Patents

Literature

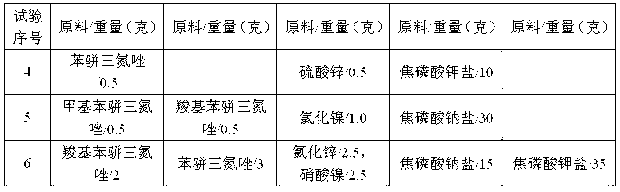

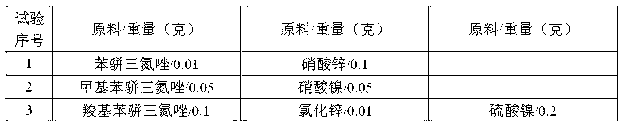

787 results about "Chrome plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chrome plating (less commonly chromium plating), often referred to simply as chrome, is a technique of electroplating a thin layer of chromium onto a metal object. The chromed layer can be decorative, provide corrosion resistance, ease cleaning procedures, or increase surface hardness. Sometimes, a less expensive imitator of chrome may be used for aesthetic purposes.

Non-chrome plating on plastic

InactiveUS20050199587A1Insulating substrate metal adhesion improvementDecorative surface effectsPERMANGANATE IONBiological activation

The invention comprises a process of preparing a non-conductive substrate for subsequent metalization. The process replaces the traditional chromic acid etching step with an etching solution comprising a permanganate and a mineral acid. The process also includes a novel activation solution comprising a palladium salt and an amine complexor. The new process of the invention is more environmentally friendly than the traditional chromic acid etching solutions but achieves a comparable result on most non-conductive substrates.

Owner:MACDERMID INC

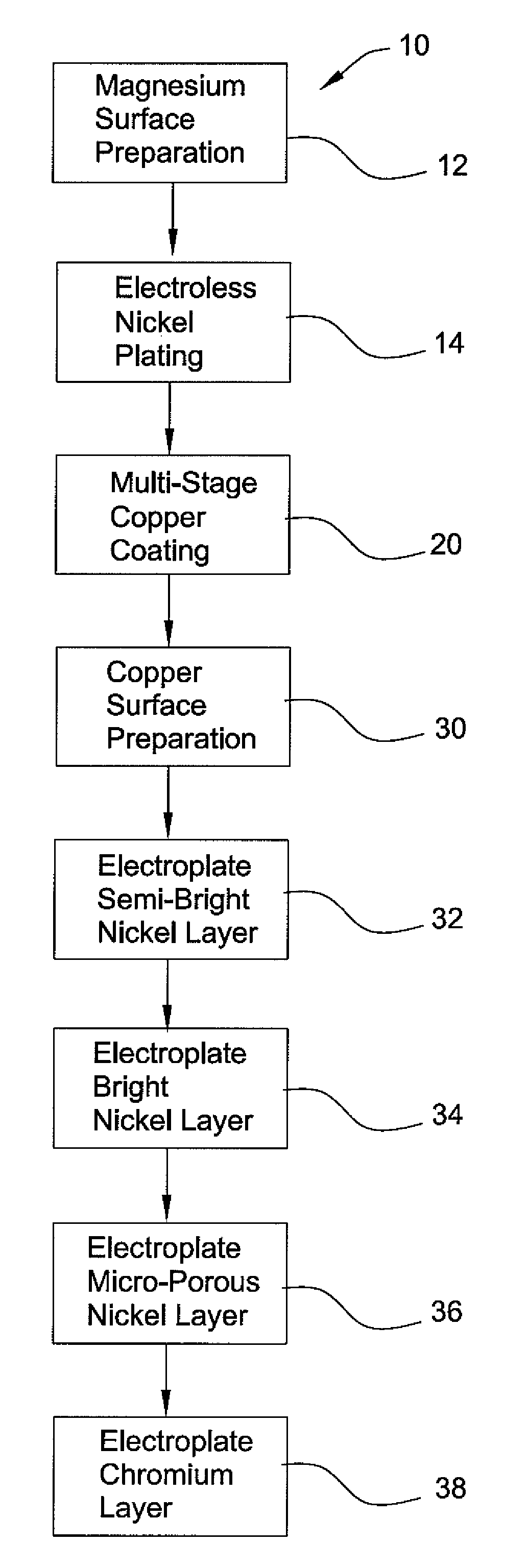

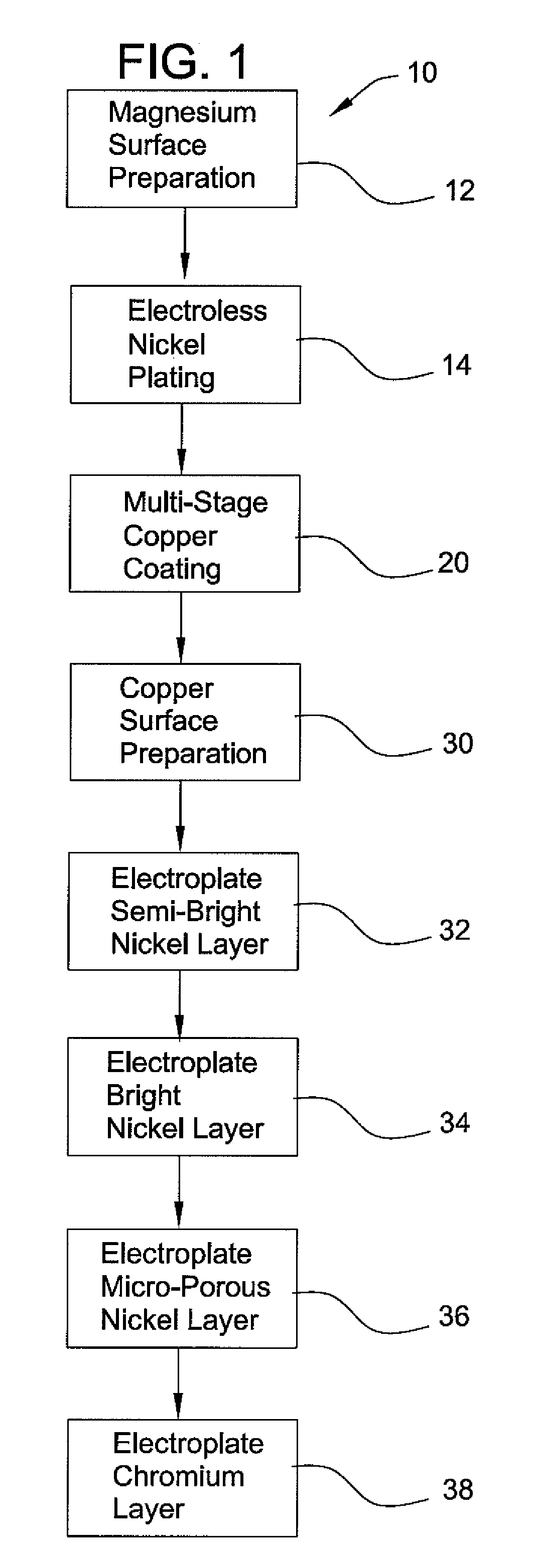

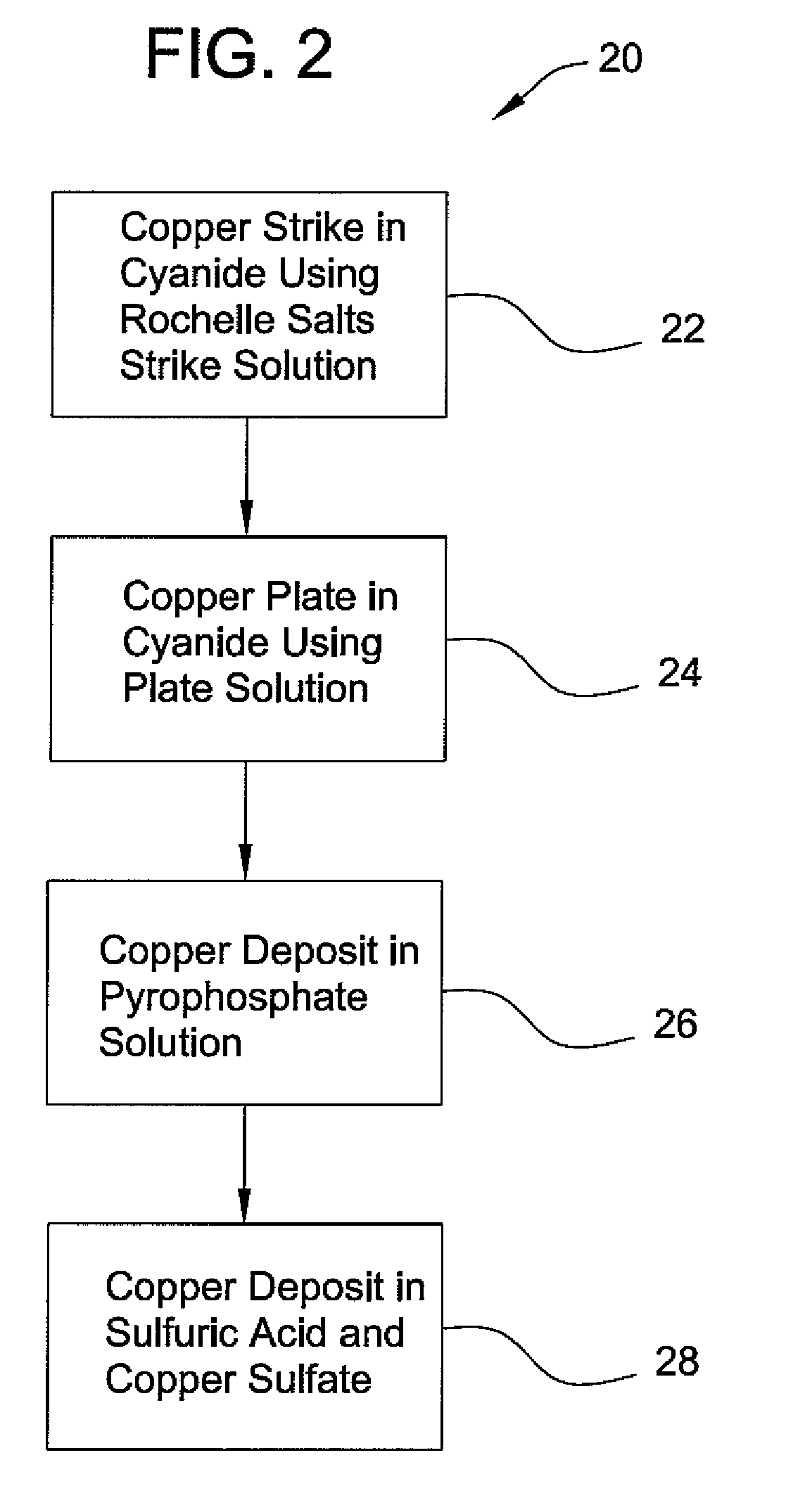

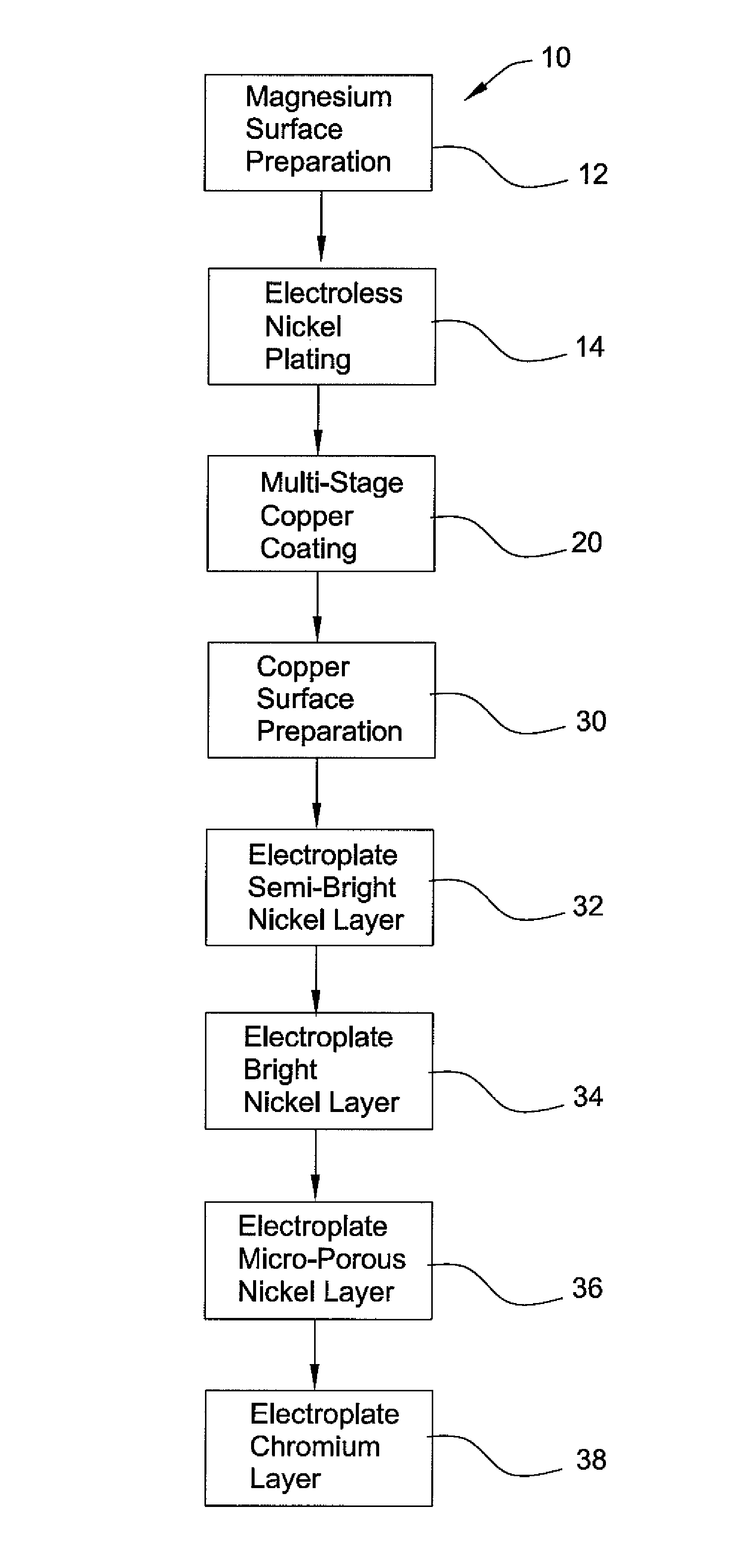

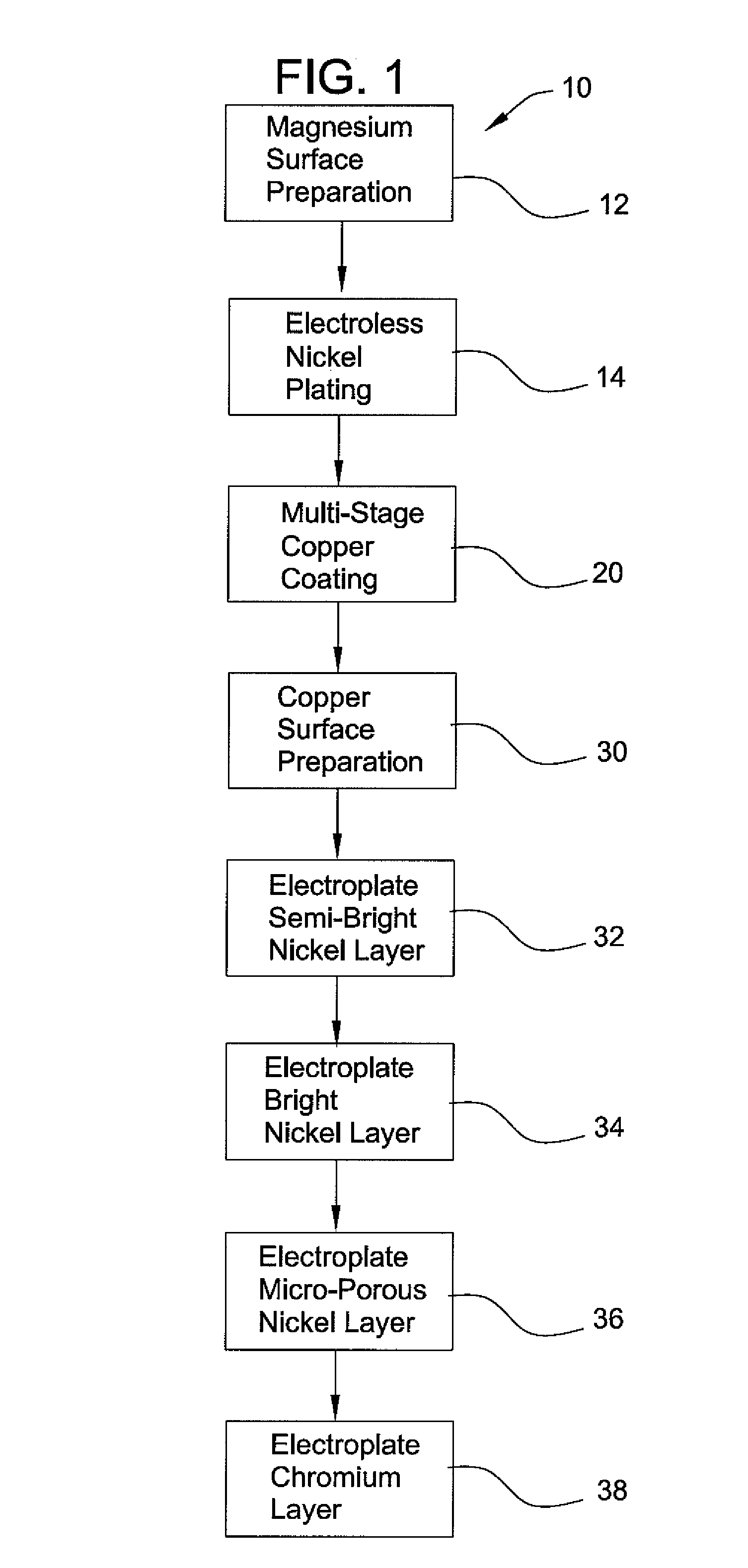

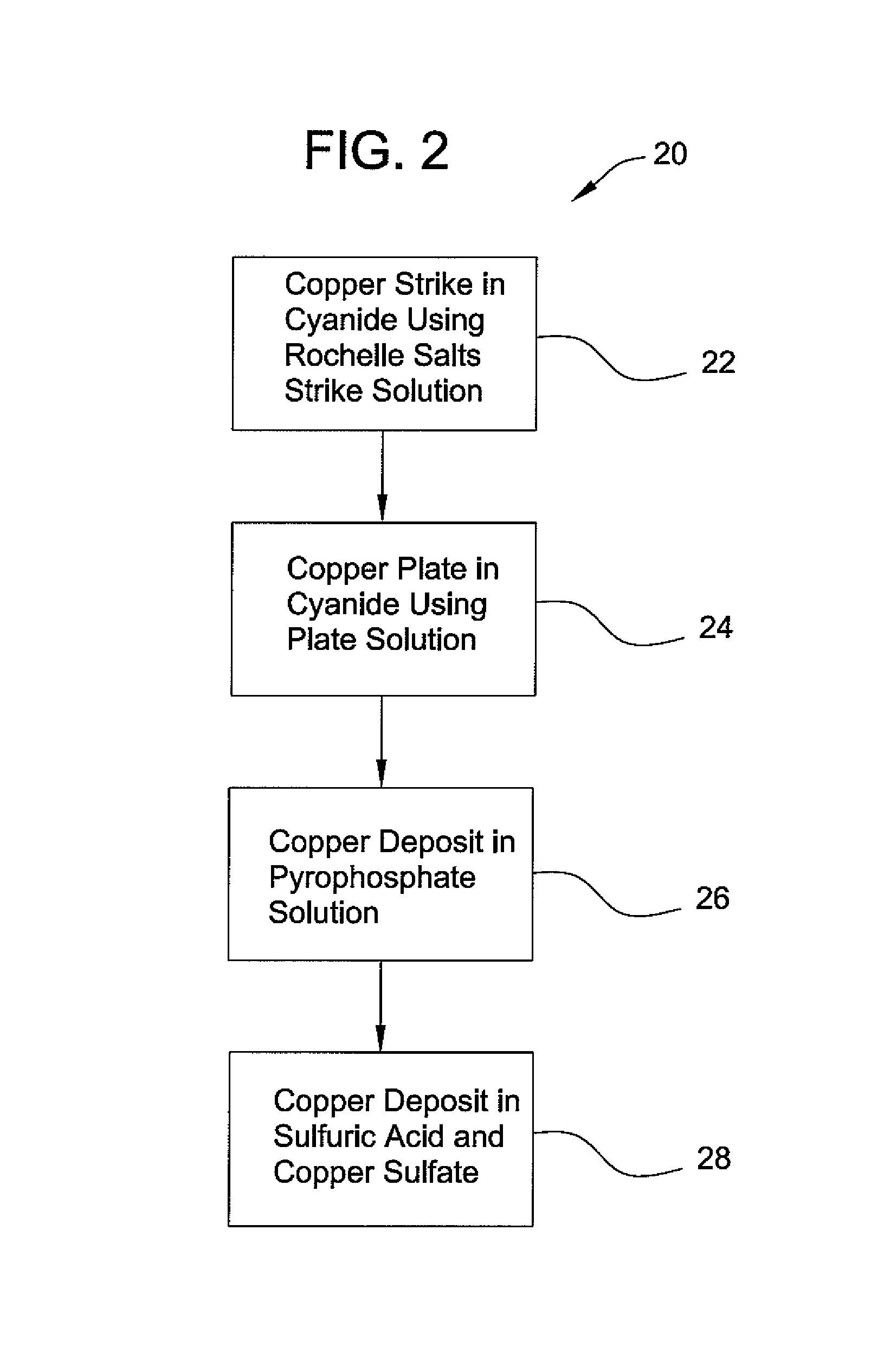

Method of Chrome Plating Magnesium and Magnesium Alloys

ActiveUS20090317556A1Liquid surface applicatorsLiquid/solution decomposition chemical coatingCopper coatingChrome plating

A process for chrome plating magnesium and its alloys. The process uses a combination of electroless nickel plating, a multi-stage copper coating transition system and multiple layers of electrodeposited nickel to form a corrosion resistant system of substantial impermeability and interlayer adherence suitable for direct chromium electroplating.

