Patents

Literature

1151 results about "Nanodiamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

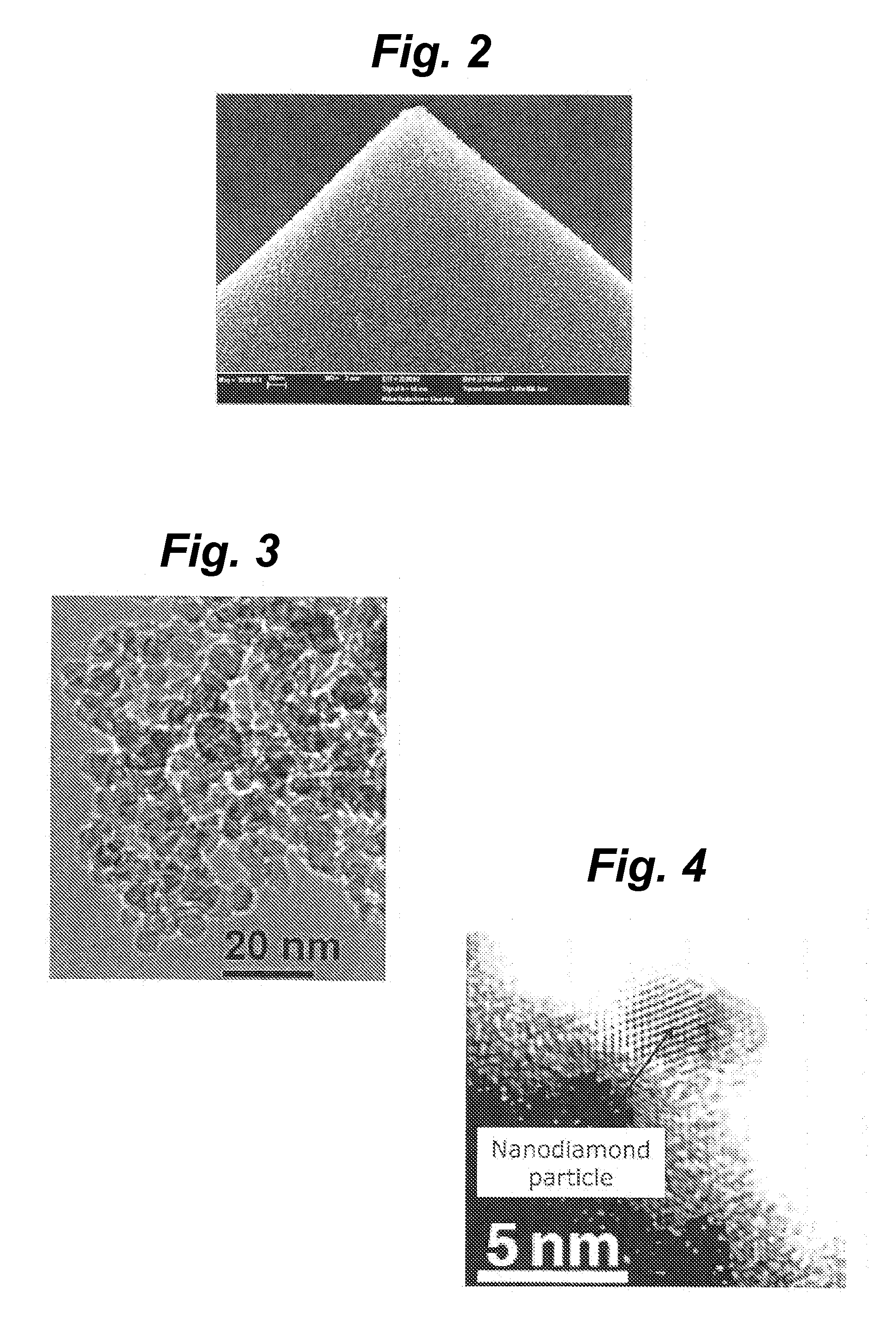

Nanodiamonds or diamond nanoparticles (medical use) are diamonds with a size below 1 micrometre. They can be produced by impact events such as an explosion or meteoritic impacts. Because of their inexpensive, large-scale synthesis, potential for surface functionalization, and high biocompatibility, nanodiamonds are widely investigated as a potential material in biological and electronic applications and quantum engineering.

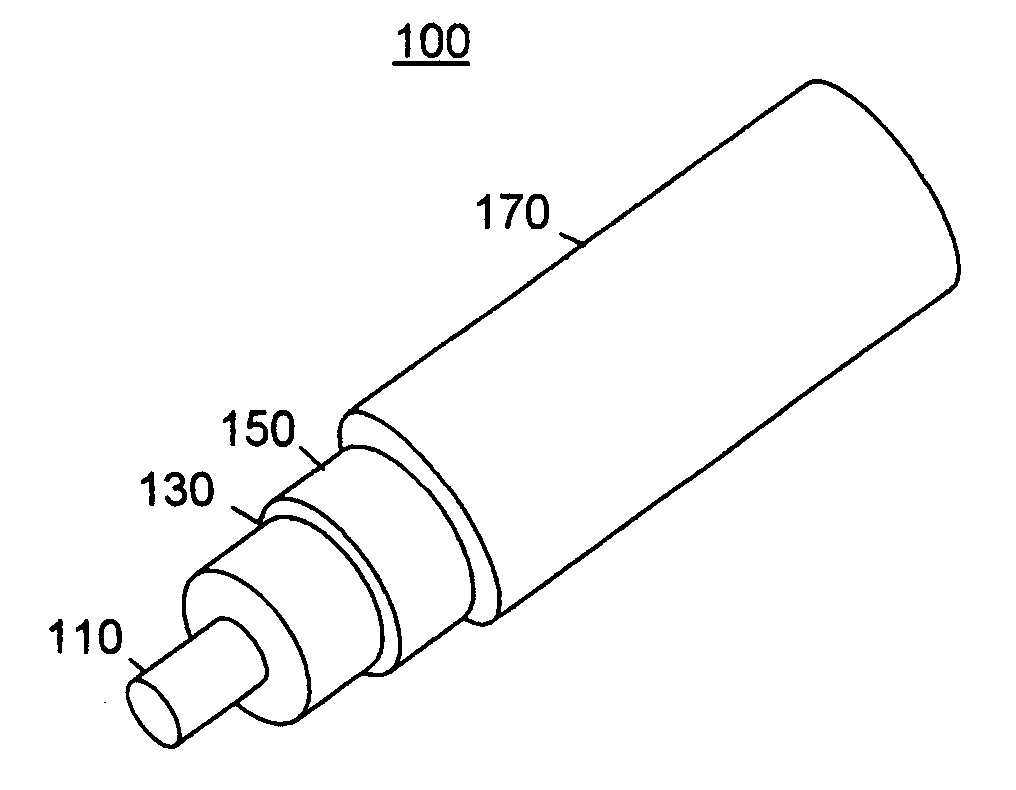

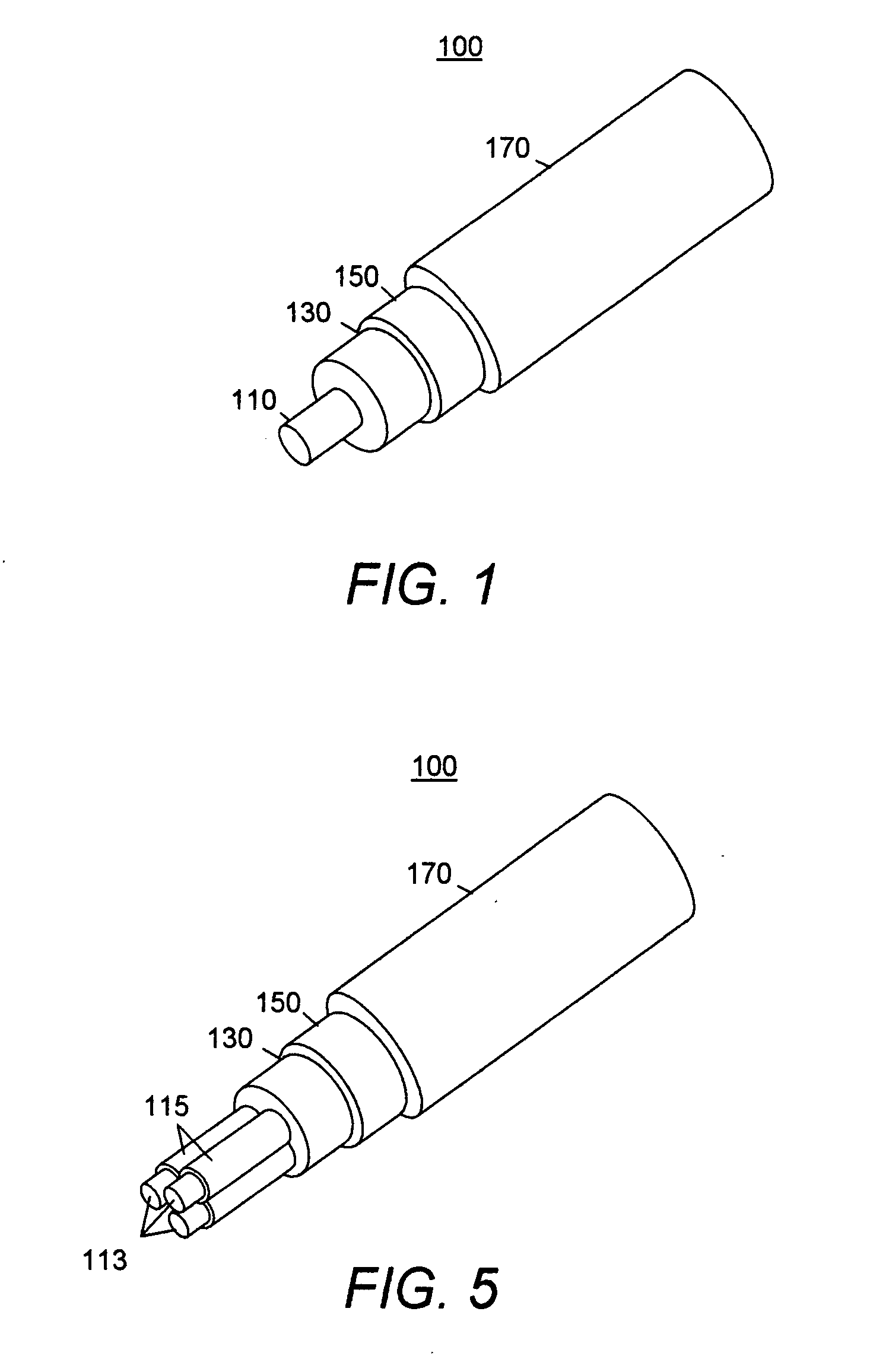

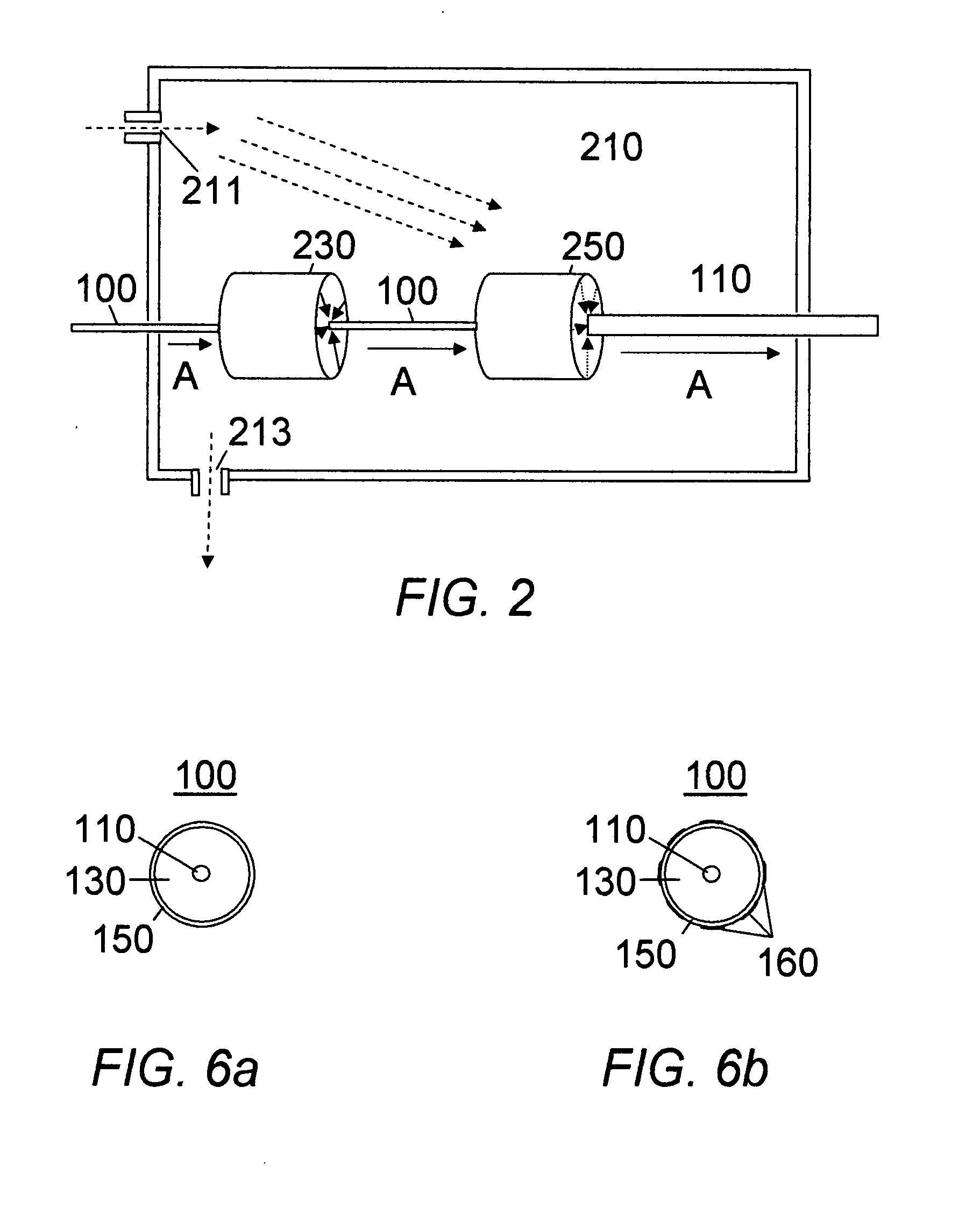

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

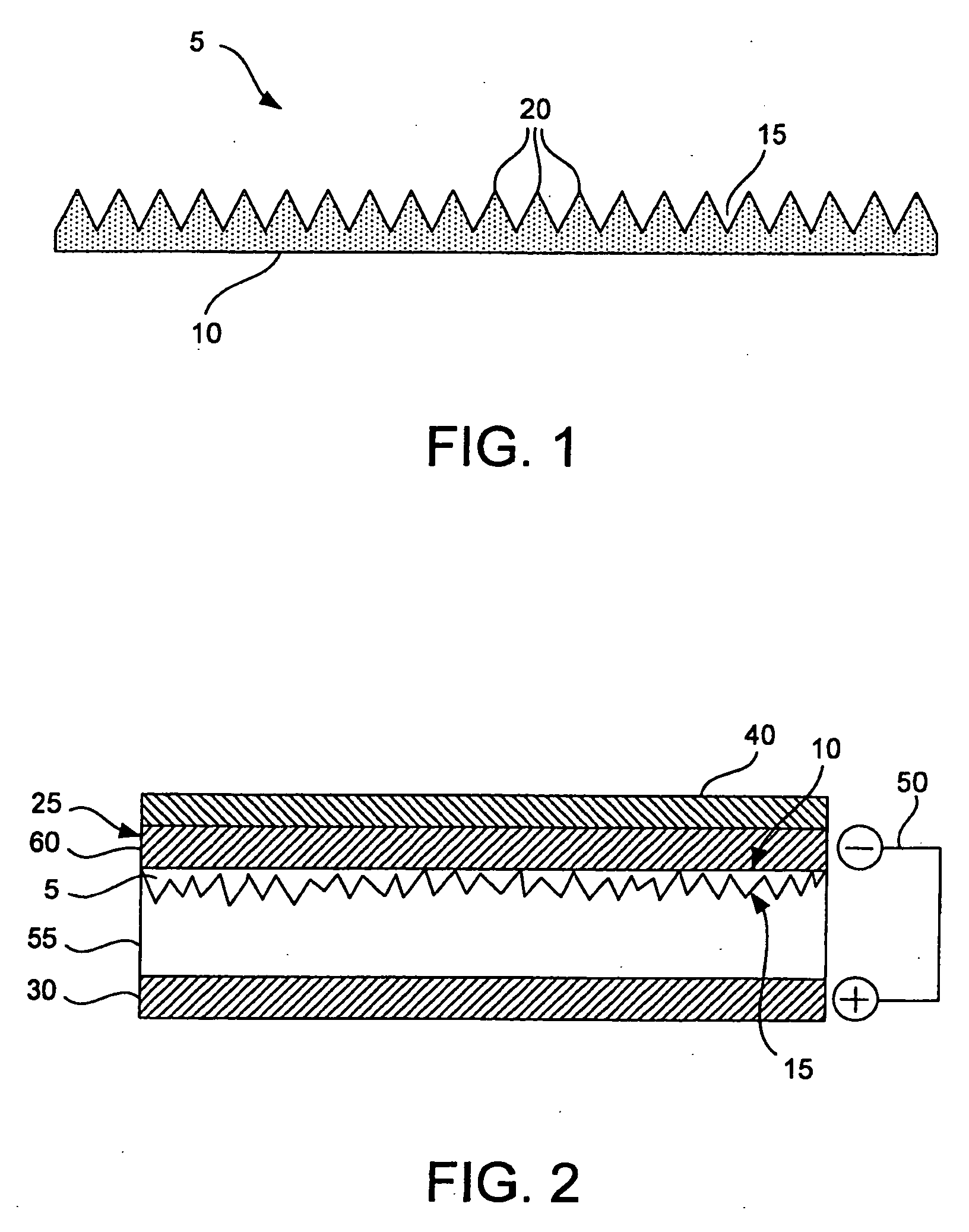

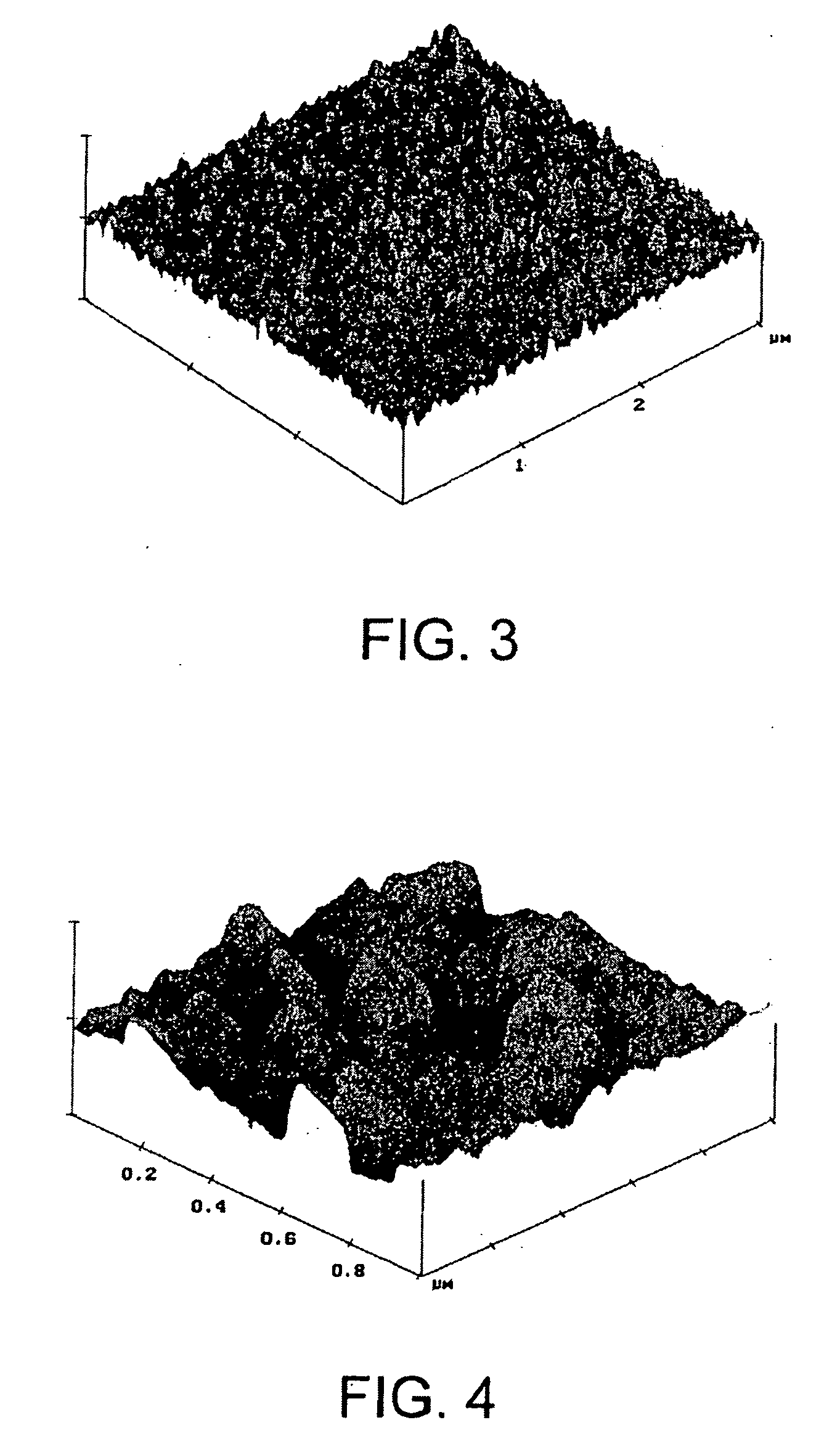

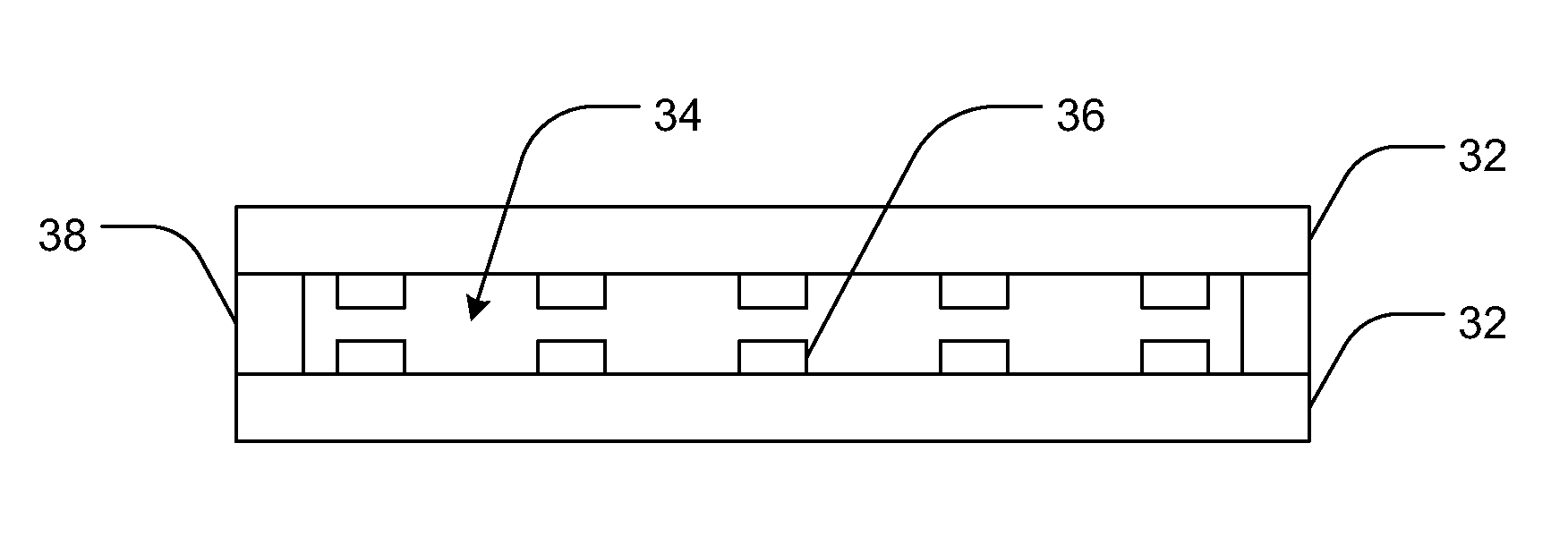

Fixed abrasive tools and associated methods

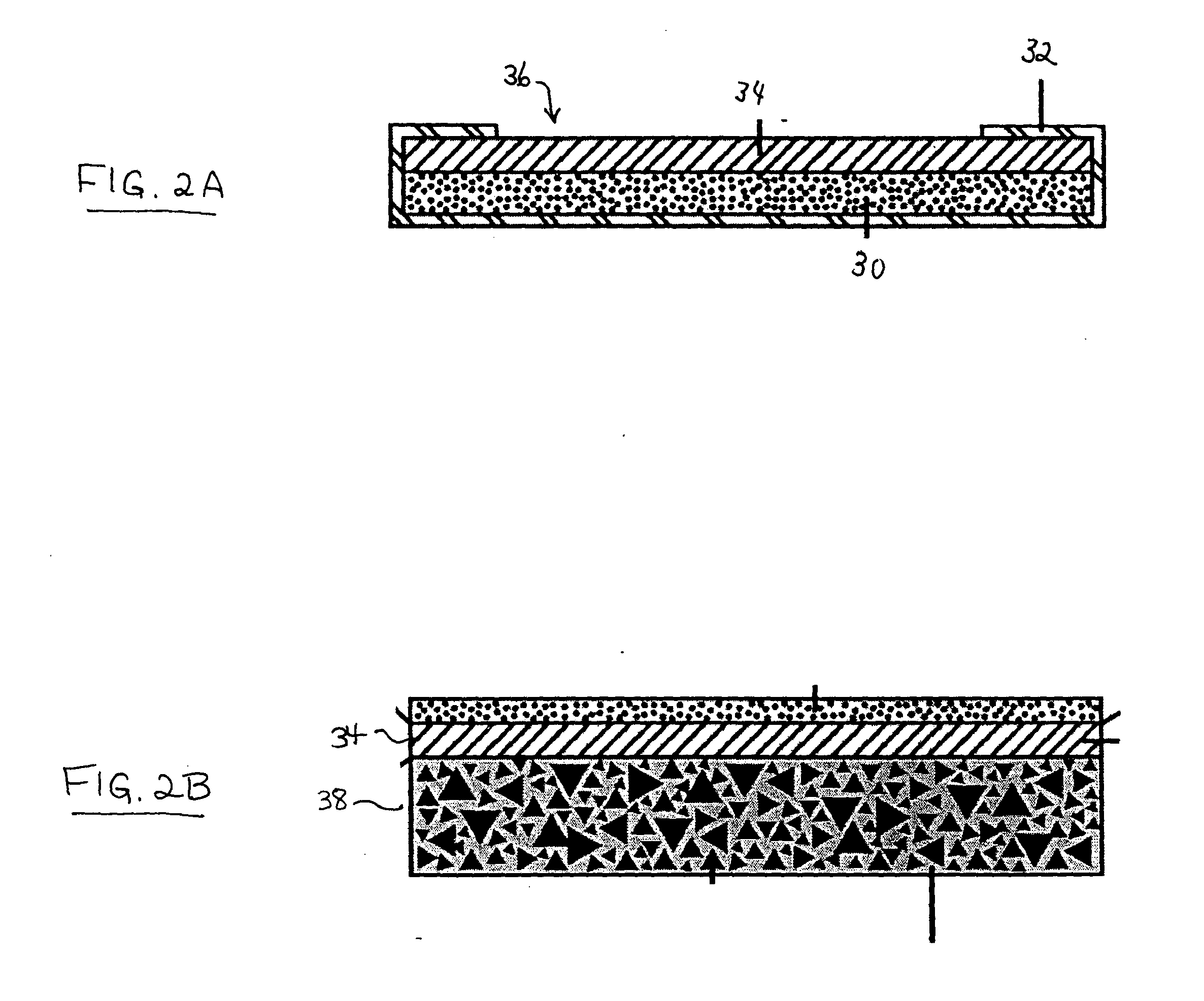

InactiveUS20050227590A1Easy to remove debrisAdequate material removal rateAbrasion apparatusPlane surface grinding machinesScreen printingMostly True

