Patents

Literature

482 results about "Liquid chlorine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

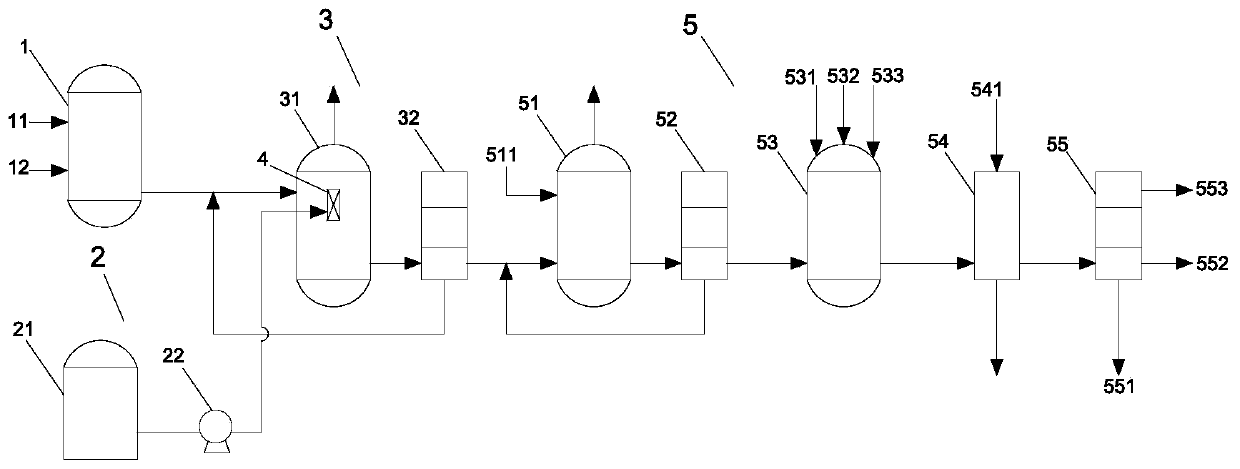

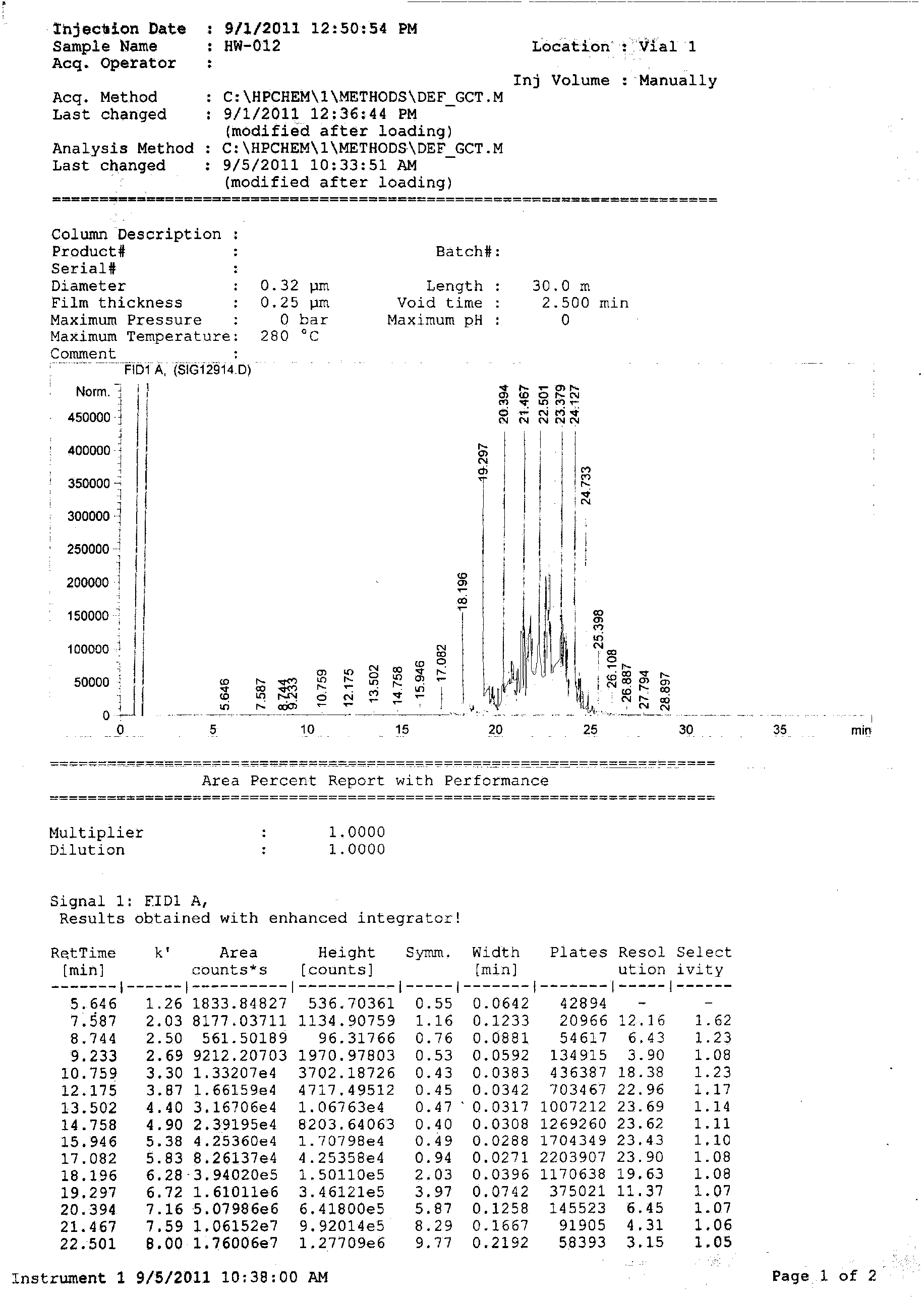

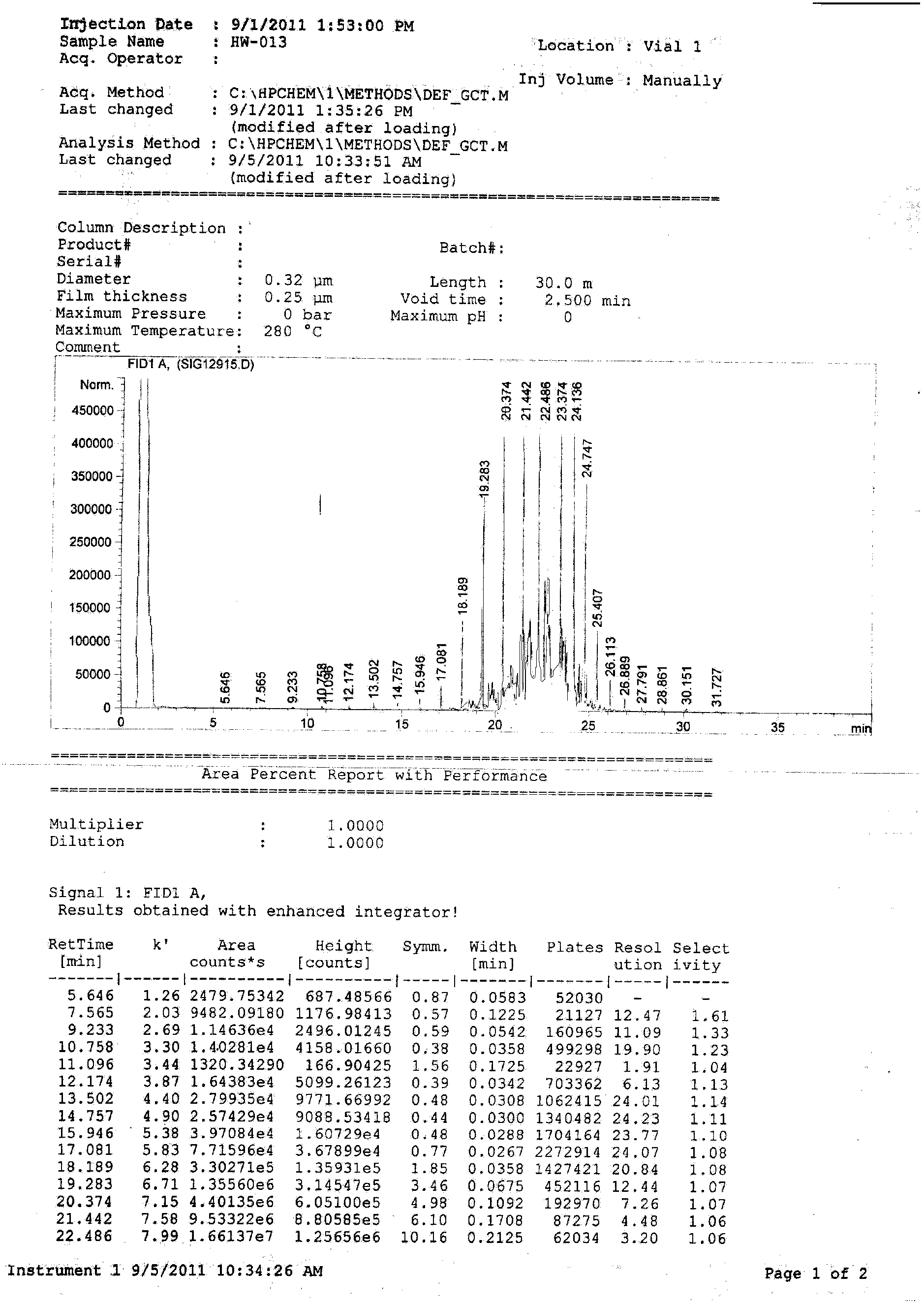

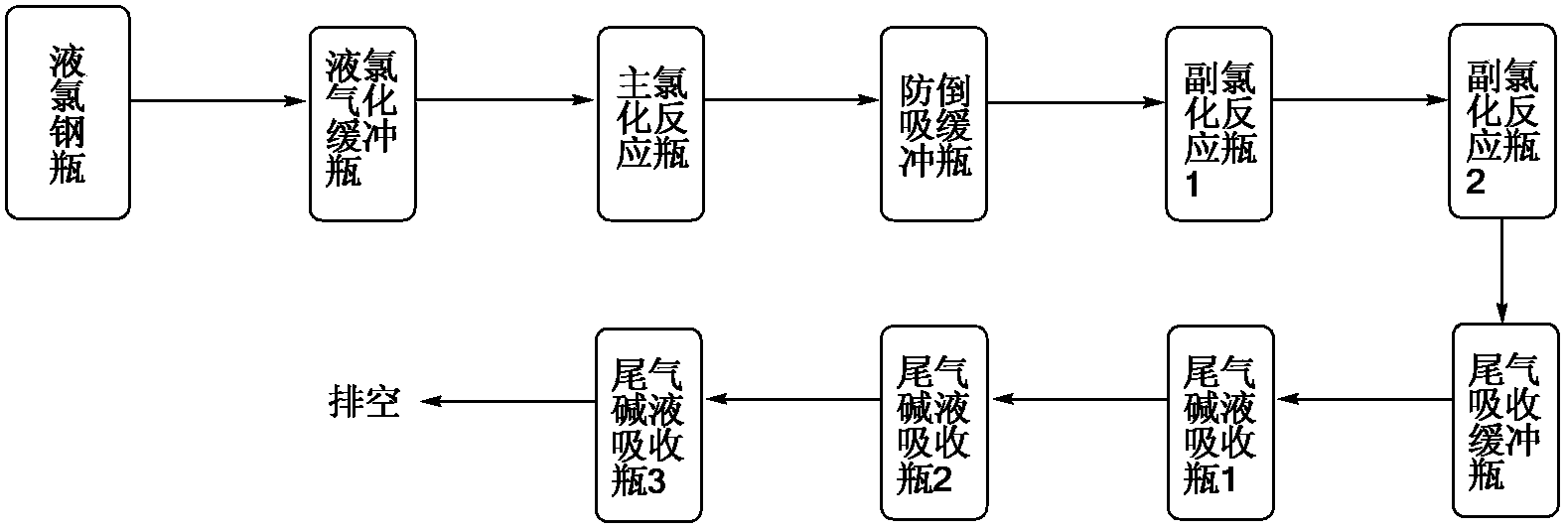

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

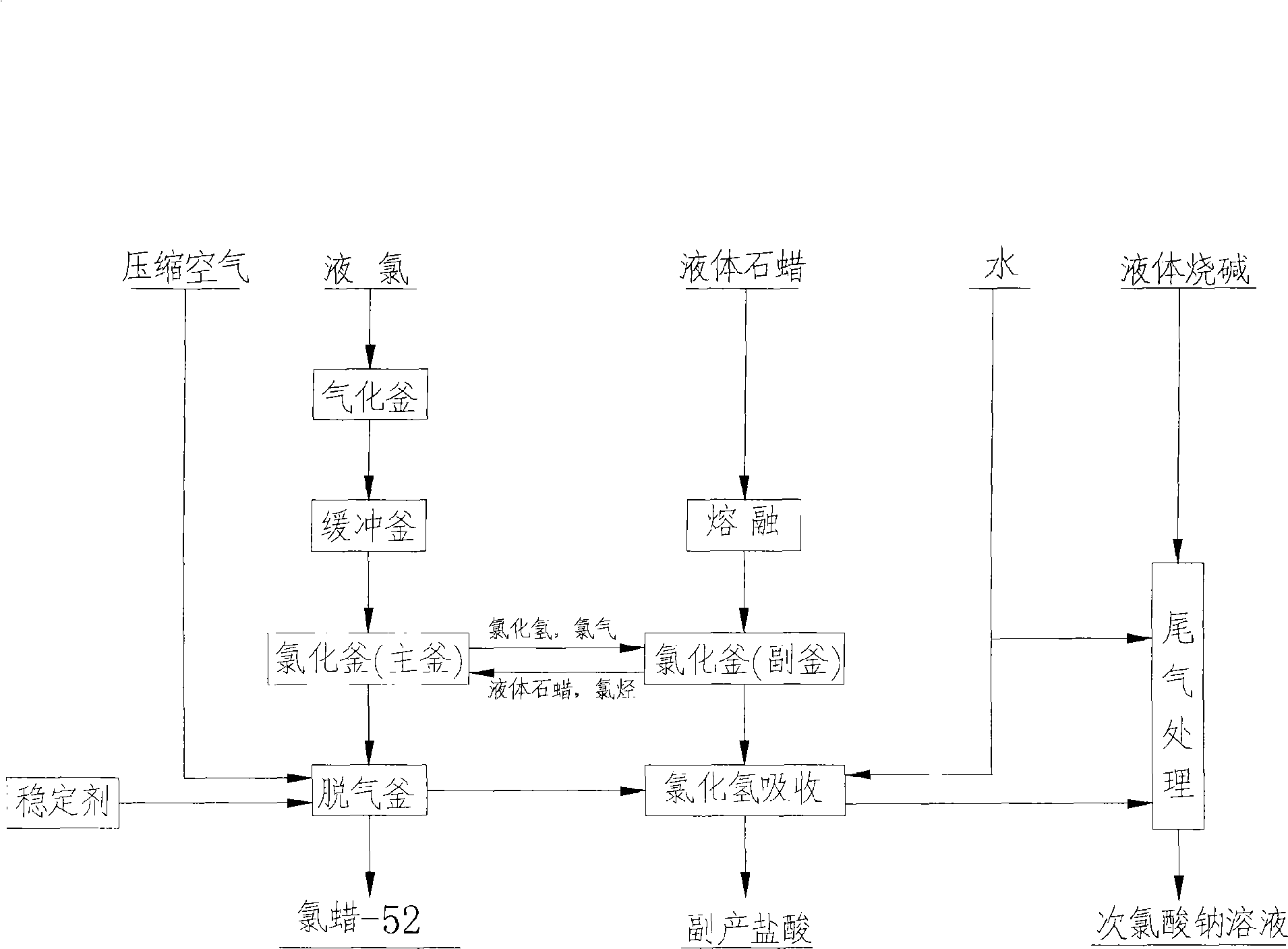

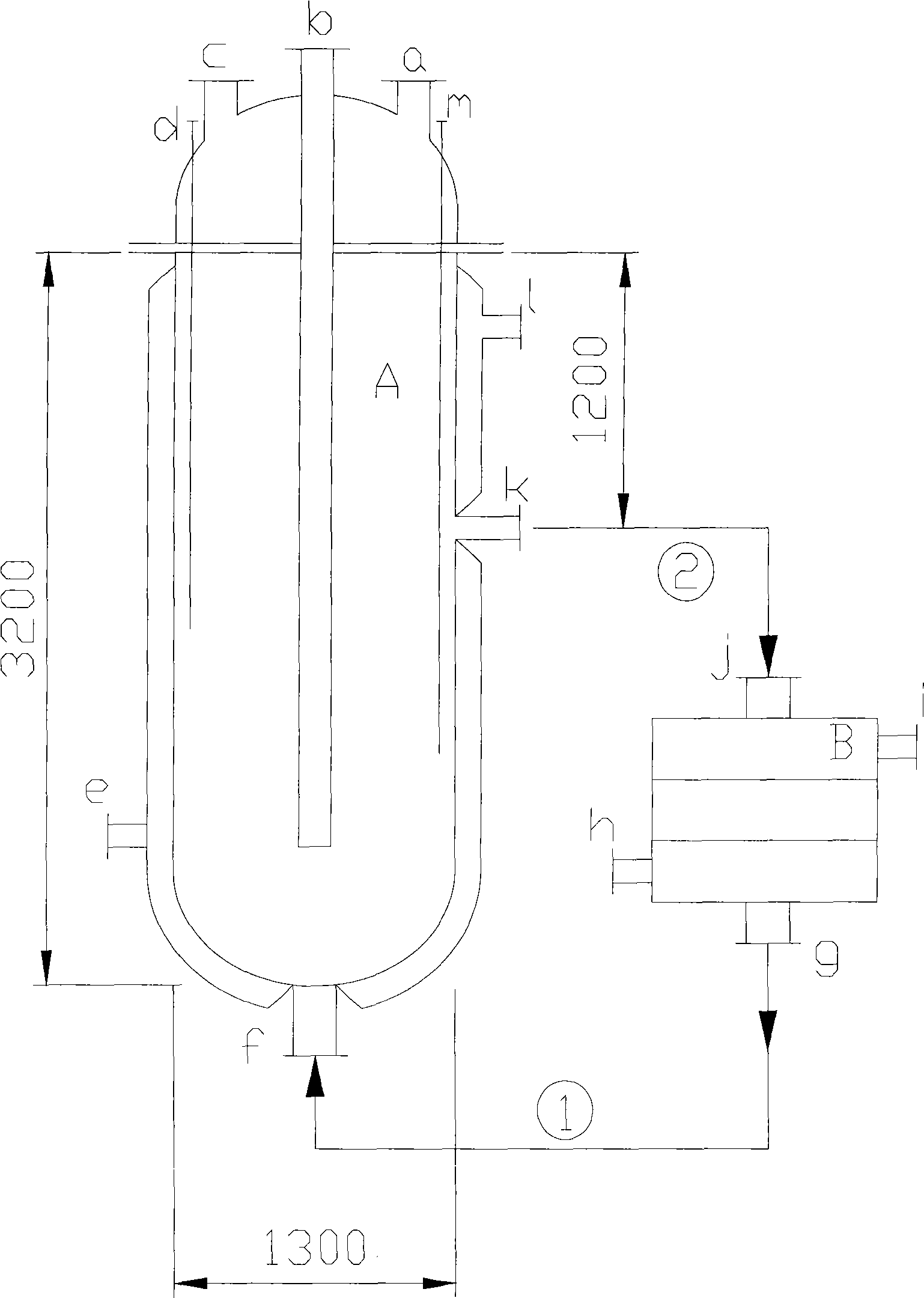

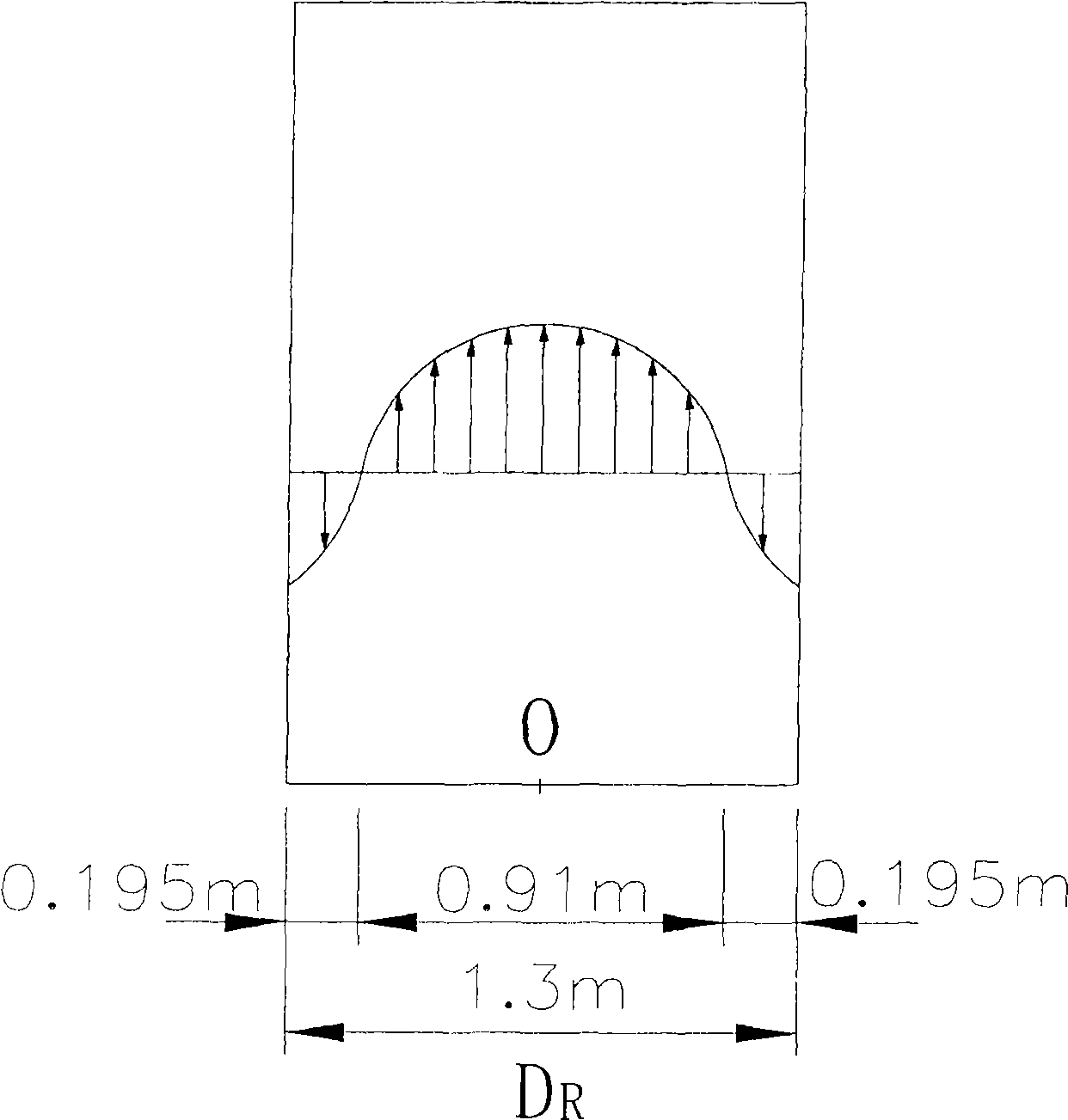

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

Sterilizing bath lotion for furry pets

InactiveCN101810542AEasy to rinse offMild in natureCosmetic preparationsHair cosmeticsLotionSodium chlorite

The invention provides sterilizing bath lotion for furry pets, which comprises surfactant, humectant, hair care agent, chelating agent, bactericide, thickening agent and essence, wherein the bactericide is one of stable liquid chlorine dioxide, stable solid chlorine dioxide or sodium chlorite. The sterilizing bath lotion of the invention overcomes the defects of the existing product or the prior art, and really realizes synchronous completion of three effects of removing dirt, caring hair and quickly sterilizing. The sterilizing bath lotion has the advantages of mild property, no any stimulation to the fur of animals and the skin of people, good dirt removing and sterilizing effects, low foam, easy cleaning, no residue, safety and environment friendliness, and meanwhile plays a role in caring the fur of the animals so that the fur of the washed pet does not knot; and the sterilizing bath lotion is glossy, flexible and easy to card, and is quite suitable for the daily care of the furry pets.

Owner:BEIJING OKEANOS TECH

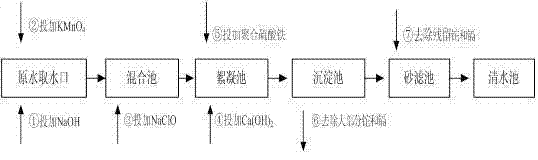

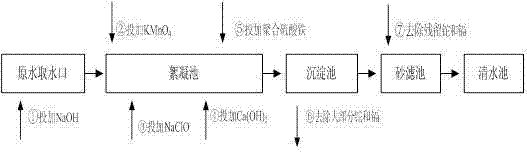

Method for simultaneous removal of cadmium and thallium in raw water

ActiveCN103693774ASimple processEasy to implementWater contaminantsMultistage water/sewage treatmentCadmium CationTreated water

The invention provides a method for simultaneous removal of cadmium and thallium in raw water. The method comprises the following steps: step A, adding sodium hydroxide into raw water, adjusting a pH value to alkalescence and then adding potassium permanganate with a concentration of 0.3 to 0.8 mg / L; step B, adding sodium hypochlorite or liquid chlorine, wherein the concentration of added sodium hypochlorite or liquid chlorine is 0.5 to 2.5 mg / L in term of effective chlorine; step C, adding limewash into raw water having undergone a full oxidation reaction and adjusting a pH value to 8.5 to 9.0; step D, adding a flocculating agent, carrying out a flocculation reaction for 10 to 20 min and then carrying out deposition for at least 0.5 h so as to remove cadmium, thallium and colloids of manganese hydroxide and iron hydroxide through coprecipitation, wherein the pH value of water after precipitation drops to 7.0 to 8.5; and step E, filtering raw water obtained after precipitation by using quartz sand. The invention has the following beneficial effects: cadmium concentration of treated water is as small as the limit of a detection method, i.e., 0.02 mu g / L, or less than 0.02 mu g / L; thallium concentration of treated water is as small as the limit of a detection method, i.e., 0.01 mu g / L, or less than 0.01 mu g / L; and the pH value, manganese ions and iron ions of the treated water all meet requirements prescribed in drinking water quality standards.

Owner:SHENZHEN WATER GRP CO LTD

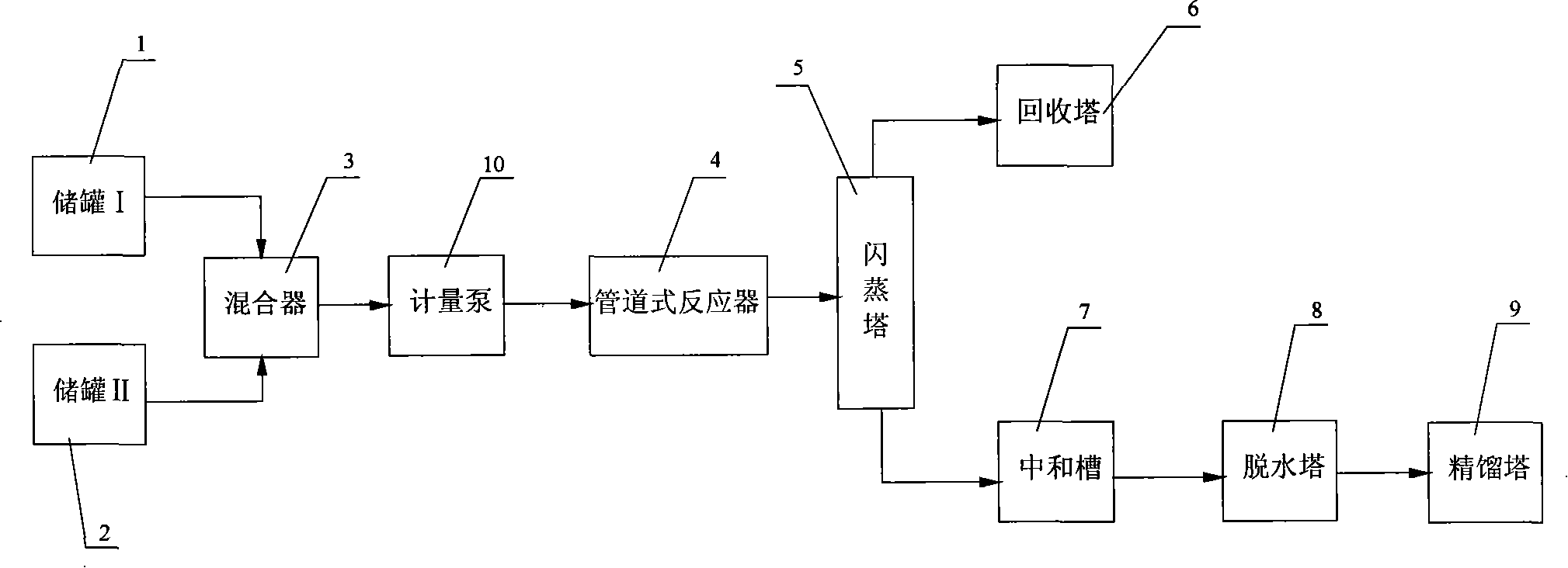

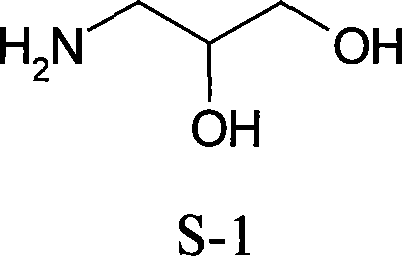

Method for synthesizing 3-amido-1,2-propanediol by pipe reactor

ActiveCN101250115AShort reaction timeHigh yieldChemical/physical/physico-chemical stationary reactorsAmino preparation by functional substitutionReaction temperatureGlycerol

