Patents

Literature

815 results about "Jet fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jet fuel, aviation turbine fuel (ATF), or avtur, is a type of aviation fuel designed for use in aircraft powered by gas-turbine engines. It is colorless to straw-colored in appearance. The most commonly used fuels for commercial aviation are Jet A and Jet A-1, which are produced to a standardized international specification. The only other jet fuel commonly used in civilian turbine-engine powered aviation is Jet B, which is used for its enhanced cold-weather performance.

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

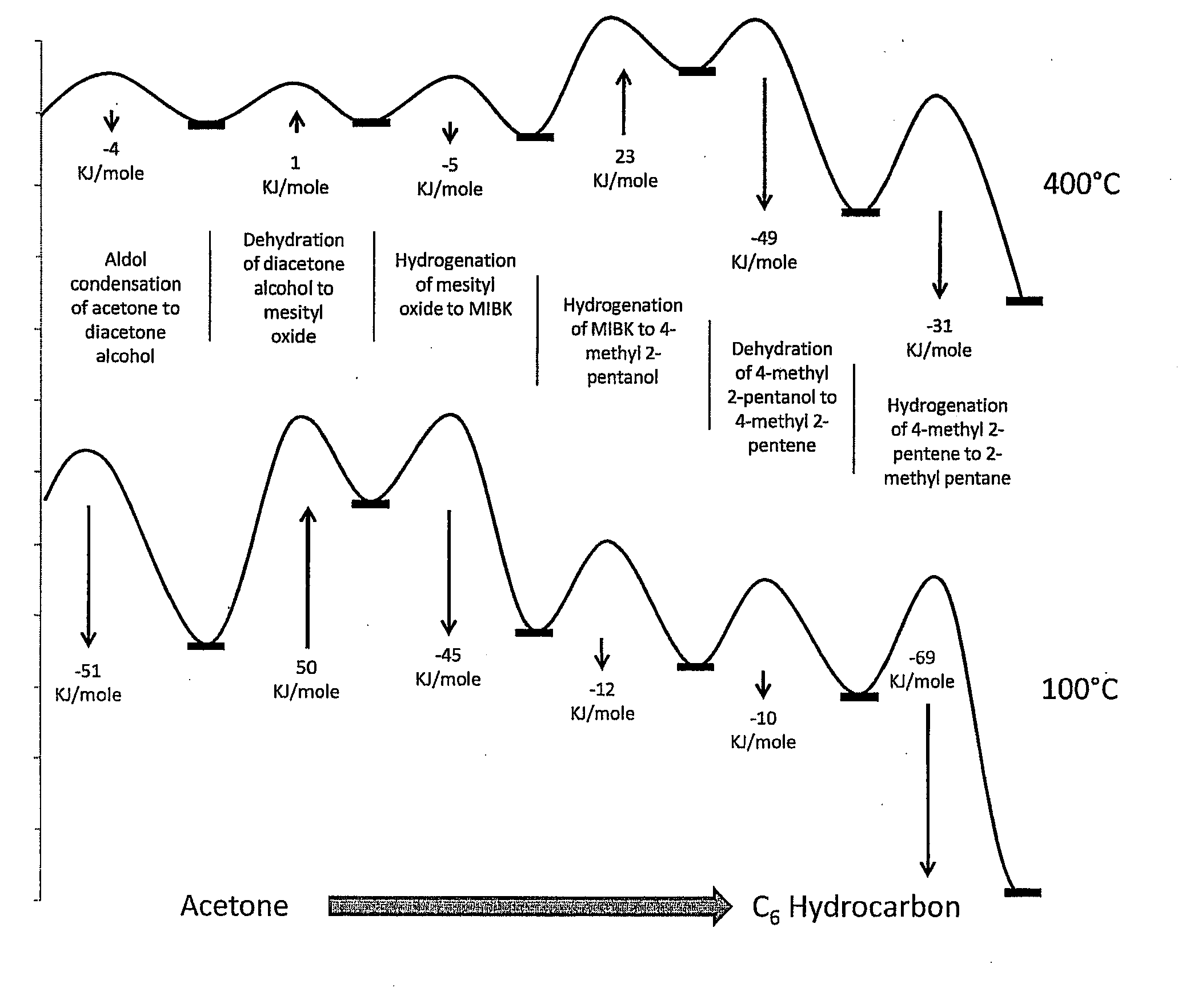

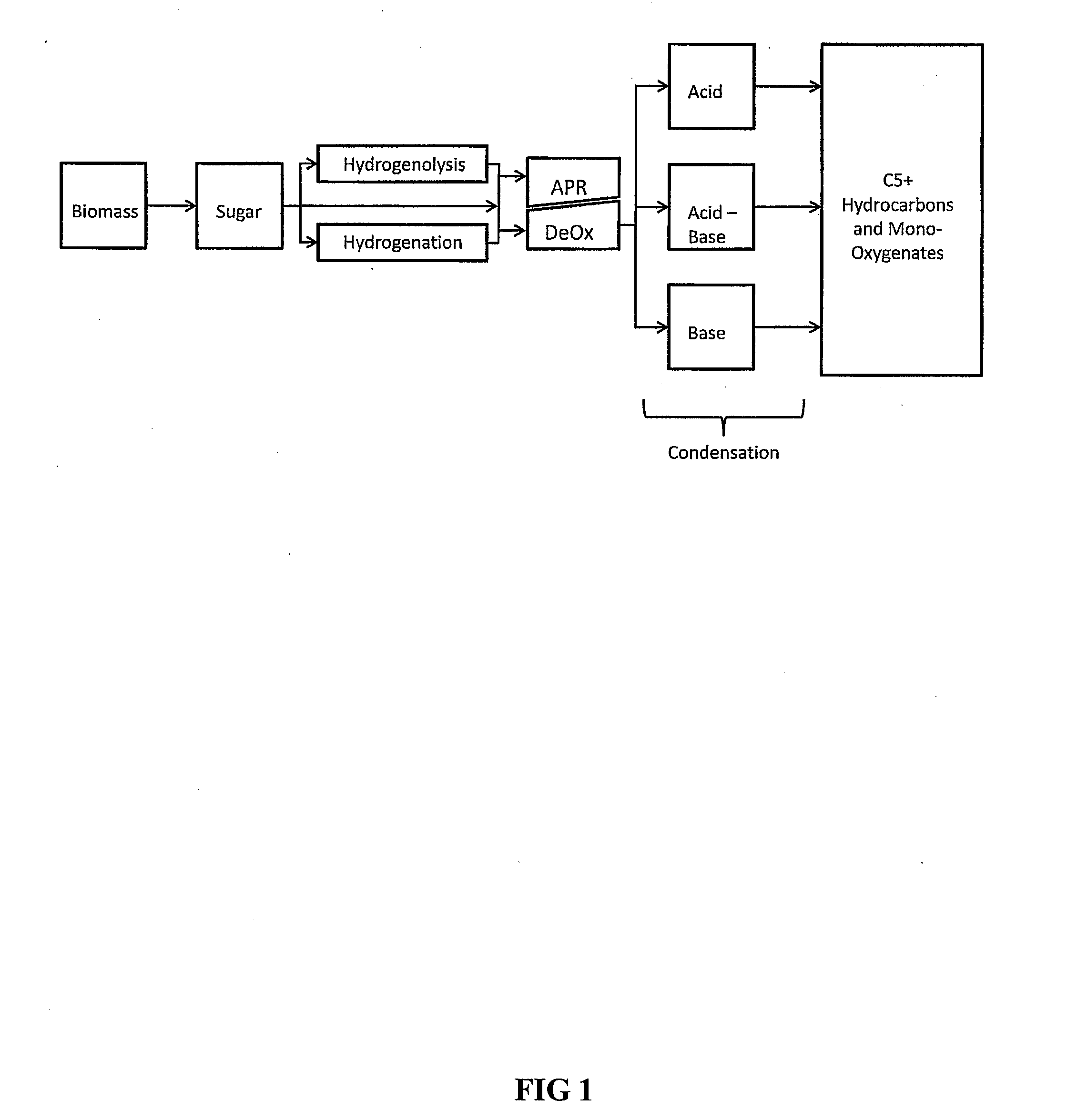

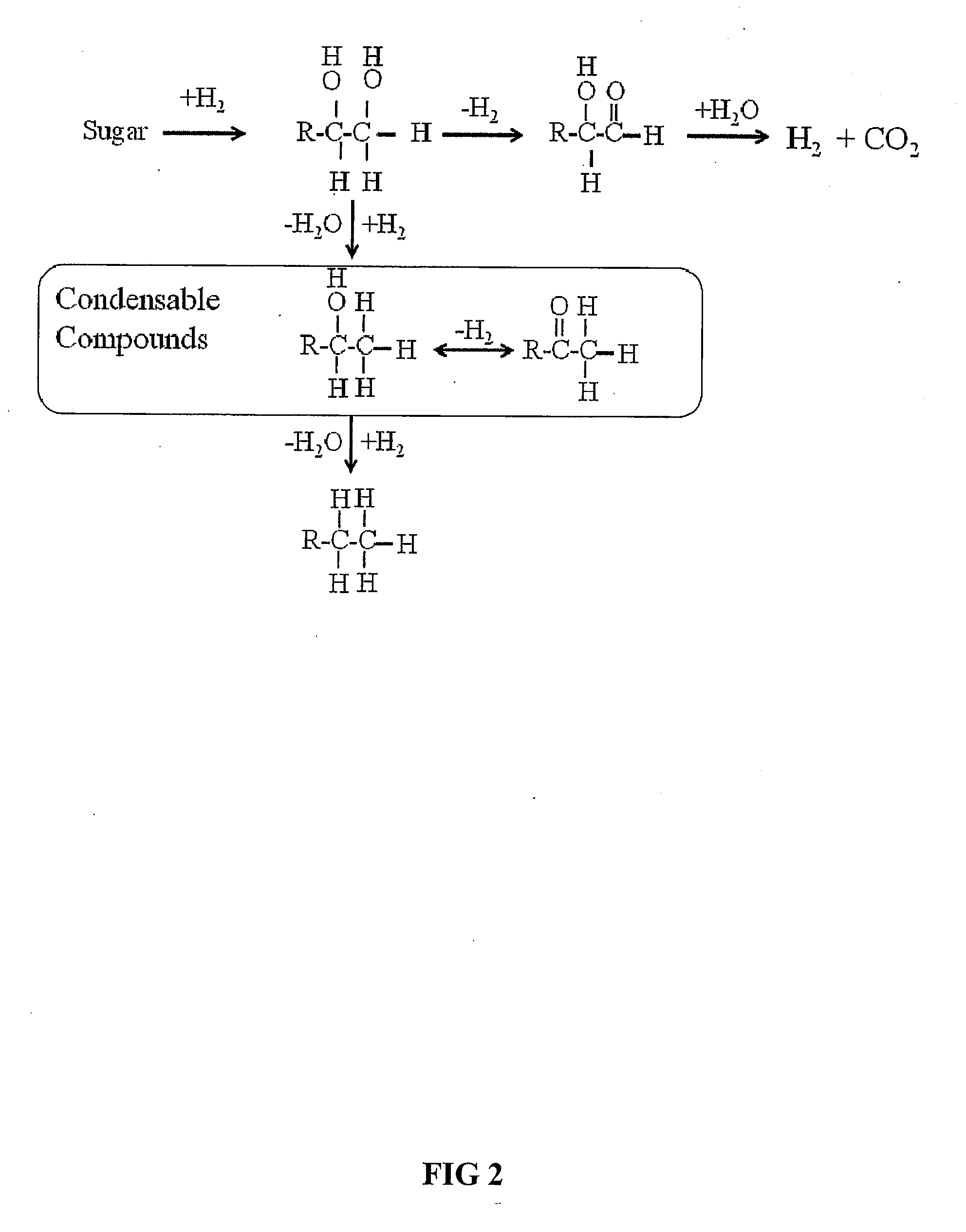

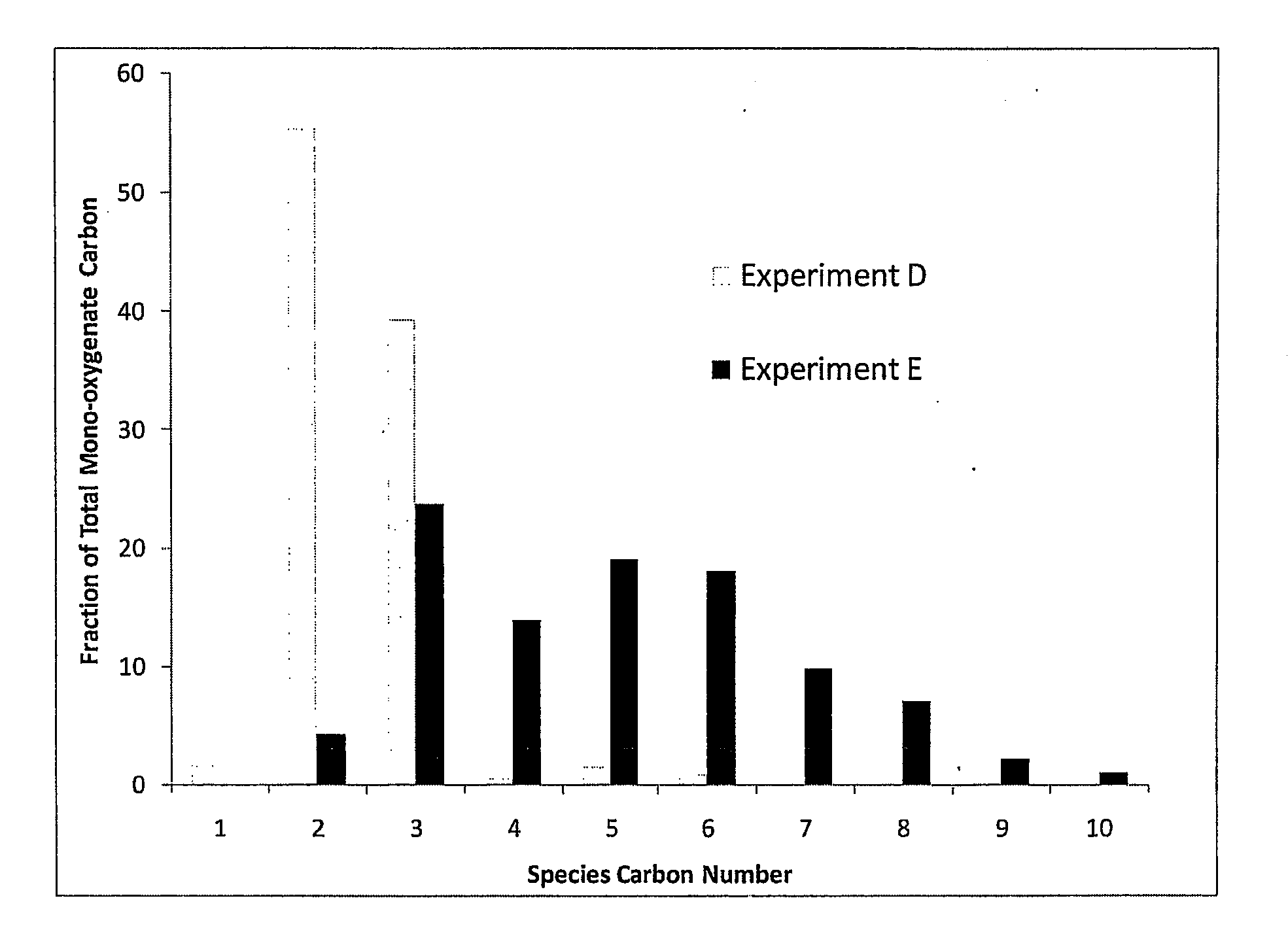

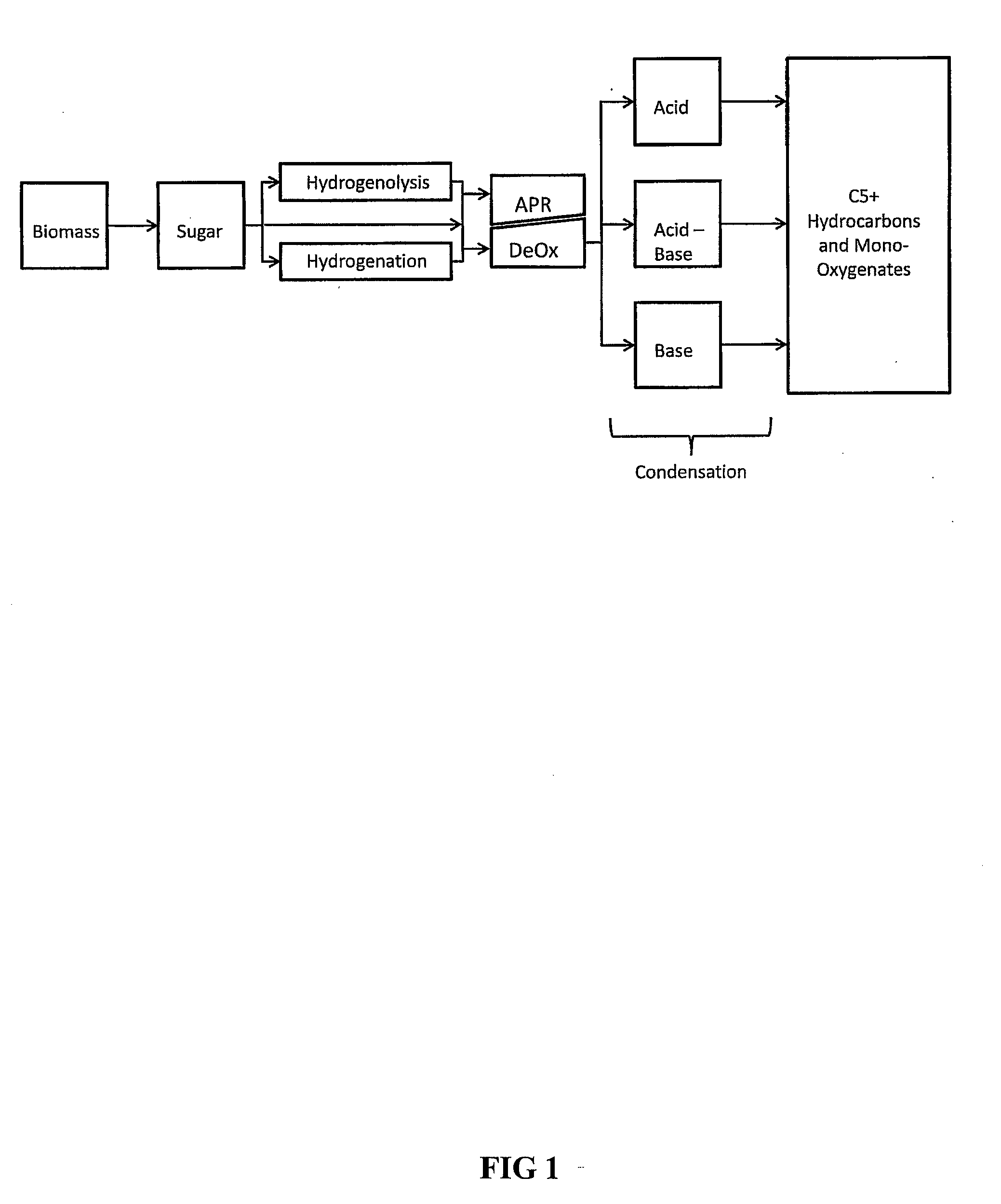

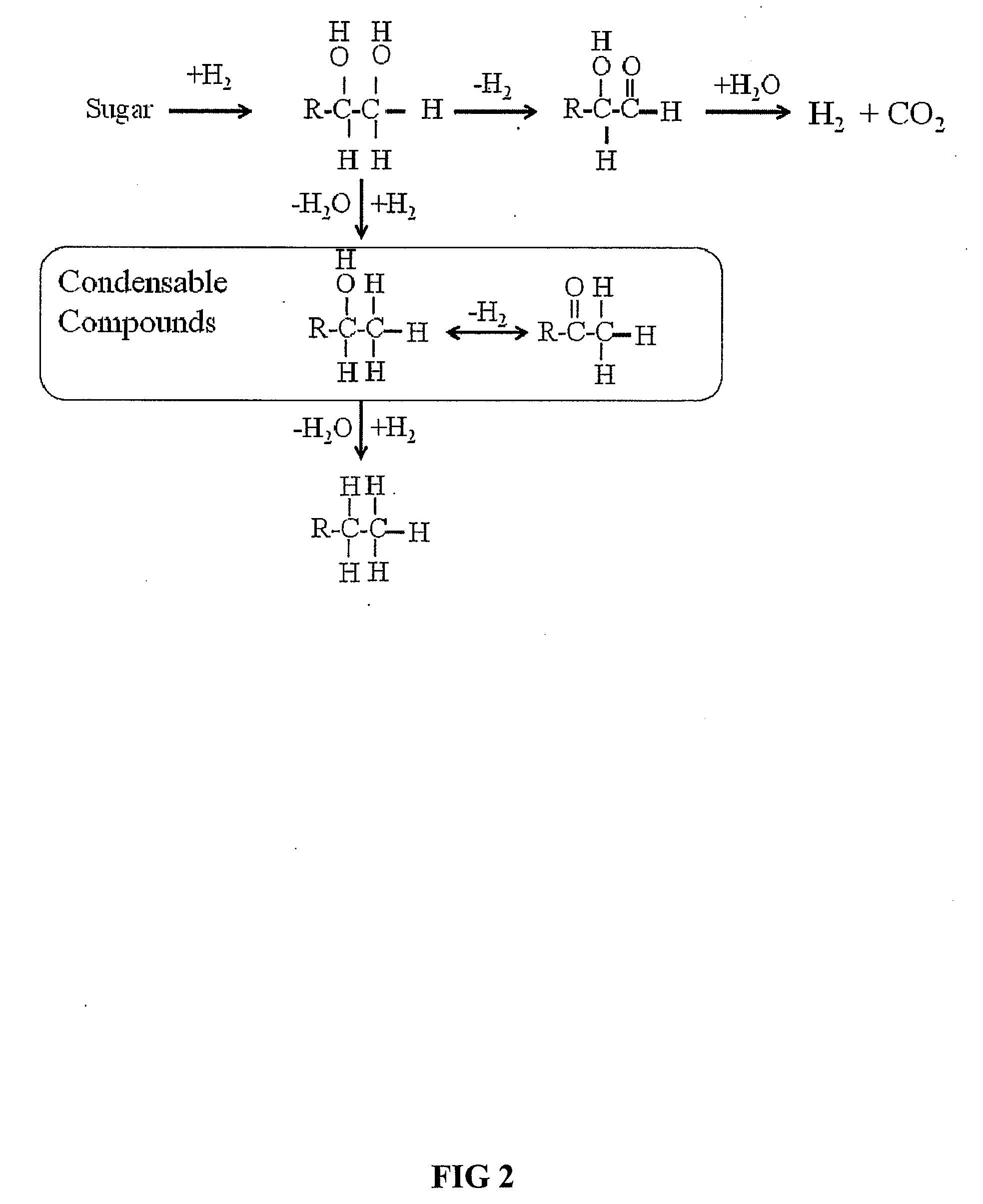

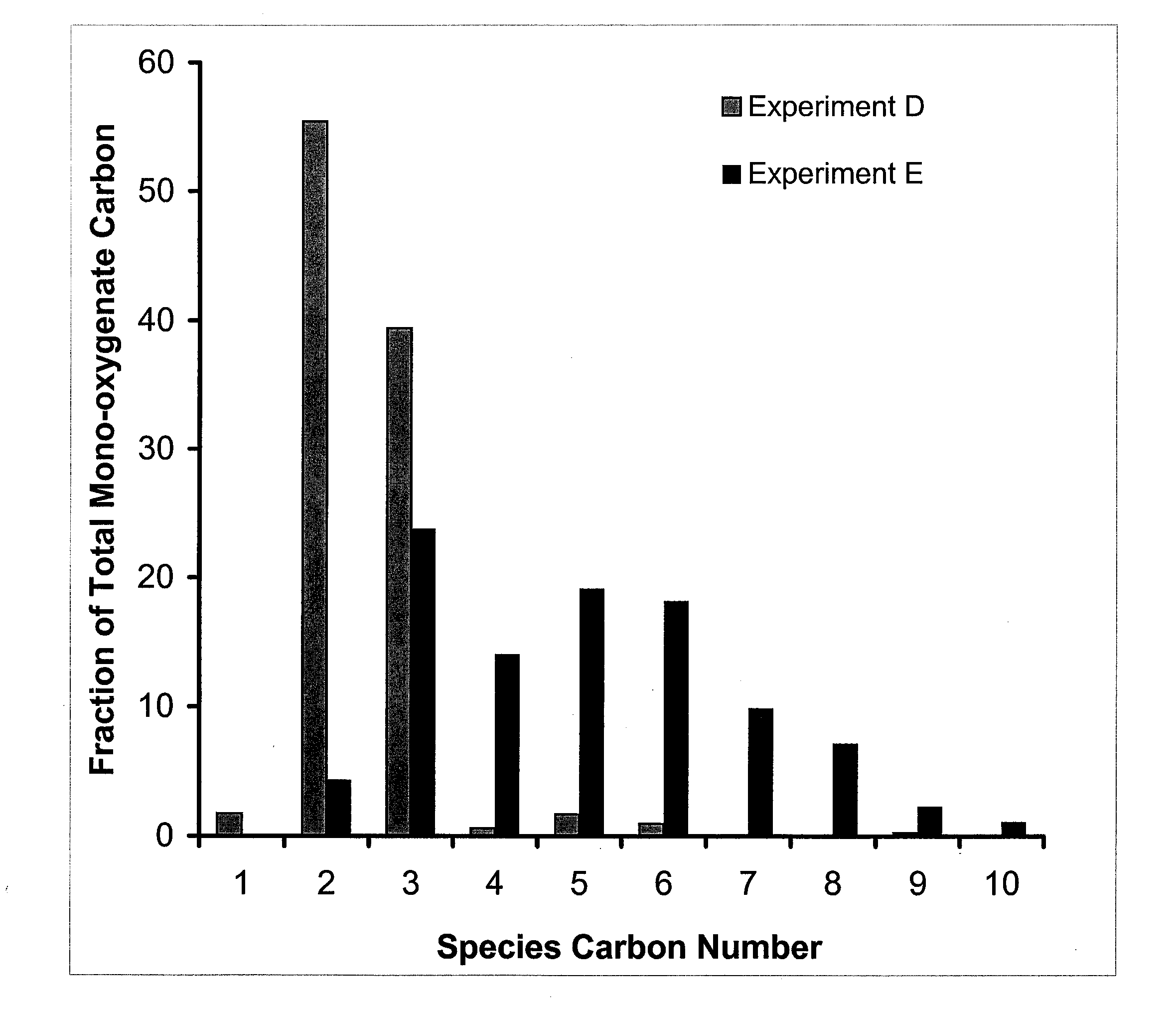

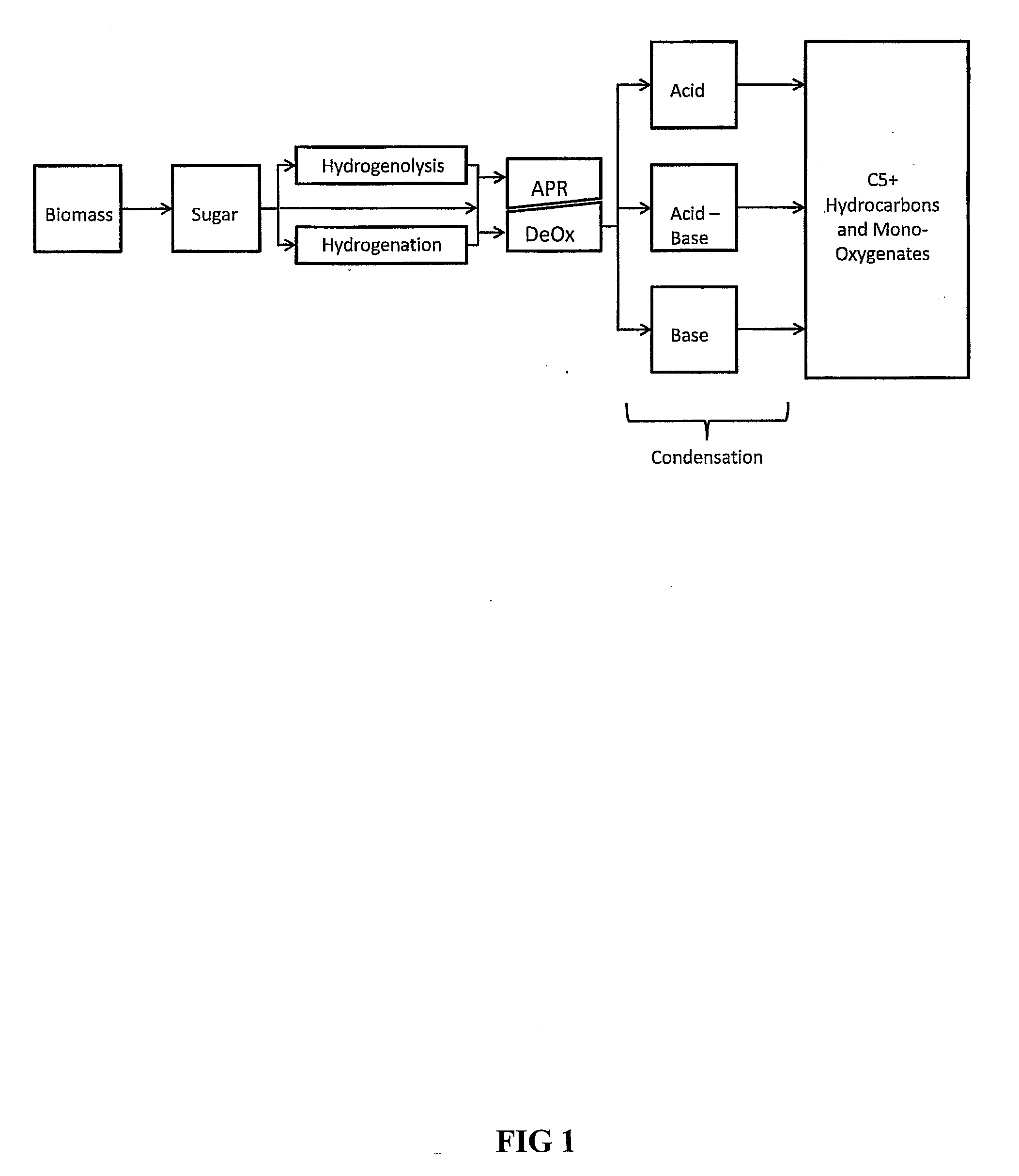

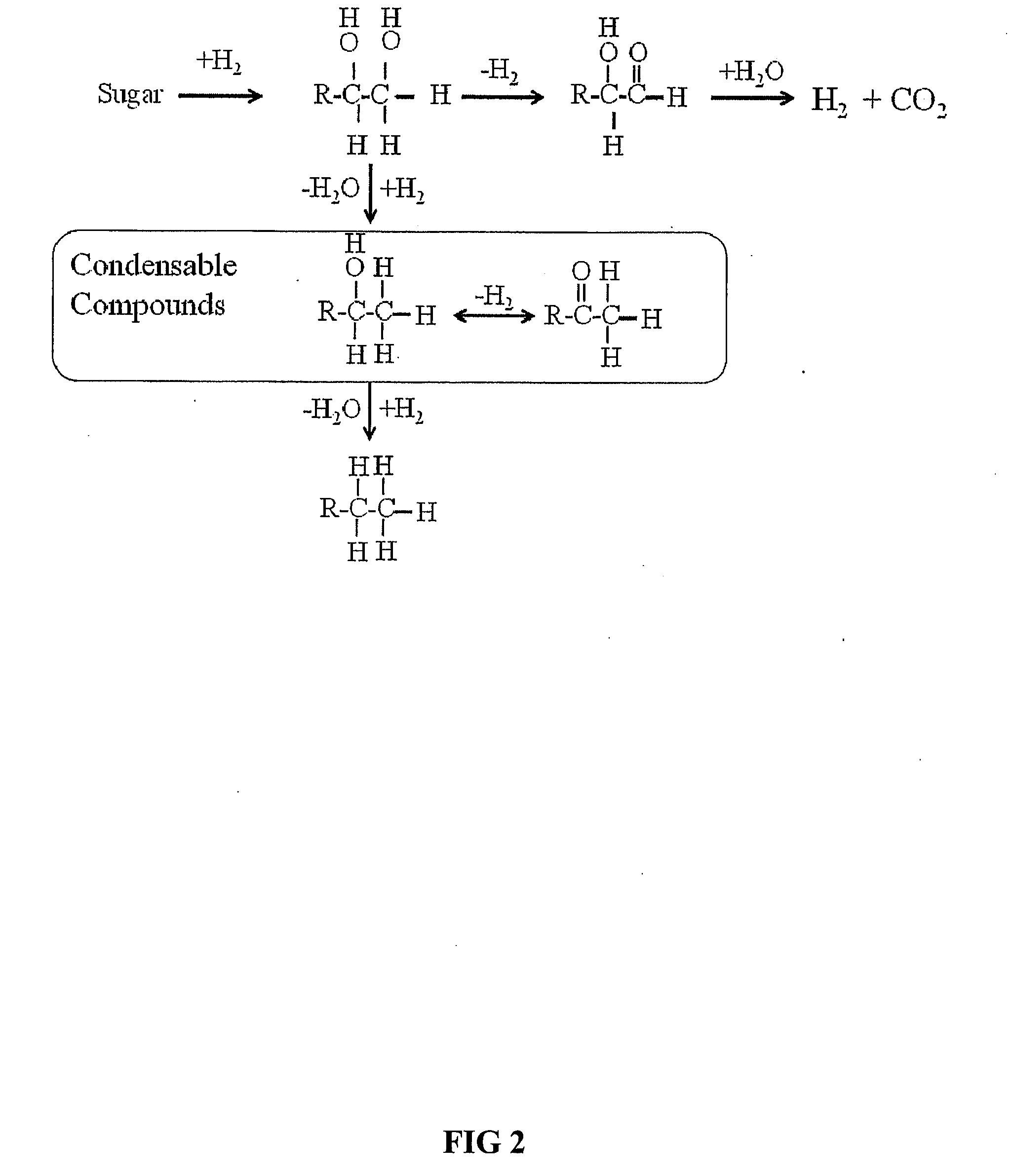

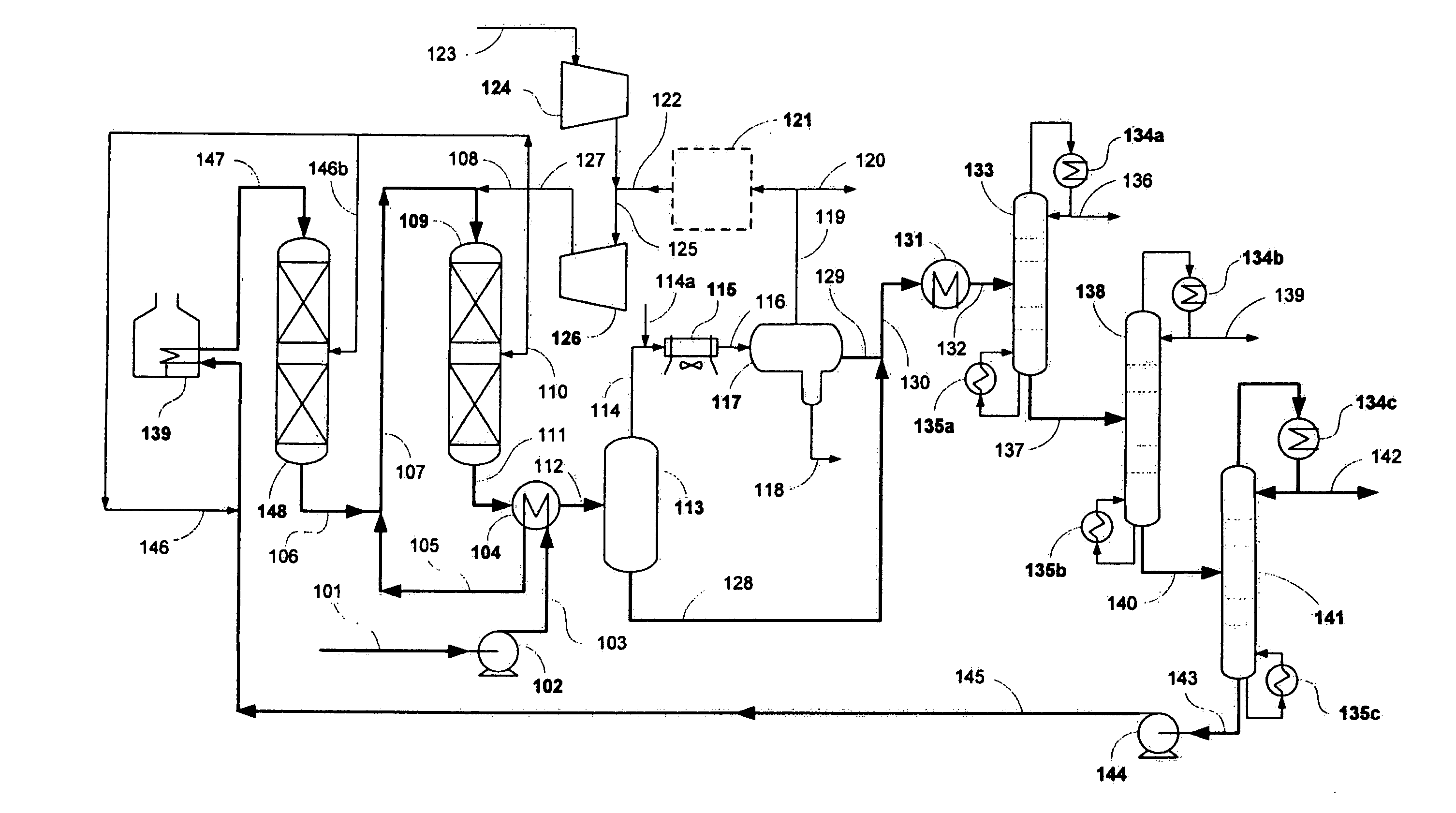

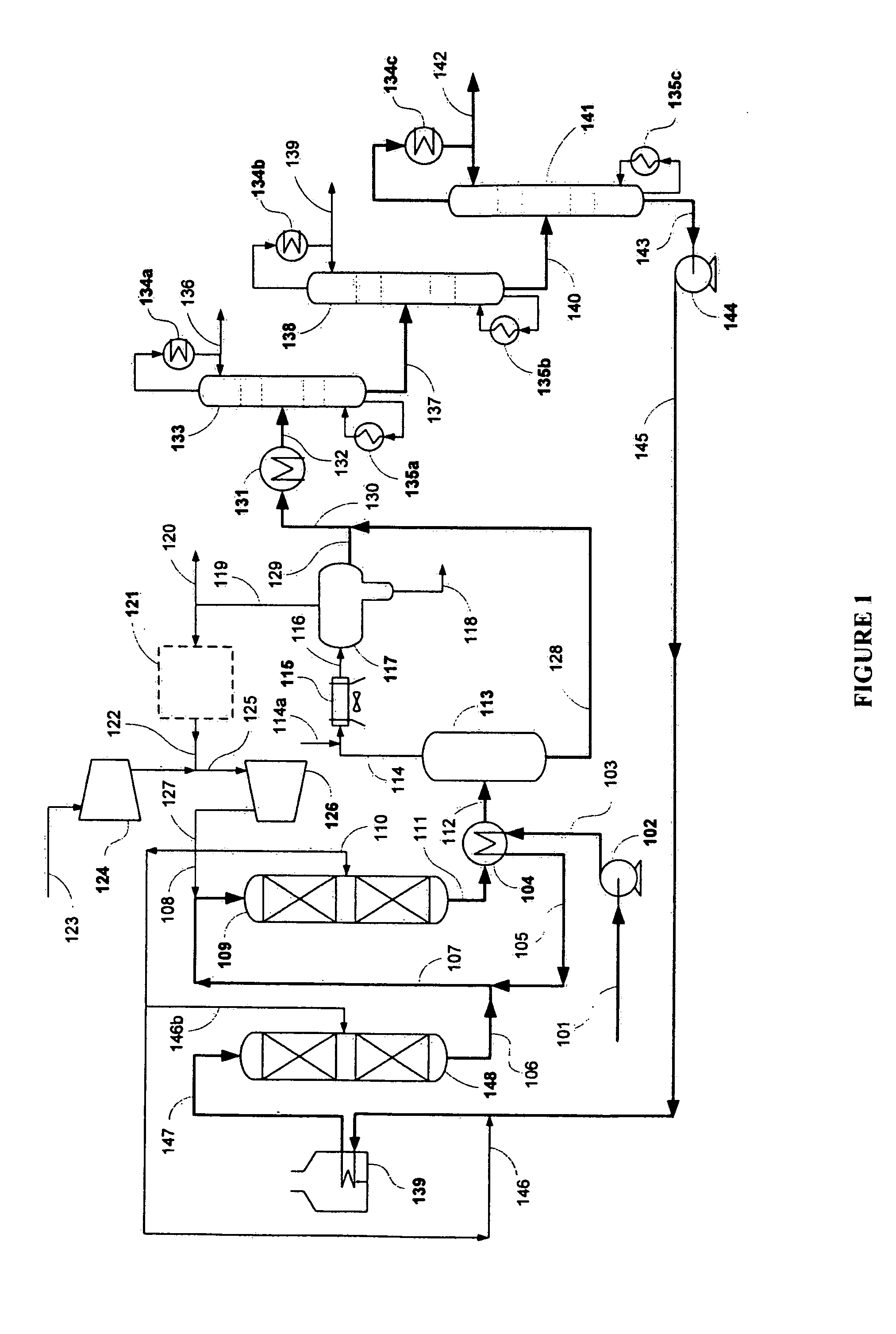

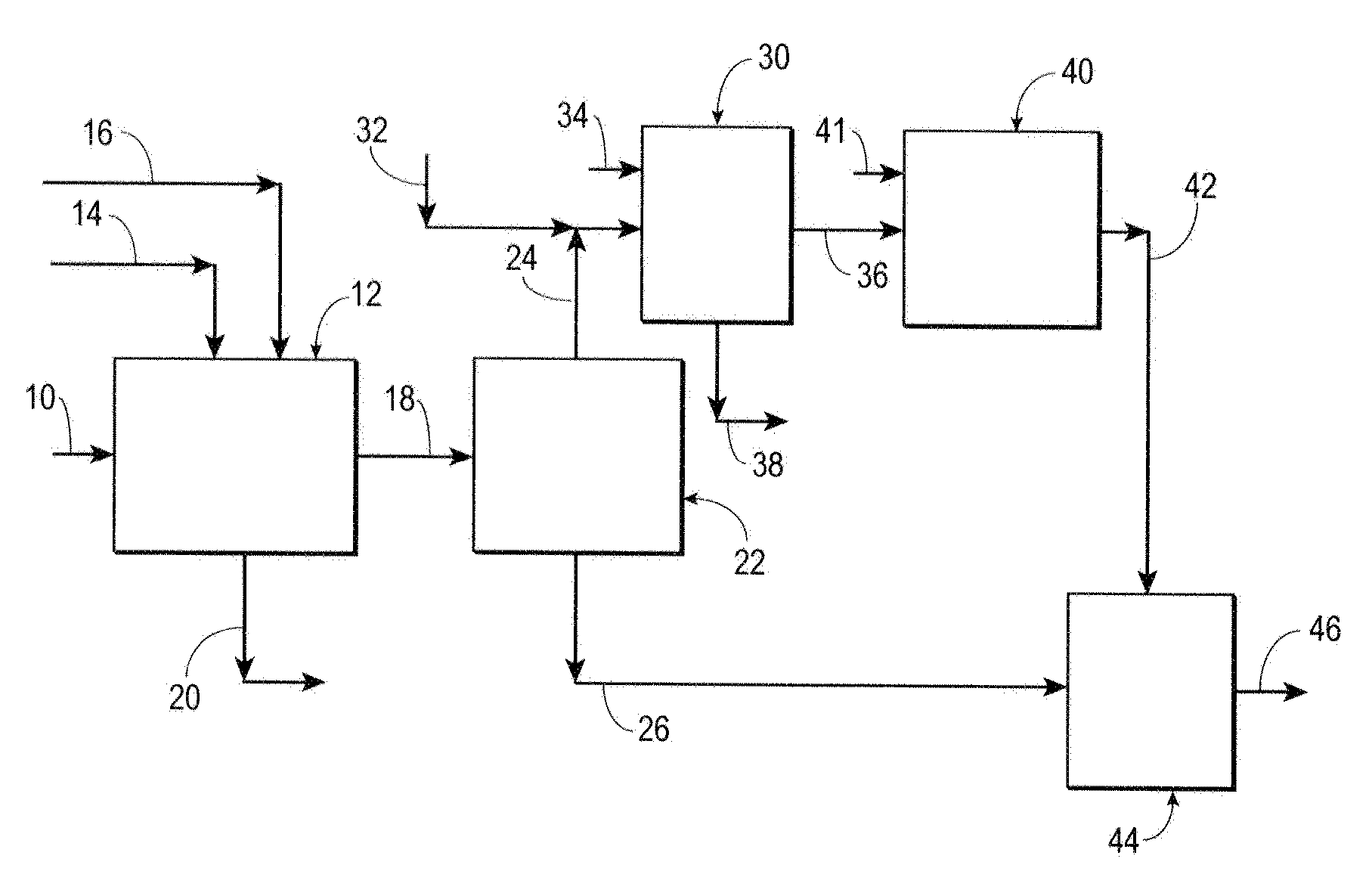

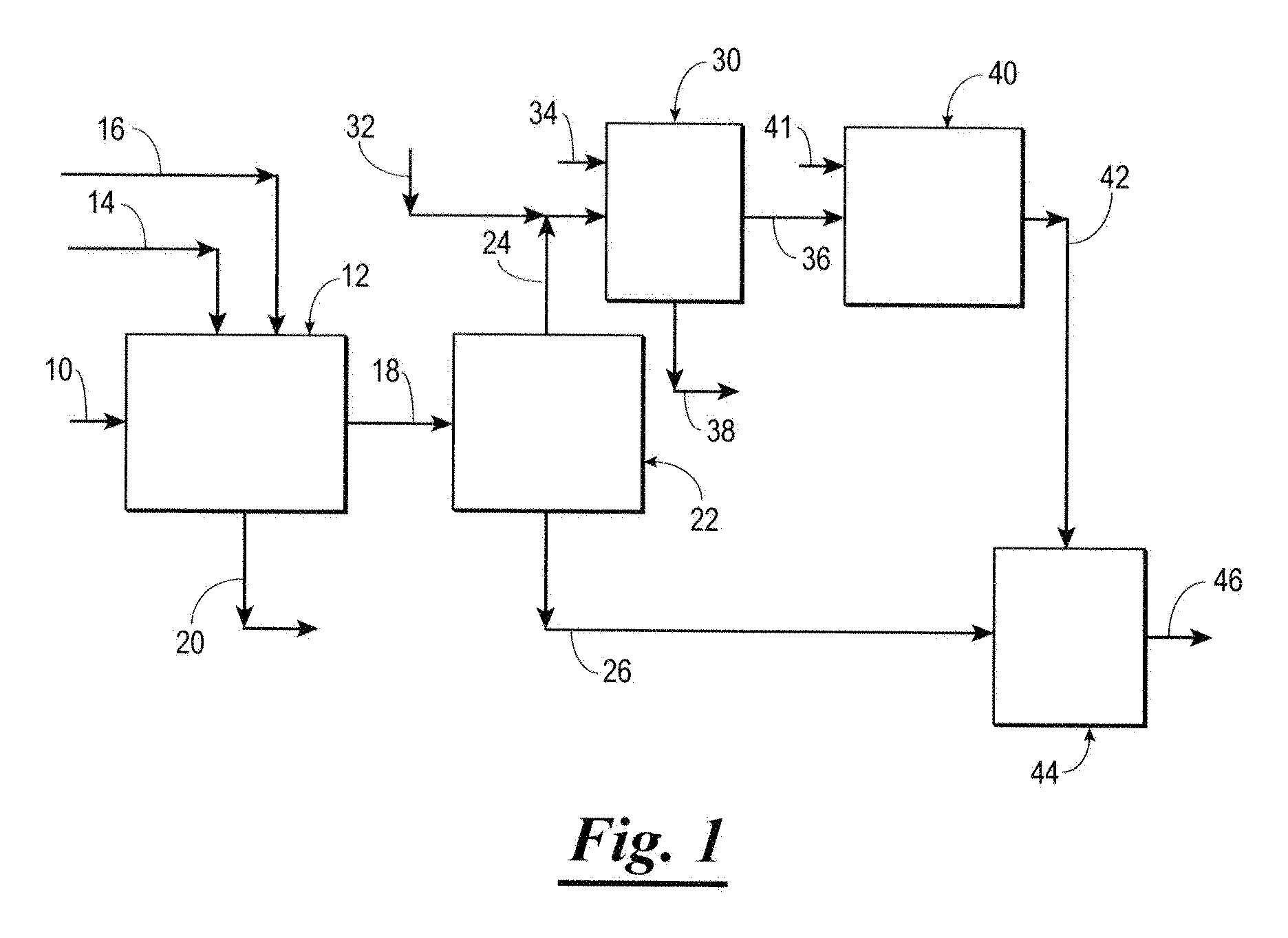

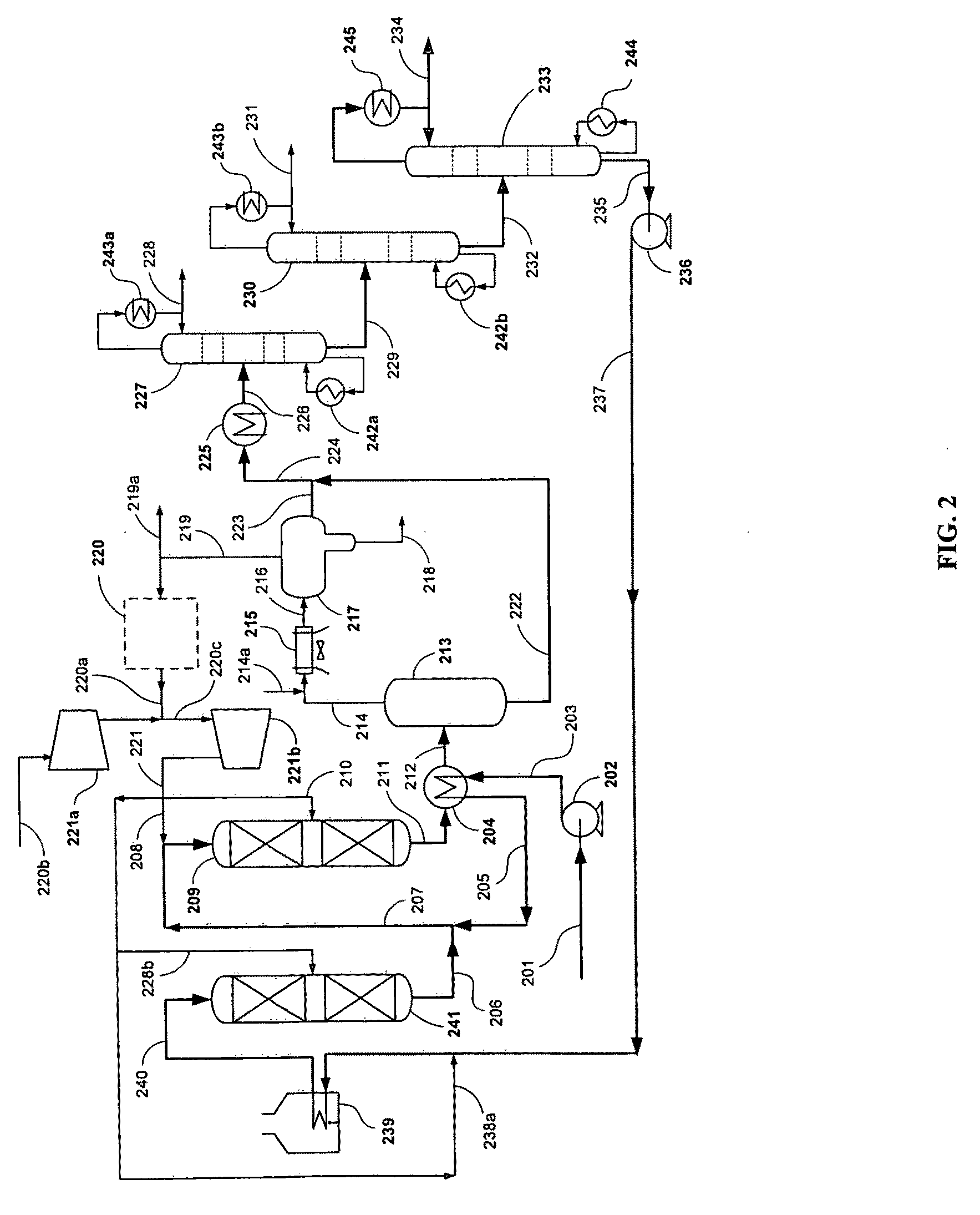

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

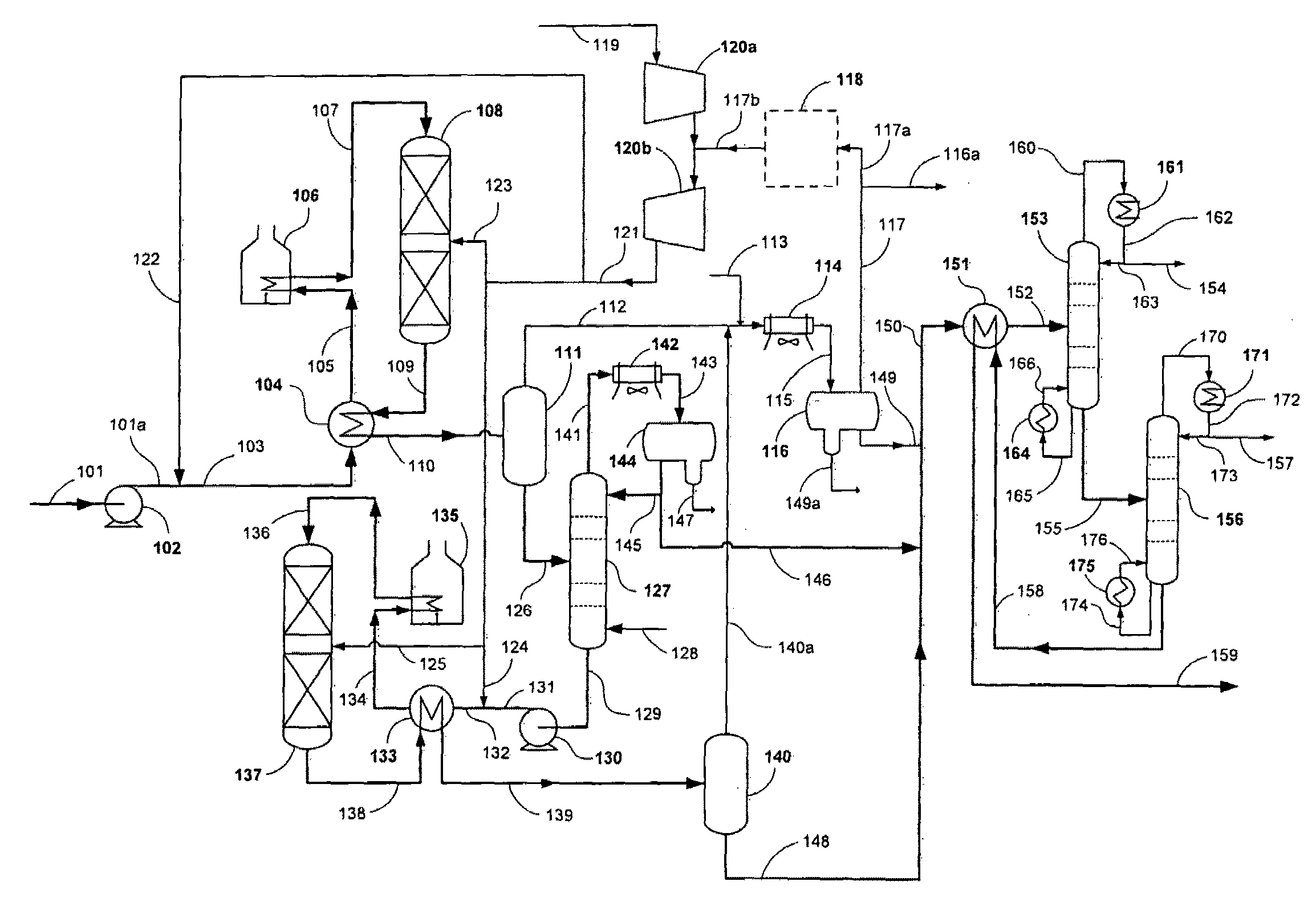

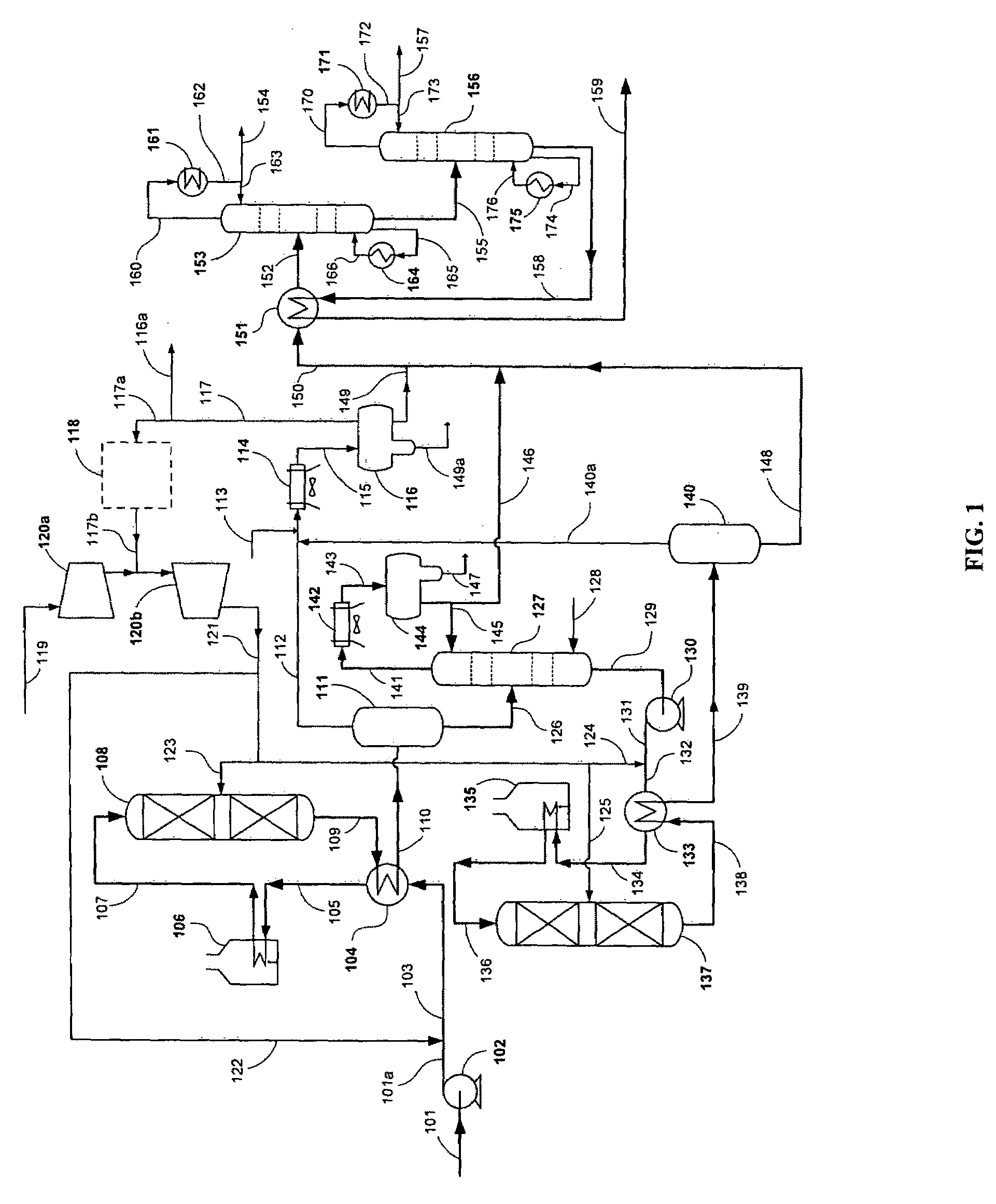

Process for Co-Producing Jet Fuel and LPG from Renewable Sources

ActiveUS20080244962A1Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

Process for producing bio-derived fuel with alkyl ester and iso-paraffin components

InactiveUS20080163543A1Improve low temperature performanceImprove the lubrication effectBiofuelsLiquid carbonaceous fuelsAlkaneParaffin oils

A process for producing a diesel fuel of biological origin. The process includes a biological component to be trans-esterified into a fatty acid alkyl ester. A fraction of the fatty acid alkyl ester is hydrodeoxygenated and hydroisomerized to produce an iso-paraffinic hydrocarbon. The fatty acid alkyl ester and the iso-paraffin components are combined into a middle distillate product suitable for direct use as diesel or jet fuel.

Owner:REG SYNTHETIC FUELS LLC

Fuel compositions comprising farnesane and farnesane derivatives and method of making and using same

A fuel composition comprises farnesane and / or farnesane derivatives and a conventional fuel component selected from diesel fuel, jet fuel, kerosene or gasoline. The farnesane or farnesane derivative can be used as a fuel component or as a fuel additive in the fuel composition. The fuel composition may further comprise a conventional fuel additive. Methods of making and using the fuel composition are also disclosed.

