Patents

Literature

1588results about How to "High flame retardant efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and preparation method thereof

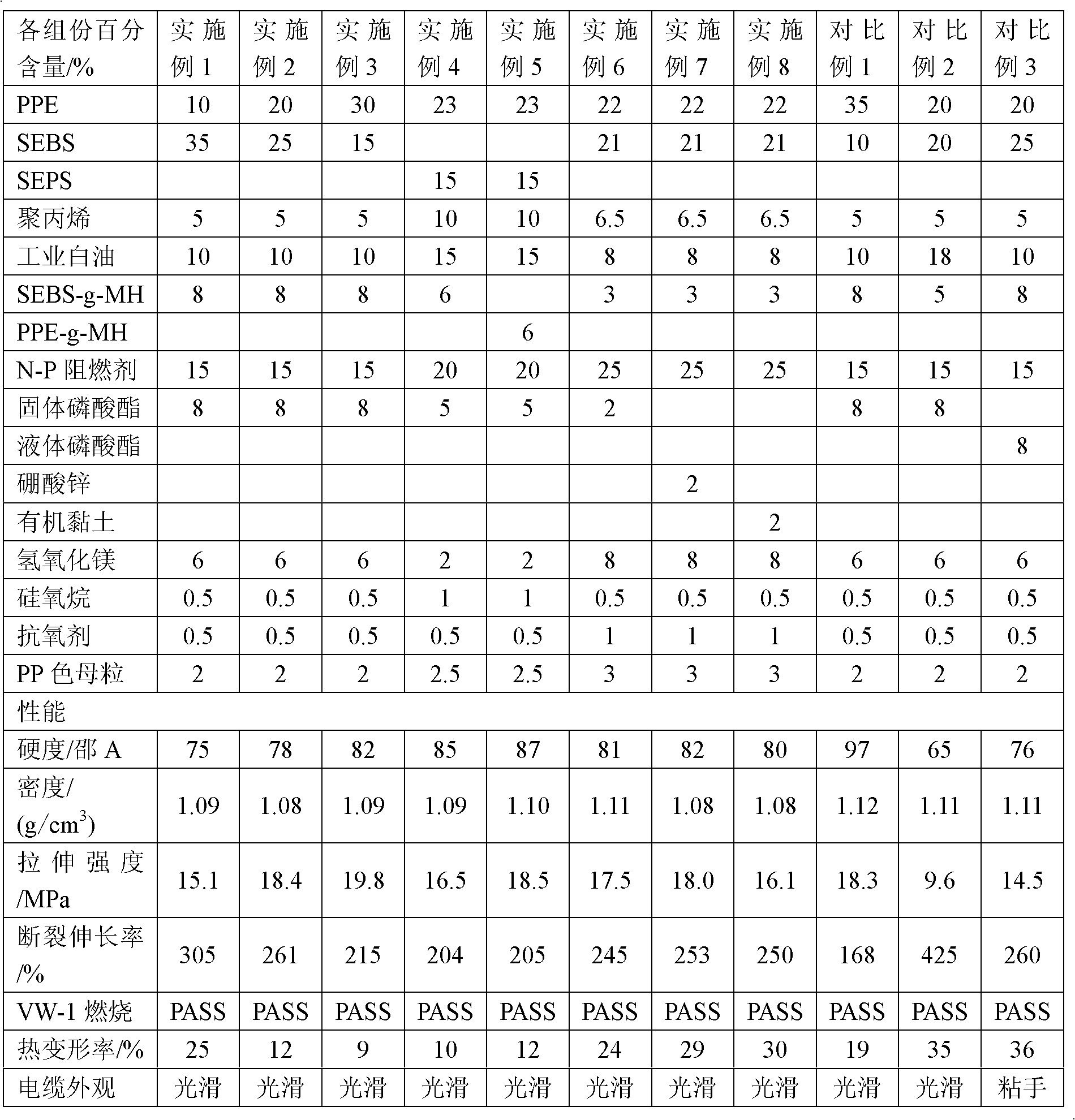

The invention discloses a halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and a preparation method thereof. The composite material consists of the following components in percentage by mass: 25 to 80 percent of polyolefin resin, 5 to 60 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of flame retardant and flame retardance synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood plastic composite material, the halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material has the characteristics of simple production flow, little using amount of the flame retardant, good halogen-free flame retardant effect, wide range of molding modes and the like and is applicable to various injection molding products, such as electric appliance shells, automobile parts, furniture, buildings and other parts.

Owner:GUANGDONG KINGFA TECH CO LTD

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

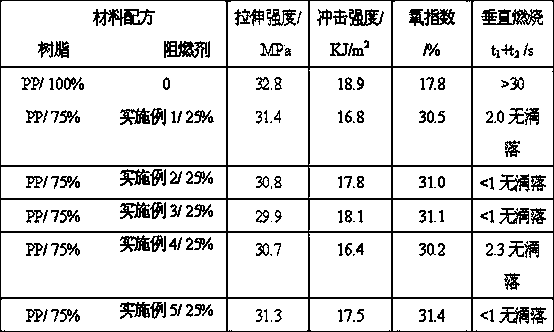

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

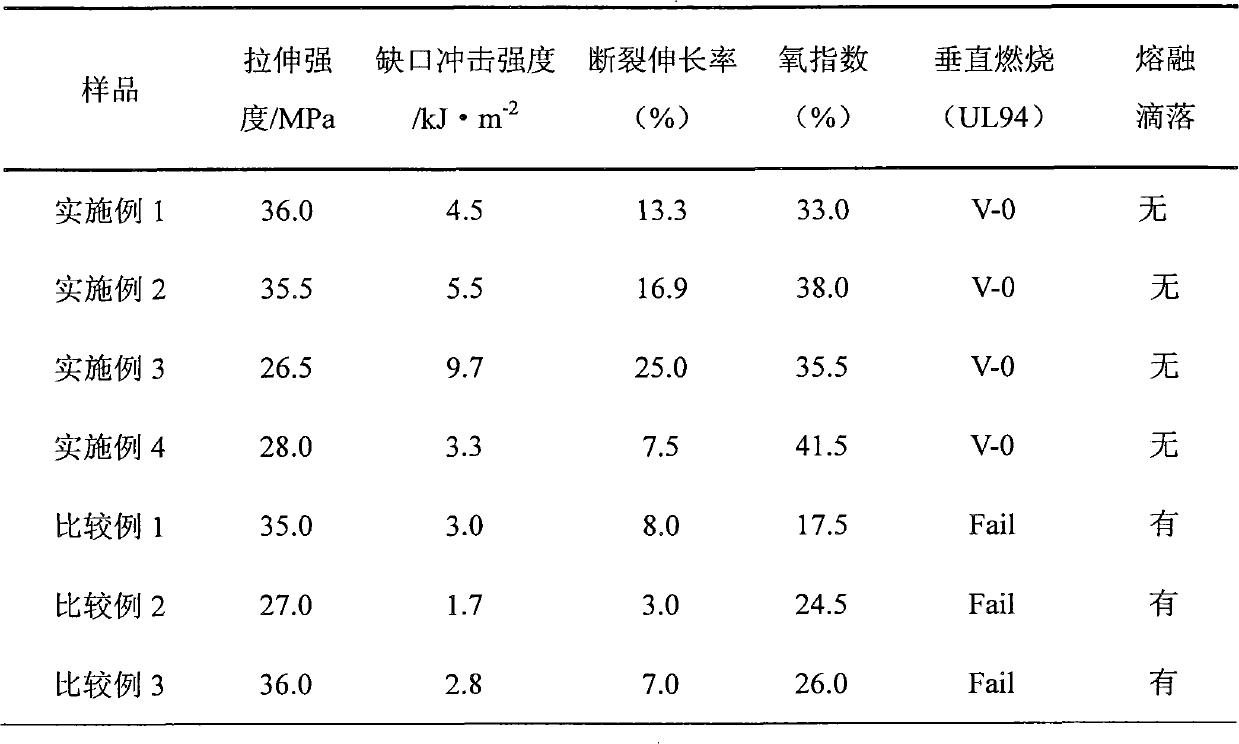

Microencapsulation expansion type flame retardant and application in epoxy resin composite material thereof

The invention discloses a microencapsulation expansion type flame retardant and application in an epoxy resin composite material thereof. The microencapsulation expansion type flame retardant uses ammonium polyphosphate as a capsule core and uses a thermosetting resin melamine-formaldehyde resin as a capsule material. The microencapsulation expansion type flame retardant epoxy resin composite material consists of the epoxy resin, a curing agent, a curing accelerator, the microencapsulation expansion type flame retardant and a flame-retardant carbon-forming accelerator. The microencapsulation expansion type flame retardant and the application are economic, simple and convenient; the flame retardant has good flame-retardant synergistic effects; and under the condition of little flame retardant addition, the composite material can pass V-0 level of UL-94 test, and the oxygen index reaches over 30.0 percent.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

Phosphaphenanthrene flame-retardant compound containing s-triazine structure, and preparation and use thereof

