Patents

Literature

4306results about "Cutting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

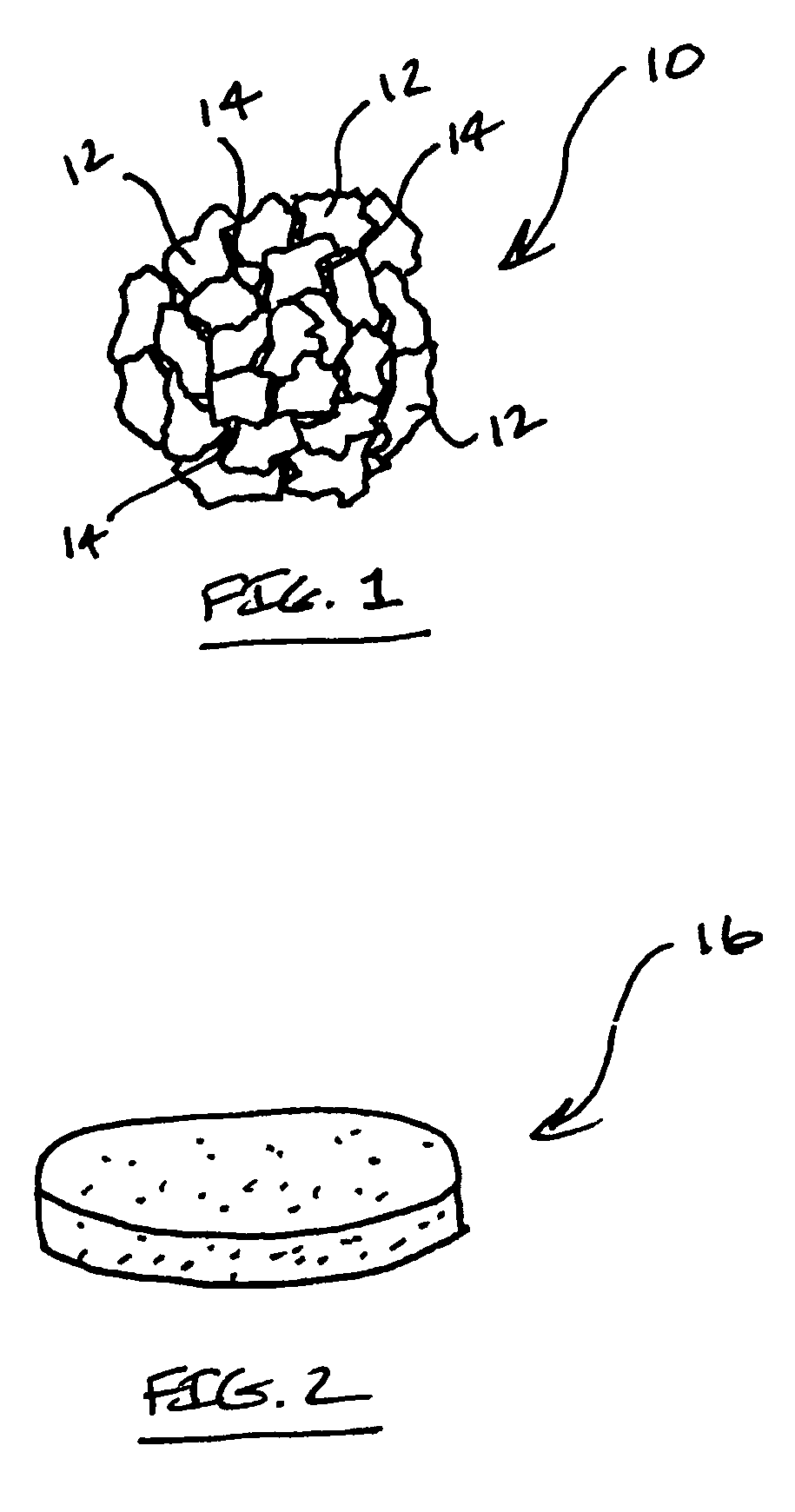

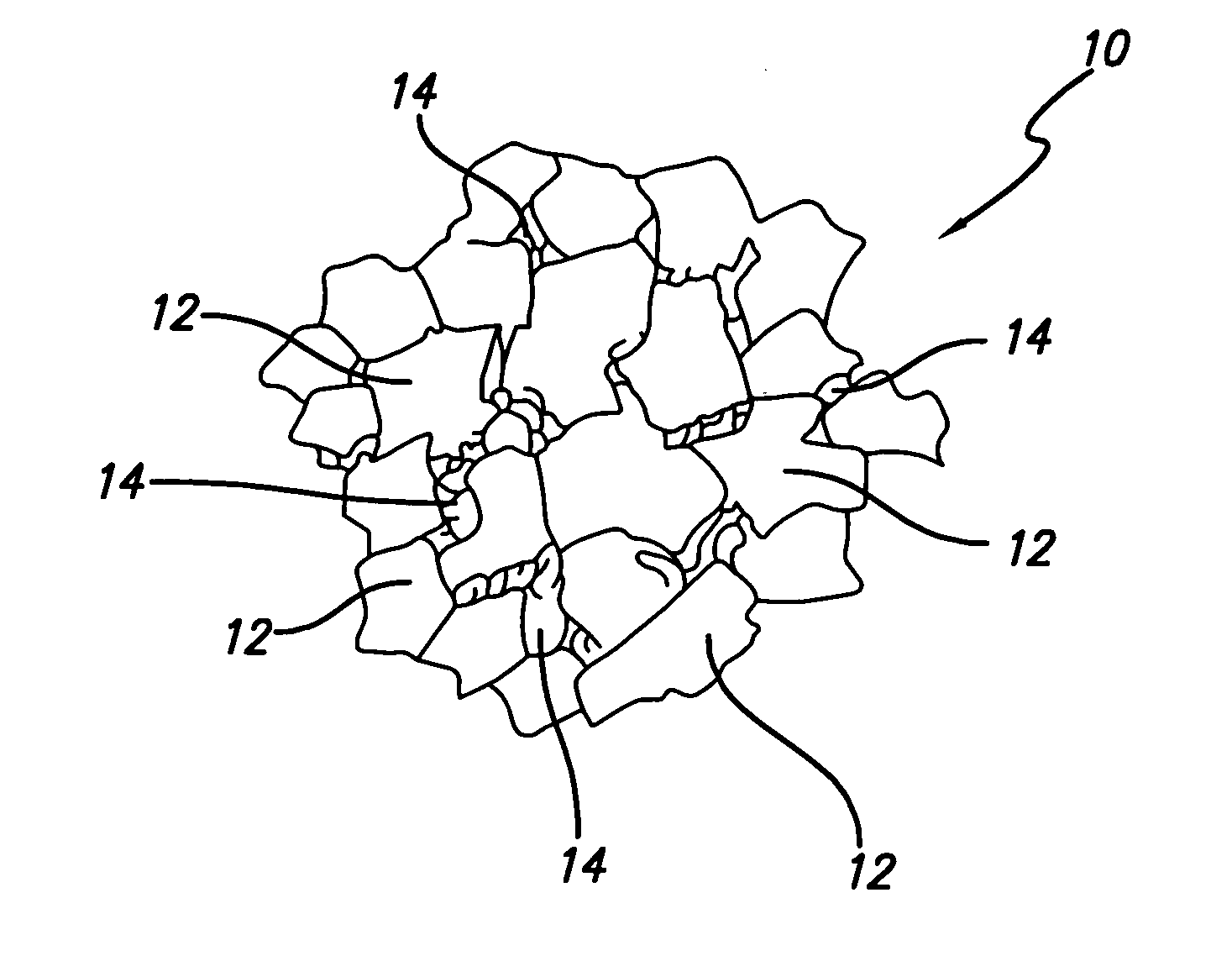

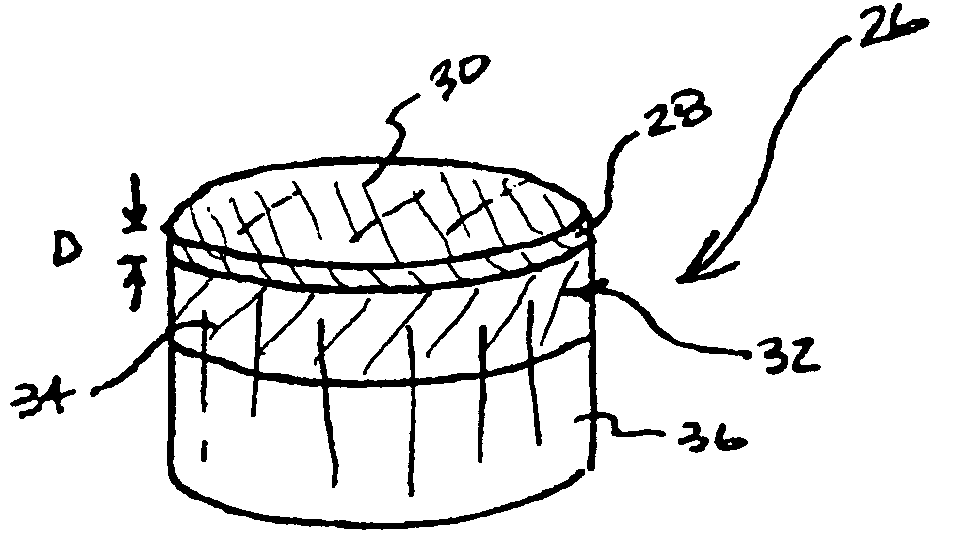

Nano-reinforced wc-co for improved properties

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

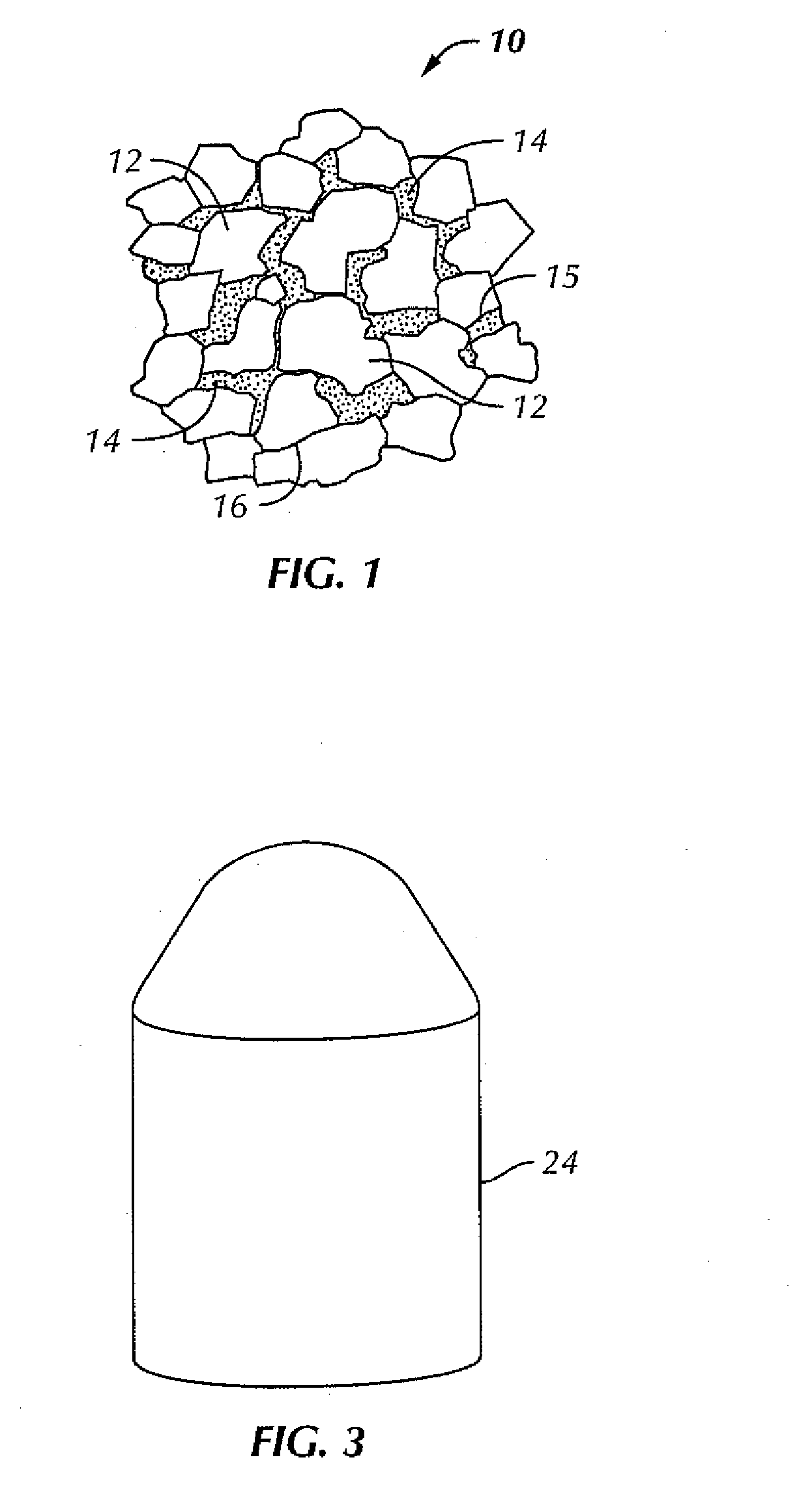

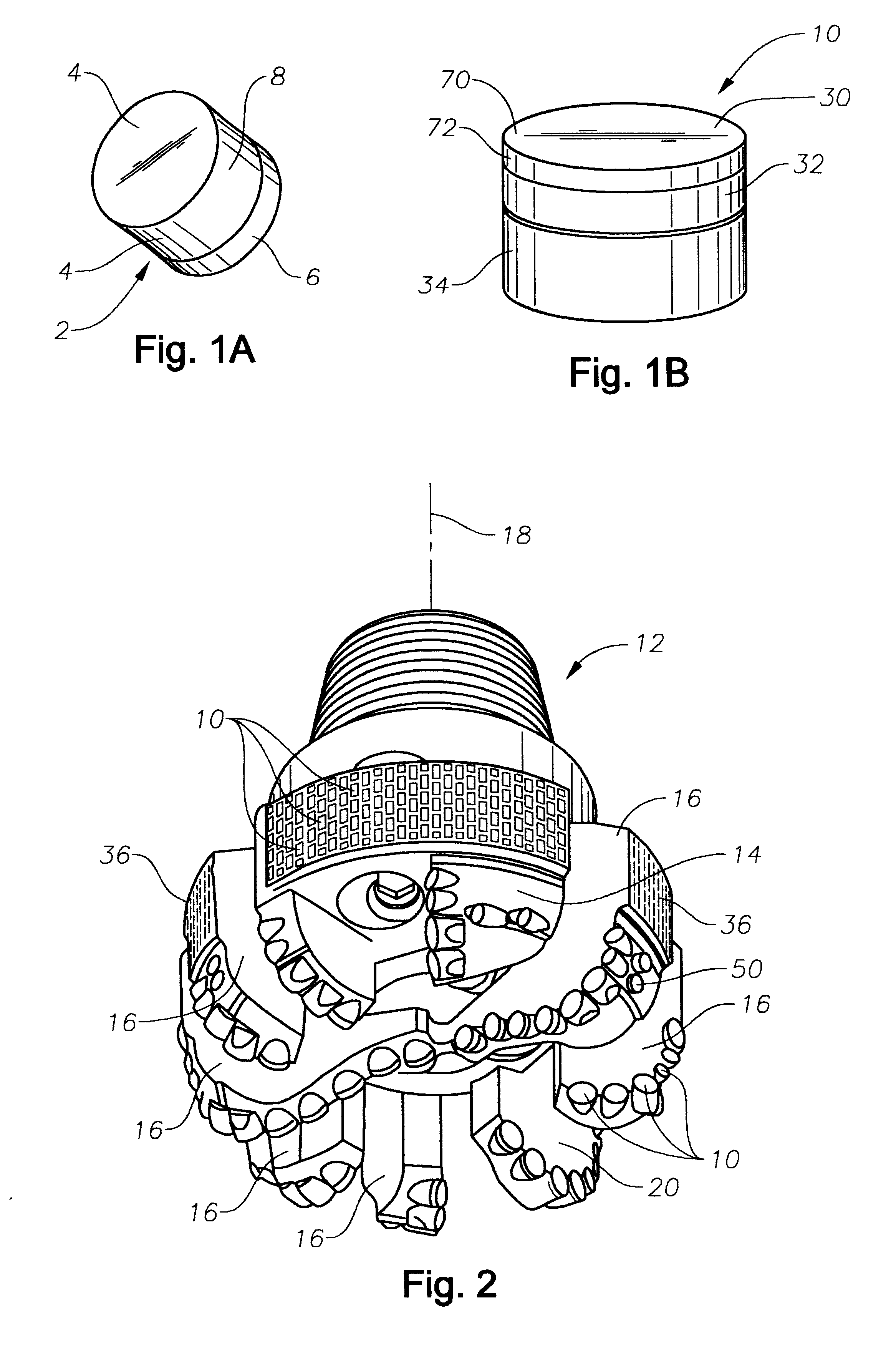

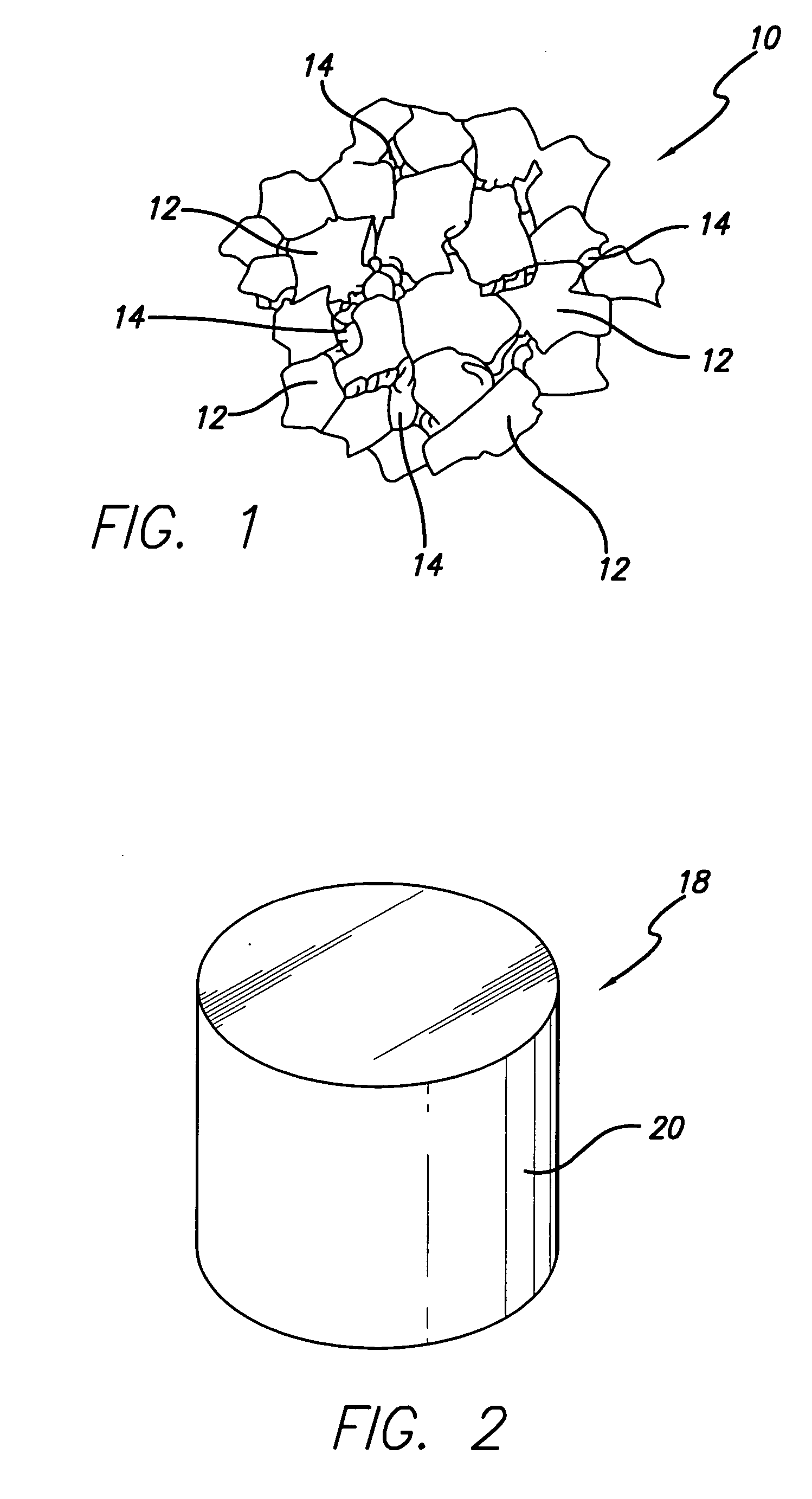

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

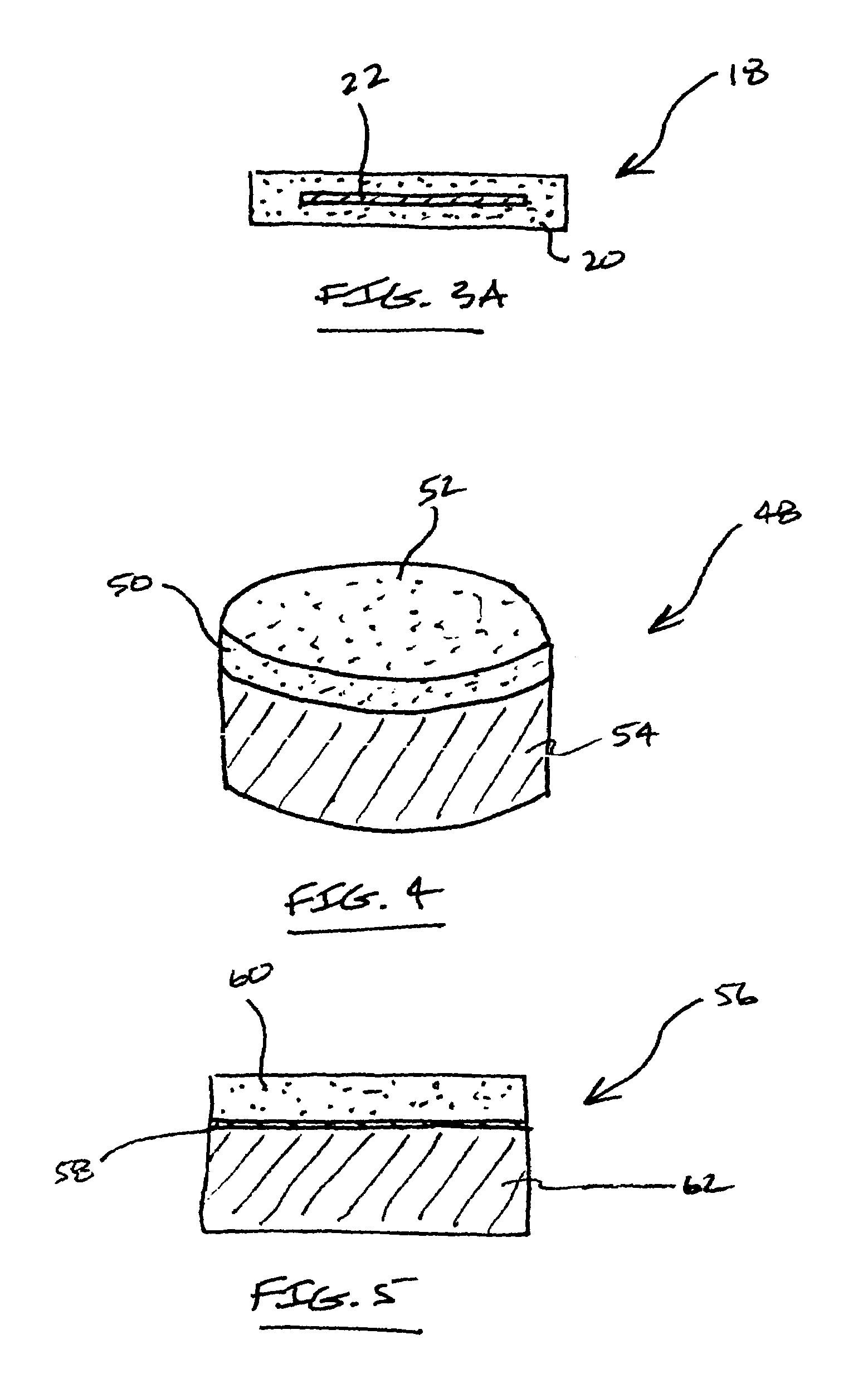

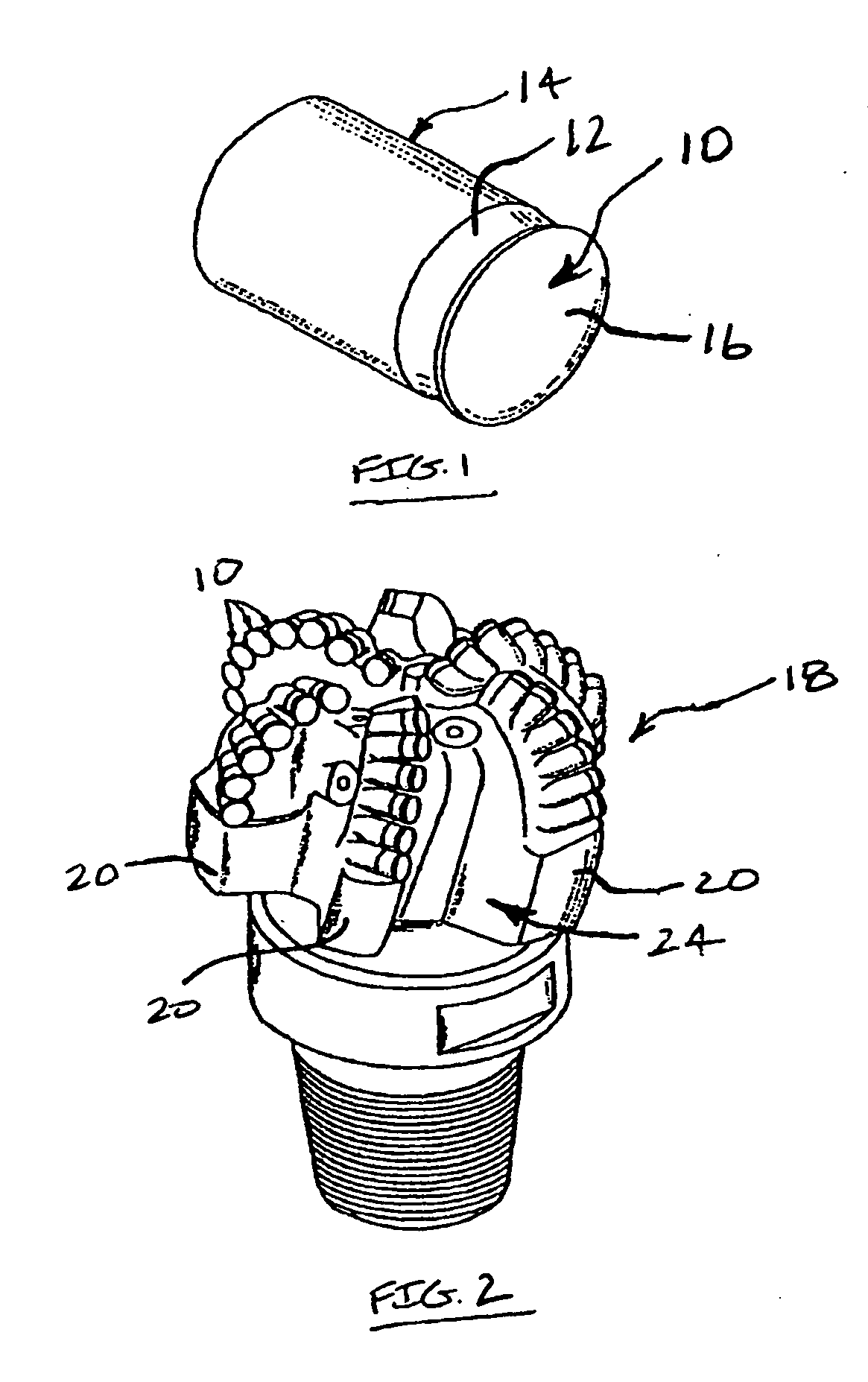

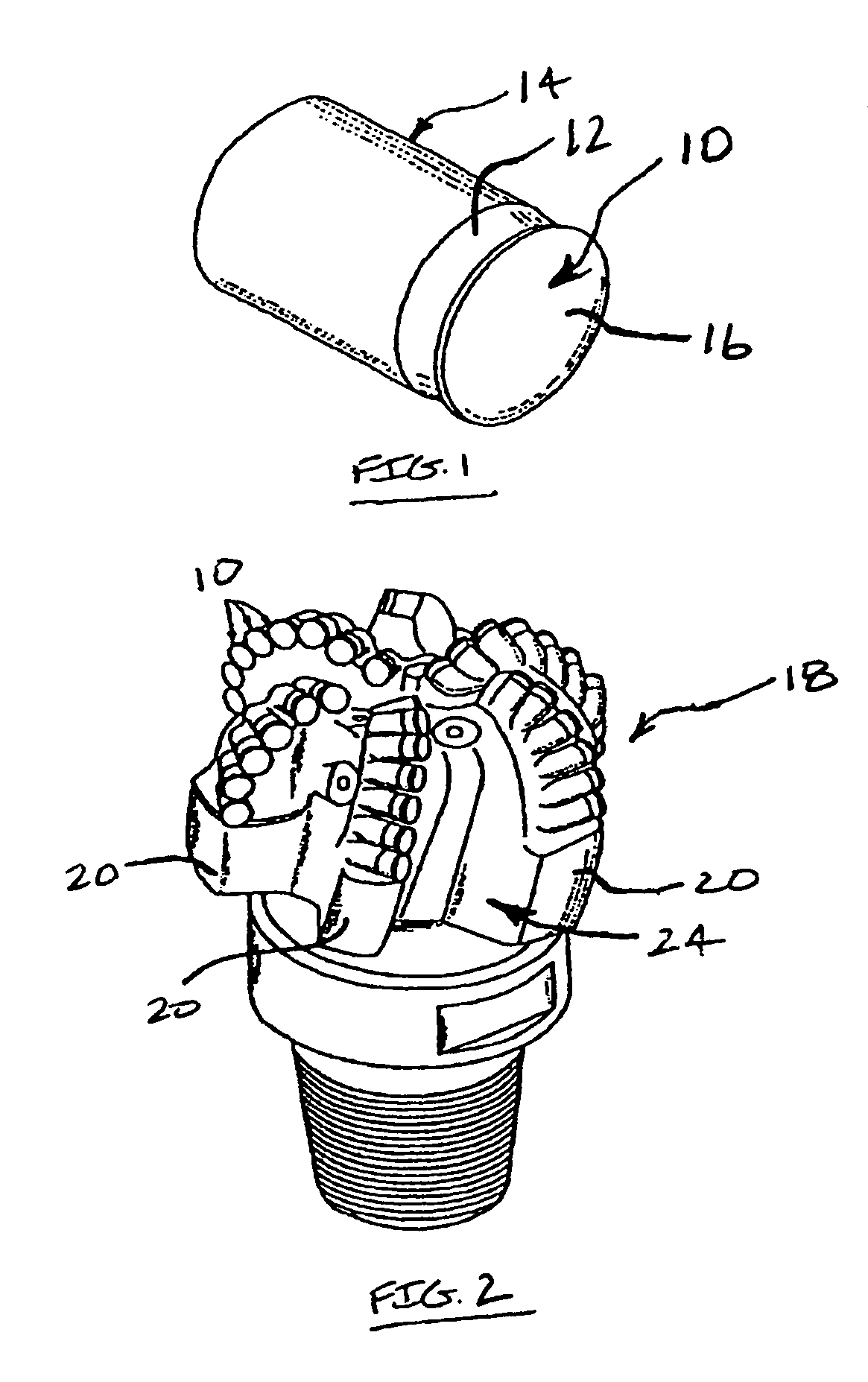

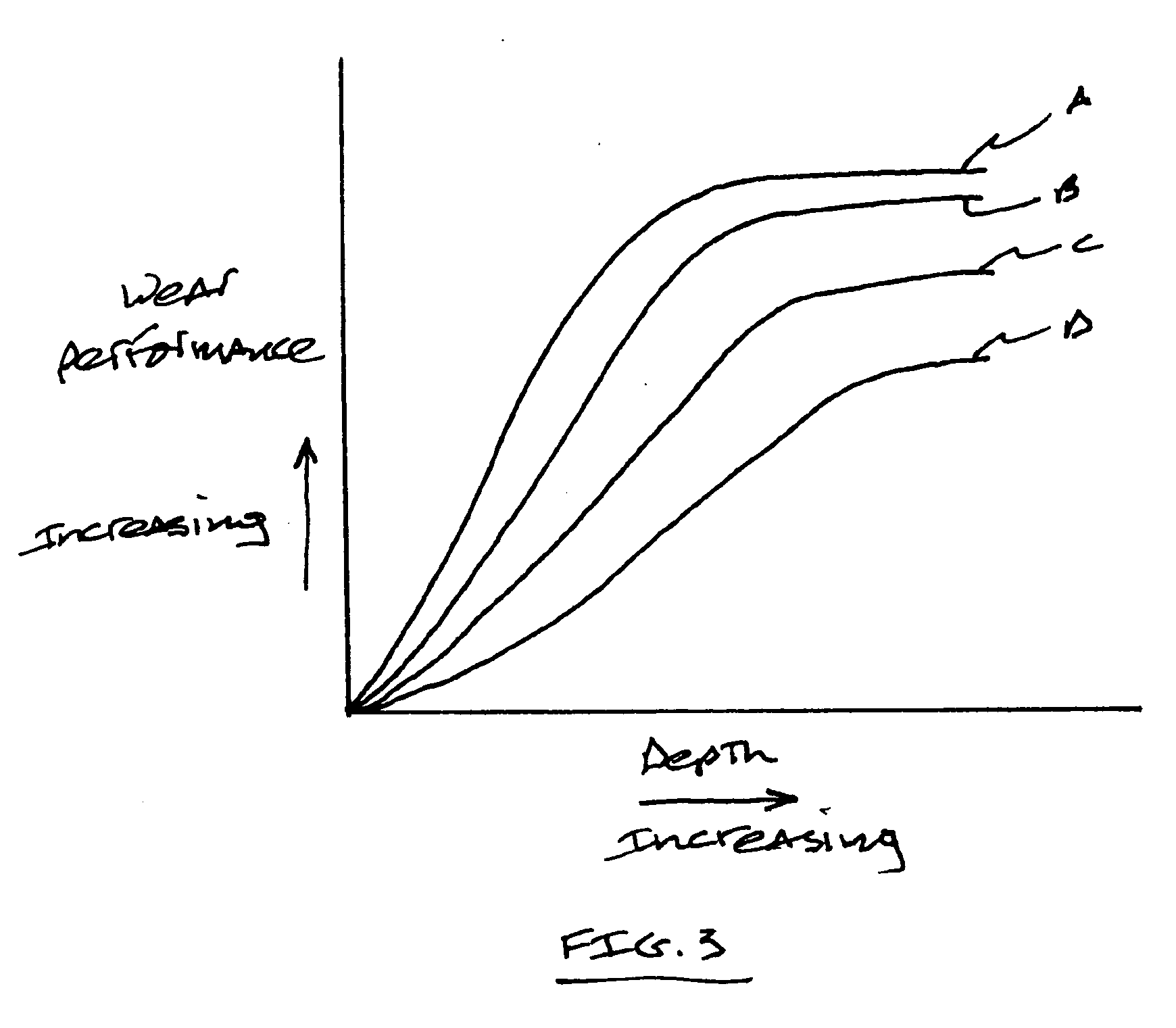

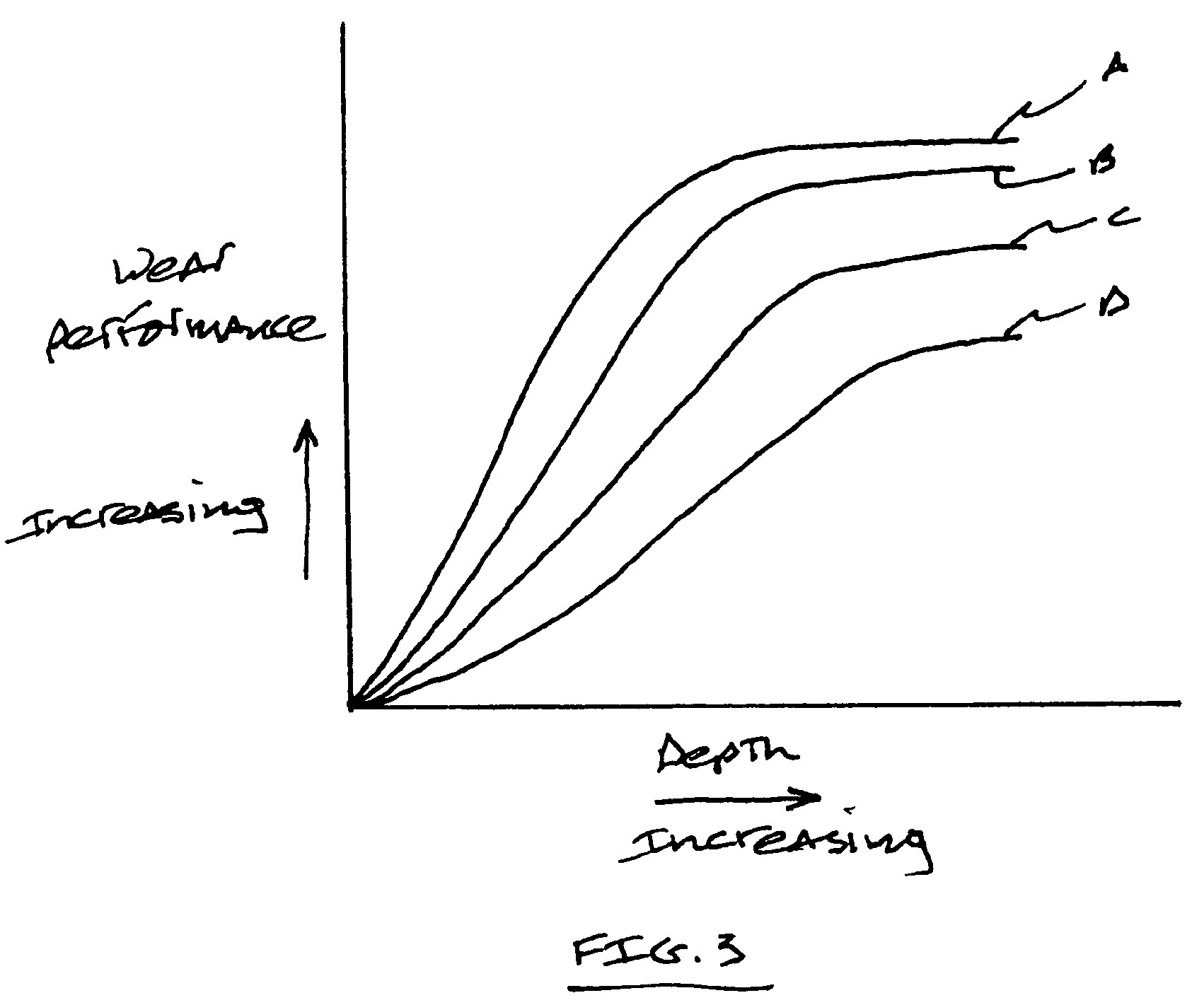

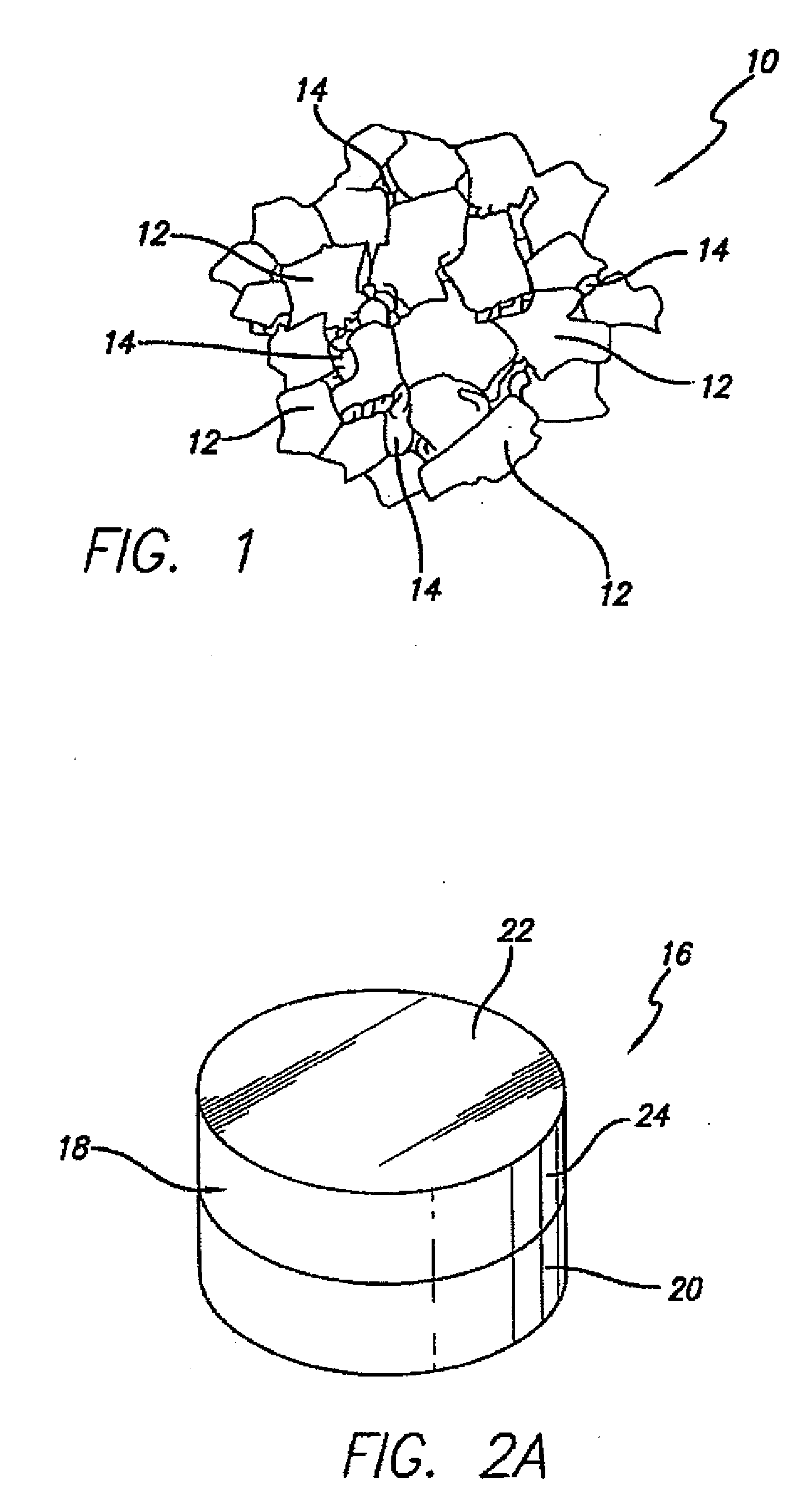

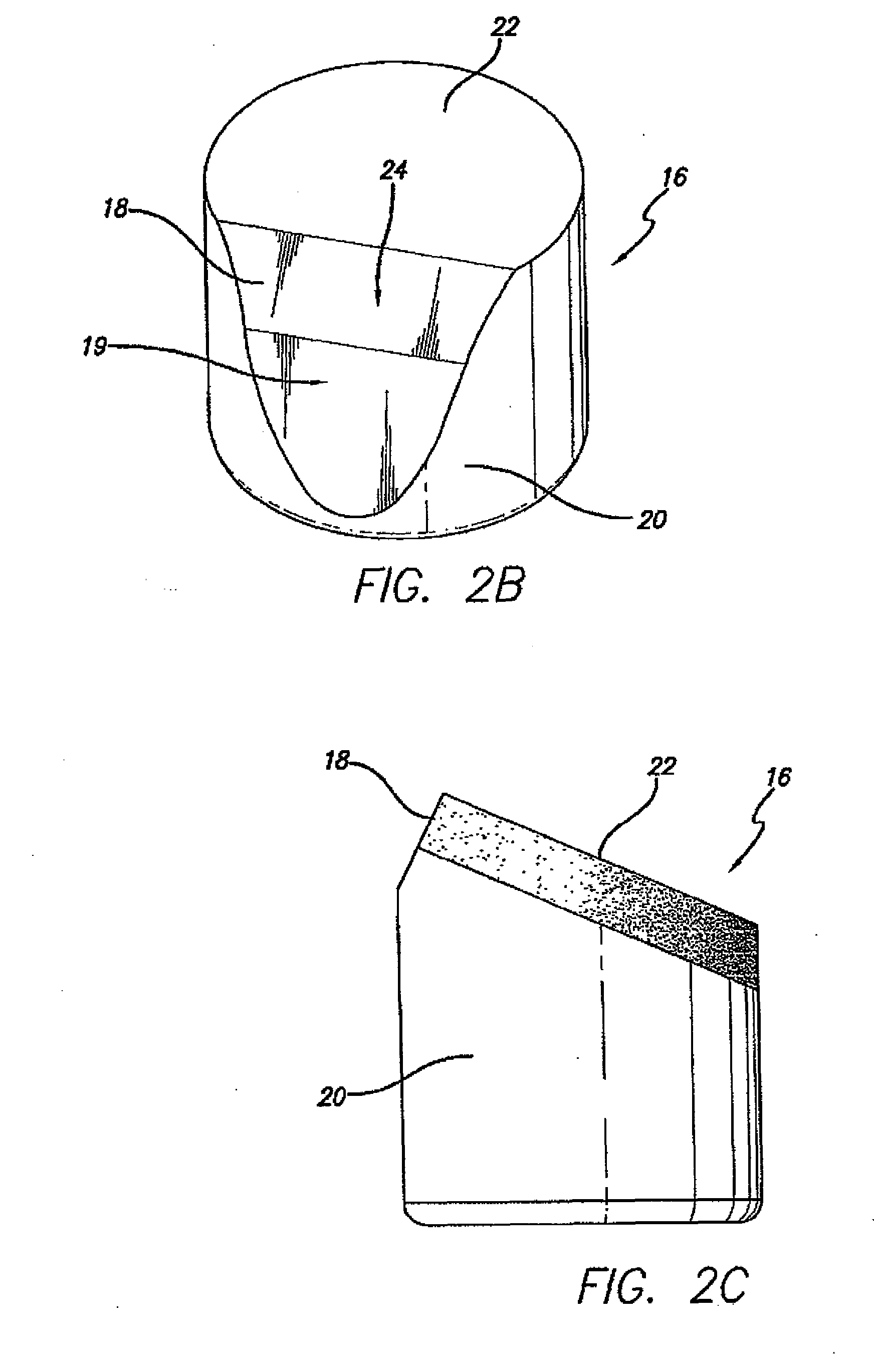

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

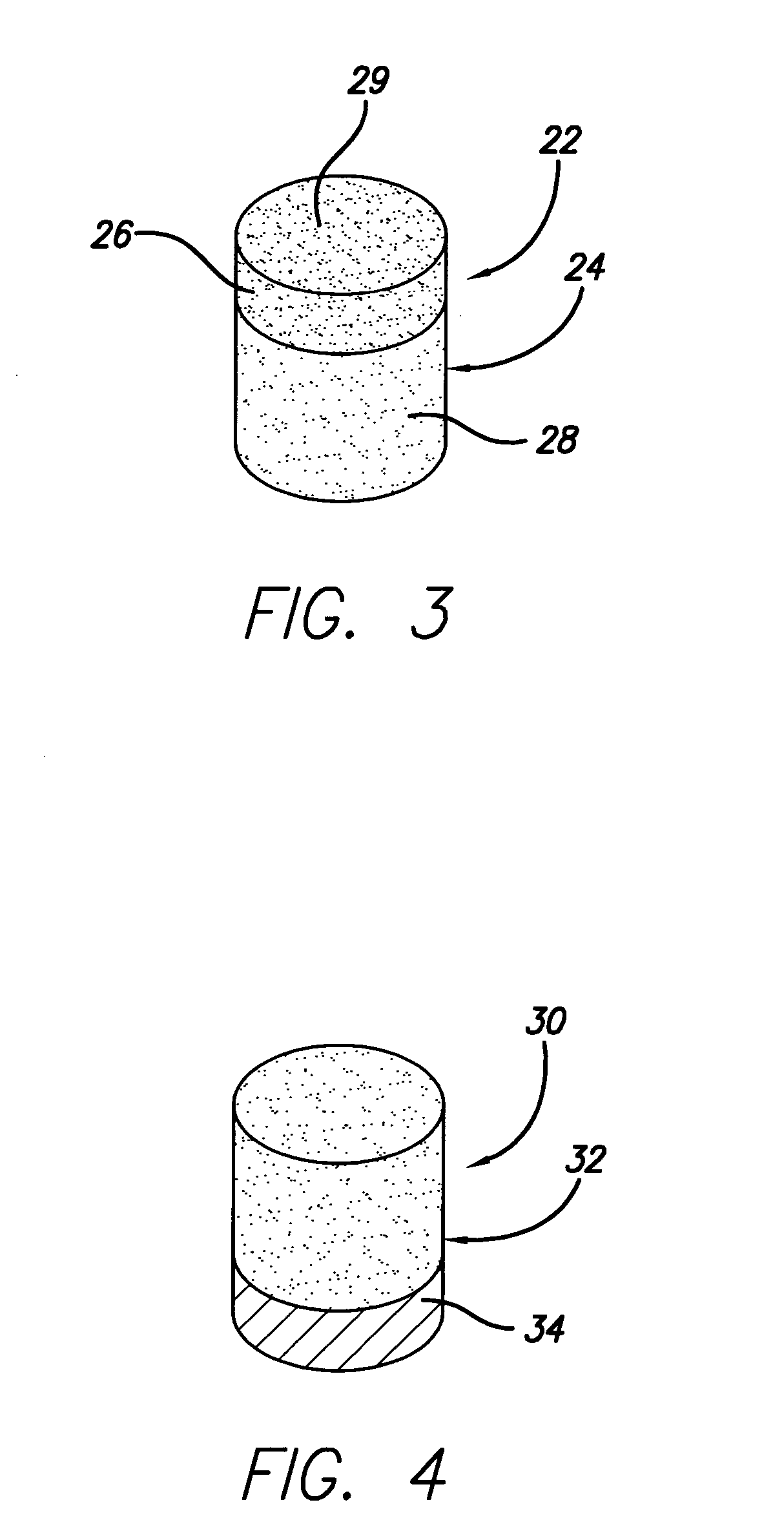

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

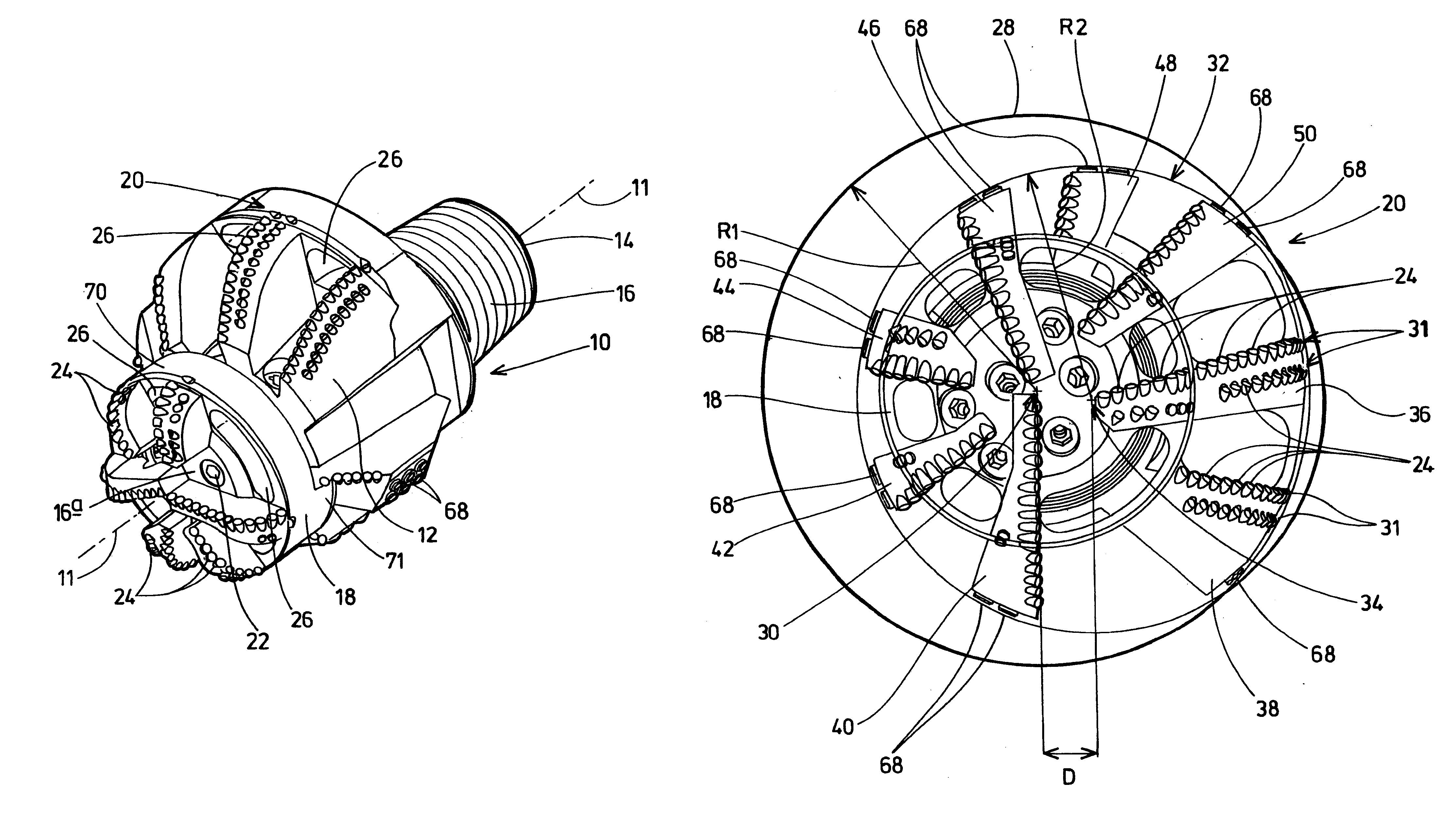

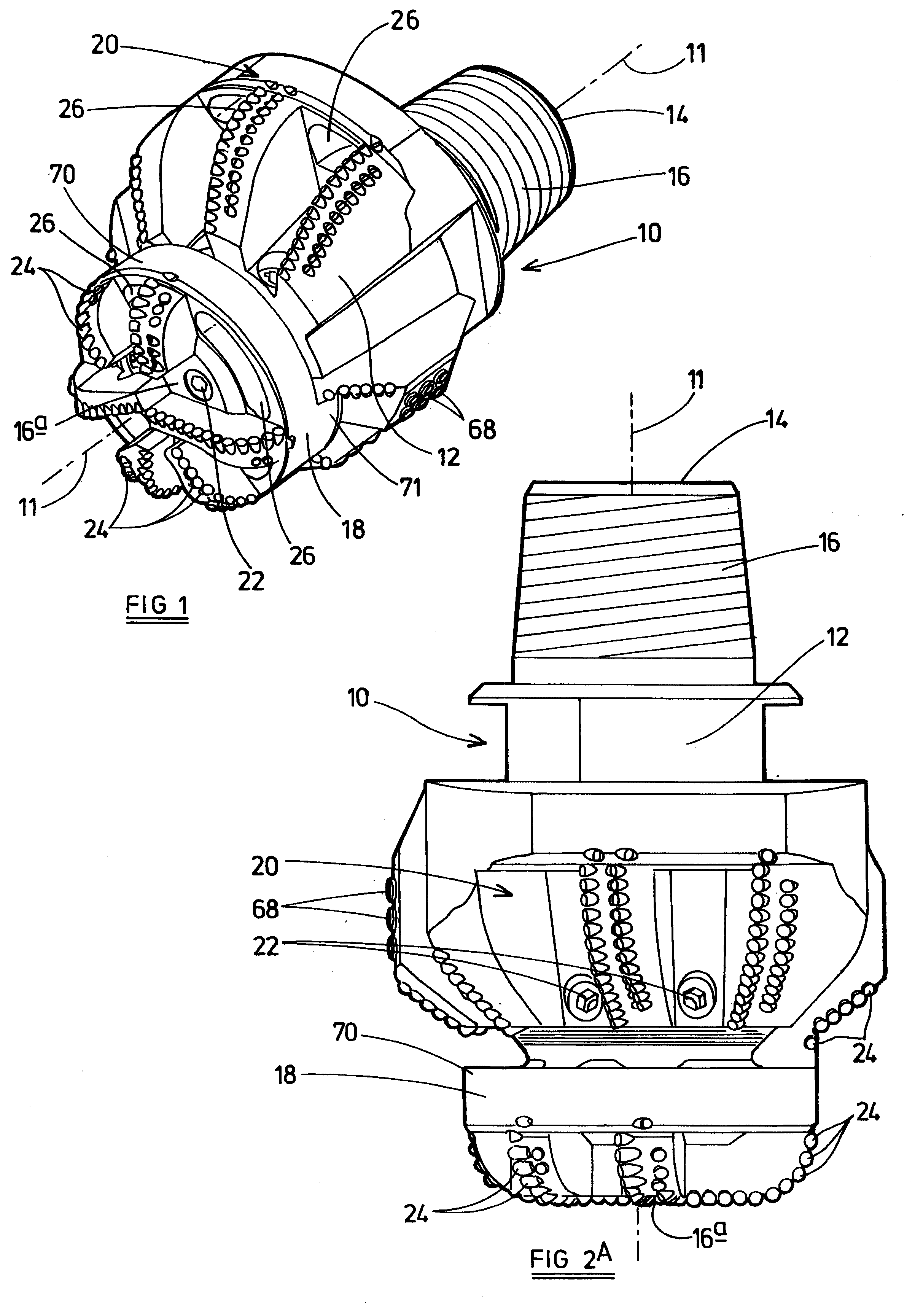

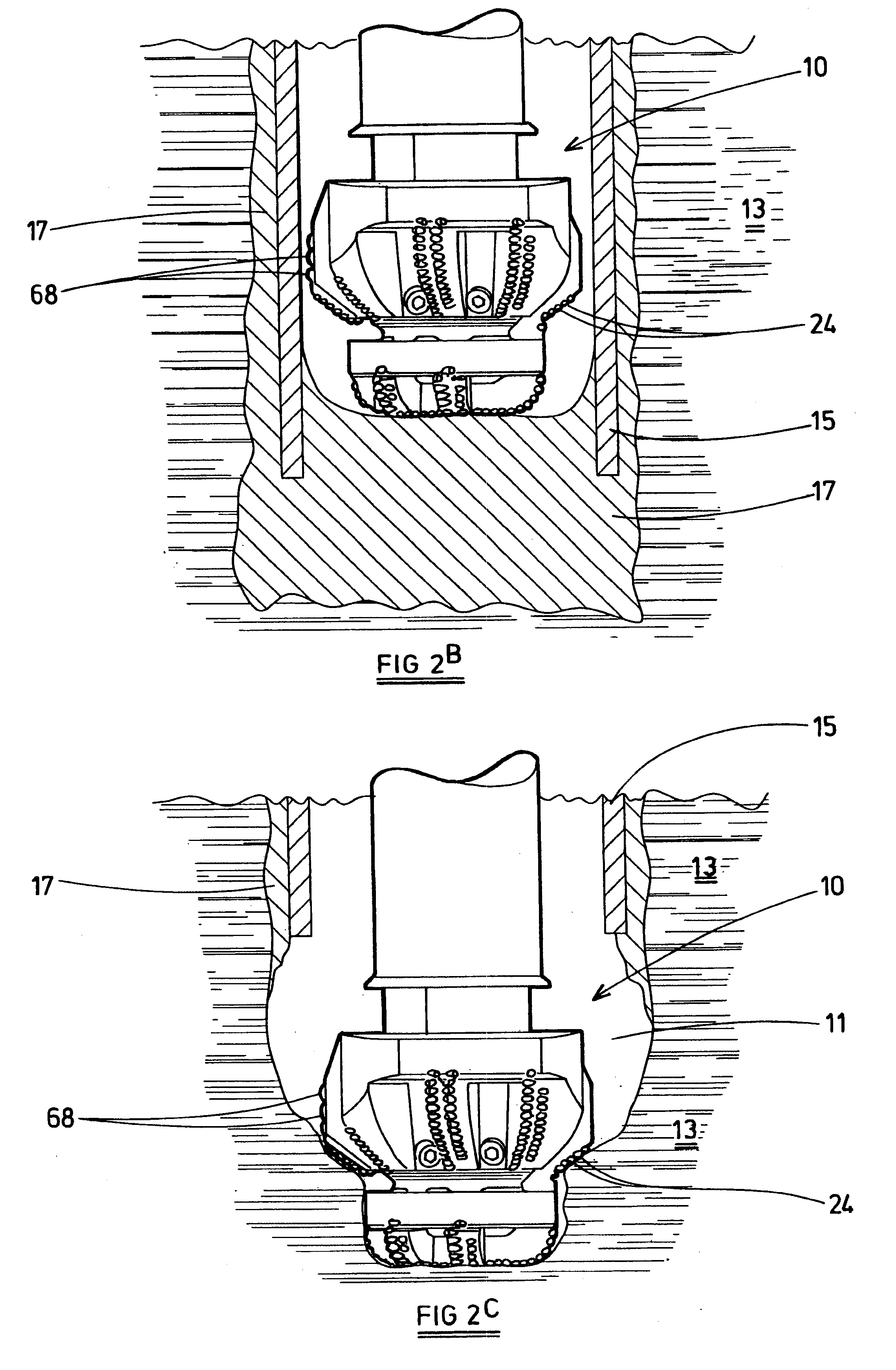

