Patents

Literature

31results about How to "Changing the relative volatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

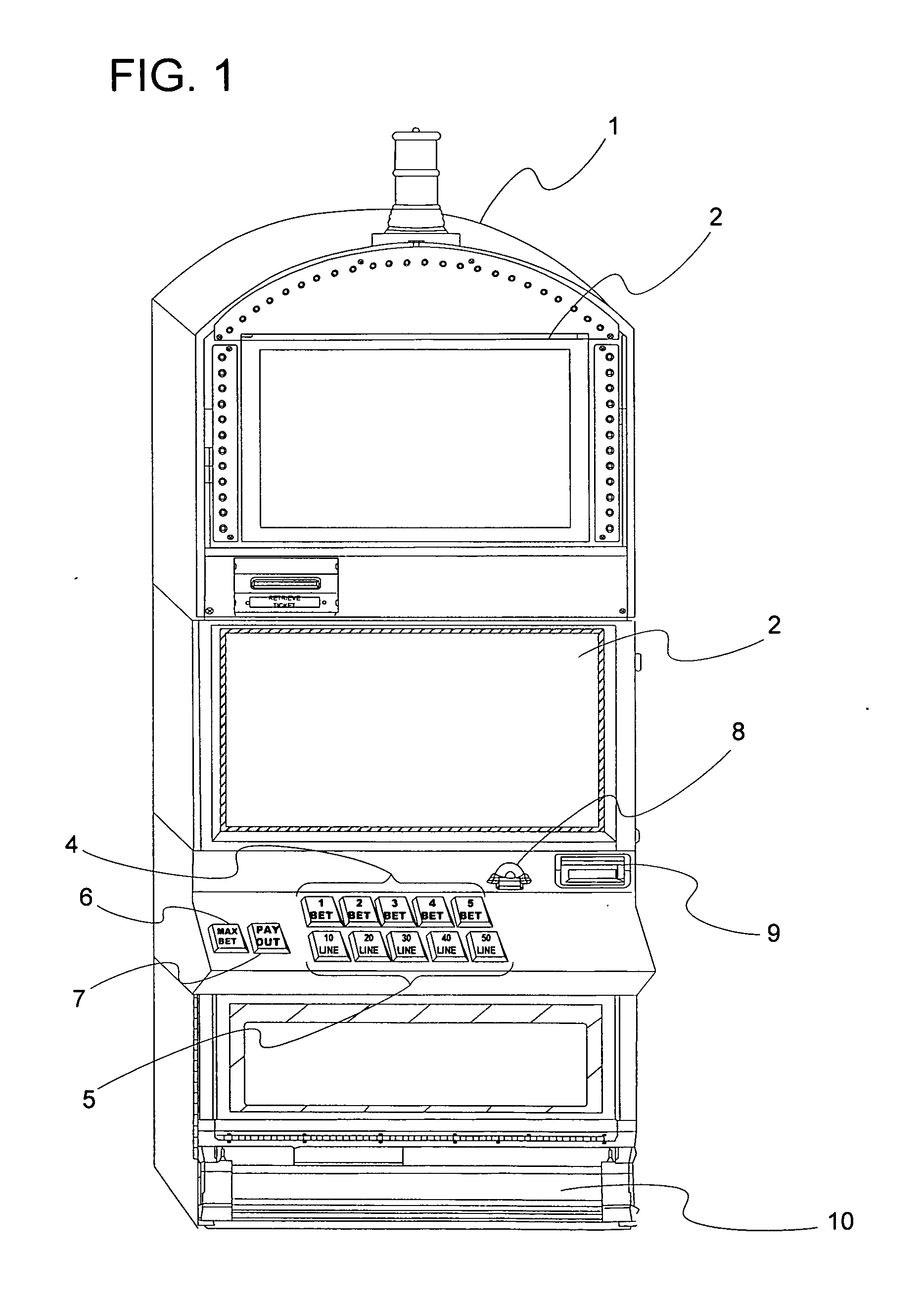

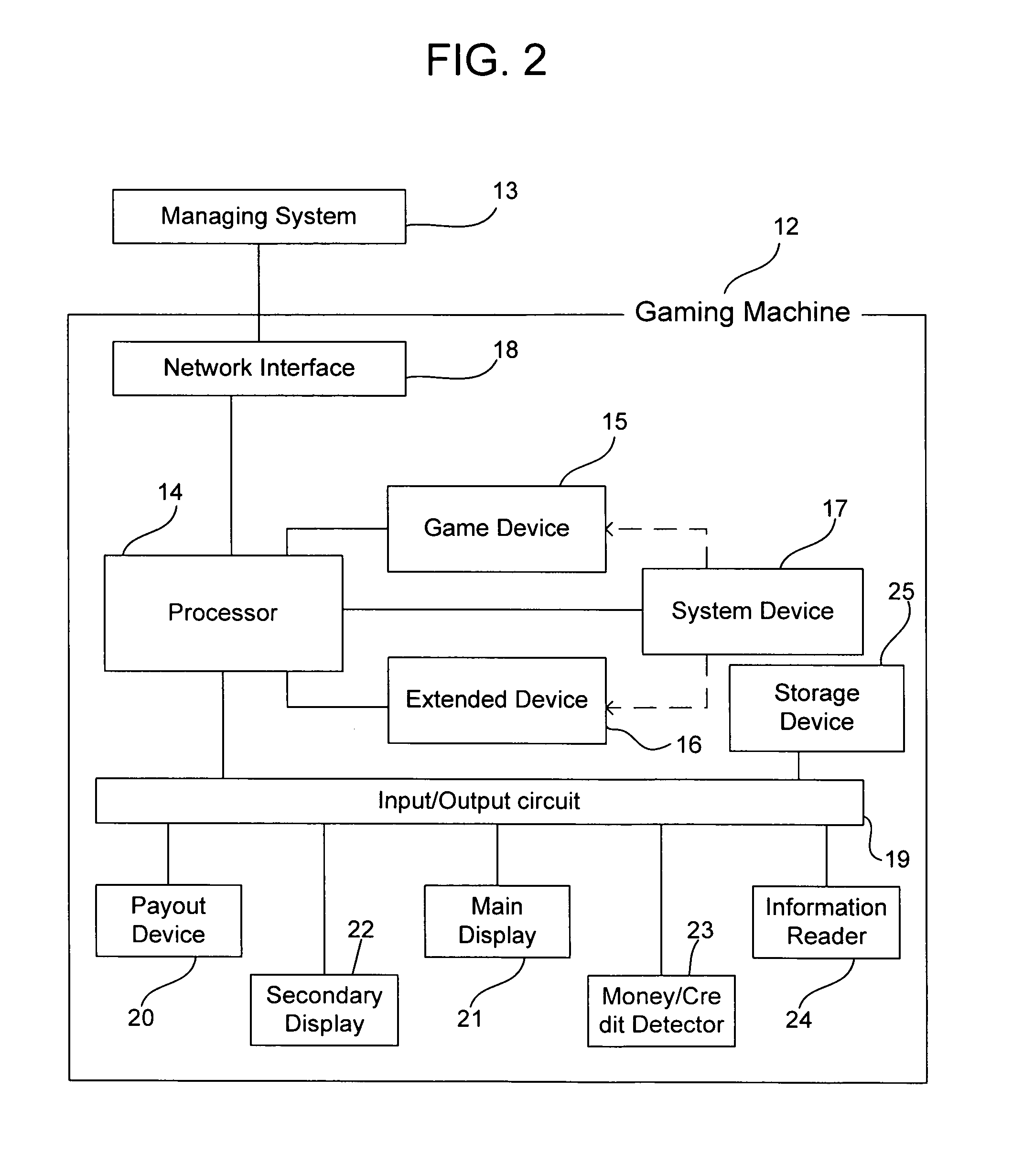

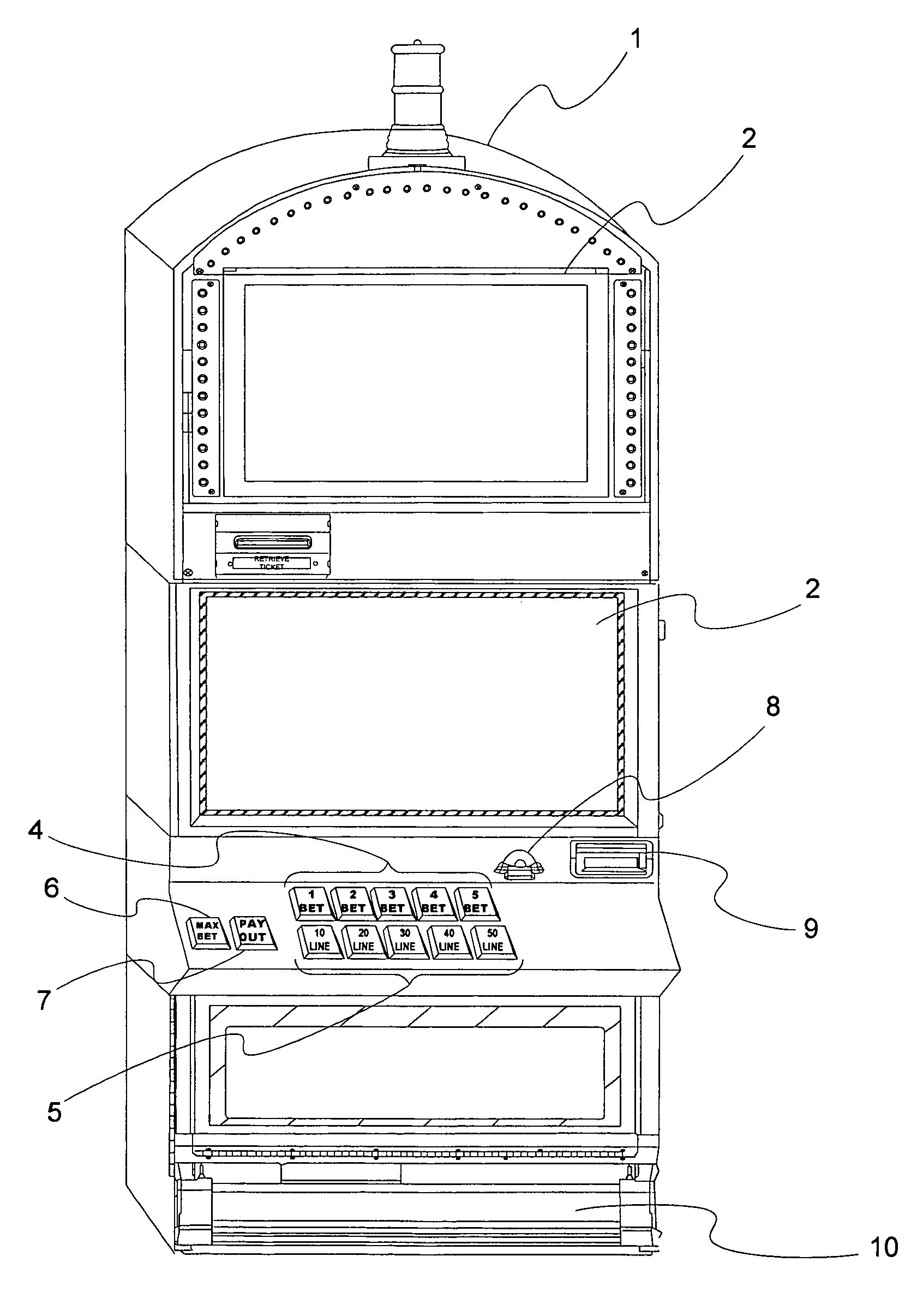

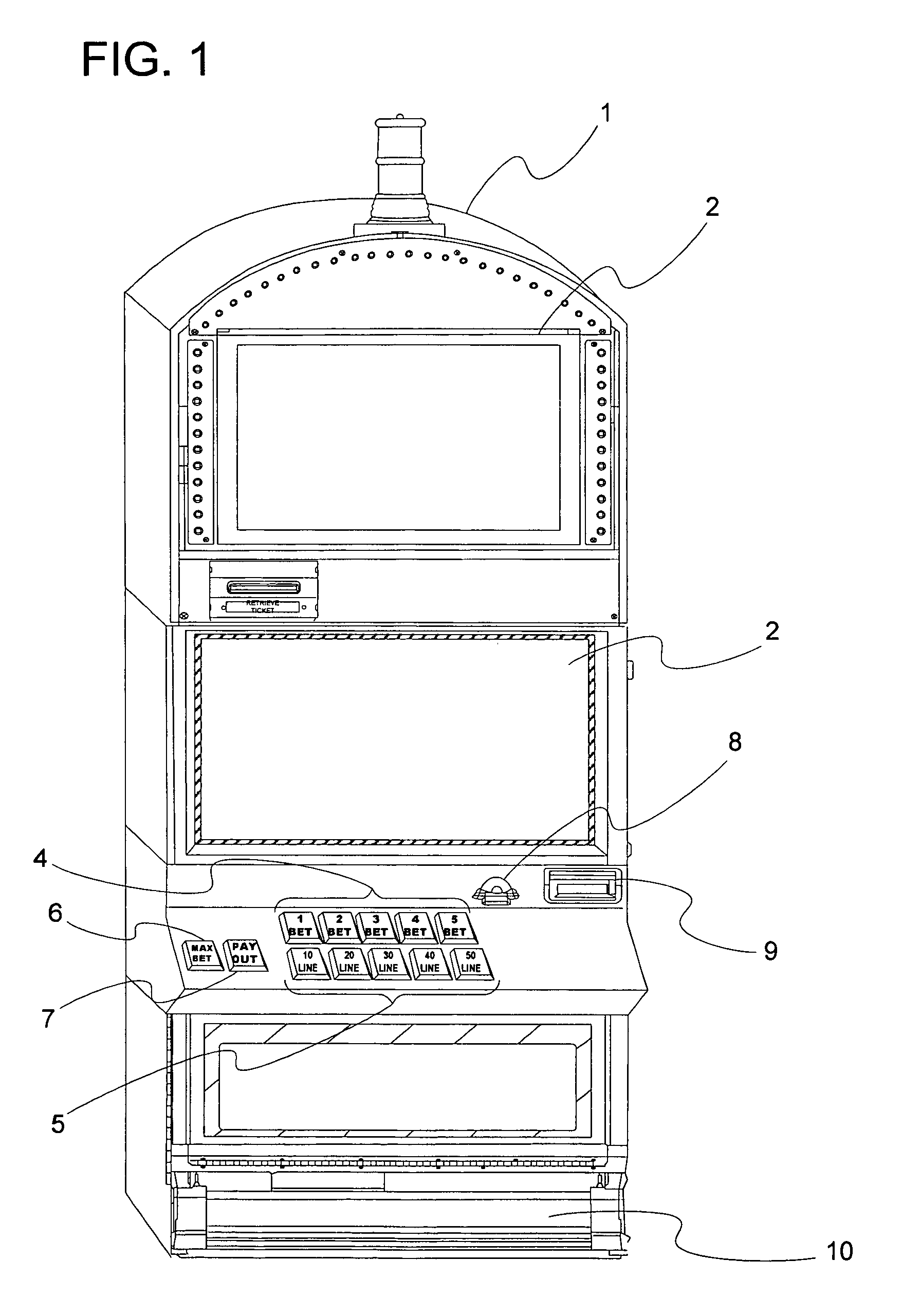

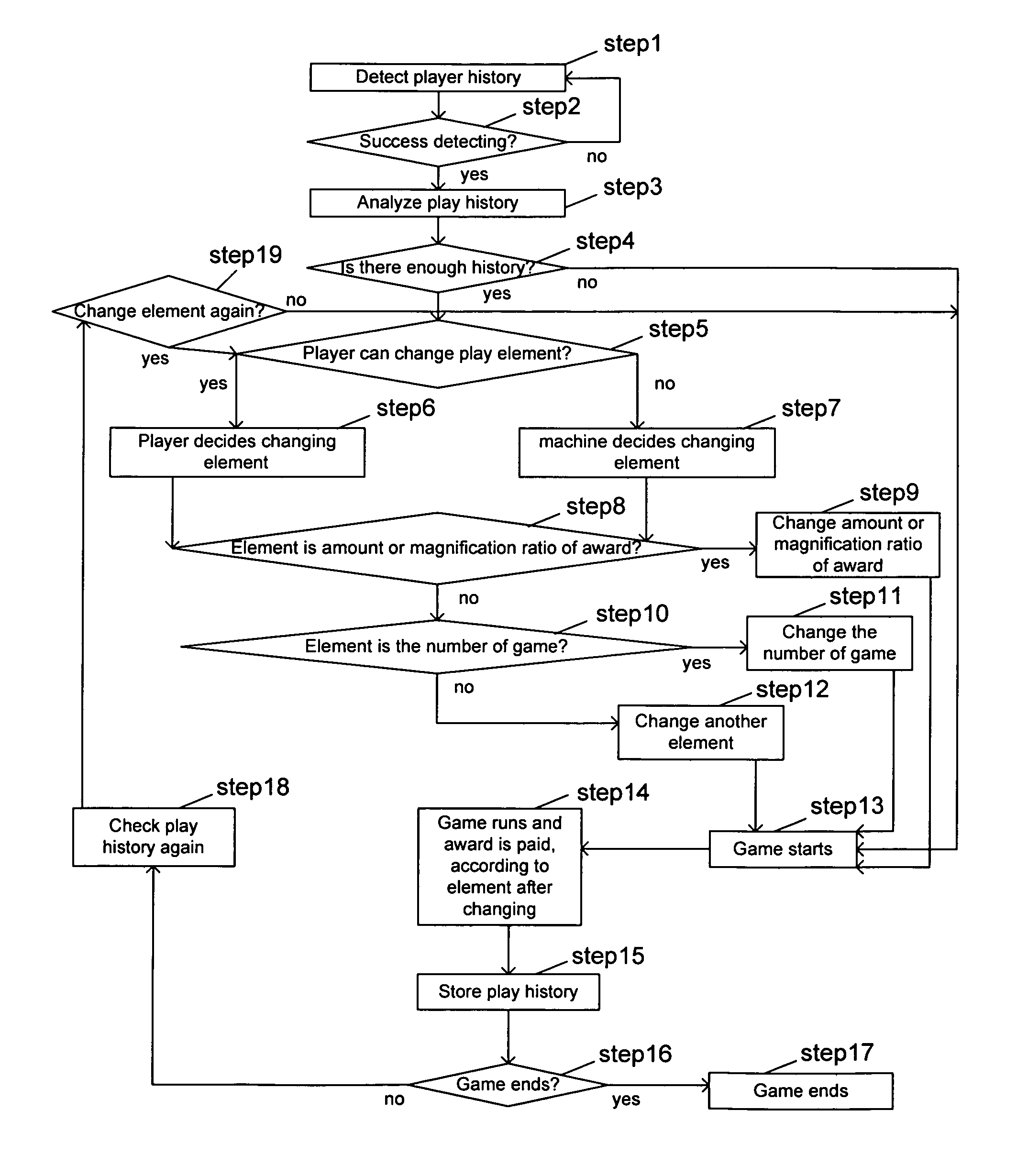

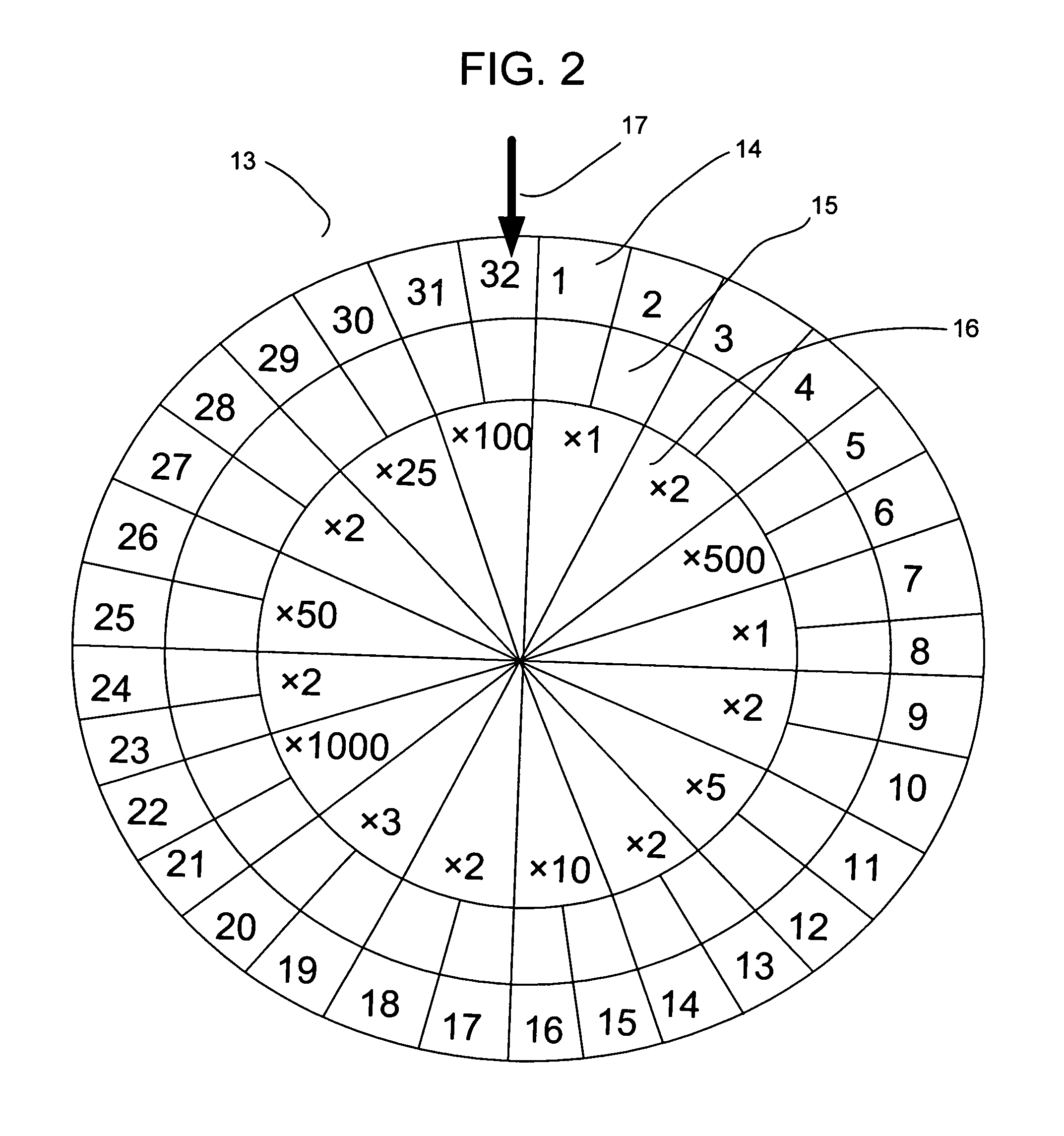

Gaming machine changing the volatility of the game

ActiveUS20090247284A1Changing the relative volatilityExcessive qualityApparatus for meter-controlled dispensingVideo gamesEngineeringGame play

