Patents

Literature

1415 results about "Feed pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A feed pump is a type of pump that supplies water to a boiler to produce steam. For industrial purposes, a feed pump supplies a liquid for further processing.

Use of perfusion to enhance production of fed-batch cell culture in bioreactors

InactiveUS20090042253A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationFeed pump

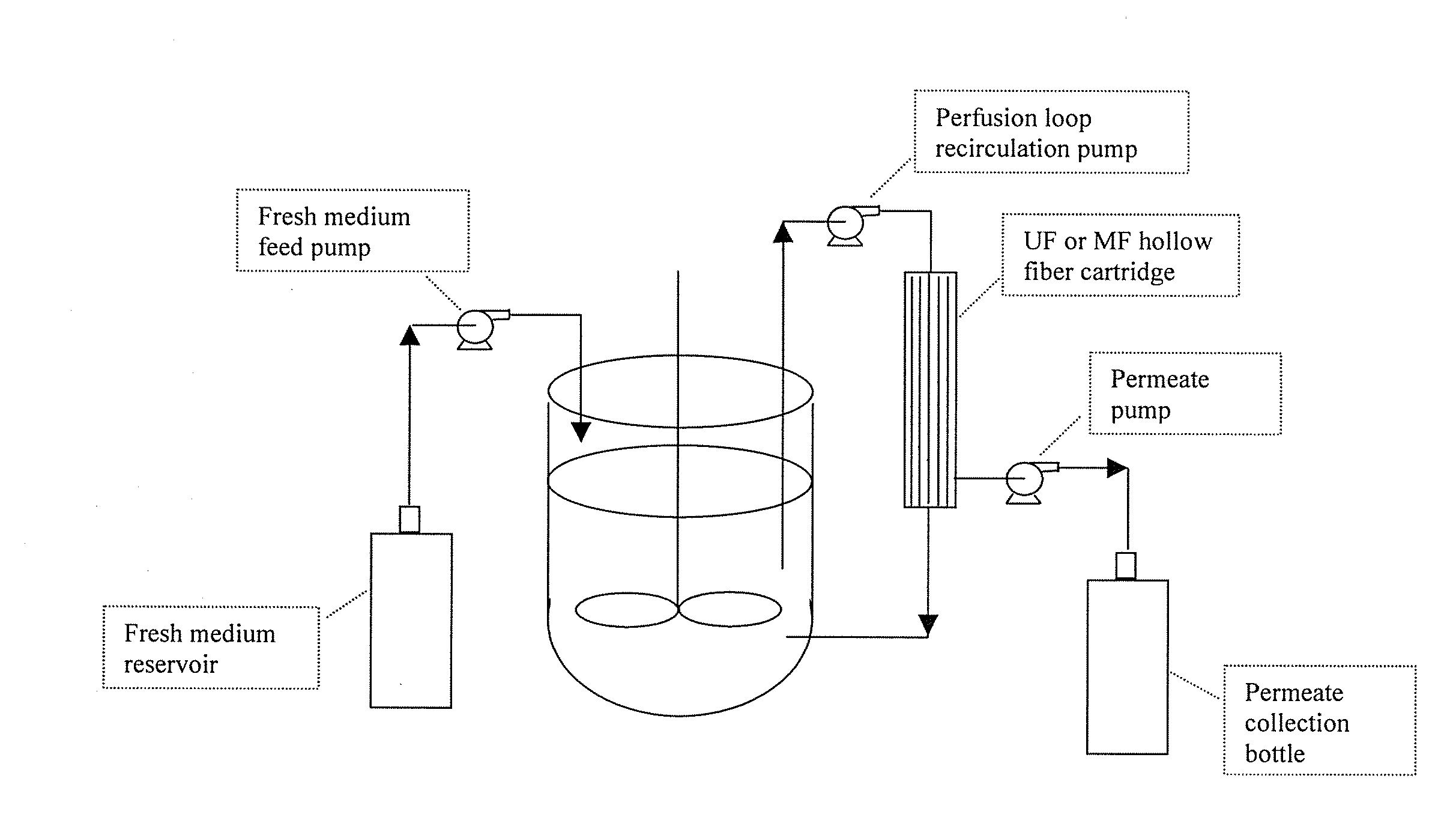

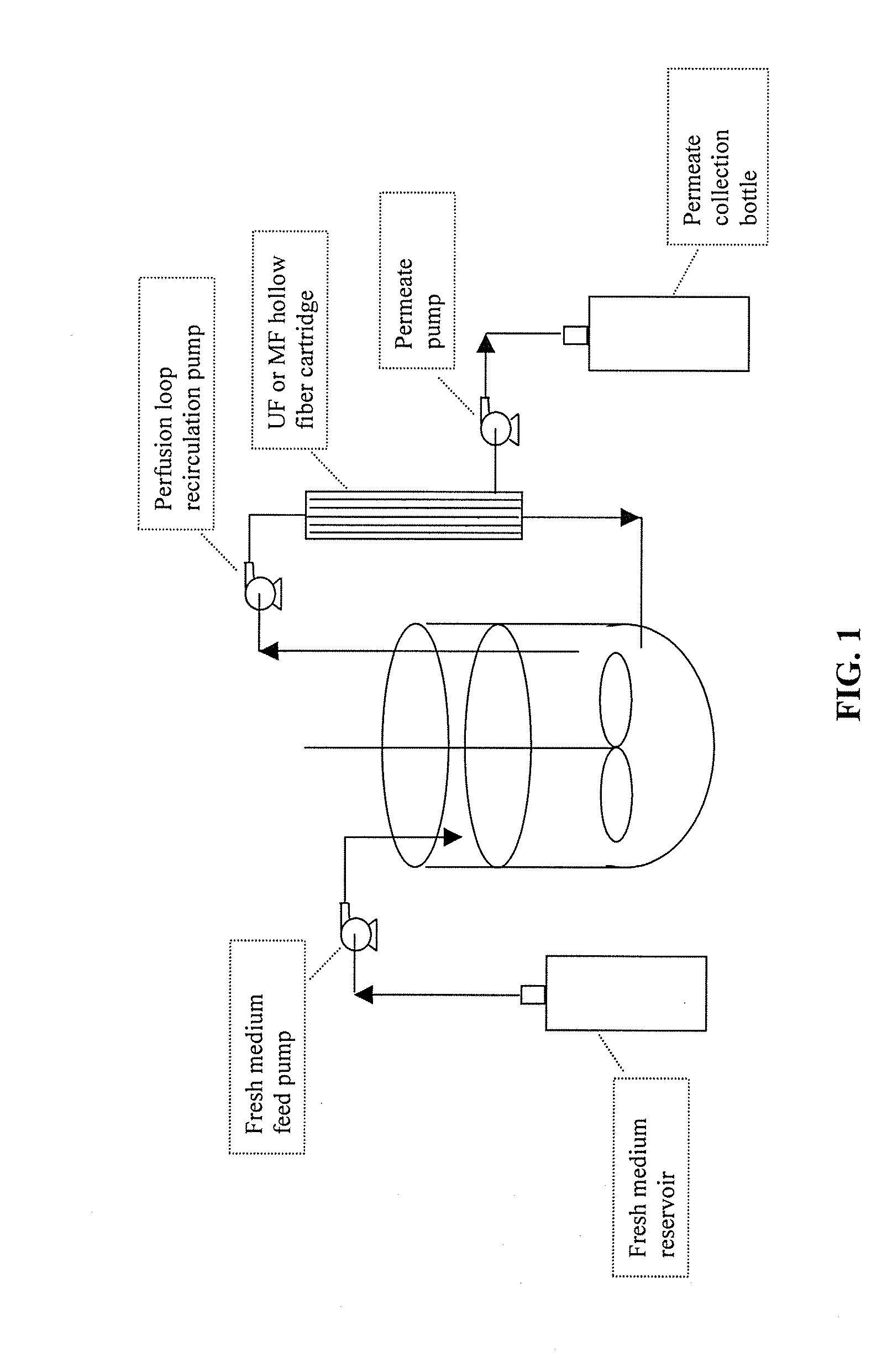

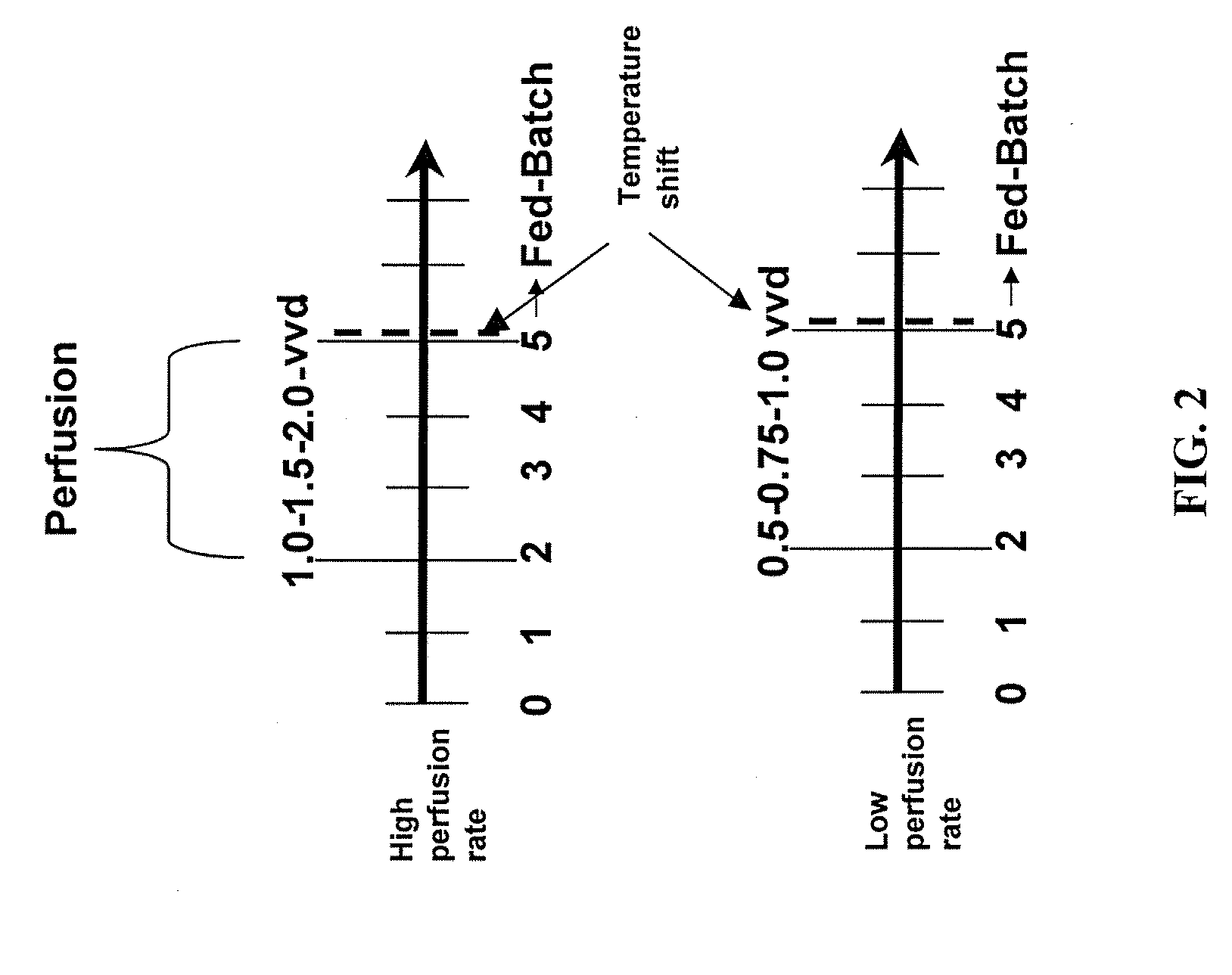

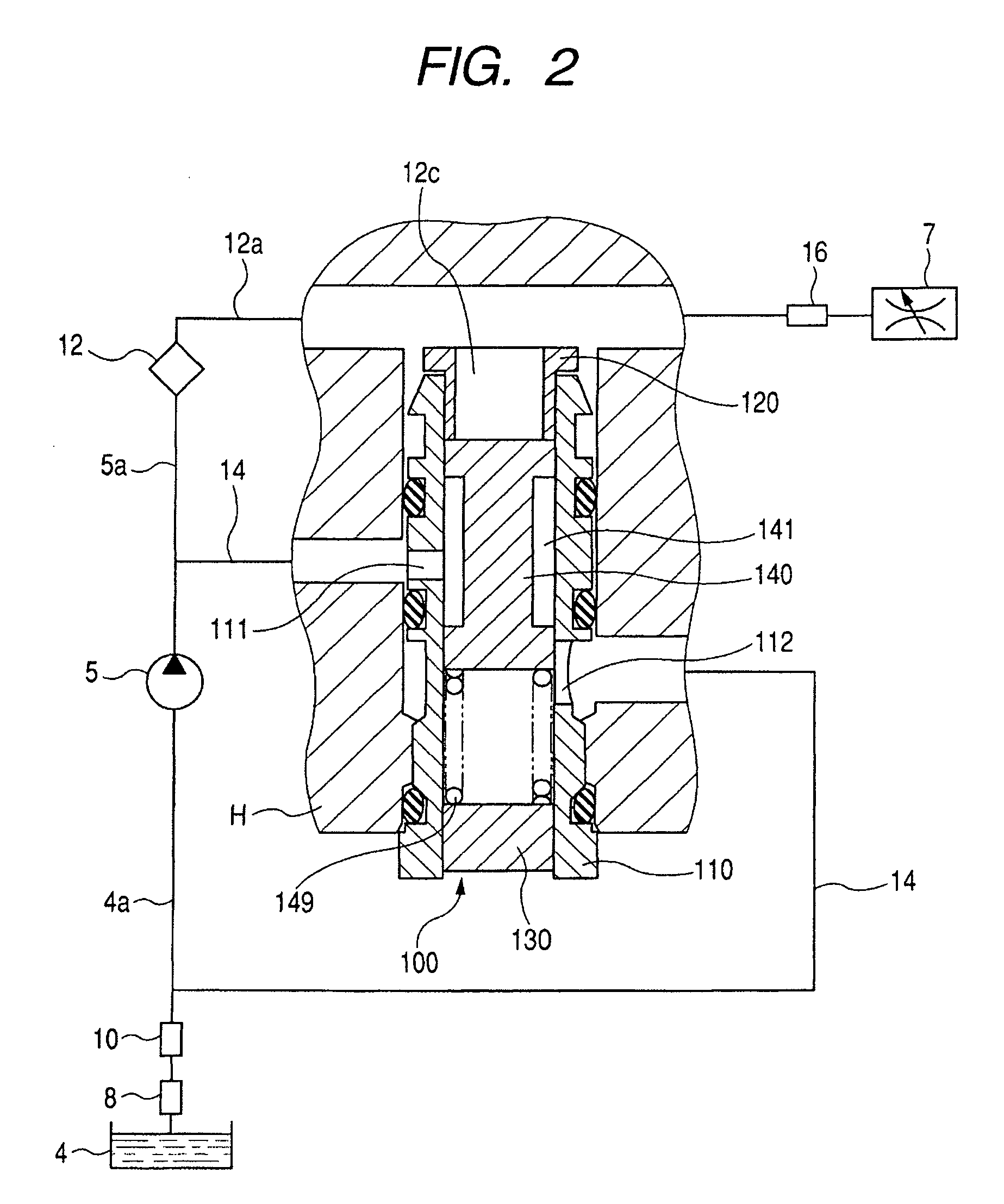

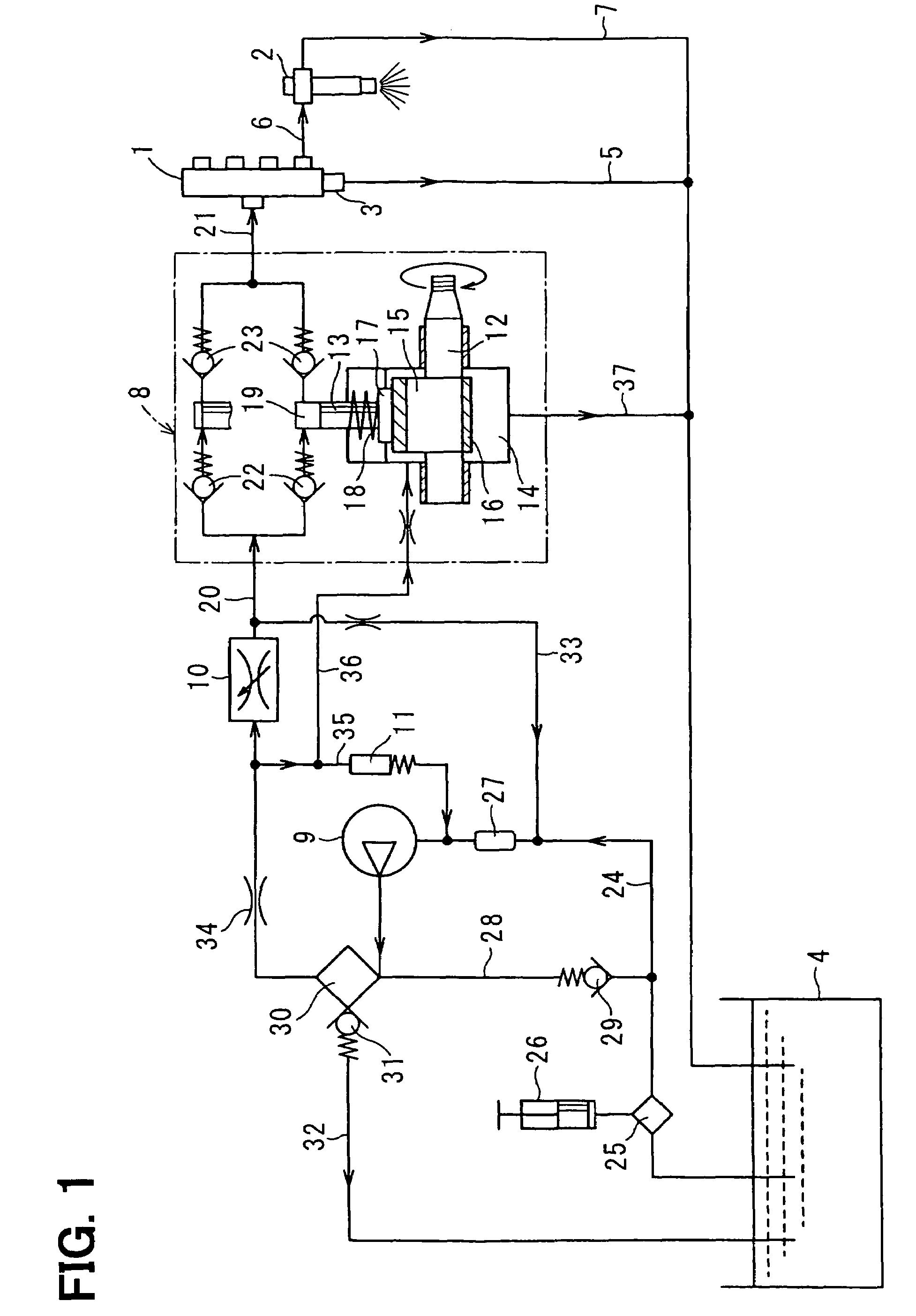

The invention relates to methods of improving protein production, e.g., large-scale commercial protein production, e.g., antibody production, utilizing a modified fed-batch cell culture method comprising a cell growth phase and a polypeptide production phase. The modified fed-batch cell culture method combines both cell culture perfusion and fed-batch methods to achieve higher titers of polypeptide products. Because the modified fed-batch cell culture method of the invention produces higher polypeptide product titers than fed-batch culture alone, it will substantially improve commercial-scale protein production. The invention also relates to a perfusion bioreactor apparatus comprising a fresh medium reservoir connected to a bioreactor by a feed pump, a recirculation loop connected to the bioreactor, wherein the recirculation loop comprises a filtration device, e.g., ultrafiltration or microfiltration, and a permeate pump connecting the filtration device to a permeate collection container.

Owner:WYETH LLC

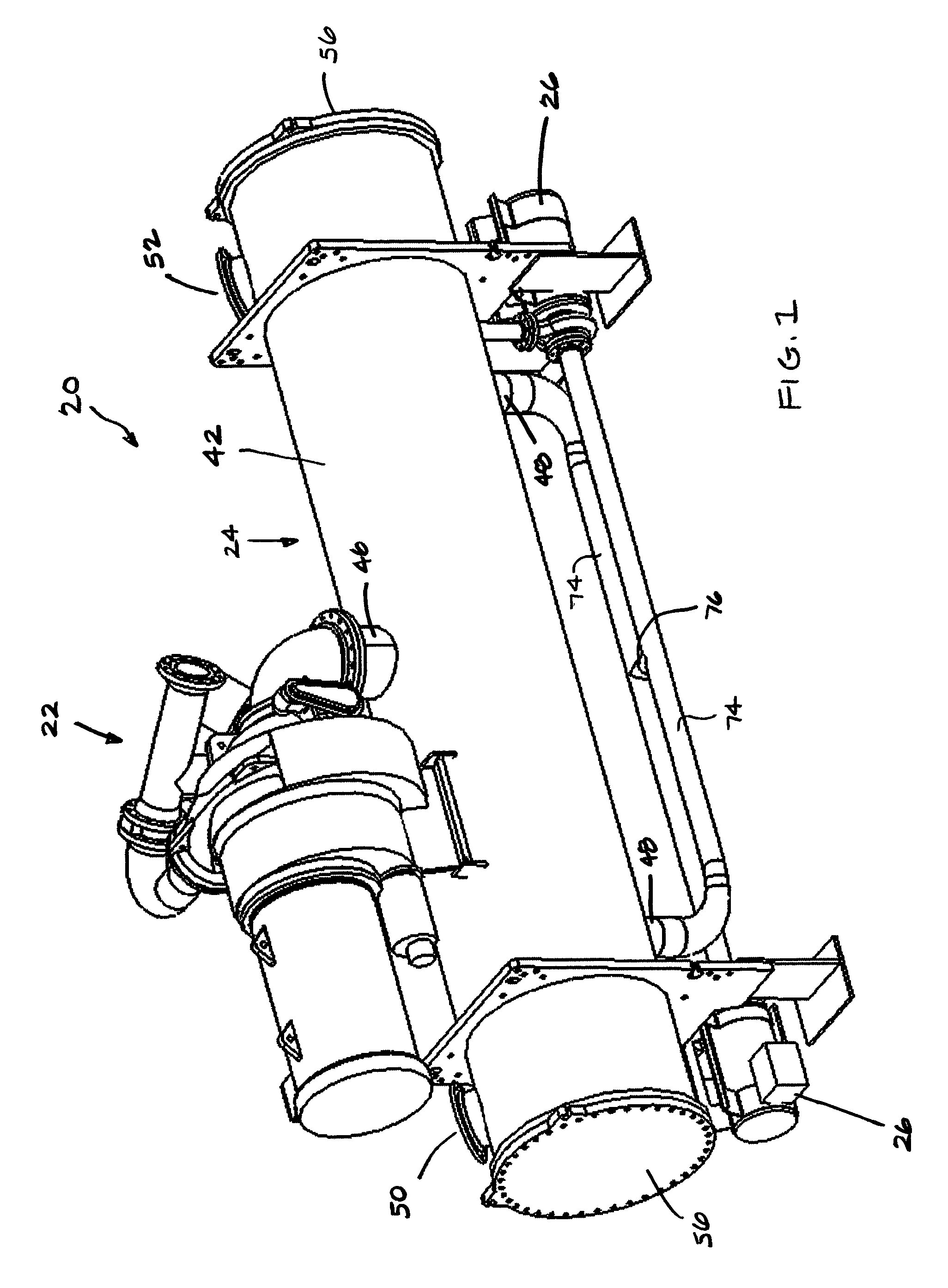

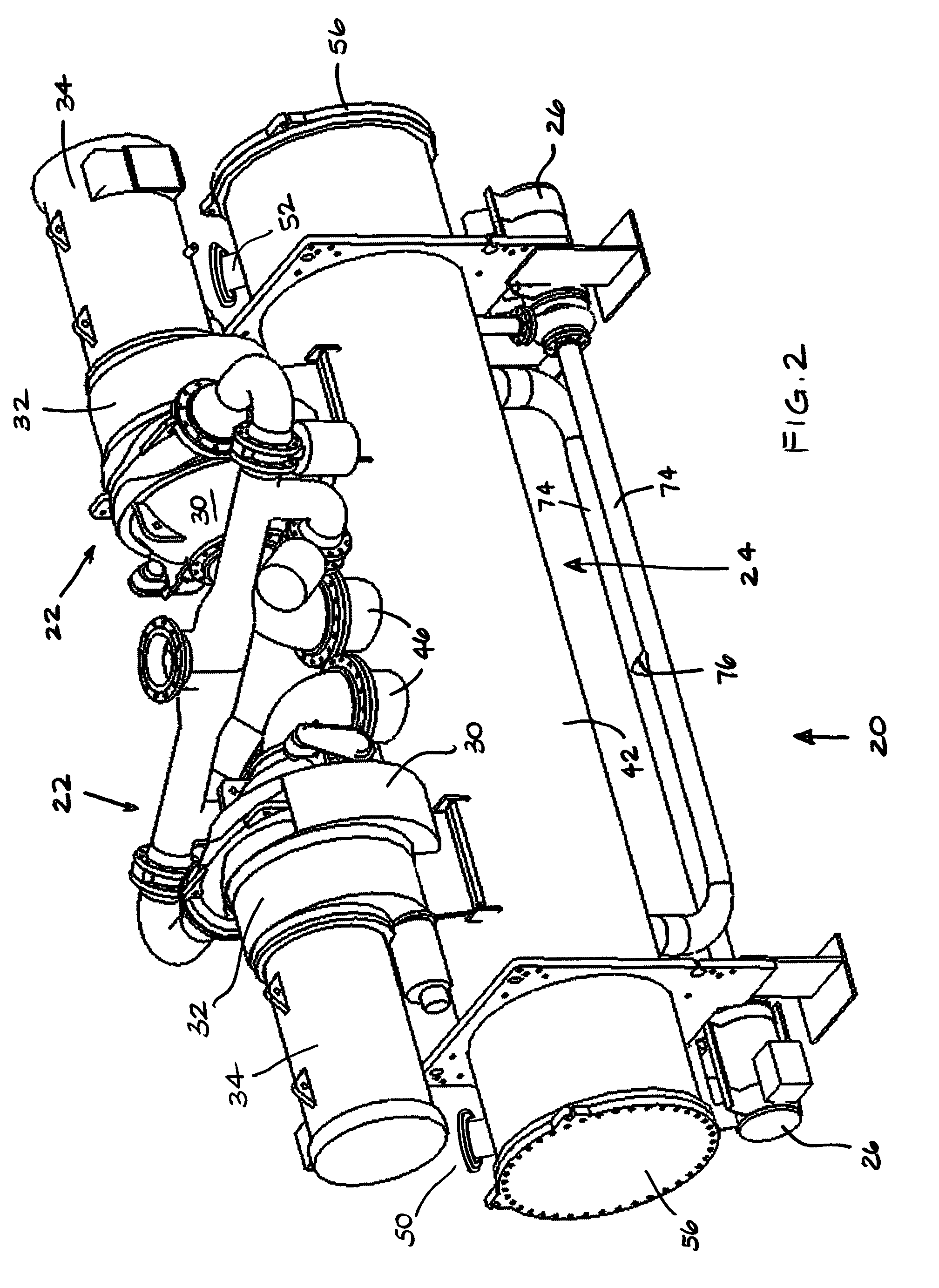

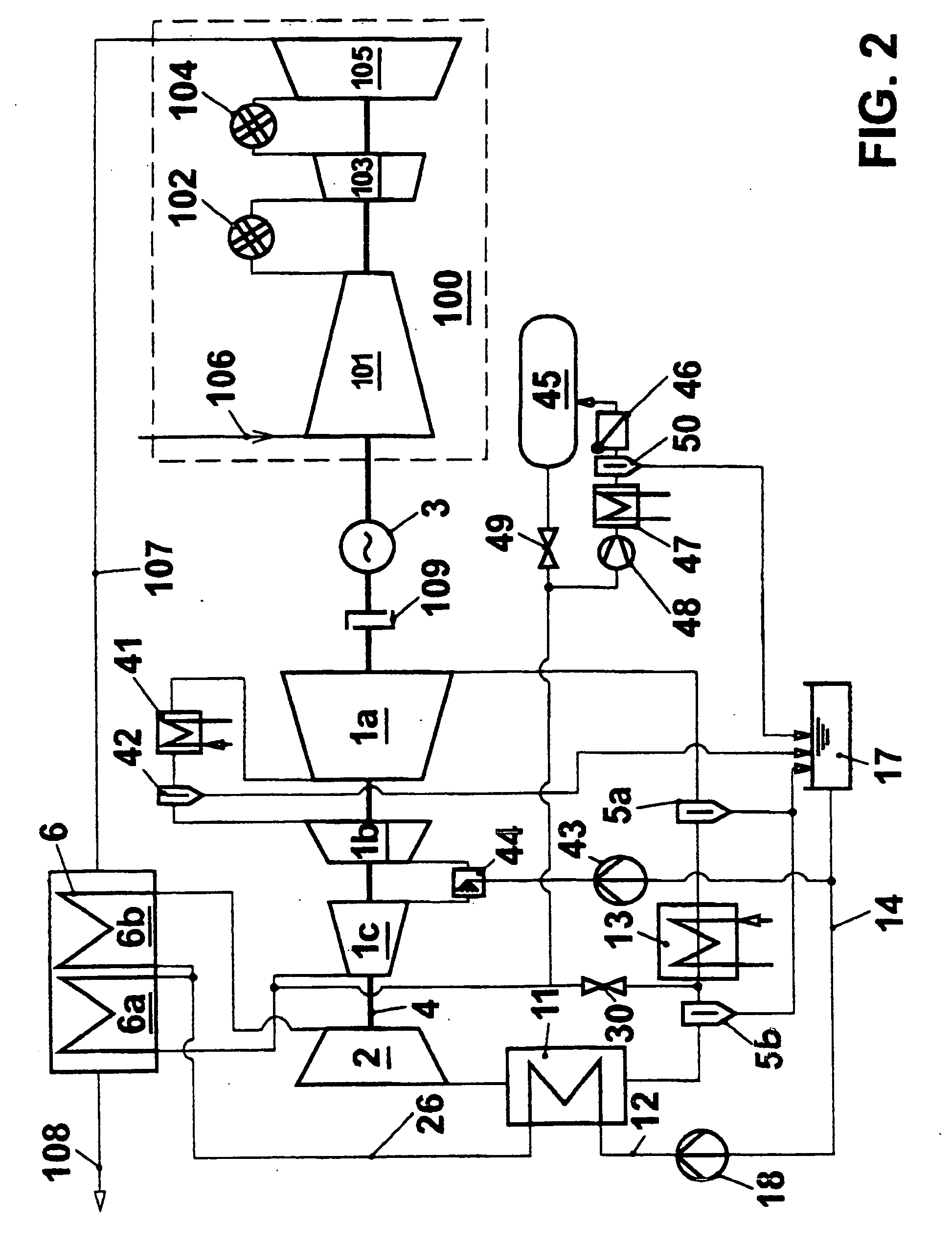

Rankine cycle device having multiple turbo-generators

A method for generating power, comprising the steps of: a) providing a Rankine Cycle device that includes a plurality of turbo-generators, each including a turbine coupled with an electrical generator, and at least one of each of an evaporator, a condenser, and a refrigerant feed pump; b) disposing the one or more evaporators within an exhaust duct of a power plant of a marine vessel; c) operating the power plant; and d) selectively pumping refrigerant through the Rankine Cycle device.

Owner:NANJING TICA AIR CONDITIONING CO LTD +1

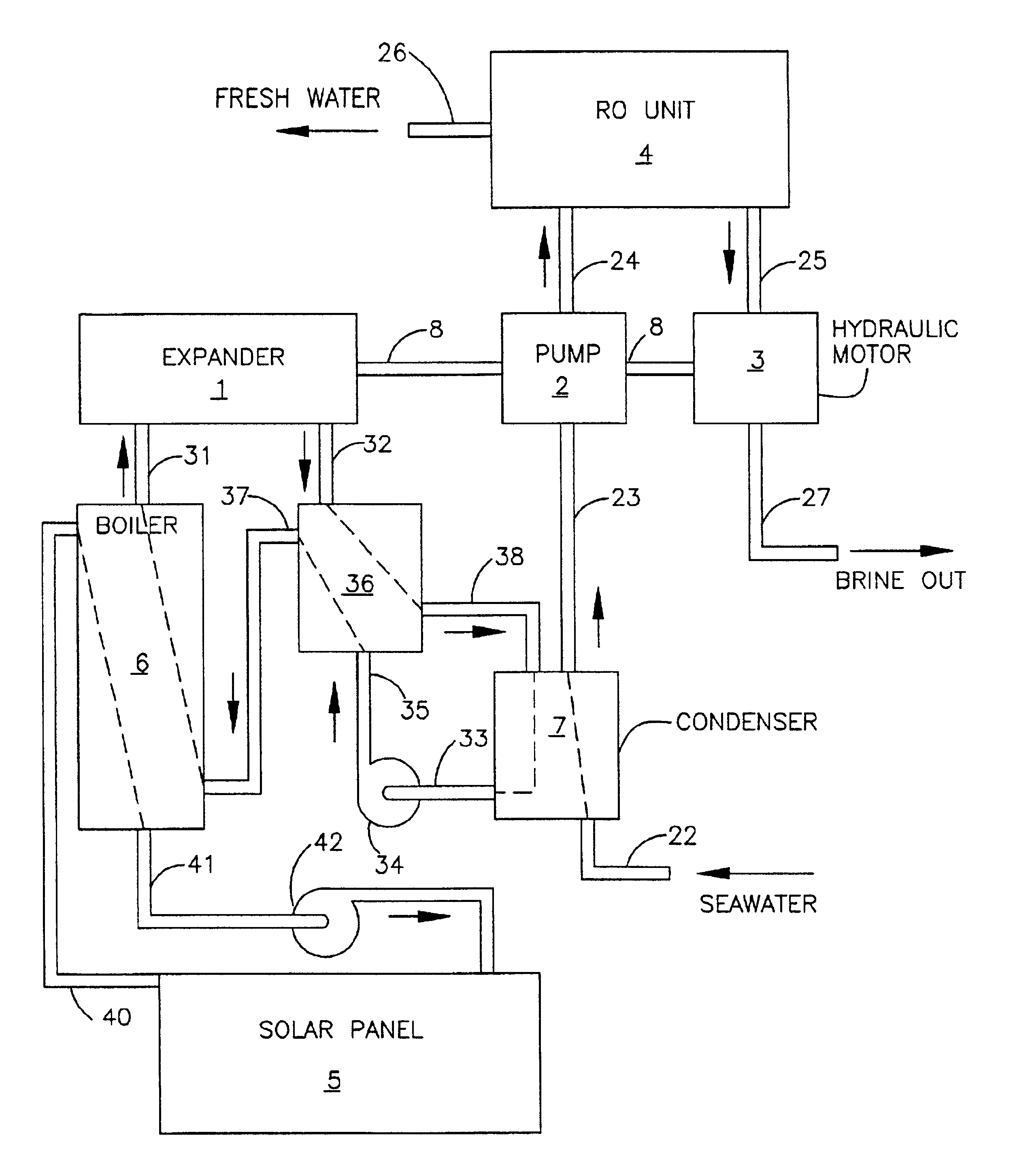

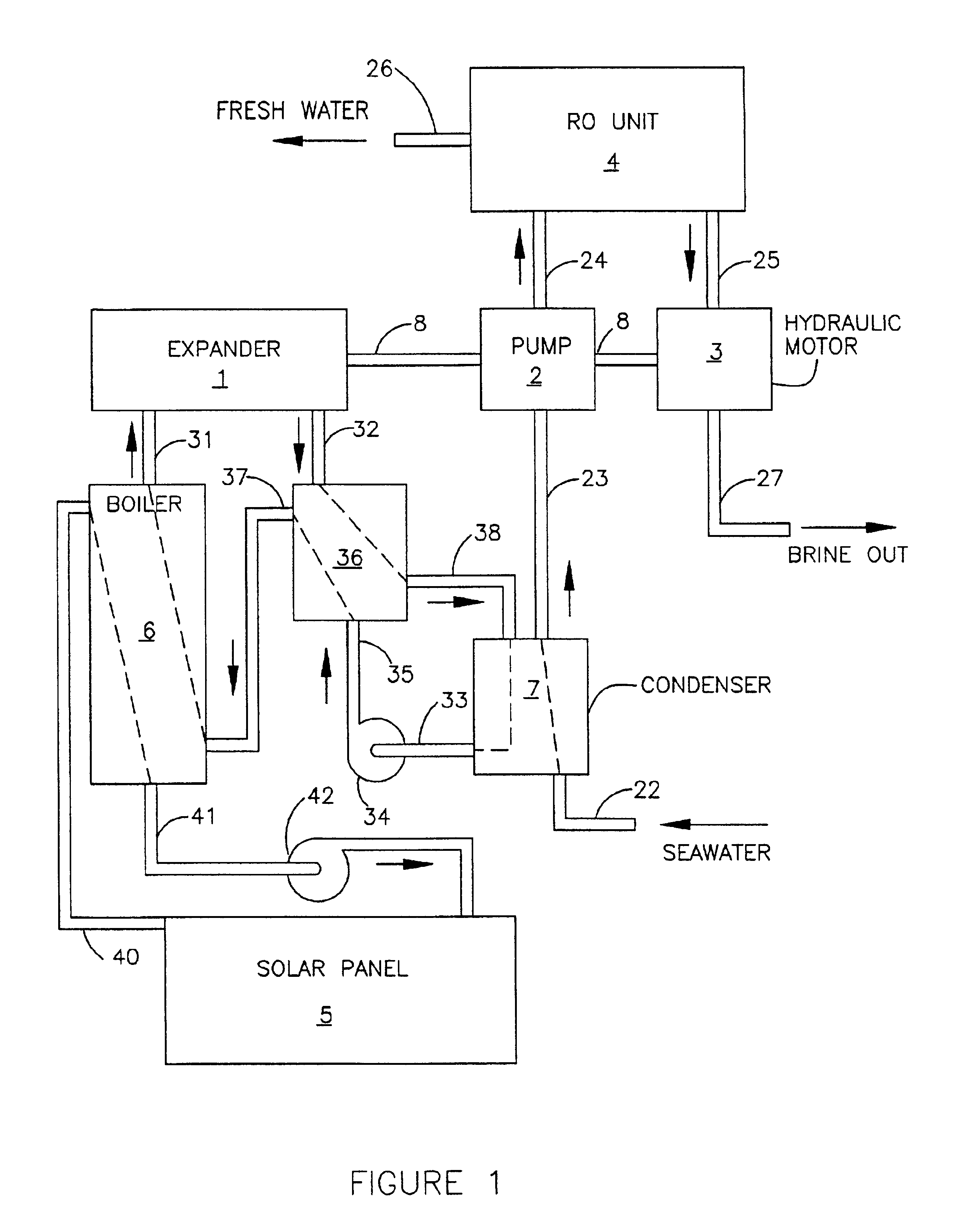

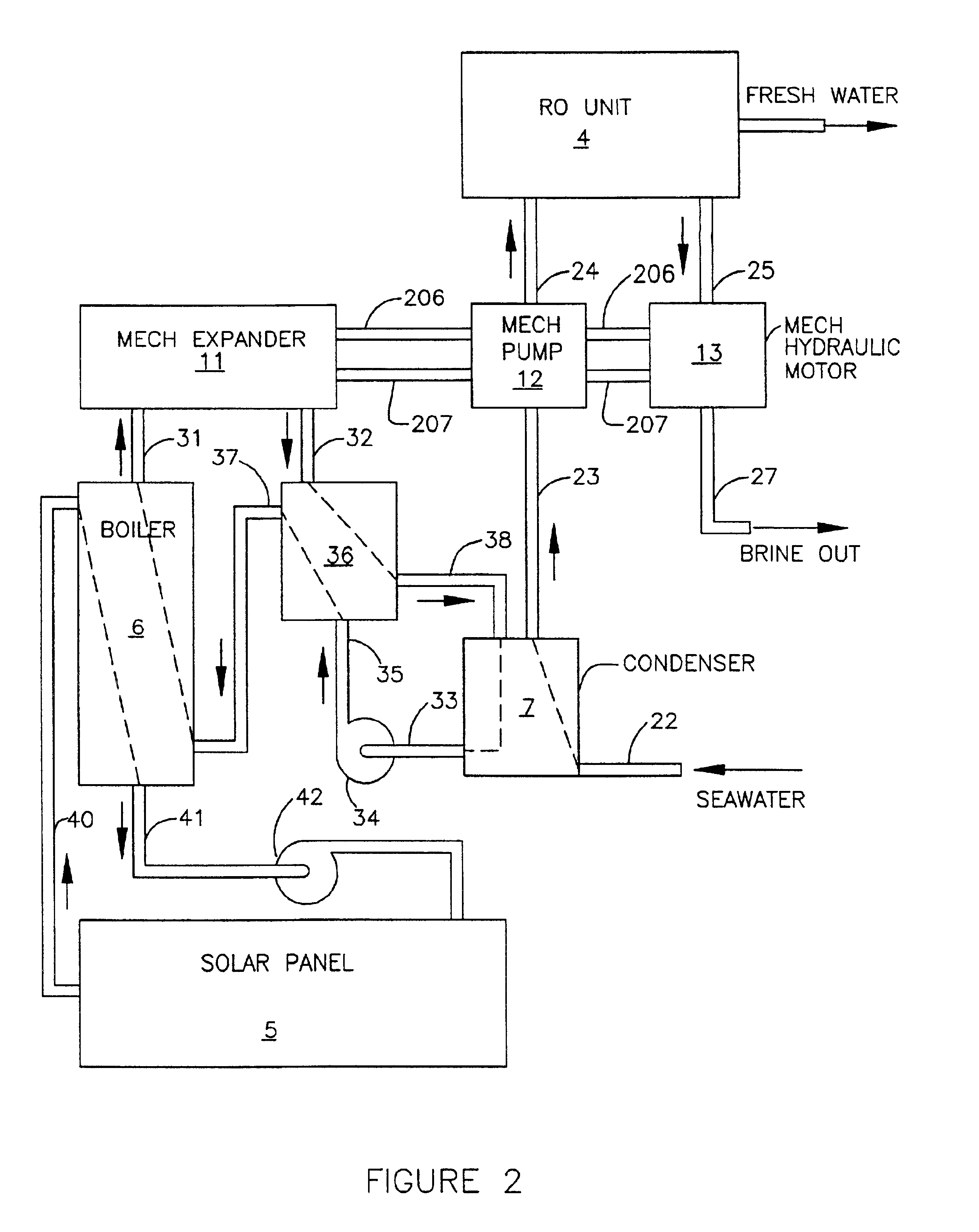

Solar energy desalination system

A desalination system is driven by a solar powered boiler that outputs a pressurized vapor to drive an expander that generates output motive force. A pump is responsive to the motive force to output pressurized saline water. A reverse osmosis unit receives the pressurized saline water to output fresh water and pressurized brine. A recuperator that transfers heat from the expander exhaust to the boiler feed liquid is incorporated to improve the efficiency of the system. In a particular embodiment, a hydraulic motor receives the pressurized brine and outputs an augmenting motive force to the pump. In another embodiment, a novel motorless boiler feed pump is defined.

