Patents

Literature

120results about How to "Promote curing reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof

The invention relates to the technical field of curing agents and particularly relates to a curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, comprises the following components in percentage by weight: 0.1-2% of fluorosilicate, 0.001-0.02% of surfactant, 5.0-30.0% of at least one of silica sol or silicate and the balance of water. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, has the advantages of short curing time, thick surface hardened layer and high surface hardness, and can be widely used for surface hardening and curing treatment of concrete buildings or structures of highways, squares, garages, supermarkets, factory buildings and the like.

Owner:DONGGUAN MERROCK IND

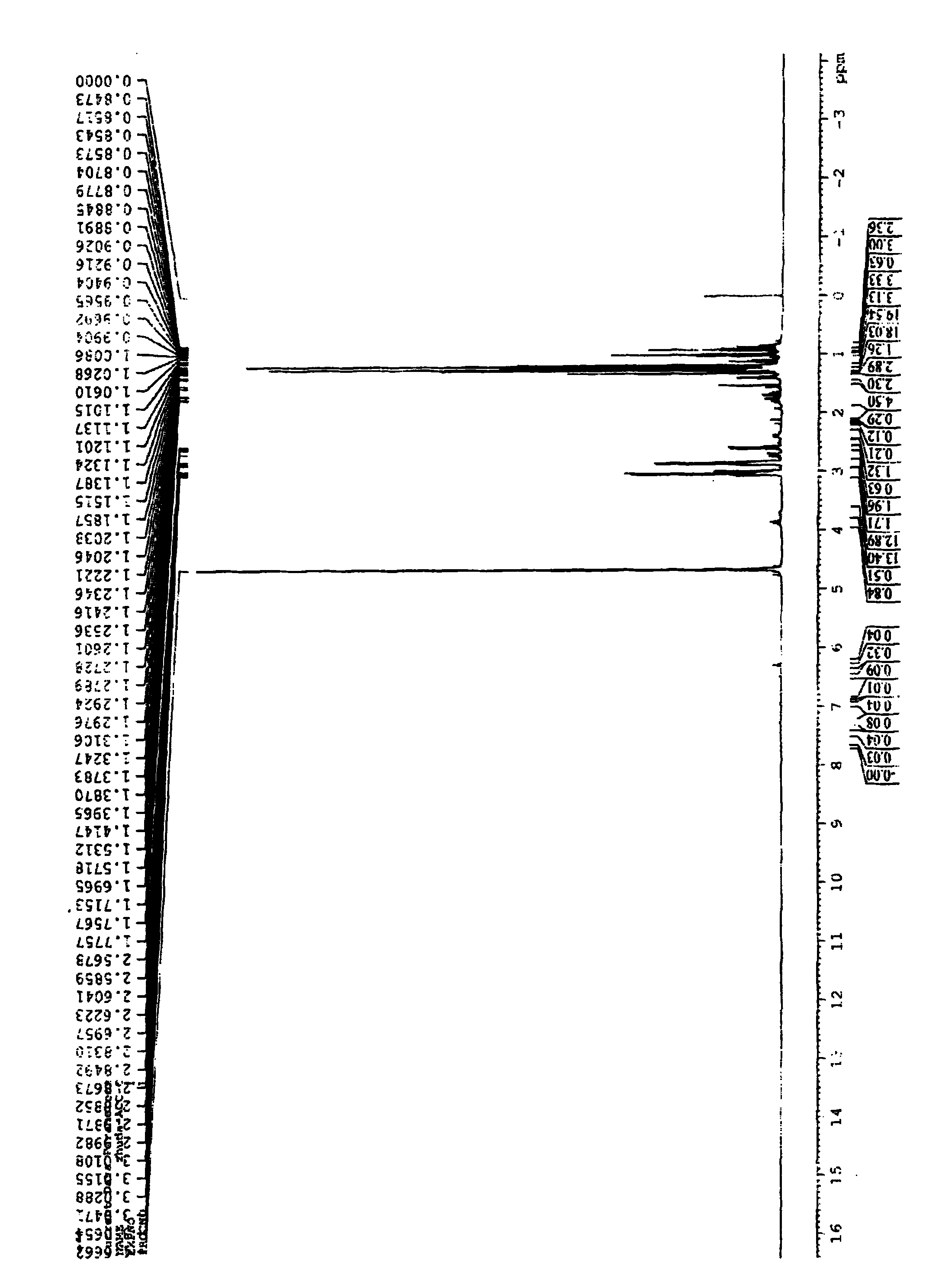

Method for preparing methyl phenyl vinyl silicone resin

The invention discloses a method for preparing a methyl phenyl vinyl silicone resin, which comprises the following steps of: under a condition of a nitrogen atmosphere at the temperature of between 30 and 45 DEG C, dissolving a certain amount of methyl trimethoxy silane, vinyl trimethoxy silane and alkyl dimethoxy silane in ethanol; adjusting the pH of the system to between 2.8 and 3.5; after full reaction, adding the methyl trimethoxy silane, the vinyl trimethoxy silane, the alkyl dimethoxy silane and deionized water into the mixture to perform isothermal reaction for 0.5 to 1 hour at the temperature of between 50 and 60 DEG C; raising the temperature to between 72 and 78 DEG C, performing the isothermal reaction again for 8 to 10 hours, and then dropping an end capping agent and deionized water into the mixture; performing reaction at the temperature of between 72 and 78 DEG C for 6 to 10 hours to obtain a white emulsion; and standing the mixture until complete demixing, separating the mixture to obtain an oily matter at a lower layer, and performing vacuum drying on the oily matter to obtain a product of the methyl phenyl vinyl silicone resin. In the method, the process is simple, the product is easy to separate and purify, the reactions are mild and are easy to control, and the processability is greatly improved.

Owner:SUZHOU UNIV

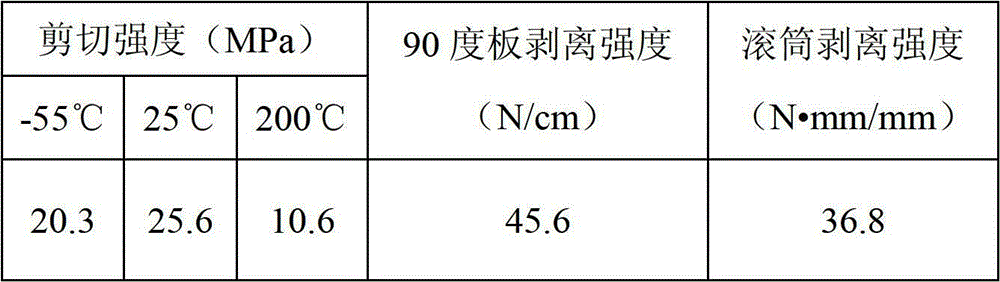

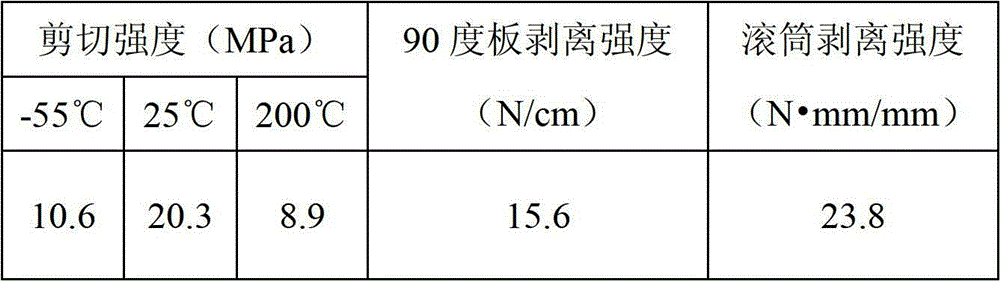

Modified cyanate adhesive film and preparation method thereof

ActiveCN102876247AGood mechanical propertiesEasy to operateNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention relates to a modified cyanate adhesive film and a preparation method thereof, belonging to the field of modified cyanate adhesive films and preparation methods thereof. The invention aims at solving the technical problems that the surface of the cyanate adhesive film prepared by using the existing cyanate adhesive film preparation method is apt to be crystallized during placing at room temperature, the mechanical performance is low and the curing temperature is high. The modified cyanate adhesive film is prepared by using the following components in parts by weight: 60-100 parts of cyanate resin, 5-40 parts of epoxy resin, 1-50 parts of toughened resin, 1-10 parts of activated thinner and 1-5 parts of accelerator. The preparation method comprises the following steps of: 1) weighing raw materials; 2) preparing matrix resin; 3) preparing adhesive; and 4) preparing the modified cyanate adhesive film. The modified cyanate adhesive film and the preparation method thereof are used in the fields of aerospace and electronic information.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

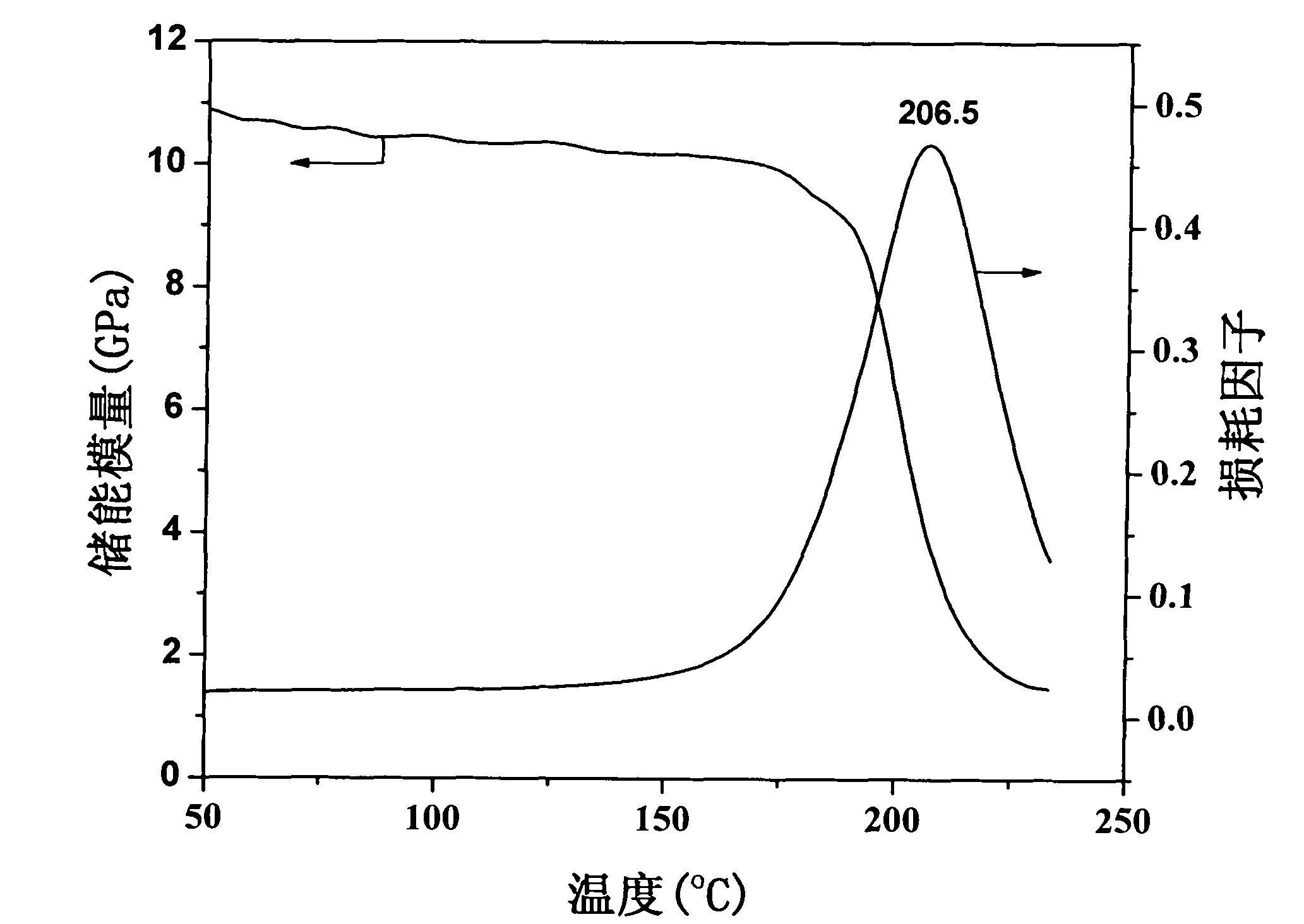

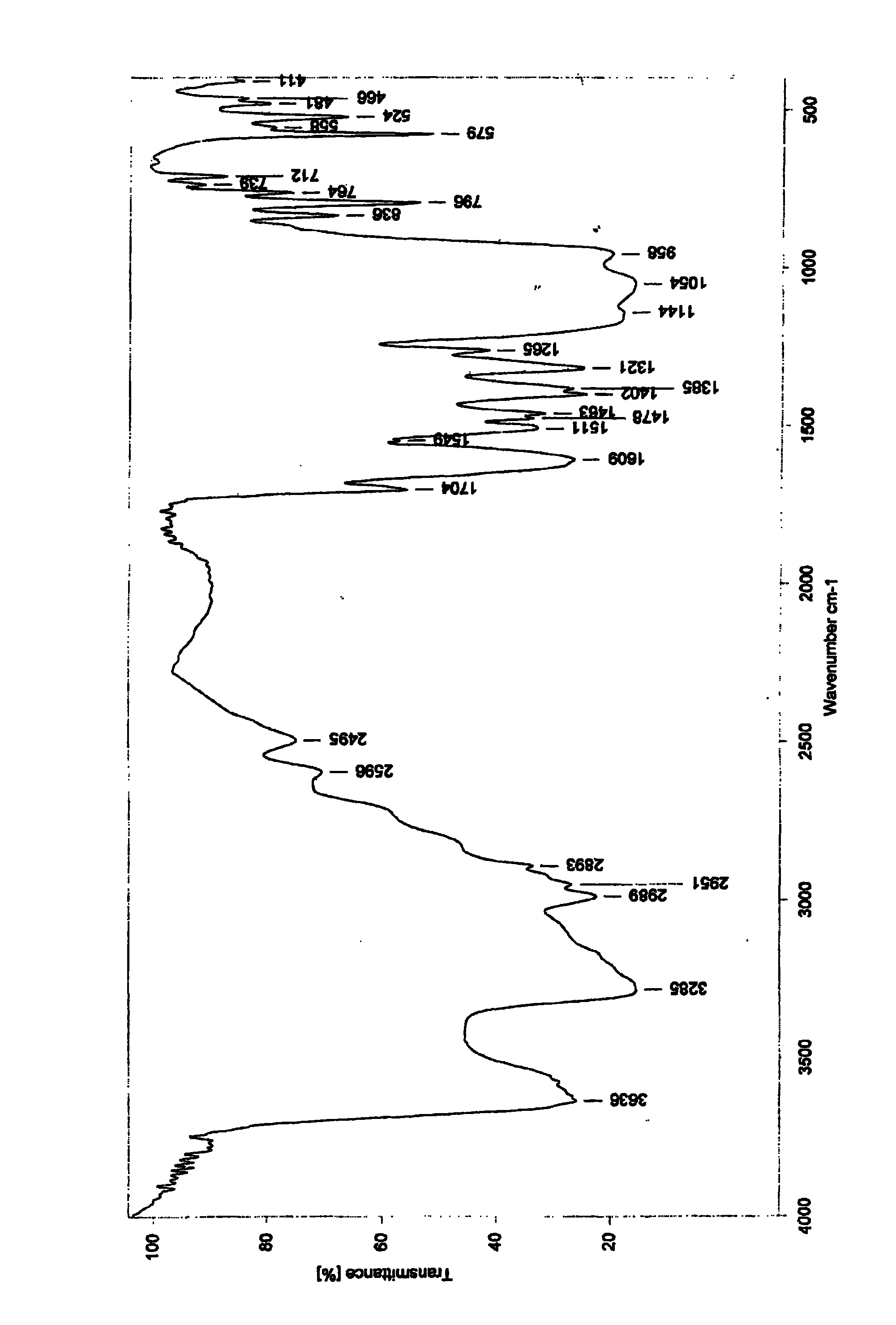

High-temperature resistance carbon fiber/epoxy resin composite material, preparation method and use

The invention discloses a high-temperature resistance carbon fiber / epoxy resin composite material, a preparation method and use. The method comprises the steps of preimpregnation material preparation and composite material curing forming. Through introducing a kind of latent accelerating agents of fatty amine hydrofluoride, the method reduces the forming time of the composite materials in a mold, effectively improves the production efficiency, reduces the production cost, and can not shorten the storage period of the preimpregnation materials. Through the high-temperature heat treatment, the invention further improves the crosslink density of the resin, and is favorable for improving the vitrification conversion temperature of the composite materials, and at the same time, the high-temperature heat treatment can effectively eliminate the inner stress produced by fast curing. The prepared composite material has good mechanical property and abrasion resistance performance, the vitrification conversion temperature of the composite material is between 190 and 210 DEG C, and the 180 DEG C high-temperature environment resistance requirements can be met.

