Patents

Literature

17256results about How to "Improve the lubrication effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

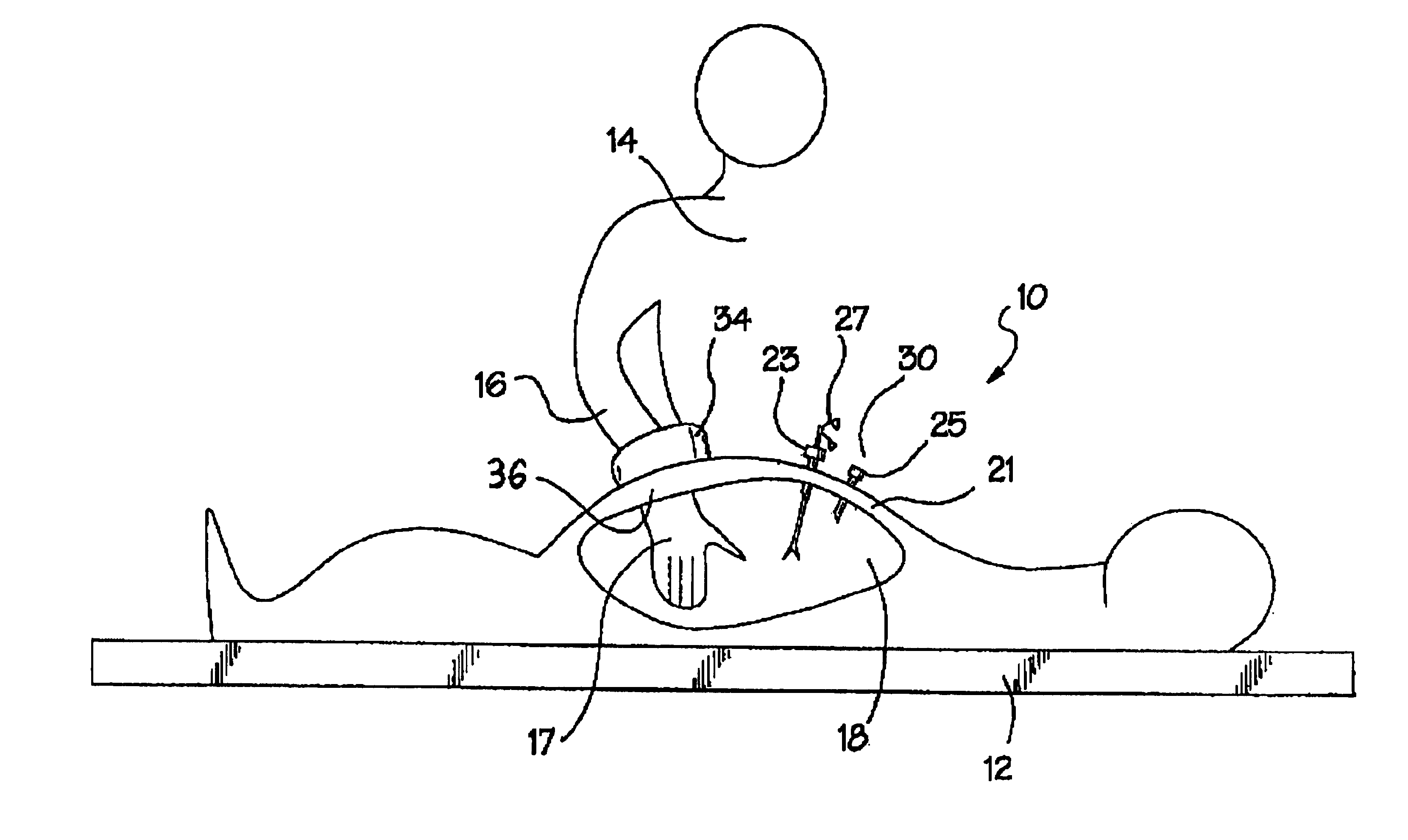

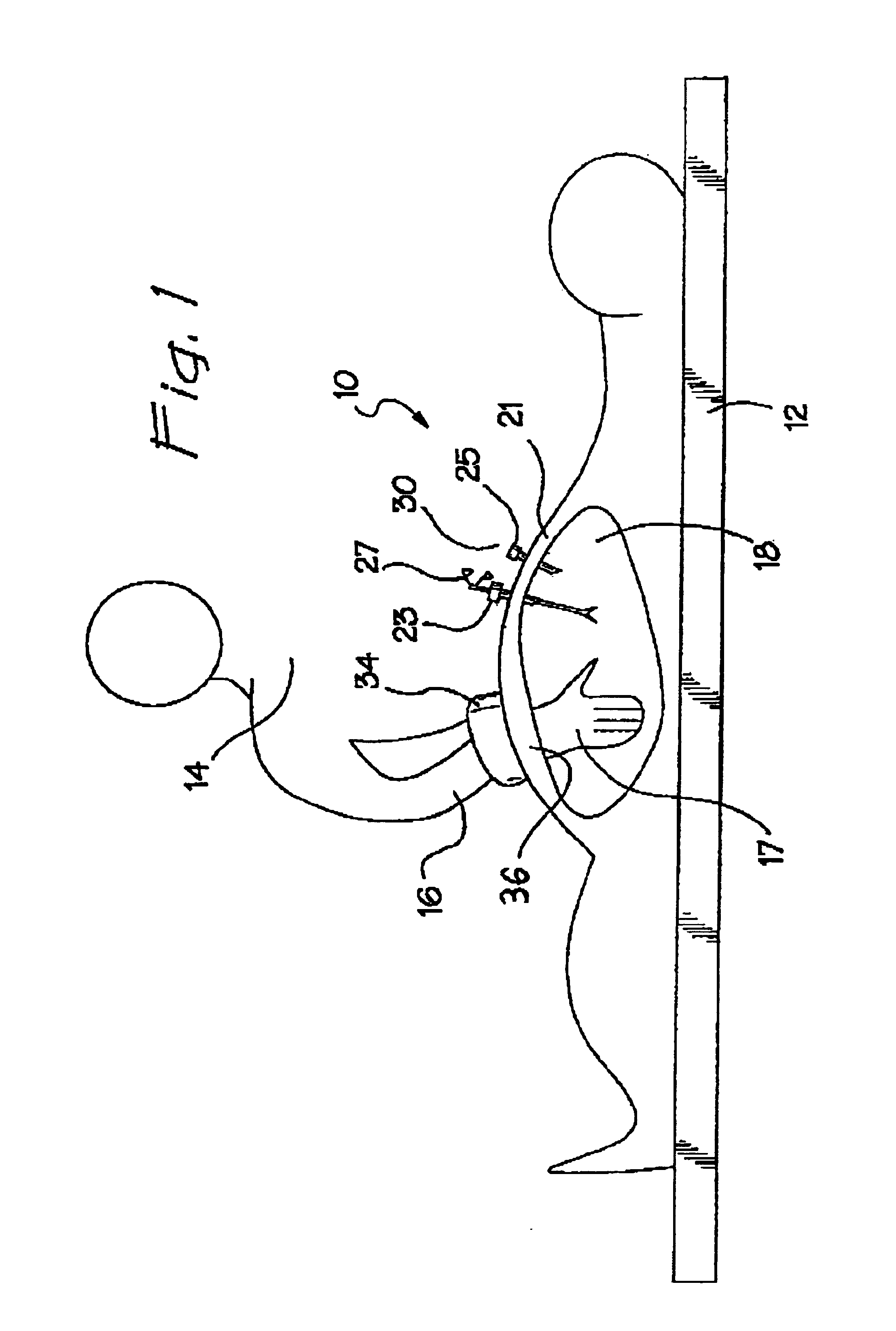

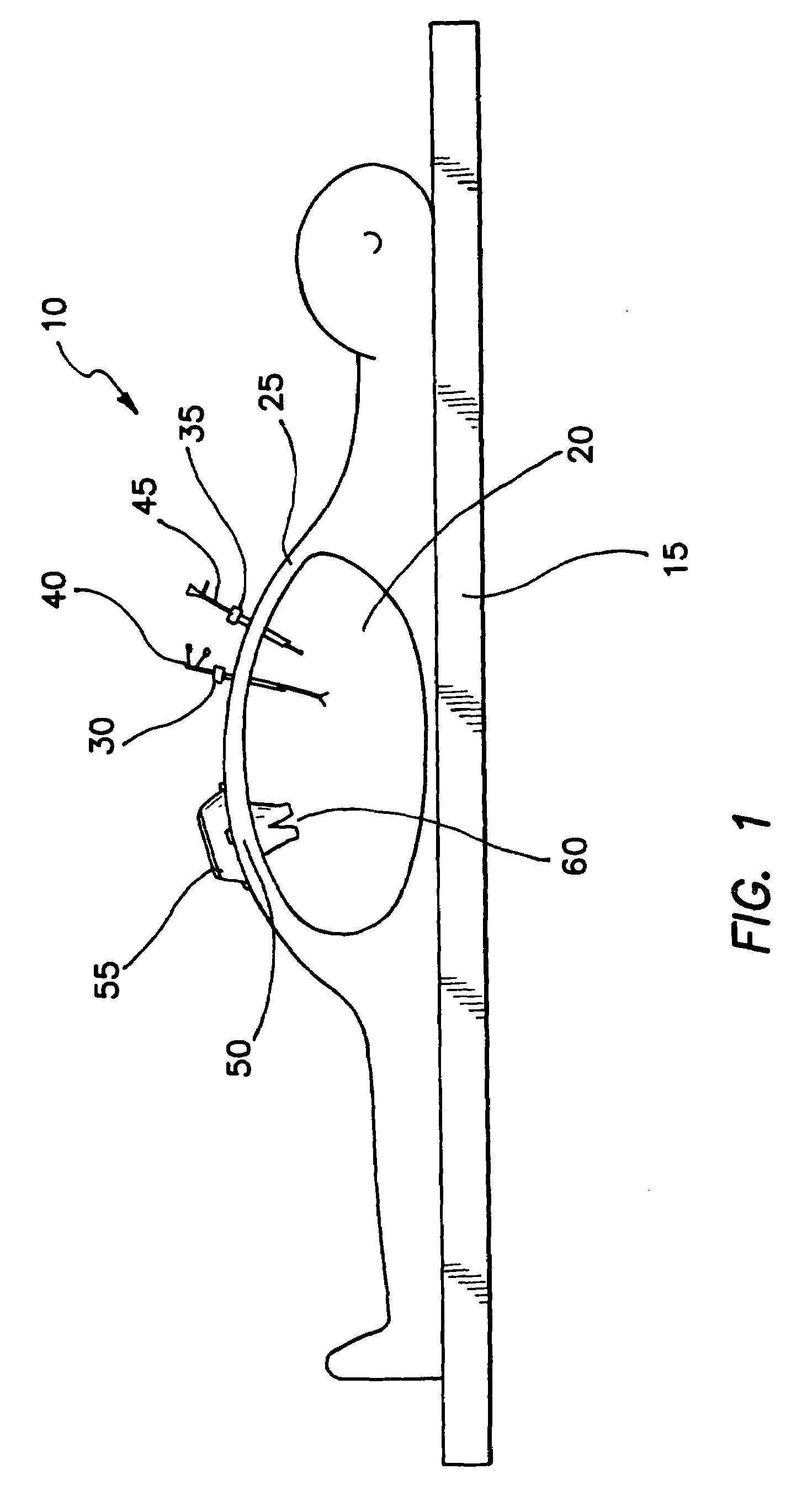

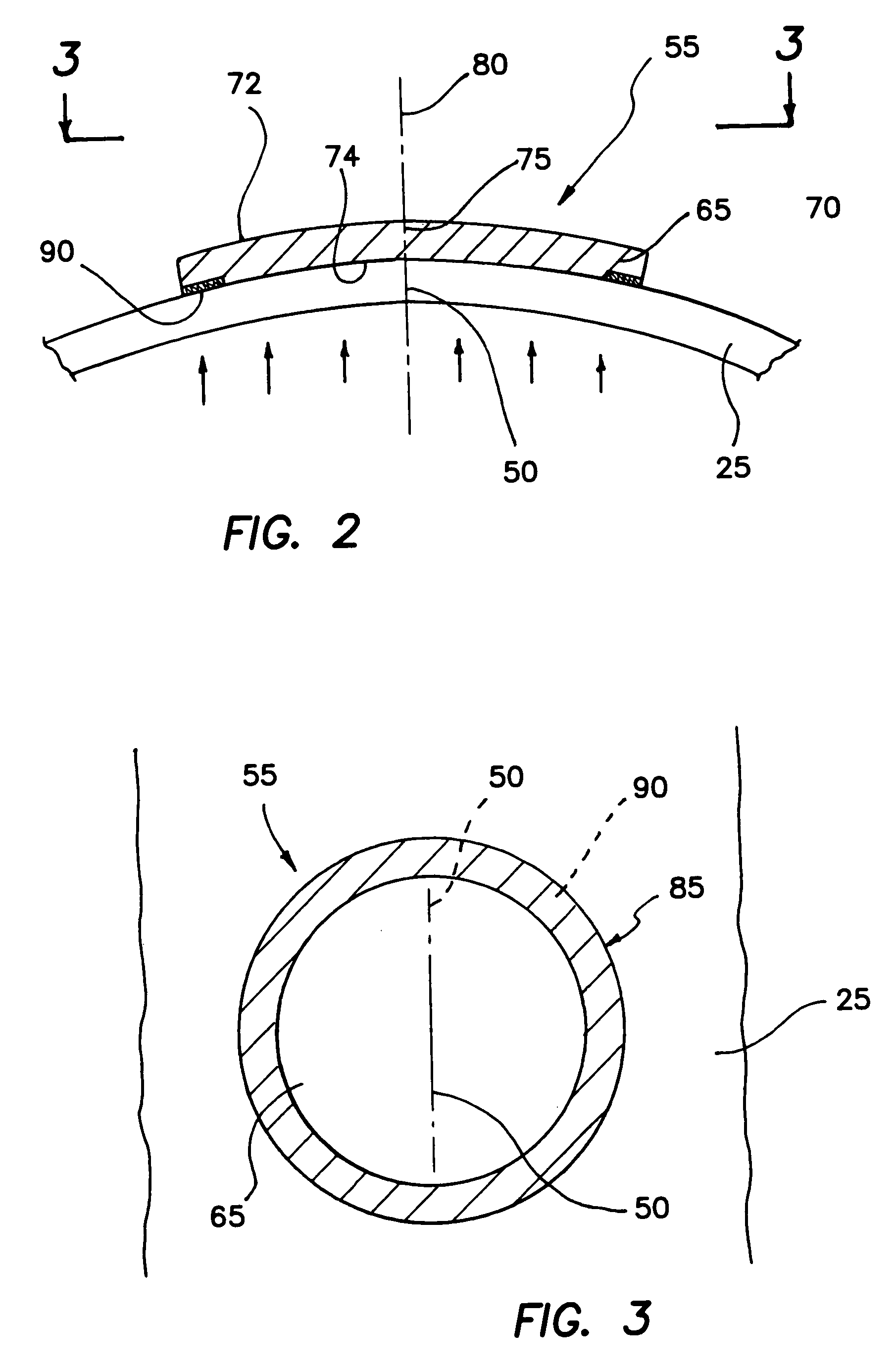

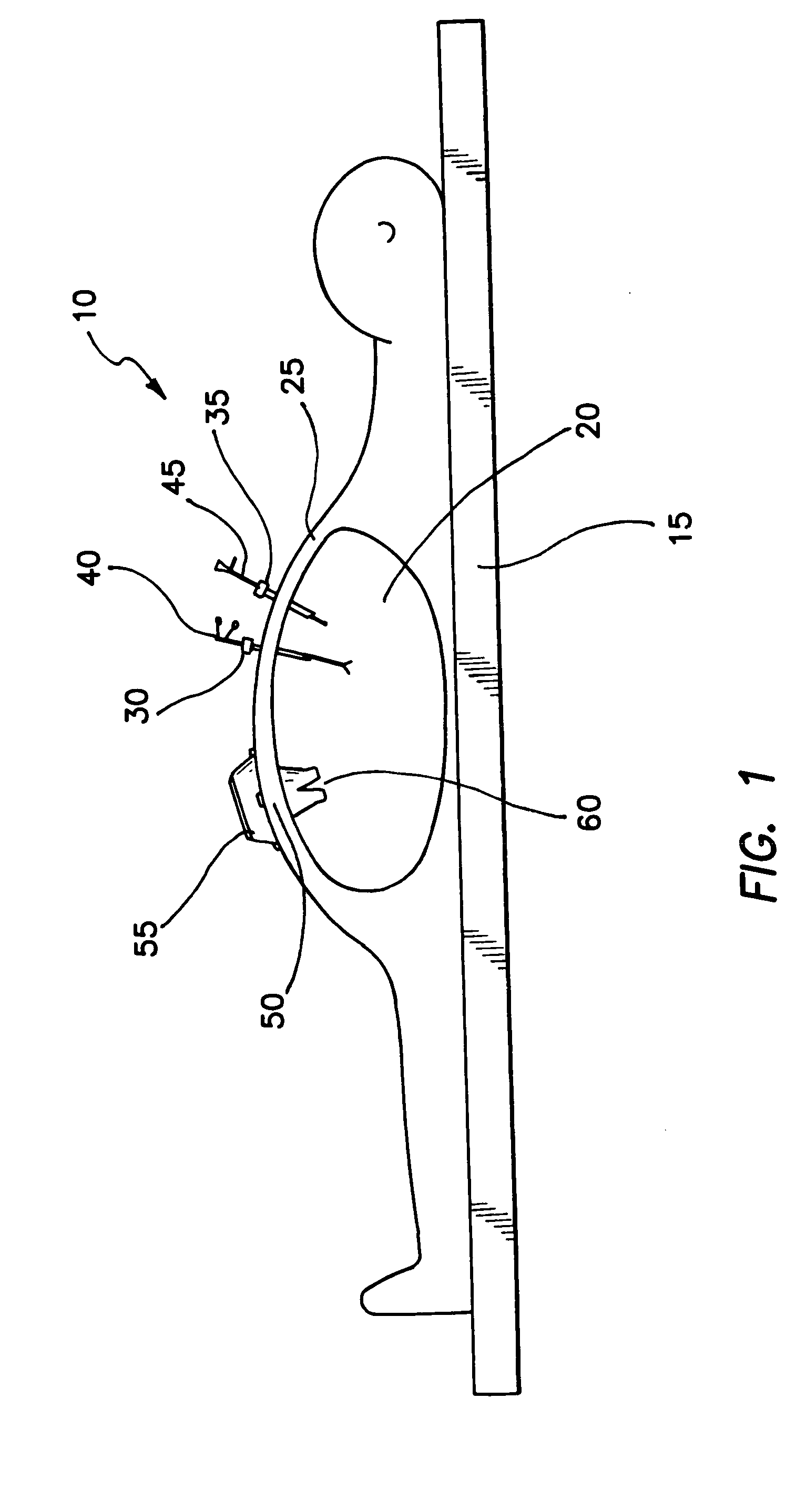

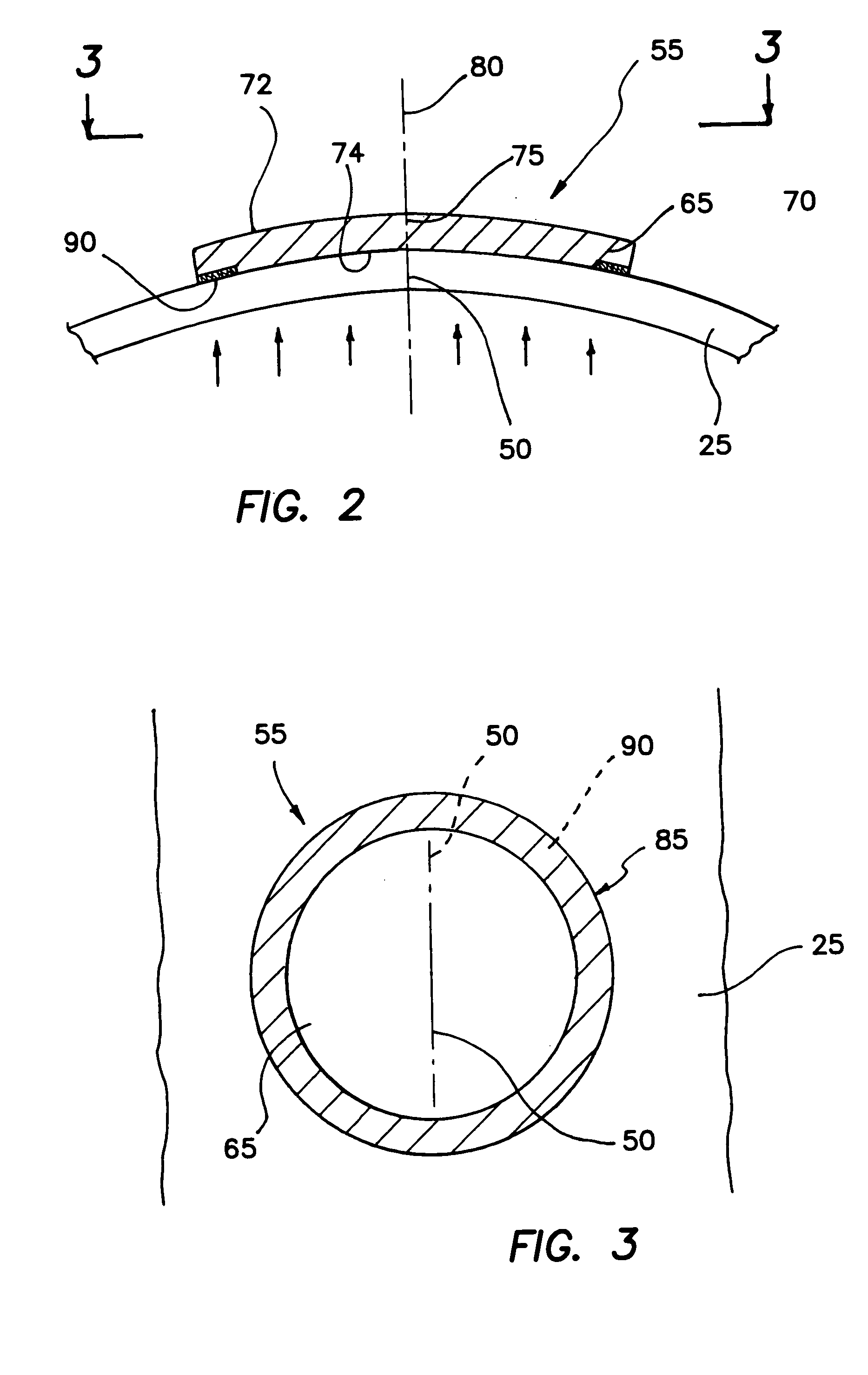

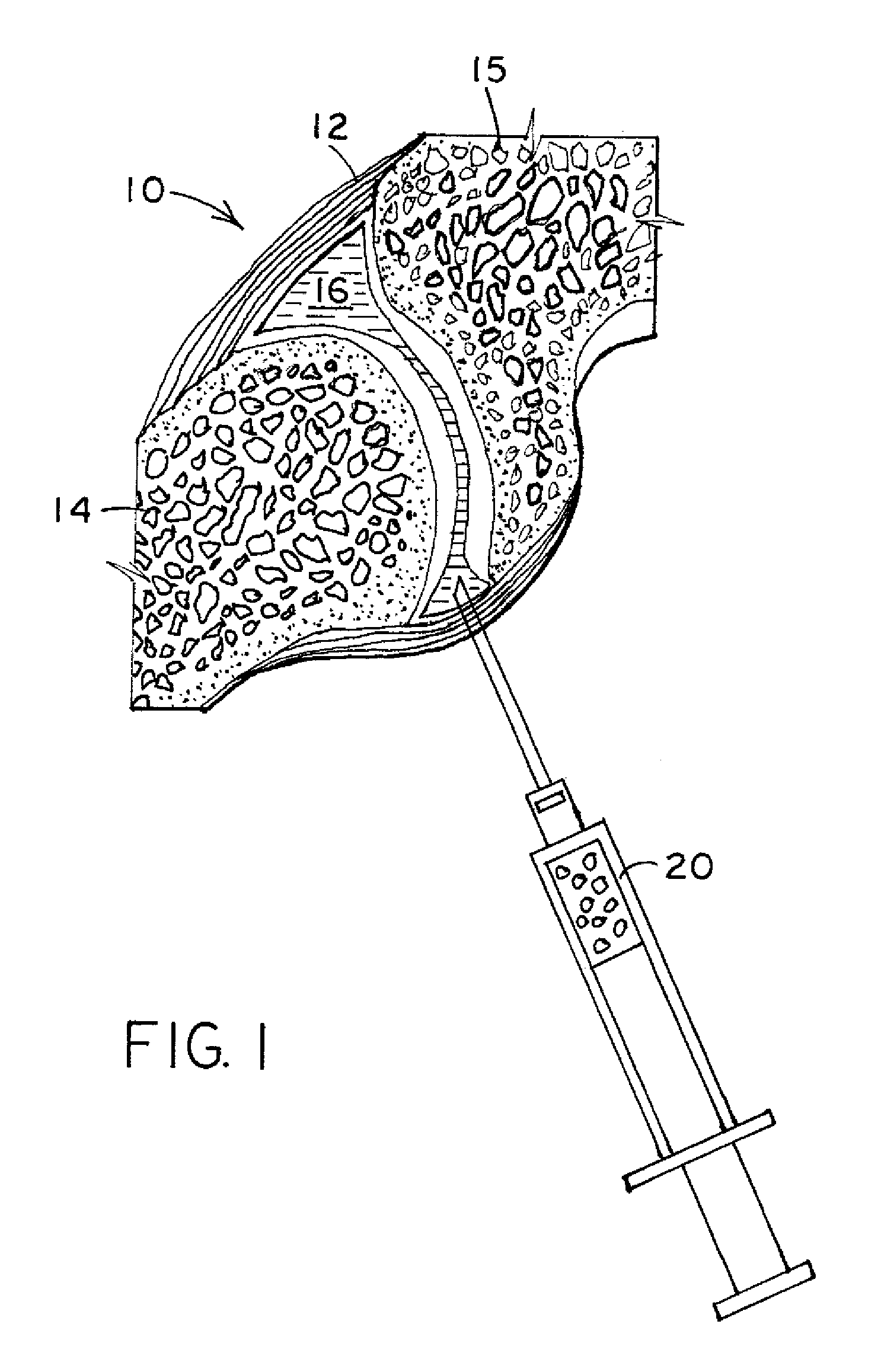

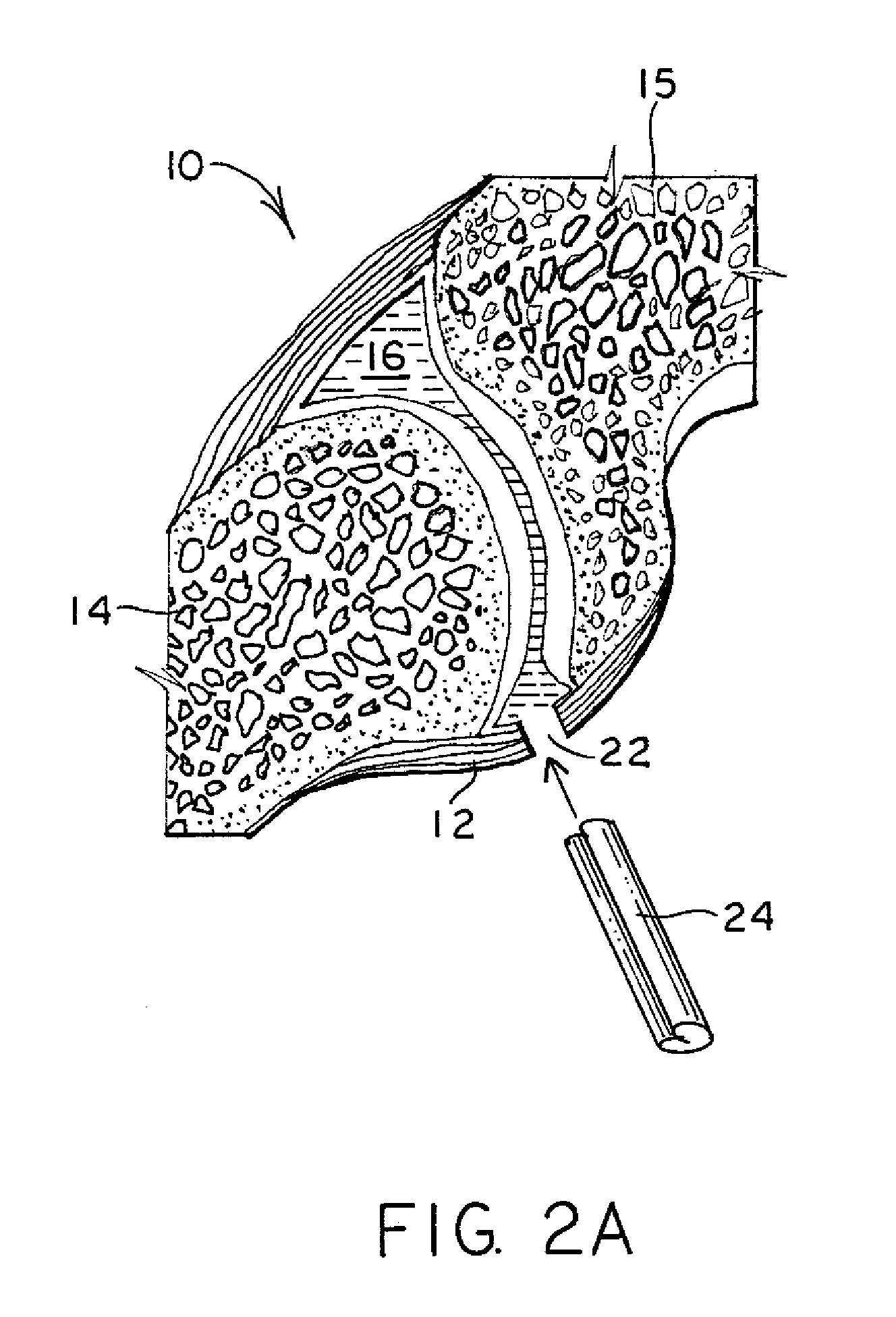

Laparoscopic illumination apparatus and method

InactiveUS6939296B2Improve rendering capabilitiesImprove tear resistanceCannulasRestraining devicesPERITONEOSCOPESurgical site

An access device particularly adapted for use in laparoscopic surgery facilitates access with instruments, such as the hand of the surgeon, across a body wall and into a body cavity. The device can be formed of a gel material having properties for forming a zero seal, or an instrument seal with a wide range of instrument diameters. The gel material can be translucent facilitating illumination and visualization of the surgical site through the access device.

Owner:APPL MEDICAL RESOURCES CORP

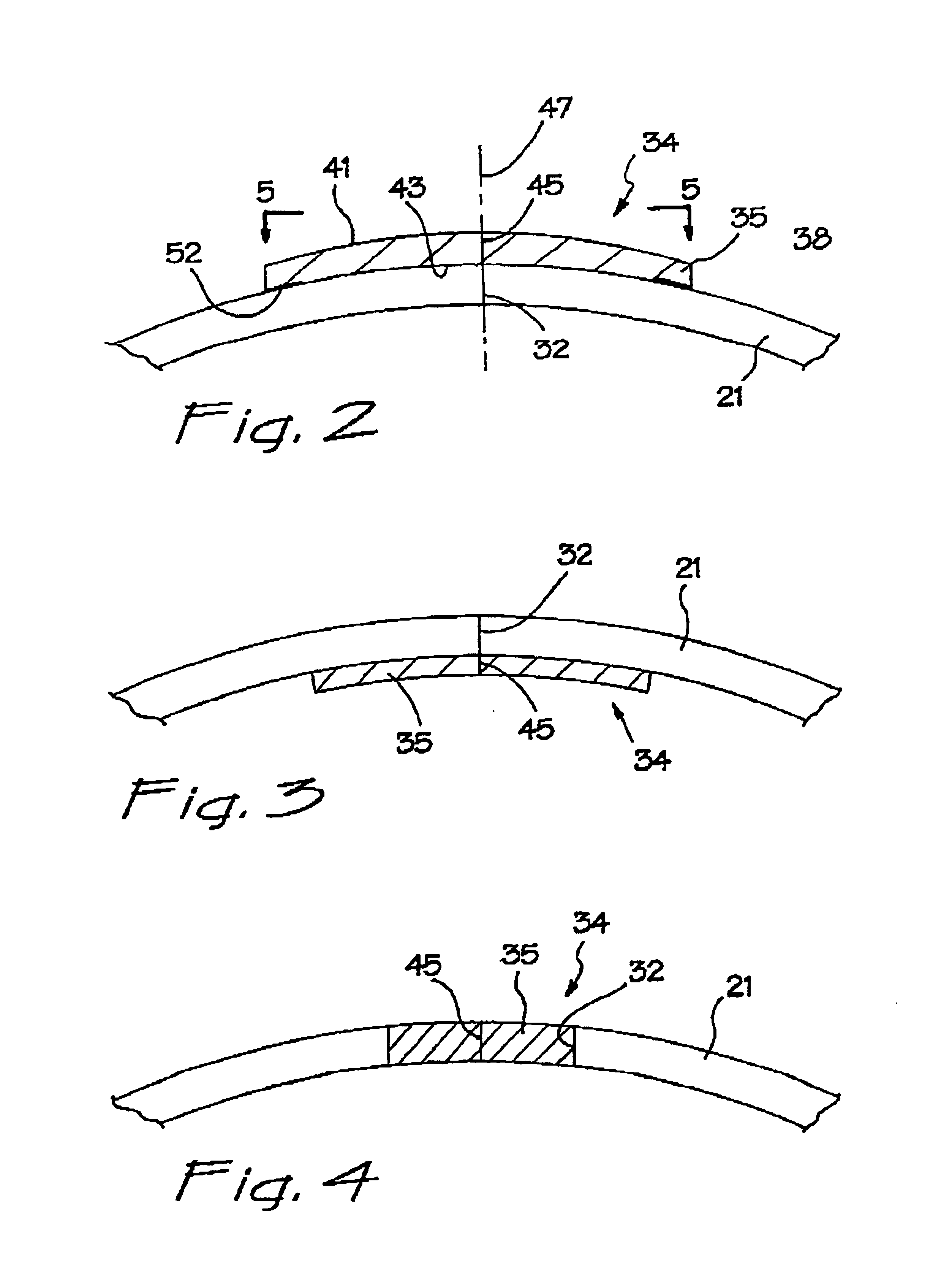

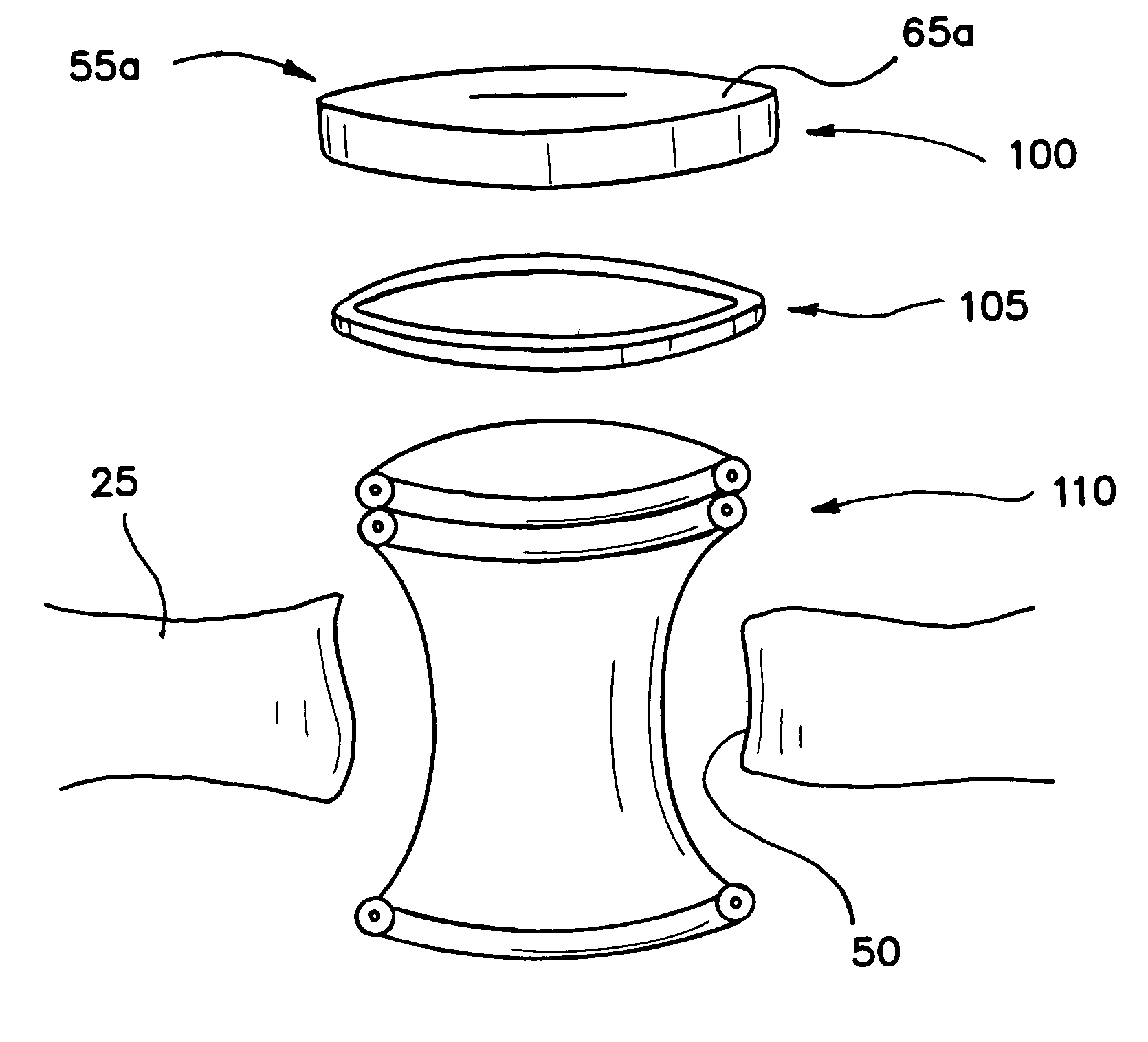

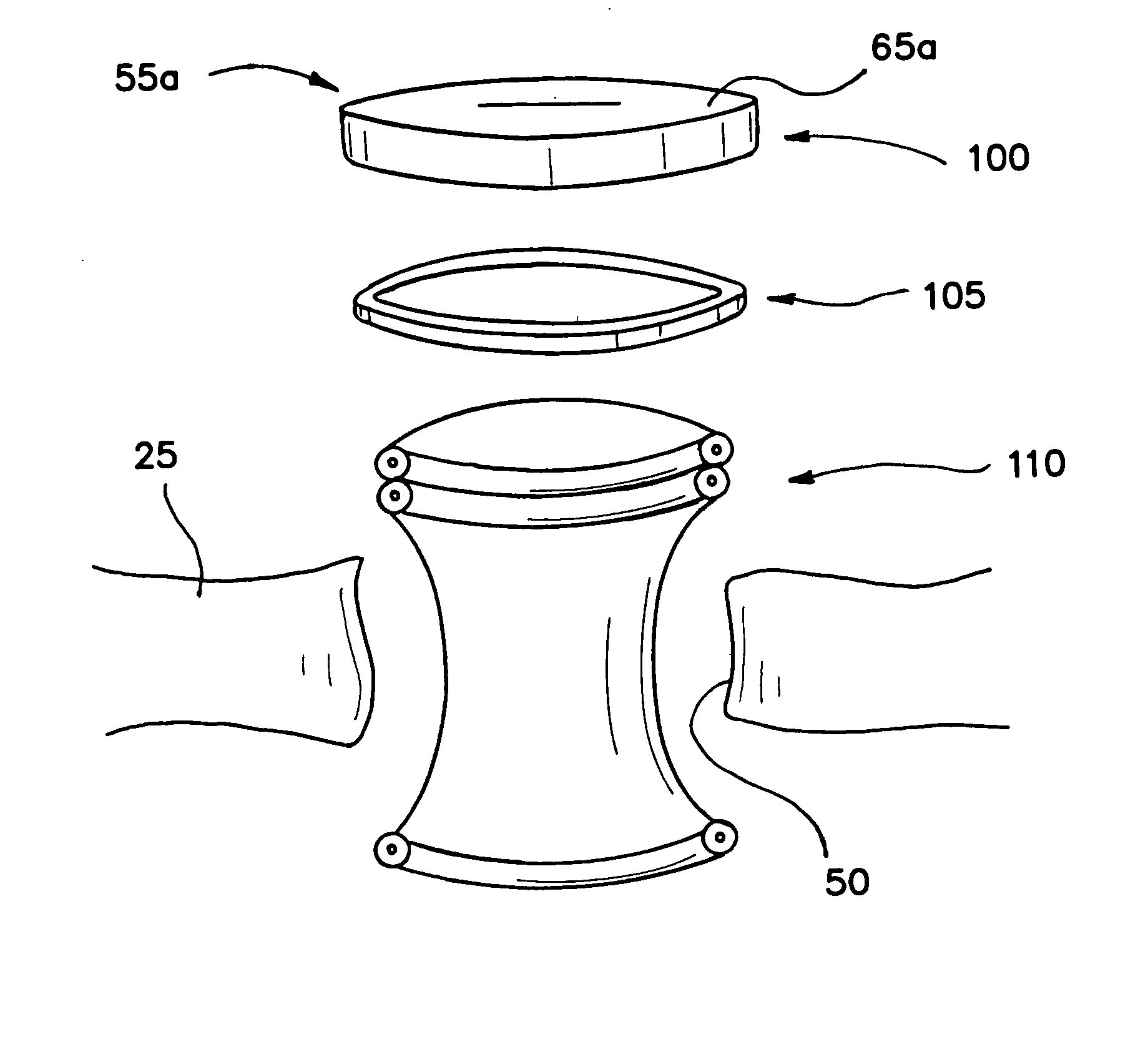

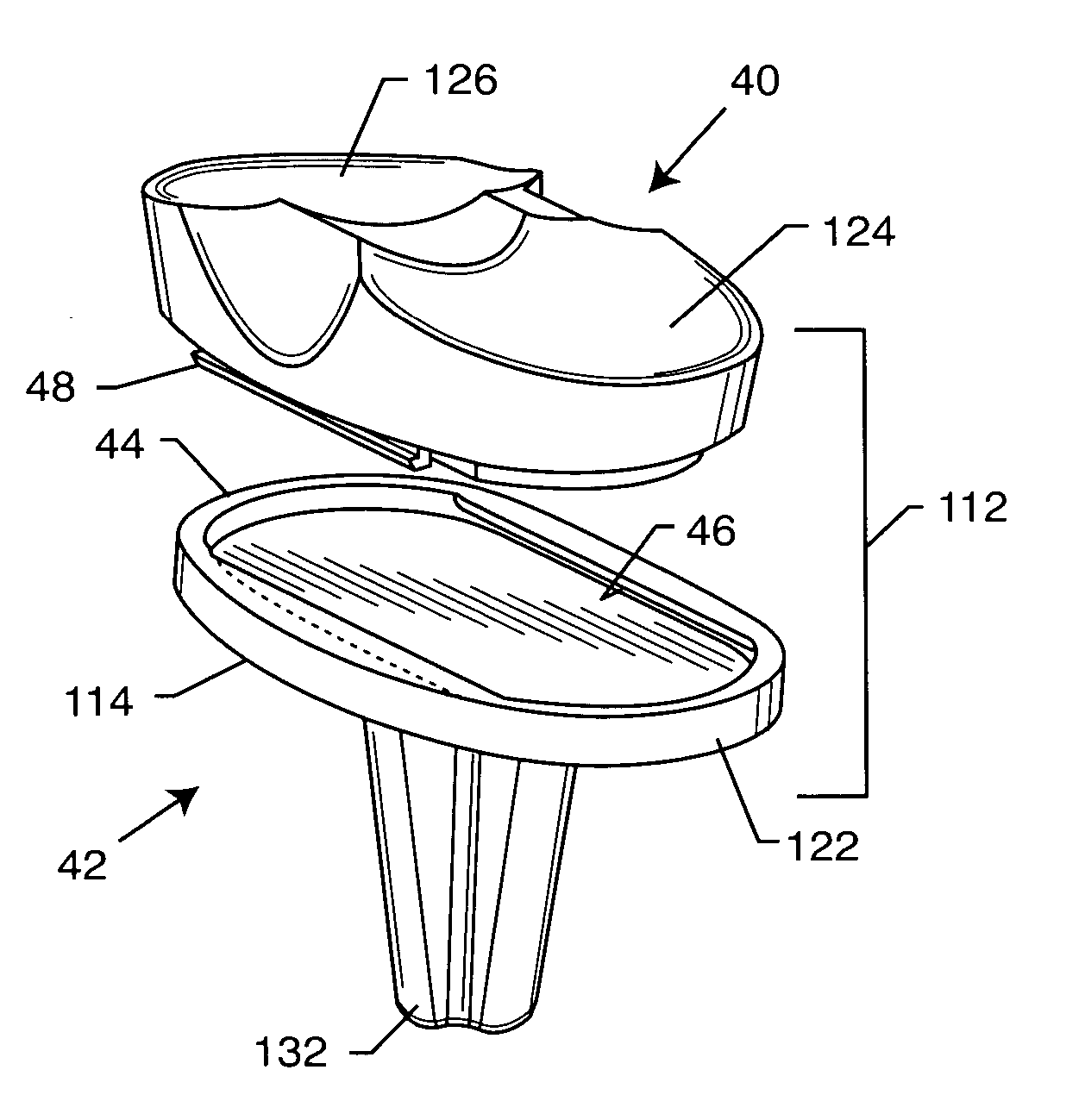

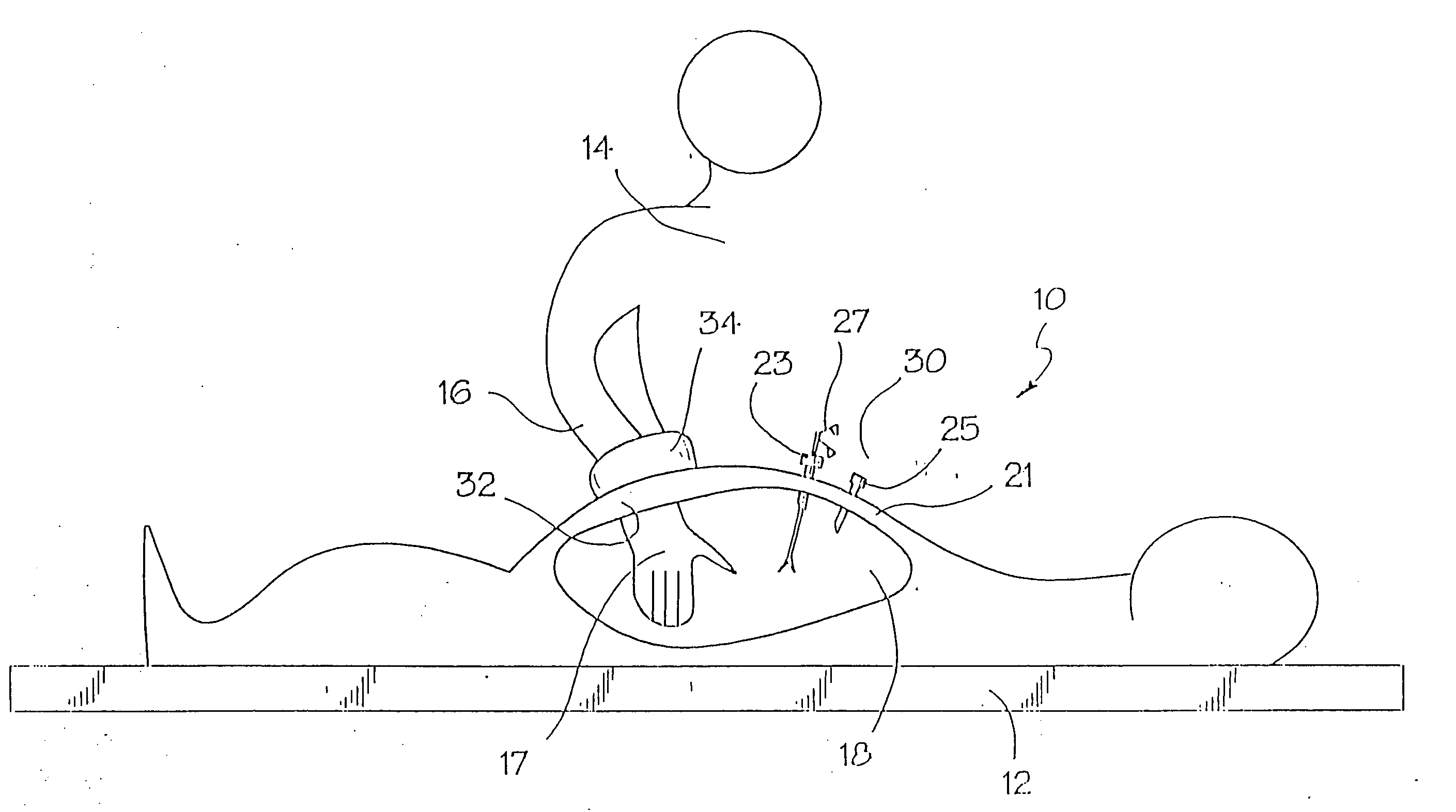

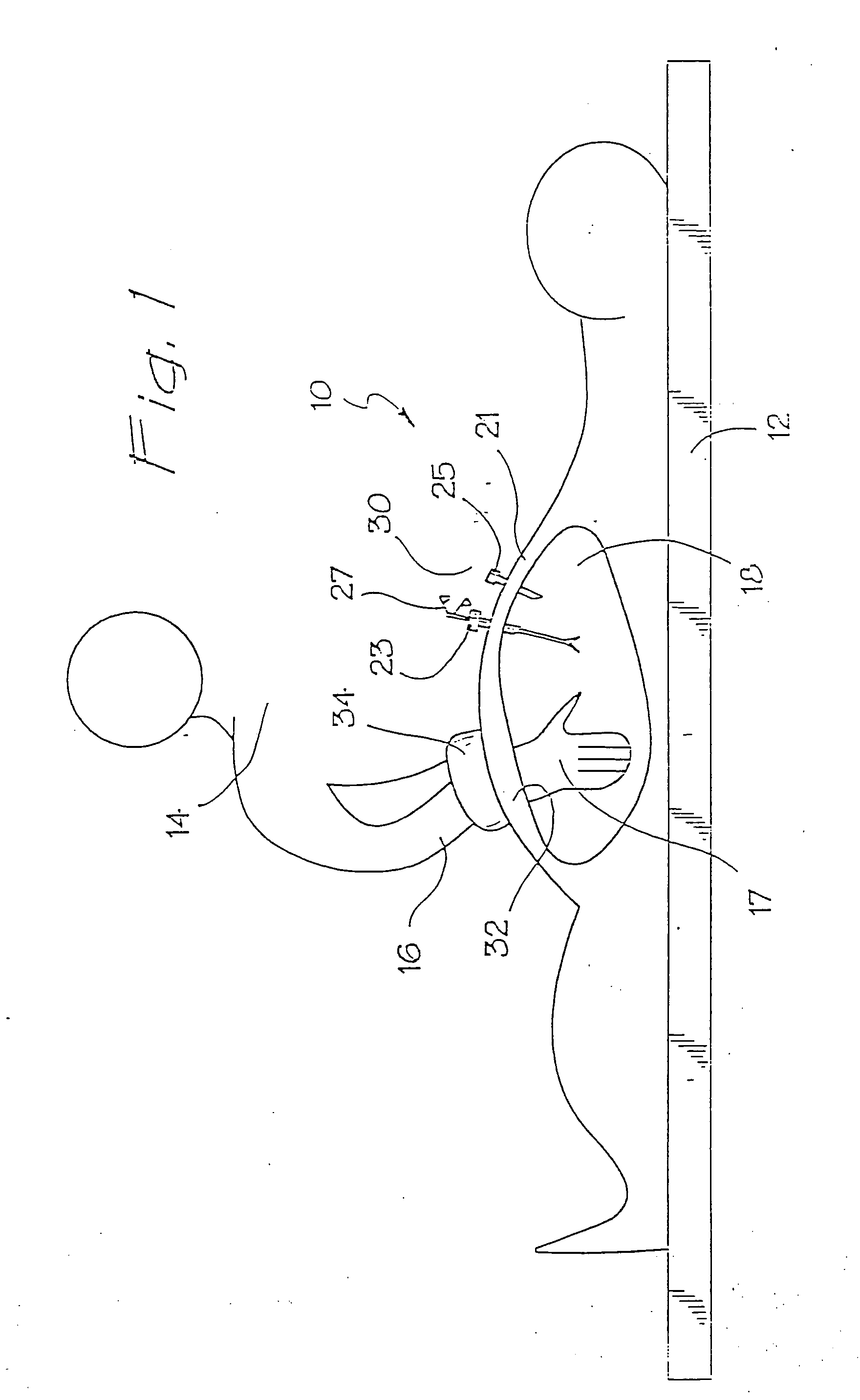

Surgical instrument access device

ActiveUS7163510B2High tear strengthHigh elongationCannulasInfusion syringesSurgical departmentVALVE PORT

A surgical access device includes a single valve that forms a seal with a body wall and provides an access channel into a body cavity. The valve has properties for creating a zero seal in the absence of an instrument as well as an instrument seal for an instrument having a diameter up to about 37 mm. The valve can include a gel material and the access channel can include a protective sleeve to provide for wound protection during insertion and withdrawal of a sharp surgical instrument. The valve further comprises a cap ring which may be inserted or molded with the gel material. The protective sleeve may be bonded or molded around an inner diameter of the cap ring. The protective sleeve may be a single tubular member, or may comprise a plurality of axially extending sleeve members having a plurality of axial slits. The protective sleeve and the cap ring may comprise of the same or different materials. The surgical access device further comprises at least one support ring disposed circumferentially of the valve forming a hollow space, and a wound retractor operatively placed in the hollow space. The wound retractor includes an inner ring, an outer ring, and a flexible sleeve connecting the inner ring and the outer ring.