Owner:PRUEITT MELVIN L

Thermal power process

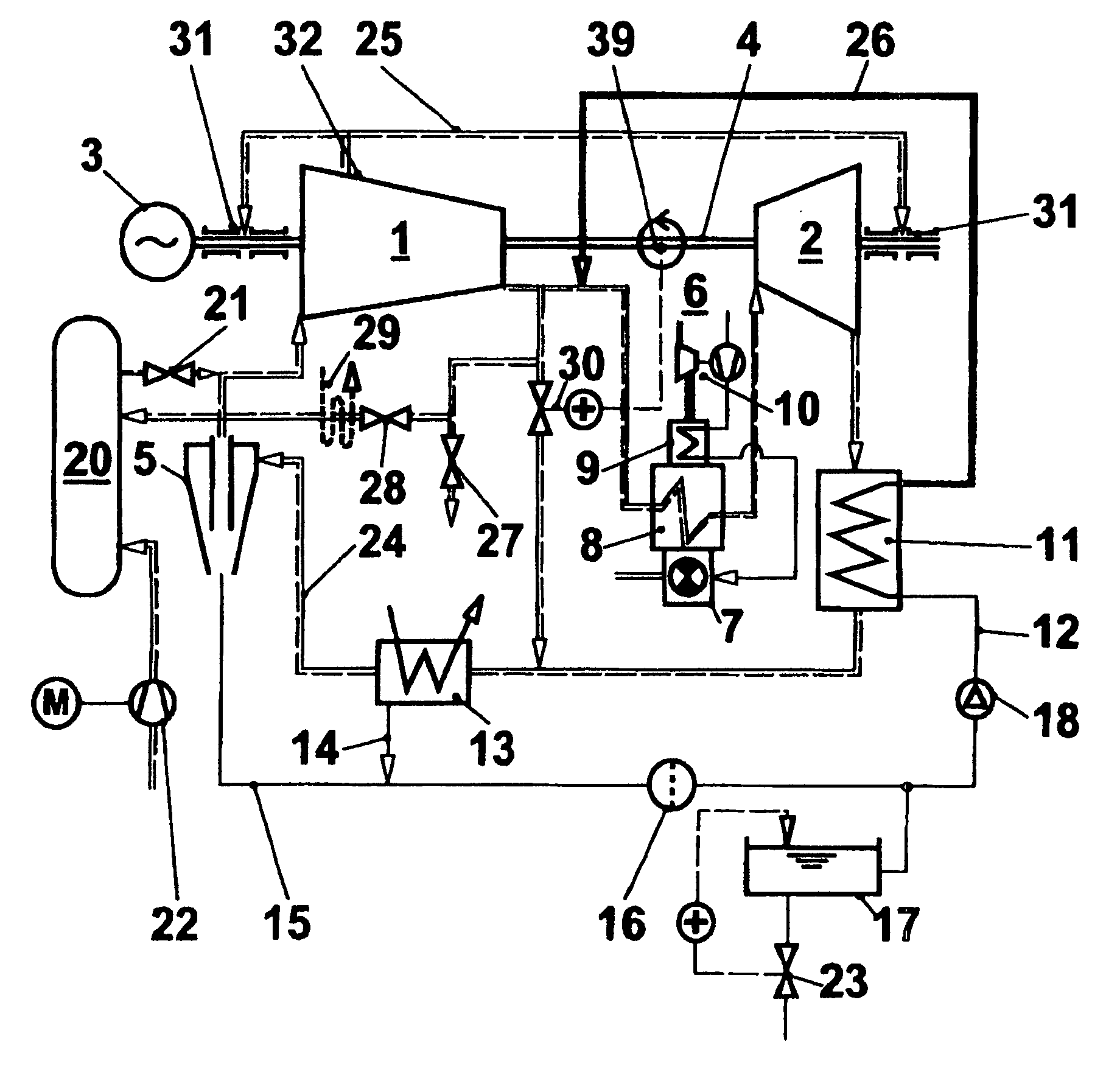

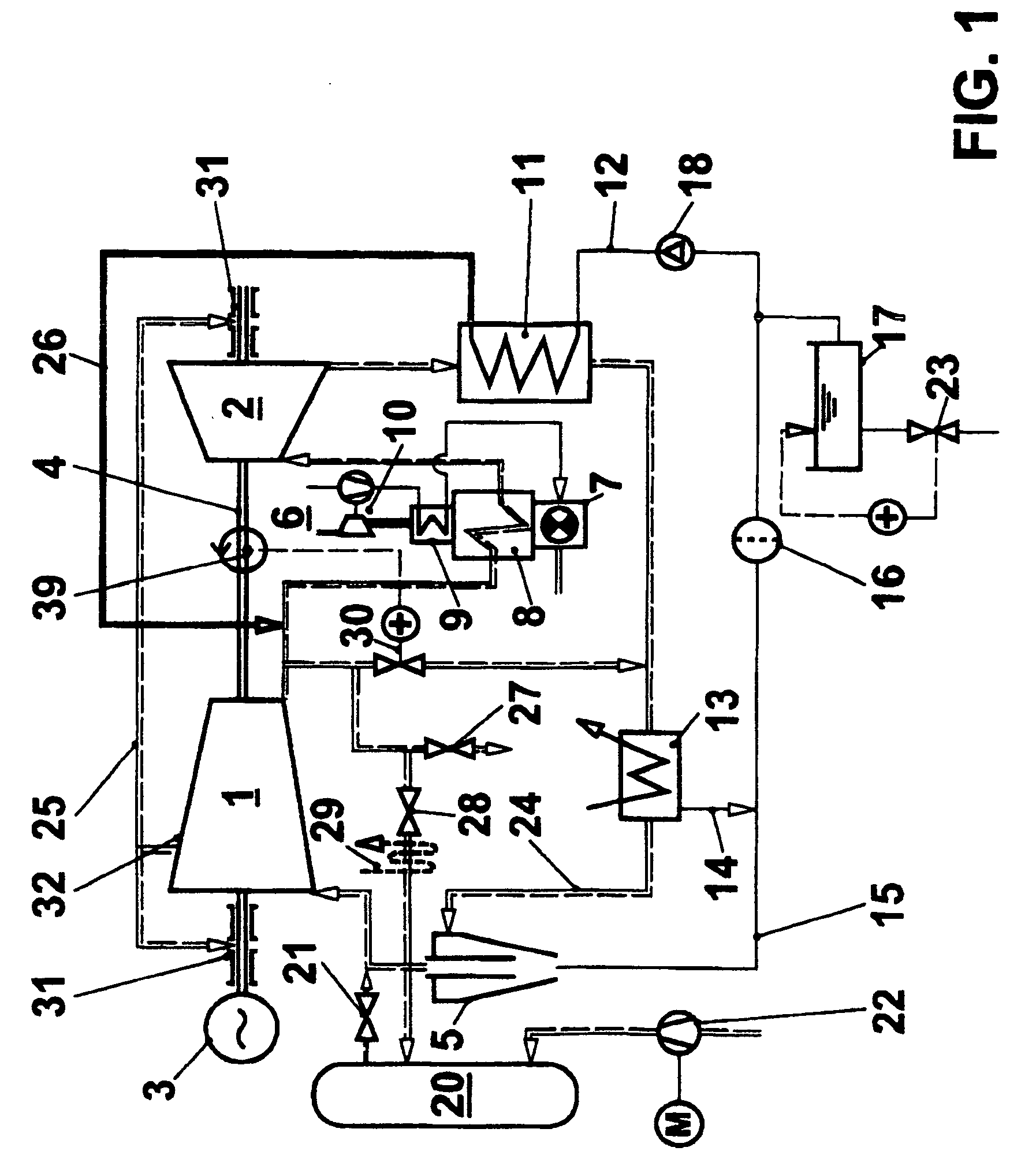

InactiveUS20050072154A1Increased processing pressureStrong dimensionSteam accumulatorsGas turbine plantsCompression deviceEngineering

In a power generation unit, especially in a gasturbo group, a gaseous process fluid is guided in a closed cycle. The gaseous process fluid flows through a compression device (1), a heater (6) and an expansion device (2), especially a turbine. Downstream from the expansion device at least one heat sink (11, 13) is arranged in which the gaseous process fluid is cooled before it is returned to the compressor device (1). At least one heat sink includes a waste heat steam generator in which an overheated amount of steam (26) is generated that is added to the compressed gaseous process fluid. Together with the gaseous process fluid the steam flows through the heater (6) if necessary and is expanded together with it. The expanded steam condenses in the waste heat steam generator (11) and another heat sink (13); the condensate is processed in a filter (16) and is returned to the waste heat steam generator (11) under pressure via a feed pump (18). Due to the closed process any kind of process fluid and process filling for controlling performance can be used.