Owner:ARLINGTON PLATING

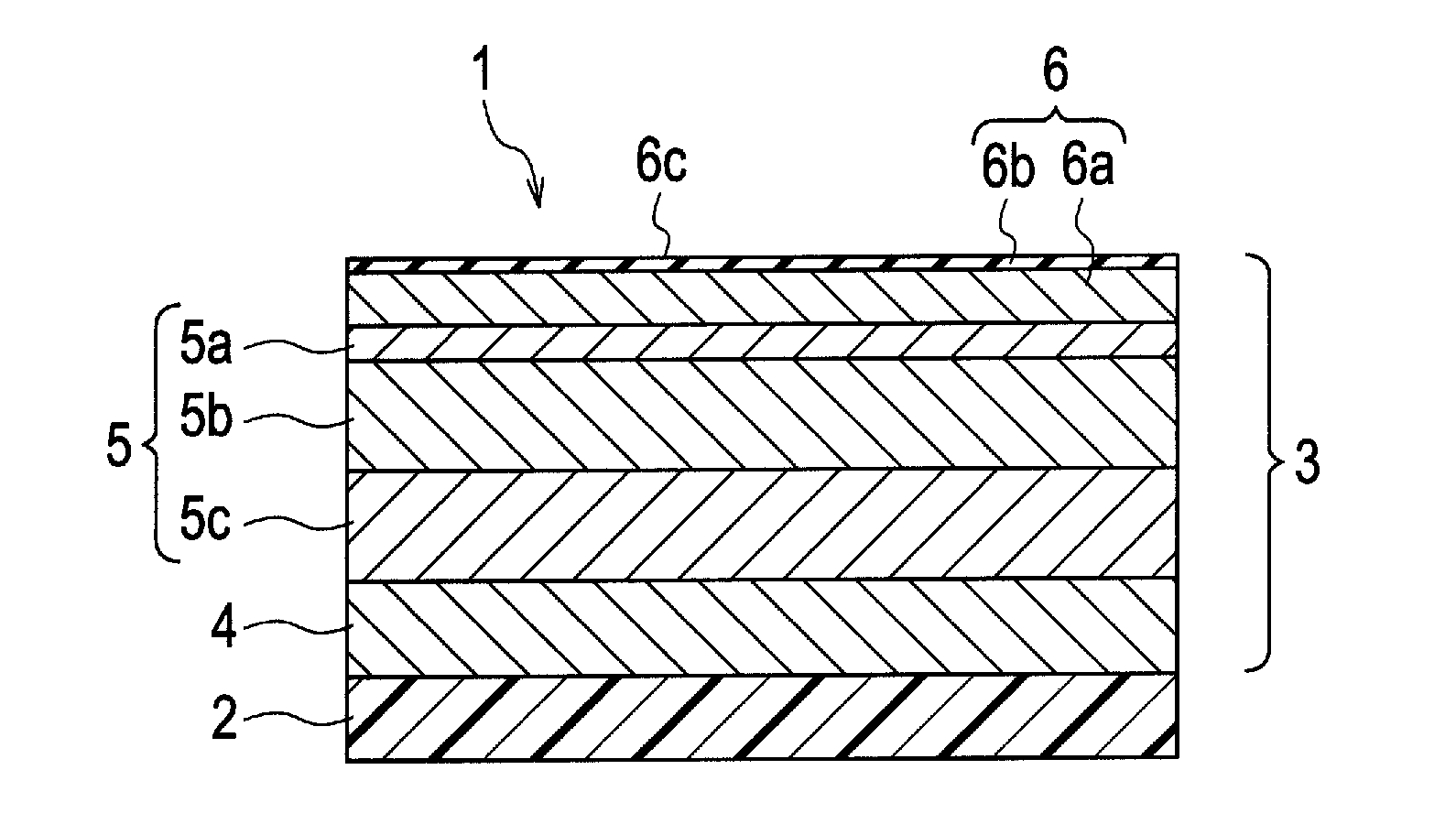

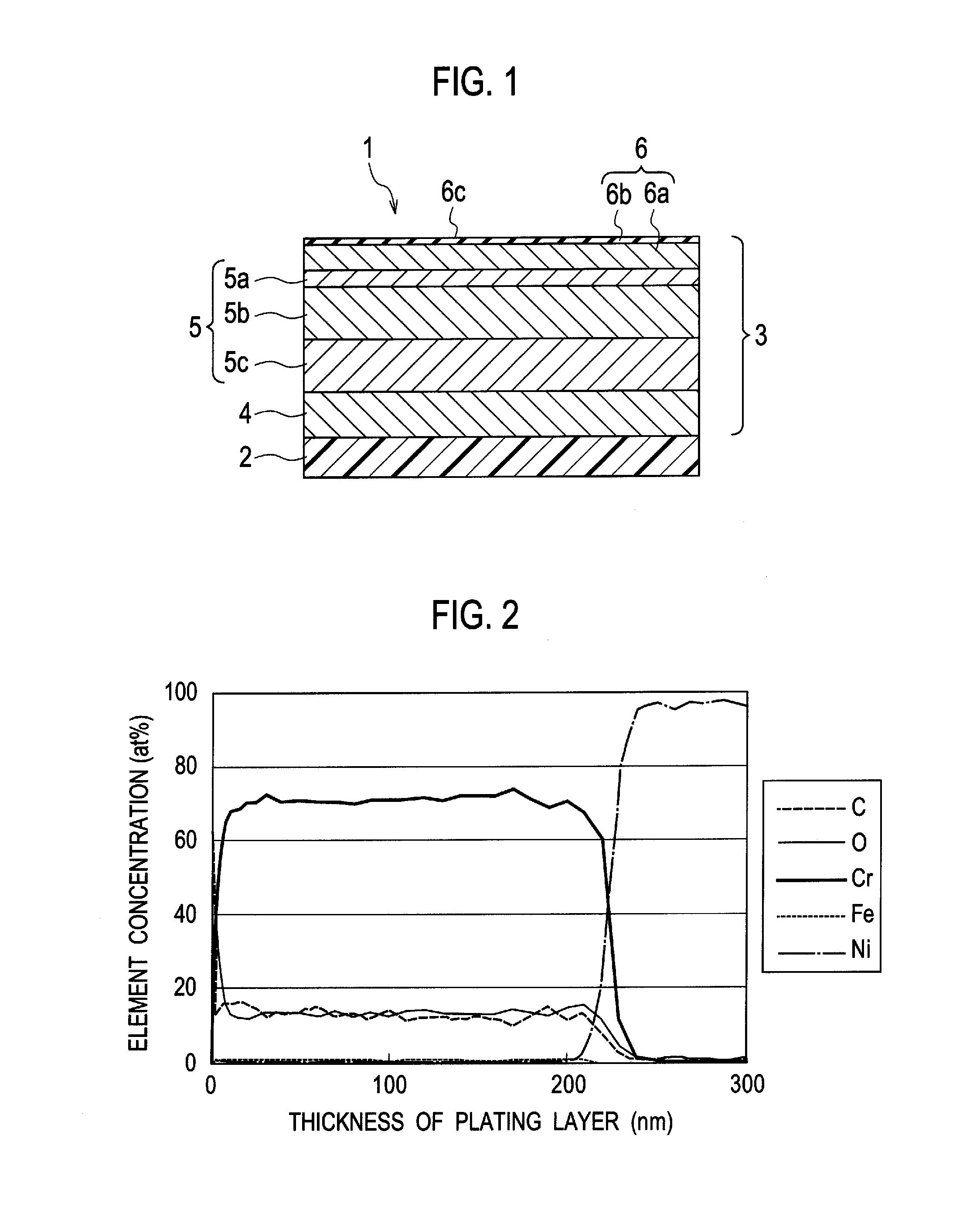

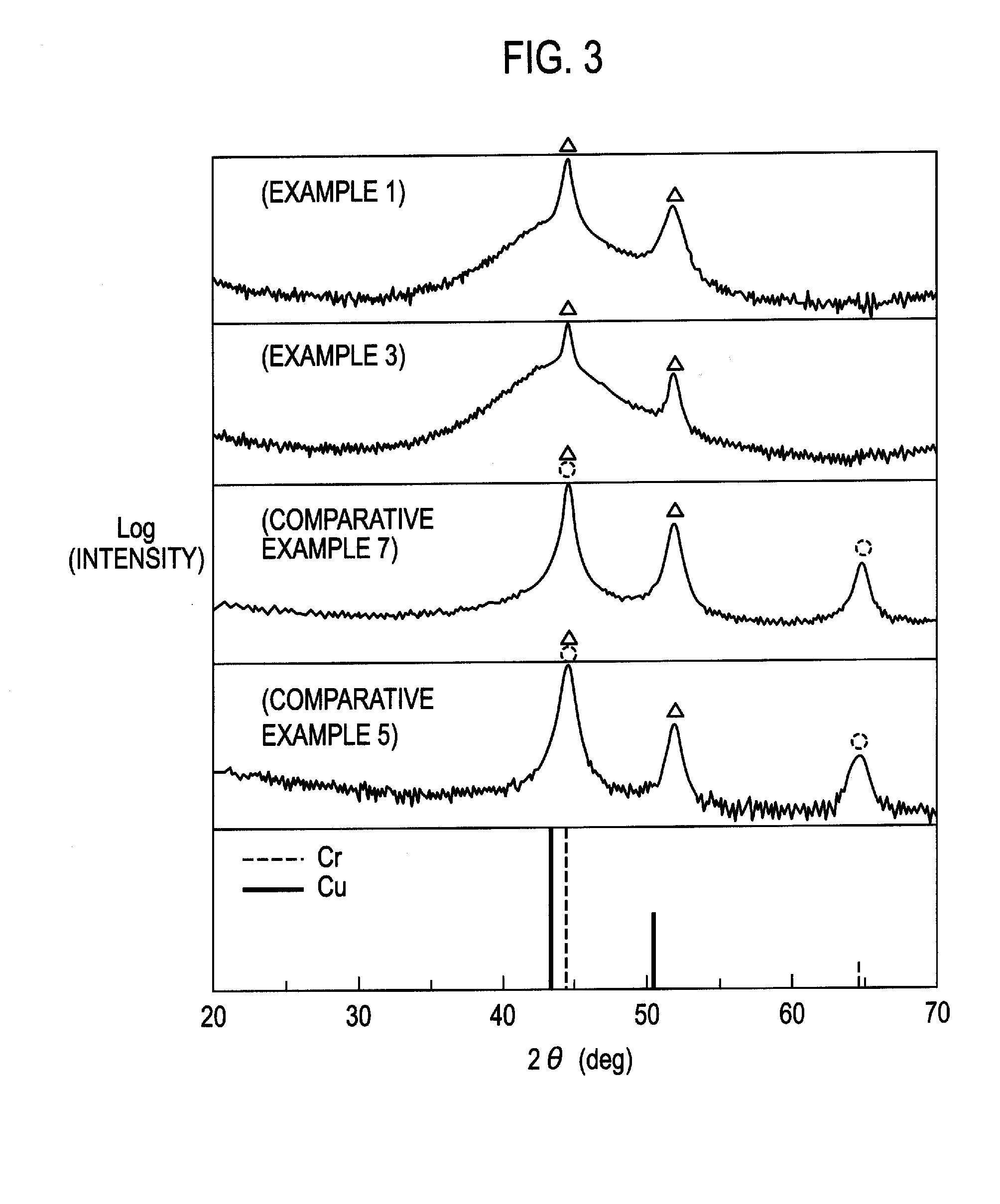

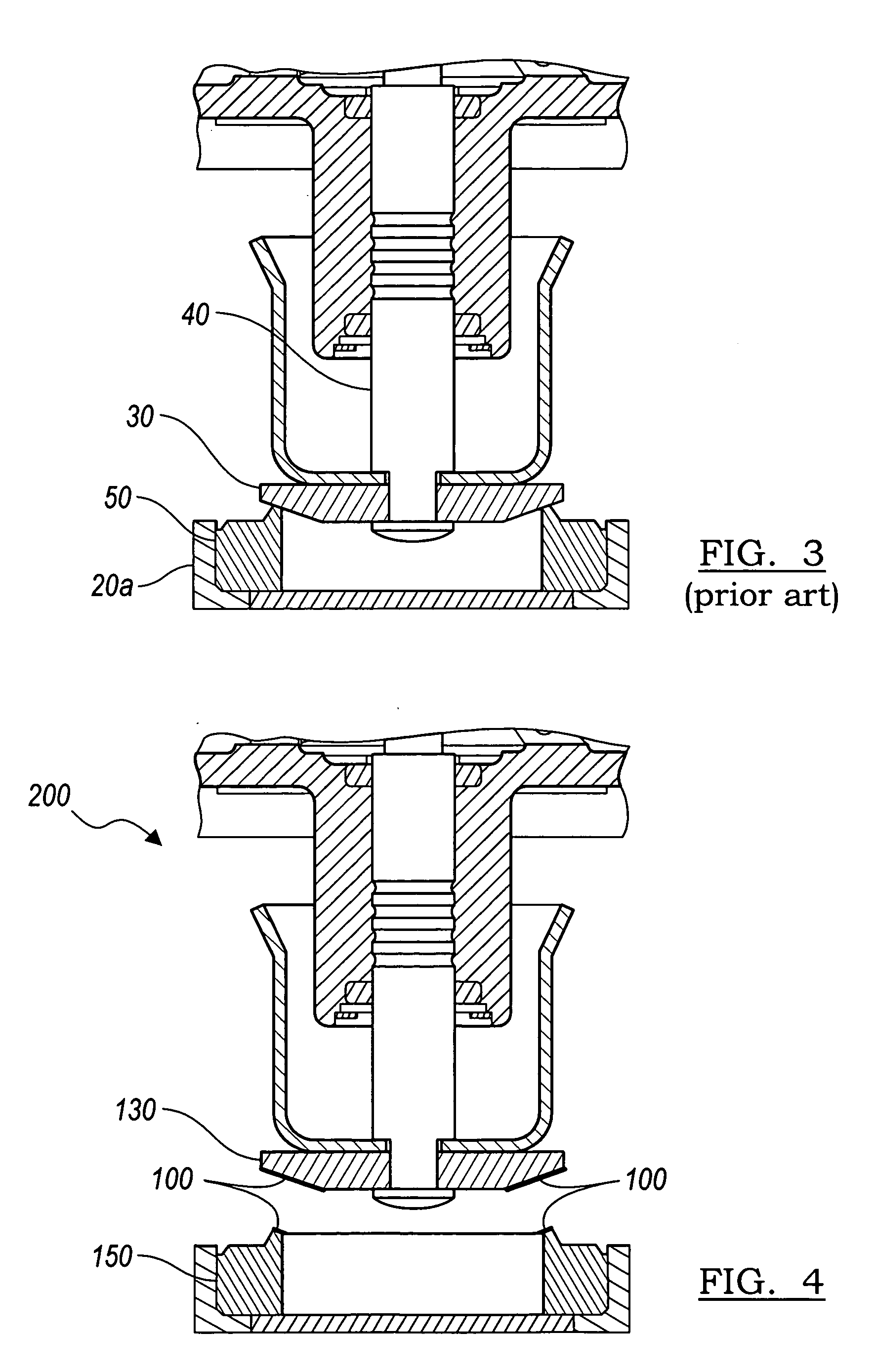

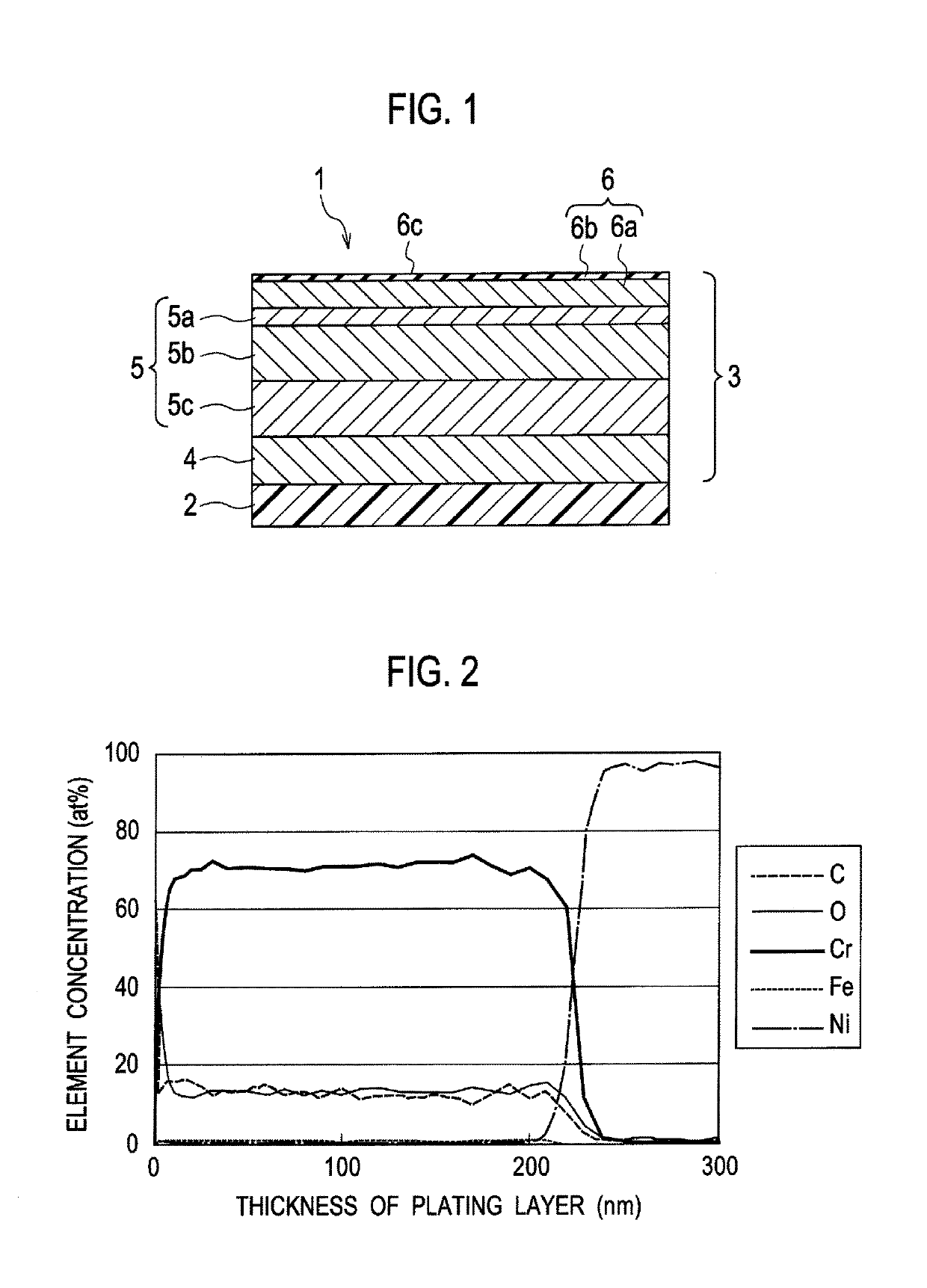

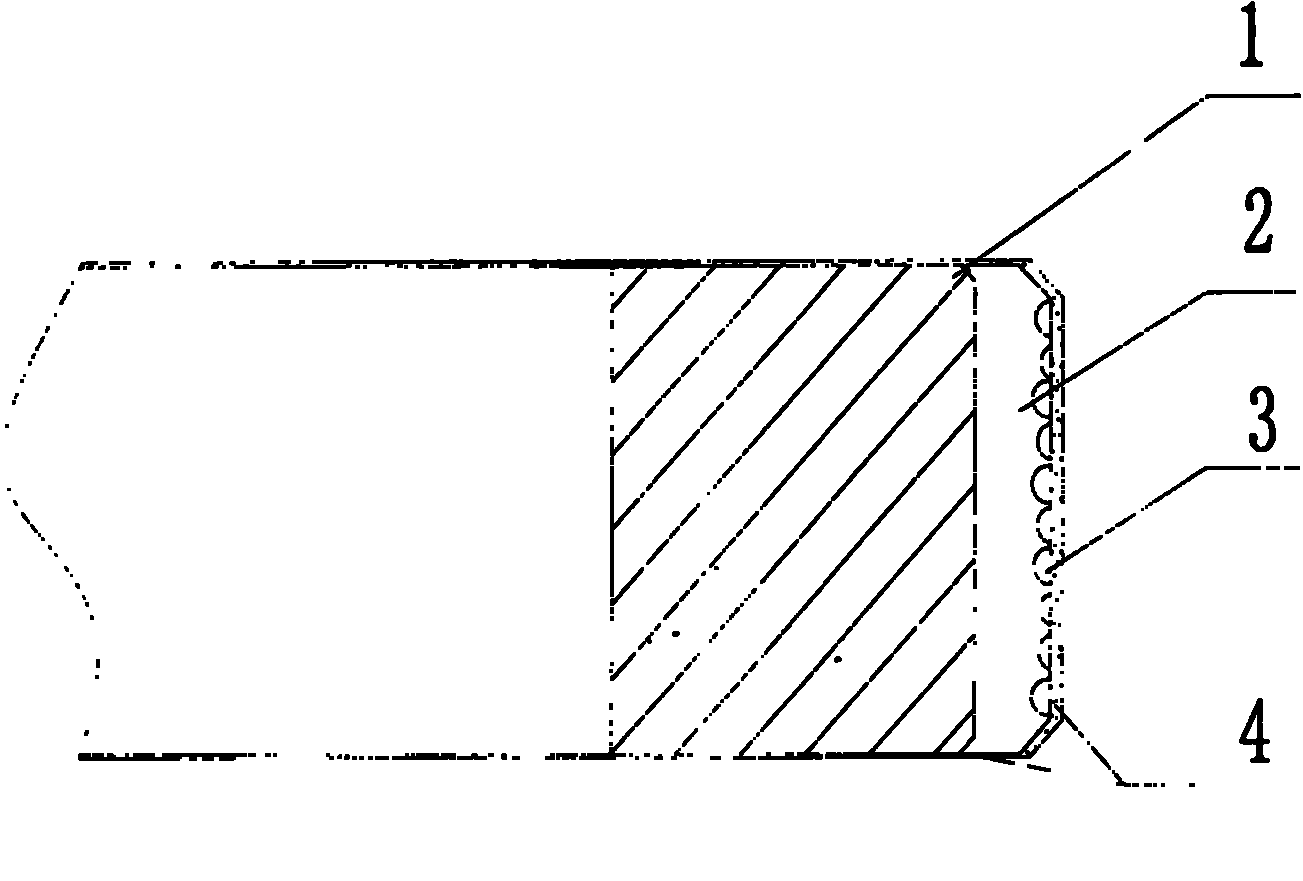

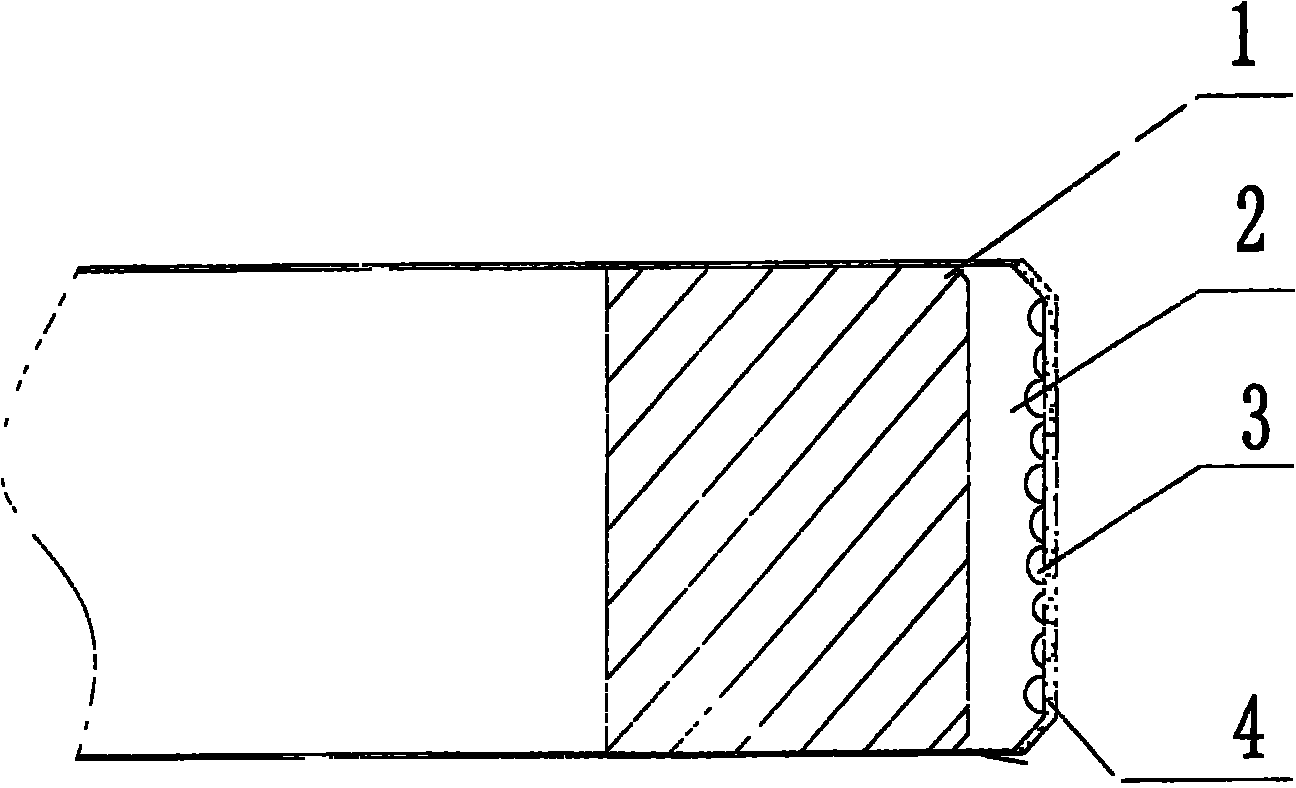

Chrome-plated part and manufacturing method of the same

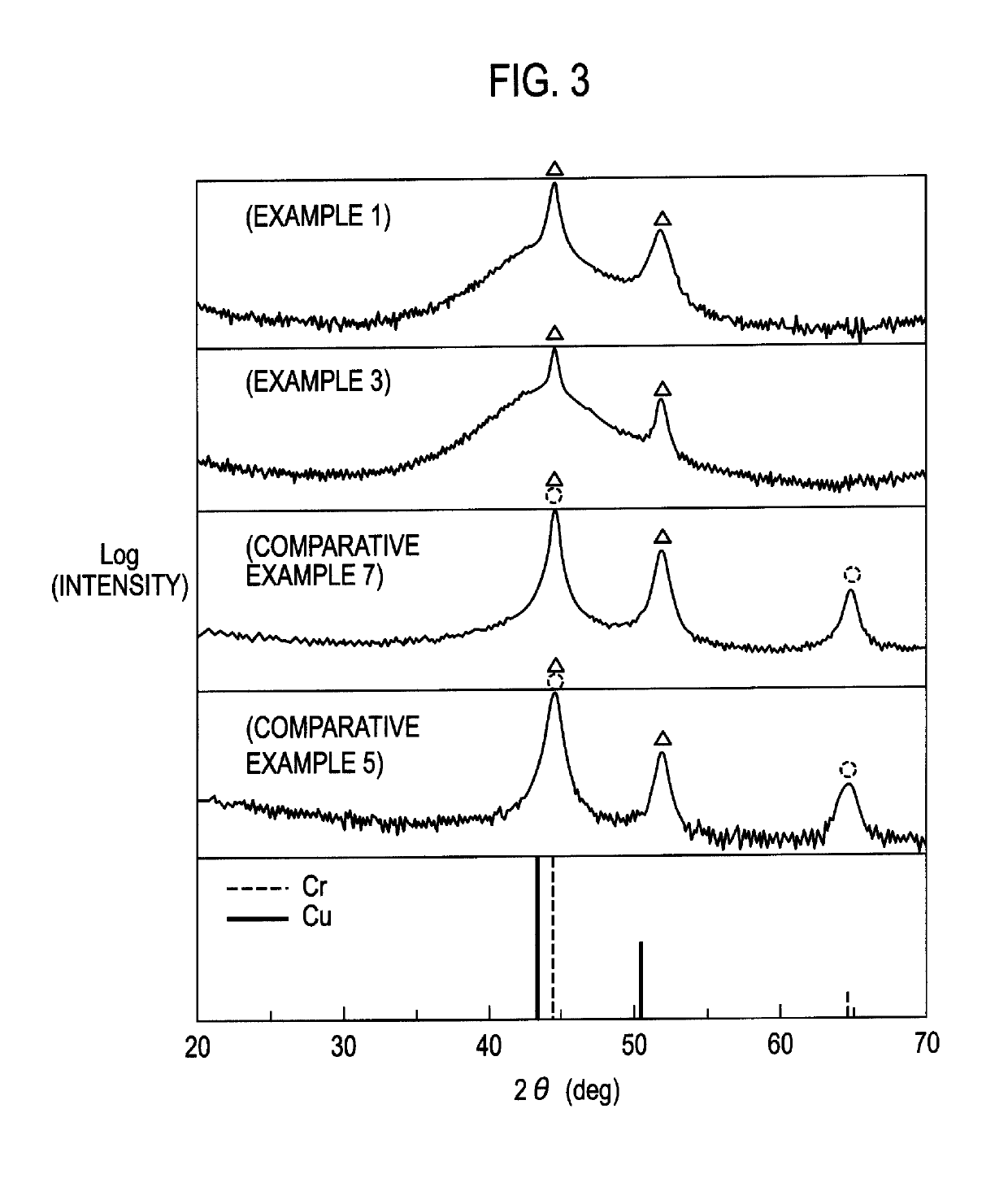

ActiveUS20120052319A1Corrosion resistanceLayered productsSuperimposed coating processChrome platingNickel

The present invention is to provide a chrome-plated part having a corrosion resistance in normal and specific circumstances and not requiring additional treatments after chrome plating, and to provide a manufacturing method of such a chrome plated part. The chrome -plated part 1 includes: a substrate 2; a bright nickel plating layer 5b formed over the substrate 2; a noble potential nickel plating layer 5a formed on the bright nickel plating layer 5b. An electric potential difference between the bright nickel plating layer 5b and the noble potential nickel plating layer 5a is within a range from 40 mV to 150 mV. The chrome-plated part 1 further includes: a trivalent chrome plating layer 6 formed on the noble potential nickel plating layer 5a and having at least any one of a microporous structure and a microcrack structure.