Owner:APPL MEDICAL RESOURCES CORP

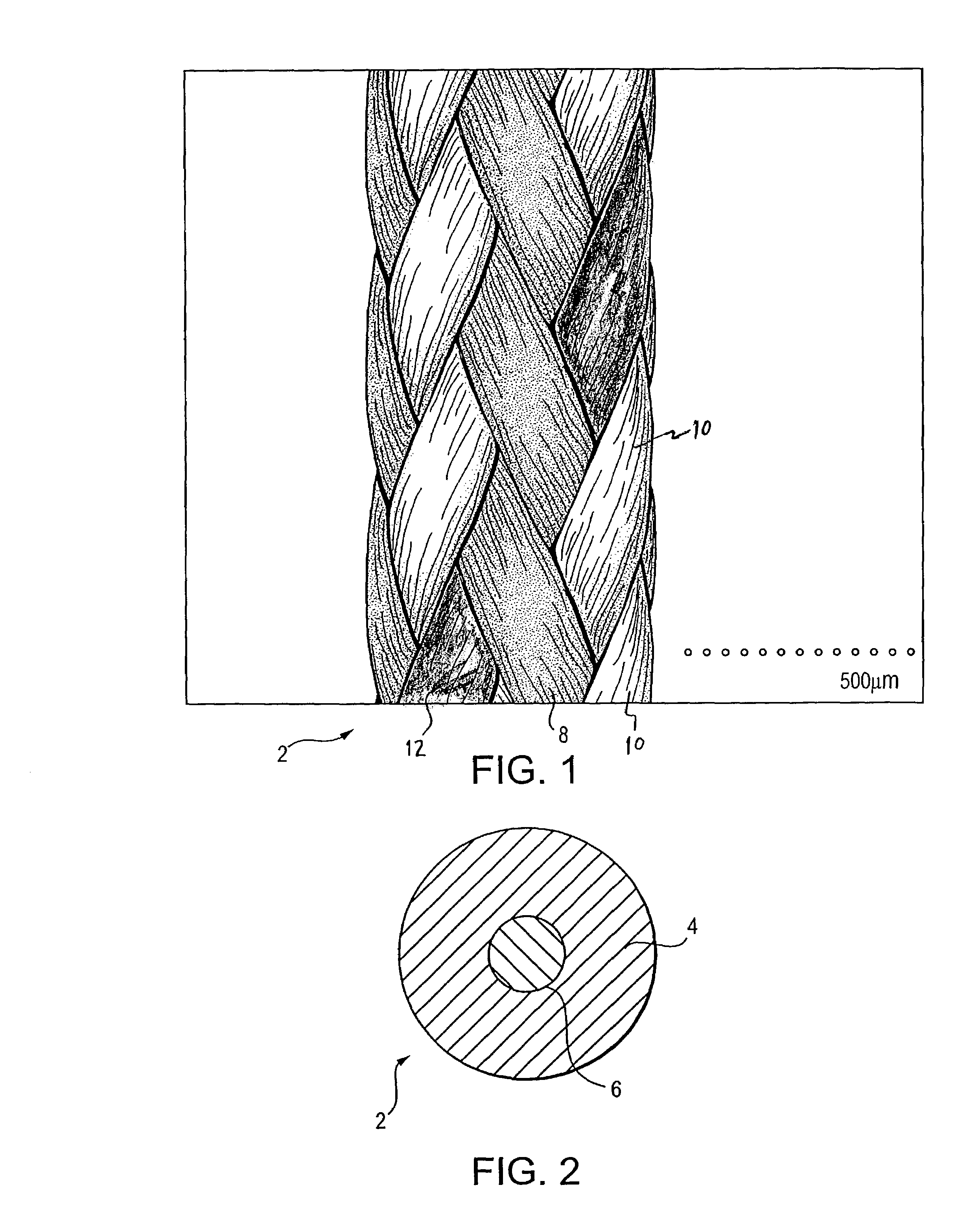

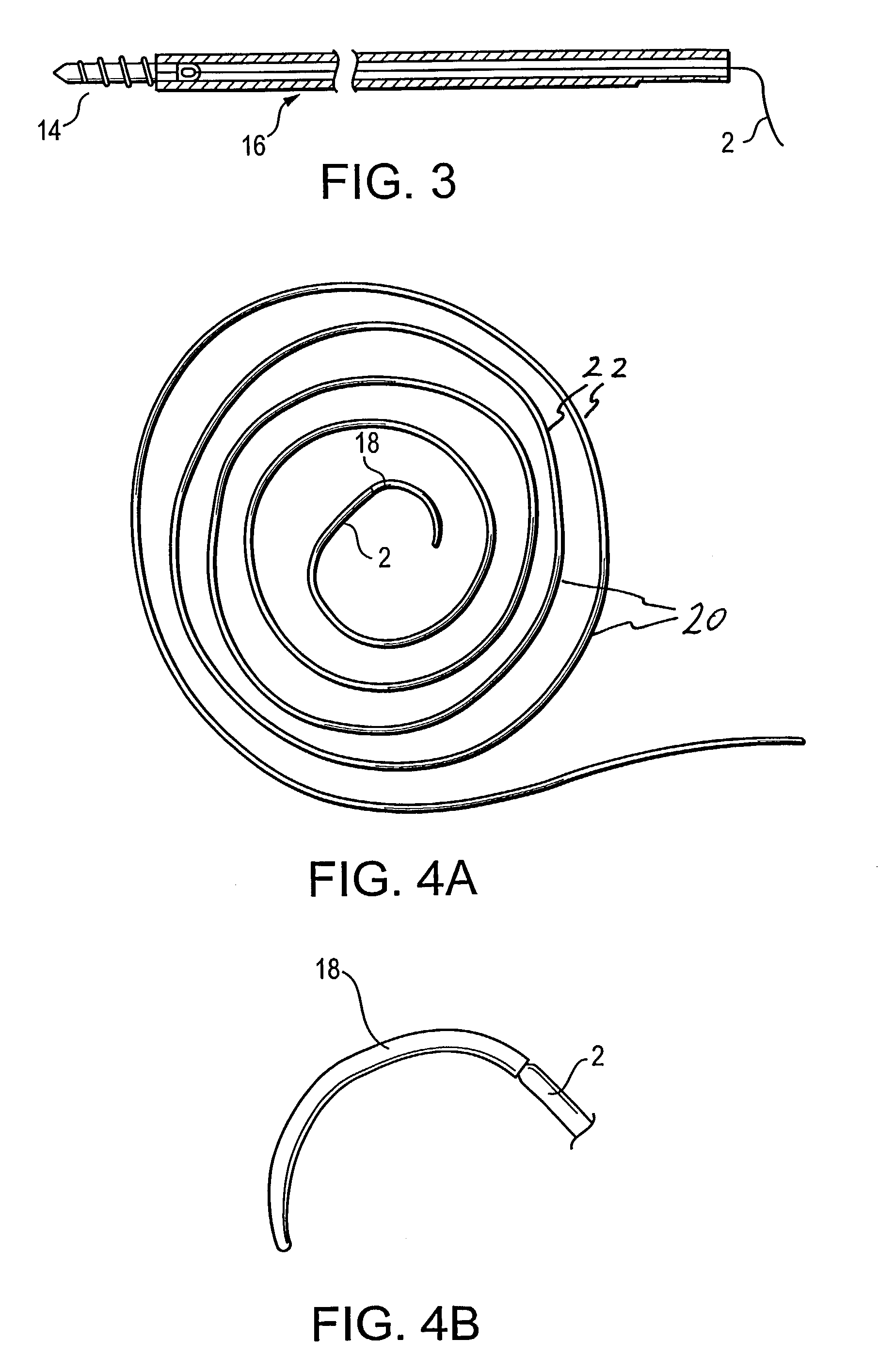

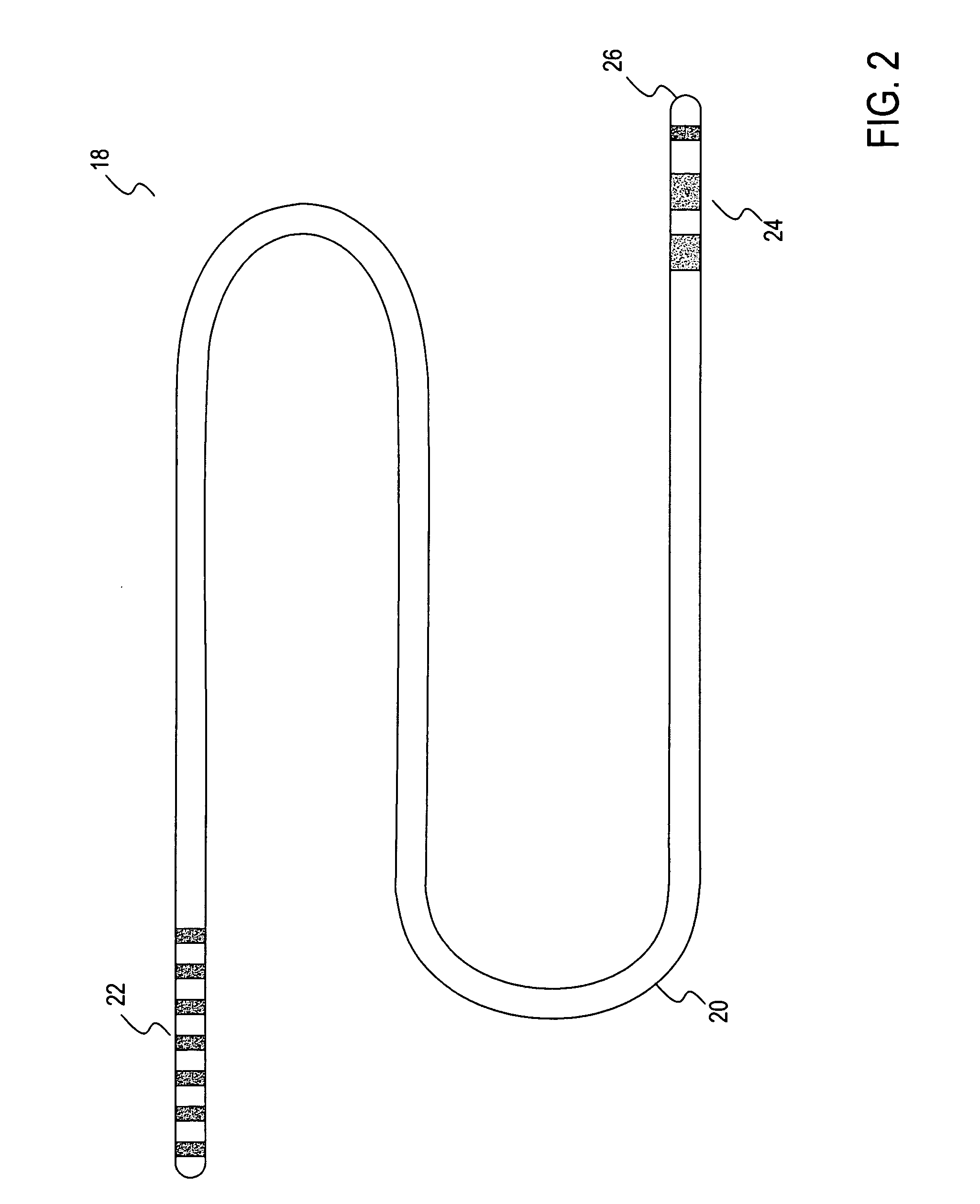

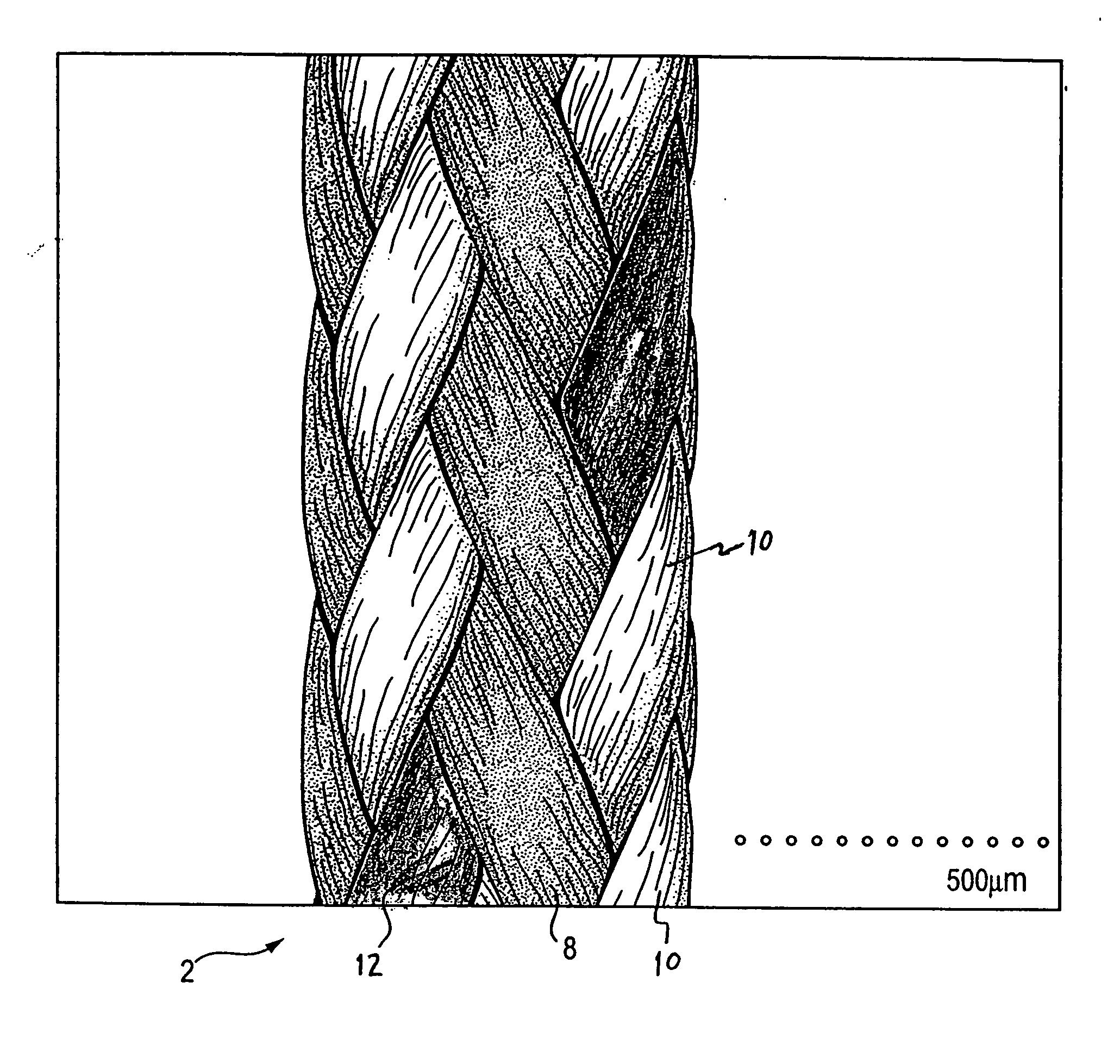

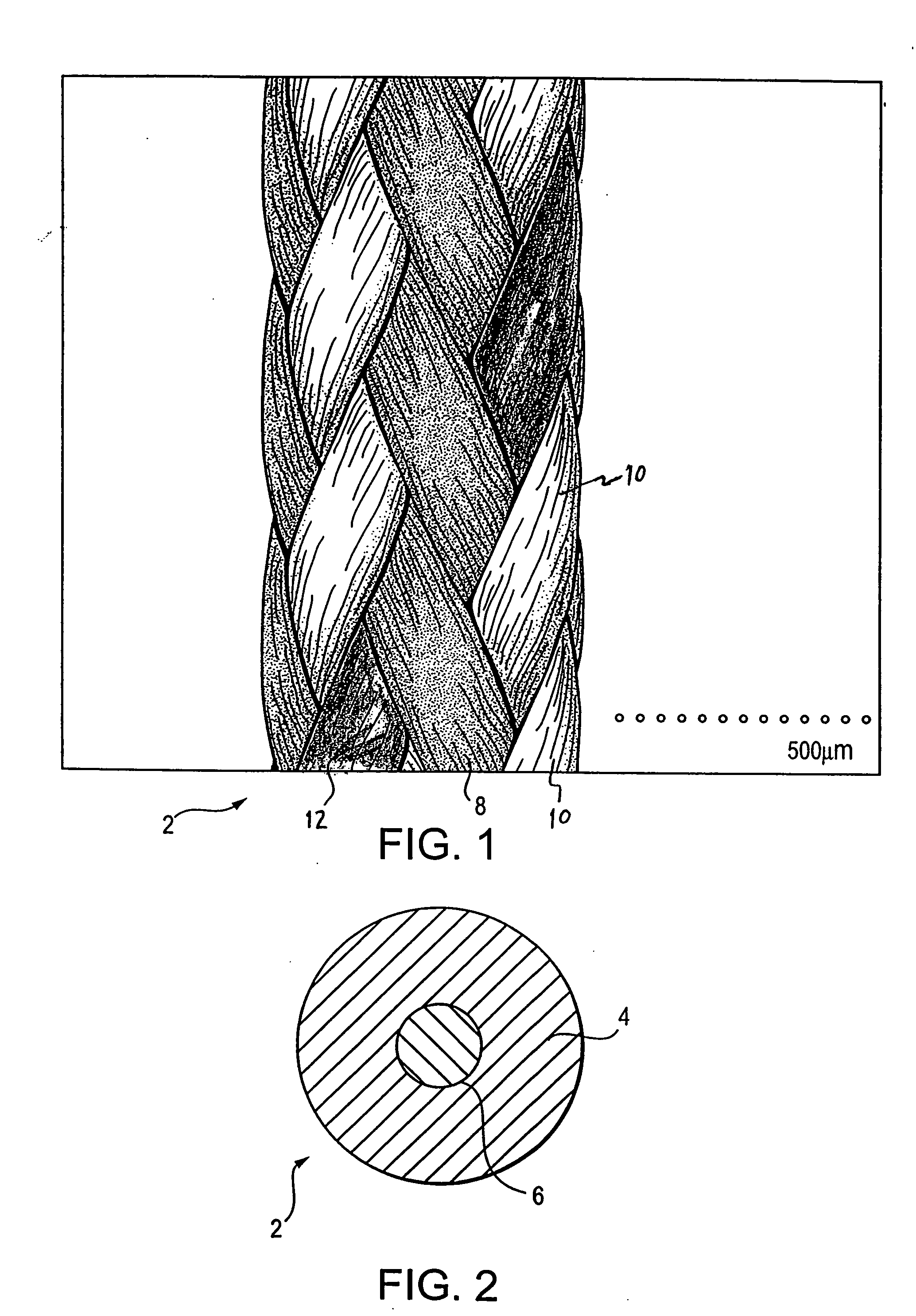

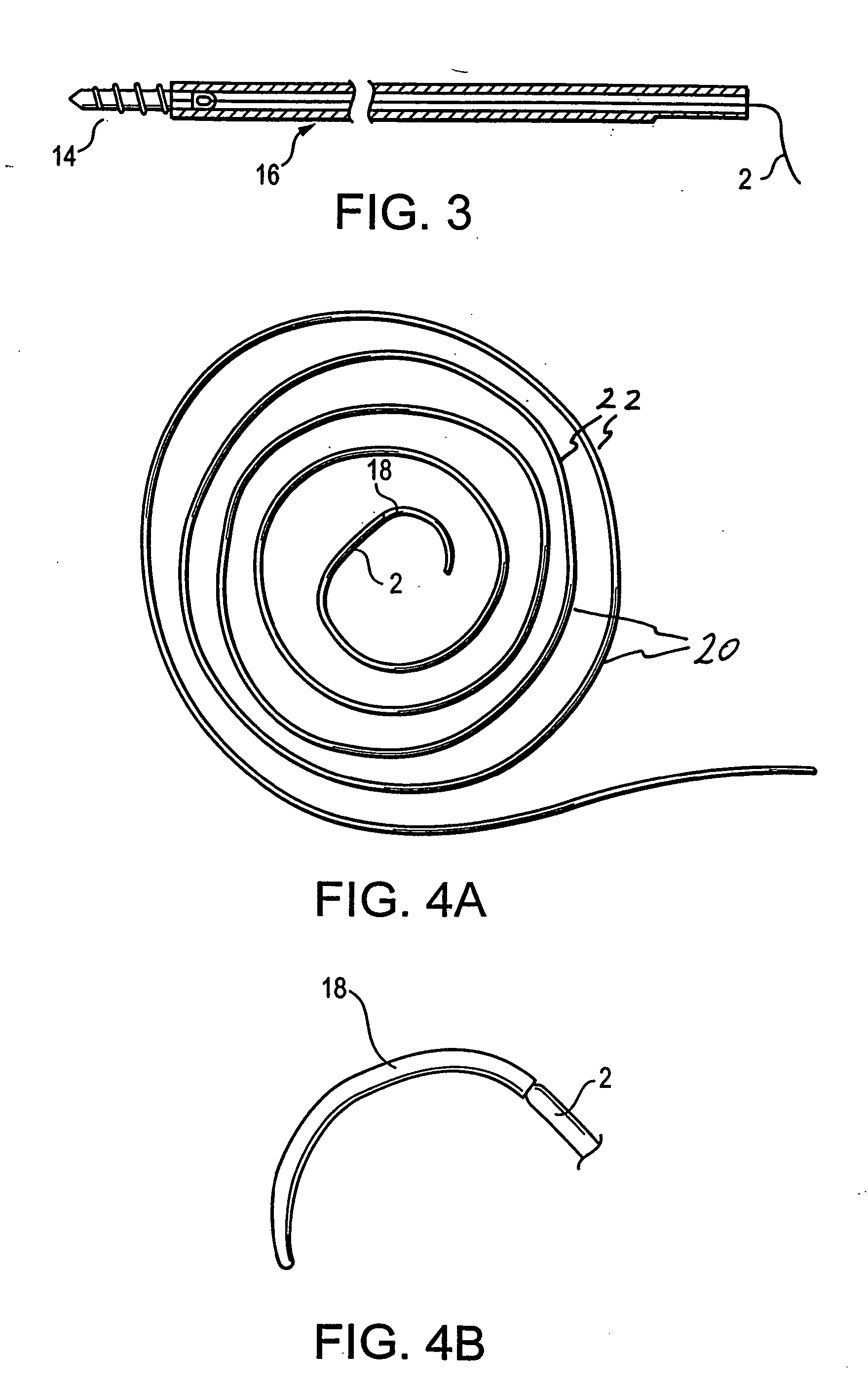

High strength suture with colored trace at one end

InactiveUS6994719B2High strengthImproved tie down characteristicSuture equipmentsDiagnosticsPolyesterEngineering

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable trace preferably is provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily identified.

