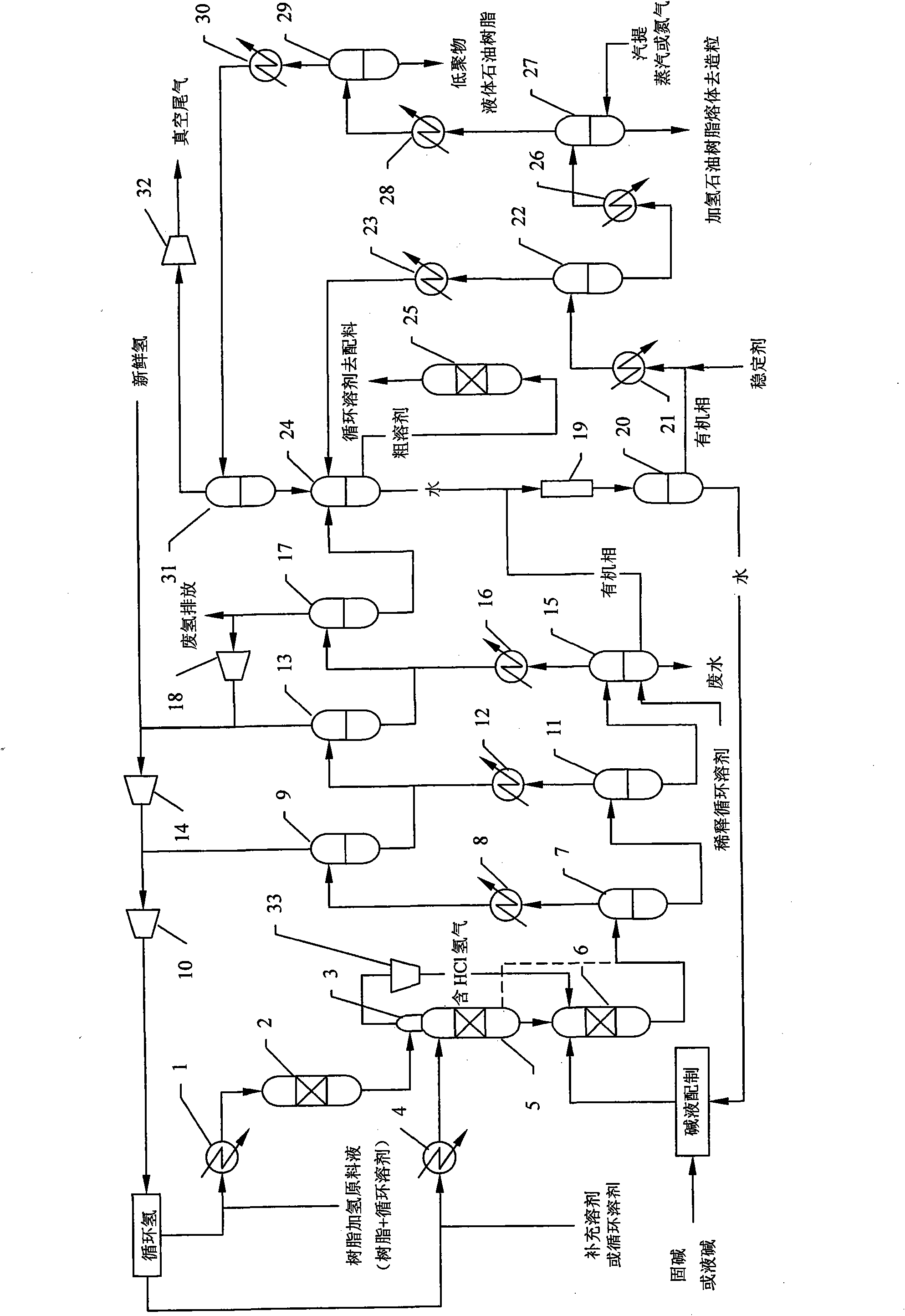

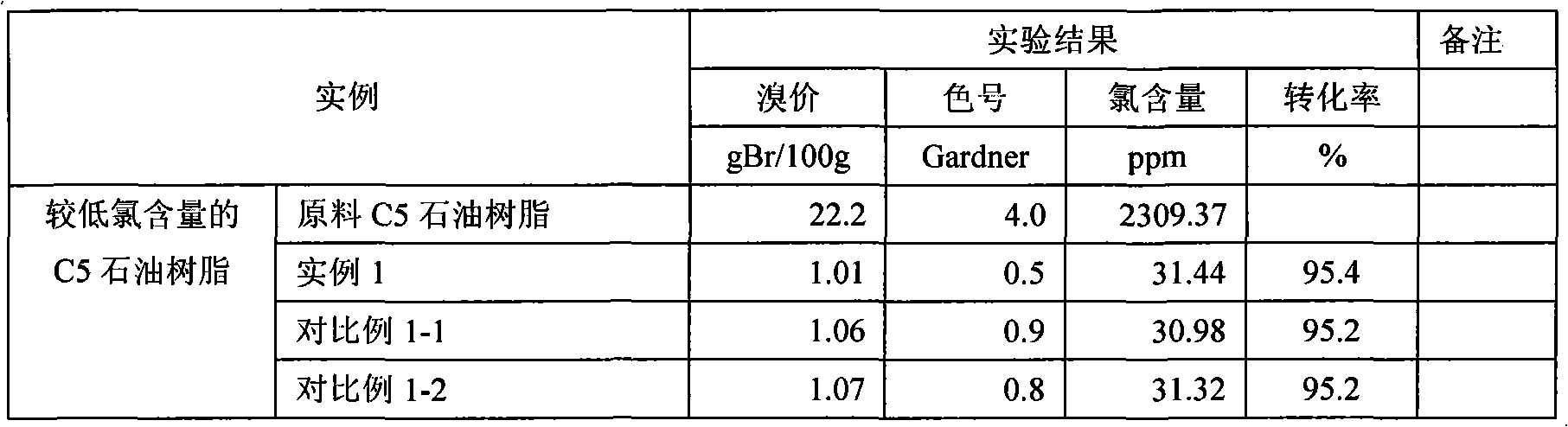

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

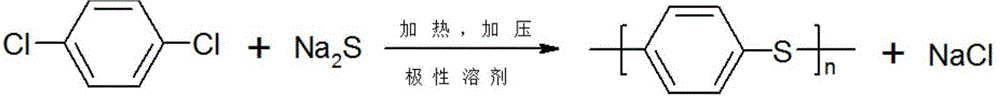

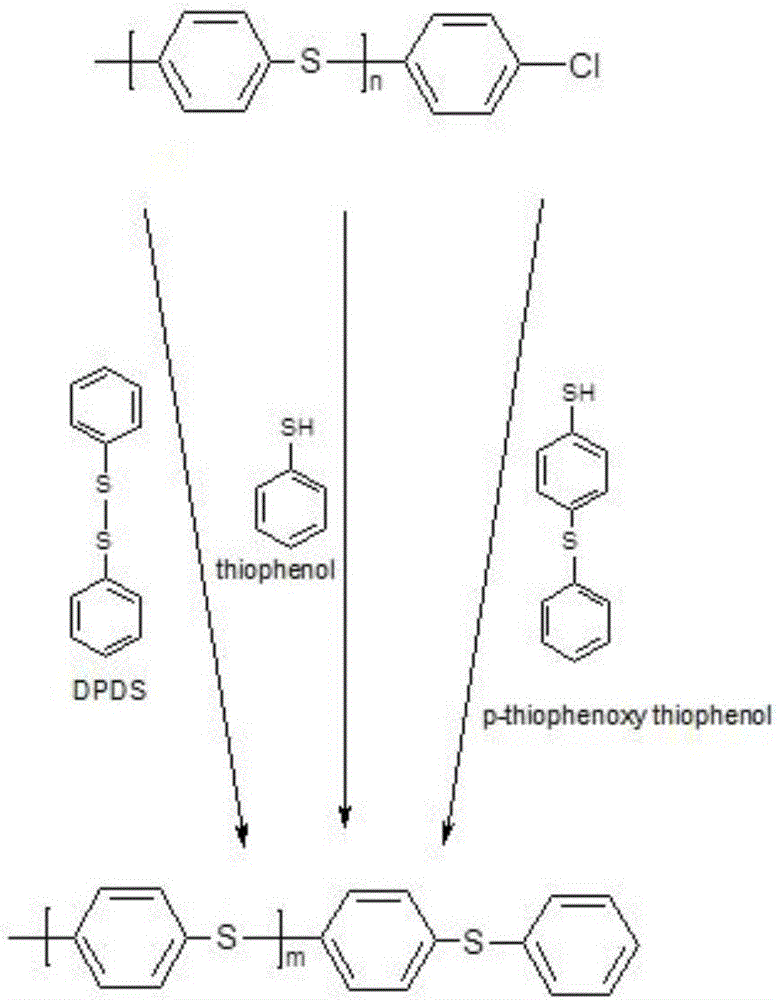

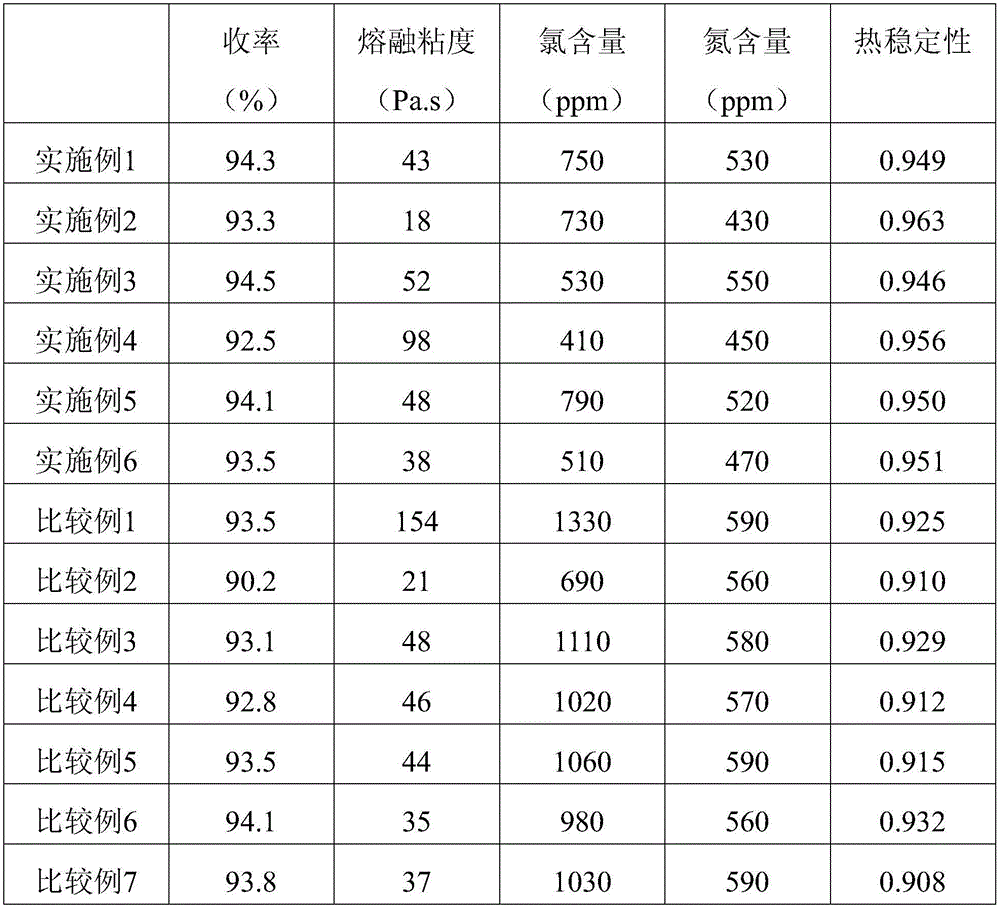

Polyphenylene sulfide with low chlorine content, preparation method of polyphenylene sulfide, resin composition and formed body

ActiveCN106633062AGood environmental friendlinessExcellent fluidity and thermal stabilitySulfur containingEthyl Chloride

The invention discloses polyphenylene sulfide with low chlorine content, a preparation method of the polyphenylene sulfide, a resin composition and a formed body. The polyphenylene sulfide with low chlorine content is prepared by performing end-capping 4-thiophenyl-benzenethiol. The method for preparing the polyphenylene sulfide disclosed by the invention comprises the following steps: taking a sulfur-containing compound, an alkaline matter and paradichlorobenzene as raw materials, taking fatty acids as polycondensation additives, taking 4-thiophenyl-benzenethiol (PTT) as an end group regulator, and carrying out a condensation polymerization reaction. The method disclosed by the invention is high in product yield and low in cost, the obtained polyphenylene sulfide product is low in chlorine content and has excellent fluidity and heat resistance. Therefore, the operating requirements of low chlorine and high fluidity in electronic enterprises can be met.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +2

Preparation method of medium-viscosity poly alpha-olefin base oil

ActiveCN103666552AEasy to separateReduce pollutionTreatment with polymerisationOligomerDistilled water

The invention relates to a preparation method of medium-viscosity poly alpha-olefin base oil. The preparation method comprises the following steps: under conditions with a temperature of 20 DEG C-120 DEG C, reaction pressure of 0.1 MPa-1.4 MPa and a volume ratio of alpha-olefin / a solvent of (1:0)-(1:3), catalyzing 1-decene or 1-decene and alpha-olefin of C8-C12 for oligomerization for 2 hours-12 hours by using an alkaline-modified AlCl3 / Al2O3 immobilized catalyst; and filtering the catalyst after stopping reaction, washing by distilled water, distilling under the normal pressure to remove the solvent, distilling under reduced pressure to remove un-reacted alpha-olefin to obtain alpha-olefin oligomer base oil, wherein the yield of the poly alpha-olefin is greater than 60 omega%, the movement viscosity of the oligomer at 100 DEG C is 10.0mm<2> / s-25.0mm<2> / s, and the chlorine content of the oligomer is less than 2.0 omega%.

