Patents

Literature

3619 results about "Liquid paraffin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid paraffin, also known as paraffinum liquidum or Russian mineral oil, is a very highly refined mineral oil used in cosmetics and medicine. Cosmetic or medicinal liquid paraffin should not be confused with the paraffin (or kerosene) used as a fuel.It is transparent, colorless, nearly odorless, and oily and is composed of saturated hydrocarbons derived from petroleum.

Porcine circovirus 2 type inactivated vaccine

InactiveCN101240264ASimple processEasy to operateViral antigen ingredientsMicroorganism based processesAdjuvantVaccine Production

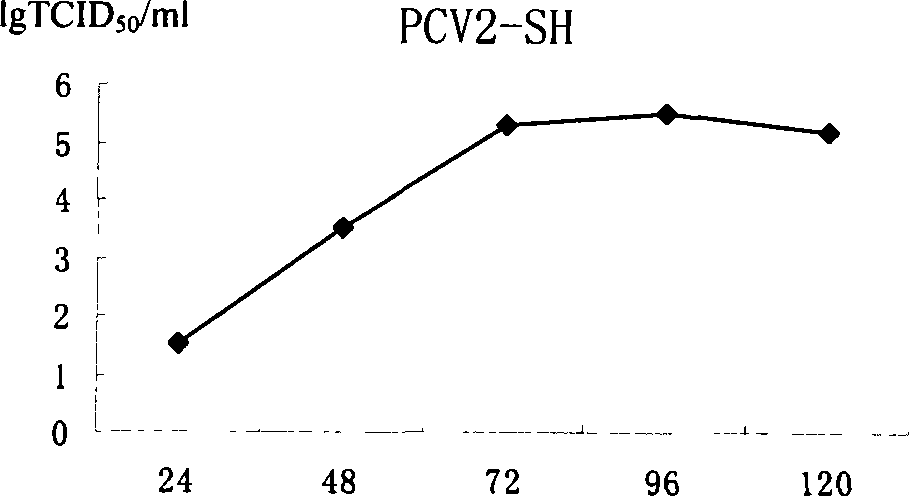

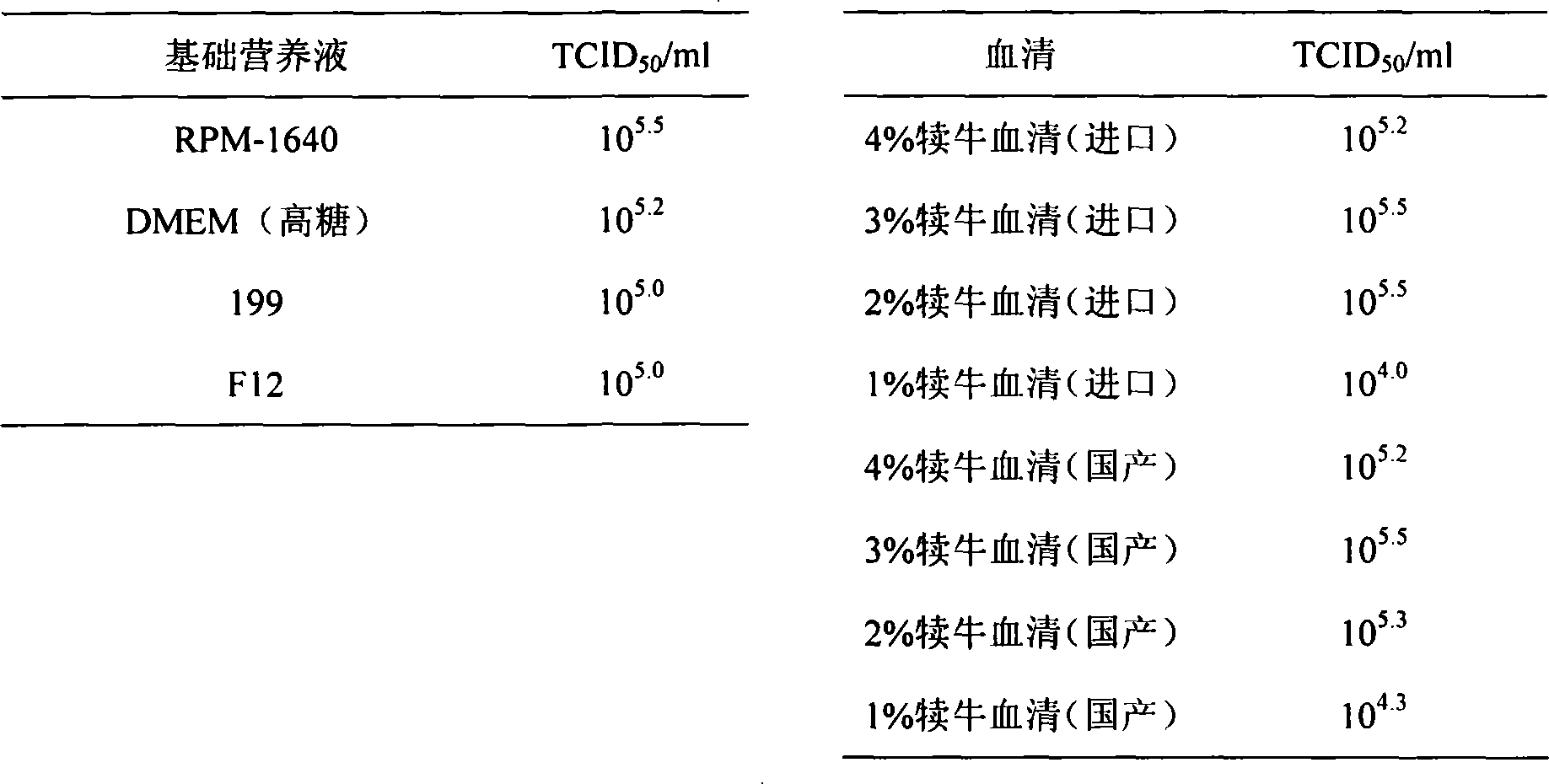

The pig circular ring virus 2 type (PVC2) inactivated vaccine (SH individual plant) of the invention belongs to biotechnology field. The pig circular ring virus 2 type poisonous individual plant SH belongs to circular ring virus section circular ring virus genus which has been preserved in Wuhan institute of virology, Chinese academy of sciences. The shanghai separated individual plant SH of purified PCV2 virus is obtained by gathering raw material from hogpen which happened bad weaning piglet multisystem exhaustion failure syndrome in Shanghai in 2002 year, separating, appraising and purifying virus. The PCV2-SH plant is proliferated in mass in PK-15 cell, inactivated through methyl aldehyde and emulsified with liquid paraffine adjuvant to prepare conventional liquid paraffin(e) adjuvant immunomodulators for vaccines. The laboratory has trial-manufactured five lots vaccines successfully which are good safety and also can induce pig bring immune protection effect, made out a draft rules for vaccines production and testing. The inactivated vaccine proved by every aspects experiment has met state biological products standard completely.

Owner:NANJING AGRICULTURAL UNIVERSITY

Oil-based ink-jet recording ink

InactiveUS6730153B2Maintain good propertiesSatisfactory pigment dispersibilityDuplicating/marking methodsInksParaffin waxVegetable oil

An ink-jet recording oil-based ink which has satisfactory pigment dispersibility both at the beginning of storage and even during long-term storage and provides excellent spouting stability without being influenced by temperature changes in printing circumstances. The ink comprises a pigment; a dispersing agent comprising a reaction product of a polyamine compound and a self condensation product of 12-hydroxystearic acid; a saturated hydrocarbon solvent comprising a liquid paraffin as a main component; and a vegetable oil, the ink having a surface tension of 26 to 30 dyne / cm at 25° C. and a contact angle on a polytetrafluoroethylene plate of 40° to 50° at 25° C., and satisfying the following relationship:wherein WHC is the weight of the saturated hydrocarbon solvent and WVC is the weight of the vegetable oil.

Owner:SAKATA INX

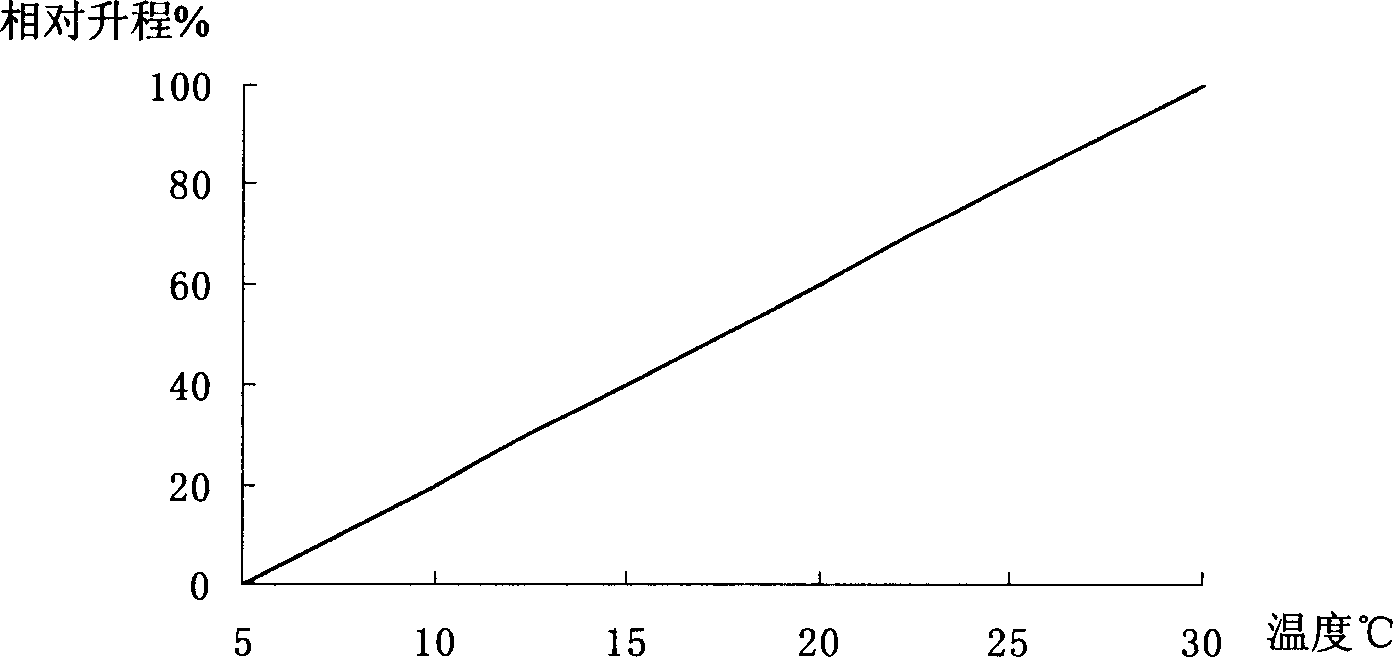

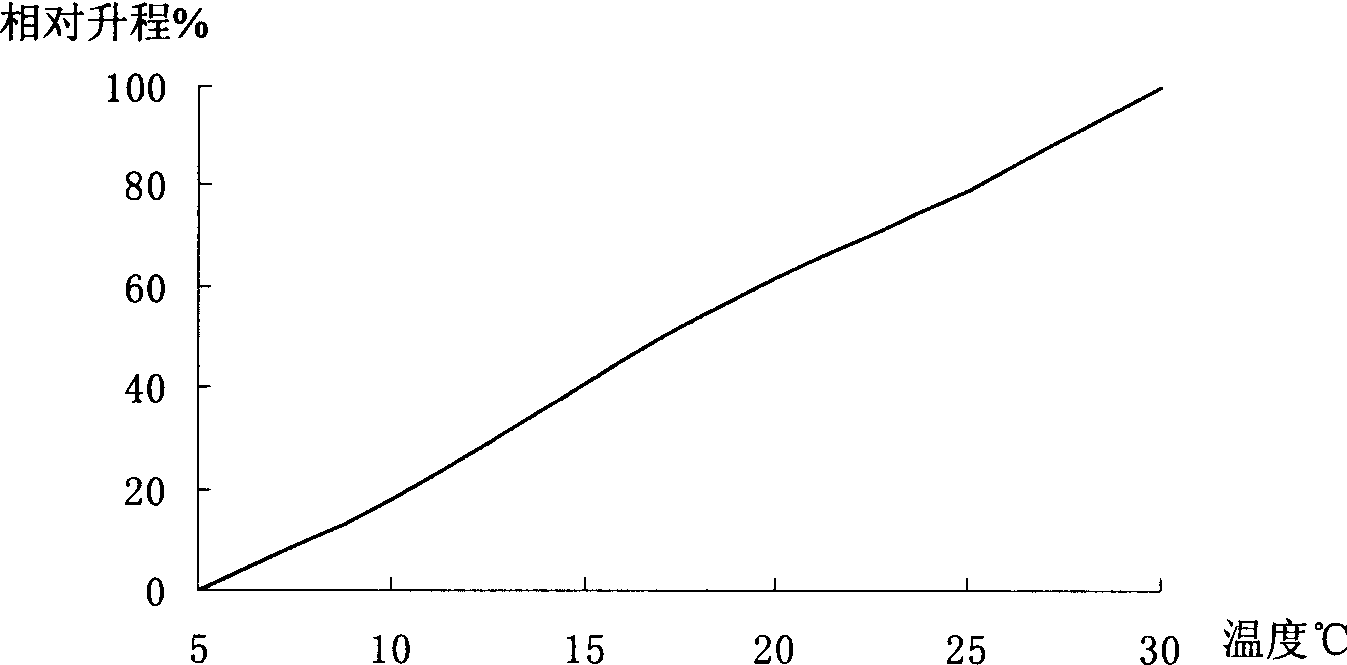

Temerature sensitive medium for wax temperature controlling valve and its prepn process

