Patents

Literature

73results about How to "Improve oiliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

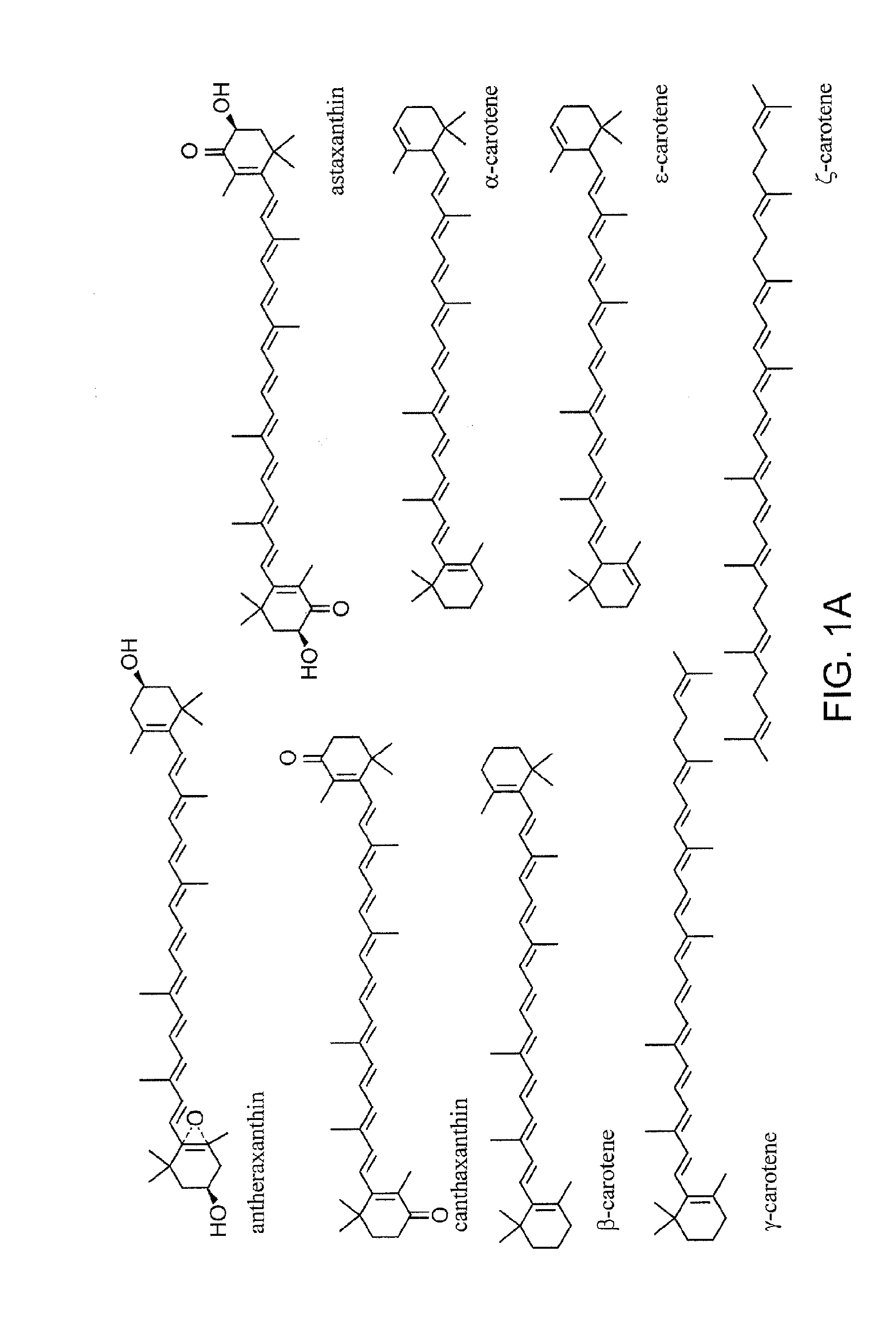

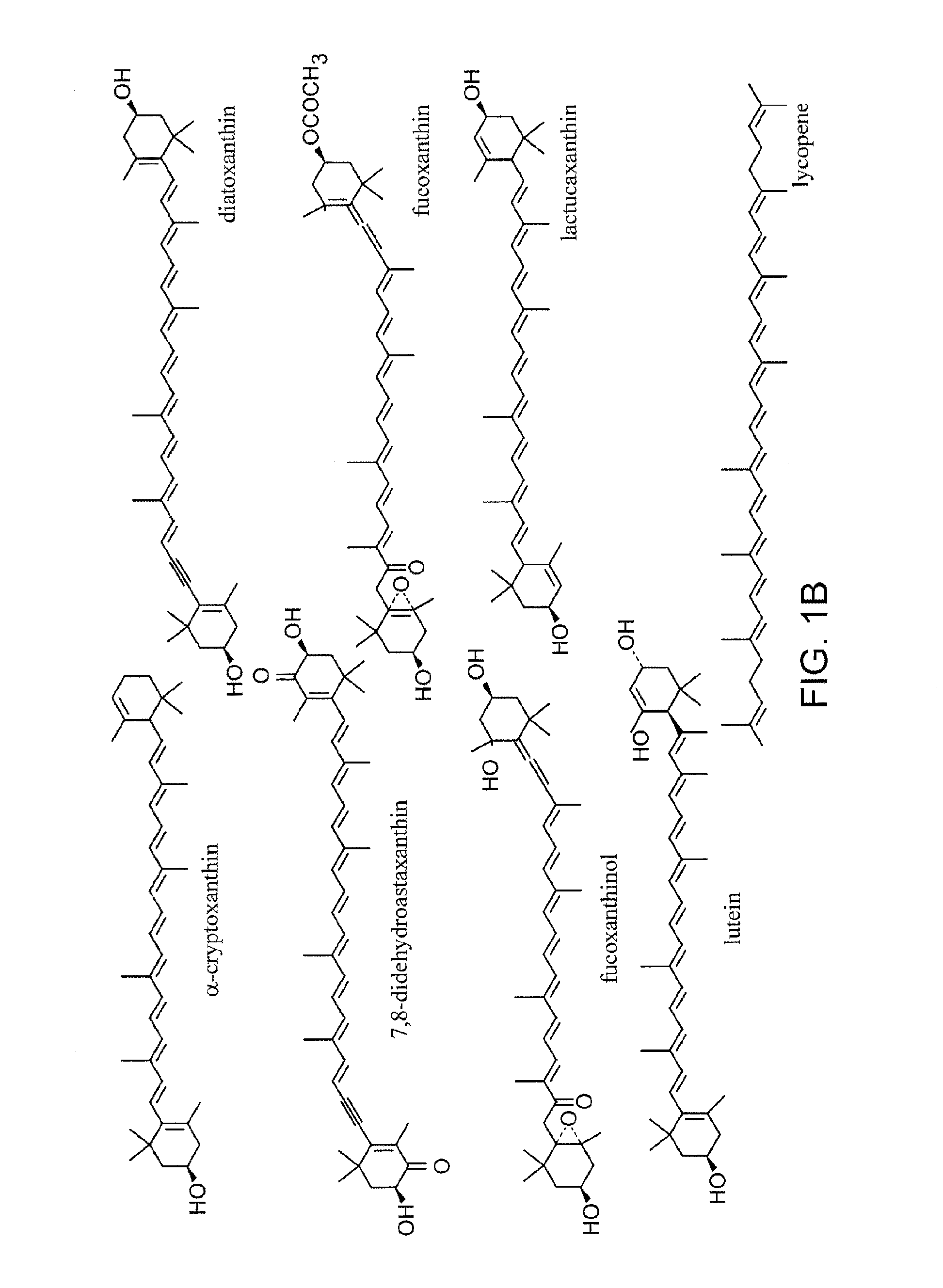

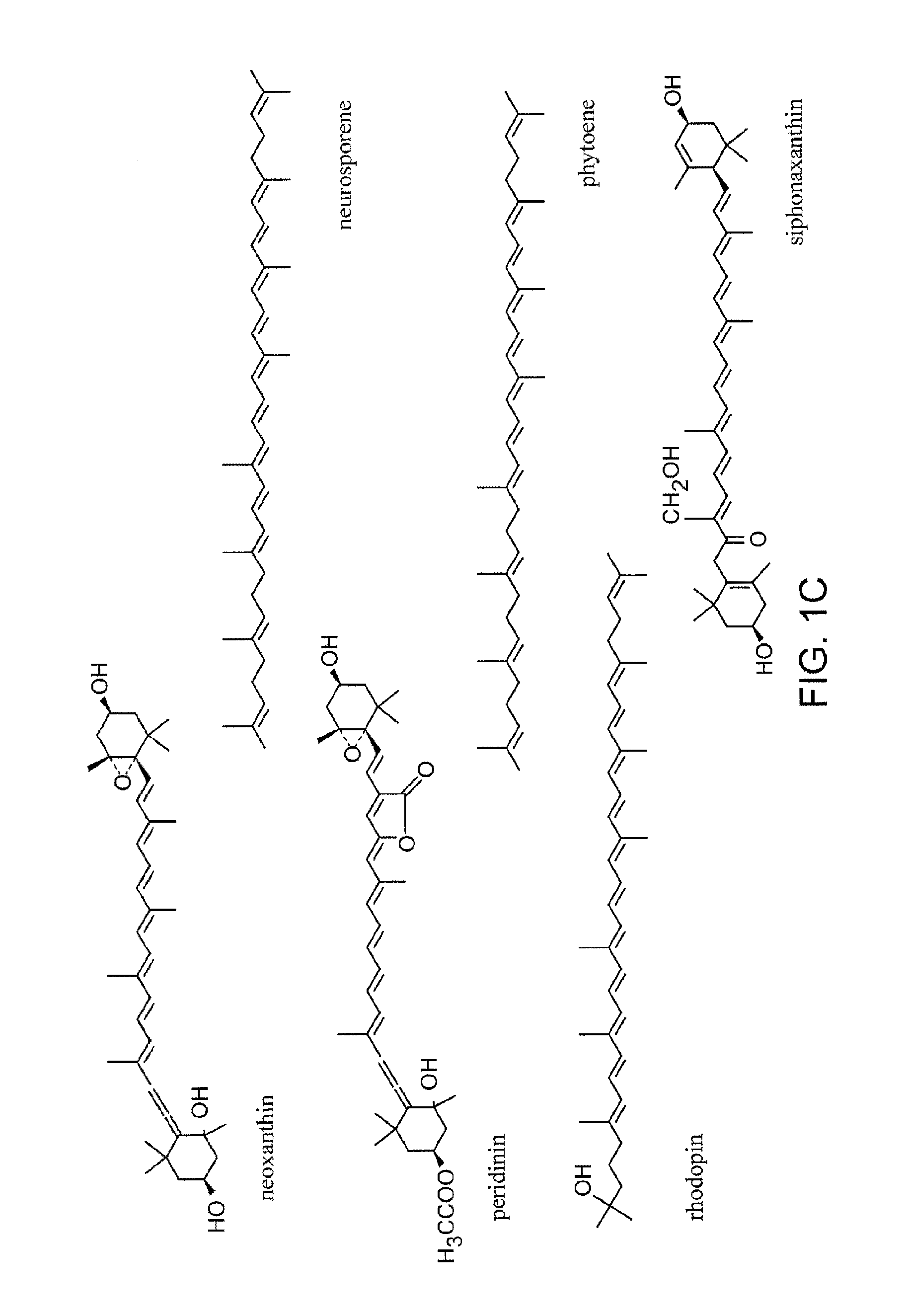

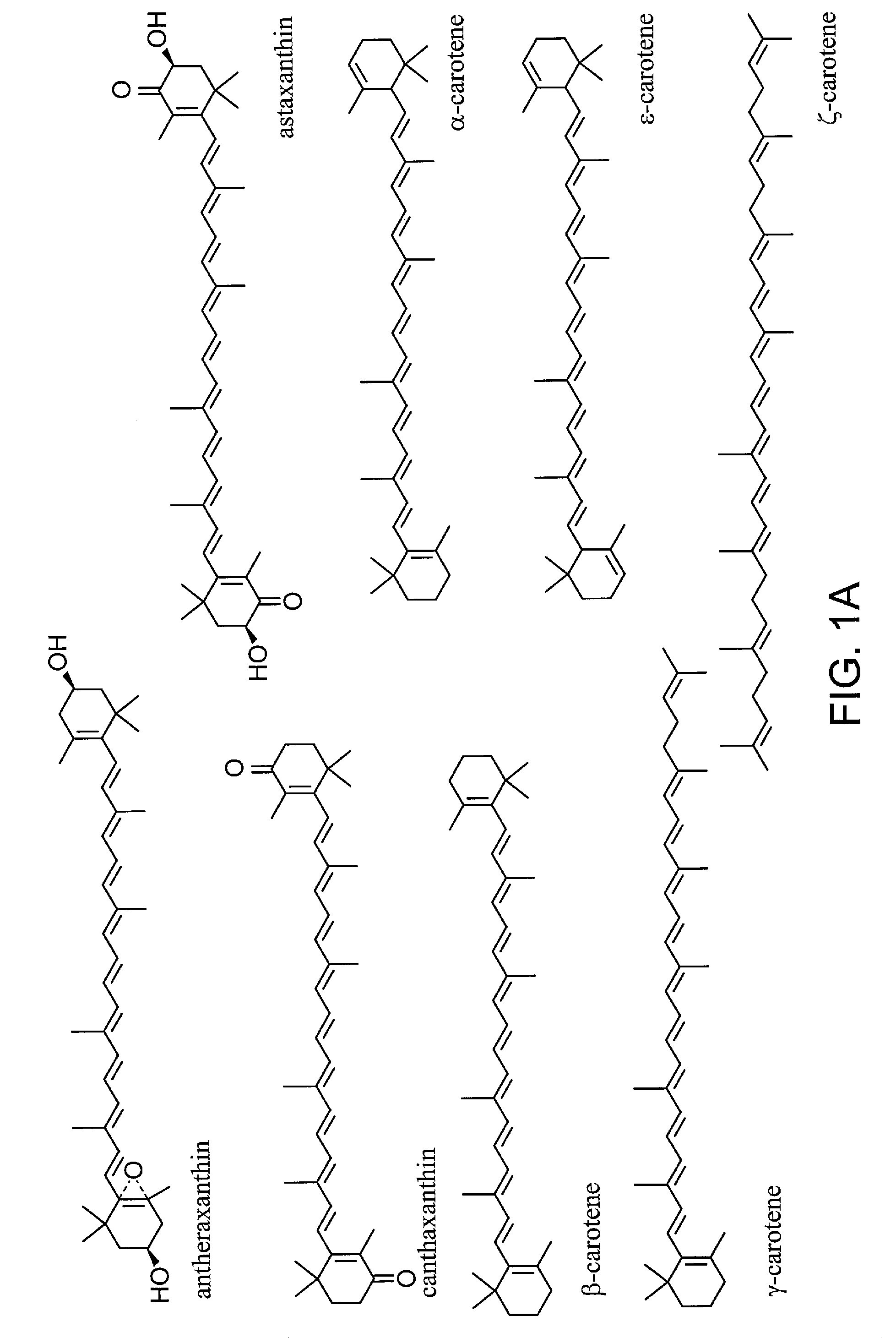

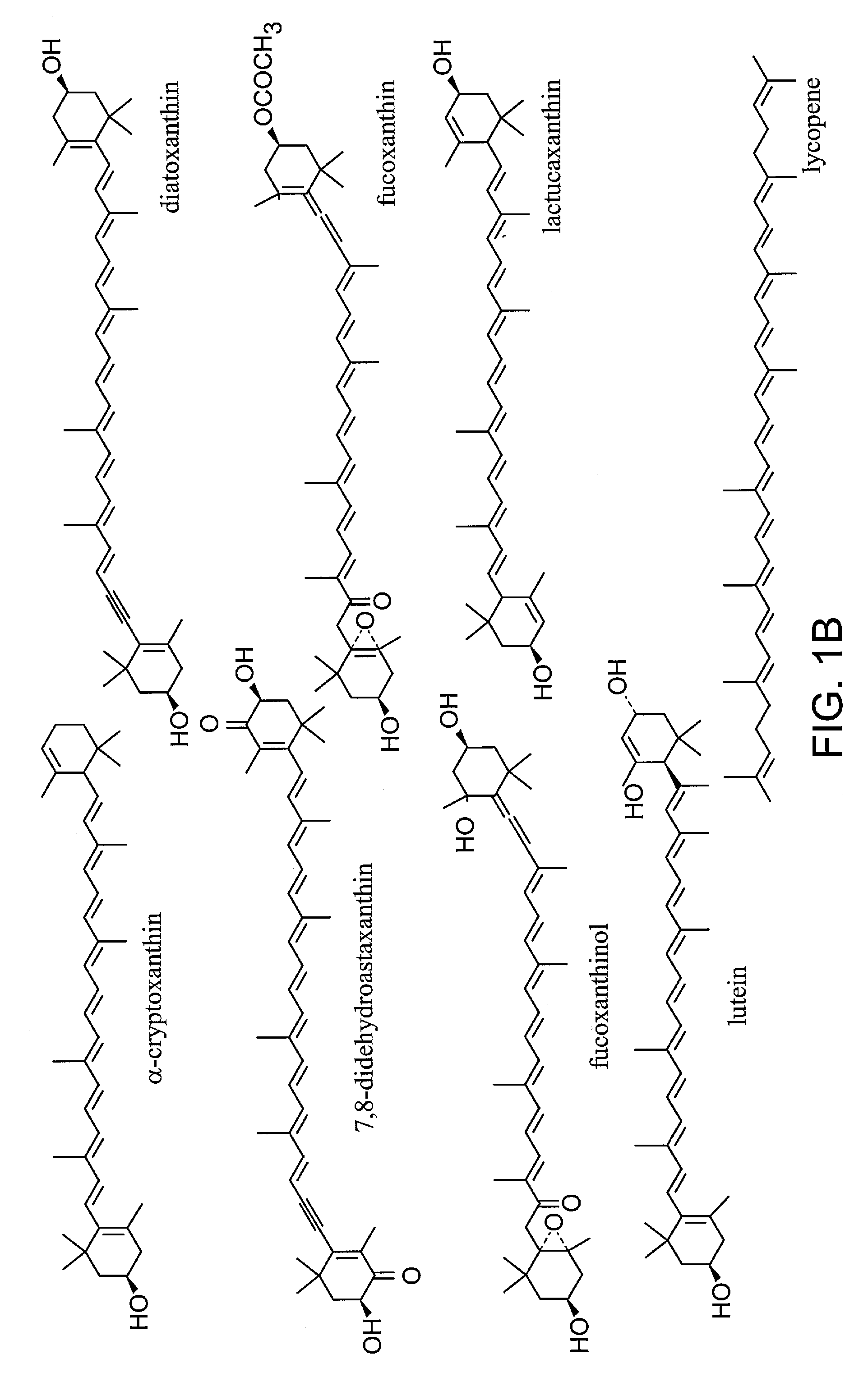