Owner:SUN YAT SEN UNIV +1

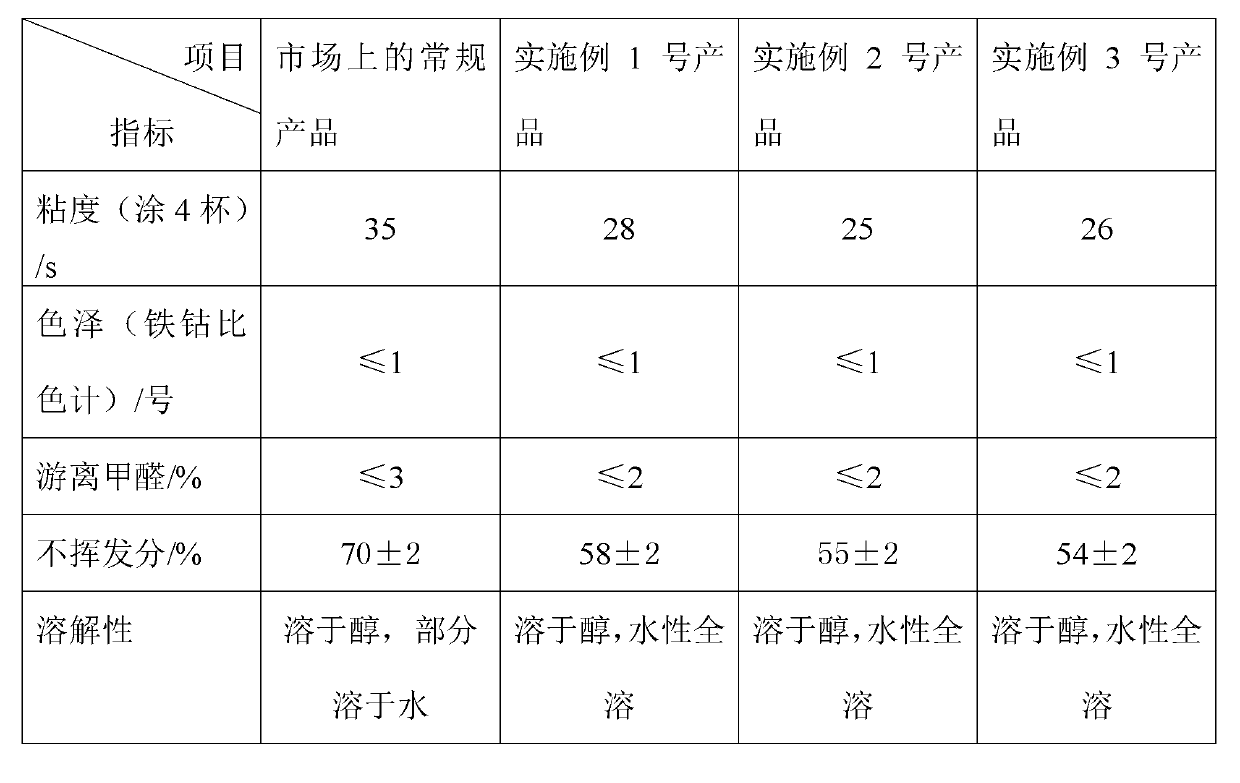

Preparation method of high imino methylated melamine resin

The invention relates to a preparation method of high imino methylated melamine resin. According to the preparation method, by adjusting the components of raw materials, the adding sequence of the components, the time, the proportion of the components in parts by weight, reaction parameters of the process of the method and the like in the steps of the method, the oiliness of the obtained high imino methylated melamine resin can be greatly improved, the weight loss in baking is small, a strong acid is not required for catalysis, the resin can perform rapid curing reaction under the general baking condition of 110-150 DEG C, and the resin has higher anti-curing performance; and in addition, the resin is fully water soluble, the range of applications of the resin is greatly expanded and the popularization and application value is further higher.

Owner:SHANDONG ZHANHUA OSITER CHEM

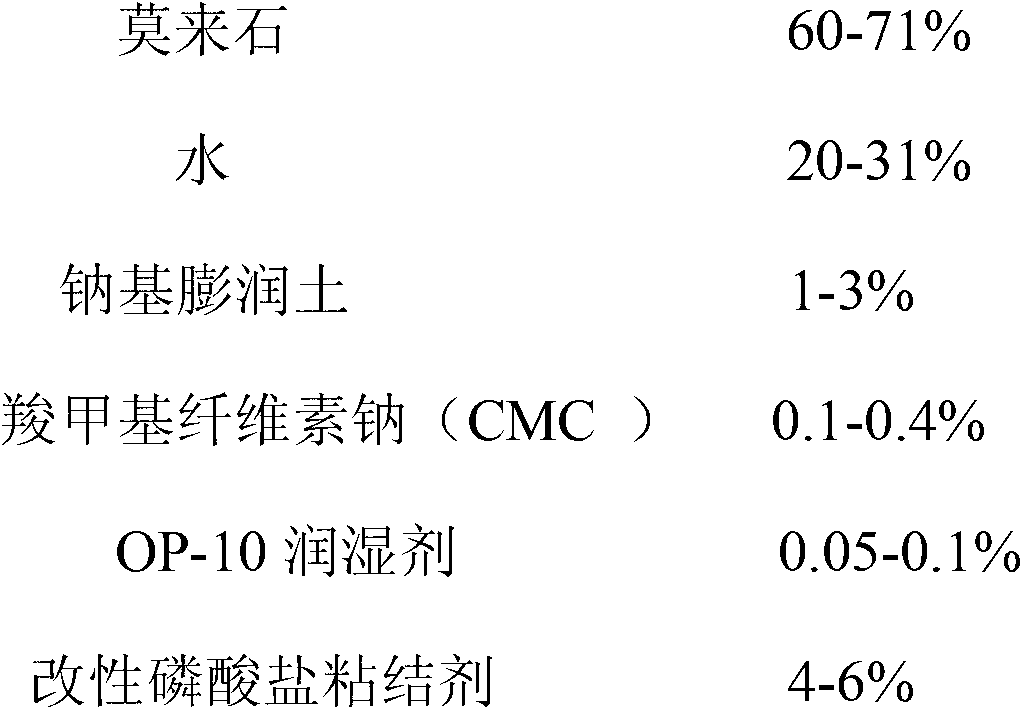

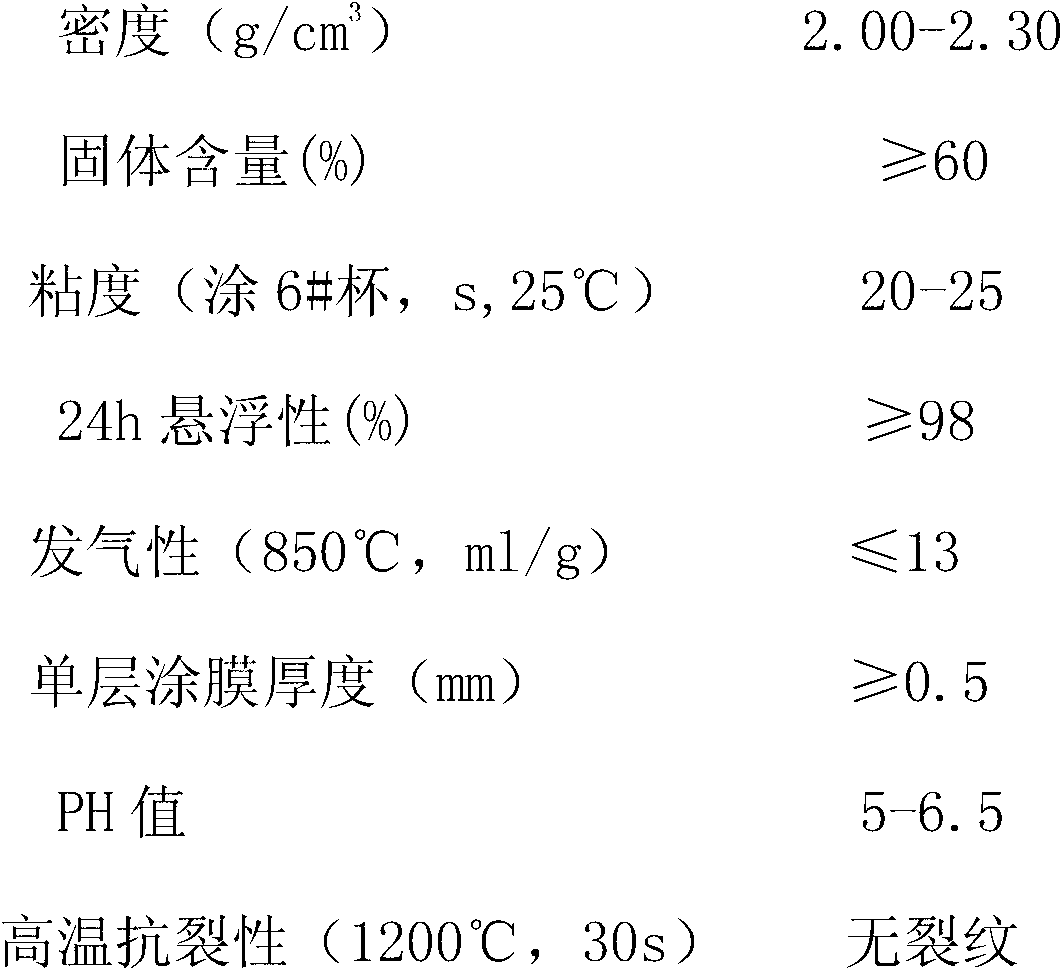

Water-based self-drying casting paint, and preparation method and application method

InactiveCN103223458ATightly boundImprove rheologyFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention provides a water-based self-drying casting paint, and a preparation method and an application method. According to the invention, 1-3% of sodium-based bentonite and water 1-1.5 times the weight of bentonite are uniformly stirred with high speed; the mixture is added in a sealed container and is subjected to standing, where the mixture is sufficiently wetted and activated, such that a liquid A is prepared; 0.1-0.4% of sodium carboxymethyl cellulose is dispersed by using ethanol with a concentration no lower than 95% according to a weight ratio of 1:1; water with an amount 30-50 times that of the mixture is added; the mixture is uniformly stirred and is subjected to standing and sufficient initiation; the mixture is mixed with the liquid A; the obtained mixture is stirred with a proper amount of water; a composite suspension is prepared by grinding by using a colloid mill; the suspension is mixed and grinded with 60-71% of mullite, 0.05-0.1% of a wetting agent, and 4-6% of a modified phosphate binder, such that a pasty paint is prepared; and the pasty paint is diluted by using water, such that the paint is obtained. After a reaction with an alcohol-based paint comprising magnesia powder, the paint can be self-dried. Therefore, cost of independent use of an alcohol-based paint or a water-based paint is greatly reduced, and the influence to the environment is greatly ameliorated.

Owner:HUBEI UNIV OF TECH

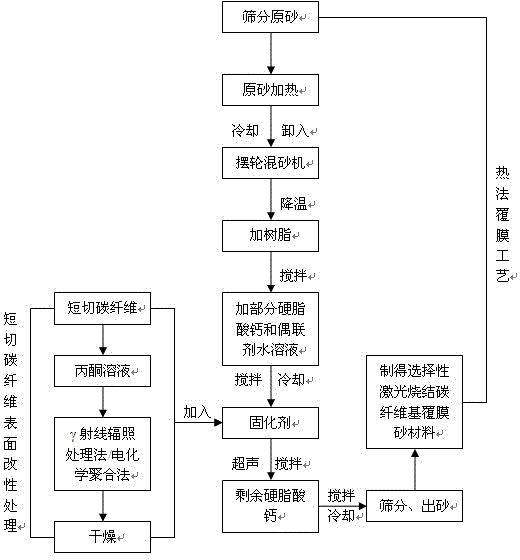

Carbon fiber-based precoated sand material for selective laser sintering and preparation method thereof

InactiveCN104308072AImprove thermal stabilityEnhancement effect is goodFoundry mouldsFoundry coresFiberSelective laser sintering

The invention discloses a carbon fiber-based precoated sand material for selective laser sintering and a preparation method thereof. The carbon fiber-based precoated sand material comprises chopped carbon fibers, crude sand, an organic binder, a curing agent, a lubricant, a coupling agent and a dispersant. The preparation method comprises the following steps of carrying out surface modification treatment on the chopped carbon fibers, heating the crude sand, adding resin, adding a part of calcium stearate and a prepared coupling agent aqueous solution, adding a chopped fiber-containing urotropine curing agent, adding the rest of the calcium stearate, carrying out cooling and carrying out screening and sand discharge to obtain the product. The carbon fiber-based precoated sand material has the advantages that 1, the carbon fibers have thermal conduction effects, limit integral shrinkage of a sintered part to a certain degree and reduce warp phenomenon in molding, and 2, through laser sintering, the precoated sand substantially improves resin precoated sand thermostability, promotes curing reaction of phenolic resin at locals in the sintered layer and between the sintered layers and obviously improves laser sintering forming part blank strength.