The invention discloses a method for synthesizing 3-amino-1, 2-propanediol via a tubular reactor, which comprises (1) ammoniation such as premixing liquid chlorine glycerol and ammonia water via a mixer, and reacting in a tubular reactor while the reaction temperature is 60-100DEG C, the pressure is 3-6MPa and the time is 6-12min, and obtain the mixture solution of 3-amino-1, 2-propanediol and ammonia water, (2) purification such as treating the mixture solution by depressurizing, flash evaporation and deamination, and treating the liquid after the deamination by adding alkali to neutralize, dehydrating, depressurizing and distilling, to obtain 3-amino-1, 2-propanediol. The synthesized 3-amino-1, 2-propanediol has the advantages of high yield.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD

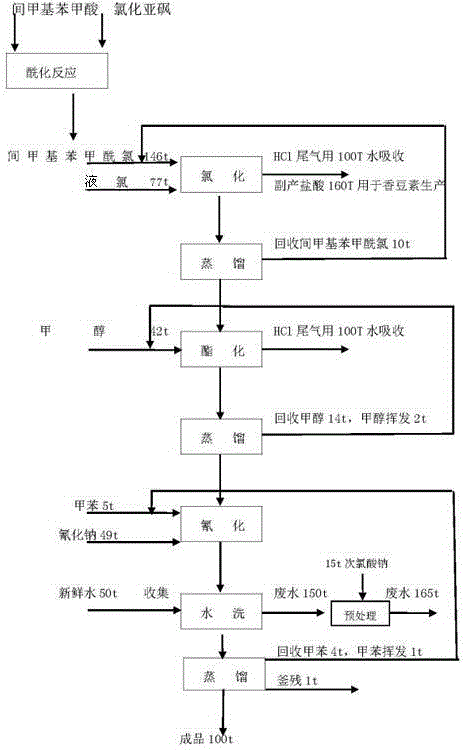

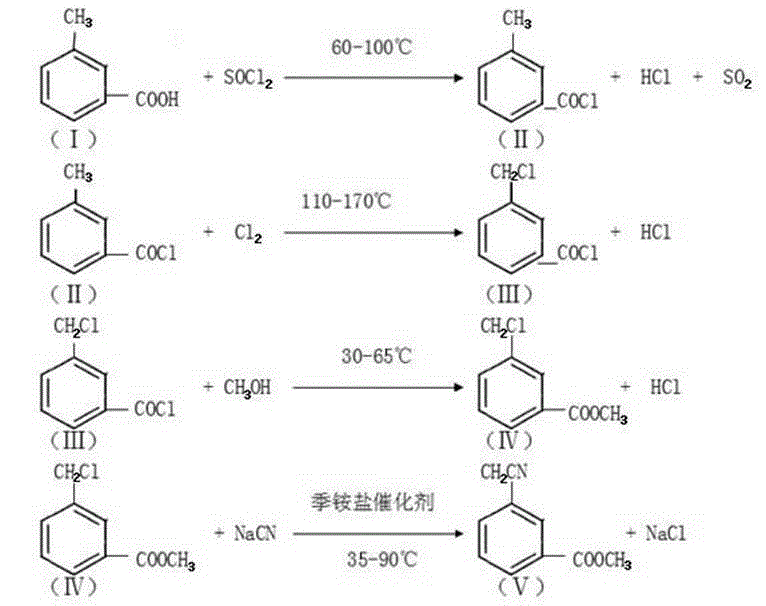

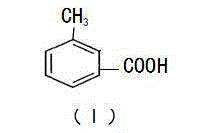

Synthetic system of 3-cyanomethylbenzoic acid methyl ester and method thereof

InactiveCN110002993AIncrease the mass transfer area of the phase boundaryImprove mass transfer efficiencyOrganic compound preparationPreparation by cyanide reactionChlorideMethyl benzoate

The invention provides a synthetic system of 3-cyanomethylbenzoic acid methyl ester and a method thereof. The system comprises an acylation reaction vessel used for preparation of m-Toluoyl chloride;a liquid chlorine feeding unit used for storing and conveying liquid chlorine; a chlorination reaction unit which is connected with the acylation reaction vessel and used as a chlorination reaction chamber of m-Toluoyl chloride; a micro-interface generator which is respectively connected with the liquid chlorine feeding unit and the chlorination reaction unit and used for receiving liquid chlorineconveyed by the liquid chlorine feeding unit, crushing the liquid chlorine into micro-droplets with the diameter being micron level and conveying the micro-droplets to the chlorination reaction unitafter the crushing; and an esterification and cyanation reaction unit which is connected with the chlorination reaction unit. In the prior art, m-Toluoyl chloride and liquid chlorine cannot be fully mixed when m-Toluoyl chloride and liquid chlorine react such that yield of 3-cyanomethylbenzoic acid methyl ester is reduced. The above problem is solved by the synthetic system and the method of the invention.

Owner:NANJING UNIV

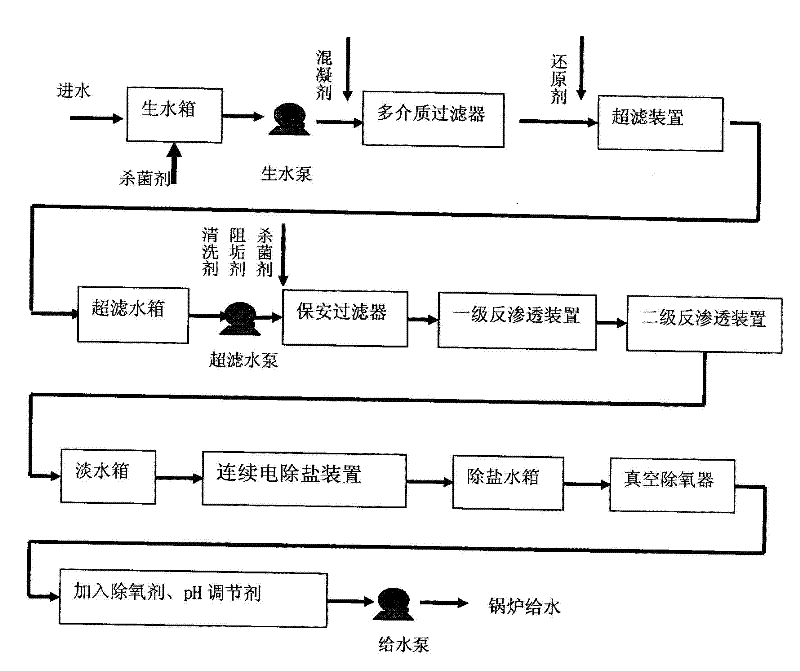

Novel water treatment method for boiler feedwater

ActiveCN102344215AAvoid breedingDecreased water conductivityGeneral water supply conservationMultistage water/sewage treatmentChlorine dioxideUltrafiltration

A novel water treatment method for boiler feedwater of the invention comprises the following steps: sterilization, that is adding liquid chlorine, sodium hypochlorite or stabilized chlorine dioxide into a raw water tank, controlling the residual chlorine amount in water to be 0.2-0.5 mg / L; filtration, that is adding a polyaluminium chloride coagulant before a multimedium filter with an amount of 10-20 mg / L, controlling the water turbidity of the ultrafiltration feedwater to be not more than 0.1 NTU and the SDI to be not more than 3; adding a reducing agent of sodium bisulfite before ultrafiltration with an adding amount of 3-5 mg / L; reverse osmosis, that is performing desalination treatment by a reverse osmosis membrane device, continuously adding a PTP-0100 scale inhibitor before a security filter with an adding amount of 3-5 mg / L; continuously adding a Micro Treat BIO bactericide with an adding amount of 3-5 mg / L; additionally adding cleaning agents of Dimamite and High Flux once a month with an amount of 3-5% of the water amount to be produced; desalination, that is performing desalination by an electrical desalination system (EDI); deoxygenation, that is performing deoxygenation by a vacuum deoxygenator, adding 10-20 microgram / L of deoxidants, controlling the agent residual amount to be 5-20 microgram / L, adding a corrosion-inhibiting pH regulator to control the pH value to be 8.8-9.3.