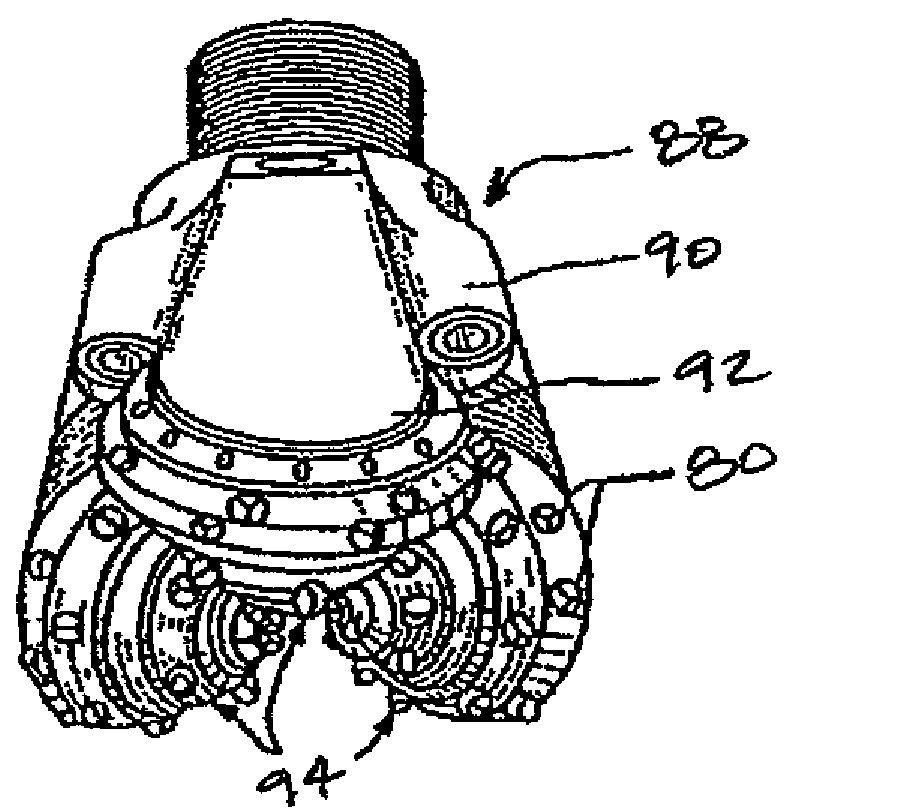

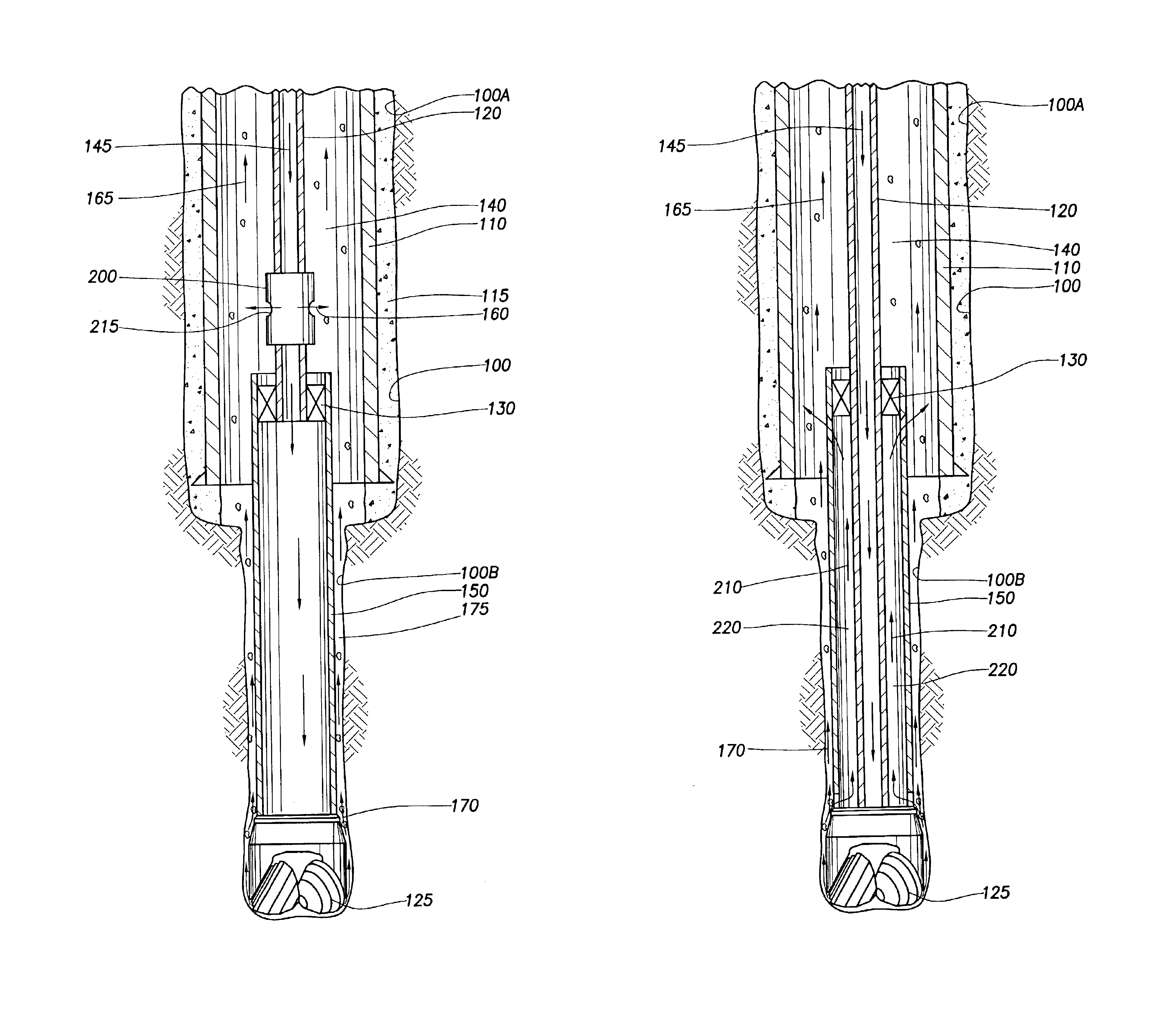

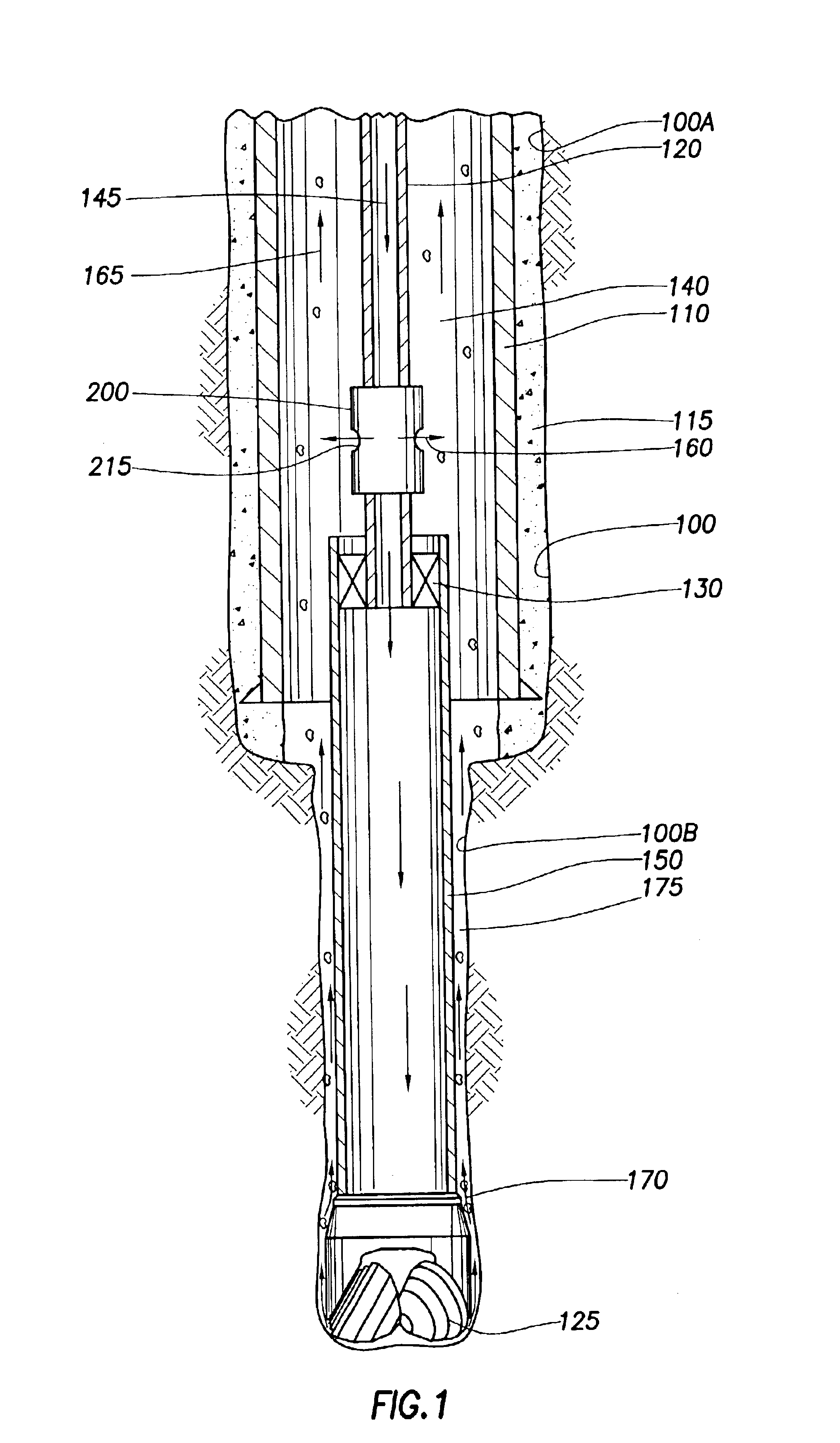

Expandable underreamer/stabilizer

A downhole tool that functions as an underreamer, or alternatively, as a stabilizer in an underreamed borehole. The tool includes one or more moveable arms disposed within a body having a flowbore therethrough in fluid communication with the wellbore annulus. The tool alternates between collapsed and expanded positions in response to differential fluid pressure between the flowbore and the wellbore annulus. In one embodiment, the tool moves automatically in response to differential pressure. In a second embodiment, the tool must be selectively actuated before it is moveable. When the tool expands, the arms are preferably translated axially upwardly, while simultaneously being extended radially outwardly from the body. The expanded tool diameter is adjustable at the surface without changing components. The arms may include borehole engaging pads that comprise cutting structures or wear structures or both, depending upon the function of the tool.