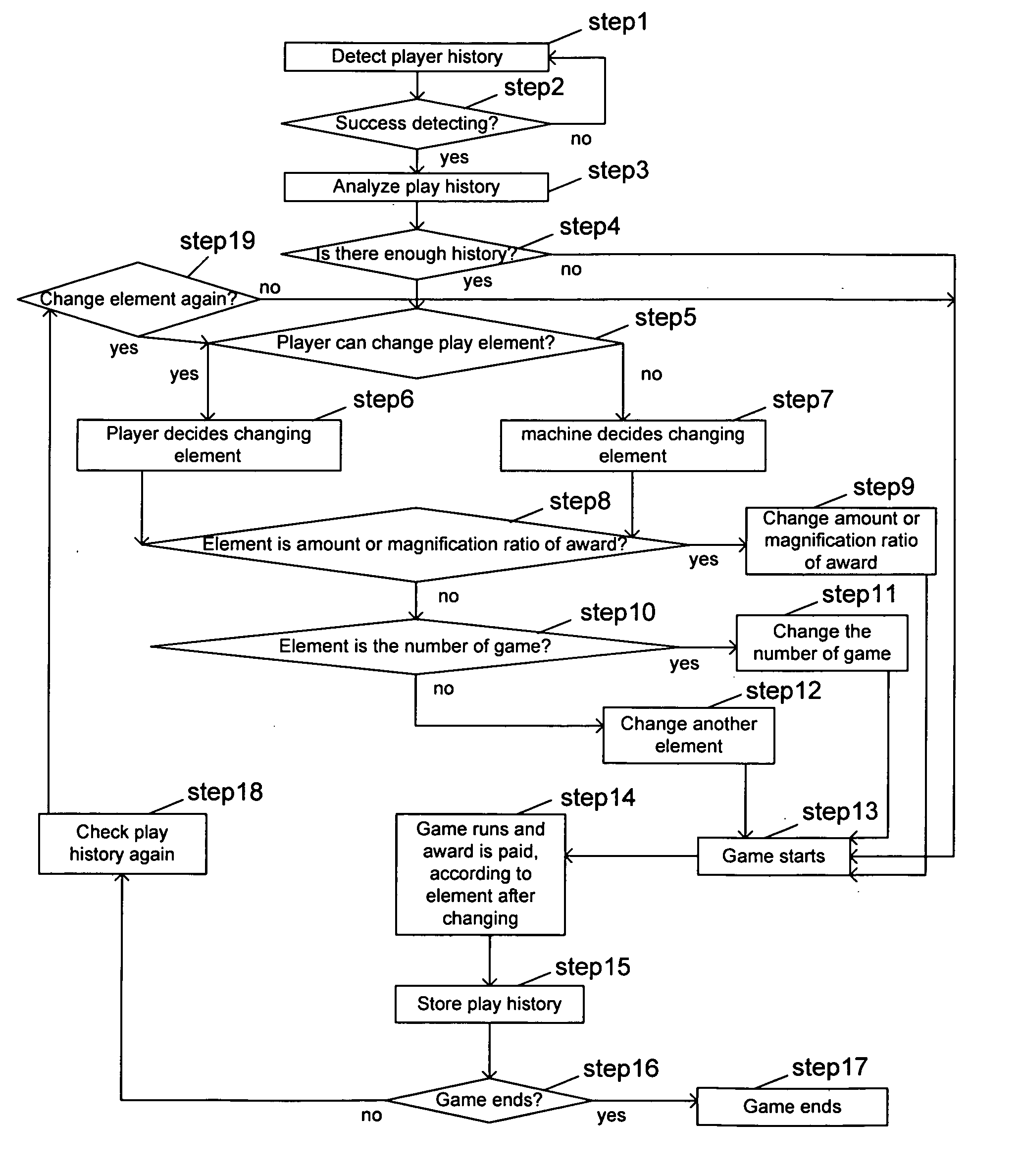

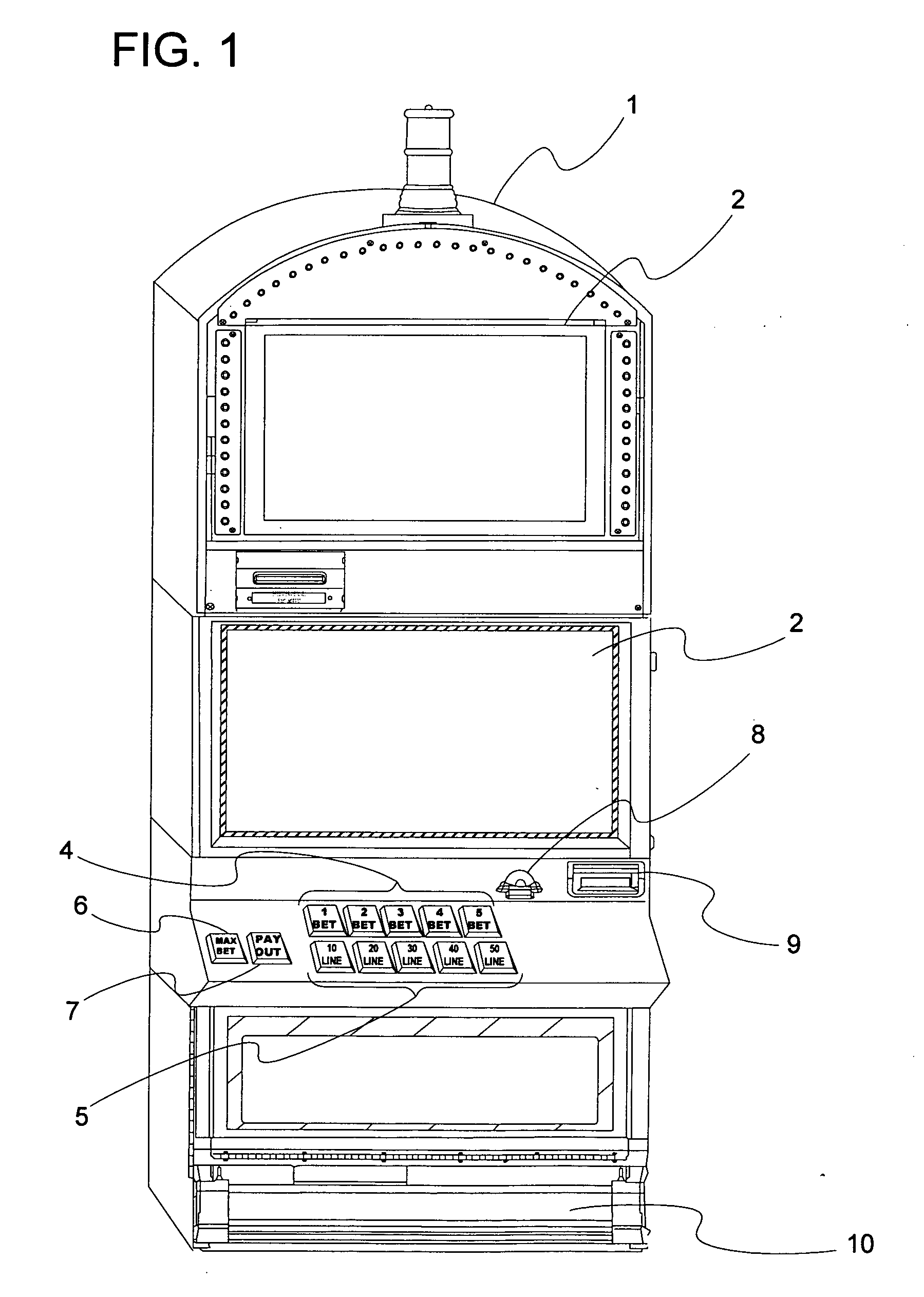

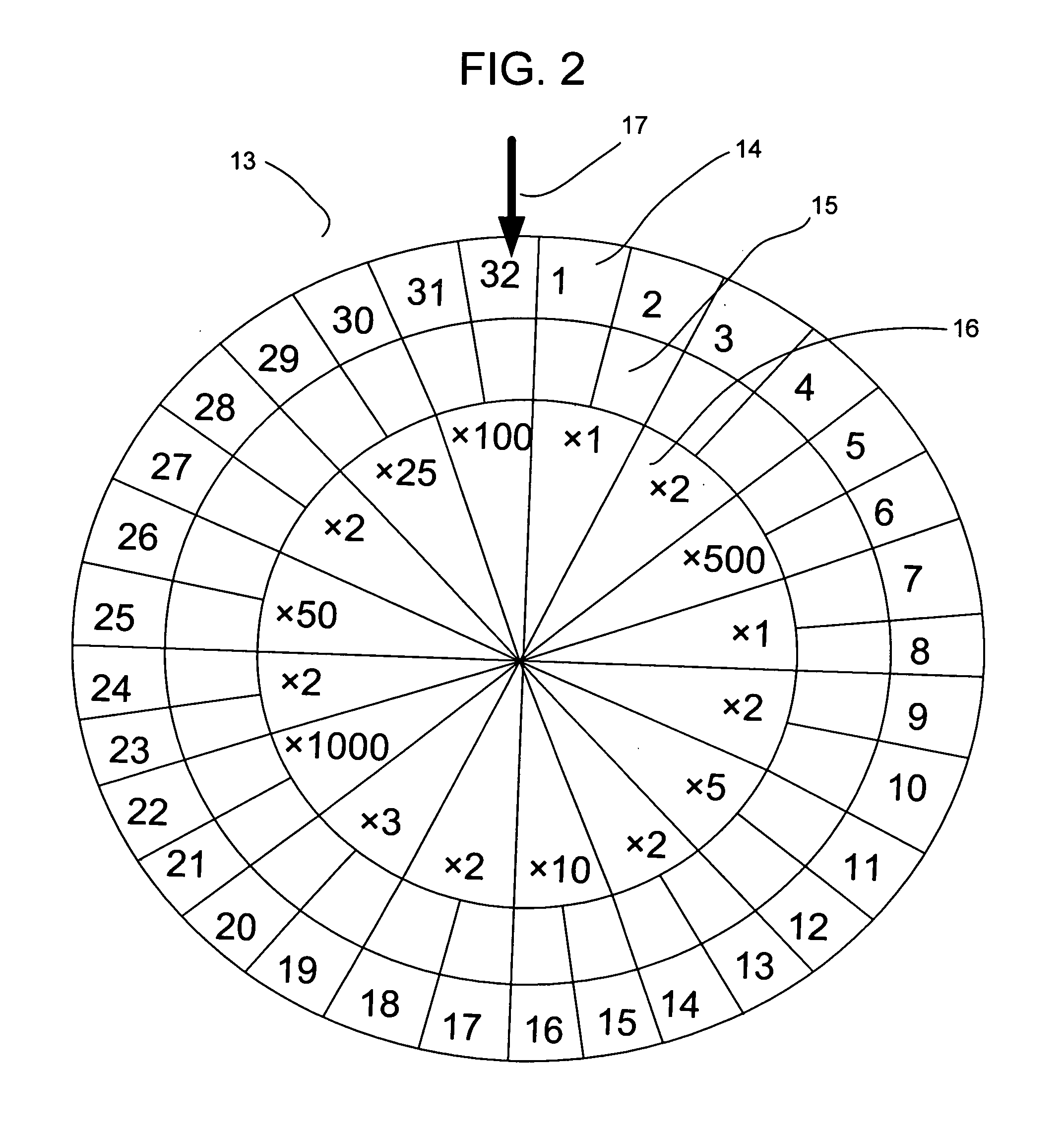

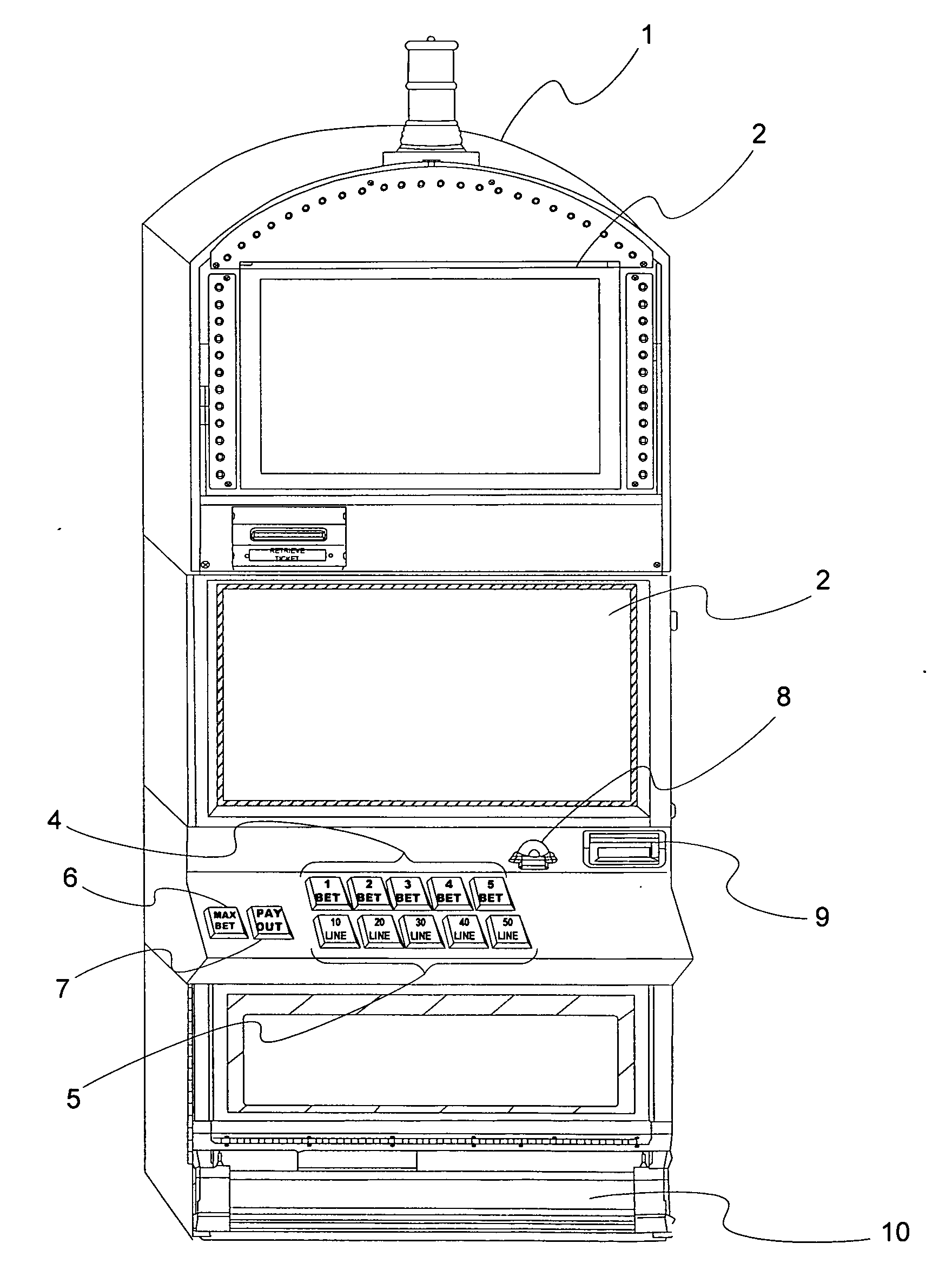

The present invention is a gaming machine for playing a game and paying out an award according to play results, comprising a detector which recognizes a play history of a player, an analyzer which analyzes the play history, a controller which changes a volatility of the game according to the play history, and an initiator which initiates the game with changed volatility.