Owner:XINJIANG DELAND

Producing method for bright yellow anti-myopia health-care paper

This invention refers to a kind of peak yellow health-care paper protecting from myopia, and its preparation. The process includes crushing wheat stalk, mixing sodium sulfite, sodium hydroxide and anthraquinone with wheat stalk fibers, steam-boiling the said mixture in water to form paper pulp materials, sifting out them to remove impurities, adding liquid chlorine, sodium hydroxide and sodium hypochlorite into them, heating to bleach pulp materials, pulverizing pulp materials; Adding alkali peak yellow, acid violet, aluminum sulphate, rosin glue, dithionite oil etc into pulp materials, diluting paper pulp with water in order to adjust colour, putting paper pulp on shaped net according to meet finished paper thickness, heating and drying to get products. This health-care paper is peak yellow, pretty and without lost fresh and hurt eyes. Its surface is smoothness, water tolerance and oil tolerance, and physical strength and surface strength reaching the write paper standard.

Owner:高立明

Lithium adsorbent and preparation method of lithium adsorbent

ActiveCN106975436AImprove performanceImprove adsorption efficiencyOther chemical processesAlkali metal oxides/hydroxidesAluminium chlorideLithium chloride

The invention discloses a lithium adsorbent and a preparation method of the lithium adsorbent. The preparation method comprises the following steps: step S1: sufficiently mixing an aluminum chloride solution with the lithium compound to form a reaction preliminary body, wherein the amount of substance of the aluminum chloride to the lithium compound is (1.8 to 2.2) to 1, and the lithium compound is one of the lithium hydroxide, lithium carbonate and lithium chloride; step S2: adding a sodium hydroxide solution in the reaction preliminary body, wherein the amount of the substance of the sodium hydroxide to the aluminum chloride is (2.5 to 3.5) to 1; reacting to generate LiCl.2.2-2.8Al(OH)3.2.7-3.9H2O so as to form a first product; step S3, performing solid-liquid separation, drying, grinding and smashing on the first product to form a second product; step S4, adding adhesive and the liquid chlorine in the second product to realize mixing granulation, thereby forming a third product; and step S5, crushing and sieving the third product to obtain the lithium adsorbent. The preparation process of the lithium adsorbent is simple and efficient, the prepared lithium adsorbent is excellent in property, and the raw material has great selectivity, so that the preparation cost of the lithium adsorbent is effectively saved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

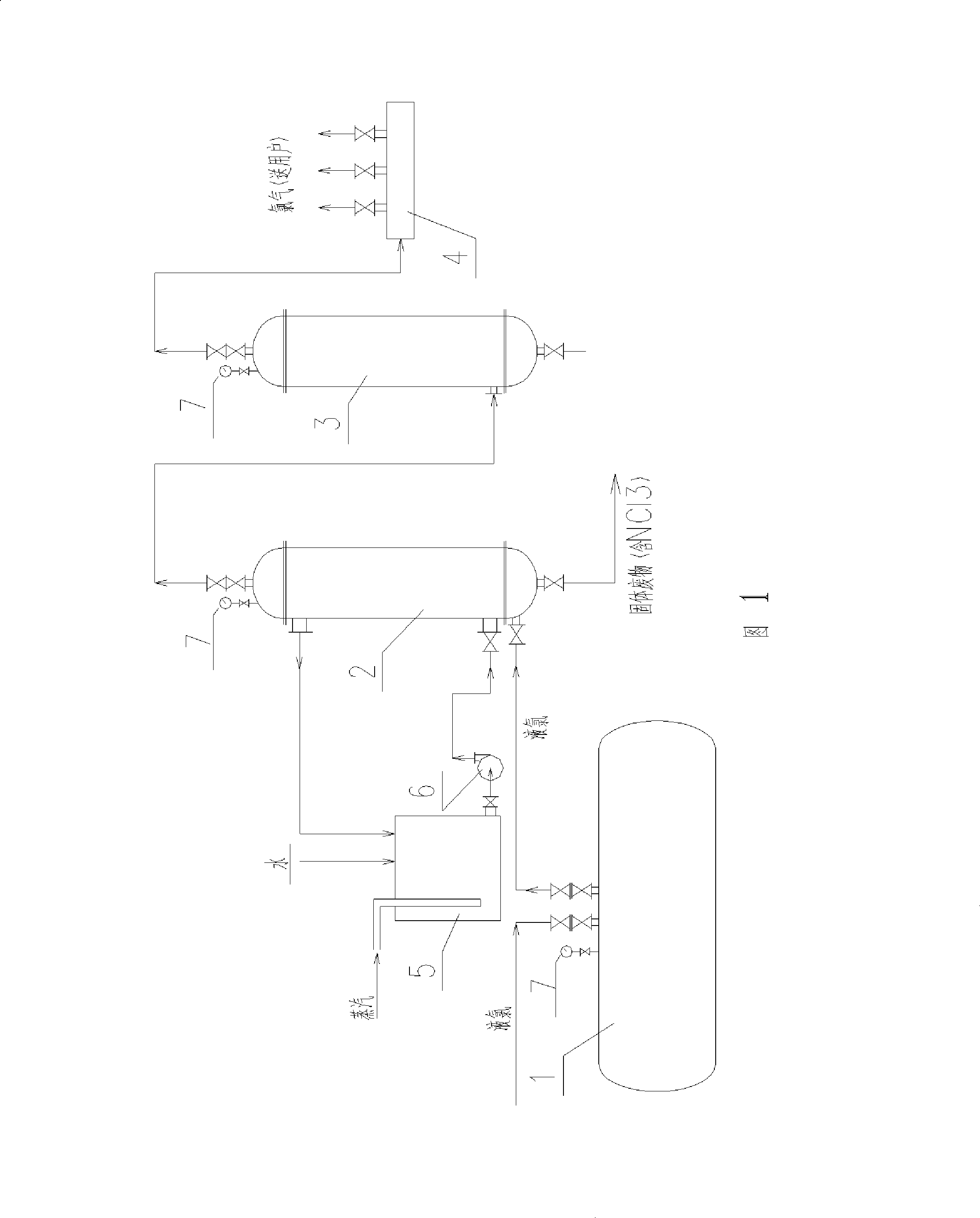

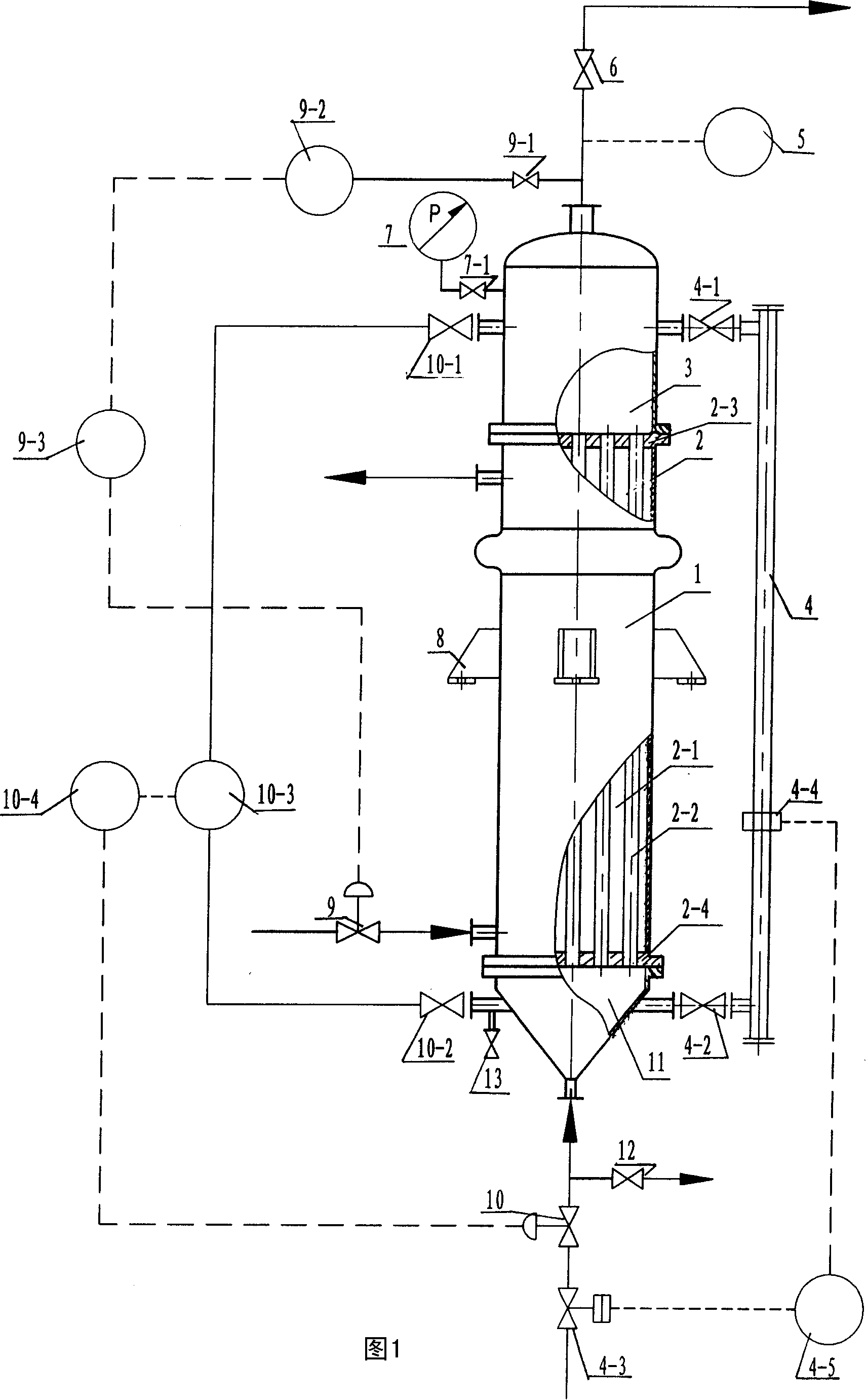

Method for storing and gasifying liquefied chlorine gas and complete equipments thereof

InactiveCN101446381ASmall temperature fluctuationsEnsure safetyPressure vesselsContainer discharging from pressure vesselsComing outBuffer tank

The invention discloses a method for storing and gasifying liquefied chlorine gas and complete equipments thereof in an electrolytic magnesium factory. The method is as follows: liquefied chlorine gas is loaded into a liquefied chlorine gas storage vat (1) and pressed into an evaporator (2) by depending on the pressure in the vat; hot water in a hot water vat (5) is sent into the evaporator (2) for heating; chlorine gas comes out from the top of the evaporator, sequentially goes into a buffer tank (3), a distributor device (4), decompressed by a reducing valve, and then sent to users. The device is characterized in that the liquefied chlorine gas storage vat (1) is connected with the evaporator (2) which is connected with the buffer tank (3); the buffer tank (3) is connected with the distributor device (4); the hot water vat (5) is connected with the evaporator (2). The liquefied chlorine gas storage vat (1) is put in a basement. The top of the basement is covered by heat insulator. In the invention, the high capacity liquefied chlorine gas storage vat is selected, used, and be put in the basement, which has little temperature variation and can guarantee safety; the liquefied chlorine gas evaporator is used and heated by hot water with better steady temperature; the generated chlorine gas has stable pressure, thus avoiding that accidents happen because of hypertension pressure.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for preparing electronic grade high-purity hydrogen chloride from industrially synthesized hydrogen chloride

ActiveCN103387211ALow costIncrease incomeChlorine/hydrogen-chloride purificationNitrogen gasLiquid chlorine

Owner:HANGZHOU ELECTROCHEM GROUP

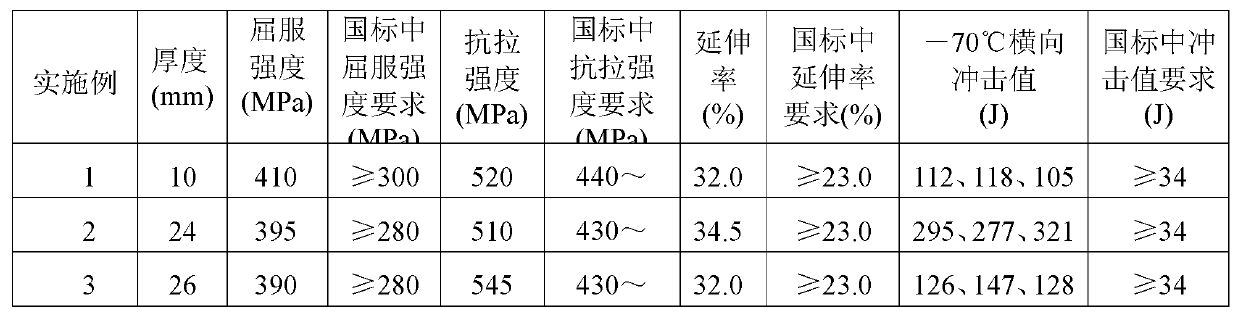

Steel plate for normalizing type low-temperature pressure vessel at-70 DEG C

InactiveCN103122436AImprove plasticityExcellent -70℃ low temperature impact toughnessHeat treatment process controlNitrogenHigh pressure

The invention relates to a steel plate for a normalizing type low-temperature pressure vessel at-70 DEG C. The steel plate comprises the chemical ingredients by weight percent: 0.09-0.12% of C, 0.15-0.50% of Si, 1.2-1.6% of Mn, 0.015% or less of P, 0.005% or less of S, 0.02-0.04% of Nb, 0.40-0.80% of Ni, 0.006-0.010% of Ti, 0.020-0.034% of Alt and the balance of Fe and inevitable impurity. The preparation method comprises the steps of: by taking iron water and waste steel after desulphurization pretreatment as materials, carrying out converter smelting, LF refining, RH vacuum treatment, continuously casting, heating, rolling, cooling, normalizing heat treatment and the like to obtain steel plate for the normalizing low-temperature pressure vessel at -70 DEG C. The steel plate has the advantages that the yield strength is greater than 380MPa; and the steel plate has good plasticity and excellent low temperature impact toughness at -70 DEG C, and can be applied to fabrication of low-temperature pressure container equipments such as a liquid chlorine storage tank, a high-pressure nitrogen storage tank, and an ammonia cooler.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