Owner:SMITH INT INC

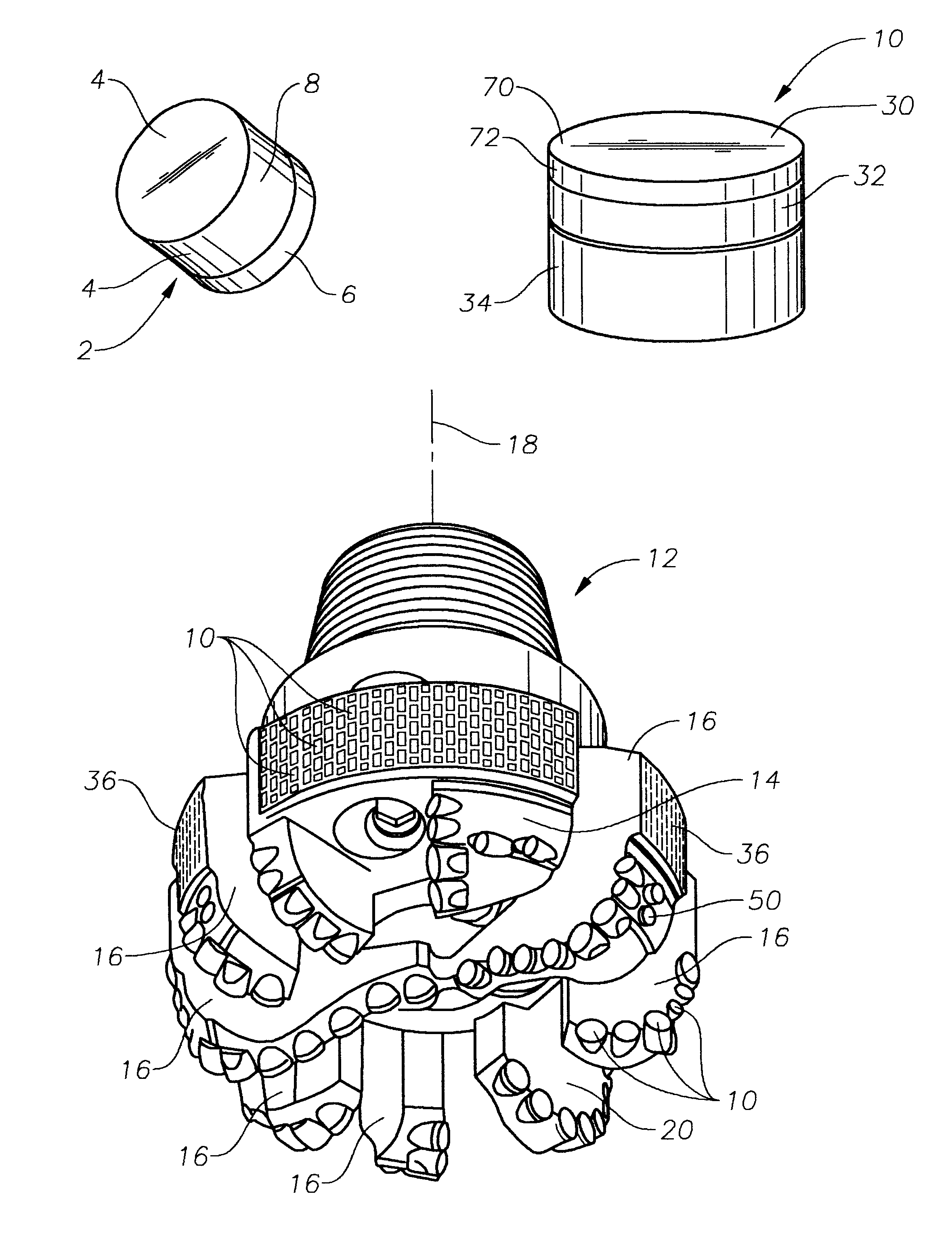

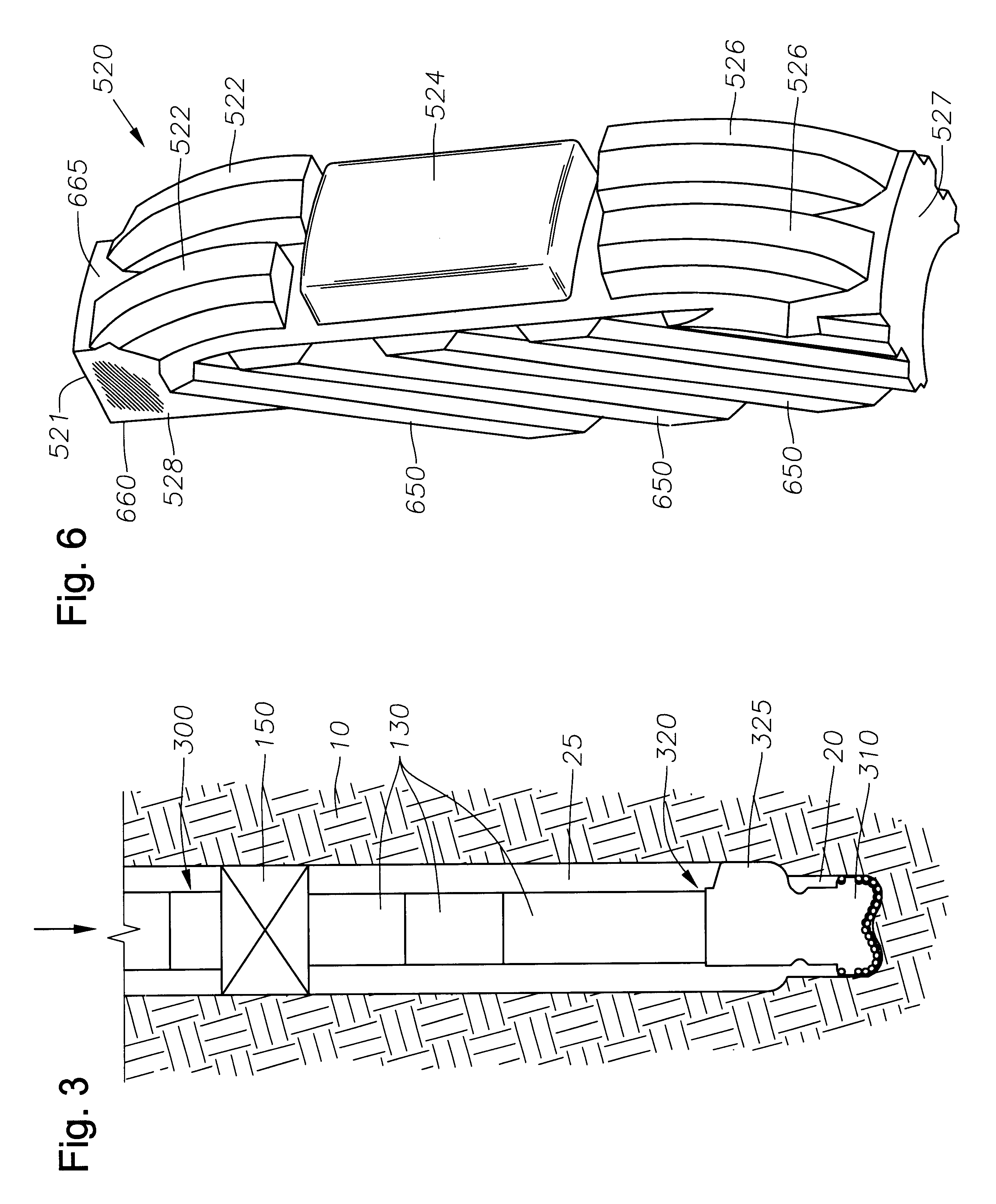

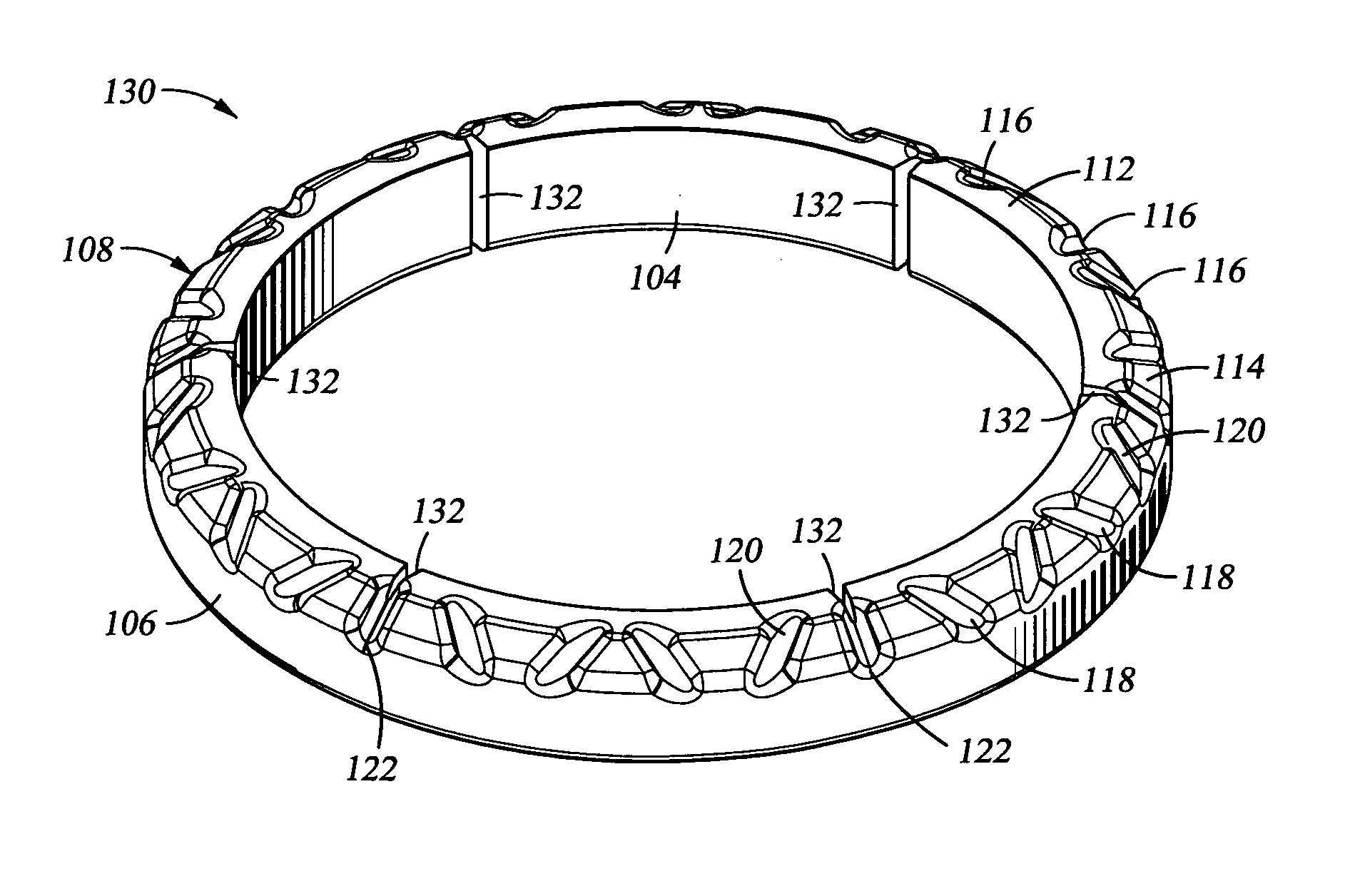

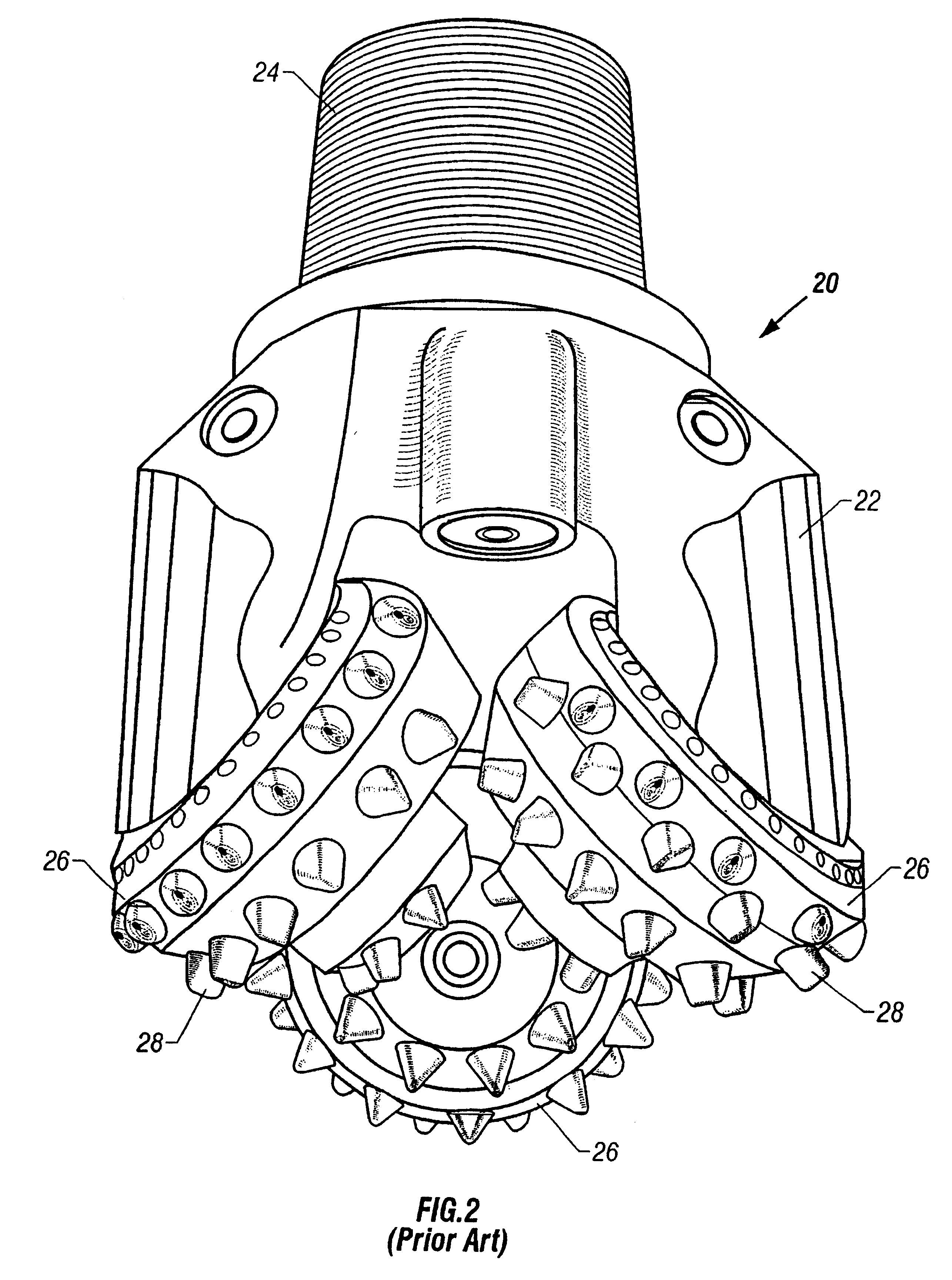

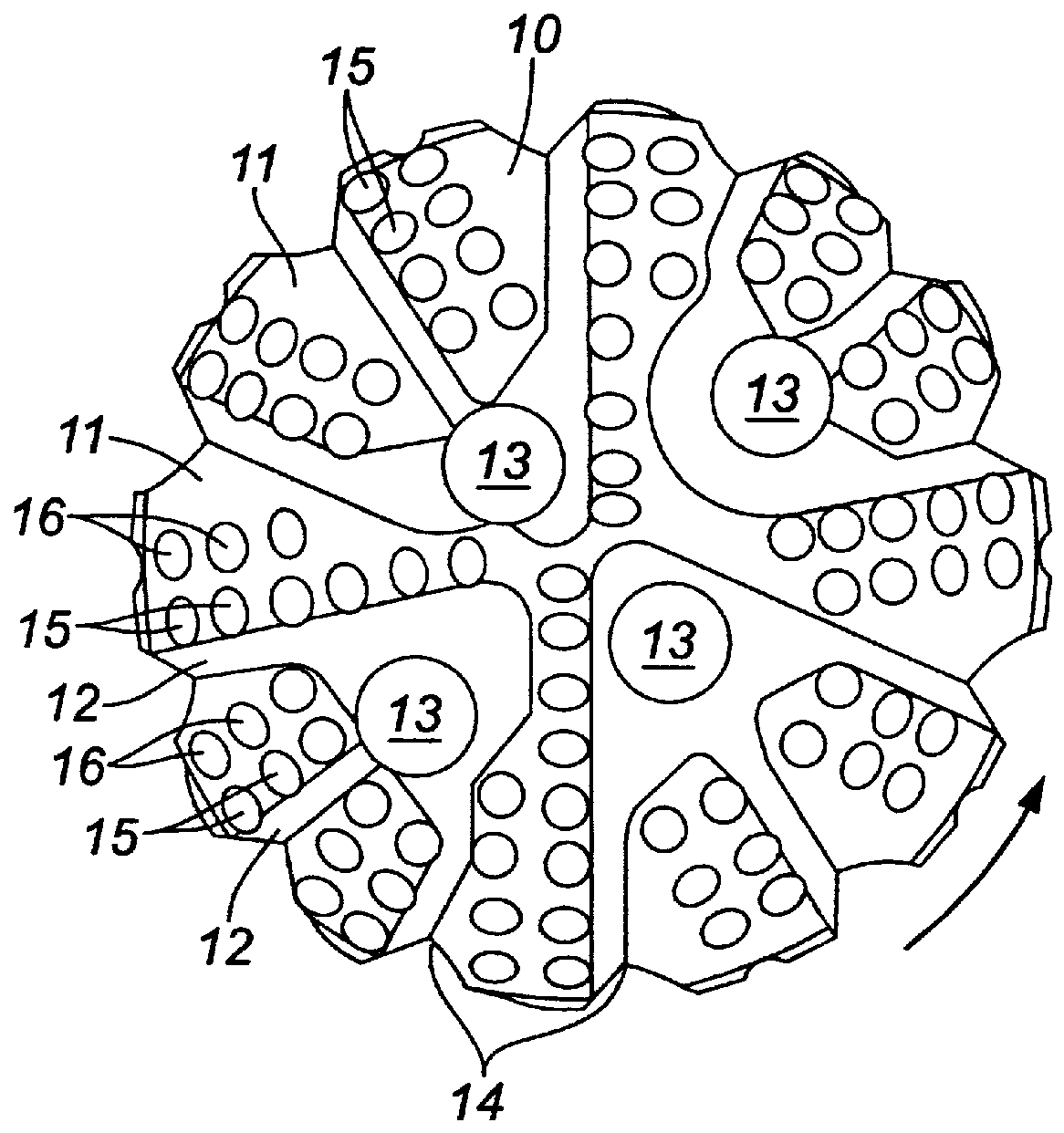

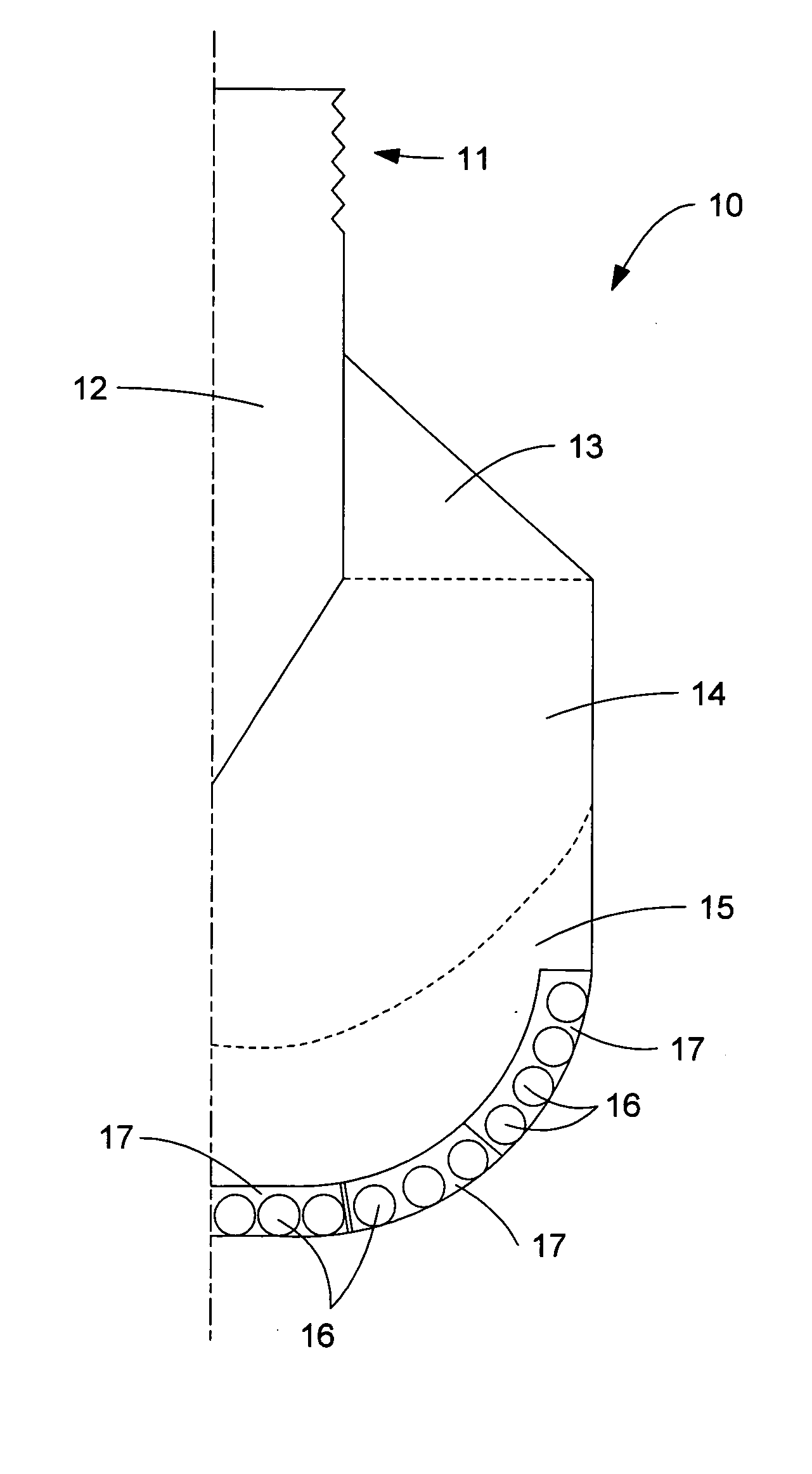

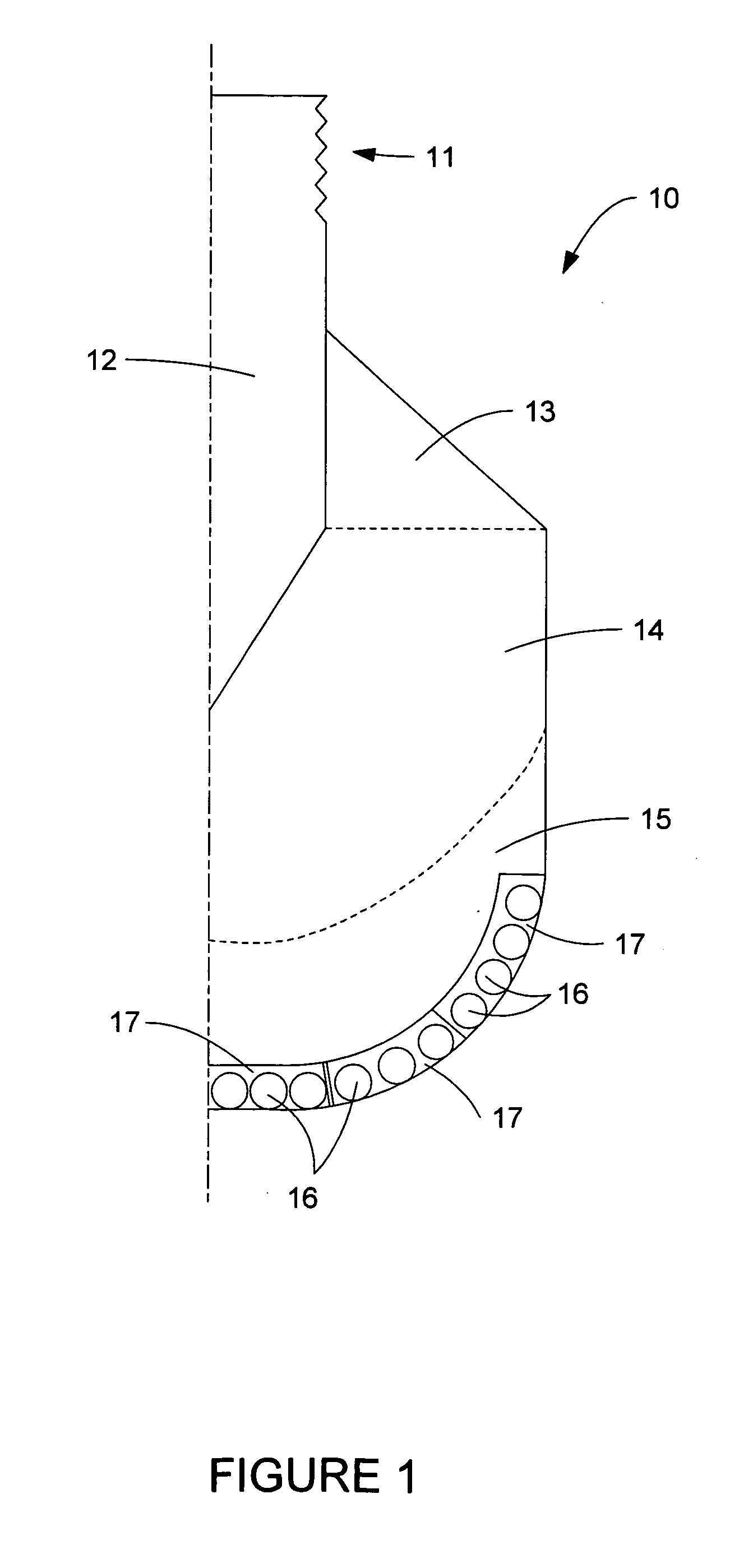

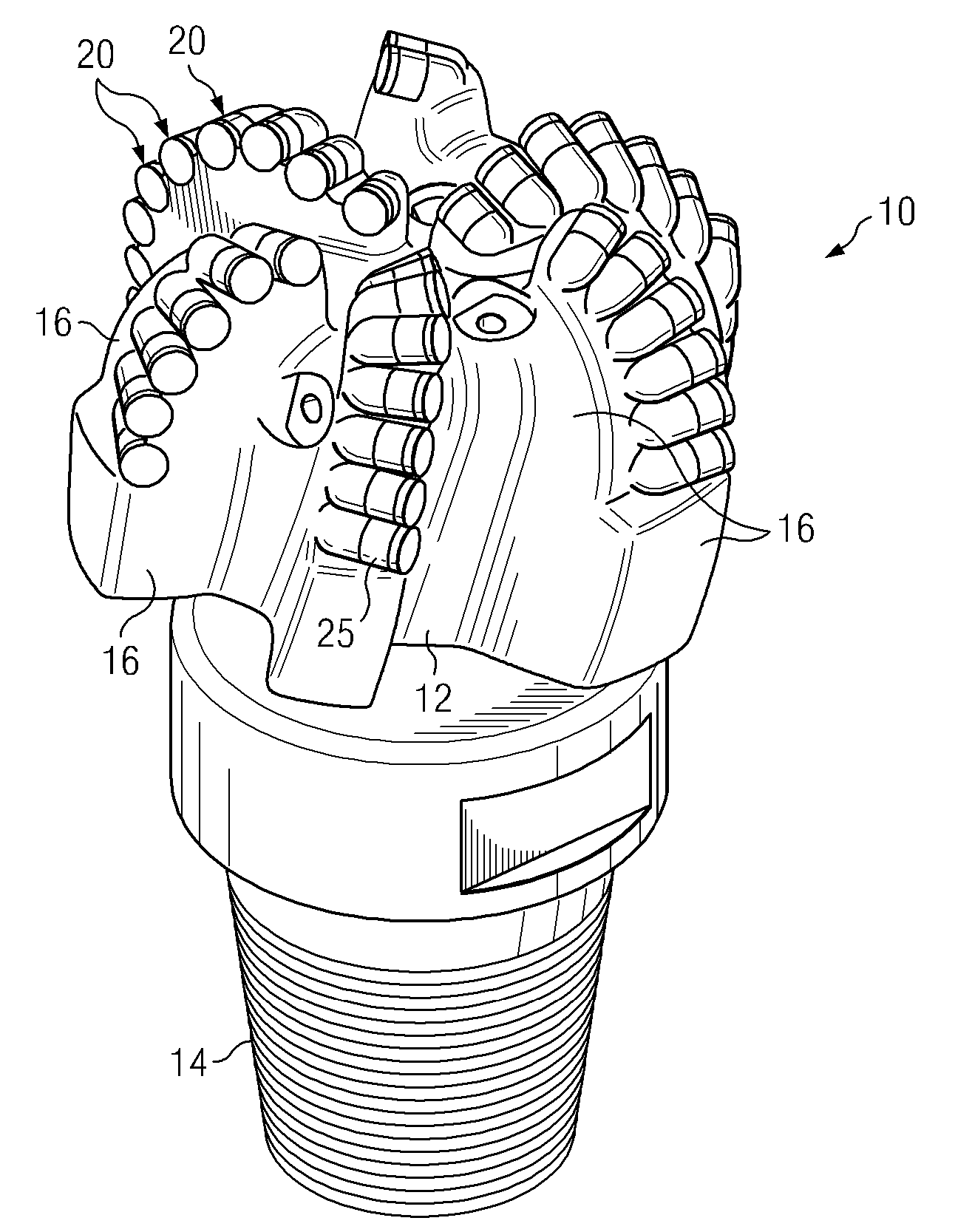

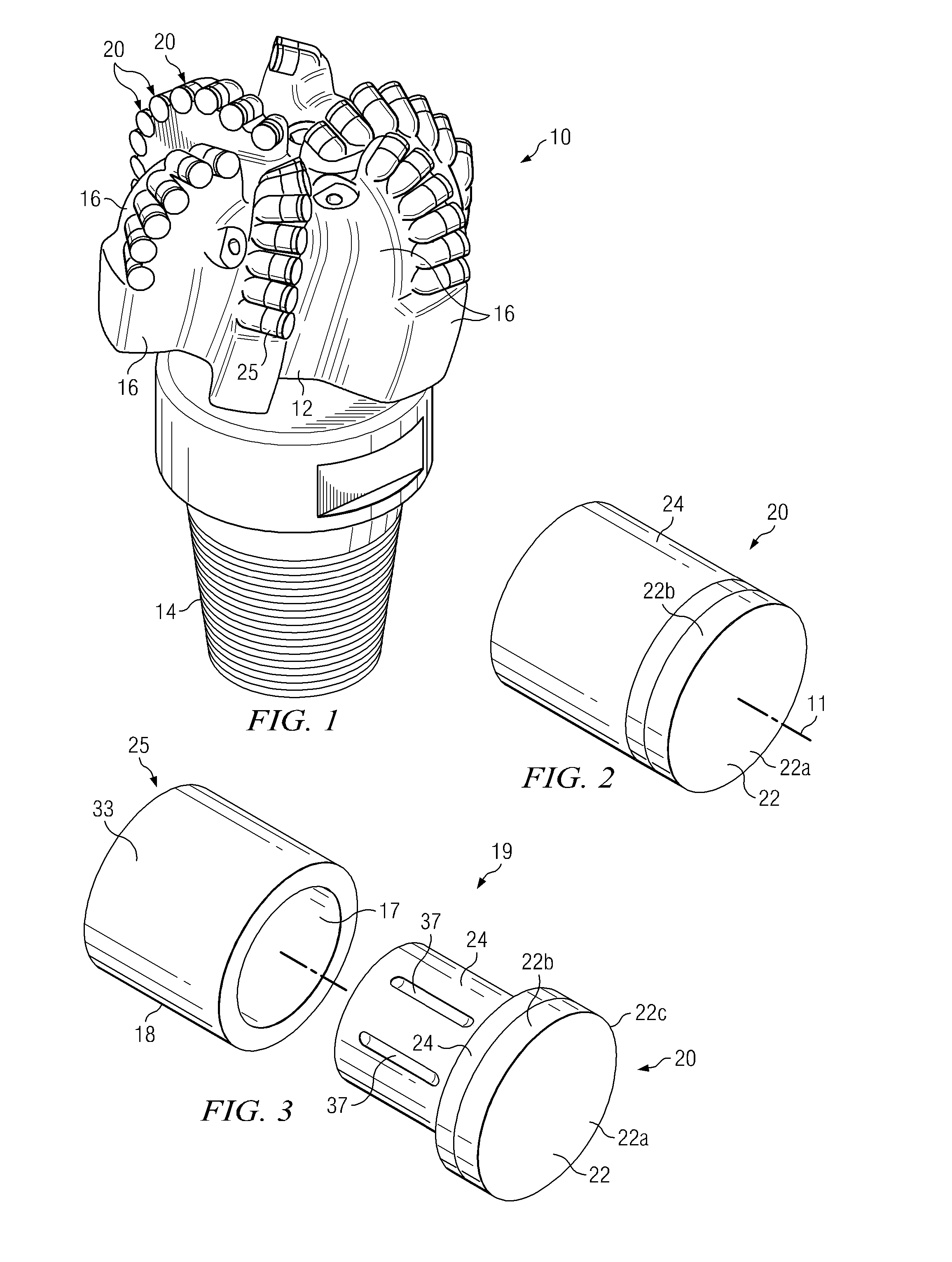

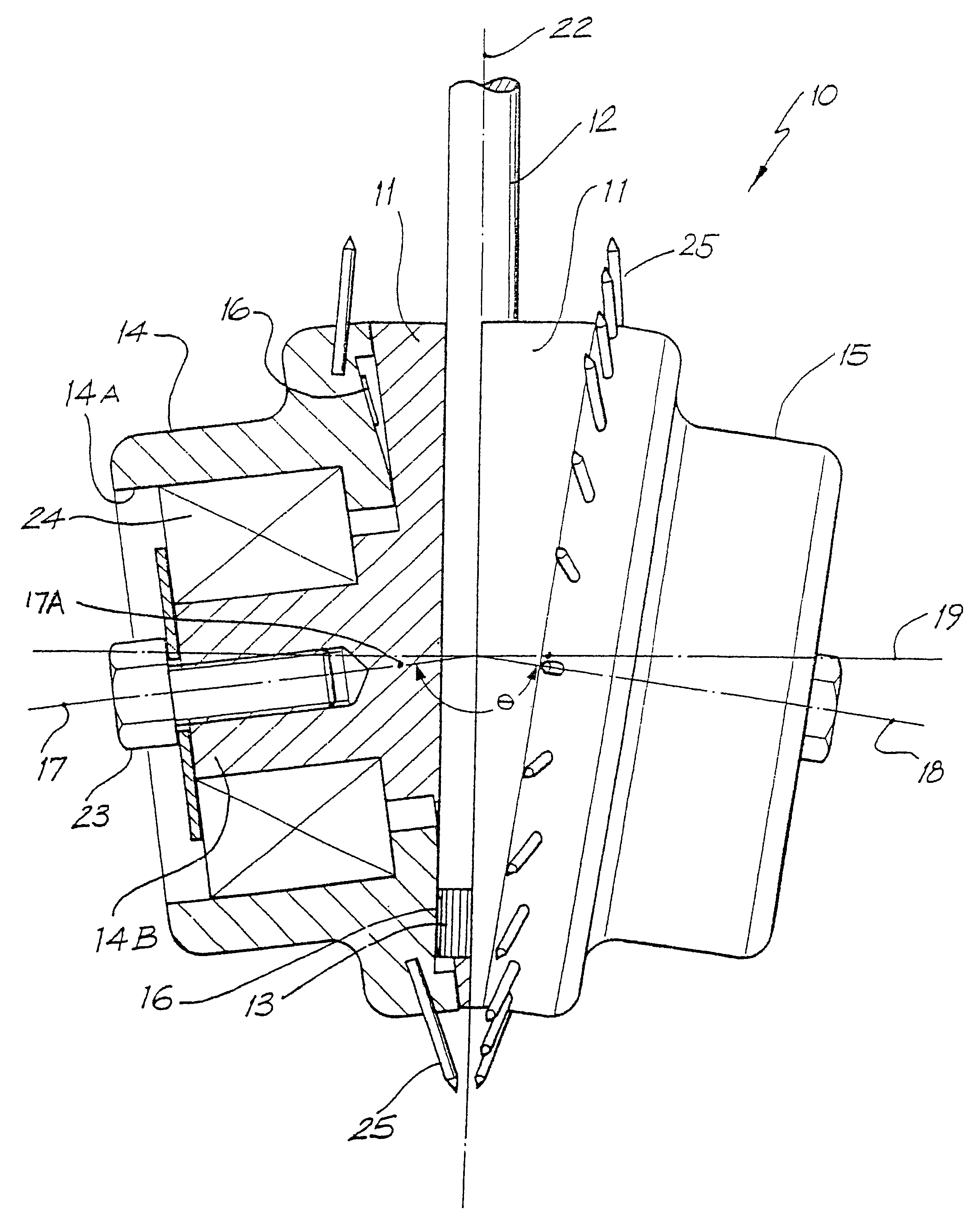

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

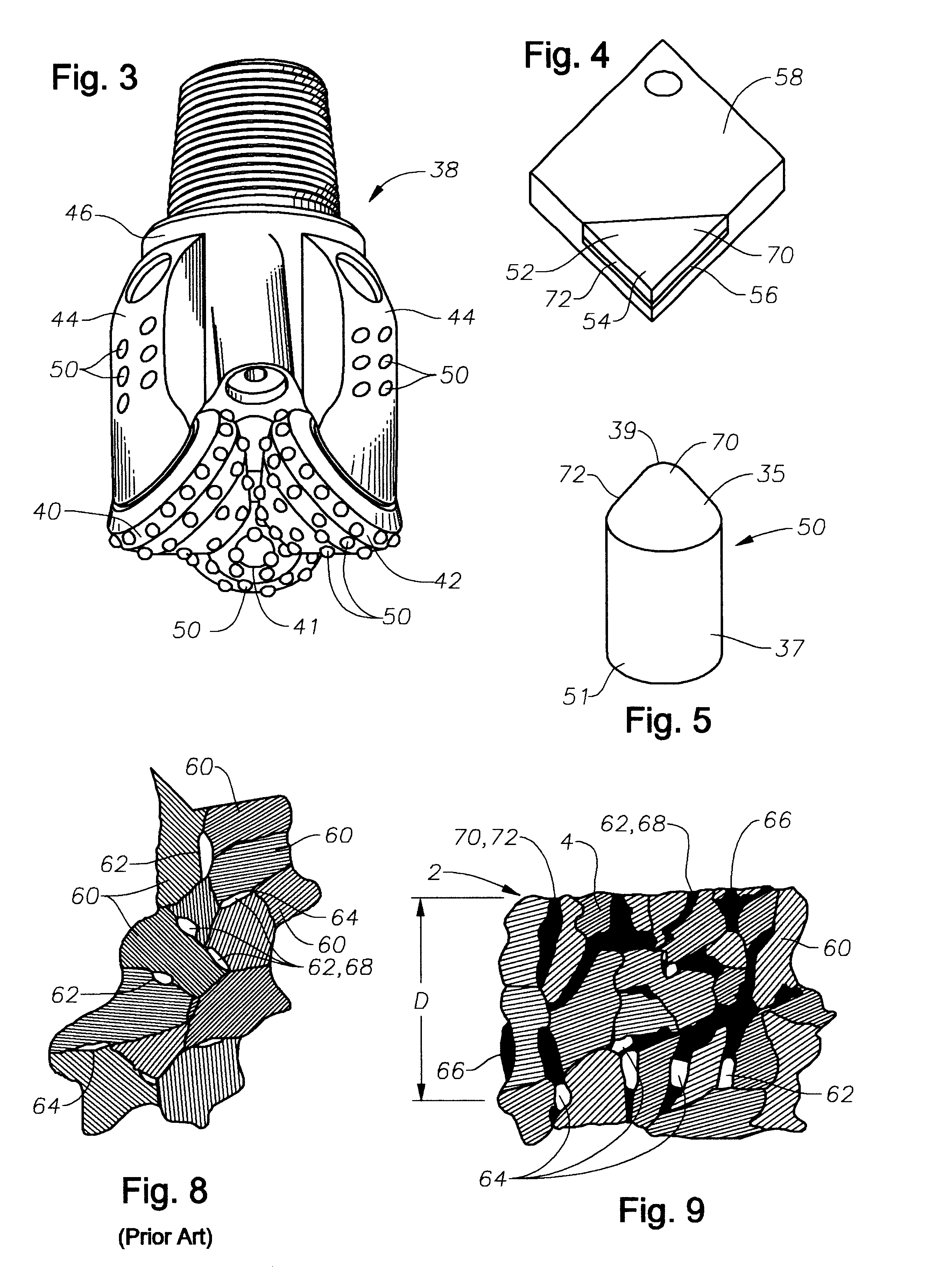

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

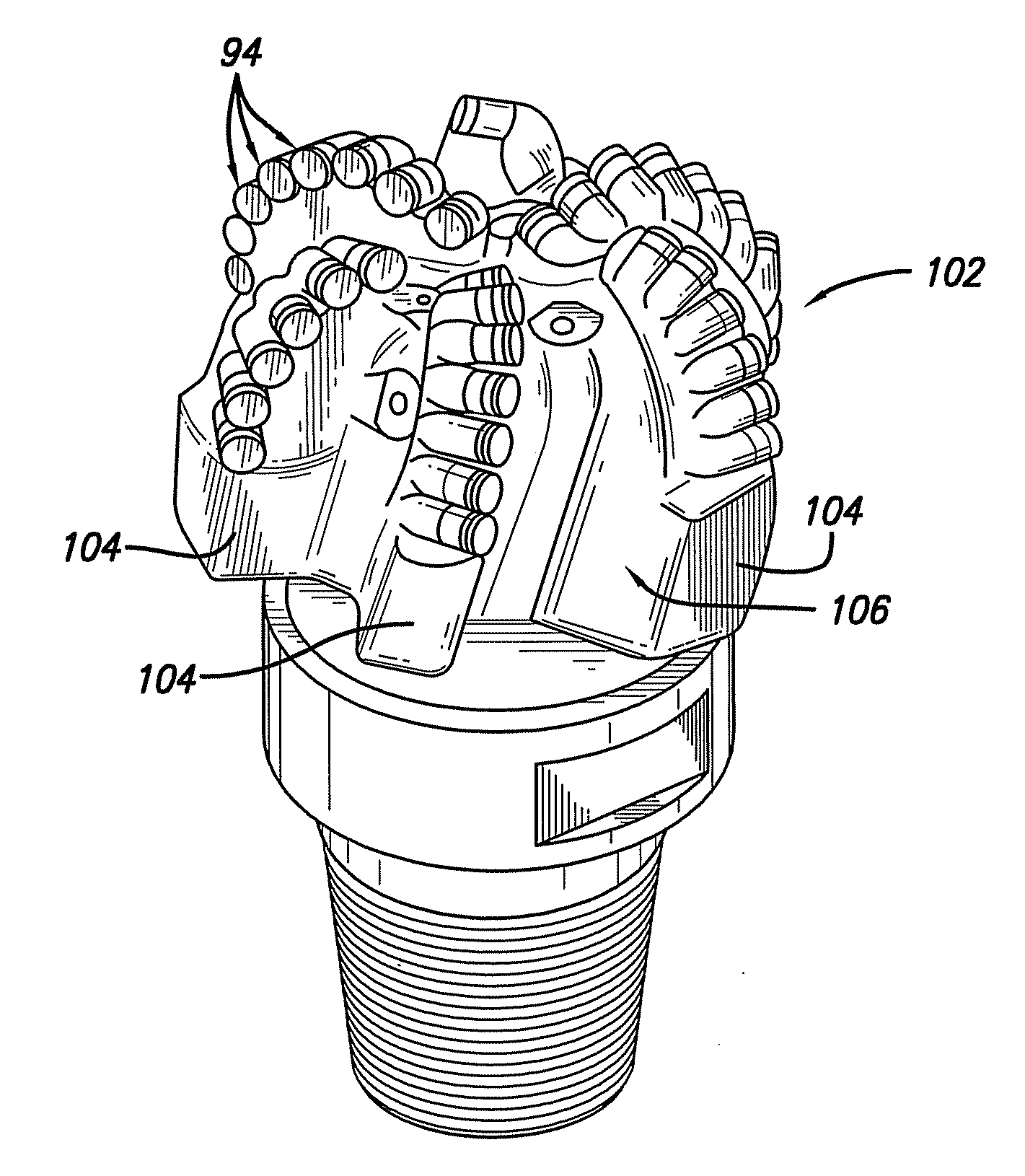

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

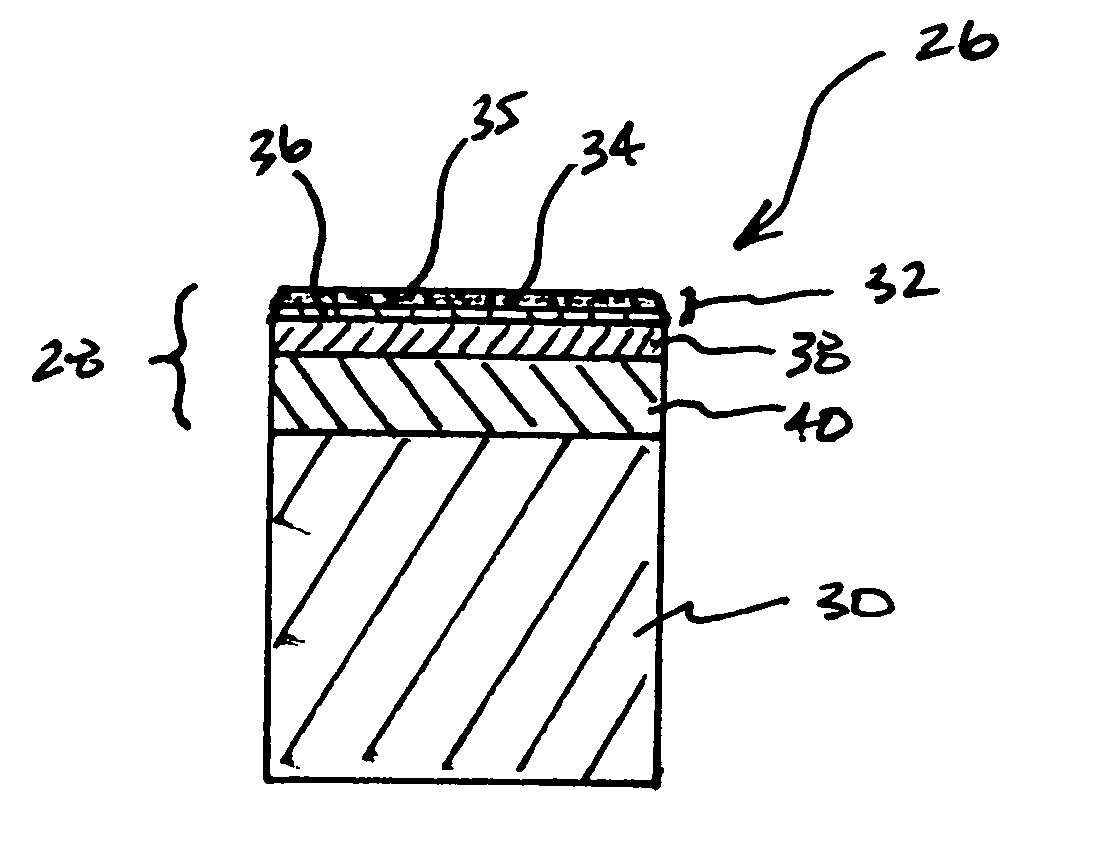

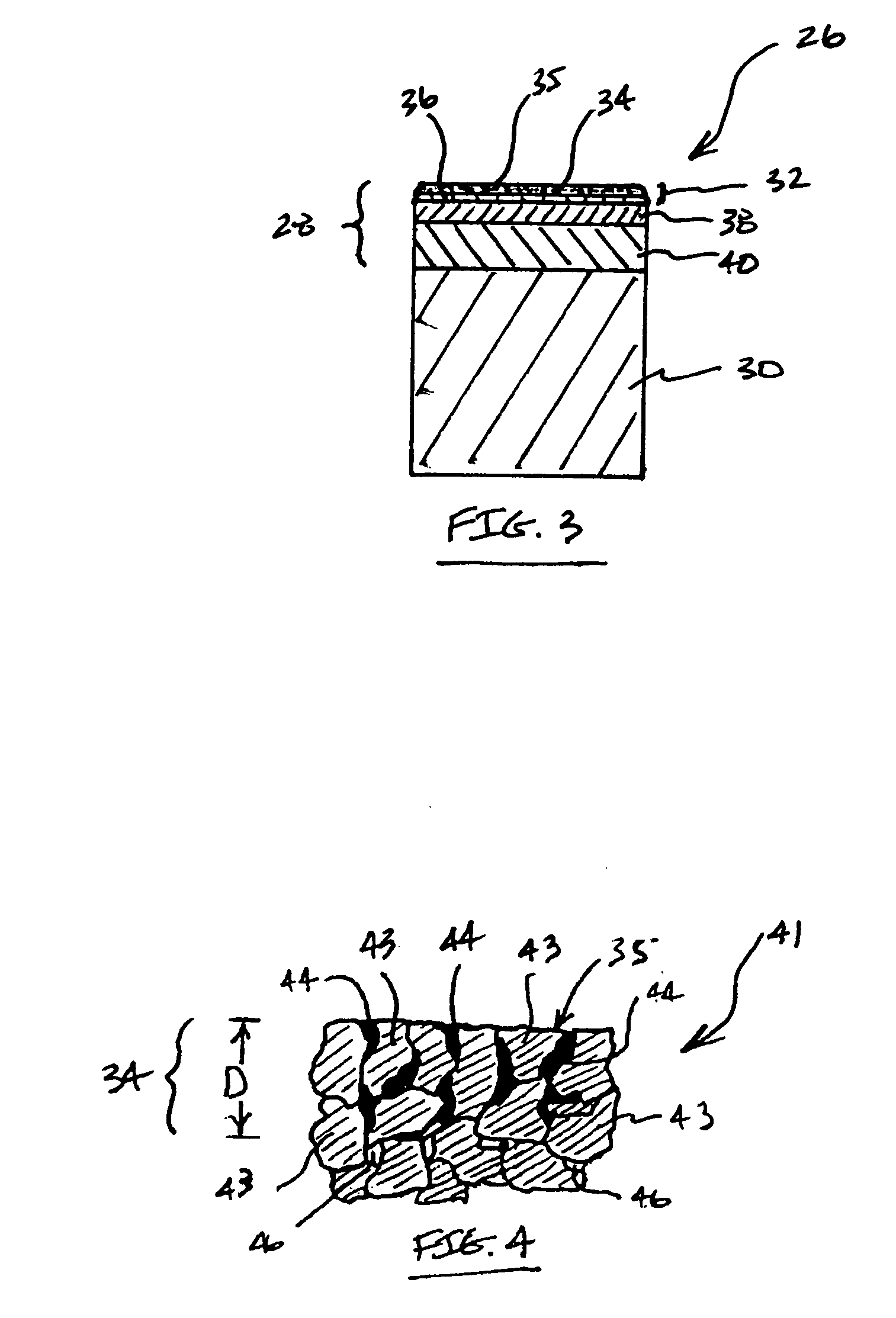

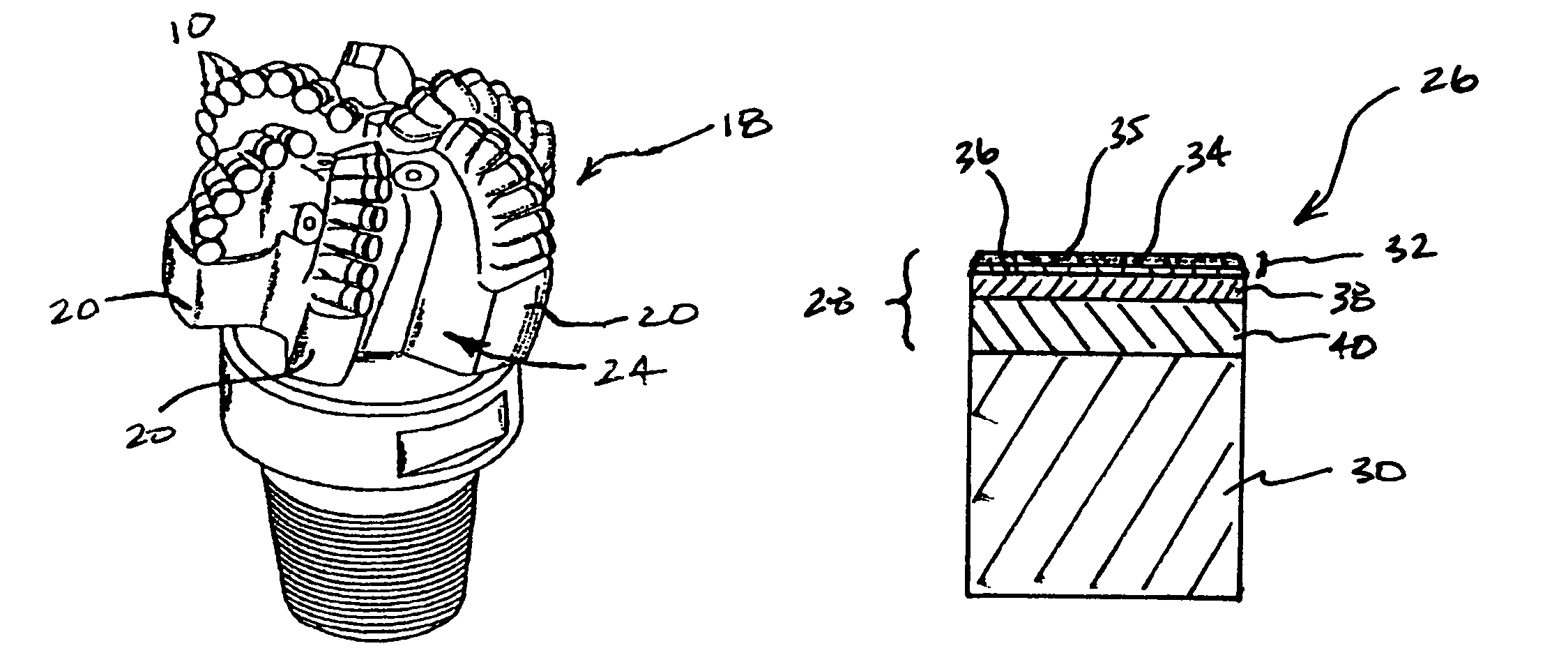

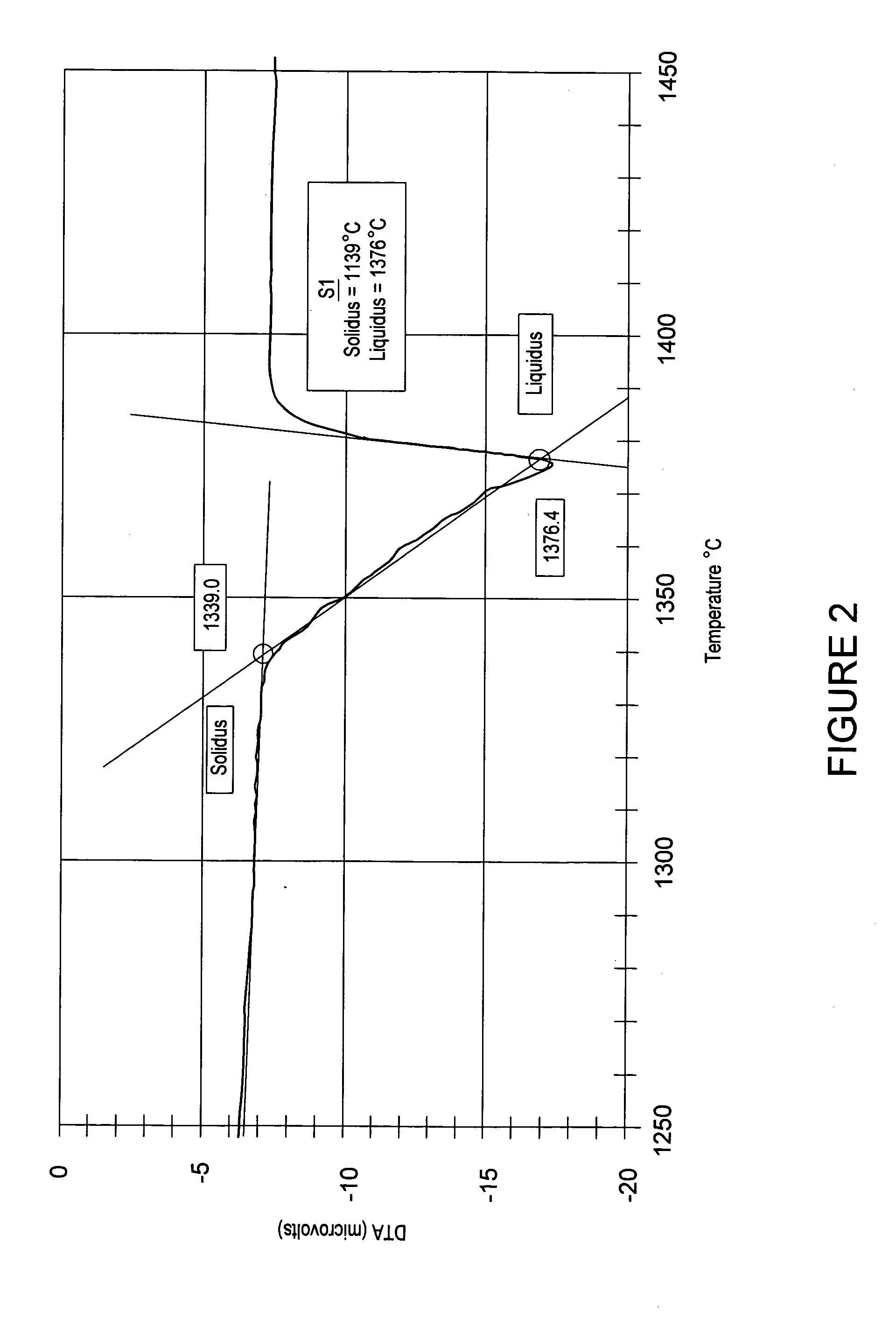

Thermally stable ultra-hard material compact construction

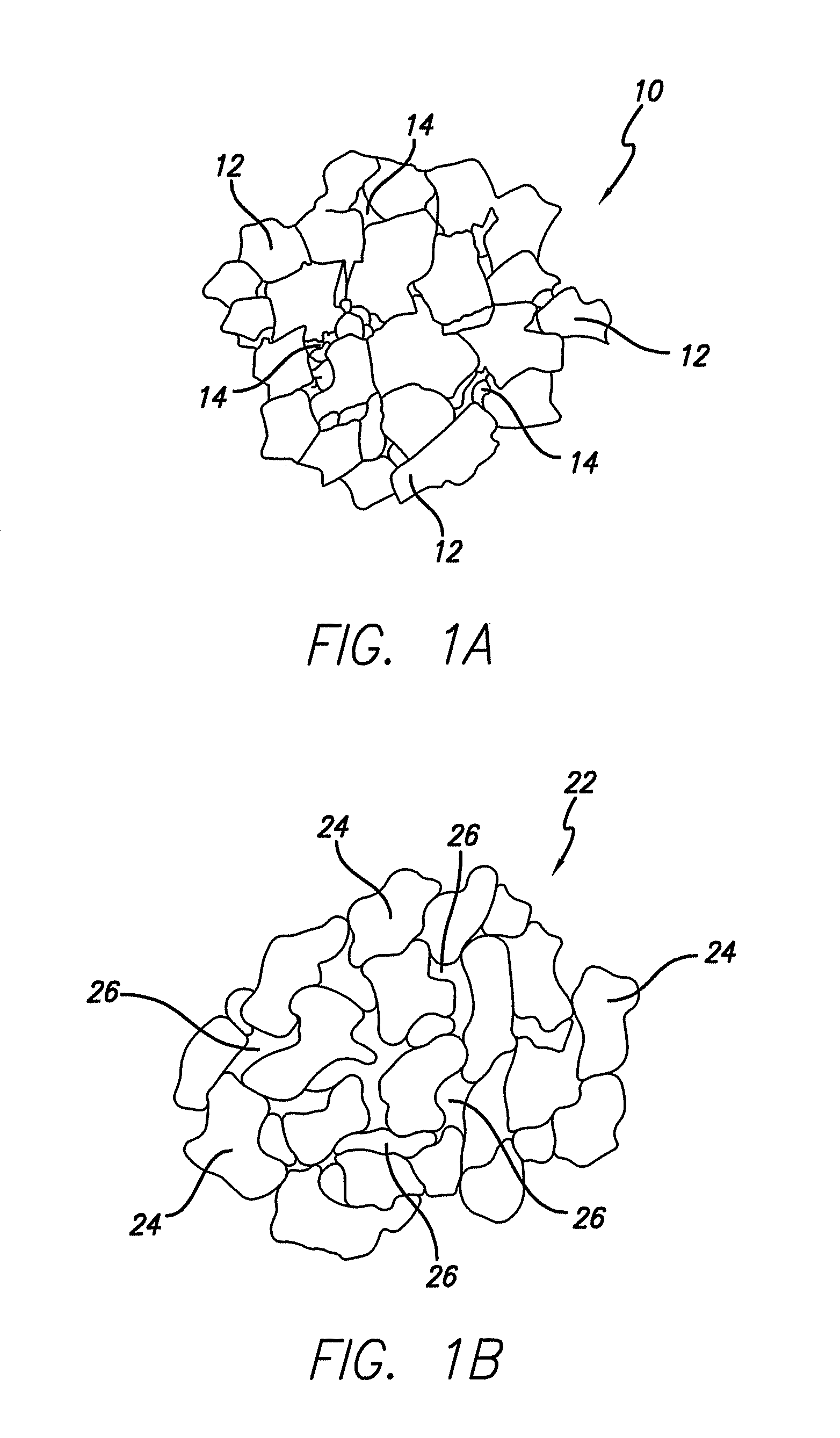

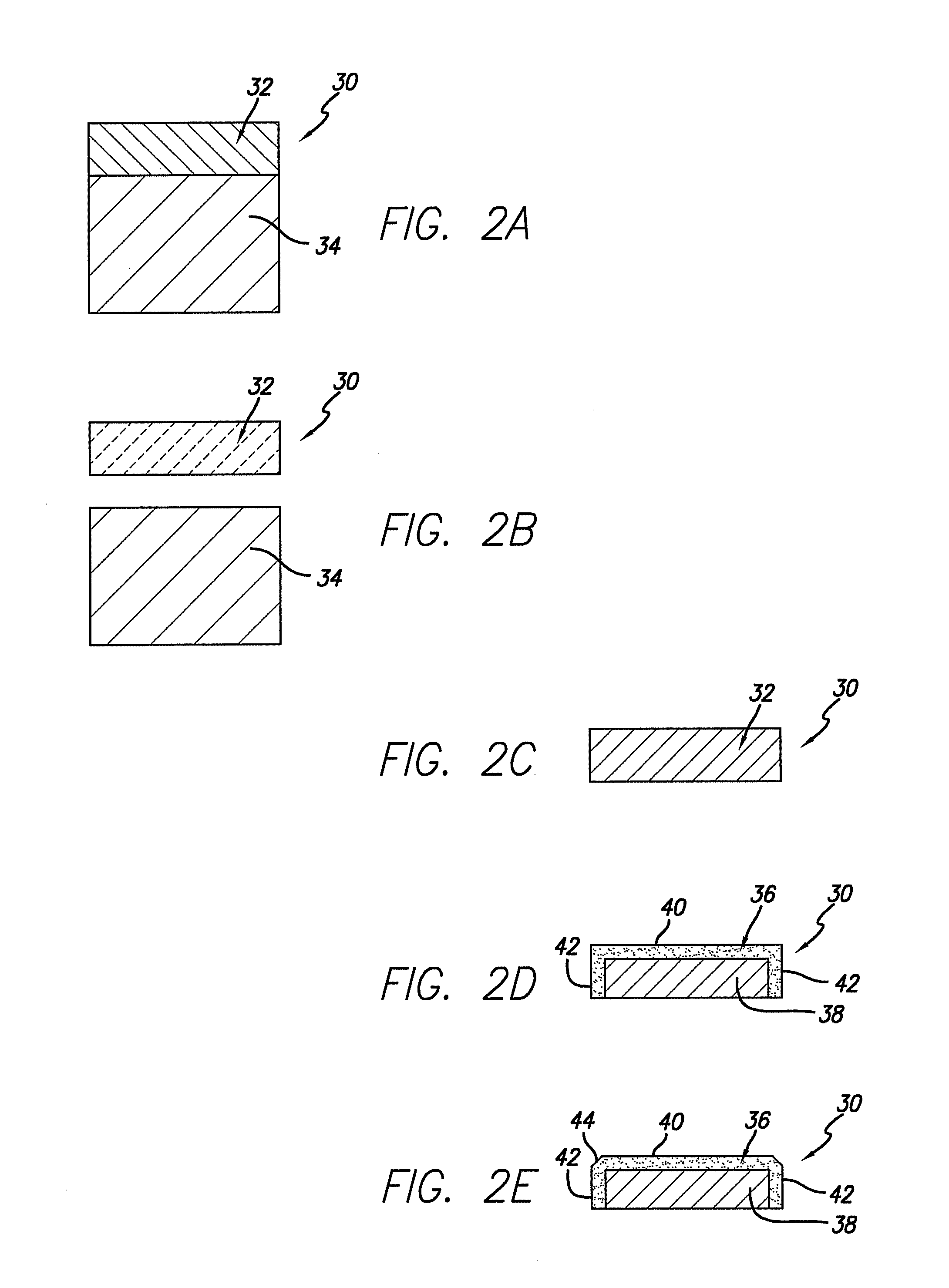

InactiveUS7377341B2Improve adhesionMatch thermal expansion characteristicDrill bitsConstructionsSuperhard materialHigh pressure

Thermally stable ultra-hard compact constructions of this invention comprise an ultra-hard material body that includes a thermally stable region positioned adjacent a surface of the body. The thermally stable region is formed from consolidated materials that are thermally stable at temperatures greater than about 750° C. The thermally stable region can occupy a partial portion of or the entire ultra-hard material body. The ultra-hard material body can comprise a composite of separate ultra-hard material elements that each form different regions of the body, at least one of the regions being thermally stable. The ultra-hard material body is attached to a desired substrate, an intermediate material is interposed between the body and the substrate, and the intermediate material joins the substrate and body together by high pressure / high temperature process.

Owner:SMITH INT INC

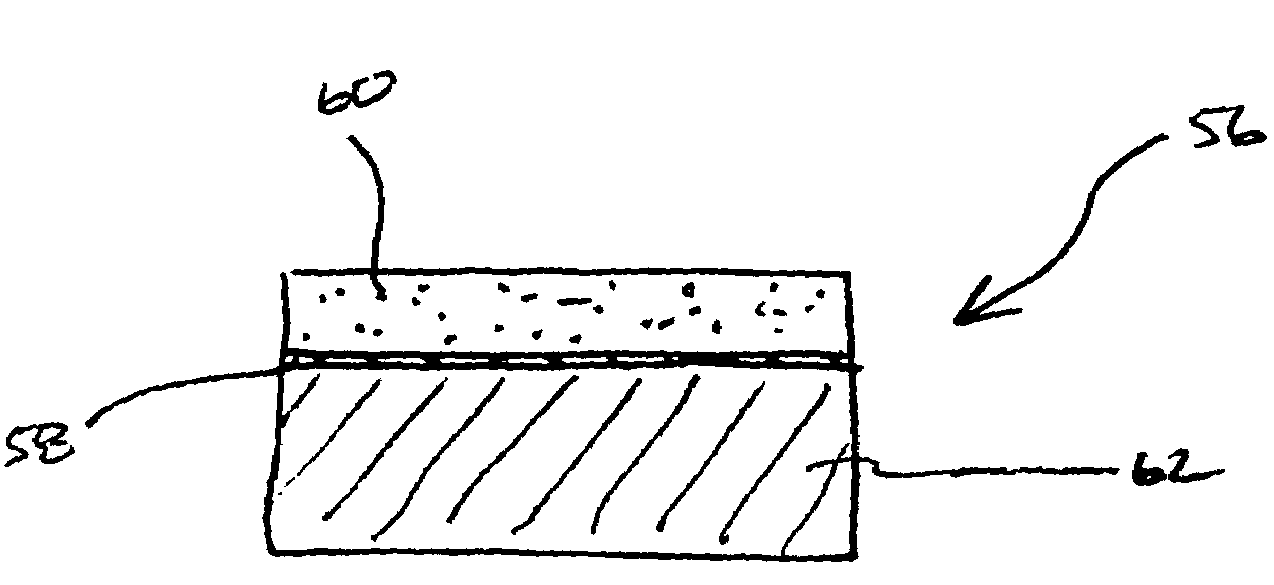

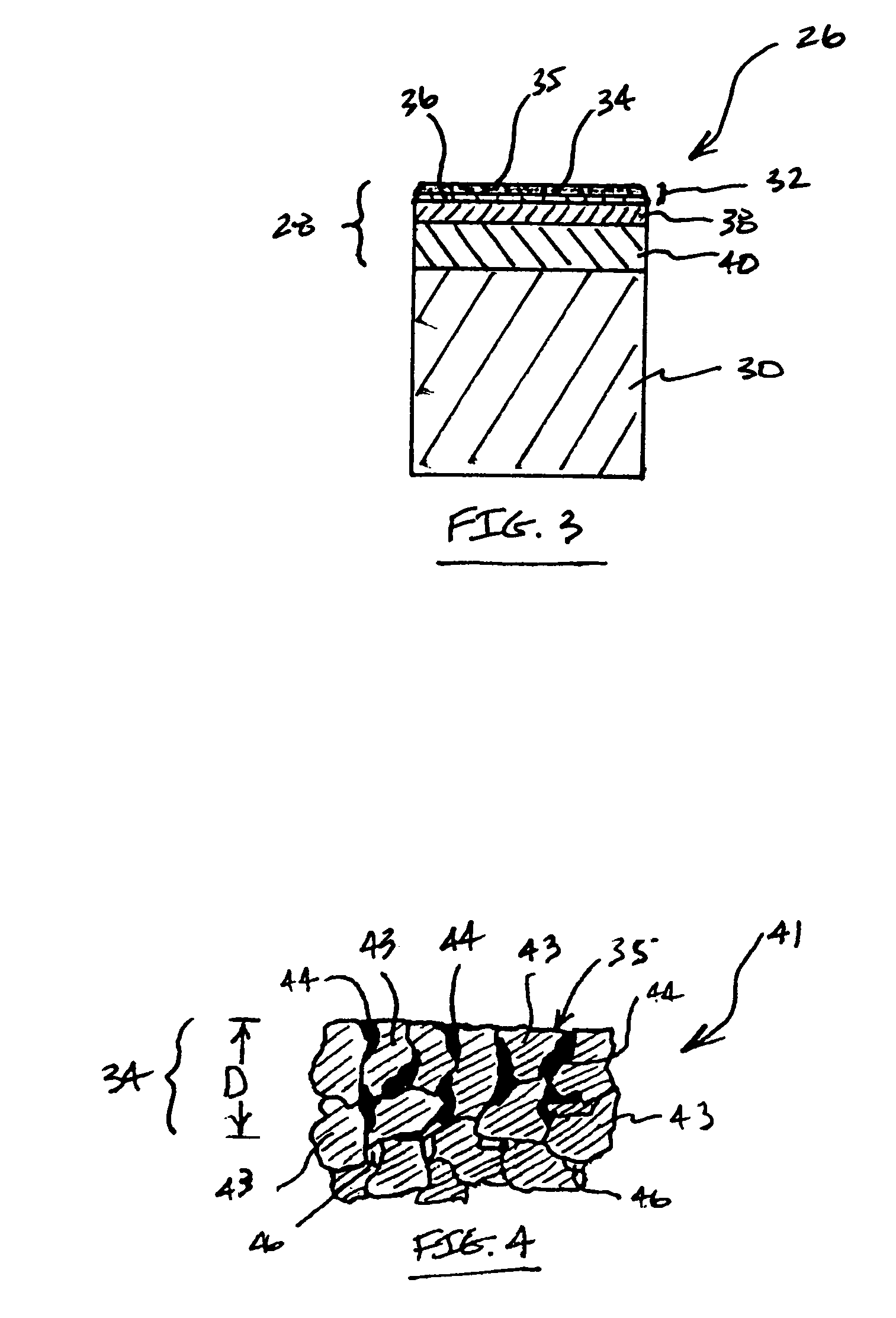

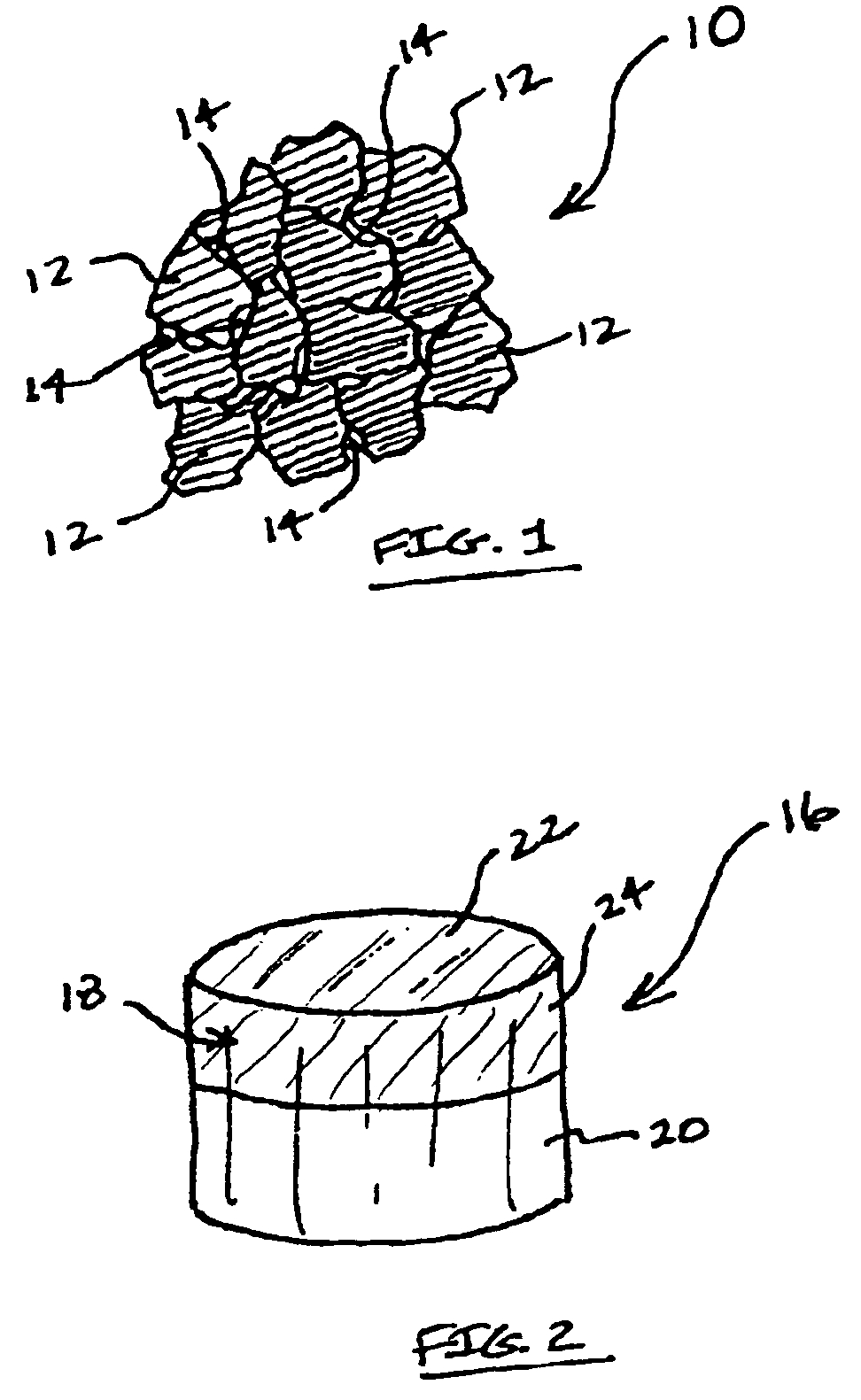

