Patents

Literature

82results about How to "The mixing ratio is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

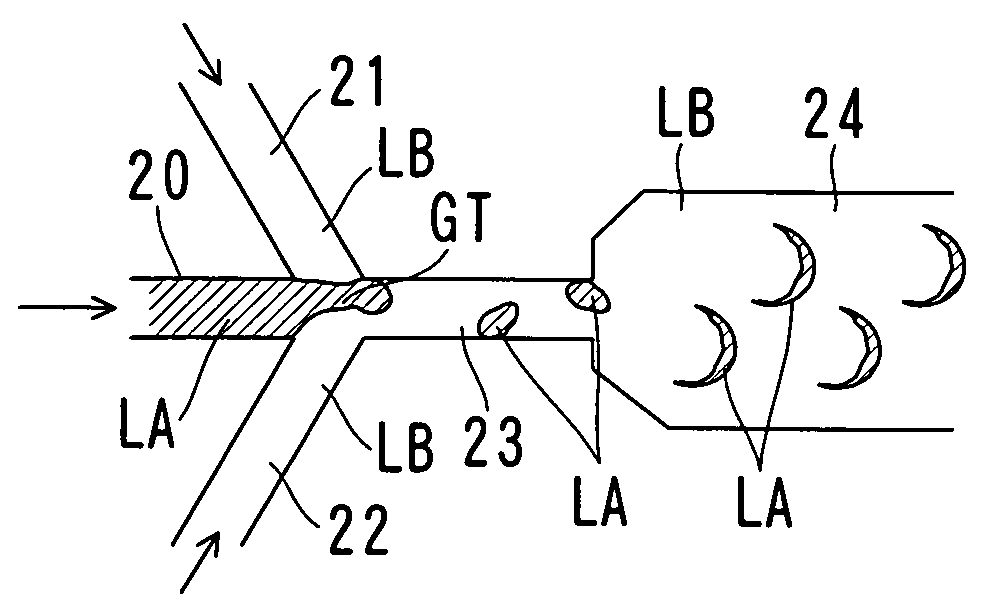

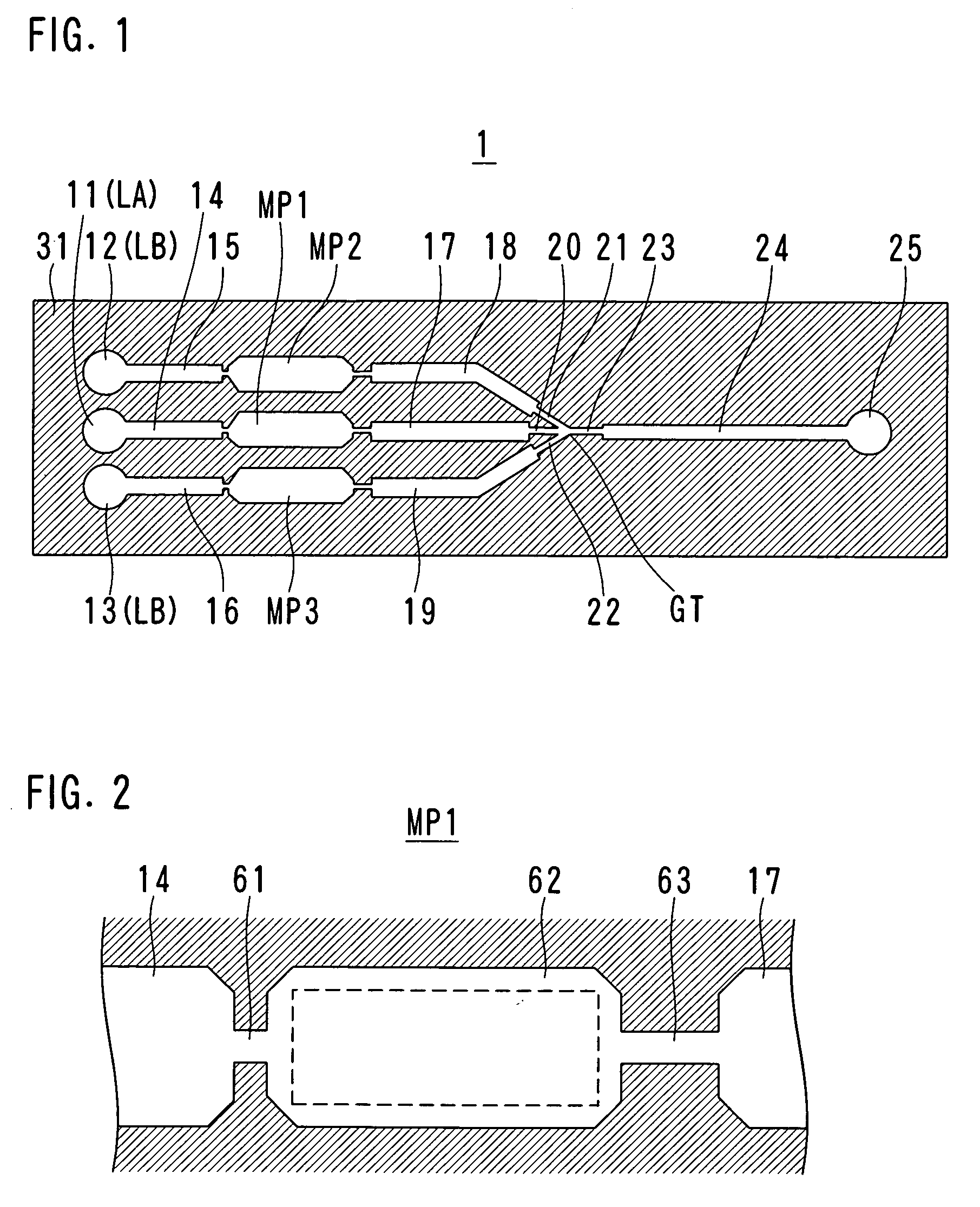

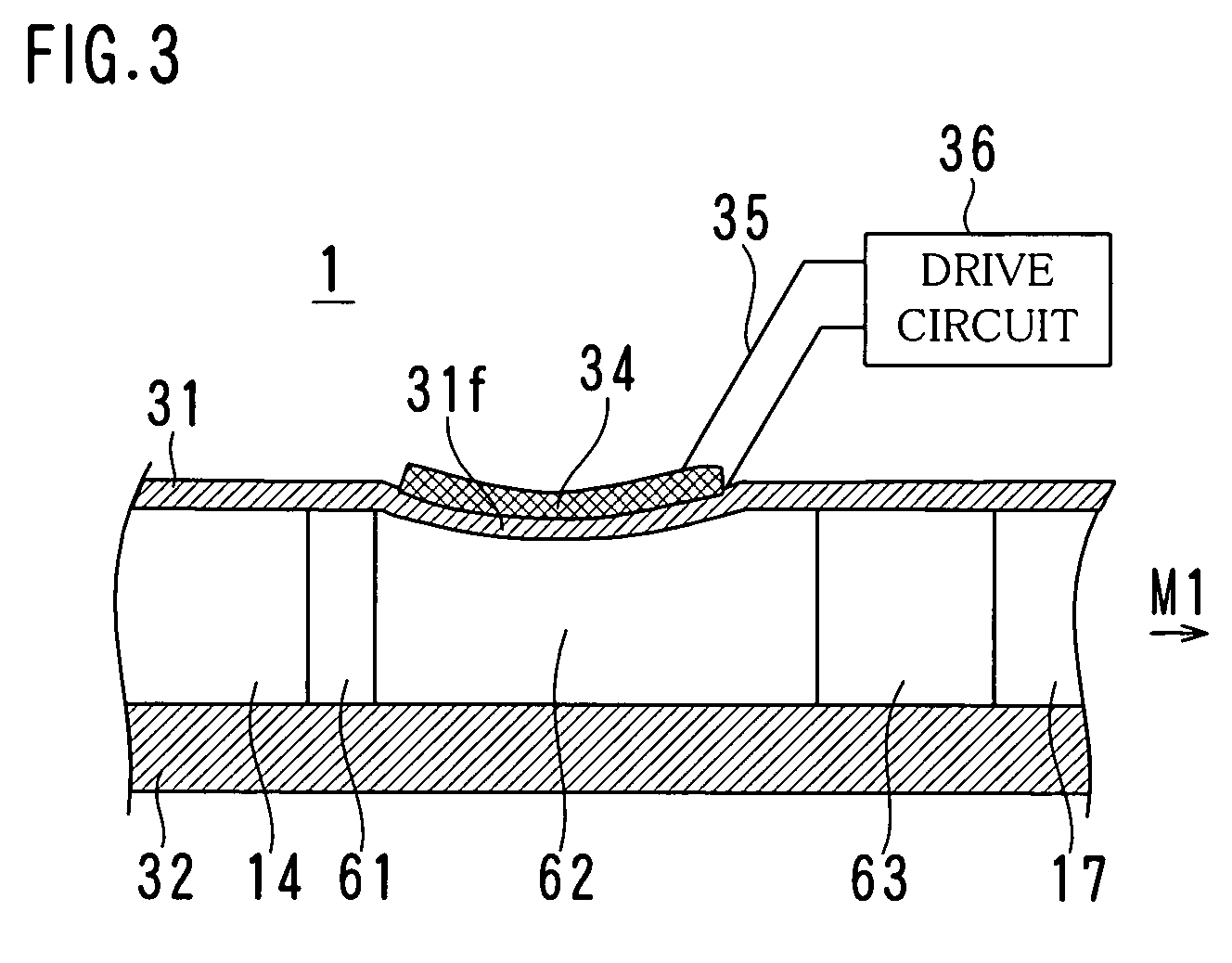

Method, device and system for mixing liquids

InactiveUS20050092681A1Minimize unevennessThe mixing ratio is accurateFlow mixersMixing methodsEngineeringMixing ratio

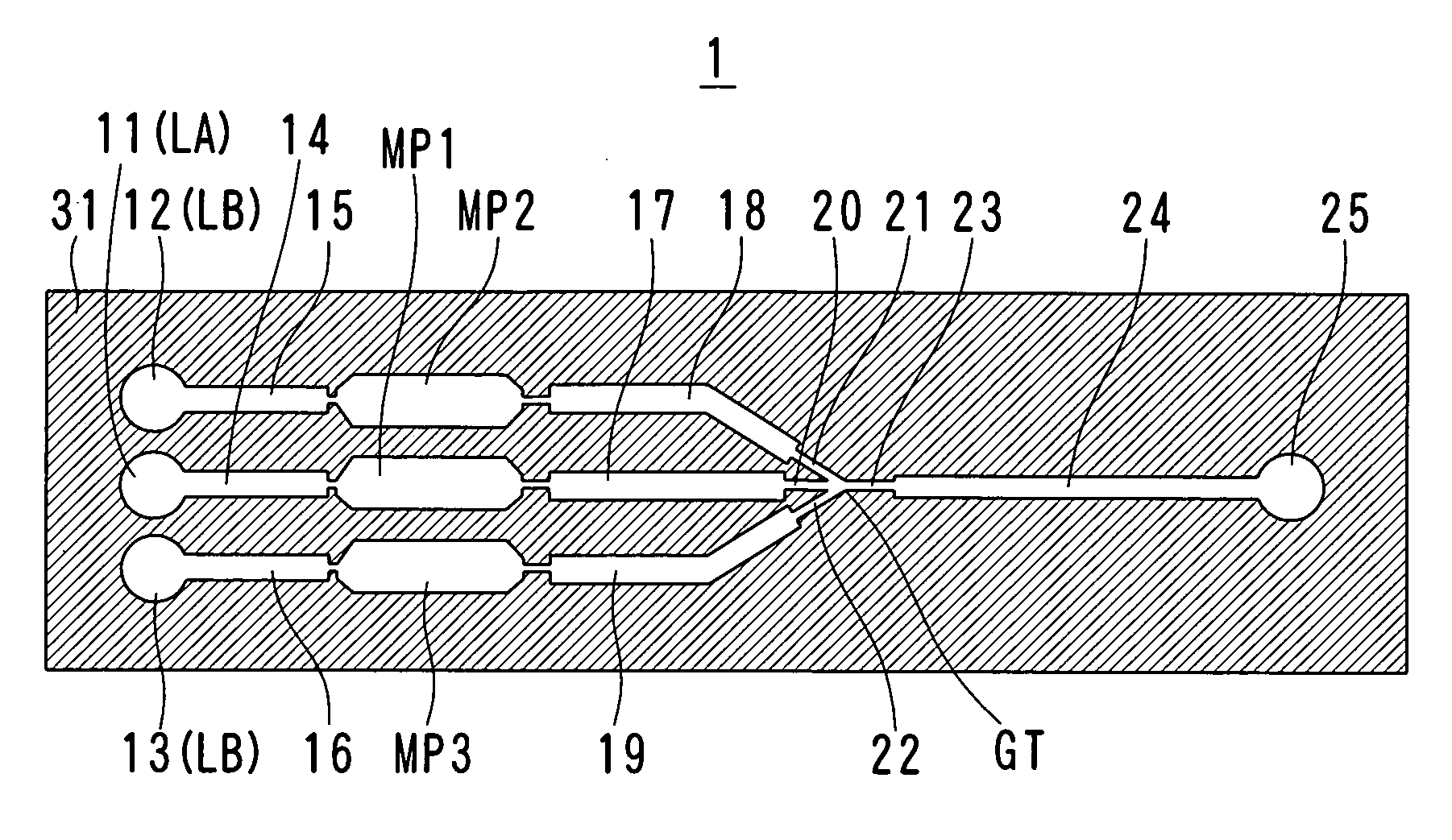

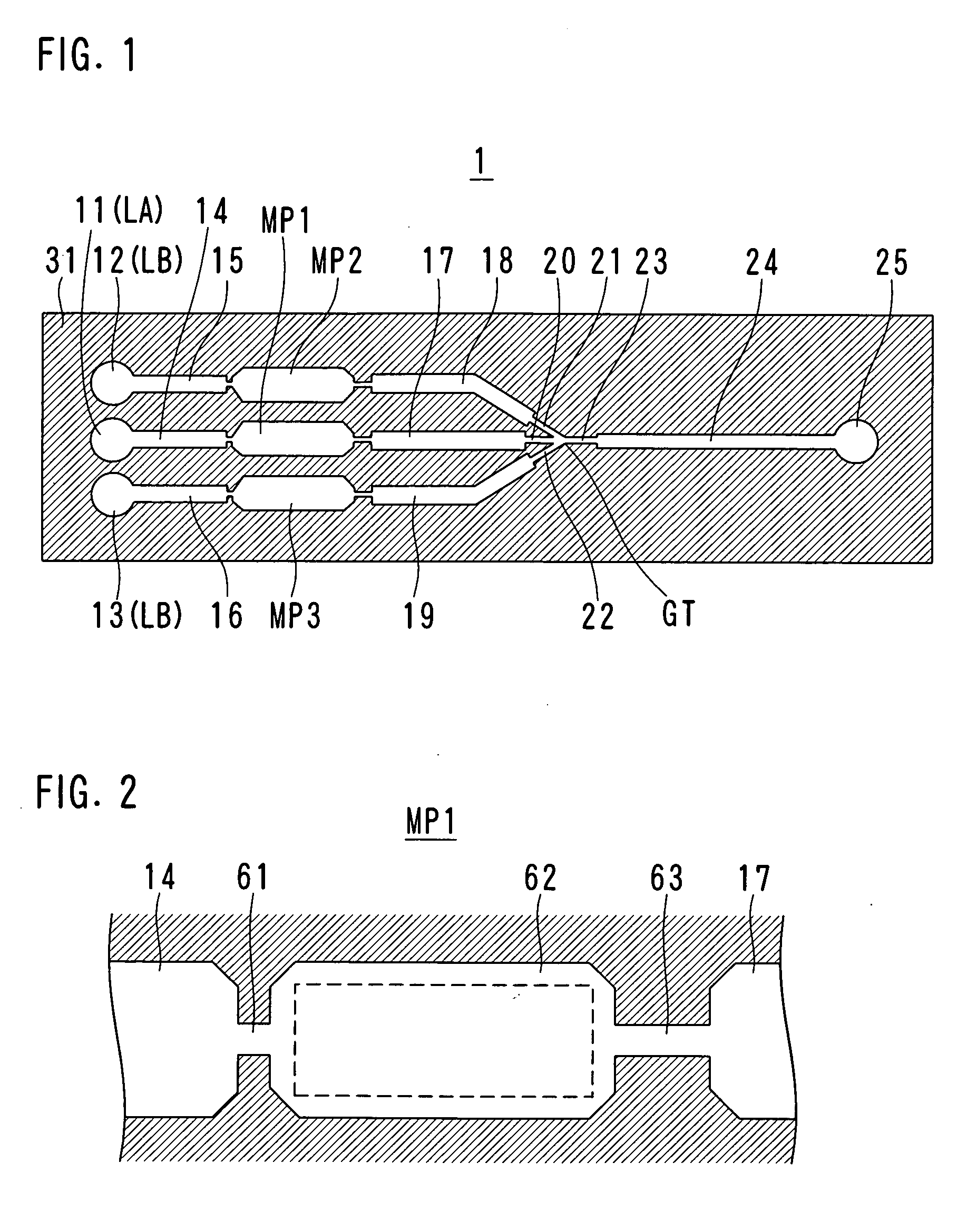

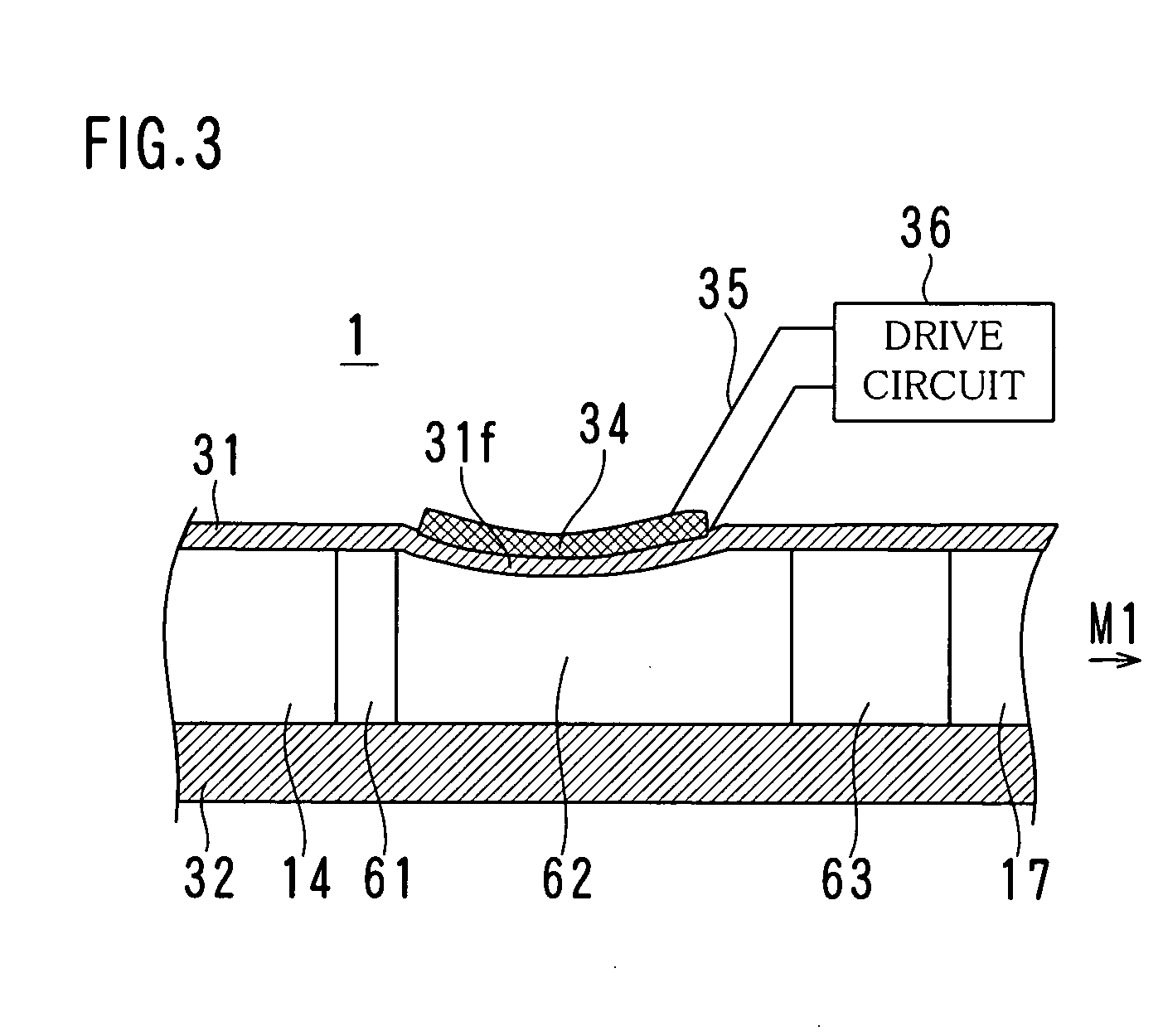

A method and a device are provided which can mix two liquids faster at a precise mixing ratio. The method for mixing at least two liquids transported in respective channels includes transporting, of the two liquids, a liquid having a low mixing rate intermittently in one of the channels, and transporting, of the two liquids, a liquid having a high mixing rate so as to join the liquid having a low mixing rate from both sides of the channel for the liquid having a low mixing rate.