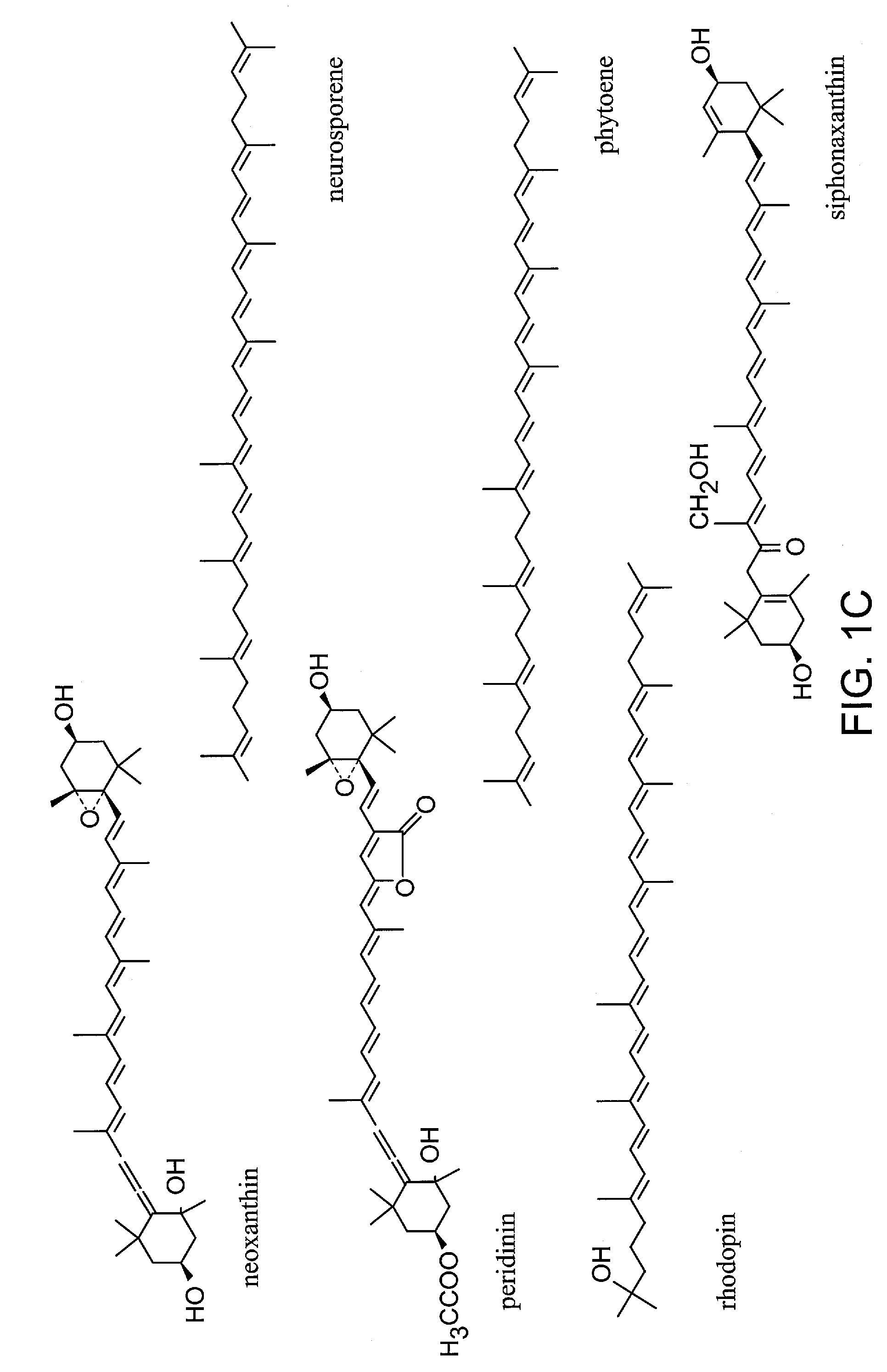

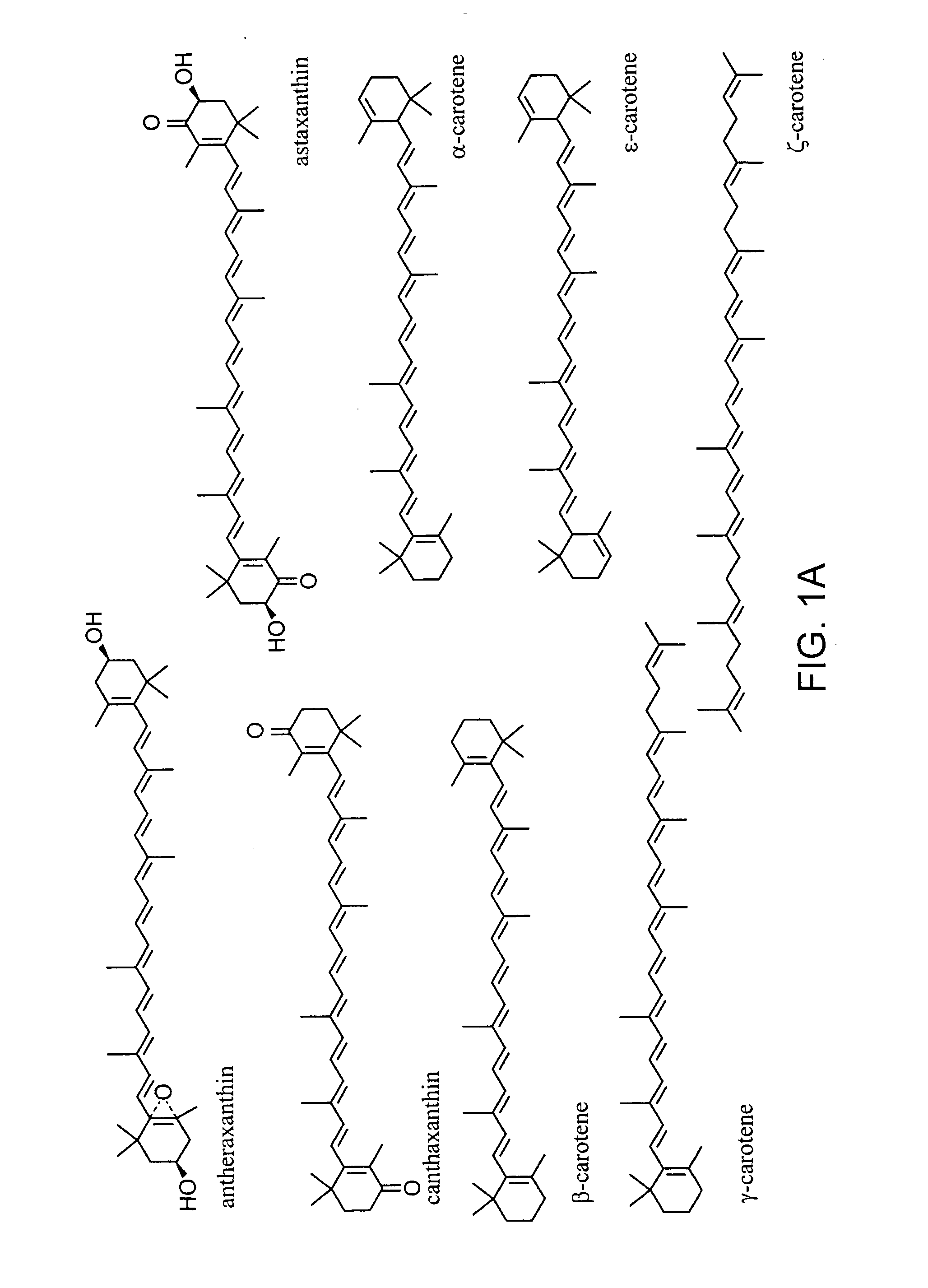

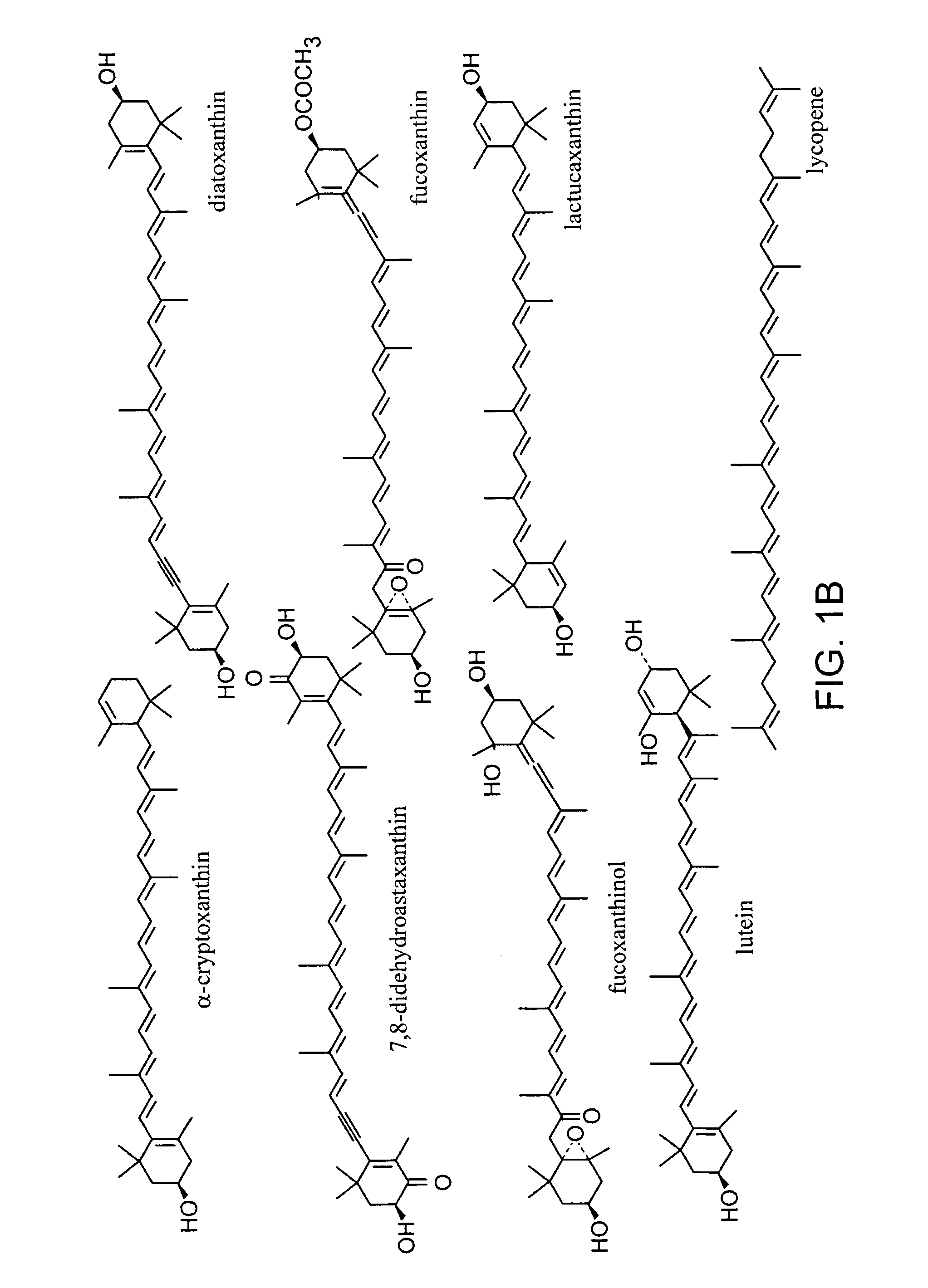

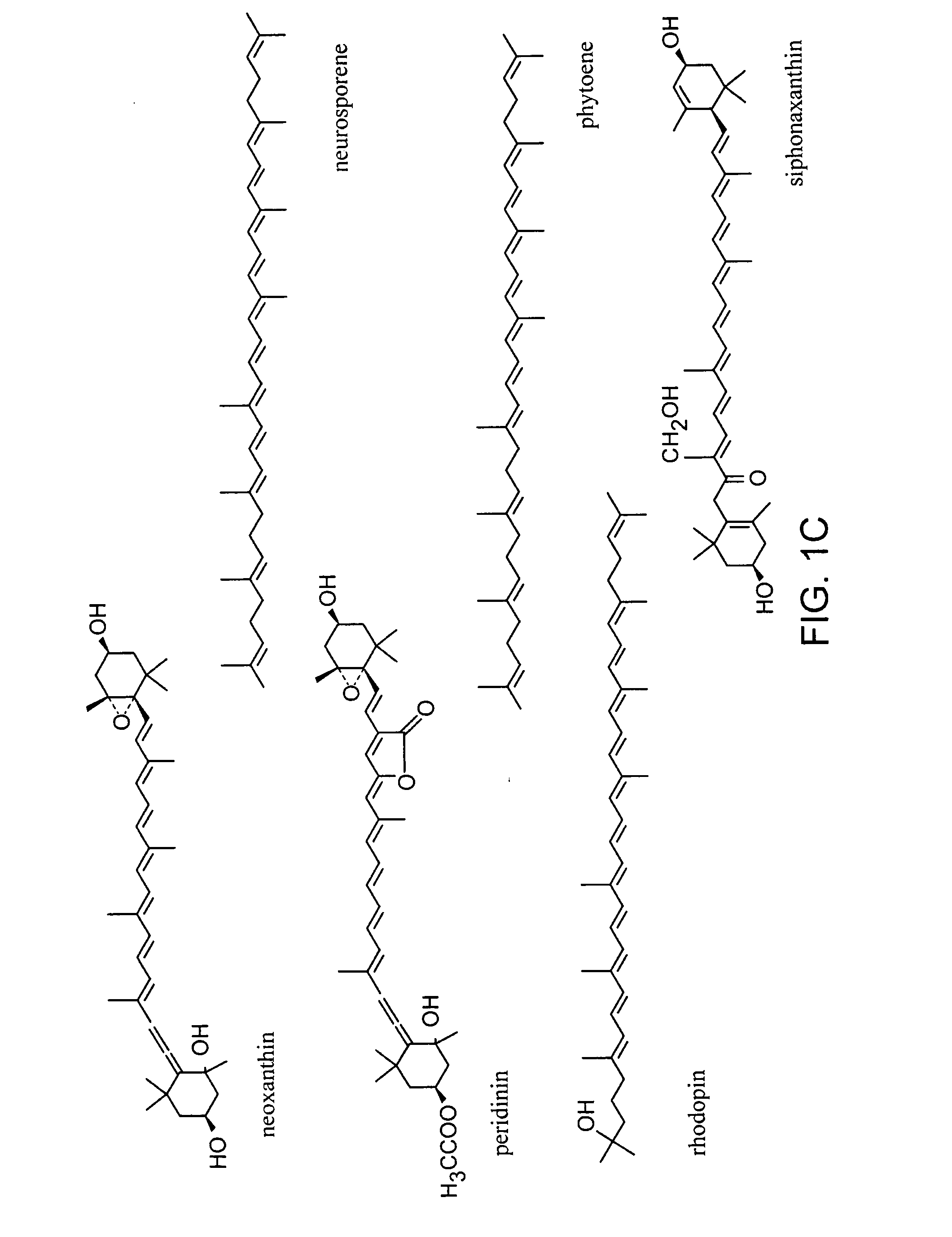

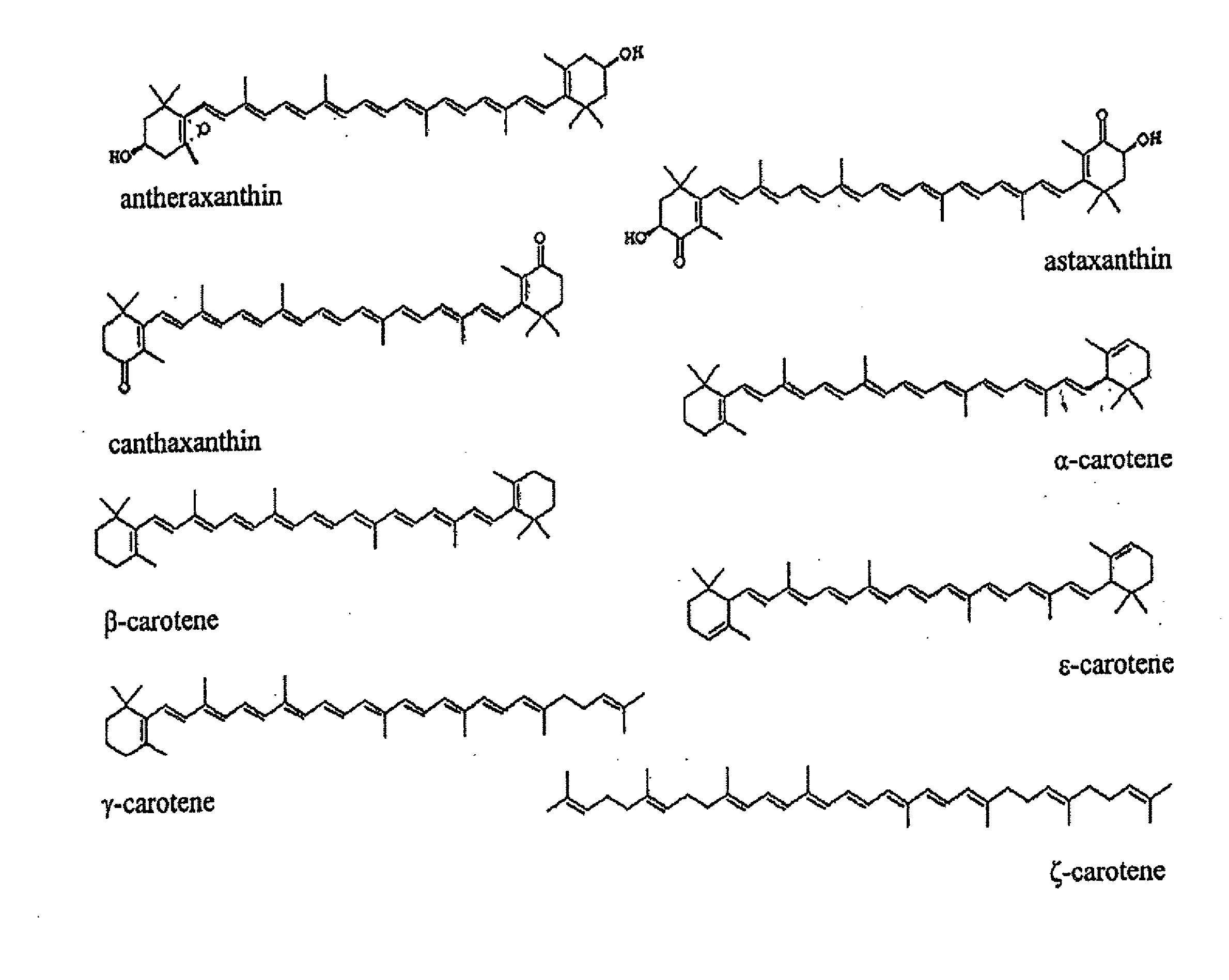

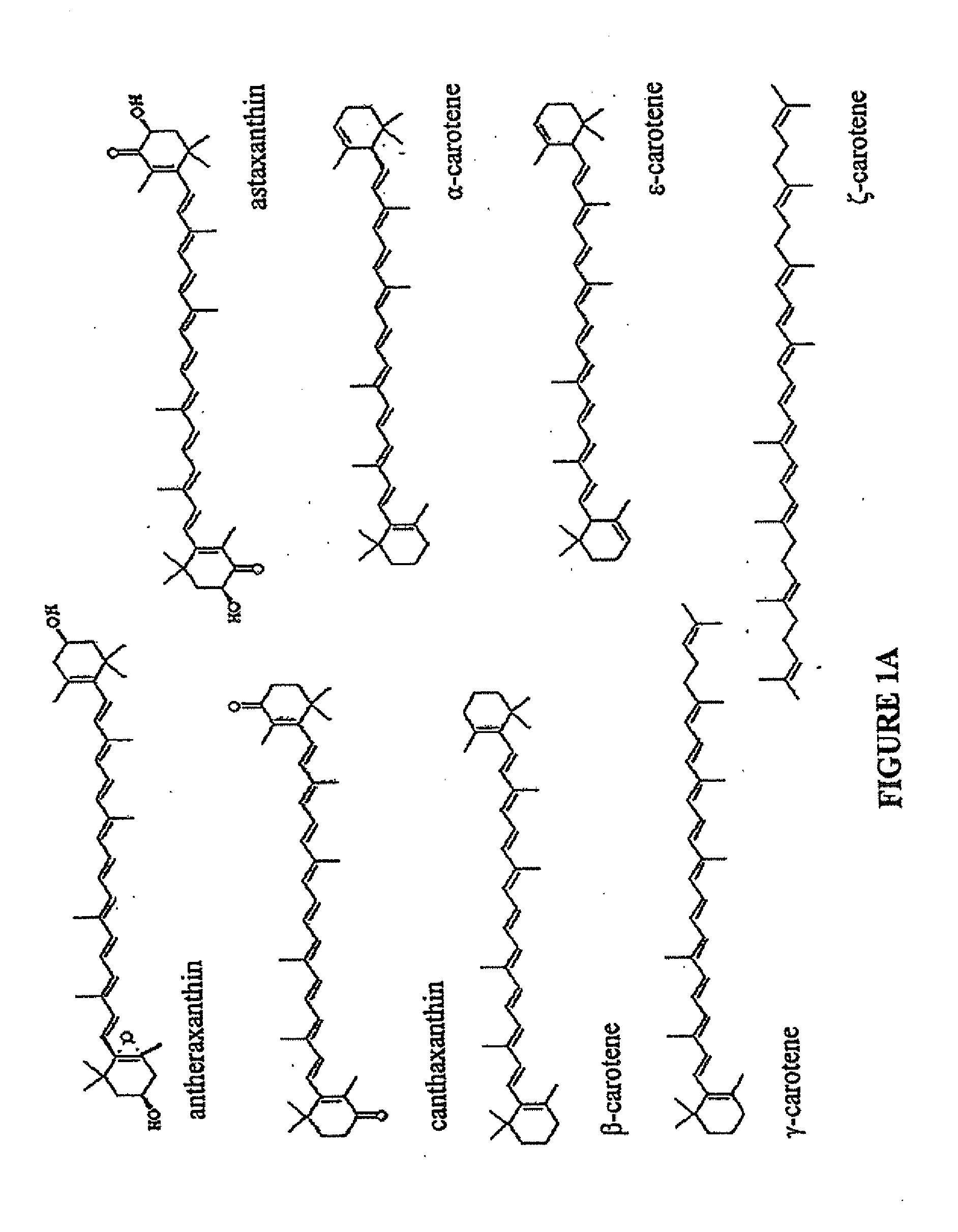

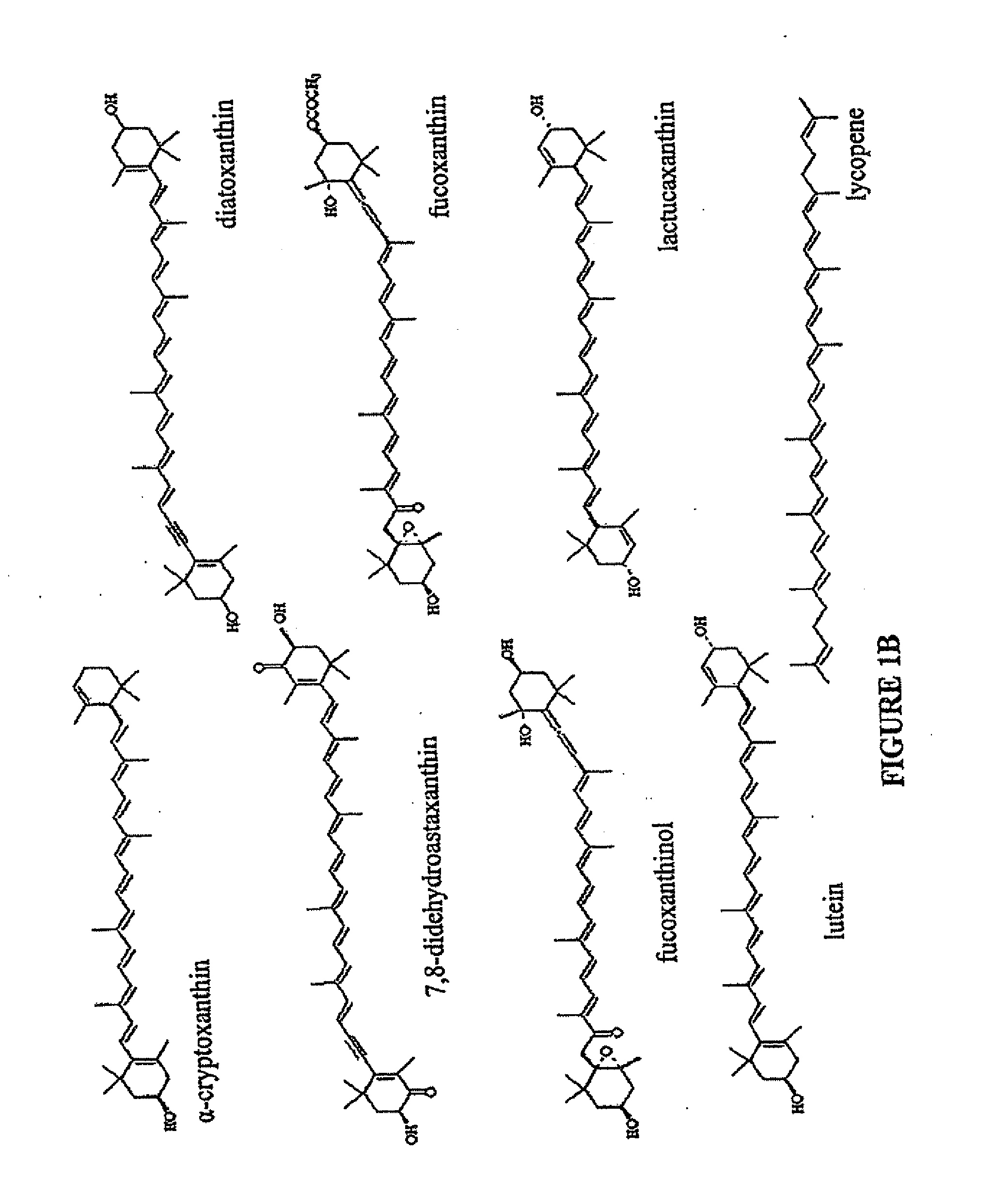

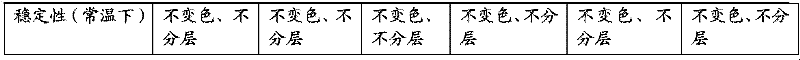