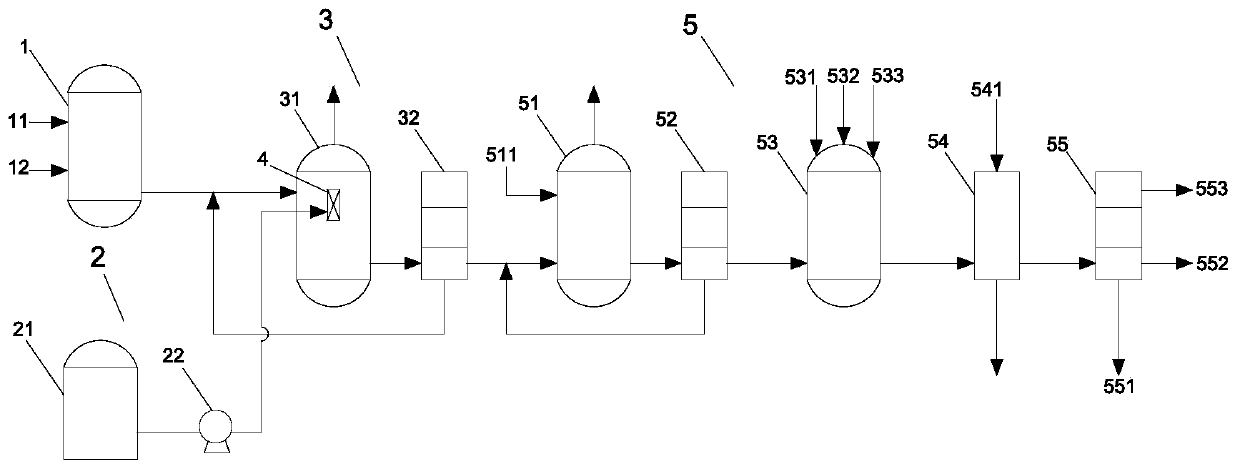

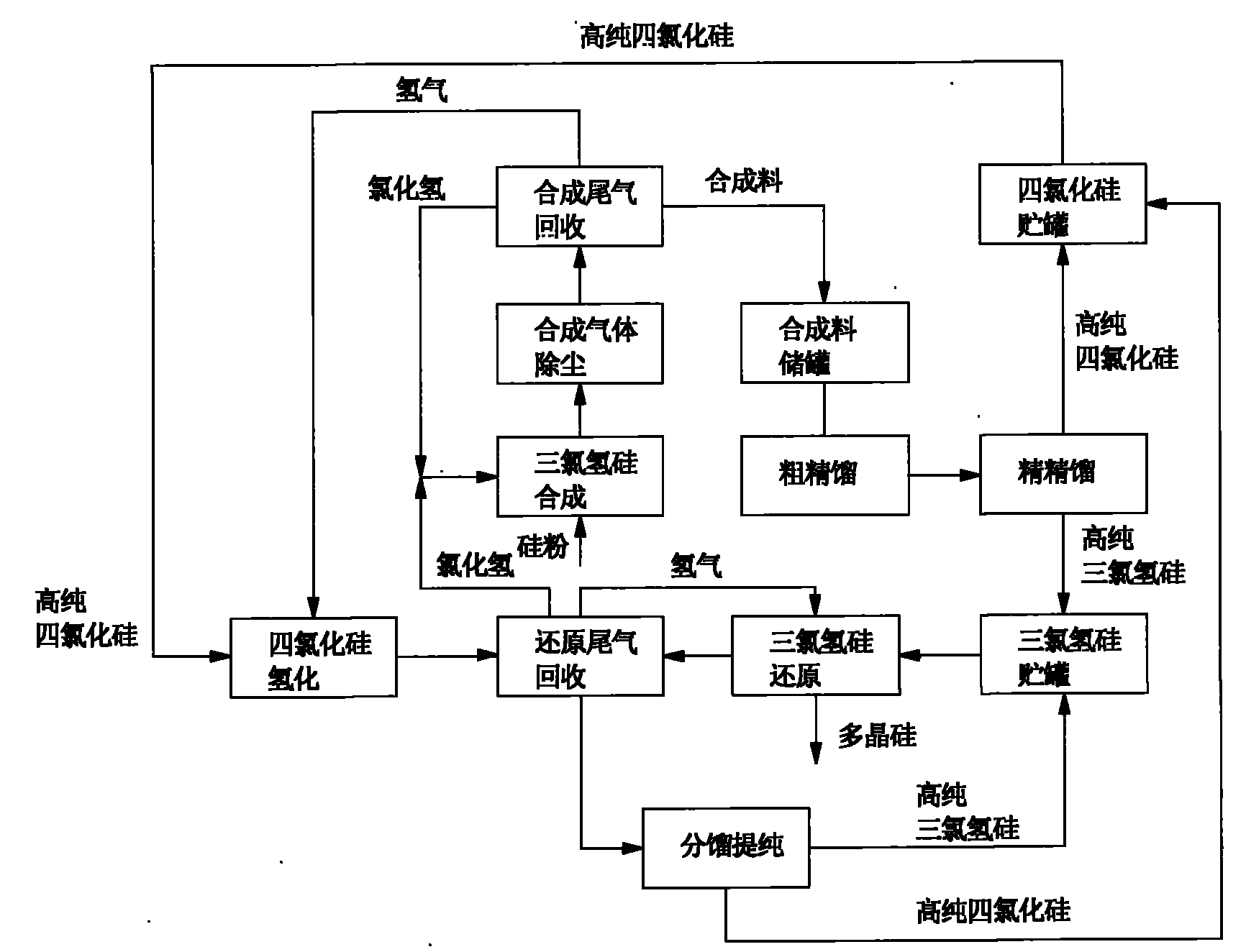

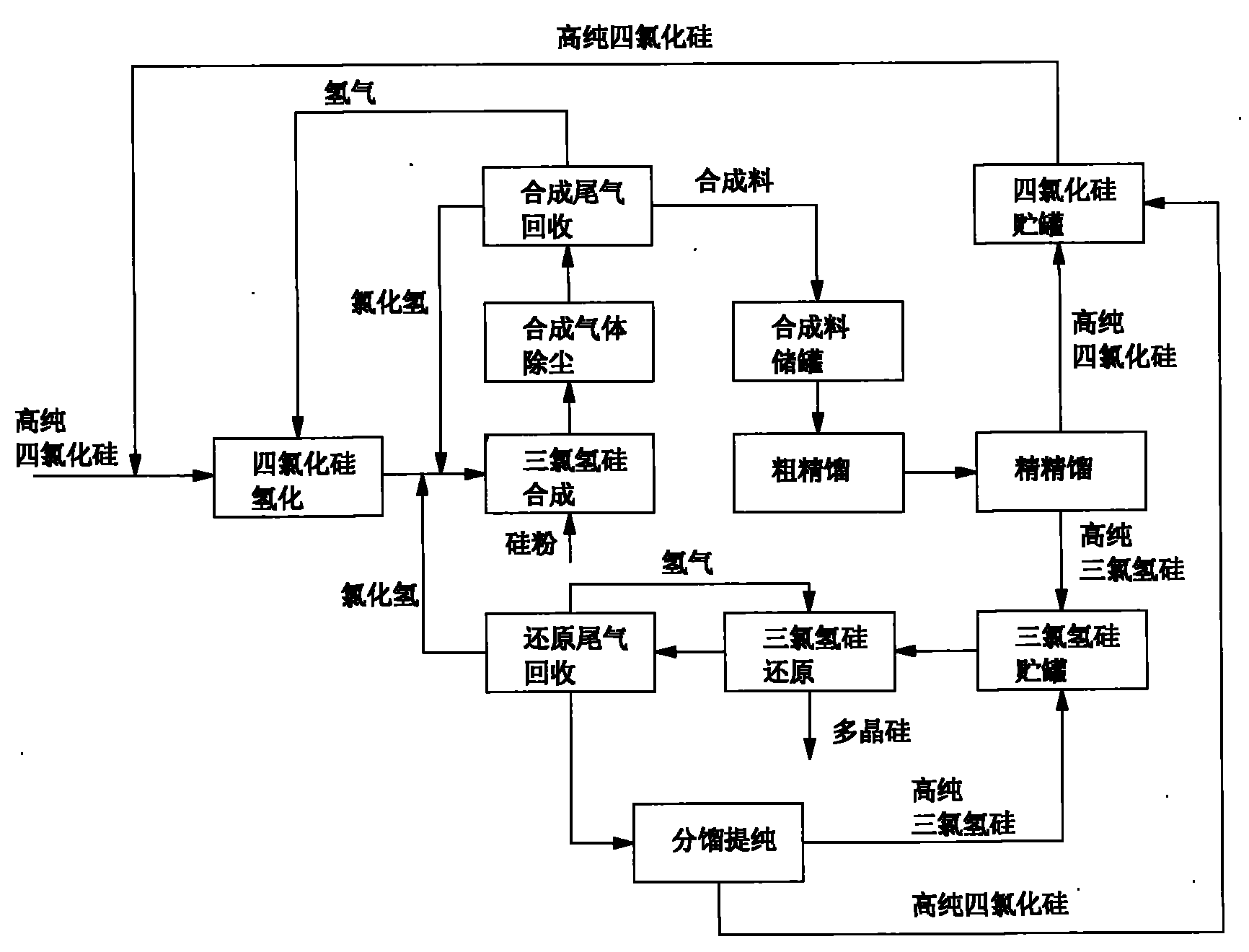

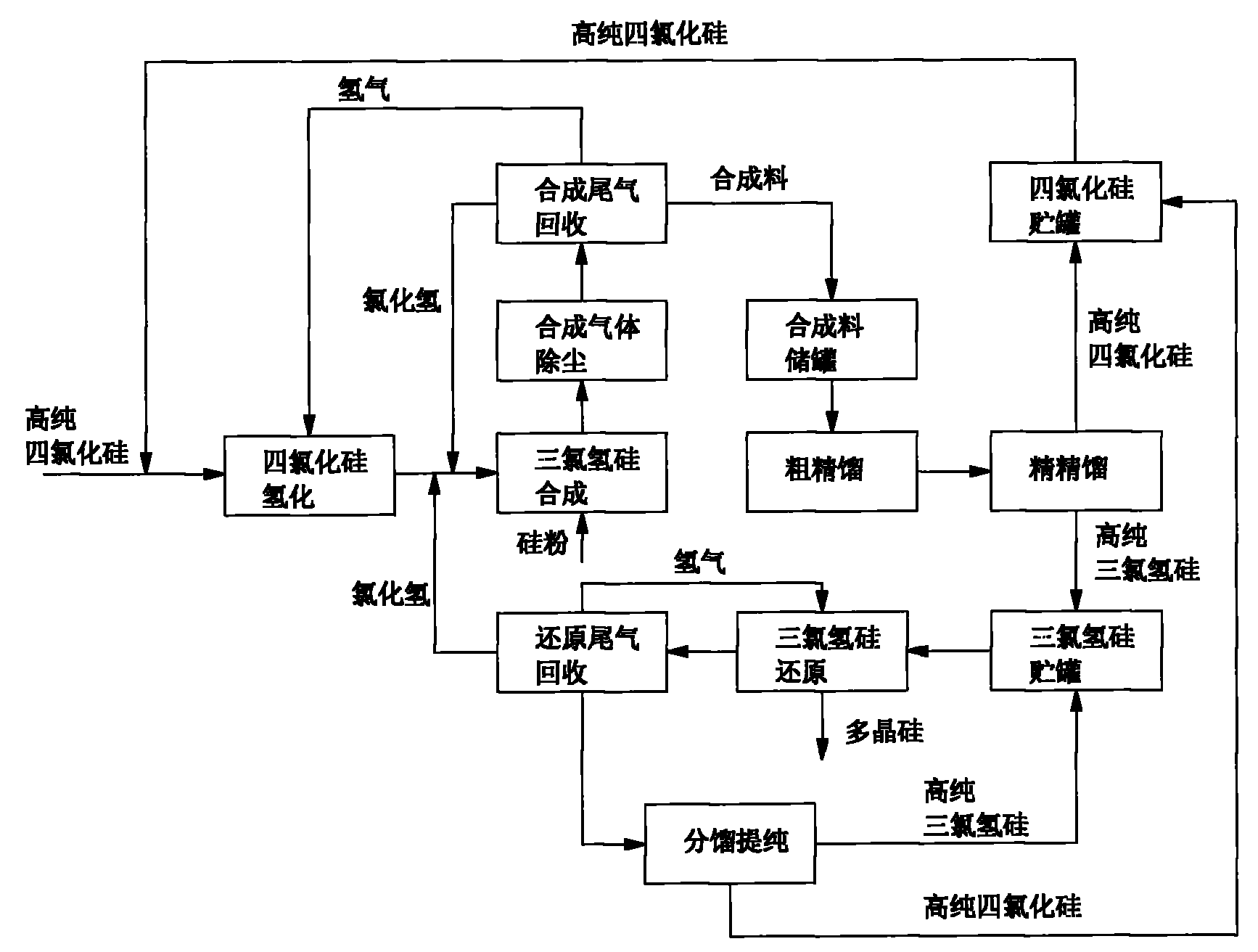

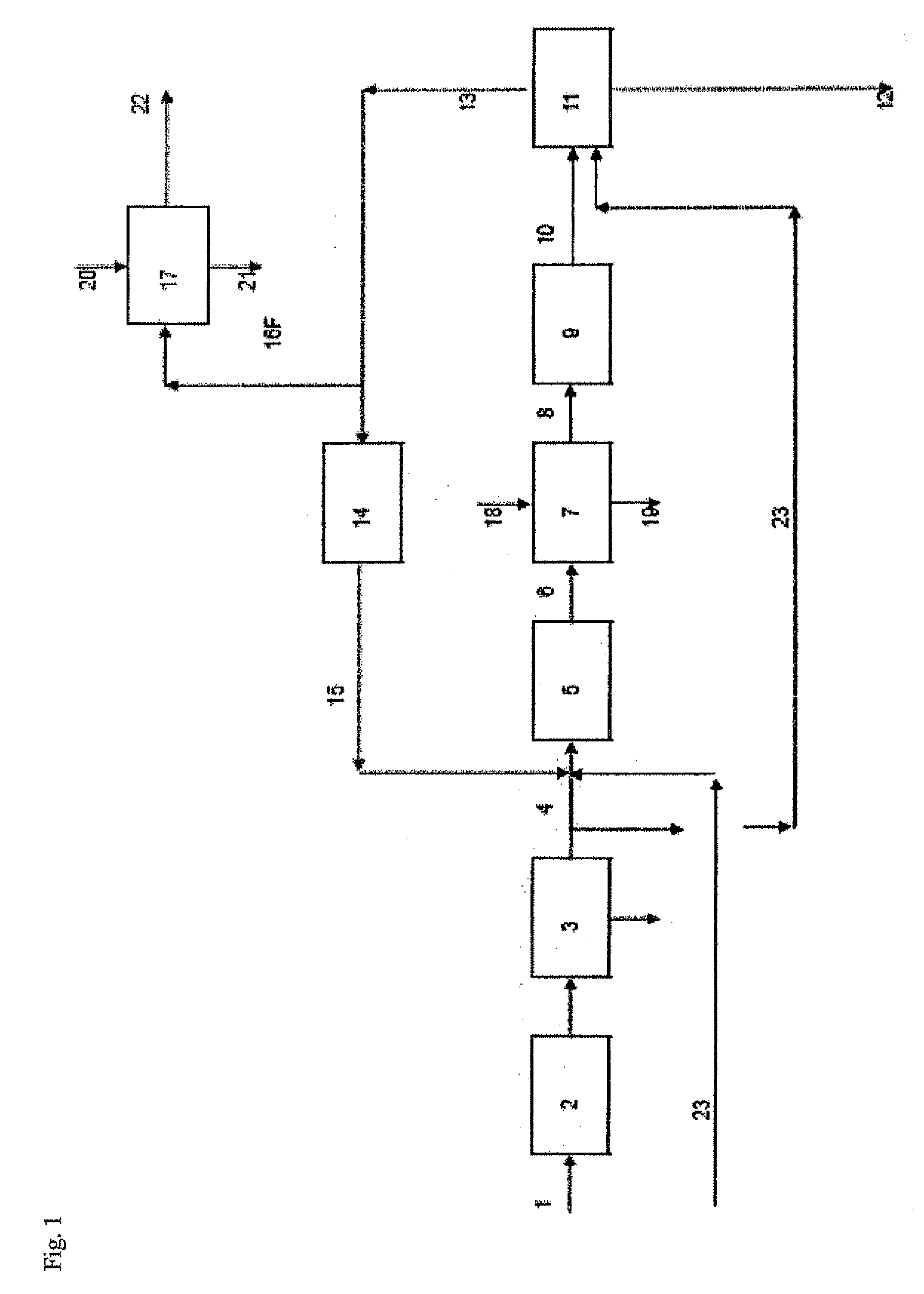

Polycrystalline silicon producing device and process

ActiveCN102030329AImprove conversion rateHigh puritySiliconHalogenated silanesClosed loopHydrogen chloride

The invention provides a polycrystalline silicon producing device, comprising a trichlorosilane synthesis furnace, a trichlorosilane reduction furnace, a silicon tetrachloride hydrogenation furnace, a trichlorosilane synthesis tail gas recycling device and a trichlorosilane reduction tail gas recycling device, wherein the tail gas outlet of the silicon tetrachloride hydrogenation furnace is connected with the feeding hole of the trichlorosilane synthesis furnace, and the air inlet of the trichlorosilane reduction tail gas recycling device is connected with the air outlet of the trichlorosilane reduction furnace. In the invention, the tail gas outlet of the silicon tetrachloride hydrogenation furnace is connected with the feeding hole of the trichlorosilane synthesis furnace, and tail gas produced by silicon tetrachloride hydrogenation directly enters the trichlorosilane synthesis furnace, thus achieving high yield of trichlorosilane and higher purity of polycrystalline product, avoiding discharge of massive impurity of chlorosilane, saving raw material and eliminating a film pressing machine, a liquid chlorine gasification device and a hydrogen chloride synthesis device; meanwhile, the whole production technological process is a material closed-loop circulation formed by silicon tetrachloride hydrogenation and trichlorosilane reduction, and no waste is discharged, thus being beneficial to environmental protection.

Owner:XINJIANG DAQO NEW ENERGY

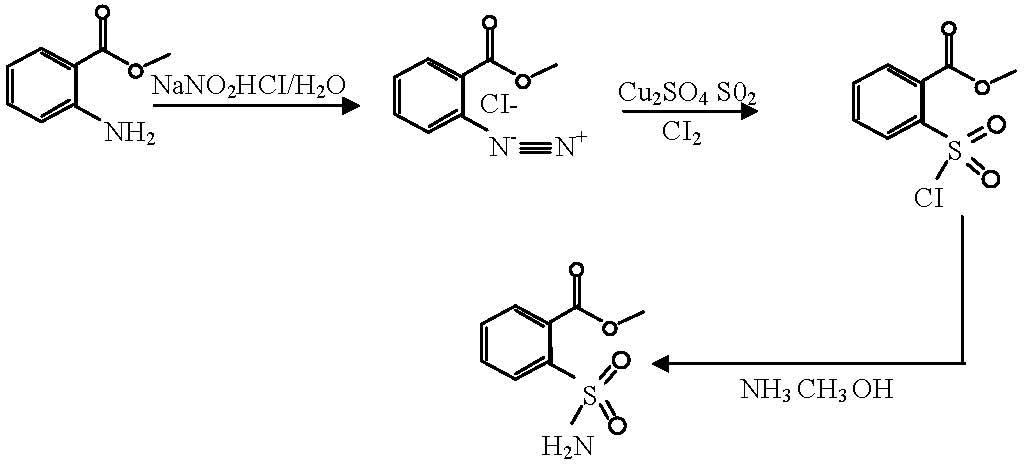

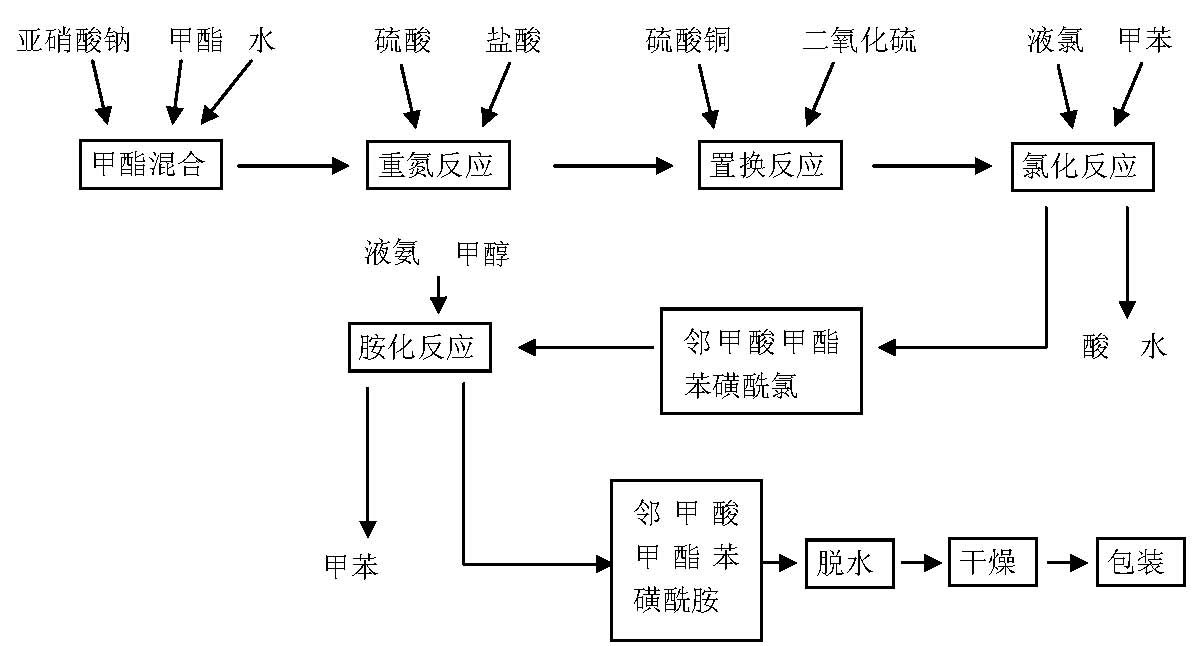

Method for synthesizing o-methyl formate benzene sulfonamide

InactiveCN102603582ASimple methodEasy to operateChemical industrySulfonic acid amide preparationSodium nitriteLiquid chlorine

The invention relates to a method for synthesizing o-methyl formate benzene sulfonamide which is capable of effectively solving the problems that a conventional o-methyl formate benzene sulfonamide synthesizing method is complex in process, high in cost, low in efficiency and pollutes environment and comprises the steps of: heating water, adding sodium nitrite, dissolving, and adding methyl o-aminobenzoate to obtain a methyl ester mixture; putting the water in a diazo pot, adding sulfuric acid and hydrochloric acid to obtained mixed acid; reducing the temperature of the mixed acid, adding the methyl ester mixture, reacting to obtain a diazonium salt solution, adding copper sulfate, introducing sulfur dioxide, determining by utilizing an H acid reagent solution and fading by utilizing the H acid; adding toluene, introducing liquid chlorine, determining to be darkgreen by utilizing a benzidine reagent solution, standing and layering to obtain an o-methyl formate benzene sulfonamide solution at the upper layer; and adding anhydrous toluene and carbinol, introducing liquid ammonia, adjusting pH (potential Of Hydrogen) value to be neutral by using acetic acid, removing the acetic acid, washing till being colourless by using the toluene, removing the toluene, beating by using the water, washing to be neutral, removing the water and drying. The method disclosed by the invention has the advantages of easiness in operation, high efficiency, low cost and good quality, and saves energy and raw material, and is environment-friendly.