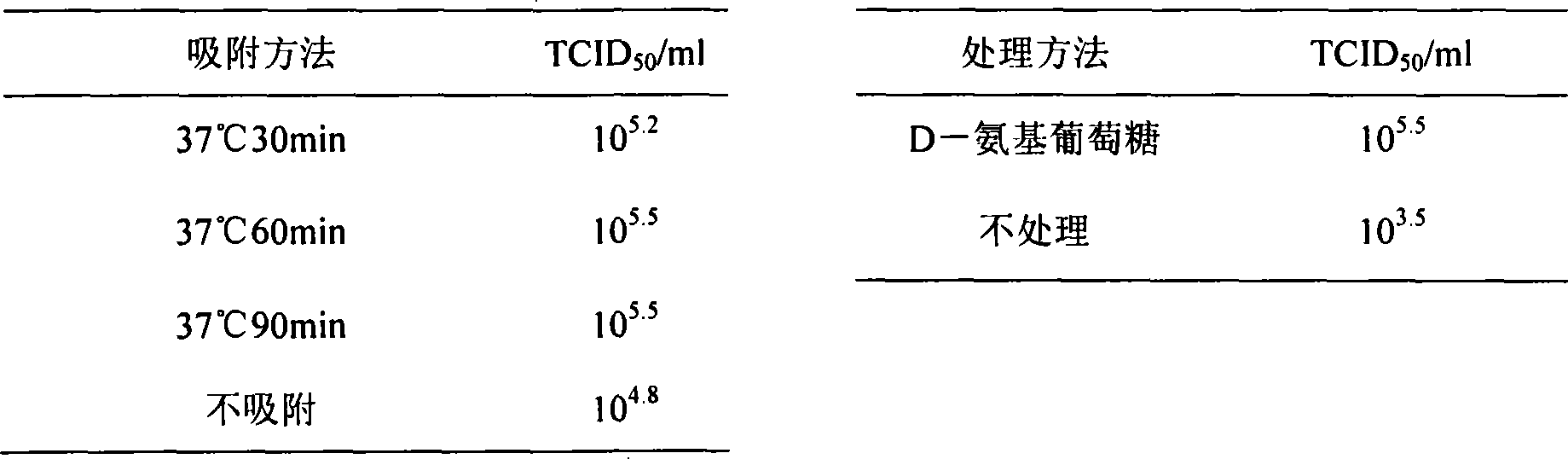

The present invention is temperature sensitive medium for wax temperature controlling valve and its preparation process. The destination product is prepared with liquid paraffin containing C9-C20 components, cerate or other material and through decompression distillation, mixing, refining and other steps. During the mixing, partial commercial wax may be added to lower the production cost. The wax temperature controlling valve with the product of the present invention may be used in controlling temperature in 5-30 deg.c with the basically the same stroke each degree. The product of the present invention may be used in automatic temperature controlling device requiring homogeneous stroke, especially in heating temperature controlling valve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recipe of breviscapine drop pills and preparing method

InactiveCN1408392AReduce the number of medicationsSmooth releaseUnknown materialsPill deliveryParaffin waxIce water

The breviscaping drop pill prepared via a solid dispersing process has the recipe comprising breviscapine 20-30 wt%, polyglycol-6000 40-60 wt%, stearic acid 10-30 wt% and poloxamer-188 5-25 wt%. The preparation process includes heating to smelt polyglycol-6000, adding stearic acid and poloxamer-188, adding breviscaping powder while stirring, transferring to dropping pipe while maintaining the temperature, dropping the molten into liquid paraffin in ice water bath to solidify into pill and washing out the liquid paraffin. The present invention has high biological utilization of medicine, delays the medicine release time and reduces medicine taking times.

Owner:HUAZHONG UNIV OF SCI & TECH +2

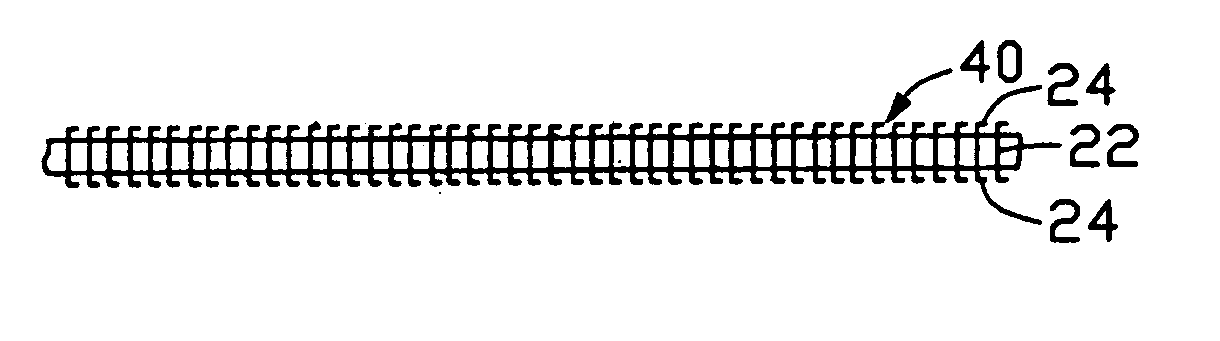

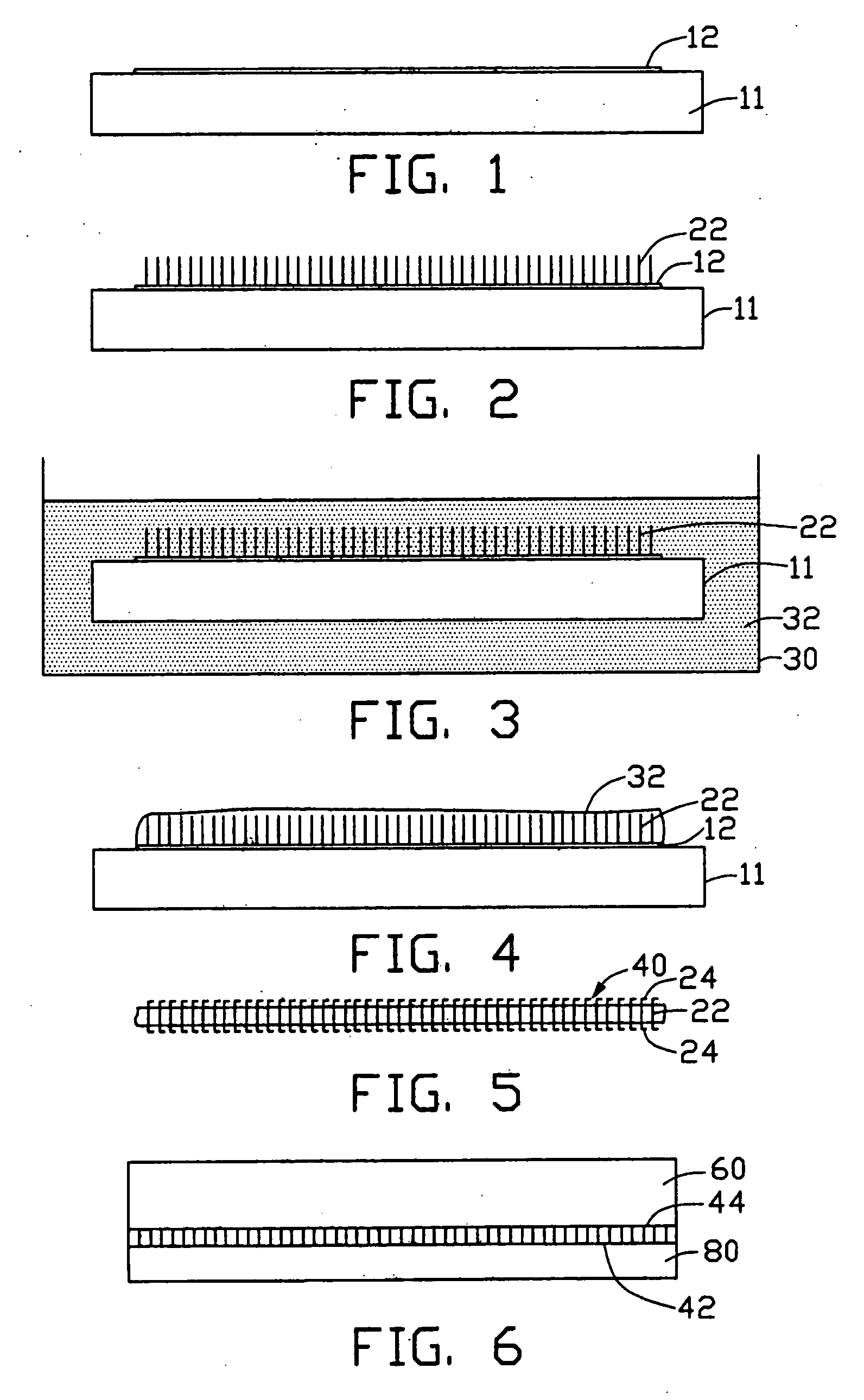

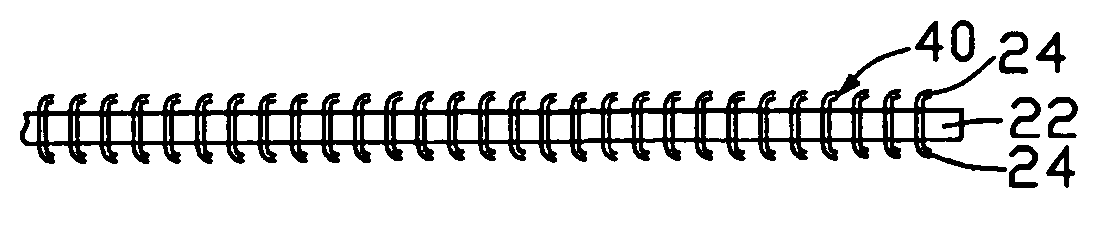

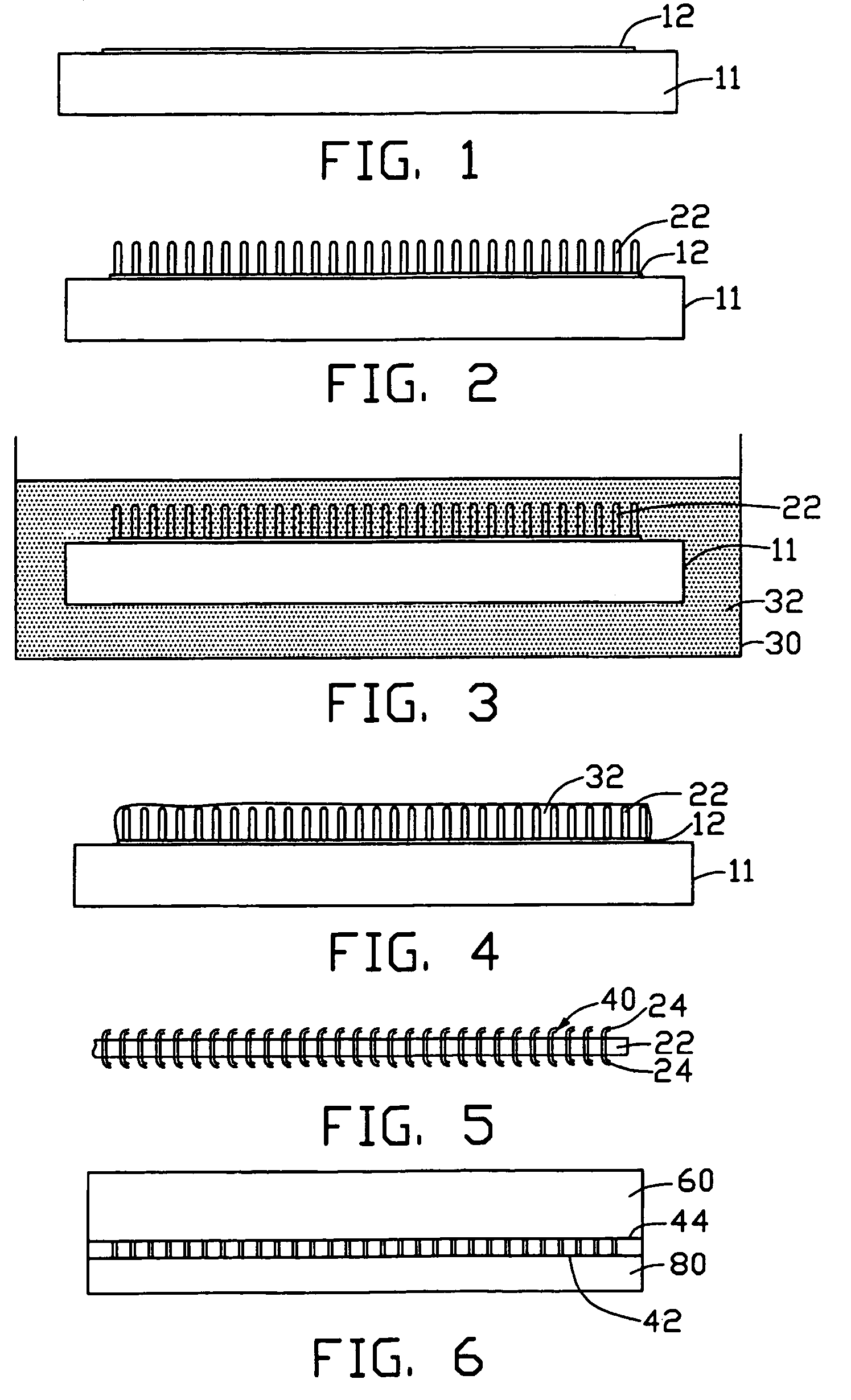

Thermal interface material and method for manufacturing same

ActiveUS20060073332A1Reduce thicknessSmall thermal interface resistanceMaterial nanotechnologySemiconductor/solid-state device detailsParaffin oilsLong axis

A thermal interface material (TIM) includes a macromolecular material and carbon nanotubes embedded in the macromolecular material. The TIM has a first surface and an opposite second surface. Each nanotube is open at opposite ends thereof, and extends from the first surface to the second surface. Two ends of each nanotube extend out from the two surfaces of the thermal interface material and form two bent ends. A method for manufacturing the TIM includes: (a) forming an array of carbon nanotubes on a substrate; (b) submerging the nanotubes in a liquid paraffin; (c) solidifying the liquid paraffin; (d) cutting the paraffin in a direction perpendicular to long axes of the nanotubes, whereby each nanotube is open; and (e) cutting the paraffin in the same direction according to a predetermined thickness to obtain the thermal interface material, whereby each nanotube is open.