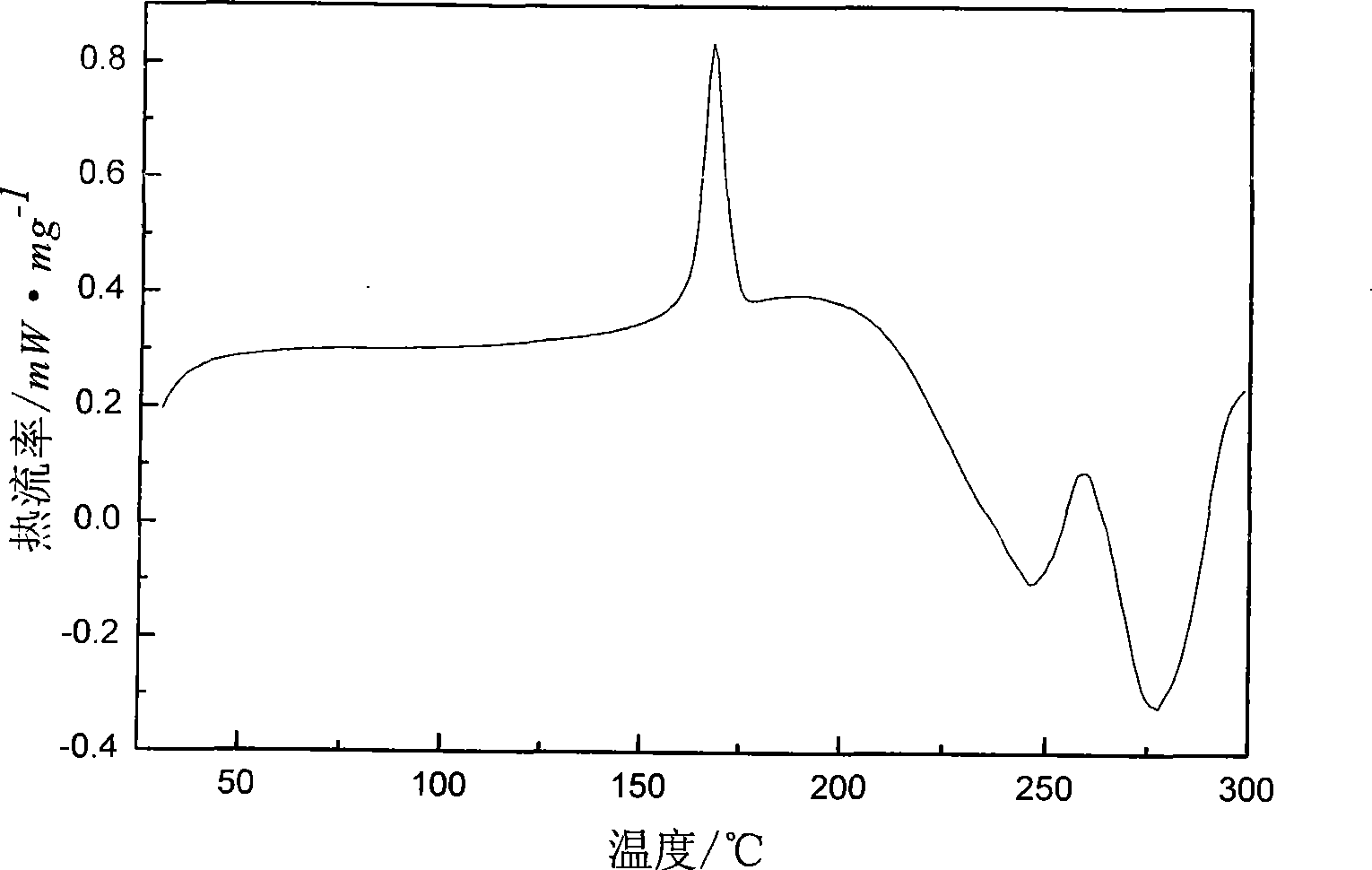

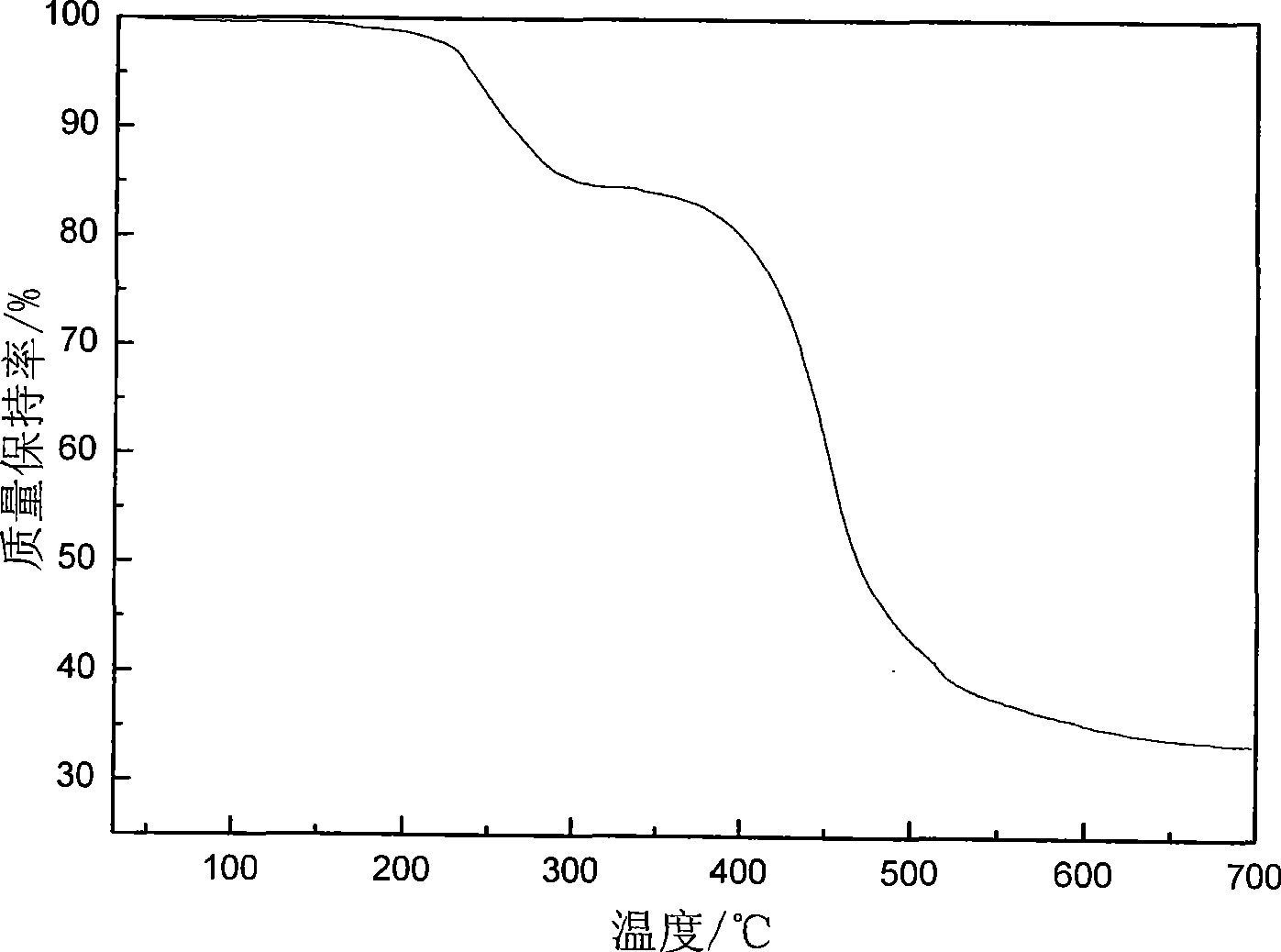

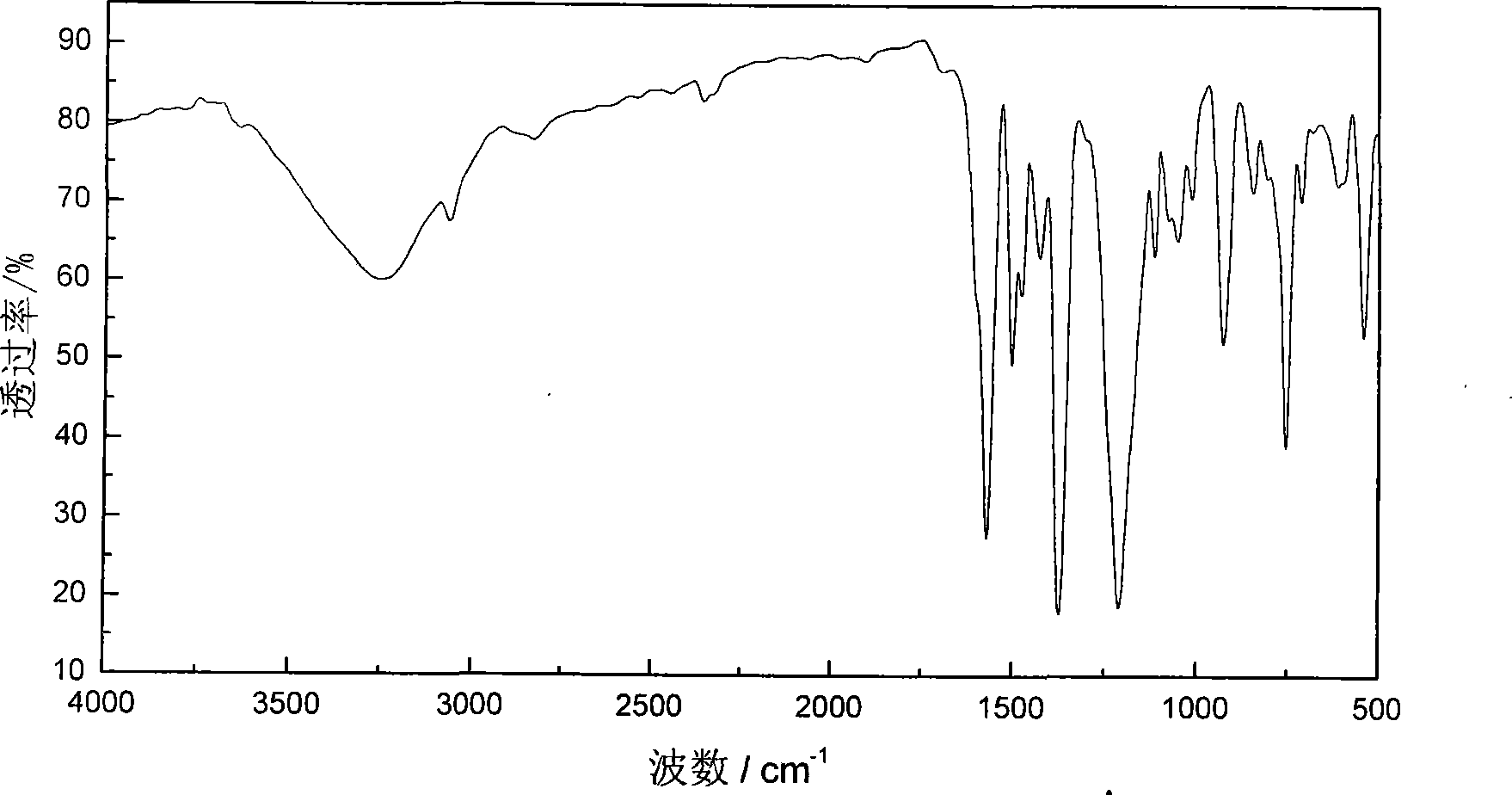

ActiveCN101376665AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsEpoxyPolymer science