Owner:王继龙

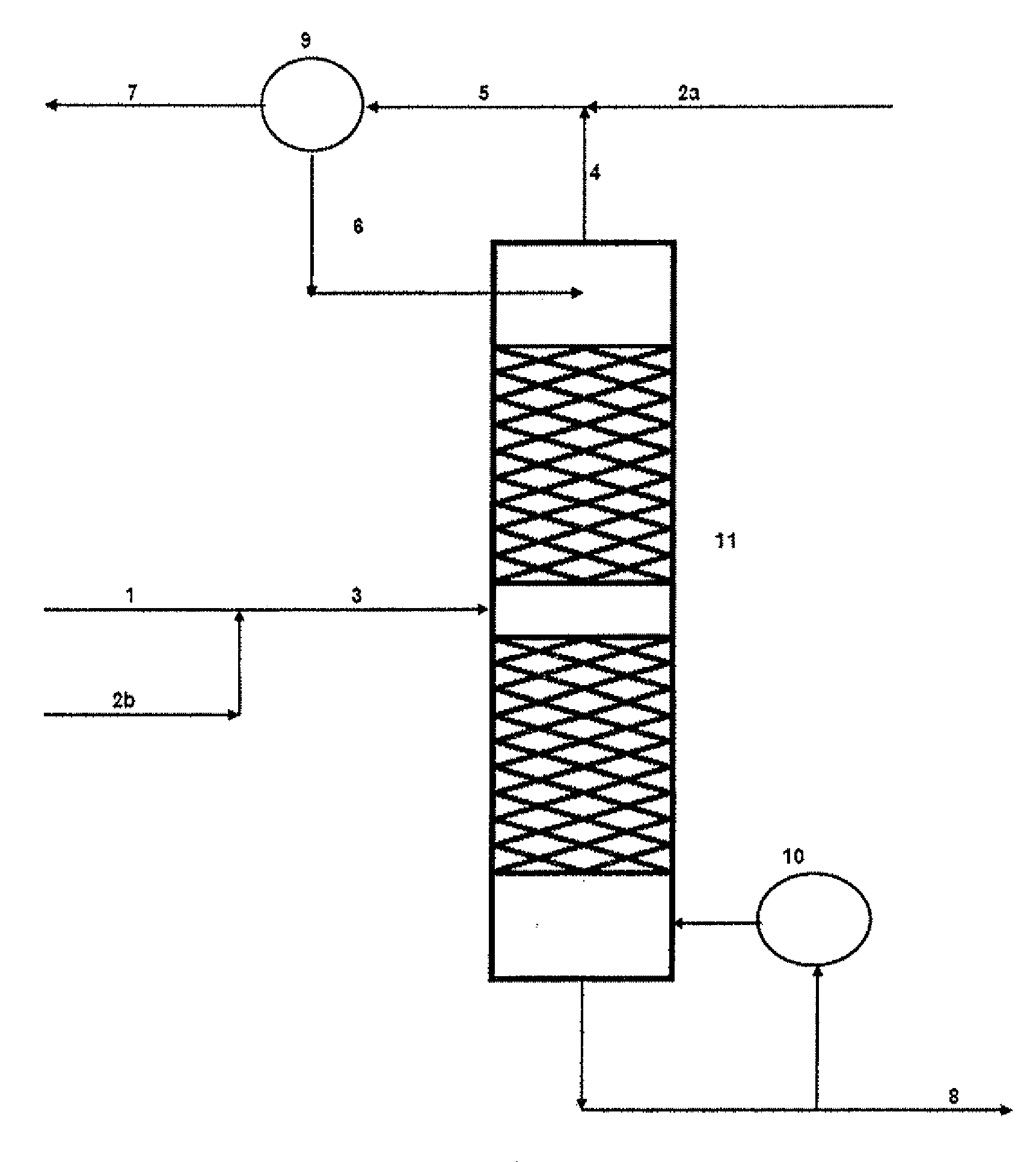

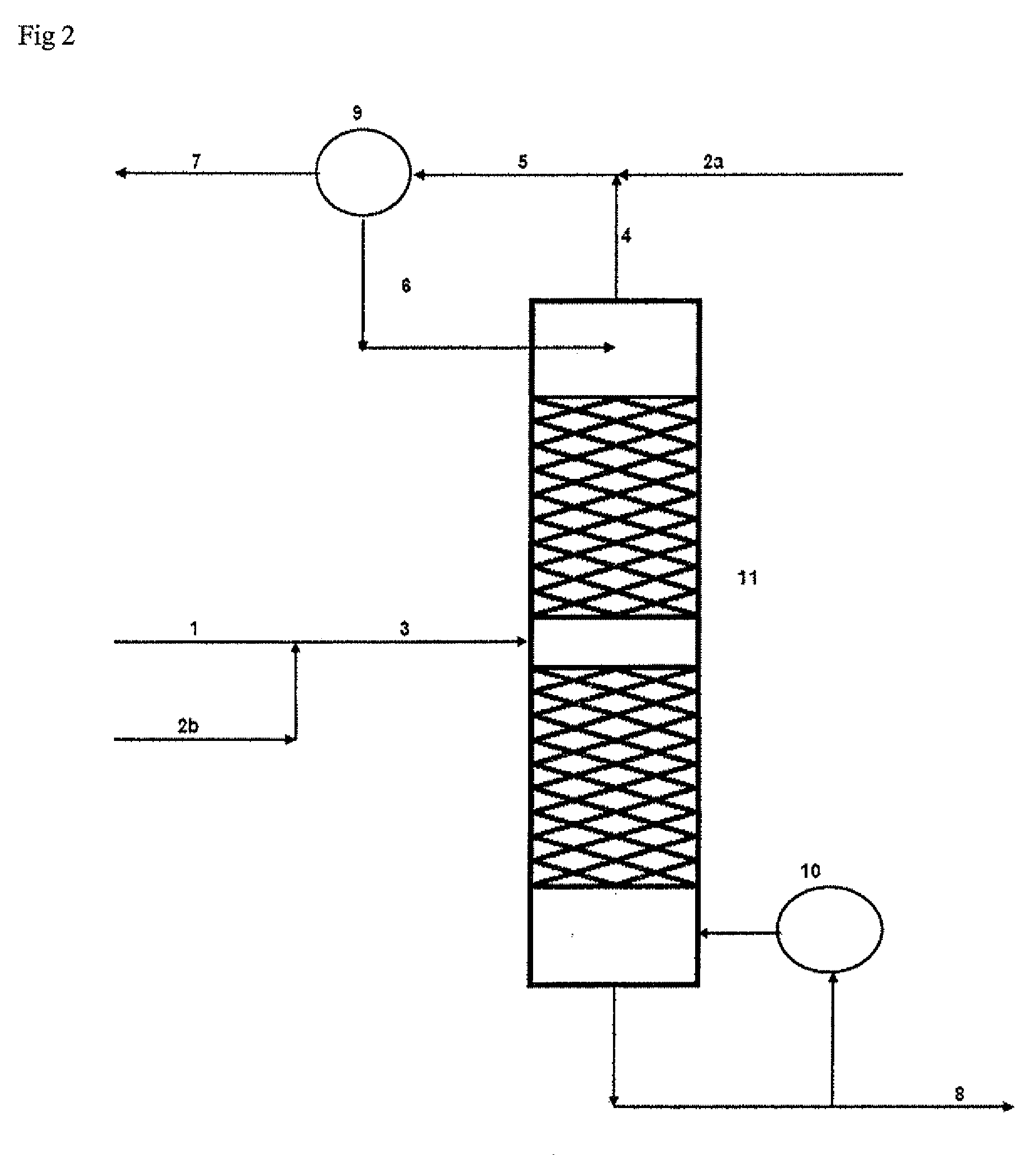

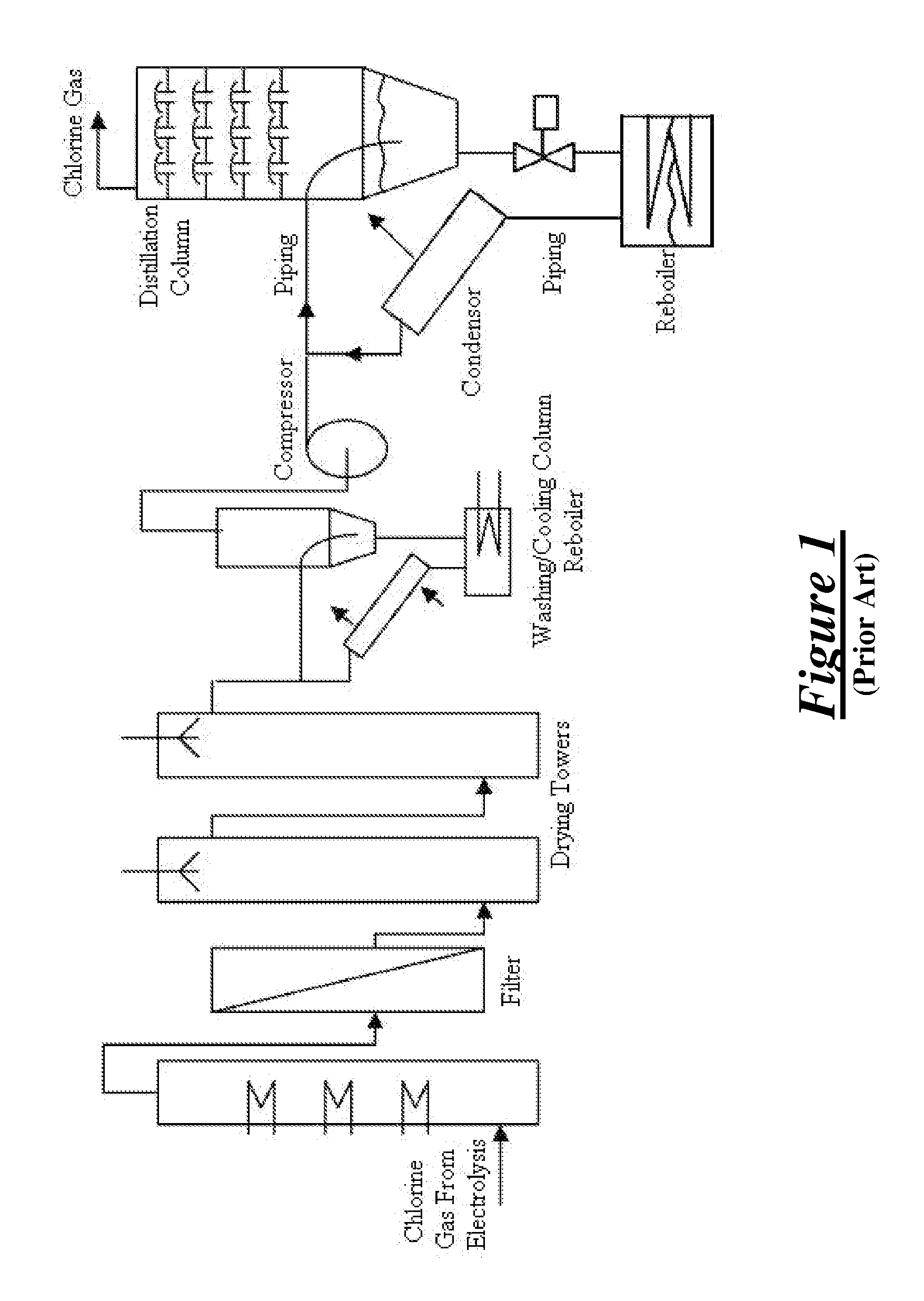

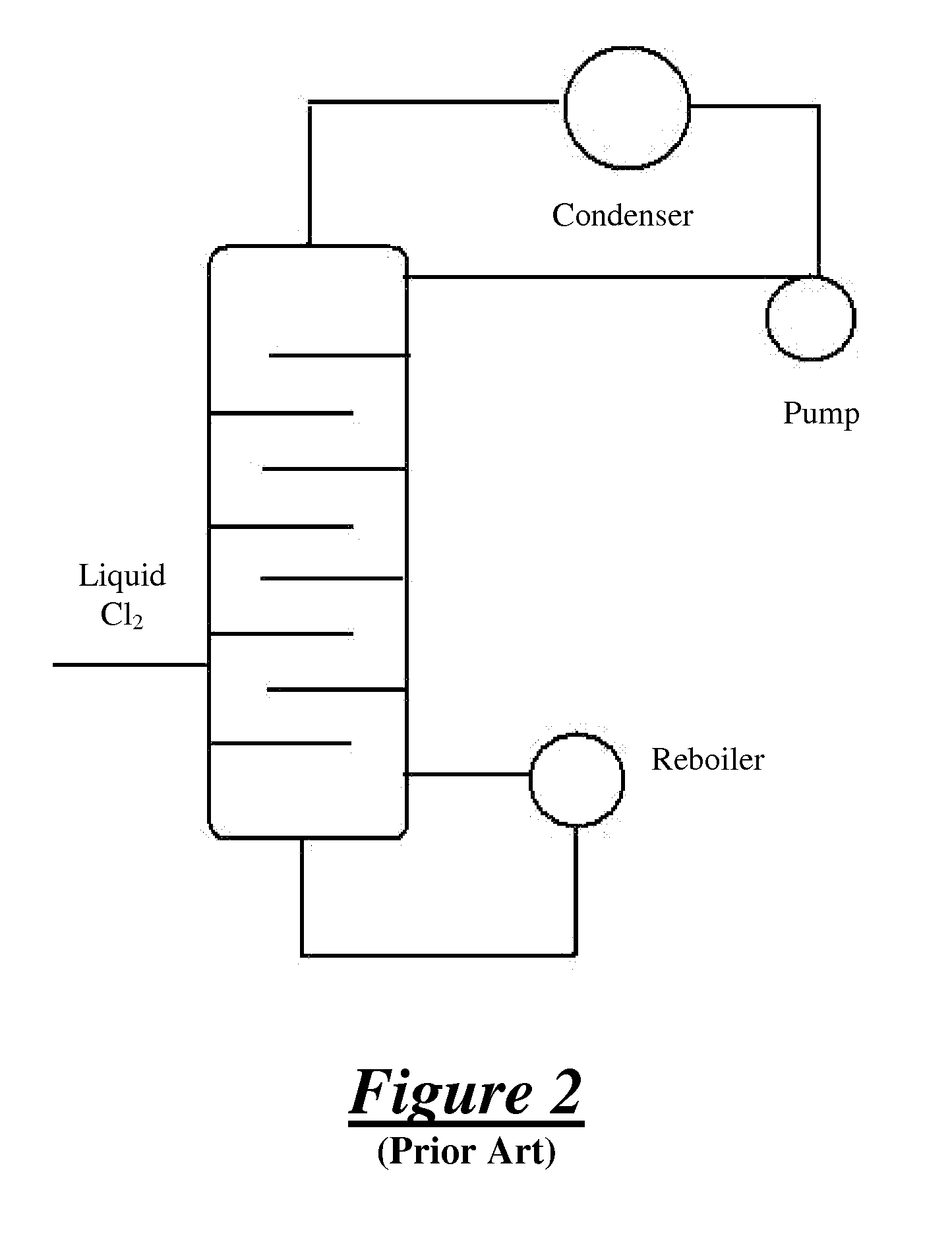

Processes for separating chlorine from a gas stream containing chlorine, oxygen and carbon dioxide

InactiveUS20070277551A1Speed up the processEasy to operateSolidificationChlorine/hydrogen-chloride purificationDistillationOxygen

Processes are disclosed which include: (a) providing a gas comprising chlorine, oxygen, and carbon dioxide; (b) feeding the gas to a distillation column having a head, a bottom, a rectifying section and a stripping section, wherein the gas is fed to the distillation column at an introduction point between the rectifying section and the stripping section; (c) distilling the gas in the column at a pressure of 8 to 30 bar and at a column head temperature of −10° C. to −60° C., to form liquid chlorine and a head mixture comprising carbon dioxide and oxygen; (d) removing the liquid chlorine from the distillation column at the bottom of the column; and (e) removing a first portion of the head mixture from the head of the distillation column, and refluxing a second portion of the head mixture in the column.

Owner:COVESTRO DEUTSCHLAND AG

Prepn of cholrinated paraffin-70

InactiveCN1526796AAvoid pollutionAvoid destructionPetroleum chemical modificationParaffin waxTemperature control

The preparation of chlorinated paraffin-70 with liquid chlorine and solid paraffin as material includes mixing gasified chlorine and molten paraffin in the reactor, and three-stage substitution reaction in temperature controlled in 50-200 deg.c and controlled time to produce chlorinated paraffin-70. The product has no carbon tetrachloride contained, high chlorine content, high softening point and good use performance. The preparation process has low cost and no corrosion to apparatus.