Owner:NISSAN MOTOR CO LTD +1

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

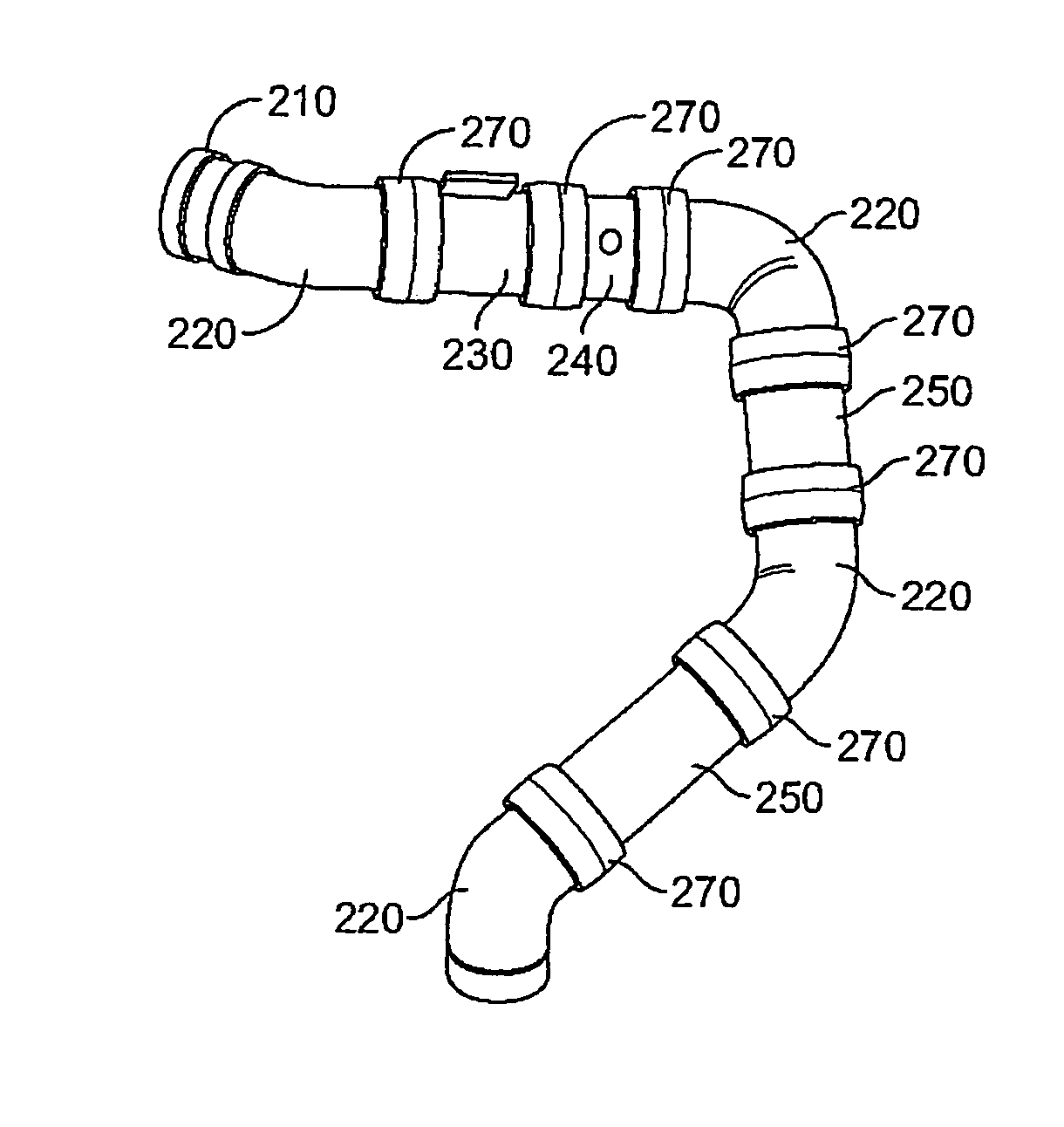

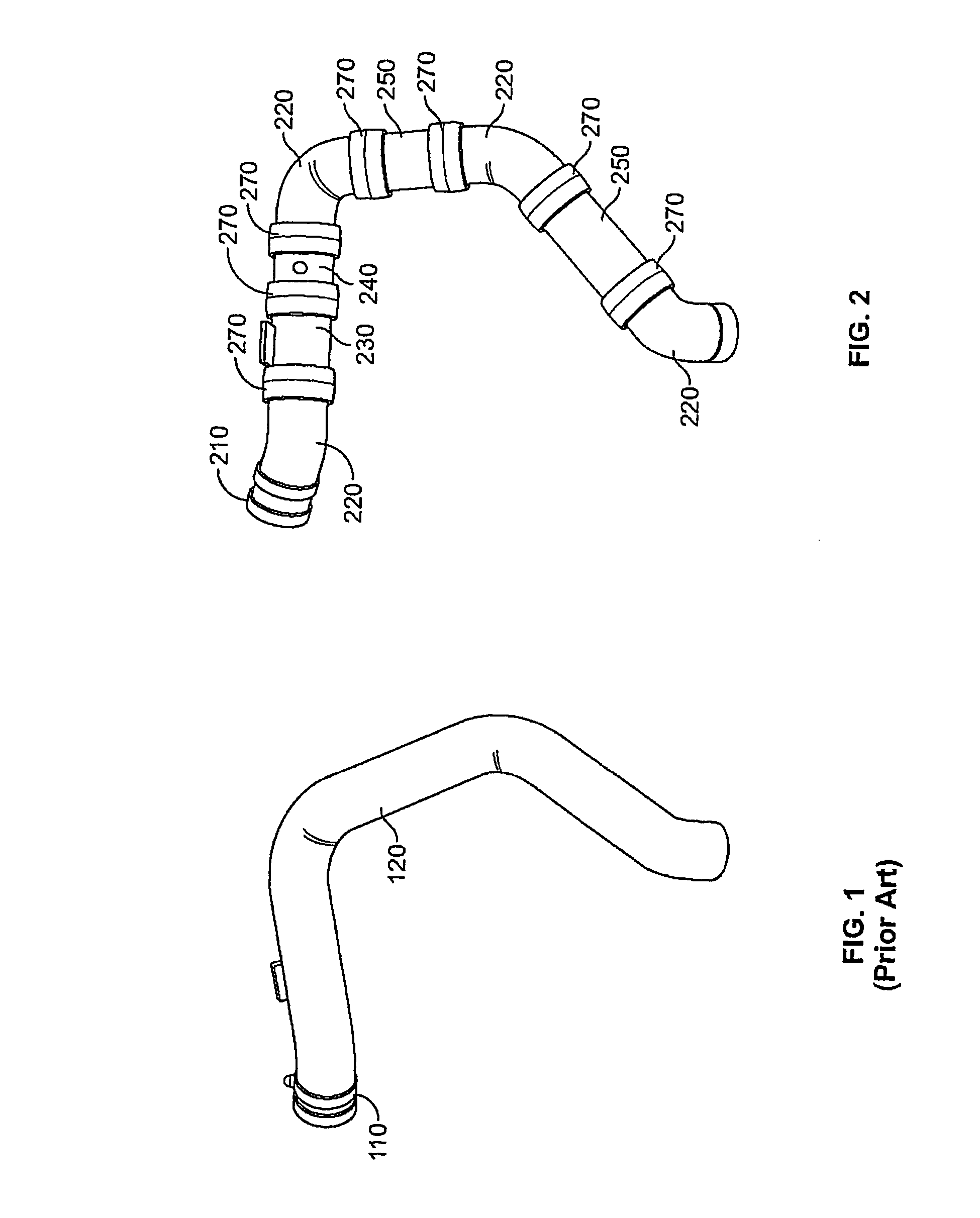

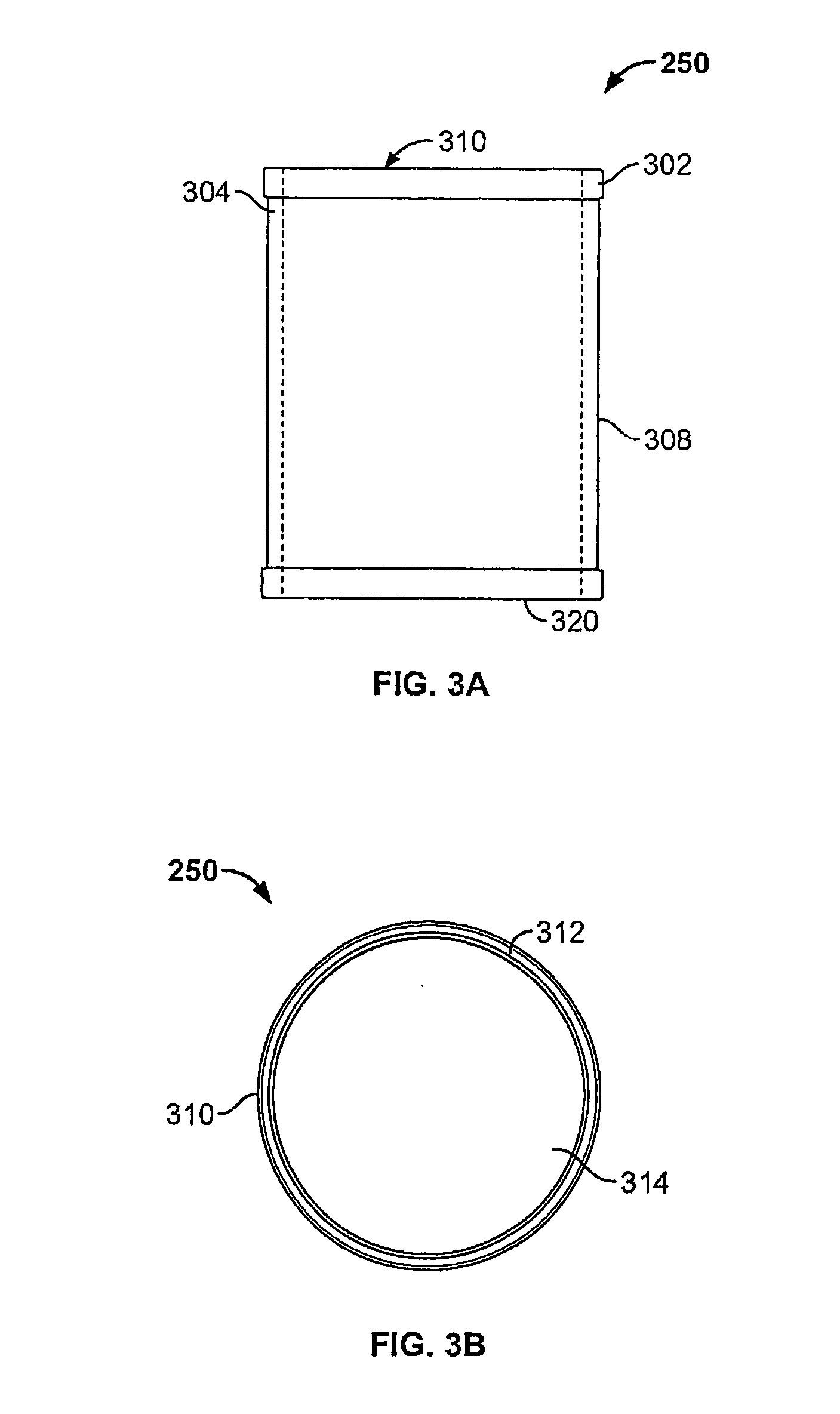

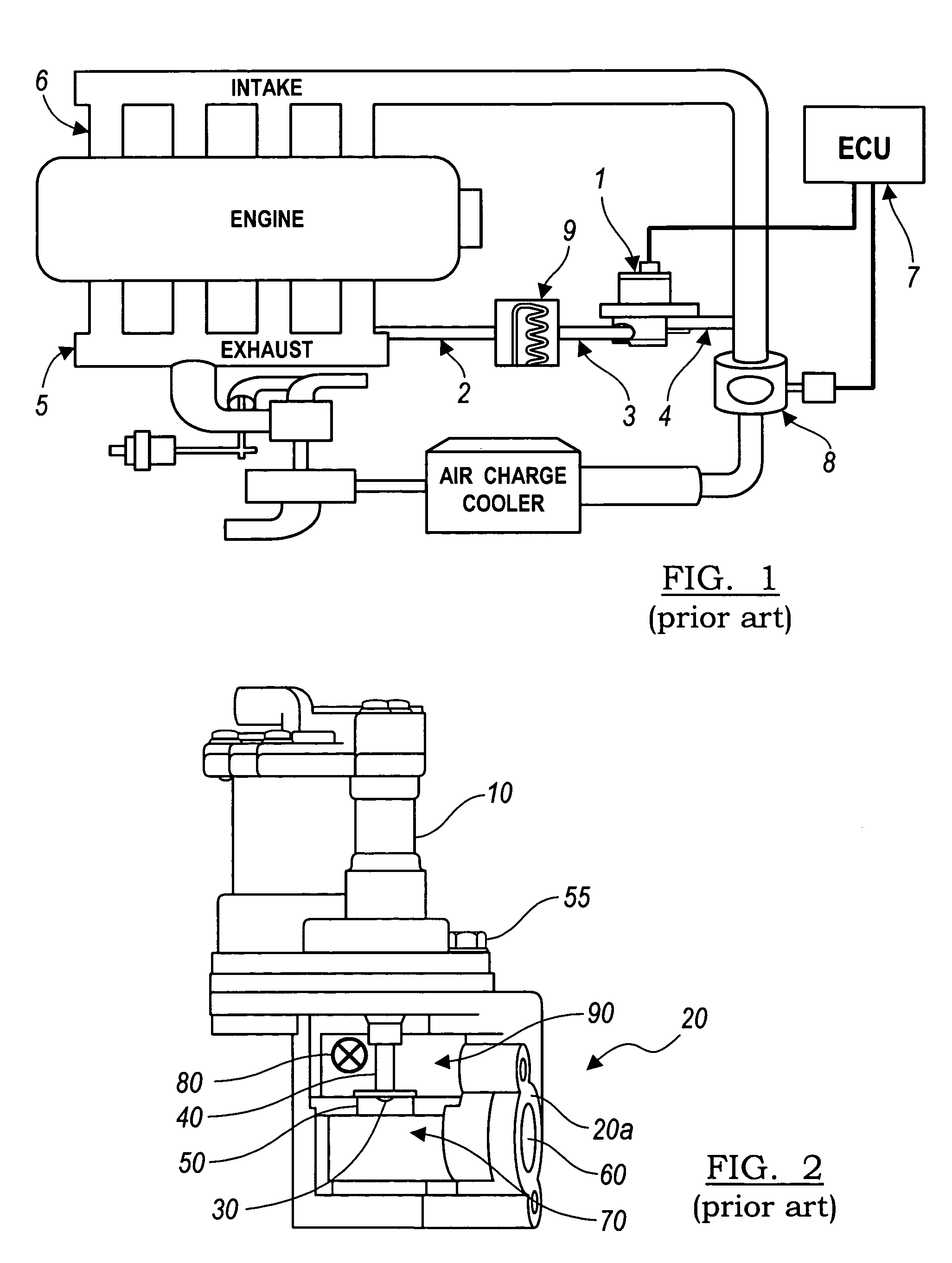

Modular intake system

InactiveUS20060185639A1Improve engine performanceMetal-working apparatusMachines/enginesModularitySystem configuration

A modular air intake system is presented. The system comprises a variety of modular components that may be coupled together to form a desired air intake system configuration for an automobile engine. Each modular component has a plastic structure with chrome plating, resulting in improved insulation and heat reflection characteristics for better engine performance. An intake system may be configured to fit into virtually any automobile engine compartment, because the components may be coupled in any combination, and the angular connection relationship between any two components is adjustable. A locking split-collar may be used to lock the junctions between modular components to provide a fixed configuration.

Owner:SPECTRE INDS

Metal surface multilayer nickel plating process with excellent corrosion resistance

The invention relates to a metal surface multilayer nickel plating process with excellent corrosion resistance. The manufacture process comprises the following steps of: plating a semi-bright layer firstly, plating a high-sulfur layer secondly, plating a bright layer thirdly and plating a nickel sealing layer fourthly from inside to outside. By adopting the technical scheme, the invention has the advantages of improving plating covering effect of a low current area, increasing the potential difference among nickel layers, protecting a matrix, slowing down the corrosion and greatly strengthening the corrosion resistance of the matrix by adopting the low concentration multilayer nickel (semi-bright nickel, high-sulfur nickel, bright nickel and nickel sealing) plus chrome plating process in an electroplating process, and by adopting the semi-bright nickel plating at the bottom layer, excellent leveling capability and scalability can be obtained, a plating solution is easy to control, harmful products cannot be produced after long-time operation, and the plating contains no sulfur and has higher corrosion resistance.

Owner:JIANGSU ZHENYU AUTOMOBILE PARTS

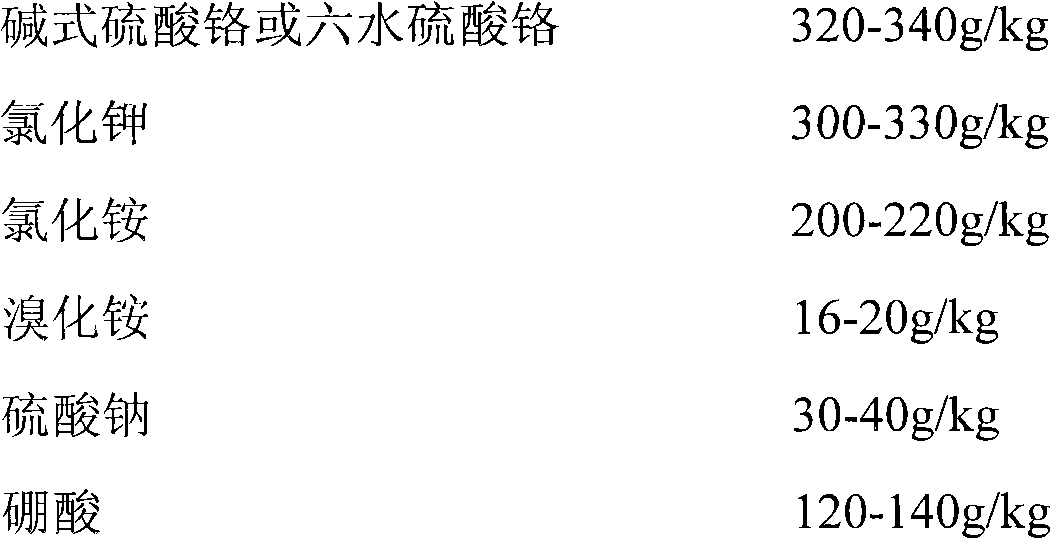

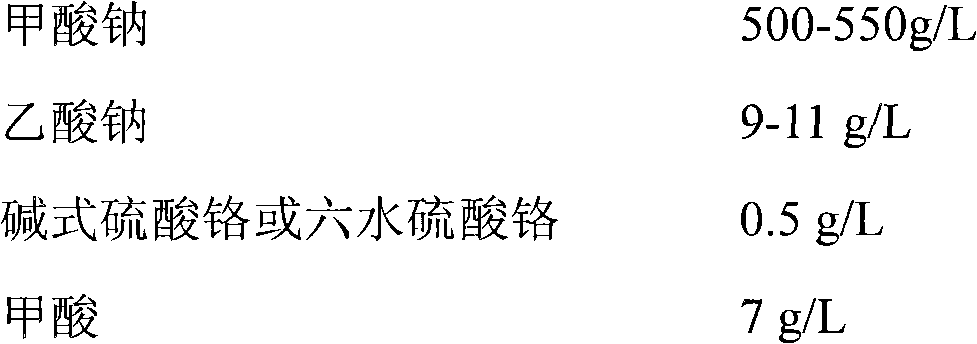

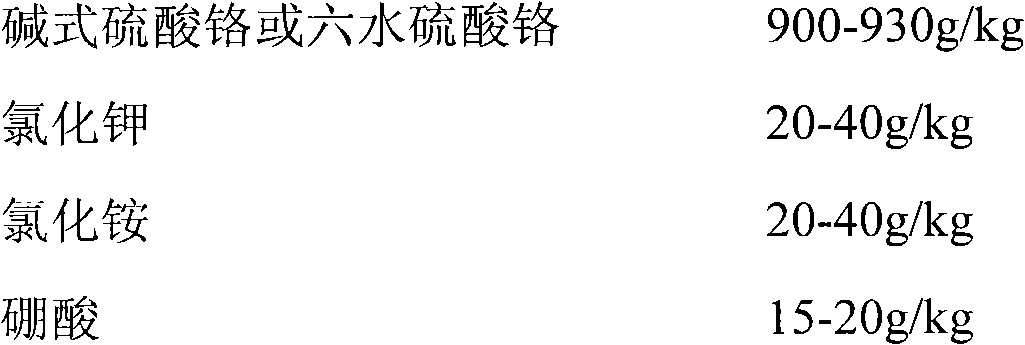

Trivalent chromium plating solution composite, preparation method thereof and chromium plating process

The invention aims at providing a trivalent chromium plating solution composite, preparation and chromium plating process thereof. The plating solution composite comprises main salt, conductive salt, a pH stabilizing agent, a complexing agent, a wetting agent and a displacement agent; and five addition agents of a cylinder opening agent, a stabilizing agent, a bending agent, a modifying agent and a regulating agent are adopted and added to the main salt, the conductive salt, the pH stabilizing agent, the complexing agent, the wetting agent and the displacement agent to be prepared into the plating solution composite. The chromium plating process adopting the plating solution composite has characteristics of high current efficiency, good displacement performance, simple management, lower cost and the like; the obtained plating layer is bright and is close to a product obtained through a hexavalent chromium process in color and lustre.

Owner:济南德锡科技有限公司

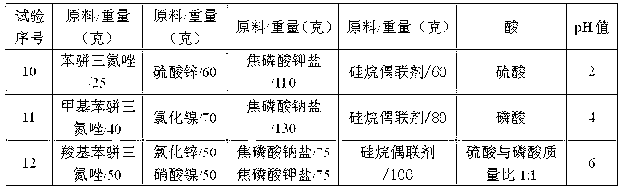

Copper foil surface passivation liquid and treatment method thereof, and treated copper foil

The invention provides a copper foil surface passivation liquid which comprises one or more compositions selected from benzotriazole and benzotriazole derivative, and one or two compositions selected from soluble zinc salt and soluble nickel salt and has the pH value of 1-7. A copper foil surface treatment method comprises the following steps of: (1) preserving the temperature of the passivation liquid at 25-45 DEG C; (2) spraying the passivation liquid to the surface of a copper foil for 2-10 seconds; (3) uniformly distributing the passivation liquid on the surface of the copper foil by a water extrusion roller; and (4) drying at the temperature of 110-180 DEG C for 2-10 seconds. The invention also provides the copper foil. The oxidization resistance temperature of the surface of the copper foil is 213 DEG C, and the oxidization resistance can be maintained for 120 minutes at the temperature of 213 DEG C. According to the conventional passivation technology, the surface of the copper foil is passivated by a chromium plating mode, and sexavalence chromium ions contained in the electroplating liquid pollute the environment; and the surface of the copper foil is passivated by the chromium-free passivation liquid, so that the waste liquid cannot pollute the environment.

Owner:JIANGXI COPPER

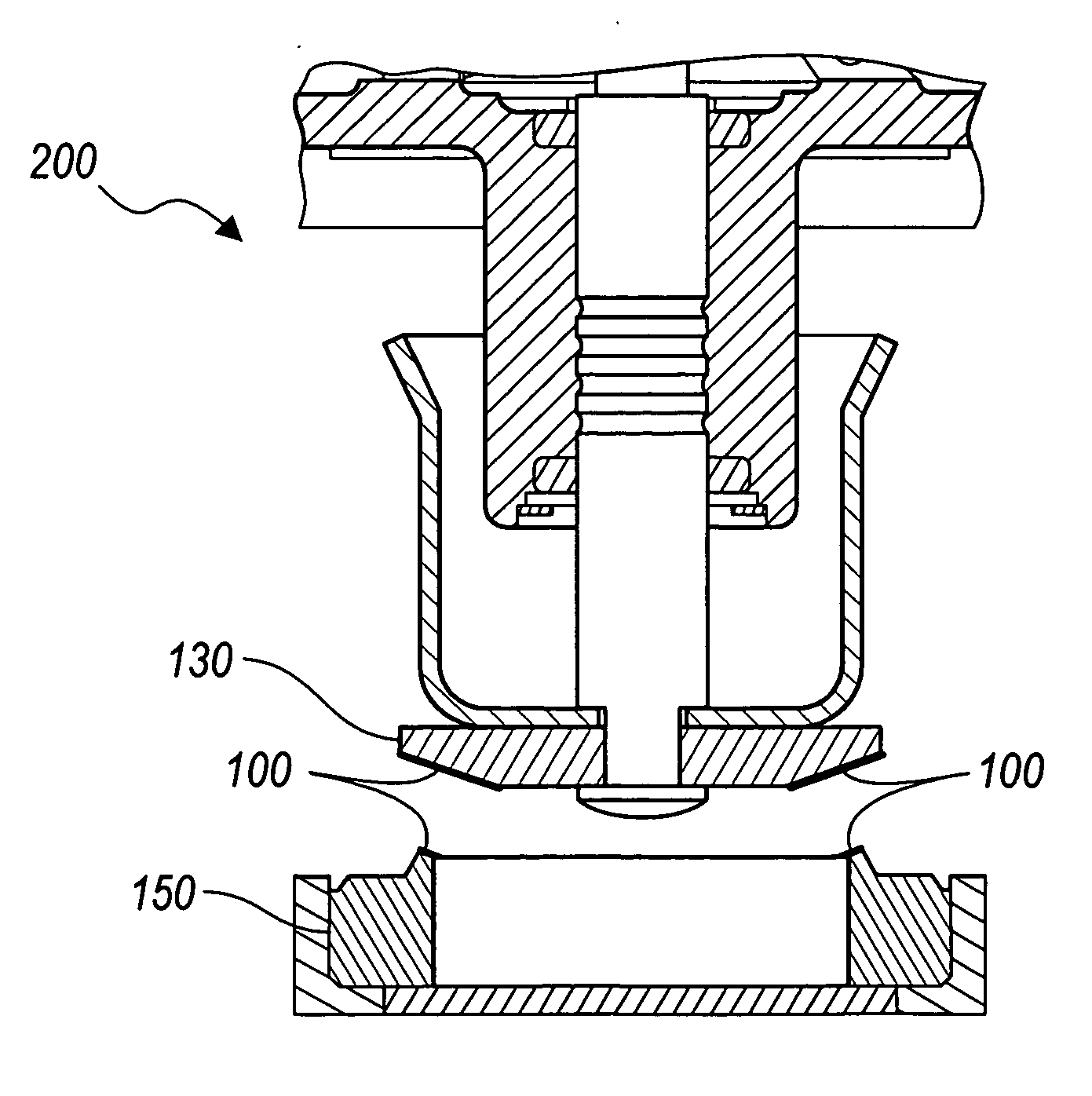

Exhaust gas recirculation valve

ActiveUS20060032485A1Non-fuel substance addition to fuelInternal combustion piston enginesCold sideEngineering

Mechanical systems having anti-stick mediums applied thereto are provided. In one aspect, exhaust gas recirculation (EGR) valve systems having anti-stick mediums applied thereto are also provided. The anti-stick medium can be applied to any contacting surface, such as but not limited to the valve surface and / or the valve seat surface. The anti-stick medium is intended to prevent the valve surface and the valve seat surface sticking or bonding together, especially with respect to the operation of cooled or cold side EGR systems. If any materials should stick to the anti-stick medium, a portion of the anti-stick medium will break away from the surface, allowing the surface and / or component to function normally. The anti-stick medium can include, without limitation, boron nitride coatings, boron nitride aerosols, boron nitride greases, thin dense chrome platings, perfluoroalkoxy, and combinations thereof.