Owner:ALSTOM TECH LTD

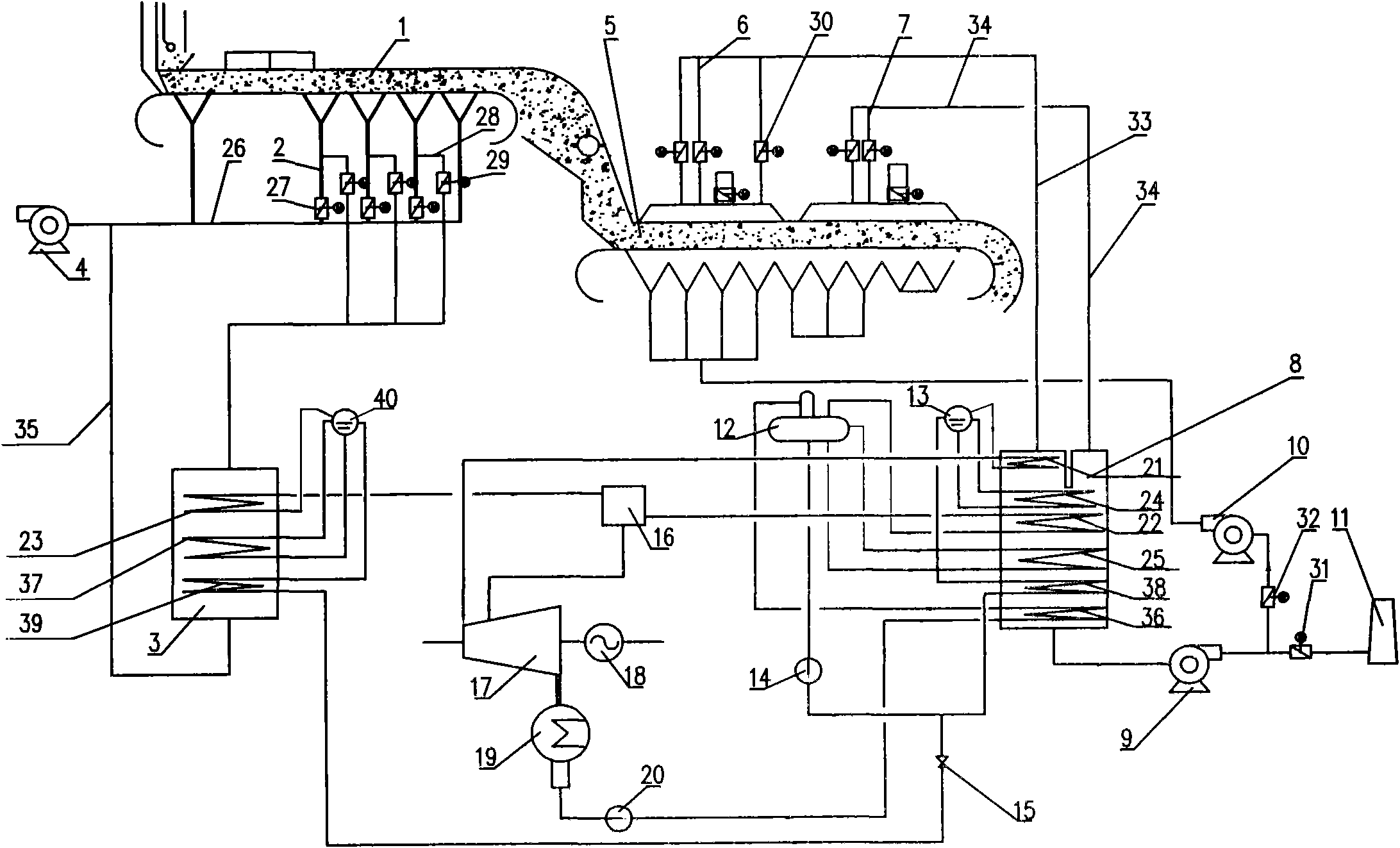

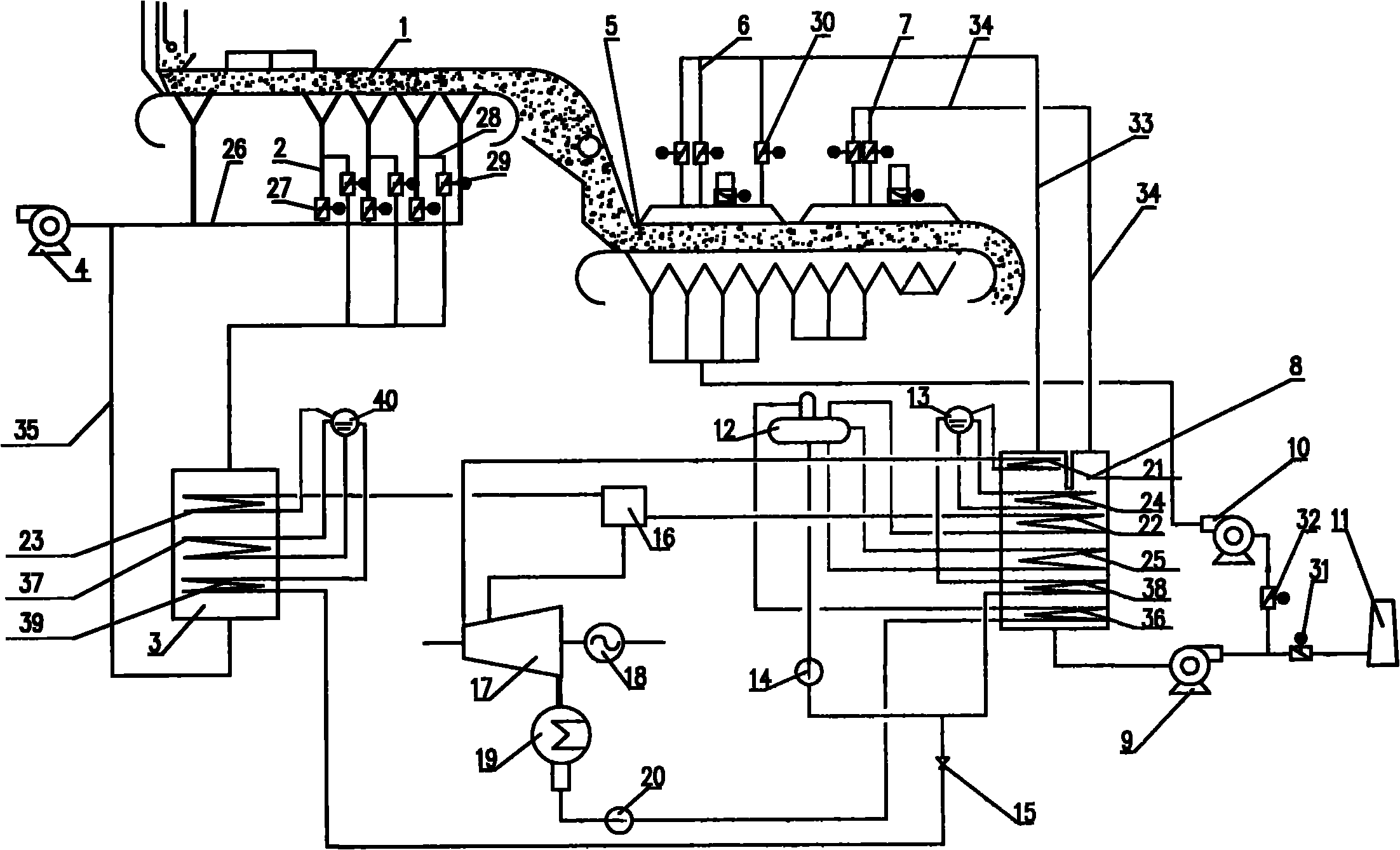

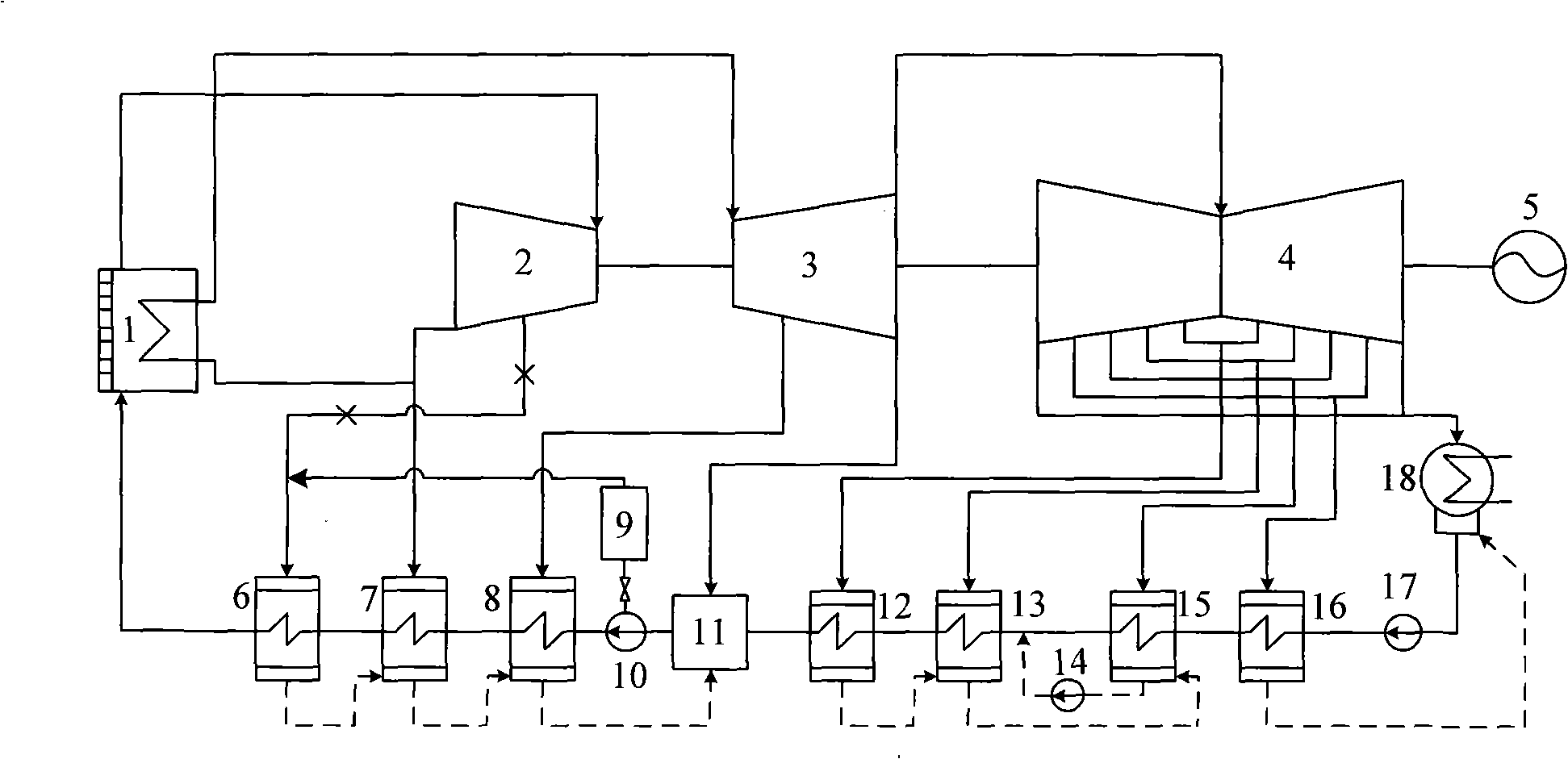

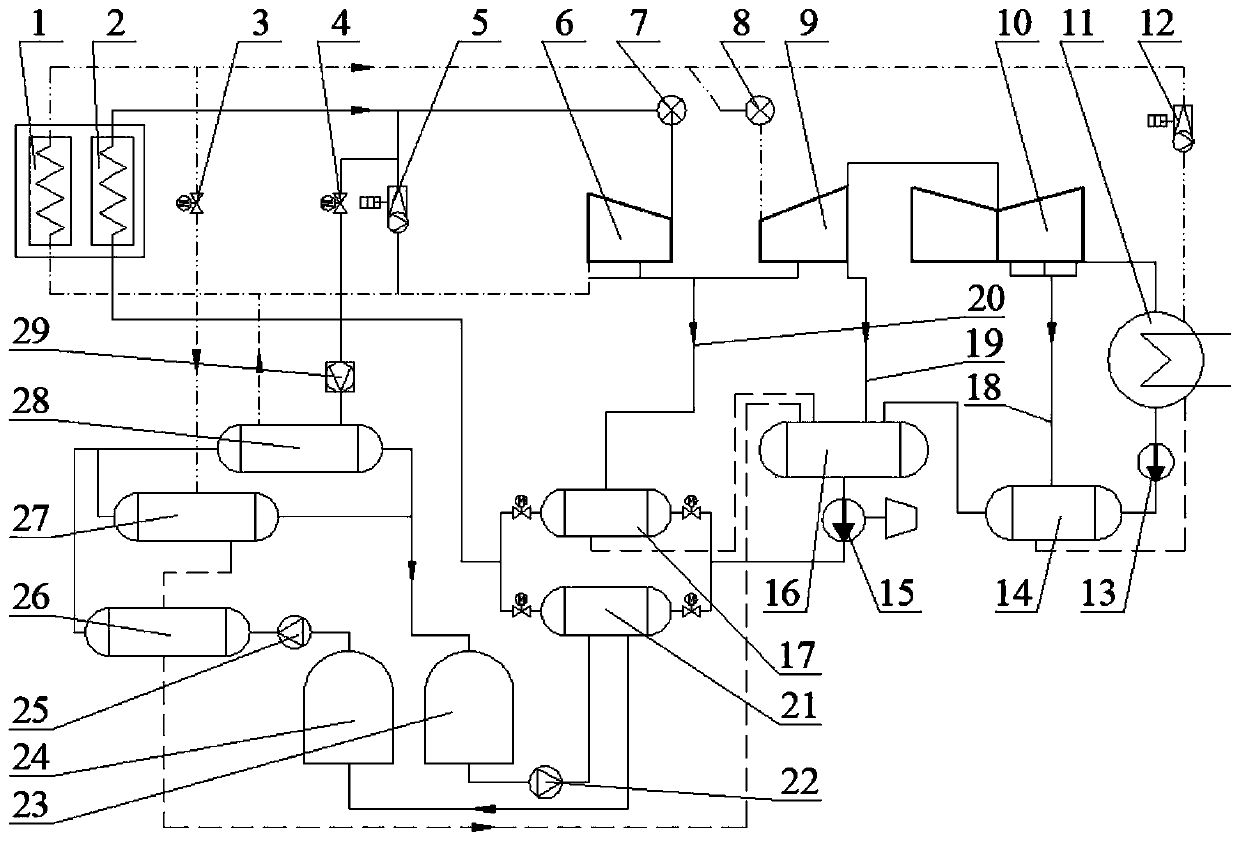

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

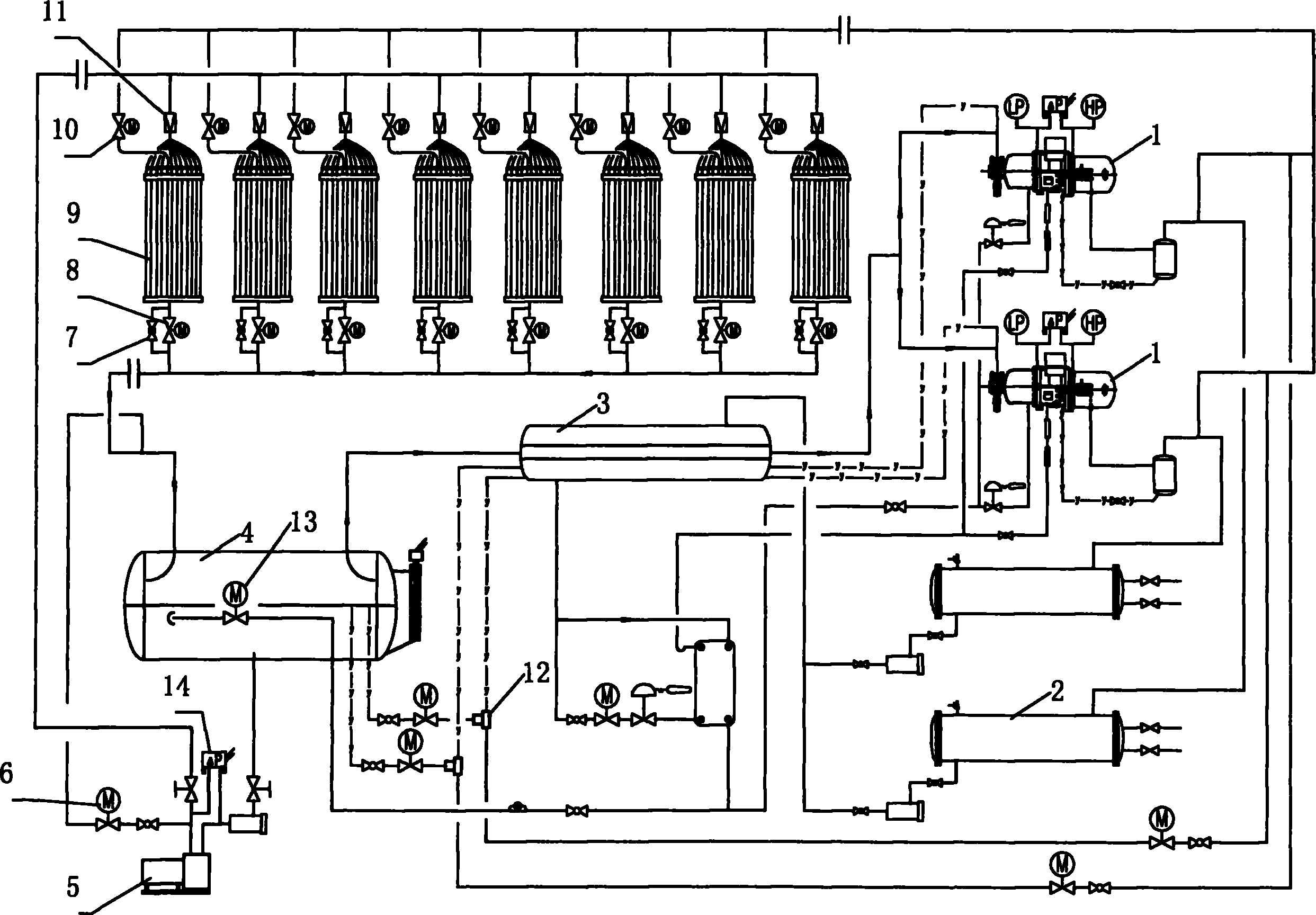

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

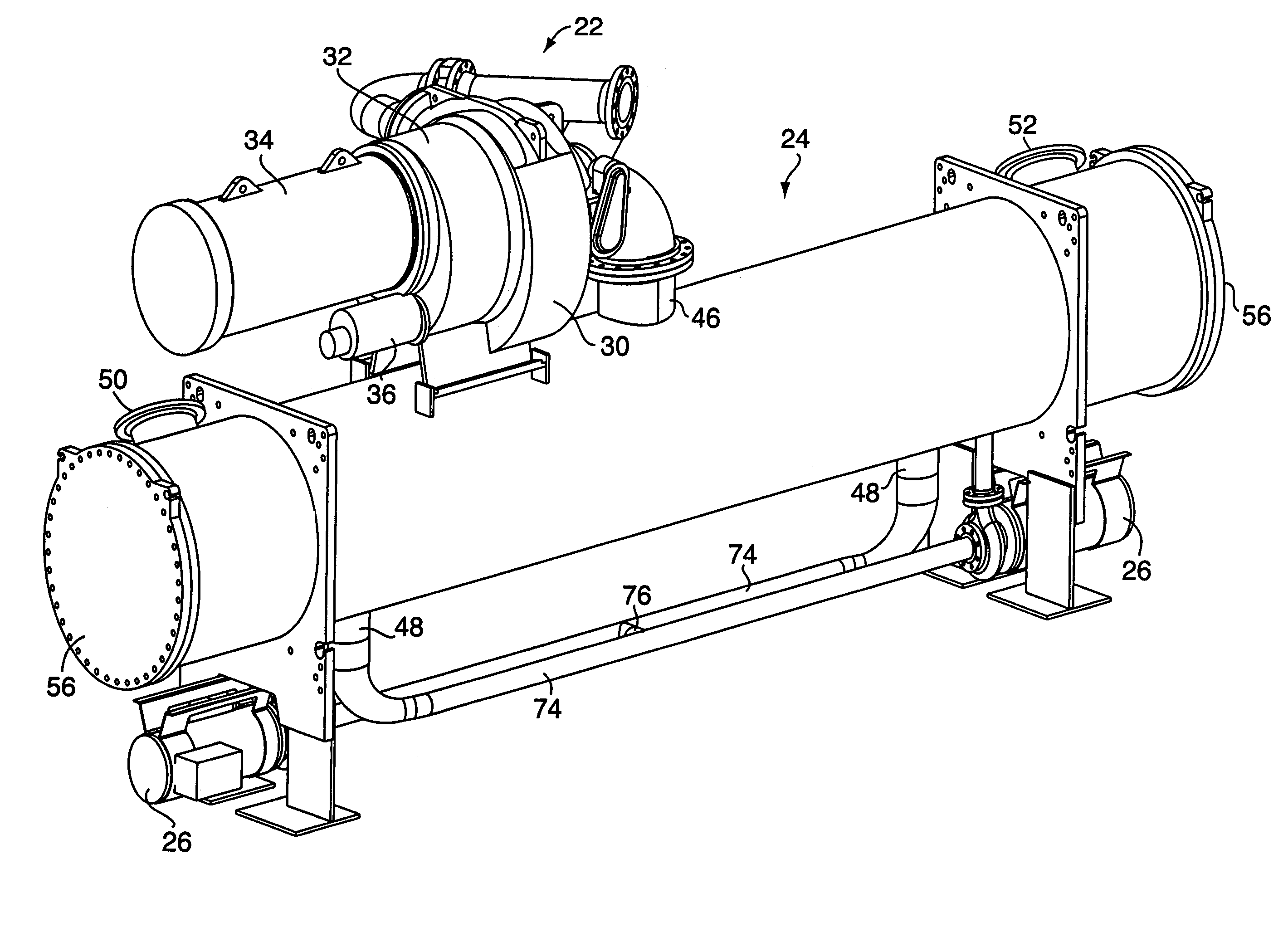

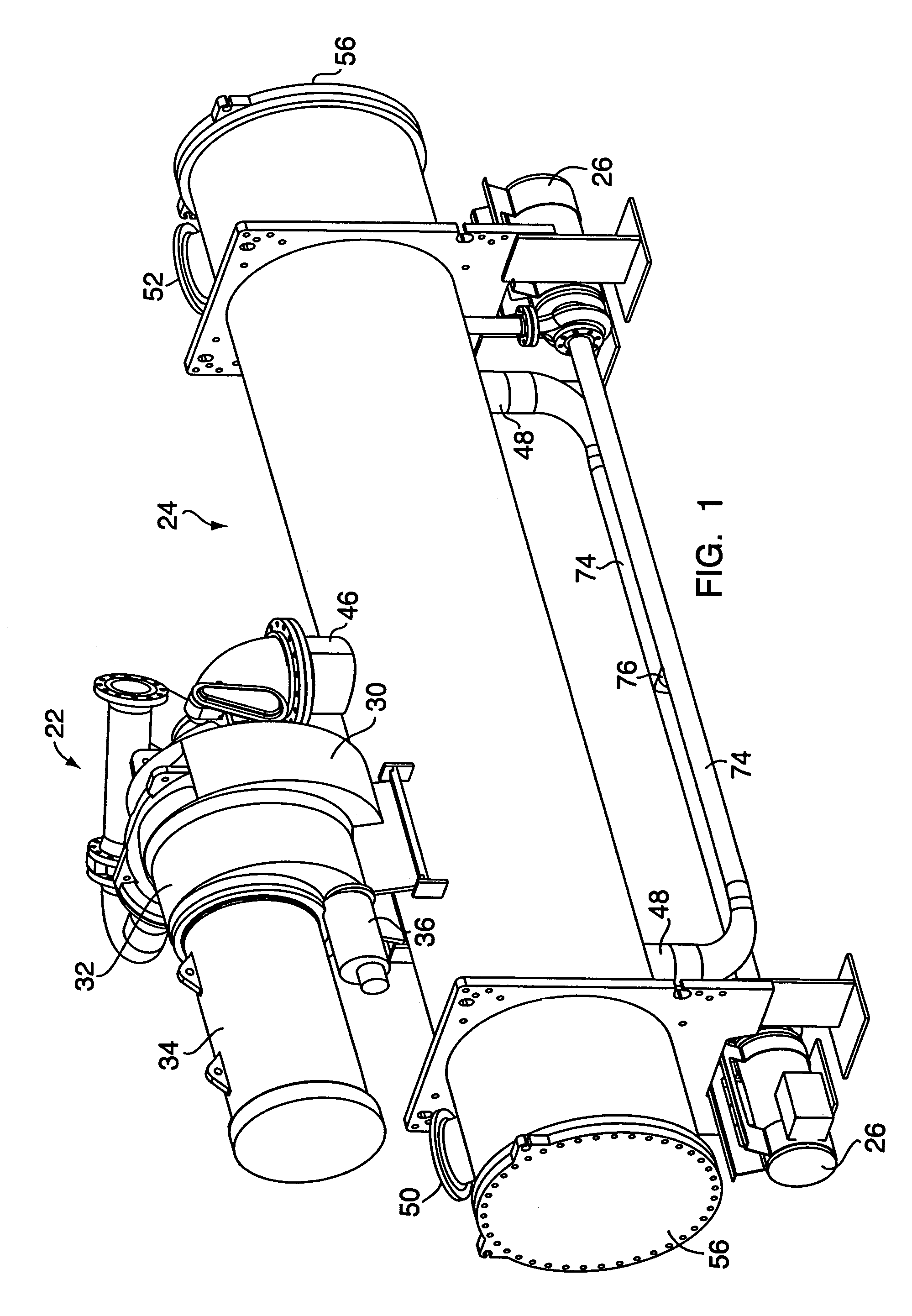

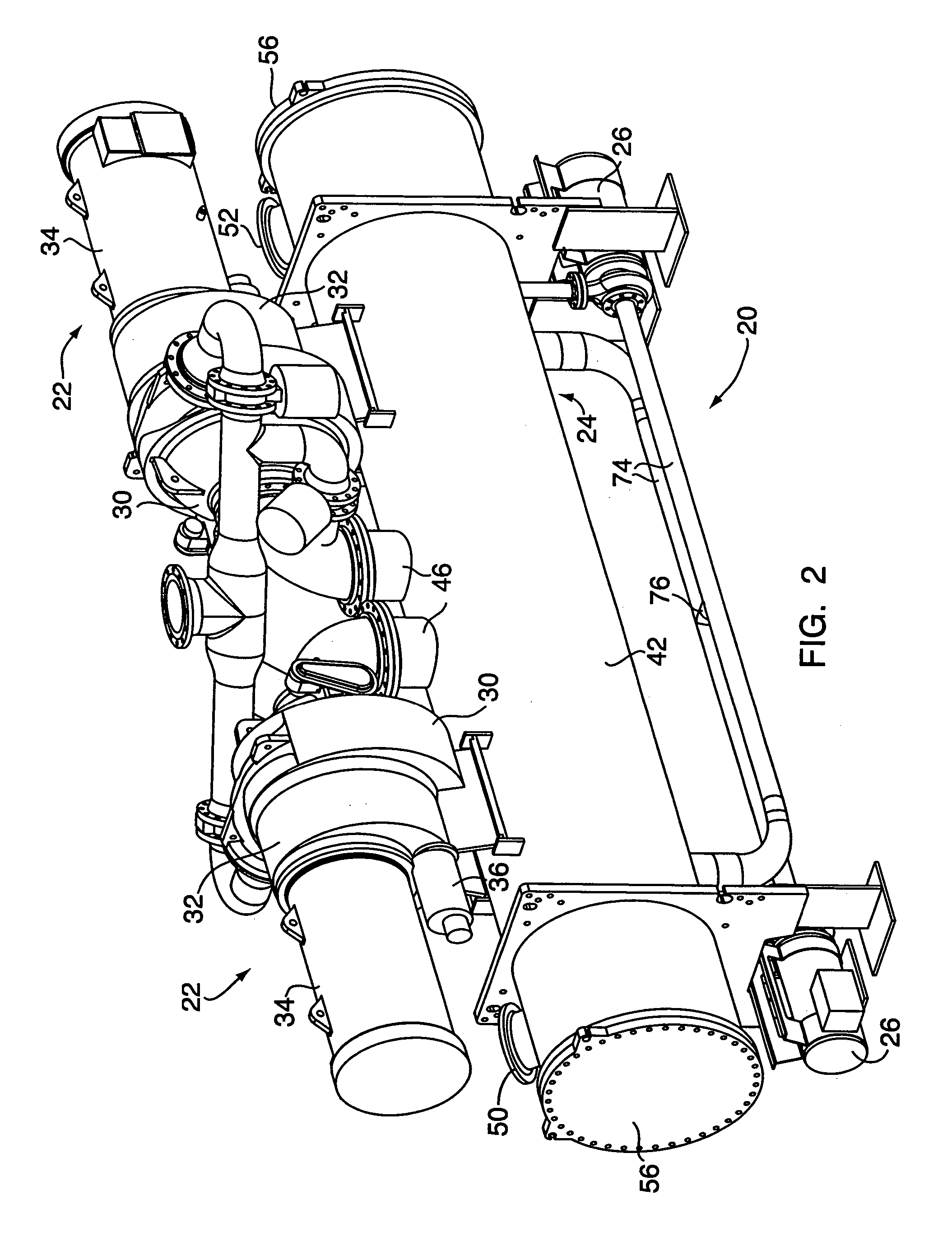

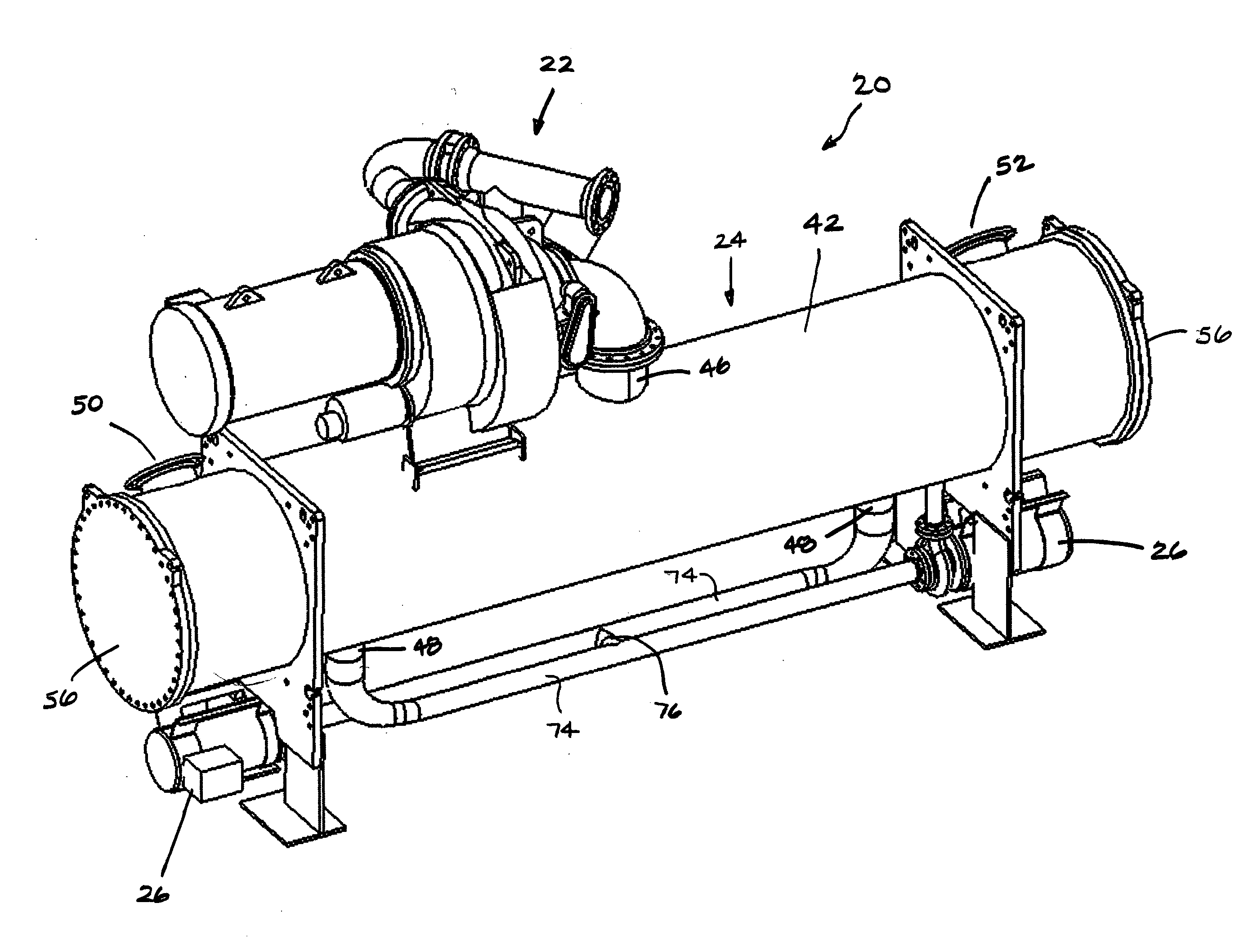

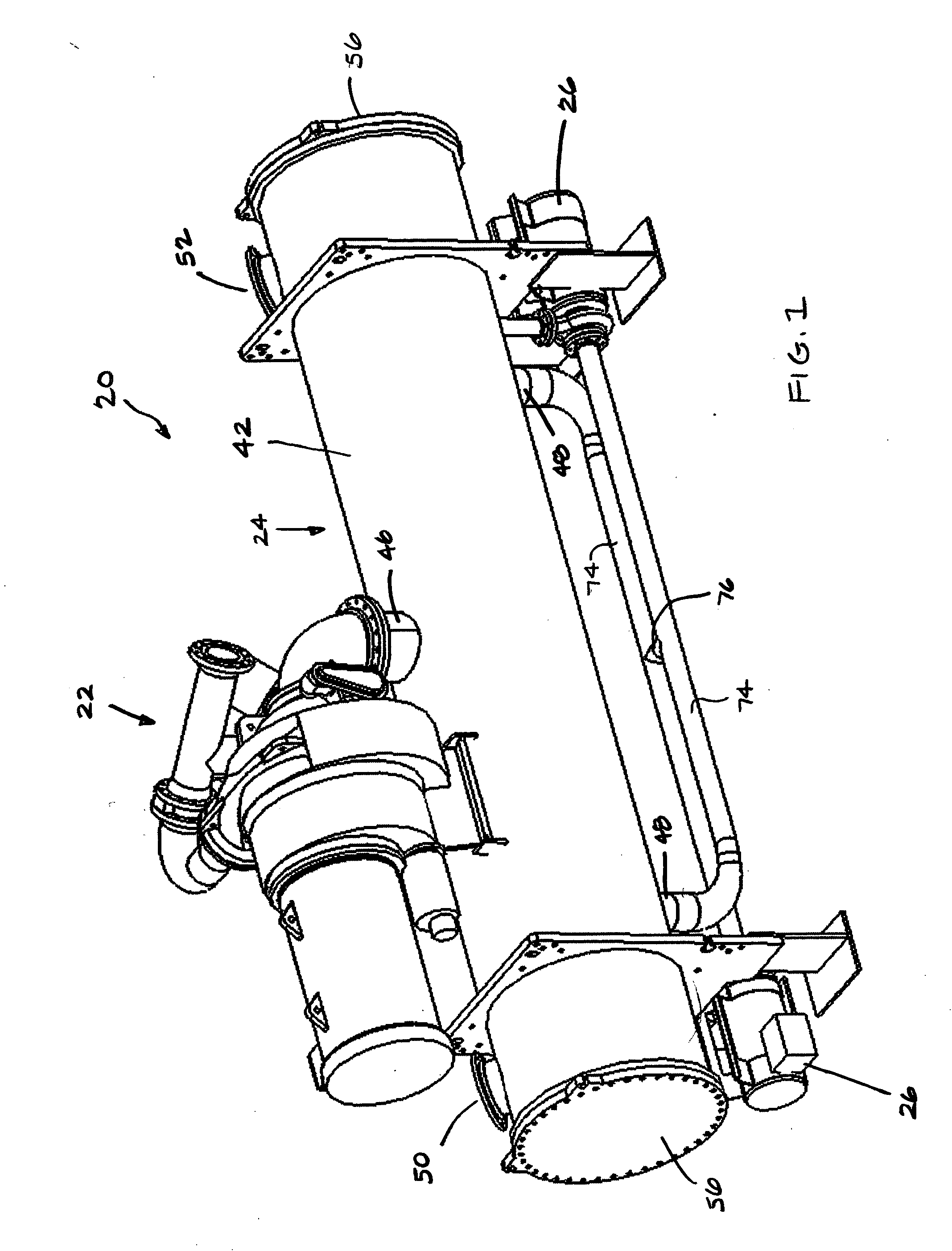

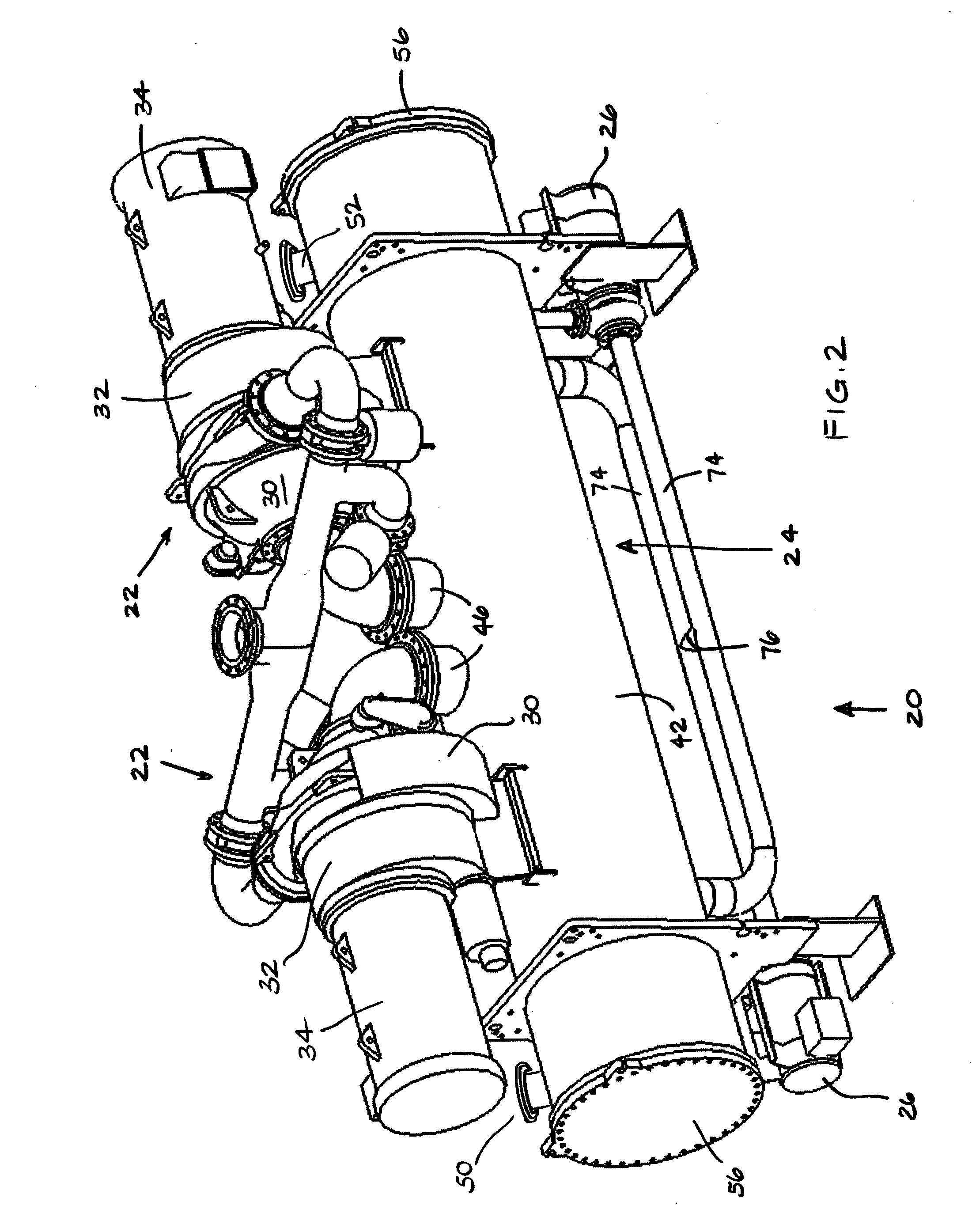

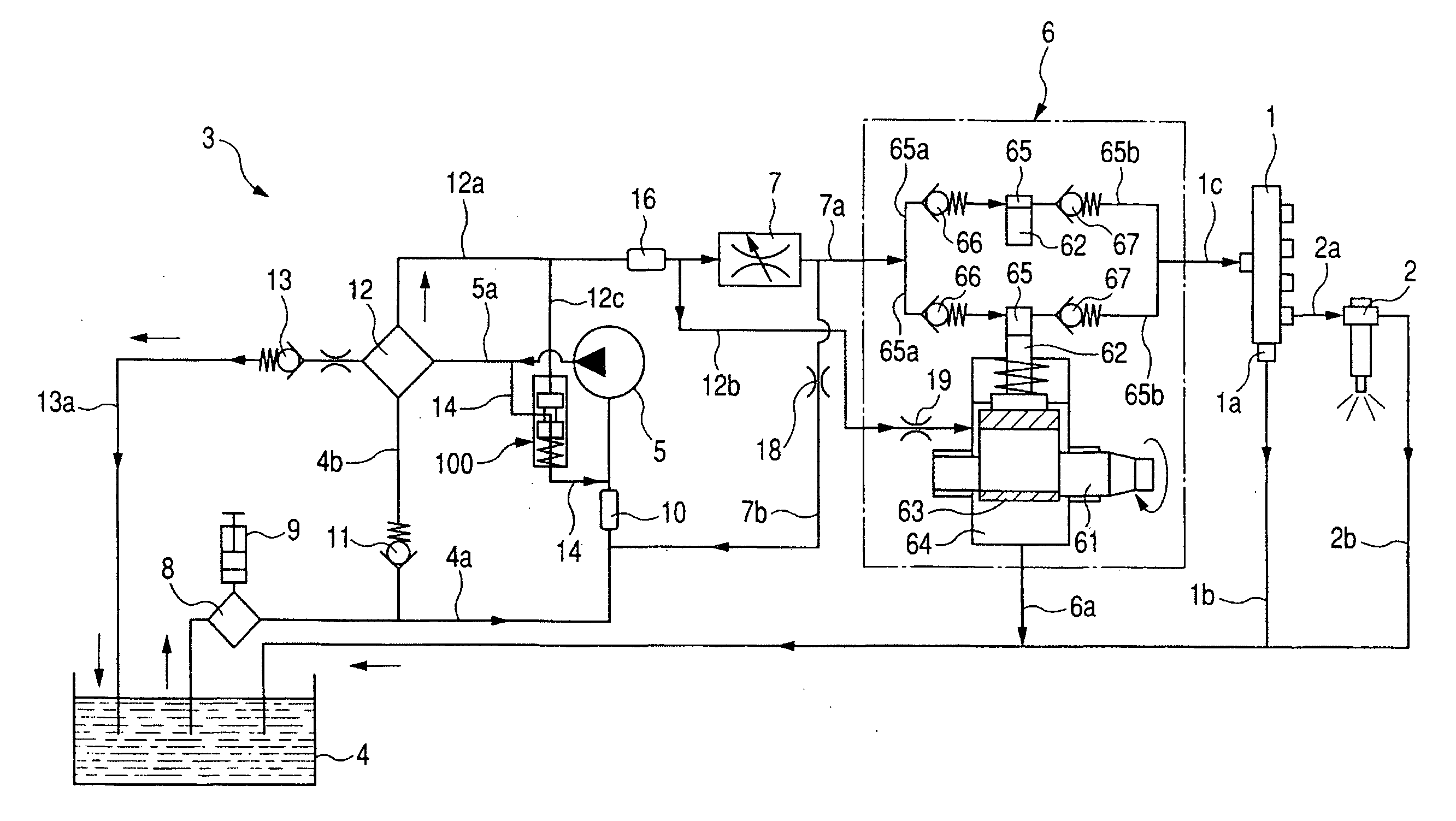

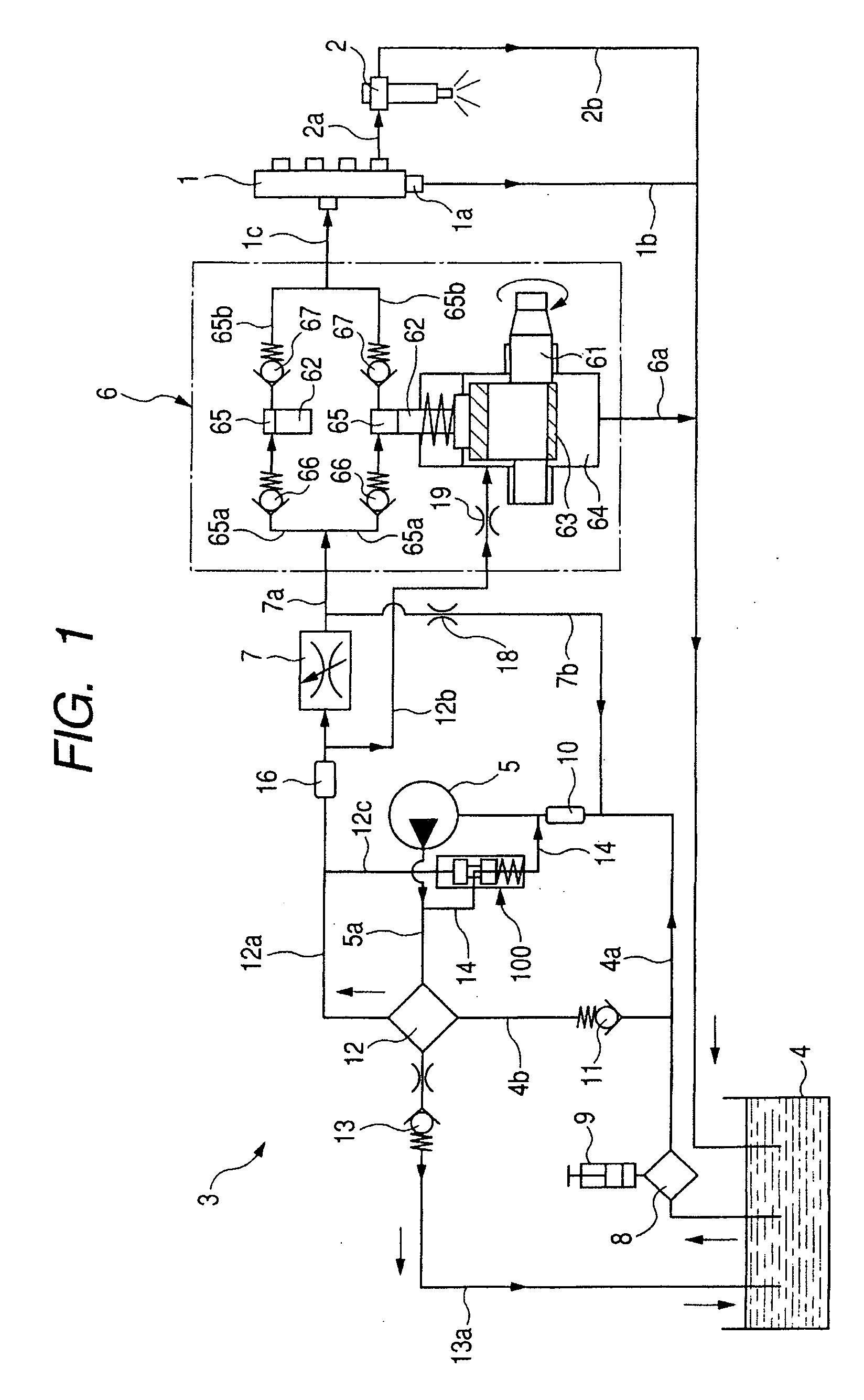

Method and apparatus for decreasing marine vessel power plant exhaust temperature

InactiveUS7121906B2Reduce exhaust temperatureReduce signalingDefensive equipmentLiquid coolingPower stationEngineering

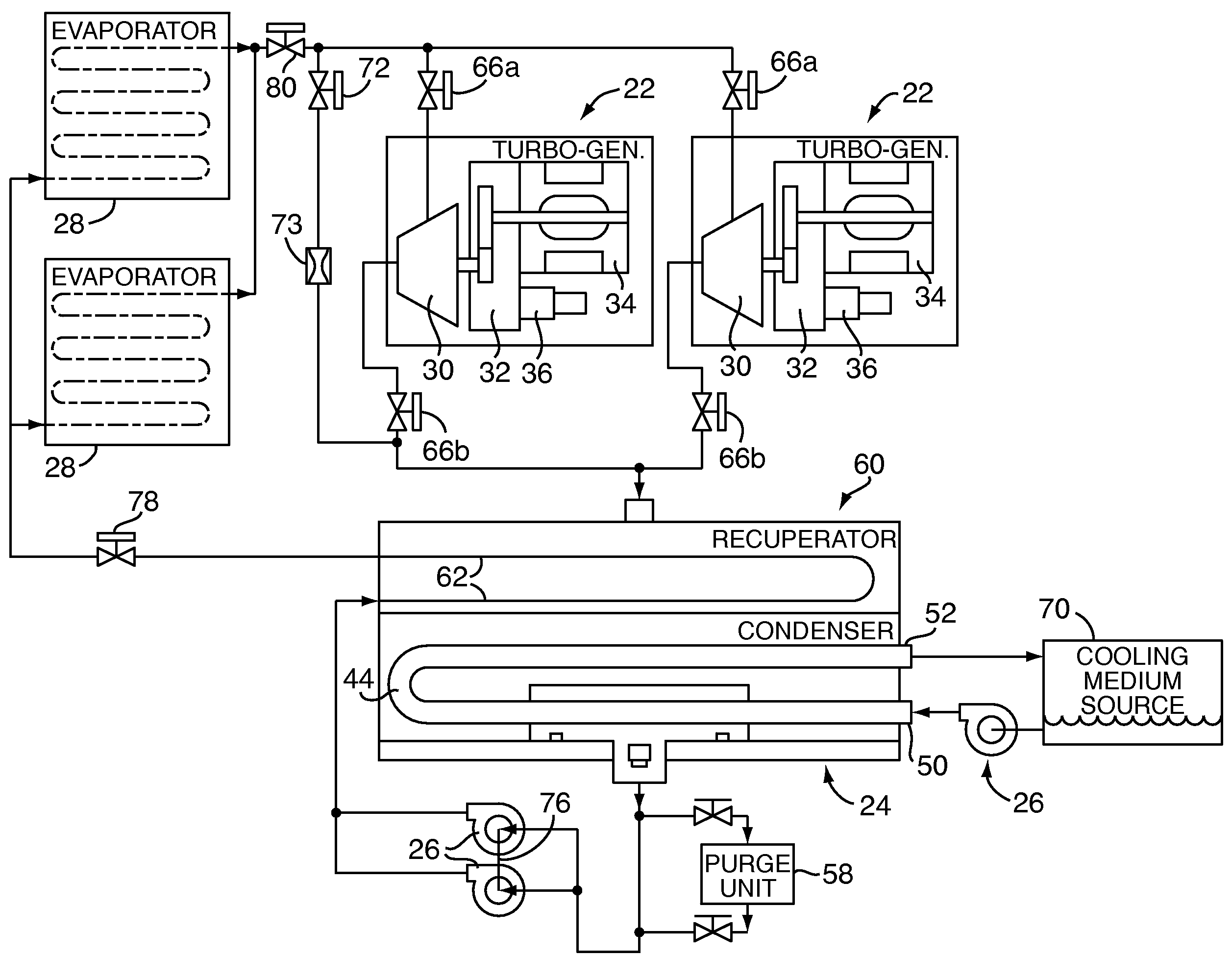

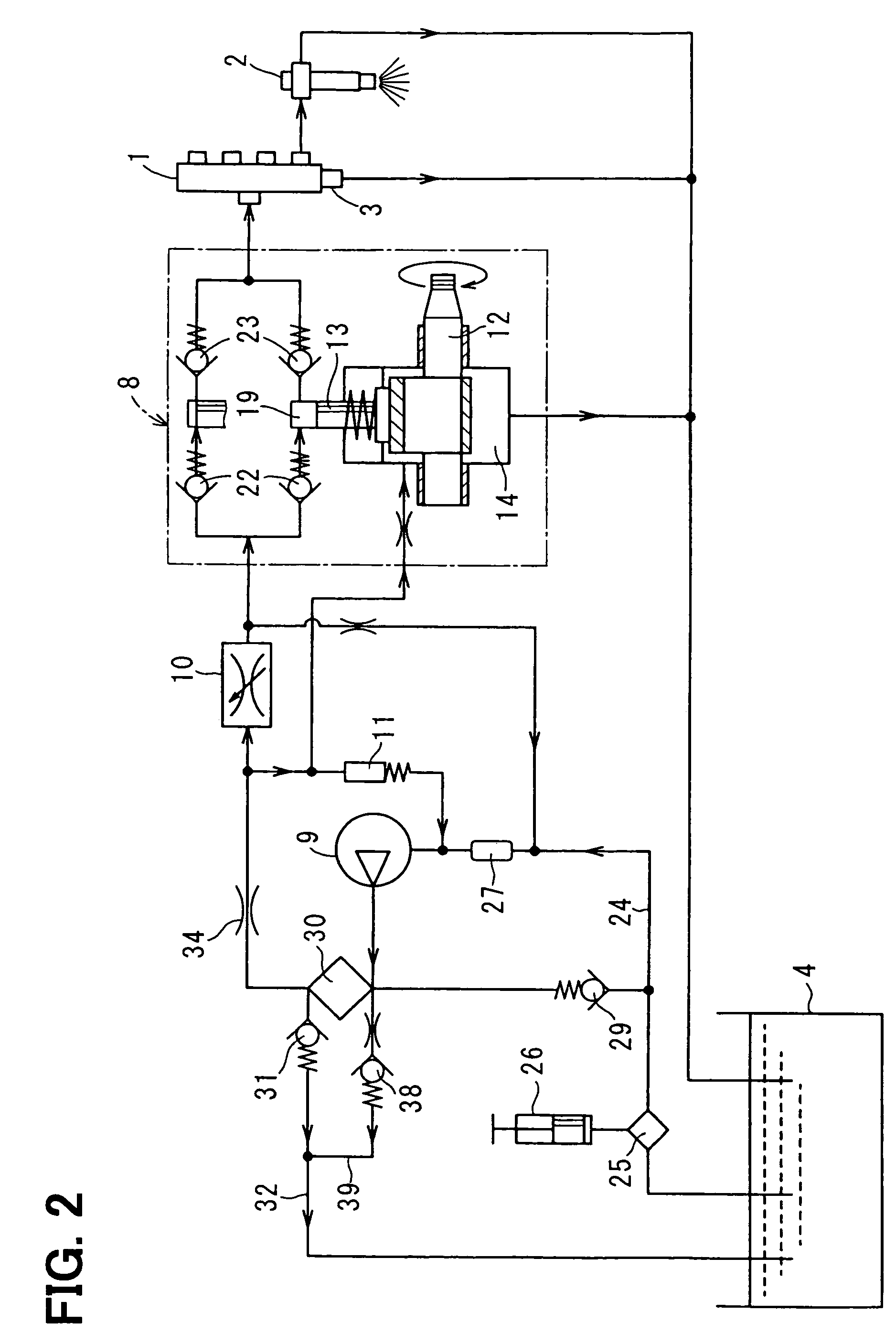

According to the present invention, a method and apparatus for generating power aboard a marine vessel is provided. The method comprises the steps of: (a) providing a Rankine Cycle device that includes at least one of each of an evaporator, a turbo-generator that includes a turbine coupled with an electrical generator, a condenser, and a refrigerant feed pump; (b) disposing the one or more evaporators within an exhaust duct of a power plant of the marine vessel; (c) operating the power plant; and (d) selectively pumping refrigerant through the Rankine Cycle device, wherein refrigerant exiting the evaporator powers the turbine, which in turn powers the generator to produce power.

Owner:CARRIER CORP

Rankine cycle device having multiple turbo-generators

ActiveUS20060112692A1Reduce exhaust temperatureDecreases fuel reserve requirementSteam useTurbineRefrigerant

A method for generating power, comprising the steps of: a) providing a Rankine Cycle device that includes a plurality of turbo-generators, each including a turbine coupled with an electrical generator, and at least one of each of an evaporator, a condenser, and a refrigerant feed pump; b) disposing the one or more evaporators within an exhaust duct of a power plant of a marine vessel; c) operating the power plant; and d) selectively pumping refrigerant through the Rankine Cycle device.

Owner:NANJING TICA AIR CONDITIONING CO LTD +1

Turbine engine lubrication method and system

InactiveUS20100028127A1Light weightConsumes little oil and compressed airLeakage preventionPump controlStream flowFuel tank

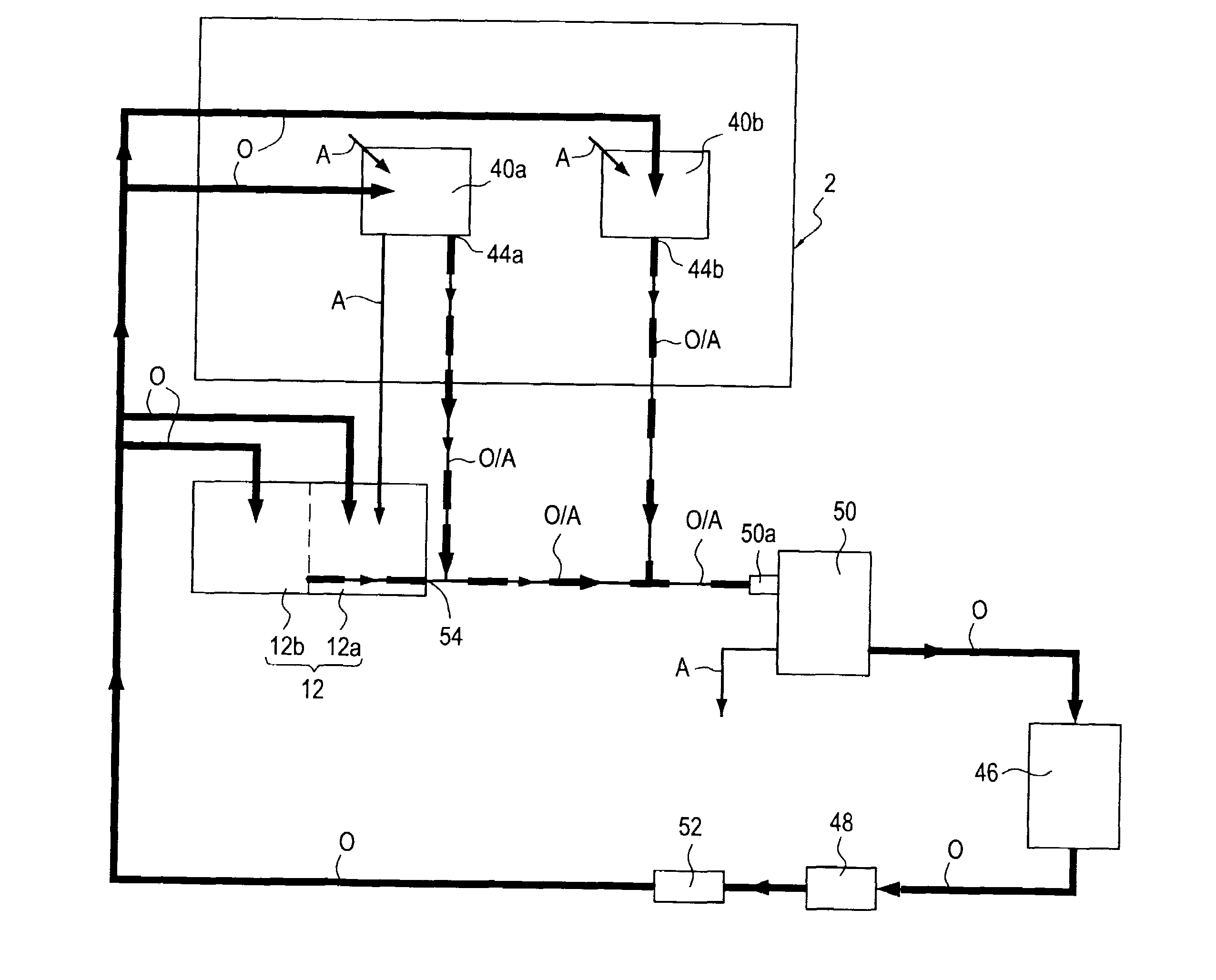

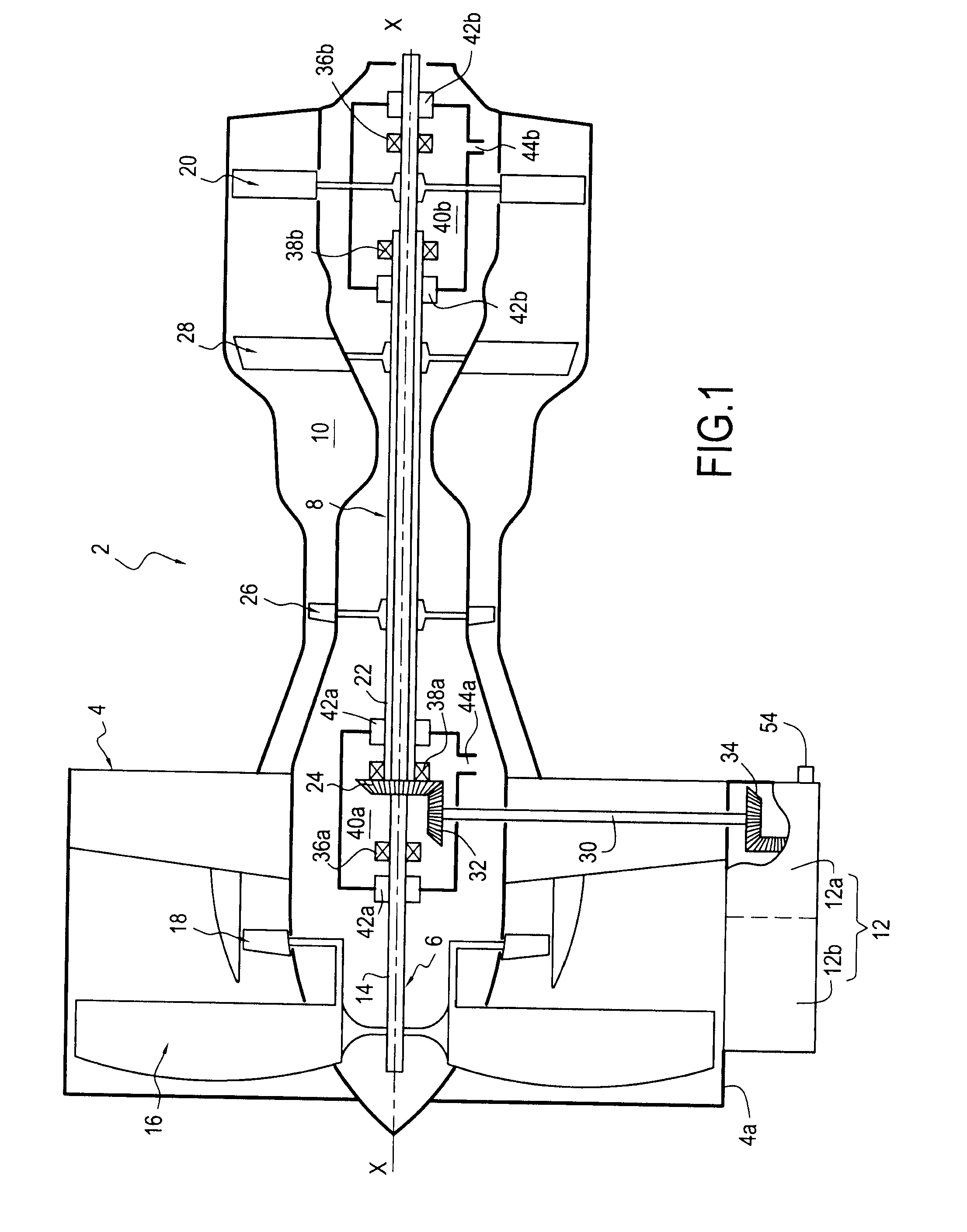

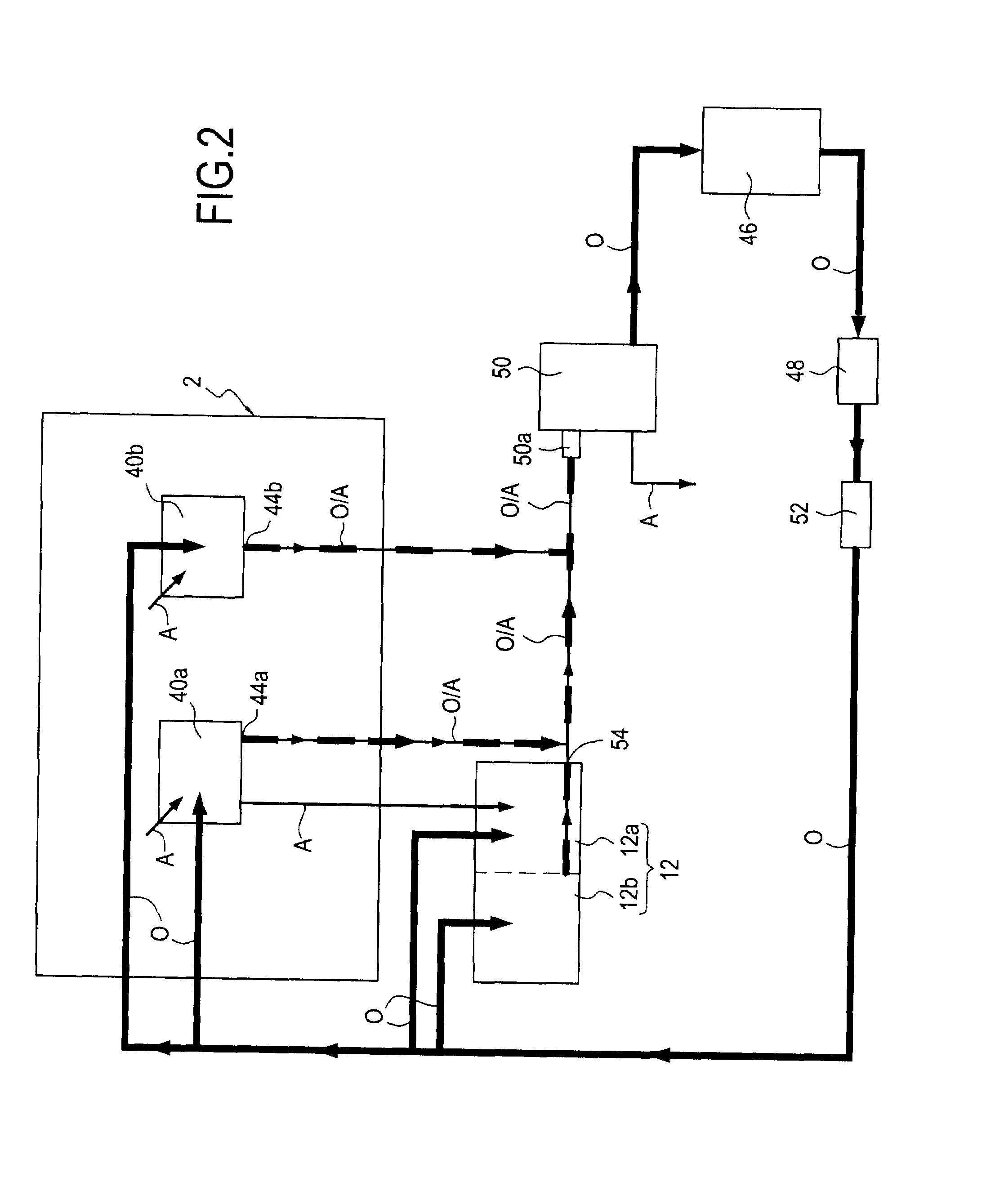

A method and a system for lubricating a turbomachine including an oil tank, an oil feed pump, an oil / air separator, and at least two enclosures closed by air flow rate seals, each including a low outlet and housing shaft-supporting rolling bearings. The method injects oil from the tank into the enclosures by the pump to lubricate the bearings, introduces compressed air at a low flow rate into the enclosures via the seals to pressurize the enclosures, recuperates all of the air and the oil introduced into the enclosures via their low outlet, uses gravity and the pressurization of the enclosures to convey the oil / air mixture as recovered in this way to the oil / air separator, separates the oil and the air of the mixture by the oil / air separator, returns the oil to the tank, and exhausts the air to outside the turbomachine.

