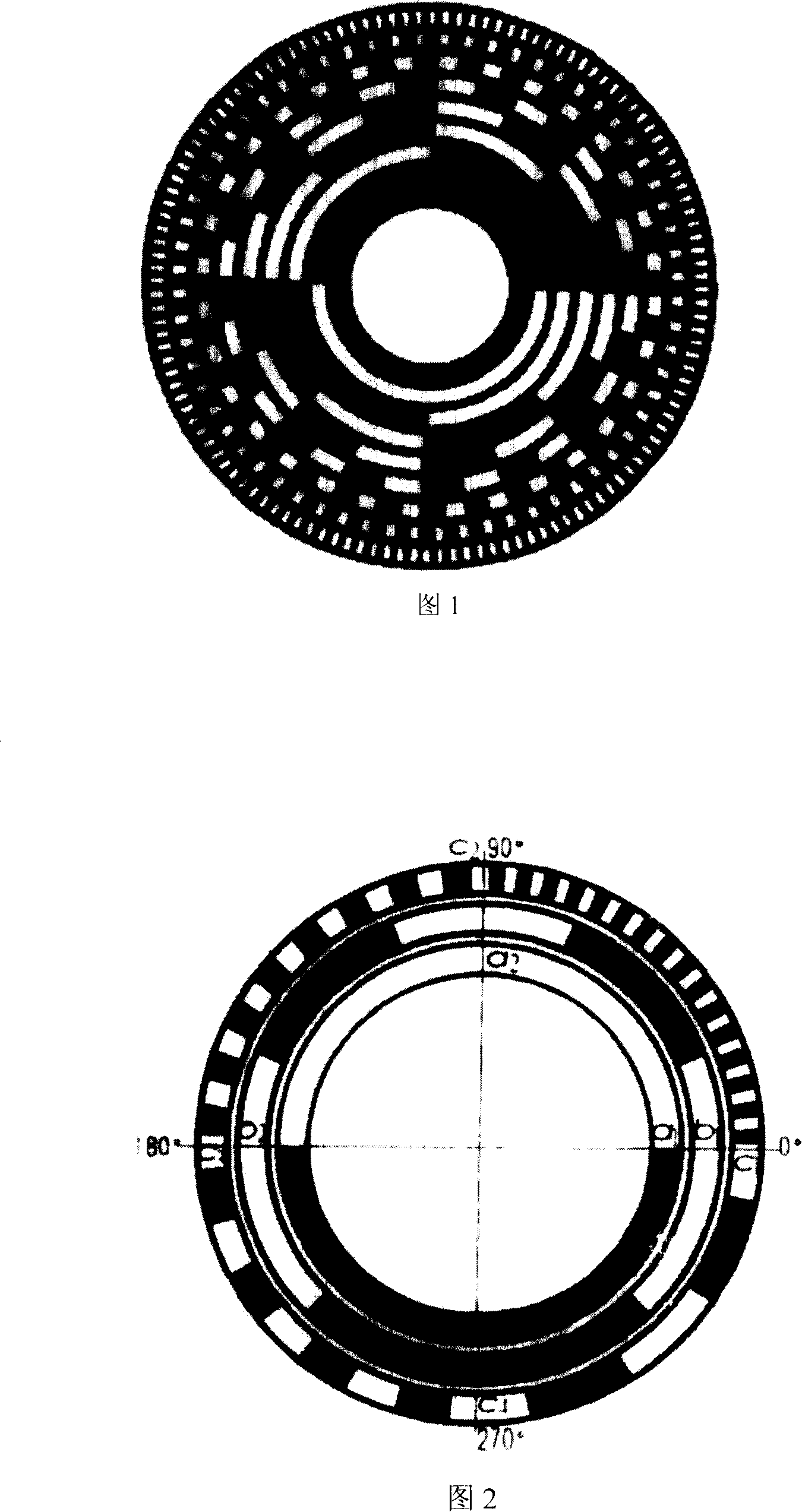

Single ring absolute coded disk

A single-turn absolute type and code disc technology, which is applied in the direction of converting sensor output, measuring devices, instruments, etc., can solve the problems of increasing the difficulty of assembly and adjustment process and reducing the structural size of the code disc, so as to realize miniaturization, reduce the structural size and The effect of volume, size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