Owner:PETROCHINA CO LTD +1

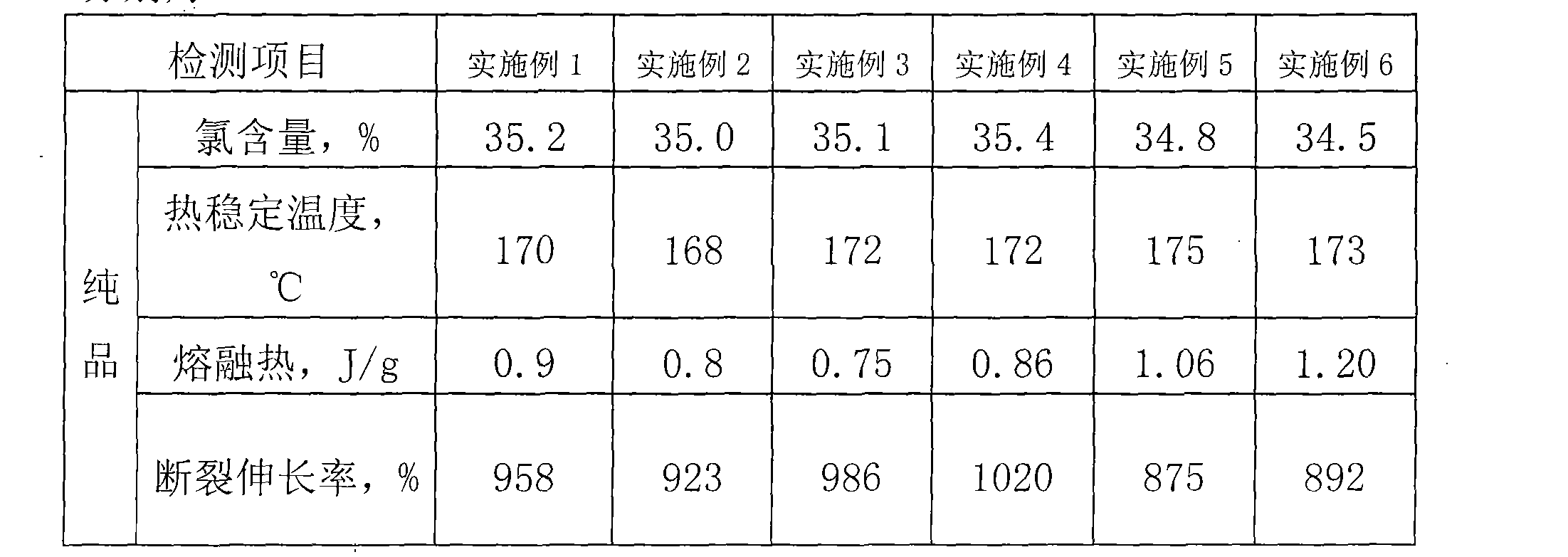

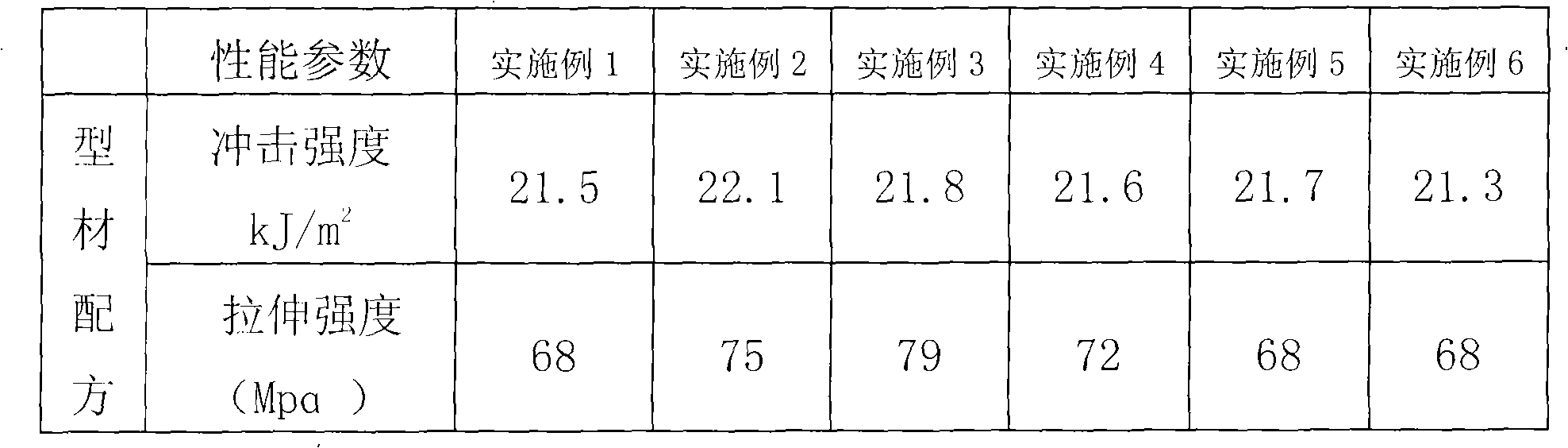

Preparation of chlorinated polythylene

InactiveCN101280030AReduce chlorination timeThe degree of chlorination in depthPolymer scienceChlorinated polyethylene

The invention belongs to plastic profile product modifier technical field and discloses a preparation method for a PVC anti-impact modifier chlorinated polyethylene. The invention is mainly technically characterized in that after dispersant, emulsifier, initiator and powdery high-density polyethylene resin are added into a chlorinating reactor with water inside in a stirring state, then the mixture is heated and processed through three chlorine reactions at different temperature ranges; after the reaction, the enwrapped HCl formed in the reactor is discharged; after repeated hot water washing, centrifugal dehydration and drying, calcium stearate, calcium carbonate and lanthanum carbonate are added to obtain the finished product through stirring, mixing and screening. As the high-density polyethylene resin in the preparation technology is high-mesh powdery material and three chlorine reactions are needed in the process, the chlorinated polyethylene prepared by the technology has higher thermal stable temperature and lower melting heat; if the chlorinated polyethylene serves as the anti-impact modifier of PVC products, the PVC product produced thereby has strong impact strength and tensile strength.

Owner:HEBEI JINGXIN CHEM GRP CO LTD

Technological process for preprocessing refuse burning fly-ash to be cement raw materials

InactiveCN101333084AReduce chlorine contentRealize resource utilizationSolid waste managementResource utilizationMaterials science

The invention provides a technique which makes the solid waste incineration fly ash into cement raw materials, comprising the following steps: washing, stirring, adding heavy metal stabilizer, separating liquid from solid waste incineration fly ash, mixing the solid waste incineration fly ash into the cement raw meal and sending the raw meal into a cement rotary kiln to calcine the raw meal so as to prepare the cement clinker. The invention also provides a method for treating the wastewater generated in the washing process. The solid waste incineration fly ash treated through the method disclosed in the invention can partially substitute for cement raw materials to prepare cement, while all the indicators of the cement can meet the relevant standards so as to effectively realize solid waste incineration fly ash resource utilization.

Owner:SHANGHAI UNIV

Processing method of titanium extraction tailings

InactiveCN104056841AReduce chlorine contentAchieve reuseCalcium/strontium/barium chloridesSolid waste disposalWater solubleChloride

The invention provides a processing method of titanium extraction tailings. The titanium extraction tailings contain a water soluble chloride; the method includes washing the titanium extraction tailings with water, so that the content of chlorine elements in the processed titanium extraction tailings is below 0.06 wt%. Through the processing method of the titanium extraction tailings, the titanium extraction tailings with the chlorine element content below 0.06% can be obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Fertilizer special for soybean

InactiveCN1508097AMeet nutritional needsNitrogen fixationHorticultureFertilizer mixturesSulfate radicalsPlant nodule

The present invention relates to a special-purpose fertilizer for soyabean. It is characterized by that it comprises nitrogen, phosphorus and potassium, also includes additive with slow-releasing action and special-purpose microfertilizer. The weight percentage of nitrogen, phosphorus and potassium is 0.4-1:0.1-0.3:0.2-0.4. Said invention is complete in nutrients and reasonable in formula, can fully meet nutrient requirement for soyabean growth and development process, also contains the nutrient components of nitrate nitrogen, sulfate radical, boron and molybdenum, so that it is favorable for soyabean nitrogen-fixing root nodule.

Owner:中国石油化工股份有限公司巴陵分公司

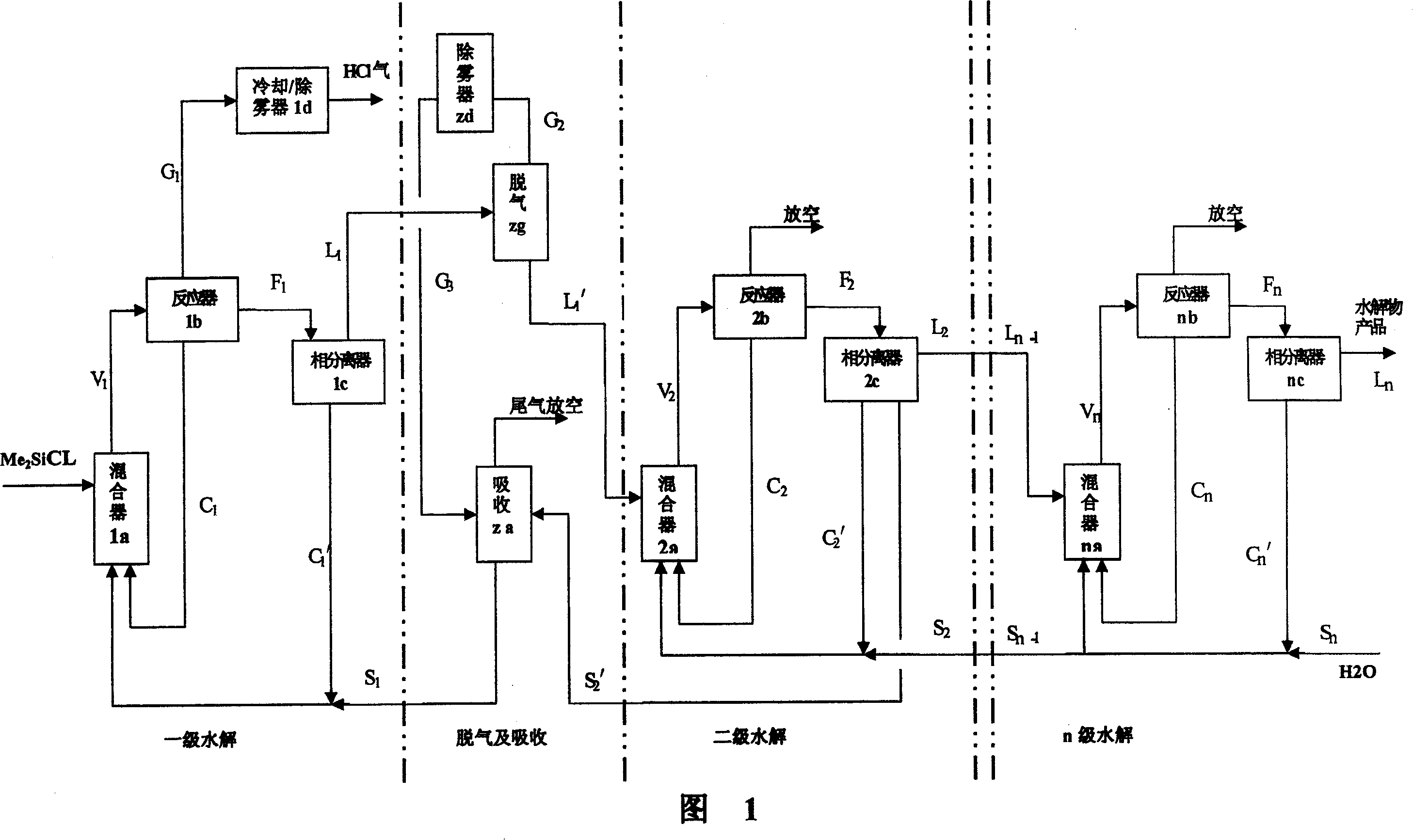

Method for preparing polyorganosiloxane and gas phase hydrogen chloride by multi-stage continuously hydrolyzing dichlorosilane

InactiveCN101148510AReduce pollutionReduce manufacturing costChlorine/hydrogen-chlorideDegasserGas phase

The present invention relates to continuous multistage organic dichlorosilane hydrolyzing process for preparing organic siloxane polymer and gaseous hydrogen chloride. Organic dichlorosilane is hydrolyzed continuously in a circulating hydrolysis reaction system with at least thee stages, each of which includes one inner circulating unit and one outer circulating unit. In the relatively independent hydrolysis reaction stages, the hydrolyzed organic siloxane polymer is fed continuously from the upper stage to the lower stage through one degasser to eliminate great amount of free hydrogen chloride, while hydrolyzed hydrochloric acid is replenished from the lower stage to the upper stage. The present invention has low gaseous hydrogen chloride content in each hydrolysis reaction stage, easy operation, stable product quality, high yield and stable pressure of anhydrous gaseous hydrogen chloride.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Ferrite particles and production method thereof

InactiveUS20090246526A1Reduce the amount of adhesionImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsReducing atmosphereSlurry

A method for producing ferrite particles by weighing, mixing, then crushing ferrite raw materials, and granulating the resultant slurry, and then sintering the resultant granulated material using a rotary furnace, wherein the sintering is carried out under a positive pressure reducing atmosphere.

Owner:POWDERTECH

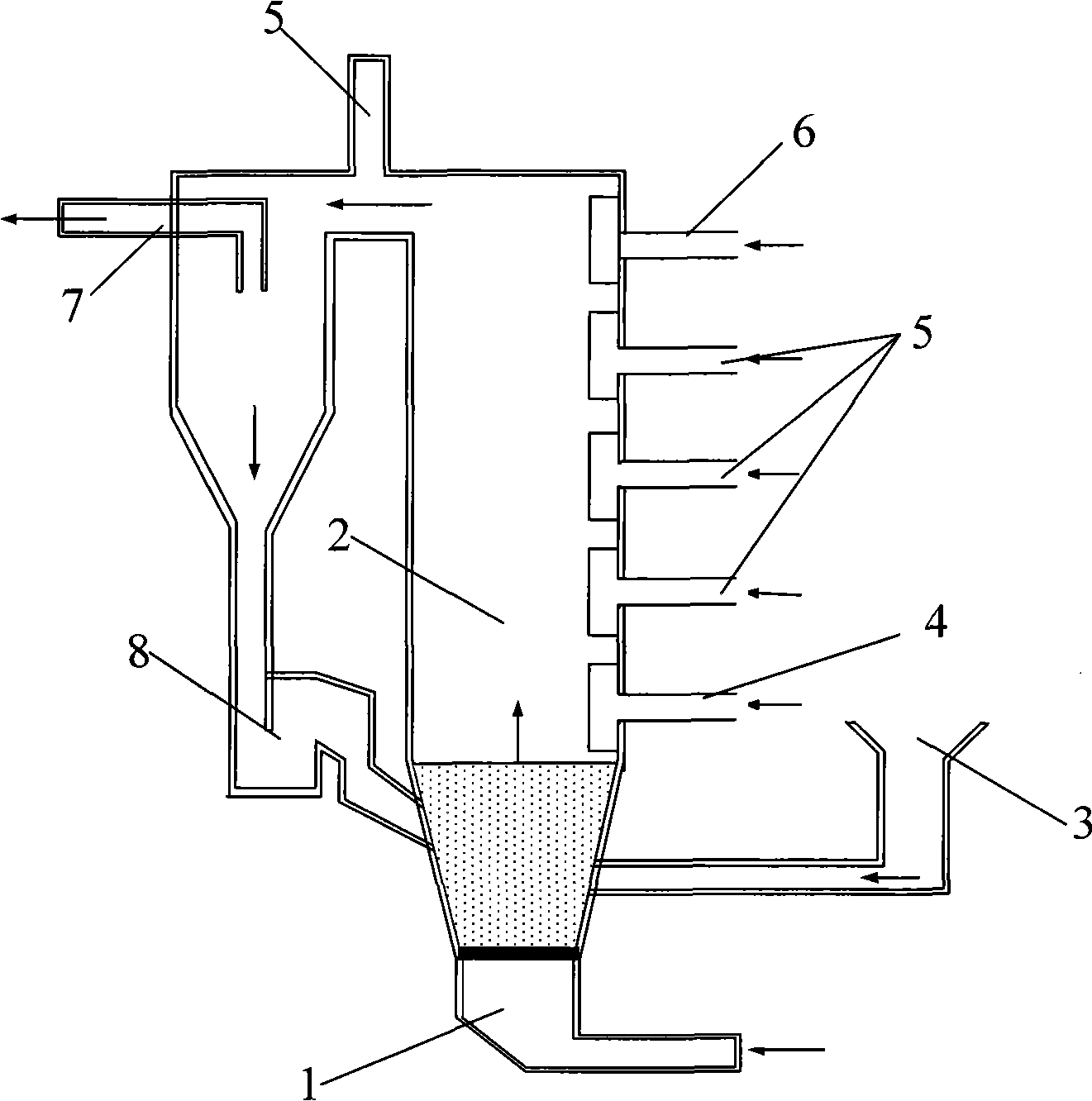

Biomass gasified gas re-burning mode and system for coal-fired fluidized bed

InactiveCN101915419AImprove combustion efficiencyImprove emission reduction efficiencyFluidized bed combustionApparatus for fluidised bed combustionSlagCoal dust

The invention belongs to the technical field of N2O emission reduction in a coal-fired fluidized bed, and particularly relates to a biomass gasified gas re-burning mode and a biomass gasified gas re-burning system for a coal-fired fluidized bed. The wall of a fluidized bed boiler is provided with a plurality of biomass gasified gas nozzles, biomass gasified gas is introduced into a hearth of the fluidized bed boiler, and the biomass gasified gas is reacted with N2O-containing smoke generated by burning of coal dust in the hearth to realize multi-stage re-burning so as to improve the burning efficiency of the whole fluidized bed and reduce the emission of N2O. Compared with pyrolysis and direct burning, the biomass gas rich in combustible substances such as H2, CH4, CO and the like has low ash content and extremely low sulfur content, has no sulfur removal problem, is ideal re-burning fuel and can effectively reduce the emission of nitrogen oxides by using mixed burning of the biomass gasified gas and the coal dust; and because of low alkali metal and chlorine content in the gasified gas, problems of slag formation and corrosion can be avoided, utilization of the coal dust is not affected and efficient clean utilization of the biomass can be realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method of butyronitrile gloves

ActiveCN106397894AReduce chlorine contentImprove cleanlinessGlovesProtective garmentMineralogyRaw material

The invention discloses a preparation method of butyronitrile gloves, and belongs to the technical field of butyronitrile gloves. The preparation method comprises following steps: a rubber latex raw material of the butyronitrile gloves is prepared; a hand mould is subjected to acid pickling, a first time of water washing, alkali washing, a second time of water washing, drying, and chlorine washing, is immersed in a coagulating agent solution for immersion, and is subjected to impregnation in the rubber latex raw material; and obtained rubber film is subjected to washing and demoulding. According to the preparation method, only one time of chlorine washing is carried out before hand mould impregnation, so that the surfaces of the butyronitrile gloves obtained via impregnation moulding are smooth, the butyronitrile gloves are convenient to wear, no adhesion is caused, processing process is simplified, and the chlorine content of the butyronitrile gloves is reduced greatly; and in addition, DI water is used for washing so as to remove particles and surface ions on the surfaces of the butyronitrile gloves, and the cleanliness of the butyronitrile gloves is improved.