Owner:BORGWARNER INC

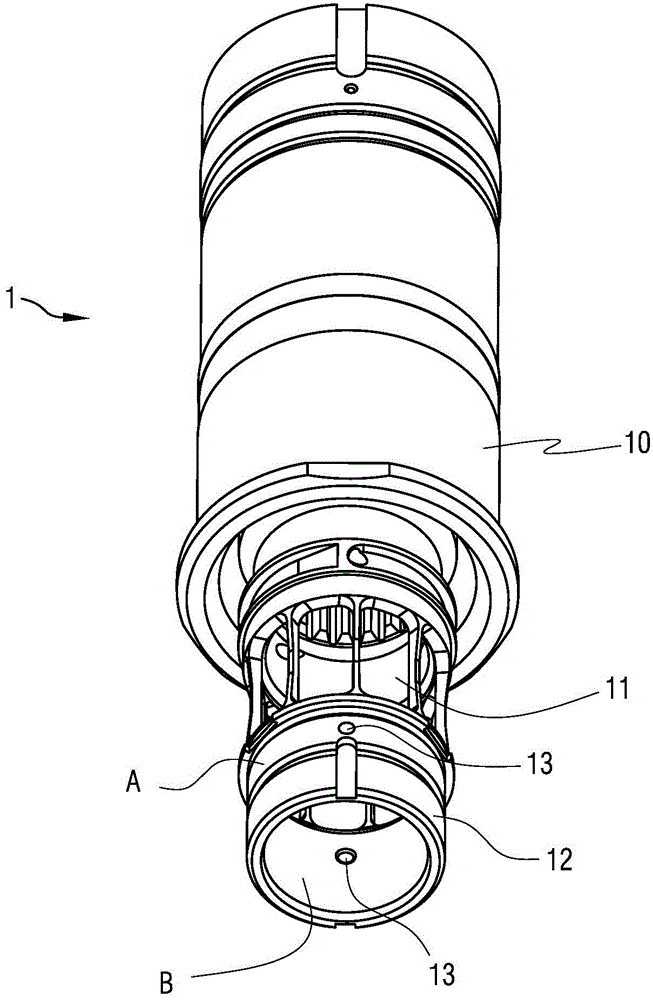

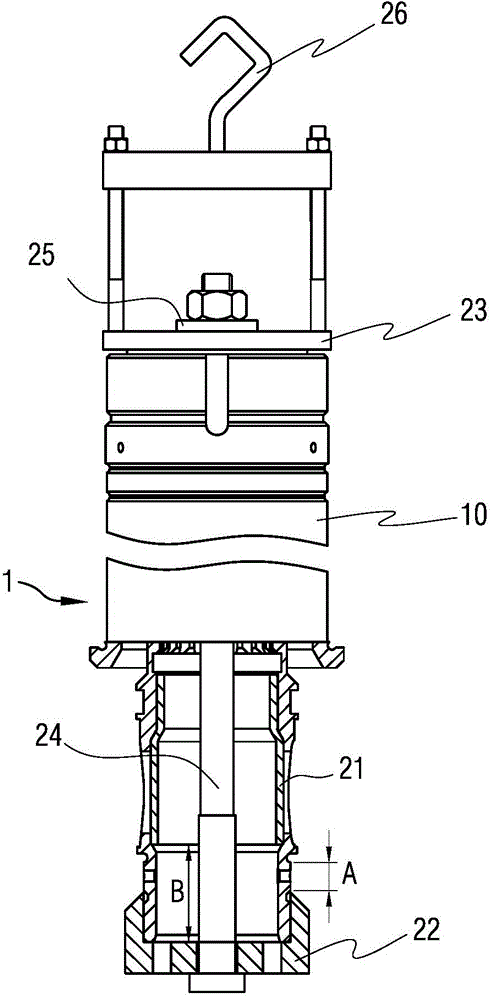

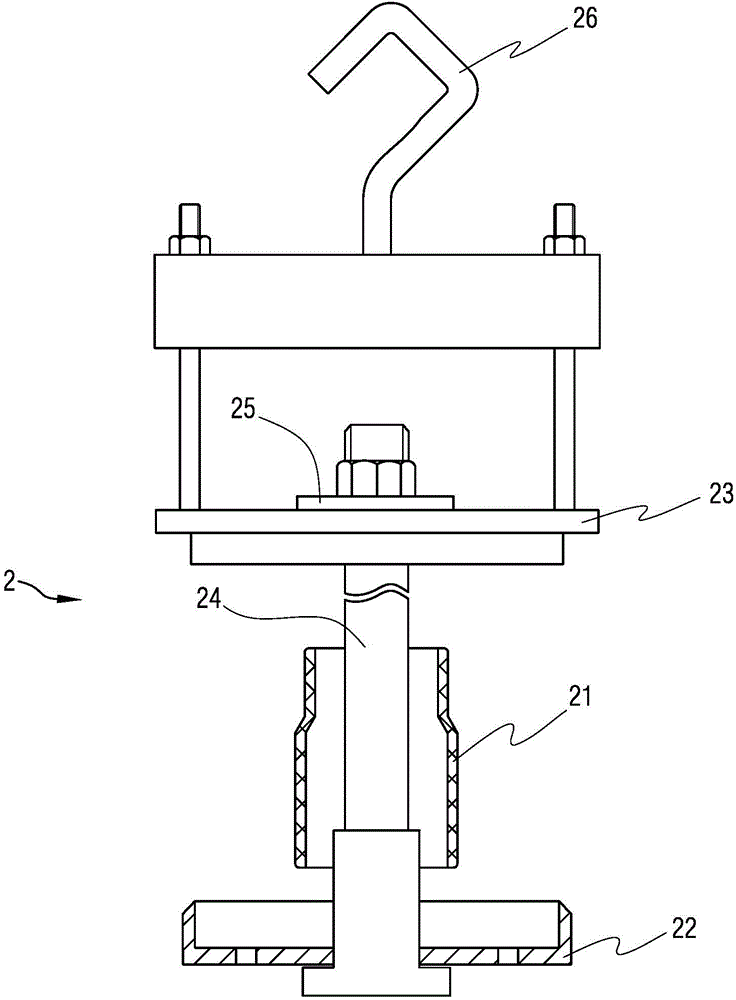

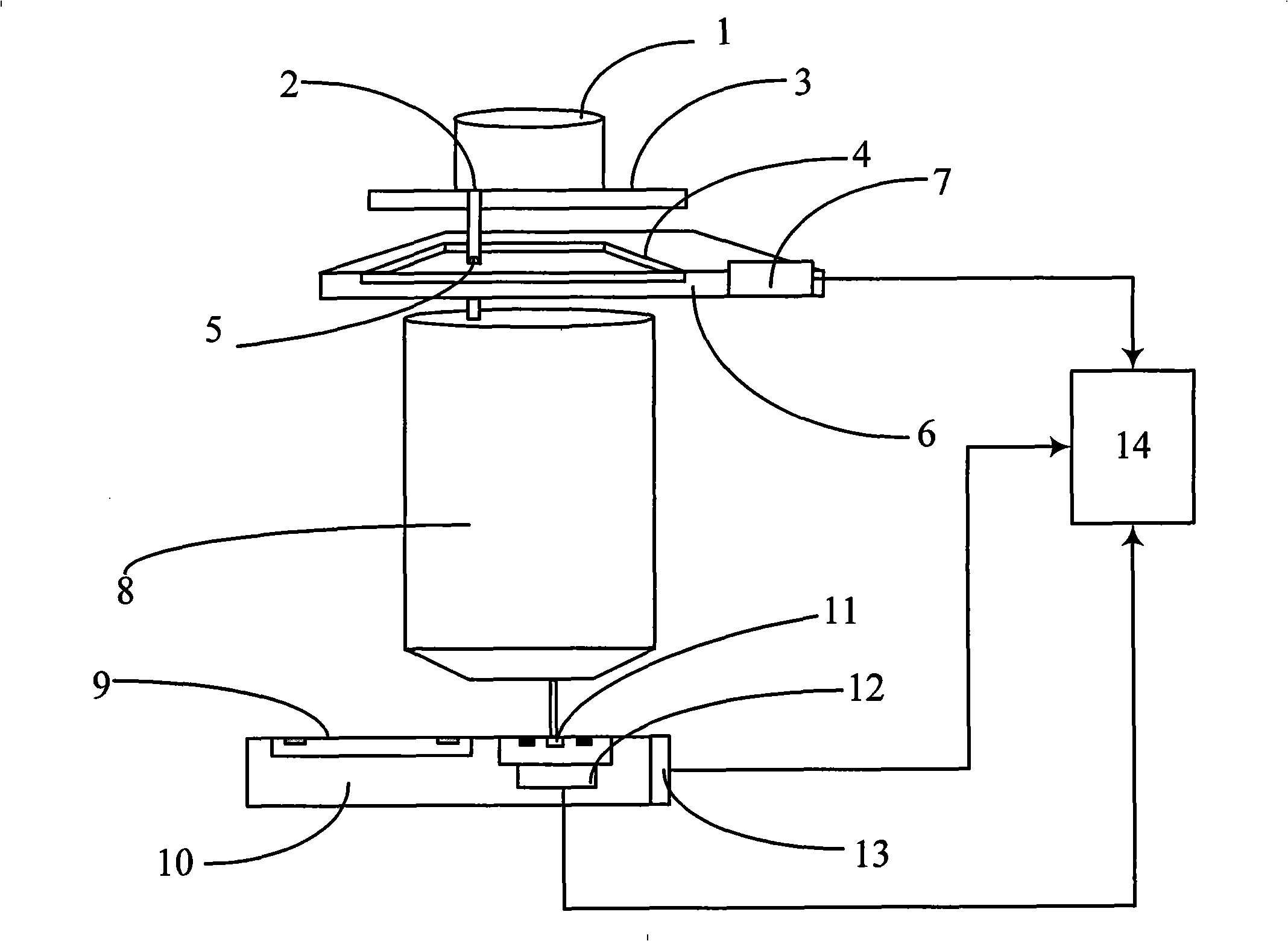

Output shaft chrome plating method and output shaft chrome plating fixture

ActiveCN104831325AShorten the processing cycleReduce repair rateElectrolysis componentsEngineeringChrome plating

The invention provides an output shaft chrome plating method and an output shaft chrome plating fixture. An output shaft comprises a cylindrical main body, and an outer circle area for chrome plating and an inner circle area for chrome plating are arranged at the first end of the main body. The fixture comprises a fluororubber sleeve, a lower cover plate, an upper cover plate and an anode center pole, the fluororubber sleeve shields an inner circle surface of a non-chrome-plating window area, and the anode center pole is connected with the upper cover plate and the lower cover plate. An insulating sleeve is arranged at the joint between the anode center pole and the upper cover plate. According to the chrome plating method, the special chrome plating fixture is provided, integral assembly and suspension are adopted, component matching tightness is achieved, anode positions for inner circle plating are fixed, the plating thickness of an inner circle is uniform, and the phenomenon that part of a chromium layer of an inner hole is too thin to grind is prevented; the method is simple and rapid to operate, the inner circle and an outer circle can be plated with chrome by the same fixture at a time, processing cycle of components is shortened greatly, repair rate of the components is reduced and production efficiency is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

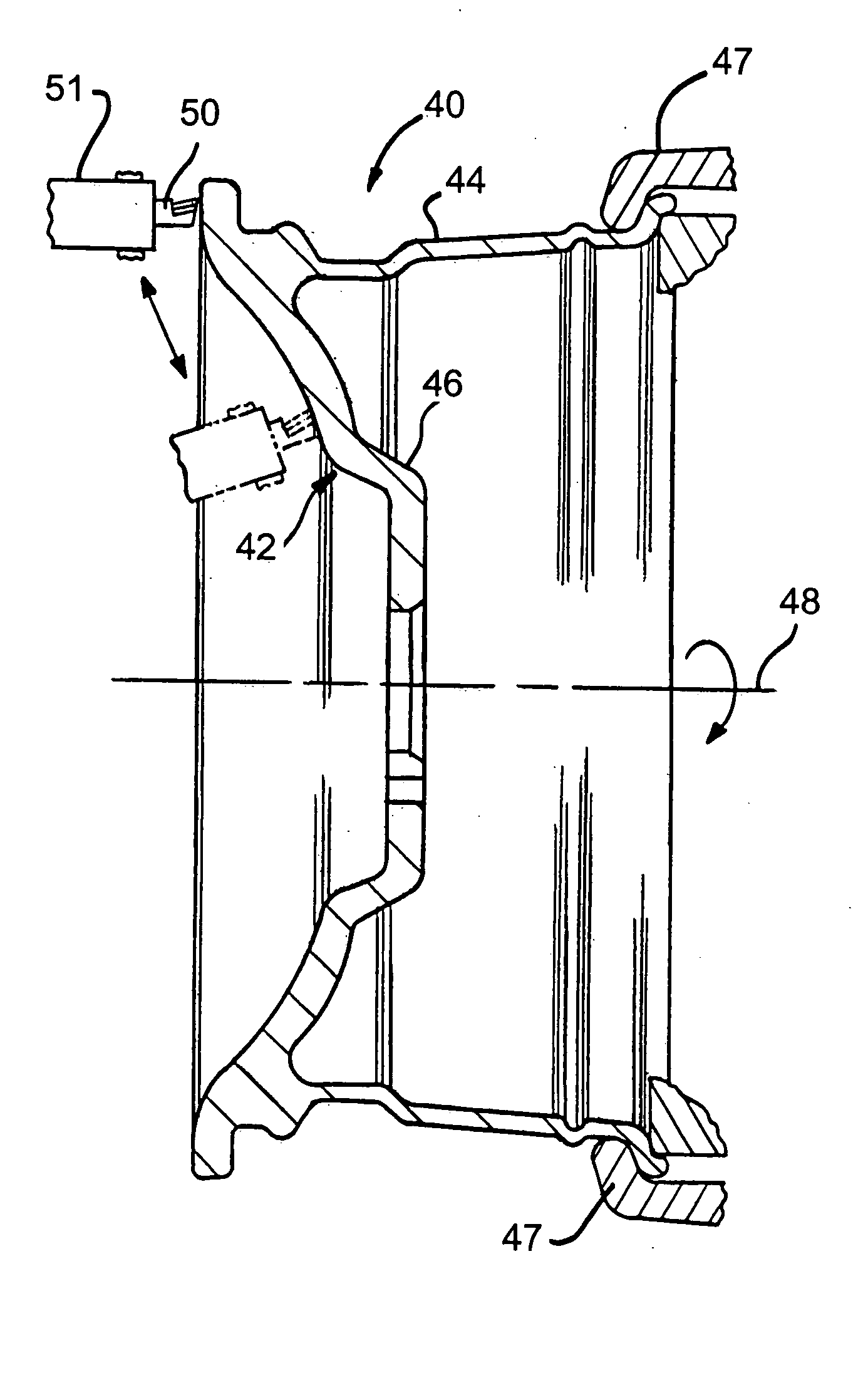

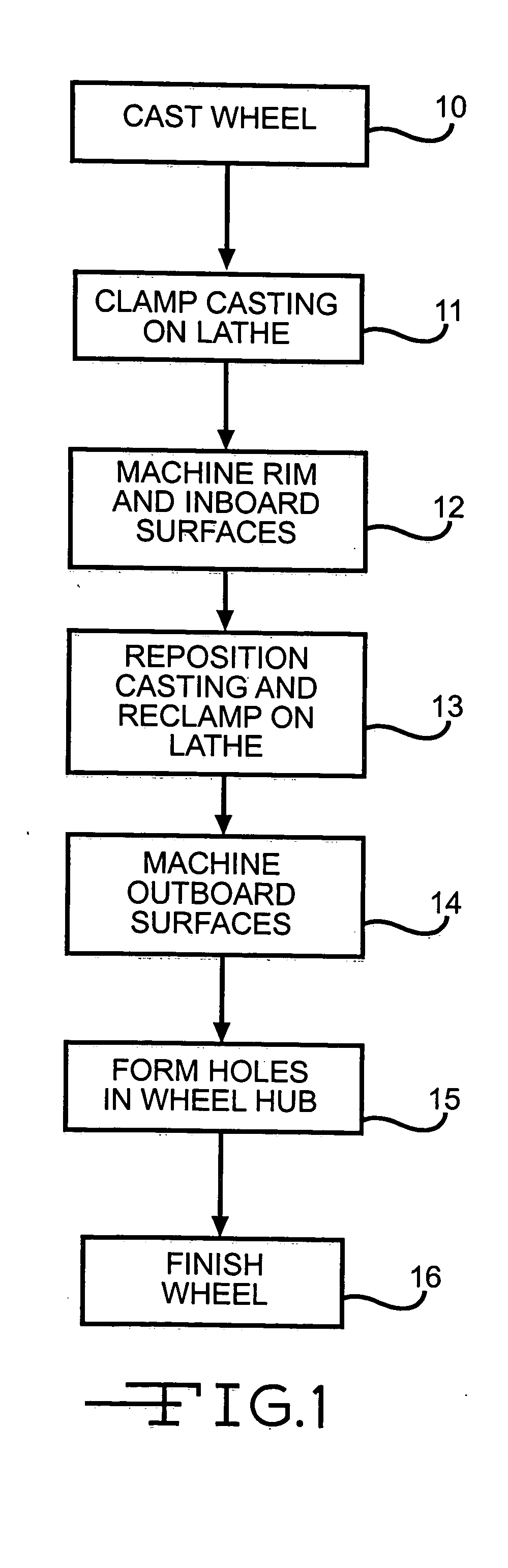

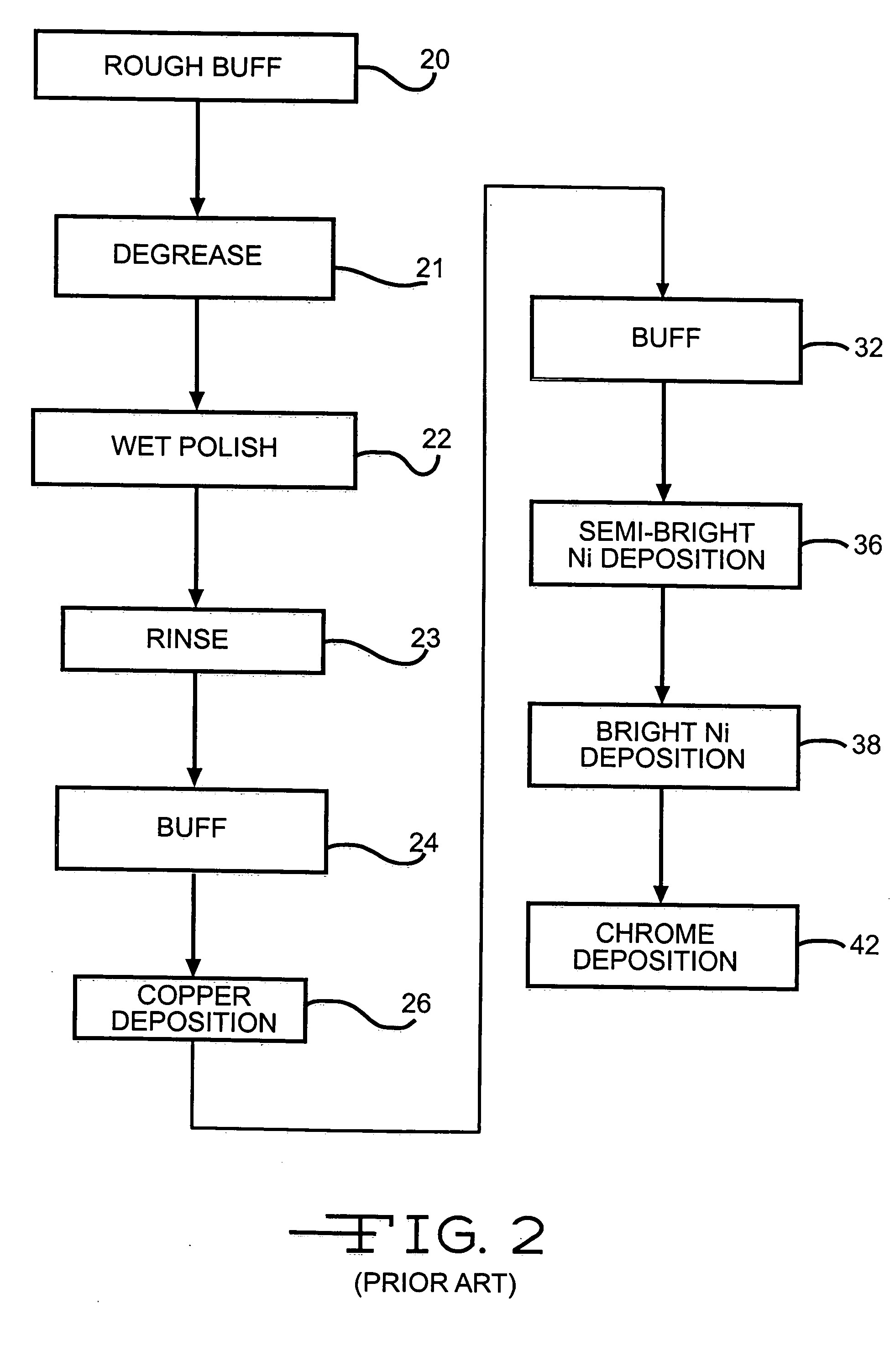

Process for copper free chrome plating of a vehicle wheel surface

A cutting tool having a hard tip is pressed with a uniform pressure against a surface of a vehicle wheel as the wheel is rotated to smooth and seal the surface. The smoothed and sealed wheel surface is then chrome plated with a process that includes applying a nickel layer directly upon smoothed and sealed wheel surface and a chromium layer over the nickel layer.

Owner:HAYES LEMMERZ INT

Method of chrome plating magnesium and magnesium alloys

ActiveUS8152985B2Liquid surface applicatorsLiquid/solution decomposition chemical coatingCopper coatingChrome plating

A process for chrome plating magnesium and its alloys. The process uses a combination of electroless nickel plating, a multi-stage copper coating transition system and multiple layers of electrodeposited nickel to form a corrosion resistant system of substantial impermeability and interlayer adherence suitable for direct chromium electroplating.

Owner:ARLINGTON PLATING

Large forged high-speed steel cold roll and manufacturing method thereof

ActiveCN103409688AImprove hardenabilityHigh hardnessRollsMetal rolling arrangementsHardnessHigh-speed steel

The invention discloses a large forged high-speed steel cold roll and a manufacturing method thereof. The cold roll comprises the following chemical constituents in percentage by mass: 0.90-1.20% of C, 0.20-1.20% of Si, 0.20-1.00% of Mn, 6.00-12.00% of Cr, 2.00-5.00% of Mo, 1.00-4.00% of V, 0.80-2.00% of W, not greater than 0.80% of Ni, not greater than 0.02% of P, not greater than 0.02% of S, and the balance of Fe and inevitable impurities. The manufacturing method for the cold roll comprises the process steps of steel ingot refining, billet forging, pre-heat treatment, machining, final heat treatment and the like. The surface layer hardness of a roll body of the cold roll manufactured by the manufacturing method disclosed by the invention is 88-98 HSD; the cold roll is excellent in wear resistance, high in roughness holding capacity and high in structure stability. According to the manufacturing process disclosed by the invention, chroming process steps are reduced and production cost is decreased.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Process for repairing a coated component

The invention relates to a process of repairing a MCrAlY-coating of an article, which has being exposed to the hot gases of, for example, a gas turbine. The MCrAlY-coating is examined and repaired only locally where it is needed and then, subsequently, on top of the MCrAlY-coating the article is aluminized and / or chromized, avoiding the stripping of the whole coating and re-coating over the entire surface of the article. This is for replenishing the coating of Al and / or Cr that become depleted during engine operation, in an easy, cost and time saving manner.