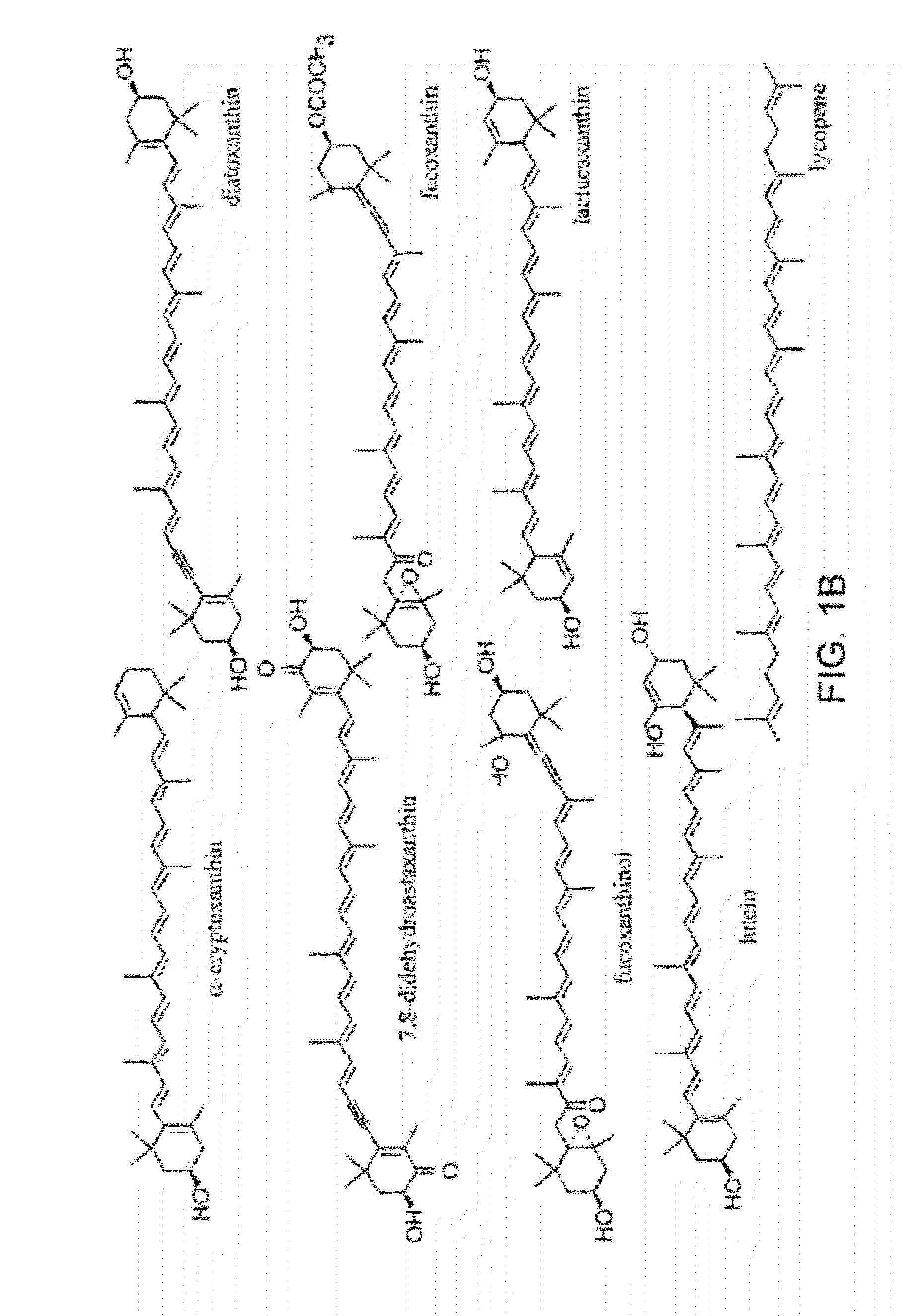

Production of carotenoids in oleaginous yeast and fungi

ActiveUS7851199B2Improve oilinessAlter their carotenoid-producing capabilitiesSenses disorderFungiYeastCarotenoid

The present invention provides systems for producing engineered oleaginous yeast or fungi that express carotenoids.