Owner:AMYRIS INC

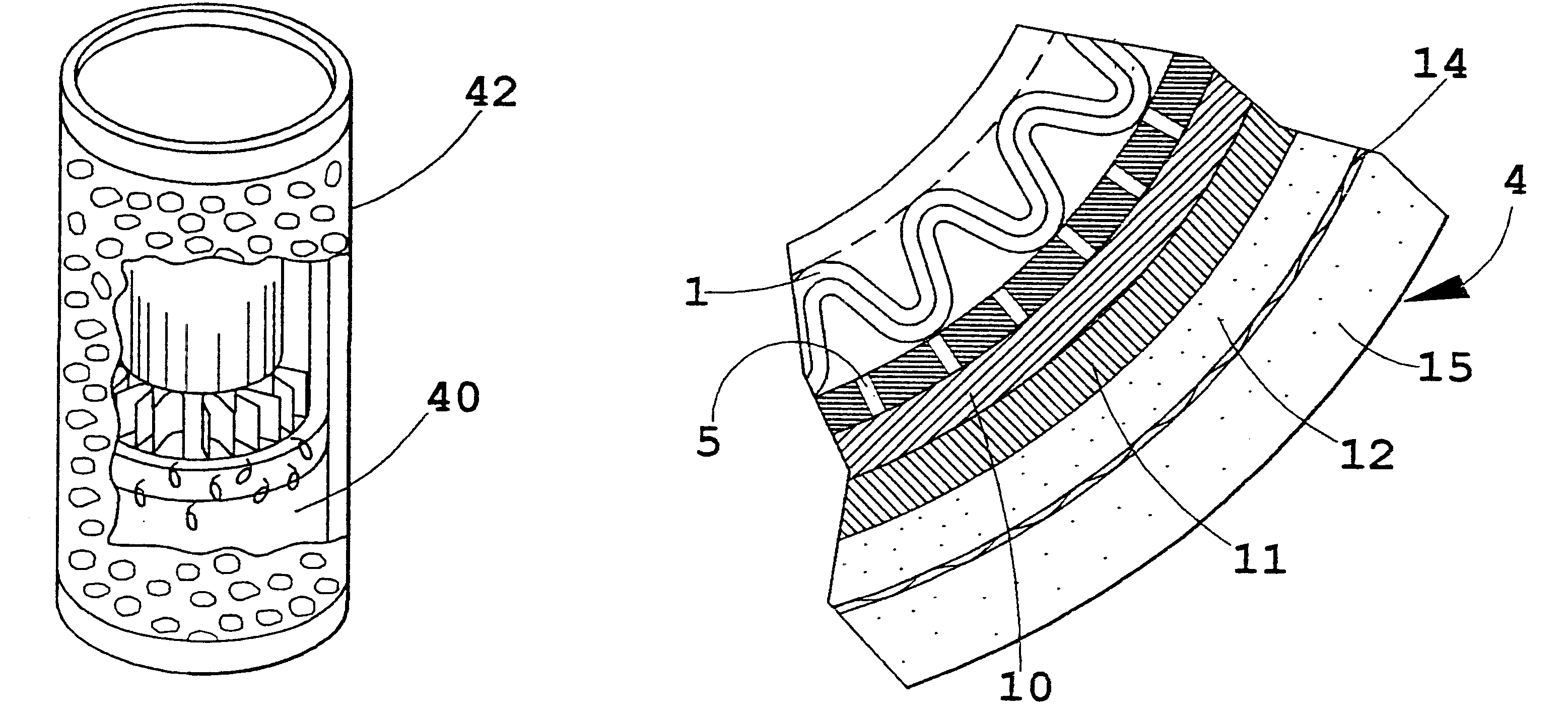

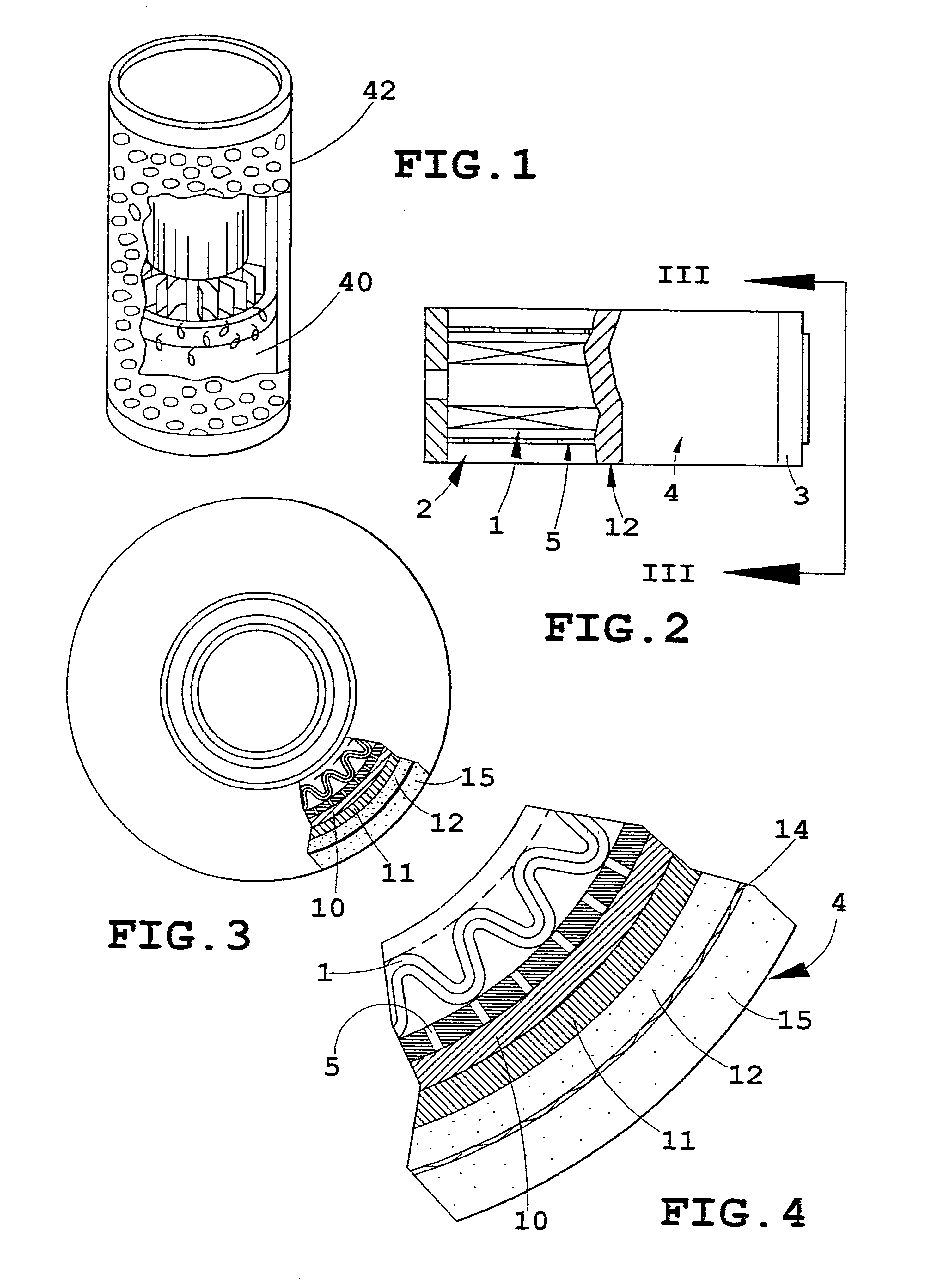

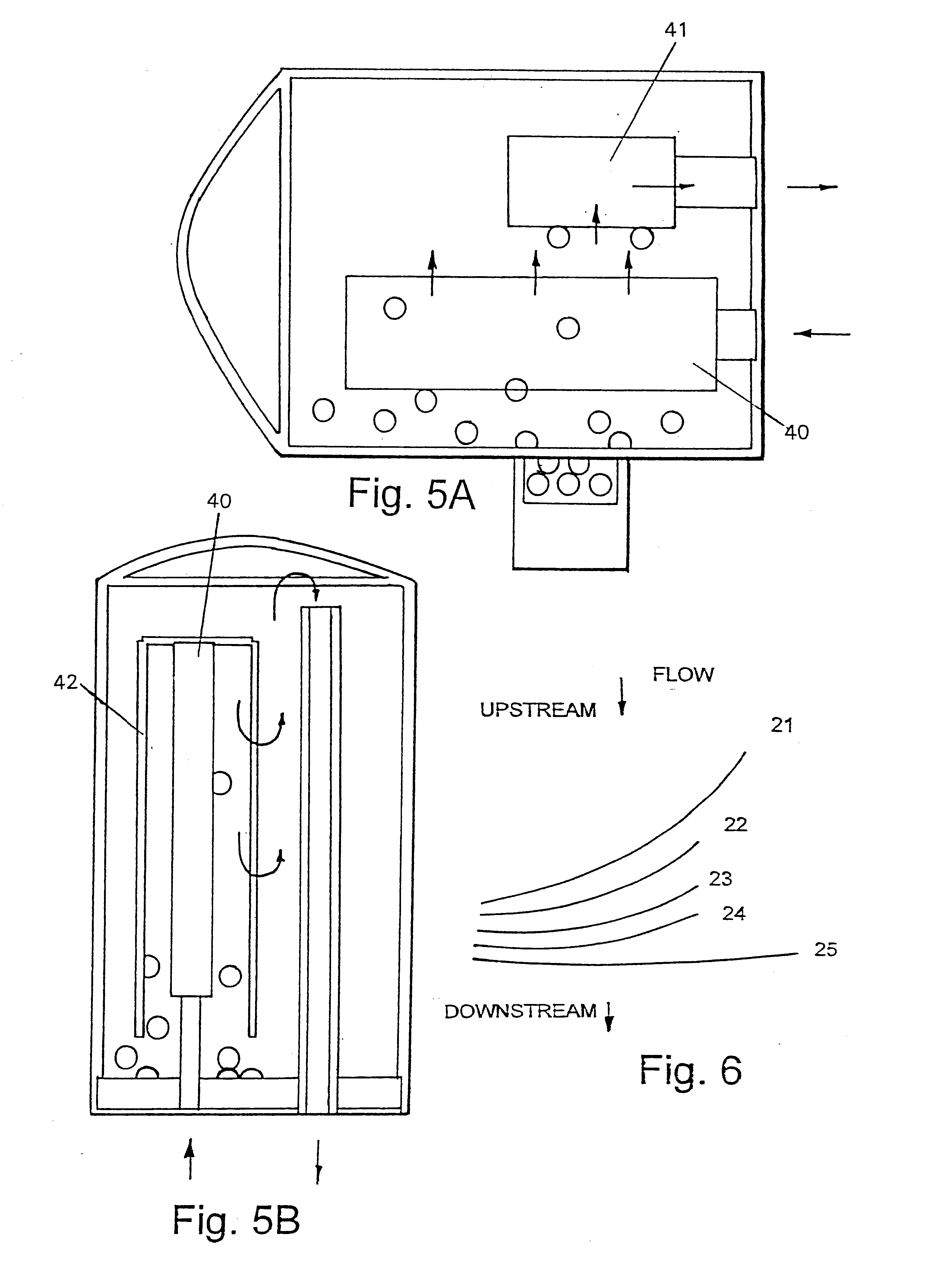

Coalescer for hydrocarbons containing surfactant

A coalescer filter element for the separation of water from hydrocarbon fluids, such as kerosene, jet fuel, diesel fuel, and gasoline under surfactant conditions such as thermal stability additive and dispersant. Coalescer fibrous material has hydrophobic properties which resist surfactant coating of the fibers thereby allowing breakdown of water emulsion in the hydrocarbon fluids. The coalescer has a negative media density gradient in the liquid flow direction.

Owner:KAYDON CUSTOM FILTRATION CORP

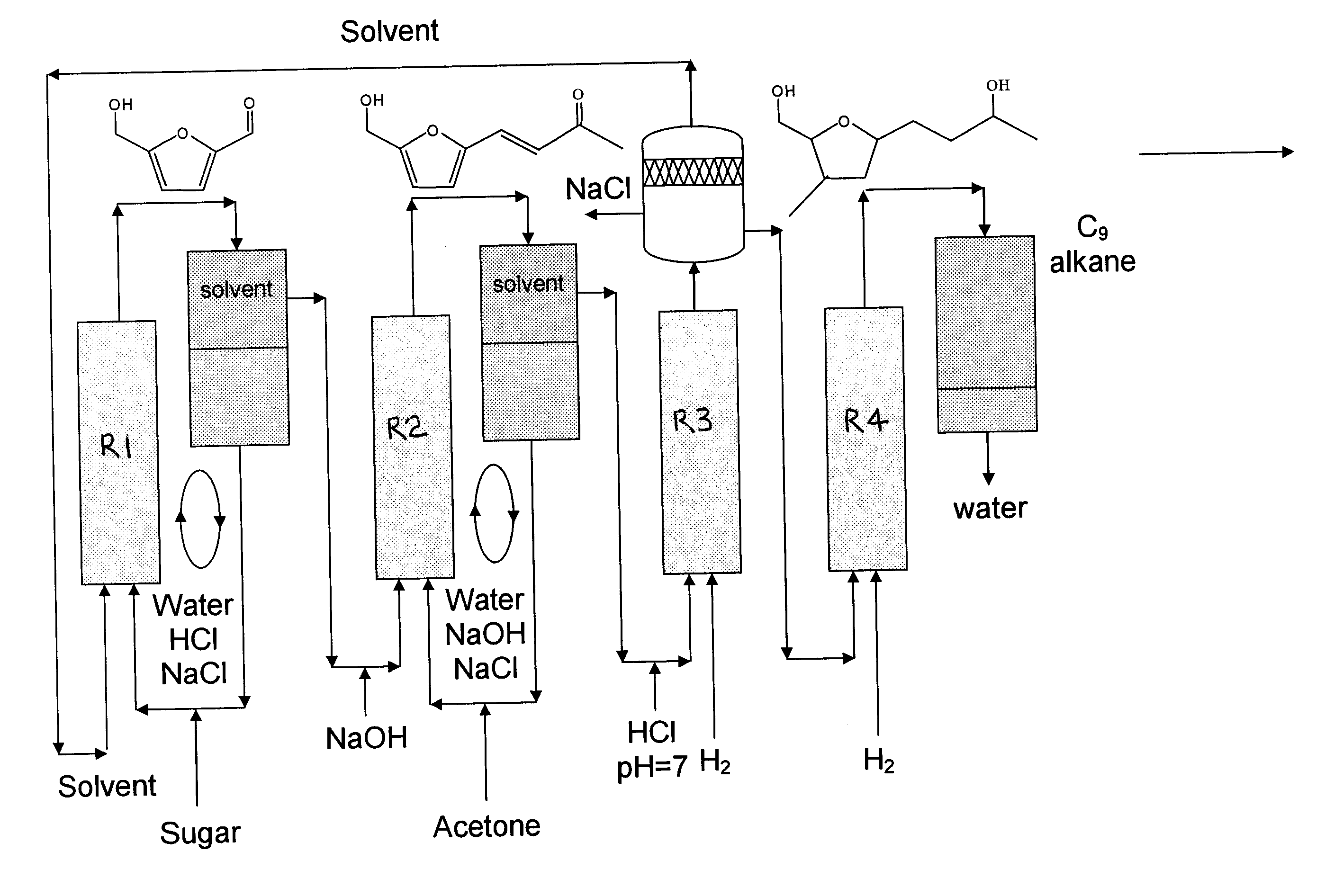

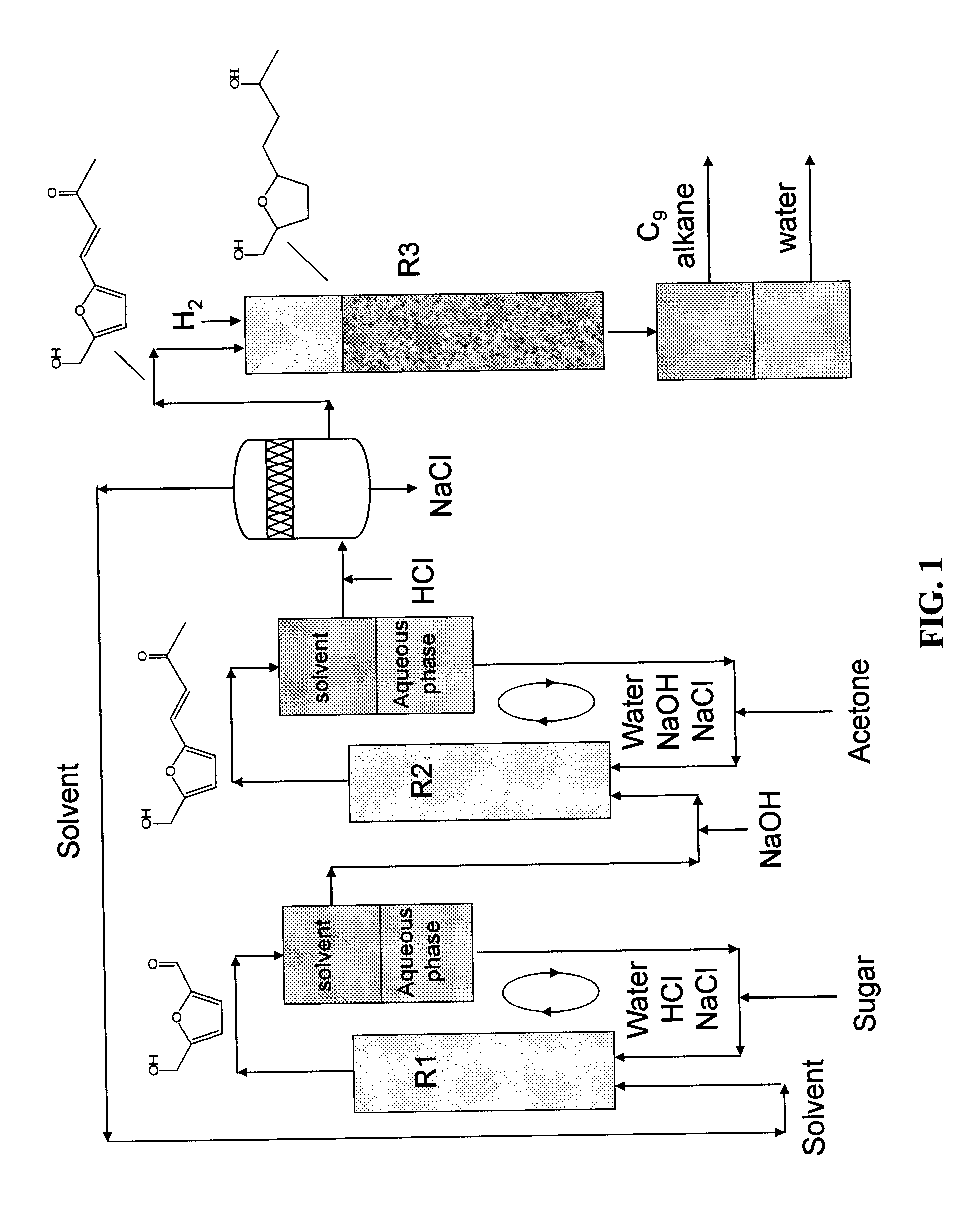

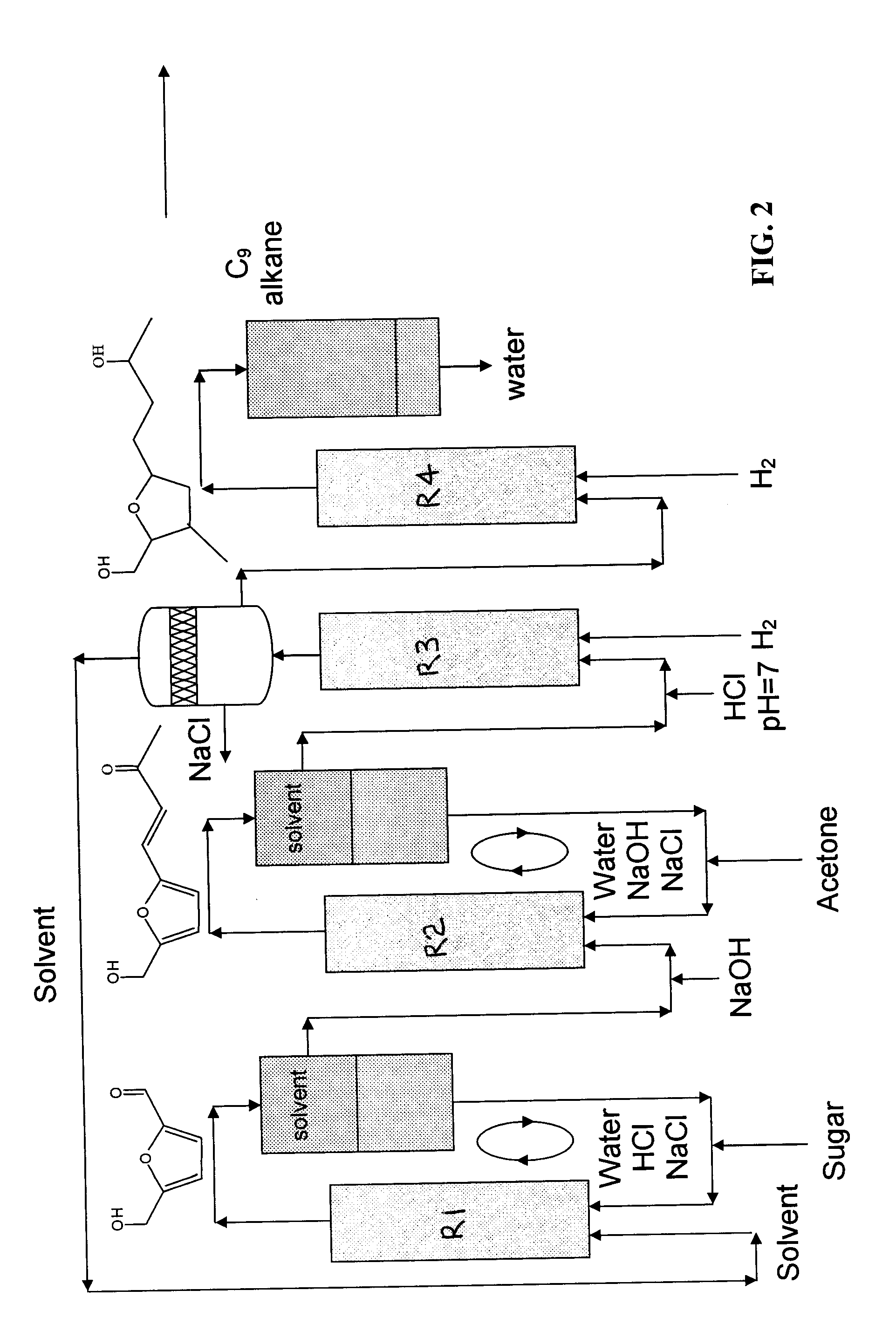

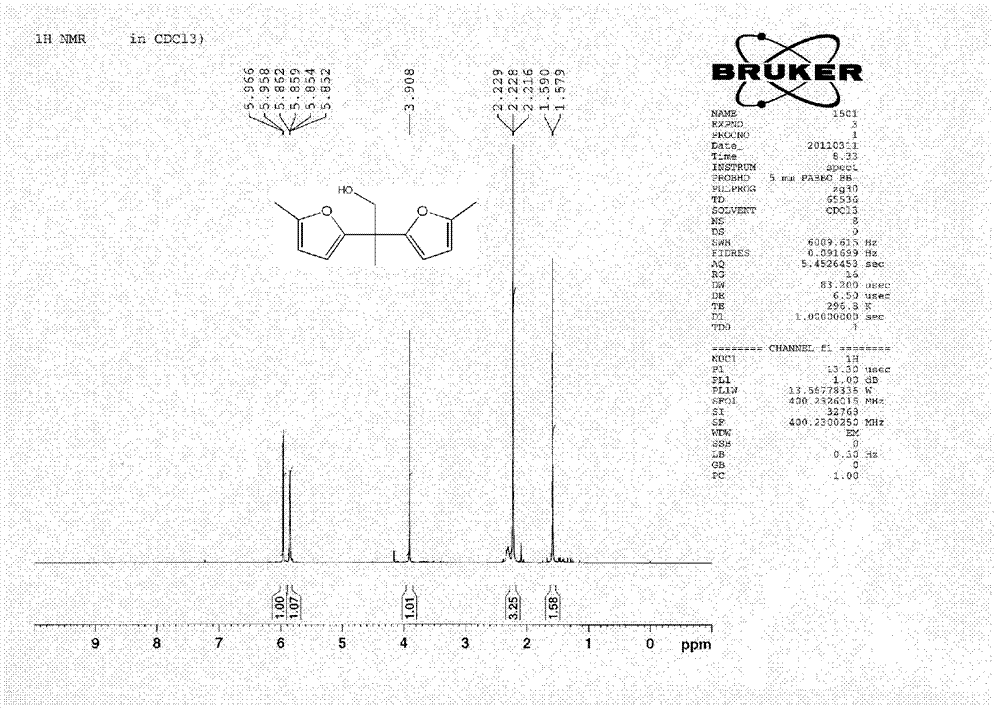

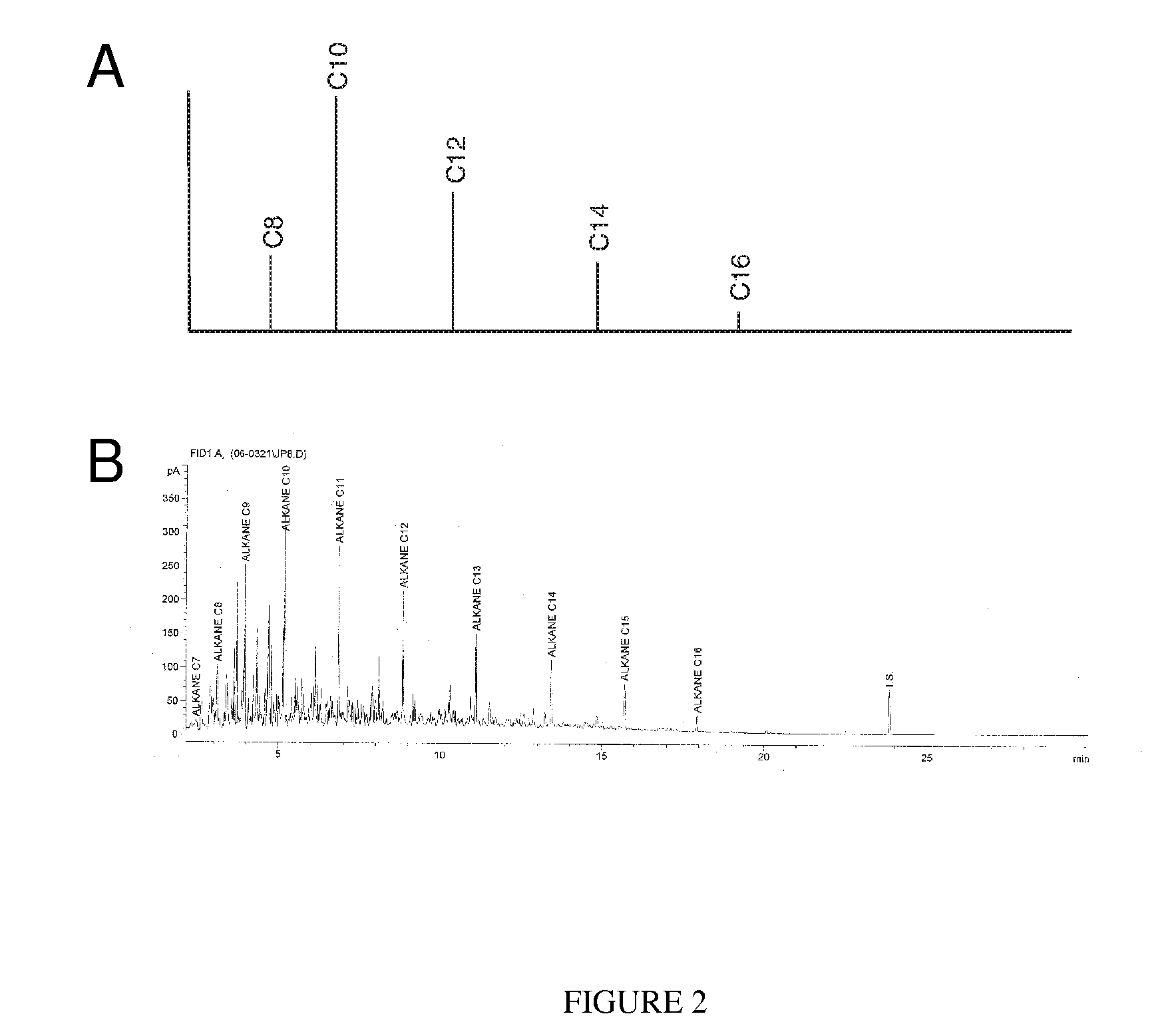

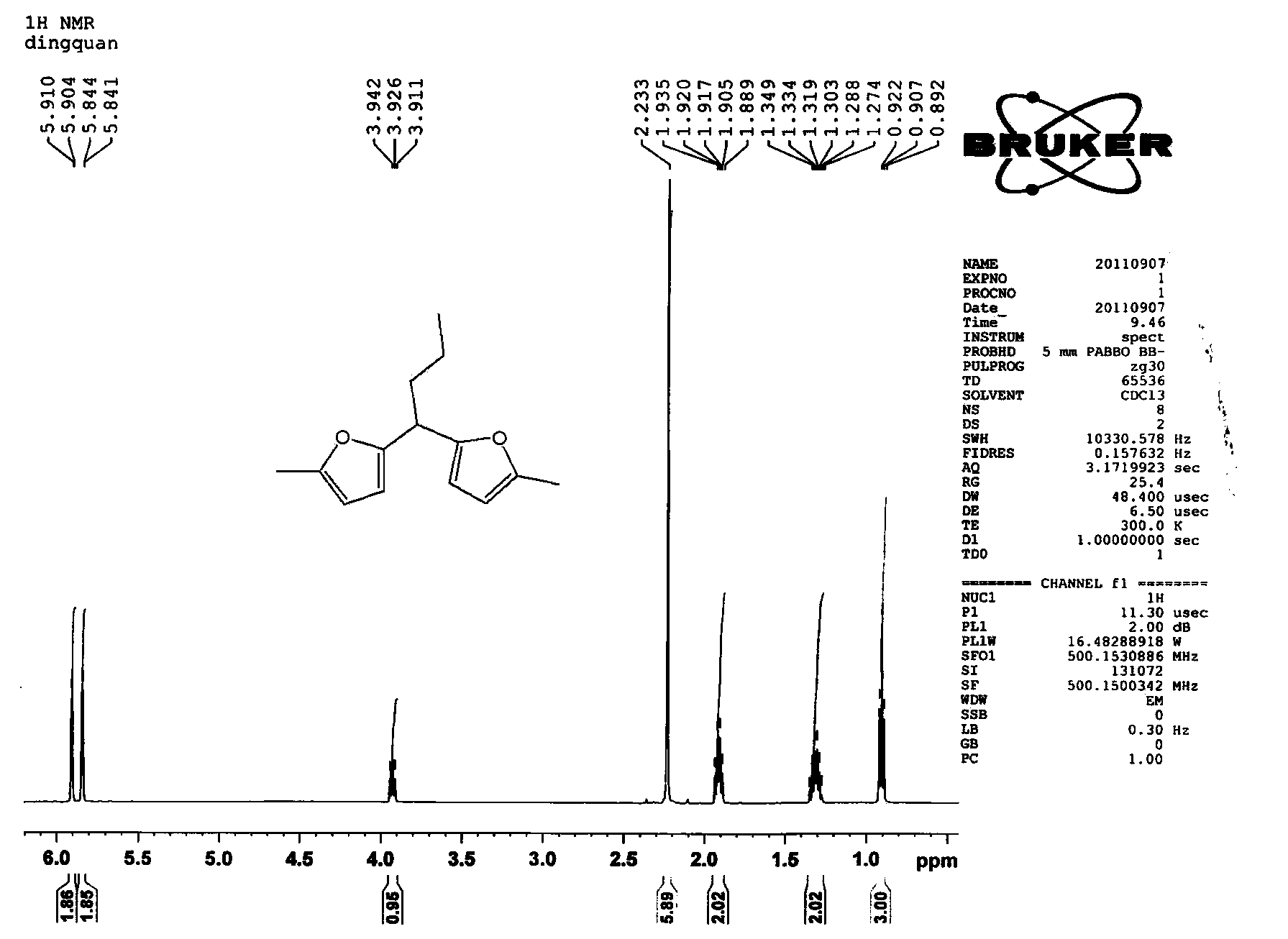

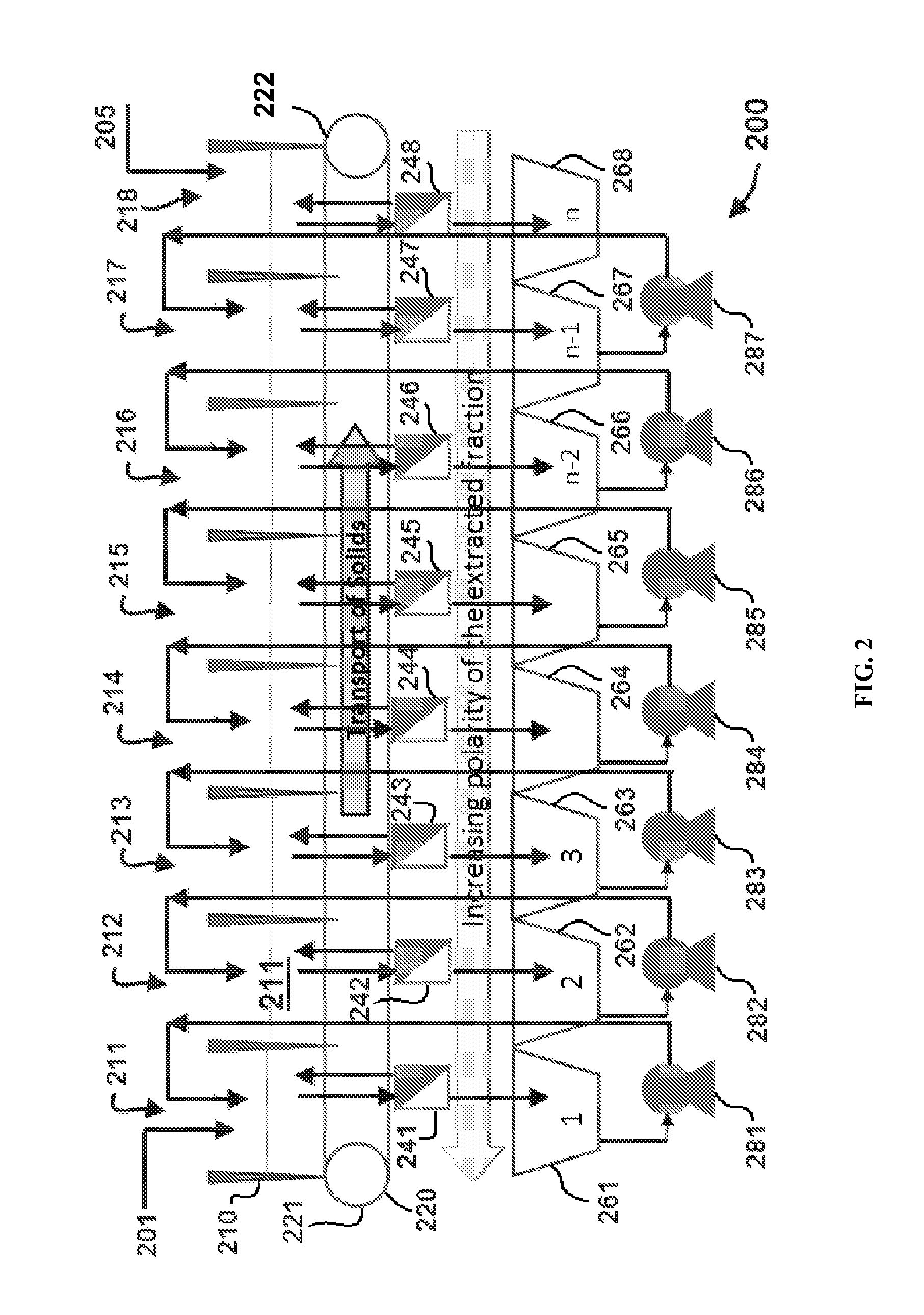

Production of liquid alkanes in the jet fuel range (c8-c15) from biomass-derived carbohydrates