The invention discloses an oxa-phosphaphenanthrene flame retardant compound containing the sym-triazine structure and a preparation method thereof. The method is characterized in that an intermediate is synthesized from 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO) and p-hydroxybenzaldehyde as raw material by the solution method, and then reacts with cyanuric chloride in the presence of phase transfer catalyst to obtain a 2,4,6-tri(4-(10-methenyl hydroxy-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)phenoxy)-1,3,5-triazine product. The compound is white crystal, and has a melting point of 166 to 169 DEG C, good thermal stability and high flame retardation efficiency, and can be adopted as a reactive flame retardant for the flame retardation of thermosetting resins such as epoxy resin, polyurethane and the like, and also as an additive flame retardant for the flame retardation of engineering plastics such as ABS, nylon and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Halogen-free expansible flame-retardant thermoplastic resin composition

The invention discloses a halogen-free expansible flame-retardant thermoplastic resin composition, which is prepared by fusing and blending the following components in percentage by weight: 40 to 80 percent of thermoplastic resin, 18 to 25 percent of halogen-free expansible flame retardant, 0 to 5 percent of flame-retardant synergetic agent, 0 to 30 percent of glass fiber, 0 to 2 percent of coupling agent and 0.5 to 1 percent of antioxidant, wherein the thermoplastic resin is any one of polyamide 6, polyamide 66 and polylactic acid or glass fiber reinforced product thereof. The halogen-free expansible flame retardant in the flame-retardant thermoplastic resin composition has low additive amount and good flame retardancy, and the compound flame-retardant synergetic agent does not affect various inherent properties of the resin and can improve the flame retardancy of the material and reduce the cost of the material so as to fill the blank that the prior art has no thermoplastic resin compositions of halogen-free expansible flame-retardant polyamide, polylactic acid and the like.

Owner:SICHUAN UNIV

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Styrene series non-halogen flame retardant injection-grade wood plastic composite and preparation method thereof

The invention discloses a styrene series non-halogen flame retardant injection-grade wood plastic composite and a preparation method thereof. The styrene series non-halogen flame retardant injection-grade wood plastic composite is prepared from the following components in percentage by mass: 25-60 percent of styrene series resin, 5-60 percent of plant fiber, 0.5-20 percent of compatilizer, 0-30 percent of flexibilizer, 0.5-8 percent of dispersing agent, 5-40 percent of fire retardant and synergetic fire retardant and 0-1 percent of antioxidant. Compared with the traditional wood plastic composite, the styrene series non-halogen flame retardant injection-grade wood plastic composite prepared by the invention has the characteristics of simple production flow, less consumption amount of fireretardant, good non-halogen flame retardant effect, wide range of moulding ways, and the like, and is suitable for various injection moulded parts such as shells of electric appliances, parts for vehicles, and parts for furniture and buildings, and the like.

Owner:GUANGDONG KINGFA TECH CO LTD

Continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound

The invention relates to the field of composite materials, in particular to a continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound. The continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound comprises the following components in part by weight: 15 to 50 parts of unsaturated polyester resin, 5 to 12 parts of low astringent, 8 to 20 parts of chopped glass fibers of 12 to 26 millimeters, 1.5 to 8 parts of directional continuous glass fibers, 10 to 50 parts of calcium carbonate, 10 to 50 parts of aluminum hydroxide, 0.2 to 1 part of organic peroxide, 1 to 4 parts of styrene, 0.2 to 1 part of thickening agent, and 1 to 3 parts of mold discharging agent. The continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound has the advantages of reasonable formula design, good flame retardance, high strength, low manufacturing cost and stable quality.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

Core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and preparation method thereof

ActiveCN101608060AHigh flame retardant efficiencyImprove efficiencyPolyurethane elastomerFire protection

The invention discloses a core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and a preparation method thereof, which is characterized in that the polyurethane elastic composite material containing core-shell type ammonium polyphosphate can be obtained by melting and co-mixing 75-94.9% of polyurethane, 5-25% of core-shell type ammonium polyphosphate and 0.1-5% of synergistic agent at the temperature of 160-220 DEG C for 5-30 minutes by weight percentage. The composite material can ensure that the adding amount of flame retardant is reduced while ensuring the flame retardance effect, and the composite material has good resistance of melt drip, simultaneously improves the shortcoming of poor water resistance of the flame-retardant composite material containing the ammonium polyphosphate, enhances the compatibility of the flame retardant and a polyurethane elastomer and improves the mechanical properties of the material, such as tensile strength, fracture strength and flame retardance performance, thereby meeting the requirements of fire protection safety and engineering applications.