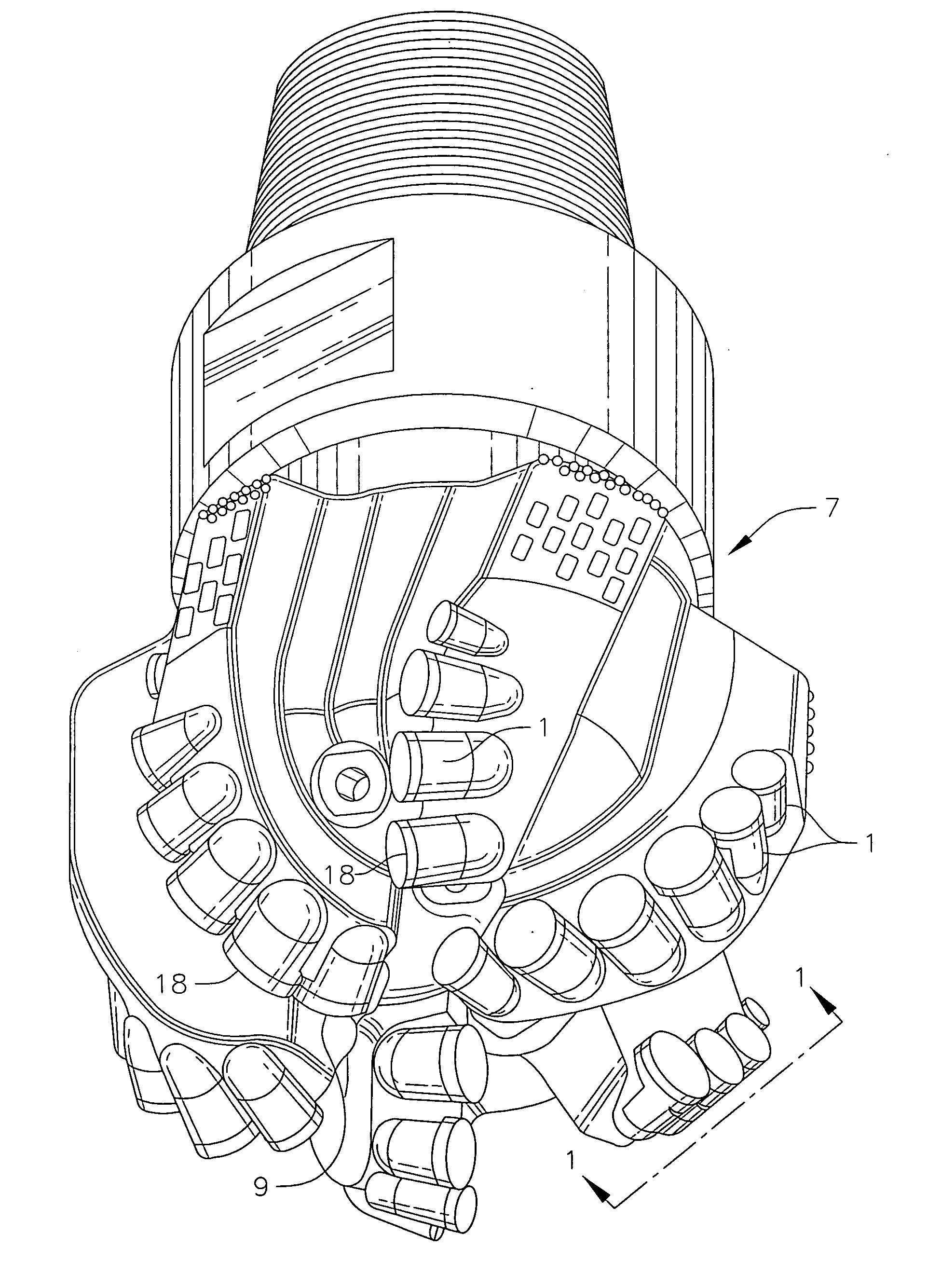

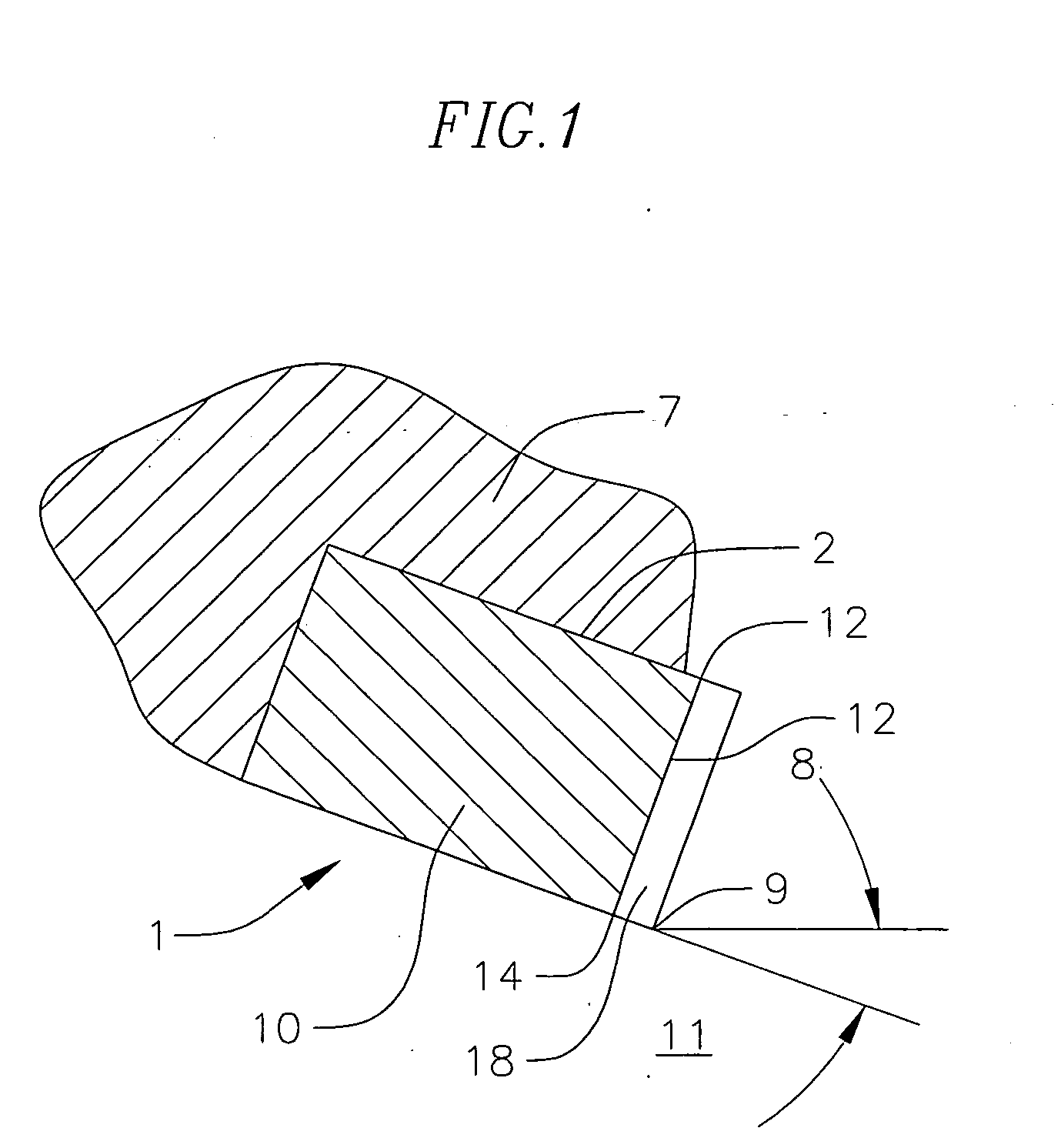

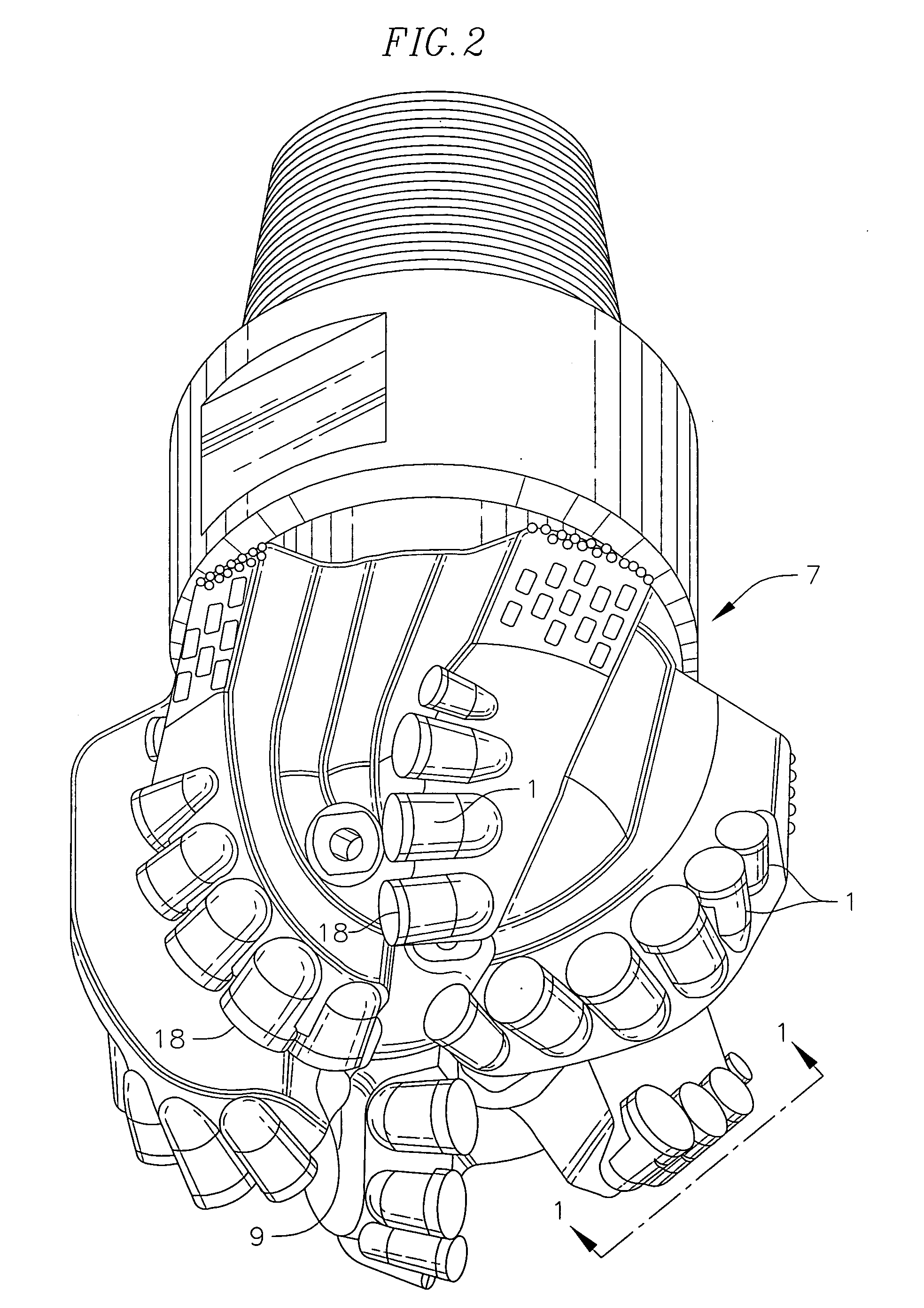

Cutting elements formed from ultra hard materials having an enhanced construction

InactiveUS20060162969A1Eliminate or resist any cracking during useDifferential wear resistanceDrill bitsConstructionsSuperhard materialInter layer

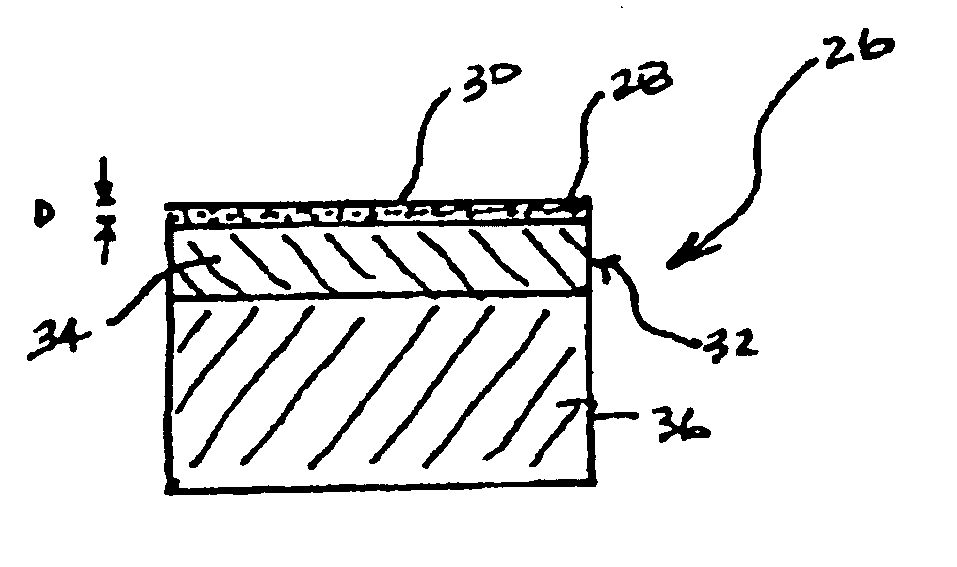

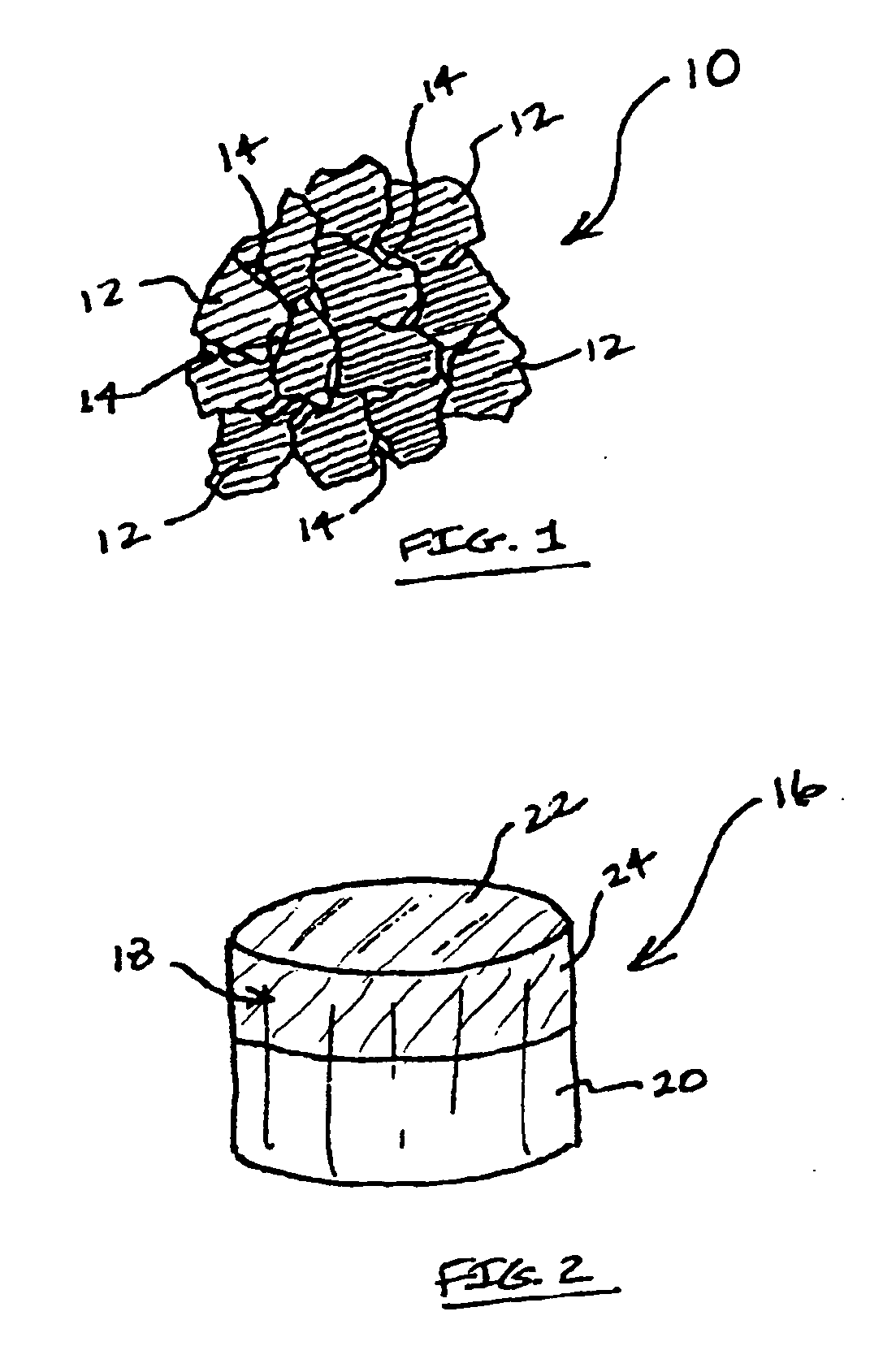

Cutting elements of this invention include an ultra hard body joined with a metallic substrate. The body includes an uppermost layer comprising a plurality of bonded ultra hard crystals and interstitial regions, and that defines a body working surface. The uppermost layer includes an outer region that is relatively more thermally stable than a remaining portion of the uppermost layer. The body further includes an intermediate layer joined to the uppermost layer, comprising a plurality of bonded ultra hard crystals, and having a wear resistance less than that of the uppermost layer remaining region. The body may additionally include a lowermost PCD layer that is interposed between and attached to the intermediate layer and the substrate.

Owner:SMITH INT INC

Cutting elements formed from ultra hard materials having an enhanced construction

InactiveUS7350601B2Eliminate or resist any cracking during useDifferential wear resistanceDrill bitsConstructionsSuperhard materialWear resistance

Cutting elements of this invention include an ultra hard body joined with a metallic substrate. The body includes an uppermost layer comprising a plurality of bonded ultra hard crystals and interstitial regions, and that defines a body working surface. The uppermost layer includes an outer region that is relatively more thermally stable than a remaining portion of the uppermost layer. The body further includes an intermediate layer joined to the uppermost layer, comprising a plurality of bonded ultra hard crystals, and having a wear resistance less than that of the uppermost layer remaining region. The body may additionally include a lowermost PCD layer that is interposed between and attached to the intermediate layer and the substrate.