Owner:KONAMI GAMING

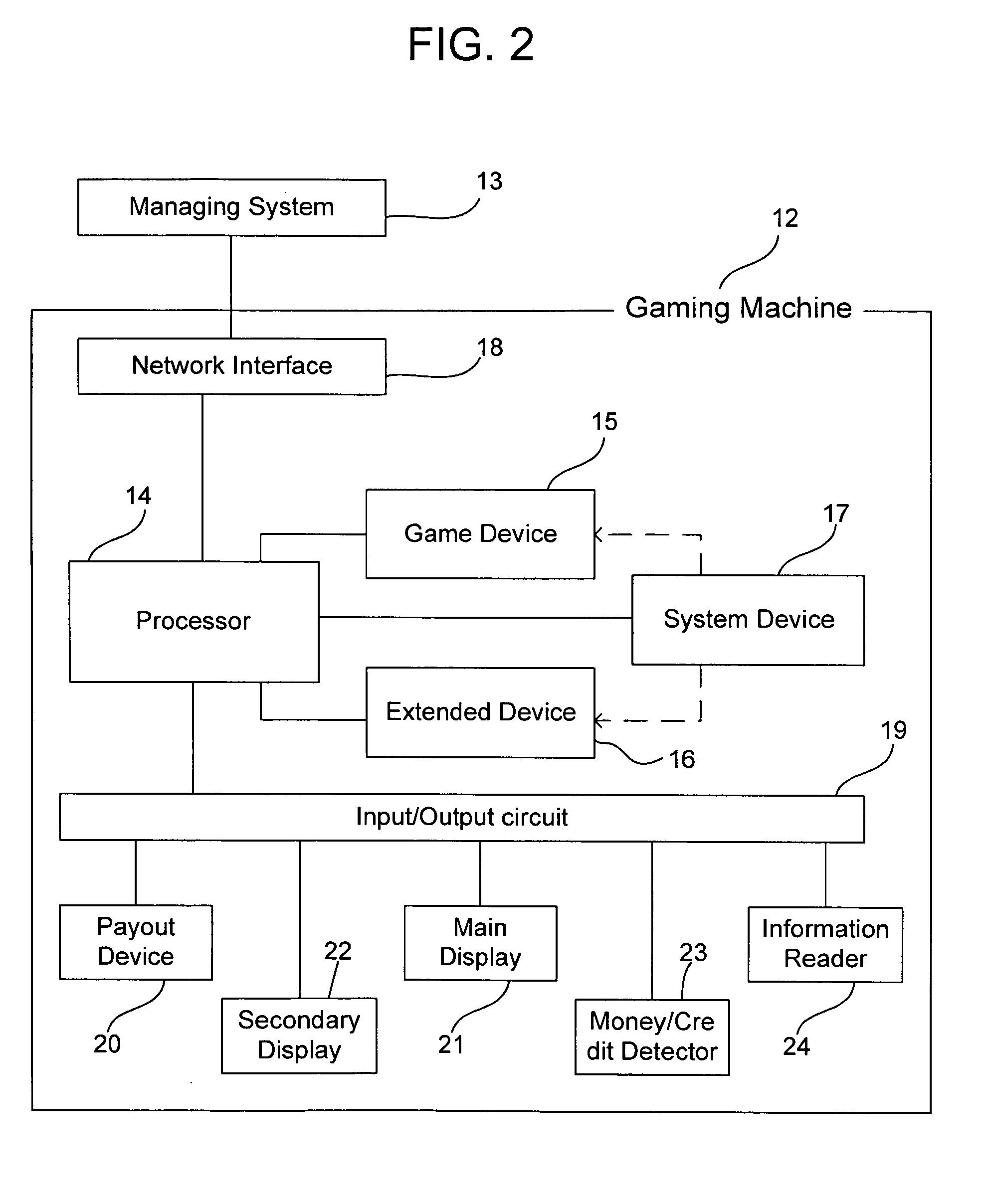

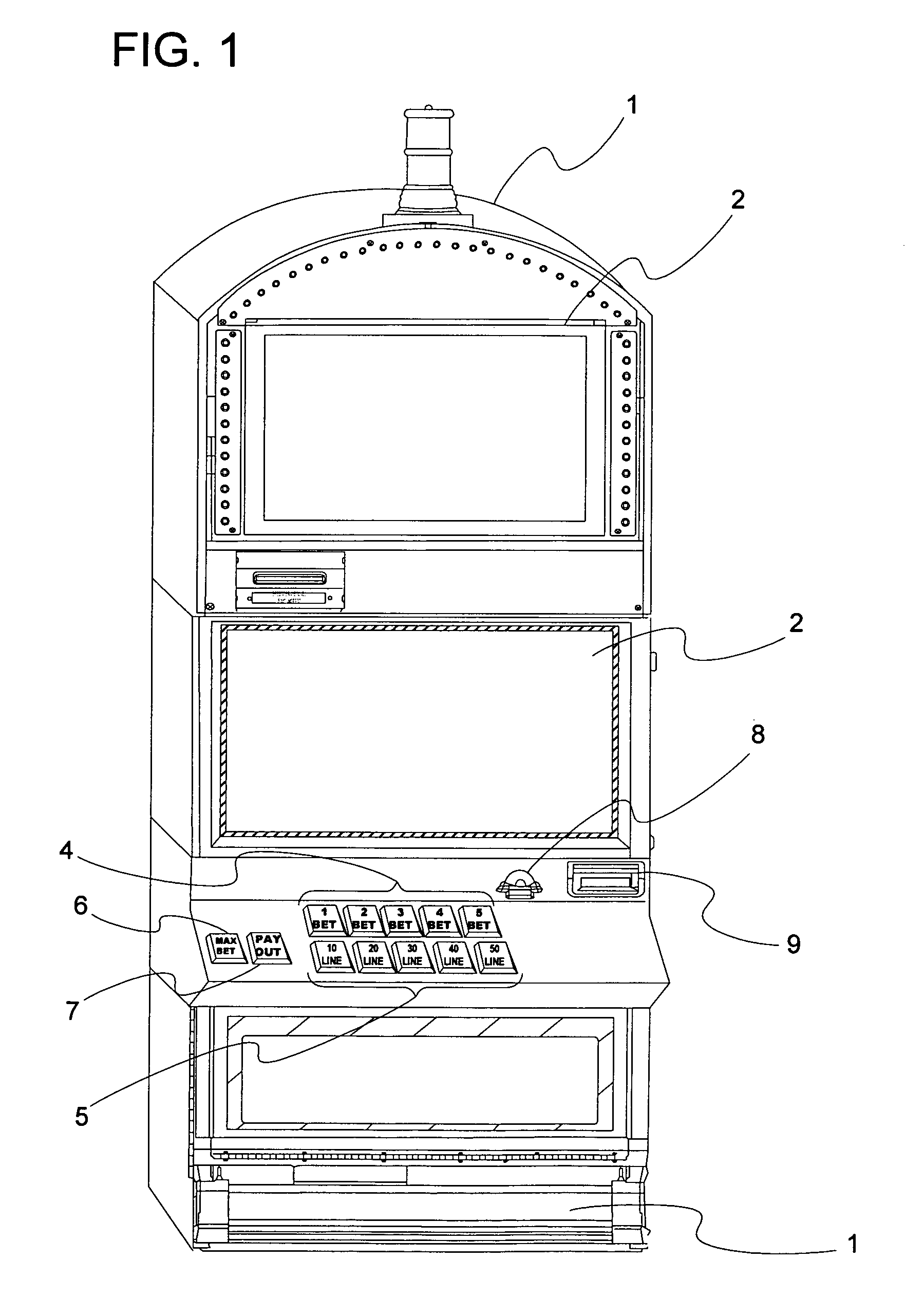

Gaming machine with extensive symbols

InactiveUS20100113130A1Rich varietyImprove expectationsApparatus for meter-controlled dispensingVideo gamesGame elementGame machine

The present invention is a gaming machine for providing a display and paying out award, including a storage device which stores a game data to implement at least two games of the same type, an extended device which adds a game element to the two games and a game device which implements the two games of the same type, wherein the extended device works independently of the game device.