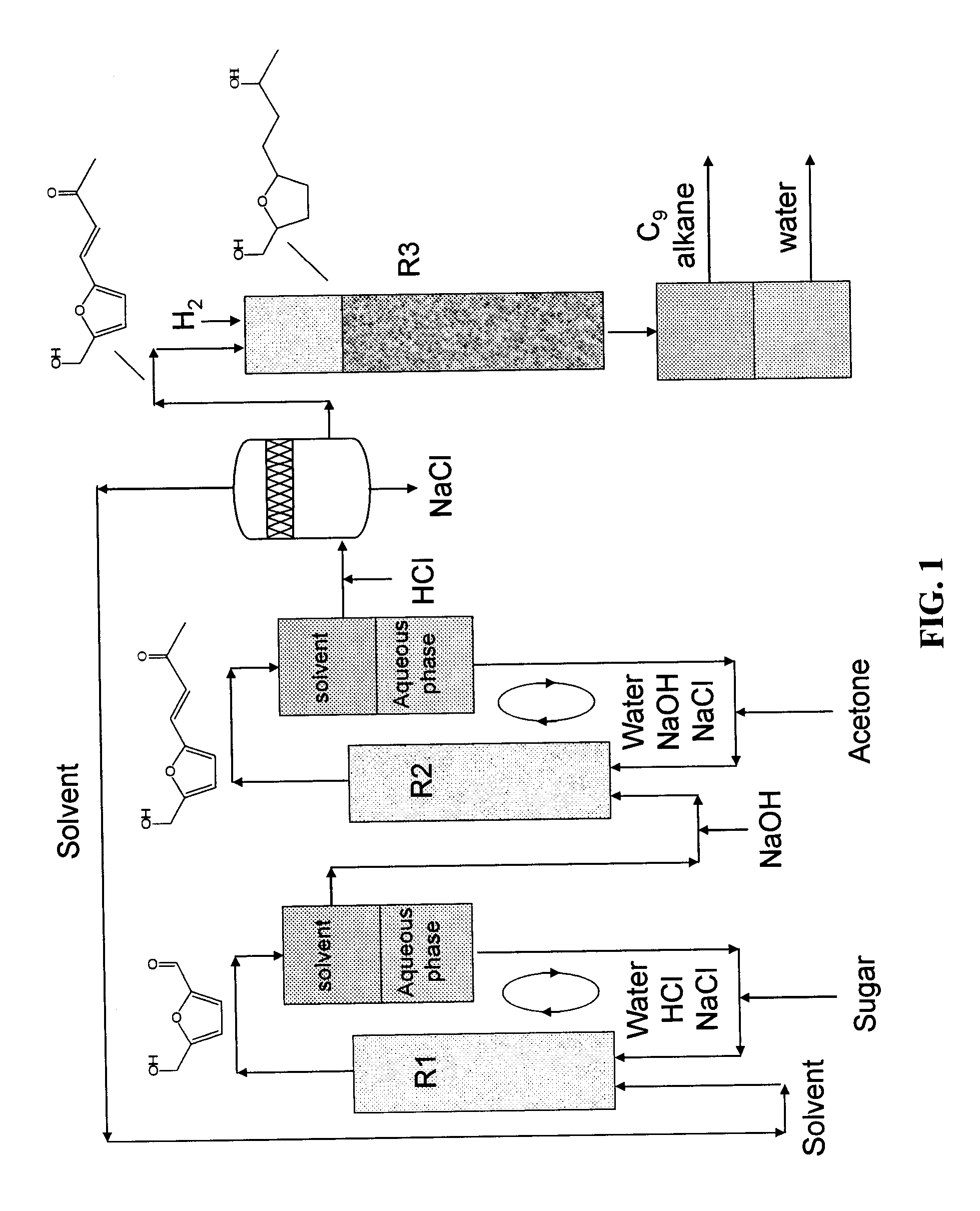

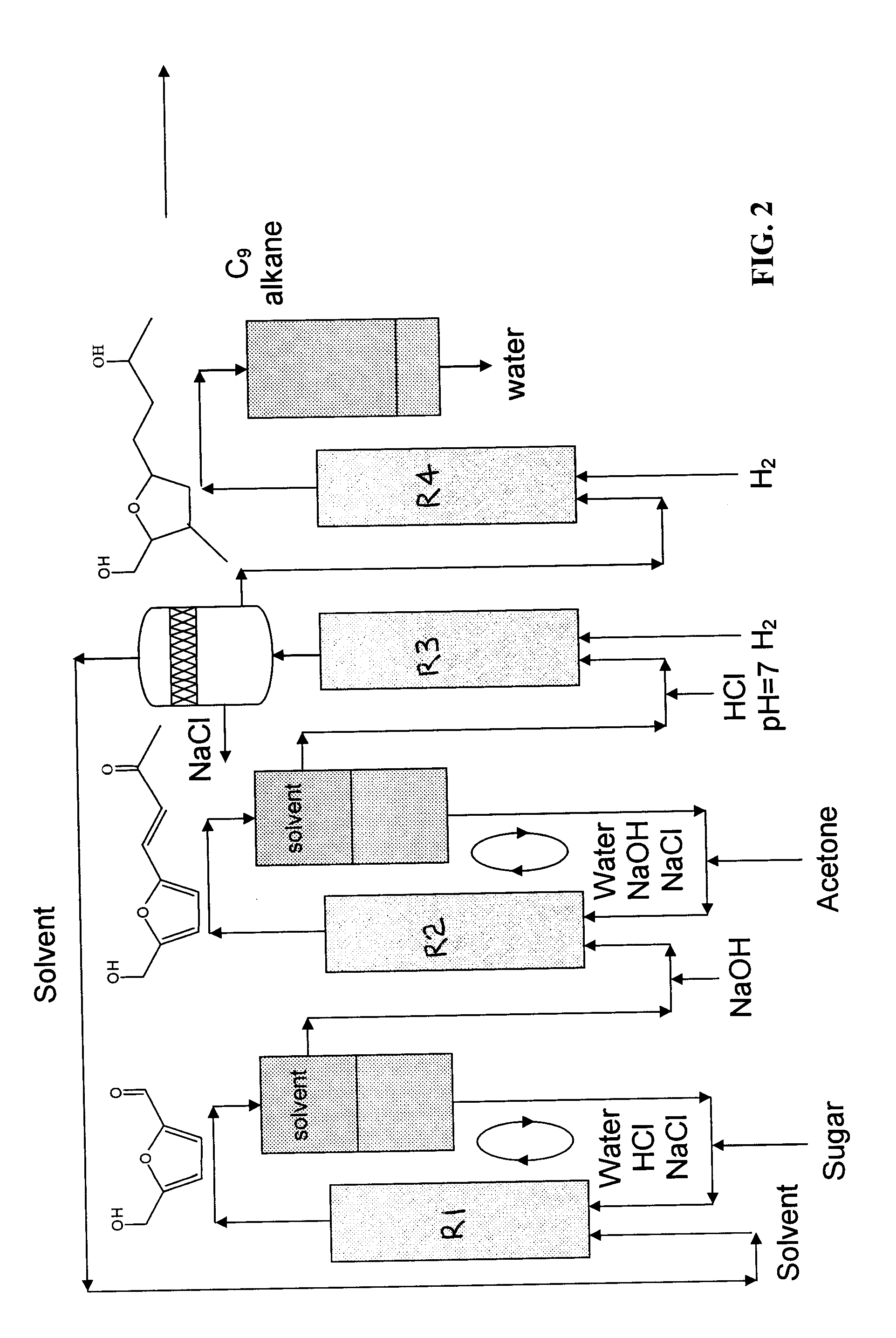

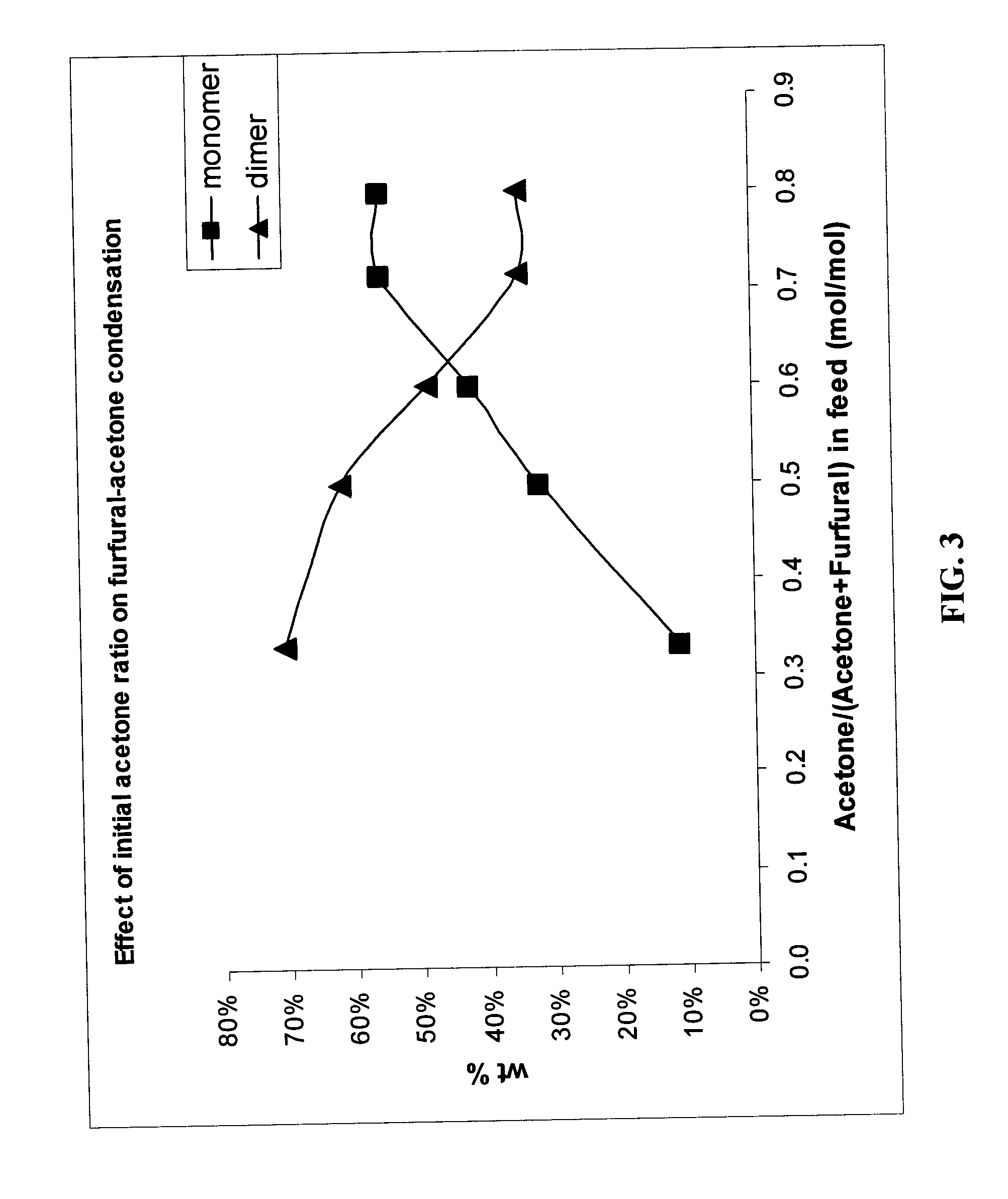

Described is a method for making a composition comprising alkanes. The composition is suitable for use as a liquid transportation fuel in general, and jet fuel in particular. The method includes dehydrating a feedstock solution comprising a carbohydrate, in the presence of an acid catalyst, to yield at least one furan derivative compound, in a reaction vessel containing a biphasic reaction medium: an aqueous reaction solution and a substantially immiscible organic extraction solution. The furan derivative compound is then subjected to a self-aldol condensation reaction or a crossed-aldol condensation reaction with another carbonyl compound to yield a beta-hydroxy carbonyl compound and / or an alpha-beta unsaturated carbonyl compound. The beta-hydroxy carbonyl and / or alpha-beta unsaturated compounds are then hydrogenated to yield a saturated or partially saturated compound, followed by hydrodeoxygenation (e.g., dehydrating and hydrogenating) of the saturated or partially saturated compound to yield a composition of matter comprising alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

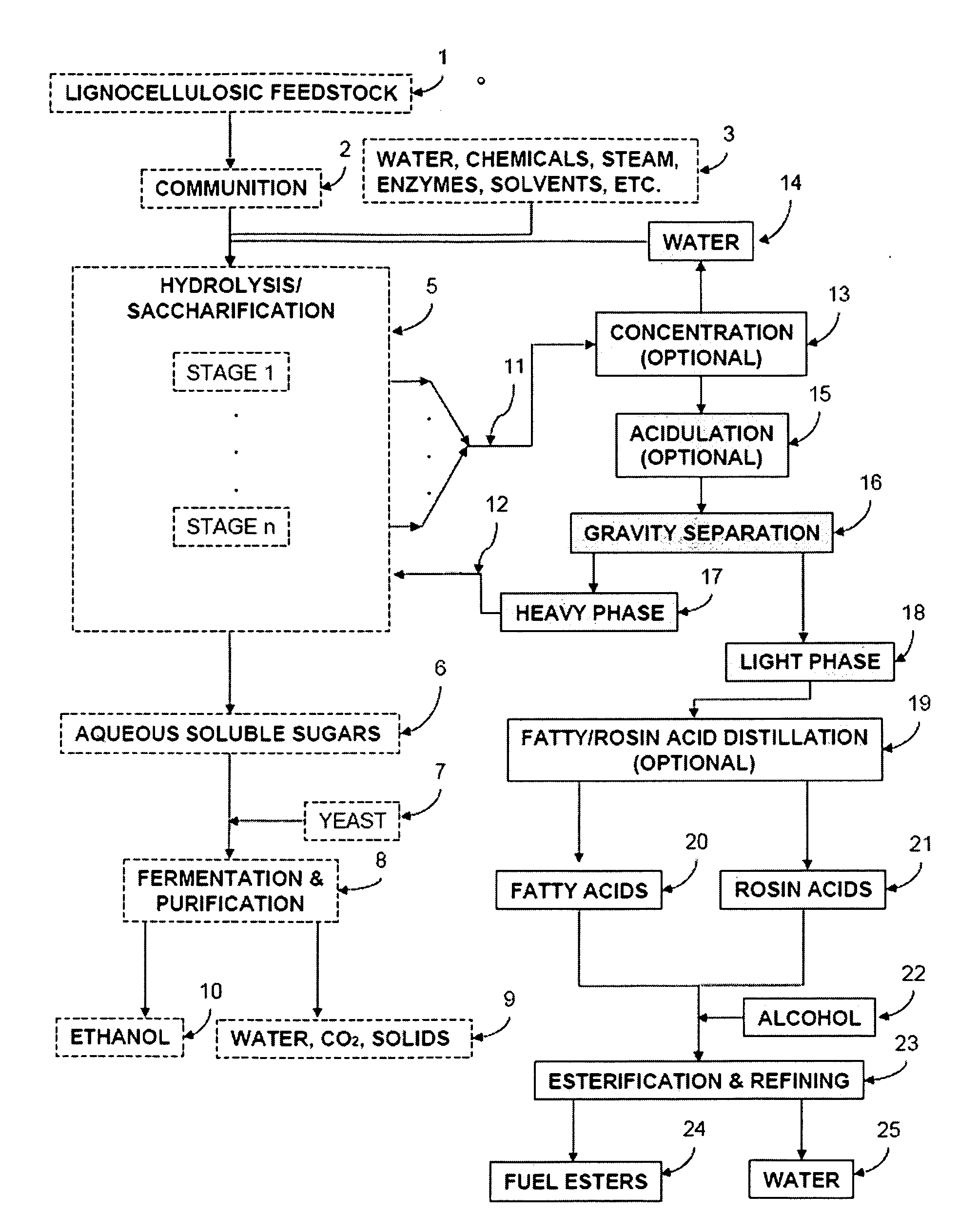

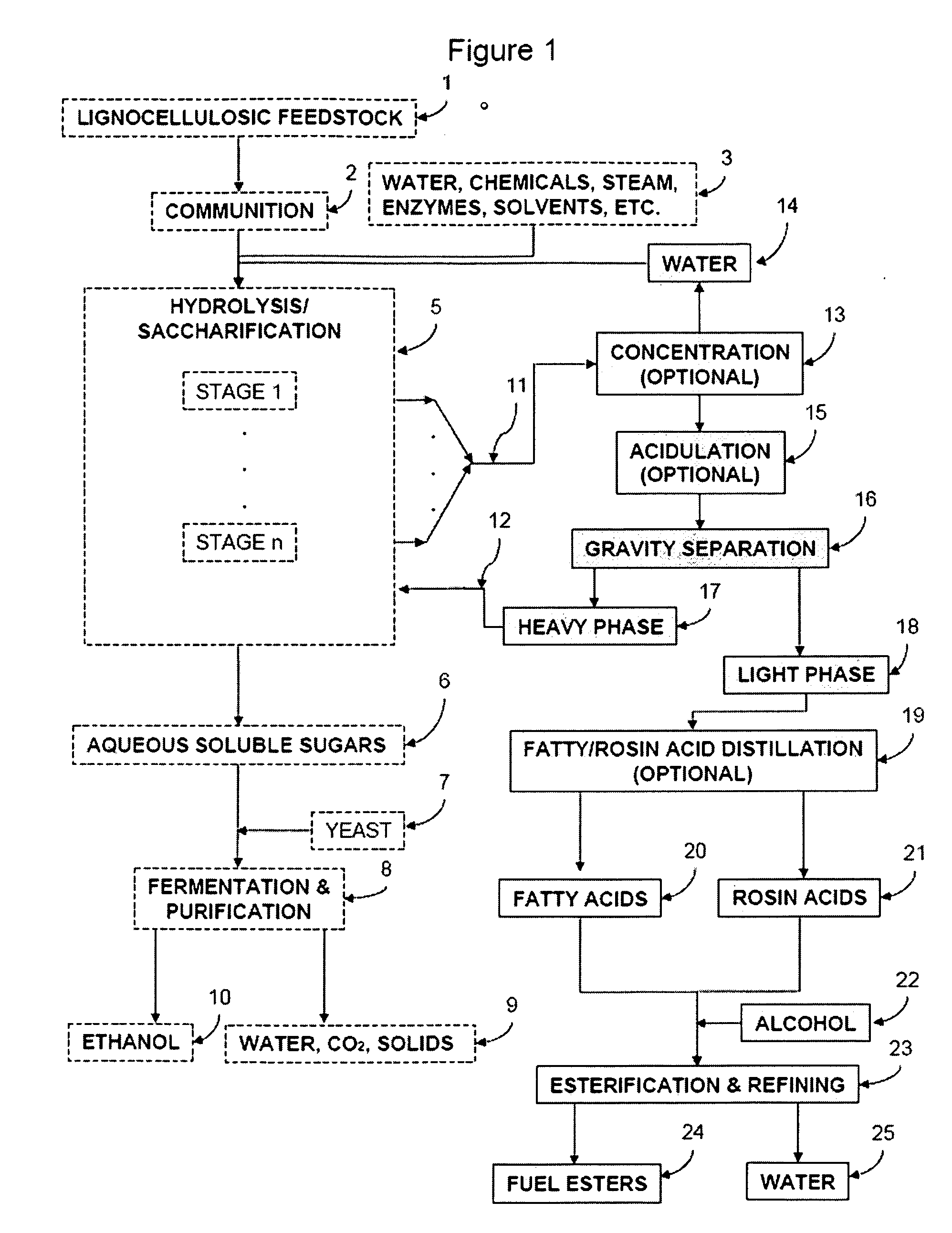

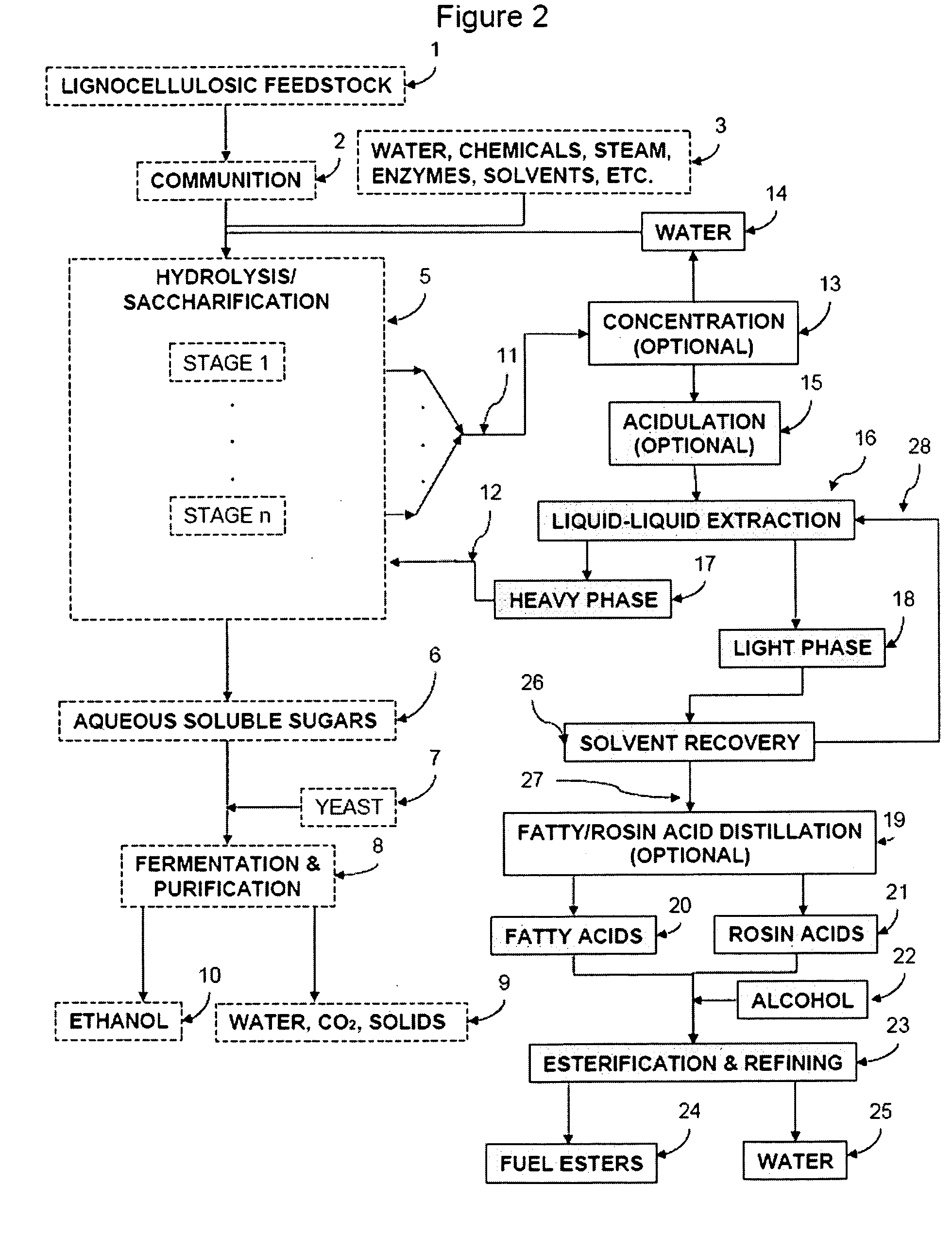

Production of Ester-based Fuels Such As Biodiesel From Renewable Starting Materials

ActiveUS20090056201A1Fatty oils/acids recovery from wasteFatty acid esterificationCelluloseBiodiesel

Production of ester-based fuels such as biodiesel or jet fuel from renewable starting materials such as lignocellulosic material or algae is disclosed. Pulping and saccharification of the renewable starting materials produces carboxylic acids such as fatty acids or rosin acids, which are esterified via a gas sparged, slurry form of heterogeneous reactive distillation to yield ester-based fuels.