Owner:SMITH INT INC

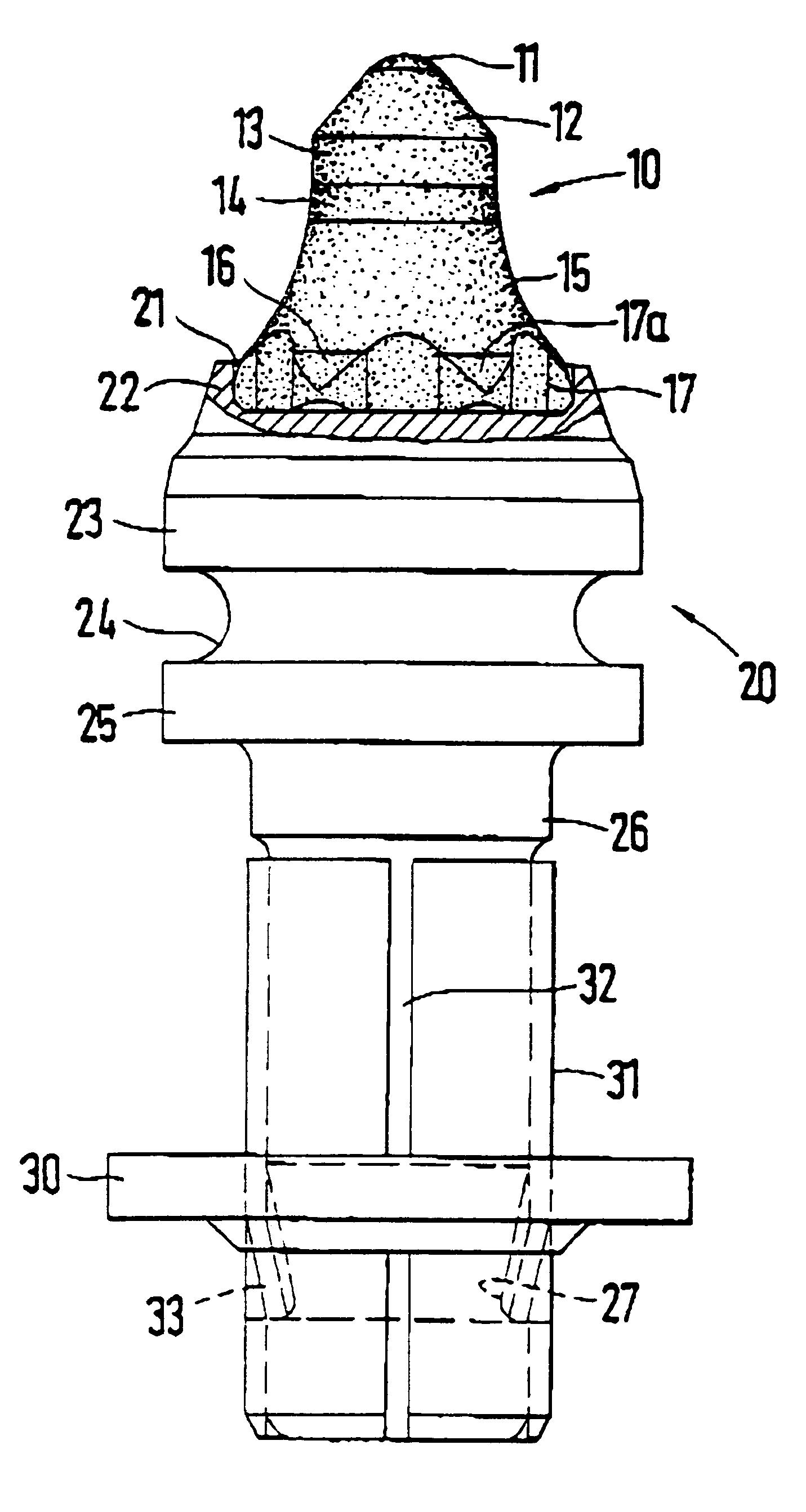

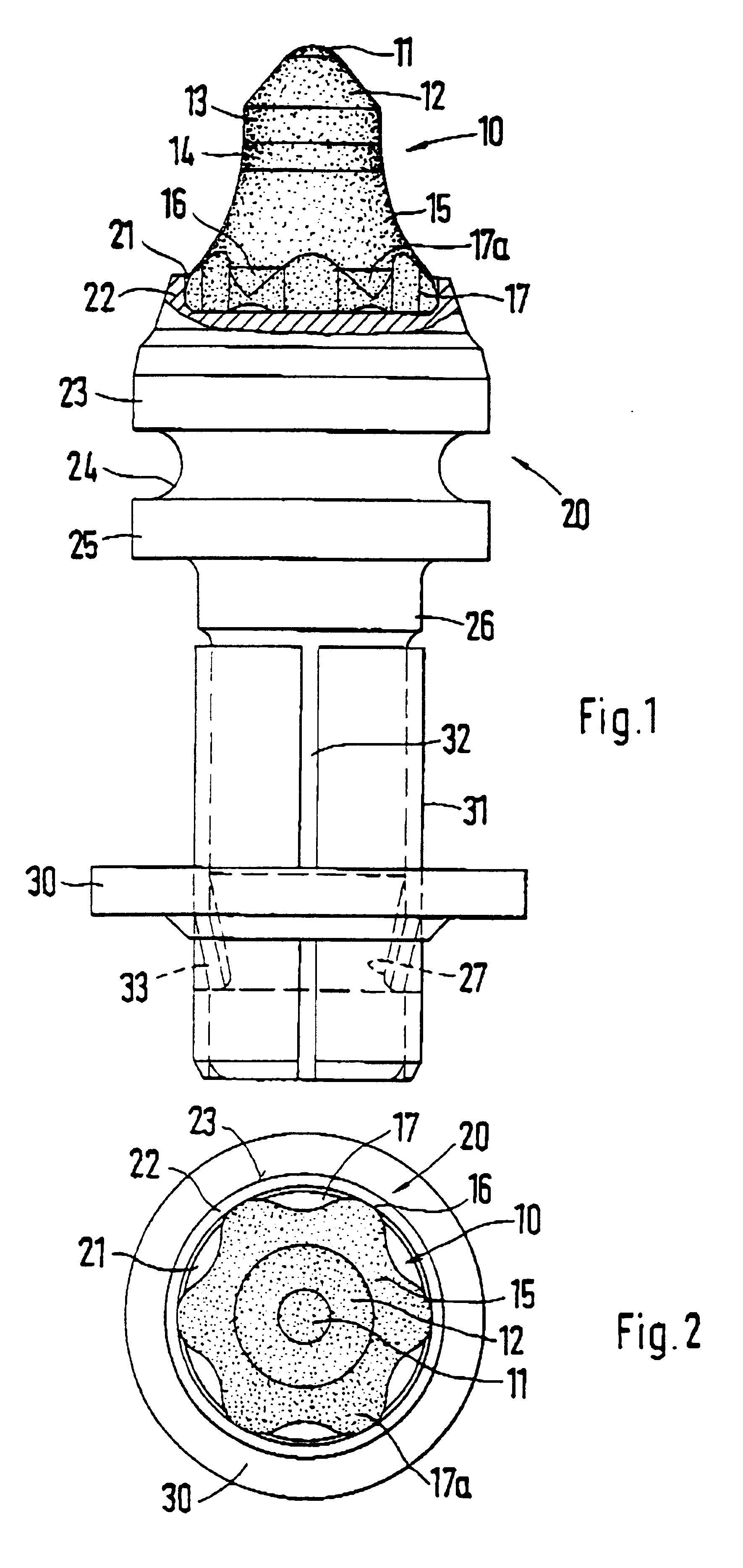

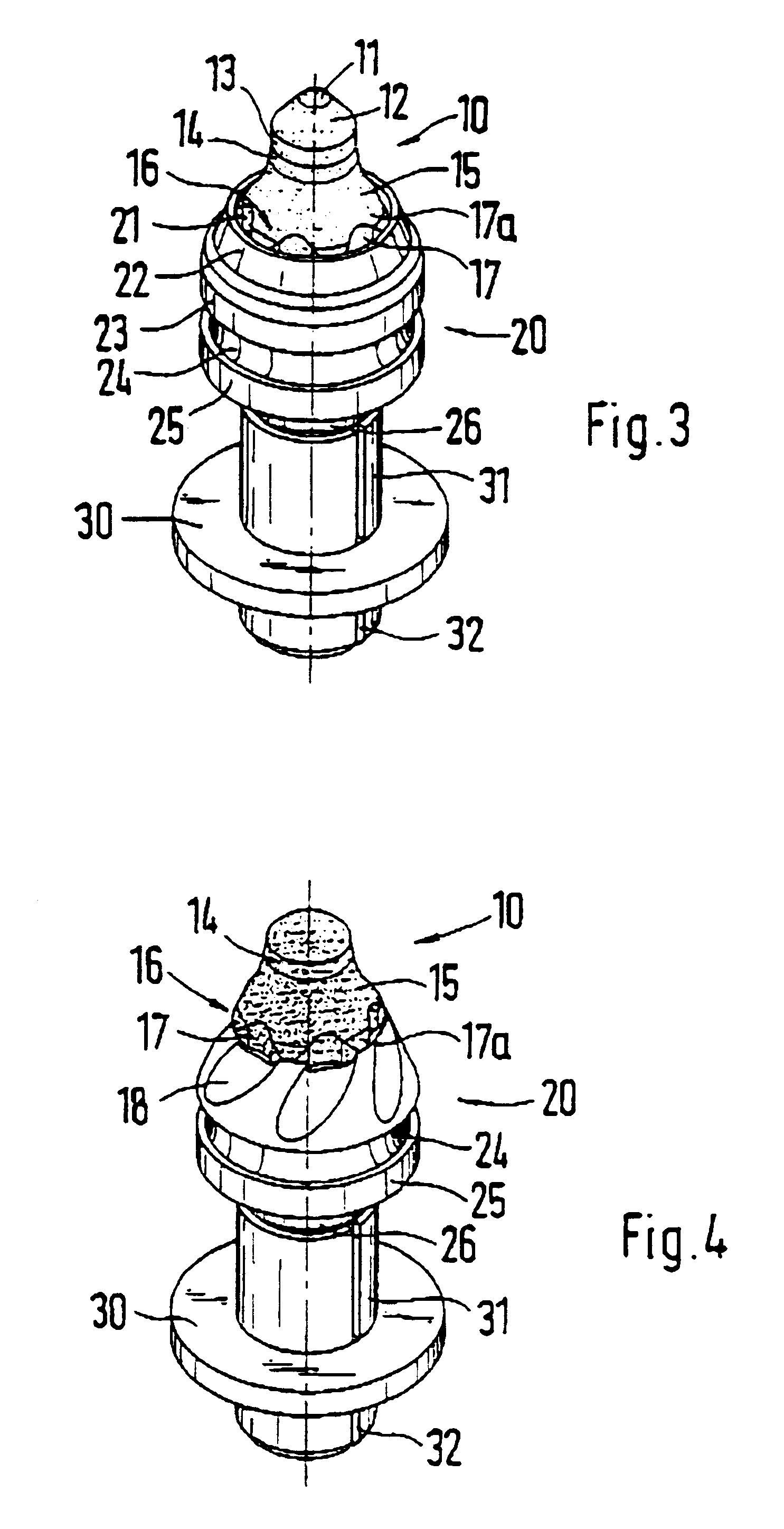

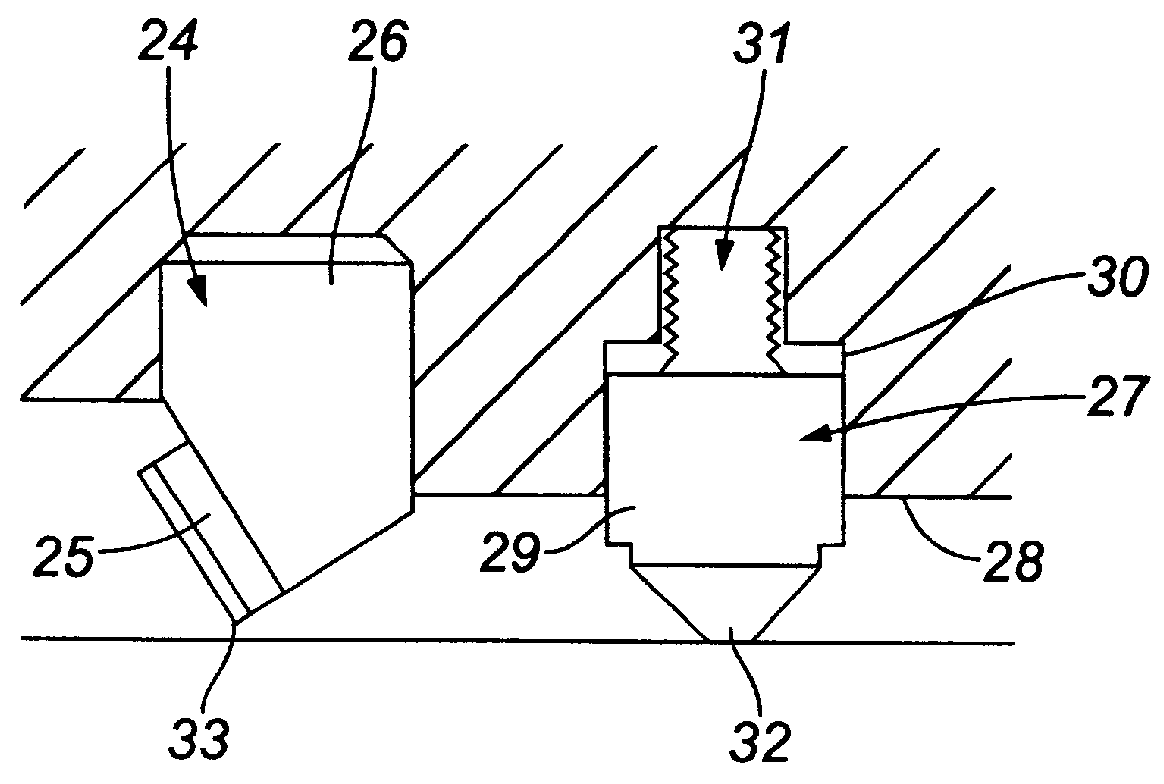

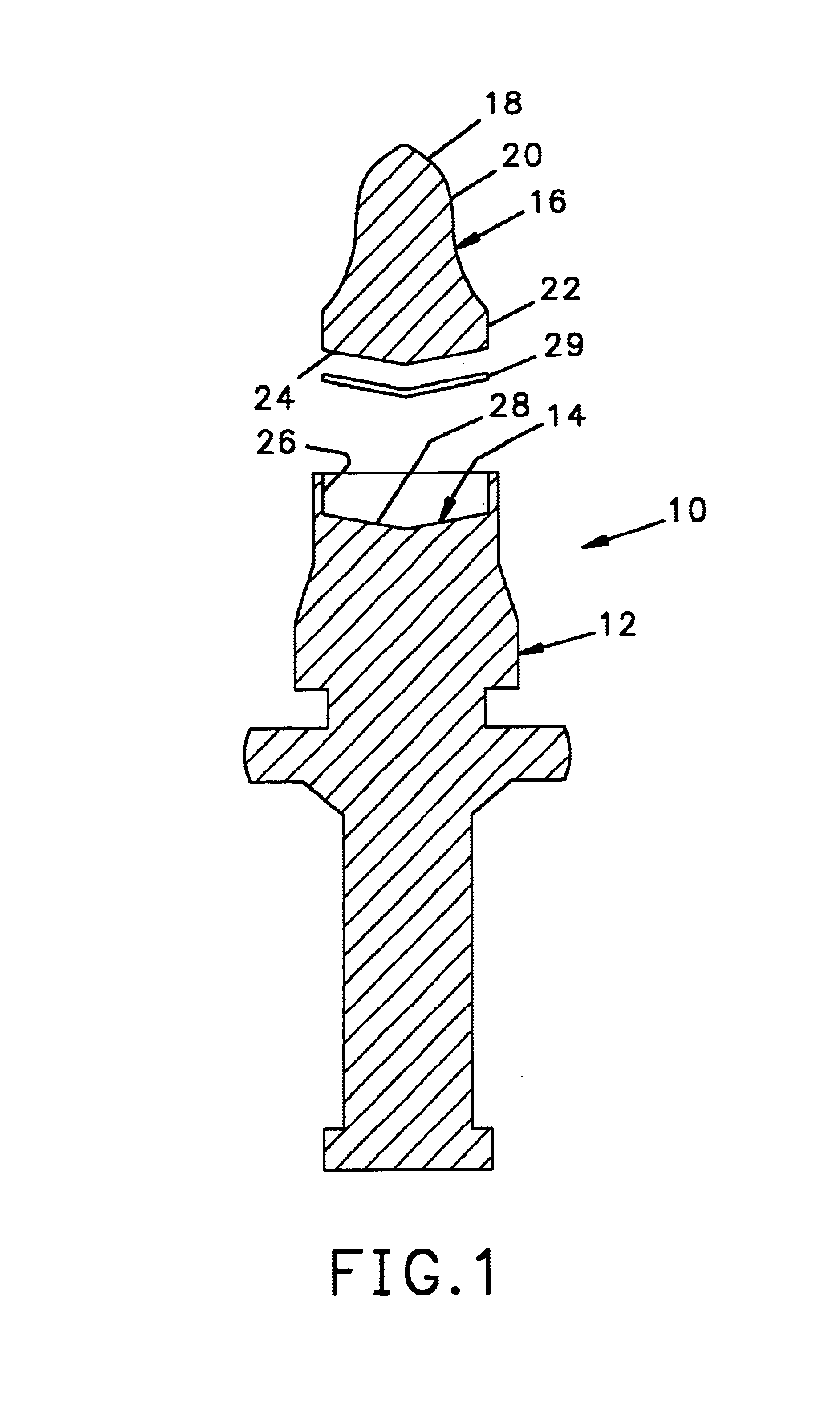

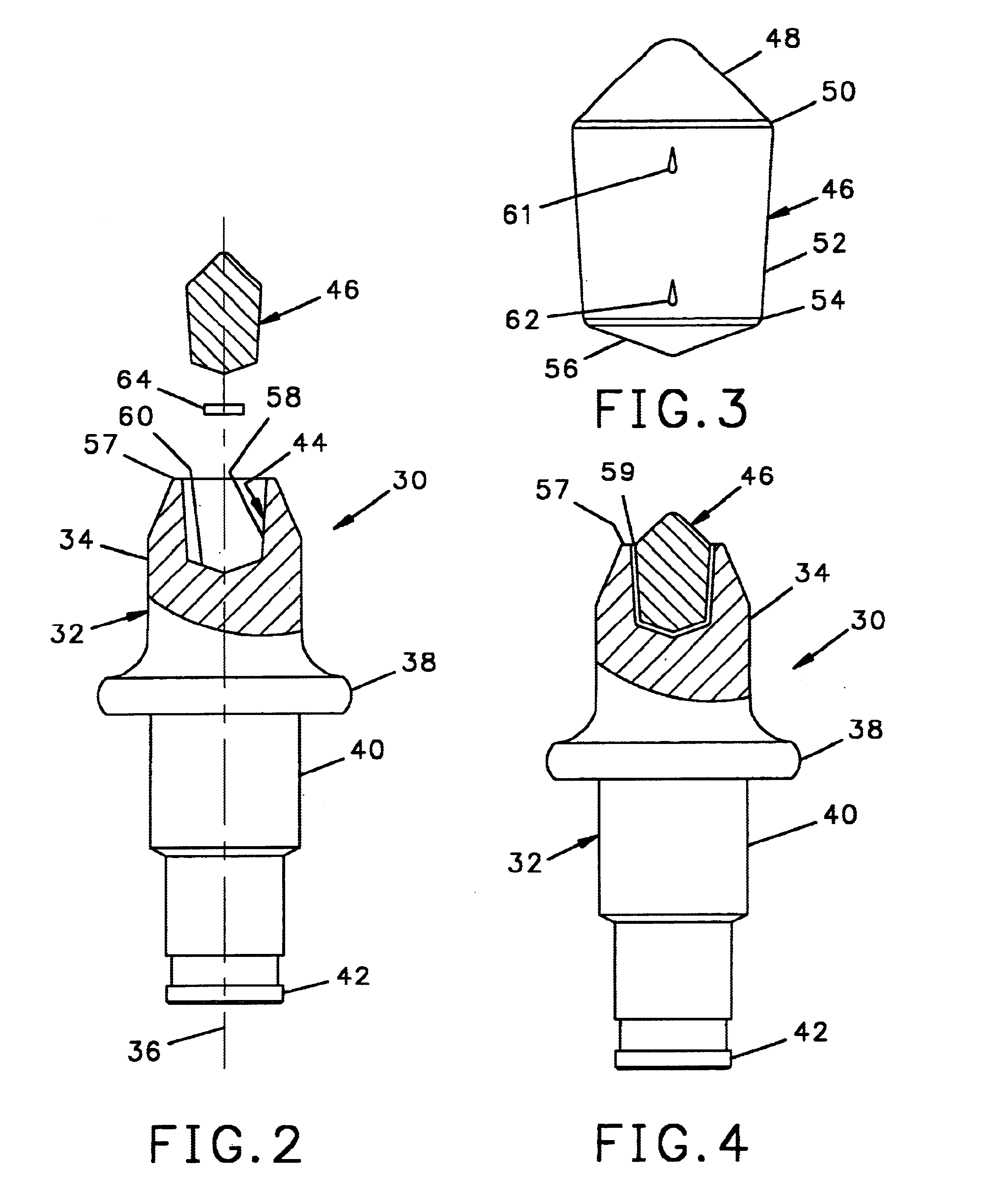

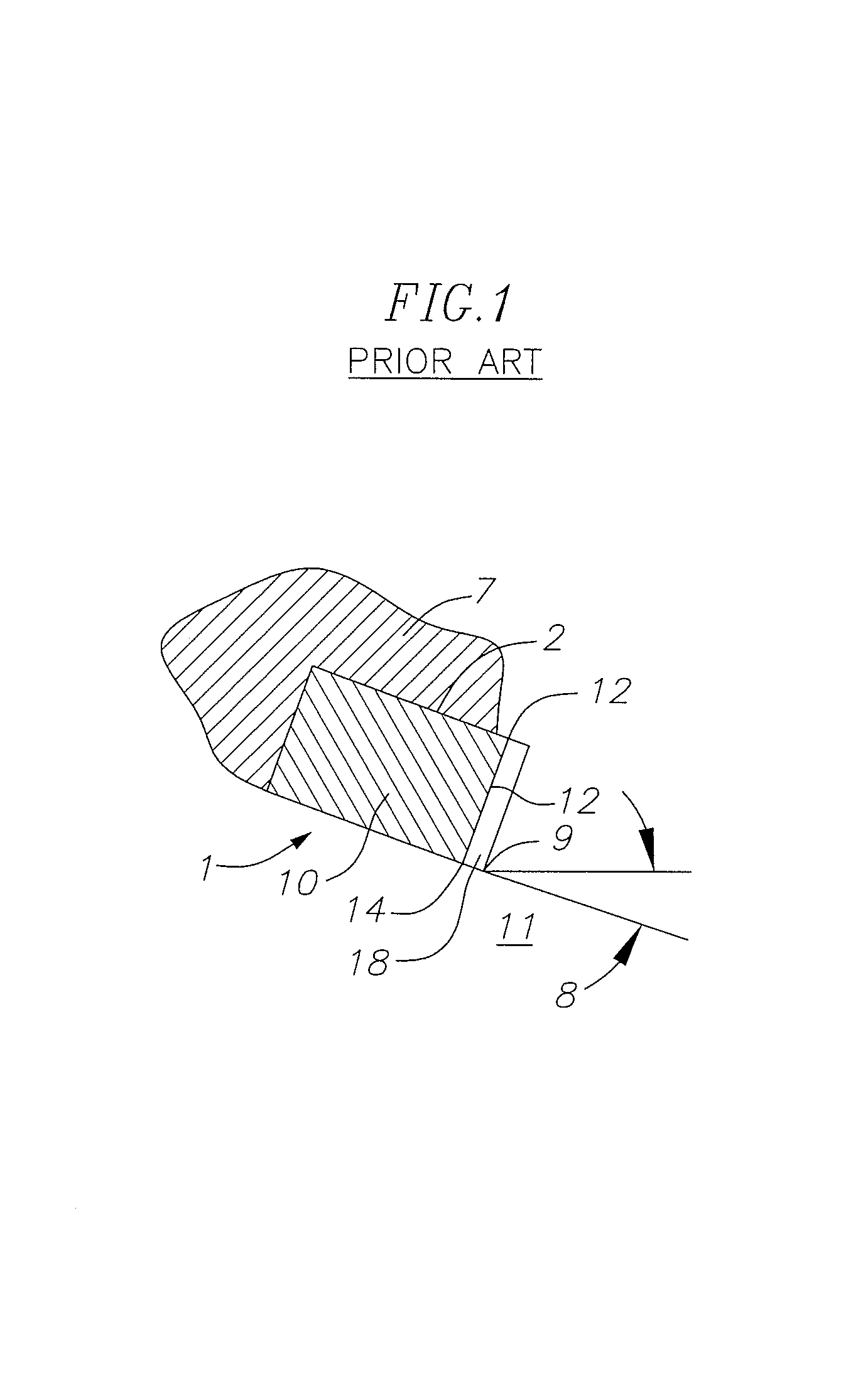

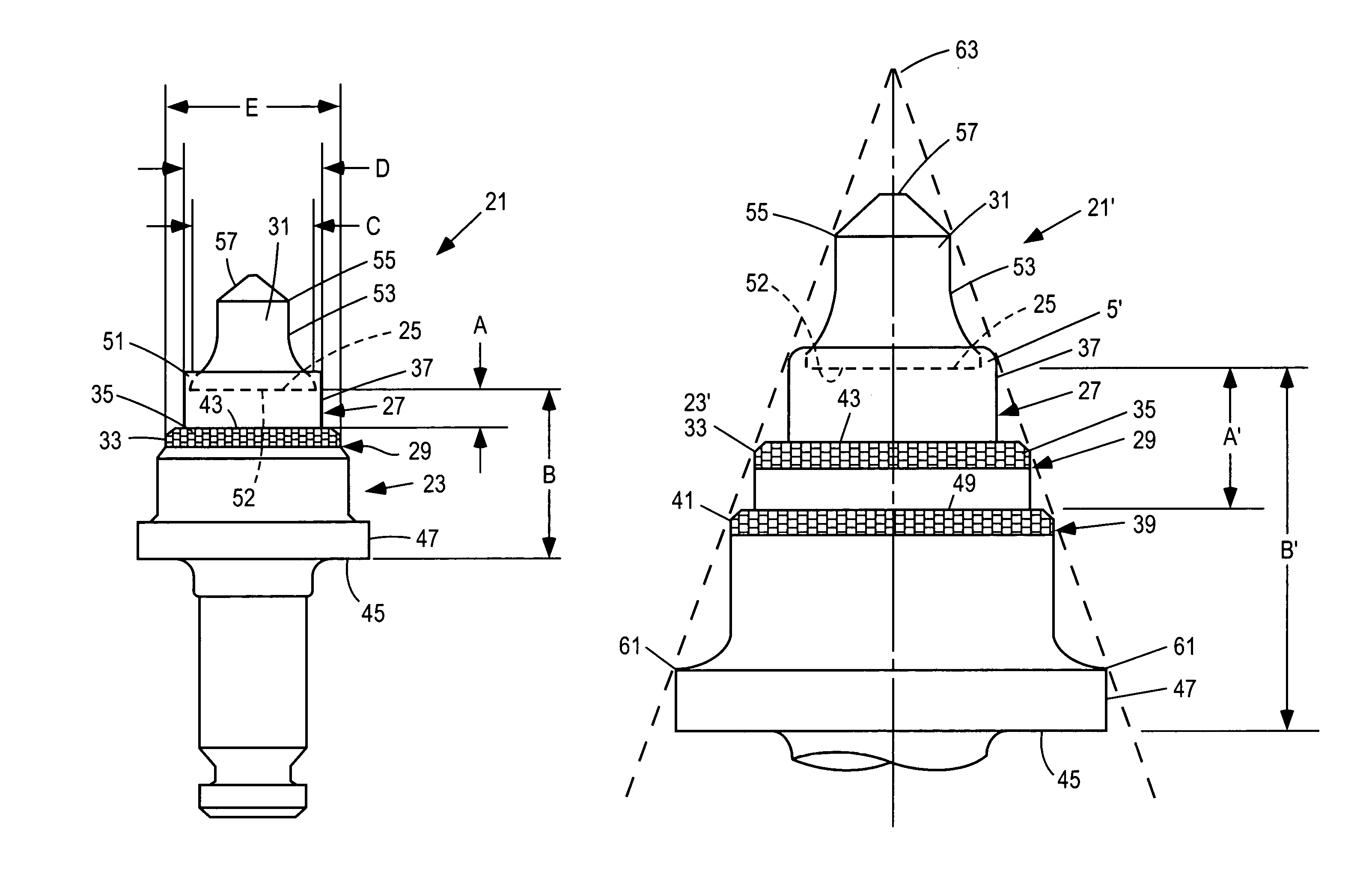

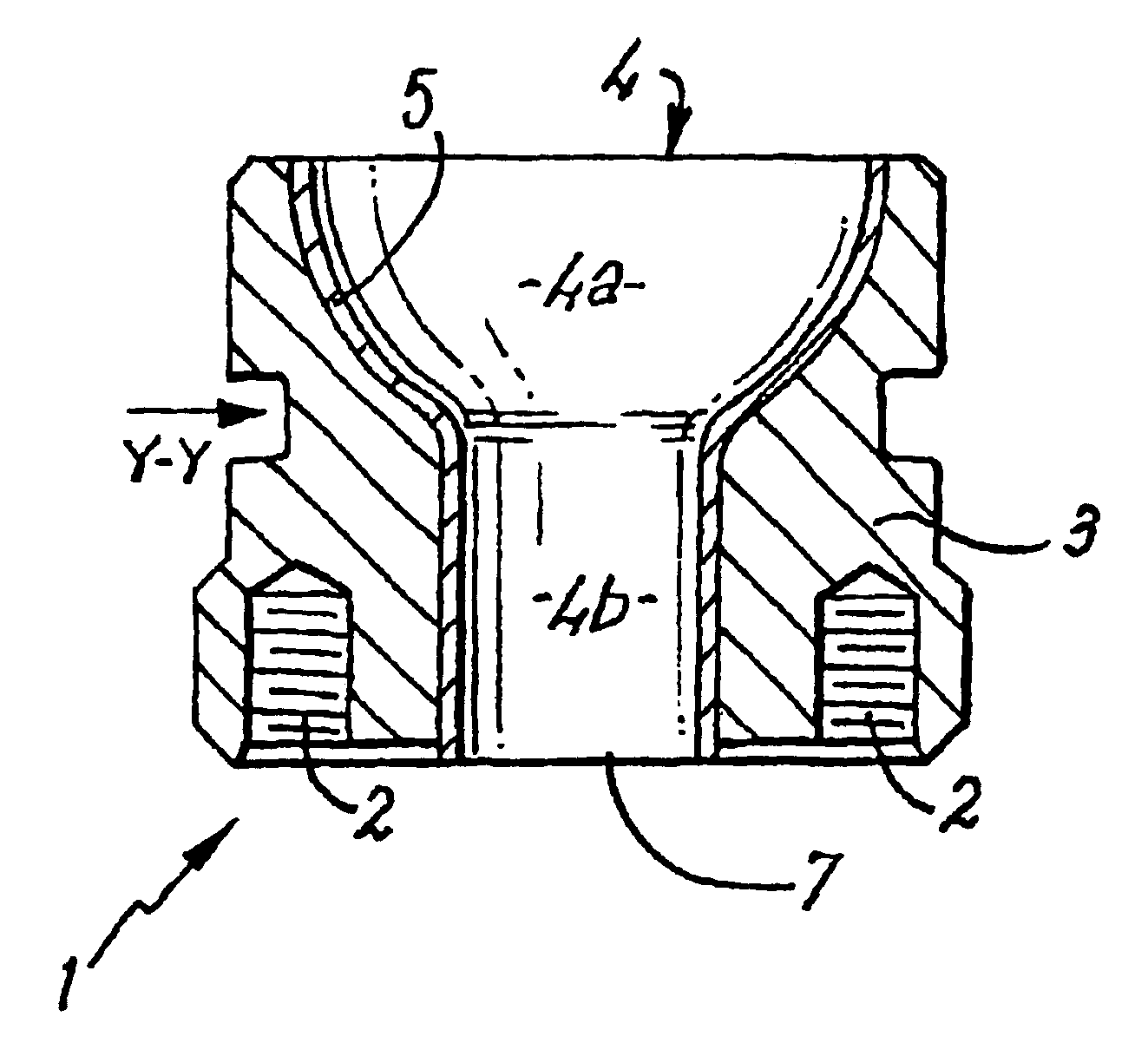

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

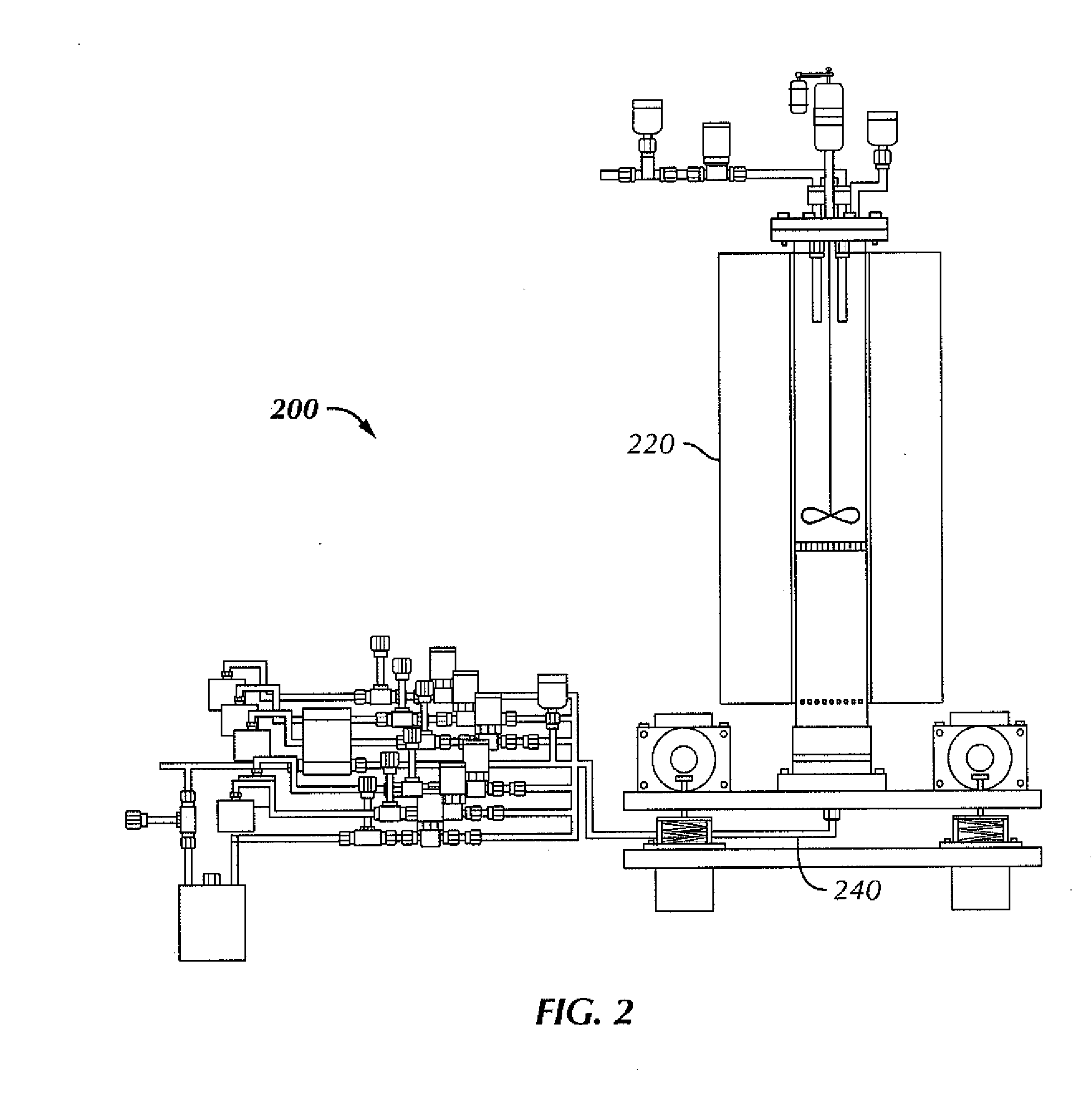

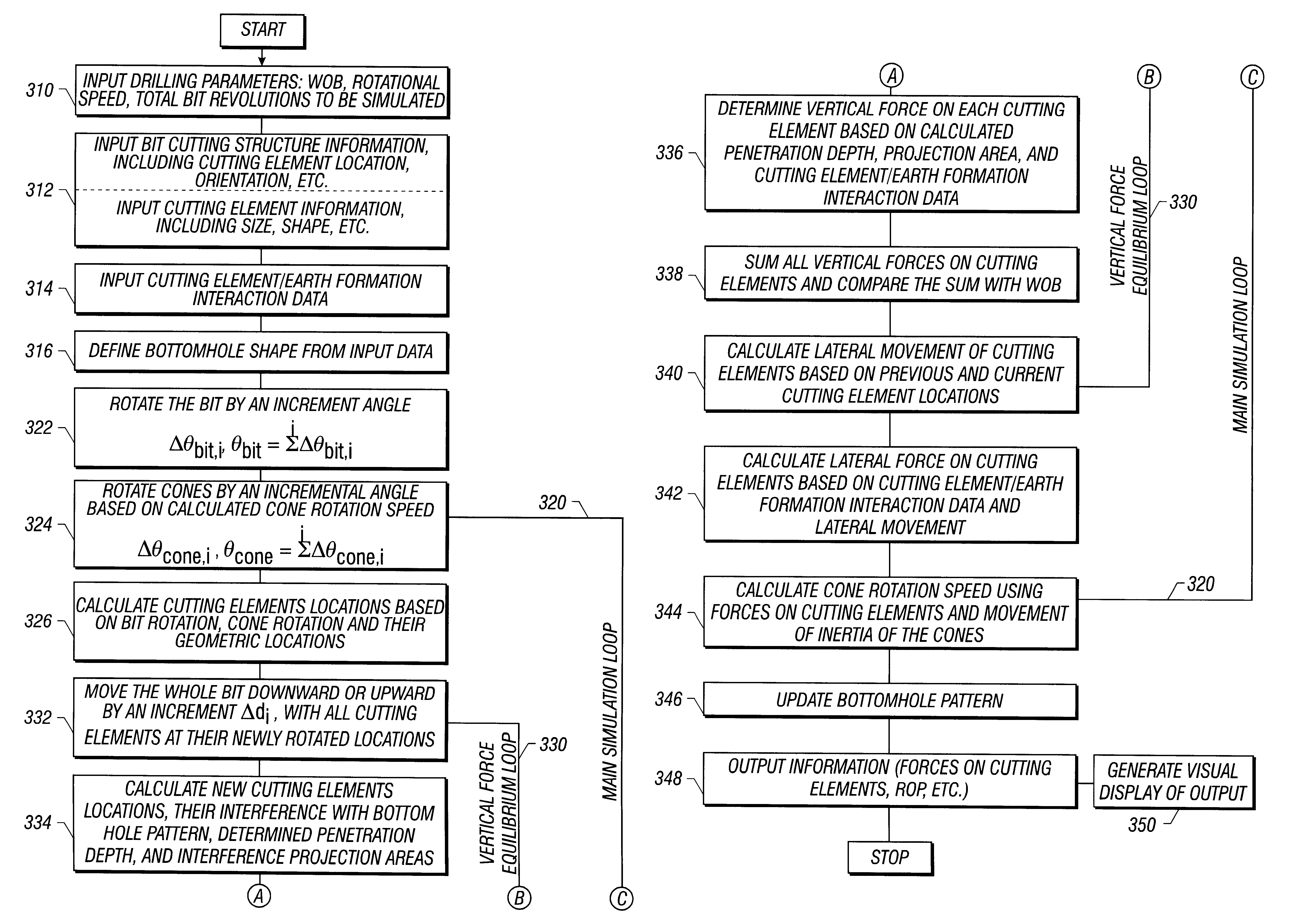

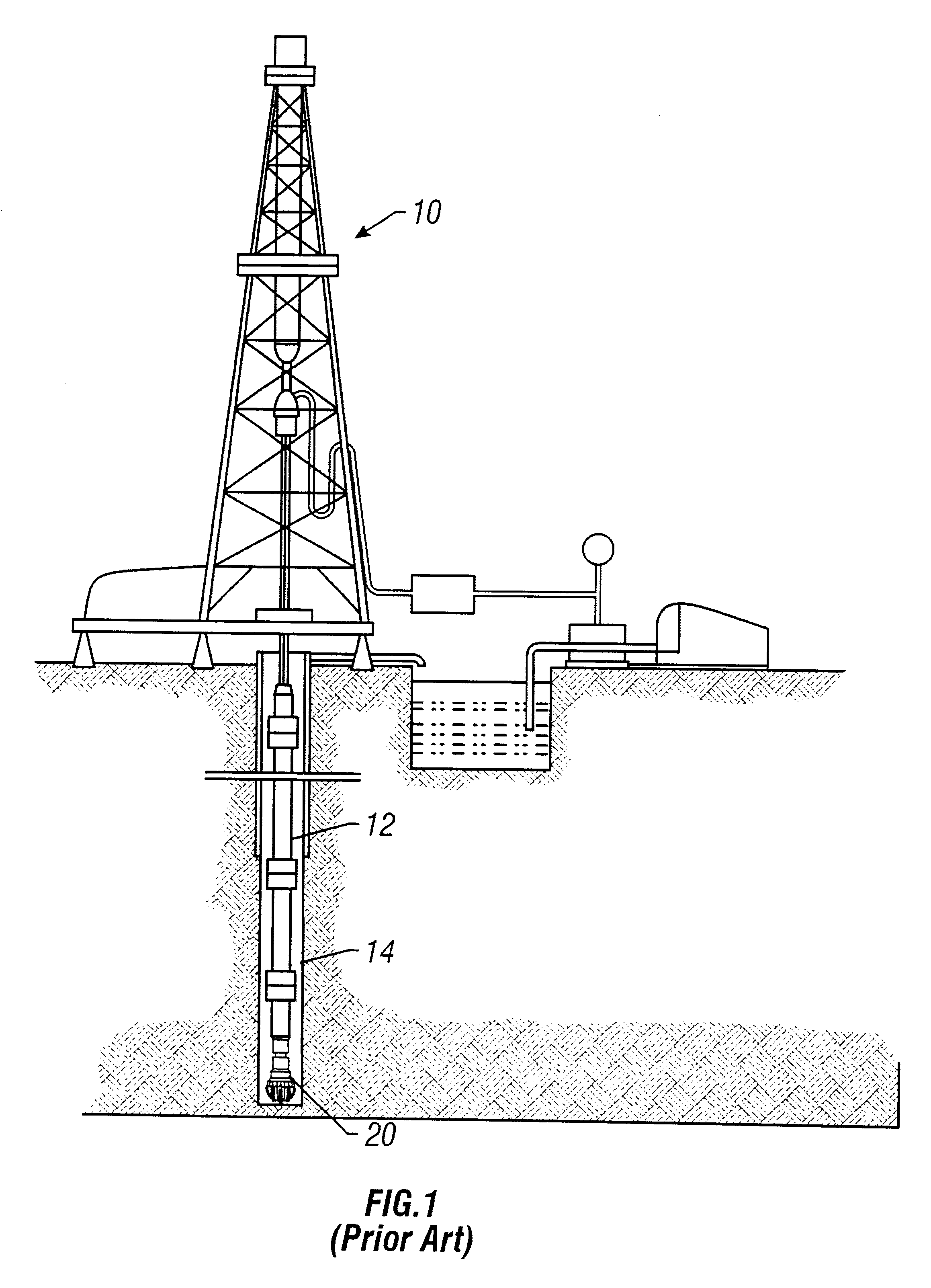

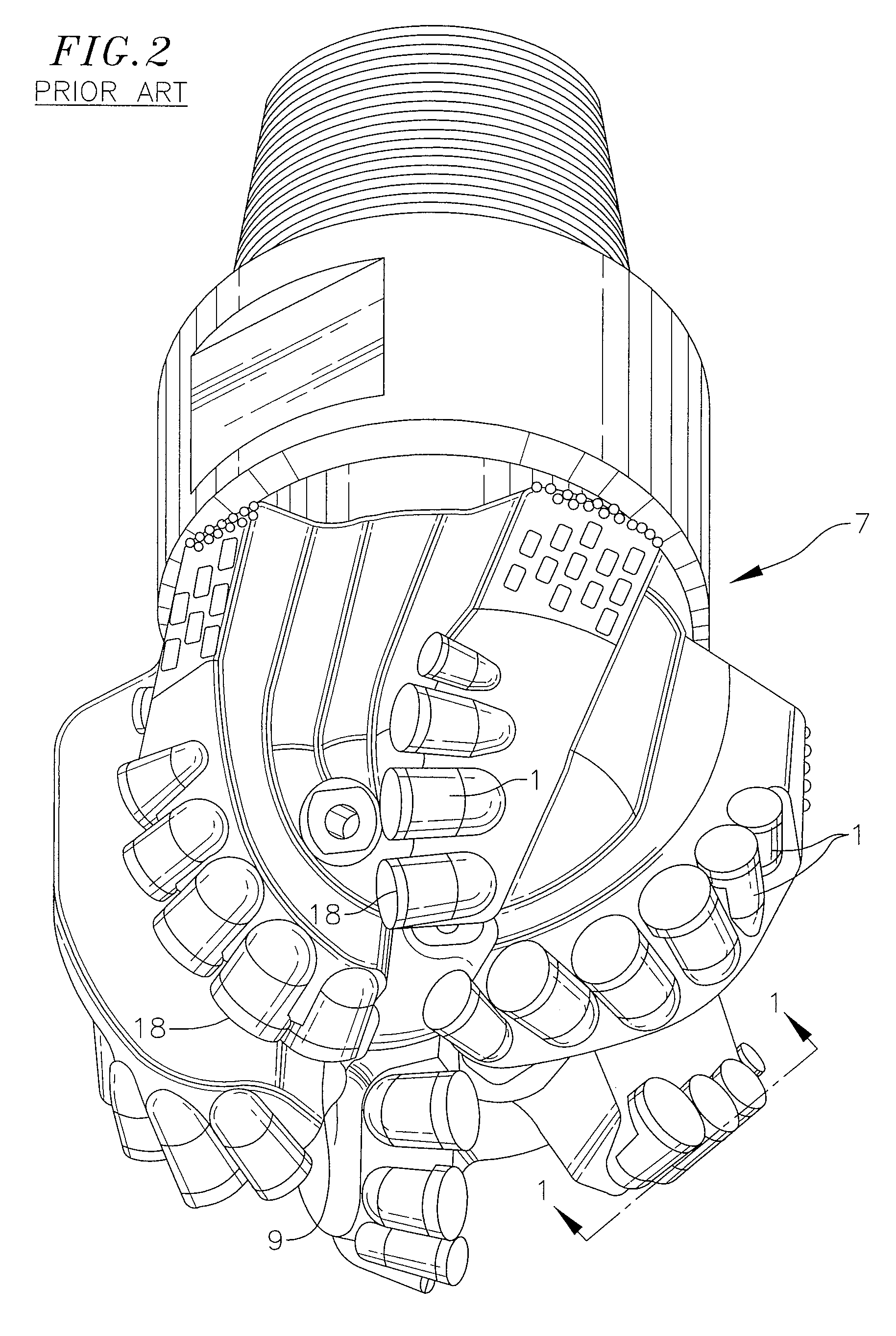

Method for simulating drilling of roller cone bits and its application to roller cone bit design and performance

InactiveUS6516293B1Electric/magnetic detection for well-loggingDrill bitsEngineeringVisual perception

A method for simulating the drilling performance of a roller cone bit drilling an earth formation may be used to generate a visual representation of drilling, to design roller cone drill bits, and to optimize the drilling performance of a roller cone bit. The method for generating a visual representation of a roller cone bit drilling earth formations includes selecting bit design parameters, selecting drilling parameters, and selecting an earth formation to be drilled. The method further includes calculating, from the bit design parameters, drilling parameters and earth formation, parameters of a crater formed when one of a plurality of cutting elements contacts the earth formation. The method further includes calculating a bottomhole geometry, wherein the crater is removed from a bottomhole surface. The method also includes incrementally rotating the bit and repeating the calculating of crater parameters and bottomhole geometry based on calculated roller cone rotation speed and geometrical location with respect to rotation of said roller cone drill bit about its axis. The method also includes converting the crater and bottomhole geometry parameters into a visual representation.