Owner:SUZHOU HONBEST CLEAN TECH CO LTD

Biomass fuel with good formability

InactiveCN103666620AStrong coagulationCompact structureSolid fuelsWaste based fuelFiberEnvironmental resistance

The invention relates to environment-friendly biomass fuel with good formability. The biomass fuel is renewable biomass fuel free of any harmful substance, which is prepared by mixing wood dust powder and an additive, wherein the additive is high clay having high viscosity and strong adsorptive power; and the biomass fuel is prepared by mixing the wood dust and the additive according to a ratio of 9:1. The high clay additive is beneficial to formation of wood dust particles, and the multiporous fiber-like structure of the high clay additive can adsorb tar in flue gas from a heating system in the biomass fuel processing course, thereby preventing the tar from being attached to a granulator and a chimney and further avoiding influencing the granulating effect. Besides, the additive also solves the problem that the tar is difficult to remove and clean.

Owner:广州金安源节能科技股份有限公司

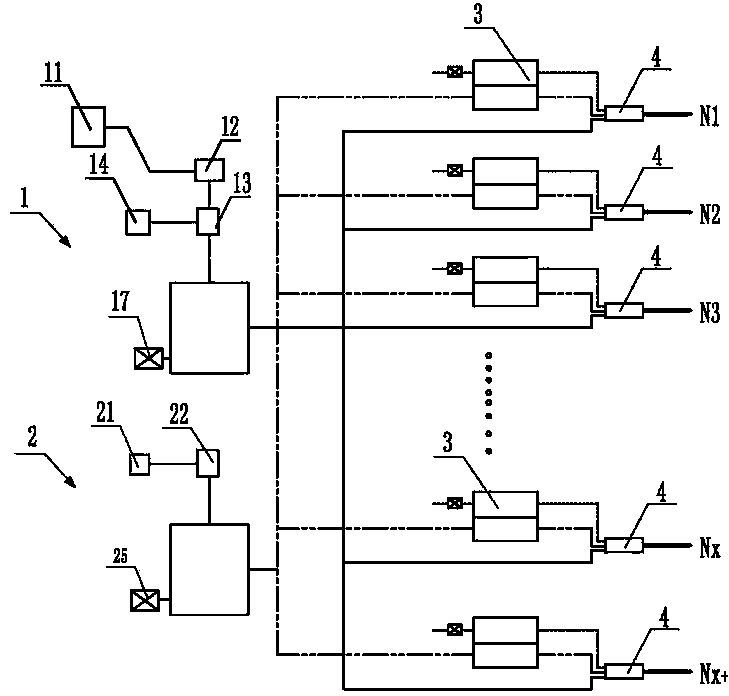

Automatic supply system of composite spray cooling oil for machining

ActiveCN104227494AImprove anti-corrosion performanceGuaranteed cleanlinessMaintainance and safety accessoriesAssistive device/technologySpray nozzle

The invention relates to the technical field of auxiliary equipment for machining, in particular to an automatic supply system of a composite spray cooling oil for machining. The automatic supply system comprises an automatic water supply system, an automatic oil supply system, a minimal quantity lubricating and cooling system and a composite atomizing spray nozzle, wherein a water outlet of the automatic water supply system is connected with a liquid inlet of the composite atomizing spray nozzle through a conveying pipe; an oil outlet of the automatic oil supply system is connected with a liquid inlet of the minimal quantity lubricating and cooling system through the conveying pipe; a liquid outlet of the minimal quantity lubricating and cooling system is connected with the liquid inlet of the composite atomizing spray nozzle. According to the automatic supply system disclosed by the invention, cutting oil can be automatically replenished, the problems that a manual mode of replenishing the cutting oil is miscellaneous and a long time is consumed are solved, the production efficiency is improved, and the application range of a minimal quantity lubricating technology is effectively widened.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