Owner:HON HAI PRECISION IND CO LTD +1

Toughened hard alloy and preparation method thereof

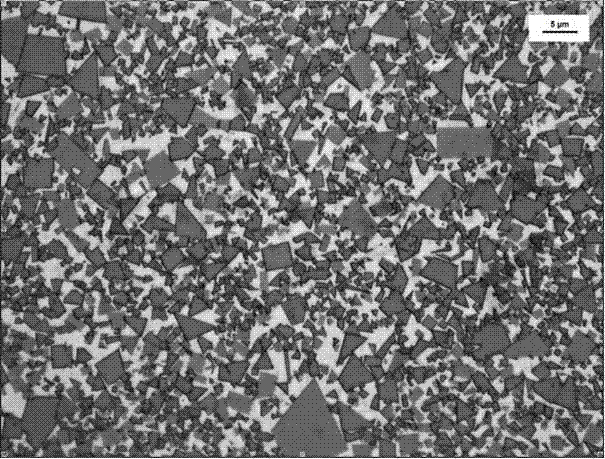

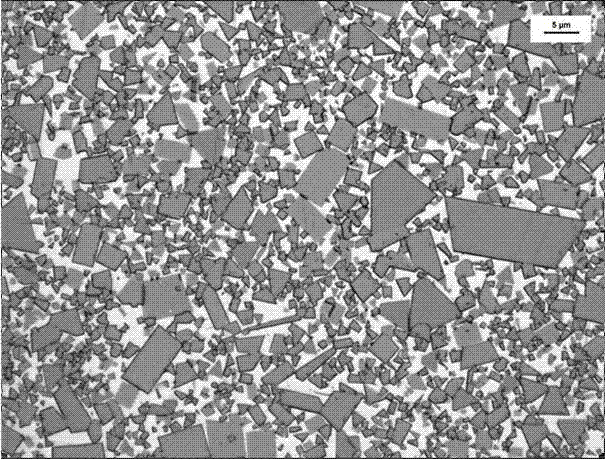

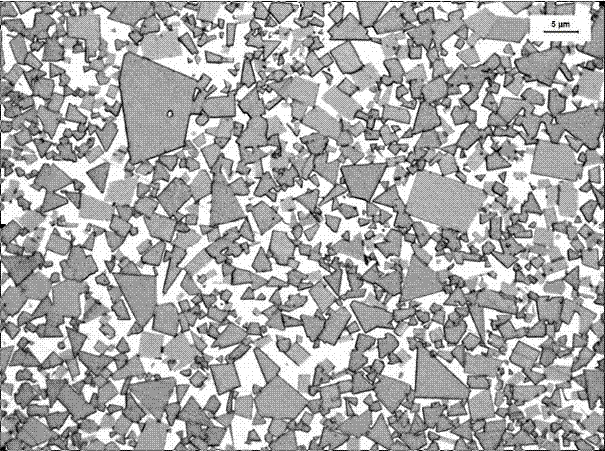

The invention discloses a high-toughness toughened hard alloy which comprises 10%-30% of Co or Co and Ni serving as a binding phase, 0-1.5% of Cr3C2 serving as an inhibitor, and the balance of hard phase WC, wherein the hard phase consists of WC crystalline grains with coarse, medium and fine grain sizes, the grain size of coarse grains is 9-15 mu m, the grain size of medium grains is 4-7 mu m, the grain size of the fine grains is less than 2 mu m, and the mean grain size of the hard phase WC is 1.6-3.2 mu m. The preparation method of the toughened hard alloy comprises the following steps of: preparing materials including 10%-30% of cobalt powder or cobalt powder and nickel powder, 0-1.5% of chromium carbide powder, and the balance of tungsten carbide powder, wherein Fsss grain size of the coarse grains WC is 9.0-11.0 mu m, the coarse grains WC account for 20%-42% of the prepared powder, the Fsss grain size of the medium grains WC is 4.0-6.0 mu m, the medium grains account for 10%-25% of the prepared powder, the Fsss grain size of the fine grains WC is 1.0-2.0 mu m, and the fine grains account for 20%-40% of the prepared powder; grinding, wherein a liquid paraffin forming agent which accounts for 2% of the prepared materials is added, mixed with absolute ethyl alcohol in a liquid-solid ratio of 300 ml / kg-350ml / kg, wet-ground for 20-28 hours according to the condition that the ratio of grinding media to material is 4:1, and sprayed and dried to obtain mixed materials; pressing; vacuum-sintering and isostatic-pressing and sintering. According to the invention, the toughness is improved on the premise of ensuring the hardness of the alloy, so that the operation field is expanded, special requirements of a cold-heating and cold-punching mould and a holt-rolling hard alloy roller ring are satisfied, and the service life of the high-toughness toughened hard alloy is prolonged.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

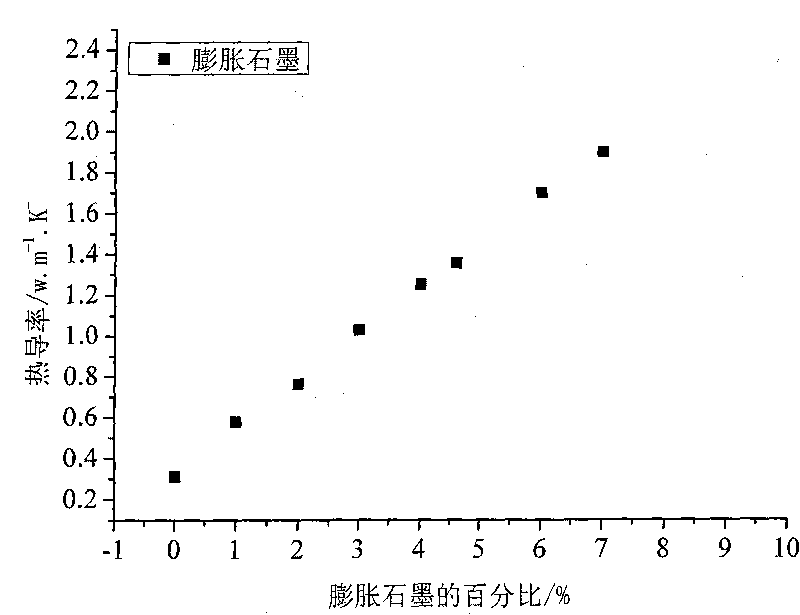

Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

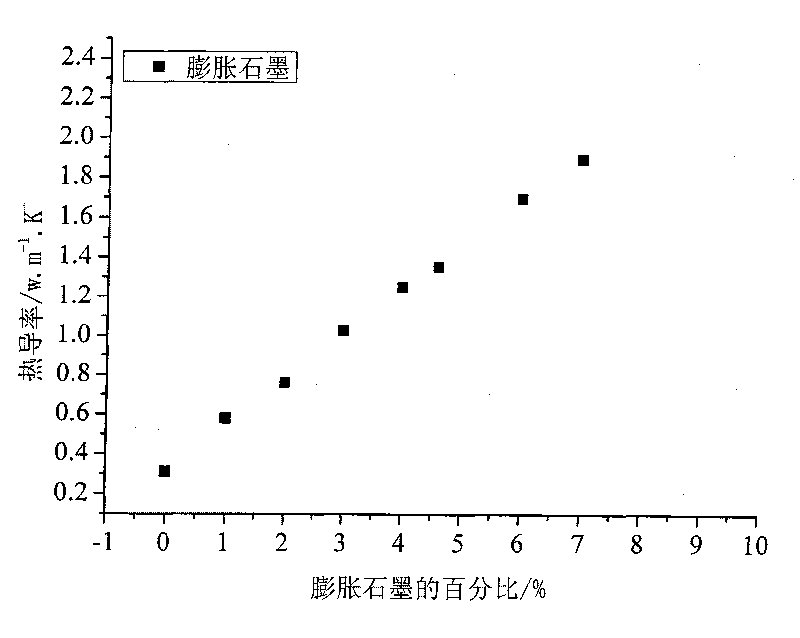

InactiveCN101724381AImprove thermal conductivityImprove heat transfer characteristicsHeat-exchange elementsMolten stateMaterials science

The invention relates to a setting phase change energy storage material with high-thermal conductivity and a preparation method thereof, belonging to the field of phase change heat storage materials. The setting phase change energy storage material with high-thermal conductivity is characterized by containing 65-90 percent by mass of paraffin substances as a phase-change material, 9-34 percent by mass of high-density polyethylene as a support material and 1-7 percent by mass of expanded graphite as a heat conduction intensifier; a method for adding a proper amount of expanded graphite to paraffin / high-density polyethylene in a molten state is adopted to enable the heat conductivity of the setting phase change material to be increased to 1.35W / (m.K) or higher. The method comprises the following steps of: heating to melt the paraffin substances with the mass percent of 65-90 percent, and heating to enable the temperature of the liquid paraffin to reach 120-190 DEG C; adding high-density polyethylene with the mass percent of 9-34 percent and the expanded graphite with the mass percent of 1-7 percent to the liquid paraffin, and then melting and evenly stirring in vacuum; putting the mixture in a hot mould for pressing and molding; taking the mixture from the mould after naturally cooling. The setting phase change material has high thermal conductivity, does not need to be packaged in containers and can directly contact heat-transfer media.

Owner:UNIV OF SCI & TECH OF CHINA

Color master batch for polyolefin grass fiber and its preparation method

InactiveCN101187076AReduce dosageGood weather resistanceGround pavingsMonocomponent polyolefin artificial filamentYarnParaffin wax

The invention relates to a technology of color master batches for a polyolefin yarn fiber, which comprises pigments, plastic additives and carrier resin, wherein the plastic additives comprise dispersed lubricant, an antioxidant, a light stabilizer, a coupling agent and liquid paraffin. The process for preparation is that the pigments, a part of plastic additives and the carrier resin are added into a high-speed mixer to be mixed, and then the coupling agent and the liquid paraffin are added to be stirred in a high speed, and at last the above stirred mixture is sent to a twin-screw extruder to be extruded, cooled, dried and granulated. The invention has the characteristics of less dosage, excellent weathering resistance, easy dispersing and excellent processability, and is suitable for the yarn fiber which takes polyethylene, polypropylene and other copolymer as base materials.

Owner:EAST CHINA UNIV OF SCI & TECH

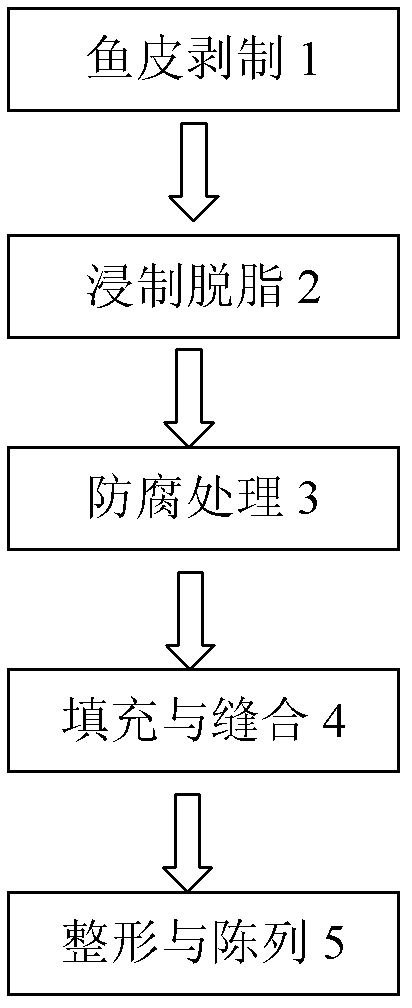

Harmless fabrication method of sturgeon taxidermy specimen

InactiveCN102499231ADip and degrease thoroughlyPrevent mold and insectsDead animal preservationLiquid wasteOcular prosthesis

The invention discloses a harmless fabrication method of sturgeon taxidermy specimen. The harmless fabrication method comprises the following steps: A. stripping fish skin: dissecting the part from the pelvic fin to the anus along the centerline of the belly of a fish, and removing internal organs, muscles and the like; B. infusing and degreasing: moving the stripped fish skin together with the head into an infusing container, soaking the fish skin and the head by high-concentration alcohol, changing the alcohol at regular intervals, and conducting harmless treatment on liquid waste; C. conducting antiseptic treatment: arranging the soaked fish in clear water for softening, coating antiseptic miscellaneous reagents for fish specimens inside and outside the fish skin and the head; D. filling and sewing: taking a tree trunk as a support shaft rod so as to enable the fish skin to be stretched completely, and using nylon threads to sew the cut of the specimen; and E. shaping and displaying: fixing the fin rays of the specimen by a clamping plate, naturally drying the fin rays by air, filling the gill, installing ocular prosthesis, coating liquid paraffin on the whole specimen, and fixing the specimen on a display stand. The method is easy to implement, the operation is convenient, the specimen is infused and degreased thoroughly, the harmless reagent is long in antiseptic effect, and the specimen fabricated by the method is safe and environment-friendly.