Owner:ARTHREX INC

Surgical instrument access device

ActiveUS20050059865A1High tear strengthHigh elongationCannulasSurgical needlesVALVE PORTWound retractor

A surgical access device includes a single valve that forms a seal with a body wall and provides an access channel into a body cavity. The valve has properties for creating a zero seal in the absence of an instrument as well as an instrument seal for an instrument having a diameter up to about 37 mm. The valve can include a gel material and the access channel can include a protective sleeve to provide for wound protection during insertion and withdrawal of a sharp surgical instrument. The valve further comprises a cap ring which may be inserted or molded with the gel material. The protective sleeve may be bonded or molded around an inner diameter of the cap ring. The protective sleeve may be a single tubular member, or may comprise a plurality of axially extending sleeve members having a plurality of axial slits. The protective sleeve and the cap ring may comprise of the same or different materials. The surgical access device further comprises at least one support ring disposed circumferentially of the valve forming a hollow space, and a wound retractor operatively placed in the hollow space. The wound retractor includes an inner ring, an outer ring, and a flexible sleeve connecting the inner ring and the outer ring.

Owner:APPL MEDICAL RESOURCES CORP

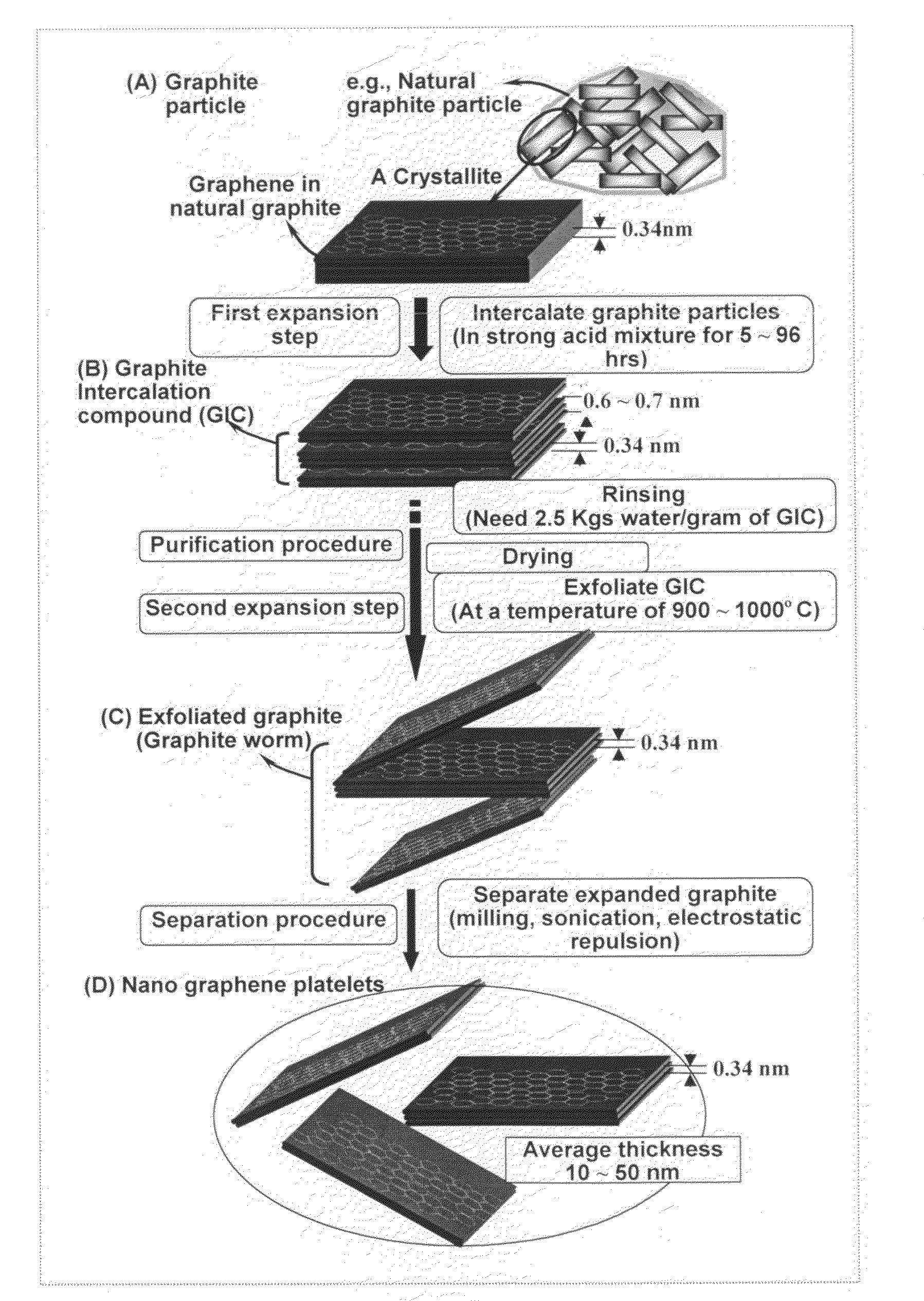

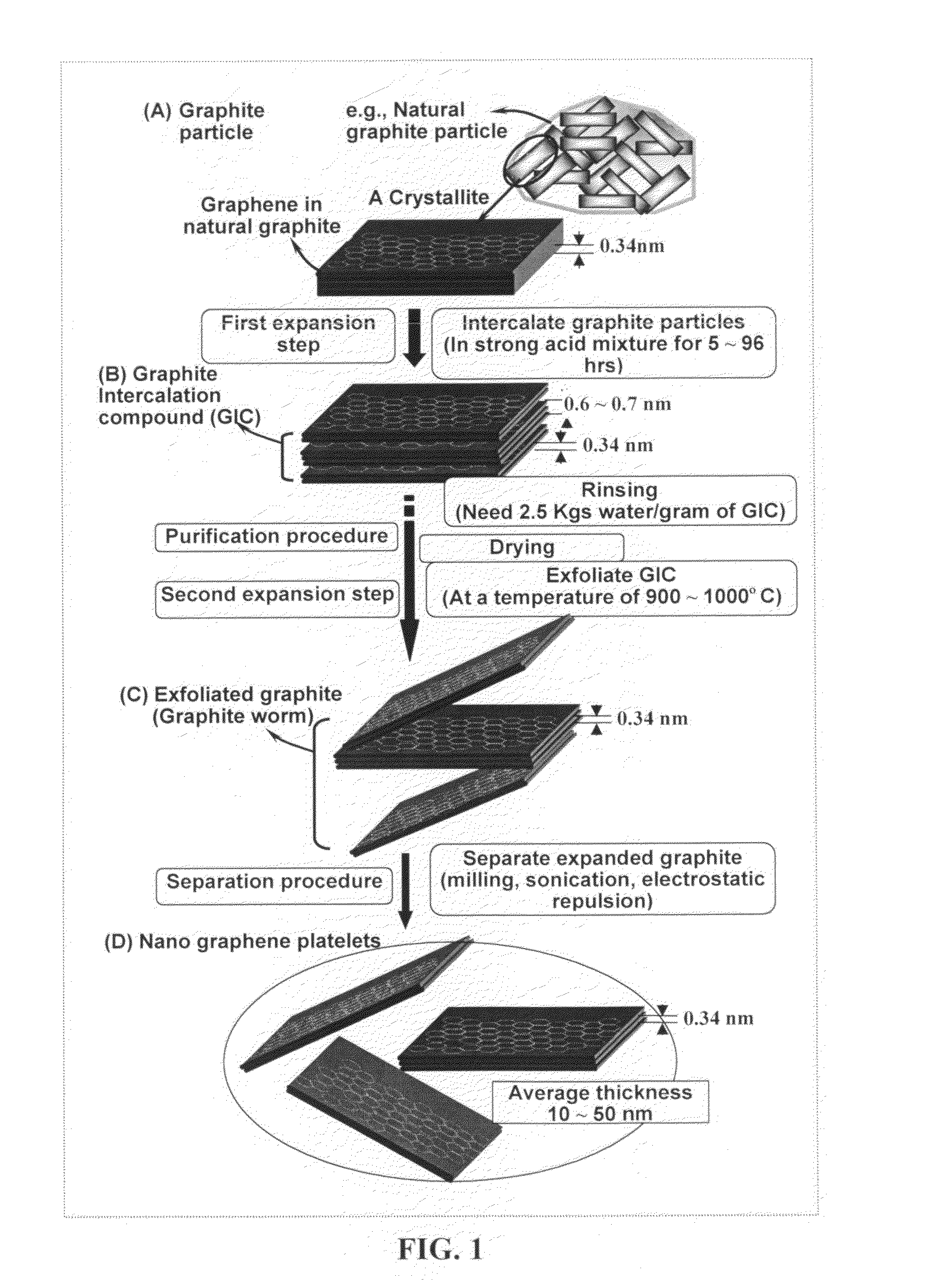

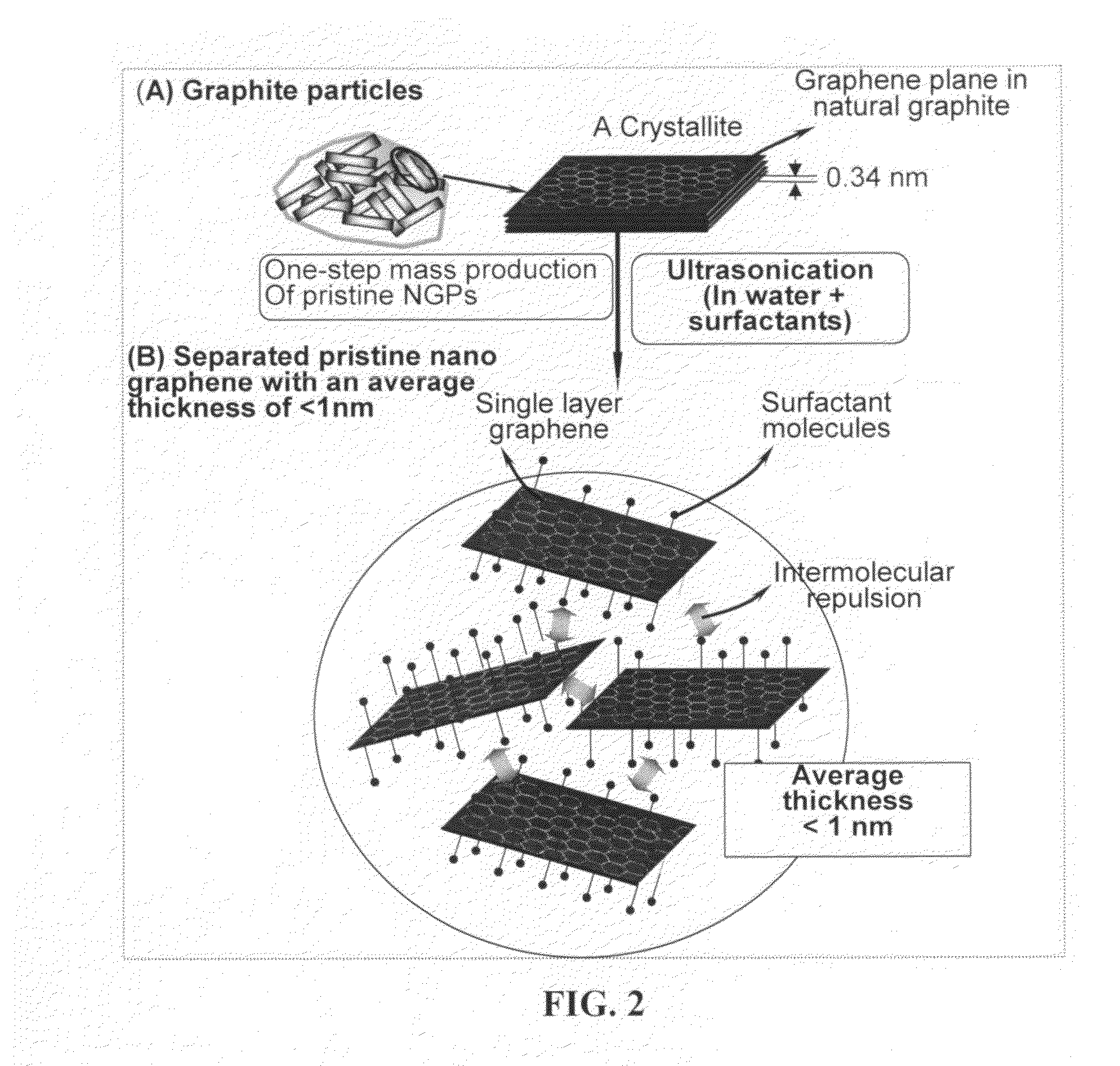

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

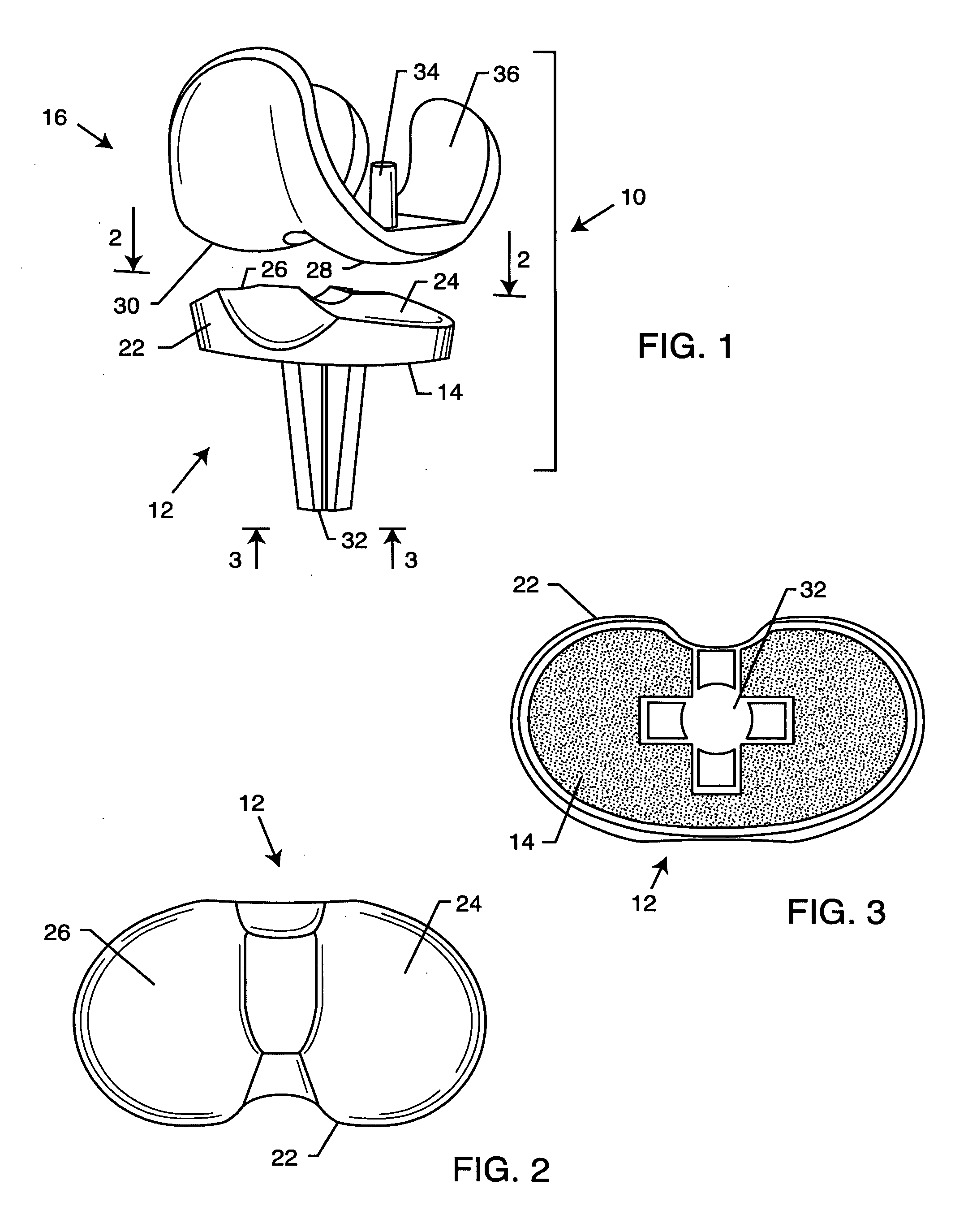

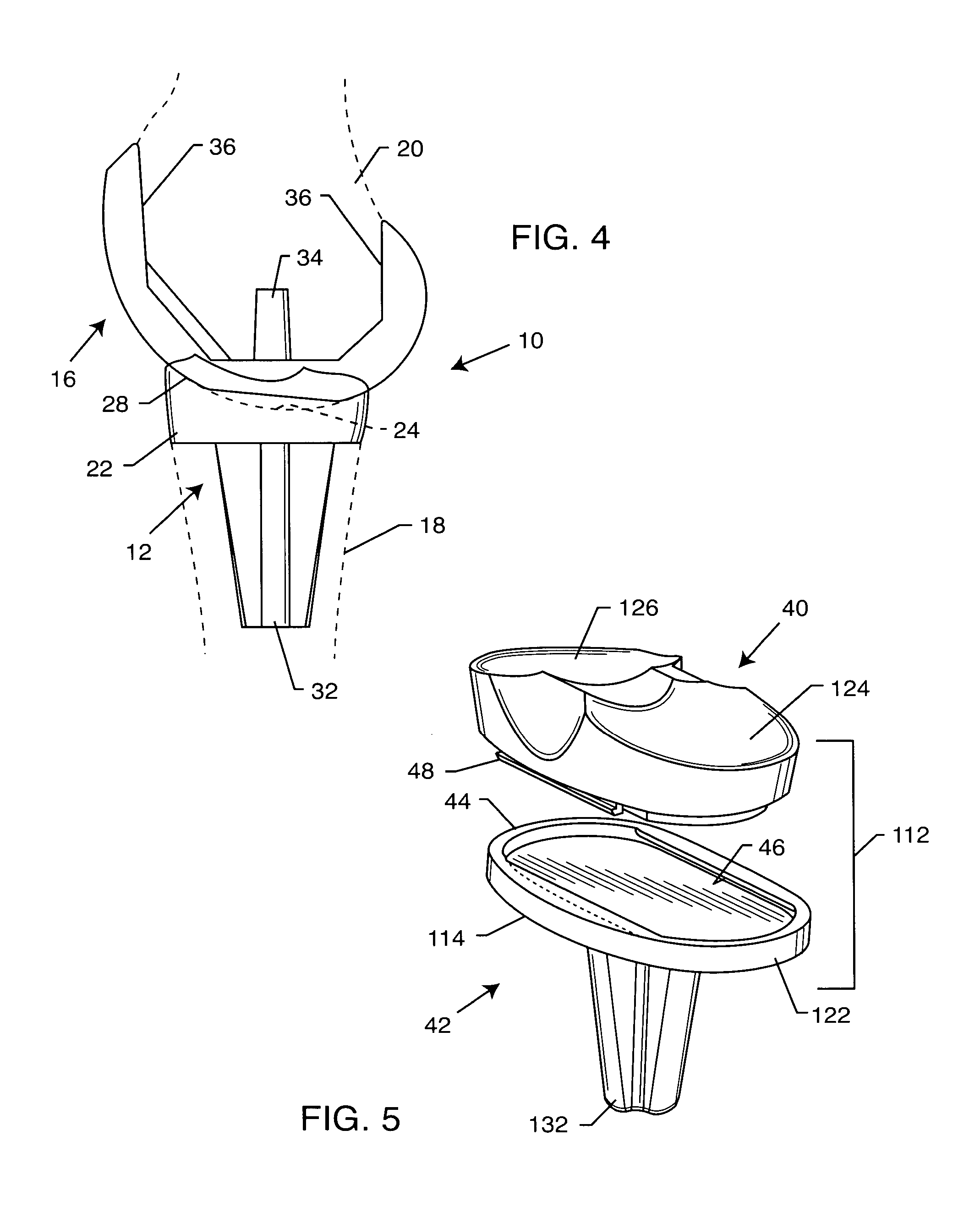

Knee prosthesis with ceramic tibial component

InactiveUS20060052875A1Reduce wearHigh strengthHeart valvesJoint implantsArticular surfacesTibial bone