Owner:KONICA MINOLTA INC

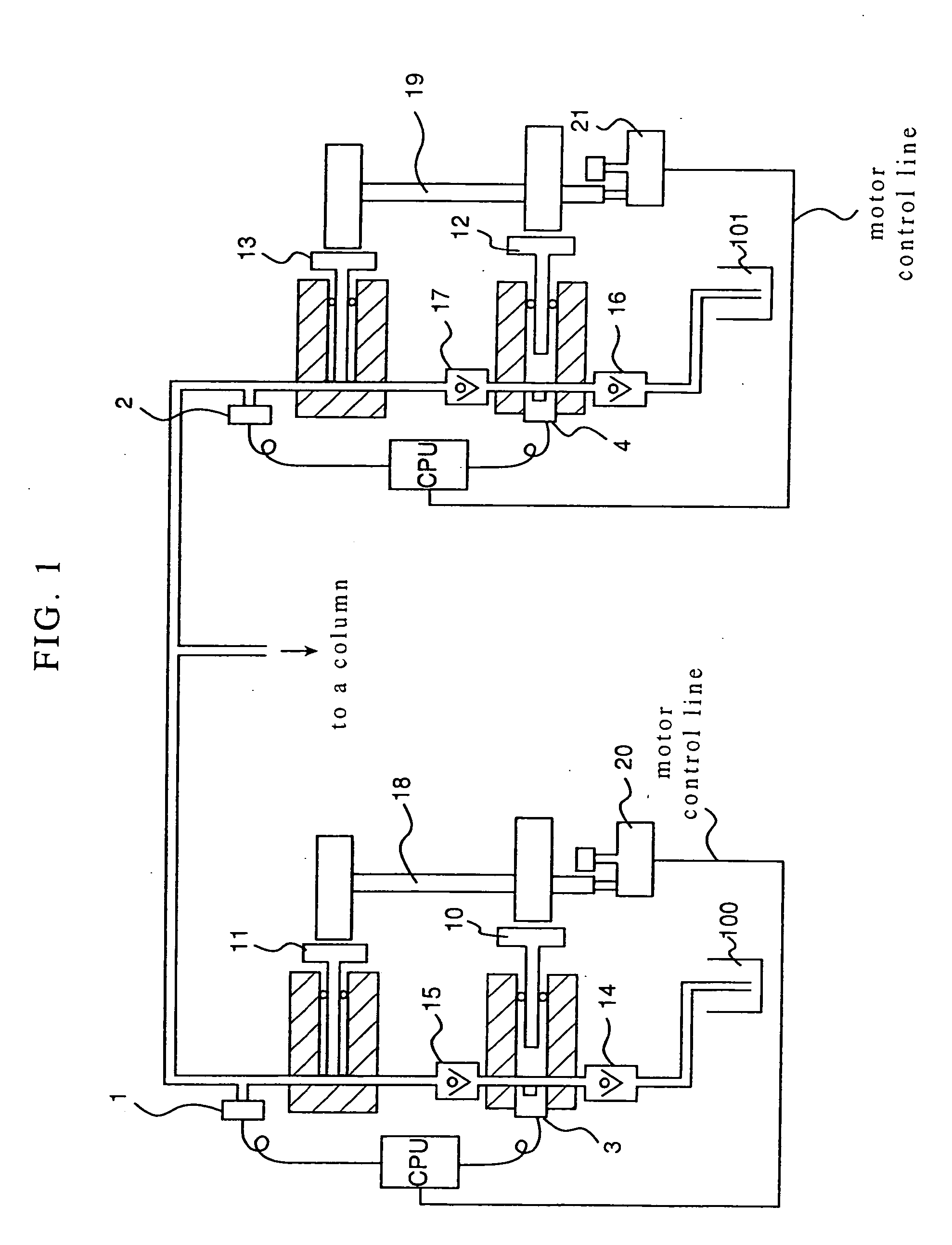

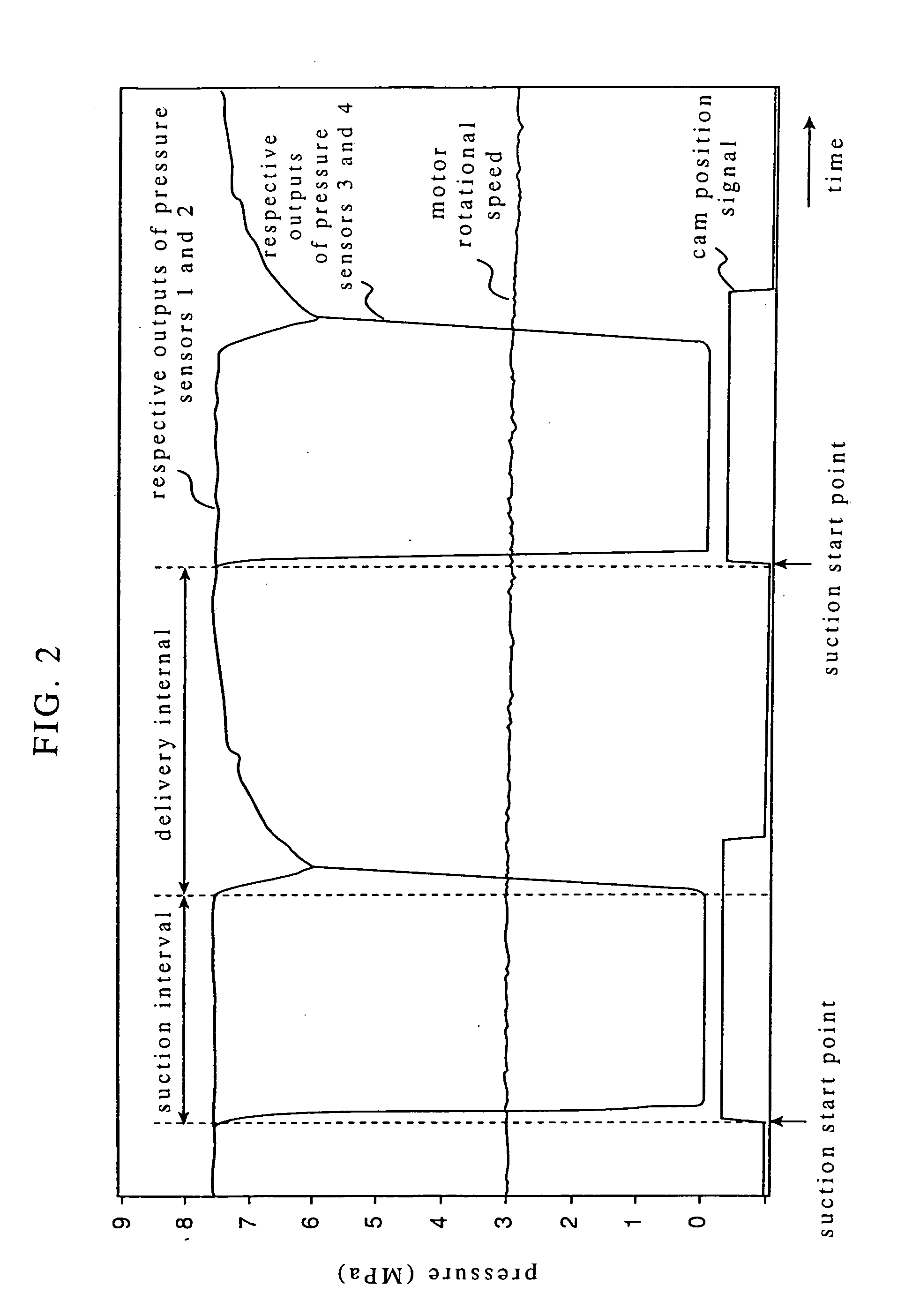

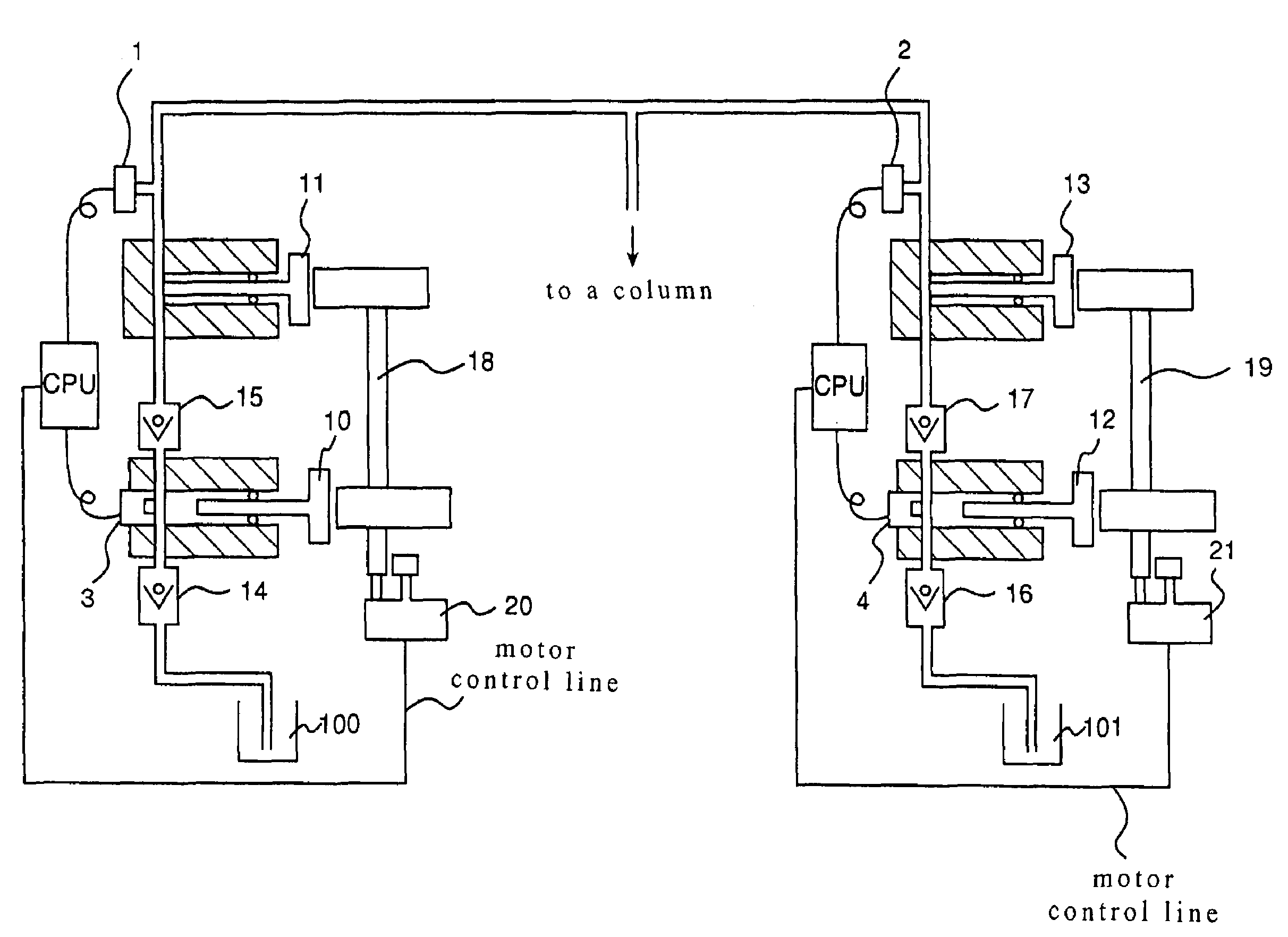

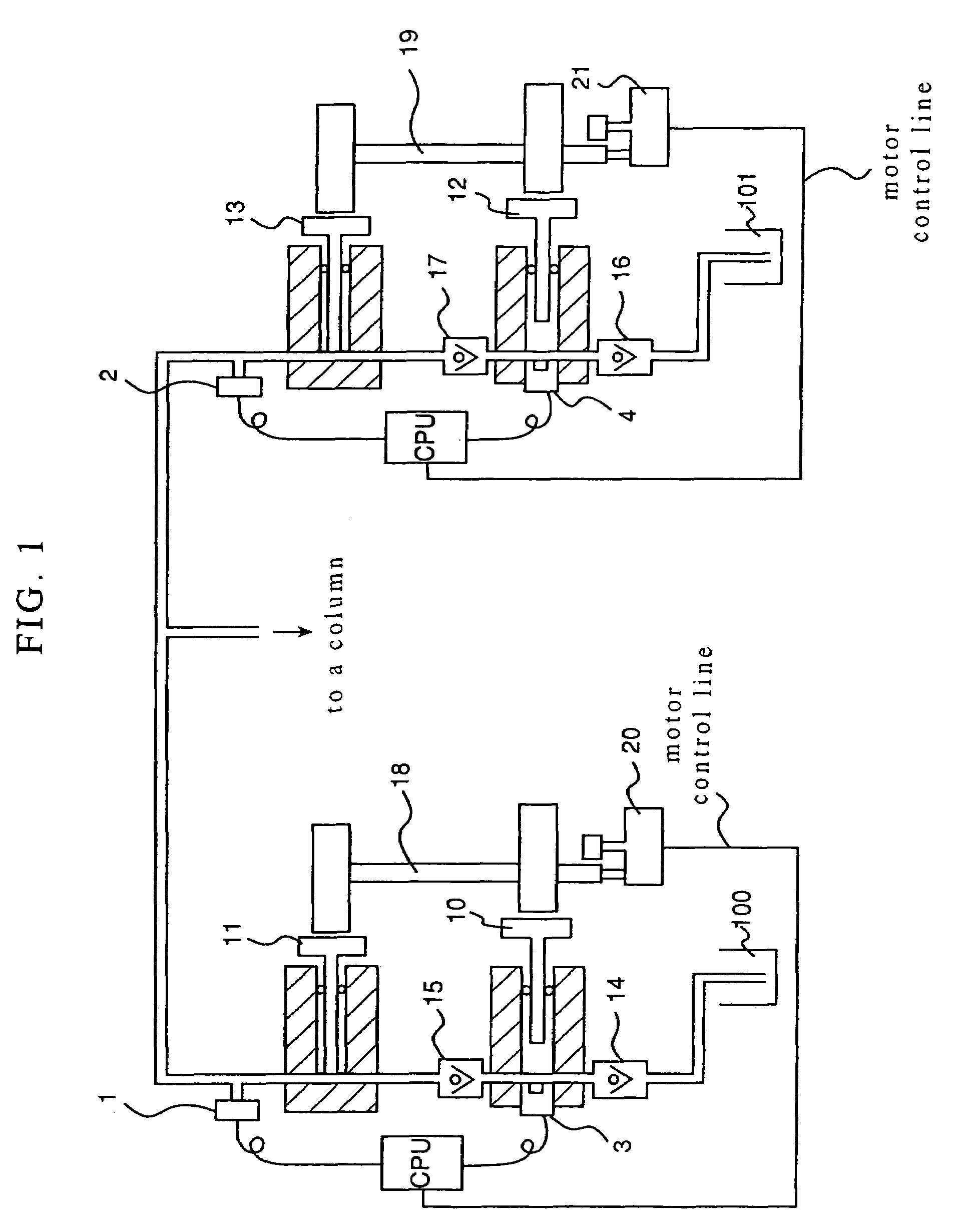

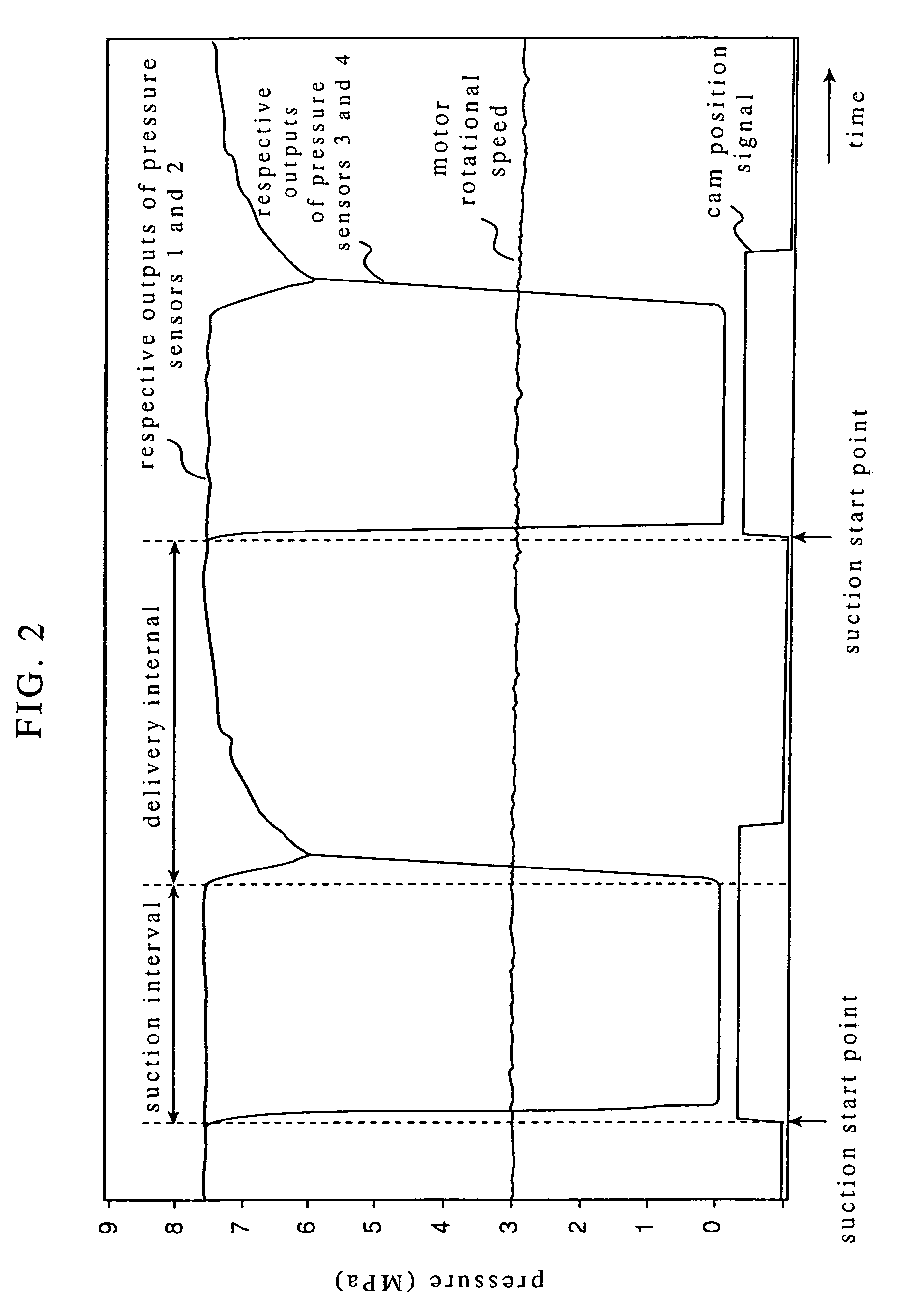

Gradient liquid feed pump system, and liquid chromatograph

InactiveUS20050084386A1Reduce impactThe mixing ratio is accurateFluid parameterComponent separationEngineeringCam

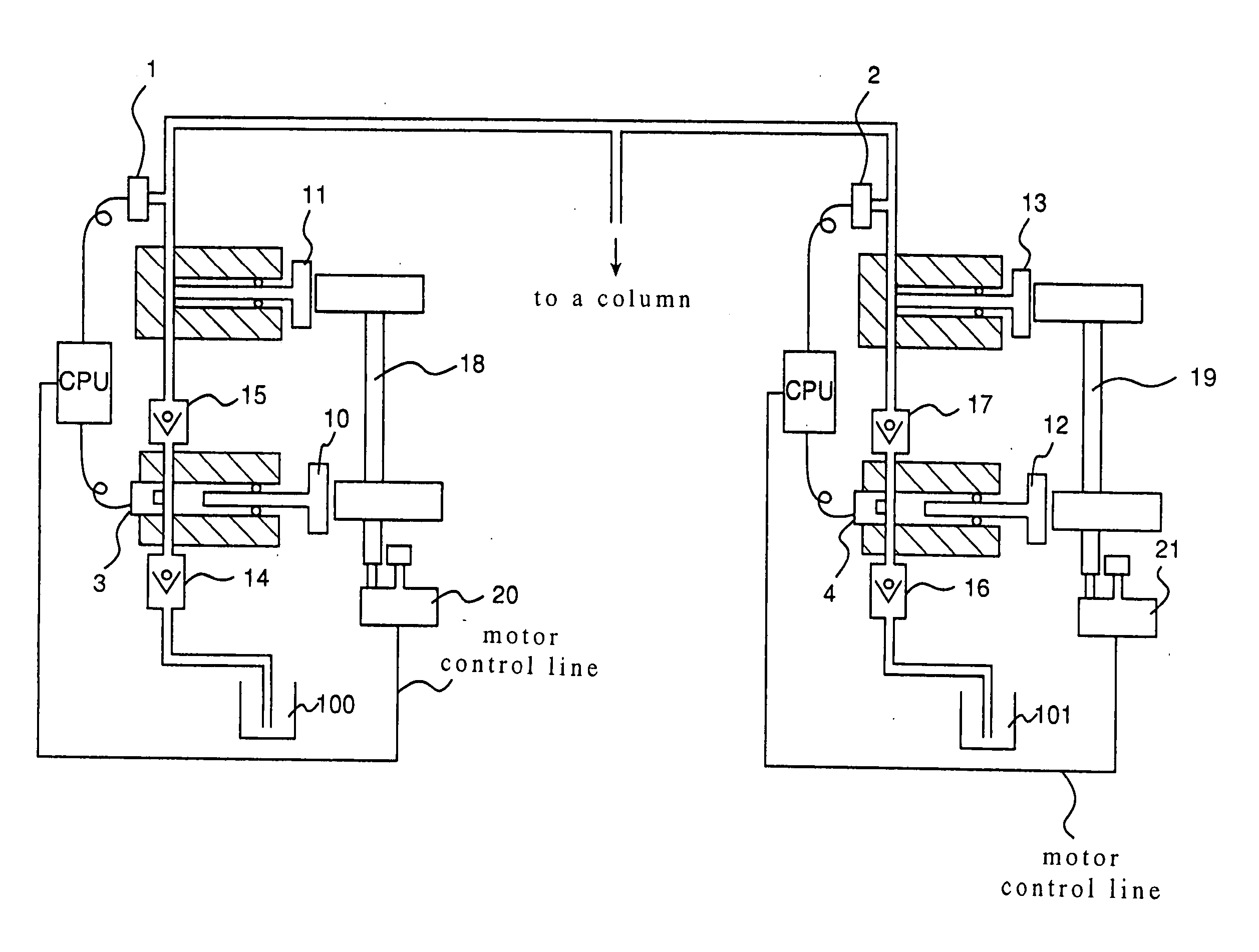

A gradient liquid feed pump system capable of liquid feed in a correct mixing ratio even in the case of liquid feed in which the mixing ratio varies. Specifically, it comprises a first plunger pump for sucking and delivering an eluate, a second the first and second plunger pumps through a cam, a first pressure sensor for measuring the pressure in the flow path of the second plunger pump, a second pressure sensor for measuring the pressure in the fist plunger pump, a cam position detecting sensor for detecting the cam position, wherein when the cam position is in a delivery interval, the rotary speed of the motor is increased, and the period for decreasing the rotary speed is determined on the basis of the difference between the pressure values obtained from the first and second pressure sensors, respectively. Thereby, liquid feed can be smoothly effected with correct mixing ratio while avoiding pressure interference between pumps.

Owner:HITACHI HIGH-TECH CORP +1

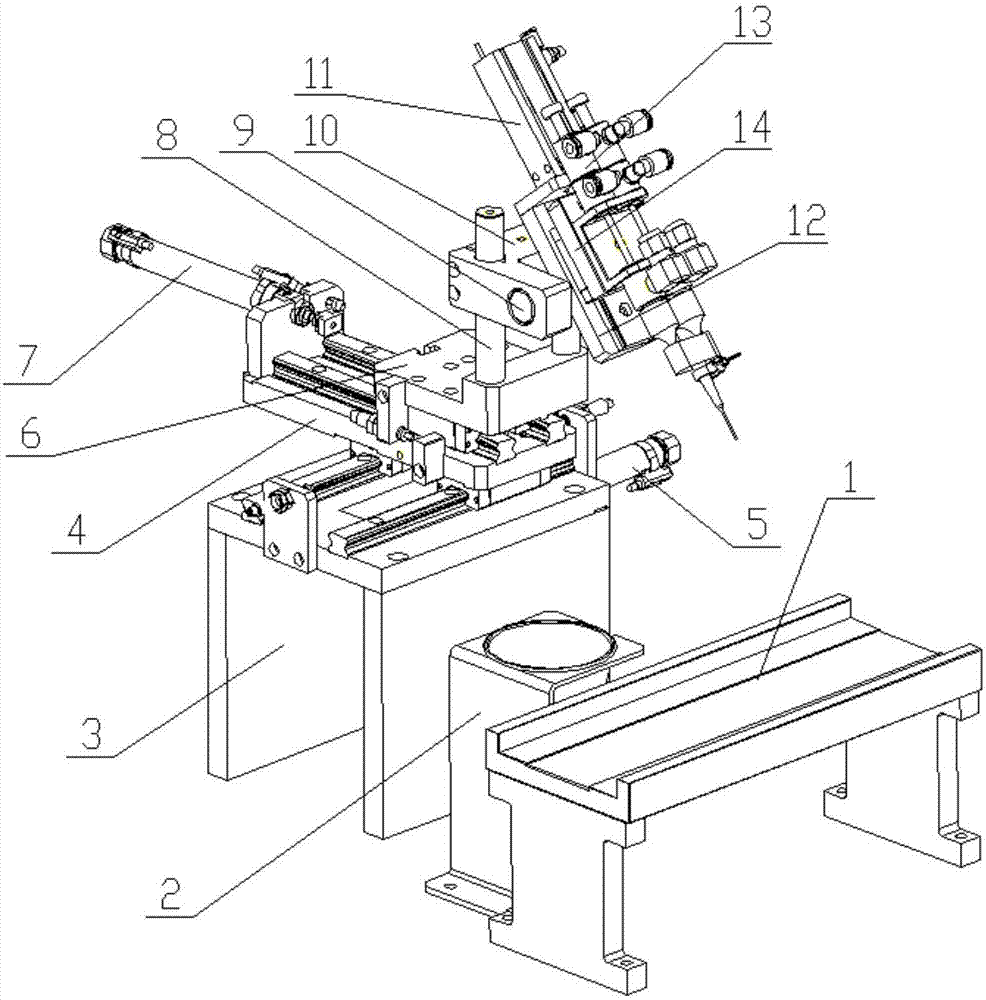

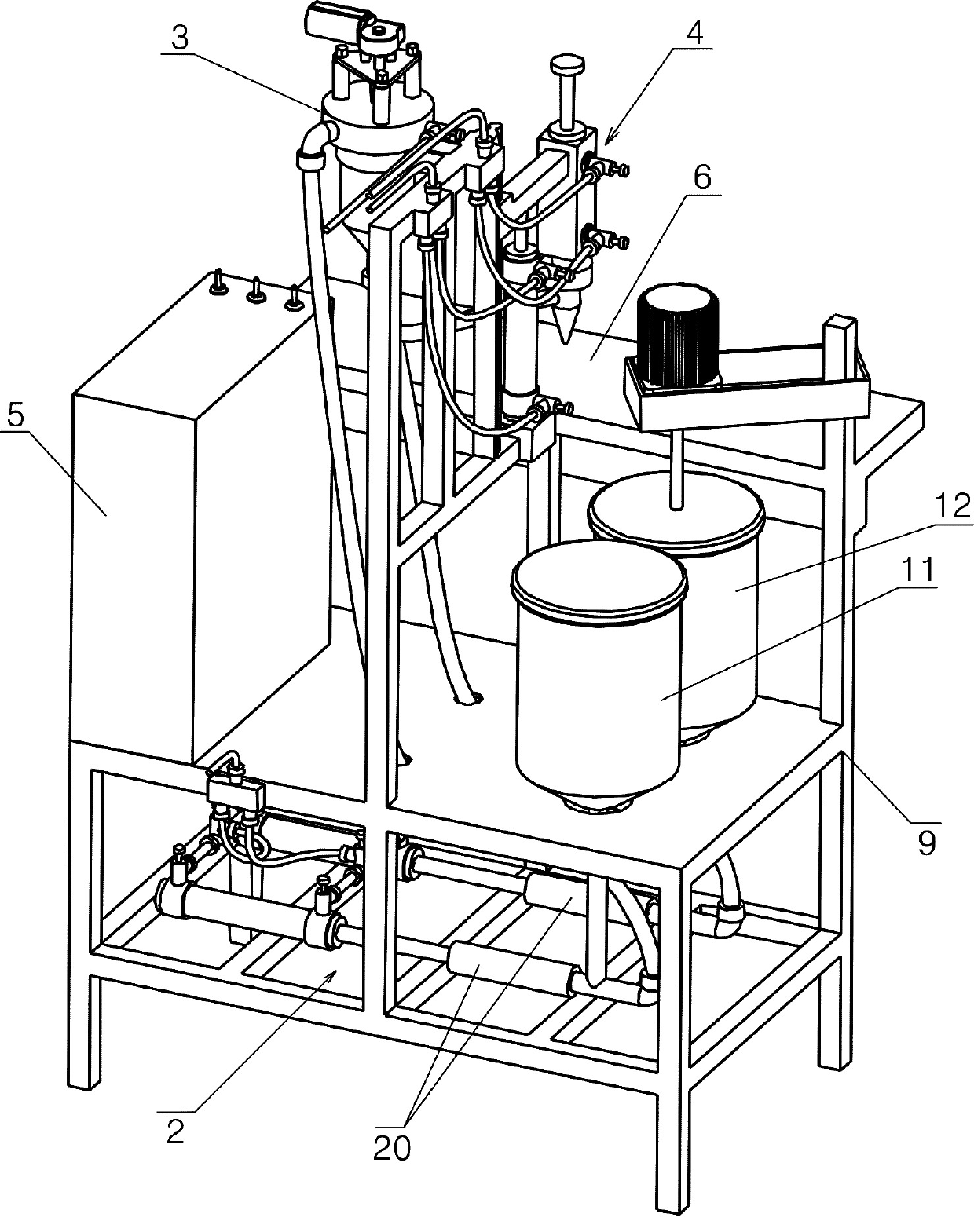

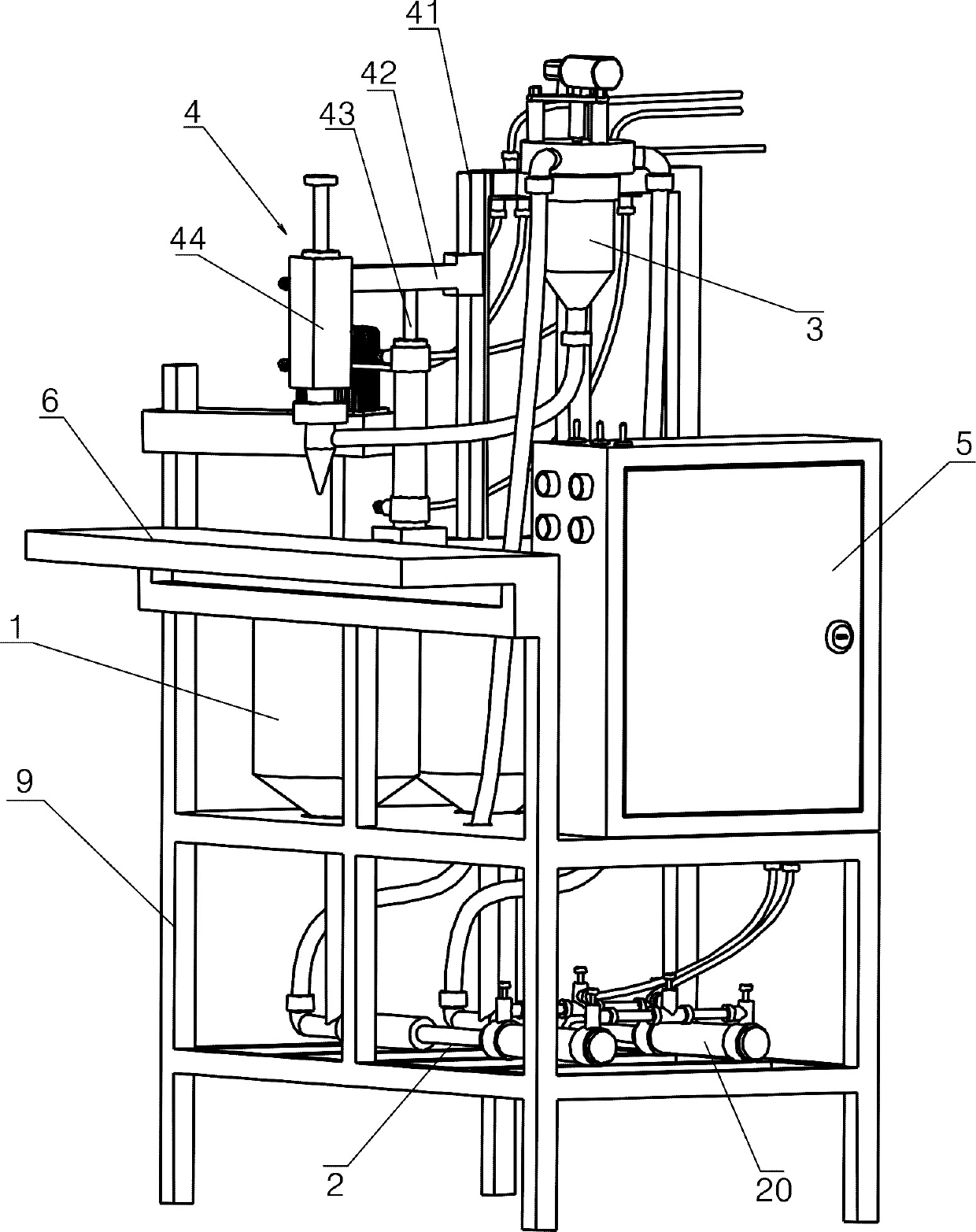

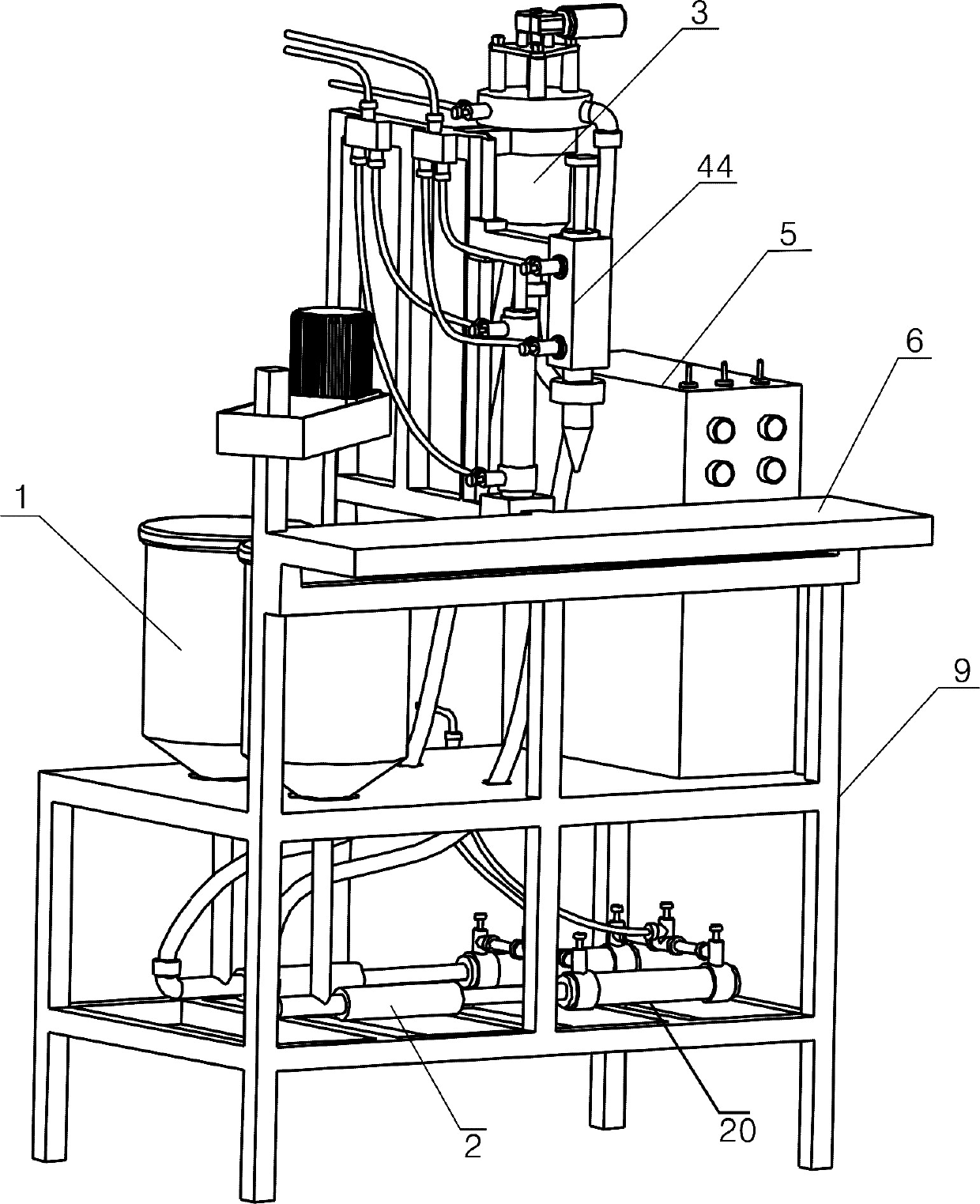

Glue dispensing equipment and glue dispensing method thereof

PendingCN107309136APrecise control of glue outputThe mixing ratio is accurateLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention discloses glue dispensing equipment and a glue dispensing method thereof. The glue dispensing equipment comprises a base, a transverse moving plate, a transverse air cylinder, a longitudinal moving plate, a longitudinal air cylinder, a regulating column, a regulating block, a lifting air cylinder, an angular gauge block, a glue dispensing device, a lifting block and a sliding rail; the transverse moving plate is connected to the base by the sliding rail; the transverse air cylinder is arranged on the base; a power rod of the transverse air cylinder is connected with the transverse moving plate; the longitudinal moving plate is connected to the transverse moving plate by the sliding rail; the longitudinal air cylinder is arranged on the transverse moving plate; and a power rod of the longitudinal air cylinder is connected with the longitudinal moving plate. The glue dispensing equipment disclosed by the invention, the moving speed of a sealing sheet is controlled by controlling the speed of injecting or exhausting gas from two ends of a sealing pot by an air cylinder regulating valve, and the distance from a tapered sealing head to a glue outlet is controlled by driving a sealing rod by the sealing sheet, so that the glue volume of a glue pot is precisely controlled, the mixing ratio of various glues can be kept to be more accurate, and the mixed glue can meet the requirement for the viscosity of a product.

