Patents

Literature

2725results about How to "Reduce the cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

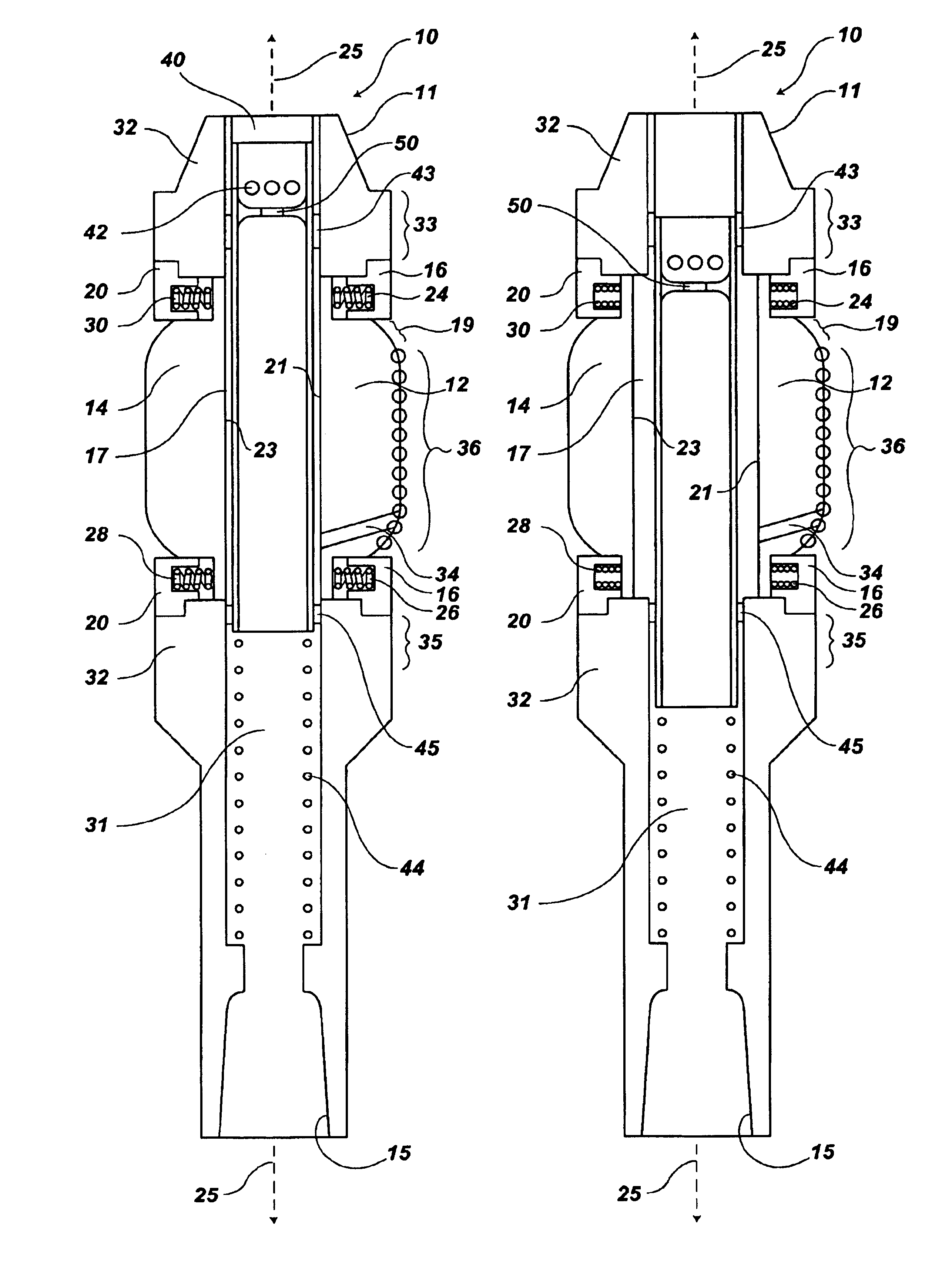

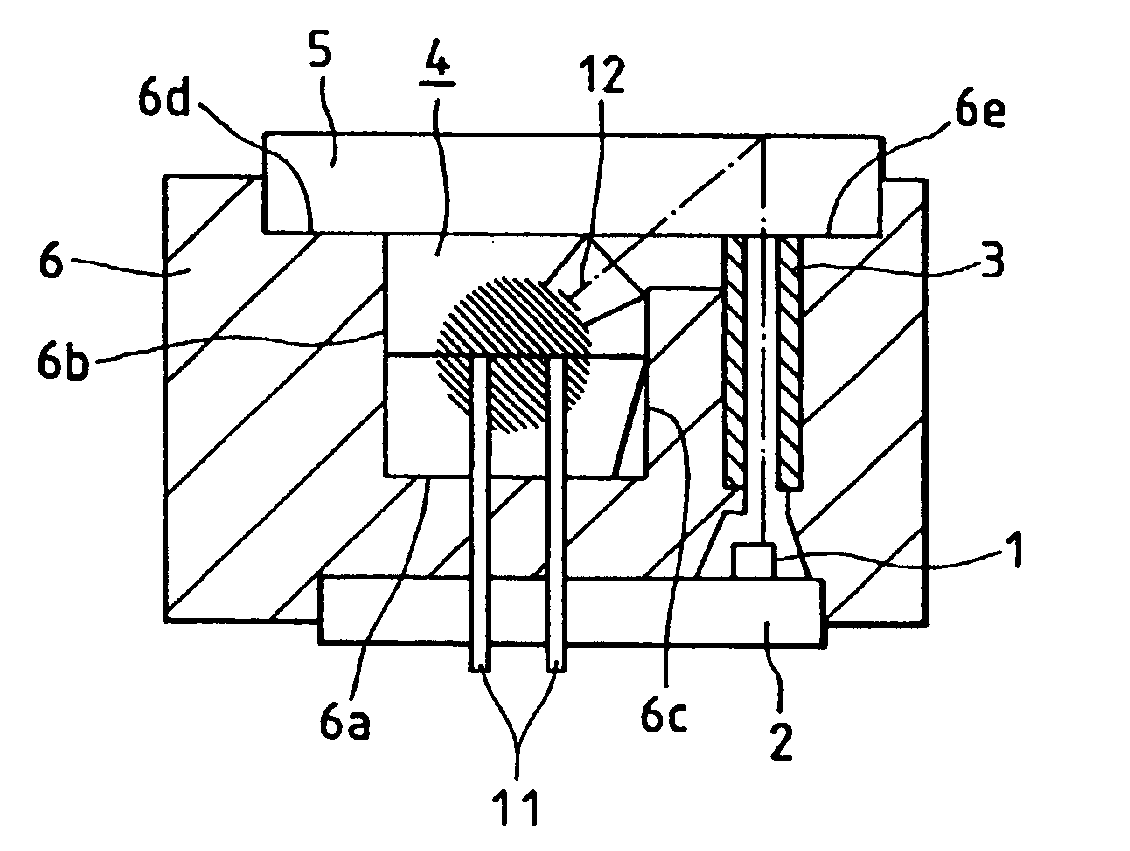

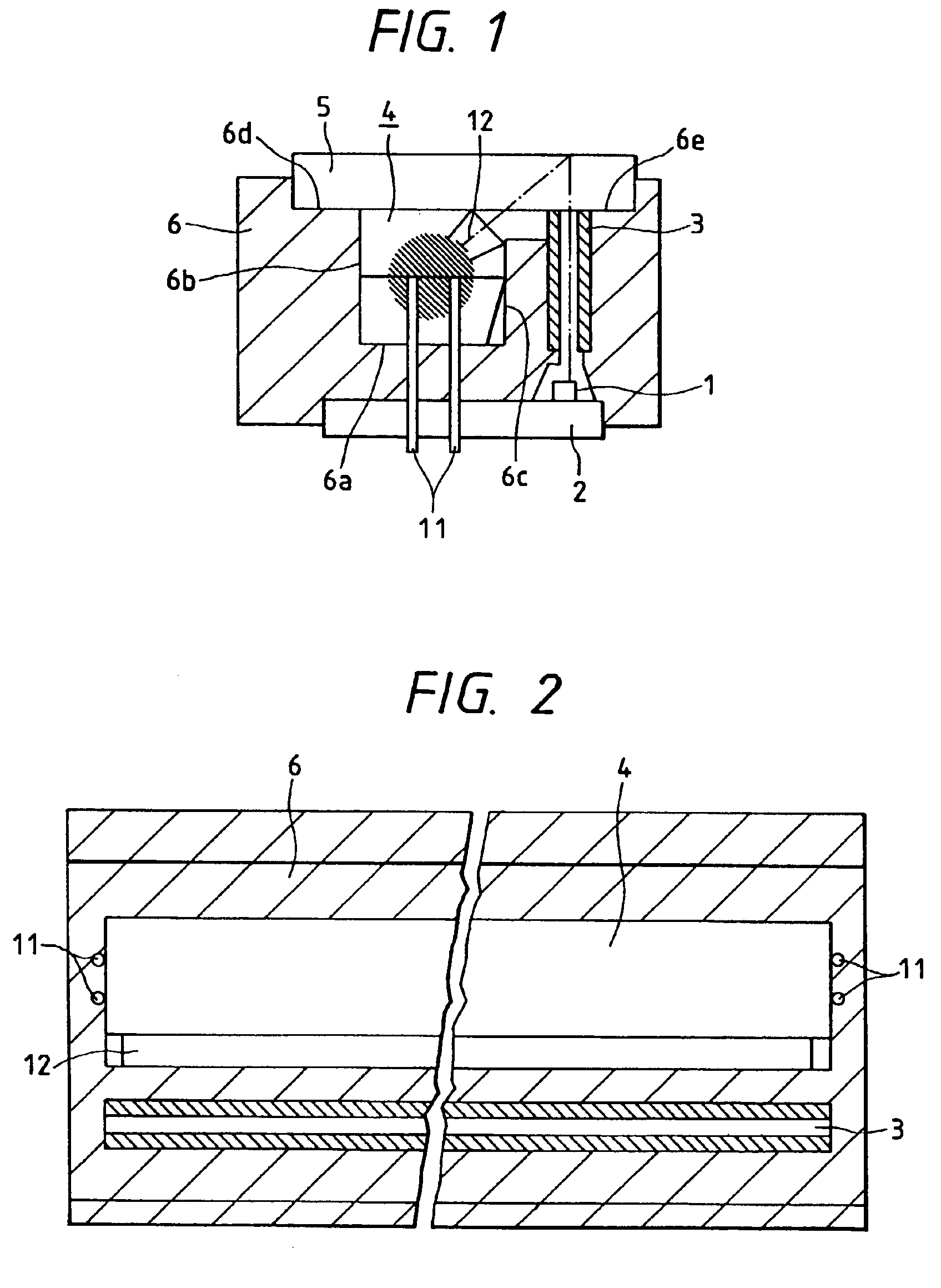

Surgical Instrument

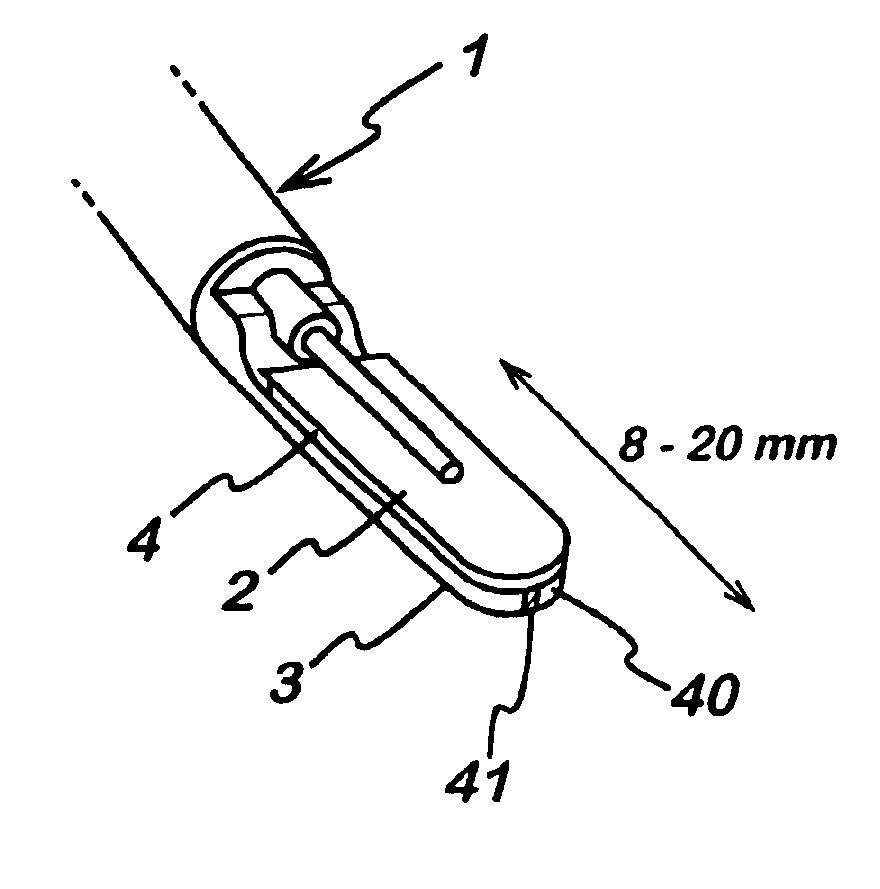

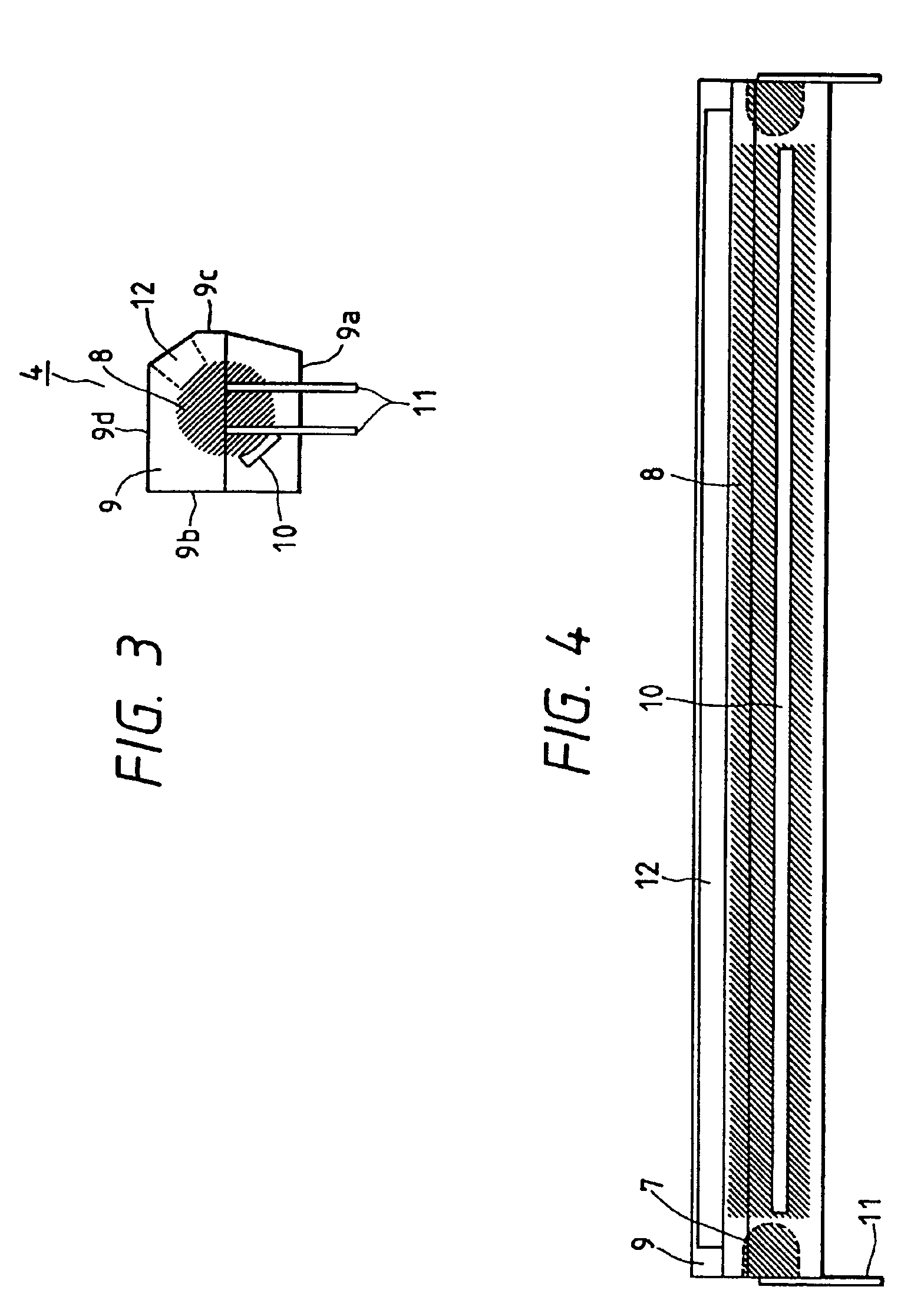

InactiveUS6942662B2High initial impedanceInitial impedanceSurgical instruments for heatingActive electrodeSurgical device

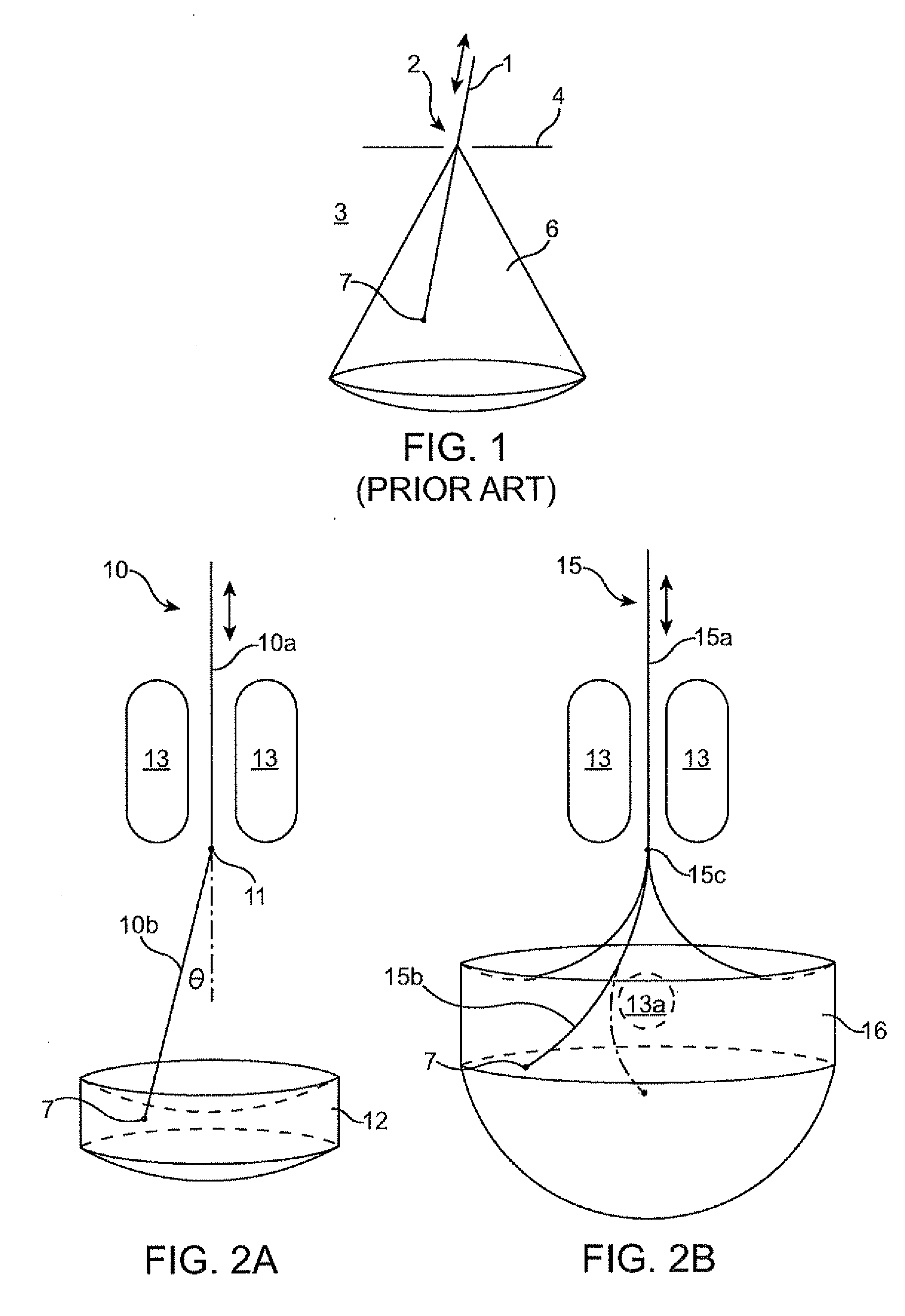

An electrosurgical cutting blade (1) comprises a first electrode (2), a second electrode (3), and an electrical insulator (4) separating the first and second electrodes. The first and second electrodes have dissimilar characteristics (cross-sectional area, thermal conductivity etc.) such that the first electrode (2) is encouraged to become an active electrode and the second electrode (3) is encouraged to become a return electrode. The spacing between the first and second electrodes (between 0.25 mm and 3.0 mm) and the peak voltage supplied to the electrodes (2 and 3) are both selected such that arcing does not occur directly between the electrodes, but between the first electrode and the tissue at the target site. The arrangement is such that, in use, a thermal differential of at least 50° C. is established between the first and second electrodes (2 and 3), such that the second electrode is maintained below a temperature of 70° C. This is achieved either by thermally insulating the second electrode from the first electrode, and / or by transferring heat away from the second electrode, e.g. by conduction, forced cooling, or by means of a heat pipe (27).