Owner:DSM IP ASSETS BV

Production of carotenoids in oleaginous yeast and fungi

ActiveUS20070015237A1Increase oleaginicityAlter their carotenoid produce capabilitySenses disorderFungiBiologyMolecular biology

The present invention provides systems for producing engineered oleaginous yeast or fungi that express carotenoids

Owner:DSM IP ASSETS BV

Production of carotenoids in oleaginous yeast and fungi

The present invention provides systems for producing engineered oleaginous yeast or fungi that express carotenoids.

Owner:DSM IP ASSETS BV

Combination of oil for pair of gear worm

A composite oil for worm gear set contains mineral lubricating oil, at least one pour depressor and / or viscosity index improver chosen from polymethylacrylate, poly-alpha-olefin, alkylnaphthalene, etc, at least one S-contained extreme pressure agent and / or P-contained extreme-pressure antiwear agent, at least one oil agent or friction improver, at least one phenol-type or amine-type antioxidizing agent, at least one phenyltriazole or thiabiazole type metallic deactivator, and at least one poly-alcohol-ether type antiemulsifying agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

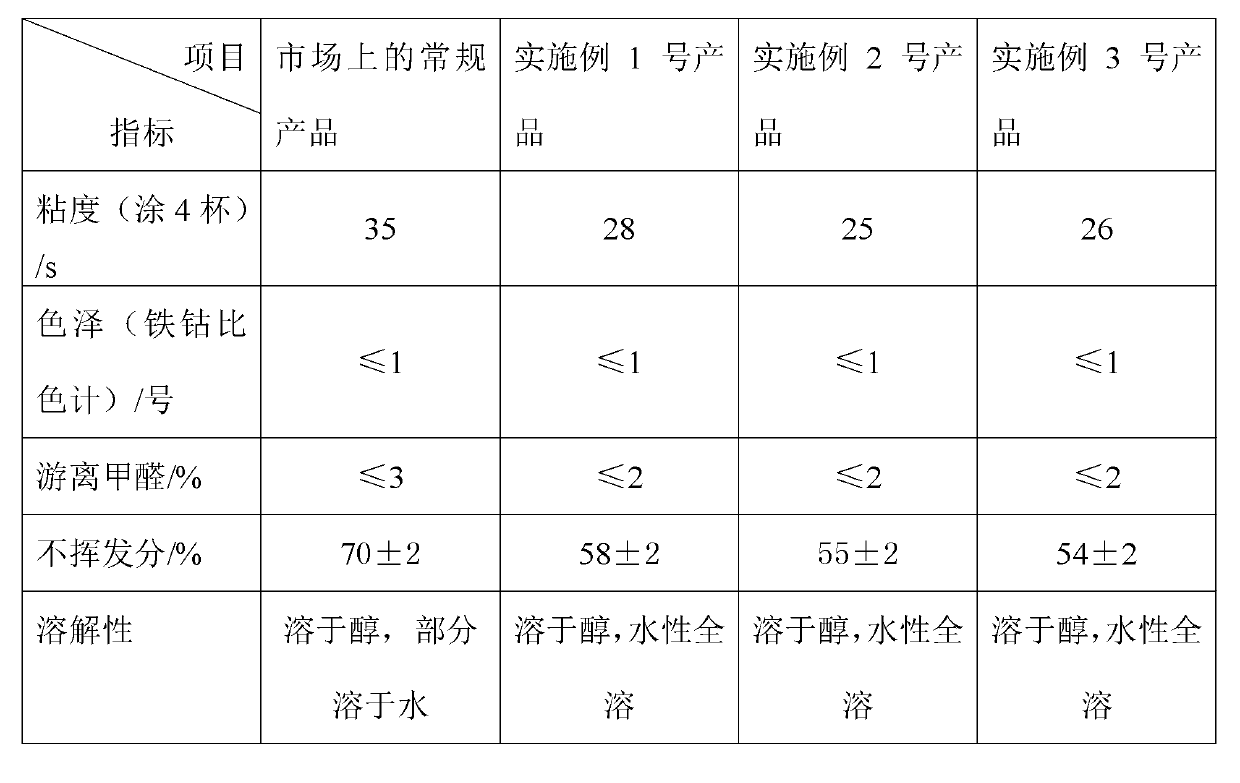

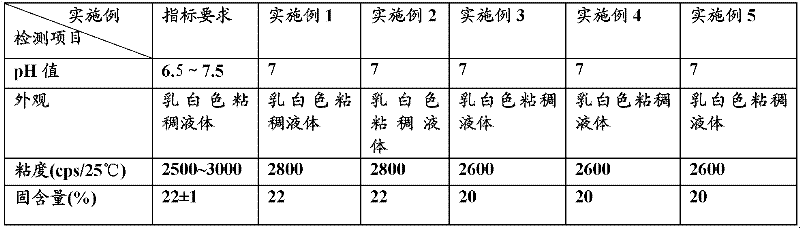

Preparation method of high imino methylated melamine resin

The invention relates to a preparation method of high imino methylated melamine resin. According to the preparation method, by adjusting the components of raw materials, the adding sequence of the components, the time, the proportion of the components in parts by weight, reaction parameters of the process of the method and the like in the steps of the method, the oiliness of the obtained high imino methylated melamine resin can be greatly improved, the weight loss in baking is small, a strong acid is not required for catalysis, the resin can perform rapid curing reaction under the general baking condition of 110-150 DEG C, and the resin has higher anti-curing performance; and in addition, the resin is fully water soluble, the range of applications of the resin is greatly expanded and the popularization and application value is further higher.

Owner:SHANDONG ZHANHUA OSITER CHEM

Compound type vegetable oil lubricating agent for drilling fluid and preparation method thereof

InactiveCN101760186ANon-toxicInhibits hydration swellingDrilling compositionVegetable oilFluorescence

The invention discloses a compound type vegetable oil lubricating agent for a drilling fluid and a preparation method thereof. The compound type vegetable oil lubricating agent for the drilling fluid with favorable oiliness, no toxicity, low fluorescent level and favorable bearing and thermostabilized performance is prepared by taking a vegetable oil leftover which is low in price and easy to obtain, lauryl sodium sulfate, sbane 80, sodium carboxymethylcellulose, polyvinylpyrrolidone and the like as main raw materials, adding a solid lubricating agent which is graphite or serpentine and usinga simple and environment-friendly production method, so that not only the production cost is greatly reduced, but also any toxic and harmful action on the environment is not generated in the production process. The compound type vegetable oil lubricating agent for the drilling fluid is not only applied to drilling, but also can be applied to producing wells, can effectively inhibit the hydrous expansion of mud shale, consolidate the well wall and prevent the sticking accidents and is especially suitable for industrial production on a large scale.

Owner:无锡润鹏复合新材料有限公司

Velvet finishing agent for synthetic leather and preparation method thereof

The invention relates to a velvet finishing agent for synthetic leather and a preparation method thereof. The velvet finishing agent consists of the following raw materials in parts by weight: 80-120 parts of polyurethane resin, 3-10 parts of dry smooth wax powder, 2-8 parts of silicon dioxide extinction powder, 6-15 parts of glass microspheres with particle size of 5-60 microns, 1-6 parts of epoxidized soybean oil, 1-6 parts of phenmethyl silicon oil, 1-6 parts of plasticizer, 30-60 parts of dimethylformamide, 30-50 parts of butyl acetate, 20-40 parts of methylal and 20-40 parts of dimethylbenzene. The velvet finishing agent for synthetic leather provided by the invention has low cost and good velvet feel, can be used through multiple technologies such as roller painting, printing and the like, and is widely applicable. In the invention, a preparation technology of uniformly dispersing before grinding and filtering is adopted, and the prepared finishing agent can obtain more delicate velvet feel; and moreover, as the yangbuck powder requiring accurate temperature control and long-time foaming is not used, the preparation is easier.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

Osmanthus handmade soap and manufacturing method thereof

InactiveCN103242991AThe production process is simple and safeWhitening processHair cosmeticsSkin careNatural productJojoba oil

The invention discloses an osmanthus cold-worked handmade soap and a manufacturing method thereof. The invention is mainly technically characterized in that the main raw materials are osmanthus olive infused oil, coconut oil and jojoba oil, and the water phase is composed of osmanthus pure dew, NaOH, and osmanthus essential oil or osmanthus essence. The manufacturing method comprises the following steps: 1) proportionally mixing osmanthus olive infused oil, coconut oil, jojoba oil and the like, and heating to 40-50 DEG C; 2) adding refrigerated osmanthus pure dew into NaOH, evenly mixing, and cooling to 40-50 DEG C; 3) slowly adding NaOH into the mixed oil until the oil is completely mixed with the NaOH; 4) adding osmanthus essential oil or osmanthus essence, and uniformly stirring; 5) adding a small amount of fresh or dried osmanthus, and uniformly stirring; and 6) forming in a reverse mold. The osmanthus handmade soap has the effects of whitening skin, reducing blackspots, and improving dry, coarse, dark and oily skin or skin with pimples; the osmanthus fragrance can slowly soothe the anxiety and dejection, refresh the emotions, restore the mental balance and relieve pressure. The osmanthus handmade soap is suitable for people with various skin types. The osmanthus handmade soap is a pure natural product, and thus, is harmless to the human body.

Owner:HUBEI UNIV OF SCI & TECH

Production of carotenoids in oleaginous yeast and fungi

The present disclosure provides systems for producing engineered oleaginous yeast or fungi that express carotenoids.

Owner:MICROBIA

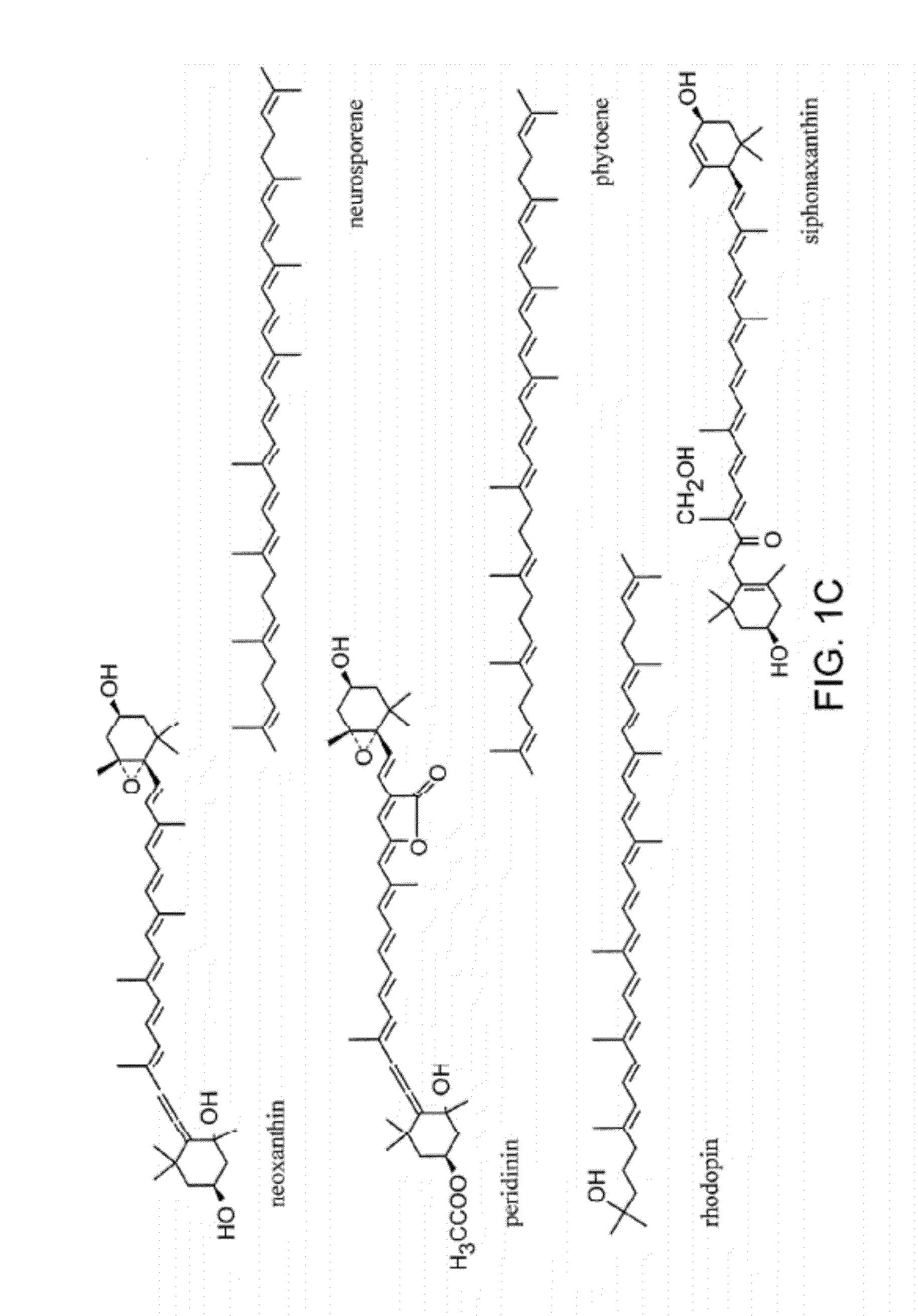

Additive for improving resisting phase separation performance and heat value of methanol gasoline

InactiveCN102344837AImprove oilinessReduce fuel consumptionLiquid carbonaceous fuelsAmyl acetateN-Butyl Alcohol

The invention discloses an additive for improving resisting phase separation performance and a heat value of methanol gasoline. The additive consists of the following raw materials in percentage by weight: 35-45 percent of aliphatic alcohol, 10-20 percent of aliphatic ether, 15-30 percent of aliphatic ester, 5-15 percent of aliphatic acid, 1-5 percent of aliphatic amine and 0.1-3 percent of emulsifier OP, wherein the aliphatic alcohol is one or more of isopropyl alcohol, n-propanol, n-amyl alcohol, isoamyl alcohol and n-butyl alcohol; the aliphatic ether is one or more of ethylene glycol methyl ether, ethylene glycol ethyl ether and ethylene glycol butyl ether; the aliphatic ester is one or more of butyl acetate, n-amyl acetate and isoamyl acetate; the aliphatic acid is oleic acid and / or naphthenic acid; the aliphatic amine is dimethylamine and / or diethylamine; and the emulsifier OP is emulsifier OP-15 and / or emulsifier OP-20. The methanol gasoline in which the additive is added has superior low-temperature resisting phase separation and water resisting phase separation performances and an obviously improved heat value.