Owner:UNIV OF SCI & TECH OF CHINA

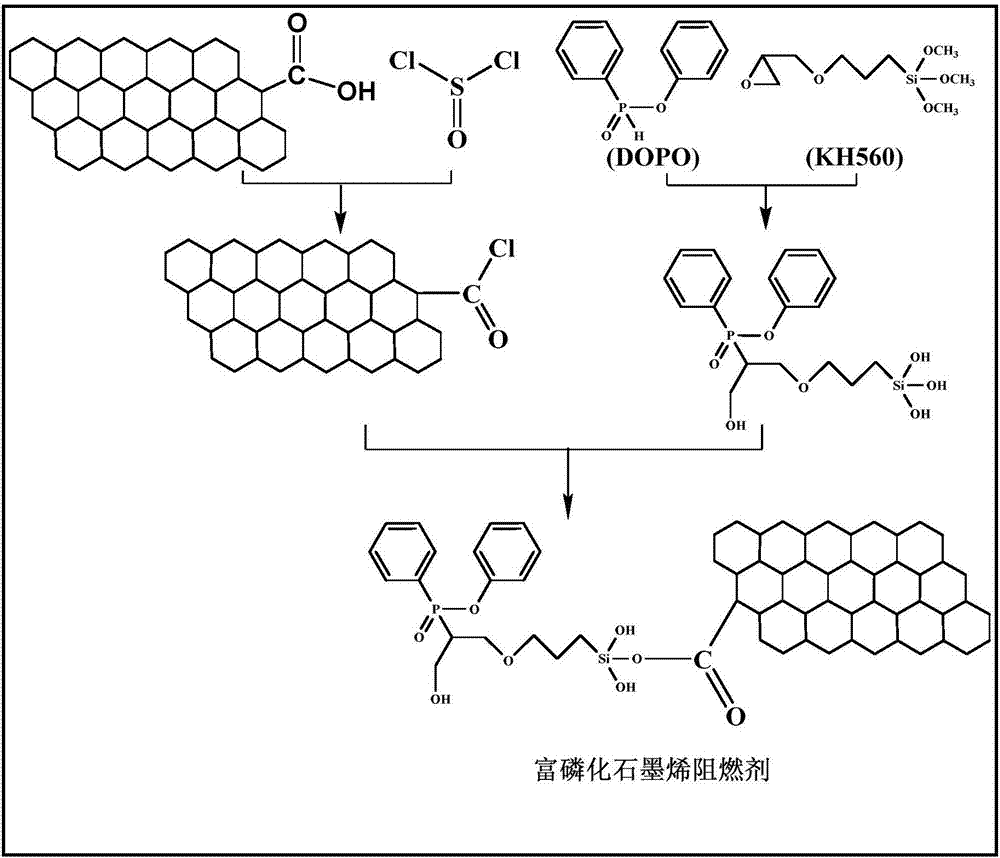

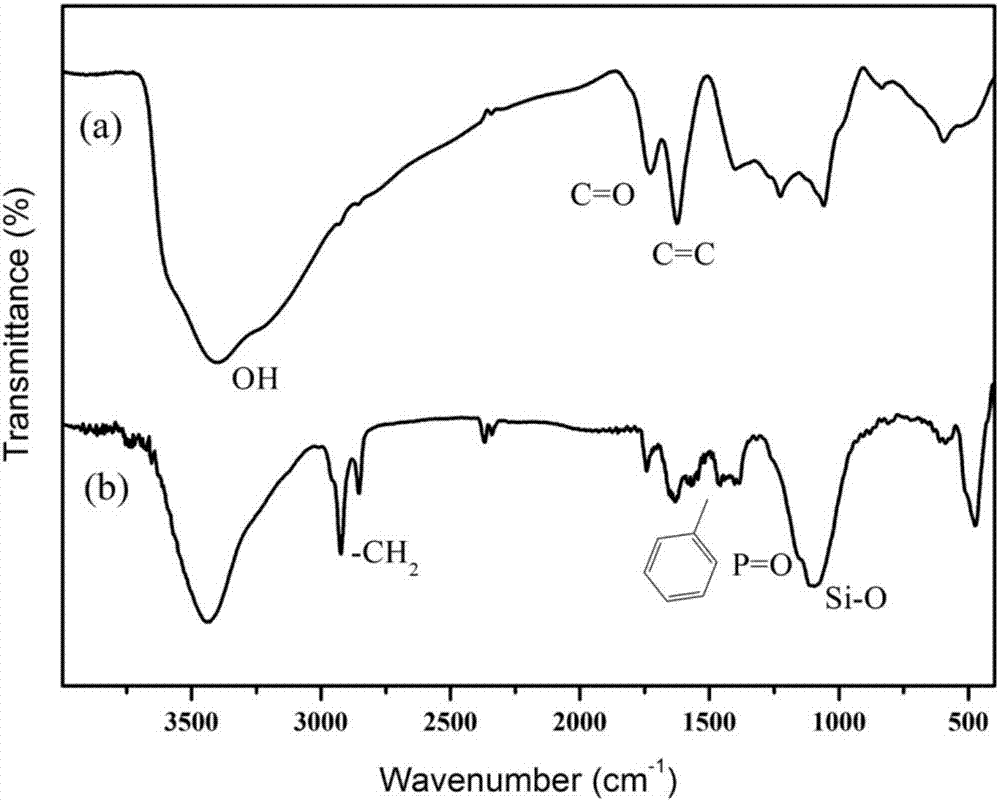

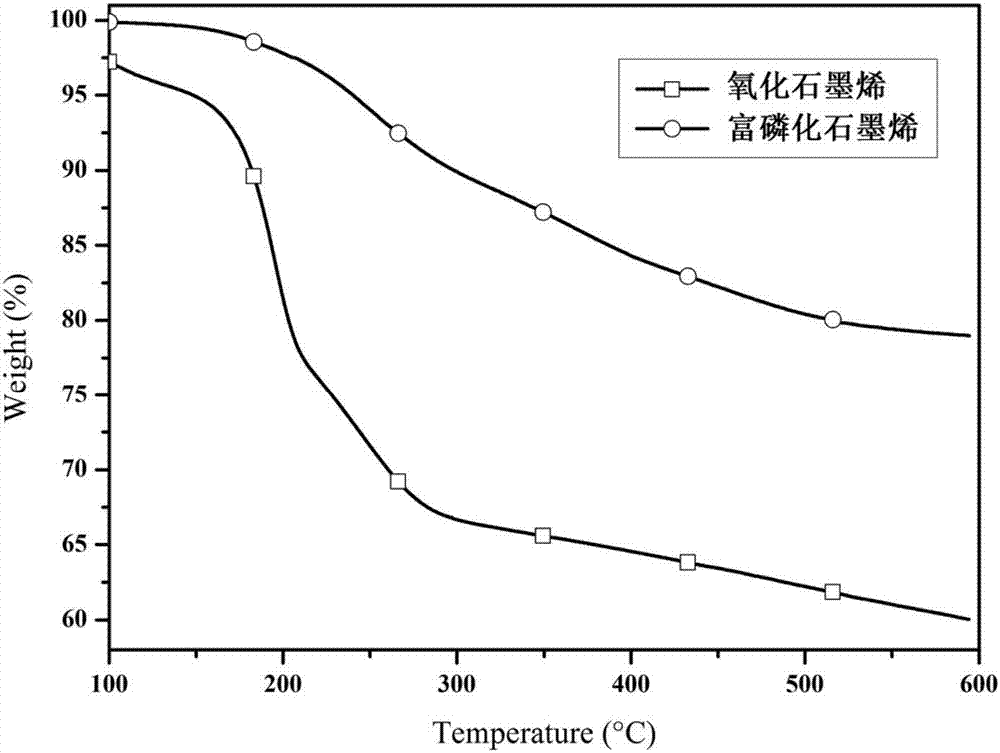

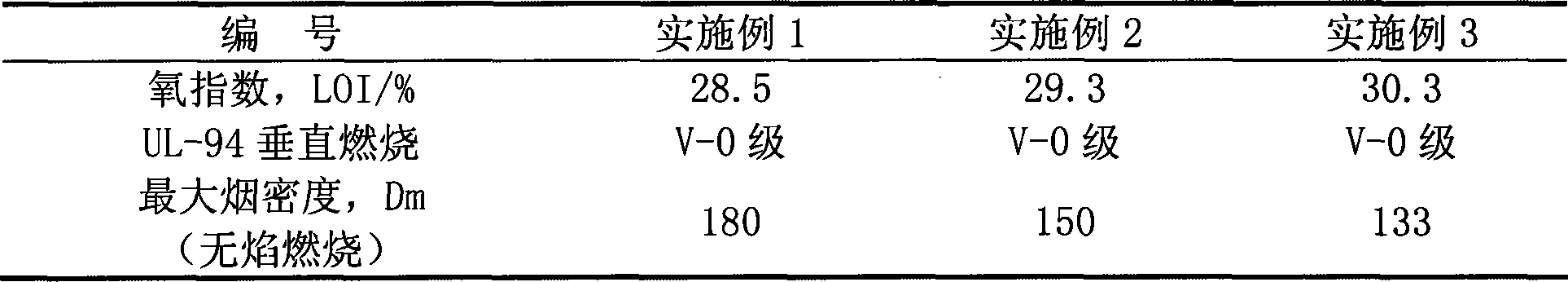

Phosphor-rich graphene flame-retardant agent and preparation method thereof

ActiveCN106883450AHigh flame retardant efficiencyConducive to synergistic flame retardantFireproof paintsPolyurea/polyurethane coatingsCarbon layerSilanes

The invention provides a phosphor-rich graphene flame-retardant agent with a structural formula shown in the description. The invention also provides a preparation method of the phosphor-rich graphene flame-retardant agent. The preparation method is characterized in that graphene oxide is used as a basic raw material, reactive groups at both ends of a silane coupler containing a silicon carbon layer improving agent are fully utilized, one end of the silane coupler is connected with acid source components, such as CEPPA (carboxyethyl phenyl phosphinic acid), DOPO or derivatives, and the other end of the silane coupler is connected with the graphene oxide, so as to obtain a macromolecular flame retardant integrating a physical carbon layer, an acid source and the carbon layer improving agent. The phosphor-rich graphene flame-retardant agent has the advantages that the flame-retardant efficiency is high, the polarity is low, the moisture absorbing property is little, and the mechanical property of the material can be well maintained; by not containing halogen, the flame-retardant agent is friendly to the human body and environment, and meets the green development direction of future flame-retardant agents.

Owner:宿迁聚萃功能复合材料研究所有限公司 +1

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

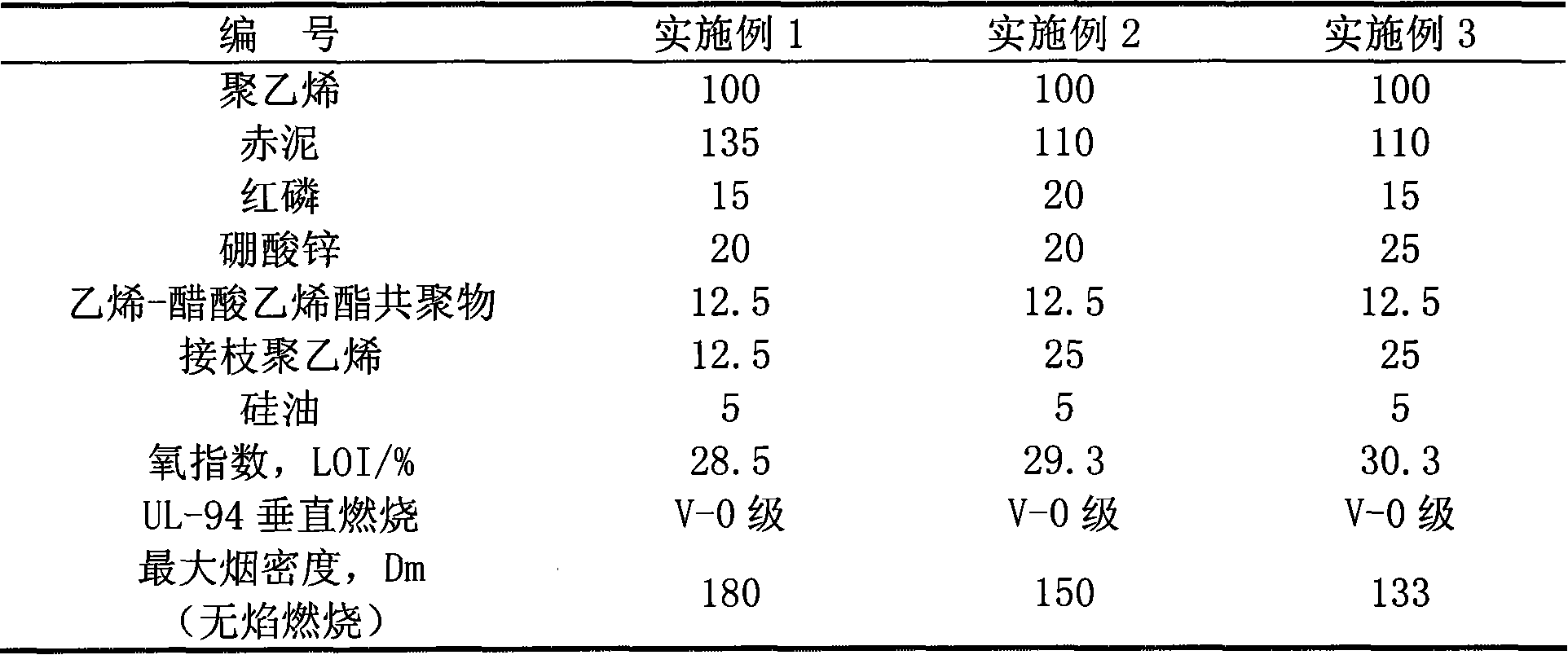

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Surface precipitation-free flame-retardant polypropylene compound and preparation method thereof

ActiveCN101880420AMeet the use requirementsHigh flame retardant efficiencyHydrobromideProcedure Agents

The invention relates to a surface precipitation-free flame-retardant polypropylene compound and a preparation method thereof. The surface precipitation-free flame-retardant polypropylene compound comprises the following components by weight percent: 70-98.5% of polypropylene resin, 1-15% of melamine hydrobromide, 0.3-7% of phosphinates, 0.2-4% of flame retardant synergist, 0-2% of synergetic flame retardant, 0-1% of antioxidant and 0-1% of processing acid. The preparation method thereof is implemented as follows: weighting the above components based on proportion, evenly mixing, melt-mixing the above mixture, pelletizing and drying to obtain the product in the invention. The surface precipitation-free flame-retardant polypropylene compound has high flame retardant efficiency, good flowability, no precipitation, and high flame retardant rating up to UL94 V-0, and can satisfy the use requirements of flame retardant materials in building materials, electrical appliance casings, sockets, bellows, lighting lamps and the like.