Owner:TECHSPACE AERO

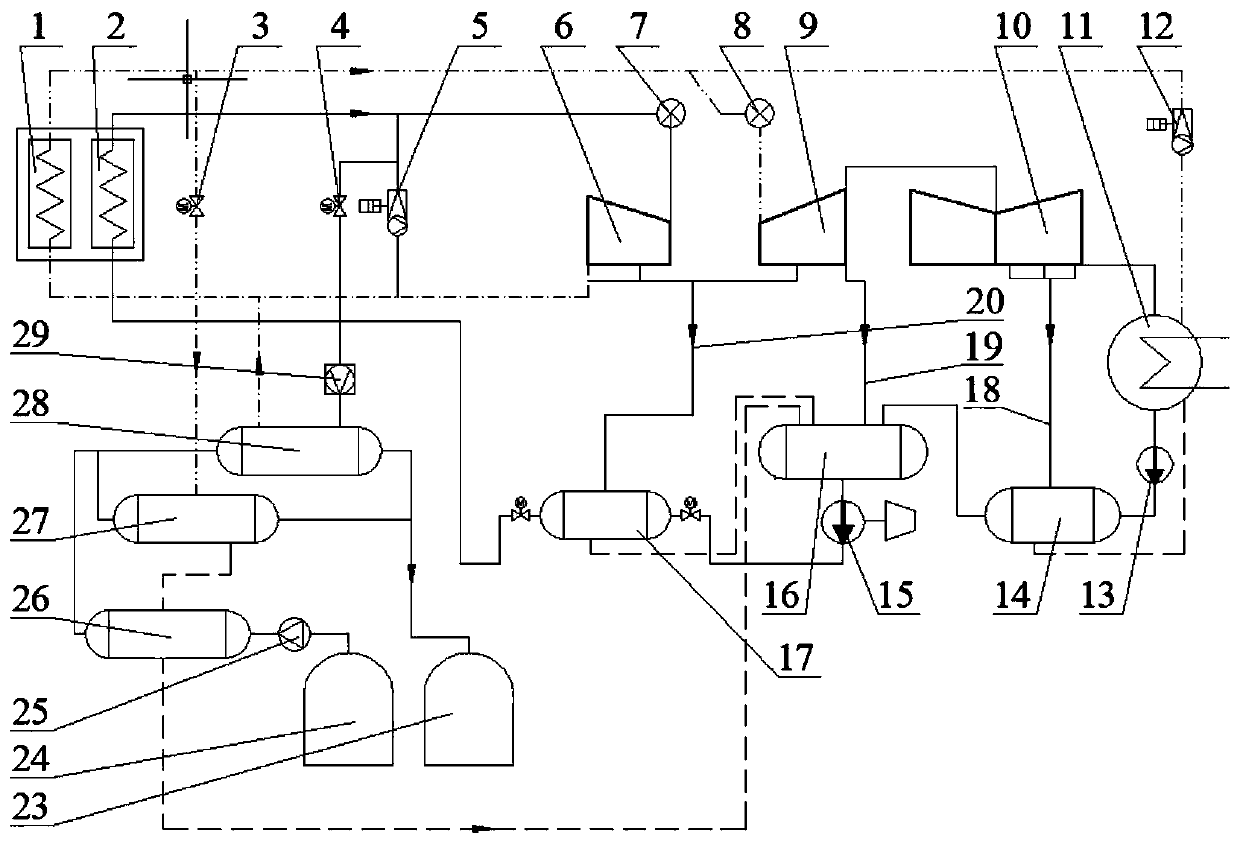

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

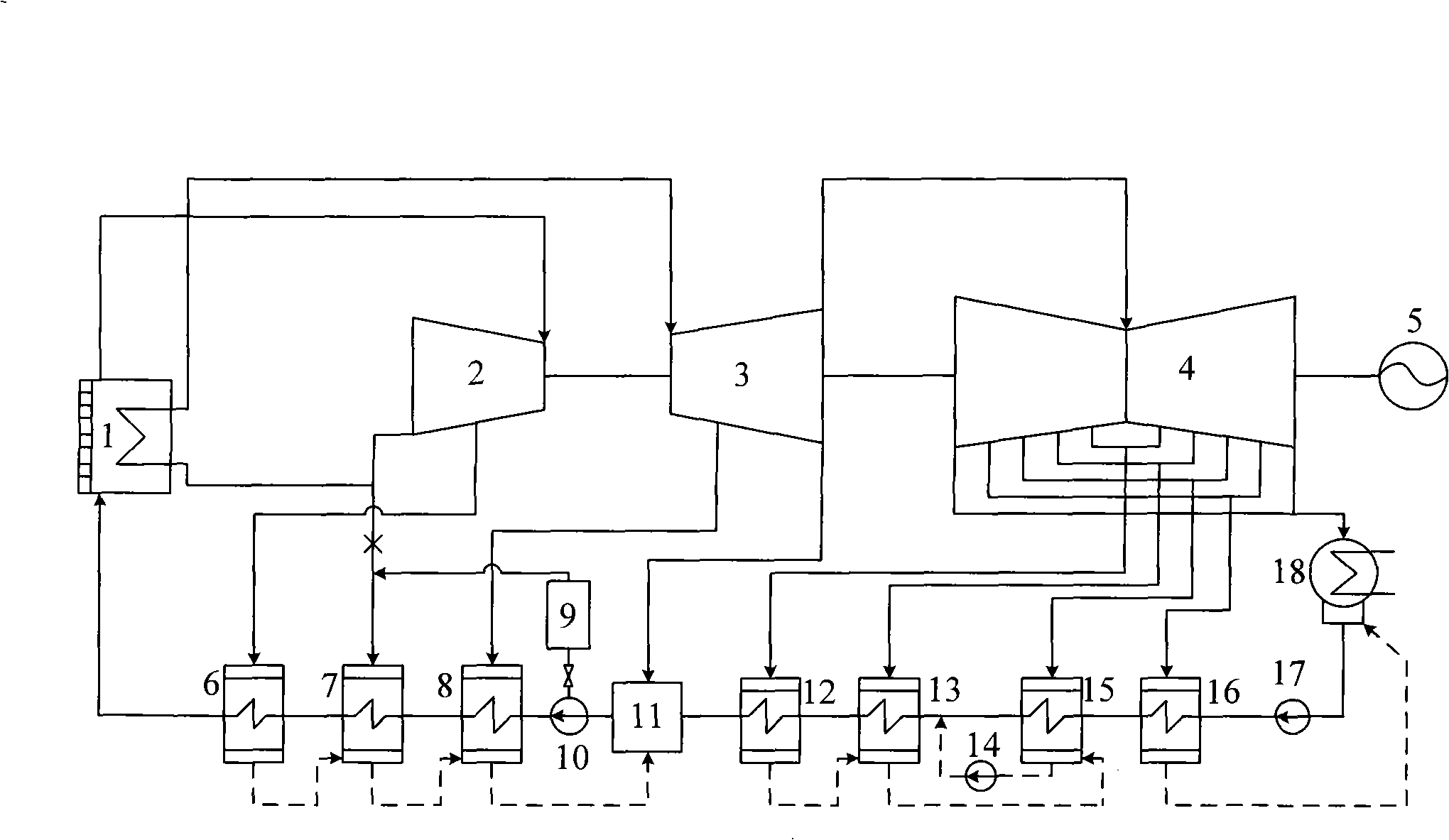

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method and apparatus for treatment of concentrated reverse osmosis drainage through coupled forward osmosis and reverse osmosis

InactiveCN102745776AImprove utilizationNo pollution in the processSemi-permeable membranesGeneral water supply conservationHigh pressureReverse osmosis plant

The invention discloses a method and an apparatus for treatment of a concentrated reverse osmosis drainage through coupled forward osmosis and reverse osmosis. The method comprises the following steps that: a raw forward osmosis solution directly enters into a forward osmosis assembly, a concentrated reverse osmosis drainage is used as a driving solution for forward osmosis, water of the raw forward osmosis solution permeates a membrane, the concentrated reverse osmosis drain is diluted and then mixed with raw reverse osmosis water, then flows through a high-pressure pump and enters into a reverse osmosis assembly as inflowing reverse osmosis water, water penetrating to one side of the driving solution from the raw forward osmosis solution is recycled through reverse osmosis, and the concentrated reverse osmosis drainage is circulated as the driving solution for forward osmosis. The apparatus comprises a first feed pump, a second feed pump, the forward osmosis assembly, the high-pressure pump and the reverse osmosis assembly. According to the invention, the utilization rate of the concentrated reverse osmosis drain can be increased; pollution of the concentrated reverse osmosis drainage to the environment can be reduced; the method and the apparatus can also be used for liquid concentration and desalination, producing significant economic values; and the apparatus provided by the invention has the advantages of a small occupied land area, a compact structure, simple operation, low running cost and low energy consumption.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

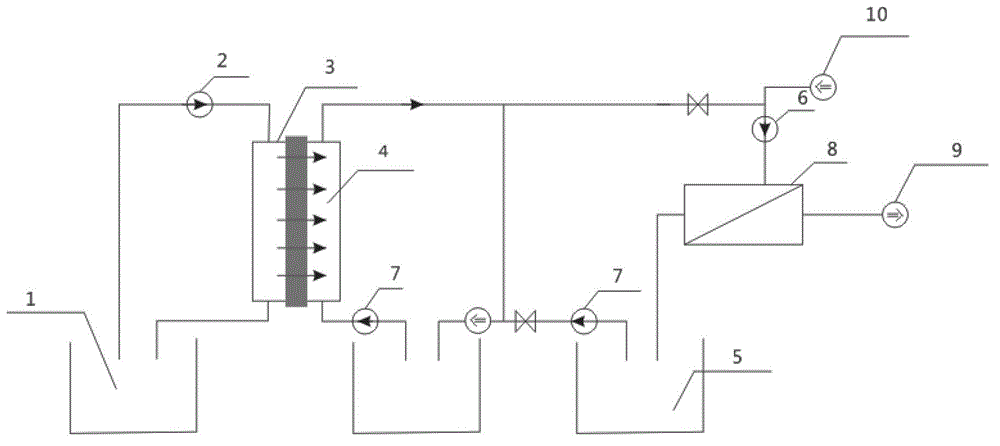

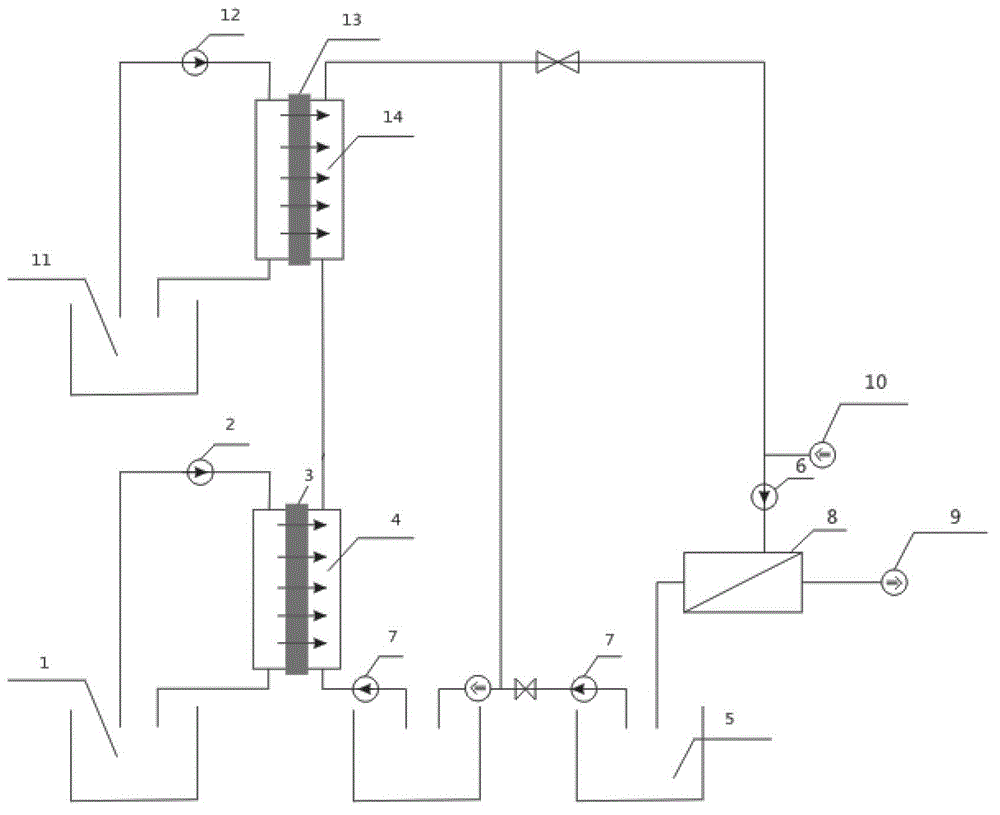

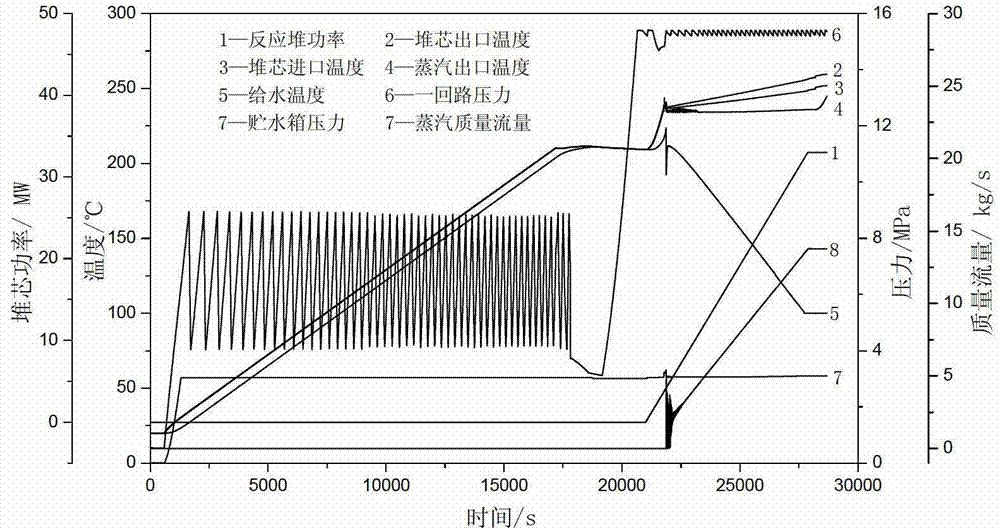

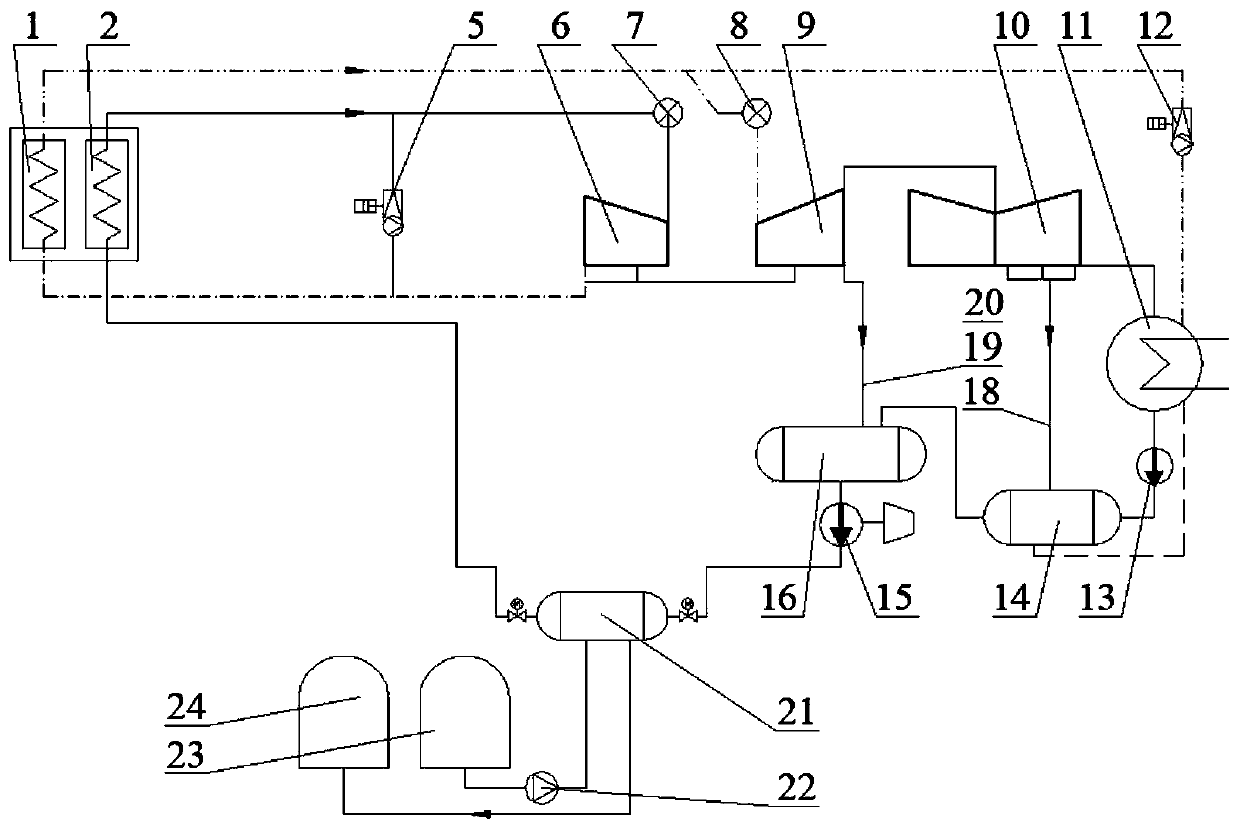

Start-stop auxiliary device used in integral reactor and cold starting method of integral reactor

ActiveCN103117101AShorten the timeSafe and stable operationPlant parameters regulationNuclear energy generationStart timeWater storage tank

The invention provides a start-stop auxiliary device used in an integral reactor and a cold starting method of the integral reactor. An inlet of a starting separator is connected with an outlet conduit of a once-through steam generator, an outlet of the starting separator is connected with a main steam pipe through a steam valve, and a drain outlet is connected with a water storage tank. An outlet at the bottom of the water storage tank is connected with a circulating water pump, and one conduit at the outlet of the water storage tank is connected with a condenser through an outlet stop valve of the water storage tank, a water storage tank water level control valve and a thermoreduction and dropping device. The circulating water pump is connected with a water supply conduit at the inlet of the once-through steam generator through a circulating water-carrying control valve. A water feed pump is connected with the condenser, the water feed pump is further connected with the inlet conduit of the once-through steam generator through a main water feed valve and with the water storage tank through a cold water valve. The start-stop auxiliary device is capable of increasing the temperature and pressure of refrigerant in a first circuit when the reactor starts, starting pressure and starting flow of a second circuit are established effectively, phenomenon of unstable flow is avoided, working media and heat energy are recycled effectively, and starting time is shortened.

Owner:HARBIN ENG UNIV

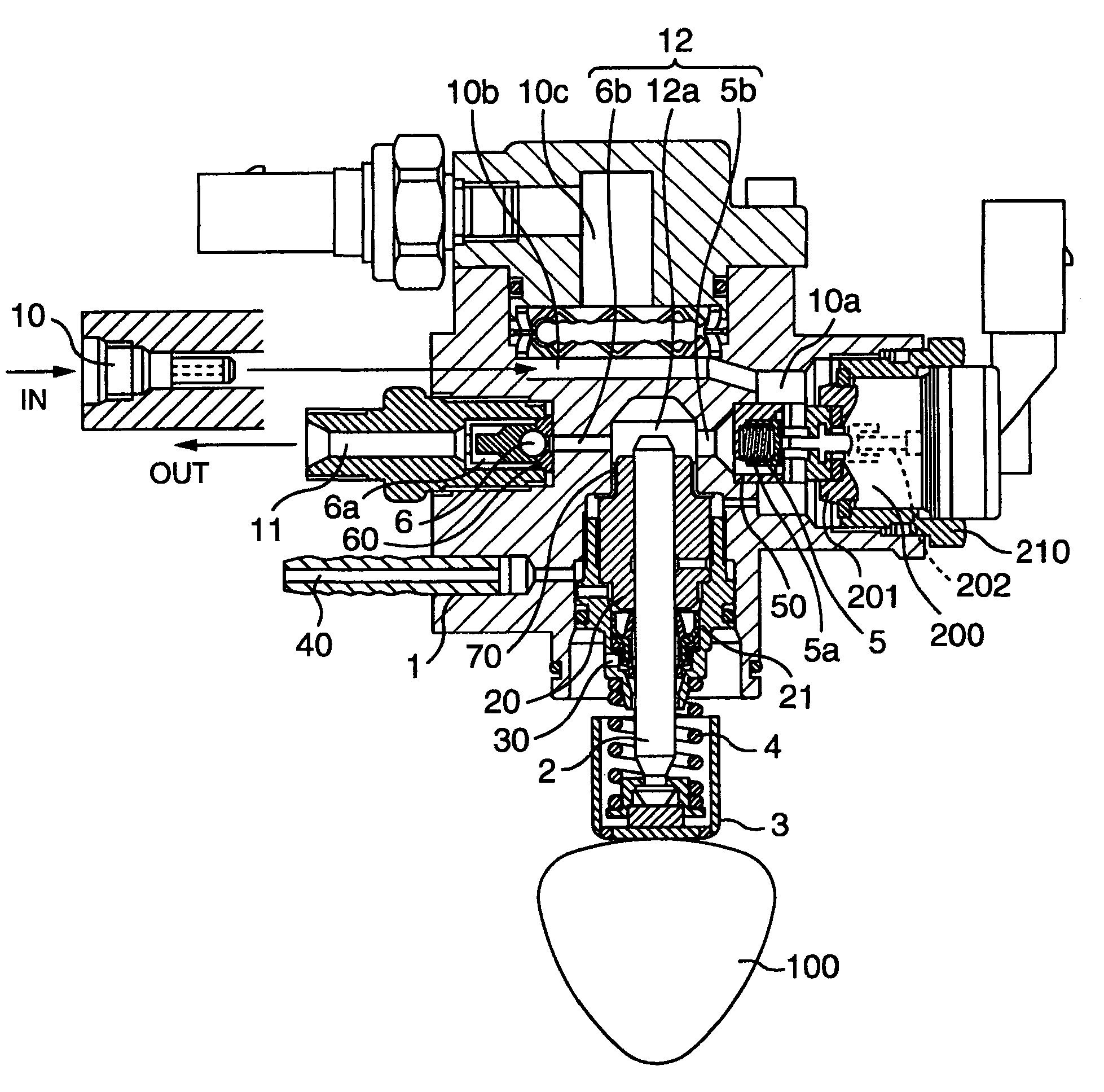

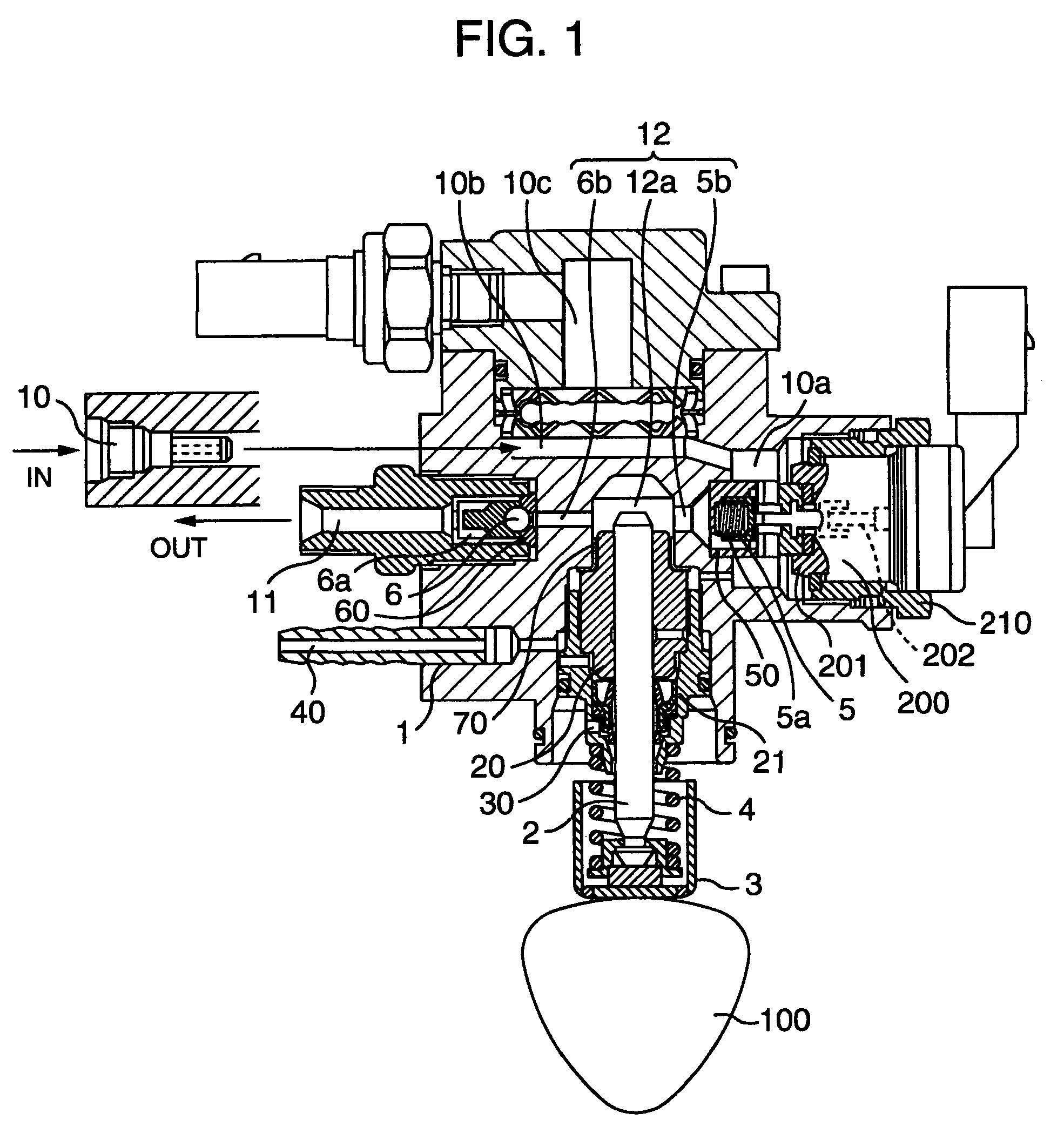

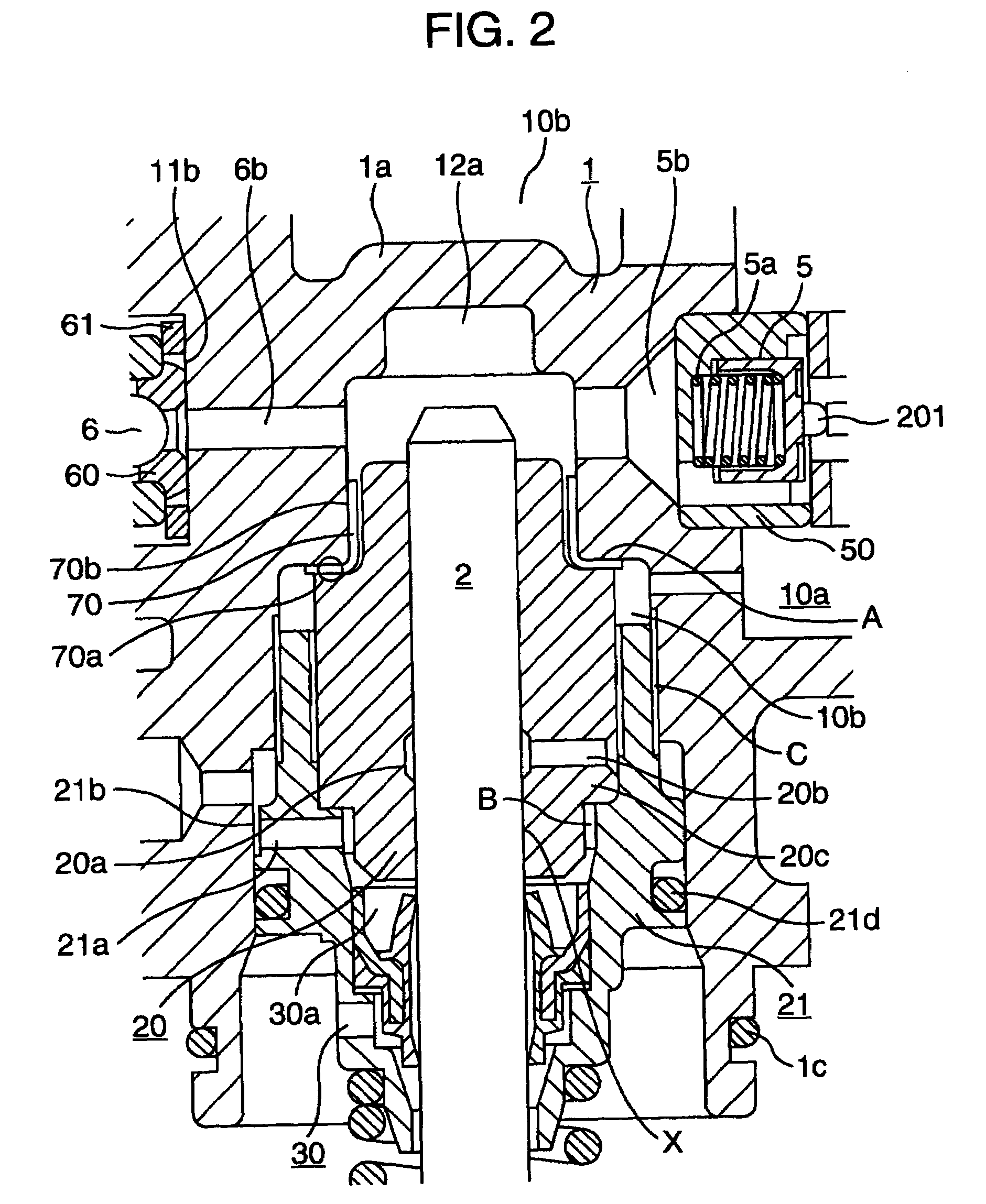

High pressure fuel pump provided with damper

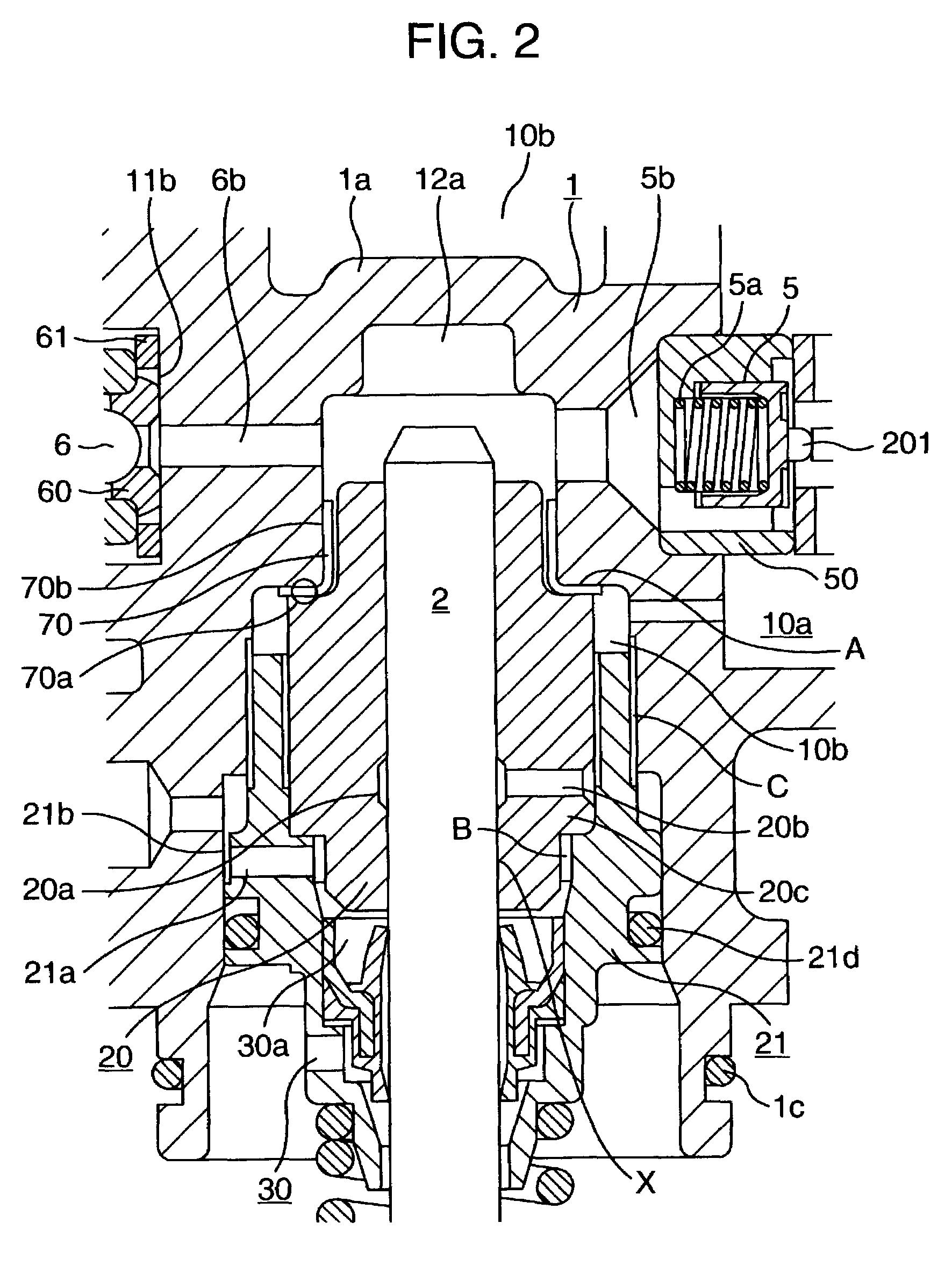

InactiveUS7513240B2Improve stabilityHigh capacity of absorbing pulsationFluid parameterPipe elementsWave shapeInlet valve

A fuel feed system capable of feeding a fuel to fuel injection valves at a fuel pressure with improved stability is provided. A fuel feed system for an internal combustion engine including a fuel tank and a low-pressure pump for feeding the fuel in the fuel tank to fuel injection valves, is provided with a diaphragm type damper having a wave-shape cross section at a position in contact with the fuel. Also, in a high-pressure fuel feed pump including a pressurizing chamber for pressurizing the fuel, a plunger for pumping the fuel within the pressurizing chamber, an intake valve provided at a fuel inlet of the pressurizing chamber, a discharge valve provided at a fuel outlet of the pressurizing chamber, and a low-pressure chamber provided in an upstream of the intake valve, a mechanism for reducing fuel pressure pulsation is disposed in a space of the low-pressure chamber provided in the upstream of the intake valve, and a fuel pressure sensor for measuring the fuel pressure is mounted near the mechanism for reducing fuel pressure pulsation.

