On-line SPM generating system and control method thereof

A generation system, flow control technology, applied in the direction of ratio control, cleaning methods and appliances, non-electric variable control, etc., can solve the problems of the surface material ruthenium reflectance reduction, damage, etc., to achieve the best treatment process, accurate mixing ratio, Active and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

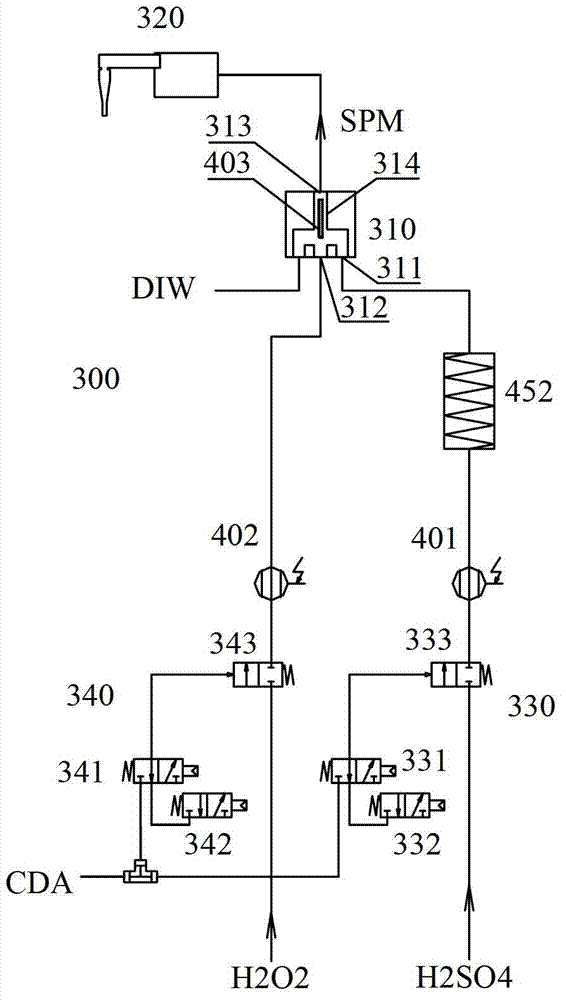

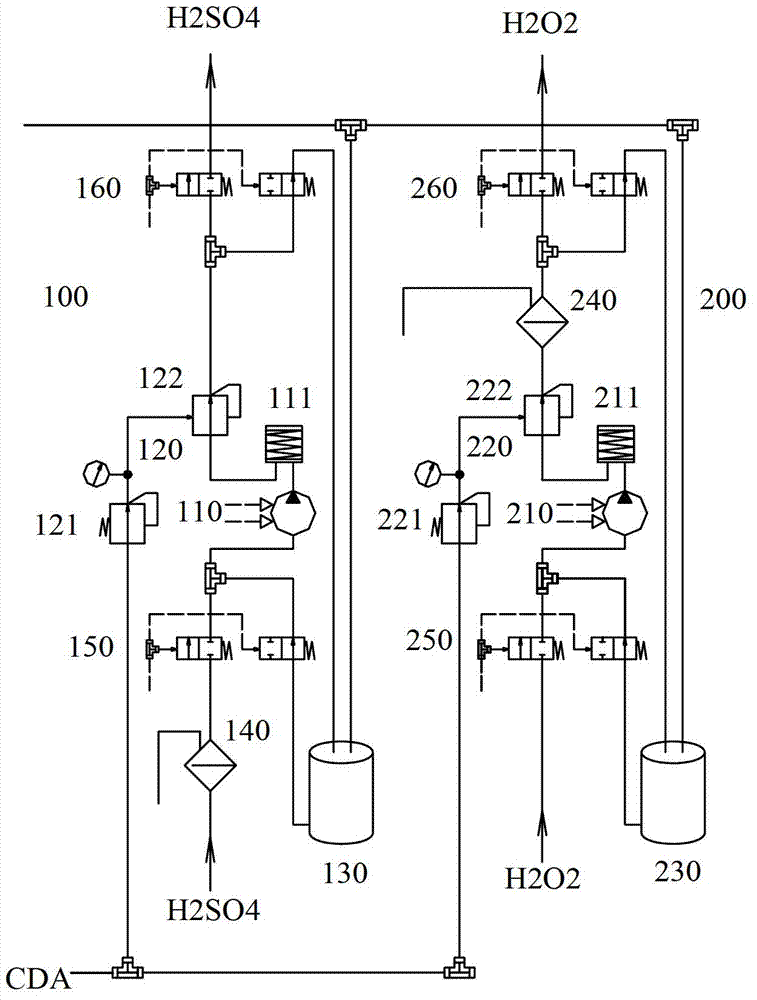

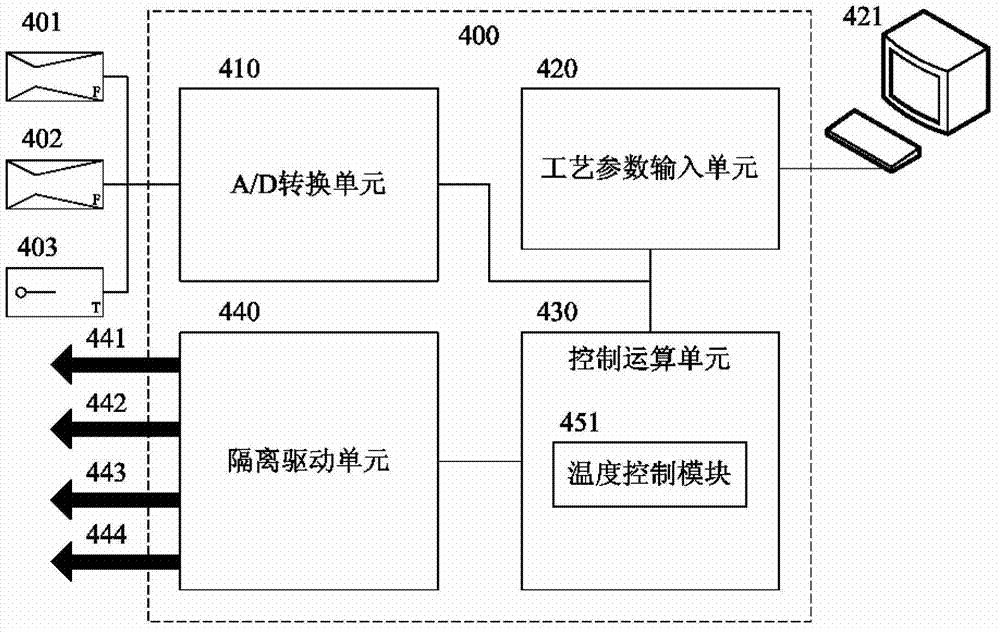

[0041] Online SPM generation system of the present invention such as figure 1 and figure 2 As shown, it includes H2SO4 supply unit 100, H2O2 supply unit 200, SPM mixing spray unit 300 and control unit 400, the functional block diagram of the control unit is shown in image 3 .

[0042] H2SO4 supply unit 100 includes H2SO4 flow control element 120, H2SO4 flow control element 120 is connected to SPM mixing spray unit 300 through H2SO4 delivery pipeline;

[0043] The H2O2 supply unit 200 includes a H2O2 flow control element 220, and the H2O2 flow control element 220 is connected to the SPM mixing spray unit 300 through the H2O2 delivery pipeline;

[0044] The SPM mixing spray unit 300 includes an SPM mixing element 310 and at least one SPM shower head 320; the SPM mixing element 310 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com