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

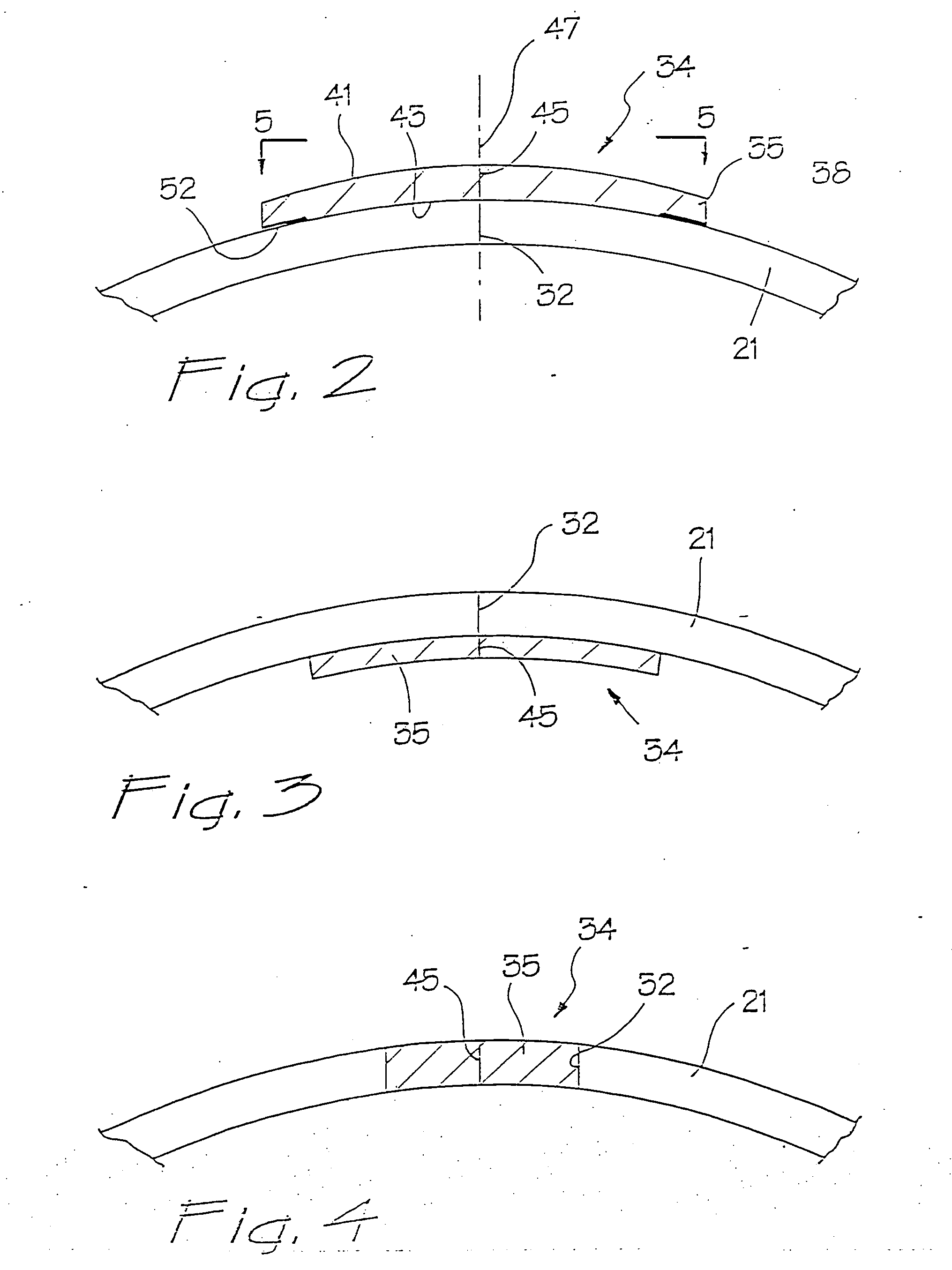

Surgical access apparatus and method

Owner:APPL MEDICAL RESOURCES CORP

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

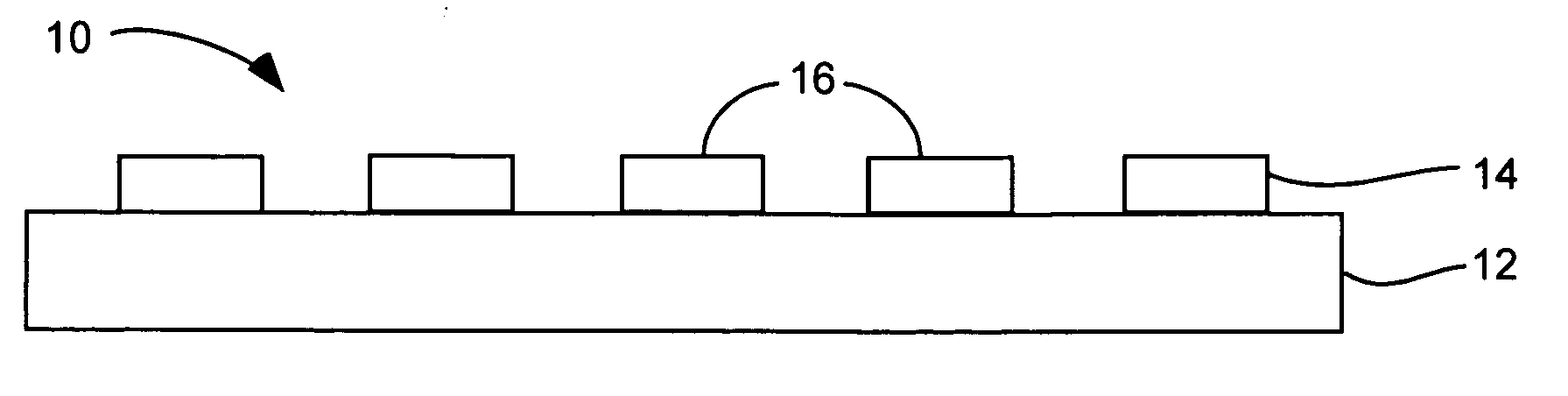

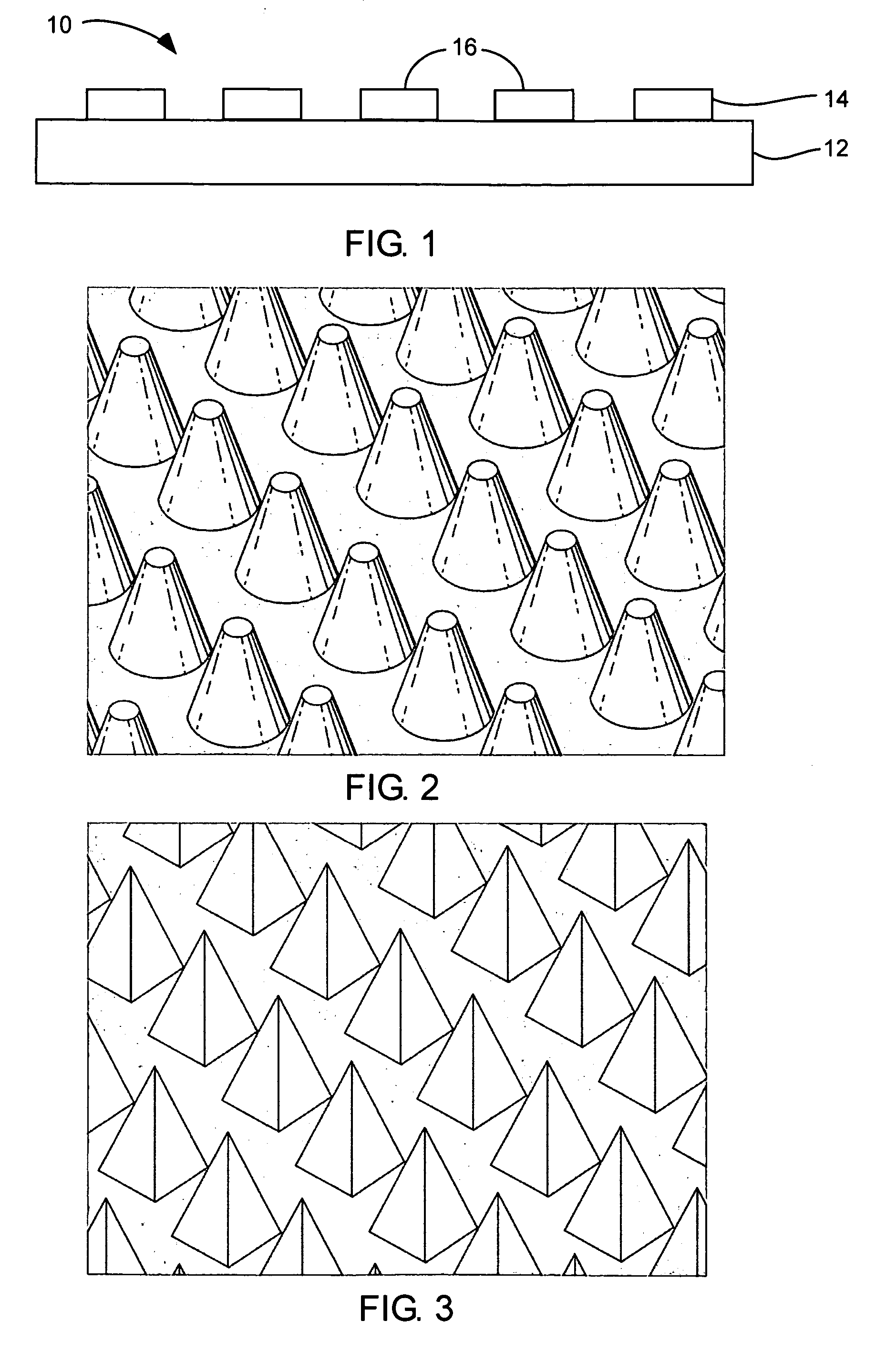

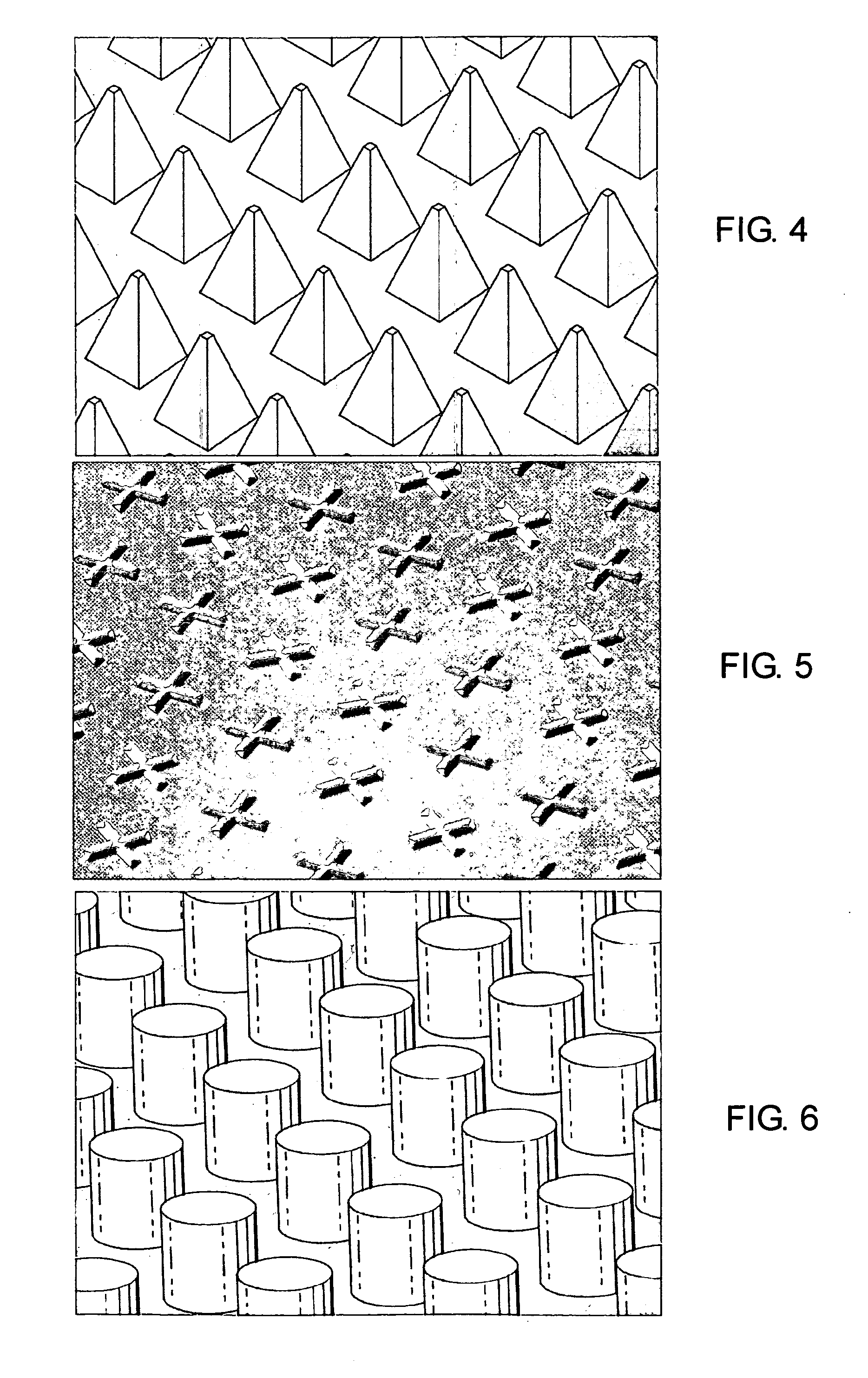

Fixed abrasive tools and associated methods

InactiveUS20050227590A1Easy to remove debrisAdequate material removal rateAbrasion apparatusPlane surface grinding machinesScreen printingMostly True

A fixed abrasive tool incorporating nanodiamond particles is described and disclosed. A fixed abrasive tool can include a polishing layer on a substrate. The polishing layer can include an organic matrix with nanodiamond particles therein. The polishing layer can be formed in a wide variety of configurations, depending on the specific polishing application. Most often, the polishing layer can include a plurality of projections which can have a wide variety of configurations in order to achieve a particular polishing performance. Nanodiamond particles used in the present invention can have a particle size from about 1 nm to about 50 nm, and preferably about 2 nm to about 10 nm. Optionally, the nanodiamond particles can include a carbonaceous coating. Such fixed abrasive tools can be formed by screen printing of a slurry of nanodiamond particles and an organic binder to form a predetermined three-dimensional pattern. Other methods can also be used to form the disclosed nanodiamond fixed abrasive tools. These fixed abrasive tools are particularly suitable for polishing expensive workpieces such as silicon wafers, integrated circuitry, gemstones, and hard drive platters.

Owner:SUNG CHIEN MIN

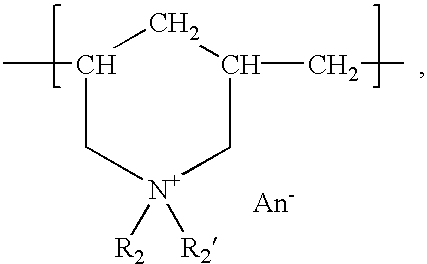

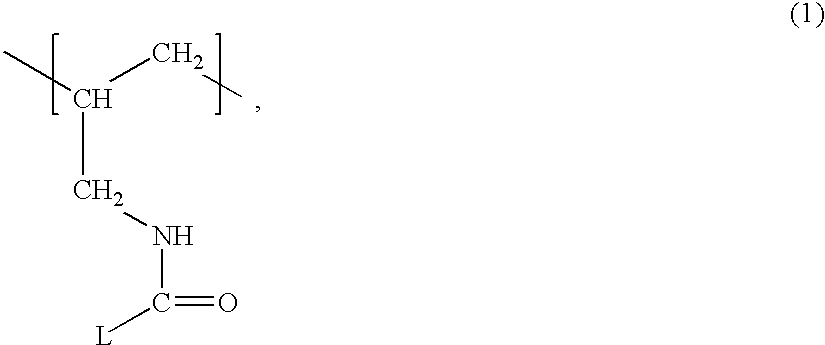

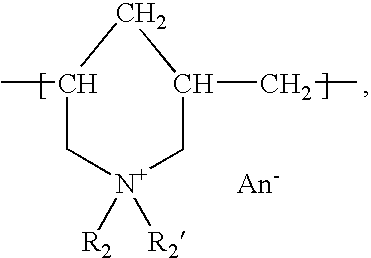

Polymeric articles having a lubricious coating and method for making the same

InactiveUS6940580B2Improve hydrophilicityImprove the lubrication effectSynthetic resin layered productsCellulosic plastic layered productsExtended wear contact lensesLens materials

The present invention provides a medical device, preferably an ophthalmic device, more preferably a contact lens, which comprises a lubricious coating including a capping layer of polyvinylpyrrolidone and / or at least one layer of a lubricious coating material and one layer of a polyionic material having charges opposite of the charges of the lubricious coating material. The lubricious coating on the medical device of the invention has increased lubricity, preferably characterized by an averaged CoF of about 3.0 or less, increased hydrophilicity characterized by an averaged contact angle of about 80 degree or less, and increased bacterial adhesion resistance, while maintaining the desired bulk properties such as oxygen permeability and ion permeability of lens material. Such lenses are useful as extended-wear contact lenses. In addition, the invention provides a method for making a medical device, preferably a contact lens, having a lubricious coating thereon.

Owner:ALCON INC

LbL-coated medical device and method for making the same

InactiveUS6926965B2Reduce charge densityImprove hydrophilicitySynthetic resin layered productsOptical articlesMedical deviceBiomedical engineering

The present invention provides a medical device, preferably an ophthalmic device, more preferably a contact lens, which comprises a core material and a biocompatible LbL coating non-covalently attached to said core material. The biocompatible LbL coating comprises at least one charge / non-charge bilayer, wherein said charge / non-charge bilayer is composed of, in no particular order, one layer of a charged polymeric material and one layer of a non-charged polymeric material which is capable of being non-covalently bond to the charged polymeric material.

Owner:ALCON INC

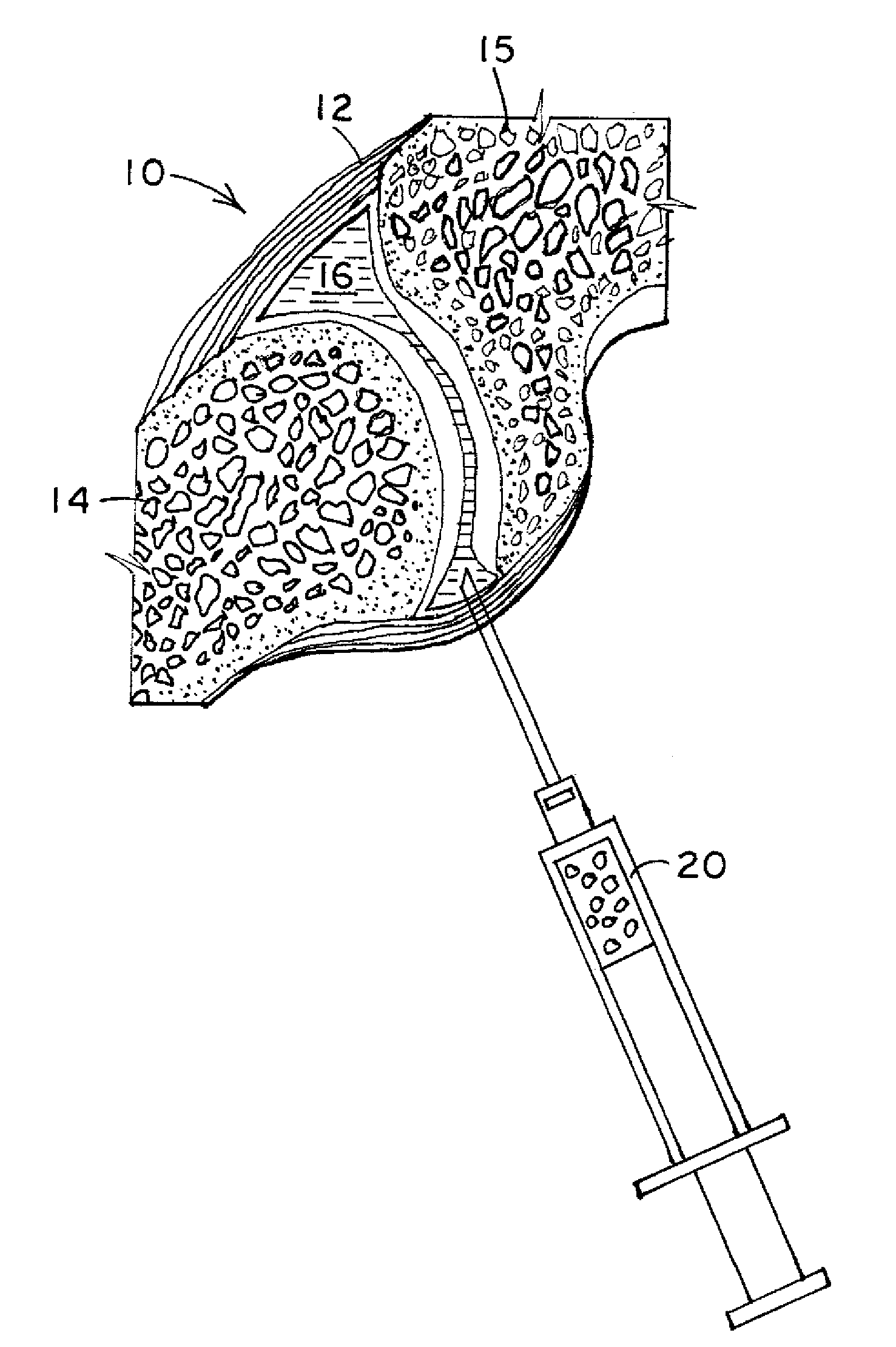

Facet joint implant and procedure

InactiveUS20070118218A1Improve the lubrication effectRelieve painBone implantSurgerySacroiliac jointBiomedical engineering

A method for repairing a facet joint of a human vertebra having a joint capsule surrounding the facet joint. In the method, a synthetic elastic material is introduced into the facet joint. The synthetic elastic material can be a solid, swellable polymer that expands when hydrated upon being placed in the facet joint. The invention includes the implant and the method of making the implant.

Owner:ZIMMER SPINE INC

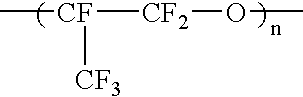

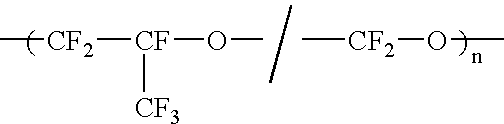

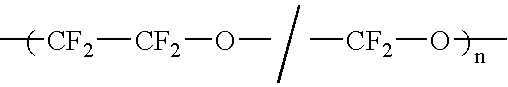

Liquid perfluoropolymers and medical applications incorporating same

InactiveUS20050142315A1Promote tissue growthImprove survivabilitySuture equipmentsElectrotherapyPerfluoropolyetherOxygen

Liquid curable perfluoropolyether (PFPE) materials are provided for use as coatings, sealants, flexible fillers, and structural parts for a wide variety of medical applications, particularly where silicone has been utilized conventionally. The PFPE material is oxygen permeable and bacterial impermeable and may contain one or more pharmacological agents elutably trapped therewithin for delivery within the body of a subject.

Owner:LIQUIDIA TECH

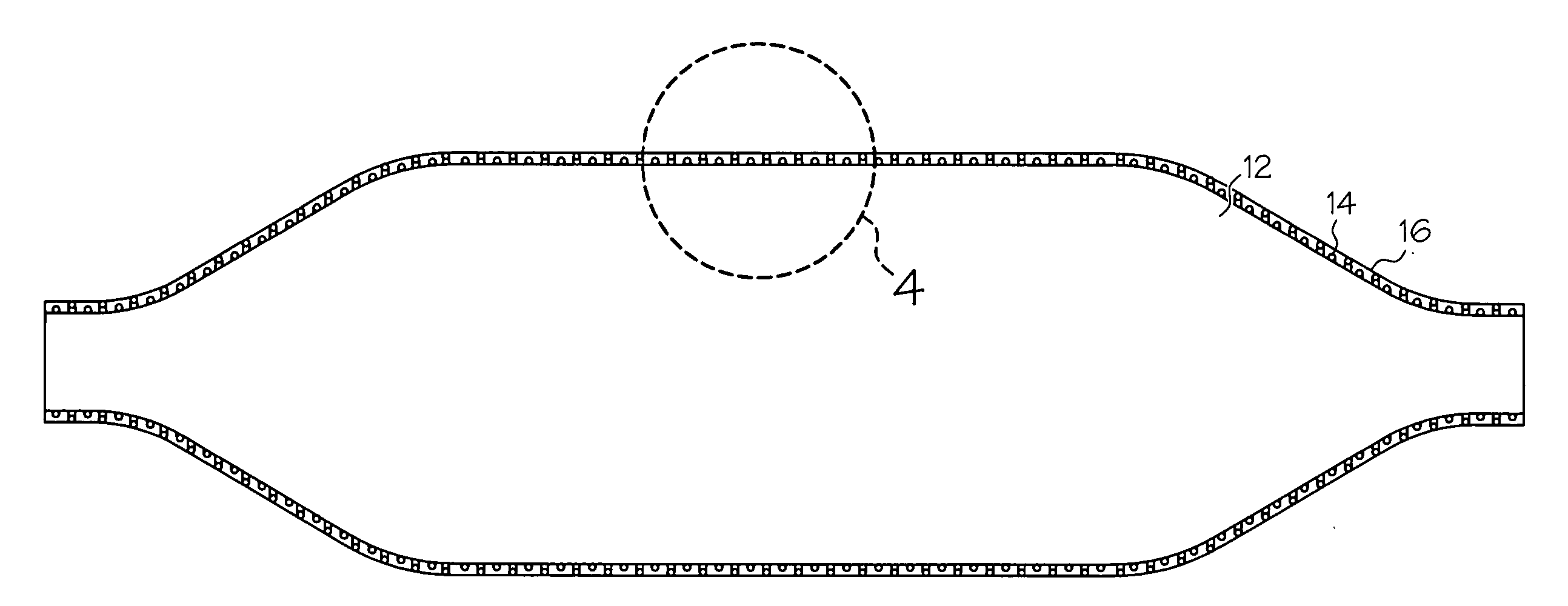

Artificial silk reinforcement of PTCA balloon

InactiveUS20050271844A1Prevent penetrationImprove integrityBalloon catheterPedestrian/occupant safety arrangementMedical deviceBiomedical engineering

A medical device formed from at least one first layer defining the shape of the medical device, the first layer having an inner surface and an outer surface and a web formed with silk fiber provided over at least a portion of the inner surface, the outer surface or both of the first layer.