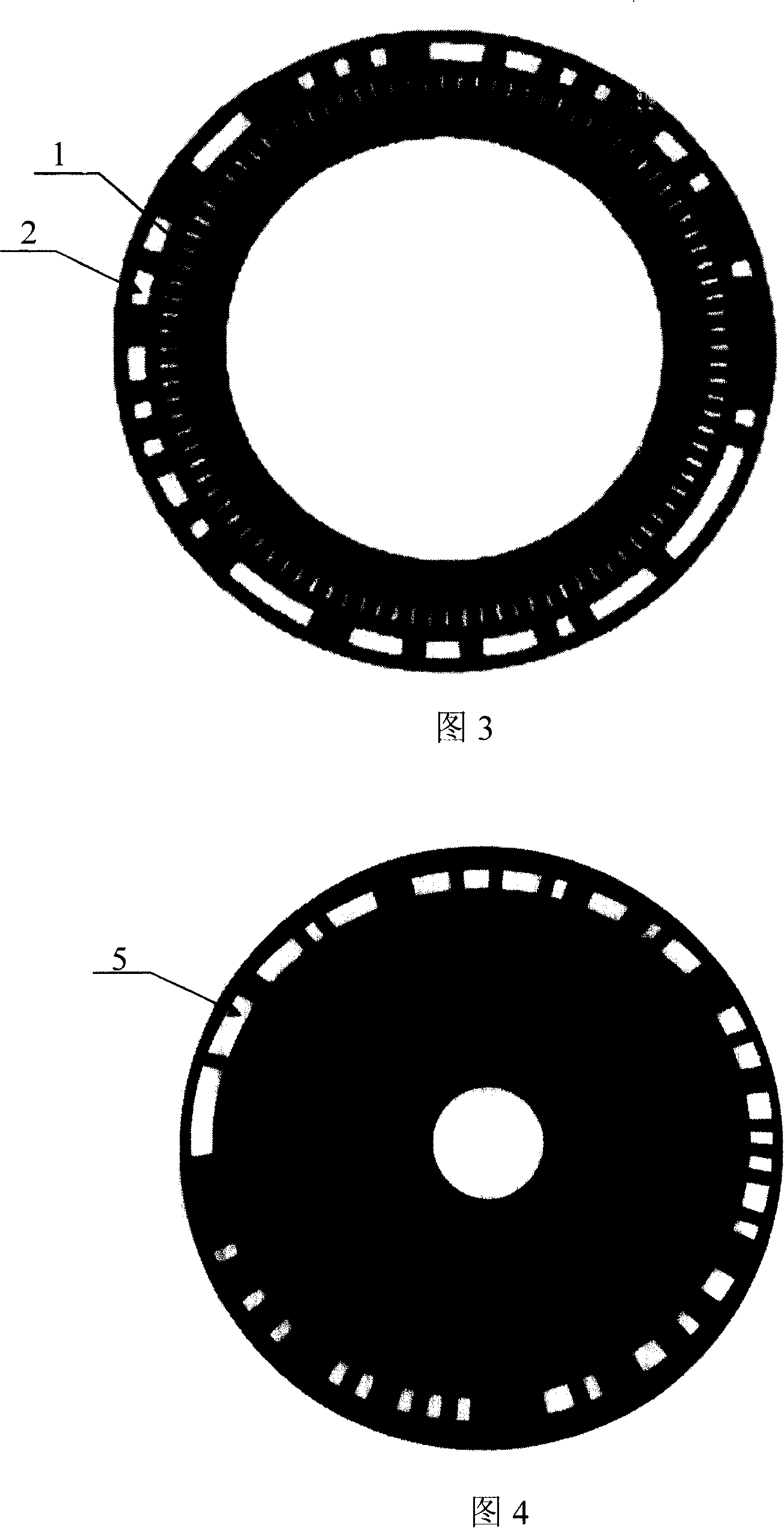

[0012] The present invention is implemented by the structure shown in FIG. 4 . The material is K9 glass, put the cleaned K9 glass into a vacuum coating machine for chrome plating; apply positive photoresist BP212; pre-bake for 1 min at a temperature of 100-110°C; expose with a GGZL1000 straight-tube ultraviolet high-pressure mercury lamp; Afterwards, at a temperature of 20±1°C, put it in a 0.5% sodium hydroxide solution for development for 5 minutes; post-bake for 20-30 minutes at a temperature of 120°C; put it in a cerium sulfate solution for 20 minutes; and finally Obtained after degumming with acetone. The exposure is completed on the circular engraving machine by making a perforated belt according to the pattern of the single-turn absolute code disc to control the exposure device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com