Owner:ENDICOTT BIOFUELS II

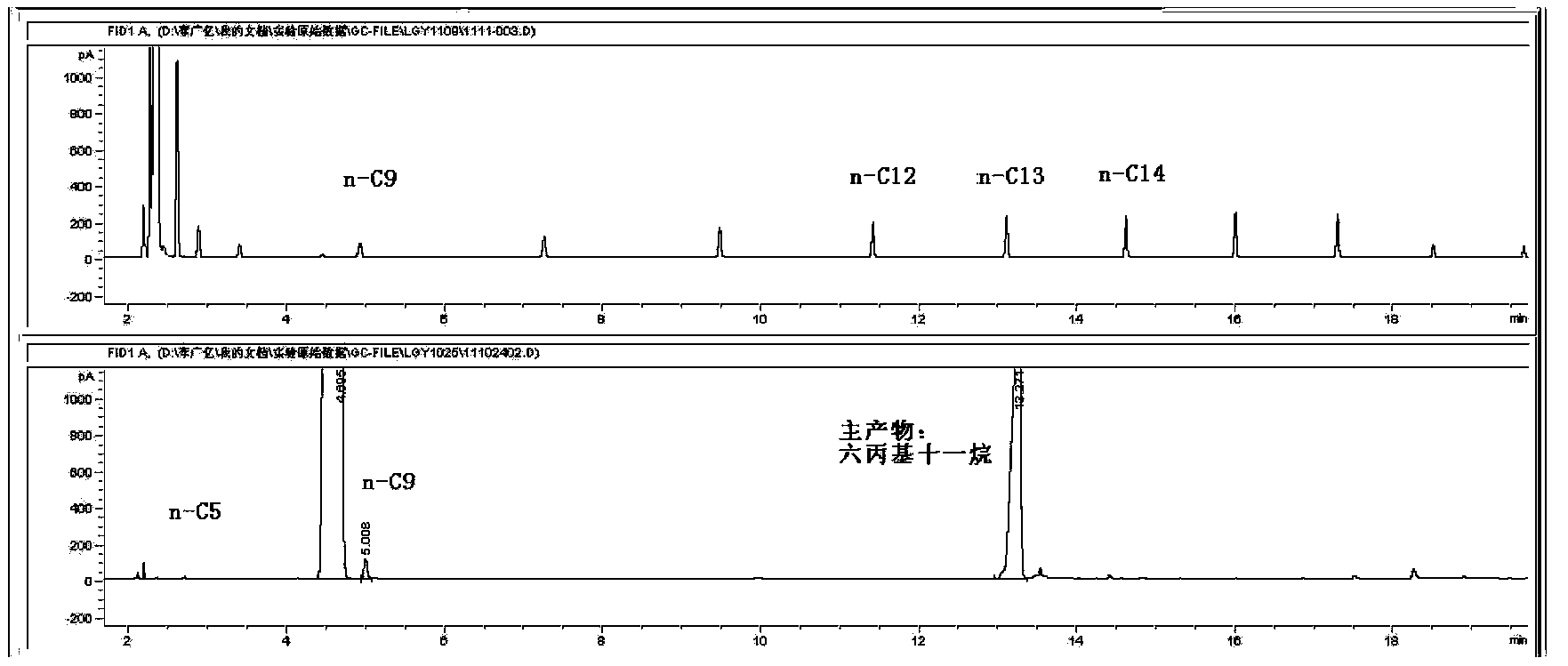

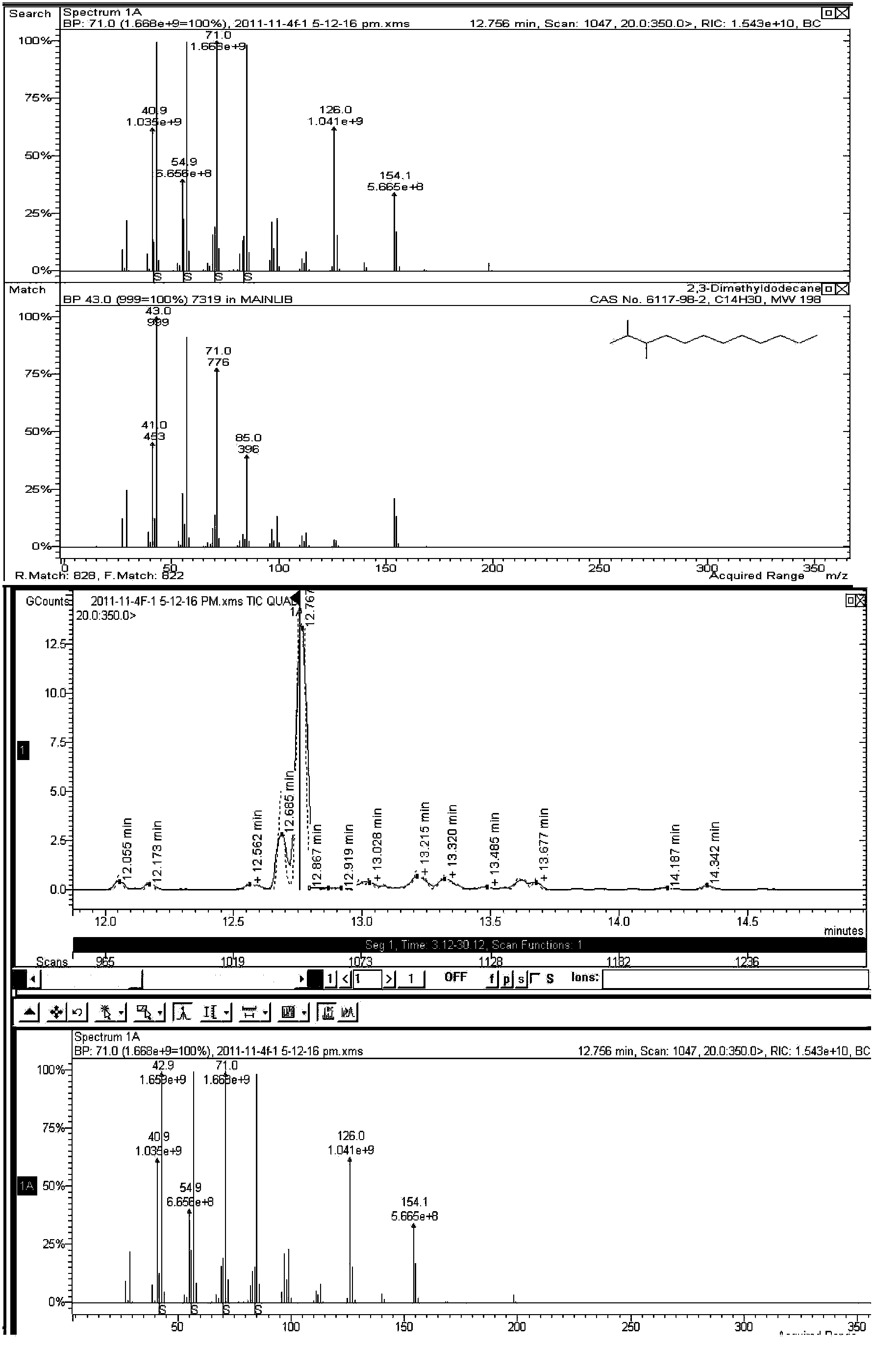

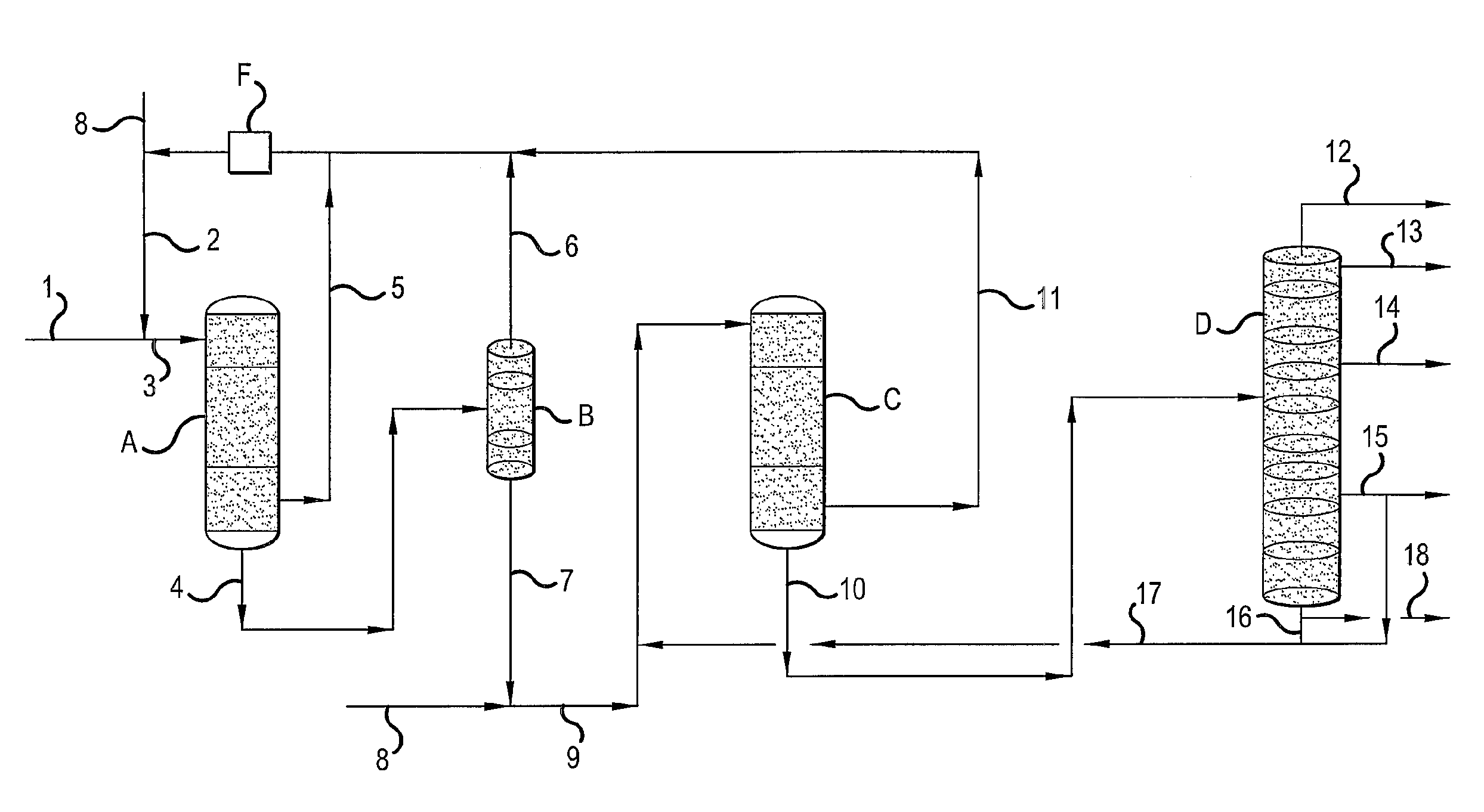

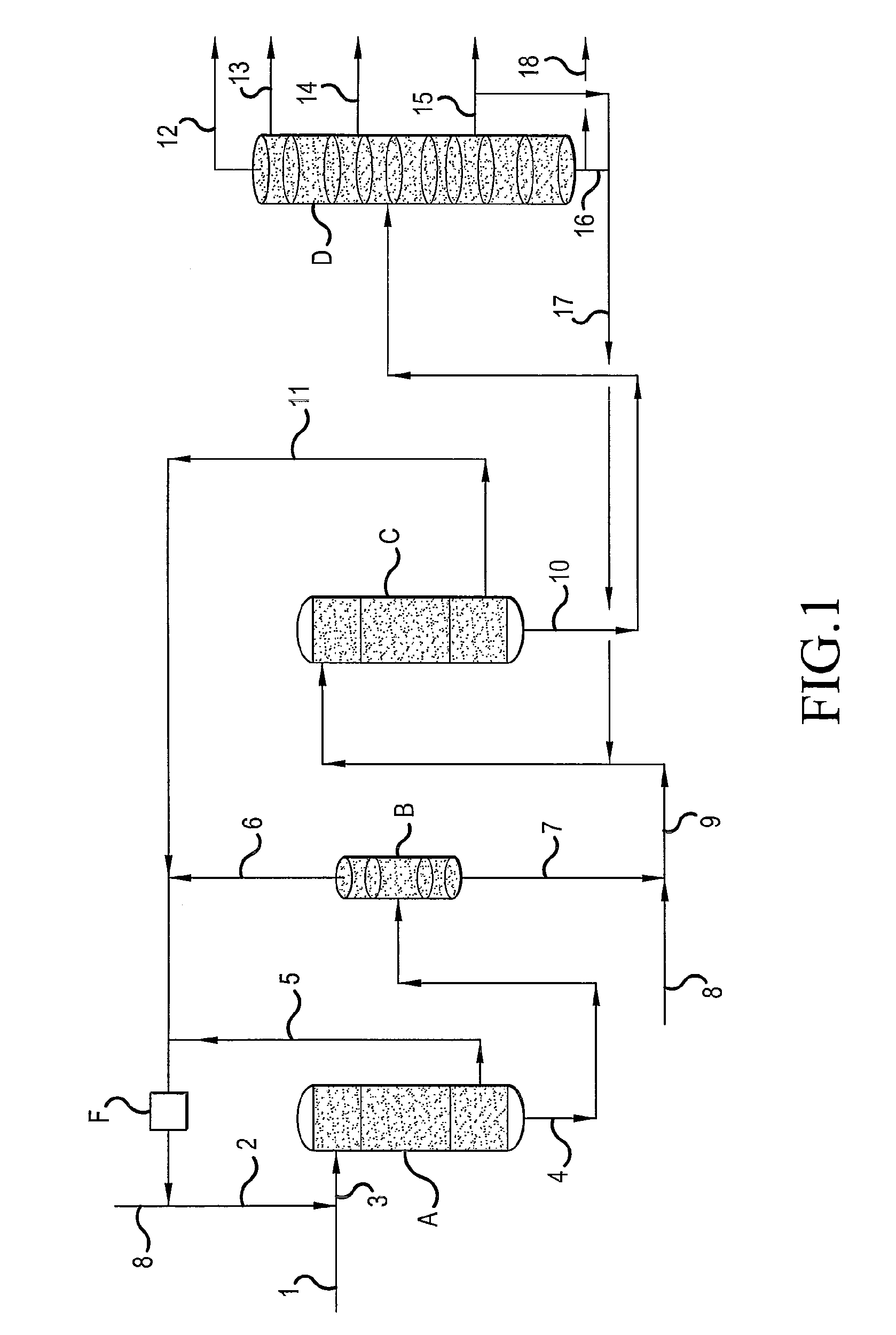

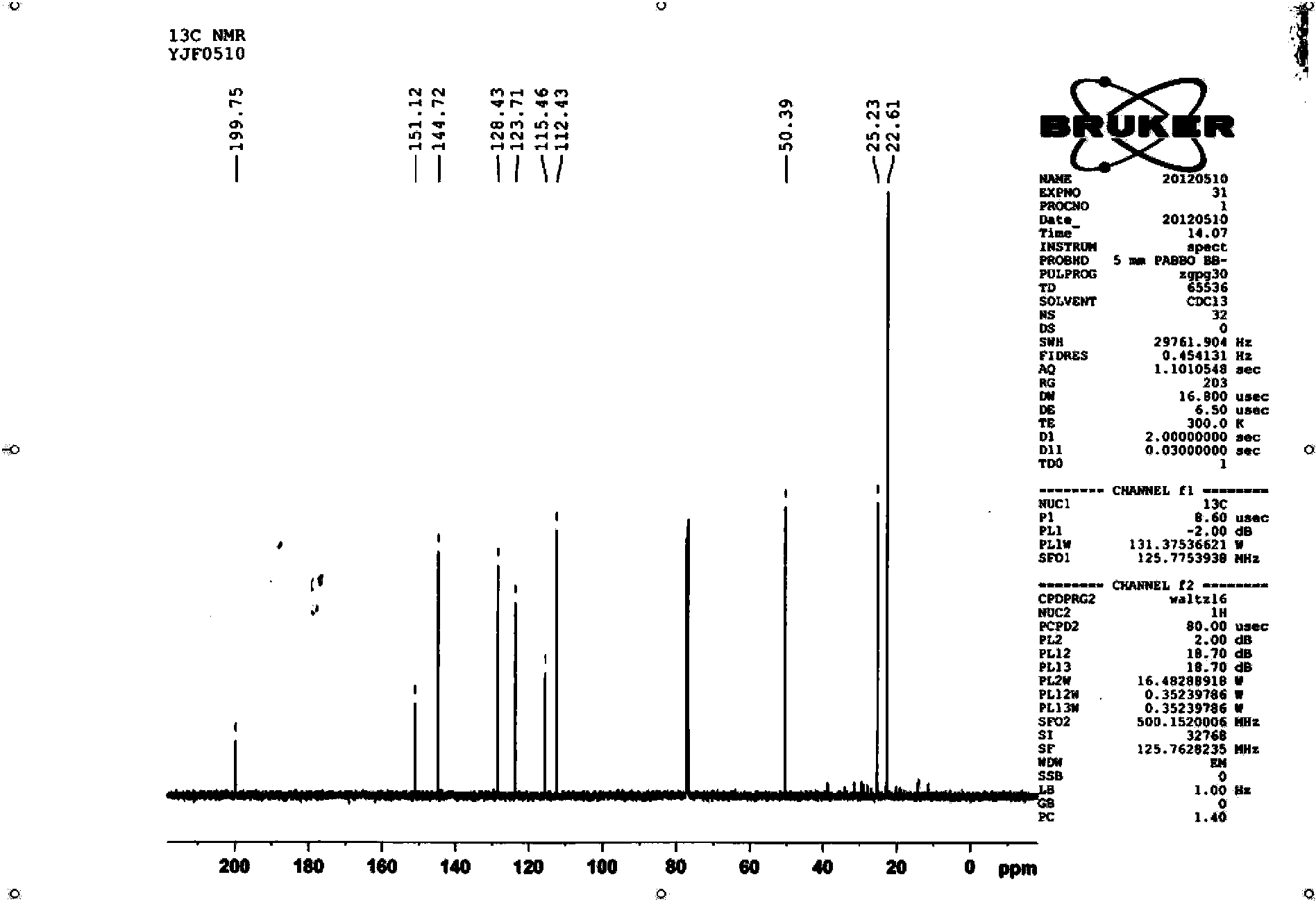

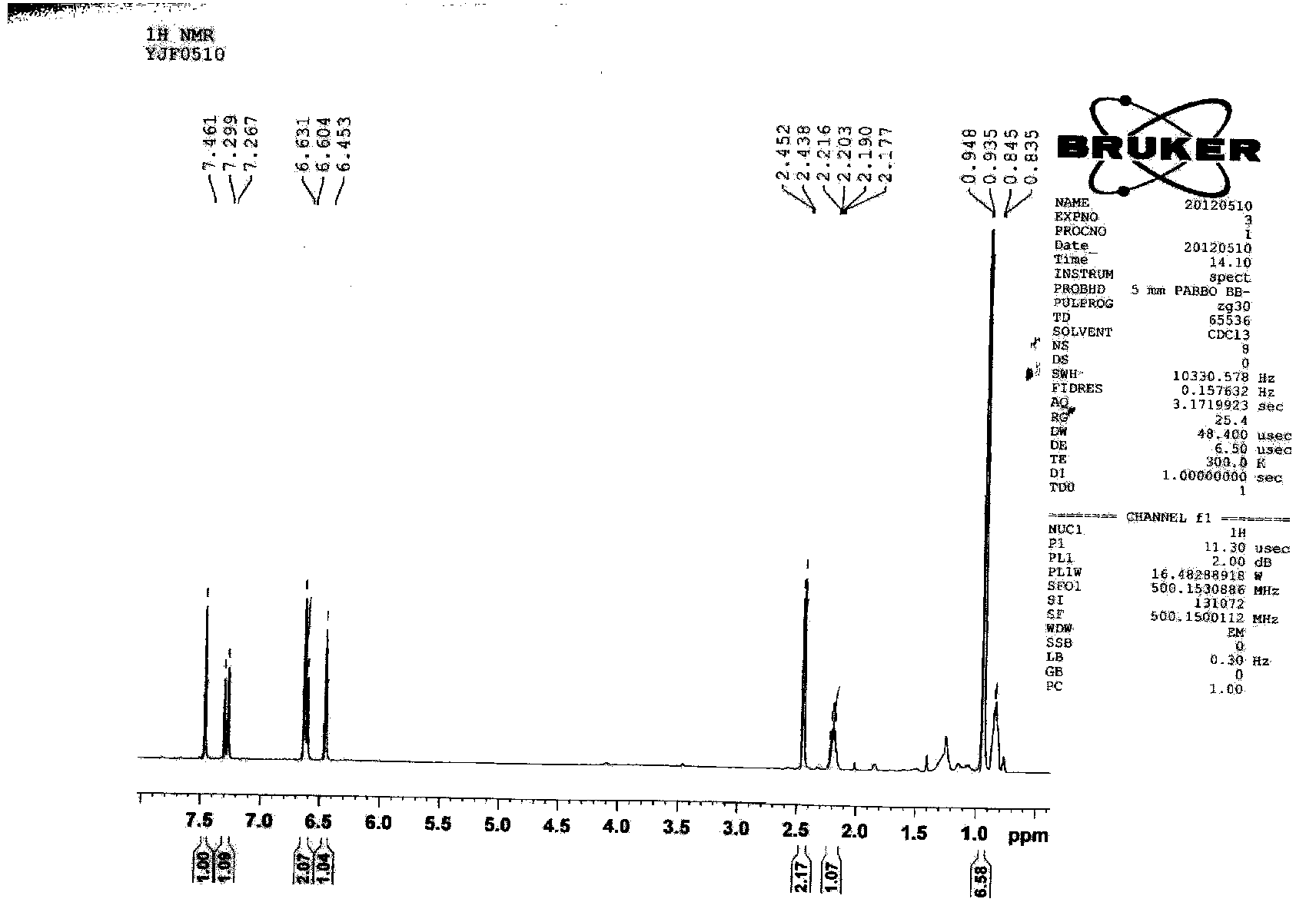

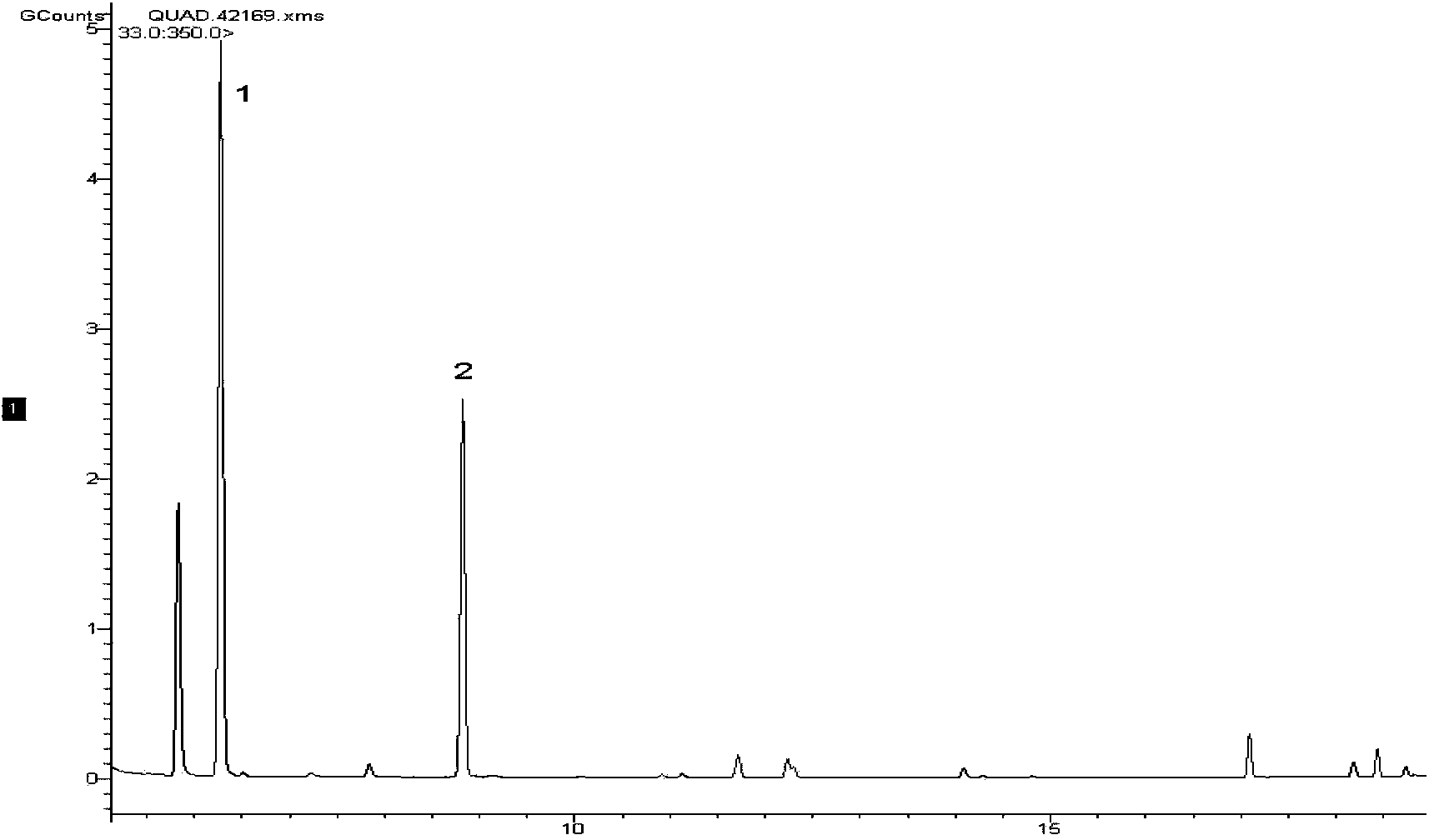

Preparation method of aviation kerosene or diesel

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

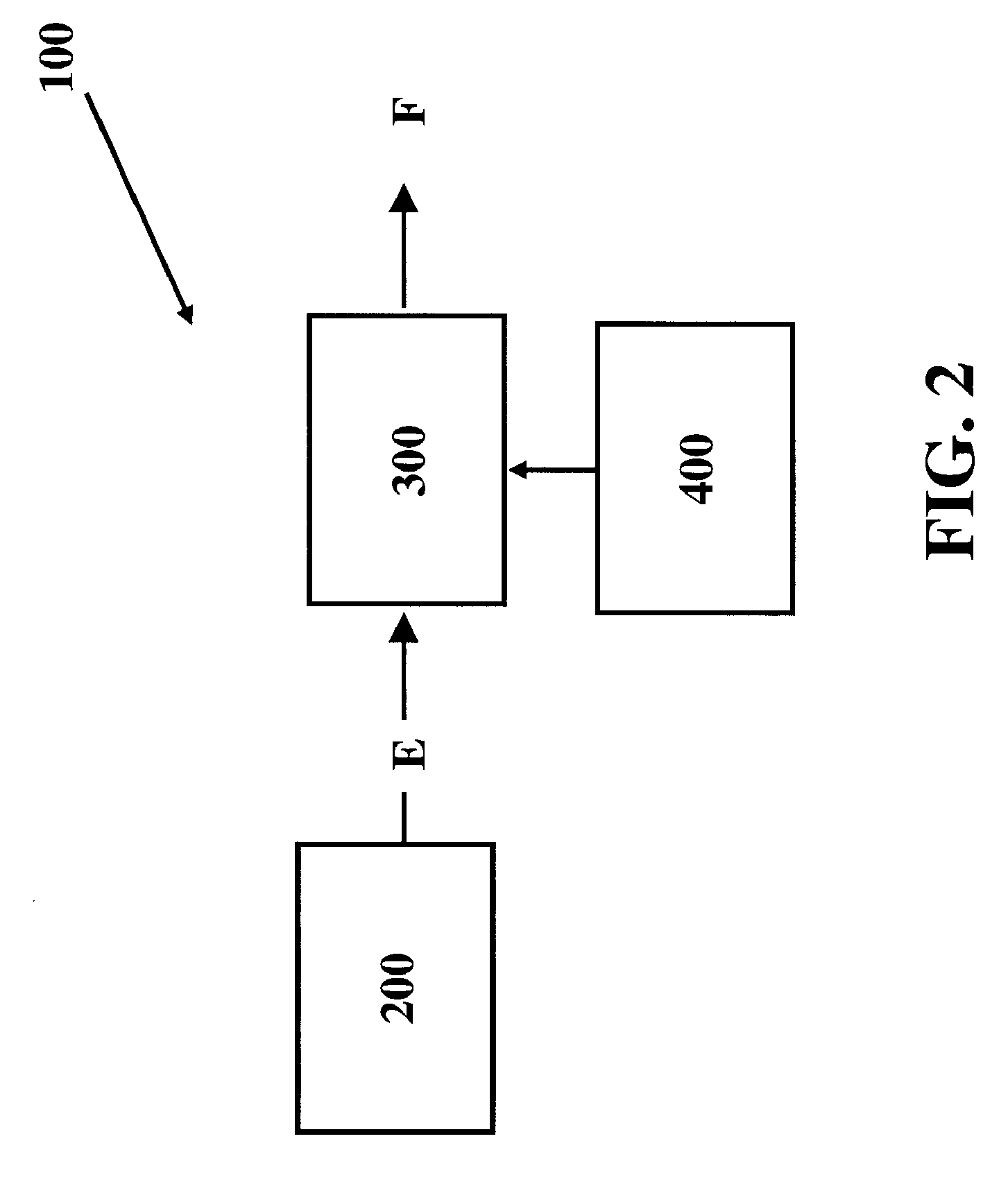

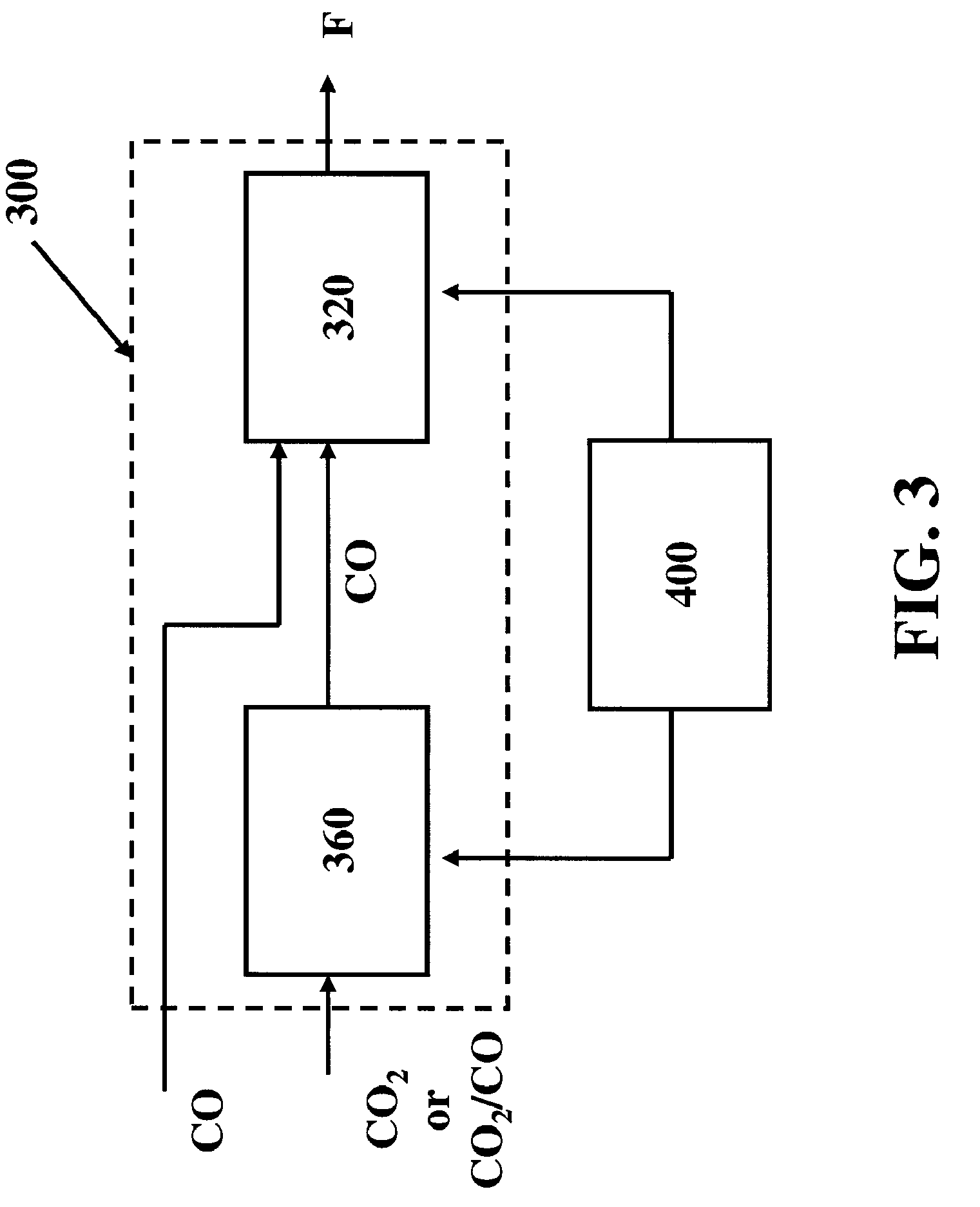

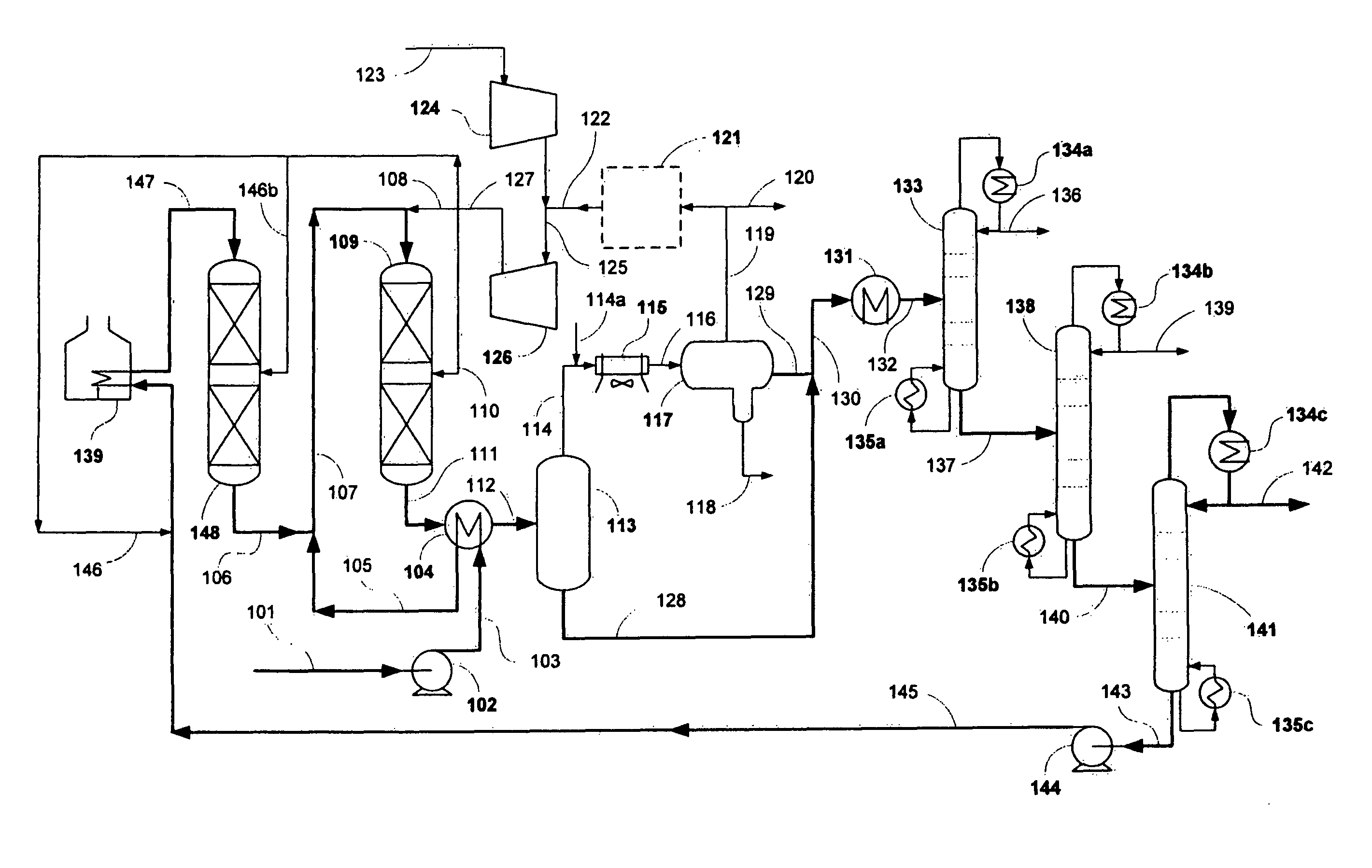

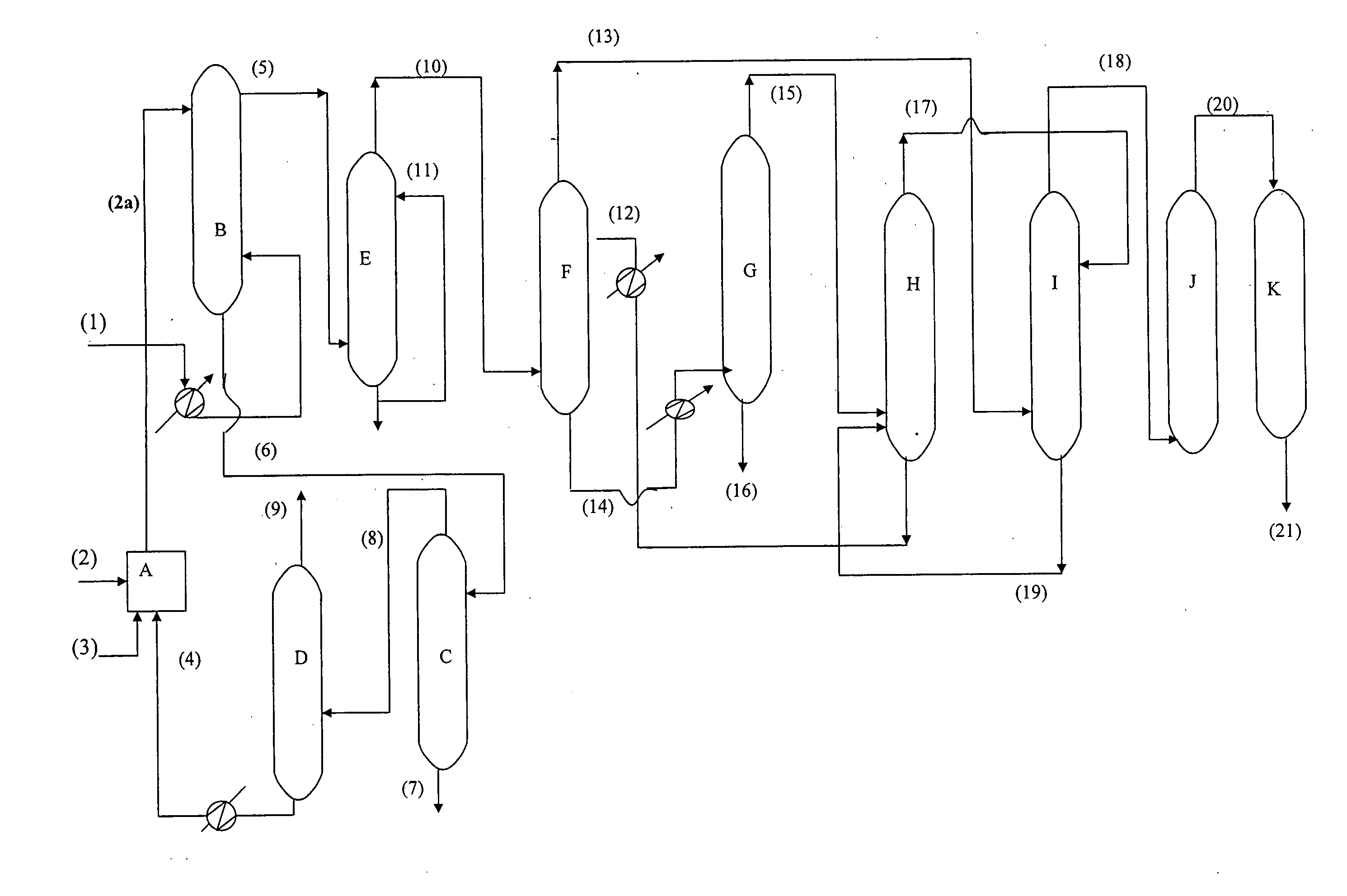

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS20060211777A1Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneHydrocotyle bowlesioides

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolysing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