Owner:江西迪迪工业智能设备有限公司

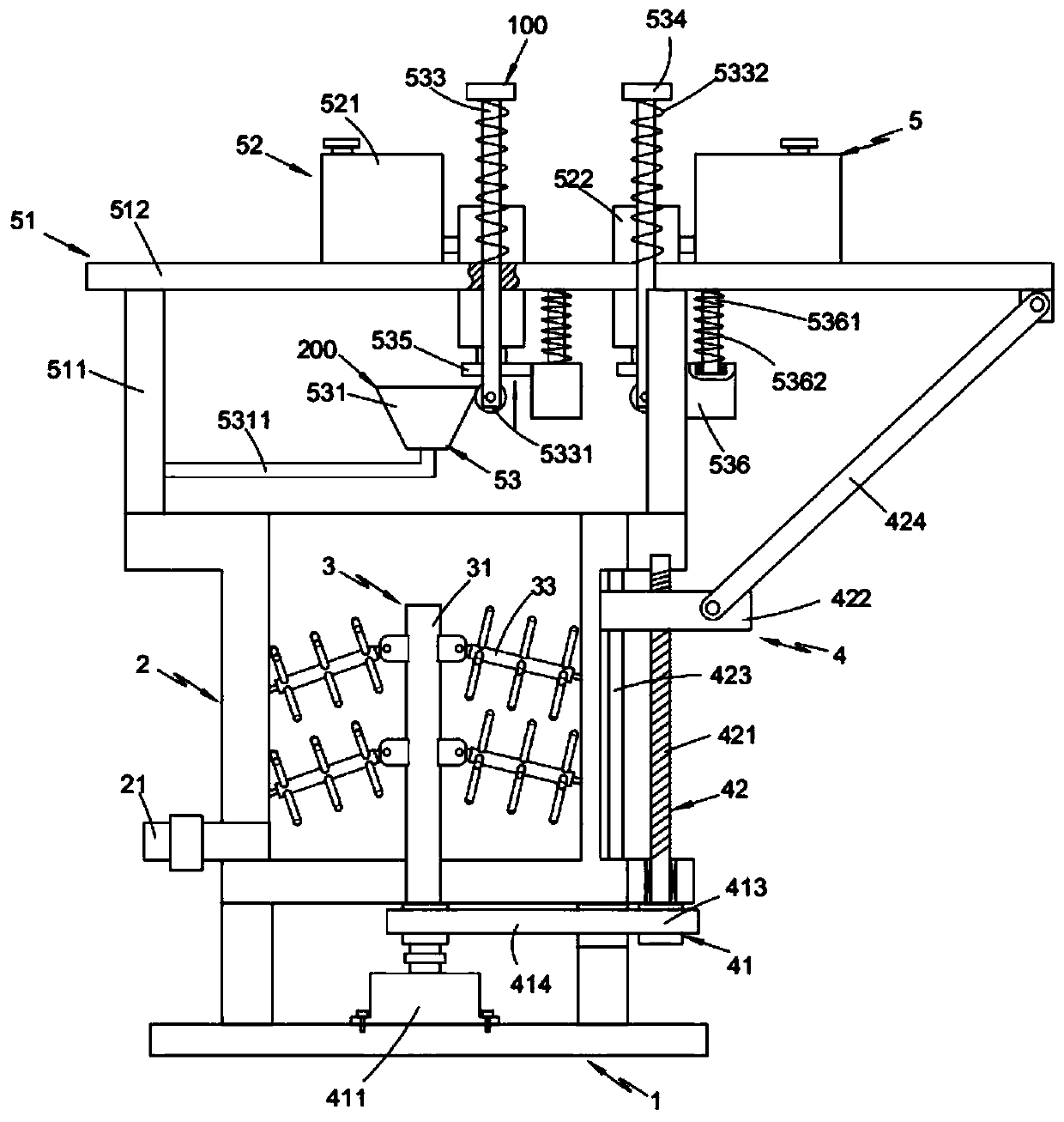

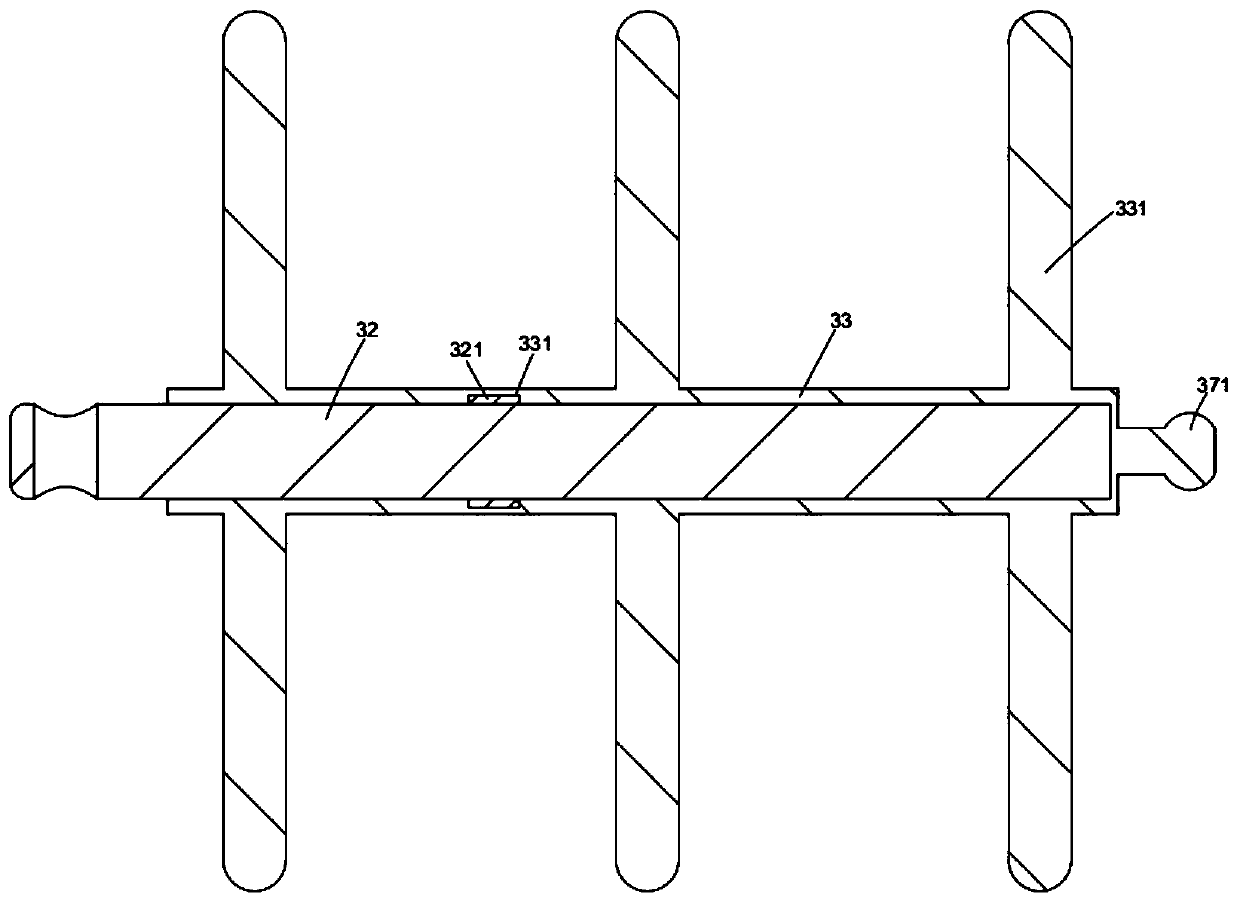

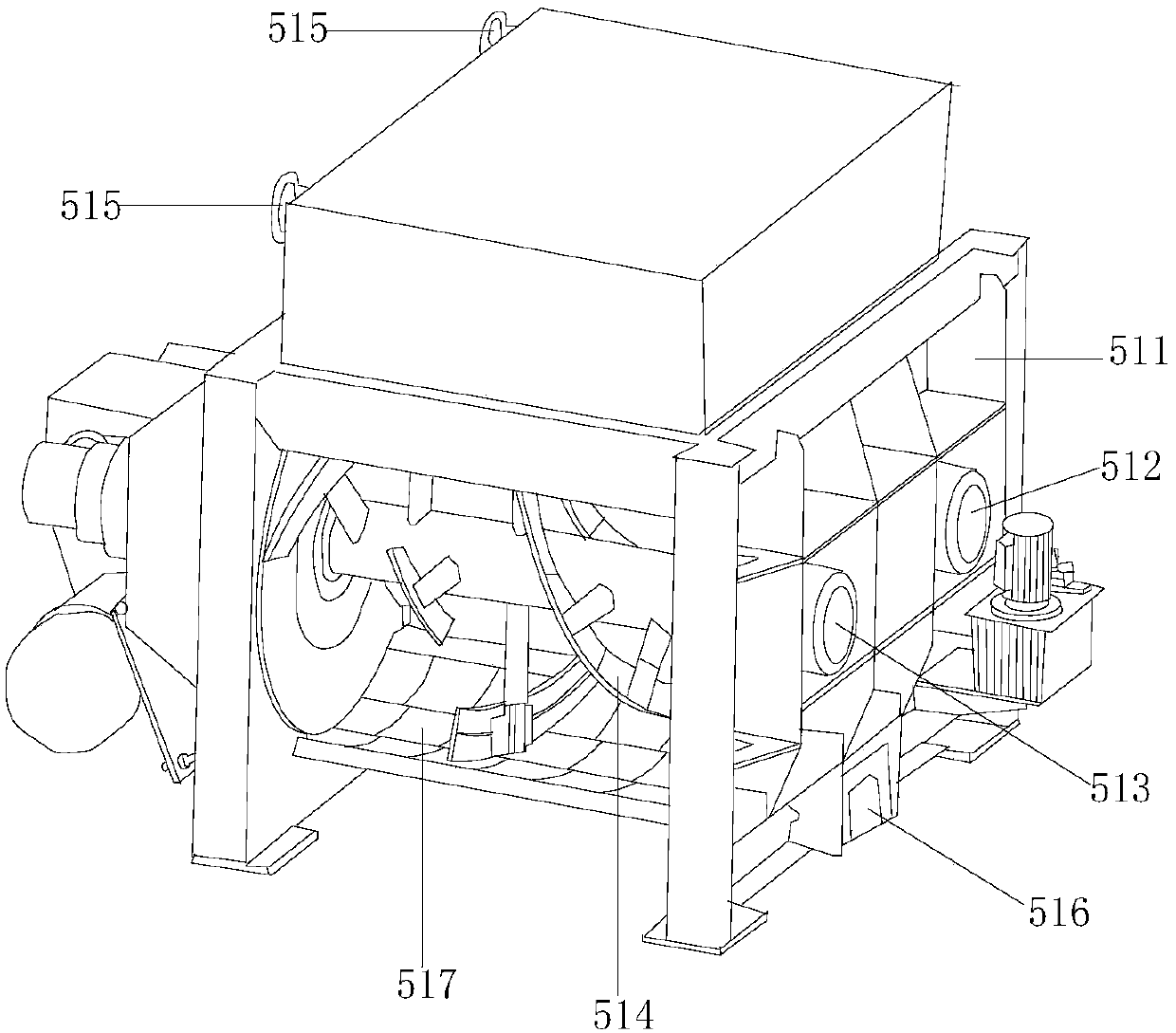

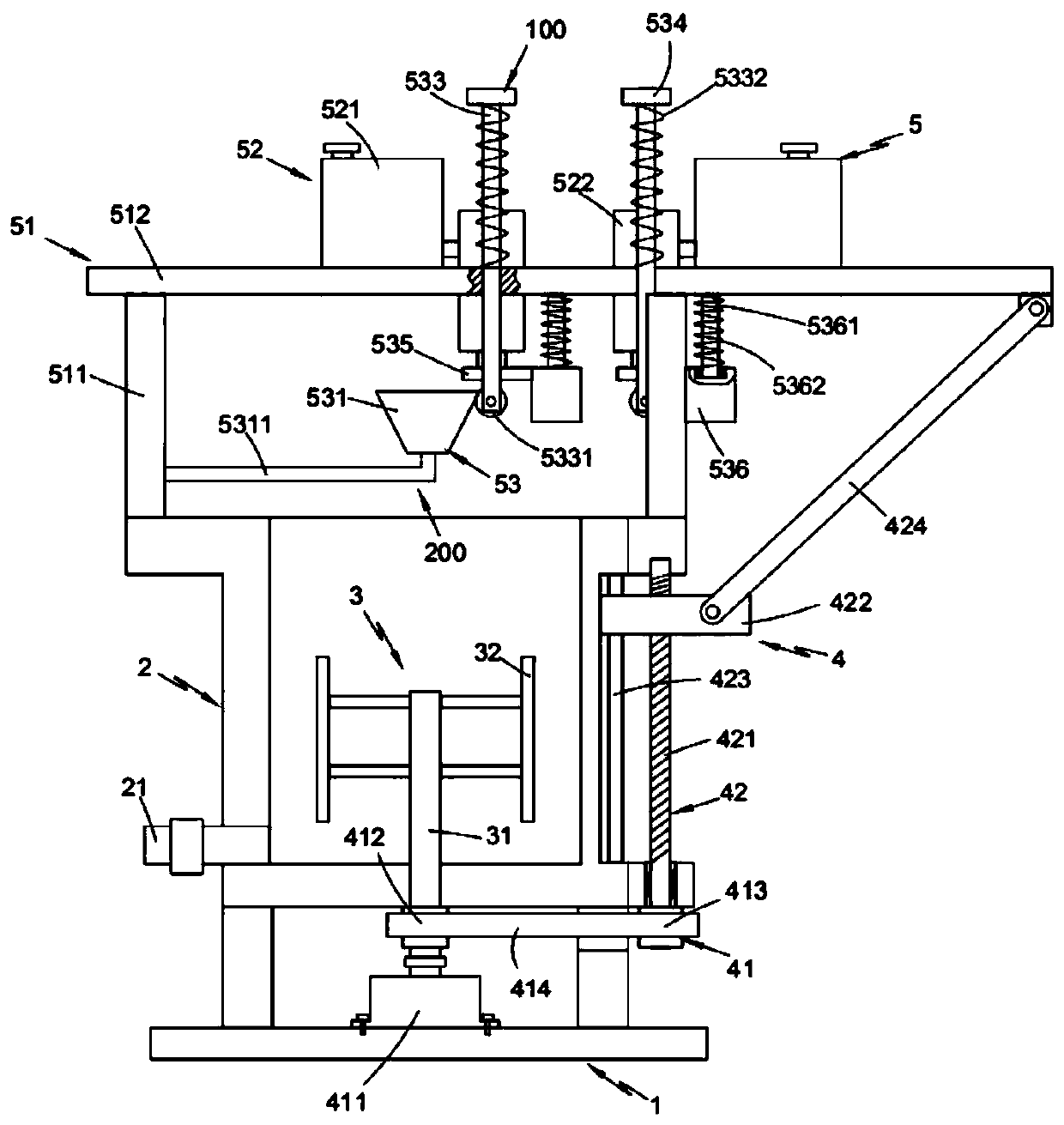

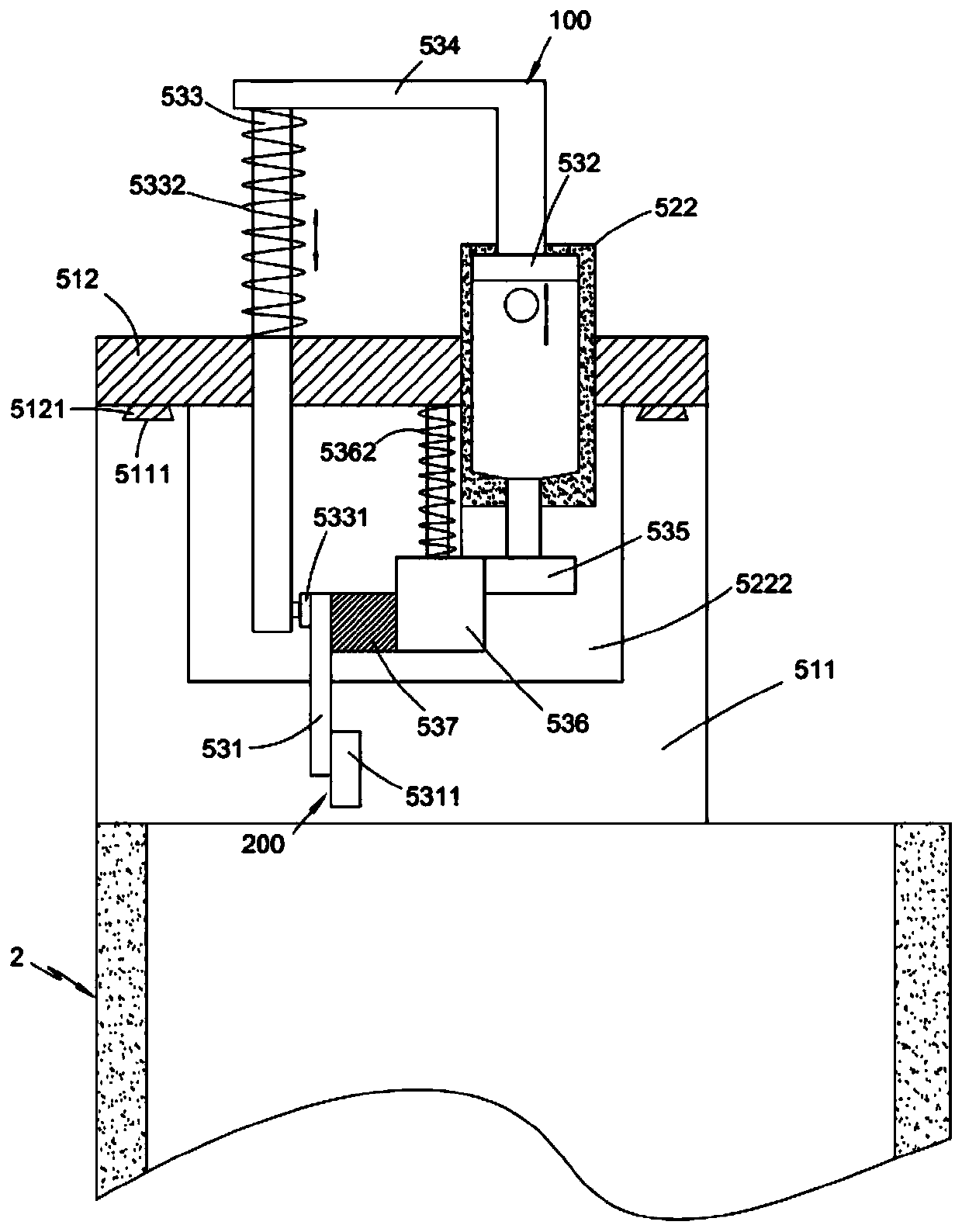

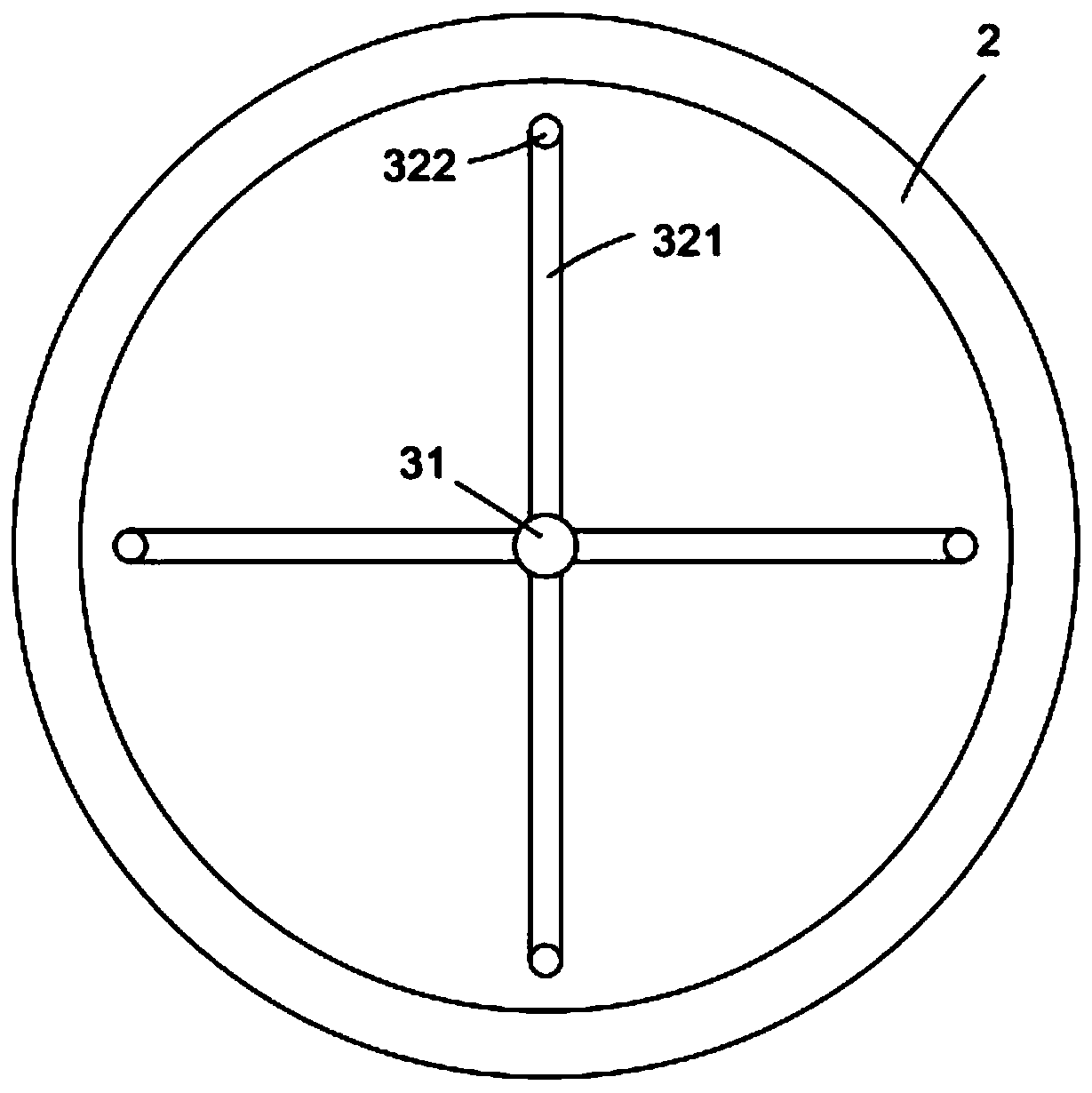

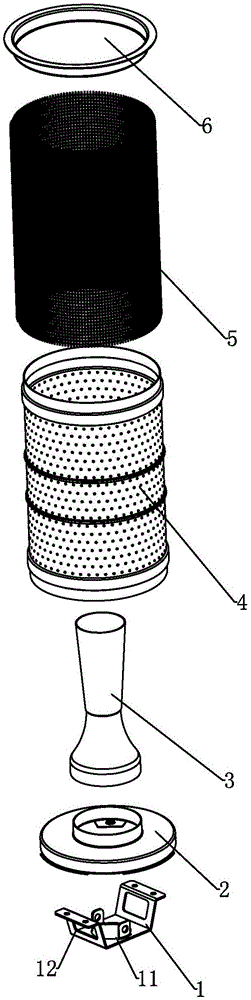

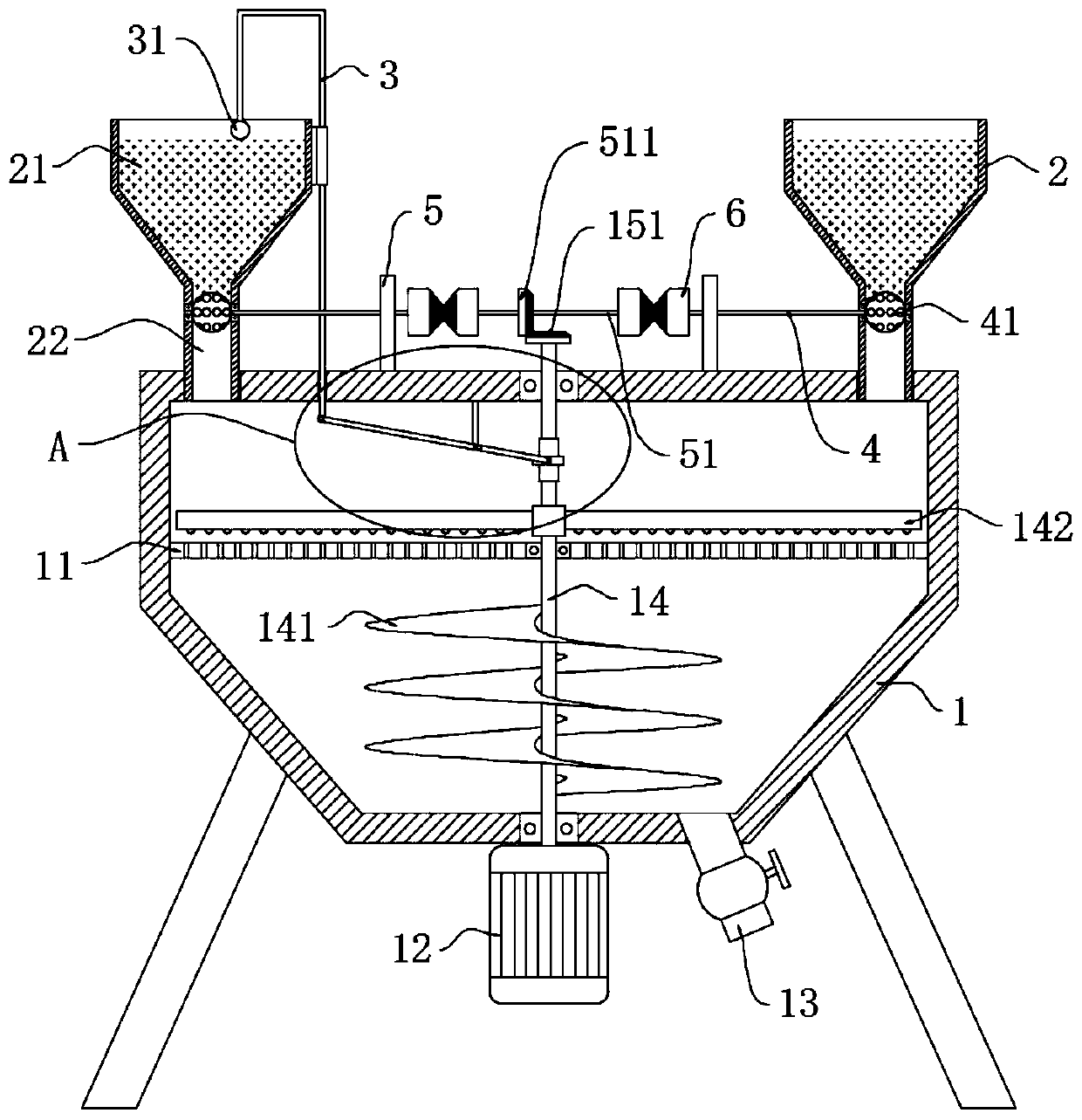

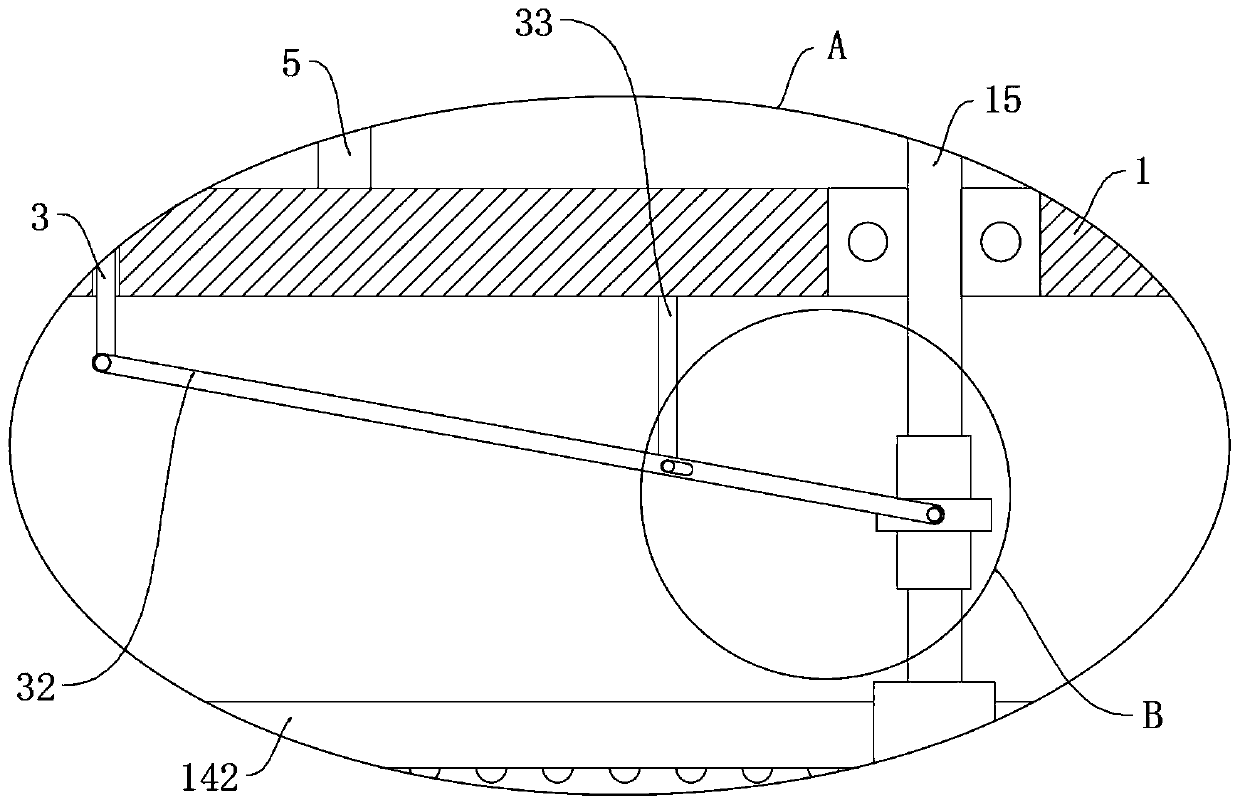

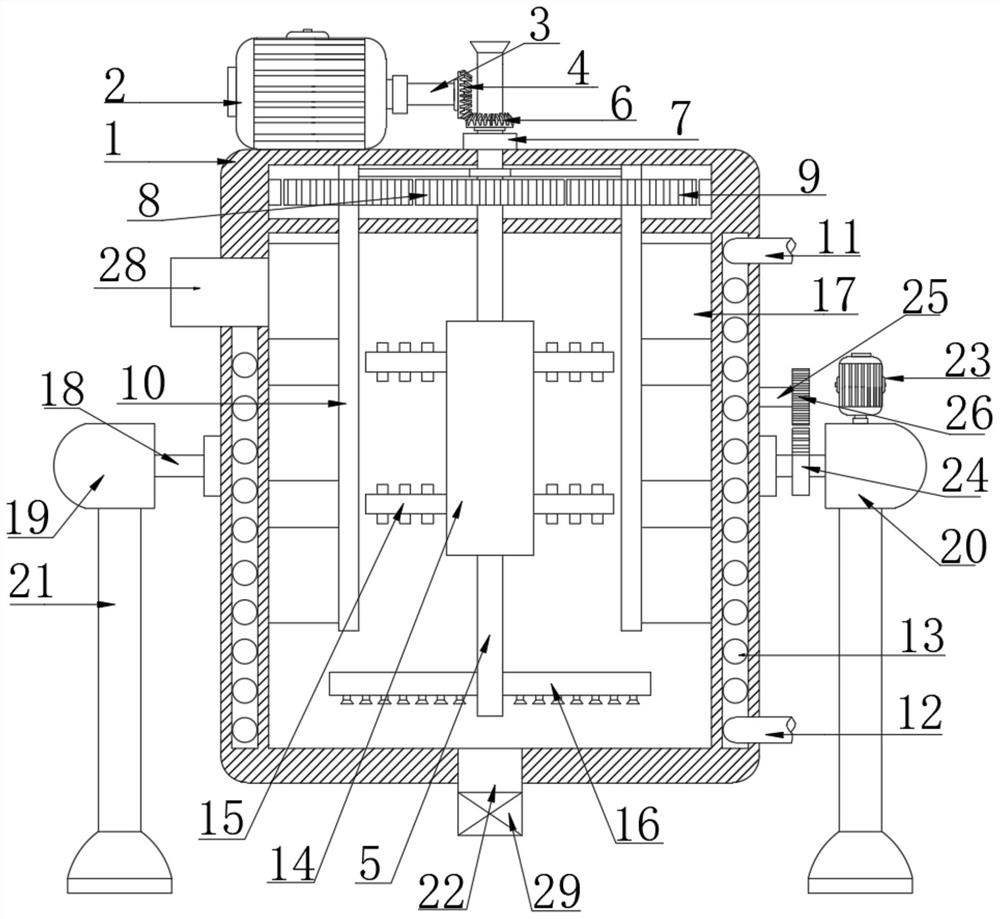

Raw material quantitative mixing equipment for refractory brick production

InactiveCN110721618AGood mixing effectWell mixedShaking/oscillating/vibrating mixersTransportation and packagingPistonEngineering

The invention provides raw material quantitative mixing equipment for refractory brick production. The raw material quantitative mixing equipment comprises a base and a material mixing barrel, whereina stirring assembly, a power assembly and a material falling assembly are arranged on the material mixing barrel, the stirring assembly comprises a rotating shaft, a stirring rod and a guide groove,the power assembly comprises a transmission member and a driving member, the material falling assembly comprises a sliding member, a material storage member and a material control member, the transmission member is in transmission connection with the driving member and a stirrer, the driving member drives the sliding member to perform reciprocating motion, and the material control member controlsa material discharging member arranged on the sliding member to fall a material. According to the invention, the material falling assembly is driven by the power mechanism assembly to do reciprocatingmotion, the piston is matched with the material blocking plate to extrude the raw material in the quantitative material cylinder into the material mixing barrel, the power assembly drives the rotating shaft in the material mixing barrel to rotate, and the gear and the gear rack a are matched to drive the stirring rod to do circumferential motion along with the up-down fluctuation of the rotatingshaft and can rotate, so that the technical problems that automatic quantitative feeding cannot be achieved and raw materials are mixed unevenly in the prior art are solved.

