Patents

Literature

4118 results about "Biodiesel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

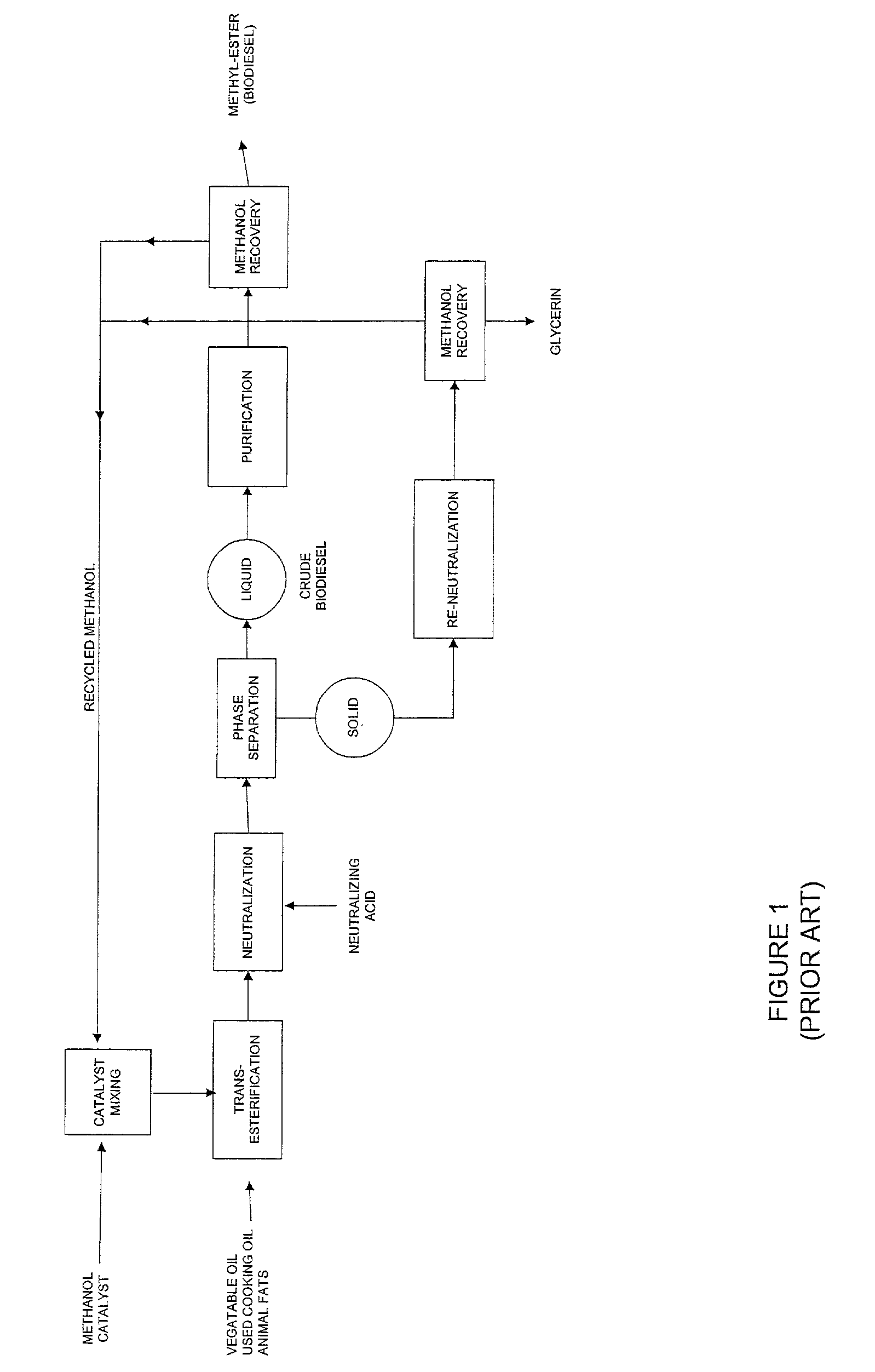

Biodiesel refers to a vegetable oil- or animal fat-based diesel fuel consisting of long-chain alkyl (methyl, ethyl, or propyl) esters. Biodiesel is typically made by chemically reacting lipids (e.g., vegetable oil, soybean oil, animal fat (tallow)) with an alcohol producing fatty acid esters.

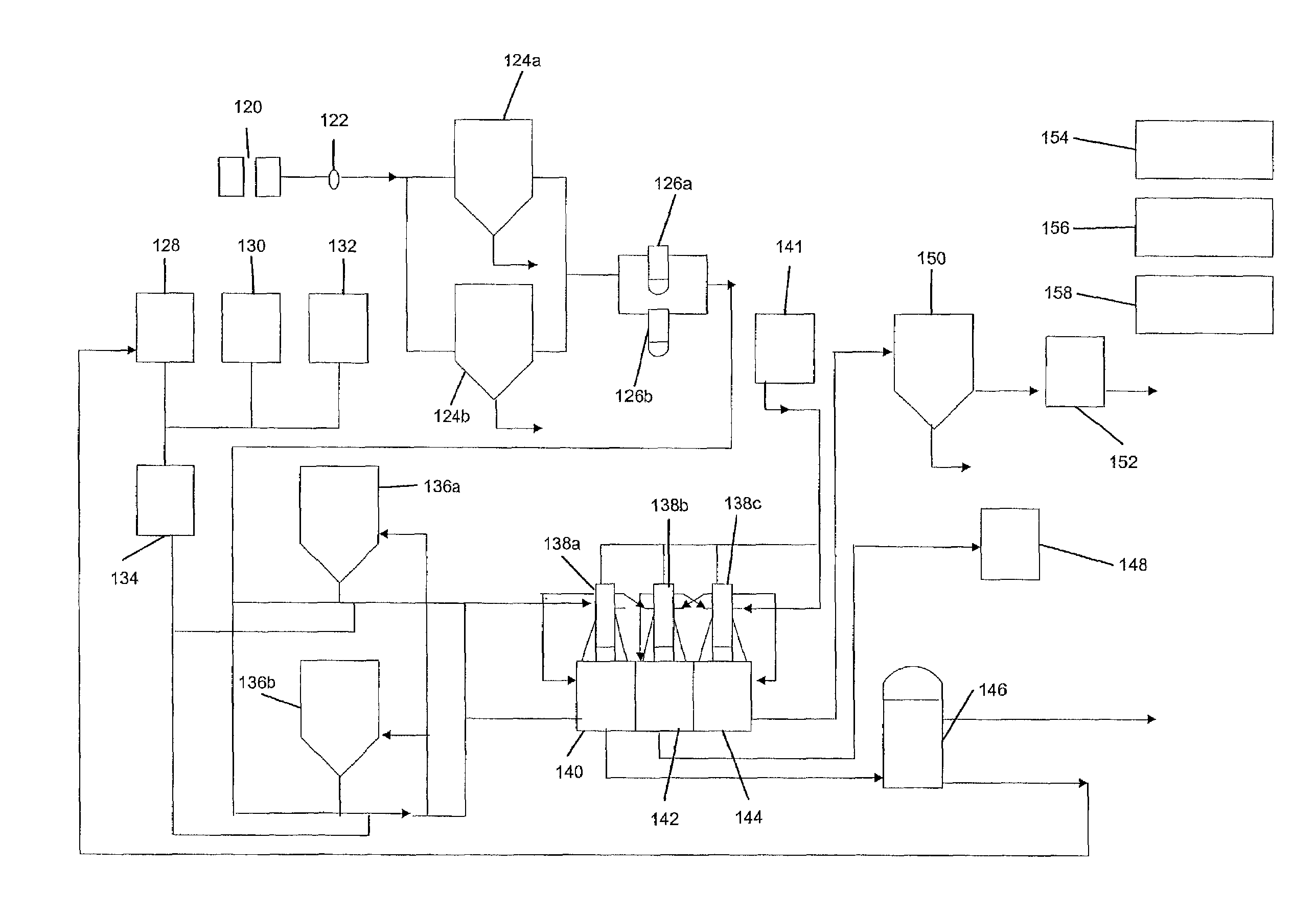

Synthetic and biologically-derived products produced using biomass produced by photobioreactors configured for mitigation of pollutants in flue gases