Owner:GYRUS MEDICAL LTD +1

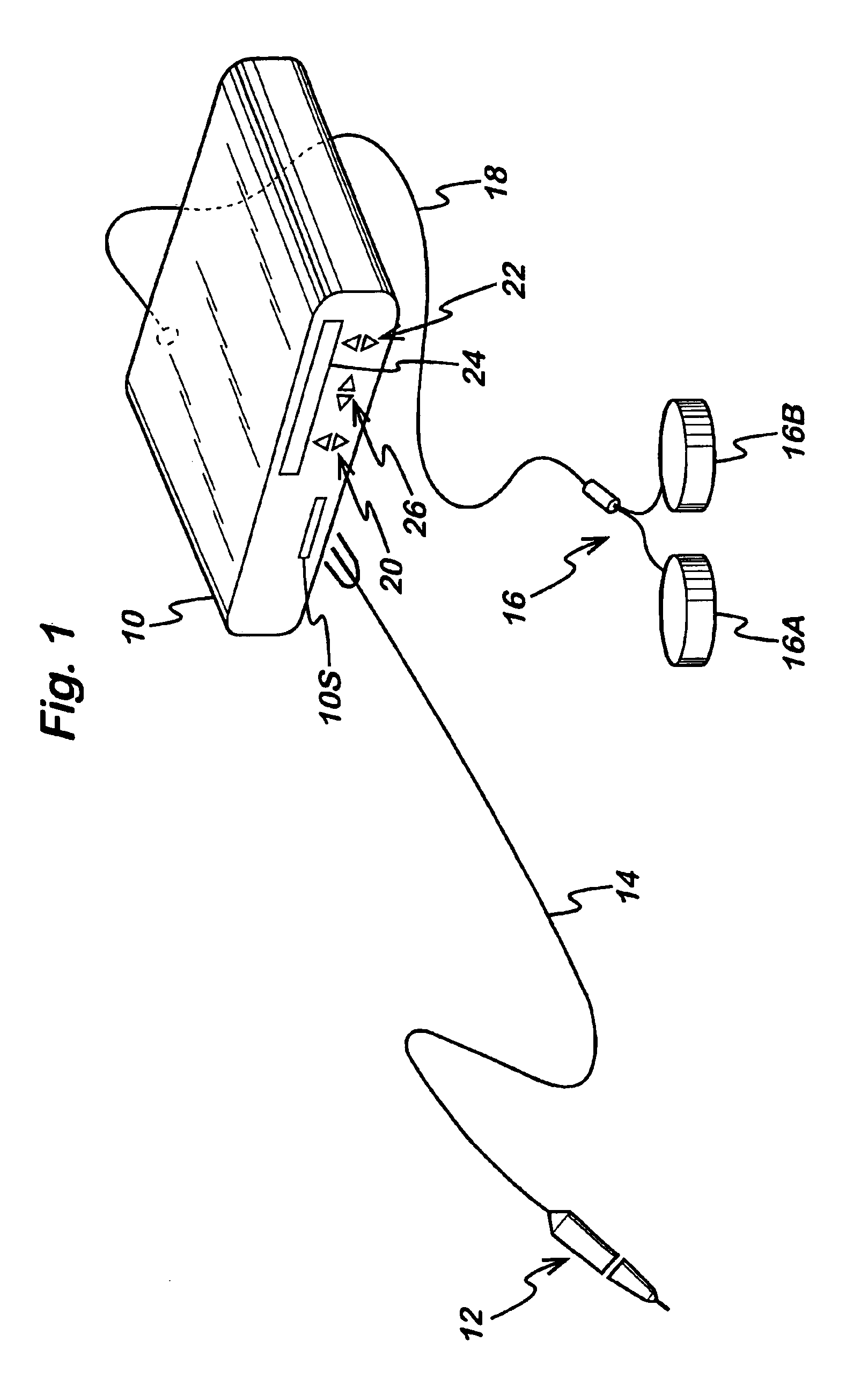

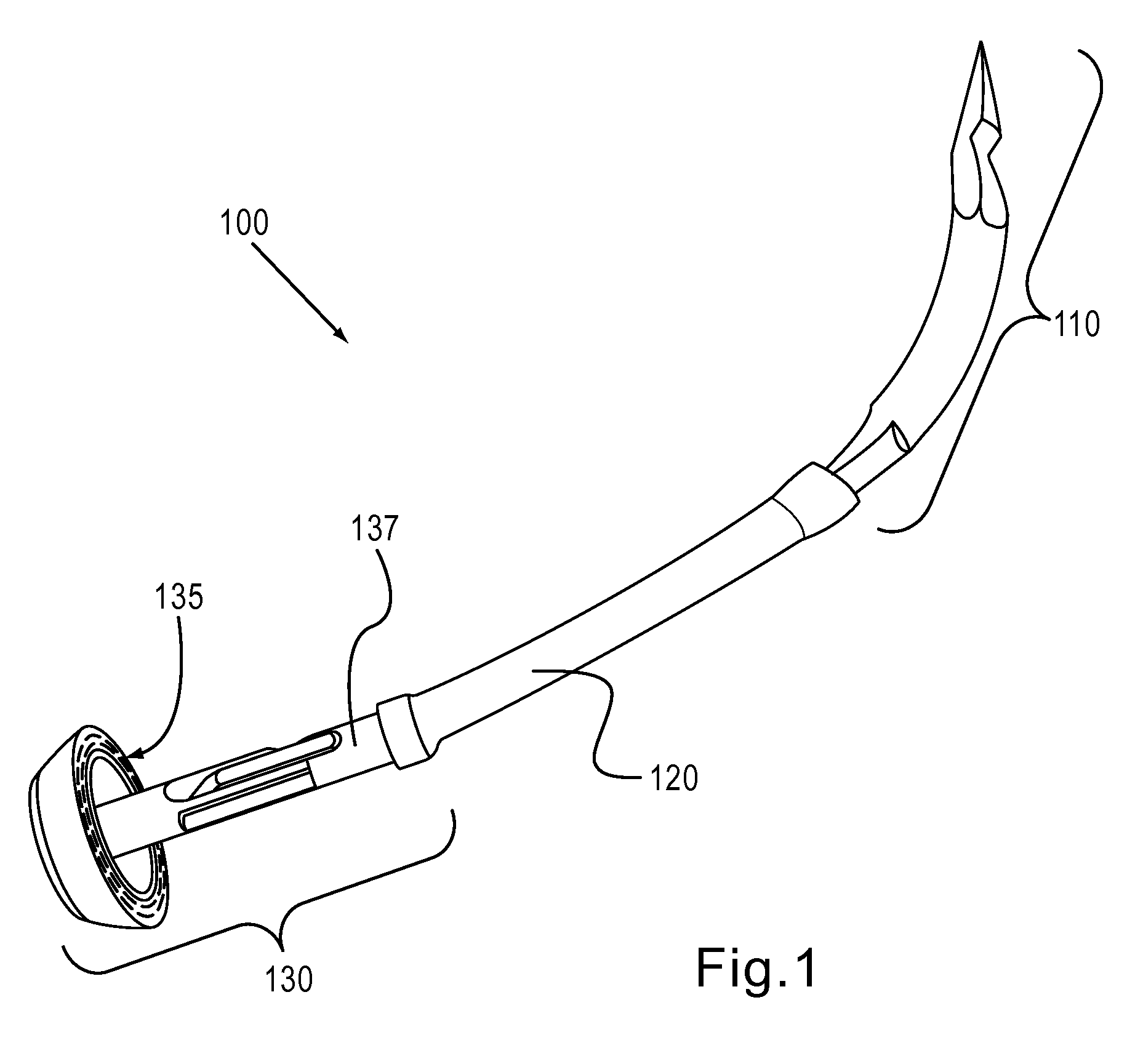

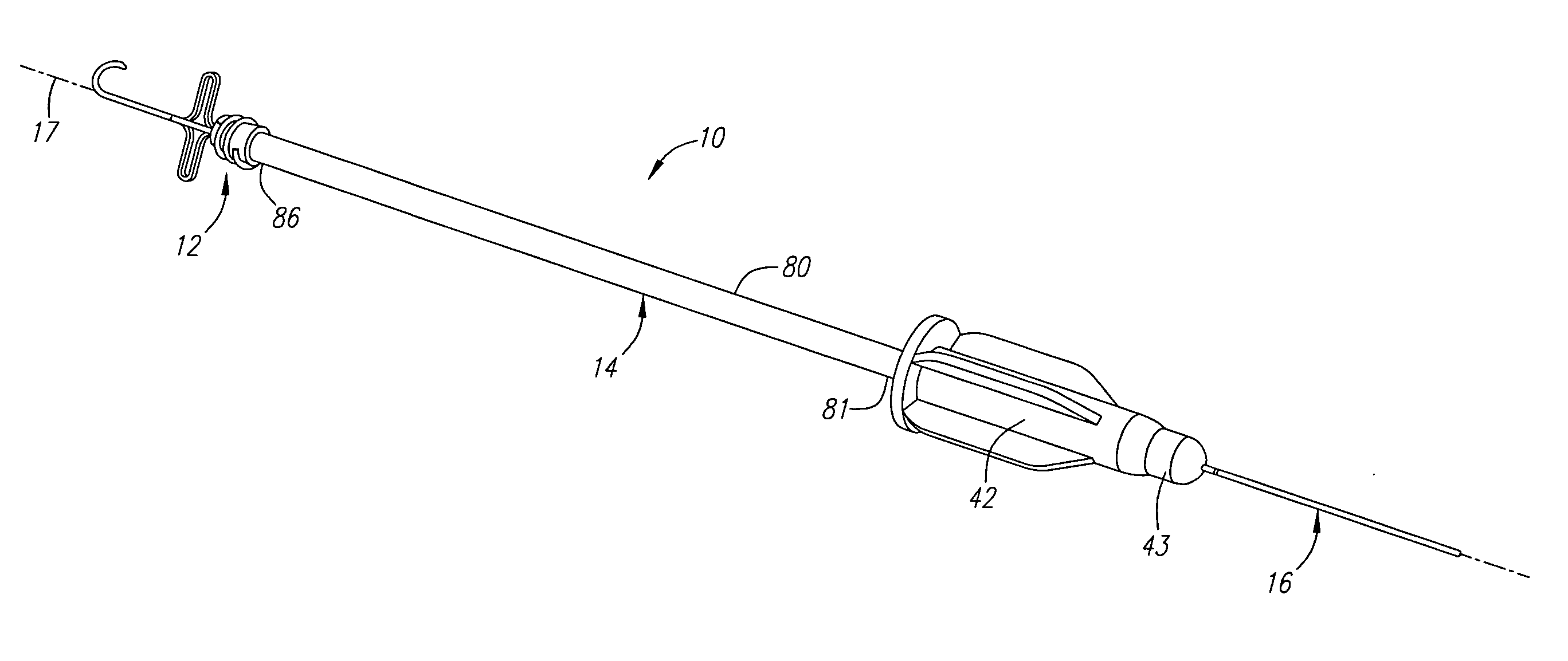

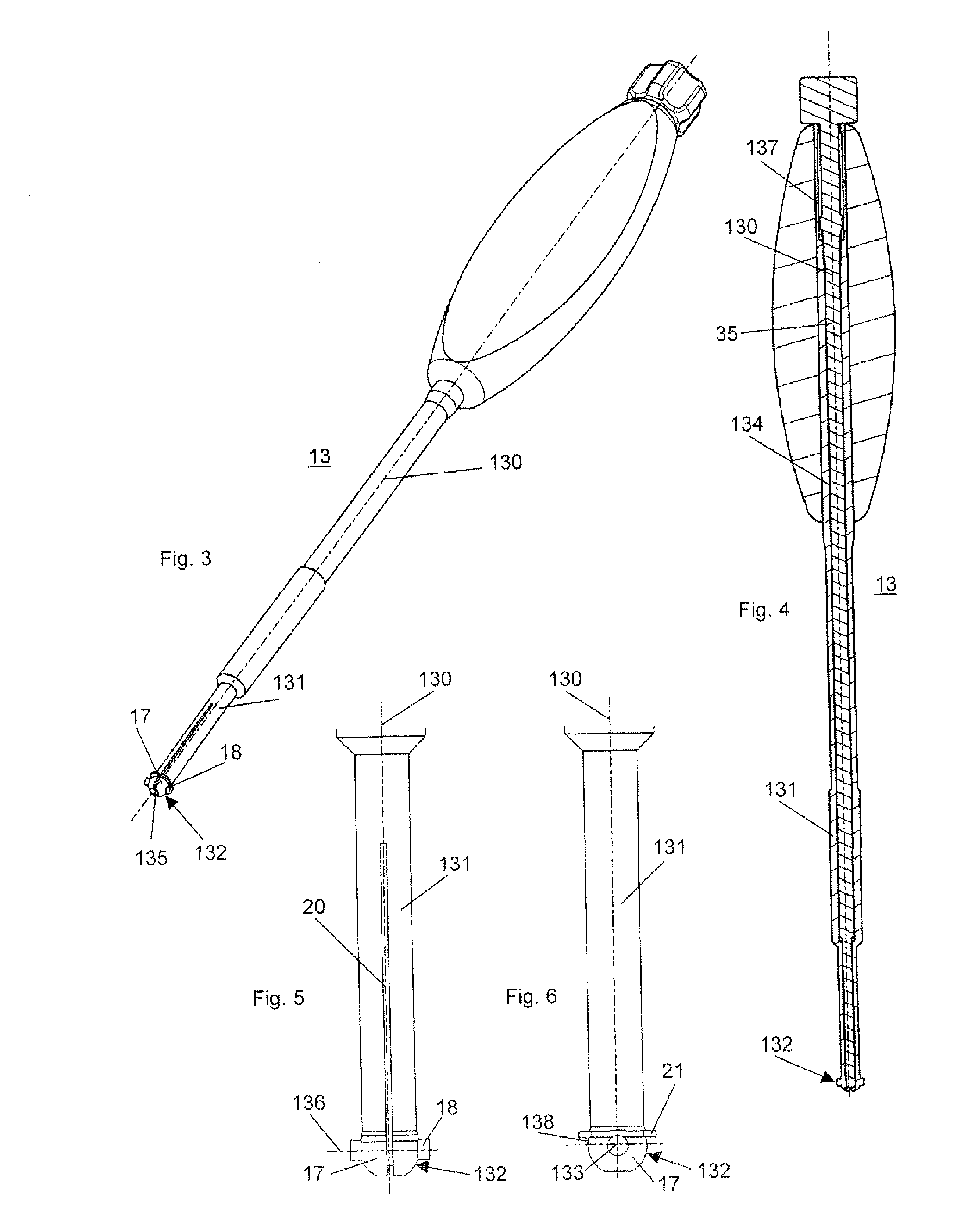

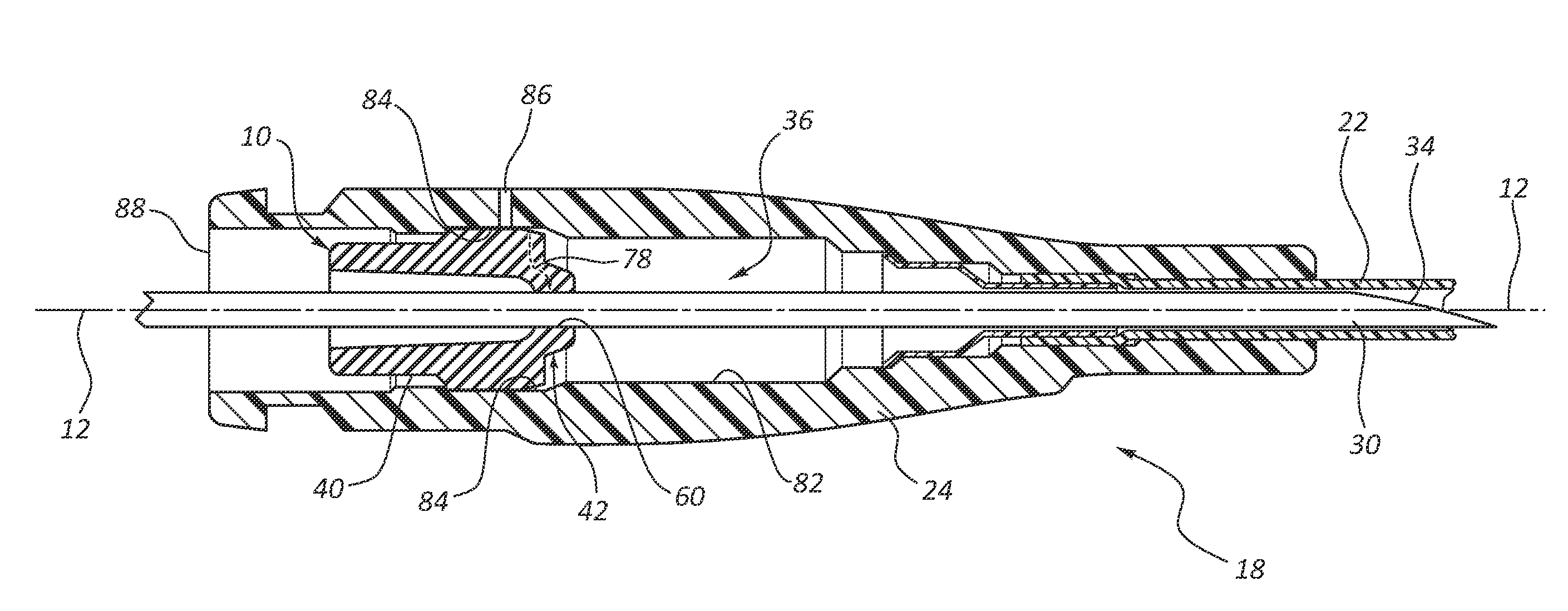

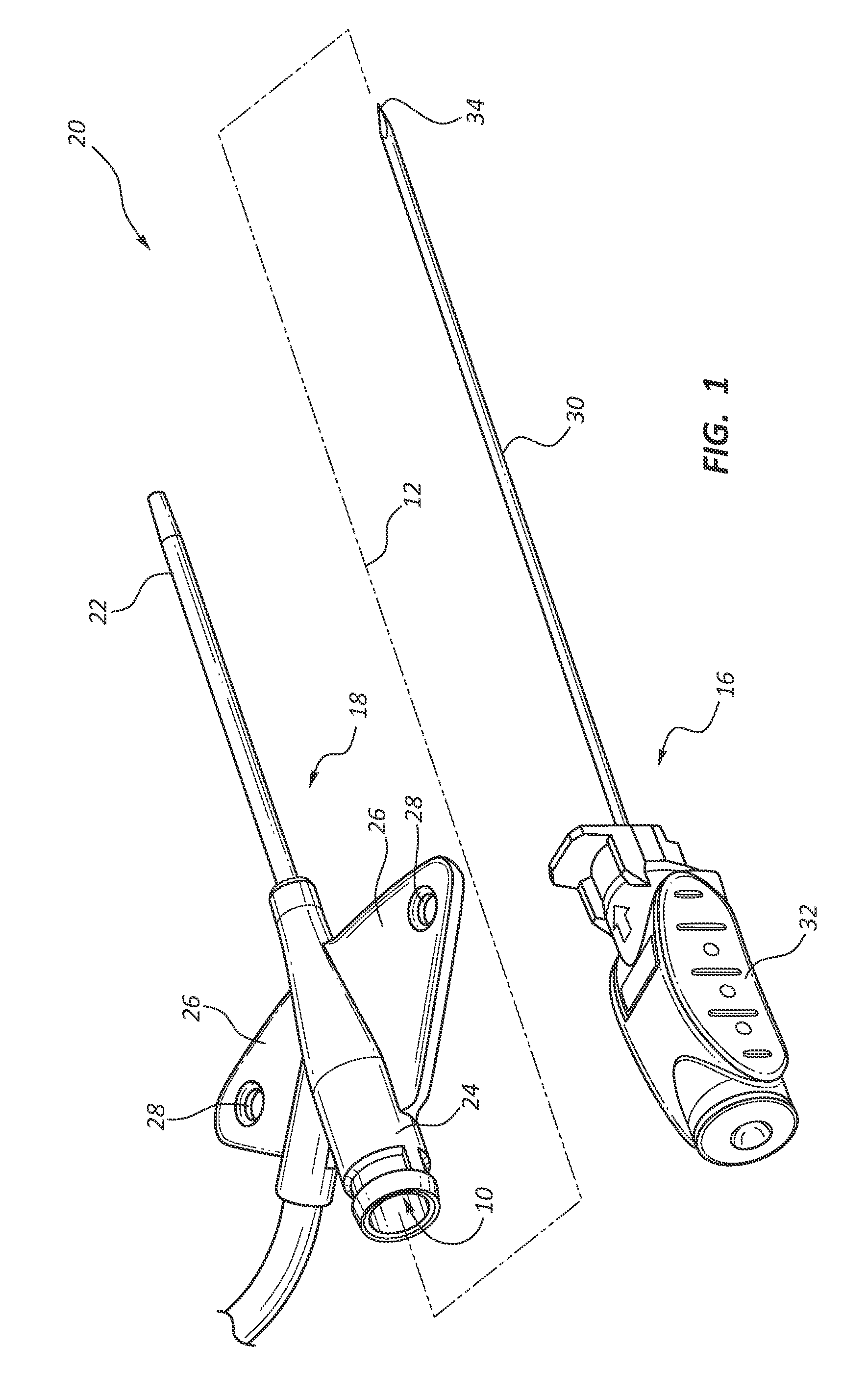

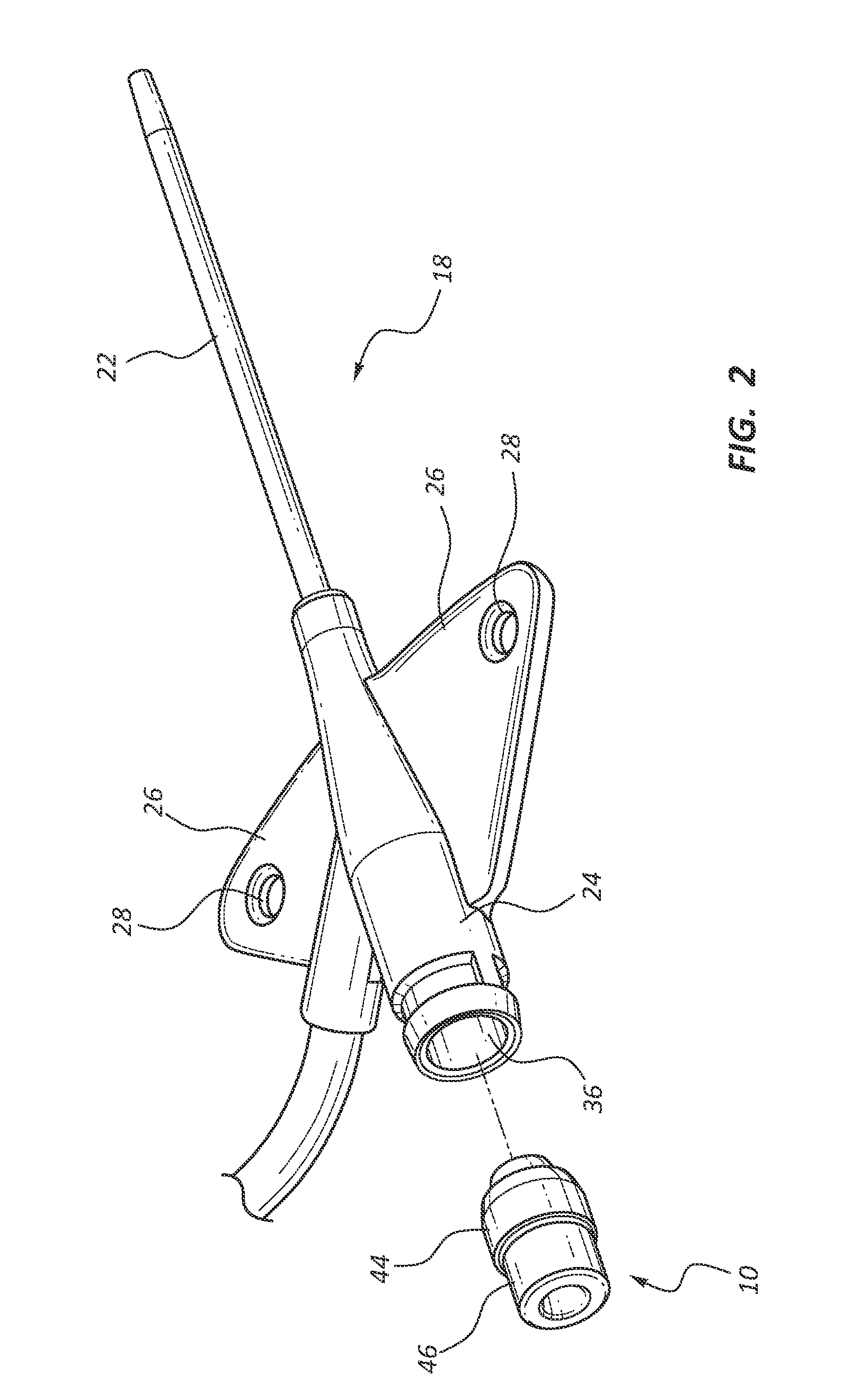

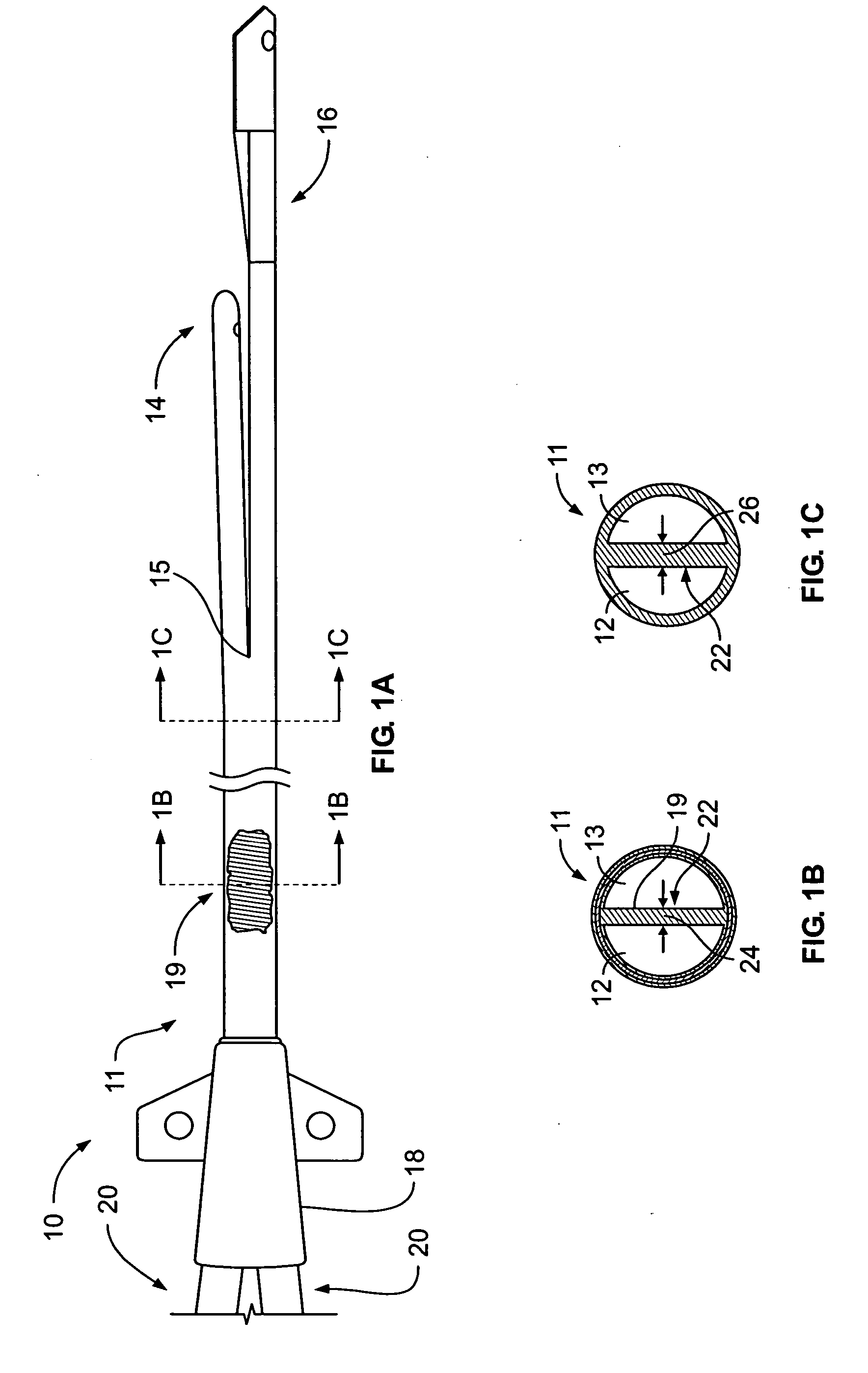

Laparoscopic gastric and intestinal trocar

InactiveUS8795308B2Easy to holdReduce the cross-sectional areaInfusion syringesSurgical needlesDistal portionSurgery

A trocar needle includes an elongate body having a distal end portion and a proximal end portion, a penetrating tip formed at the distal end portion of the body, and an attachment portion formed at the proximal end portion for attaching a tether thereto. A grip region can further be provided and can be formed for example, at the proximal end portion of the body to facilitate gripping by a surgical grasping device. Additionally or alternatively, a notch or otherwise reduced cross-sectional area can be provided. Such a feature can be formed, for example, at the distal end portion of the body, arranged proximal from a distal end thereof for enhancing haptic perception by a surgeon when utilizing the needle.

Owner:VALIN ELMER

Surgical templates

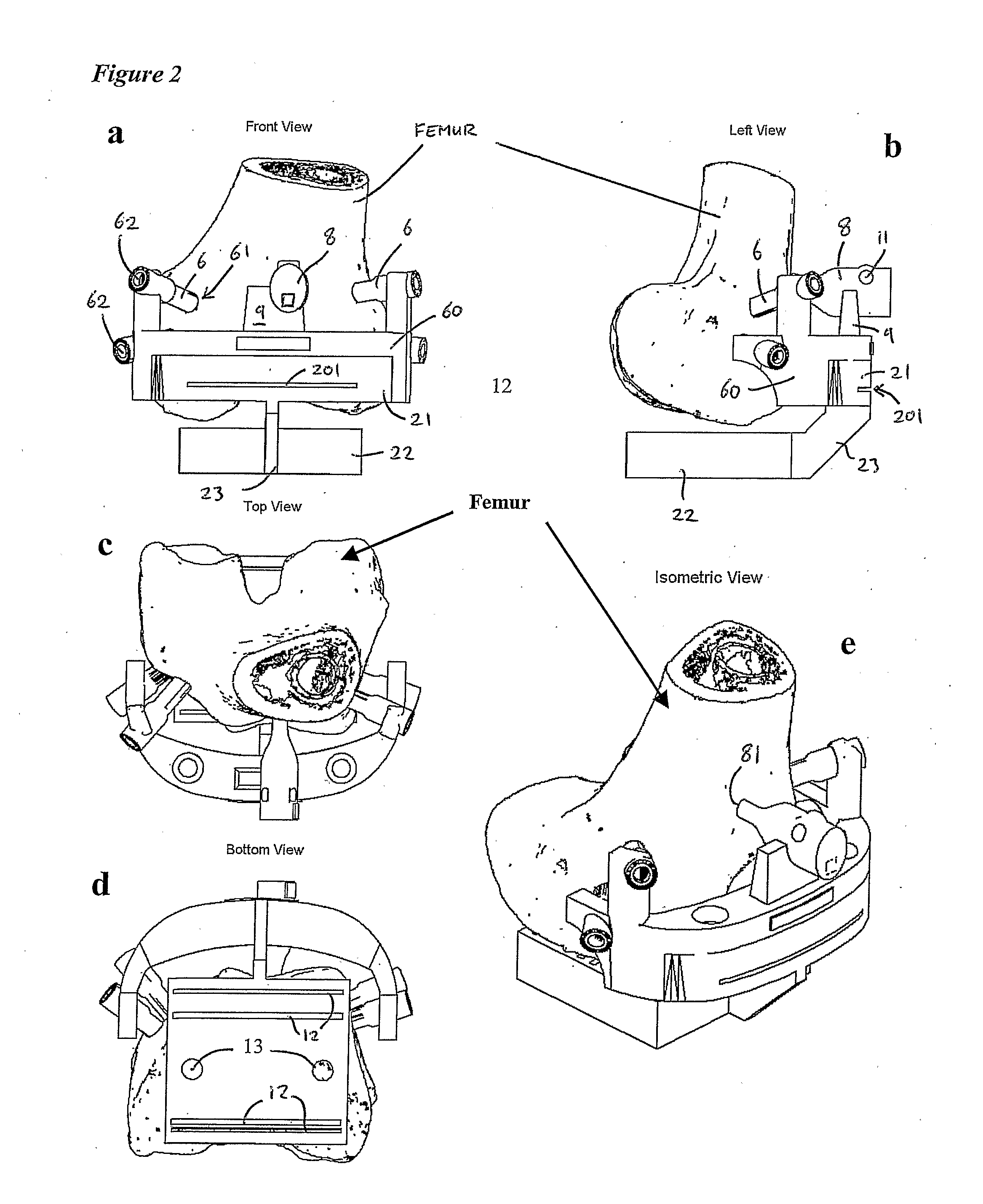

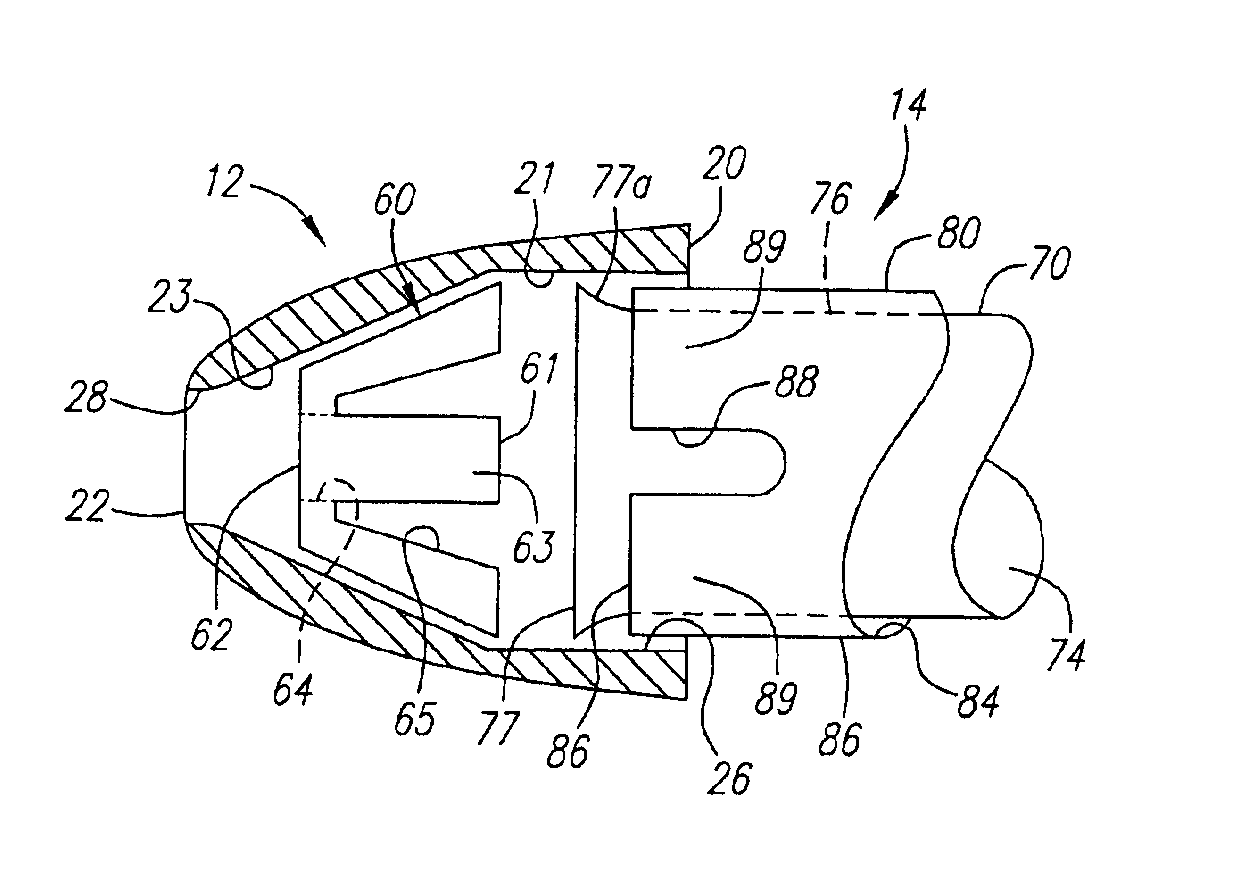

ActiveUS20100191244A1Quick checkShort timeAdditive manufacturing apparatusDiagnosticsProsthesisSurgical template

A surgical template system for use in working on a bone comprises: a tool guide block comprising at least one guide aperture for receiving and guiding a tool to work on a bone; locating means comprising a plurality of locating members, each member having a respective end surface for positioning against a surface of the bone; and attachment means for non-adjustably attaching the tool guide block to the locating means such that, when attached, the member end surfaces are secured in fixed position with, respect to each other, for engaging different respective portions of the surface of the bone, and the at least one guide aperture is secured in a fixed position with respect to the end surfaces. Corresponding methods of manufacturing a surgical template system, methods of manufacturing locating means for a surgical template system, methods of fitting a prosthesis to a bone, surgical methods, and surgical apparatus are described.