Owner:JINGXIE CHEM PLANT MOUPING DISTRICT YANTAI

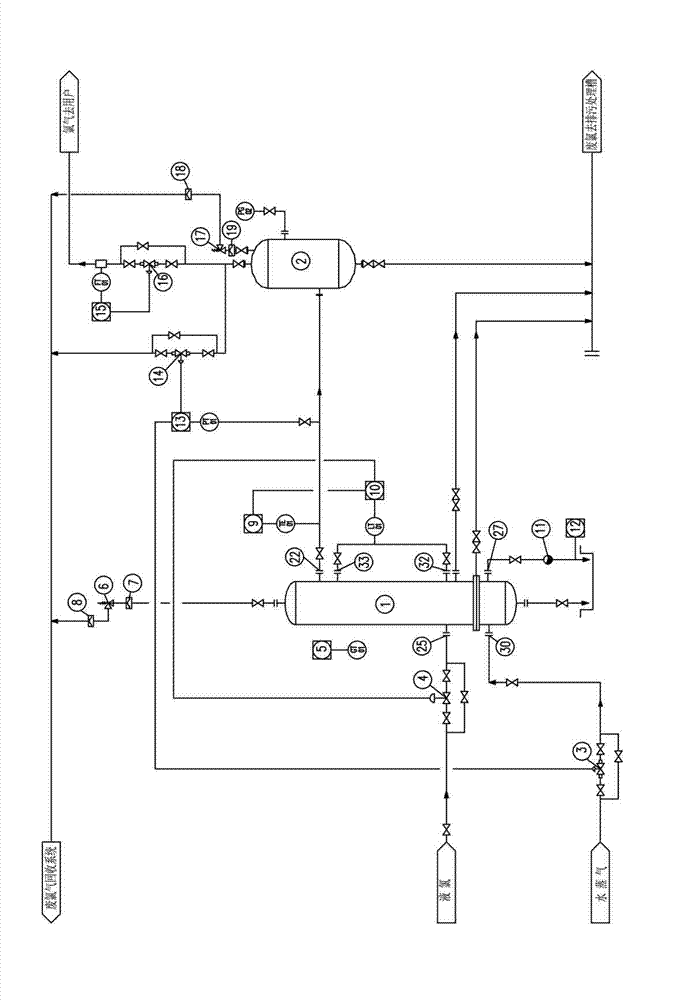

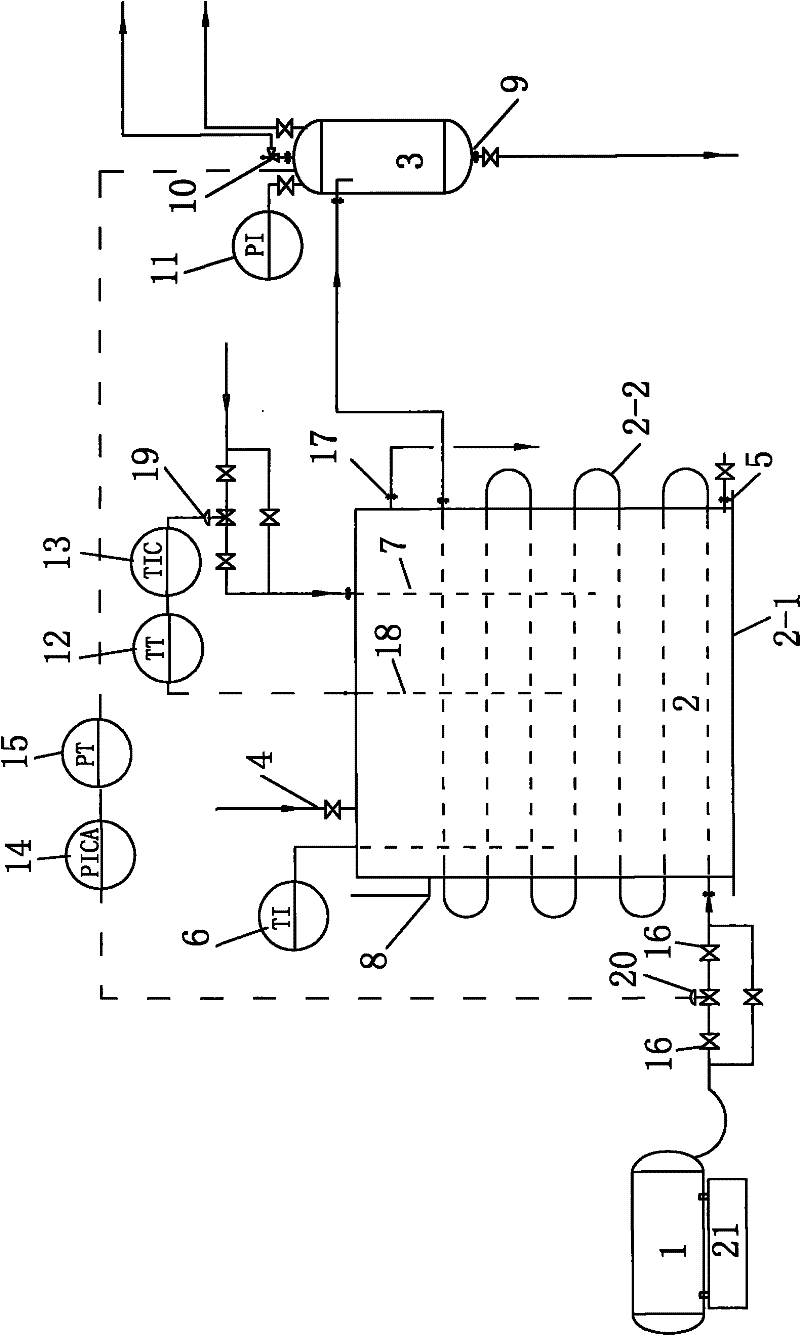

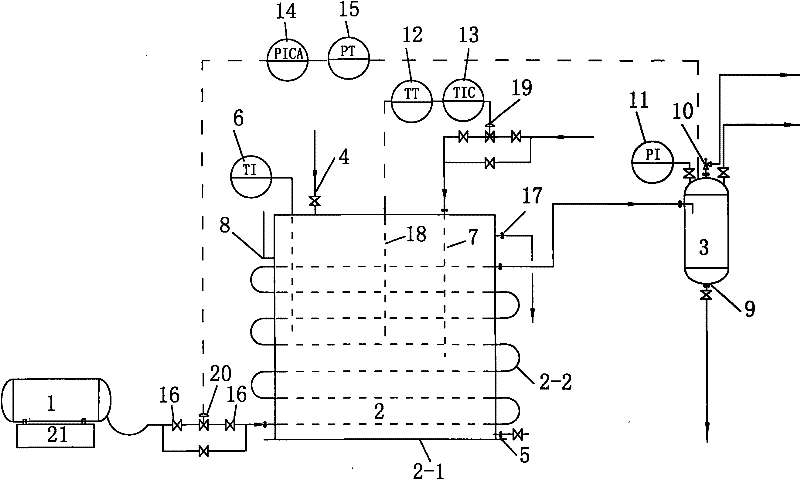

Liquid chlorine gasifying system

ActiveCN102767692AIncrease productivityReduce heat transfer areaContainer filling methodsPressure vesselsBuffer tankHeat transfer efficiency

The invention relates to a liquid chlorine gasifying system. The technical scheme is as follows: the liquid chlorine gasifying system is formed by a liquid chlorine gasifying part, a water steam heating part and a chlorine gas buffering part; the liquid chlorine gasifying part is characterized in that a liquid chlorine inlet of a gasifying device is connected with a liquid level adjusting valve; a pipeline between a chlorine gas outlet and a buffering tank is provided with a temperature measuring meter and a pressure measuring meter; the temperature measuring meter and the pressure measuring meter are connected in series, and a liquid level measuring meter is connected with a liquid level meter opening and the liquid level adjusting valve respectively; and a chlorine gas leakage detection alarming instrument is arranged outside the gasifying device. The water steam heating part is characterized in that a water steam inlet is connected with a pressure adjusting valve, and a condensed water outlet is sequentially connected with a condensed water steam trap and an acidic degree analyzer; and the pressure adjusting valve is connected with the pressure measuring meter. The chlorine gas buffering part is characterized in that a flow adjusting valve and a flow meter are sequentially arranged on a chlorine gas outlet pipeline of the buffering tank; a leaking valve is arranged on a pipeline between the buffering tank and the flow adjusting valve; and the leaking valve is connected with the pressure measuring meter. The liquid chlorine gasifying system has the advantages of stability in production and operation, safety and reliability, high gasification efficiency and heat transferring efficiency, and low energy consumption.

Owner:沈阳东方钛业股份有限公司

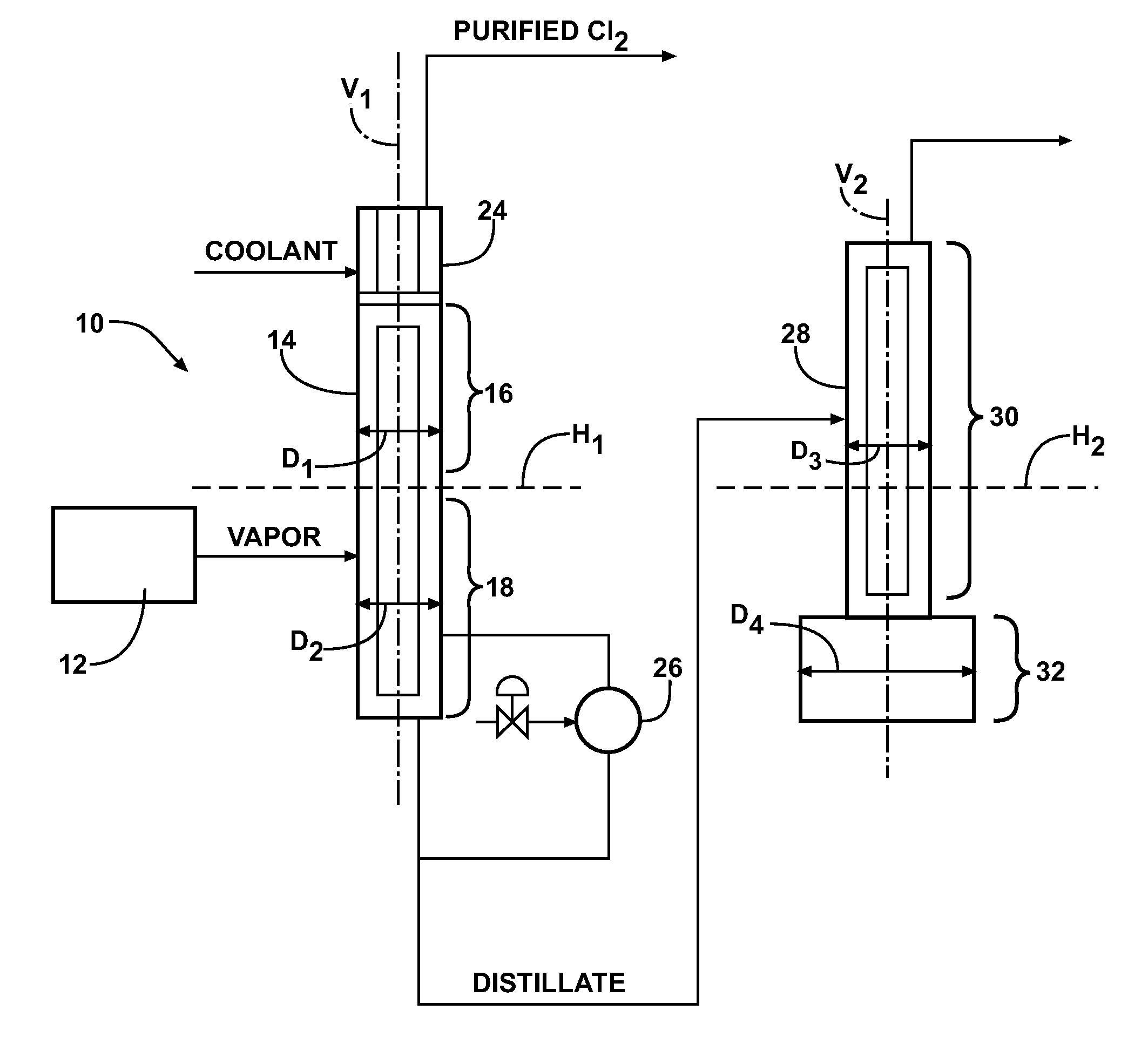

Method for purifying a chlorine supply

ActiveUS20110144381A1Improve energy efficiencyReduce environmental problemsIsocyanic acid derivatives preparationLiquid degasificationRefluxReboiler

This invention provides a method for purifying a chlorine supply that includes a chlorine component, a bromine component, and nitrogen trichloride. The method includes the steps of introducing the chlorine supply into a vaporizer, heating the chlorine supply in the vaporizer to form a vapor, and introducing the vapor into a distillation system to provide purified chlorine gas, a distillate that includes liquid chlorine and the bromine component, and a bottoms component including the nitrogen trichloride. The method also includes the steps of condensing the vapor in a reflux condenser, heating the condensate in a reboiler, removing the purified chlorine gas from the distillation system, and removing the distillate from the distillation system.

Owner:BASF AG

Disinfecting body wash

InactiveCN101810541AGood killing effectGood cleaning and decontamination effectCosmetic preparationsToilet preparationsSodium chloriteSURFACTANT BLEND

The invention provides disinfecting body wash, which comprises a surfactant, a humectant, a chelant, a bactericide, a thickener and essence, wherein the bactericide may be stable liquid chlorine dioxide, stable solid chlorine dioxide or sodium chlorite. The body wash prepared by the invention overcomes the drawbacks of the traditional bacteriocidal body wash and realizes synchronous cleaning, body moisturizing and sterilization. The body wash is mild in nature, safe and environmentally friendly.

Owner:BEIJING OKEANOS TECH

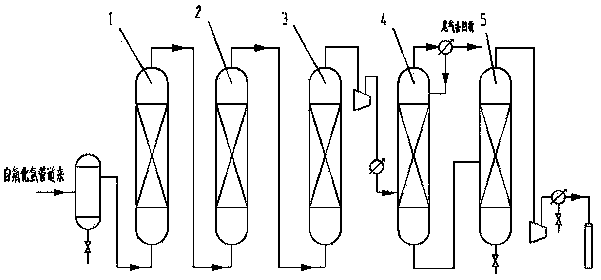

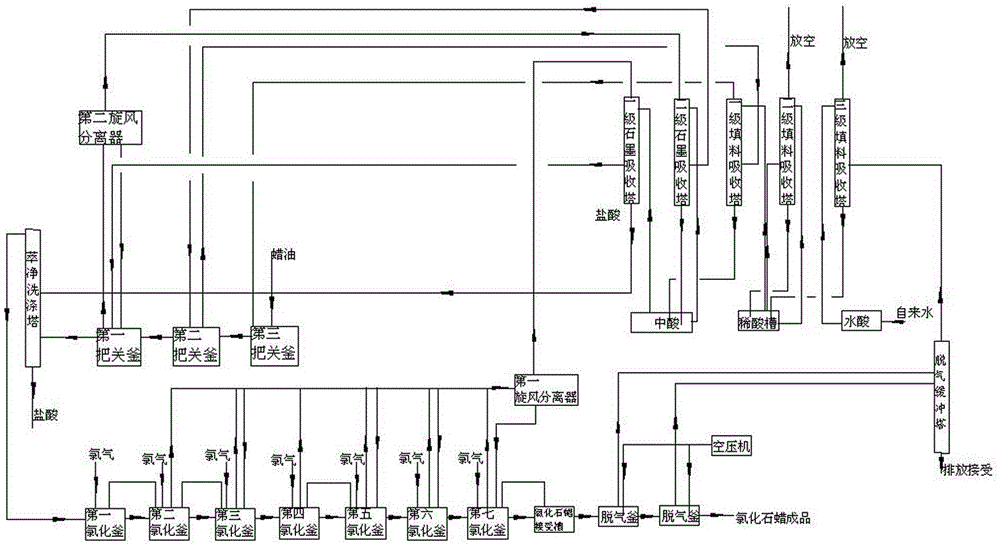

Processing technology for chlorinated paraffin

ActiveCN105296004ASimple processing technologyShort reaction timeDispersed particle separationHalogenated hydrocarbon preparationParaffin oilsEconomic benefits

The invention relates to a processing technology for chlorinated paraffin. A chlorinated paraffin product is obtained by using wax oil and chlorine as raw materials and adopting a seven-stage continuous photo-thermal catalytic chlorination process and a bubbling degassing technology. The processing technology for the chlorinated paraffin, which is disclosed by the invention, comprises the following steps of: liquid chlorine gasification, chlorination and chlorinated tail gas adsorption. The processing technology which is disclosed by the invention is simple, is short in reaction time, and is high in conversion rate; production cost is reduced; economic benefits of enterprises are increased.

Owner:江西塑星材料有限公司

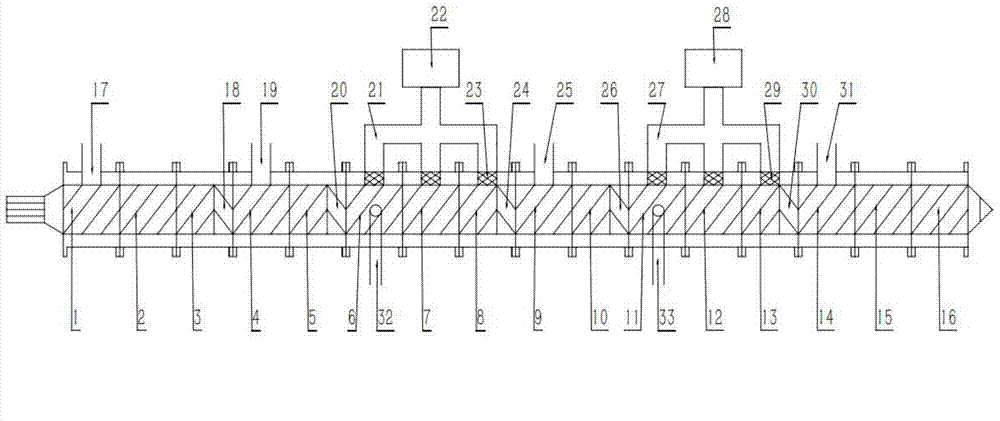

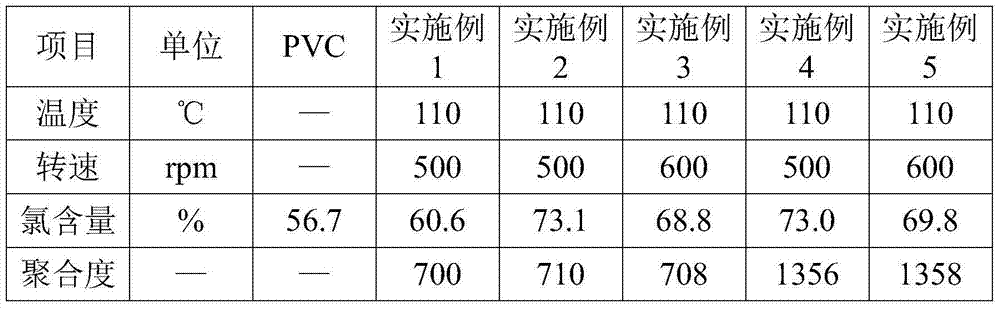

Microwave radiation melt method chlorination production method of chlorinated polyvinyl chloride (CPVC) resin

The invention discloses a microwave radiation melt method chlorination production method of chlorinated polyvinyl chloride (CPVC) resin. The production method comprises the steps of injecting liquid chlorine into molten polyvinyl chloride (PVC) in a double-screw extruder reactor at a high pressure, and feeding microwaves to assist chlorination of the molten polyvinyl chloride (PVC) at the same time, thereby realizing high-quality, high-chlorine-content, low-cost, quick, environment-friendly and continuous production of chlorinated polyvinyl chloride (CPVC) resin. Compared with international commonly-used chlorination methods including an aqueous suspension method and the like at present, the method disclosed by the invention has the advantages that polyvinyl chloride (PVC) resin is subjected to accelerated chlorination by using the microwaves in a molten state, a chlorination process does not have special requirements on the raw material namely the polyvinyl chloride (PVC) resin, the chlorination reaction is performed uniformly, the molecular chains during chlorination are basically not degraded and branched, a product is high in chlorine content which can be easily controlled and adjusted, the chlorination speed is high, the reaction is complete, the product is high in mechanical strength, the chlorine utilization ratio is high, the temperature control is accurate, the production process is green and environment-friendly, scale production can be realized easily, and the like.