InactiveUS20050239182A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

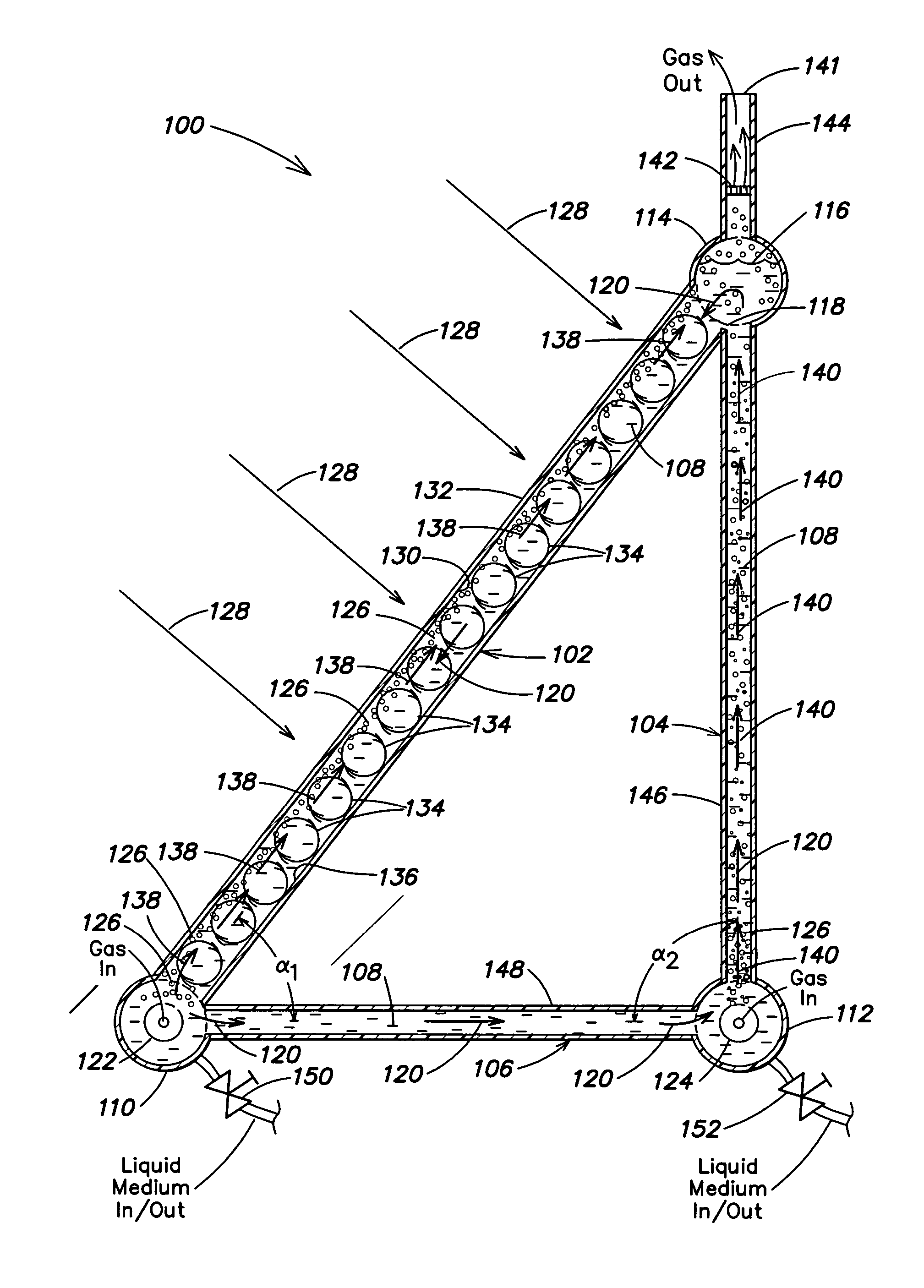

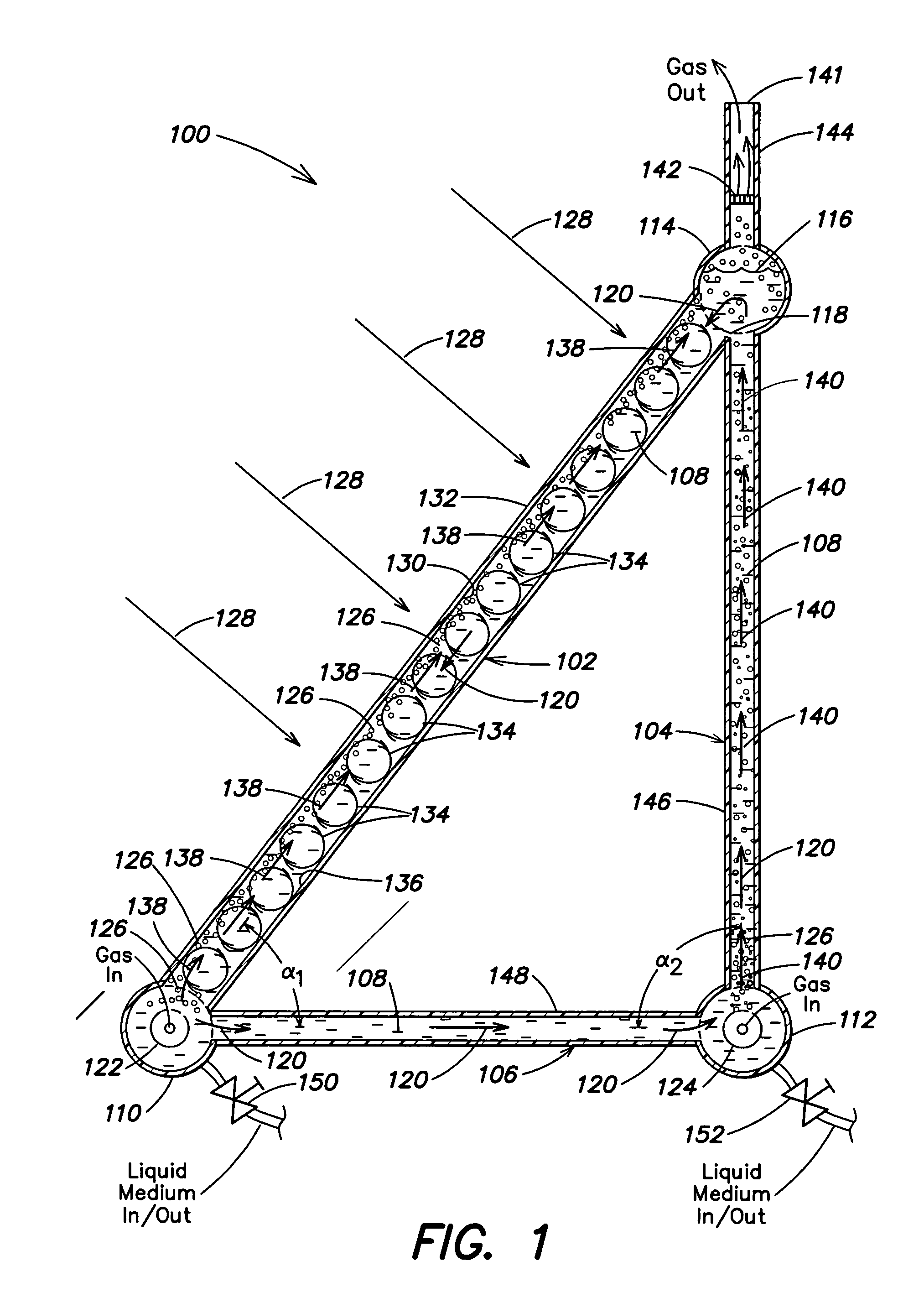

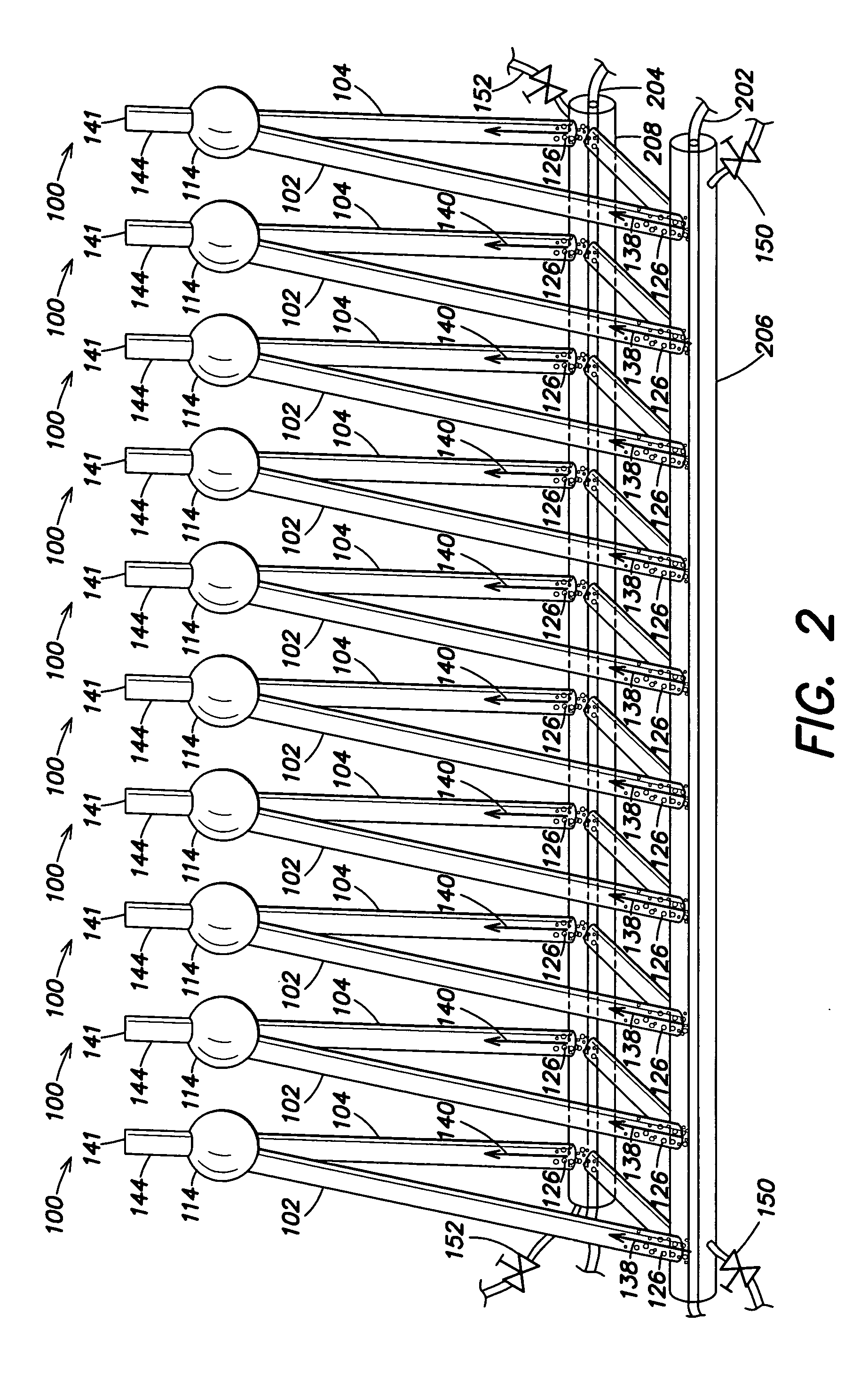

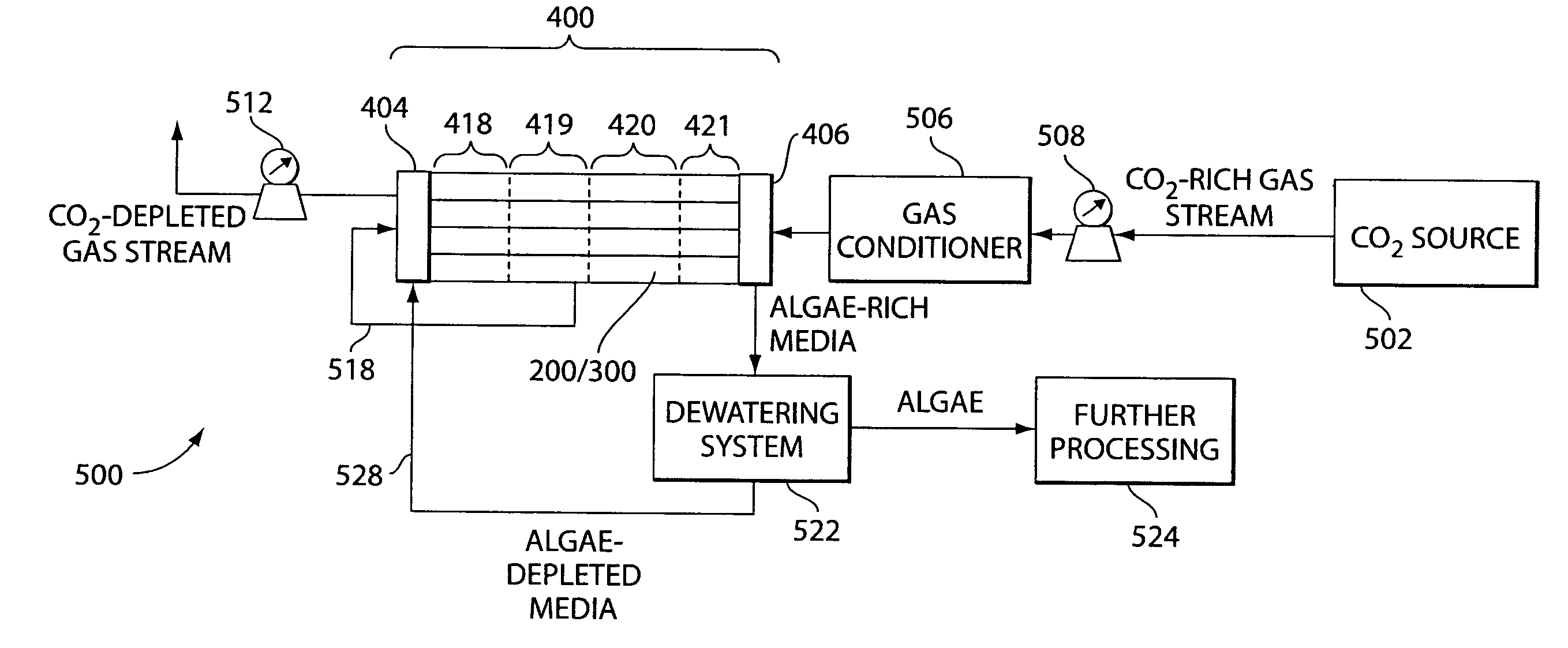

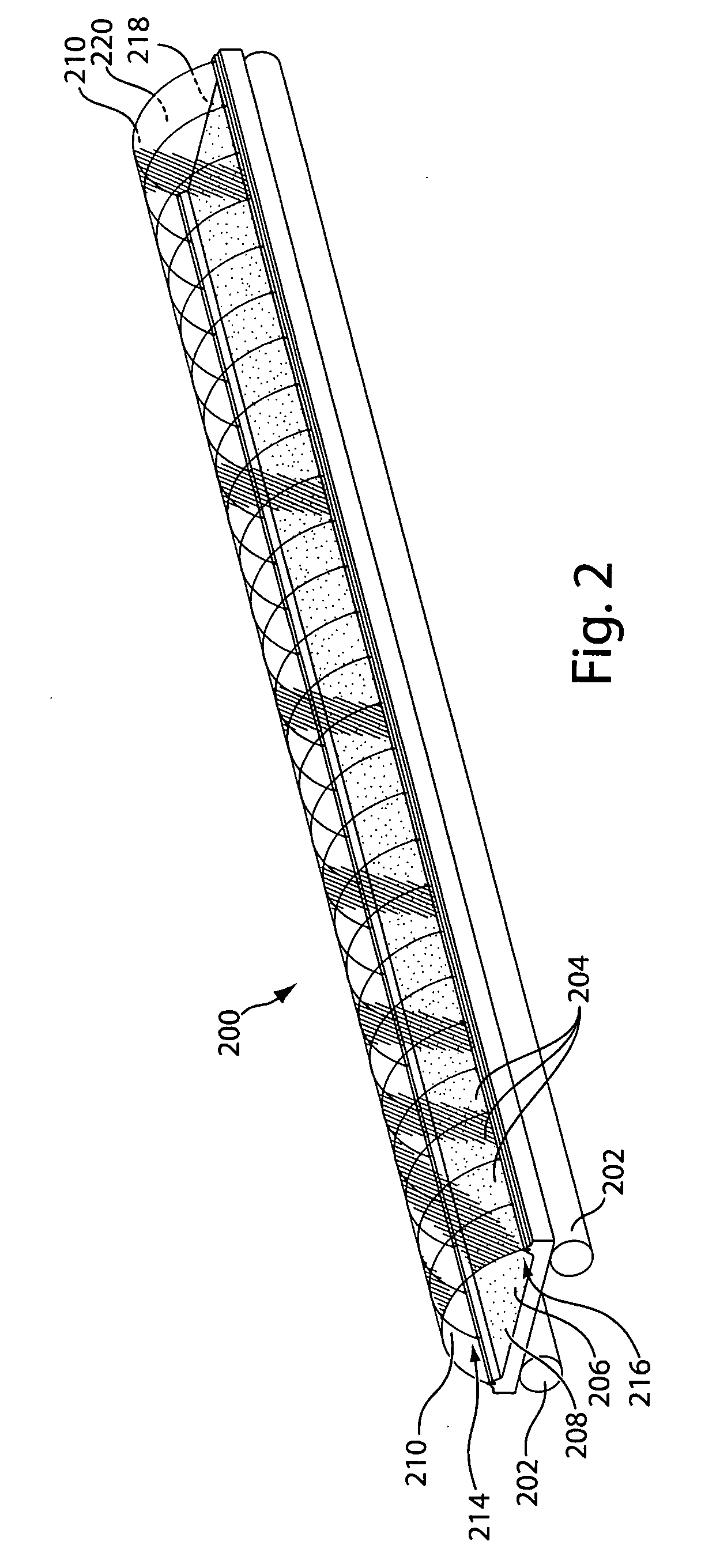

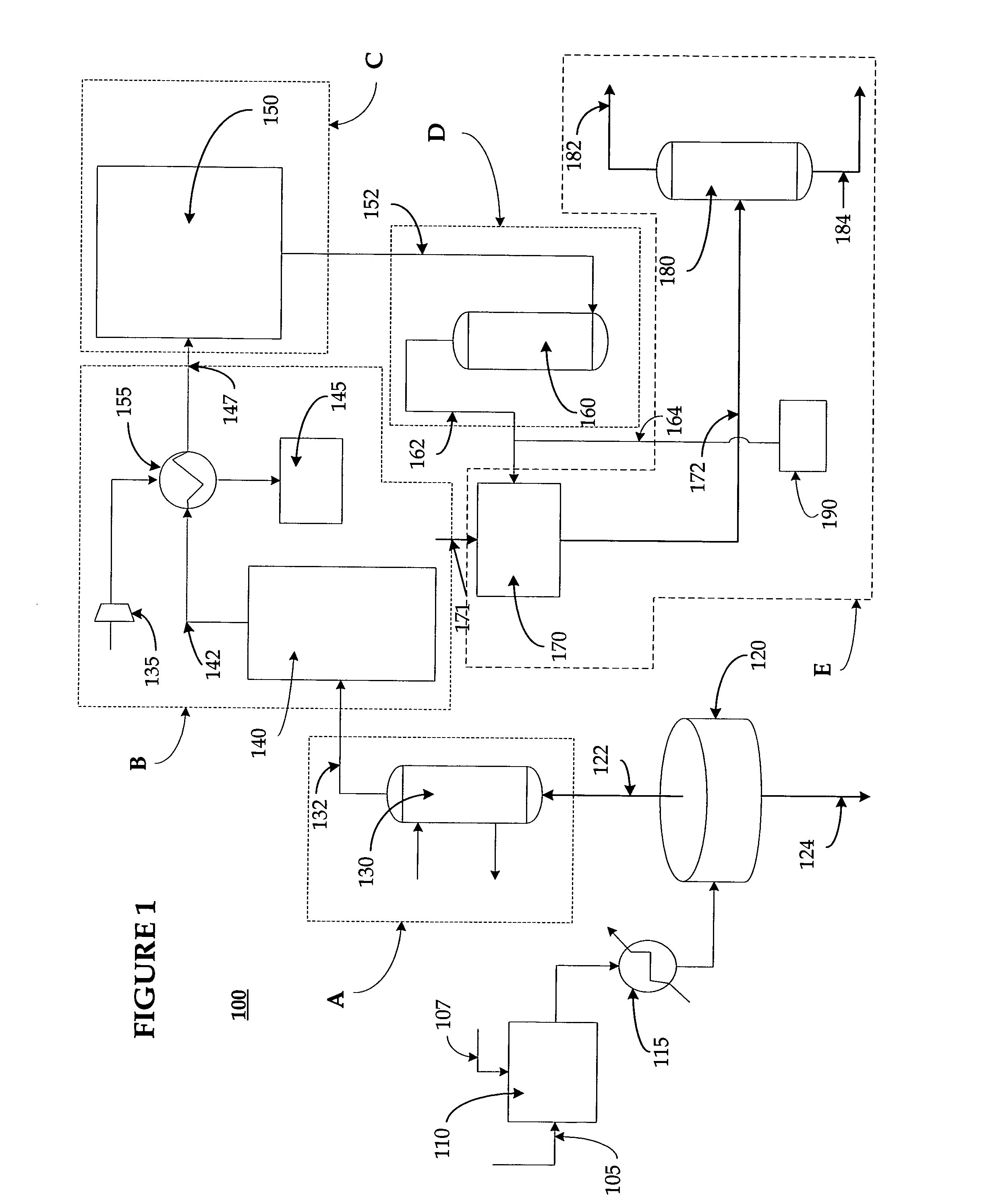

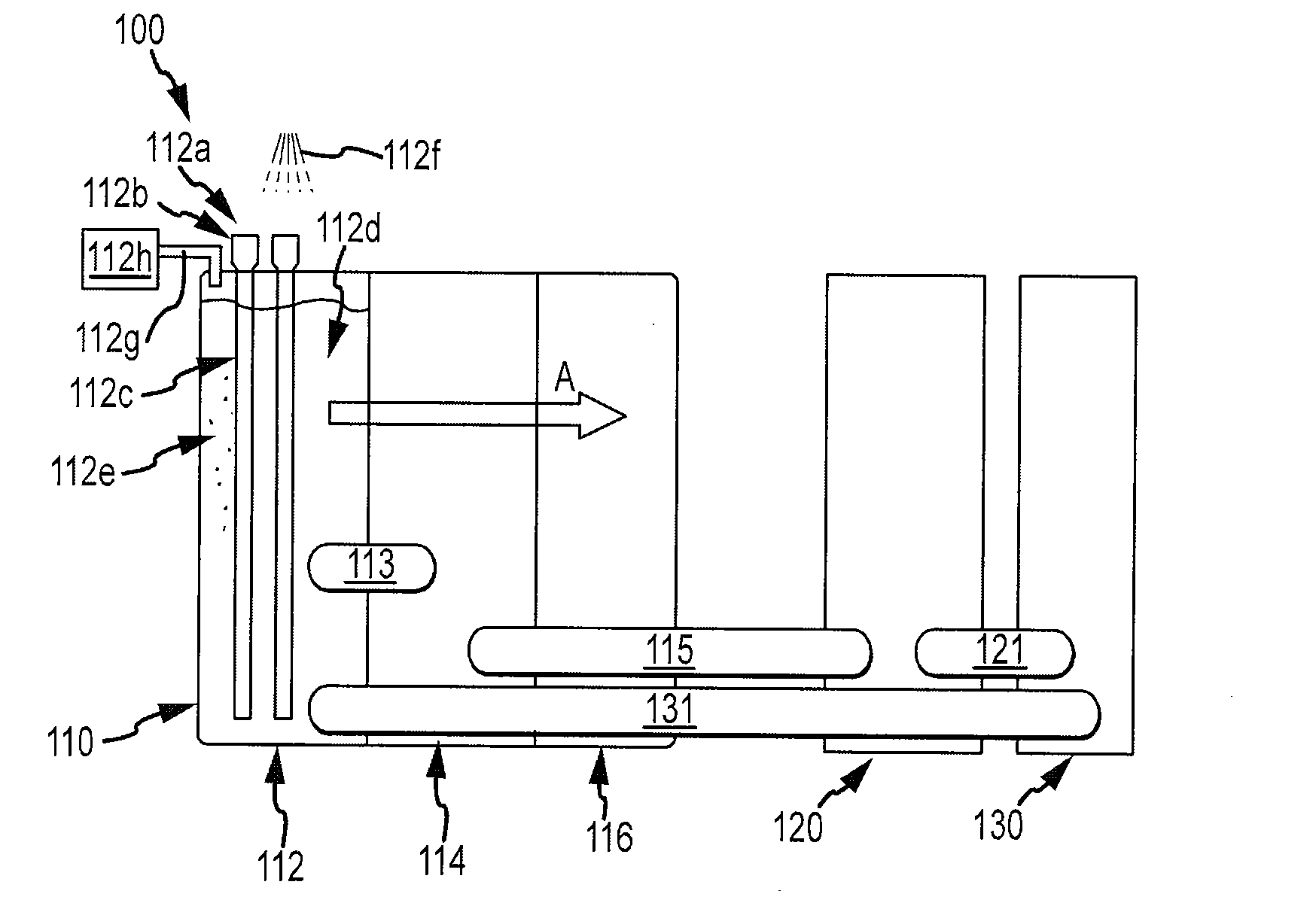

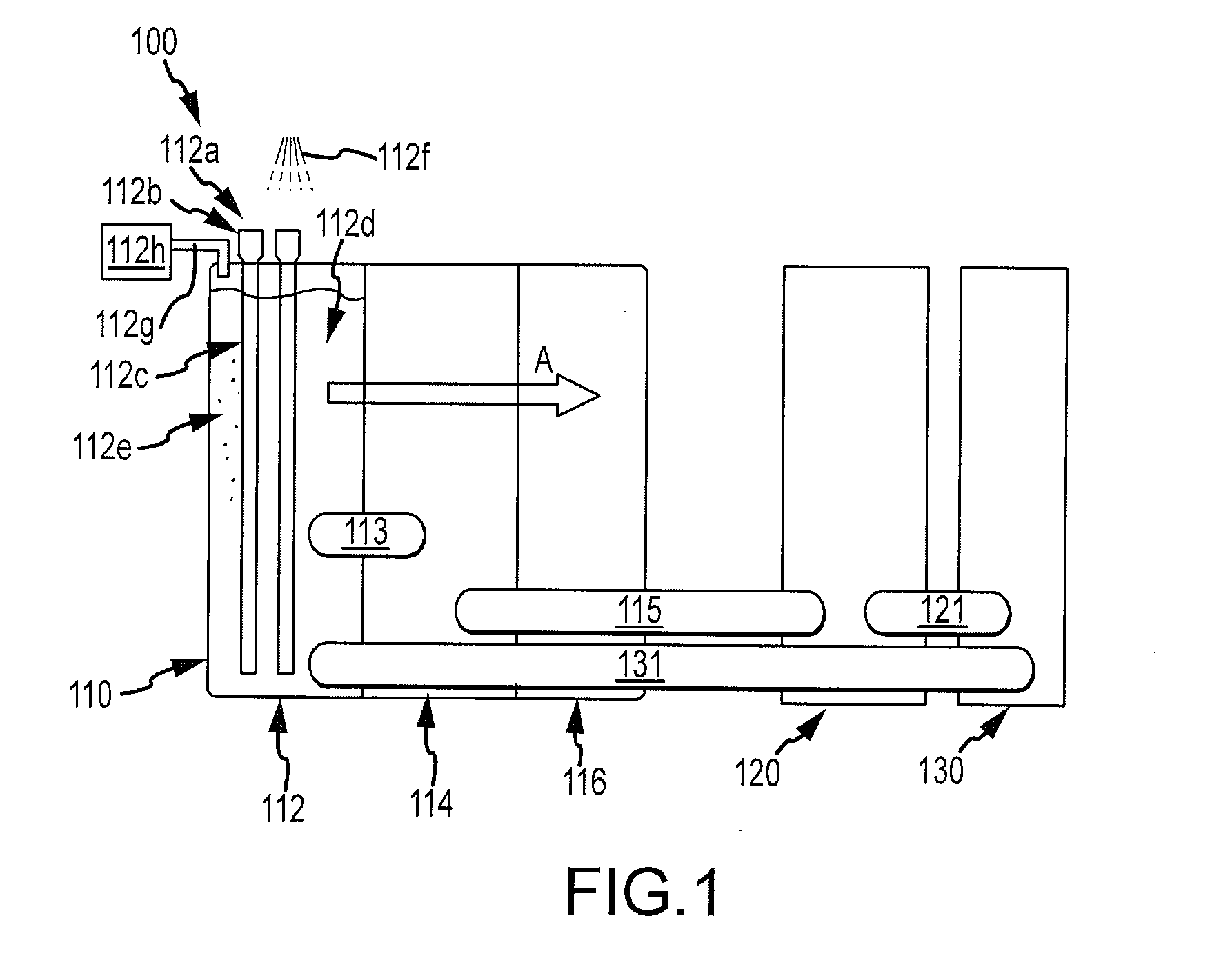

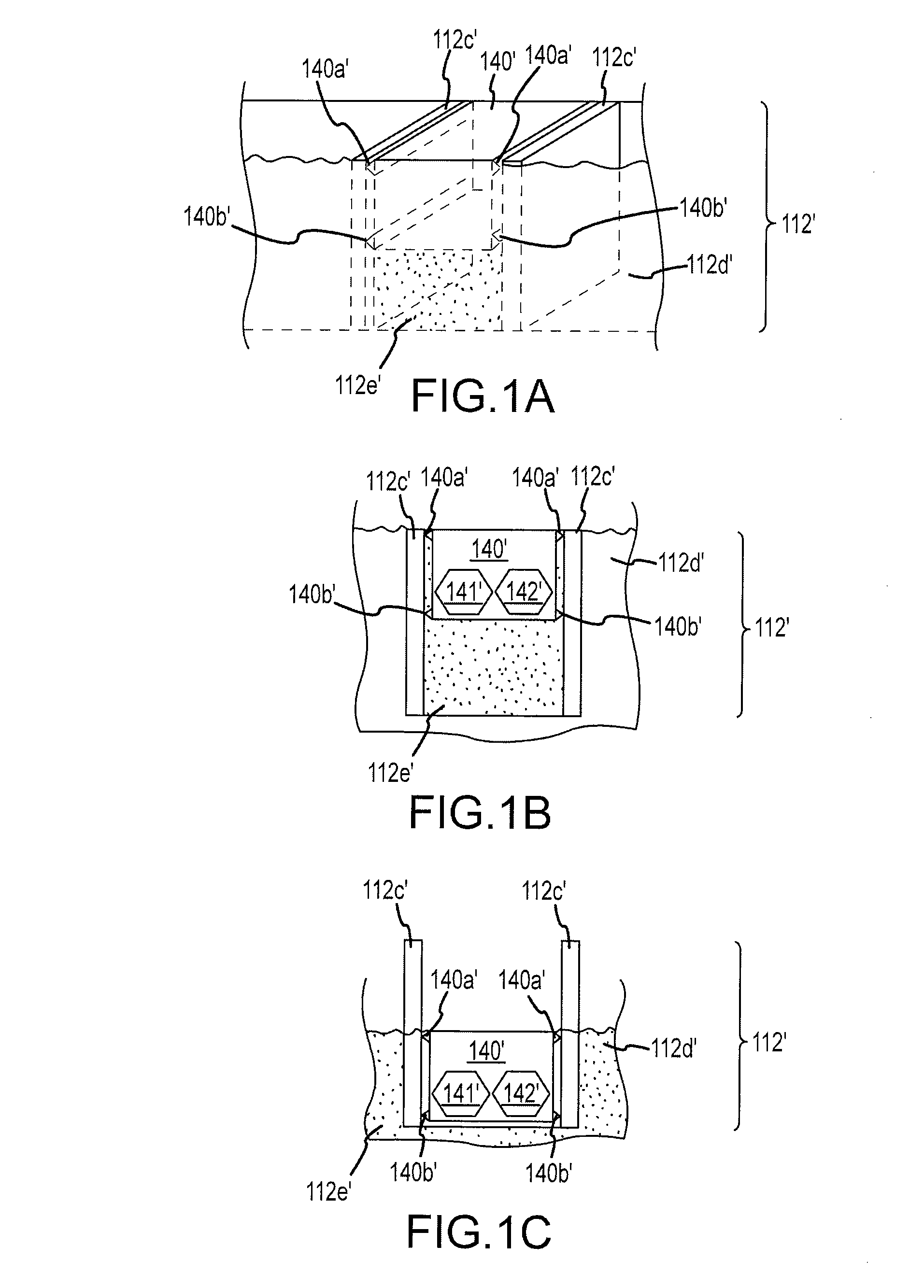

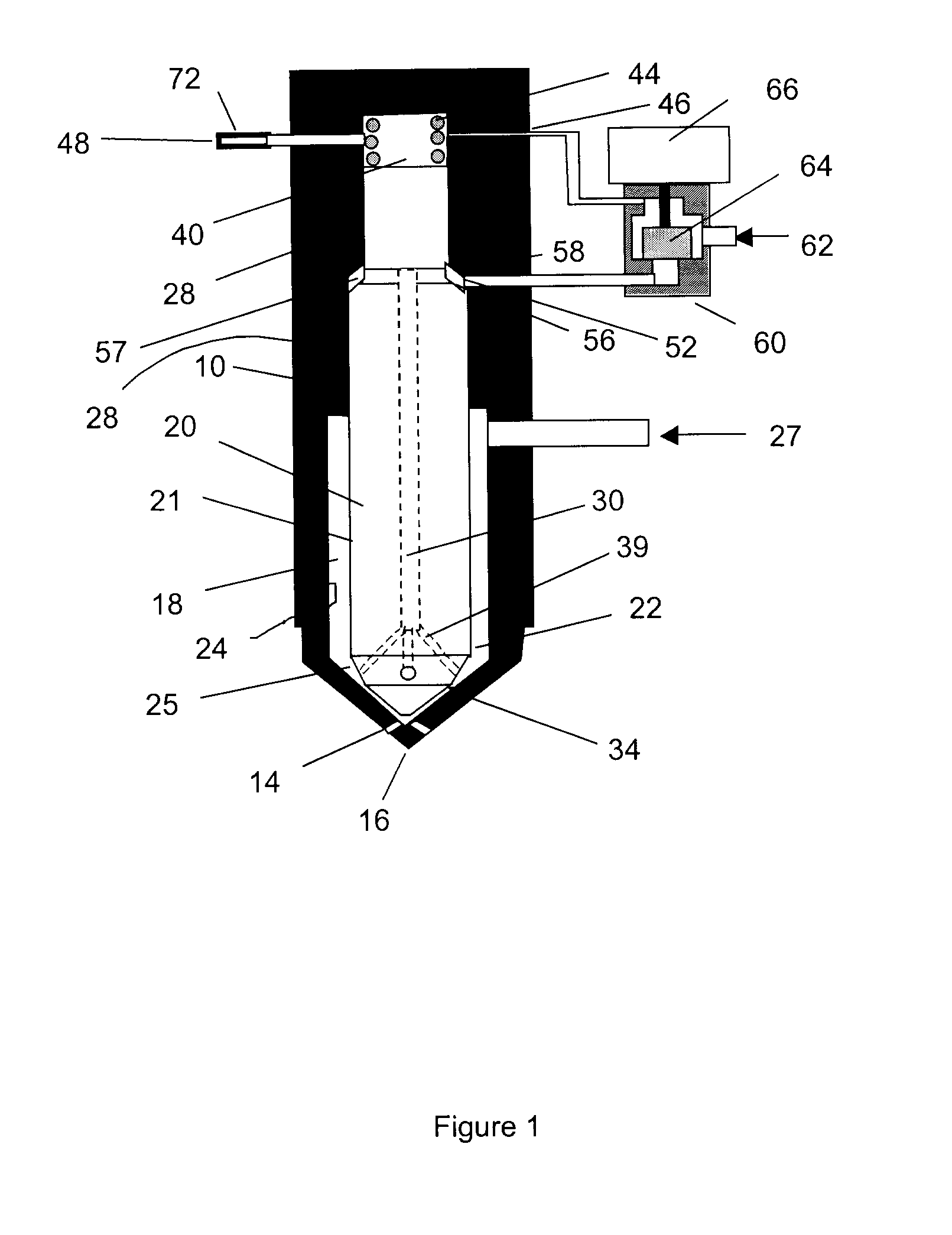

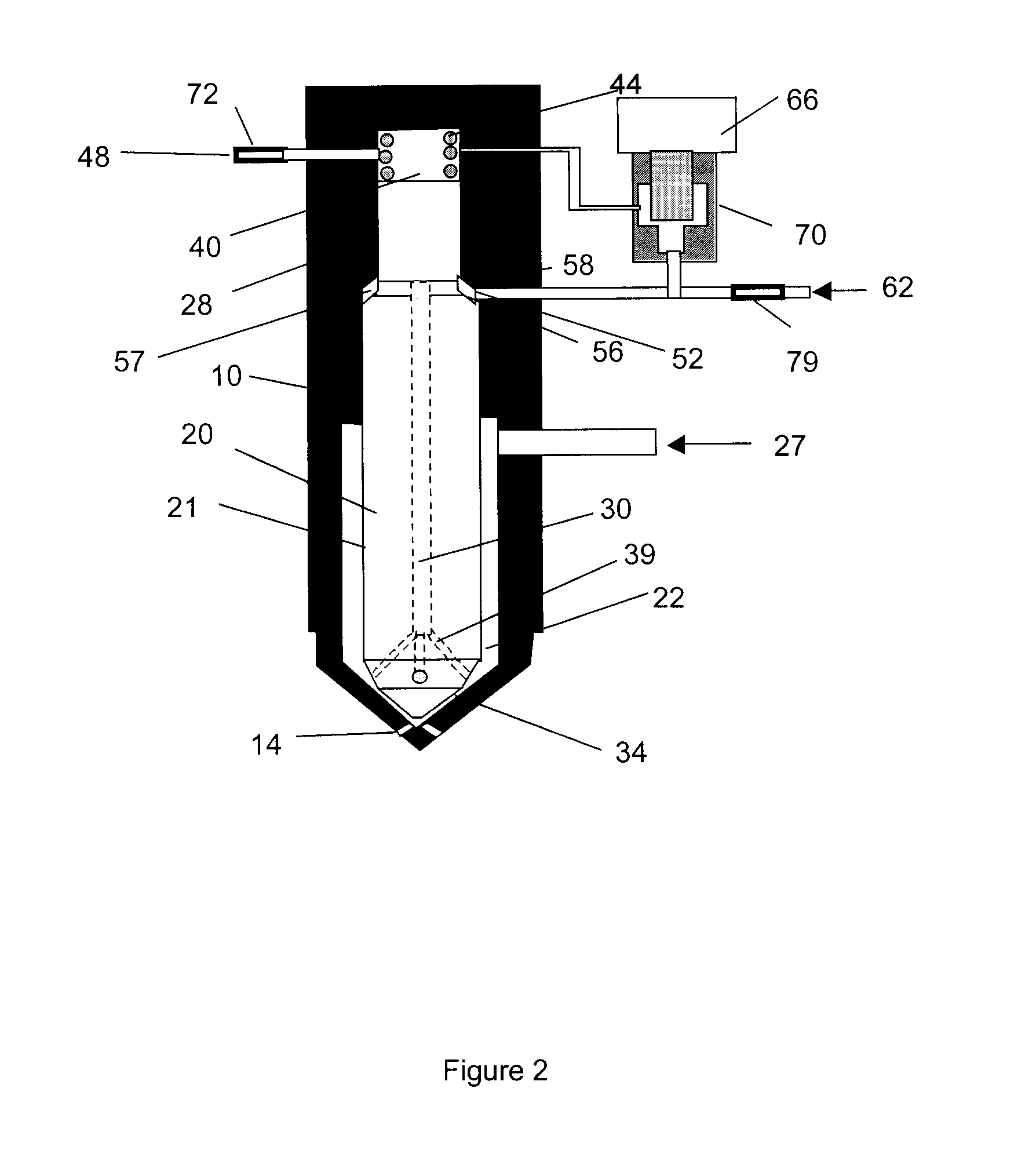

Certain embodiments and aspects of the present invention relate to photobioreactor apparatus designed to contain a liquid medium comprising at least one species of photosynthetic organisms therein, and to methods of using the photobioreactor apparatus as part of a production process for forming an organic molecule-containing product, such as a polymeric material and / or fuel-grade oil (e.g. biodiesel), from biomass produced in the photobioreactor apparatus. In certain embodiments, the disclosed organic molecule / polymer production systems and methods, photobioreactor apparatus, methods of using such apparatus, and / or gas treatment systems and methods provided herein can be utilized as part of an integrated combustion and polymer and / or fuel-grade oil (e.g. biodiesel) production method and system, wherein photosynthetic organisms utilized within the photobioreactor are used to at least partially remove certain pollutant compounds contained within combustion gases, e.g. CO2 and / or NOx, and are subsequently harvested from the photobioreactor, processed, and utilized as a source for generating polymers and / or organic molecule-containing products (e.g. fuel-grade oil (e.g. biodiesel)) and / or as a fuel source for a combustion device (e.g. an electric power plant generator and / or incinerator).