Owner:SMITH INT INC

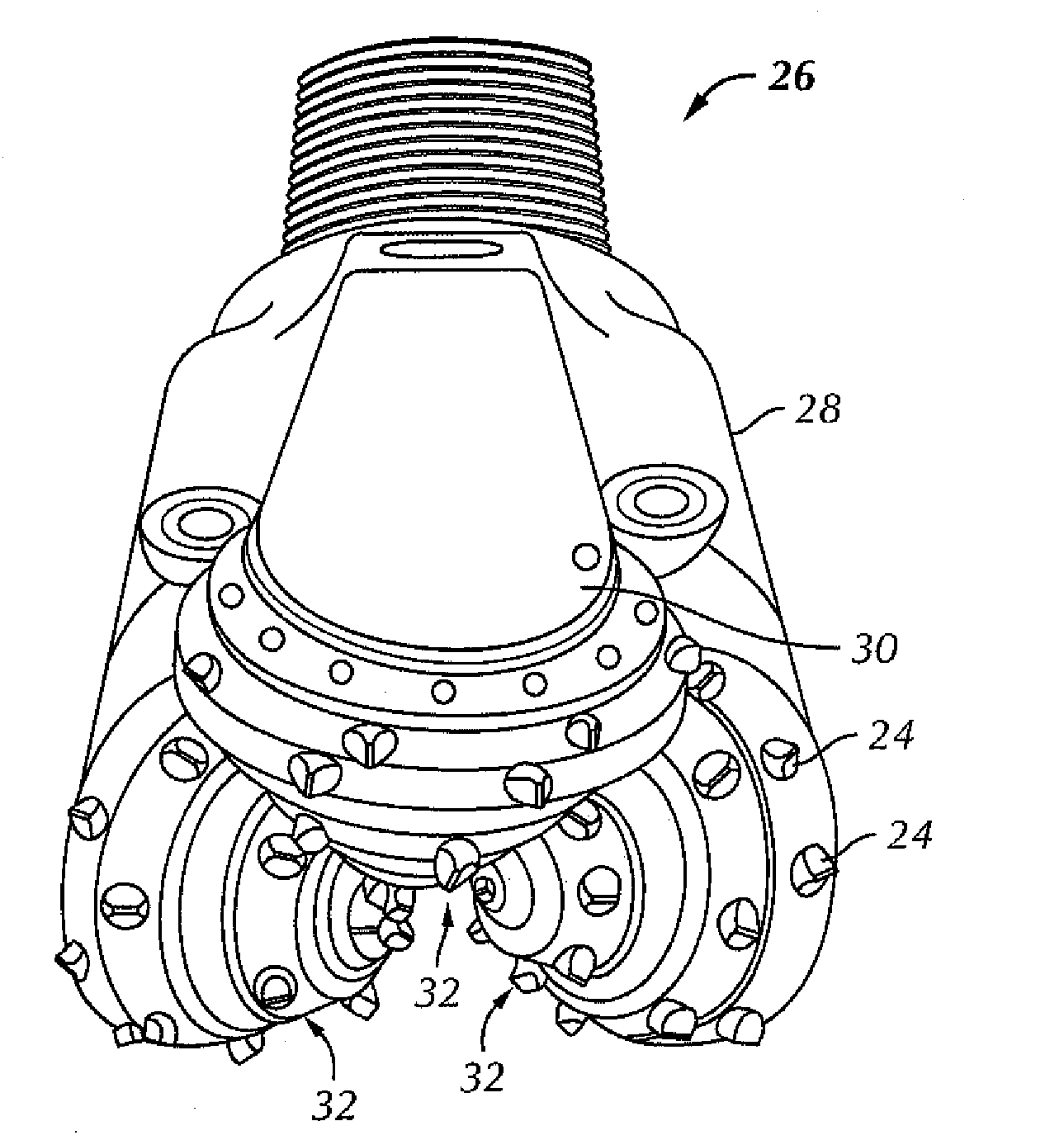

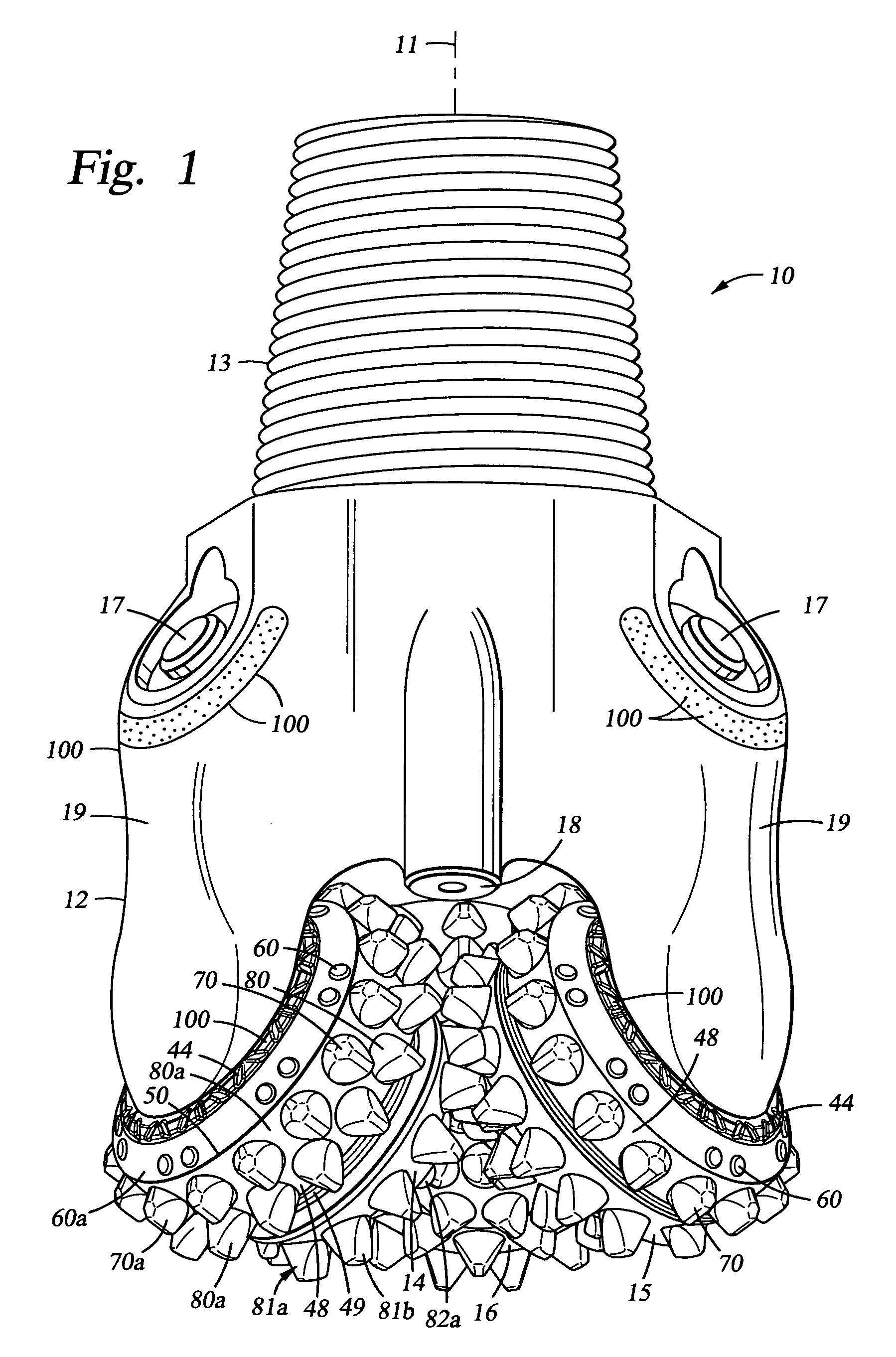

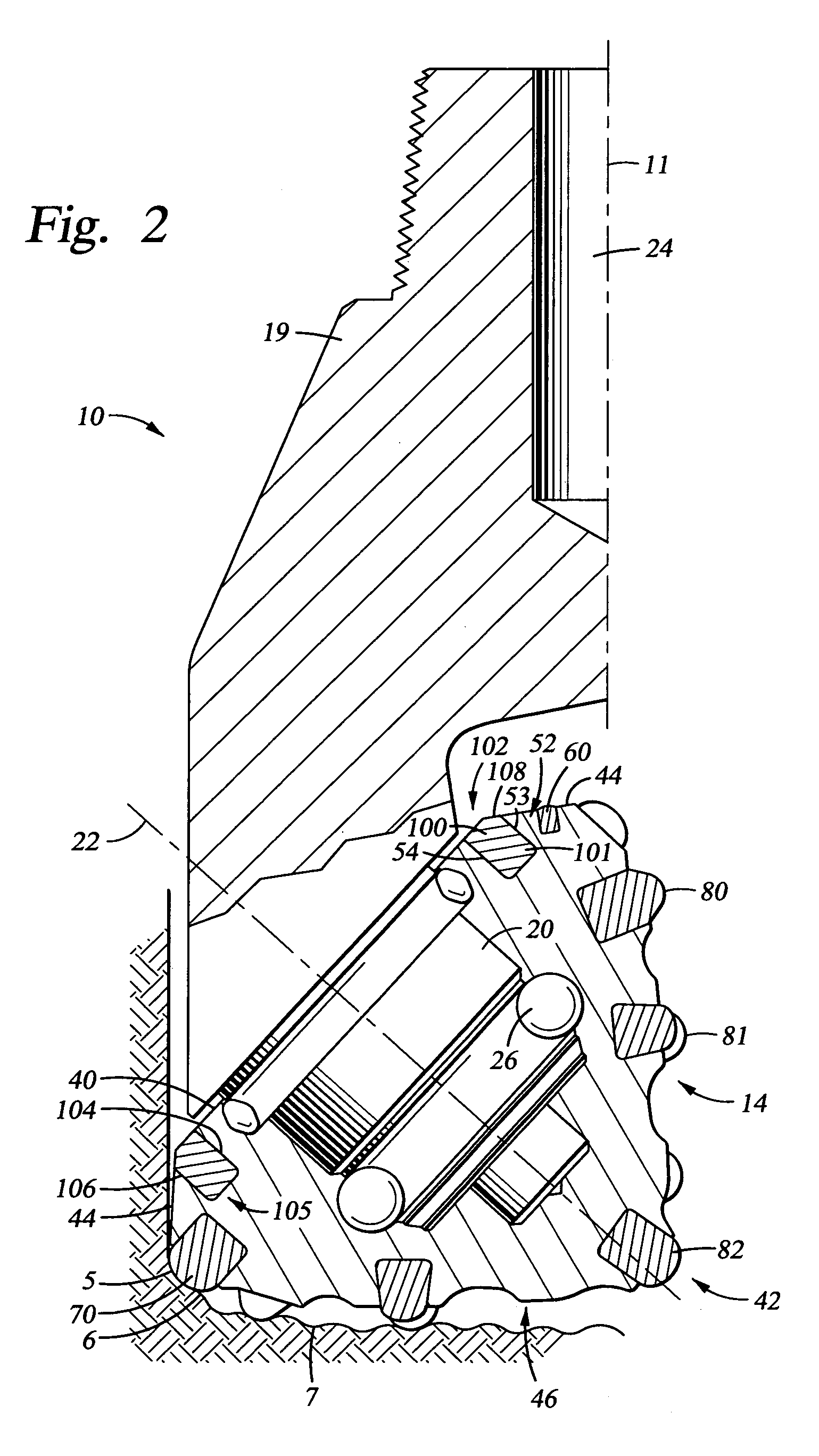

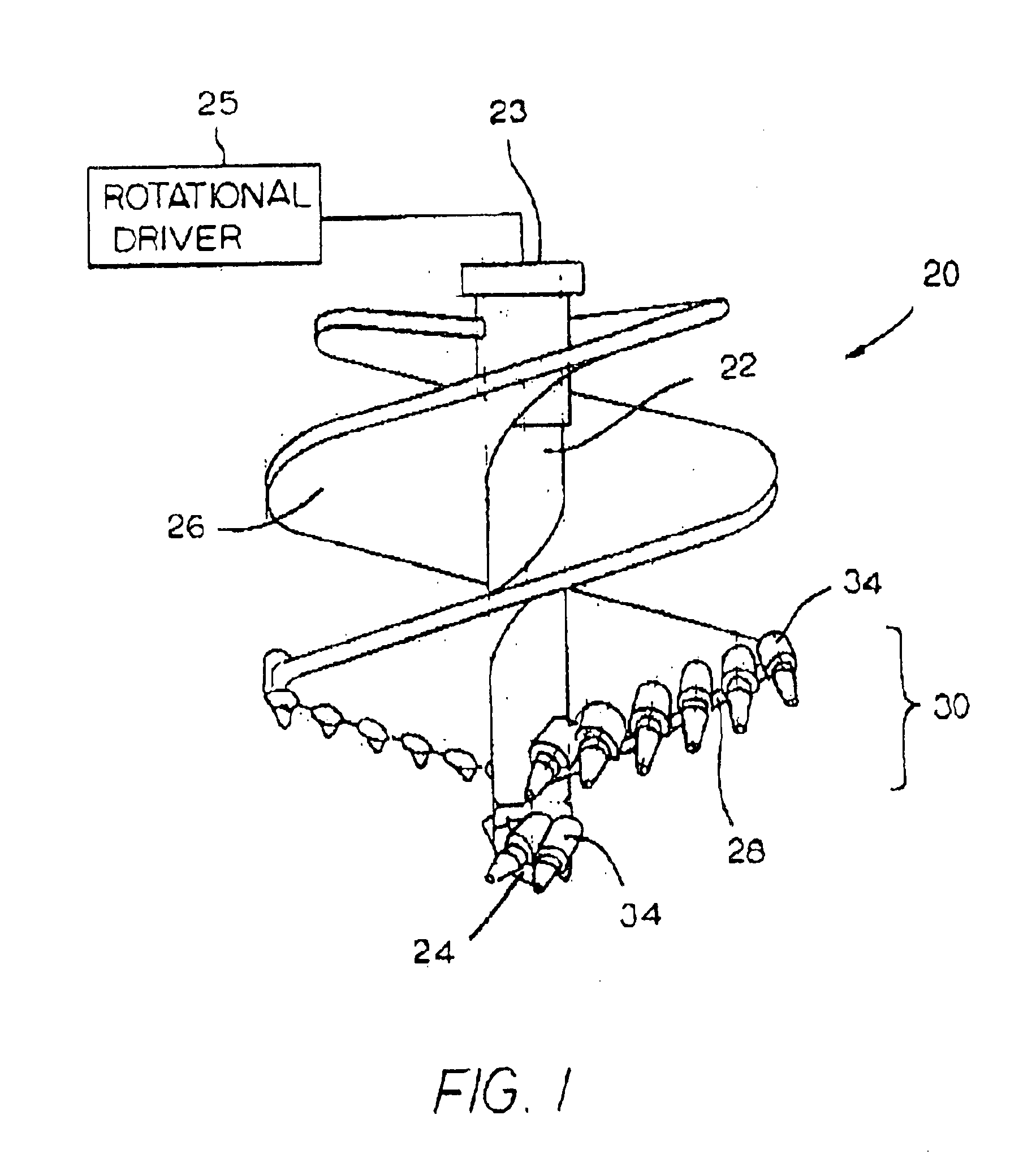

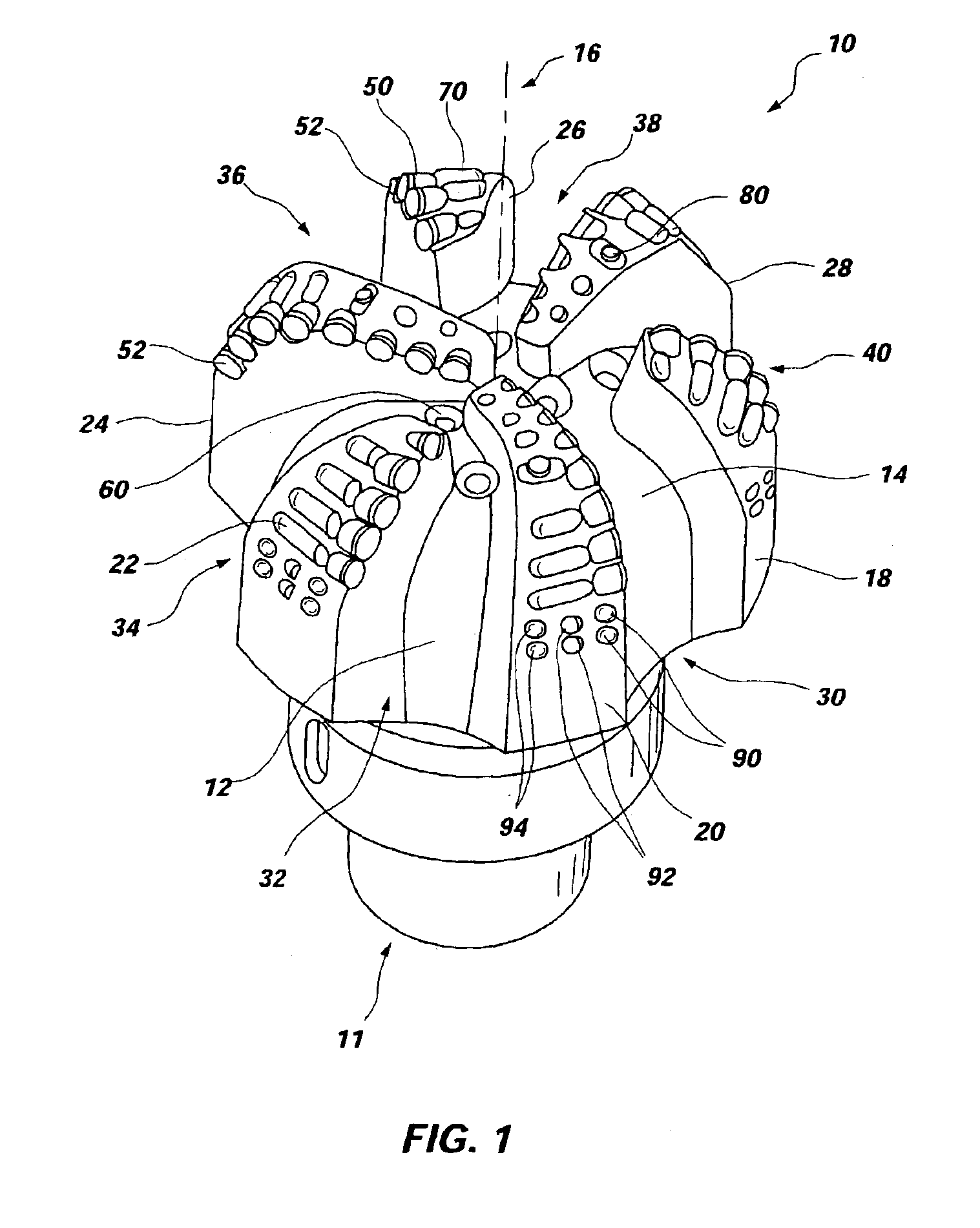

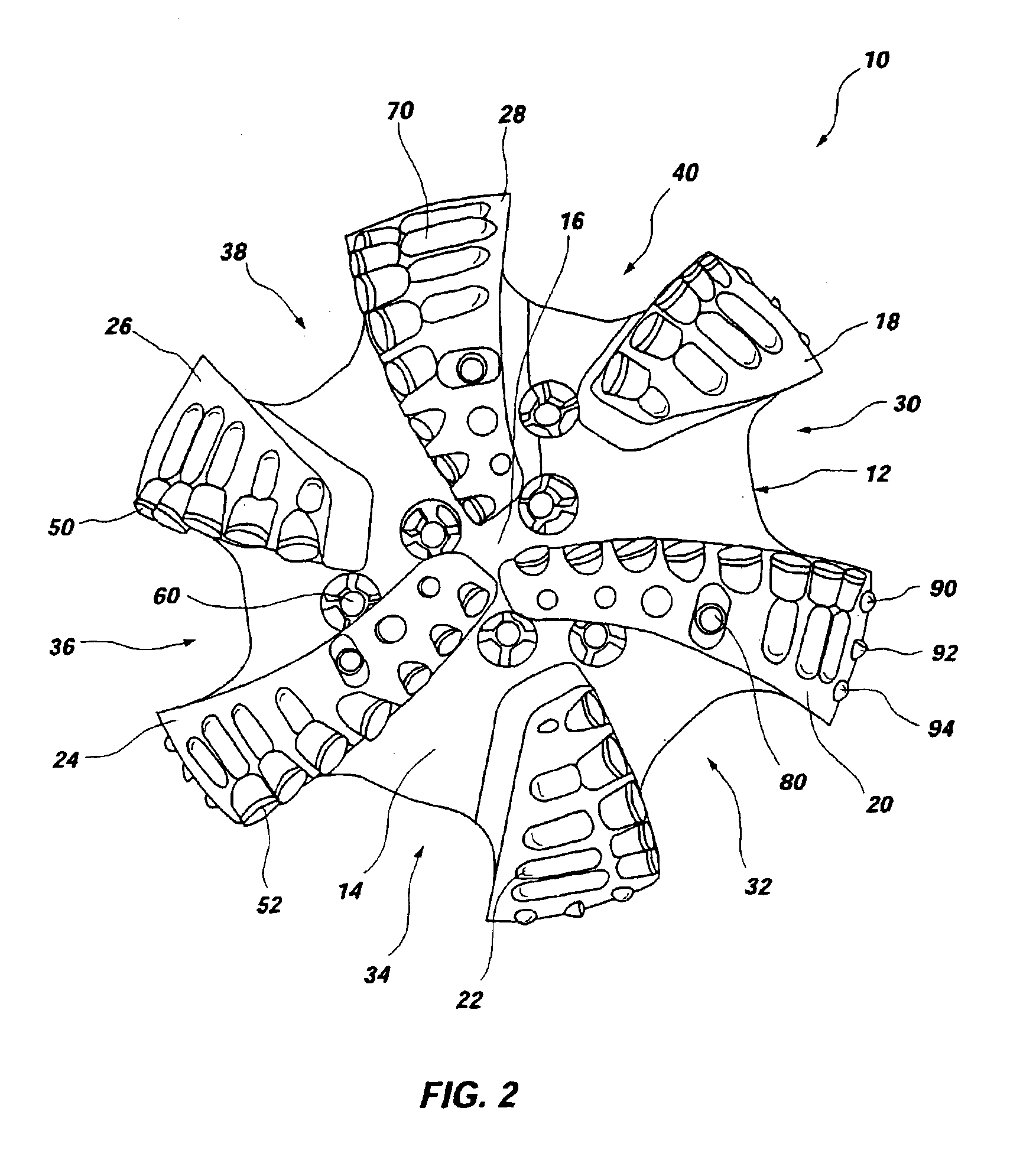

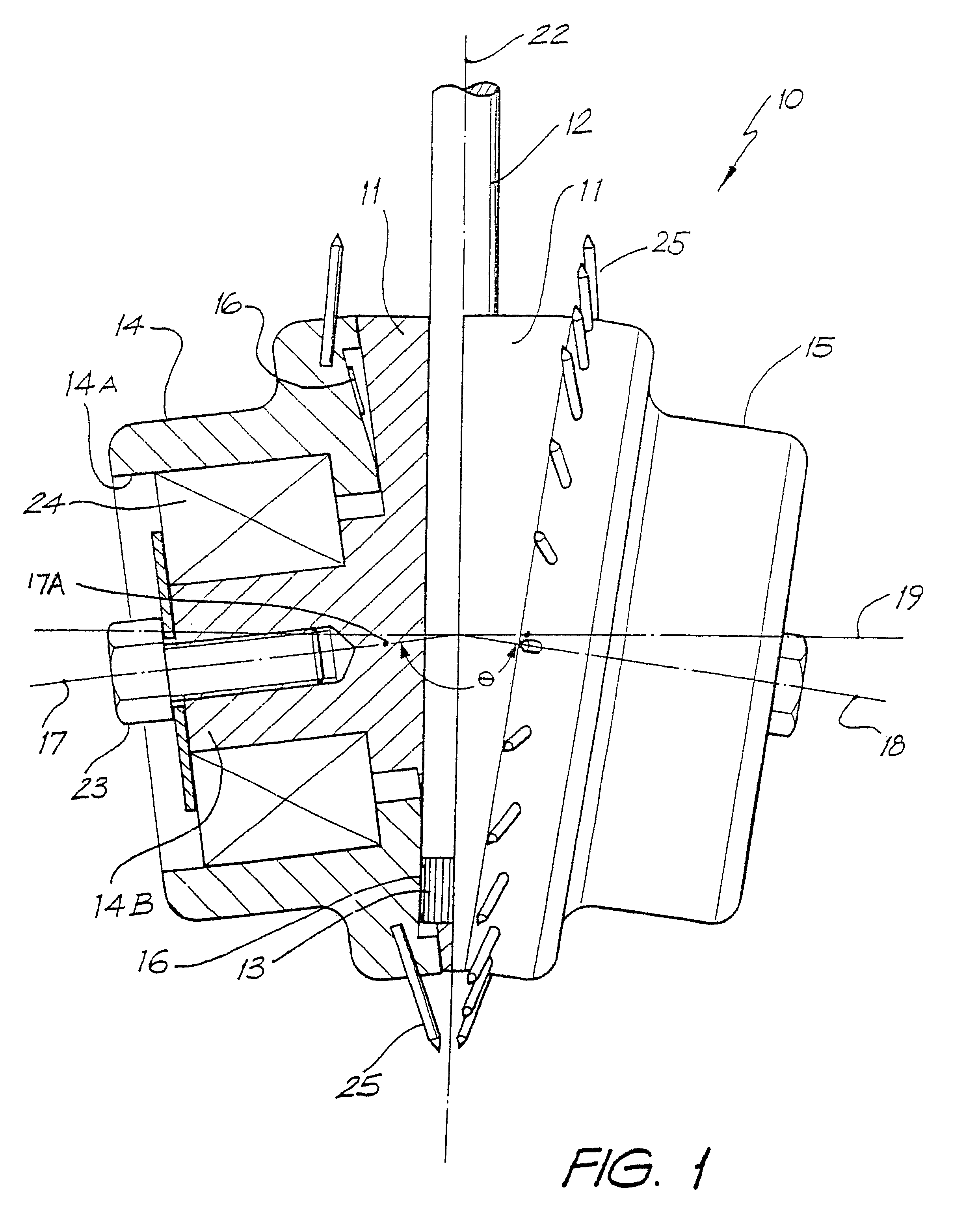

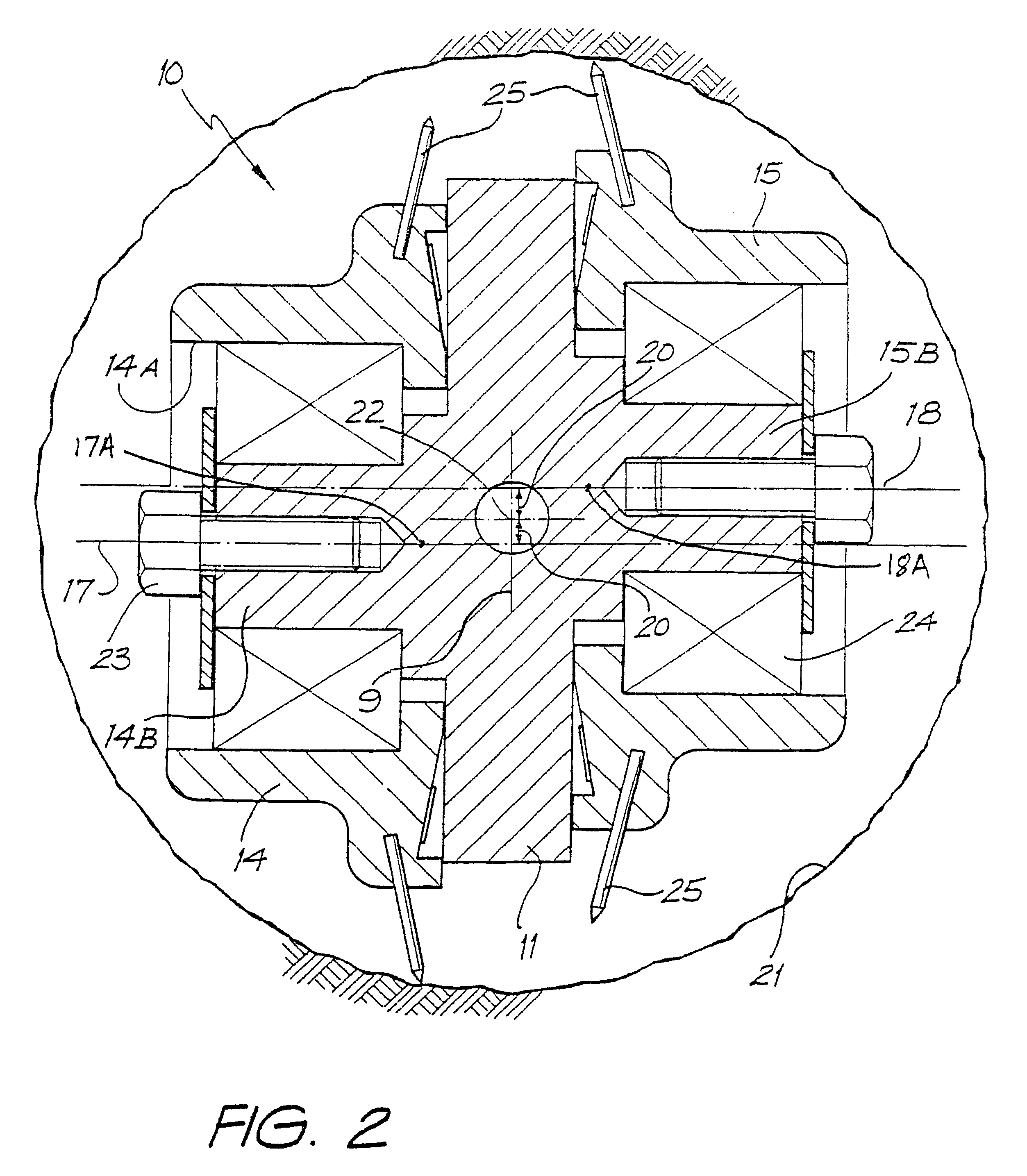

Rotary drill bit having moveable formation-engaging members

Formation engaging elements are moveably mounted onto a drill bit. Such elements may be used to protect other rigidly mounted formation engaging elements from impacts that occur during use of the drill bit, or they may be used to alter the aggressiveness of the drill bit when used in directional drilling operations.