Owner:西安祺祥能源科技发展有限公司

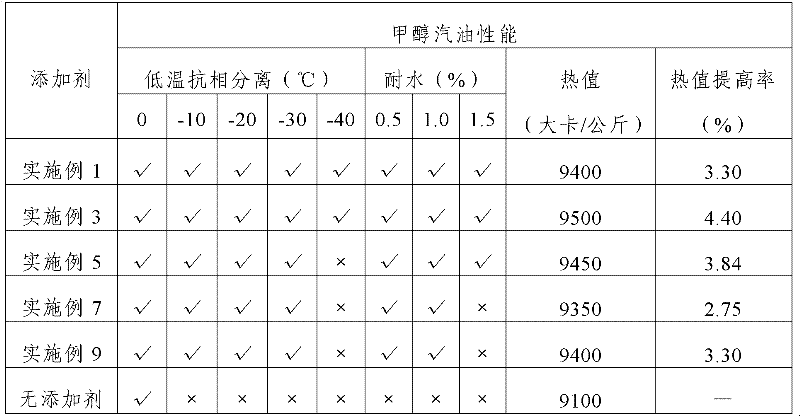

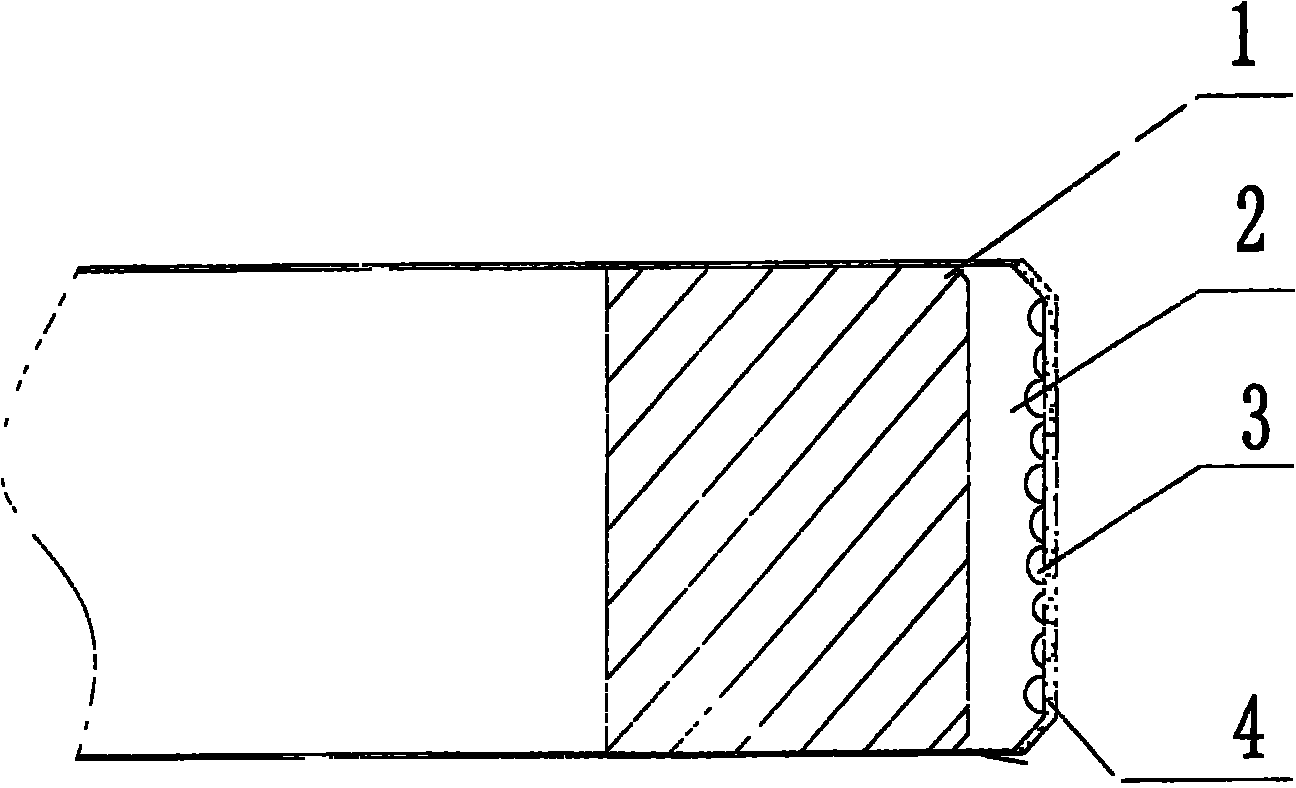

Piston ring and surface spongy tin plating technique thereof

The invention relates to a piston ring and a surface spongy tin plating technique thereof. The technical scheme thereof is as follows: the surface of a piston ring body is provided with a chromium plating layer, the outer surface of the chromium plating layer is provided with a spongy reticulate pattern, and the outer surface of the spongy reticulate pattern is provided with a tin plating layer. The invention comprises the following procedures: preplating, etching, chromium plating, washing, removal of hydrogen, hole loosing, washing and drying and tin plating treatment. The invention utilizes a reticulate pattern groove on the surface of the piston ring to store lubricating oil, thus greatly reducing the friction coefficient between the piston ring and a cylinder sleeve, improving oil absorbing property, and prolonging the service life of the piston ring and the cylinder sleeve; and compared with the prior art, the invention prolongs the service life of the piston ring and the cylinder sleeve by more than three thousand hours, improves the power of an internal combustion engine by more than 30 percent, saves oil by 25 percent, is capable of reducing the exhaust amount of gas / smoke of the internal combustion engine, reduces the environment requirements of atmosphere pollution, solves the mechanical wear of the piston ring during running-in period and obtains more perfect use performances.

Owner:XIANGFAN XINLI HENGXING PISTON RINGS

Rose flower handmade soup and manufacturing method thereof

InactiveCN105695173AThe production process is simple and safeWhitening processHair cosmeticsSkin careNatural productCoconut oil

The invention discloses rose flower cold-made handmade soup and a manufacturing method thereof. The soap is mainly characterized in that main raw materials comprise rose flower olive dipped oil, coconut oil, rice bran oil, rose flower hydrosol, NaOH and rose flower essence oil. The method includes 1) mixing the rose flower olive dipped oil, the coconut oil, the rice bran oil, and the like according to a ratio and heating to 40-50 DEG C, 2) adding the froze rose flower hydrosol into the NaOH, fully mixing, and cooling to 40-50 DEG C, 3) slowly adding the NaOH into the mixed oil until the NaOH and the oil are fully mixed, 4) adding the rose flower essence oil or rose flower essence and fully stirring, 5) adding a small amount of fresh or dry rose flowers and fully stirring, and 6) moulding by reserving a mould. The soap has functions of whitening skin, fading speckles, improving dry, coarse, dark, gloomy, oily and acne skin, and the like. Fragrance of rose flowers can slowly eliminate anxiety and depression, boost mood, restore mental equilibrium and relieve pressure. The soap is suitable for persons with various skin types. The soap is a purely natural product and is free of any harm to human bodies.