Owner:HITACHI AUTOMATIVE SYST ENG +1

Spray coating method for producing dielectric ceramic powder body and obtained products thereof

The invention relates to a spray coating method for preparing dielectric ceramic powder and the dielectric ceramic powder prepared. The spray coating method comprises the following steps: A. main crystal phase ceramic powder and modified metallic ion composite soluble inorganic salt precursor or sol are processed into slurry with good fluidity; B. the slurry in the step A is prepared by deionized water into slurry with a solid content between 5 and 70 percent; and C. the slurry obtained in the step B is stirred and simultaneously conveyed to a spray drier by a feed pump, the feed rate is controlled to between 0.01 and 6.01 liters per minute, and the dielectric ceramic powder required is prepared after spray drying of the slurry at a hot blast temperature of between 120 and 450 DEG C; or D. the dielectric ceramic powder obtained in the step C is placed into a high temperature furnace at a temperature of between 250 and 1200 DEG C for calcinating 0.5 to 6 hours. The method is economic and simple; doped compositions and main crystal phase materials are uniformly distributed; and prepared dielectric powder crystal grains reach submicron or nano level and have superhigh evenness and dispersity.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

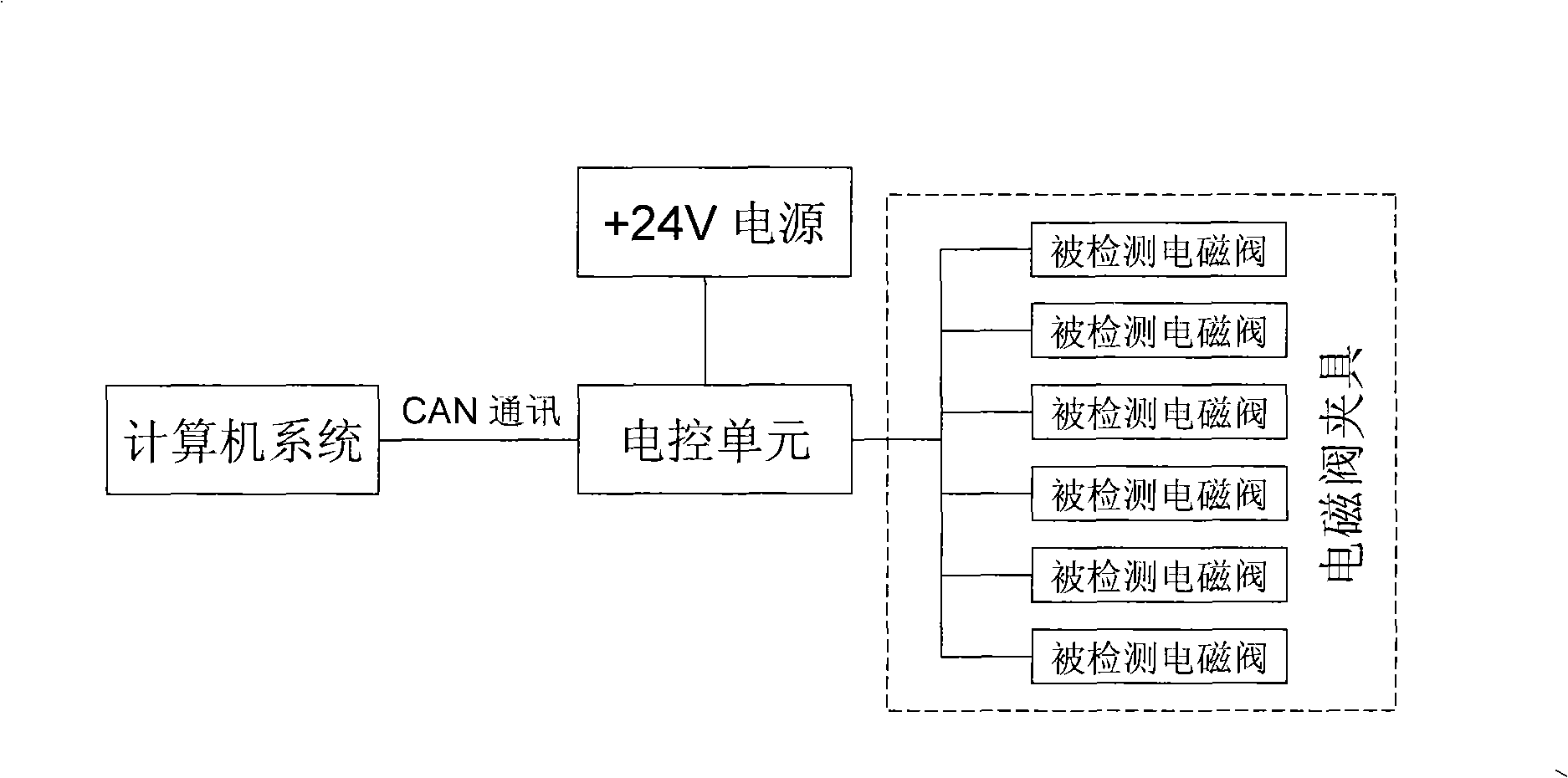

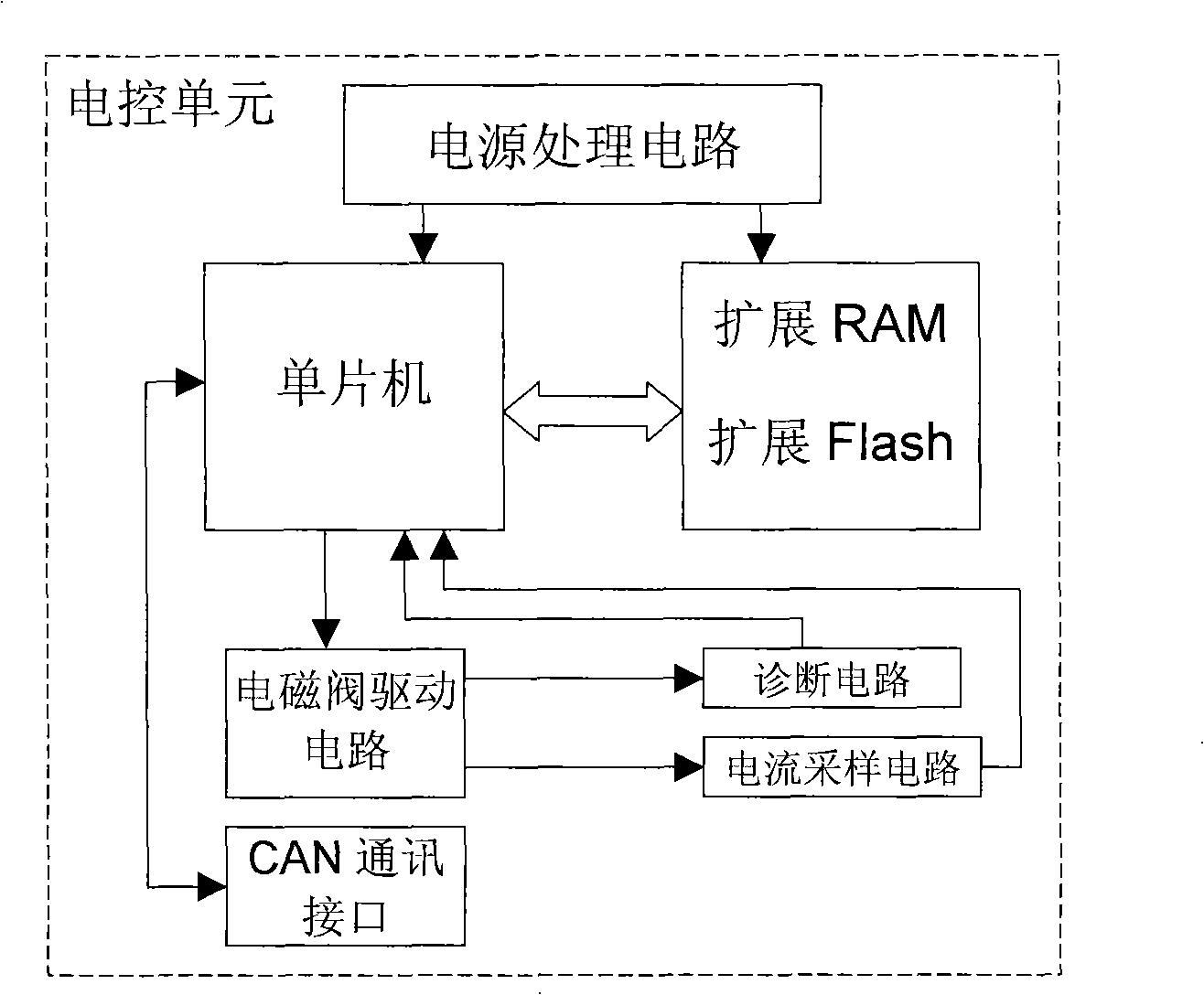

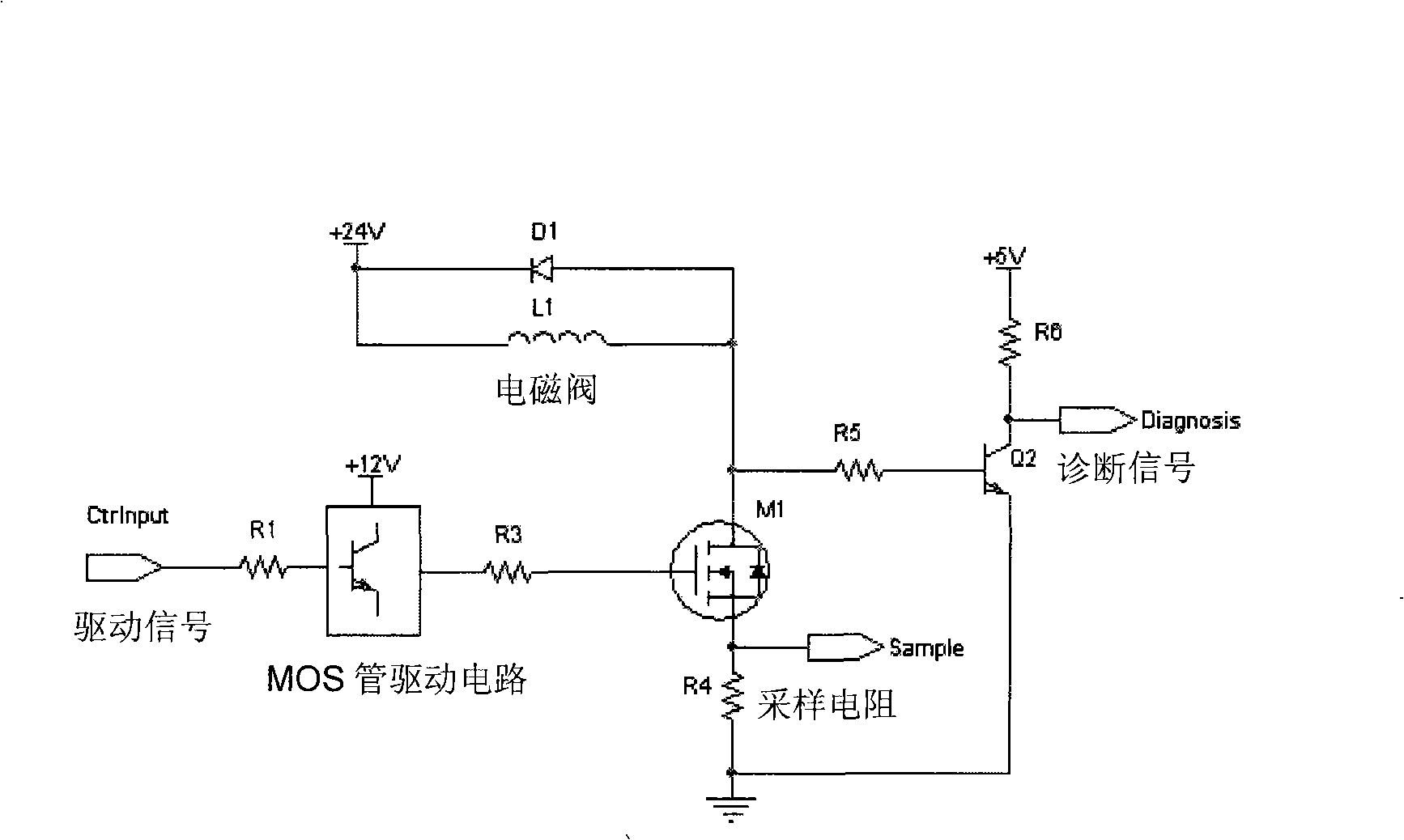

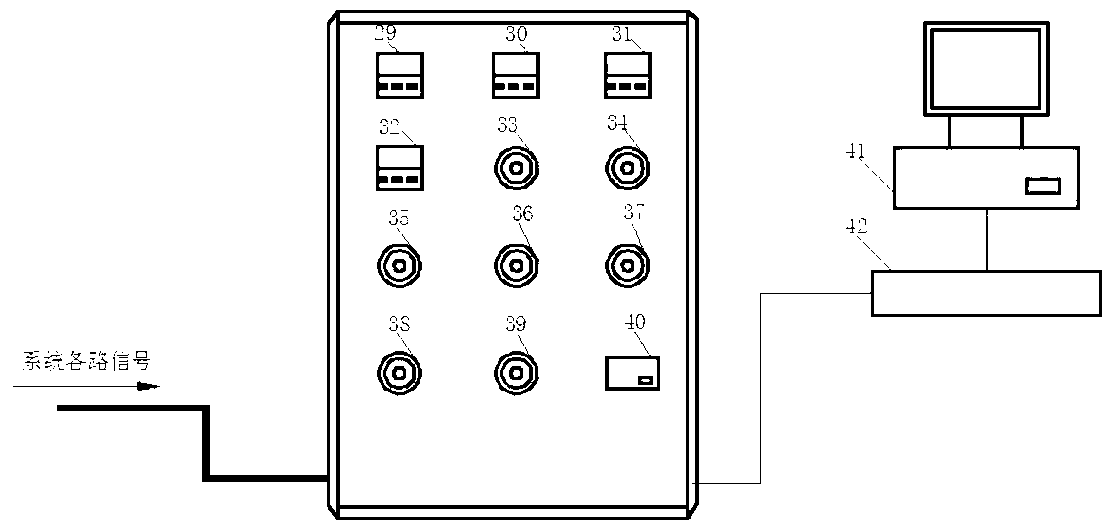

Solenoid valve diagnosis detecting method and device for electric-controlled co-rail fuel feed pump

InactiveCN101294534AImprove consistencyImprove performanceEngine testingFuel injection apparatusSolenoid valveCommon rail

The invention relates to a diagnosis and detection method and a device for an electromagnetic valve used for an electrically controlled common rail fuel feed pump. The method is characterized in that control parameters predetermined by test is input by a monitor program, current waveform during the drive of the electromagnetic valve is detected in real time and curve fitting is conducted; accordingly, the characteristics of the electromagnetic valve are judged, the movement circumstances when turning-on and shutting-down of the electromagnetic valve delays are measured and then whether the electromagnetic valve has the fault of deadlocking or open circuit can be analyzed. When the electromagnetic valve diagnosis and detection device is in use, no fuel injection pump test stand is needed; the use of the device can improve the consistence of the performance of the fuel feed pump electromagnetic valve, thereby greatly improving the performance and reliability of a common rail fuel injection system. The electromagnetic valve detection device has the advantages of low manufacture cost, convenient use, good self-diagnostic function and easy implementation in mass production.

Owner:CHINA FIRST AUTOMOBILE

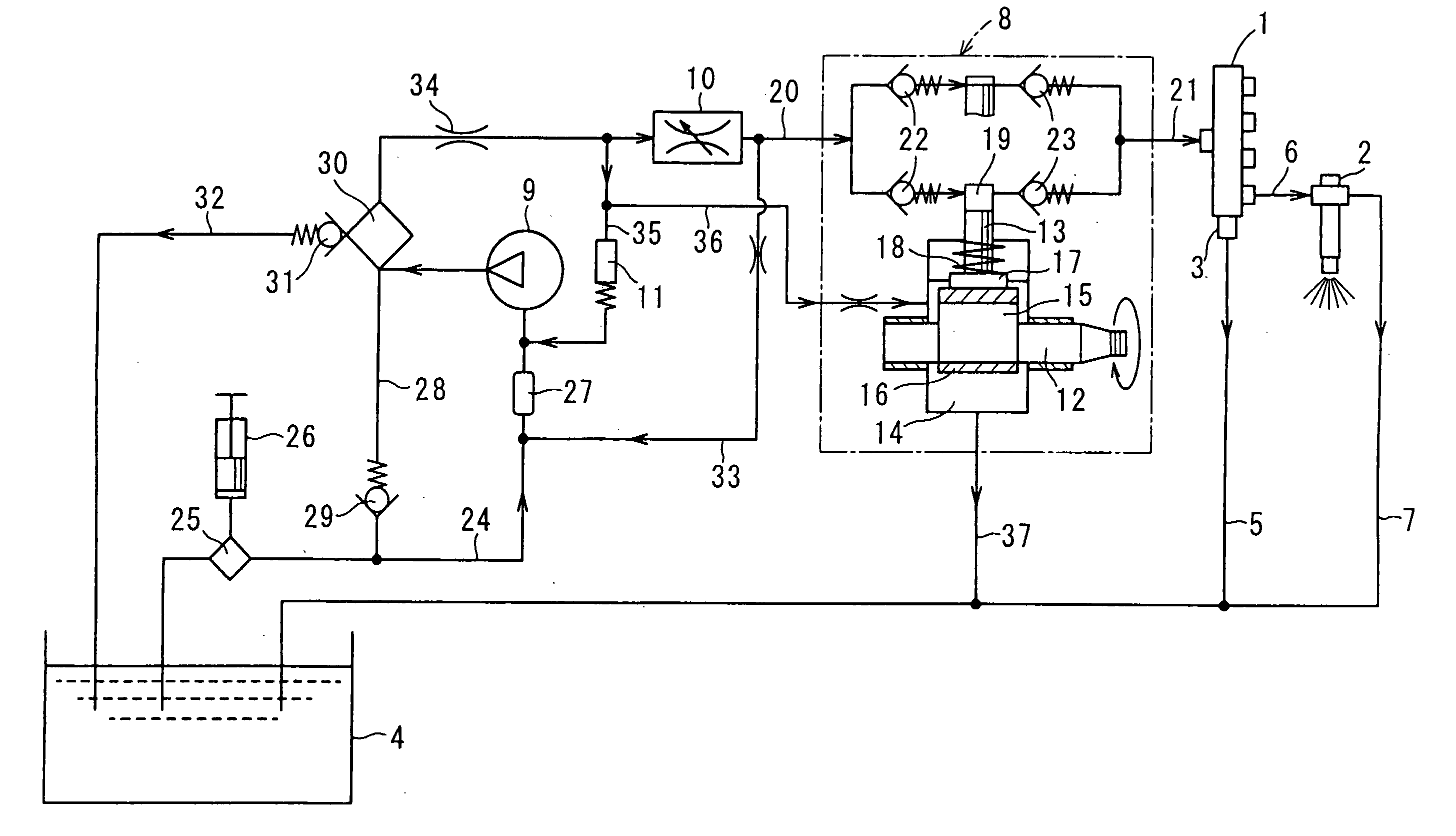

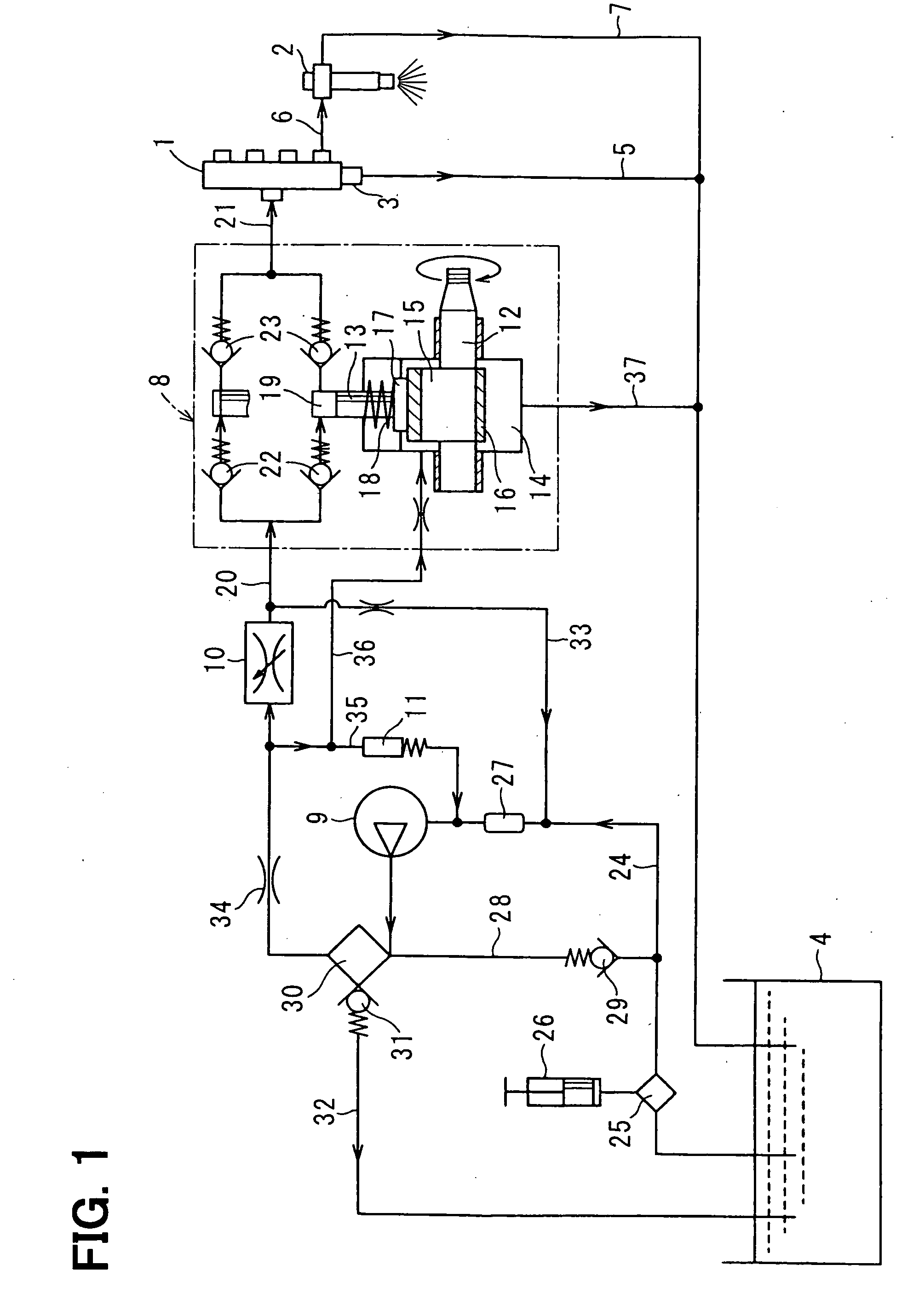

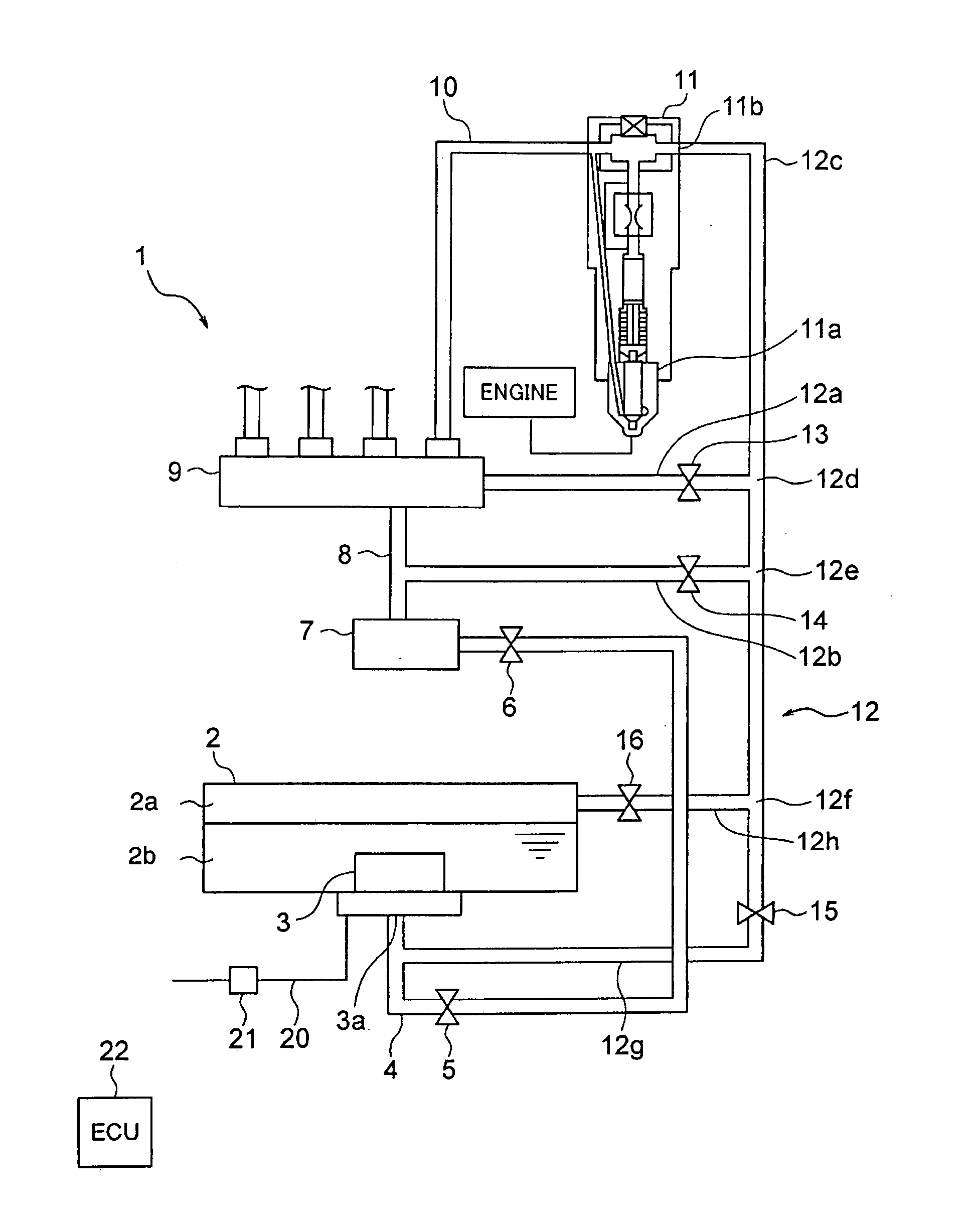

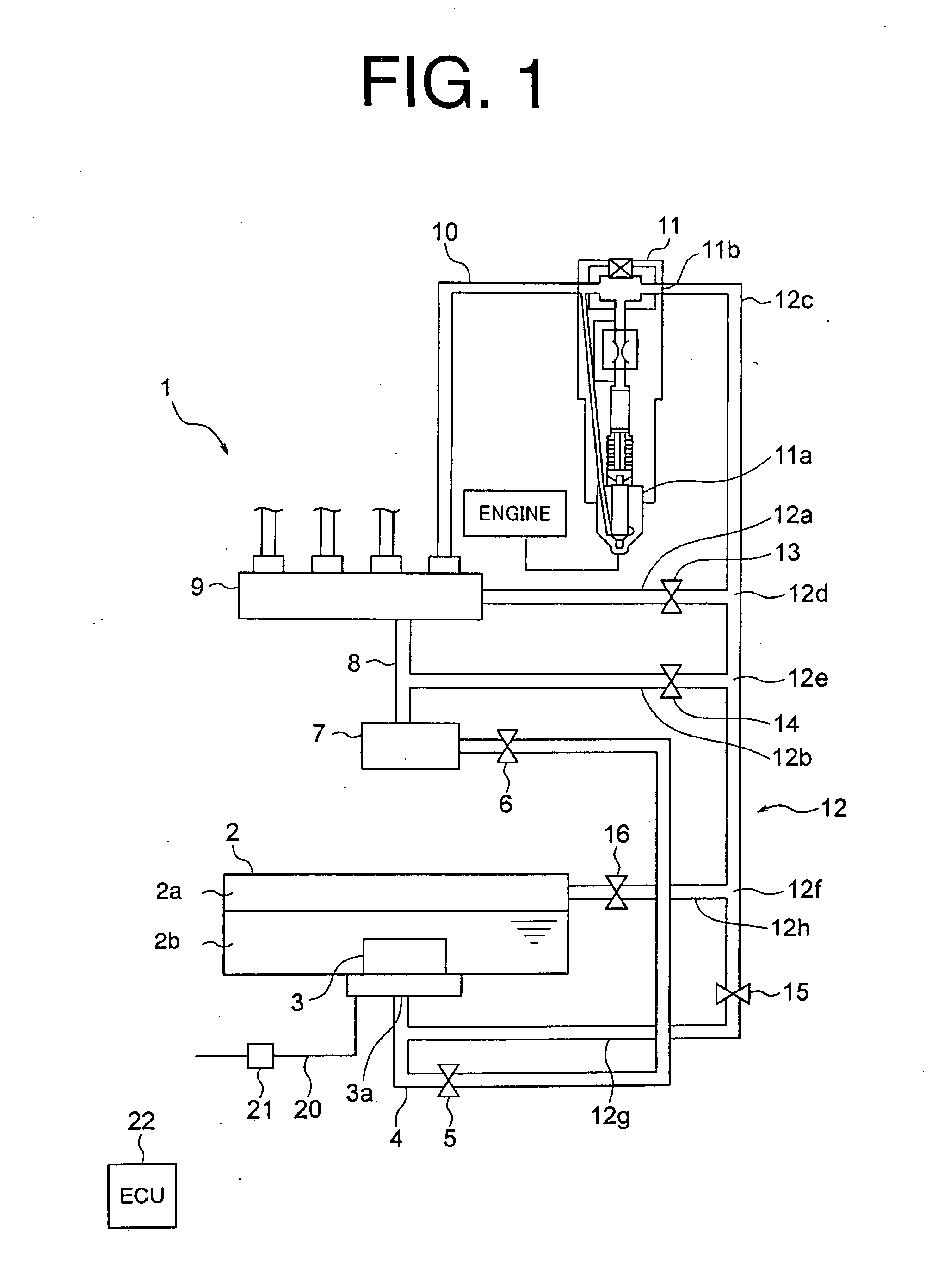

Fuel supply system having fuel filter installed downstream of feed pump

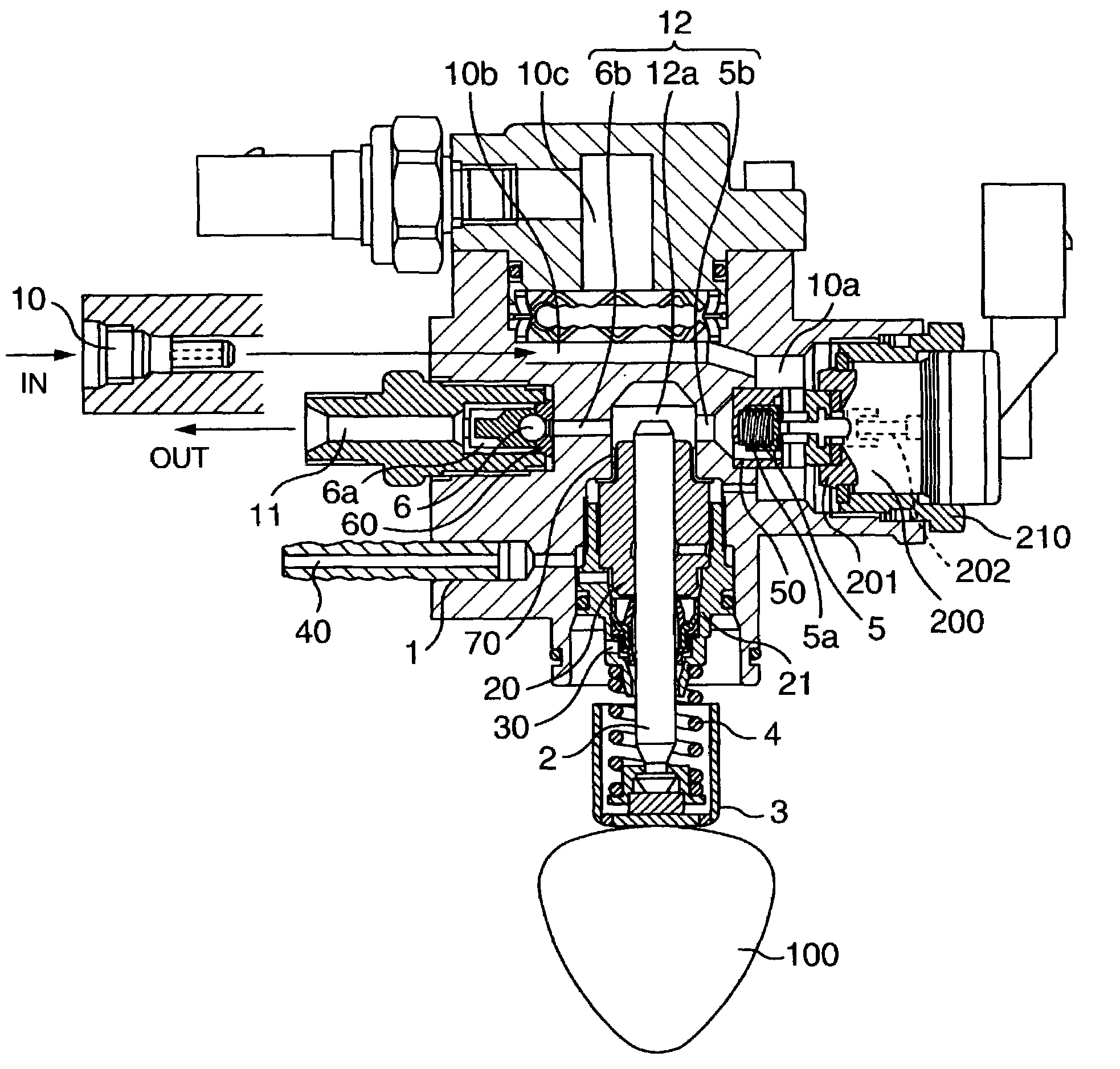

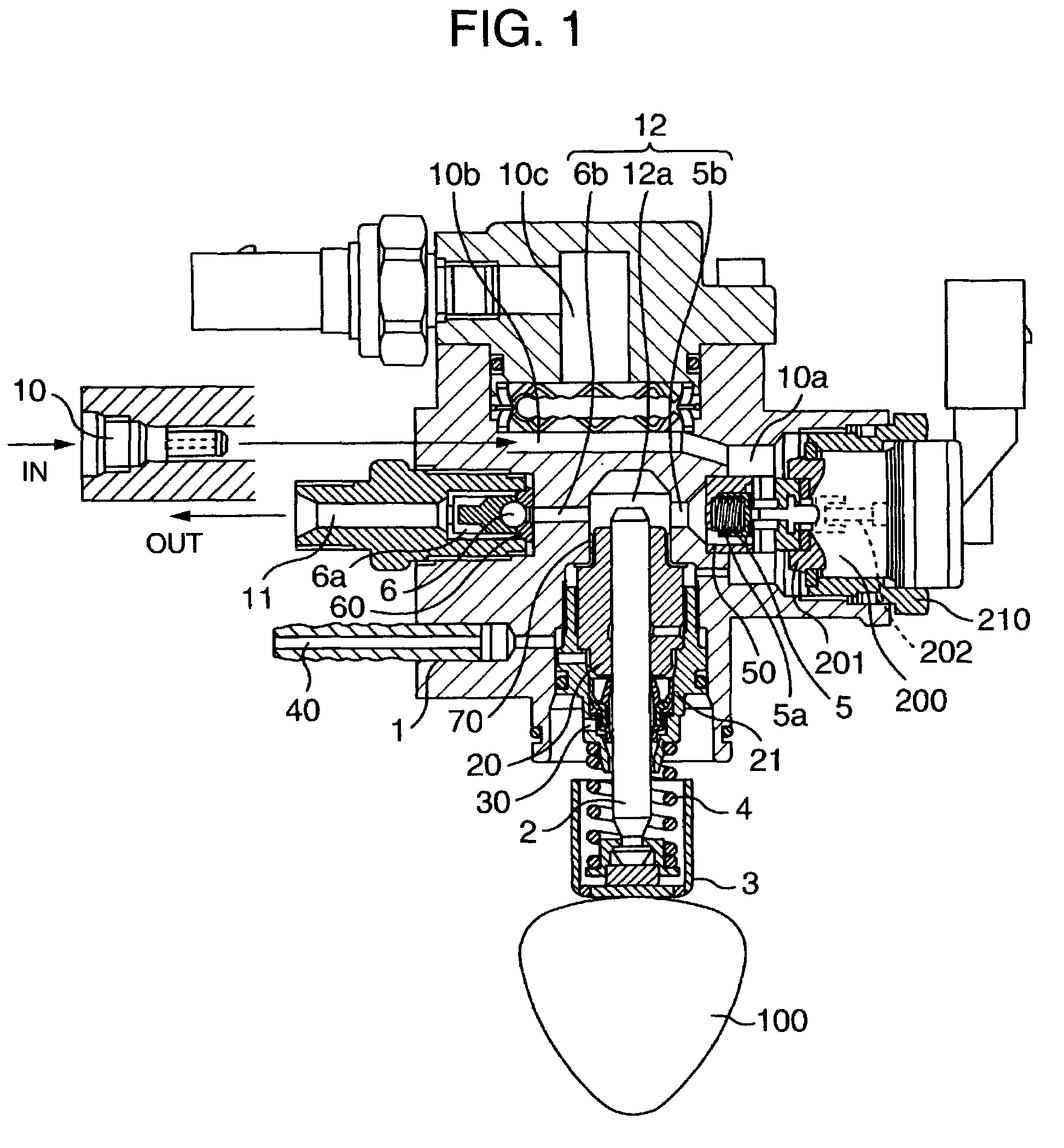

ActiveUS20090145402A1Simple structureEnsure mountabilityLow pressure fuel injectionMachines/enginesSystems designFuel tank

A fuel supply system for an accumulator fuel injection system designed to inject fuel, as stored in an accumulator, into an internal combustion engine through a fuel injector The fuel supply system includes a feed pump working to pump the fuel out of a fuel tank and a fuel filter disposed between the feed pump and a high-pressure pump working to deliver the fuel to the accumulator. The fuel supply system also includes a return path and a control valve. When the pressure of the fuel between the fuel filter and the flow rate control valve exceeds a first set pressure, the control valve opens the return path to return the fuel from downstream to upstream of the feed pump to keep the pressure of fuel supplied to the flow rate control valve below the first set pressure, thereby controlling the flow rate of the fuel passing through the fuel filter.