Owner:REEDHYCALOG UK

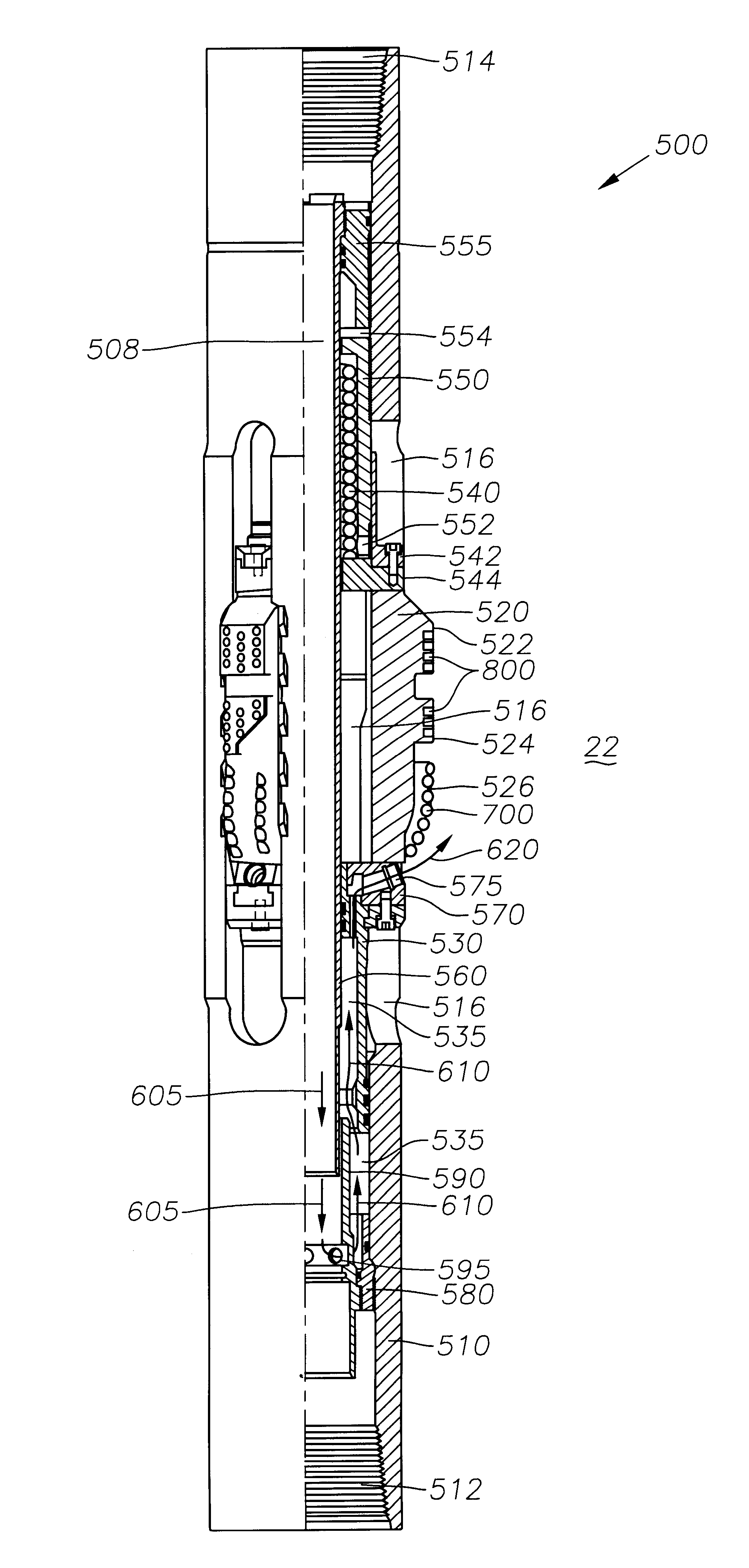

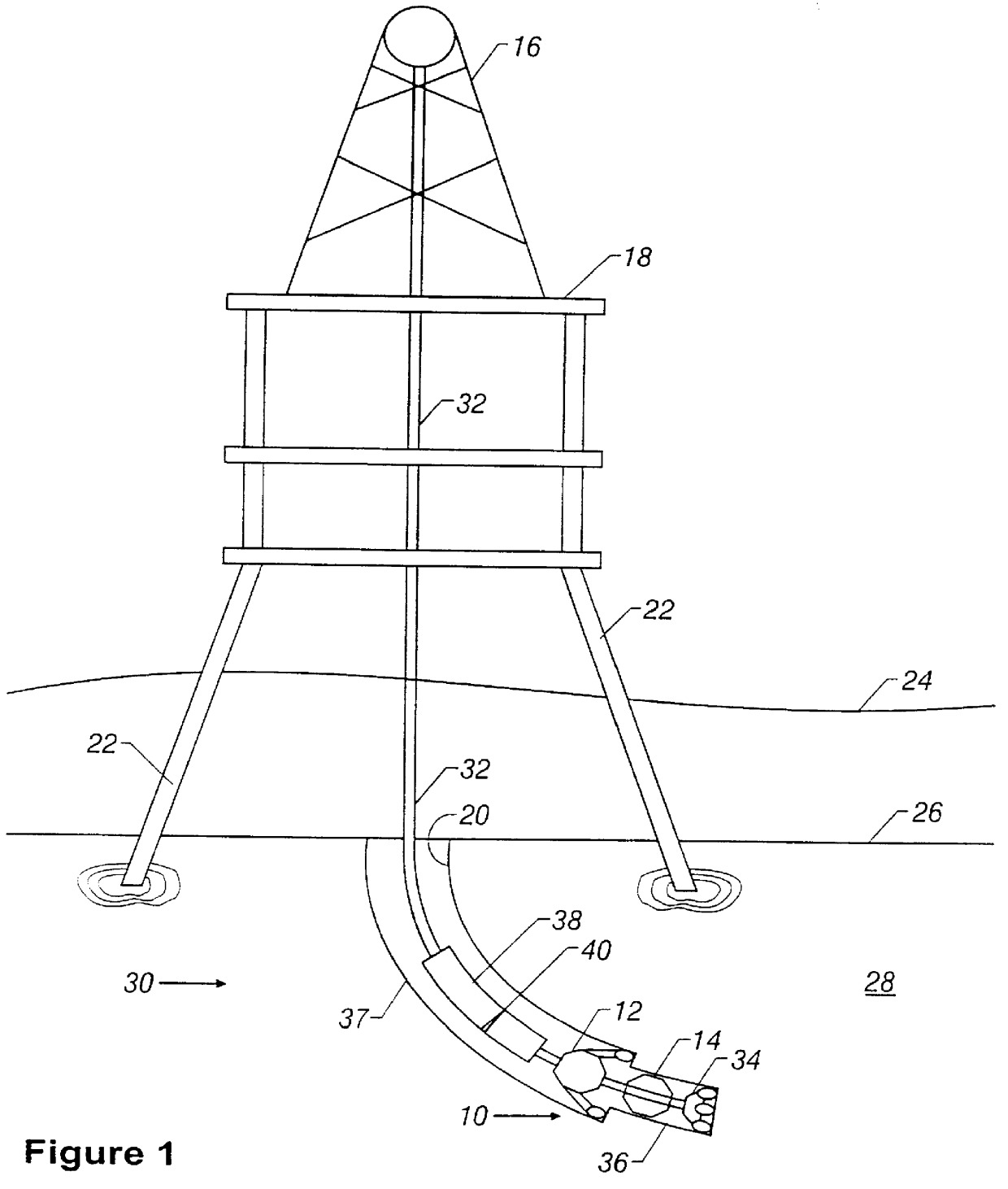

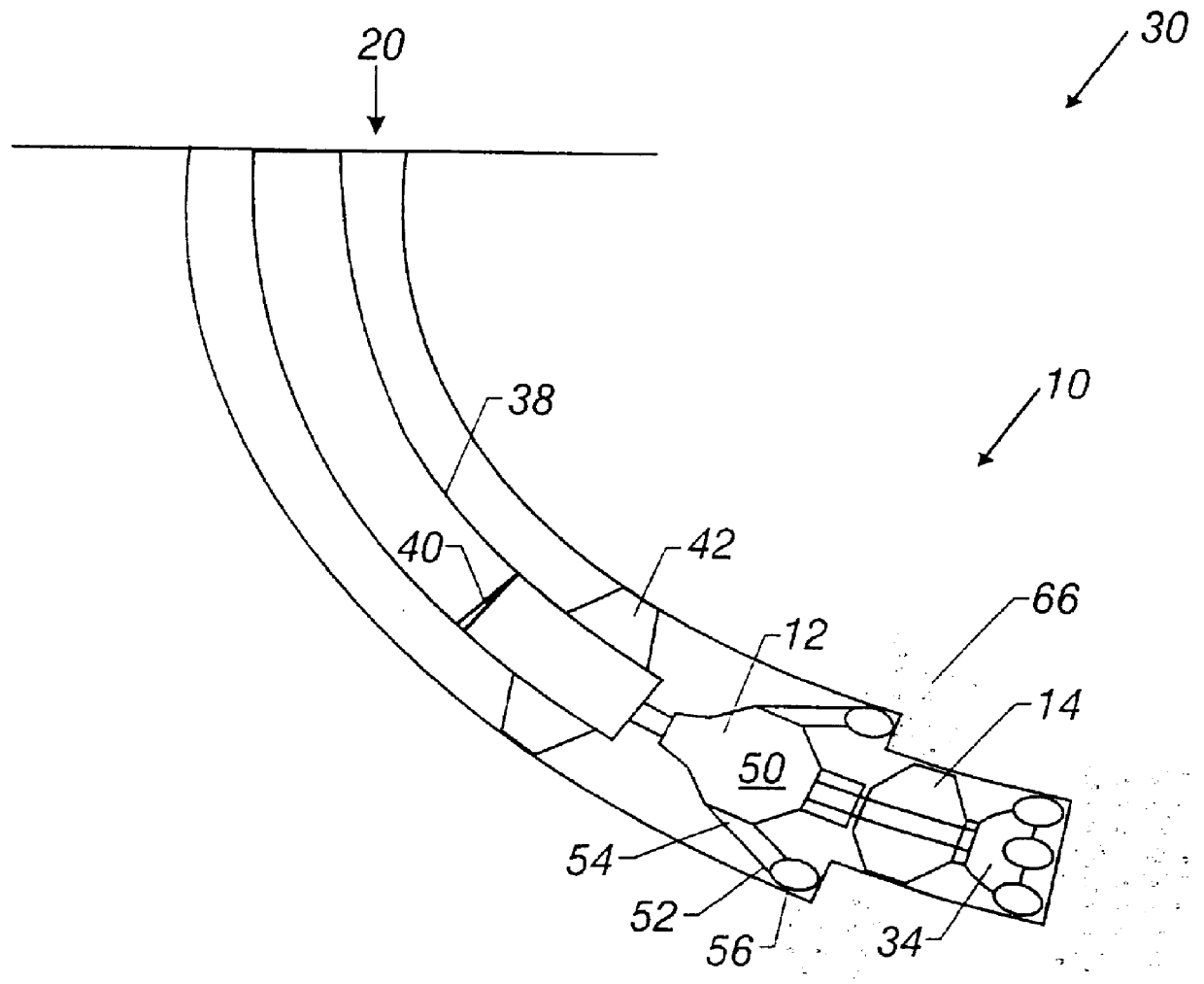

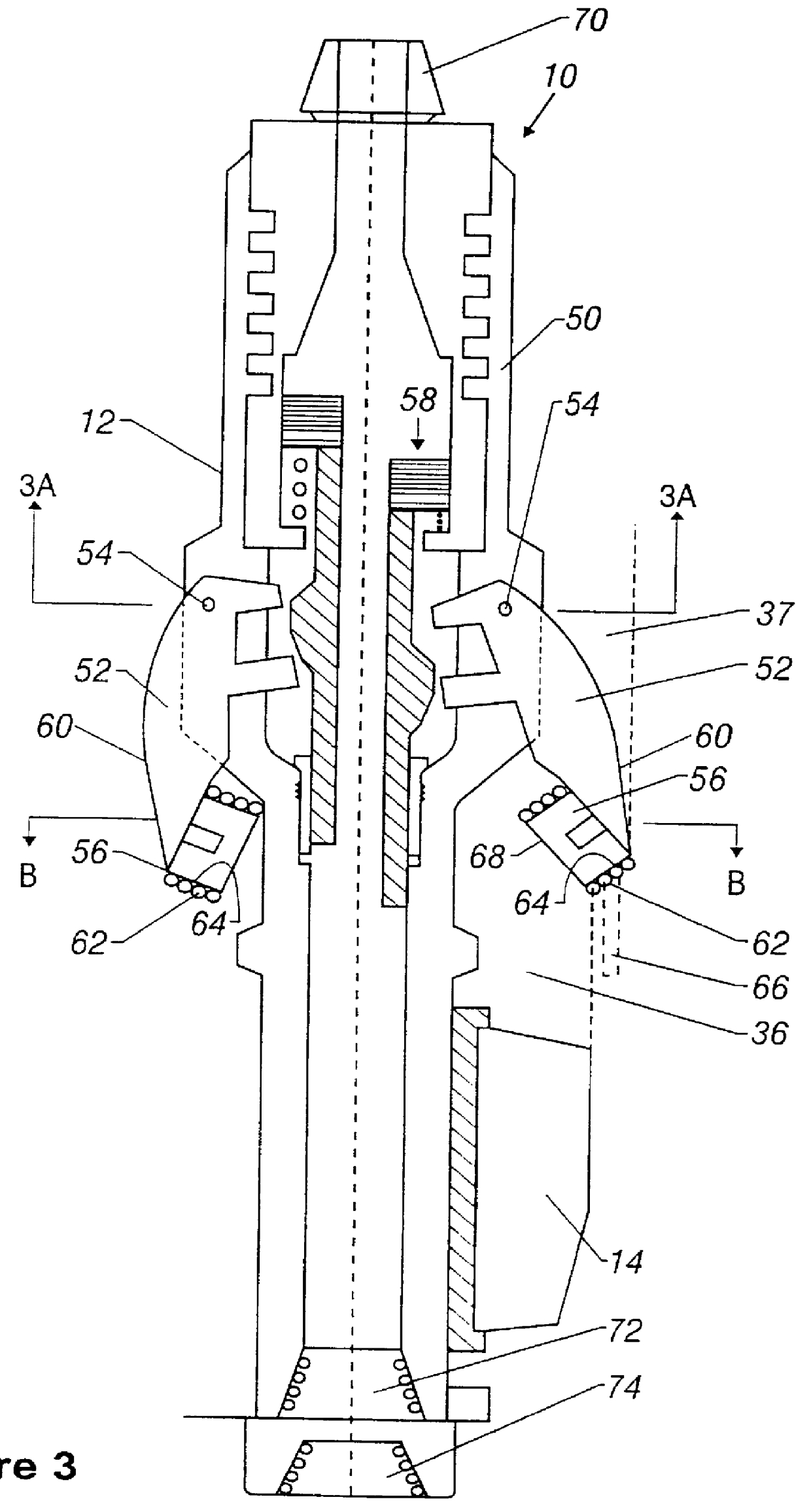

Integrated directional under-reamer and stabilizer

The present invention is an apparatus for use in drilling operations. It uses an under-reamer having a plurality of elongated arms with cutting elements at the ends of the arms for enlarging a previously drilled borehole drilled by a drill bit. One or more stabilizers in close proximity to the under-reamer provide stability to the under-reamer and the drill bit. The stabilizer could be rotating or non-rotating; and could be positioned between the under-reamer and the drill bit, or above the under reamer or above a directional device on the drillstring. The cutting arms are selectively operable to perform the enlargement. The stabilizer may be provided with members that closely fit the size of the borehole.

Owner:BAKER HUGHES INC

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

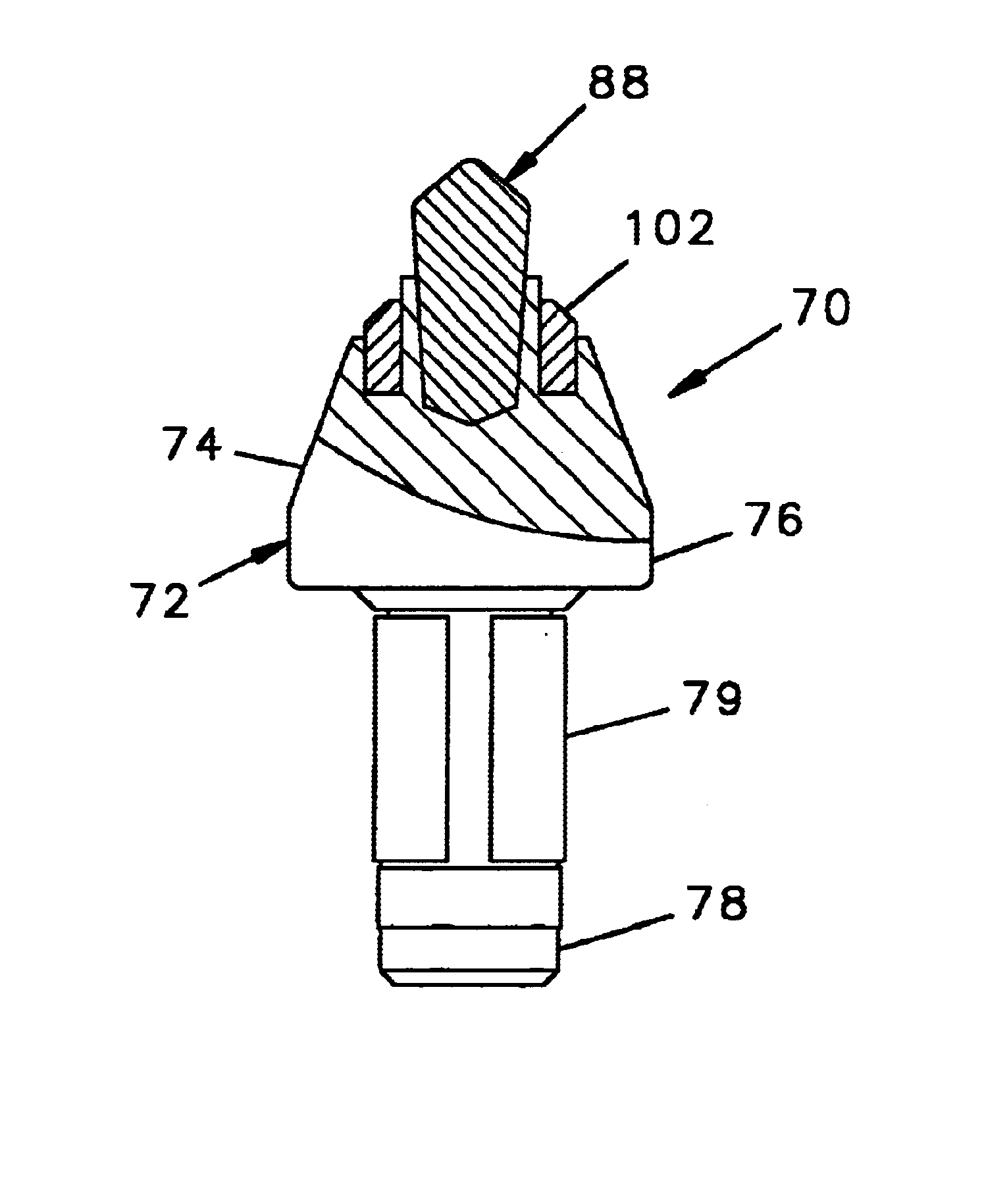

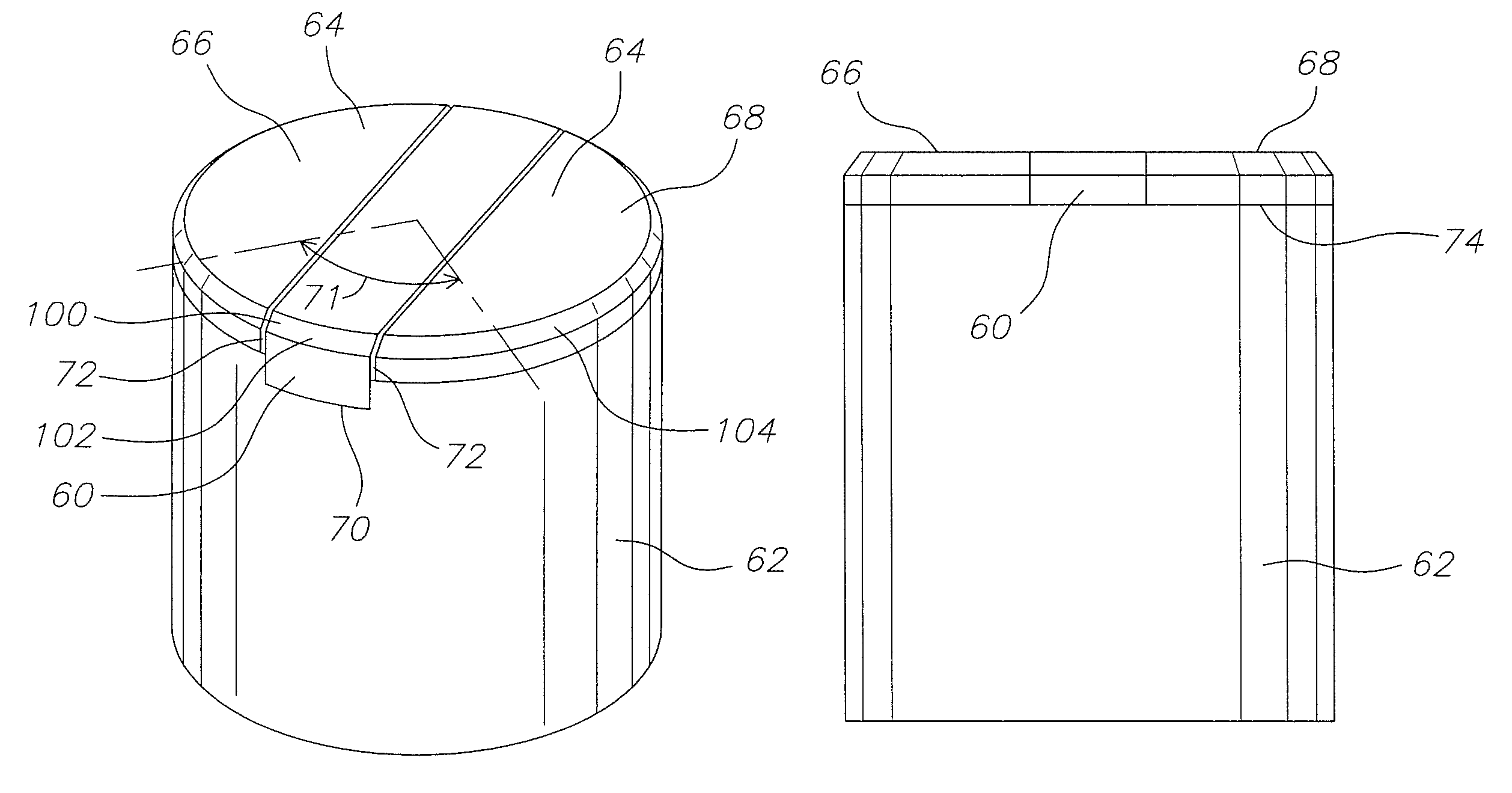

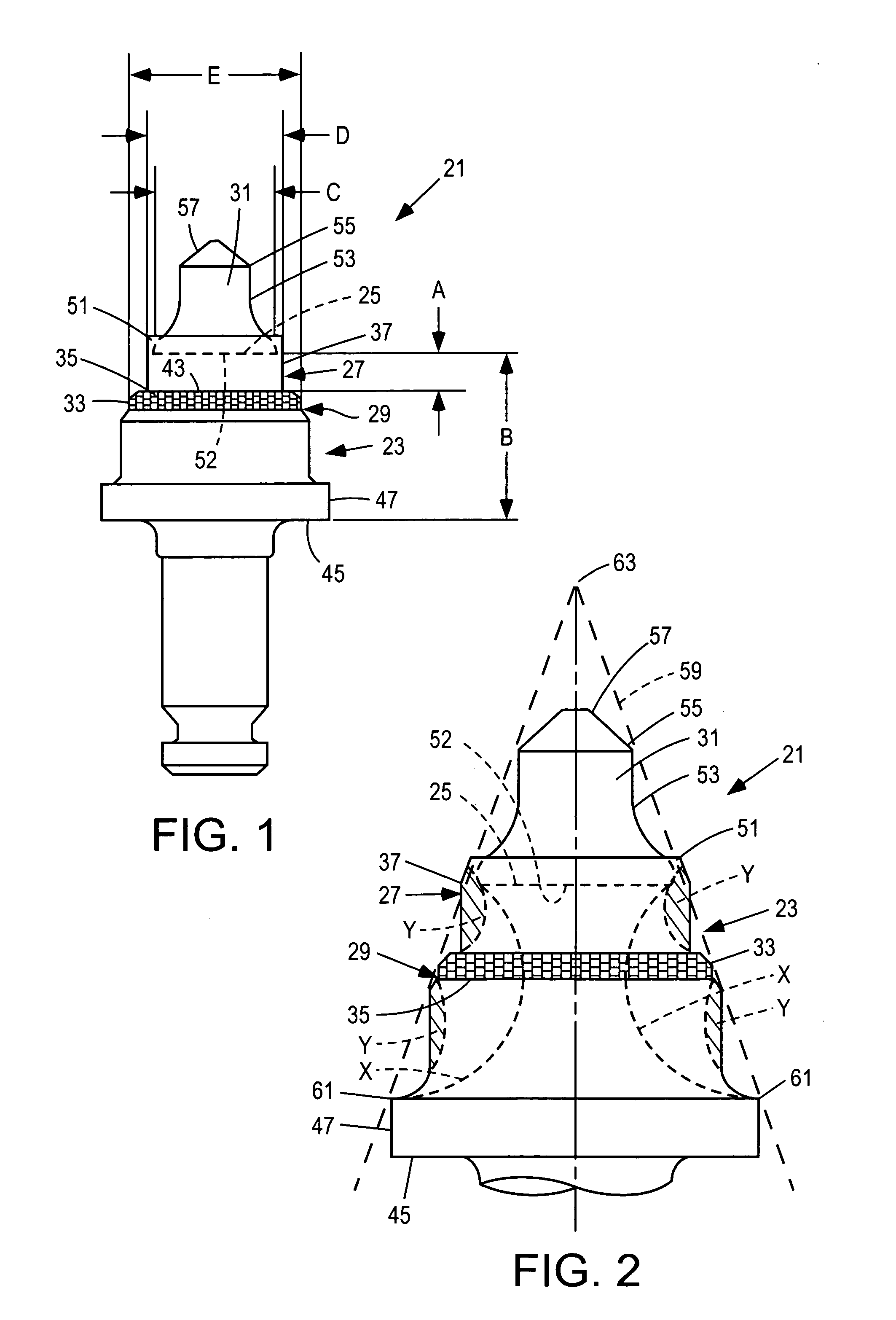

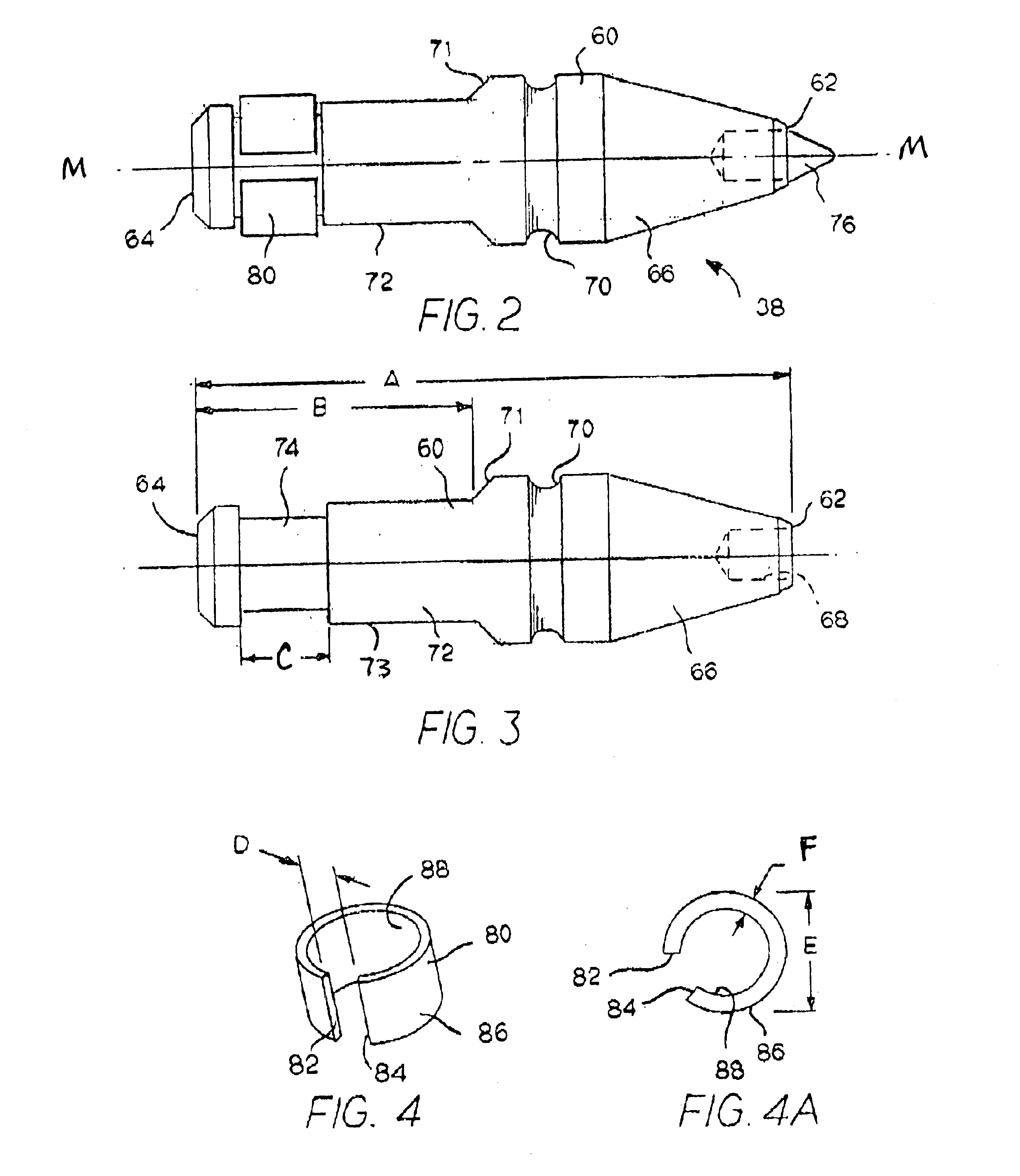

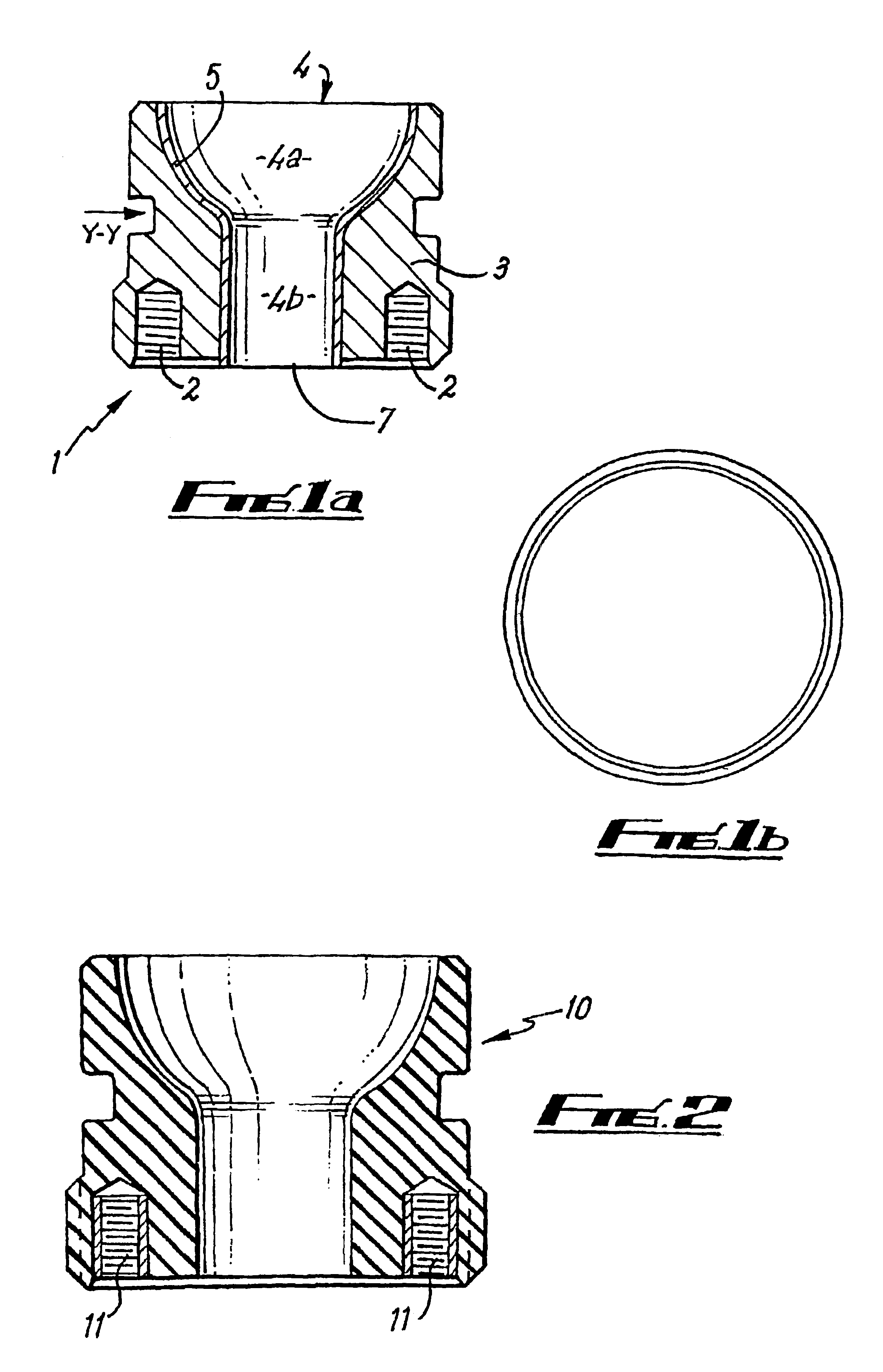

Cutting tool with hardened tip having a tapered base

InactiveUS6739327B2Improved cutting tipReduce harmSlitting machinesFine working devicesEngineeringMechanical engineering

A cutting tool has a centrally located tungsten carbide insert brazed into a seat at the forward end of the tool. The seat has a circular mouth and rearward of the mouth is a frustoconical inner wall. At the bottom of the seat is a transverse surface. A tungsten carbide insert is brazed into the seat and the base of the insert is complementary in shape to the seat. A second annular insert may also be brazed into a complementary shaped annular seat that surrounds the centrally located seat.

Owner:THE SOLLAMI COMPANY

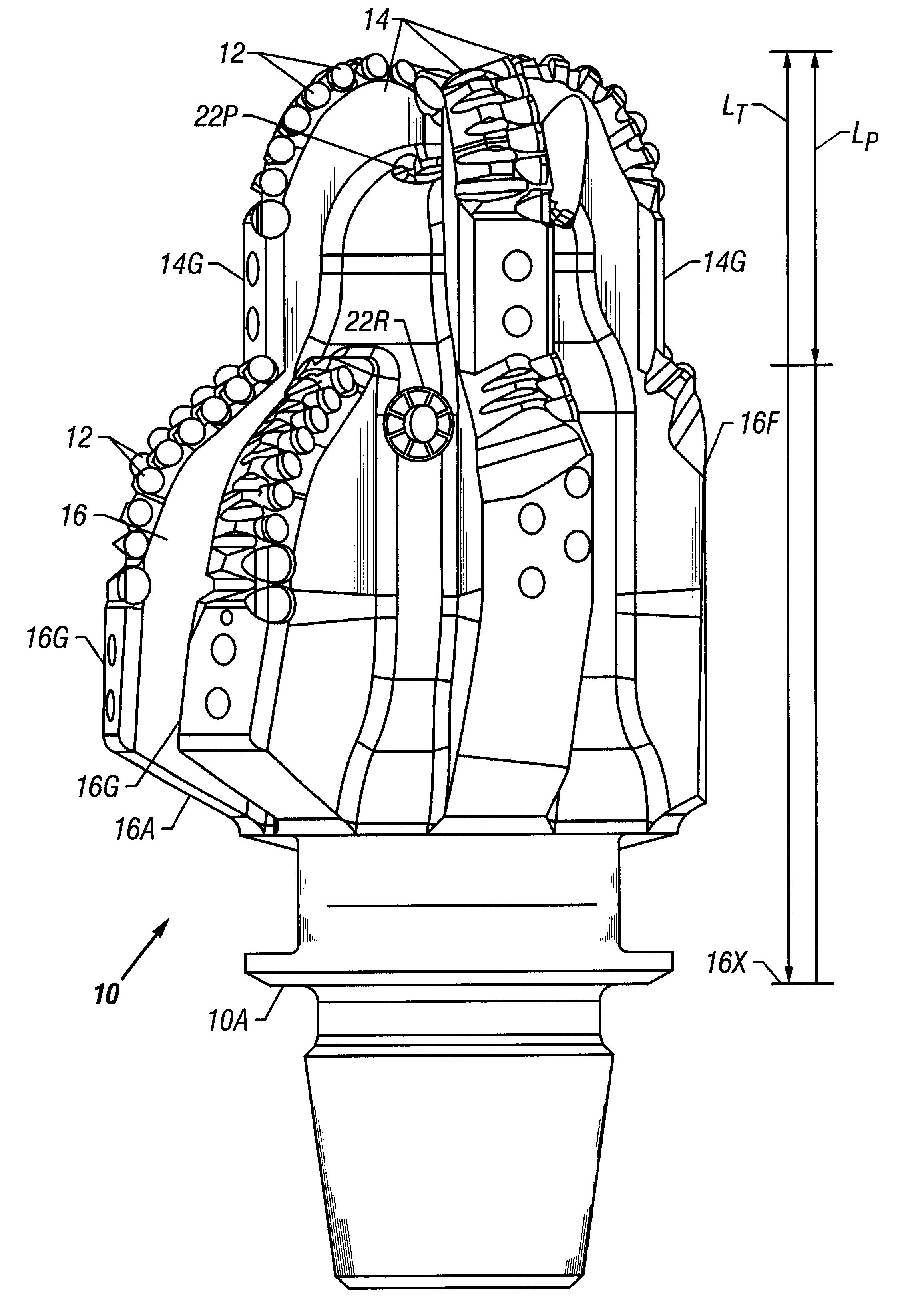

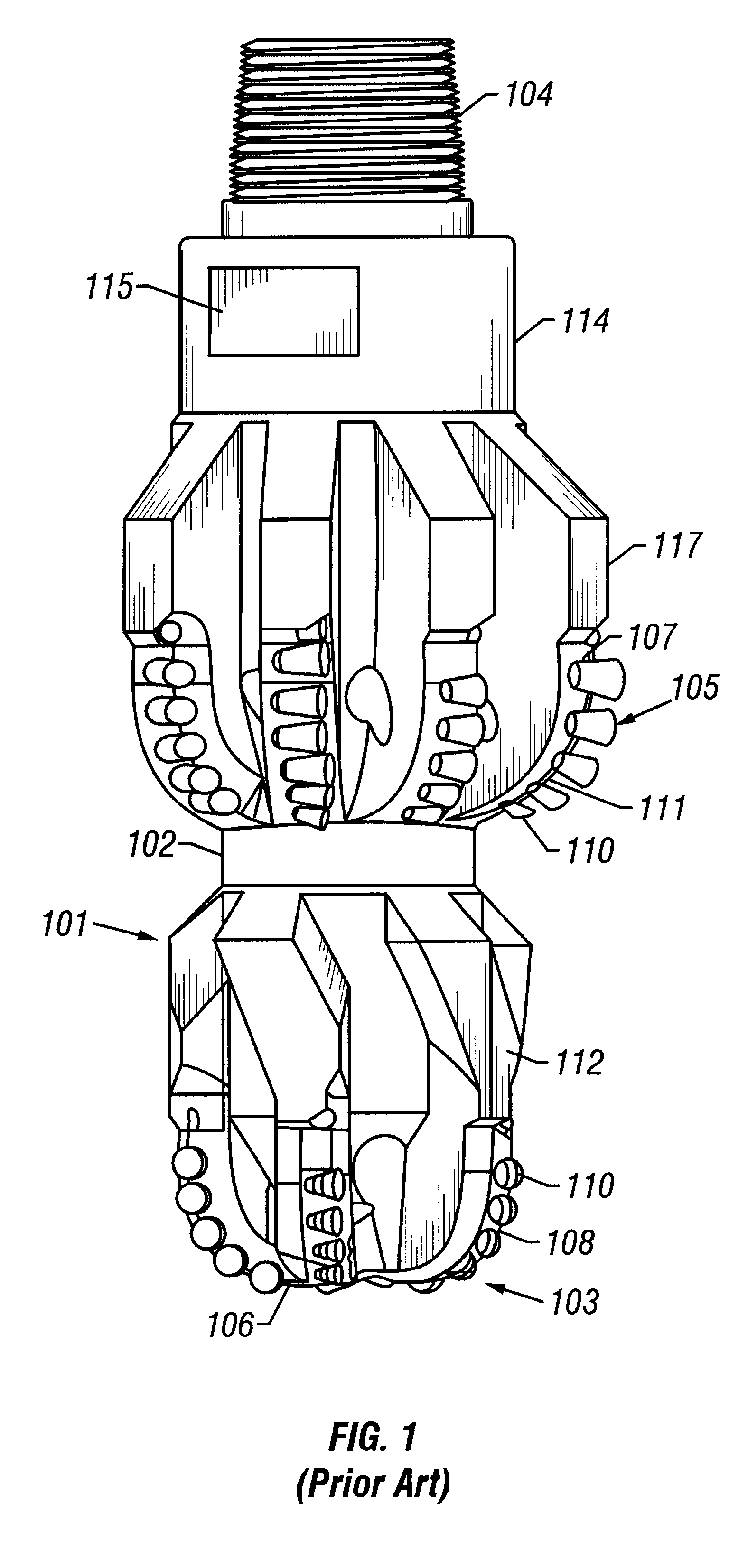

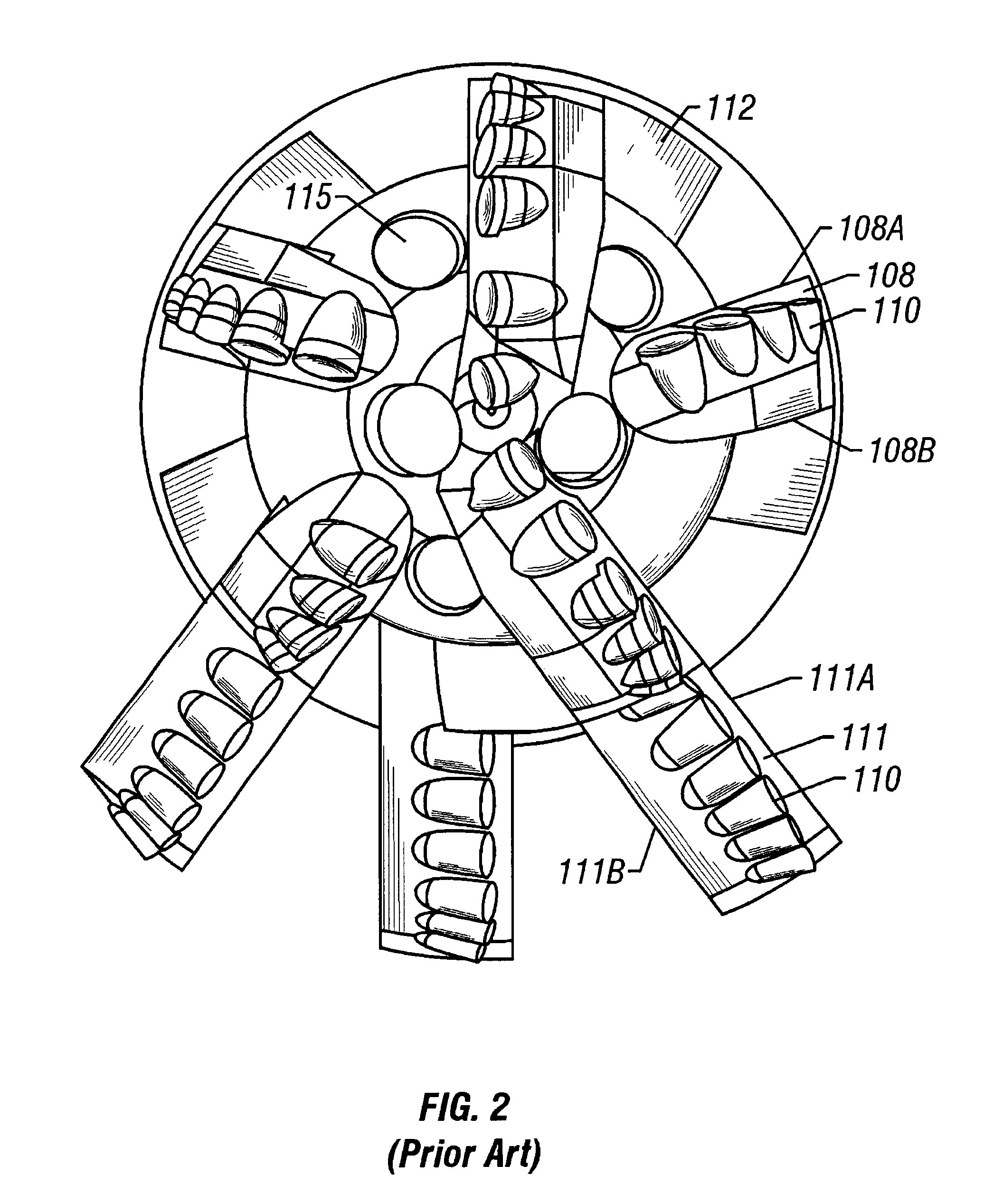

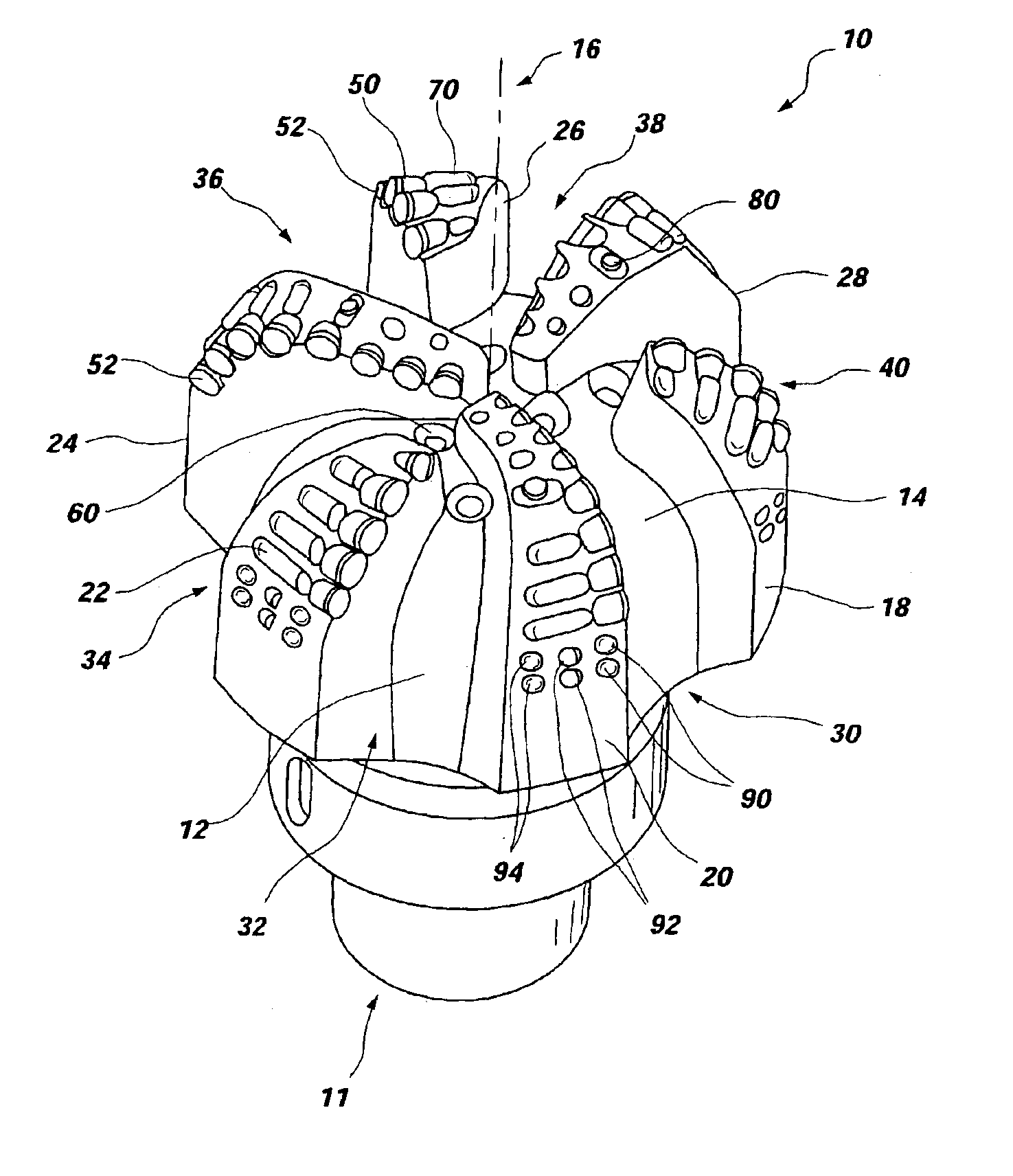

Bi-centered drill bit having improved drilling stability mud hydraulics and resistance to cutter damage

A bi-center drill bit includes pilot and reaming blades affixed to a body at azimuthally spaced locations. The blades have PDC cutters attached at selected positions. In one aspect, the pilot blades form a section having length along the bit axis less than about 80 percent of a diameter of the section. In another aspect, selected pilot blades and corresponding reaming blades are formed into single spiral structures. In another aspect, shapes and positions of the blades and inserts are selected so that lateral forces exerted by the reaming and the pilot sections are balanced as a single structure. Lateral forces are preferably balanced to within 10 percent of the total axial force on the bit. In another aspect, the center of mass of the bit is located less than about 2.5 percent of the diameter of the bit from the axis of rotation. In another aspect, jets are disposed in the reaming section oriented so that their axes are within about 30 degrees of normal to the axis of the bit. In another aspect, the reaming blades are shaped to conform to the radially least extensive, from the longitudinal axis, of a pass-through circle or a drill circle, so the cutters on the reaming blades drill at the drill diameter, without contact to the cutters on the reaming blades when the bit passes through an opening having about the pass-through diameter.