Owner:BOSTON SCI SCIMED INC

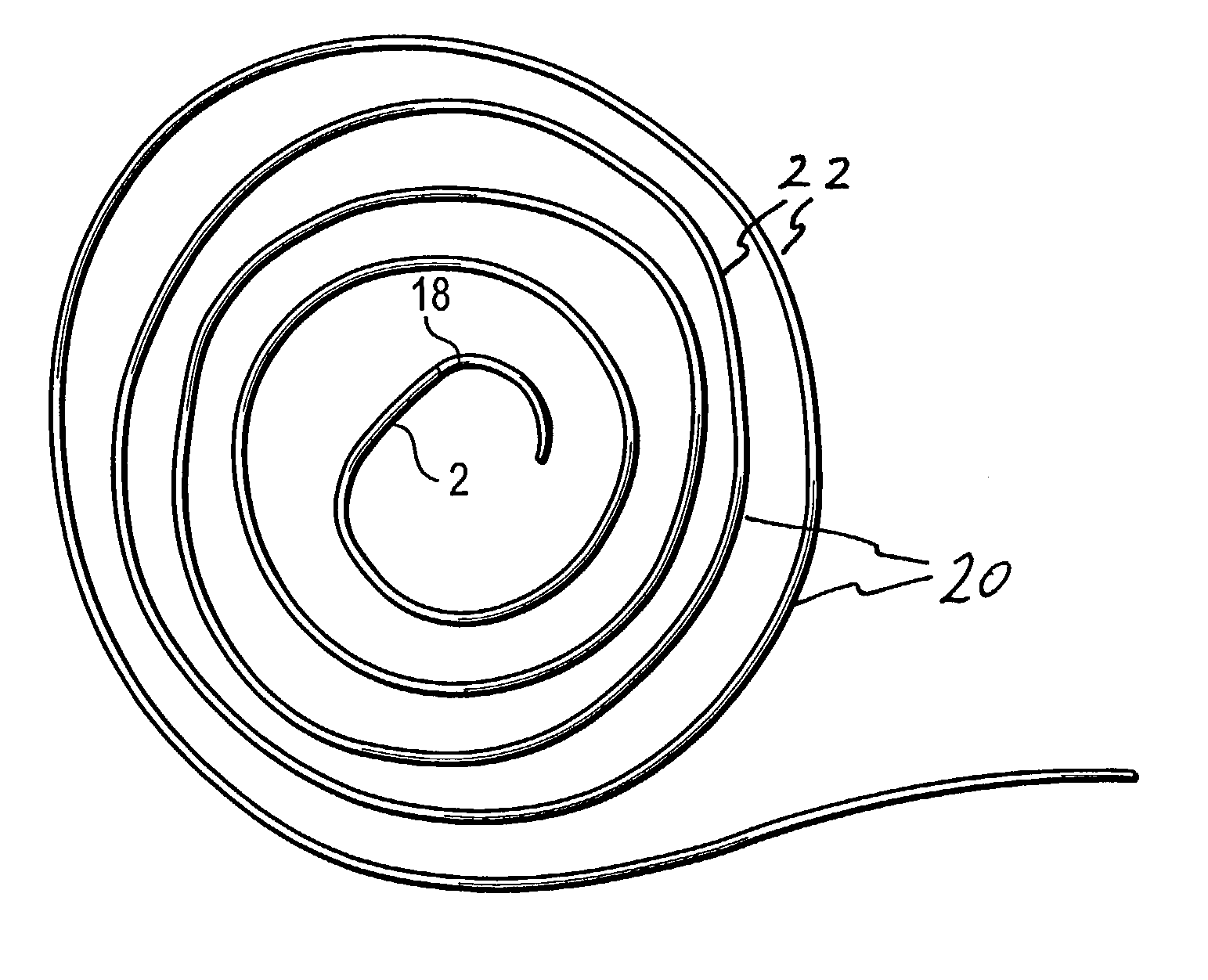

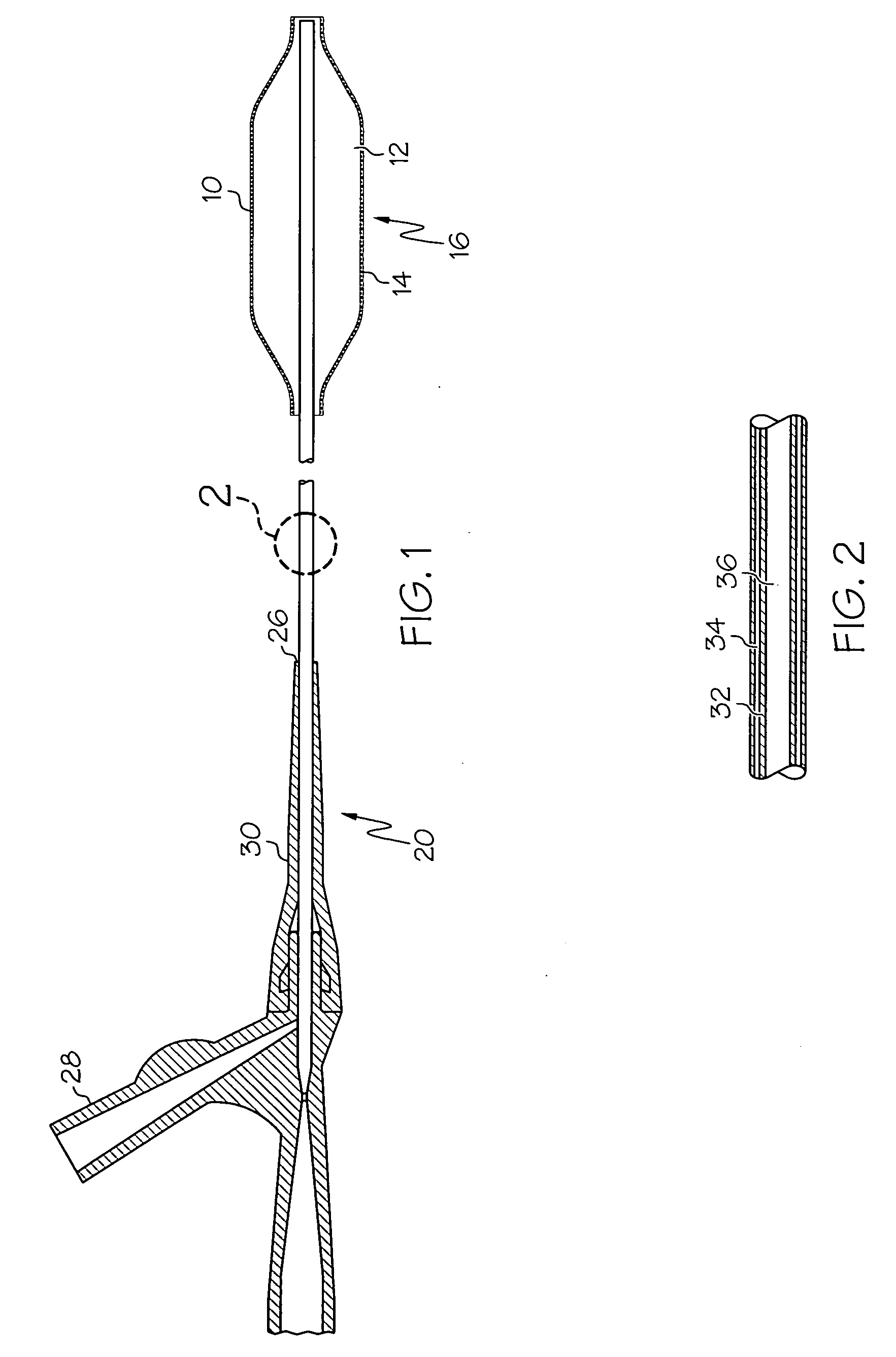

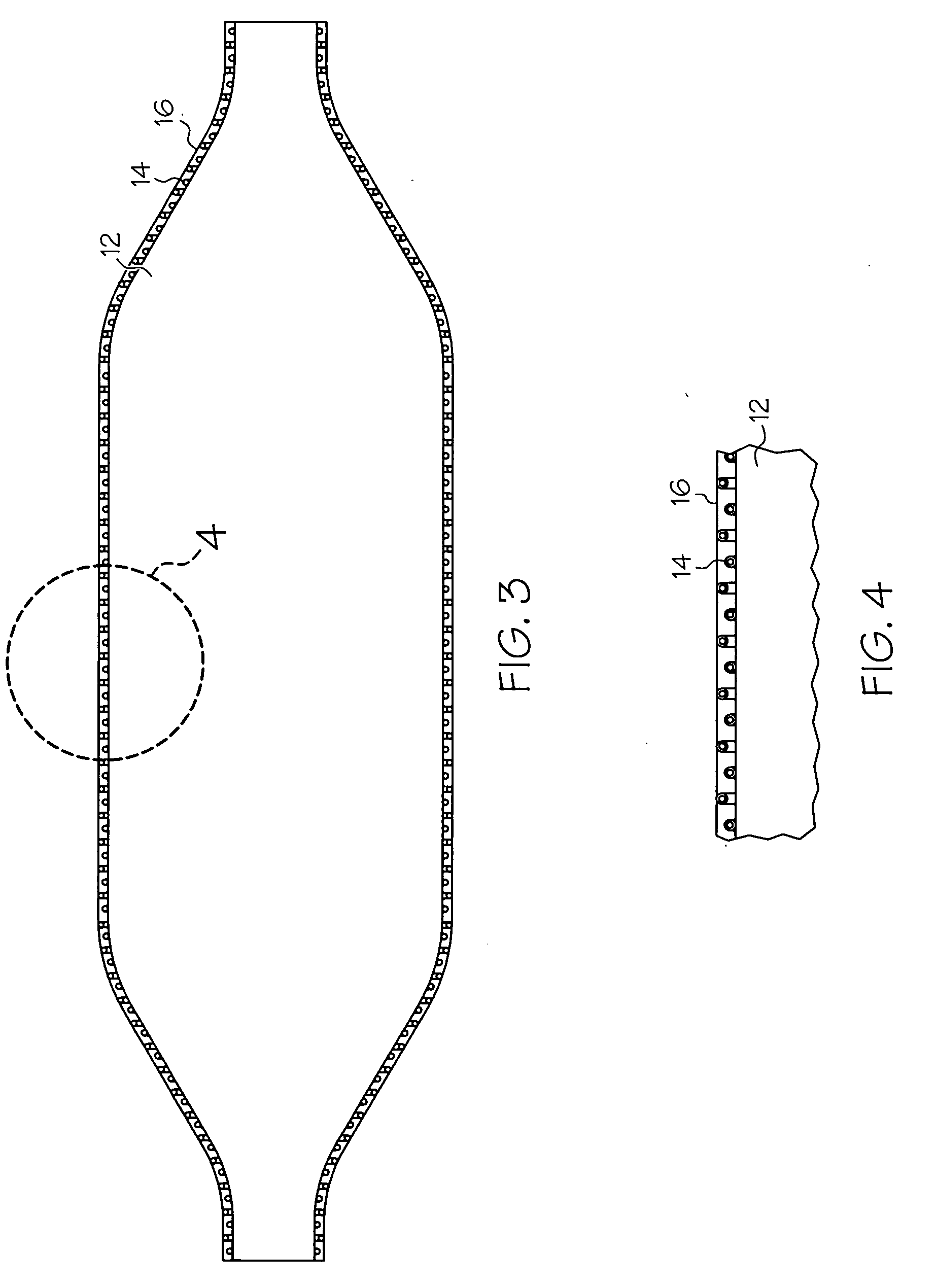

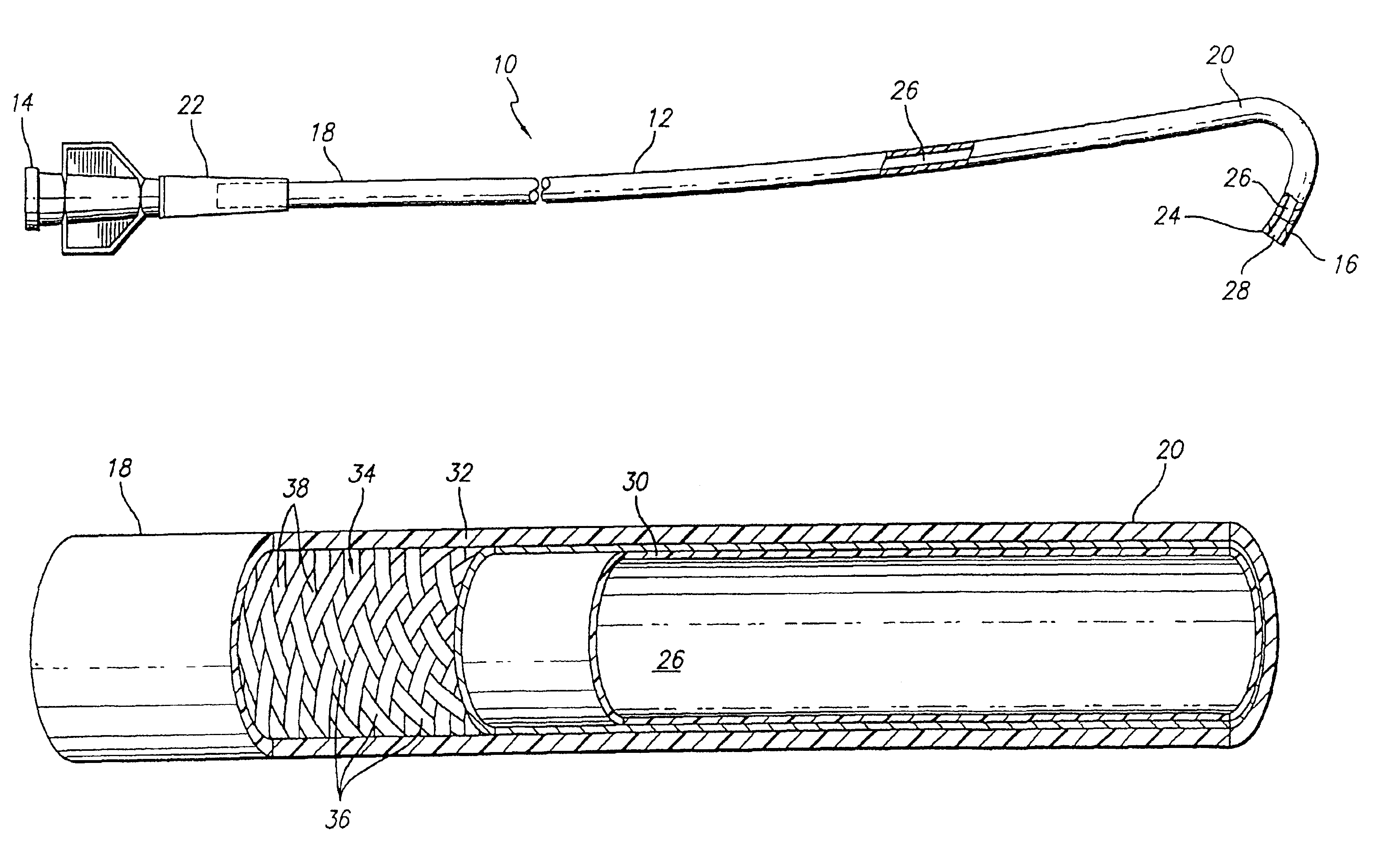

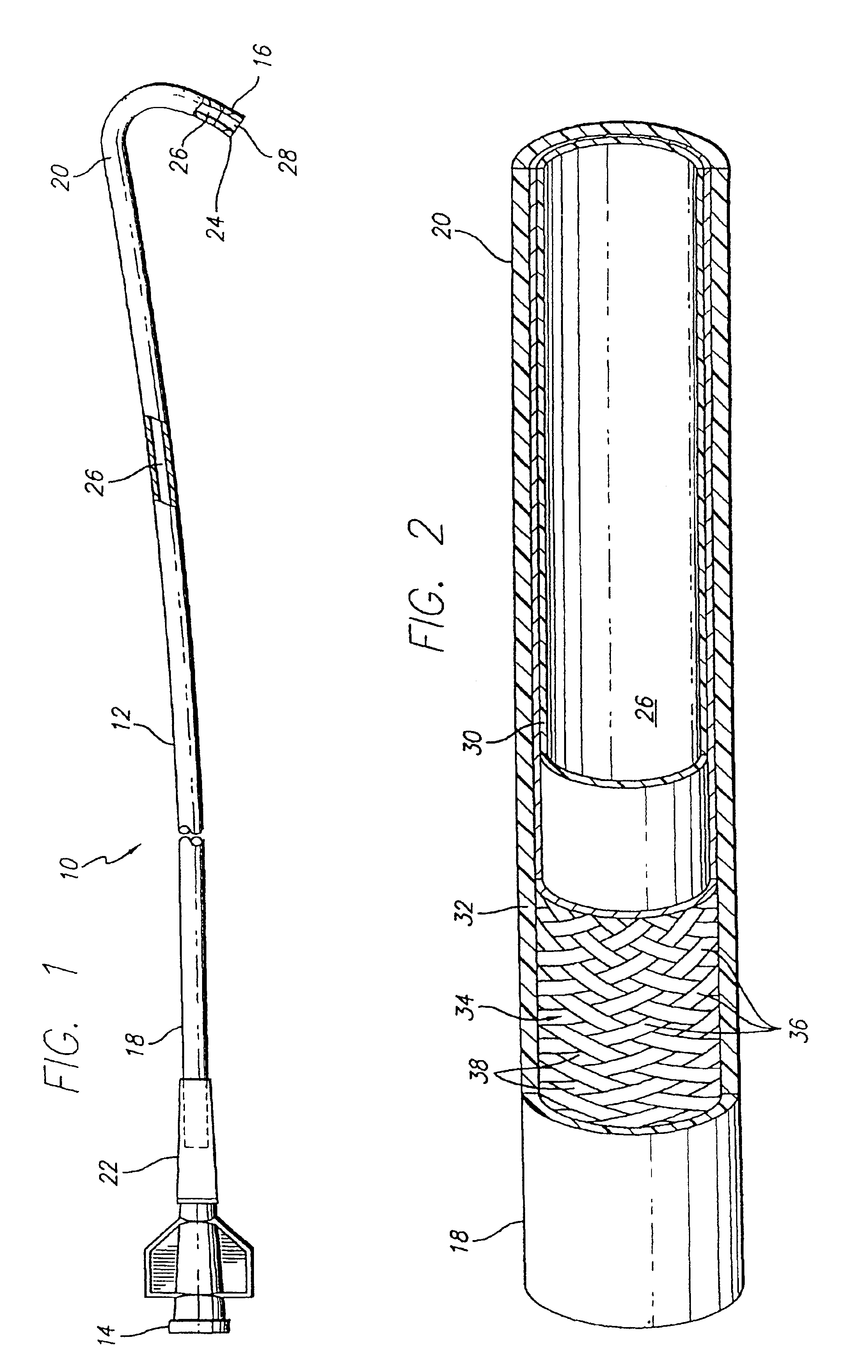

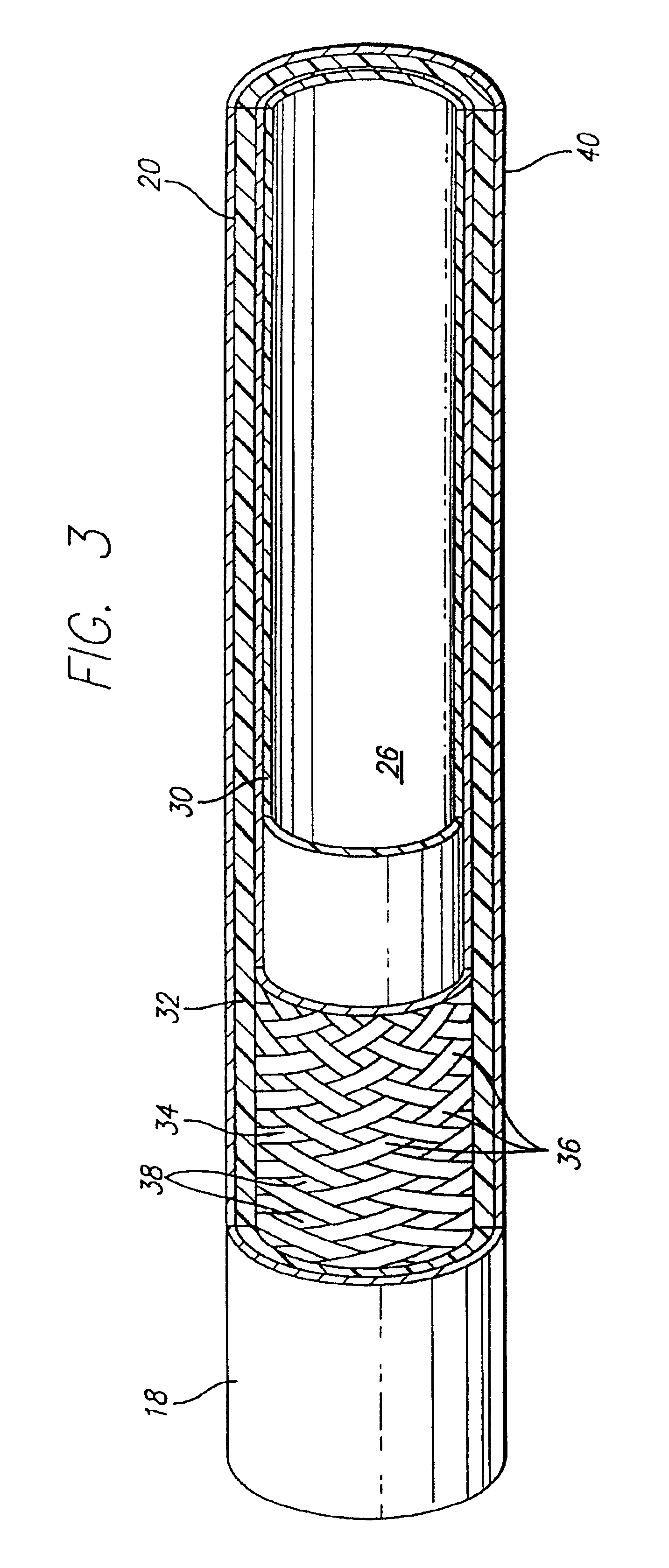

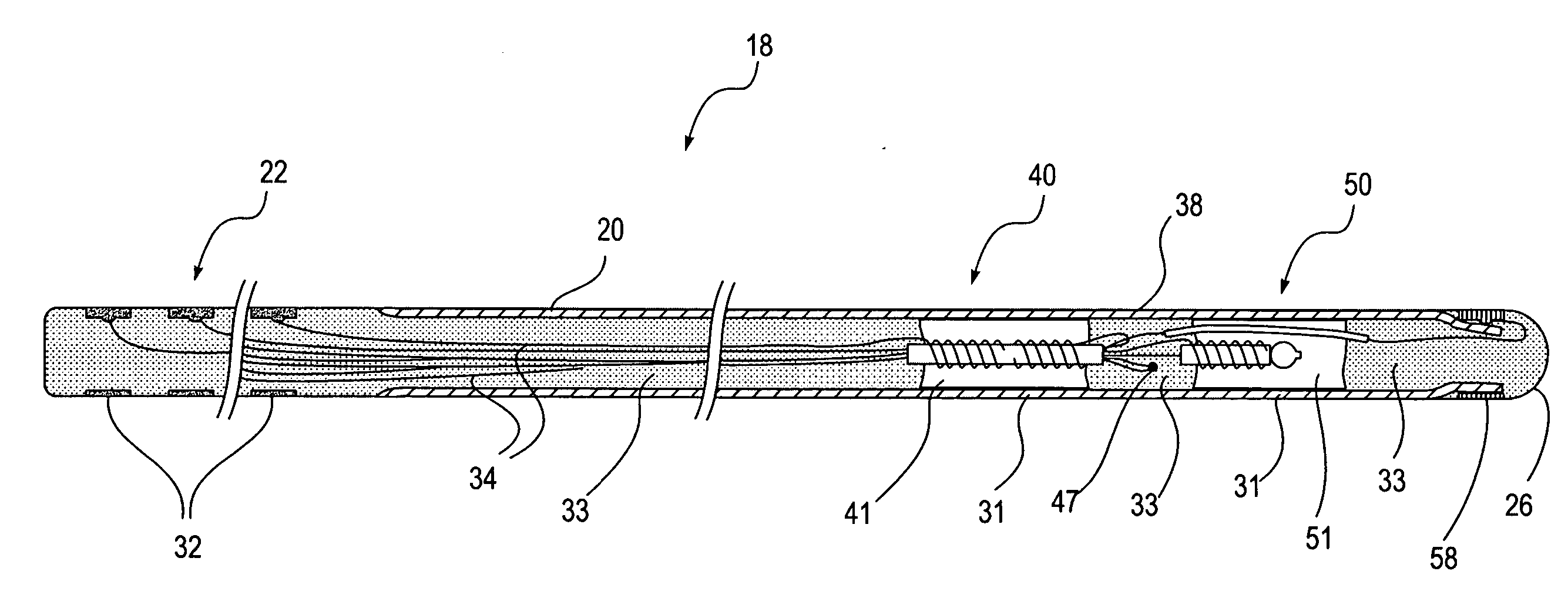

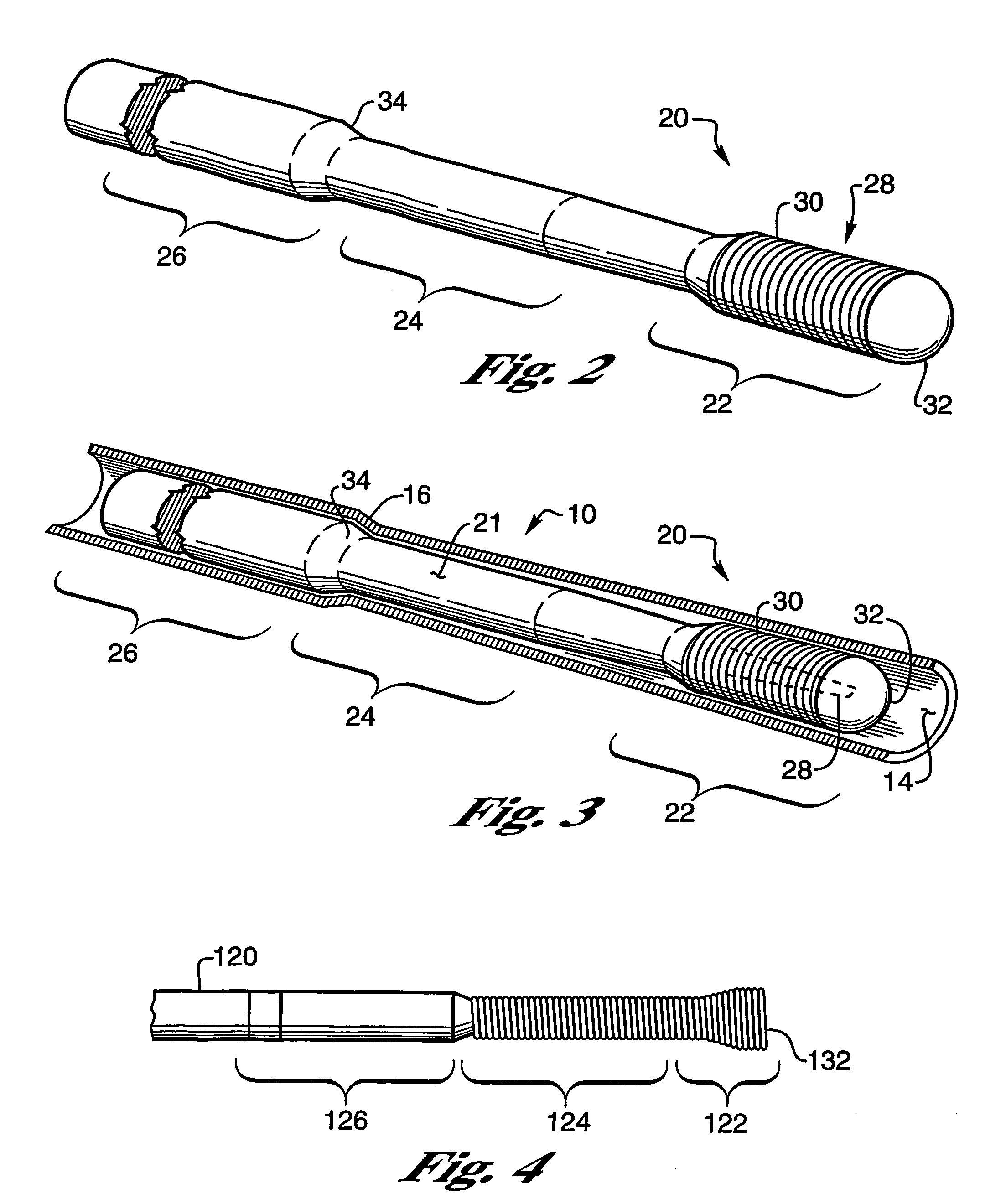

Expanded UHMWPE for guiding catheter liners and other lubricious coatings

An intraluminal catheter, such as a guiding catheter, employed for intravascular procedures and having an inner liner formed of expanded Ultra High Molecular Weight Polyethylene (UHMWPE) is disclosed. The expanded UHMWPE is microporous and has an oriented microstructure structure characterized by nodes interconnected by fibrils. The inner liner formed of expanded UHMWPE is very thin to maximize the inner lumen diameter and has excellent mechanical properties.