Owner:XIROS

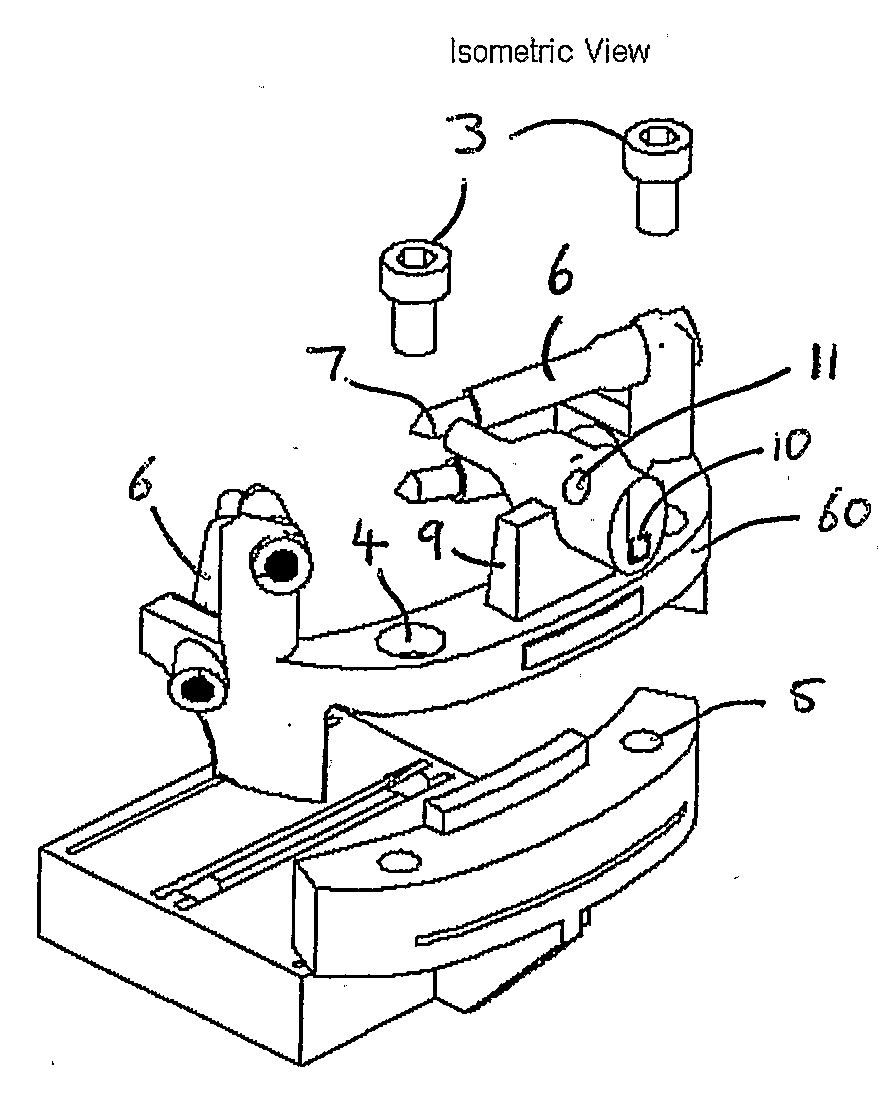

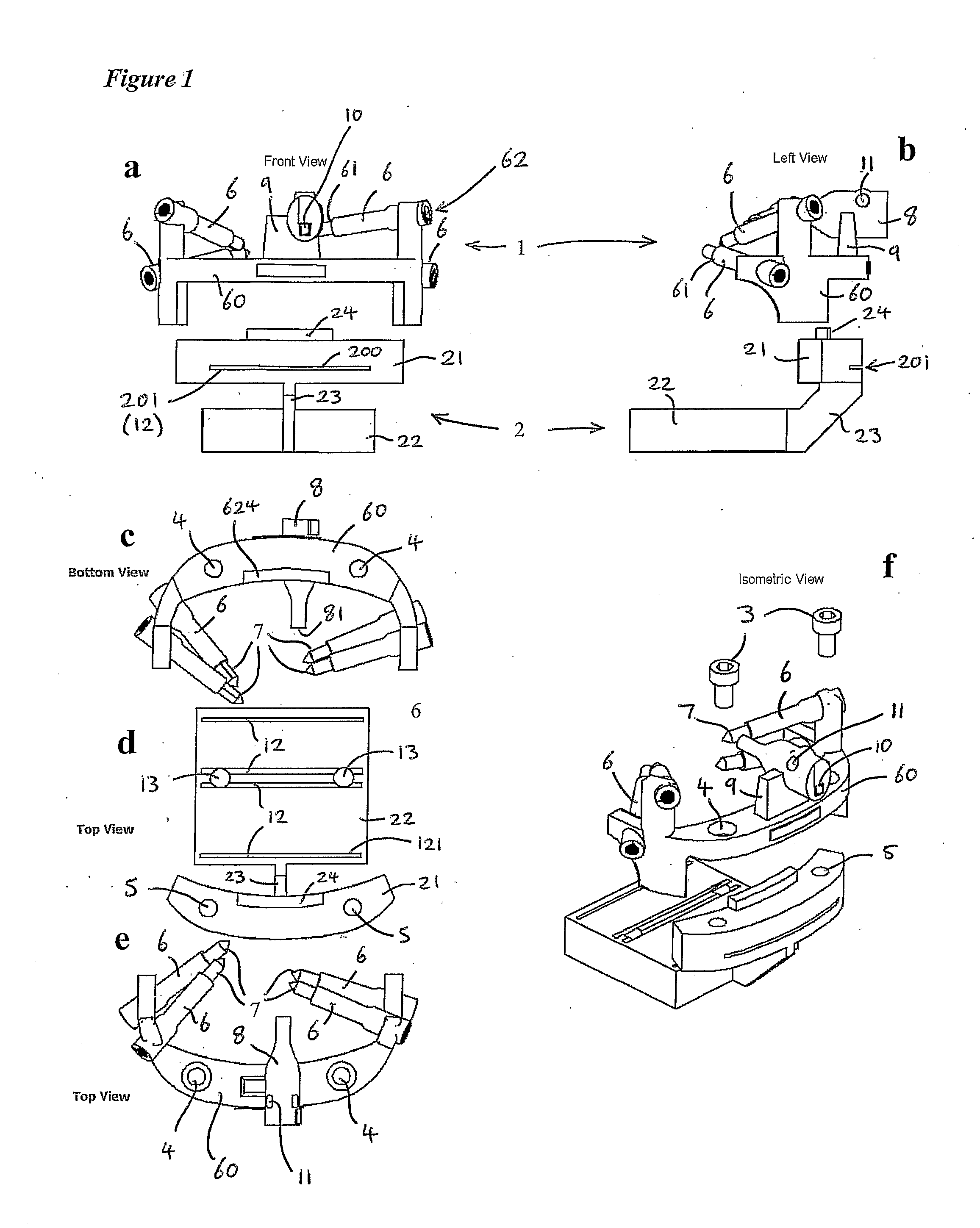

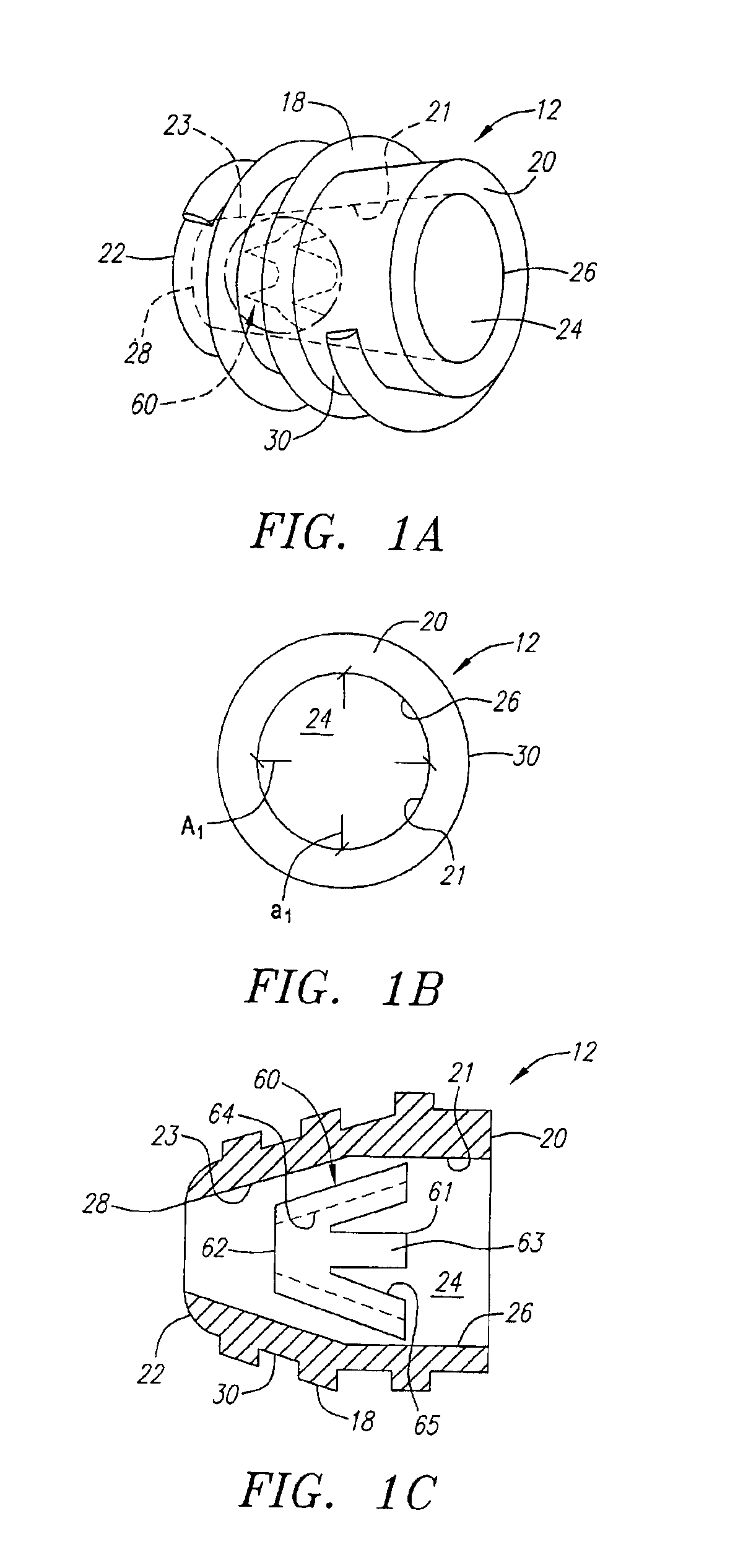

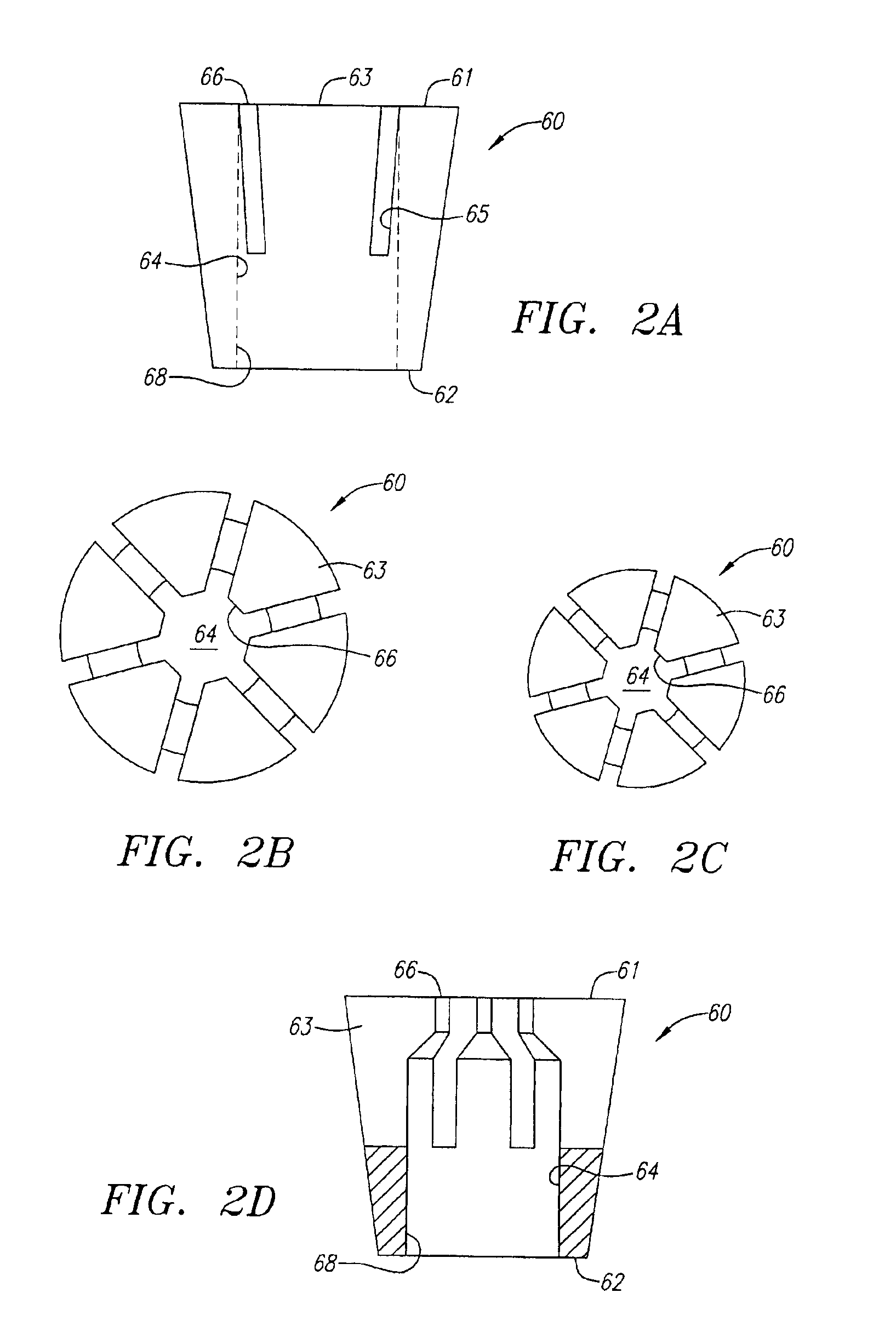

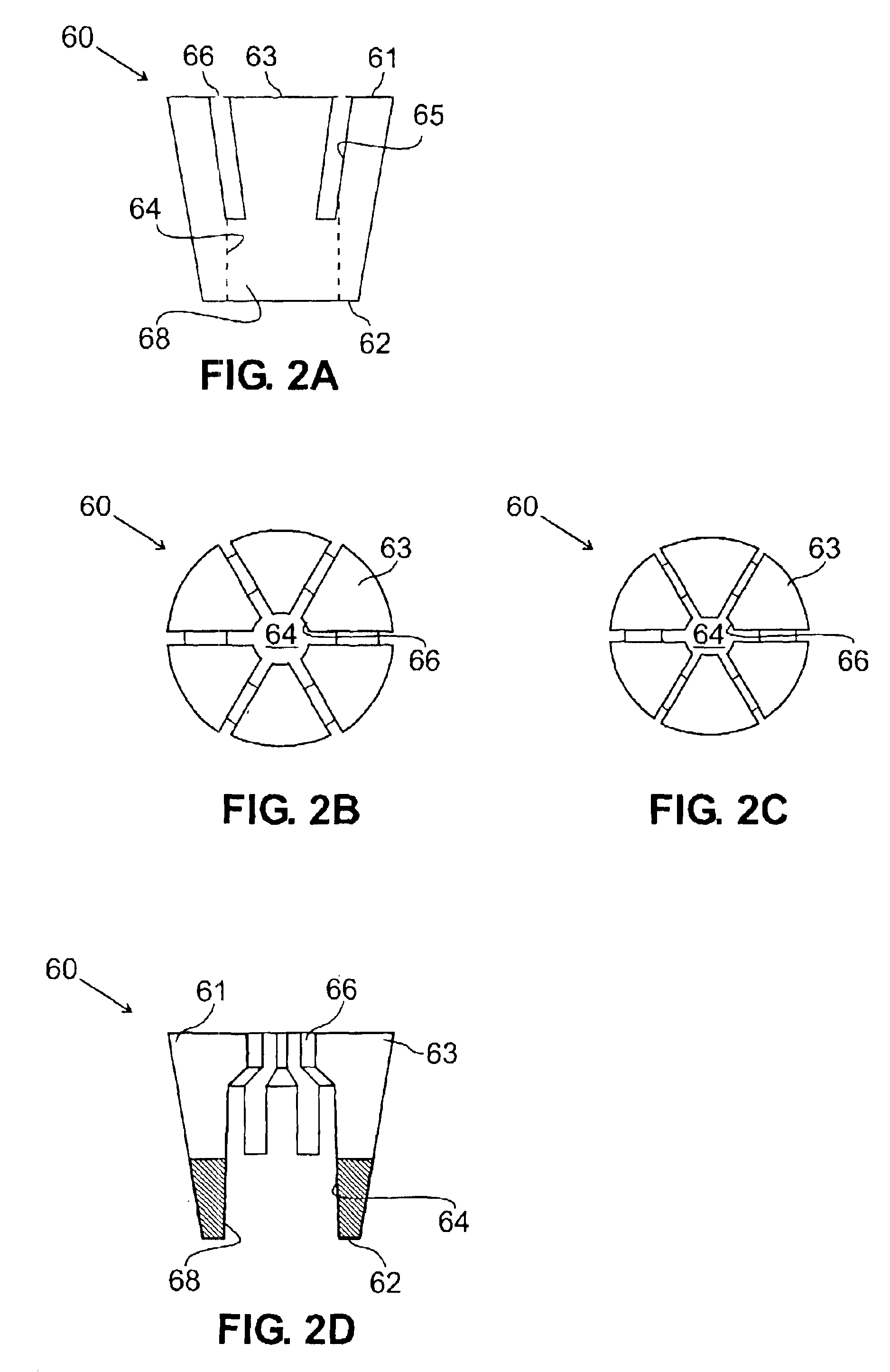

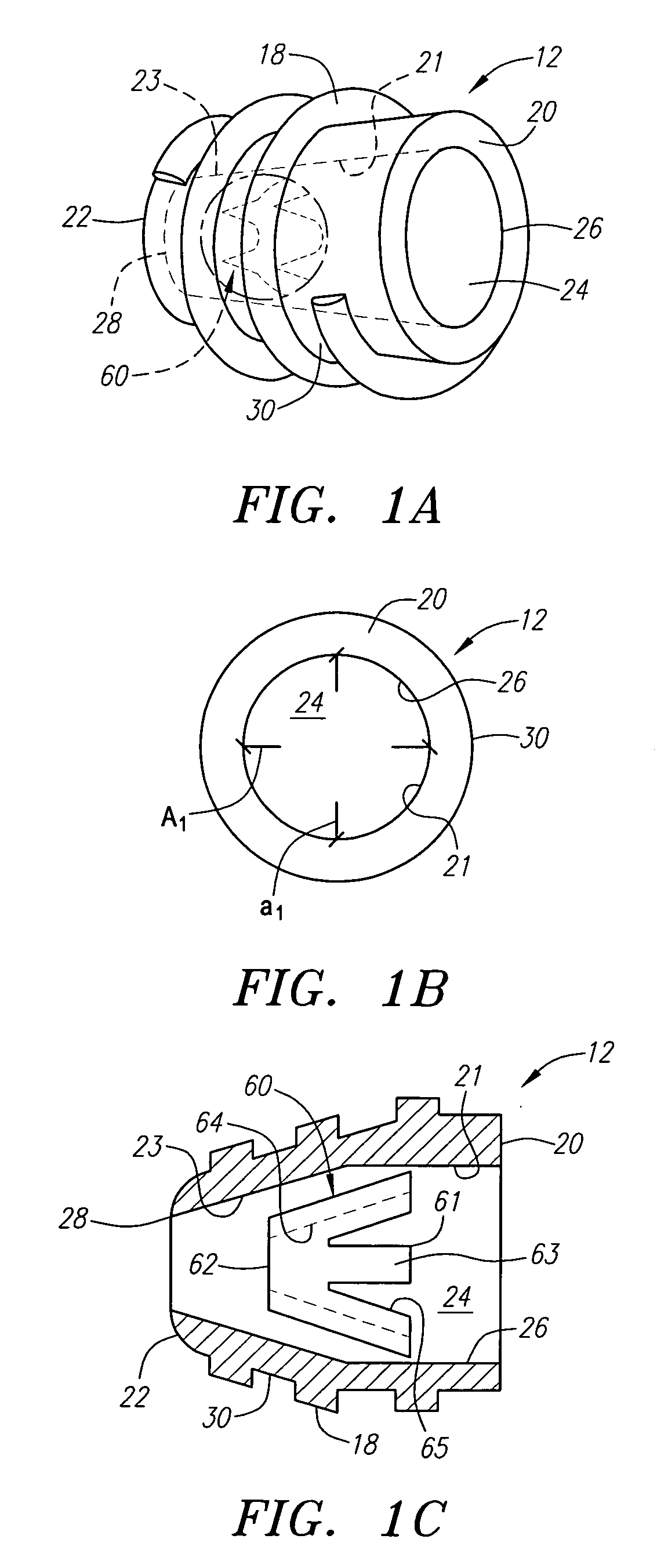

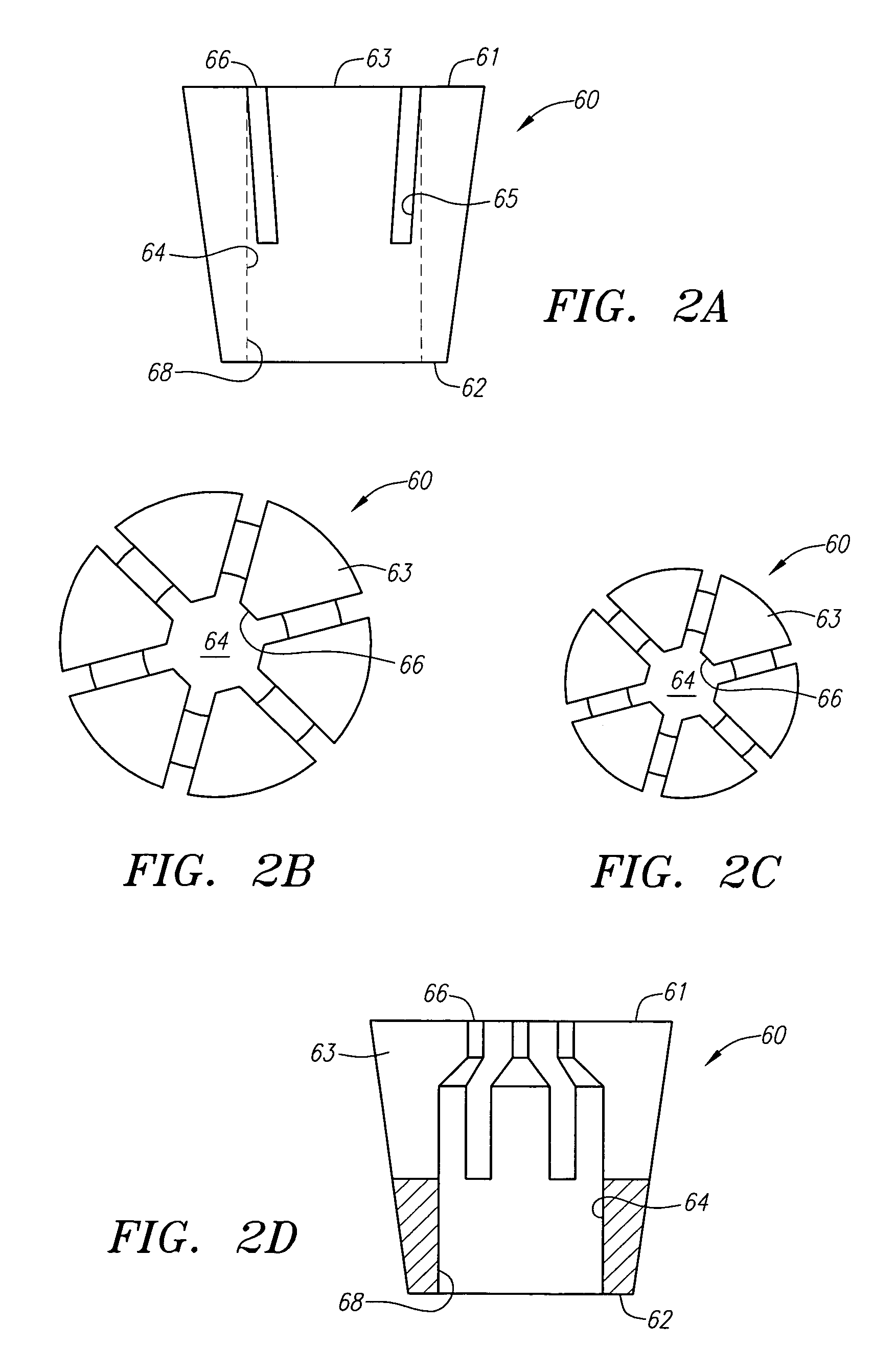

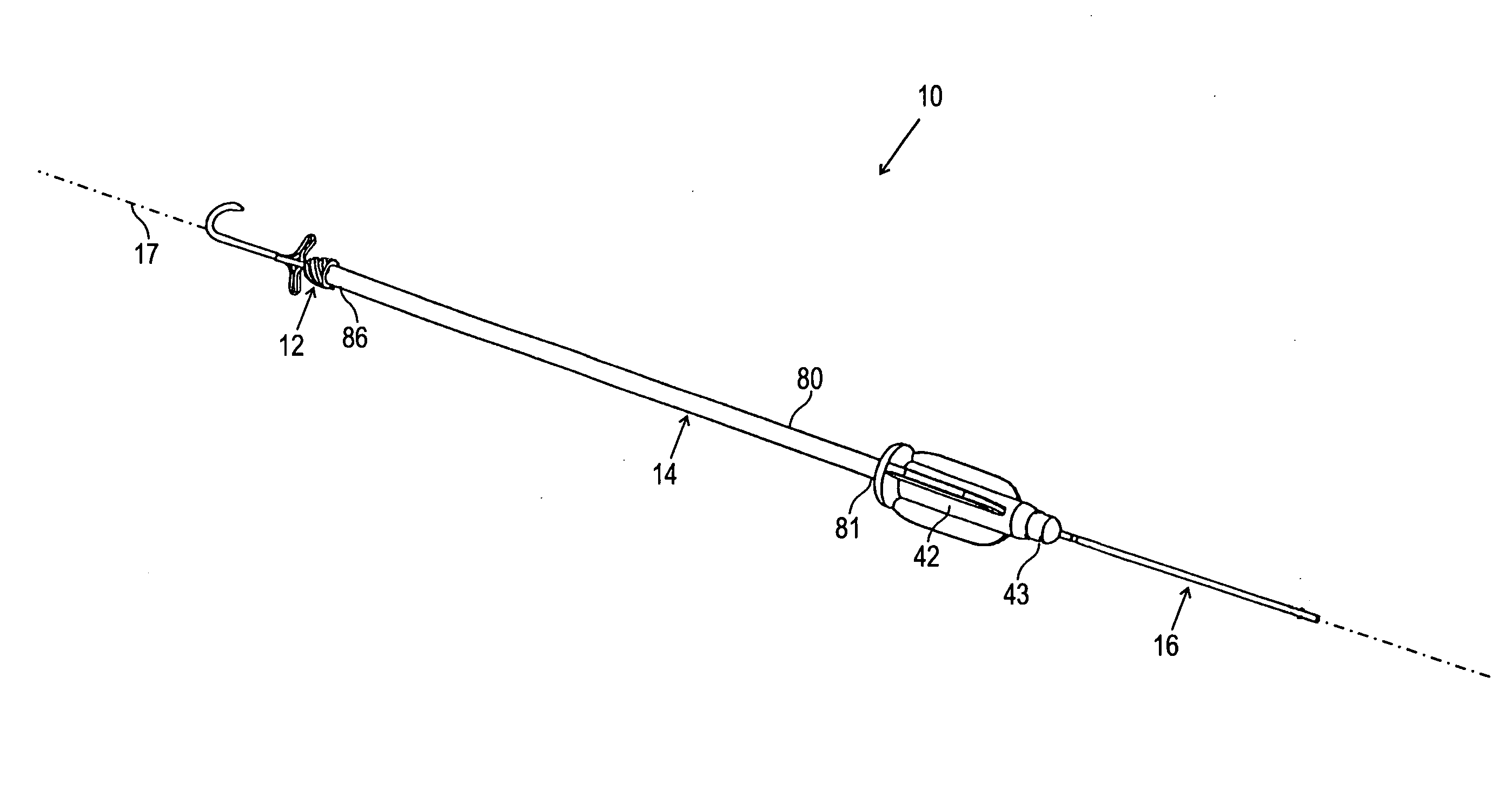

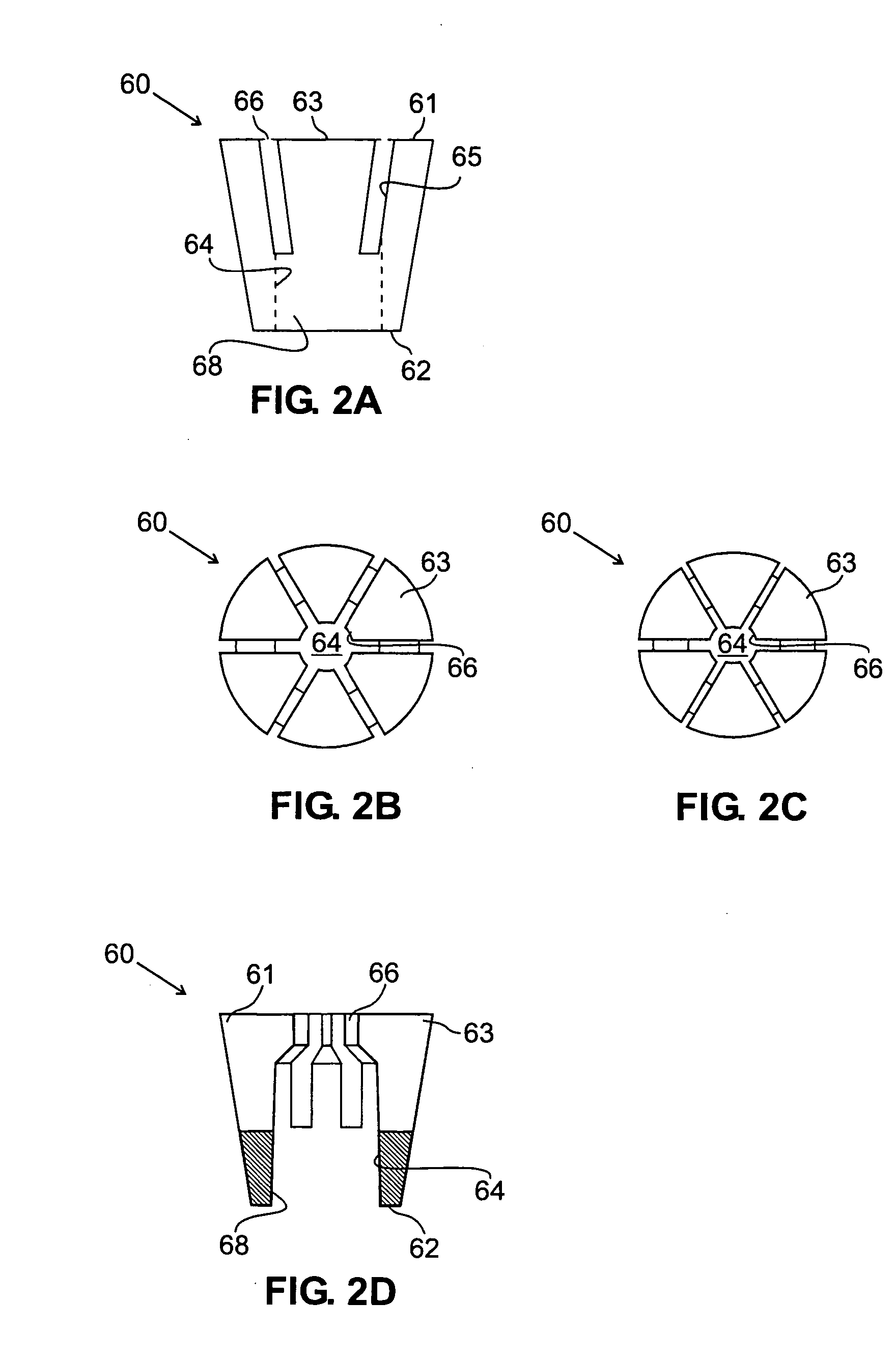

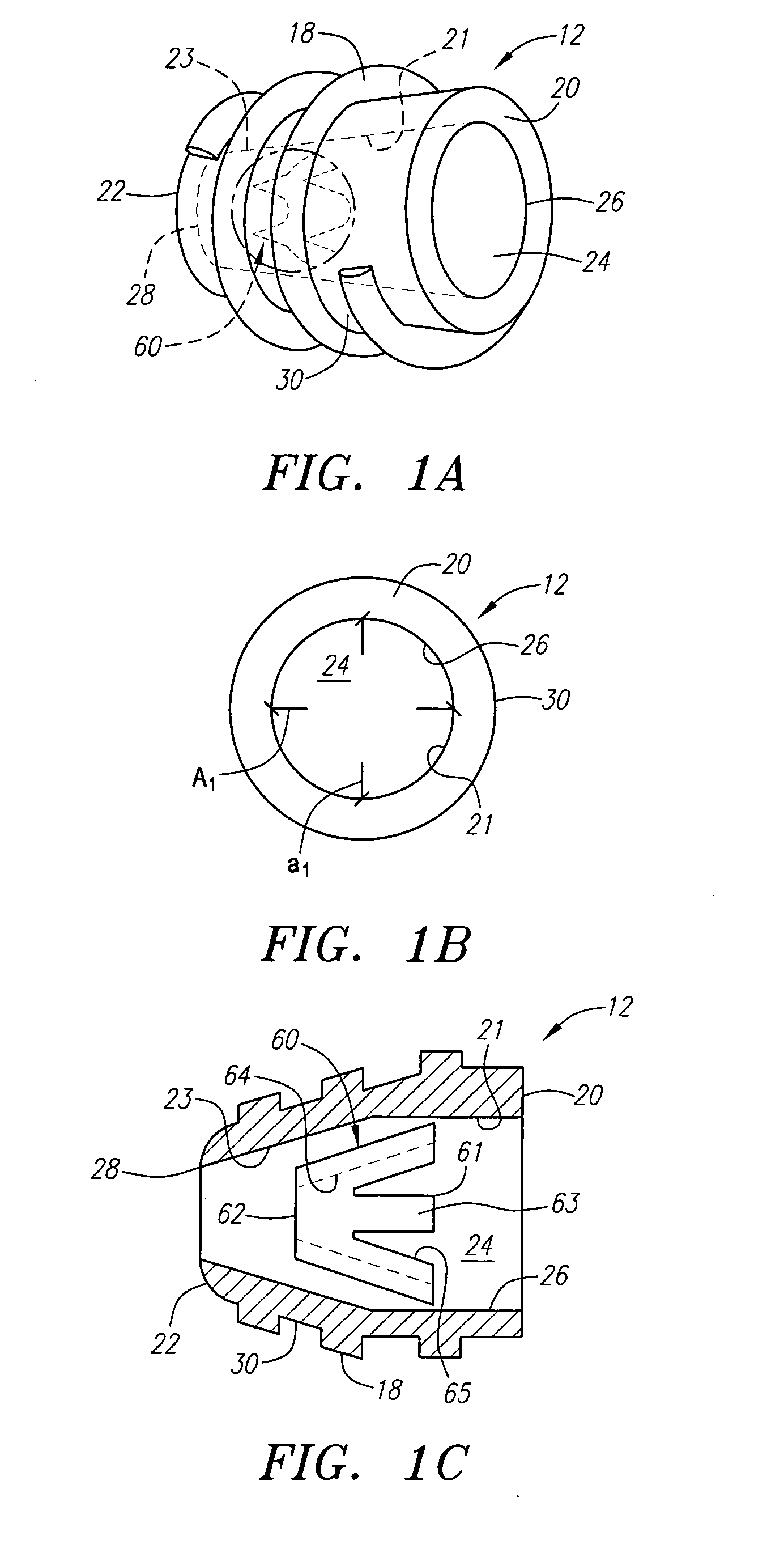

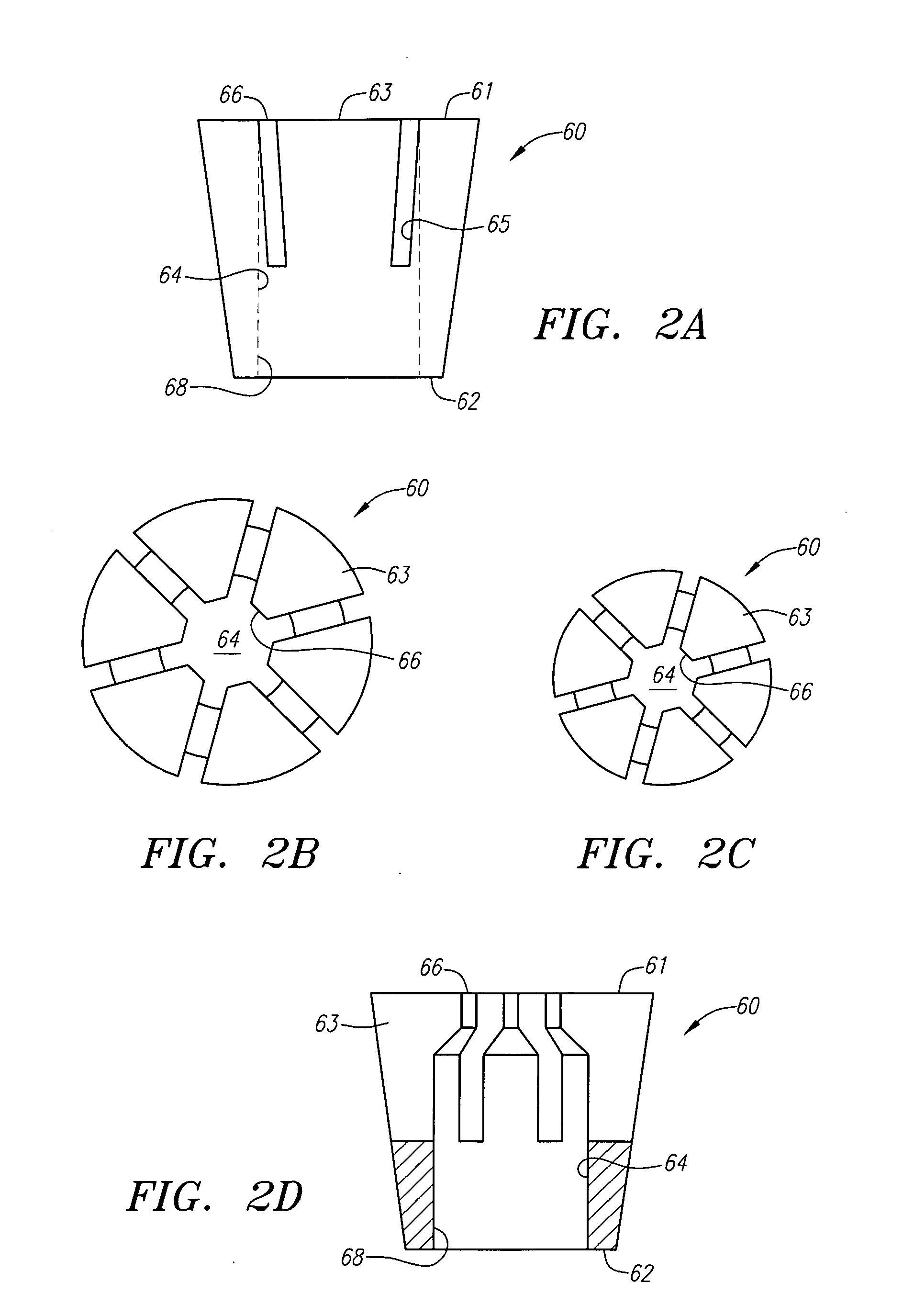

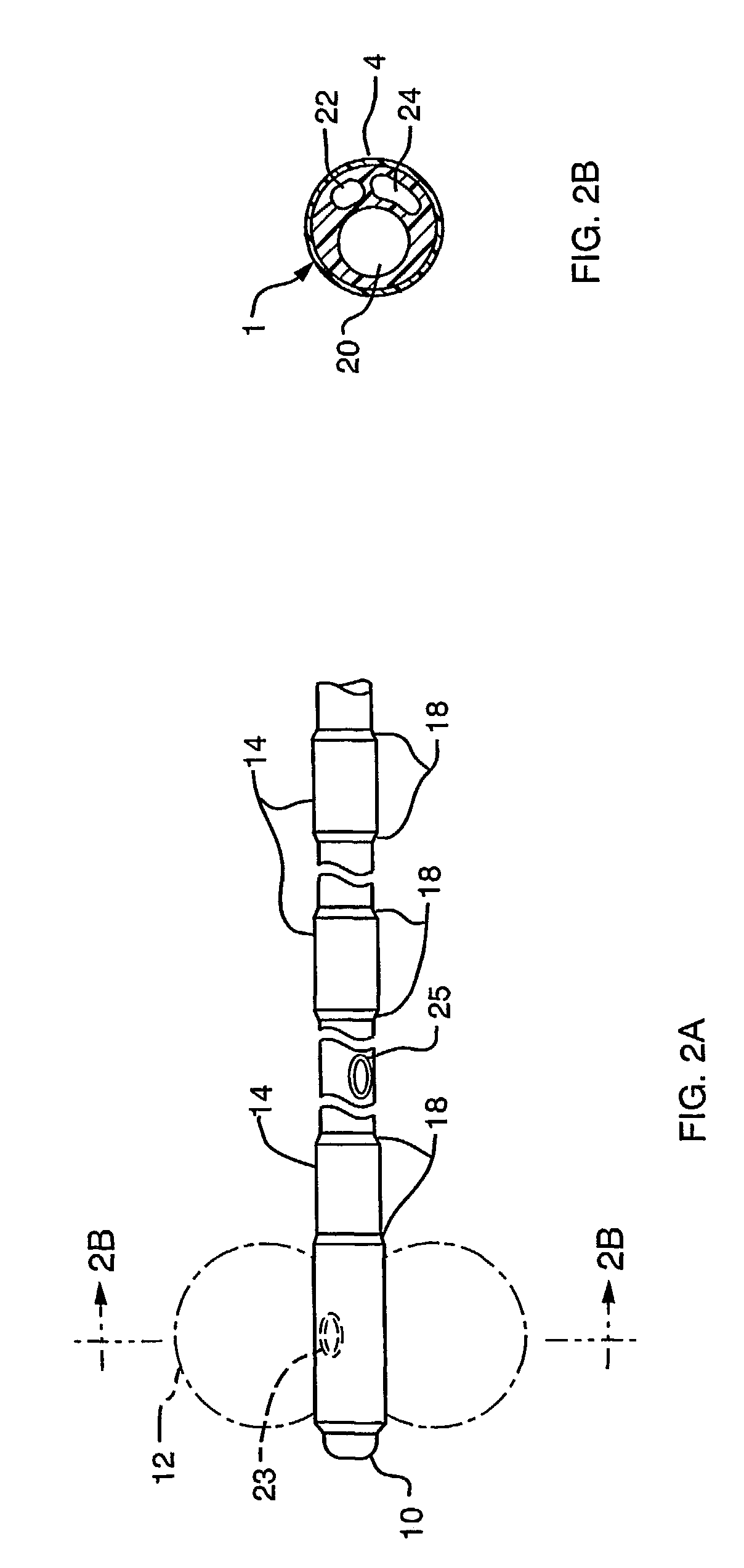

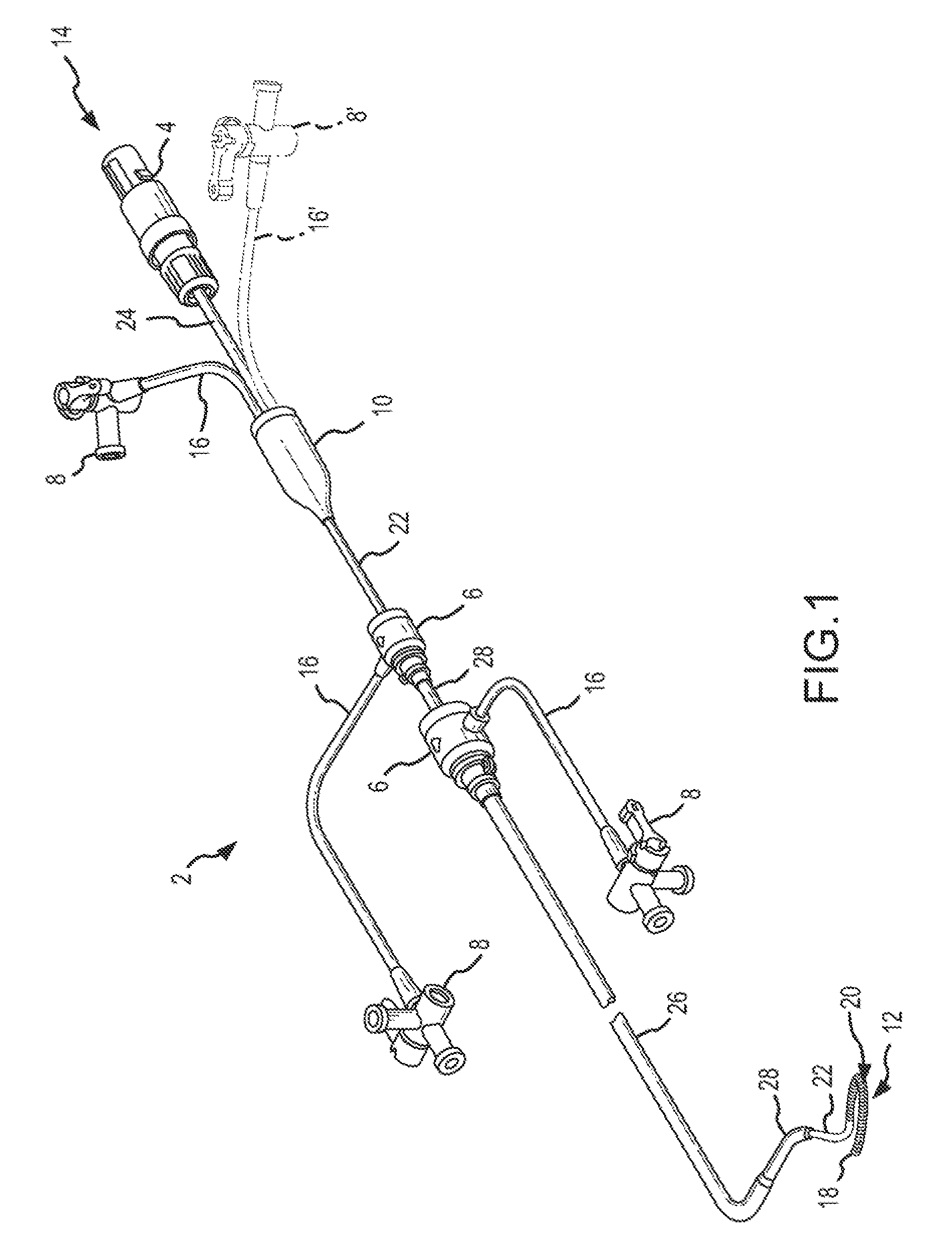

Plug with collet and apparatus and method for delivering such plugs

InactiveUS6896692B2Low profilePromote progressVaccination/ovulation diagnosticsTubular organ implantsEngineeringGuide wires

An apparatus for sealing a passage through tissue includes a plug including external threads, a lumen extending between its proximal and distal ends, and an annular collet slidably disposed within the lumen. The plug is carried on a distal end of a handle device that includes an inner member with a distal end that is slidable axially within the lumen of the body for moving the collet into a reduced cross-sectional region of the lumen, thereby compressing the collet to seal the lumen, and for deploying the plug from the handle device. During use, the plug is threaded into a passage through tissue over a guide wire. Once a desired location is reached, the plug is deployed from the handle device, thereby compressing the collet and sealing the lumen. The guide wire and handle device are removed, leaving the plug to seal the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

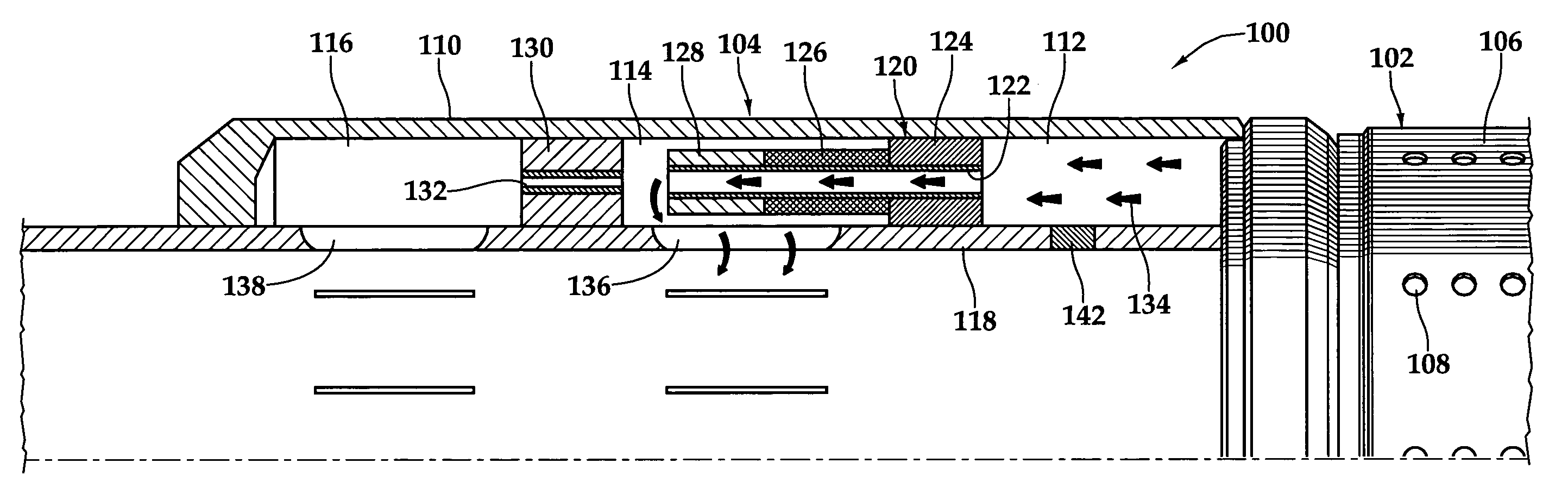

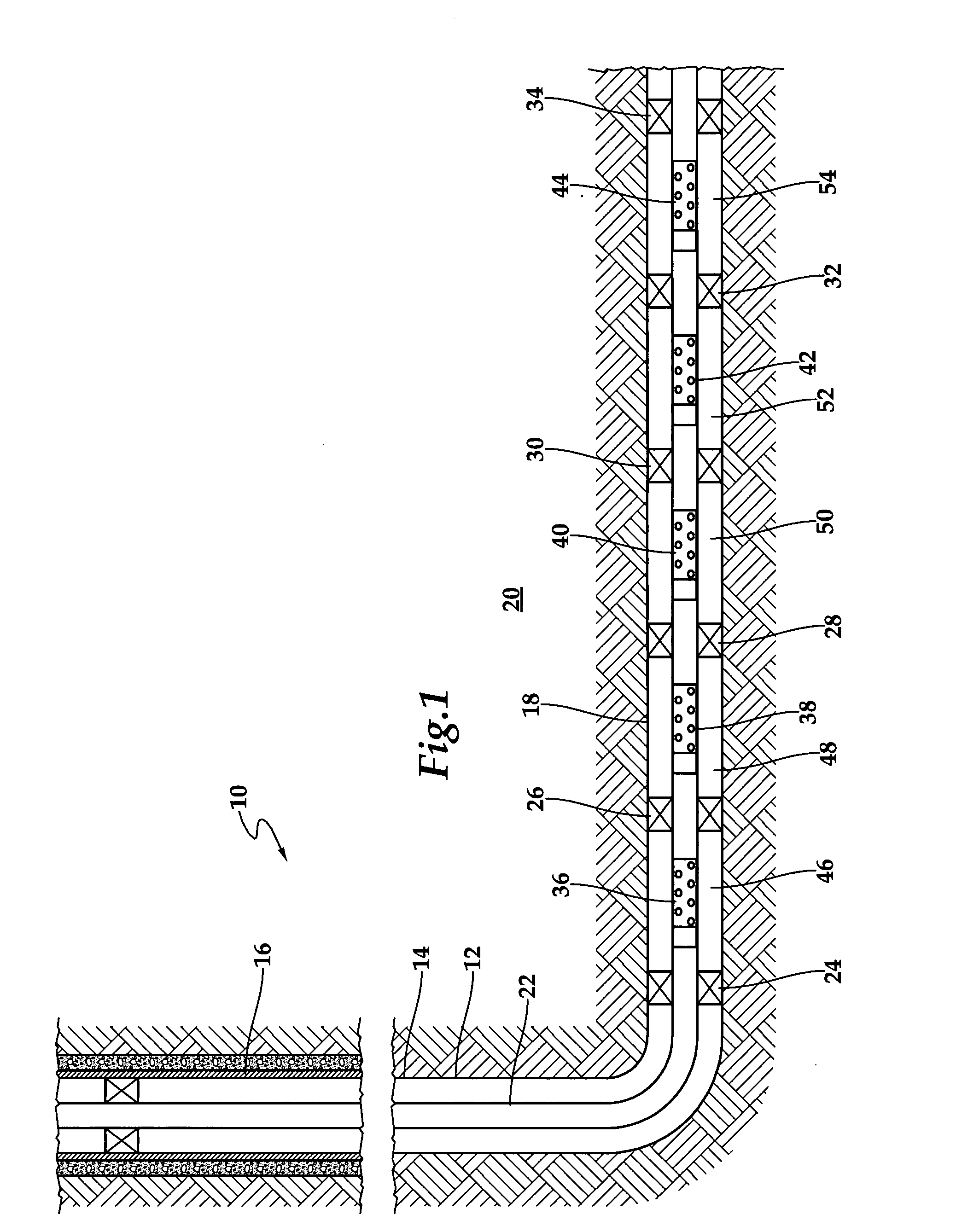

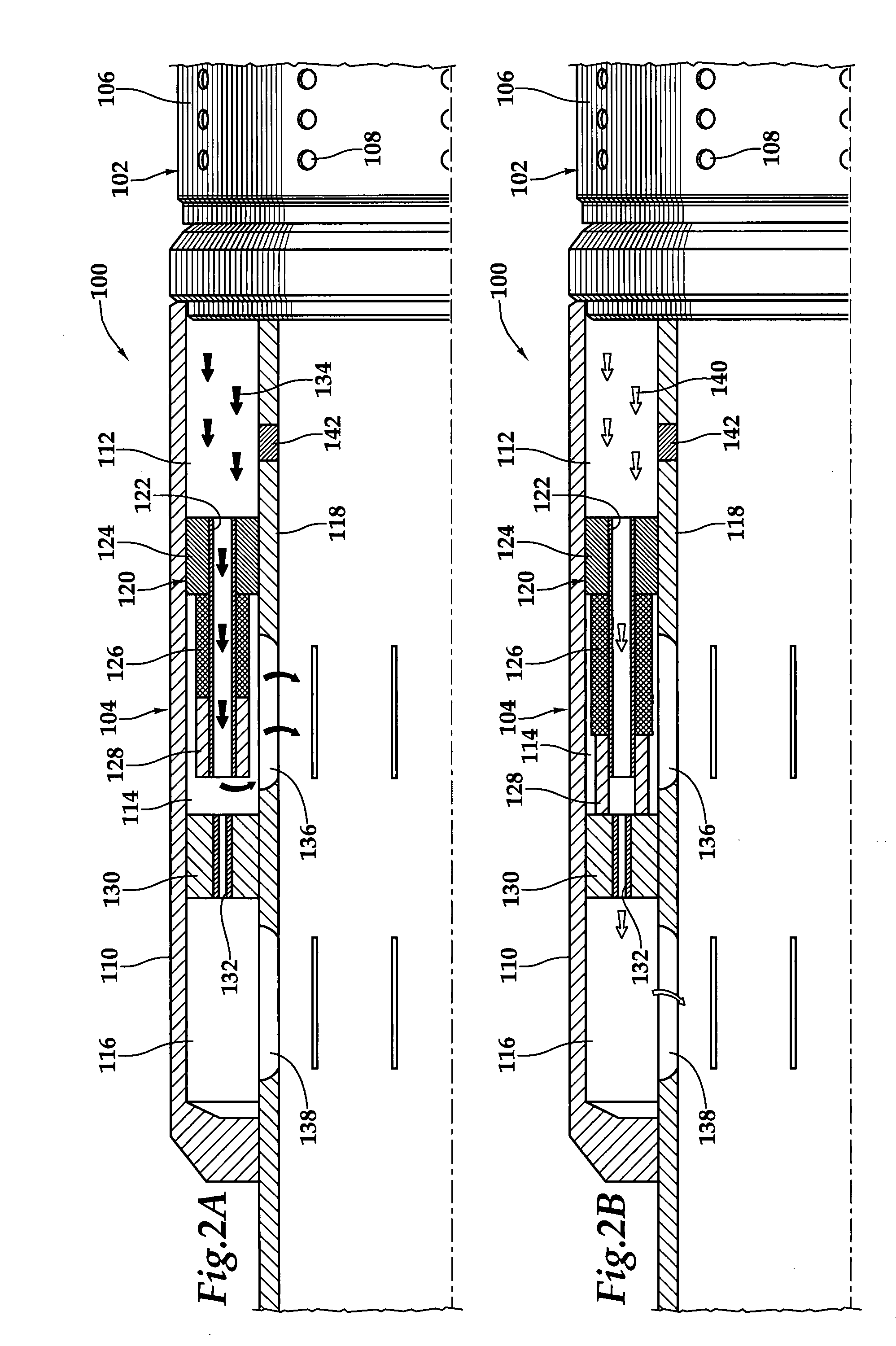

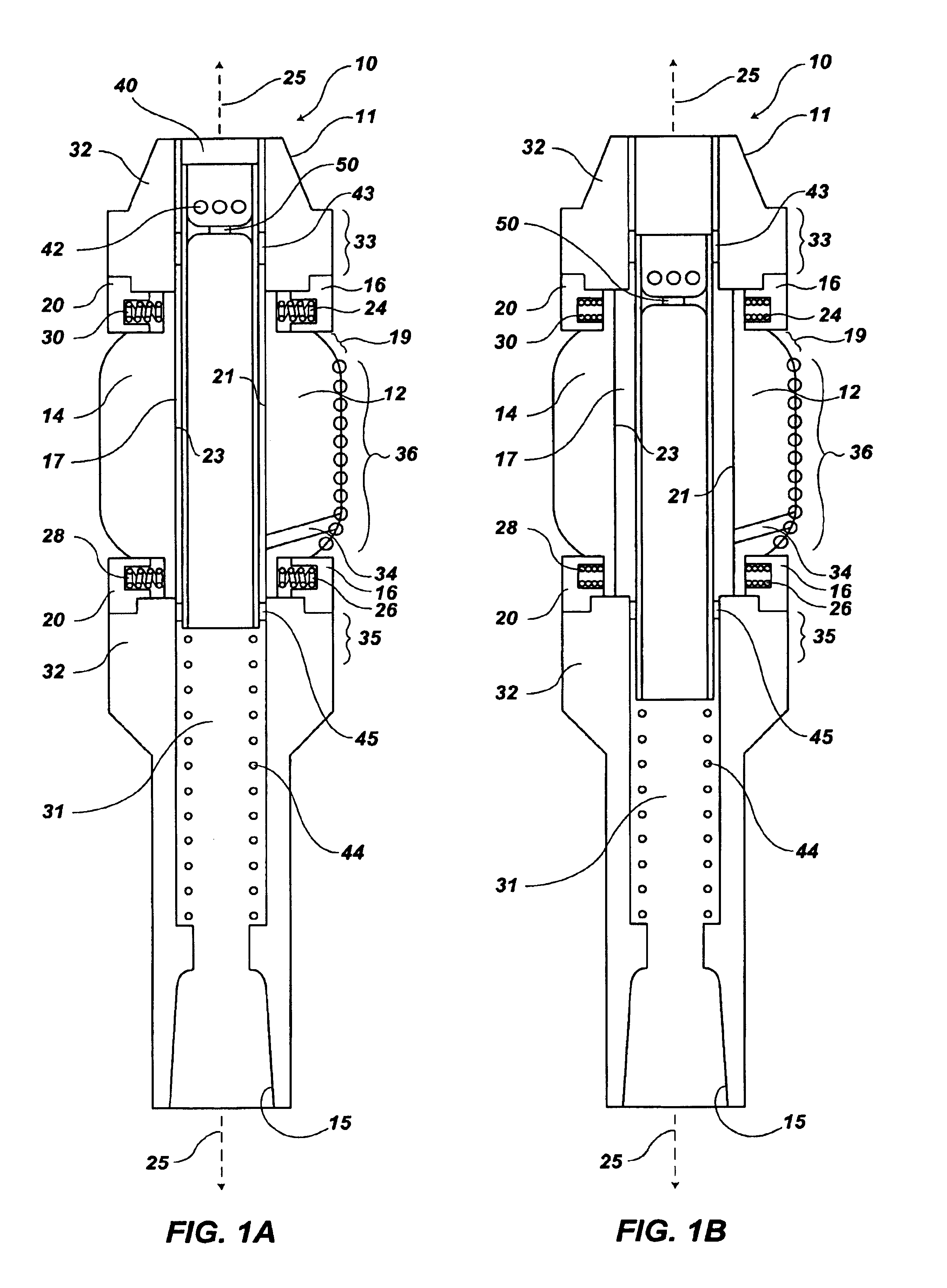

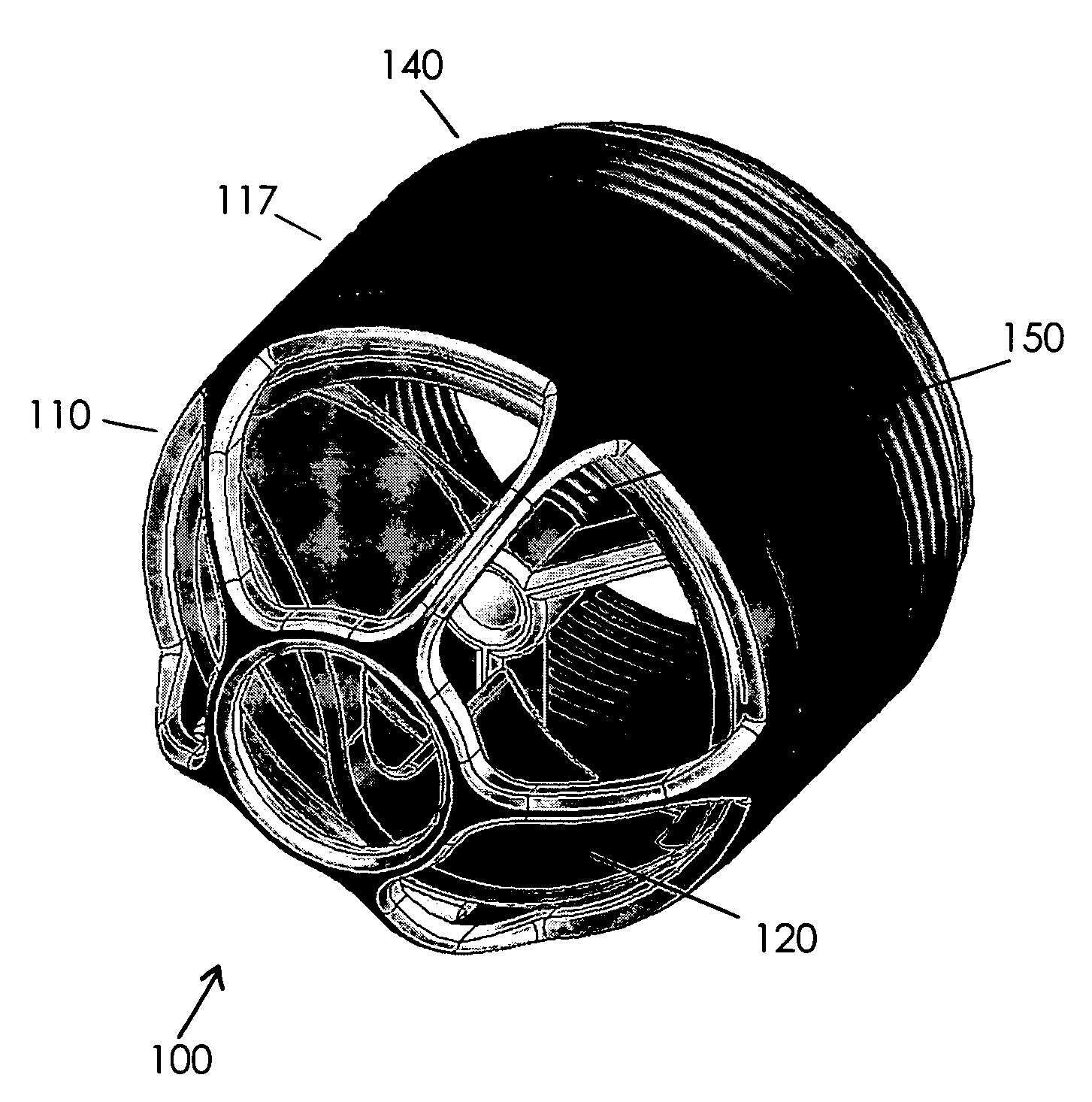

Apparatus for autonomously controlling the inflow of production fluids from a subterranean well

InactiveUS20080283238A1Reduce trafficReduce the cross-sectional areaFluid removalWell/borehole valve arrangementsEngineeringActuator

A flow control apparatus (100) for controlling the inflow of production fluids (134, 140) from a subterranean well includes a tubular member (118) having at least one opening (138) that allows fluid flow between an exterior of the tubular member (118) and an interior flow path of the tubular member (118) and a flow restricting device (120) operably positioned in a fluid flow path between a fluid source and the at least one opening (138). The flow restricting device (120) includes a valve (128, 130) and an actuator (126). The actuator (126) includes a material that swells in response to contact with an undesired fluid (140), such as water or gas. The flow restricting device (120) is operable to autonomously reduce the fluid flow through the flow control apparatus (100) in response to contact between the material and the undesired fluid (140).