Owner:NANCHANG HANGKONG UNIVERSITY

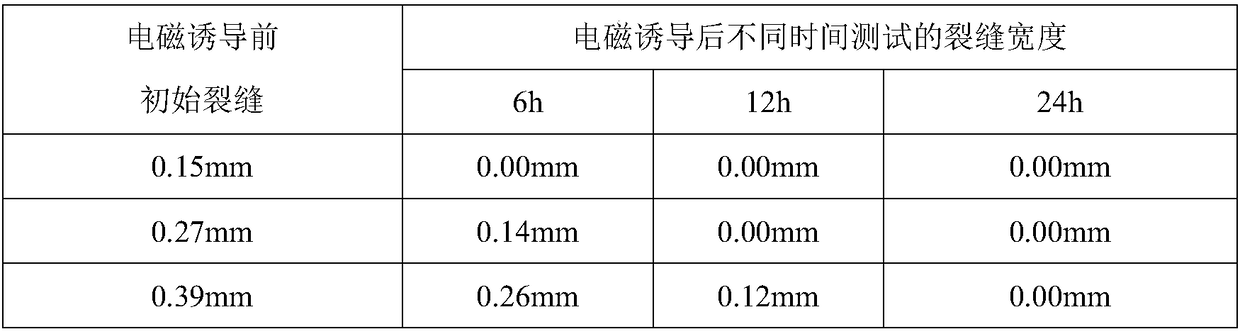

Electromagnetically-induced self-repairing epoxy resin type microcapsule for cement concrete cracks and preparation method thereof

ActiveCN108395137AStrong self-healing abilityExtend service lifeMicroballoon preparationMicrocapsule preparationPolyamidePOLYETHYLENE WAX

The invention belongs to the technical field of concrete, and particularly relates to an electromagnetically-induced self-repairing epoxy resin type microcapsule for cement concrete cracks and a preparation method thereof. The microcapsule consists of an epoxy resin microcapsule body and a curing agent microcapsule body. According to the microcapsule and the preparation method thereof, a paraffin / petroleum resin / polyethylene wax / iron powder mixture serves as a capsule wall, and epoxy resin and a low-molecular polyamide curing agent serve as a capsule core of the microcapsule; and when concretegenerates the cracks, the propagation tip stress of part of the cracks is large, so that the capsule wall of the microcapsule can be broken, the epoxy resin or the low-molecular polyamide curing agent inside the capsule flows out and is diffused to enter the cracks, curing reaction is generated to form a cross-linked product, so that the cracks can be repaired in time, cracks which are not repaired in time can enable the capsule wall of the microcapsule to be heated and melted under the action of an applied electromagnetic field, and the epoxy resin or the low-molecular polyamide curing agentis diffused to enter the cracks, so that the cracks can be repaired. The epoxy resin microcapsule has the advantages of being capable of endowing the concrete with stronger crack self-repairing capability and capable of prolong the service life of the concrete.

Owner:WUHAN UNIV OF TECH

A kind of epoxy resin composition with high heat resistance and high toughness and preparation method thereof

The invention relates to an epoxy resin composition and preparation thereof. The composition comprises the following blended components : 100 weight parts of epoxy resins; 30 to 120 weight parts of anhydride curing agents; 1 to 45 weight parts of powdery nitrile rubbers; no curing accelerator is included in the composition. The composition of the invention has both higher heat resistance and higher toughness, and is suitable for the fields which require high heat resistance, such as circuit board, electronics packaging, binder and electrical insulating coating etc..

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano porous ceramic for atomizing core and preparation method of nano porous ceramic

ActiveCN112592200AUnbreakableSolve the problem of cracking and oil leakageMedical atomisersTobaccoParaffin waxMolten state

The invention discloses nano porous ceramic for an atomizing core and a preparation method. The ceramic is prepared from 1 to 60 parts of nano silicon oxide, 10 to 80 parts of ceramic powder, 1 to 50parts of a pore-forming agent and 1 to 40 parts of a sintering aid. The preparation method comprises the steps of (1) weighing raw materials including nano silicon dioxide, ceramic powder, a pore forming agent and a sintering aid, and putting the raw materials into a ball milling device for mixing and ball milling; (2) baking and drying the ball-milled mixture to obtain mixed powder; (3) heating paraffin to a molten state, adding the mixed powder while stirring, and continuously stirring for 1-8 hours after the addition is finished so as to obtain paraffin slurry; (4) injecting the paraffin slurry into a pre-prepared mold, cooling and molding, and demolding to obtain a wax mold; (5) preheating the wax mold to remove wax to obtain a dewaxed sample; and (6) sintering the dewaxed sample, andcooling to obtain the nano-porous ceramic. The preparation method has the beneficial effects that the problem that the requirements of high porosity and high strength cannot be met simultaneously in the prior art is solved, and the problem that impurities and heavy metals are easy to separate out is solved.

Owner:HUIZHOU HAPPY VAPING TECH LTD

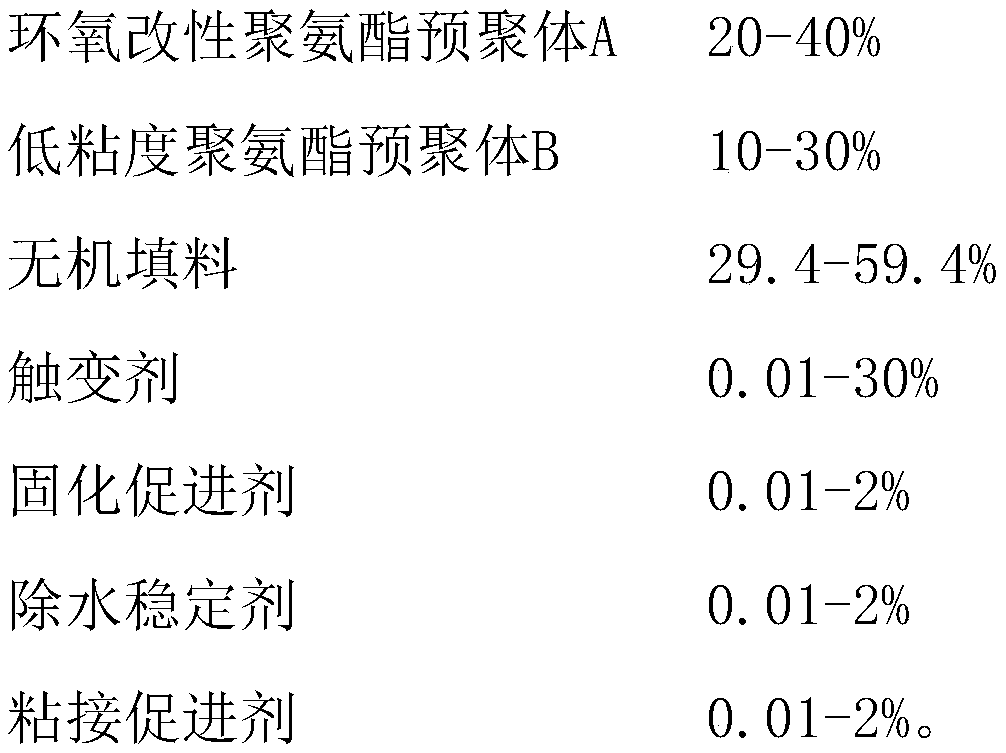

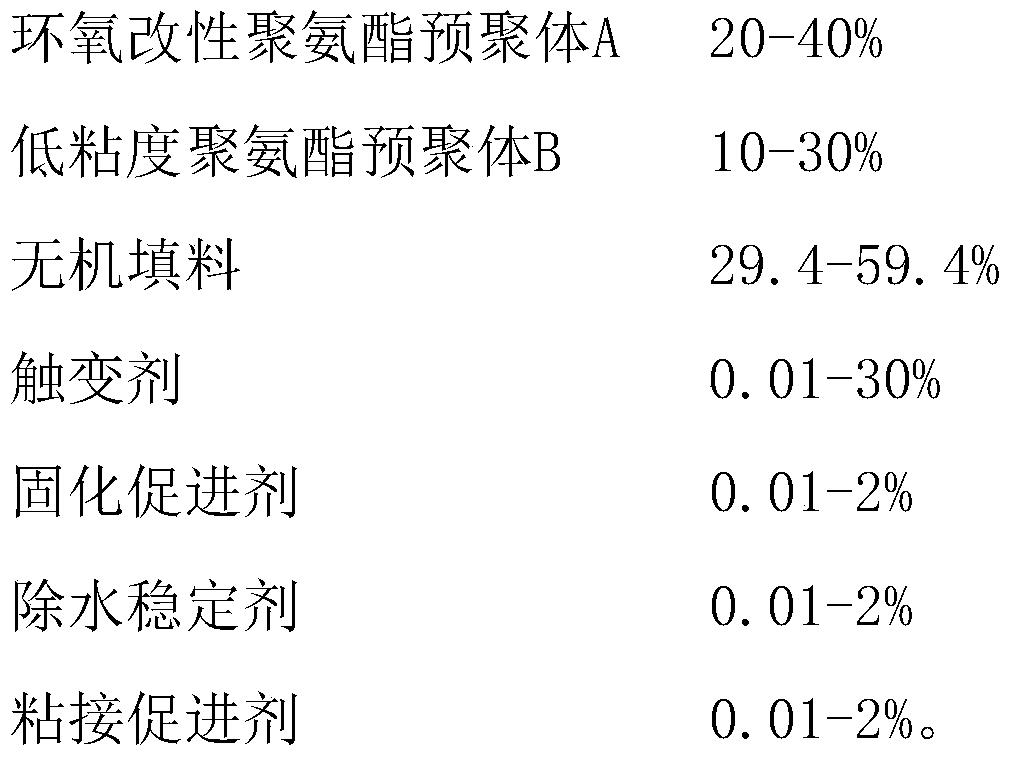

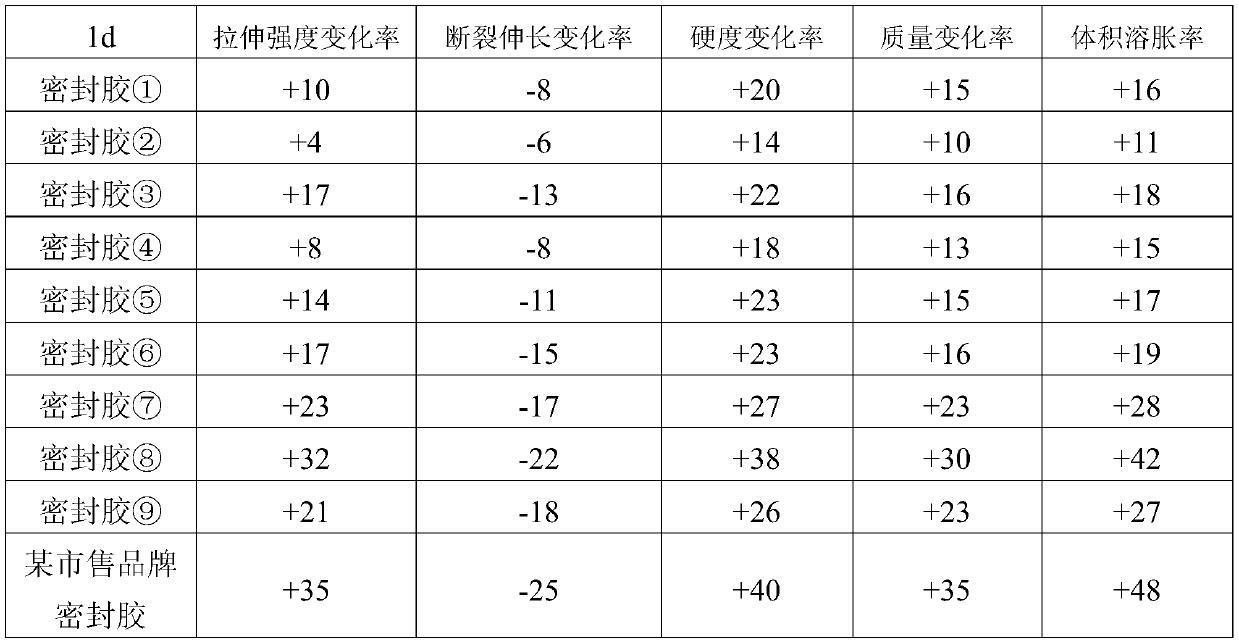

Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

ActiveCN110172323AGood chemical resistanceGood mechanicalNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

The invention relates to the technical field of sealants, in particular to a solvent-resistant epoxy modified polyurethane sealant and a preparation method thereof. The sealant is prepared from, by weight, 20-40% of an epoxy modified polyurethane prepolymer A, 10-30% of a low-viscosity polyurethane prepolymer B, 29.4-59.4% of an inorganic filler, 0.01-30% of a thixotropic agent, 0.01-2% of a curing promoter, 0.01-2% of a water removal stabilizer and 0.01-2% of an adhesion promoter. The epoxy modified polyurethane sealant has excellent chemical corrosion resistance and mechanical properties, through a chemical corrosion test in the industry standard of a membrane-type gas meter, after liquid immersion, the mechanical properties, mass change rate and volume change rate of the sealant can allbe kept at a very small change rate, the adhesive sealing effect is good, and the sealant can keep the good adhesive sealing function during long-term use in the gas meter.