Owner:DENSO CORP

Fuel feed system

InactiveUS7165534B2Improve stabilityHigh capacity of absorbing pulsationFluid parameterLow-pressure fuel injectionWave shapeInlet valve

A fuel feed system capable of feeding a fuel to fuel injection valves at a fuel pressure with improved stability is provided. A fuel feed system for an internal combustion engine including a fuel tank and a low-pressure pump for feeding the fuel in the fuel tank to fuel injection valves, is provided with a diaphragm type damper having a wave-shape cross section at a position in contact with the fuel. Also, in a high-pressure fuel feed pump including a pressurizing chamber for pressurizing the fuel, a plunger for pumping the fuel within the pressurizing chamber, an intake valve provided at a fuel inlet of the pressurizing chamber, a discharge valve provided at a fuel outlet of the pressurizing chamber, and a low-pressure chamber provided in an upstream of the intake valve, a mechanism for reducing fuel pressure pulsation is disposed in a space of the low-pressure chamber provided in the upstream of the intake valve, and a fuel pressure sensor for measuring the fuel pressure is mounted near the mechanism for reducing fuel pressure pulsation.

Owner:HITACHI AUTOMATIVE SYST ENG +1

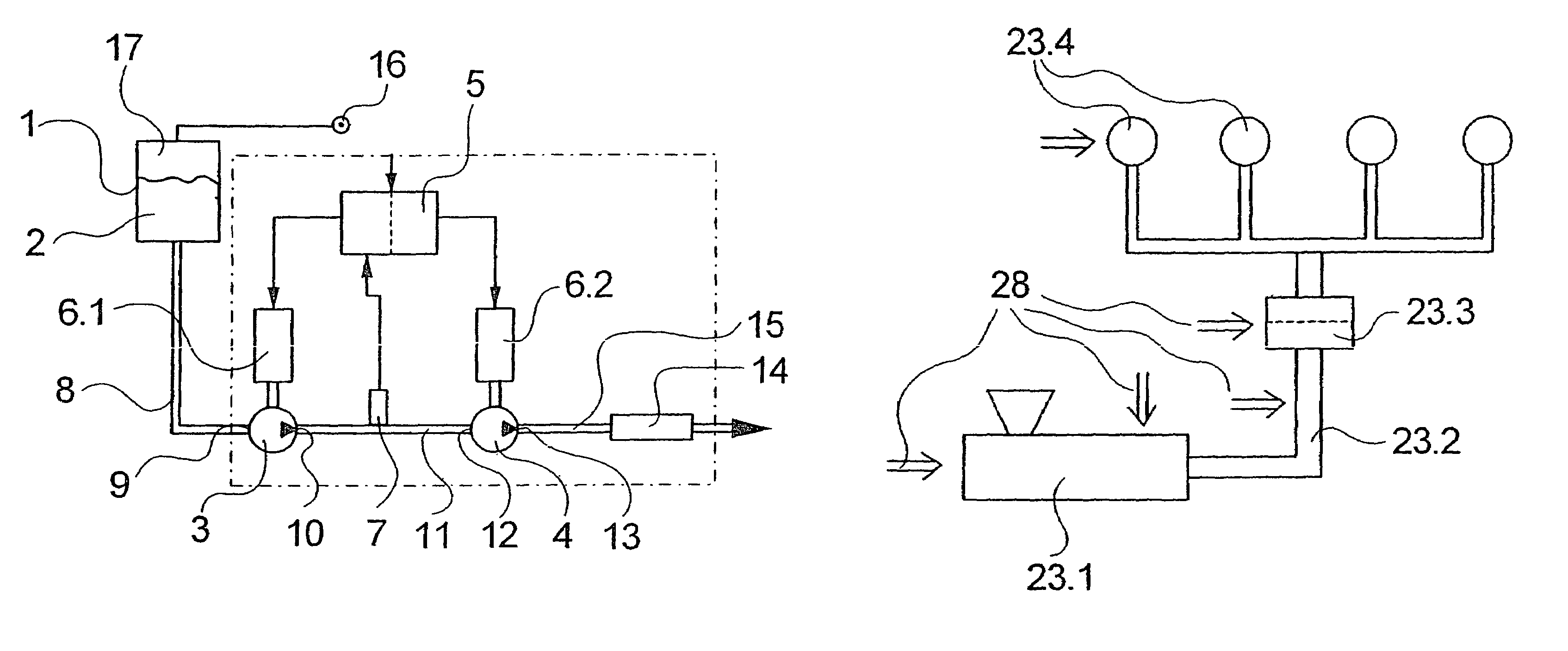

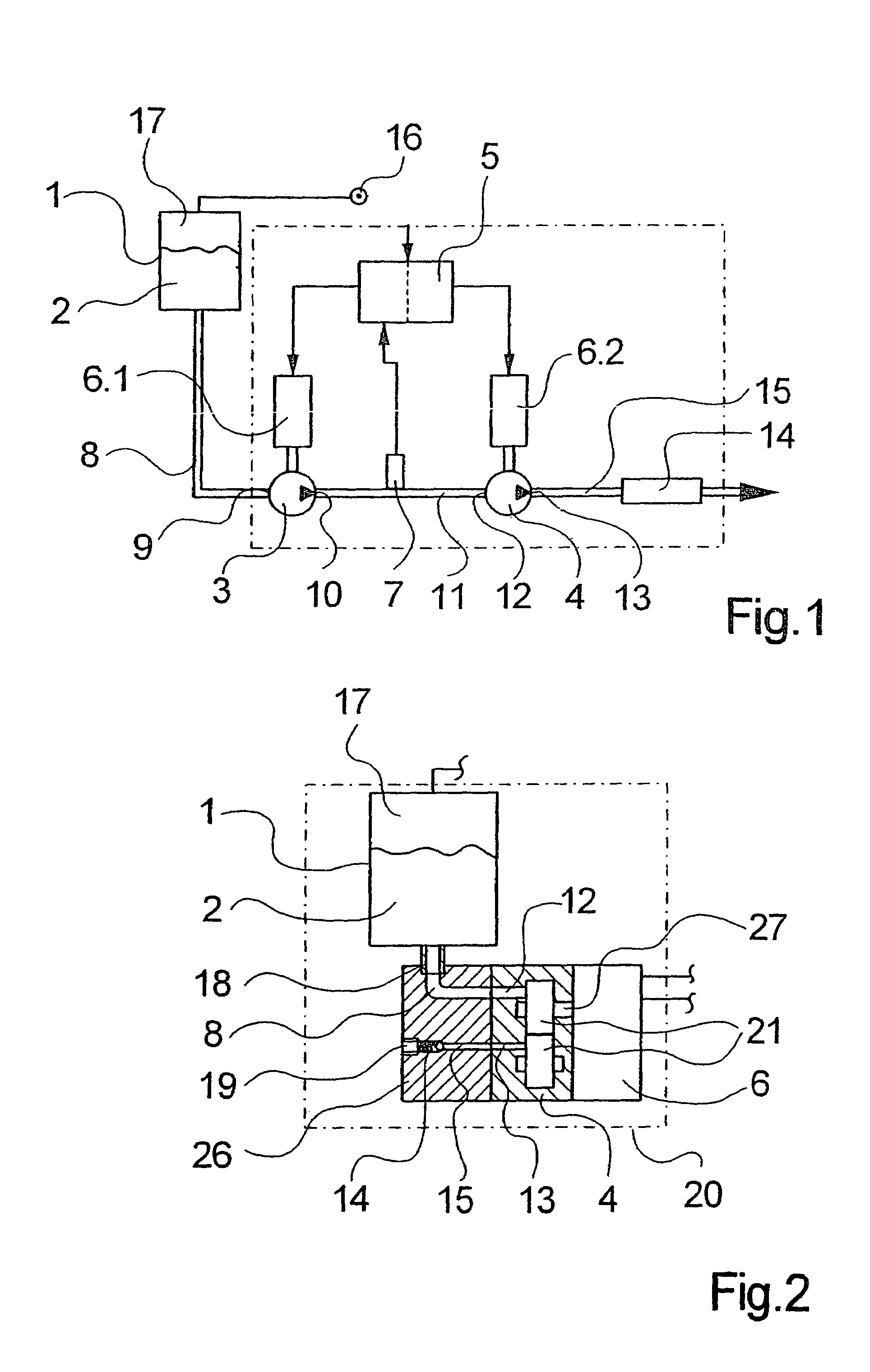

Apparatus and method for injecting a liquid dye into a polymer melt

InactiveUS7278776B2Easy to addImprove accuracyPump componentsSpinning head liquid feederInjection pressureFuel tank

An apparatus and a method for injecting a liquid dye into a polymer melt, which includes a metering pump with a metering inlet and a metering outlet. The metering inlet connects to a dye tank and the metering outlet connects to a polymer melt carrying component. To add the liquid dye to the polymer melt in the melt carrying component in a quantity that is as uniform and accurate as possible, the invention provides for connecting the metering inlet of the metering pump to a feed outlet of a feed pump, which connects with its feed inlet to the tank. With that, it is possible to generate a feed pressure at the metering inlet of the metering pump, which can be adapted to an injection pressure at the metering outlet of the metering pump.

Owner:SAURER GMBH & CO KG

Fuel supply device

ActiveUS7343901B2Small sizeIncrease in sizeLow pressure fuel injectionMachines/enginesPositive pressureFuel filter

A fuel filter is located downstream of a feed pump to filter fuel discharged from the feed pump. An orifice is located between the fuel filter and a suction quantity control valve to restrict a flow rate of the fuel passing through the fuel filter. A positive pressure of the feed pump is applied to the fuel filter, and a passing pressure at the fuel filter increases. Even if viscosity of the fuel increases and the fuel becomes wax-like at low temperature, clogging of the fuel filter or an insufficient flow rate can be inhibited. The orifice restricts the flow rate of the fuel passing through the fuel filter. Accordingly, an increase in size of the fuel filter can be prevented even if the fuel filter is located downstream of the feed pump.

Owner:DENSO CORP

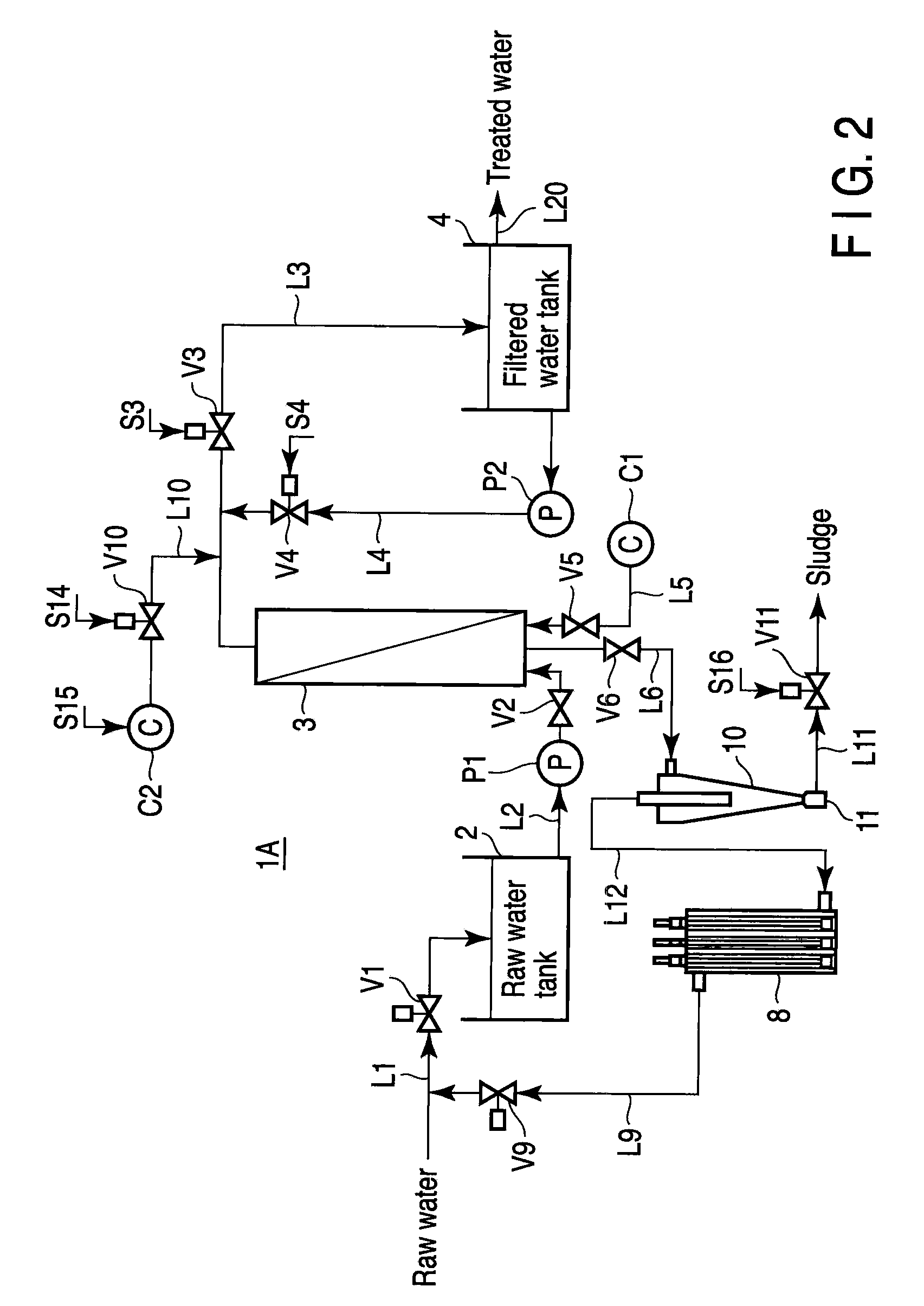

Water treatment system

ActiveUS20090166276A1Effective disinfectionReduce water purification costsWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltration membraneWater treatment system

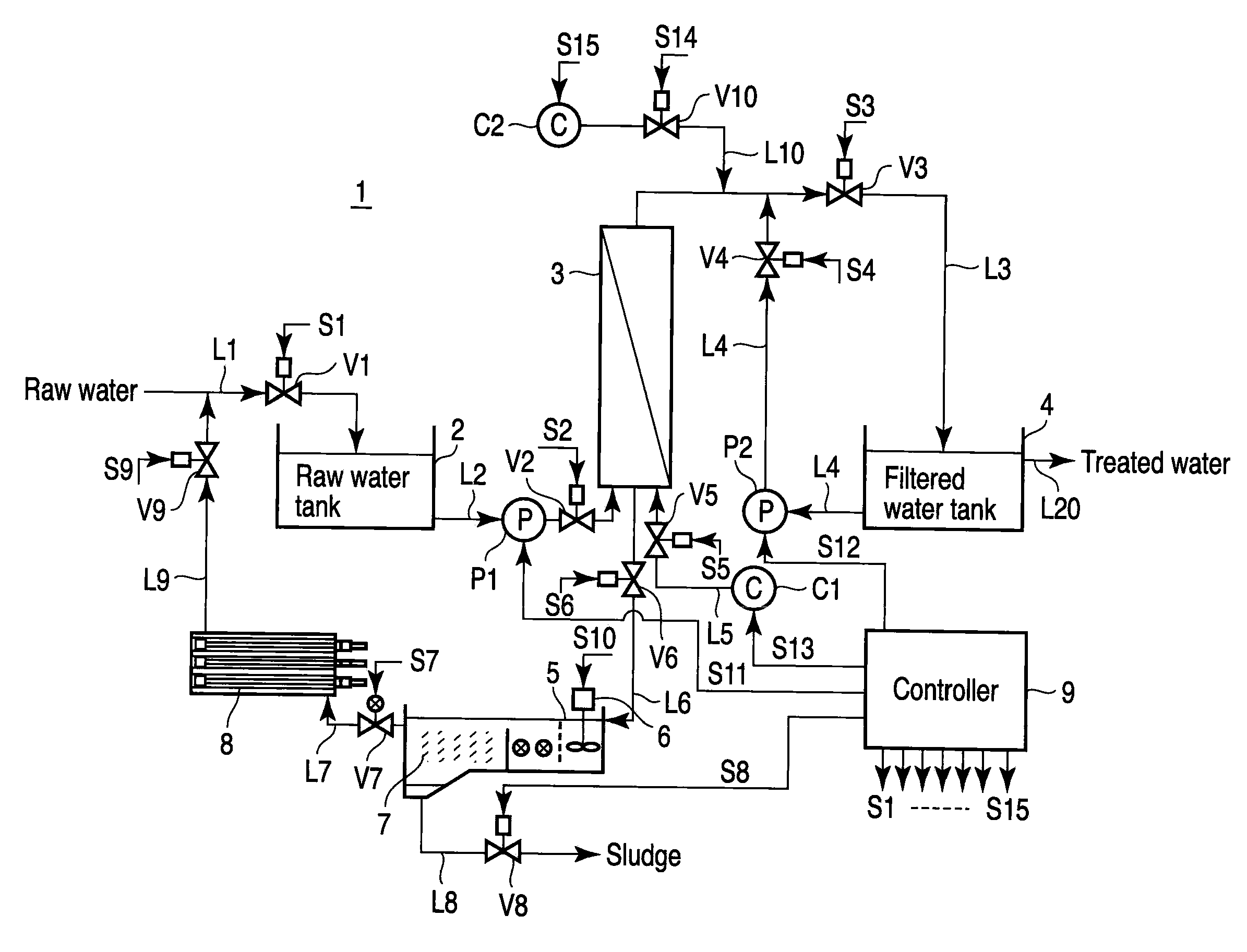

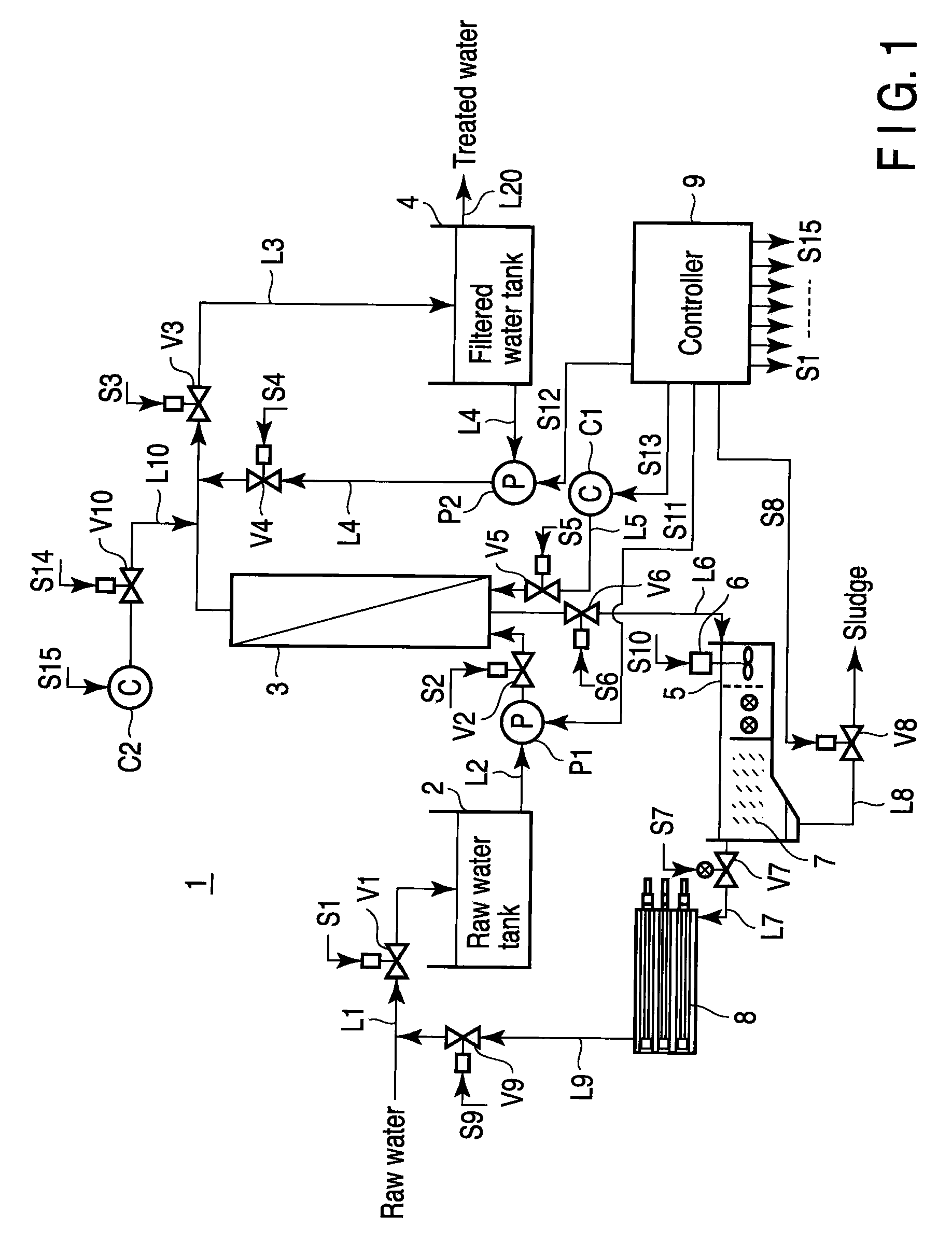

Disclosed is a water treatment system including a raw water tank, a module which includes a filtration membrane, a feed pump, a filtered water tank, a backwash pump which flows filtered water backward from the filtered water tank to the module, a valve and a channel which switch the direction of the water flow between the forward and reverse directions, a controller which suspends the supply of raw water from the raw water tank to the module, switches the valve and channel to the reverse direction, makes the backwash pump to supply filtered water from the filtered water tank to the module thereby backwashing the filtration membrane, and washing drainage treatment line including which treats backwashing drainage generated by backwashing of the filtration membrane, and returns the water to the raw water tank.

Owner:KK TOSHIBA

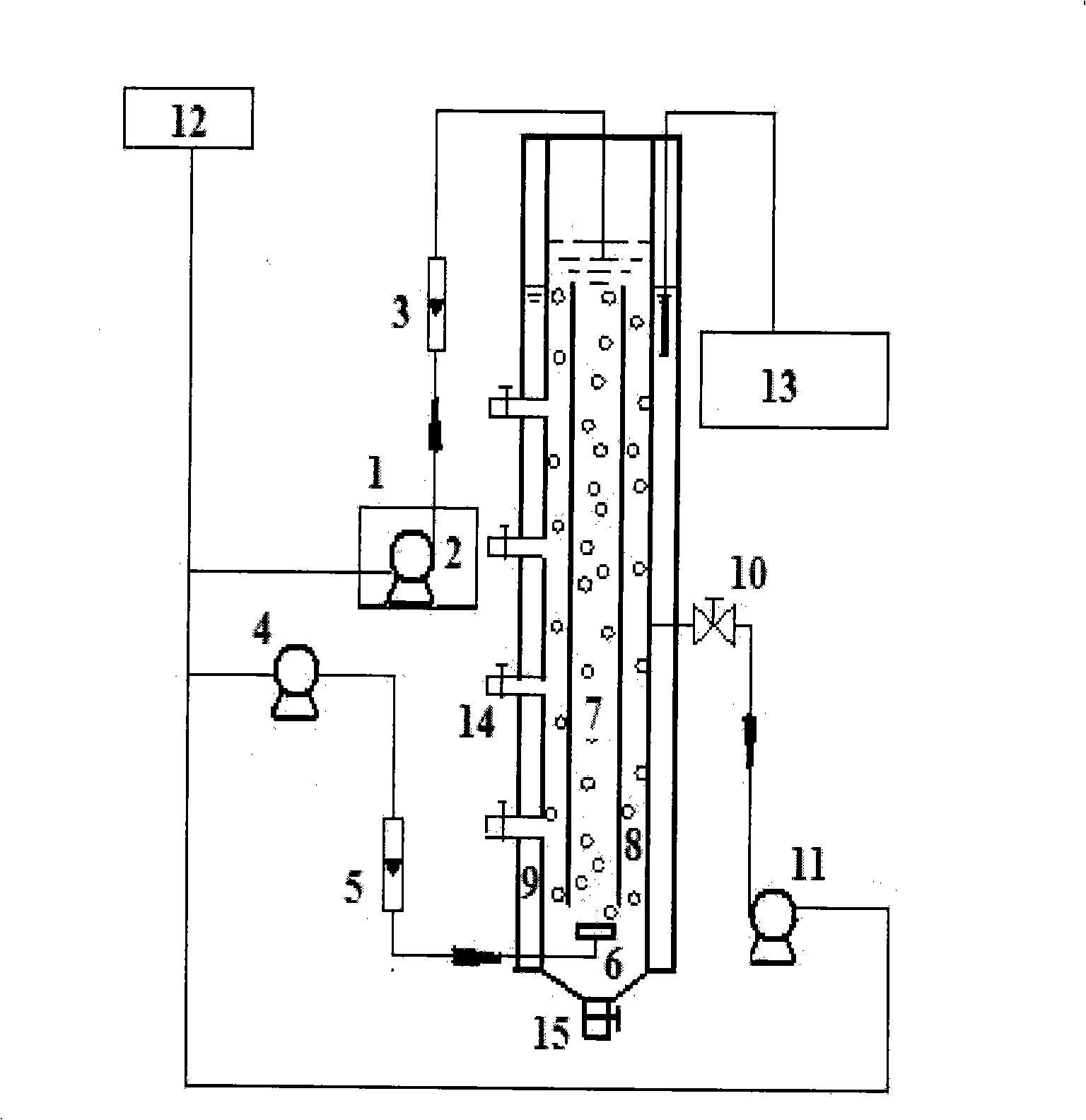

Gas-lifting internal circulation intermission aerobic granule sludge reactor and water treatment process thereof

InactiveCN101333037AEnhanced mass transferImprove the mixing effectSustainable biological treatmentBiological water/sewage treatmentWater bathsMicroecosystem

The invention discloses an airlift type internal circulation intermittent aerobic granular sludge reactor, which comprises an organic glass column, a temperature controller, a water inlet tank, an aeration pump, a water feed pump, a draining pump, a flow meter, a programmable logical controller, etc. The main body of the reactor is the organic glass column and can be divided into an inner sleeve and an outer sleeve, and the inner one is an upspout, while the outer one is a downcast pipe; the ratio of height to diameter is 15. The exterior of the downcast pipe is provided with a water bath heating casing for controlling reaction temperature. Mixed liquor in the reactor flows between the upspout and the downcast pipe in internal circulation to endow granular sludge with a self-balanced micro-ecosystem, the property of the micro-ecosystem is suitable for an up-flow type wastewater treatment system. The reactor adopts the sequence batch operation mode and can realize automatic control by the programmable logical controller. The reactor of the invention has the advantages of flexible operation, compact structure, little sludge remained, good treatment effect, and the like, and can bear high volume load and impact load; furthermore, the reactor has small occupying space and can reduce pork barrel due to relatively large H / D.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

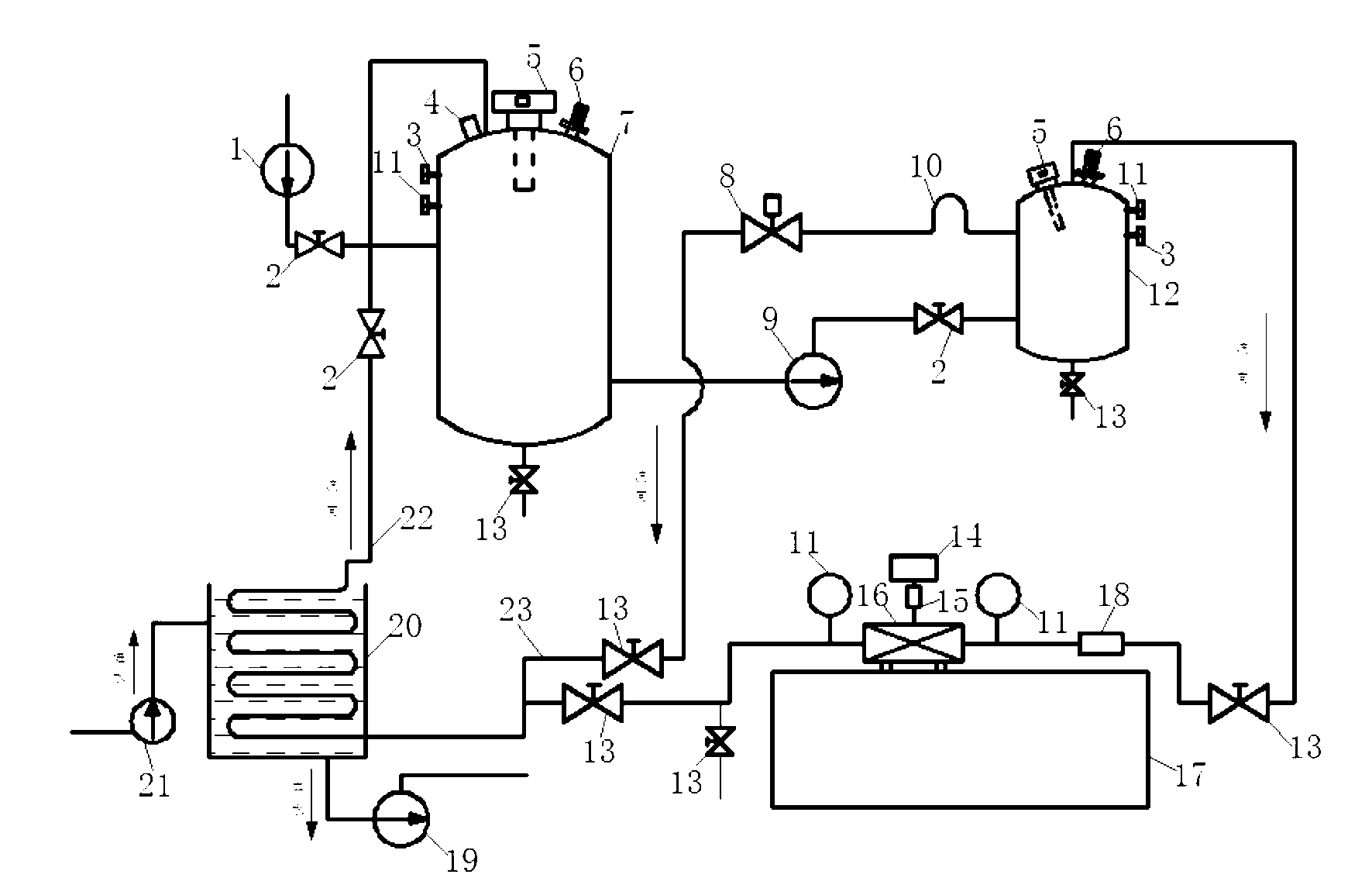

High temperature valve detecting and testing system

InactiveCN103308293ASimple structureHigh precisionMachine part testingFluid-tightness measurement using fluid/vacuumBuffer tankEngineering

The invention discloses a high temperature valve detecting and testing system, comprising an oil feed pump, an oil storage tank, a pressure pump, a buffer tank, a detecting device and a condensing device, wherein an electric heater and a pressure transmitter are installed on the top part of the oil storage tank; the bottom part of the oil storage tank is connected with the buffer tank through a third trunk pipeline; another pressure transmitter and a temperature sensor are installed on the inner side wall of the buffer tank; the buffer tank is connected with an oil inlet of a to-be-detected valve through a fourth trunk pipeline; the detecting device comprises a detecting table and a torque testing device; the valve rod of the to-be-detected valve is connected with the torque testing device; and the oil outlet of the to-be-detected valve is connected with the oil storage tank through a fifth trunk pipeline, the condensing device and a second trunk pipeline in sequence. The high temperature valve detecting and testing system is simple in structure and convenient to operate; and by the adoption of the detecting and testing system, the resistance coefficient and the torque performance of a high temperature valve and the flow characteristic can be tested, and the leakage amount can be detected.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