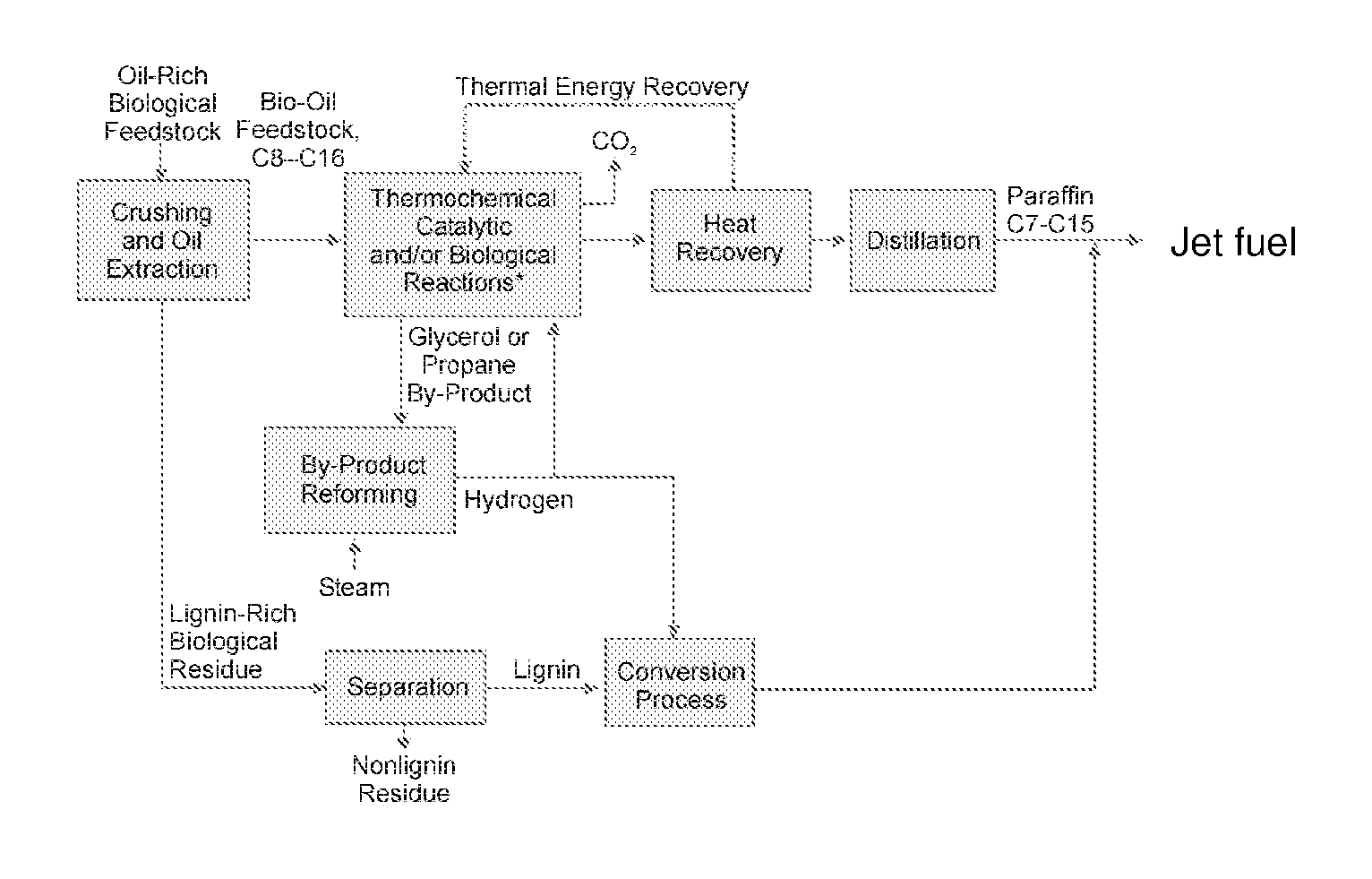

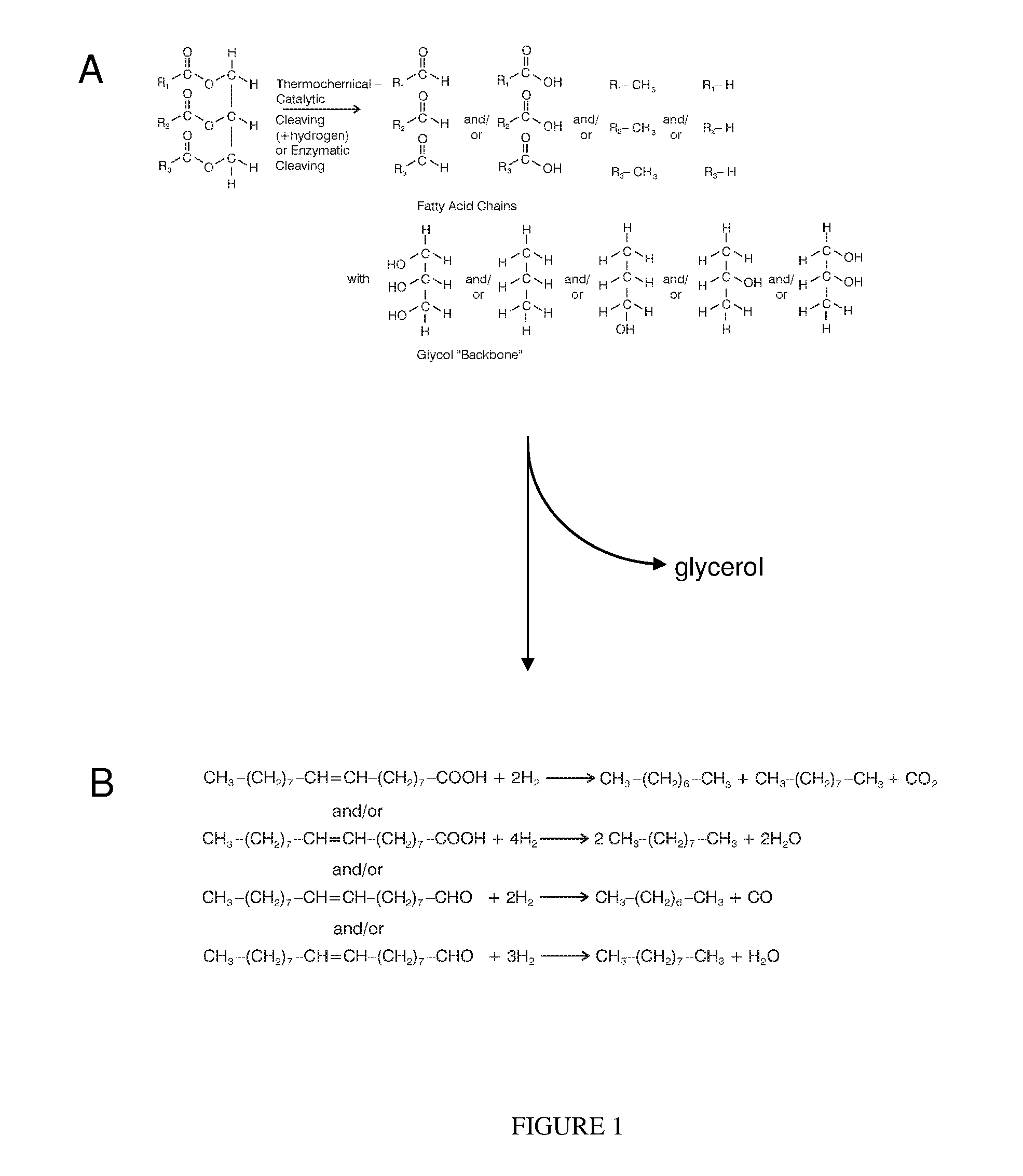

Optimal energy pathway to renewable domestic and other fuels

A novel, energy efficient process of producing jet fuel is disclosed herein. The process is based on utilizing a medium chain fatty acid source such as cuphea oil, which precludes the need for high-energy fatty acid chain cracking to achieve the shorter molecules needed for jet fuels and other fuels with low-temperature flow requirements. In an embodiment, a process for producing a jet fuel comprises providing a medium chain fatty acid source. The method also comprises cleaving the one or more medium chain fatty acid groups from the glycerides to form glycerol and one or more free fatty acids. The method further comprises decarboxylating the one or more medium chain fatty acids to form one or more hydrocarbons for the production of the jet fuel.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

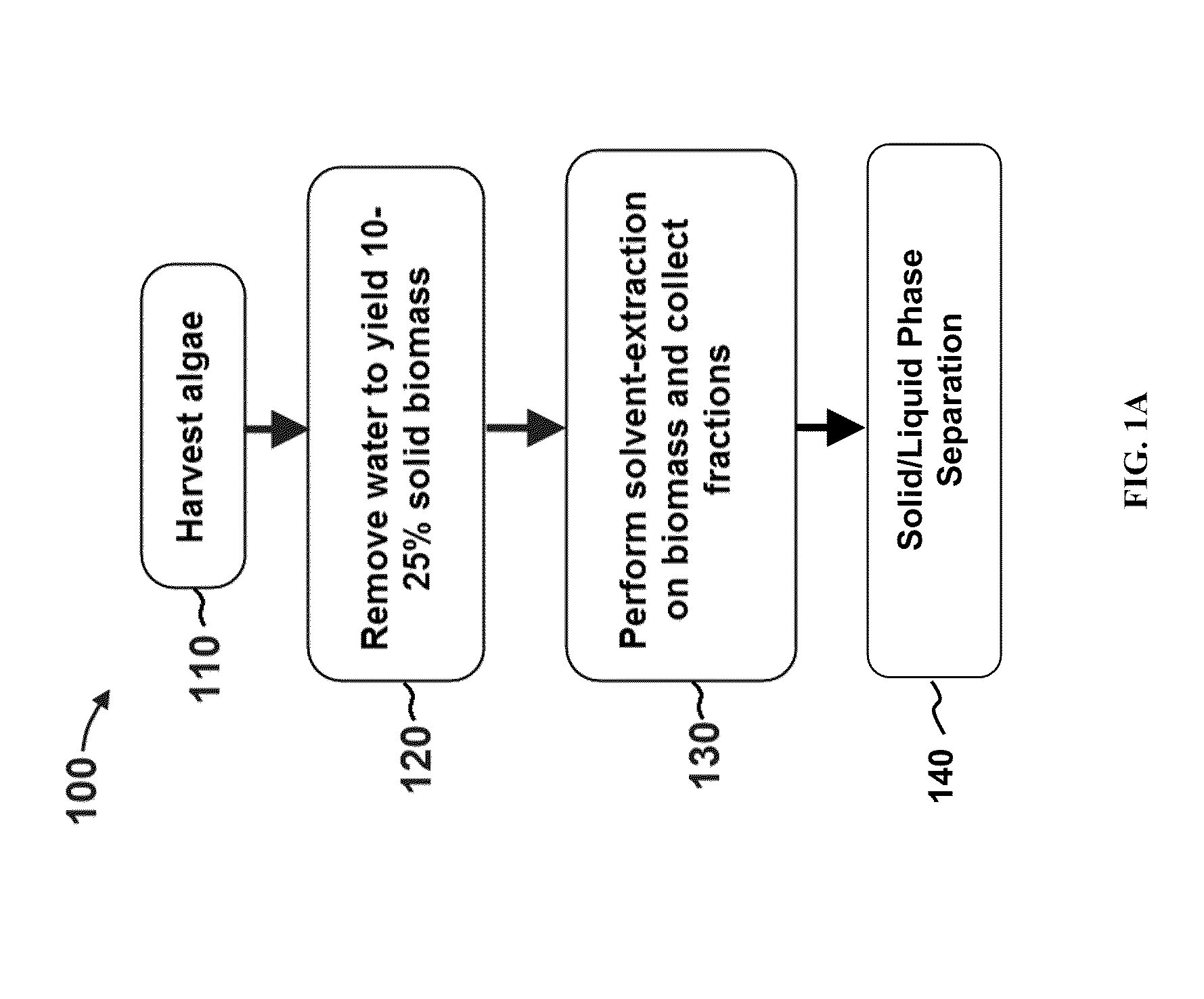

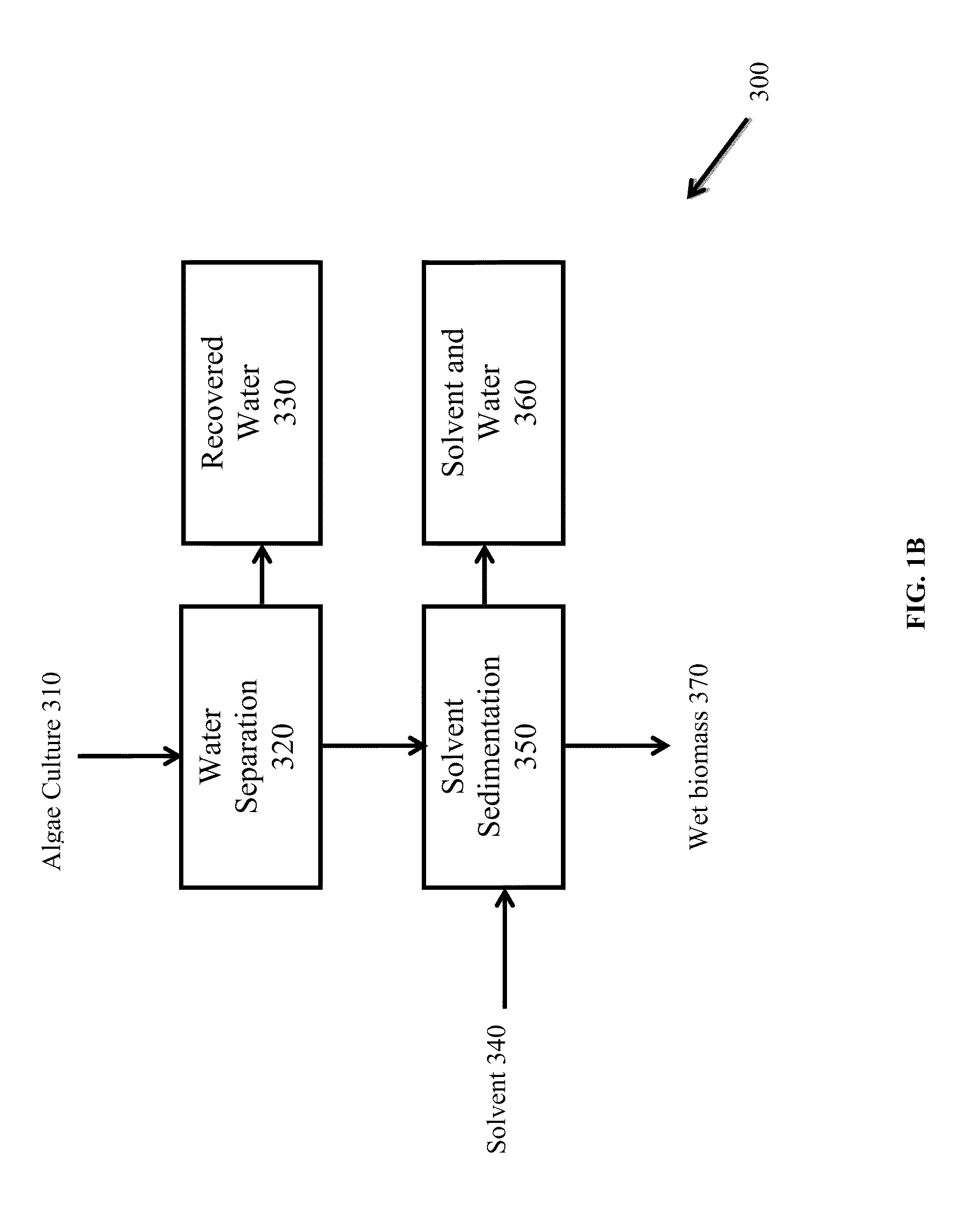

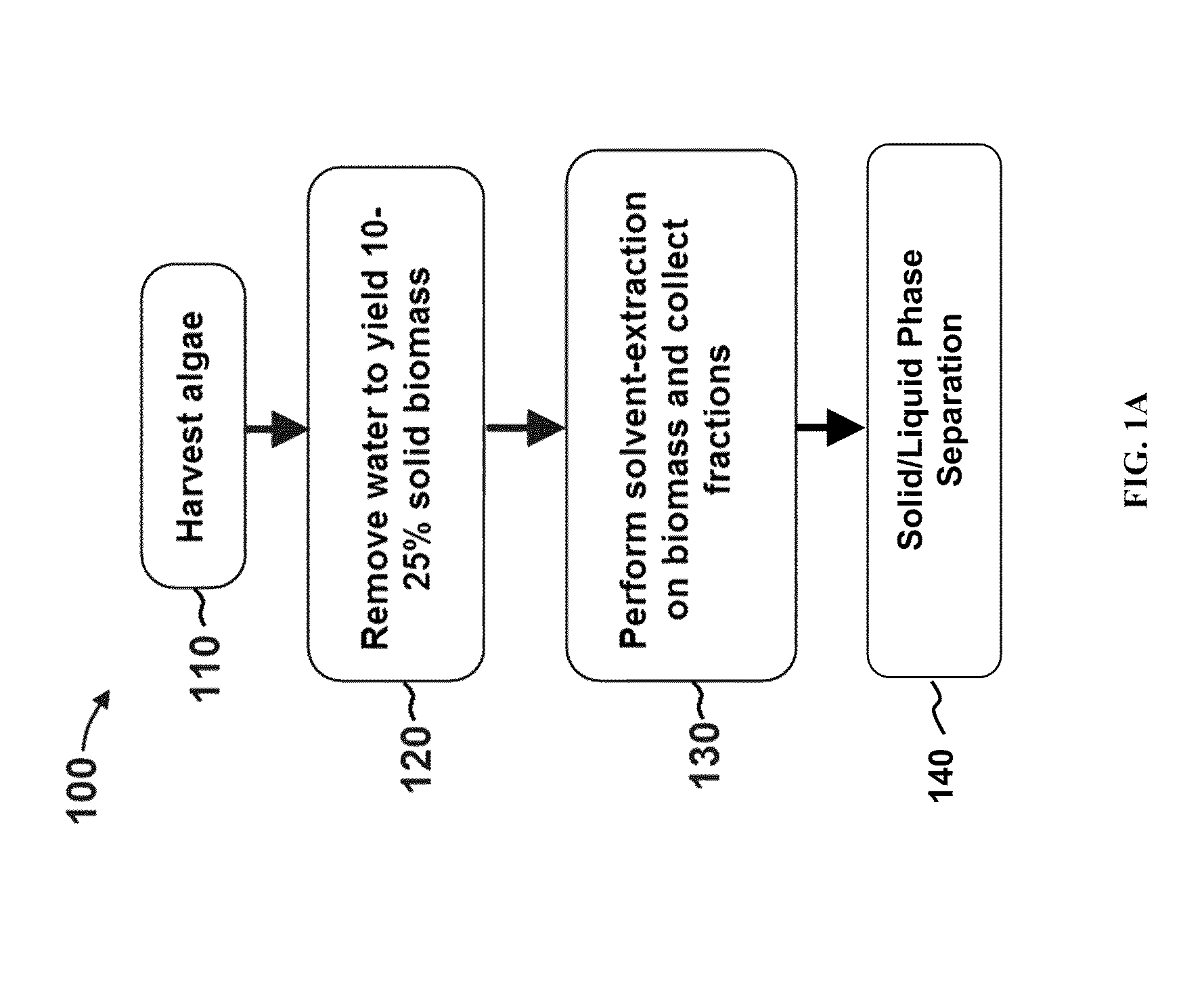

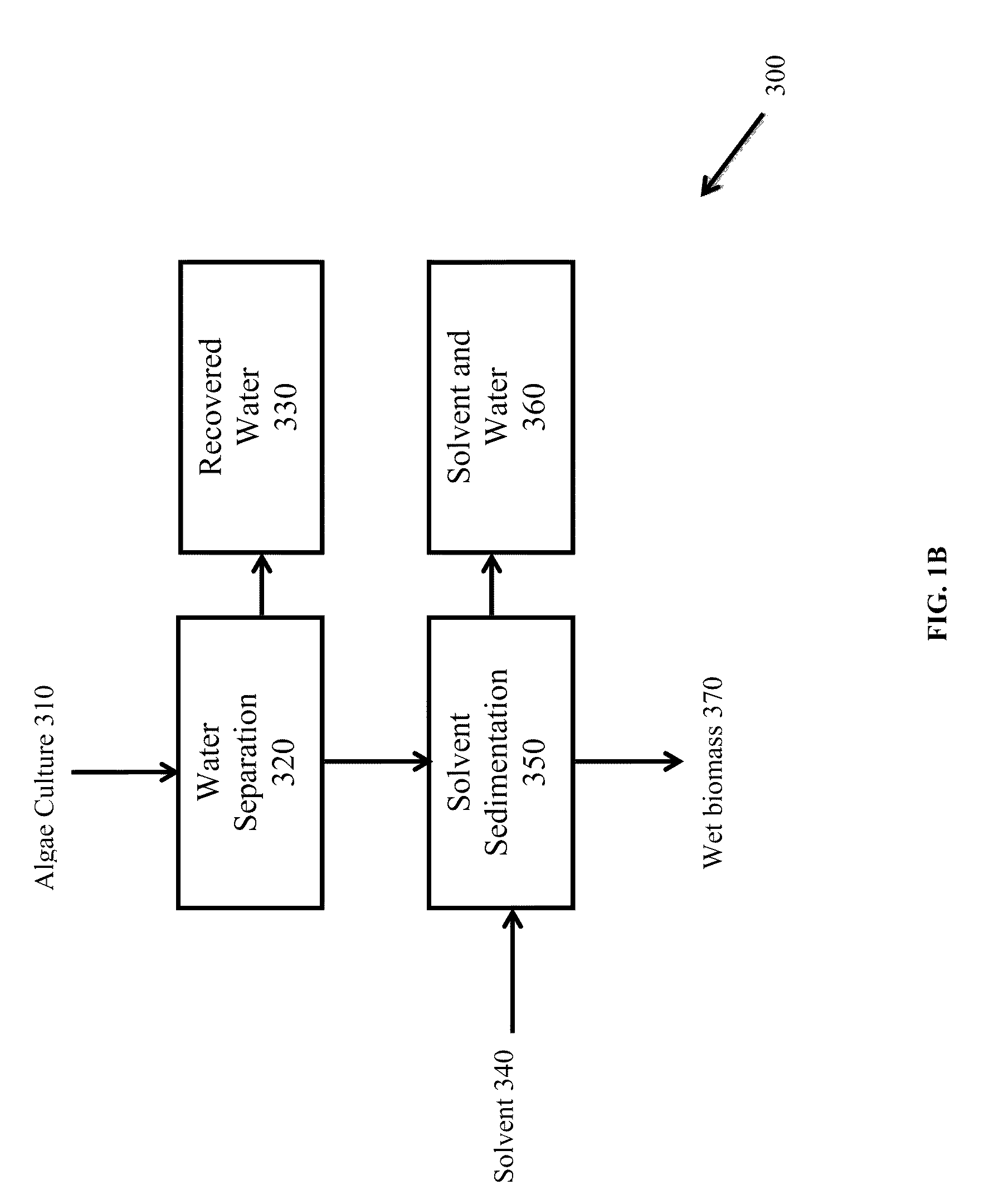

Methods of producing biofuels, chlorophylls and carotenoids

InactiveUS20110263886A1Fatty oils/acids recovery from wasteFatty acid esterificationWater insolubleBiofuel

A method for producing biofuels along with valuable food and neutraceutical products is provided. A method of making biofuels includes dewatering substantially intact algal cells to make an algal biomass, extracting neutral lipids along with carotenoids and chlorophylls from the algal biomass, and separation of the carotenoids and chlorophylls using adsorption or membrane diafiltration or other methods. The remaining neutral lipids are esterified with a catalyst in the presence of an alcohol. The method also includes separating a water soluble fraction comprising glycerin from a water insoluble fraction comprising fuel esters and distilling the fuel esters under vacuum to obtain a C16 or shorter fuel esters fraction, a C16 or longer fuel ester fraction, and a residue comprising omega-3 fatty acids esters and remaining carotenoids. The method further includes hydrogenating and deoxygenating at least one of (i) the C16 or shorter fuel esters to obtain a jet fuel blend stock and (ii) the C16 or longer fuel esters to obtain a diesel blend stock.

