Methyl 3-(cyanomethyl)benzoate synthetic method

A technology of methyl m-cyanomethyl benzoate and methyl cyanomethyl benzoate is applied in the field of synthesis of methyl m-cyanomethyl benzoate, and can solve the complex production process of methyl m-cyanomethyl benzoate and the high yield. low cost, high cost, to achieve the effect of environmental friendliness, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

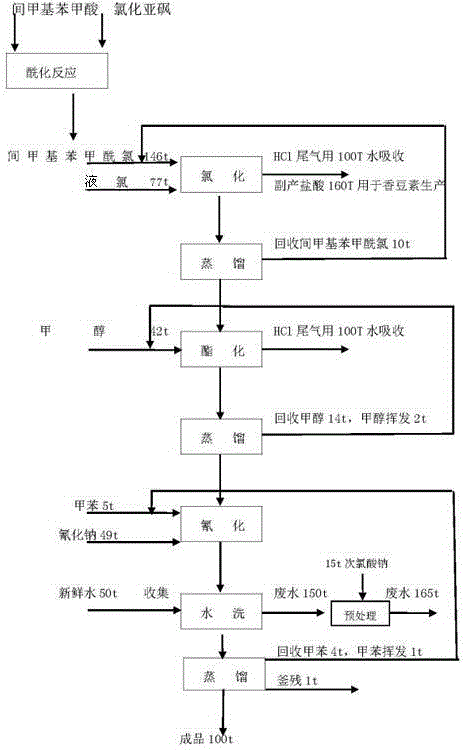

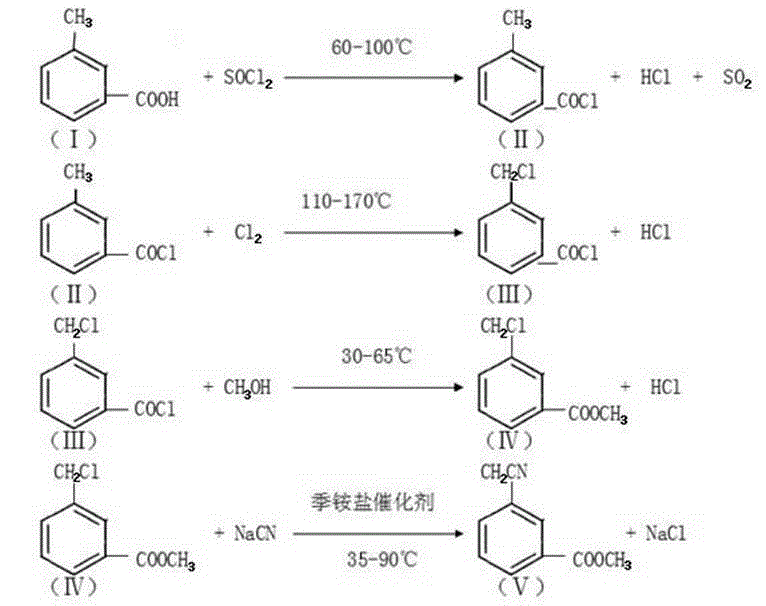

[0024] Such as figure 1 , m-cyanomethylbenzoic acid methyl ester synthetic method, take m-toluic acid as starting raw material, and its synthetic route is as follows:

[0025] The specific steps are as follows:

[0026] a): Pump 400 parts of m-toluic acid (I) into the chlorination kettle, add 410 parts of thionyl chloride, and make m-toluoyl chloride (II) by acylation reaction at 70°C. The rate is 90-97%;

[0027] b): Pump m-toluoyl chloride (II) into the chlorination kettle, and feed liquid chlorine with 4.6% weight of m-toluoyl chloride at 125°C to partially convert the acylate into chloride (Ⅲ ), distilling and recovering m-toluoyl chloride that did not participate in the reaction to the chlorination kettle for chlorination again until finally obtaining high-quality m-chloromethylbenzoyl chloride (Ⅲ);

[0028] c): Chloride (Ⅲ) is pumped into the esterification tank, and 80 parts of anhydrous methanol is added dropwise, and the esterification reaction is carried out at 40...

Embodiment 2

[0033] Such as figure 1 , m-cyanomethylbenzoic acid methyl ester synthetic method, take m-toluic acid as starting raw material, and its synthetic route is as follows:

[0034] The specific steps are as follows:

[0035] a): Take 400 parts of m-toluic acid (I) into the chlorination kettle, add 370 parts of thionyl chloride, and make m-toluoyl chloride (II) by acylation at 80°C. The rate is 90-97%;

[0036] b): Pump m-toluoyl chloride (II) into the chlorination kettle, and feed liquid chlorine with 13.8% weight of m-toluoyl chloride at 145°C to partially convert the acylate into chloride (Ⅲ ), distilling and recovering m-toluoyl chloride that did not participate in the reaction to the chlorination kettle for chlorination again until finally obtaining high-quality m-chloromethylbenzoyl chloride (Ⅲ);

[0037] c): Chloride (Ⅲ) is pumped into the esterification kettle, and 80 parts of anhydrous methanol is added dropwise, and the esterification reaction is carried out at 60°C to ...

Embodiment 3

[0041] Such as figure 1 , m-cyanomethylbenzoic acid methyl ester synthetic method, take m-toluic acid as starting raw material, and its synthetic route is as follows:

[0042] The specific steps are as follows:

[0043] a): Take 400 parts of m-toluic acid (I) into the chlorination kettle, add 380 parts of thionyl chloride, and make m-toluoyl chloride (II) by acylation at 60°C. The rate is 90-97%;

[0044] b): Pump m-toluoyl chloride (II) into the chlorination kettle, and feed liquid chlorine with 17.8% weight of m-toluoyl chloride at 170°C to partially convert the acylate into chloride (Ⅲ ), distill and recover the m-toluoyl chloride that did not participate in the reaction, and then chlorinate it again in the chlorination kettle until finally high-quality m-chloromethylbenzoyl chloride (Ⅲ) is obtained;

[0045] c): Chloride (Ⅲ) is pumped into the esterification kettle, and 80-120 parts of anhydrous methanol is added dropwise, and the esterification reaction is carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com