Distillation separation method of ethyl alcohol, tertiary butanol and water

A separation method and technology of tert-butanol, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of organic compounds, etc., can solve the difficulty in meeting the purity requirements of ethanol and tert-butanol, and separate ethanol and tert-butanol Increased difficulty, high energy consumption of the separation process, etc., to achieve the effect of increasing the added value of the enterprise, small investment, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

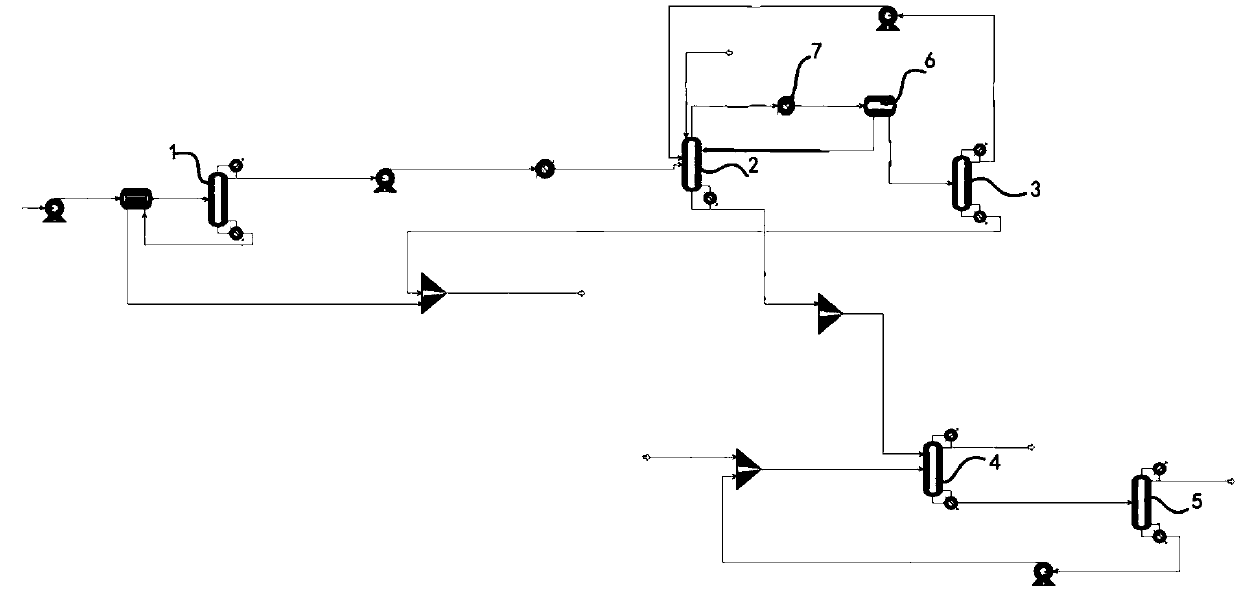

[0040] Embodiment 1: as figure 1 shown, including the following steps:

[0041] S1. The raw material enters the pre-dehydration tower 1 for pre-dehydration treatment. The operating pressure of the pre-dehydration tower 1 is 101kpa, the operating temperature at the top of the tower is 85-100°C, and the number of theoretical plates is 36-85, preferably 44; the optimal feed Position 26-44 blocks, preferably 29 blocks; the operating reflux ratio of the pre-dehydration tower is 1.8 to obtain gas phase material and water, the gas phase material is a mixture of ethanol, tert-butanol and a small amount of water, and the pre-dehydration tower 1 passes through the preheater at the bottom of the tower The heat of the tower kettle is recovered to effectively save energy consumption, and the water in the tower kettle meets the second-level water quality discharge standard of the national comprehensive sewage discharge standard (GB8978-2002) and is directly discharged;

[0042] S2. enter t...

Embodiment 2

[0048] A1. The raw material enters the pre-dehydration tower 1 for pre-dehydration treatment. The operating pressure of the pre-dehydration tower 1 is 105kpa, the operating temperature at the top of the tower is 85-100°C, the number of theoretical plates is 55, and the optimal feeding position is 38; the pre-dehydration tower The operating reflux ratio is 1.4, and the liquid phase material and water are obtained. The gas phase material is a mixture of ethanol, tert-butanol and a small amount of water. The pre-dehydration tower 1 recovers the heat of the tower kettle through the tower bottom preheater, which effectively saves energy consumption. The water in the kettle meets the national comprehensive sewage discharge standard (GB8978-2002) secondary water quality discharge standard and is discharged directly;

[0049] A2. The liquid phase material that A1 obtains enters azeotropic tower 2 and adds cyclopentane to carry out azeotropic rectification, obtains the mixture of low-bo...

Embodiment 3

[0054] C1. The raw material enters the pre-dehydration tower 1 for pre-dehydration treatment. The operating pressure of the pre-dehydration tower 1 is 110kpa, the operating temperature at the top of the tower is 88-108°C, the number of theoretical plates is 44, and the optimal feeding position is 26; the pre-dehydration tower The operating reflux ratio is 1.6, and the liquid phase material and water are obtained. The gas phase material is a mixture of ethanol, tert-butanol and a small amount of water. The pre-dehydration tower 1 recovers the heat of the tower kettle through the tower bottom preheater, which effectively saves energy consumption. The water in the kettle meets the second-level water quality discharge standard of the national comprehensive sewage discharge standard (GB8978-2002), and is directly discharged

[0055] C2. The liquid phase material that C1 is obtained enters azeotropic tower 2 and adds cyclopentane to carry out azeotropic rectification, obtains the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com