Owner:长兴县威尔特耐火材料有限公司

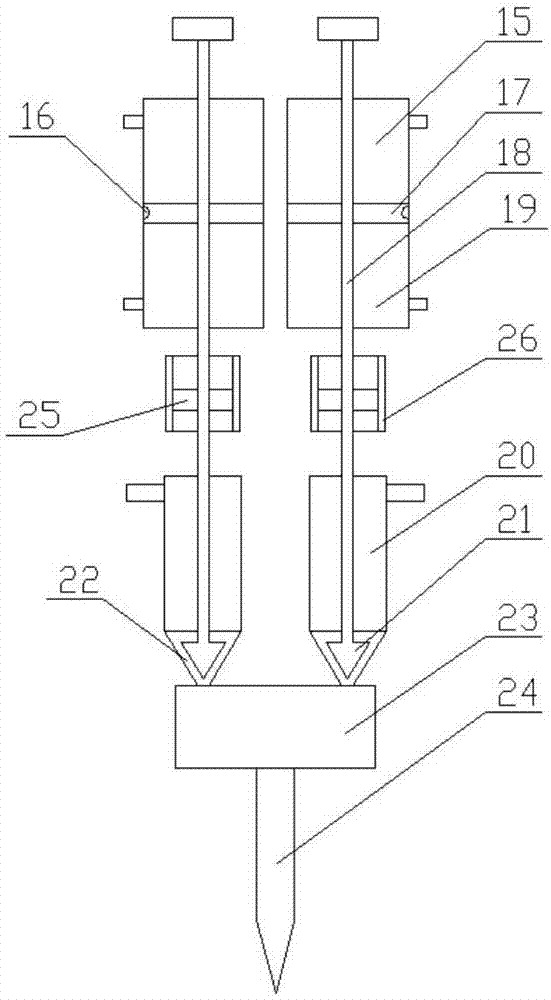

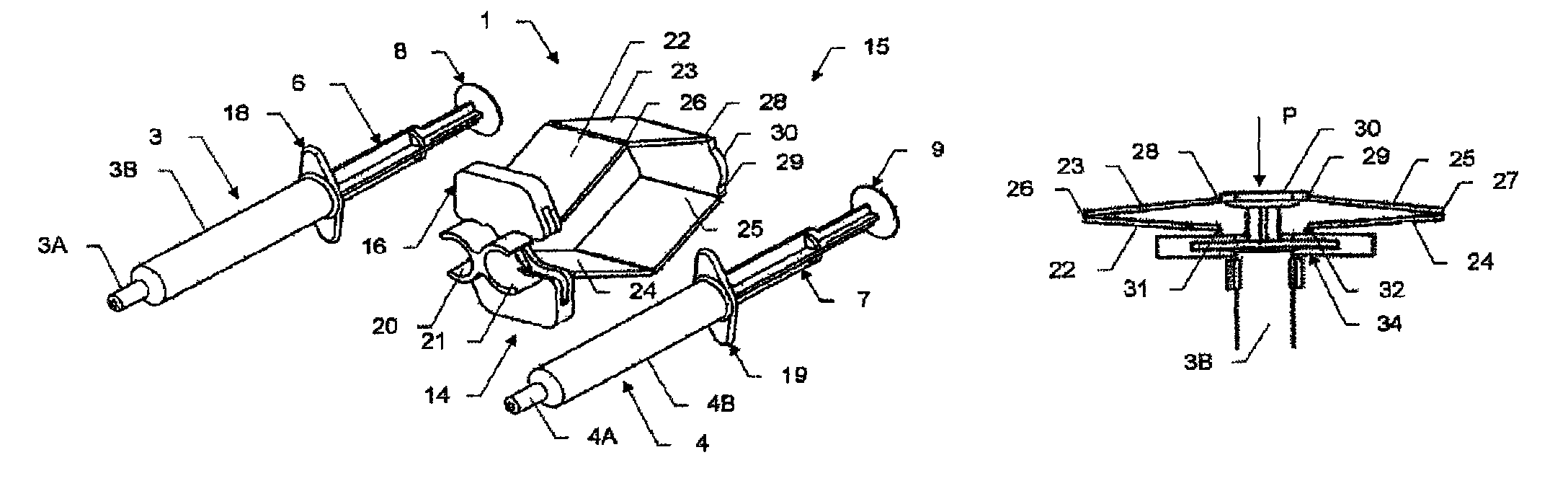

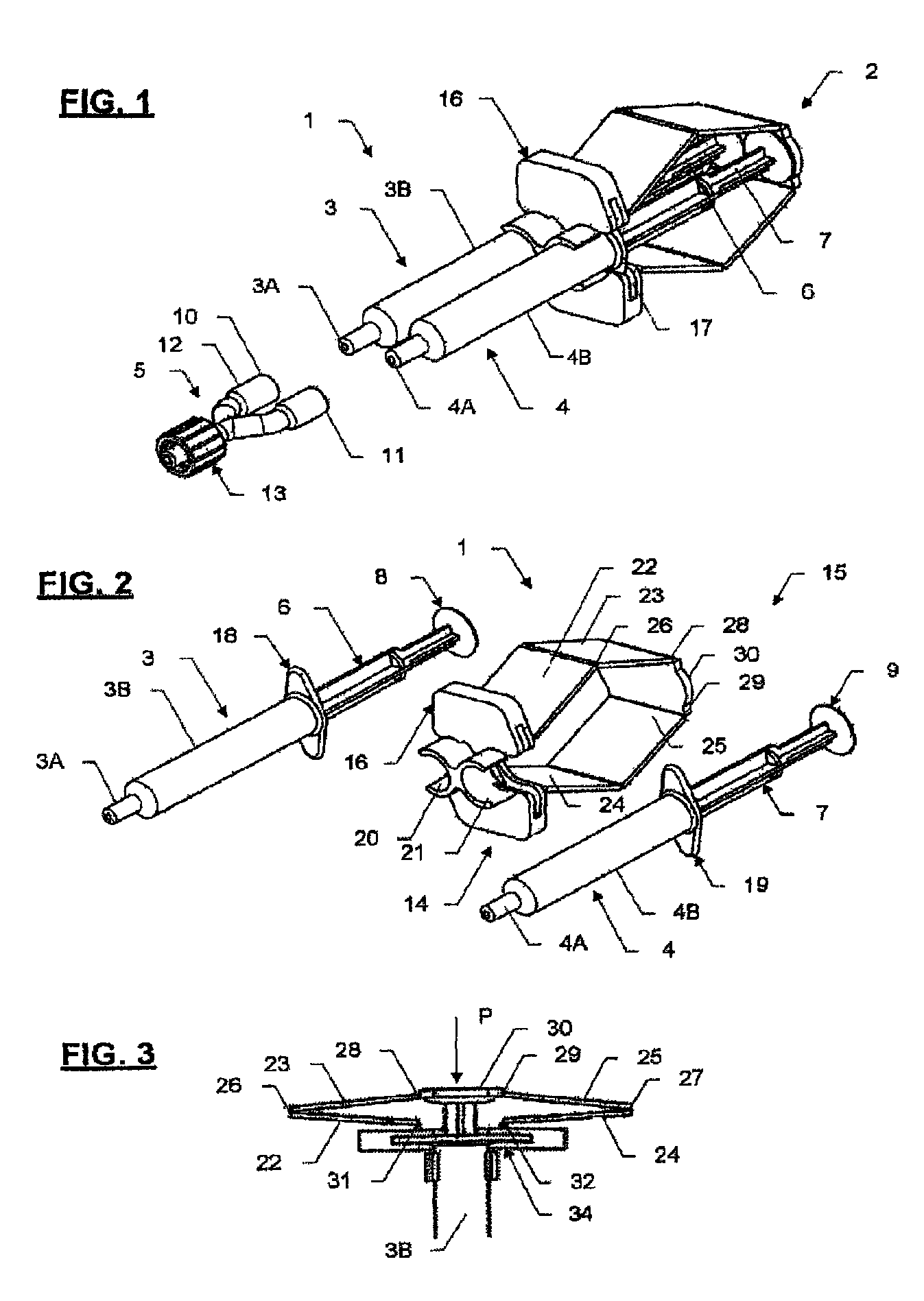

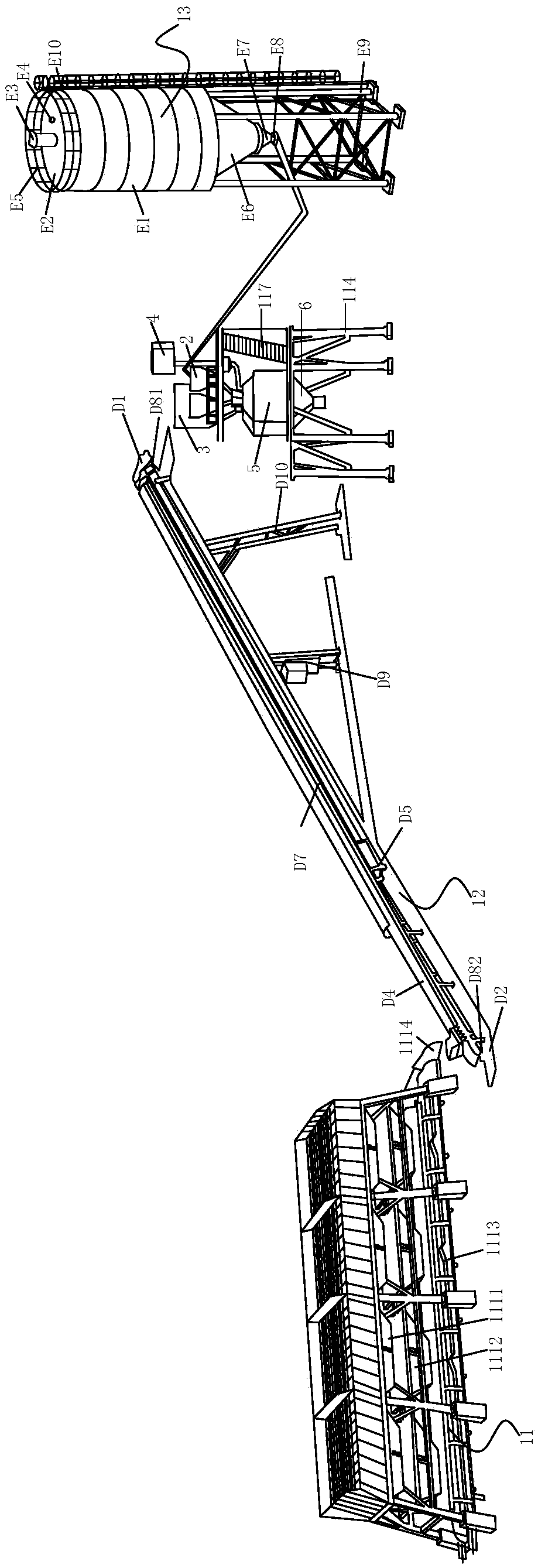

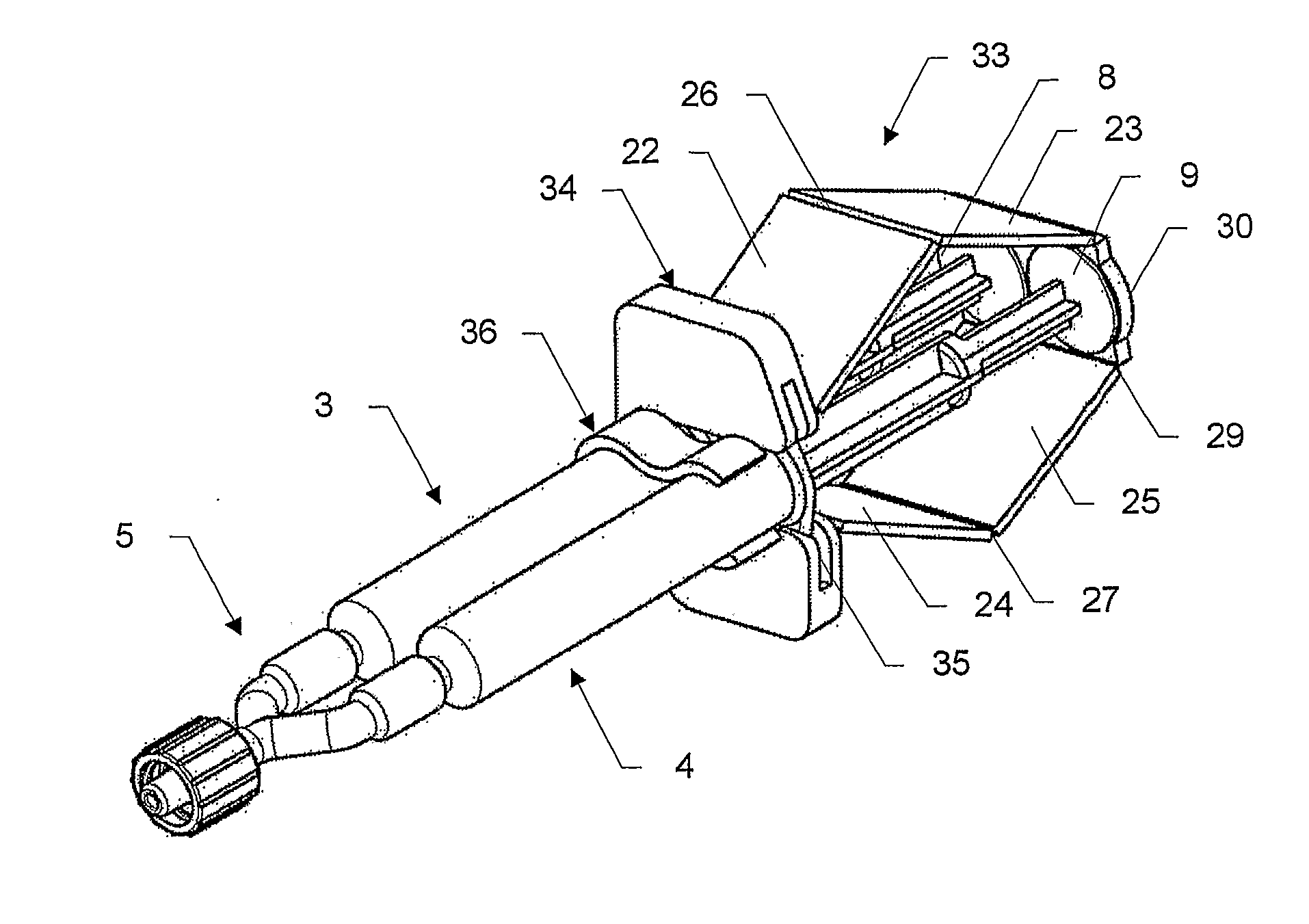

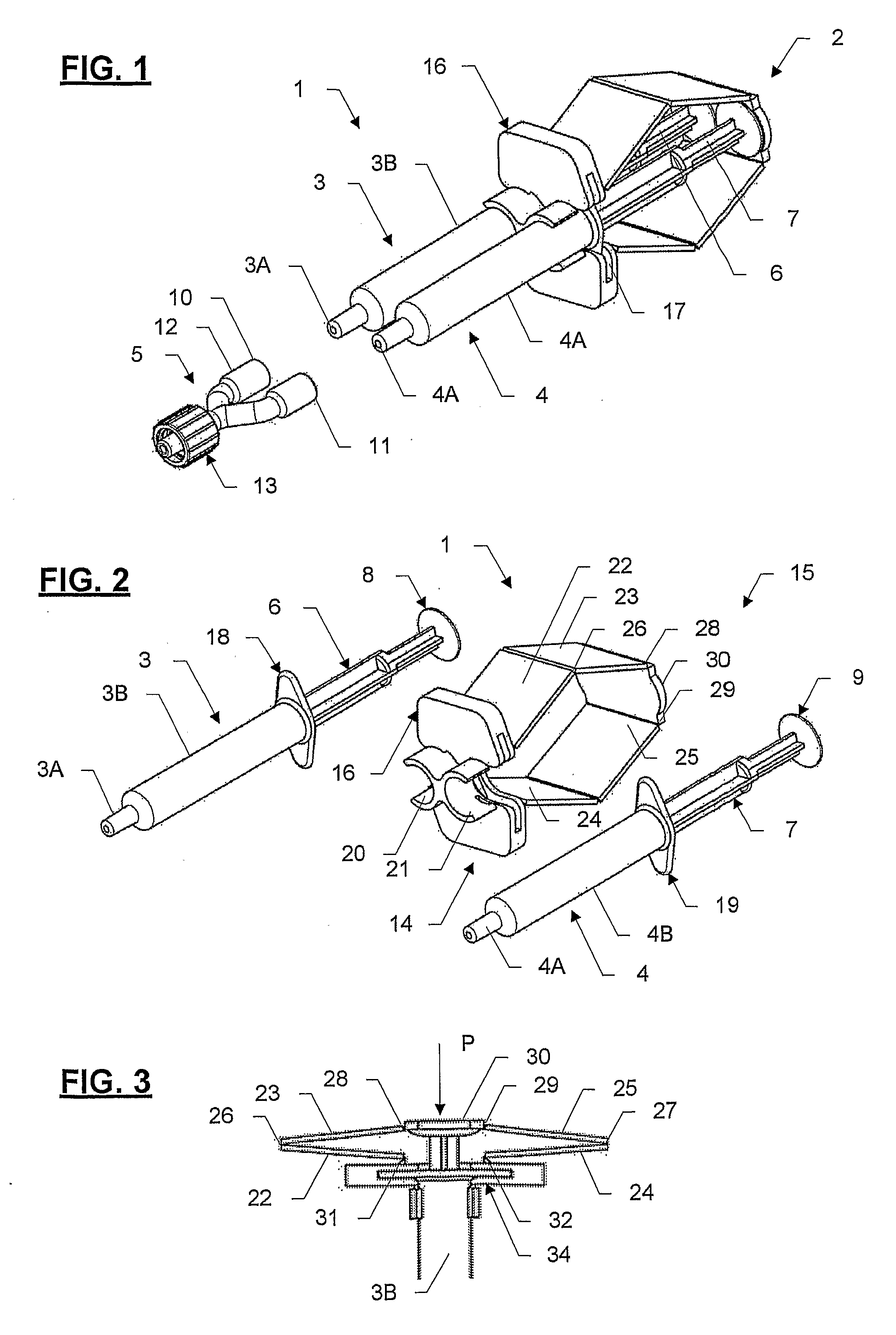

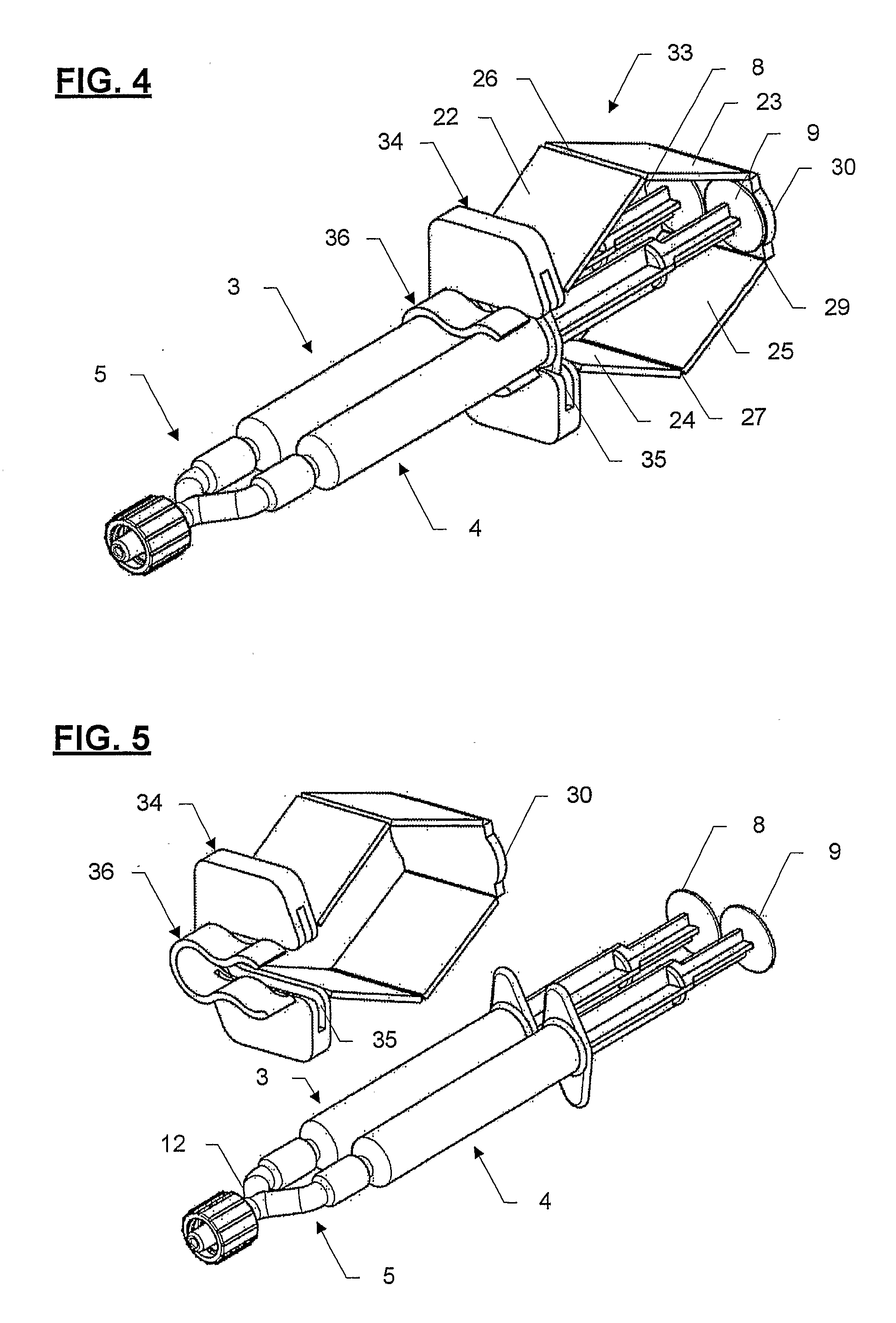

Dispensing assembly with separate syringes and syringe holder

ActiveUS8240511B2Simple designEasy to operateLiquid surface applicatorsInfusion syringesBiomedical engineeringSyringe

The dispensing assembly has a one-piece syringe holder in which two separate syringes are placed and which includes a thumb rest that acts upon the thrust plates of the syringes jointly. The integral design of the syringe holder and the thumb rest results in a synchronous dispensing of both syringes. Preferentially, the syringe holder comprises guiding and fastening means for the separate syringes.

Owner:MEDMIX SWITZERLAND AG

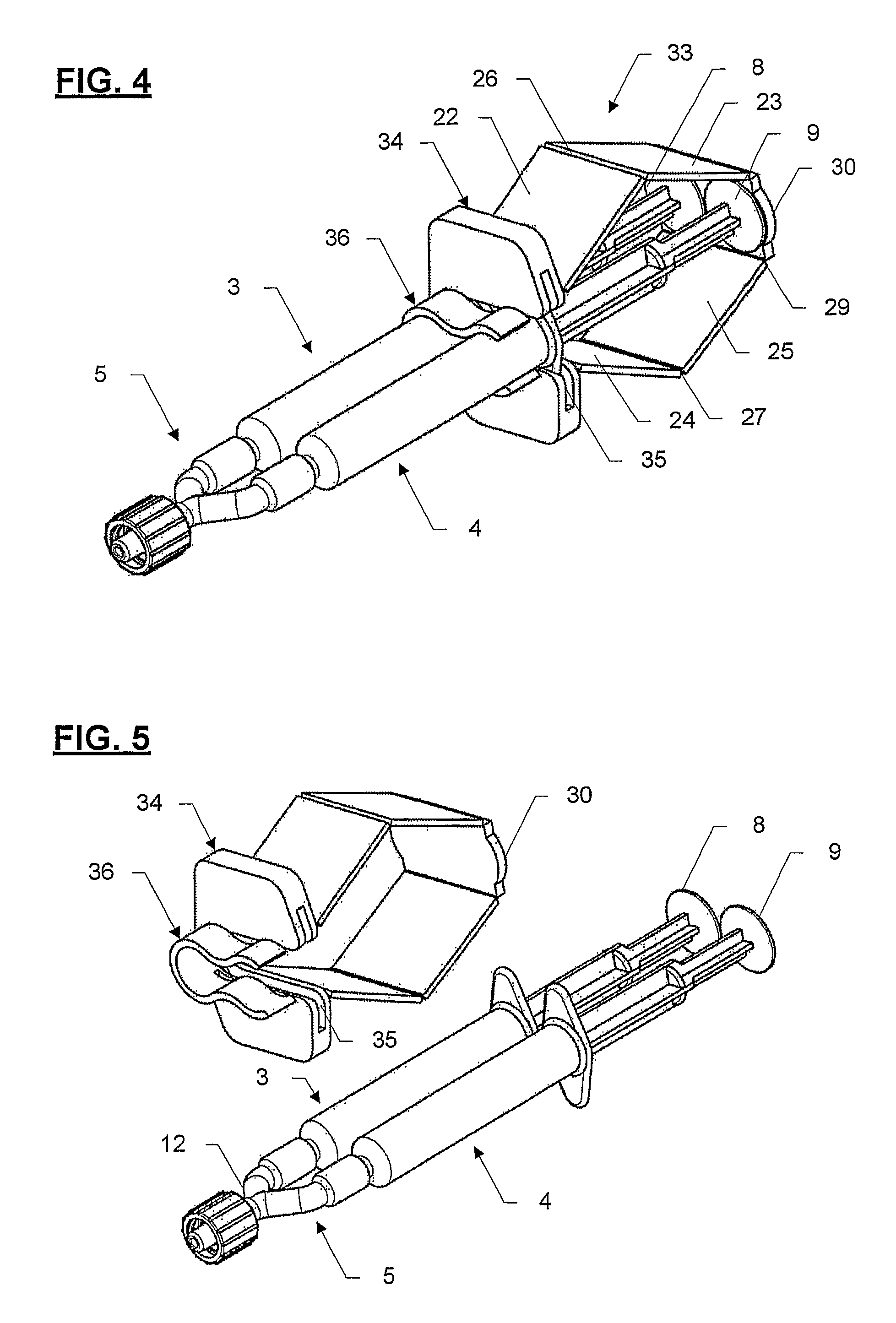

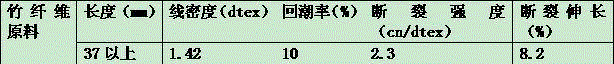

Bamboo fiber yarns and production method thereof

InactiveCN101967710AReduce tensionDecreased elastic strengthFibre mixingYarnEnvironmental resistanceYarn

The invention discloses bamboo fiber yarns and a production method thereof. The bamboo fiber yarns are prepared by spinning the following blended raw materials in part by weight: more than 5 and less than or equal to 95 parts of bamboo fibers (preferably 20 to 40 parts) and 60 to 80 parts of natural fibers (such as cotton) or environmentally-friendly differential fibers. The production method comprises the following steps of: blending slivers made of the bamboo fibers and the natural fibers (such as the cotton) or the environmentally-friendly differential fibers again; and drawing, roving, spinning and spooling for 2 to 3 times to prepare various blended bamboo fiber yarns with low bamboo fiber content, which have naturally antibacterial, bacteriostatic, anti-ultraviolet, hygroscopic, air-permeable characteristics and the like. A plurality of superfine grooves on the surfaces of the bamboo fibers contributes to the improvement on moisture absorption, so that the yarns have the function of dehumidifying. The production method has the advantages of uniqueness, effectiveness, easily controllable manufacturing process, basically no need of equipment replacement, low manufacturing cost and high production efficiency.