Owner:KONAMI GAMING

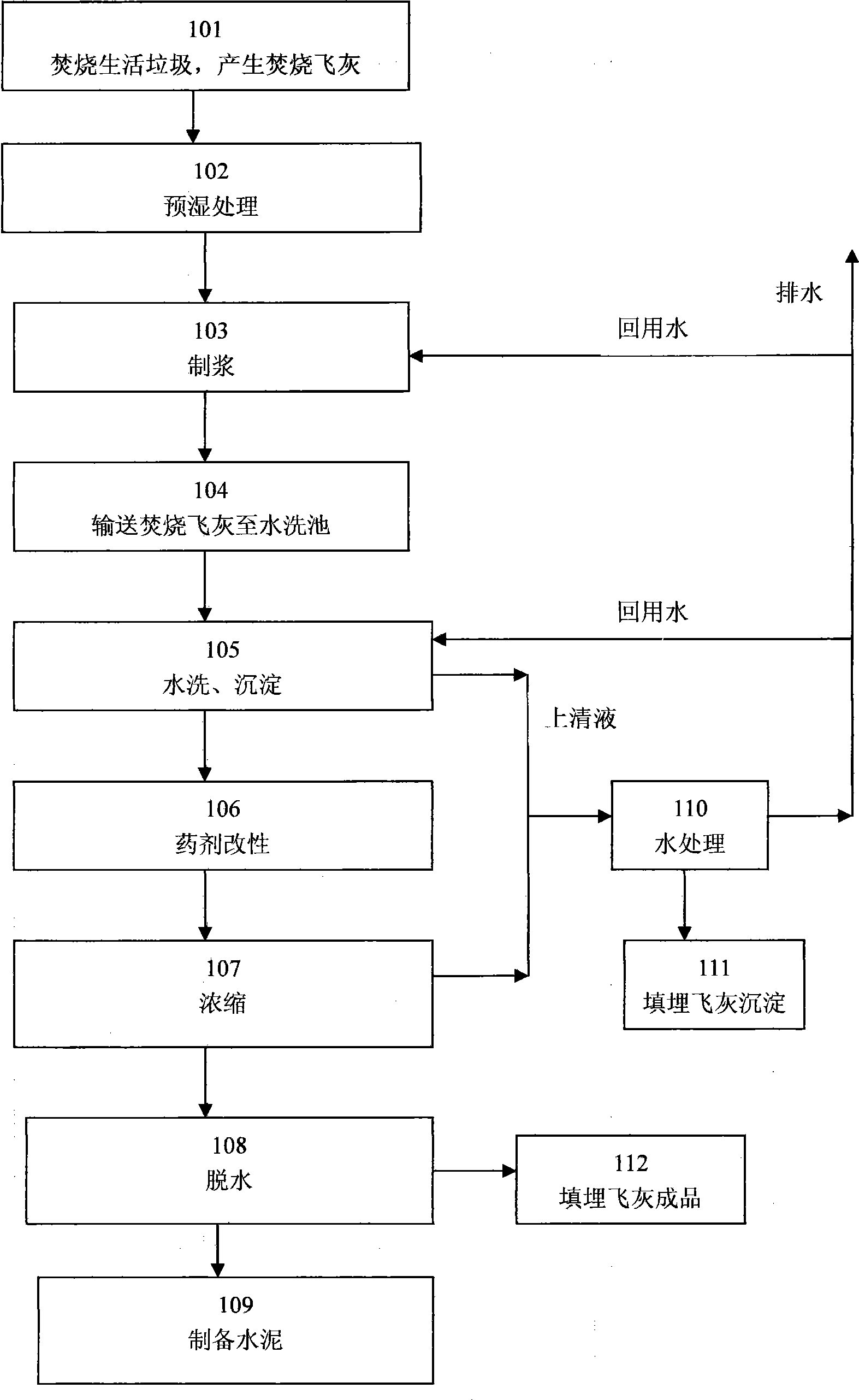

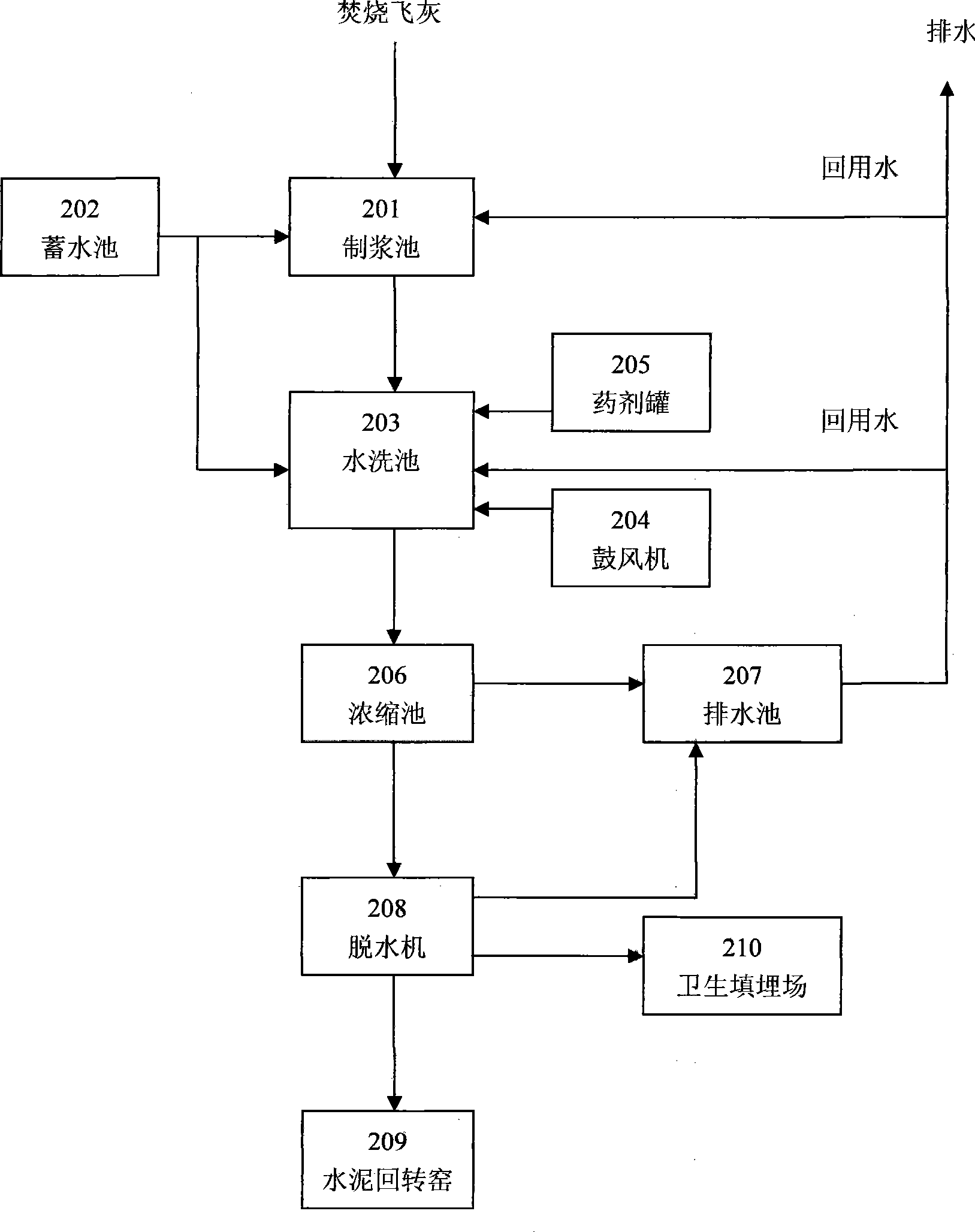

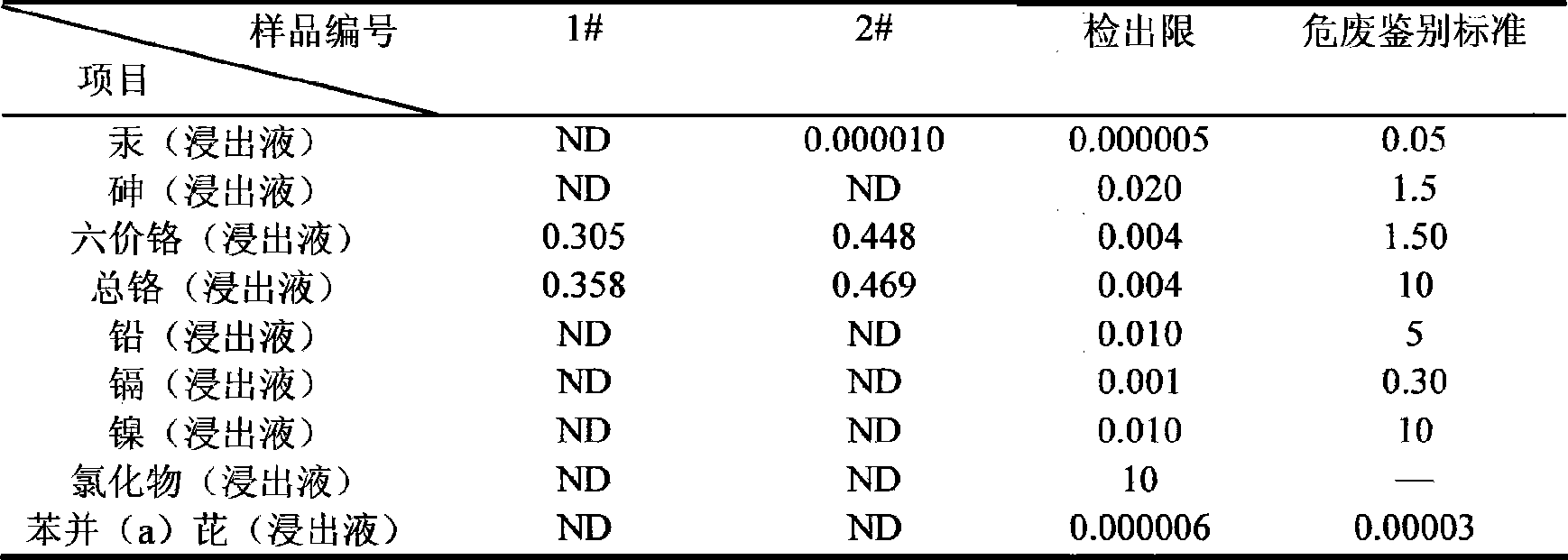

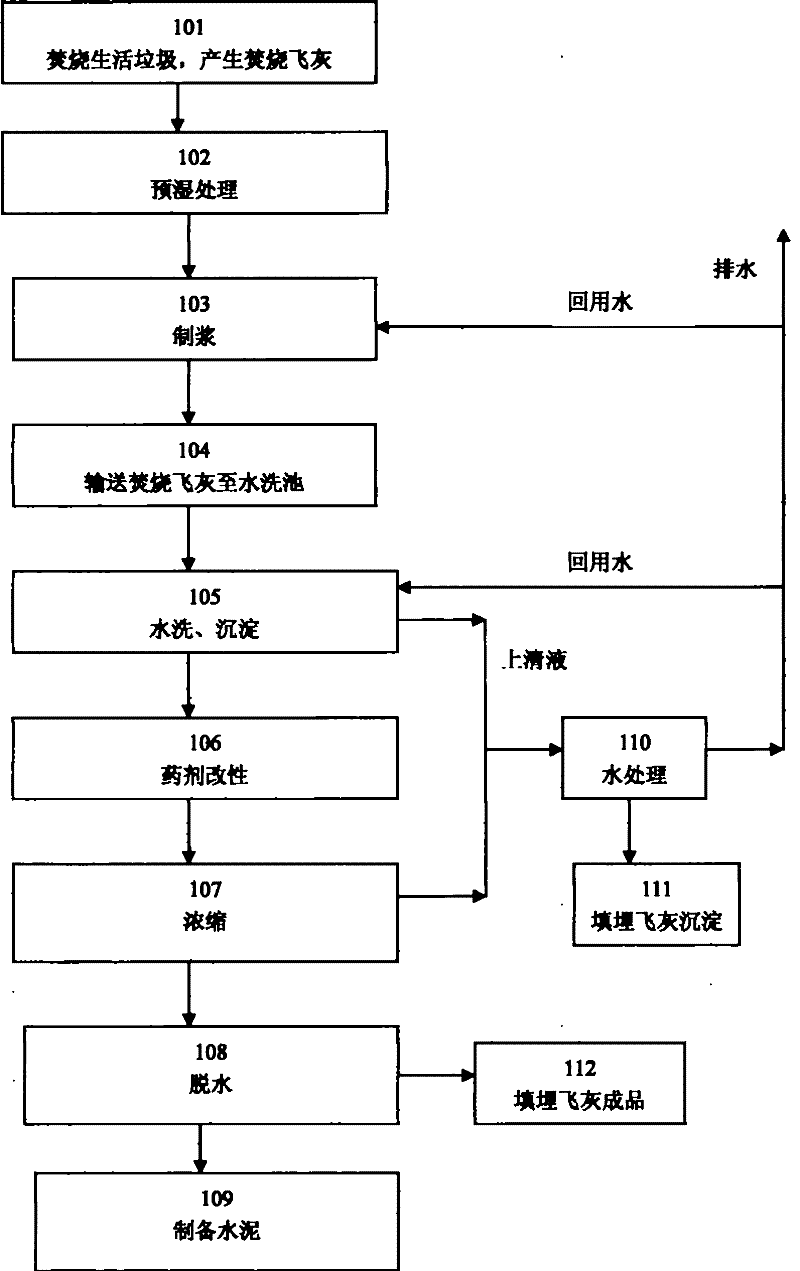

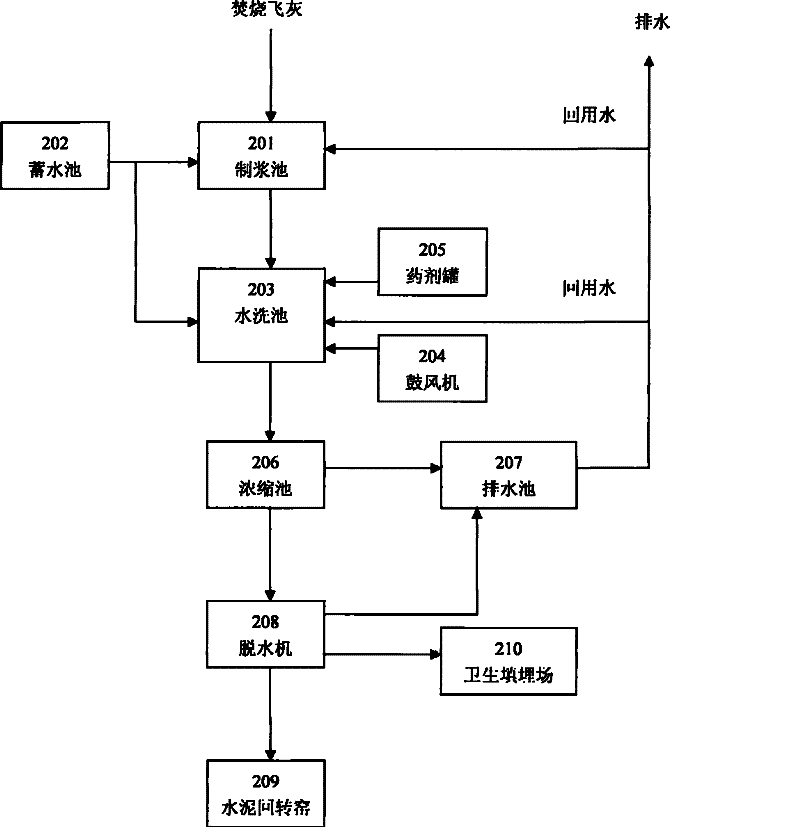

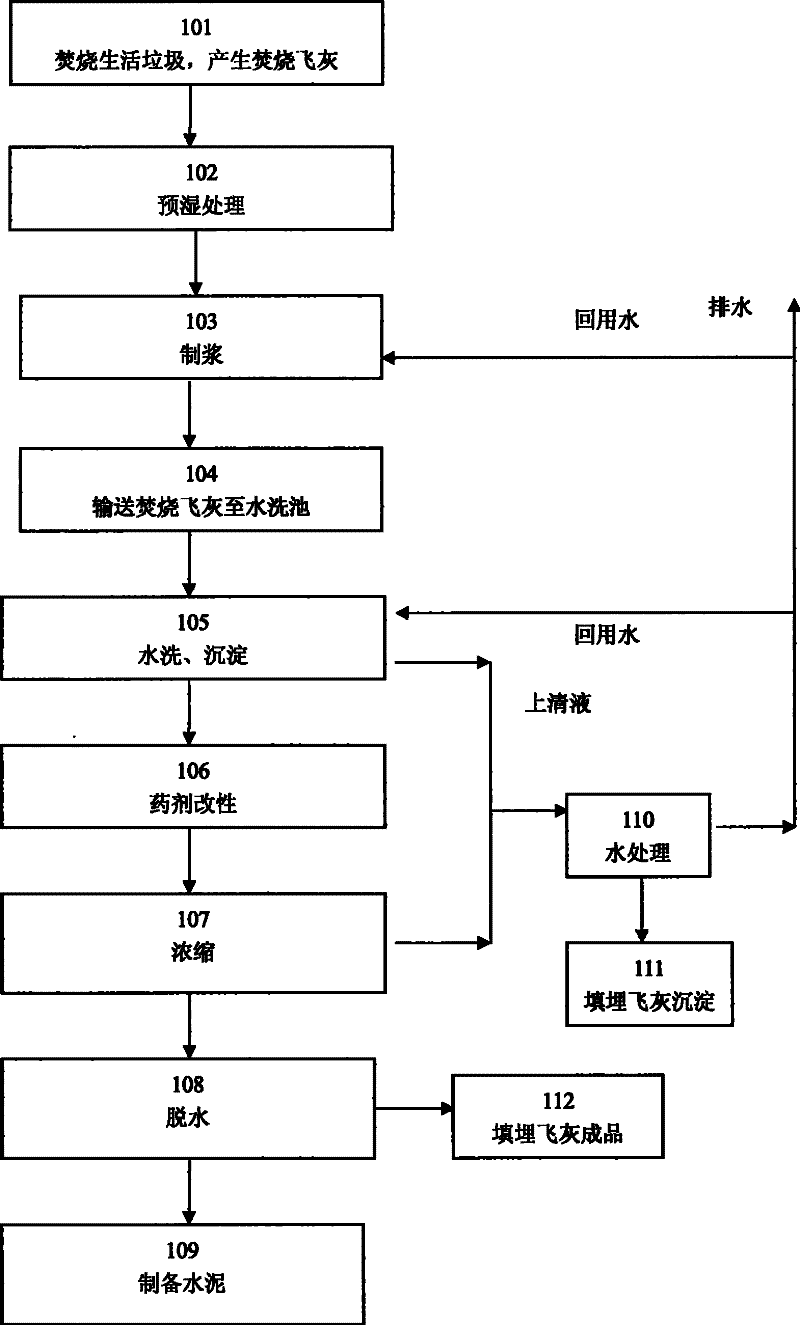

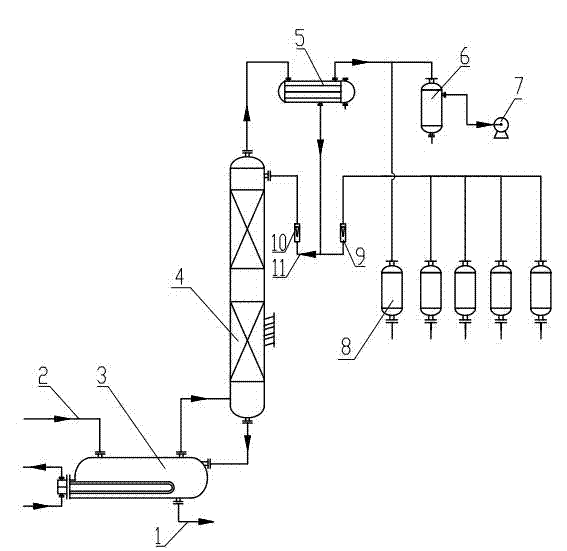

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

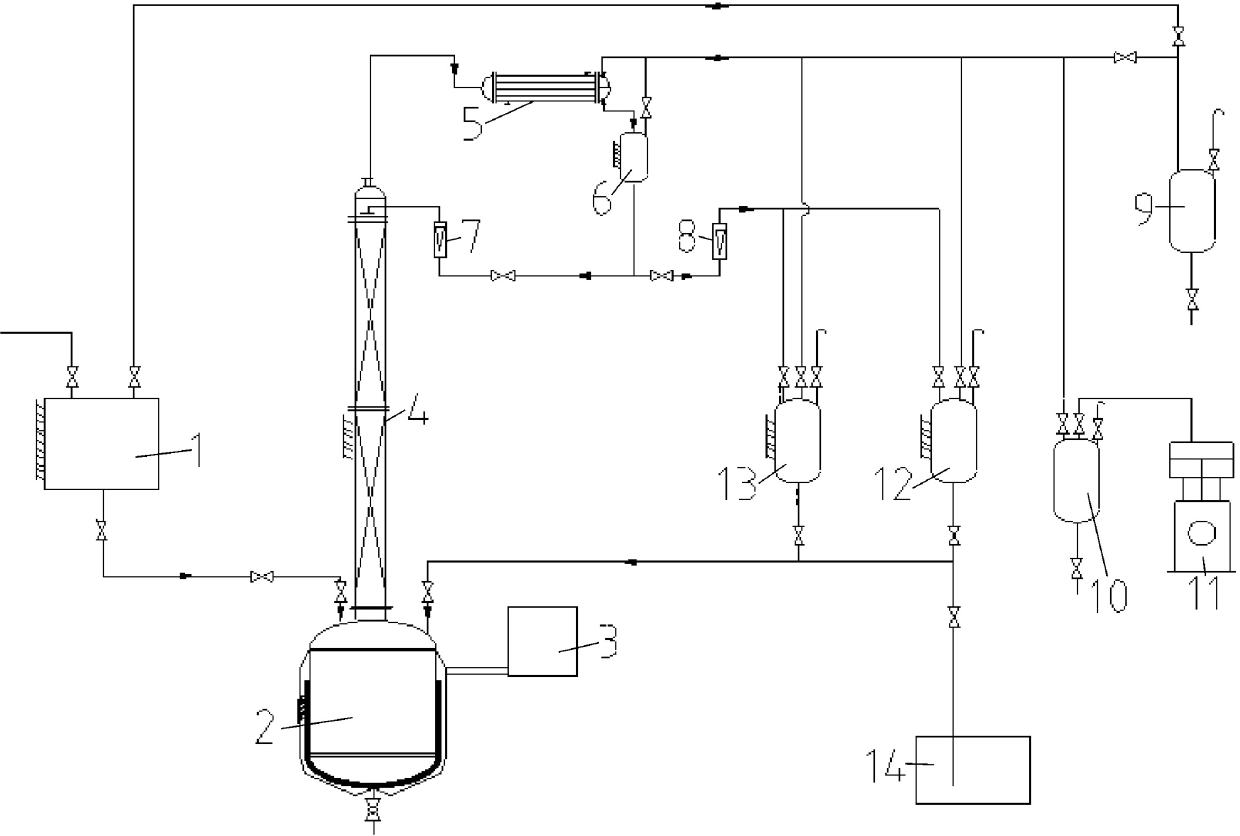

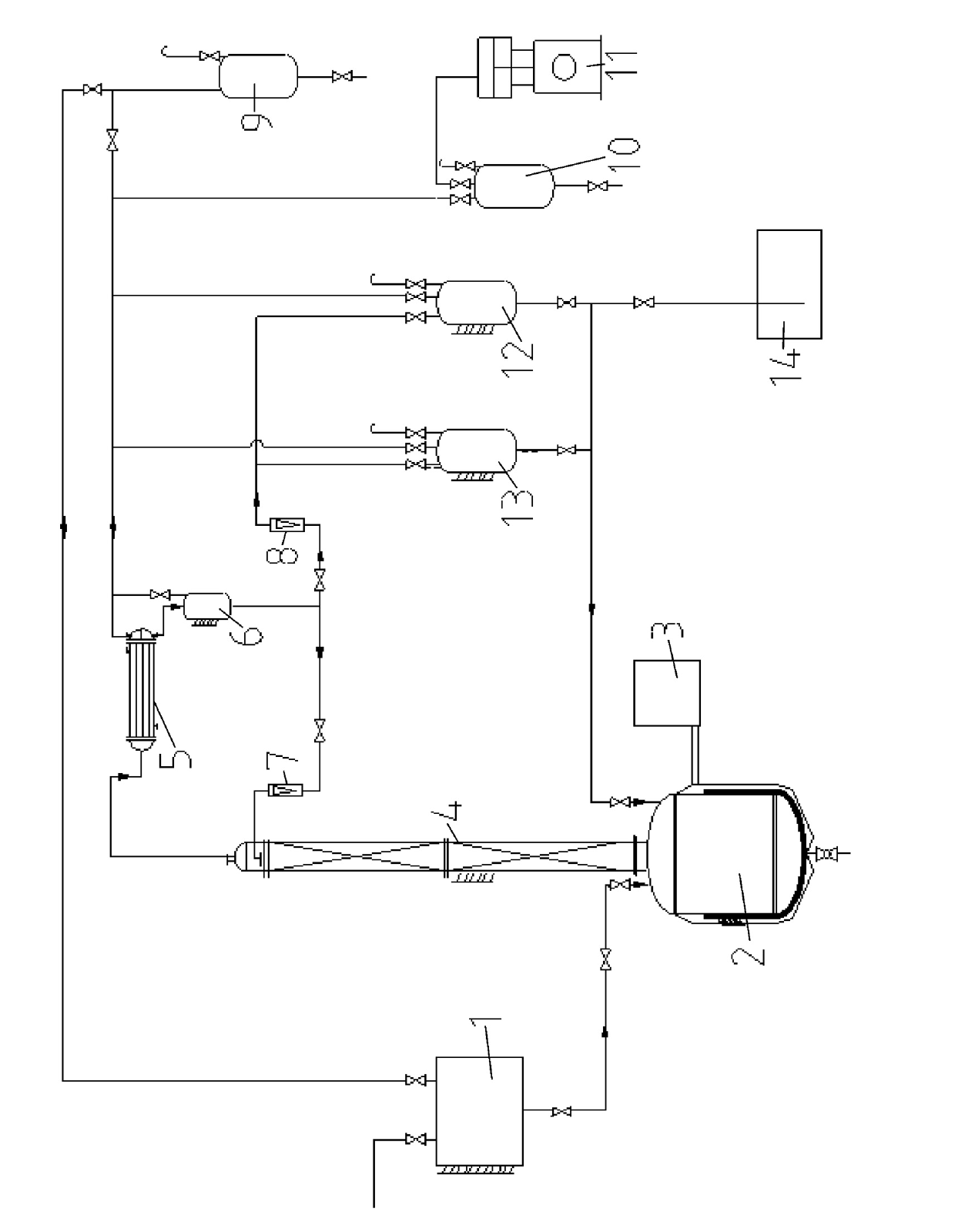

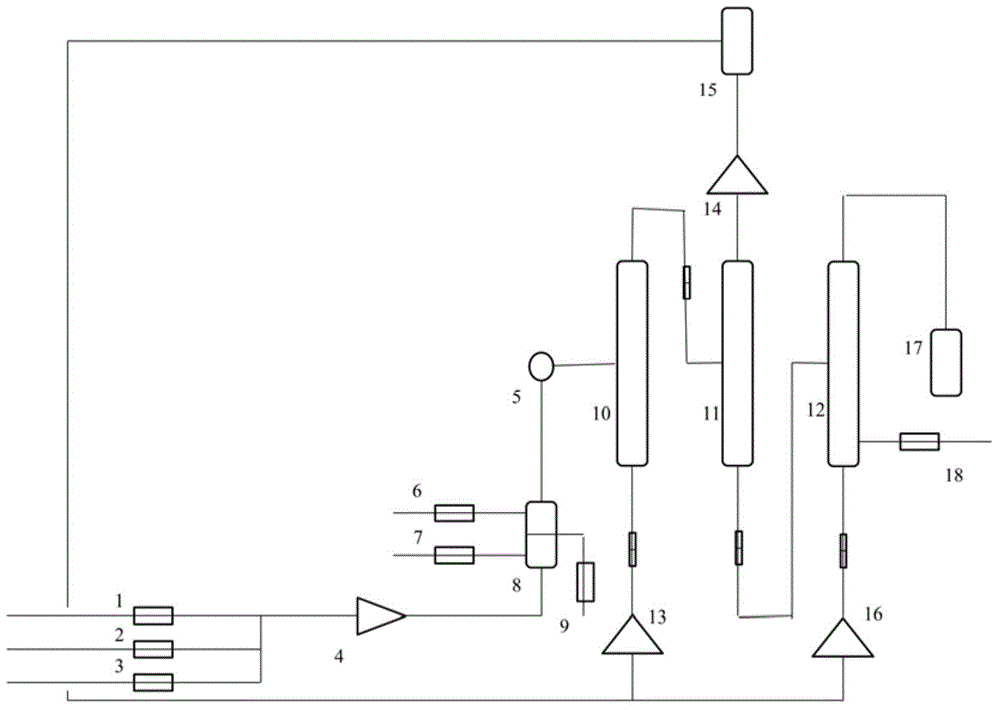

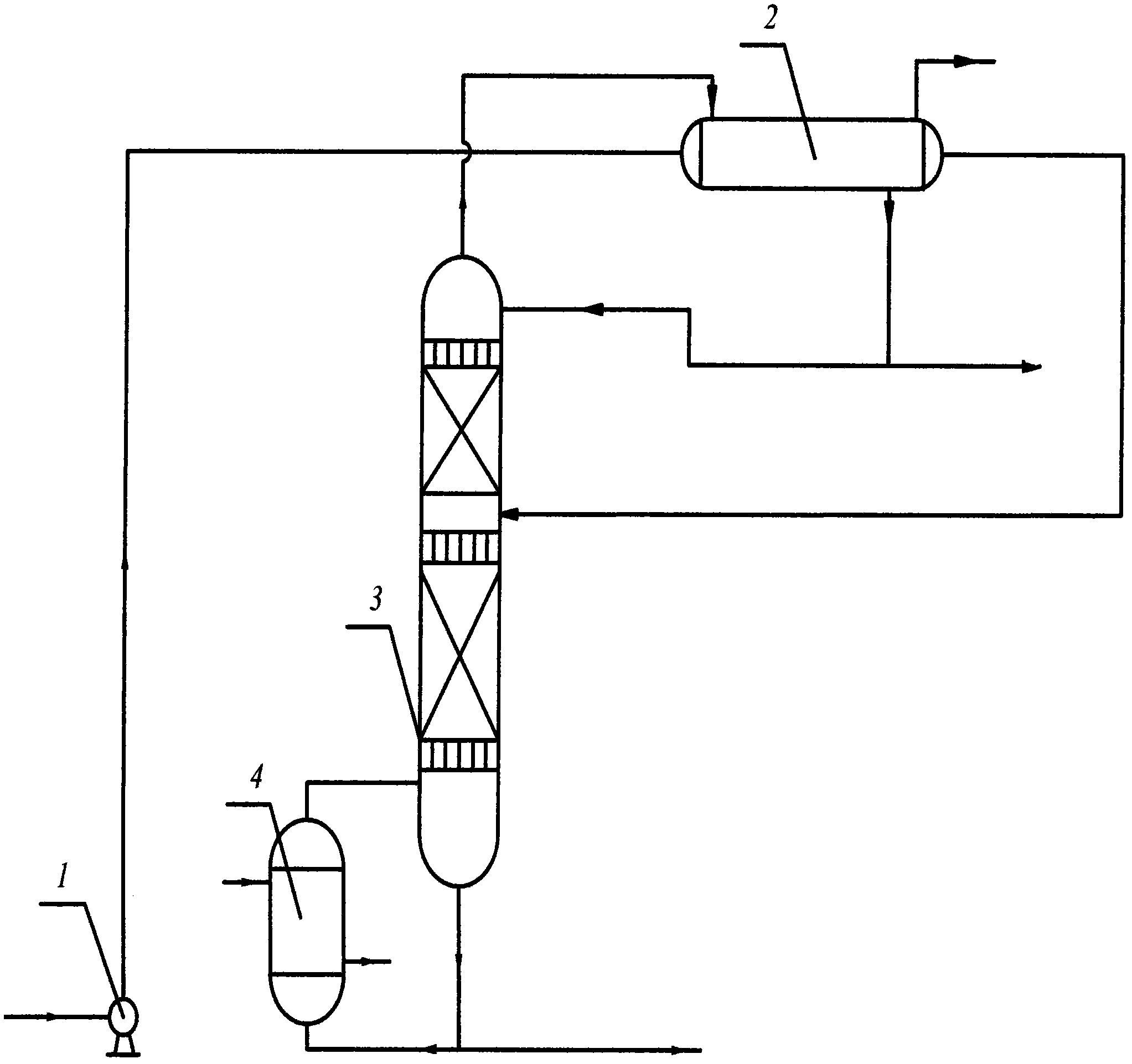

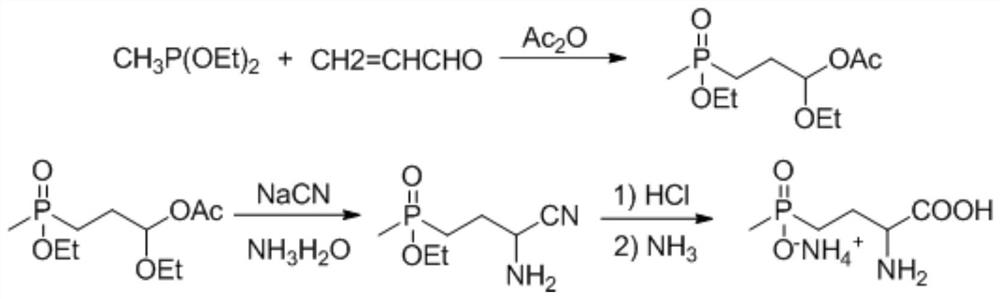

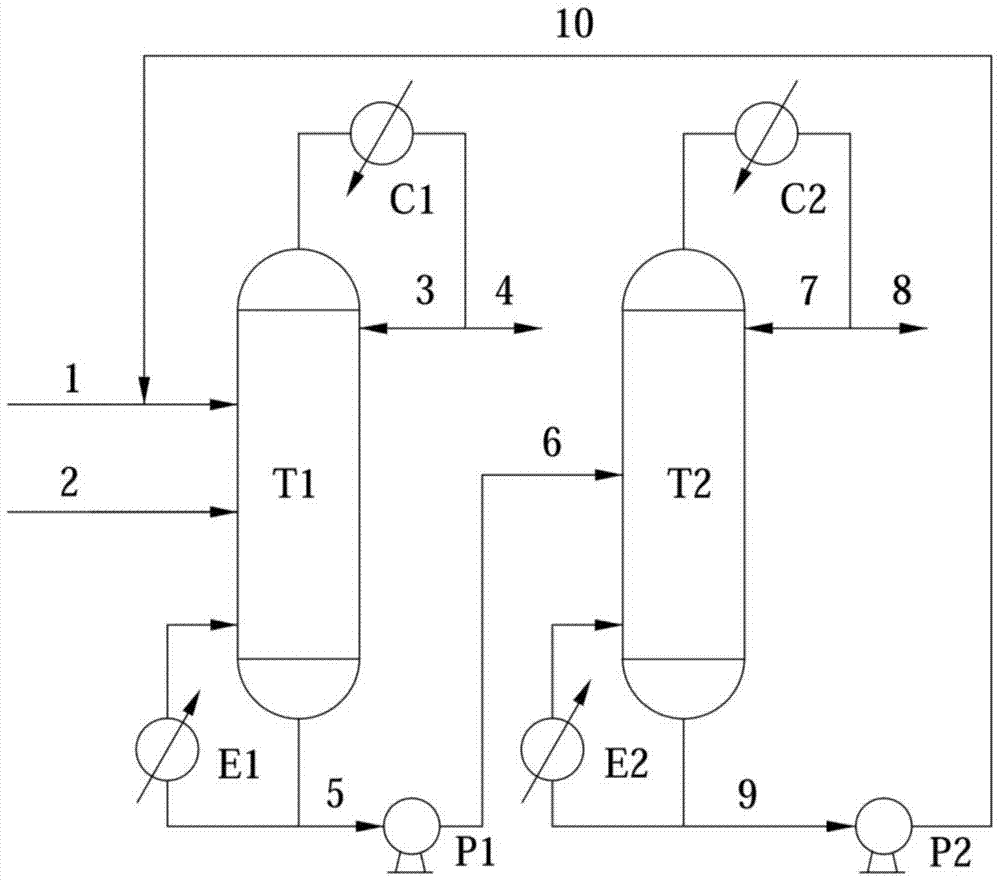

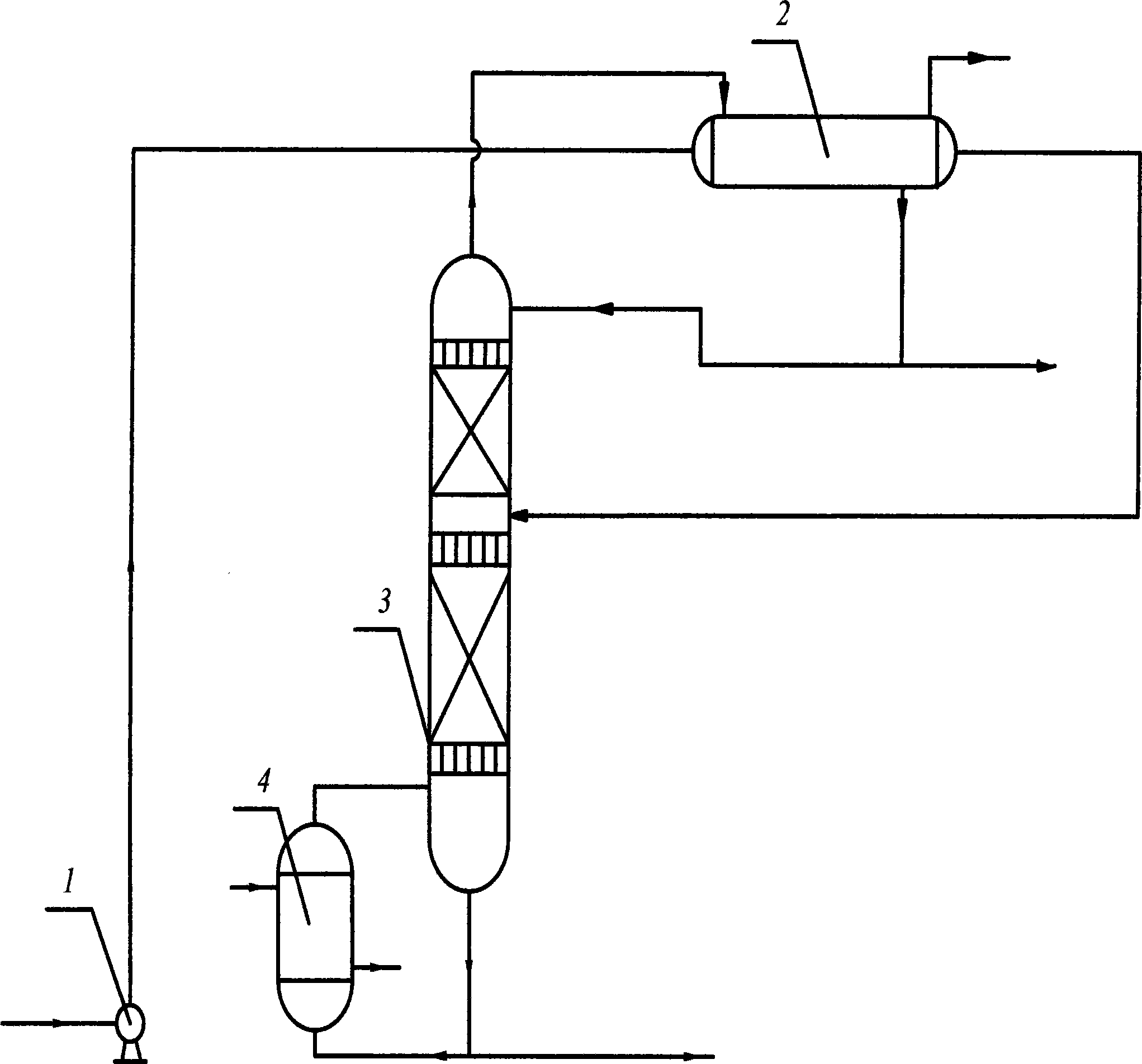

Method and device for performing refined separation on high-purity yellow phosphorous

ActiveCN101912691AImprove separation efficiencyLow boiling pointVacuum distillation separationPhosphorus compoundsBuffer tankBoiling point

The invention discloses a method and a device for performing refined separation on high-purity yellow phosphorous. A raw material storage tank is connected with a tower bottom; a rectifying tower is positioned above the tower bottom; one end of a condenser is connected with a tower top of the rectifying tower, while the other end is connected with a return tank; the return tank is connected with the tower top of the rectifying tower through a return flowmeter and connected with a front fraction tank and a product tank through a product flowmeter, and a discharge pipe of the product tank is connected with a product collecting tank; a vacuum pump is connected with the condenser, the return tank, the front fraction tank and the product tank through a buffer tank; and a nitrogen tank is connected with the raw material storage tank, the condenser, the return tank, the front fraction tank and the product tank. Through operation of performing rectification under reduced pressure and changinga reflux ratio, the method and the device reduce the boiling point of each component of the material greatly, change the relative volatility among the components, and have the advantages of uniform heating in the tower bottom, simple operation process, high separation efficiency and high purity of the product at the same time.