Owner:GUANGXI UNIV

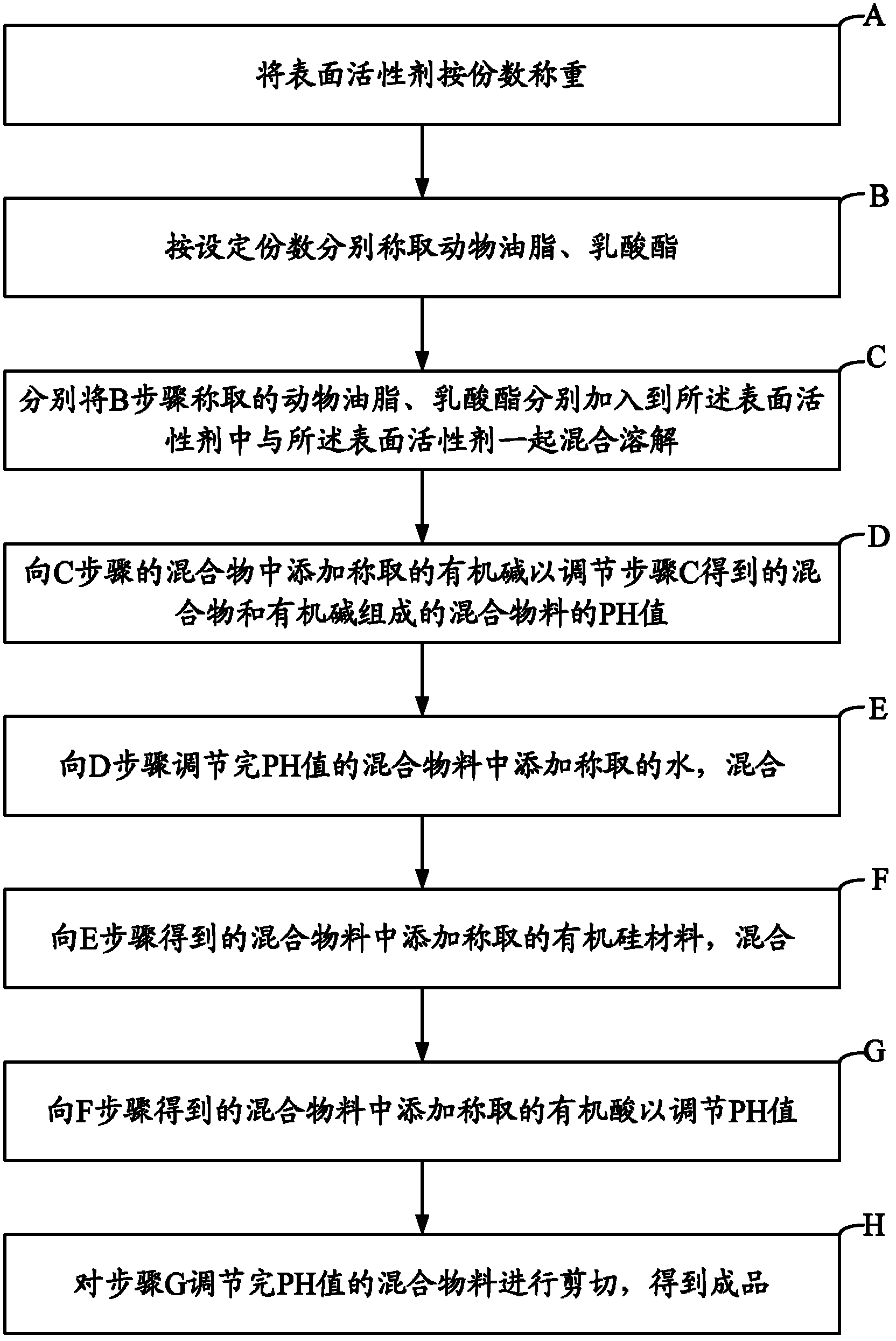

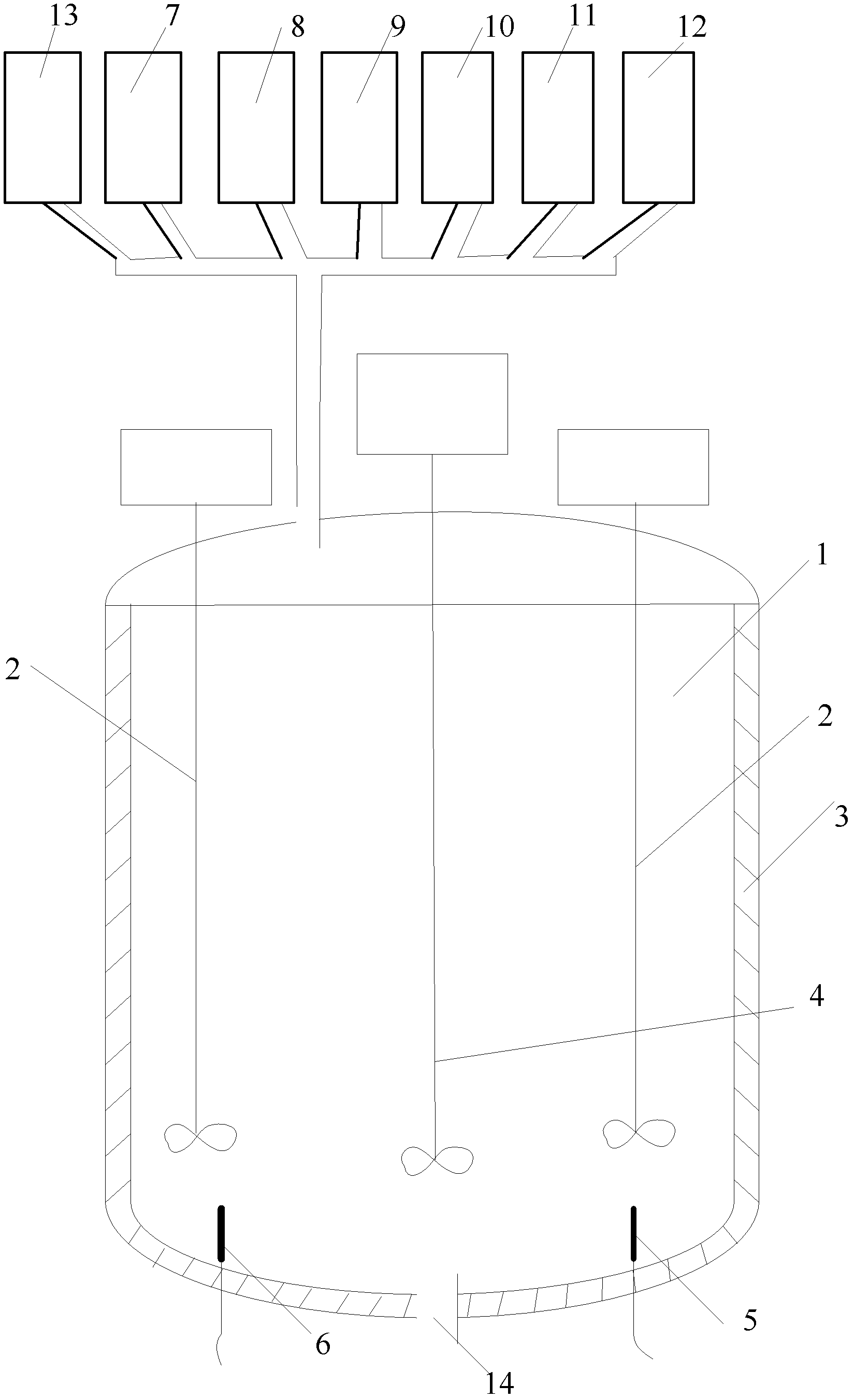

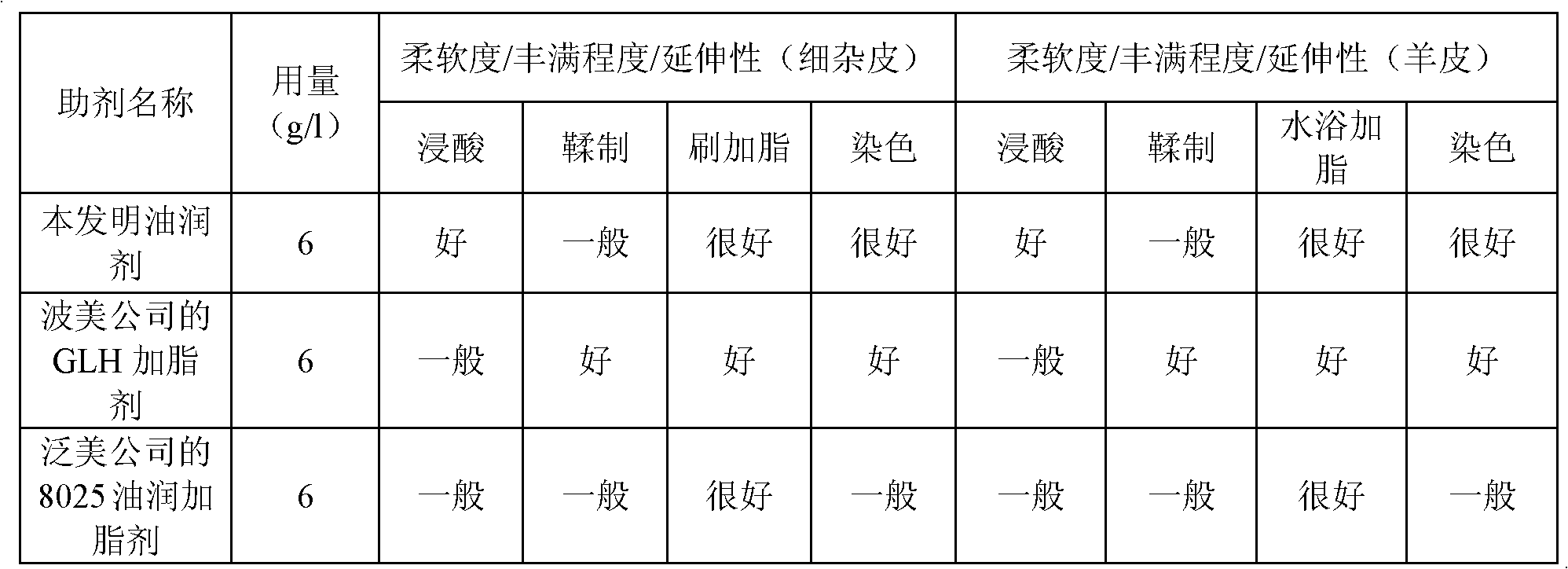

Leather care agent as well as preparation method and preparation device thereof

InactiveCN102492789AImprove permeabilityImprove breathabilityLeather impregnationOrganic acidOrganic base

The invention relates to the field of leather, and particularly relates to a leather care agent as well as a preparation method and a preparation device thereof. The leather care agent is prepared from the following raw materials in parts by weight: 10-100 parts of lactate, 1-100 parts of animal oil, 5-100 parts of surfactant, 5-200 parts of organosilicone material, 1-10 parts of organic base, 1-5 parts of organic acid and 1-250 parts of water through mixing. According to the leather care agent as well as the preparation method and the preparation device thereof, provided by the invention, the penetrability of the care agent can be improved.

Owner:BEIJING FANBO CHEM

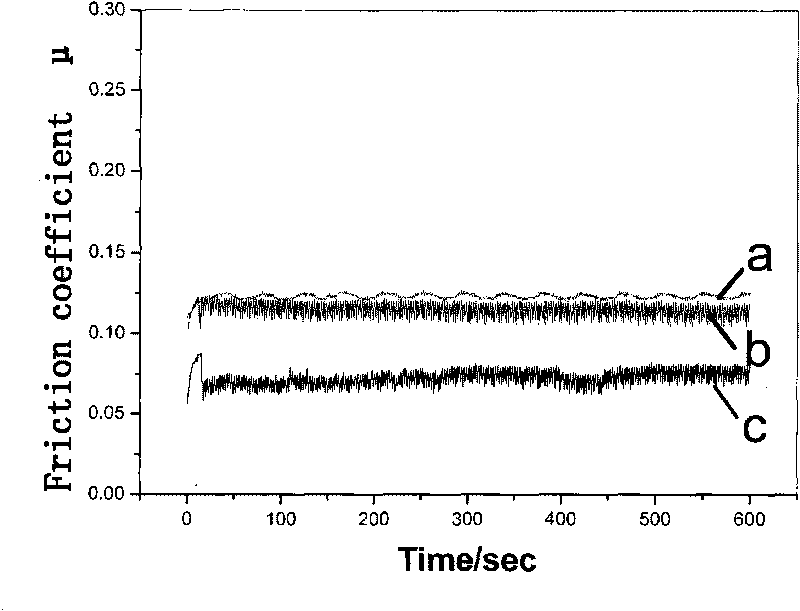

Hexakis-addition [60] fullerene derivative and application thereof in lubrication field

ActiveCN105523924AImprove oilinessImprove the lubrication effectPreparation from carboxylic acid halidesOrganic compound preparationDouble bondStructural formula

The invention discloses a hexakis-addition [60] fullerene derivative and an application thereof in the lubrication field; the hexakis-addition [60] fullerene derivative has the structural formula defined in the specification; addition positions of the hexakis-addition [60] fullerene derivative are all generated on [6,6] double bonds on an equator. Through introduction of 12 flexible ester chains onto hard C60, the solubleness is greatly increased, and the dispersion problem of [60] fullerene in lubricating oil is improved; through symmetric introduction of six long-chain ester groups to the periphery of a C60 sphere, the compound is endowed with viscoelasticity and toughness, and existence of the ester groups ensures the adsorbability of the compound on friction surfaces; with the introduction of long-chain alkyl, the oiliness of the compound can be increased, so as to better hinder direct contact between two friction pair surfaces and improve the lubricating performance of the lubricating oil. The hexakis-addition [60] fullerene derivative can be used as an anti-wear lubricating additive in the lubrication field.

Owner:NEUFTECH BIOTECH HEFEI

Special UV type PVD (plating vacuum deposition) primer for improving vibration abrasion resistance

InactiveCN104119791AThe production process is simpleGood flexibilityEpoxy resin coatingsPolyester coatingsChemistryPhotoinitiator

The invention relates to a special UV type PVD (plating vacuum deposition) primer for improving vibration abrasion resistance. The primer comprises the following components in percentage by weight: 20-40 percent of urethane acrylate, 2-10 percent of modified epoxy acrylate, 2-10 percent of thermoplastic acrylic ester, 1-5 percent of auxiliary resin, 5-20 percent of active diluent, 2-5 percent of photoinitiator, 0.2-0.5 percent of flatting agent and 40-60 percent of diluent. The special UV type PVD primer for improving vibration abrasion resistance has the advantages of low cost, high adhesion, excellent construction performance, good oil attachment and good flexibility, and can be widely applied to PC, ABS / PC, ABS and other materials.

Owner:YIXING HONGTAI CHEM

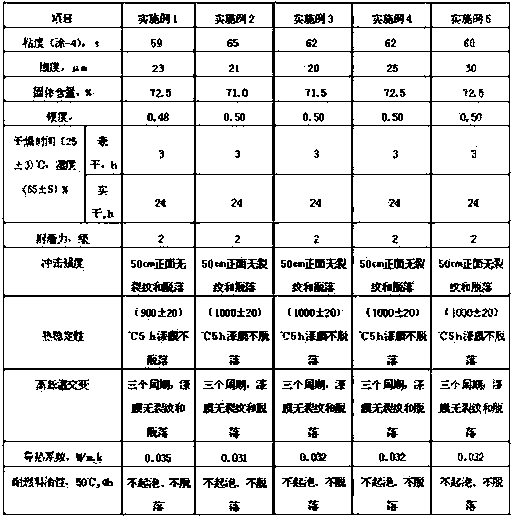

Environment-friendly room temperature curing organic silicon high-temperature resistant coating and preparation method thereof

ActiveCN103409063ASolving room temperature curing problemsIncrease crosslink densityCoatingsFiberAlcohol

The invention belongs to the field of coating technology, and especially relates to an environment-friendly room temperature curing organic silicon high-temperature resistant coating. The environment-friendly room temperature curing organic silicon high-temperature resistant coating is composed of A component and B component. A component comprises organic silicon resin, a pigment, a thermal insulation material, a high-temperature binding material, and a rust-resisting material with the balance being an organic solvent; B component comprises triethylenetetramine, a catalyst, an adhesion promoter, and absolute ethyl alcohol. The mass ratio of A component to B component is 20-25:1; and the thermal insulation material is a mixture prepared by mixing mica powder, alumina silicate fiber and aluminum oxide short fiber at a mass ratio of 10-12:8-10:5-20. The environment-friendly room temperature curing organic silicon high-temperature resistant coating is capable of solving the room temperature solidification problem of organic silicon high-temperature resistant thermal-insulating coatings, simplifying construction technologies, reducing construction energy consumption, and expanding the application range of organic silicon high-temperature resistant thermal-insulating coatings. Crosslink density of films made of the environment-friendly room temperature curing organic silicon high-temperature resistant coating is high, and fuel oil resistance is excellent. Aluminum oxide short fiber is used as the thermal insulation material, no coating additive is used, no priming paint is needed, the high-temperature resistance of the environment-friendly room temperature curing organic silicon high-temperature resistant coating is high, and the environment-friendly room temperature curing organic silicon high-temperature resistant coating is capable of resisting a temperature higher than 900 DEG C.

Owner:SHANDONG NORTH MODERN CHEM IND

Production of carotenoids in oleaginous yeast and fungi

Owner:DSM IP ASSETS BV

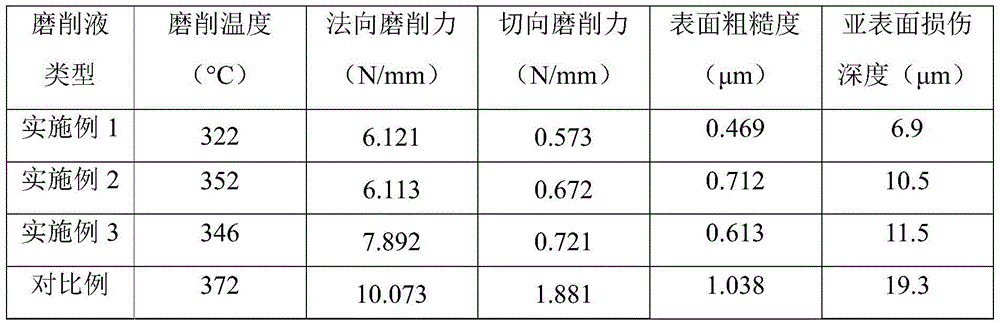

Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

ActiveCN105586142AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsDimethyl siloxaneMachining process

The invention relates to a special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels. The special grinding fluid comprises 4.8%-6.2% of fatty acid methyl ester polyoxyethylene ether, 2.5%-2.9% of an alkyl synthol alkoxy compound, 2.2%-2.5% of tungsten disulfide, 4.2%-4.4% of cyclopentasiloxane, 3.5%-3.7% of an anti-wear reagent at extreme pressure, 2.3%-3% of a corrosion inhibitor, 2.5%-3.5% of a friction modifier and the balance of deionized water. The special grinding fluid for grinding of the silicon carbide ceramic by the diamond grinding wheels has excellent lubricating, cooling and cleaning effects, has the long service cycle and can substantially reduce the grinding temperature, the normal grinding force and the tangential grinding force in the machining process of the silicon carbide ceramic, reduce abrasions of the grinding wheels, effectively improve surface quality and precision of ground surfaces of the silicon carbide engineering ceramic and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

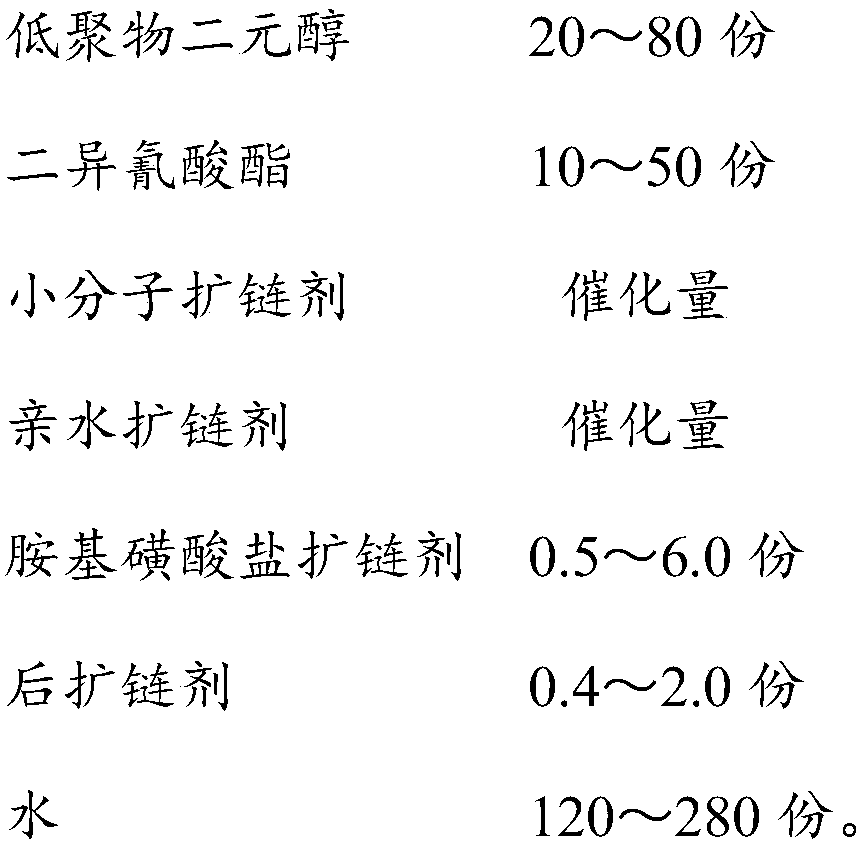

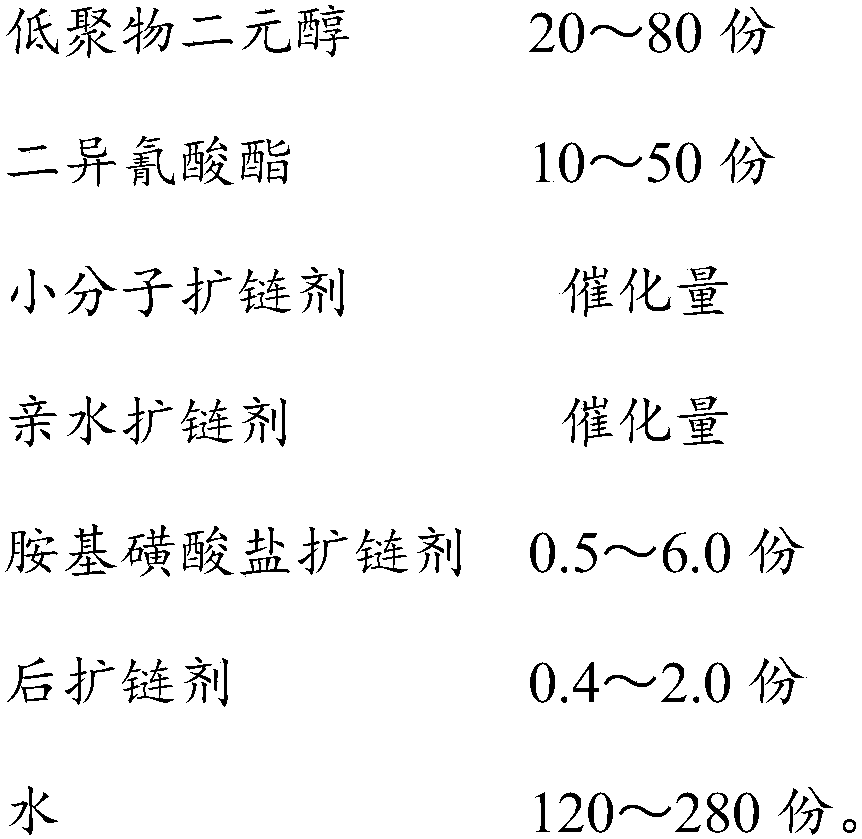

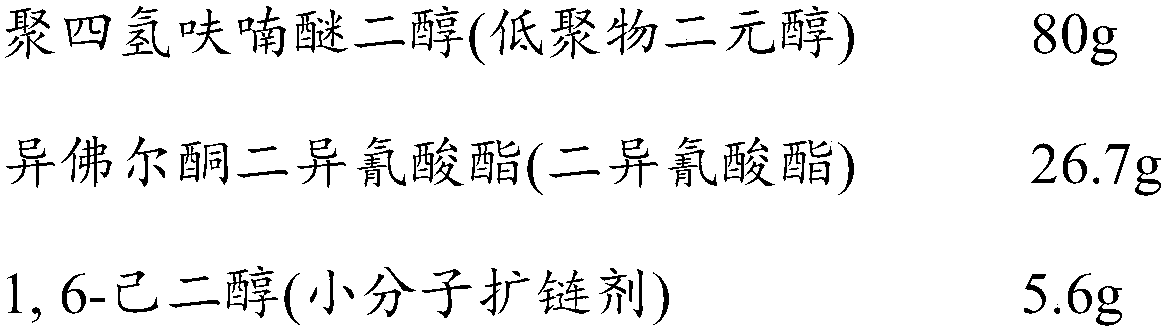

Waterborne polyurethane resin for nail polish and preparation method of waterborne polyurethane resin for nail polish