Owner:湖南美莱珀科技发展有限公司

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

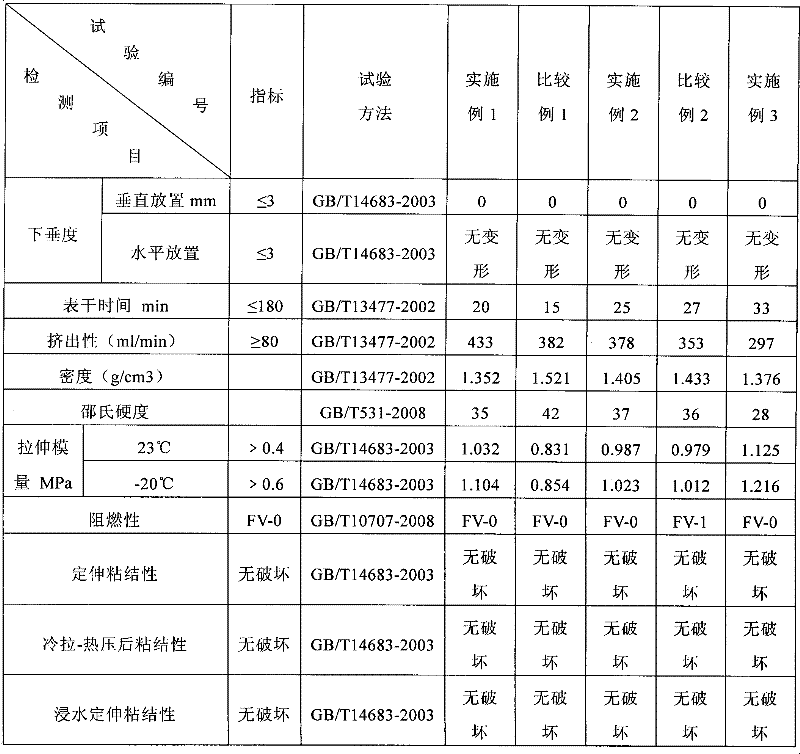

Silicone fireproof sealant for construction and preparation method thereof

InactiveCN101747859ALess corrosiveHigh flame retardant efficiencyNon-macromolecular adhesive additivesOther chemical processesRoom temperatureNitrogen

The invention discloses a silicone fireproof sealant for construction and a preparation method thereof. The preparation comprises the steps of adding alpha, omega-dihydroxy polysiloxane, a filler, an inorganic flame retardant and a nitrogen system flame retardant into a kneading machine, carrying out dehydration at the temperature of 100-180 DEG C and the vacuum degree of 0.06-0.1MPa for 0.5-4 hours, cooling, and then preparing a base material. The base material, polydimethylsiloxane, an inorganic pigment, a crosslinking agent, a silane coupling agent and a catalyst are added into a planetary mixer at the room temperature, keeping the vacuum degree at 0.06-0.1MPa, stirring at the speed of 20-80 r / min, carrying out reaction under stirring for 0.5-6 hours, and preparing the silicone fireproof sealant for construction with no pollution to the base material, flame retardance and excellent adhesion and storage stability. The inorganic flame retardant and the nitrogen system flame retardant are in synergistic flame retardance, and the silicone fireproof sealant can effectively reduce the adding amount of the inorganic flame retardant and greatly improve the mechanical processing performance of a product under the situation of achieving the equivalent flame retardant grade FV-0.

Owner:浙江凌志新材料有限公司

Method for synthesizing phosphorus-containing polyester for fire retardant electronic packaging material

The invention relates to a method for synthesizing phosphorous polyester used for fire-retardant electronic packaging materials, aiming to obtain the polyester with high fire resistance to solve the fire-retardant problem of the electronic packaging materials. The method for synthesizing the phosphorous polyester comprises the following steps that: firstly, polylol is added into a four-mouth flask, and the temperature is increased to over 100 DEG C so that the polylol is stirred to be melt; secondly, polyatomic acid / estolide, reactive phosphorous compound and catalyst are respectively added into the molten polylol; the esterification reaction begins and esterifying water is generated and distilled off; thirdly, vacuum-pumping is performed for polycondensation when the esterification rate reaches over 95 percent; fourthly, end capping reagent is added and then the finished phosphorous polyester can be prepared, wherein, the acid value range is between 50 and 250 KOH / g, and the fusing temperature range is between 60 and 130 DEG C. The phosphorous polyester prepared by the method is used for the fire-retardant electronic packaging materials and can realize non-halogenation of the electronic packaging materials.

Owner:天津凯华绝缘材料股份有限公司

Fire retardant for wood, and preparation method and treatment process thereof

ActiveCN102069519ASimple processRealize industrial productionPressure impregnationWood impregnation detailsEnvironmental resistanceSilicon dioxide

The invention discloses a fire retardant for wood, and a preparation method and a treatment process thereof. The fire retardant for wood is prepared from the following raw materials in percentage by weight: 40 to 60 percent of silica sol, 5 to 20 percent of sodium octaborate tetrahydrate, 1 to 20 percent of ammonium polyphosphate, 1 to 20 percent of carbonate and 0 to 53 percent of water. The preparation method comprises steps of: putting the substances into a stirrer, and uniformly mixing fully to obtain the flame retardant. During use, wood is put into a treatment tank, and is vacuumized, the flame retardant is injected at normal temperature, the treatment tank is vacuumized and the vacuum is eliminated so as to obtain the flame-retardant wood. By utilizing advantages of nontoxicity, environmental friendliness, high flame-retardant efficiency, low price, wide sources and easy preparation of the materials such as the sodium octaborate tetrahydrate and the silica sol, after the materials are compounded, the flame retardant with good anti-loss performance is obtained and can be used for flame-retardant protection of interior and exterior decorative wood and wood structures of buildings.

Owner:ZHEJIANG UNIV

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Enhanced toughened halogen-free flame-retardant polypropylene mixture and preparation method thereof

The invention discloses an enhanced toughened halogen-free flame-retardant polypropylene mixture and a preparation method thereof. The method comprises the steps of: diluting 0.5-3 parts by weight of surfactants with 20-30 parts by weight of absolute ethyl alcohol, then adding into 100 parts by weight of alkaline magnesium sulfate whiskers, mixing for 15-30 min in a mixer, and then drying in a dryer to obtain the modified alkaline magnesium sulfate whiskers, wherein the alkaline magnesium sulfate whiskers is required to be 10-60 mum in average length and less than 10 mu m in diameter; adding polypropylene resin firstly on an open type warming mill with double-roll temperature of 170-180 DEG C, sequentially adding an antioxidant, a toughened modifier, the modified alkaline magnesium sulfate whiskers, a synergistic flame retardant, a molten-drop prevention modifier and a compatibilization modifier after the polypropylene resin is molten and covers the rolls, and evenly mixing to obtain the enhanced toughened halogen-free flame-retardant polypropylene mixture. The polypropylene mixture prepared in the invention has the advantages of high strength, good toughness, low smoke, no toxicity, no molten drop, remarkable flame retardant property and the like.

Owner:SOUTH CHINA UNIV OF TECH

Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

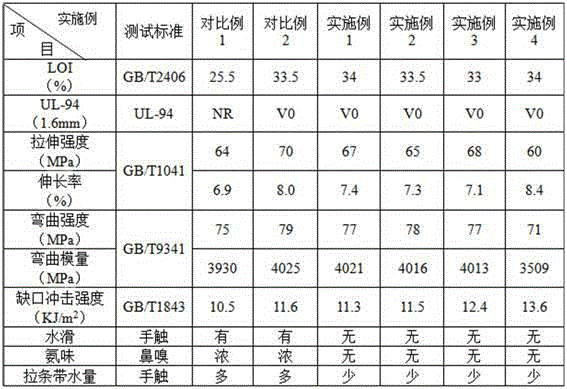

The invention relates to a halogen-free flame retardant glass-fiber reinforced polypropylene composite material, which comprises the following components in weight percentage: 33-59% of polypropylene resin, 15-35% of compound flame retardant, 20-30% of glass fiber, 3-10% of compatibilizing agent, 0.4-2.5% of coupling agent and 1-3% of thermal stabilizer; the compound flame retardant is prepared by mixing and compounding a main flame retardant and an auxiliary flame retardant with a mass ratio of 41-79: 21-59; the main flame retardant is one or a mixture of melamine polyphosphate, melamine phosphate and melamine cyanurate; and the auxiliary flame retardant is one or a mixture of inorganic hypophosphite, diethyl hypophosphite and diphenyl hypophosphite. The polypropylene material is good in fire retardant performance and high in fire retardant efficiency; because ammonium polyphosphate component is excluded, the polypropylene material has the advantages of non-hydroplaning in processing, no release of ammonia gas and less water in bracing.

Owner:苏州安鸿泰新材料有限公司

Polyelectrolyte nanometer flame-retardant coating by adoption of layer-by-layer assembly and preparation method thereof

ActiveCN105080814AHigh flame retardant efficiencySuitable for fire protectionFireproof paintsSpecial surfacesCationic polyelectrolytesLayer by layer self assembly

The invention discloses a polyelectrolyte nanometer flame-retardant coating by adoption of layer-by-layer assembly and a preparation method thereof. The preparation method comprises following steps of: 1), preprocessing: putting and soaking base material into an acid solution and cleaning and drying base material with water; 2), self-assembly: putting and soaking pre-processed base material to a cationic polyelectrolyte solution in order to from a layer of ion membrane, taking out the layer of ion membrane and cleaning the ion membrane with water for drying, putting and soaking the ion membrane into the cationic polyelectrolyte solution in order to form an layer of anionic membrane, and cleaning the layer of anionic membrane with water and drying; sequentially repeating above self-assembly process for multiple times so that the polyelectrolyte nanometer flame-retardant coating is prepared by adoption of layer-by-layer assembly on the surface of the base material. The polyelectrolyte nanometer flame-retardant coating by adoption of layer-by-layer assembly and the preparation method thereof have following beneficial effects: the polyelectrolyte nanometer flame-retardant coating is green and eco-friendly and has a simple and feasible preparation method; damage to the internal structure of base material is avoided; high flame-retardant efficiency is obtained; and the preparation method is suitable for formation of flame-retardant coatings on material surfaces including fabric, wood, foam and plastics.