Owner:广东盛业化学科技有限公司

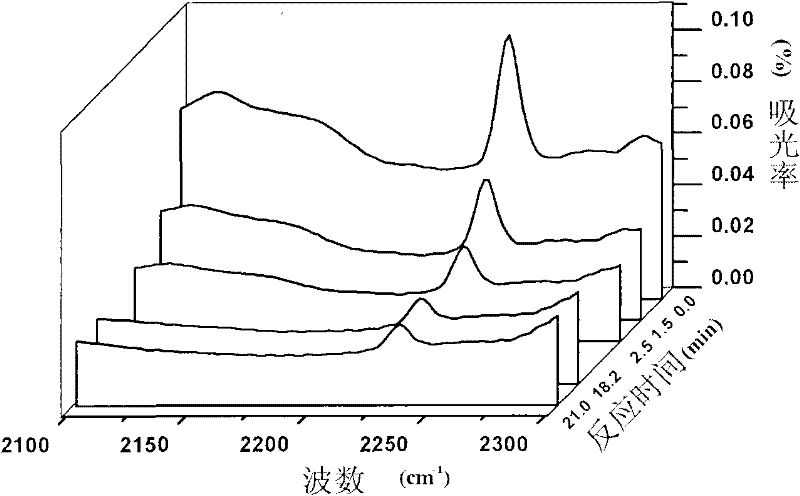

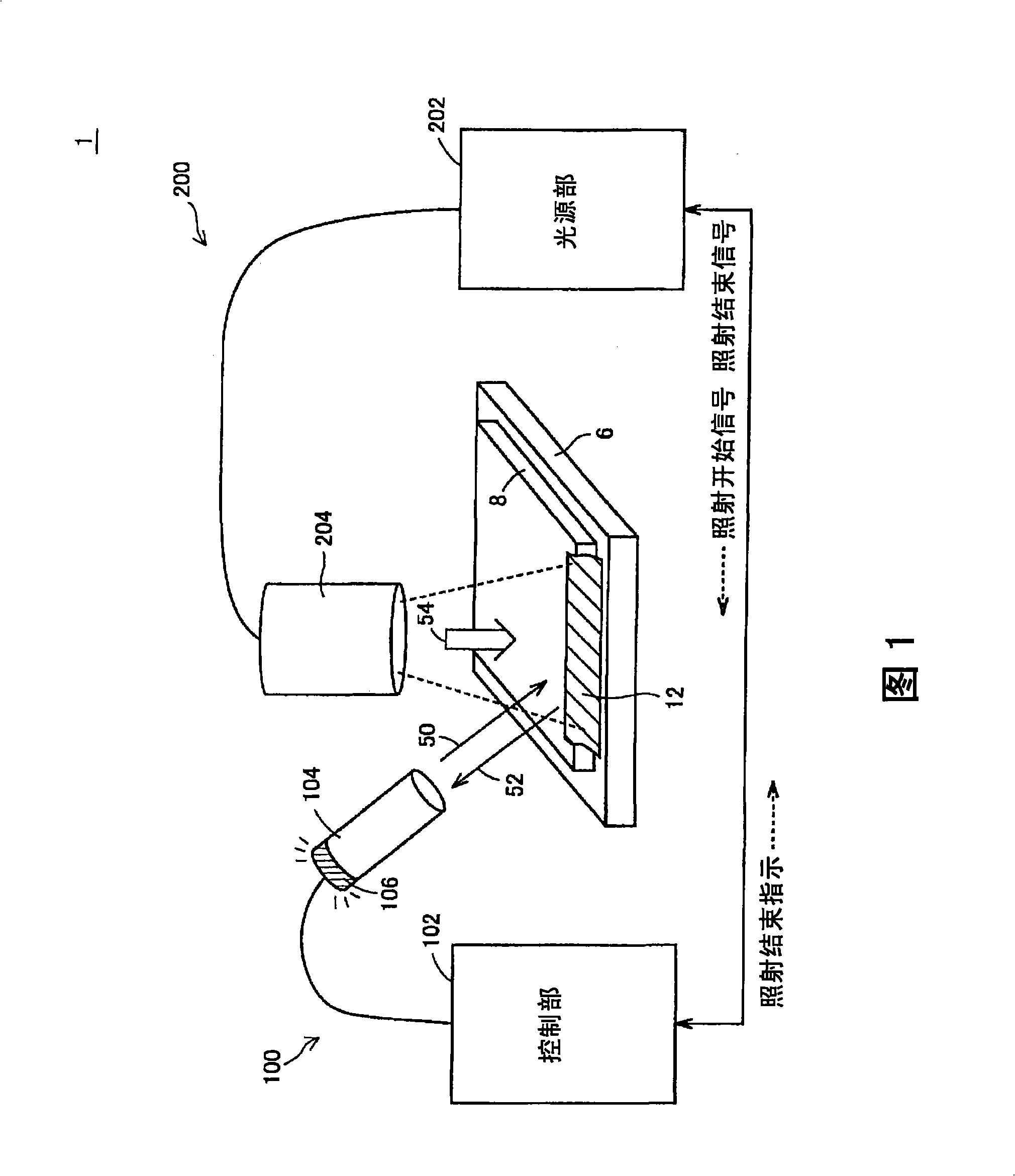

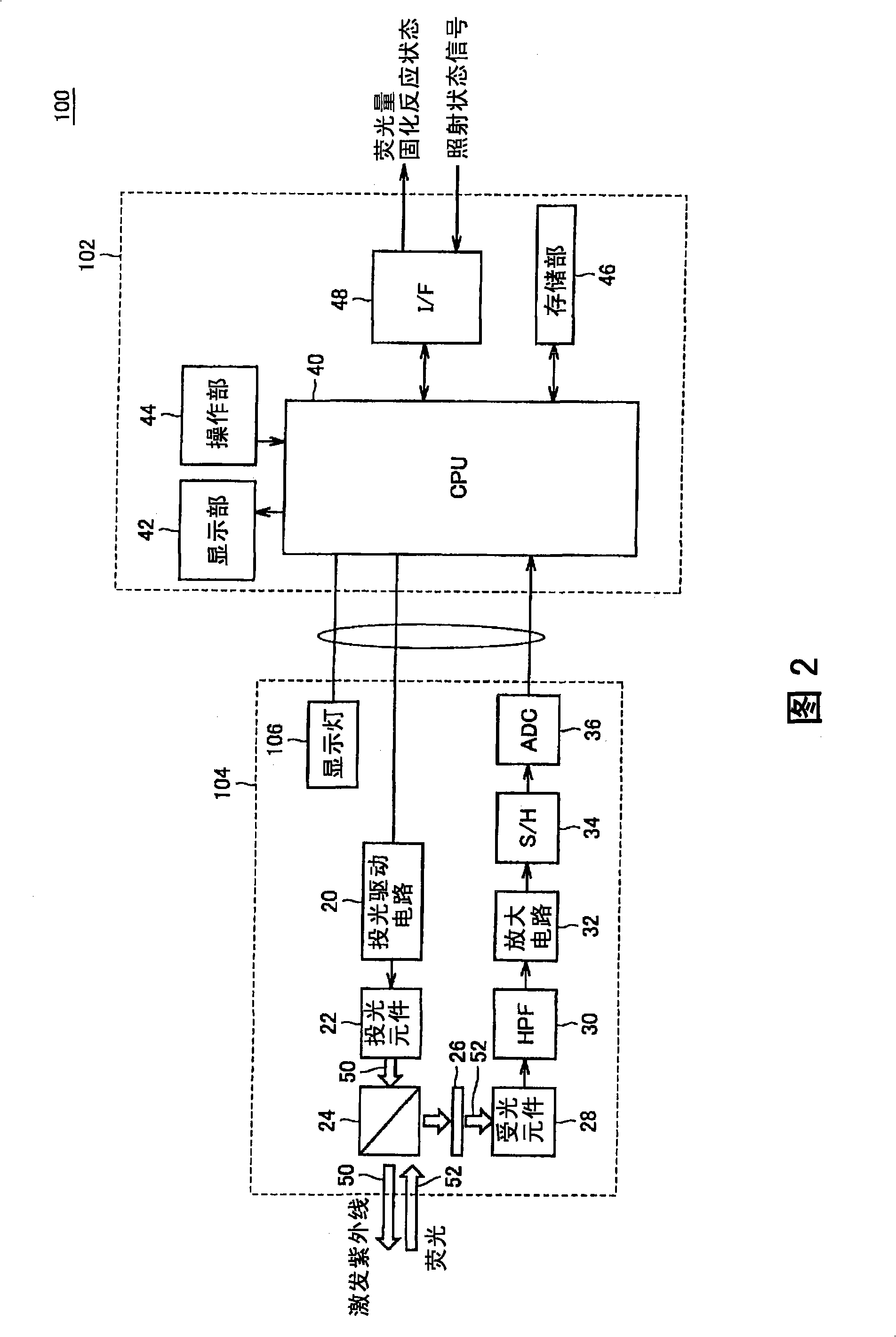

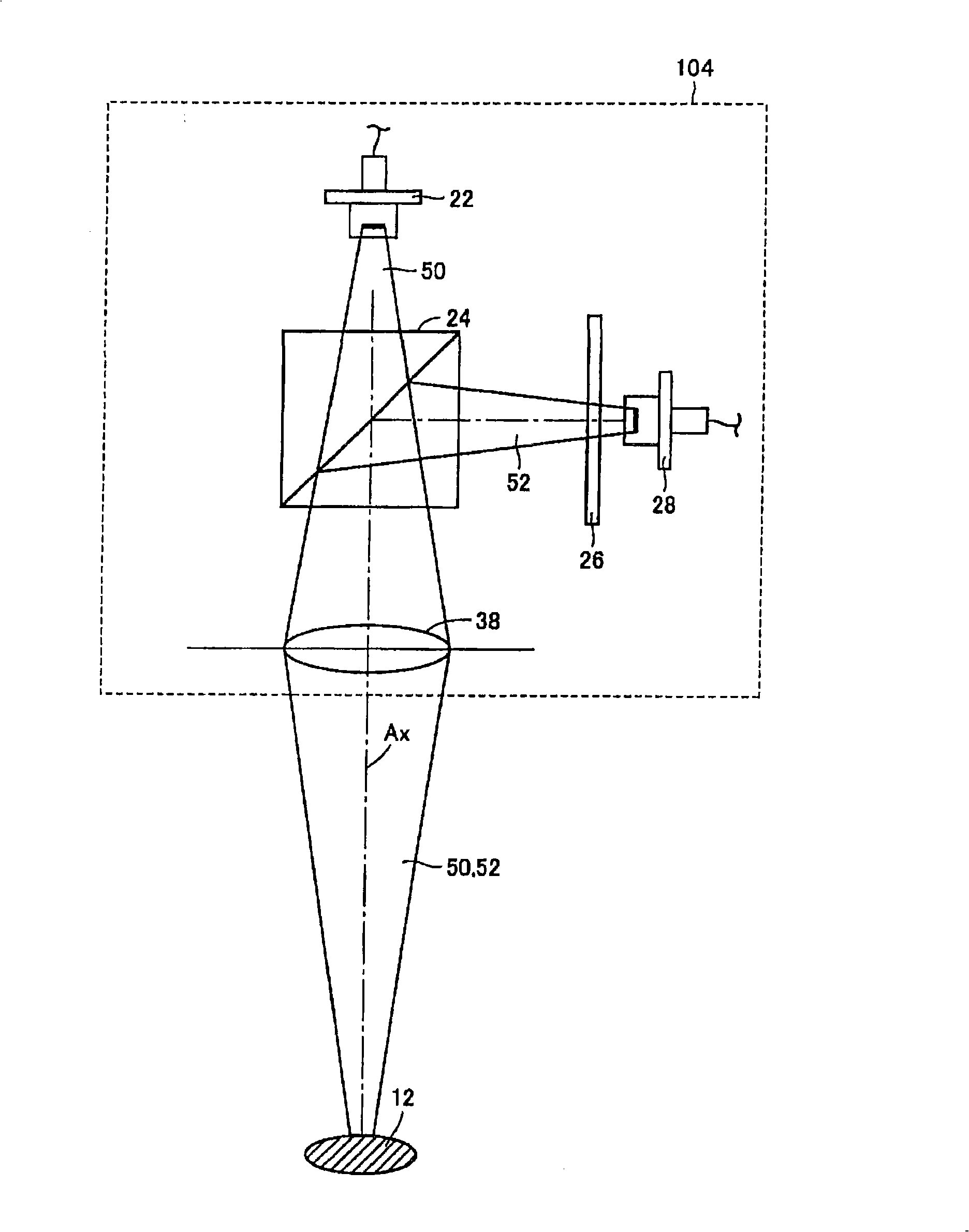

Ultraviolet irradiation system, curing reaction detector and curing method of resin

InactiveCN101266211APromote curing reactionReal-time judgment of curing reaction statusPretreated surfacesFluorescence/phosphorescenceUV curingFluorescence