Owner:湖北兴福电子材料股份有限公司

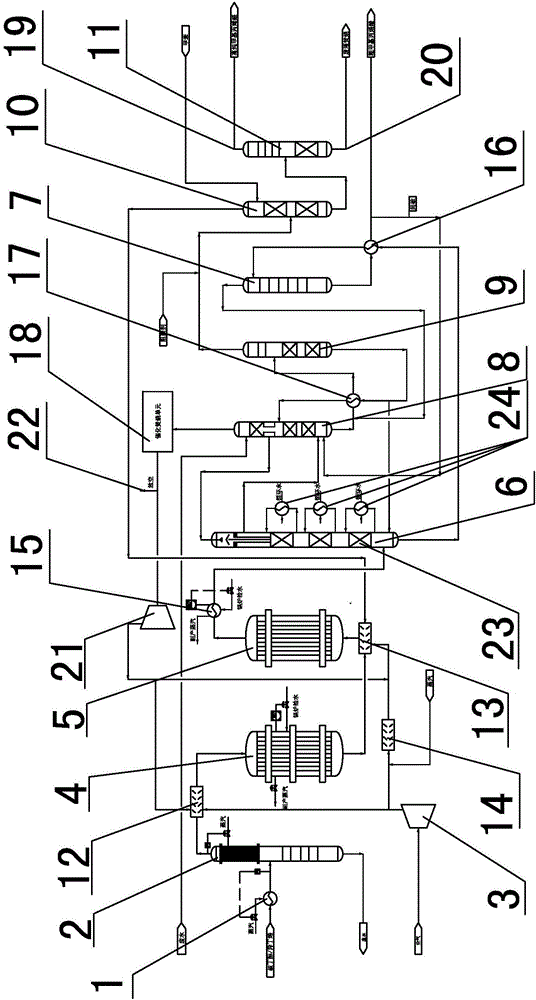

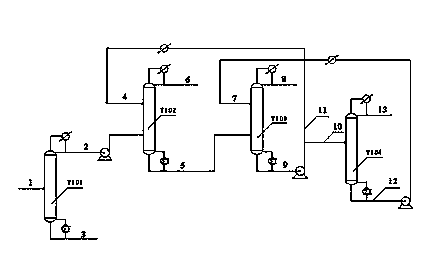

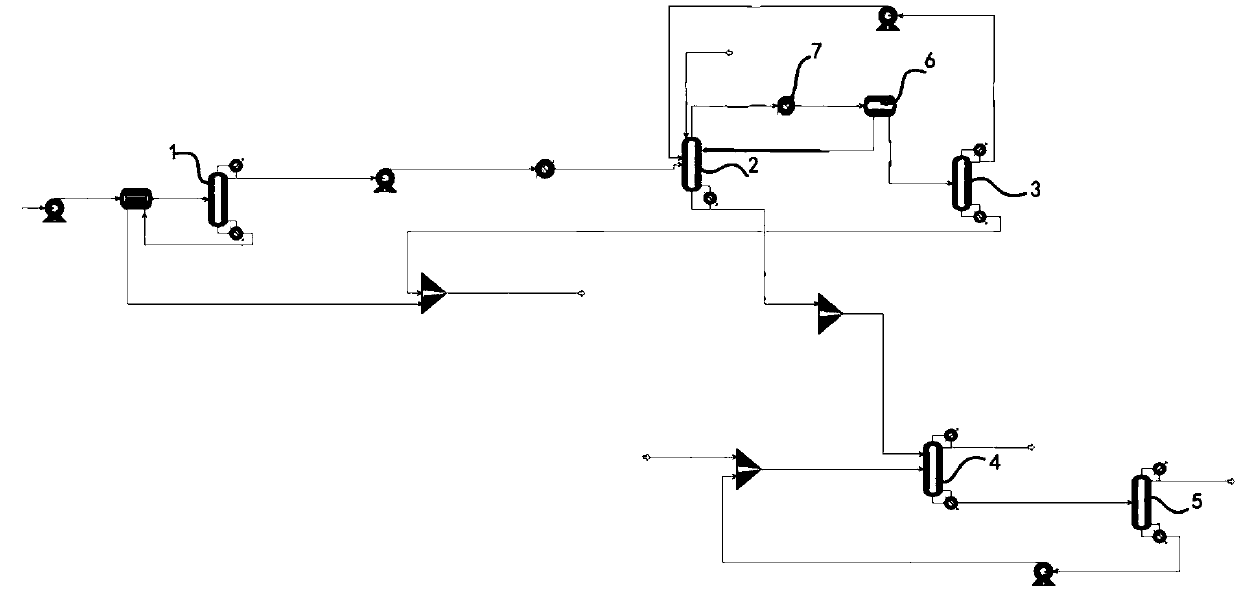

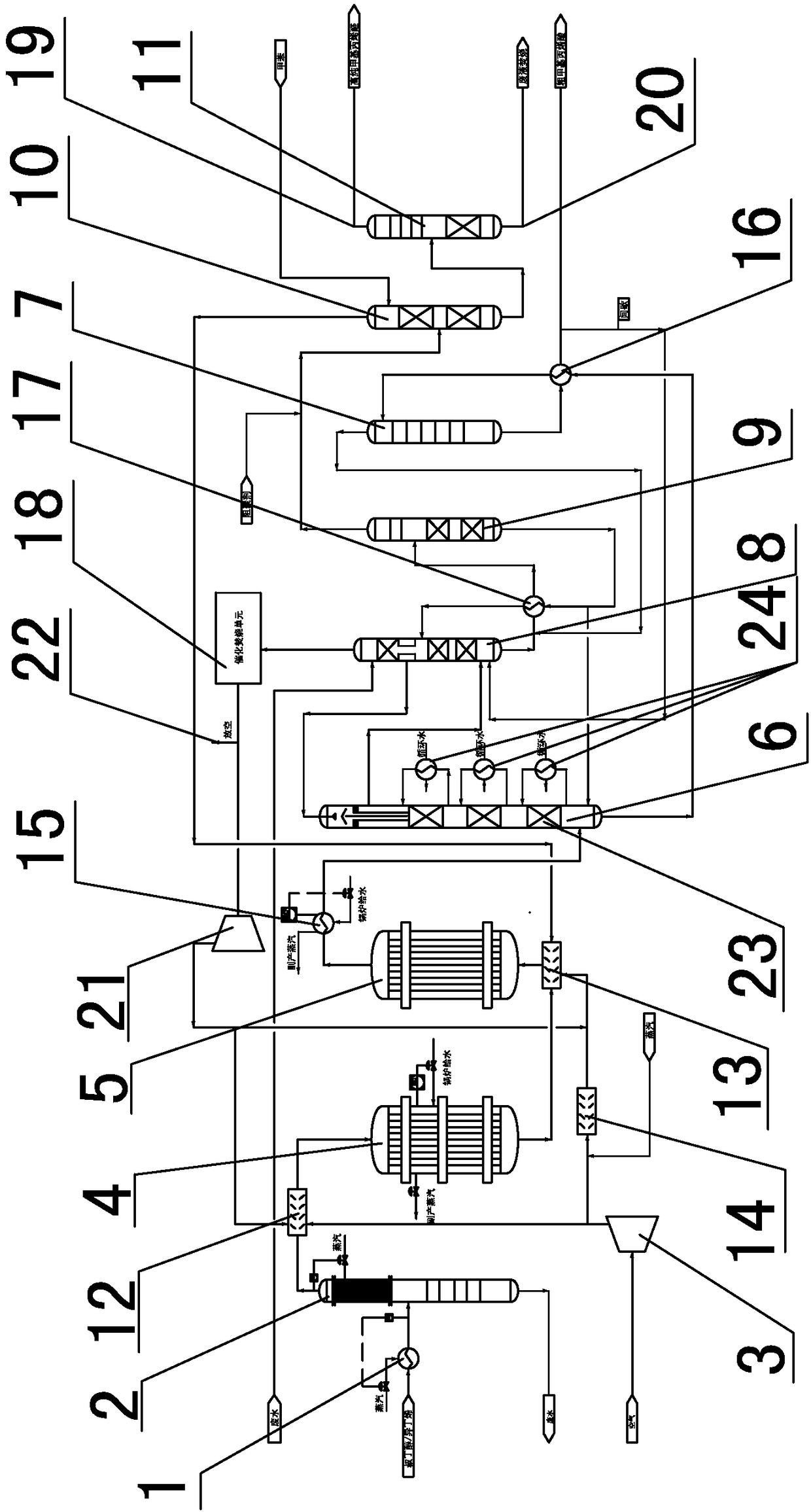

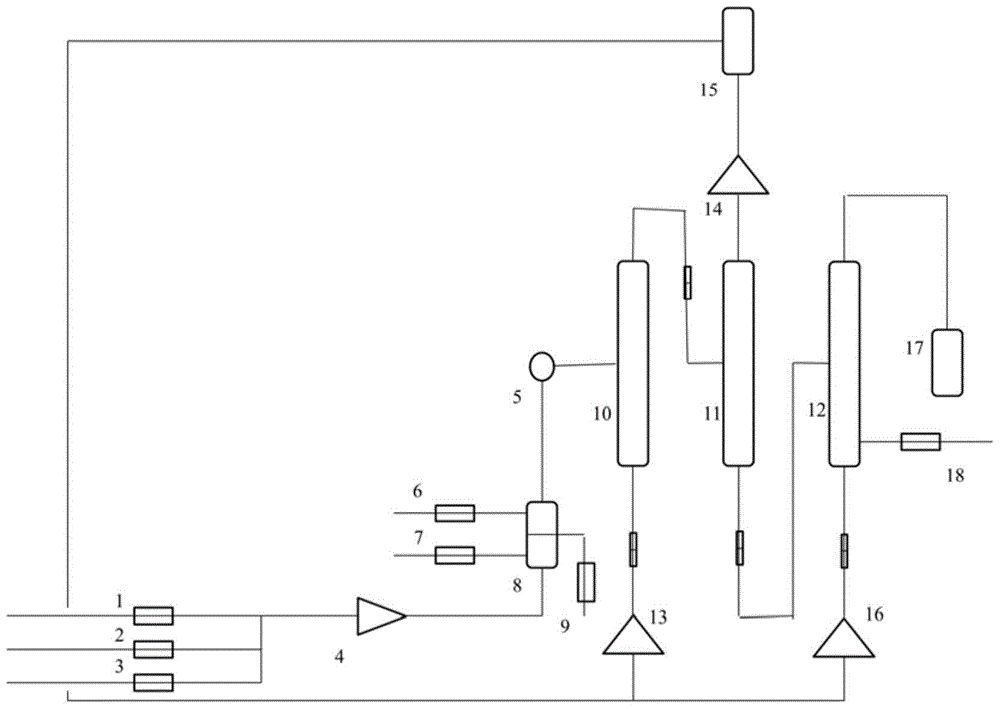

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

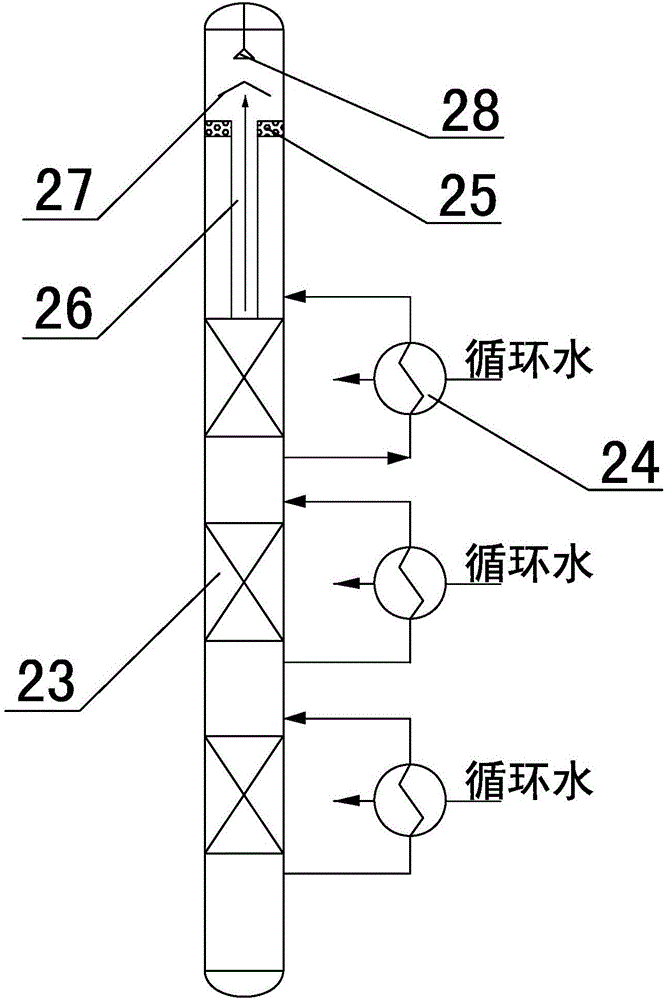

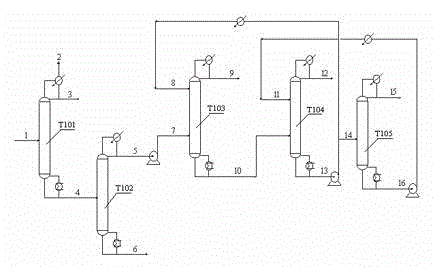

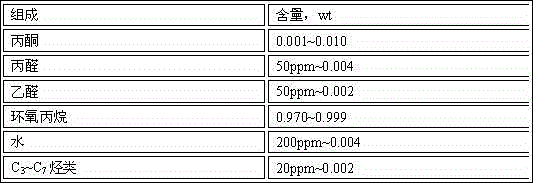

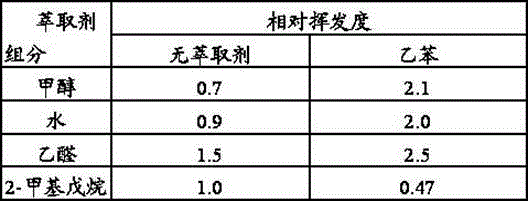

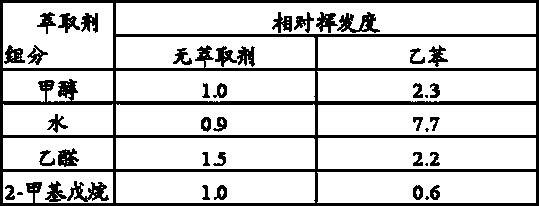

Method for refining epoxypropane

InactiveCN104151270AChanging the relative volatilityReduce adverse effectsOrganic chemistryExtractive distillationImpurity

The invention relates to a method for refining epoxypropane and is mainly used for solving the problems of high cost of an extraction agent and poor quality of a product caused by introduction of an outside-of-system medium existing in the prior art. The method for refining epoxypropane disclosed by the invention comprises the following steps of: by virtue of an extraction agent, extracting the crude epoxypropane solution obtained by reacting hydrogen peroxide ethylbenzene with propylene and containing epoxypropane, water, acetaldehyde, propionaldehyde, methanol, acetone and C3-C7 hydrocarbon impurities and distilling. The problem is well solved by the technical scheme that ethylbenzene is adopted as the extraction agent; the method can be used in the industrial production of refining epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

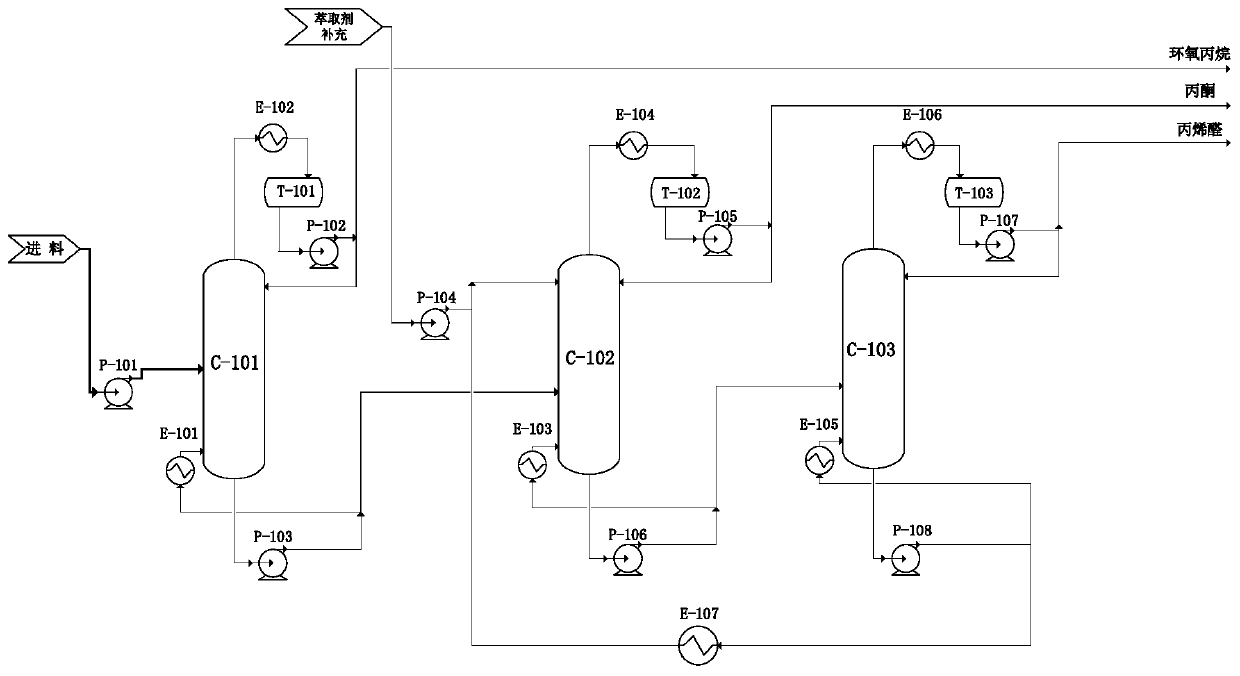

Technique and system for preparing propylene oxide by directly oxidizing propylene with oxygen and hydrogen

ActiveCN104650008AAvoid damageAvoid pollutionOrganic chemistryBulk chemical productionEnvironmental resistanceOrganic sulfide compound

The invention provides a technique and a system for preparing propylene oxide by directly oxidizing propylene with oxygen and hydrogen. The technique comprises the following steps that: (1) propylene, circulation propylene, and high-boiling-point organic sulfide are added to a mixed solvent of methanol and hydrazine hydrate, hydrogen and oxygen are accessed, and raw propylene oxide is produced; (2) raw propylene oxide is cooled and pumped into a rough separation tower by a pump, and organic sulfide and a few of high-boiling-point by-products in raw propylene oxide are removed; (3) a balance mixture of propylene and propylene oxide enters a propylene stripping tower, and unreacted propylene and a little propylene oxide in the mixture are removed; and (4) balance propylene oxide mixed liquor enters an extraction purification tower containing cumin and an alkaline solution, and is further extracted and rectified to form propylene oxide with high purity. The technique and the system are energy-saving and environmentally friendly, can increase the purity and the yield of propylene oxide significantly, reduce the losses of propylene oxide, and are suitable for industrialized production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Epoxypropane purifying method

InactiveCN104109138AChanging the relative volatilityReduce adverse effectsOrganic chemistryExtractive distillationBiochemical engineering

The invention relates to an epoxypropane purifying method. The problems of high extractant cost and bad product quality due to the introduction of a system outside medium in the prior art are mainly solved. The epoxypropane purifying method is characterized in that a crude epoxypropane solution containing epoxypropane, water, acetaldehyde, propionaldehyde, methanol, acetone and C5C7 hydrocarbon impurities and obtained after a reaction of cumene hydroperoxide and propylene is extracted and distilled by an extractant, wherein the extractant is isopropyl benzene. The epoxypropane purifying method well solves the problems, and can be used in the industrial production of epoxypropane purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gaming machine with extensive symbols

InactiveUS20100081493A1Change propertiesChanging the relative volatilityApparatus for meter-controlled dispensingVideo gamesGame playGame machine

The present invention is a gaming machine for providing a game play and a payout according to a game result, including a storage device which stores a game using a symbol with a function, an executor which executes the game and an extended device which adds other function to the symbol, wherein the extended device works independently of the executor.