Owner:马德里高等材料研究院 +1

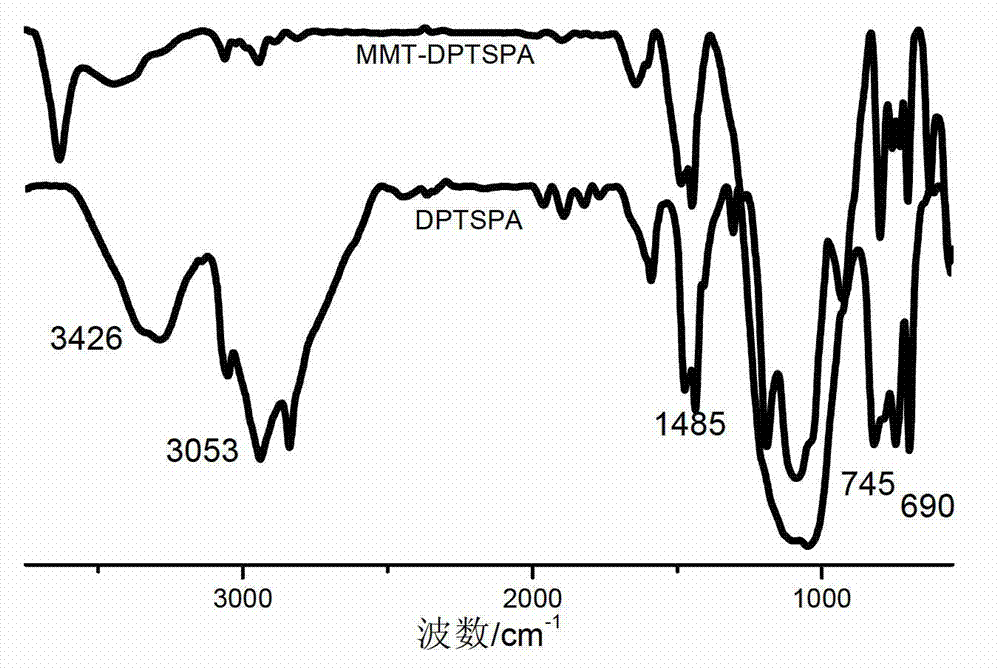

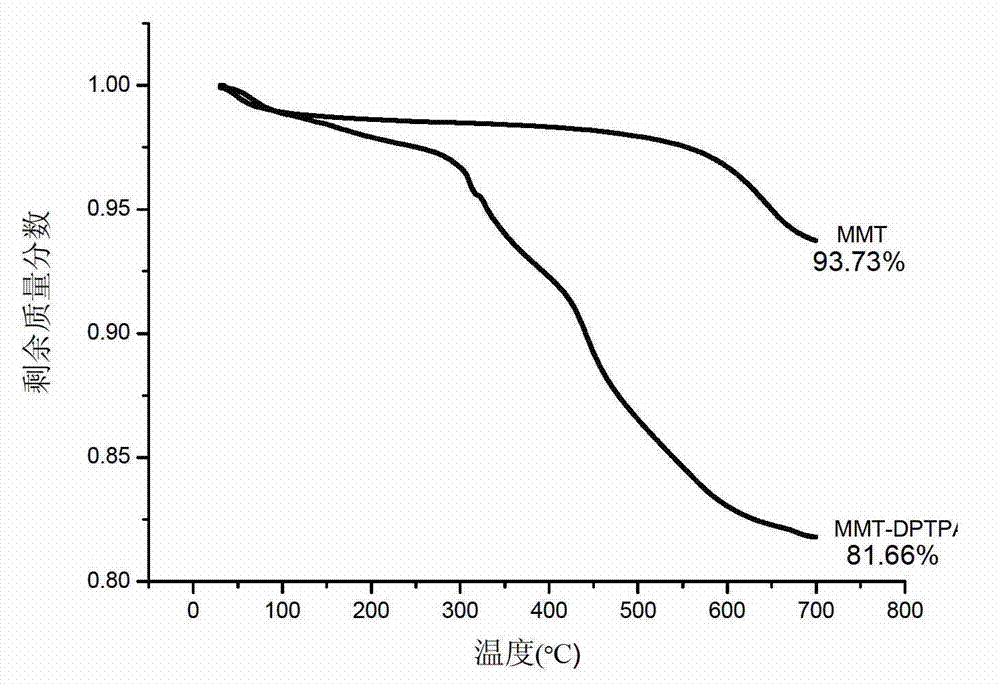

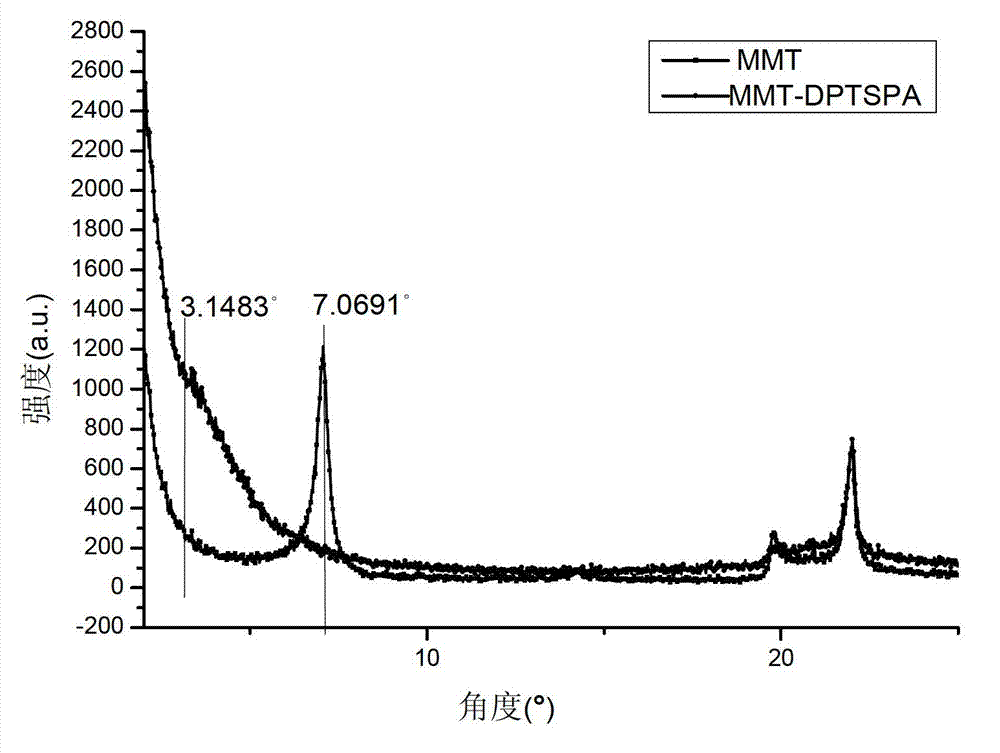

Intumescent flame retardant functional silicate and preparation method thereof

ActiveCN102757581AHigh grafting rateHigh flame retardant efficiencyPigment treatment with organosilicon compoundsNitrogenFire retardant

The invention discloses an intumescent flame retardant functional silicate and a preparation method thereof. According to the invention, the preparation method comprises the following two methods: one method comprises the steps of first preparing silane coupling agent organic functional silicate, and then preparing the intumescent flame retardant functional silicate on the basis of the former step; and the second method comprises the steps of first preparing a modified silane coupling agent containing phosphorus and nitrogen flame retardant elements, and then modifying inorganic silicate by using the modified silane coupling agent on the basis of the former step. According to the invention, the intumescent flame retardant functional silicate comprises an organic part B and an inorganic part A, wherein the organic part B is grafted to the inorganic part A in such a way that a silanol group formed by after a silane coupling agent containing amino has dehydration reaction with hydroxyls on the surface and between layers of the inorganic part A; and the organic part B is formed in such a way that a phosphoryl chloride compound has elimination reaction with an amino silane coupling agent. The intumescent flame retardant functional silicate disclosed by the invention is integrated with reinforcing, flame retardant and smoke suppressing functions.