Owner:ABBOTT CARDIOVASCULAR

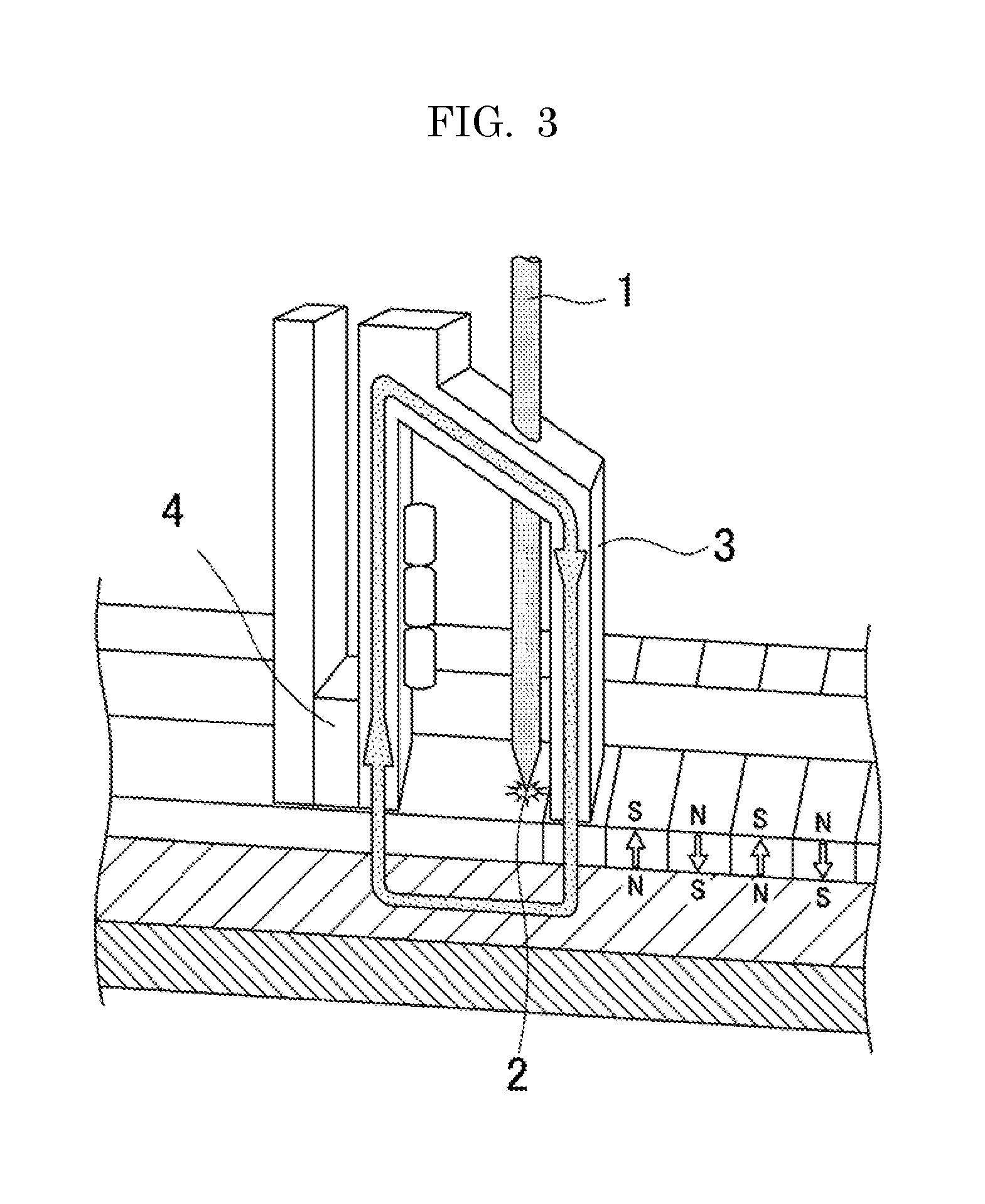

Ionic liquid, lubricant, and magnetic recording medium

ActiveUS20170058227A1Improve the lubrication effectMaintain good propertiesProtective coatings for layersRecord information storageConjugate acidIonic liquid

A lubricant including an ionic liquid, which includes a conjugate acid (B+) and a conjugate base (X−), and is protic, wherein the conjugate acid includes a straight-chain hydrocarbon group having 10 or more carbon atoms, and wherein the conjugate base is represented by the following general formula (1):where n is an integer of from 0 to 6 in the general formula (1).

Owner:DEXERIALS CORP

Drilling fluids

The invention is a novel drilling fluid additive comprising particles of elastomer which are capable of swelling upon contact with a hydrocarbon fluid. The swelling of the elastomer is gradual, allowing the elastomer to reach the lost circulation zone before significant swelling occurs. Once in the lost circulation zone, the polymer expands sealing off the lost circulation zone. A method for preventing drilling fluid loss is also provided.

Owner:WOOD ROBERT R

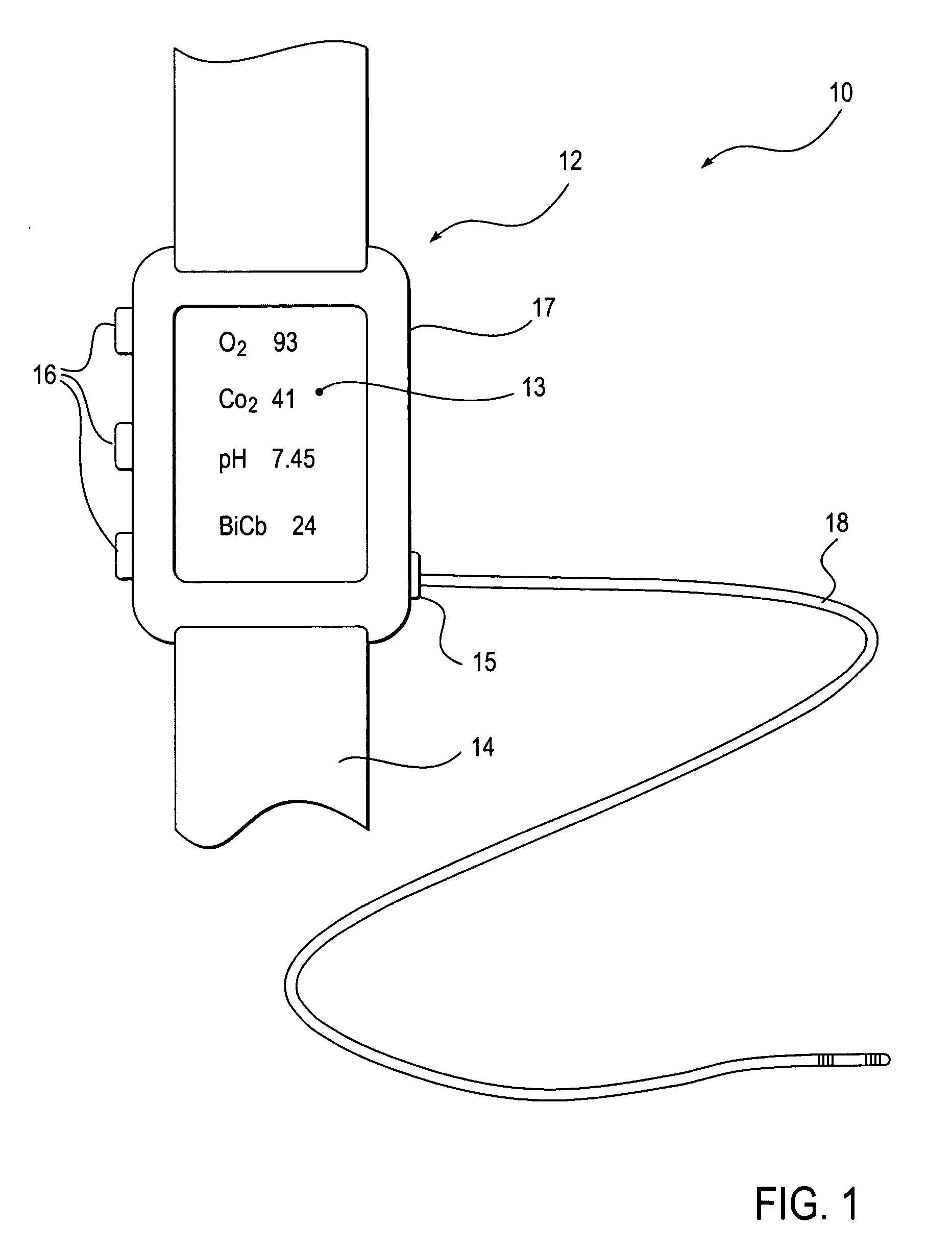

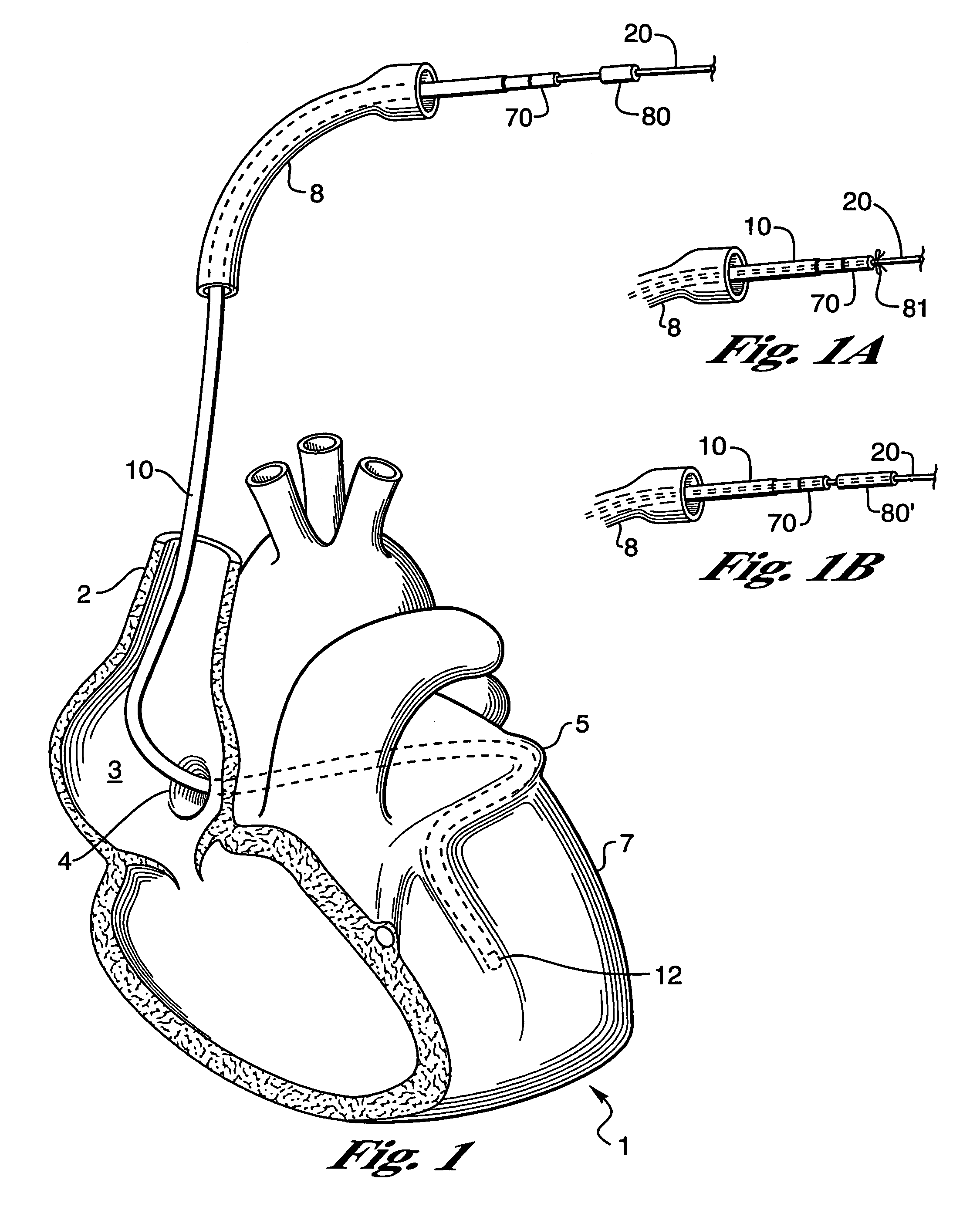

Apparatus for ascertaining blood characteristics and probe for use therewith

InactiveUS20050054905A1Heightened risk of mechanical and therapeutic misadventureImprove the lubrication effectCatheterDiagnostic recording/measuringBlood componentAntithrombogenic surface

An apparatus for use with a patient having a vessel carrying blood to ascertain characteristics of the blood. The apparatus includes a display module and a probe having a distal extremity adapted to be inserted into the vessel of the patient and having a proximal extremity coupled to the display module. The probe includes a sensor in the distal extremity for providing an electrical signal to the display module when the probe is disposed in the blood. The probe can have an antithrombogenic surface treatment for inhibiting the adhesion of blood components to the probe when disposed in the blood.

Owner:KEIMAR INC

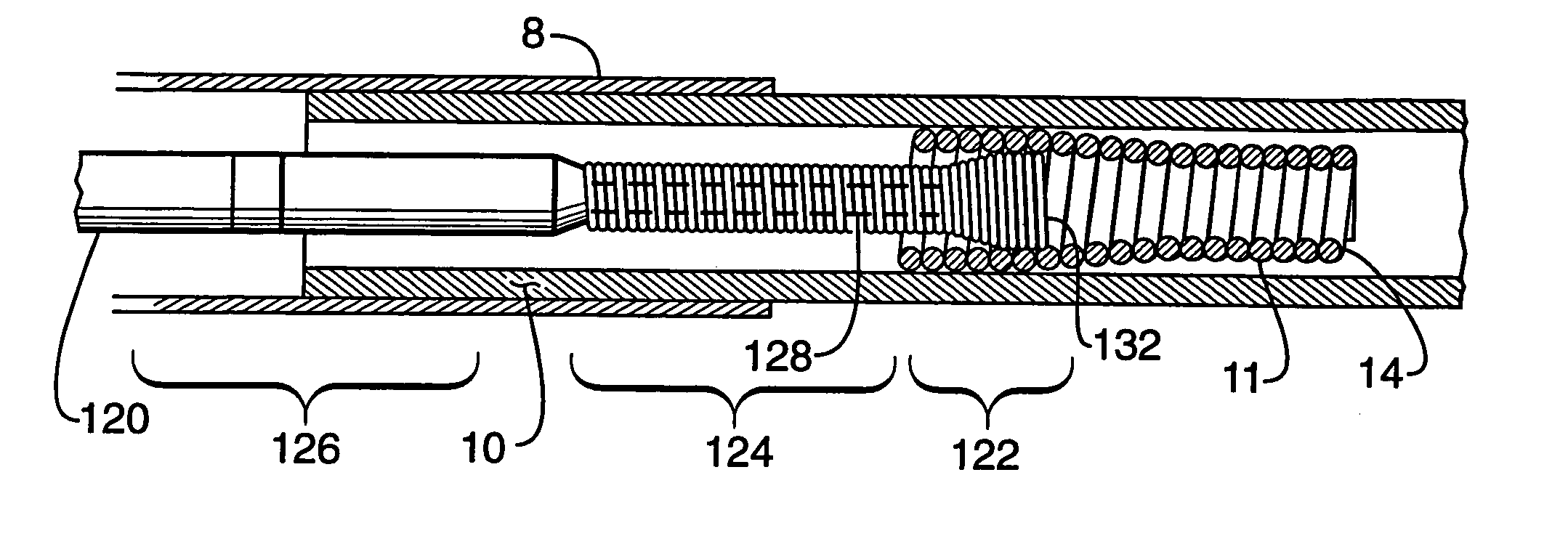

Modified guidewire for left ventricular access lead

InactiveUS7089065B2Maintain good propertiesImprove the forceGuide wiresTransvascular endocardial electrodesLeft ventricular sizeGuiding catheter

An improved guidewire for assisting in implantation of a cardiac lead includes three sections. The most distal zone is sufficiently floppy to prevent trauma to the vessel walls through which the guidewire and lead are inserted. An intermediate zone is generally stiffer and has a cross-section less than or equal to the cross-section of the distal zone. The third zone is stiffer yet and is joined to the intermediate zone by a shoulder. The shoulder cooperates with protrusions on the lead to transfer forces between the guidewire and lead. A finishing wire having temporary locking means to lock the finishing wire to the lead is employed to remove the guide catheter without moving the lead from its desired location. Lubricious coatings are also provided to reduce friction between the lead and guidewire.

Owner:CARDIAC PACEMAKERS INC

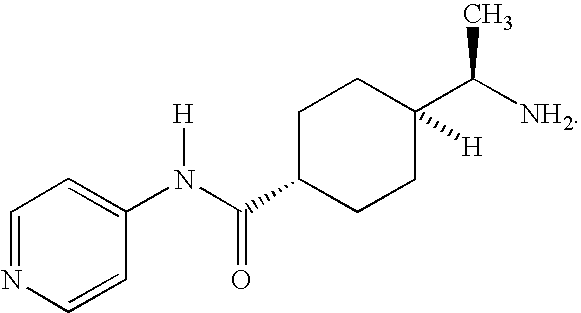

Treatment of female sexual dysfunction with vasoactive intestinal polypeptide agonists

InactiveUS7226910B2Good for healthImprove the lubrication effectBiocidePeptide/protein ingredientsObstetricsActive agent