Owner:KONAMI GAMING

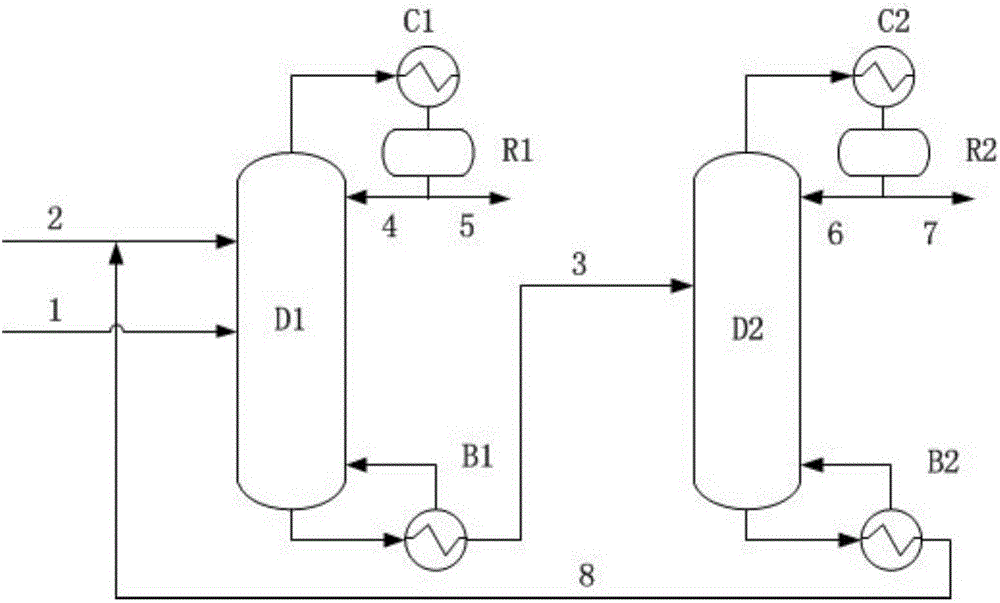

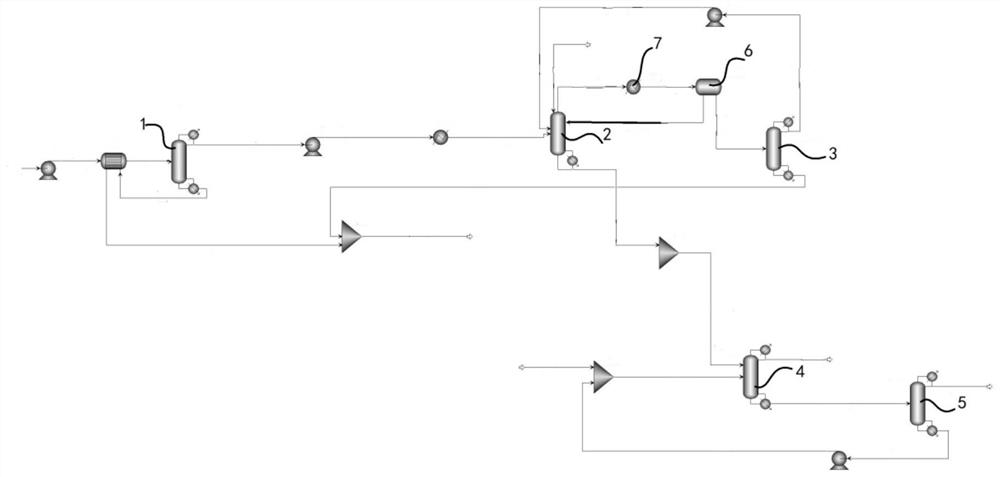

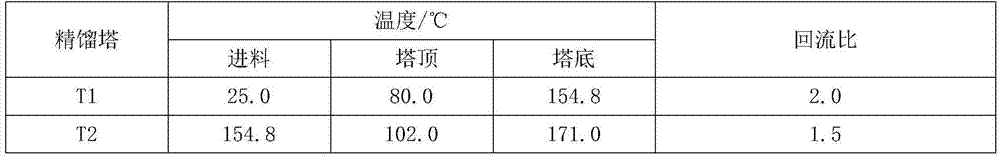

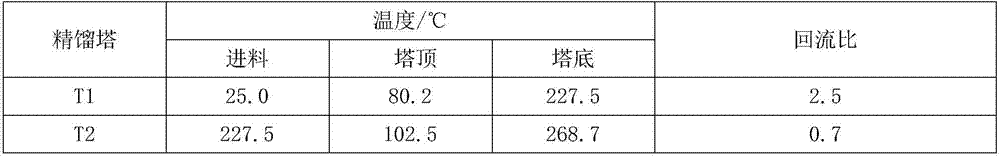

Method for separating acetonitrile and triethylamine azeotropic mixture by extractive distillation

ActiveCN106220532AChanging the relative volatilityHigh recovery rateAmino compound purification/separationCarboxylic acid nitrile purification/separationChemistryReboiler

The invention relates to a method for separating an acetonitrile and triethylamine azeotropic mixture by extractive distillation. An extractive distillation column and a solvent recovery tower adopt negative pressure operation; the acetonitrile and triethylamine mixture are introduced from the upper middle part of the extractive distillation column; ethylene glycol as an extractant is introduced from the upper part of the column; after the extractive distillation column, acetonitrile is extracted from the top of the extractive distillation column; the extractant and triethylamine are extracted from the bottom of the extractive distillation column and introduced from the upper middle part of the recovery tower; the triethylamine is extracted from the top of the solvent recovery tower; and the extractant ethylene glycol is extracted from the bottom of the recovery tower for recycling. The negative pressure operation adopted by the invention can reduce the heat load of the reboiler, and reduce the energy consumption for operation; the extractant ethylene glycol can significantly improve the relative volatility of acetonitrile and triethylamine; and the recovery rate is as high as 99.9%.

Owner:QINGDAO UNIV OF SCI & TECH

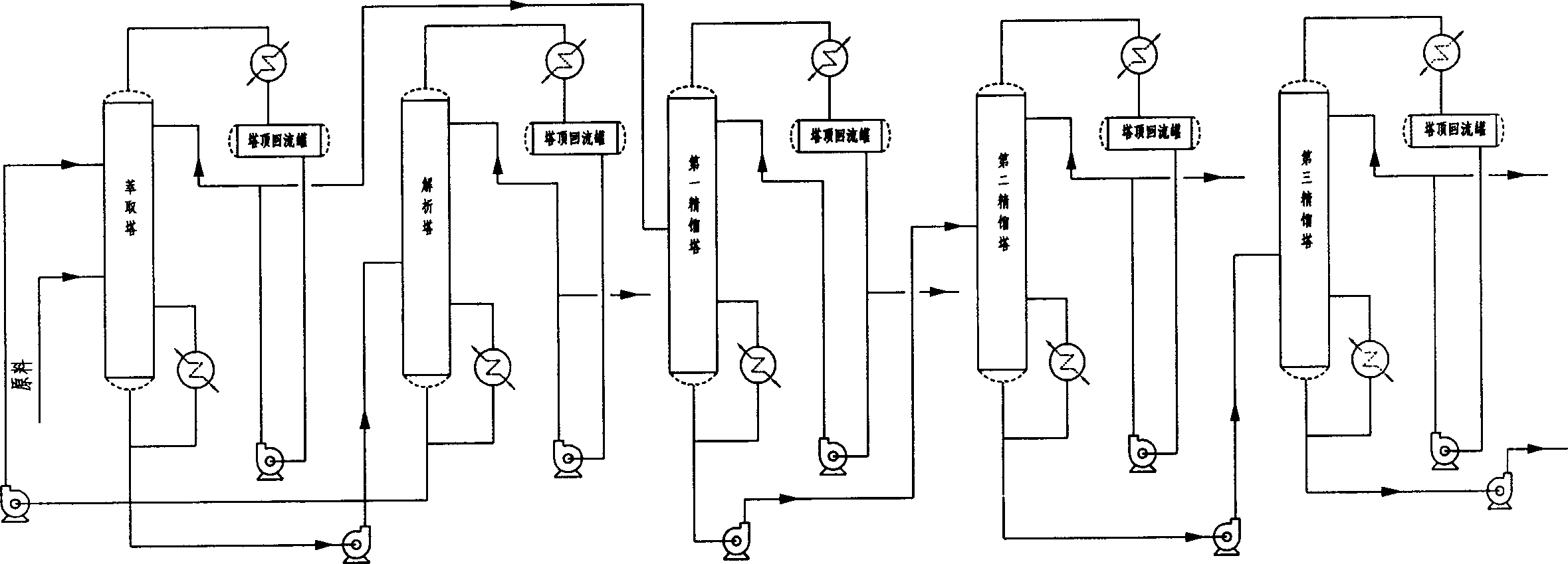

Method for producing high-purity cyclopentadiene and cyclopentane by coarse piperyene

ActiveCN1789221AChanging the relative volatilityTo achieve the effect of easy separationHydrocarbon by isomerisationCyclopenteneExtractive distillation

The invention discloses a method for preparing cyclopentene and cyclopentene of high purity by using coarse pentadiene got from petroleum cracking ethylene by-product carbon five separation. Feeding the coarse pentadiene into extraction tower in existence of polymerization inhibitor, getting mixing material of cyclopentene and cyclopentane in the tower top, extracting agent and pentadiene being in the tower still; feeding the material got in tower top to the first fractionating tower, stipping light component in tower top, getting mixing material of cyclopentene and cyclopentane in the tower still; feeding the material got from the first fractionating tower still into the second fractionating tower, getting cyclopentene of above 99% in tower top, and cyclopentane in tower still; feeding the material got from the second fractionating tower still into the third fractionating tower, steeping the heavy component in the tower still and getting the cyclopentane product in tower top. The invention employs extractive distillation method and is characterized by the high extraction accuracy, stable product quality and easy for industrial production.

Owner:山东玉皇盛世化工股份有限公司

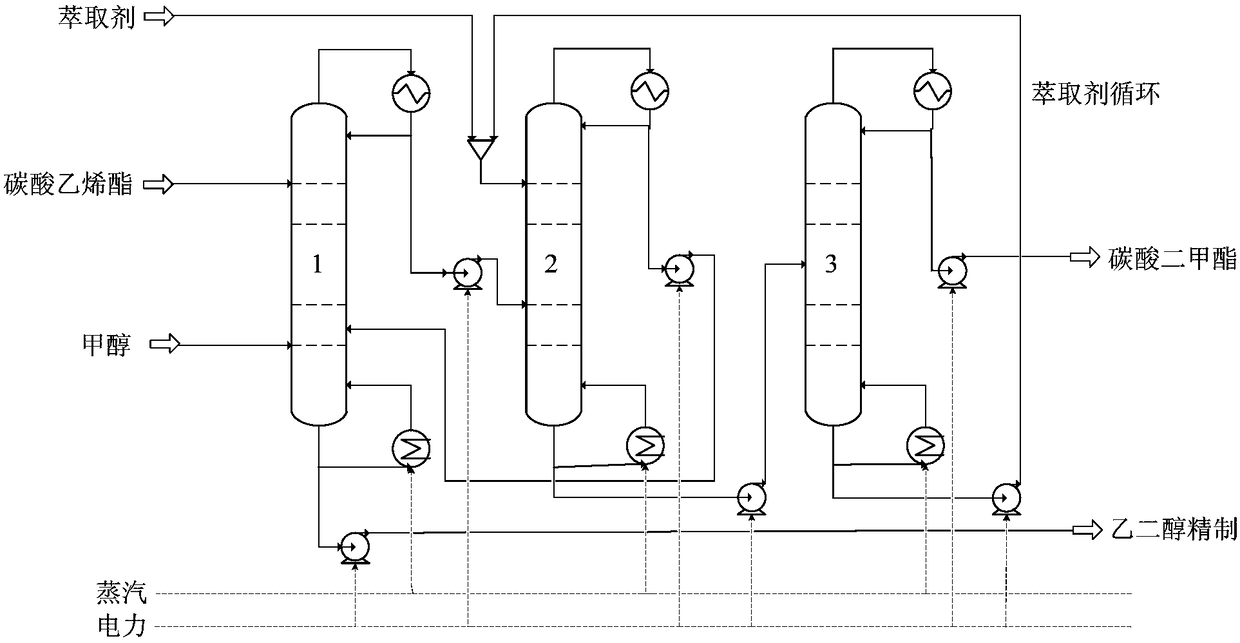

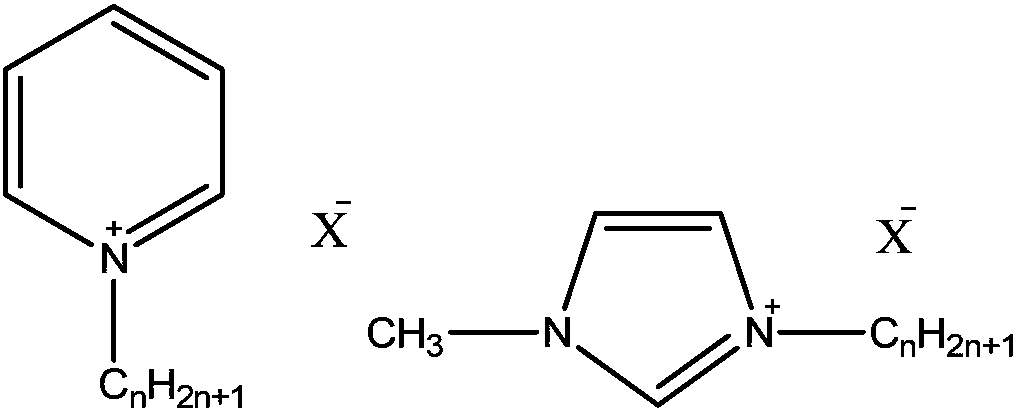

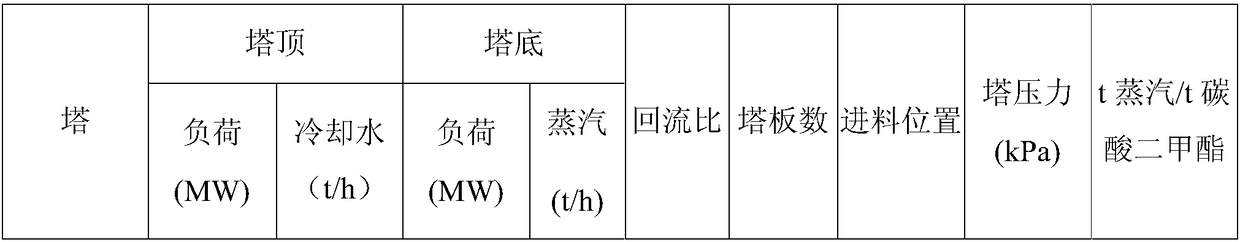

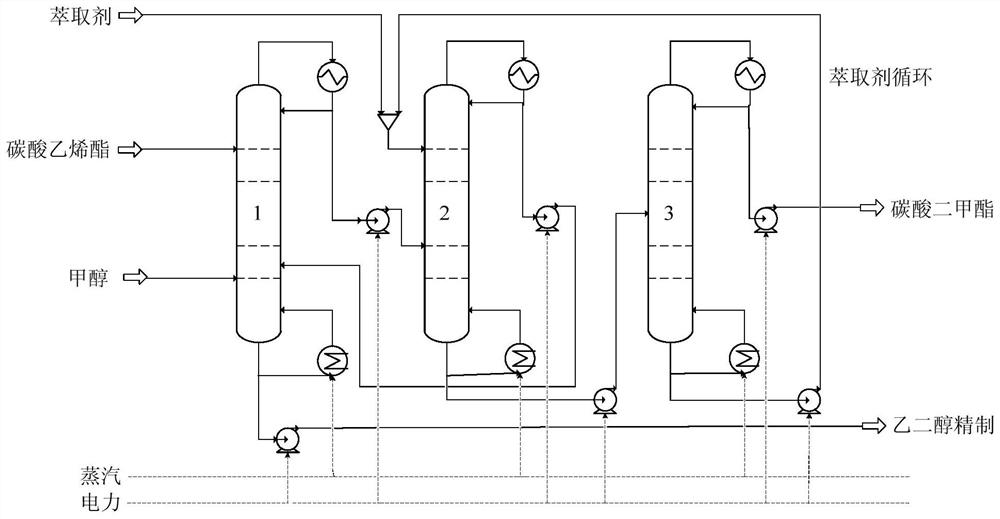

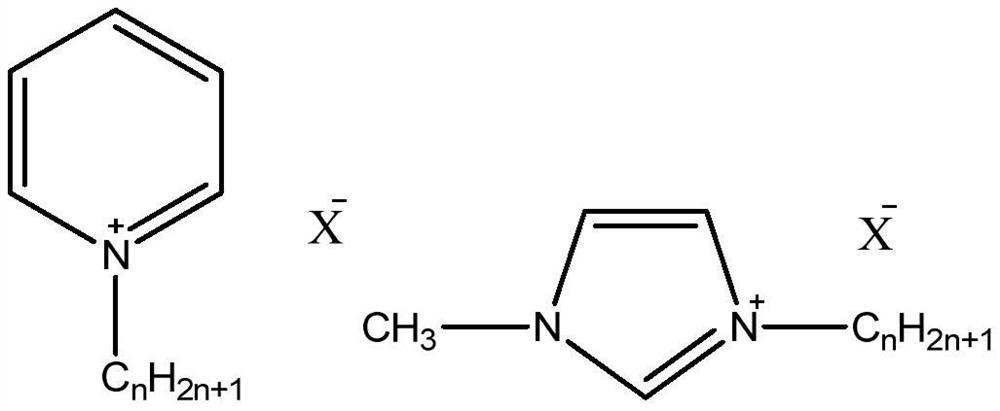

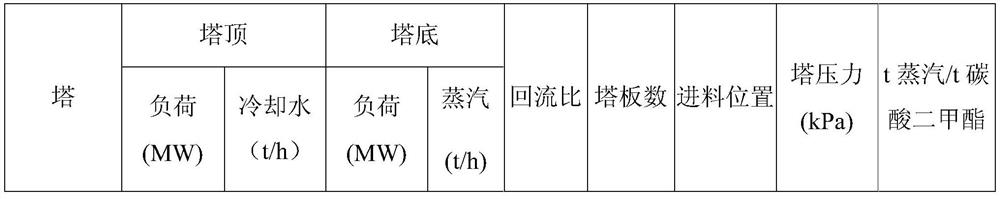

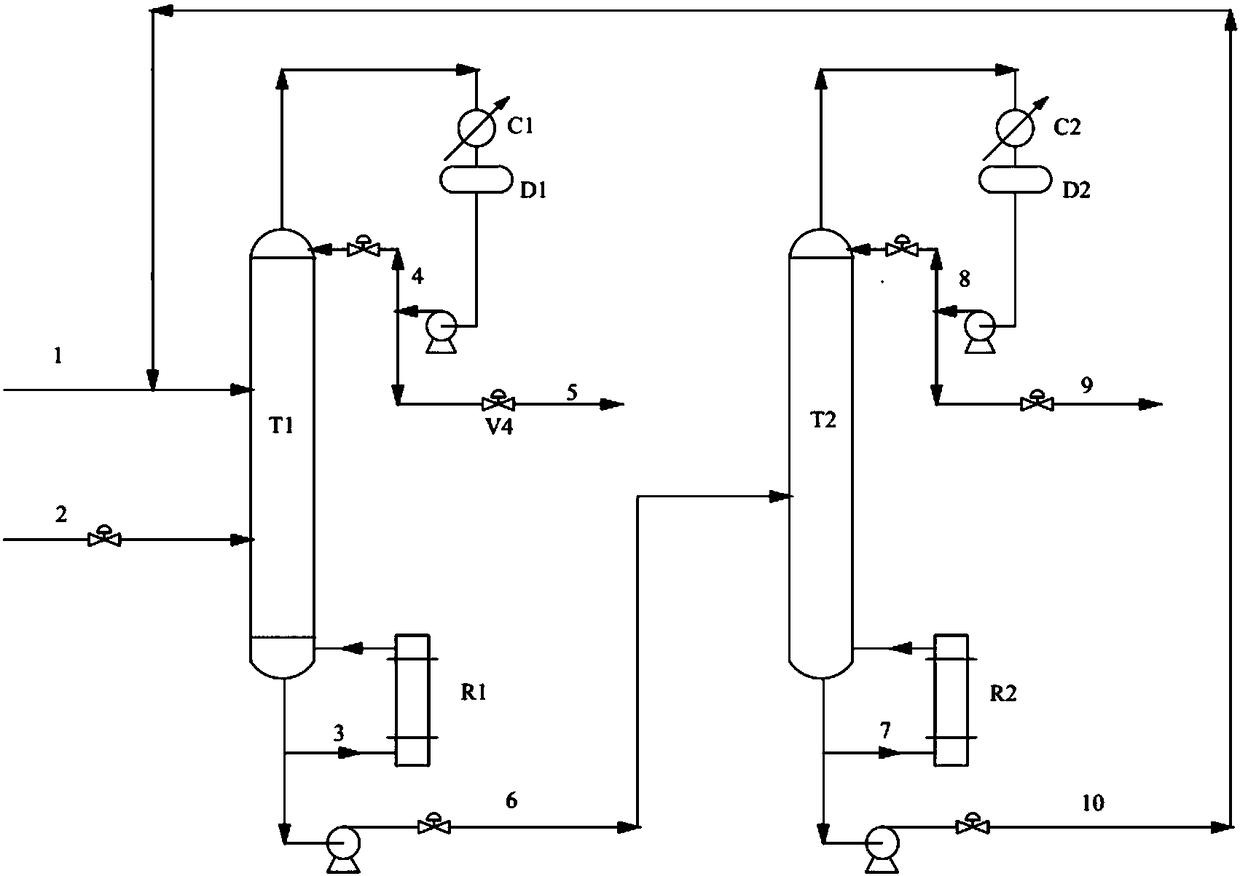

Extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of extraction agent, and treatment method