Owner:深圳兰品科技有限公司

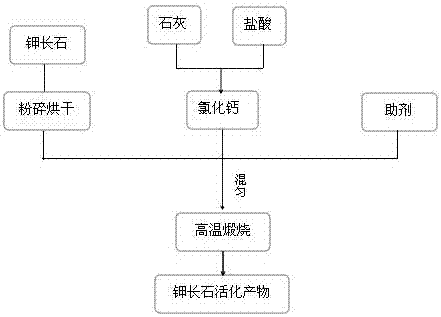

High-temperature activated potash feldspar, and preparation method thereof

InactiveCN107098735ATake advantage ofSolve excess capacityOrganic fertilisersSoil conditioning compositionsRare earthReaction temperature

The invention relates to a method used for high temperature activation of potash feldspar, and belongs to the technical field of chemical engineering, environment protection, and agriculture. According to the method, potash feldspar, anhydrous calcium chloride, and an auxiliary agent are mixed at a certain mass ratio, an obtained mixture is smashed, is mixed to be uniform, and is subjected to high temperature calcining in a kiln so as to realize high temperature activation of potash feldspar. Potash feldspar is rare earth ore associated potassium-enriched ore, hydrochloric acid is prepared from side product liquid chlorine of the chlor-alkali industry. Reaction temperature is low, energy consumption is low, yield is high, an obtained activated product contains a large amount of elements such as potassium, silicon, and calcium, and is capable of promoting growth of crops, and a novel method is provided for solving a difficult problem of scarcity of water-soluble potassium resources in our country.

Owner:包头市盐湖镁钾有限公司

Preparation method of chlorinated paraffin

The invention provides a preparation method of chlorinated paraffin. Paraffin and liquid chlorine are used as raw materials and an azoic compound is used as a catalyst to prepare the chlorinated paraffin through catalytic chlorination. Compared with the current thermal chlorination method, the preparation method has the advantages that the reaction rate is obviously improved and the production cycle is shortened; the long-chain paraffin alkane does not have obvious carbon chain crack phenomenon in the chlorination process; the content of the short-chain chlorinated paraffin in the product can be well controlled by adopting the preparation method provided by the invention. The method is simple in process, easy to operate, and suitable for industrialized production of the chlorinated paraffin.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

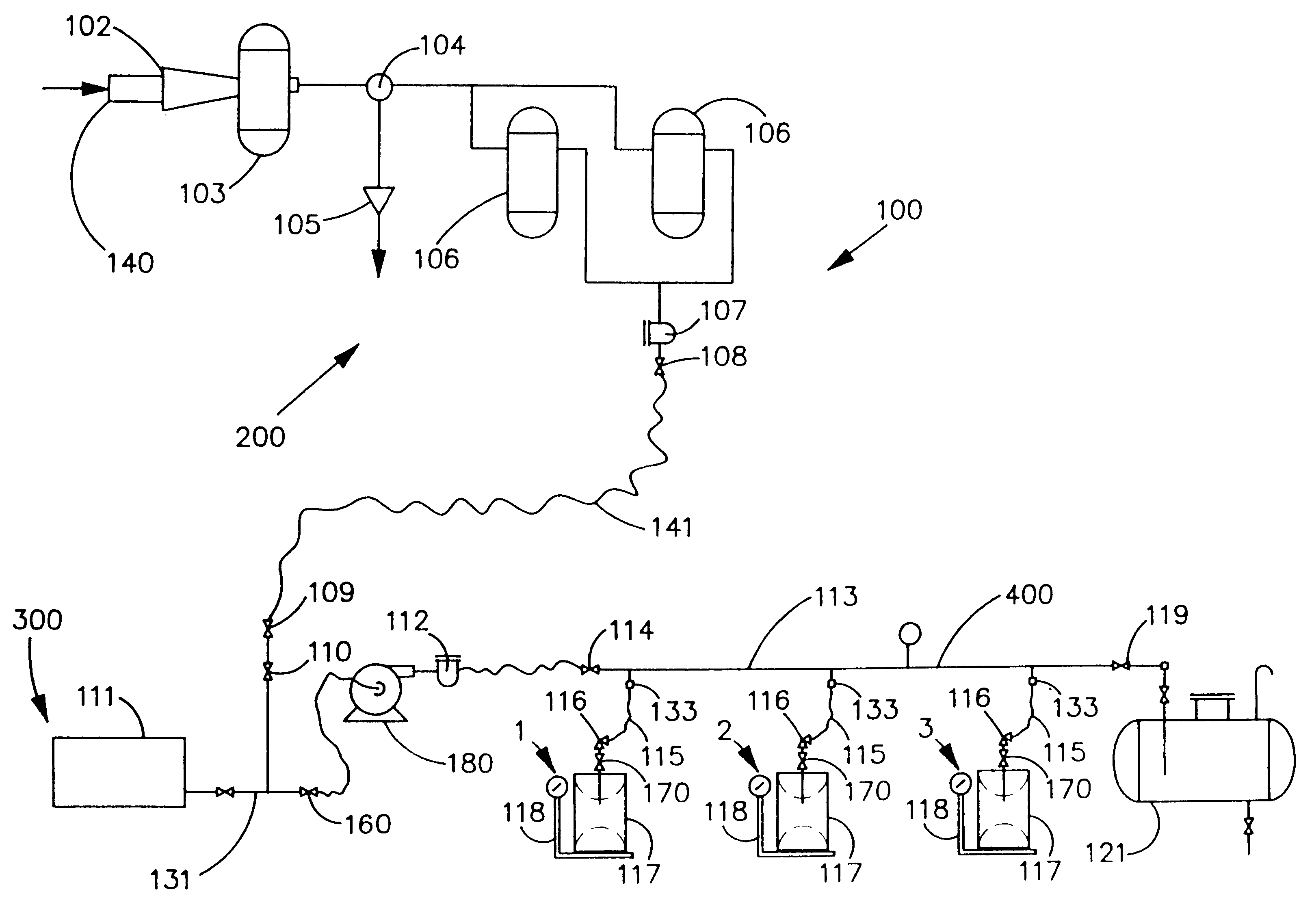

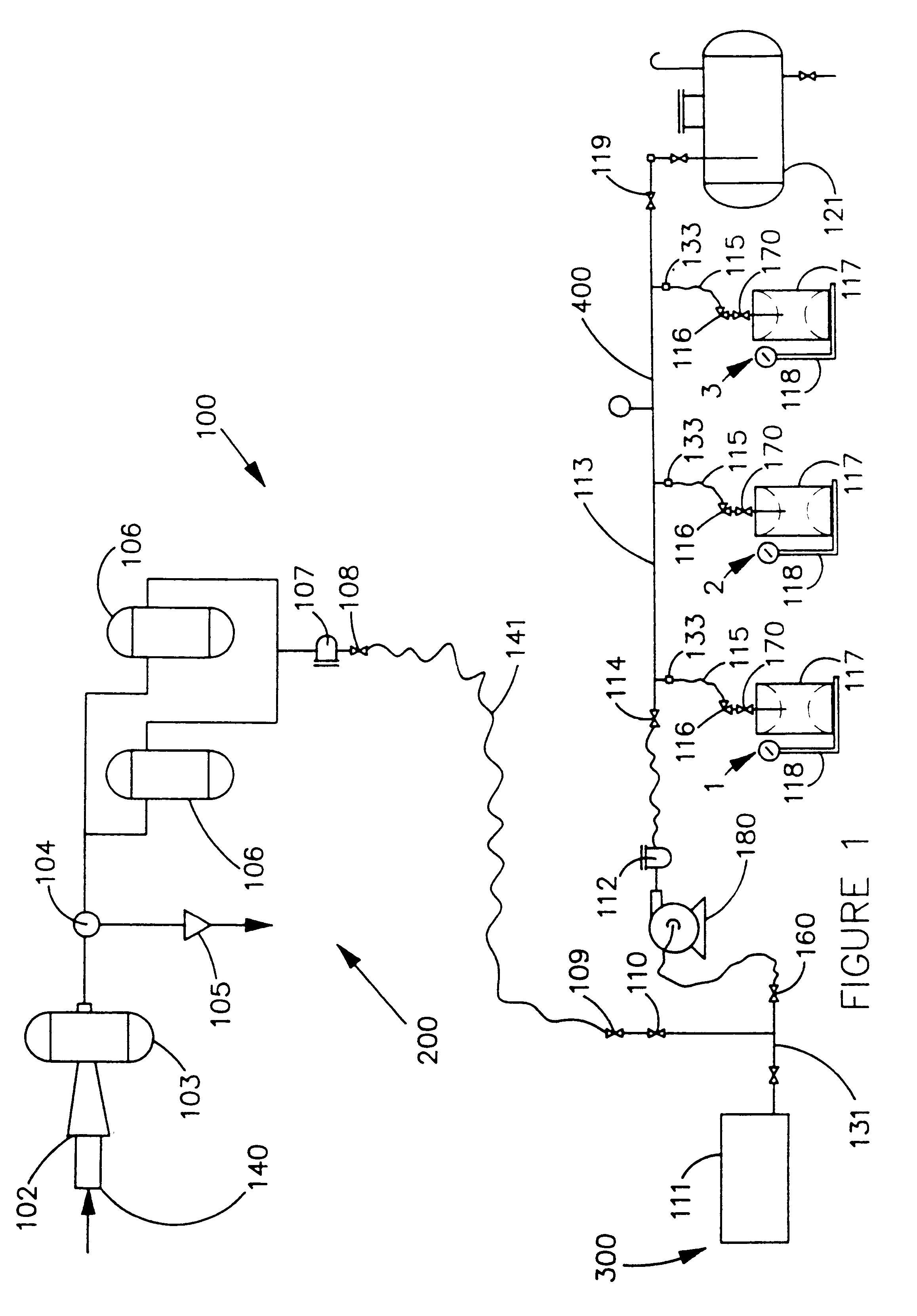

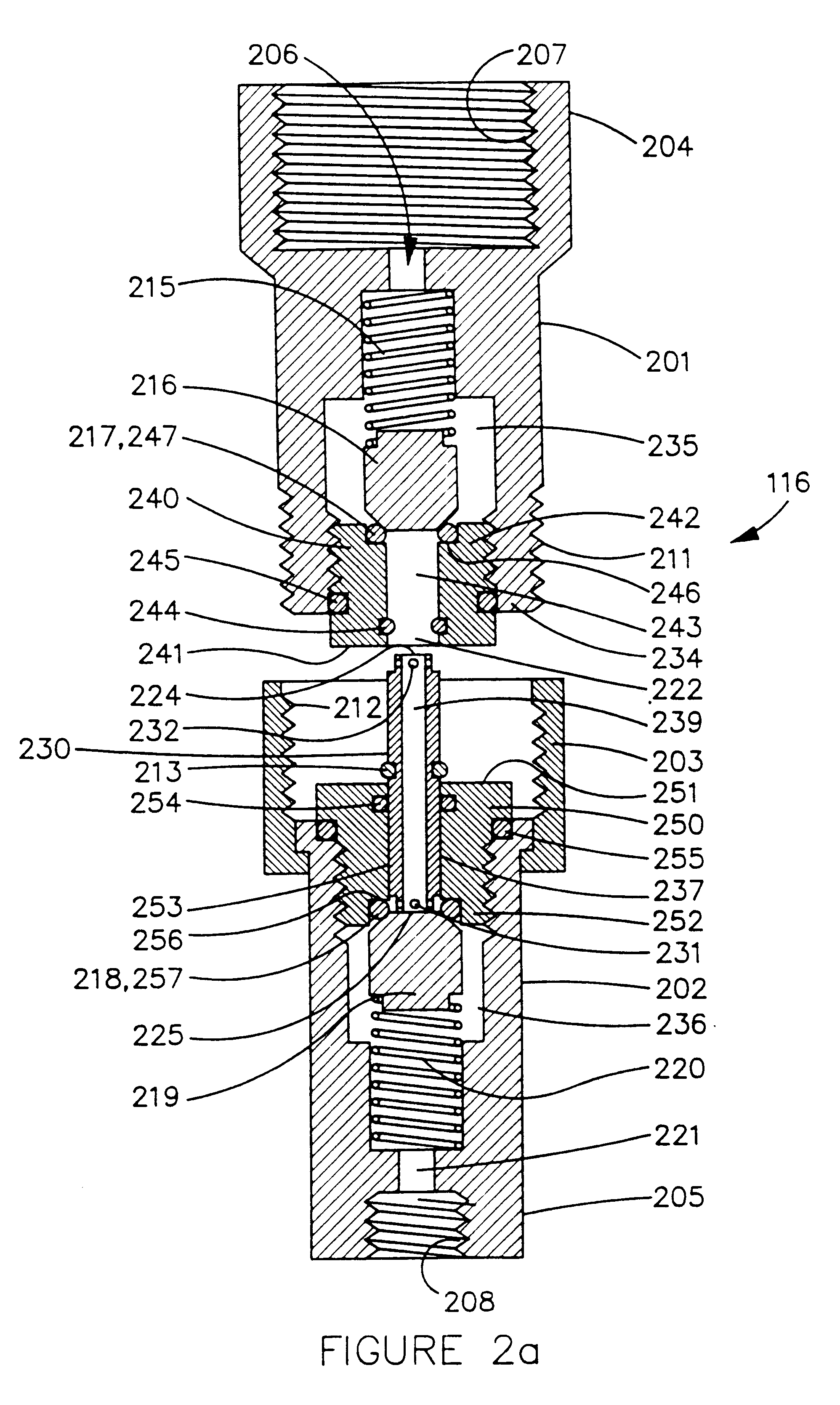

Tank filling apparatus and method

InactiveUS6435227B1Reduce connectionsIncrease expensesLiquid fillingGas handling/storage effectsEngineeringMechanical engineering

An apparatus and method for transferring liquid chlorine or other process material from a larger container to one or more smaller containers, including a valve assembly used to minimize chemical loss, is disclosed herein. The valve assembly minimizes chlorine or other process material loss to the environment by sealing the manifold and the filled cylinder from the environment while the valve assembly is disconnected. The apparatus and methods disclosed herein minimize caustic use associated with purging of the apparatus.

Owner:CALIFORNIA INT CHEM CORP

Methyl 3-(cyanomethyl)benzoate synthetic method

InactiveCN105130846AMild reaction conditionsEasy to operatePreparation by cyanide reactionMethyl benzoateSodium cyanide

The invention discloses a methyl 3-(cyanomethyl)benzoate synthetic method. The method comprises the following steps: taking m-toluic acid as a starting material, adding sulphone chloride for an acylation reaction, and flowing into liquid chlorine for a chlorination reaction, adding non-aqueous methanol dropwise for an esterification reaction to prepare ester, adding toluene and sodium cyanide into a cyanation reaction still, raising the temperature for backflow, adding the ester dropwise, carrying out backflow for 2 hours to prepare the methyl 3-(cyanomethyl)benzoate, and after the reaction, adding water to extract the methyl 3-(cyanomethyl)benzoate. The methyl 3-(cyanomethyl)benzoate synthetic method is high in yield, avoids serious three-waste pollution, and is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

A sanitizer and production process

The invention discloses disinfector, in particular discloses disinfector and the producing method thereof. The invention is characterized in that the disinfector is made by materials with the following weight proportions that: cyanuric acid is 0.585-0.715 parts, calcium carbonate is 0.459-0.561 parts, liquid chlorine is 0.648-0.792 parts, water is 5.4-6.6 parts, and sodium carbonate is 0.156-0.191 parts. After being amended by new technique of first making grains (wet grain-making), then drying, and so on; the invention has the advantages that: first, the manufacturing circumstance is good; second, the invention can save the consumption of the coal as well as can meet the policy of the state to lower the energy-consuming; third, the appearance of the product assumes a sphere shape, a column shape, or a pearl shape, and so on. The disinfector can ensure that the product has the advantages of smooth, beautiful, and high rigid, etc.

Owner:HEZE HUAYI CHEM

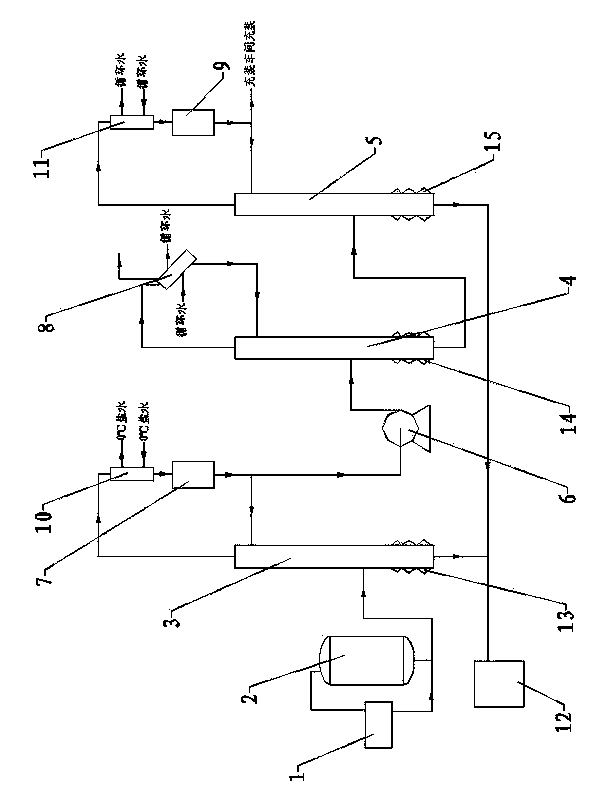

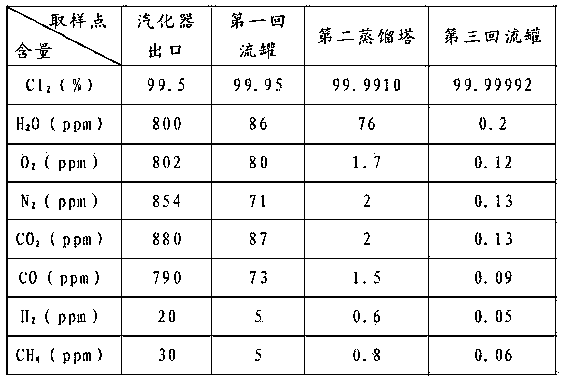

High-purity chlorine gas rectifying technology and equipment thereof

ActiveCN103466549AEasy to control temperatureSave energyChlorine/hydrogen-chloride purificationRefluxFractionating column

The invention relates to a high-purity chlorine gas rectifying technology. The technology comprises the following steps: delivering industrial liquid chlorine to a vaporizer, and sending vaporized chlorine into a first distillation tower under the pressure of 1.2 Mpa until the liquid level of the first distillation tower reach 85%; boosting the pressure of the first distillation tower to 1.0 Mpa, condensing the vaporized chlorine by a first condenser, then sending into a first reflux tank, and delivering 60% residue in the first reflux tank to a second distillation tower; enabling the liquid level of the first reflux tank to be 30% to 40%, and boosting the pressure of the second distillation tower to be 1.8 Mpa; back flowing residue condensed by a second condenser in to the second distillation tower, then sending into a third distillation tower, controlling the liquid level of the second distillation tower to be 60% to 75% until the liquid level of the third distillation tower reaches 85%, and boosting the pressure of the third distillation tower to be 1.5 Mpa; condensing by a third condenser, then sending into a third reflux tank until the purity reaches 99.9999%, enabling the liquid level of the third reflux tank to reach 60%, enabling the purity of the liquid chlorine in the third reflux tank to be 99.9999%, and obtaining high-purity chlorine gas. Through the adoption of the method, raw material input and product output can be carried out stably and continually, the production capacity can be improved, energy consumption can be reduced through continuous rectification, the running is stable, and the operation is safe.