Owner:HALLIBURTON ENERGY SERVICES INC

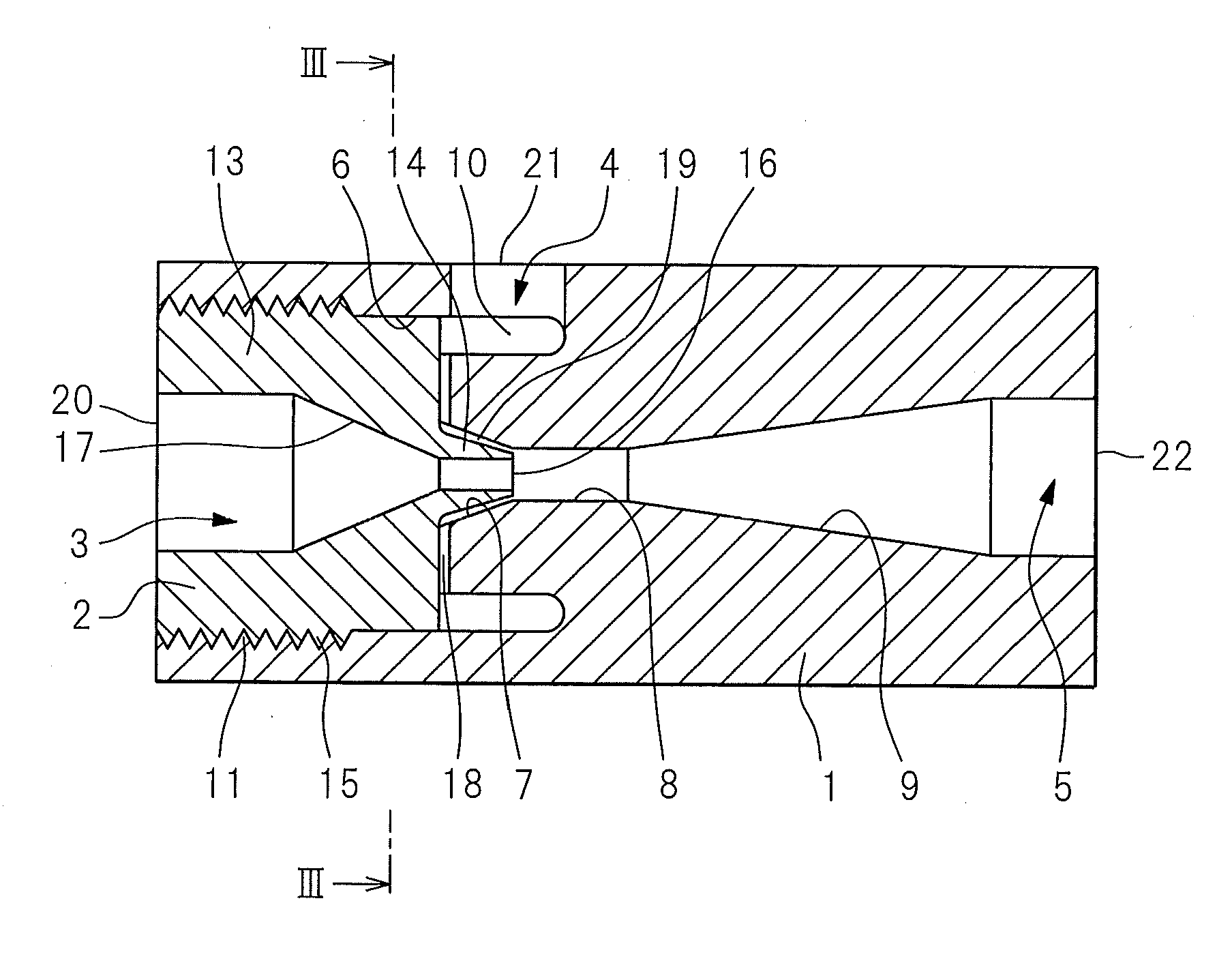

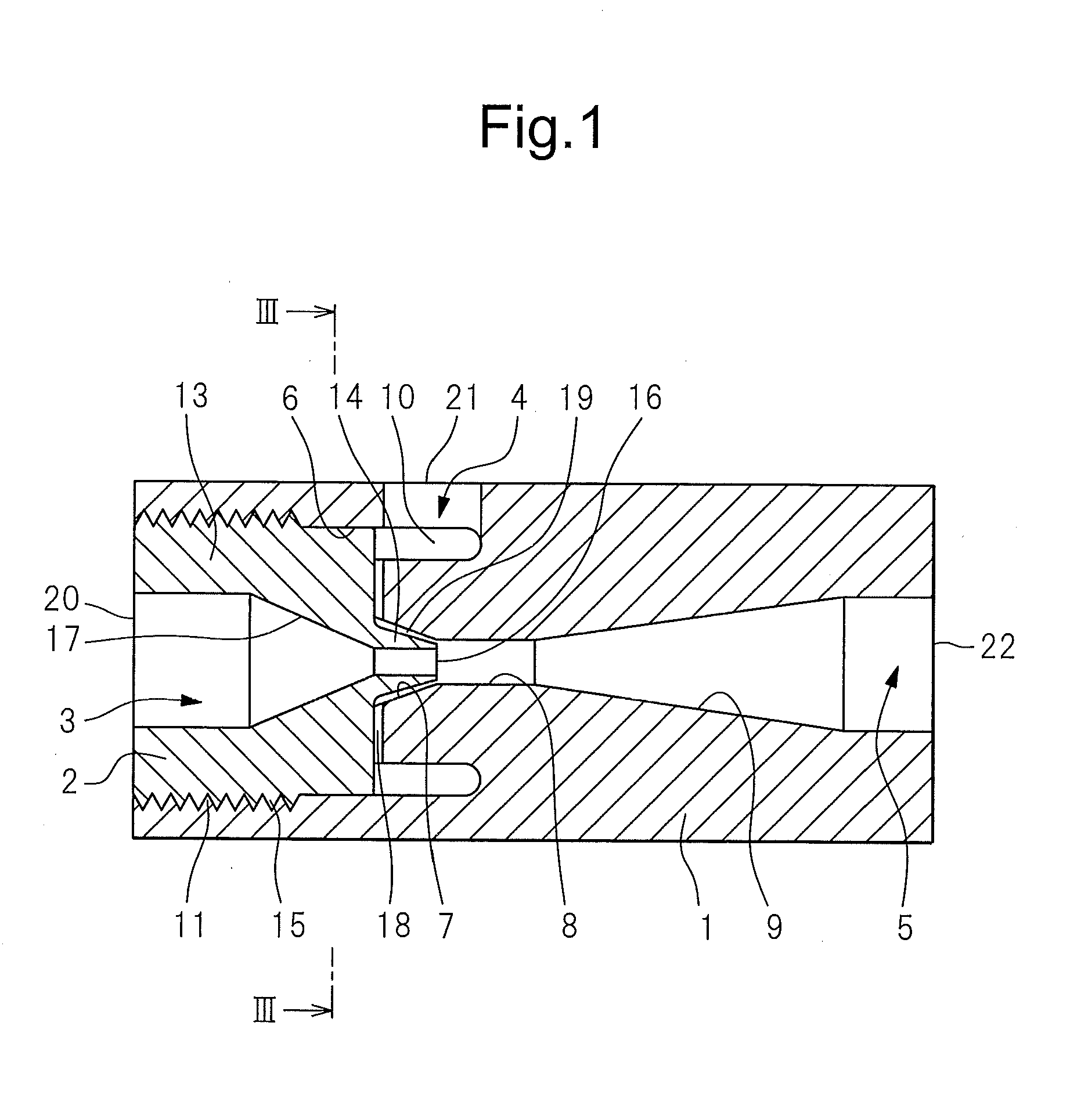

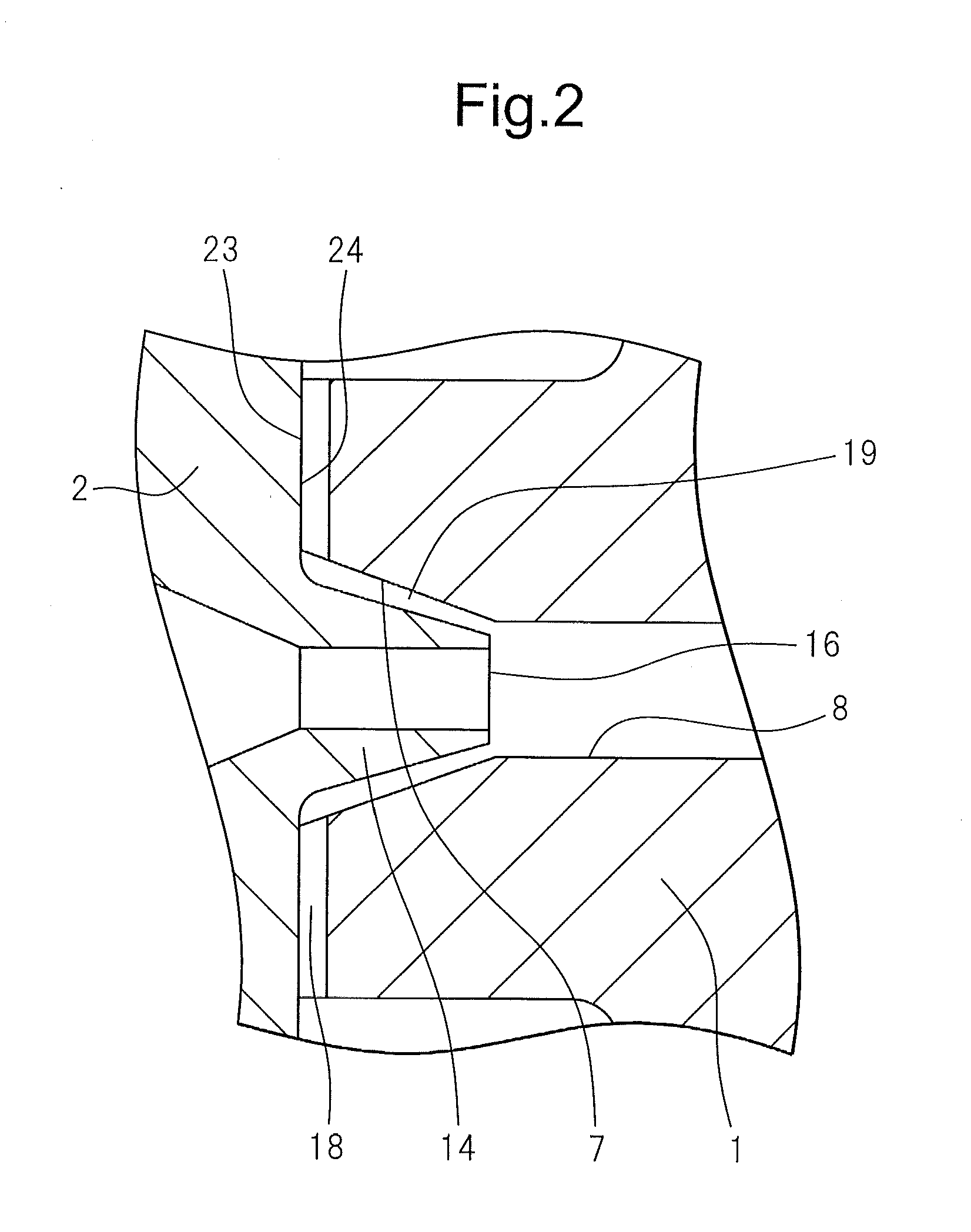

In-line-type fluid mixer

InactiveUS20120307588A1Reduce the cross-sectional areaHigh speedFlow mixersMixer accessoriesInlet channelEngineering

An in-line-type fluid mixer is provided, which includes a first channel-forming part defining a first inlet channel from a first inlet portion to a first passage portion; a second channel-forming part defining a second inlet channel from a second inlet portion to a second passage portion; a third channel-forming part defining an outlet channel having a sectional area that increases from a narrower portion through a flaring portion to an outlet portion, and being communicated with the first inlet channel and the second inlet channel, respectively, at an end of the narrow portion; and a whirling stream-generating part for generating a whirling stream in at least one of the first inlet channel and the second inlet channel.

Owner:ASAHI YUKIZAI KOGYO CO LTD

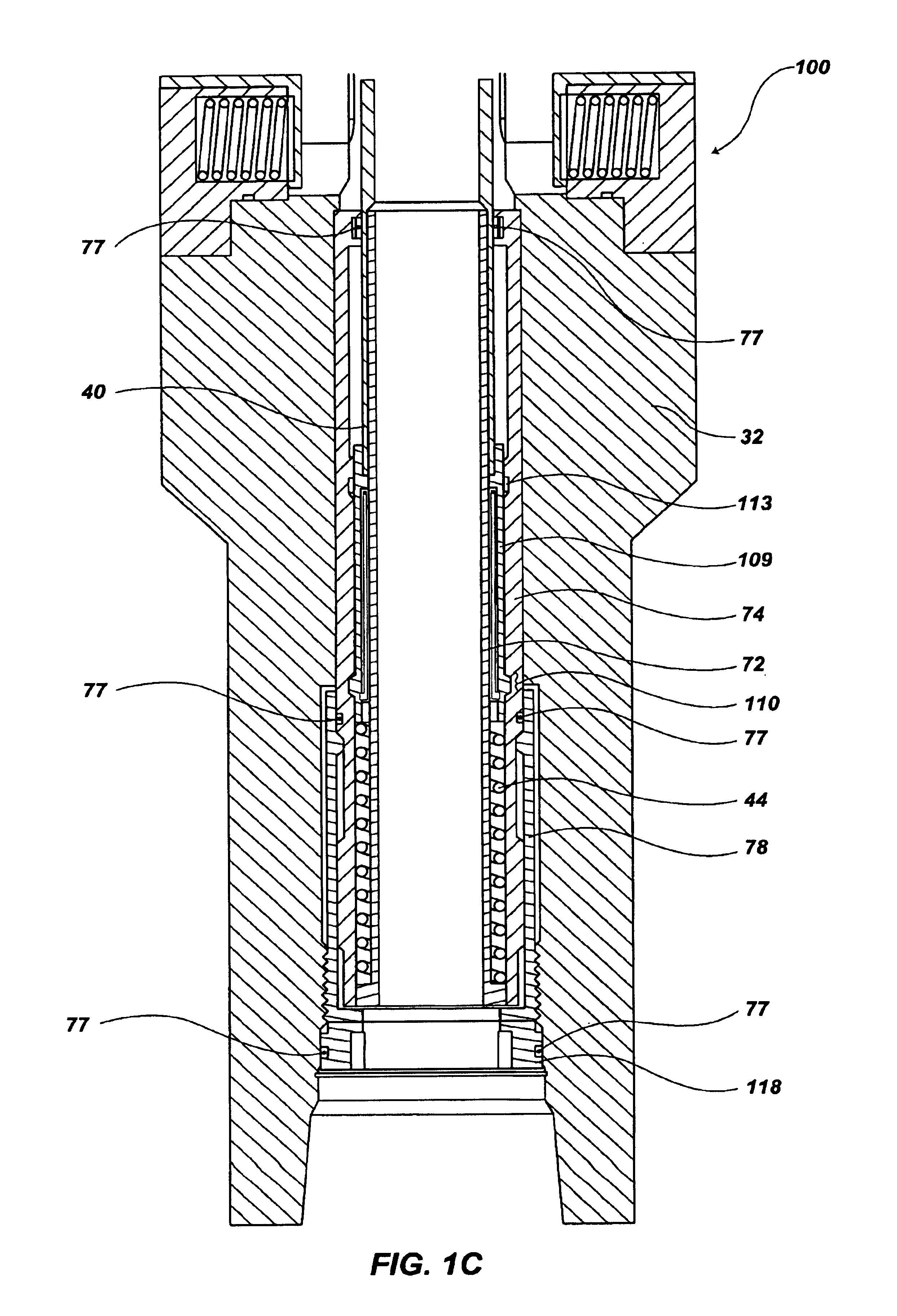

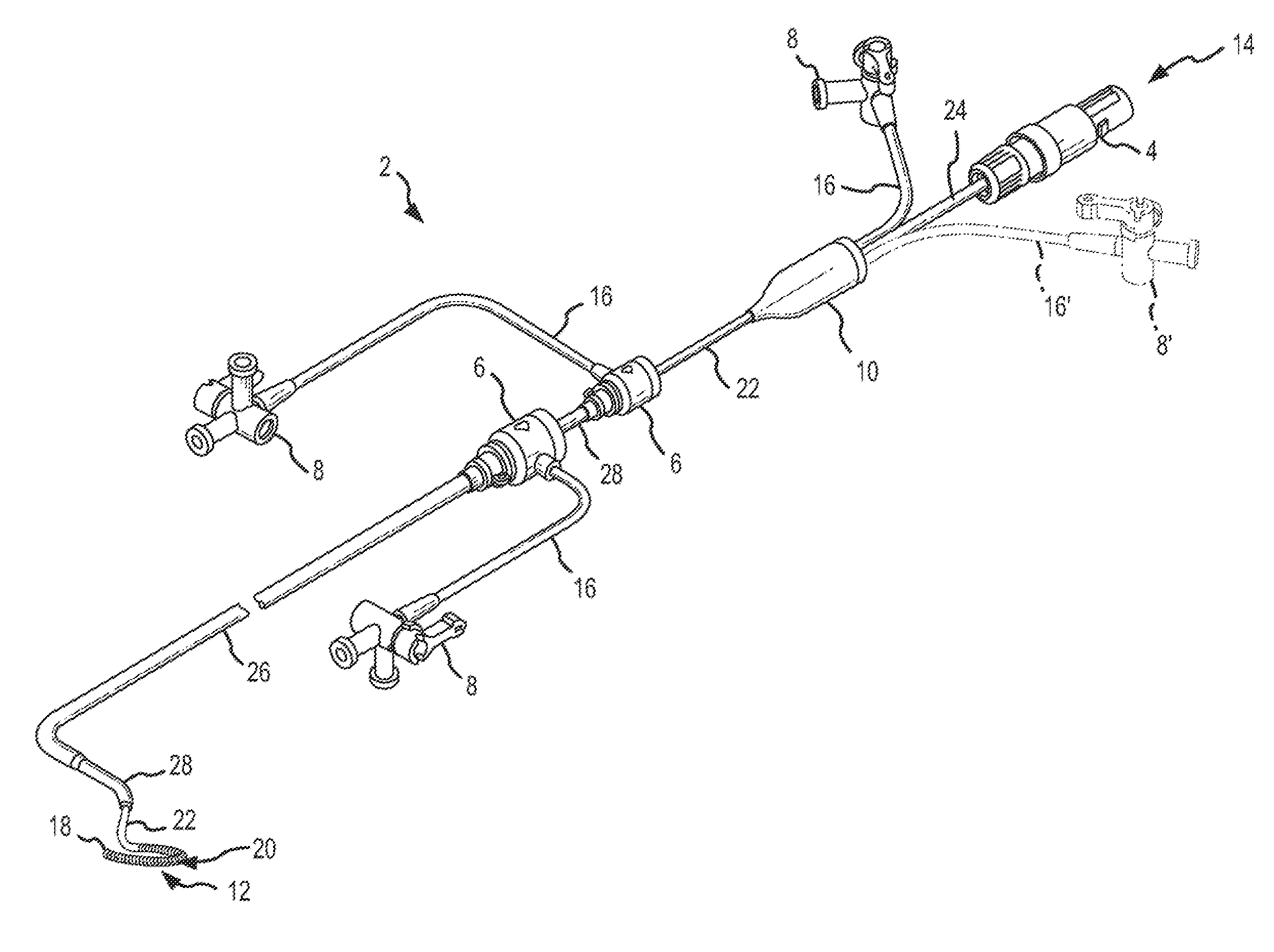

Plug with detachable guidewire element and methods for use

InactiveUS6890343B2Low profilePromote progressVaccination/ovulation diagnosticsSurgical veterinaryDistal portionGuide wires

An apparatus for sealing a passage through tissue includes a bioabsorbable, threaded plug carried by a delivery device. A guide wire is receivable through lumens in the plug and delivery device that includes wings on a bioabsorbable distal portion. With the wings collapsed, the guide wire is advanced through the passage into a blood vessel, the wings expanding once located within the vessel, and the guide wire is withdrawn until the wings contact the vessel wall. The plug is threaded into the passage over the guide wire until the plug is disposed adjacent the wings. The distal portion of the guide wire is secured to the plug, e.g., by compressing a collet within the plug lumen that seals the lumen, and is severed from a proximal portion thereof. Thus, the plug and distal portion are deployed with the plug sealing the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Guide wire element for positioning vascular closure devices and methods for use

InactiveUS6969397B2Reduce profileReduce the cross-sectional areaEar treatmentVaccination/ovulation diagnosticsBlood vesselGuide wires

An apparatus for sealing a passage through tissue includes a threaded plug detachably carried on a distal end of a delivery device. A guide wire element is receivable through the lumens extending through the plug and delivery device that includes expandable wings adjacent its distal end, and markers adjacent its proximal end. During use, the guide wire element is advanced through a passage through tissue into a blood vessel. The wings on the distal end are expanded within the vessel, and the guide wire element withdrawn until the wings contact a wall of the vessel. The plug is threaded into the passage over the guide wire element until the markers appear from the delivery device, and released from the delivery device, thereby deploying the plug member adjacent the vessel to seal the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