Owner:GREENFUEL TECHNOLOGIES CORPORATION

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

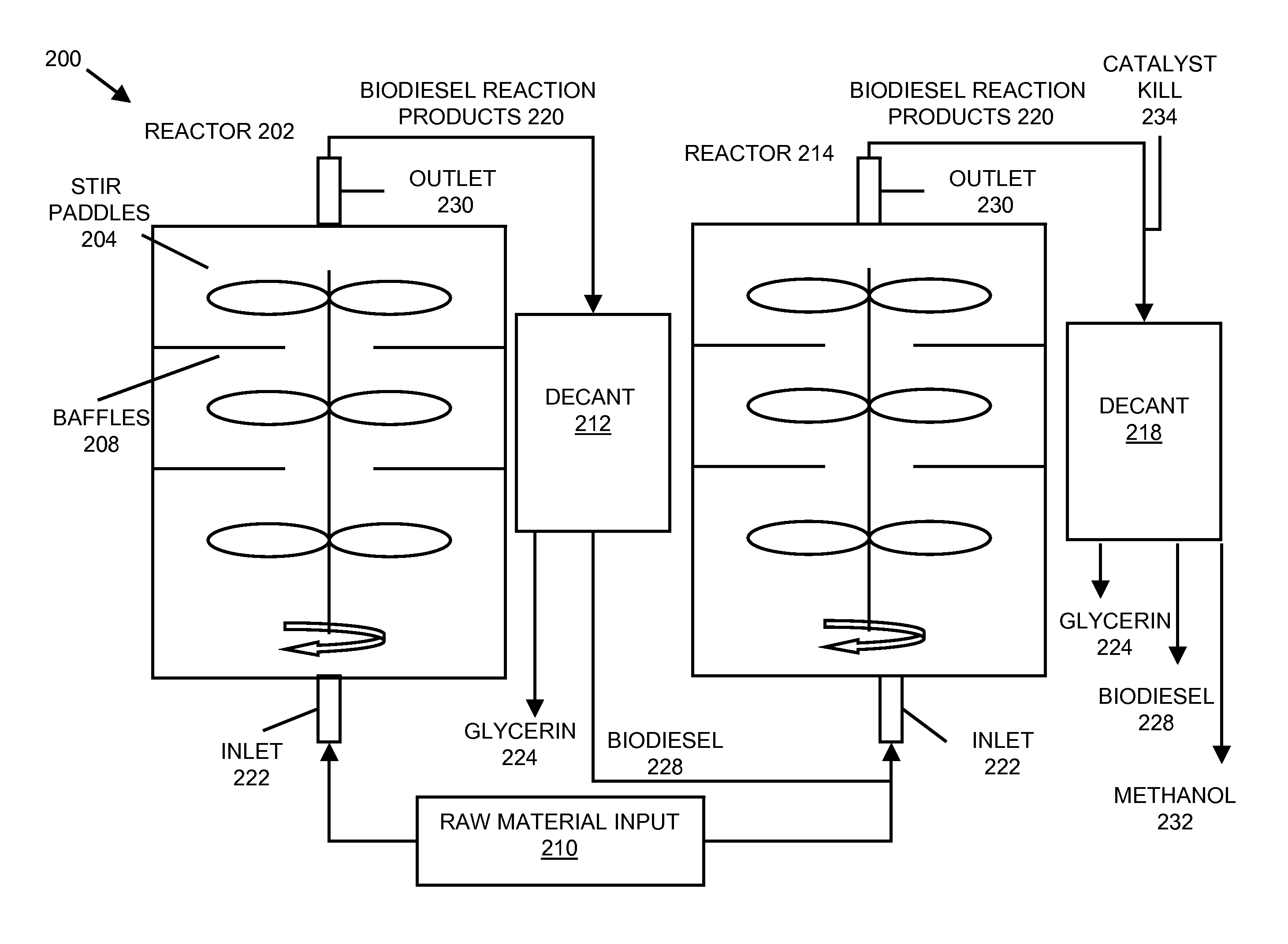

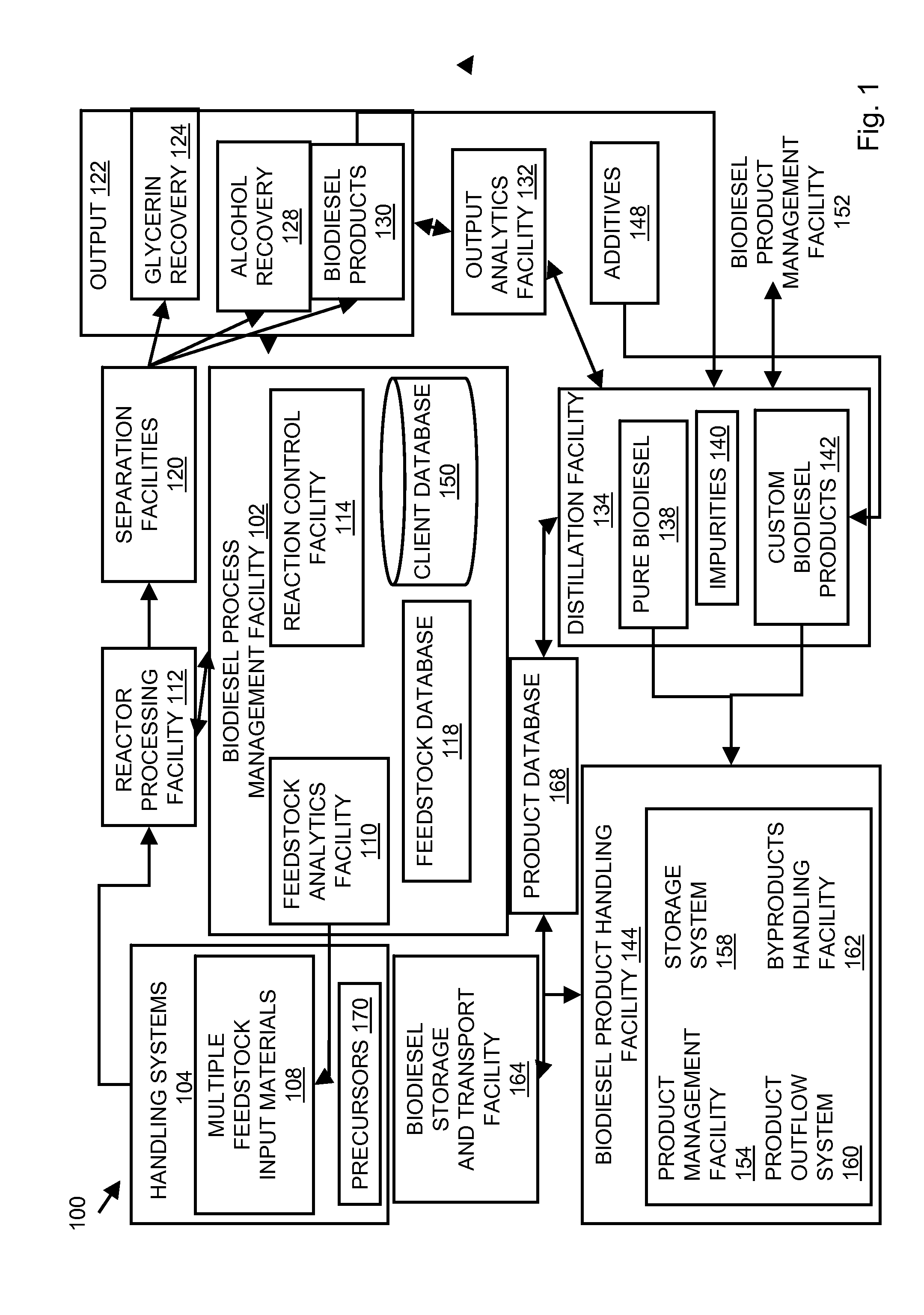

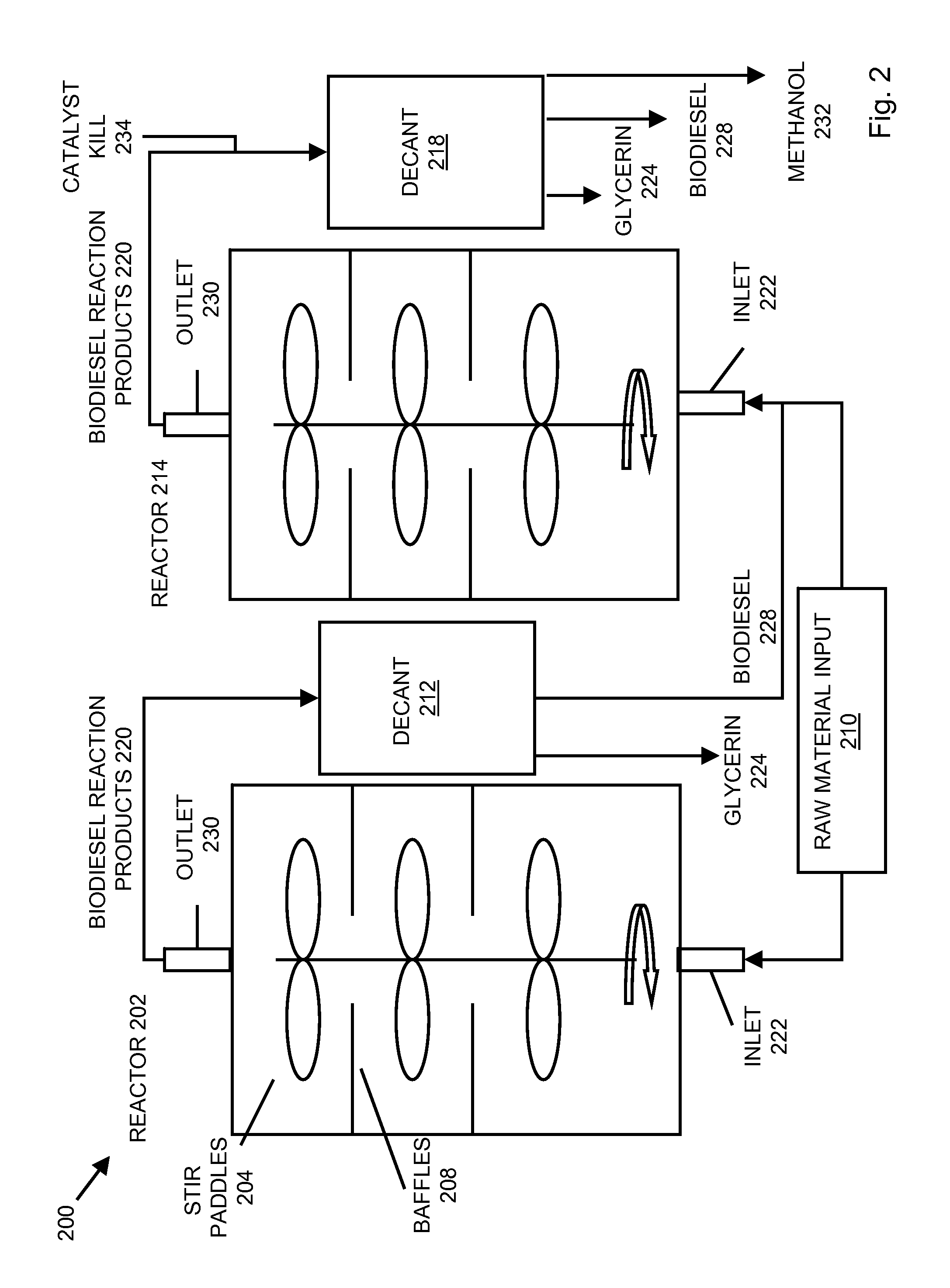

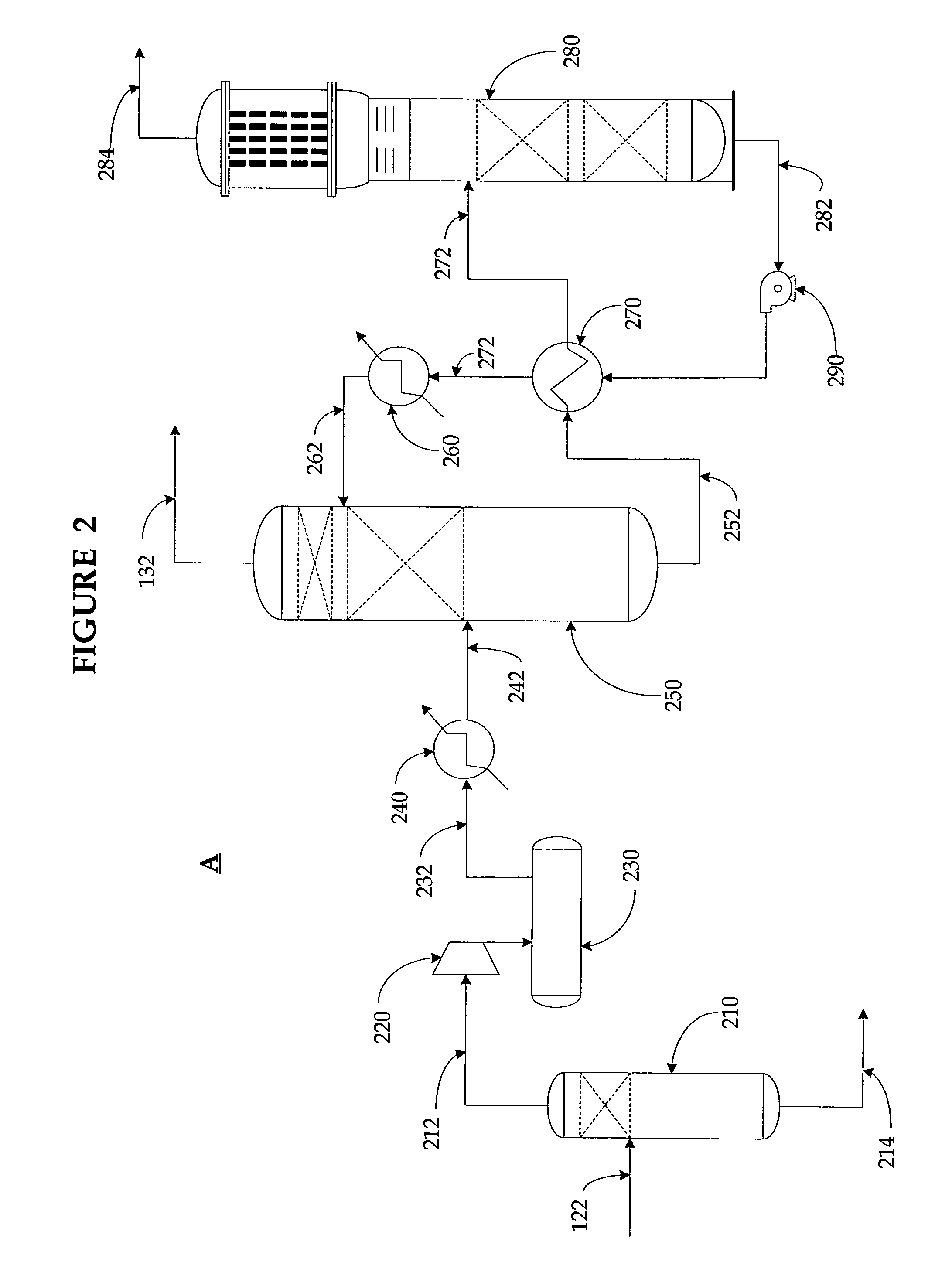

System and process for producing biodiesel

InactiveUS20080282606A1Reducing filter blocking tendencyEnhance biodiesel stabilityFatty acid esterificationFatty acids production/refiningBiodieselDistillation

In embodiments of the present invention, systems for producing a biodiesel product from multiple feedstocks may include a biodiesel reactor, a decanter, a flash evaporator and a distillation column. In other embodiments of the present invention, a process for producing a biodiesel comprises distilling a biodiesel reaction product to remove tocopherols and sterol glucosides and, optionally, adding biodiesel stabilizers to the resultant biodiesel to enhance thermal stability. The components of the system are interrelated so that parameters may be regulated to allow production of a custom biodiesel product.

Owner:IMPERIUM PROCESS TECH

Production of biological diesel oil by integrated hydrogenation

InactiveCN101029245AAchieve reliabilityAchieve economyBiofuelsLiquid hydrocarbon mixture productionDistillates petroleumBiodiesel

Production of biological diesel oil by integrated hydrogenation is carried out by mixing straight-run diesel oil with soya-bean, hydrogenation refinery reacting at 3.0-8.0MPa and 250-400degree and under existence of catalyst and converting vegetable oil into biological diesel oil. It's simple and cheap.

Owner:TSINGHUA UNIV

Biodiesel fuel compositions having increased oxidative stability

The present invention relates to biodiesel fuel compositions that have improved oxidation stability. More specifically, the biodiesel fuel compositions include at least one antioxidant that increases the oxidative stability of the fuel. The biodiesel fuel compositions may also include an antioxidant mixture, or an antioxidant mixture in combination with a polar and / or nonpolar solvent, that increases the oxidative stability of the fuel.

Owner:NOVUS INTERNATIONAL INC

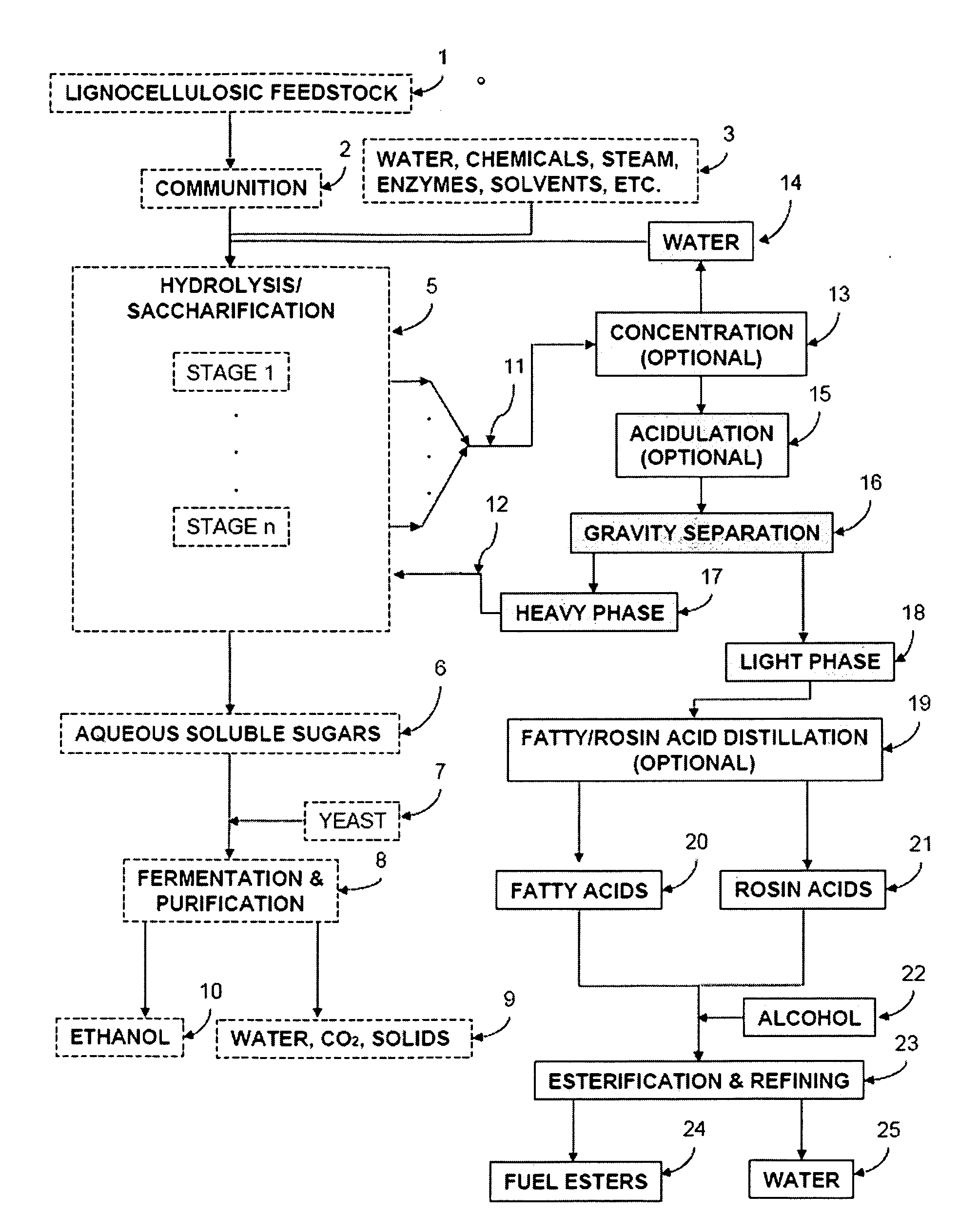

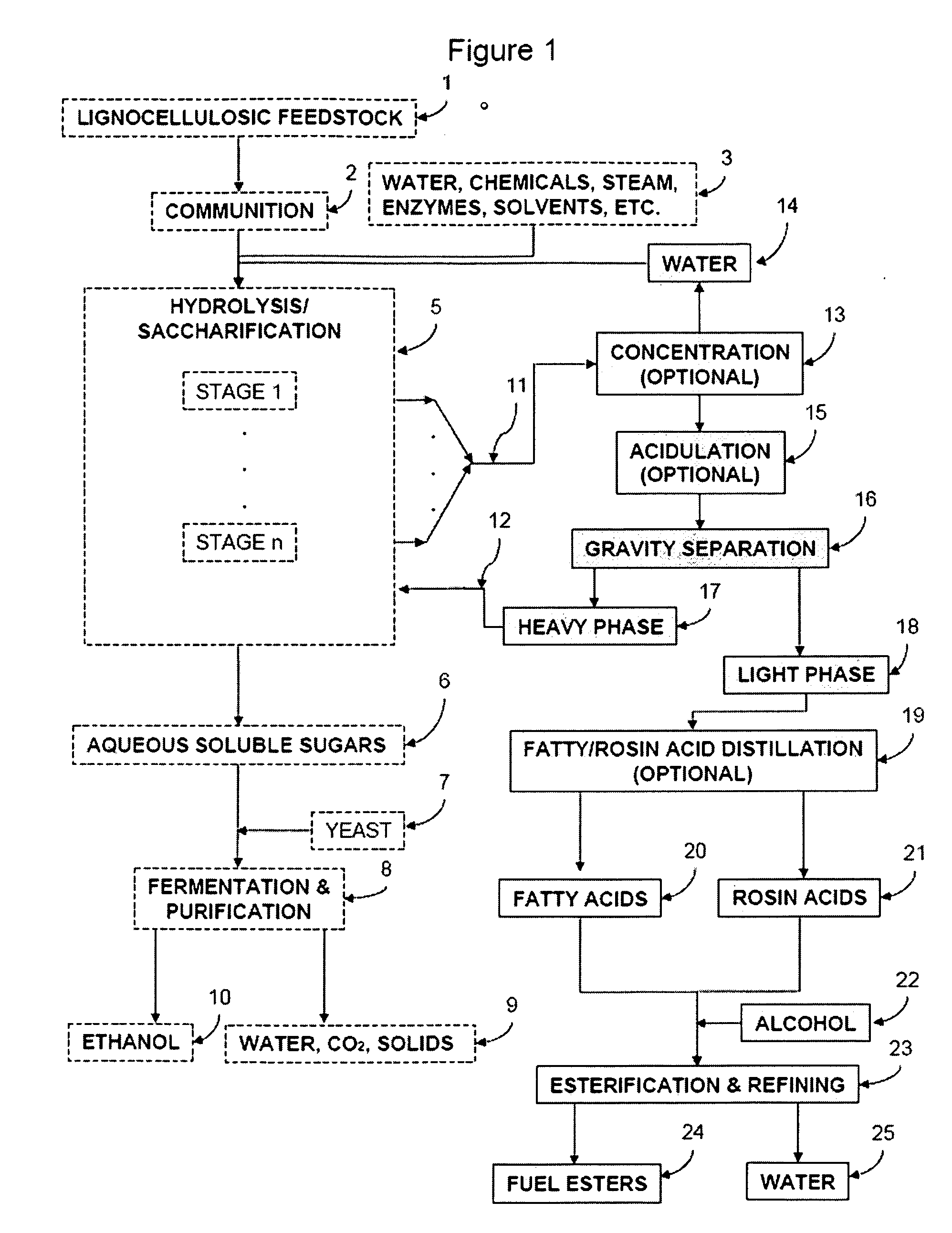

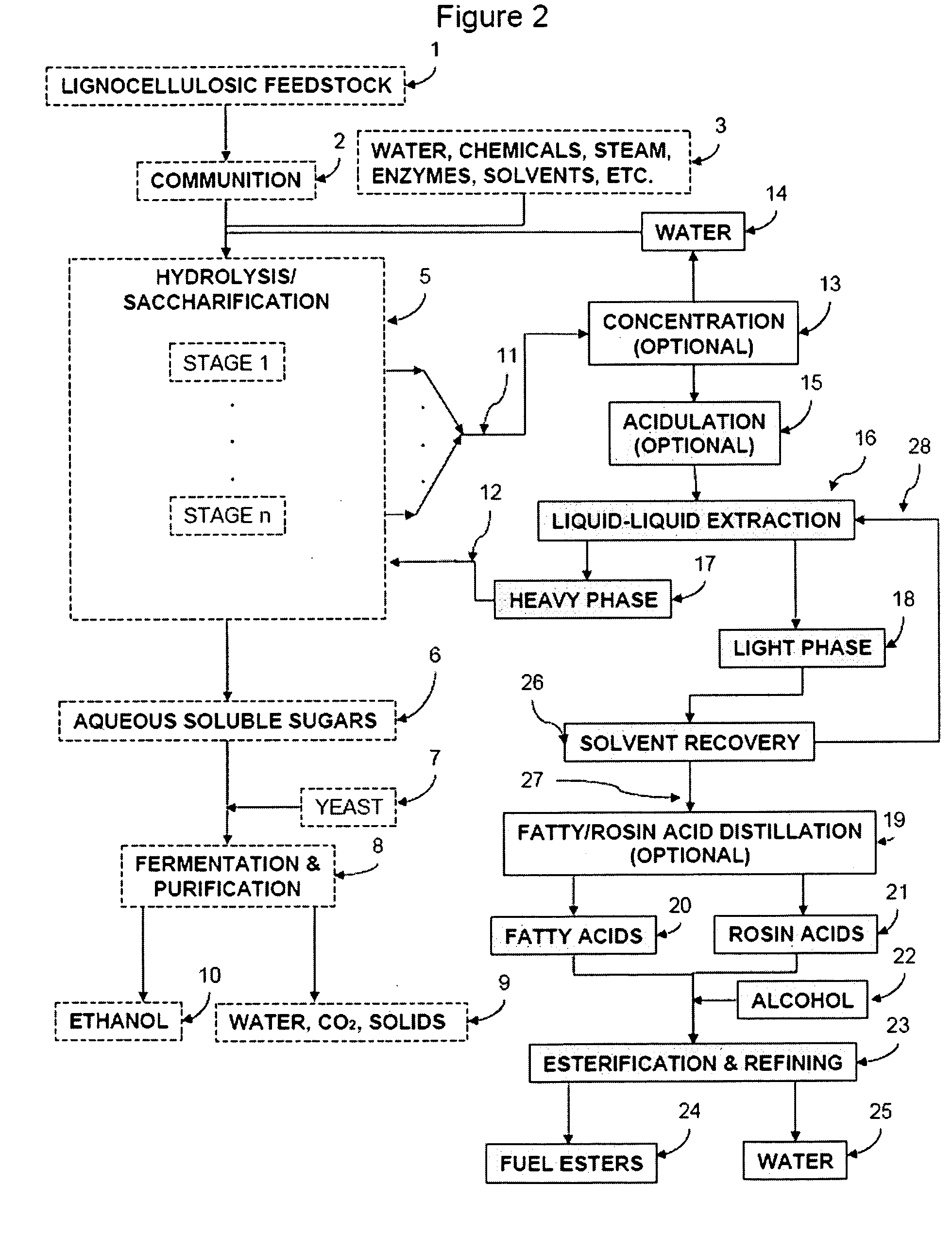

Production of Ester-based Fuels Such As Biodiesel From Renewable Starting Materials

ActiveUS20090056201A1Fatty oils/acids recovery from wasteFatty acid esterificationCelluloseBiodiesel

Production of ester-based fuels such as biodiesel or jet fuel from renewable starting materials such as lignocellulosic material or algae is disclosed. Pulping and saccharification of the renewable starting materials produces carboxylic acids such as fatty acids or rosin acids, which are esterified via a gas sparged, slurry form of heterogeneous reactive distillation to yield ester-based fuels.

Owner:ENDICOTT BIOFUELS II

System and method for extracting energy from agricultural waste

InactiveUS7169821B2Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

Owner:BEST BIOFUELS LLC

Process for the production of ethanol from algae

The present invention describes a process for the production of ethanol by harvesting starch-accumulating filament-forming or colony-forming algae to form a biomass, initiating cellular decay of the biomass in a dark and anaerobic environment, fermenting the biomass in the presence of a yeast, and the isolating the ethanol produced. The present invention further relates to processing of the biomass remaining after ethanol production to recovering biodiesel starting materials and / or generation of heat and carbon dioxide via combustion.

Owner:PROPULSION LOGIC

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

Process for supercritical preparation of biologic diesel oil

InactiveCN1594504AReduce pollutionRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionBiodieselPhase splitting

The invention discloses a process for supercritical preparation of biologic diesel oil by using animal or plant oil, waste edible oil, oiling crop seeds as raw material through the steps of filtering, dewatering, esterification, ester interchange, filtering, steaming methanol and phase-splitting.

Owner:WUHAN CHEM COLLEGE

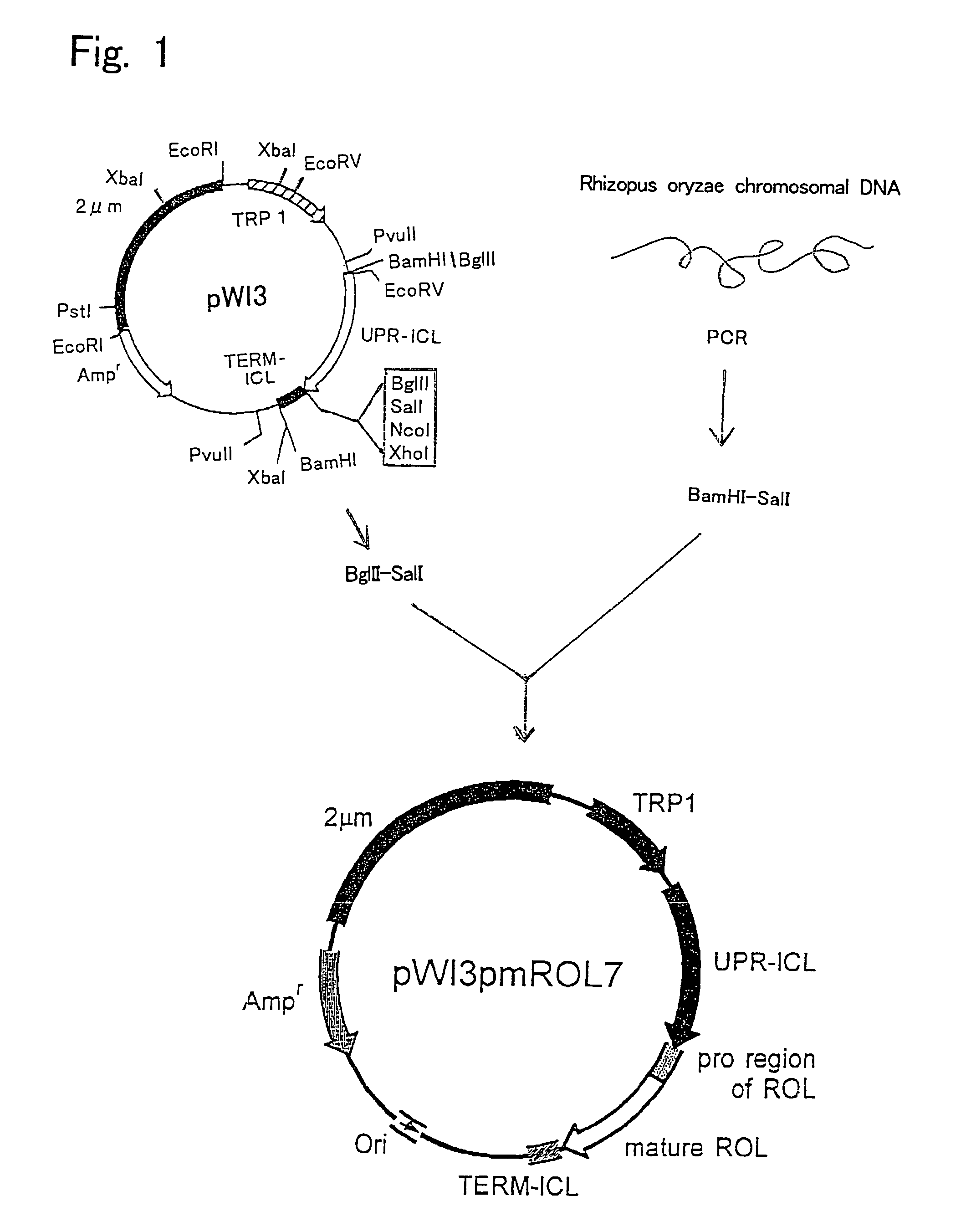

Process for producing fatty acid lower alcohol ester

InactiveUS6982155B1Efficient productionImprove permeabilityFatty acid chemical modificationOrganic compound preparationOil and greaseMicroorganism

The present invention provides a method for producing a fatty acid ester inexpensively and efficiently by reacting a lipase or an intact mircroorganism containing a lipase, an oil and fat, and a linear lower alcohol in a system containing little or no solvent in the presence of water. The intact microorganism has not been treated with a solvent or the like, and is used as such, so that a fatty acid ester can be prepared in a simple manner. An oil and fat, a natural oil and fat such as a vegetable oil and fat, an animal oil and fat, as well as a waste oil thereof can be used. According to the method of the present invention, a reaction proceeds even in the presence of water, so that waste oils containing a large amount of water can be used as a raw material. Therefore, the waste oil to be dumped into the environment can be recycled, and a biodiesel fuel, which hardly pollutes the environment, can be provided at the same time.

Owner:KANSAI CHEM ENG CO LTD

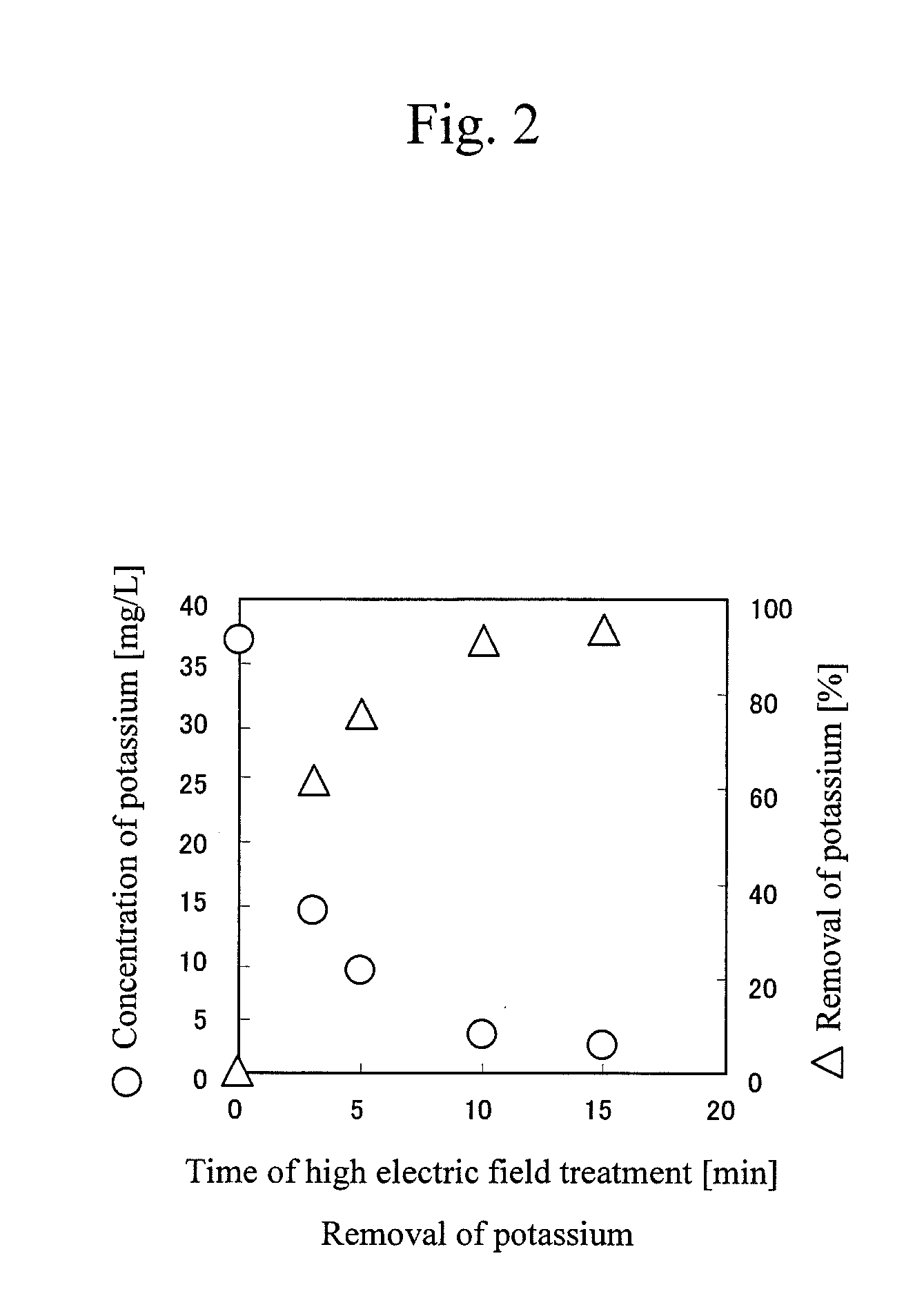

Method for purifying biodiesel fuel

InactiveUS20090025277A1Preventing and greatly reducing generationWater/sewage treatment by irradiationLiquid separation by electricityDemulsifierBiodiesel