Owner:ORMON CORP

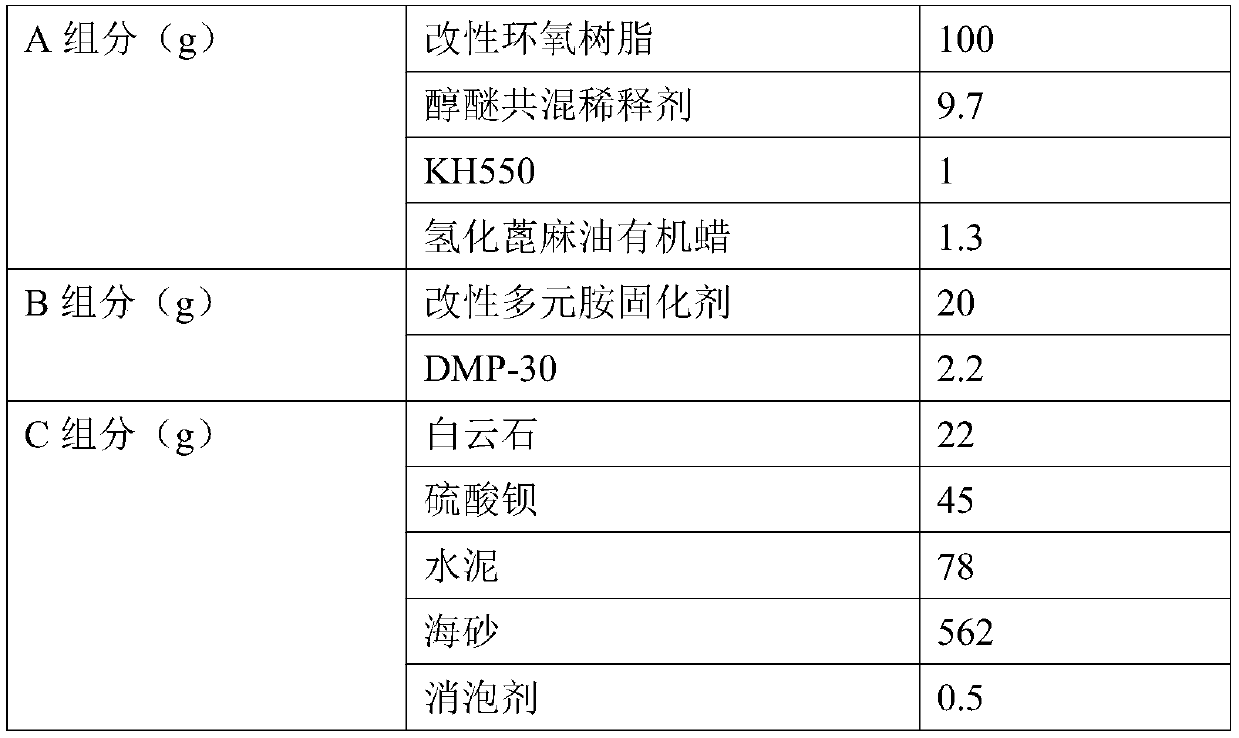

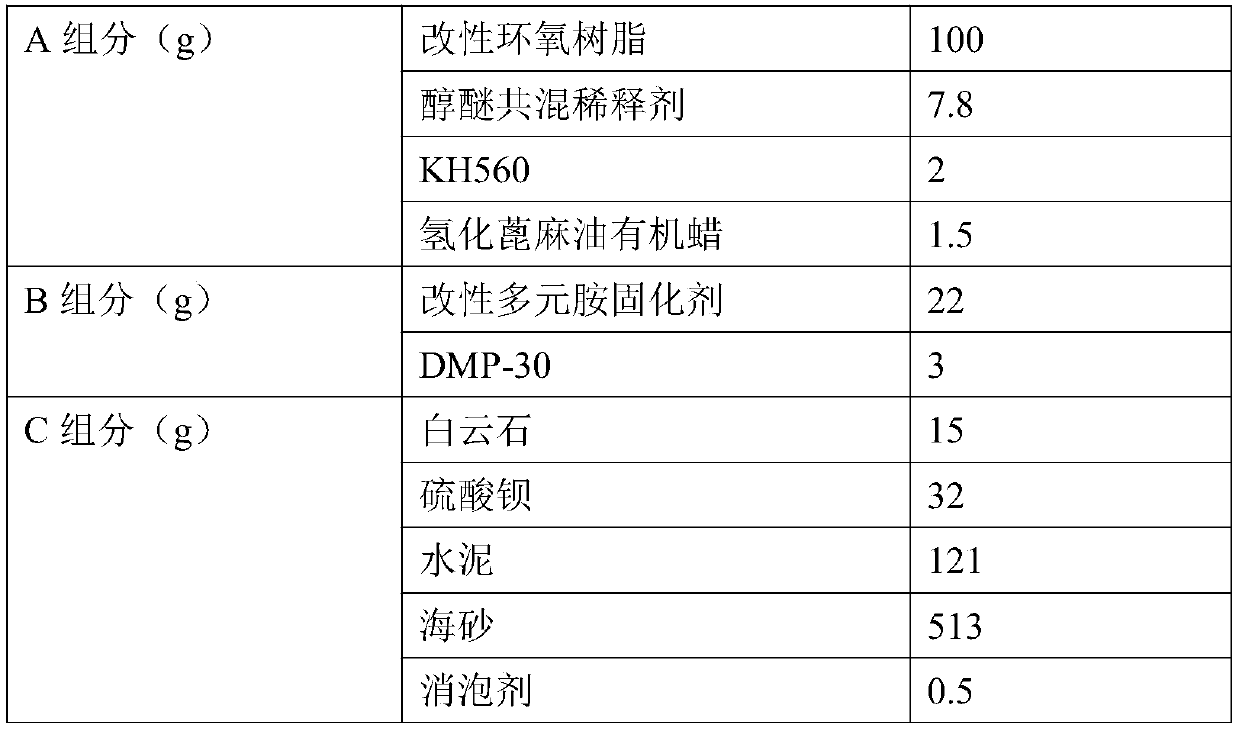

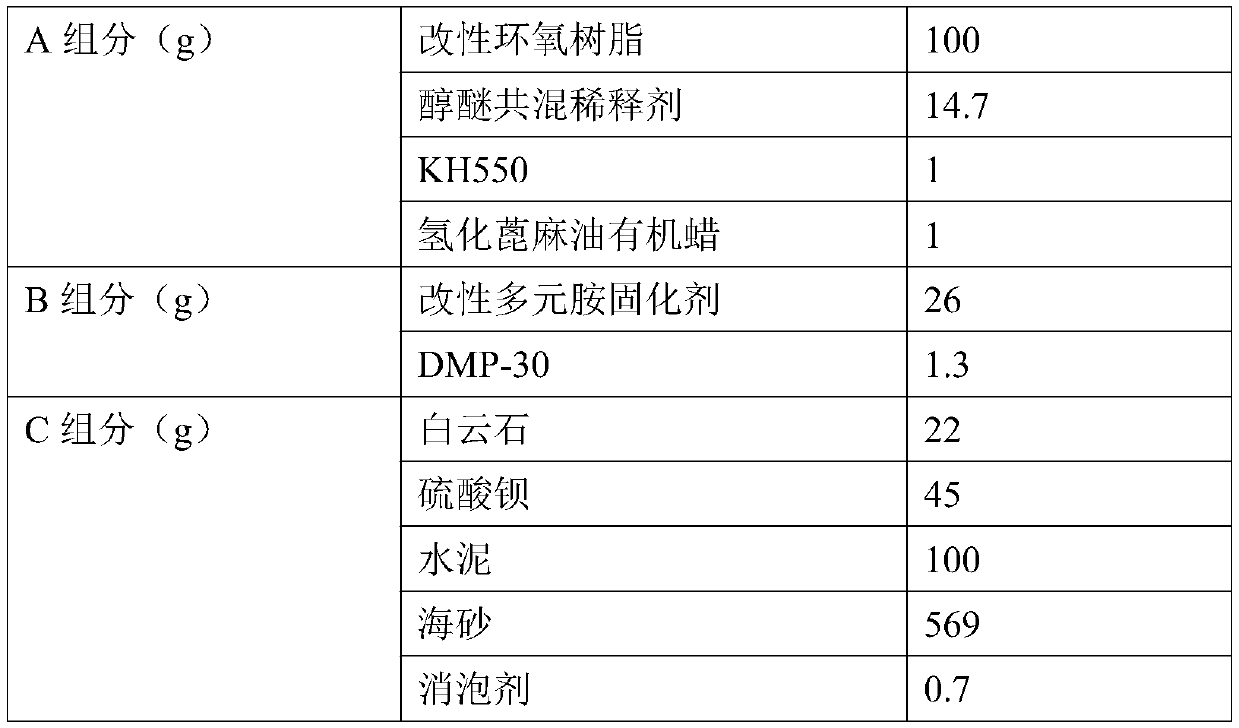

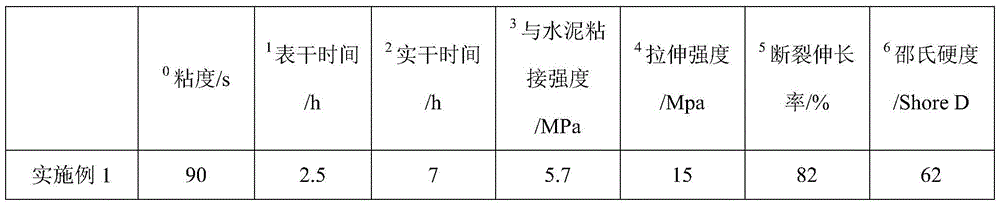

Quick-setting epoxy grouting mortar suitable for summer first-aid repair construction

The invention discloses a quick-setting epoxy grouting mortar suitable for summer first-aid repair construction. The quick-setting epoxy grouting mortar is formed by mixing of a resin component A, a curing agent component B and a bone powder component C in a mass ratio of 1:(0.2-0.26):(5-7) during use. Specifically, the component A comprises the following components by weight: 100 parts of modified epoxy resin, 1-15 parts of an alcohol ether composite diluent, 1-3 parts of a coupling agent, and 0.5-3 parts of a rheological agent; the component B comprises the following components by weight: 16-23 parts of a modified polyamine curing agent, and 1-3 parts of an accelerator; and the component C comprises the following components by weight: 1-23 parts of dolomite powder, 15-46 parts of bariumsulfate powder, 10-121 parts of cement, 385-588 parts of sea sand, and 0.1-1.5 parts of a defoamer. The quick-setting epoxy grouting mortar provided by the invention has the technical characteristicsof short curing time, high hour strength, and no flash polymerization during high temperature construction, at the same time is non-toxic and harmless, and is simple to prepare, and is widely applicable to concrete structure repair with quick-setting and early strength requirements and construction of installation and anchoring projects, especially suitable for summer repair construction.

Owner:中冶武汉冶金建筑研究院有限公司

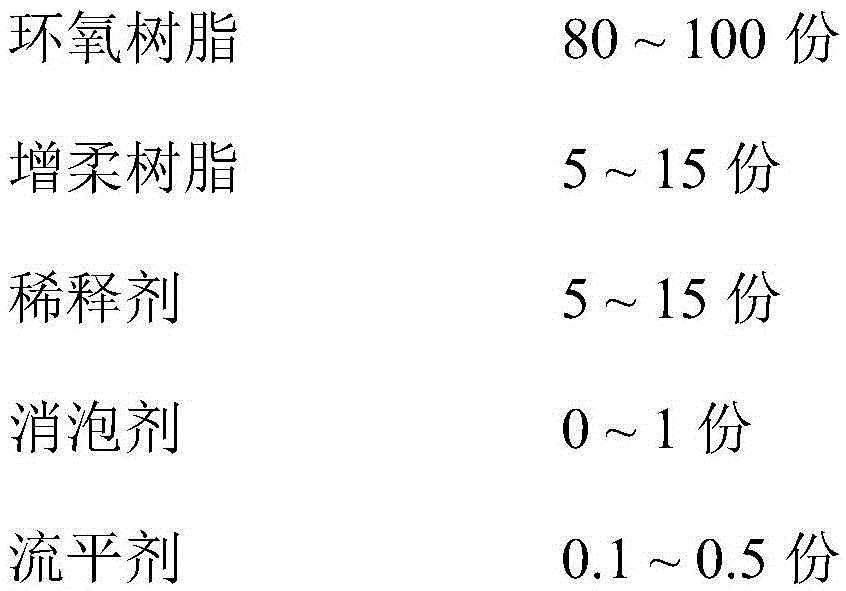

Solvent-free epoxy anti-permeability barrier coating and method for preparing same

InactiveCN105670455AImprove mechanical propertiesLow viscosityIn situ pavingsBridge structural detailsEpoxySilanes

The invention relates to a solvent-free epoxy anti-permeability barrier coating.The solvent-free epoxy anti-permeability barrier coating comprises components A and components B.The components A comprise, by weight, 80-100 parts of epoxy resin, 5-15 parts of flexibility improving resin, 5-15 parts of diluents, 0-1 part of defoaming agents and 0.1-0.5 part of leveling agents; the components B comprise, by weight, 80-100 parts of modified amine curing agents and 0-5 parts of silane coupling agents.The solvent-free epoxy anti-permeability barrier coating is mainly used for waterproof treatment on cement base planes and has the advantages of low viscosity, high elongation, adhesion and toughness and the like.

Owner:TONSAN ADHESIVES INC

High-strength and high-modulus thermosetting resin composition

The invention relates to a high-strength and high-modulus thermosetting resin composition, which is characterized in that the raw materials of the resin is a mixture of component A and component B. The raw materials of component A consist of cyanate ester monomer, bismaleimide monomer, bifunctional epoxy compound and bisoxazoline compound. The component B is glycidyl amine epoxy compound of trifunctional degree or tetrafunctional degree, wherein the glycidyl amine epoxy compound of trifunctional degree or tetrafunctional degree is carried out curing reaction with other components as a crosslinking agent to obtain the high-strength and high-modulus thermosetting resin composition.