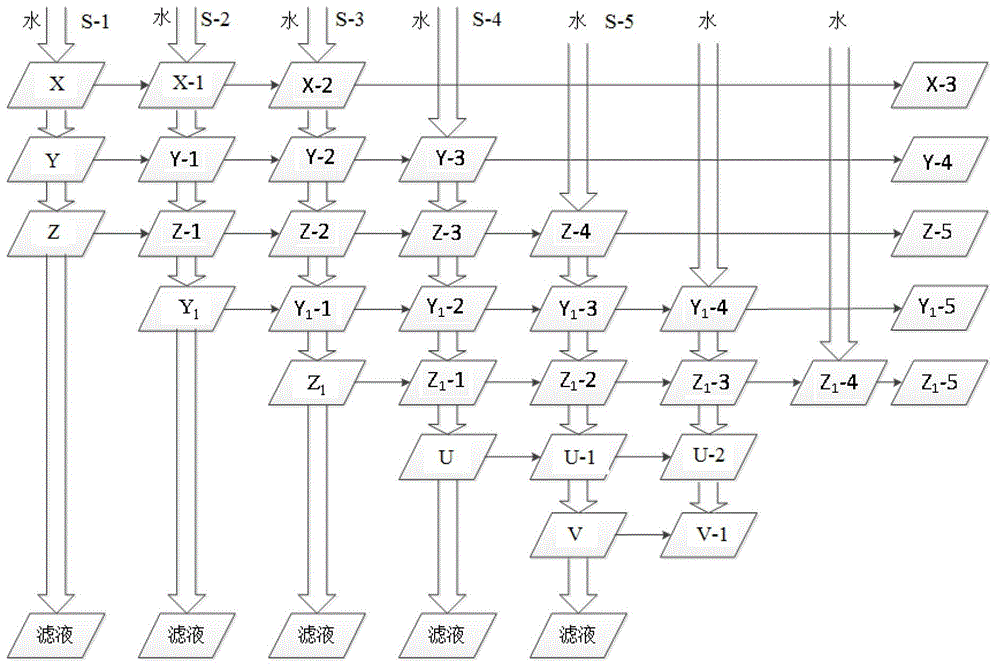

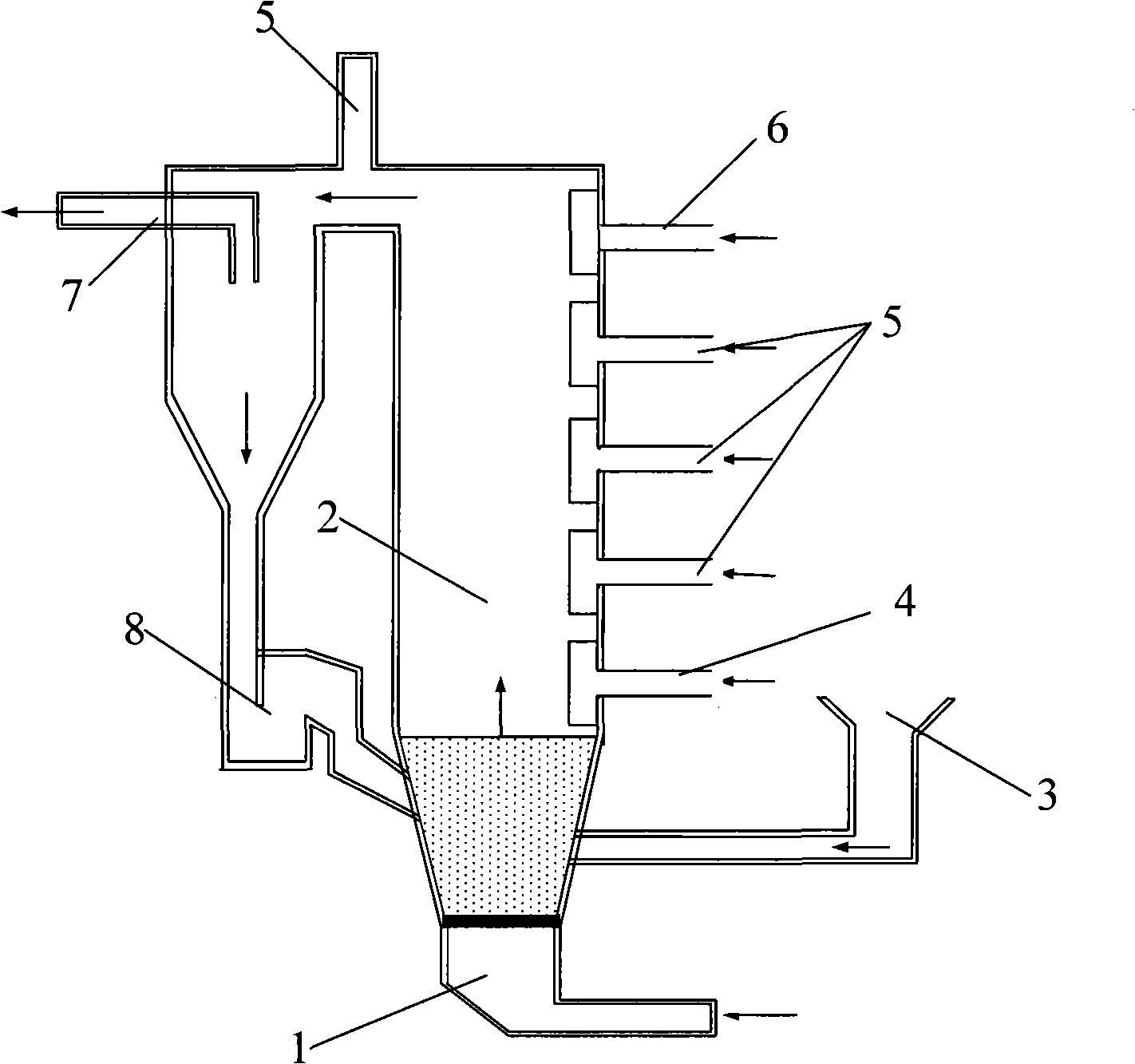

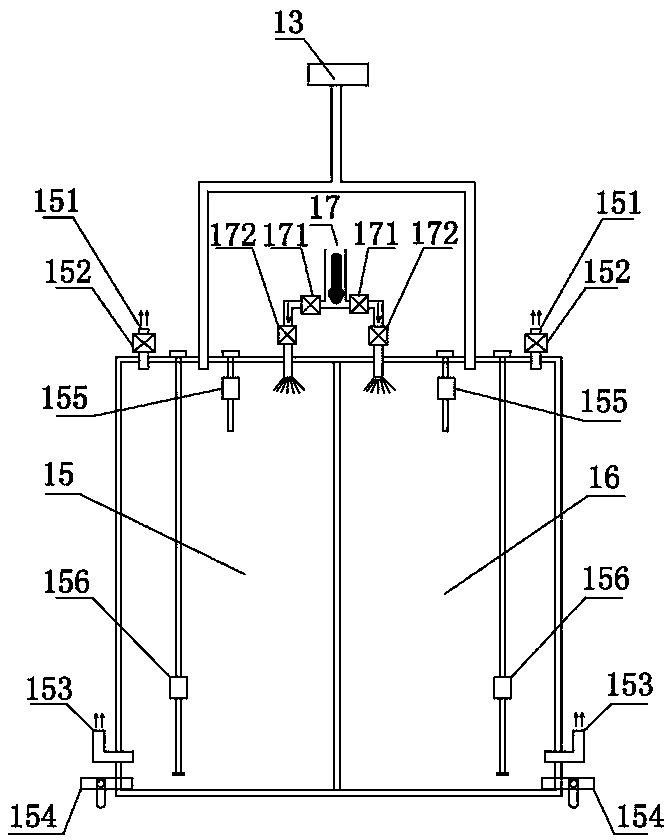

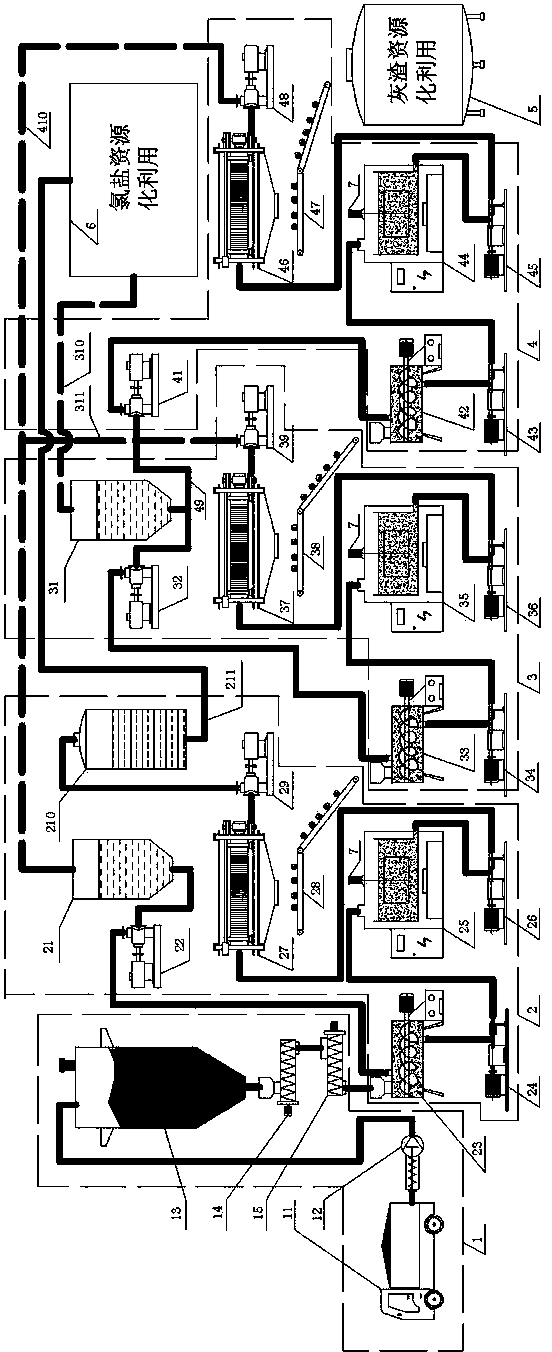

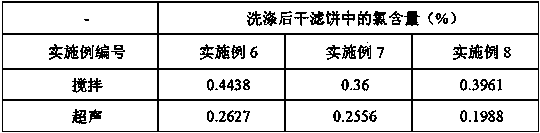

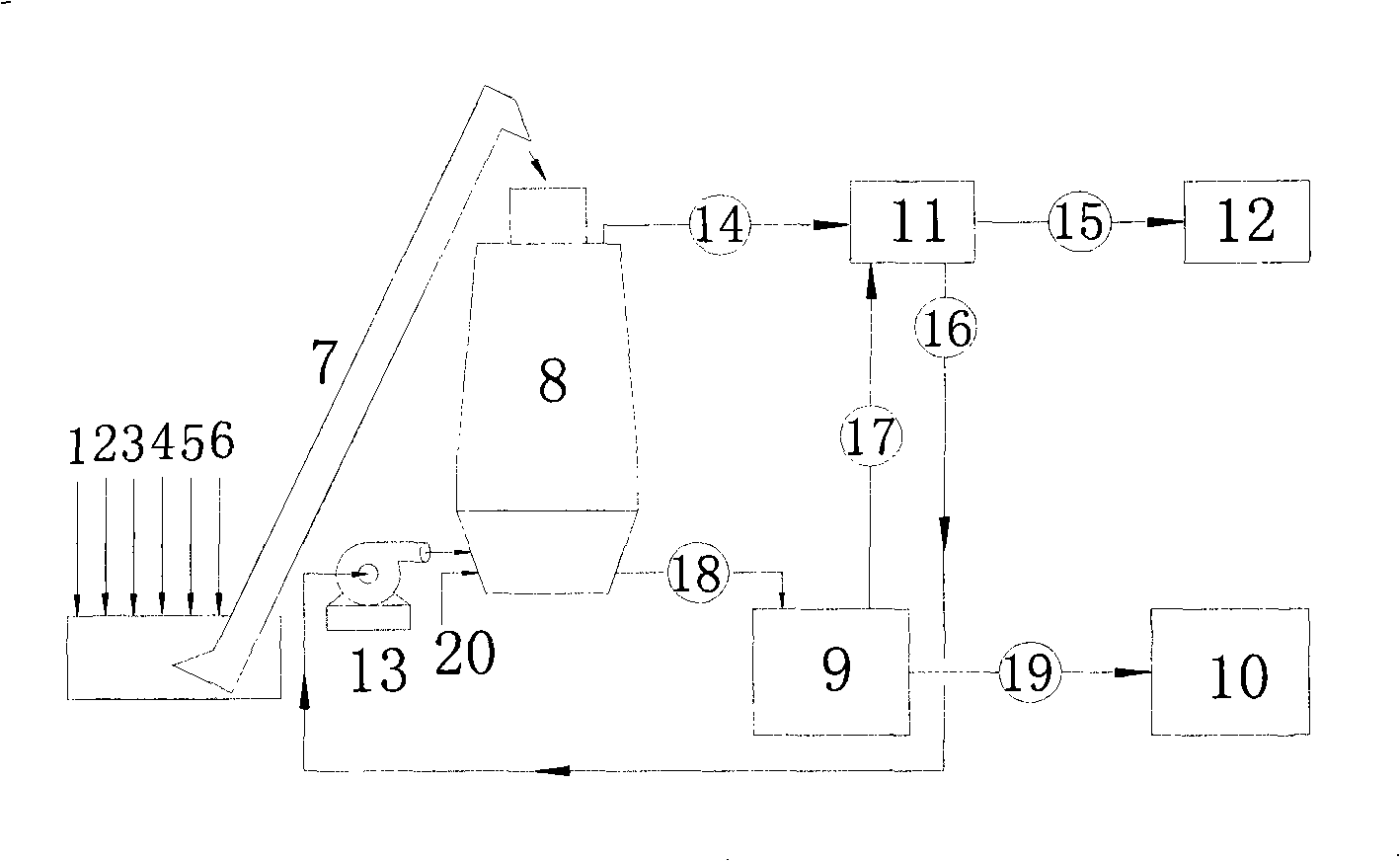

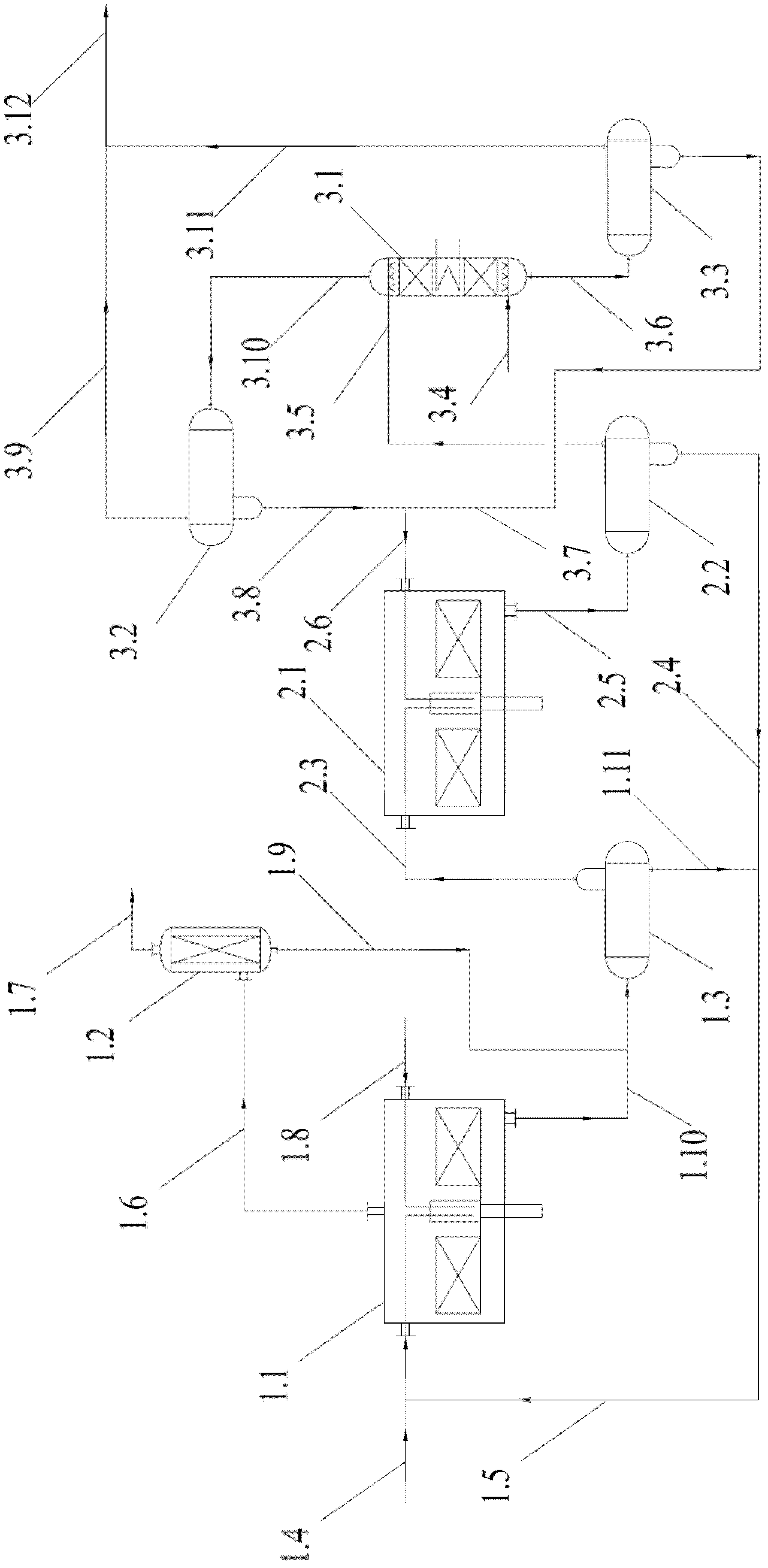

System and method for removing chlorine salt from waste incineration fly ash

ActiveCN103978017ASimple structureReduce operating and maintenance costsCalcium/strontium/barium chloridesSolid waste disposalIncinerationEnvironmental engineering

The invention discloses a system and a method for removing chlorine salt from waste incineration fly ash. The system comprises a fly ash storing-conveying device, a first ultrasonic washing device, a second ultrasonic washing device, a third ultrasonic washing device, an ash residue resource utilization device and a chlorine salt resource utilization device. The method comprises the steps of firstly mixing fly ash with filter liquid in the first ultrasonic washing device for first ultrasonic washing, then mixing the fly ash with water in the second ultrasonic washing device for second ultrasonic washing, mixing the fly ash with water in the third ultrasonic washing device for third ultrasonic washing, and finally carrying out resource utilization. By virtue of the system and the method, a water resource can be circularly utilized, the rate of removing chlorine salt in waste incineration fly ash is high, the residual quantity of chlorine salt is low, and the hazard-free treatment and reutilization of fly ash are realized.

Owner:HUNAN UNIV

Method for preparing glass sand by utilizing synergic fusion of electroplating sludge and household garbage incineration fly ash

The invention relates to a method for preparing glass sand by utilizing synergic fusion of electroplating sludge and household garbage incineration fly ash. The method comprises the main following steps that 1, the household garbage incineration fly ash is washed according to the mass ratio of 1:8 for 2 times; 2, solid-liquid separation is performed through a filtration and dehydration device; 3, the washed fly ash is evenly stirred and mixed with the electroplating sludge; 4, the electroplating sludge and fly ash mixture is subjected to air-drying treatment or waste heat drying treatment; 5, the mixture is added to a fusion furnace, and a proper amount of auxiliary material (water glass) is added for high-temperature fusion; 6, the high-temperature molten mass is introduced to a water quenching tank containing circulating water, water quenching treatment is performed to obtain glass residues, and crushing treatment is performed; 7, incineration smoke is led to the fly ash washing solution for aeration treatment, and heavy-metal carbonate precipitate is produced, and can serve as industrial salt after filtration; 8, the supernate subjected to aeration treatment flows back to a fly ash washing device for reutilization; 9, a TCLP toxicity leaching test is conducted on the glass body.

Owner:SHANGHAI UNIV

Treatment method of standard exceeding of content of chlorine in titanium sponge

The invention provides a treatment method of standard exceeding of content of chlorine in titanium sponge. The titanium sponge is titanium sponge produced by adopting a magnesiothermic reduction method. The treatment method comprises the following steps: placing the titanium sponge in a reactor, vacuumizing the reactor until the vacuum degree in the reactor is not more than 100Pa; heating the reactor to ensure that the titanium sponge in the reactor is firstly subjected to low-temperature degassing of a temperature phase of 150-200 DEG C and intermediate temperature degassing of four constant temperature phases of 200-300 DEG C, 350-400 DEG C, 450-500 DEG C and 500-550 DEG C to remove water and gas impurities in magnesium chloride hydrate in the titanium sponge; and after degassing is ended, continuously raising the temperature to 900-1020 DEG C for vacuum distillation to remove magnesium chloride in the titanium sponge. According to the method, the content of chlorine in the titanium sponge, which exceeds the standard, can be effectively reduced, and the grade rate of the titanium sponge is increased.