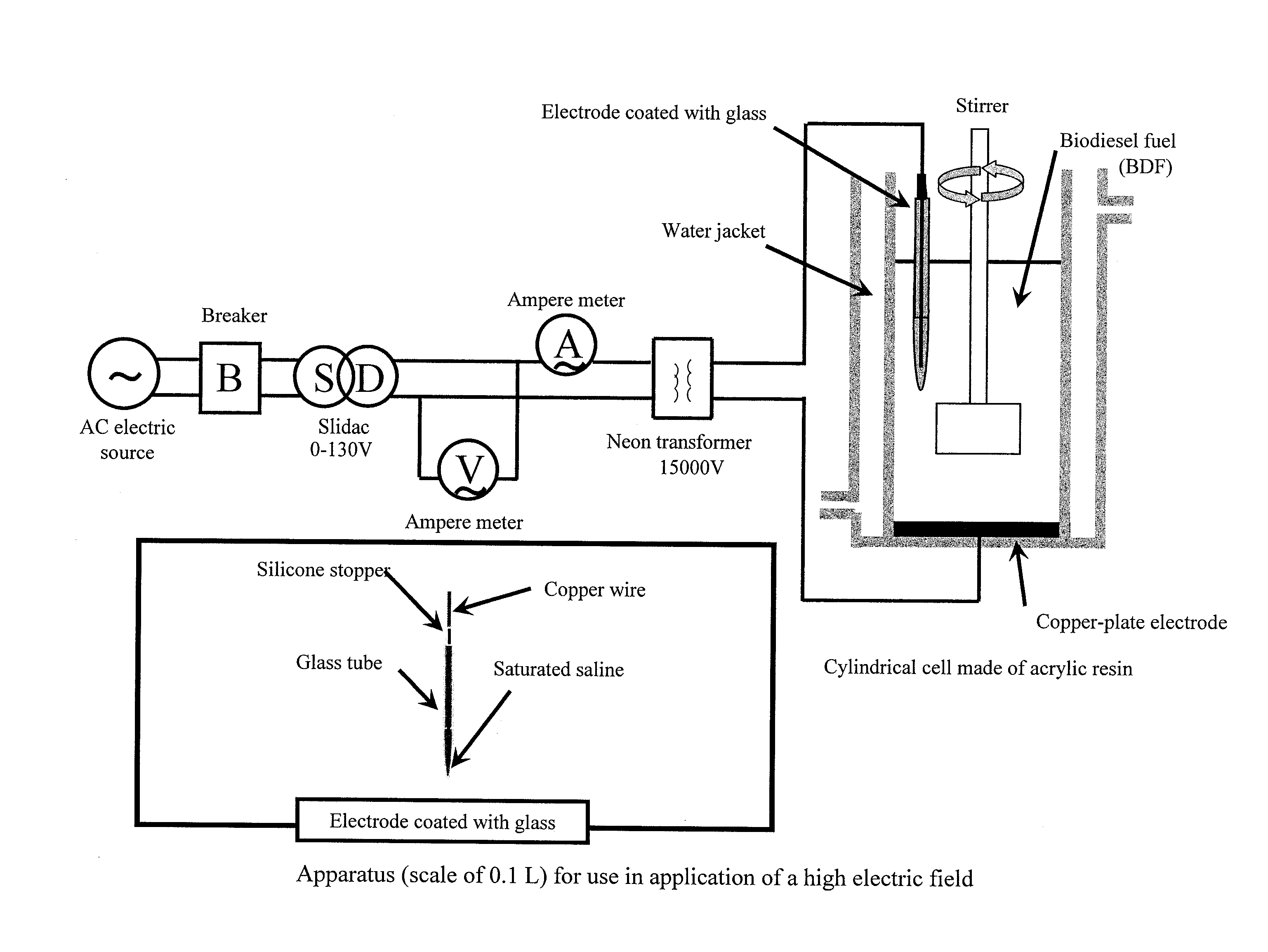

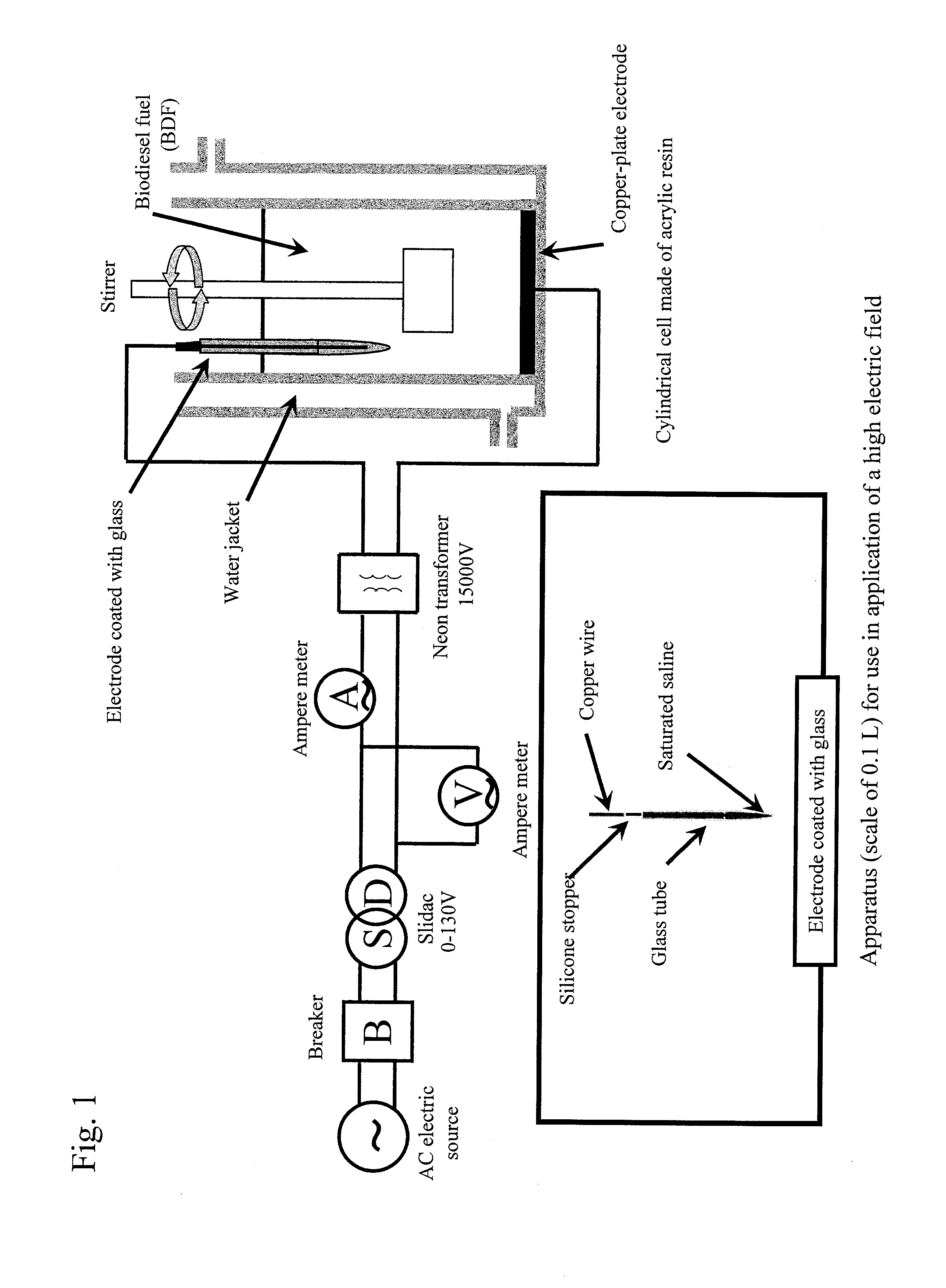

Provided is a method for purifying a biodiesel fuel while completely preventing or greatly reducing generation of waste water. The present invention relates to a method for purifying a biodiesel fuel characterized by applying an electric field to or heating a crude biodiesel fuel and a method for purifying a biodiesel fuel characterized by adding water (preferably containing a demulsifier such as an inorganic calcium salt or a magnesium salt) to a crude biodiesel fuel to form W / O emulsion, and breaking the emulsion by application of an electric field or heating, etc.

Owner:KAGOSHIMA UNIV

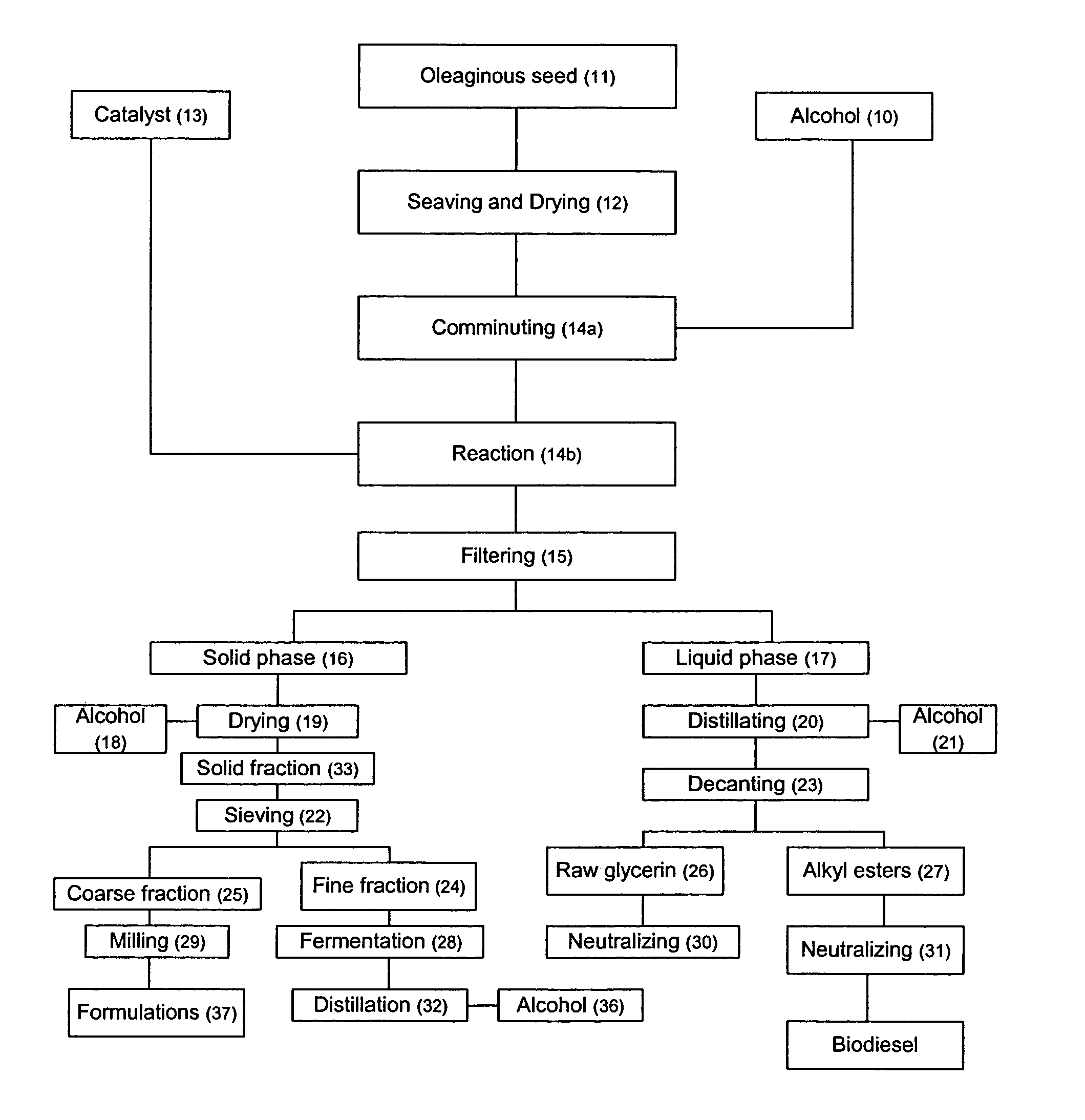

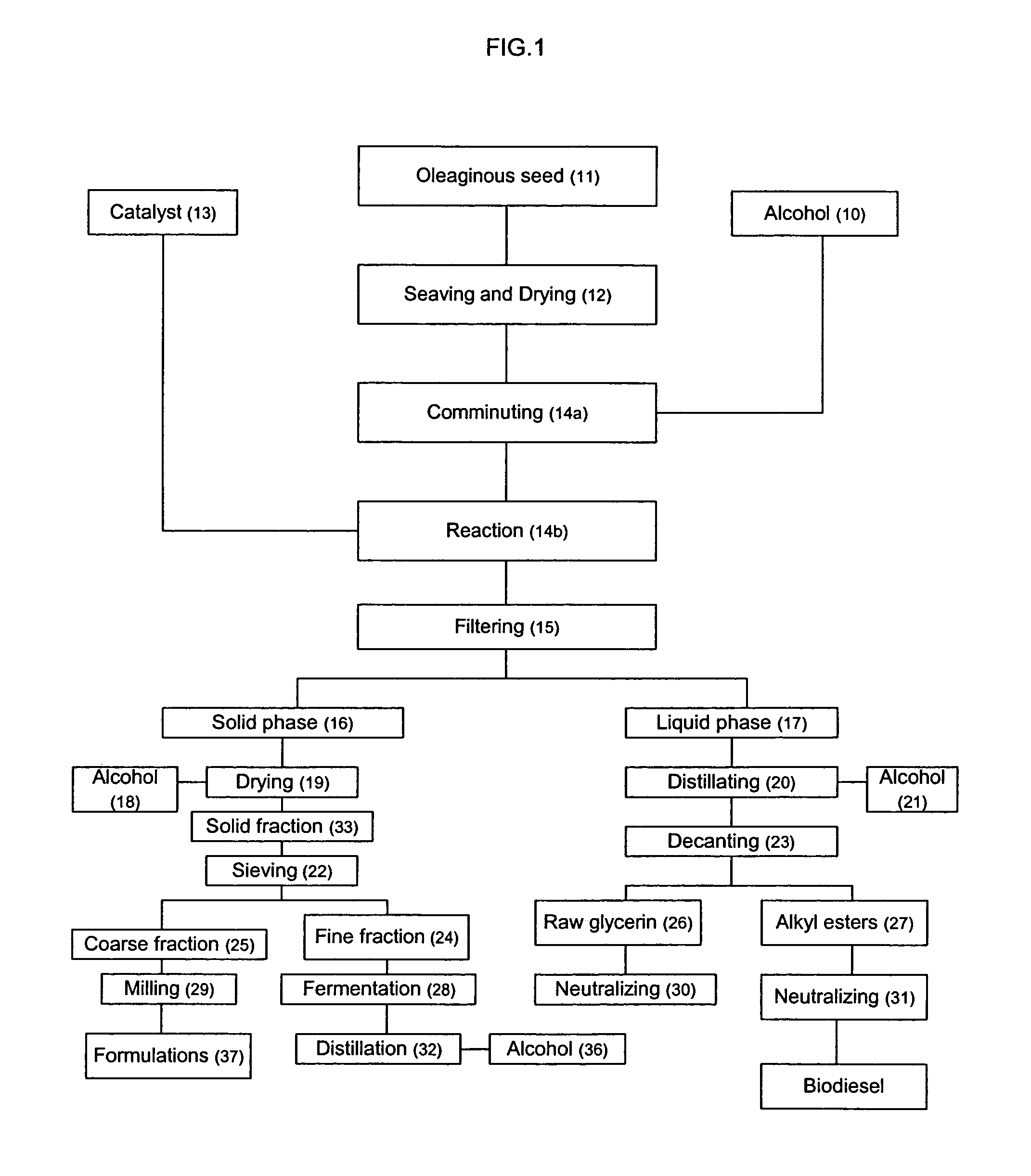

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

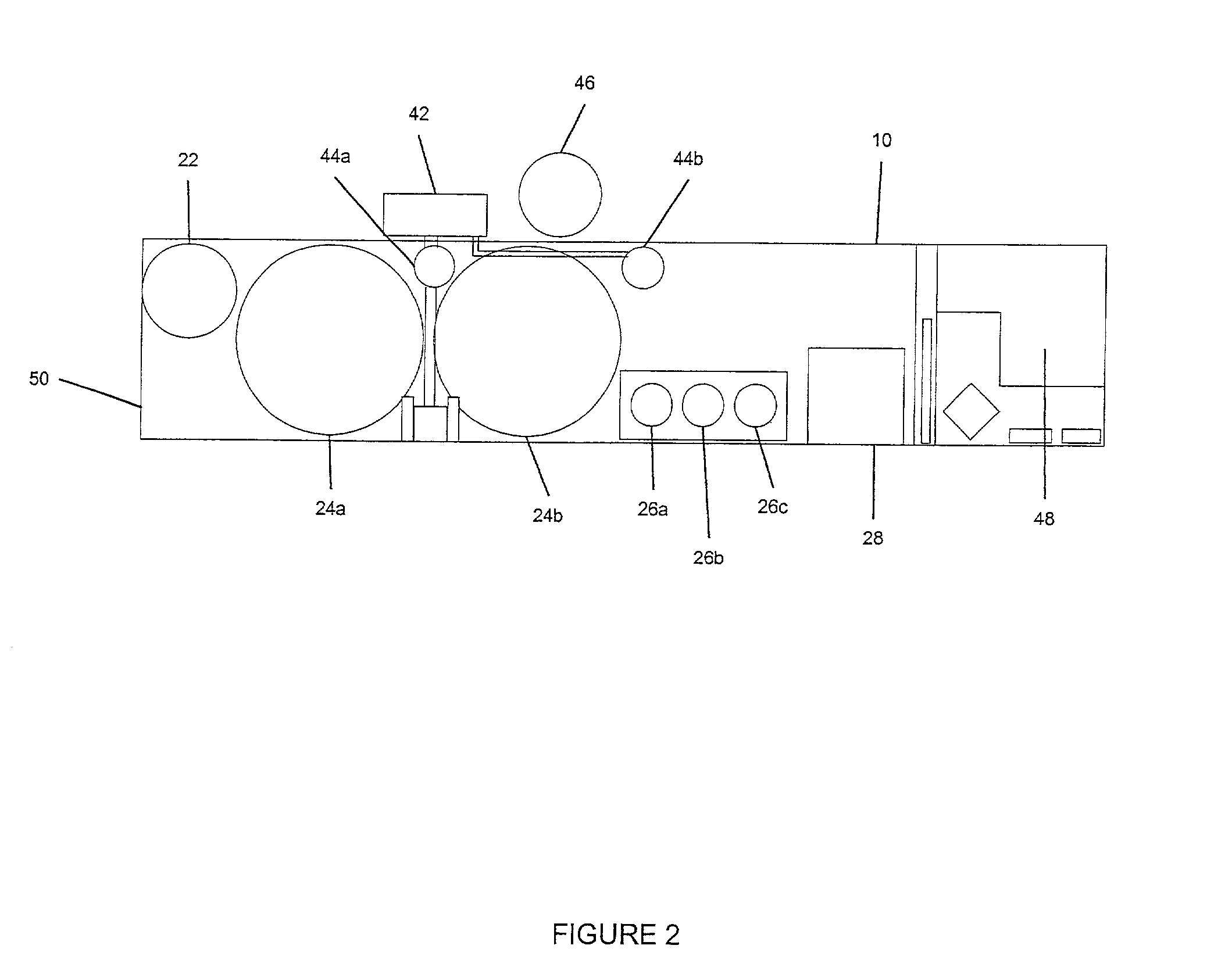

Biodiesel production unit

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

Chemical markers

Owner:ROHM & HAAS CO

Apparatus and methods for production of biodiesel

InactiveUS20080220515A1Improve efficiencyImprove cost effectivenessBioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselPhotobioreactor

A photobioreactor includes a cultivation zone configured to contain a liquid culture medium and facilitate growth of a microalgae biomass, a plurality of parallel edge-lit light transmitting devices mounted within the cultivation zone, and a collection zone oriented in relation to the cultivation zone such that at least a portion of the liquid culture medium and microalgae from the cultivation zone may be periodically harvested. Methods for illuminating algae, for dissolving materials into an algae medium, for extracting oil from algae, and for producing biodiesel from algal oil are also provided.

Owner:MIP

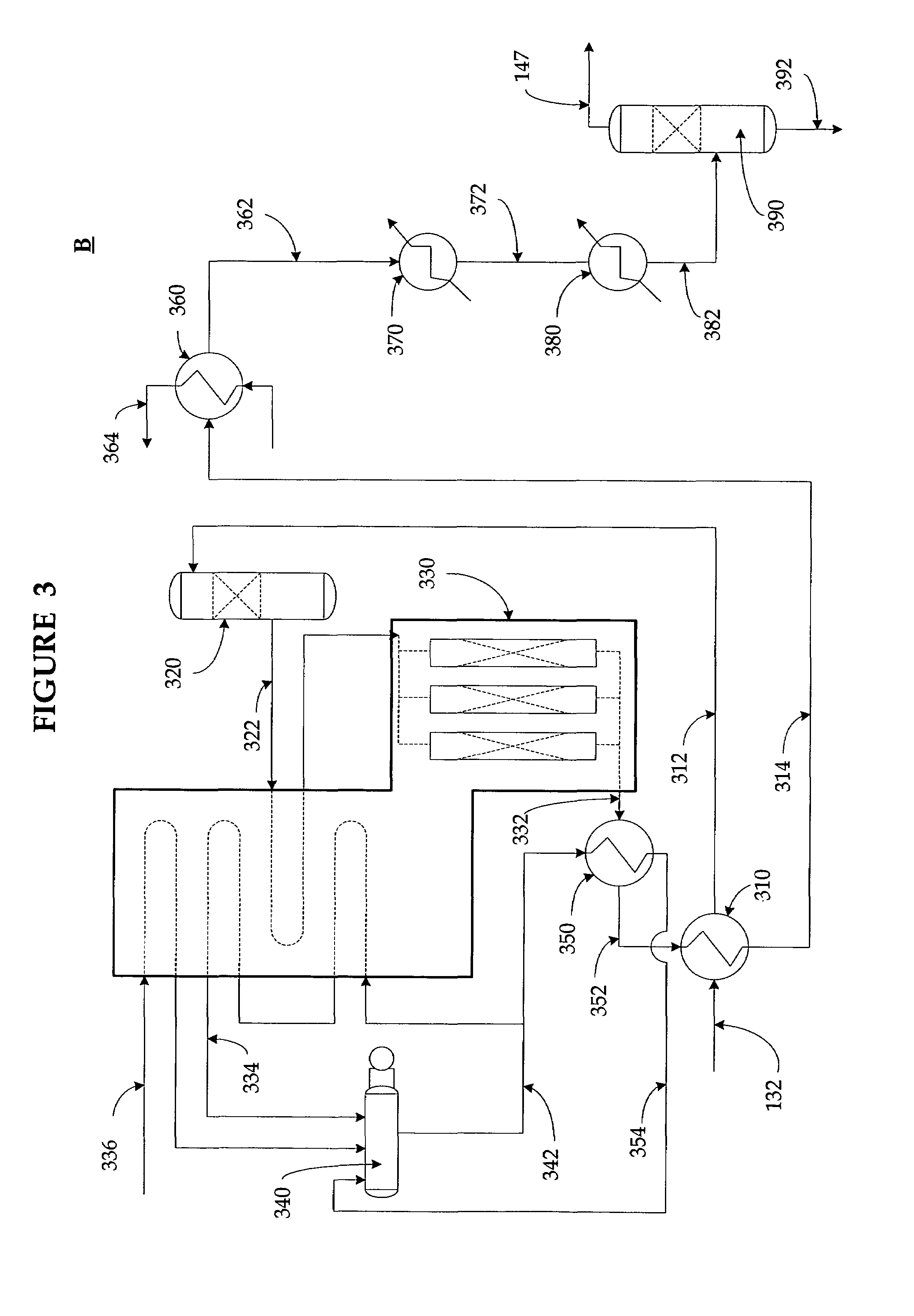

Method for producing bio-fuel that integrates heat from carbon-carbon bond-forming reactions to drive biomass gasification reactions

ActiveUS20070225383A1Improve thermal efficiencyImprove economyCatalytic crackingBiofuelsSyngasBiodiesel