ActiveCN108067012AReduced cycle lossChanging the relative volatilityOrganic compound preparationChemical industryLoss rateMethyl carbonate

The invention provides an extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of the extraction agent, and a treatment method. The extraction agent is a mixed extraction agent containing ionic liquid. A system for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope comprises a reaction rectifying tower, an extraction rectifying tower and an extraction agent regeneration tower which are sequentially connected, wherein the extraction rectifying tower uses the extraction agent to perform extraction and rectification. The extraction agent has the advantages that the extraction agent can effectively change the relative volatility of methanol and dimethyl carbonate azeotrope, increase the separation effectof the methanol and dimethyl carbonate azeotrope, the purity of obtained dimethyl carbonate can reach 99.8wt% or above, and the circulating loss rate of the extraction agent can be lowered to 0.01% orbelow; the extraction agent can guarantee the conversion rate of ethylene carbonate and lower the concentration of circulating methanol, and accordingly thermal load is reduced, and separation energyconsumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing high-purity optical isoamylol through decompression and rectification and technical process thereof

ActiveCN102010292AChanging the relative volatilityImprove the distillation effectOrganic compound preparationHydroxy compound preparationGas phaseReboiler

The invention relates to a method for producing high-purity optical isoamylol through decompression and rectification. The method comprises the following steps of: lowering the operating pressure of input materials to be separated through a vacuum system by using a decompression and rectification tower and a tower-top condenser; increasing the relative volatility of optical isoamylol and isoamylol; dividing the optical isoamylol and isoamylol passed through the decompression and rectification tower into a gas-phase substance at the tower top and a liquid-phase substance at the tower bottom under the heat and mass transferring function; and setting a thermosyphon reboiler at the bottom of the decompression and rectification tower so that the gas-phase substance and liquid-phase substance flow back and are in reverse multistage contact. The invention solves the technical problems of low separation efficiency, complex process, high processing cost, and the like in the traditional separation method.

Owner:QINGDAO UNIV OF SCI & TECH

Distillation separation method of ethyl alcohol, tertiary butanol and water

ActiveCN109678668ASolve sizeSmall investmentOrganic compound preparationHydroxy compound separation/purificationAlcoholExtractive distillation

The invention discloses a distillation separation method of ethyl alcohol and tertiary butanol contained in wastewater, and belongs to the field of multi-component azeotrope separation. According to the distillation separation method of the ethyl alcohol, the tertiary butanol and water, the investment is less, energy consumption is low, emission of three wastes is avoided, and the yield is high. The distillation separation method is characterized in that the wastewater containing the ethyl alcohol, the tertiary butanol and the water is subjected to predewatering treatment, azeotropic treatment, steam stripping treatment and extractive distillation treatment, then the ethyl alcohol and the tertiary butanol are separated, and the products, namely the ethyl alcohol and the tertiary butanol are obtained; and at the azeotropic treatment stage, an entrainer is added to remove the water in surplus materials. The wastewater difficult to treat is removed to eliminate pollution to the environment, and meanwhile the products with the high additional value are recovered.

Owner:BINZHOU UNIV

Gaming machine allowing a player to change the volatility of a game based on an amount of play history

ActiveUS8235809B2Changing the relative volatilityExcessive qualityApparatus for meter-controlled dispensingVideo gamesEngineeringGame based

The present invention is a gaming machine for playing a game and paying out an award according to play results, comprising a detector which recognizes a play history of a player, an analyzer which analyzes the play history, a controller which changes a volatility of the game according to the play history, and an initiator which initiates the game with changed volatility.

Owner:KONAMI GAMING

Method for producing high-purity cyclopentadiene and cyclopentane by coarse piperyene

ActiveCN100393676CIncrease added valueChanging the relative volatilityHydrocarbon by isomerisationCyclopenteneExtractive distillation

The invention discloses a method for preparing cyclopentene and cyclopentene of high purity by using coarse pentadiene got from petroleum cracking ethylene by-product carbon five separation. Feeding the coarse pentadiene into extraction tower in existence of polymerization inhibitor, getting mixing material of cyclopentene and cyclopentane in the tower top, extracting agent and pentadiene being in the tower still; feeding the material got in tower top to the first fractionating tower, stipping light component in tower top, getting mixing material of cyclopentene and cyclopentane in the tower still; feeding the material got from the first fractionating tower still into the second fractionating tower, getting cyclopentene of above 99% in tower top, and cyclopentane in tower still; feeding the material got from the second fractionating tower still into the third fractionating tower, steeping the heavy component in the tower still and getting the cyclopentane product in tower top. The invention employs extractive distillation method and is characterized by the high extraction accuracy, stable product quality and easy for industrial production.

Owner:山东玉皇盛世化工股份有限公司

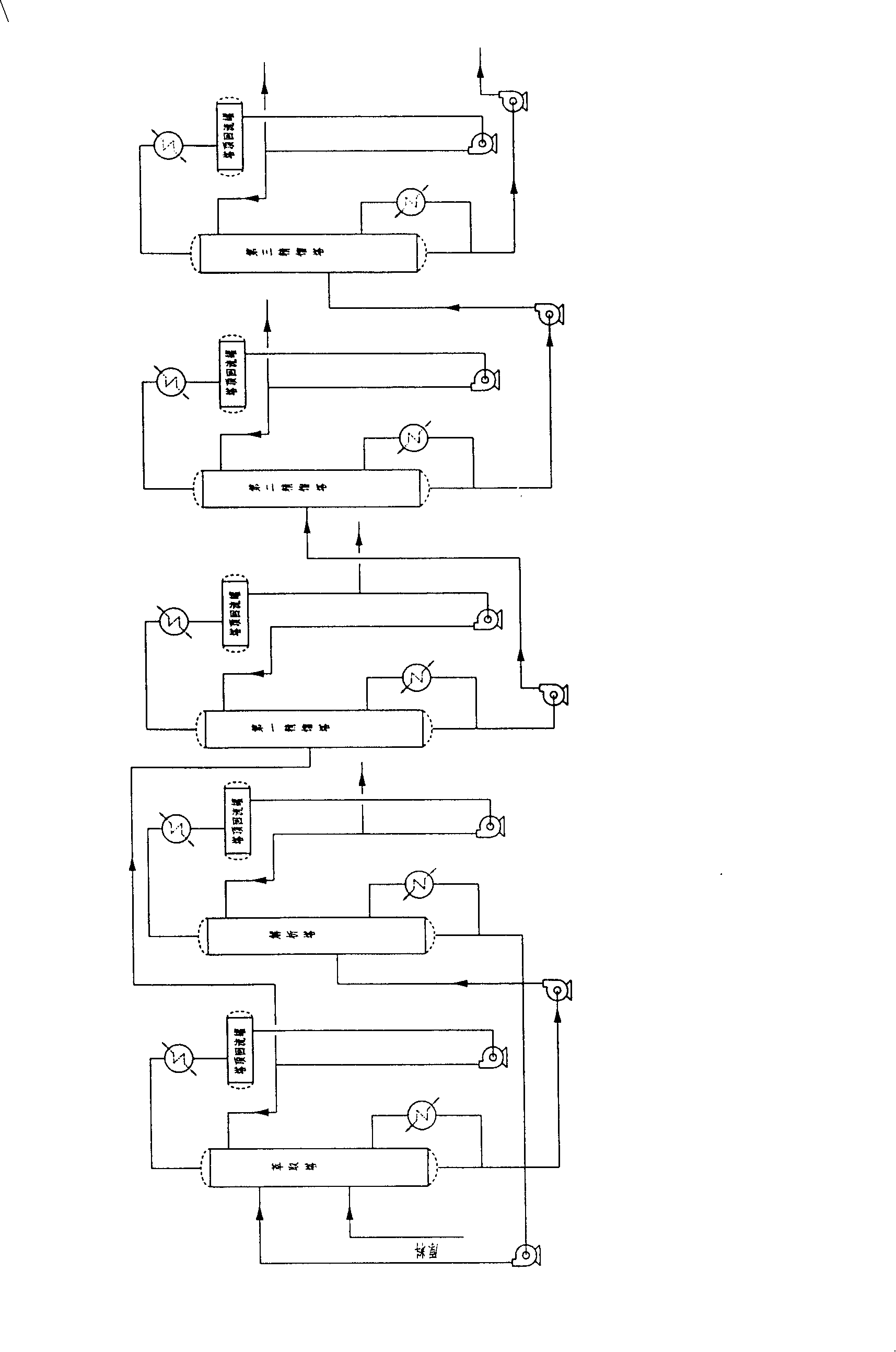

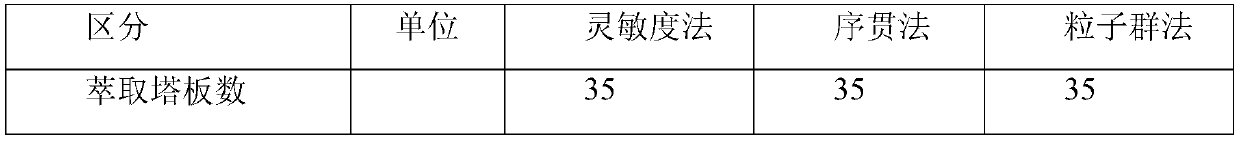

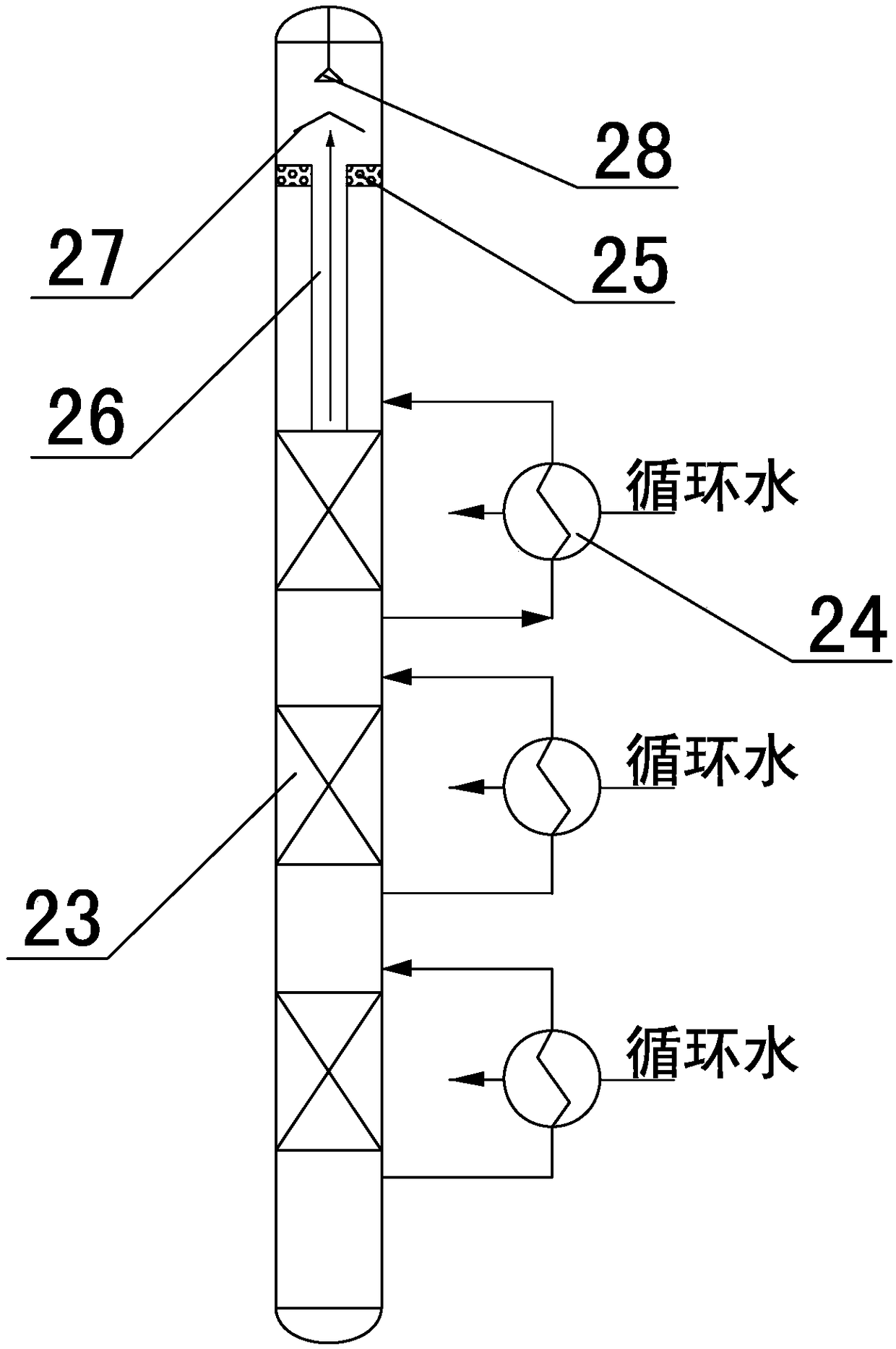

Separation method of propylene oxidation products epoxypropane, acrolein and acetone

InactiveCN111100095AHigh purityHigh recovery rateCarbonyl compound separation/purificationExtractive distillationExtractive distillationAcrolein

The invention relates to a separation method of propylene oxidation products epoxypropane, acrolein and acetone, and belongs to the technical field of propylene oxidation product separation. Materialsto be separated enter an epoxypropane separation tower from the middle section of a tower section for rectification separation, epoxypropane is extracted from the top of the tower, and acrolein and acetone extracted from the bottom of the tower enter an extractive distillation tower; a mixture of the to-be-separated materials acrolein and acetone and an extraction agent are divided into two pathsto enter the extractive distillation tower for extractive distillation separation, and acetone is extracted from the top of the tower; the acrolein and the extraction agent distilled from the tower kettle enter a solvent recovery tower to be subjected to rectification separation, the acrolein is extracted from the tower top, and the extraction agent is extracted from the tower kettle; and the extraction agent is recycled back to the extractive distillation tower for use. The method is scientific and reasonable in design, high-purity and high-recovery-rate separation of the materials is achieved, more economical separation is achieved on the basis of comprehensively considering process cost such as energy consumption and material consumption, and the method has a large application prospectin industry.

Owner:山东联创产业发展集团股份有限公司

A system and method for producing methacrylic acid and co-producing methacrolein

ActiveCN106631759BGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryAcid washingFixed bed

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

A kind of ethanol-tert-butanol-water rectification separation method

ActiveCN109678668BEfficient separationReduce wasteOrganic compound preparationHydroxy compound separation/purificationExtractive distillationAlcohol ethyl

Owner:BINZHOU UNIV

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835BReduce chlorine contentSolve the blockageSolid waste disposalMultistage water/sewage treatmentWater qualitySlurry

The present invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 by weight to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent by weight; dehydration for reducing the water content of the ash slurry to below 35 percent by weight; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

A kind of extraction agent used for extracting and rectifying separation of methanol and dimethyl carbonate azeotrope and its use and treatment method

ActiveCN108067012BReduced cycle lossChanging the relative volatilityOrganic compound preparationChemical industryExtractive distillationPhysical chemistry

The invention provides an extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of the extraction agent, and a treatment method. The extraction agent is a mixed extraction agent containing ionic liquid. A system for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope comprises a reaction rectifying tower, an extraction rectifying tower and an extraction agent regeneration tower which are sequentially connected, wherein the extraction rectifying tower uses the extraction agent to perform extraction and rectification. The extraction agent has the advantages that the extraction agent can effectively change the relative volatility of methanol and dimethyl carbonate azeotrope, increase the separation effectof the methanol and dimethyl carbonate azeotrope, the purity of obtained dimethyl carbonate can reach 99.8wt% or above, and the circulating loss rate of the extraction agent can be lowered to 0.01% orbelow; the extraction agent can guarantee the conversion rate of ethylene carbonate and lower the concentration of circulating methanol, and accordingly thermal load is reduced, and separation energyconsumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for extracting and rectifying separation of toluene and n-butanol mixture

ActiveCN106220466BHigh purityChanging the relative volatilityOrganic compound preparationDistillation purification/separationExtractive distillationN-Butanol

The invention relates to a method for separating methylbenzene and n-butyl alcohol mixture through extractive distillation. The method comprises the steps that dimethyl sulfoxide is used as an extracting agent to be introduced from the upper portion of an extractive distillation tower to make sufficient contact with the methylbenzene and n-butyl alcohol mixture introduced from the middle of the extractive distillation tower, after extractive distillation, methylbenzene is extracted from the top of the extractive distillation tower, and the extracting agent and n-butyl alcohol mixture enters an extracting agent recycling tower from the bottom of the extractive distillation tower. Through effective separation, n-butyl alcohol is extracted from the top of the extracting agent recycling tower, and the extracting agent is extracted from the bottom of the extracting agent recycling tower to be recycled. The process has the advantages of being low in energy consumption, simple in process, high in separation purity and the like.