Owner:VIVUS

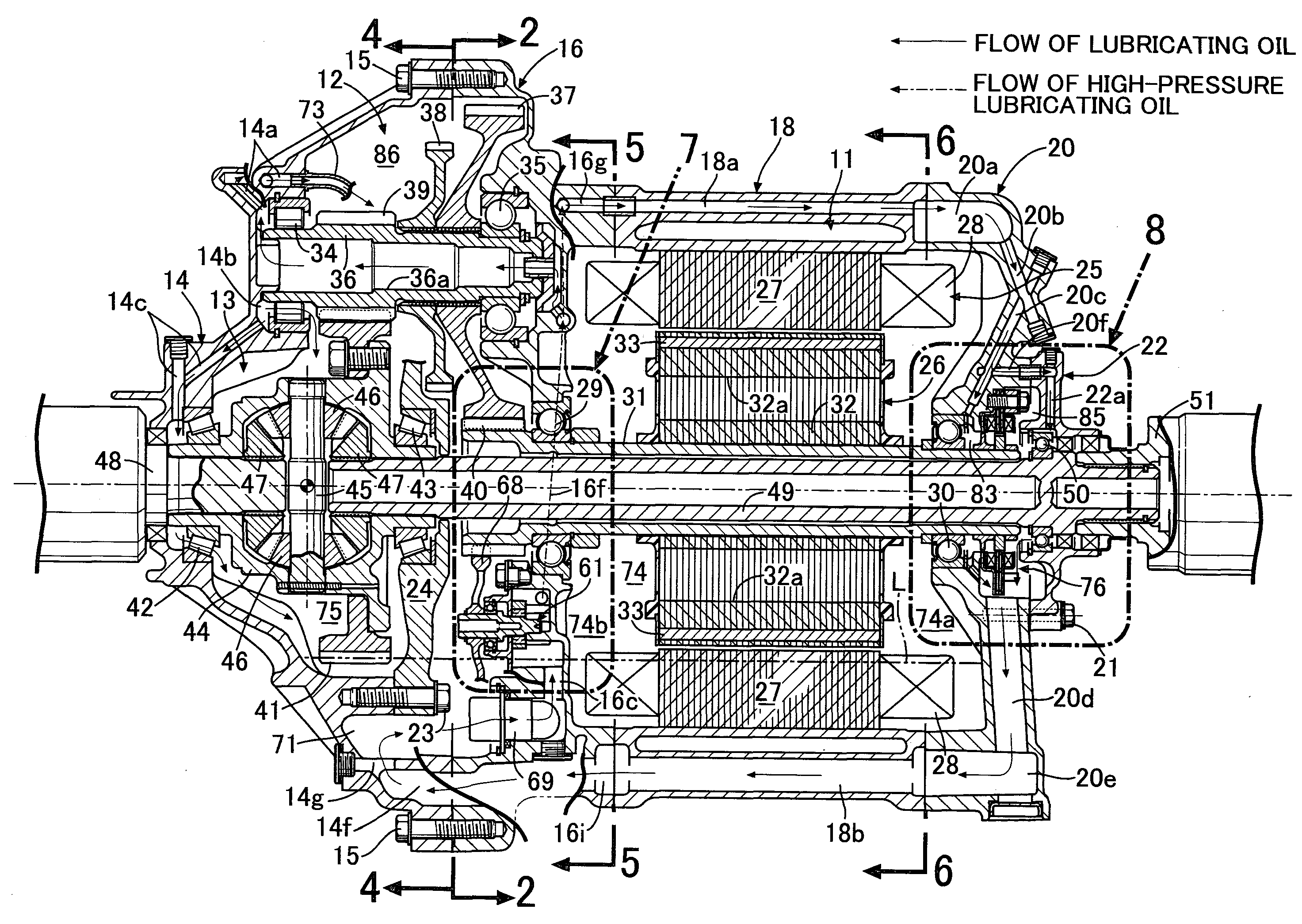

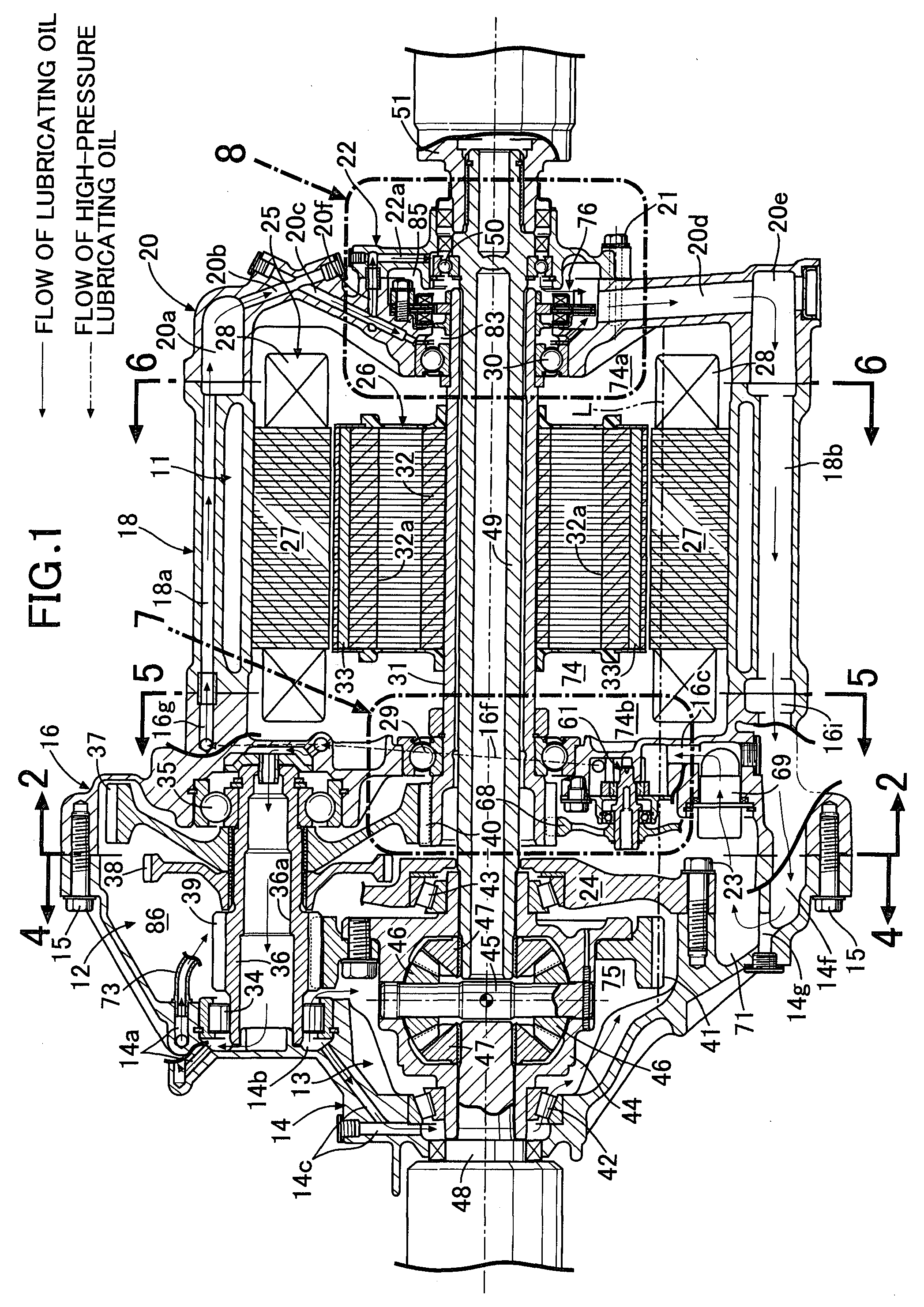

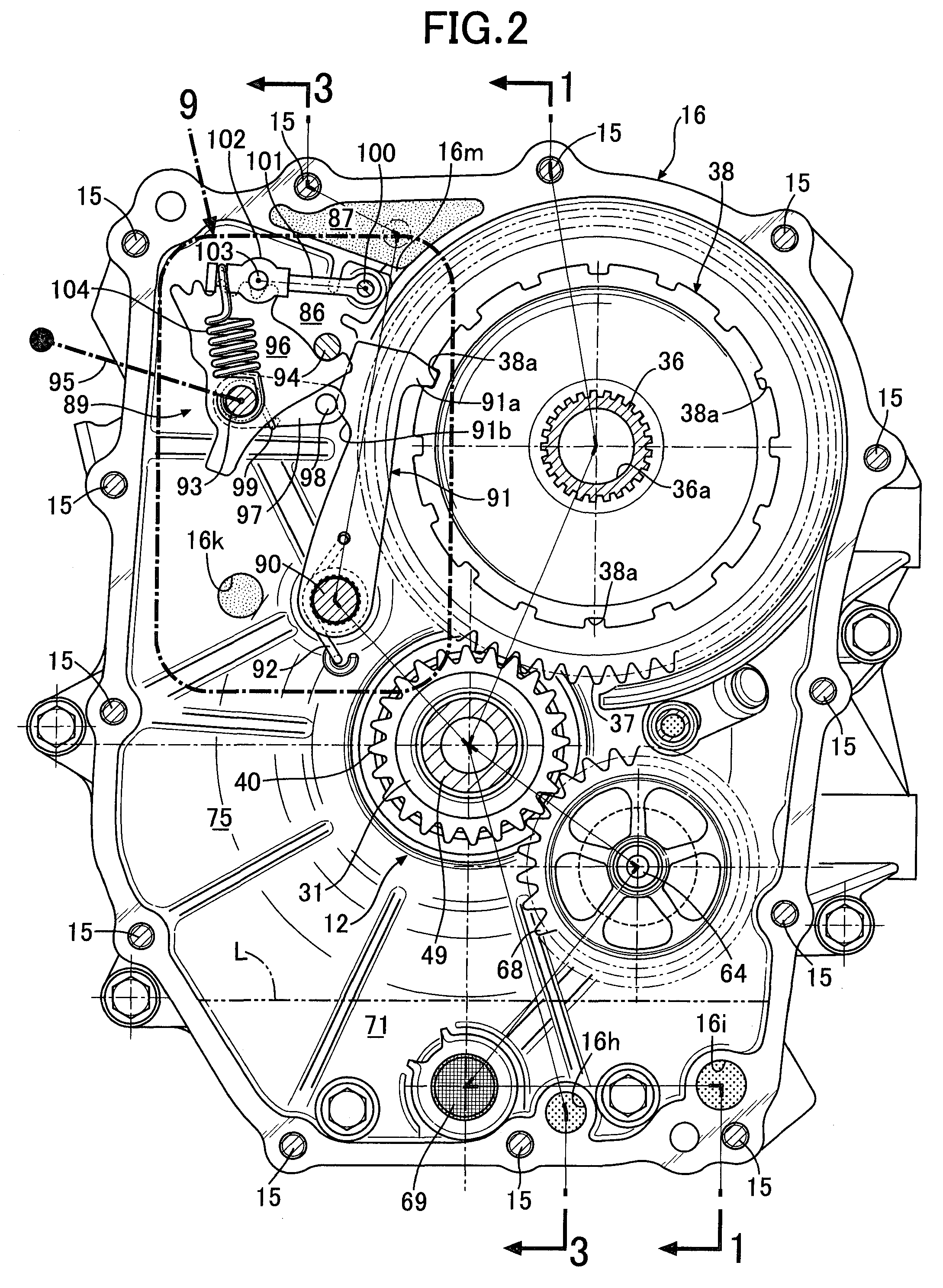

Motor-type power device

ActiveUS20090127954A1Suppress stirring resistance of oilEnsure performanceGearboxesGear lubrication/coolingEngineeringCentrifugal force

Due to a centrifugal force in a vehicle width direction due to turning of an automobile, oil in an electric motor housing chamber housing an electric motor and oil in a transmission housing chamber housing a reduction gear and a differential gear flows to-and-fro via oil communication passages that penetrate a partitioning wall. An opening on the transmission housing chamber side of the oil communication passages is spaced from the partitioning wall. Hence, when oil moves from the transmission housing chamber side to the electric motor housing chamber side, it is possible to prevent the oil quantity on the electric motor housing chamber side from increasing excessively and suppress an increase in resistance to oil stirring by a rotor of the electric motor while retaining a constant oil amount on the transmission housing chamber side to ensure lubricating performance for the reduction gear and the differential gear.

Owner:HONDA MOTOR CO LTD

High strength suture with silk trace

InactiveUS20050055051A1High strengthImproved tie down characteristicSuture equipmentsPolyesterSuture anchors

A high strength abrasion resistant surgical suture material with improved tie down characteristics and tissue compliance is color coded for visualization and identification purposes. The suture features a multifilament jacket formed of braided strands of ultra high molecular weight polyethylene and polyester, with silk fibers included in a color contrasting with the other jacket fibers to provide an identifiable trace. In one embodiment, the braided jacket surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a No. 2 size, has the strength of No. 5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable silk trace preferably may be provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily distinguished.

Owner:ARTHREX

Carbon nanoparticle-containing lubricant and grease

InactiveUS20070158609A1Modulate viscosityImprove thermal conductivityMaterial nanotechnologyHeat-exchange elementsCarbon nanotubeMaterials science

The present invention relates to processes for preparing a stable suspension of carbon nanoparticles in a thermal transfer fluid to enhance thermal conductive properties, viscosity, and lubricity. One process is to disperse carbon nanoparticles directly into a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The second process is carried out in three stages. First, carbon nanoparticles are dispersed into a volatile solvent. Then, a thermal transfer fluid, surfactants, and other additives are added into this intermediate dispersion and mixed thoroughly. At last, the volatile solvent is removed to produce a uniformly dispersed nanofluid. The third process is to disperse carbon nanoparticles at an elevated temperature into a homogeneous mixture of surfactants and other additives in a thermal transfer fluid with help of a physical agitation. The present invention also relates to compositions of carbon nanoparticle nanofluids, such as nanolubricants and nanogreases. The nanofluid of the present invention is a dispersion of carbon nanoparticles, particularly carbon nanotubes, in a thermal transfer fluid in the present of surfactants. Addition of surfactants significantly increases the stability of nanoparticle dispersion. For nanogreases, carbon nanoparticles function both as a thickener to modulate viscosity and as a solid heat transfer medium to enhance thermal conductivity and high temperature resistance.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

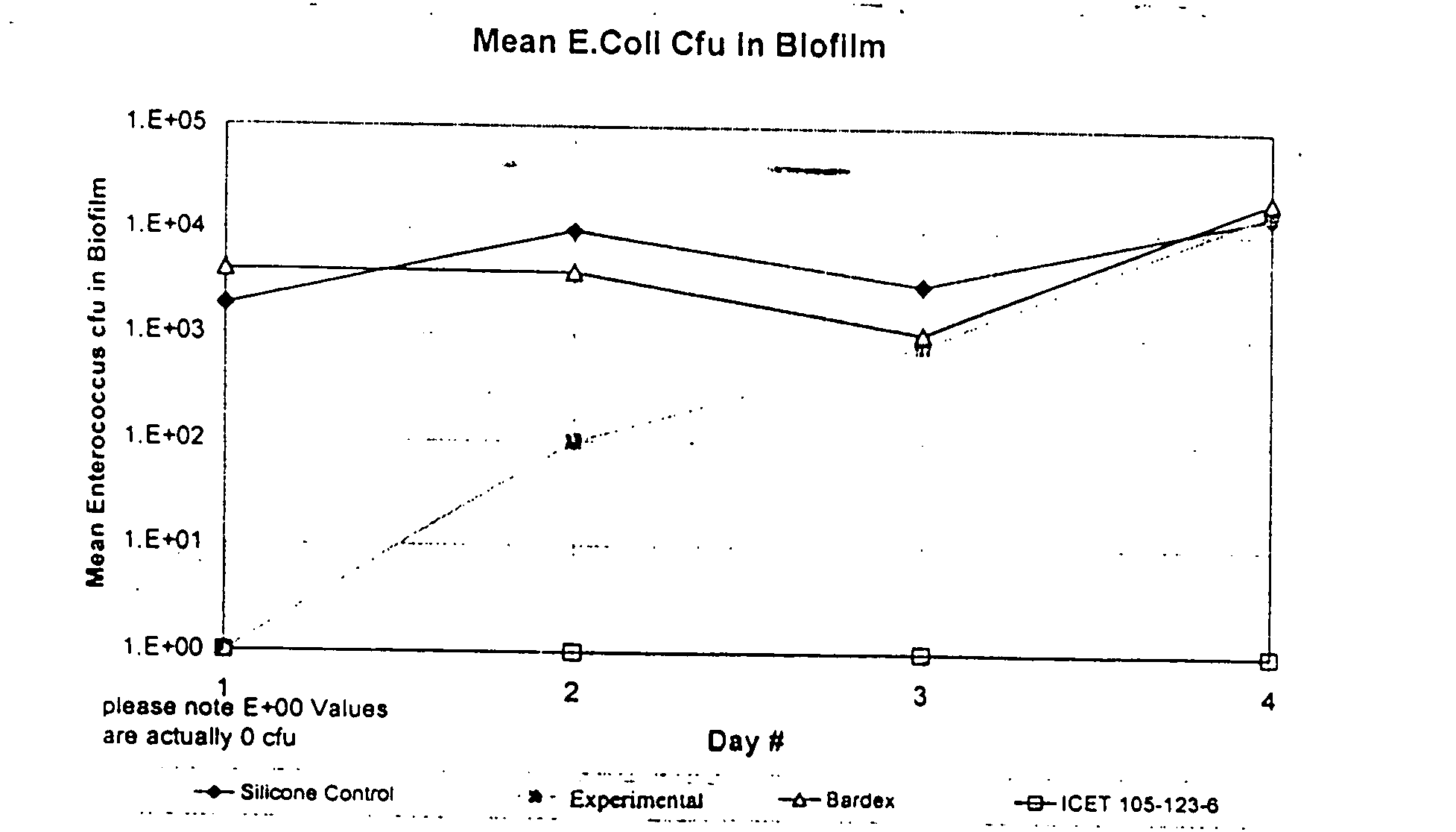

Antimicrobial composition for medical articles

InactiveUS20050048124A1Inhibition formationImprove the lubrication effectPowder deliveryBiocideSolventCalcium Chelator

An antimicrobial composition is formed from about 5 to about 25 wt % of an antimicrobial formulation and about 75 to about 95 wt % of a silicone resin. The antimicrobial formulation is formed from about 60 to about 95 wt % of an antimicrobial material, about 1 to about 30 wt % calcium chelator, about 0.001 to about 0.25 wt % pigment, and about 0.5 to about 3.5 wt % lubricant. The silicone resin may be a dispersion of about 40 to about 60 w / v % of an RTV silicone resin in a solvent, a liquid silicone resin, or a solid silicone resin. An antimicrobial coating may be formed on the surface of an article by applying an antimicrobial composition to the article and permitting the solvent to evaporate. It may also be formed by making a mixture of about 5 to about 12 wt % of an antimicrobial formulation and about 88 to about 95 wt % of a liquid or solid silicone resin and molding, overmolding, or extruding the article from the compounded mixture.

Owner:ICET

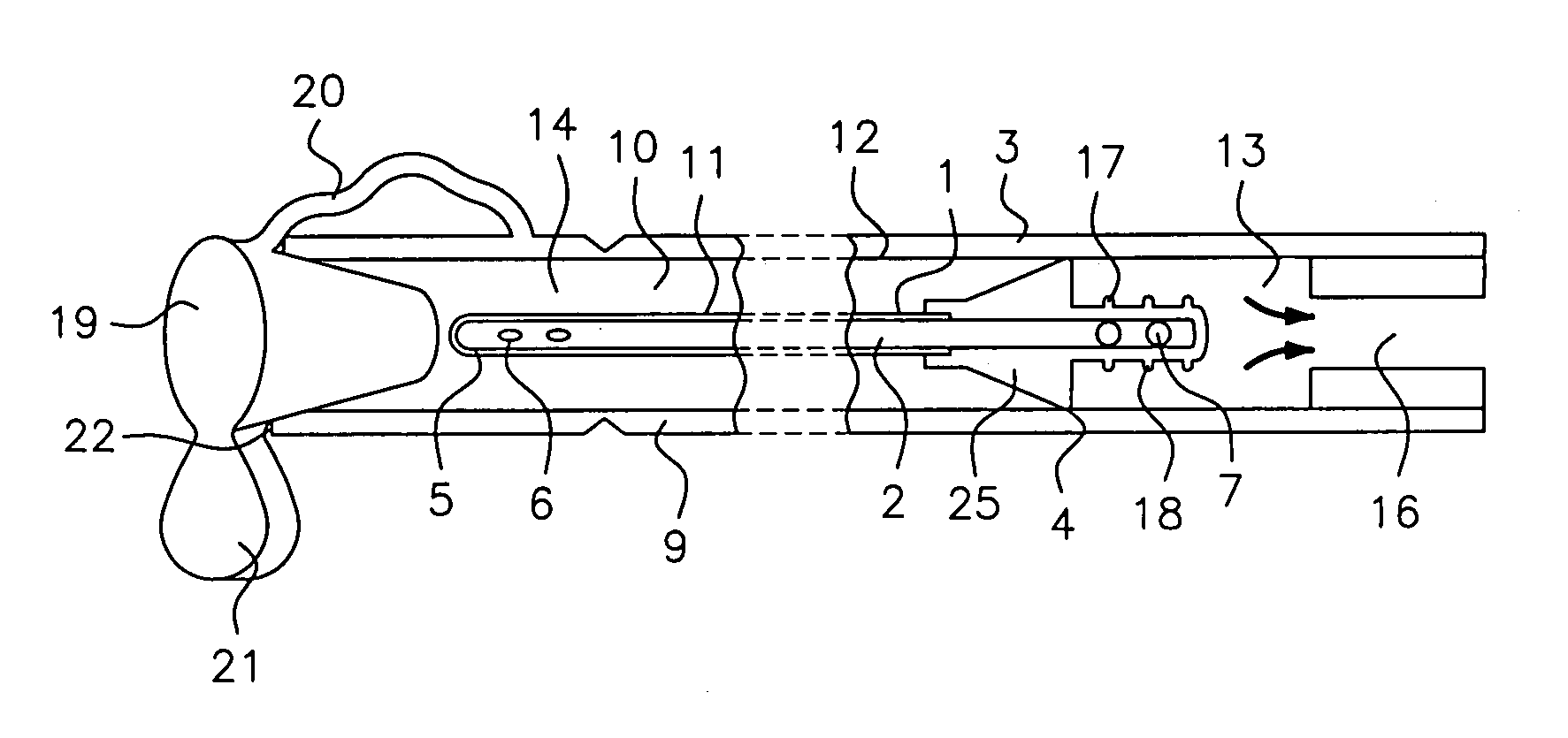

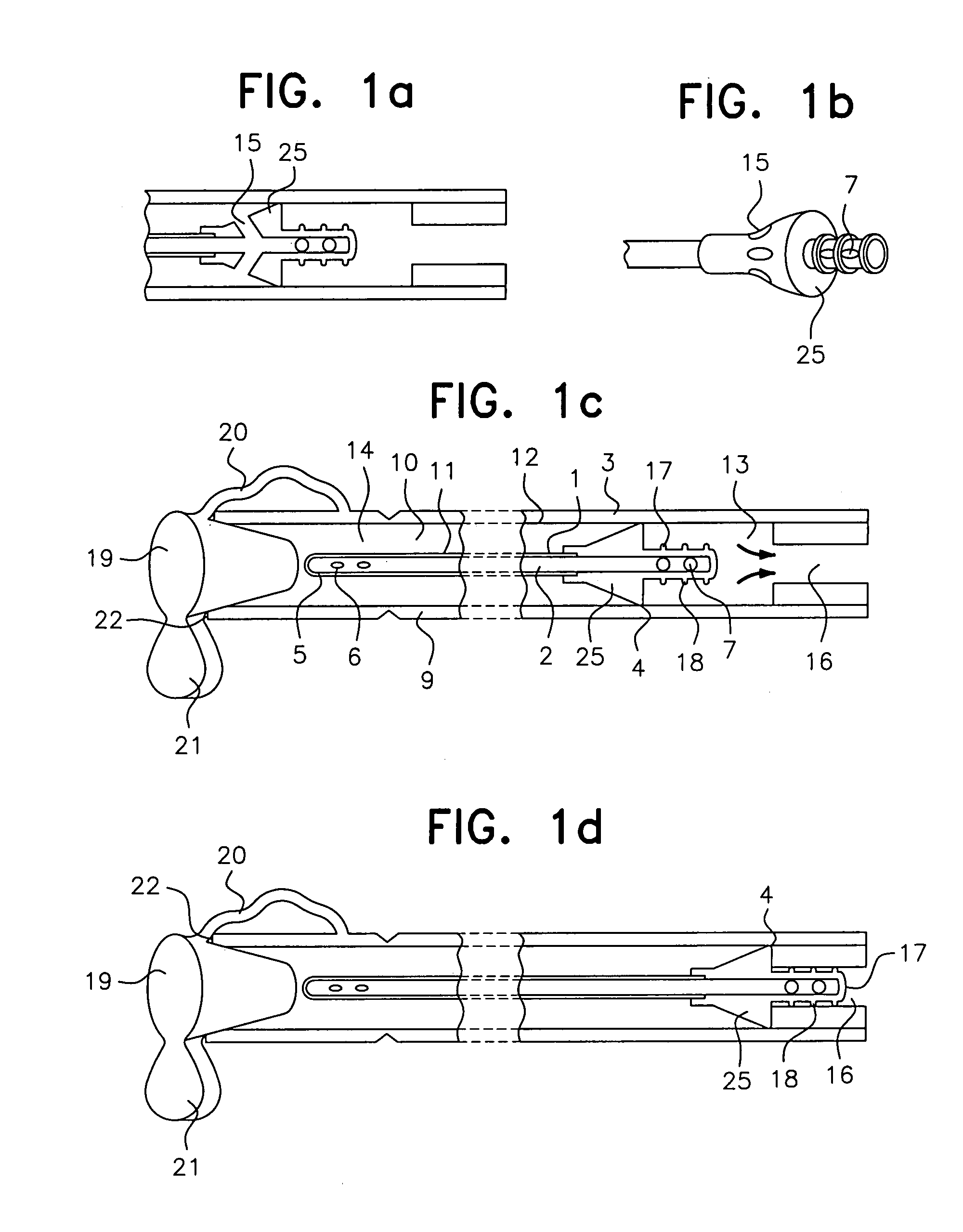

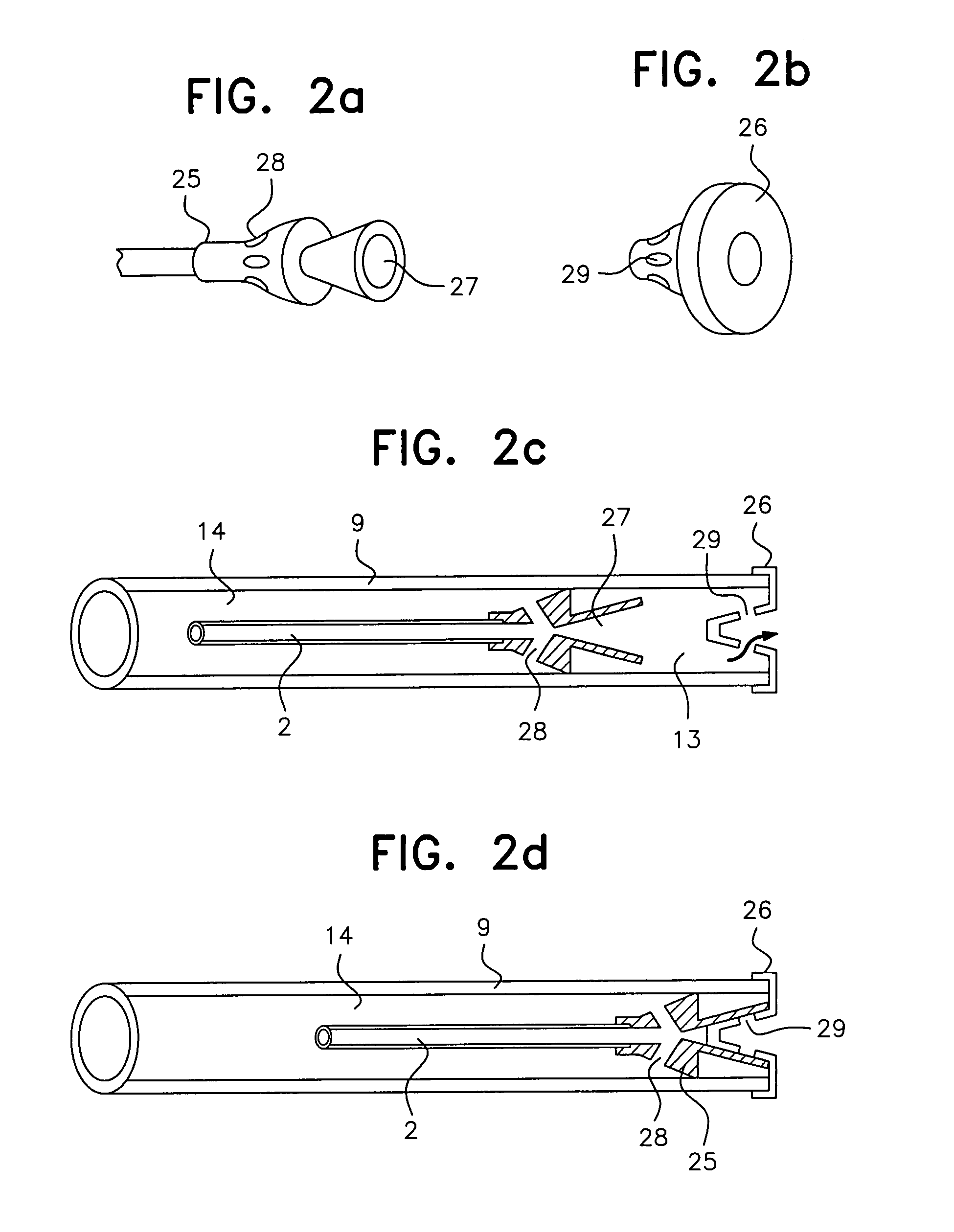

Urinary catheter assembly allowing for non-contaminated insertion of the catheter into a urinary canal

InactiveUS7311698B2Improve the lubrication effectProvide compatibilityDispensing apparatusWound drainsUrinary catheterUrethra

A catheter assembly allowing for non-contaminated insertion of the catheter into the urinary canal. The catheter assembly includes a urinary catheter, a catheter package and a sealing member. The urinary catheter defines a conduit and has a proximal end adapted for insertion into the urinary canal and an opposite distal end. The catheter package has a hose with a cavity for accommodation of the catheter, and a catheter outlet adapted to dismantle the proximal end of the catheter from the catheter package. The sealing member is adapted to provide a substantially liquid-tight seal between the catheter package and the urinary catheter while the catheter is being dismantled.

Owner:COLOPLAST AS

Composition for wet wipes that enhances the efficacy of cleansing while being gentle to the skin

InactiveUS20050008680A1Reduced skin gentleness indexSatisfy cleanlinessCosmetic preparationsToilet preparationsMedicineAdditive ingredient

The present invention describes wet wipe impregnated with a lotion composition where the lotion includes a preservative system and soothing ingredients to mitigate stinging.

Owner:THE PROCTER & GAMBLE COMPANY

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

Antimicrobial composition for medical articles

InactiveUS20060045899A1Inhibition formationImprove the lubrication effectBiocideOrganic active ingredientsPrepolymerMoisture

An antimicrobial composition is formed from about 30 to about 70 wt % of an antimicrobial formulation and about 30 to about 70 wt % of a polyurethane resin or polyurethane hybrids, copolymers, or mixtures with other polymers such as polyesters, nitrites, PVC, and synthetic rubber latexes. The antimicrobial formulation is formed from about 60 to about 95 wt % of an antimicrobial material, about 1 to about 30 wt % calcium chelator, about 0.001 to about 0.25 wt % pigment, and about 0.5 to about 3.5 wt % lubricant. The polyurethane resin may be a prepolymer that polymerizes when exposed to moisture or it may be a latex dispersion in water. An antimicrobial coating may be formed on the surface of an article by applying an antimicrobial composition to the article; if a polyurethane prepolymer is used, the composition is exposed to moisture and if an aqueous dispersion is used, the water is evaporated. A coating may also be formed by making a mixture of the antimicrobial formulation and a resin and molding, overmolding, or extruding the article from the compounded mixture.

Owner:ICET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com