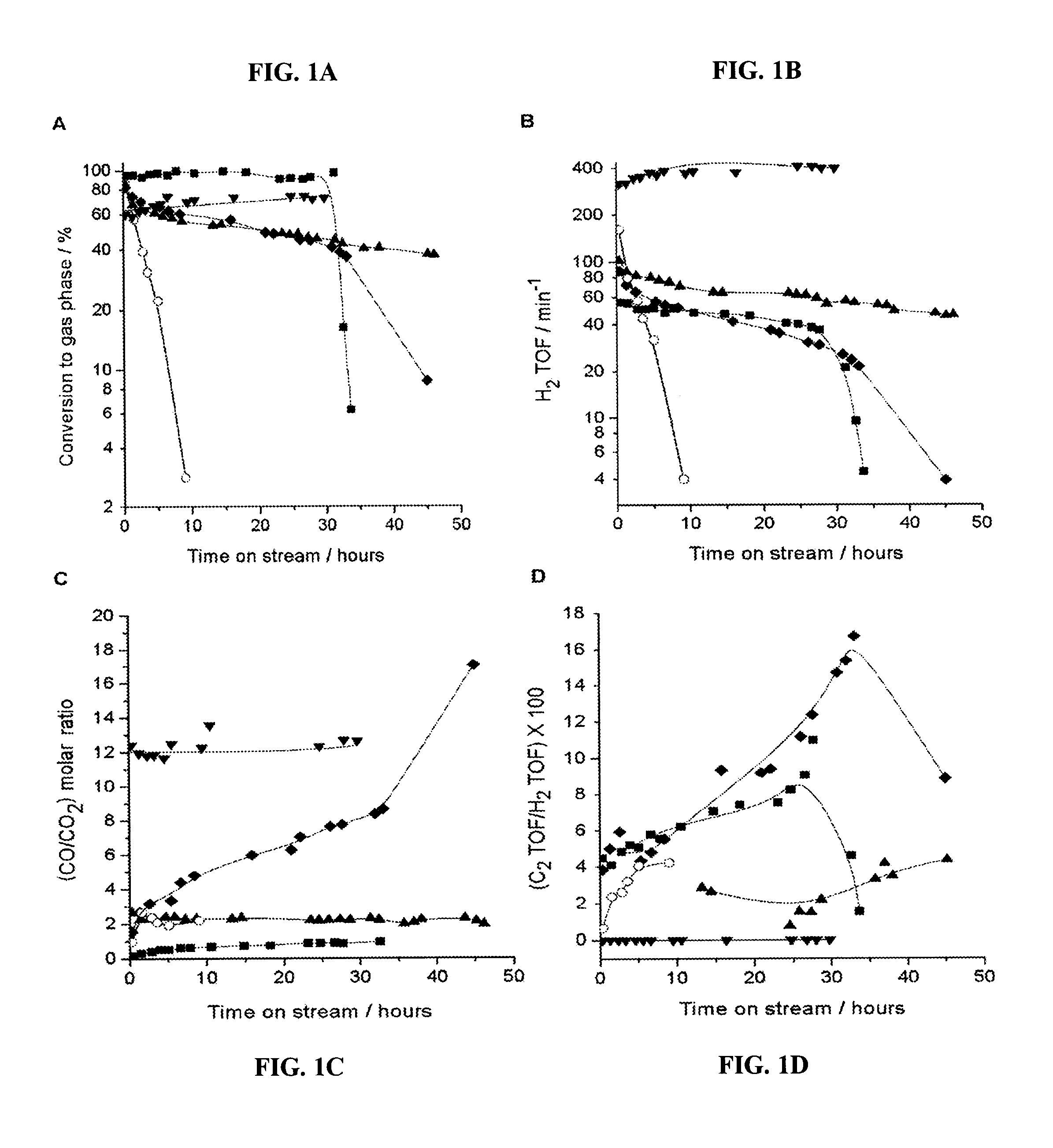

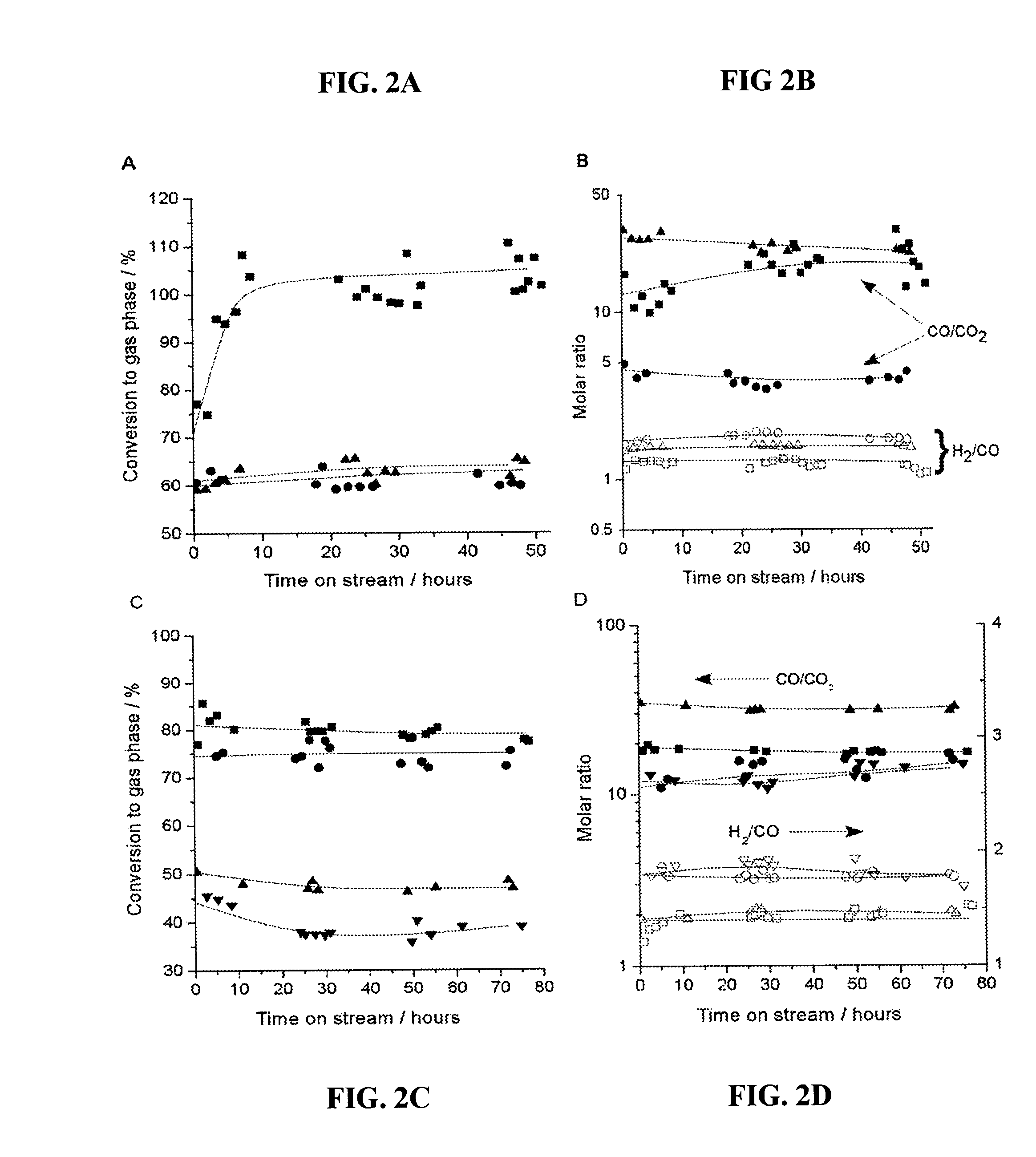

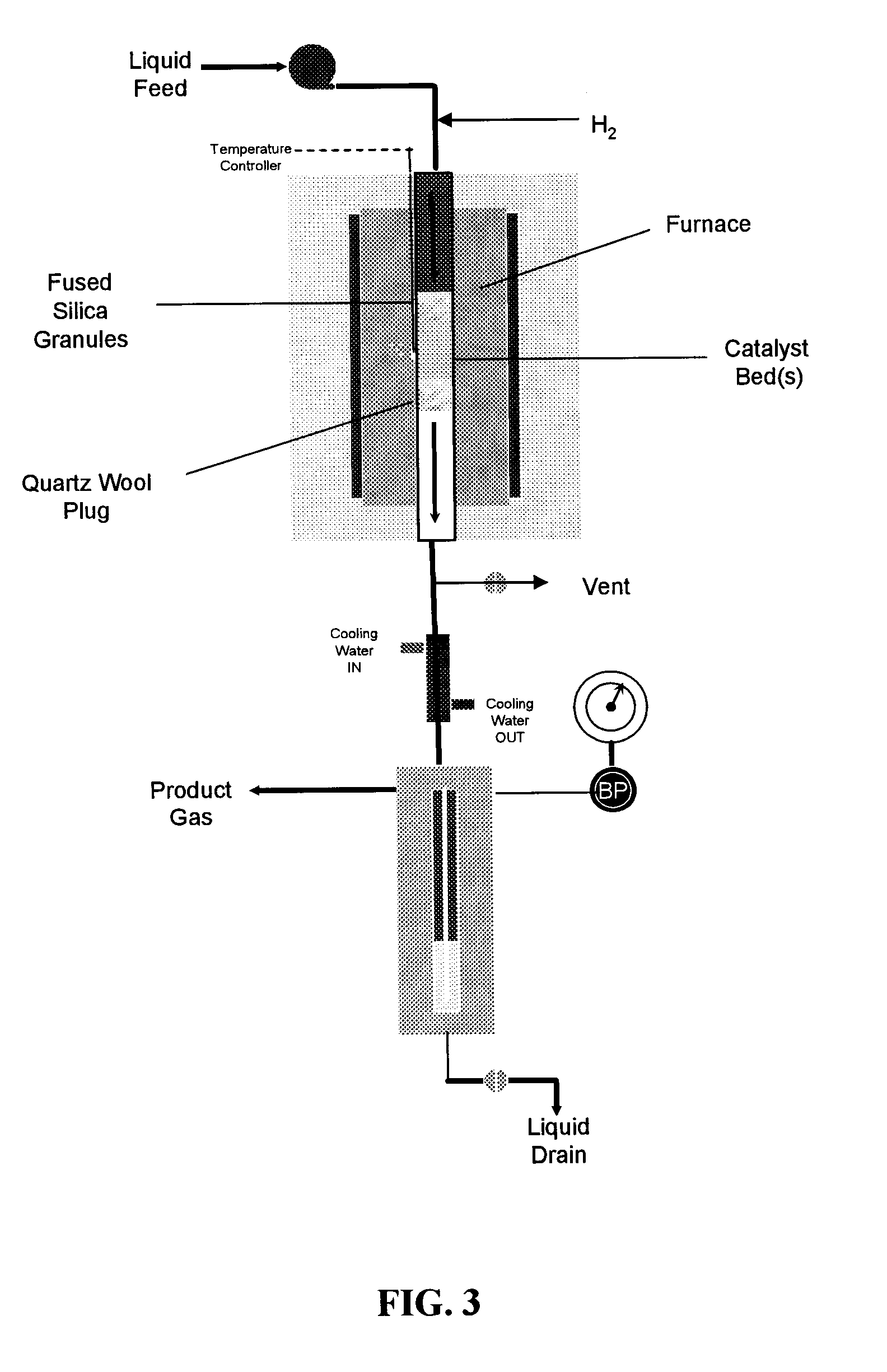

A low-temperature catalytic process for converting biomass (preferably glycerol recovered from the fabrication of bio-diesel) to synthesis gas (i.e., H2 / CO gas mixture) in an endothermic gasification reaction is described. The synthesis gas is used in exothermic carbon-carbon bond-forming reactions, such as Fischer-Tropsch, methanol, or dimethylether syntheses. The heat from the exothermic carbon-carbon bond-forming reaction is integrated with the endothermic gasification reaction, thus providing an energy-efficient route for producing fuels and chemicals from renewable biomass resources.

Owner:VIRENT +1

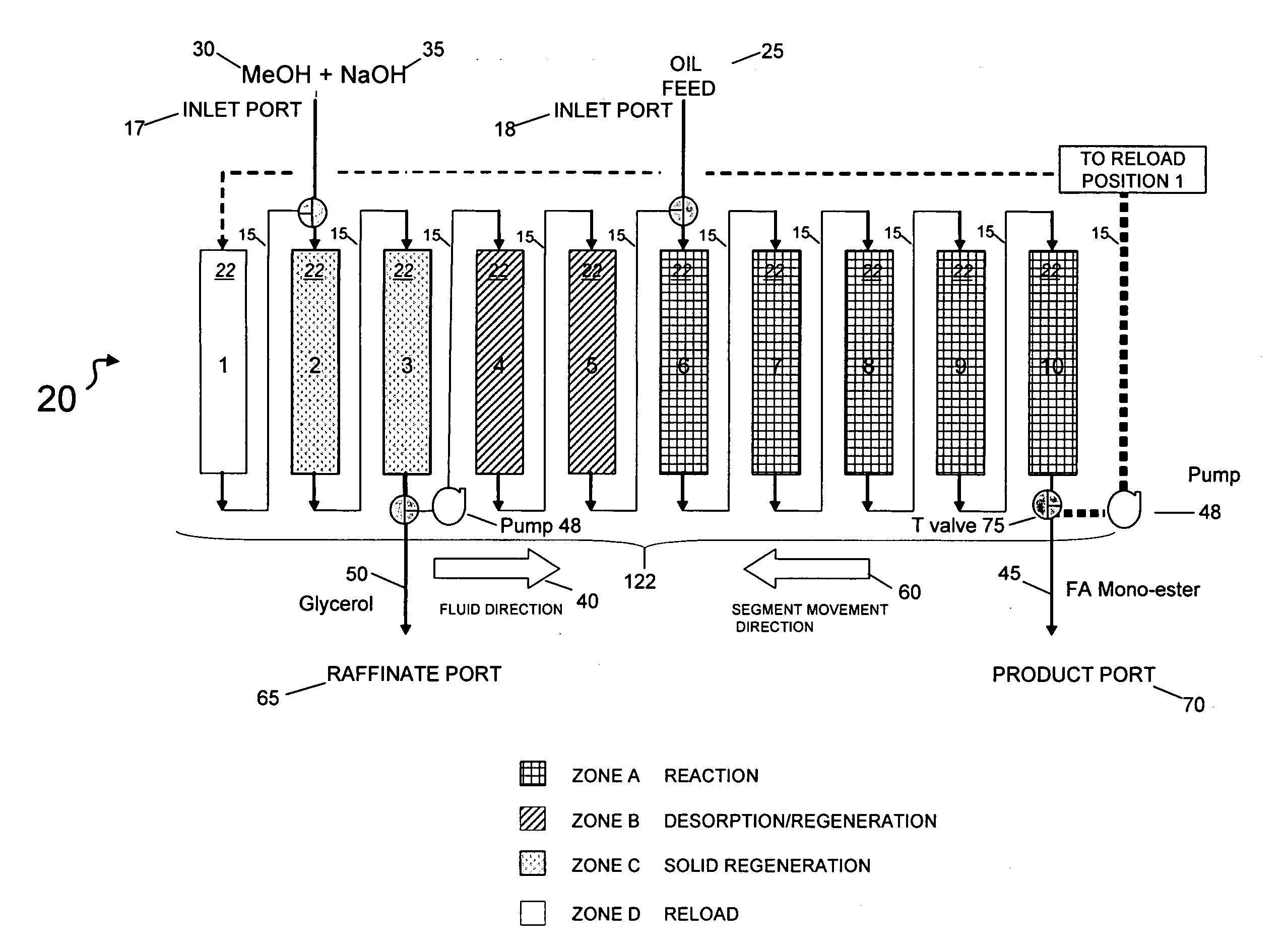

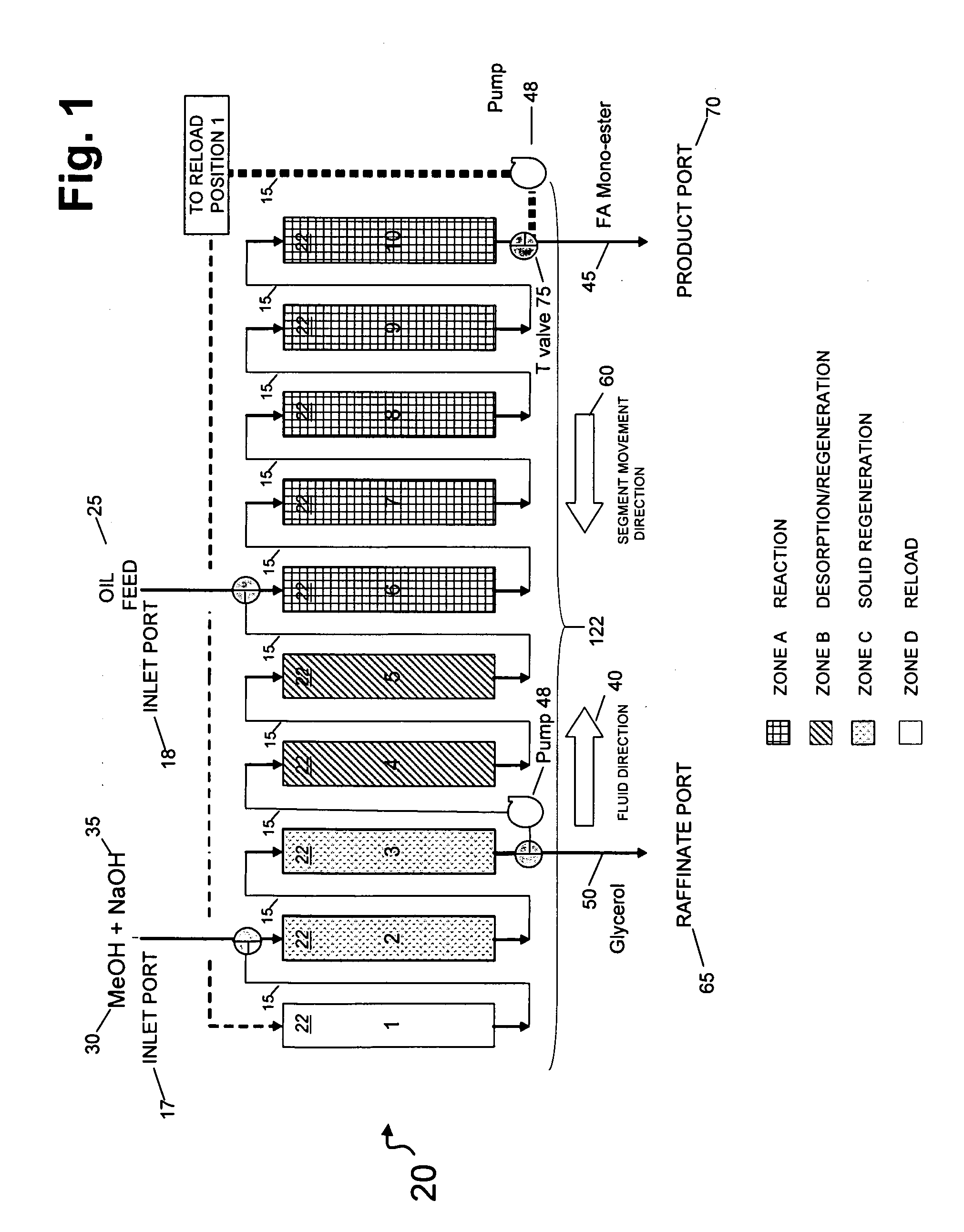

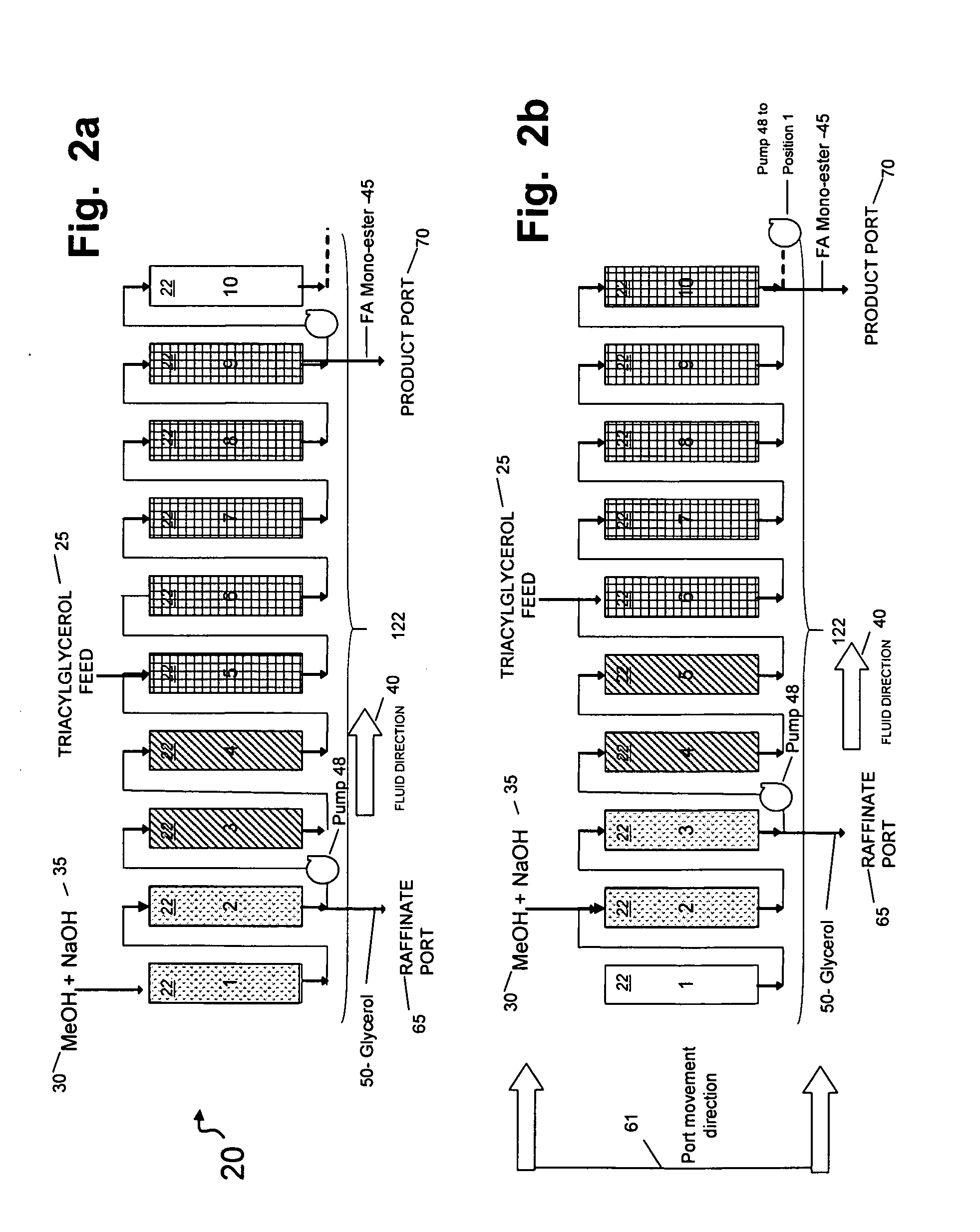

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel

ActiveUS20070158270A1Reduce contentLow costFatty oils/acids recovery from wasteFatty acid esterificationBiodieselAlcohol

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel from a triacylglycerol feedstock is described. In an exemplary method, the triacylglycerol feedstock is continuously contacted with a catalytic chromatographic bed comprising a first (solid phase) basic catalyst through a first port of a simulated moving bed chromatographic apparatus. A monohydric alcohol and optional second (mobile phase) basic catalyst is continuously contacted with the catalytic chromatographic bed through a second port and pumped in a first direction toward the triacylglycerol feedstock to contact the triacylglycerol in a reaction zone of the catalytic chromatographic bed where the fatty acid monoester and glycerol coproduct are formed. The fatty acid monoester is removed from the reaction zone through a product port of the simulated moving bed apparatus. Segments of the catalytic chromatographic bed are incrementally moved in a second direction, opposite the first direction, and the glycerol is removed from a raffinate port located opposite the product port of the apparatus.

Owner:ARCHER DANIELS MIDLAND CO

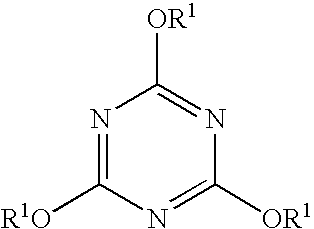

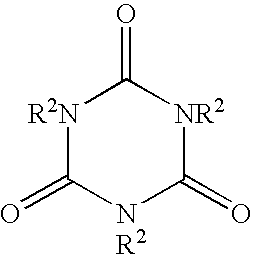

Method of increasing the oxidation stability of biodiesel

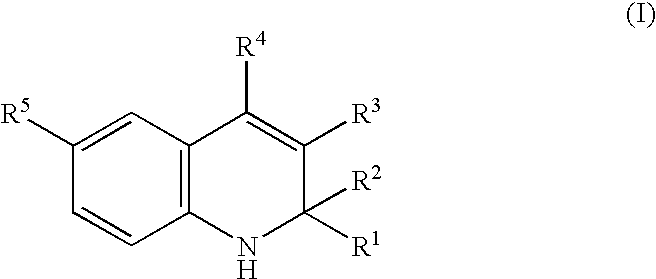

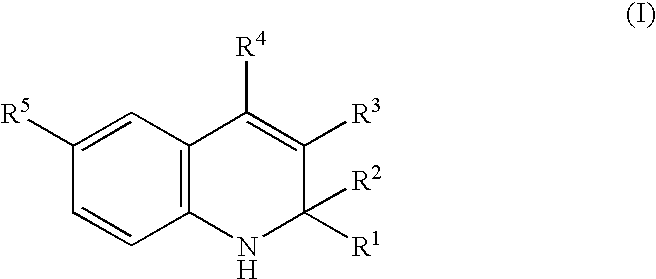

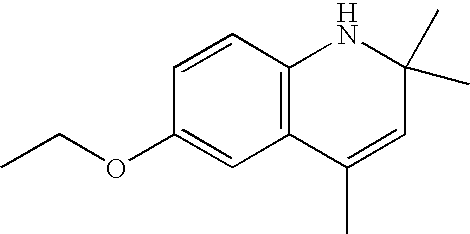

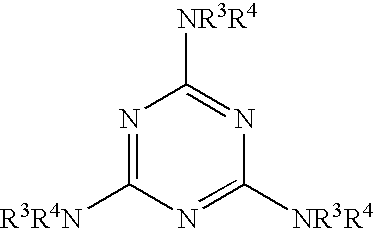

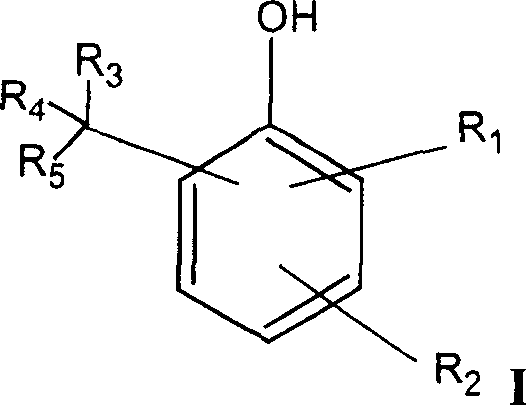

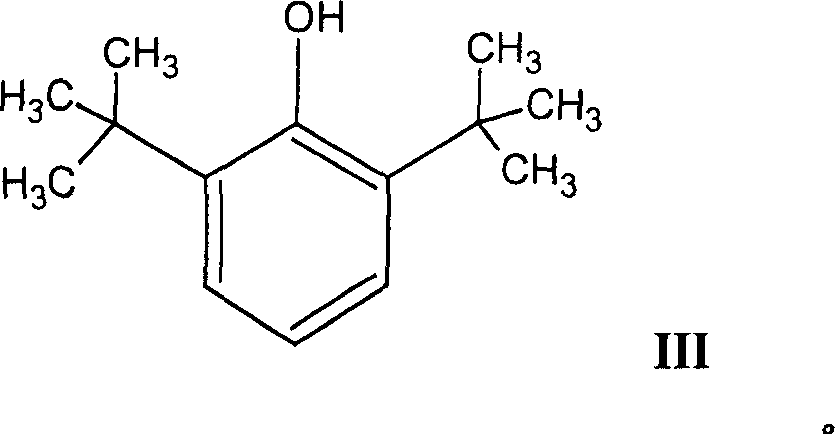

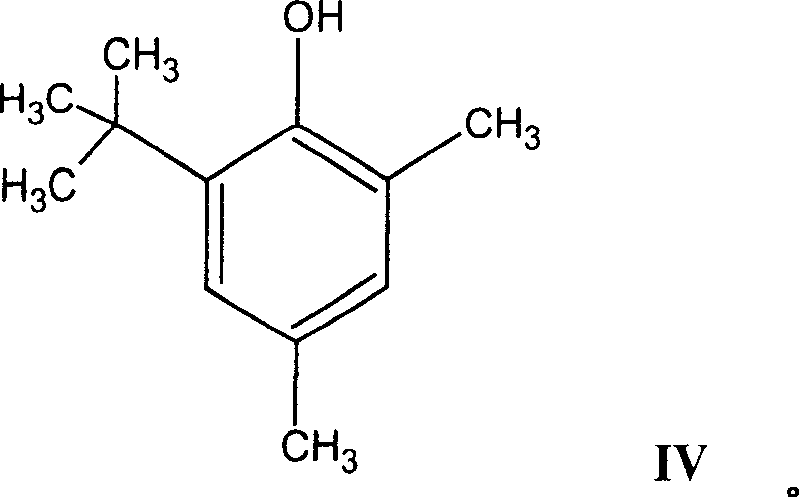

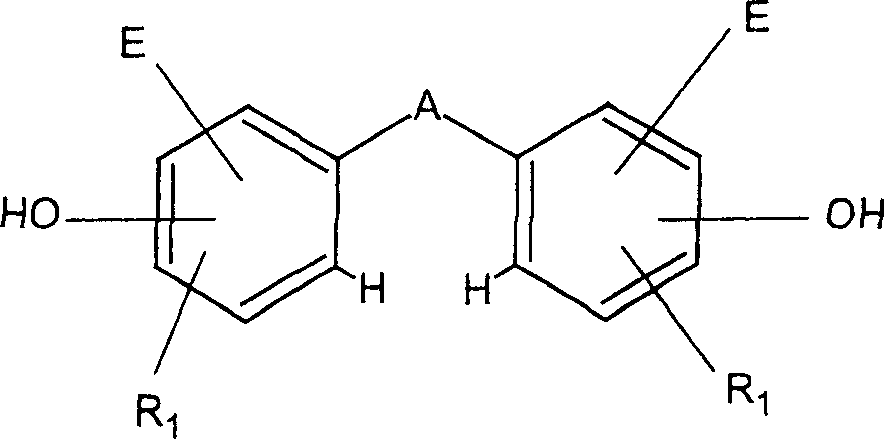

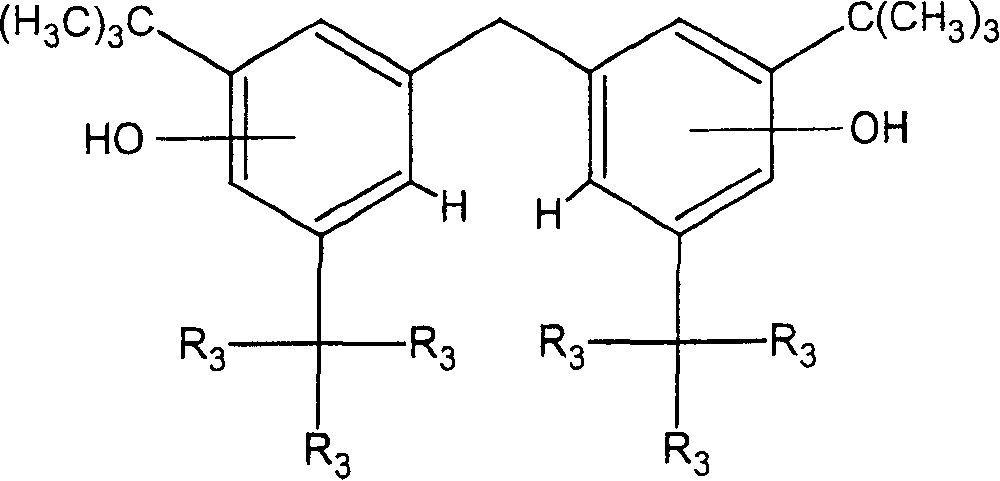

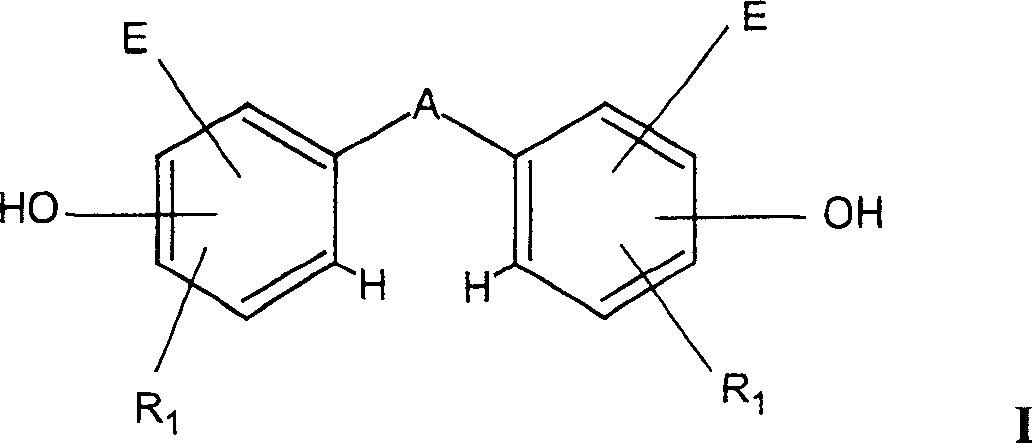

The present invention relates to a method for increasing the oxidation stability of biodiesel, which includes adding a main antioxidant with a melting point of less than or equal to 40°C in an amount of 10-20000 ppm (w / w) into the biodiesel to be stabilized, wherein the The primary antioxidant contains at least one compound of structure I, wherein R1, R2 = hydrogen, a linear alkyl group having 1 to 20 carbon atoms or, where * is a carbon atom of an aromatic ring system, R3, R5 = hydrogen, straight-chain alkyl group having 1 to 20 carbon atoms, R4 = hydrogen, straight-chain alkyl group having 1 to 40 carbon atoms, where the substituents of type R1 and R2 are the same as the substituents of type R3 and R5. Either the same or different in each case.