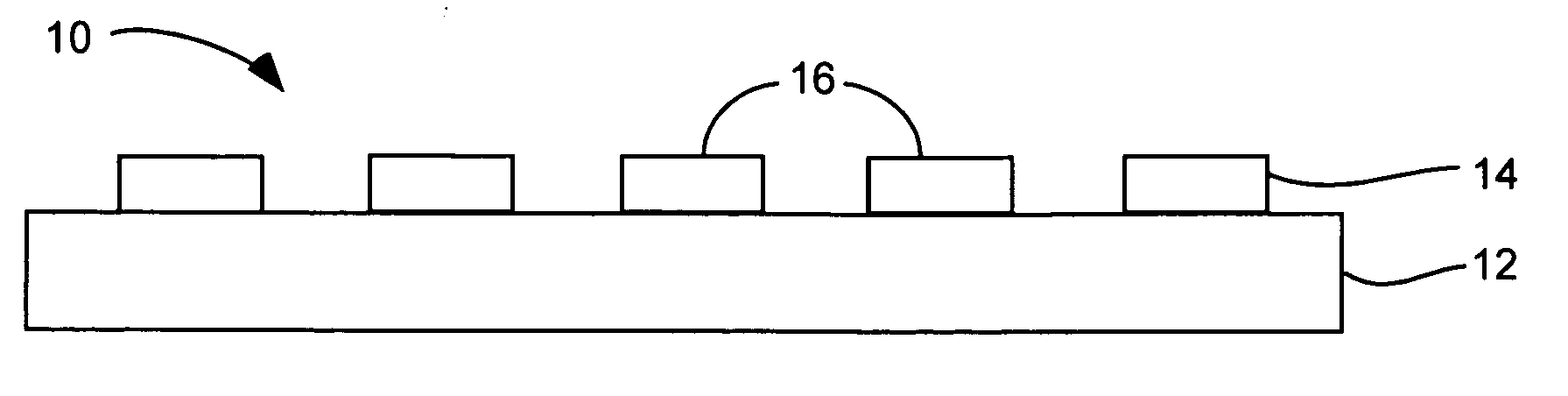

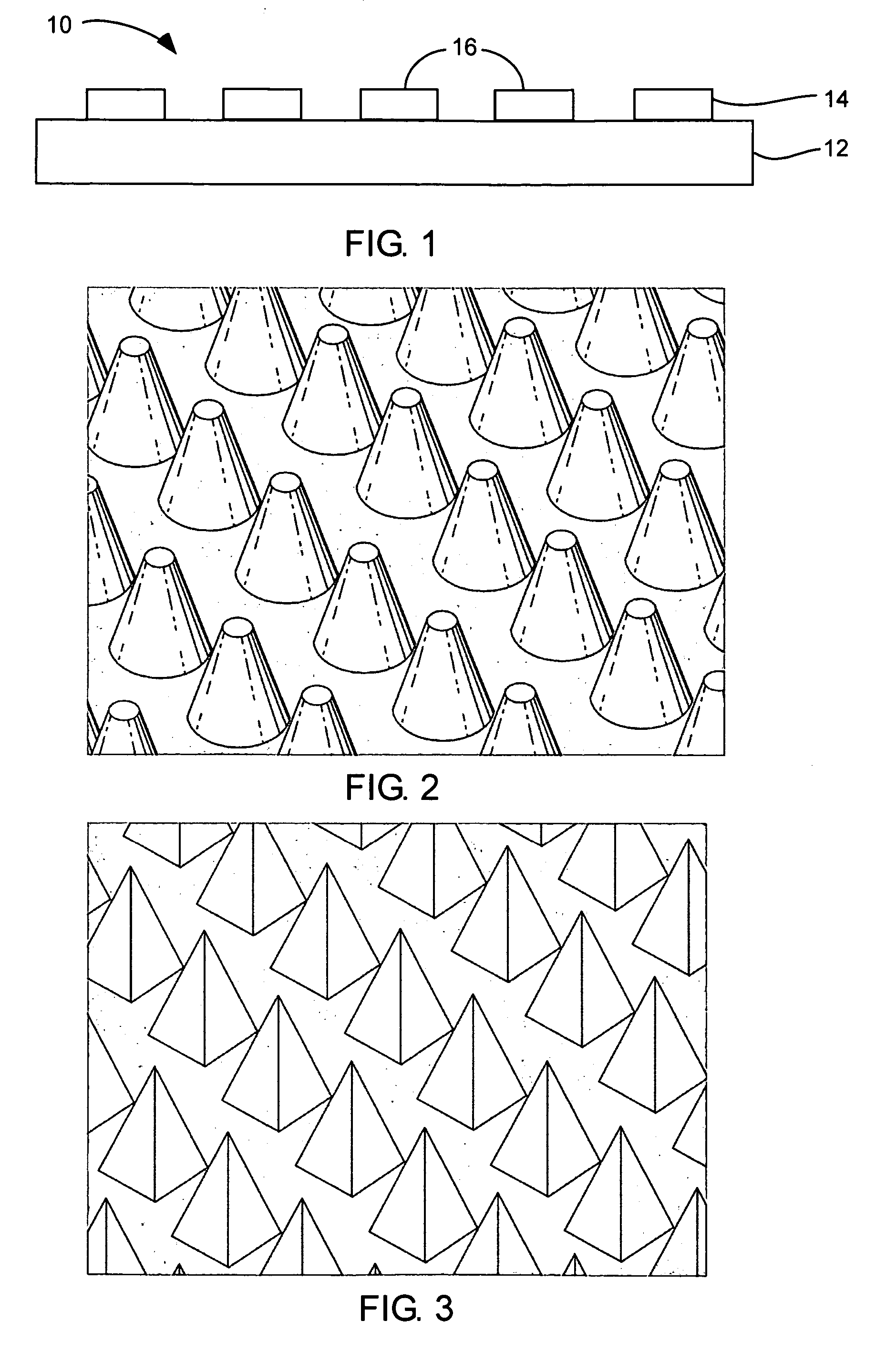

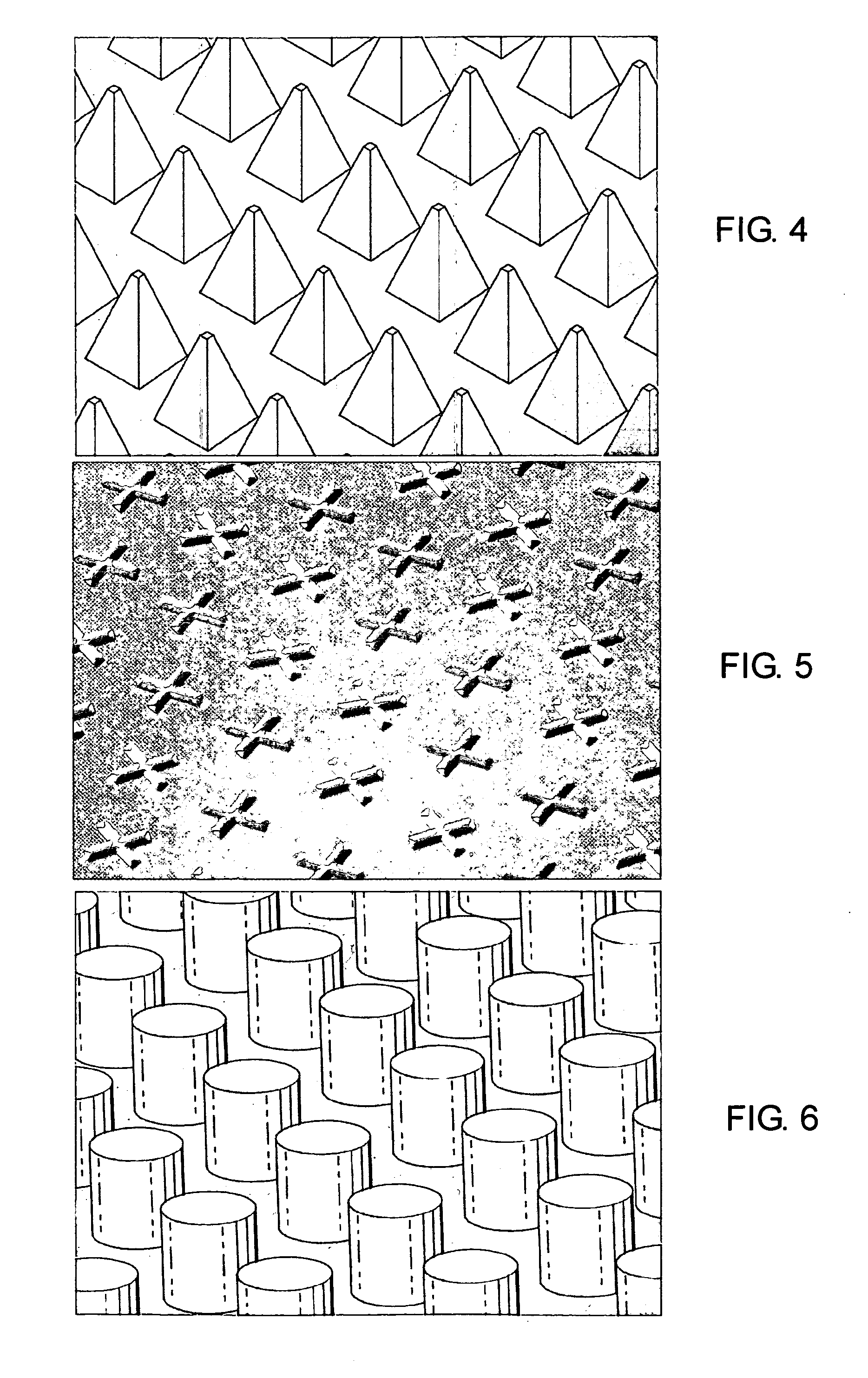

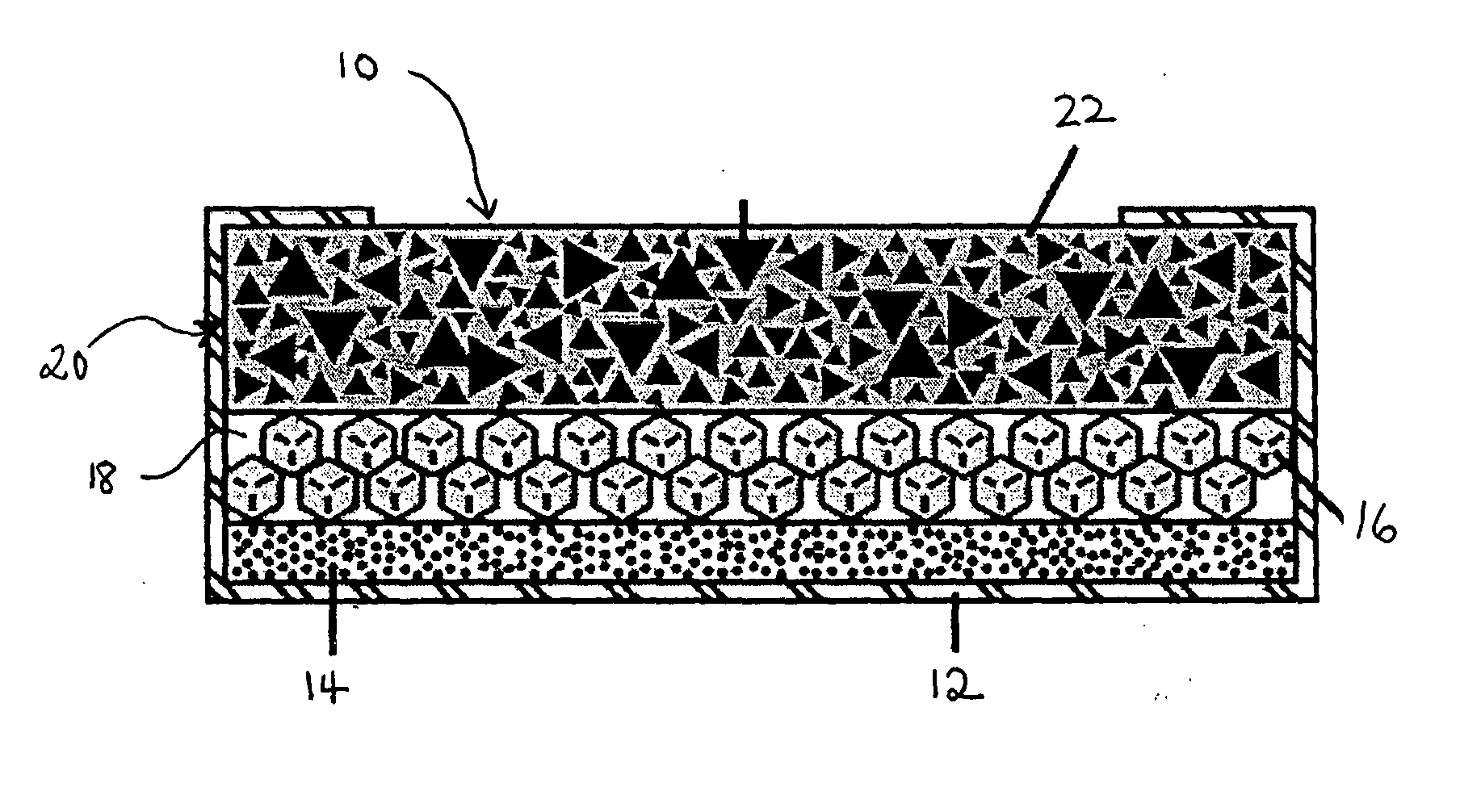

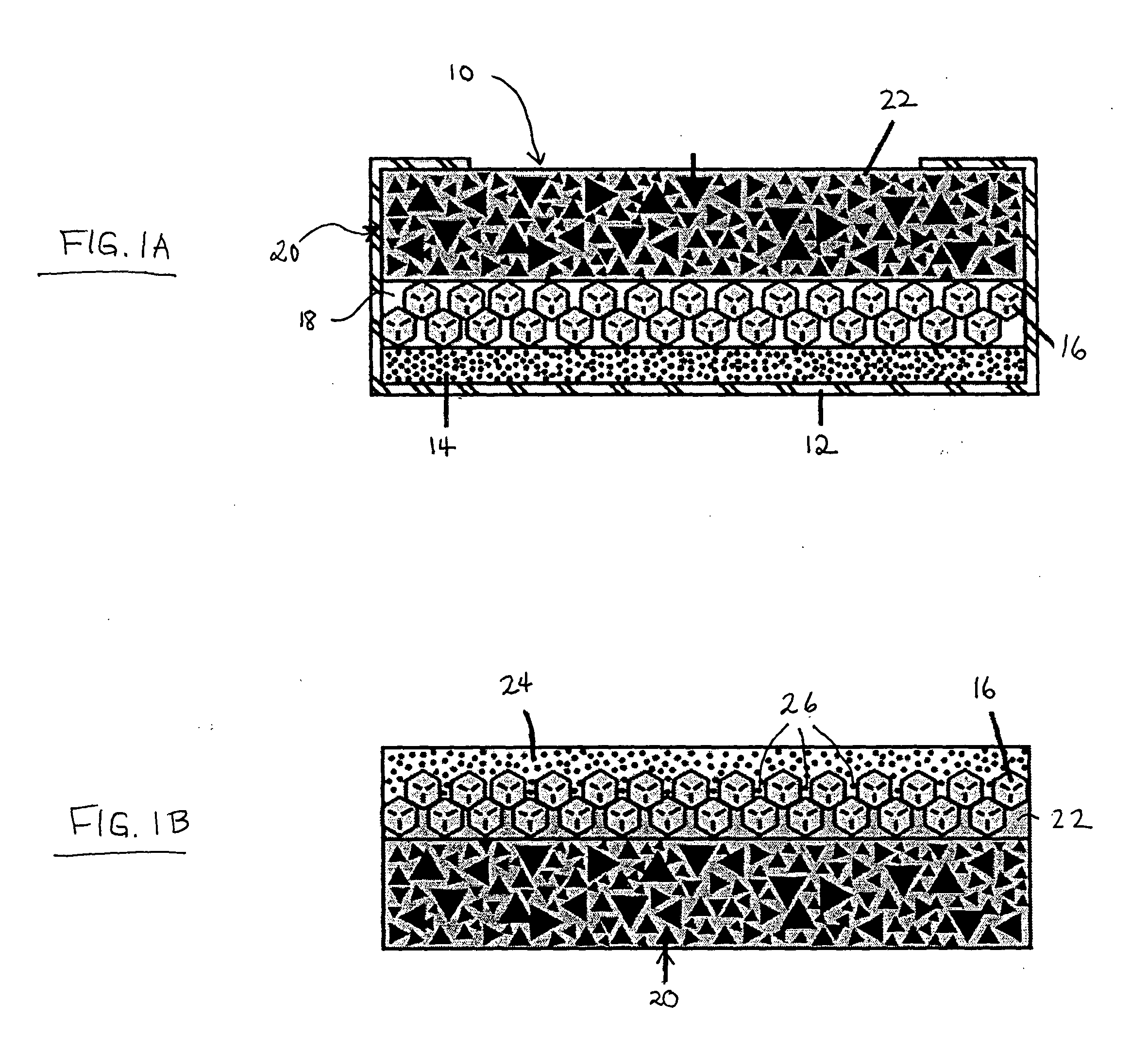

A fixed abrasive tool incorporating nanodiamond particles is described and disclosed. A fixed abrasive tool can include a polishing layer on a substrate. The polishing layer can include an organic matrix with nanodiamond particles therein. The polishing layer can be formed in a wide variety of configurations, depending on the specific polishing application. Most often, the polishing layer can include a plurality of projections which can have a wide variety of configurations in order to achieve a particular polishing performance. Nanodiamond particles used in the present invention can have a particle size from about 1 nm to about 50 nm, and preferably about 2 nm to about 10 nm. Optionally, the nanodiamond particles can include a carbonaceous coating. Such fixed abrasive tools can be formed by screen printing of a slurry of nanodiamond particles and an organic binder to form a predetermined three-dimensional pattern. Other methods can also be used to form the disclosed nanodiamond fixed abrasive tools. These fixed abrasive tools are particularly suitable for polishing expensive workpieces such as silicon wafers, integrated circuitry, gemstones, and hard drive platters.

Owner:SUNG CHIEN MIN

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

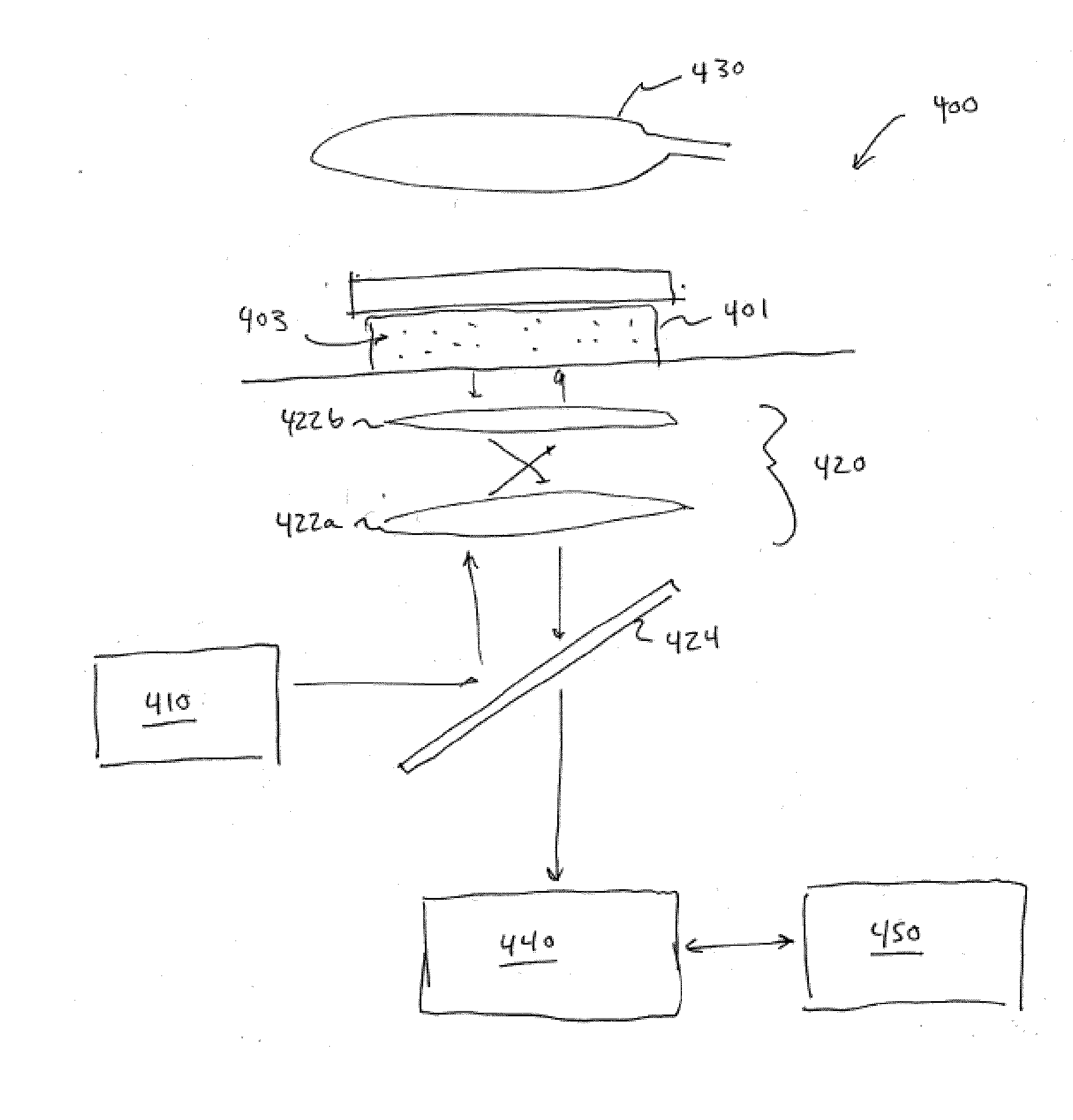

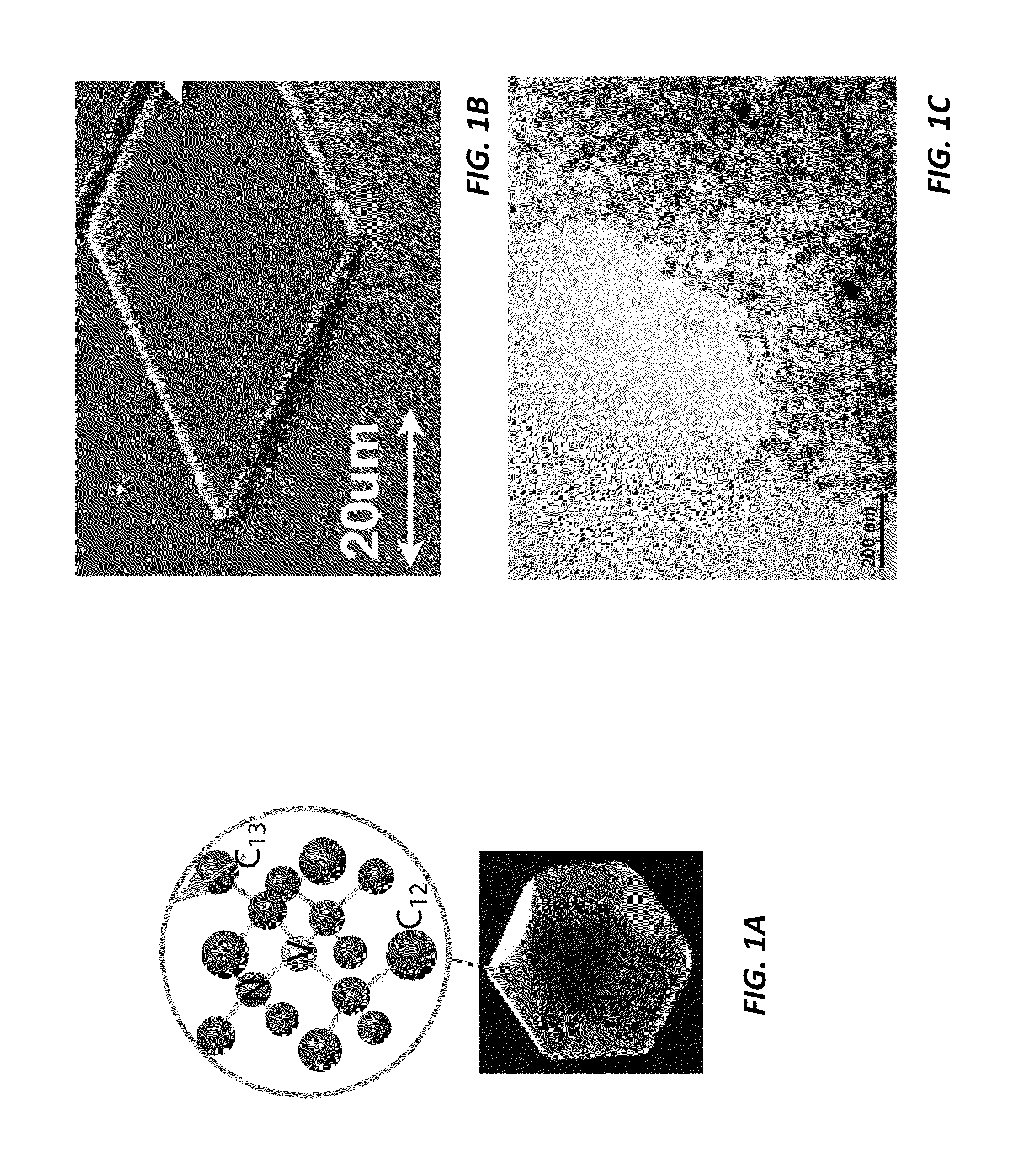

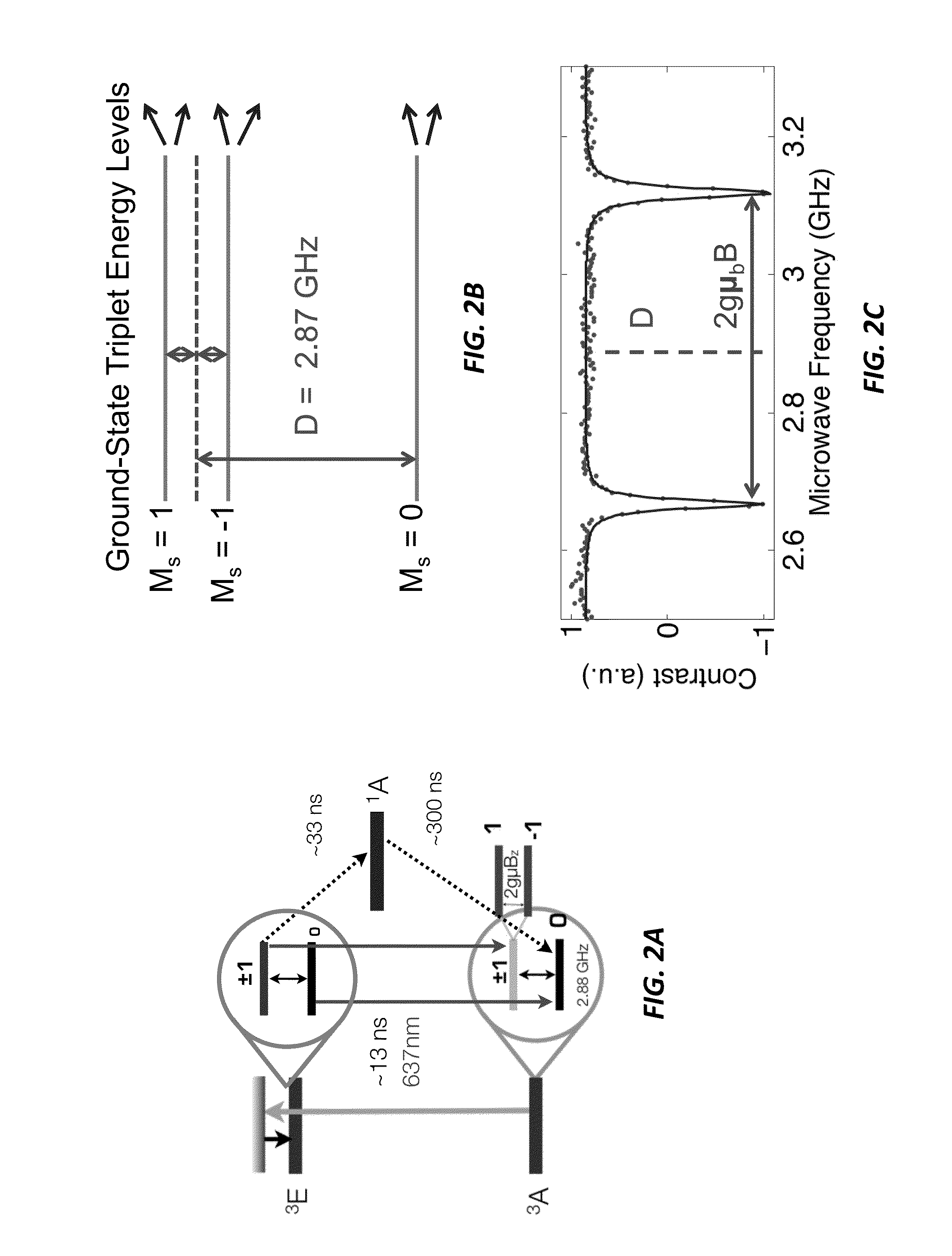

Wide-field imaging using nitrogen vacancies

Nitrogen vacancies in bulk diamonds and nanodiamonds can be used to sense temperature, pressure, electromagnetic fields, and pH. Unfortunately, conventional sensing techniques use gated detection and confocal imaging, limiting the measurement sensitivity and precluding wide-field imaging. Conversely, the present sensing techniques do not require gated detection or confocal imaging and can therefore be used to image temperature, pressure, electromagnetic fields, and pH over wide fields of view. In some cases, wide-field imaging supports spatial localization of the NVs to precisions at or below the diffraction limit. Moreover, the measurement range can extend over extremely wide dynamic range at very high sensitivity.