Owner:WATER ENG ECOLOGICAL INST CHINESE ACAD OF SCI

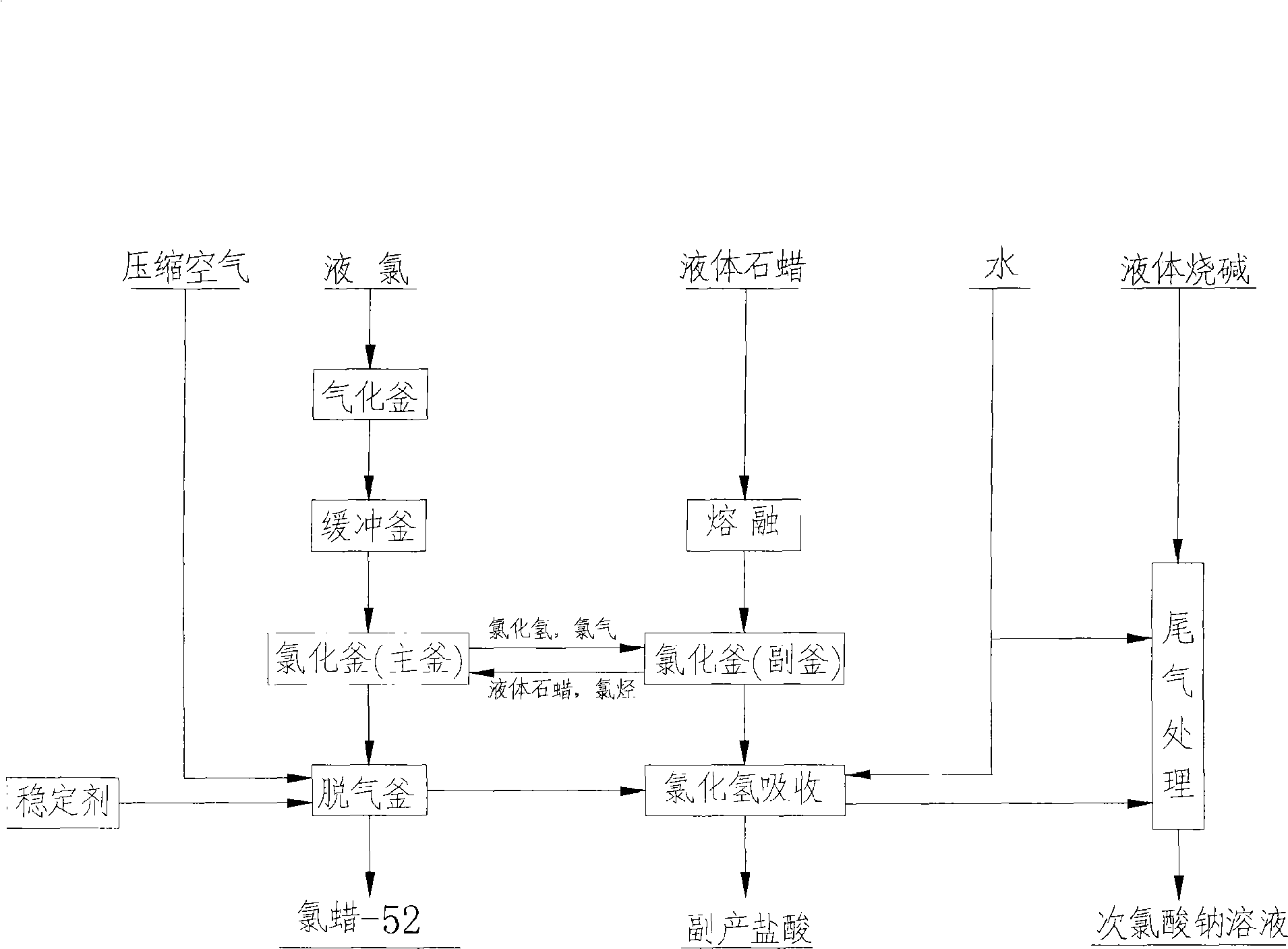

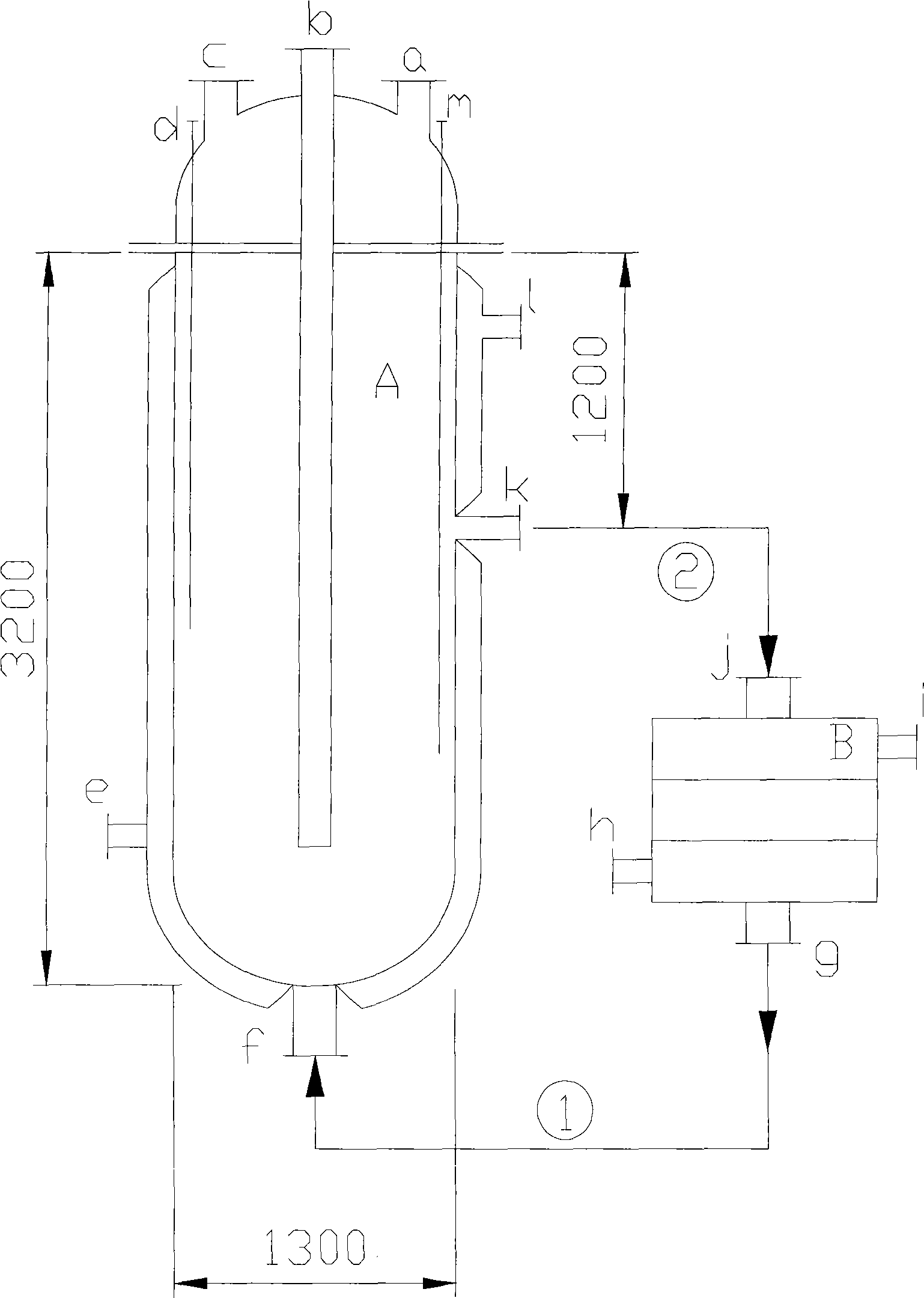

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

Pressure-sensitive adhesive product

InactiveUS20060154097A1Easy to peelSynthetic resin layered productsEster polymer adhesivesParaffin waxRosin

Owner:NITTO DENKO CORP

Method for preparing dropping pill using cool air and equipment using the method

ActiveCN101279220ALow costEasy to clearPharmaceutical product form changeGranulation by liquid drop formationOrganic solventEngineering