ActiveCN107936212AImproves anti-flocculation stabilityHigh fastnessCosmetic preparationsToilet preparationsTemperature resistanceControllability

The invention discloses waterborne polyurethane resin for nail polish and a preparation method of the waterborne polyurethane resin for the nail polish. The waterborne polyurethane resin for the nailpolish is prepared from raw materials of oligomer diol, diisocyanate, a small molecule chain extender, a hydrophilic chain extender, an amine sulfonate chain extender, a rear chain extender, water andthe like; the waterborne polyurethane resin for the nail polish, disclosed by the invention, has the advantages of environmental protection, good stability, durability, high strength, excellent waterresistance, good greasiness, temperature resistance, low product cost and the like, provides basic resin with high cost performance for environmentally friendly nail polish cosmetics, can be widely used in the field of nails and skin protection, and is especially suitable for nail surface protection; the waterborne polyurethane resin for the nail polish, disclosed by the invention, is simple in synthesis process, strong in controllability and obviously reduced in requirements for equipment, and further avoids multiple influence factors brought by multi-modification products in a synthesis process.

Owner:英德市国彩精细化工有限公司

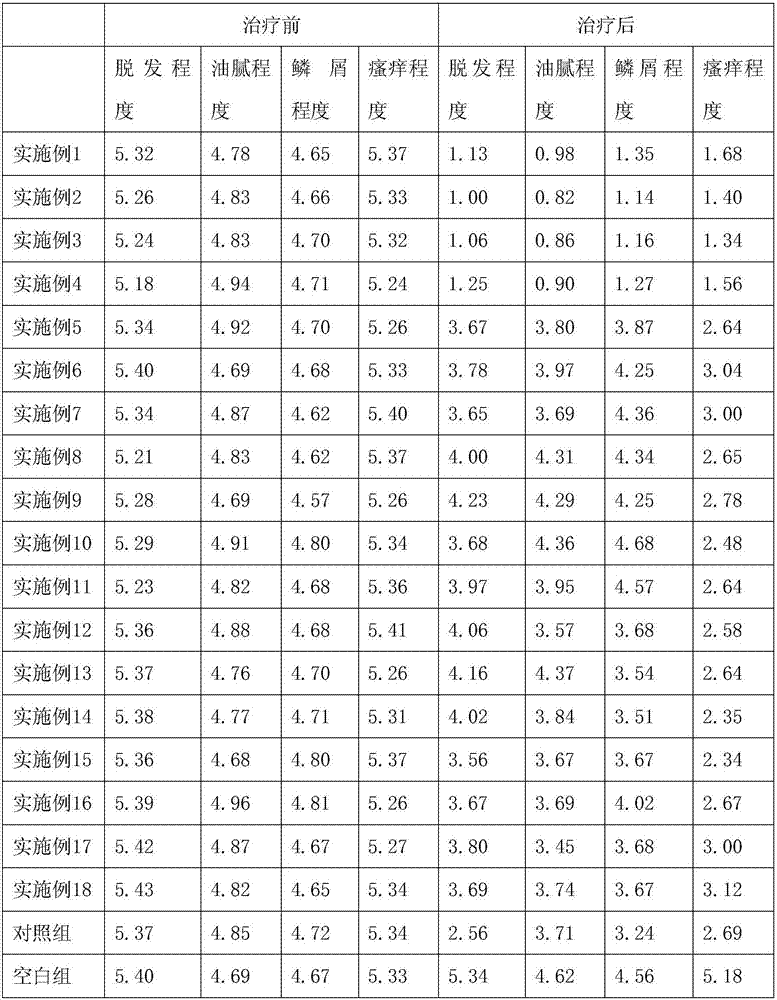

Composition for promoting hair growth and preventing hair loss, and preparation method and application thereof

InactiveCN109908067AImprove oilinessMaintain water and oil balanceCosmetic preparationsHair cosmeticsHair follicleHair growth

The invention provides a composition for promoting hair growth and preventing hair loss, and a preparation method and application thereof. The composition comprises, by weight, 1-15 parts of beta-nicotinamide mononucleotide and 42-80 parts of purified water. The composition for promoting hair growth and preventing hair loss can activate hair follicles, stabilize hair roots, prevent hair loss, increase the hair, obviously regulate the oiliness of the scalp, soothe the scalp, and maintain the balance of water and oil of the scalp, thereby having a good business prospect.

Owner:聂乐明

Cold extrusion forming lubricant for low carbon steel part used for automobile and preparation method thereof

The invention discloses a cold extrusion forming lubricant for a low carbon steel part used for an automobile. The main body of the lubricant comprises the following components by mass: 1% to 3% of an oiliness additive, 0.3% to 0.8% of a preservative, 3% to 6% of an antifriction agent, 0.1% to 0.5% of an antioxidant, 0.2% to 0.5% of a defoaming agent, 2% to 5% a dispersion agent, 1% to 3% of a cleaning agent, 0.1% to 0.5% of an active agent, 0.3% to 1.0% of an extreme pressure agent and 1% to 4% of an adsorbent, with the balance being deionized water. The invention also discloses a preparation method for the cold extrusion forming lubricant for the low carbon steel part used for the automobile. The lubricant and the preparation method provided by the invention have the advantages of low energy consumption, low pollution, low emission, etc.

Owner:CHONGQING TELECOMM POLYTECHNIC COLLEGE

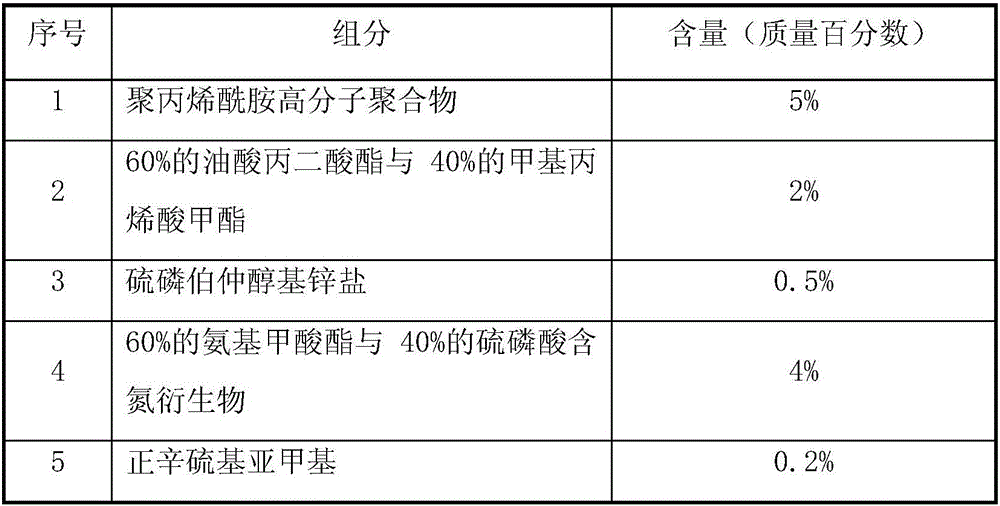

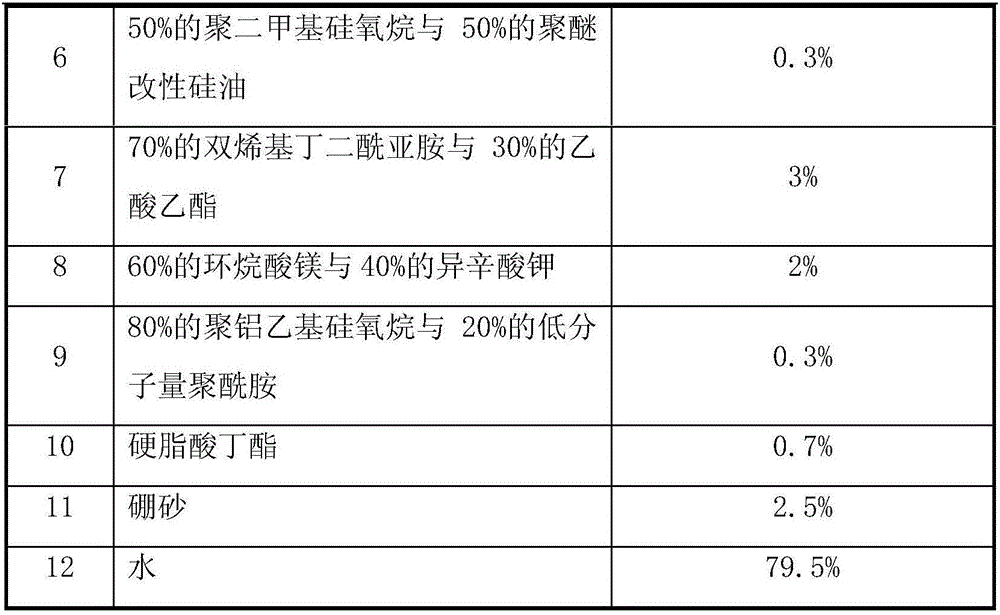

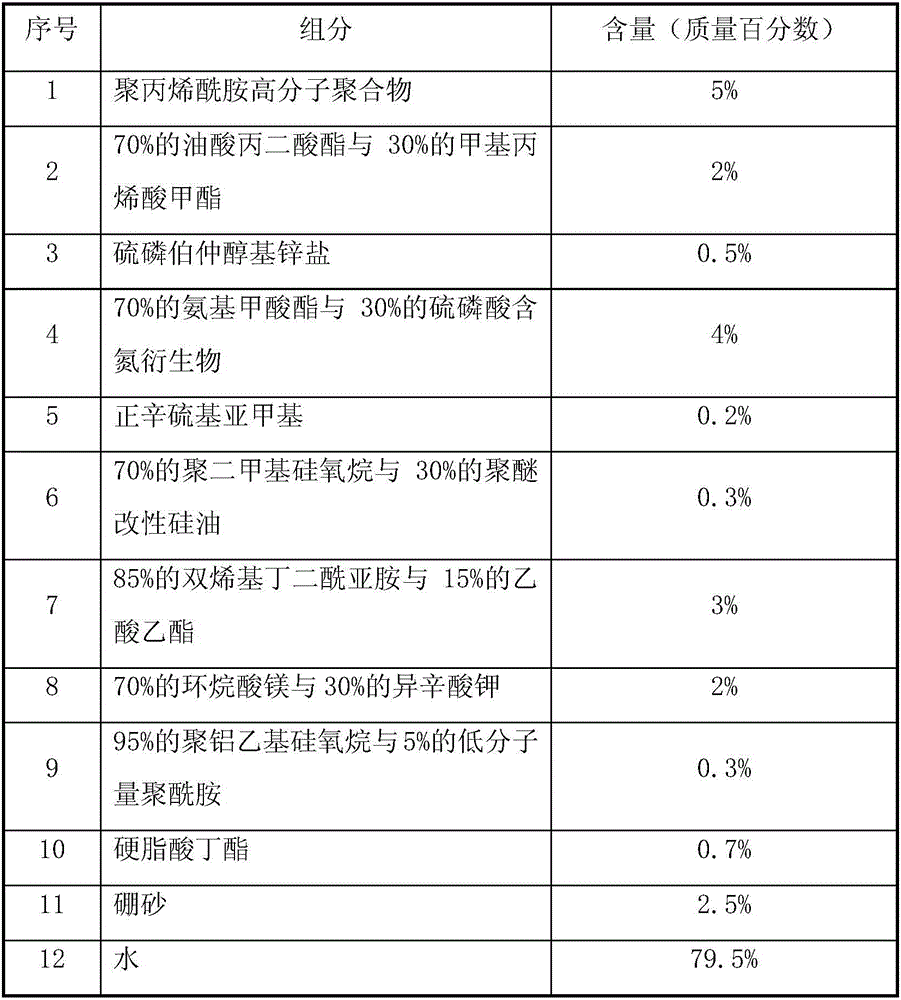

Lubricating agent for combined-cold-extrusion plastic forming of shaped charge liner and preparation method of lubricating agent

The invention belongs to the technical field of lubricating agents and discloses a lubricating agent for the combined-cold-extrusion plastic forming of a shaped charge liner and a preparation method of the lubricating agent. The lubricating agent comprises, by weight percentage, 2-8% of polyacrylamide high-molecular polymer, 1-3% of mixture of oleic acid malonate, 0.3-0.8% of sulfur phosphorus primary-secondary-alcohol-group zinc salt, 3-6% of mixture of carbamate and dialkylthiophosphoric acid derivatives containing nitrogen, 0.1-0.5% of n-octyl sulfur-based methylene, 0.2-0.5% of mixture of polydimethyl siloxane and polyether modified silicone oil, 2-5% of mixture of dialkenyl succinimide and ethyl acetate, 1-3% of mixture of magnesium naphthenate and potassium isooctanoate, 0.1-0.5% of mixture of polyaluminium ethyl siloxane and low-molecular-weight polyamide, 0.3-1.0% of butyl stearate, 1-4% of boric acid and the balance water. The lubricating agent is prepared by evenly mixing the substances above. By the lubricating agent, phenomena such as galling and cracking during the forming of the shaped charge liner can be avoided.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

High gloss wax emulsion for waterborne varnish printing, and preparation method of high gloss wax emulsion

The invention relates to the field of petrochemical industry, in particular to high gloss wax emulsion for waterborne varnish printing, and a preparation method of the high gloss wax emulsion. The high gloss wax emulsion for waterborne varnish printing is prepared from high density polyethylene wax, Fischer-Tropsch wax, an emulsifying agent, alkali, a wetting dispersant and water; the high densitypolyethylene wax and the Fischer-Tropsch wax are mixed and emulsified; the molecular weight of the high density polyethylene wax is within a range of 500-5000, and the molecular weight of the Fischer-Tropsch wax is within a range of 500-1000; the emulsifying agent is an environment-friendly emulsifying agent which has a cyclic structure and has a carbon number of 10-35. According to the method, the wax emulsion is prepared by mixing and emulsifying the polar oxidized polyethylene wax and the non-polar Fischer-Tropsch wax, and is applied to the waterborne varnish printing, so that a high oilyfeeling and glossiness is provided for varnish, and the surface of the varnish has a high degree of fineness; furthermore, due to smoothness of the Fischer-Tropsch wax, the viscosity, caused by acrylate, of the varnish is greatly reduced, the surface friction coefficient is reduced, and the wear resistance and the scratch resistance are improved; the environmentally friendly emulsifying agent is used and water is used as a solvent, so that pollution caused by adopting NP / OP emulsifying agents in the past is avoided.