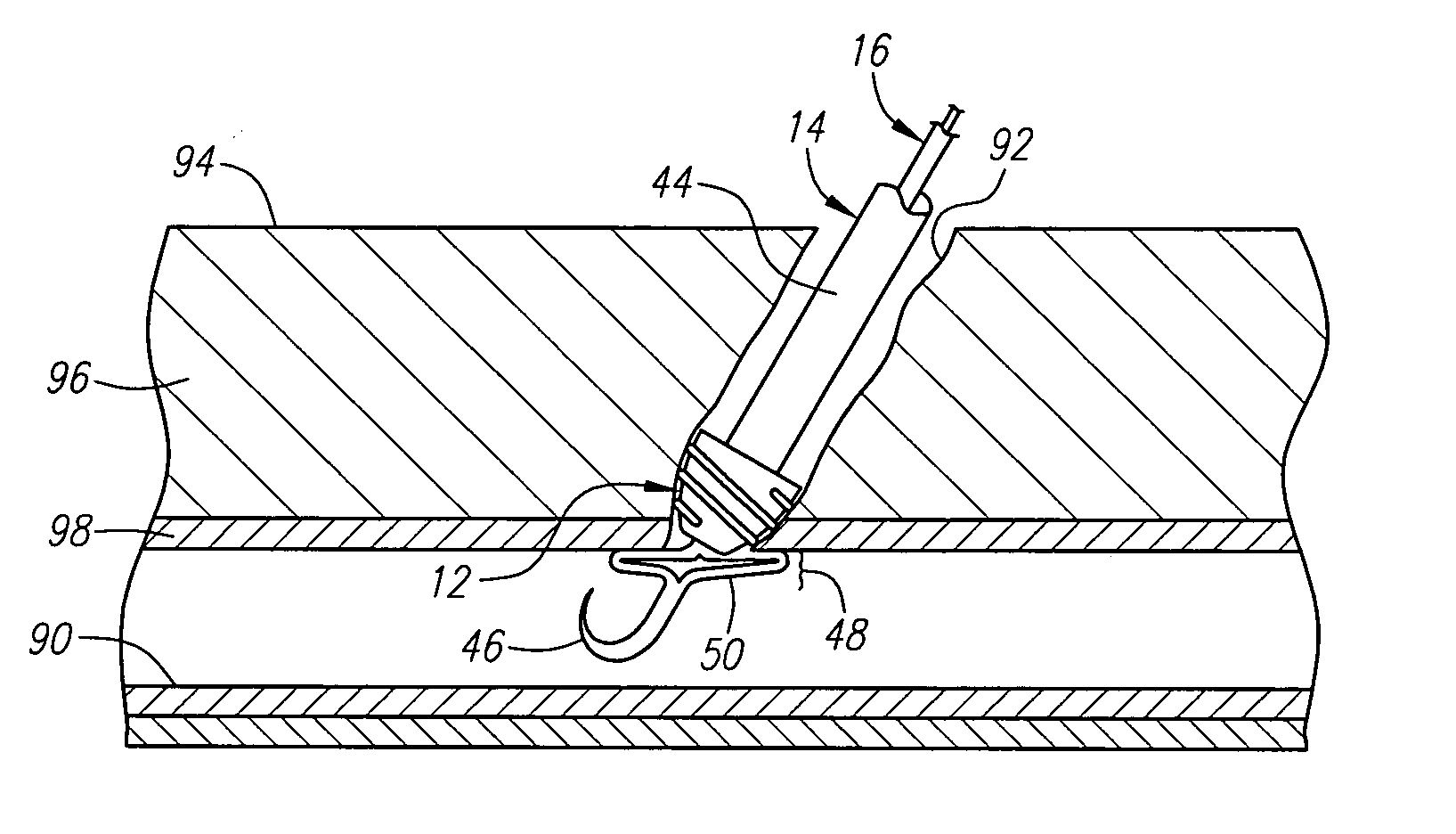

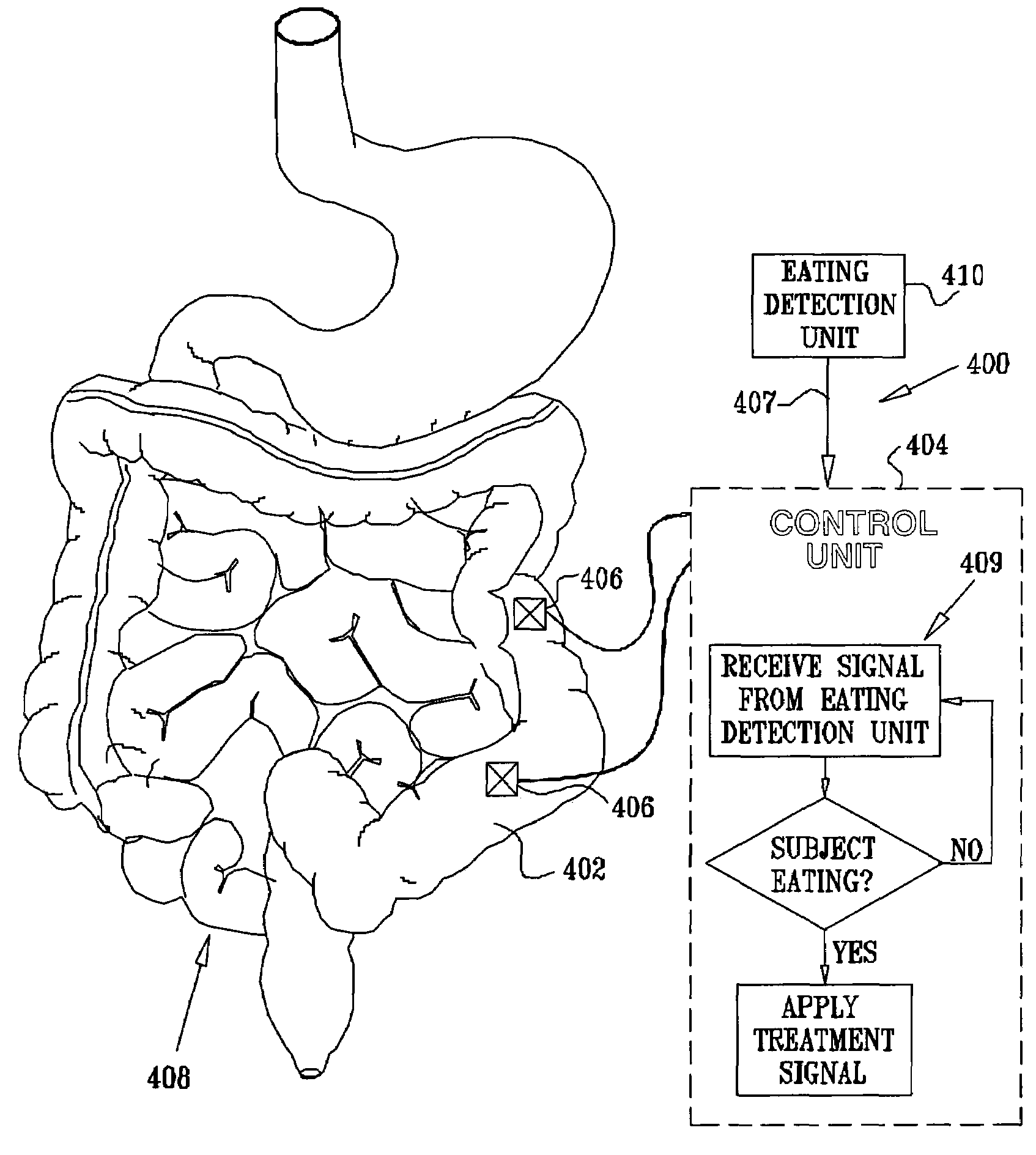

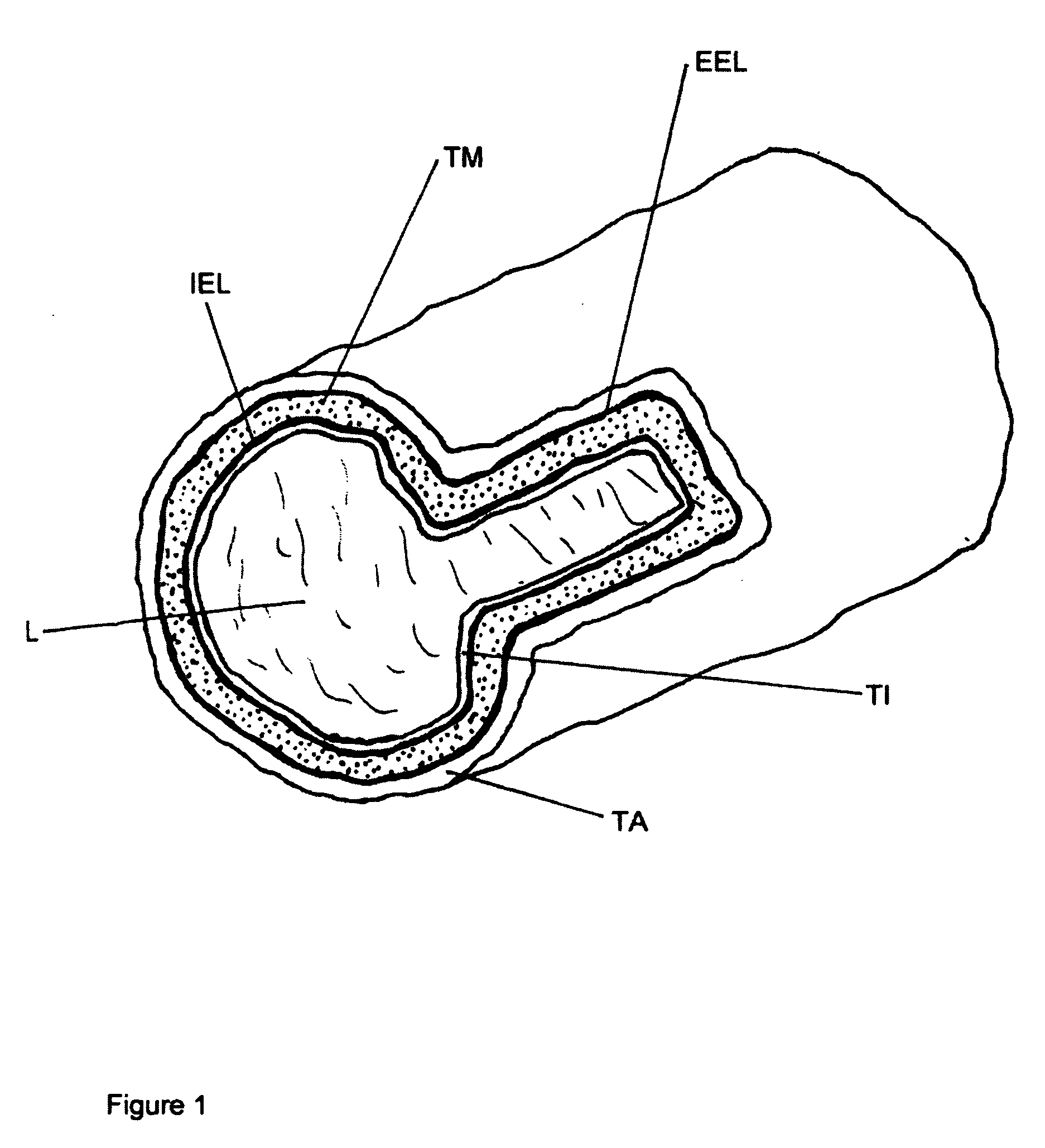

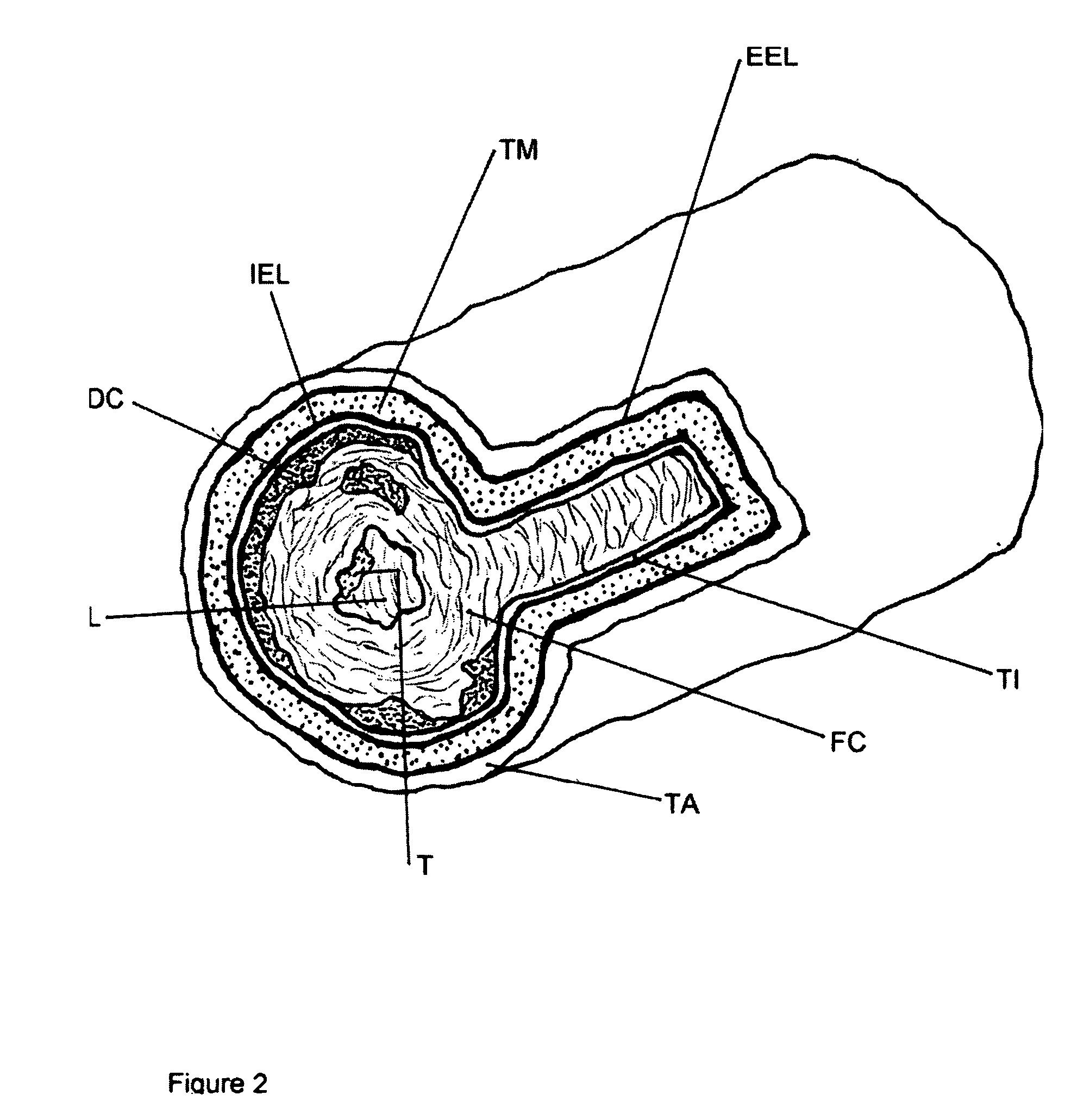

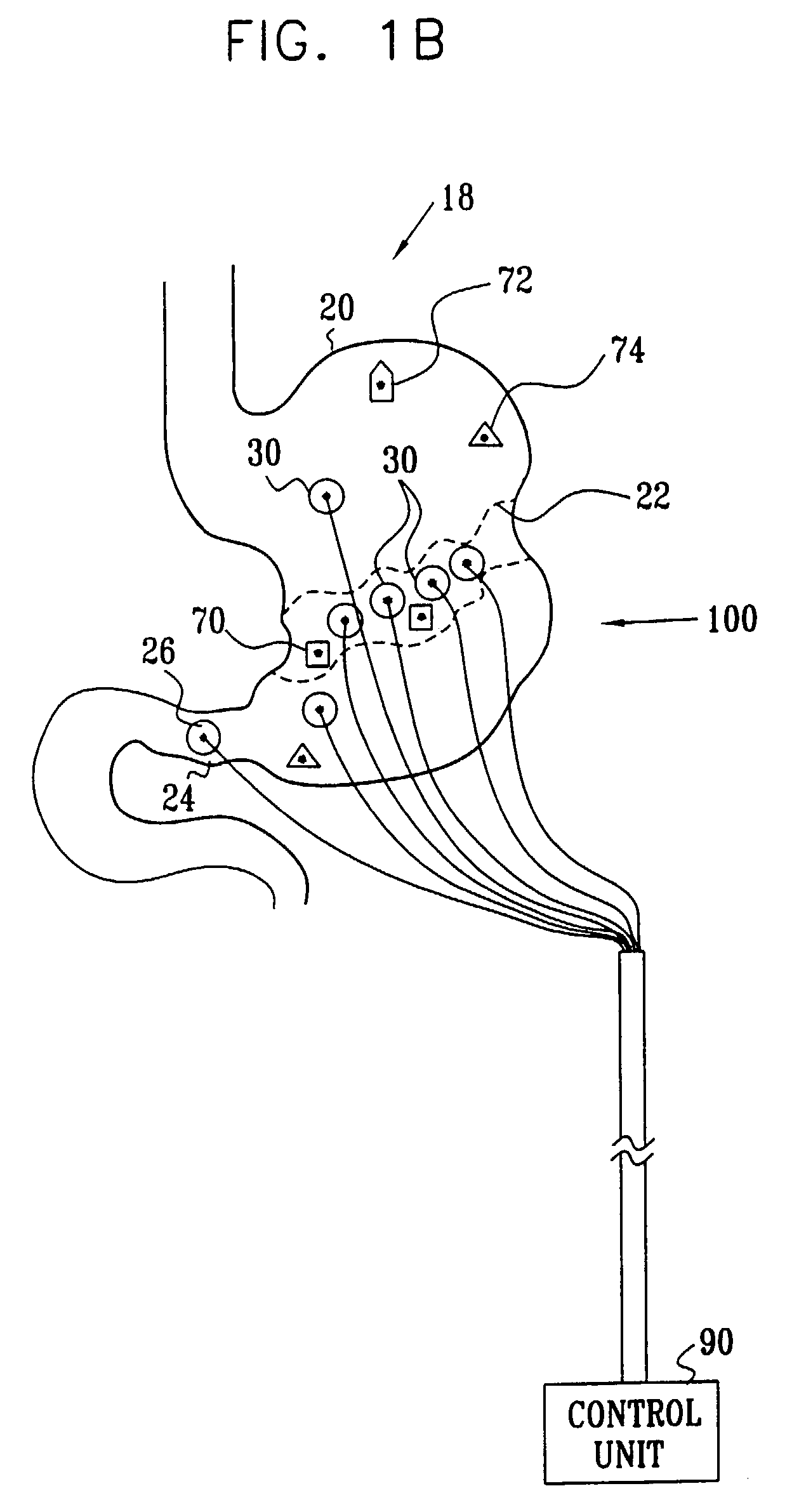

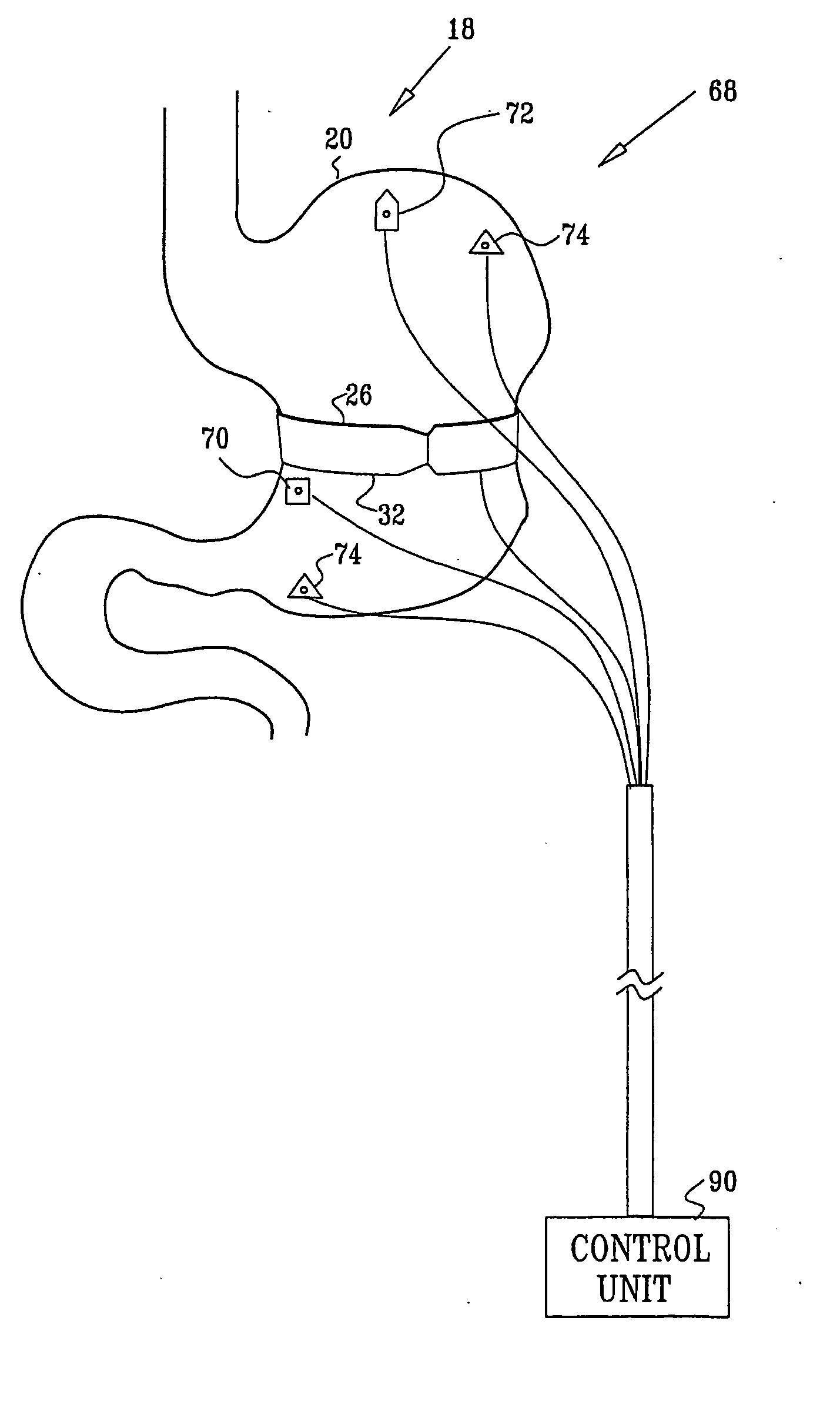

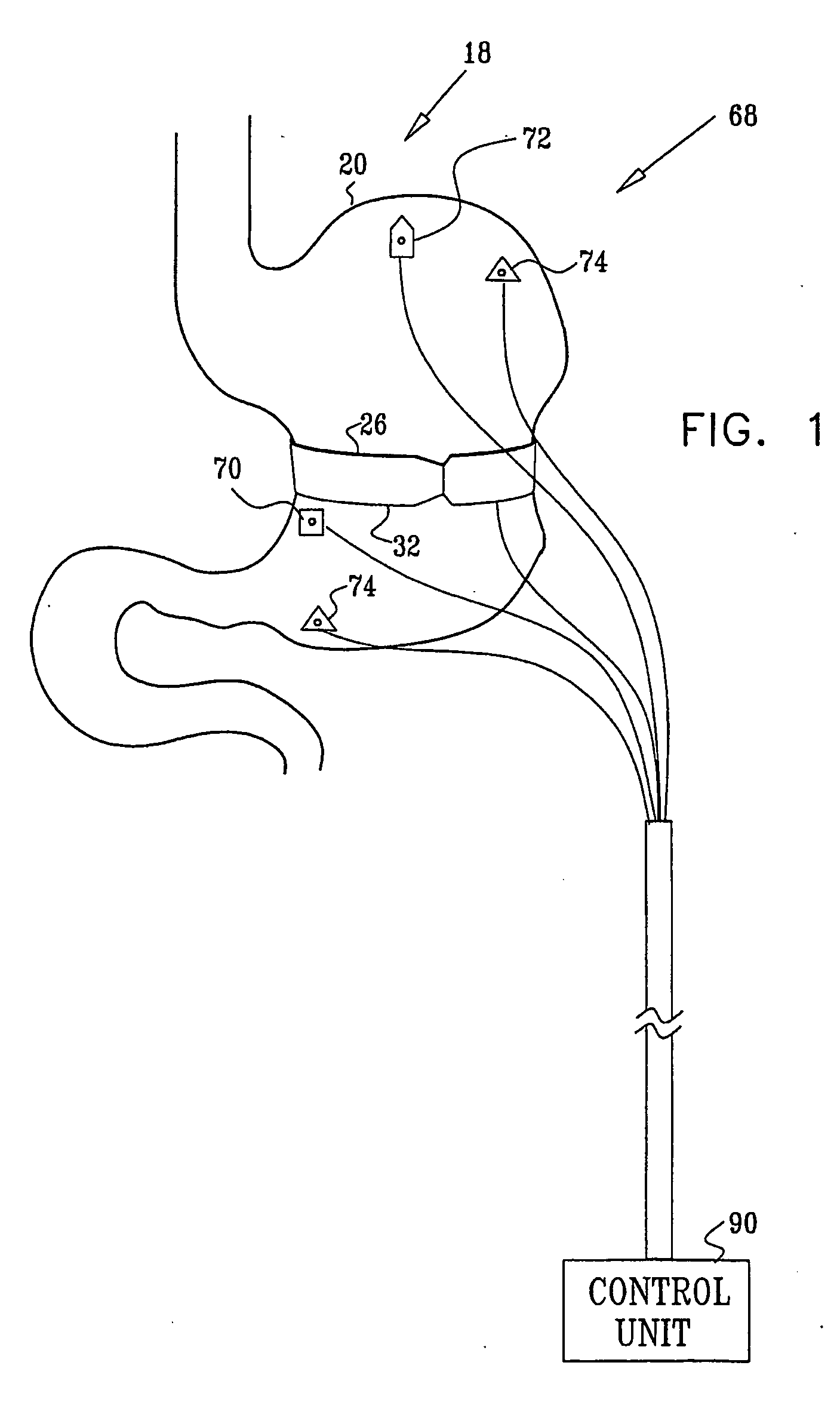

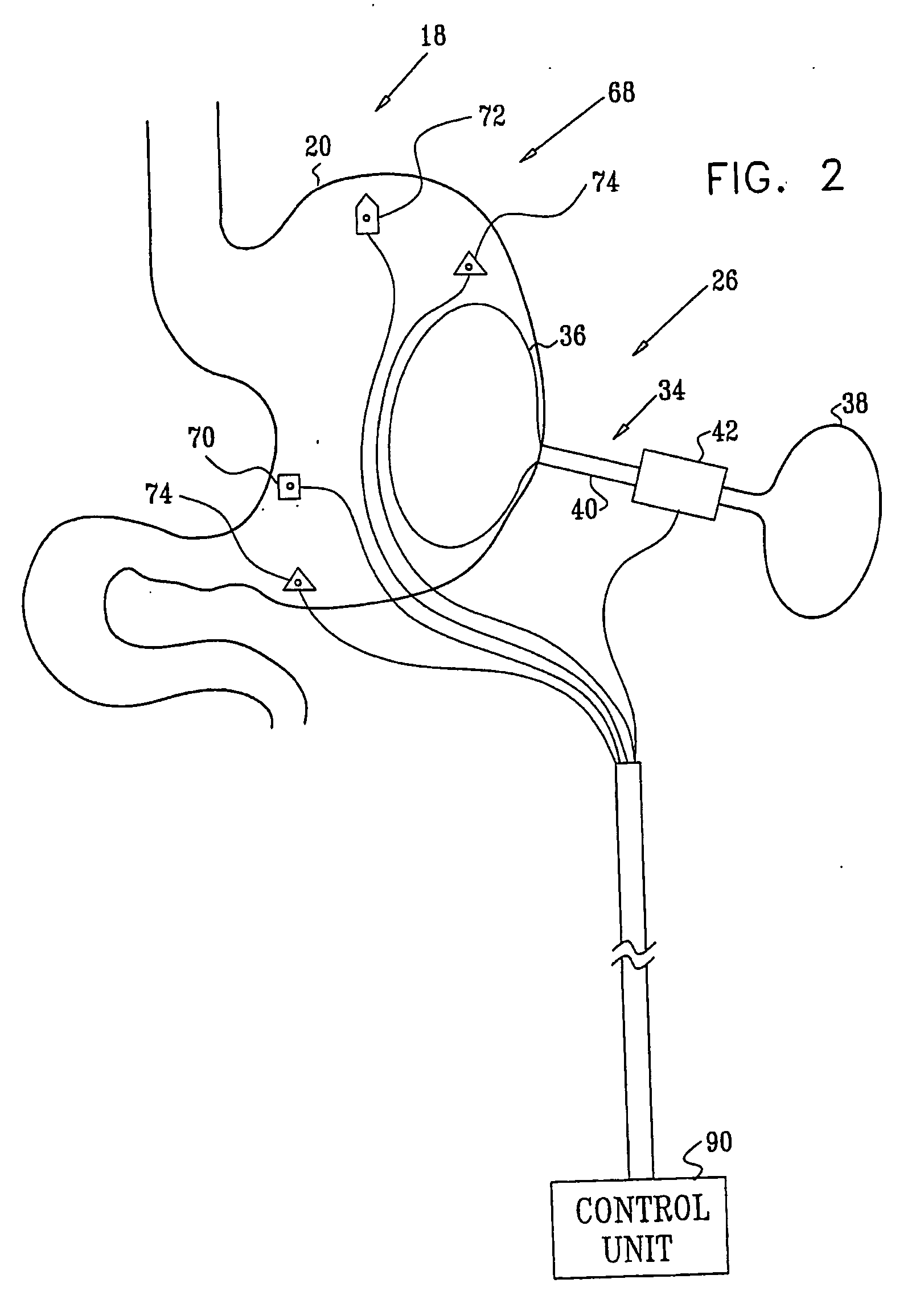

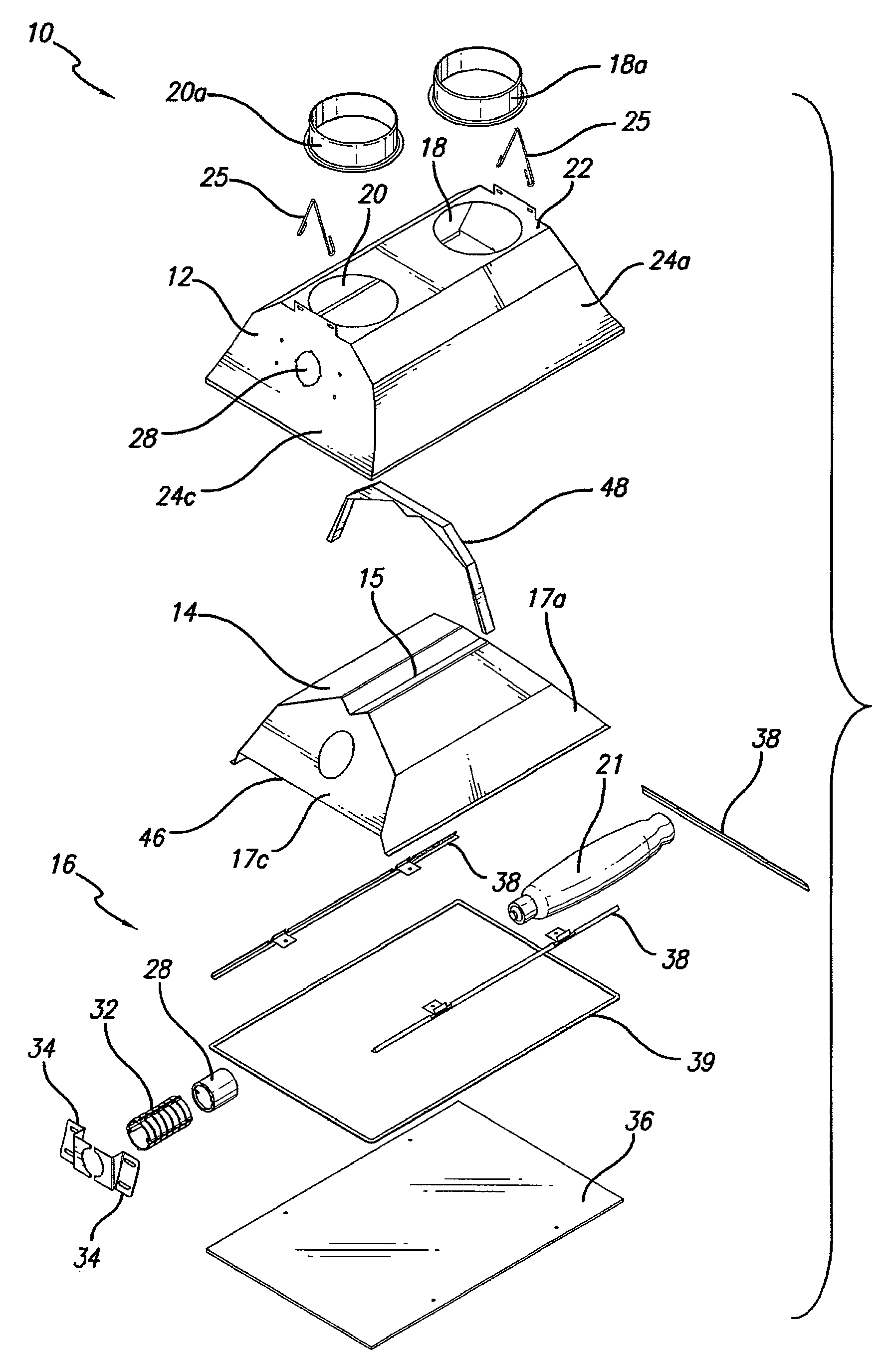

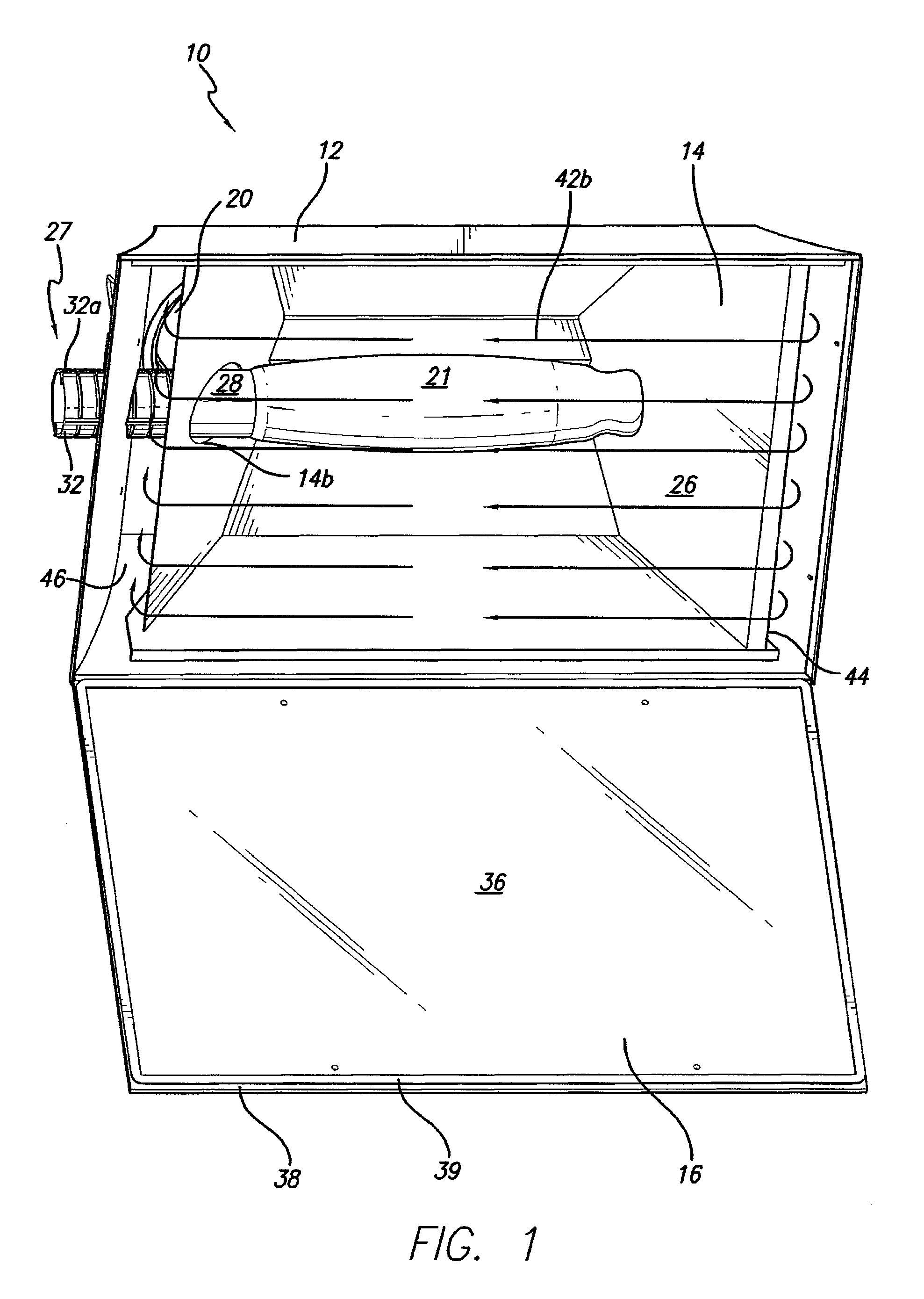

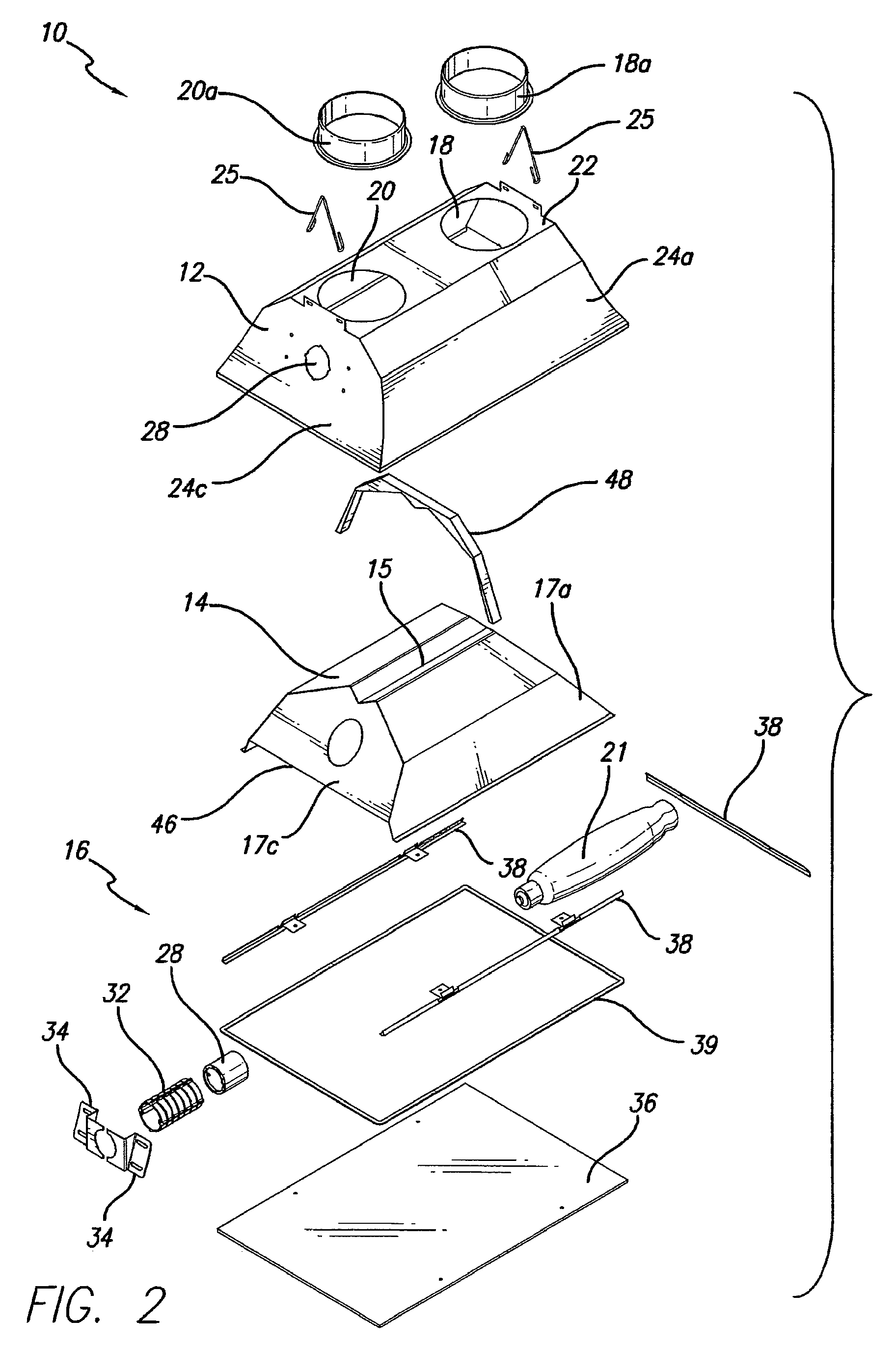

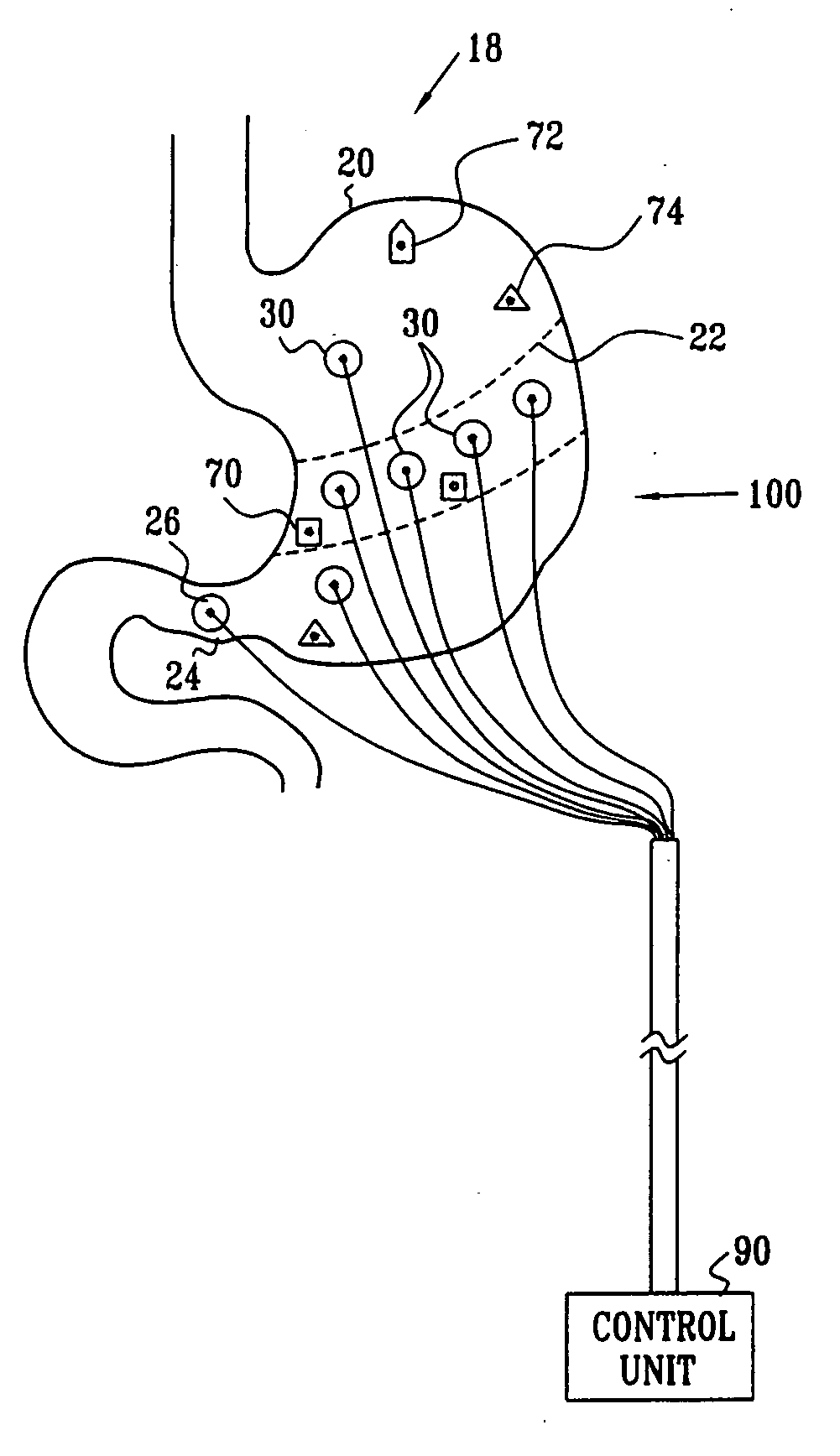

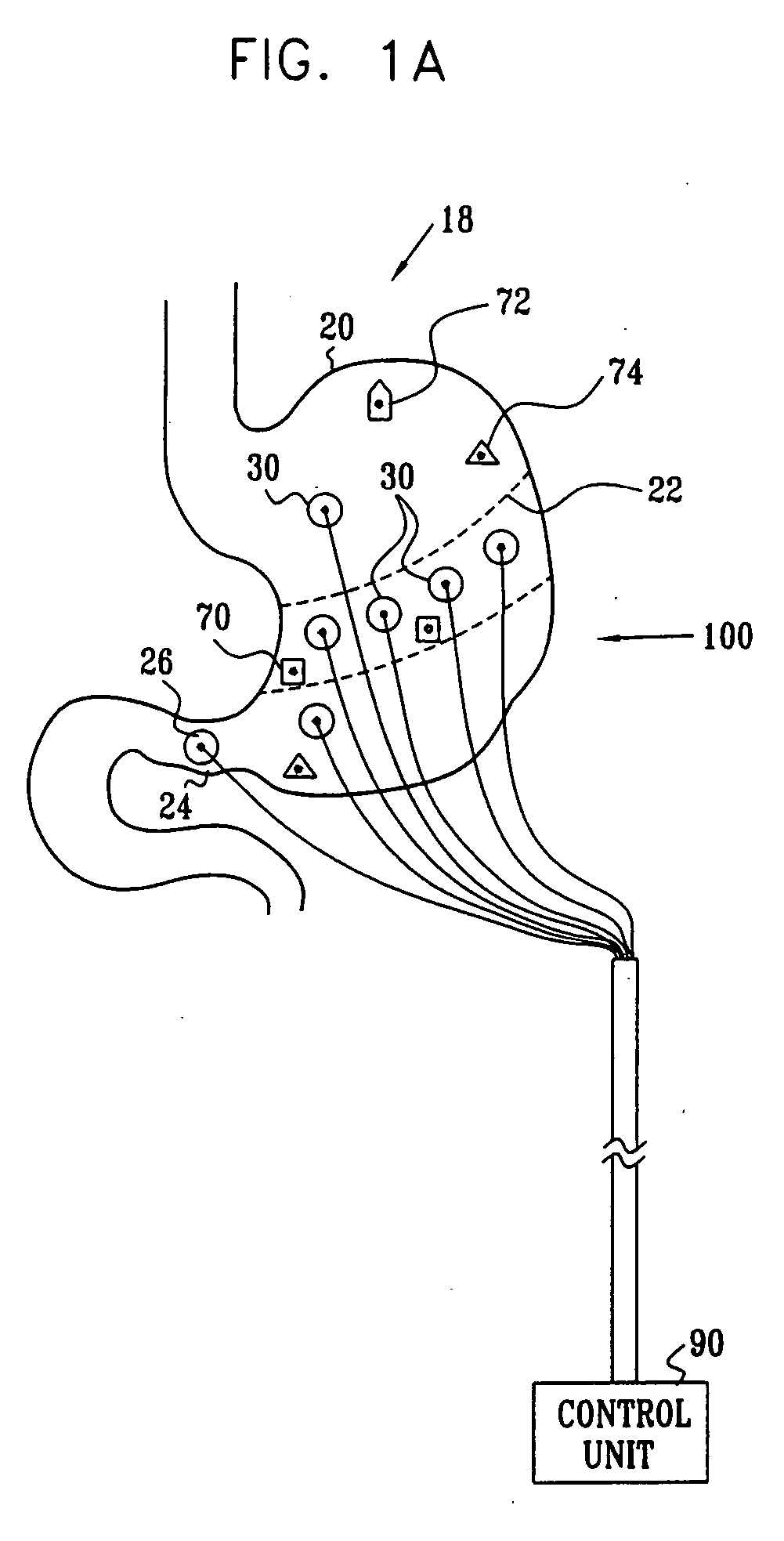

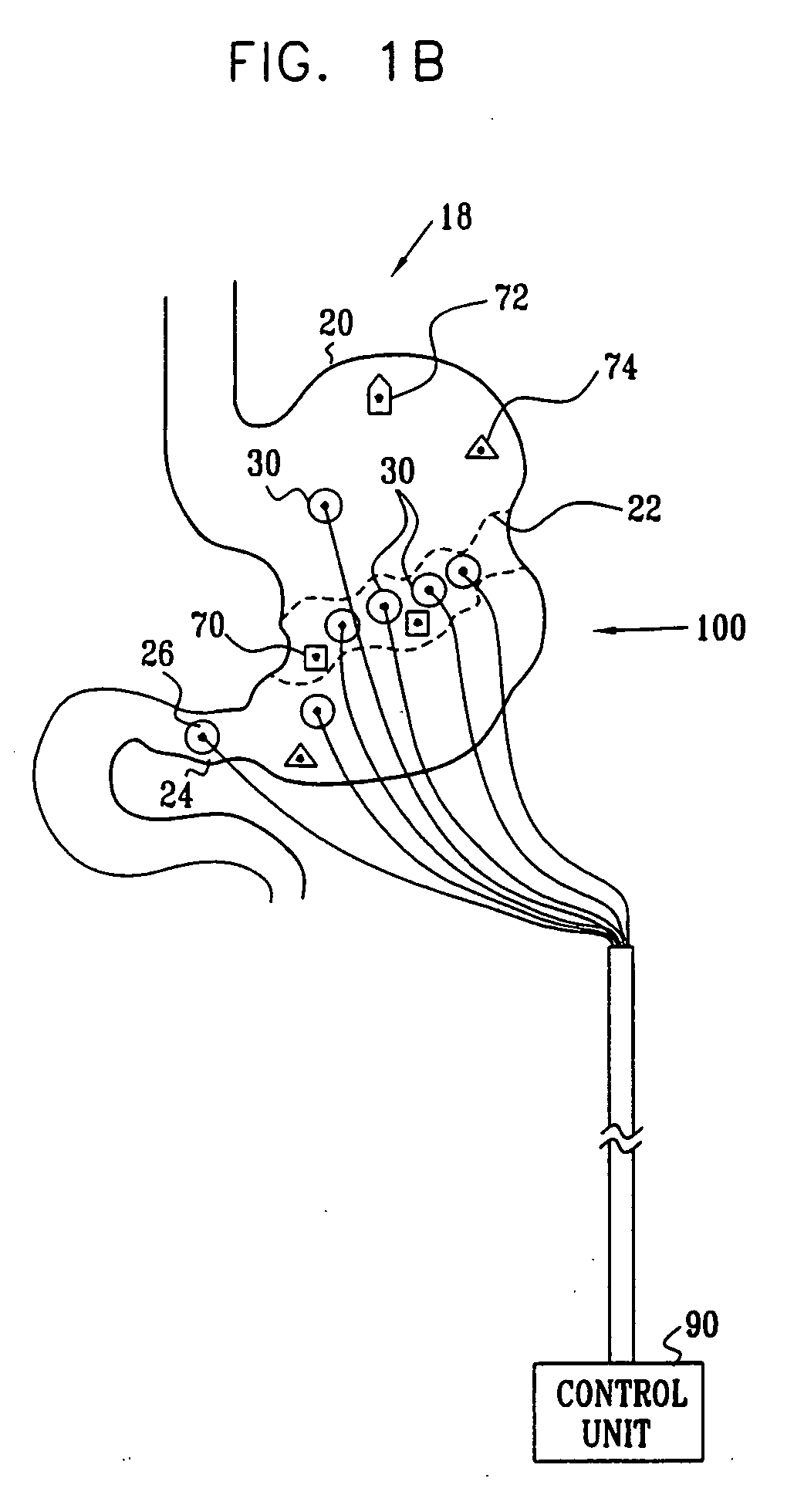

Gastrointestinal methods and apparatus for use in treating disorders

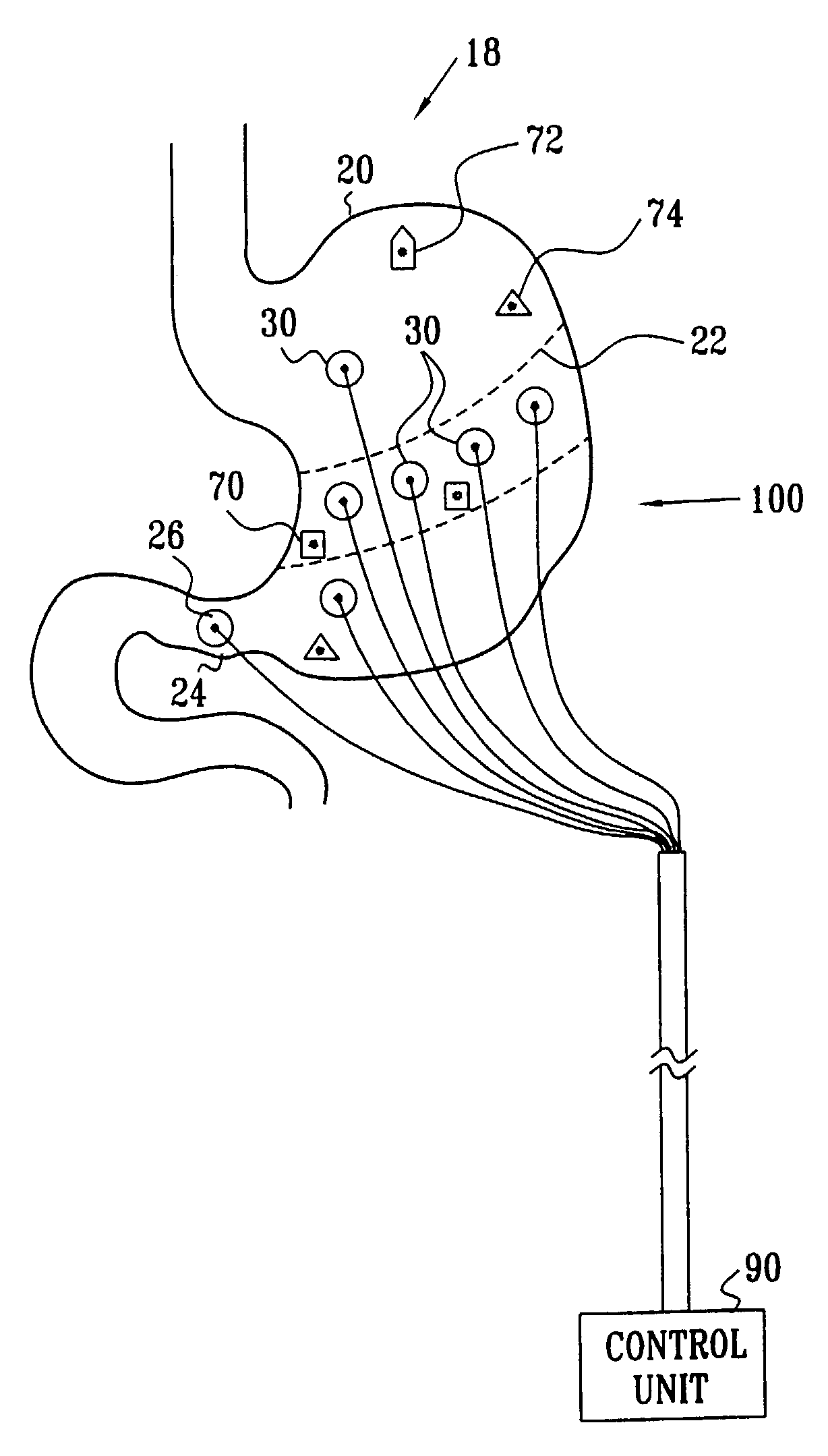

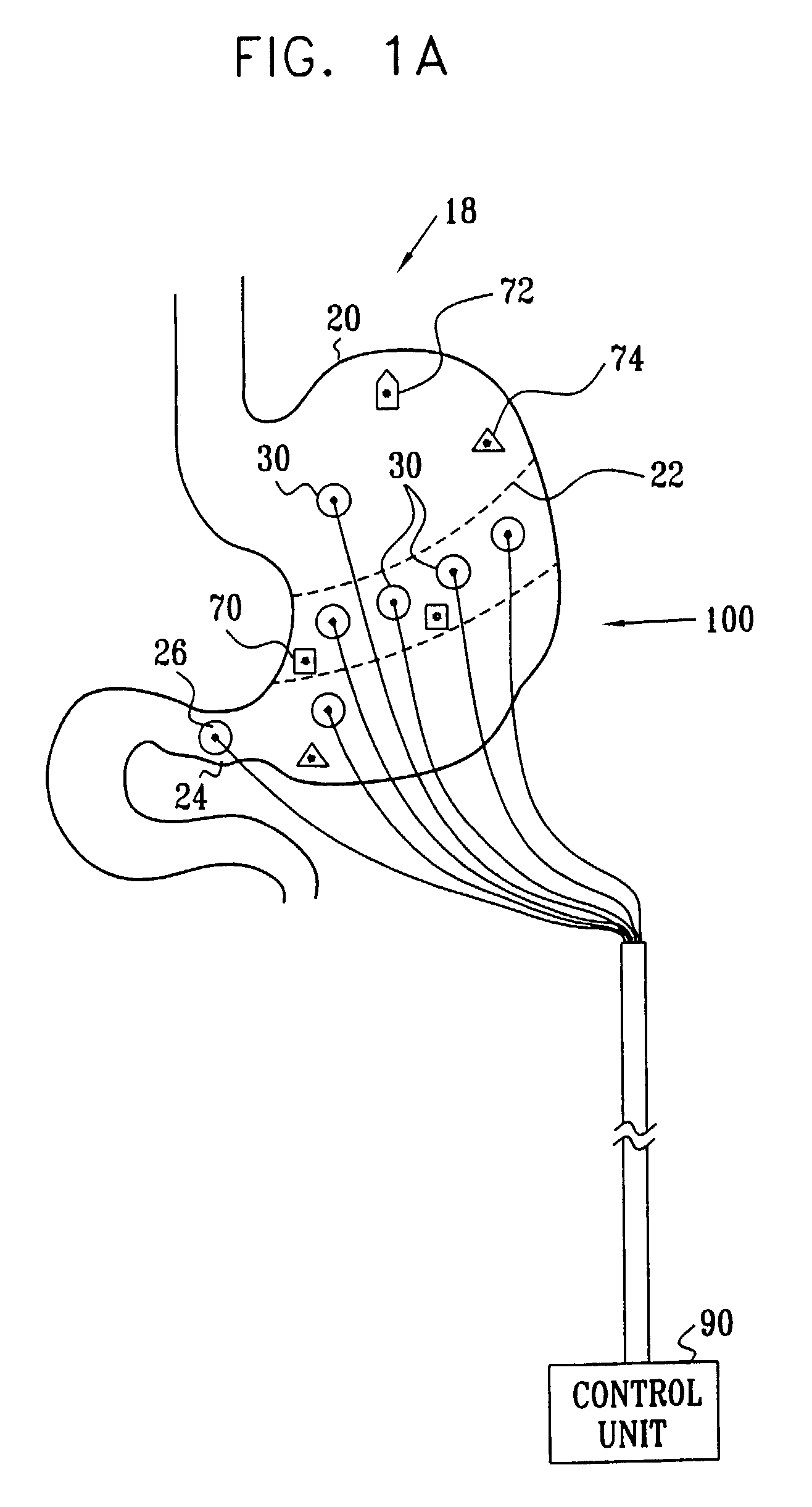

InactiveUS7502649B2Reduce volumeCause a sensation of satiety felt by the patientElectrotherapyMetabolism disorderElectrical resistance and conductanceDisease

A method is provided for detecting a change in posture of a subject. An electrical impedance is measured between two or more sites on a stomach (20) of the subject, and an impedance signal is generated responsive thereto. The change in posture is detected by performing a posture analysis of the impedance signal. A method is also provided for treating a subject. The method includes applying an electrical signal to a site of the subject selected from the list consisting of: a colon (402) of the subject, and a distal small intestine (408) of the subject. The signal is configured to stimulate cells of the subject to increase secretion of glucagon-like-peptide-1 (GLP-1) or PYY, or to decrease secretion of ghrelin, in order to treat the subject.

Owner:TYLERTON INT INC

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Plug with detachable guidewire element and methods for use

InactiveUS20050177189A1Reduce the cross-sectional areaEasy to optimizeVaccination/ovulation diagnosticsSurgical veterinaryDistal portionGuide wires

An apparatus for sealing a passage through tissue includes a bioabsorbable, threaded plug carried by a delivery device. A guide wire is receivable through lumens in the plug and delivery device that includes wings on a bioabsorbable distal portion. With the wings collapsed, the guide wire is advanced through the passage into a blood vessel, the wings expanding once located within the vessel, and the guide wire is withdrawn until the wings contact the vessel wall. The plug is threaded into the passage over the guide wire until the plug is disposed adjacent the wings. The distal portion of the guide wire is secured to the plug, e.g., by compressing a collet within the plug lumen that seals the lumen, and is severed from a proximal portion thereof. Thus, the plug and distal portion are deployed with the plug sealing the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Plug with collet and apparatus and method for delivering such plugs

InactiveUS20050222614A1Reduce the cross-sectional areaEasy to optimizeVaccination/ovulation diagnosticsSurgical veterinaryEngineeringGuide wires

An apparatus for sealing a passage through tissue includes a plug including external threads, a lumen extending between its proximal and distal ends, and an annular collet slidably disposed within the lumen. The plug is carried on a distal end of a handle device that includes an inner member with a distal end that is slidable axially within the lumen of the body for moving the collet into a reduced cross-sectional region of the lumen, thereby compressing the collet to seal the lumen, and for deploying the plug from the handle device. During use, the plug is delivered into a passage through tissue over a guide wire. Once a desired location is reached, the plug is deployed from the handle device, thereby compressing the collet and sealing the lumen. The guide wire and handle device are removed, leaving the plug to seal the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Forward-directed atherectomy catheter

InactiveUS20060229646A1Great relative stretch forceReduce the cross-sectional areaCannulasExcision instrumentsAtherectomyDrive shaft

Owner:SPARKS KURT D

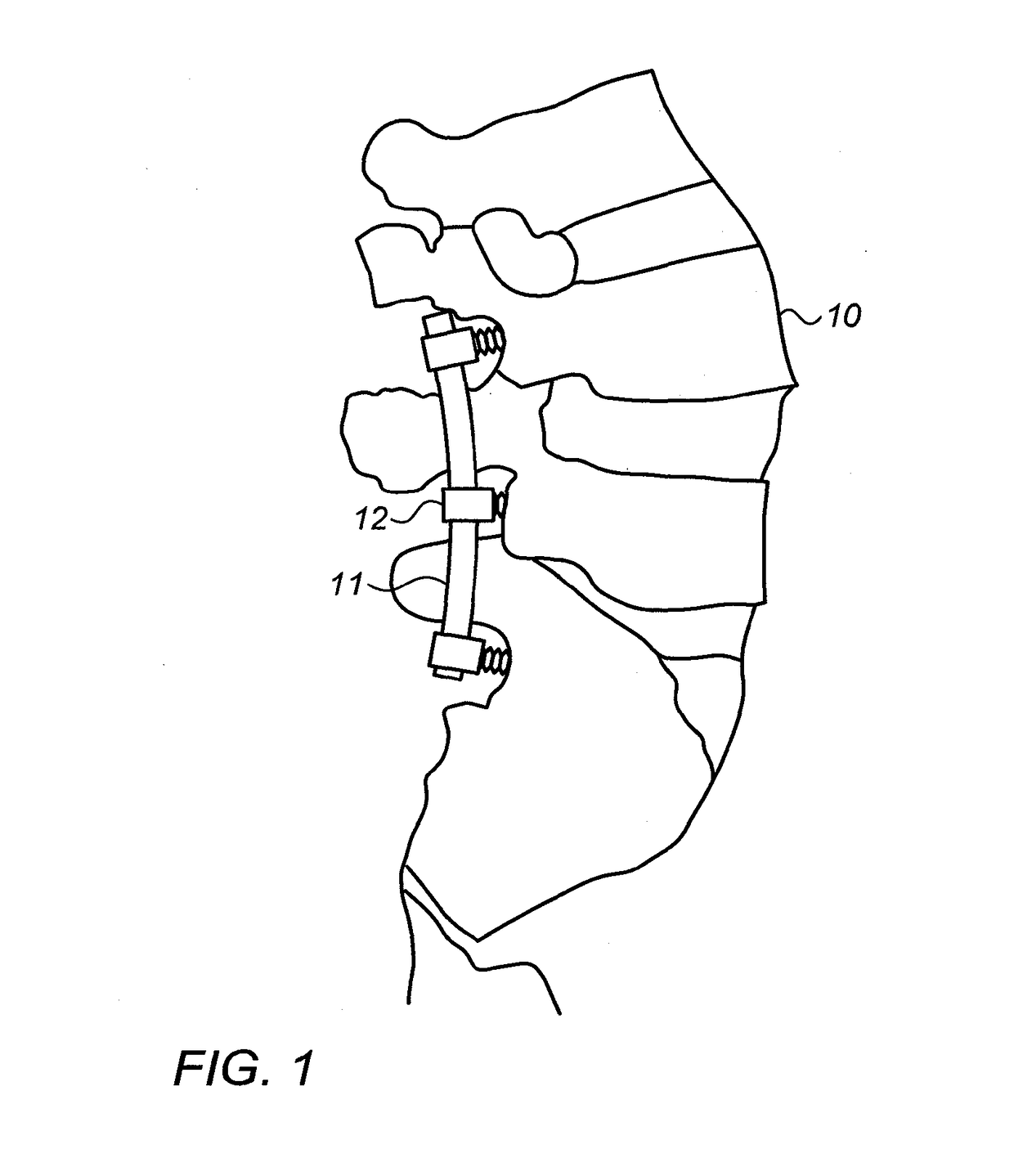

Shaper for vertebral fixation rods

ActiveUS20170360493A1Reduce the cross-sectional areaIncrease flexibilityInternal osteosythesisComputer-aided planning/modellingControl systemRobot control system

A system for rod bending for use in robotic spinal surgery, enabling the correct bending of a fusion rod to match the shape required to accurately pass through the heads of the pedicle screws. The system uses data generated by information provided to the robot by the surgeon's preoperative plan, optionally augmented by feedback from the robot control system of deviations encountered intraoperatively. Such deviations could occur, for example, when the surgeon decides intraoperatively on a different trajectory or even to skip screws on one vertebra, in which case, the robot will be commanded to perform the alternative procedure, with commensurate instructions relayed to the control system of the rod-bending machine. The system is also able to thin down the rod at predetermined locations along its length, adapted to be at selected intervertebral locations, for maintaining limited flexibility between vertebrae, instead of fixating them.

