Use of nanosized particulates and fibers in elastomer seals for improved performance metrics for roller cone bits

a technology of elastomer seals and nano-sized parts, which is applied in the direction of drilling accessories, cutting machines, construction, etc., can solve the problems of drilling operations that cannot meet the requirements of bit replacement, drill bit wear and failure, and the amount of time required for a bit replacement trip produces drilling operations downtim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

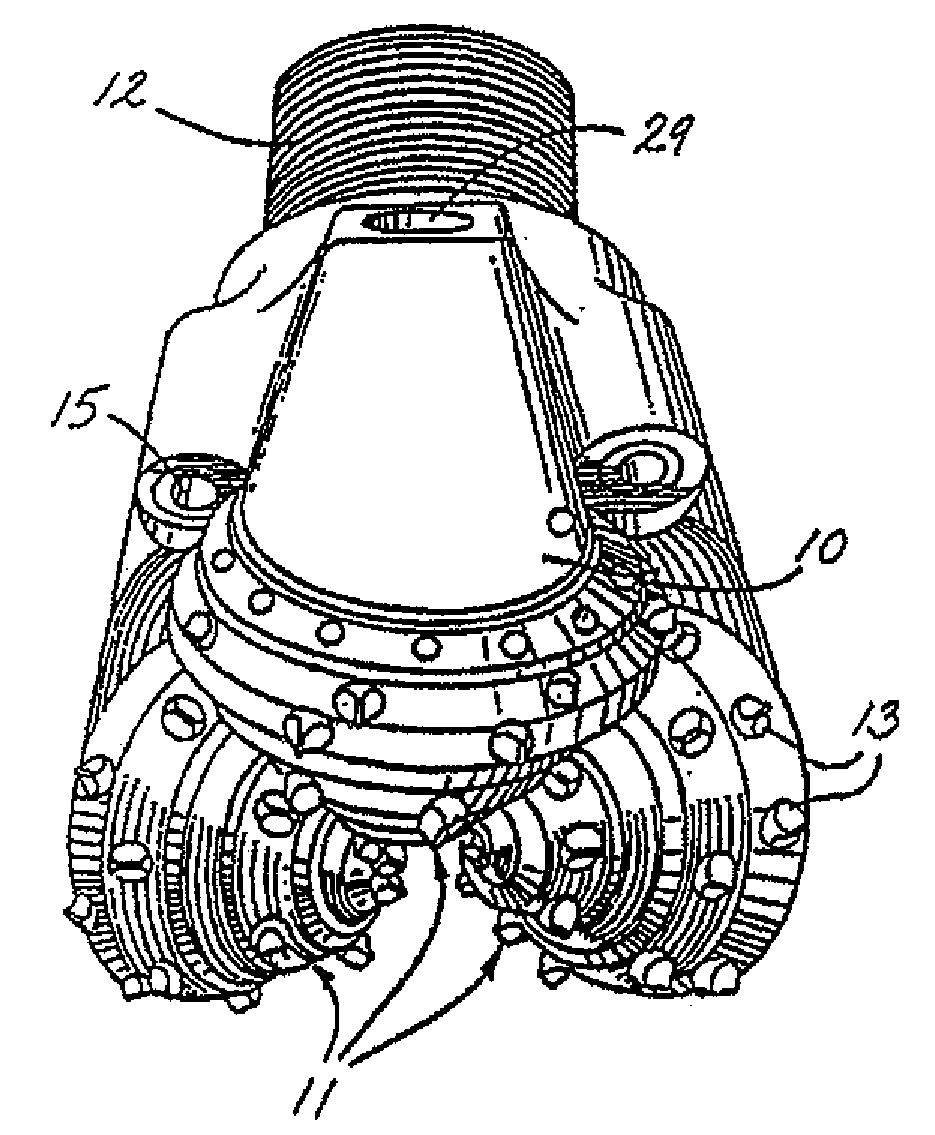

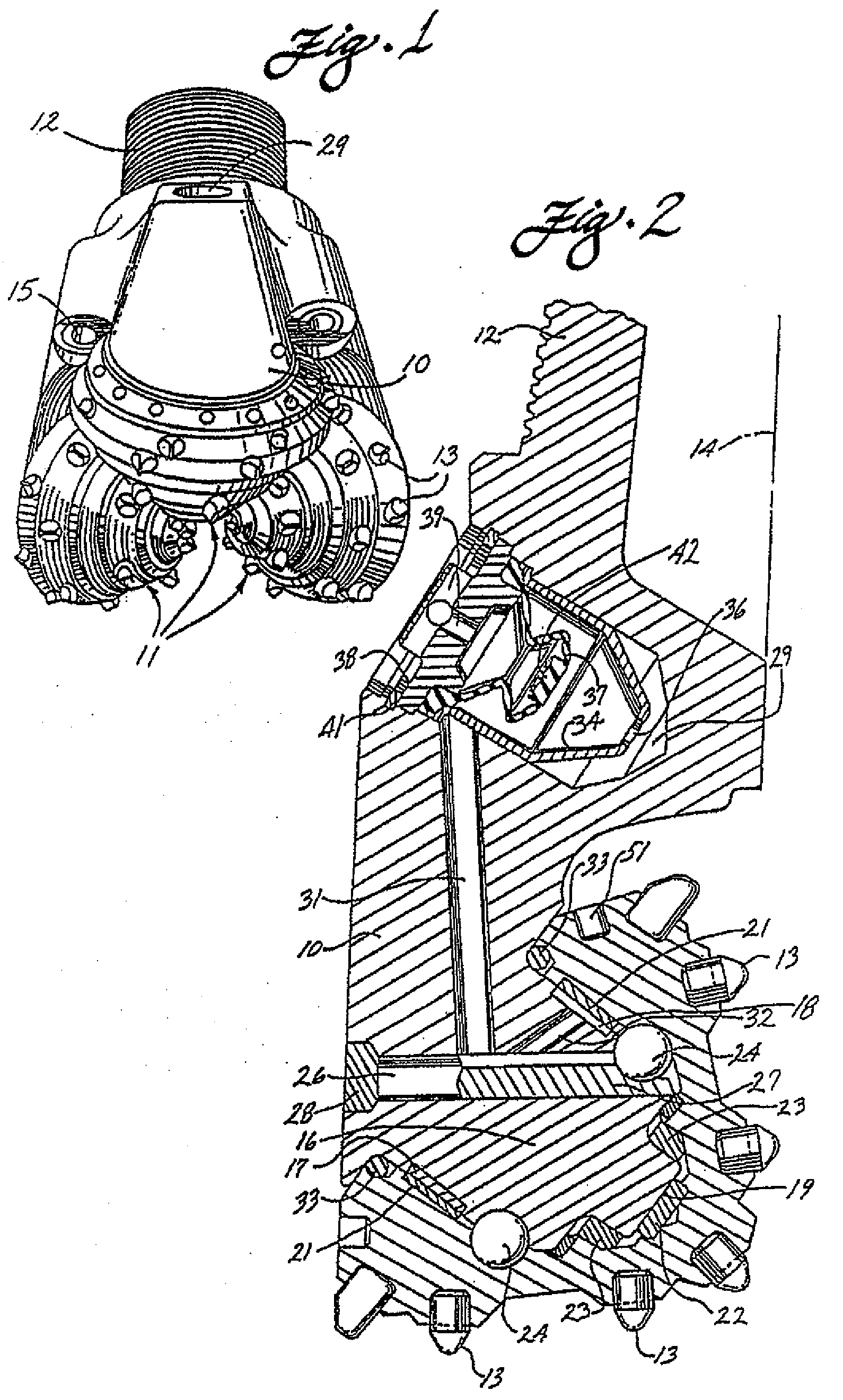

[0018]In one aspect, embodiments disclosed herein relate to elastomer seals used in components of downhole cutting tools, including drill bits, core bits, etc. In particular, embodiments disclosed herein relate to seals reinforced with nanomaterials.

[0019]In addition, embodiments of the present disclosure provide rock bits comprising seals which are reinforced by nanomaterials. Such a reinforced seal may have enhanced bulk properties such as tensile modulus, elastic modulus, hardness, and such like, as compared with the native seal, while maintaining wear and erosion resistance. Embodiments of the present disclosure are based, in part, on the determination that the life of a seal is directly related to the service life of the rock bit.

[0020]It is therefore desirable to provide a consistently reliable seal for maintaining the lubricant within a rock bit, where the seal has a long useful life, is resistant to oil well chemical compositions, has high heat resistance, and is highly resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com