Owner:MASSACHUSETTS INST OF TECH

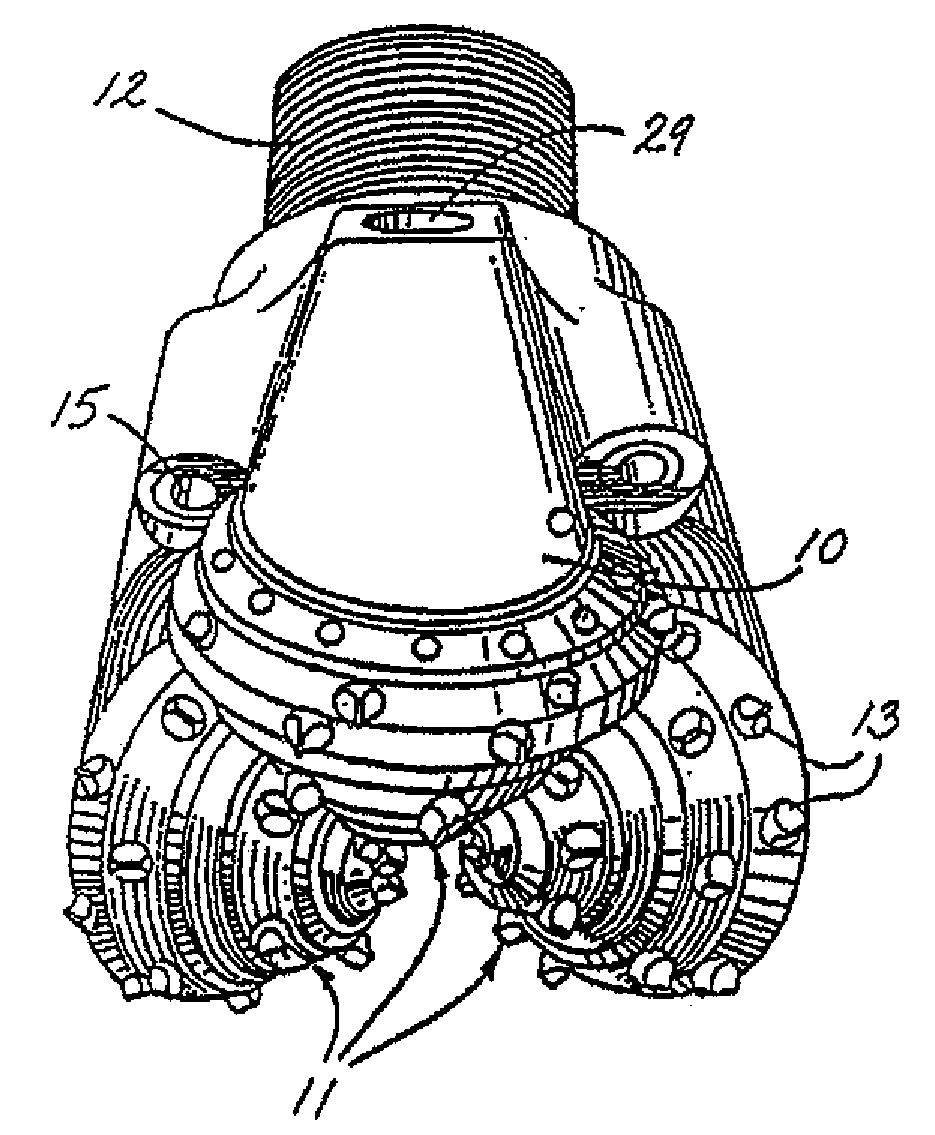

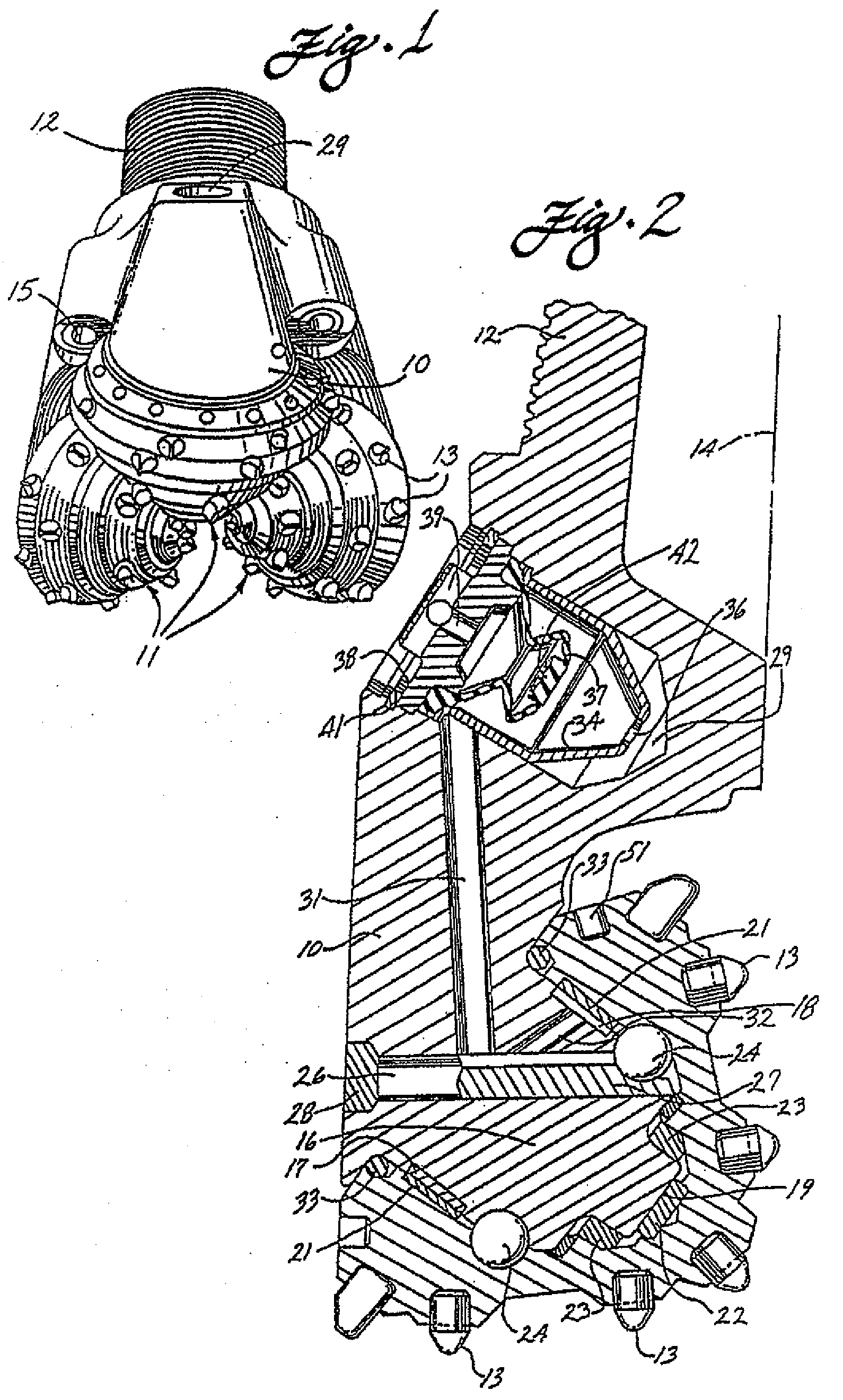

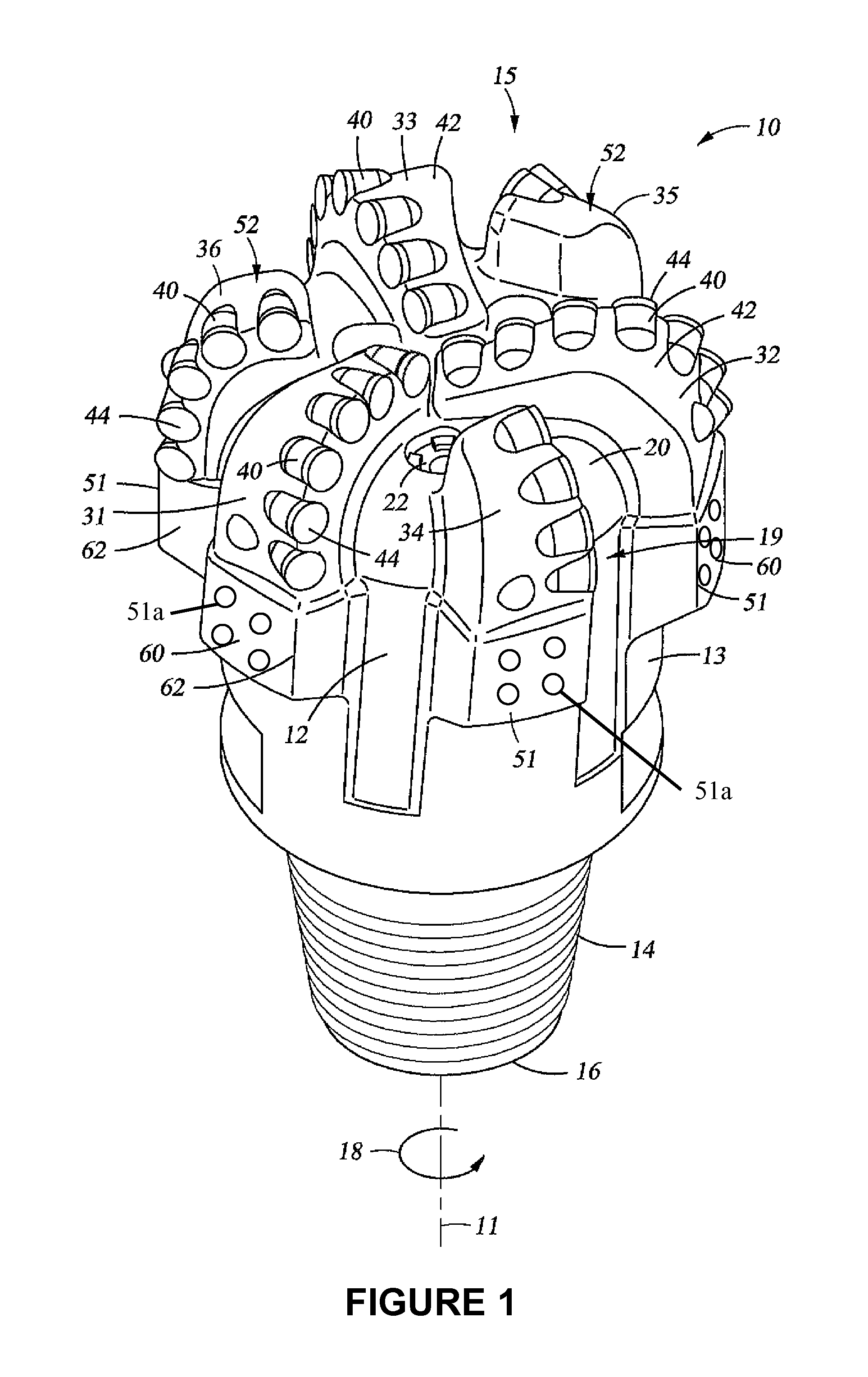

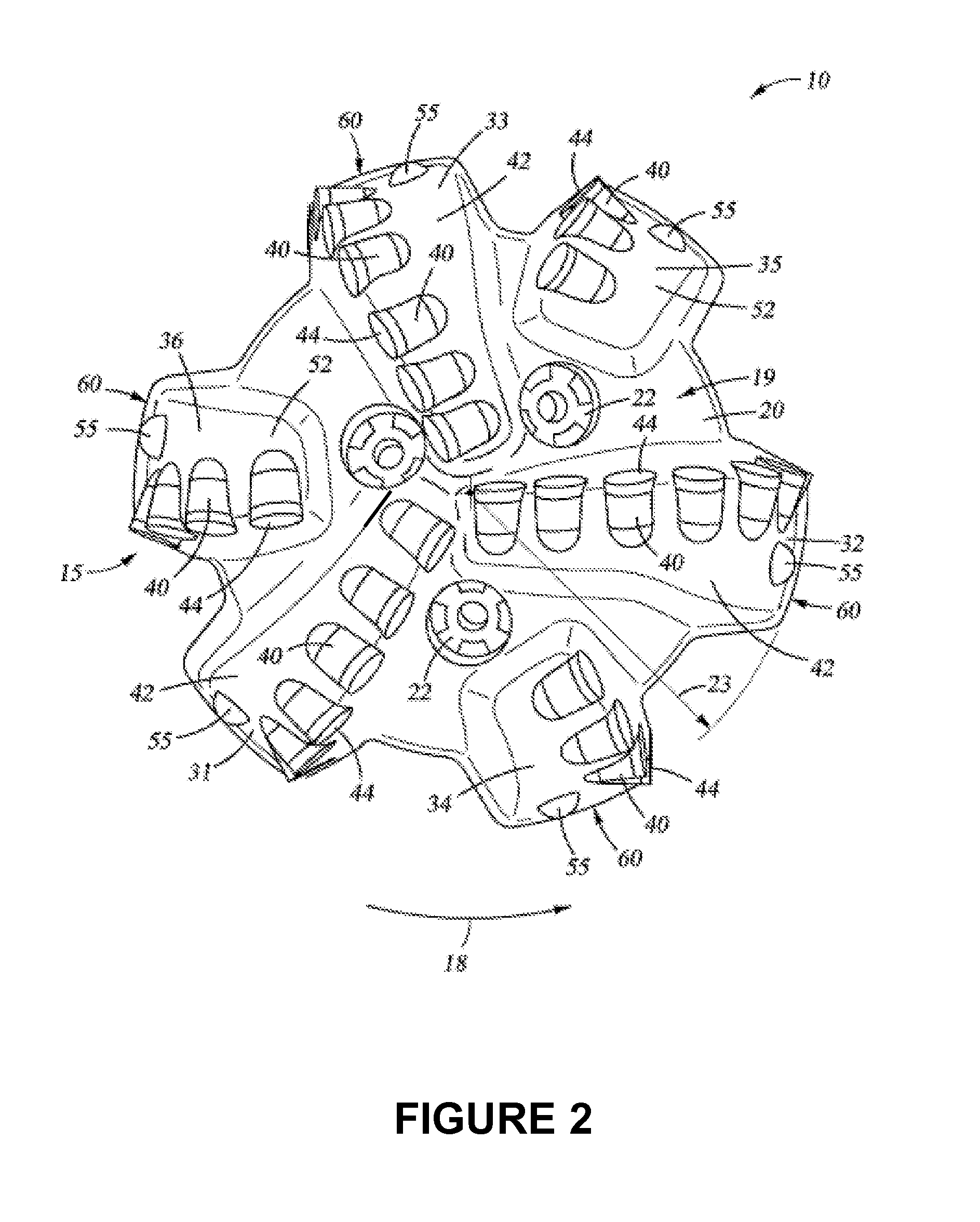

Use of nanosized particulates and fibers in elastomer seals for improved performance metrics for roller cone bits

A bit for drilling subterranean formations that includes a bit body including a bearing surface; a cutting structure mounted on the bit body, and including a bearing surface, and an annular seal for retaining a grease between the bearing surfaces, the annular seal comprising a flexible and resilient seal body formed from an elastomer composition, wherein the elastomer composition comprises an elastomer material, a curing agent, and 10% or less by volume of a nanomaterial additive selected from one of nanotubes and clustered nanodiamonds is disclosed.

Owner:SMITH INT INC

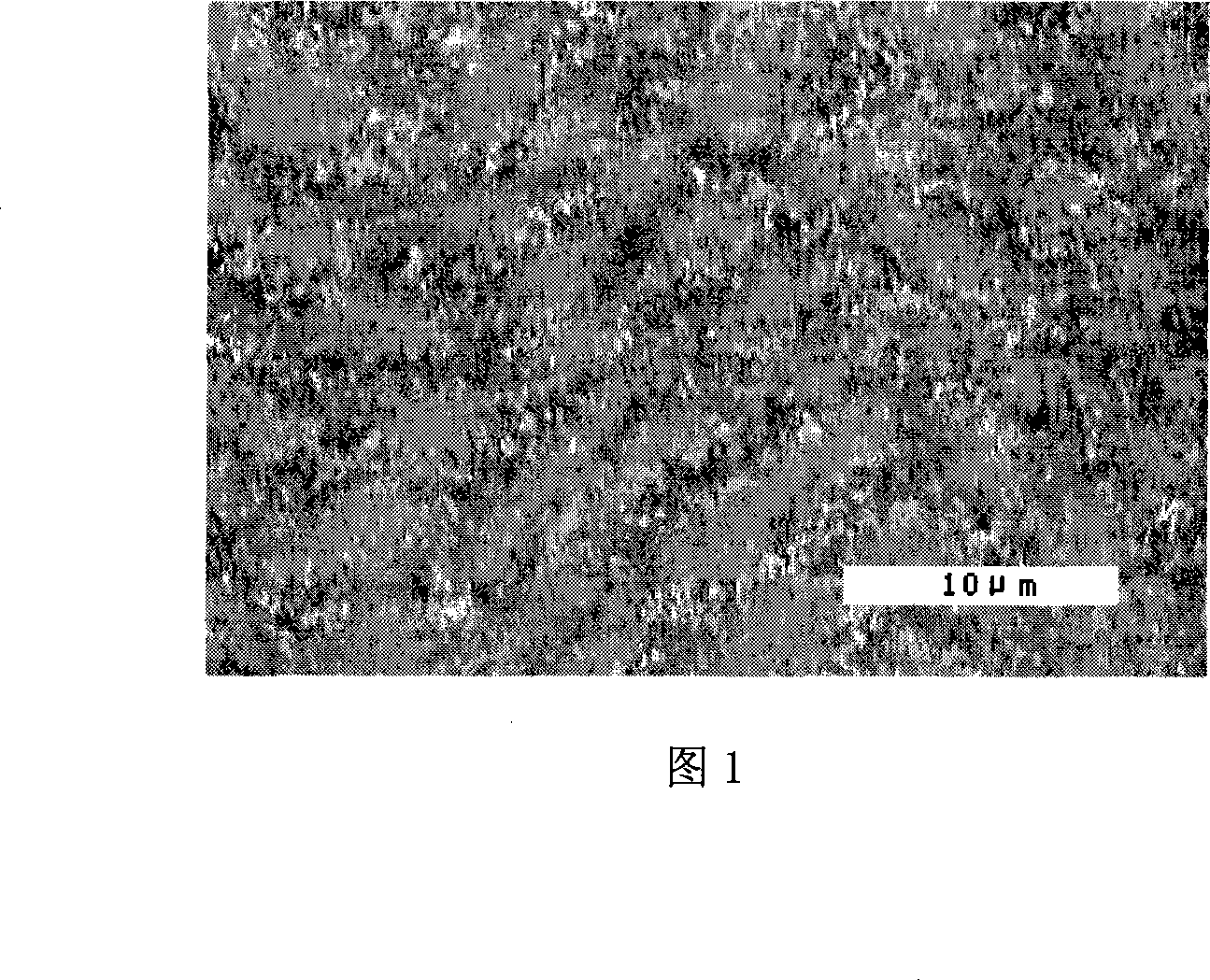

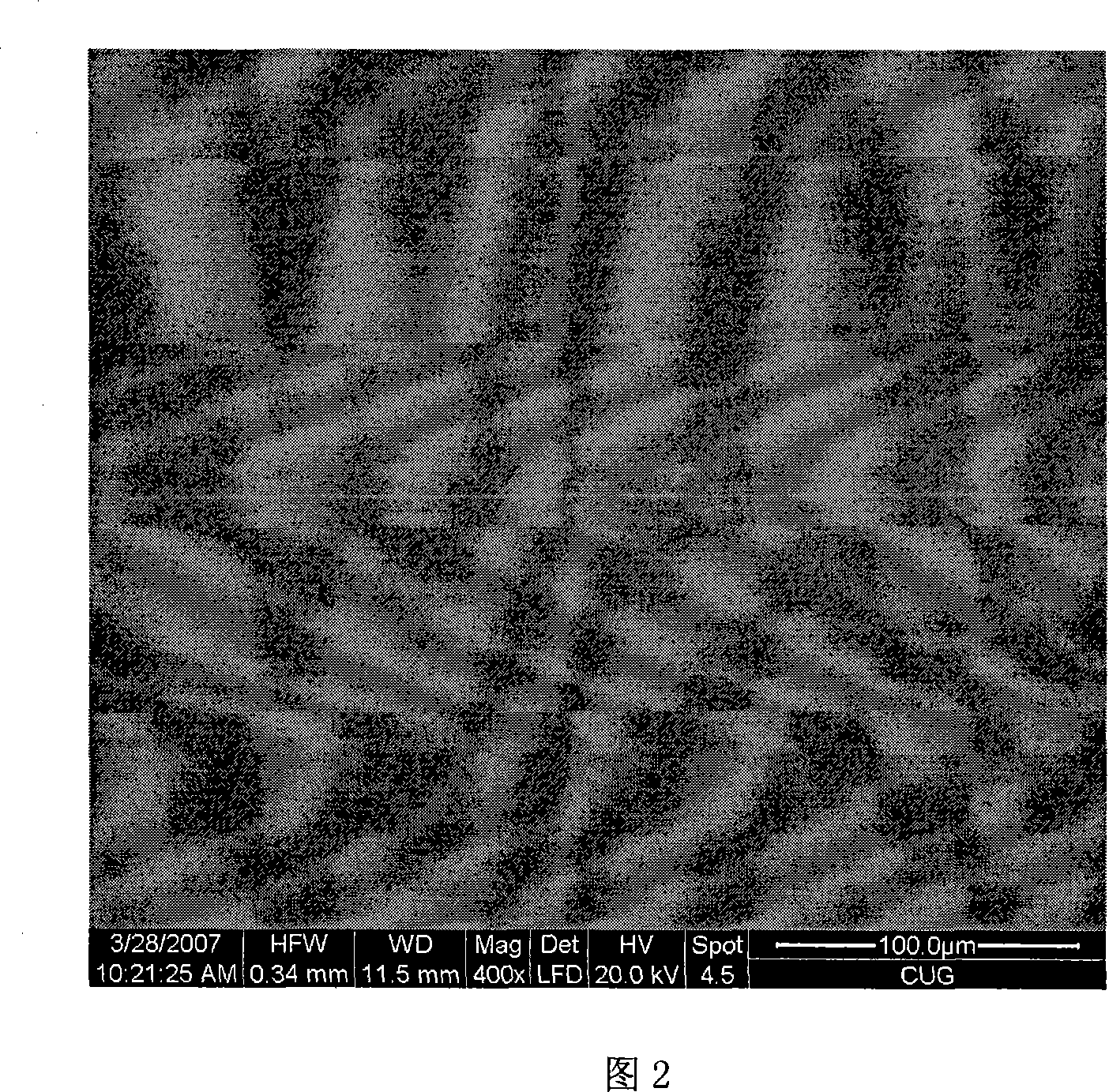

High-purity nano diamond polishing liquid and preparing method thereof

InactiveCN101033374AEvenly dispersedImprove dispersion stabilityOther chemical processesPolishing compositions with abrasivesGranularitySlurry

The invention relates to a kind of high purity nano-scale diamond polishing slurry for ultra-precision processing and its preparation. The high-purity polishing slurry is prepared with nano-scale diamond, wetting agent, surface modification agent, dispersing agent, chemical additives and water, and the percentage of the raw materials by weight share are as follow: 0.05~10% of the nano-scale diamond, 0.01~2% of the wetting agent, 1~5% of the surface modification agent, 0.1~10% of the dispersing agent, 0.2~1% of the chemical additives, 88.69~98.64% of water. The amounts of all the materials are weighted as 100%. The amounts of the described wetting agent, surface modification agent, dispersing agent, and chemical additives are referred to solid content. The purity of the nano-scale diamond is 99.9% and the particle size of distribution is 10~200 nm.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

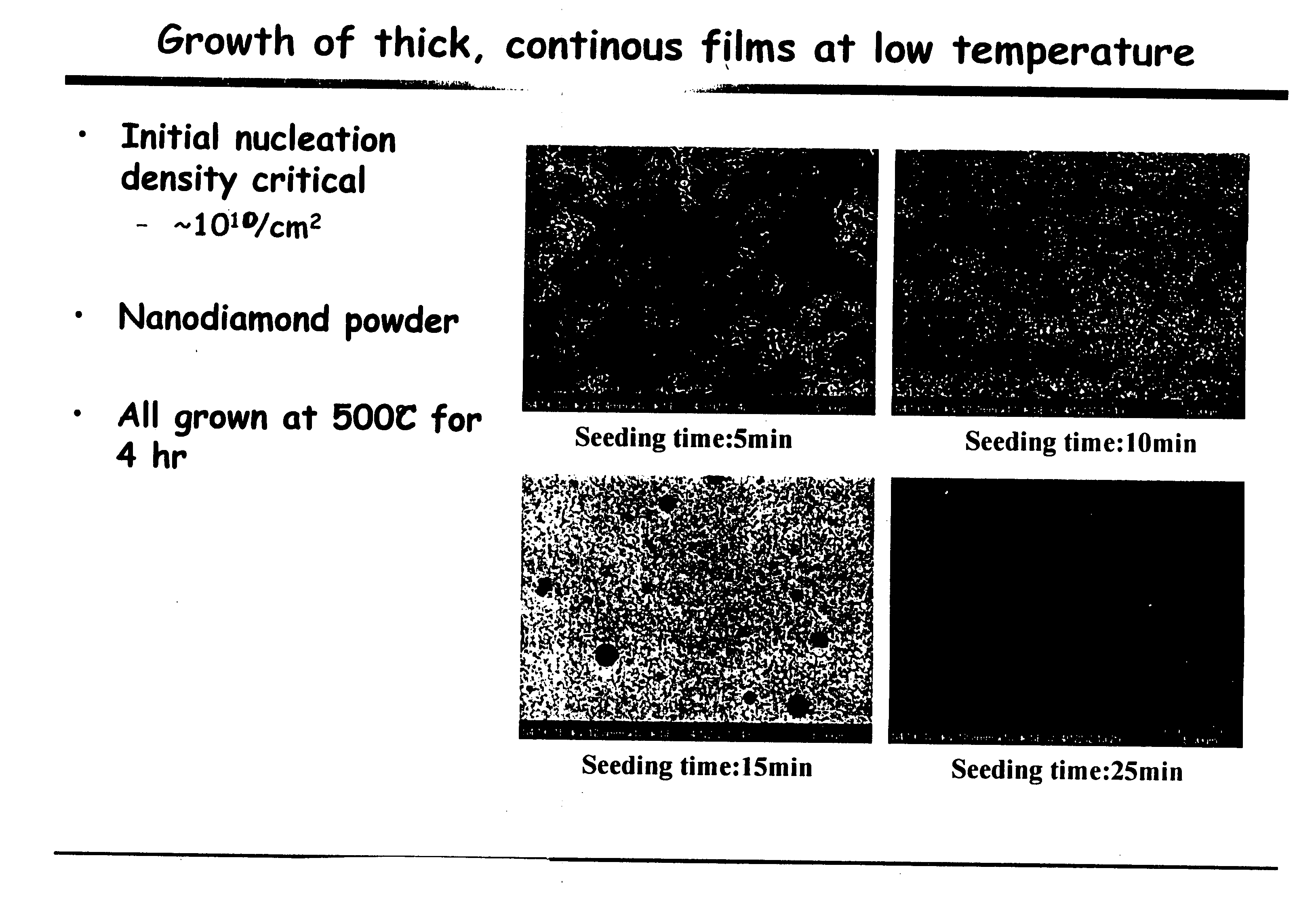

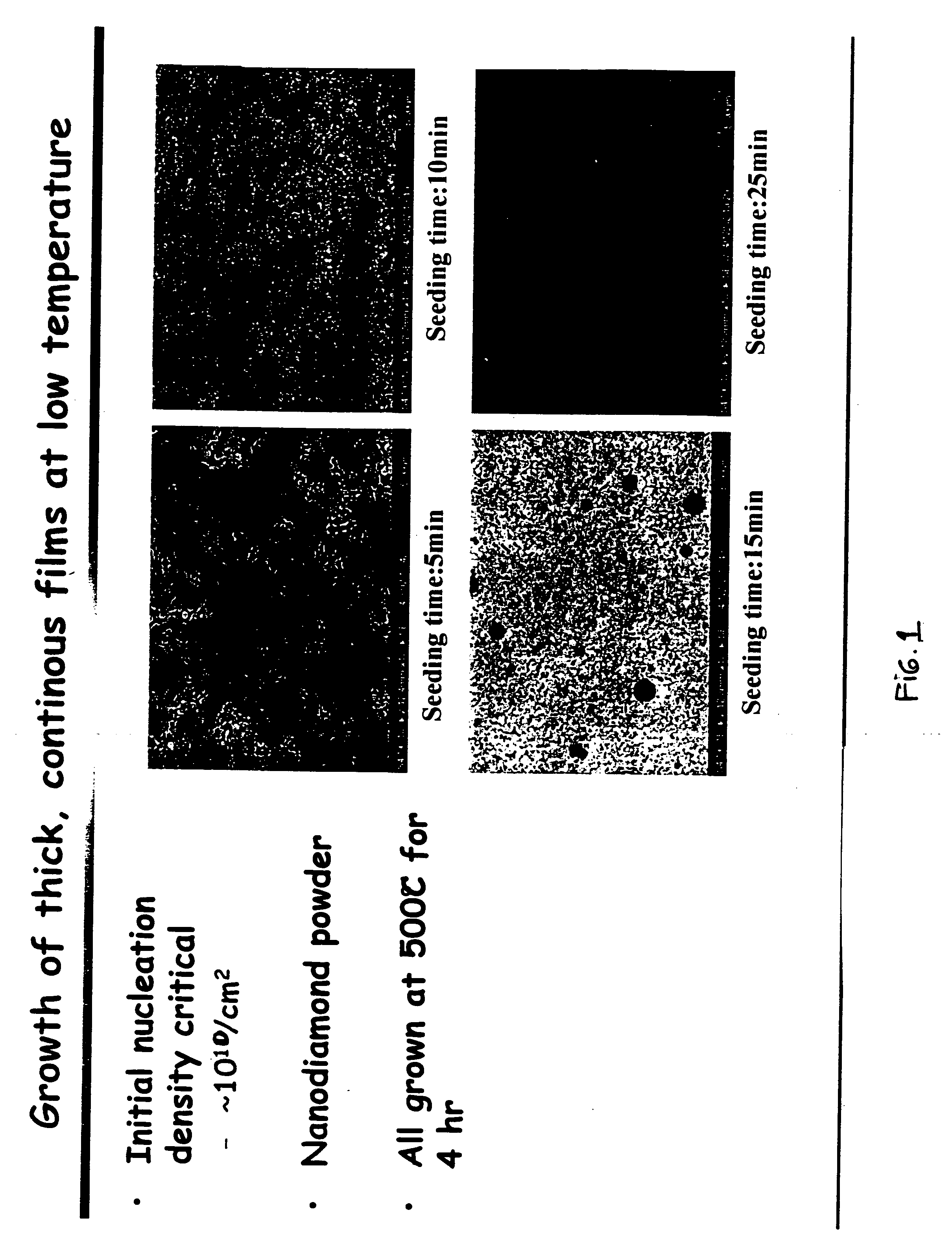

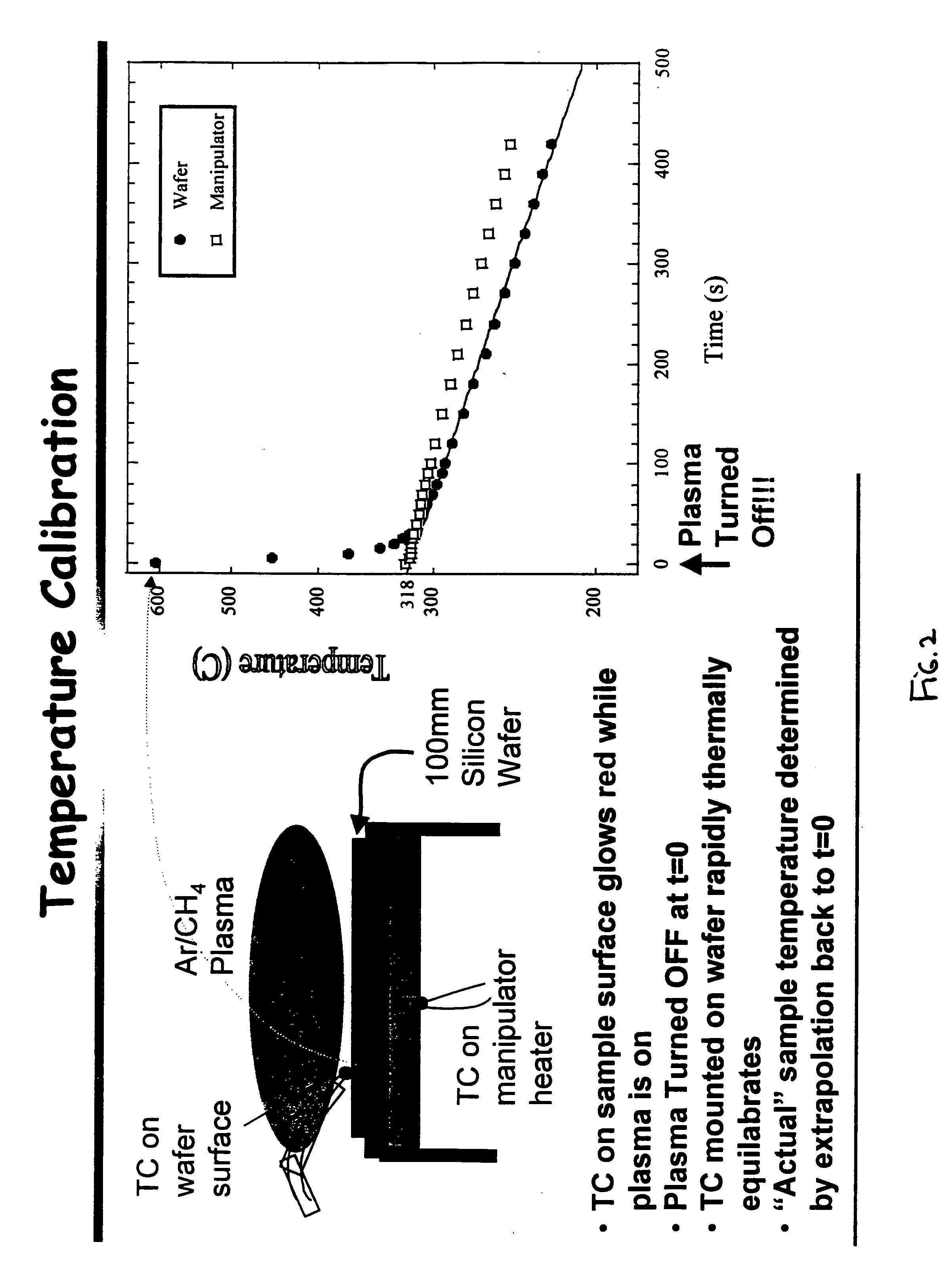

Method to grow pure nanocrystalline diamond films at low temperatures and high deposition rates

ActiveUS20050031785A1Increase deposition rateEnhanced vapor depositionLayered productsSemiconductor/solid-state device manufacturingMetallurgyVolumetric Mass Density

A method of depositing nanocrystalline diamond film on a substrate at a rate of not less than about 0.2 microns / hour at a substrate temperature less than about 500° C. The method includes seeding the substrate surface with nanocrystalline diamond powder to an areal density of not less than about 1010sites / cm2, and contacting the seeded substrate surface with a gas of about 99% by volume of an inert gas other than helium and about 1% by volume of methane or hydrogen and one or more of acetylene, fullerene and anthracene in the presence of a microwave induced plasma while maintaining the substrate temperature less than about 500° C. to deposit nanocrystalline diamond on the seeded substrate surface at a rate not less than about 0.2 microns / hour. Coatings of nanocrystalline diamond with average particle diameters of less than about 20 nanometers can be deposited with thermal budgets of 500° C.-4 hours or less onto a variety of substrates such as MEMS devices.