Owner:DEGUSSA AG

Method of increasing the oxidation stability of biodiesel

Owner:DEGUSSA AG

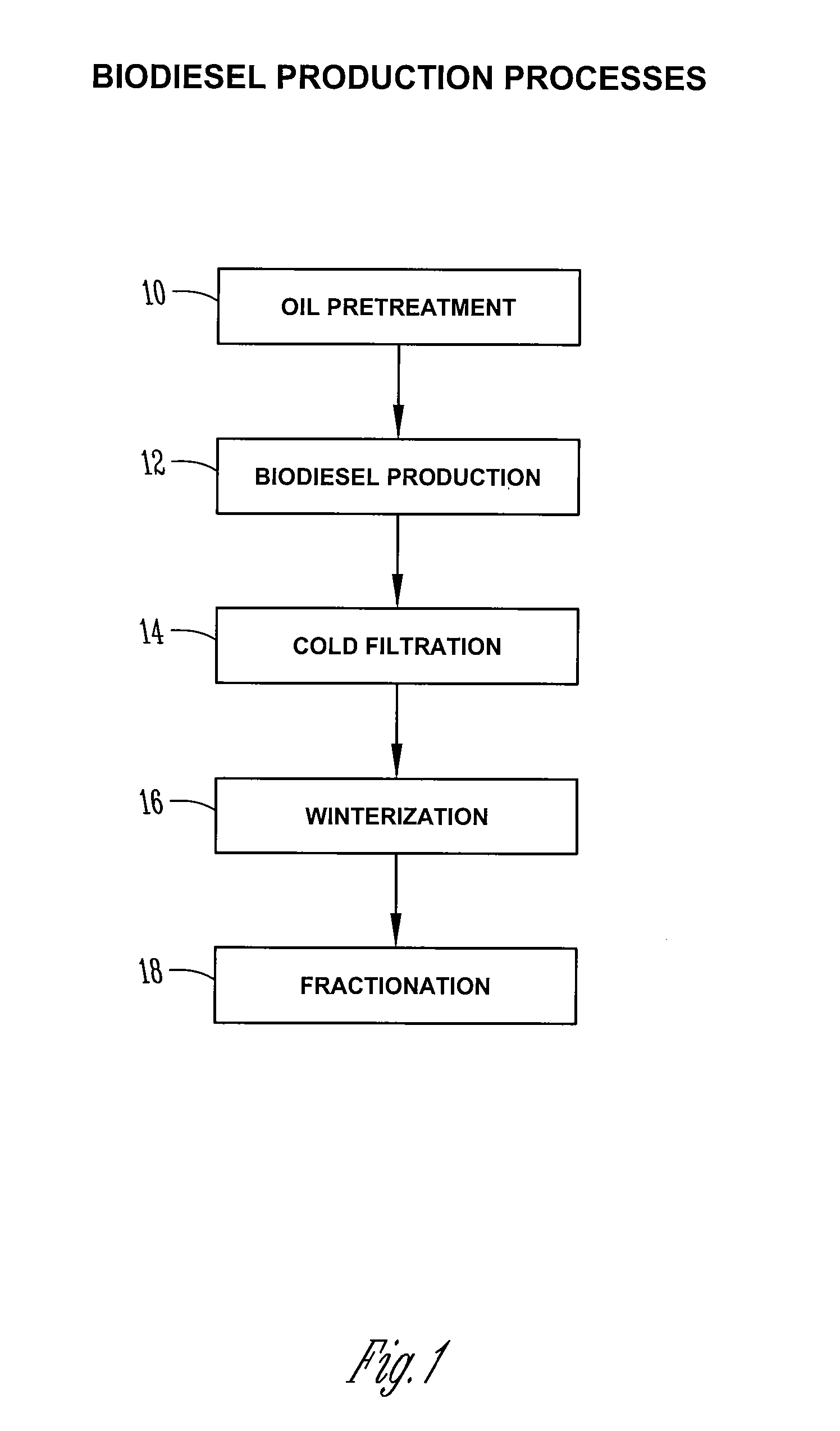

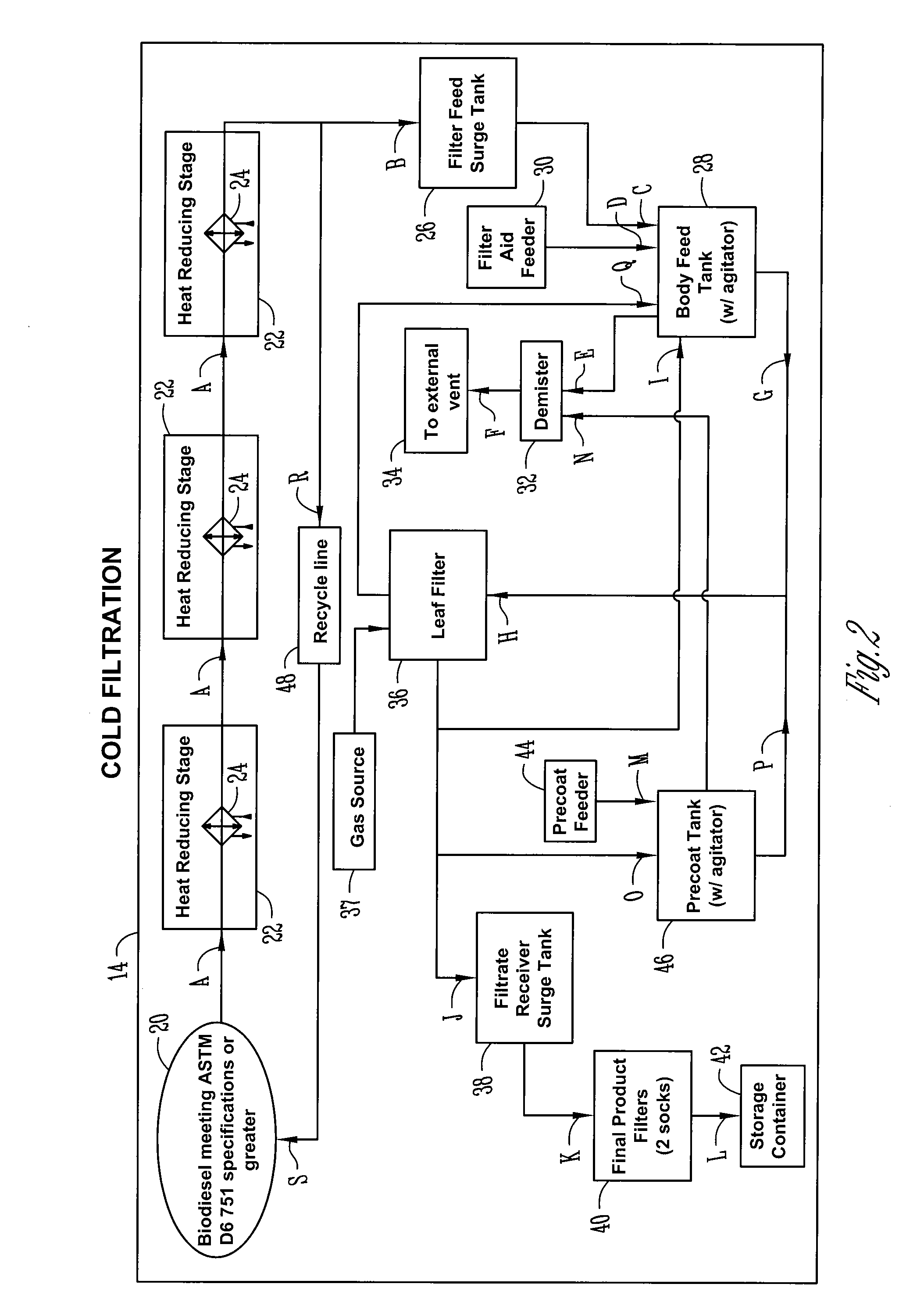

Biodiesel cold filtration process

An improved biodiesel production process includes the steps of processing a feedstock to produce biodiesel, cooling the biodiesel so as to form sediment, and filtering the biodiesel to remove the sediment. The resulting biodiesel from the cold filtration process avoids problems of sediment formation during storage and transportation.

Owner:REG BIOFUELS

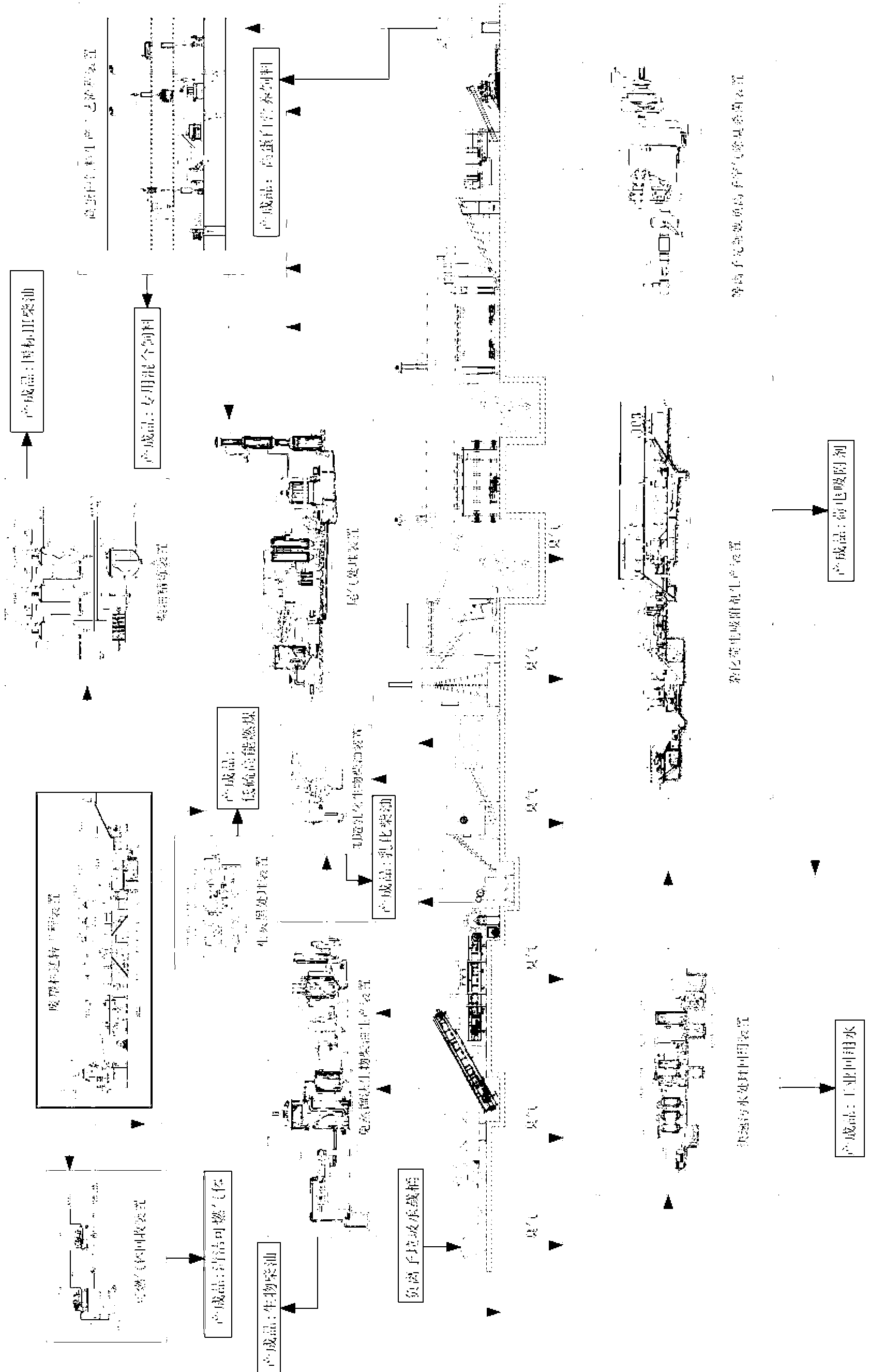

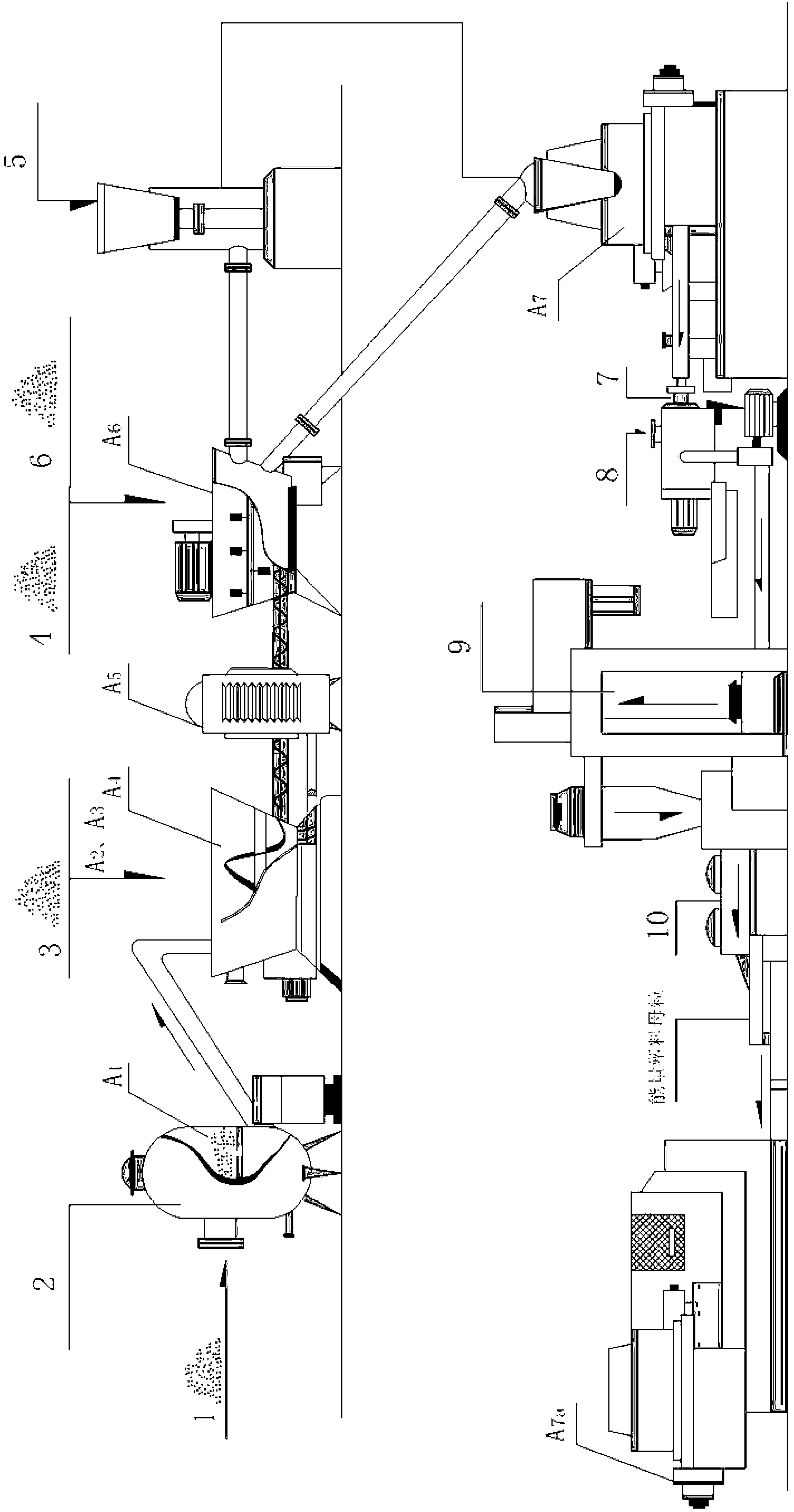

Integrated equipment for omnibearing treatment of kitchen garbage and production method of products

InactiveCN103071666ANo secondary pollutionIncrease added valueSolid waste disposalBiofuelsAutomatic controlBiodiesel

The invention discloses integrated equipment for omnibearing treatment of kitchen garbage and a production method of products. The equipment comprises a central intelligent automatic control system, an air treatment system, a straw biochemical system, an advanced oxidization artificial forced inactivation system, a combined screening and impurity removal system, a compound biochemical system, an automatic drying system, a combined conveying system, a waste plastic reversion engineering system, a sludge treatment system, a sewage treatment system, an oil treatment system and a hot smoke combined treatment system. Produced finished products comprise high-nutrition microbial protein feed, mineral state III diesel, biodiesel, emulsification diesel, low-sulfur clean fire coal, hybrid charge adsorbents and industrial recycle water. A recycling rate of the kitchen garbage reaches above 95%; basically no waste water is discharged, no sludge is transferred, no room temperature discharge exists, no peculiar smell or smoke is discharged and no residue is transferred during production; and the environment-friendly, safe and reliable highly-integrated production equipment and the production method are provided for the treatment of the kitchen garbage.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

Method for preparing biodiesel by solid acid-base catalyst

InactiveCN1580190AWide variety of sourcesNo pollution in the processBiofuelsLiquid hydrocarbon mixture productionWater bathsBiodiesel

The invention relates a kind of preparation method of bio-diesel oil under the condition of solid ac and alk catalyzing. The character is that under the condition of solid ac and alk catalyzing, gain the bio-diesel oil using the craft of exchange reaction of soja oil with carbinol. Afer the reaction, apart catalyser from reaction liquor by centrifugal machine till delimination in quiet placing, the above is rough output, the below is admixture of glycerol and carbinol. Distil the of above to gain bio-diesel oil and to gain the pure glycerin in the same way. The distilled carbinol can be used again and again. The invention has many advantages, for example, its raw material can be rebirth, its craft is easy and only need normal equipment. Even treat the used oil, the whole process is easier compared with the method in solid ac and alk catalyzing, besides, the process will not produce foul water so it is environmental. Every plant of the bio-diesel accords with standards compared with foreign similar competitive grade and the main plants are close to its of 0# (GB252-1994, superior product)diesel of China.

Owner:BEIJING UNIV OF CHEM TECH

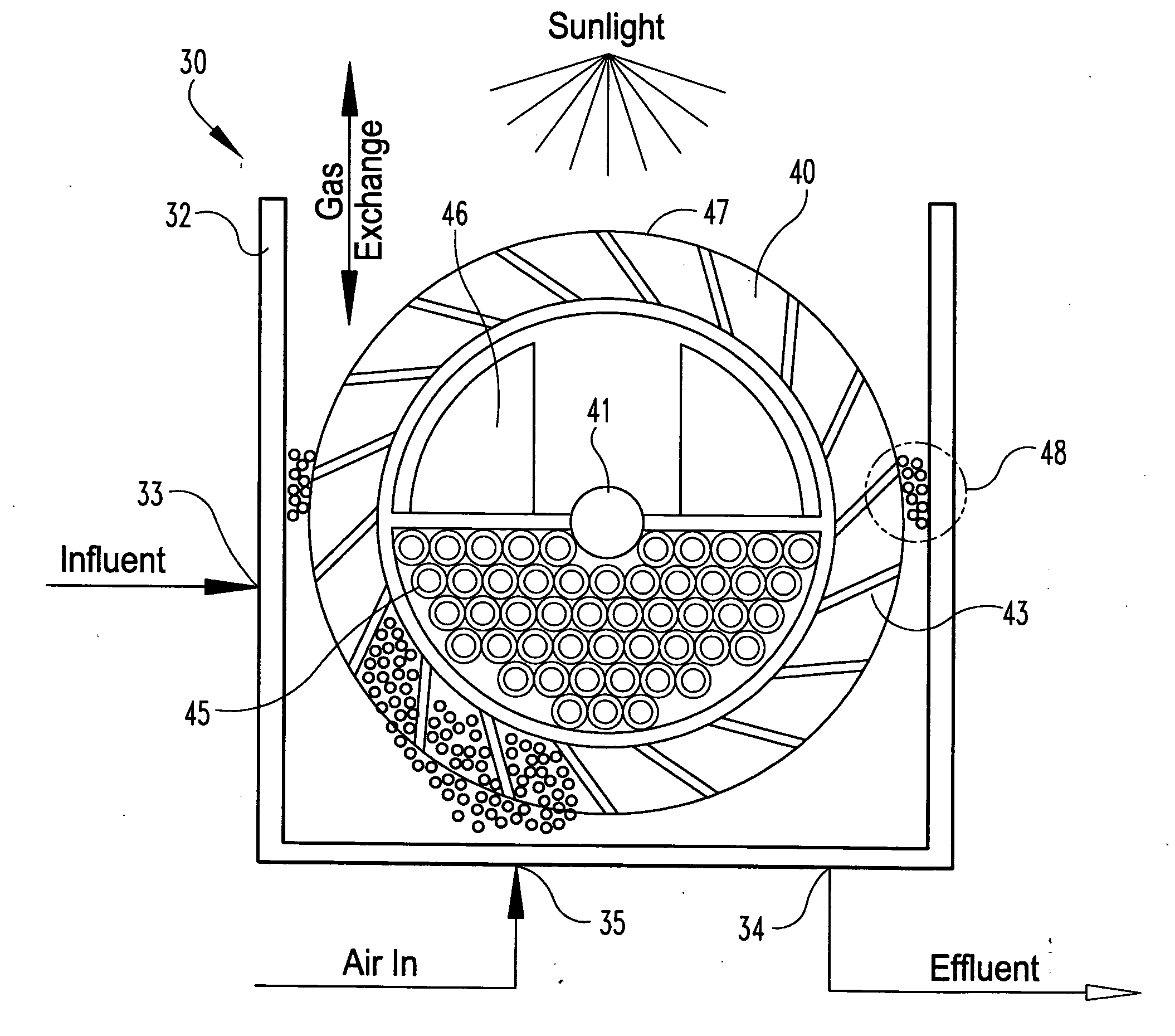

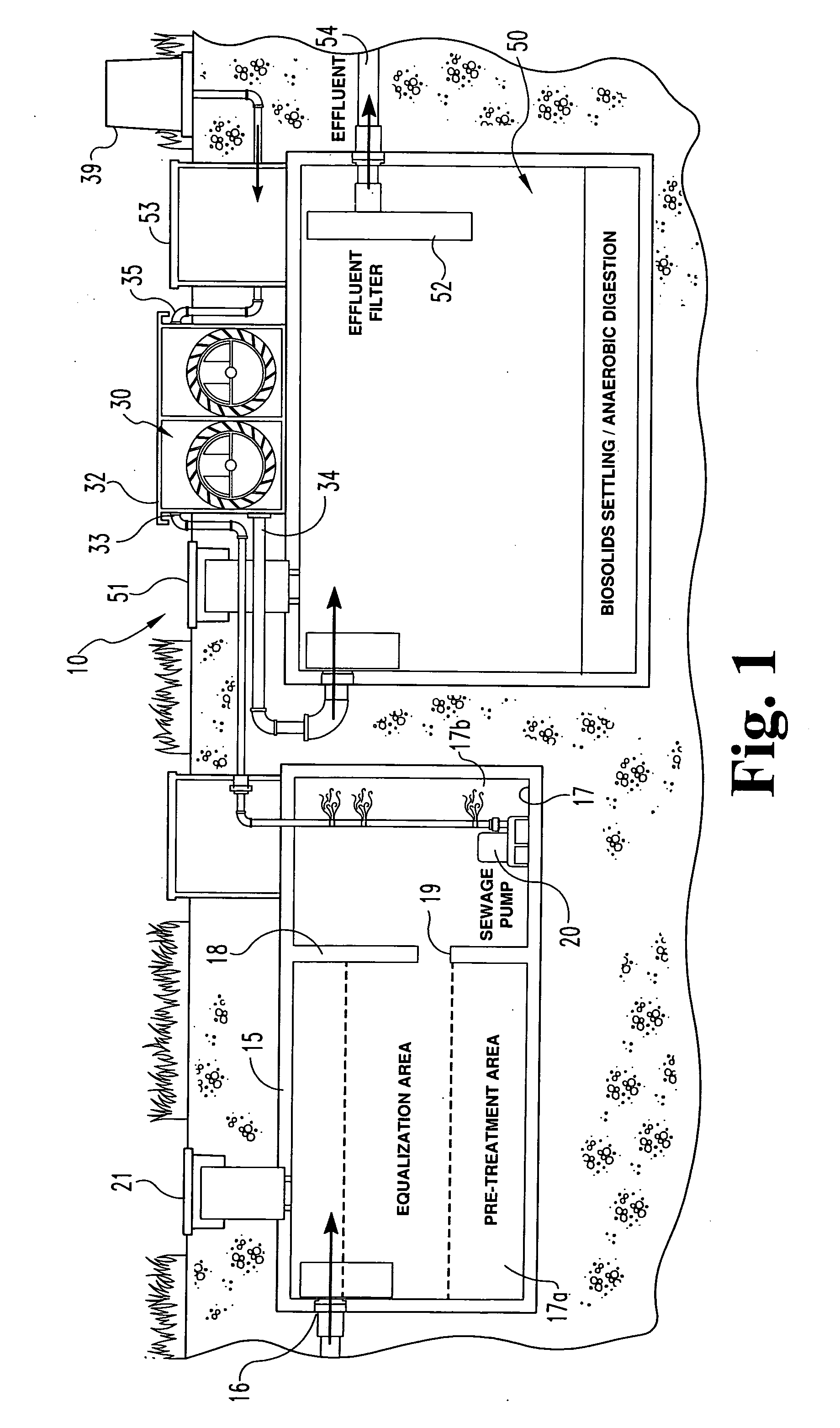

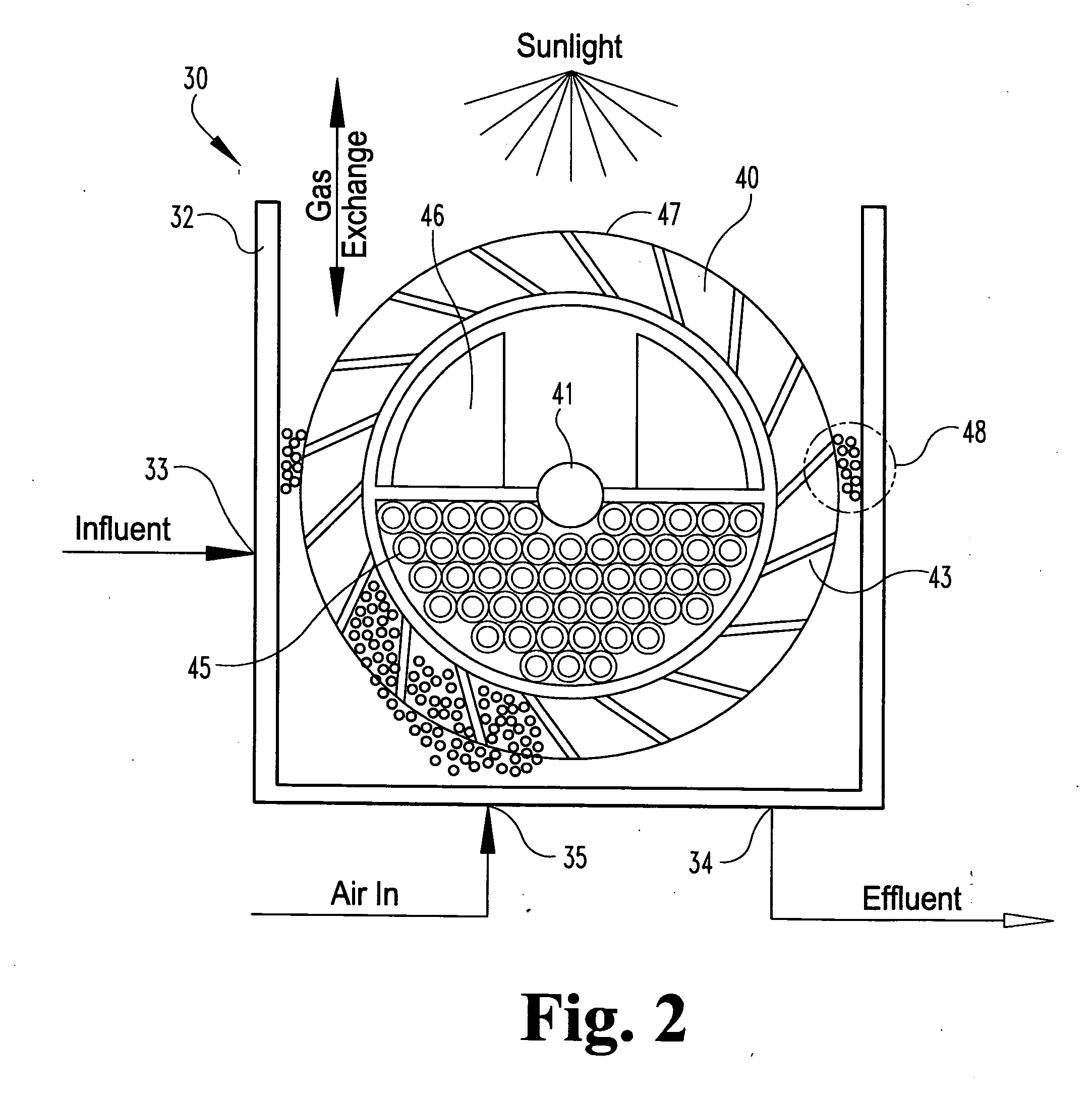

System and Method for Biological Wastewater Treatment and for Using the Byproduct Thereof

ActiveUS20080135474A1Cost effectiveFree energyTreatment using aerobic processesOther chemical processesBiodieselToxic material

A wastewater treatment system and process includes a treatment system for biologically treating wastewater to produce substantially clean water effluent and byproducts. The treatment system includes an array of rotating media wheels for sustained algae growth. The media wheels are supported so that the algae rotates into and out of the wastewater for exposure to sunlight. One byproduct is algae removed from the rotating media wheels, which may be provided to other processing facilities to produce, for instance, bio-diesel fuel. Waste CO2 may also be provided to the facility for enhanced algae growth. Bacteria is provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. Rotation of the media wheels can be accomplished by air jets that also operate to dislodge excess algae as a byproduct of the system and process.