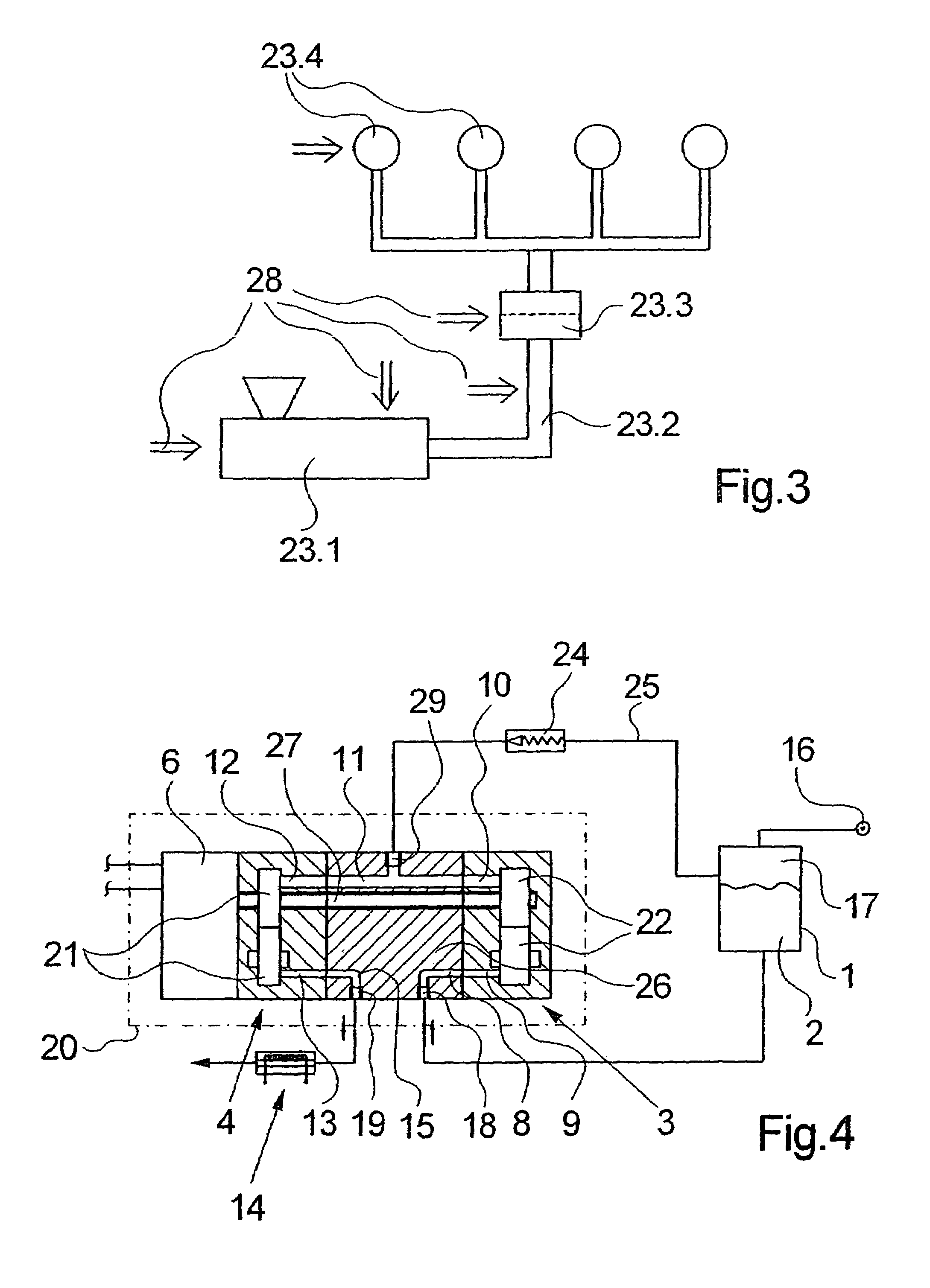

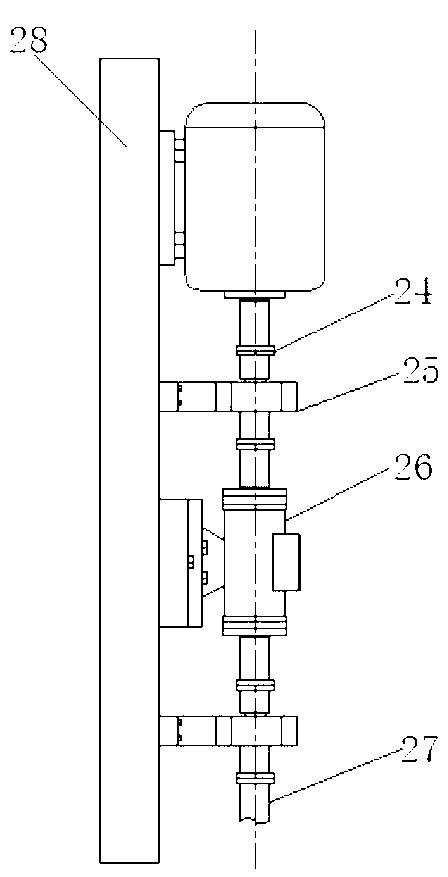

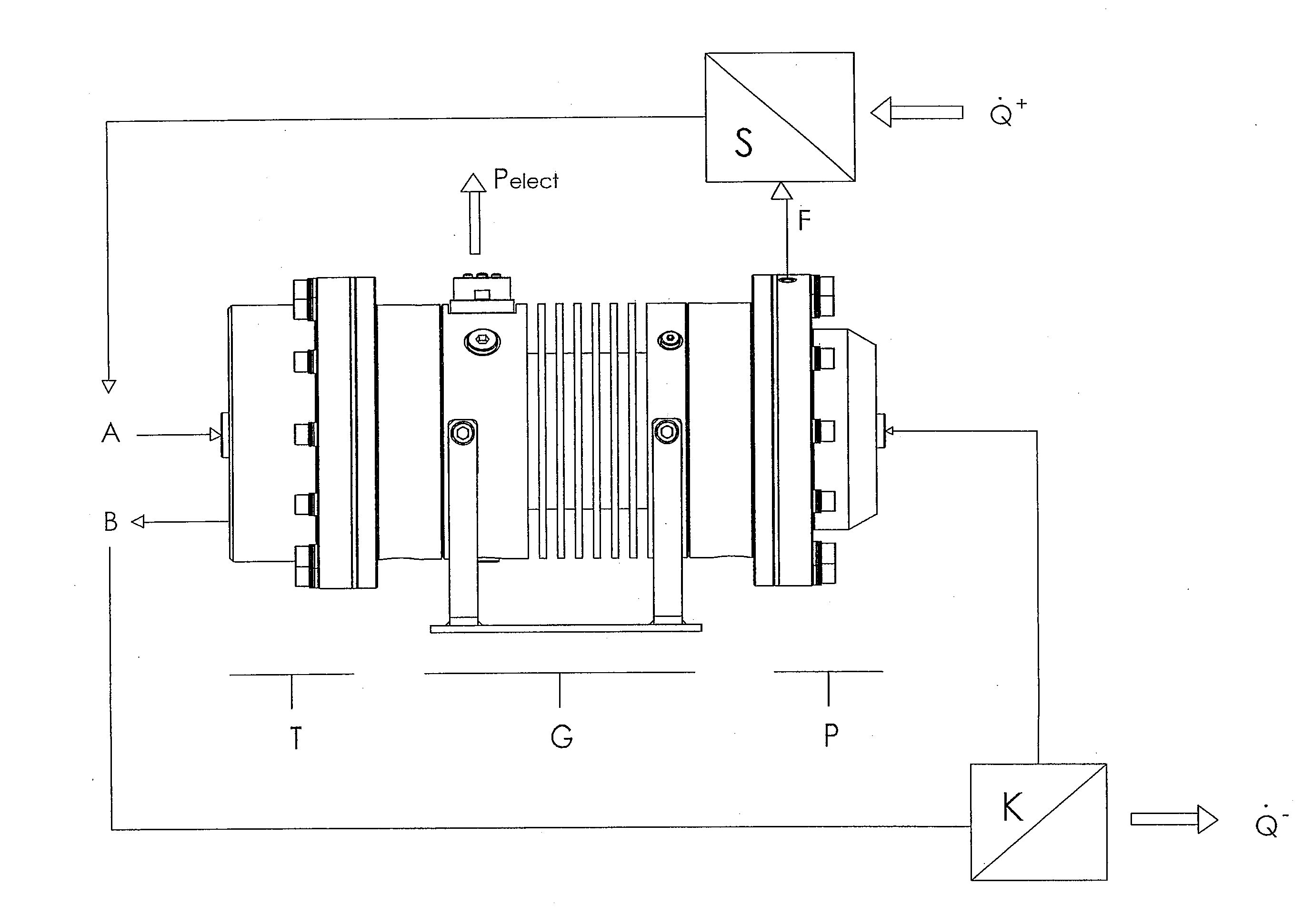

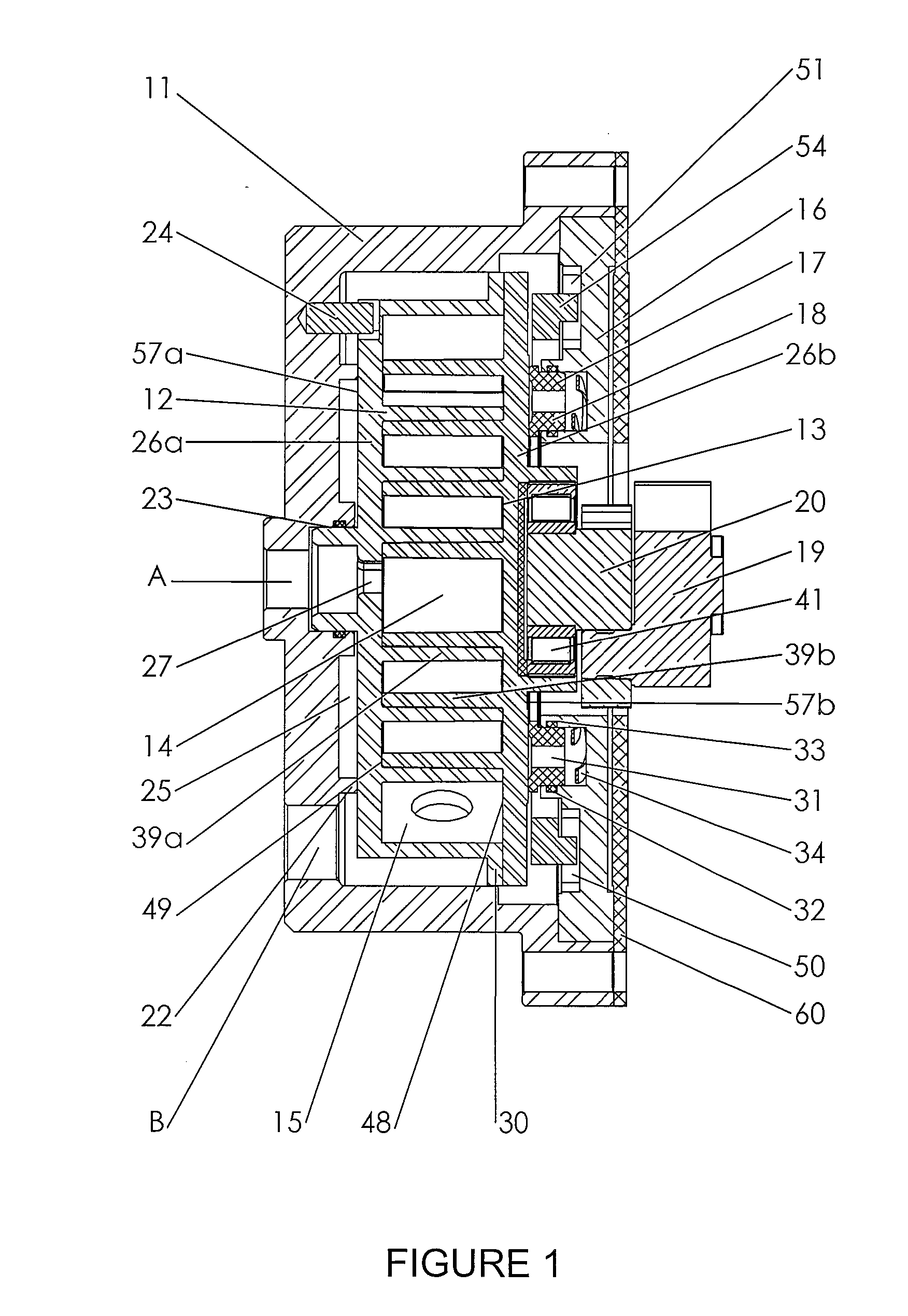

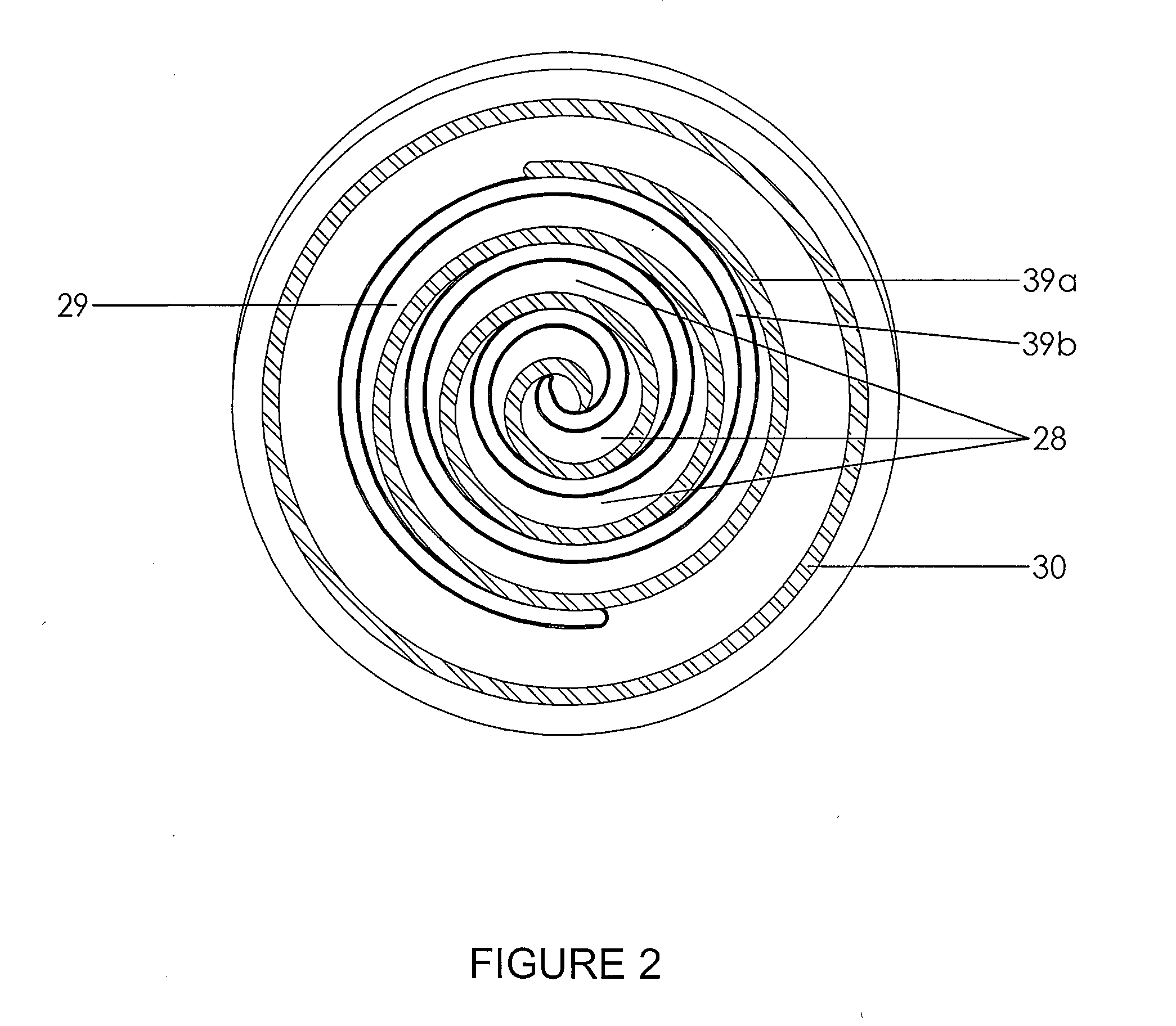

Scroll device integrating a feed pump

InactiveUS20100254835A1Prevent thermal deformationMaximum flexibilityRoller bearingsEngine of arcuate-engagement typeWorking fluidEngineering

A scroll device including two coupled stages on a rotary shaft, at both ends of an intermediate electric power device, wherein the first stage is formed by a first pressure variation device of an operating fluid, comprising a scroll case containing a fixed scroll and a mobile scroll relatively to the case, and with admission and outlet ports, and wherein the second stage is a feed pump which pumps the operating liquid and provides it in return.

Owner:ENEFTECH INNOVATION

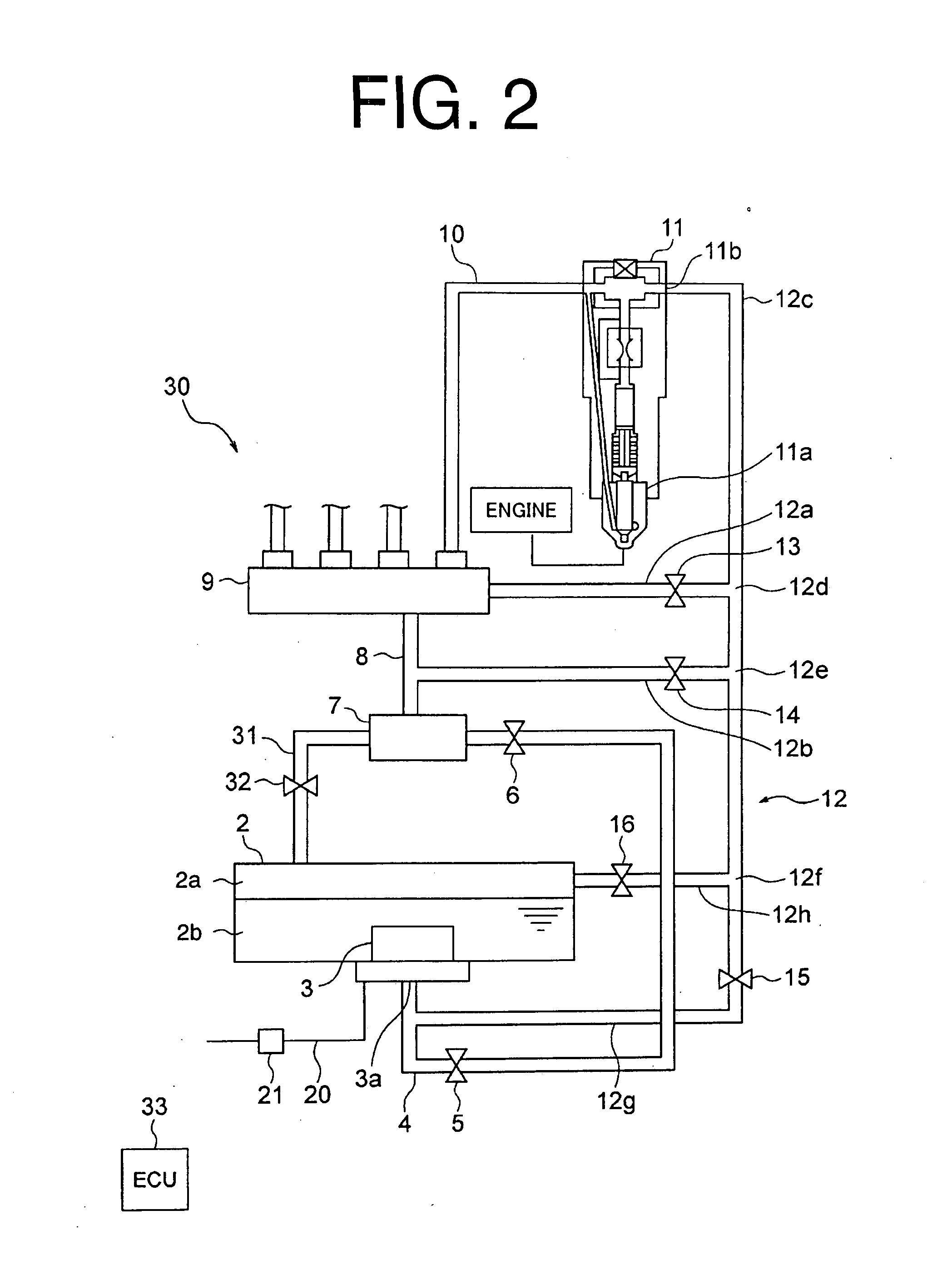

Fuel supply device

ActiveUS20060169251A1Increase in sizeReduce spacingLow-pressure fuel injectionMachines/enginesPositive pressureEngineering

A fuel filter is located downstream of a feed pump to filter fuel discharged from the feed pump. An orifice is located between the fuel filter and a suction quantity control valve to restrict a flow rate of the fuel passing through the fuel filter. A positive pressure of the feed pump is applied to the fuel filter, and a passing pressure at the fuel filter increases. Even if viscosity of the fuel increases and the fuel becomes wax-like at low temperature, clogging of the fuel filter or an insufficient flow rate can be inhibited. The orifice restricts the flow rate of the fuel passing through the fuel filter. Accordingly, an increase in size of the fuel filter can be prevented even if the fuel filter is located downstream of the feed pump.

Owner:DENSO CORP

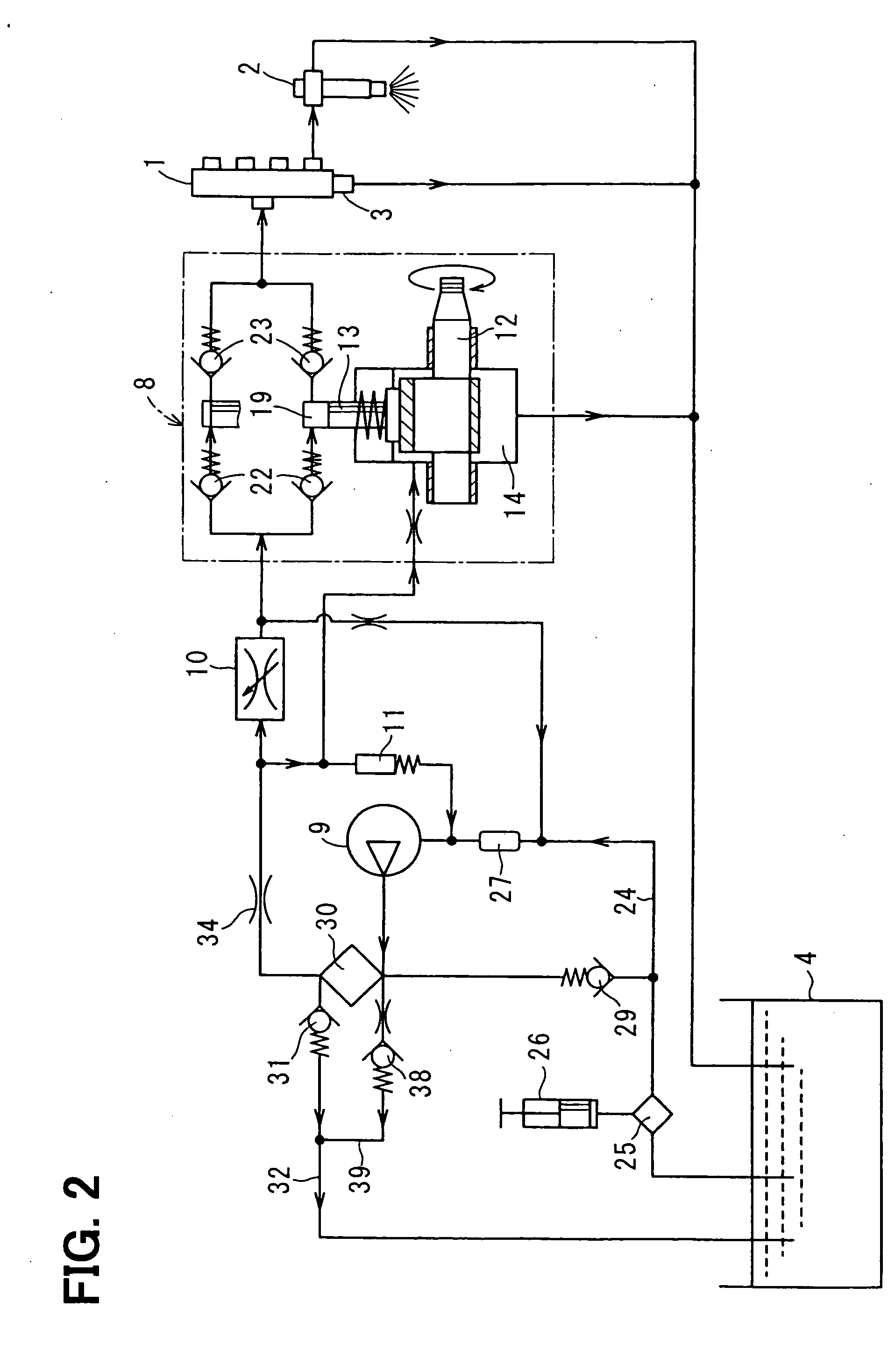

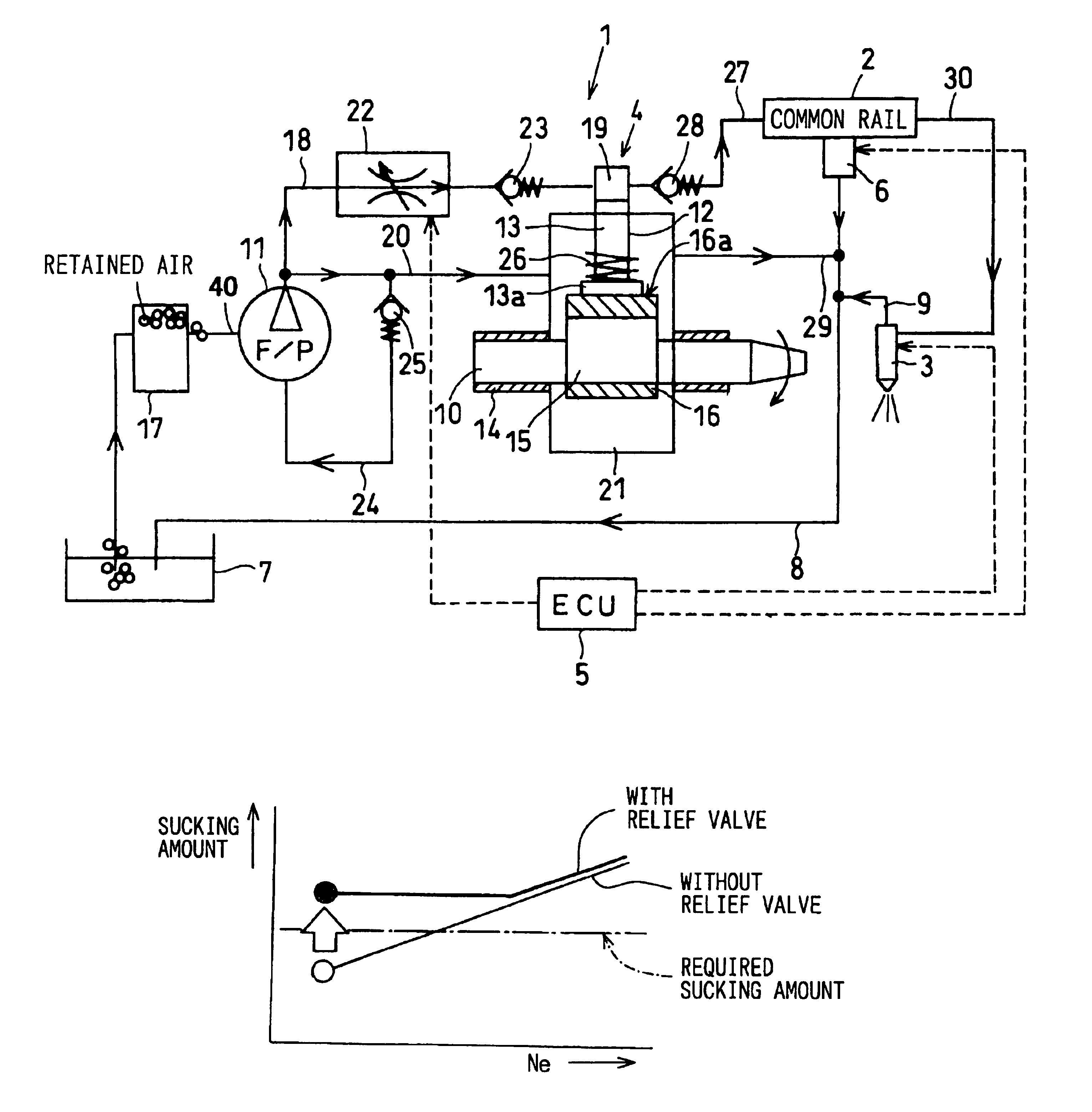

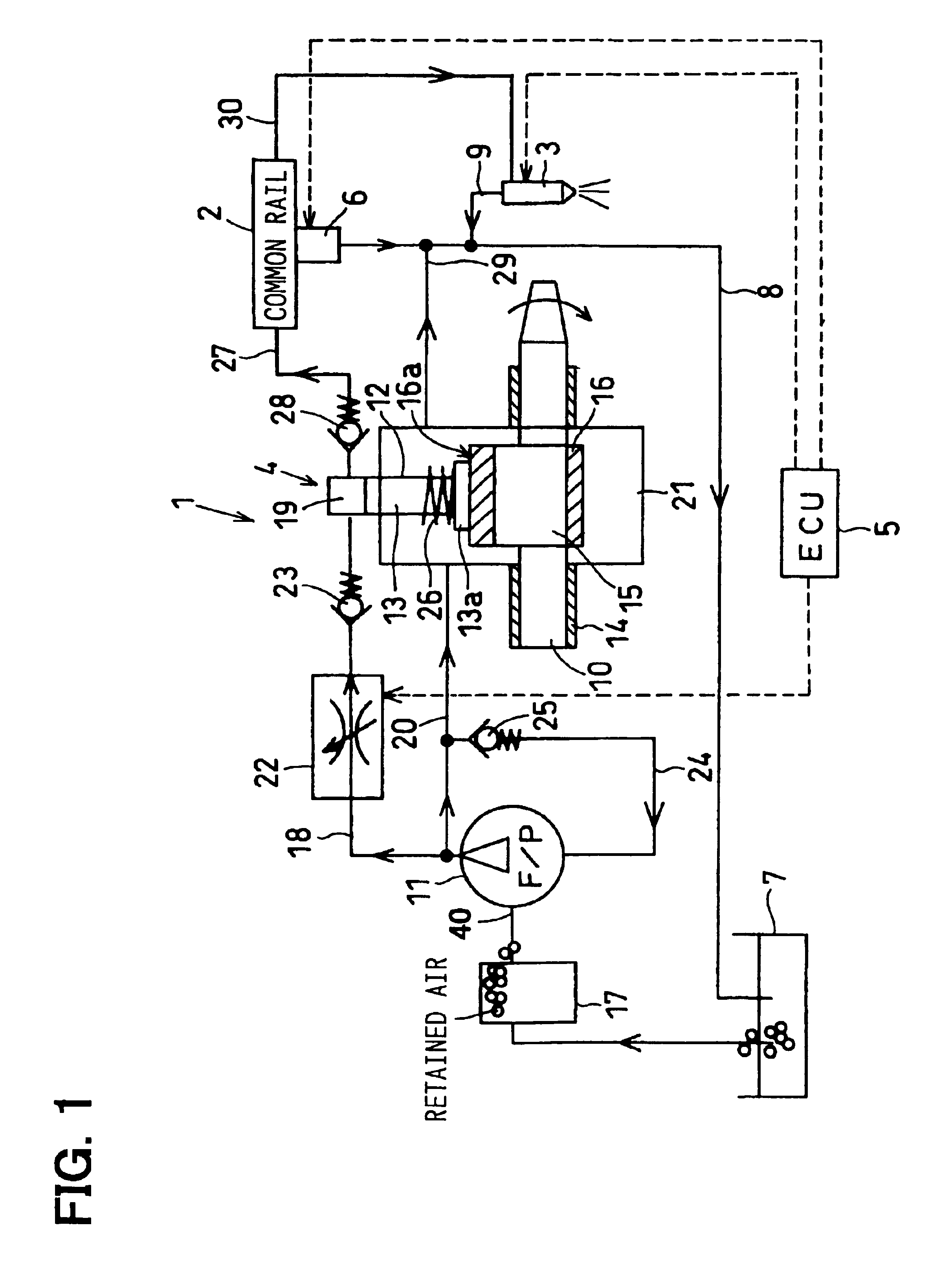

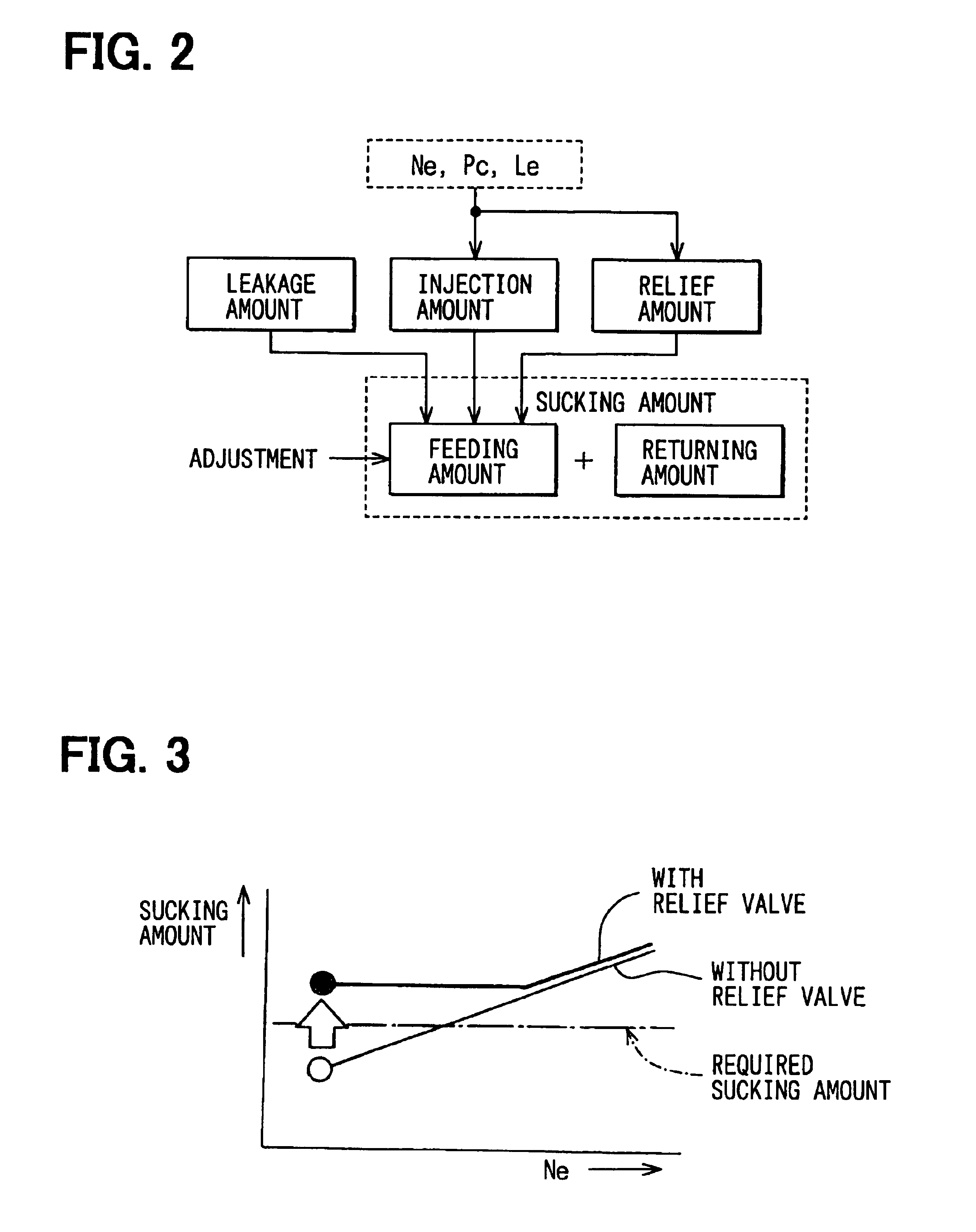

Common rail type fuel injection system

ActiveUS6895936B2Large amount of air is preventedLarge amount of airElectrical controlLow-pressure fuel injectionCommon railFuel tank

In a common rail type fuel injection system, fuel in a fuel tank is sucked by a feed pump and fed to a pressurizing pump. Fuel pressurized in the pressurizing pump is supplied to a common rail. The pressurized fuel accumulated in the common rail is injected into a cylinder of an internal combustion engine from an injector. All of these operations are electronically controlled by an electronic control unit. To gradually suck air in the fuel tank together with fuel and to avoid air accumulation in a fuel filter, a relief valve is connected to the common rail. The relief valve is opened when the engine is idling thereby to increase an amount of fuel sucked by the feed pump and to gradually suck the air together with the fuel. The relief valve is opened only in interval periods in which fuel is not injected from the injector.