Owner:UCHICAGO ARGONNE LLC

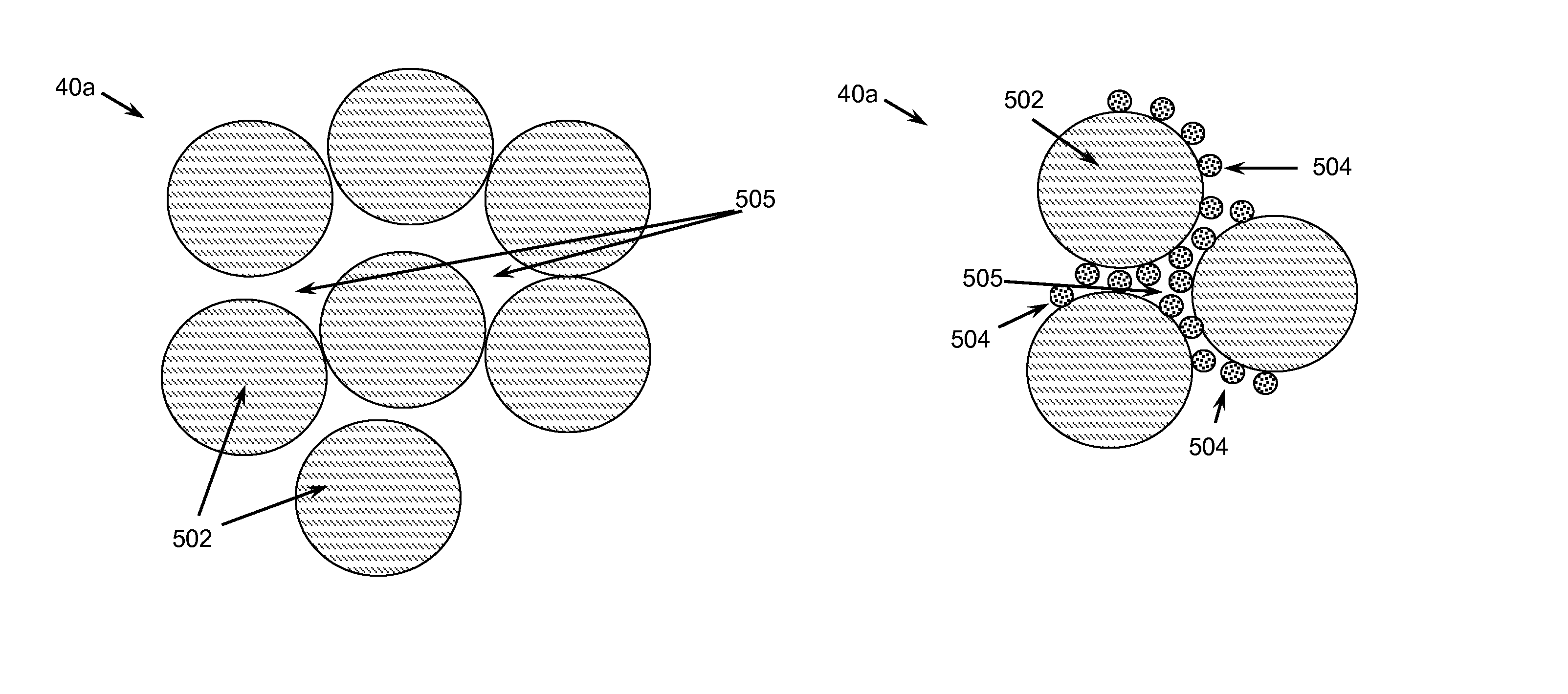

Preparation of Nanocrystalline Diamond Coated Diamond Particles and Applications Thereof

ActiveUS20130180181A1Pigmenting treatmentMaterial nanotechnologyPolycrystalline diamondHigh pressure

A method of making a polycrystalline diamond cutter element includes forming a blend, comprising a first particle size of polycrystalline diamond particles and a second particle size of polycrystalline diamond particles; forming a suspension of nanocrystalline diamond particles suspended in a solvent; and mixing the blend into the suspension to form a polycrystalline diamond mixture comprising nanocrystalline diamond coated polycrystalline diamond particles. The mixture is sintered with a substrate at high temperature and high pressure to form the polycrystalline diamond cutter element.

Owner:NAT OILWELL DHT

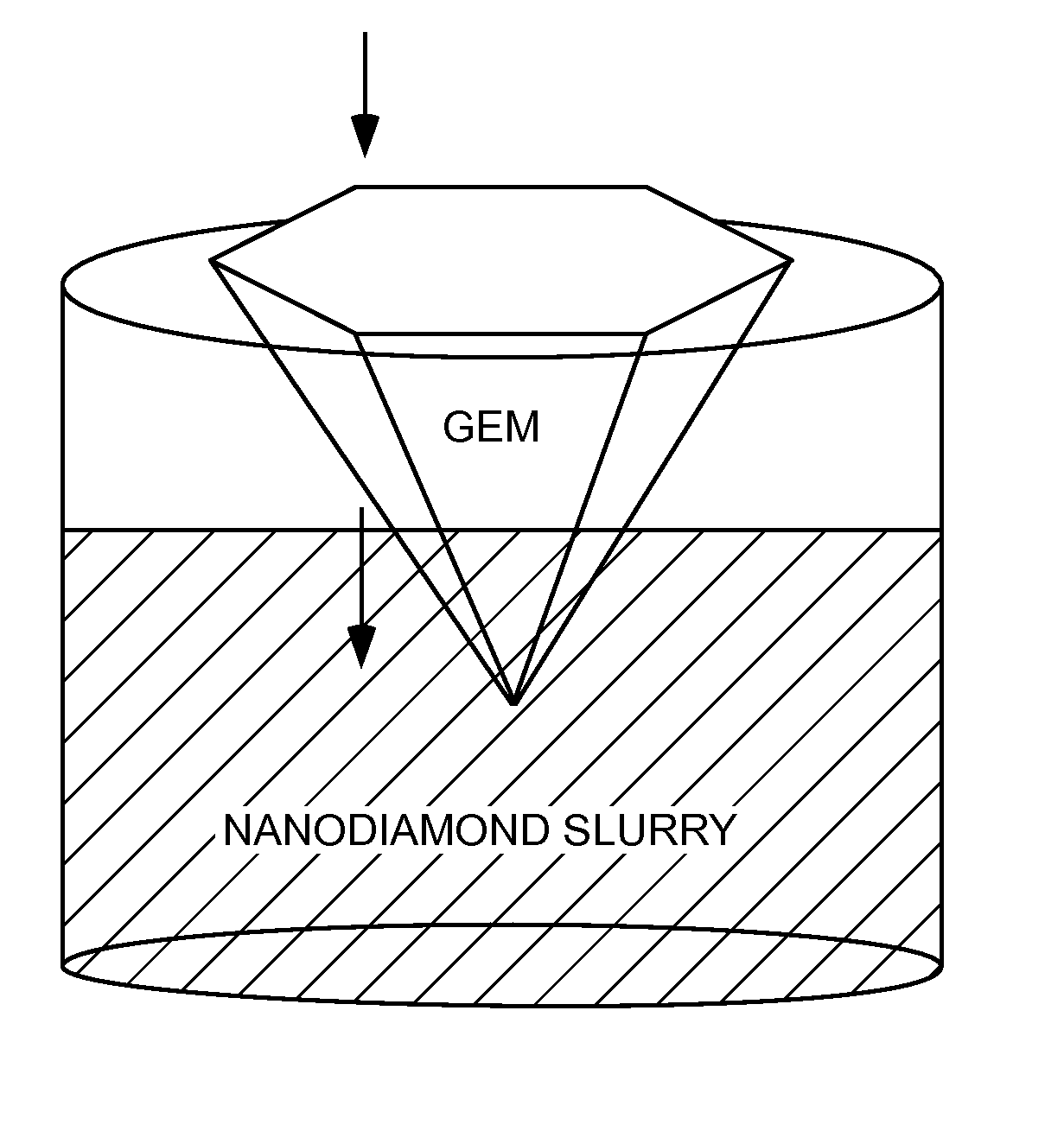

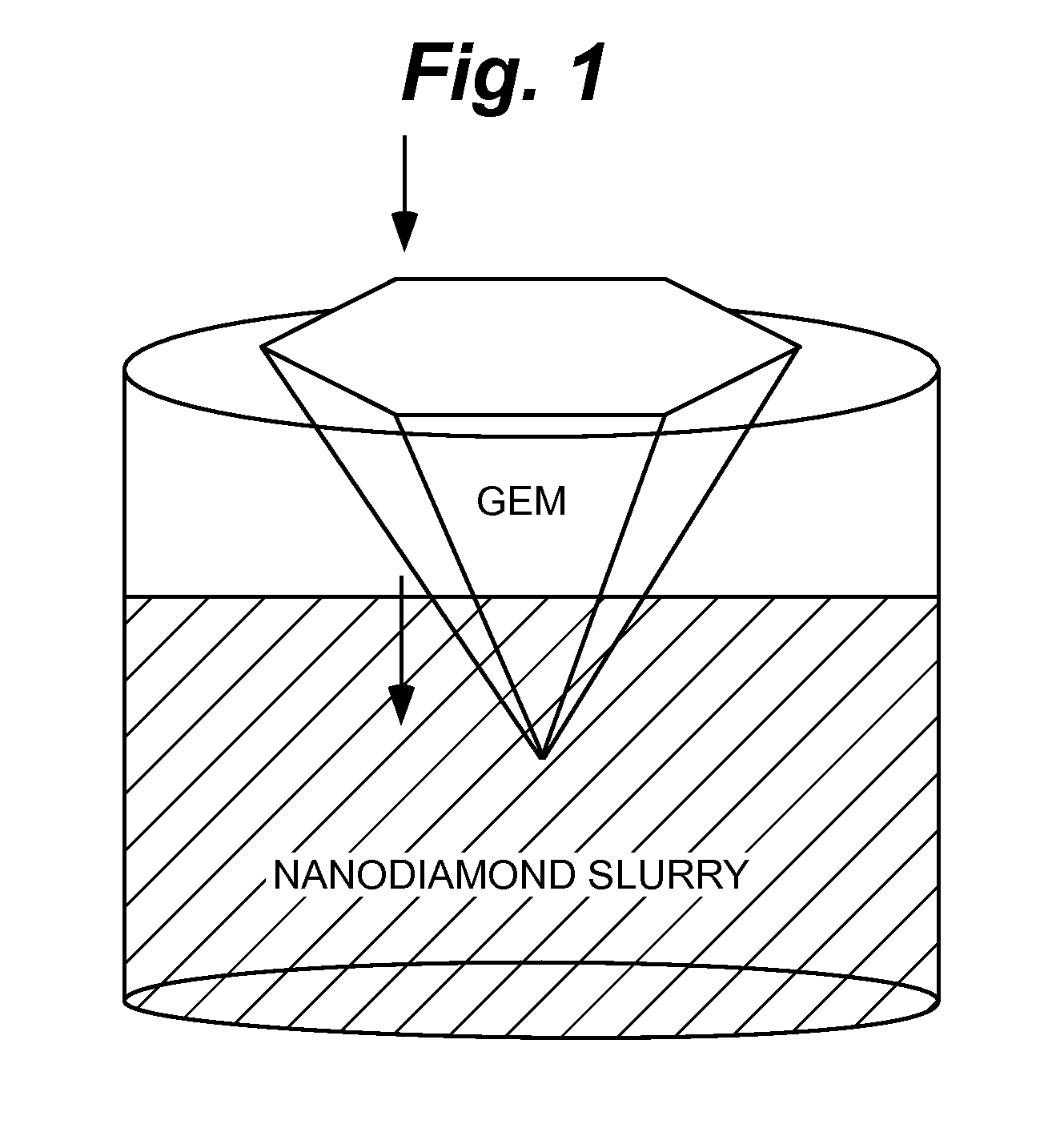

Method for producing nanocrystalline diamond coatings on gemstones and other substrates

ActiveUS20100068503A1Reduce usageEasy to storeElectric discharge heatingLayered productsGemstoneSlurry

A method to apply nano-crystalline diamond onto a selected substrate, including preparing Nanodiamond slurry of nanodiamond particles dispersed in a medium. The medium may include a liquid or a sol-gel. The selected substrate is immersed in the Nanodiamond slurry for a predetermined period of time. Then the substrate is removed from the slurry. The substrate is then dried with a flow of inert gas. The substrate is left coated with a coating of the nanodiamond particles that are highly adherently held by van der Waals forces.

Owner:ARYAMOND SINGAPORE PTE LTD

Water-based diamond polishing solution used for crystal processing

The invention provides a method for preparing multi-granularity water-based diamond polishing liquid used for crystal processing. The polishing solution is suitable for polishing a variety of crystals. A high shear emulsifying machine is used, the diameter of the stirring work head of the machine is not less than 56mm, and the maximum rotating speed of the stirring work head is not lower than 15000rpm; and a viscosity modifier is used to prepare the polishing solution with different viscosities in order to meet the different needs of many users. The polishing solution obtained in the invention has the polishing, lubricating, cooling and chip removing functions. The ingredients of the polishing solution comprise water, diamond, a wetting agent, a surfactant, the viscosity modifier, an antirust agent, a lubricating agent, an antifoaming agent, an antiseptic bactericide and a pH regulator. When the 1mum monocrystalline diamond polishing solution is used to polish SiC crystals, the polishing efficiency reaches 0.08mum / min, and the surface roughness Ra of the SiC crystals decrease to 0.91nm from original 80nm after polishing; and when a 0.125mum polycrystalline nano-diamond polishing solution is used to polish the SiC crystals, the surface roughness Ra of the SiC crystals reaches 0.1-0.3nm.

Owner:TIANJIN CHANYU SUPERHARD SCI TECH CO LTD

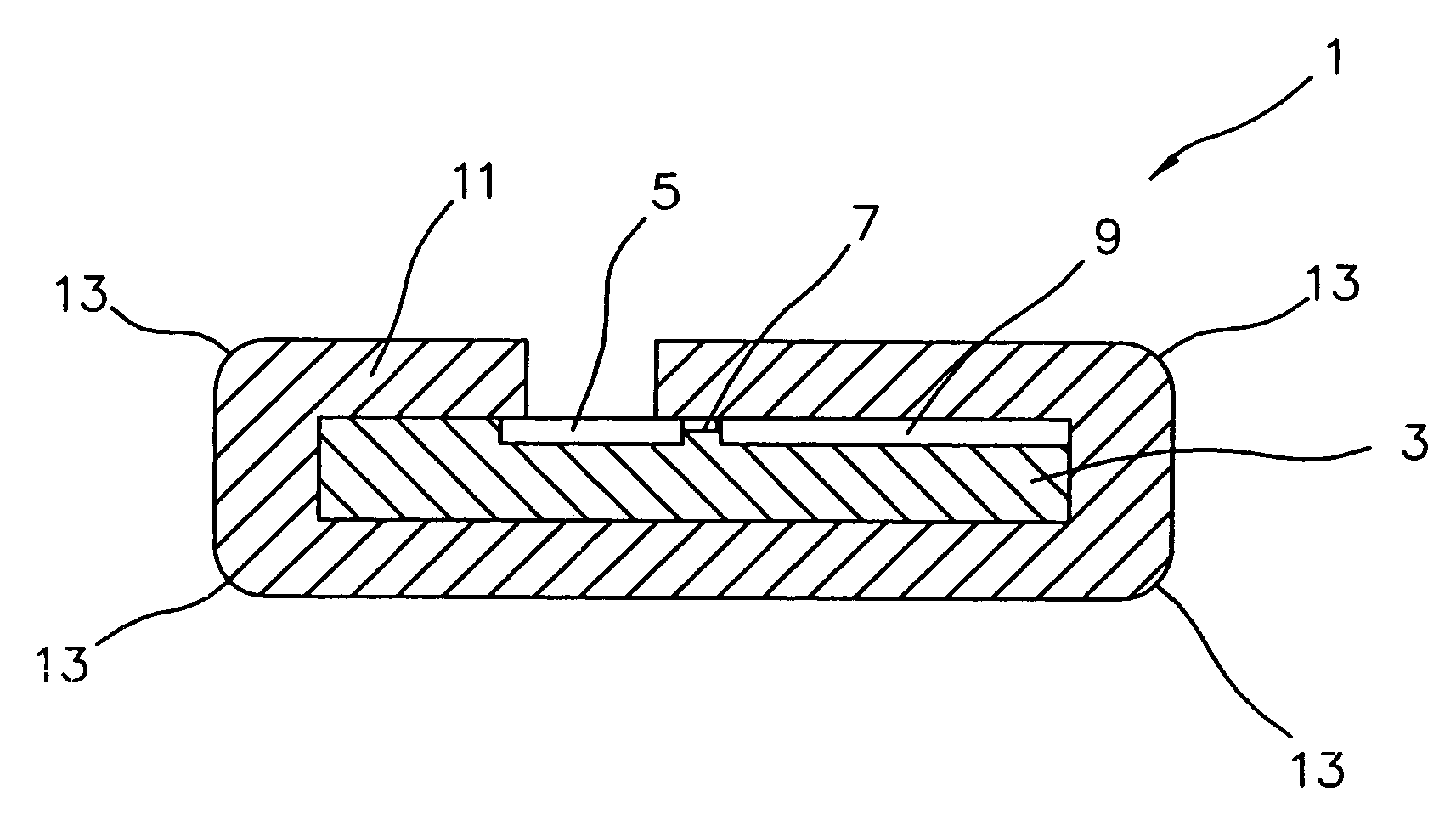

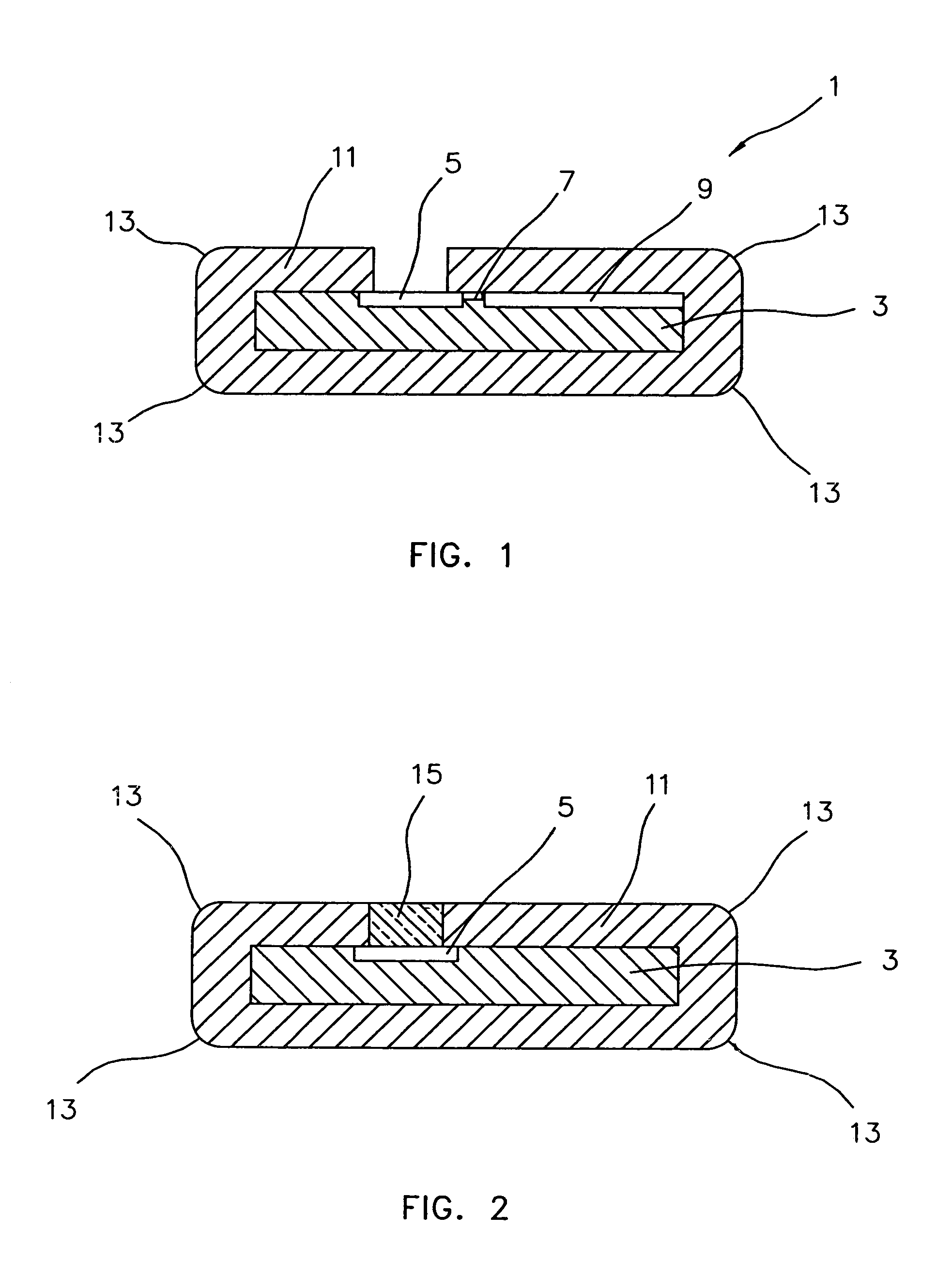

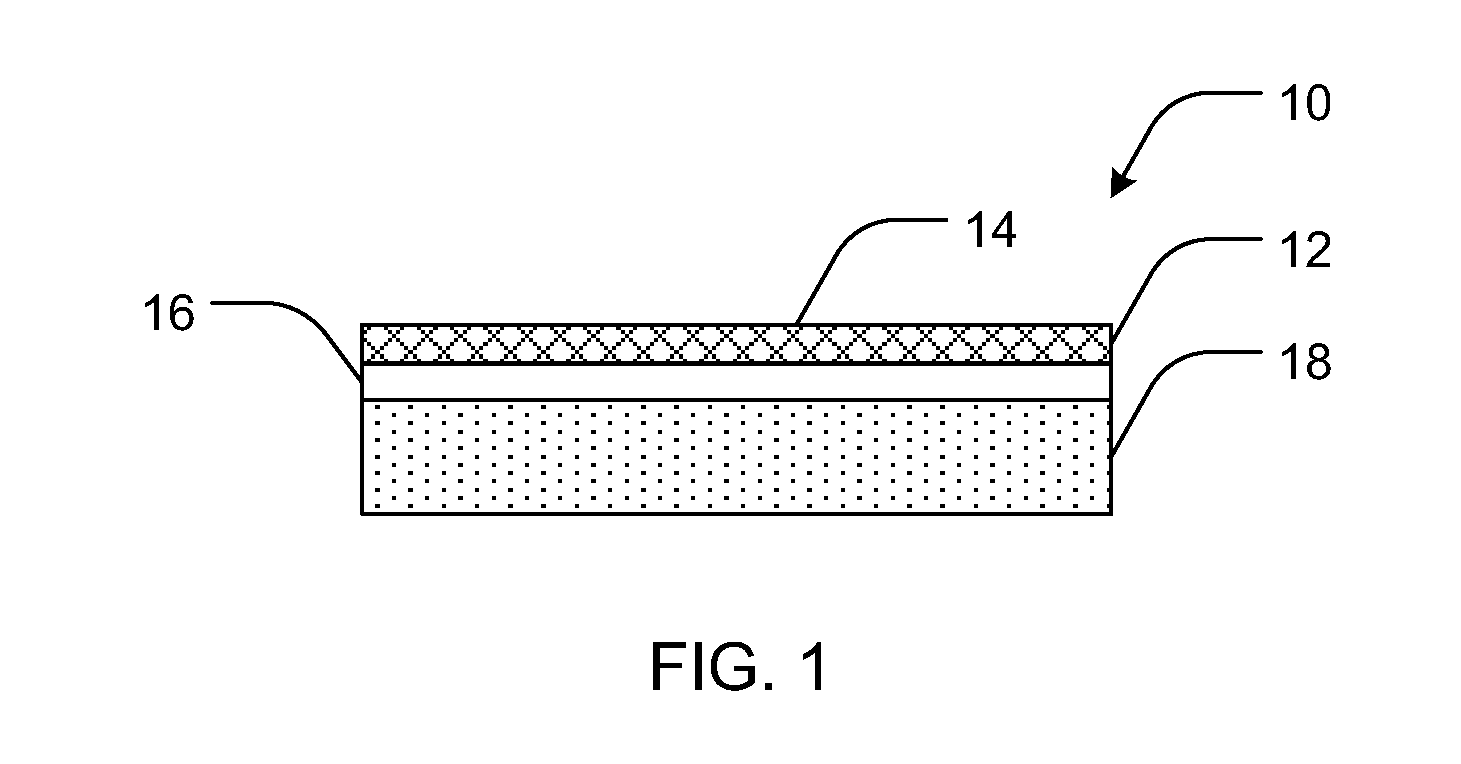

Implantable device using ultra-nanocrystalline diamond

An implantable biocompatible device, that may be either a sensor or stimulator, having electronic circuitry and electrodes formed on a substrate, is uniformly covered with a coating approximately one-micron thick of ultra-nanocrystalline diamond, hermetically sealing the electronic circuitry. Selected electrodes are either left uncovered during coating or uncovered by conventional patterning techniques, allowing the electrodes to be exposed to living tissue and fluids. The ultra-nanocrystalline diamond coating may be doped to create electrically conductive electrodes. These approaches eliminate the need for a hermetically sealed lid or cover to protect hybrid electronic circuitry, and thus allow the device to be thinner than otherwise possible. The conformal ultra-nanocrystalline diamond coating uniformly covers the device, providing relief from sharp edges and producing a strong, uniformly thick hermetic coating around sharp edges and on high aspect-ratio parts.

Owner:SECOND SIGHT MEDICAL PRODS

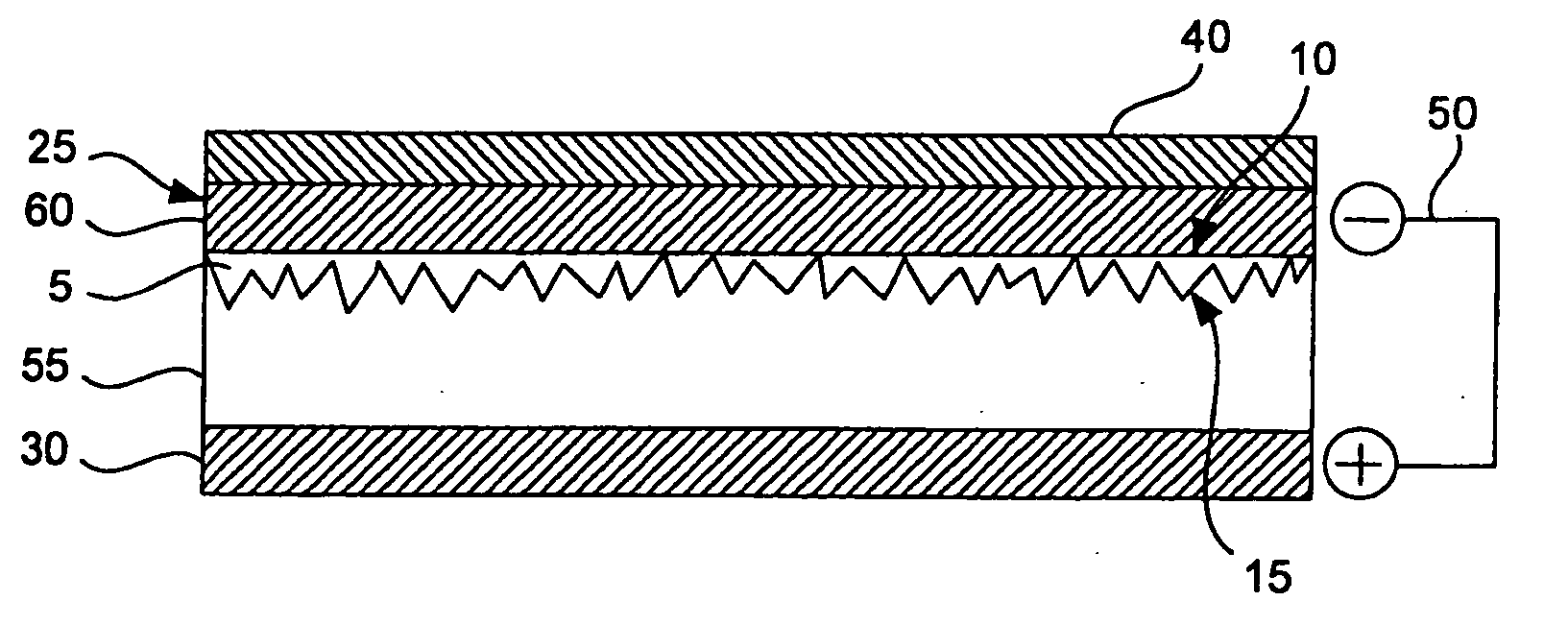

DLC field emission with nano-diamond impregnated metals

InactiveUS20070126312A1Improve electron emission efficiencyCathode ray tubes/electron beam tubesDischarge tube/lamp detailsDiamond-like carbonMaterials science

Diamond-like carbon based energy conversion devices and methods of making and using the same which have improved conversion efficiencies and increased reliability are provided. In one aspect, such a device may include a cathode having a plurality of nano-diamond particles disposed in a metal matrix, where the plurality of nano-diamond particles protrude partially from the metal matrix. A layer of diamond-like carbon (DLC) may be deposited on the plurality of nano-diamond particles and the metal matrix. Additionally, an anode may be located in a position to face the plurality of nano-diamond particle protrusions.