Owner:MAZOR ROBOTICS

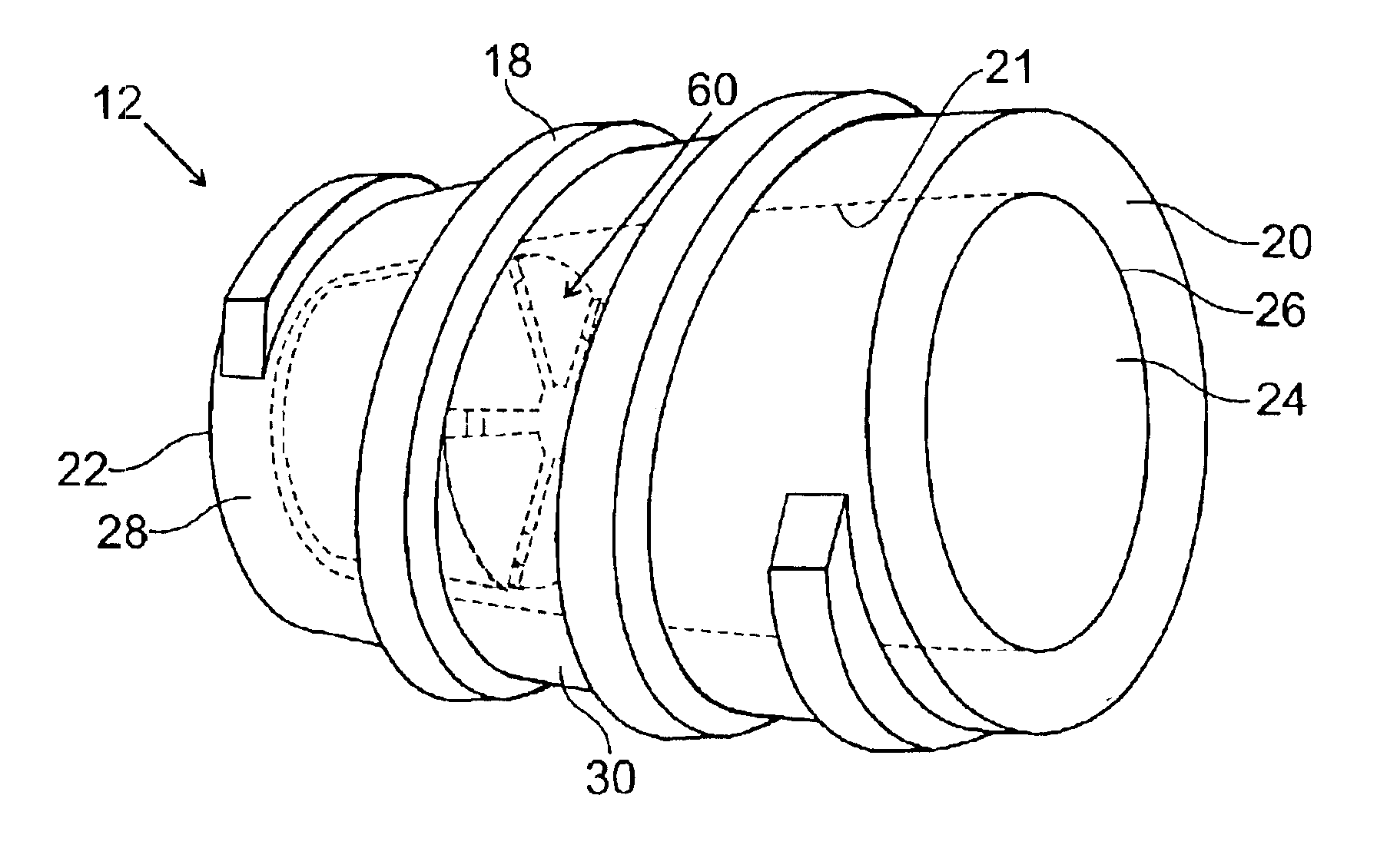

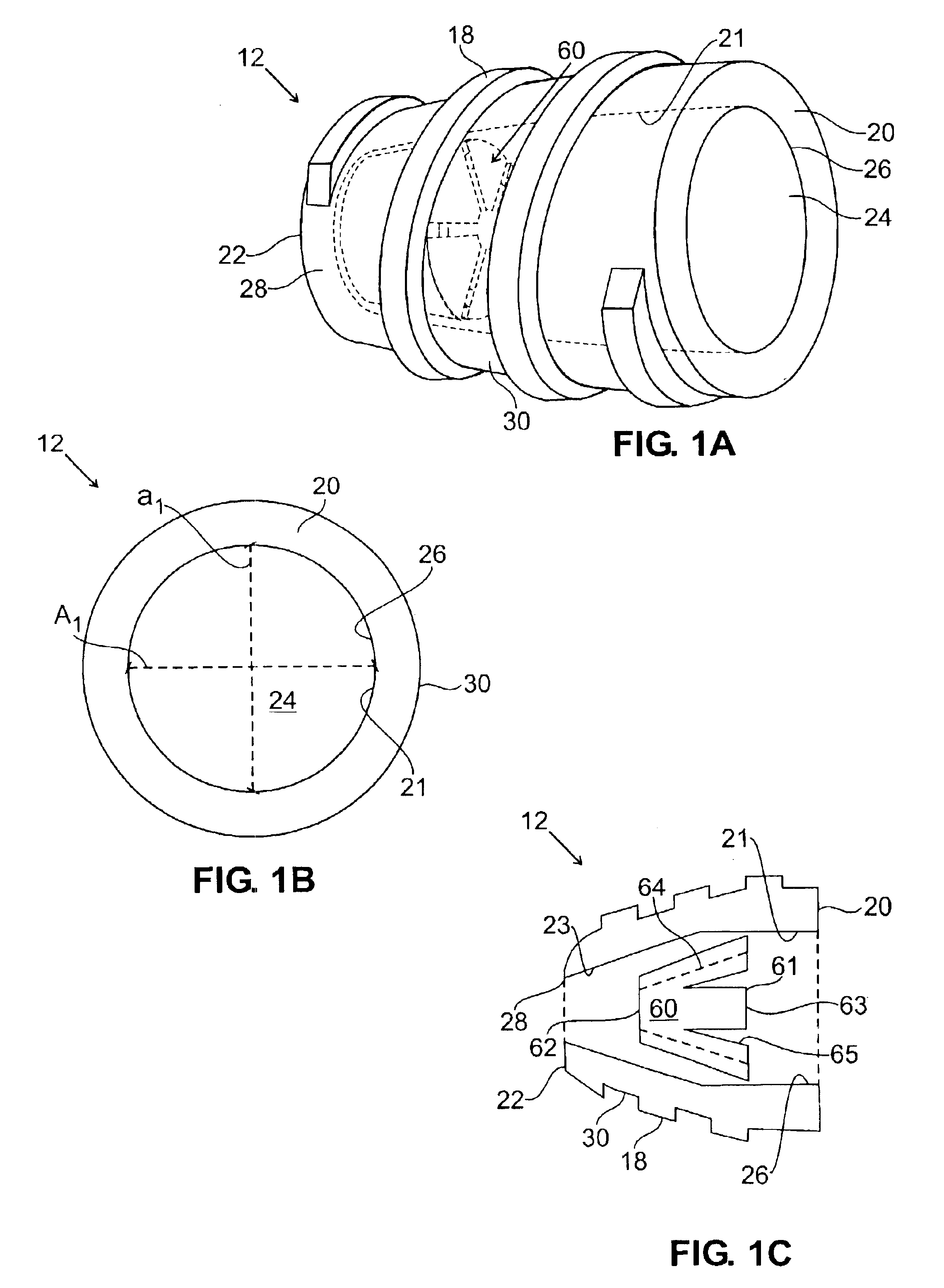

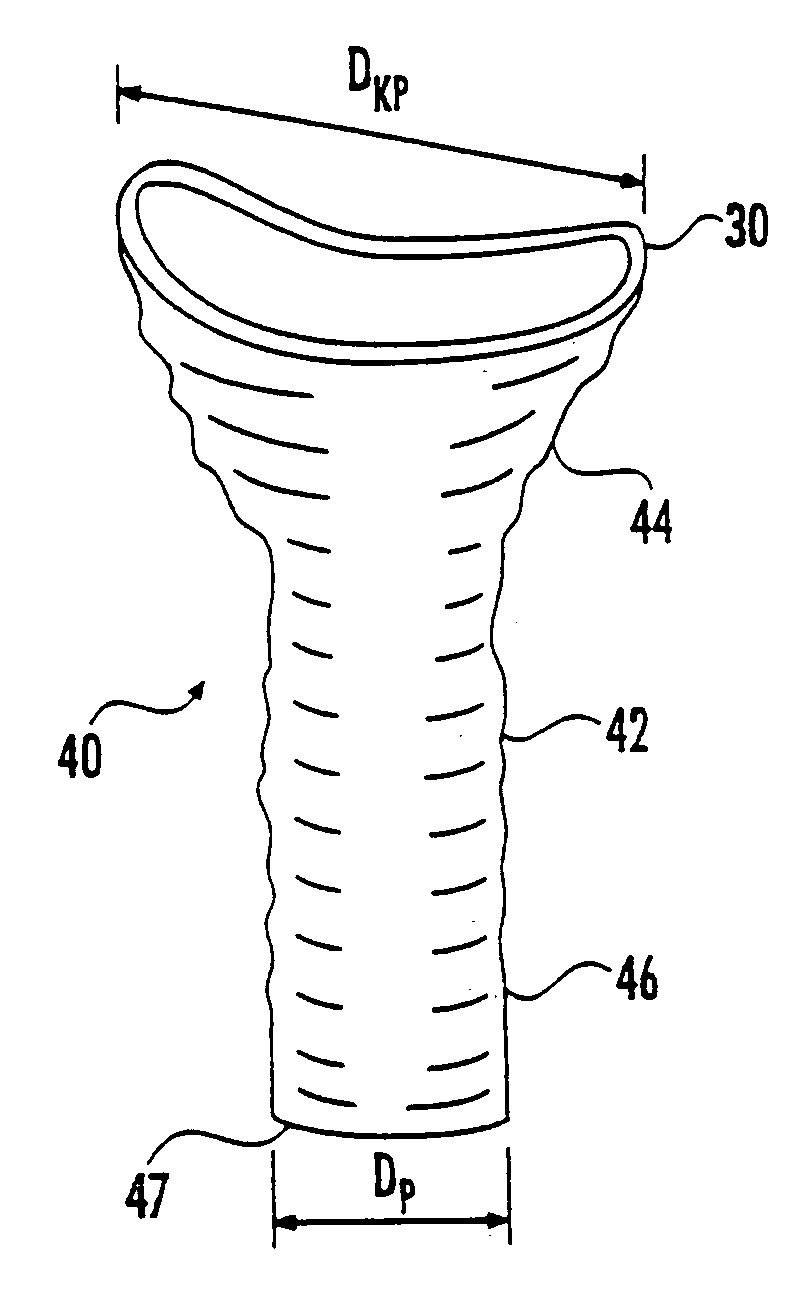

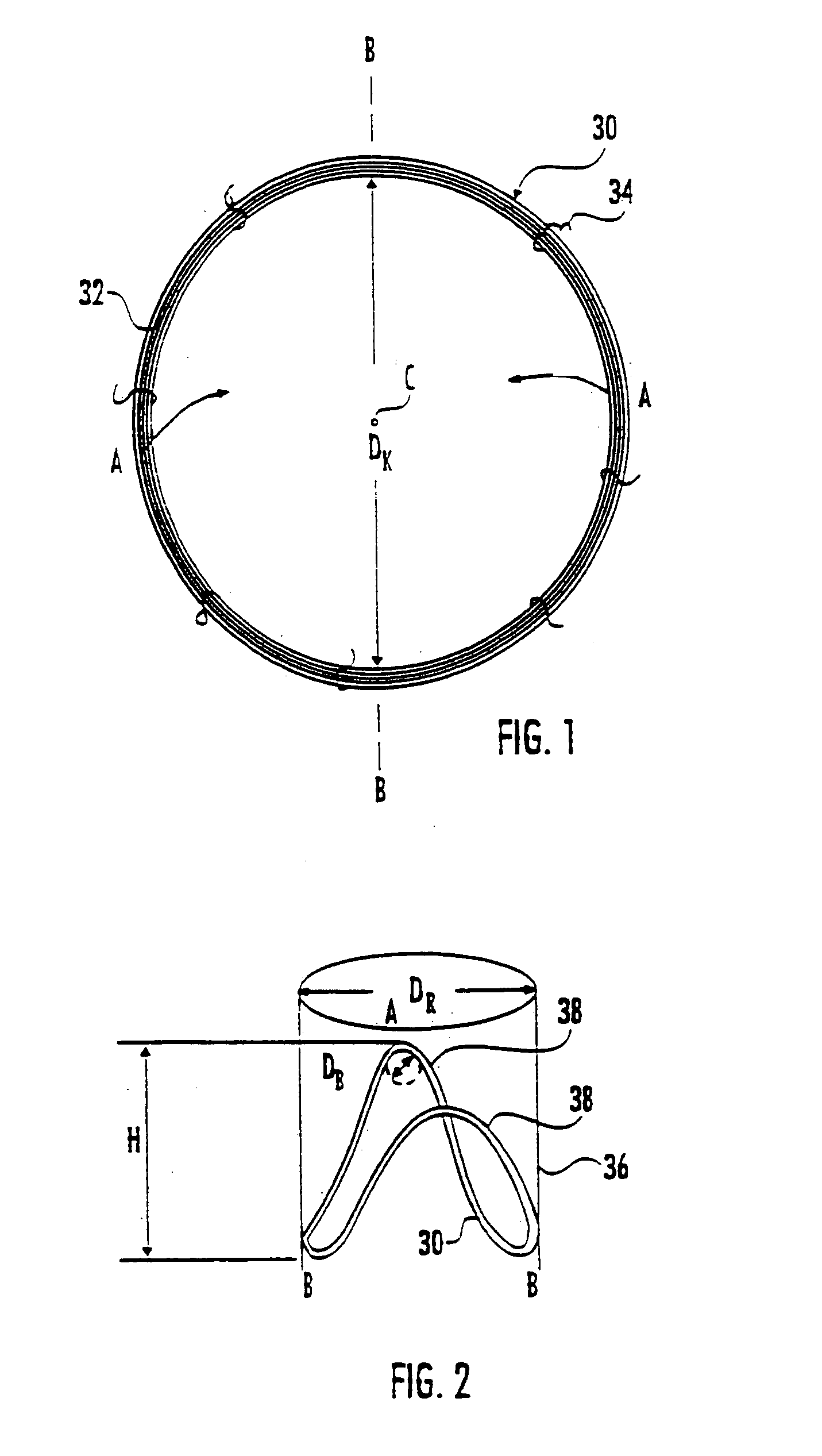

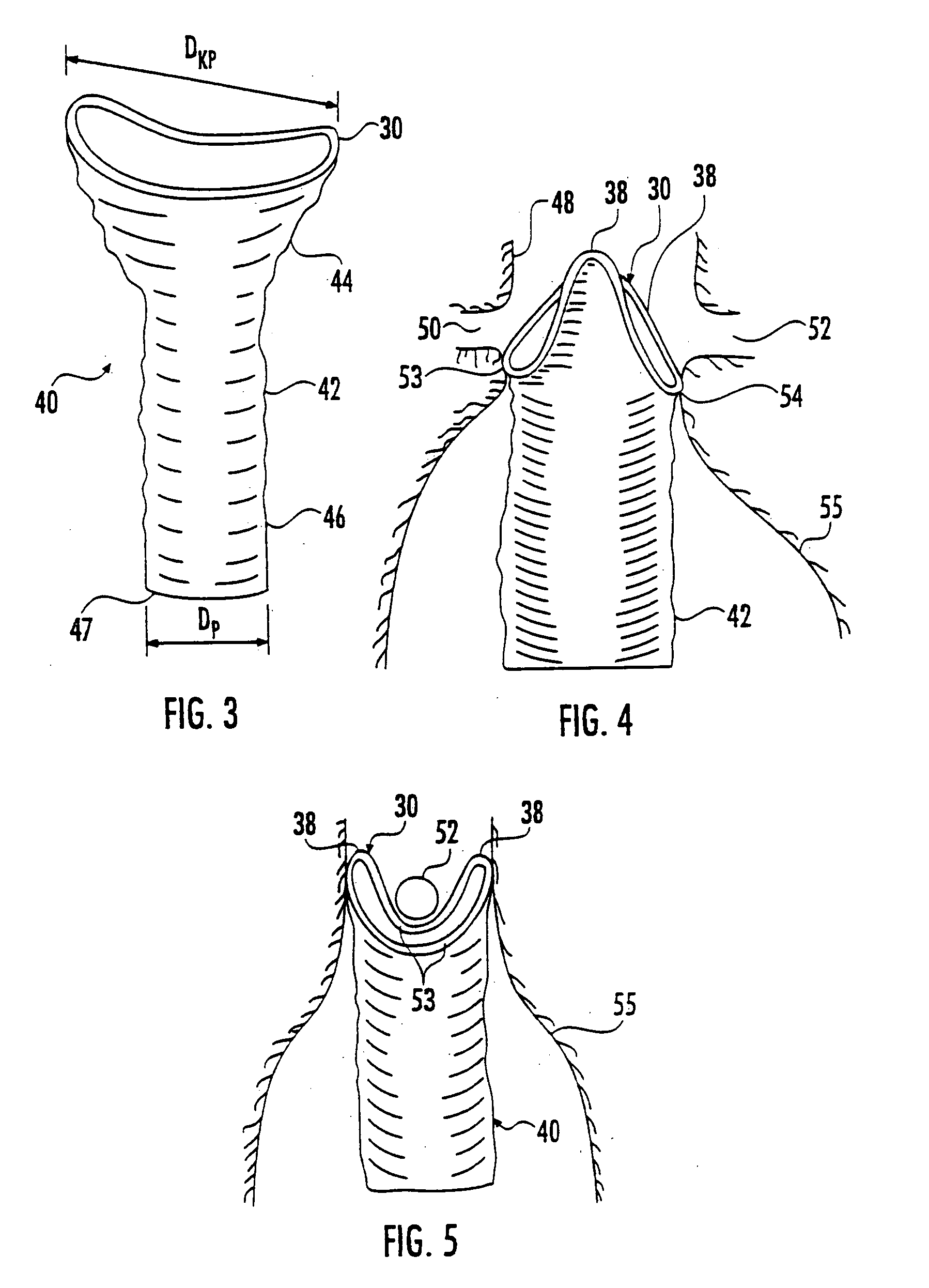

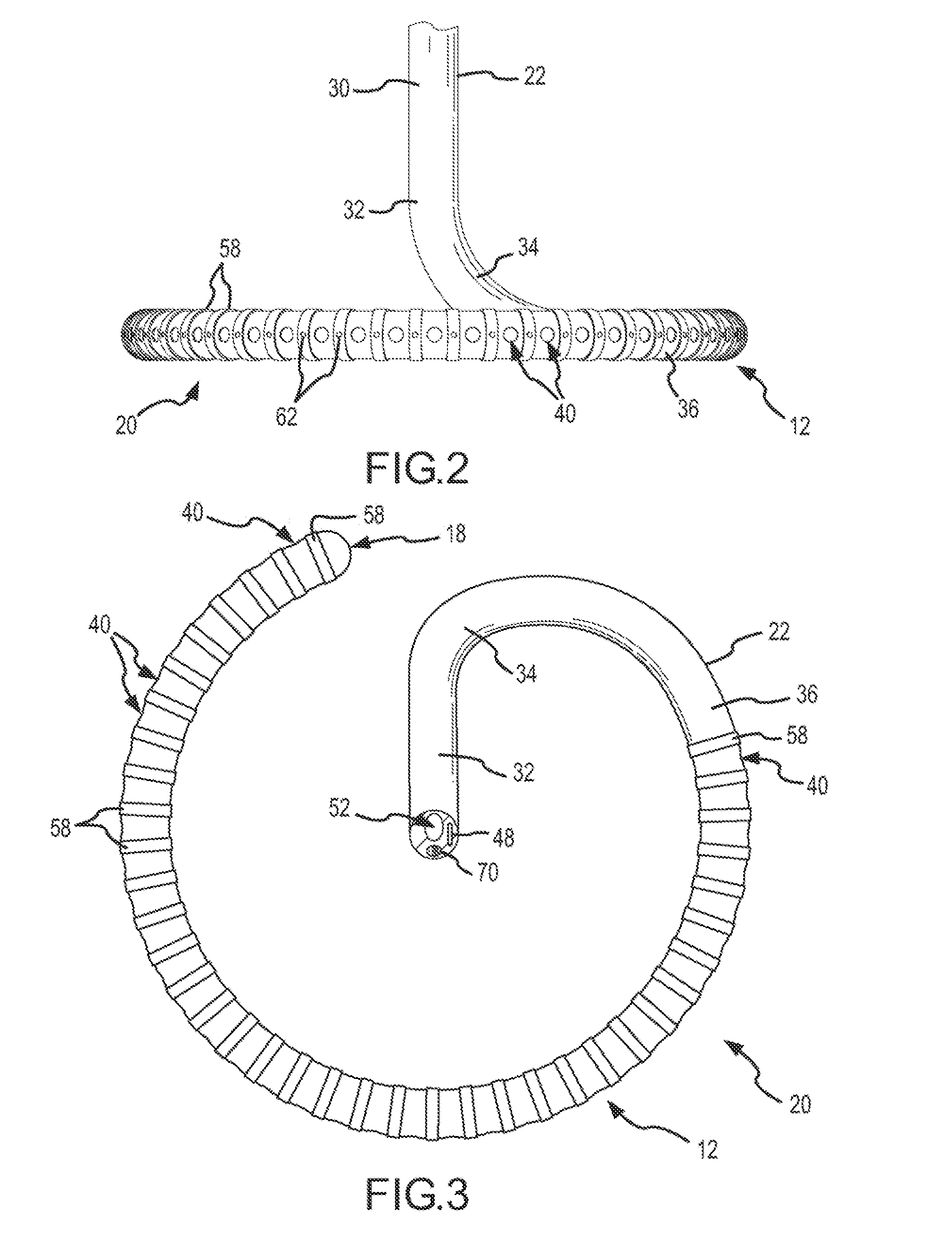

Prosthetic repair of body passages

ActiveUS20060041305A1Large caliberReduce the cross-sectional areaStentsHeart valvesProsthesisVascular stent

A prosthesis that resiliently engages a body passage includes an annular clamping ring which may be folded along a diametric axis for insertion into the body passage. The clamping ring is adapted to resiliently spring outwardly, once in position inside the body passage, and to be continually resiliently biased against the interior surface of the body passage. One or more of the clamping rings may be attached to opposed ends of a tubular graft. The rings and connected graft may be positioned in the body passage using a applicator which selectively permits expansion and / or in some embodiments contraction of the annular ring in position within a body passage. Alternatively a retaining member may be used to retain the annular ring in a compressed condition until it is in a desired position within a body passage. Among other potential uses, the present invention may be useful as a vascular stent for treating abdominal aortic aneurysms.

Owner:VASCUTEK

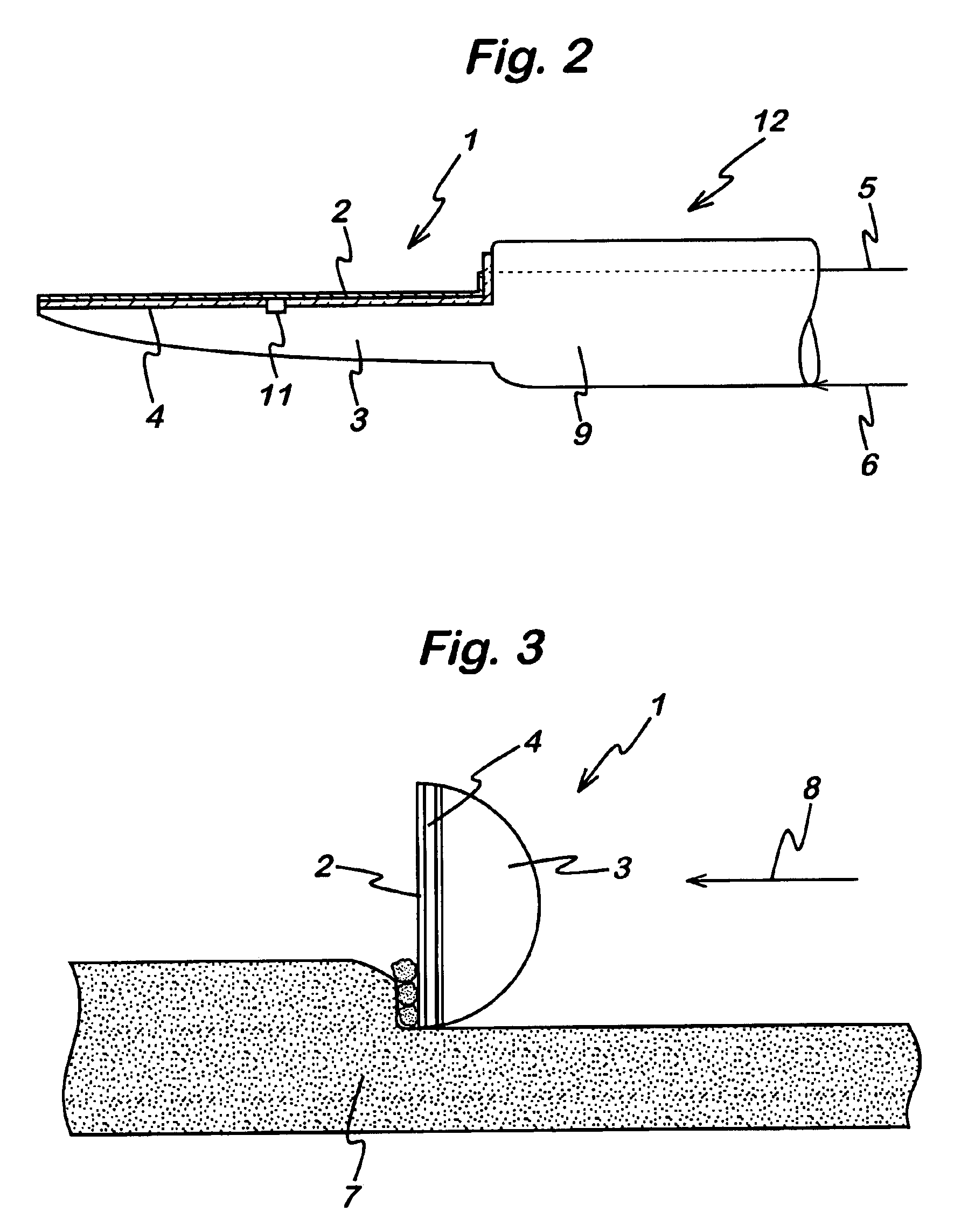

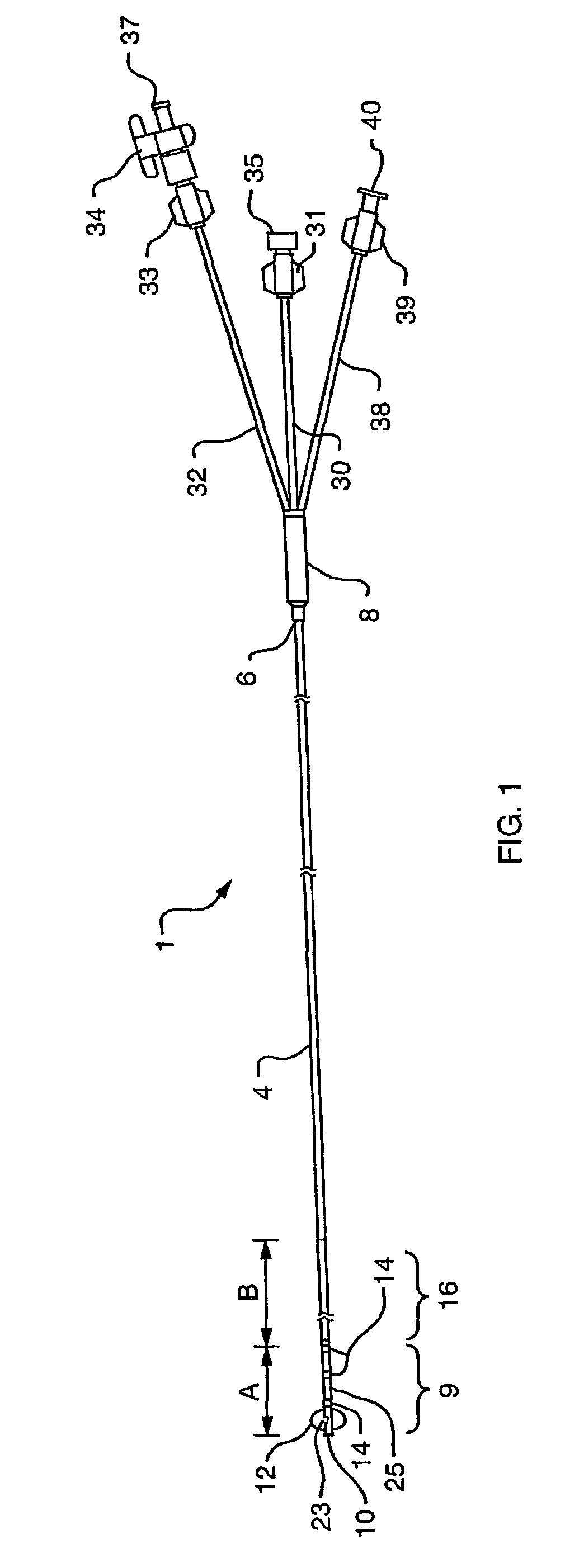

Triple lumen stone balloon catheter and method

InactiveUS7481800B2Acceptable inflationAcceptable deflation rateStentsBalloon catheterBalloon catheterKidney

A triple lumen stone balloon catheter (1) having a tapered distal end (9). A lumen (24) dedicated to transmitting contrast media is dimensioned and adapted to conform to the shape of a kidney in a main shaft of the catheter and conform to the shape of a crescent in a distal end of the catheter. The geometric shaping of the contrast media lumen (24) enables wall thickness to be maintained within acceptable ranges to sustain desirable mechanical characteristics while allowing for enhanced contrast media flow. A method for employing the balloon catheter (1) is also disclosed.

Owner:COMMAND ENDOSCOPIC TECH

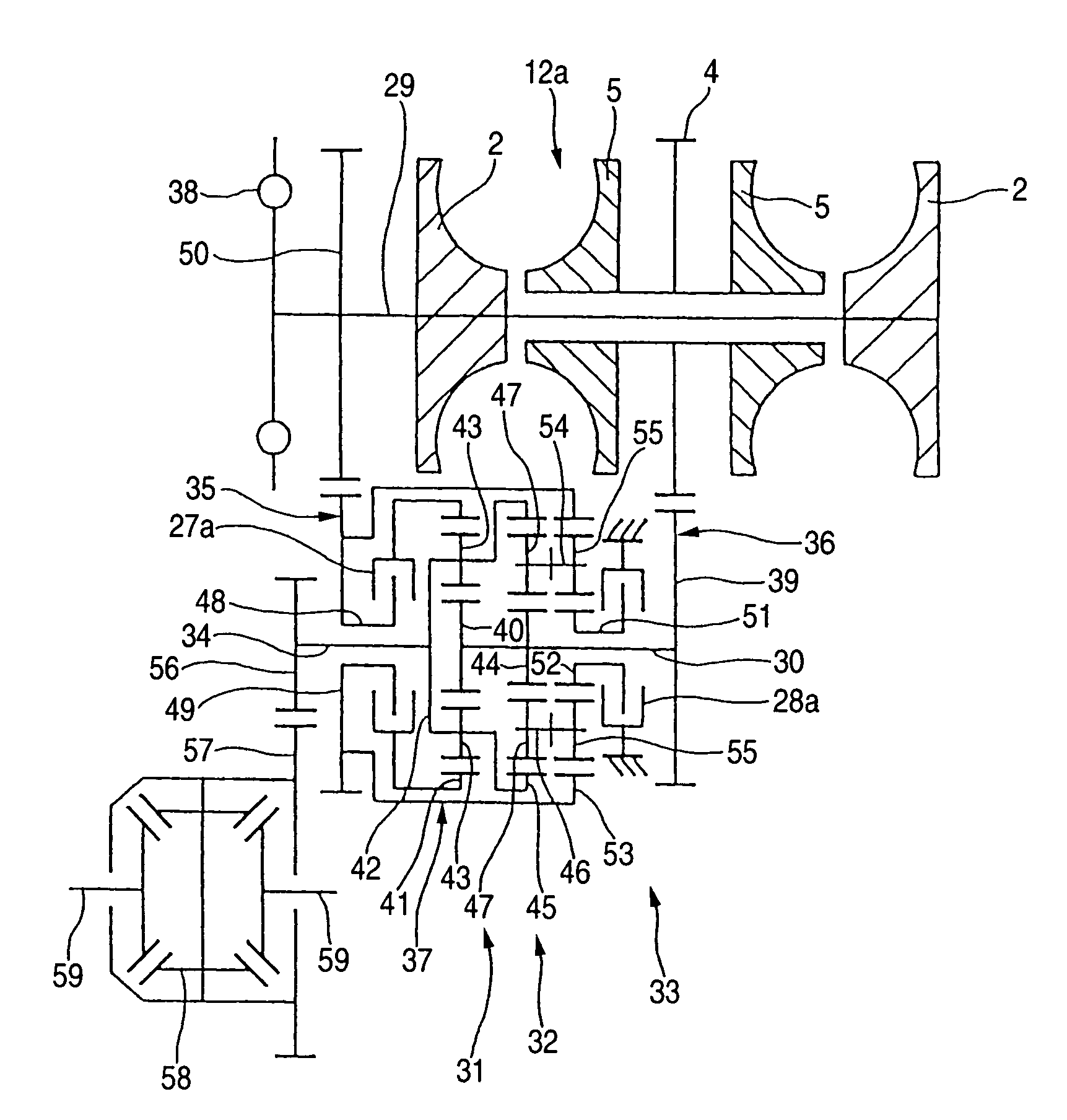

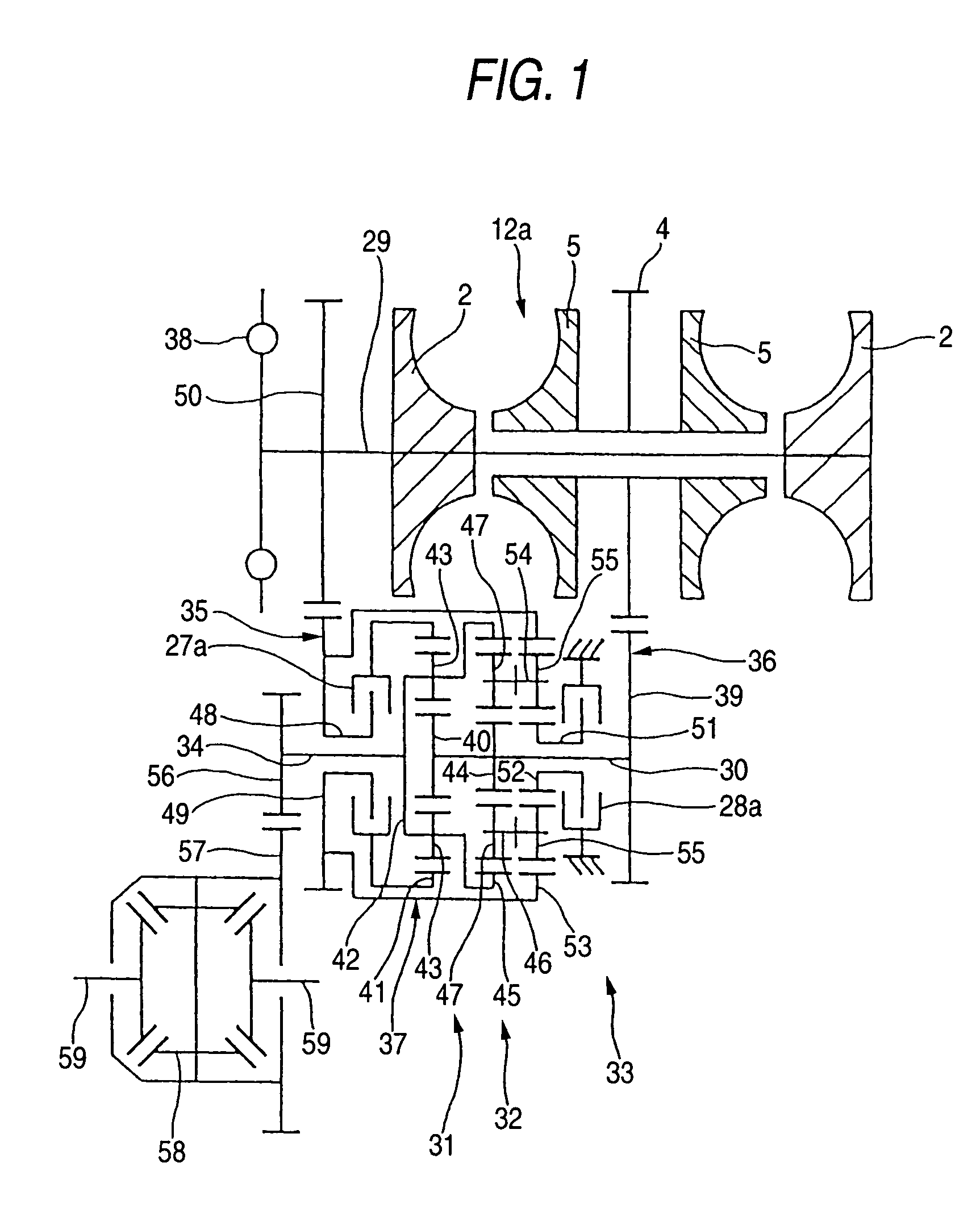

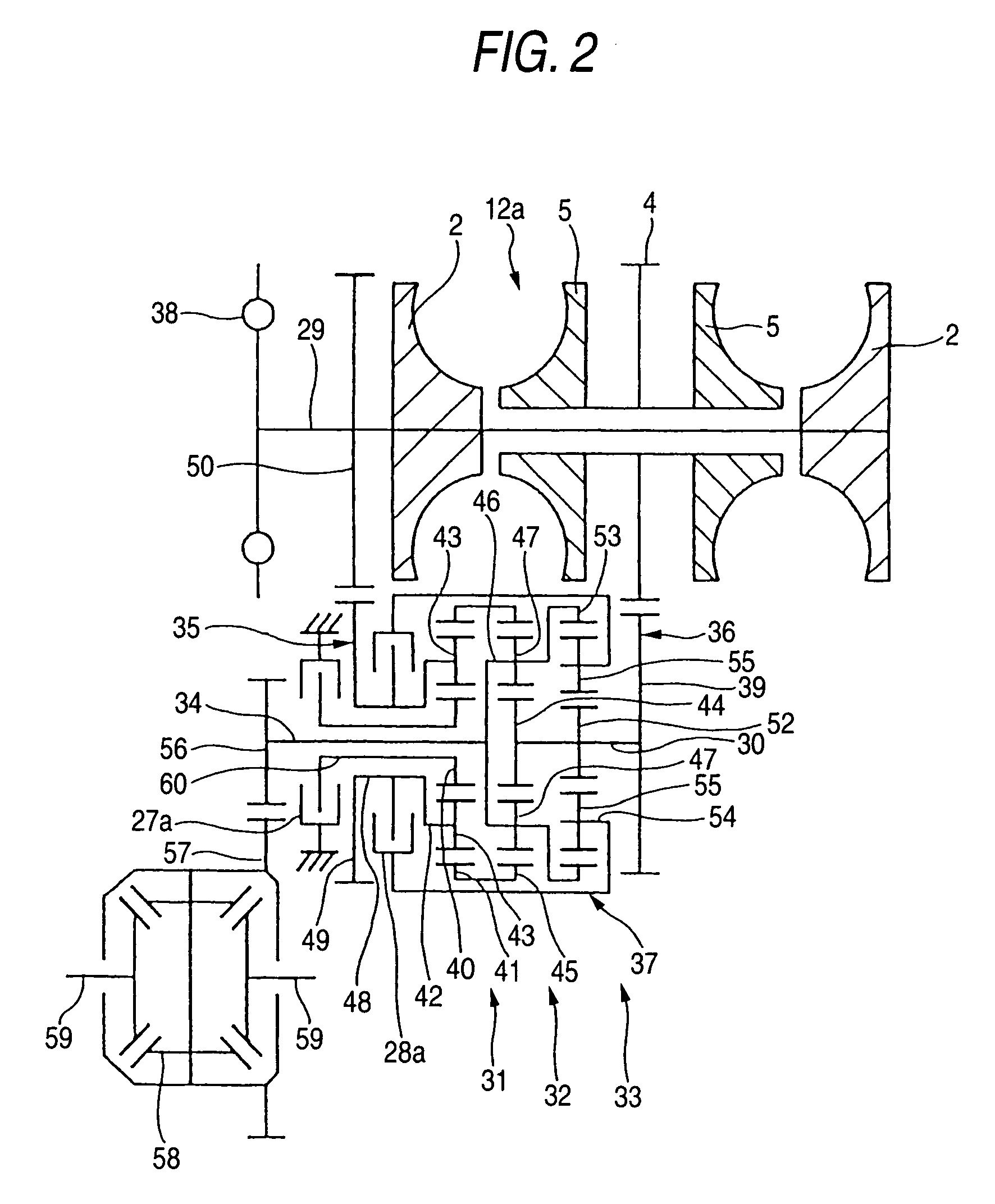

Continuously variable transmission apparatus

ActiveUS7094171B2Save spaceAxial-direction dimension can be reducedFriction gearingsGear wheelDrive shaft

A continuously variable transmission apparatus, has: an input shaft; a toroidal-type continuously variable transmission; a rotation transmission shaft; first, second and third planetary-gear-type transmissions; a first power transmission mechanism; a second power transmission mechanism; a third power transmission mechanism; and, a switching mechanism, wherein the second sun gear and one of the first and third sun gears are rotated together with the rotation transmission shaft to thereby execute the power transmission through the rotation transmission shaft and one of the first and second planetary-gear-type transmissions, and, in a state where the power transmission through the third planetary-gear-type transmission is cut off, in accordance with the control of the transmission ratio of the toroidal-type continuously variable transmission, the output shaft is stopped while the input shaft is rotating.