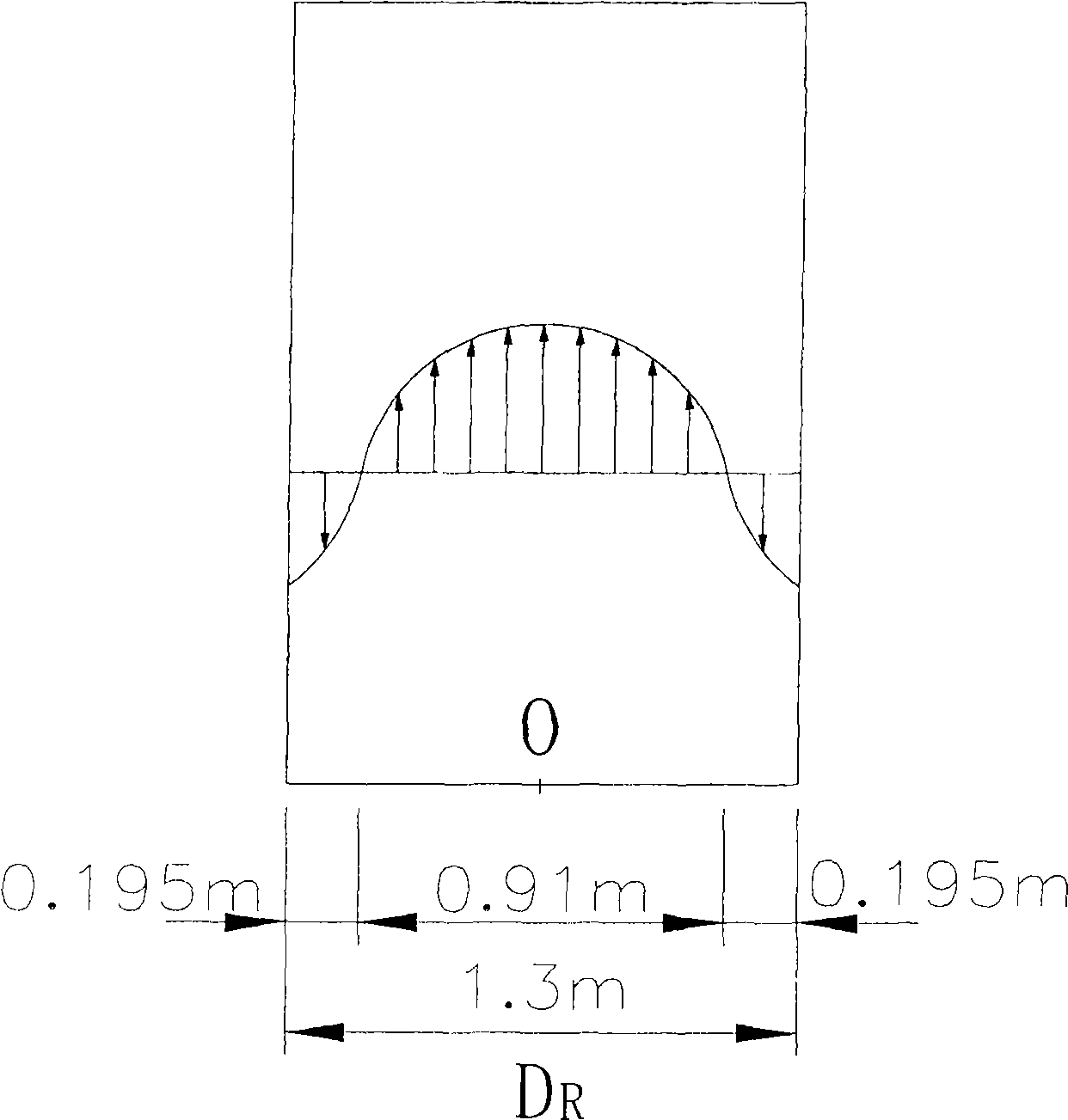

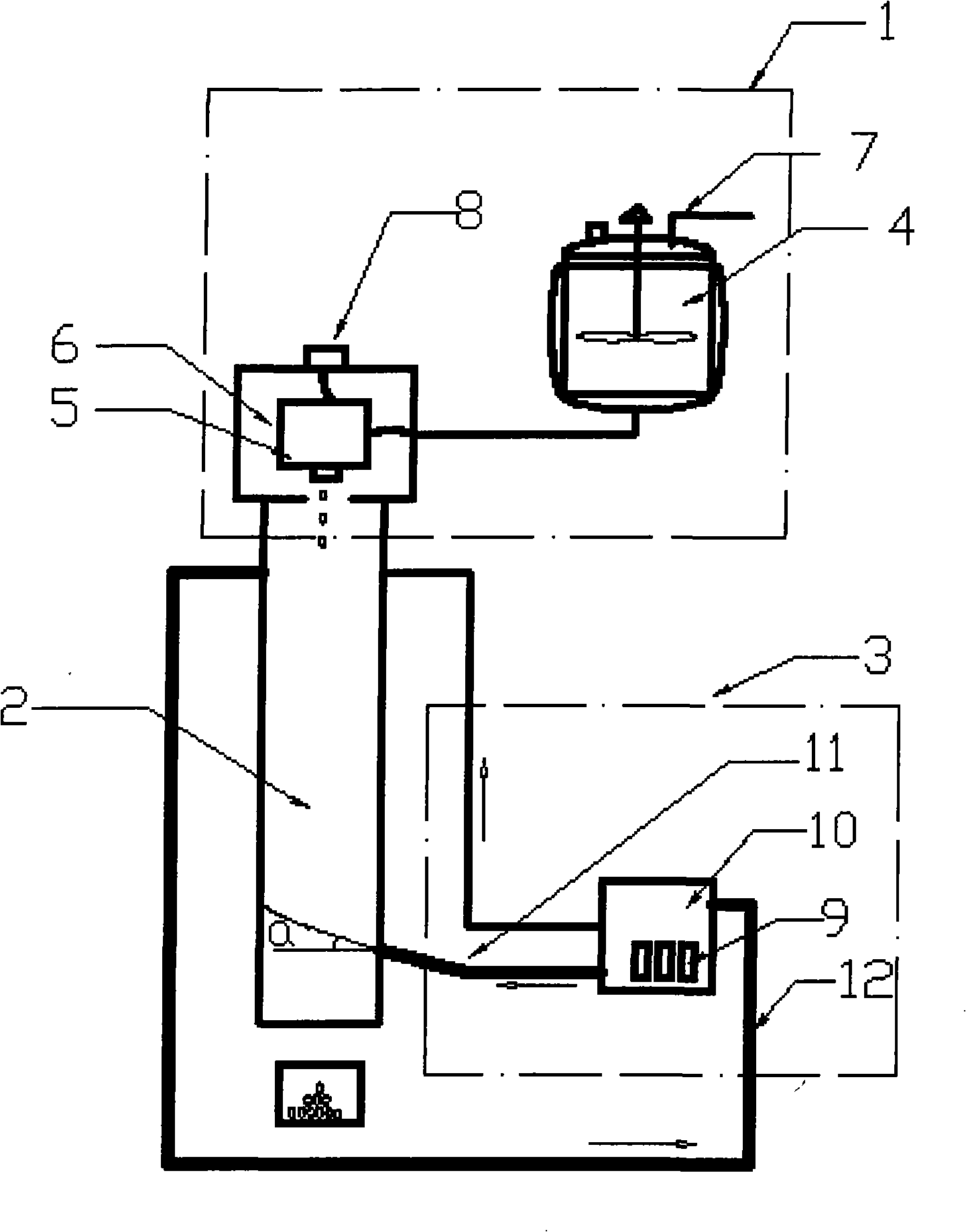

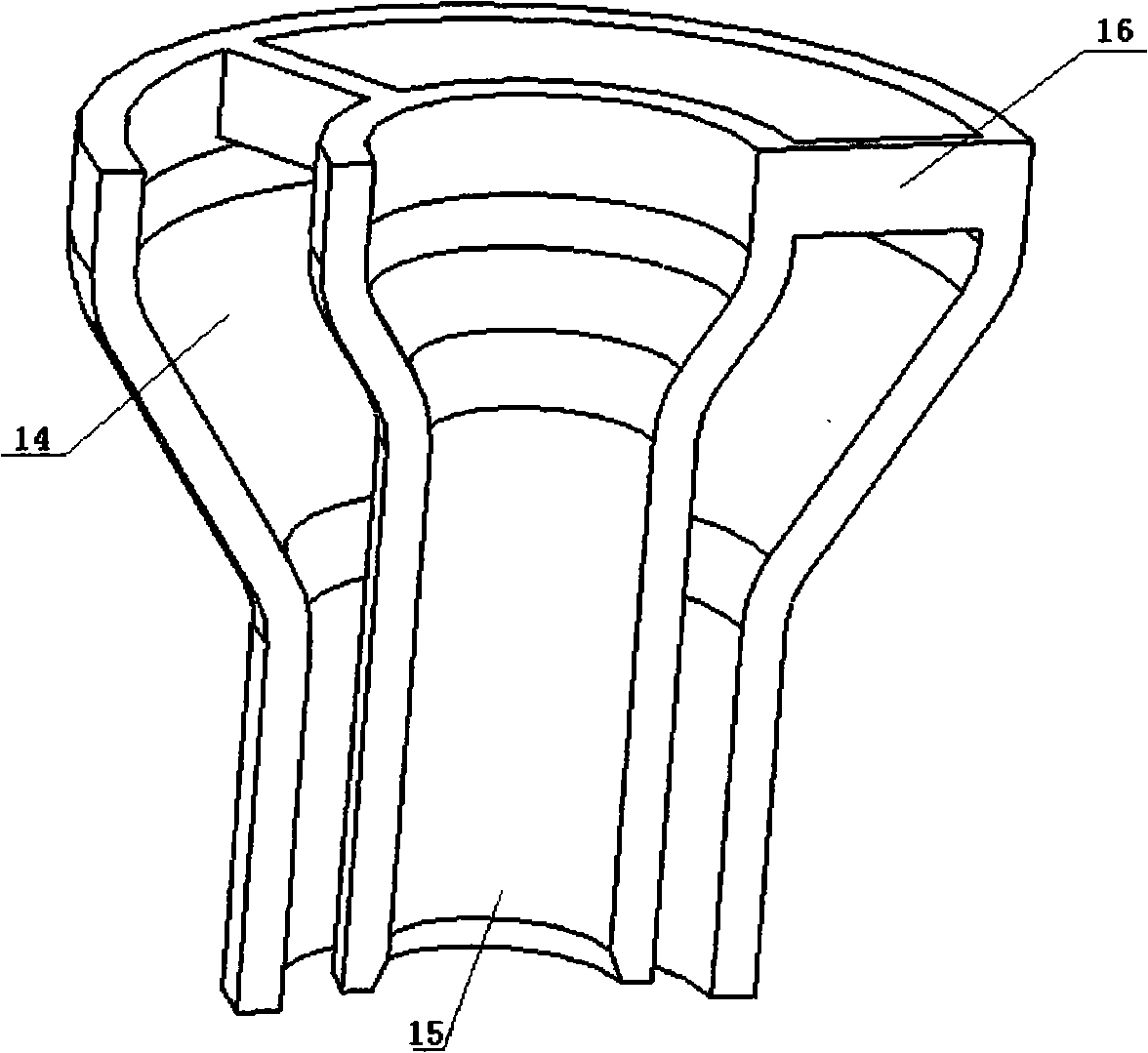

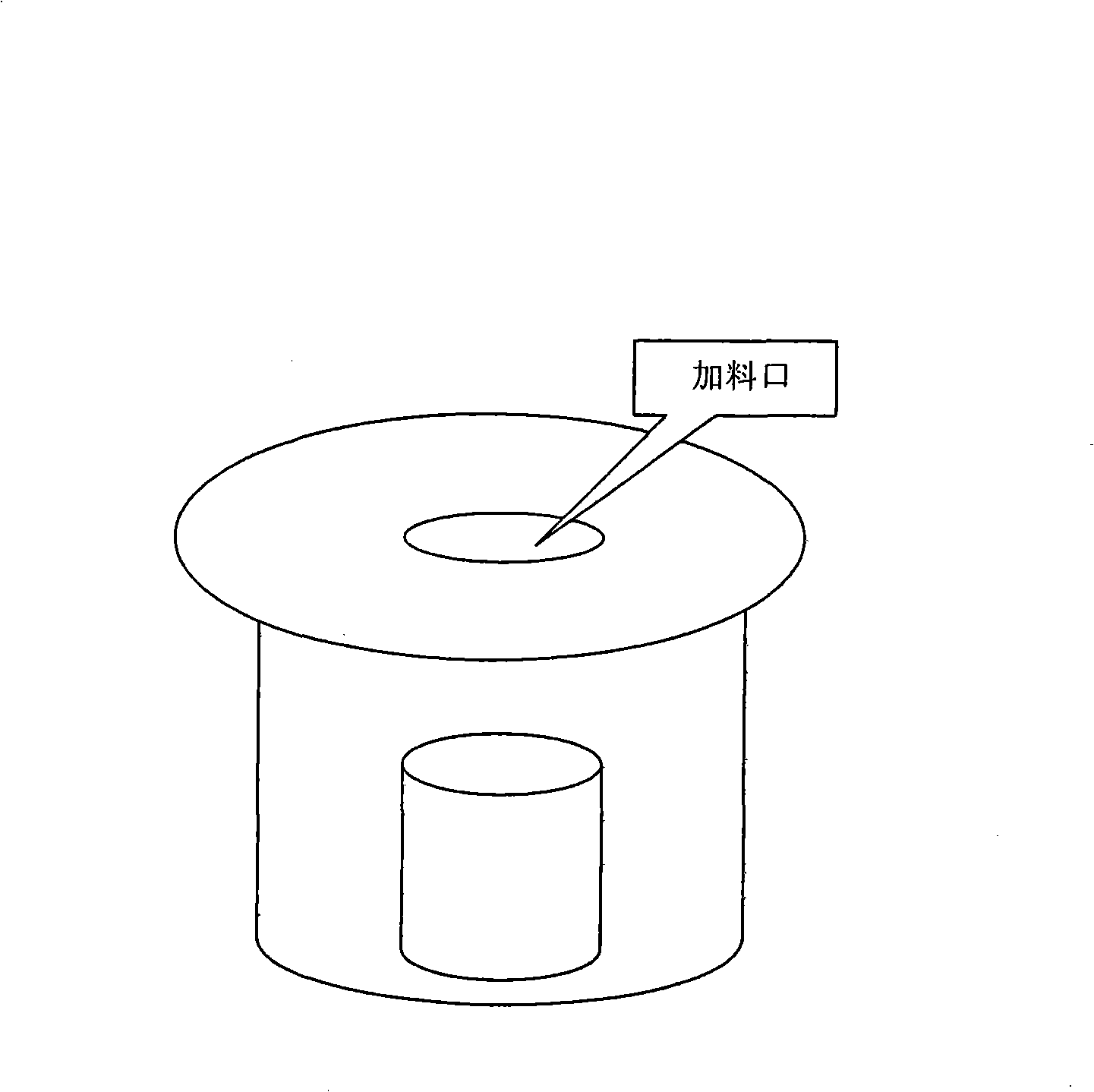

The invention relates to a method for preparing pills by using an air coolant and a device using the method, wherein, the method includes the following steps: heating drugs and accessories in a melting can to be an even liquid, transferring the even liquid to a dripper arranged in a heat preserving chamber, dripping the mixed liquid from the dripper into a cooling duct, starting a refrigerating mode at the same time when the liquid drips so as to maintain the air in the cooling duct at a temperature that the drug drops can be solidified, so that the drug liquid can be cooled and solidified into solid particles in the cooling duct and be dropped into a collecting vessel through an outlet at the lower end of the cooling duct. The device comprises a pill device, a cooling duct hermetically communicated with the pill device and a gas refrigeration device communicated with the cooling duct and circularly conveying cooling air to the cooling duct. The method can avoid the subsequent residual solution process in the traditional condensing way by adopting liquids like whiteruss, silicone oil and so on, having no organic solvent residual and reducing the cost for preparing the pills. The device is characterized by having no dead angle for cleaning, being convenient for cleaning and being able to avoid the cross contamination in the production process, which is beneficial for the stability of the product.

Owner:TIANJIN TASLY PHARMA CO LTD

Low-dust unshaped refractory

The invention relates to a low-dust unshaped refractory, which comprises 0.1-1.0 wt percent of oil substances chosen from mineral oil, vegetable oil, synthetic oil, fluid wax or biodegradable petroleum to be used as the binder and combined materials calculated by the total weight of the refractory. The unshaped refractory is characterized by reducing dust in the carrying and instillation process. The unshaped refractory not only comprises spray coating, but also comprises compact and insulating refractory castables and dry materials. The low-dust unshaped refractory can reduce the dust suction quantity of the personnel exposed to the construction field by at least 70 percent, reduce the pollution to the environment and improve the life of the respirators used by the personnel.

Owner:ALLIED MINERAL PRODS TIANJIN

High heat conducting nylon composite material and preparation method thereof

The invention discloses a high heat conducting nylon composite material and a preparation method thereof. The high heat conducting nylon composite material belongs to one of functional high molecules. The composite material is prepared from a thermoplastic nylon resin base body, heat conducting filler and other processing agents. The heat conducting coefficient is greater than 2.7W / m.K. The resin base body can be nylon 6 or a compound of nylon 6, nylon 9, nylon 66, nylon 610 and nylon 1010. The heat conducting filler can be one or more of magnesium oxide, aluminum oxide, aluminum nitride, boron nitride, silicon nitride, a multiwalled carbon nanotube and a graphite flake layer. The processing agents can be octadecanamide, polyethylene wax, liquid paraffin and the like. The method disclosed by the invention is simple to operate and low in cost, and can prepare the heat conducting composite material with excellent comprehensive performance by one step. The method is easy to realize industrialized production and can be widely applied to the fields of automobiles, household appliances, meter cases, circuit elements and the like.

Owner:BEIJING UNIV OF CHEM TECH

Thermal phase-separating process for preparing microporous film of hollow polypropylene fibres

A thermal phase-separating process for preparing millipore membrane of hollow polypropylene fibres from polypropylene includes preparing spinning solution from diluent (plant oil, atoleine, diphenyl ether and machine oil), assistant (adipic acid and benzoic acid) and polypropylene, heating, spinning, cooling, extracting diluent and recovering diluent. The pore diameter of resultant membrane is 0.01-0.1 micron, and is easily controlled.

Owner:TIANJIN UNIV

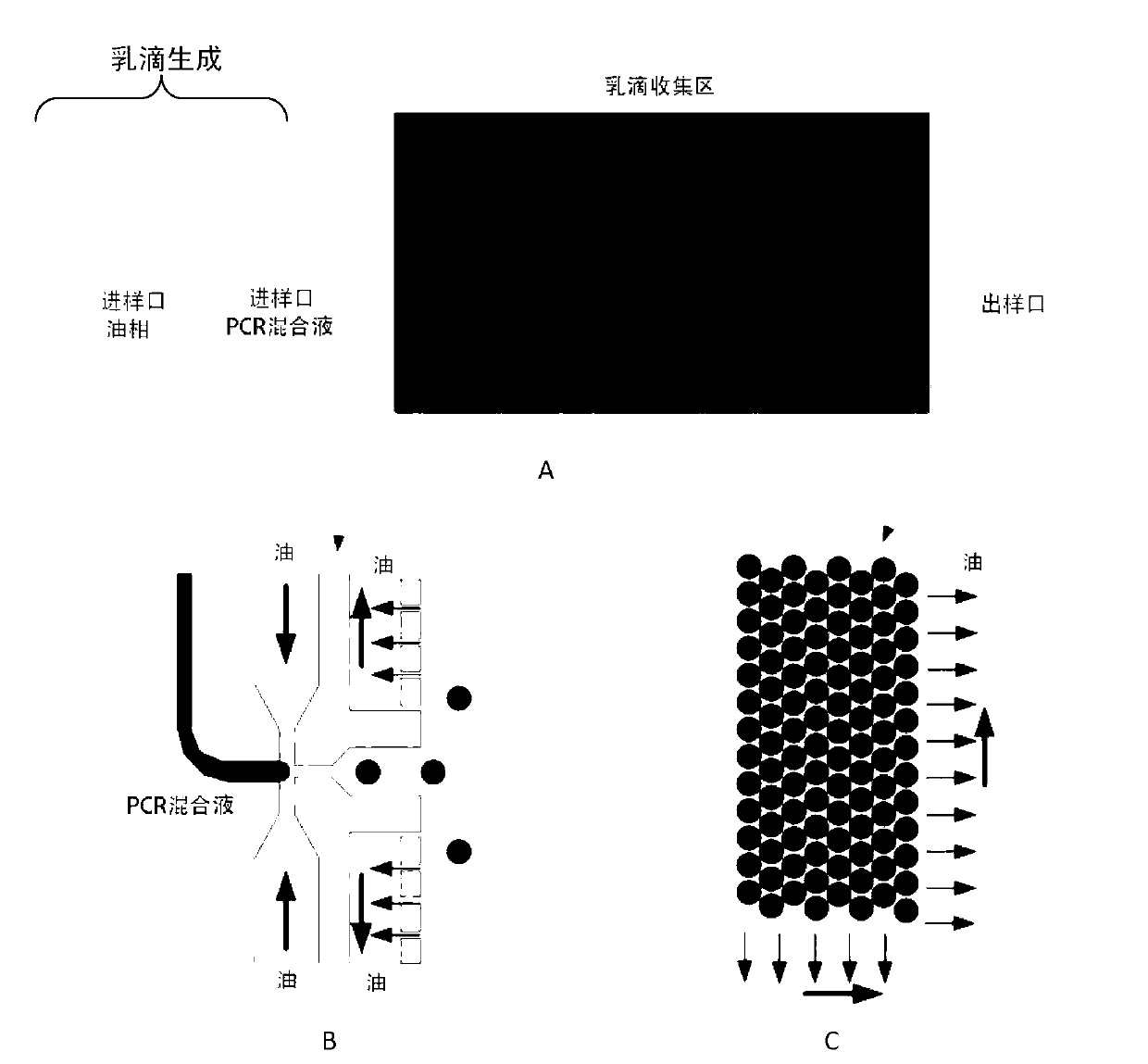

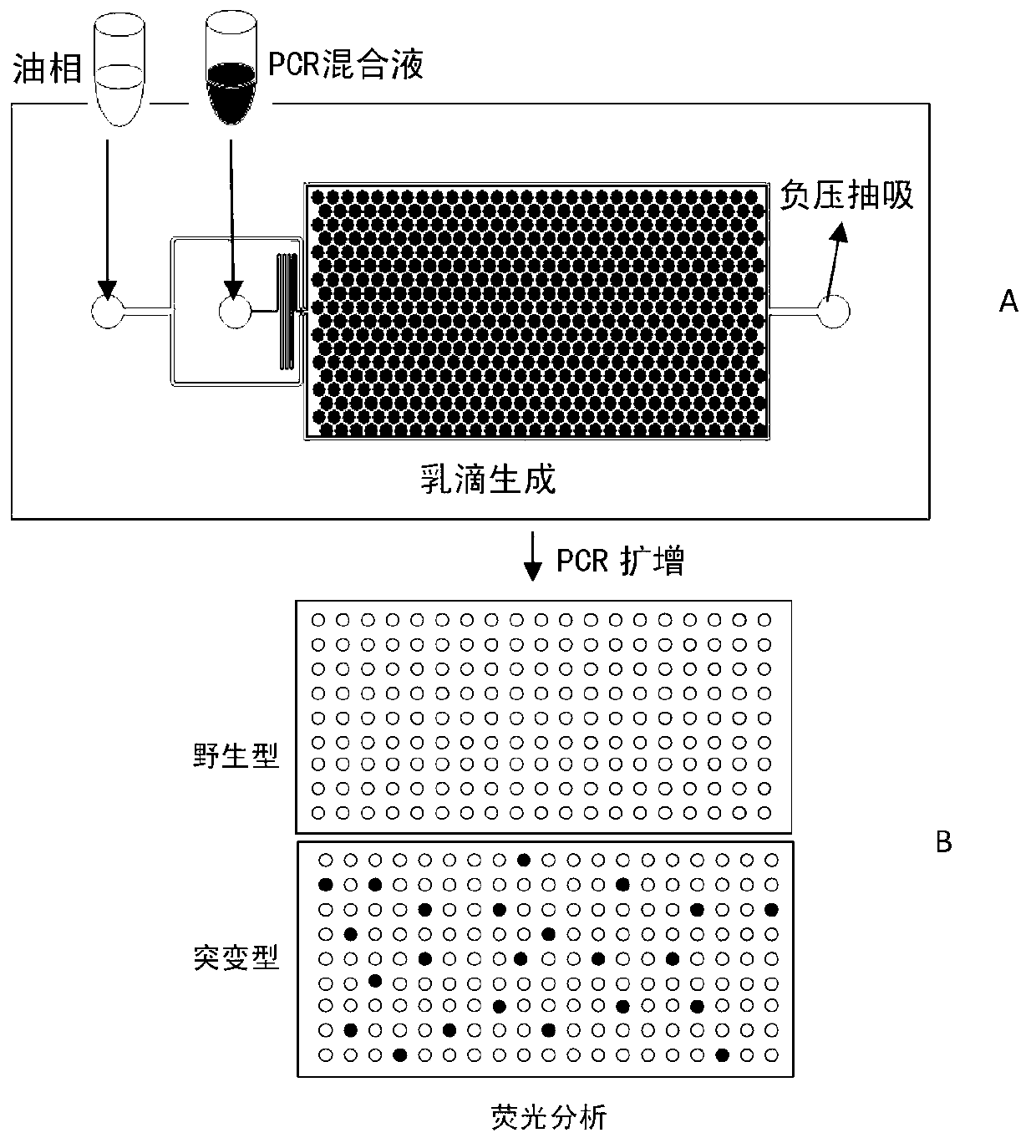

Method for manufacturing digital PCR (polymerase chain reaction) chip based on mineral-oil saturated PDMS (polydimethylsiloxane) material