Owner:SUNG CHIEN MIN

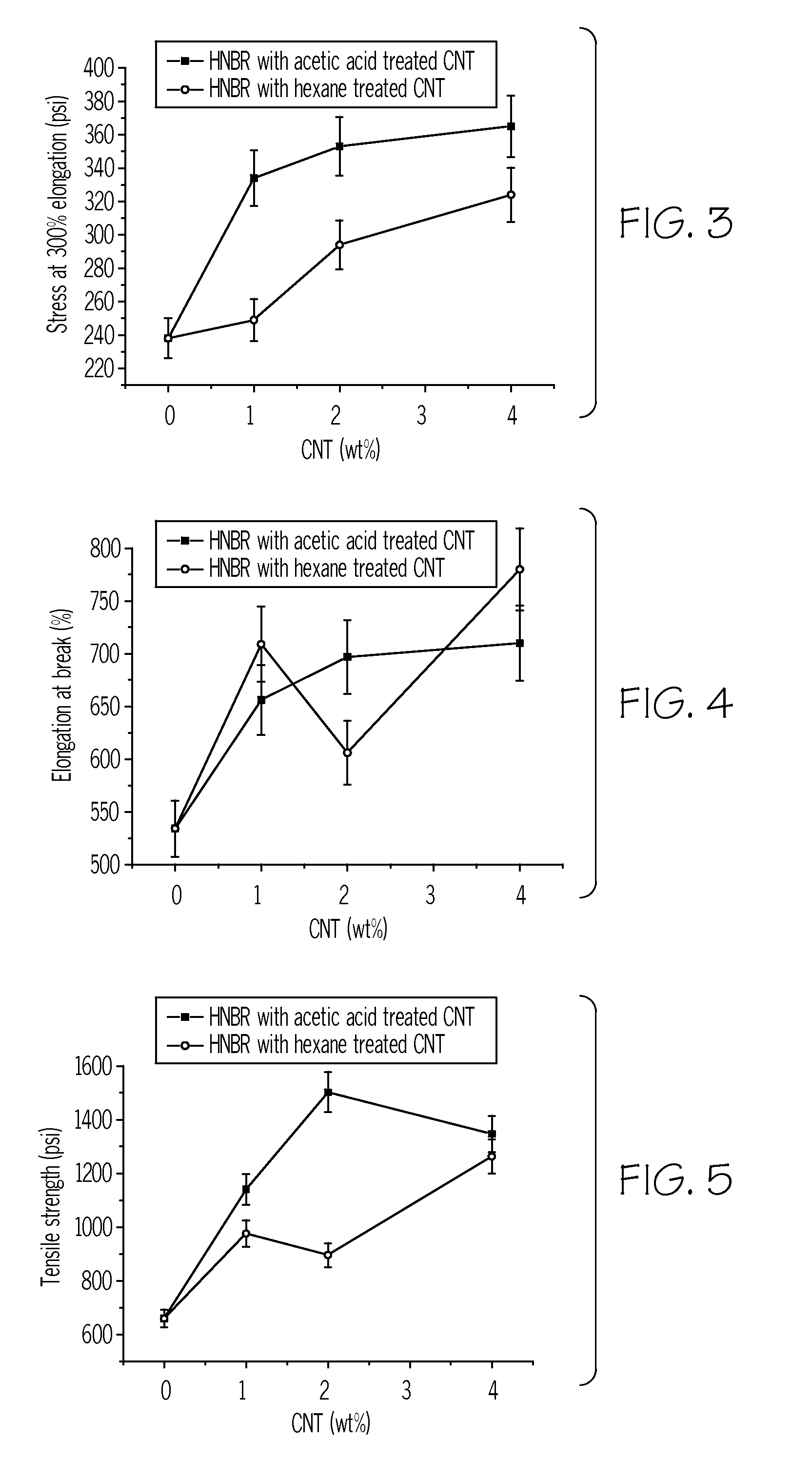

Method of modifying carbon nanomaterials, composites incorporating modified carbon nanomaterials and method of producing the composites

A polymer-carbon nanomaterial composite. The composite includes a polymer matrix; and plasma-modified carbon nanomaterials having surface functional groups attached thereto, wherein the carbon nanomaterial is selected from carbon nanotubes, carbon nanofibers, carbon nanoparticles, carbon black, nanodiamond, fullerenes, or combinations thereof. The invention also involves a method of making a polymer-carbon nanomaterial composite, and a method of modifying carbon nanomaterials.

Owner:UNIV OF DAYTON

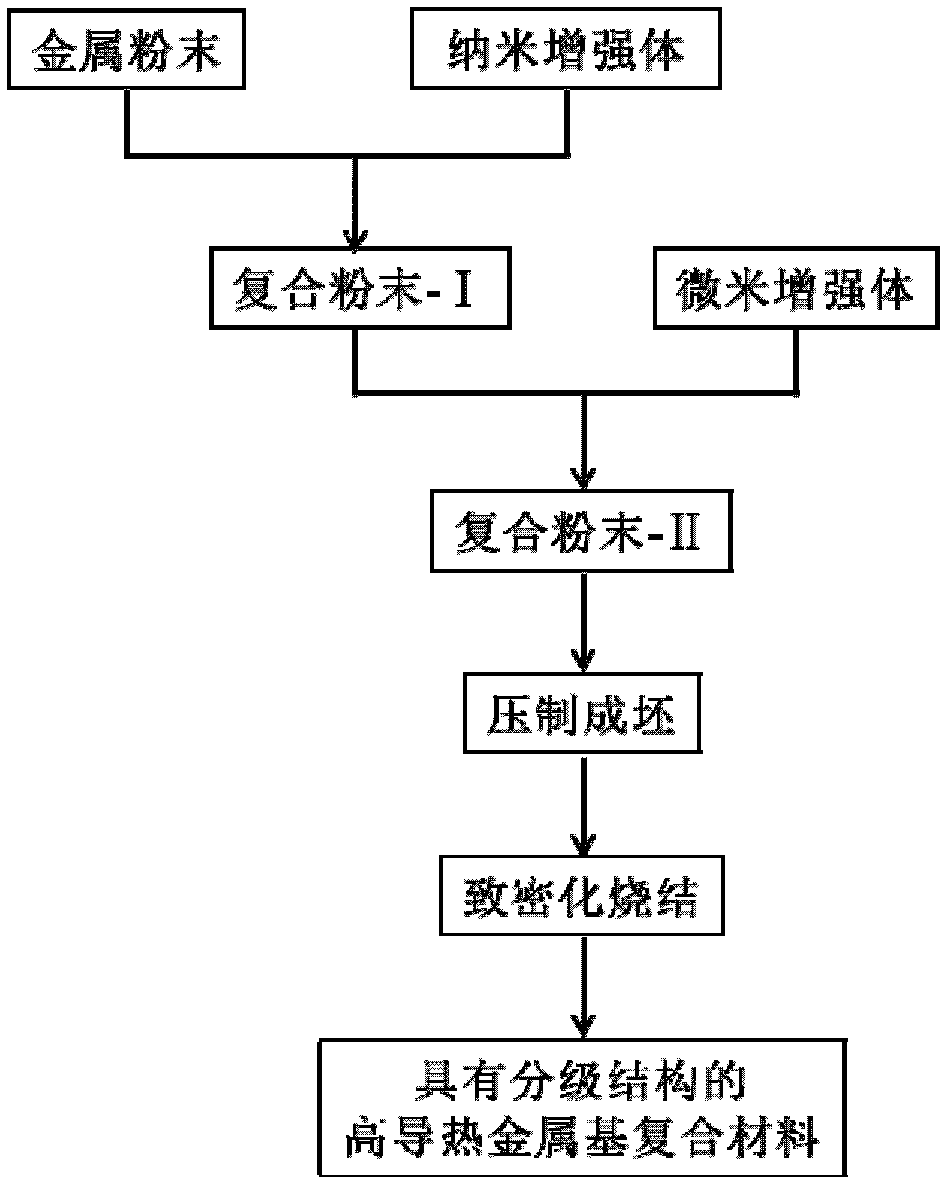

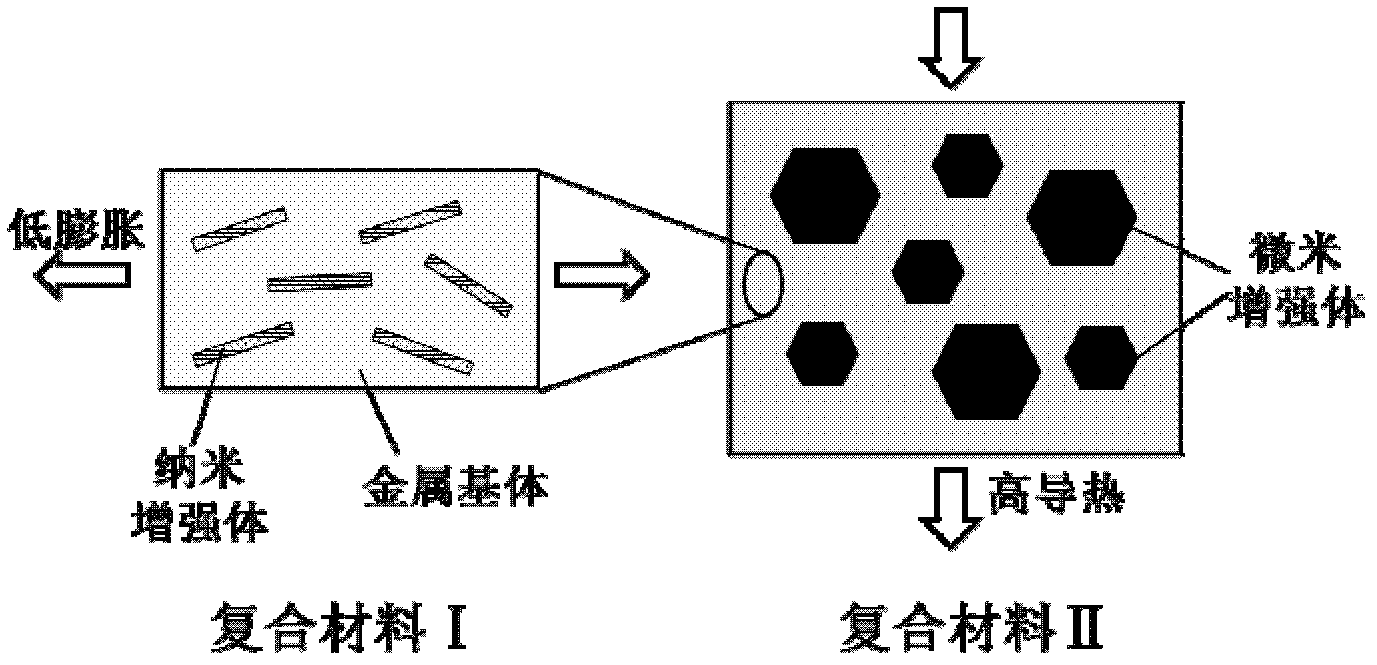

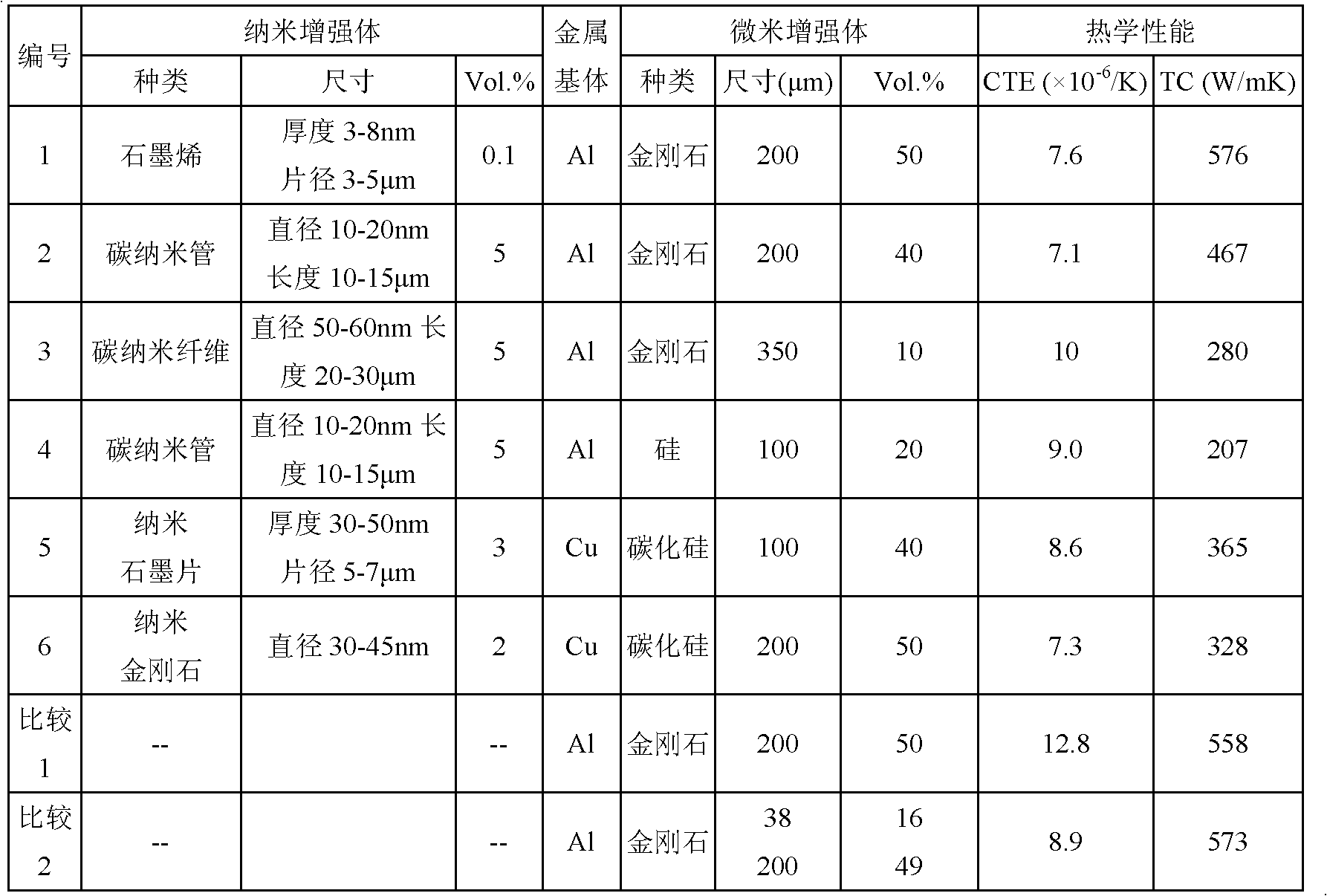

High thermal conductivity metal-based composite material with hierarchical structure, and preparation method thereof

The invention discloses a high thermal conductivity metal-based composite material with a hierarchical structure, and a preparation method of the high thermal conductivity metal-based composite material; the high thermal conductivity metal-based composite material and the preparation method are characterized in that a first stage composite material (composite material I) is formed by at least one nano-reinforced body and a metallic matrix, and a second stage composite material (composite material II) is formed by at least one micron-reinforced body and the composite material I, wherein the nano-reinforced body is selected from graphene, a carbon nano tube, carbon nano-fiber, a nano-graphite flake and nano-diamond, and at least has the size of 1-100nm along the one-dimensional direction; and the micron-reinforced body is selected from diamond, silicon carbide and silicon, and has the equivalent grain size of 30-600 mu m. The composite material has low and controllable coefficient of thermal expansion, high heat conductivity, thus being used as various heat management materials.

Owner:SHANGHAI JIAO TONG UNIV

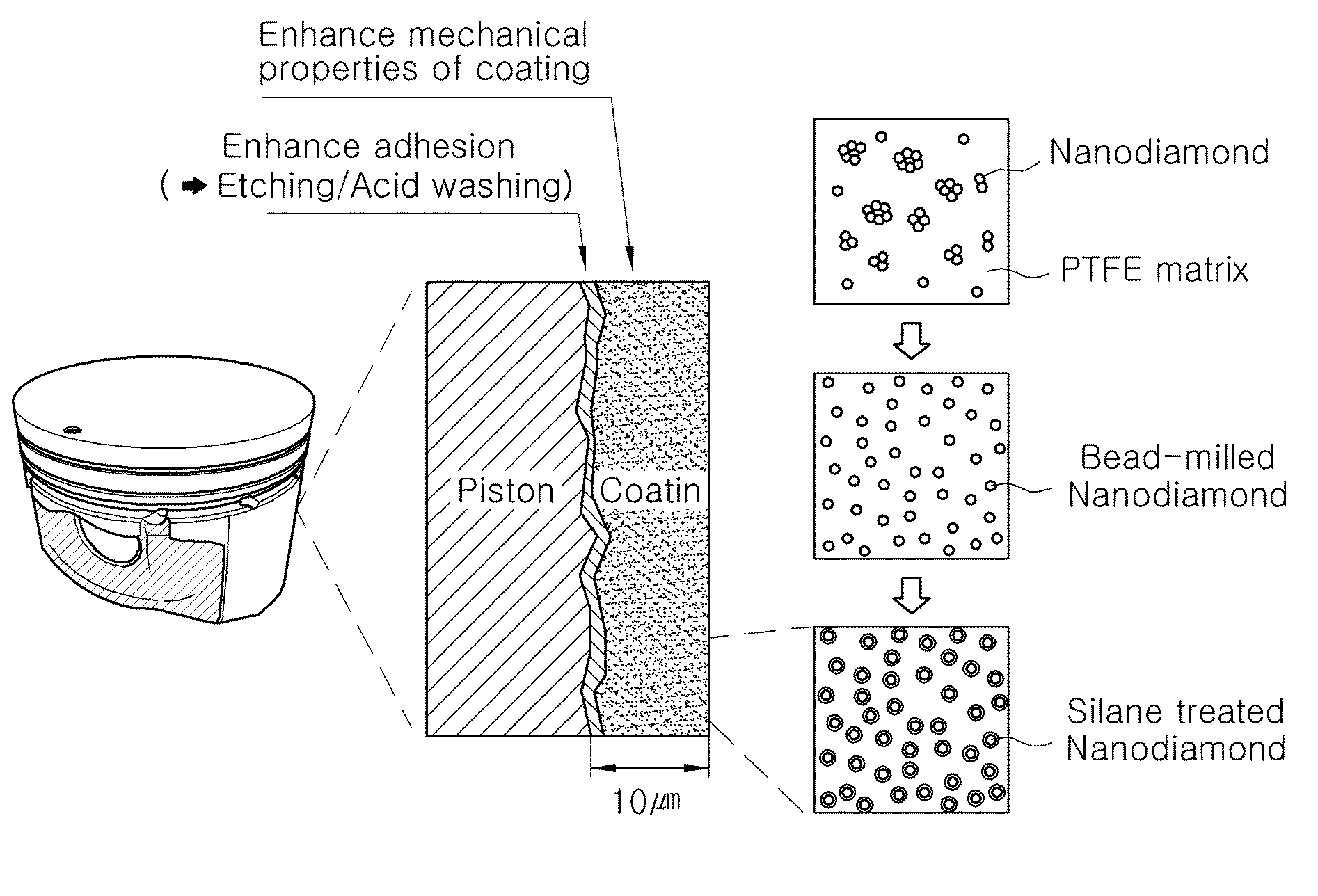

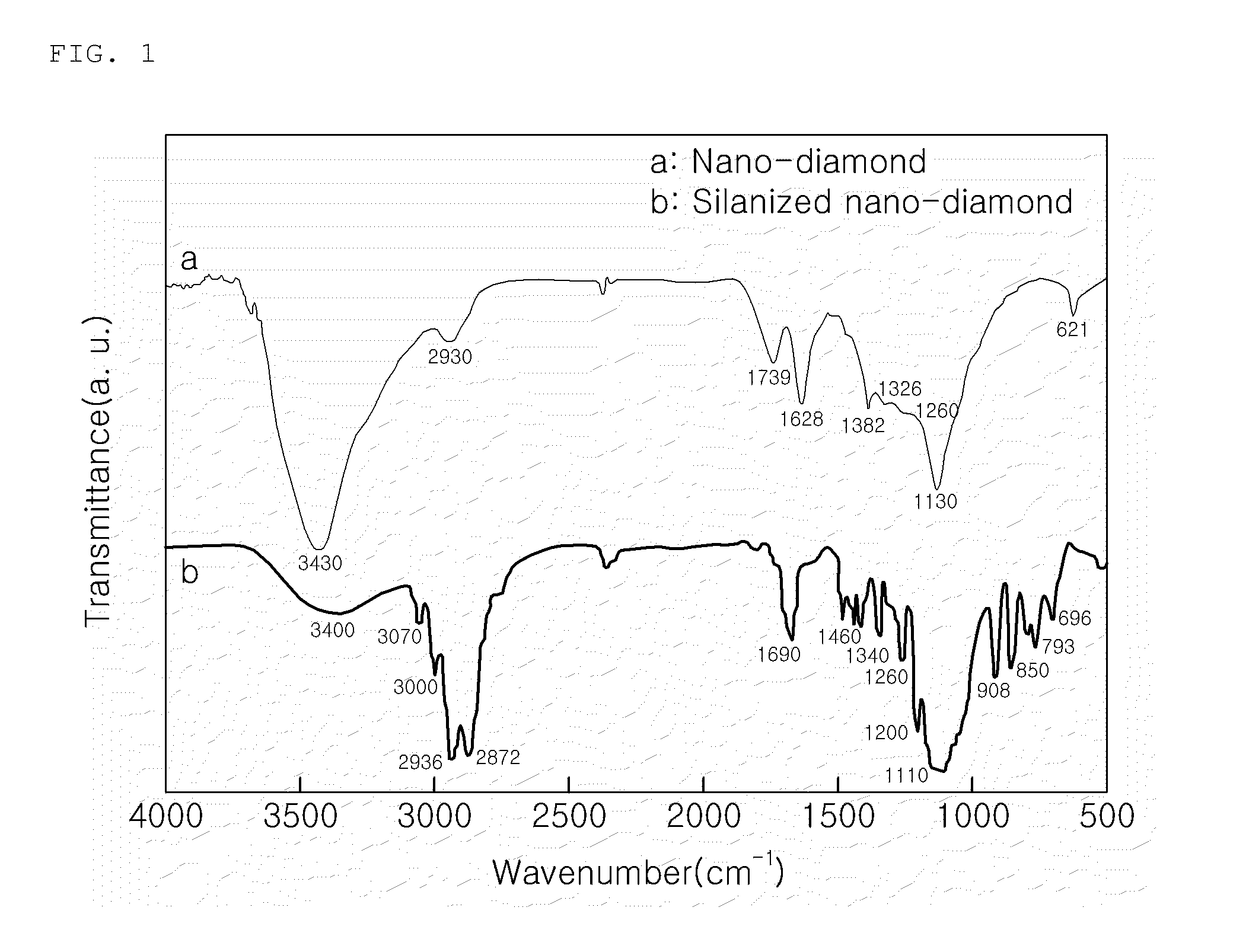

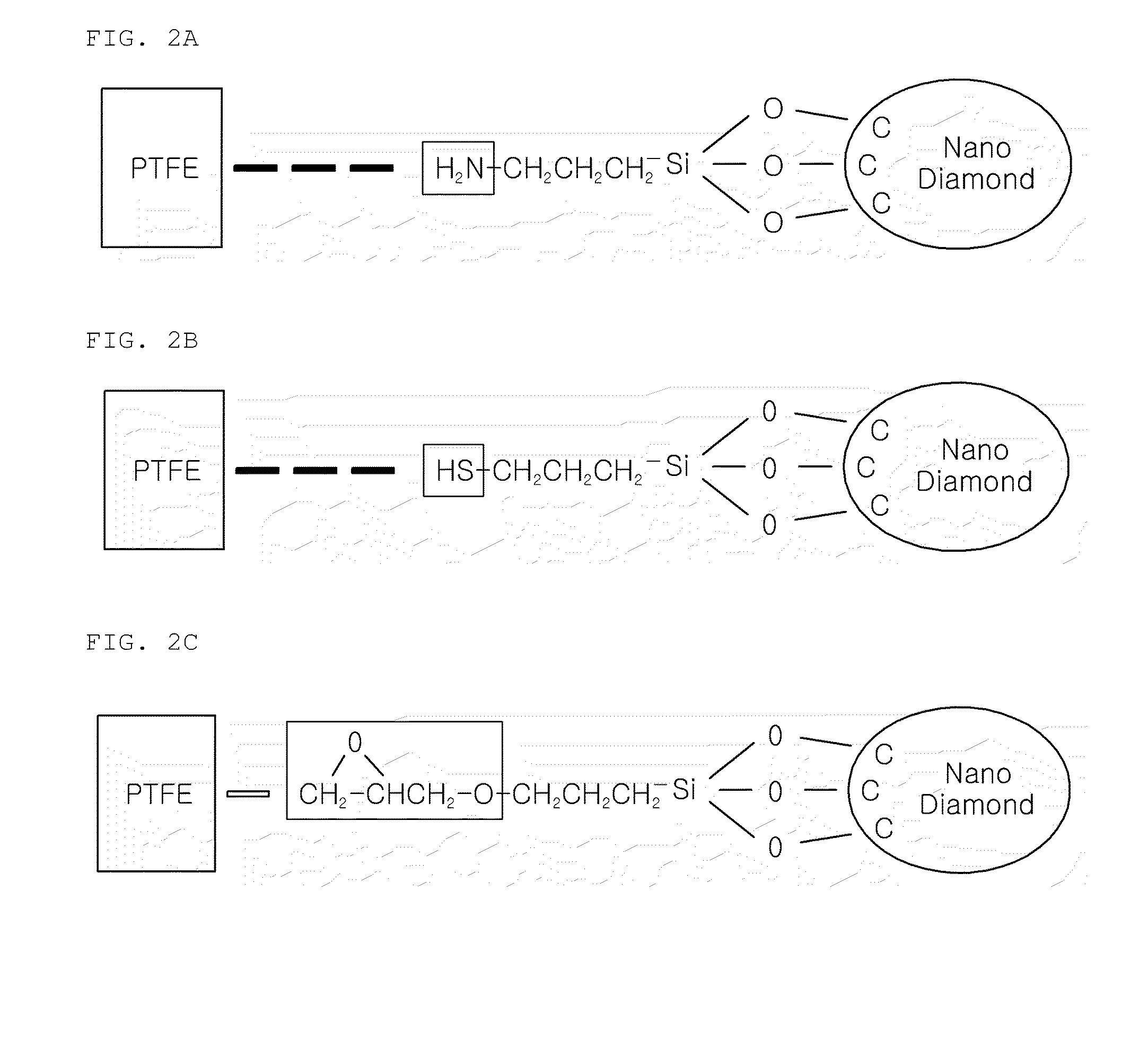

Polytetrafluoroethylene coating agent, method of preparation and use

InactiveUS20100233371A1Reduce frictionImprove wear resistanceMaterial nanotechnologyNanostructure manufactureOrganic solventHigh wear resistance

Disclosed is a polytetrafluoroethylene coating agent having low friction and high wear resistance, obtained by dispersing nanodiamond powder in a polar organic solvent, stirring the nanodiamond dispersion solution and a silane coupling agent, and stirring the silane-treated dispersion solution and an oily polytetrafluoroethylene coating solution, in which the silane coupling agent has at least one organic functional group selected from, but not limited to, a mercapto group and an amino group, the organic functional group exhibiting high bondability to polytetrafluoroethylene. A method of preparing the polytetrafluoroethylene coating agent and a method of using the polytetrafluoroethylene coating agent are also provided.

Owner:HYUNDAI MOTOR CO LTD +2

Healthcare and cosmetic compositions containing nanodiamond

Nanodiamonds can be included in various compositions to take advantage of the ability of nanodiamond to bond with biological materials and to improve mechanical strength. Nanodiamonds can be dispersed in a biologically acceptable carrier to form various nanodiamond compositions. The presence of nanodiamonds can increase binding with many biological materials, making the compositions of the present invention useful for a large variety of purposes such as cleansing, testing and identification of materials, and treatment of adverse conditions. Specific examples of nanodiamond compositions that can be formulated include deodorants, toothpastes, shampoos, antibiotics, dermal strips, DNA test strips, skin cleansers, and the like. Similarly, nanodiamond particles can be included in a cosmetic nanodiamond composition within a cosmetically acceptable carrier. Cosmetic nanodiamond compositions can include, for example, nail polish, eyeliner, lip gloss, exfoliant, and the like.