Owner:ANSALDO ENERGIA IP UK LTD

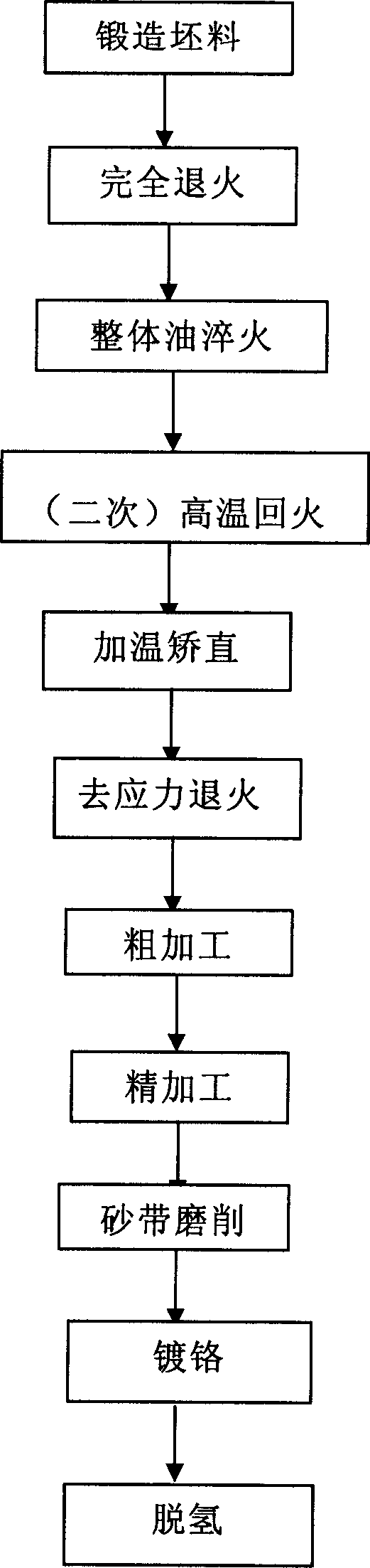

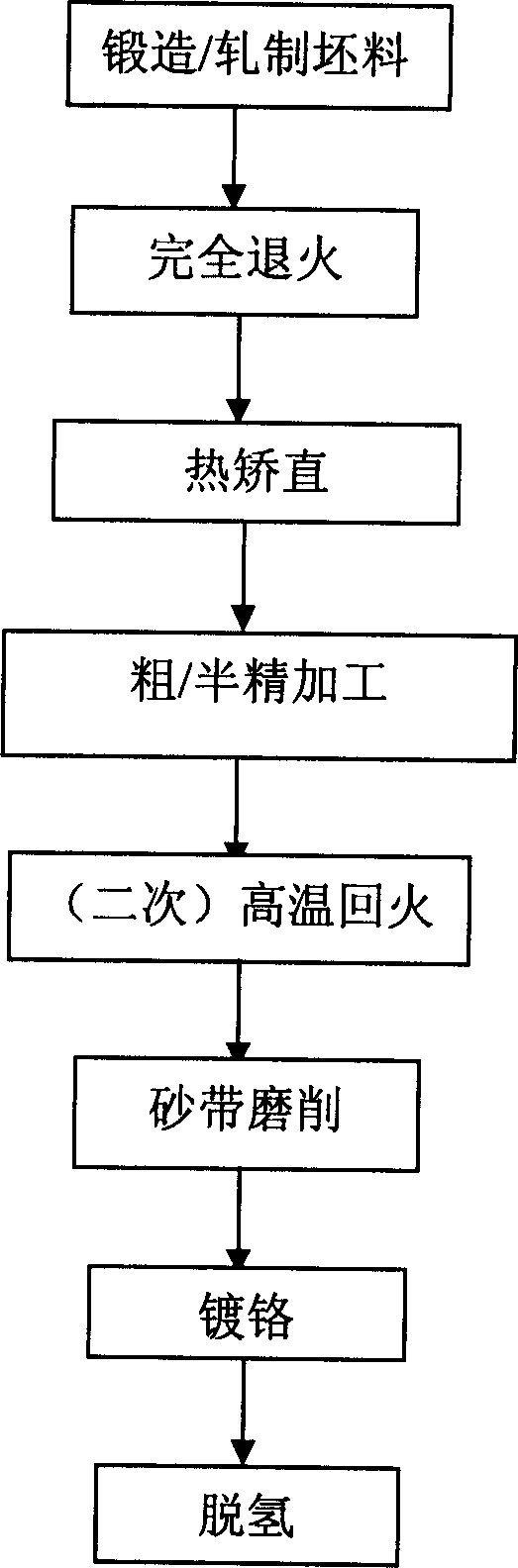

Novel process for manufacturing retained mandrel for continuous rolling of steel pipe

InactiveCN1840286AReduce hardnessLow costMandrelsOther manufacturing equipments/toolsChrome platingContinuous rolling

The invention discloses a steel pipe tandem rolling restraint mandril preparing method, which comprises the following steps: forging / rolling blank; annealing outright; hot straightening; rough / semi-finish; heat hardening; (twice) high tempering; grinding belt; chrome plating; dehydrogenating. The invention reduces the material cost, which improves the blank yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Electroplating process for automobile central controller

The invention relates to an electroplating process for an automobile central controller. The electroplating process comprises the steps of pretreatment, nickel preplating, copper replacement, acid copper plating, semi-finished nickel plating, pearl nickel plating, nickel sealing, chromium plating and drying. In addition, acid activation treatment is added before both the steps of semi-finished nickel plating and chromium plating, and acid pickling is added before the step of pearl nickel plating. Meanwhile, an F90R color scheme is selected and used as the color scheme of pearl nickel, and the pearl nickel is formed by mixing K5 with the concentration being 0.06 ml / L and K6Al with the concentration being 0.4 ml / L. The electroplating process for the automobile central controller has the advantages that mixed liquid of copper and sulfuric acid is adopted for copper replacement, so that cleanliness and flatness of the surface of a to-be-plated product are improved; in addition, an acid pickling procedure or an acidification procedure is added before all the plating steps, thus binding force between coatings can be improved, and separation between the coatings is reduced; meanwhile, specific to the A10 automobile central controller, the pearl nickel of the F90R color scheme is selected and used; and in the pearl nickel plating process, the concentration requirements of the F90R color scheme always needs to be kept, and thus the color of the product is uniform.

Owner:浙江泛源科技股份有限公司

Manufacturing method of surface-quenching chromium-plating winded-welding roller

InactiveCN101134277AAvoid crackingGuaranteed depth uniformityFurnace typesHeat treatment process controlManufacturing cost reductionSand blasting

The present invention discloses surface quenched chrome plated wound and welded roller making process, which includes the steps of hot winding, bottoming welding and processing bevel, coarse turning, surface quenching, semi-finish turning, assembling welding, finish machining and post-treatment. The process of the present invention is suitable for making roller of 500-1200 mm diameter, 25 mm wall thickness and 2050-2200 mm length, and roller surface is treated through quenching, sand blasting to roughen and chrome plating. The present invention has the advantages of saving in material, low making cost and short production period.

Owner:MCC SFRE HEAVY IND EQUIP

Manufacturing method of gravure roller capable of printing three-dimensional effect

InactiveCN102529308AGood three-dimensionalStrong touch bumpy textureForme preparationComputer graphics (images)Separation technology

The invention discloses a manufacturing method of a gravure roller capable of printing a three-dimensional effect, and the method comprises the following steps that: a computer image processing technology is applied to analyze the data of an image file which is scanned from an original pattern; the image data which can highlight the three-dimensional effect can be determined according to the content of an image; an image color separation technology is adopted to extract the image data which can highlight the three-dimensional effect, and the data is made into the image file; the image is carved on the gravure roller through an electronic carving machine; and finally mesh holes which are carved on the gravure roller and lined into the pattern are etched to required depths, and the gravure roller capable of printing the three-dimensional effect is manufactured by chrome plating. After the gravure roller which is manufactured through the method prints transparent ink onto the surface of a plane pattern which is printed from an original, the pattern can show a significant three-dimensional visual effect and intense concave and convex texture for touching.