ActiveCN103343092AOptimizationSimple methodBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipOil phase

The invention relates to a method for manufacturing a digital PCR (polymerase chain reaction) chip based on a mineral-oil saturated PDMS (polydimethylsiloxane) material. The method is characterized in that the digital PCR chip based on PDMS is prepared from a PDMS monomer of a certain amount of mineral oil (liquid paraffin) and comprises an emulsion droplet generation structure and an emulsion droplet collection structure. After the emulsion droplets are made and collected on the same chip, the emulsion droplets are subjected to PCR amplification on the same chip. The phagocytosis to the oil phase in the digital PCR system by the PDMS of the chip can be avoided, the emulsion droplets can be kept stable during PCR, and the stability of the PCR can be guaranteed. In addition, compared with the existing technology of the digital PCR chip, the method provided by the invention is low in cost, is convenient to operate and has a very wide application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

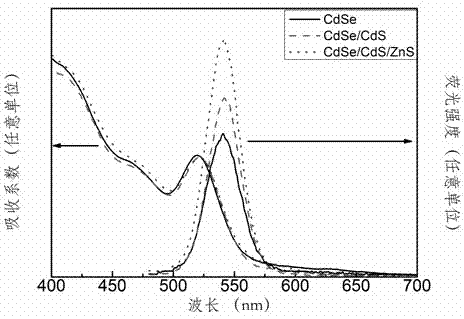

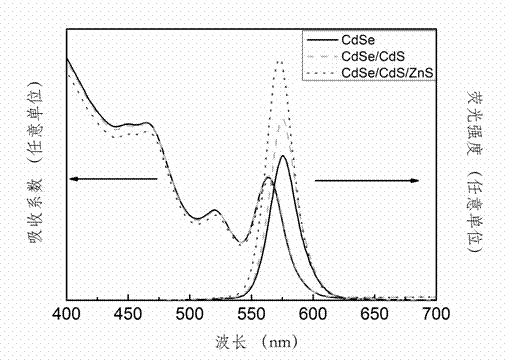

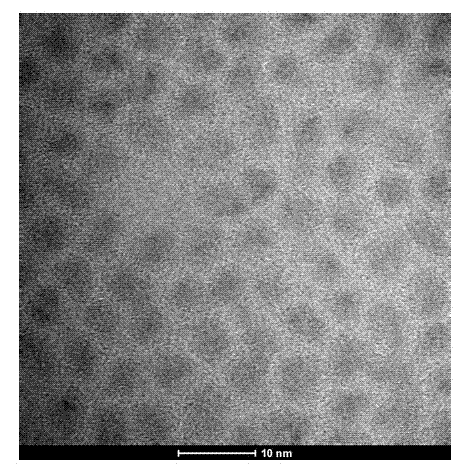

Synthetic method for preparing CdSe/CdS/ZnS core-shell structure quantum dots by acid assistance

InactiveCN104498039ASmall emission wavelength effectCoating method is simpleLuminescent compositionsOrganic acidParaffin oils

The invention discloses a synthetic method for preparing CdSe / CdS / ZnS core-shell structure quantum dots by acid assistance. The synthetic method comprises the following steps: synthesizing a CdSe core quantum dot solution in a paraffin oleic acid system, using cadmium oleate as a precursor of a shell layer CdS, using a sulfur source dissolved in liquid paraffin as a precursor of the shell layers CdS and ZnS, using a zinc source dissolved in the liquid paraffin as a precursor of the shell layer ZnS, adding an organic acid in a precursor of S, and dripping the organic acid into the core quantum dot solution, wherein the organic acid reinforces the activity of the precursors of the shell layers, reduces the surface ligands of the core quantum dot, promotes the growth of the CdS shell layer on the surface of the CdSe core quantum dot and achieves epitaxial coating; dripping the precursor of Zn to wrap the ZnS shell layer to obtain a CdSe / CdS / ZnS core-shell structure quantum dot solution. The synthetic method disclosed by the invention has the advantages that the CdSe / CdS / ZnS core-shell structure quantum dots can be synthesized in the atmosphere under a non-phosphor system, the raw materials are cheap, the reaction temperature is low, the growth of the shell layers is fast, the operation is simple and mass production is suitable.

Owner:HUBEI UNIV

Synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical

The present invention discloses the synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical. The synthesis process of the present invention adopts styrene as monomer, divinyl benzene as cross-liking agent, liquid paraffin and other material as pore creating agent, magnesium sulfate and other material as dispersant, benzoyl peroxide as initiator, nitrobenzene and dichloro ethane or chloroben as sweller, and zinc chloride, ferric trichloride or tin tetrachloride and Lewis acid as catalyst, and prepares composite functional resin through preparing chloromethylated low cross-linked polystyrene resin, post-crosslinking reaction to obtain composite functional resin precursor of different crosslinking degree and final sulfonating with high concentration sulfuric acid to obtain composite functional resin with different specific surface area and different exchange capacity. The resin product has both adsorption and ion exchange function and thus wide application range.

Owner:NANJING UNIV +1

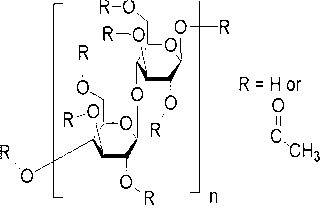

Preparation method and uses of carboxymethyl chitosan and sodium alginate blend microcapsule

InactiveCN1546557AGood drug release functionIncrease release rateCapsule deliveryMicroballoon preparationFlavorWax

The invention discloses the preparation method and uses of carboxymethyl chitosan and sodium alginate blend microcapsule wherein the method comprises, using water as solvent to blend the water solution of carboxymethyl chitosan and sodium alginate into blending liquid I, dissolving the contained medicament bovine serum albumin into the blended solvent I and mixing homogeneously, obtaining blended liquid II, dispersing the blended liquid II into fluid wax containing emulsifying agent, dropping CaCl2 coagulated liquid into the system, charging 10-30 mL alcohol isopropylicum and hardening to obtain micro-encapsulation, which exhibits sensitive response function to the pH changes.

Owner:WUHAN UNIV

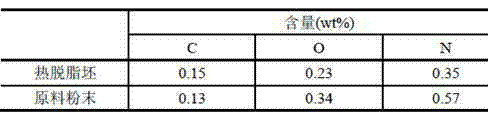

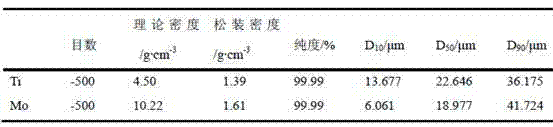

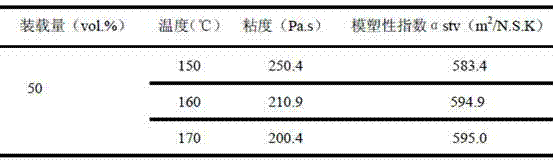

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

Laser-welding diamond disc and preparation method thereof

ActiveCN101456216AGood self-sharpeningGood edge cutting effectStone-like material working toolsLow speedCobalt

The invention relates to a laser welding diamond round saw blade and a preparation method thereof, which belong to the technical field of powder metallurgy material. The saw blade is used for solving the problem that the laser welding diamond round saw blade has lower speed and easy edge feed when used for cutting hard stones. The material of a cutting head is prepared from the following powder raw materials by weight percentage: 36 to 46 percent of copper, 28 to 38 percent of iron, 10 to 20 percent of cobalt, 3 to 10 percent of nickel, 3 to 9 percent of tin, 1 to 2.5 percent of silicon-chromium alloy, 1 to 1.6 percent of liquid paraffin wax and 1.0 to 2.2 percent of diamond, wherein the silicon-chromium alloy contains 40 percent of silicon, 30 percent of chromium and the balance being iron and small quantities of impurities according to mass proportion. The method adopts a mixed base material of the copper, the iron and the cobalt to improve the service life and the sintering performance of the saw blade and the added silicon-chromium alloy powder is dispersively distributed in a fetal body, thereby effectively improving the sintering performance of the fetal body so as to make the fetal body accelerate an alloying process. At the same time, the self-sharpening performance of the fetal body is improved, the holding force of the fetal body to the diamond is enhanced and the service life and the cutting performance of the saw blade are improved, thereby making the wear performance of the fetal body and the wear performance of the diamond be matched.

Owner:BOSUN TOOLS CO LTD

Thermal interface material and method for manufacturing same

ActiveUS7160620B2Reduce thicknessSmall resistanceMaterial nanotechnologySemiconductor/solid-state device detailsLong axisNanotube array

A thermal interface material (TIM) includes a macromolecular material and carbon nanotubes embedded in the macromolecular material. The TIM has a first surface and an opposite second surface. Each nanotube is open at opposite ends thereof, and extends from the first surface to the second surface. Two ends of each nanotube extend out from the two surfaces of the thermal interface material and form two bent ends. A method for manufacturing the TIM includes: (a) forming an array of carbon nanotubes on a substrate; (b) submerging the nanotubes in a liquid paraffin; (c) solidifying the liquid paraffin; (d) cutting the paraffin in a direction perpendicular to long axes of the nanotubes, whereby each nanotube is open; and (e) cutting the paraffin in the same direction according to a predetermined thickness to obtain the thermal interface material, whereby each nanotube is open.

Owner:HON HAI PRECISION IND CO LTD +1

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and preparation method thereof

ActiveCN102226016AHigh flame retardant efficiencyMeet the mechanical propertiesMolecular sieveRubber material

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and a preparation method thereof relate to flame-retardant rubber and the preparation method thereof. The flame-retardant rubber provided by the invention comprises, by weight, 100 parts of a rubber matrix, 1.5-2.8 parts of a vulcanizing agent, 1-1.5 parts of a promoter CZ, 1-3 parts of stearic acid, 4.5-5 parts of zinc oxide, 1-2 parts of an antioxidant 4010, 1-3 parts of liquid paraffin, 30-40 parts of carbon black, 60-80 parts of an intumescent flame retardant, and 0-5 parts of nano-mesoporous molecular sieve. The preparation method provided by the invention comprises the following steps of: plasticating rubber in an open mill, successively adding eleaostearic acid, zinc oxide, the promoter CZ, the antioxidant 4010, the nano-mesoporous molecular sieve, carbon black, liquid paraffin, IFR and sulphur, mixing and discharging tablets, followed by sulfuration. By the adoption of the nano-mesoporous molecular sieve synergistic intumescent flame retardant, its excellent flame-retardant synergistic effect and interfacial compatibility effect greatly improve the flame-retardant performance and mechanical properties of the rubber material.

Owner:沈阳双骥橡塑科技有限公司

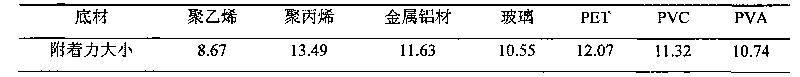

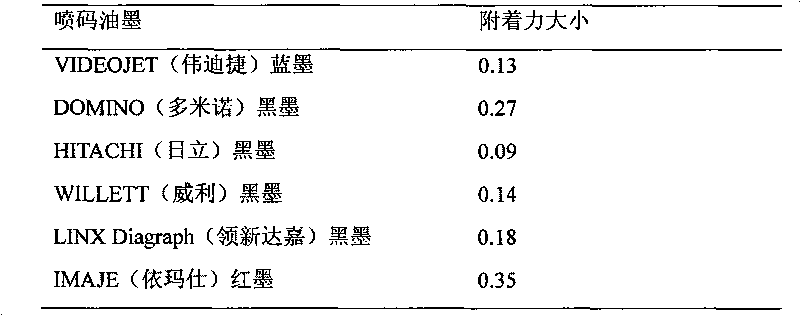

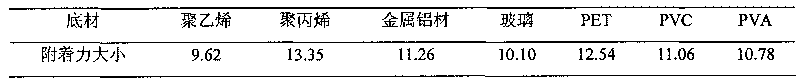

High-adhesion benzene-free environmentally-friendly universal jet ink and preparation method thereof

The invention discloses a high-adhesion benzene-free environmentally-friendly universal jet ink and a preparation method thereof, the jet ink is prepared by the following raw materials and solvents by weight percent: 5-10 of modified chlorinated polypropylene resin; 1-5 of complex resin; 70-89 of butanone; 2-6 of dye; 0.5-1.5 of conductive auxiliary agent; 1-3 of plasticizing agent; 0.5-1.5 of liquid paraffin; and 1-3 of other auxiliary agents. During the preparation, the modified chlorinated polypropylene resin and the complex resin are dissolved in 50-70% of butanone based on the total quantity, the rest butanone is used for the dissolution of other ingredients, the ink jet can be prepared by mixing both, and the resultant ink jet has excellent adhesion for the surface of polyethylene, polypropylene, metallic aluminum material, glass, PET, PVC and PVA materials; since only butanone is used as the solvent, the environmental friendliness of the jet ink is greatly enhanced; and the jet ink with stable system, clear print and fast drying can take the place of a large number of commercial jet ink products at present.