Owner:TONGJI UNIV

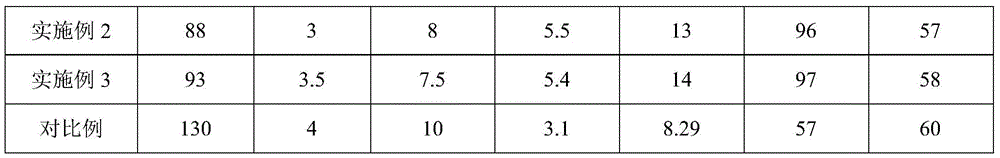

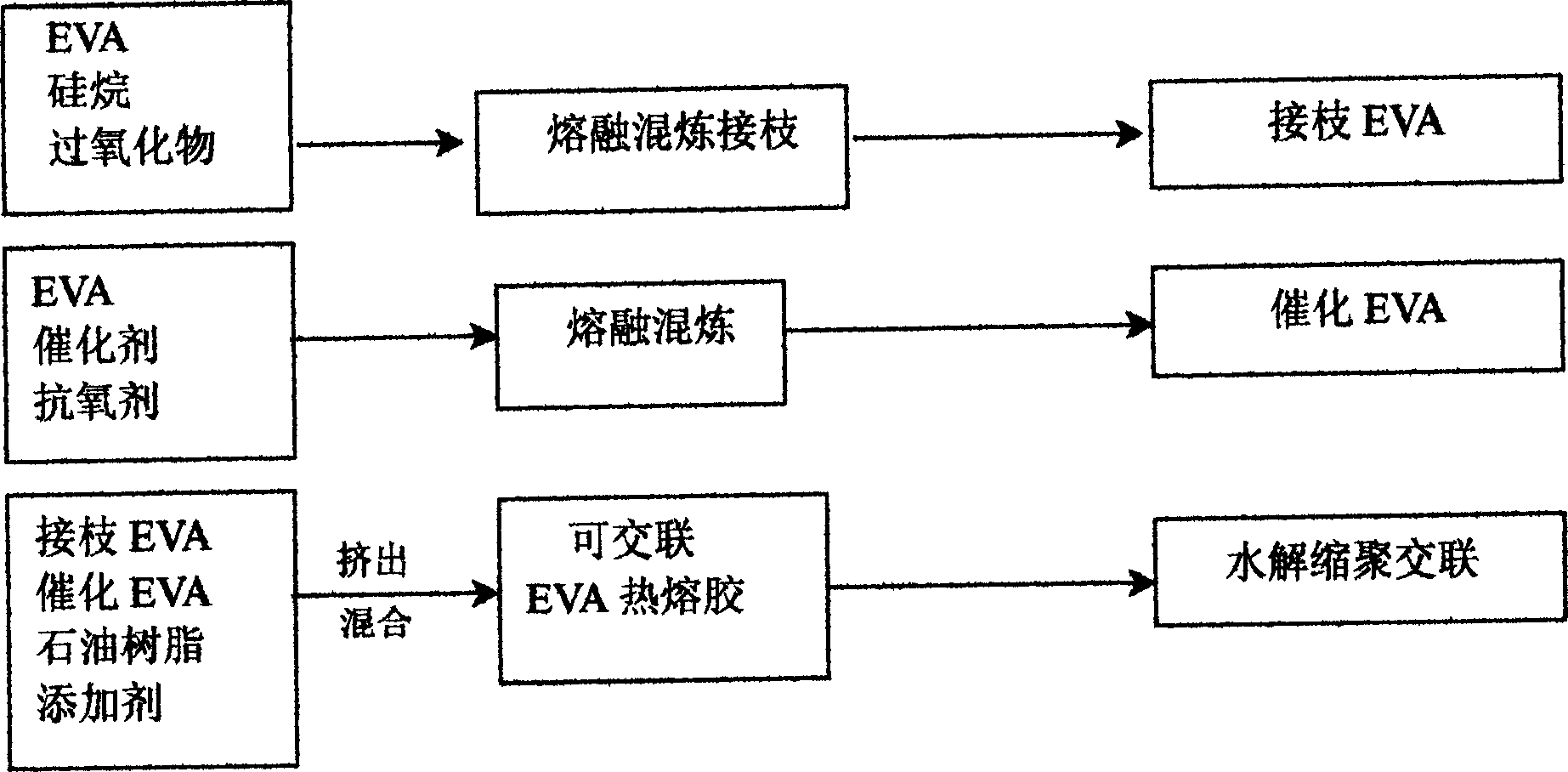

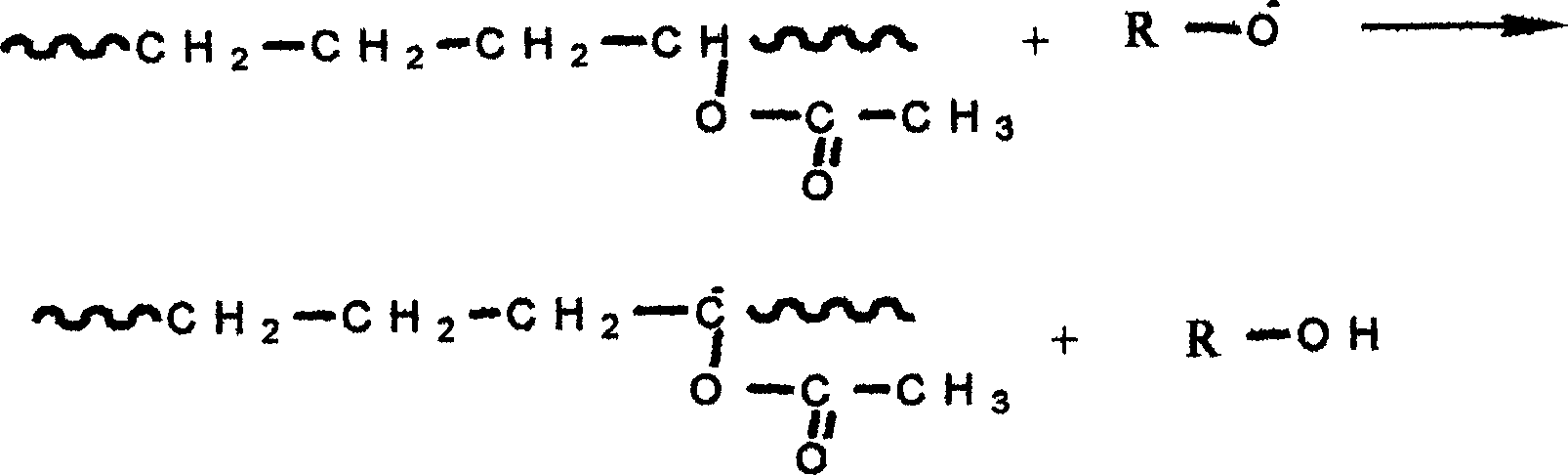

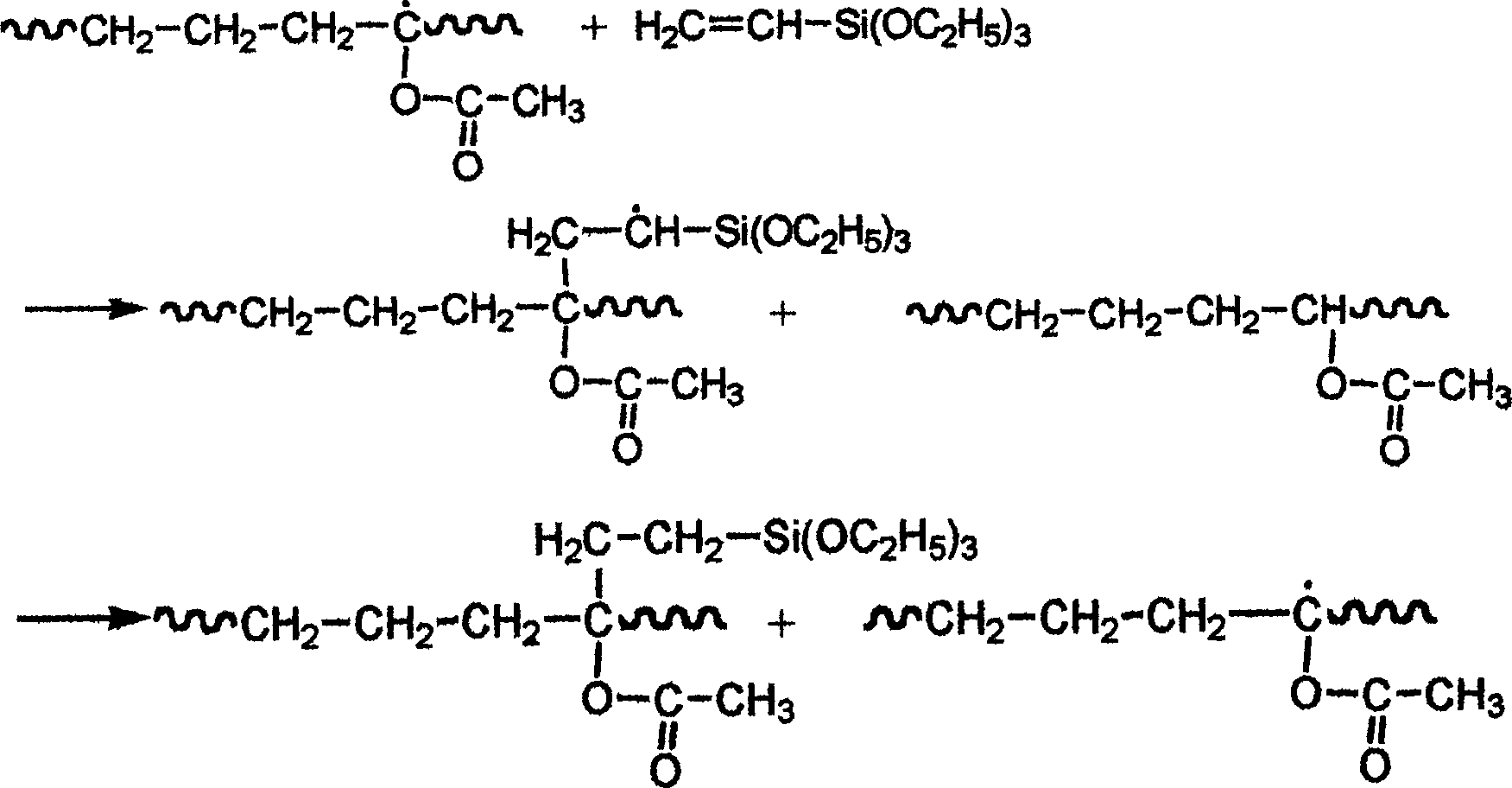

Preparation of silane modified EVA hot-melt adhesive composition

InactiveCN1800287APromote curing reactionMonocarboxylic acid ester polymer adhesivesHeat fusionQuenching

The invention provides a silicon alky quenching EVA heat fusion glue compound which grafts the active silane group on the EVA resin macro-chain by squeezing or fusion reaction and uses the silane group to do cross bonding reaction to improve the heat preservation and adhesion property of the heat fusion glue series.

Owner:杨隽

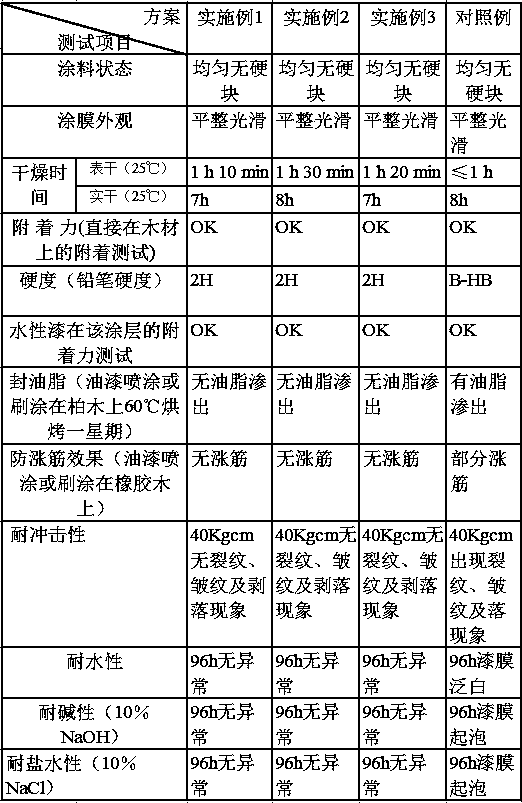

Epoxy sealing agent for timber product and preparation method and application thereof

The invention relates to the field of high polymer materials, in particular to an epoxy sealing agent for a timber product. The epoxy sealing agent for the timber product comprises a first component and a second component; the first component comprises, by mass percentage, 49-56% of non-ionic water-borne epoxy emulsion, 16-19% of epoxy-acrylic emulsion, 3.2-8.7% of first auxiliary and 16.3-31.8% of water, wherein the mass ratio of the non-ionic water-borne epoxy emulsion to the epoxy-acrylic emulsion is 3:0.8-1.2, and the sum of the mass percentages of the compositions of the first component is 100%; the second component comprises, by mass percentage, 14.8-24.6% of water, 75-85% of water-borne epoxy hardener and 0.2-0.4 % of second auxiliary, wherein the sum of the mass percentages of thecompositions of the second component is 100%. The sealing agent not only has a good sealing effect, but also has a better rib swelling resistance effect; meanwhile, compact paint film is formed, so that the hardness of timber is enhanced in disguised form, and construction attachment of subsequent water paint is not affected; no organic solvent exists, and VOC emission is low, so that the sealingagent is more environmentally friendly. The invention further discloses a preparation method and application of the sealing agent.

Owner:深圳澳达新材料有限公司

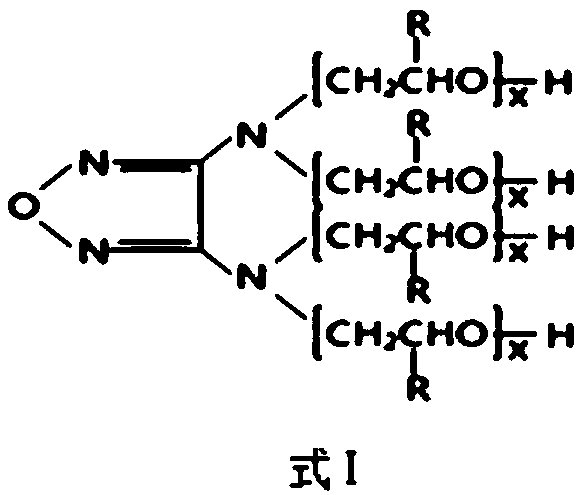

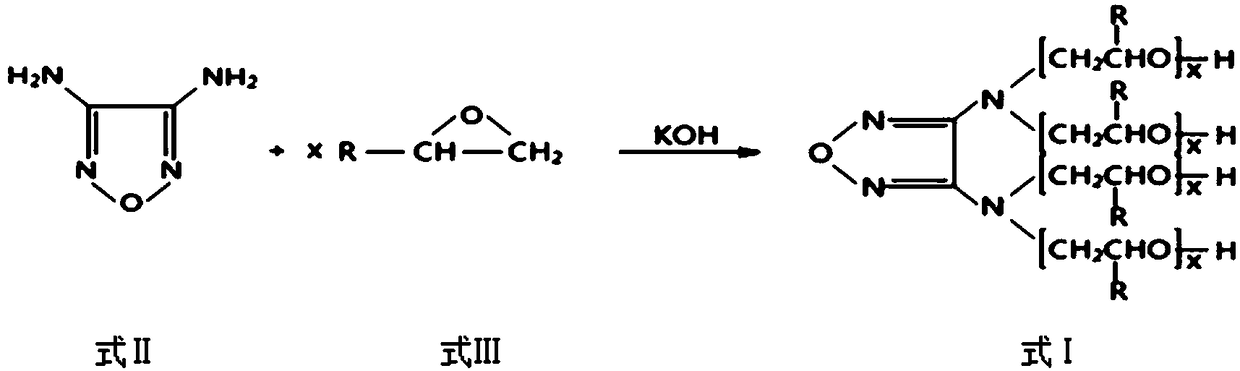

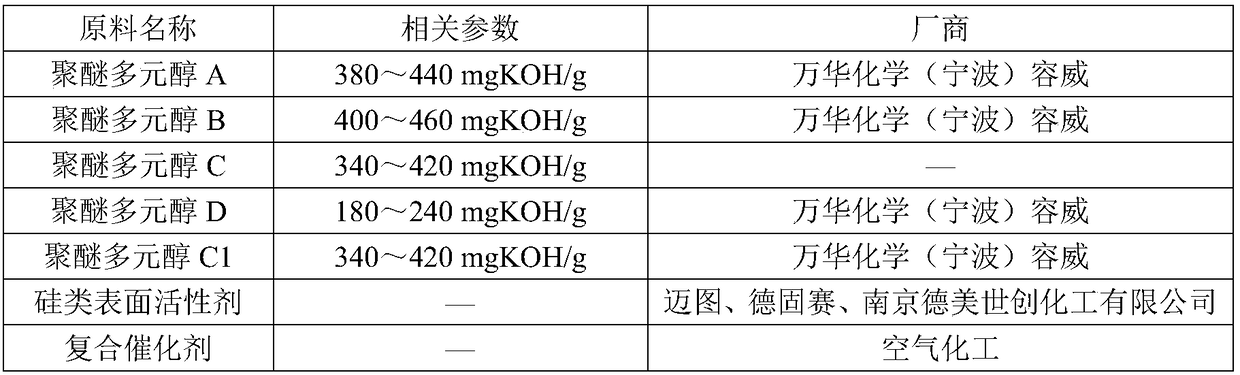

3,4-diaminofurazan polyether polyol, preparation method, rigid polyurethane foam prepared from 3,4-diaminofurazan polyether polyol and preparation method

The invention discloses 3,4-diaminofurazan polyether polyol, a preparation method, a rigid polyurethane foam prepared from the 3,4-diaminofurazan polyether polyol and a preparation method. The 3,4-diaminofurazan polyether polyol is prepared by taking 3,4-diaminofurazan as a starting material and carrying out addition reaction on the 3,4-diaminofurazan and olefin oxide to obtain the 3,4-diaminofurazan polyether polyol. The raw materials of the rigid polyurethane foam comprise compound polyether, a foaming agent and polyisocyanates according to the mass ratio of 100: 12-23: 130-160, the compoundpolyether contains 3,4-diaminofurazan polyether polyol, and the foaming agent contains HFC-134a. The 3,4-diaminofurazan is used as a novel polyether monomer of an initiator, and is compatible to HFC-134a well, and the prepared polyurethane foam has good dimensional stability and heat-insulation property when at low density.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

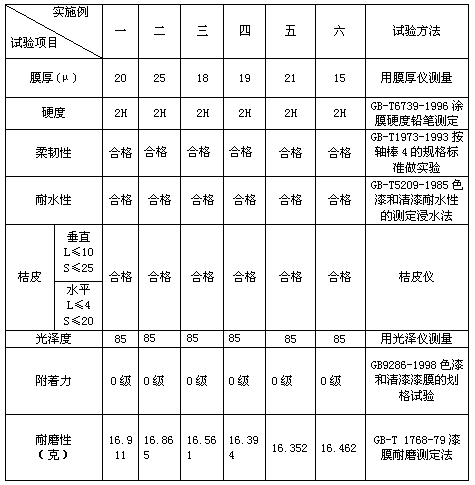

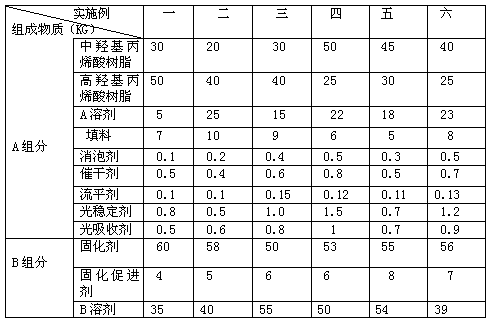

Low-temperature quick-drying dual-component automotive trim paint

The invention relates to low-temperature quick-drying dual-component automotive trim paint, which is used for solving the problems of long baking time, high baking temperature and low hardness in the conventional automobile plastic trim paint. The low-temperature quick-drying dual-component automotive trim paint consists of a component A and a component B, wherein a mass ratio of the component A to the component B is 4:1; the component A consists of the following substances in part by mass: 60 to 80 parts of hydroxy acrylic resin mixture, 5 to 25 parts of solvent A, 5 to 10 parts of filler, 0.1 to 0.5 part of defoamer, 0.1 to 0.15 part of flatting agent, 0.4 to 0.8 part of drier, 0.5 to 1.5 parts of light stabilizer and 0.5 to 1 part of light absorber; and the component B consists of the following substances in part by mass: 50 to 60 parts of curing agent, 4 to 8 parts of curing accelerator and 35 to 55 parts of solvent B. According to an automotive interior trim part sprayed by the automotive trim paint, the baking time can be reduced by nearly 50 percent, the baking temperature is reduced by about 20 DEG C, and the hardness of pencils is improved to 2H; and the low-temperature quick-drying dual-component automotive trim paint has the characteristics of improving production efficiency and quality of products along with energy conservation.