Owner:PANGANG GROUP TITANIUM INDAL

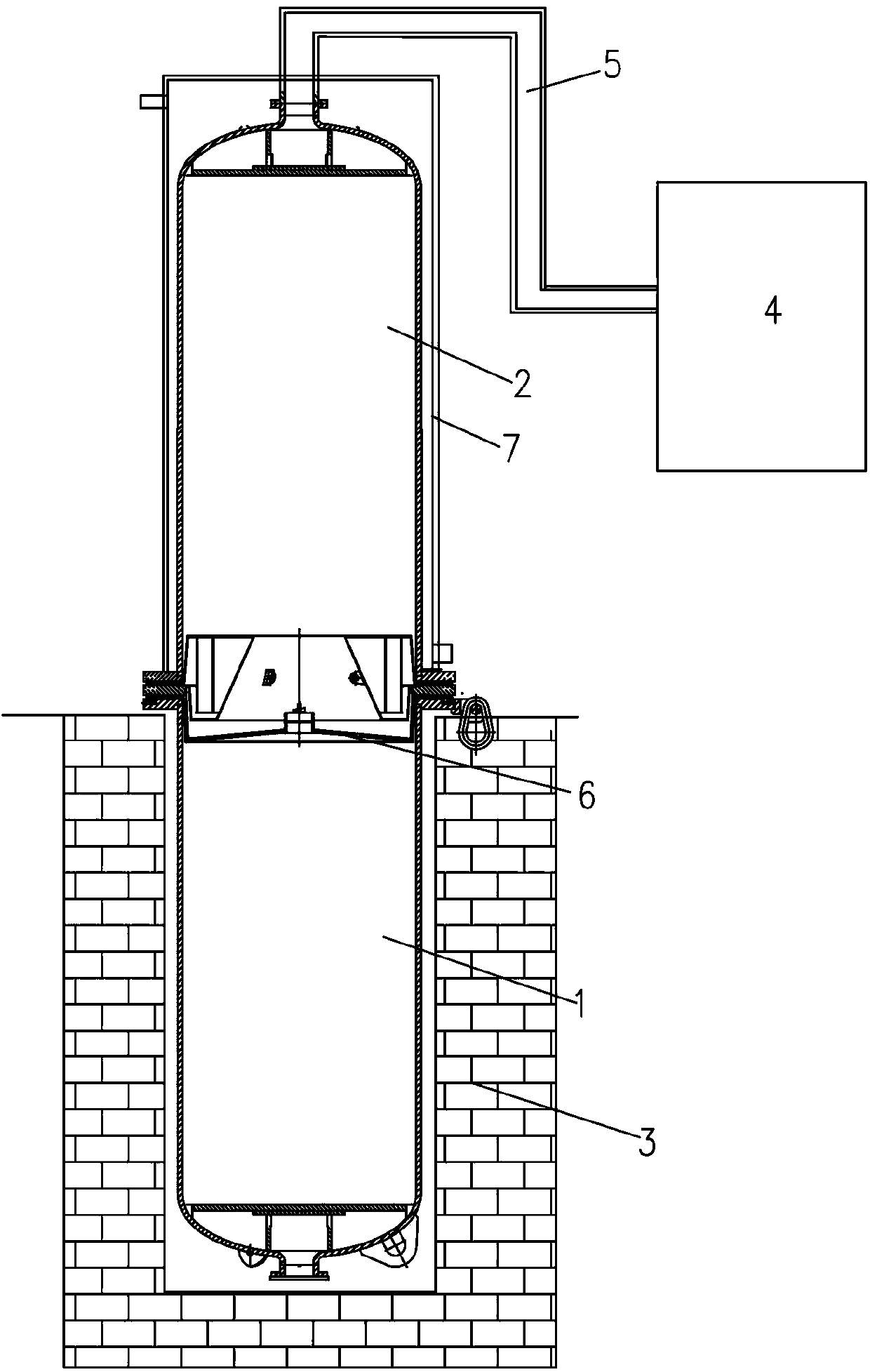

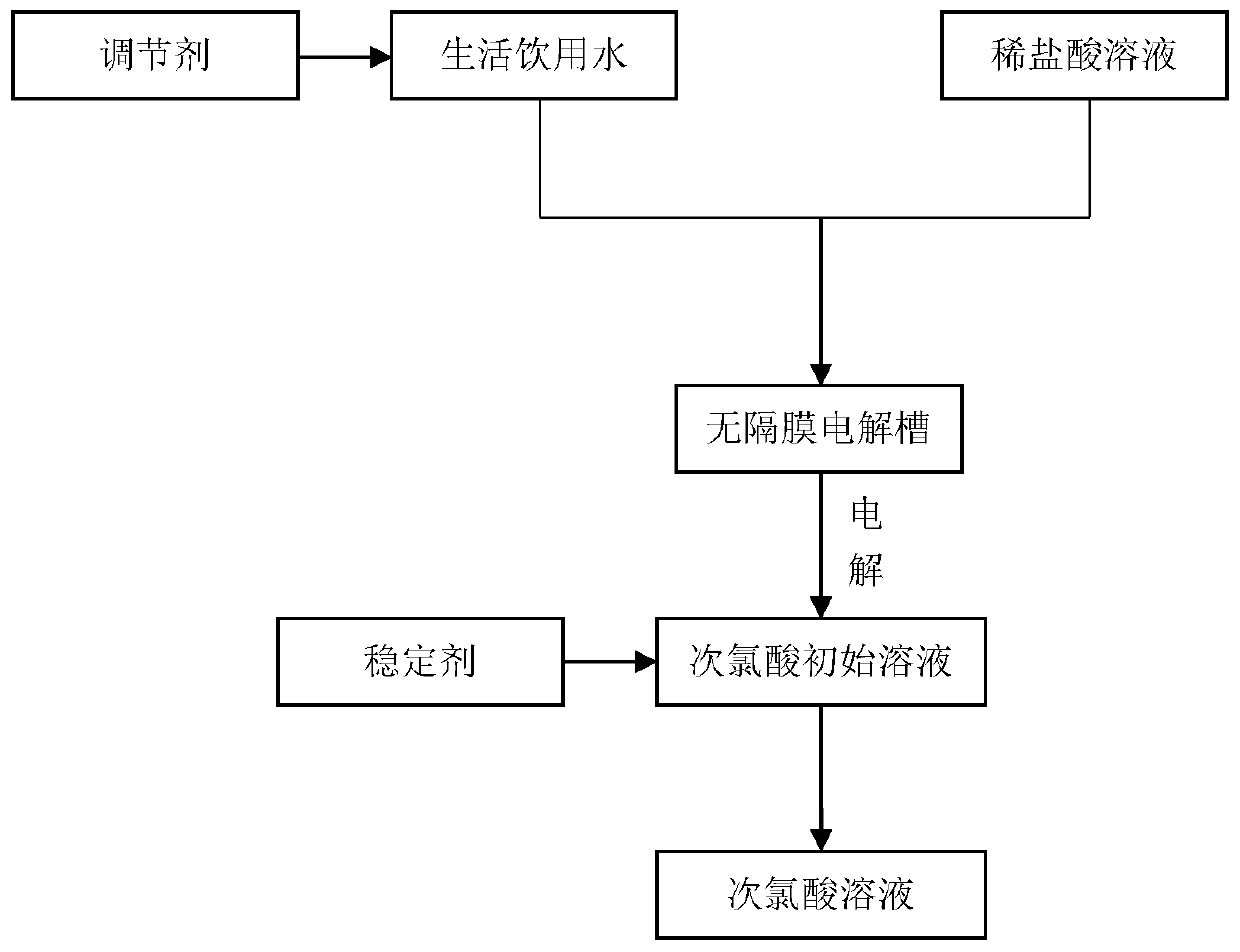

Production method for improving hypochlorous acid solution stability

The invention discloses a production method for improving hypochlorous acid solution stability and belongs to the technical field of hypochlorous acid solution production. In order to improve the stability of a hypochlorous acid solution and prolong the validity period of the hypochlorous acid solution, the invention provides the production method for improving the stability of the hypochlorous acid solution. The production method comprises the following steps: adding 10-50ppm of a regulator into domestic drinking water; introducing a diluted hydrochloric acid solution and the domestic drinking water added with the regulator into a diaphragm-free electrolytic cell in a hypochlorous acid generator through a pump body, and carrying out mixing and electrolysis to generate a hypochlorous acidinitial solution; adding 50-300 ppm of a stabilizer into the generated hypochlorous acid initial solution to generate the hypochlorous acid solution; wherein the effective content is 40-60 mg / L, the pH value is 5.0-7.0, and the residual chloride ions are less than 1000 mg / L. And in an opaque sealed container and under a dark condition, the product is placed in a thermotank at 54-57 DEG C for 14 days, the content of available chlorine is reduced by less than or equal to 10%, and the validity period of the product can be up to 1 year.

Owner:北大荒绿源食品加工有限公司

Low-chloride phosphorus potassium fertilizer and preparation method thereof

InactiveCN101525256AHigh in nutrientsReduce chlorine contentEnergy inputPotassium fertilisersWater vaporHearth

The invention relates to a low-chloride phosphorus potassium fertilizer and a preparation method thereof, in particular to a method for preparing the low-chloride phosphorus potassium fertilizer by melting and sintering potassium chloride, phosphorite powder and quartz sand, and the invention belongs to the production field of phosphorus potassium compound fertilizer. In the method, the potassium chloride, the phosphorite powder, the quartz sand or diatomite, insoluble potassic ore and boric anhydride are used as raw materials; coal, heavy oil or natural gas are used as fuel; or an electric cooker is used as a high-temperature heat source; and the phosphorus potassium fertilizer is produced by melting and sintering in steam atmosphere. The reaction is carried out in a blast furnace, an open hearth or the electric cooker, and the melting temperature is 800-1600 DEG C. The method produces the phosphorus potassium fertilizer by the potassium chloride and the phosphorite powder directly and has simplified process; the prepared phosphorus potassium fertilizer has high total nutrient and the low content of chloride and can be used for chlorophobic crops; the phosphorus potassium fertilizer contains two elements of phosphor and potassium required by the crops in large amount at the same time; the percentage content of K2O is 10%-18%; the percentage content of P2O5 is 15%-30%; the content of chlorine ion is less than 3%; and the total nutrient is 30%-45%.

Owner:中国-阿拉伯化肥有限公司

Preparation method for glucosamine sulfate

ActiveCN104710483AAvoid damageMild reaction conditionsSugar derivativesSugar derivatives preparationOrganosolvPotassium

The invention relates to a preparation method for glucosamine sulfate. According to a technical scheme in the invention, the preparation method comprises the following steps: step 1, dispersing D-glucosamine hydrochloride in an alcoholic solvent; step 2, neutralizing D-glucosamine hydrochloride with alkali; step 3, adding sulfuric acid into a glucosamine solution drop by drop so as to form a salt; step 4, carrying out precipitation and separation; and step 5, carrying out refining by repeatedly washing a solid with a small amount of an organic solvent until no chloride ion is eluted and carrying out drying under reduced pressure, wherein the organic reagent is ethanol, propyl alcohol, acetone or the like with a concentration of 80 to 100%. With the technical scheme, glucosamine sulfate with low sodium or potassium content is obtained.