Owner:广州聚科环保科技有限公司

Antirust paint used for boat bottom and preparation method thereof

ActiveCN103602211AImprove adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphoric acid

The invention discloses antirust paint used for a boat bottom. The antirust paint is prepared from following raw materials in parts by weight: 12-15 of an amino resin, 2-3 of zinc powder, 1-2 of nano silicon carbide, 1-2 of phosphoric acid, 70-75 of an E-12 epoxy resin, 7-9 of aluminium triphosphate, 4-5 of butanol, 12-14 of an E-42 epoxy resin, 2-3 of tert-butyl hydroperoxide, 6-8 of zinc oxide, 6-9 of bistetradecanol ester, 15-19 of ethyl acetate, and 3-4 of a film-forming resin. The antirust paint comprises the film-forming resin in the formula, thus improving compatibility of each component and improving the film-forming effect. Paint film obtained by using the antirust paint has excellent adhesive force and impact resistance, and good wear resistance, oil resistance, solvent resistance, water proofness, brine resistance and adhesion force between layers.

Owner:ANHUI ZHENXIN PAINT

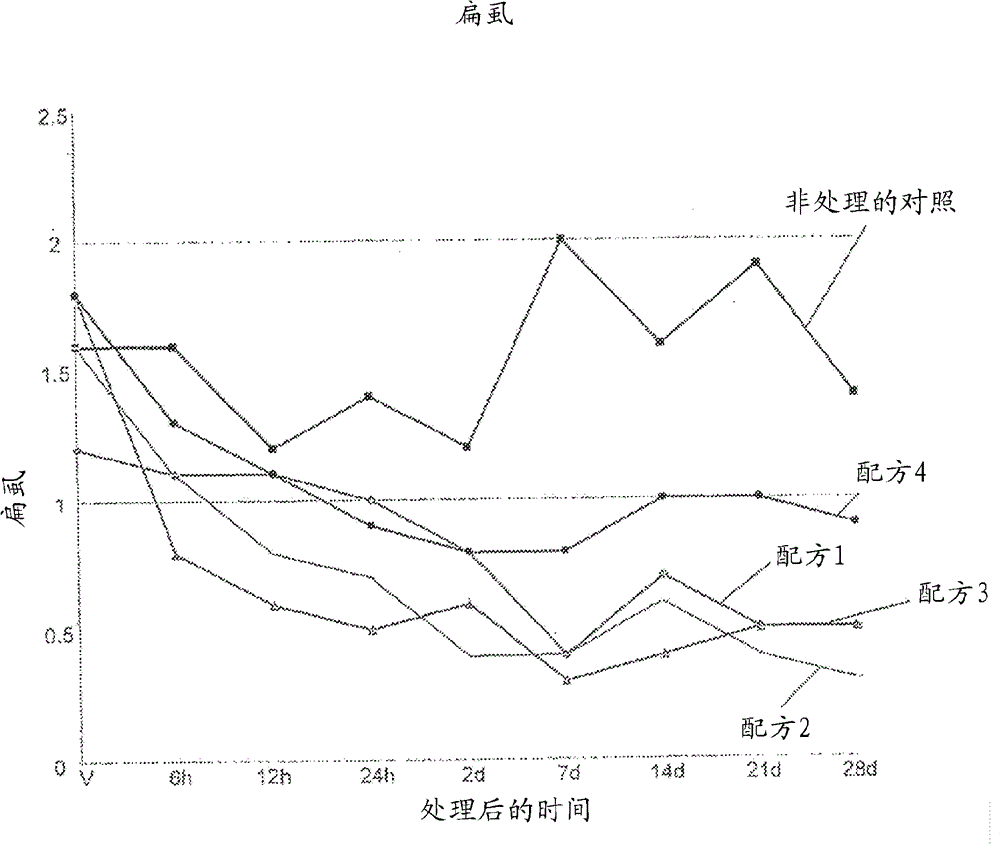

Spot-on preparation

InactiveCN103947689AImprove smellImprove oilinessBiocideCosmetic preparationsActive agentFatty acid ester

The invention relates to a spot-on preparation with a parasite-repelling action for topical application to animals. Repellent composition comprises 3-12 wt.% of an active agent component, at least 80 wt.% of a spreading agent component and 0-10 wt.% of a carrier and / or an excipient, where the active agent component contains one or more natural repellents, in which at least 50 wt.% are neem extract and / or decanoic acid, and the spreading agent component contains at least 50 wt.% of 6-12C-fatty acid ester or a mixture of two or more of 6-12C-fatty acid esters.

Owner:SOLNOVA

Quick-frozen pork reel

The invention discloses a quick-frozen pork reel and belongs to the technical field of food processing. Specifically, a method comprises the following steps: taking pork as a main raw material for preparing meat stuffing; cooking the meat stuffing and forming with a mold; coating a layer of lettuce leaves on the exterior; coating a layer of tofu skin on the exterior of the lettuce leaves. The meat stuffing is prepared from pork, chive, celery, ginger, onion, corn starch, black pepper and flavoring agent; the flavoring agent is prepared from salt, soy sauce, aginomoto and white sugar; the weight ratio of the meat stuffing to the lettuce leaves to the tofu skin is (7-8):(2-3):(4-5). The quick-frozen pork reel prepared according to the invention is high in edible value; the nutritional ingredients are reasonably matched with each other; the taste is nice; the quick-frozen pork reel is suitable for people of all ages; the hypertension and hyperglycemia symptoms can be effectively improved; besides, the preparation method is simple and standard; the quick-frozen pork reel is suitable for industrial production and is high in marketing value.

Owner:阜阳市春天食品有限公司

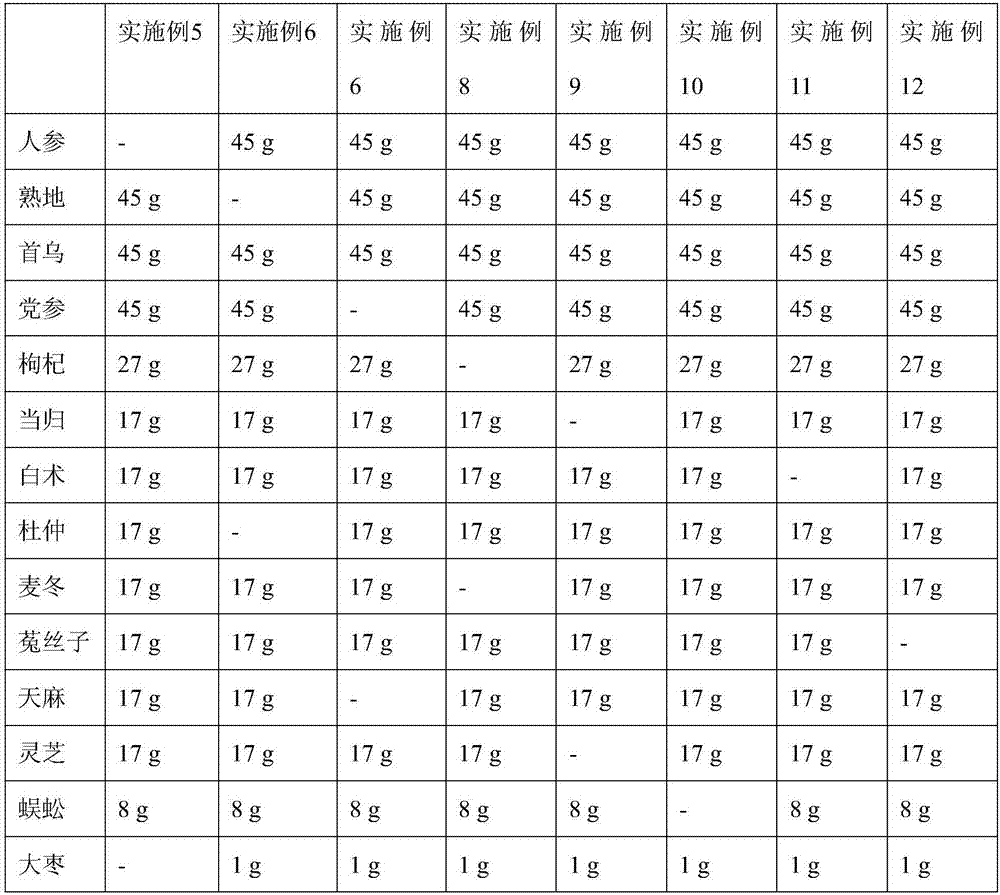

Hair growing traditional Chinese medicine composition and preparation method thereof

InactiveCN107982445AComposition is easy to getSimple recipeUnknown materialsDermatological disorderSide effectAcute toxicity testing

The invention belongs to the technical field of traditional Chinese medicines, and particularly relates to a hair growing traditional Chinese medicine composition and a preparation method thereof. Theformula is simple, and raw material constituents are easy to obtain, so that the treatment cost is reduced. The hair growing traditional Chinese medicine composition can be prepared into wine, soup,tablets and granules. The preparation method is simple, high in operability and convenient to use. An animal acute toxicity test shows that the medicine disclosed by the invention is actually nontoxicand cannot cause other side effects on the body of a patient. The medicine is safe and effective. The clinical experimental analysis shows that the effective rate of the medicine disclosed by the invention for the patient is up to 90 percent or above, and fair loss, the greasy degree, the scale degree and the itchy degree of hairs of the patient are obviously improved.

Owner:杨应科

Traditional Chinese medicine for mask

InactiveCN107029144AImprove oilinessIncrease elasticityCosmetic preparationsToilet preparationsSkin whiteningDisease

The invention discloses a traditional Chinese medicine for a mask. The traditional Chinese medicine for the mask is characterized by comprising the following raw materials in parts by mass: 5-35 parts of Radix Angelicae Dahuricae, 5-35 parts of Radix Ampelopsis, 8-30 parts of Pseudobulbus Bletillae, 6-40 parts of almond, 5-30 parts of pearl powder, 10-30 parts of white sesame, 15-35 parts of ginseng, 10-30 parts of Cortex Mori, 10-35 parts of Radix Puerariae, 8-30 parts of Semen Coicis, 5-35 parts of Rhizoma Atractylodis Macrocephalae, 10-30 parts of mung bean, 10-30 parts of Radix Paeoniae Alba, 10-35 parts of Fructus Atriplicis Sibiricae and 5-35 parts of Chinaroot Greenbrier Rhizome. By the traditional Chinese medicine for the mask, oiliness of skin is improved, elasticity of the skin is enhanced, and the skin is nourished. The traditional Chinese medicine is effective for macula, comedo and acnes, and has a skin whitening effect; the making cost is low; the mesh number of ground particles ranges from 100-700 meshes, and therefore, the traditional Chinese medicine can be absorbed by the skin; skin hysteresis is facilitated, and skin blood is smooth; and the immunity and the disease resistance of the skin are improved, because modern people excessively use cosmetics and lots of skin care products on the skin, the immunity and the disease resistance of the skin are reduced, and the skin is badly in need of being repaired.

Owner:王素芳

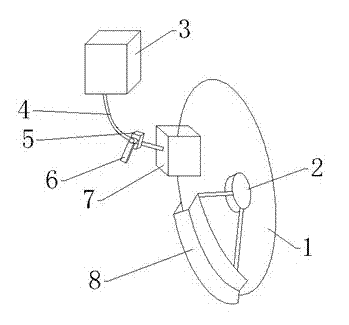

Oil-applying and scrap-removing device for circular cutter

The invention discloses an oil-applying and scrap-removing device for a circular cutter, comprising an oil inlet tube. A sucking pump is arranged at the oil outlet end of the oil inlet tube; the oil outlet of the oil inlet tube is inserted into a sponge; the sponge is arranged at the cutting edge of the circular cutter; a semicircular retaining plate is arranged at the clockwise lower part of the sponge; the section of the retaining plate is U-shaped; the horizontal section of the U shape is a flange covering the upper side of the cutting edge of the circular cutter and the upper end of the vertical section of the U shape is fixed at the circular cutter central shaft; the cutting edge extends into the sponge; and the sucking pump is equipped with a flow control valve. The device is economical, easy to use, simple in structure and low in manufacturing cost. The device can take good effect of protecting the cutting edge.

Owner:吴江久升纸业有限公司

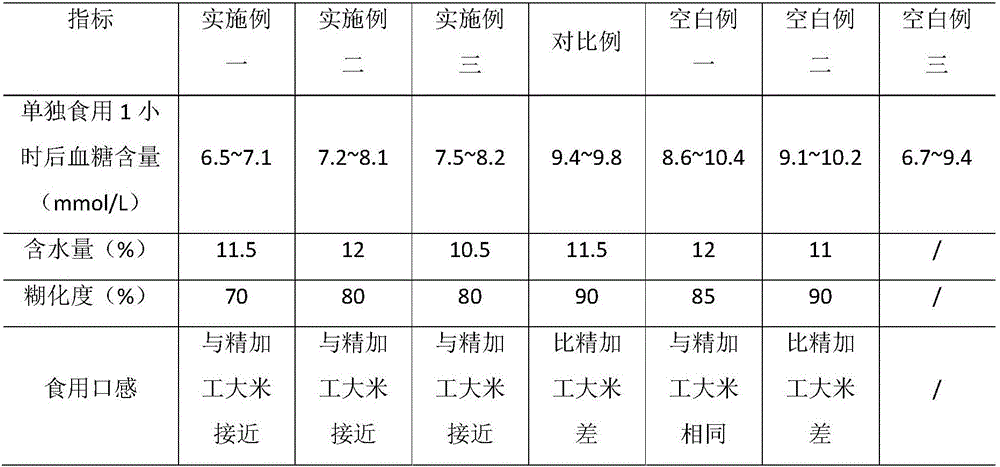

Low-sugar regenerated rice production process and product thereof

InactiveCN106071837ASufficient water absorptionIncreased internal viscosityFood dryingFood ingredient functionsDrying timeRice grain

The invention discloses a low-sugar regenerated rice production process and a product thereof and belongs to the field of food processing. The process includes the steps of raw material smashing, water adding for quenching and tempering, extruding and pelleting, surface hardening and drying. 15-45 parts by weight of broken rice flour, 5-10 parts by weight of rice bran powder, 5-10 parts by weight of coarse powder, 16-23 parts by weight of bitter gourd powder, 5-8 parts by weight of yam flour, 8-12 parts by weight of lotus seed powder, 8-12 parts by weight of coix seed powder and 8-10 parts by weight of taro powder are adopted as raw materials; an extruder with the compression section temperature being 85-95 DEG C and the screw speed being 240-270 r / min is used for extruding and pelleting, and after the raw materials are extruded, the raw materials are shaped through a die head and cut into rice grains through a cutter; secondary gradient hot air is adopted for drying till the water content ranges from 11% to 12%; the temperature of primary drying airflow ranges from 55 DEG C to 60 DEG C, and the drying time ranges from 15 min to 20 min; the temperature of secondary drying airflow ranges from 20 DEG C to 25 DEG C, the drying time ranges from 5 min to 10 min, and low-sugar regenerated rice is obtained. The problems that the edible utilization rate of rice processed byproducts is low, part of grain waste exists, and rise of blood glucose is rapid after cereal rice (or refrigerated rice) is eaten are solved.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hexakis-addition [60] fullerene derivative and application thereof in lubrication field Hexakis-addition [60] fullerene derivative and application thereof in lubrication field](https://images-eureka.patsnap.com/patent_img/29d9e71a-7750-4991-860d-fcc70998cfeb/HDA0000881736340000011.PNG)

![Hexakis-addition [60] fullerene derivative and application thereof in lubrication field Hexakis-addition [60] fullerene derivative and application thereof in lubrication field](https://images-eureka.patsnap.com/patent_img/29d9e71a-7750-4991-860d-fcc70998cfeb/BDA0000881736330000021.PNG)

![Hexakis-addition [60] fullerene derivative and application thereof in lubrication field Hexakis-addition [60] fullerene derivative and application thereof in lubrication field](https://images-eureka.patsnap.com/patent_img/29d9e71a-7750-4991-860d-fcc70998cfeb/BDA0000881736330000031.PNG)