Owner:GREAT WALL MOTOR CO LTD

Stable curing repair system for polluted soil

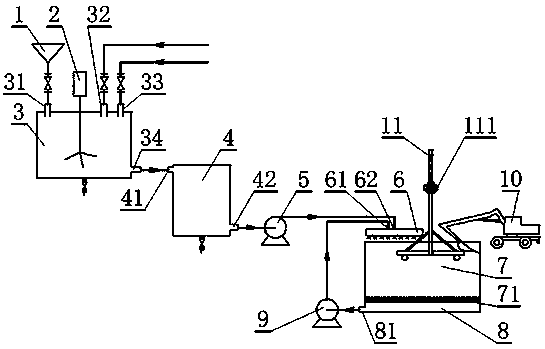

InactiveCN103894409AQuick fixAccelerates the curing reactionContaminated soil reclamationCentrifugal pumpCirculating pump

The invention relates to a stable curing repair system for polluted soil. The system consists of a dispensing tank, a chemical storage box, a centrifugal pump, a spraying device, a reaction tank, a recovery tank, a circulating pump, a backhoe excavator and a movable gantry mixer; the system can be used for rapidly repairing the polluted soil by adopting repair chemicals with different forms, types and concentrations at different temperatures according to the characteristics of the different polluted soil; the system is mainly suitable for the soil polluted by heavy metals such as Cr, Cd, Pb, Zn and Cu. The stable curing repair system is reasonable in arrangement, wide in application scope, rapid in reaction speed, short in repair period, good in flexibility, safe and stable in operation and economically feasible, and can be used for heterotopic or in-situ repair of the polluted soil; the repaired soil can meet the relevant standard, and comprehensive resource utilization of the polluted soil can be realized, so that the system has good environmental protection benefit and social benefit.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

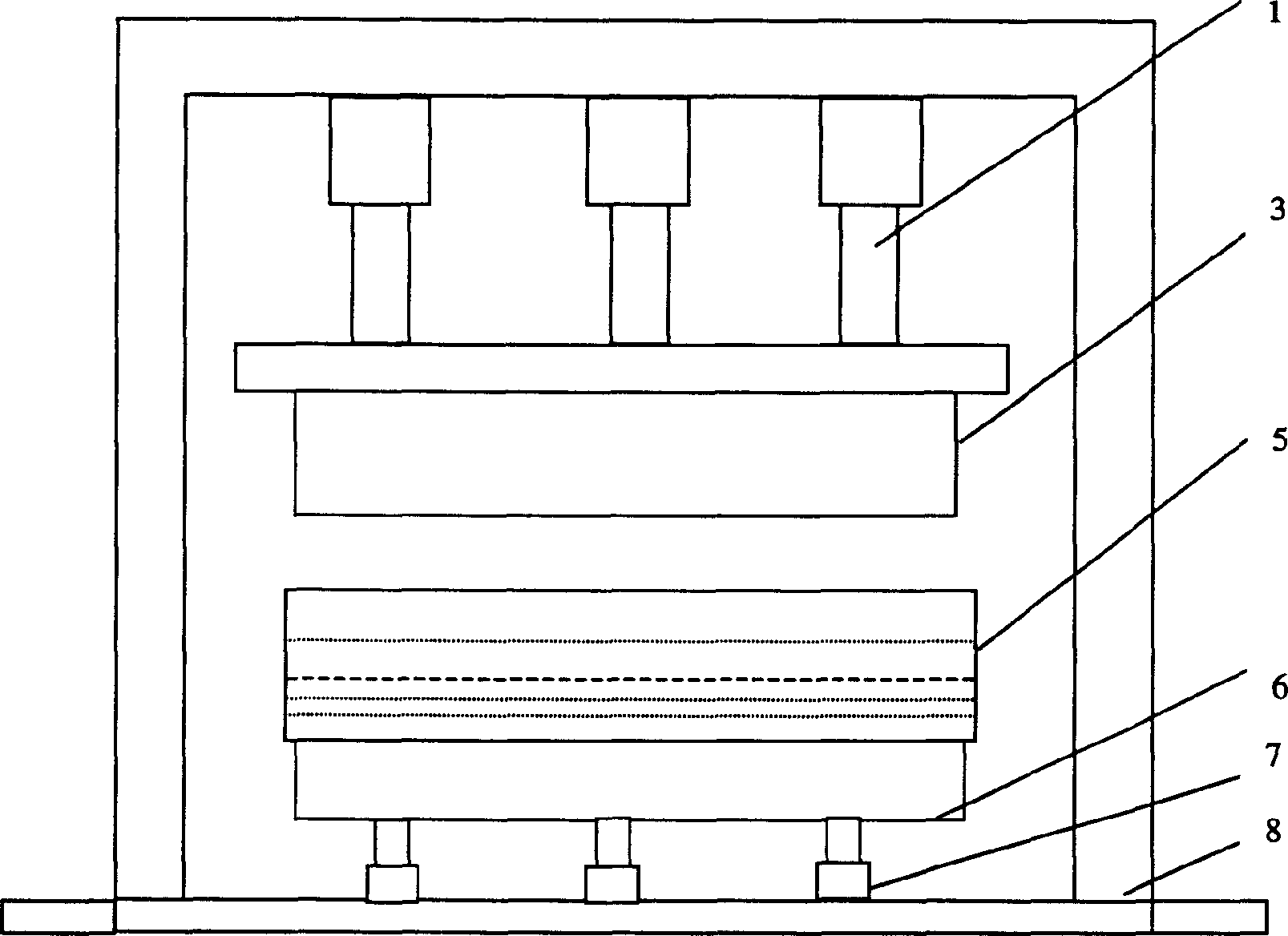

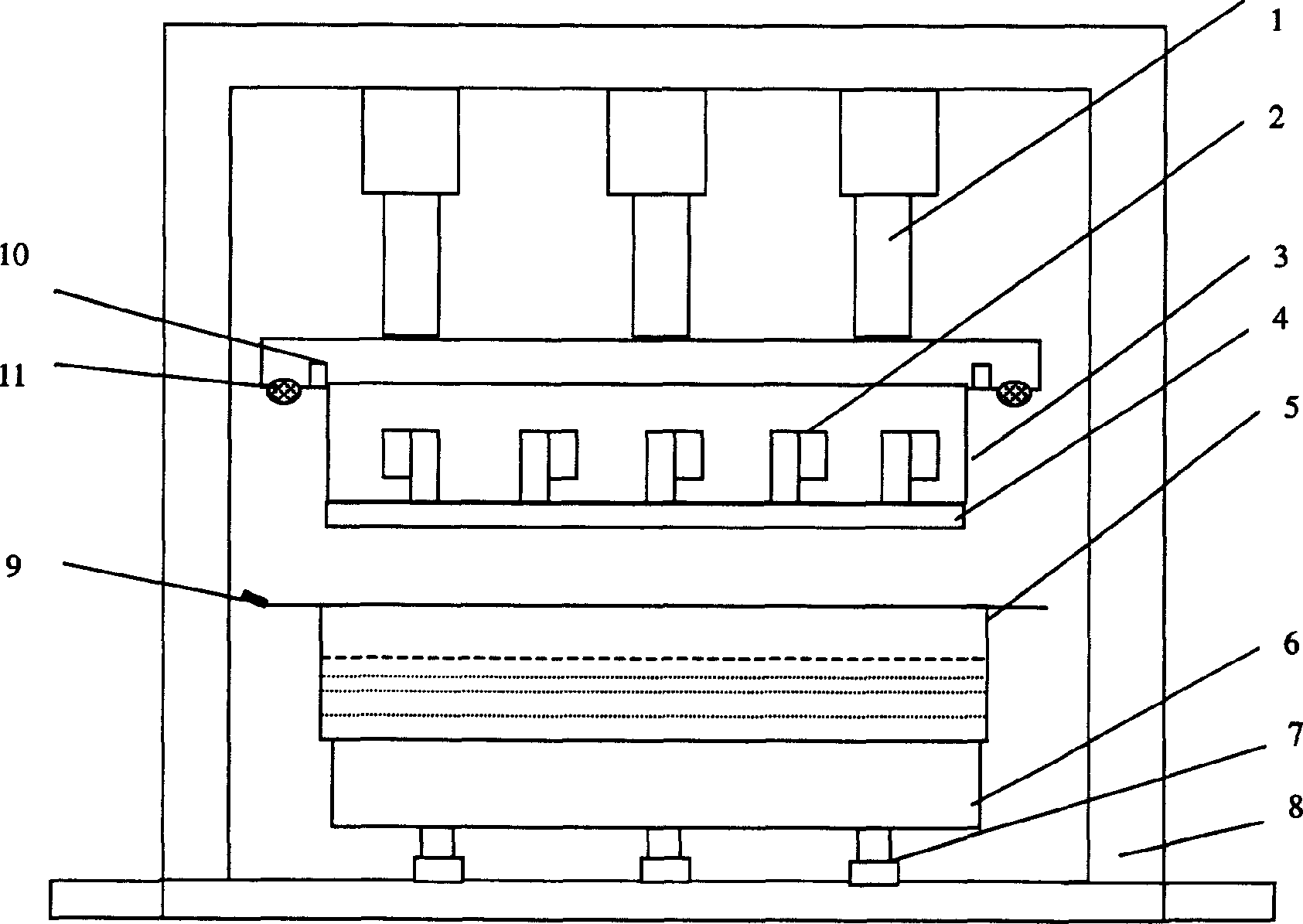

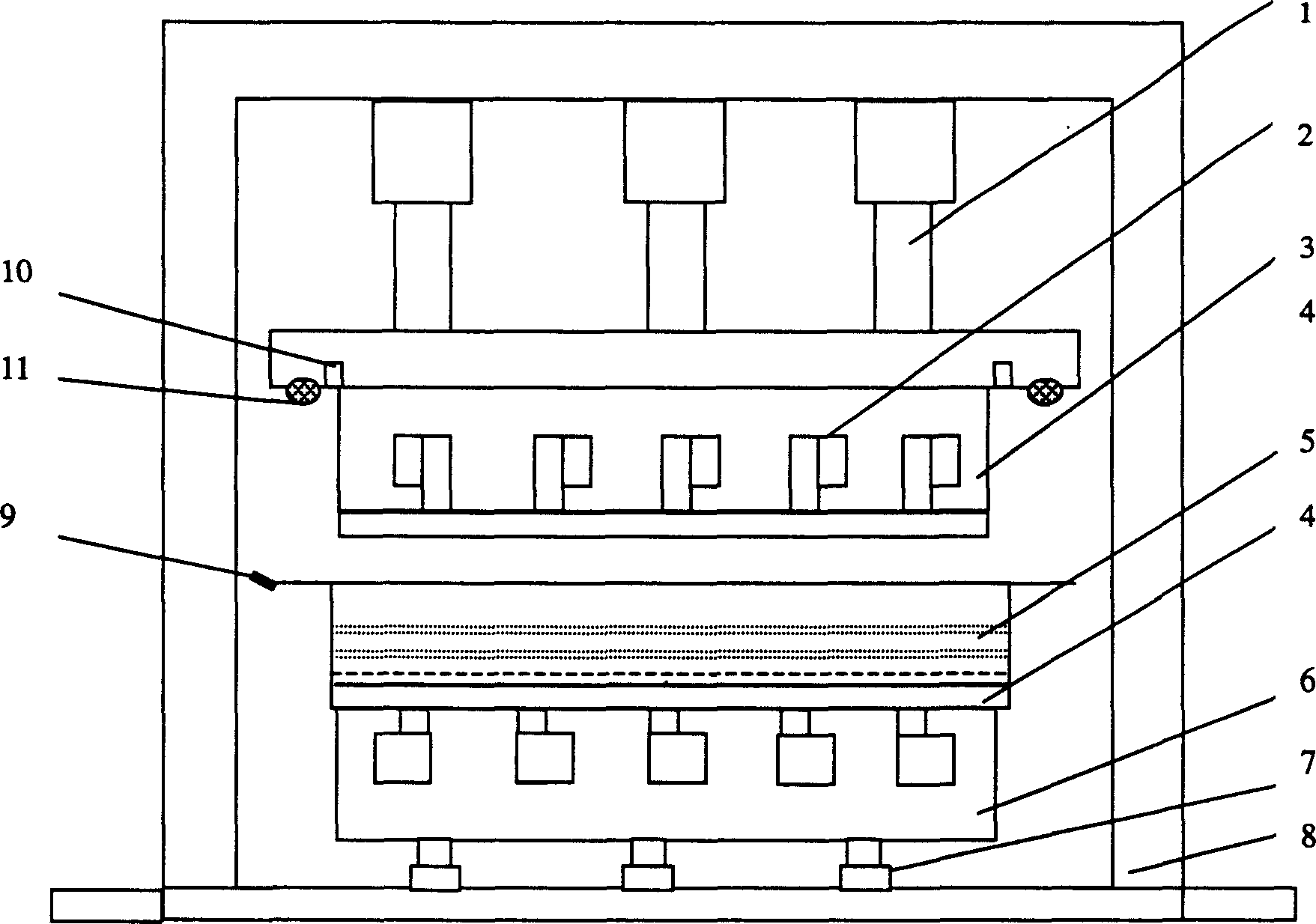

Microwave hot forming apparatus

The present invention combines microwave heating technology and traditional press. The microwave hot forming apparatus includes pressing unit, microwave heater, upper and lower molds and demolding unit. The microwave heater is set inside the upper mold and / or in the bottom of the lower mold, microwave acts on the material via the energy locking port and microwave transparent window in the bottom board to heat the material via its dielectric loss. While heating, the material is microwave heated to cure and form. The present invention has the simultaneous heating of inside and outside of the material, and the heating is homogeneous, fast and high in efficiency. The present invention combines formation, curing and stoving.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Curing agent of epoxy resin and synthesis method thereof

InactiveCN102827351AHigh mechanical strengthImprove temperature resistancePolymer scienceMannich reaction

The invention relates to a curing agent of epoxy resin and a synthesis method of the curing agent. The curing agent is prepared through Mannich reaction by using bisphenol A, an aldehyde compound and an ether amine compound as raw materials at a ratio of bisphenol A:the aldehyde compound:the ether amine compound of 1:(1-4):(1-4). The curing agent of epoxy resin prepared by the method has many benzene rings, phenolic structures, phenolic hydroxy groups, ether bonds and amino groups in the molecule. The benzene ring and the phenolic structure endue the cured product with higher mechanical strength and higher temperature resistance; the phenolic hydroxy group can accelerate the cure reaction so that the cure reaction can be carried out at a lower temperature; the ether bond can improve mechanical properties of the cured product so that the cured product has good flexibility. The product cured by the curing agent has good mechanical property, and also has good resistance to temperature, medium and aging.

Owner:HUNAN SHENLI IND

Aqueous coating material composition and coating film forming method

InactiveCN108713048AExcellent film propertiesPromote curing reactionPretreated surfacesPolyurea/polyurethane coatingsHydrophilizationPolymer science

The objective of the present invention is to provide an aqueous coating material composition which has excellent curability at low temperatures. The present invention provides an aqueous coating material composition which contains (A) an aqueous resin having a hydroxyl group and a carboxyl group, (B) a water-dispersible blocked polyisocyanate compound, (C) a hydrophilization modified carbodiimidecompound and (D) an aqueous polyurethane resin. The aqueous resin (A) having a hydroxyl group and a carboxyl group has a hydroxyl number of 80-200 mgKOH / g and an acid value of 10-40 mgKOH / g in terms of resin solid content; the aqueous polyurethane resin (D) has a glass transition point (Tg) of -50 DEG C or less; and a cured film of the aqueous polyurethane resin (D) has an elongation at break of 400% or more at -20 DEG C.