Owner:SUNG CHIEN MIN

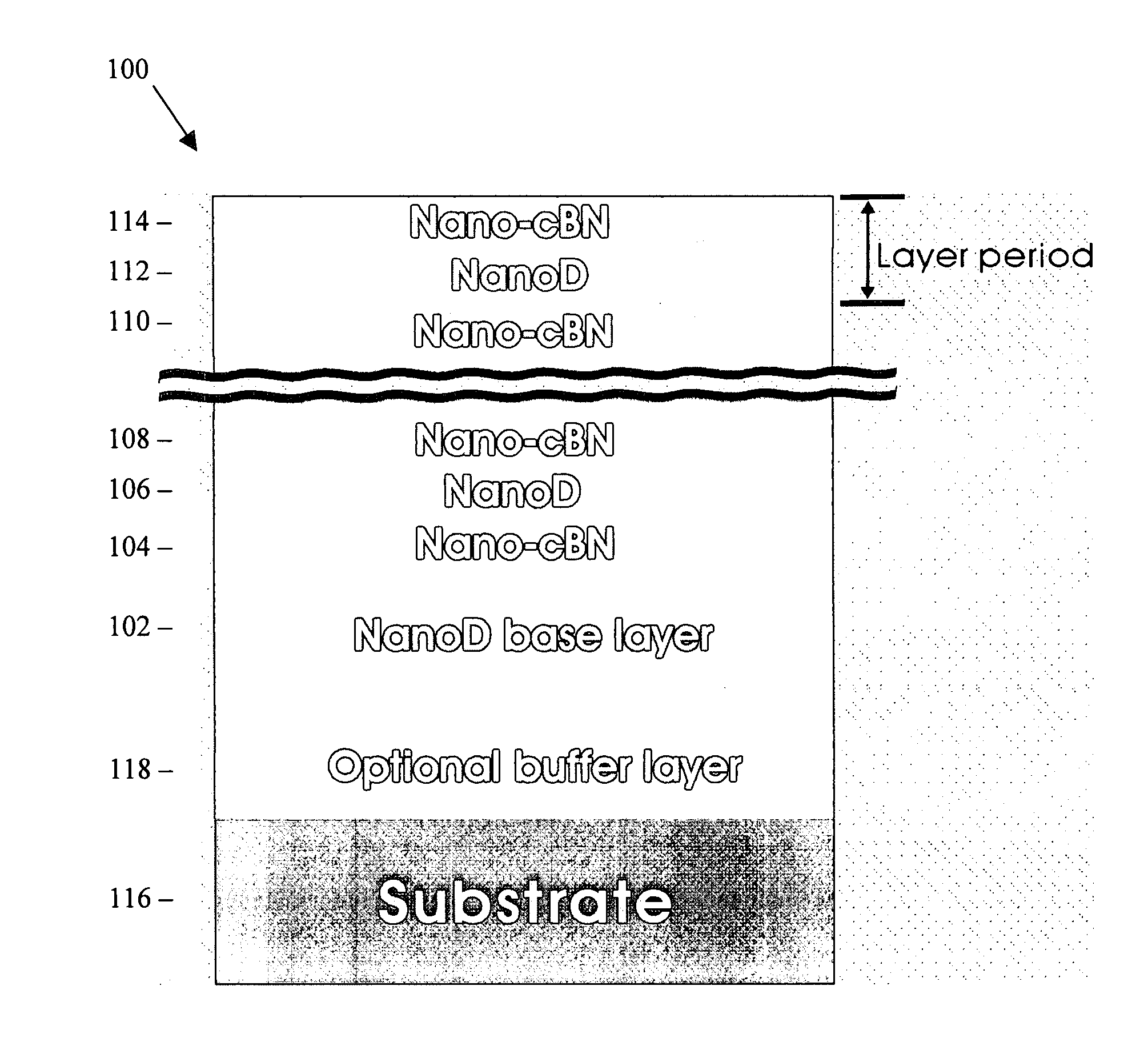

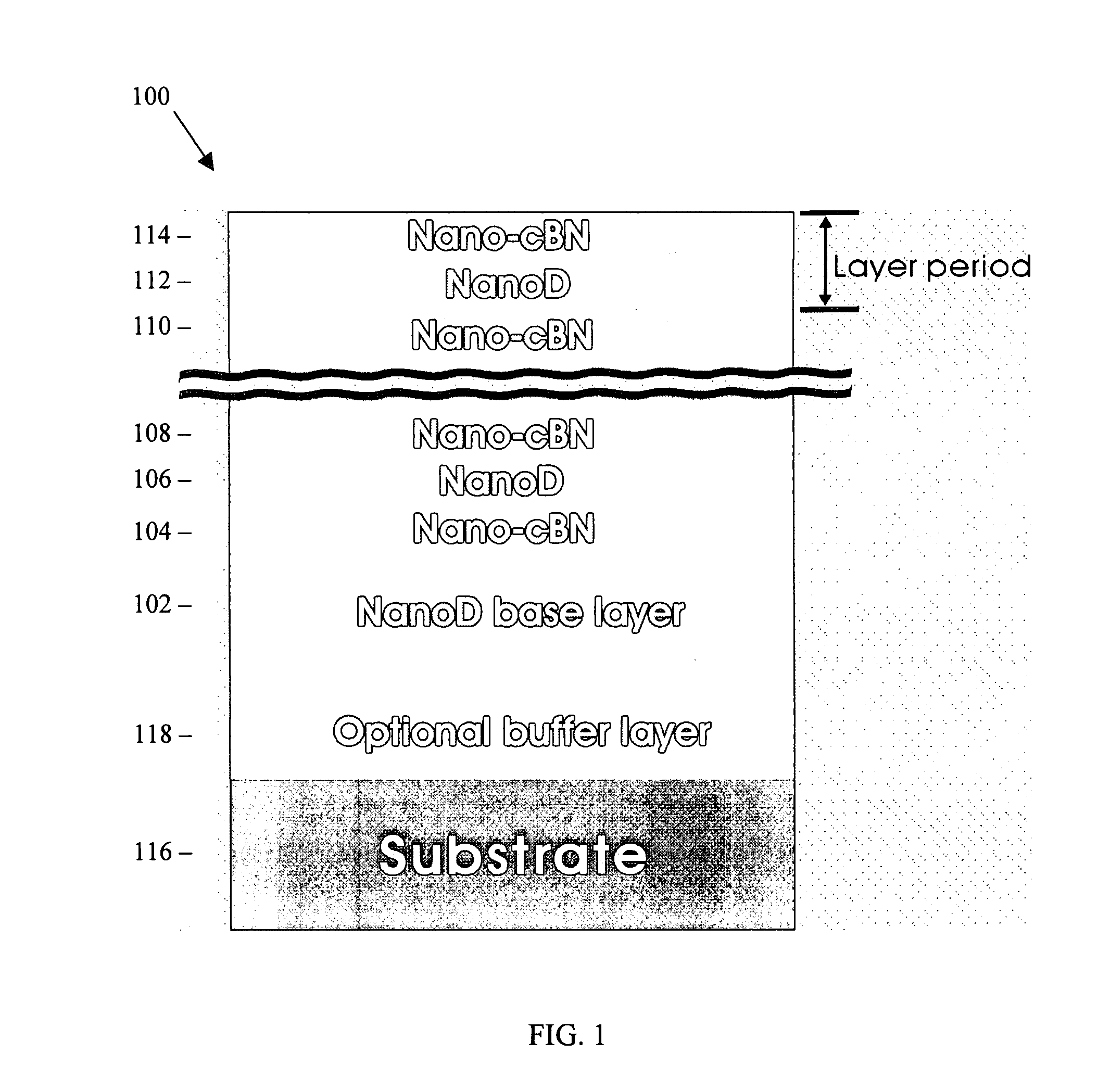

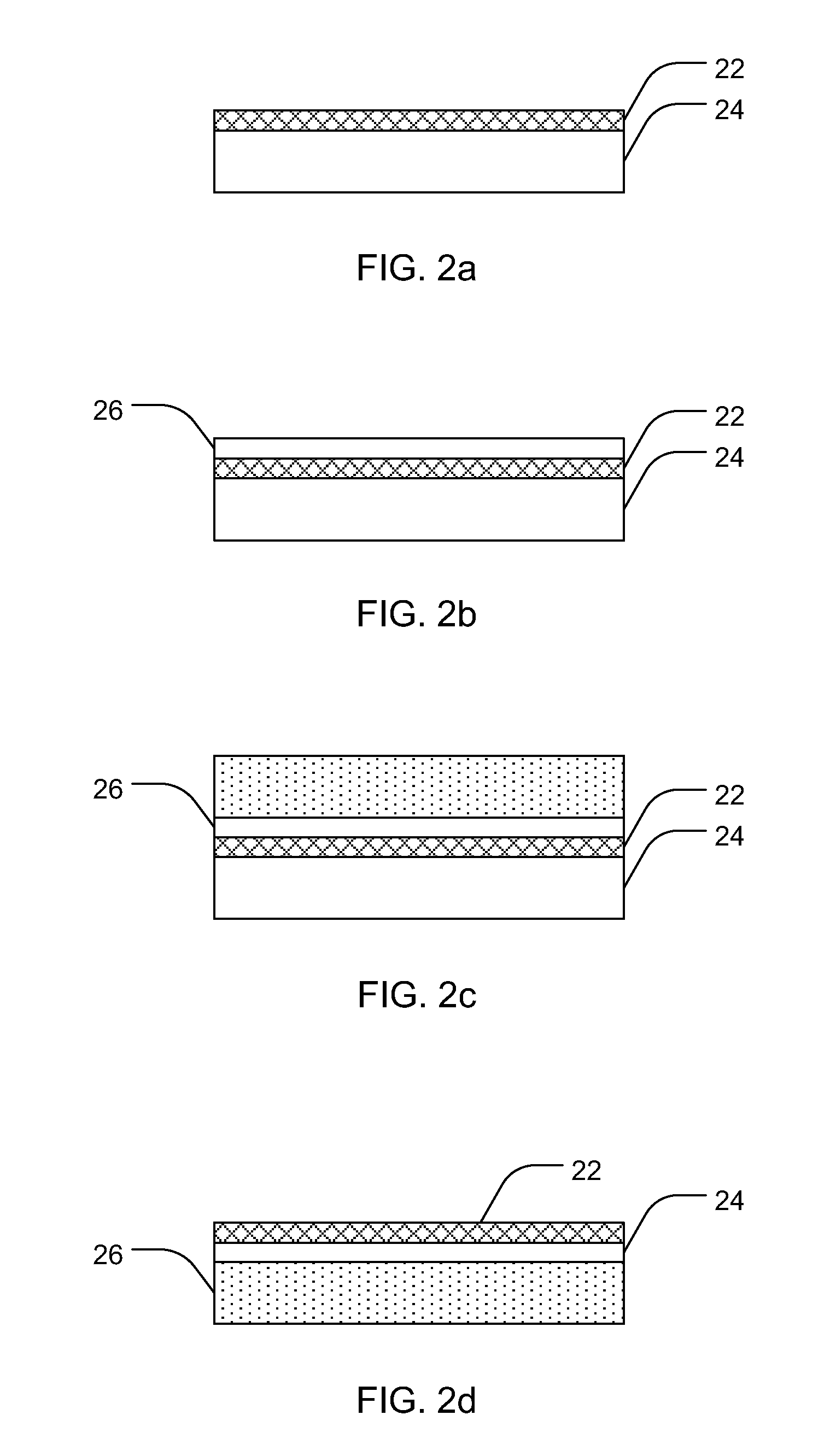

Ultrahard multilayer coating comprising nanocrystalline diamond and nanocrystalline cubic boron nitride

A multilayer coating (MLC) is composed of two chemically different layered nanocrystalline materials, nanodiamond (nanoD) and nano-cubic boron nitride (nono-cBN). The structure of the MLC and fabrication sequence of layered structure are disclosed. The base layer is preferably nanoD and is the first deposited layer serving as an accommodation layer on a pretreated substrate. It can be designed with a larger thickness whereas subsequent alternate nano-cBN and nanoD layers are typically prepared with a thickness of 2 to 100 nm. The thickness of these layers can be engineered for a specific use. The deposition of the nanoD layer, by either cold or thermal plasma CVD, is preceded by diamond nucleation on a pretreated and / or precoated substrate, which has the capacity to accommodate the MLC and provides excellent adhesion. Nano-cBN layers are directly grown on nanodiamond crystallites using ion-assisted physical vapor deposition (PVD) and ion-assisted plasma enhanced chemical vapor deposition (PECVD), again followed by nanodiamond deposition using CVD methods in cycles until the intended number of layers of the MLC is obtained.

Owner:CITY UNIVERSITY OF HONG KONG

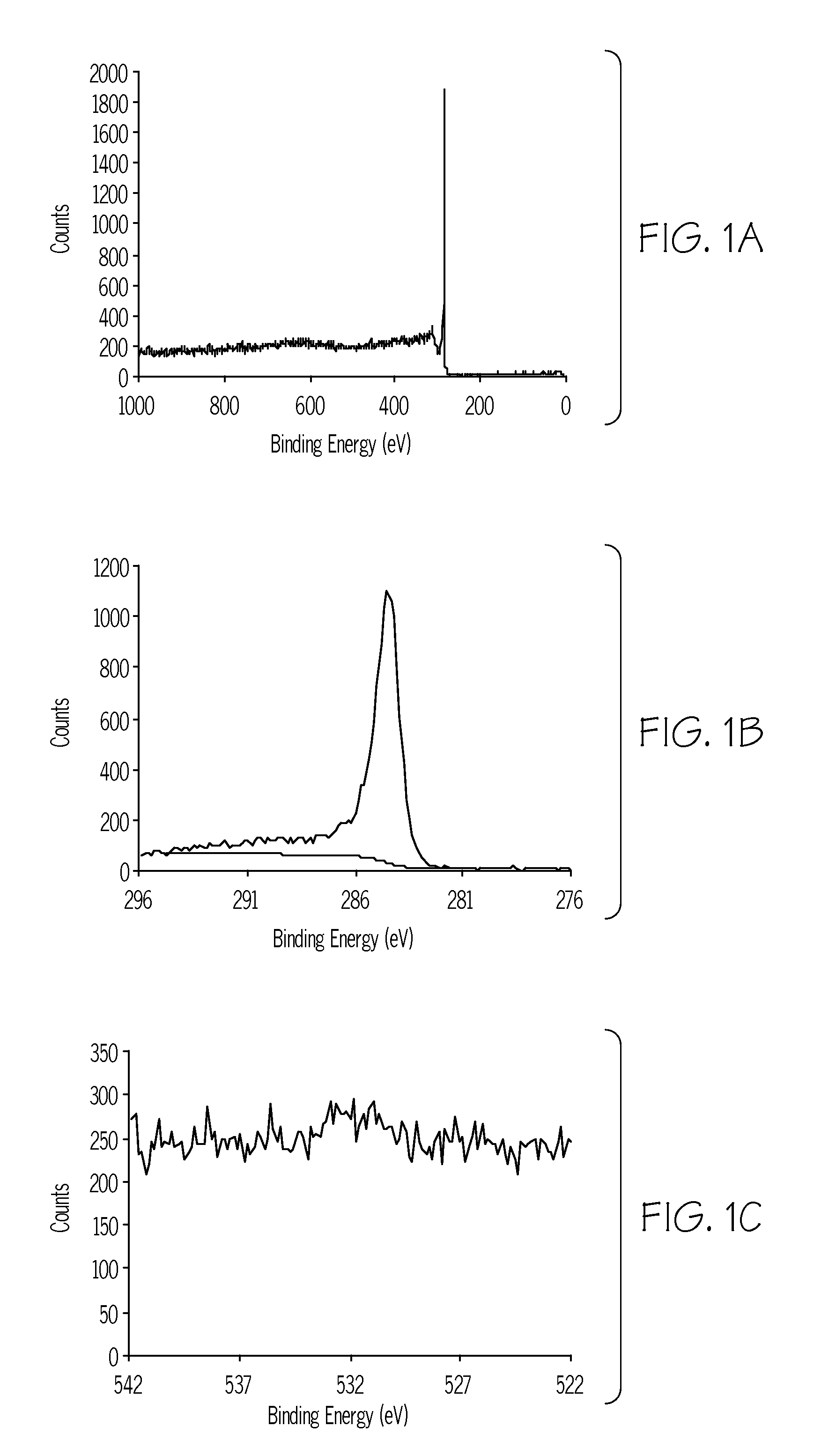

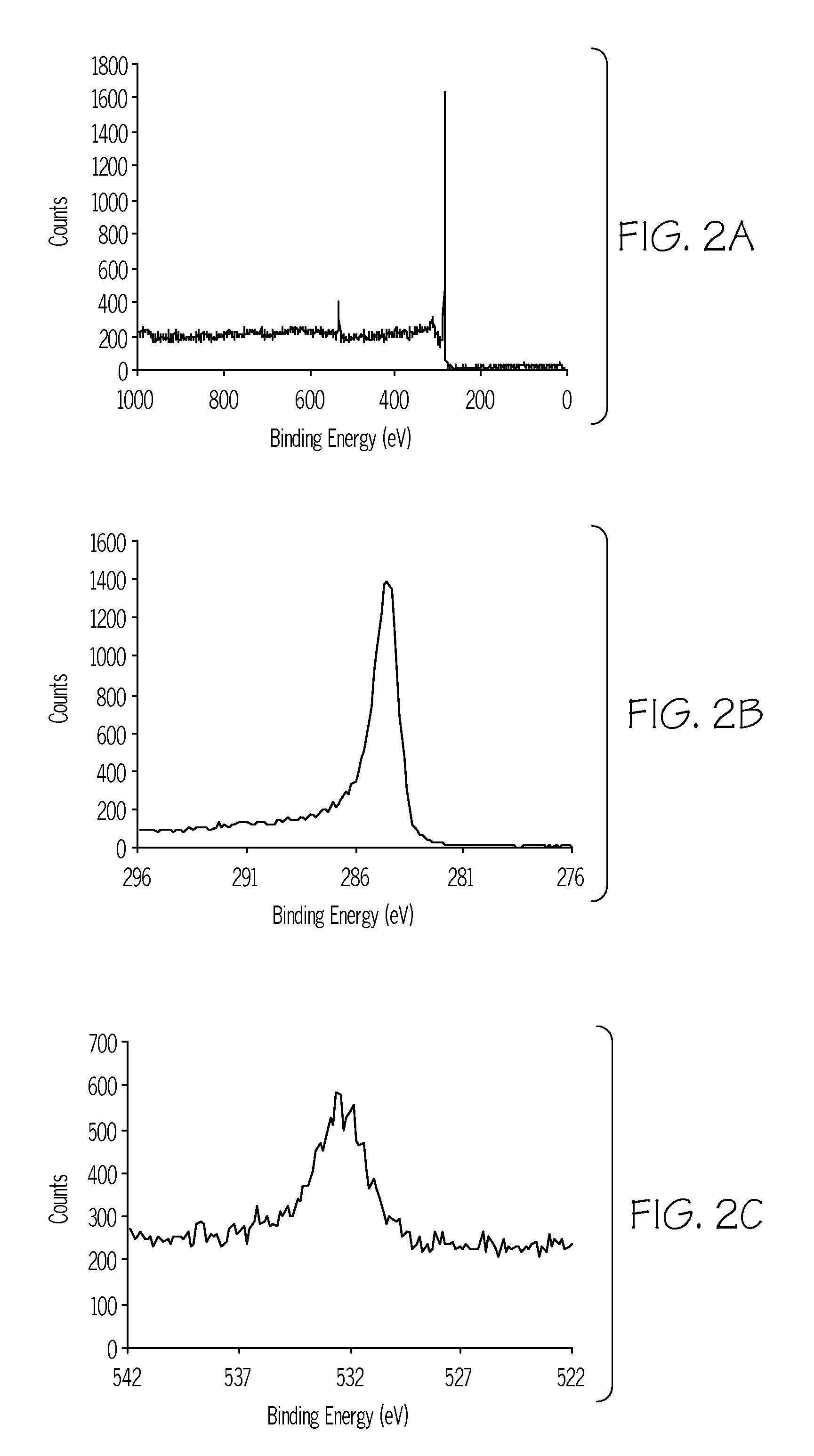

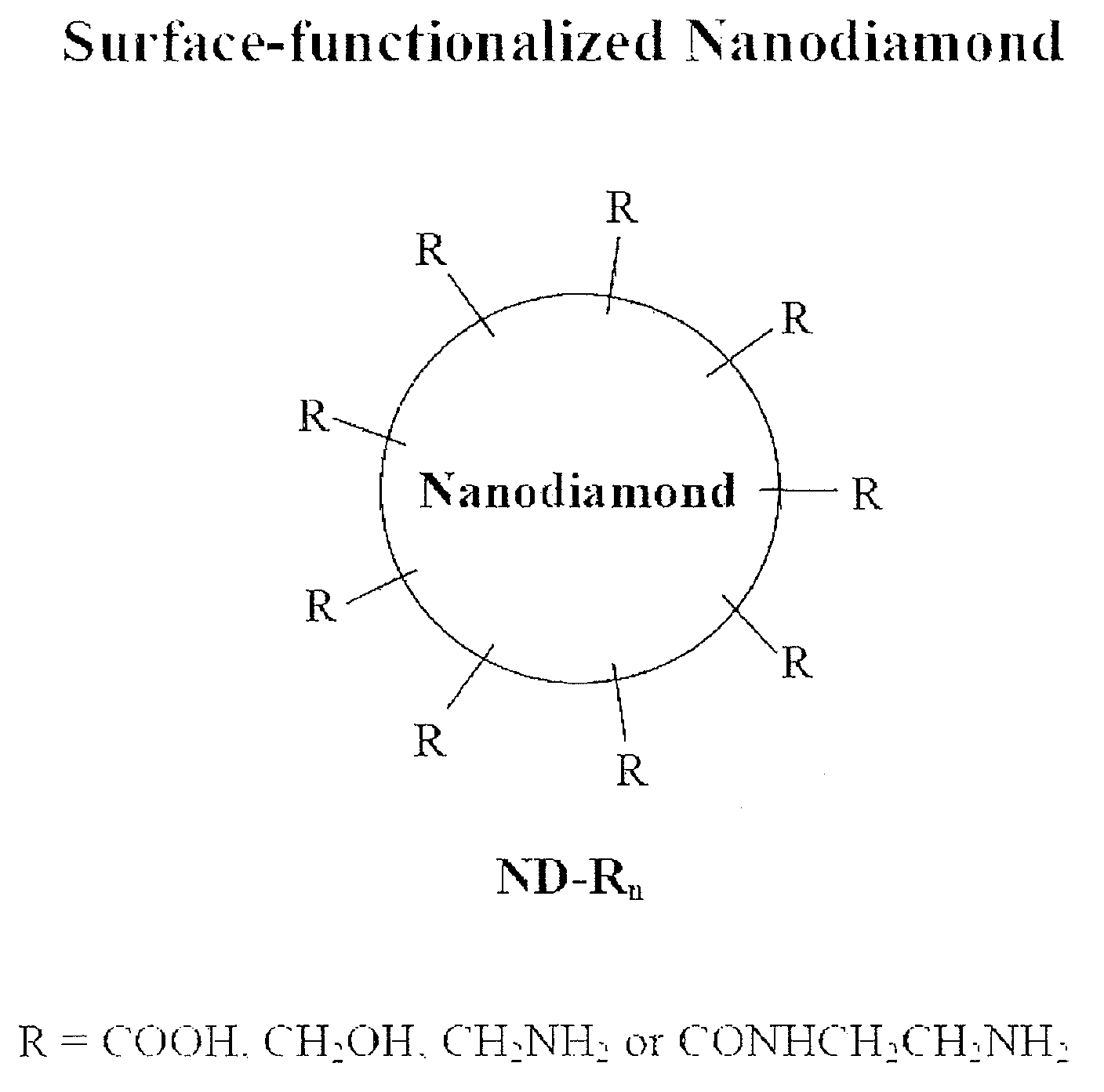

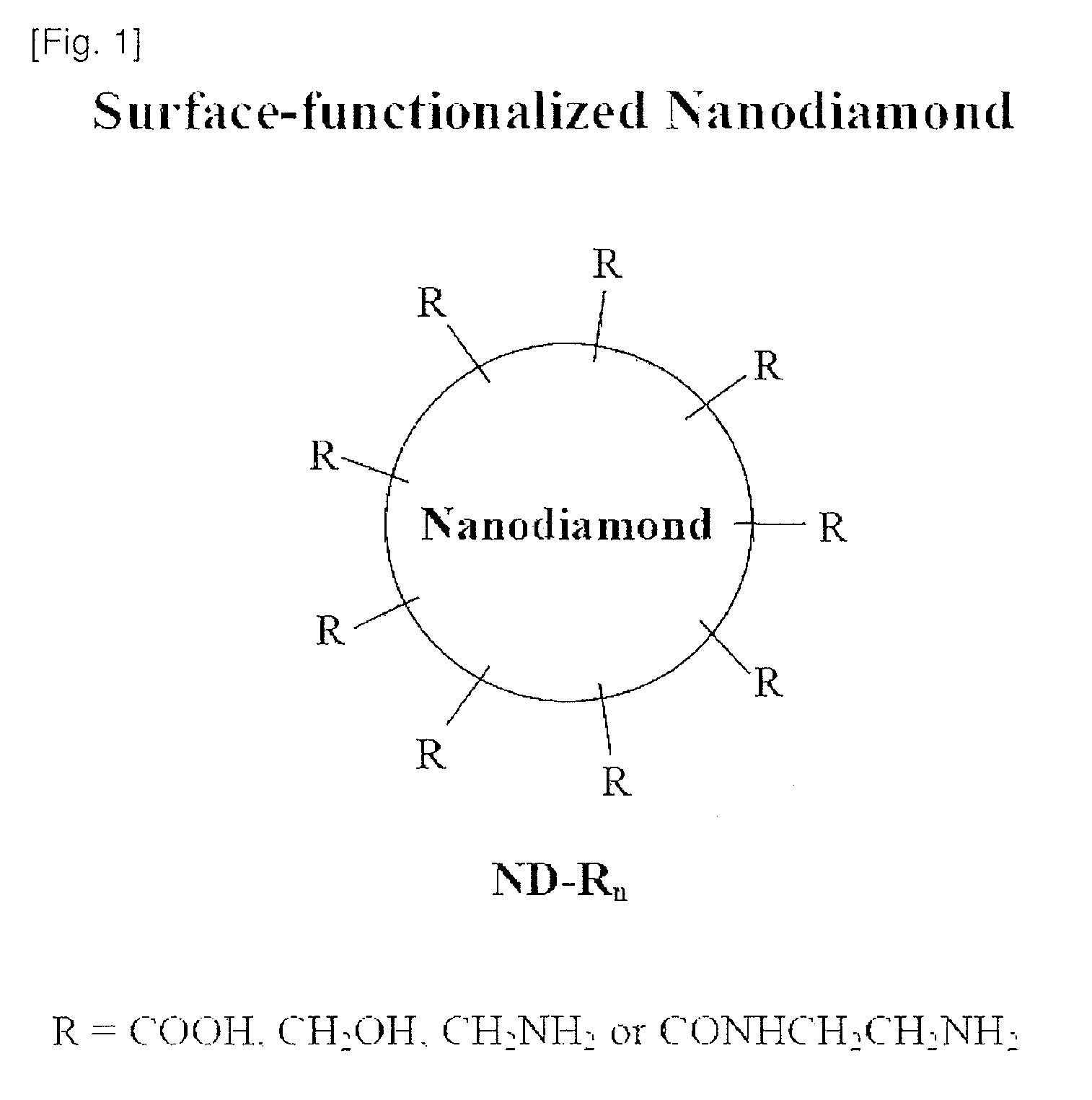

Nanodiamond compounds synthesized by surface functionalization

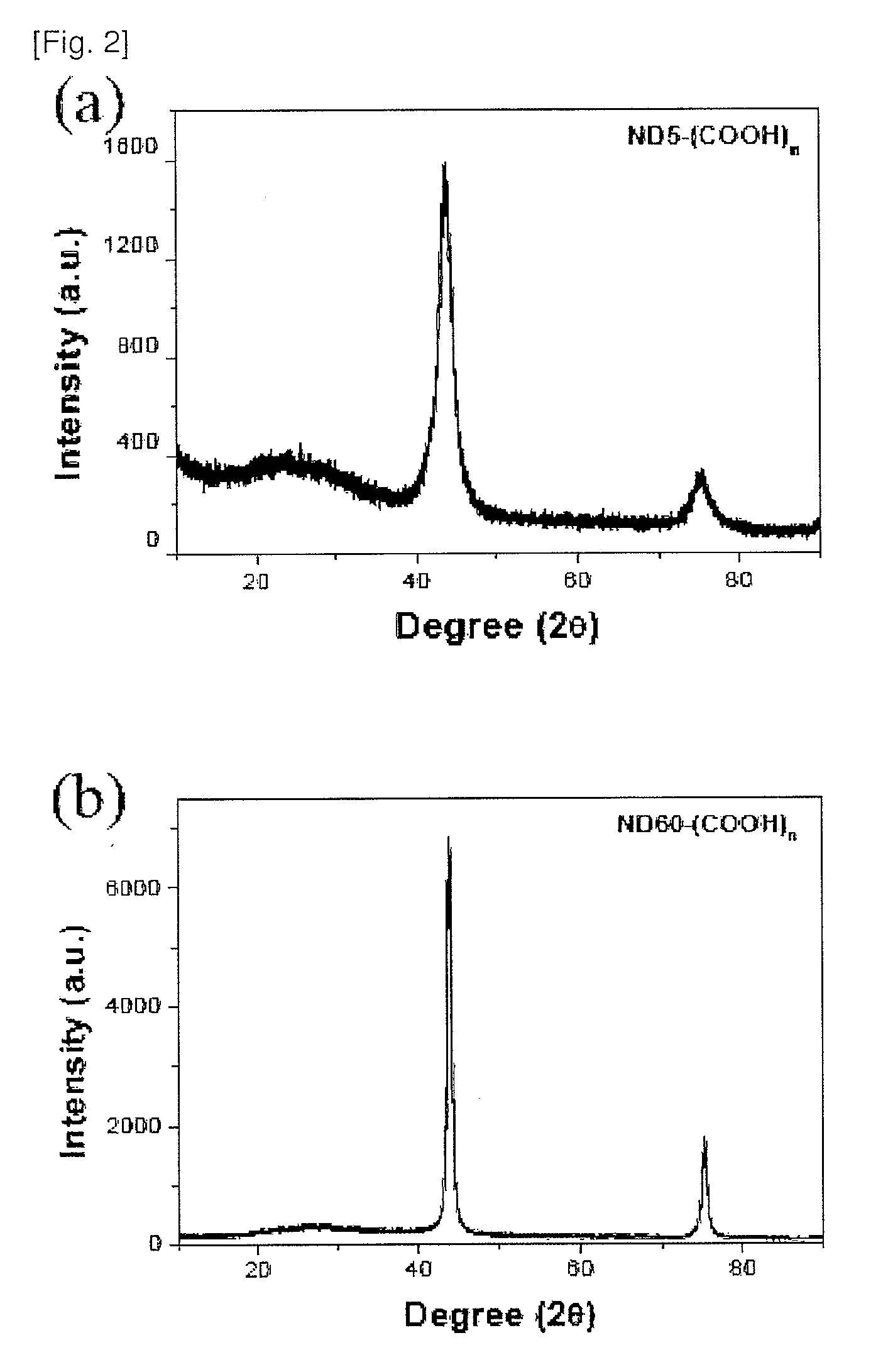

InactiveUS20100298600A1Improve solubilityMaterial nanotechnologyOxygen-containing compound preparationSolubilityStrong acids

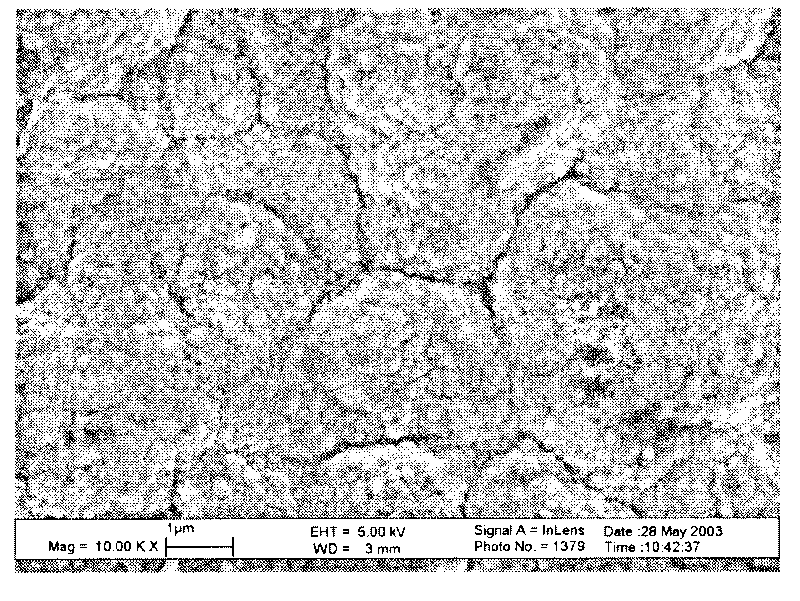

Disclosed herein is a method for chemically attaching carboxyl, alcohol, amine or amide groups to the surface of nanodiamond (ND) in a liquid phase. Also disclosed herein are a functional ND compound obtained by the method and use thereof. The method includes treating synthetic ND with a size of 1 nm-1OO nm with sonication and a strong acid to provide ND-(COOH)n. The ND-(COOH)n compound is used as a starting material to provide ND compounds having alcohol, amine or amide groups attached to the surfaces thereof. The surface-functionalized ND compounds are characterized by using an X-ray diffractometer, FTIR, AFM, particle size analyzer and zeta sizer. The ND compounds show functionalities as well as high solubility to provide stable ND solutions in a liquid phase. Therefore, the ND compounds may be used as diamond coating agents. The powder of the ND compounds may be used as materials for producing composites of polymers, plastics, synthetic fibers, ceramics, etc., or as additives for toothpaste, shampoos, soap and cosmetic compositions.