Owner:广东省南方彩色制版有限公司

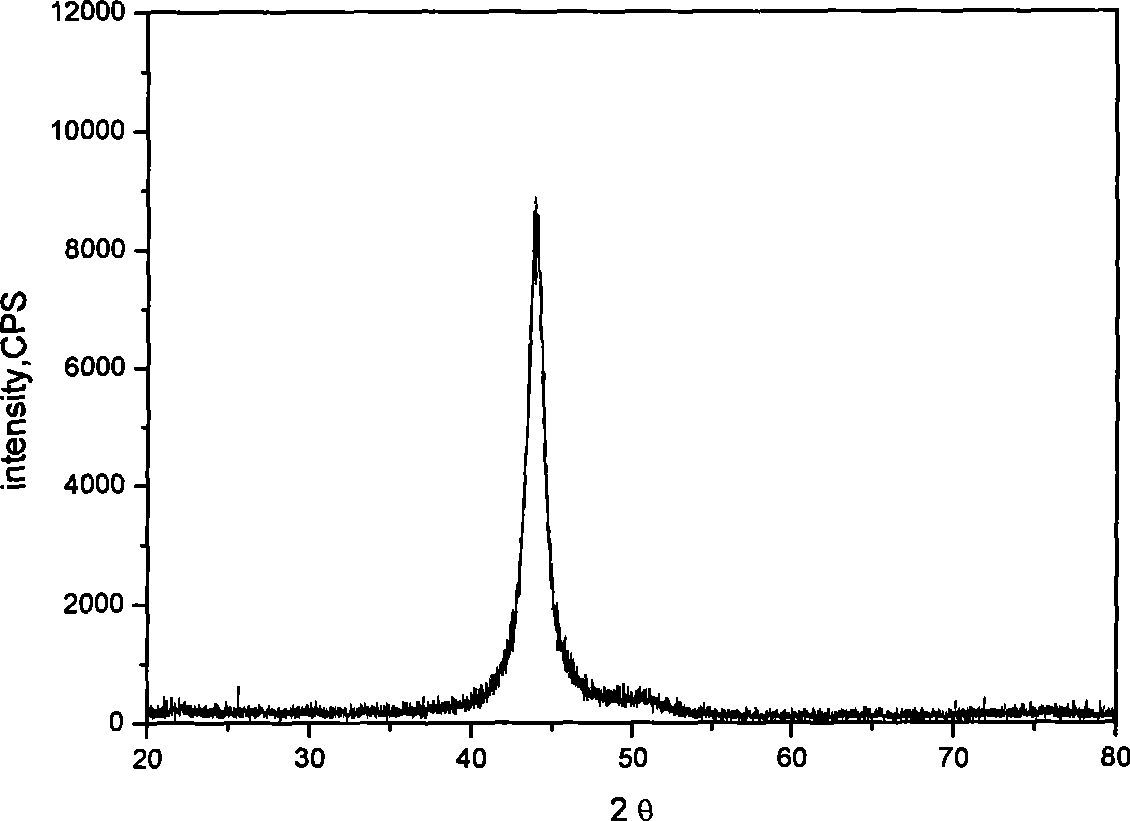

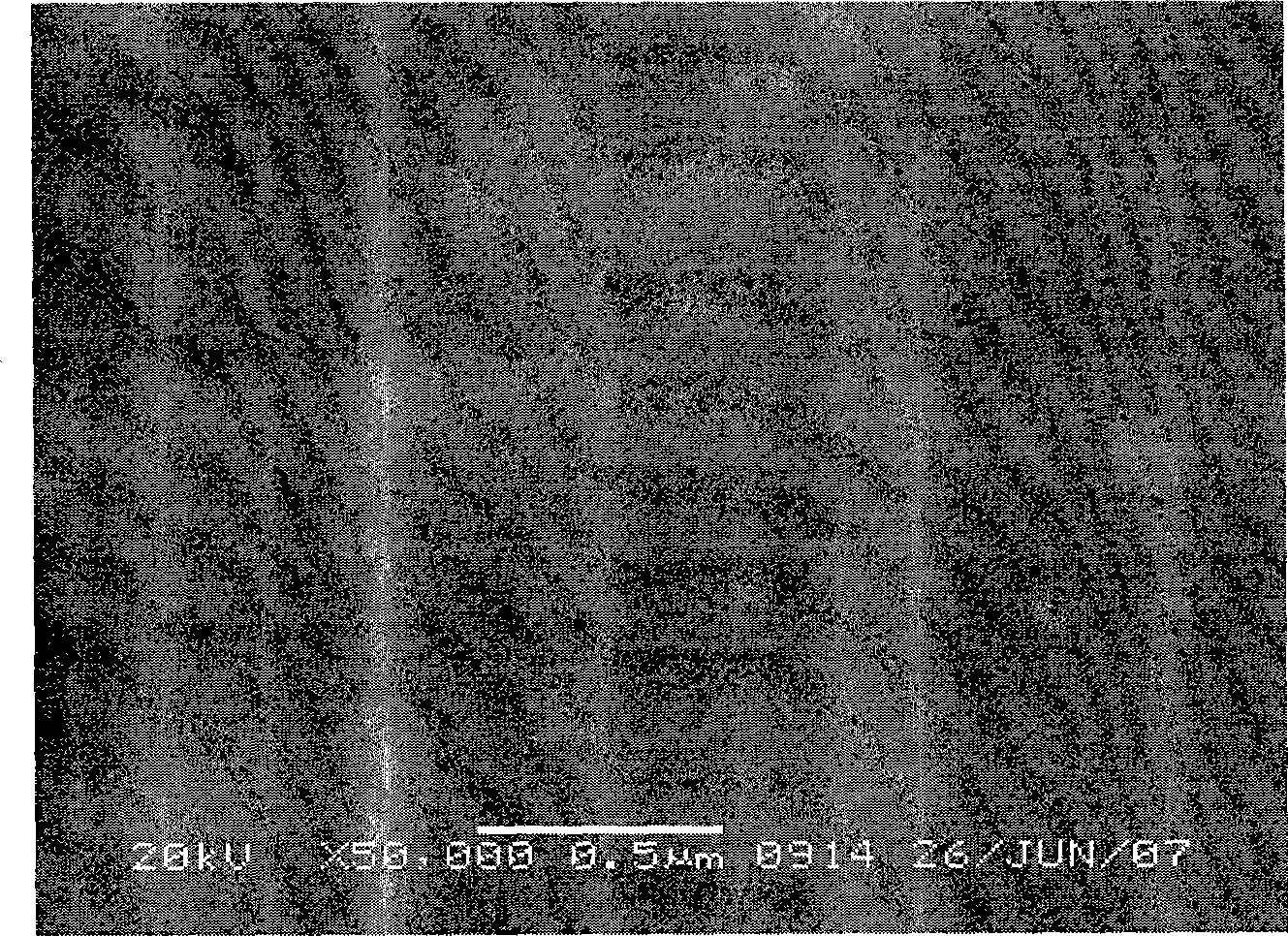

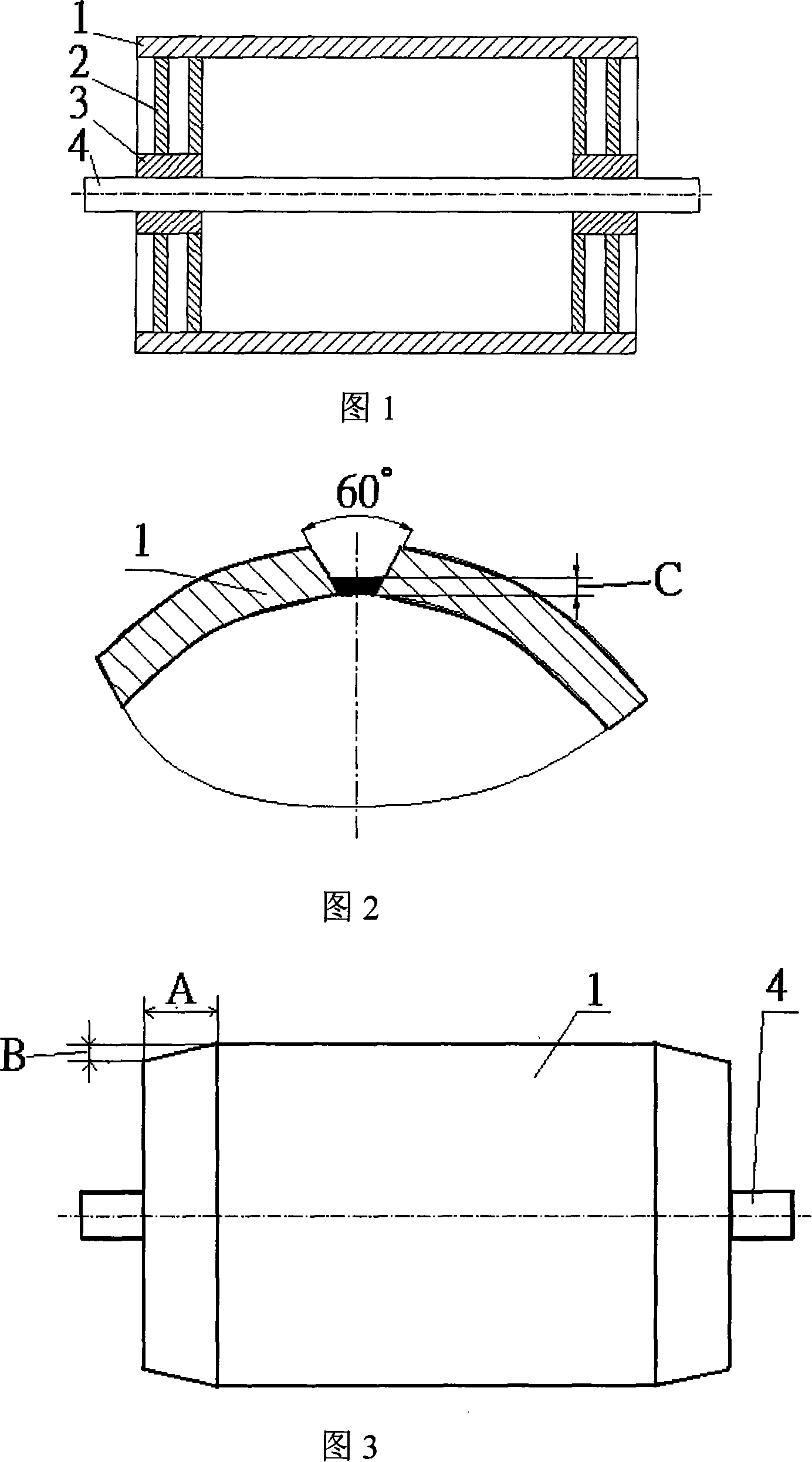

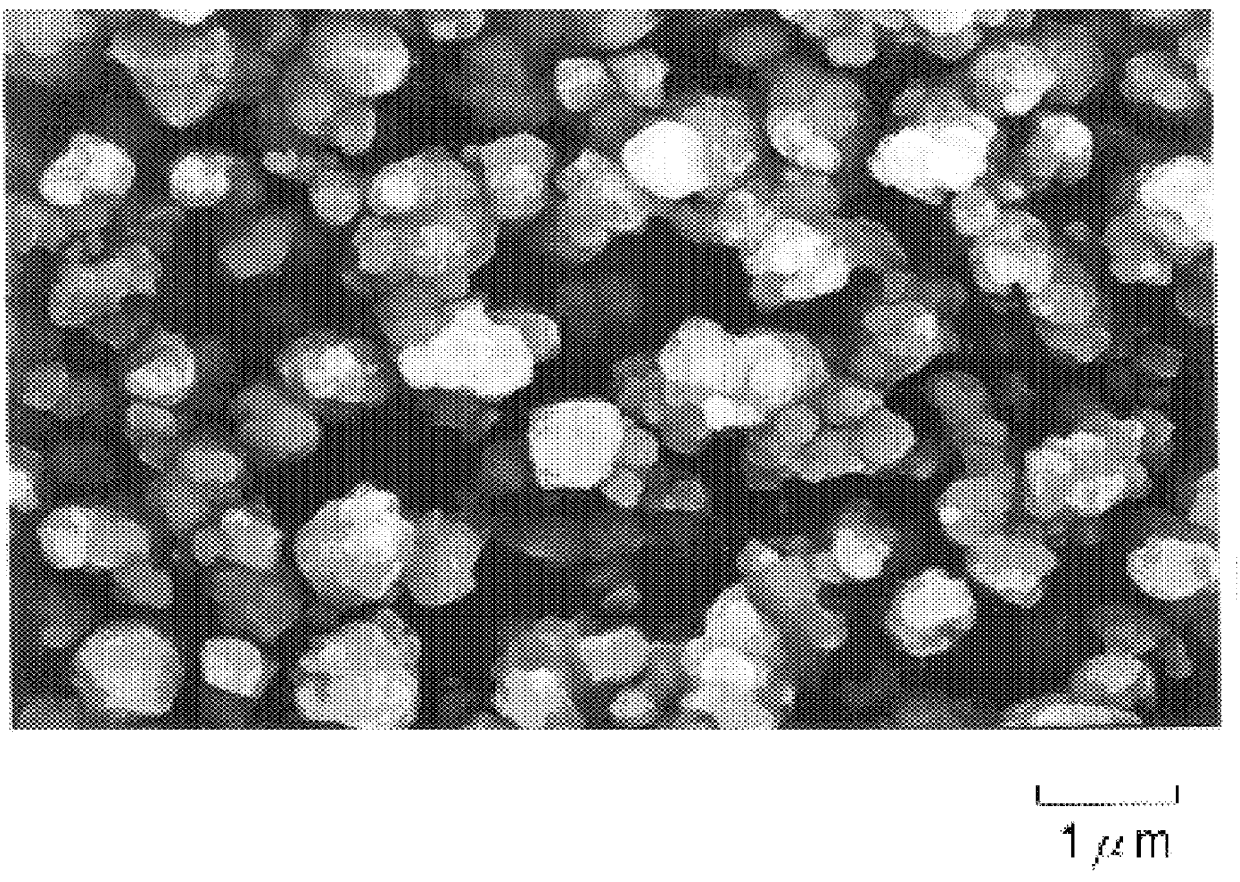

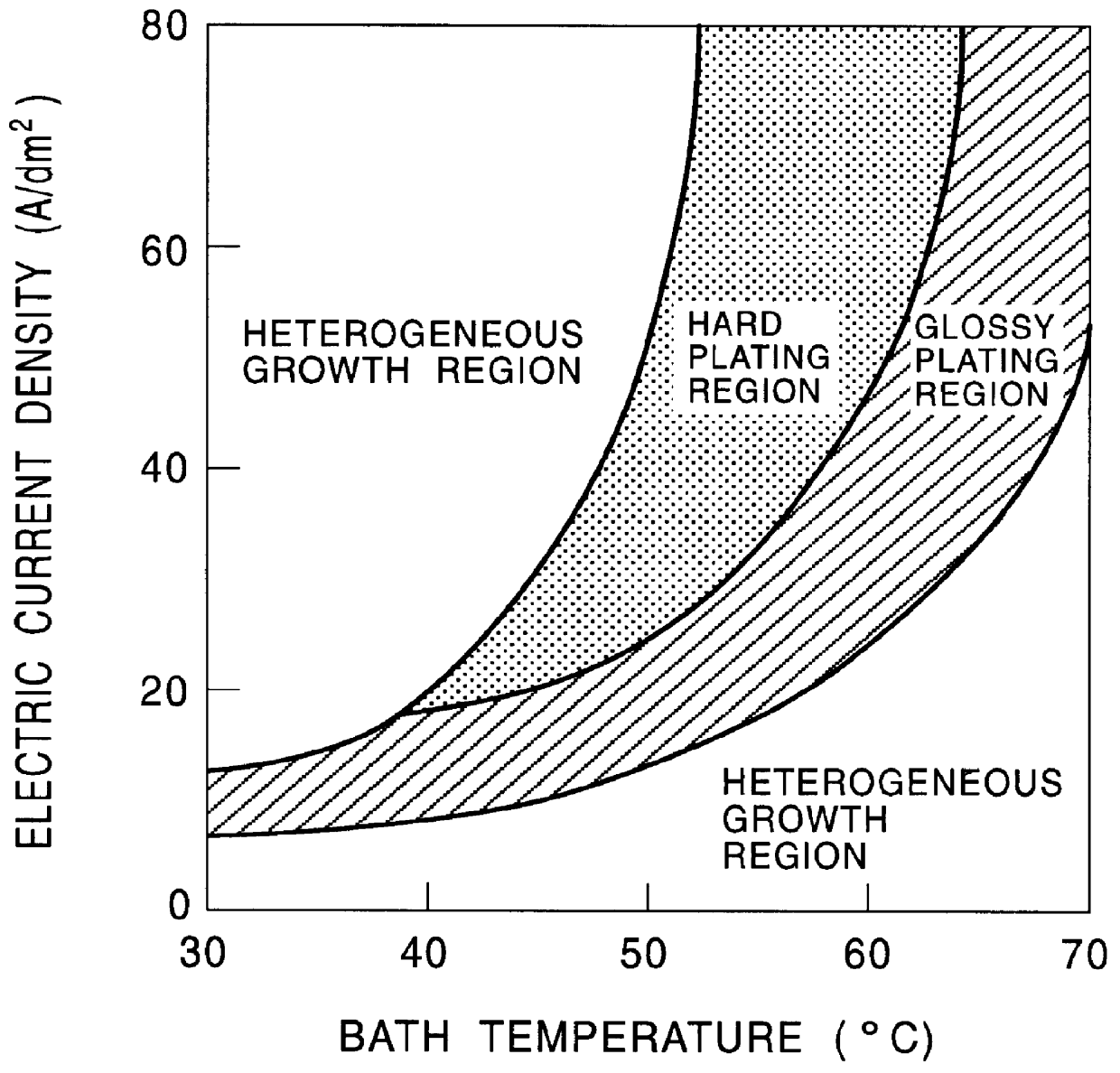

Grain oriented electrical steel sheet and method

InactiveUS6136456AVacuum evaporation coatingSurface reaction electrolytic coatingCrystalliteSheet steel

Grain oriented electrical steel sheet with a very low iron loss and a method for producing the same, wherein the surface of the iron substrate of the grain oriented electrical steel sheet is subjected to an enhancement treatment of crystal grain orientation or surface smoothing to a mean roughness of about 0.20 mu m or less, electroplating a chromium plating layer on the substrate with heterogeneous growth, and applying a tension coating film to the plating layer.

Owner:KAWASAKI STEEL CORP

New process for electroplating non-metal material surface and its special conductive paint

InactiveCN1944718ATo achieve the purpose of metallizationThe purpose of metallization is wideElectrically-conductive paintsCopper platingMetallic materials

The simplified process for electroplating non-metal material surface includes the steps of chemically deoiling the surface of non-metal material, spraying conducting paint for metallizing the non-metal material, and final electroplating copper, nickel or chromium. The conducting paint consists of filming resin 20-40 wt% , flaky conducting metal powder 28-40 wt%, coupler 0.5-2 wt%, orientating arranging agent 1-1.25 wt%, mixed diluent 20-40 wt% and assistant 0.5-2 wt%. The process is simple, low in production cost, high in work efficiency and environment friendship, and may be used in matallizing various non-metal material with complicated shape.

Owner:昆明亘宏源科技有限公司

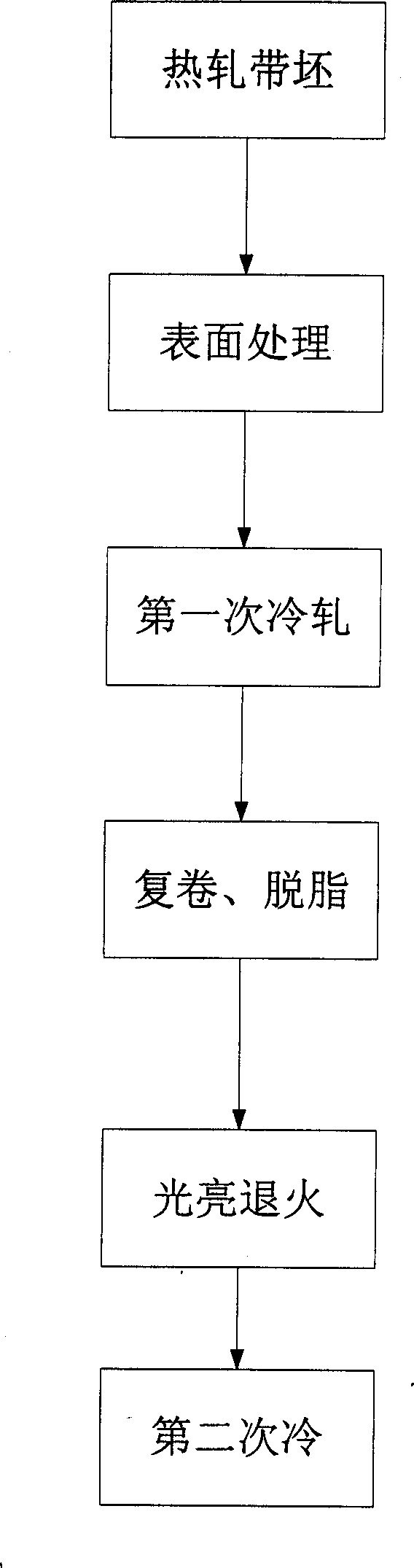

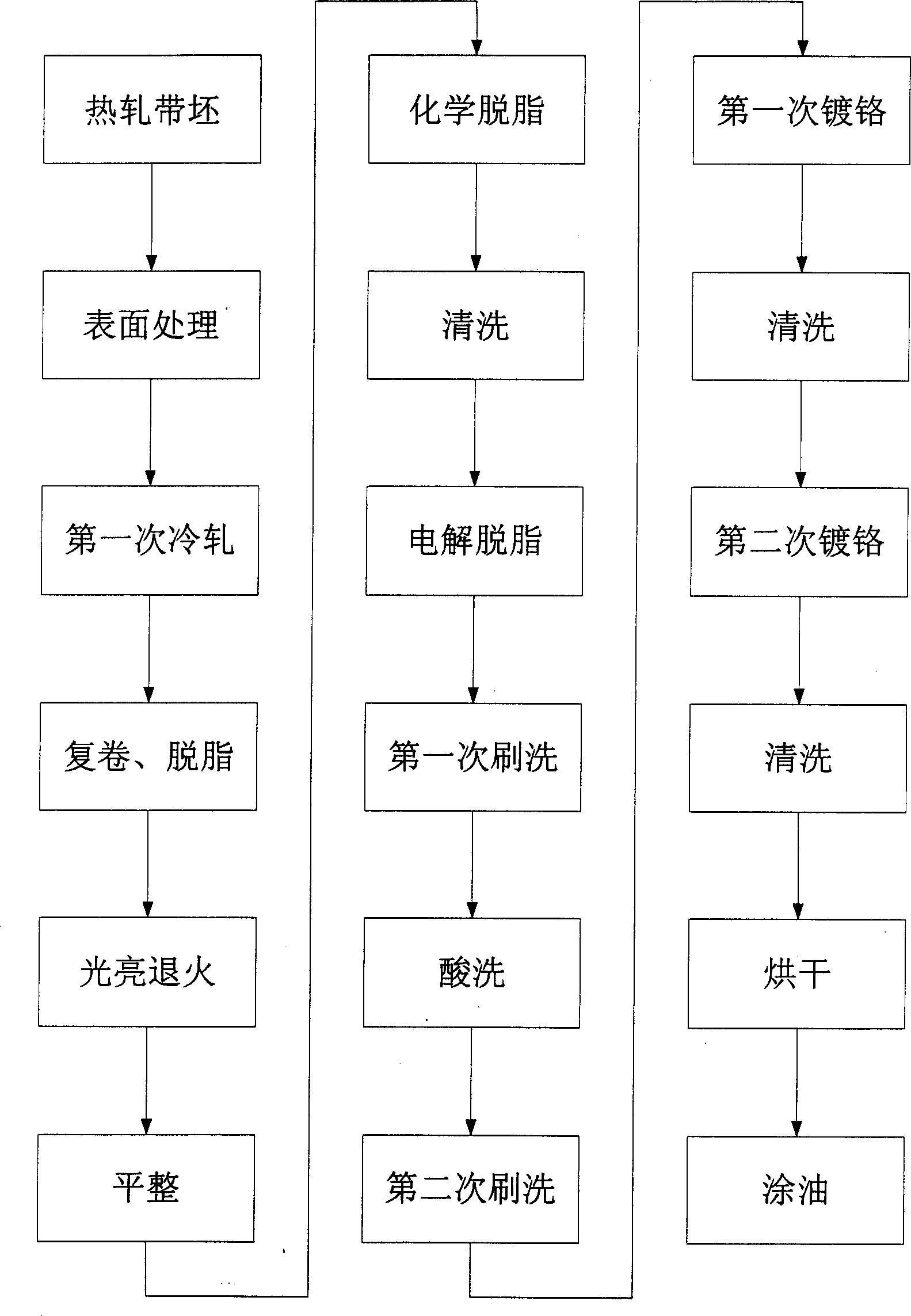

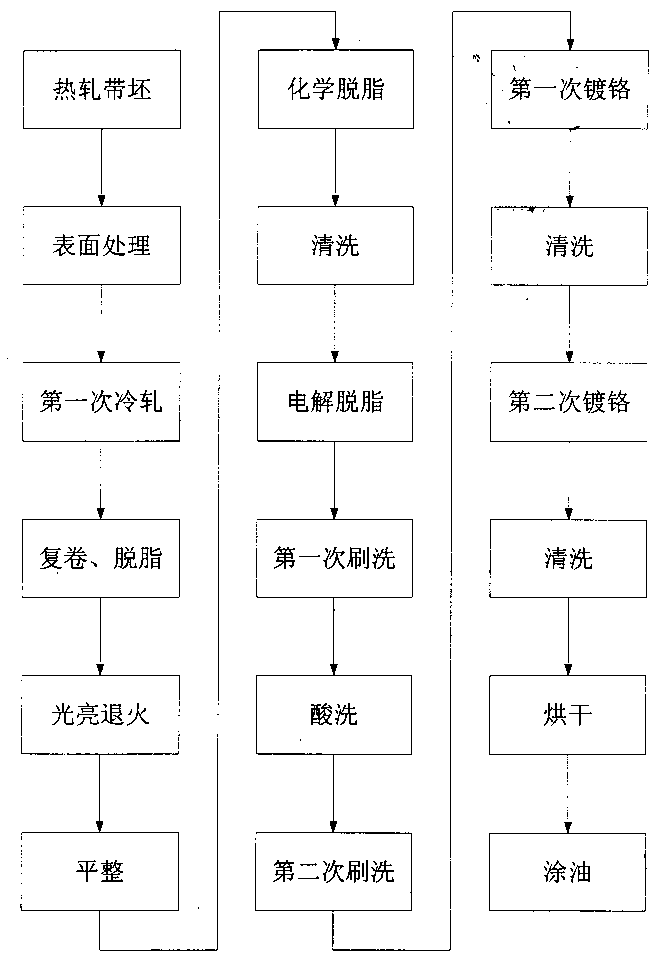

High-precision ultra-thin very-wide cold-rolled steel band, chrome-plated steel band for shield of optical fibre cable and technology thereof

A technology for making high-precision super-thin very-wide cold-rolled steel band and the chrome-plated steel band dedicated as shield of optical cable includes treating the surface of hot-rolled raw band, cold rolling with large-diameter 4-roller reversible cold rolling mill to make its thickness to be 0.1-0.25 mm, recoiling, degreasing, bright annealing, cold rolling again to make its thickness to be 0.06-0.08 mm to obtain said high-precesion steel band, chemical degreasing, washing, electrolytic degreasing, pickling, plating chrome, washing, plating chrome again, washing, baking and coating oil to obtain the said shield of optical cable.

Owner:YONGXIN PRECISION MATERIAL WUXI

Manufacturing process of corrosion-resistant piston rod of shock absorber for vehicle

The invention discloses a manufacturing process of a corrosion-resistant piston rod of a shock absorber for a vehicle, comprising the following steps of: (1) blanking; (2) straightening for the first time; (3) grinding for the first time; (4) quenching; (5) tempering; (6) straightening for the second time; (7) grinding for the second time; (8) finely turning; (9) punching a mounting hole; (10) finely grinding; (11) polishing a resin grinding wheel; (12) supergrinding; (13) checking poriness; (14) automatically plating an upper suspension of a chrome wire workpiece; (15) electrolytic degreasing before the plating: carrying out the electrolytic degreasing on the workpiece as an anode in a lye tank; (16) etching the anode; (17) microcrack hard chrome plating: enabling a plating solution to flow from bottom to top in a plating tank till the plating solution overflows out of the plating tank; (18) cleaning; (19) automatically plating a lower suspension of the chrome wire workpiece; (20) removing hydrogen; and (21) supergrinding after the plating. The invention can effectively enhance the corrosion resistance of the piston rod, ensure the finished product ratio and prevent from generating hydrogen embrittlement, thereby enhancing the safety of the piston rod.