Owner:HELIAE DEVMENT

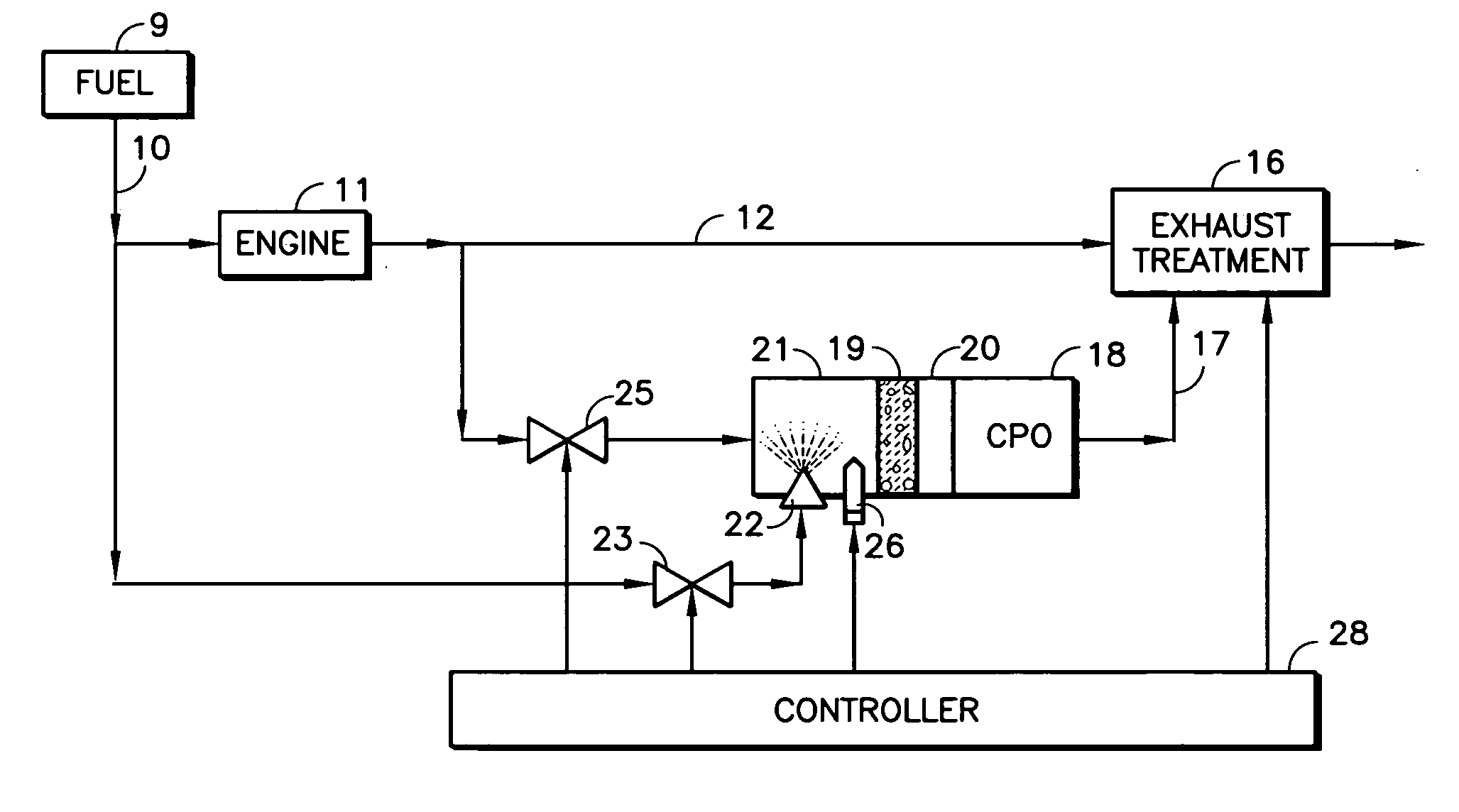

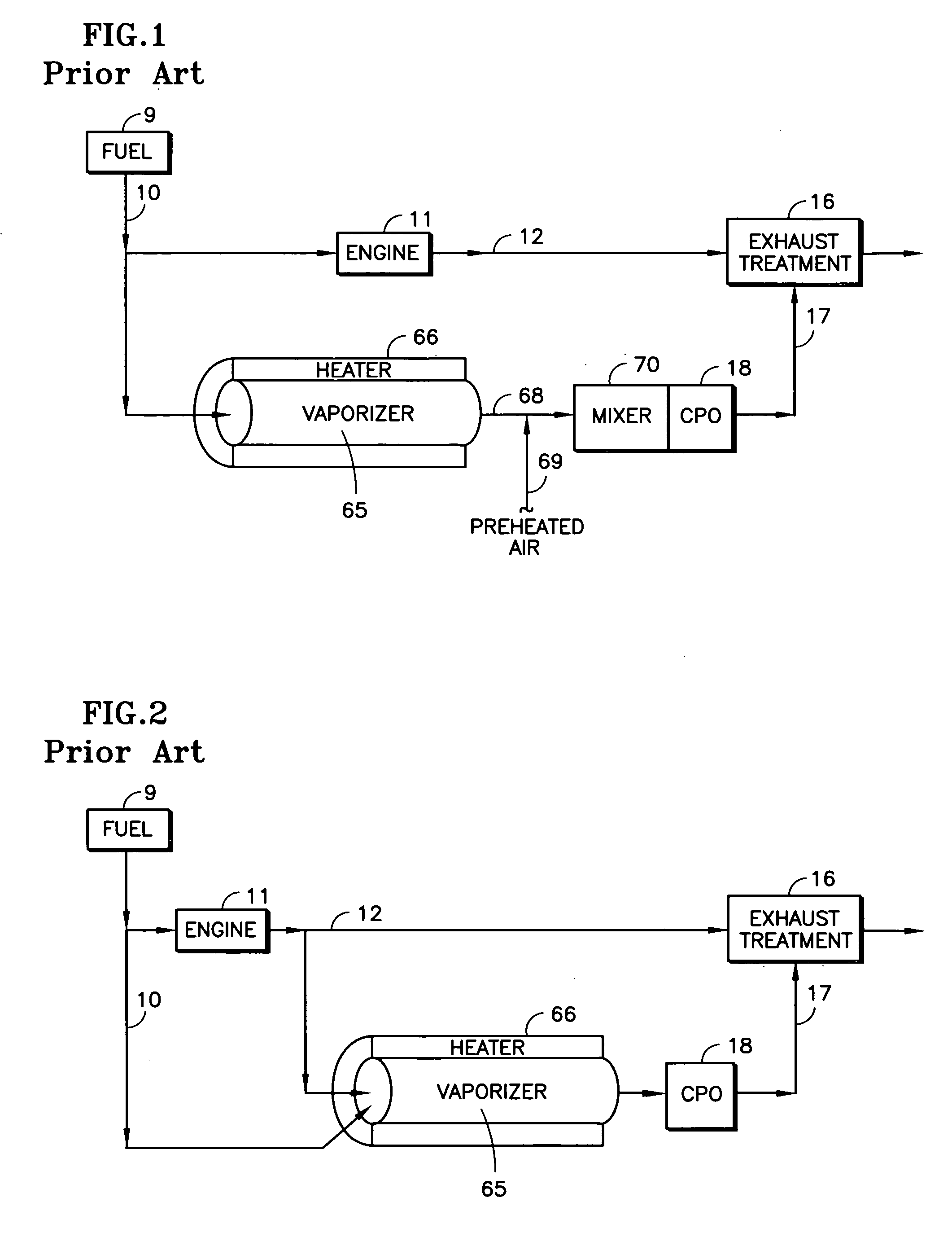

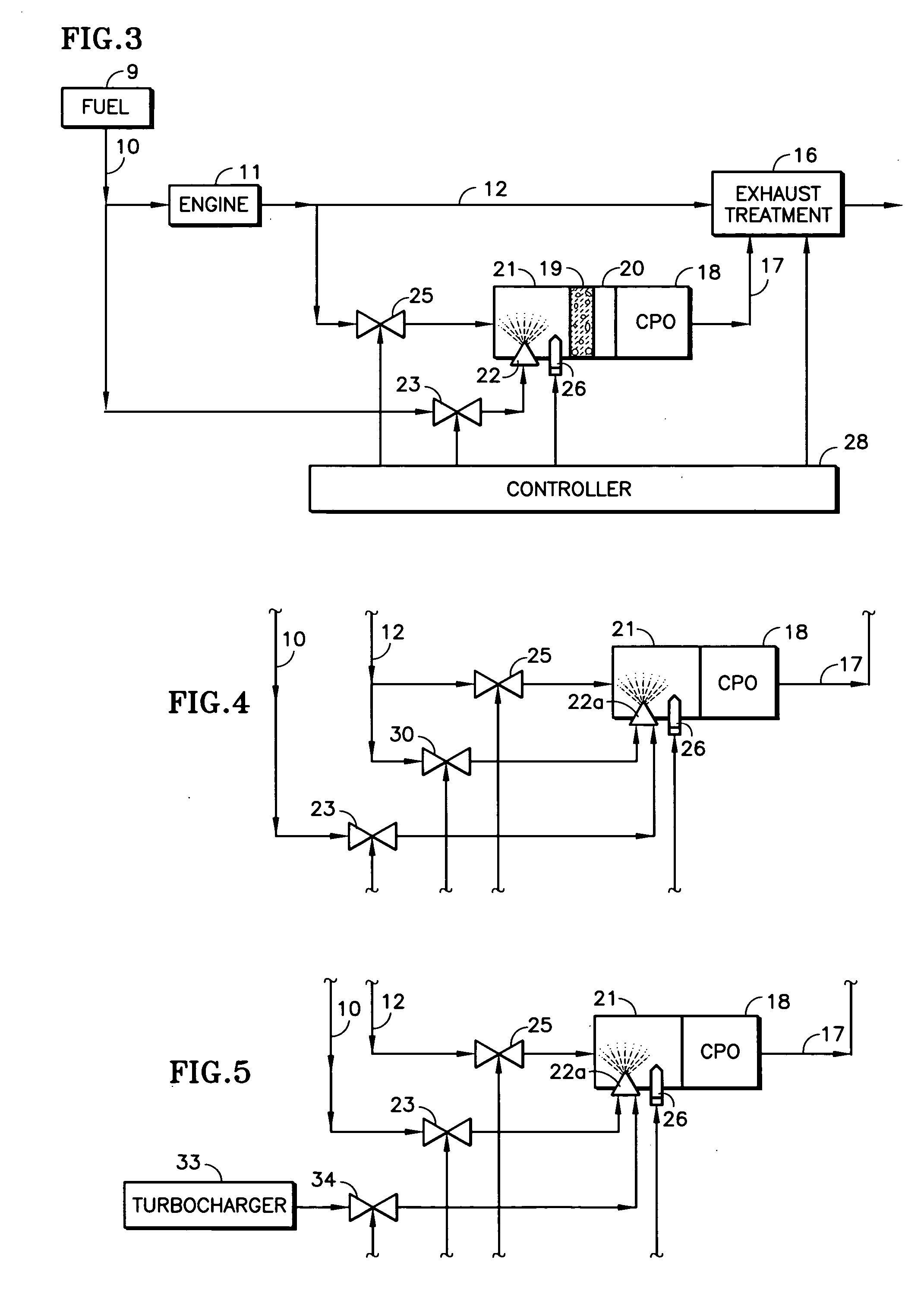

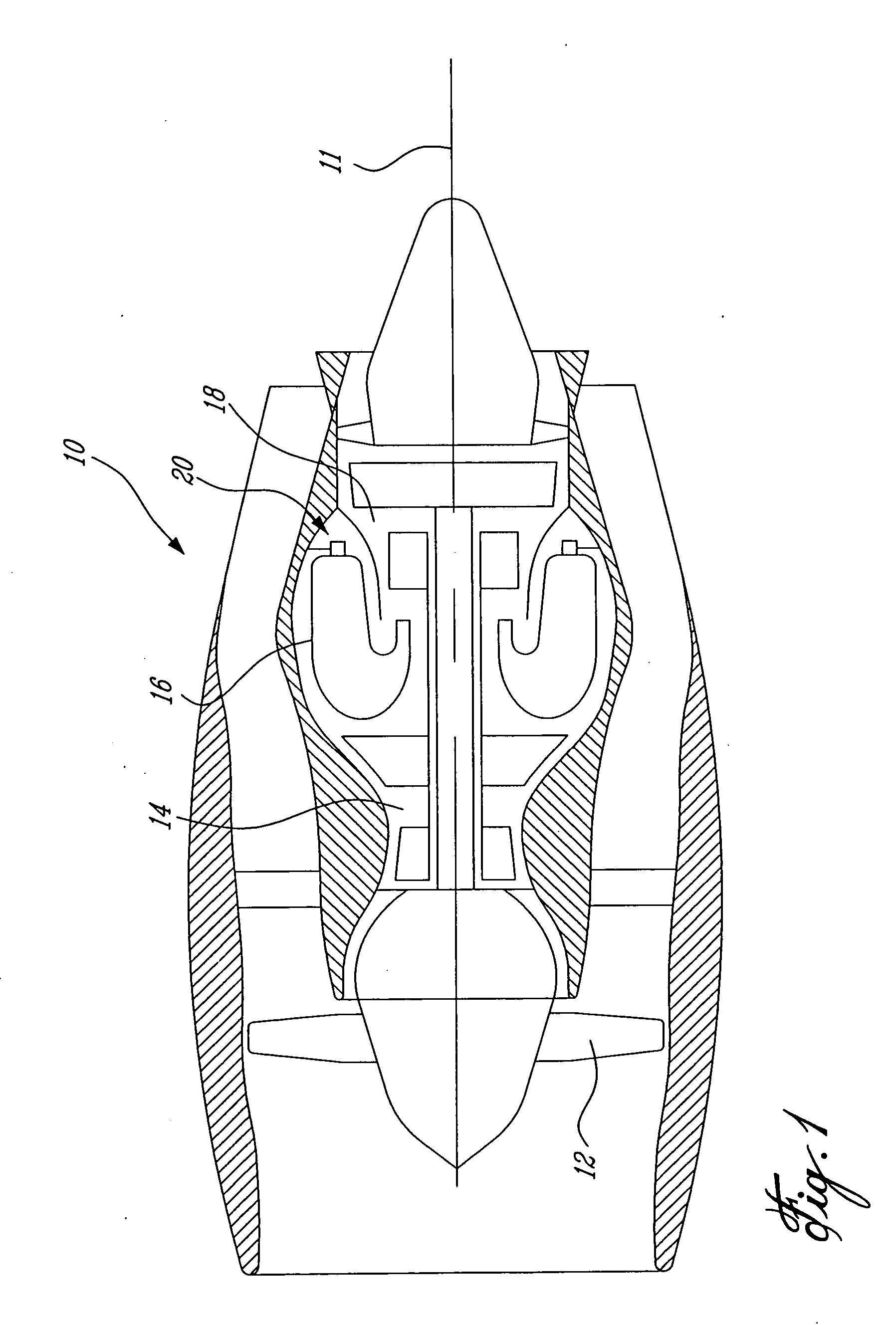

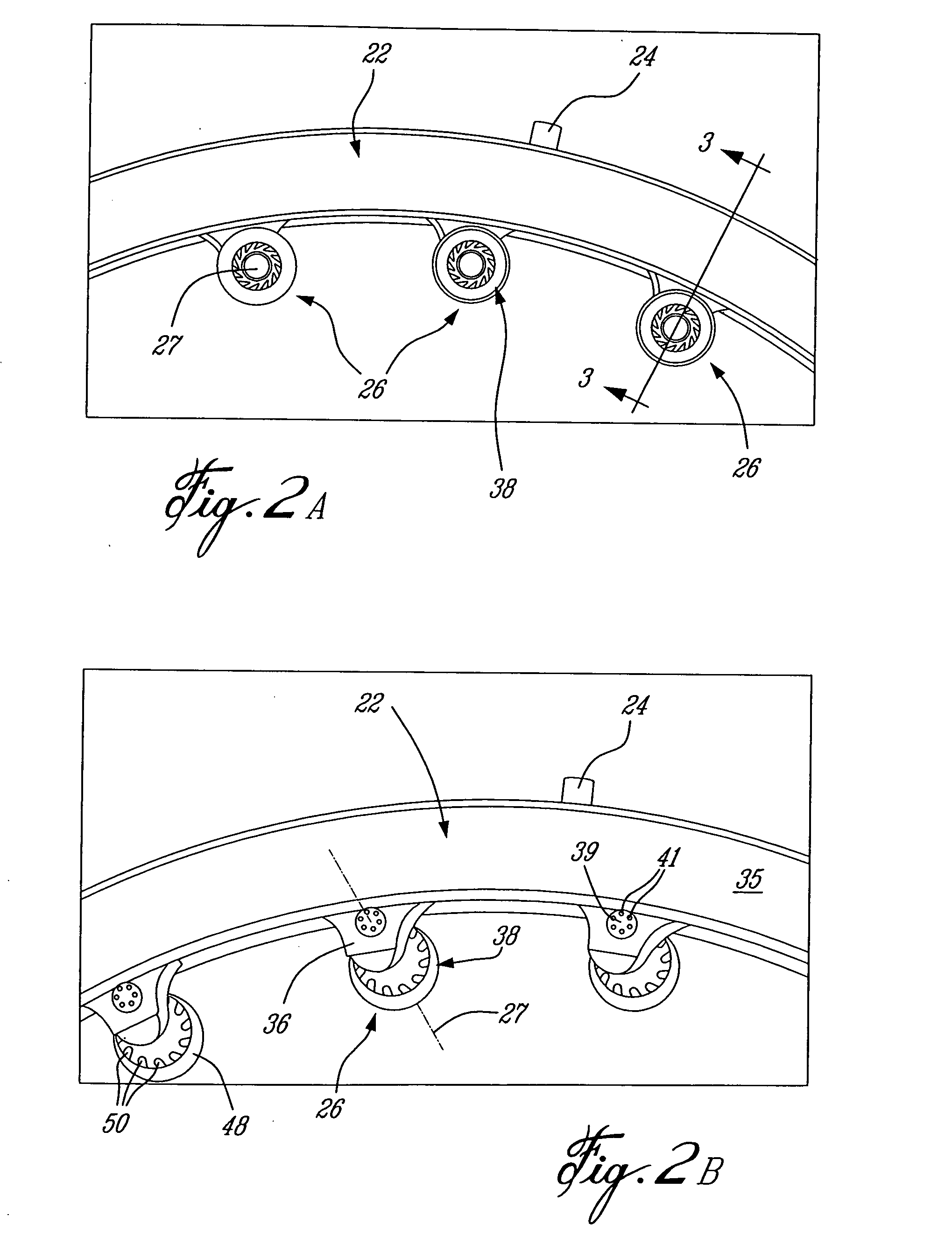

Reforming unvaporized, atomized hydrocarbon fuel

InactiveUS20050274107A1Improved hydrogen generationLow costHydrogenExhaust apparatusKeroseneTurbocharger

A reformer such as a CPO (18) receives a mix of fuel, moisture and oxygen from a mixing region (21) having an igniter (26, 66), which may include an inert ceramic foam (19), the fuel being provided by an atomizing nozzle (22), thereby avoiding the need for a vaporizer before use. The oxygen and moisture may comprise engine exhaust (11, 12). Fuel from a vehicle fuel tank (9), may be gasoline, diesel fuel, kerosene, jet fuel, or JP-8. The atomizing nozzle may be a gas-assist nozzle (22a), receiving the assisting gas from (a) engine exhaust (10), (b) a turbocharger (33), (c) an air pump (50) or (d) a steam generator (57). The oxygen and moisture may comprise moisturized air, which may be achieved by an ejector (41) which ingests water from a tank (43) in response to the flow of air from a pump (50) through a conduit (47). The air may be regeneratively heated (48) with the CPO exhaust. The igniter may be a glow plug (26) or a heater wire (66) coated with catalyst.

Owner:SHELL OIL CO

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

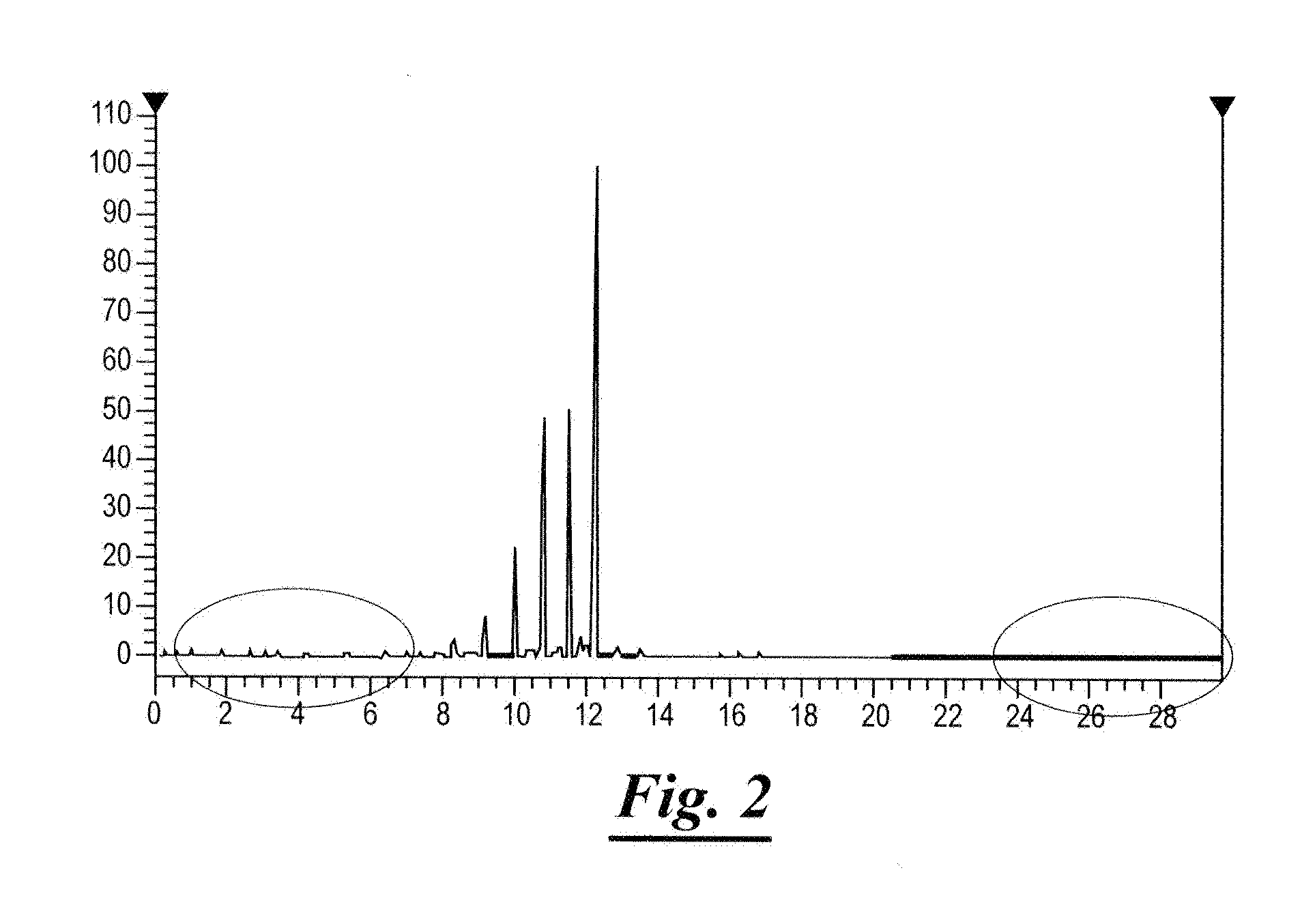

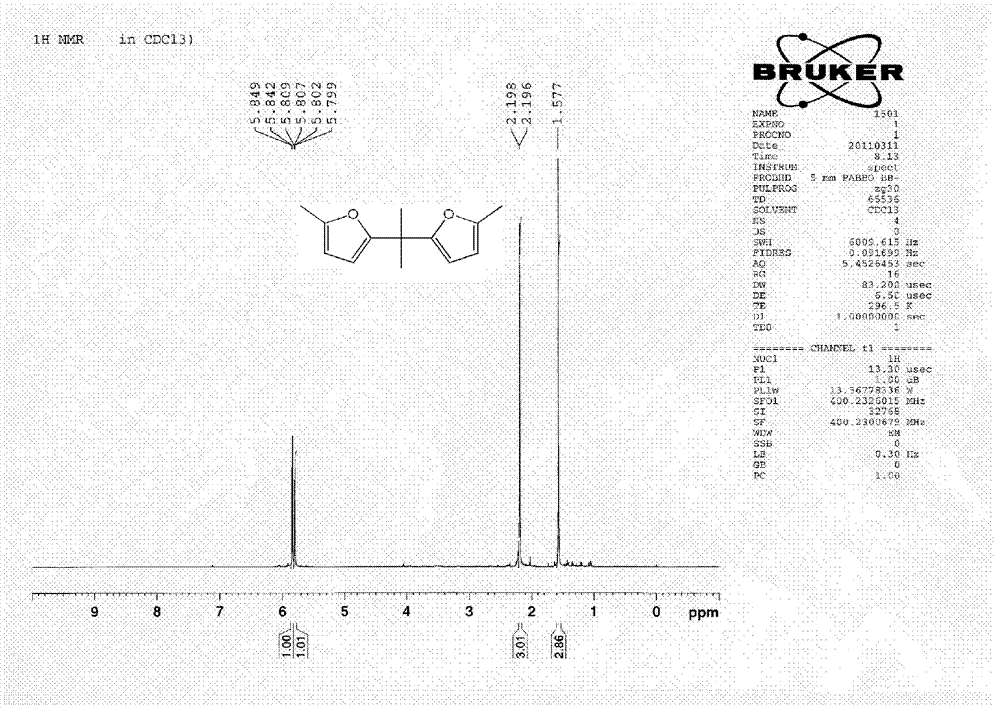

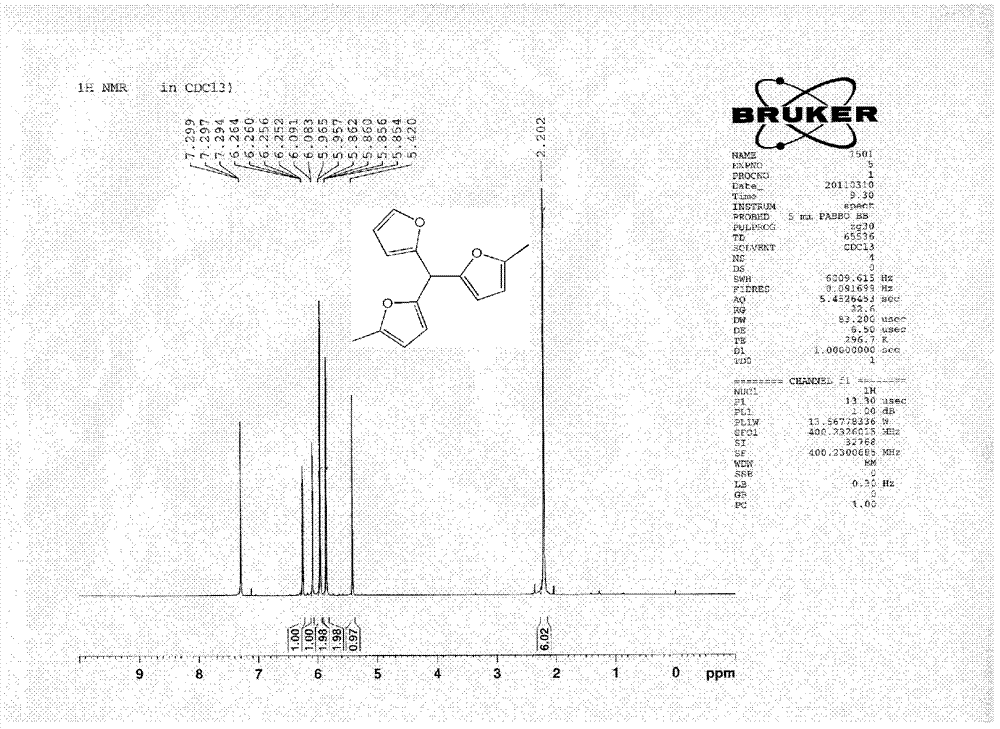

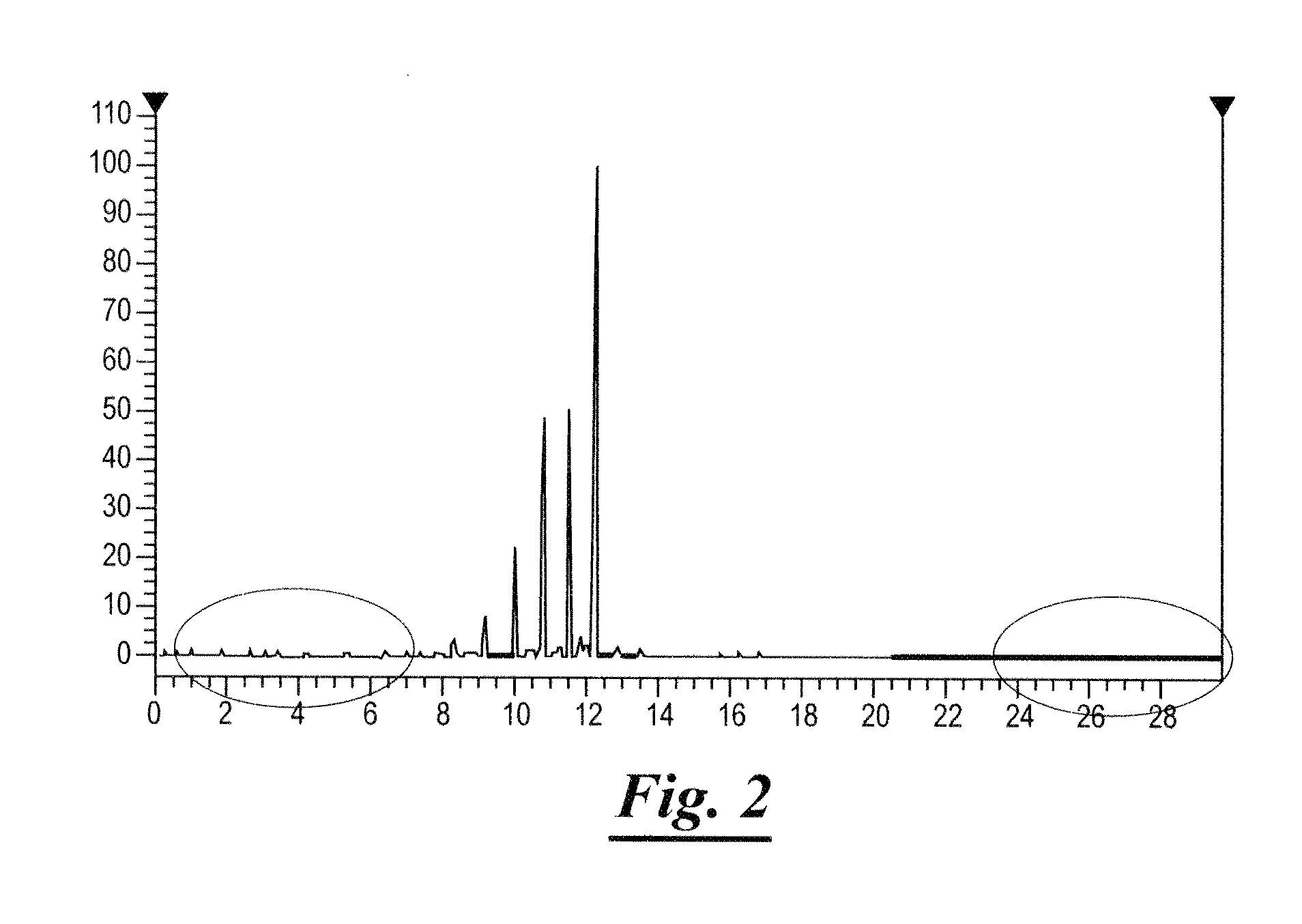

Production of liquid alkanes in the jet fuel range (C8-C15) from biomass-derived carbohydrates

ActiveUS7880049B2High selectivityHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlkaneFuran

Described is a method for making a composition comprising alkanes. The composition is suitable for use as a liquid transportation fuel in general, and jet fuel in particular. The method includes dehydrating a feedstock solution comprising a carbohydrate, in the presence of an acid catalyst, to yield at least one furan derivative compound, in a reaction vessel containing a biphasic reaction medium: an aqueous reaction solution and a substantially immiscible organic extraction solution. The furan derivative compound is then subjected to a self-aldol condensation reaction or a crossed-aldol condensation reaction with another carbonyl compound to yield a beta-hydroxy carbonyl compound and / or an alpha-beta unsaturated carbonyl compound. The beta-hydroxy carbonyl and / or alpha-beta unsaturated compounds are then hydrogenated to yield a saturated or partially saturated compound, followed by hydrodeoxygenation (e.g., dehydrating and hydrogenating) of the saturated or partially saturated compound to yield a composition of matter comprising alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Process for producing a renewable fuel in the gasoline or jet fuel range

ActiveUS7928273B2Yield maximizationFatty acid isomerisationFatty acid oxidationVegetable oilGasoline

Processes for producing hydrocarbons in the gasoline and jet fuel range. The processes involve the thermal decarboxylation of fatty acids, which can be derived from the hydrolysis of triglycerides, which triglycerides can be vegetable oils, animal fats, or combinations thereof. The resulting hydrocarbons can be hydrocracked, and, optionally, isomerized and / or hydrotreated, to yield hydrocarbons in the jet fuel or gasoline range. Where the resulting hydrocarbons include olefinic double bonds, they can alternatively be combined with low molecular weight olefins, and subjected to olefin metathesis to yield hydrocarbons in the jet fuel or gasoline range.