Owner:北京华宇同方化工科技开发有限公司

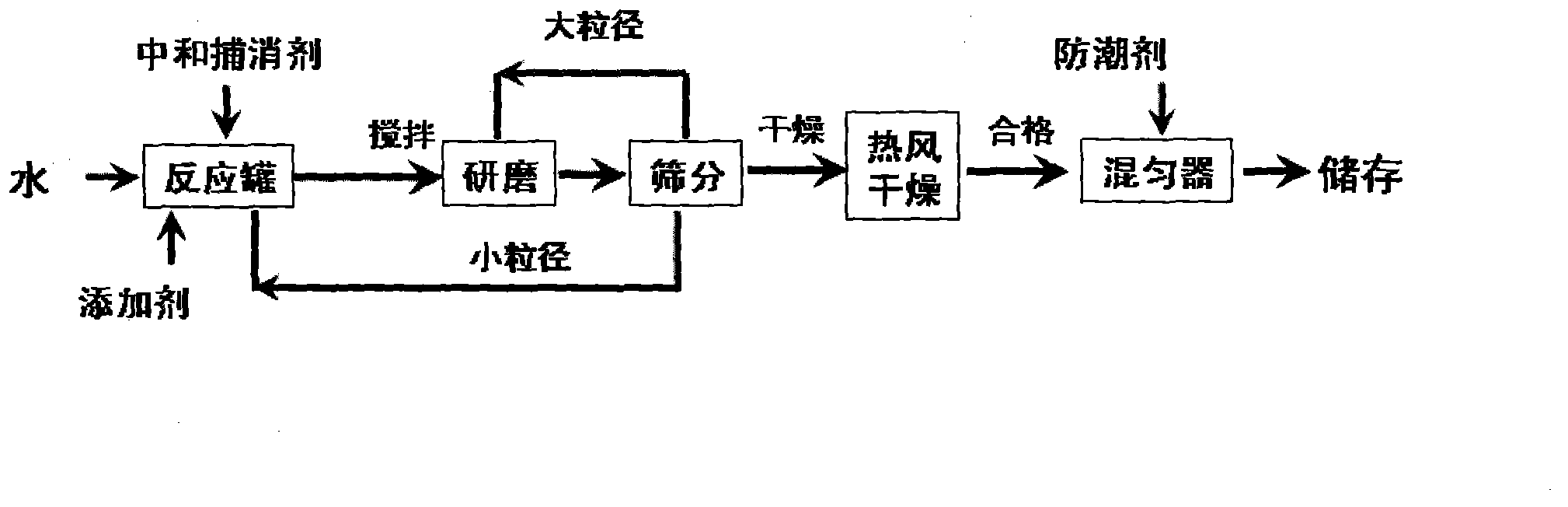

Alkaline powder for treating leaked liquid chlorine and chlorine gas and preparation method of alkaline powder

InactiveCN103263844AAccelerated settlementGood dispersionDispersed particle separationPhysical chemistryAbsorption rate

The invention provides an alkaline powder for treating leaked liquid chlorine and chlorine gas and a preparation method of the alkaline powder. The alkaline powder is prepared from three components including a capturing agent, a moisture-proof agent and an additive according to a specific proportion through a specific method. The materials for preparing the alkaline powder are easily available, the preparation method is simple, the energy consumption is low, the grain size of the prepared powder is 80 meshes-150 meshes, the specific surface area is bigger than 50m<2> / g, the bulk density is bigger than 0.83g / cm<3>, the powder does not block, and the relevant requirements of standard AQ3015 are satisfied. In a sealed non-wind environment, the chlorine gas absorption rate is not smaller than 95% within three minutes, and not smaller than 99% within 10 minutes; moreover, the alkaline powder has good settling performance after being sprayed and has a settling recovery rate not smaller than 98% within 2 minutes.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +1

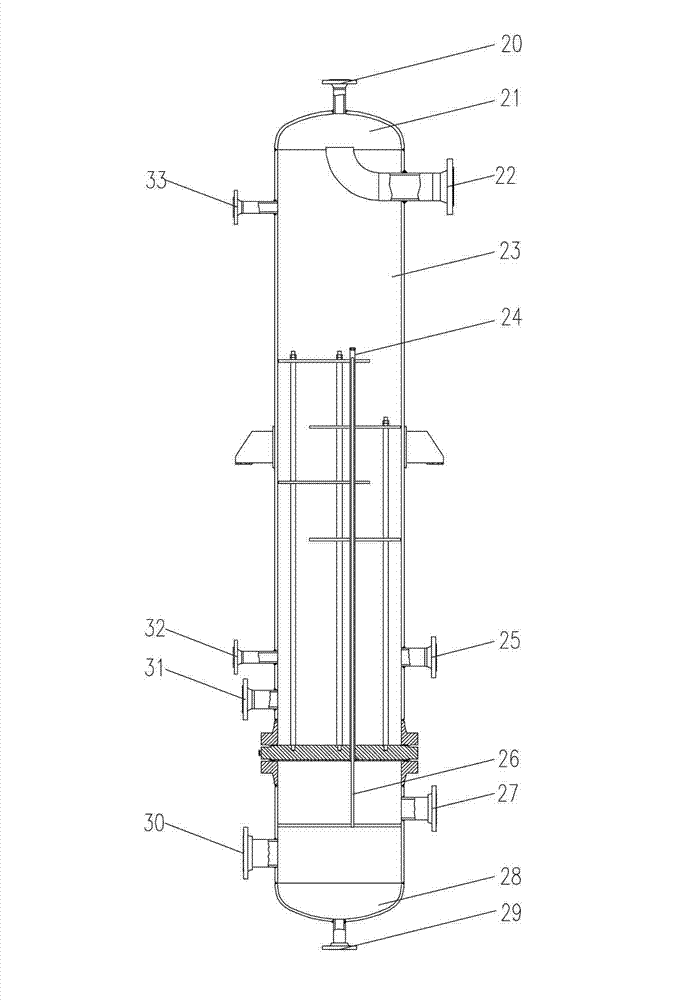

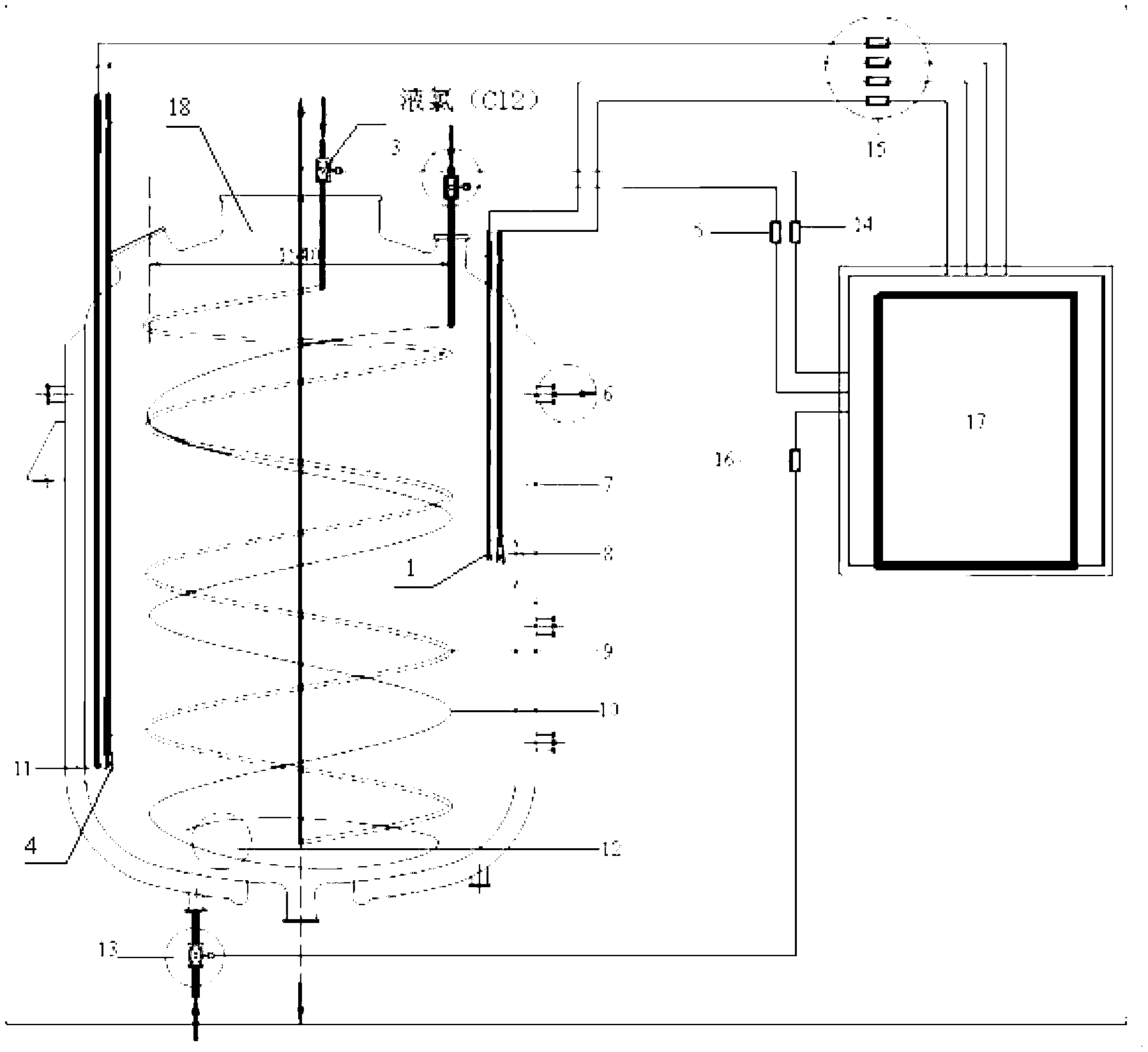

Liquid chlorine gasification device and gasification method

InactiveCN101118028AIncrease concentrationReduce concentrationPressure vesselsContainer discharging from pressure vesselsChemical industryDisplay device

The present invention belongs to a gasifying device and a gasifying method for the chlorine-alkali and chlorine product chemical industry to transform the liquid chlorine to the chlorine gas (raw gas). The device comprises a cylindrical shaped tower body which is provided with a gasifying cavity with a hot water circulation chamber and a gasifying pipe group as well as a gas-liquid separating cavity, a raw liquid chlorine cavity is arranged in the cylindrical shaped tower body; a chlorine gas output pipe provided with a temperature display device and a low temperature alarm device, the chlorine gas output pipe is arranged on the top of the column body; a liquid chlorine input pipe with a liquid chlorine transfer valve and a switch valve, the liquid chlorine input pipe is arranged on the bottom of the column body, a liquid level meter; a signal acquisition controller; a switch valve controller; and an auto regulation mechanism of a hot water input valve and a liquid chlorine input valve and a corresponding valve opening; and a pressure meter. The method of the liquid chlorine gasifying includes readiness for operation, debugging operation and automatic operation. The present invention stops the explosion caused by the accumulation of NC13 in the gasifying cavity and improves the gasifying efficiency because of adding the raw liquid chlorine cavity and adopting the gasifying pipe group to gasify; the present invention has the advantages that the gasifying process is safe and reliable, the performance is stable, the accommodation limit is wide, and the gasifying efficiency is high.

Owner:自贡鸿鹤化工股份有限公司

Liquid chlorine vaporization system for phosphorus trichloride production

InactiveCN102221127AAvoid safety hazardsAvoid heatPressure vesselsContainer discharging from pressure vesselsEngineeringBottle

The invention belongs to the field of chemical equipment, and discloses a liquid chlorine vaporization system for phosphorus trichloride production. The system is composed of a liquid chlorine steel bottle, a box-type calandria vaporizer and a chlorine buffer tank; the box-type calandria vaporizer is composed of a box body and a calandria; the calandria is a horizontal snake-shaped pipe structure, the horizontal pipe section of the structure is positioned in the box body, the bend pipe section of the structure is positioned out of the box body, and the bend pipe section and the horizontal pipe section are welded out of the box body. The calandria in the box body of the box-type calandria vaporizer provided by the invention has no welding line, the welding line is arranged at the bend head out of the box body, thus the safety hazard of liquid chlorine leakage caused by the heating of the welding line and the corrosion of the inner surface and the outer surface by the complete immersion of the calandria in hot water in the prior art is avoided; and the system has simple structure, is easy to operate, and is save and reliable.

Owner:JIANGSU DAMING TECH

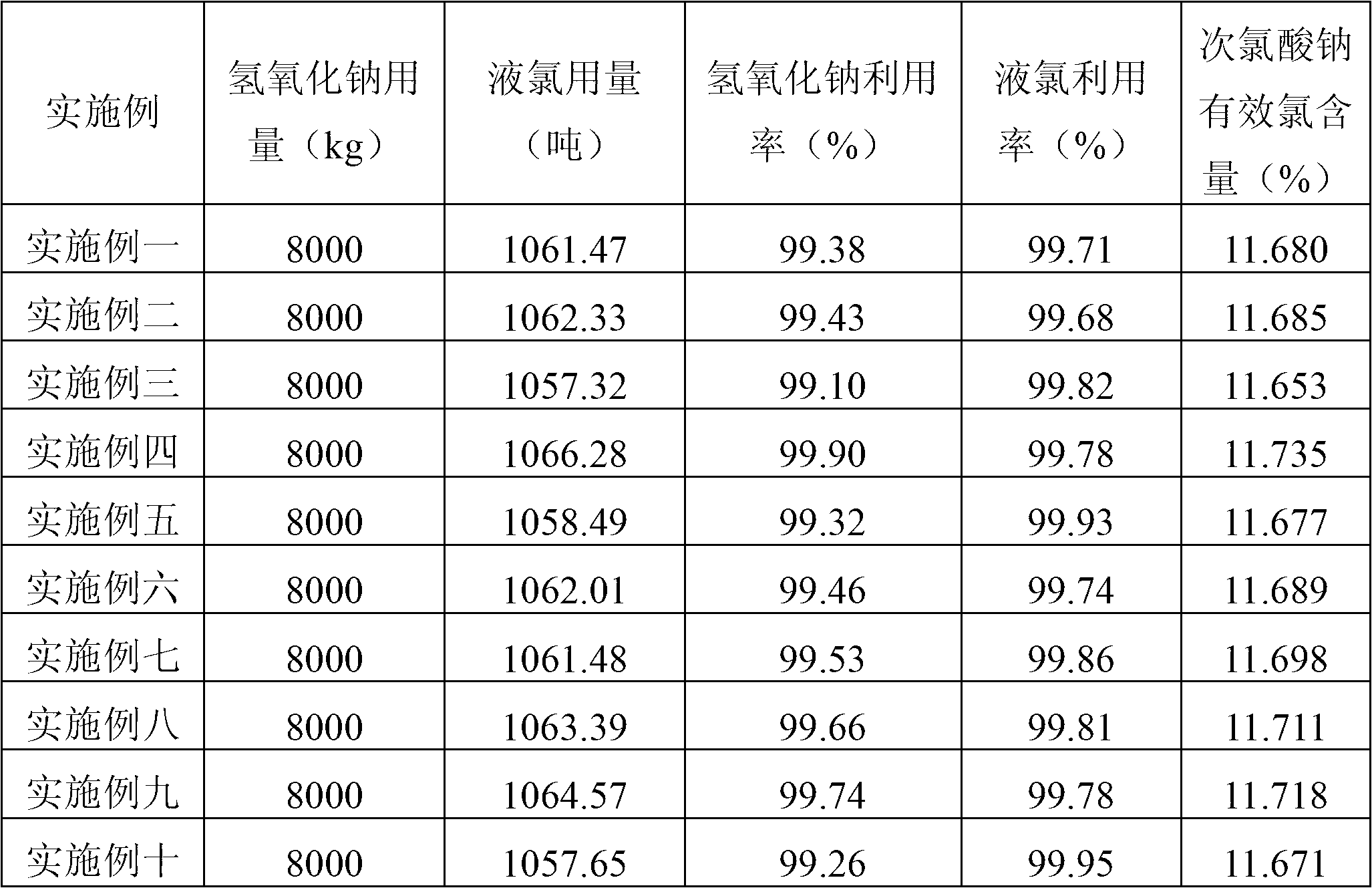

Method and device for producing sodium hypochlorite

ActiveCN102701157APrecise temperature controlGuaranteed uniformityHypochloriteAutomatic controlMaterial resources

The invention discloses a method and a device for producing sodium hypochlorite. The method comprises the steps as follows: adding a caustic soda solution into a reactor; adding chlorine, adjusting the chlorine adding speed of a chlorine adding device according to a temperature value, controlling the opening and closing of a cooling device to enable the temperature value of the reaction liquid to be not more than 45 DEG C, and adjusting the chlorine adding speed of the chlorine adding device according to the pH value to enable the pH value of the reaction liquid to be not less than 10; and the reaction is finished when the pH value of the reaction liquid is kept less than 12 within a first time interval. The device comprises the reactor, the chlorine adding device, a pH value detection device, a temperature detection device, the cooling device and a control device. According to the device and the method provided by the invention, accuracy control of the production process is realized, side reaction is suppressed, the reaction end point can be judged accurately, chlorination reaction is avoided, the utilization ratio of liquid chlorine reaches 99.68 to 99.95 percent, and the available chlorine content of the sodium hypochlorite is greater than or equal to 11.5 percent. According to the device provided by the invention, automatic control of the production process of the sodium hypochlorite is realized, manual labor and material resources are saved, and the production efficiency is improved.

Owner:北京万水净水剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com