Owner:NANODIAMOND

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

Diamond polishing paste in high purity, and preparation method

InactiveCN101050339AImprove polishing efficiencyModerate viscosityOther chemical processesCoupling light guidesDispersion stabilityOptical fiber connector

This invention relates to a method for preparing polishing paste containing high-purity nanoscale diamond for precision polishing of the small inner pores of ceramic ferrule used in optical fiber connector. The polishing paste is prepared from: diamond micropowder 0.05-5 wt.%, wetting agent 0.01-25 wt.%, surfactant 0.1-5 wt.%, dispersion stabilizer 0.1-50 wt.%, pH regulator 0.1-1 wt.%, and glycerol 14-99.64 wt.%. The purity of the diamond micropowder is greater than or equal to 99.9%, and the particle sizes are 100-200 nm. The polishing paste is amphipathic, and has such advantages as high polishing speed, high dispersion stability, and appropriate viscosity. The polishing paste can effectively prevent the generation of small inner pores on the surface of polished ceramic ferrule.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

N-type nano-diamond film and preparation method

ActiveCN101717913ALow resistivityImprove mobilityVacuum evaporation coatingSputtering coatingPhosphoniumGas phase

The invention provides an n-type nano-diamond film and a preparation method. The preparation method comprises the following steps: injecting donor impurity ions into a nano-diamond film by adopting an ion injection method; and performing vacuum annealing on the film to obtain the n-type nano-diamond film. The method uses the ion injection method to finish the step of doping, so that the phosphonium ions or oxonium ions of which the injected dose is 1,014 to 1,016 cm-2 are doped to nano-diamond crystal grains and crystal boundaries, and the defect that impurities are centralized in the crystal boundaries but cannot enter diamond crystal grains in the processes of chemical vapor deposition and doping is avoided; and after the vacuum annealing at the temperature of between 700 and 1,000 DEG C, the n-type diamond film which has lower resistivity and higher Hall mobility is obtained. Therefore, the n-type nano-diamond film has very important scientific significance and engineering value for the application of the film in the field of semiconductor devices, field emission displays, electrochemistry and the like.

Owner:ZHEJIANG UNIV OF TECH

Casting infiltration method capable of increasing hardness and wear resistance of castings

A casting infiltration method capable of increasing the hardness and the wear resistance of castings comprises the following steps: preparing composite coating, coating the prepared composite coating on lost foams or sand molds corresponding to the set position of which the hardness and the wear resistance are needed to increase, forming a composite coating layer, closing the molds, then casting according to the known conventional method; after depanning, quenching and tempering to the composite coating layer position; the key point is that the composite coating is paste coating which is prepared by mixing 65-70wt% of diamond nanometer powder or ceramic nanometer powder with 35-30wt% of polyving alcohol condensation product and then adding water, and the composite coating is coated on the set position of lost foams or sand molds for 3-4 times to reach the set thickness. The invention has simple process; by adopting nanometer diamond powder, the hardness and the wear resistance on the set position of the castings can be greatly improved and no interfacial effect can be generated between the castings substrate and the penetration layer; in addition, the penetration layer part has strong impact resistance.

Owner:杨树桐

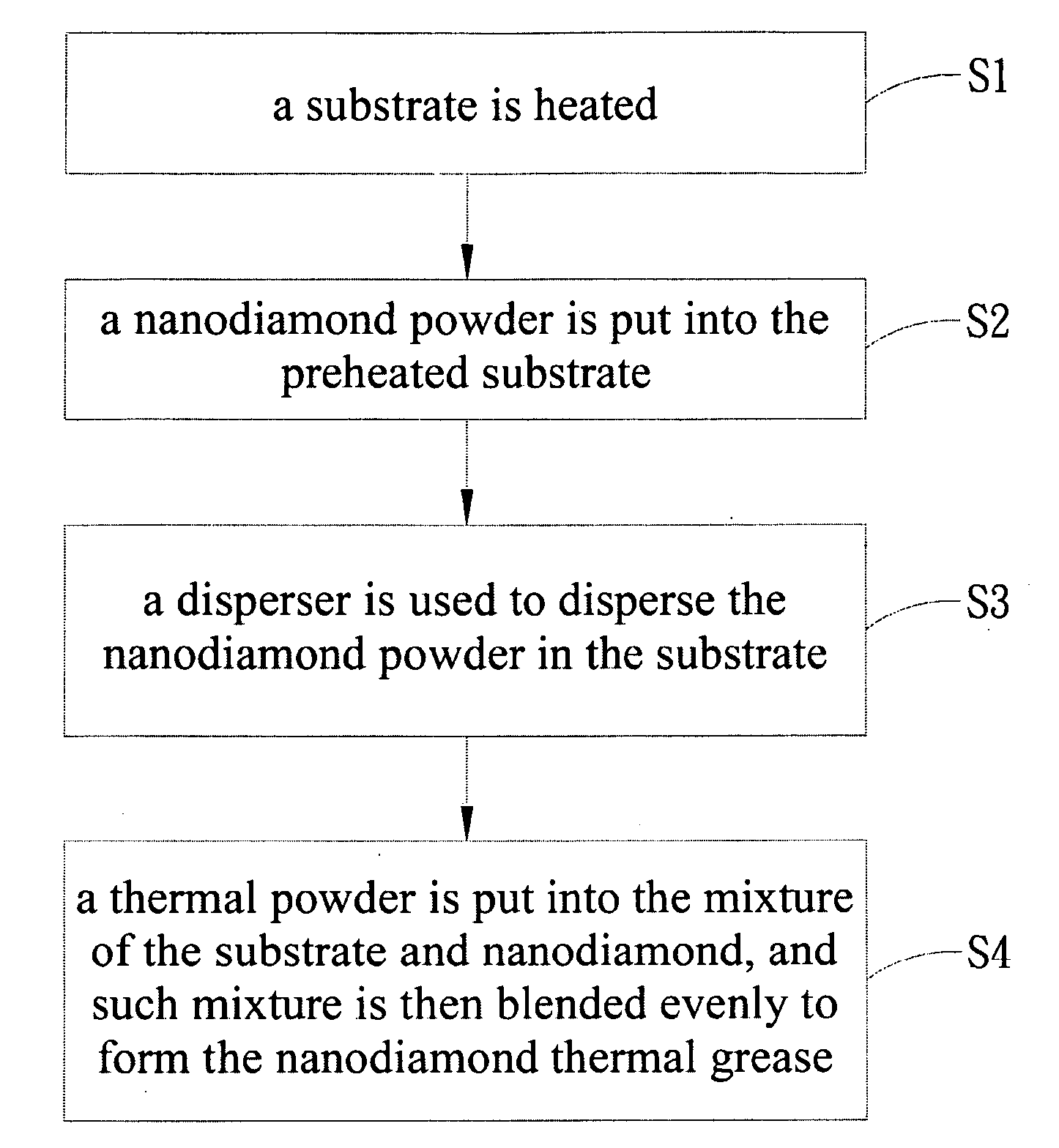

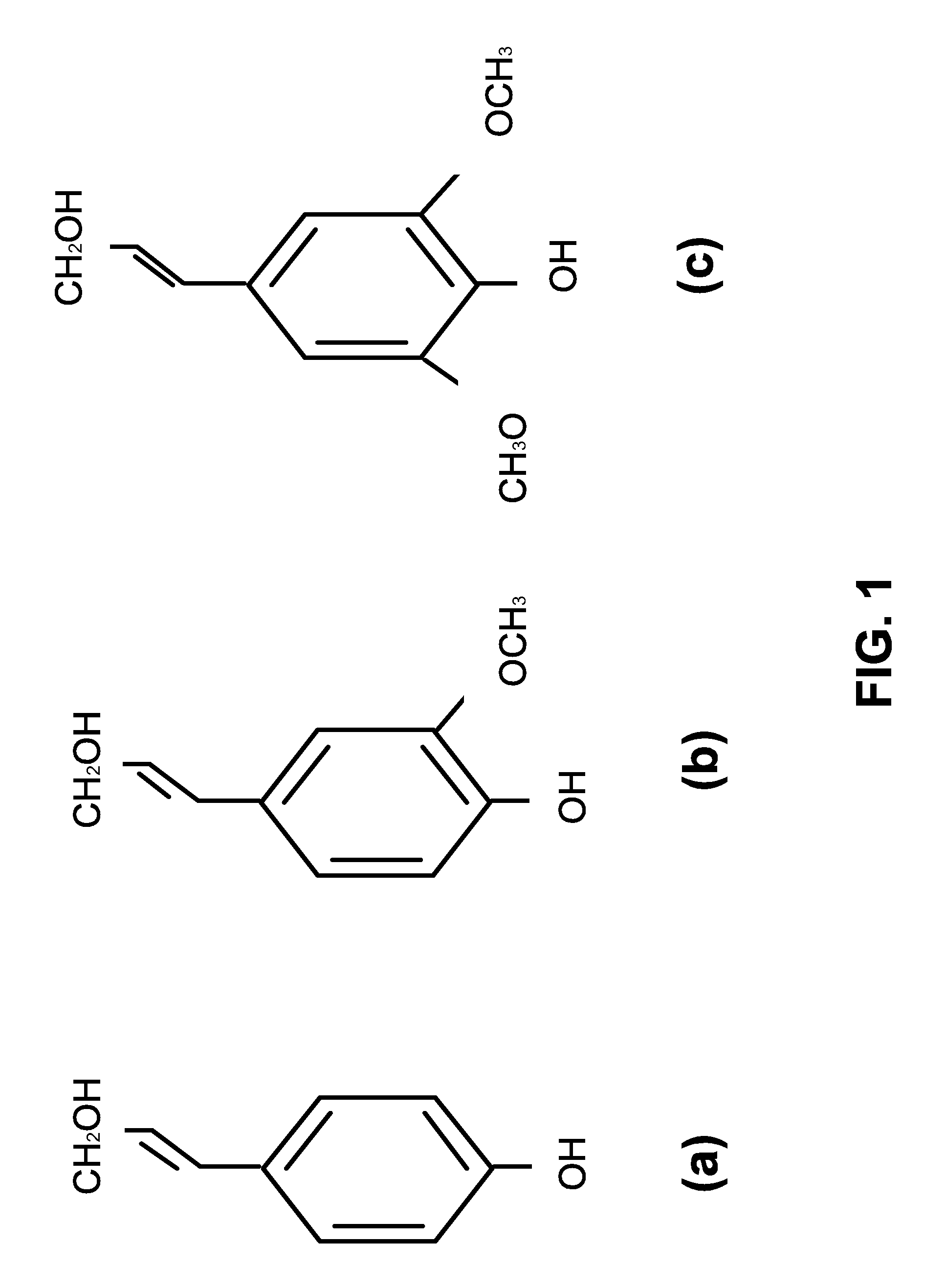

Nanodiamond thermal grease

ActiveUS20100022423A1Low costImprove cooling efficiencyMaterial nanotechnologySemiconductor/solid-state device detailsThermal greaseNanometre

The present invention discloses a nanodiamond thermal grease, which comprises a nanodiamond powder, a thermal powder and a substrate. The nanodiamond powder has volume percentage of 5% to 30%, the thermal powder has volume percentage of 40% to 90%, and the substrate has volume percentage of 5% to 30%. The nanodiamond powder and the thermal powder are distributed uniformly in the substrate to form the nanodiamond thermal grease having high thermal conductivity.

Owner:KUNSHAN NANO NEW MATERIAL TECH

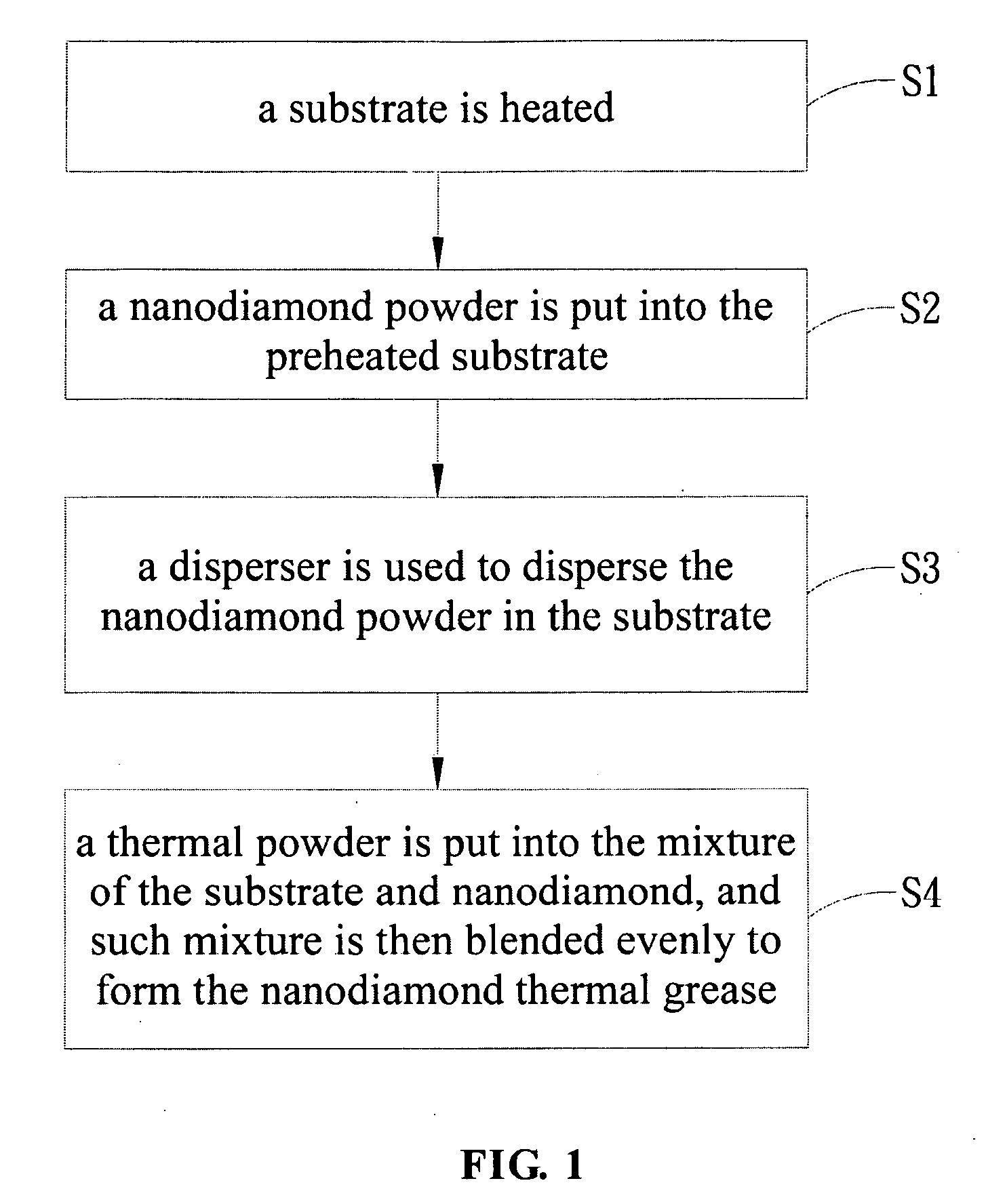

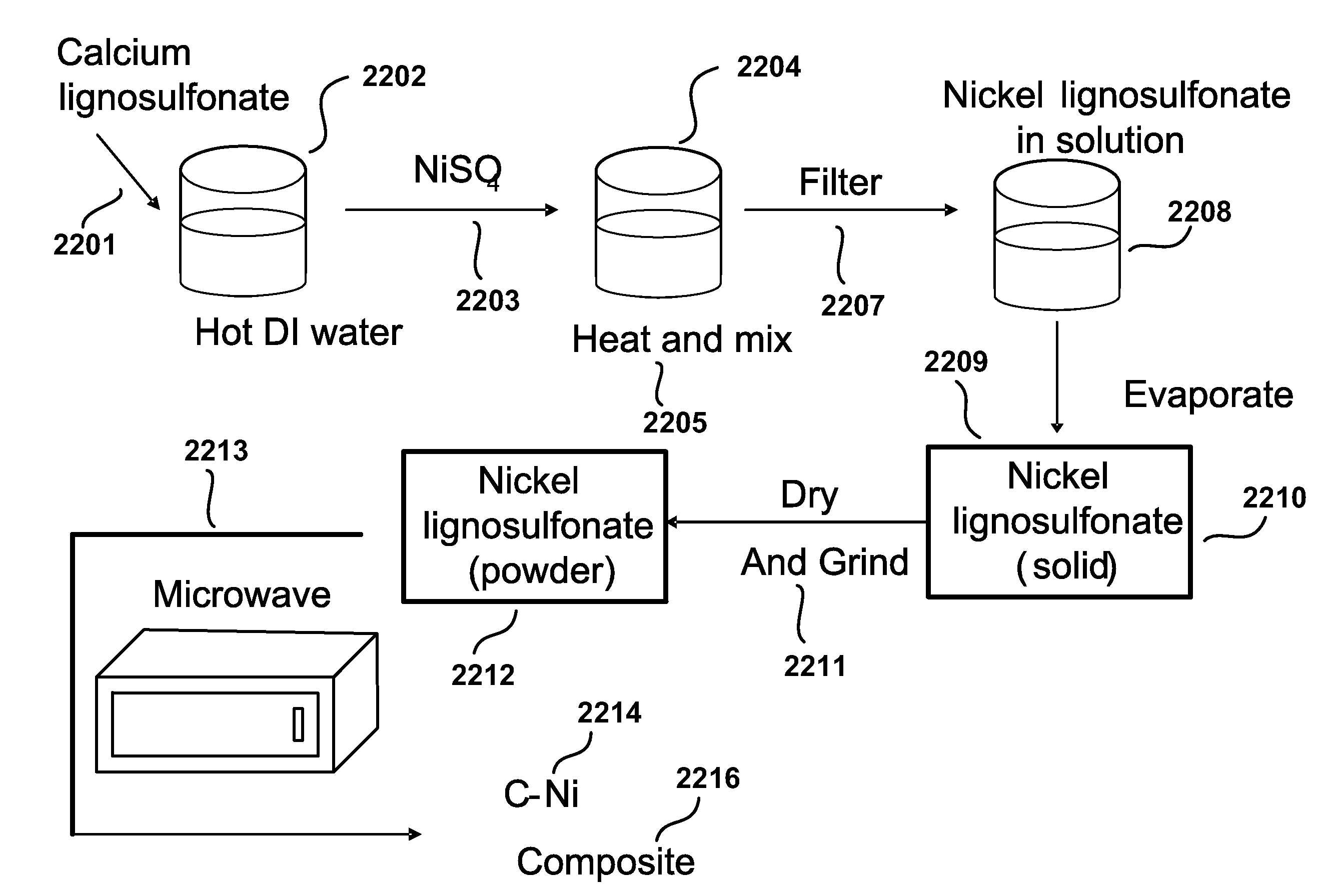

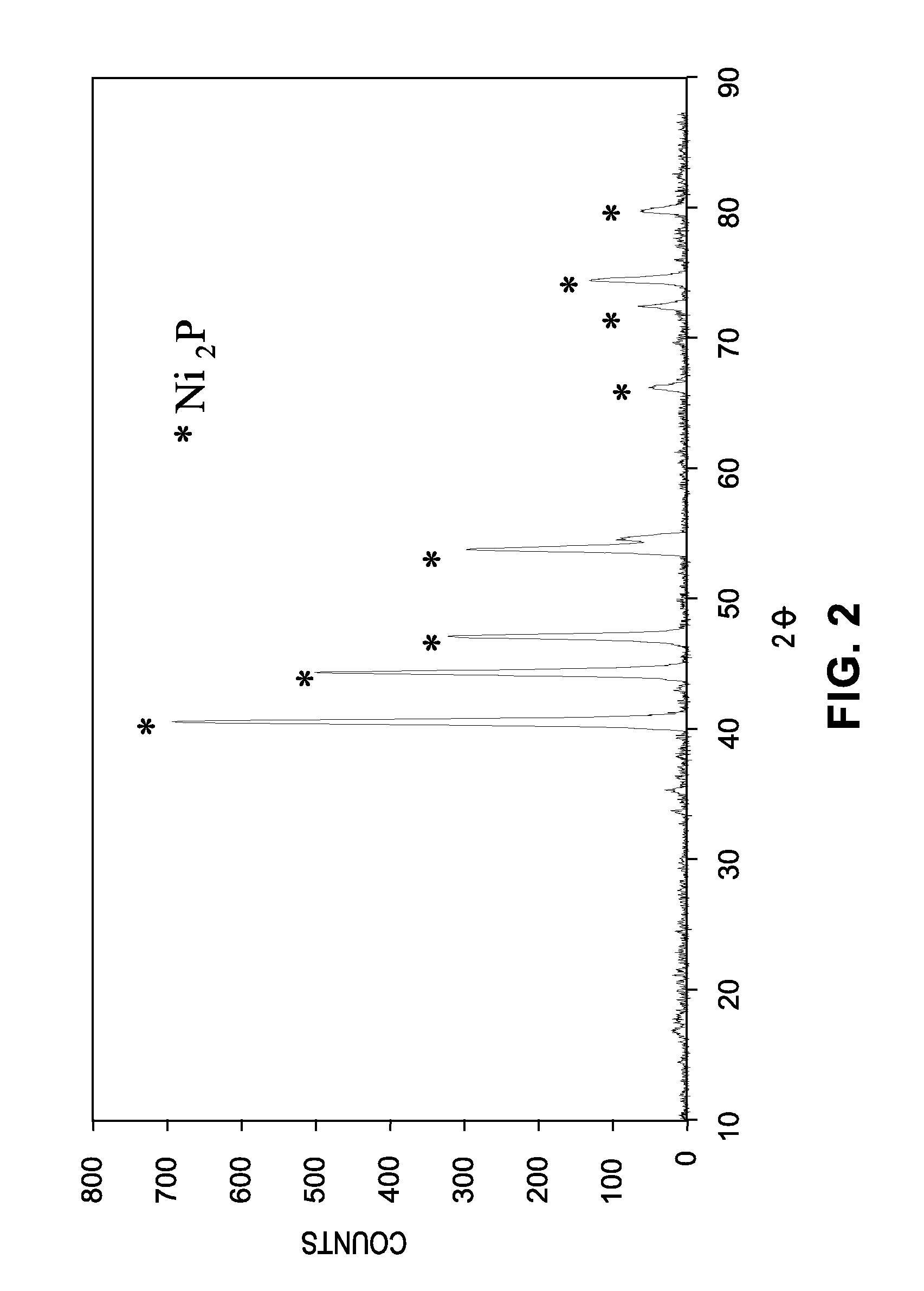

Microwave-assisted synthesis of carbon and carbon-metal composites from lignin, tannin and asphalt derivatives and applications of same

InactiveUS20100035775A1Quick and inexpensiveLarge specific surface areaNanotechConductive materialNanocompositeMicrowave irradiation

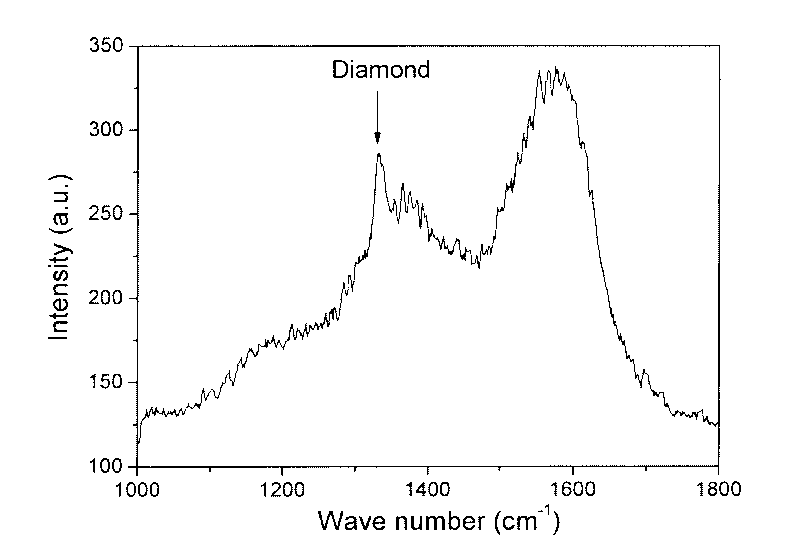

A plurality of carbon-metal nanocomposites. In one embodiment, the plurality of carbon-metal nanocomposites includes a plurality of carbons with a molecular structure that shows a first peak in the range of 1585 to 1565 cm−1 in a corresponding Raman spectrum, and a second peak in the range of 1325 to 1355 cm−1 in the corresponding Raman spectrum, wherein the first peak represents carbons with a graphitic nature and the second peak represents nanodiamonds, and wherein the plurality of carbon-metal nanocomposites is made from a metal derivative or metal chelated derivative of a carbon-containing precursor in solid form that is subjected to microwave radiation at a frequency in the range of 900 MHz to 5.8 GHz, for a period of time effective to allow the plurality of carbon-metal nanocomposites to be formed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