Owner:NSK LTD

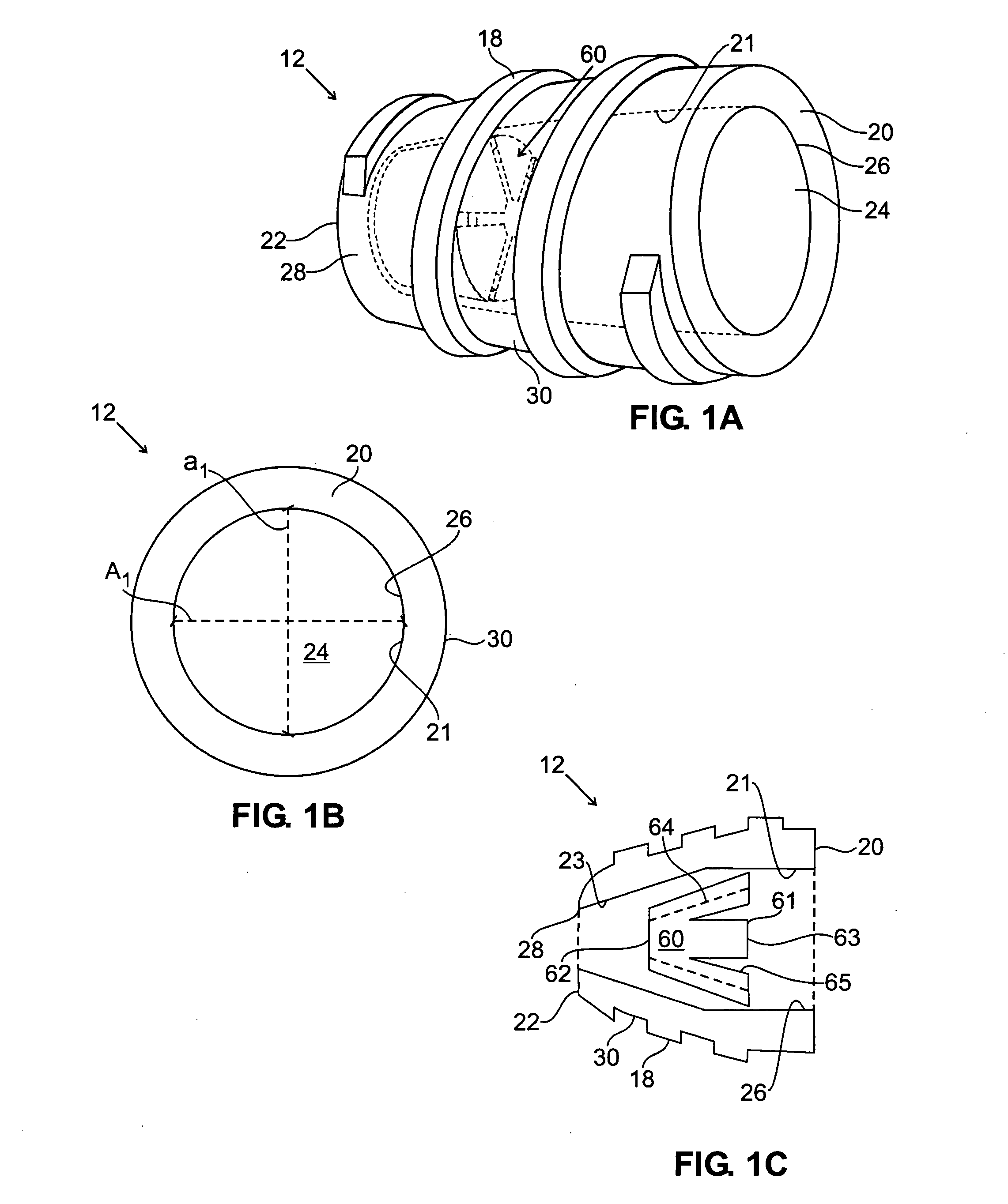

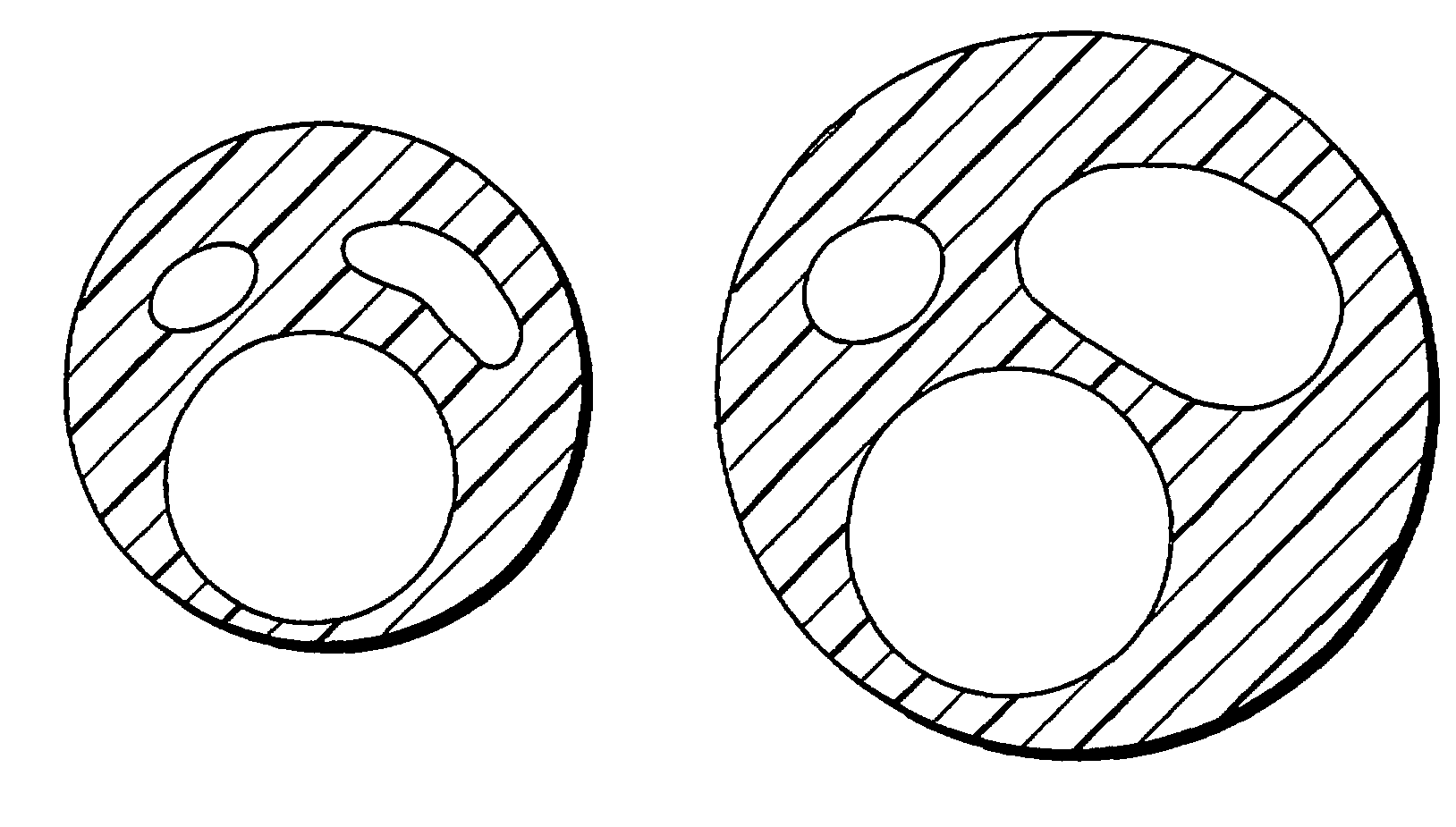

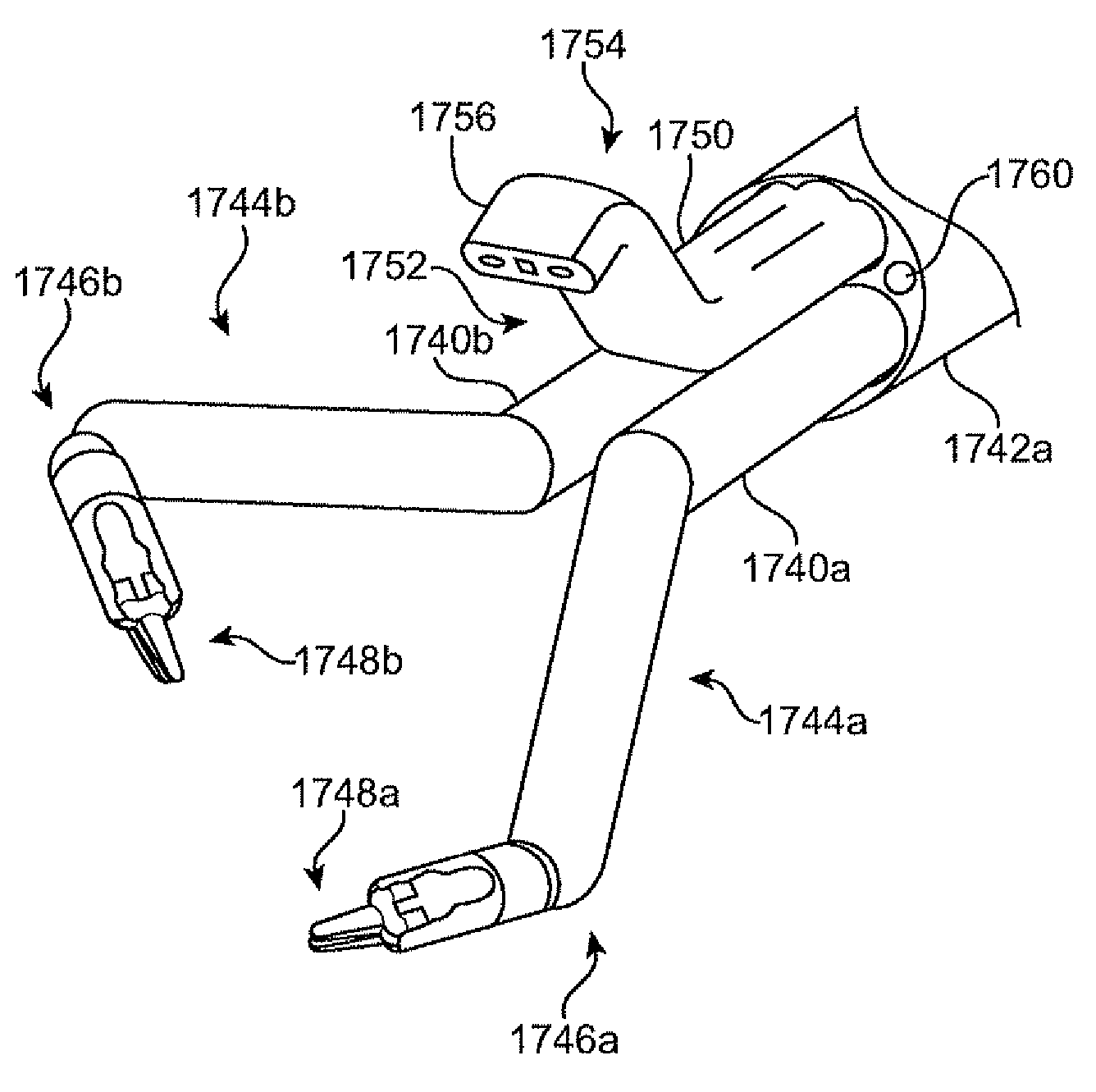

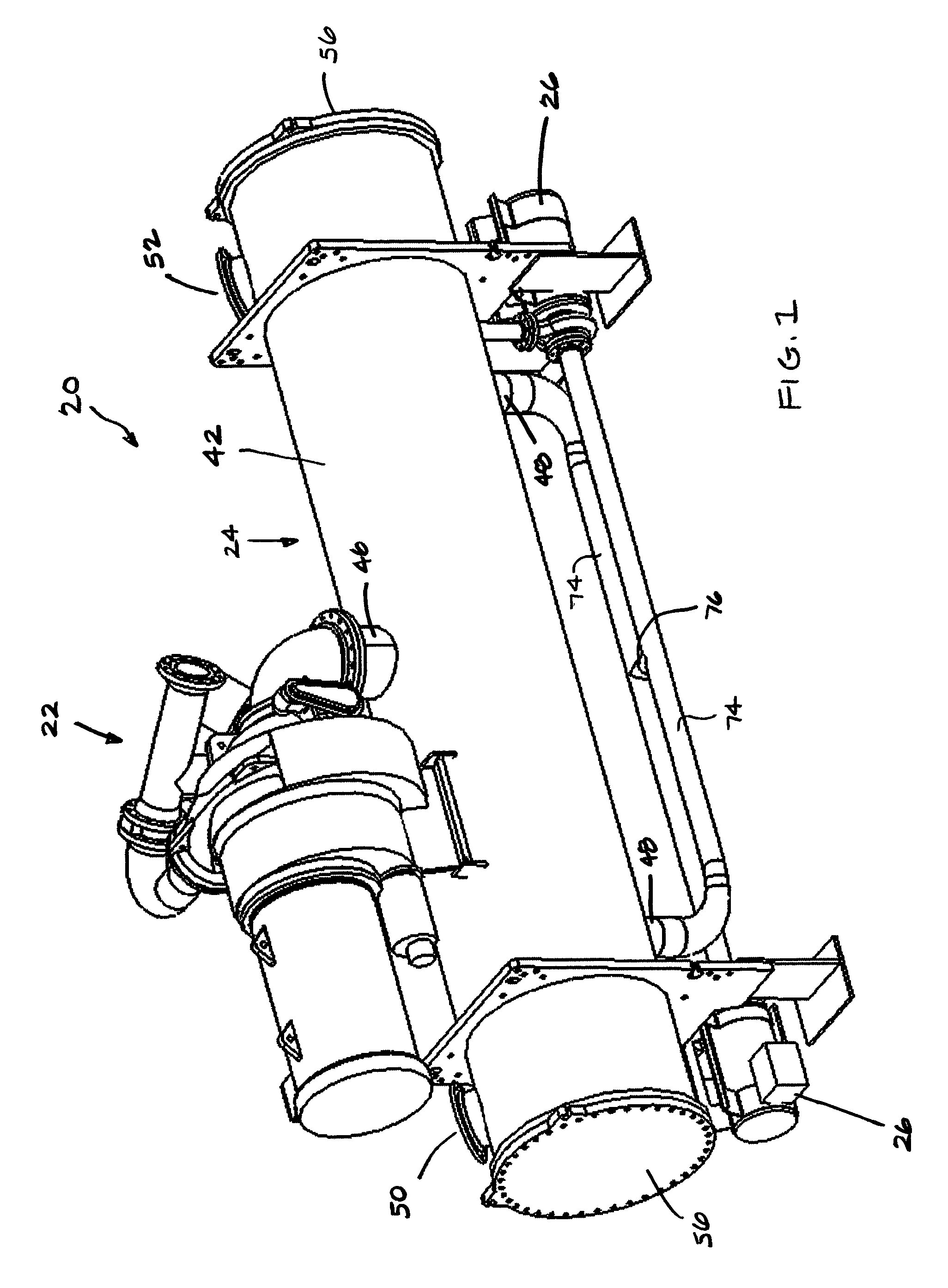

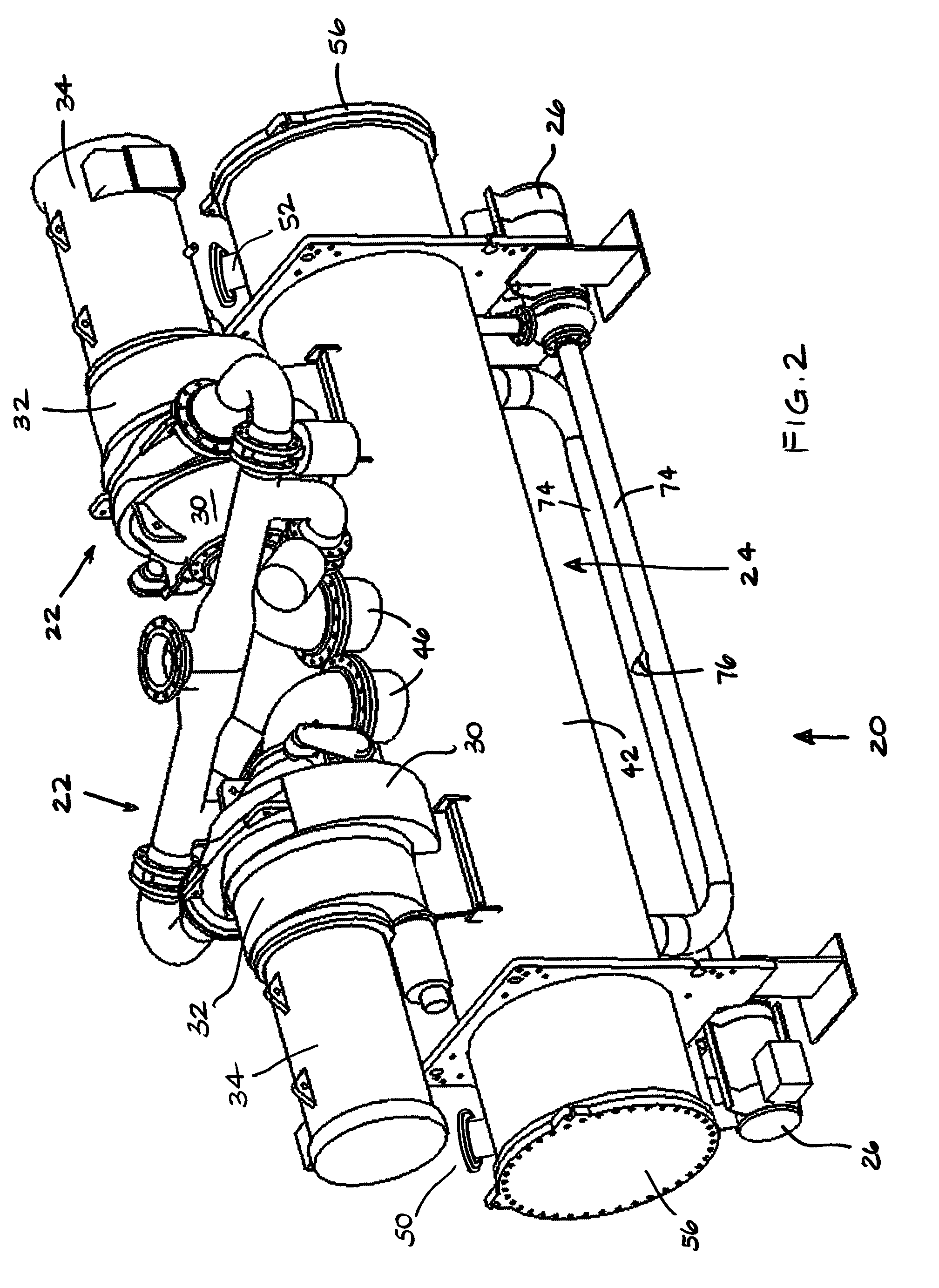

Minimally invasive surgical apparatus with side exit instruments

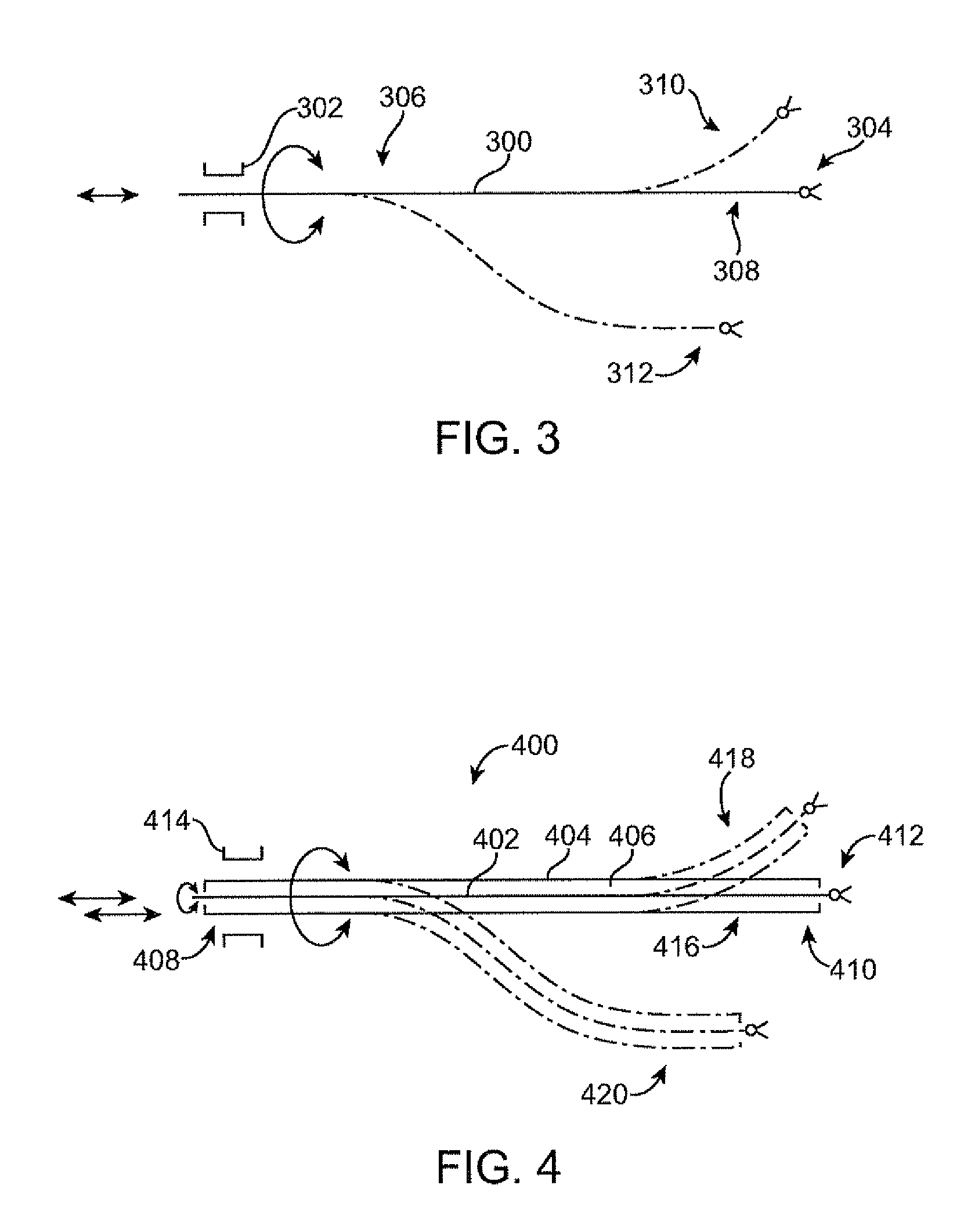

InactiveUS20080065101A1Reduce the cross-sectional areaMechanical/radiation/invasive therapiesCannulasSurgical departmentGuide tube

Two surgical instruments are inserted through a guide tube and exit via side exit ports of the guide tube. The side exit ports are on opposite sides of the guide tube. A stereoscopic image capture component is at the distal end of the guide tube. Both the surgical instruments and the guide tube may be flexible, and in some aspects the guide tube is retroflexive. The guide tube and the instruments are telemanipulatively controlled. The guide tube has an oblong-shaped cross section, and the instruments pass through opposite ends of the oblong shape, which allows the guide tube to have a reduced cross sectional area.

Owner:INTUITIVE SURGICAL OPERATIONS INC

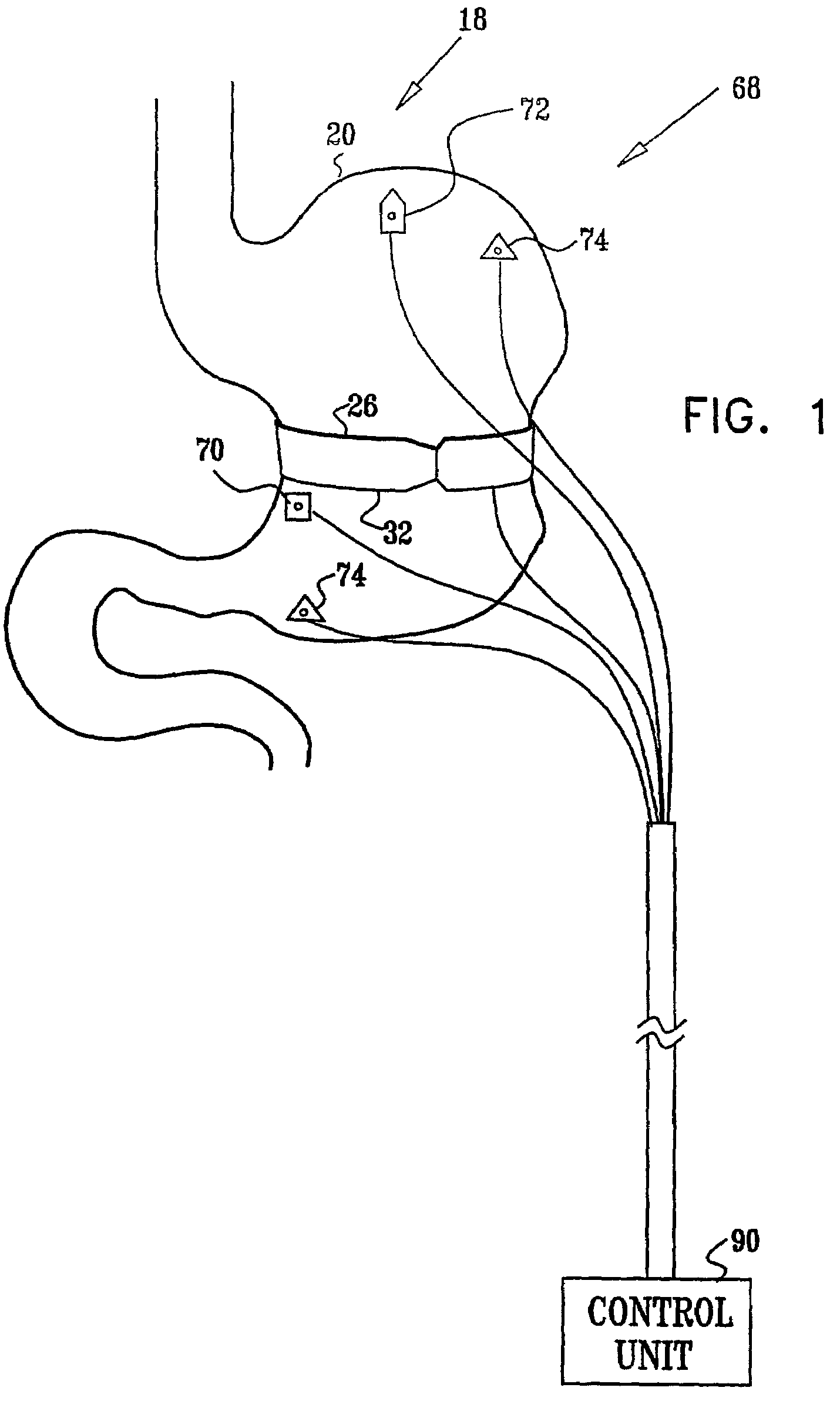

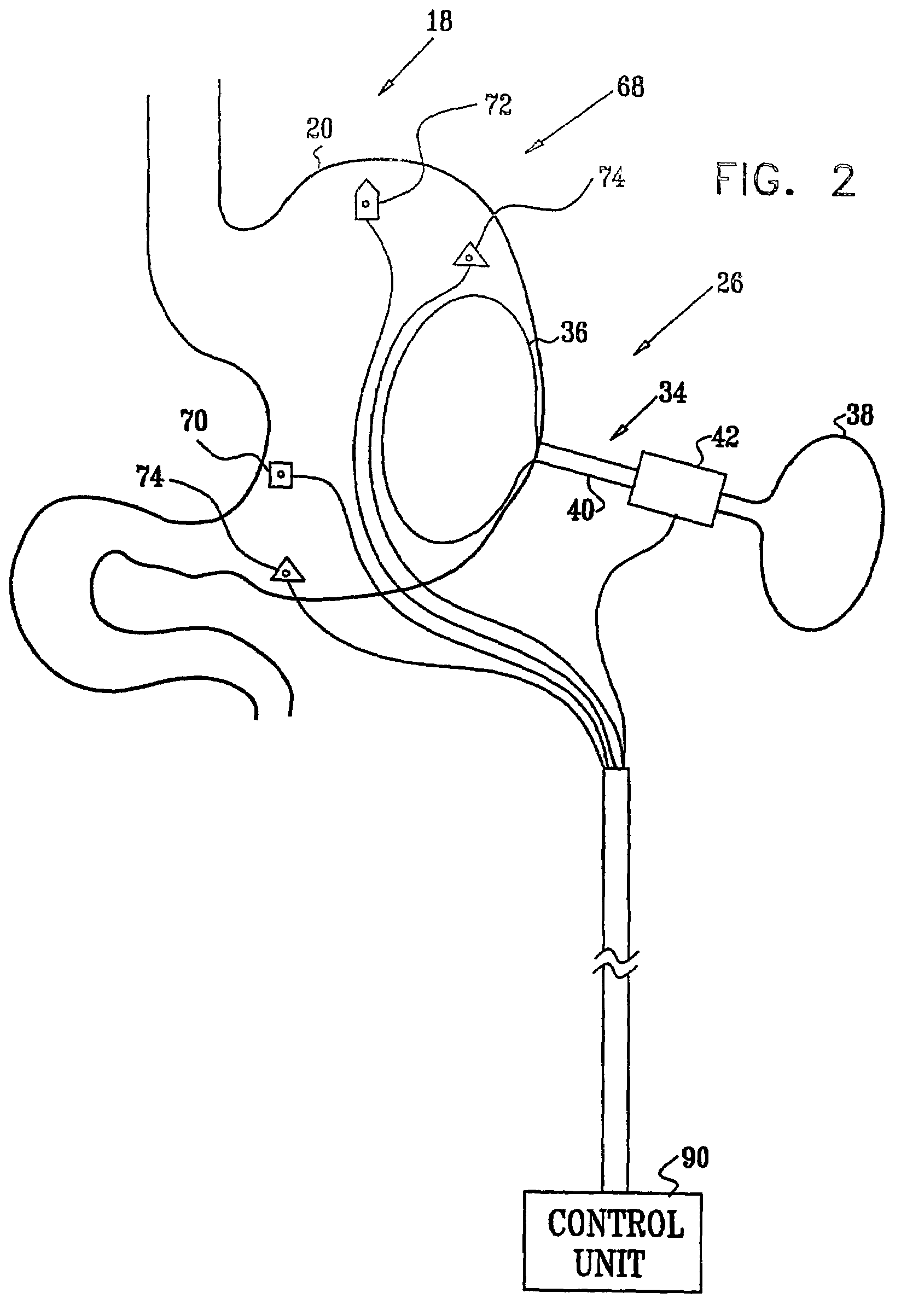

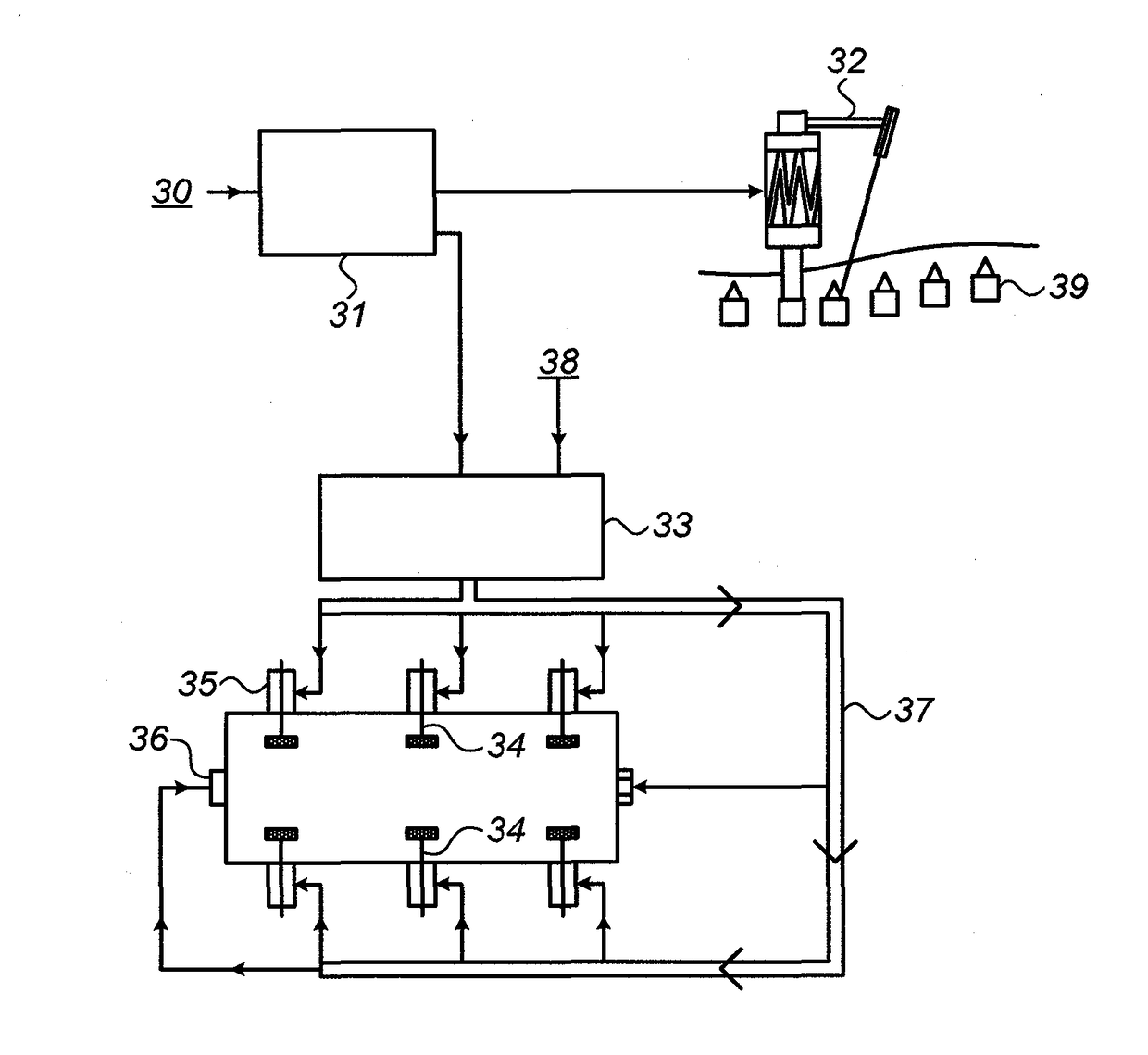

Acute and chronic electrical signal therapy for obesity

InactiveUS6993391B2Reduce the cross-sectional areaLower the volumeInternal electrodesExternal electrodesMuscle tissueObesity

Apparatus is provided for treating a condition such as obesity. The apparatus includes a set of one or more electrodes, which are adapted to be applied to one or more respective sites in a vicinity of a body of a stomach of a patient. A control unit is adapted to drive the electrode set to apply to the body of the stomach a signal, configured such that application thereof increases a level of contraction of muscle tissue of the body of the stomach, and decreases a cross-sectional area of a portion of the body of the stomach for a substantially continuous period greater than about 3 seconds.

Owner:TYLERTON INT INC

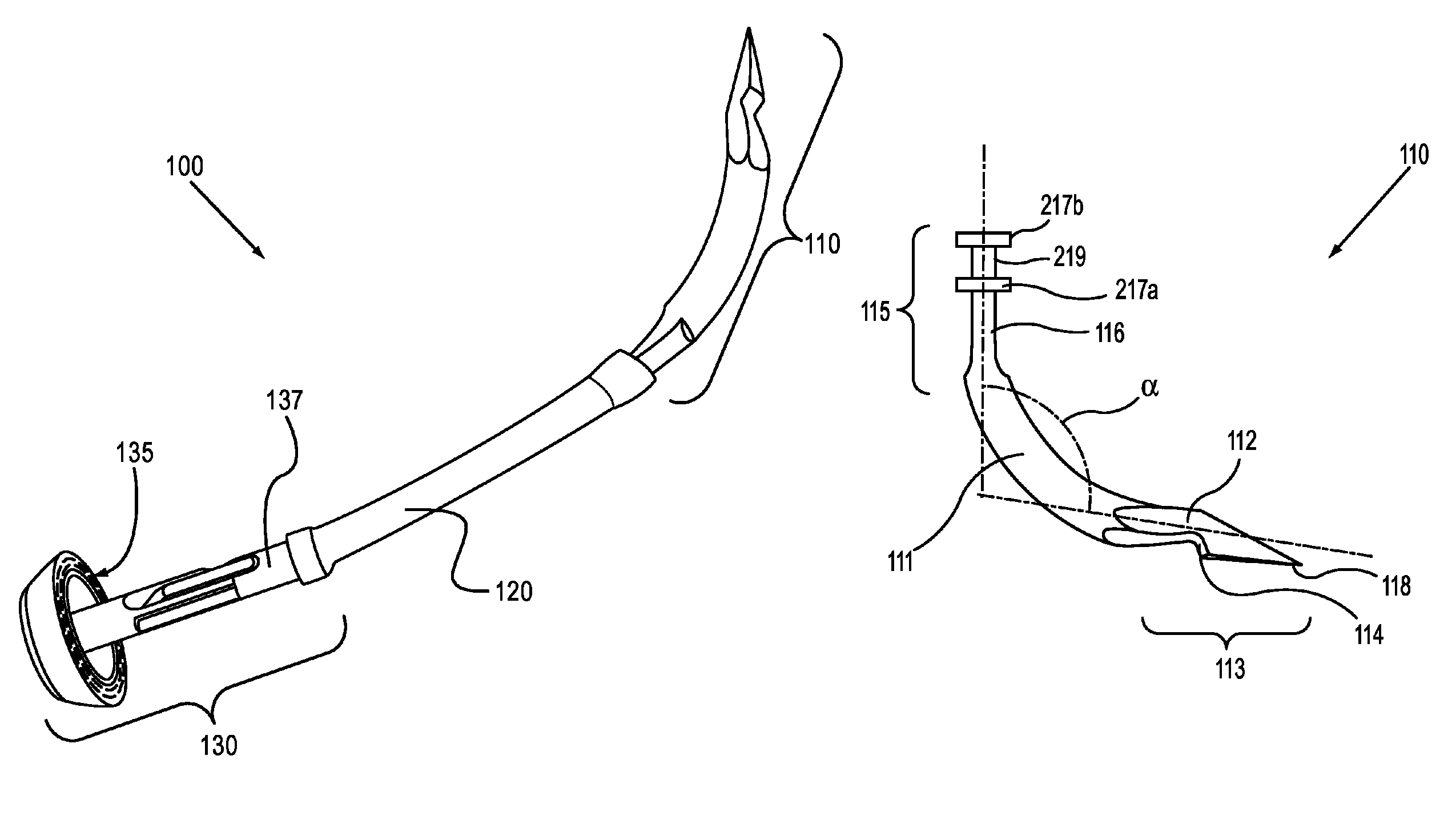

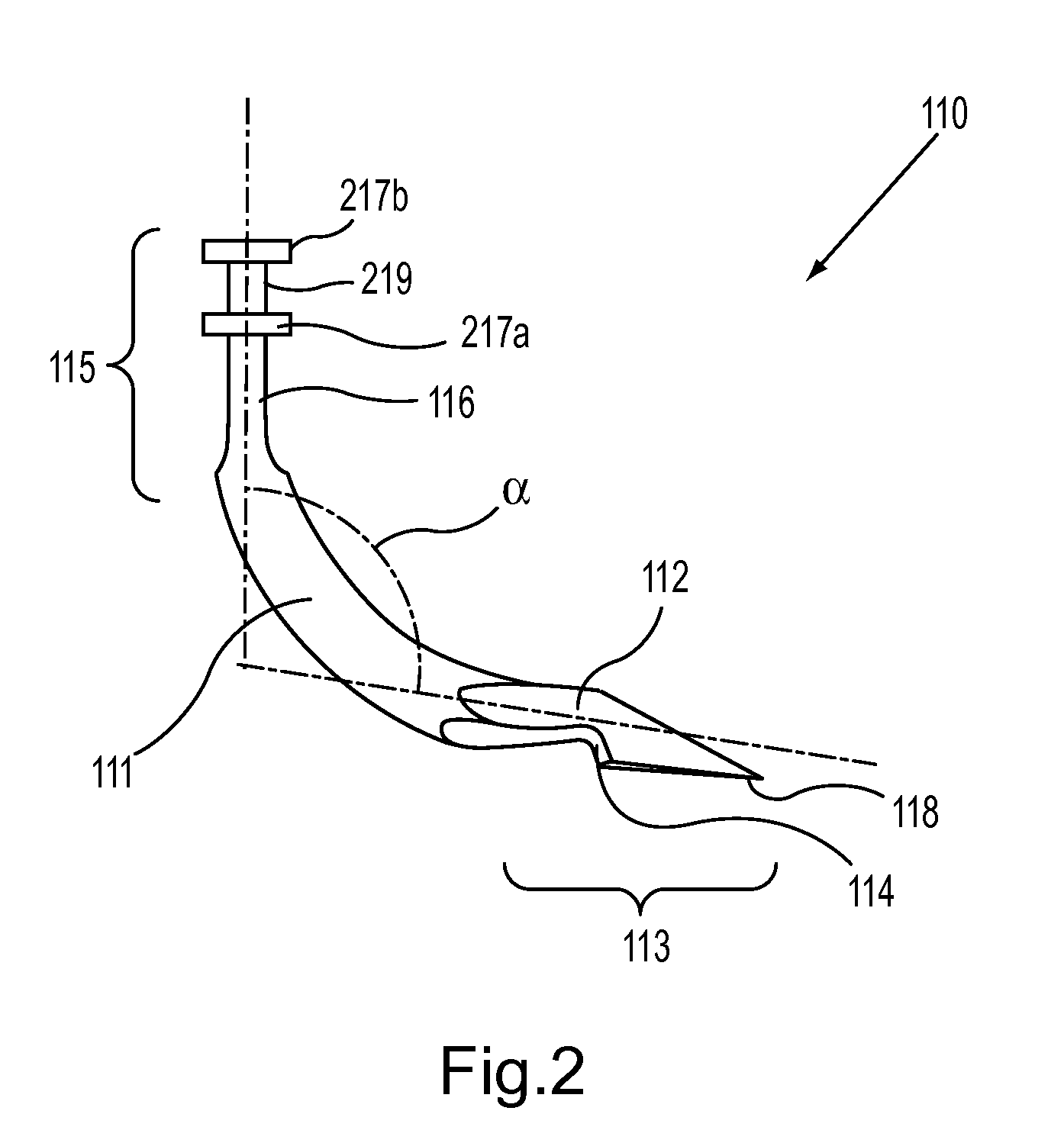

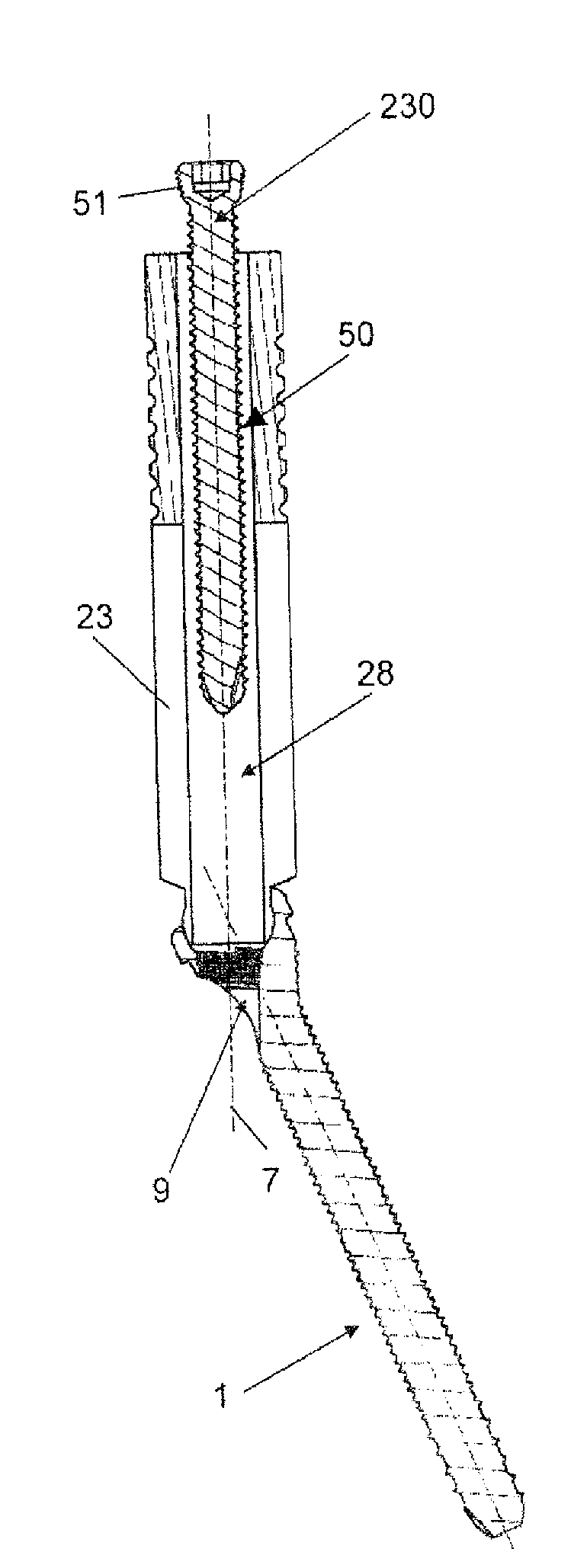

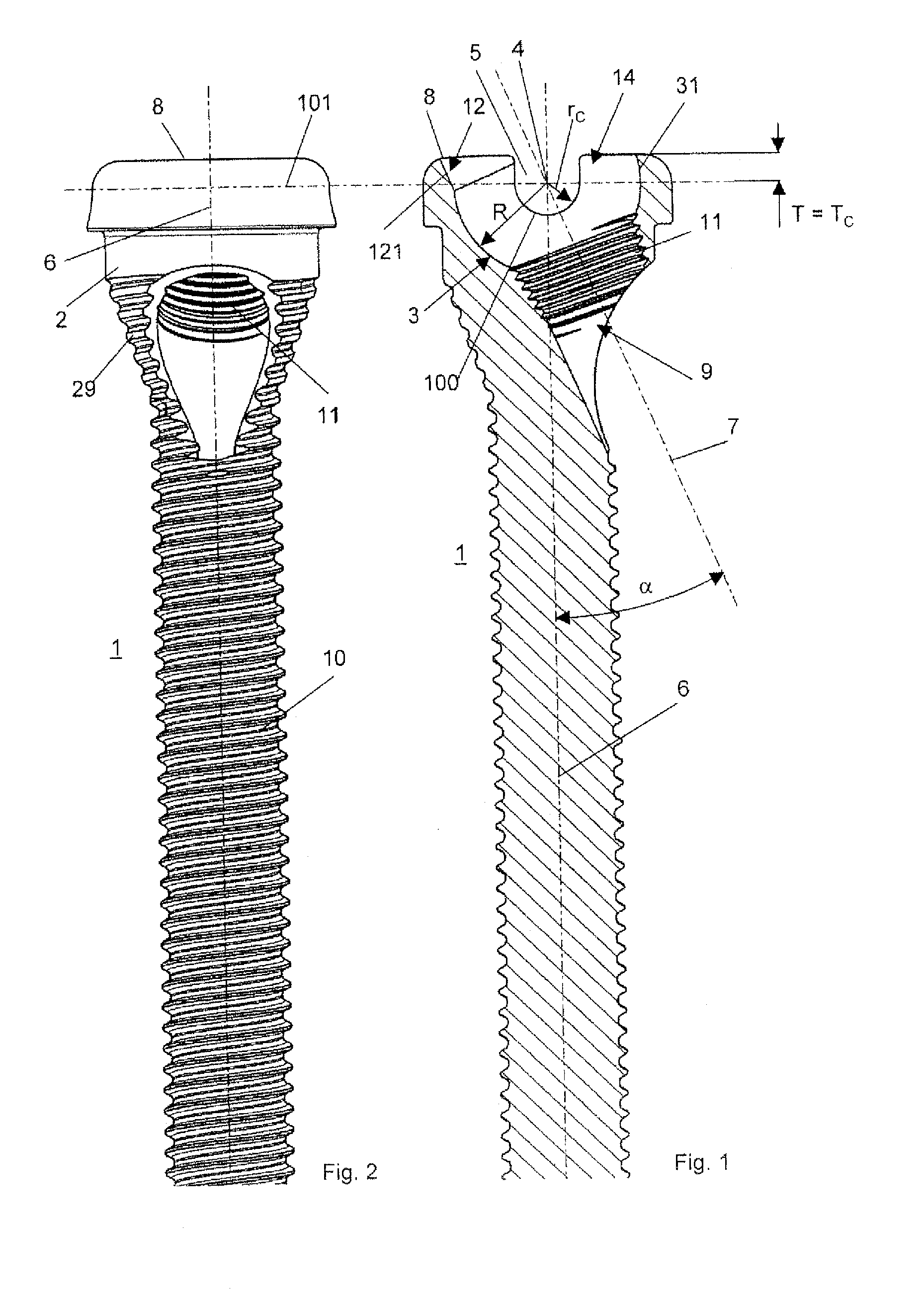

Bone Screw Assembly and Instruments for Implantation of the Same

InactiveUS20110282398A1Prevent crashReduce the cross-sectional areaSuture equipmentsInternal osteosythesisAcute angleEngineering

A bone screw includes a screw shaft extending longitudinally along a screw axis and a screw head extending from a proximal end of the screw shaft and configured to be releasably coupled to a surgical tool. The bone screw also includes a through hole defining a through hole axis and extending through the screw head, the through hole axis intersecting the screw axis at an acute angle α, the through hole being adapted to receive therein a second screw and tapering from a first end at a proximal end of the screw head to a second end opening to an outer surface of the screw head.