Owner:SOUTH CHINA UNIV OF TECH

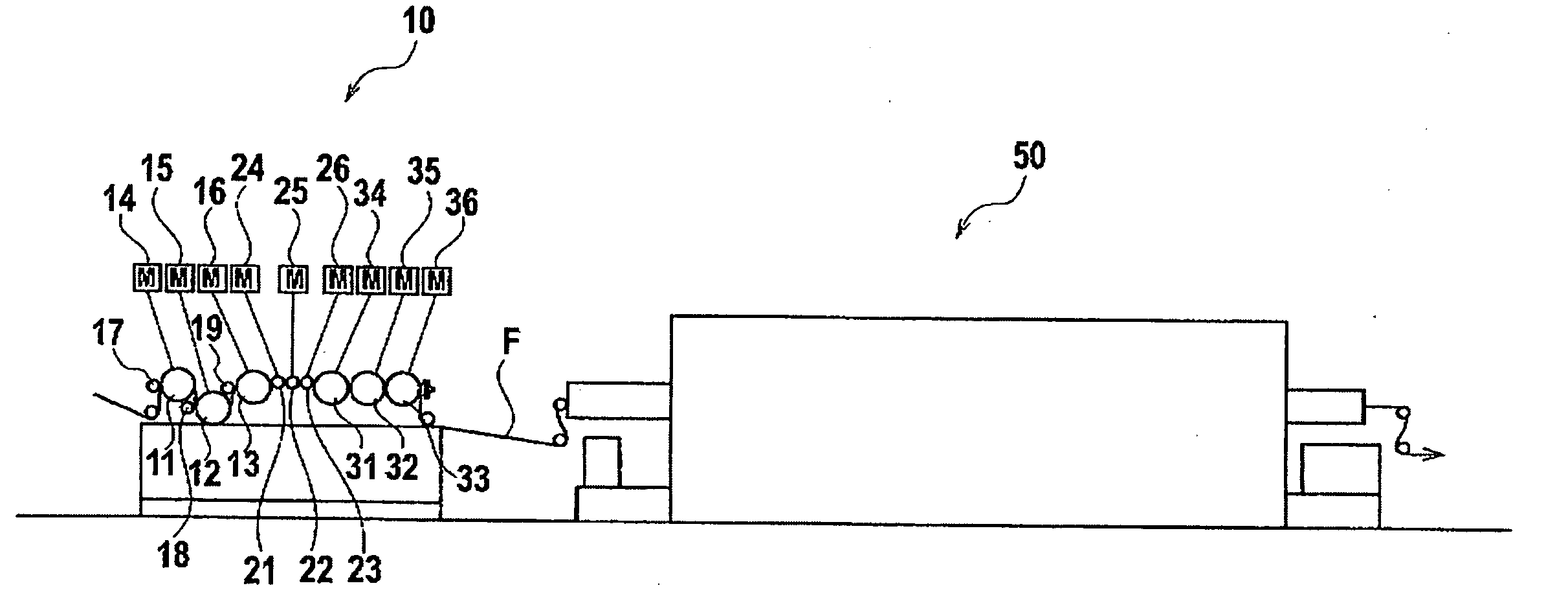

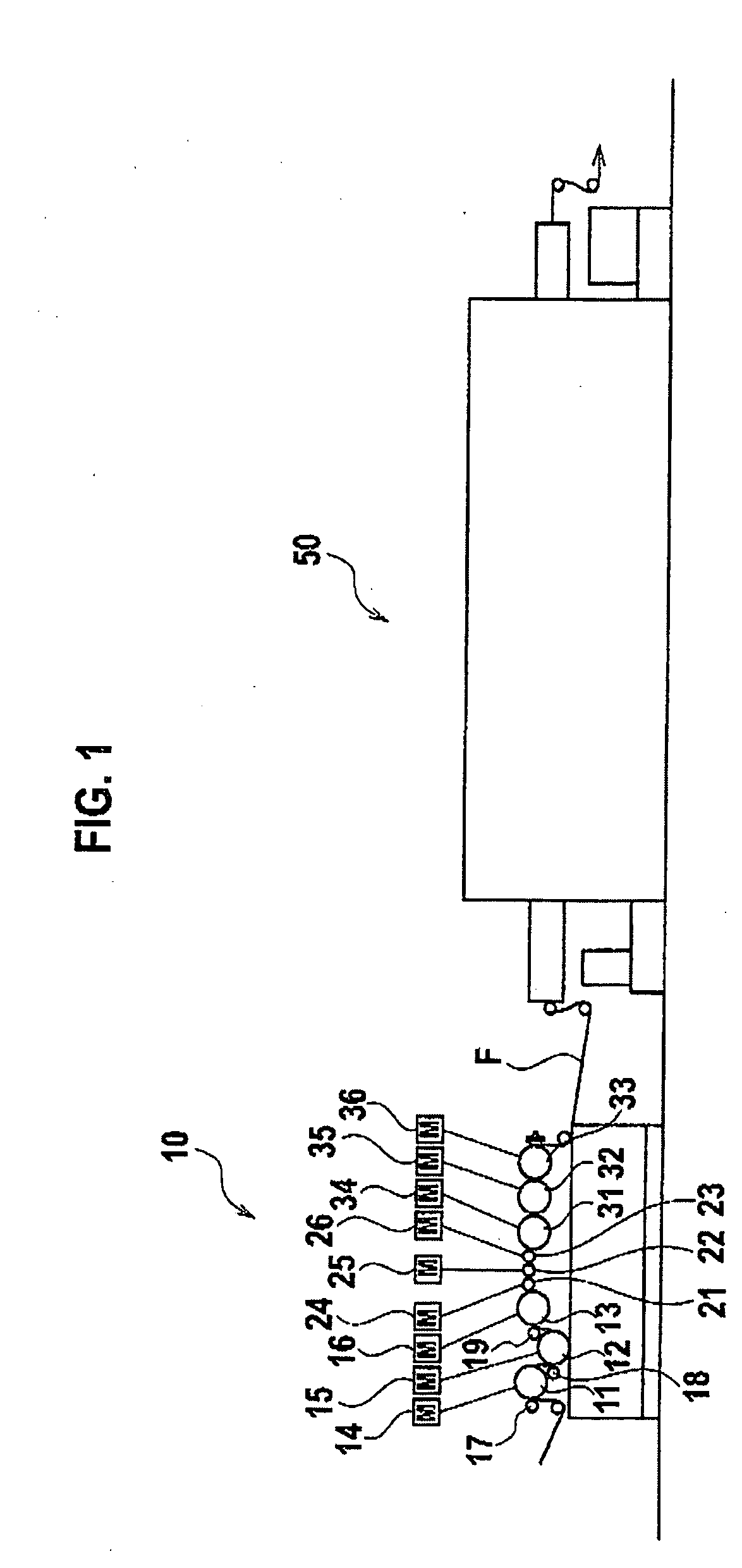

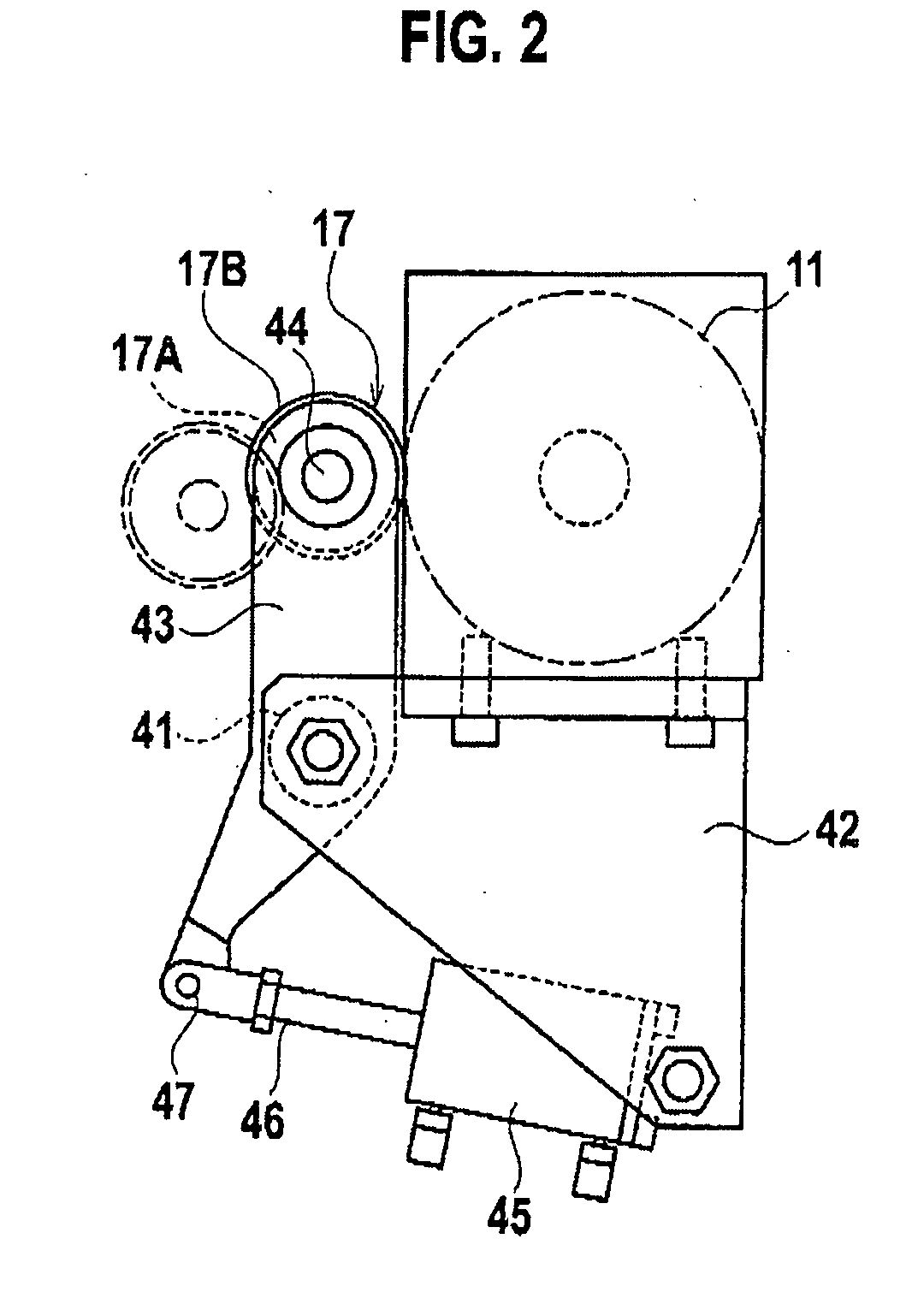

Porous film manufacturing method and successive biaxial stretching apparatus for manufacturing porous film

ActiveUS20090250838A1Prevent slippingStretched stablyDough-sheeters/rolling-machines/rolling-pinsConfectionerySolventMechanical engineering

Provided is a method for manufacturing a high-quality porous film. Here, while the porous film is being manufactured through forming micropores by stretching, a raw film is prevented from slipping on the surfaces of the respective rolls as much as possible even though the raw film includes oil or liquid paraffin as a solvent. The method is for manufacturing a porous film through forming micropores by successive biaxial stretching. A tensile force applied to the raw film F transferring from the longitudinal stretching machine (10) to the transverse stretching machine (50) is set not less than a stretching force necessary for the longitudinal stretching, and thus the raw film is prevented from slipping on a contact surface between the raw film and each roll of the longitudinal stretching machine (10).

Owner:TOSHIBA MASCH CO LTD

Starch-based composite blown film and preparation process of same

InactiveCN103122079AGood component compatibilityPromote environmental protectionCellulosePolymer science

The invention relates to a starch-based composite blown film material with a high starch content and a preparation process of the same. The starch-based composite blown film material is prepared from base materials comprising natural starch, acetylated starch, plant fibres, esterified cellulose and polyethylene resin, and appropriate auxiliaries comprising starch plasticizer glycerol, enhancer agar, nano-SiO2, coupling agent DL-171, stearic acid, antioxidant 1076, light stabilizer o-hydroxyl benzophenone, and processing lubricant liquid paraffin, and is prepared by adopting a melting-blowing process. The environment-friendly type starch-based composite blown film material disclosed by the invention has the following characteristics that the added amount of starch is high; the ratio of degradation constituents can achieve 80% of the weight of the film; the film is good in surface smoothness and transparency, and high in physical and mechanical properties; the processing equipment is low in requirements; the processing technique is simple; and the material is low in cost and easy to degrade, and is a green and environment-friendly type film material which can be widely applied.