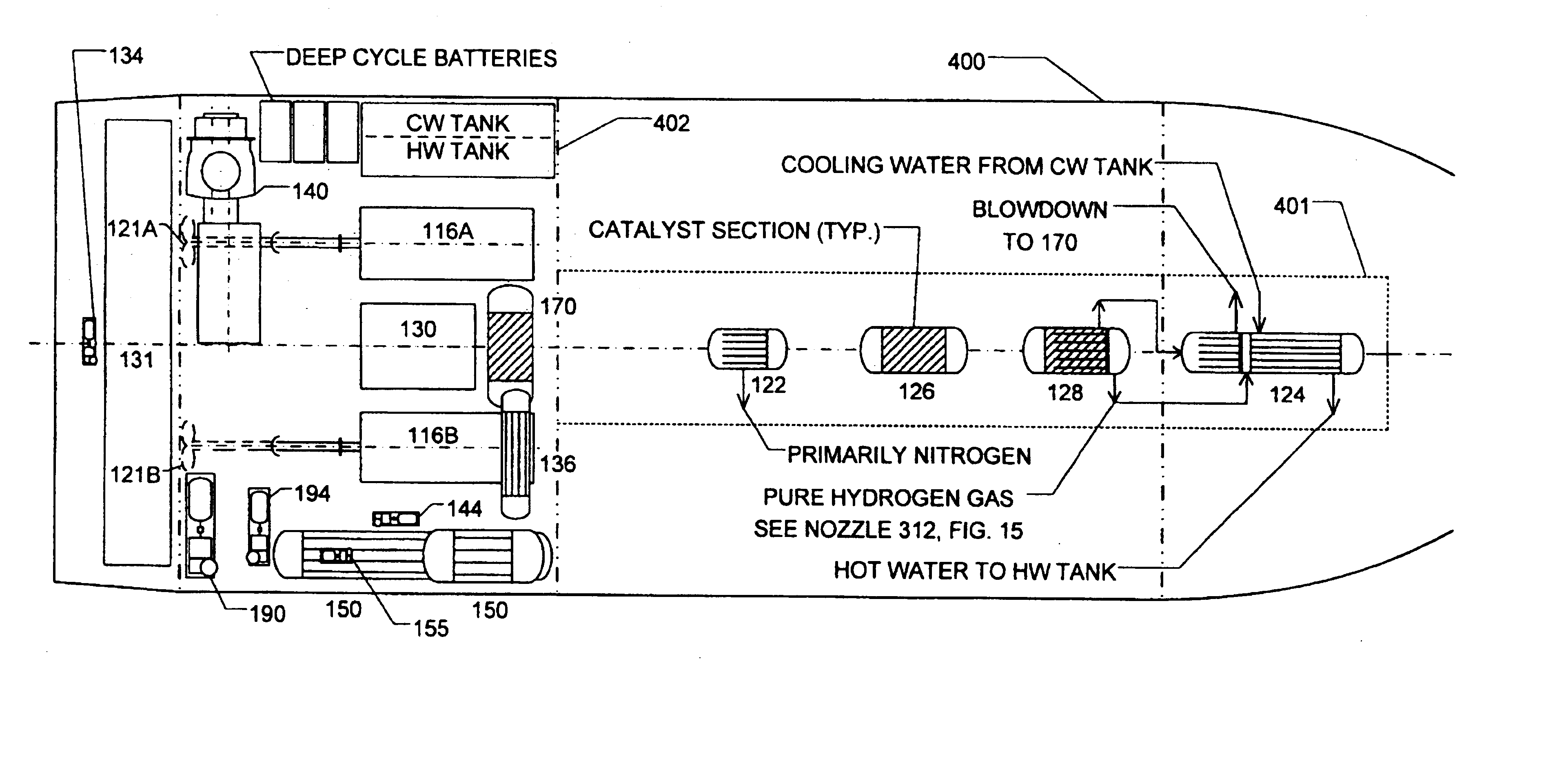

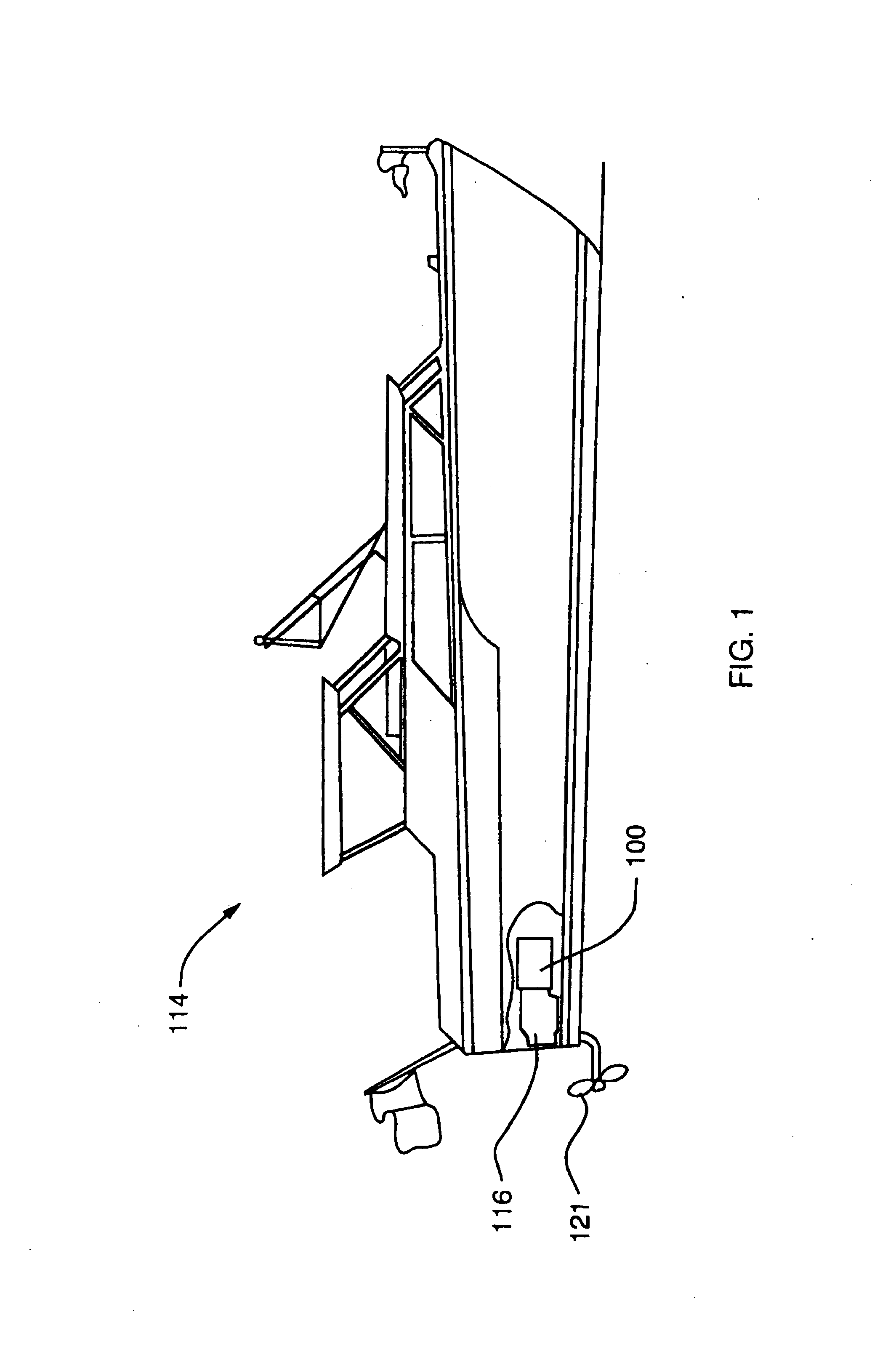

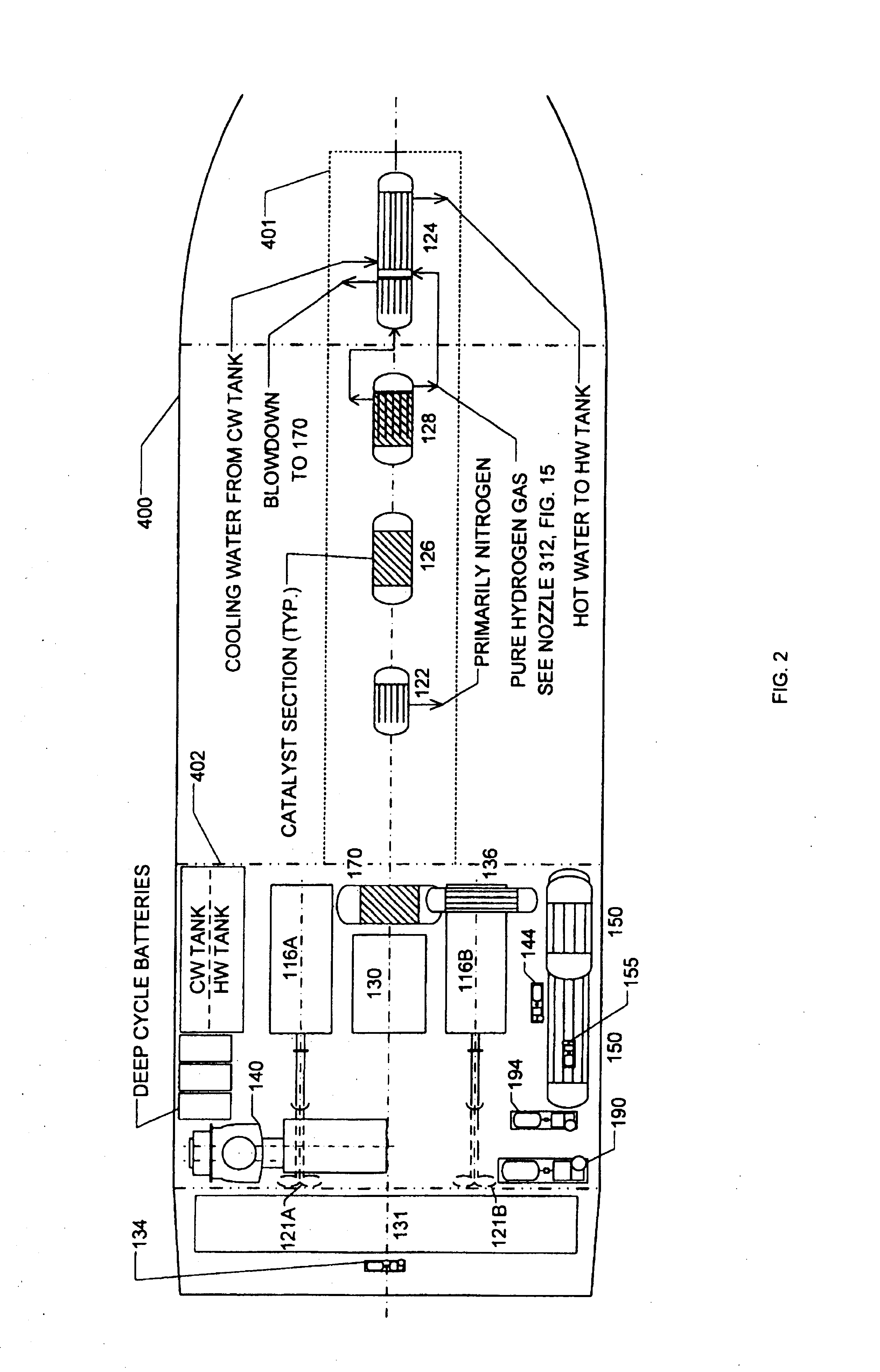

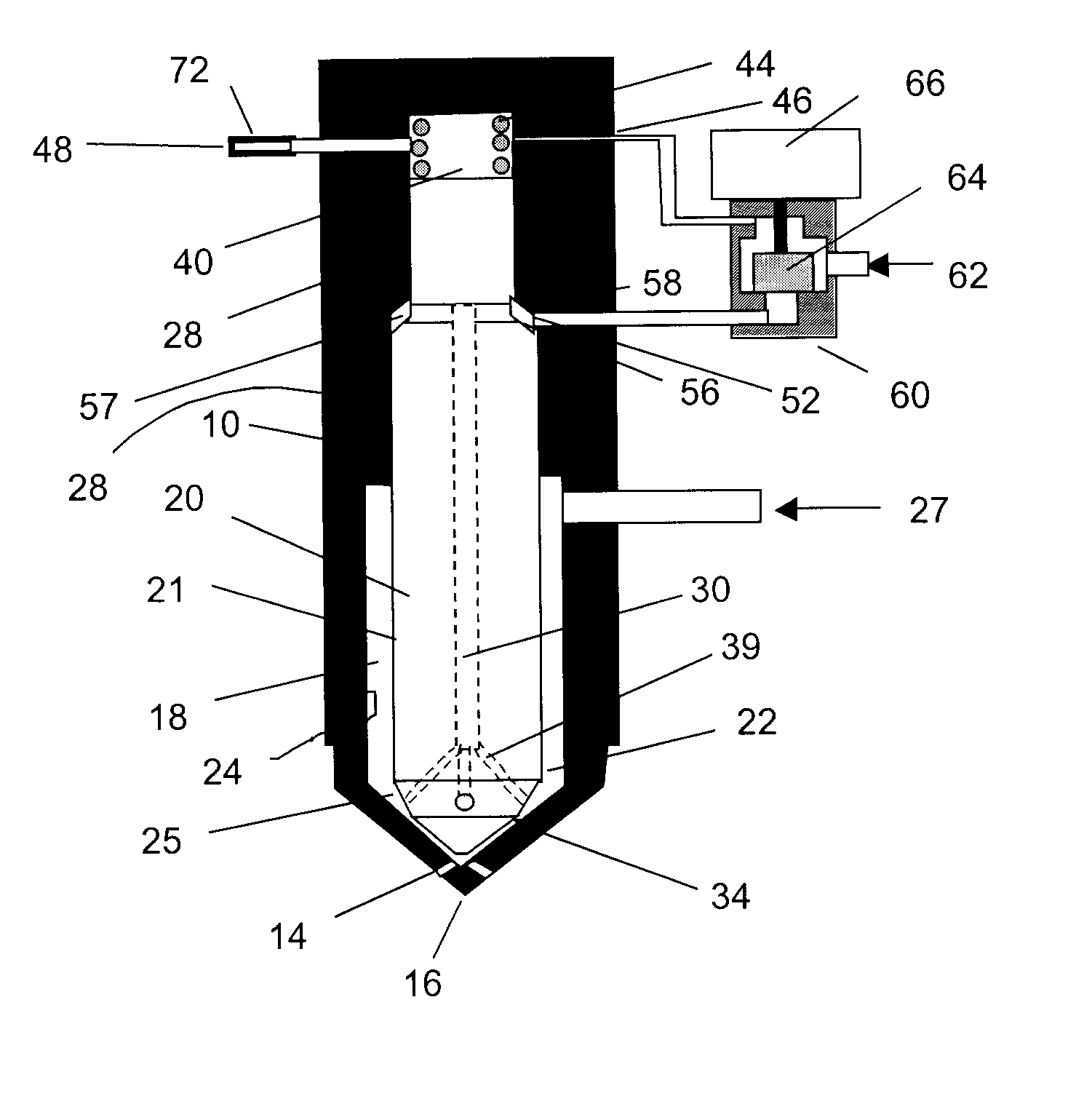

Fuel cell system with integrated fuel processor

InactiveUS20070122667A1MinimizesMaximize heat utilizationHydrogenOxygen/ozone/oxide/hydroxideBiodieselWater balance

A fuel cell system with fuel processor for integration with a marine vessel propulsion system. The system includes an auto thermal reactor that is the fuel processor for producing hydrogen from a fuel source. The fuel source is preferably ethanol or biodiesel or a mixture thereof, but can also be a sulfur containing fuel like petrodiesel of JP-8. The system further includes a gas-water shift reactor for further production and concentration of the hydrogen from the auto thermal reactor output. The system also includes a hydrogen permeable membrane separator for generating suitable quantities of essentially pure hydrogen to the fuel cell. The system also includes an oxygen permeable membrane separator for concentrating oxygen and reducing nitrogen to improve the partial pressure of hydrogen in subsequent fuel processing steps. The system contemplates the use of a Polymer Electrolyte Membrane (PEM) fuel cell. The system minimizes preheating of catalysts or other components to the extent just needed to initiate the fuel processor. To that end, heat sources and sinks of the system and associated usage systems are matched so as to minimize heat collection, storage and distribution systems. Water is recycled within the system to the extent necessary to maintain a water balance in the fuel processor and the fuel cell stack(s). The system includes cooling of the fuel cell stack(s) and integrated heat recovery with exothermic and endothermic catalysts. The fuel processor / fuel cell system components are configured to conform to and take advantage of the available space and limitations, such as the space constraints and opportunities associated with a marine vessel.

Owner:KELLEY RICHARD H

Concurrent Injection Of Liquid And Gaseous Fuels In An Engine

InactiveUS20100199948A1Internal combustion piston enginesFuel supply apparatusBiodieselCombustion chamber

Disclosed is a method and corresponding fuel injector for injecting gaseous and liquid fuel into an engine. The method comprises delivering a liquid fuel to a fuel injector, delivering a pressurized gaseous fuel to the fuel injector, entraining the liquid fuel within the gaseous fuel within a chamber of the fuel injector and injecting the gaseous fuel and atomized liquid fuel into the combustion chamber. The liquid fuel can be passed through and dispensed from a needle into a chamber in the injector nozzle where it is entrained in the gaseous fuel during an injection event. The liquid / gas mass ratio is controlled by the needle movement, hydraulic resistances or electronic valves so that the majority of the liquid is injected during the first part of the gas injection. The injector can be used for late cycle direct injection of natural gas, or any number of gaseous fuel blends combined with many liquid fuels such as diesel, biodiesel and DME.

Owner:THE UNIV OF BRITISH COLUMBIA

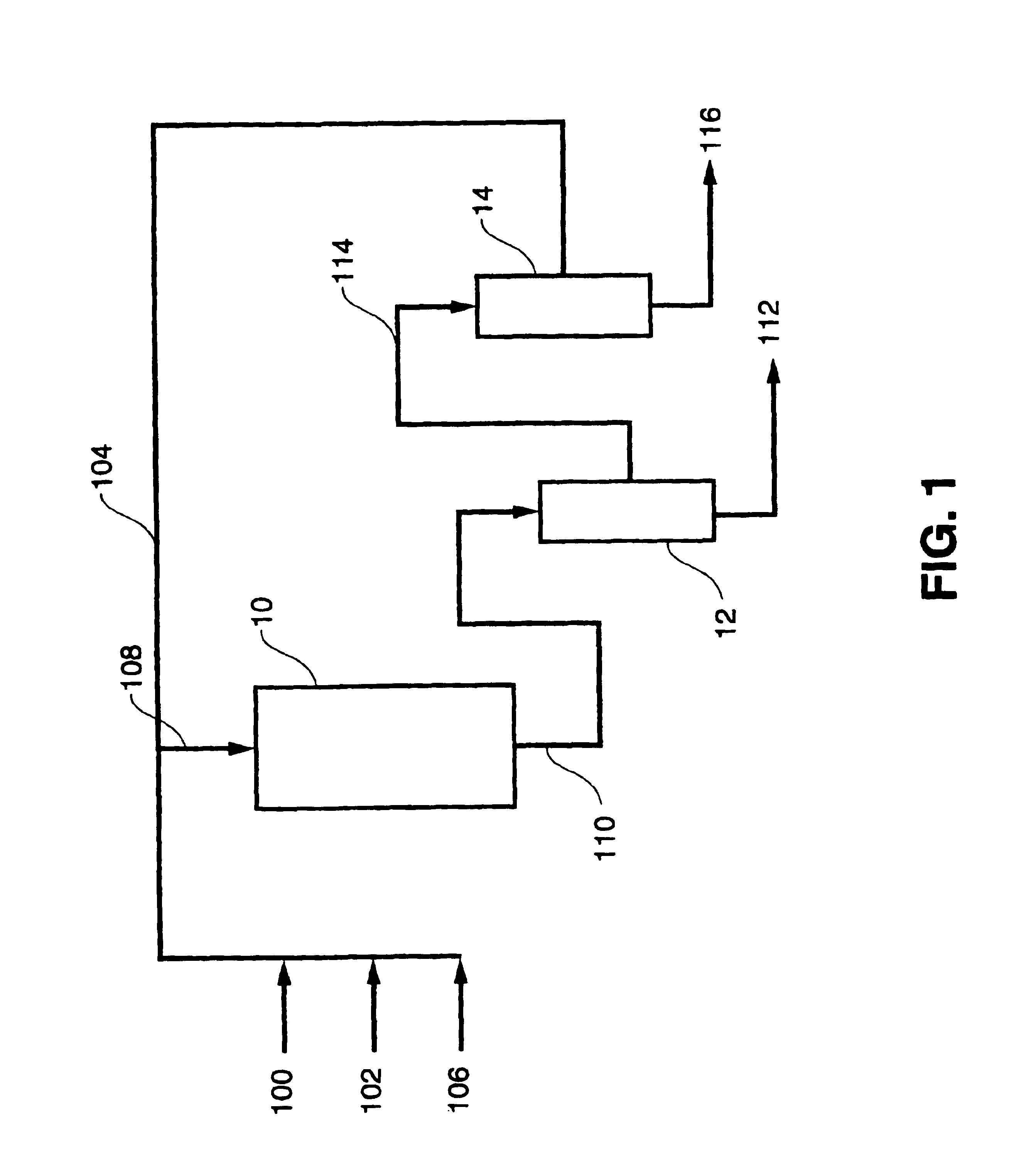

System and method for extracting energy from agricultural waste

InactiveUS20050113467A1Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

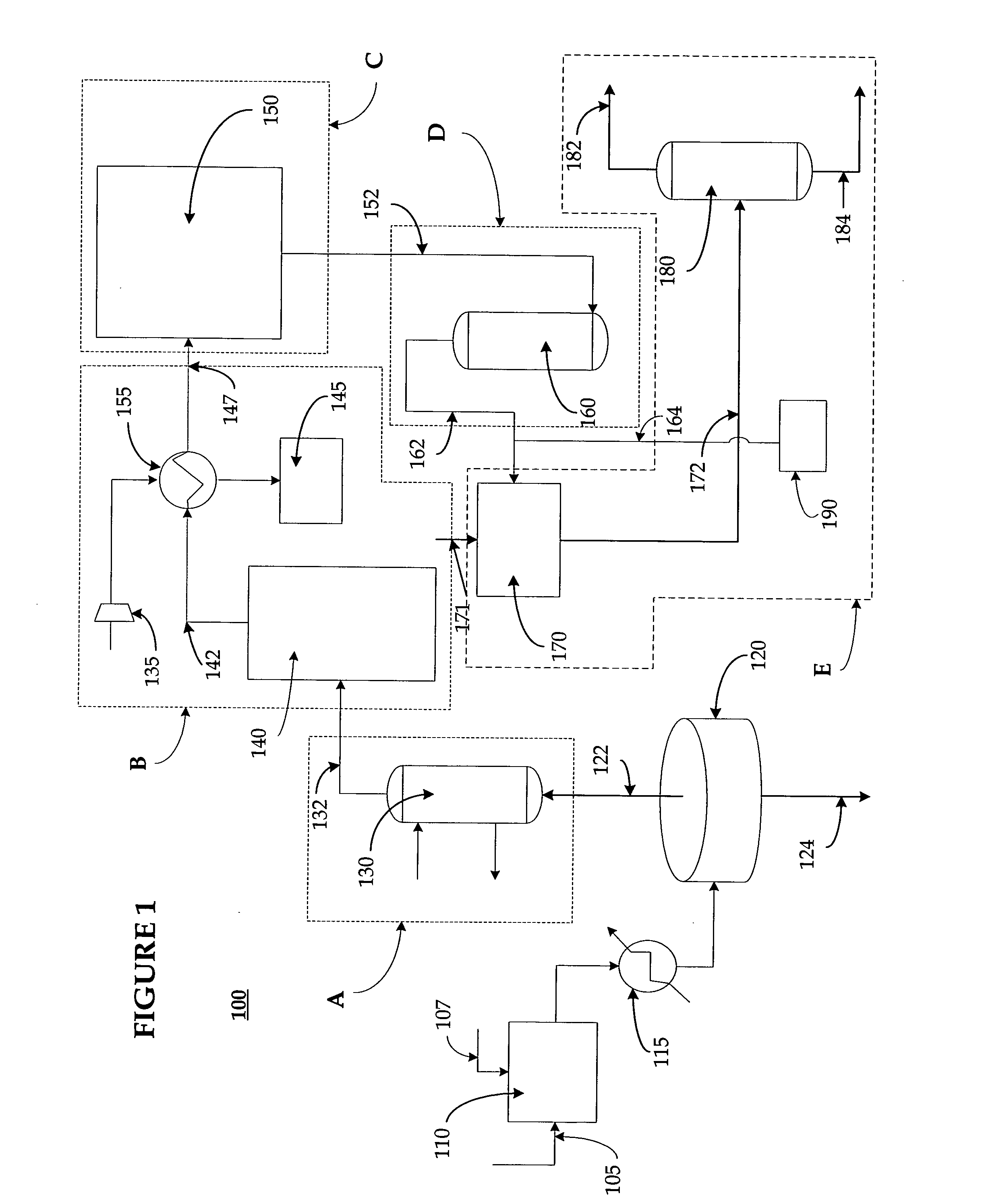

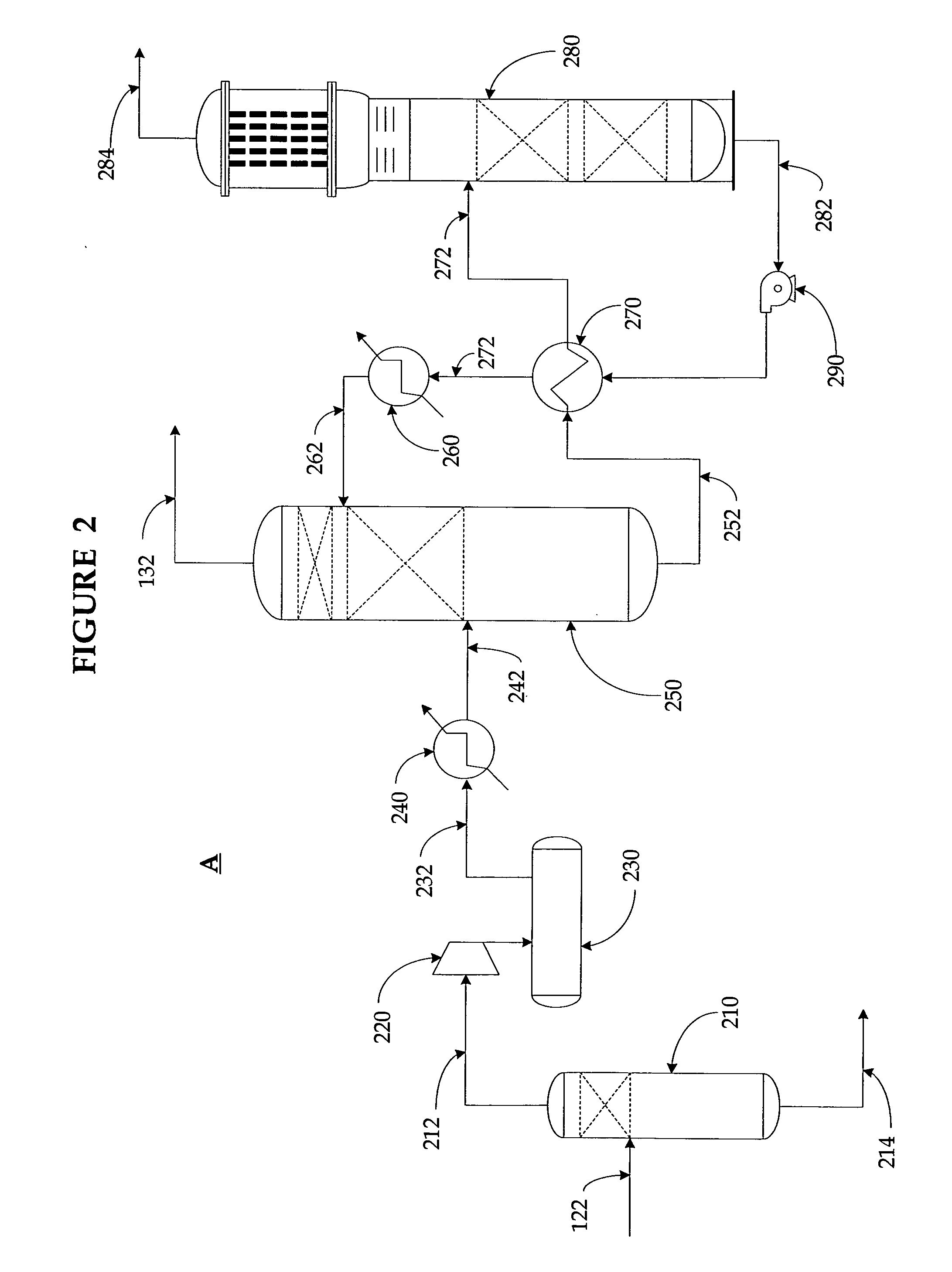

The present invention relates to a process and apparatus for processing agricultural waste to make alcohol and / or biodiesel. The agricultural wastes are subjected to anaerobic digestion which produces a biogas stream containing methane, which is subsequently reformed to a syngas containing carbon monoxide and hydrogen. The syngas is converted to an alcohol which may be stored, sold, used, or fed directly to a reactor for production of biodiesel. The solids effluent from the anaerobic digester can be further utilized as slow release, organic certified fertilizer. Additionally, the wastewater from the process is acceptable for immediate reuse in agricultural operations.