Owner:迪嘉药业集团股份有限公司

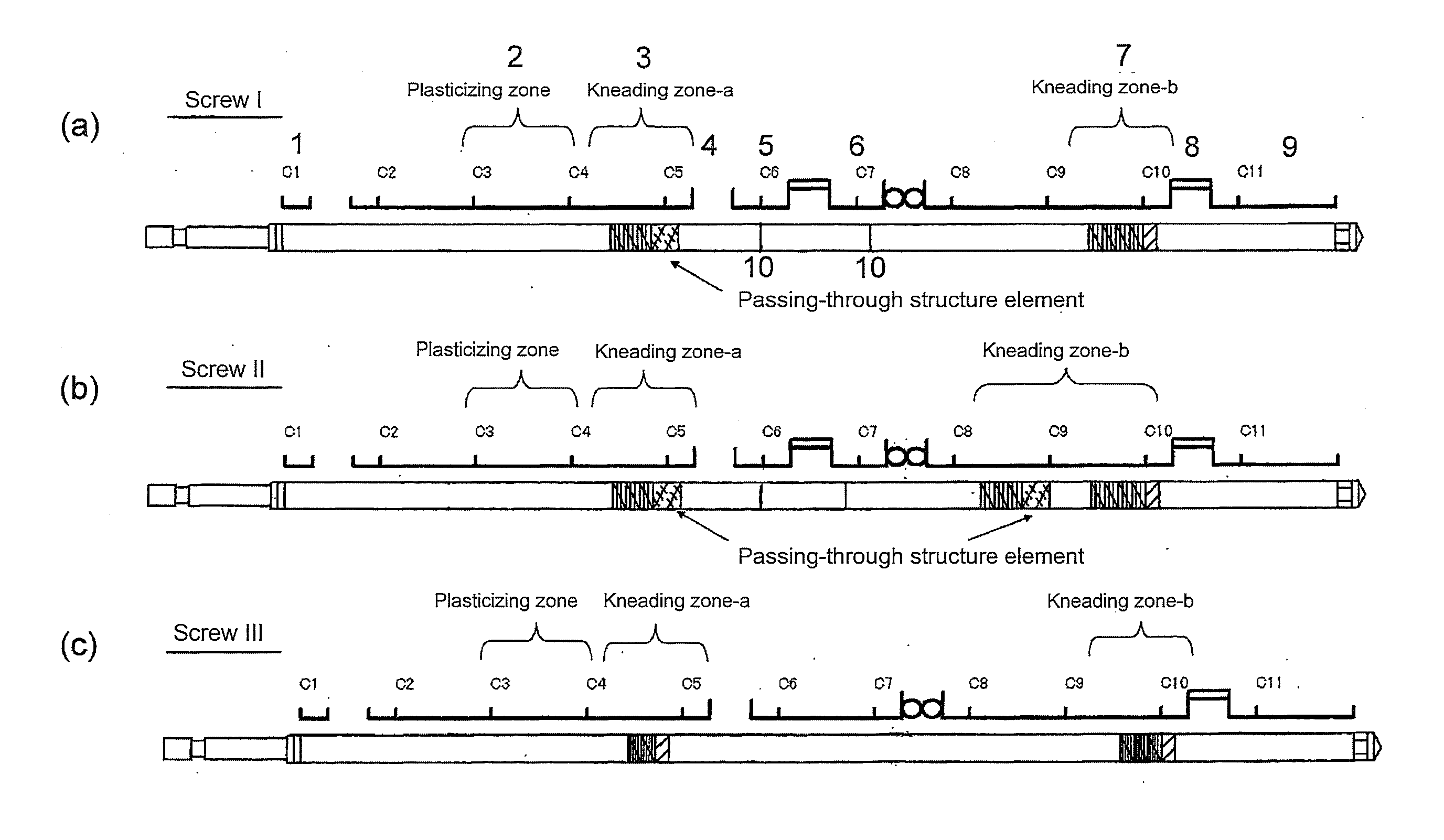

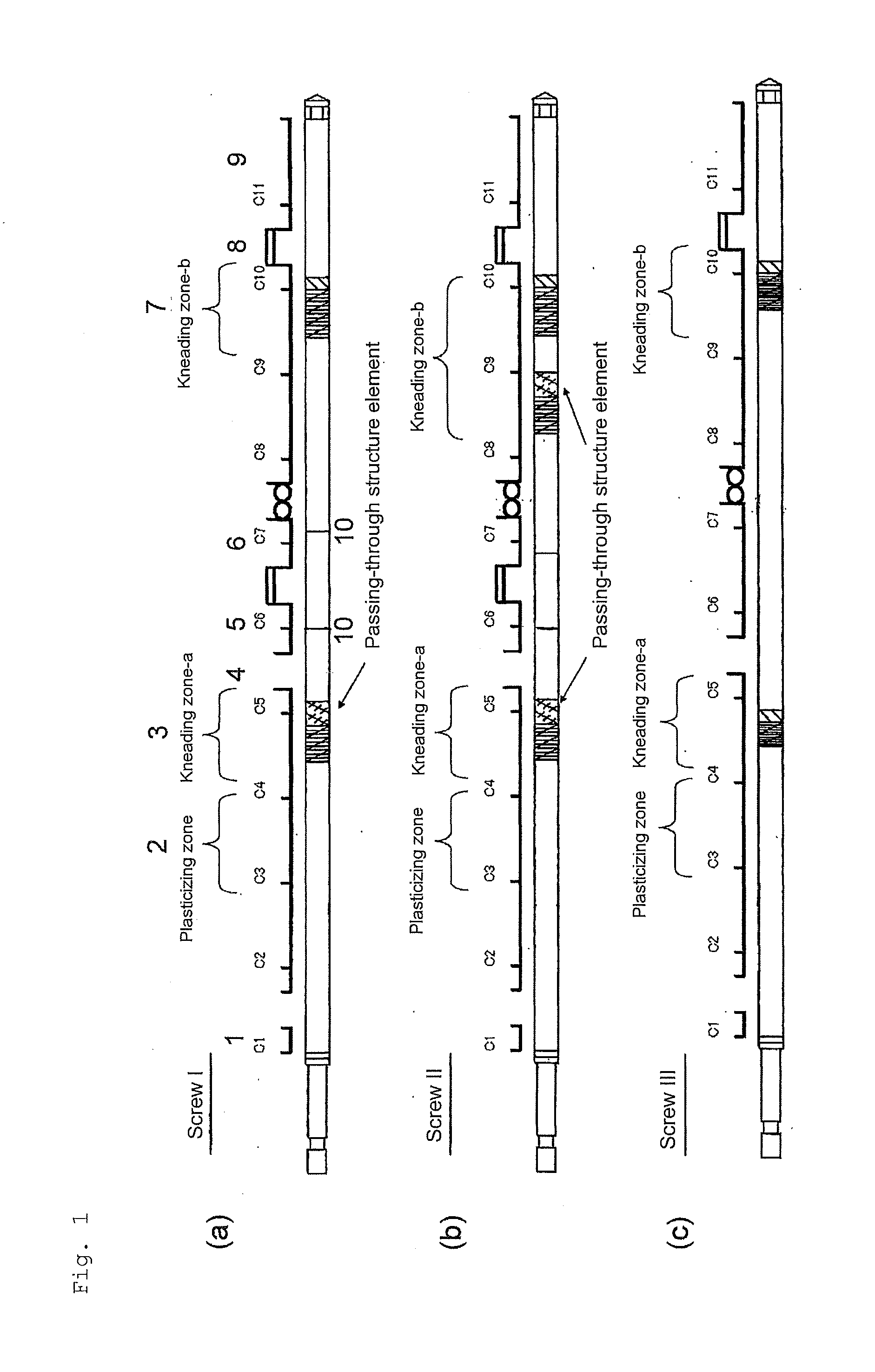

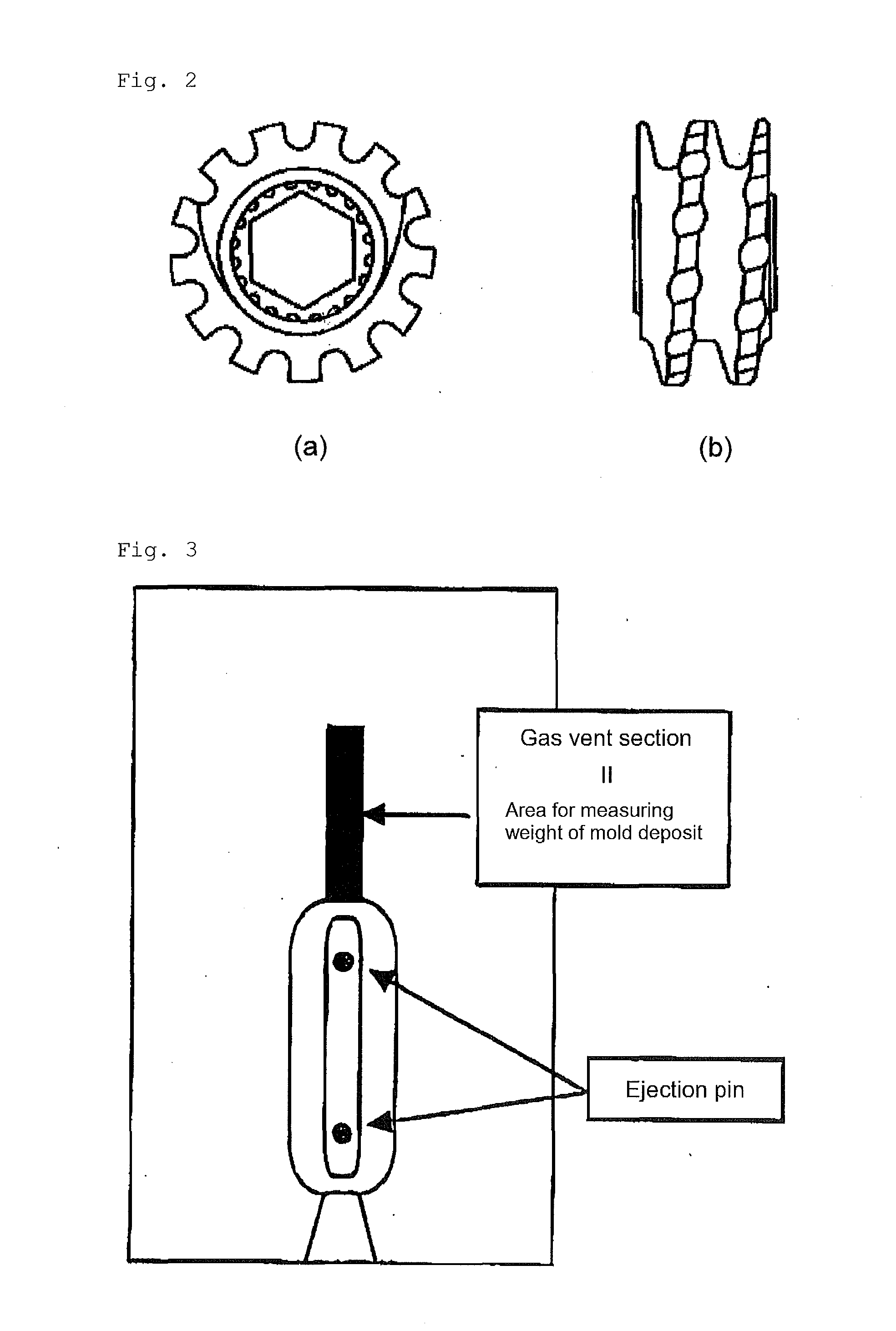

Method for producing polyarylene sulfide resin composition

InactiveUS20110037193A1Reduced flashing defectImprove liquidityArtifical filament manufactureShear rateInorganic filler

A method is provided for obtaining a polyarylene sulfide resin composition with a low chlorine content, which has high fluidity and high quality and produces less burrs. Specifically, a method is provided wherein a polyarylene sulfide resin composition is produced by melting and mixing (A) a polyarylene sulfide resin, (B) an inorganic filler, and (C) an alkoxysilane compound. In this method, (A) a polyarylene sulfide resin having a melt viscosity of 80-400 Pa·s (at a temperature of 310° C. and a shear rate of 1200 / sec) and a chlorine content of 1000-2000 ppm is supplied from a raw material feed port of a specific extruder, and then extruded at two kneading parts within the range of [shear rate (1 / sec)×kneading time (sec)=1600-6000], thereby producing a polyarylene sulfide resin composition having a melt viscosity of 150-330 Pa·s (at a temperature of 310° C. and a shear rate of 1200 / sec) and a chlorine content of not more than 950 ppm.

Owner:POLYPLASTICS CO LTD

Special-purpose tuanke foliage fertilizer for flue-cured tobacco

InactiveCN101104569AIncrease productionHigh outputFertilisers by pryogenic processesAmmonium salt fertilisersPhosphateMonopotassium phosphate

The present invention is spherical plant foliar fertilizer especially used for flue-cured tobacco, which is basically composed of the following substances: fulvic acid, zinc sulfate, copper sulfate, ferrous sulfate, boric acid, potassium dihydrogen phosphate, potassium nitrate, rooting powder, ammonium molybdate and acetic acid. Wherein, the ferrous sulfate refers to the ferrous sulfate heptahydrate; the copper sulfate refers to the copper sulphate pentahydrate; the zinc sulfate refers to the zinc sulfate heptahydrate; the acetic acid refers to the acetic acid glacial; the ammonium molybdate and the boric acid are without crystal water. The production method of the foliar fertilizer is as follows: first, a certain amount of 36% acetic acid is added to the mixture of the 25 g / L fulvic acid, followed by zinc sulfate, copper sulfate, ferrous sulfate, boric acid, potassium dihydrogen phosphate and potassium nitrate in sequence, and then 0.1% alcohol containing 5g / L rooting powder is also added to the 25 g / L fulvic acid; then, upon ongoing stirring, 145g / L ammonium molybdate is slowly added to the mixture of the 25 g / L fulvic acid; the mixture is then shaken up and filled into a glass or plastic bottle(do not use metal containers), and then the bottle is sealed, and the spherical plant foliar fertilizer is thus obtained. Compared with the similar foliar fertilizer, the foliar fertilizer provided by the invention can significantly promote the growth and development in tobacco plant resettling period and budding period, markedly increase the yield and value of flue-cured tobacco, significantly increase potassium content of flue-cured tobacco and reduce chlorine content to enable more moderate nicotine content and coordinated chemical composition of tobacco leaves. Therefore, the invention has significant economic and social benefits.

Owner:介晓磊 +2

Polyarylene sulfide resin composition

InactiveUS20130035440A1Reduce the amount presentImprove liquidityCoatingsPolyesterLiquid crystalline

To provide a polyarylene sulfide resin composition which contains decreased amount of chlorine, which has a high fluidity and generates small flashes at the time of molding, which has an excellent heat resistance, which can resist heat-processing under the condition of a high temperature, which has moldability at a low mold temperature, a molded article of which has an extremely small change in surface hue before and after reflow. The resin composition is obtained by blending: 100 parts by weight of a polyarylene sulfide resin (A) containing 500 to 2,000 ppm of chlorine and having 10 to 200 Pa·s of melt viscosity, 10 to 100 parts by weight of a liquid crystalline polyester amide resin (B), and 5 to 250 parts by weight of glass fiber (C) containing 100 ppm or less of nitrogen, and having a total chlorine content of 950 ppm or less,