Owner:DENSO CORP

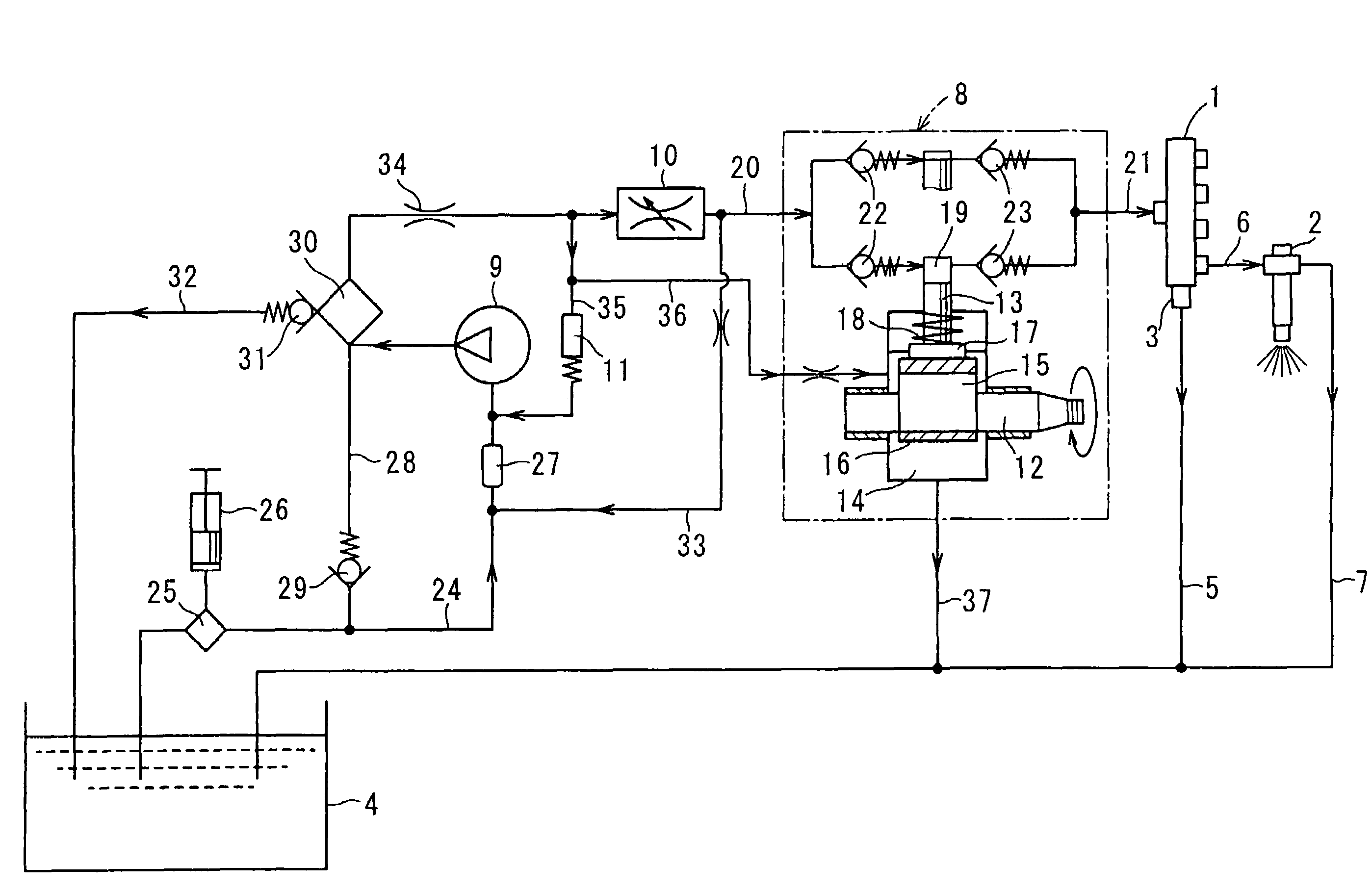

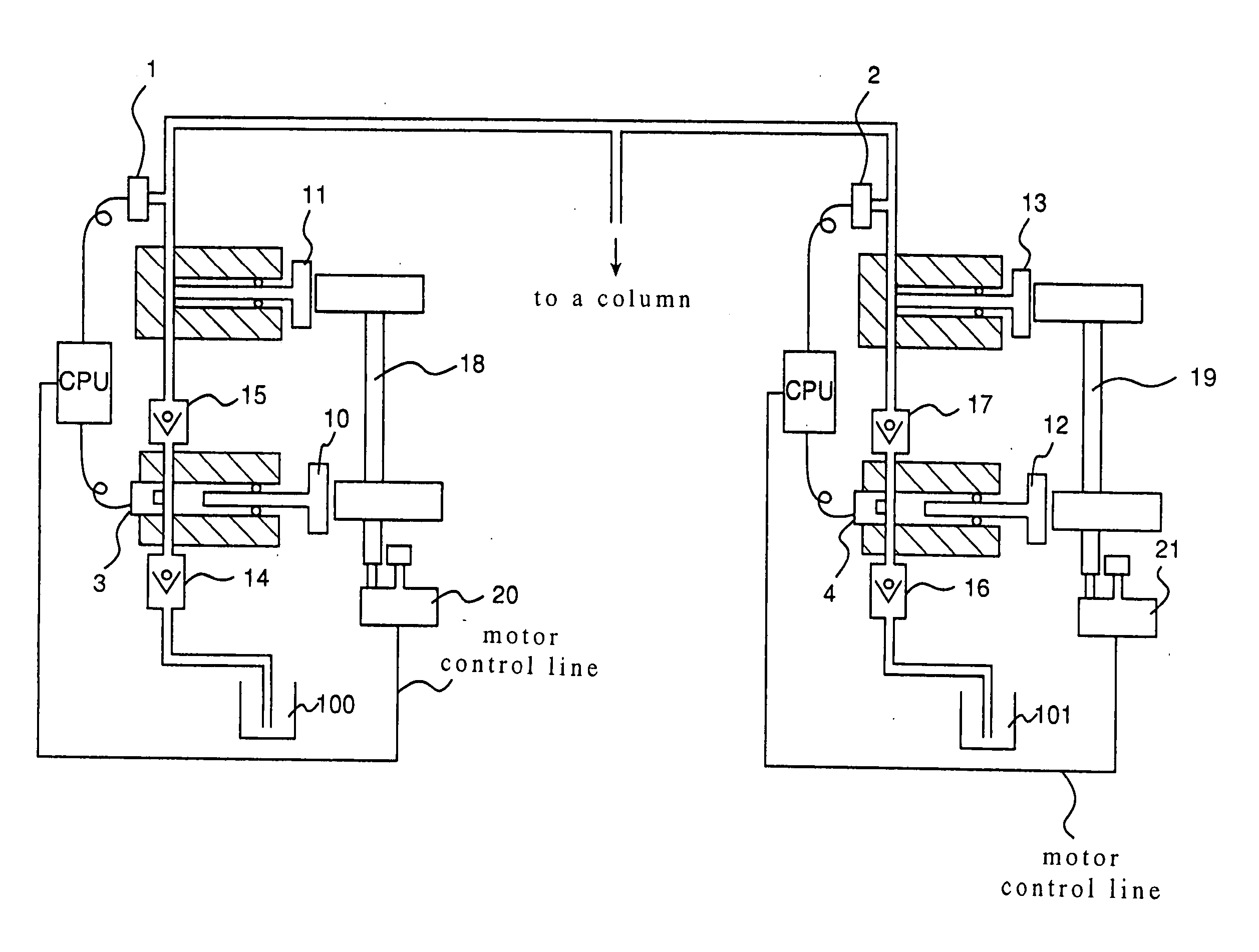

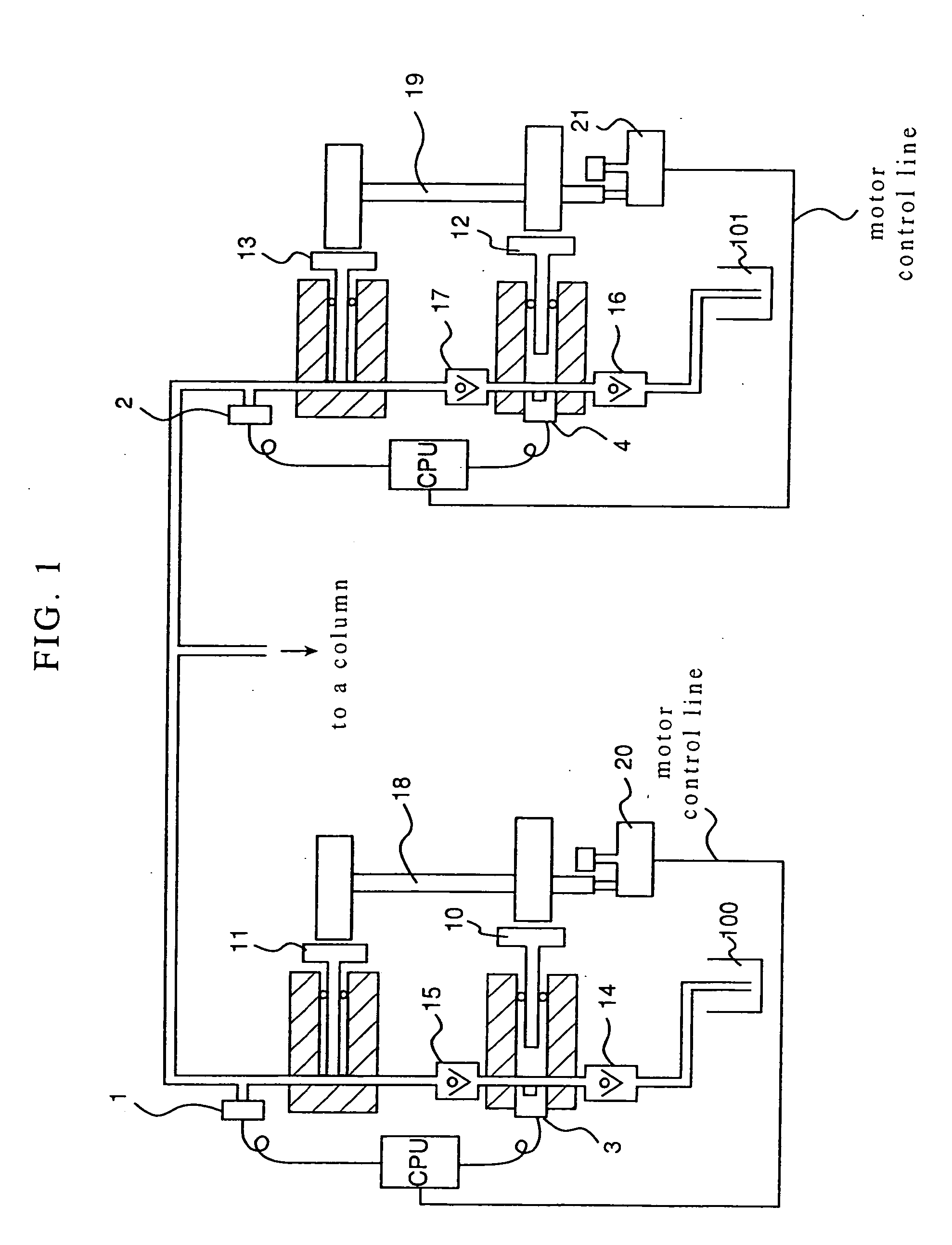

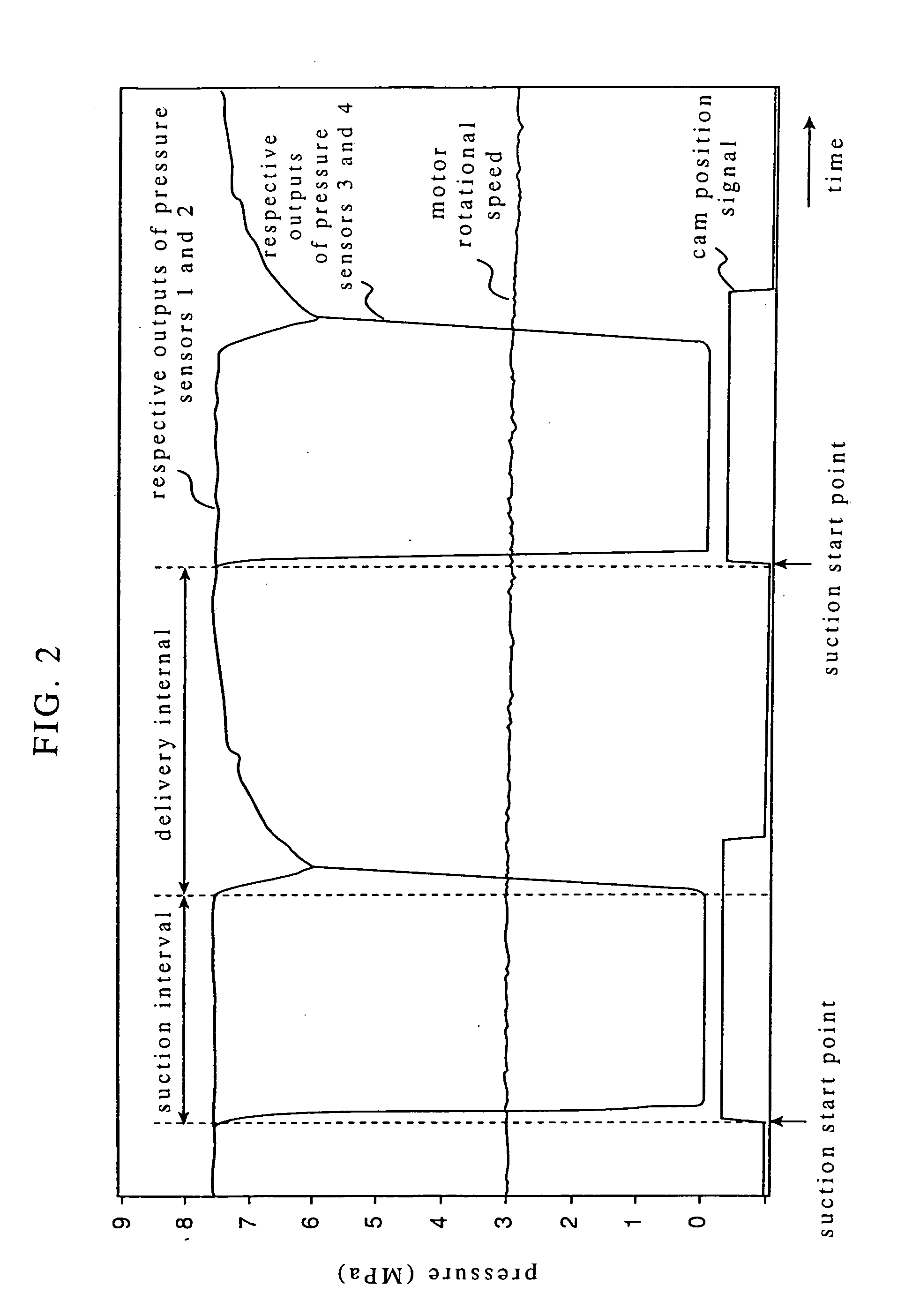

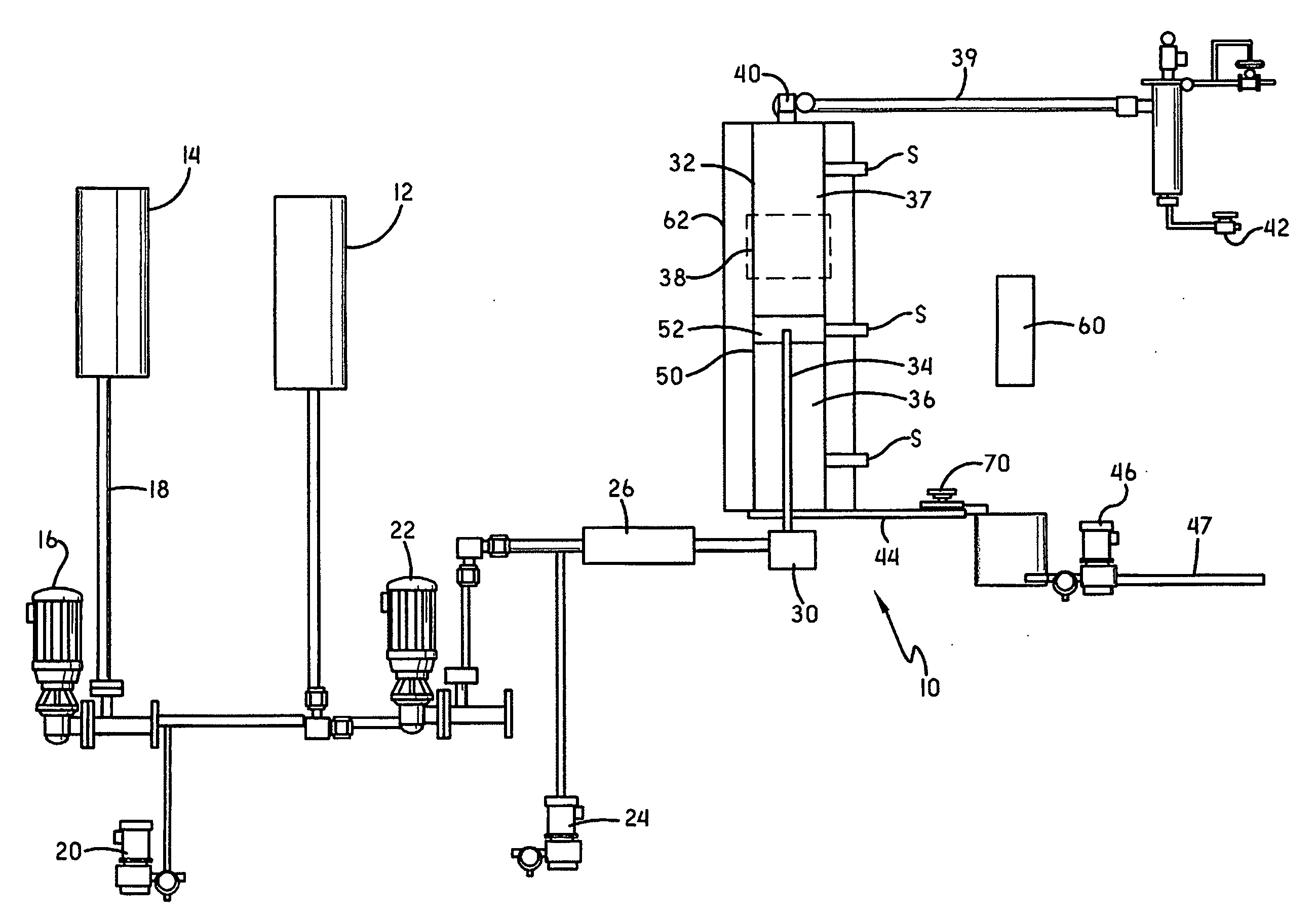

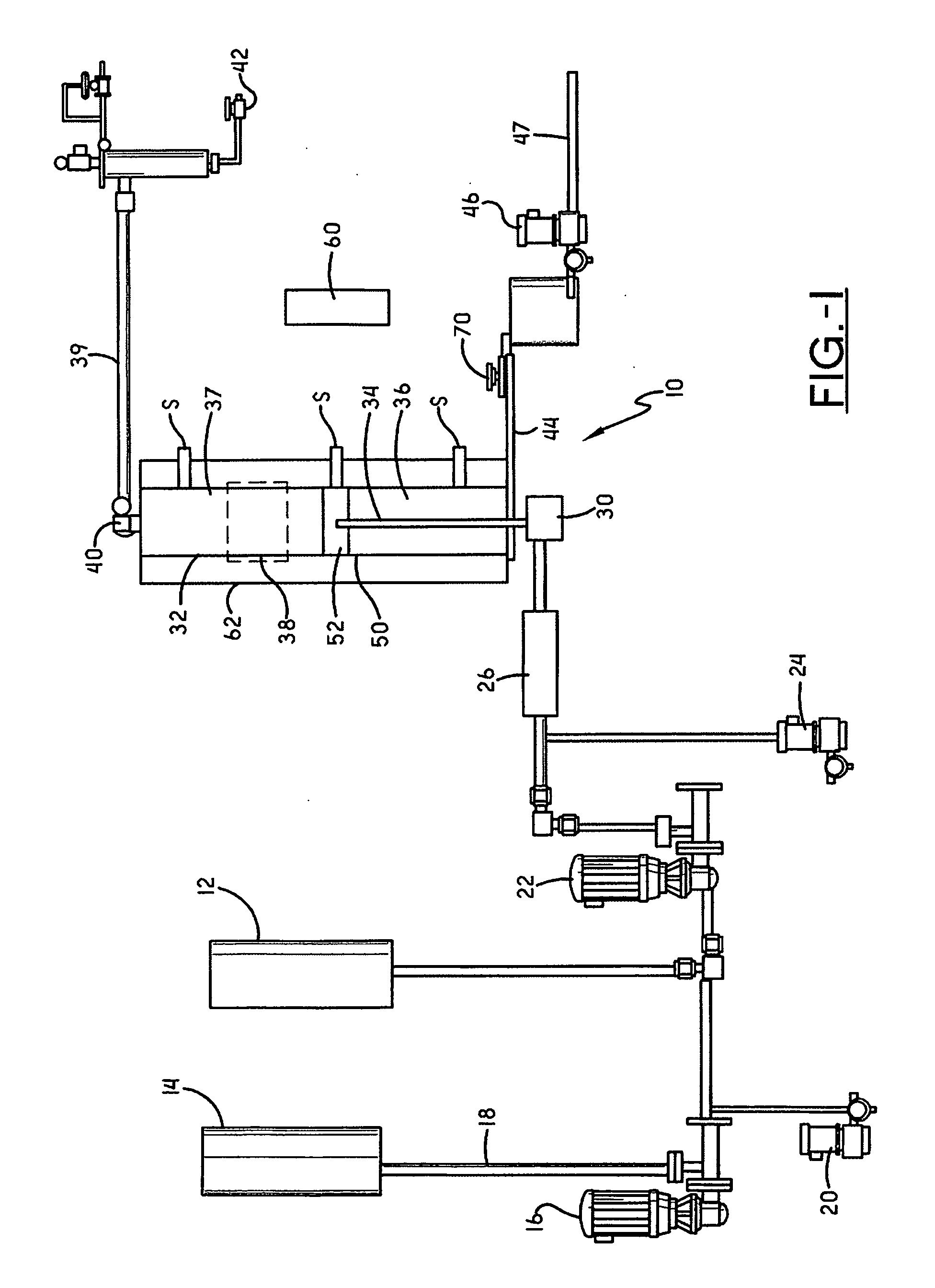

Gradient liquid feed pump system, and liquid chromatograph

InactiveUS20050084386A1Reduce impactThe mixing ratio is accurateFluid parameterComponent separationEngineeringCam

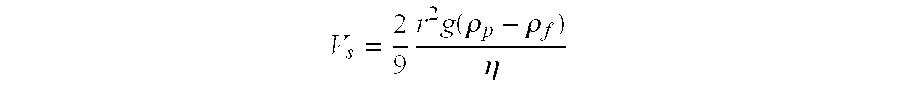

A gradient liquid feed pump system capable of liquid feed in a correct mixing ratio even in the case of liquid feed in which the mixing ratio varies. Specifically, it comprises a first plunger pump for sucking and delivering an eluate, a second the first and second plunger pumps through a cam, a first pressure sensor for measuring the pressure in the flow path of the second plunger pump, a second pressure sensor for measuring the pressure in the fist plunger pump, a cam position detecting sensor for detecting the cam position, wherein when the cam position is in a delivery interval, the rotary speed of the motor is increased, and the period for decreasing the rotary speed is determined on the basis of the difference between the pressure values obtained from the first and second pressure sensors, respectively. Thereby, liquid feed can be smoothly effected with correct mixing ratio while avoiding pressure interference between pumps.

Owner:HITACHI HIGH-TECH CORP +1

Dynamic desalter simulator

InactiveUS20100015720A1Dewatering/demulsification with chemical meansMixing methodsEmulsionWash water

A small-scale dynamic simulator for crude oil refinery desalters has a pressurized oil deviblis configured to hold a supply of crude oil and a water deviblis configured to hold a supply of wash water. At least one chemical feed pump selectively adds emulsion breaker chemicals to the desalter simulator and a low shear metering pump is configured to pump crude oil and wash water through the desalter simulator. An emulsion forming device forms a crude oil-wash water emulsion that is then received in a desalter vessel. The desalting vessel is fitted with electric grids which simulate those found in electric desalters. The emulsion is resolved within the desalter vessel with the assistance of the emulsion breaker chemicals so the wash water and crude oil form distinct phases, with substantially desalted crude oil removed from an upper portion of the desalter vessel and substantially oil-free wash water removed from a bottom portion of the desalter vessel. A portion of the desalter vessel is substantially transparent to allow visualization of the demulsification process and at least one light source is positioned adjacent to the desalter vessel to aid in visualization of a rag layer formed in the desalter vessel. A heated jacket surrounds the desalter vessel to maintain the desalter vessel at the desired temperature.

Owner:GENERAL ELECTRIC CO

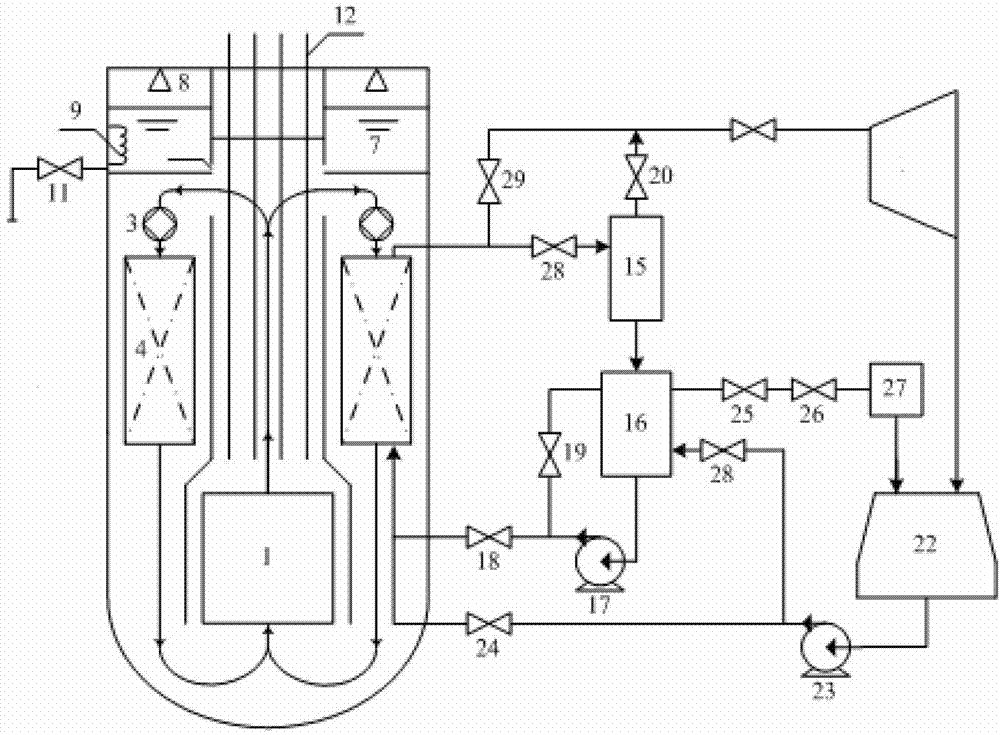

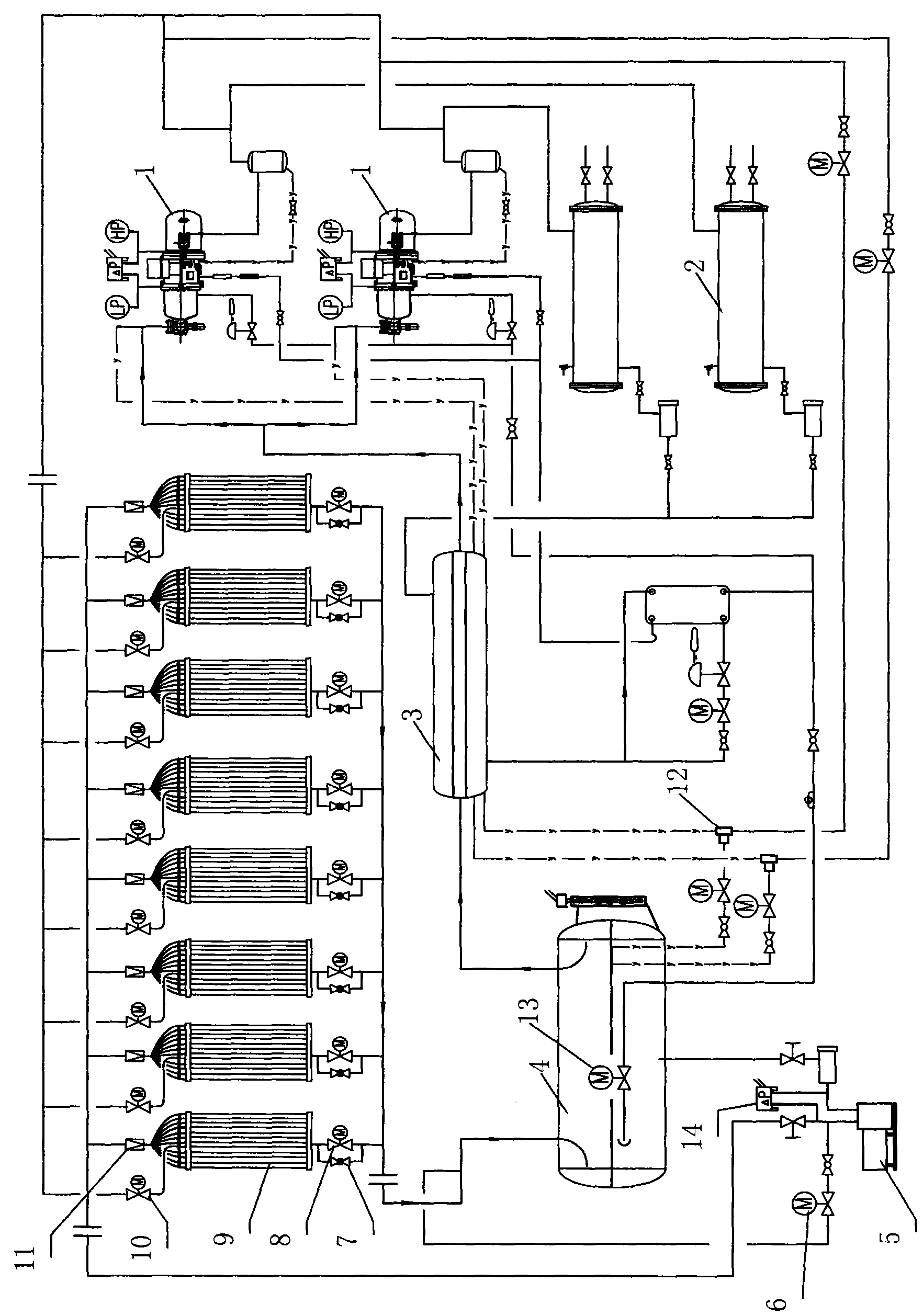

Deep peak shaving system of thermal power plant

PendingCN110006026AImprove operational efficiencyImprove economyLiquid degasificationHeat storage plantsSteam pressureSteam condensation

The invention discloses a deep peak shaving system of a thermal power plant. The deep peak shaving system comprises a superheater, a reheater, a high-pressure cylinder, a reheating steam electric regulating valve, a main steam electric regulating valve, a medium-pressure cylinder, a low-pressure cylinder, a condenser, a condensation water pump, a low-pressure heating water feeding heat exchanger,a water feeding pump set, a deaerator, a high-pressure heating water feeding heat exchanger, a steam turbine low-pressure steam extraction system, four-stage extraction, a steam turbine high-pressuresteam extraction system, a high-temperature molten salt water feeding heat exchanger, a high-temperature molten salt pump, a high-temperature molten salt storage tank, a low-temperature molten salt storage tank, a low-temperature molten salt pump, a molten salt preheater, a steam condensation type heat exchanger, a steam non-condensation type heat exchanger, a steam pressure reduction device and the like. According to the system, the molten salt heat storage technology is utilized, redundant steam heat is stored during load reducing peak shaving of a unit, in the process of load increasing peak shaving of the unit, high-temperature molten salt is used for heating high-pressure fed water to reduce steam extraction of a steam turbine, the output of the steam turbine is increased, the heat efficiency of the unit is improved, and the flexible and deep peak shaving of the thermal power plant is realized.

Owner:BEIJING UNIV OF TECH

Dual working condition refrigeration system for making ice and cold water

InactiveCN101929753ARealize double working condition operationImprove cooling efficiencyCompressorIce productionRefrigeration compressorSolenoid valve

The invention discloses a dual working condition refrigeration system for making ice and cold water, which comprises a refrigeration compressor, a condenser and an evaporator serving as ice-making equipment, and also comprises a refrigerant feed pump used for supplying a liquid refrigerant condensed by the condenser to the evaporator. A pipeline between the feed pump and the evaporator is provided with a one-way valve; a refrigerant outlet of the evaporator is connected in parallel with an air return valve and an air return bypass throttle valve; an air outlet of the refrigeration compressor is communicated with the evaporator through a hot air deicing electromagnetic valve for deicing. The dual working condition refrigeration system also comprises a temperature sensor for measuring the water inlet temperature of the evaporator and a controller. The temperature sensor is used as the input of the controller; the evaporation temperature of the evaporator is not controlled; and the controller is connected with the air return valve, the air return bypass throttle valve and the hot air deicing electromagnetic valve and controls the on / off of the air return valve, the air return bypass throttle valve and the hot air deicing electromagnetic valve in various working conditions. The refrigeration system can work under dual working conditions, and has high efficiency.

Owner:中机西南能源科技有限公司

Fuel supply system for DME engine

A feed pump of a fuel supply system for a DME engine rotates in a normal direction to supply DME fuel in a fuel tank to a high-pressure supply pump through a low-pressure fuel supply passage. The high-pressure supply pump pressurizes the DME fuel and discharges the DME fuel therefrom. The discharged DME fuel is distributed by a high-pressure fuel supply passage and injected by a fuel injector. A first fuel recovery passage connects the high-pressure fuel supply passage to the low-pressure fuel supply passage. When the engine is operated, a first solenoid valve closes the first fuel recovery passage. When the engine is stopped, the first solenoid valve opens the first fuel recovery passage and the feed pump rotates in a reverse direction, thereby the DME fuel in the low-pressure fuel supply passage and in the high-pressure fuel supply passage is recovered into the fuel tank.

Owner:TOYOTA IND CORP

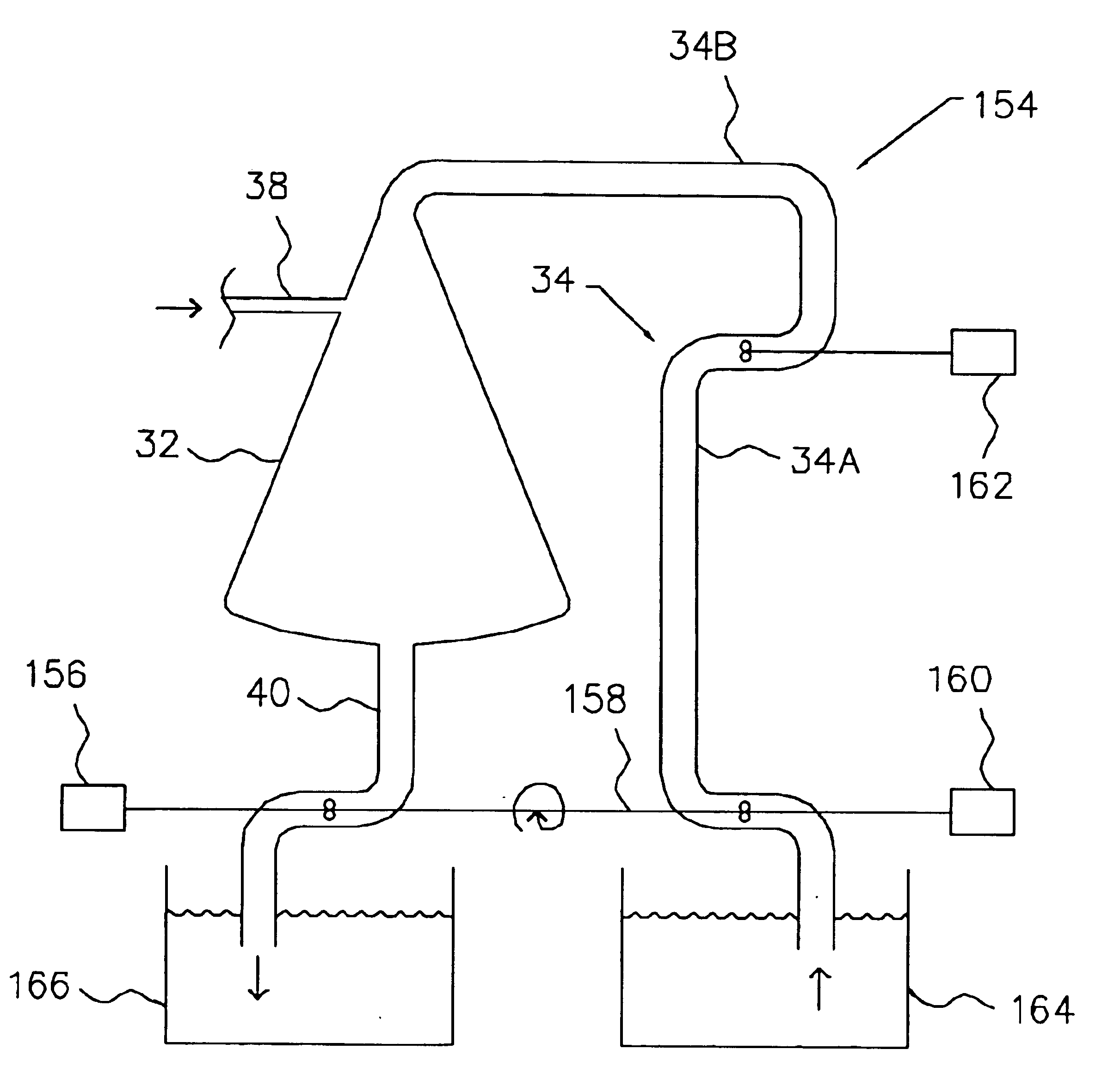

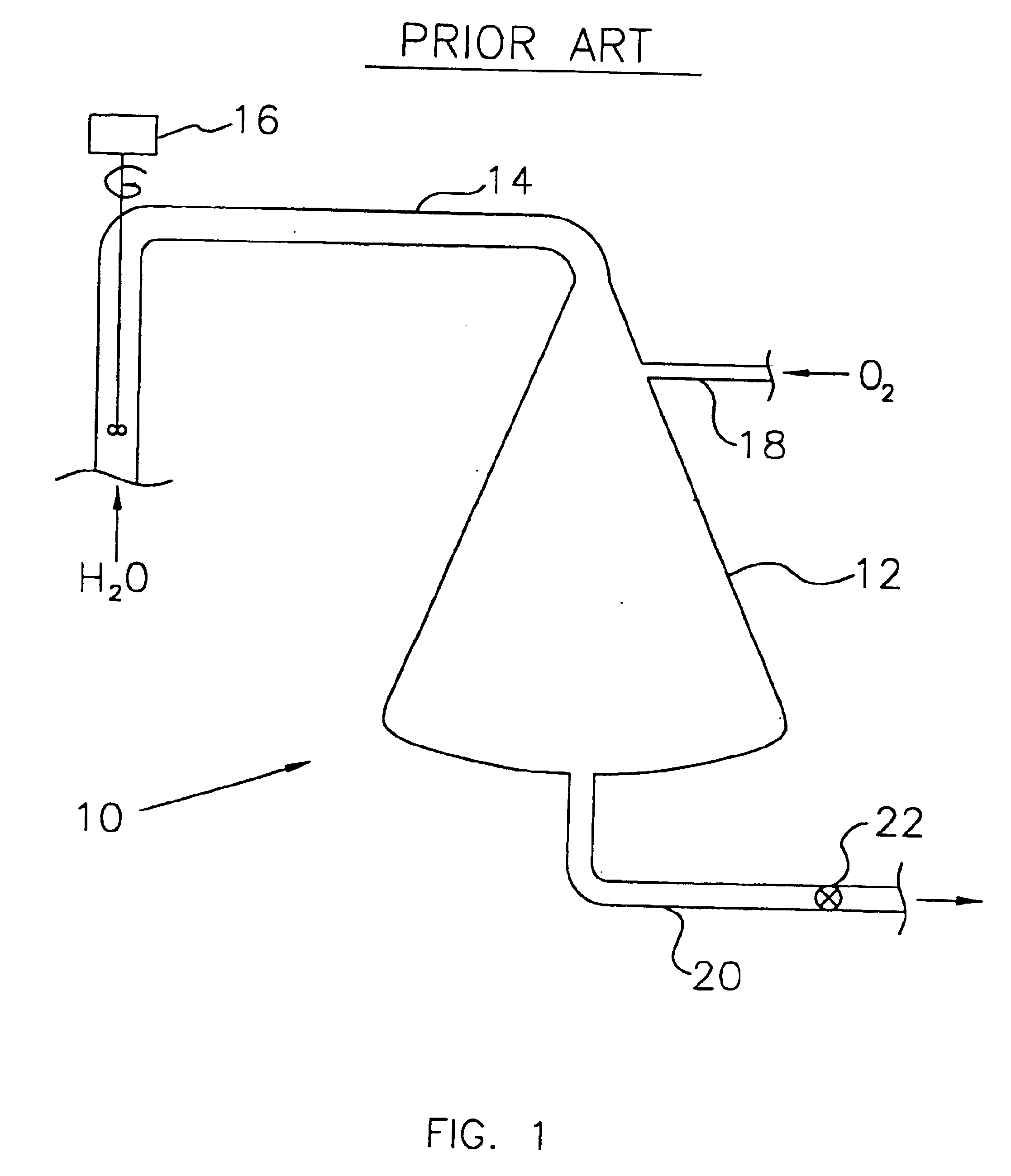

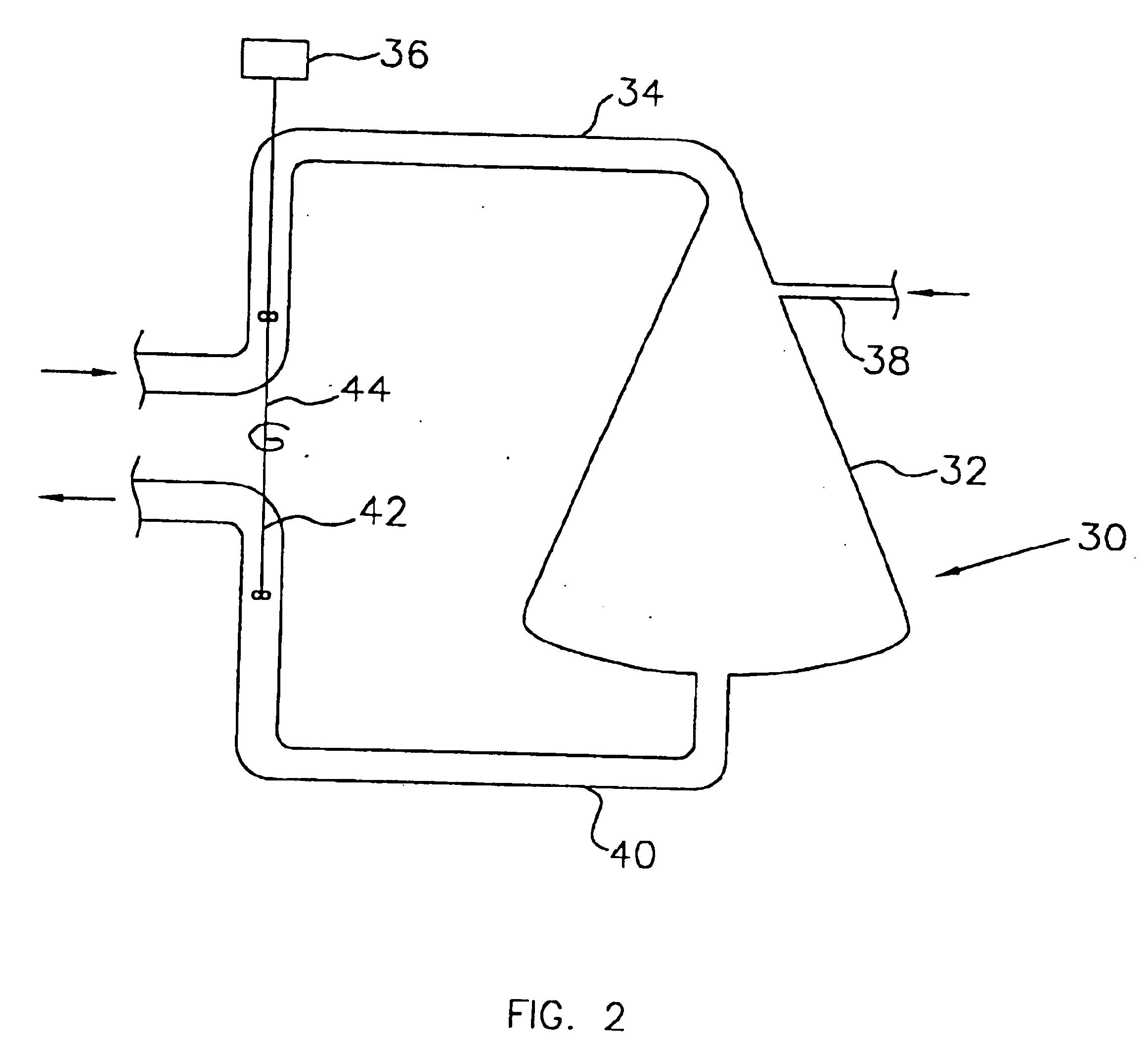

Gas transfer energy recovery and effervescence prevention apparatus and method

InactiveUS6848258B1Minimize consumptionProhibitively expensive to installTreatment using aerobic processesTransportation and packagingProduct gasEnergy recovery

A gas transfer system and method for dissolving at least one gas into a liquid. The system includes a gas transfer vessel also known as a reactor. A liquid inlet feed is connected to the reactor for transferring the liquid into the reactor. A gas inlet is connected to the reactor for feeding the gas into the reactor. An outlet is connected to the reactor for transferring the liquid with at least some of the gas therein away from the reactor. The system also includes a feed pump connected to the inlet feed to pressurize the contents of the inlet feed and the reactor, and a regenerative turbine connected to the feed pump and to the outlet. The various embodiments of the gas transfer system use pressurization in the gas transfer vessel to enhance gas transfer therein, minimize the net energy consumption, and retain highly supersaturated dissolved gas in solution. Some embodiments further help to reduce effervescence loss. The method of the present invention utilizes the system of the present invention and operates the feed pump and regenerative turbine to accomplish these advantages.

Owner:ECO OXYGEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com