Owner:SMITH INT INC

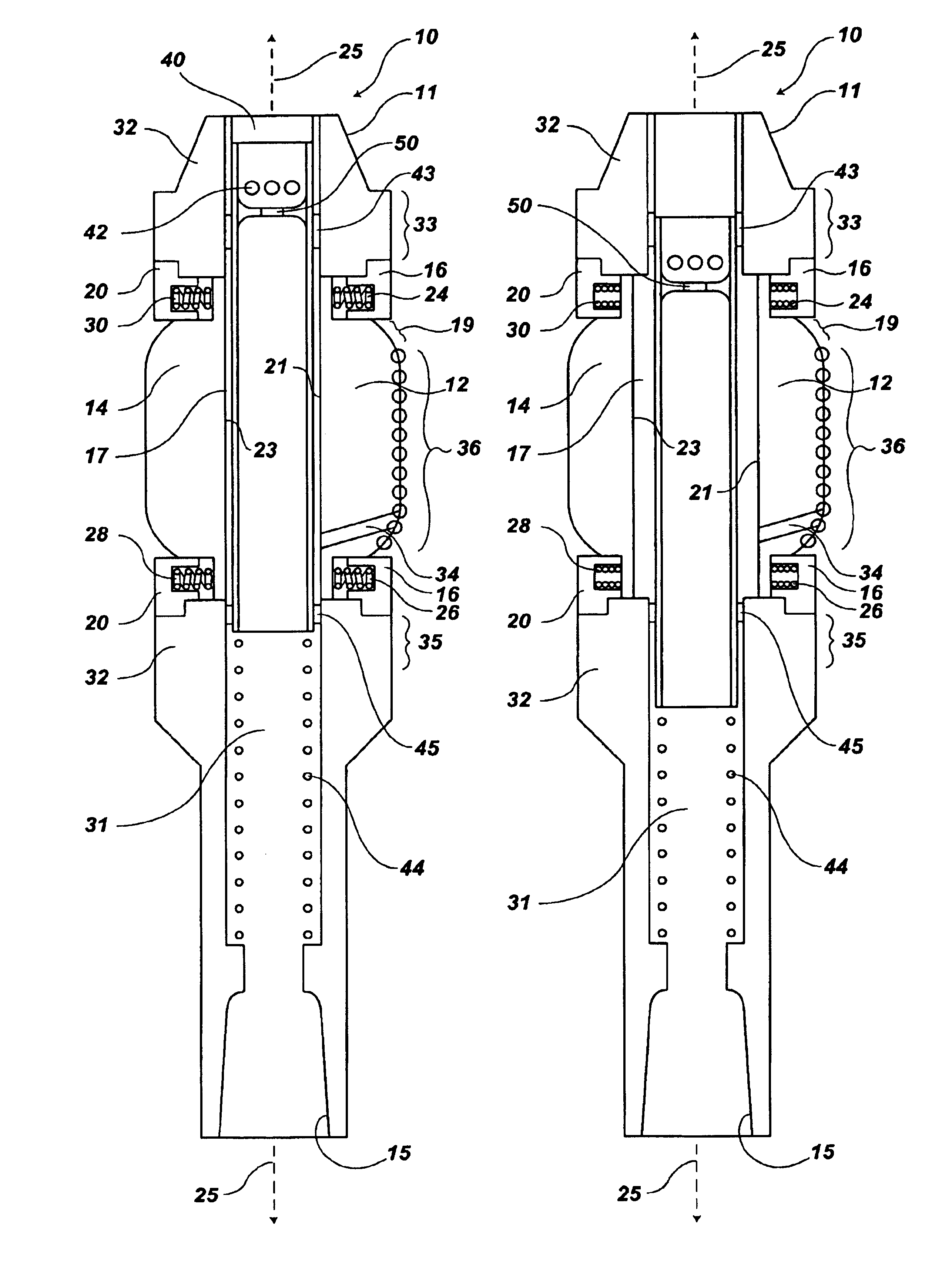

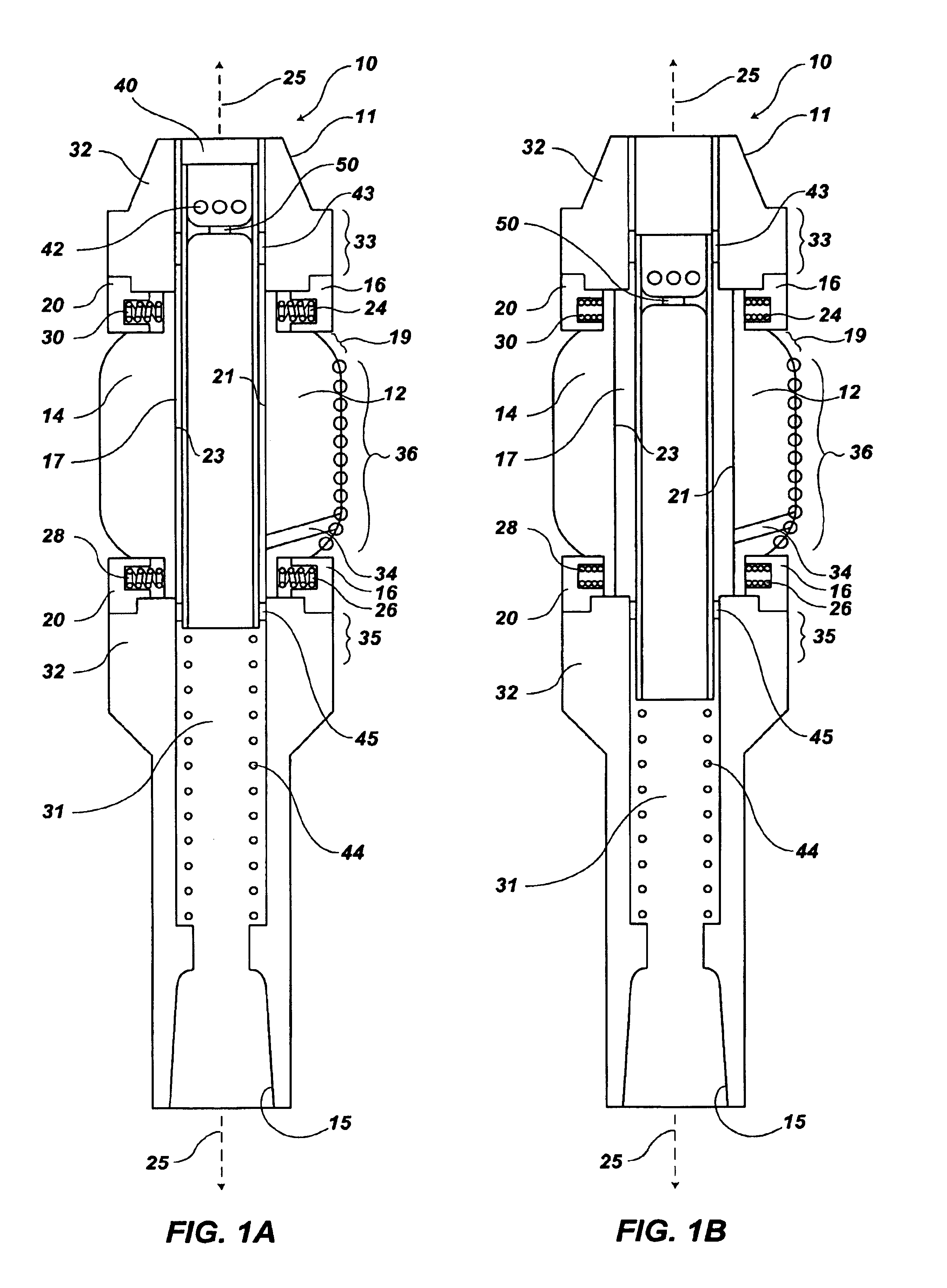

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Polycrystalline diamond constructions having improved thermal stability

ActiveUS20080223623A1Good adhesionImprove thermal stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Owner:SMITH INT INC

Thermally stable polycrystalline diamond cutting elements and bits incorporating the same

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

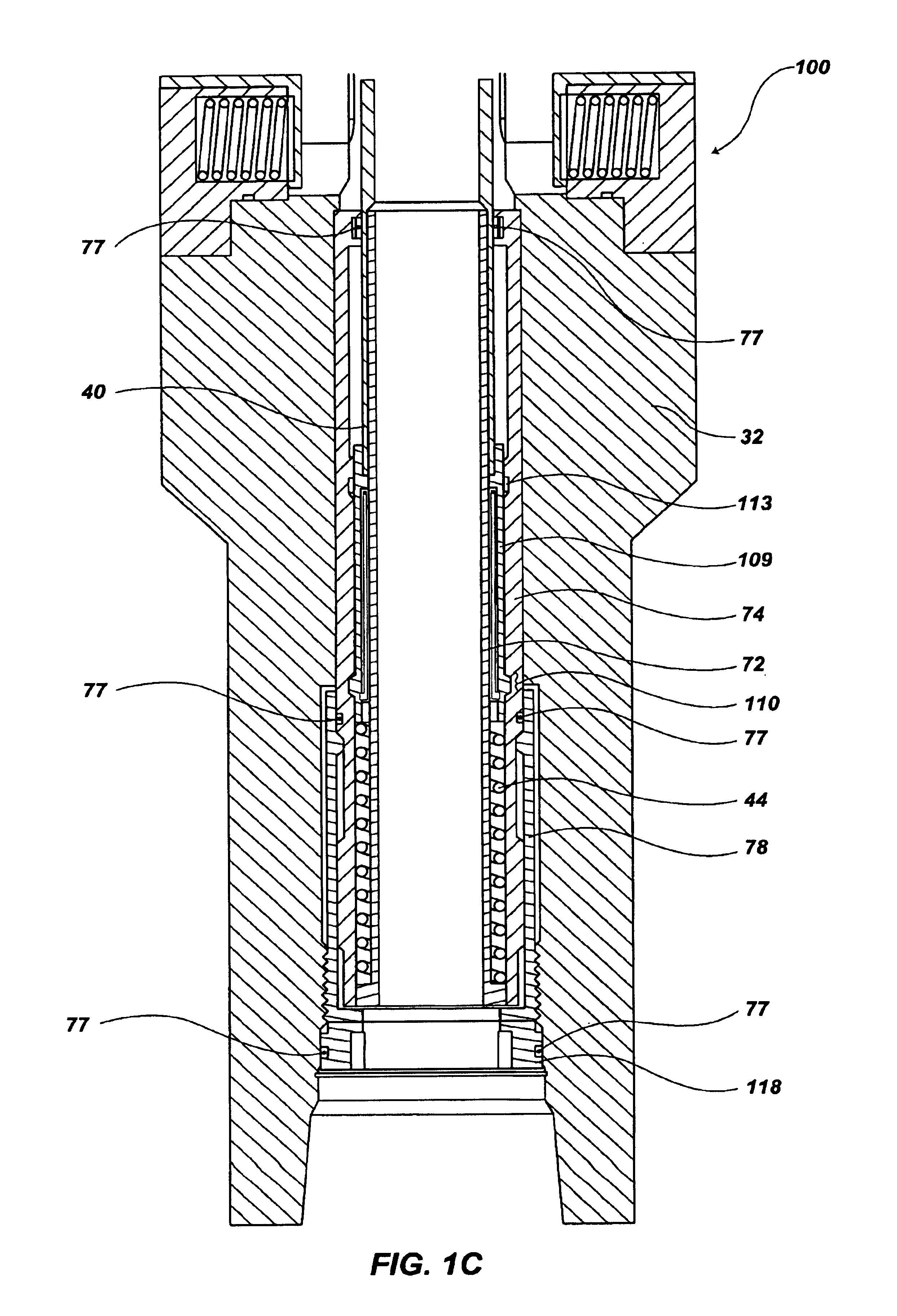

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

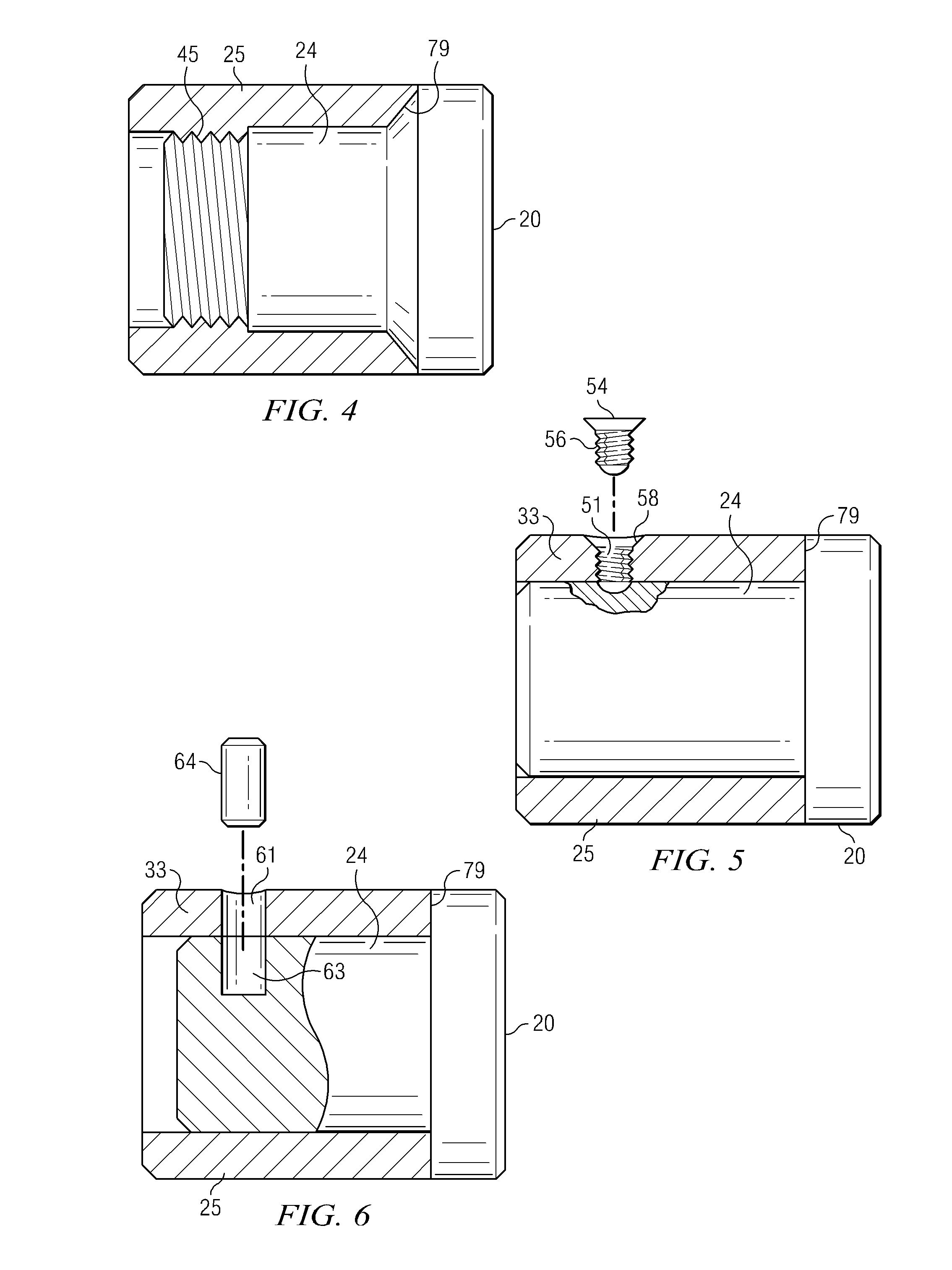

Cutter assemblies, downhole tools incorporating such cutter assemblies and methods of making such downhole tools

Owner:SMITH INT INC

Drillout bi-center bit

The present invention is a bi-center drill bit designed to drill out the cement and other material in the casing and then proceed to drill out the full gauge drilling diameter borehole with a diameter greater than the inside of the casing. The bi-center drill bit is configured with non-drilling bearing elements that contact with the casing when the bit is drilling the cement without allowing the gauge cutting elements of the bi-center drill bit to contact the casing. The bi-center drill bit also has a cutting element configuration which prevents reverse scraping of the cutting elements when drilling both the cement and the formation.

Owner:CAMCO INT

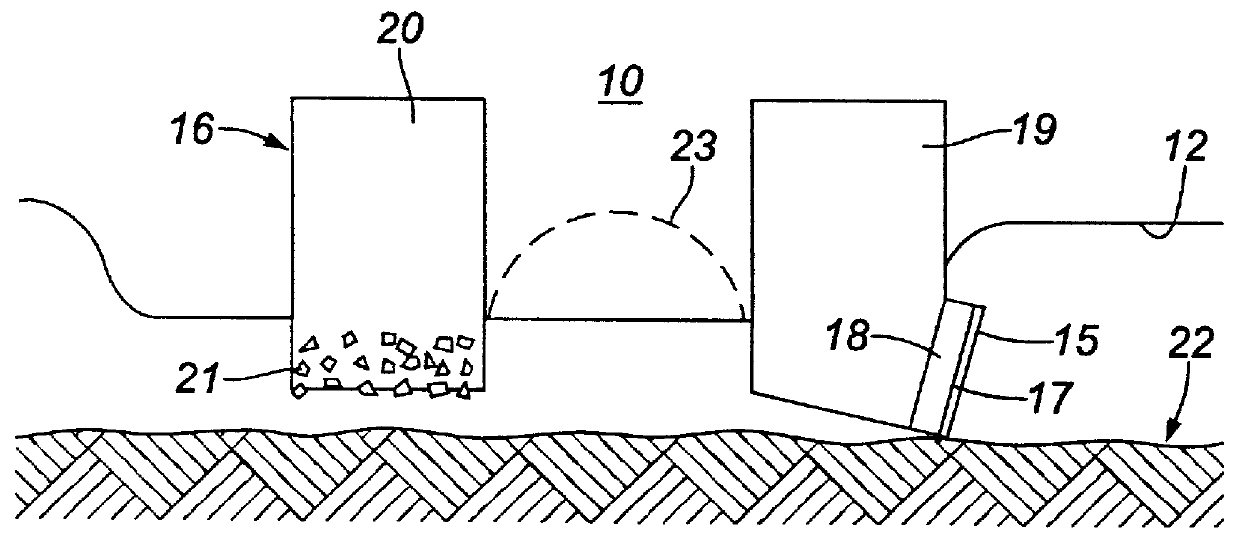

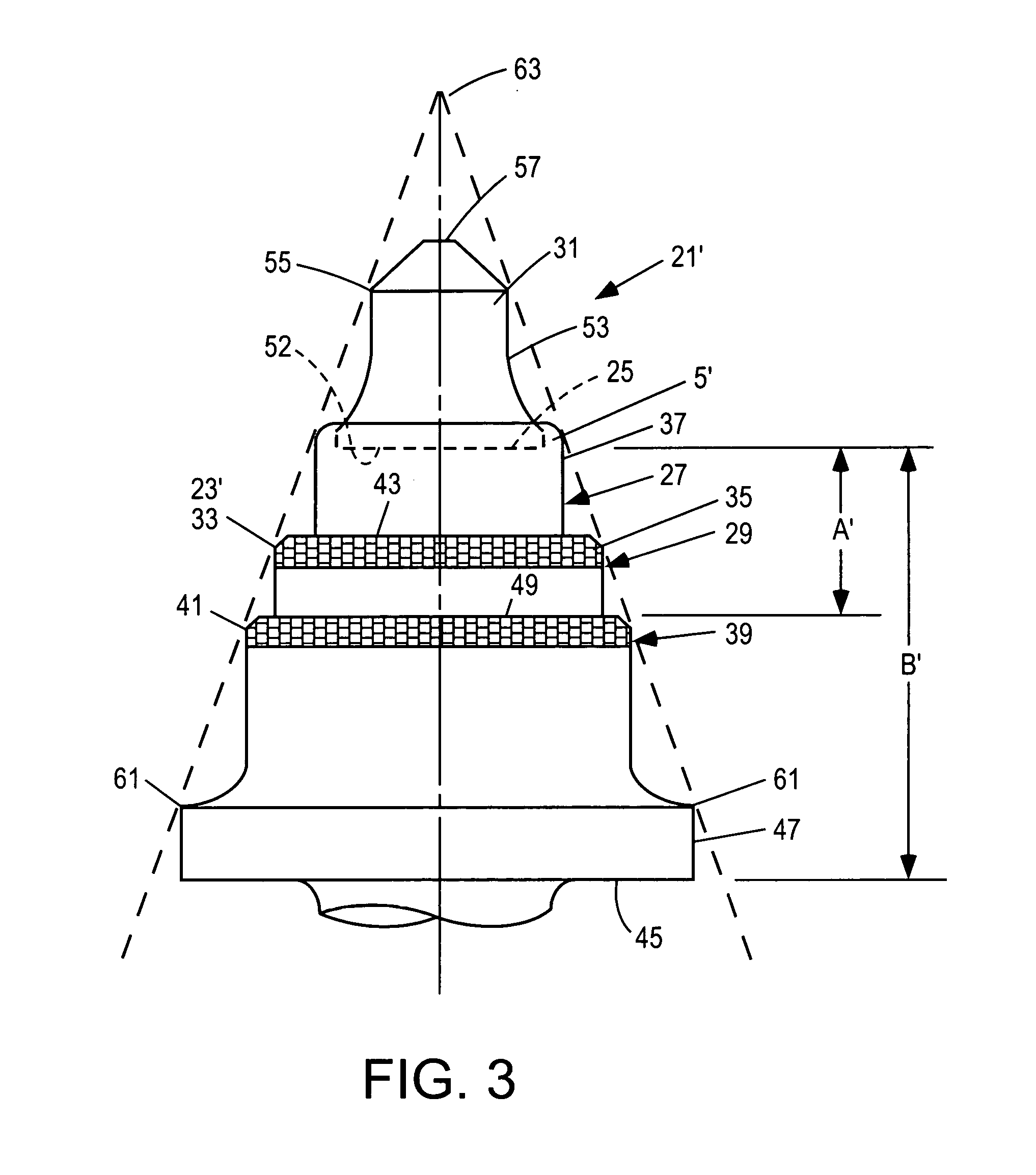

Rotary cutting bit with material-deflecting ledge

InactiveUS7204560B2Prolong lifeEasy to manufactureSlitting machinesRoads maintainenceBiomedical engineeringDrill bit

A cutting bit includes a body having a front surface and a side surface, the side surface including a shoulder below the front surface and extending substantially perpendicular to a central axis of the body, and a ring that is harder than the body attached to the body at a front surface of the shoulder. Wear life of the cutting bit is enhanced by maintaining particular dimensional relationships regarding the position of the ring on the body, and the diameter of portions of the body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Thermally stable polycrystalline diamond materials, cutting elements incorporating the same and bits incorporating such cutting elements

A cutting element is provided including a substrate and a TSP material layer over the substrate. The TSP material layer includes at least a property having a value that varies through the layer.

Owner:SMITH INT INC

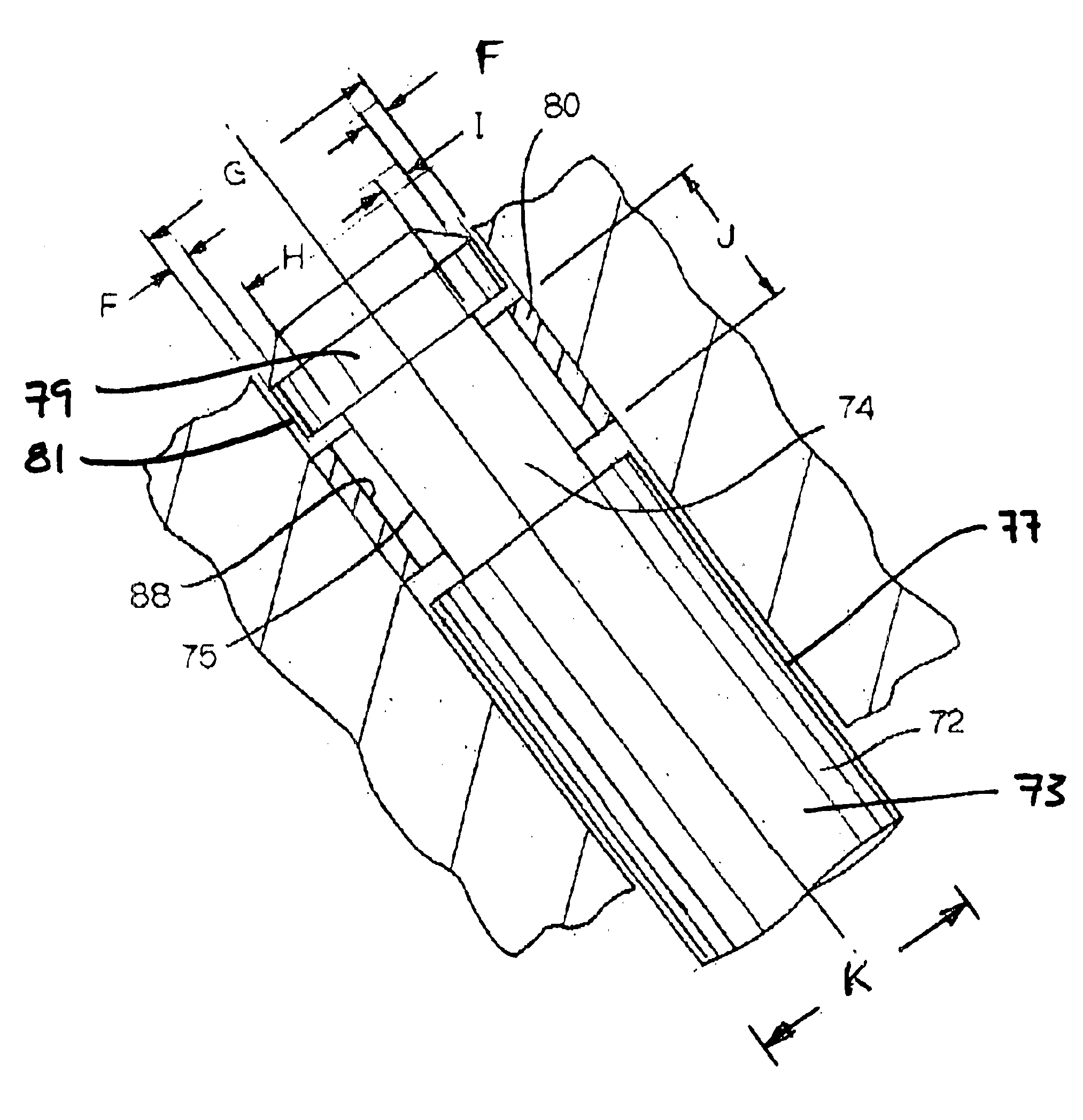

Rotatable bit having a resilient retainer sleeve with clearance

InactiveUS6851758B2Reduce the overall diameterDrill bitsDisloding machinesBiomedical engineeringDrill bit

A drilling bit for use in conjunction with a holder that has a bore wherein the drilling bit has a drilling bit body that has an axial forward end and an axial rearward end. The drilling bit body further includes a reduced diameter portion adjacent to the axial rearward end thereof so as to define a reduced diameter surface. A hard insert is affixed to the drilling bit body at the axial forward end thereof. A resilient retainer sleeve has a first thickness and presents an interior surface. The retainer sleeve is carried by the drilling bit body within the reduced diameter portion. The resilient retainer sleeve is in an expanded condition when the drilling bit is not within the bore of the holder and the resilient retainer sleeve is in a compressed condition when the drilling bit being within the bore of the holder. The clearance between the reduced diameter surface of the drilling bit body and the interior surface of the resilient retainer sleeve when the resilient retainer sleeve is in its compressed condition is at least as great as the thickness of the resilient retainer sleeve.

Owner:KENNAMETAL INC

Earth boring apparatus and method offering improved gage trimmer protection

InactiveUS6883623B2Less wear resistantWear down quicklyDrill bitsDrilling rodsLeading edgeEngineering

A rotary drill bit for drilling subterranean formations configured with at least one protective structure proximate to the rotationally leading and trailing edges of a gage trimmer, wherein the at least one protective structure is positioned at substantially the same exposure as its associated gage trimmer. Particularly, the apparatus of the present invention may provide protection for gage trimmers during drilling, tripping, and / or rotation within a casing; i.e., when changing a drilling fluid. Protective structures may be configured and located according to anticipated drilling conditions including helix angles. In addition, a protective structure may be proximate to more than one gage trimmer while having a substantially equal exposure to each associated gage trimmer. Methods of use and a method of rotary bit design are also disclosed.

Owner:BAKER HUGHES INC

Drillable drill bit nozzle

InactiveUS6848517B2Thin structureImprove corrosion resistanceDrill bitsDrilling rodsHigh resistanceRubber material

A drill bit nozzle providing a through bore for the passage of drilling fluid through a drill bit. The nozzle is made of a material or materials which can be drilled through by standard well bore drilling equipment. The material(s) are selected to provide a surface to the through bore which has a relatively high resistance to erosion to withstand the abrasive and corrosive impact of jetted drilling fluid. Embodiments are described using a hard chrome / copper combination and a single rubber material.

Owner:WEATHERFORD TECH HLDG LLC

Diamond-bonded constrcutions with improved thermal and mechanical properties

InactiveUS20090090563A1Excellent characteristicsImprove thermal stabilityDrill bitsConstructionsDiamond crystalCarbide

Diamond-bonded constructions include a diamond-bonded body having a thermally stable region extending a distance below a diamond-bonded body surface. The thermally stable region comprises a matrix phase of bonded-together diamond crystals, and interstitial regions comprising a reaction product. The reaction product is formed by reaction between the diamond crystals and a reactive material. The reactant is a carbide former and the reaction product is a carbide. The diamond-bonded body includes a further diamond region extending from the thermally stable region that comprises the matrix phase and a Group VIII metal disposed within interstitial regions of the matrix phase. The thermally stable region is substantially free of a catalyst material used to initially form the diamond-bonded body. The diamond-bonded body may include a material layer formed from the reaction product that is disposed on a surface of the diamond-bonded body thermally stable region.

Owner:SMITH INT INC

Excavation bit for a drilling apparatus

The invention provides an excavation bit, which is constructed from either a single or double carrier. If two carriers are present the carriers are contra-rotating. By the off setting of the axes of rotation of single or dual carriers from a longitudinal axis of the bit, and by driving to carriers to rotate, a ground engaging thrust is produced, as well as the rotation of the excavation bit in the ground as a consequence of the rotation of the carriers, and not vice versa as is the case with prior art. By the invention, there can result sufficient thrust on the bit, by the rotation of the carriers, so that the need to apply thrust down the bore via the drill rod is reduced or eliminated. As a result of the invention the number and or size of the ground engaging tools are not a function of the bore diameter to be drilled. Thus as the excavation bit is scaled up for larger diameter bores more ground engaging tools and or an increase in their size is not required. By the invention, thrust applied (either via the drill rod or from the rotation of the carriers) is thought to be, through a quasi lever system, multiplied at some of the ground engaging tools in the radial direction. That is the total thrust in the longitudinal axis direction (whether externally applied or resultant from the contra-rotation of the carriers), is multiplied so that the outward forces exerted (by the cutters onto the rock surface in the region approaching perpendicular to the longitudinal axis of the bore) is thought to be significantly higher than the magnitude of the total thrust.

Owner:MOLLOY ANTHONY

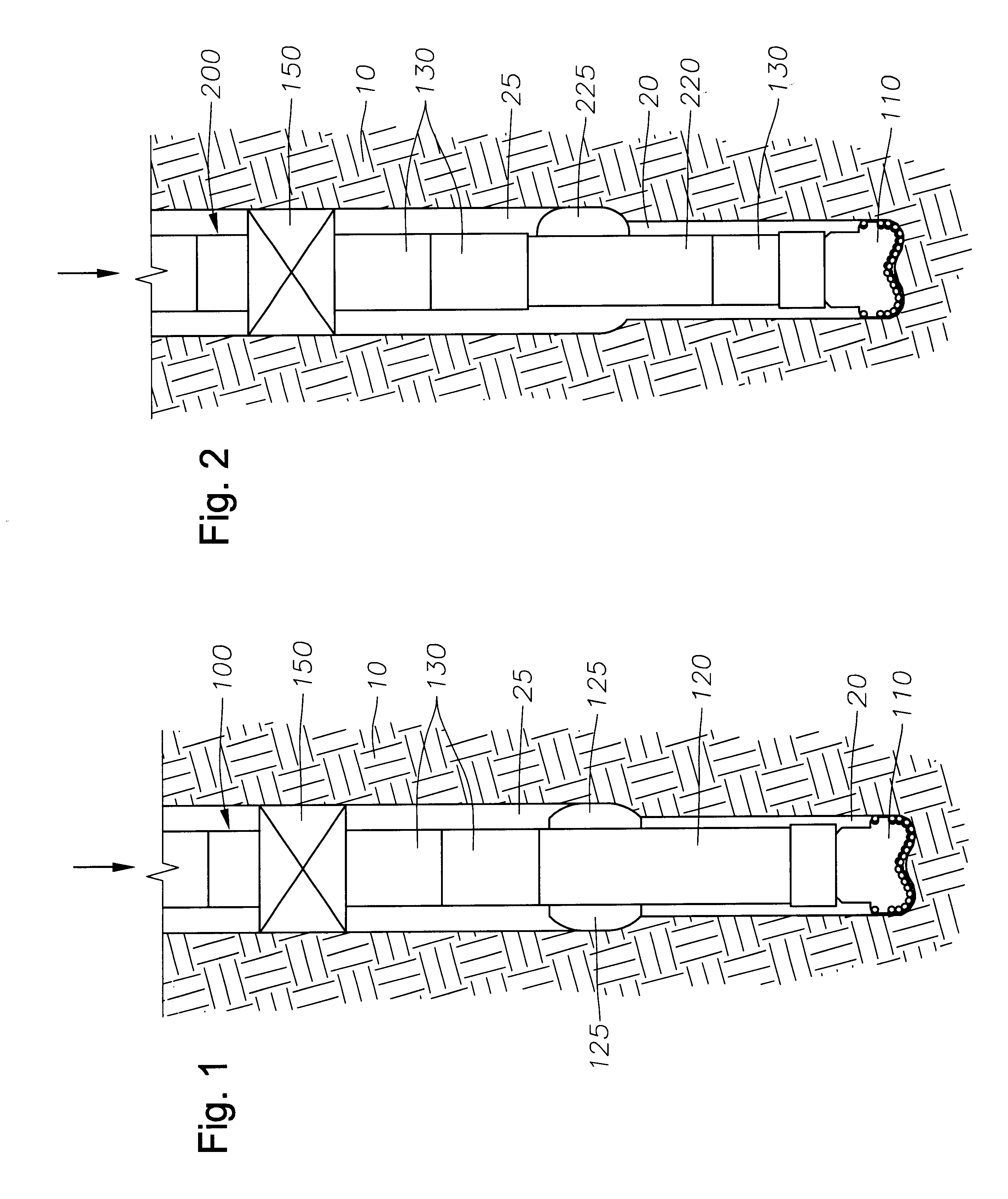

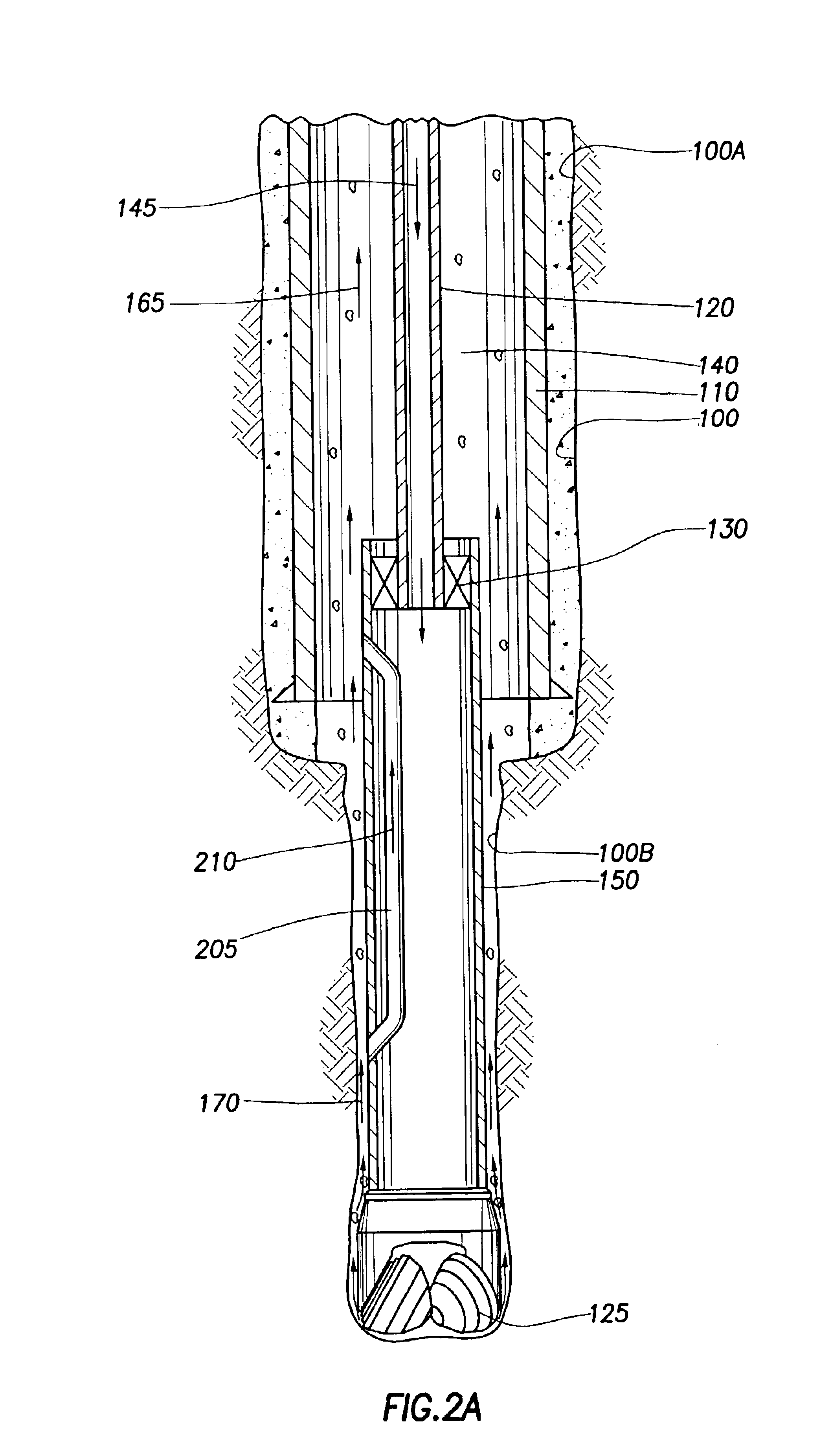

Apparatus and method for drilling with casing

The present invention generally relates to a method and an apparatus for drilling with casing. In one aspect, a method of drilling a wellbore with casing is provided, including placing a string of casing with a drill bit at the lower end thereof into a previously formed wellbore and urging the string of casing axially downward to form a new section of wellbore. The method further includes pumping fluid through the string of casing into an annulus formed between the casing string and the new section of wellbore. The method also includes diverting a portion of the fluid into an upper annulus in the previously formed wellbore. In another aspect, a method of drilling with casing to form a wellbore is provided. In yet another aspect, an apparatus for forming a wellbore is provided. In still another aspect, a method of casing a wellbore while drilling the wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com