Owner:隆昌山川机械有限责任公司

Manufacturing process for printing roller multi-depth forme

InactiveCN102423955AEmbossed effect arrivesFull of three-dimensional sensePrinting pre-treatmentForme preparationManufacturing technologyLaser engraving

The invention relates to a printing roller manufacturing technology, and concretely relates to a manufacturing process for a printing roller multi-depth foaming forme. The process comprises steps of mechanical processing, nickel plating, grinding, manuscript manufacturing, glue spraying, laser engraving, and corroding. The process is characterized in that: secondary glue spraying processing, secondary laser engraving processing, secondary corrosion processing and chrome plating processing are carried out after the corrosion step. Compared with the prior art, different patterns can have different depths on the printing roller as needed in the invention, so embossing effects on pure raw paper and nonwoven paper which can reach embossing effects on rubber surface wallpaper have rich stereoscopic and layered sense.

Owner:上海希尔彩印制版有限公司

Method for engraving gravure grinding roller by laser

InactiveCN102935755AControl thicknessUniform ink contentPrinting pre-treatmentForme preparationScreentoneLaser engraving

The invention relates to a method for engraving a gravure grinding roller by laser, which is applied to realizing gravure grinding printing. The method comprises the following specific manufacturing steps of (1) rubber coating, (2) rubber sintering, (3) corroding, (4) rubber removing, (5) chromium plating, and (6) checking. The method for engraving a gravure grinding roller by laser, disclosed by the invention, has the advantages that the depth requirement is strict, and 0.05mesh of net points can be controlled so that the printing ink content of each net point is uniform in a printing process; after the printing ink is subjected to gravure transfer printing, the thickness of a whole layout can be uniform, the leveling is good, the concave-convex feeling can be generated; compared with a silk screen manner, the gravure printing manner has the advantages of good third dimension, large printing format, high speed and high efficiency; and the thickness of the printing oil can be precisely controlled, the waste is reduced and the environment protection is realized.

Owner:武汉东运制版有限公司

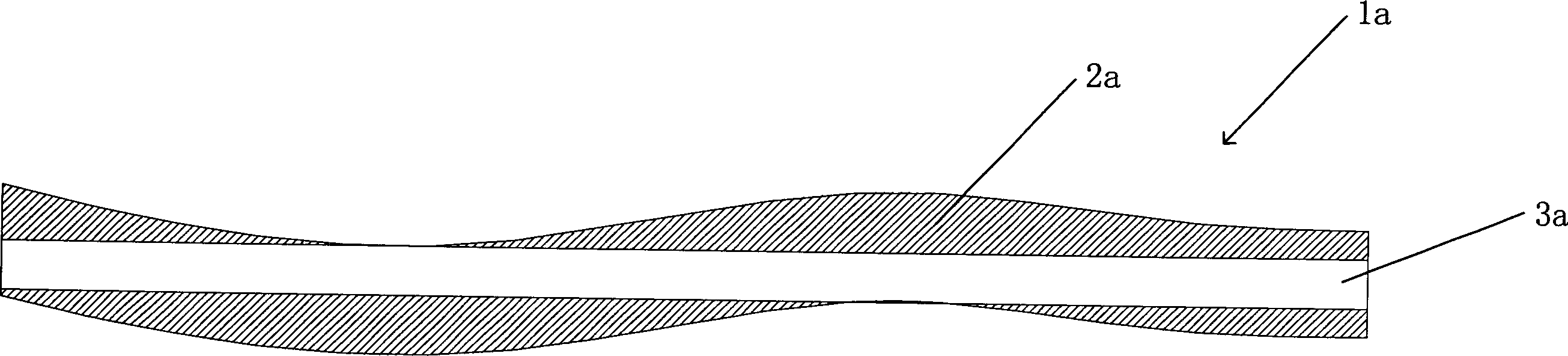

Chrome-plated part and manufacturing method of the same

The present invention is to provide a chrome-plated part having a corrosion resistance in normal and specific circumstances and not requiring additional treatments after chrome plating, and to provide a manufacturing method of such a chrome plated part. The chrome-plated part 1 includes: a substrate 2; a bright nickel plating layer 5b formed over the substrate 2; a noble potential nickel plating layer 5a formed on the bright nickel plating layer 5b. An electric potential difference between the bright nickel plating layer 5b and the noble potential nickel plating layer 5a is within a range from 40 mV to 150 mV. The chrome-plated part 1 further includes: a trivalent chrome plating layer 6 formed on the noble potential nickel plating layer 5a and having at least any one of a microporous structure and a microcrack structure.

Owner:NISSAN MOTOR CO LTD +1

Nickel substitute chrome-plating process

InactiveCN1766165AHigh hardnessImprove the finishLiquid/solution decomposition chemical coatingHardnessCopper

The substituting nickel coating chrome technique comprises: removing dirt to coat piece surface; roughing, sensitizing, activating and reducing to the coat piece; chemical coating nickel and copper; substituting nickel by trivalent chromium. This invention integrates techniques, overcomes opposite difficulty, and makes the coat layer has well hardness and clean.