Owner:DEPUY SYNTHES PROD INC

Gastrointestinal methods and apparatus for use in treating disorders and controlling blood sugar

InactiveUS20070027493A1Reduce rise in blood insulin levelReduce volumeElectrotherapyElectricityGlucose polymers

Owner:TYLERTON INT INC

Low drag, high pressure septum

ActiveUS20130218082A1Drag minimizationImprove sealingGuide needlesInfusion syringesCatheterEngineering

A septum is disclosed that can be utilized in a catheter assembly to selectively seal an opening in the catheter assembly. The septum has a tube portion and a plug portion. The plug portion has a slit extending through it. The septum can transition from a non-collapsed state to a collapsed state. When the septum is in a non-collapsed state, the plug portion is offset from the tube portion such that some of the length of the slit extends outward from the distal end of the tube portion. When the septum transitions to the collapsed state, the plug portion is moved inward into the internal cavity such that some of the length of the slit may or may not extend outward from the distal end of the tube portion.

Owner:BECTON DICKINSON & CO

Illuminating unit having diffusion means

InactiveUS6858837B2High mechanical strengthSuppress mutationMechanical apparatusBeam/ray focussing/reflecting arrangementsLine sensorDiffusion

There is disclosed an image reading apparatus constructed by an illuminating unit for illuminating an object in a line shape, an image forming optical system for forming a light, as an image, from the object illuminated by the illuminating unit, a line sensor for converting the light formed as an image by the image forming optical system into an image signal, and a frame for holding the illuminating unit and the line sensor, wherein a shape in which vertices of at least a part of the cross section of the illuminating unit are connected by straight lines is set to a polygon of a pentagon or more, so that an image can be stably read at a high quality.

Owner:CANON KK

Lighting apparatus

InactiveUS7534011B2Reduce the cross-sectional areaIncrease the cross-sectional areaClimate change adaptationLighting heating/cooling arrangementsEngineeringMechanical engineering

Owner:INT GROWERS SUPPLY

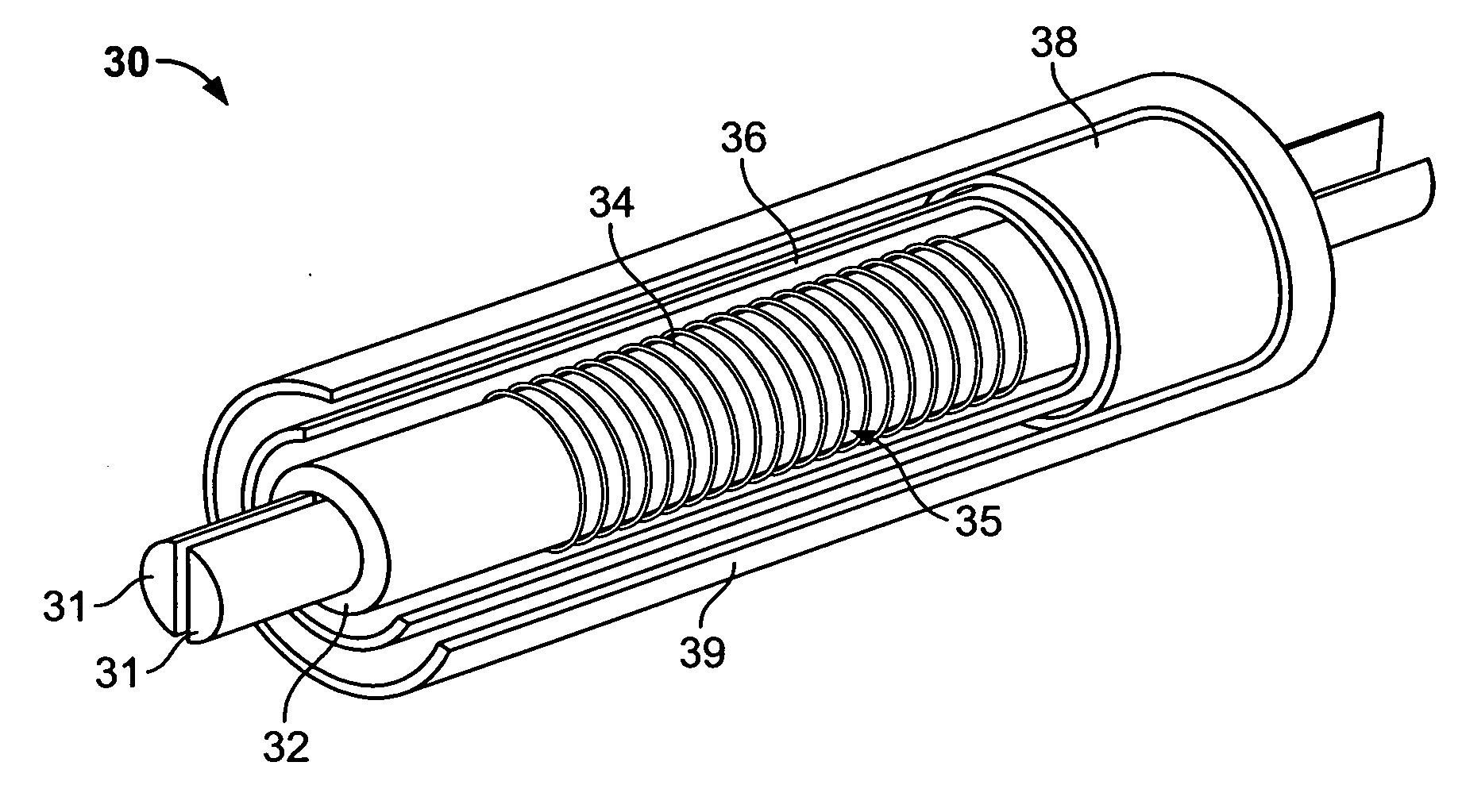

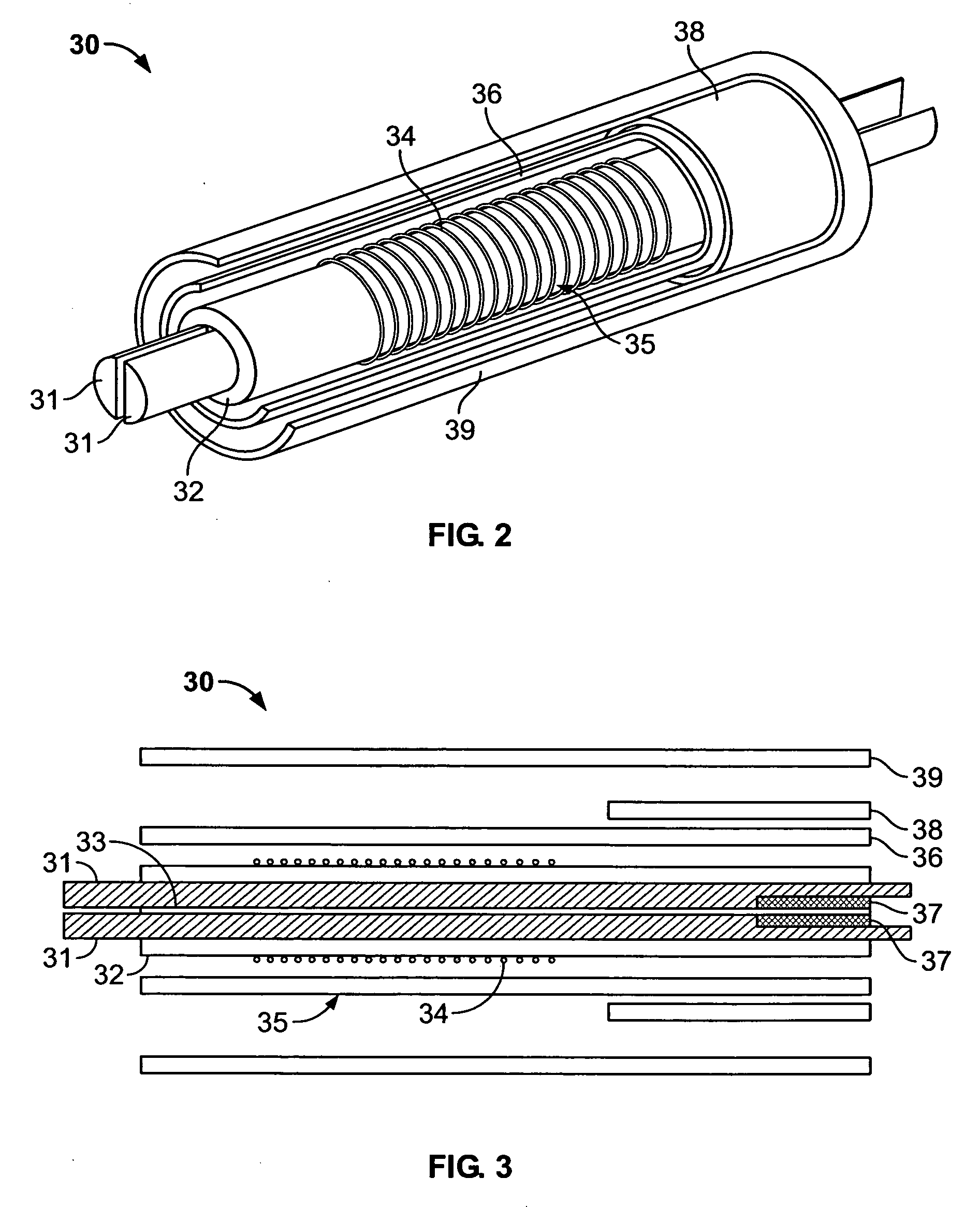

Reinforced multi-lumen catheter

InactiveUS20070005003A1Bonding strengthHigh bonding strengthMulti-lumen catheterOther blood circulation devicesCatheter device

A reinforced multi-lumen catheter and method of manufacturing the same. An assembly for manufacturing the multi-lumen catheter includes a catheter body substrate including a septum, one or more mandrels, a reinforcing element and one or more sleeves. The septum may have a distal region with a cross-sectional thickness greater than that of a proximal region. The septum can be separately formed. The septum can be split along a length of the distal region. The reinforcing element can be positioned over at least a proximal region of the catheter body substrate.

Owner:CR BARD INC

Ablation Catheter With Sensor Array And Discrimination Circuit To Minimize Variation In Power Density

InactiveUS20080161788A1Reduce connectionsReduce the numberThermometers using electric/magnetic elementsUsing electrical meansSensor arrayEngineering

A catheter is designed with a virtual electrode structure for creating a linear lesion. The catheter includes a sensor array that measures temperatures of adjacent tissue along the length of the virtual electrode section. The sensors in the sensor array include a conductive material that is substantially coated with an electrically and thermally insulating material. An aperture is formed in the insulating coating to expose an area of the conductive material. Leads are coupled with each sensor and are connected at their opposite, proximal ends with a discrimination circuit. The circuit processes the signals induced in the sensors to output a single temperature measurement, for example, the highest temperature, the lowest temperature, or the average temperature. The sensors also measure cardiac electrical activity and the leads are further connected to an electrocardiograph monitor to determine the efficacy of treatment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

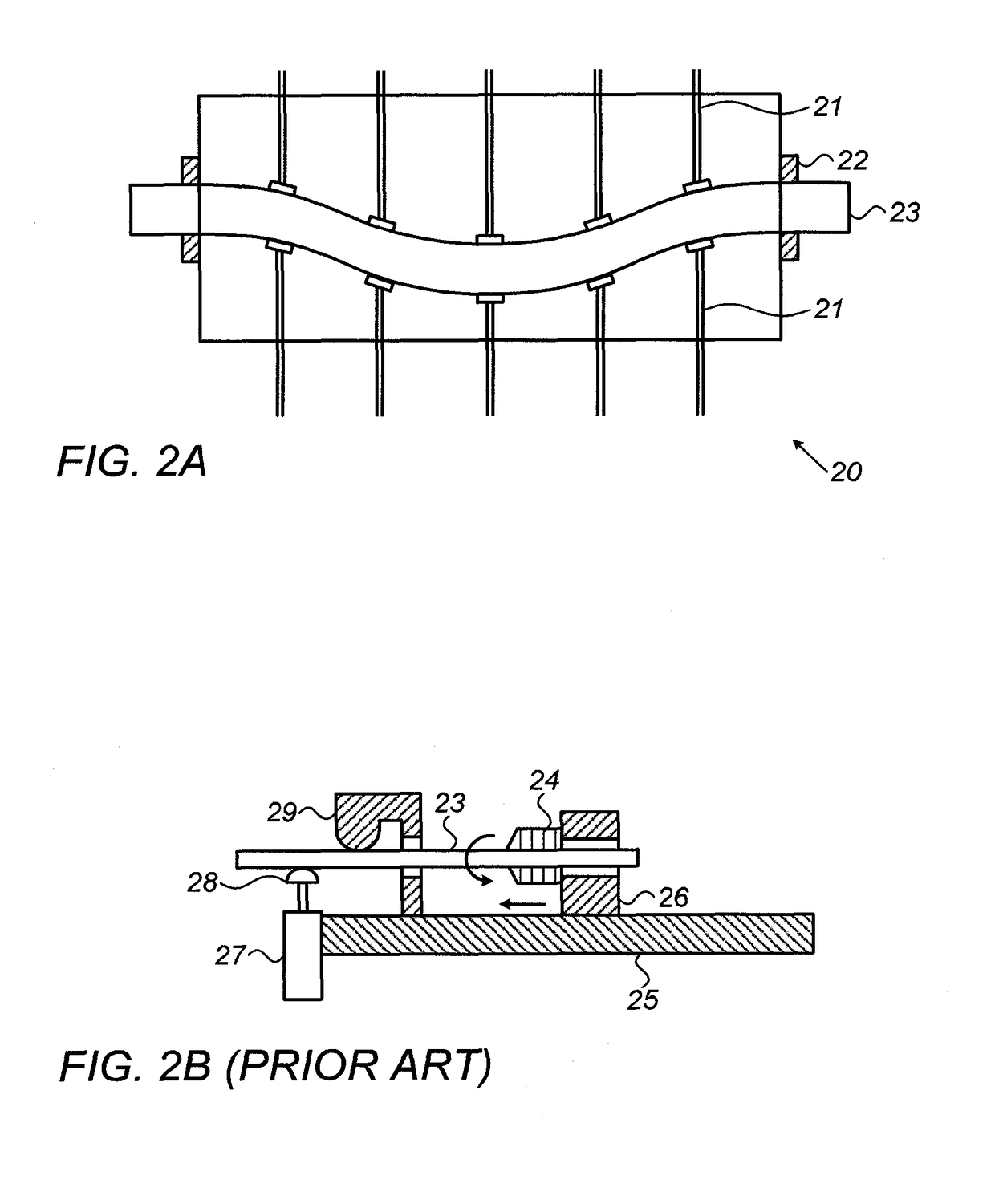

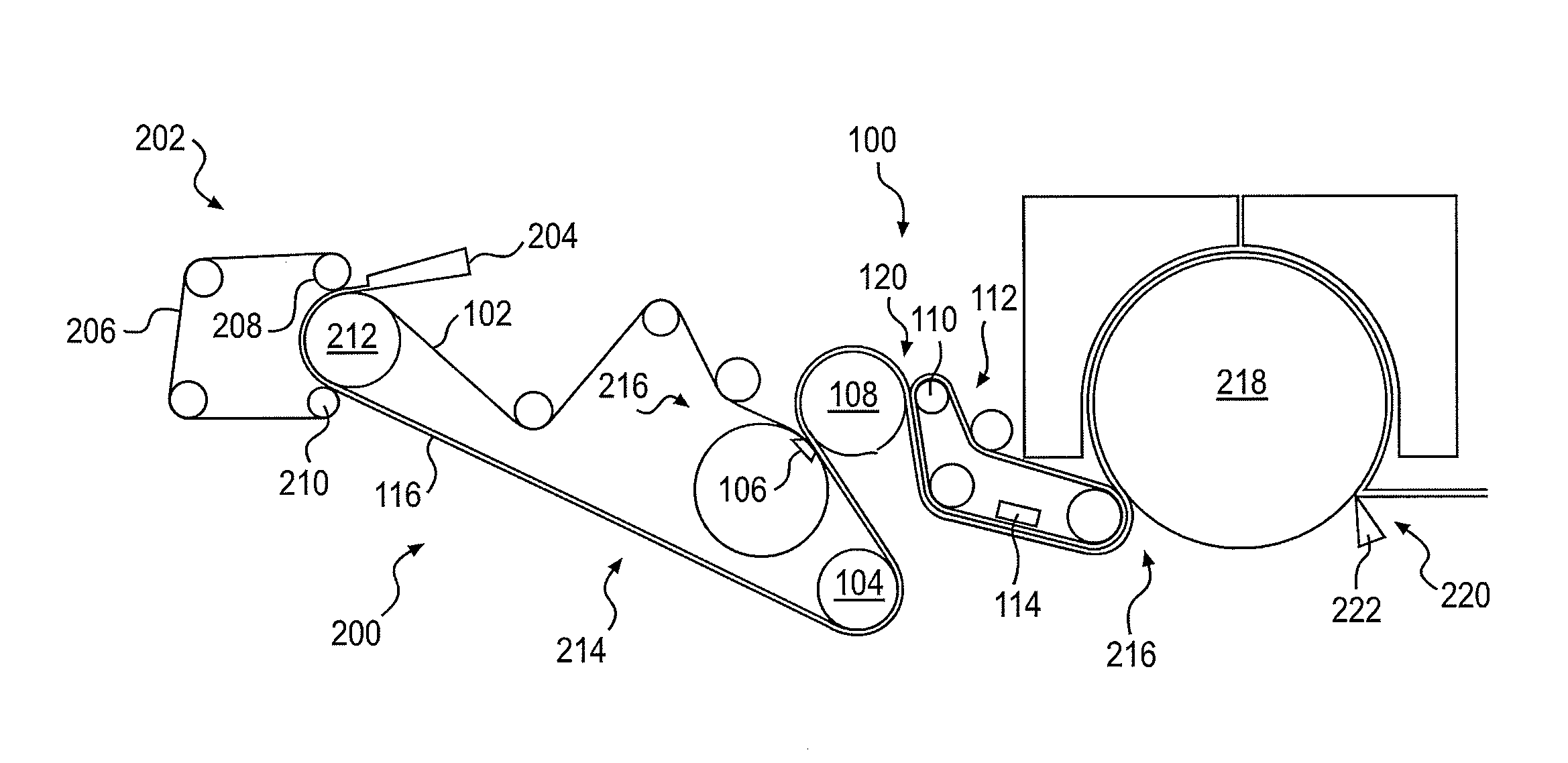

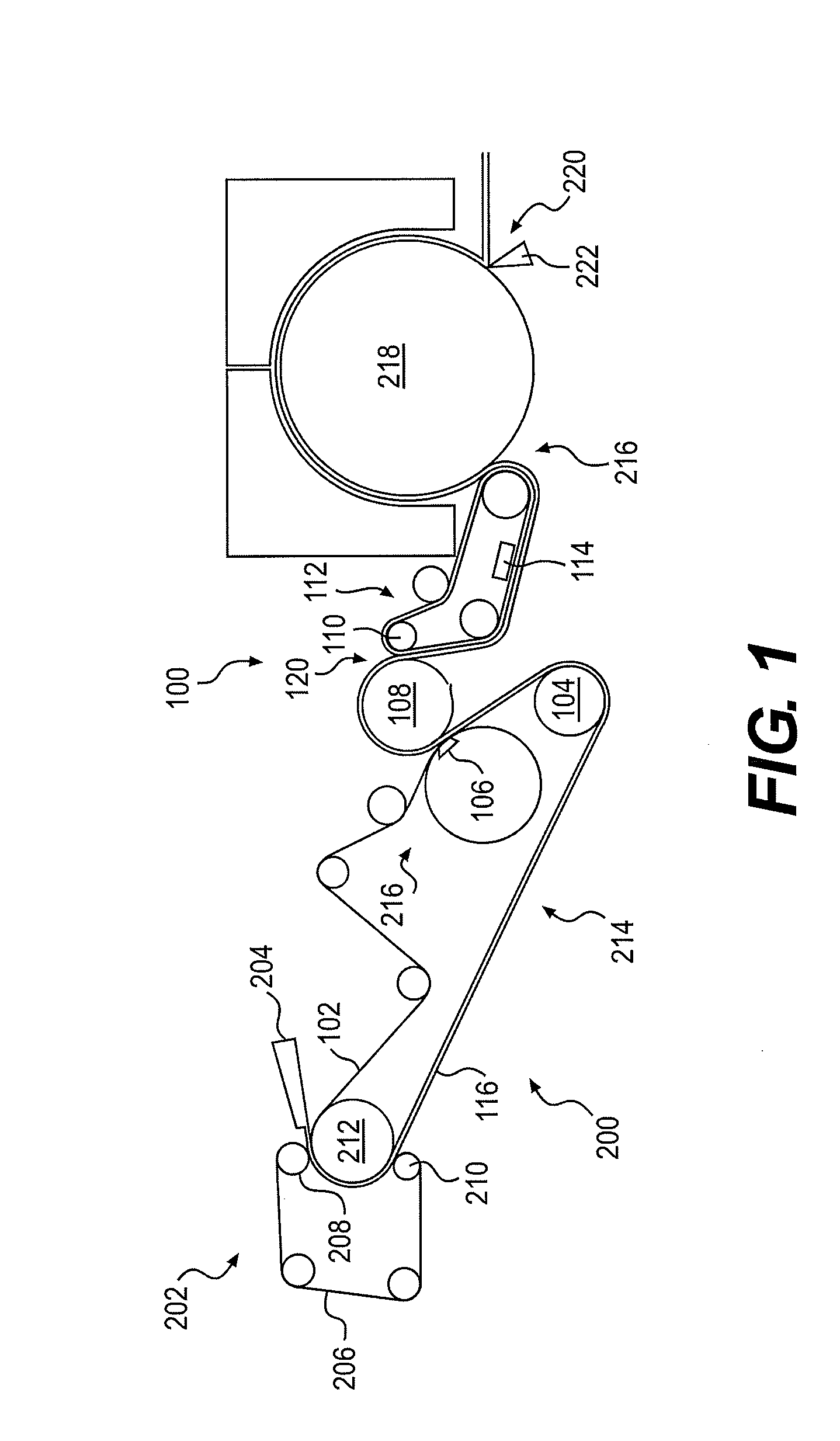

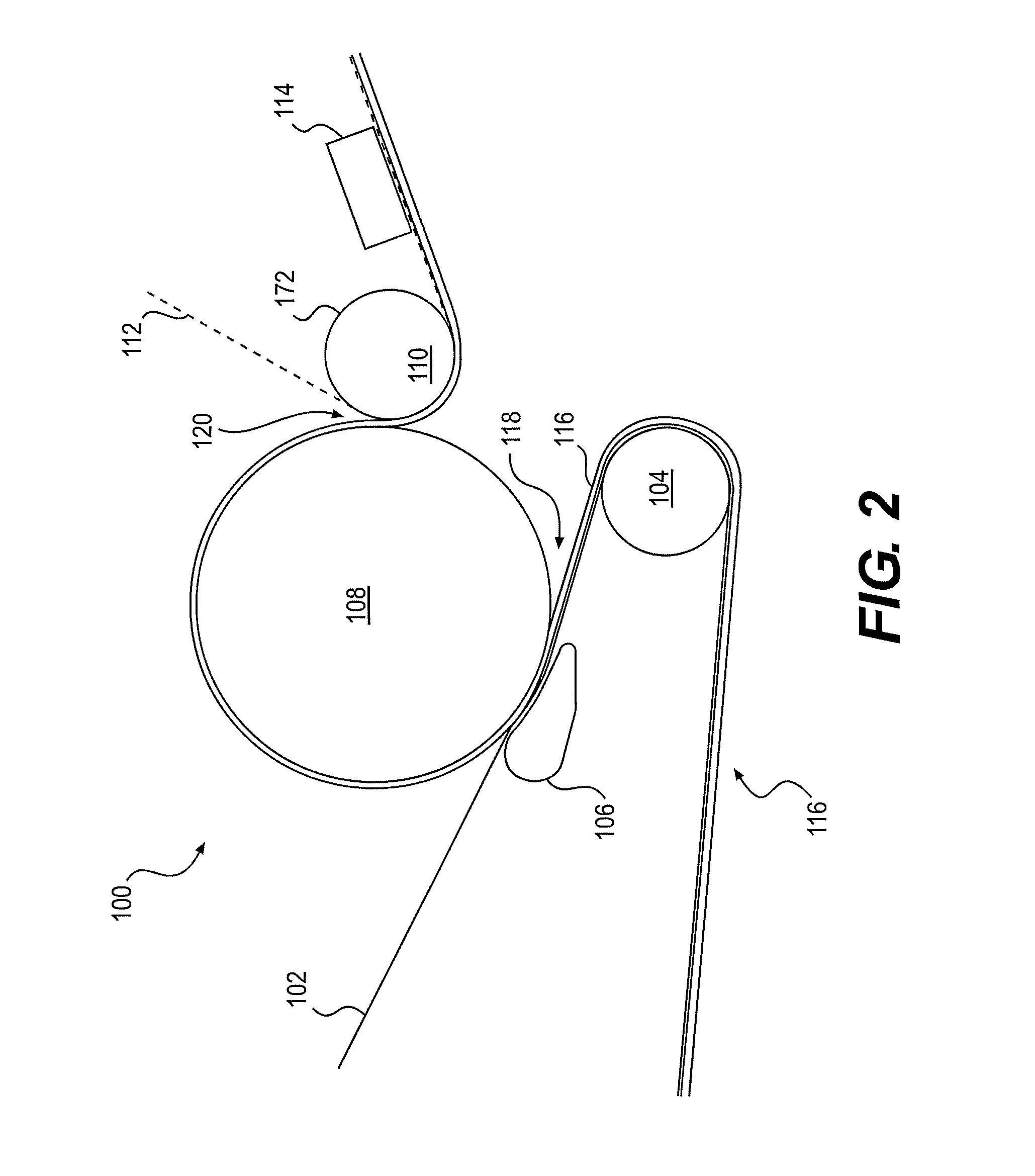

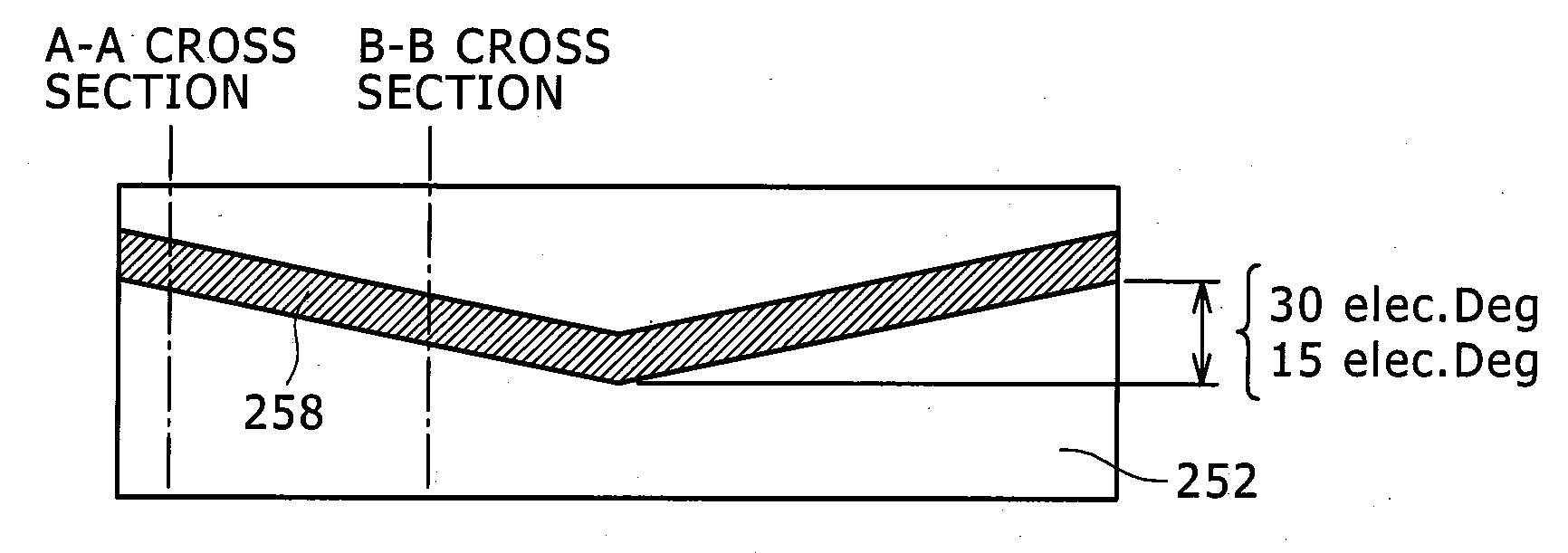

Multilayer belt for creping and structuring in a tissue making process

Owner:ALBANY INT CORP

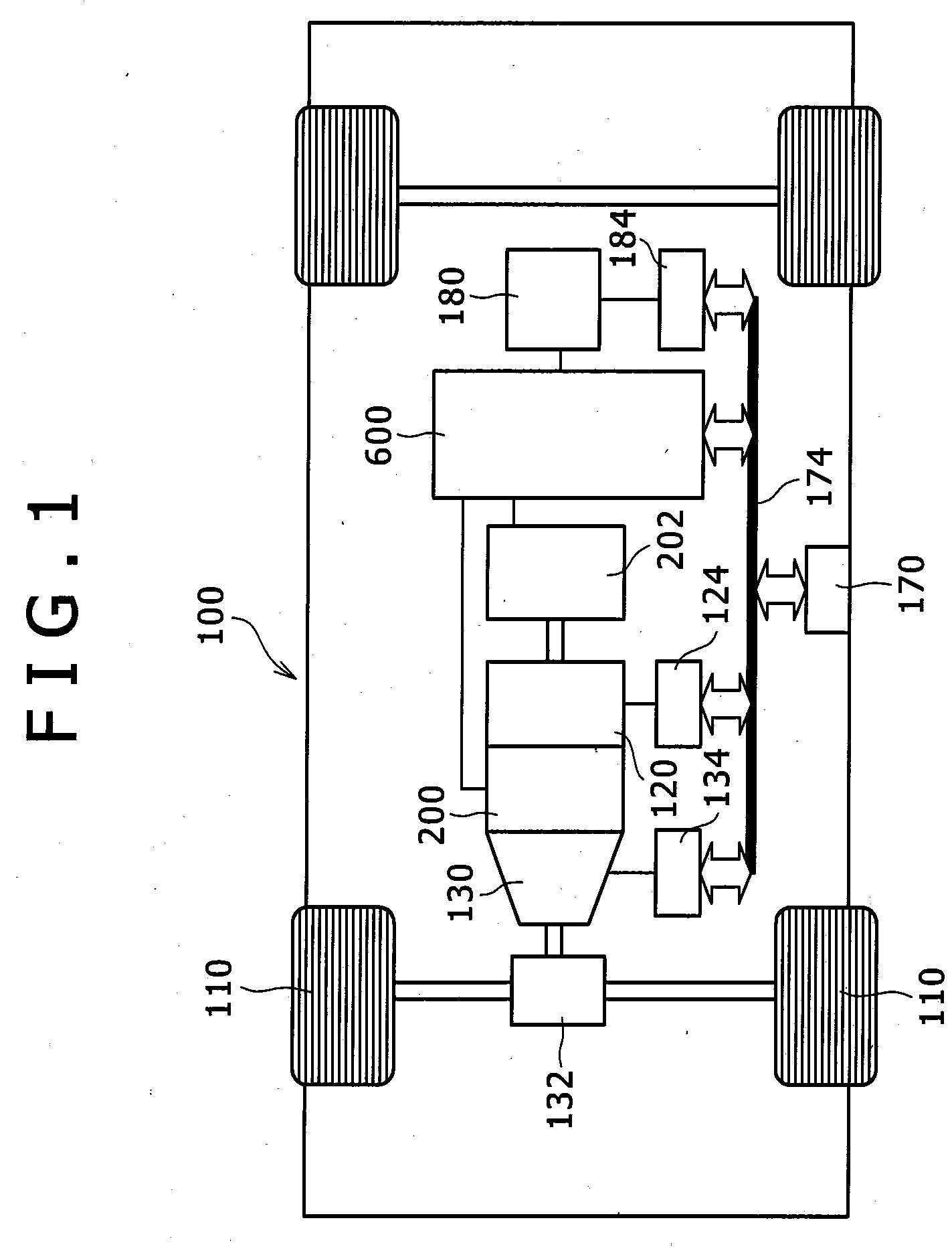

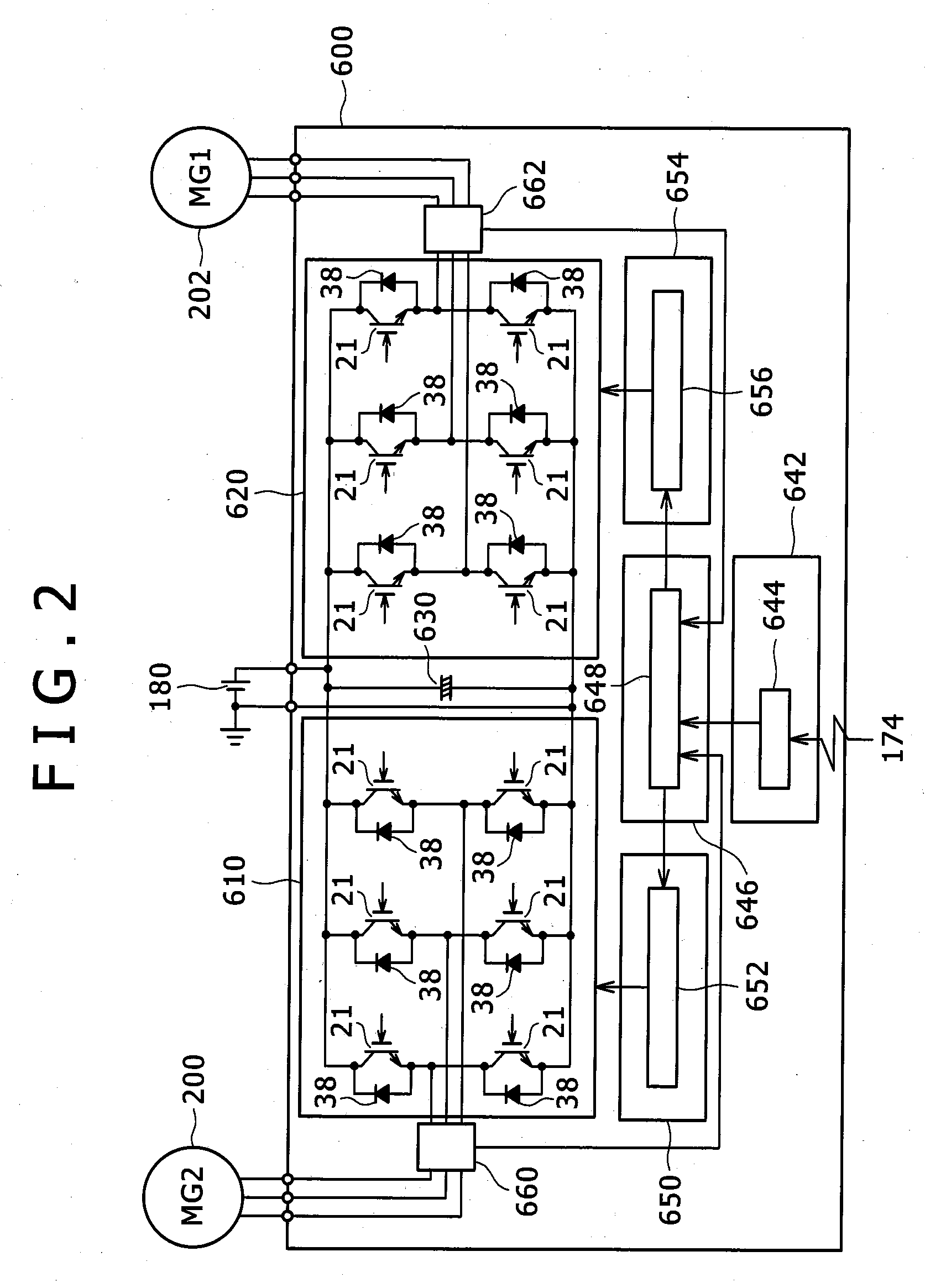

Rotary electric machine and electric vehicle

ActiveUS20090224627A1Reduce pulsationSlow down drastic changesHybrid vehiclesPropulsion by batteries/cellsElectric machineEngineering

A rotary electric machine includes a stator having stator windings; and a rotor rotatably disposed in the stator, said rotor having a rotor core provided with a plurality of magnets and a plurality of magnetic auxiliary salient poles formed between poles of the magnets. In this rotary electric machine: a magnetic air gap is provided in an axial direction of the rotor in a position shifted in a circumferential direction from a q axis passing through a center of the magnetic auxiliary salient pole within the magnetic auxiliary salient pole; and an amount of shifting the magnetic air gap from the q axis in the circumferential direction differs according to a position of the magnetic air gap in the axial direction so as to cancel torque pulsation in energization caused due to the magnetic air gap.

Owner:HITACHI ASTEMO LTD

Acute and chronic electrical signal therapy for obesity

InactiveUS20060074459A1Reduce the cross-sectional areaLower the volumeInternal electrodesExternal electrodesMuscle tissueObesity

Owner:TYLERTON INT INC

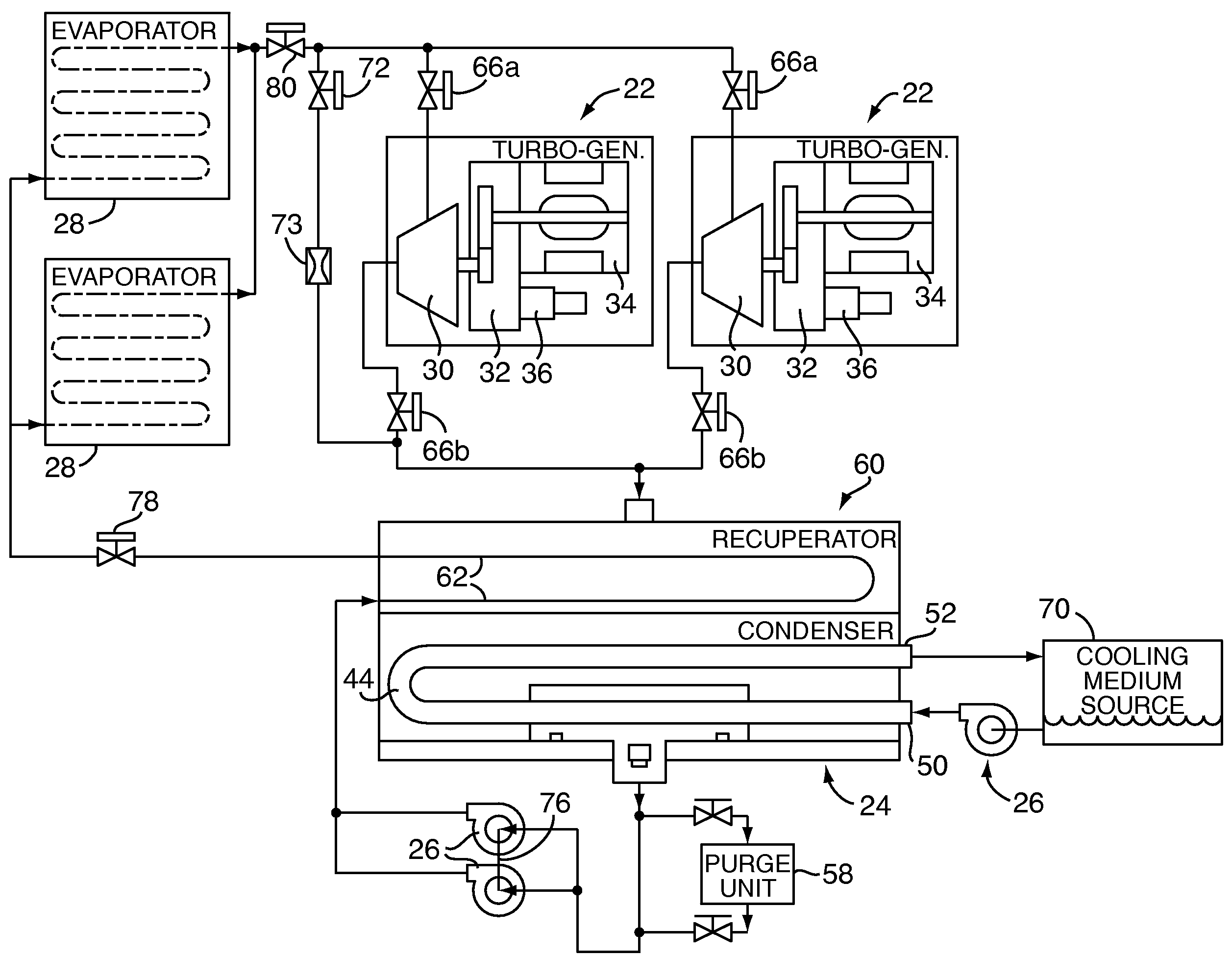

Rankine cycle device having multiple turbo-generators

A method for generating power, comprising the steps of: a) providing a Rankine Cycle device that includes a plurality of turbo-generators, each including a turbine coupled with an electrical generator, and at least one of each of an evaporator, a condenser, and a refrigerant feed pump; b) disposing the one or more evaporators within an exhaust duct of a power plant of a marine vessel; c) operating the power plant; and d) selectively pumping refrigerant through the Rankine Cycle device.

Owner:NANJING TICA AIR CONDITIONING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com