Owner:FUJIAN KARTEX TEXTILE

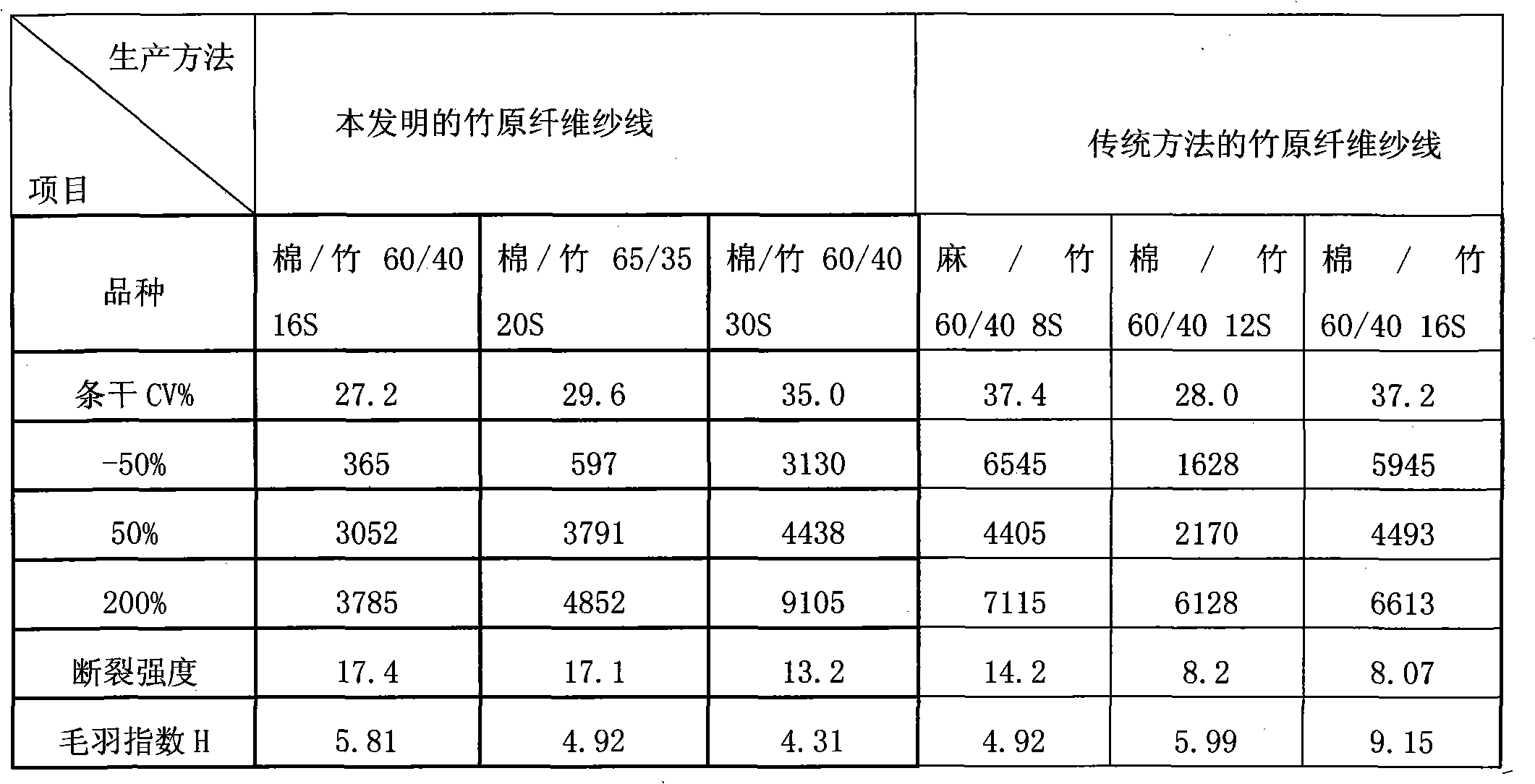

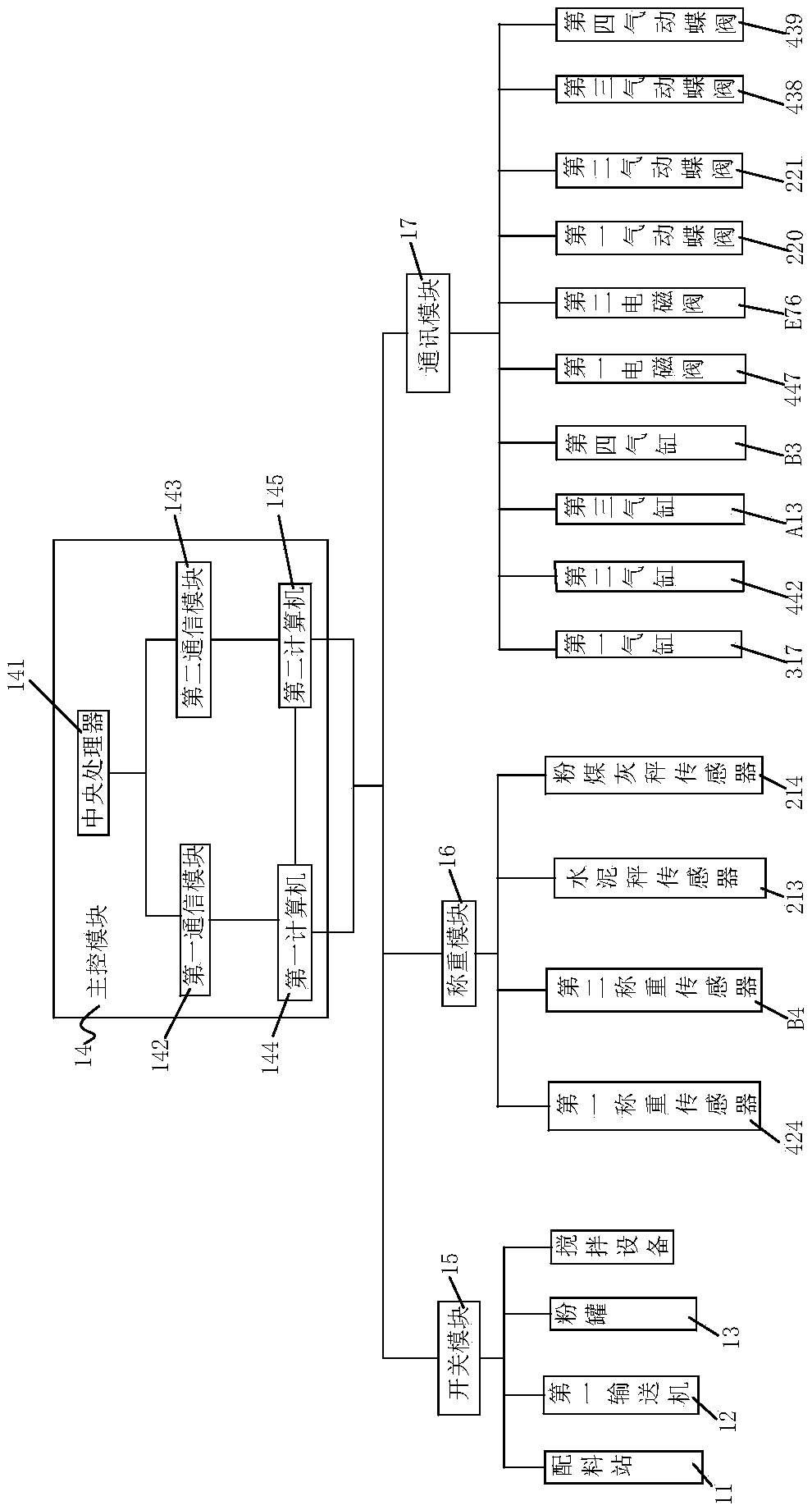

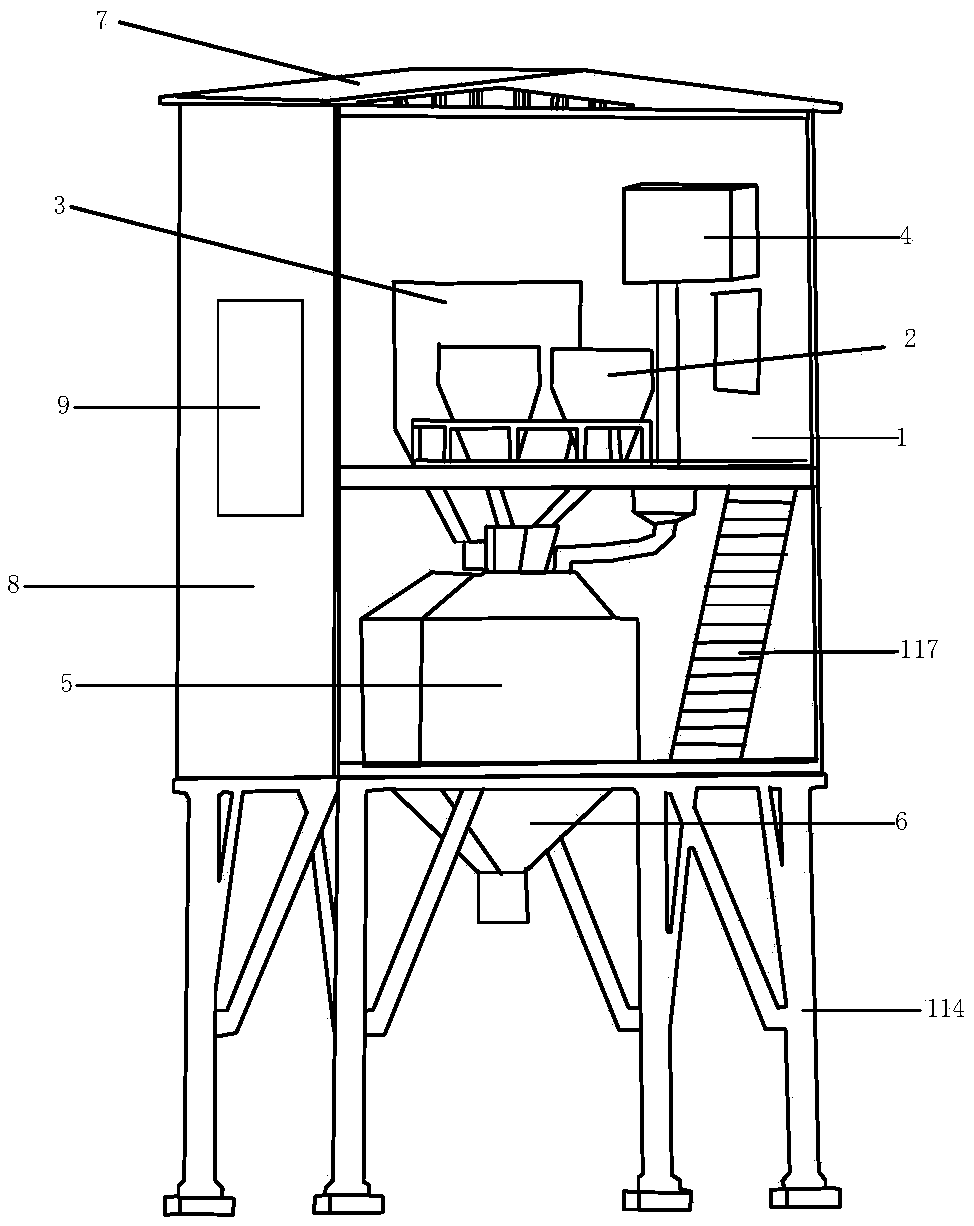

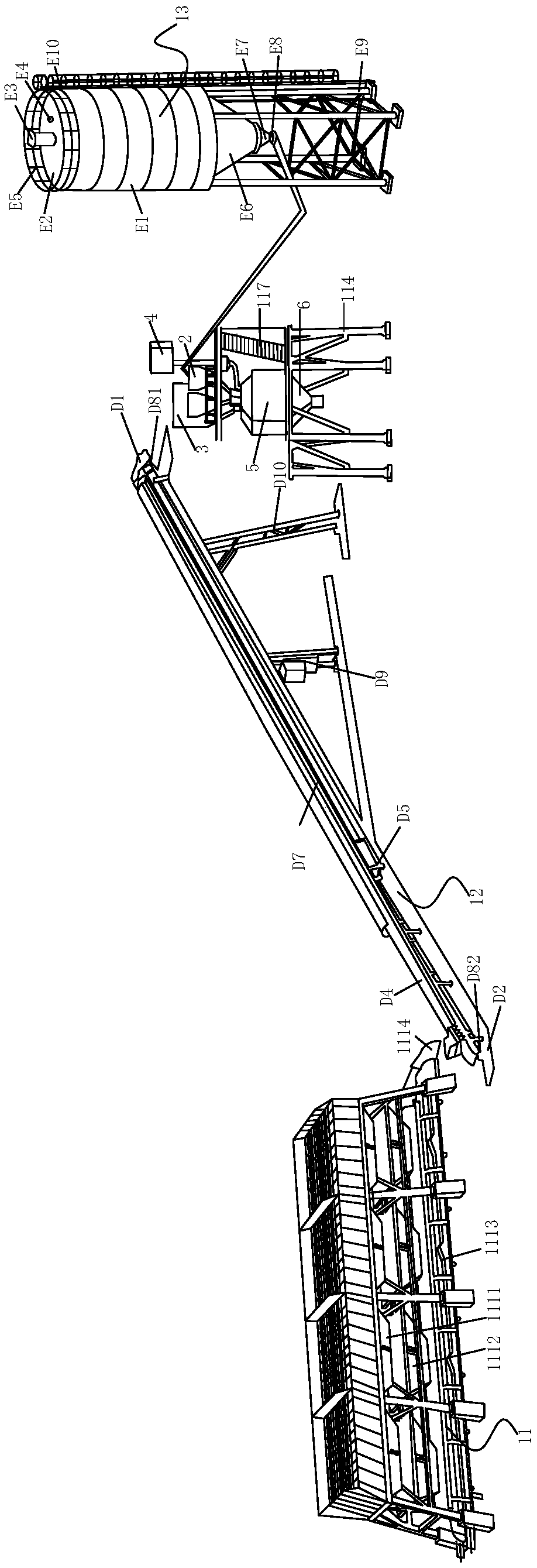

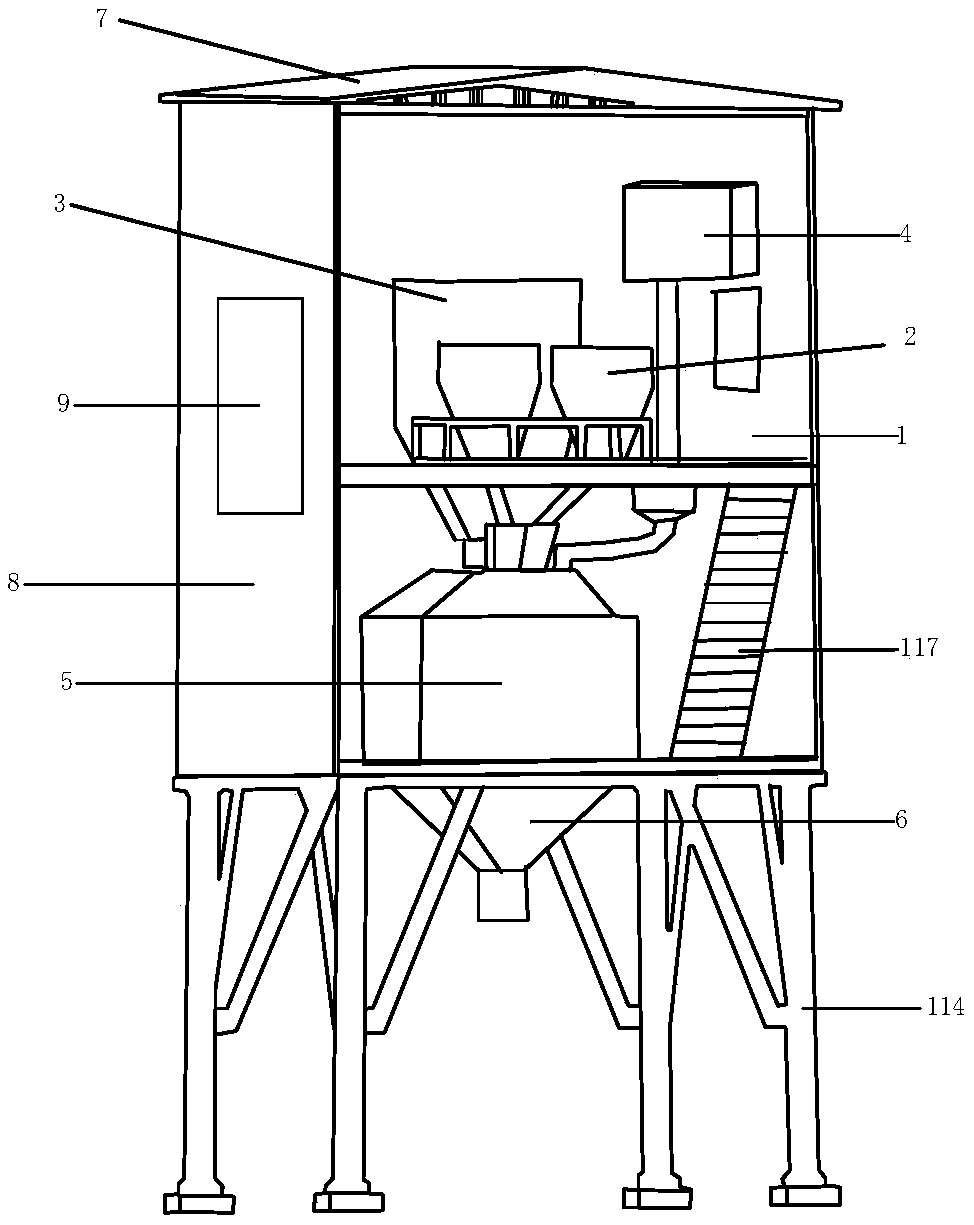

Concrete production equipment

PendingCN109352830APrevent deviationIncrease productivityMixing operation control apparatusIngredients weighing apparatusEquipment useEnergy consumption

The invention discloses concrete production equipment which comprises a concrete mixing station and a control system used for controlling the concrete mixing station. The concrete mixing station comprises a material preparation station used for supplying aggregate, a first conveyor used for transmitting aggregate, a powder tank used for storing powder and mixing equipment used for mixing, one endof the first conveyor is arranged below the material preparation station, the other end of the first conveyor is arranged on the mixing equipment, and the powder tank is connected with the mixing equipment. The control system comprises a master control module and a switch module connected with the master control module and used for controlling the concrete mixing station to be opened or closed, and the switch module is connected with the material preparation station, the first conveyor, the powder tank and the mixing equipment. The concrete production equipment has the advantages of being lowin energy consumption, high in yield, accurate in matching and convenient to control.

Owner:杭州德全建材有限公司

Concrete mixing station

PendingCN109571766APrevent deviationIncrease productivityDischarging apparatusMixing operation control apparatusMechanical engineeringConstruction aggregate

The invention discloses a concrete mixing station, comprising a batching station for supplying aggregate, a first conveyor for conveying the aggregate, a powder tank for storing powder and stirring equipment for stirring, wherein the batching station comprises a storage bin for storing the aggregate, a second conveyor for conveying the aggregate to the first conveyor and a material guiding devicefor pouring the aggregate onto the first conveyor; one end of the first conveyor is arrange under the material guiding device; the other end of the first conveyor is arrange on the stirring equipment;the powder tank is connected with the stirring equipment; the aggregate enters the stirring equipment from the batching station through the first conveyor; the powder enters the stirring equipment from the powder tank; and the stirring equipment mixes and stirs the aggregate and powder. The concrete mixing station provided by the invention has the advantages of low energy consumption, high yield,accurate proportioning, compact and reasonable design and quick installation.

Owner:郑涛涛

Method, device and system for mixing liquids

InactiveUS7374332B2Minimize unevennessThe mixing ratio is accurateFlow mixersMixing methodsEngineeringMixing ratio

A method and a device are provided which can mix two liquids faster at a precise mixing ratio. The method for mixing at least two liquids transported in respective channels includes transporting, of the two liquids, a liquid having a low mixing rate intermittently in one of the channels, and transporting, of the two liquids, a liquid having a high mixing rate so as to join the liquid having a low mixing rate from both sides of the channel for the liquid having a low mixing rate.

Owner:KONICA MINOLTA INC

Integrated LED (Light-emitting Diode) sealing machine

InactiveCN102601017AThe mixing ratio is accurateGuaranteed accuracyLiquid surface applicatorsCoatingsChemistryComposite material

The invention discloses an integrated LED (Light-emitting Diode) sealing machine, comprising a rack, and a glue storing device, a glue transporting device, a glue mixing and agitating device and a dispensing device, which are respectively fixed on the rack, wherein the glue storing device is provided with a plurality of mutually-independent cavities which respectively and correspondingly contain a plurality of sealing solvents needed by the dispensing and sealing work; the glue storing device, the glue transporting device, the glue mixing and agitating device and the dispensing device are sequentially connected; the plurality of the sealing solvents are conveyed into the glue mixing and agitating device through the glue transporting device and then are quantitatively output after being mixed and agitated; and the mixing and agitating device is internally provided with an agitating assembly for uniformly mixing the sealing solvents and a temperature control assembly for keeping a constant temperature of the sealing solvents. The integrated LED sealing machine disclosed by the invention has an accurate glue discharging speed, can realize the matching of an arriving speed and a dispensing speed of a product, and greatly improves the working efficiency.

Owner:SHANTOU NANHA ELECTRICAL

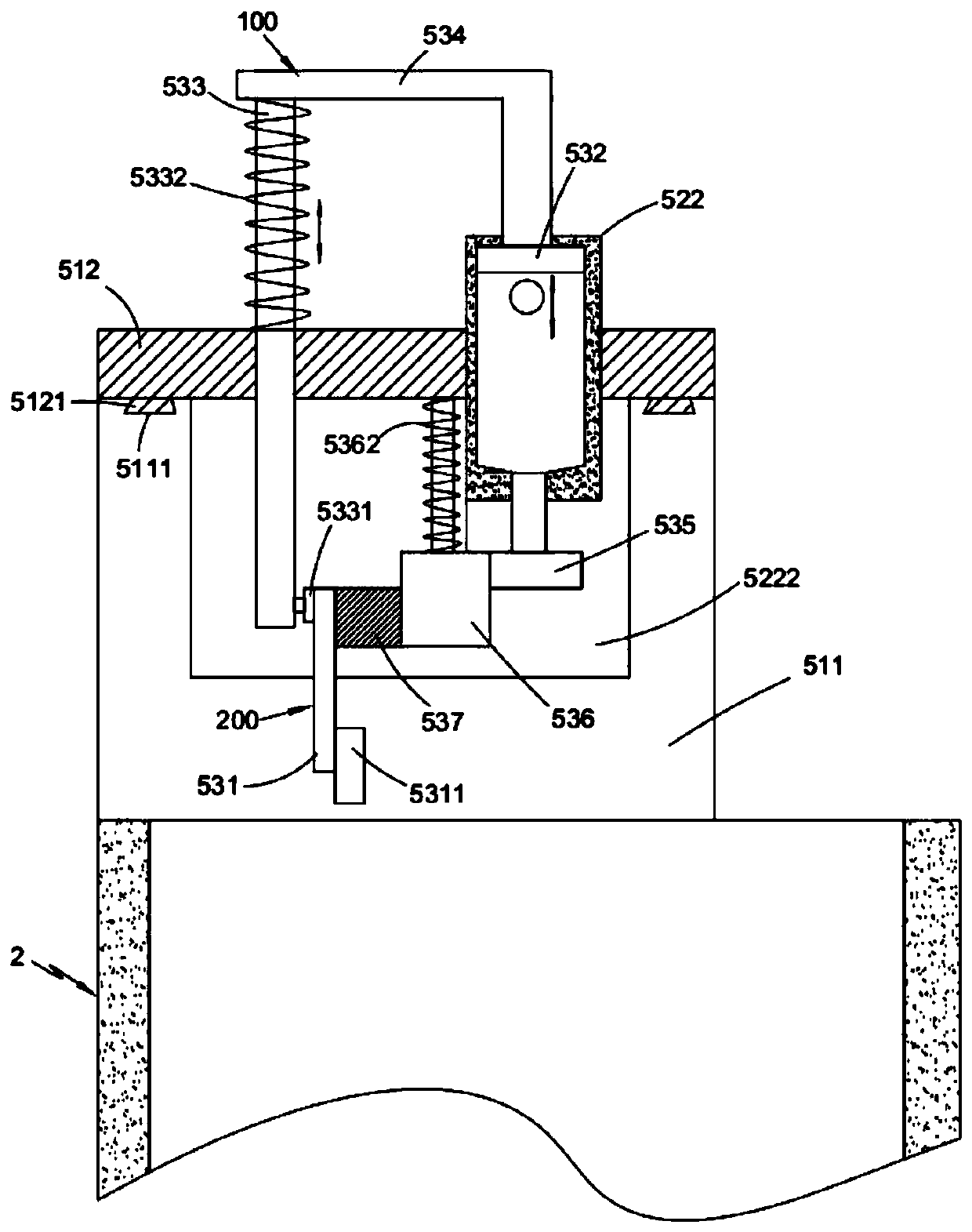

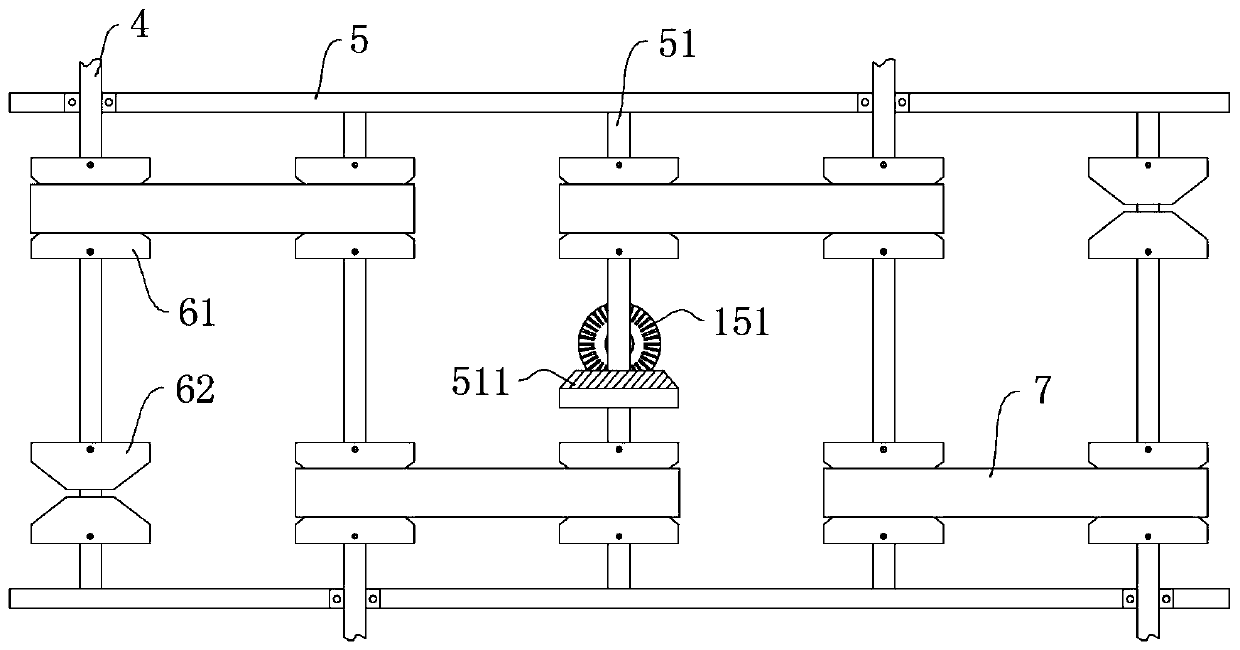

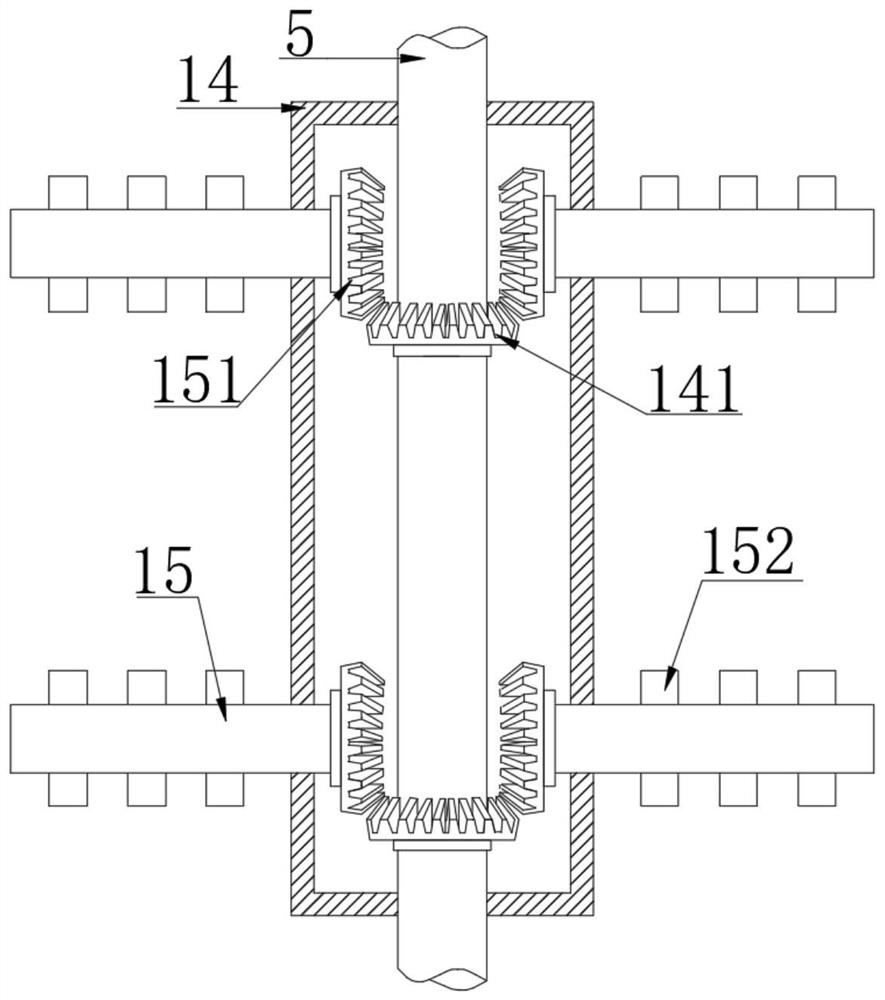

Double-working position quantitative mixing device for refractory brick materials

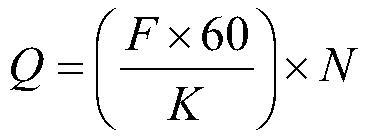

InactiveCN110721615ARealize quantitative automatic additionThe mixing ratio is accurateRotary stirring mixersTransportation and packagingReciprocating motionGear wheel

The invention provides a double-working position quantitative mixing device for refractory brick materials. The double-working position quantitative mixing device comprises a base and a material mixing box, wherein a stirring assembly, a power assembly and a material falling assembly are arranged on the material mixing box, the stirring assembly comprises a stirrer, the power assembly comprises atransmission member and a driving member, the material falling assembly comprises a sliding member, a material storage member and a material control member, the transmission part is in transmission connection with the driving member and the stirrer, the driving member drives the sliding member to perform reciprocating motion, the material control member controls a material discharging member arranged on the sliding member to fall a material, and the stirrer is used for stirring and mixing the material falling into the material mixing box. According to the invention, the quantitative material is input into the quantitative material cylinder through the material storage box, the power assembly drives the feeding device to perform reciprocating motion, the gear is matched with the gear rack,the material blocking plate is opened, the lifting rod is matched with the position limiting block, and the piston extrudes material in the quantitative material cylinder into the material mixing boxso as to be mixed, so that technical problems that the raw material ratio is difficult to control and the raw material mixing efficiency is low in the refractory brick production process are solved.

Owner:长兴县威尔特耐火材料有限公司

Dispensing assembly with separate syringes and syringe holder

ActiveUS20110118664A1Simple designEasy to operateLiquid surface applicatorsInfusion syringesBiomedical engineeringStent

The dispensing assembly has a one-piece syringe holder in which two separate syringes are placed and which includes a thumb rest that acts upon the thrust plates of the syringes jointly. The integral design of the syringe holder and the thumb rest results in a synchronous dispensing of both syringes. Preferentially, the syringe holder comprises guiding and fastening means for the separate syringes.

Owner:MEDMIX SWITZERLAND AG

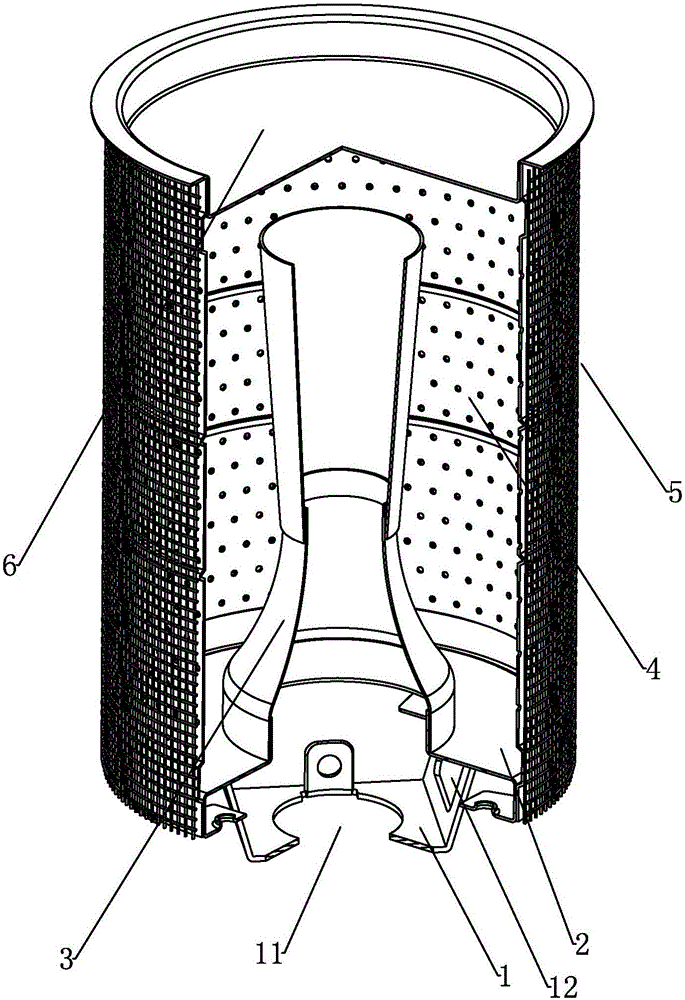

Efficient 360-DEG combustor

InactiveCN106524151AMake up for the disadvantage of one-sided burningRadiation area is wideGaseous fuel burnerCombustorEngineering

The invention relates to an efficient 360-DEG combustor comprising a nozzle support and a lower cover plate arranged on the nozzle support; the lower cover plate is vertically provided with a premixing and ejecting pipe and a fire hole surrounding plate surrounding the premixing and ejecting pipe; the outer surface of the fire hole surrounding plate is provided with a radiation net; and an upper cover plate is arranged above the fire hole surrounding plate. The scheme provides the efficient 360-DEG combustor which is capable of realizing omnidirectional heating, multifunctional and simple in structure.