Owner:惠州志发五金制品塑料电镀有限公司

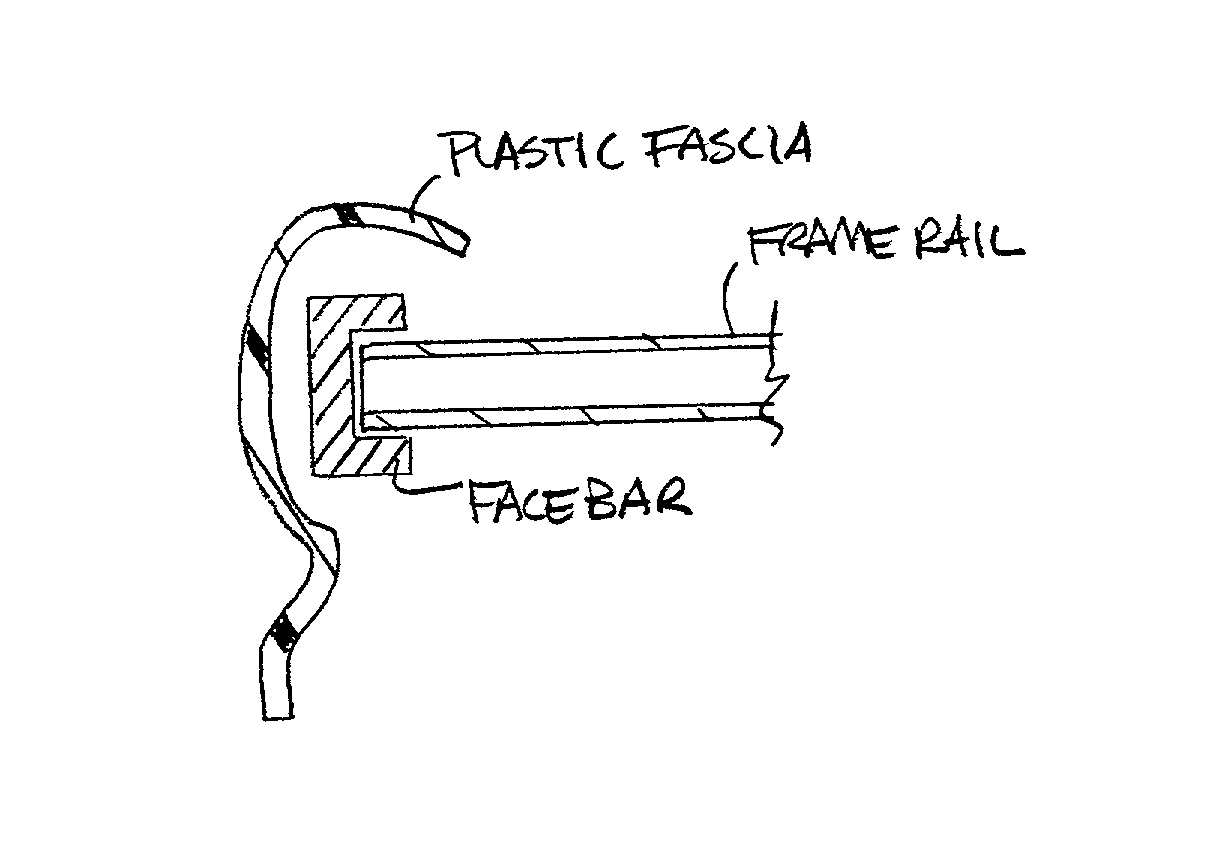

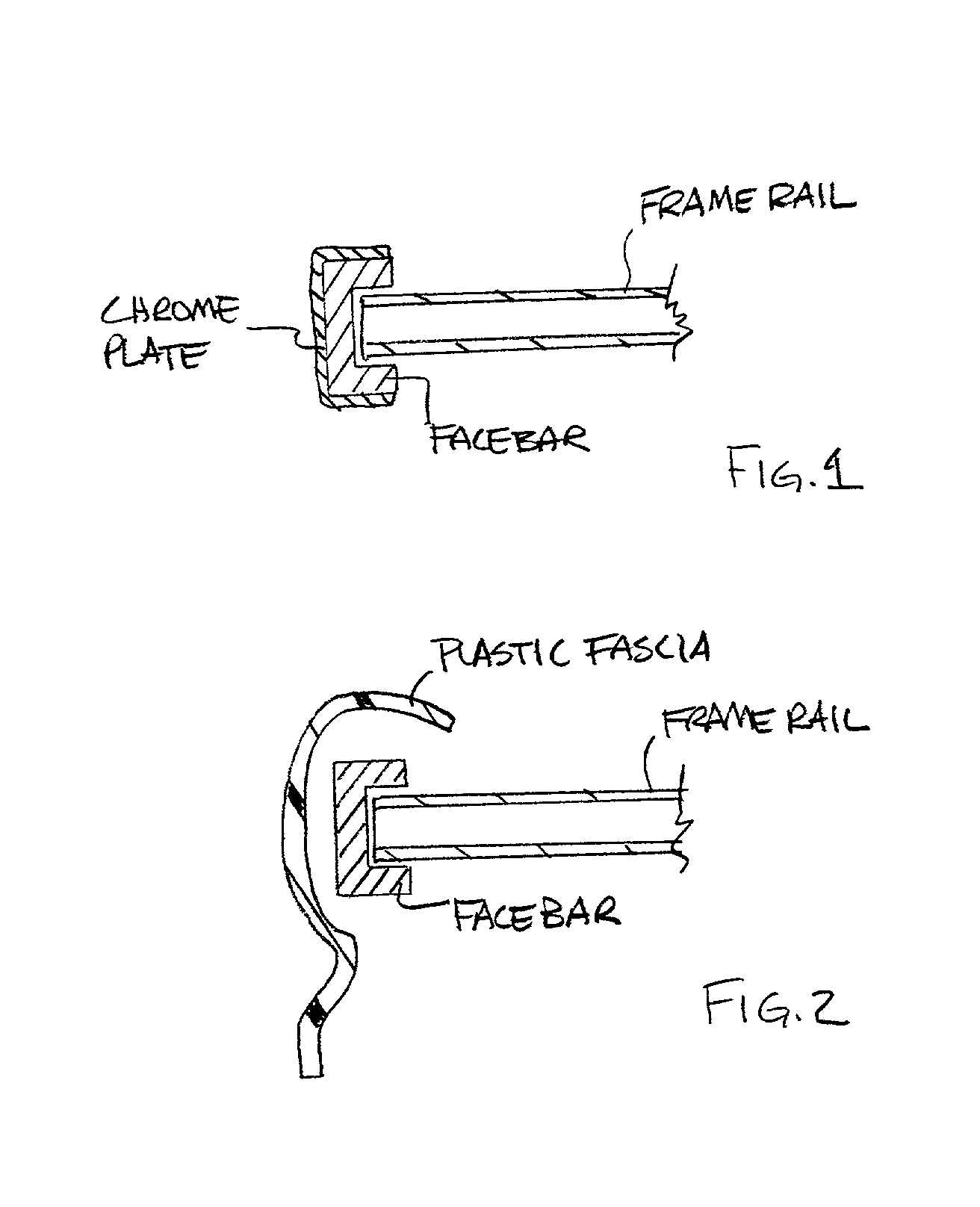

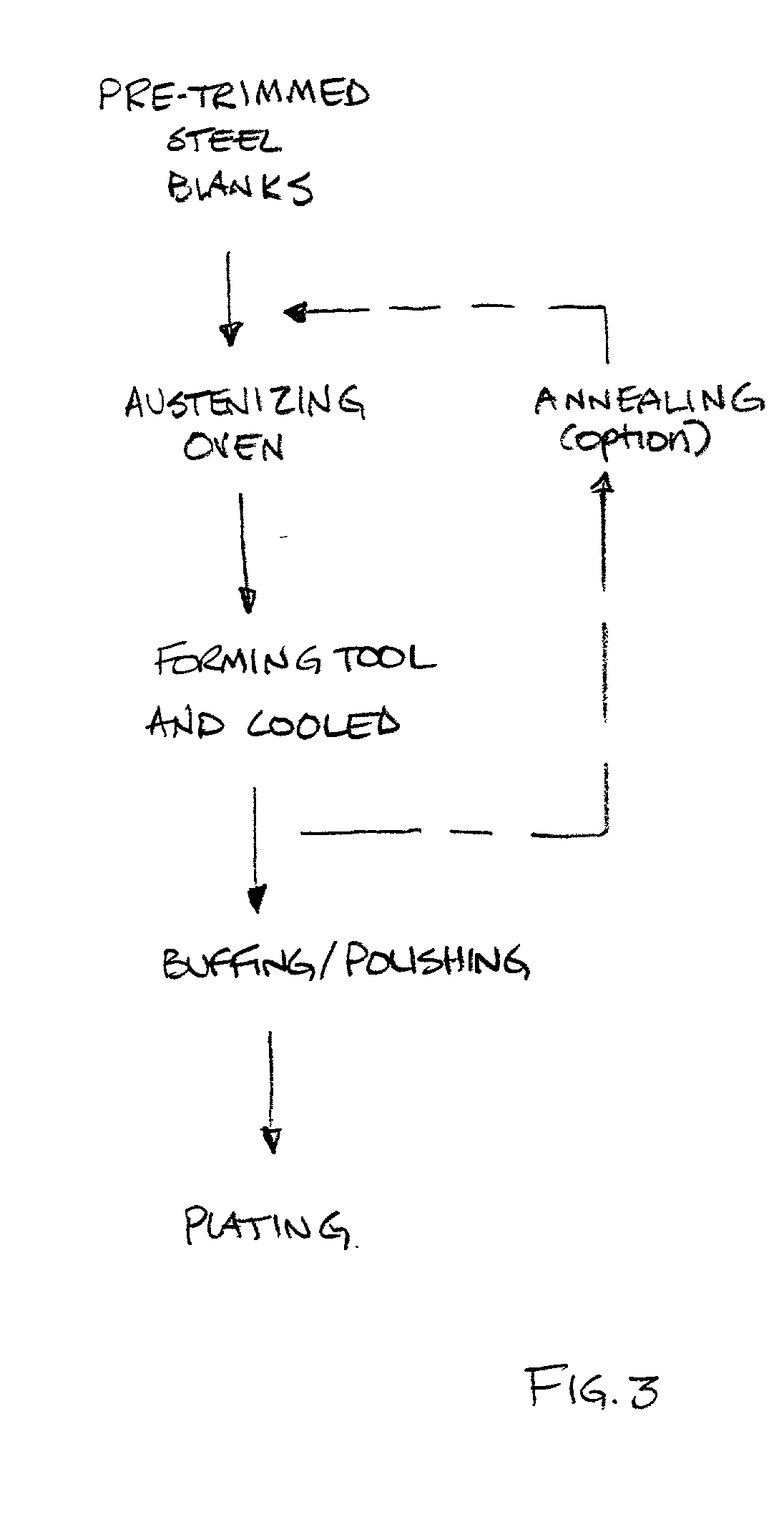

Ultra high strength bumper system facebar

An improved bumper facebar, as well as a method of manufacturing the improved bumper facebar, are disclosed. The bumper facebar includes a steel body having at least one area with improved strength exhibiting selective austinitic-martensitic hardening and a Rockwell hardness greater than 41. Moreover, the steel body includes a metallic coating or plating such as chrome plating to provide a decorative finish. The austinitic-martensitic hardening is not exhibited in the steel at those points providing coupling to other objects. The method of manufacturing the improved bumper facebar includes the steps of stamping a bumper blank from a sheet of steel, forming the desired bumper shape from the bumper blank, and hardening select portions of the bumper shape by heating and cooling the select portions to produce a rockwell hardness greater than 41. The method is well adapted to receive additional steps to improve the facebar hardness and impact characteristics.

Owner:BENTELER AUTOMOTIVE CORP

Coating technique for decoration chromium

InactiveCN101054672AUniform thicknessEvenly distributedLiquid/solution decomposition chemical coatingSuperimposed coating processSolid particleBiological activation

The present invention discloses a decorative chromium plating process capable of improving corrosion resisting property of decorative chromium composite plating. Said method comprises mainly the following steps: oil removing, activation, nickel electric plating, chemically composite plating, chromium electric plating, plating the electric plating nickel layer with a chemical composite deposite containing non-conductive solid particles, and then electric-plating the chemical composite deposite containing non-conductive solid particles with chromium to form micropore chromium. The present invention possesses the beneficial effects as follows: regardless whether or not the part external shape is complicated, chrome plating micropores are equispaced and exhibits a special performance of uniform corrosion current dissipation, the thickness of the electric plating nickel layer is reduced, and then corrosion resistant level of decorative chromium compages plating is improved remarkably.

Owner:QUANZHOU NORMAL UNIV

Piston ring and surface spongy tin plating technique thereof

The invention relates to a piston ring and a surface spongy tin plating technique thereof. The technical scheme thereof is as follows: the surface of a piston ring body is provided with a chromium plating layer, the outer surface of the chromium plating layer is provided with a spongy reticulate pattern, and the outer surface of the spongy reticulate pattern is provided with a tin plating layer. The invention comprises the following procedures: preplating, etching, chromium plating, washing, removal of hydrogen, hole loosing, washing and drying and tin plating treatment. The invention utilizes a reticulate pattern groove on the surface of the piston ring to store lubricating oil, thus greatly reducing the friction coefficient between the piston ring and a cylinder sleeve, improving oil absorbing property, and prolonging the service life of the piston ring and the cylinder sleeve; and compared with the prior art, the invention prolongs the service life of the piston ring and the cylinder sleeve by more than three thousand hours, improves the power of an internal combustion engine by more than 30 percent, saves oil by 25 percent, is capable of reducing the exhaust amount of gas / smoke of the internal combustion engine, reduces the environment requirements of atmosphere pollution, solves the mechanical wear of the piston ring during running-in period and obtains more perfect use performances.

Owner:XIANGFAN XINLI HENGXING PISTON RINGS

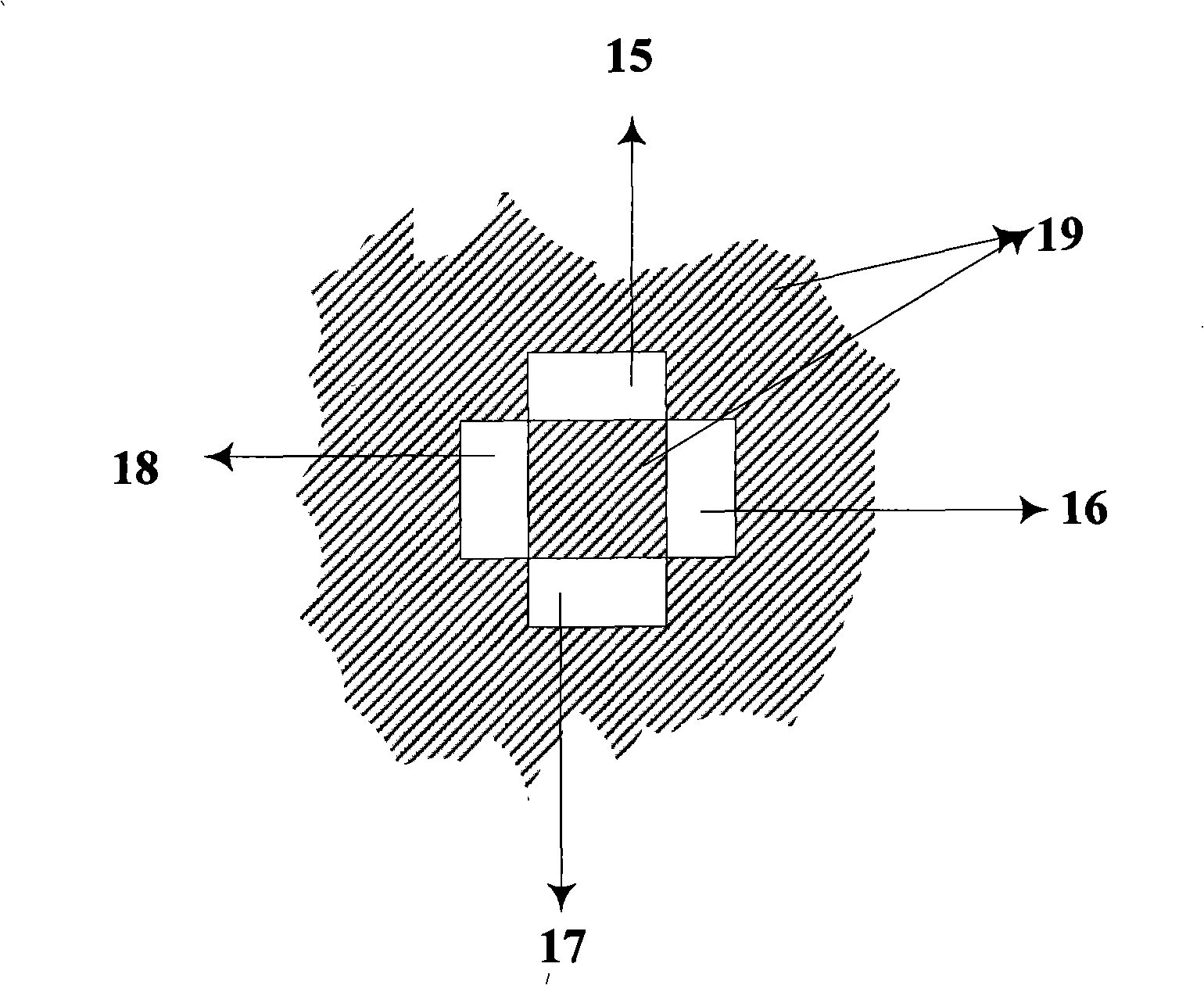

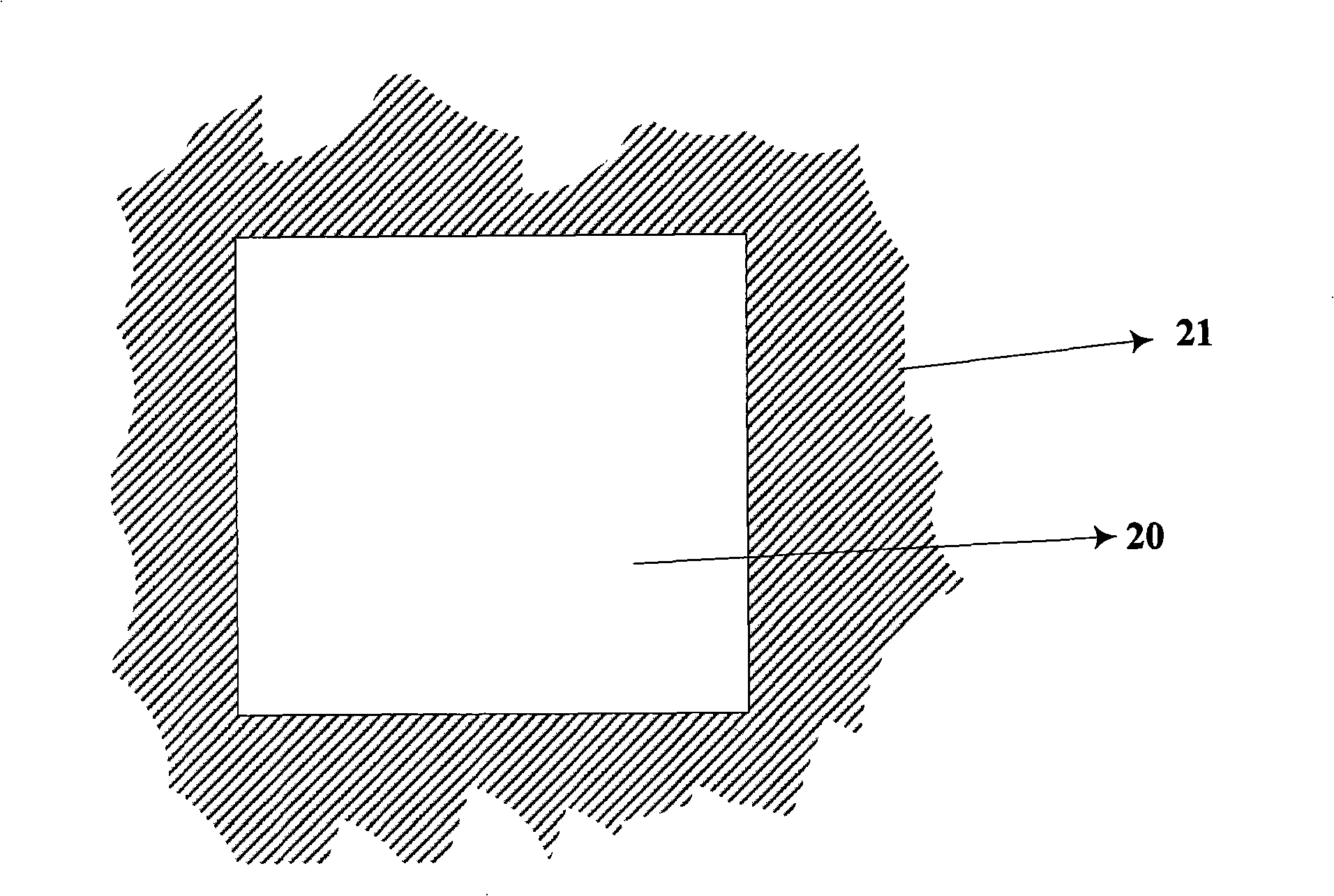

Normalization alignment mark combination and its alignment method and alignment system

ActiveCN101271281AOvercoming multi-step alignment scan signalsOvercome convexPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringProjection system

The invention discloses an uniformization aligning mark combination and an aligning method and an aligning system thereof. The uniformization aligning mark combination consists of a porous uniformization aligning mark arranged at the target composing component of a photoetching device aligning system and a single-pore uniformization aligning mark arranged at a probe composing component. The porous uniformization aligning mark consists of four transparent elements and a chromeplated shielding layer. The single-pore uniformization aligning mark consists of a transparent element and a chromeplated shielding layer. The method uses the single-pore uniformization aligning mark at the probe composing component and a probe device under the single-pore uniformization aligning mark to process twice two-dimensional aligning scanning to an image formed by the porous uniformization aligning mark at the target composing component, and radiation measure information and position measure information obtained by the two times of canning are integrated for an aligning signal processing, which obtains the position relation of a space image formed by the target composing component at a target composing component bearing table through a projection system relative to a probe composing component bearing table.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com