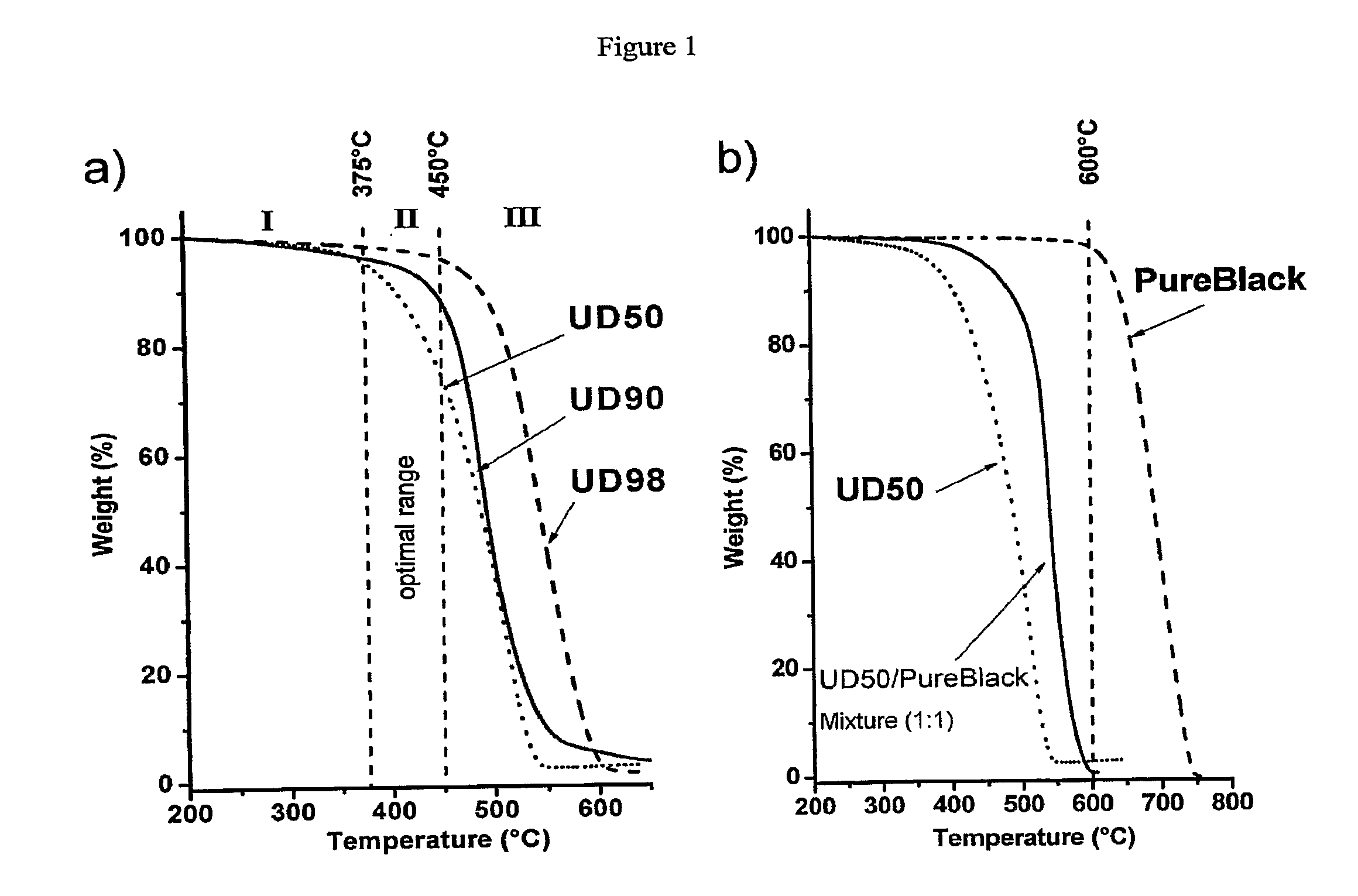

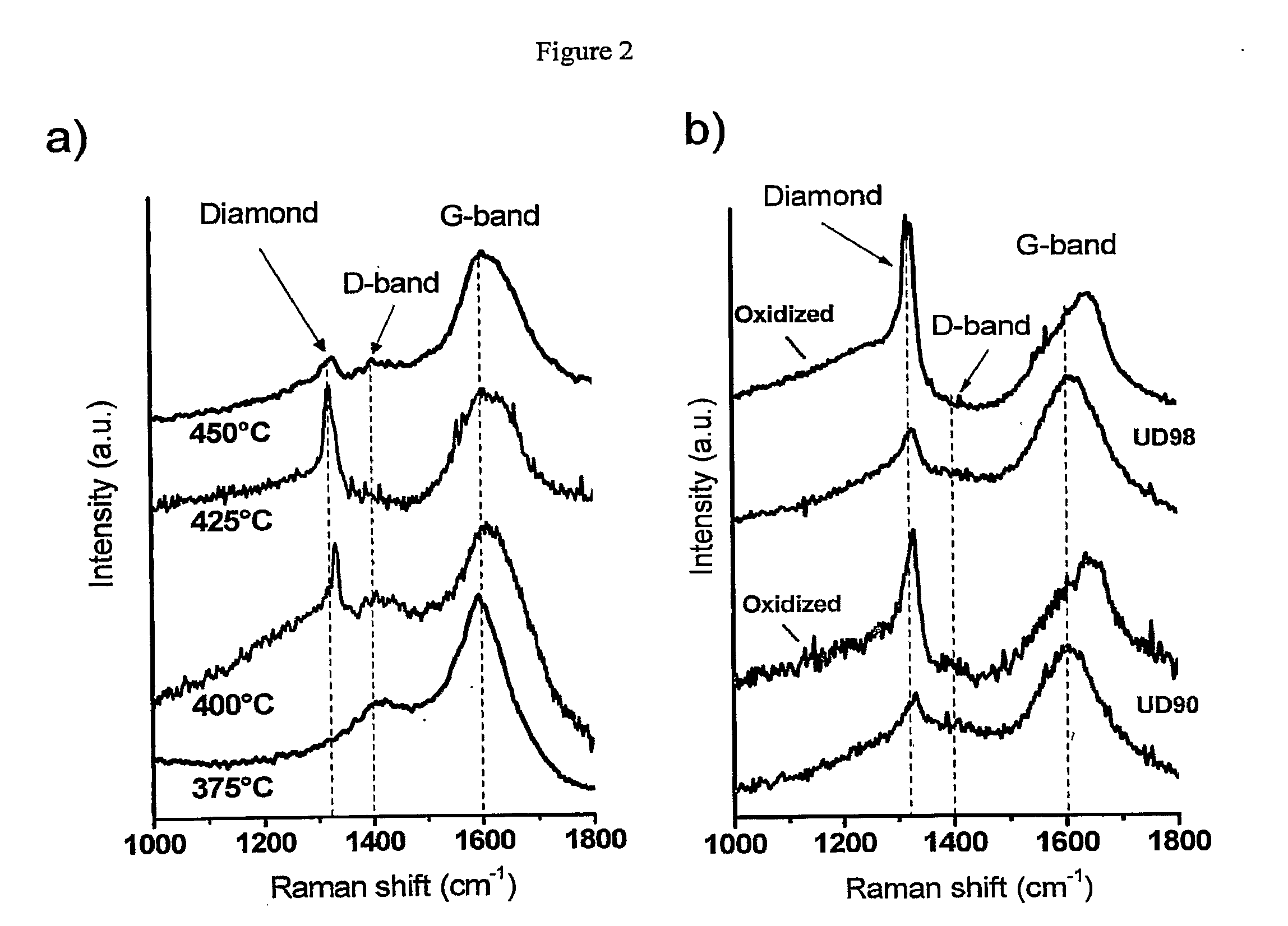

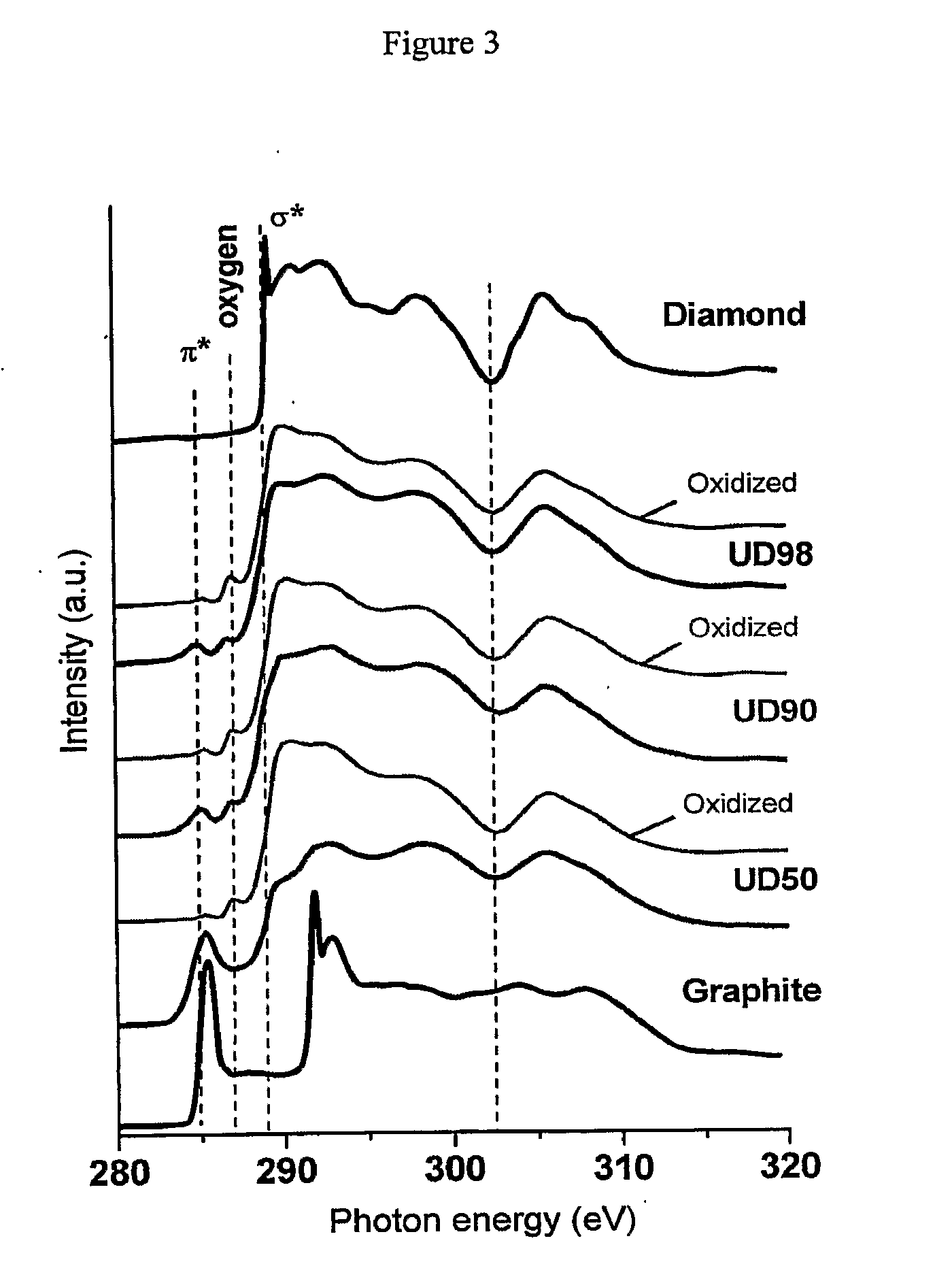

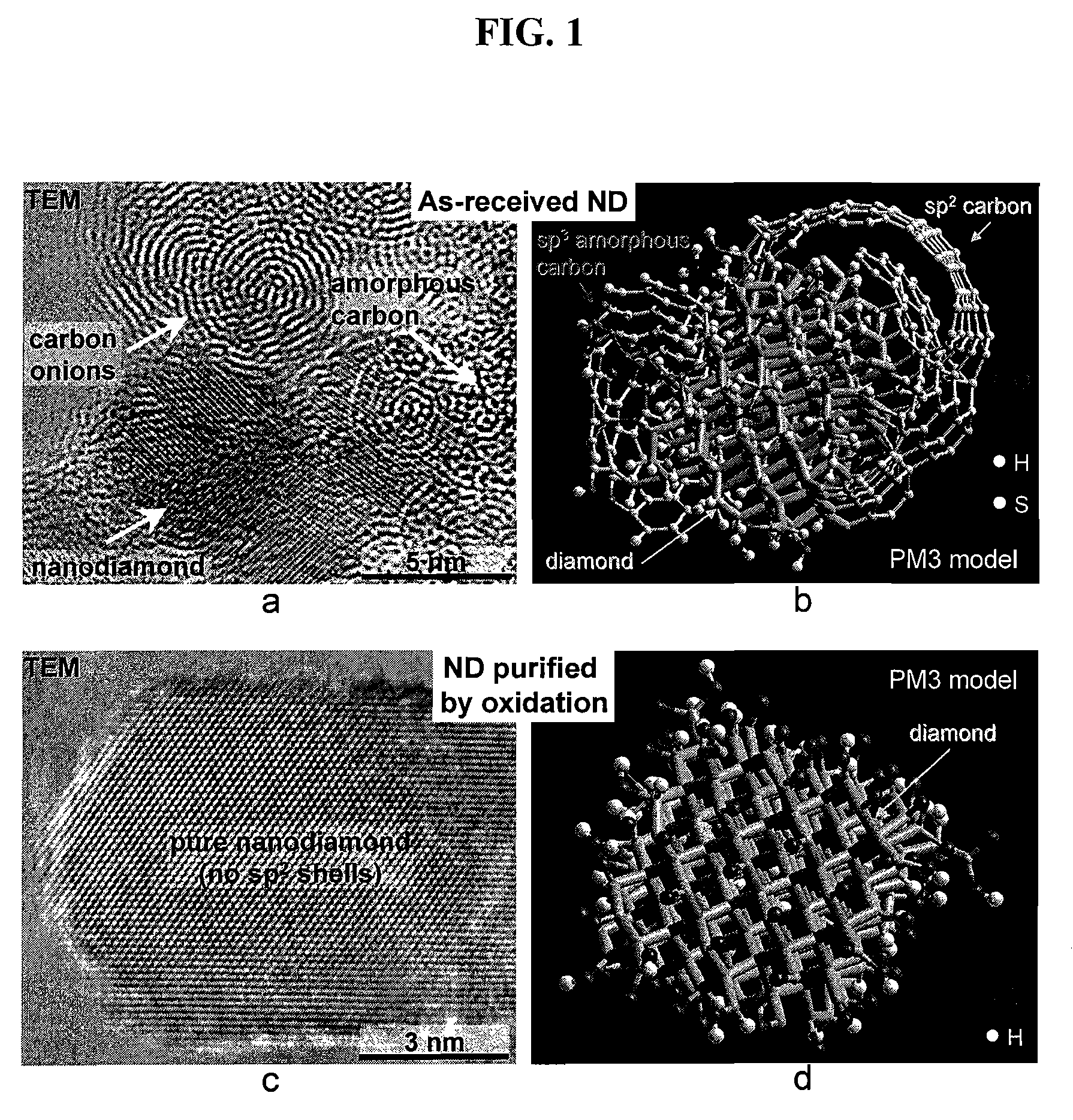

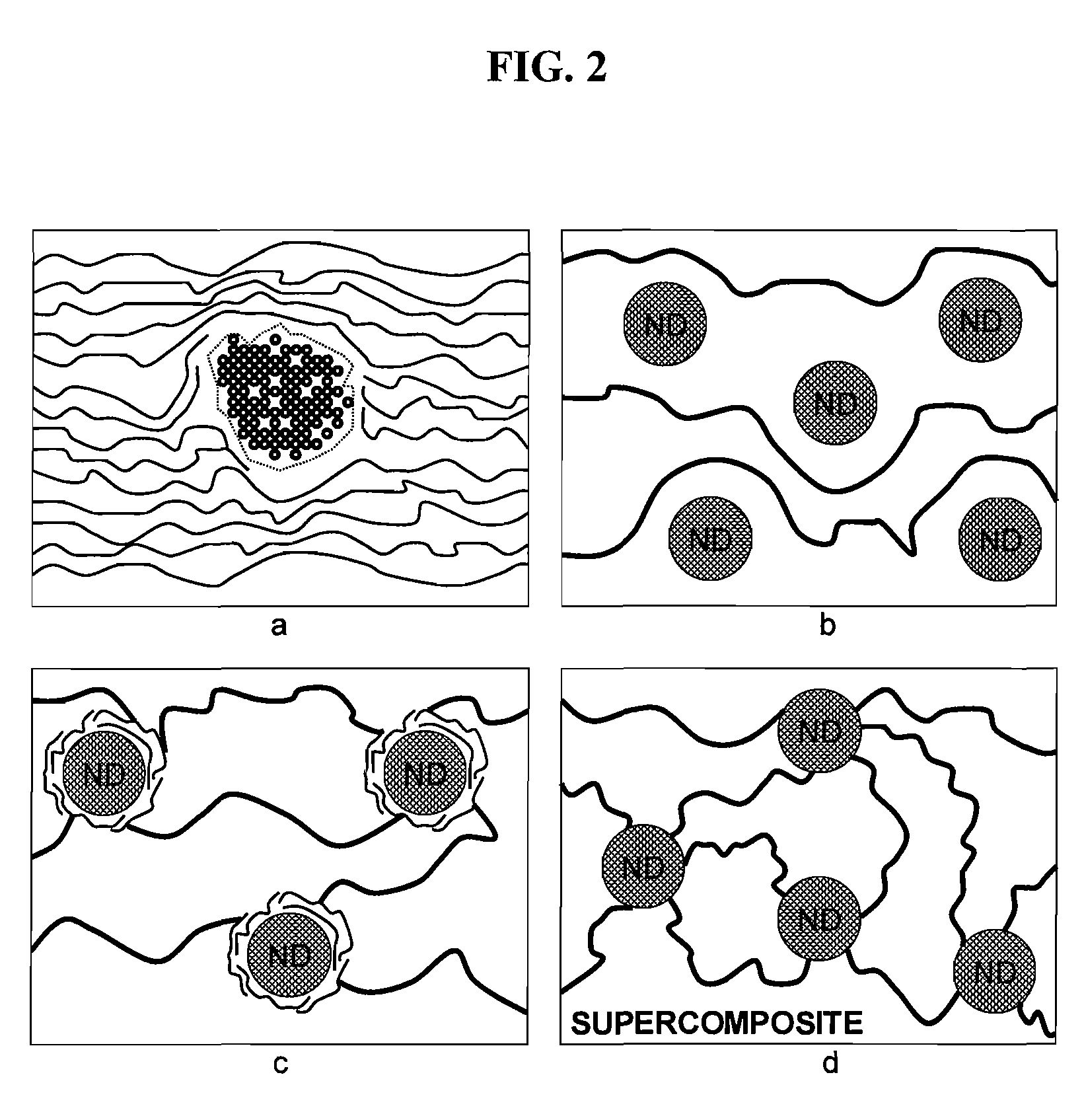

Process of purifying nanodiamond compositions and applications thereof

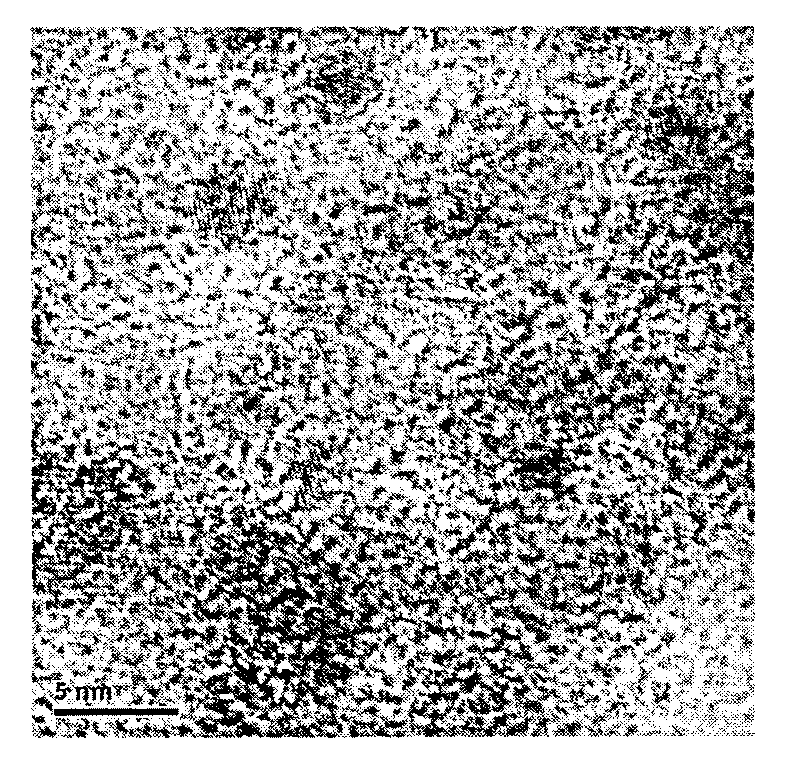

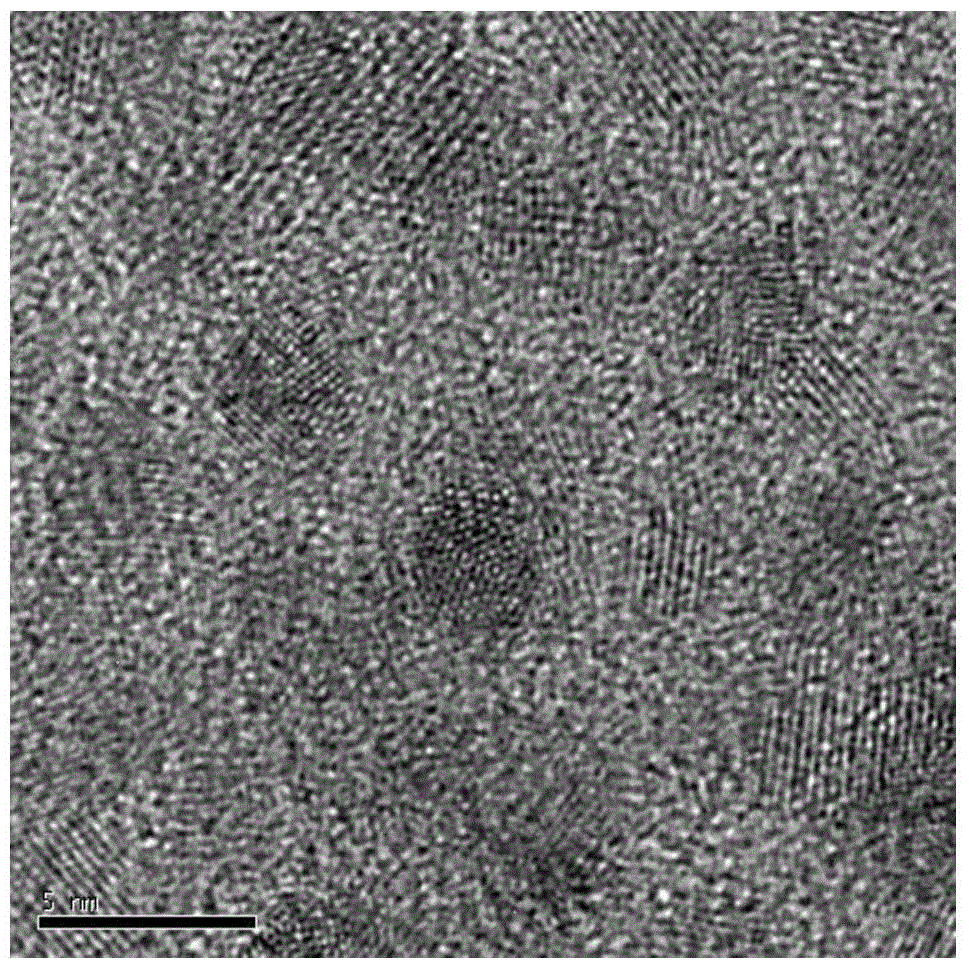

InactiveUS20100028675A1Reduce aggregationReduce the overall diameterMaterial nanotechnologyUltra-high pressure processesFourier transform infrared spectroscopyDetonation

The presence of large amounts of non-diamond carbon in detonation synthesized nanodiamond (ND) severely limits applications of this exciting nanomaterial. An environmentally-friendly process is disclosed to selectively remove sp2-bonded carbon from ND. The content of up to 96% of sp3-bonded carbon in the oxidized samples is comparable to that found in microcrystalline diamond and is unprecedented for ND powders. Transmission electron microscopy and Fourier transform infrared spectroscopy studies show high purity 5-nm ND particles covered by oxygen-containing surface functional groups. The surface functionalization can be controlled by subsequent treatments. In contrast to current purification techniques, the disclosed process does not require the use of toxic or aggressive chemicals, catalysts or inhibitors and opens avenues for numerous new applications of nanodiamond.

Owner:DREXEL UNIV

Functionalized Nanodiamond Reinforced Biopolymers

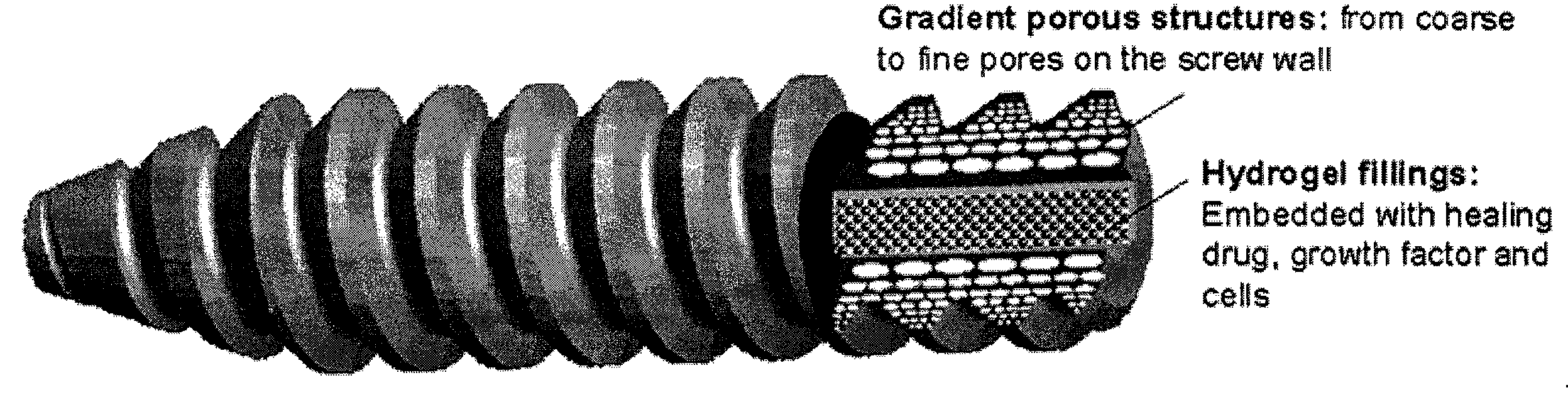

The present invention includes a composition for implantation in a patient, comprising surface-functionalized nanodiamonds and at least one biodegradable biocompatible polymer. The present invention also includes a surgical fixation device for use in a patient.

Owner:DREXEL UNIV

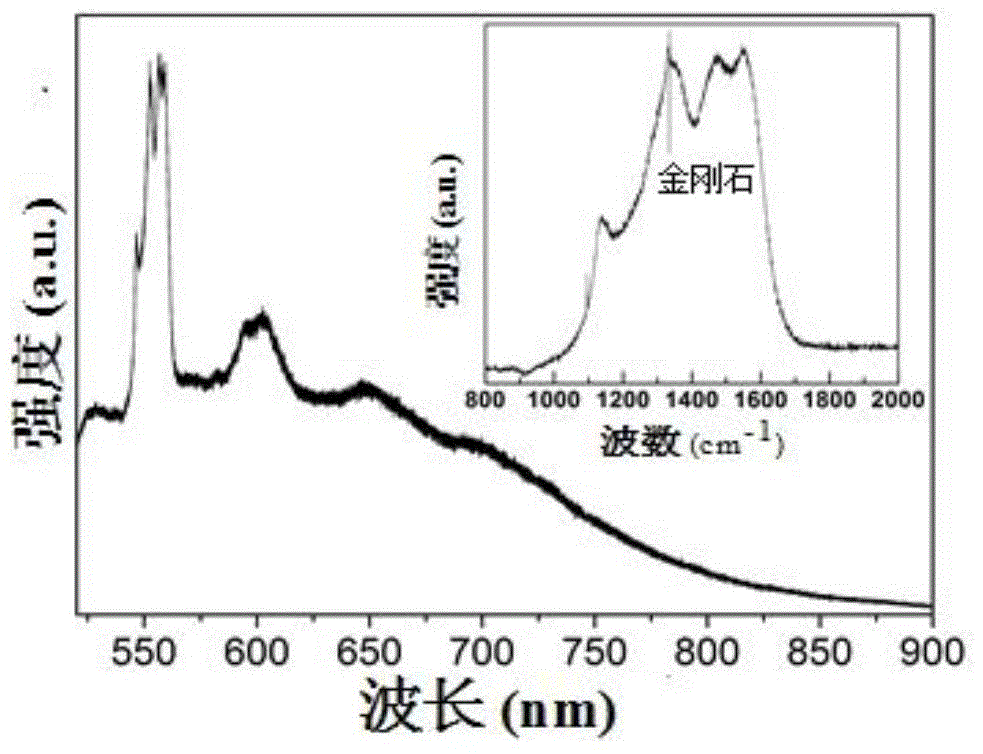

Nano-diamond film with Si-V luminescence and preparation method thereof

ActiveCN104060237AWith Si-V light emitting performanceSi-V has strong luminous performanceMaterial nanotechnologyChemical vapor deposition coatingGas phaseDisplay device

The invention provides a nano-diamond film with Si-V luminescence and a preparation method thereof. The nano-diamond film is prepared on a single crystal silicon substrate by use of a hot filament chemical vapor deposition method; heat preservation is performed on the film for 5-150 minutes in air at a temperature ranging from 500 to 700 DEG C, and then the nano-diamond film with Si-V luminescence is obtained. The nano-diamond film prepared has relatively high Si-V luminescence intensity which has very important scientific significance and engineering value for the application of the nano-diamond film in the fields such as single photon sources, quantum information processing, photoelectric devices, biomarkers, semiconductor devices and field emission displays.

Owner:ZHEJIANG UNIV OF TECH

Diamond neural devices and associated methods

InactiveUS20110282421A1Internal electrodesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The present disclosure provides devices for neuronal growth and associate methods. In one aspect, for example, a neuronal growth device is provided including a layer of nanodiamond particles having an exposed neuronal growth surface, a doped diamond layer contacting the layer of nanodiamond particles opposite the neuronal growth surface, and a semiconductor layer coupled to the doped diamond layer opposite the layer of nanodiamond particles. In one aspect, the nanodiamond particles are substantially immobilized by the doped diamond layer.

Owner:SUNG CHIEN MIN

Nano diamond-macromolecular composite abrasive for solidifying abrasive polishing pad

InactiveCN102528648AReduce hardnessAchieving "soft impactAbrasion apparatusLapping toolsEpoxySynthesis methods

The invention provides a method for preparing a diamond-macromolecular composite abrasive. The cores of composite abrasive particles are diamond powder prepared by a mechanical crushing method, an explosive synthesis method or a static pressure method, and the particle diameter range of the powder is 1 to 100 nanometers; the powder serving as the core is modified to form an intermediate transition layer through a silane coupling agent, and the intermediate transition layer is grafted and wrapped to form the composite abrasive by using epoxy resin and polyacrylate, wherein the mass of the silane coupling agent is 0.2 to 2 percent of that of the nano particles; and the mass of the epoxy resin and the polyacrylate is 0.2 to 2 percent of that of inorganic nano particles. The compatibility between the abrasive and a polishing pad base body is improved, and the nano diamond composite abrasive treated by different macromolecules can be selected according to different polishing pad base bodies. By introducing groups to the surface of the diamond abrasive, the bonding force between the diamond abrasive and the polishing pad base body is improved, drop of the diamond abrasive is reduced, and surface damage of a machined workpiece due to drop of the diamond abrasive in the polishing process is prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

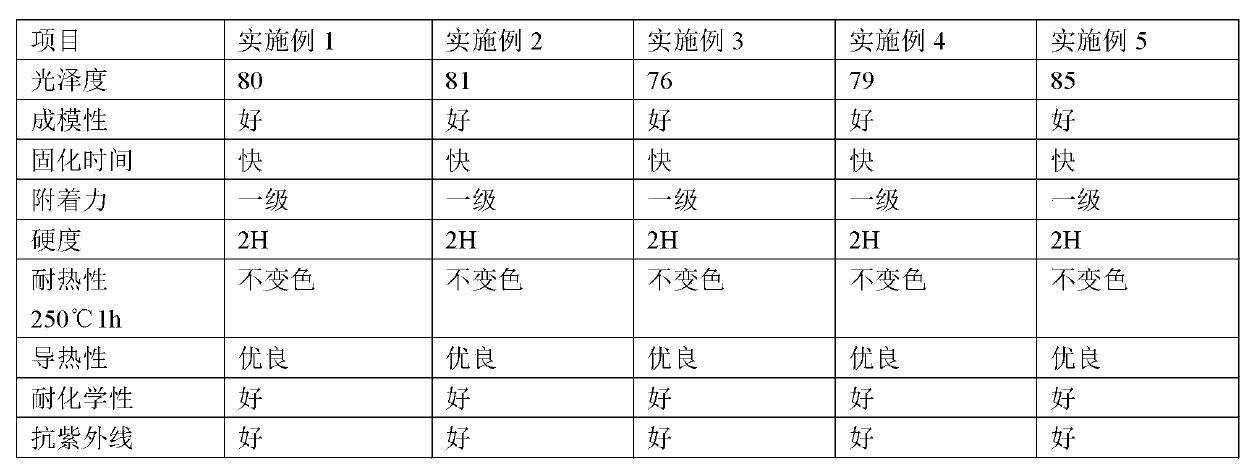

Novel graphene heat-conducting coating and preparation method thereof

ActiveCN103627223AImprove thermal conductivityGood film strengthEpoxy resin coatingsHeat conductingWear resistance

The invention relates to the technical field of coatings, specifically to a novel graphene heat-conducting coating and a preparation method thereof. The novel graphene heat-conducting coating is prepared through modification of graphene and nanometer diamond in a weight ratio of 1-10: 1, wherein the total addition amount of graphene and nanometer diamond accounts for 0.1 to 5% of the total amount of the novel graphene heat-conducting coating. Compared with the prior art, the novel graphene heat-conducting coating has the advantages of good thermal conductivity, good film forming strength, high bonding strength on a substrate, good wear resistance and microhardness, excellent corrosion stability, resistance to both chemicals and high temperature, fast curing, rust protection and ultraviolet resistance.

Owner:NINGBO MORSH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com