Owner:นิปปอน เพนท์ ออโตโมทีฟ โคทติ้งส์ โค แอลทีดี

Latent curing system used for moulding prepregs at medium or low temperature and method for preparing latent curing system

The invention belongs to the field of composite material, and specifically discloses a latent curing system used for moulding prepregs at a medium or low temperature and a method for preparing the latent curing system. The latent curing system comprises 10-50 parts of epoxy resin, 50-100 parts of a latent curing agent, 40-80 parts of a liquid room-temperature reactive curing agent, and 1-10 parts of an accelerant. The preparation method comprises the following steps: uniformly mixing the latent curing agent and the liquid room-temperature reactive curing agent; adding epoxy resin and the accelerant to carry out a reaction at the temperature of 60 to 100 DEG C for 2-6 hours; and finally obtaining a paste liquid that is the latent curing system used for moulding prepregs at a medium or low temperature. According to the invention, the latent curing system is used for moulding at a medium or low temperature, the curing temperature of the latent curing agent is reduced, and the pasty form is beneficial to uniformly dispersing the latent curing system in the epoxy. The latent curing system is simple in operation of preparation technology and is suitable for large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Anti-aging glass fiber reinforced plastic material and preparation method thereof

The invention provides an anti-aging glass fiber reinforced plastic material. The anti-aging glass fiber reinforced plastic material is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 2-8 parts of styrene, 1-3 parts of a curing agent, 1-3 parts of an accelerant, 80-120 parts of glass fibers, 10-40 parts of an illite functional powder material, 1-3 parts of a coupling agent I, 1-2 parts of zinc oxide and 5-6 parts of graphene. The preparation method comprises the following steps: pickling illite powder, washing with water to be neutral, drying, and modifying with a coupling agent II to obtain the illite functional powder material. The illite functional powder material is added and compounded with other raw materials, so that the crosslinking degree between macromolecular chains can be increased; the anti-aging glass fiber reinforced plastic material is particularly suitable for marine environments such as ships, and the salt fog resistance, the aging resistance and the strength of the anti-aging glass fiber reinforced plastic material are remarkably improved compared with those of a common glass fiber reinforced plastic material.

Owner:CHENGDE RENHE MINING CO LTD

High-frequency copper-clad plate composition applied to antenna base material

ActiveCN109942921AIncrease crosslink densityImprove heat resistanceGlass/slag layered productsMetal layered productsDielectric lossHeat resistance

The invention discloses a high-frequency copper-clad plate composition applied to an antenna base material. The high-frequency copper-clad plate composition contains the following raw materials in parts by weight: 25-50 parts of an organic polymer, 30-65 parts of an inorganic filler, 5-10 parts of a crosslinking agent, 3-10 parts of a curing agent and 2-5 parts of a coupling agent. A copper-clad plate base material prepared from the high-frequency copper-clad plate composition has the advantages of low dielectric constant and dielectric loss, good heat resistance, low thermal expansion coefficient, low water absorption rate and the like and can meet the requirements of a communication antenna to printed circuit board base materials.

Owner:CHENZHOU GONGTIAN ELECTRONICS CERAMICS TECH

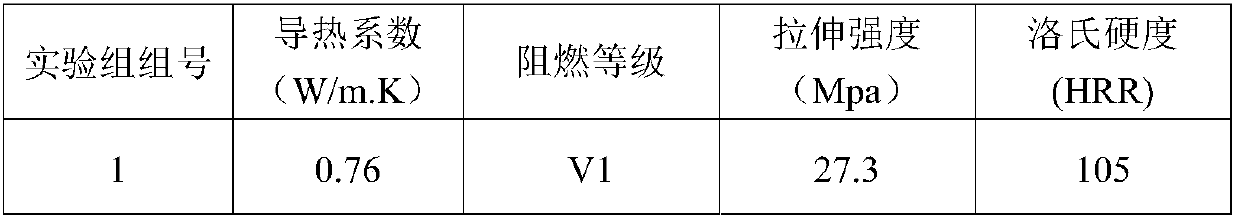

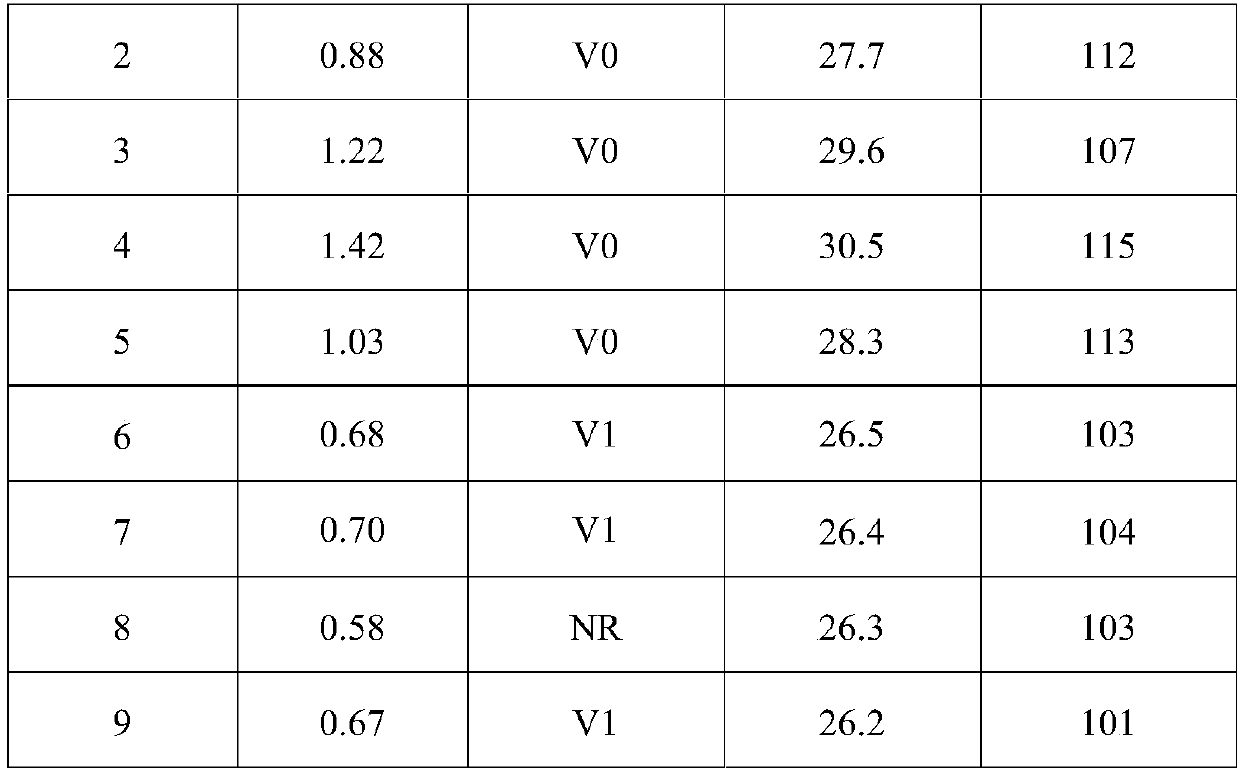

High-heat-conduction halogen-free expansion flame-retardant epoxy resin pouring sealant and preparation method thereof

InactiveCN108018010AHigh flame retardant efficiencyImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceBoron nitride

The invention relates to the technical field of flame retardant modification, and provides a high-heat-conduction halogen-free expansion flame-retardant epoxy resin pouring sealant and a preparation method thereof. The preparation method comprises the following steps: preparing a first epoxy component, namely mixing epoxy resin, a toughening agent, an epoxy active diluent, a dispersing anti-settling agent and a defoaming agent for forming a first mixture, mixing zinc oxide and boron nitride to obtain a high-heat-conduction filler component, adding the high-heat-conduction filler component intothe first mixture for forming a second mixture, preparing a halogen-free expansion flame-retardant filler component by using crystalline II type diammonium polyphosphate and dipentaerythritol, addingthe halogen-free expansion flame-retardant filler component into the second mixture, and carrying out mixing and defoaming to obtain a first epoxy component; preparing a second epoxy component, namely mixing methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride, a curing accelerator and a defoaming agent, and then carrying out defoaming to obtain a second epoxy component; and mixing the first epoxy component and the second epoxy component, carrying out defoaming, and then carrying out curing twice. The preparation method has simple operation and low production cost, and theprepared epoxy resin pouring sealant has excellent thermal conductivity and flame retardance.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT +1

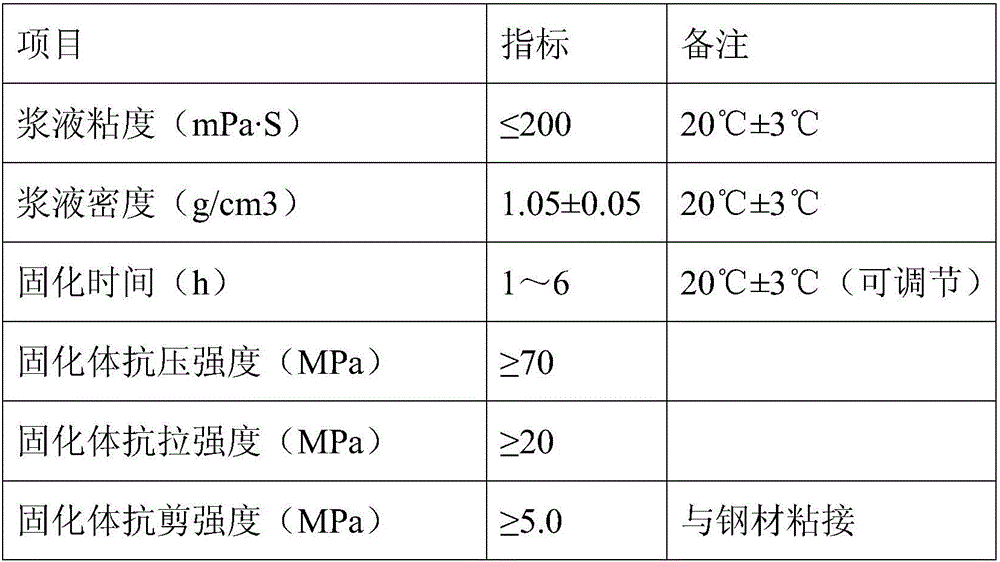

Environment-friendly low-viscosity and high-strength type epoxy-based chemical grouting material

The invention discloses an environment-friendly low-viscosity and high-strength type epoxy-based chemical grouting material. The material is prepared from, by mass, 50-80 parts of epoxy resin, 20-50 parts of a cross-linking thinning agent, 5-10 parts of a curing agent, 1-10 parts of an initiator and 1-5 parts of an accelerant. According to the environment-friendly low-viscosity and high-strength type epoxy-based chemical grouting material, the cross-linking thinning agent is selected to replace an active thinning agent in the prior art, volatile materials such as formaldehyde and acetone are not included in components of the cross-linking thinning agent, and the cross-linking thinning agent is friendly to the human body and the environment and capable of conforming to the green development concept; besides, the viscosity of initial paste is low, the initial paste is good in grouting performance, has the drainage performance, is capable of being cured in water, and is small in shrinkage rate and stable in curing volume in the gel curing process, and a cured object is excellent in mechanical property; the paste proportion is simple and easy to grasp, raw materials are easy to purchase, and storage and transportation are convenient.

Owner:POWERCHINA XIBEI ENG

Antifogging agent composition, and antifogging article with antifogging coating film

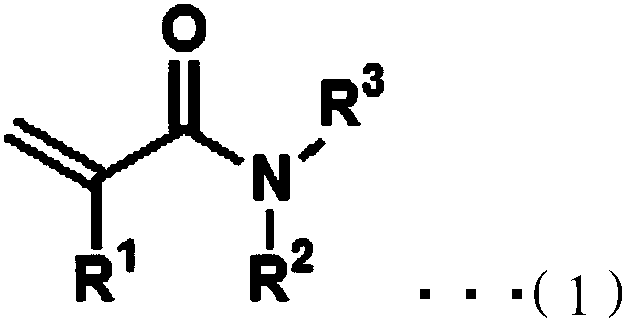

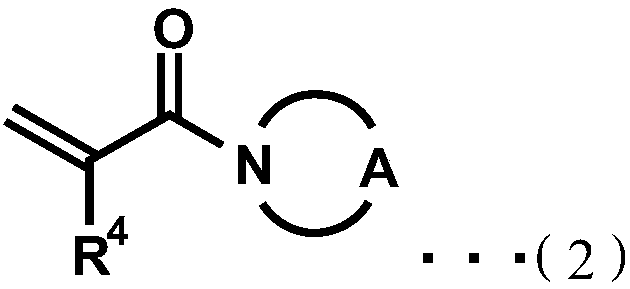

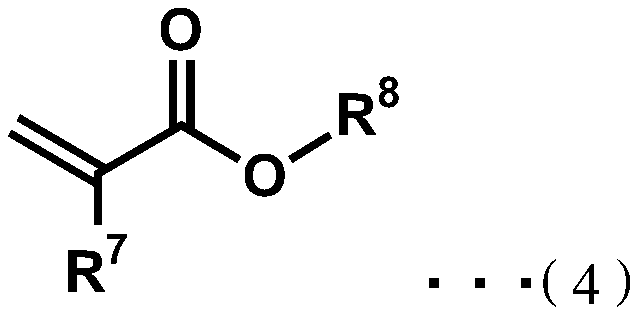

The invention provides an antifogging agent composition which can form an antifogging coating film which has under conditions of low temperature and a short time, and an antifogging article with the antifogging coating film. The antifogging coating film has the performance for which a vehicles lighting fixture is asked (especially, excellent antifogging durability). The antifogging agent composition comprises a copolymer (A), an acid catalyst (B) and a surfactant (C), wherein the copolymer (A) is an acrylate copolymer obtained from a monomeric mixture (meta), and the monomeric mixture containsthe monomer (A-1) (A-4) of a specific amount; the acid catalyst (B) contains sulfuric acid and / or a sulfonic acid system compound; and the surfactant (C) contains an anionic system surfactant (C-1) and a cation system surfactant (C-2).

Owner:NOF CORP

Pipeline hot melt adhesive and preparation method thereof

InactiveCN105086879AIncrease productionCost advantageGraft polymer adhesivesEconomic benefitsButadiene-styrene rubber

The present invention discloses a pipeline hot melt adhesive and a preparation method thereof. The pipeline hot melt adhesive comprises the following components by weight: 20%-46% of a tackifying resin, 10%-25% of a maleic anhydride graft copolymer, 0.5%-2% of an antioxidant and 28%-65% of base resin, wherein the base resin comprises 10%-40% of a styrene-butadiene-styrene block copolymer and 60%-90% of an ethylene-vinyl acetate copolymer. The hot melt adhesive is prepared in two steps: 1, mixing styrene-butadiene-styrene block copolymer with ethylene-vinyl acetate copolymer, and pelletizing by a twin-screw extruder; and 2, mixing the raw materials in a kneader by using a mixing method. The invention has the advantages of simple formula, method and technology and low cost. The obtained hot melt adhesive has stable performance and good bonding performance, can be applied to metal pipeline anticorrosion repair, and has good economic benefit and industrial production prospects.

Owner:成都长江热缩材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com