Owner:中山市三诺燃气具有限公司

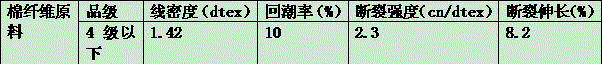

Bamboo fiber and cotton fiber towel and production method thereof

The invention discloses a bamboo fiber and cotton fiber towel and a production method thereof. The production method includes the steps of preparing semi-drawn bamboo fiber slivers, preparing semi-drawn cotton fiber slivers, preparing combed bamboo and cotton blended yarns, performing beaming and yarn arranging, weaving the yarns into towel grey cloth, performing subsequent treatment and the like. By means of the method, bamboo fibers and cotton fibers can be organically combined, and the prepared towel has the advantages of being good in water absorbency, soft in handfeel, durable, naturally antibacterial and the like; as the two raw materials are separately treated, damage to the bamboo fibers is reduced, the bamboo fibers can be easily saved, the accuracy of the blending ratio can be guaranteed, and meanwhile it can be guaranteed that the combed bamboo and cotton blended yarns made through blending are good in quality.

Owner:FOSHAN PANLONGDA TEXTILE TECH CO LTD

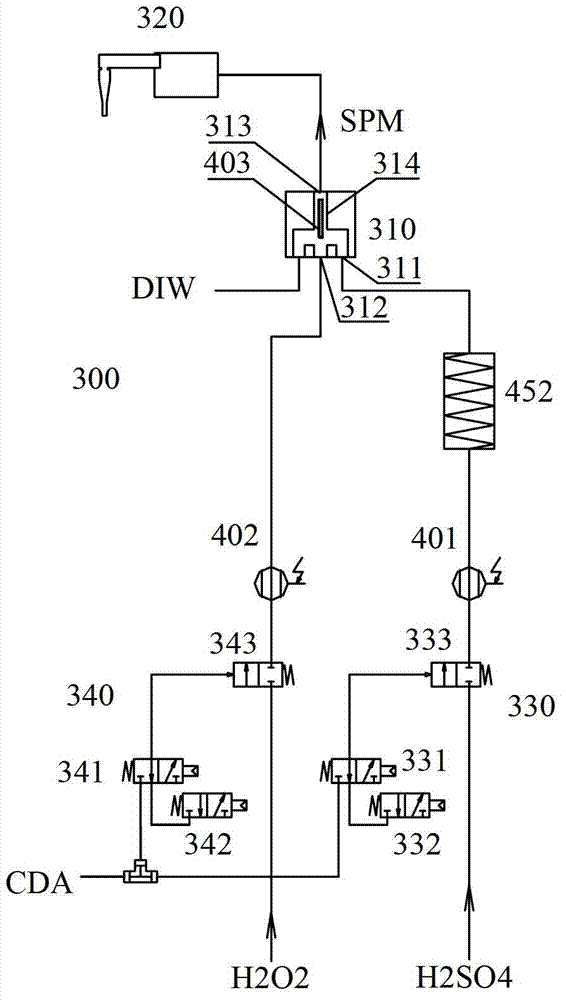

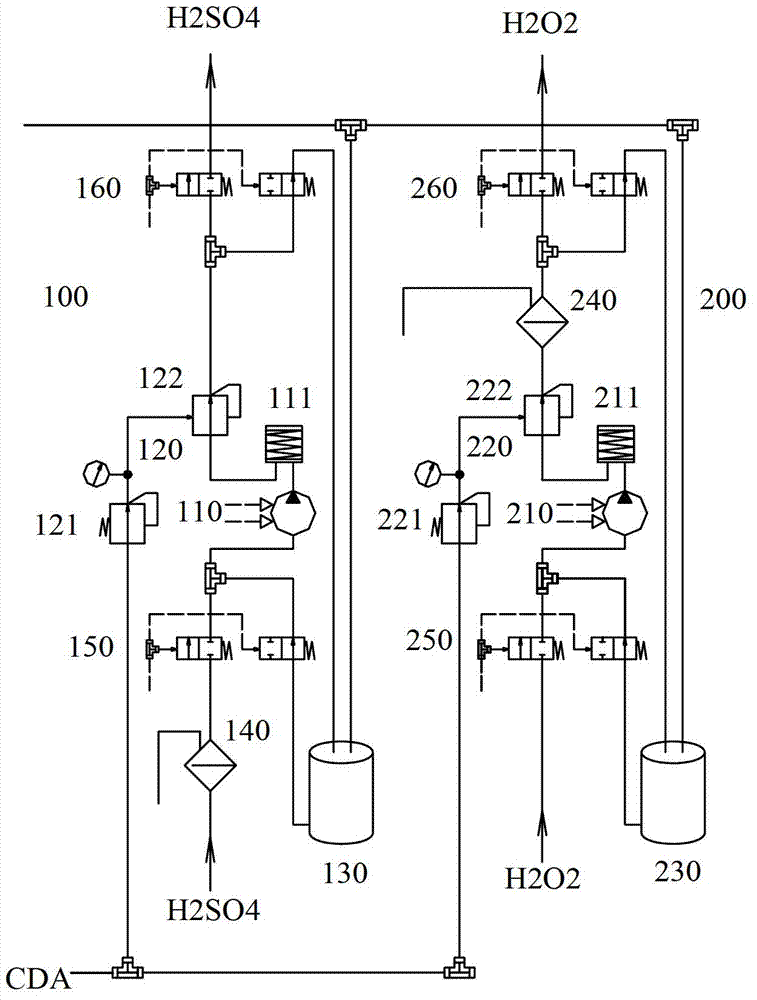

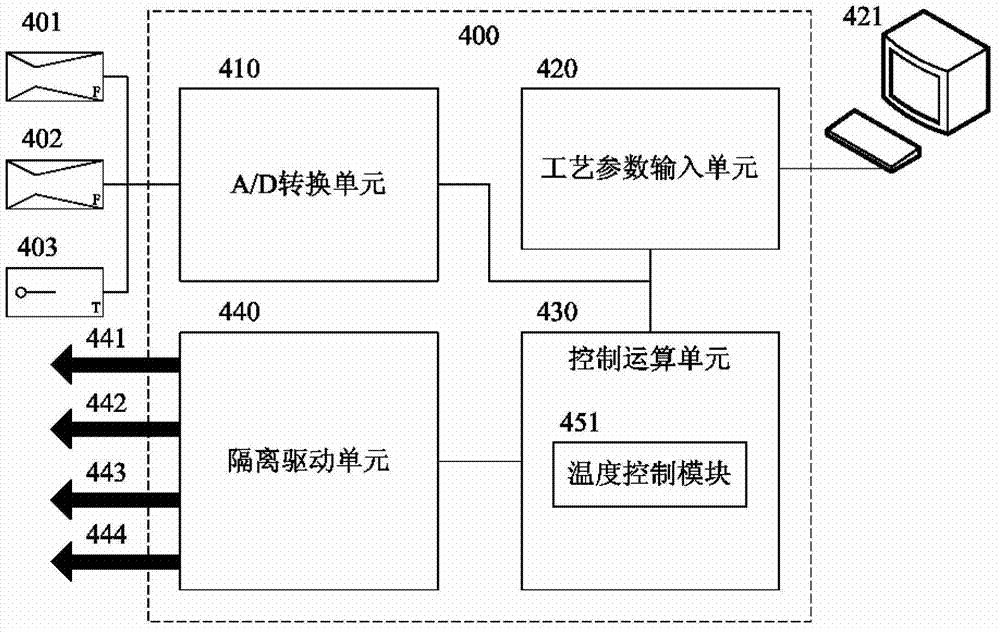

On-line SPM generating system and control method thereof

ActiveCN102755970AHigh activityNo cross contaminationPhotosensitive material processingRatio controlControl systemProcess engineering

An on-line SPM generating system and a control method thereof relate to a method or equipment specially suitable for manufacturing or processing semiconductors, solid devices or other parts, particularly a stripping agent of photo-resist materials in the integrated circuit process. The SPM generating system comprises an H2SO4 supply unit, an H2O2 supply unit, an SPM mixed spraying unit and a control unit, wherein the SPM compound spraying unit comprises an SPM compound element and at least one SPM spray header; the SPM compound element comprises at least two input ends and an SPM output end; an H2SO4 flow control element is connected with the first input end of the SPM compound element through an H2SO4 delivery pipeline; an H2O2 flow control element is connected with the second input end of the SPM compound element through an H2O2 delivery pipeline, and the SPM output end of the SPM compound element is connected with the SPM spray header. The system can control the flow of vitriol and hydrogen peroxide by flow detection and feedback, so that the control system has the advantages that the control precision is high; the flow value is stable; the mixing ratio of the prepared SPM mixed solution is accurate; and the regulating range is wide. Therefore, the activation range of the SPM mixed liquor is wide; and different requirements of cleaning can be met.

Owner:CHANGZHOU RUIZE MICROELECTRONICS

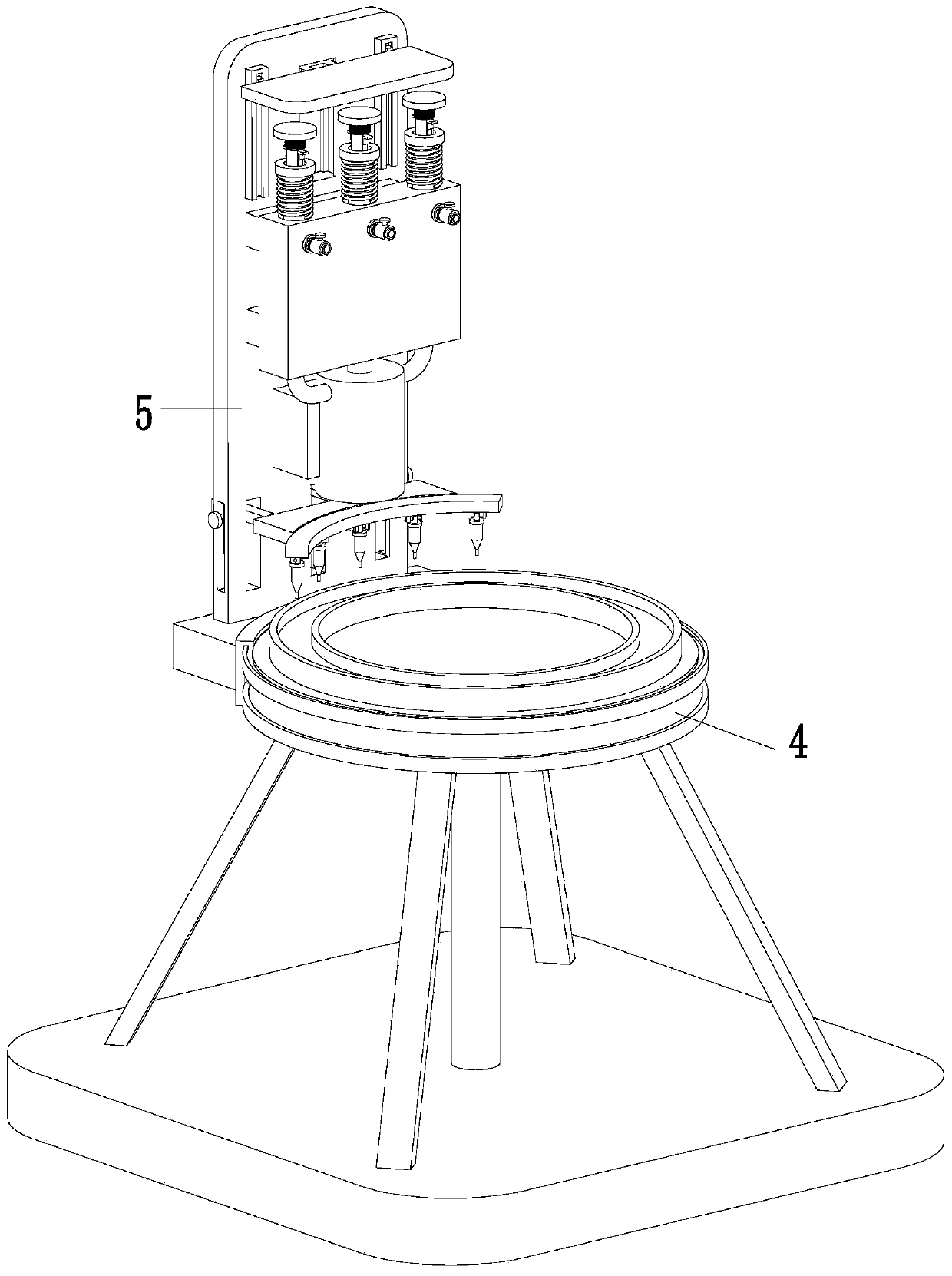

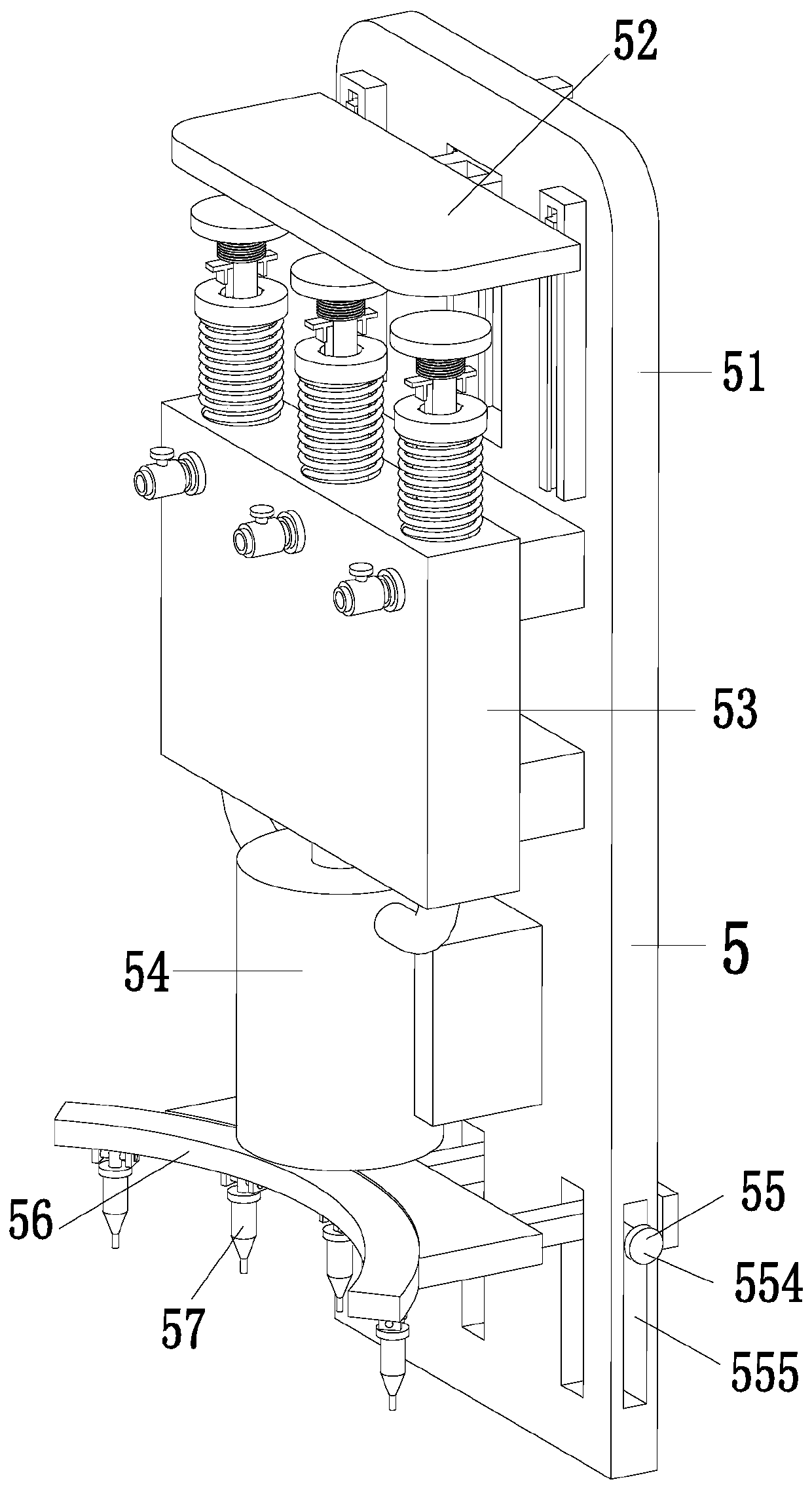

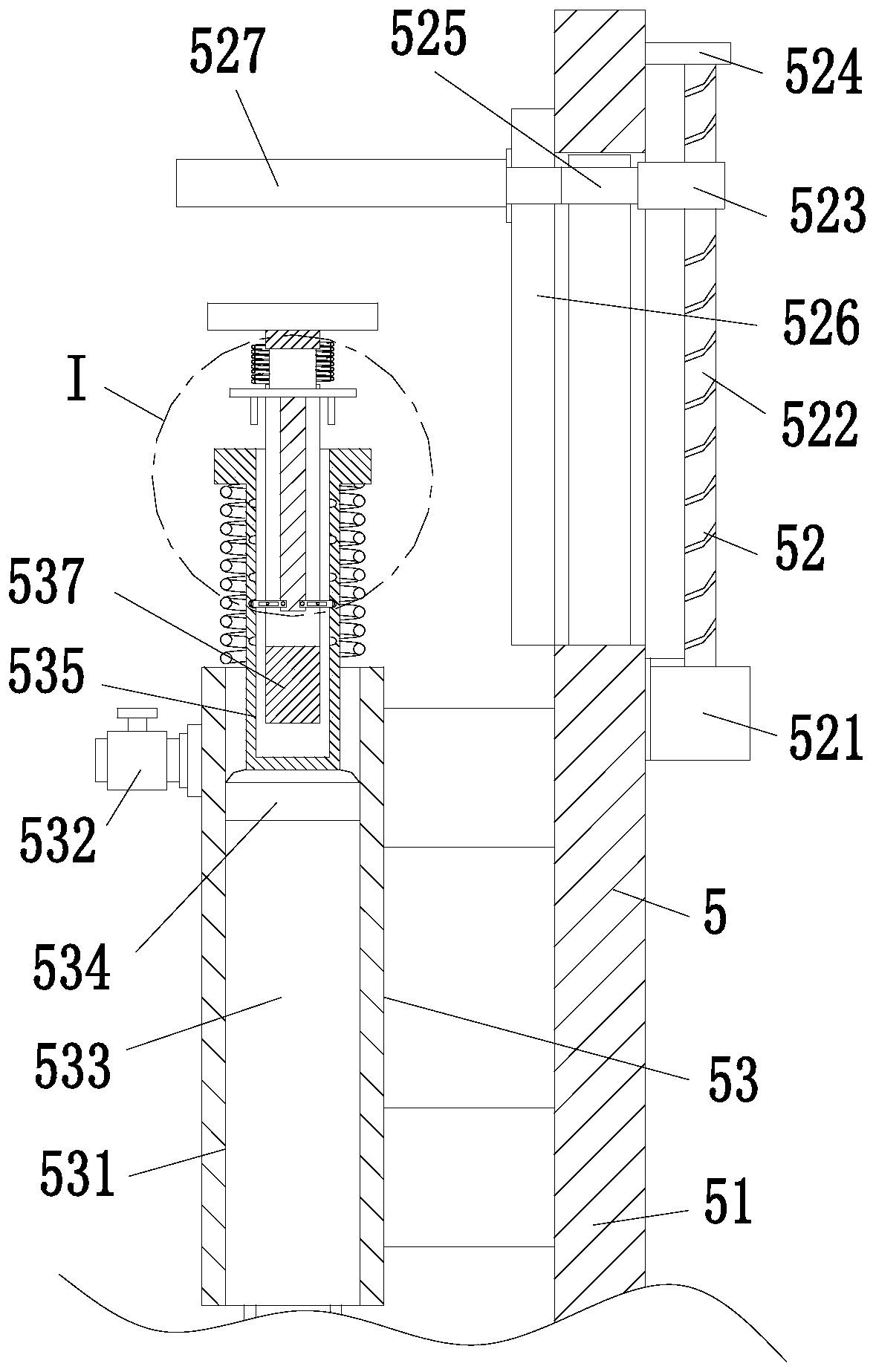

Intelligent glue dispenser

ActiveCN109894322ADispensing effect is goodImprove dispensing efficiencyLiquid surface applicatorsRotary stirring mixersAdhesiveColloid

The invention relates to an intelligent glue dispenser. The intelligent glue dispenser comprises an electric rotating disc and a glue injection device, wherein the glue injection device is fixed on the outer side wall of the electric rotating disc; and the glue injection device is capable of doing rotation motion along with the electric rotating disc. The intelligent glue dispenser is capable of solving the problems that the glue is inconveniently dispensed when injecting the glue into ring-shaped lamp bars, the adjustment is inconvenient when dispensing the glue, the glue dispensing efficiency is low, the mixing ratio of glue adhesives cannot be accurately adjusted when the glue is mixed, and the glue cannot be uniformly stirred during mixing. According to the intelligent glue dispenser,parallel multi-station glue dispensing heads are adopted, the glue dispensing effect is good, the glue dispensing efficiency is high, the mixing ratio of the glue adhesives is accurate when dispensingthe glue, meanwhile, the height of the glue injection heads can be manually adjusted, and the glue dispenser is capable of preventing the glue from splashing in the glue injection process.

Owner:ZHUHAI HUAYA MACHINERY TECH CO LTD

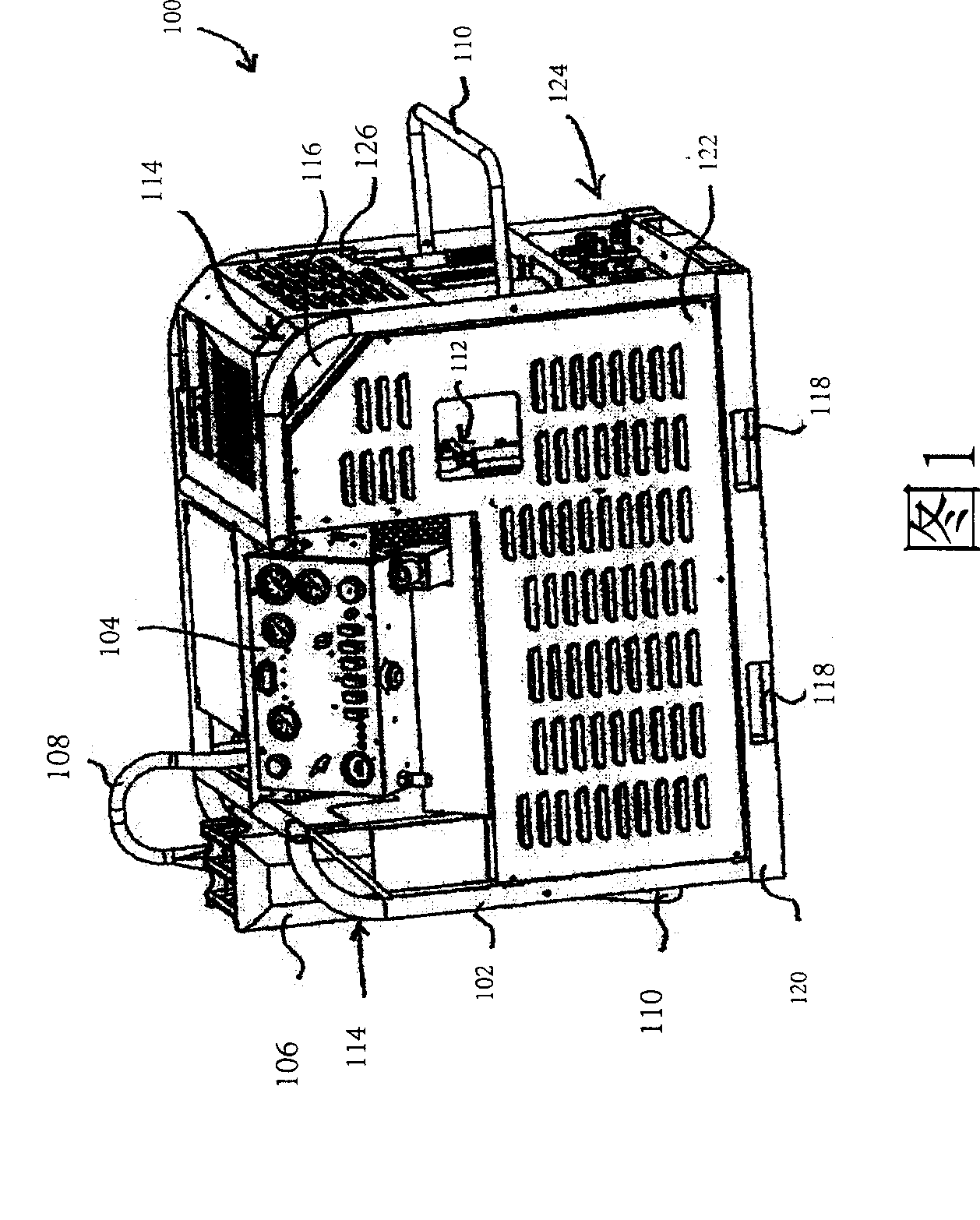

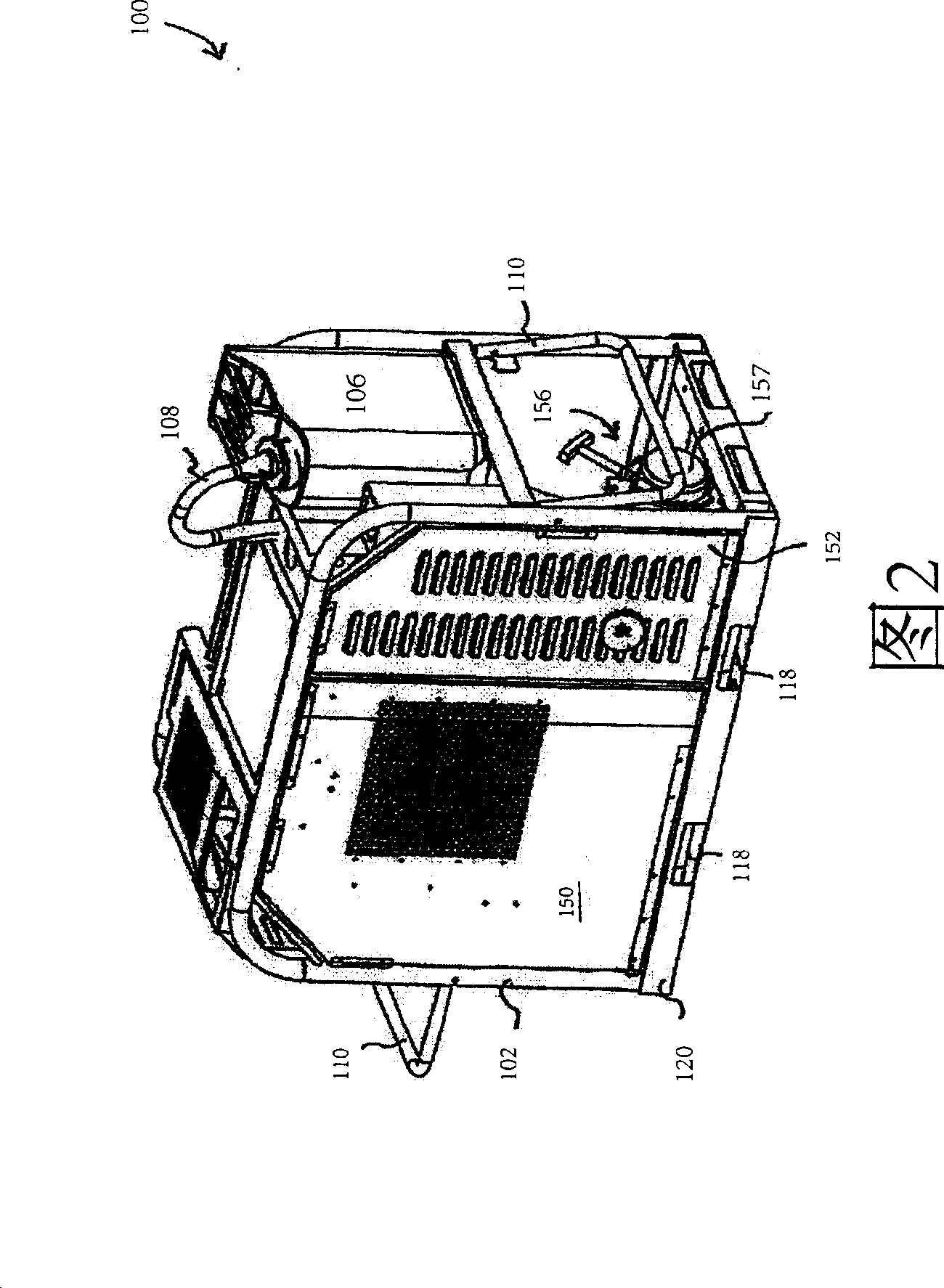

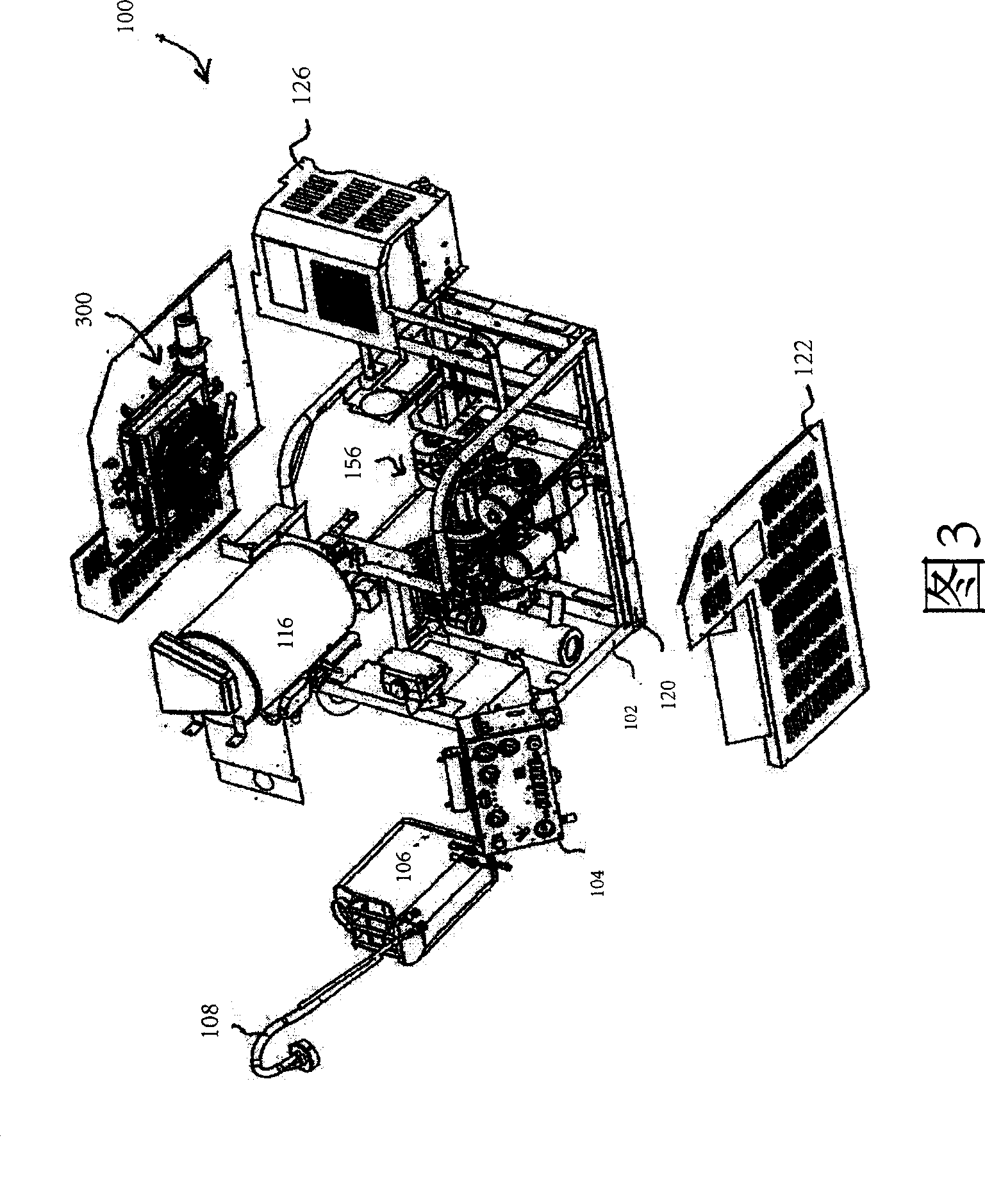

Compressed air foam and high pressure liquid dispersal system

InactiveCN101384306ARelieve pressureInhibit water contentFire rescueLiquid spraying apparatusFlight vehiclePneumatic tool

The compressed air foam and high pressure liquid dispersal system (100) provides a compressed air foam product in addition to concurrently producing a liquid under pressure for decontamination, general cleaning, vapor suppression, Hazmat remediation, fuel spills, and fire suppression support for durable equipment, vehicles, terrain, facilities, and aircraft. The system includes a power plant (157) for powering the compressed air foam (300) and high pressure liquid sub-systems (200) of the system. The high pressure sub-system further includes a boiler (116) for heating the liquid. The power plant drives an air compressor (314) for providing compressed air to the compressed air foam sub-system and an air chuck (404) for powering pneumatic tools and inflating flat tires. The power plant further drives a high pressure water pump (210) for pressurizing the water for the high pressure sub-system. The system includes a 24 VDC electrical system for charging stalled vehicles present during operations.

