Process for producing bio-derived fuel with alkyl ester and iso-paraffin components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

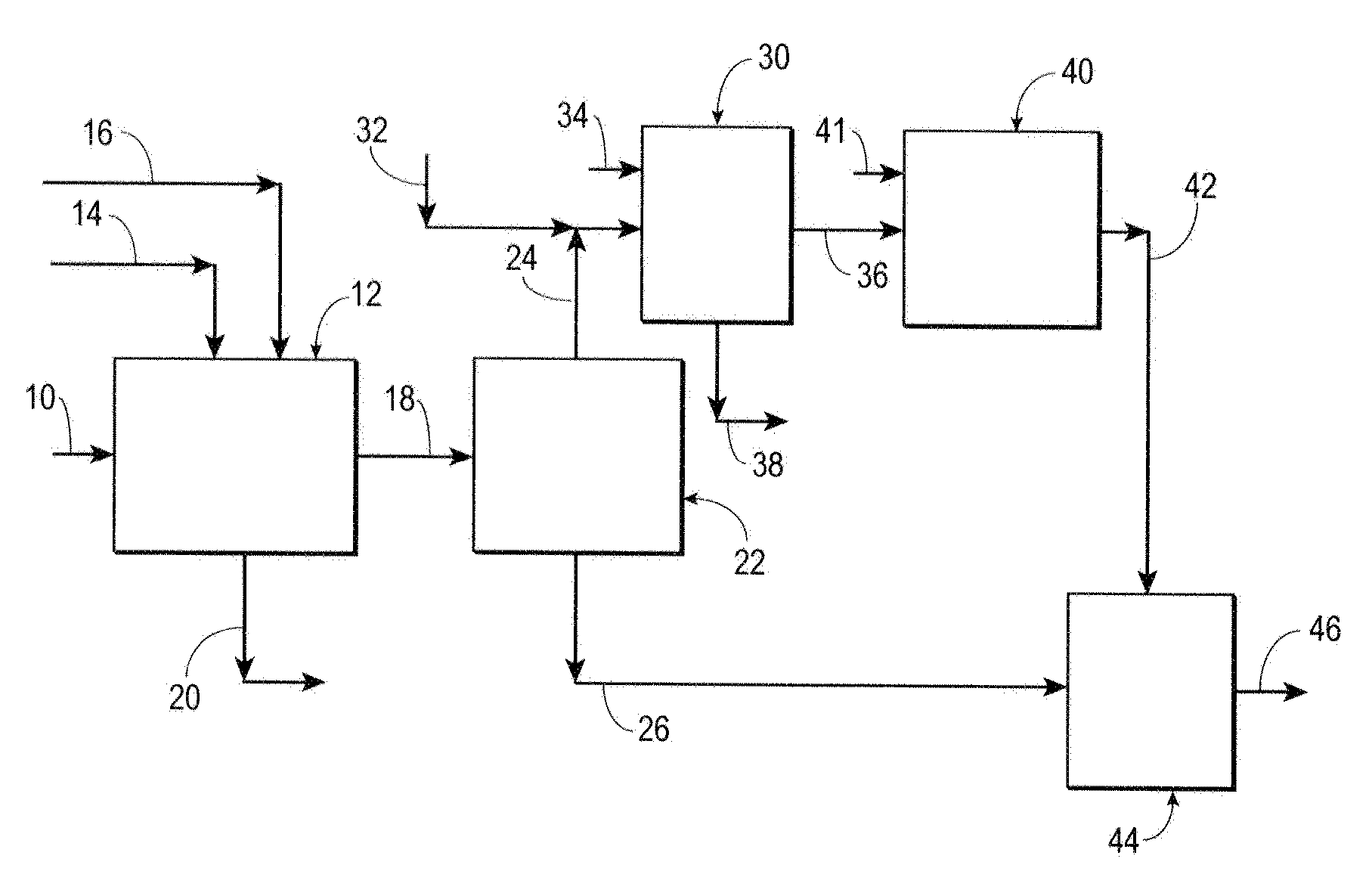

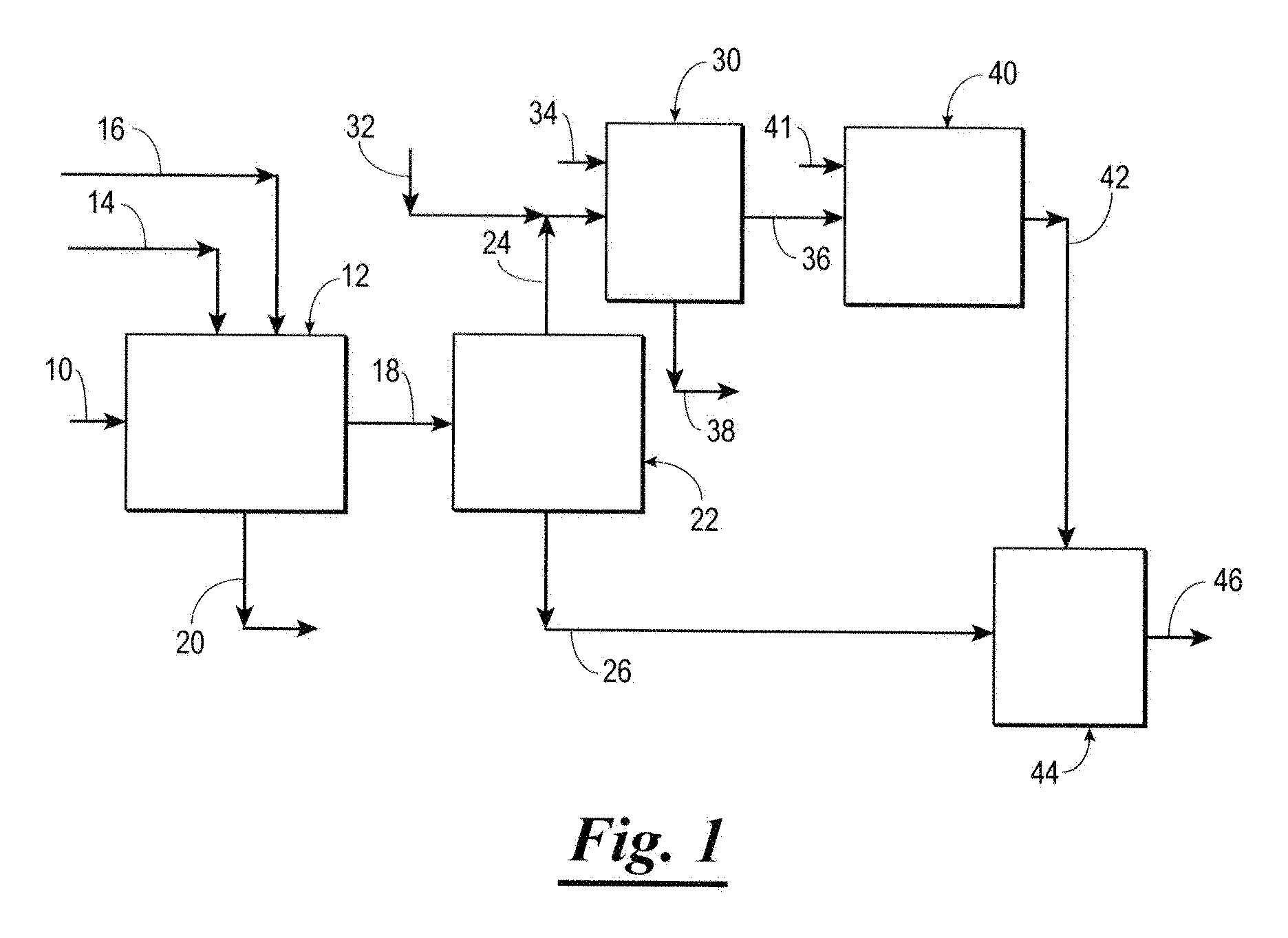

[0020]The process of the present invention relates to converting a renewable feedstock to a diesel fuel blend having improved low temperature properties. The process of the present invention produces high yields of an improved middle distillate product.

[0021]The term “renewable feedstock” refers to animal fats, vegetable oils, plant fats and oils, rendered fats, restaurant grease and waste industrial frying oils, tall oil fatty acids and combinations thereof.

[0022]The term “middle distillate product(s)” and “middle distillate” refer to hydrocarbon mixtures with a boiling point range that corresponds substantially with that of kerosene and gas oil fractions obtained in a conventional atmospheric distillation of crude oil material. The middle distillate boiling point range may include temperatures between about 150° C. and about 600° C., with a fraction boiling point between about 200° C. and about 360° C.

[0023]The term “middle distillate fuel” refers to jet fuel, kerosene, diesel fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com