Owner:POLYPLASTICS CO LTD

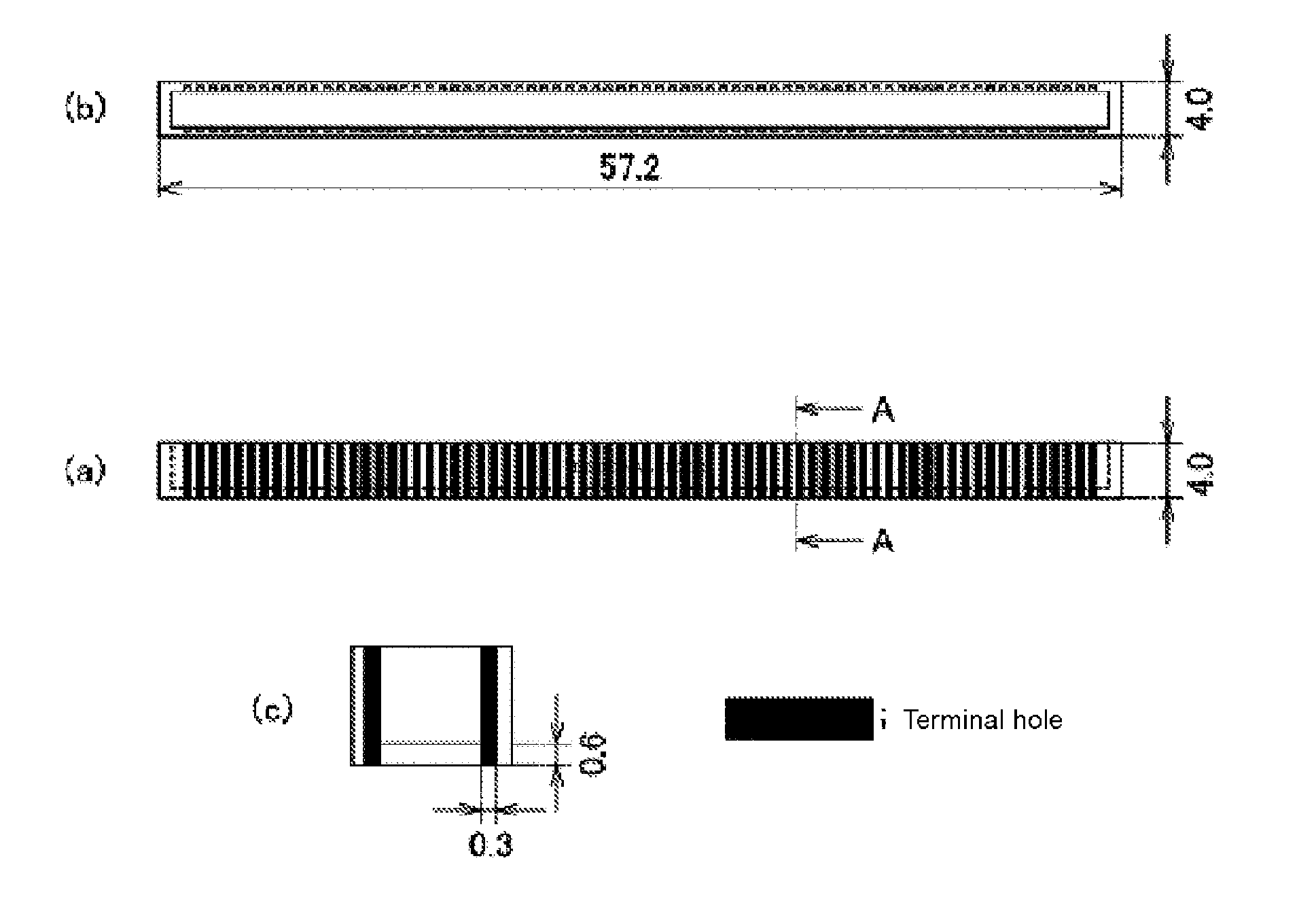

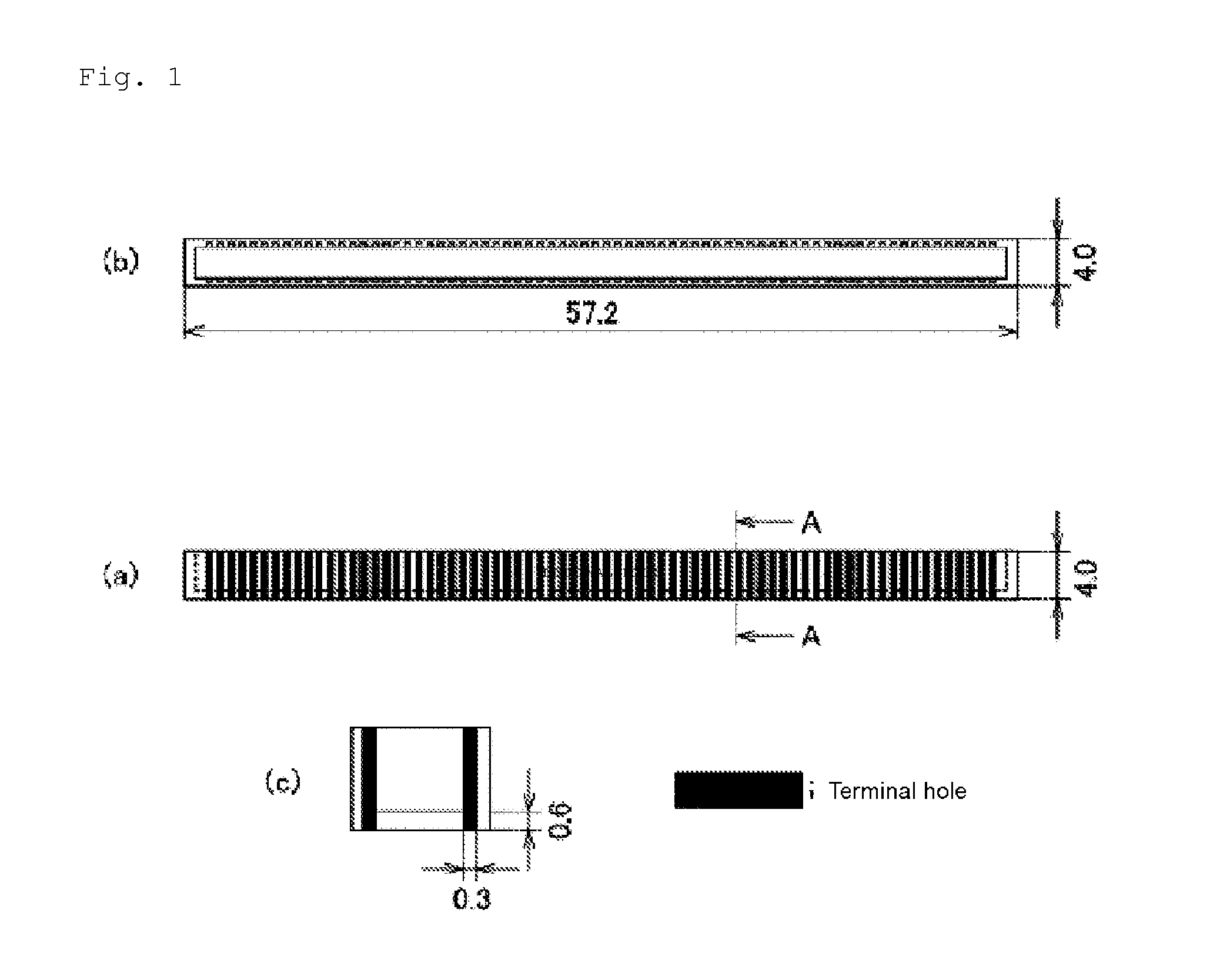

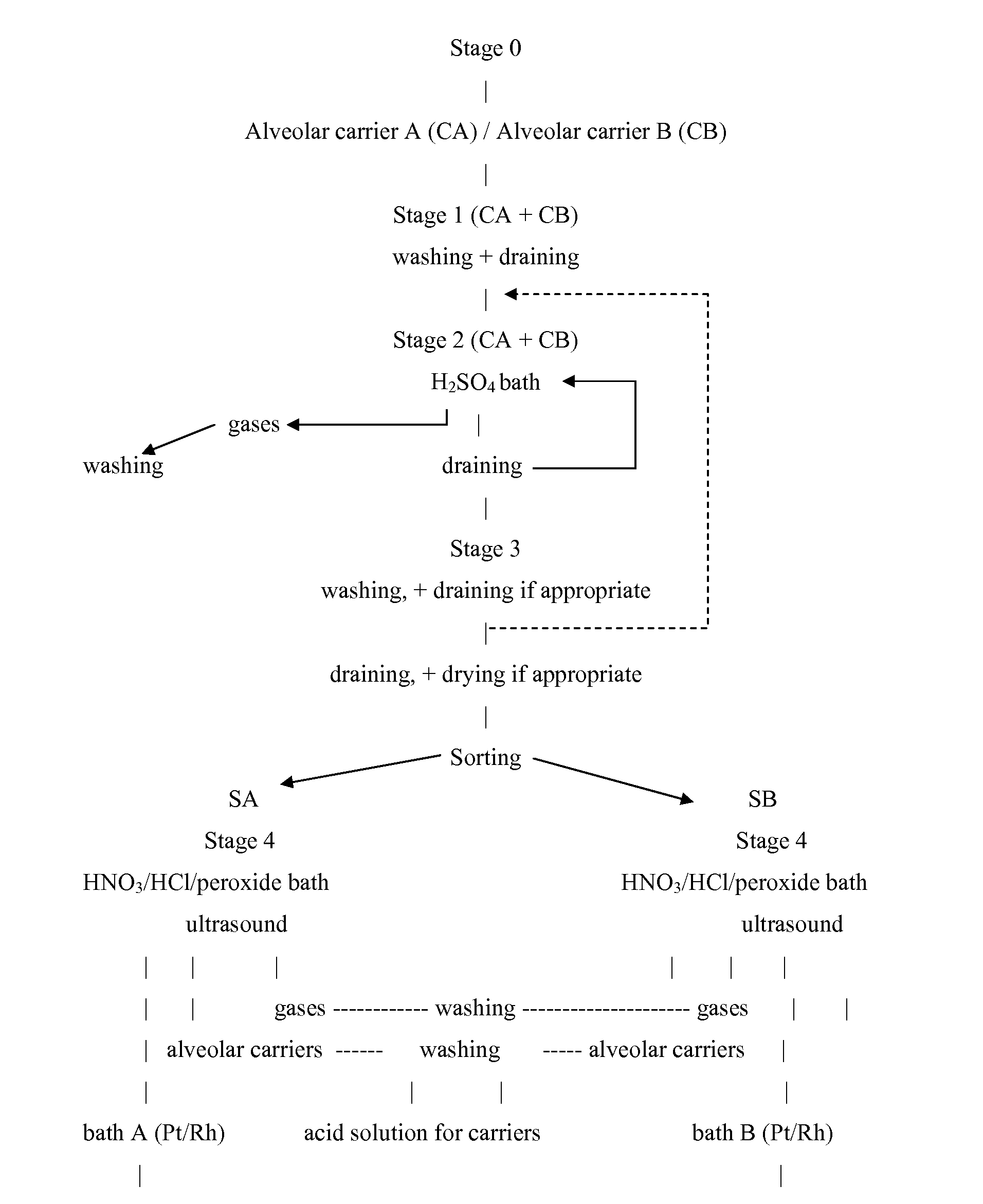

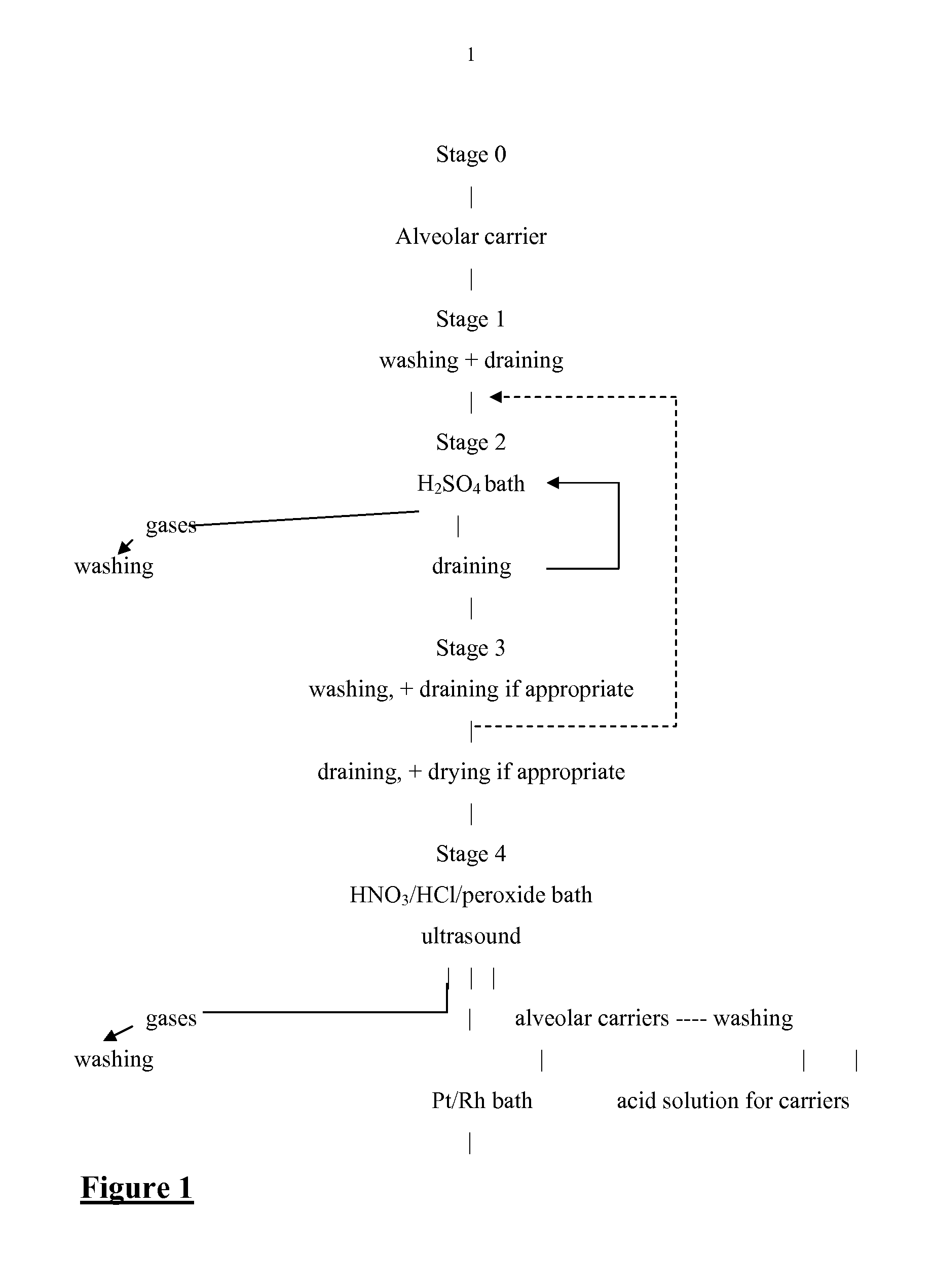

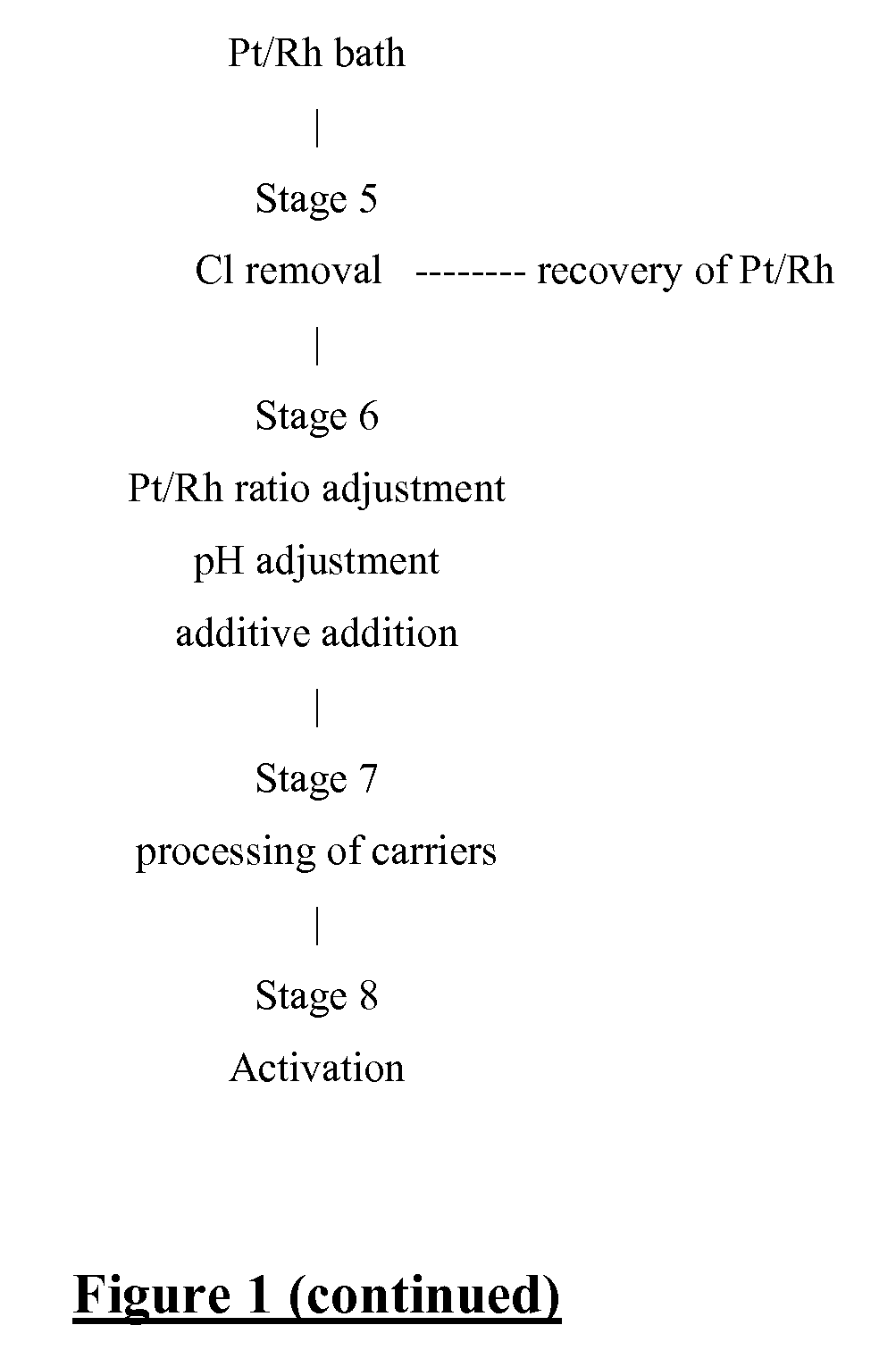

Process for the recovery of precious metals from used and/or defective catalytic carriers

InactiveUS20110028306A1Easy to useReduce chlorine contentCatalyst activation/preparationProcess efficiency improvementSulfuric acidPrecious metal

Process for recovering precious metals from catalytic carriers comprising at least the following stages:Stage 1: treatment of the carriers with at least one aqueous compositionStage 2: treatment of the carriers with an acid solution containing at least sulphuric acid but weak in nitric acidStage 3: treatment of the carriers with an acid solution containing nitric acid and hydrochloric acid.

Owner:G E CONSEILS

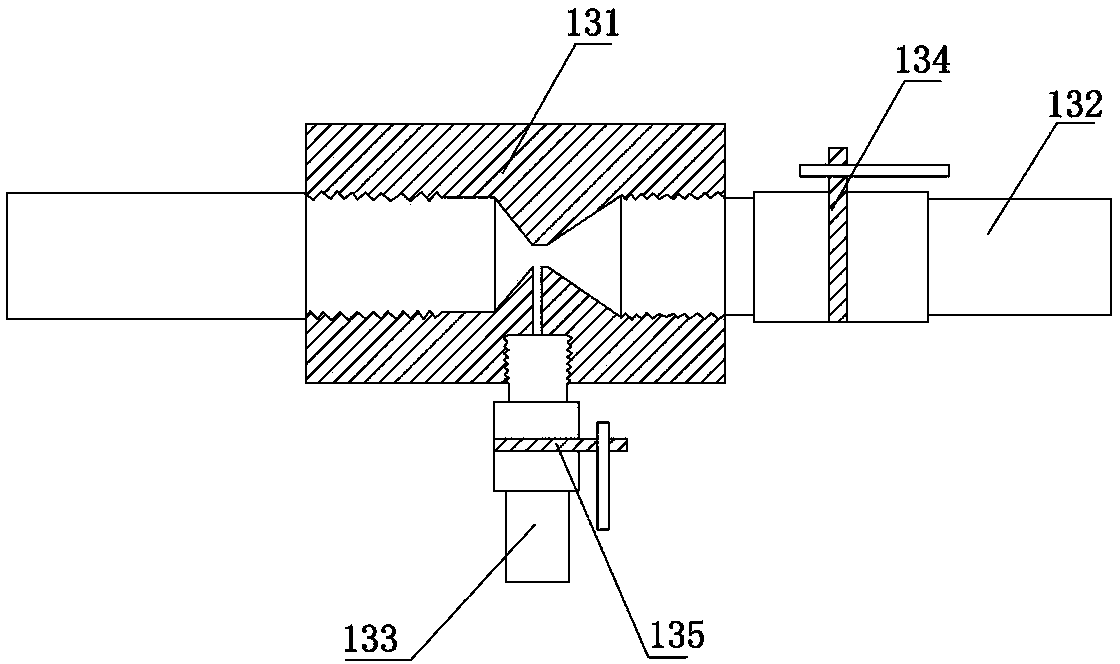

Saturated acid hydrolysis technology of alkylchlorosilane

The invention provides saturated acid hydrolysis technology of alkylchlorosilane. The first step is a saturated acid hydrolysis reaction, hydrogen chloride gas obtained through saturated acid hydrolysis can return to a chlorosilane synthesis working section through a demister, saturated acid after separation through a phase separator of the saturated acid hydrolysis returns to a saturated acid water hydrolysis device, and hydrolysate is performed according to the second step. The second step is a diluted acid hydrolysis reaction, the alkylchlorosilane without complete hydrolysis further reacts with diluted acid, and a diluted acid hydrolysis reaction comprises a diluted acid hydrolysis strengthening reactor and a diluted acid hydrolysate phase separator. Circulating diluted hydrochloric acid after being separated through the diluted acid hydrolysis phase separator is supplemented in the saturated acid hydrolysis device, and hydrolysate is performed according to the third step. The third step is steam dechlorination, chlorine concentration in coarse hydrolysate is reduced, the steam dechlorination comprises a steam dechlorination tower, a material phase separator is arranged on a tower top of the steam dechlorination tower, and a discharging material phase separator is arranged at a tower bottom of the steam dechlorination tower. Qualified polyalkysiloxane can be obtained through the three-step technology.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