Owner:INTELAGARD INC

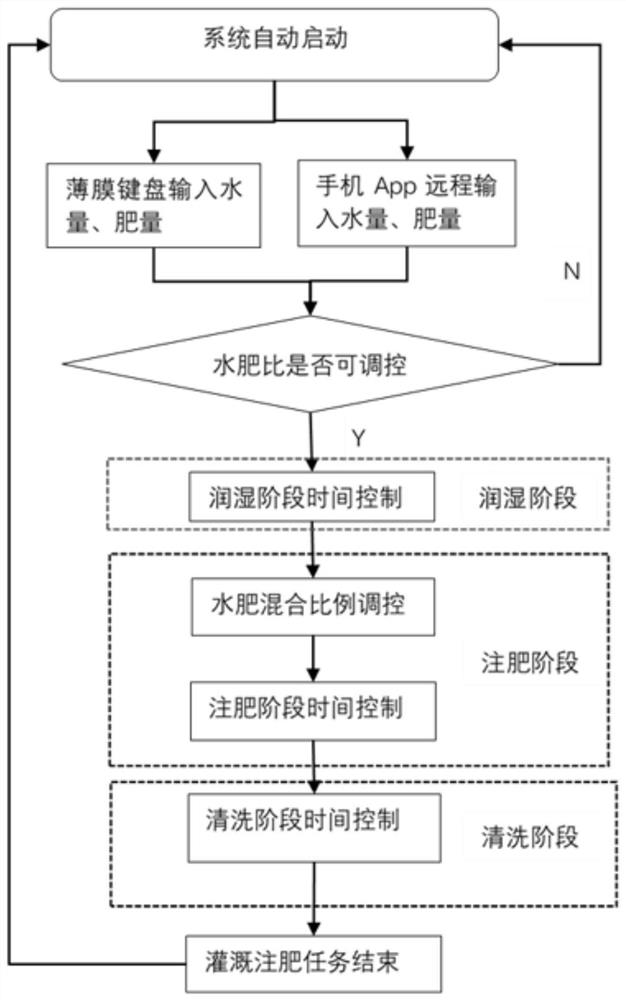

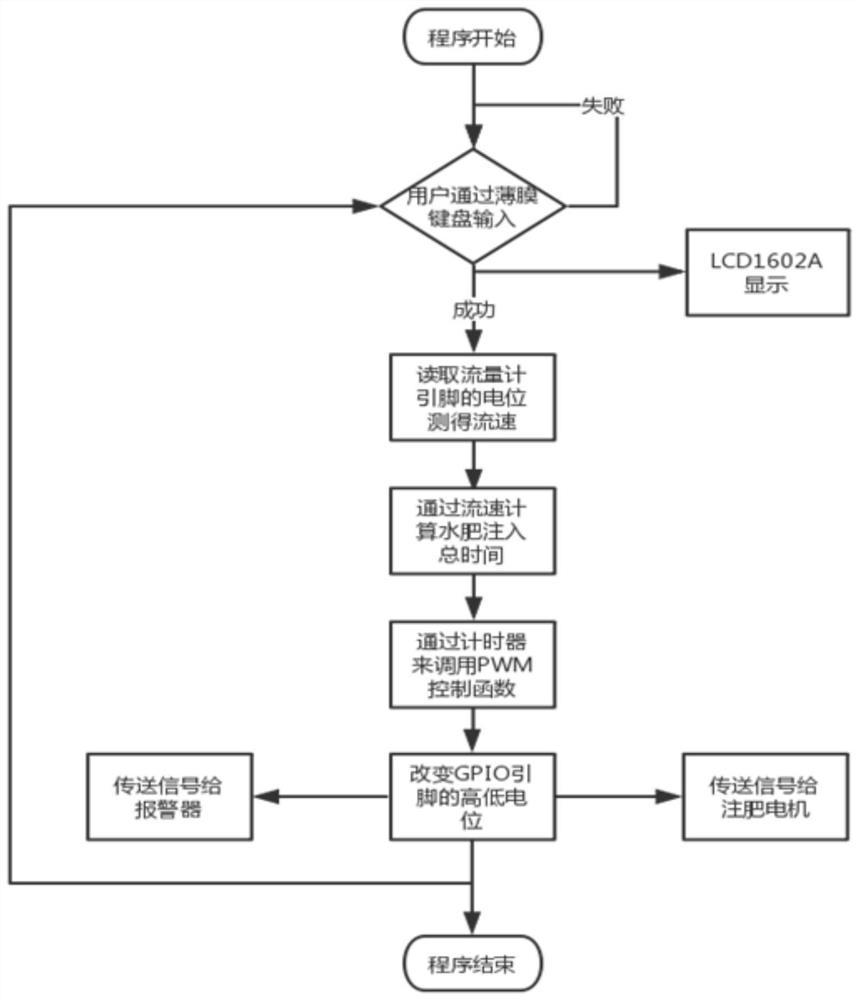

Simple water and fertilizer integrated automatically controlled fertilizer injection system and method for orchard

PendingCN111727713AEasy to operateHigh degree of automationLiquid fertiliser regulation systemsInterprogram communicationFertilizerAutomatic control

The invention discloses a simple water and fertilizer integrated automatically controlled fertilizer injection system and a fertilizer injection control method for an orchard. The system comprises anArduino-based data acquisition subsystem, a Raspberry-pi-based control system and an App remote control unit, wherein the Raspberry-pi-based control system can automatically complete a soil pre-wetting time control task, a water and fertilizer mixing ratio regulation and control and fertilizer injection time control task and a pipeline flushing time control task according to the acquired data. Thewhole system and method have the characteristics of simplicity and easiness in operation, high fertilizer pumping precision and accurate water and fertilizer ratio regulation and control; and the system is good in performance stability and high in safety.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

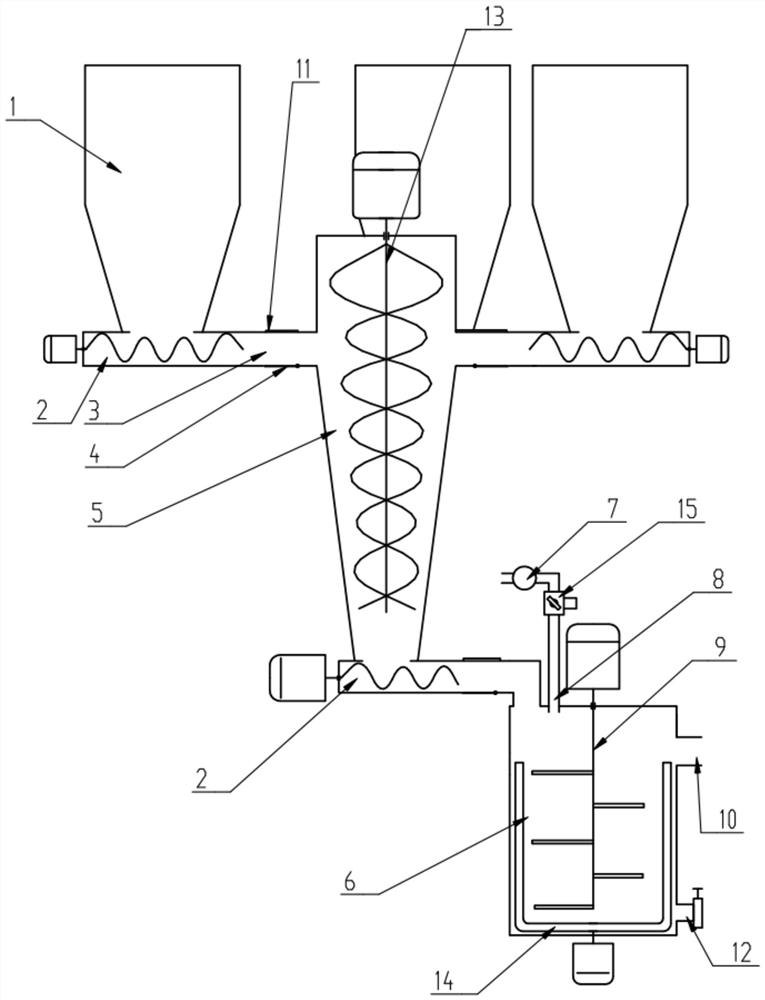

Method for proportionally mixing powder

InactiveCN111545103AReduce workloadIncrease production speedTransportation and packagingRotary stirring mixersDrive shaftMachine

The invention discloses a method for proportionally mixing powder. The method comprises the following mixing steps: preparing materials, feeding, adjusting the ratio, mixing and discharging; a mixingdevice for mixing the powder comprises a machine body, wherein a plurality of feeding funnels are symmetrically arranged on the machine body, each feeding funnel comprises a feeding hopper and a feeding pipe, two variable-speed baffles are symmetrically arranged at the upper end of the machine body, a transmission shaft is rotatably arranged between the two variable-speed baffles, and a pluralityof variable-speed shafts are symmetrically and rotatably arranged between the two variable-speed baffles. The feeding proportion is adjusted through adjustment of change wheels; the proportioning accuracy is improved; the workload is reduced; the production speed is increased; quantitative adding of powder is achieved through quantitative balls, and the proportioning accuracy is further improved;the mixing uniformity is improved through grinding and mixing, sieving, mixing and stirring and mixing in sequence, proportioning and mixing synchronization is achieved through a connecting sleeve, abent vertical rod, a gravity ball, a hanging rod and a ripping bar frame, and mixing and discharging are independent.

Owner:郭保林

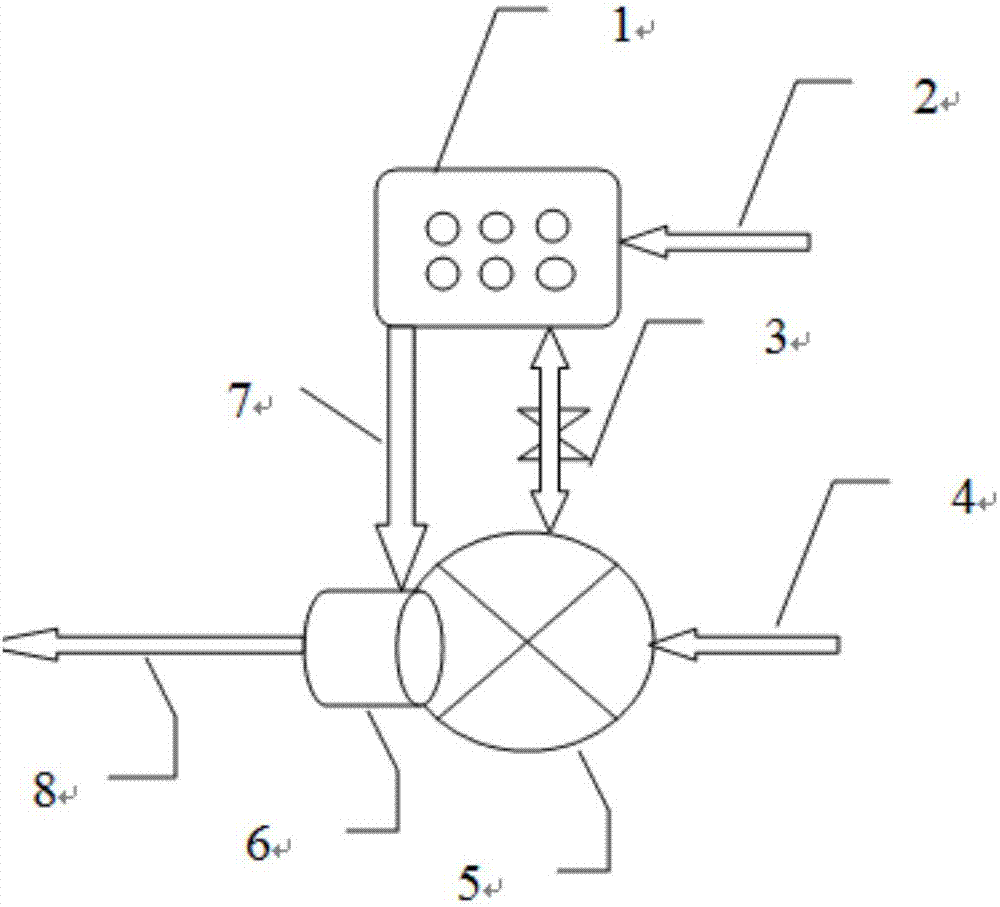

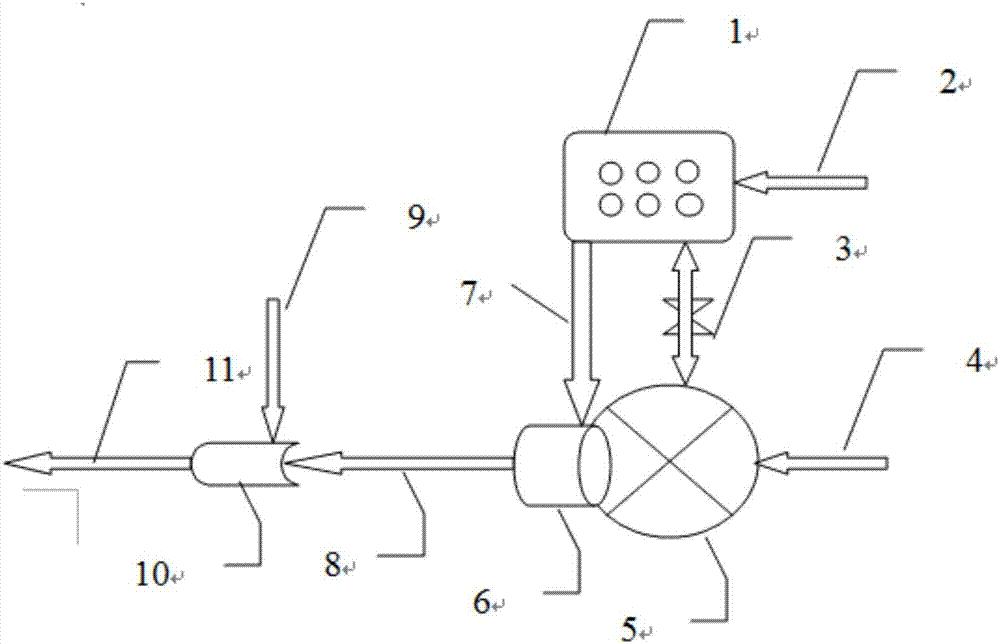

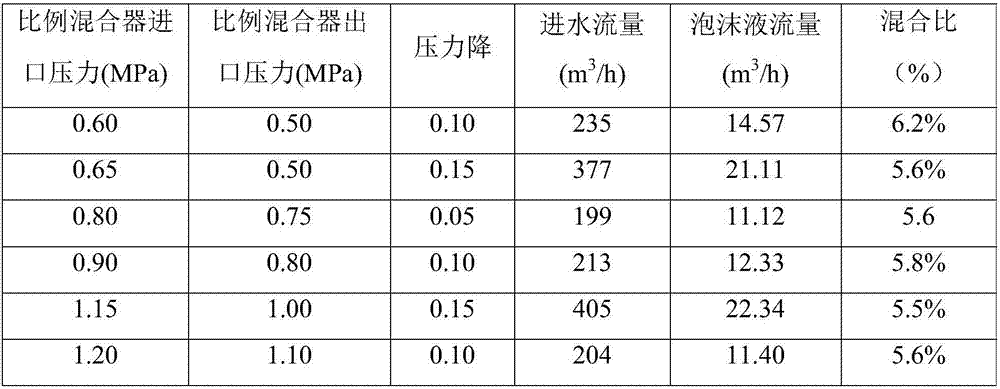

Mechanically-pumping compressed gas foam fire-extinguishing device

PendingCN107349545ASmall footprintSimple and efficient operationFire rescueHigh energyComplex control system

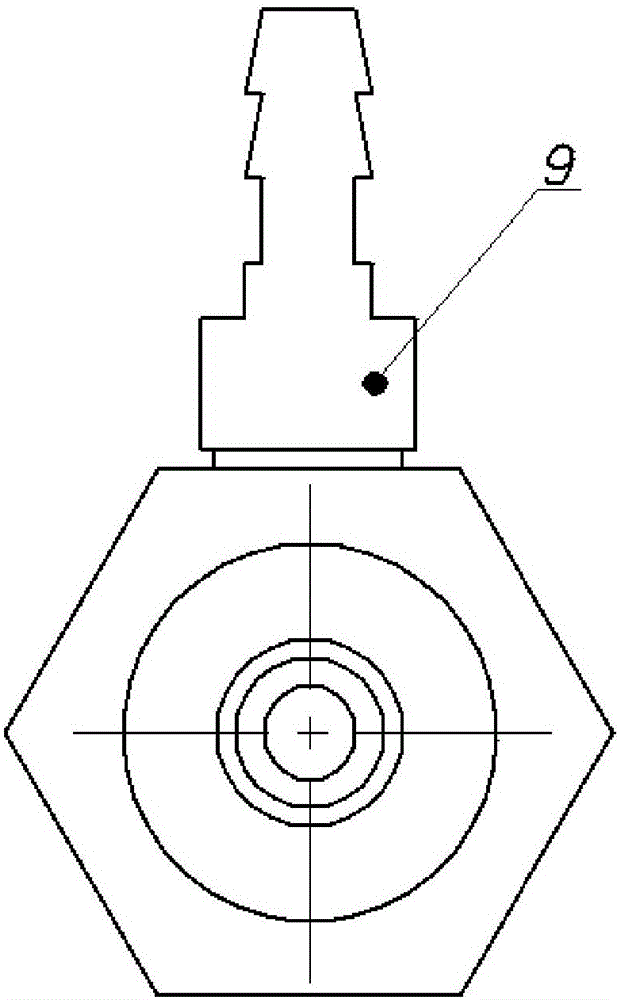

The invention relates to a mechanically-pumping compressed gas foam fire-extinguishing device, and mainly solves the problems of inaccurate mixing ratio measurement, complex control system and high energy consumption in the prior art. The problem is solved well through adopting the technical scheme that the mechanically-pumping compressed gas foam fire-extinguishing device is adopted, and comprises a foam concentrate pump 1, a foam concentrate inlet 2, a connection shaft 3, a fire-fighting pressure water source 4, a water turbine 5, a mixing cavity 6, a foam connection outlet 7, a foam mixed solution inlet 8, a gas source 9, a foam generator 10 and a foam conveying pipeline 11. The mechanically-pumping compressed gas foam fire-extinguishing device can be used in fire-fighting fire extinguishment.

Owner:CHINA PETROLEUM & CHEM CORP +1

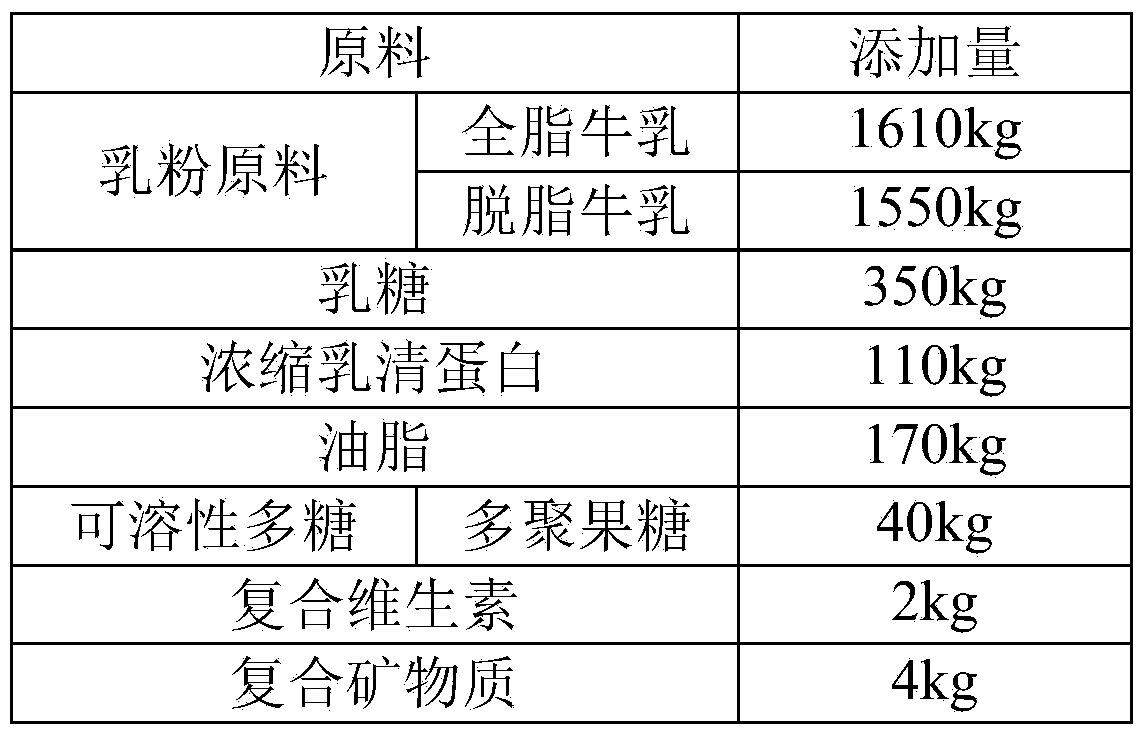

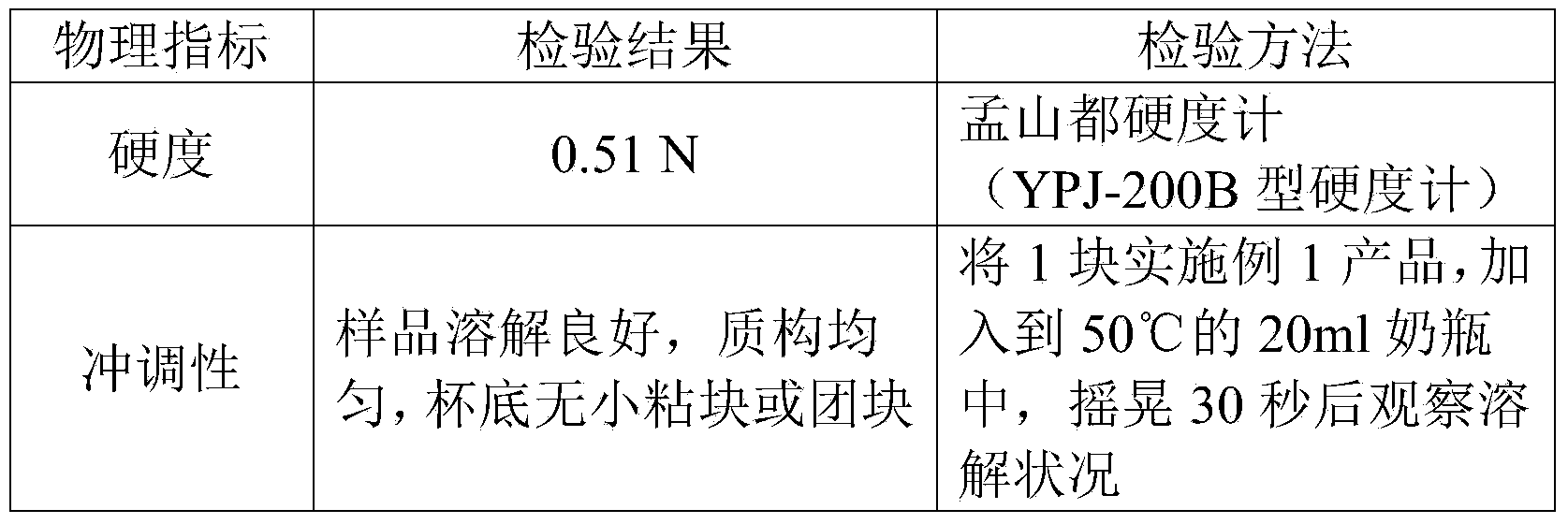

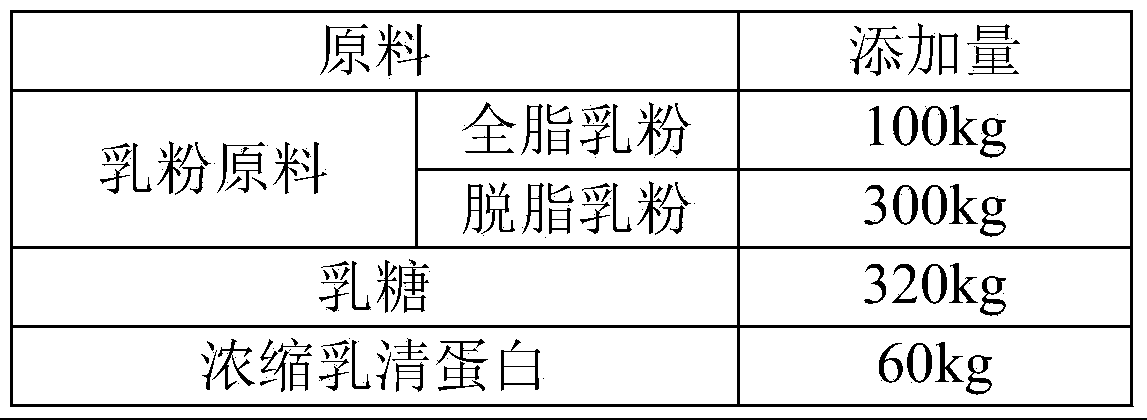

Block-shaped infantile milk powder and preparation method thereof

The invention discloses block-shaped infantile milk powder and a preparation method thereof. The milk powder comprises the following components in percentage by mass: 32-40 percent of lactose, 24-40 percent of milk powder, 14-20 percent of grease, 6-12 percent of concentrated whey protein powder, 2-4 percent of soluble polysaccharide, 0.4-0.6 percent of minerals, and 0.2-0.3 percent of vitamins. The preparation method comprises the following steps: preparing materials, namely uniformly mixing the milk powder, the grease, the vitamins, the minerals and the concentrated whey protein powder with water until the components are completely dissolved to obtain a feed liquid A; homogenizing, sterilizing, concentrating and drying the feed liquid A to obtain matrix powder B; uniformly mixing the matrix powder B, the lactose and the soluble polysaccharide, screening and tabletting, thereby obtaining the block-shaped infantile milk powder. The block-shaped infantile milk powder is excellent in formation and good in dissolubility, and does not contain cosolvent, disintegrant and other additives.

Owner:BRIGHT DAIRY & FOOD

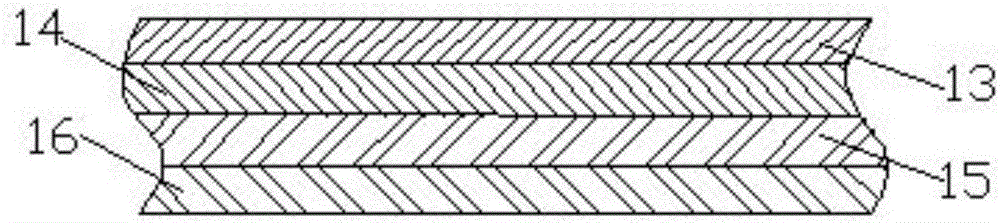

Injection-suction type medicine mixer, sprayer and spraying method of sprayer

InactiveCN105875570AEvenly mixed liquidAccurate supply of medicineInsect catchers and killersSuction forceSprayer

The invention discloses an injection-suction type medicine mixer, a sprayer and a spraying method of the sprayer. The medicine mixer comprises a water inlet pipe, a medicine inlet pipe, a mixing pipe and a flow discharging pipe, wherein the water inlet pipe, the mixing pipe and the flow discharging pipe are sequentially connected in a sealing manner; a plurality of core tubes are arranged in the mixing pipe; a plurality of annular grooves are formed in the outer surface of each core tube; an annular cavity is jointly formed between the outer surface of each core tube and the inner wall of the mixing pipe; one of annular grooves is opposite to one of medicine inlet holes in the mixing pipe; a plurality of through holes are formed in the circumferential direction of other annular grooves and are used for allowing liquid medicine injected into the annular cavities by the medicine inlet pipe to flow into the core tubes; the liquid medicine enters the annular grooves opposite to the medicine inlet holes from the medicine inlet pipe and flows into other surrounding annular grooves through the annular cavities, and enters into the core tubes through the through holes in the bottoms of the annular grooves under the action of a suction force of an external water pump, so that uniform mixing of the liquid medicine is realized; multiple medicines can be mixed by adopting multiple core tubes; the injection-suction type medicine mixer has the advantage of simple and compact structure.