Owner:BEST BIOFUELS LLC

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

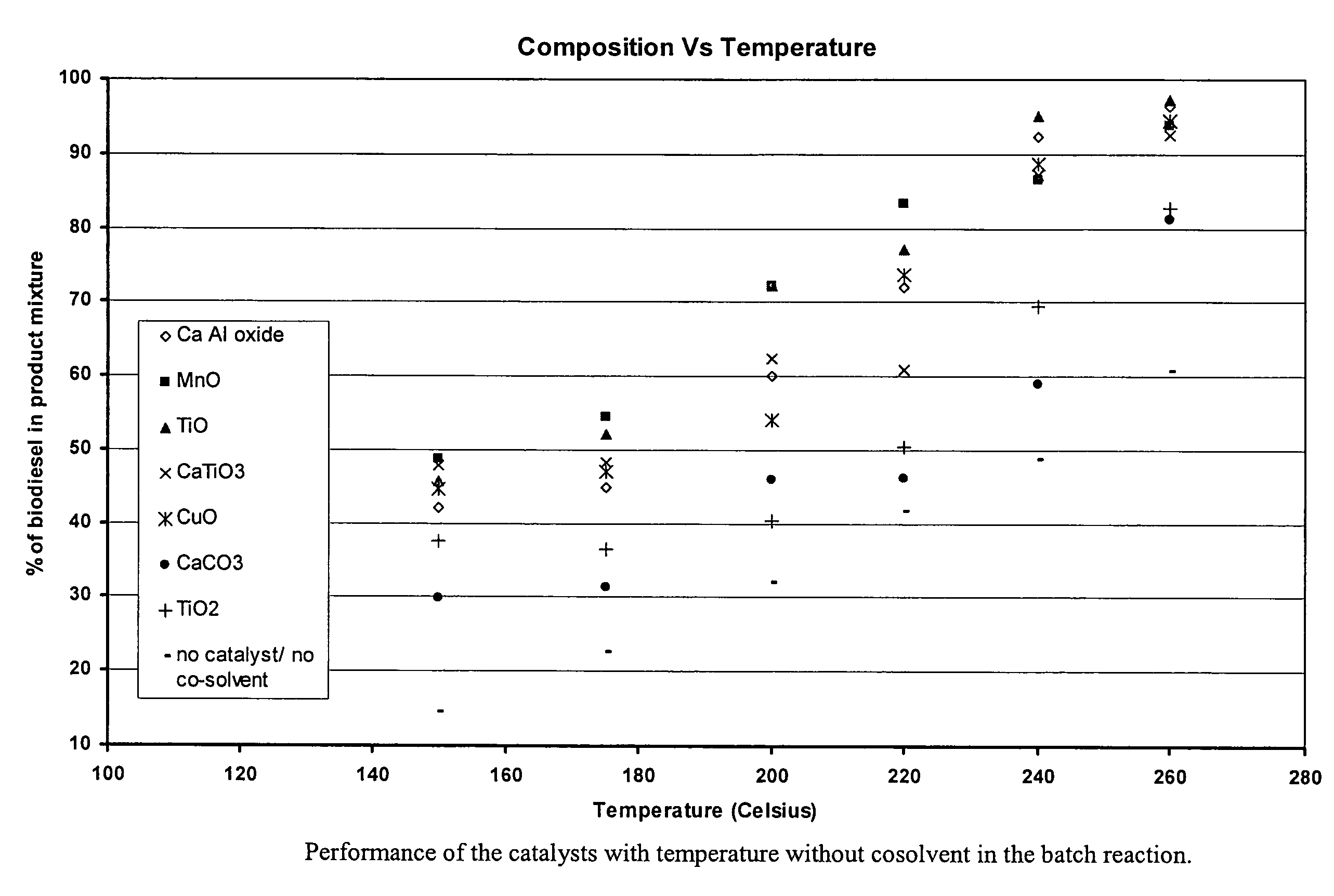

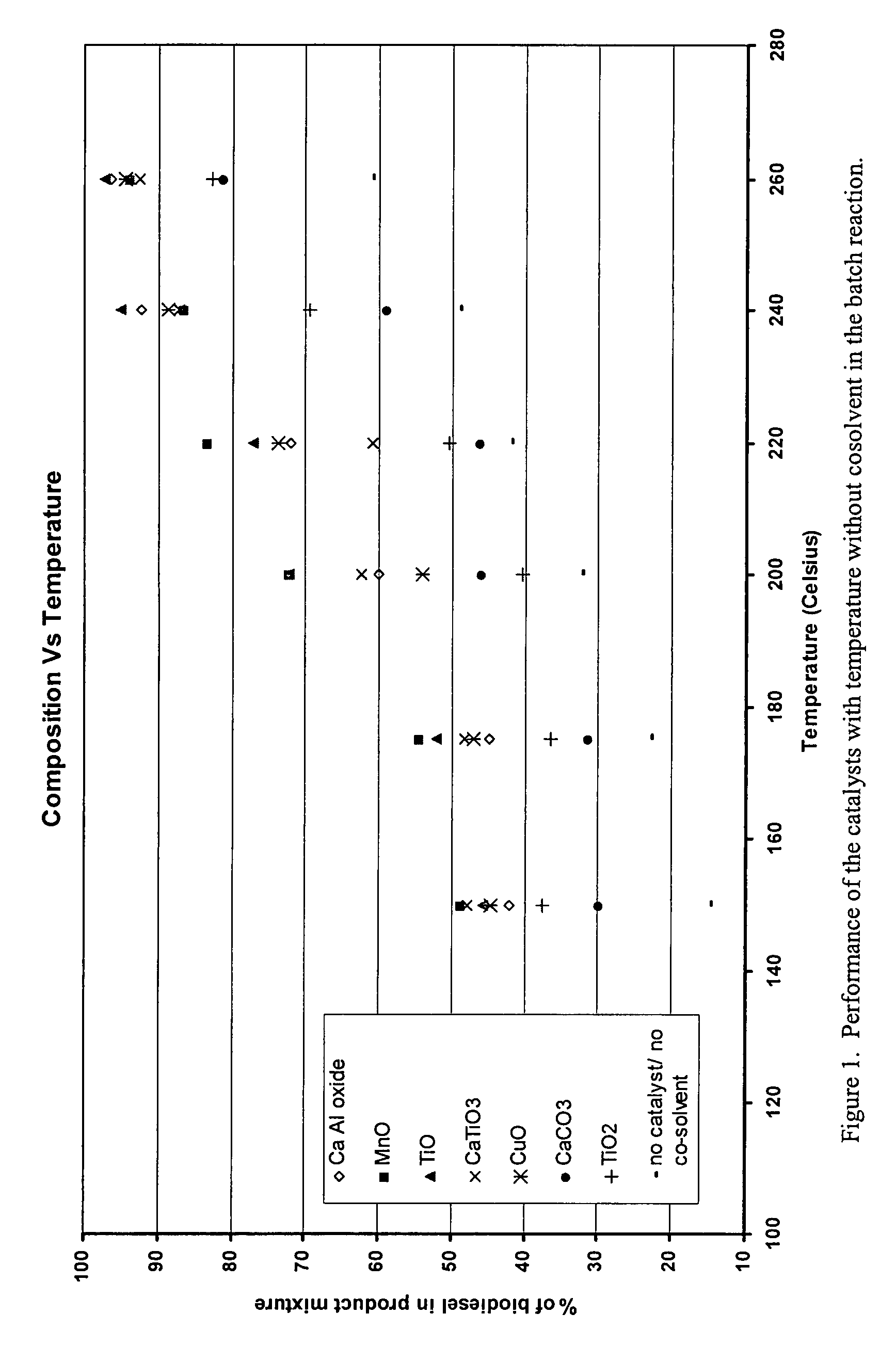

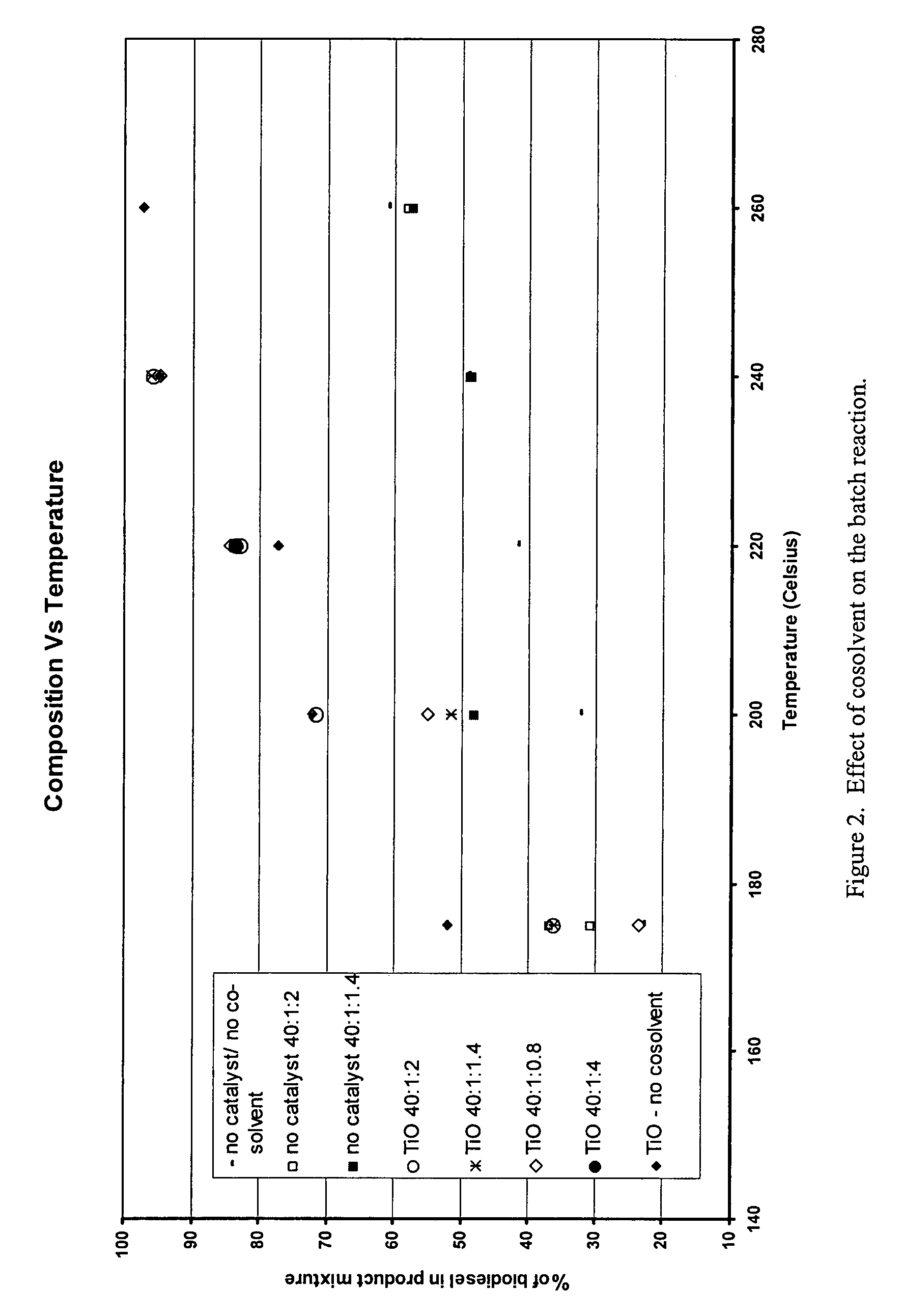

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

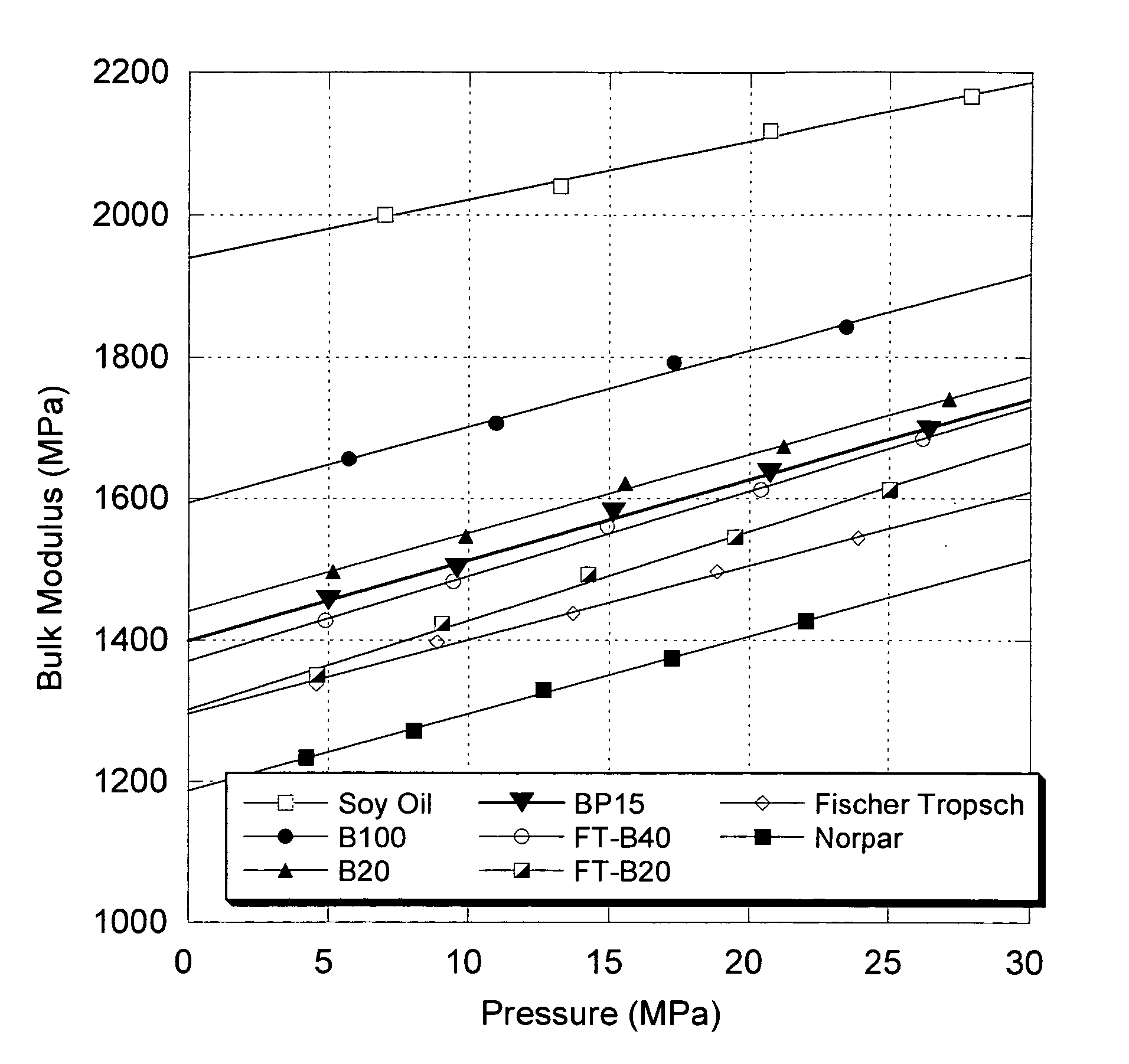

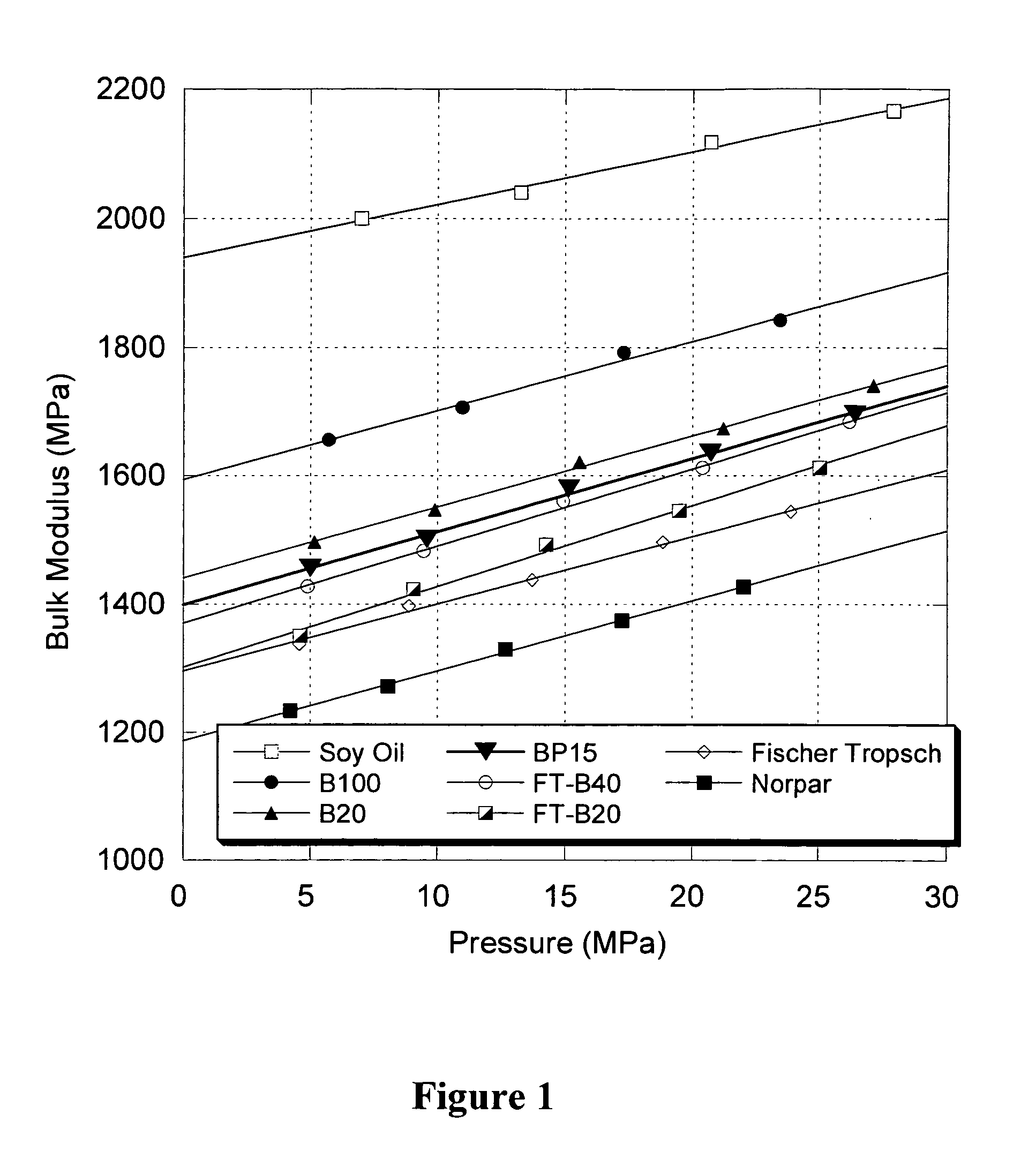

Blends of synthetic distillate and biodiesel for low nitrogen oxide emissions from diesel engines

InactiveUS20050210739A1Reduce nitrogen oxide emissionsReduced NO<sub>xBiofuelsSolid fuelsAlkaneBiodiesel

This invention shows how to make and use a biodiesel-based fuel in diesel engines without incurring the NOx penalty. Embodiments primarily relate to an optimum range of bulk modulus of compressibility for biodiesel blends, which results in generating “NOx neutral” biodiesel blends or to formulate biodiesel blends with lower NOx emissions than conventional petroleum diesel fuel. These biodiesel blends preferably comprise synthetic paraffinic middle distillate derived from a hydrocarbon synthesis to generate synthetic environmentally-friendly diesel fuels.

Owner:CONOCOPHILLIPS CO +1

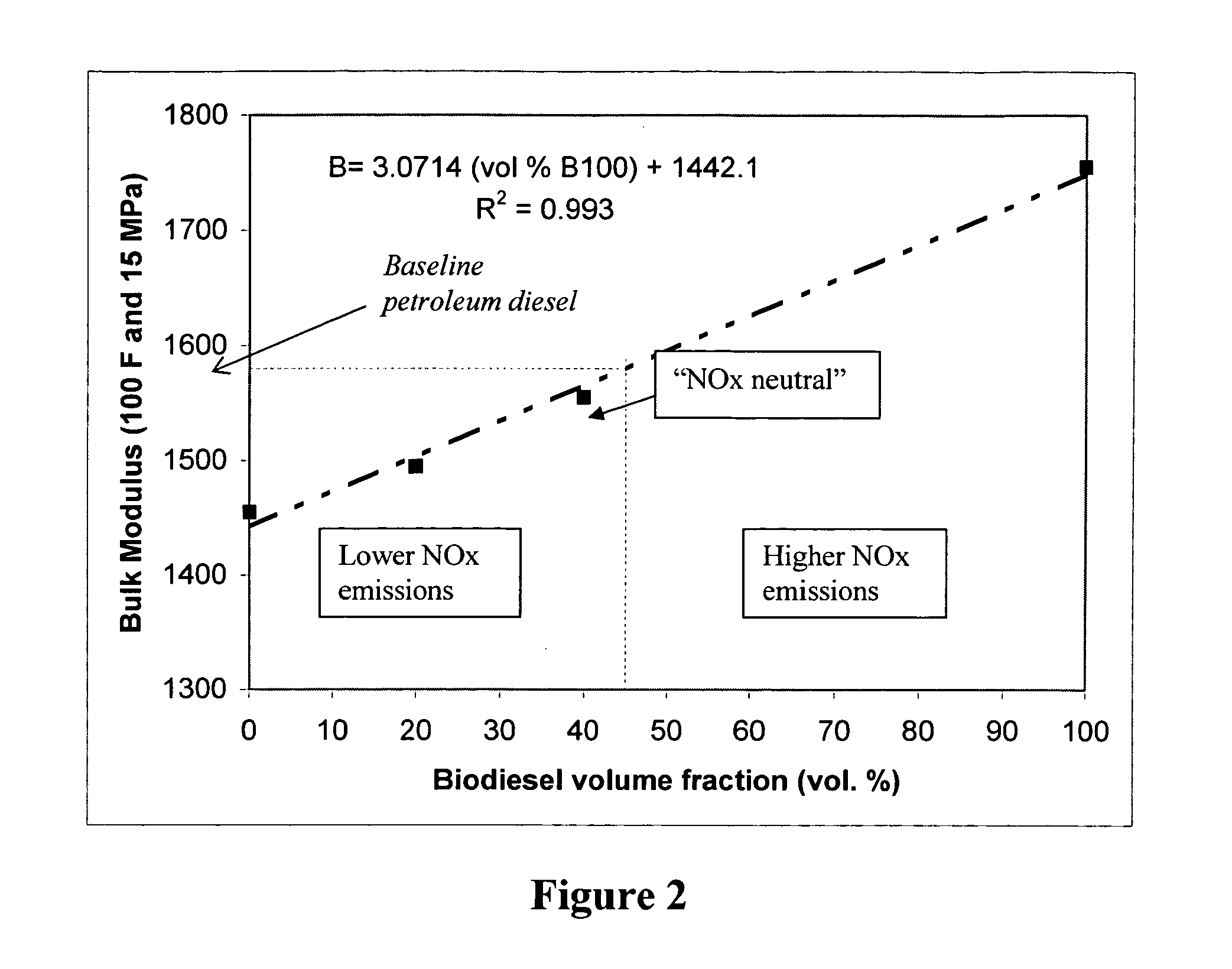

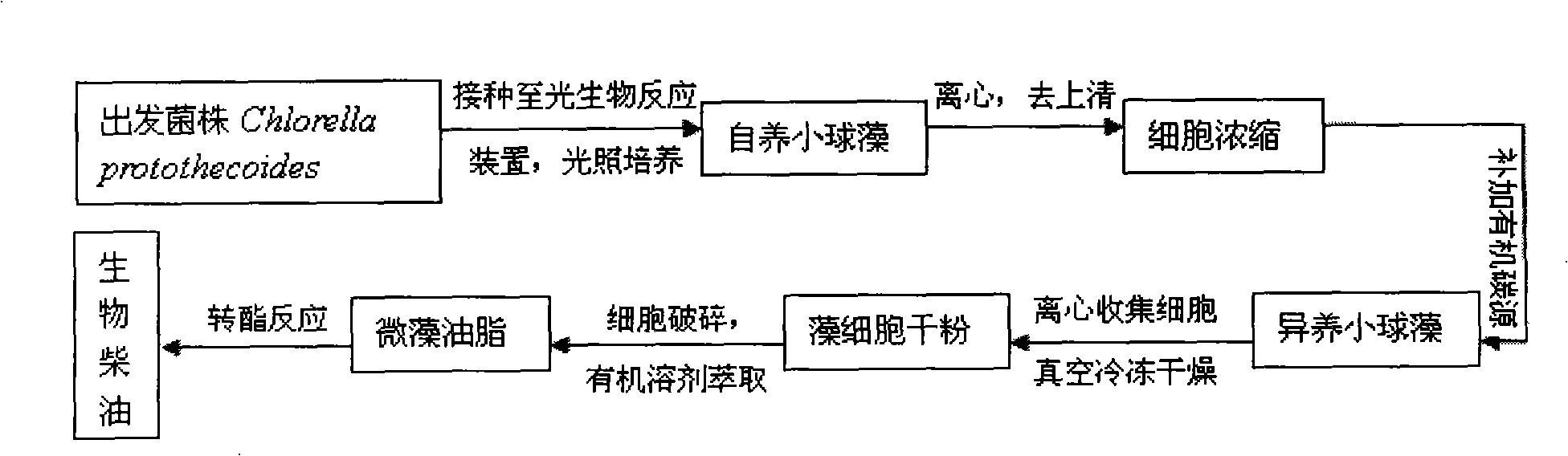

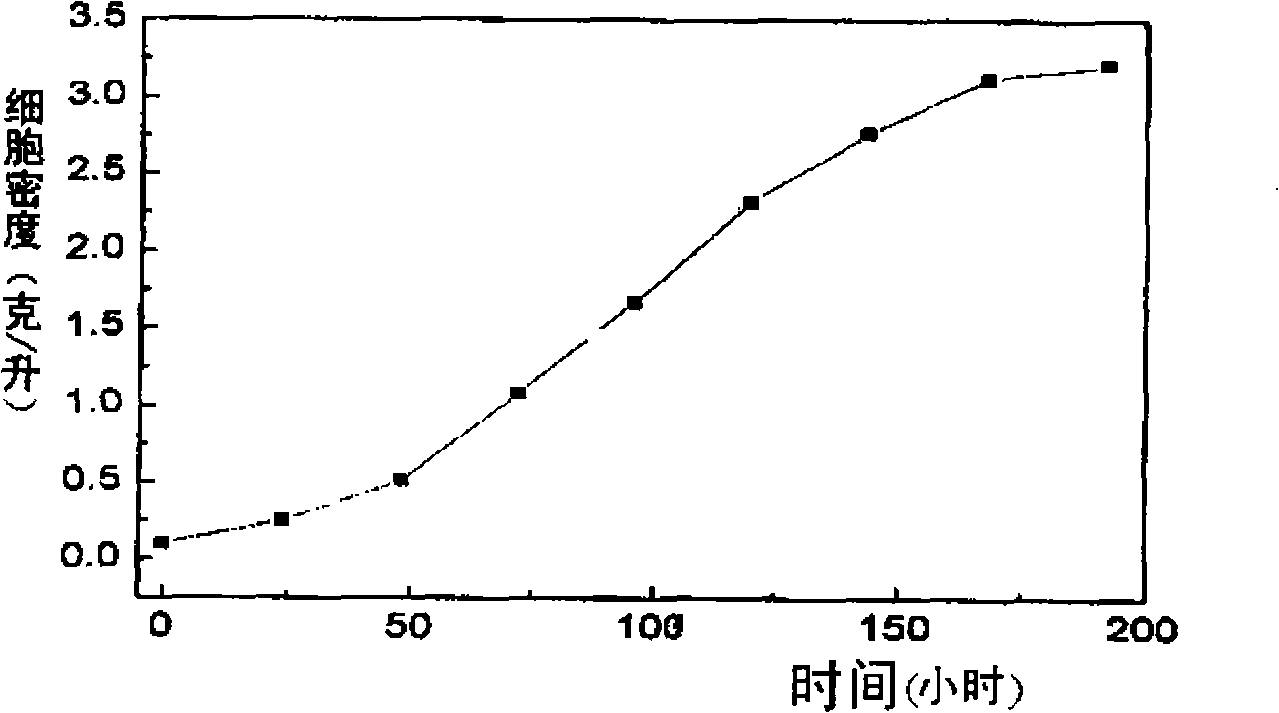

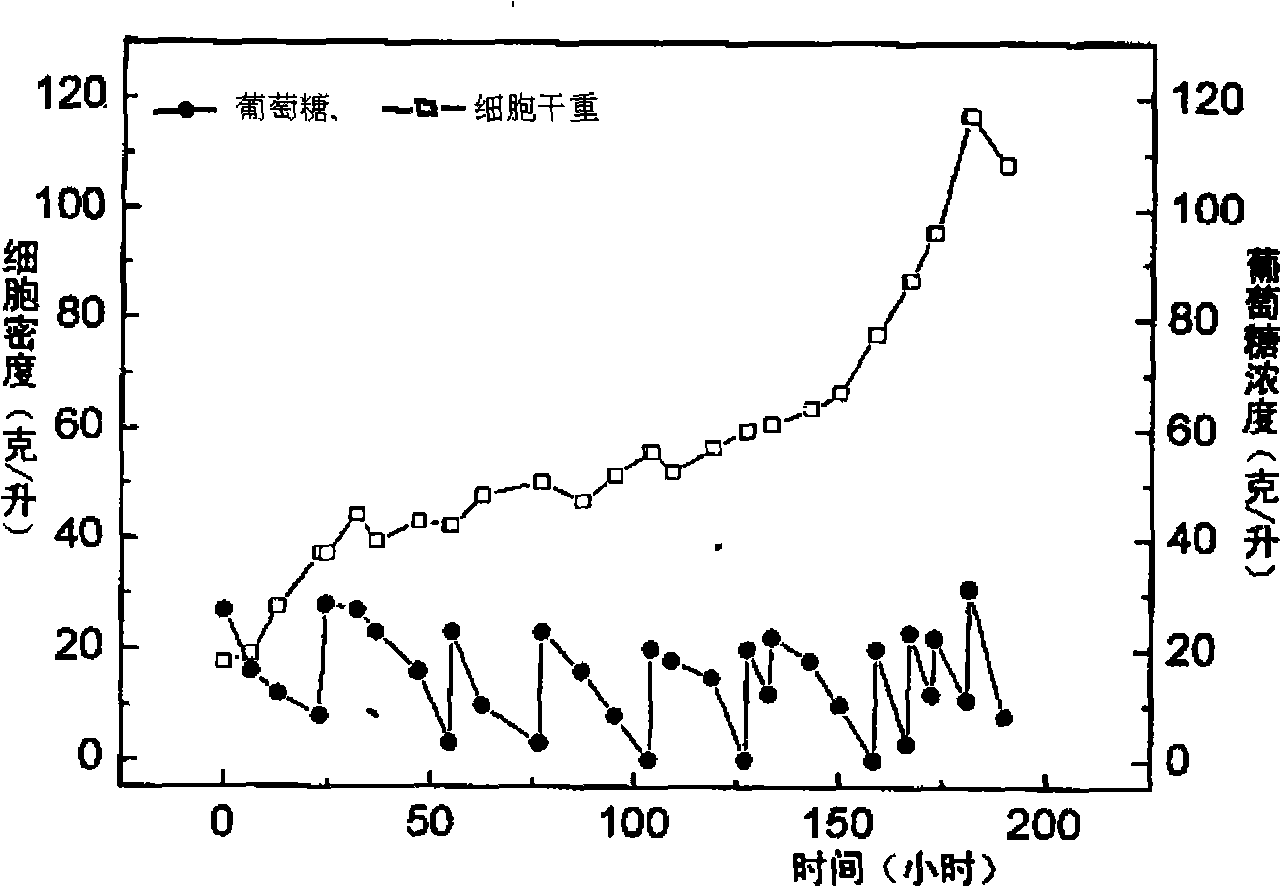

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com