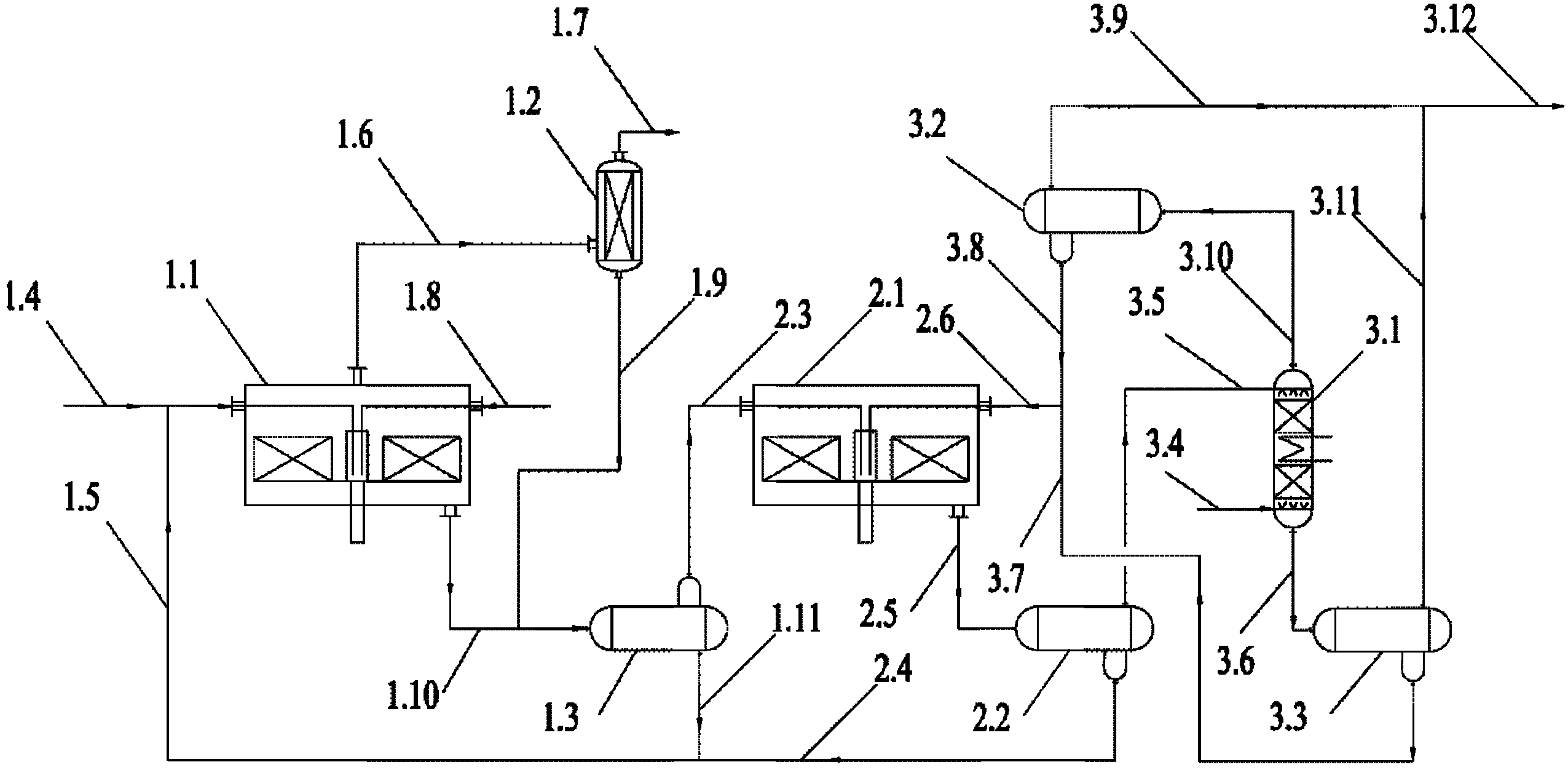

Method and device for dechlorinating and decarbonizing solid samples

InactiveCN106289928AReduce chlorine contentFulfil requirementsPreparing sample for investigationWater vaporSlag

The invention relates to the field of comprehensive utilization of vanadium-titanium resources, and discloses a method and device for dechlorinating and decarbonizing solid samples. The solid samples comprise chloride ions and uncombined carbon, the method includes the steps: leading first part of air to enable the solid samples to fluidize; performing further contact for fluidized solid samples and vapor under the condition that the temperature is higher than or equal to 500 DEG C. The temperature of the vapor is higher than or equal to 110 DEG C. The device comprises a fluidized bed (1), an air compressor (2), a vapor generator (3) and a resistance furnace (4), the air compressor (2) and a gas outlet of the vapor generator (3) are respectively connected with a gas inlet of the fluidized bed (1), and the resistance furnace (4) is used for heating the fluidized bed (1). According to the method and the device, chloride ions and uncombined carbon in the solid samples, particularly in extracted titanium tailing slag can be simultaneously removed, and both dechlorinating ratio and decarbonizing ratio are 85% or more.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

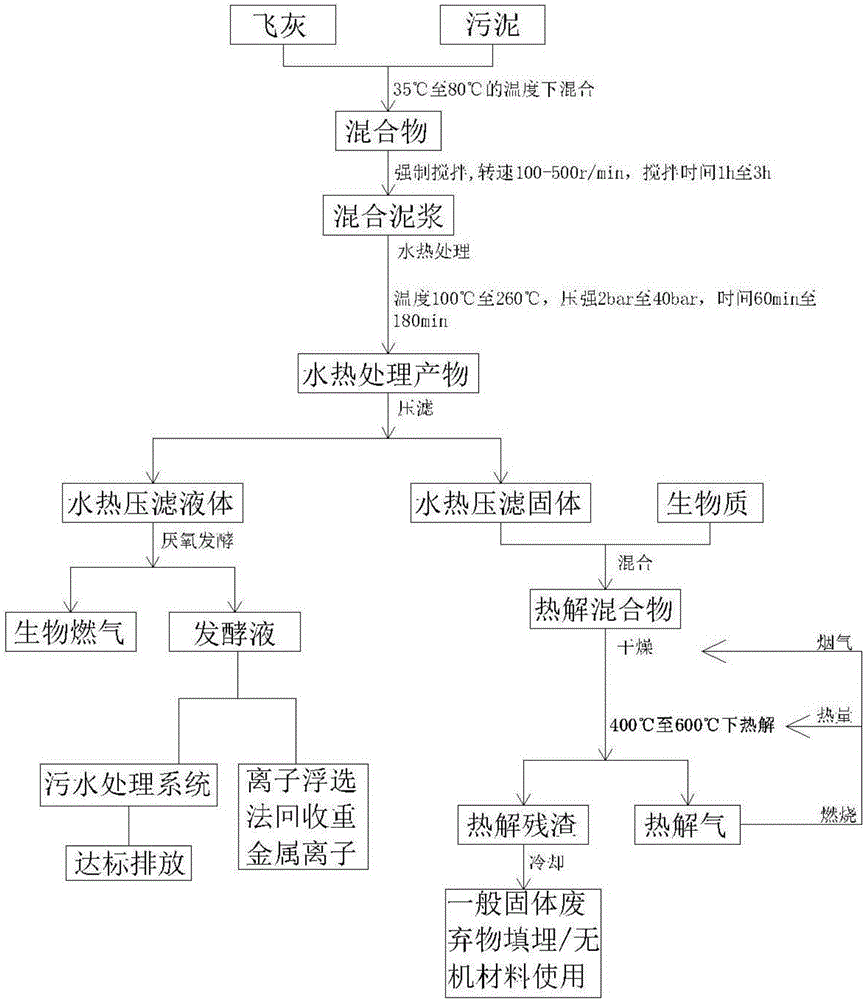

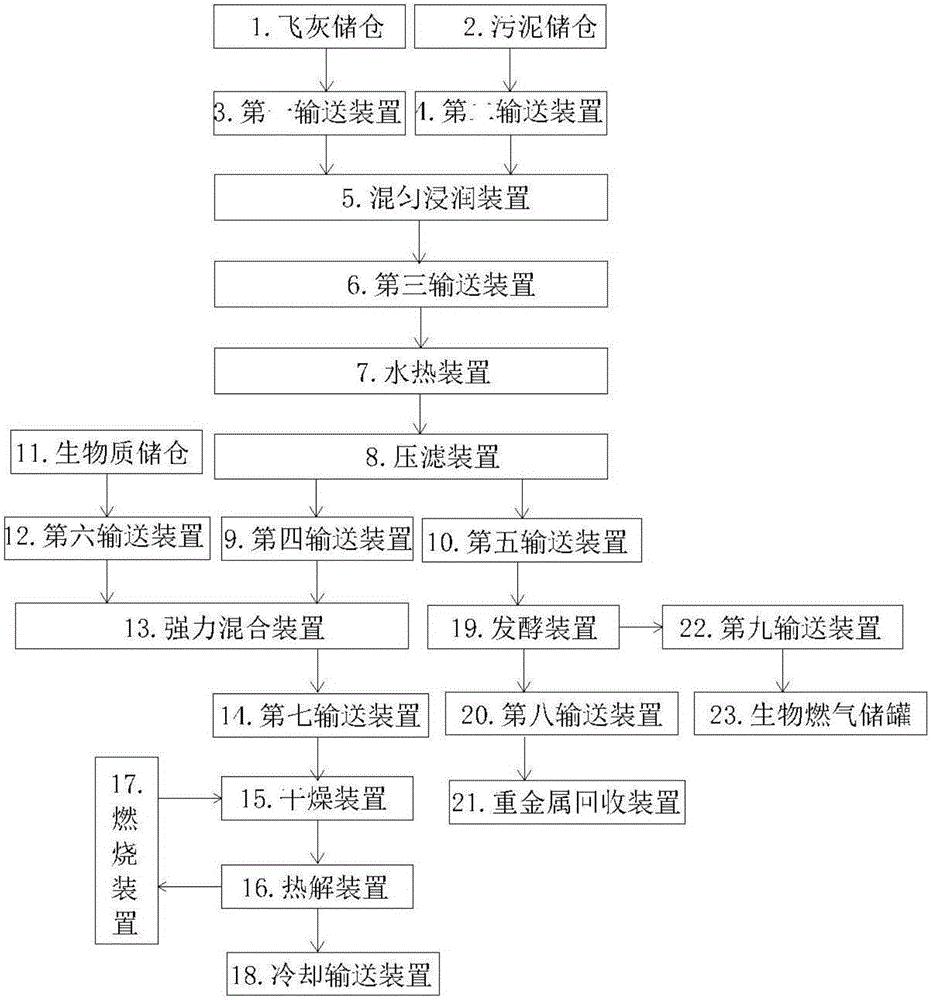

Method for treating fly sh by sludge

ActiveCN106424077AImprove dehydration efficiencyEfficient hydrolysis detoxificationSludge treatment by de-watering/drying/thickeningSolid waste disposalSludgeTreated water

The invention discloses a method and equipment for treating fly sh by sludge. The method comprises the following steps: a mixture of the fly ash and the sludge is forcedly stirred to obtain mixed mud; the mixed mud is hydrothermally treated to obtain a hydrothermal treatment product; the hydrothermal treatment product performs solid-liquid separation through a pressing filter mode to obtain hydrothermal pressing filter liquid and a hydrothermal pressing filter solid; a biomass is added in the hydrothermal pressing filter solid to form a pyrolysis mixture; the pyrolysis mixture is pyrolyzed to obtain pyrolysis residues; the pyrolysis residues serve as general solid wastes for backfilling or serve as inorganic materials for use; the hydrothermal pressing filter liquid performs anaerobic fermentation to generate gas and fermentation liquid; the fermentation liquid generated by fermentation is purified; and the treated water is qualified for emission. The invention further provides equipment for realizing the method. The method uses the sludge for realizing detoxification of the fly ash and stabilization, thoroughly eliminates dioxin substances in the fly ash to prevent secondary pollution, and realizes harmless treatment of the fly ash.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

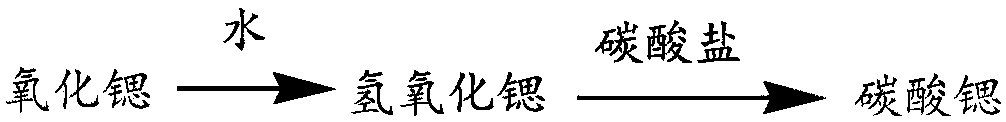

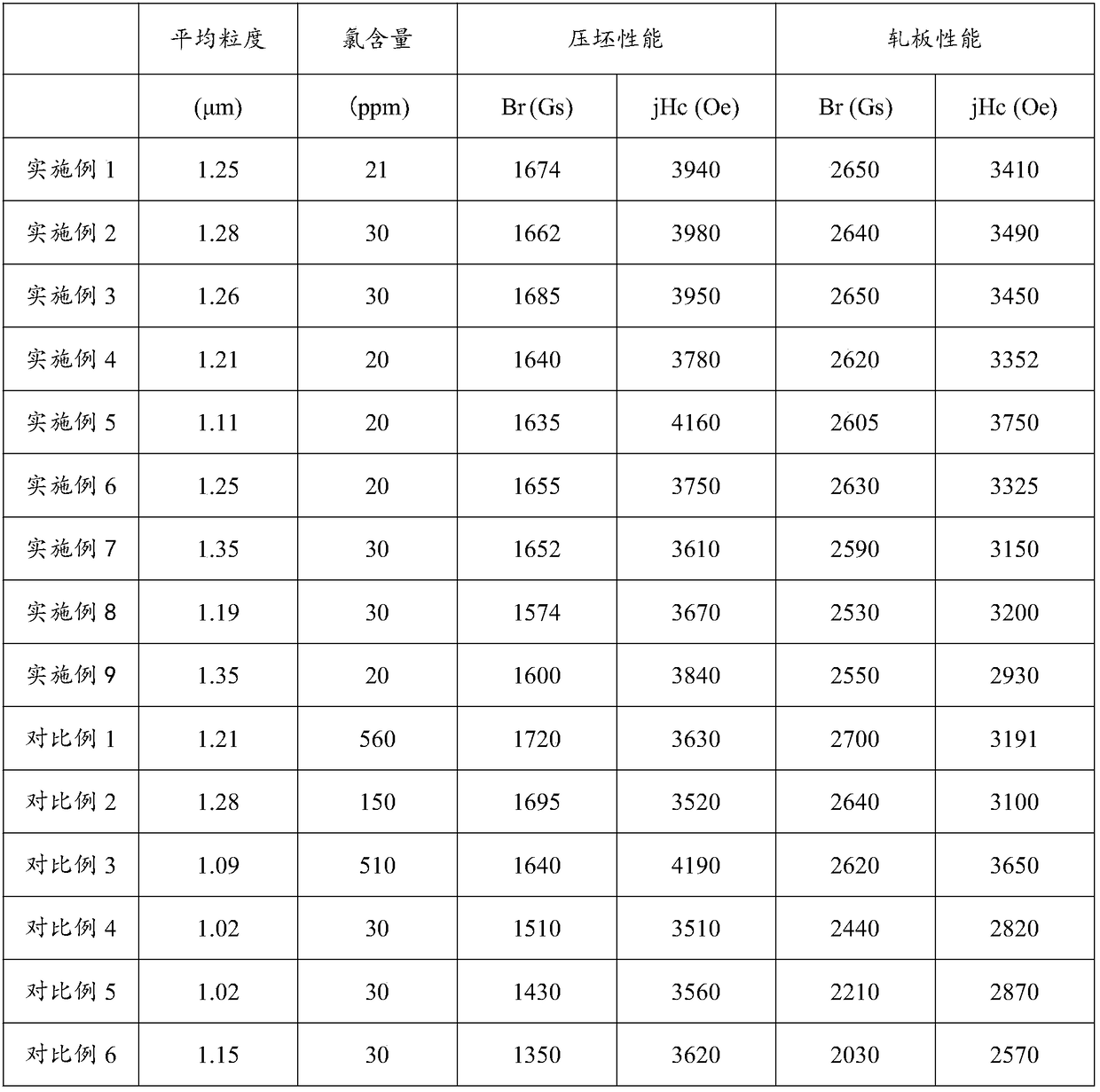

Preparation method of rubber-plastic ferrite magnetic powder

ActiveCN109437315AReduce chlorine contentImprove magnetic propertiesIron compoundsStrontium carbonateAlkaline earth metal

The invention relates to the technical field of magnetic materials, in particular to a preparation method of a rubber-plastic ferrite magnetic powder. The method comprises the following steps: mixinga first iron raw material with an alkaline earth metal salt raw material to obtain a mixed material, wherein the alkaline earth metal salt raw material comprises strontium carbonate or barium carbonate; pre-firing the mixed material to obtain pellets; coarsely crushing the pellets to obtain a coarse powder; mixing the coarse powder, a carbonate, a second iron raw material and water, and then performing wet fine grinding to obtain a slurry; and dehydrating, drying and tempering the slurry to obtain the rubber-plastic ferrite magnetic powder. The chlorine content of the prepared rubber-plastic ferrite magnetic powder is 20-30 ppm; the compact jHc is as high as 4160 Oe, and the rolled plate Br is up to 2650 Gs. The prepared rubber-plastic ferrite magnetic powder is extremely low in chlorine content and has an excellent magnetic property.

Owner:ANTE MAGNETIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com