Owner:QINGDAO UNIV OF SCI & TECH

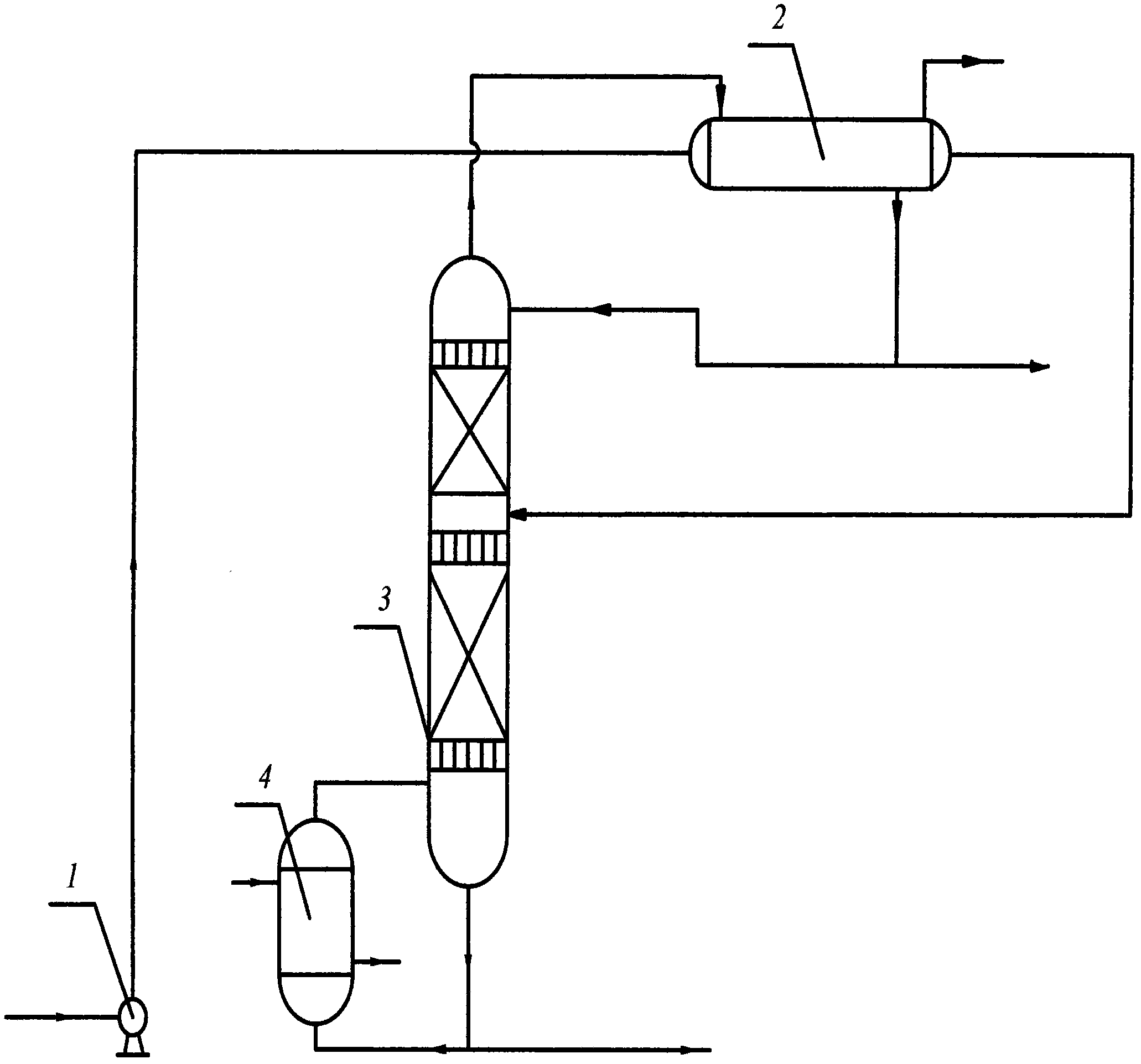

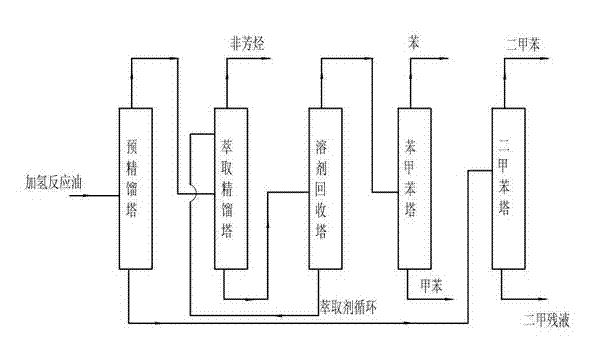

Separating and purifying device and process for heavy-component residual liquid of hydrogenation process of coking crude benzene

ActiveCN101982214BLow boiling pointChanging the relative volatilityDistillation purification/separationVacuum distillation separationBenzeneTetralin

The invention discloses a separating and purifying device and process for heavy component residual liquid of a hydrogenation process of coking crude benzene, belonging to the technical field of fractioning separation. The separating and purifying device of the invention comprises a tower kettle, a batch fractioning tower, a tower top fraction storage tank and a vacuum pump, wherein the batch fractioning tower is connected with the tower kettle; a condenser is arranged at the tower top of the batch fractionating tower; and the vacuum pump is respectively connected with the condenser and the tower top fraction storage tank through a buffer tank. The process comprises the following steps: when the tower top pressure is 10.0-15.0kPa, and the tower top temperature is 115.0-120.0 DEG C, collecting indan from the tower top by a reflux ratio of 4-5; after the indan is collected, when the tower top pressure is 10.0-15.0kPa, and the tower top temperature is 125.0-130.0 DEG C, collecting tetraline from the tower top by the reflux ratio of 8-10; and finally when the tower top pressure is 10.0-15.0kPa, and the tower top temperature is 155.0-160.0 DEG C, collecting naphthalene from the tower top by a reflux ratio of 4-5. The purity of the indan is 99.0wt%, the purity of the tetraline is 99.5wt%, and the purity of the naphthalene is 98.0wt%.

Owner:XINGTAI RISUN COAL CHEM IND

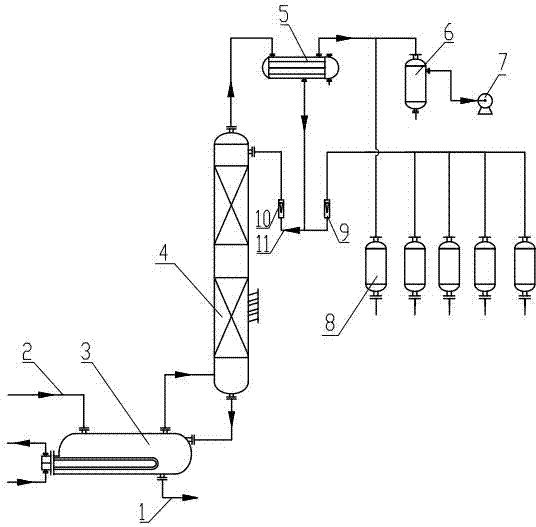

Method for producing glufosinate-ammonium with low energy consumption

ActiveCN110003269BLower gas phase vapor pressureChanging the relative volatilityGroup 5/15 element organic compoundsTriethylphosphitePhosphorous chloride

A method for producing glufosinate-ammonium with low energy consumption. A trapping agent is used to trap methane and phosphorus trichloride high-temperature cracking materials, and the obtained trapping liquid is rectified to separate most of the phosphorous trichloride, and then React with ethanol to obtain a diethyl methylphosphonite collector solution containing a small amount of triethyl phosphite, rectify and separate the heavy component triethyl phosphite, then react with acrolein to prepare acetal, and finally pass through cyanamide glufosinate-ammonium through chemical reaction and hydrolysis.

Owner:LIER CHEM CO LTD +1

A process and system for preparing propylene oxide by direct oxidation of propylene with oxygen and hydrogen

ActiveCN104650008BAvoid damageAvoid pollutionOrganic chemistryBulk chemical productionOrganic sulfide compoundHydrazine compound

The invention provides a technique and a system for preparing propylene oxide by directly oxidizing propylene with oxygen and hydrogen. The technique comprises the following steps that: (1) propylene, circulation propylene, and high-boiling-point organic sulfide are added to a mixed solvent of methanol and hydrazine hydrate, hydrogen and oxygen are accessed, and raw propylene oxide is produced; (2) raw propylene oxide is cooled and pumped into a rough separation tower by a pump, and organic sulfide and a few of high-boiling-point by-products in raw propylene oxide are removed; (3) a balance mixture of propylene and propylene oxide enters a propylene stripping tower, and unreacted propylene and a little propylene oxide in the mixture are removed; and (4) balance propylene oxide mixed liquor enters an extraction purification tower containing cumin and an alkaline solution, and is further extracted and rectified to form propylene oxide with high purity. The technique and the system are energy-saving and environmentally friendly, can increase the purity and the yield of propylene oxide significantly, reduce the losses of propylene oxide, and are suitable for industrialized production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A method for extracting and rectifying separation of tert-amyl alcohol and benzene mixture

ActiveCN105198701BReduce energy consumptionSimple processOrganic compound preparationDistillation purification/separationBenzeneT-amyl alcohol

The invention discloses a method of separating a mixture of tert-amyl alcohol and benzene by extractive distillation. According to the method, phenyl-ethanolamine compounds are taken as extraction agents, and the extraction agents are introduced to the upper part of an extractive distillation tower to fully contact with the mixture of tert-amyl alcohol and benzene introduced from the middle of the tower in the tower, then benzene is extracted from the top of the extractive distillation tower, and the extraction agents and tert-amyl alcohol are extracted from the bottom of the extractive distillation tower to enter an extraction agent recovery tower. Effective separation of the extraction agents and the tert-amyl alcohol is carried out in the extraction agent recovery tower, and the tert-amyl alcohol is extracted from the top of the extraction agent recovery tower, and the extraction agents are extracted from the bottom of the extraction agent recovery tower to be recycled. The method has the advantages of low energy consumption, simple process, realization of cyclic recovery of the extraction agents, high purity of products after the separation and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Method for producing high-purity optical isoamylol through decompression and rectification and technical process thereof

ActiveCN102010292BChanging the relative volatilityImprove the distillation effectOrganic compound preparationHydroxy compound preparationGas phaseReboiler

Owner:QINGDAO UNIV OF SCI & TECH

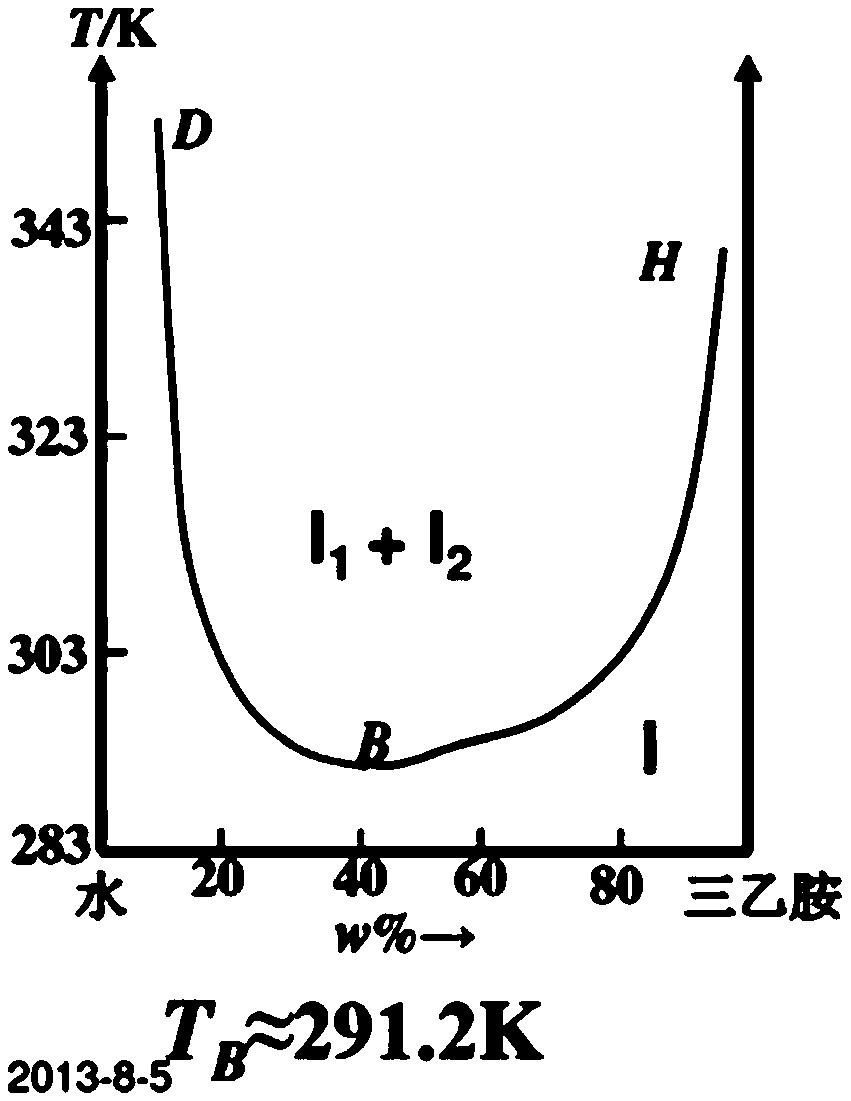

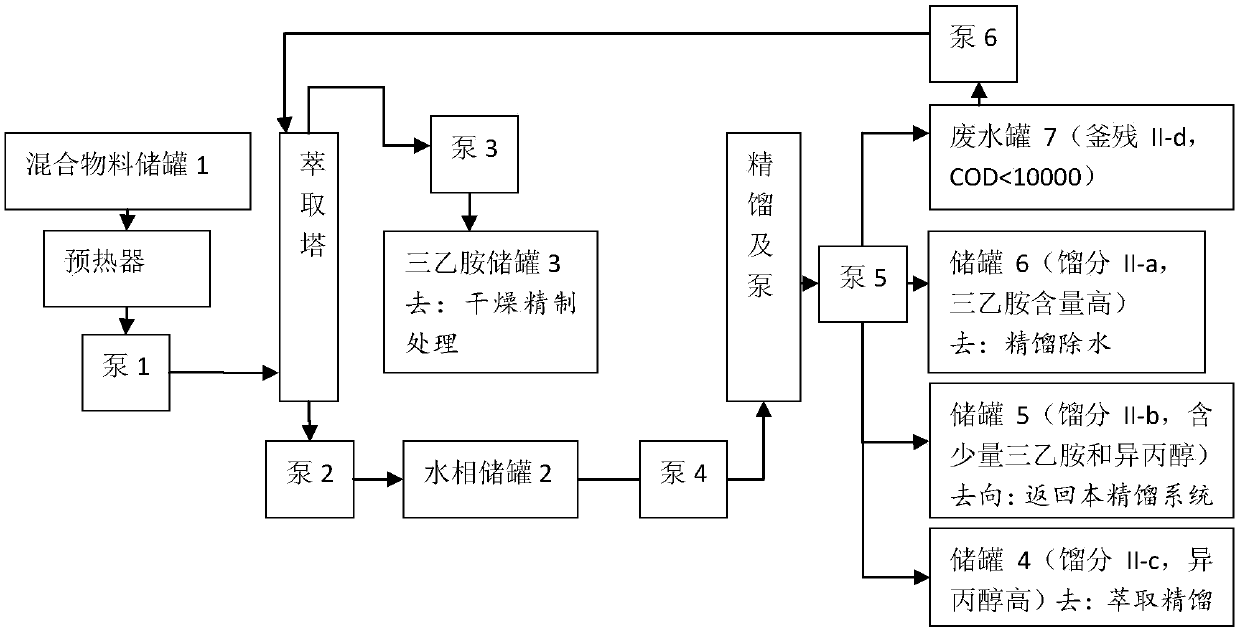

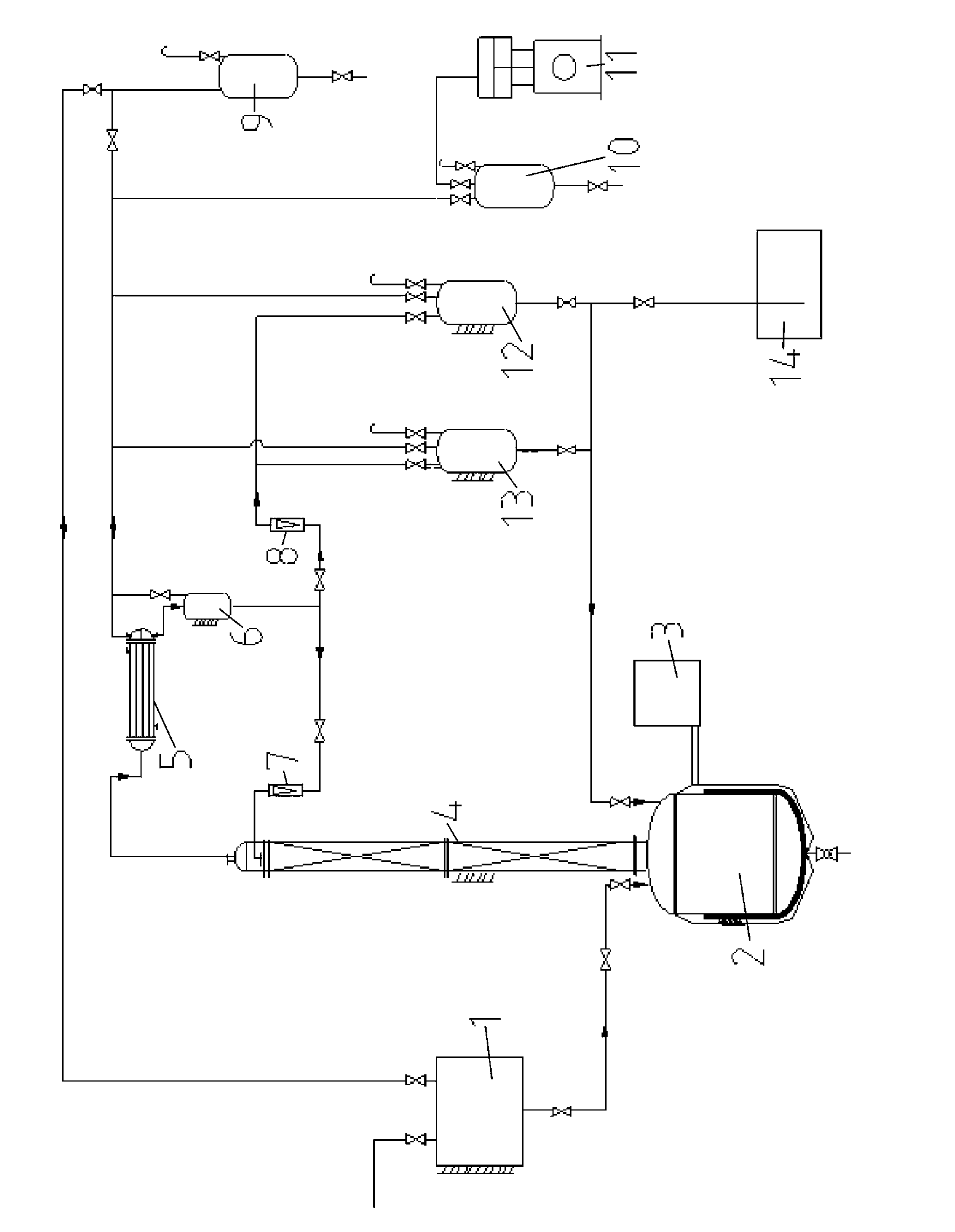

Separation method of difficult separation system containing triethylamine

ActiveCN108658785BChanging the relative volatilityEfficient recyclingAmino compound purification/separationOrganic compound preparationEvaporationNo production

The invention discloses a separation method of a triethylamine-containing system difficult to separate. According to the technical scheme, water, alkaline water or brine is adopted as an extractant, acontinuous or intermittent extraction process is adopted to separate triethylamine and a second component without introduction of new impurities, and the water can be recycled with no production of wastewater; then rectification is performed so as to remove residual triethylamine and second component in a raffinate phase, the relative volatility of the triethylamine and second component in the raffinate phase can be changed greatly, and high-content triethylamine and second component can be recovered efficiently from the raffinate phase containing low content of triethylamine and second component; and the operation in the distillation step can be completed by using a simple rectification unit, the evaporation amount is limited, and the energy consumption is controllable; therefore, extraction and rectification are coupled in the process so as to realize separation of triethylamine and the second component, and since water, alkaline water or brine is adopted as the extractant in the whole process with no introduction of other impurities, and addition of the alkali or salts is beneficial to separation of the triethylamine and the second component, the process has the advantages of simple equipment, investment cost saving, simple operation and operation cost saving, and the advantages are innovation points of the process.

Owner:杭州九清科技有限公司

Method for purifying hydrogen fluoride in trifluoromethanesulfonyl fluoride

PendingCN114470866APrevent collapseSimple processGas treatmentDispersed particle separationSulfonyl fluorideHydrogen fluoride

The invention discloses a method for purifying hydrogen fluoride in trifluoromethanesulfonyl fluoride, which comprises the following steps: firstly, pumping negative pressure in a mixing kettle, then introducing a crude trifluoromethanesulfonyl fluoride liquid, and adding an extracting agent to obtain a mixture; introducing nitrogen into the mixing kettle, transferring the mixture into a rectifying tower for rectifying, discharging heavy component impurities, and distilling out a light component trifluoromethanesulfonyl fluoride; and then introducing the evaporated light component trifluoromethanesulfonyl fluoride into an adsorption tower, adsorbing by adopting an adsorbent to obtain a refined trifluoromethanesulfonyl fluoride gas, and condensing into liquid in a refined tank. According to the invention, the extraction agent is adopted, and the action between the hydrogen fluoride and the extraction agent is utilized, so that the relative volatility between the hydrogen fluoride and the trifluoromethanesulfonyl fluoride is changed, and the vast majority of hydrogen fluoride can be removed; after the rectification process, the content of hydrogen fluoride in trifluoromethanesulfonyl fluoride is low, and the hydrogen fluoride is removed by using the adsorbent, so that the collapse of the adsorbent is avoided.

Owner:PERIC SPECIAL GASES CO LTD

Method for performing refined separation on high-purity yellow phosphorous

ActiveCN101912691BImprove separation efficiencyLow boiling pointVacuum distillation separationPhosphorus compoundsRefluxBuffer tank

The invention discloses a method and a device for performing refined separation on high-purity yellow phosphorous. A raw material storage tank is connected with a tower bottom; a rectifying tower is positioned above the tower bottom; one end of a condenser is connected with a tower top of the rectifying tower, while the other end is connected with a return tank; the return tank is connected with the tower top of the rectifying tower through a return flowmeter and connected with a front fraction tank and a product tank through a product flowmeter, and a discharge pipe of the product tank is connected with a product collecting tank; a vacuum pump is connected with the condenser, the return tank, the front fraction tank and the product tank through a buffer tank; and a nitrogen tank is connected with the raw material storage tank, the condenser, the return tank, the front fraction tank and the product tank. Through operation of performing rectification under reduced pressure and changinga reflux ratio, the method and the device reduce the boiling point of each component of the material greatly, change the relative volatility among the components, and have the advantages of uniform heating in the tower bottom, simple operation process, high separation efficiency and high purity of the product at the same time.

Owner:HUBEI SINOPHORUS ELECTRONIC MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com