Large size mobile smoke blowing and absorbing selective laser melting intelligent device

A technology of selective laser melting and intelligent equipment, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve problems such as inability to effectively suppress deformation, small forming size of selective laser melting equipment, and inability to monitor forming defects in real time, etc. Achieve effective real-time processing and ensure high-quality forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

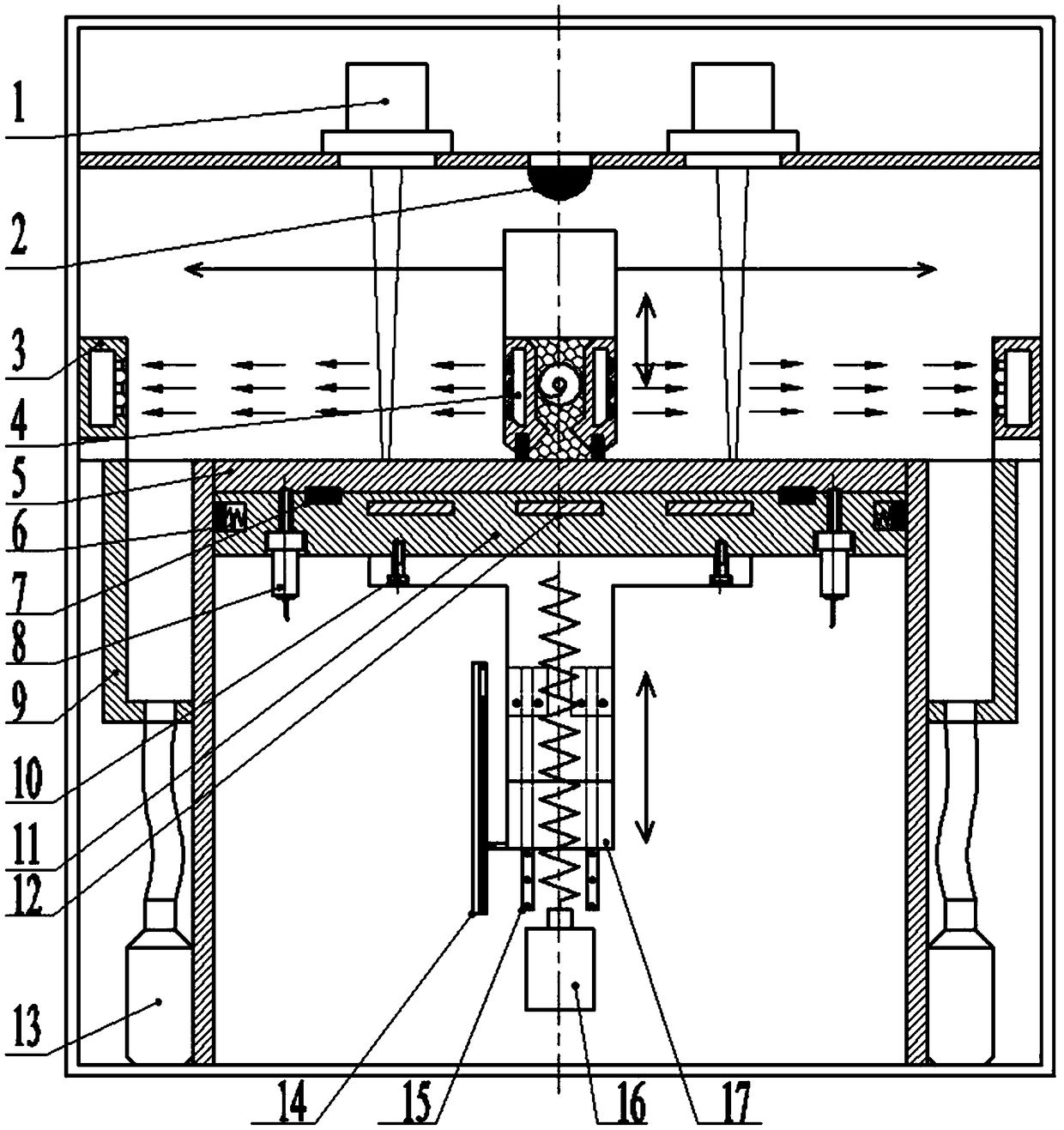

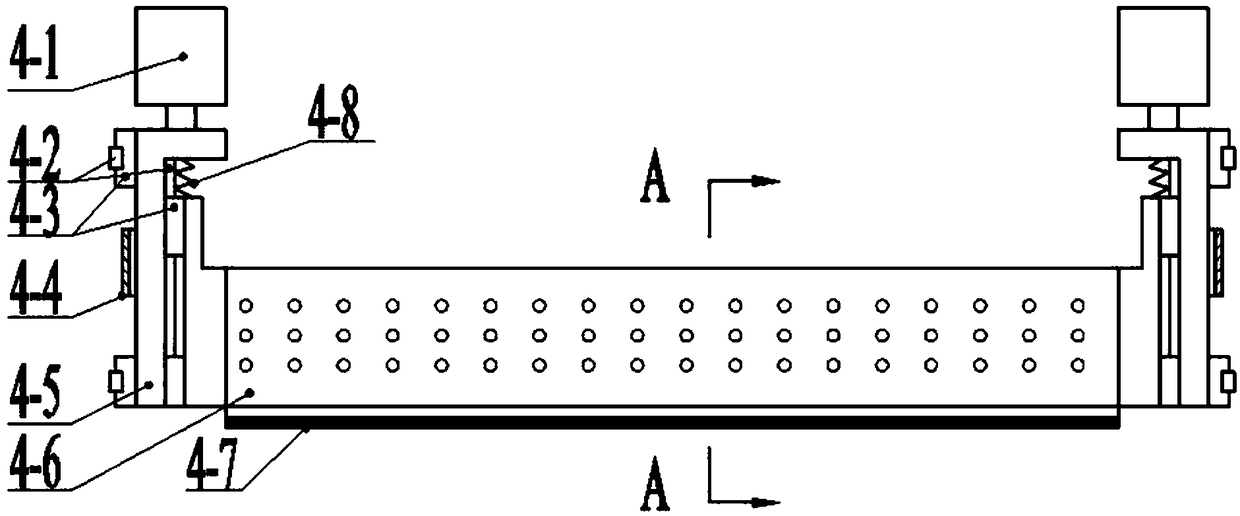

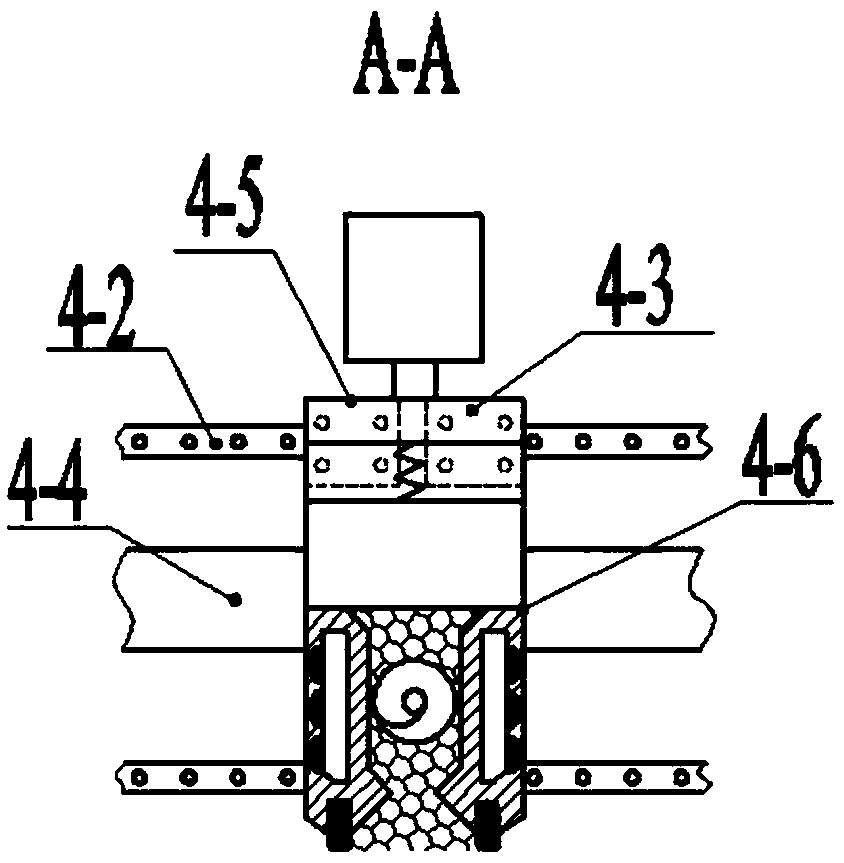

[0024] refer to figure 1 , figure 2 , image 3 The schematic diagram of the structure is shown.

[0025] A large-scale mobile blowing and smoking selected area laser melting intelligent equipment in the embodiment of the present invention includes a laser galvanometer system 1, an intelligent detection system 2, an integrated device for spreading powder and blowing and smoking, a forming workbench system, and a powder recovery system.

[0026] Wherein the integrated device for spreading powder and blowing smoke includes a smoking device 3 and an integrated device 4 for spreading powder and blowing smoke.

[0027] The forming workbench system includes a substrate 5, a spring sealing device 6, an electric magnetic suction mechanism 7; a micro leveling motor 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com