Owner:SOUTH CHINA UNIV OF TECH +1

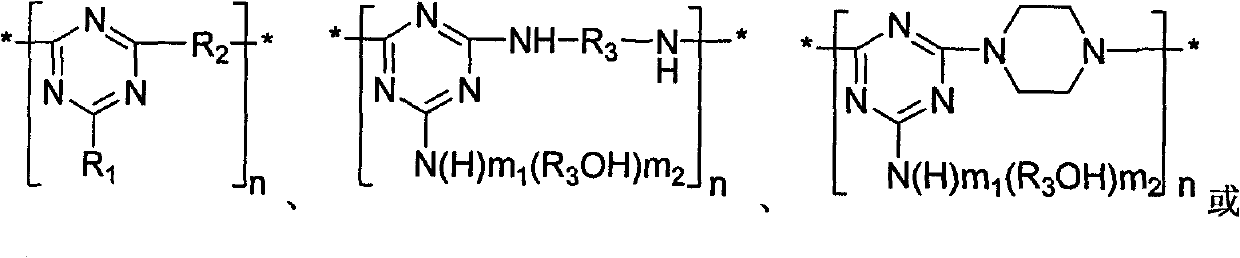

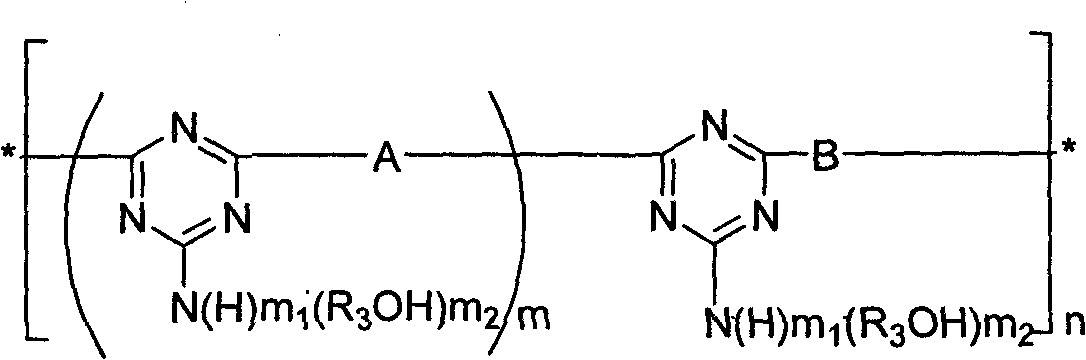

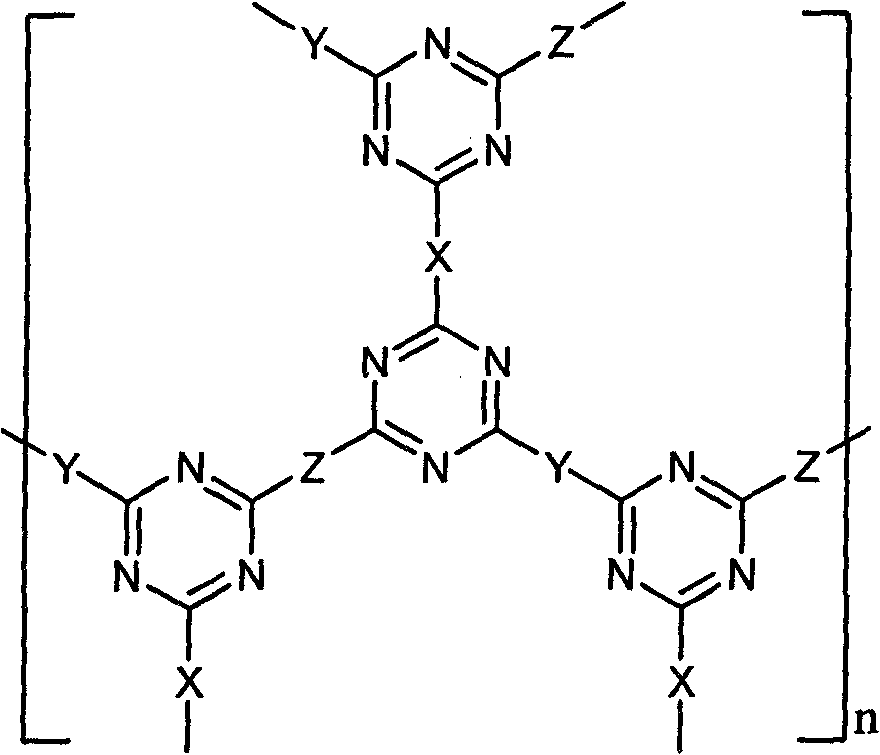

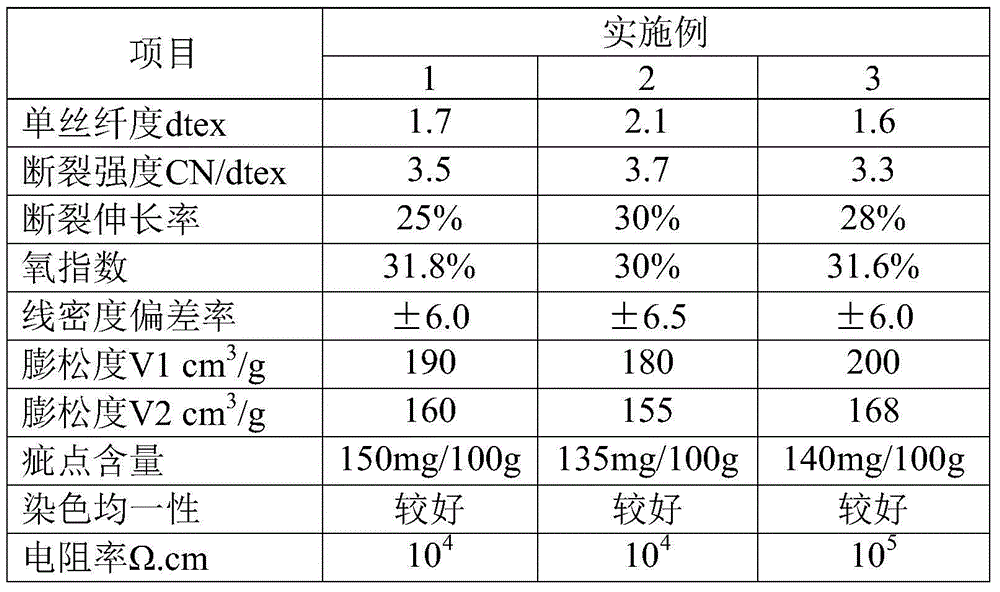

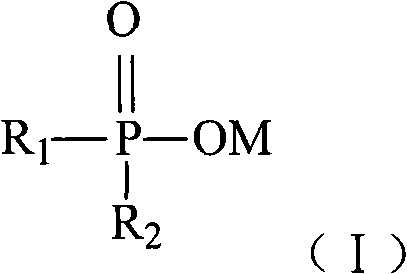

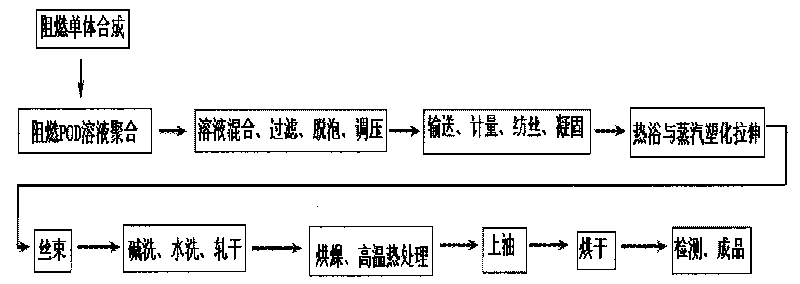

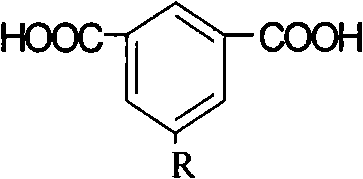

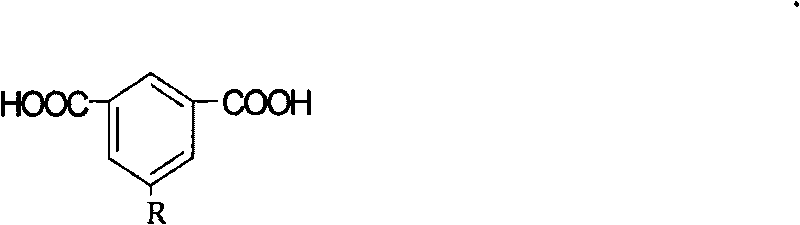

Method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof

ActiveCN101735455ASingle structureEasy to synthesizeWet spinning methodsMonocomponent synthetic polymer artificial filamentChemistryDecomposition

The invention discloses a method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof. The special aromatic polyoxadiazole is prepared by the following method that the special aromatic polyoxadiazole is prepared from terephthalic acid, compound of which the structural general formula is expressed as formula I and hydrazine salt serving as monomers through condensation polymerization reaction. The polyoxadiazole fiber with high flame retardancy and high temperature resistance is prepared by using the special aromatic polyoxadiazole as a raw material. The fiber number of the prepared polyoxadiazole fiber is 1 to 20 dtex, the breaking strength is 2.5 to 5 cN.dtex-1, the elongation at break is 10 to 40 percent, the initial modulus is 50 to 250 cN.dtex-1, the moisture regain is 5.0 to 12.0 percent, the limited oxygen index is 30 to 38 percent, and the initial decomposition temperature is above 480 DEG C. The fiber can be widely used in the fields of protective products, filter materials, electric insulating materials, frictional sealed materials, various industrial textiles, high-temperature resistant paper, aviation and aerospace materials and the like.

Owner:JIANGSU BAODE NEW MATERIAL

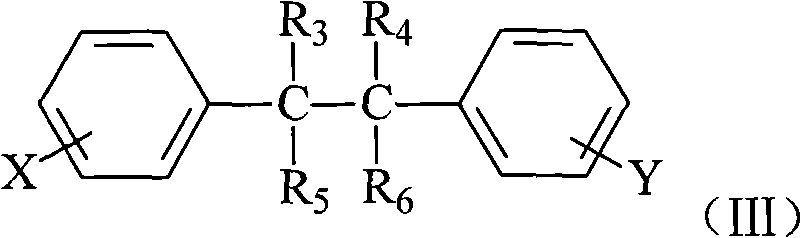

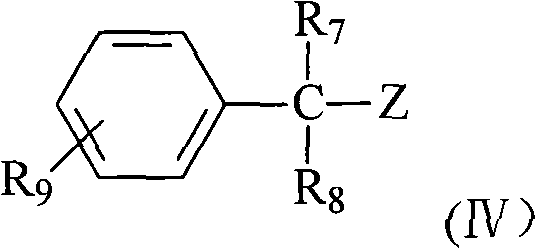

Unimolecular phosphorus-silicon-nitrogen intumescent flame retardant and preparation method thereof

InactiveCN102702575AHigh flame retardant efficiencyOvercome the disadvantage of easy water absorptionGroup 5/15 element organic compoundsPolymer scienceHalogen

The invention discloses a unimolecular phosphorus-silicon-nitrogen intumescent flame retardant and a preparation method thereof, and relates to a flame retardant and a preparation method thereof. The flame retardant has the structural formula shown in the specifications; compared with the conventional flame retardant, the flame retardant has the advantages that the flame retardant does not contain halogen and contains three elements of the intumescent flame retardant, and 10-(2,5-dihydroxyphenyl)-10H-9-oxa-10-phospha-phenantbrene-10-oxide which does not contain a phosphate structure is used as an acid source; and the flame retardant is high in flame retardant property and is non-toxic, does not absorb water easily, contributes to environment friendliness, and has good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Halogen-free flame-retardant polypropylene master batch

The invention relates to a halogen-free flame-retardant polypropylene master batch. The halogen-free flame-retardant polypropylene master batch comprises the following components in percentage by weight: 20 to 40 percent of polypropylene pellets, 40 to 60 percent of ammonium polyphosphate, 0.5 to 3.0 percent of flame-retardant synergist, 6 to 25 percent of halogen-free charring agent, and 5 to 15 percent of compatibilizer. A method for preparing the halogen-free flame-retardant polypropylene master batch comprises the following steps of: weighing raw materials according to the weight proportion, drying, and extruding and granulating by a co-rotating or counter-rotating twin-screw extruder, wherein the rotating speed of a screw is 70 to 200rpm; and the temperature is 160 to 230 DEG C. The disadvantages that the atactic polypropylene (APP) is independently added, so flame-retardant efficiency is low, the mechanical properties of matrixes are greatly influenced, great inconvenience is brought to the drying treatment of the raw materials, dust pollution is caused and the like are overcome. The invention has the advantages that: the flame-retardant synergistic effect can be well realized among components of the master batch, mixing and drying processes of the raw materials in the production process are simplified, and the production efficiency is improved; the dust in the production process is reduced, and the production environment is improved; and a flame-retardant polypropylene material prepared from the master batch has a good flame-retardant effect and excellent mechanical properties.

Owner:YANGZHOU UNIV

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and preparation method thereof

ActiveCN102226016AHigh flame retardant efficiencyMeet the mechanical propertiesMolecular sieveRubber material

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and a preparation method thereof relate to flame-retardant rubber and the preparation method thereof. The flame-retardant rubber provided by the invention comprises, by weight, 100 parts of a rubber matrix, 1.5-2.8 parts of a vulcanizing agent, 1-1.5 parts of a promoter CZ, 1-3 parts of stearic acid, 4.5-5 parts of zinc oxide, 1-2 parts of an antioxidant 4010, 1-3 parts of liquid paraffin, 30-40 parts of carbon black, 60-80 parts of an intumescent flame retardant, and 0-5 parts of nano-mesoporous molecular sieve. The preparation method provided by the invention comprises the following steps of: plasticating rubber in an open mill, successively adding eleaostearic acid, zinc oxide, the promoter CZ, the antioxidant 4010, the nano-mesoporous molecular sieve, carbon black, liquid paraffin, IFR and sulphur, mixing and discharging tablets, followed by sulfuration. By the adoption of the nano-mesoporous molecular sieve synergistic intumescent flame retardant, its excellent flame-retardant synergistic effect and interfacial compatibility effect greatly improve the flame-retardant performance and mechanical properties of the rubber material.