Owner:BRADIN DAVID

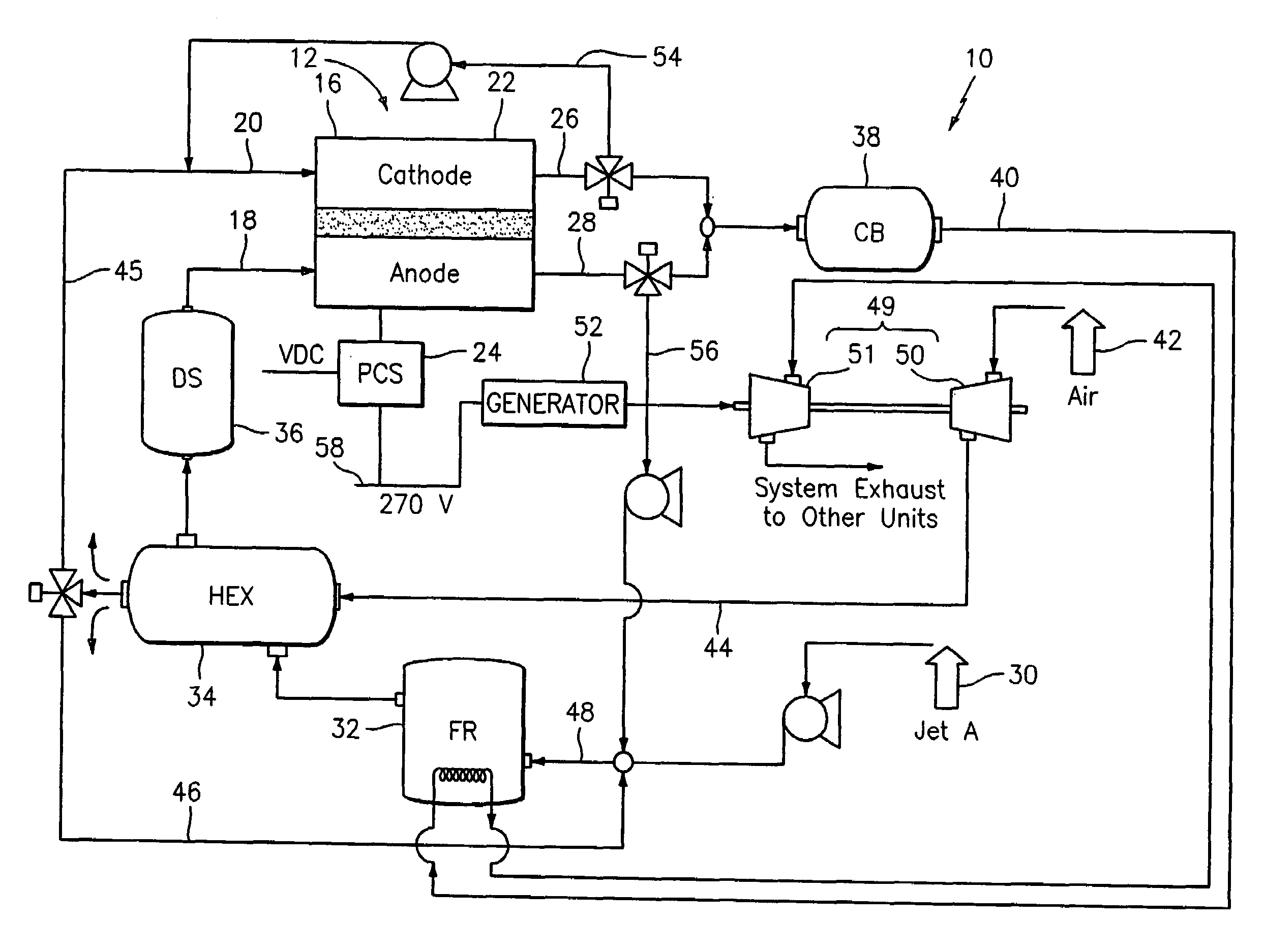

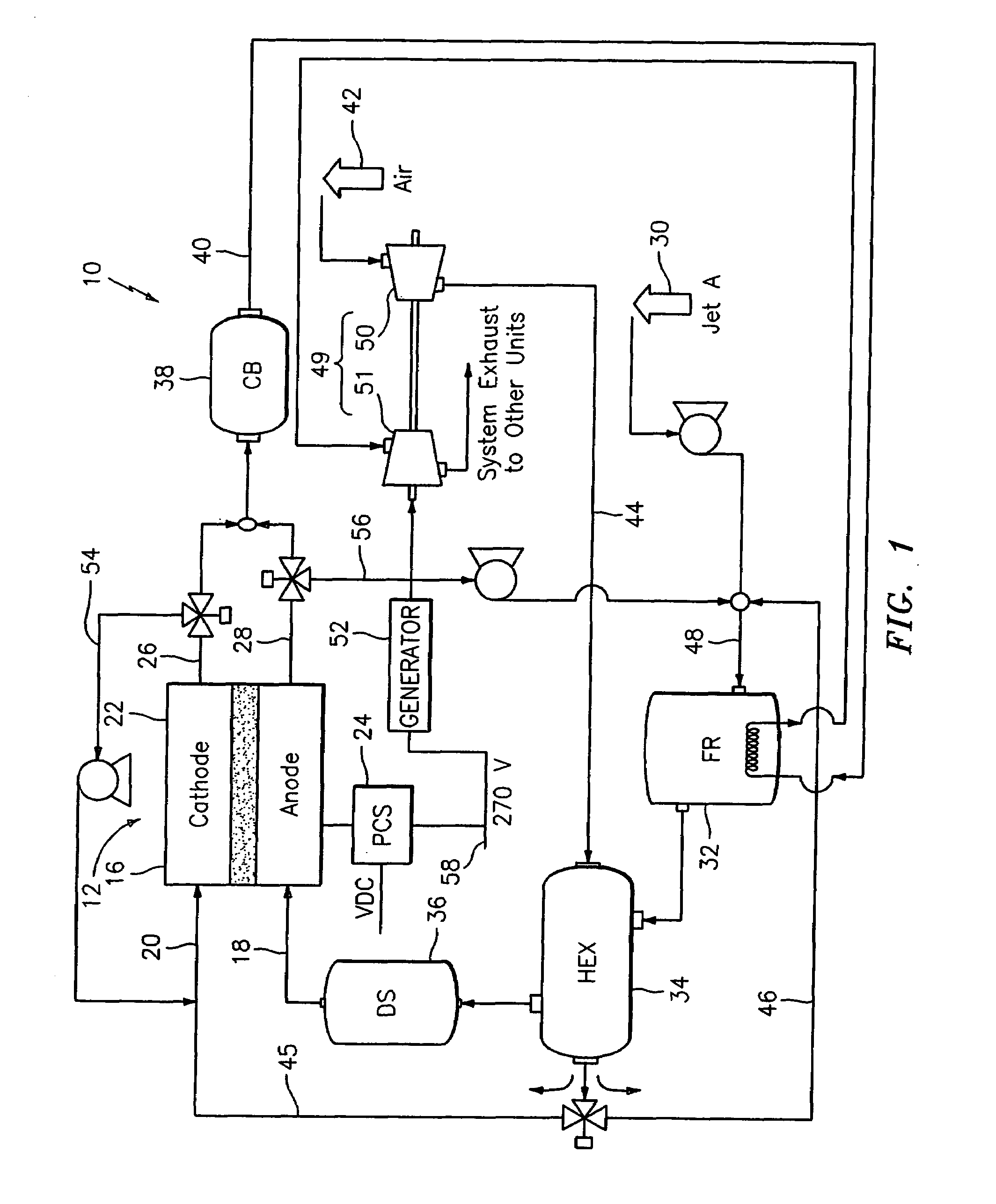

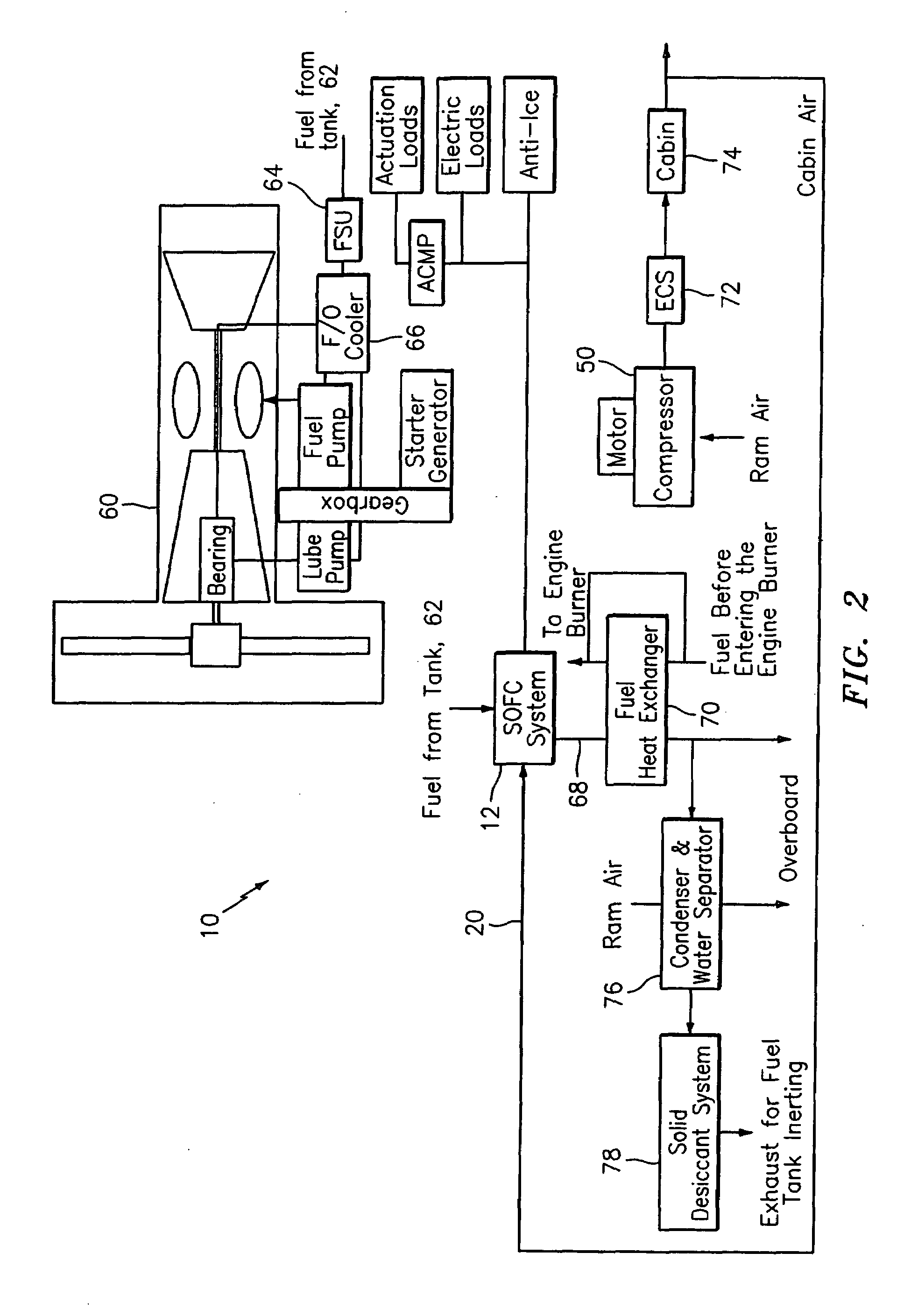

Jet fuel based high pressure solid oxide fuel cell system

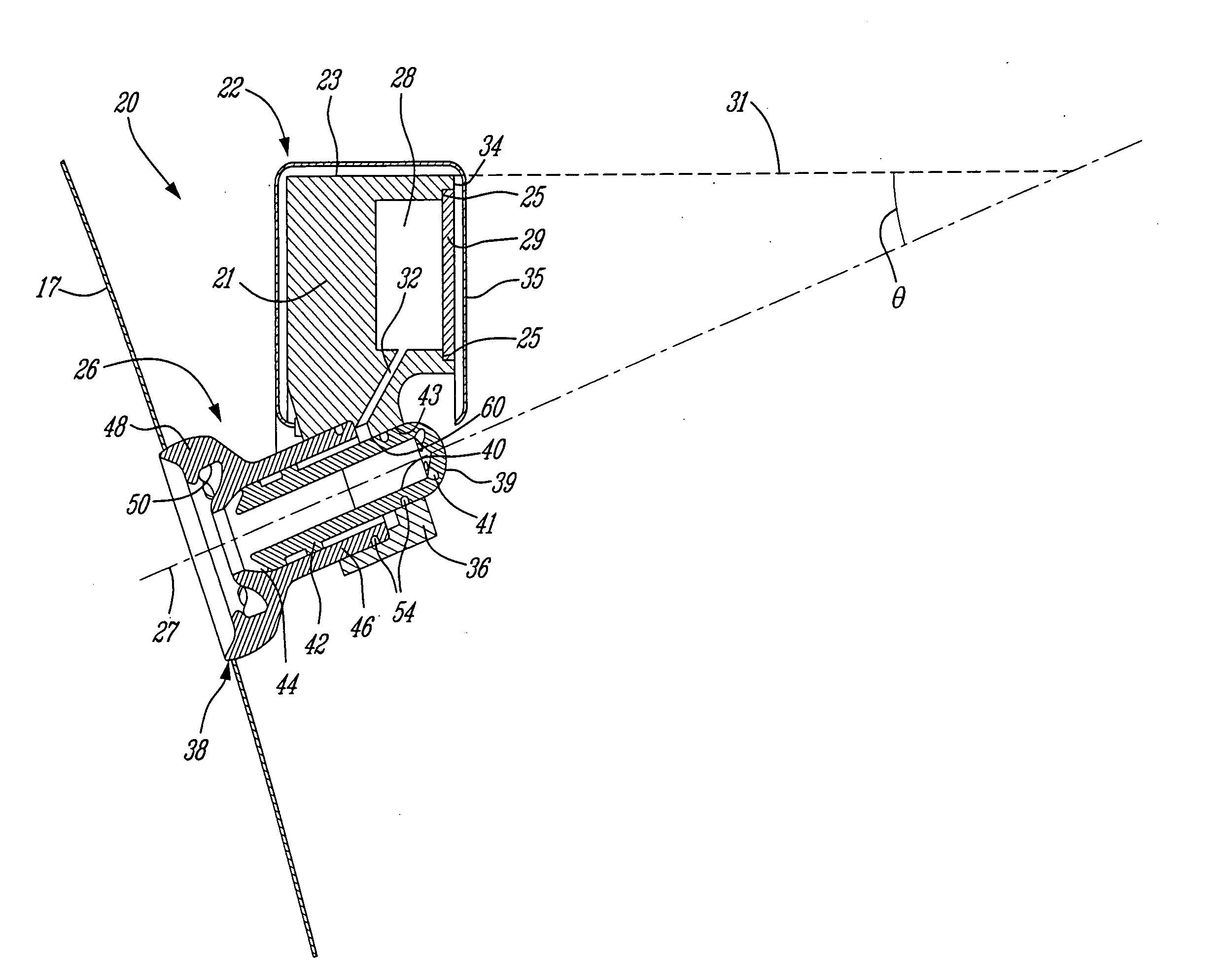

InactiveUS20080070078A1Improved fuel burn savingImprove reliabilityPower installationsFuel cell heat exchangeFuel cellsNacelle

A power system for an aircraft includes a solid oxide fuel cell system which generates electric power for the aircraft and an exhaust stream; and a heat exchanger for transferring heat from the exhaust stream of the solid oxide fuel cell to a heat requiring system or component of the aircraft. The heat can be transferred to fuel for the primary engine of the aircraft. Further, the same fuel can be used to power both the primary engine and the SOFC. A heat exchanger is positioned to cool reformate before feeding to the fuel cell. SOFC exhaust is treated and used as inerting gas. Finally, oxidant to the SOFC can be obtained from the aircraft cabin, or exterior, or both.

Owner:HAMILTON SUNDSTRAND CORP

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for the manufacture of hydrocarbon components

The present invention relates to hydrocarbons and particularly to the manufacture of hydrocarbon components suitable as aviation fuels or jet fuels and as blending stocks for aviation fuels. The process comprises the stages, wherein in the first stage an oil feed of biological origin and hydrogen gas are subjected to conditions sufficient to effect hydrodeoxygenation in the presence of a hydrodeoxygenation catalyst to yield n-paraffins;in the second stage the n-paraffins and hydrogen gas are subjected to conditions sufficient to effect isomerisation in the presence of an isomerisation catalyst to yield isoparaffins and separating fractions; andrecycling the fraction boiling at a temperature above 200° C. under atmospheric pressure obtained from the second stage to reisomerisation, where isomerisation is effected in the presence of an isomerisation catalyst.

Owner:NESTE OIL OY

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Alternative fuel and fuel additive compositions

InactiveUS20090013591A1Reduce concentrationReduce severityBiofuelsLiquid carbonaceous fuelsParticulatesAlternative fuels

Alternative gasoline, diesel fuel, marine diesel fuel, jet fuel, and flexible fuel compositions are disclosed. The compositions include an alcohol and / or a glycerol ether or mixture of glycerol ethers, which can be derived from renewable resources. When combined with gasoline / ethanol blends, the glycerol ethers can reduce the vapor pressure of the ethanol and increasing the fuel economy. When added to diesel fuel / alcohol blends, glycerol ethers improve the cetane value of the blends. All or part of the diesel fuel in the compositions described herein can be biodiesel fuel and / or synthetic fuel derived from a Fischer-Tropsch synthesis process. Fischer-Tropsch synthesis can also use feedstocks derived from sources other than crude oil, such as methane, methanol, ethanol, lignin and glycerol, which can further reduce reliance on foreign sources of crude oil. When used in jet fuel, glycerol ethers can replace all or part of conventional deicing additives, thus lowering skin toxicity, and glycerol ethers ability to reduce particulate emissions can lower the appearance of contrails. When used in marine diesel, the reduction in particulate emissions can be environmentally significant. In another embodiment, the alternative compositions comprise gasoline, ethanol, and n-butanol, and in one aspect, the ethanol and / or n-butanol can be derived from renewable resources. Fuel additive compositions, including glycerol ethers and hydrocarbons and / or alcohols, are also disclosed.

Owner:BRADIN DAVID +2

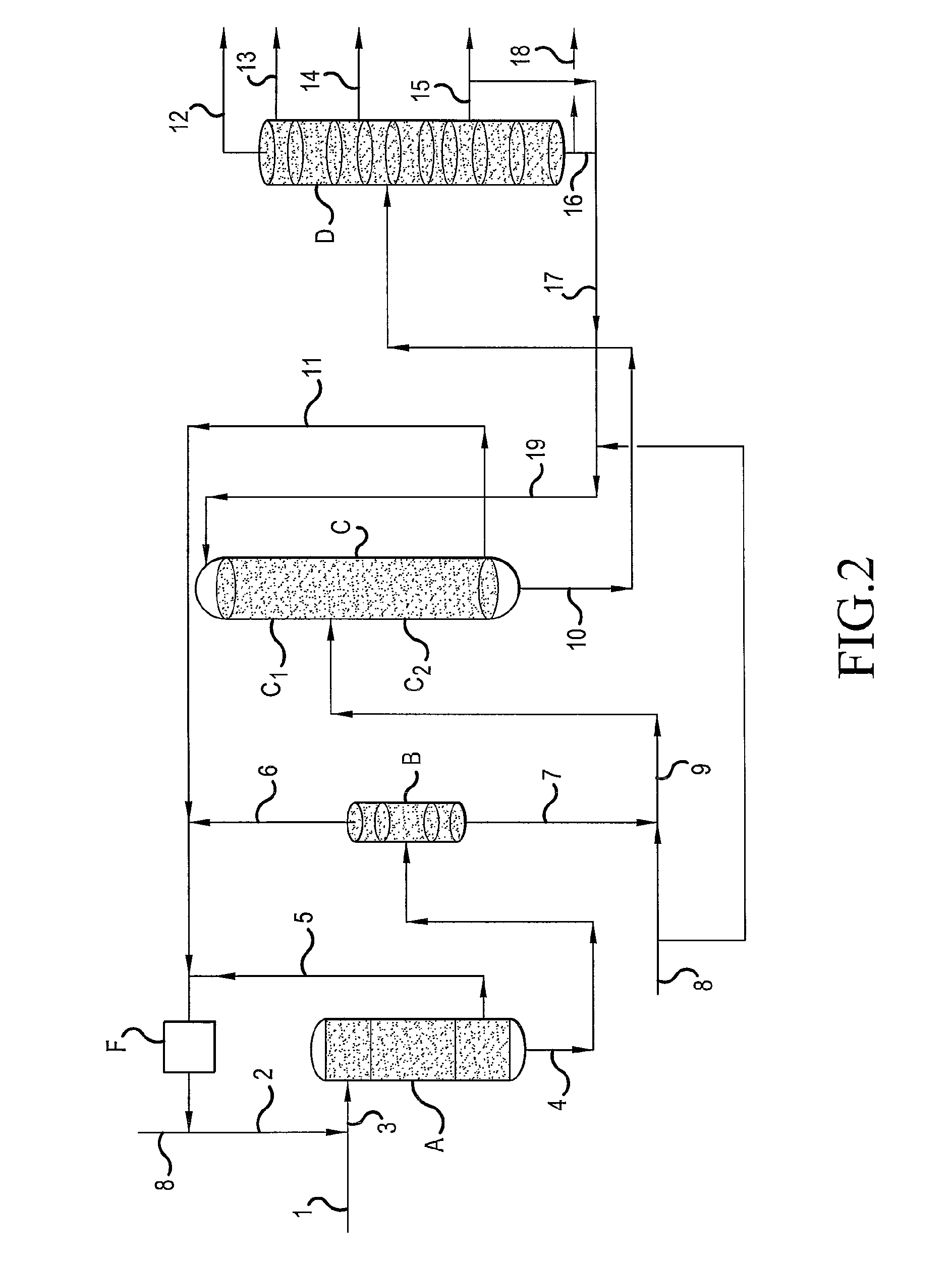

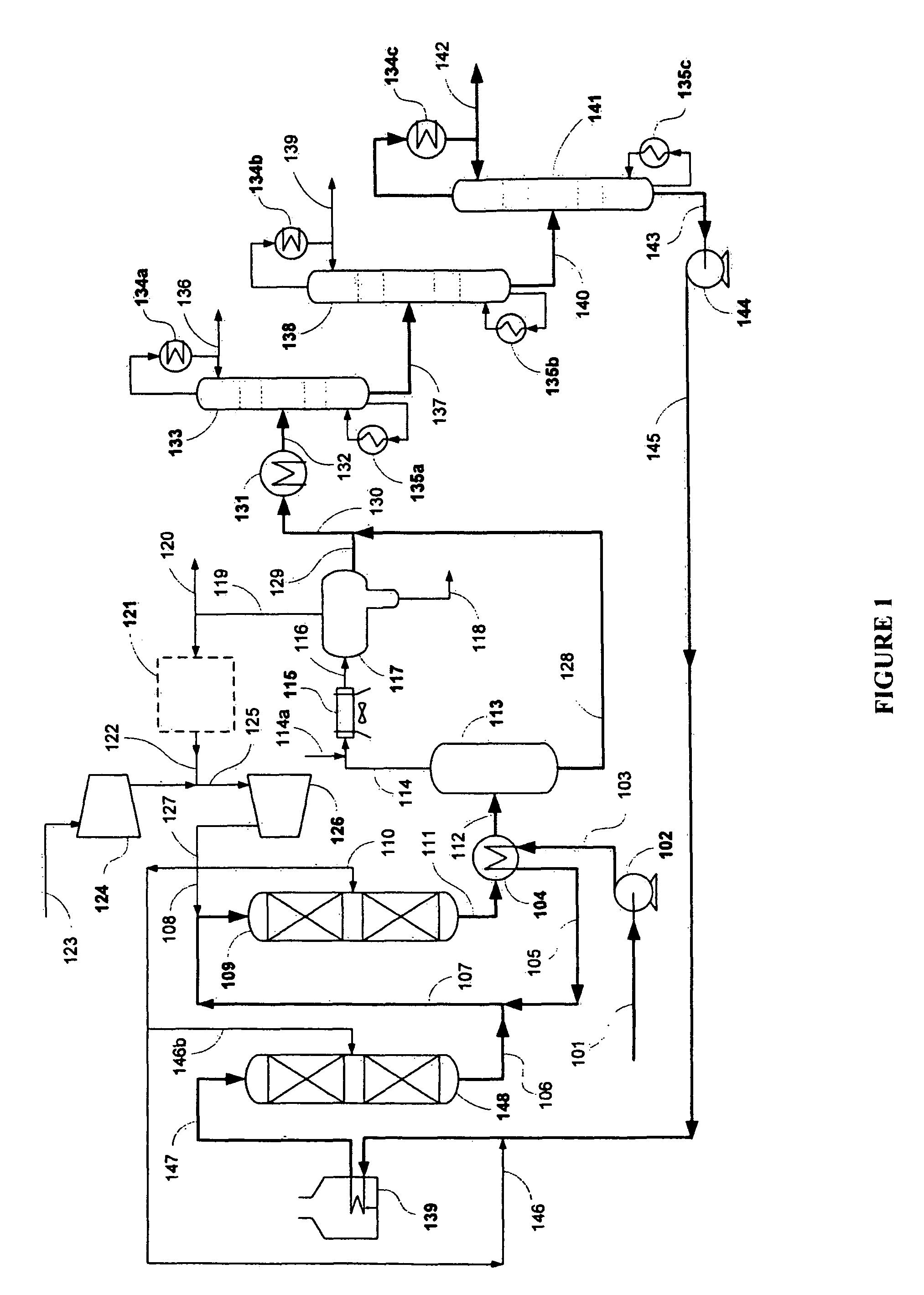

Process for co-producing jet fuel and LPG from renewable sources

ActiveUS7846323B2Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

Methods of producing biofuels, chlorophylls and carotenoids

InactiveUS8115022B2Fatty oils/acids recovery from wasteFatty acid esterificationWater insolubleBiofuel

A method for producing biofuels along with valuable food and neutraceutical products is provided. A method of making biofuels includes dewatering substantially intact algal cells to make an algal biomass, extracting neutral lipids along with carotenoids and chlorophylls from the algal biomass, and separation of the carotenoids and chlorophylls using adsorption or membrane diafiltration or other methods. The remaining neutral lipids are esterified with a catalyst in the presence of an alcohol. The method also includes separating a water soluble fraction comprising glycerin from a water insoluble fraction comprising fuel esters and distilling the fuel esters under vacuum to obtain a C16 or shorter fuel esters fraction, a C16 or longer fuel ester fraction, and a residue comprising omega-3 fatty acids esters and remaining carotenoids. The method further includes hydrogenating and deoxygenating at least one of (i) the C16 or shorter fuel esters to obtain a jet fuel blend stock and (ii) the C16 or longer fuel esters to obtain a diesel blend stock.

Owner:HELIAE DEVMENT

Hydrocracking process for biological feedstocks and hydrocarbons produced therefrom

A process for hydrocracking biomass, and the hydrocarbons produced therefrom. A feed stream having free fatty acids, fatty acid esters, or combinations thereof is contacted with a first catalyst under hydrogen pressure and heat. The hydrocarbon product stream which is comprised predominantly of n-paraffins is separated into heavy and light fractions. The heavy fraction is contacted with a second catalyst under hydrogen pressure and heat to produce an effluent stream which is combined with the light n-paraffin fraction to form a unique middle distillate product useful as a diesel or jet fuel.

Owner:REG SYNTHETIC FUELS LLC

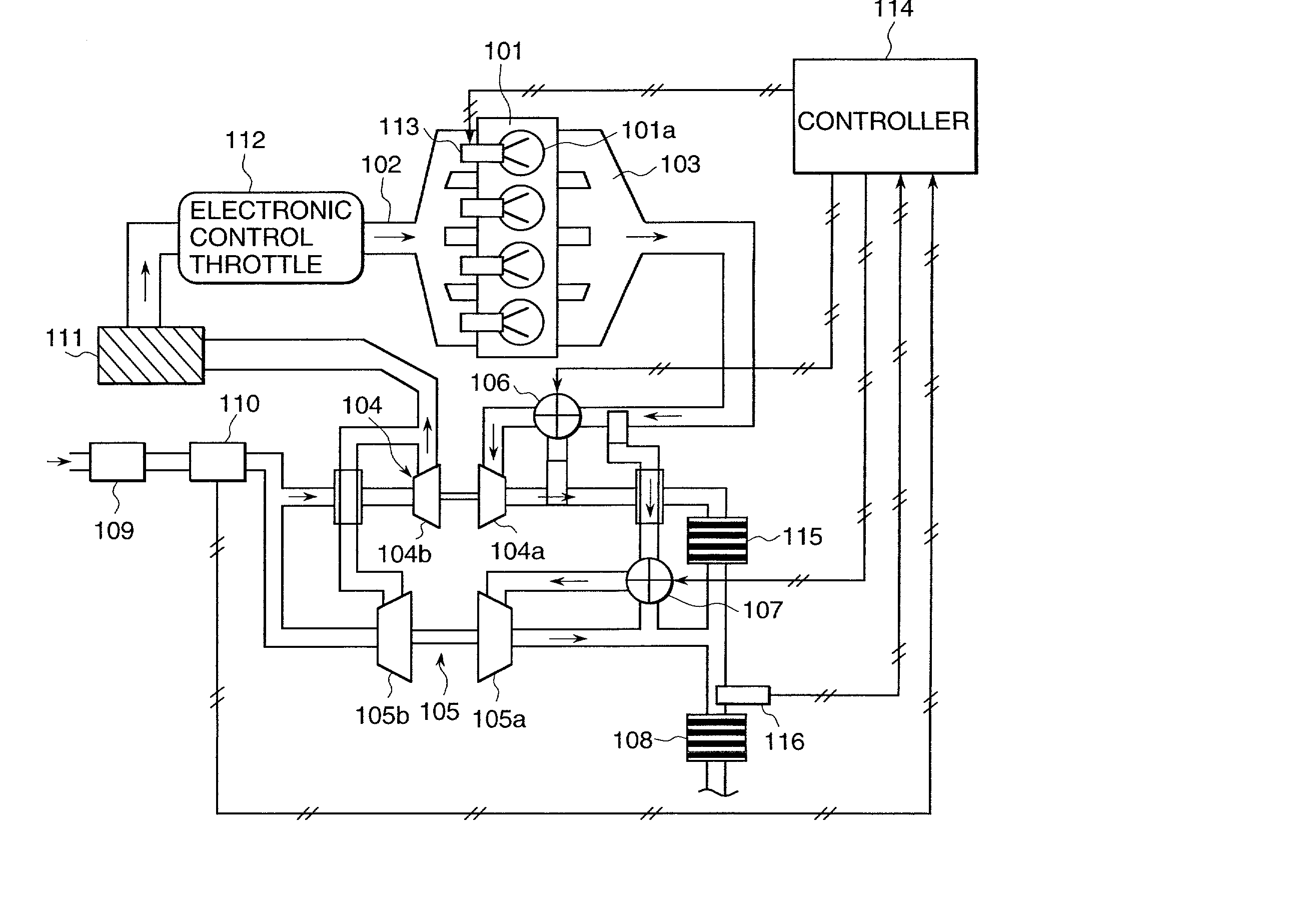

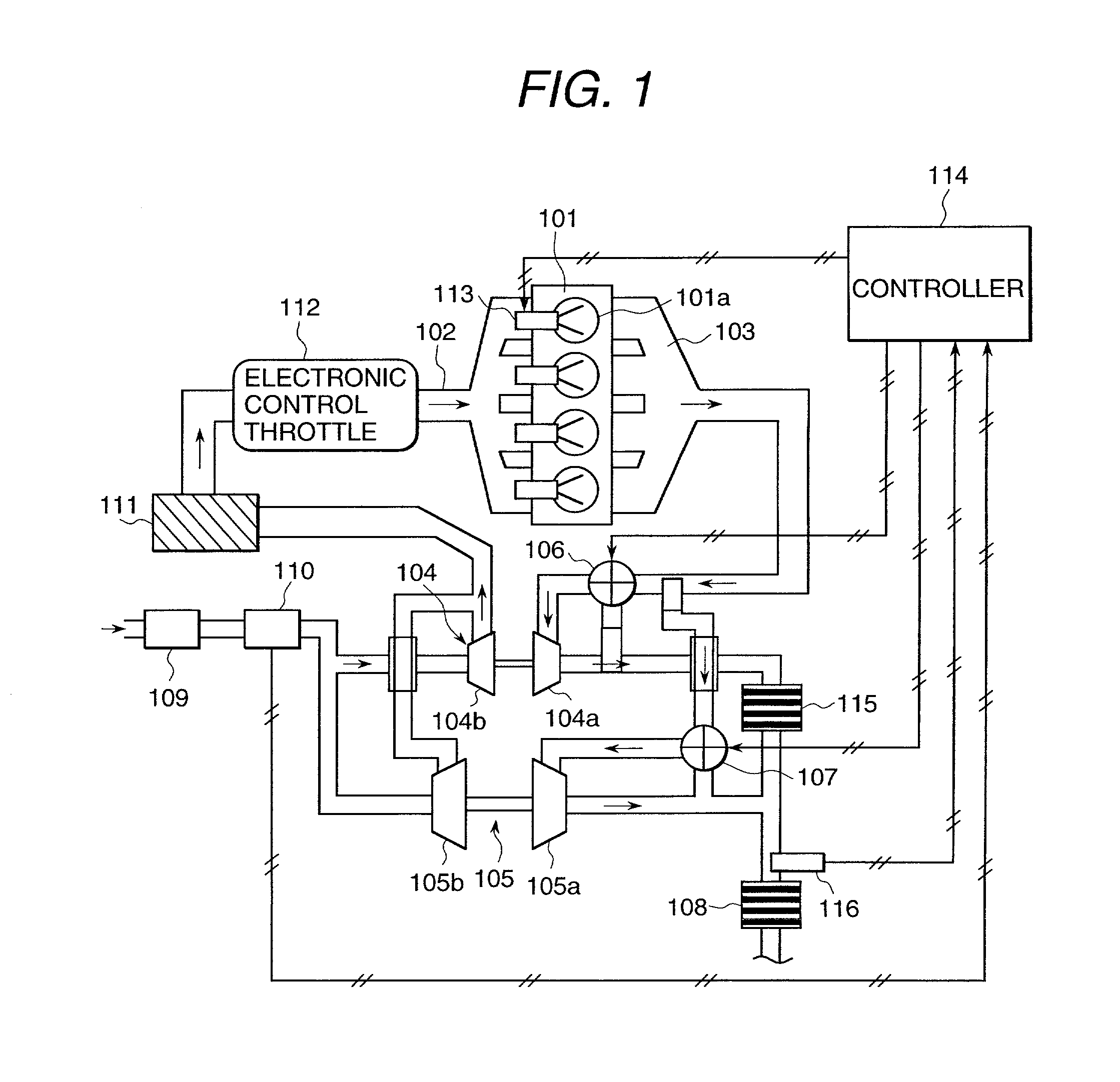

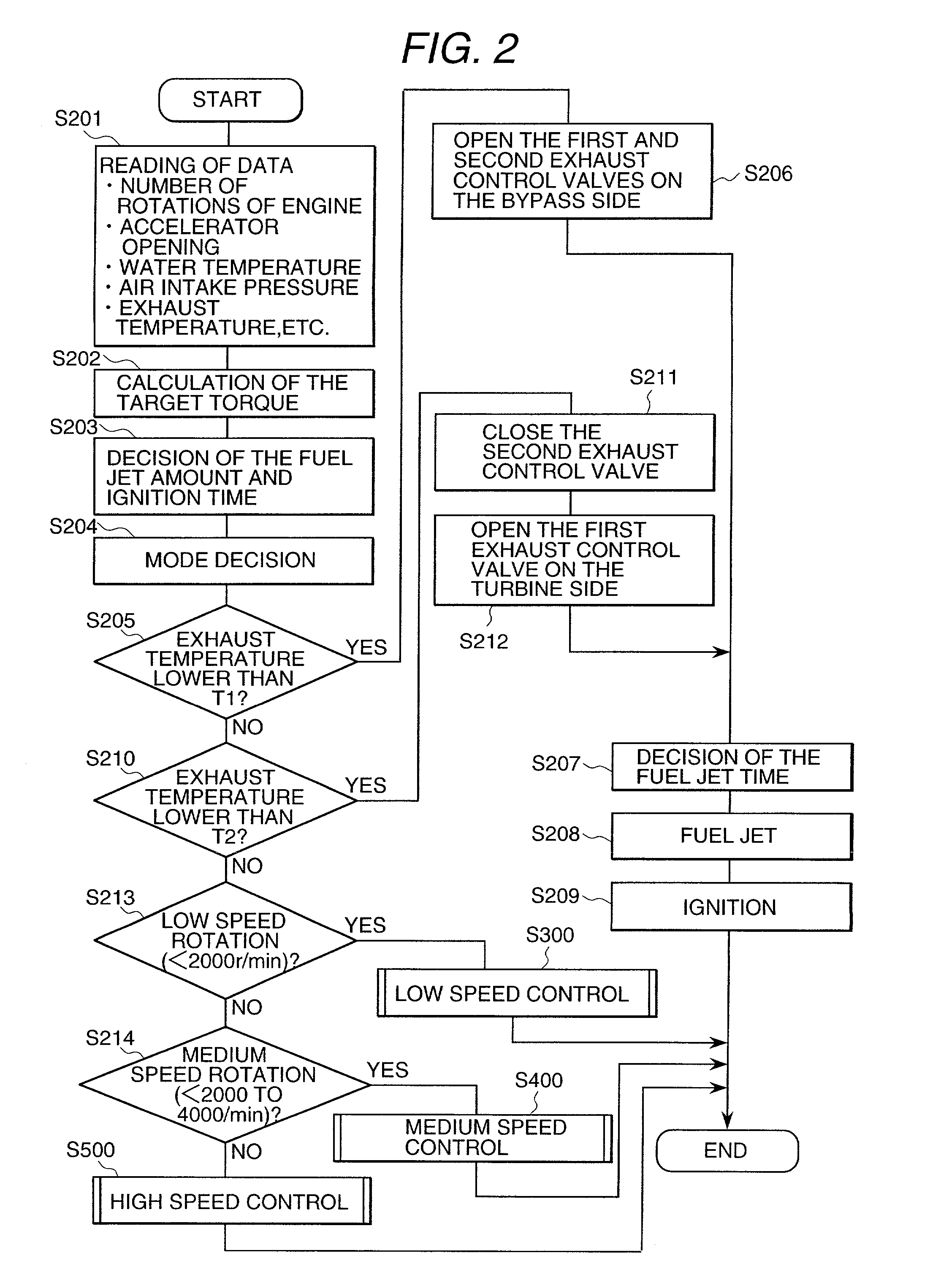

Engine supercharging system

InactiveUS20030074899A1Increase expensesHigh energyElectrical controlInternal combustion piston enginesLow speedCombustion

The present invention is intended to sufficiently fulfill the supercharging function at the time of either of low speed running of the engine and high speed running and realizing output improvement or fuel expense reduction. The present invention has the engine 101 having the jet mechanism for directly jetting fuel into the cylinder 101a, the first turbo supercharger 104 for supercharging the engine 101 at the time of low speed rotation, the second turbo supercharger 105 for supercharging at the time of high speed rotation, the first and second exhaust control valves 106 and 107 for selecting exhaust paths relating to the first and second turbo superchargers 104 and 105 and controlling the exhaust gas flow rate, and the controller 114 for controlling the switching operation of the exhaust control valves 106 and 107 so as to realize lamination combustion or homogeneous combustion using the first and second turbo superchargers 104 and 105 according to the operation conditions of the engine 101.

Owner:HITACHI LTD

Process for desulphurisation of liquid hydrocarbon fuels

InactiveUS20070151901A1Eliminate needRefining with oxygen compoundsTreatment with plural serial refining stagesPetroleum productSulfur

The present invention provides a process for oxidative desulphurization of liquid hydrocarbon fuels, such as diesel fuel, gasoline, jet fuel, fuel oils, coal liquids and similar petroleum products to ultra low sulphur hydrocarbon fuels with sulphur content less than 10 ppm. In this process, the sulfur compounds present in hydrocarbon fuel are first oxidised to more polar sulphones / sulphoxides and then removed by solvent extraction with NMP containing antisolvent followed by final polishing by passing through adsorption column.

Owner:COUNCIL OF SCI & IND RES +1

Process for the conversion of renewable oils to liquid transportation fuels

InactiveUS20120157734A1Efficient reductionEfficient processingBiofuelsSolid fuelsIsomerizationKerosene

The present invention relates to production of fuels or fuel blendstocks from renewable sources. Various embodiments provide a method of producing a hydrocarbon product by hydrotreating a feedstock including at least one of a renewable triacylglyceride (TAG), renewable free fatty acid (FFA), and renewable fatty acid C1-C5 alkyl ester (C1-C5 FAE) in the presence of a nonsulfided hydrotreating catalyst to produce a first product including hydrocarbons. In some examples, the first product can be subjected to further chemical transformations such as aromatization, cracking, or isomerization to produce a second product including hydrocarbons. In various embodiments, the first or second hydrocarbon product with minimal or substantially no further processing can be suitable as a liquid transportation fuel or fuel blendstock, including fuels such as gasoline, naptha, kerosene, jet fuel, and diesel fuels.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com