Owner:HUNAN UNIV OF TECH

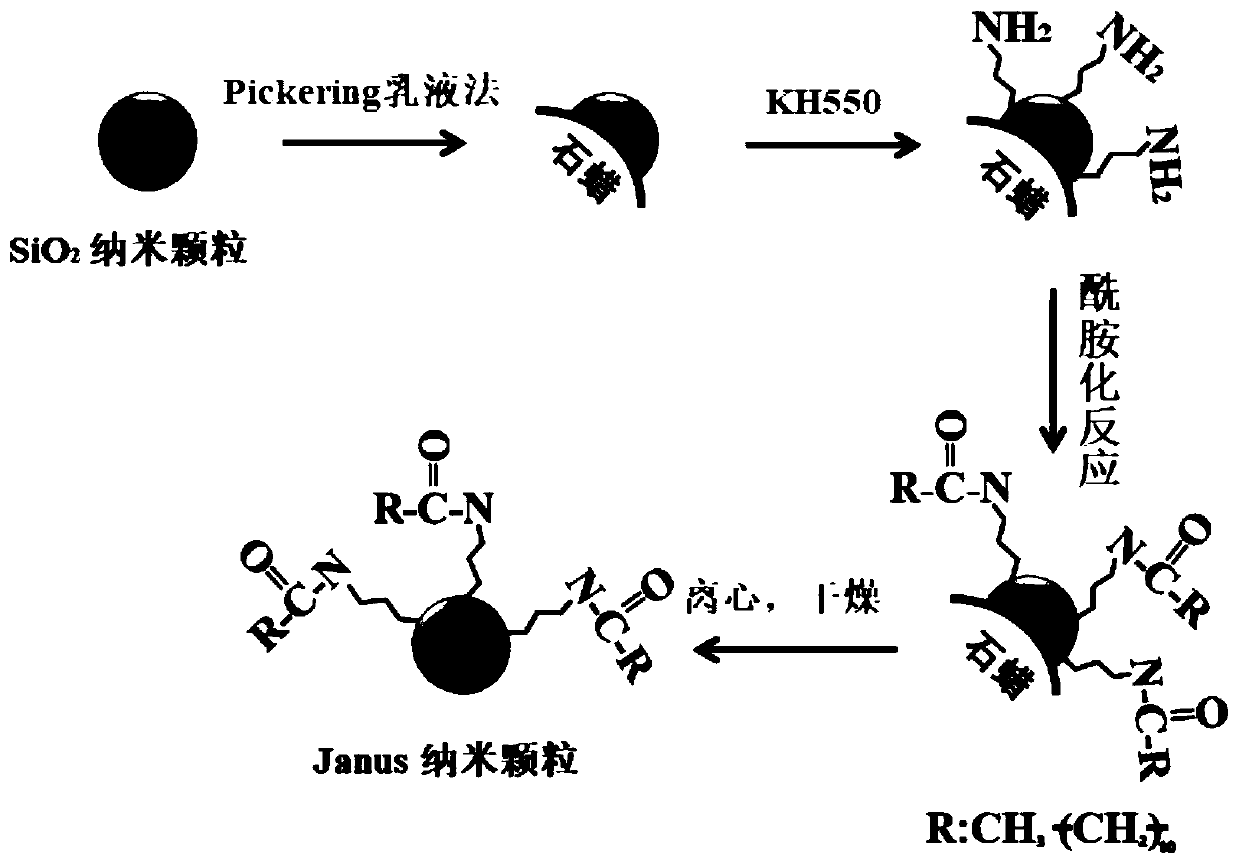

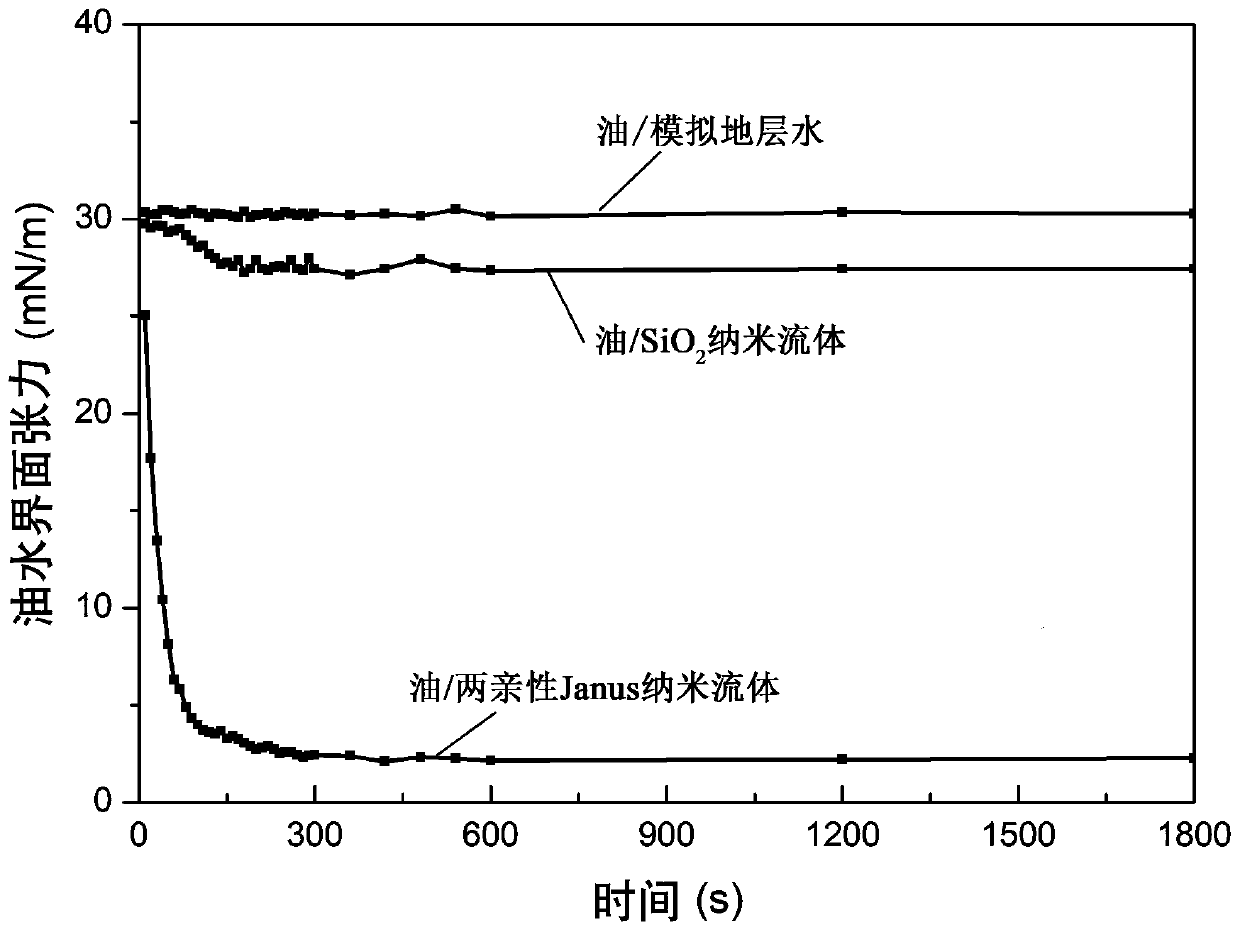

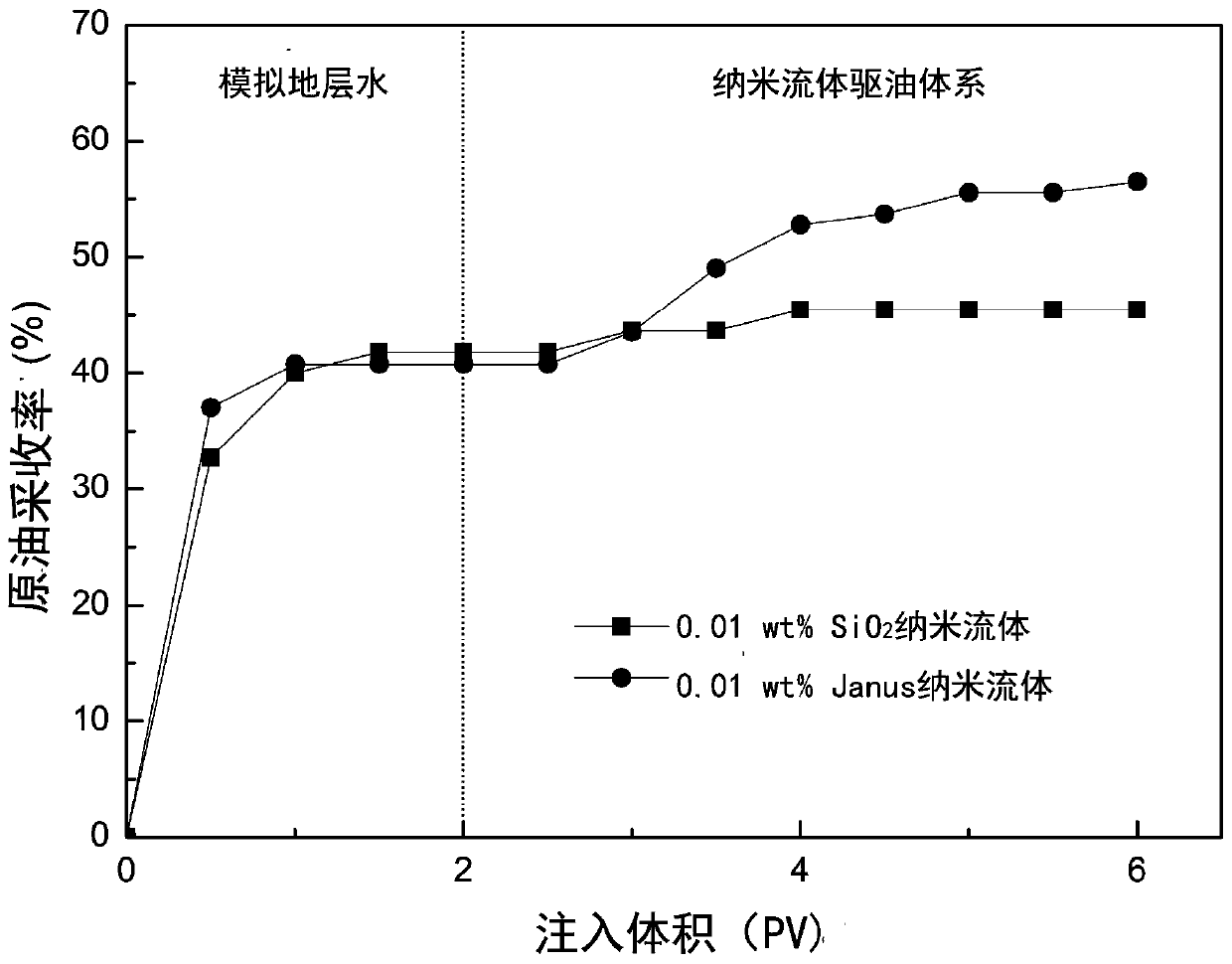

Amphiphilic Janus nano particle and preparation method and application thereof

InactiveCN111303853AThe synthesis steps are simpleGood interfacial propertiesDrilling compositionParaffin waxPtru catalyst

The invention provides an amphiphilic Janus nano particle and a preparation method and application thereof. The preparation method comprises the following steps: dispersing silicon dioxide nanoparticles in water to obtain a dispersion liquid, mixing the dispersion liquid and liquid paraffin, heating and stirring in a water bath to form a Pickering emulsion, cooling to obtain small wax balls, adding a silane coupling agent into the small wax balls for modification to obtain modified small wax balls, mixing the modified small wax balls, an amidation catalyst and C12-C18 saturated fatty acid, andcarrying out an amidation reaction process to obtain organic hydrophobic chain grafted oil-water amphiphilic nanoparticles, and removing paraffin in the organic hydrophobic chain grafted oil-water amphiphilic nanoparticles to obtain the amphiphilic Janus nano particles. When the surfactant is used as an oil-displacing agent, oil-water interfacial tension can be effectively reduced at low concentration, rock wettability is changed, oil-displacing efficiency of nanofluid is remarkably improved, economic cost is reduced, and the surfactant has a wide application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Ground calcium carbonate powder surface modification method

InactiveCN103421142AExcellent performance indexImprove application featuresPigment treatment with macromolecular organic compoundsPolymer scienceIn situ polymerization

The invention discloses a modification method for ground calcium carbonate powder (referred to as coarse whiting powder, the same below). The modifying agent of the coarse whiting powder is the composite compatilizer which comprises the components of polymer maleic anhydride-acrylamide-n-butyl methacrylate and stearic acid. Two-time modification is performed, the first modification adopts a wet method about in-situ polymerization with the modifying agent of polymer maleic anhydride-acrylamide-n-butyl methacrylate, and the second modification adopts a dry method with the modifying agent of stearic acid; the brief method comprises the steps as follows: fully mixing the coarse whiting powder, the polymer maleic anhydride-acrylamide-n-butyl methacrylate and the stearic acid, and dissolving the mixture into the mixed liquor formed by liquid paraffin and swill-cooked dirty oil, wherein the total organic matters account for 1 to 3 percent of the coarse whiting powder (mass fraction); the volume ratio of liquid paraffin to swill-cooked dirty oil is 1:1, and mass ratio of the polymer maleic anhydride-acrylamide-n-butyl methacrylate to the stearic acid is 2:1. According to the invention, the active coarse whiting powder can be used as filler of chlorinated polyvinyl chloride, polyvinyl chloride and polyethylene. The active coarse whiting powder is good in dispersion uniformity in the resin, and low in cost, and oriented towards industrialized production.

Owner:HEZHOU UNIV +1

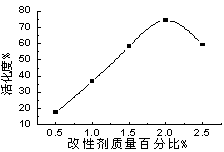

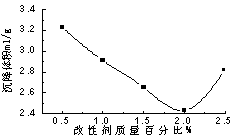

Hot melt glue for aluminum-plastic composite panel and preparation method of hot melt glue

The invention discloses hot melt glue for aluminum-plastic composite panel and a preparation method of the hot met glue. The hot melt glue is prepared by adopting the following raw materials in parts by weight: 100 parts of irradiation-modified polyethylene, 1-5 parts of maleic anhydride, 8-10 parts of ethylene vinyl acetate, 0.3-0.9 part of common modifier, 0.2-0.4 part of liquid paraffin, 0.04-0.16 part of an initiator, 10-20 parts of a solvent, 0.5-1.5 part of a cross-linking inhibitor and 5-10 parts of an antioxidant. According to the preparation method, the simplicity and the high efficiency are realized, the cost is low, the using amount of the poisonous and harmful solvent is reduced, the environment and the human health are protected, and the using range of the hot melt glue is enlarged.

Owner:SHANGHAI UNIV OF ENG SCI

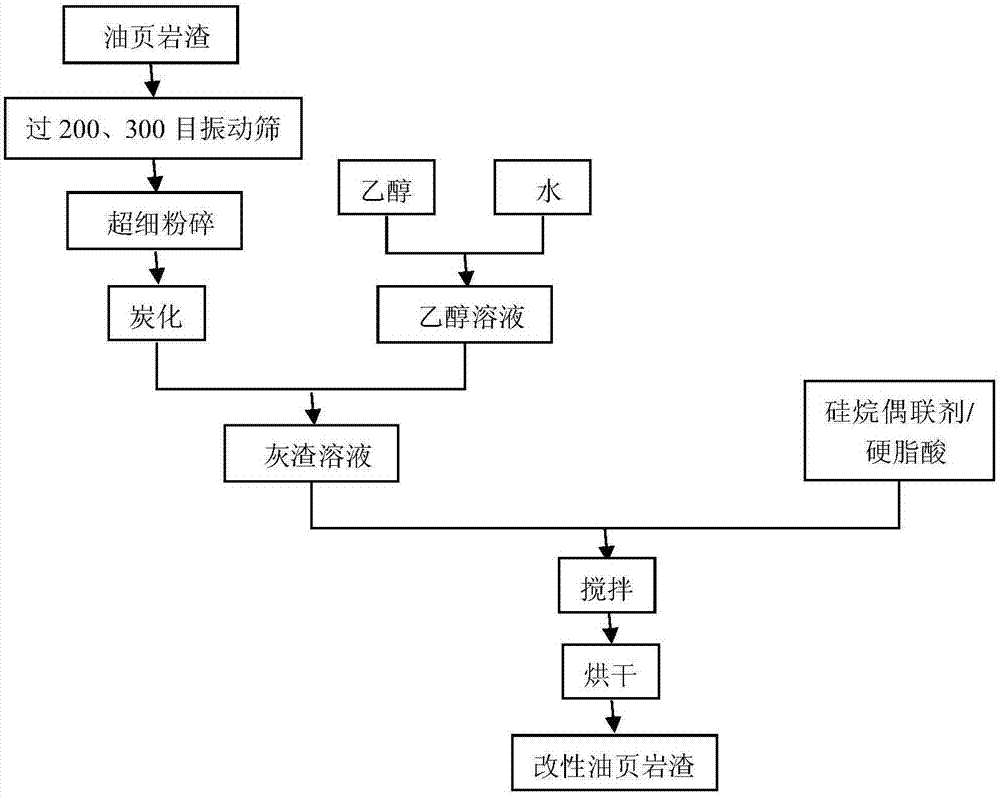

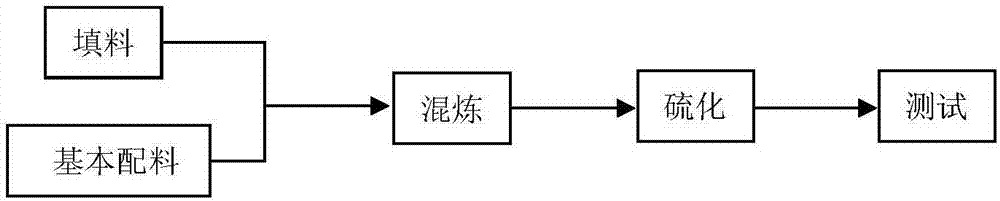

Method for preparing rubber packing from modified oil shale semicoke

The invention relates to a method for preparing rubber packing from modified oil shale semicoke. The method is characterized by comprising the following steps: 1) performing superfine crushing on oil shale semicoke after destructive distillation; 2) roasting in a high-temperature furnace, performing air insulation heat preservation, and performing furnace cooling so as to obtain carbonized oil shale semicoke; 3) modifying the carbonized oil shale semicoke superfine powder by using a surface modifier so as to obtain modified oil shale semicoke powder, wherein the addition amount of the surface modifier accounts for 2% of the mass of the powder, the modification temperature is the room temperature, and the modification time is 30 minutes; 4) smelting the modified oil shale semicoke, rubber, carbon black, zinc oxide, stearic acid, an antioxidant, liquid paraffin, sulfur and a promoter in a smelting machine at certain temperature; and 5) cooling, and molding by using a press vulcanizer. Organic matter residues in the oil shale semicoke can be sufficiently utilized, wastes can be turned into wealth, environment pollution caused by air storage can be eliminated, the carbonized oil shale semicoke powder is uniform in surface carbonization, solid in wrapping, good in organic matter compatibility, stable in performance, simple in process and low in cost. Various indexes of mechanical properties of testing samples can meet national standards.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com