Owner:沈阳双骥橡塑科技有限公司

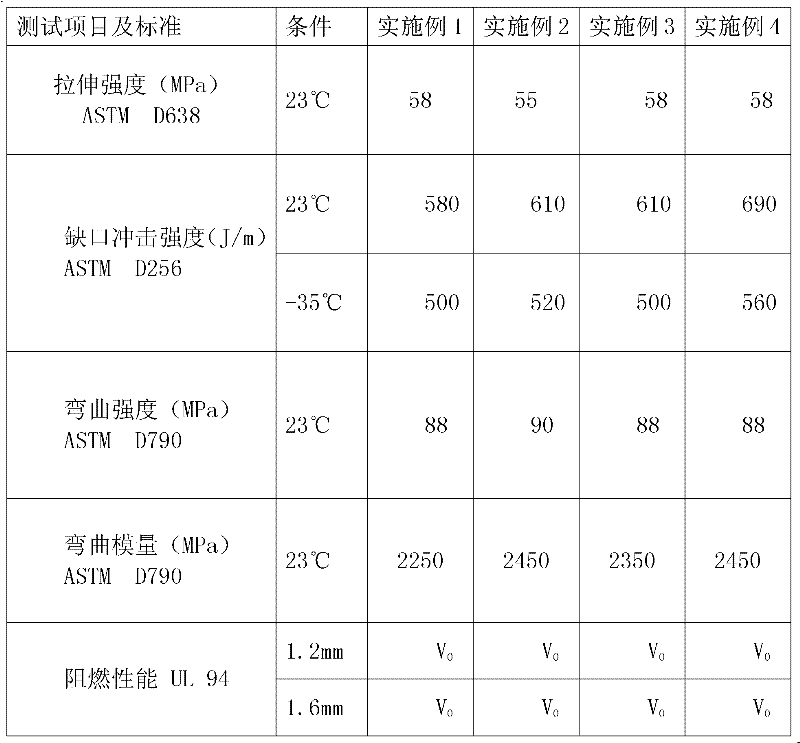

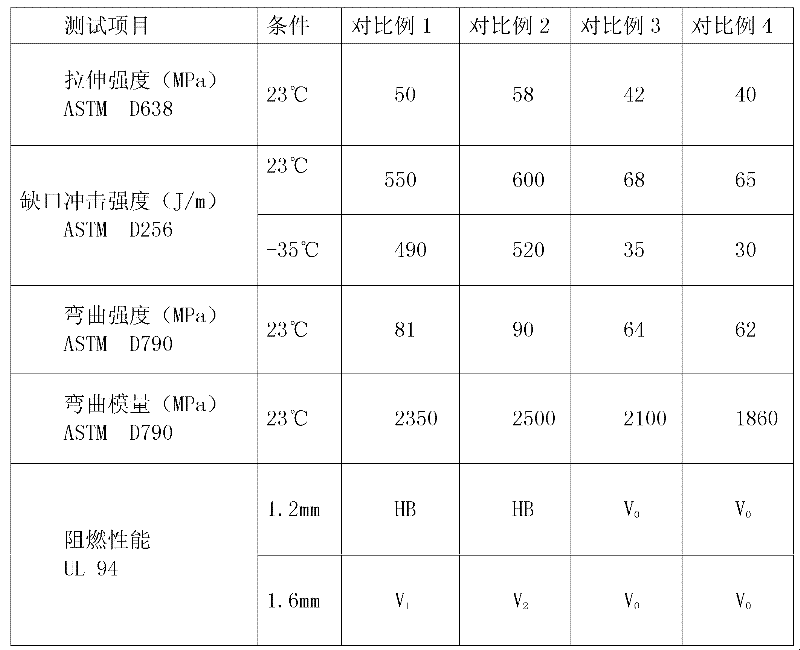

Halogen-free flame-retardant and cold-resistant PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) material and preparation method thereof

The invention discloses a halogen-free flame-retardant and cold-resistant PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) material and a preparation method thereof. The halogen-free flame-retardant and cold-resistant PC / ABS material mainly comprises components of PC and ABS and further comprises a silicon fire retardant, a phosphorus fire retardant, an anti-dripping agent, a compatilizer, a flexibilizer, a lubricant, an antioxidant, and an anti-ultraviolet agent. A preparation process is a twin-screw melting extrusion pelletizing process. According to the preparation method disclosed by the invention, the silicon fire retardant and the phosphorus fire retardant are composited so that the fire resistance 1.2 mm of the obtained PC-ABS alloy material can meet the UL94V-0 class requirement in the United States. The compatilizer MBS (Methyl methacrylate-Butadiene-Styrene) not only enables the PC and the ABS to be better dissolved but also can be used for increasing the compatibility between the silicon fire retardant and a substrate. Therefore, not only can the impact property of the alloy be improved but also the flame retardant efficiency can be effectively improved. The alloy material has the good low-temperature impact property due to the flexibilizer. The silicon fire retardant has a fire retardant synergy effect and further has a smoke suppression effect, so that the fire resistance 1.2 mm of the obtained PC-ABS alloy material can meet the UL94V-0 class requirement in the United States.

Owner:SHENZHEN KEJU NEW MATERIAL

Low-L value inflaming retarding ABS modified resin and preparation method thereof

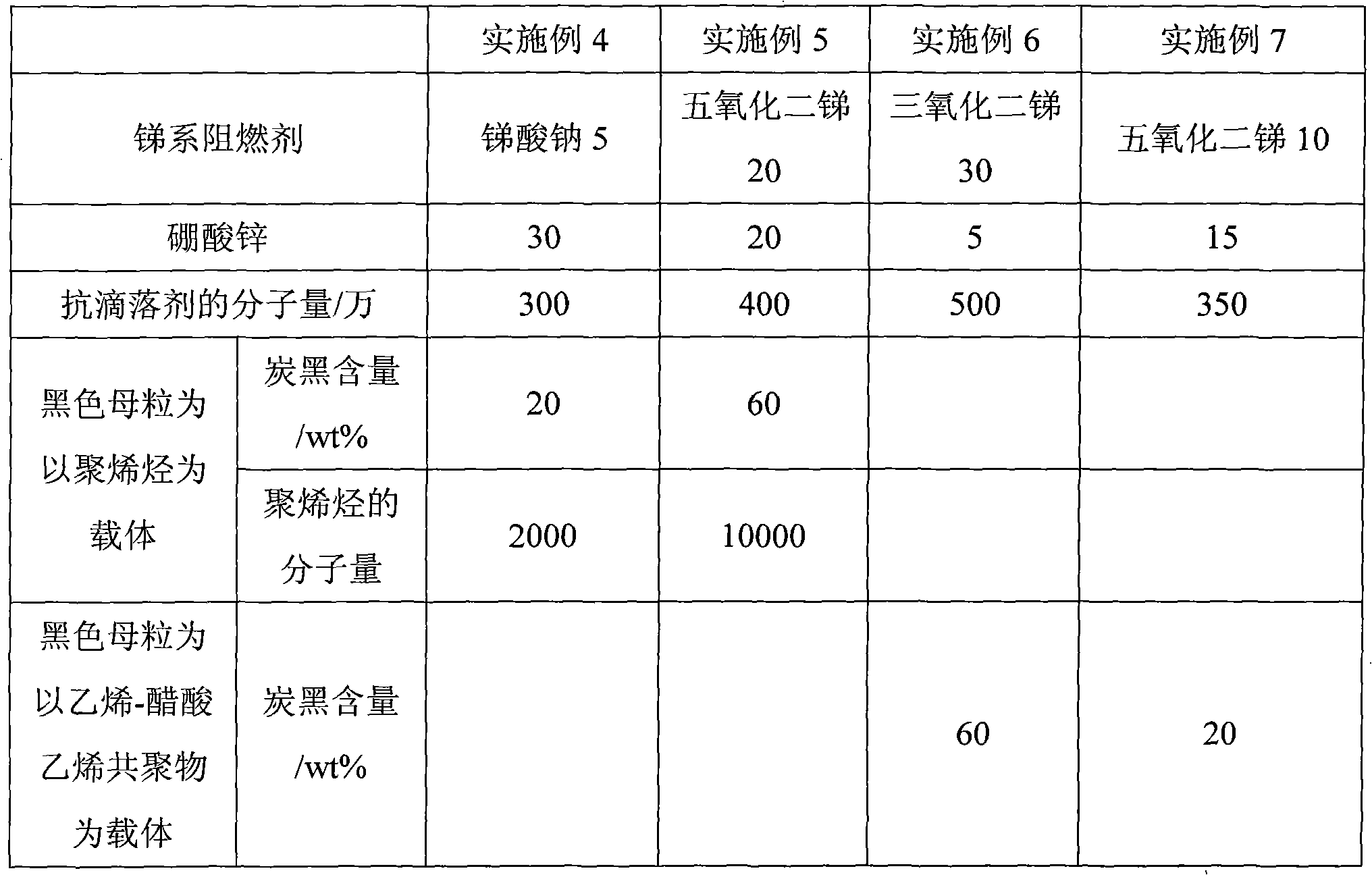

The invention relates to a low-L value (less than 27) inflaming retarding ABS modified resin and a preparation method thereof. The resin comprises the components with the content (based on parts by weight): 100 parts of ABS resin, 10-25 parts of brominated flame retardant, 20-40 parts of inorganic inflaming retarding master batch, 0.1-0.5 part of anti-dripping agent, 0.2-1 part of antioxidant, 0.1-0.5 part of light stabilizer, 1-3 parts of lubricating agent and 1-4 parts of black master batch. Compared with the prior art, the invention has reasonable technique, overcomes the defect of high L value (namely, low degree of blackness) of the existing inflaming retarding ABS resin, and adopts the novel high-efficiency inflaming retarding synergistic effect technology. The invention leads the resin has higher degree of blackness by reasonably selecting the grain diameter of antimony trioxide, a carbon black lubricating dispersion system and the processing technique of a master batch method on the basis of maintaining the excellent performance of the inflaming retarding ABS resin, and has wide application prospect in the field of the requirement of high degree of blackness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com