Owner:SOUTH CHINA AGRI UNIV

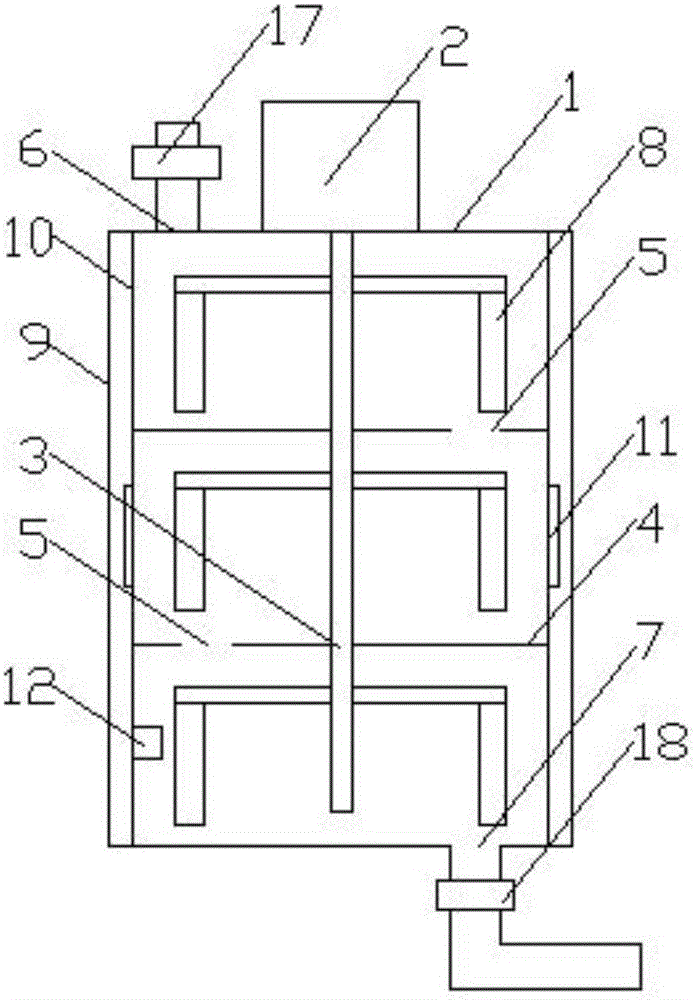

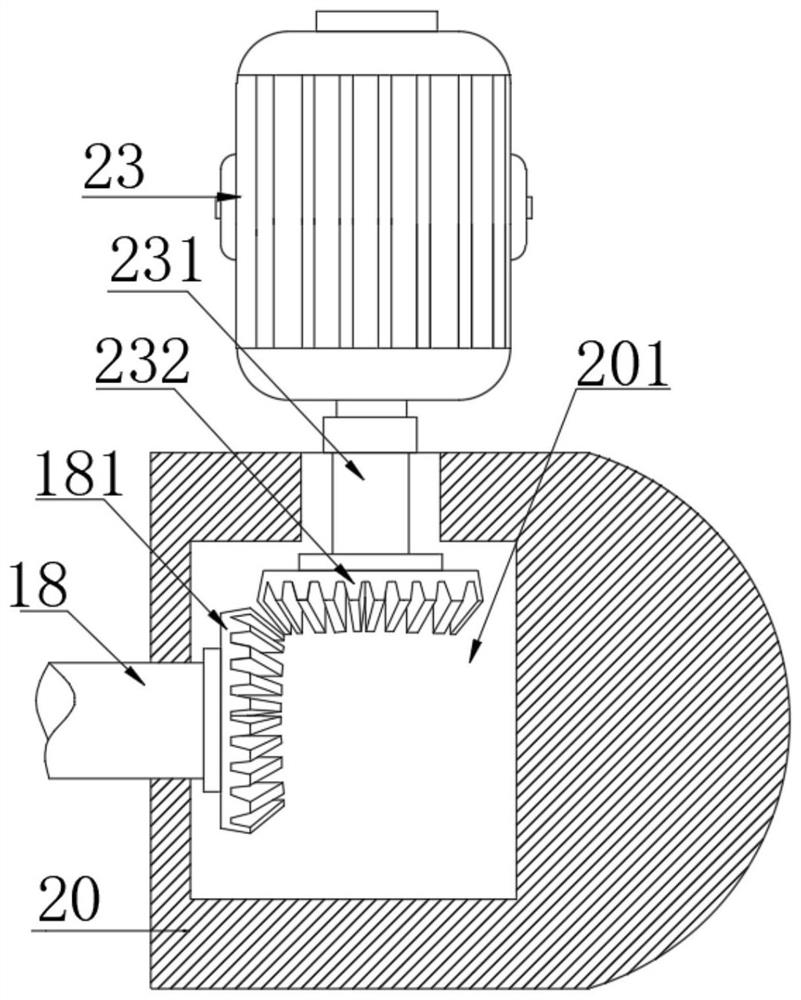

Multi-stage stirrer

InactiveCN106563370AThe mixing ratio is accurateStir wellRotary stirring mixersTransportation and packagingImpellerChinese characters

The invention discloses a multi-stage stirrer. The multi-stage stirrer comprises a machine shell and a stirring motor located on the upper side of the machine shell. A rotating shaft of the stirring motor is arranged inside the machine shell. The machine shell is divided into multiple partition chambers from up to bottom. A partition plate of each partition chamber is provided with a discharging opening. The top of the machine shell is provided with a feeding opening. The bottom of the machine shell is provided with a master discharging opening. The feeding opening, the discharging openings and the master discharging opening are distributed in a shape like the Chinese character 'gong'. The portion, located in each partition chamber, of the rotating shaft is provided with a stirring impeller. The machine shell comprises an outer wall and an inner wall. Multiple temperature adjusting devices are circumferentially distributed between the outer wall and the inner wall. A temperature sensor is arranged in the lowest partition chamber of the machine shell. The outer wall sequentially comprises a stainless steel layer, an acoustic-absorbing cotton layer, a cellular board layer and an acoustic-absorbing coating layer from inside to outside. The feeding opening is provided with a flow meter. The master discharging opening is provided with an electromagnetic valve. The multi-stage stirrer is simple in structure, adjustable in temperature, good in sound insulating effect and capable of achieving multiple stages of stirring and a good raw material stirring effect.

Owner:CHENGDU YITIAN TECH CO LTD

Temperature-adjustable graphene processing equipment and using method

ActiveCN111841423AThe mixing ratio is accurateQuality improvementTransportation and packagingGraphenePhysicsWater pipe

The invention discloses temperature-adjustable graphene processing equipment in the technical field of graphene processing equipment. The equipment comprises a mixing tank, a water pipe is arranged between the inner side and the outer side of the mixing tank; a water inlet is formed in the top end of the water pipe; a water outlet is formed in the bottom end of the water pipe; a feeding hole is formed in the top end of the left side of the mixing tank; a discharge hole is formed in the middle of the bottom end of the mixing tank; a valve is arranged on the discharge hole, a water pipe is adopted, and is externally connected with a temperature control pipe through a water inlet and a water outlet, so that the temperature of water in the water pipe is adjustable, a better processing environment is provided for graphite and ingredient mixed liquid, meanwhile, the mixing speed of the graphite and the ingredient mixed liquid is increased, the processing process is accelerated, and the yieldof graphene is increased.

Owner:杭州涸鲋科技有限公司

Mixing device for foundation raw materials for highway engineering

InactiveCN111761723AWell mixedHomogenous mixing and energy savingDischarging apparatusRotary stirring mixersArchitectural engineeringStructural engineering

The invention discloses a mixing device for foundation raw materials for highway engineering. The mixing device comprises a vertical mixing barrel and a double-helical-ribbon agitator arranged in themixing barrel. The lower part of the mixing barrel is conical, the upper part of the mixing barrel is provided with at least two feeding ports, each feeding port is provided with a quantitative feeding unit, and the bottom of the mixing barrel is provided with a discharging port. The three raw materials of cement, sand and stones are separately conveyed into the mixing barrel in proportion by thequantitative feeding unit, stirred to be uniform by the double-helical-ribbon agitator and discharged from the discharging port in the bottom of the mixing barrel, the proportion of the three raw materials is guaranteed, and the problems that when the foundation raw materials for highway engineering are mixed, the randomness is high and the proportion is inaccurate are avoided. The double-helical-ribbon agitator has the advantages of high mixing efficiency, uniform mixing and energy saving and can effectively reduce accumulated materials on the wall of the mixing barrel.

Owner:张冰琳

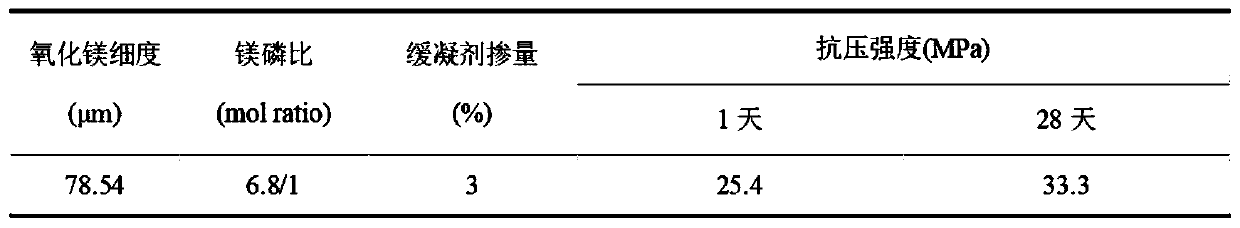

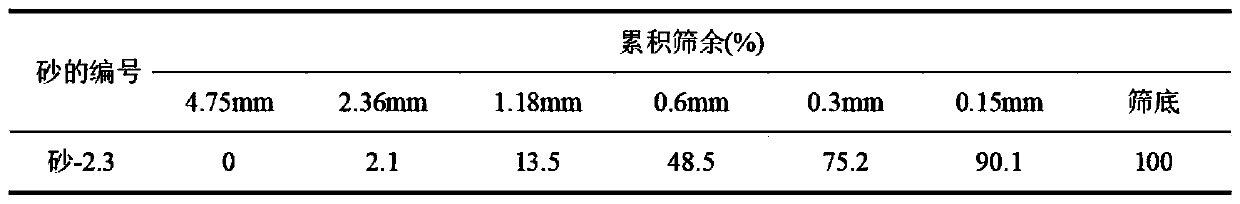

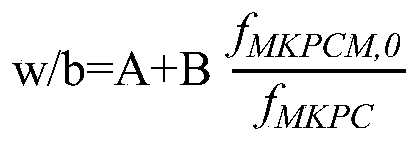

Phosphate cement mortar matching method

ActiveCN110372320AThe mixing ratio is accurateQuick mixDesign optimisation/simulationSpecial data processing applicationsWater usePhosphate

The invention discloses a phosphate cement mortar matching method. The phosphate cement mortar matching method comprises the following steps of (1) determining target performance, including a target strength average value fMKPCM, m and consistency C0 of phosphate cement mortar, of the phosphate cement mortar; (2) according to the target intensity average value fMKPCM, m, which is set in advance, of the phosphate cement mortar, determining production strength fMKPCM, 0 of the phosphate cement mortar; (3) according to the consistency C0, which is set in advance, of the phosphate cement mortar, determining unit water use Mw0 of the phosphate cement mortar; (4) determining a water-binder ratio w / b, and according to the water-binder ratio w / b, calculating the dosage of phosphate cement; and (5)determining the dosage Ms0 of sand. By means of the method, a matching ratio of the phosphate cement mortar can be obtained accurately and fast on the basis of the target use performance, operation of the method is simple, convenient and reasonable, manpower and material resource waste brought by repeated tentative production and adjustment is avoided, and the method has good operability and practicability.

Owner:SOUTHEAST UNIV

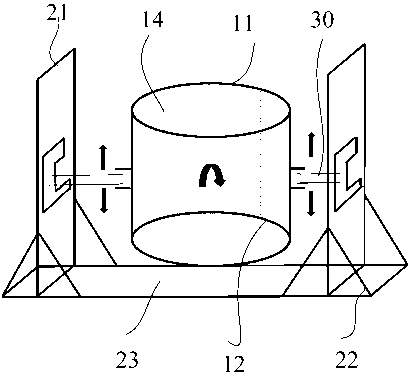

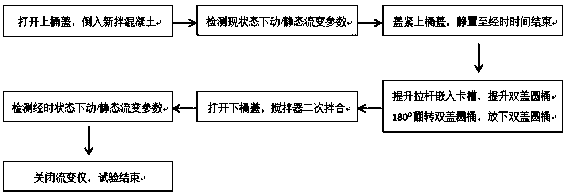

Device and method for monitoring concrete rheological parameters through time

InactiveCN109387457AImprove detection efficiencyEnsure personal safetyTransportation and packagingPreparing sample for investigationStructural engineering

The invention provides a device and a method for monitoring concrete rheological parameters through time, belongs to the technical field of concrete and establishes a novel method for detecting concrete rheological parameters through time. A barrel containing a concrete sample is set in a double-lid mode, including an upper barrel lid and a lower barrel lid, the two barrel lids can be freely opened, a lifting support is also arranged and comprises a pair of vertical support bodies arranged in parallel, and the double-lid barrel is suspended between the pair of vertical support bodies through connecting parts and can be turned over by 180 degrees with the straight line where the connecting parts are located as the axis under the action of external force. During testing, a concrete mixture is contained in the upper barrel lid, initial rheological parameter data are detected, then, the upper barrel lid is fastened down, after the concrete mixture is left to stand through time, the double-lid barrel is lifted through the connecting parts to a certain height, the double-lid barrel is turned over by 180 degrees and placed back to the ground, the lower barrel lid is opened, the mixture issecondarily mixed to be uniform, and concrete rheological parameter data through time is detected finally.

Owner:SHANGHAI CONSTRUCTION GROUP

Gradient liquid feed pump system, and liquid chromatograph

InactiveUS7163379B2Reduce impactThe mixing ratio is accurateFluid parameterComponent separationEngineeringCam

A gradient liquid feed pump system capable of liquid feed in a correct mixing ratio even in the case of liquid feed in which the mixing ratio varies. Specifically, it comprises a first plunger pump for sucking and delivering an eluate, a second the first and second plunger pumps through a cam, a first pressure sensor for measuring the pressure in the flow path of the second plunger pump, a second pressure sensor for measuring the pressure in the fist plunger pump, a cam position detecting sensor for detecting the cam position, wherein when the cam position is in a delivery interval, the rotary speed of the motor is increased, and the period for decreasing the rotary speed is determined on the basis of the difference between the pressure values obtained from the first and second pressure sensors, respectively. Thereby, liquid feed can be smoothly effected with correct mixing ratio while avoiding pressure interference between pumps.

Owner:HITACHI HIGH-TECH CORP +1

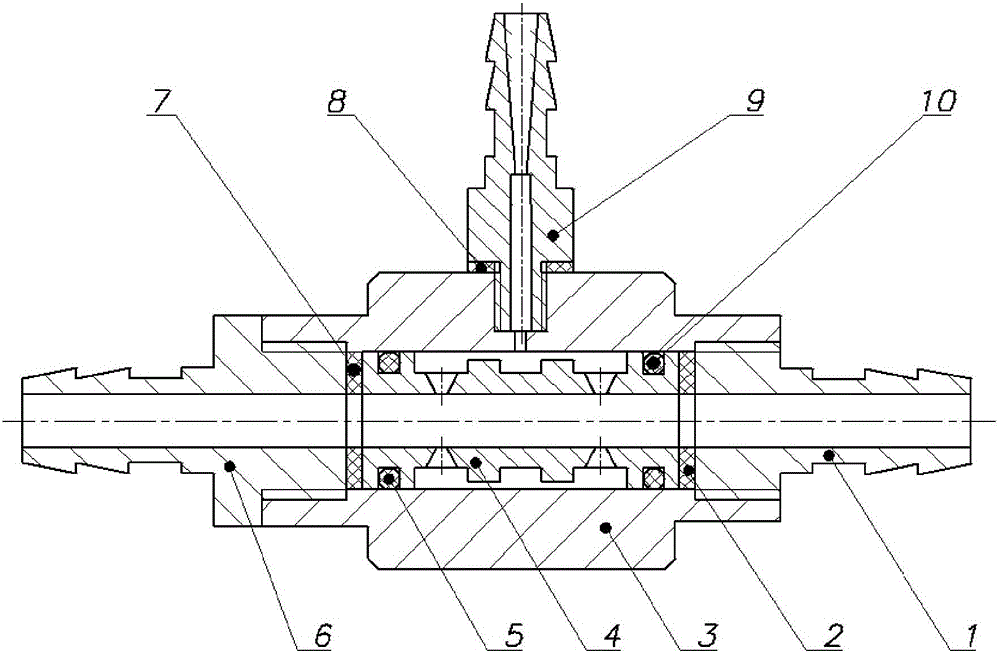

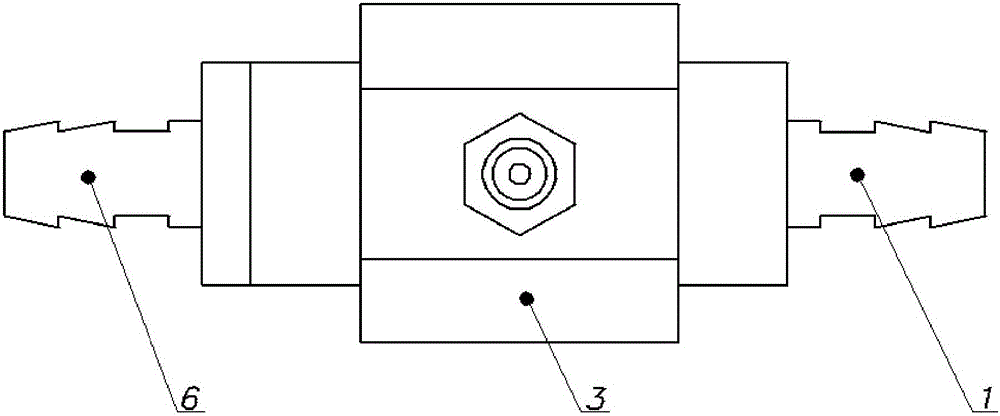

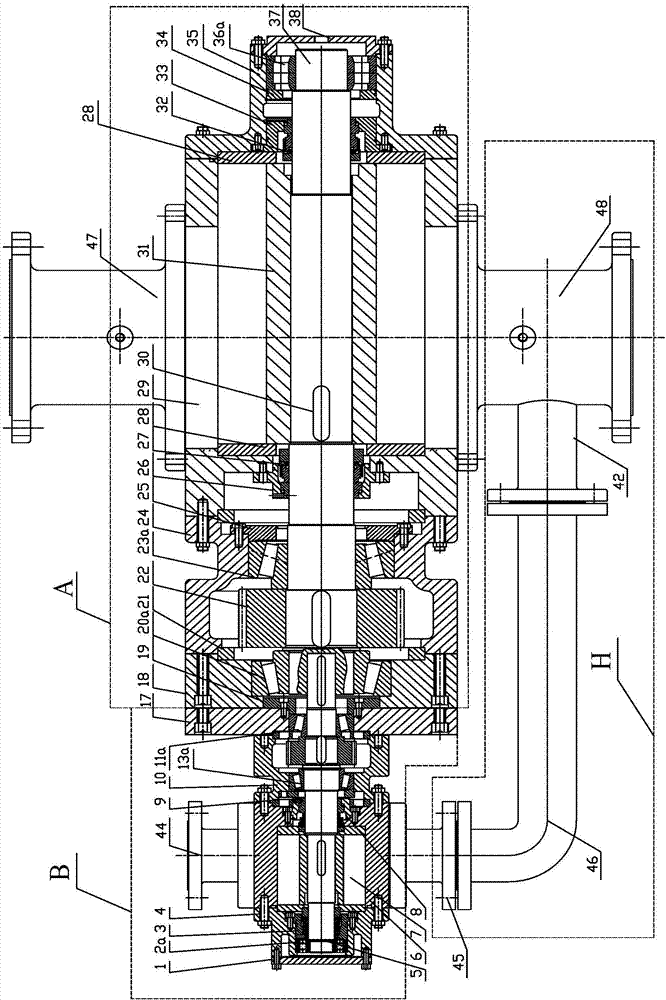

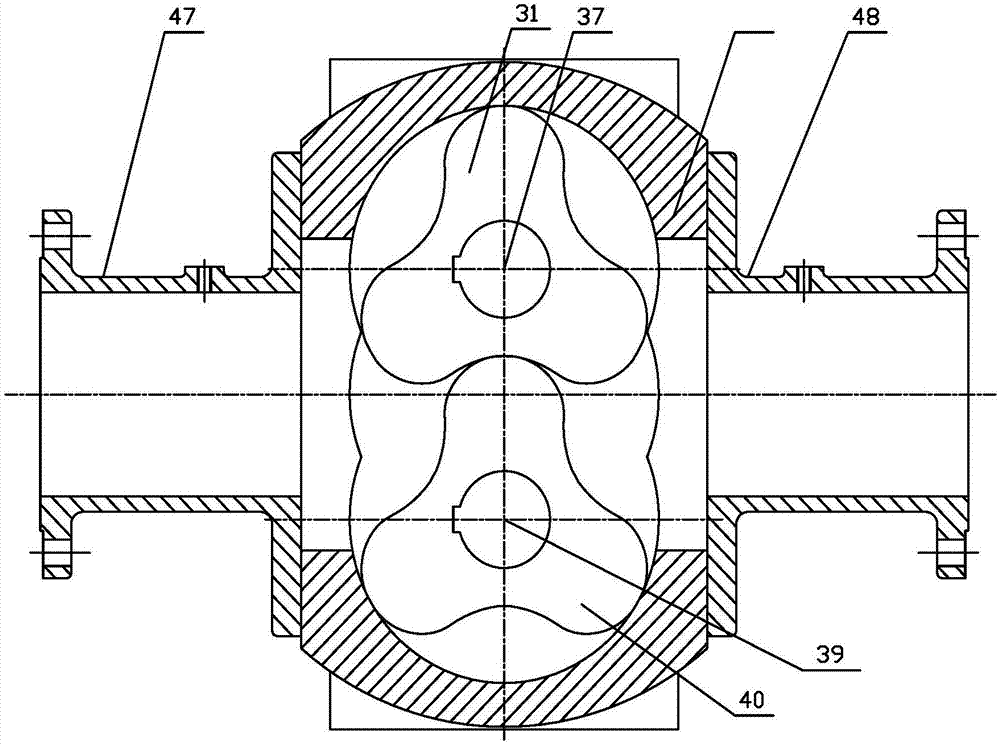

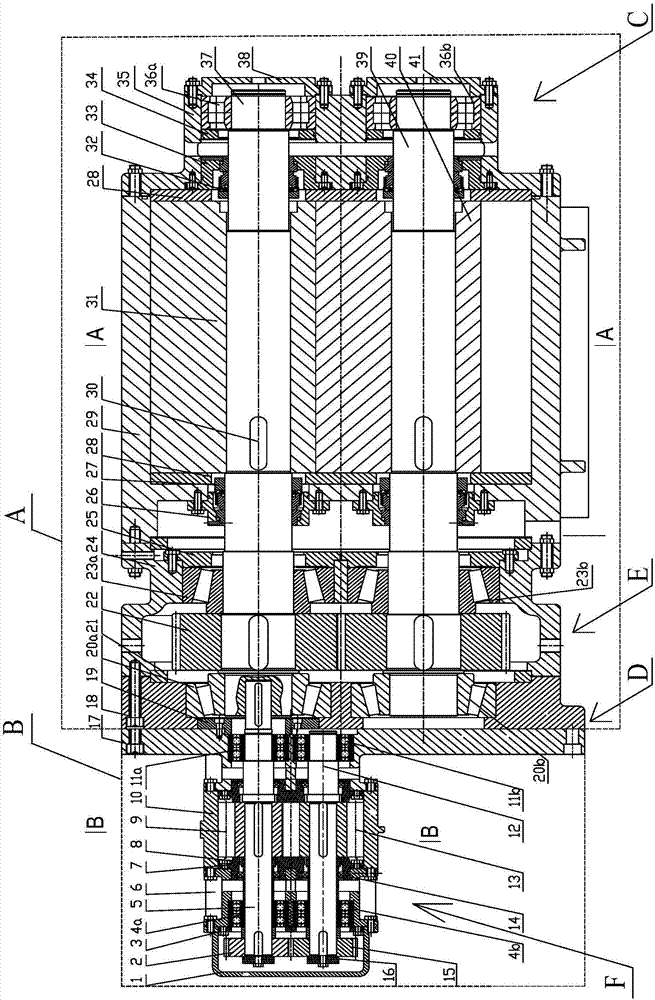

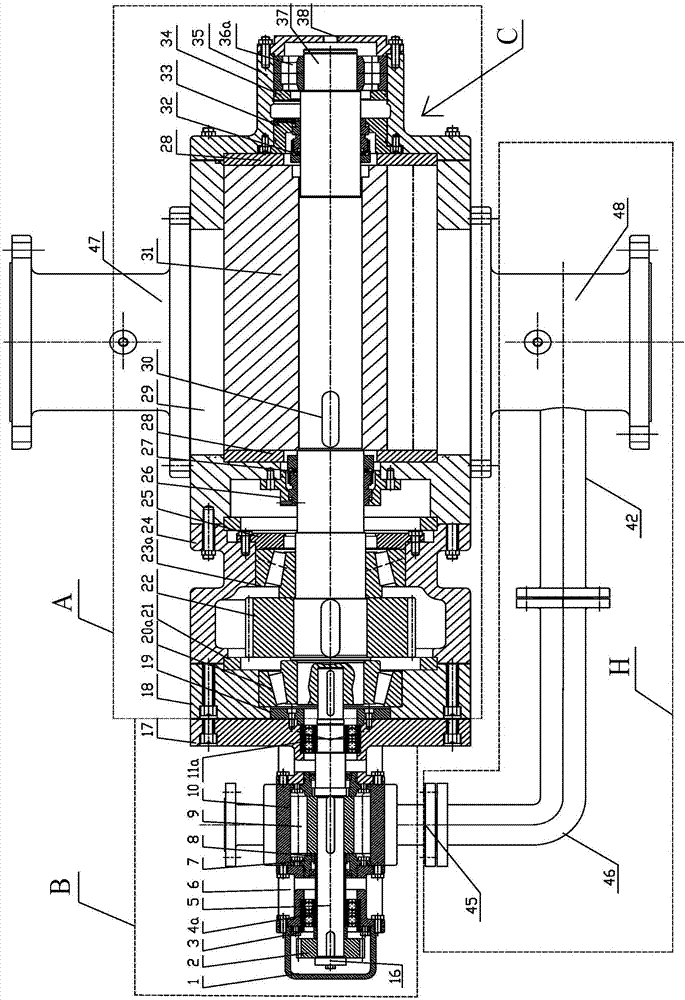

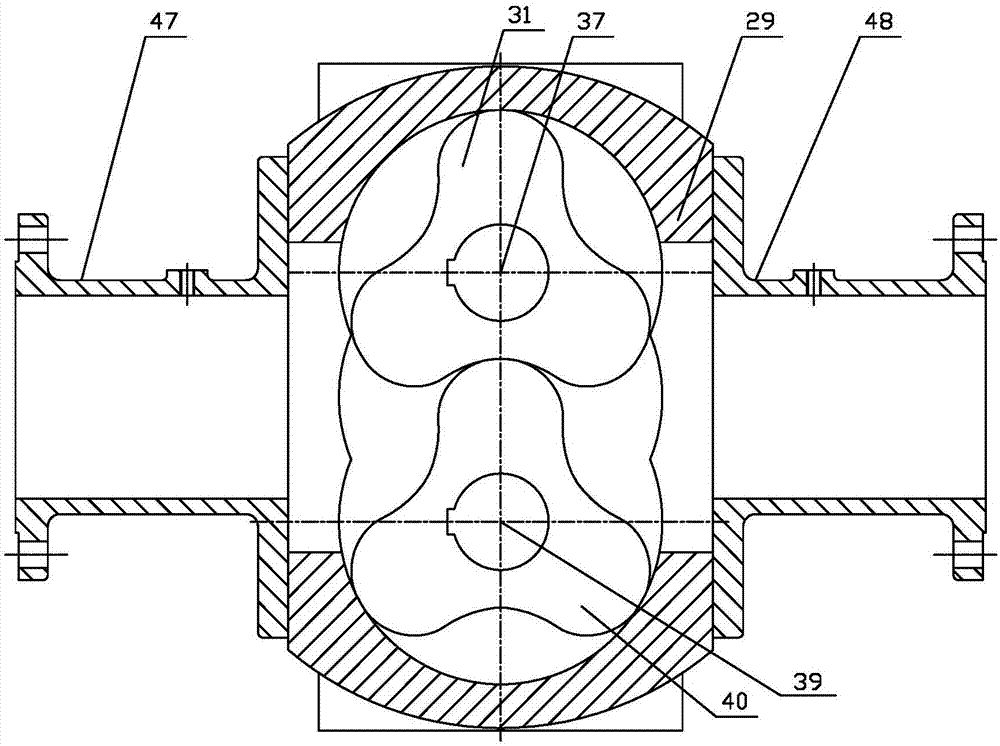

Rotor mechanical pumping foam proportional mixing device

InactiveCN107339188ALow costCompact structureFire rescueMachines/enginesFirefightingAerospace engineering

A rotor mechanical pumping foam proportional mixing device has a hydraulically driven rotor type water turbine taking firefighting water as power, a foam rotor pump connected to a driving output shaft of the hydraulically driven rotor type water turbine by a middle bearing mechanism and used for pressurizing and then discharging normal pressure foam and a firefighting mixed liquid exporting mechanism respectively connected to a water outlet of the hydraulically driven rotor type water turbine and a liquid outlet of the foam rotor pump and used for outputting firefighting mixed liquid. The hydraulically driven rotor type water turbine and the foam rotor pump are both of a driving and driven double-rotor structure, a constant gap exists between the two rotors forming each driving and driven double-rotor structure, and a main rotary shaft connected to a driving rotor in the hydraulically driven rotor type water turbine forms the driving output shaft to be connected to a main rotary shaft in the foam rotor pump. The hydraulically driven rotor type water turbine and the foam rotor pump are designed into a whole, the cost is low, the structure is compact, the size is small, a mounting space is greatly reduced, and the system will consume a lower firefighting water pressure due to high volume efficiency.

Owner:刘彤贤

Rotor mechanically-pumping type foam proportionally-mixing device

The invention provides a rotor mechanically-pumping type foam proportionally-mixing device. The rotor mechanically-pumping type foam proportionally-mixing device comprises a hydraulic drive rotor type water turbine with fire-fighting water as power, a foam gear pump connected with a drive output shaft of the hydraulic drive rotor type water turbine through a middle bearing mechanism and a fire-fighting mixed liquid guide-out mechanism connected with a water outlet of the hydraulic drive rotor type water turbine and a liquid outlet of the foam gear pump and used for outputting fire-fighting mixed liquid. The hydraulic drive rotor type water turbine is of a driving-rotor and driven-rotor structure, and a constant gap is set between two rotors forming the driving-rotor and driven-rotor structure. The foam gear pump is of a driving and driven double-gear structure. A main rotating shaft connected with the driving rotor in the hydraulic drive rotor type water turbine forms a drive output shaft connected with a main rotating shaft in the foam gear pump. According to the rotor mechanically-pumping type foam proportionally-mixing device, the hydraulic drive rotor type water turbine and a foam rotor pump are designed into a whole, the cost is low, the structure is compact, the size is small, the mounting space is reduced greatly, and the lesser fire-fighting water pressure is consumed by a system due to the fact that volume efficiency is high.

Owner:刘彤贤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com